Patents

Literature

6442 results about "Rotary kiln" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A rotary kiln is a pyroprocessing device used to raise materials to a high temperature (calcination) in a continuous process. They are also used for roasting a wide variety of sulfide ores prior to metal extraction.

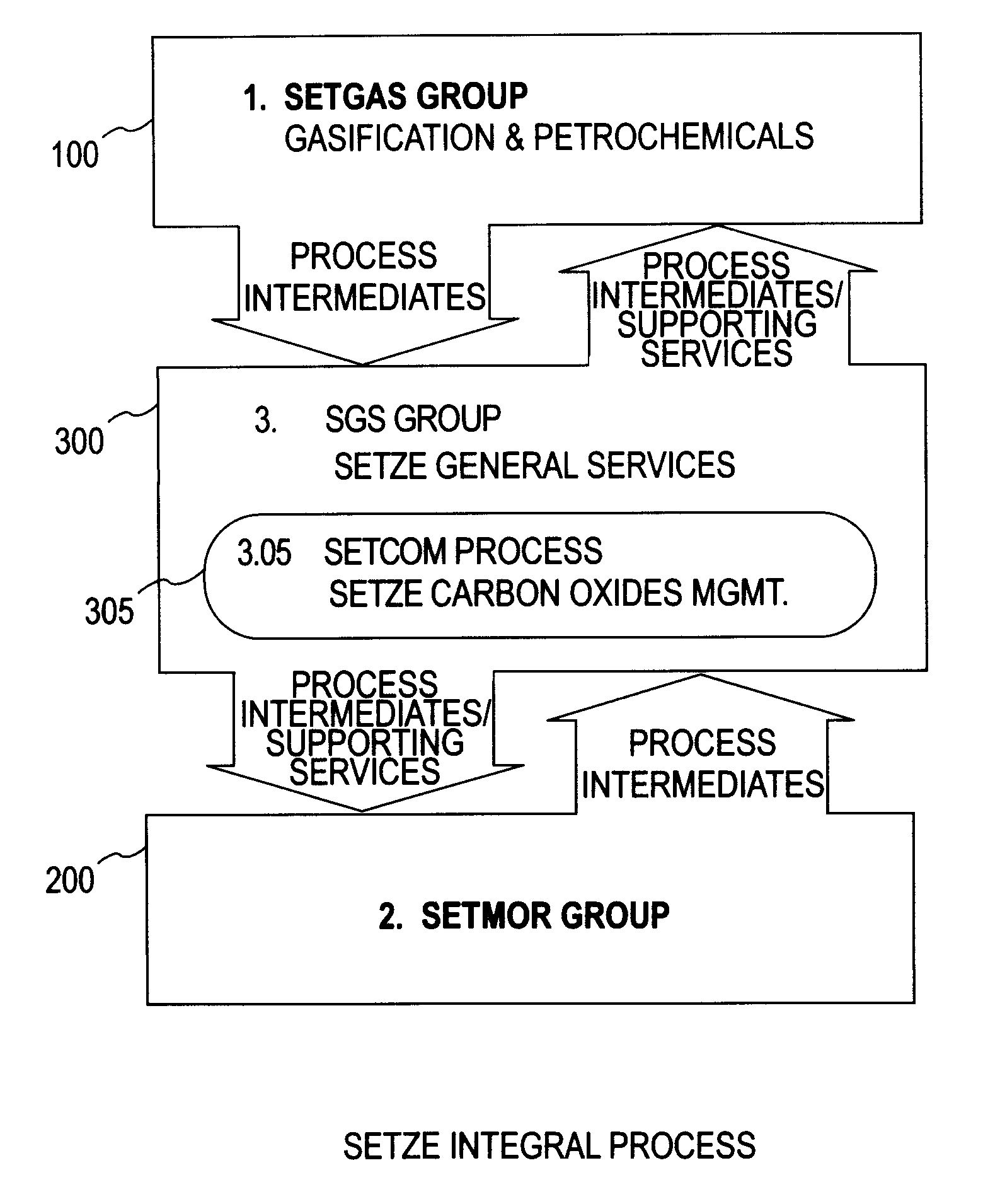

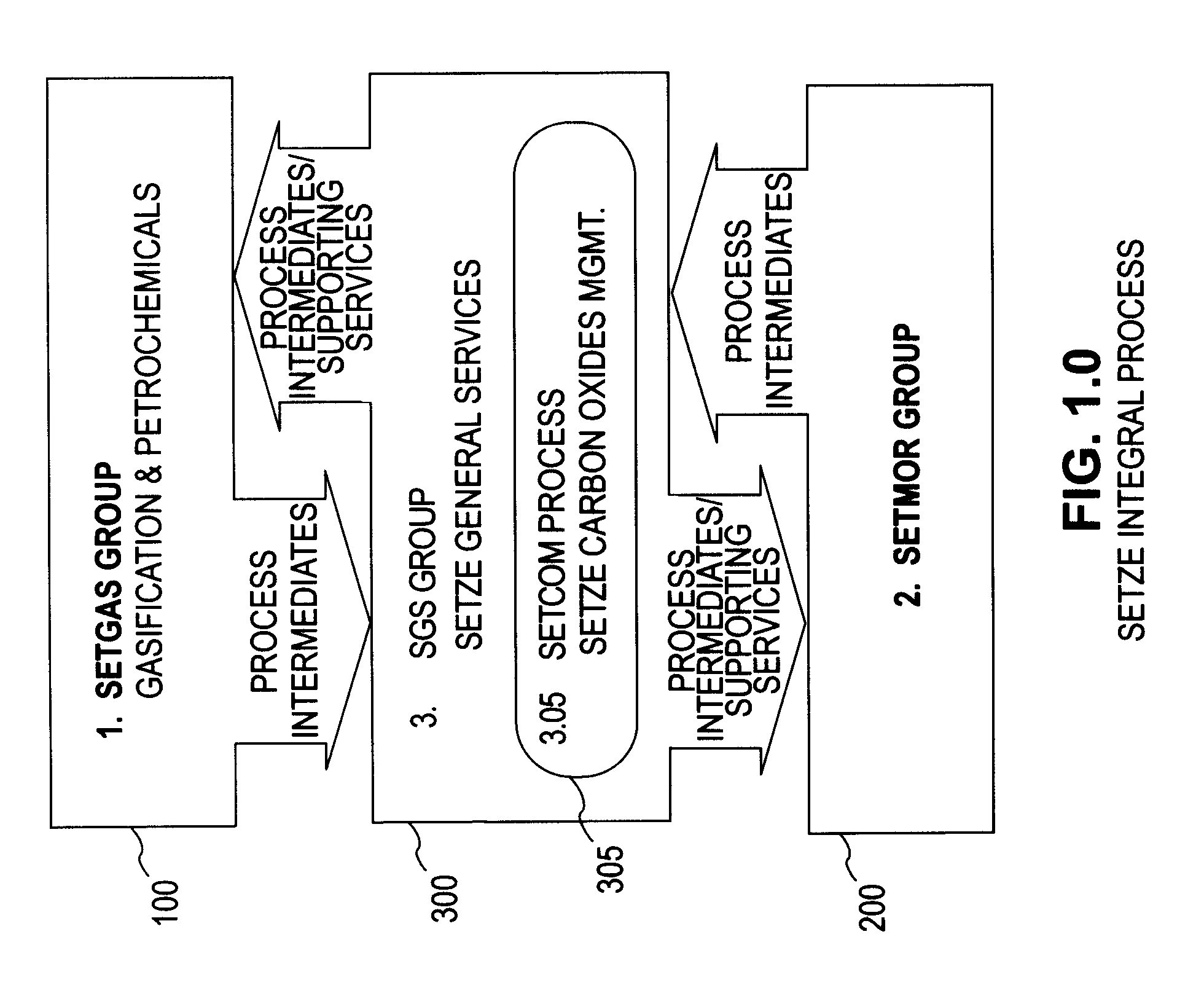

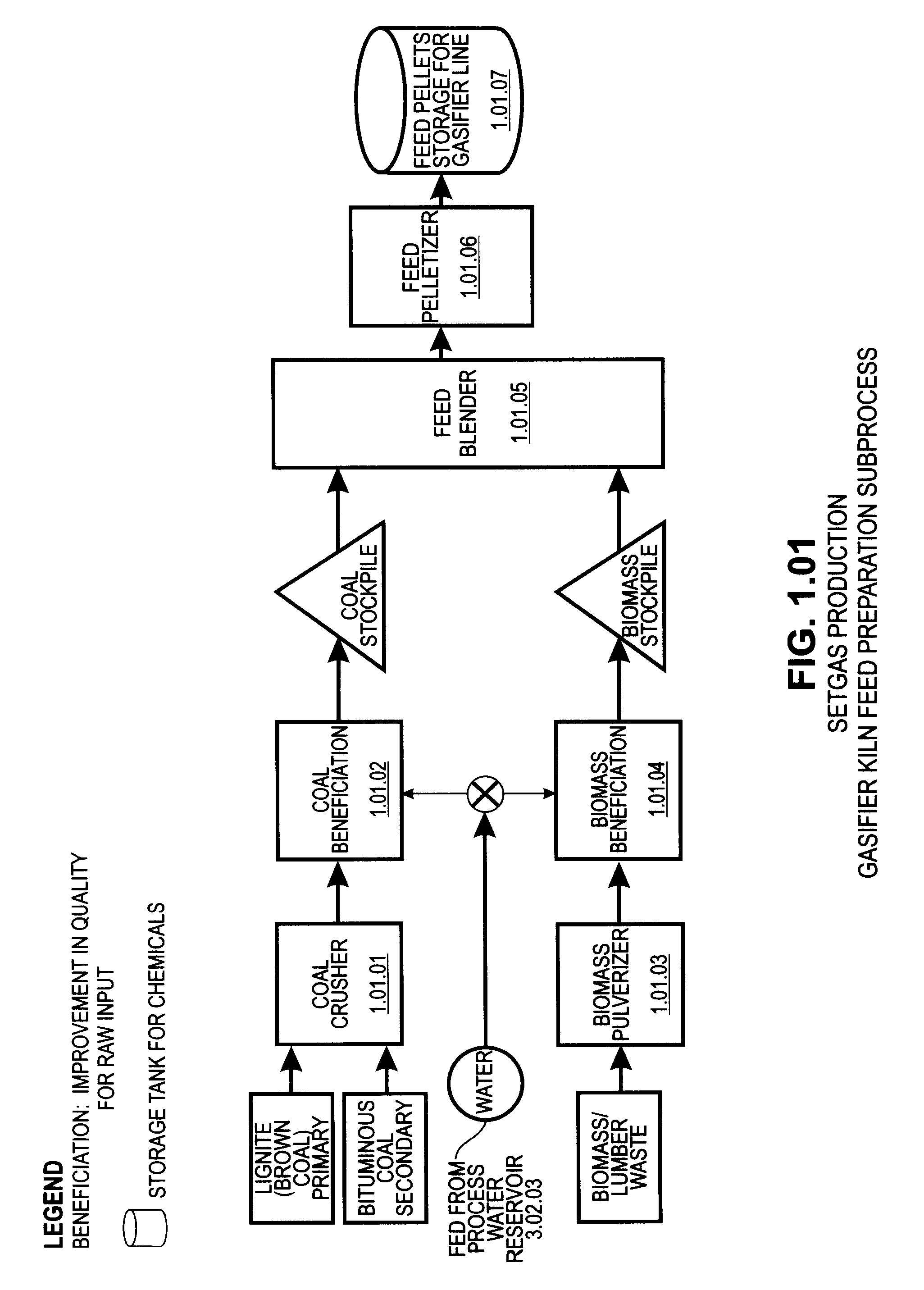

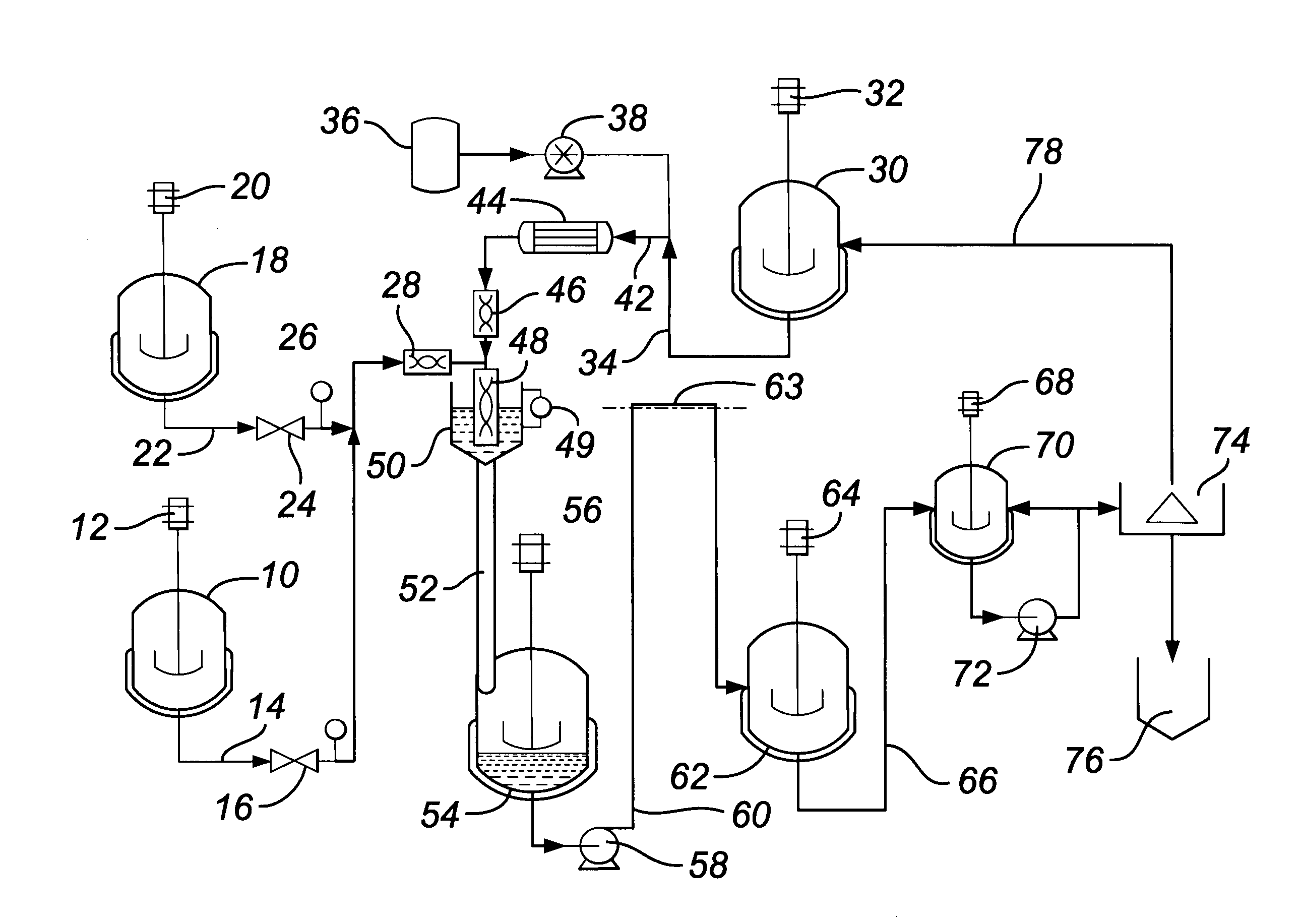

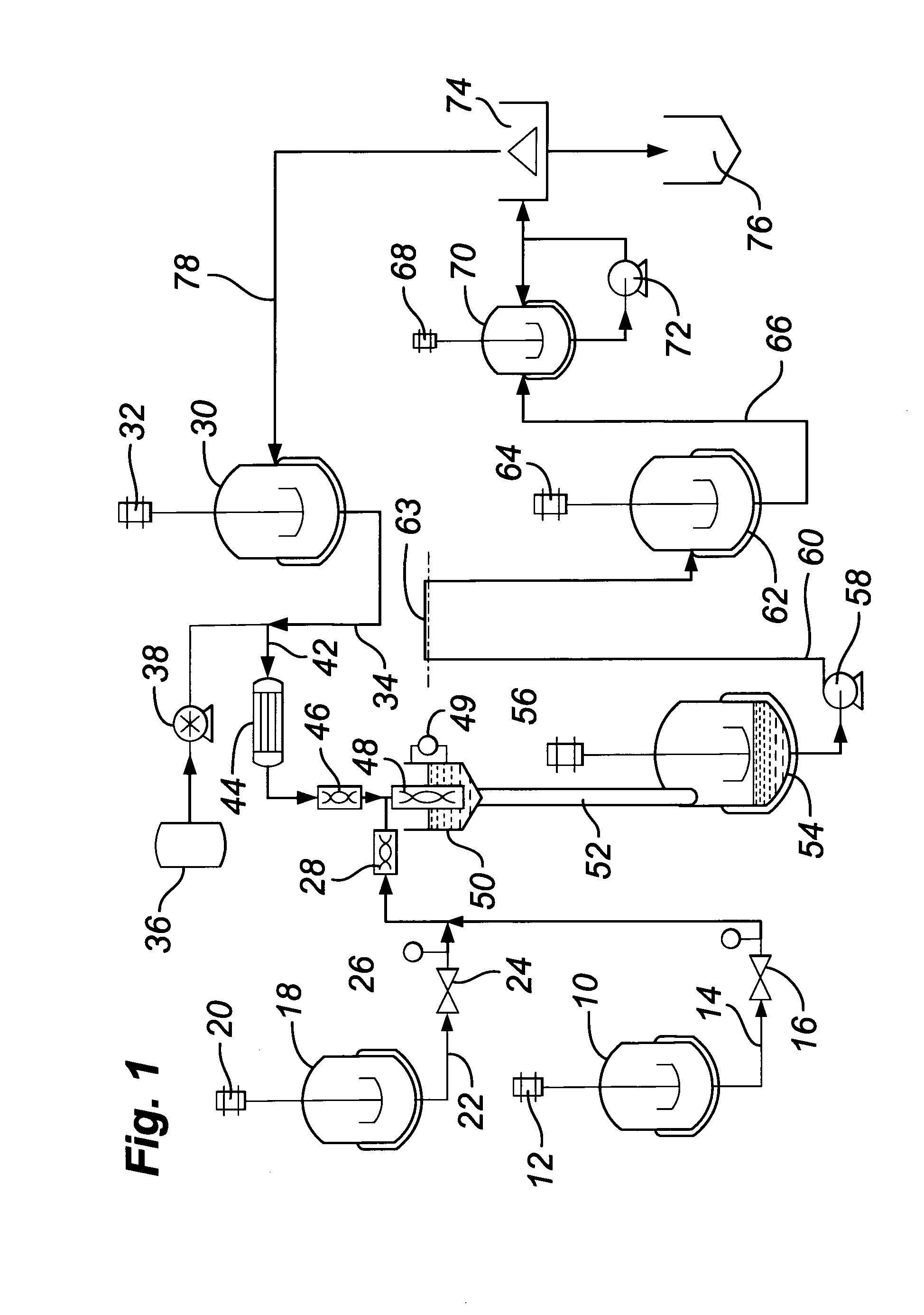

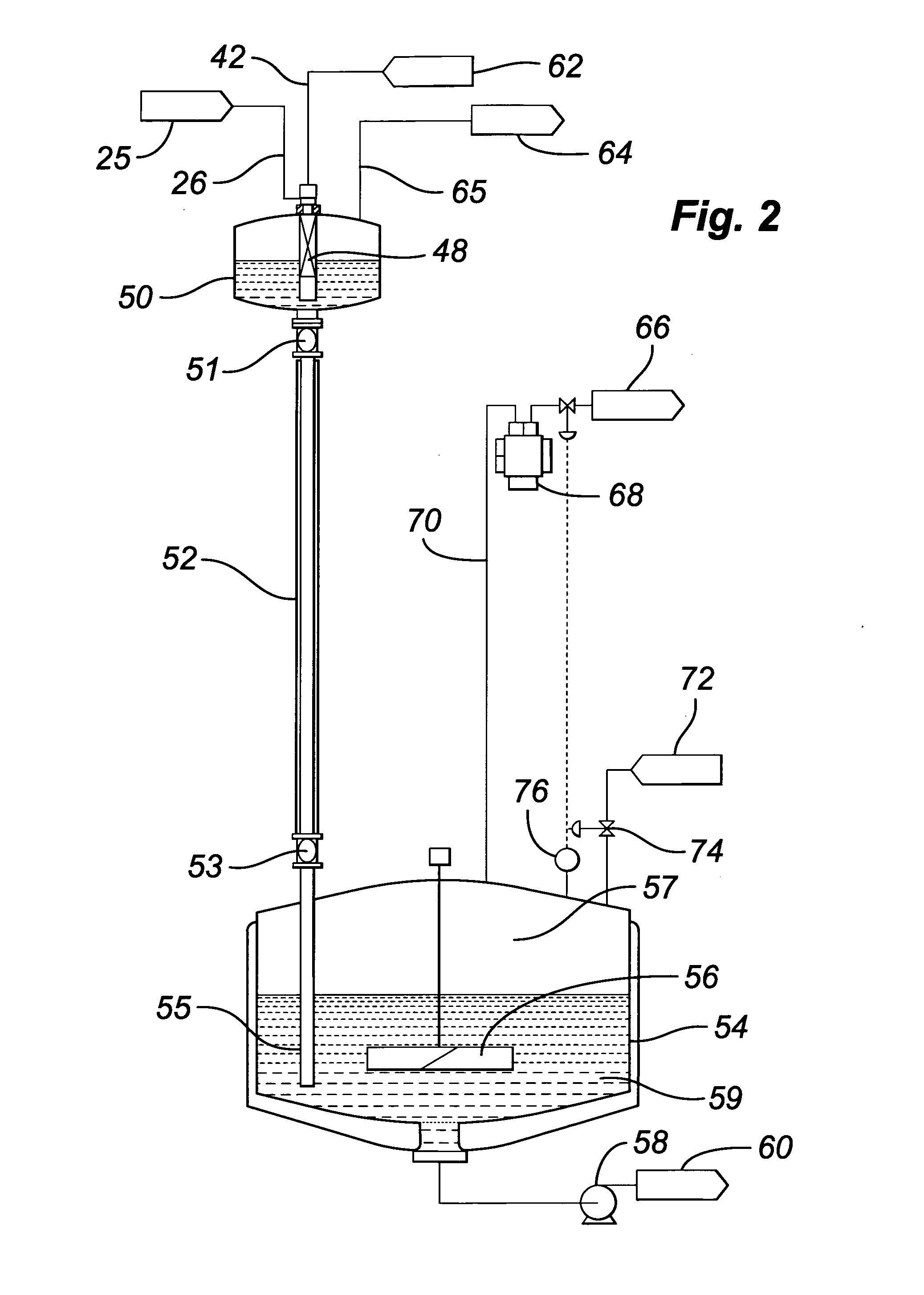

Zero emission gasification, power generation, carbon oxides management and metallurgical reduction processes, apparatus, systems, and integration thereof

ActiveUS7674443B1Improvement in individual technology componentEnhances economic performanceUsing liquid separation agentBiofuelsCyclonic separationOxygen

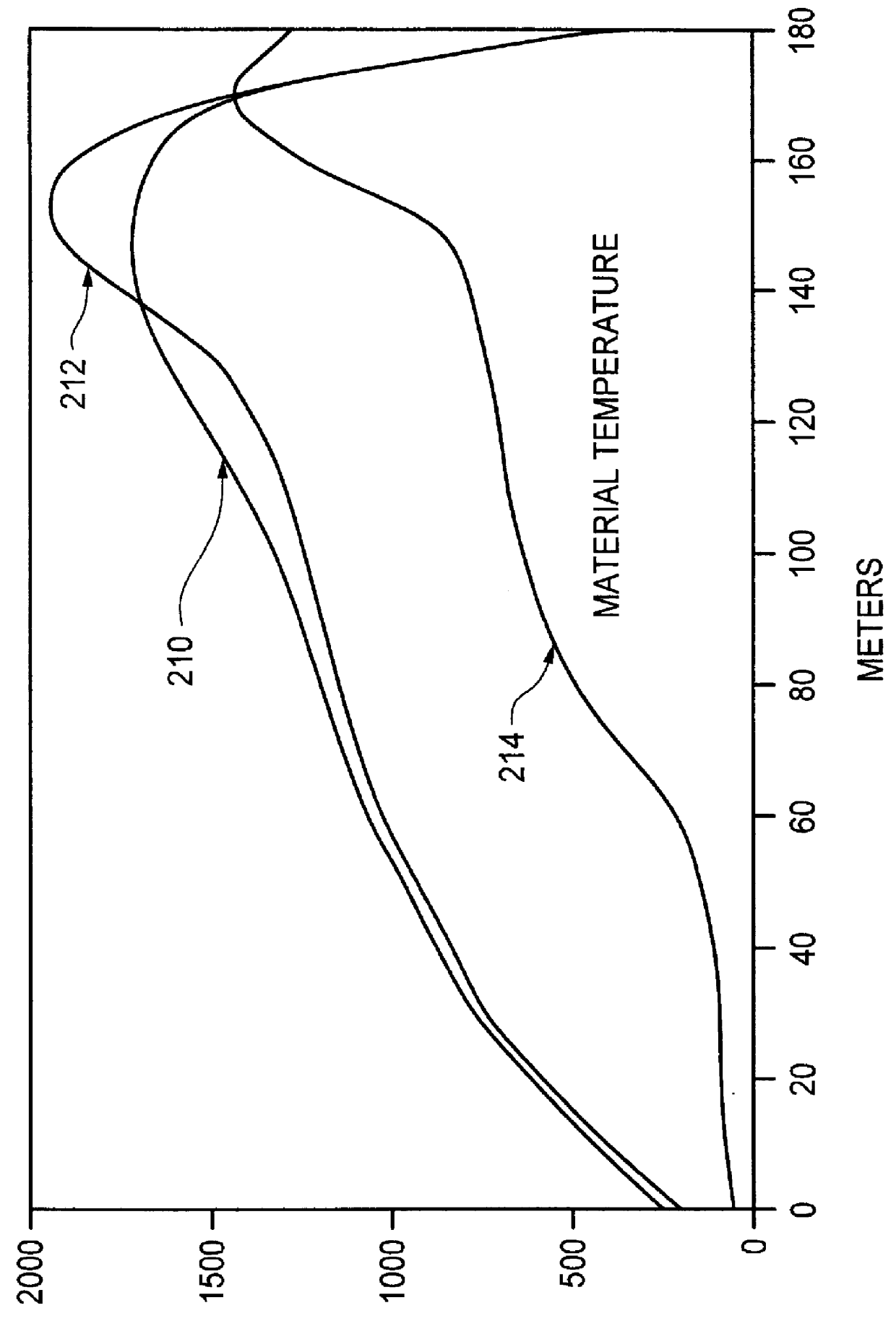

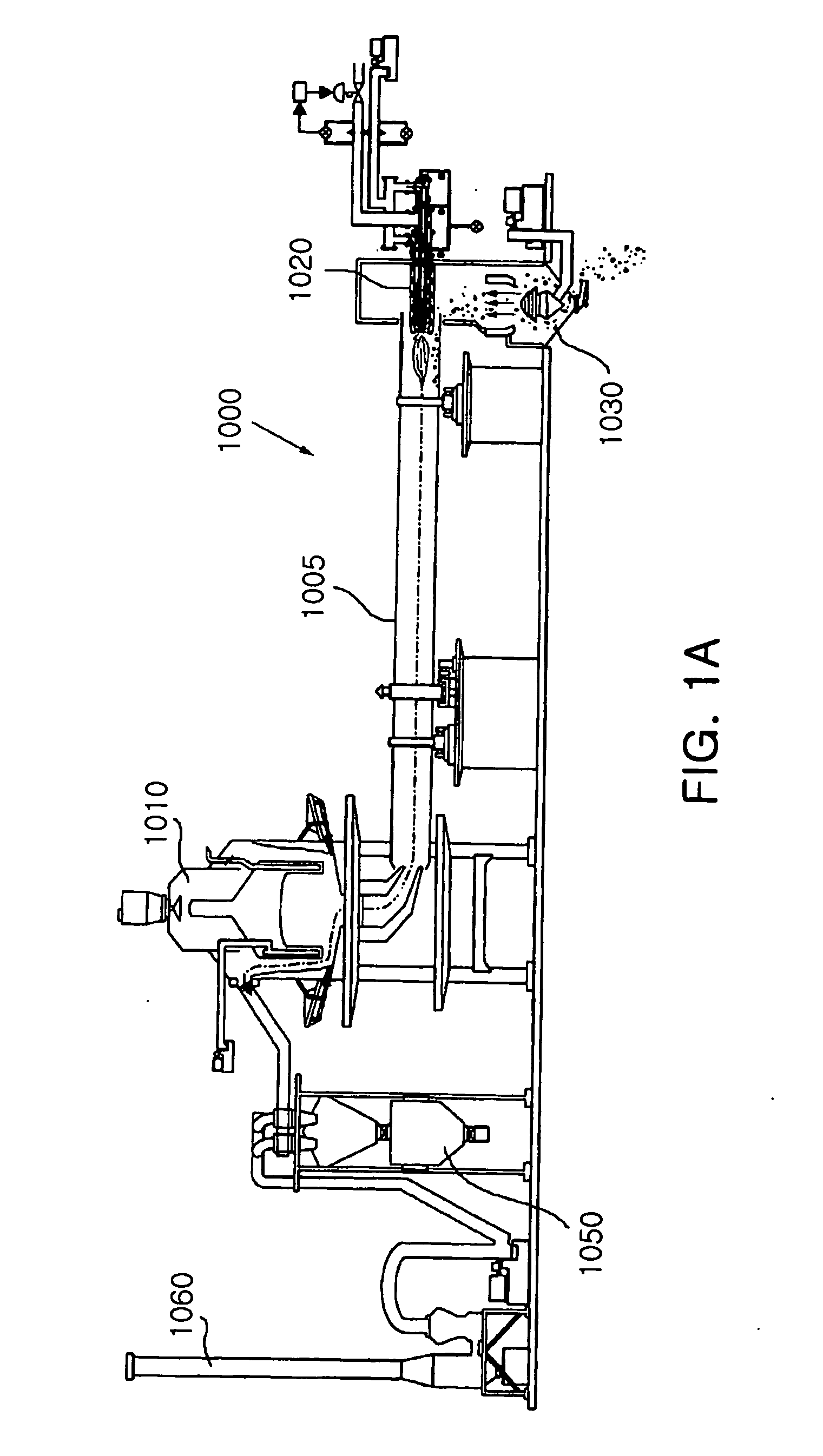

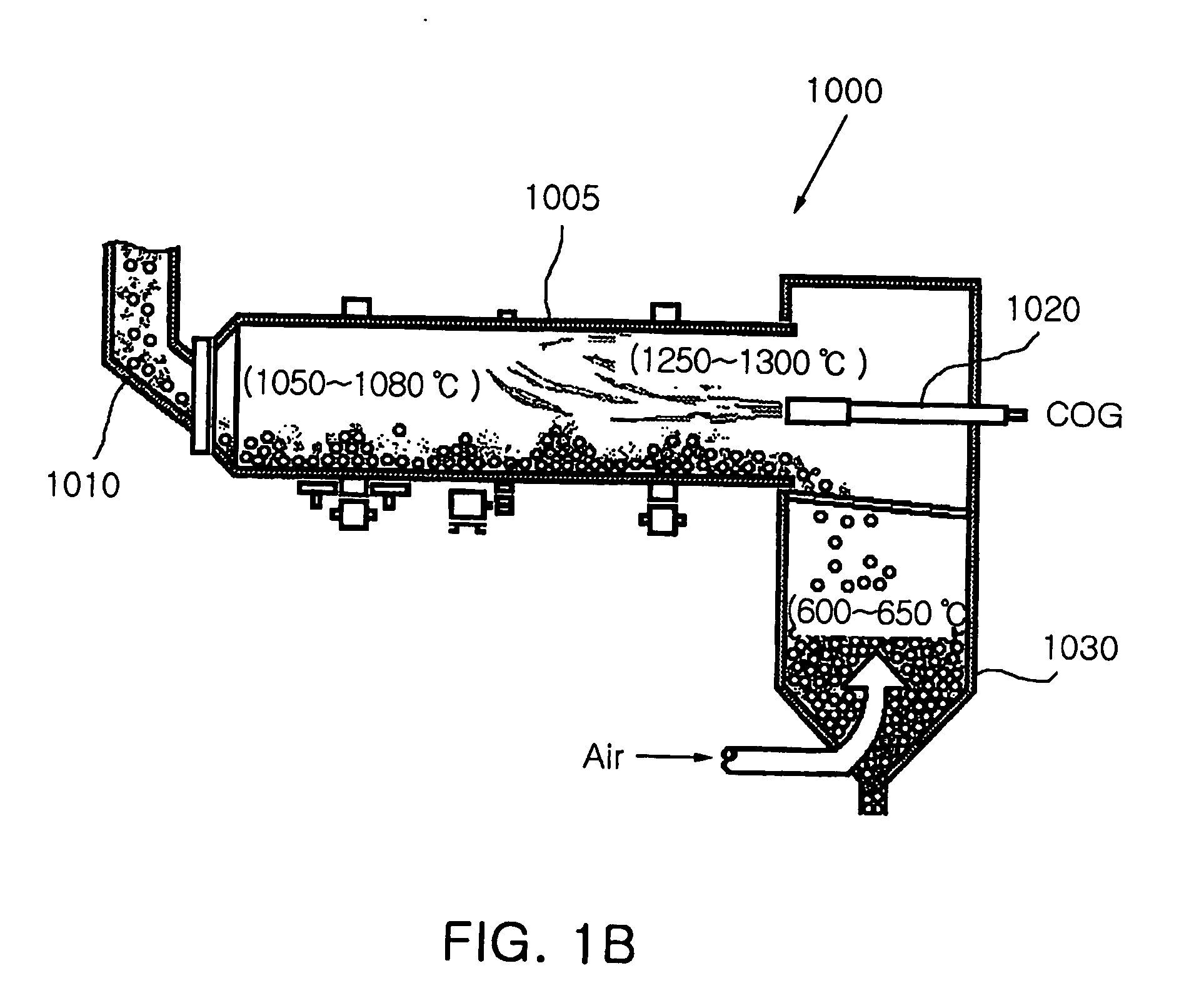

A system involving a two-step gasification of a carbonaceous source to produce bulk hydrogen that avoids the early formation of CO2 and obviates the traditional water gas shift (WGSR) step, carbochlorination of a metallic ore the production of metals found in the ore that utilizes carbon monoxide as an oxygen sink, rather than the traditional coke, and carbon oxides management that eliminates major impediments to emission-neutral power generation and the reduction of major metals. The gasification uses a rotary kiln reactor and gas-gas cyclonic separation process to separate synthesis gas into purified hydrogen and purified carbon monoxide. Purified bulk carbon monoxide issued in metallurgical reduction, and purified bulk hydrogen as fuel for an emission-neutral hydrogen combined cycle (HCC) turbine power generation station. The carbochlorination is integrated with: a) the concurrent separation and purification of all metal-chlorides (metchlors) and capture of CO2 for passage to the carbon oxides management system; b) the direct reduction of metchlors to nanoscale metallurgical powders and / or to dendritically-shaped particles, including metchlor reduction for the ultrahigh-performance semiconductor metals of the III-V group; and, c) the reforming of metal-oxides with improved crystalline structure from metchlors. The carbon oxides management collects, stores and directs to points of usage, carbon oxides that arise in various processes of the integrated system, and captures carbon monoxide for process enhancement and economic uses and captures carbon dioxide as a process intermediate and for economic uses.

Owner:DAVIS OLUMIJI B +1

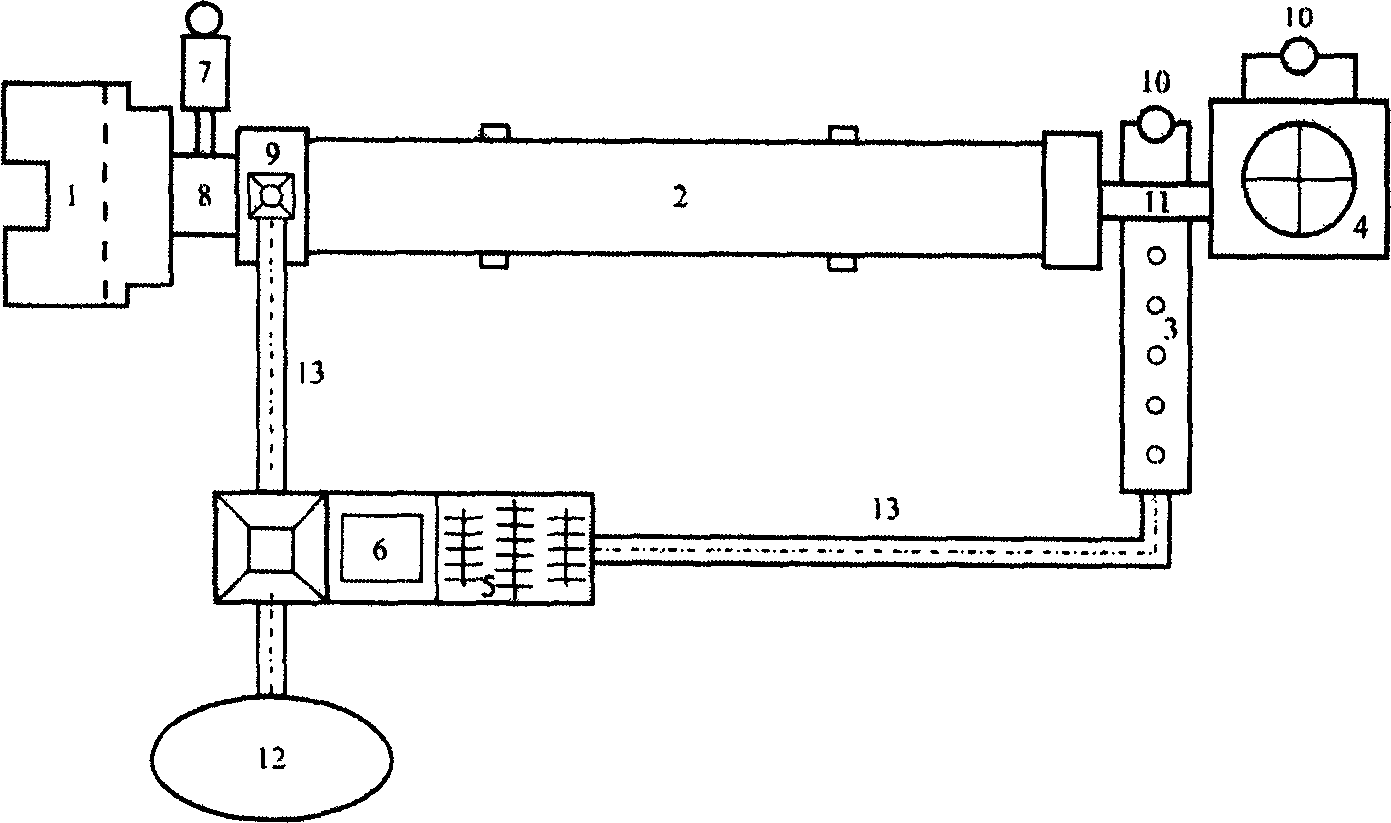

System and method for oxidant injection in rotary kilns

InactiveUS6116896AOperating means/releasing devices for valvesMuffle furnacesInjection portEngineering

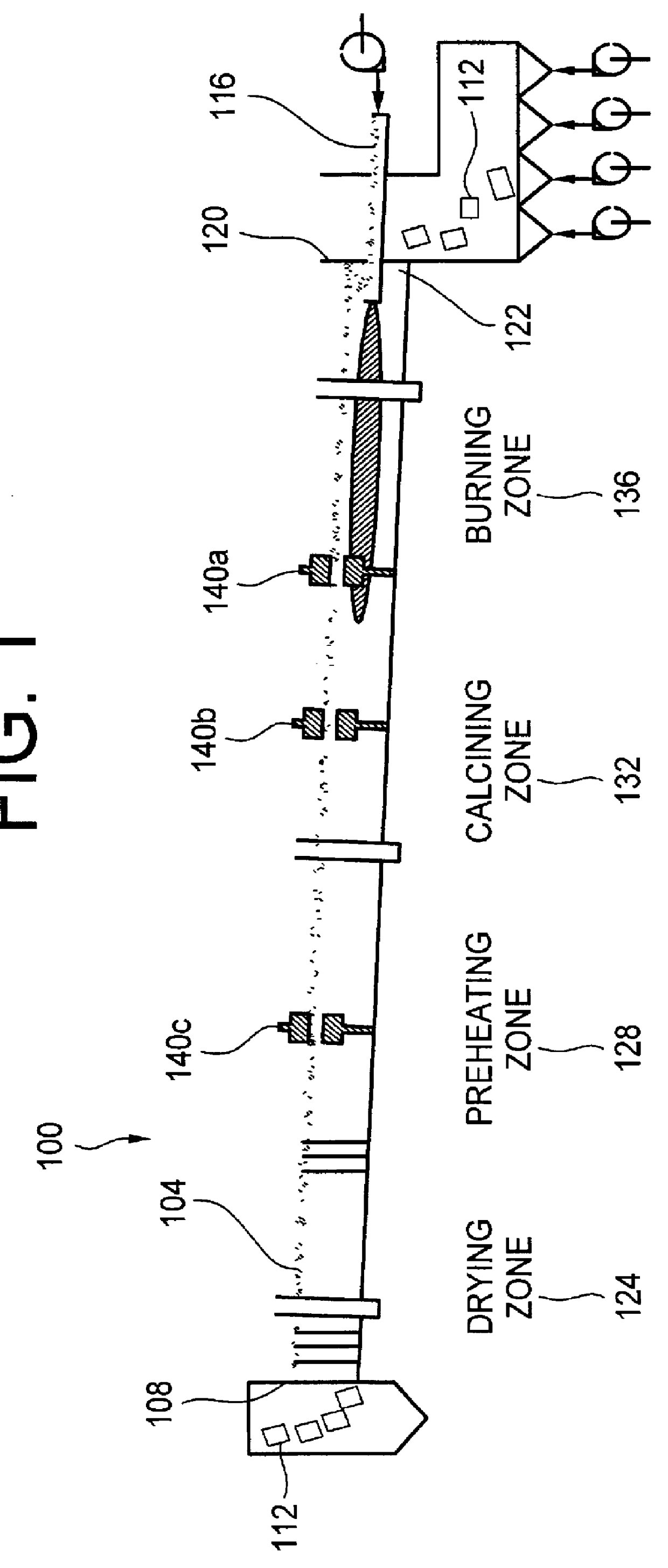

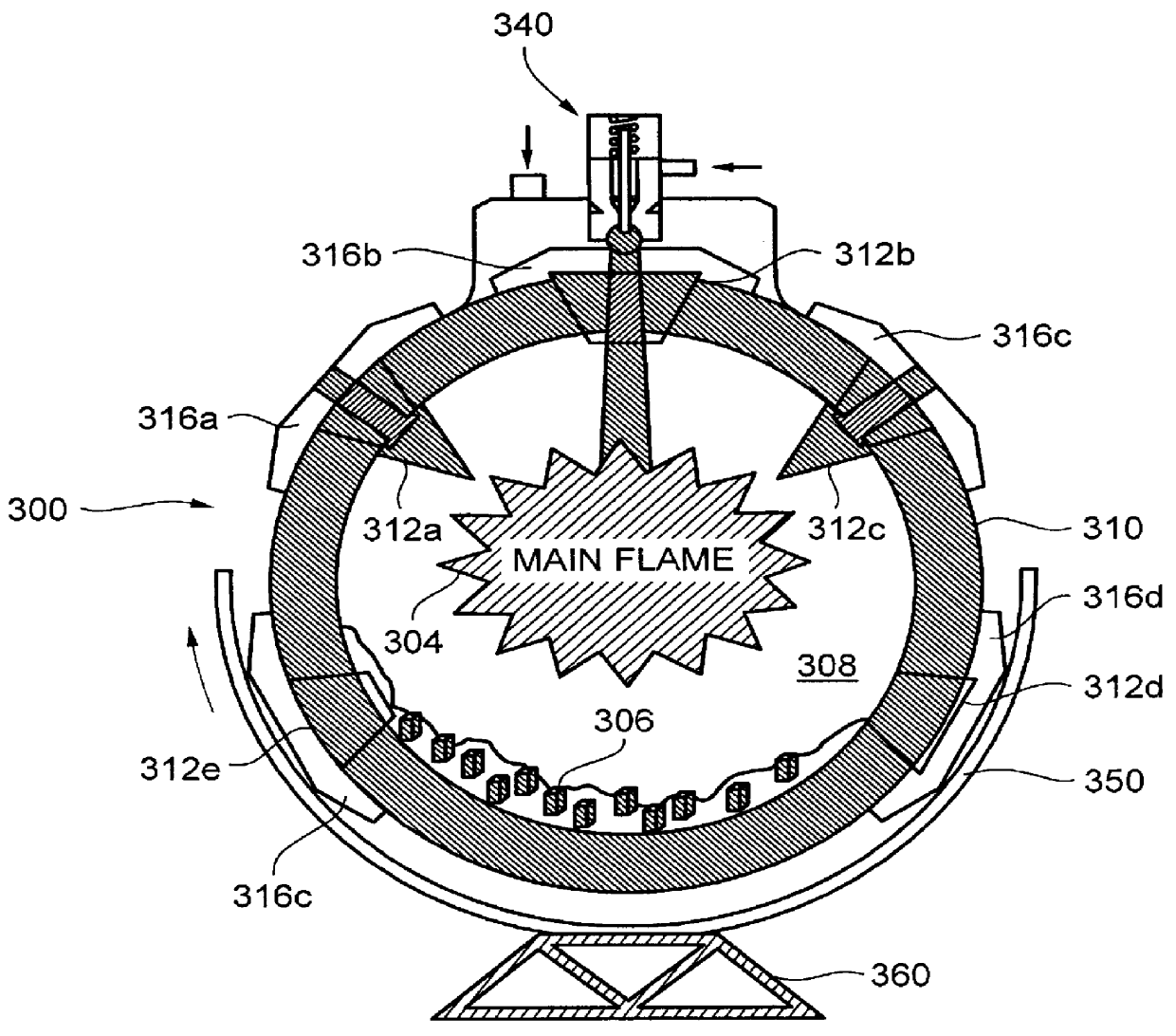

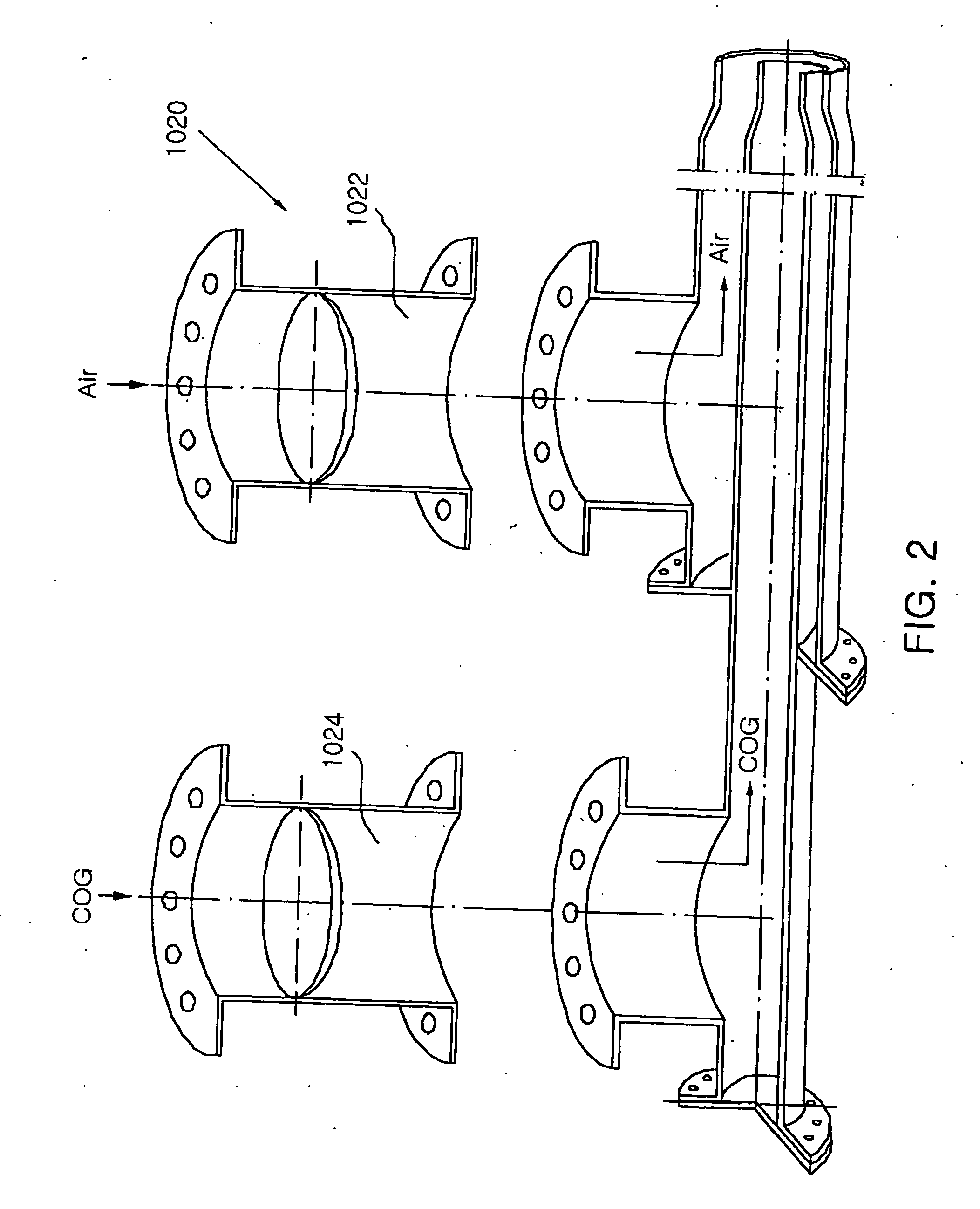

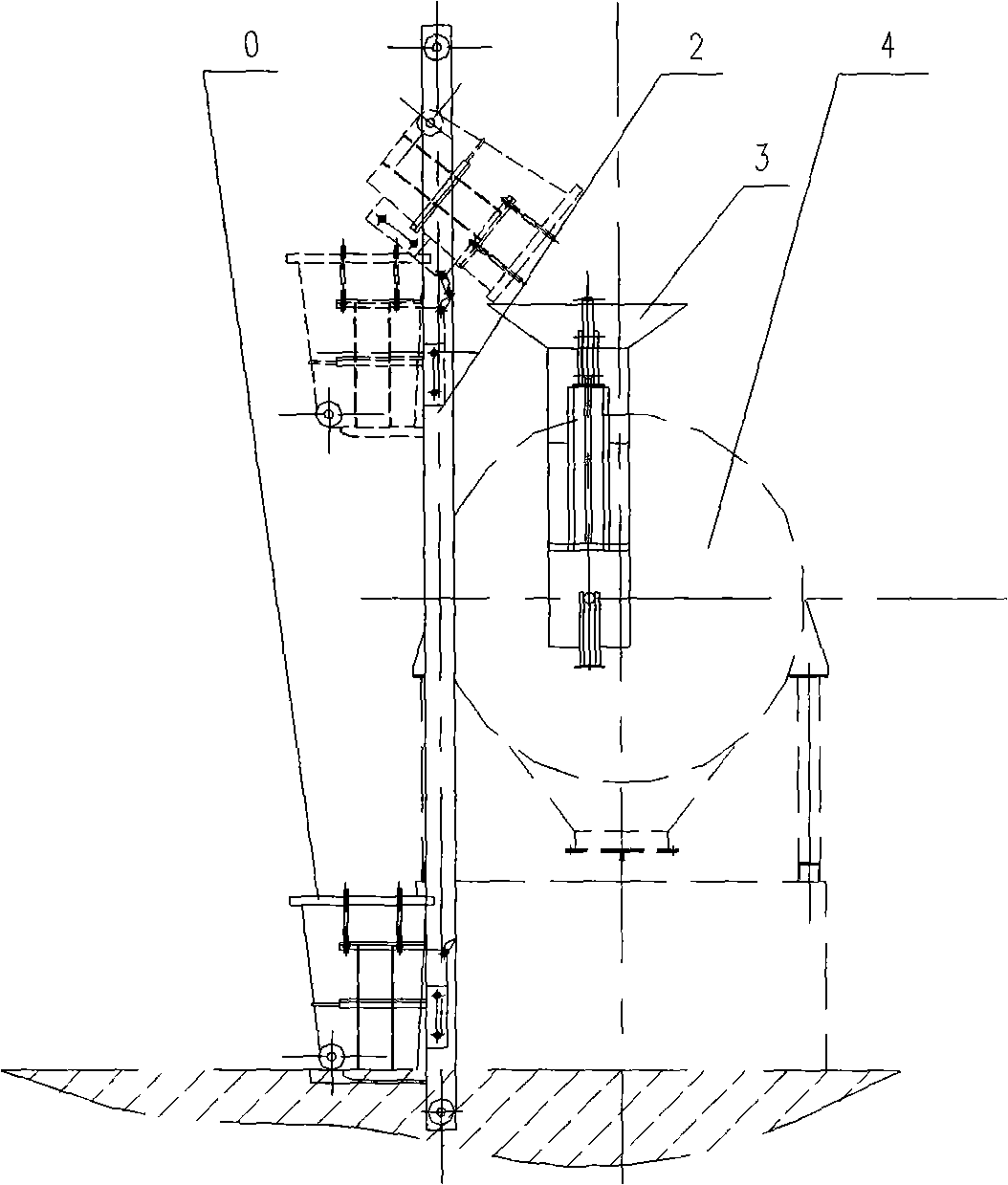

A system and method for increasing the amount of oxygen in a kiln chamber is disclosed. The radial surface of a rotatable kiln is provided with at least one oxidant injection port extending through the radial surface into the kiln chamber. A cam is connected to the radial surface adjacent the oxidant injection port. A valve assembly including a valve chamber in fluid communication with an oxidant supply is mounted adjacent the kiln substantially in fixed spatial relation with the rotatable kiln body. The valve assembly includes a follower member adapted to contact a surface to the cam to actuate the valve assembly. Rotation of the kiln body brings the cam into contact with the follower member, thereby actuating the oxidant injection assembly, and injecting oxidant through the injection port into the kiln chamber.

Owner:LAIR LIQUIDE SOCITE ANONYME POUR LETUD & LEXPL DES PROCEDES GEORCLAUDE +1

Oily sludge recycling and innocent comprehensive treatment process

InactiveCN102039301APromote resource utilizationEliminate secondary pollutionSolid waste disposalTreatment with plural serial refining stagesSlagOil sludge

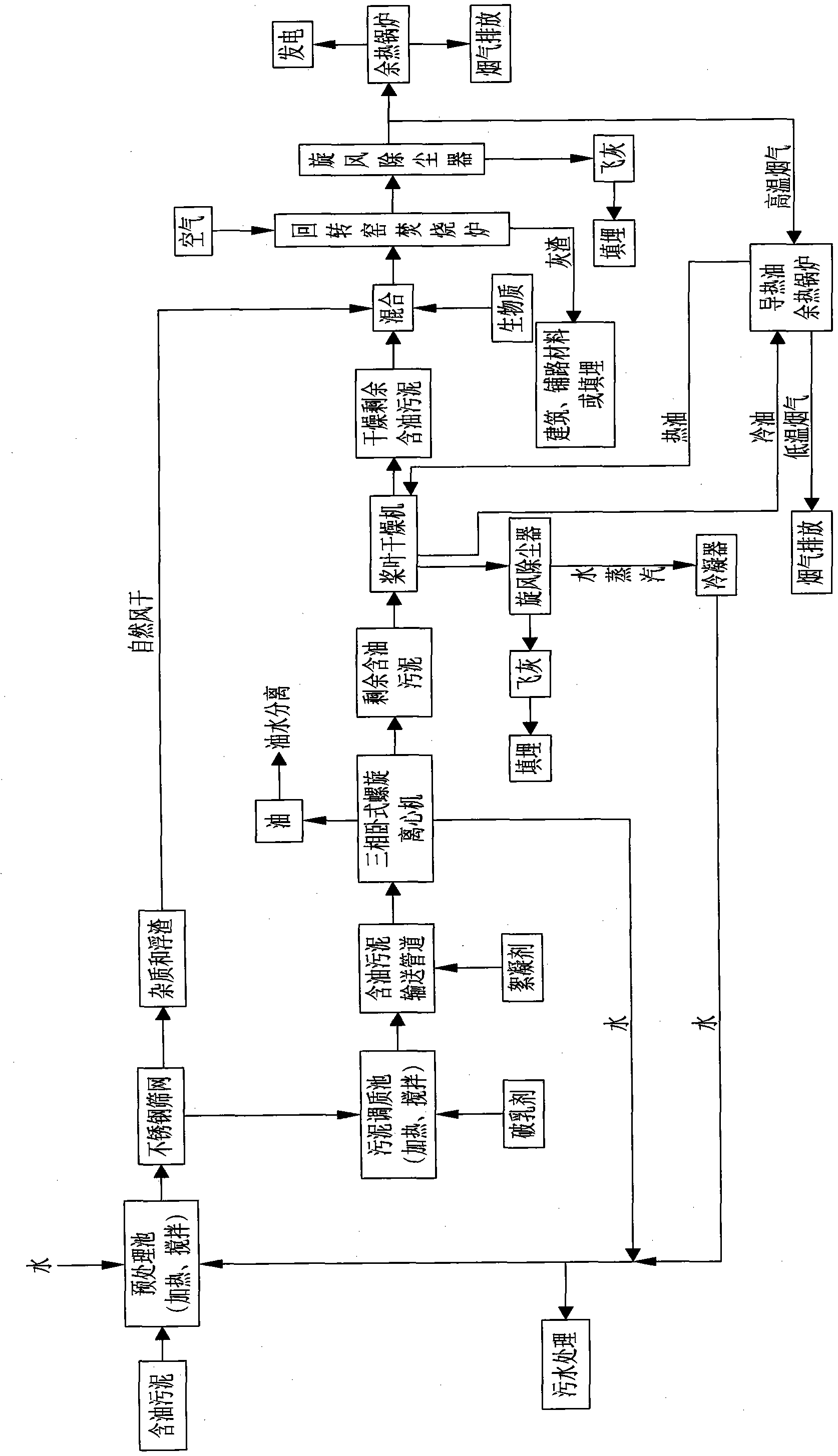

The invention provides an oily sludge recycling and innocent comprehensive treatment process, which comprises the following four steps of: 1, pretreating oily sludge: adding water into the oil sludge, heating and stirring to form fluidized sludge, and separating in a stainless steel screen; 2, conditioning the oily sludge, adding a demulsifier and a flocculant into the separated fluidized sludge for conditioning the oily sludge; 3, performing centrifugal separation on three phases of the oily sludge: introducing separated oil into an oil-water separation system for recovering crude oil, conveying separated water to the oily sludge pretreatment step for recycling, drying the separated residual oily sludge, and solid impurities and floating slag which are separated in the oily sludge pretreatment, and introducing the dried substances into a rotary kiln incinerator; and 4, performing mixed combustion on the residual oily sludge and biomass, performing high temperature incineration treatment after the residual oily sludge, the separated solid impurities and floating slag, and the biomass are mixed in a rotary kiln to remove the secondary pollution of the oily sludge, and recovering afterheat from high temperature flue gas.

Owner:KUNMING UNIV OF SCI & TECH

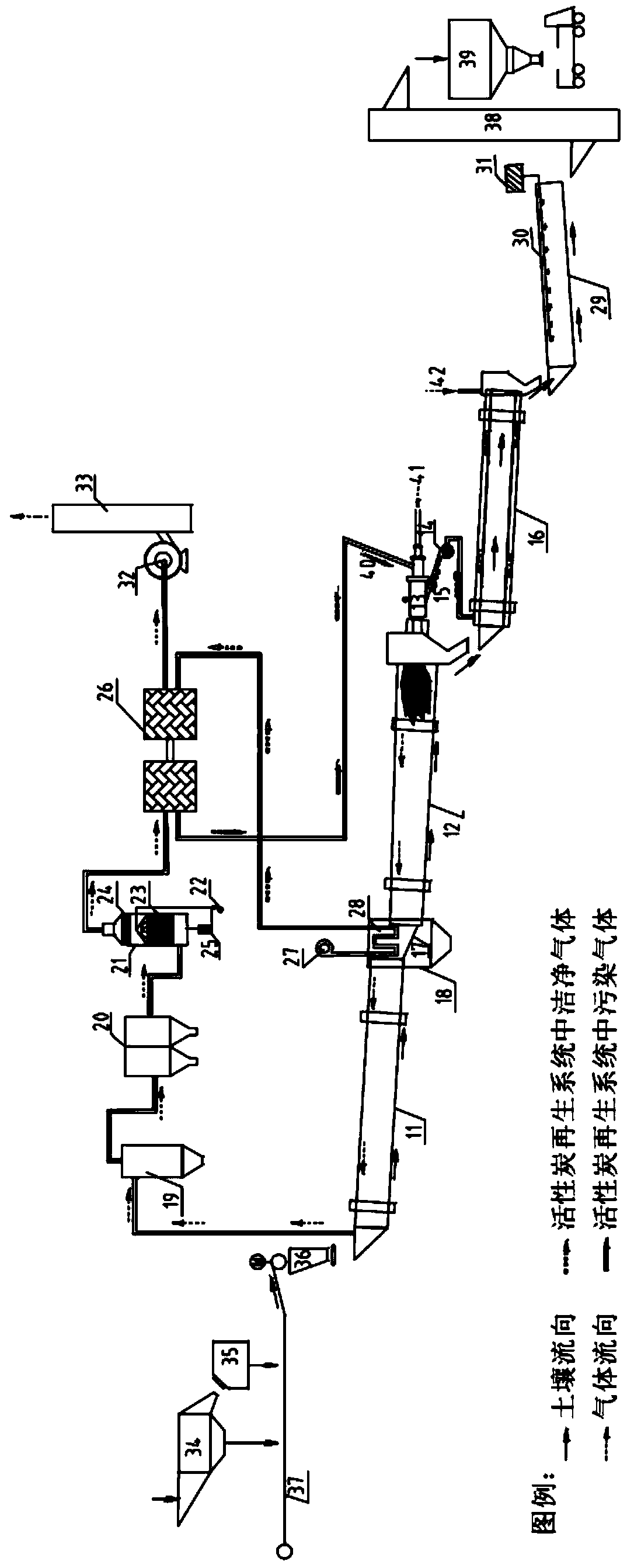

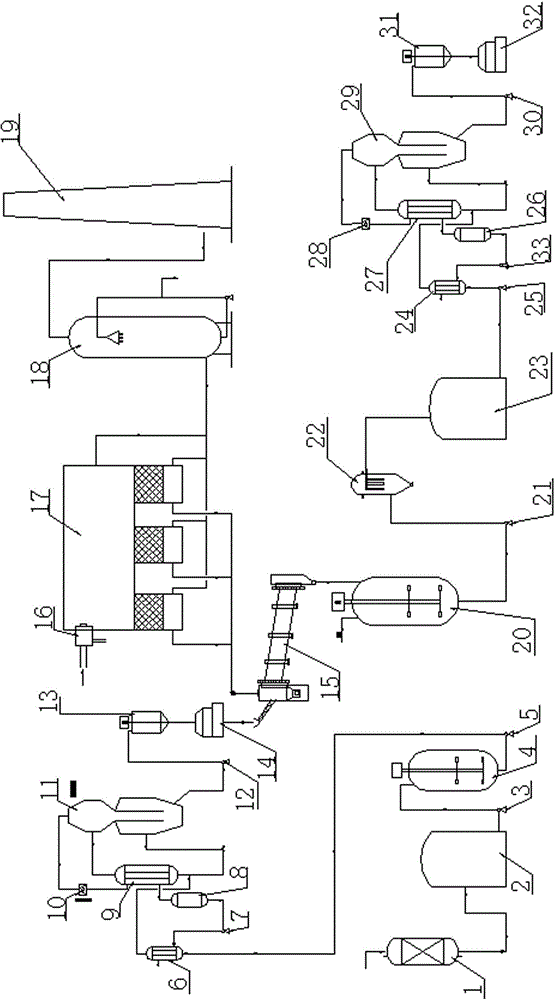

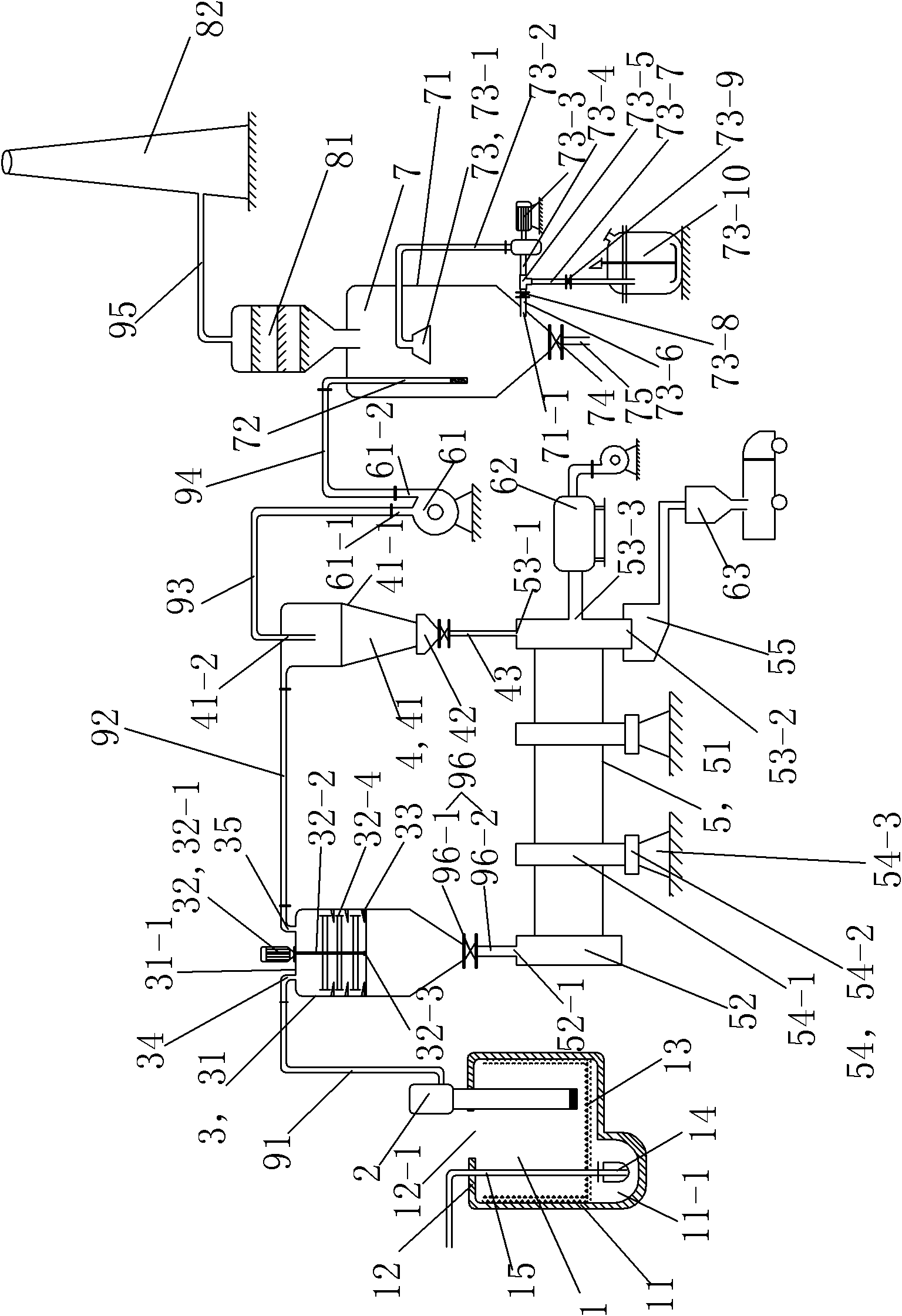

Energy-saving type thermal-desorption repairing treatment system for organic polluted soil

ActiveCN103658165AExtended stayBurn fullyContaminated soil reclamationPollution soilSewage treatment

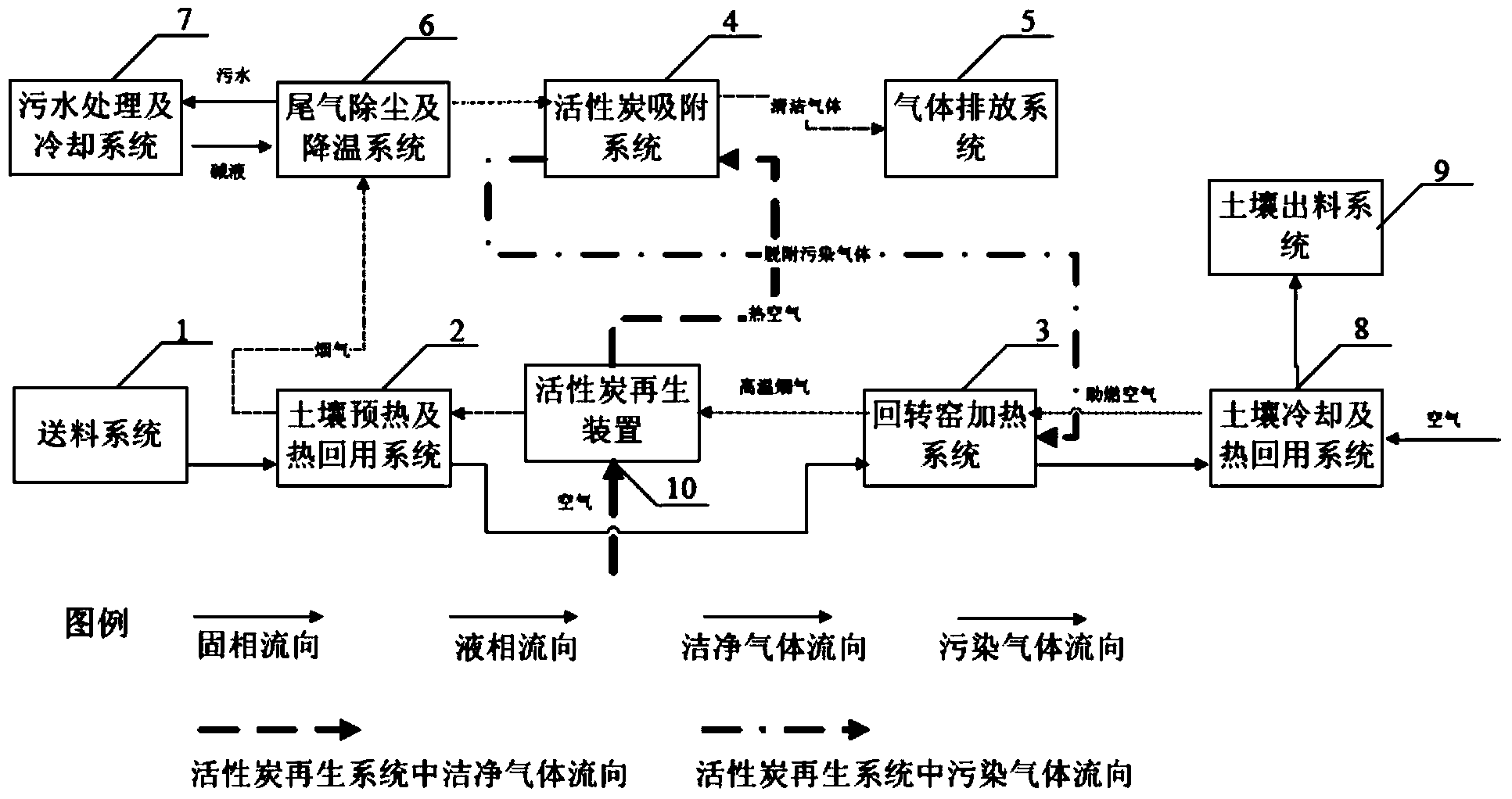

The invention relates to an energy-saving type thermal-desorption repairing treatment system for organic polluted soil and aims at providing a system for thermal-desorption repairing treatment of the organic polluted soil, which can recycle waste heat of the system fully and save resources. The energy-saving type thermal-desorption repairing treatment system comprises a feeding system, a soil preheating and heat recycling system, a rotary kiln heating system, a soil cooling and heat recycling system, a soil discharging system, a tail-gas dust removing and temperature reducing system, a sewage treatment and cooling system, an active-carbon absorbing system, an active-carbon regeneration device, a gas exhausting system and a network monitoring system.

Owner:ZHONGKE DINGSHI ENVIRONMENTAL ENG CO LTD

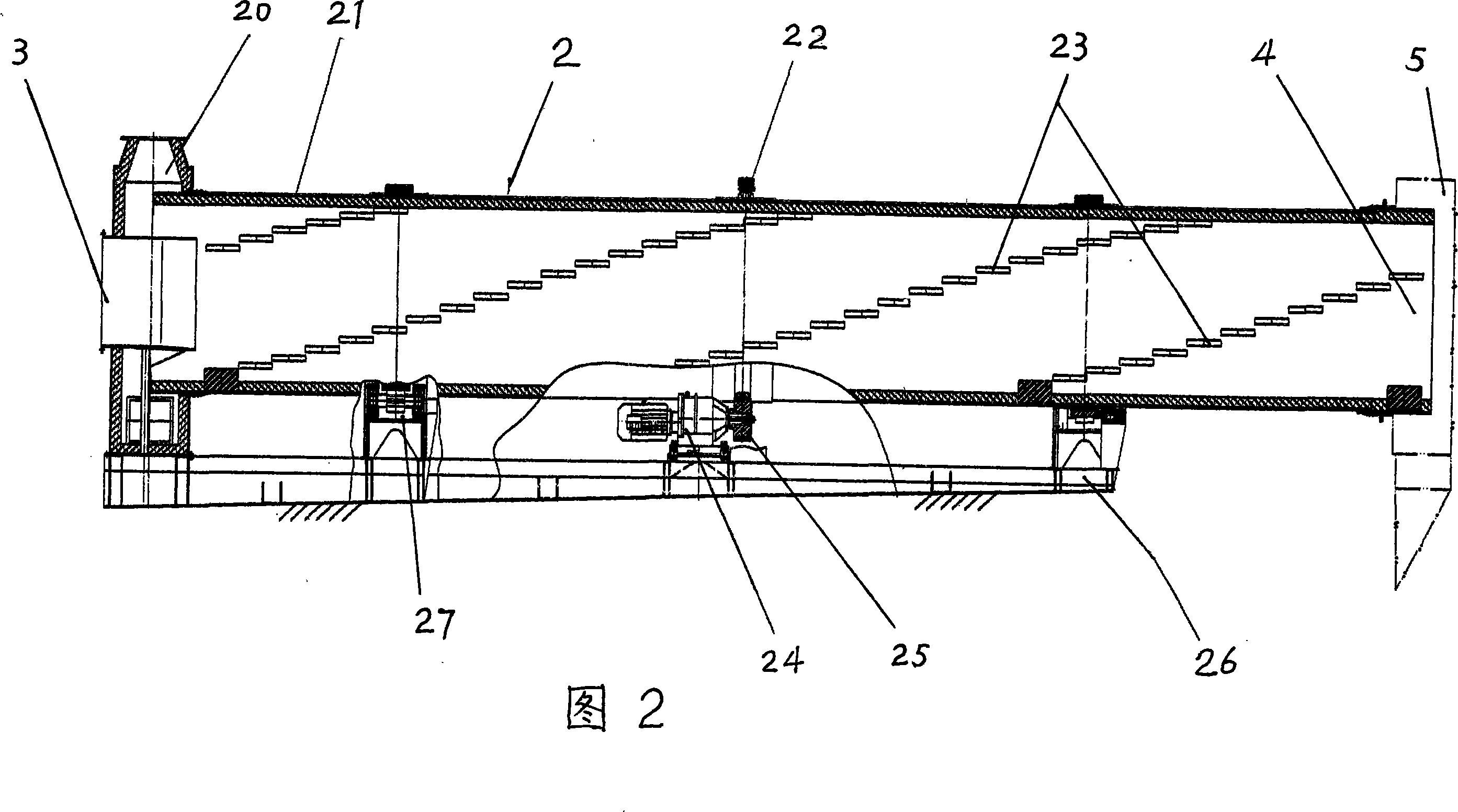

Carbonising and/or Activating Carbonaceous Material

A method is provided for carbonizing and activating carbonaceous material, which comprises supplying the material to an externally fired rotary kiln maintained at carbonizing and activating temperatures, the kiln having a downward slope to progress the material as it rotates, the kiln having an atmosphere substantially free of oxygen provided by a counter-current of steam or carbon dioxide, and annular weirs being provided at intervals along the kiln to control progress of the material. There may further be provided an externally fired rotary kiln for carbonizing and activating carbonaceous material having a hollow rotary body that has a downward slope towards a discharge end thereof, and which is provided at intervals along its length with annular weirs for controlling progress of the carbonaceous material. In embodiments, there is also provided a process is for producing discrete solid beads of polymeric material e.g. phenolic resin beads having a mesoporous structure, which may be useful as feedstock for the above mentioned carbonization / activation process or which may have other utility e.g. as ion exchange resins. The process may produce resin beads on an industrial scale without aggregates of resin building up speedily and interrupting production. The process comprises the steps of: (a) combining a stream of a polymerizable liquid precursor e.g. a novolac and hexamine as cross-linking agent dissolved in a first polar organic liquid e.g. ethylene glycol with a stream of a liquid suspension medium which is a second non-polar organic liquid with which the liquid precursor is substantially or completely immiscible e.g. transformer oil containing a drying oil; (b) mixing the combined stream to disperse the polymerizable liquid precursor as droplets in the suspension medium e.g. using an in-line static mixer; (c) allowing the droplets to polymerise in a laminar flow of the suspension medium so as to form discrete solid beads that cannot agglomerate; and (d) recovering the beads from the suspension medium. There is also provided apparatus for forming discrete solid beads of polymeric material, said apparatus comprising: a first line for conveying s stream of a polymerizable liquid precursor; a second line for conveying a stream of a dispersion medium with which the polymerizable liquid precursor is substantially or completely immiscible; an in-line mixer configured to receive a combined flow from the first and second lines and to disperse the polymerizable liquid precursor as droplets in the dispersion medium; a vertical polymerization column configured to receive the dispersion medium with the droplets dispersed therein and to permit the polymerizable liquid precursor polymerize while descending the column in a descending flow of polymerization medium; and a vessel at the base of the column for receiving the descending flow of dispersion medium and collecting polymerized solid beads.

Owner:BRITISH AMERICAN TOBACCO (INVESTMENTS) LTD

Fuel for firing into rotary kiln cement clinker

A fuel which is used for rotary kiln cement clinker firing is composed of raw materials with the following weight percentage: coal 3-80, straw substances 0-90, forest products wastes 0-95 and food industry by-product residues 0-70. The straw substances refer to rice straws, wheat straws, cotton stalks, sesame stalks, soybean straws, corn stalks, sorghum stalks, rice husks, peanut shells, soybean shells and corn sticks, the forest products wastes refer to defective bamboo, wood, tree branches, leaves, shrubs, faggot straws and sawdust and wood wool corner scrap materials in the bamboo and wood-processing industry, the food industry by-product residues refer to bran, wheat skin, squeezing meal cake, bean dregs and wine lees, and the coal refers to bituminite, anthracite and coke coal powder. The flue raw materials which are used for the rotary kiln cement clinker firing have wide selecting range, simple preparation, convenient use and rapid burning speed and are beneficial for protecting atmosphere circumstances.

Owner:吴飞龙

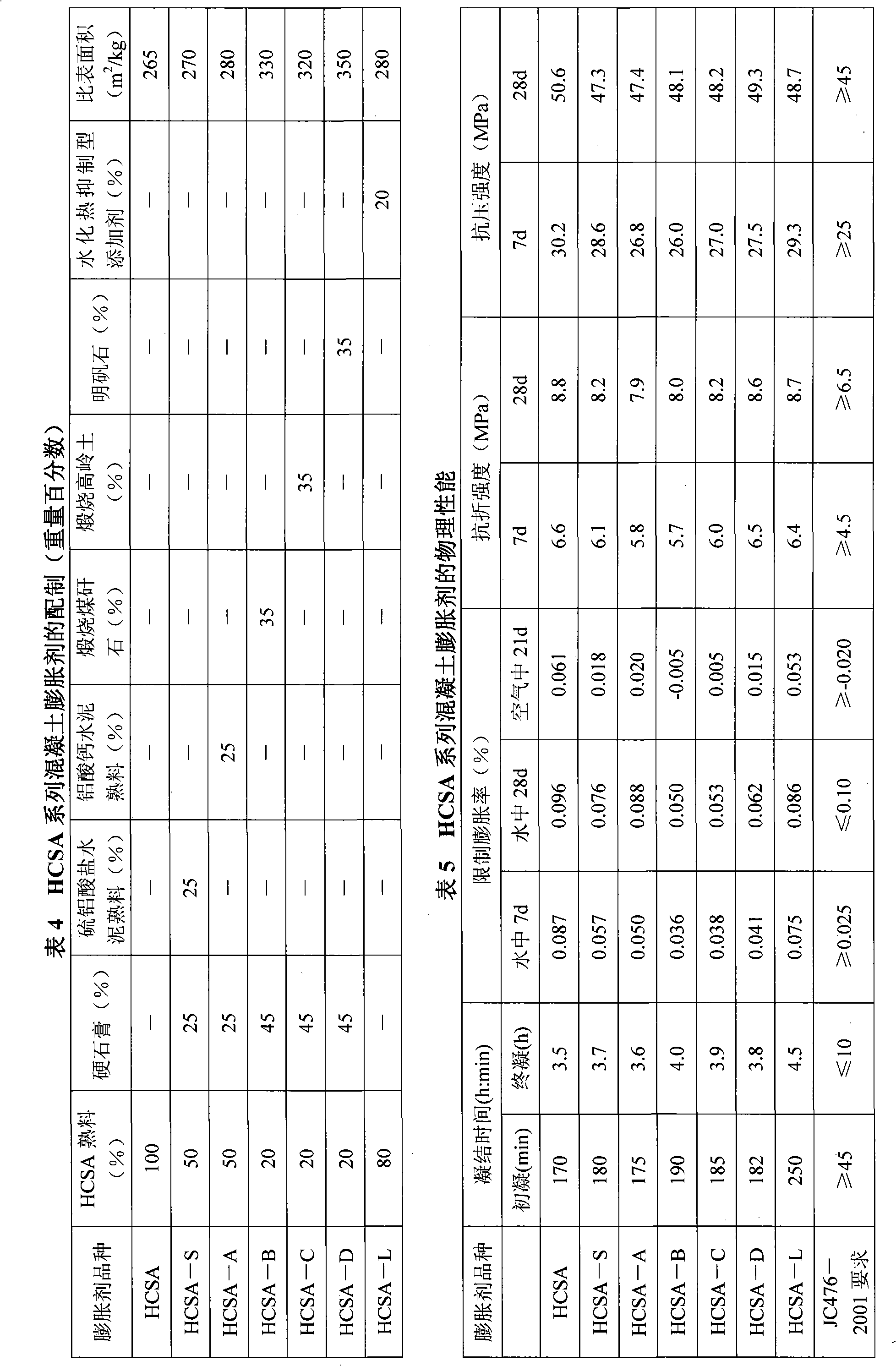

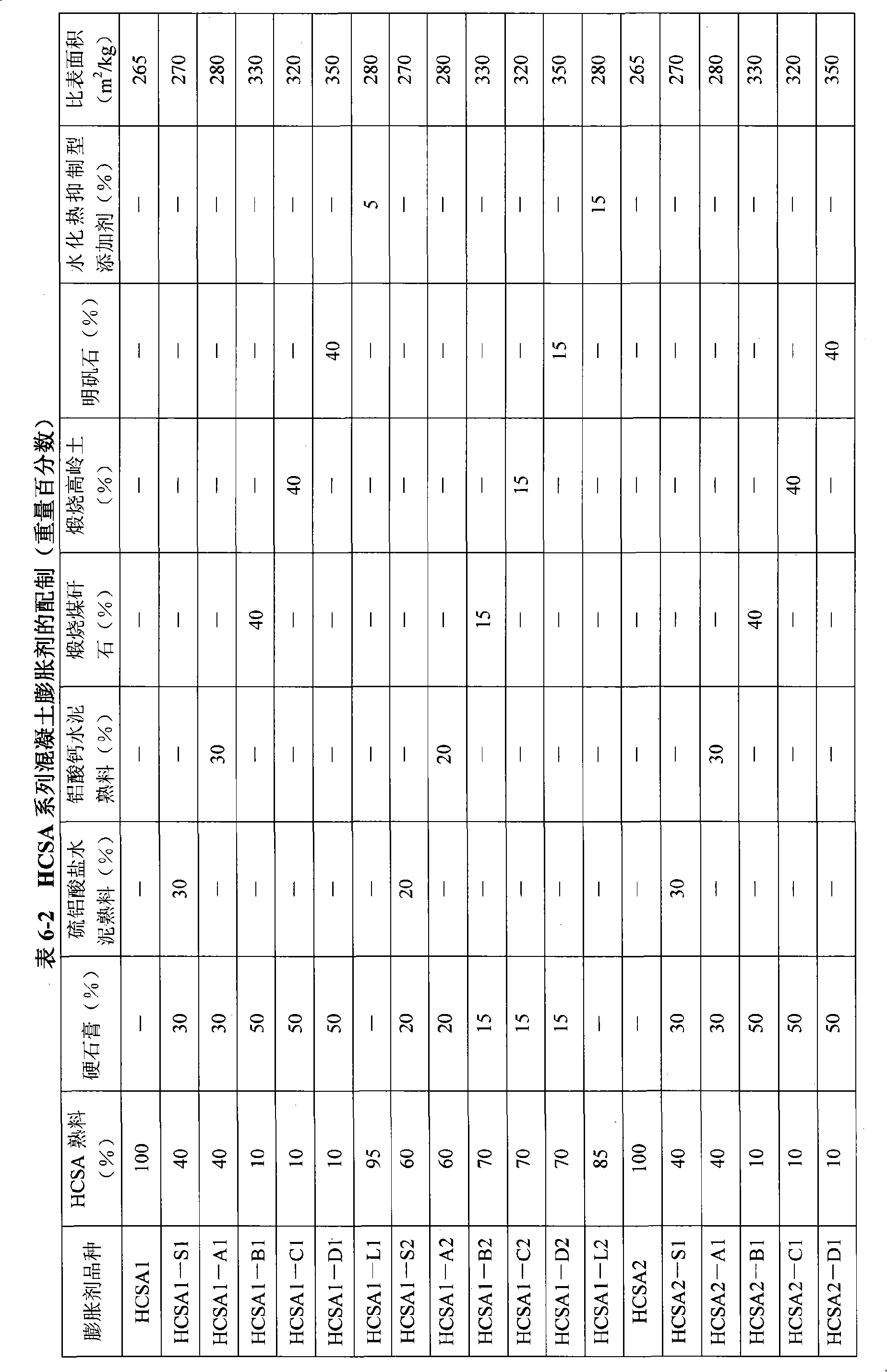

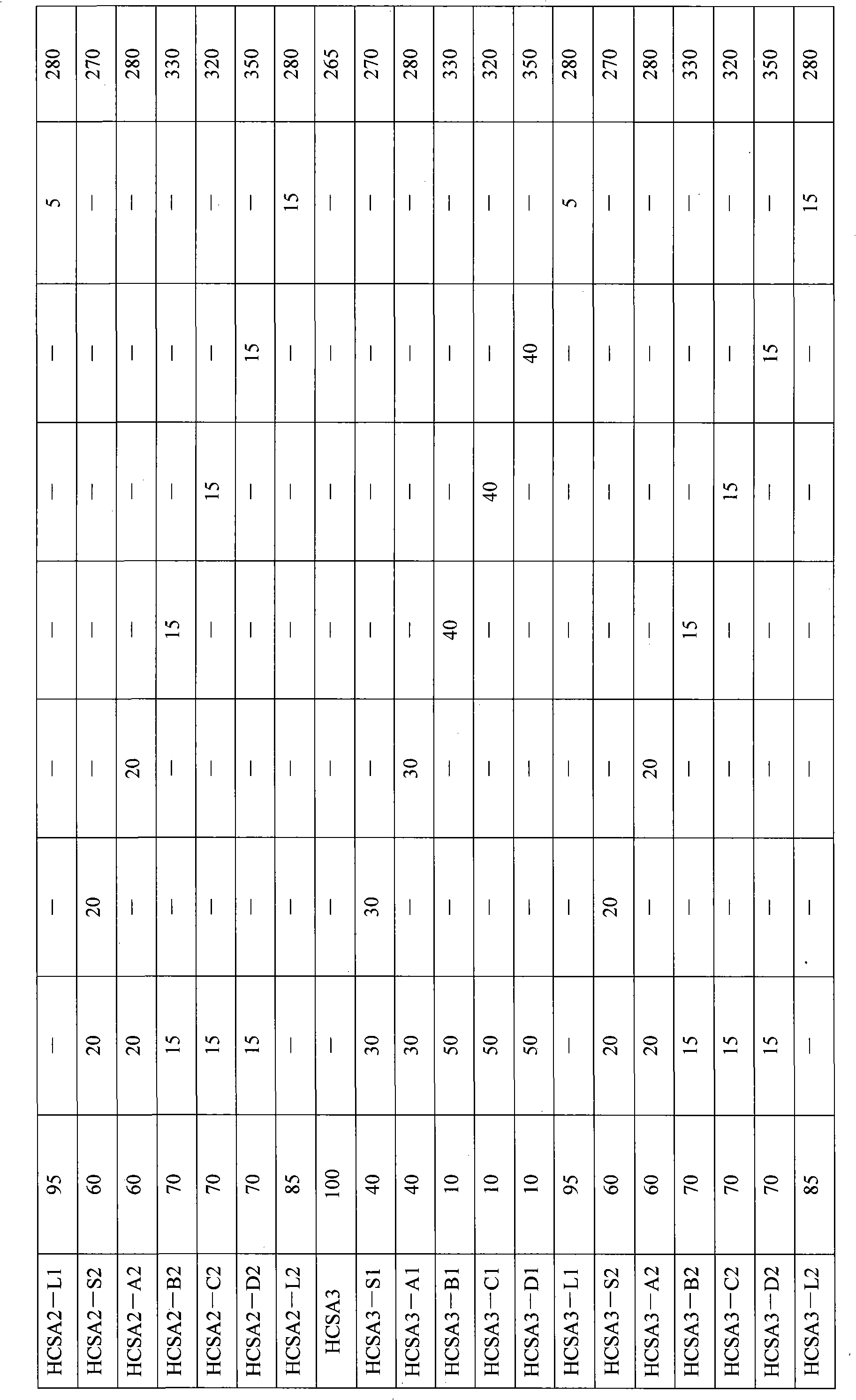

High performance expansible cement clinker expansion agent series prepared thereby

Disclosed are a high-performance expansion cement clinker, a manufacturing method of the cement clinker, a series concrete expansion agent and a manufacturing method of the concrete expansion agent. The high-performance expansion cement clinker is made as follows: firstly, 50-90 wt% of limestone, 1-20 wt% of bauxite, 5-30 wt% of gypsum and 1-5 wt% of iron powder are grinded together into raw meal, then the raw meal is calcined at 1250-1400 DEG C in a rotary kiln, a tunnel kiln or a roller kiln to get the cement clinker. The cement clinker is milled alone or in combination with sulfur calcium aluminate cement clinker, calcium aluminate cement clinker, anhydrite, calcined gangue, alunite, calcined kaolin and hydration heat inhibiting additives until the specific surface area reaches 200-400m2 / kg, so as to get the series concrete expansion agent. The high-performance expansion cement clinker disclosed in the invention is calcium hydroxide-hydrated calcium aluminate sulfate double-expansion source expansion clinker, which is fast in expansion rate and high in expansion efficiency and uses less bauxite of scarce resources; besides, the calcination temperature is low to avoid calcium oxide dead burning, so the preparation is safe and reliable.

Owner:CHINA BUILDING MATERIALS ACAD

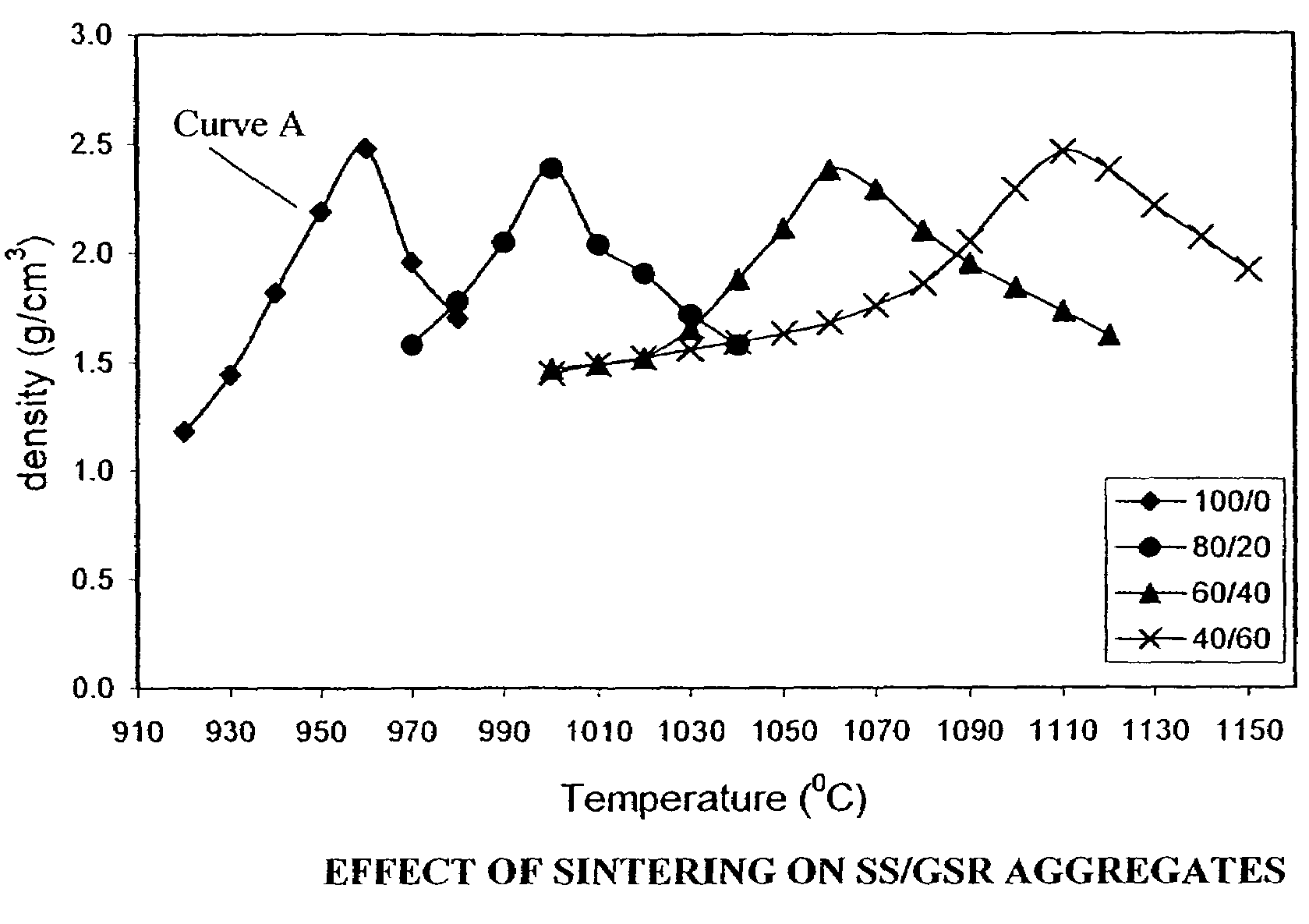

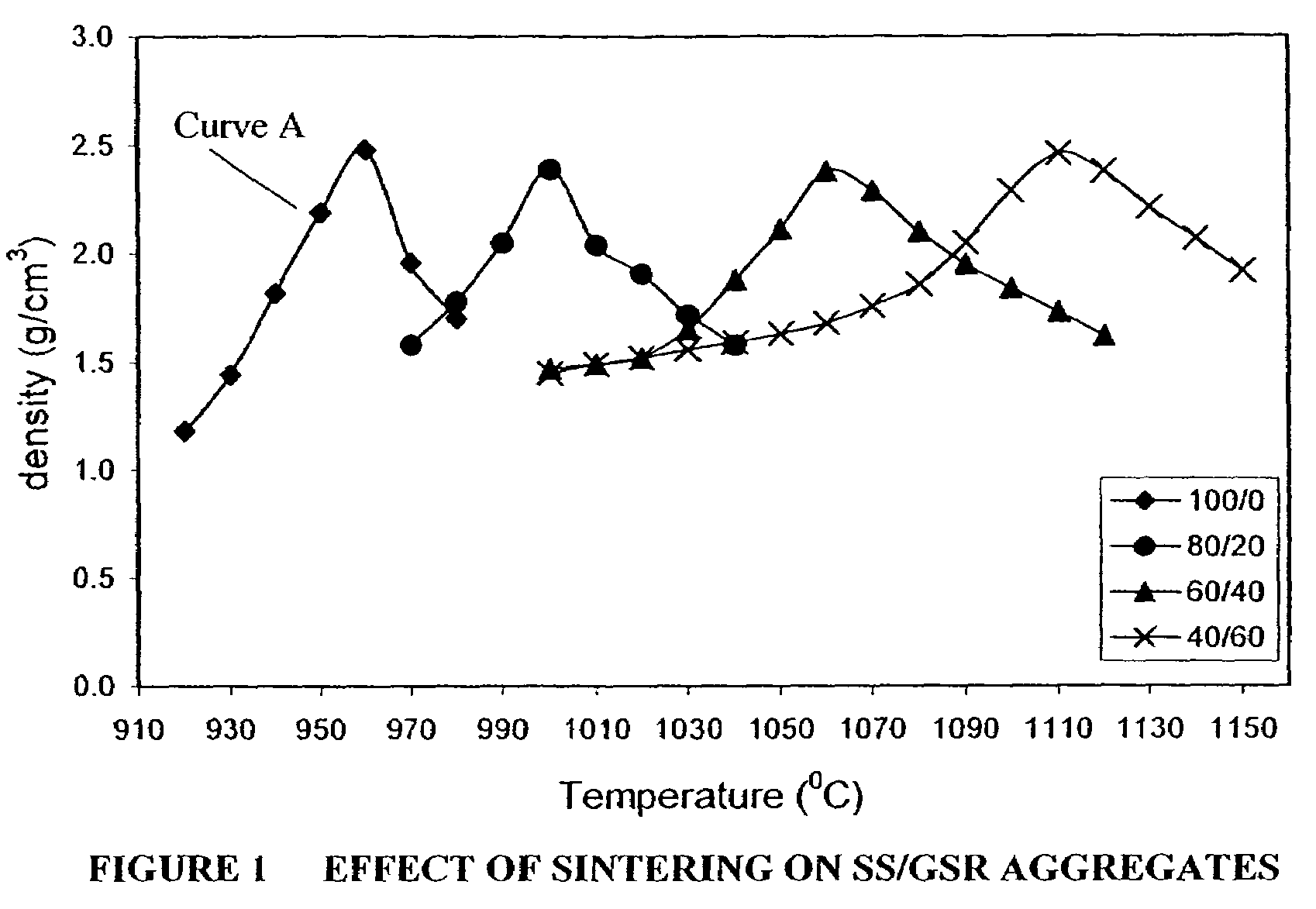

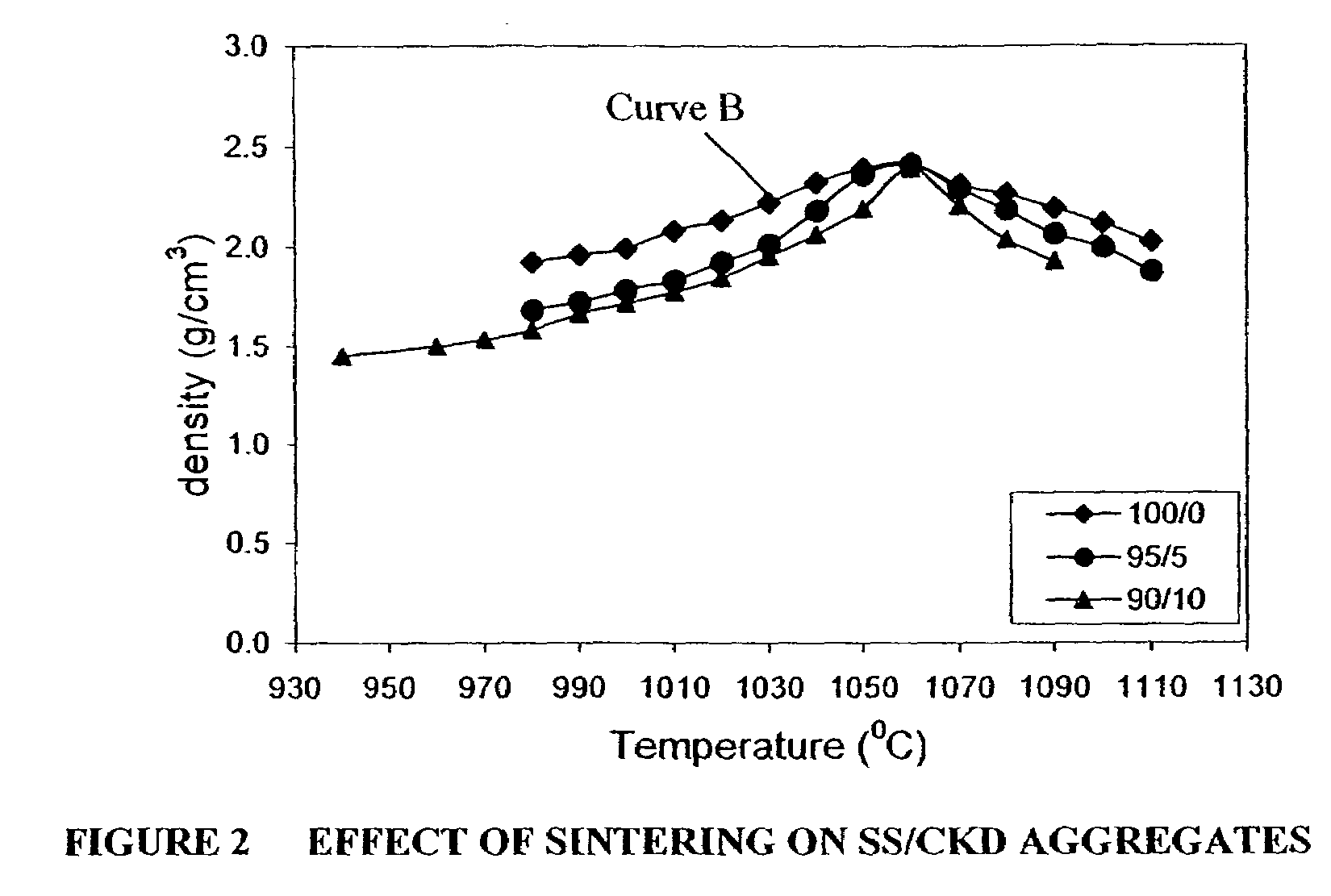

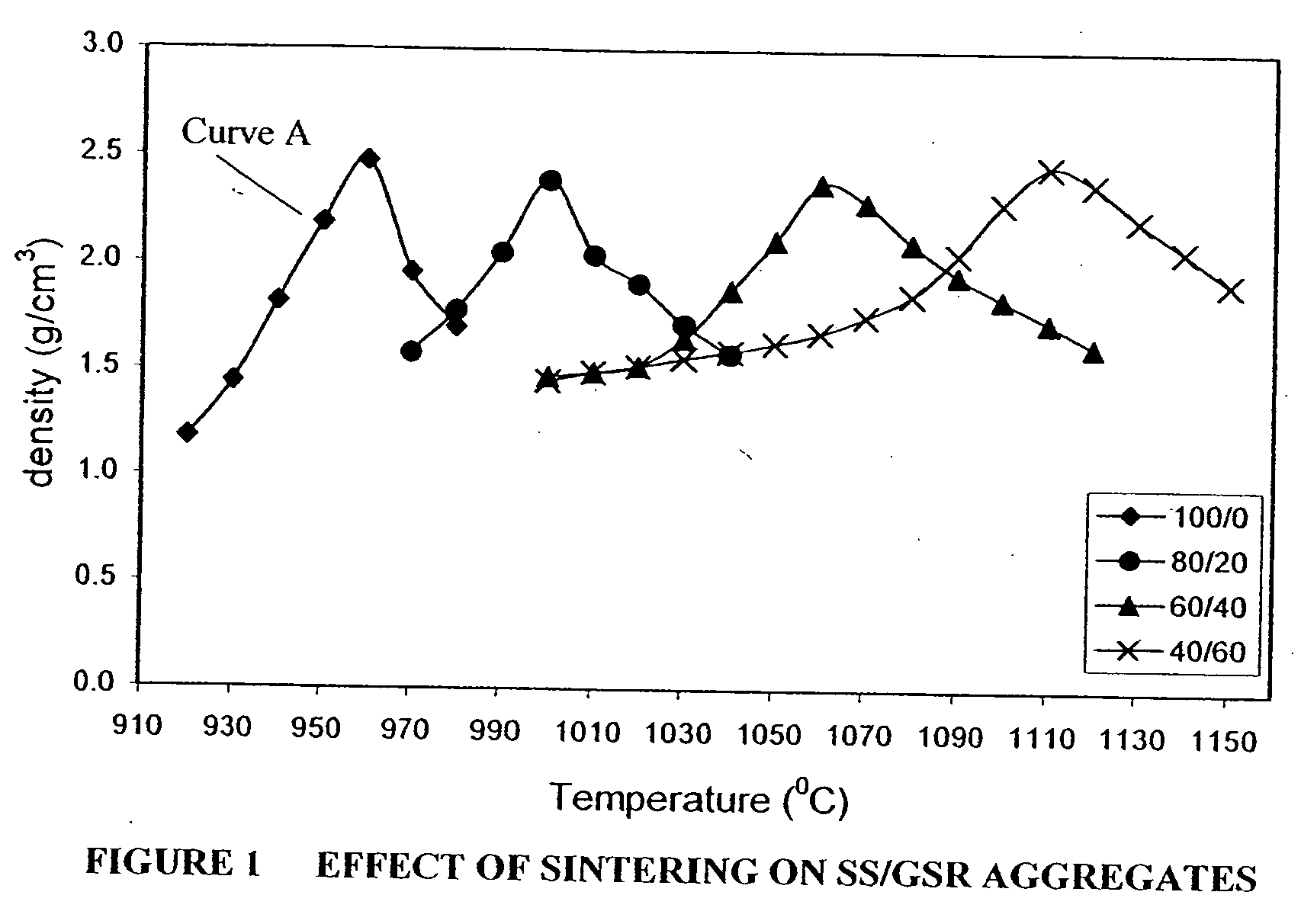

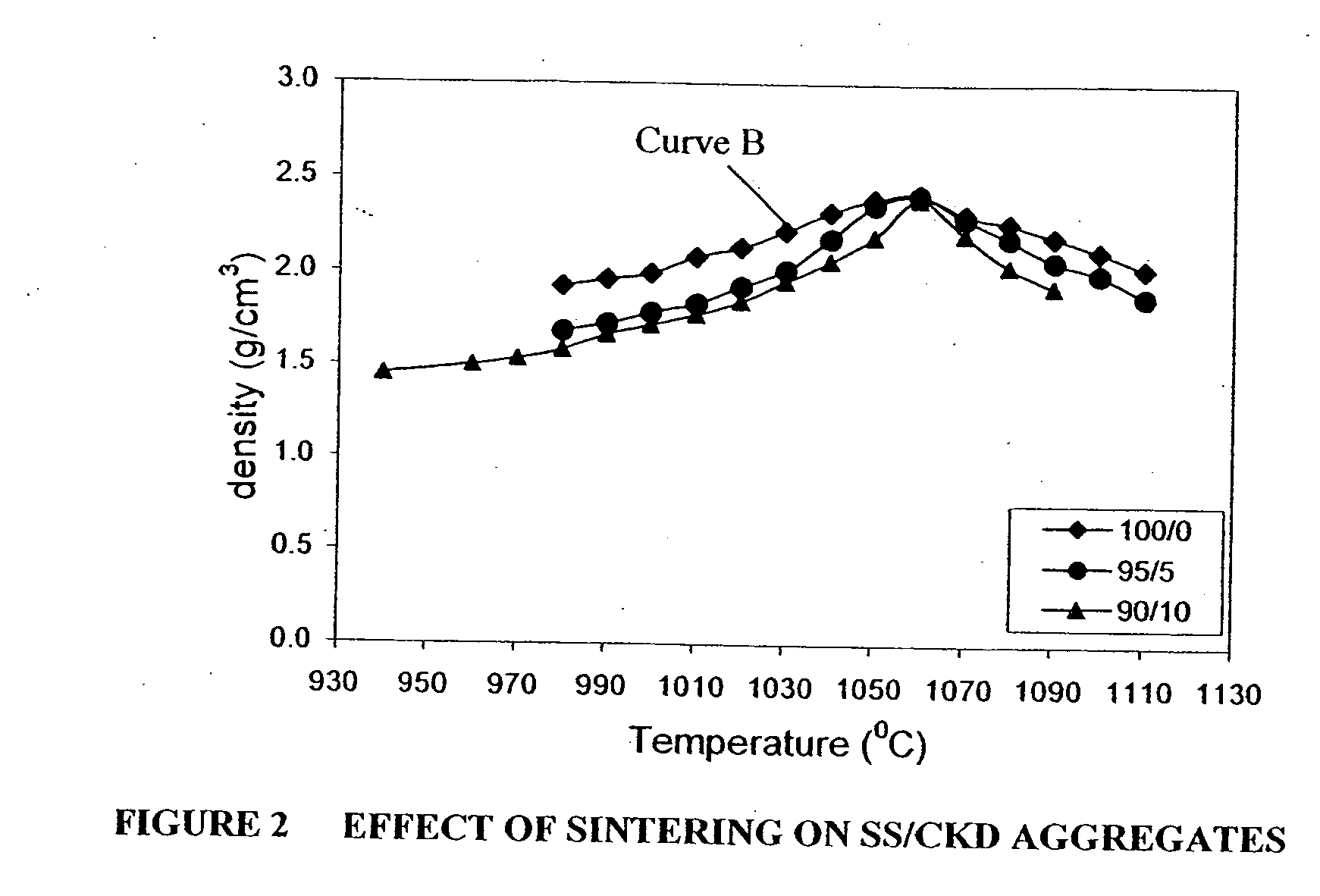

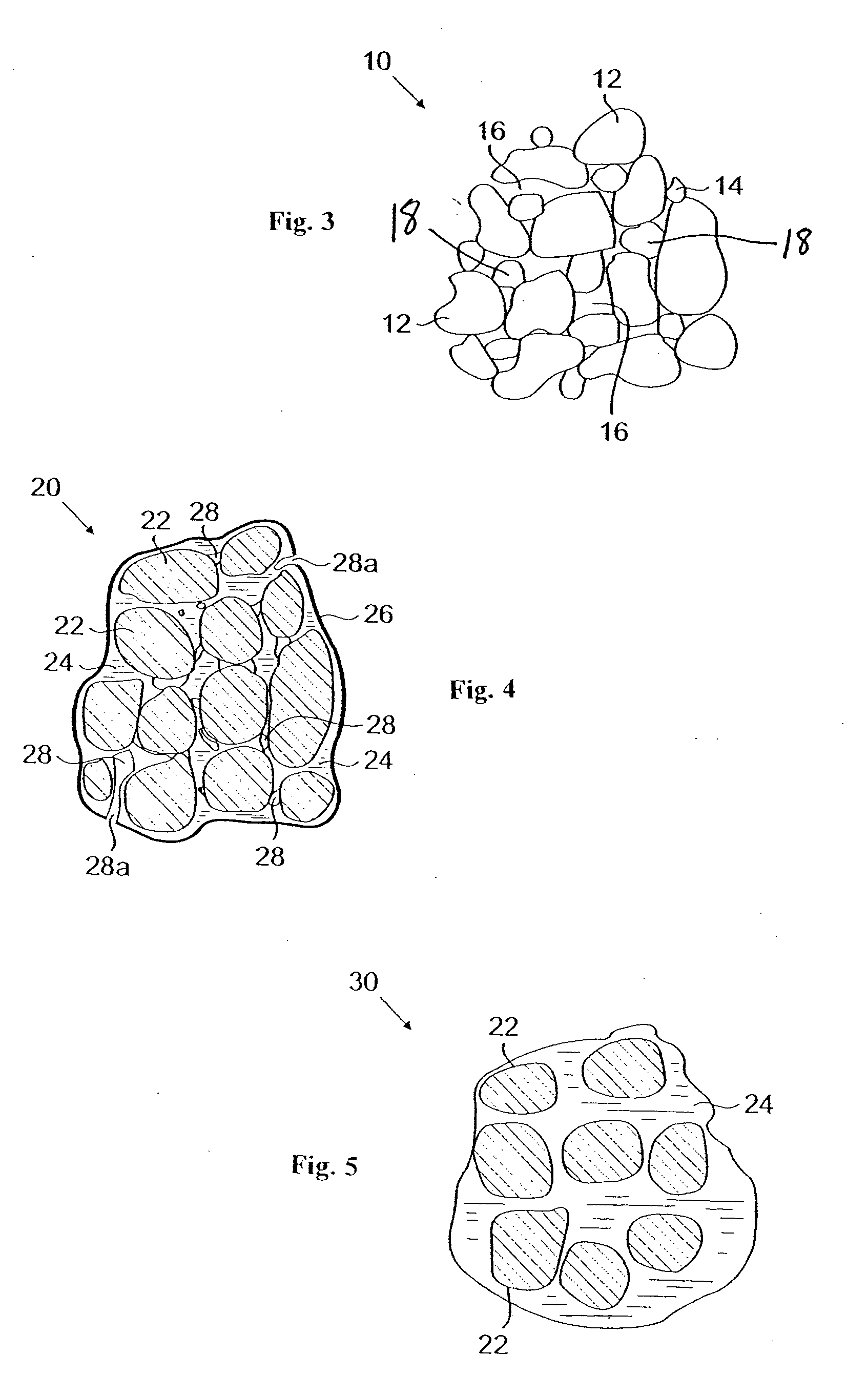

Synthetic aggregates comprising sewage sludge and other waste materials and methods for producing such aggregates

In one example of an embodiment of the invention, a method for producing an aggregate is disclosed comprising mixing sewage sludge from a waste water treatment facility with a non-coal combustion ash silicoaluminous waste material, agglomerating the mixture to form an agglomerate, and pyroprocessing the agglomerate to form an aggregate. The waste material may comprise municipal solid waste incinerator bottom ash, incinerator fly ash, incinerator filter dusts, cement kiln dusts, waste glass, blast furnace slag, kiln dusts, and / or granite sawing residues, for example. The method may further comprise milling the waste material prior to mixing. Preferably, the milling is wet milling. Pyroprocessing of the agglomerate may take place in a rotary kiln. The resulting aggregate may be a lightweight or a normal weight, sintered or vitrified aggregate. Aggregates and methods for making aggregates of high and low calcium silicoaluminous materials are also disclosed.

Owner:ALKEMY

Chemical industrial waste salt refining process

ActiveCN104649495AImprove qualityRealize resource regenerationMultistage water/sewage treatmentAlkali metal chloridesTunnel kilnEvaporation

The invention relates to a chemical industrial waste salt refining process which comprises the following steps: pretreating high salt wastewater generated in the production process of aminobenzene ether and p-nitrophenol so as to adjust the pH value, adsorbing by using activated carbon, kieselguhr or macroporous resin, removing organisms and organic salts in the wastewater, reducing the COD of the wastewater, neutralizing the high salt wastewater, performing multi-effect evaporation or mechanical recompression so as to evaporate and crystallize, and centrifuging a solid salt; performing high-temperature calcination on the centrifuged solid salt in a rotary kiln or a tunnel kiln, thereby decomposing and oxidizing the organisms at a high temperature, further thoroughly combusting the tail gas generated through calcination in a heat accumulation type tail gas combustion furnace, preheating and recycling the tail gas, performing spraying absorption, dissolving the calcinated salt with water so as to prepare a saturated solution, filtering by using a precise filter, directly supplying the filtrate to ionic membrane caustic soda for use, or performing multi-effect evaporation or mechanical recompression on the filtered saturated salt water so as to evaporate, crystallize and purify, and performing centrifugation, thereby obtaining high-quality solid sodium chloride.

Owner:JIANGSU ZHONGDAN GROUP

Method for comprehensive harmless recovery and utilization of waste lithium ion power battery

ActiveCN105428745AReduce wasteEasy to keepWaste accumulators reclaimingBattery recyclingPower batteryElectrical battery

The present invention relates to a method for comprehensive harmless recovery and utilization of a waste lithium ion power battery. The method comprises the following steps: disassembling a waste battery pack, and measuring and collecting good battery cells to re-combine the good batteries for gradient utilization; sufficiently discharging defective waste lithium ion power battery cells, and disassembling the power battery cells in an oxygen-isolated environment; performing heat treatment on a fetched core pack in a heating furnace, and collecting a distilled solvent by means of condensation; disassembling the core pack from which the solvent is distilled off to obtain a membrane material, a positive electrode plate and a negative electrode plate; placing the positive electrode plate and the negative electrode plate in a rotary kiln of 200-600 DEG C to be subjected to heat treatment; sorting electrode plates, which have been subjected to the heat treatment, by using a pulverizer and a powder sorter separately, so as to obtain an aluminum powder, a copper powder, a waste positive electrode powder and a waste negative electrode powder; and repairing the positive electrode powder and the negative electrode powder separately. According to the method provided by the present invention, a fully-dry closed-circuit recovery process is adopted, thereby achieving the harmless recovery and utilization of the waste lithium ion power battery.

Owner:北京赛德美资源再利用研究院有限公司

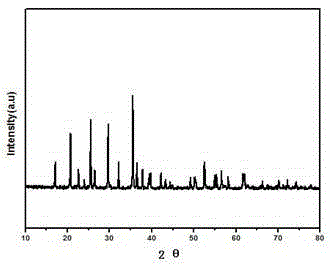

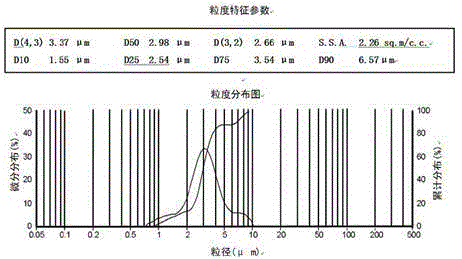

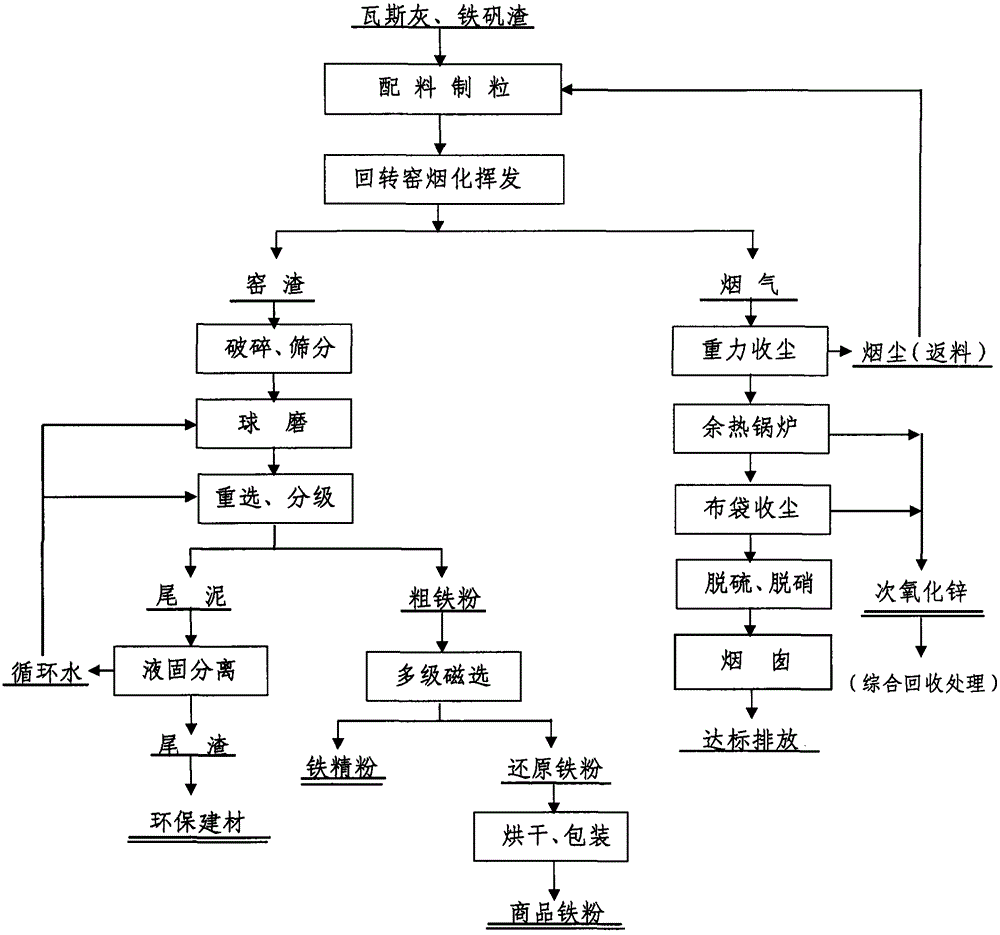

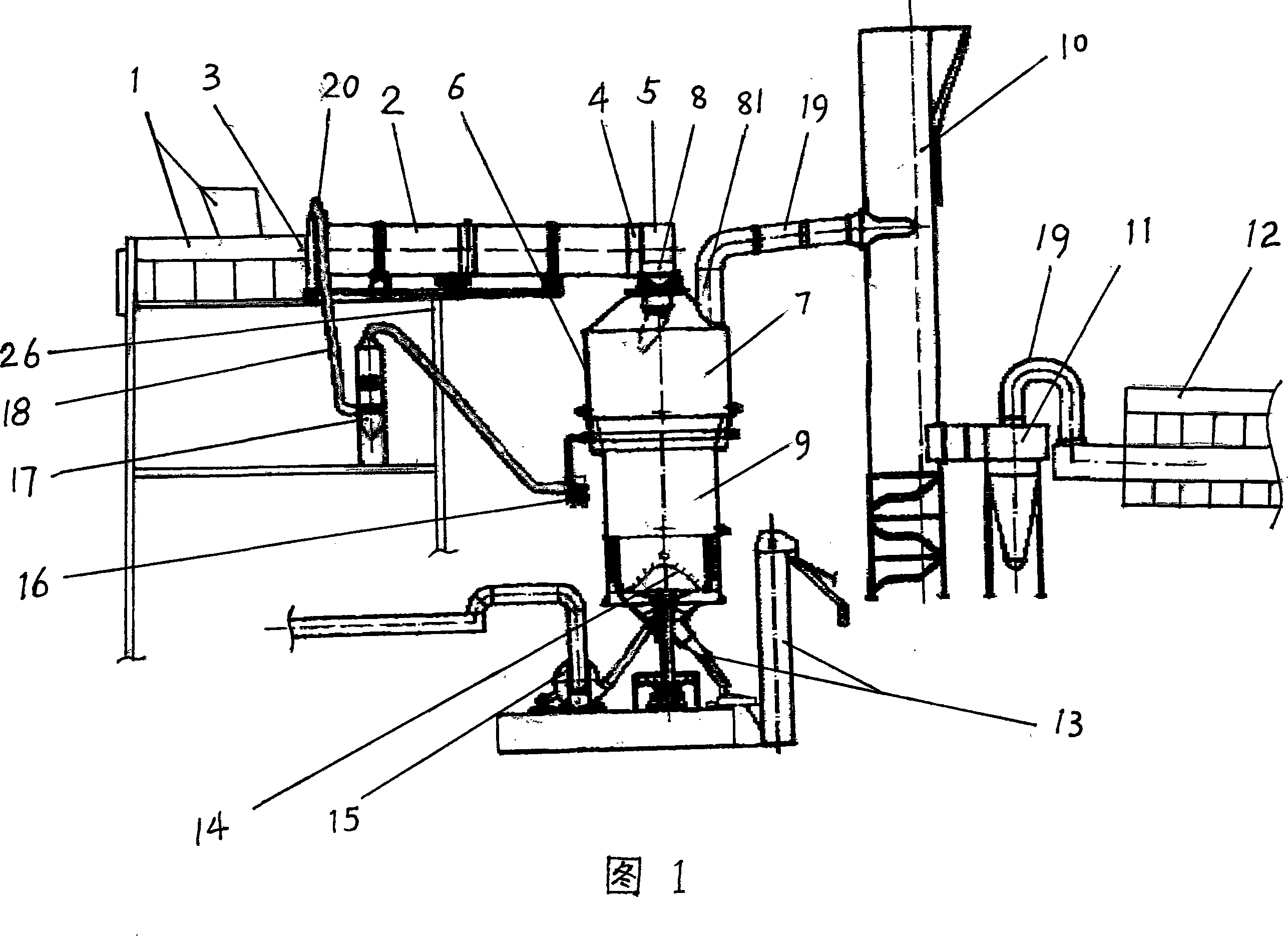

Comprehensive recovery technology of solid waste gas ash and zinc-containing ferrovanadium slag

ActiveCN104911356AImprove the level of comprehensive utilizationAchieve reductionProcess efficiency improvementSlagHigh energy

The invention provides a comprehensive recovery technology of solid waste gas ash and zinc-containing ferrovanadium slag. By combining advantages of low iron content and rich carbon of gas ash and characteristics of high iron content and rich precious metals of ferrovanadium slag, and by the adoption of a rotary-kiln fire method fuming enrichment technology, the material undergoes comprehensive recovery. Advanced equipment such as a waste heat boiler, a negative-pressure bag collector, a pneumatic emulsification desulfurization tower and the like are configured to carry out efficient recovery and harmless environmental-protection processing of flue gas so as to achieve the purpose of clean production. By a beneficiation combined method, iron-containing kiln slag undergoes high added-value exploitation. Thus, the environmental protection problem of resource disposition is solved, and the effect of comprehensive utilization with low energy consumption, high yield and high added-value is achieved. Problems of short kiln age, high energy consumption and low concentration of SO2 during the treating process of ferrovanadium slag can be solved by the technology provided by the invention, and problems of poor iron separation effect and overhigh content of fluorine and chlorine in zinc hypoxide also can be solved. The technology has good economic benefit and high popularization and practical value.

Owner:北京事竟成有色金属研究所

Double-loop double-pyrogenation incinerator for garbage harmless treatment and its usage method

InactiveCN101101120APrevent external consumptionPlay the role of thermal insulationIncinerator apparatusRefluxCombustion chamber

The invention relates to double loop double pyrolysis incinerator and its using method. Its features are that drying apparatus is formed by horizontal rotary kiln drying device, steam separator, and fume reflux line; the feed port of the horizontal rotary kiln is connected with discharge port of the feeding device; its discharge port is connected with the feed port above secondary burning chamber. While running, part of high temperature fume of secondary burning chamber can enter the rotary kiln to process reverse drying preheat and pyrolysis for the garbage; cooled fume is inducted into the secondary burning chamber by secondary fan after dehydrating by steam separator. Compared with exiting technique, the invention has the advantages of continual heat transfer, fast gasification rate, full burning, processing domestic garbage without auxiliary fuel etc.

Owner:福建省丰泉环保控股有限公司

Sludge resource treatment device and method for treating sludge

ActiveCN102276130ASave drying energyGuaranteed drynessSludge treatment by de-watering/drying/thickeningIncinerator apparatusSludgeCyclonic separation

Owner:陈海渊

Reflux type temperature controllable sludge drying device and method

InactiveCN1587127AEfficient dryingSludge treatment by de-watering/drying/thickeningTemperature controlReflux

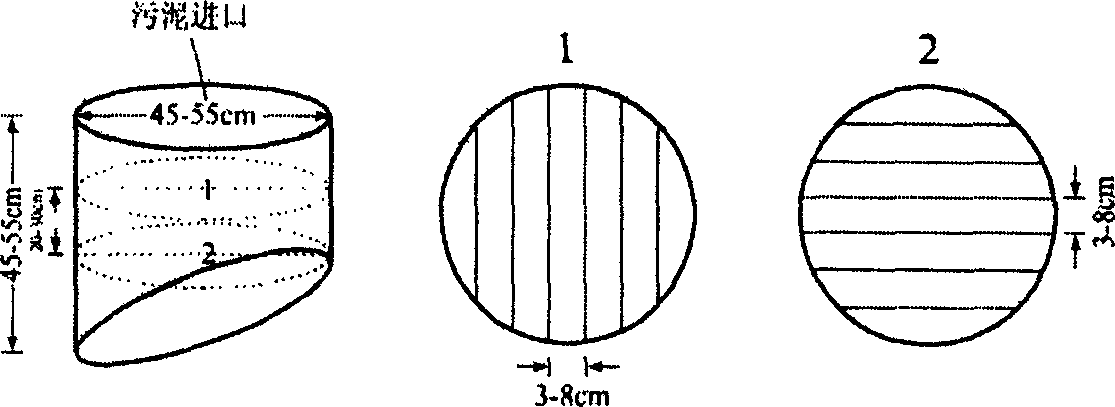

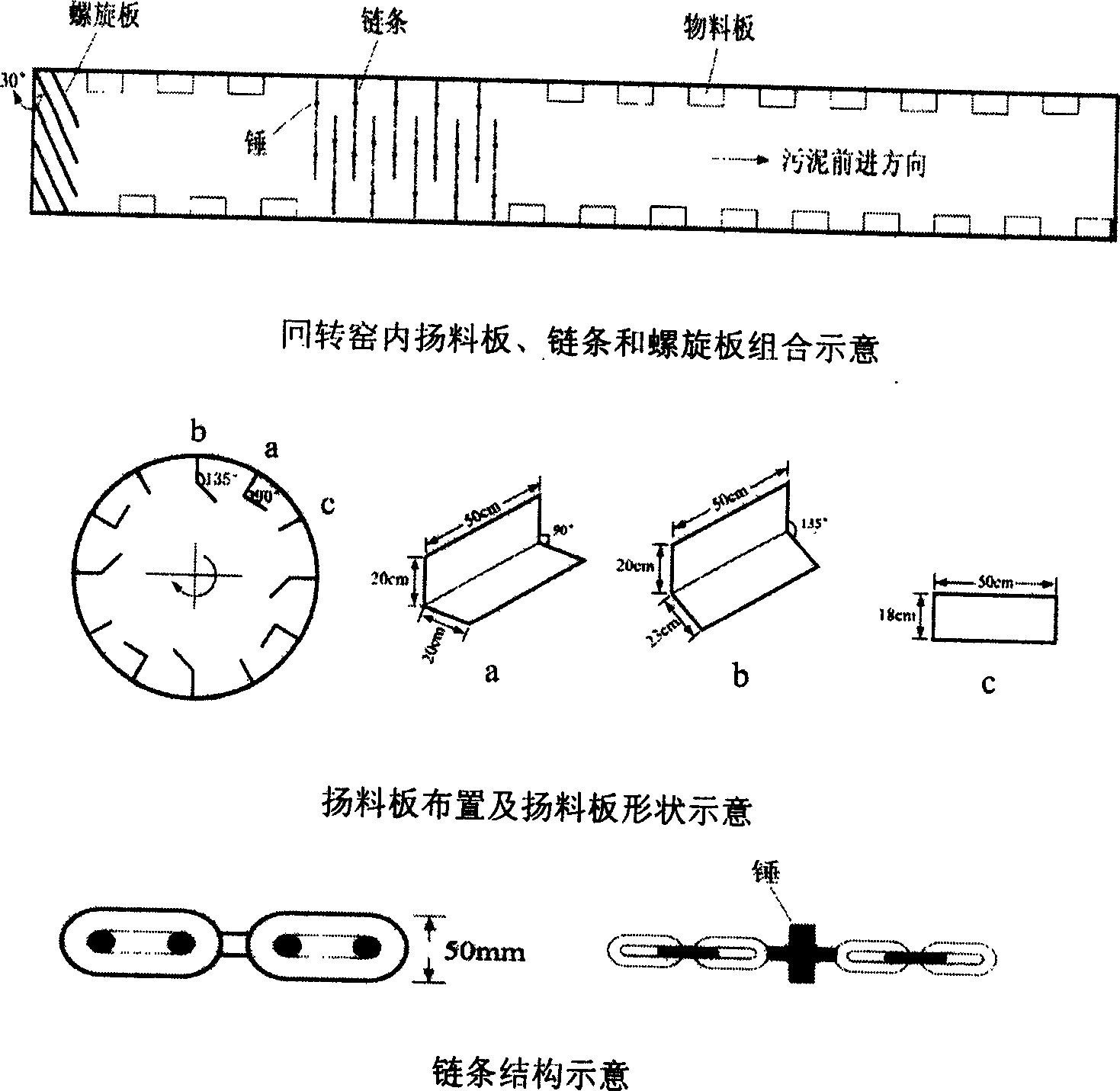

The present invention discloses one kind reflux type temperature controllable sludge drying apparatus and method. Drying sludge in 5-20 % is mixed with wet sludge and through the sludge inlet with two, one transverse and one longitudinal, layers of cutting steel wires, sludge is cut into small blocks before entering into the rotary kiln. Inside the rotary kiln, sludge is thrown and crushed by the throwing plate and chain for fast heating to dry in the temperature controlled with the jetting blower. Hot sludge from the rotary kiln is blown with the cold wind blower to further dry. The dried sludge is crushed and sieved, sludge with size below 4 mm is pelletized for comprehensive utilization and large sized sludge is refluxed. The present invention can reach ideal drying effect while maintaining over 95 % of its organic matter components.

Owner:ZHEJIANG UNIV

Method and burner apparatus for injecting a pulverized coal into rotary kilns, method and apparatus for producing cao using them

InactiveUS20060169181A1Reduce concentrationMinimize diameter variationPigmenting treatmentSolid fuel pretreatmentCombustorEngineering

The invention relates to a method and burner for injecting pulverized coal into a rotary kiln that uses pulverized coal as fuel in order to produce quick lime of excellent hydration level. The invention calcines lime stone charged into the rotary kiln, and uses pulverized coal as fuel of a heat source applied to the lime stone charged in the rotary kiln. The invention also provides a method and apparatus for producing quick lime by using the pulverized coal. The invention can use pulverized fossil fuel (hereinafter will be referred to as pulverized coal), which is created during coke manufacturing and cooling processes and collected by a dust collector, in order to produce quick lime of excellent hydration level while decreasing SOx (sulfide) and NOx (nitride) generation.

Owner:POHANG IRON & STEEL CO LTD

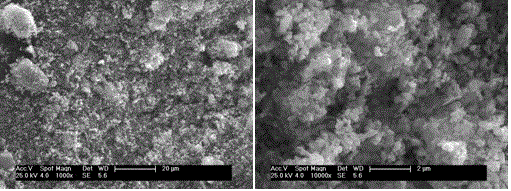

Method of forming inorganic pigments

The present invention provides a method of forming inorganic pigments using one or more metal alloys. Metal alloys used in the method of the invention are preferably milled to a mean particle size of less than about 10 microns, may be mixed with other metal oxides, and calcined in the presence of oxygen in a rotary kiln. Inorganic pigments formed in accordance with the method of the invention can be used in a wide variety of applications, including the coloration of glass matrixes, ceramic bodies, polymers, and paints.

Owner:FERRO CORP

Synthetic aggregates comprising sewage sludge and other waste materials and methods for producing such aggregates

In one example of an embodiment of the invention, a method for producing an aggregate is disclosed comprising mixing sewage sludge from a waste water treatment facility with a non-coal combustion ash silicoaluminous waste material, agglomerating the mixture to form an agglomerate, and pyroprocessing the agglomerate to form an aggregate. The waste material may comprise municipal solid waste incinerator bottom ash, incinerator fly ash, incinerator filter dusts, cement kiln dusts, waste glass, blast furnace slag, kiln dusts, and / or granite sawing residues, for example. The method may further comprise milling the waste material prior to mixing. Preferably, the milling is wet milling. Pyroprocessing of the agglomerate may take place in a rotary kiln. The resulting aggregate may be a lightweight or a normal weight, sintered or vitrified aggregate. Aggregates and methods for making aggregates of high and low calcium silicoaluminous materials are also disclosed.

Owner:ALKEMY

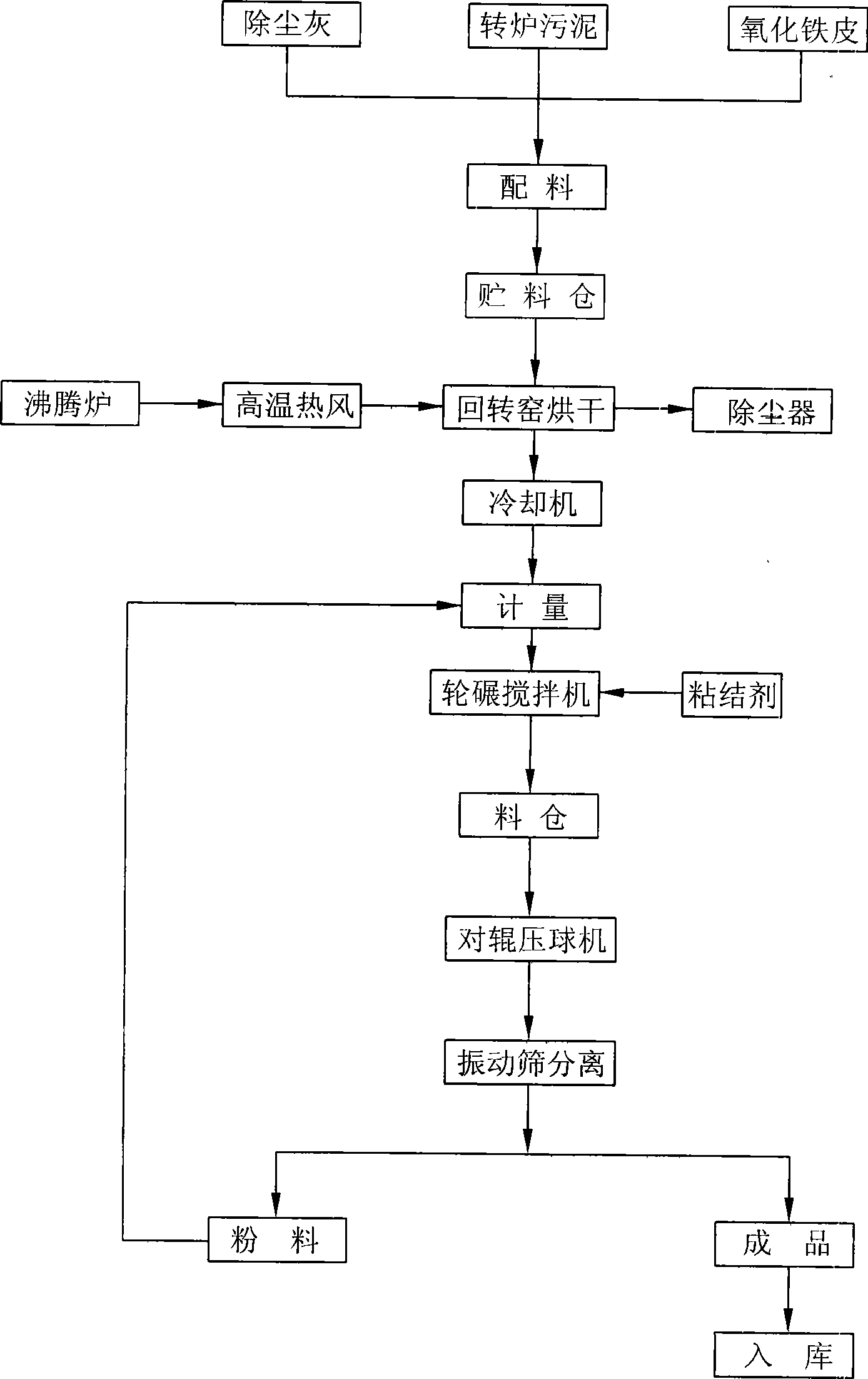

Method for utilizing iron containing metallurgical dust

The invention relates to a method for utilizing iron containing metallurgical dust, which comprises that: steel-making sludge, metallurgical dust-removing powder and iron scale are mixed; the mixed raw materials are sent into a rotary kiln and dried, and the drying temperature is determined according to moisture content of the raw materials and controlled to be between 300 and 500 DEG C; the dried materials are cooled by a cooler, the cooled materials are added with 5 to 10 percent of caking agent by weight, and the material and the caking agent are fully stirred evenly by a wheel-rolling mixer; and finally, the mixture is pressed into cooled agglomerated pellet products by a twin-roller machine, the pressure of the twin-roller machine is more than or equal to 500 Kg / cm<2>, and the cooled agglomerated pellet products are prepared into finished products after separation by a vibration sieve. The method has the advantages of low production energy consumption, high product strength, low moisture content and good quality, and can realize full effective utilization of resources; and the finished products of cooled agglomerated pellets can be directly used as a cooling agent and a slag former in steel making, can improve smelting effect and achieve functions of cooling and slag forming, and can be also used for blast furnace process.

Owner:SHAOGUAN QUJIANG SHENGDA EQUIP & MATERIALS

Municipal sludge expanded ceramsite and preparation method thereof

InactiveCN101618971ALow costSave resourcesCeramic materials productionCeramicwareSludgeExpanded clay aggregate

The invention provides municipal sludge expanded ceramsite and a preparation method thereof. The municipal sludge expanded ceramsite is prepared from the following materials by mass percentage: 20% to 45% of municipal sludge, 50% to 70% of shale, tailings or clay, 1% to 5% of organic matter and 1% to 5% of iron powder, wherein, the tailings is one of pyrite tailings, gold tailings, lead-zinc tailings and aluminum tailings; and the organic matter is sawdust. The preparation method comprises the following steps: feeding the shale, tailings or clay into a crusher, and carrying out the screening treatment; adding and mixing the municipal sludge, the organic matter and the iron powder, feeding into an ageing silo and stirring; then, feeding into a granulating machine, granulating and calcinating in a rotary kiln; and finally, cooling and stacking the calcinated ceramsite by classification. By using a great amount of municipal sludge, the invention is resource-saving and environment-friendly; compared with the original cost, the overall cost of a building is reduced by 5% to 10%; and the prepared expanded ceramsite has the advantages of light weight, fire resistance, sound absorption, good heat insulating and preserving performance, simple process and low cost, so that the invention is suitable for industrialized production.

Owner:XIAN RES & DESIGN INST OF WALL & ROOF MATERIALS CO LTD

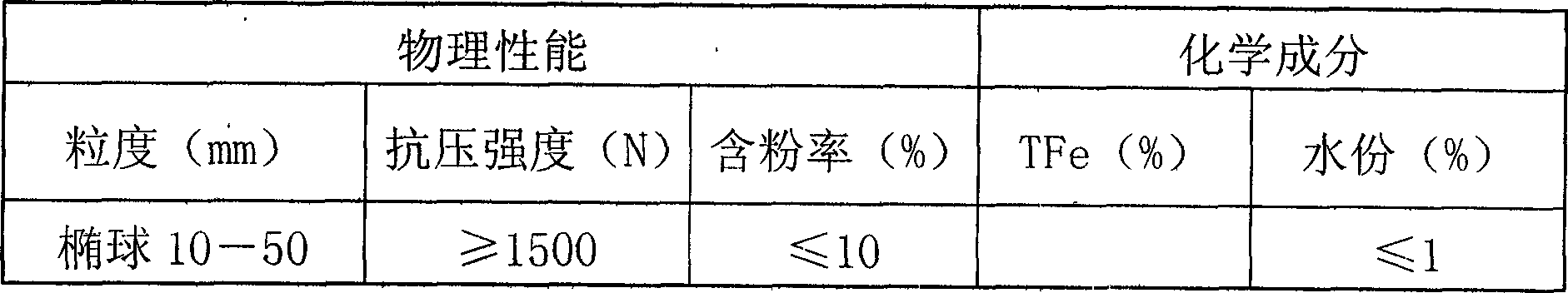

Pneumatic medical waste burning process for rotary kiln and device therefor

InactiveCN101285577AAvoid destructionAchieve turbulent combustionIndirect carbon-dioxide mitigationIncinerator apparatusCombustion chamberAtmospheric air

The invention discloses a process and a device for incinerating rotary kiln gas-controlled medical waste, relating to the environmental protection technical field. The process of the invention comprises the following steps of: collecting the whole packet of medical waste refuse bag and feeding into a feeding hopper, then feeding into a rotary kiln initial combustion chamber by a feeding mechanism which is closed by chain, and completing the processes of drying, pyrolyzing and air controlled anoxycausis of the medical waste. Waste gas generated by the rotary kiln initial combustion chamber enters to a secondary combustion chamber to undergo the process of air controlled oxygen-enriched complete combustion, wherein bottom ash with a little redial carbon is flamed at an inclined fire grate which is arranged in an ash well at the lower part of the secondary combustion chamber. The smoke gas at an outlet of the secondary combustion chamber is exhausted into the atmosphere by a draft fan through a chimney after surplus heat utilization of a surplus heat boiler, smoke gas sharp quenching of a quench tower, a dry-type deacidification and cloth-bag dust removal of a bag-type duster. Compared with the prior art, the process and the device for incinerating rotary kiln gas-controlled medical waste have the advantages of good operating economical efficiency, automatic safety continuous feeding, fluent slag tapping system and low index of pollution emission.

Owner:TSINGHUA UNIV +1

Hybrid thermal process to separate and transform contaminated or uncontaminated hydrocarbon materials into useful products, uses of the process, manufacturing of the corresponding system and plant

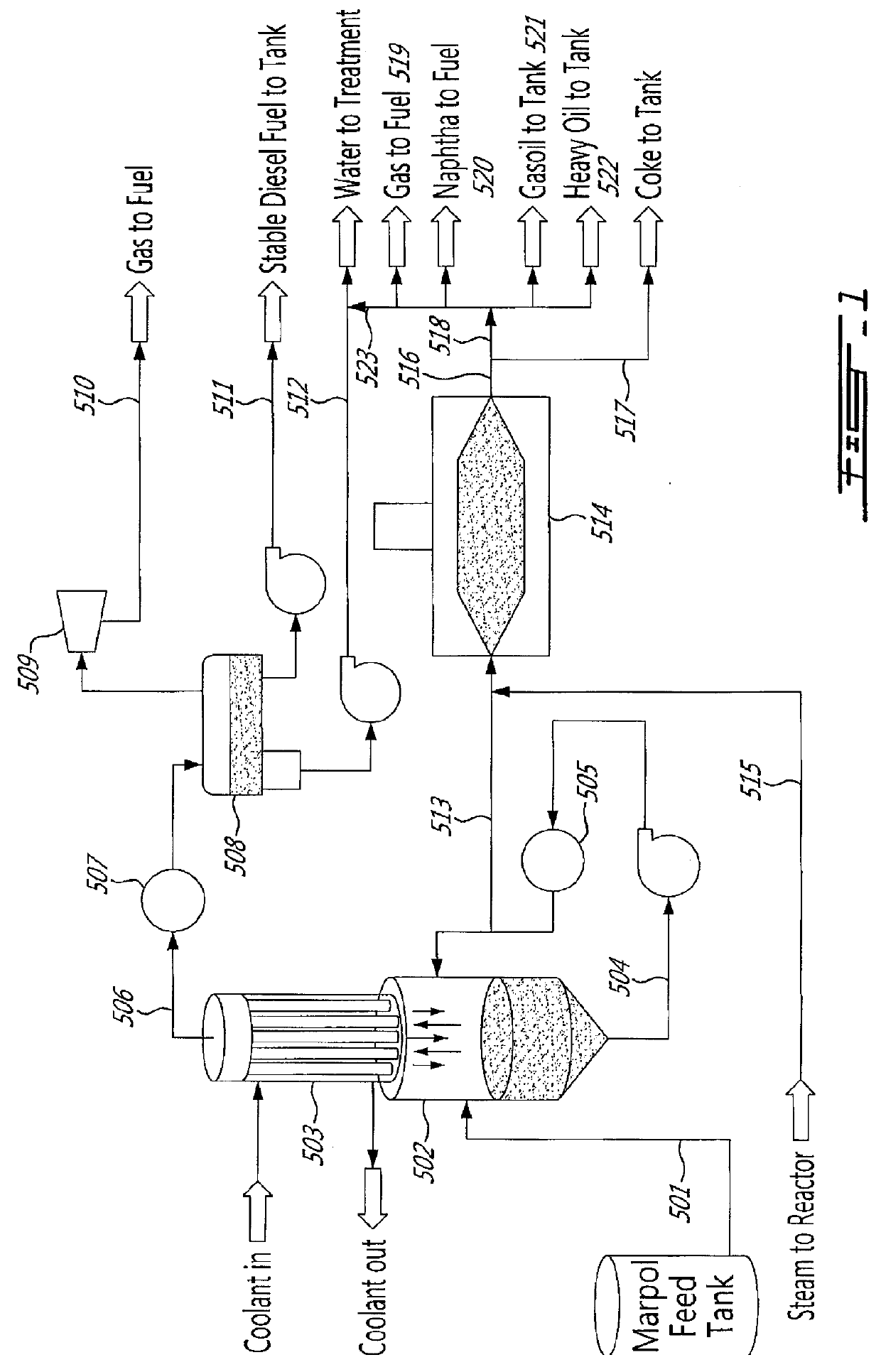

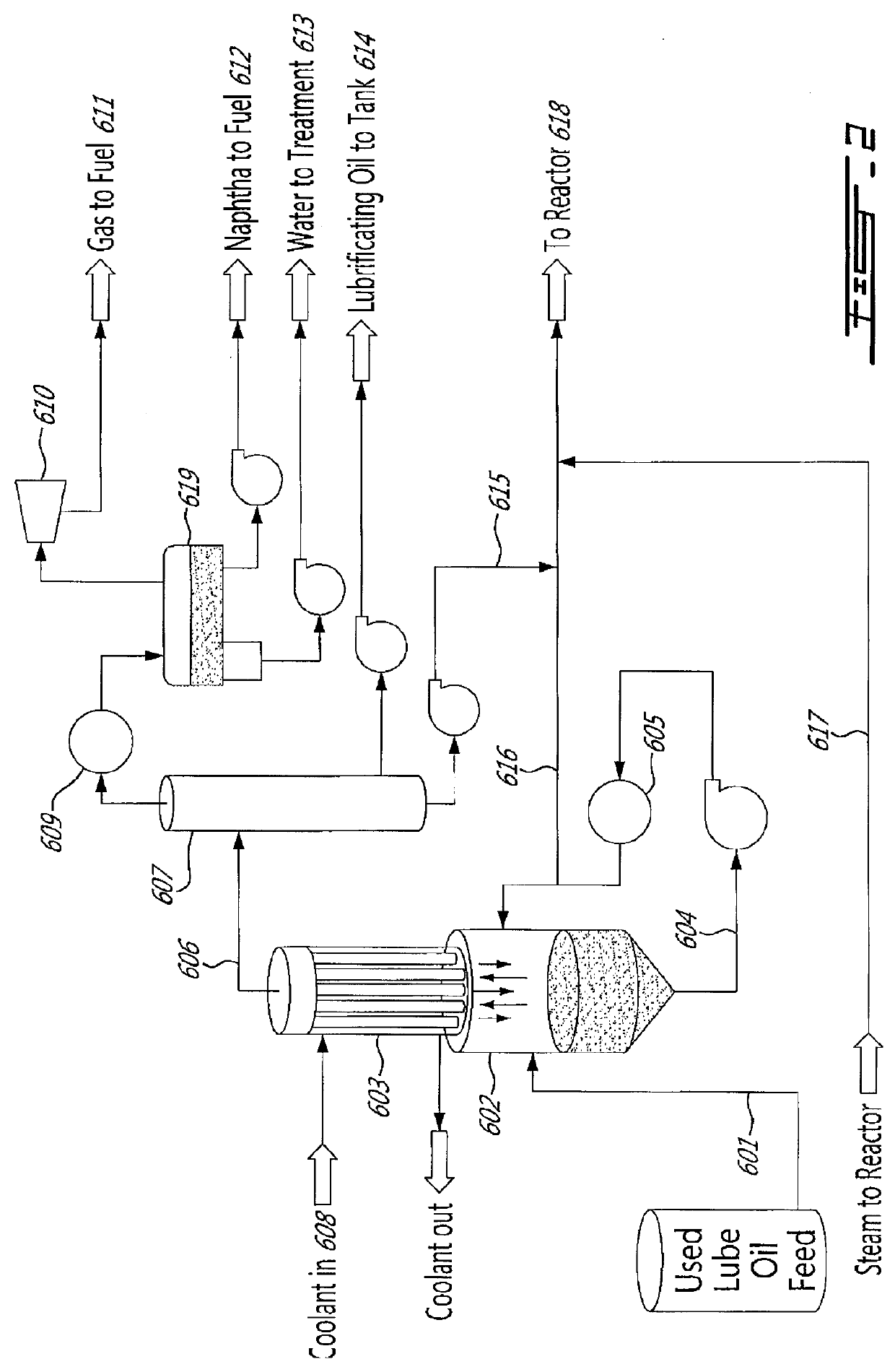

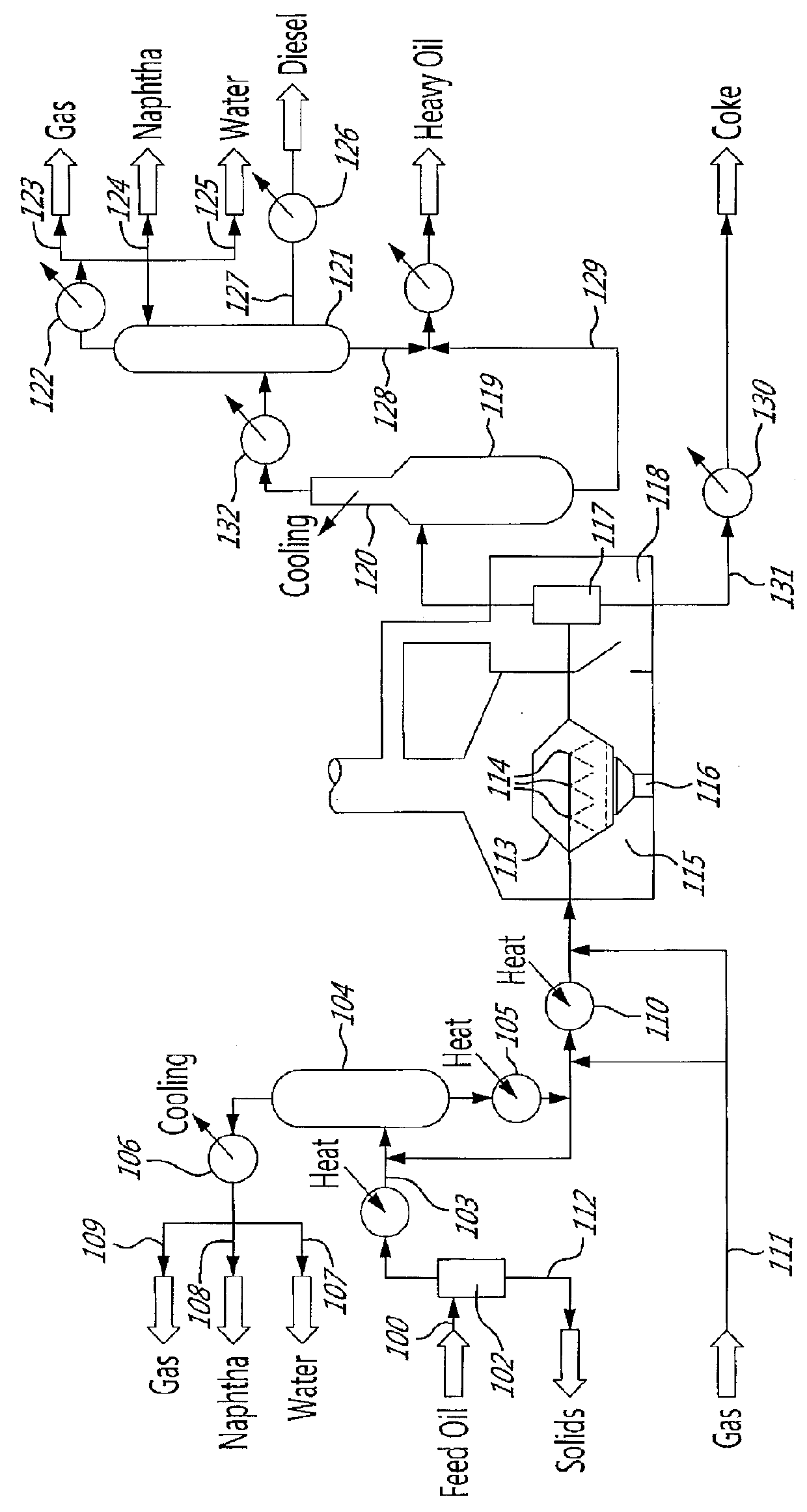

ActiveUS20160053184A1Increase volumeReduce contentThermal non-catalytic crackingChemical/physical/physico-chemical reactor detailsChemical compoundWaste oil

Process for reclaiming useful products from a waste oil, comprising a thermal separation step performed in a vessel at conditions, of temperature and pressure, allowing to substantially avoid cracking of the waste oil and to assure the separation of said heated waste oil into a first heavy oil fraction and into a second light oil fraction having, in comparison with the waste oil, a low content in solids and / or in other contaminants that are different from water and from inert gas. The process is further characterized in that while, during the thermal separation treatment, the waste oil is heated to a temperature about the boiling temperature of the heavy oil fraction, and below the cracking temperature of the waste oil, and at a pressure that is preferably below the atmospheric pressure, the heavy oil fraction of the vapours existing the vessel, in contact with a cooler surface, condenses and falls back into the vessel, while the second fraction, in a gaseous state, is eventually submitted to at least one further separation treatment. When water is present in the waste oil, said water is used to improve the amount of recovered light oils; and / or when no water is present in the waste oil, water or at least one inert gas or at least one component that may become an inert gas by heating may be added to the waste oil or to the thermal separation unit. Uses of the process for environmental applications and for treating used oils and to prepare oil products. Systems for reclaiming useful products from waste oils comprising at least one rotating kiln and at least one self-refluxing condenser and / or at least one dephlegmator.

Owner:ENVIROLLEA

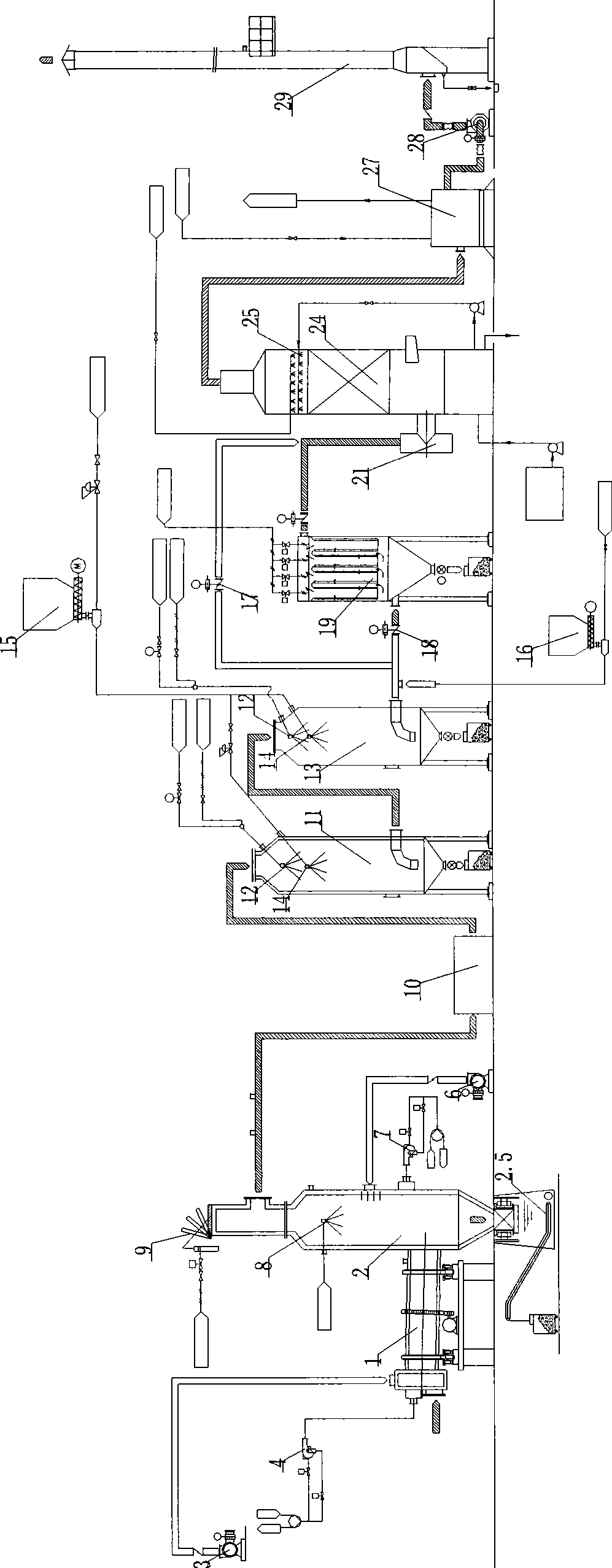

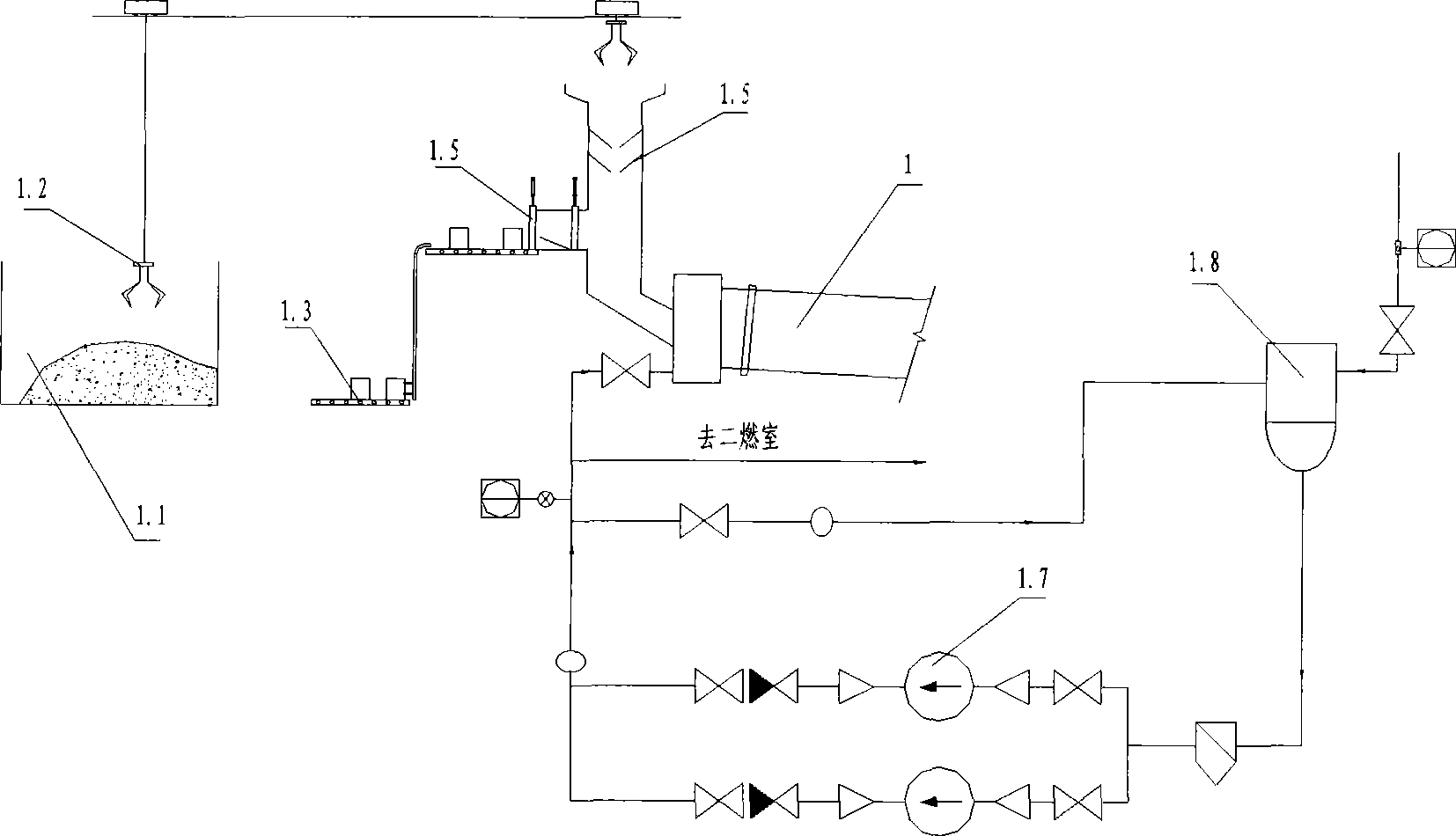

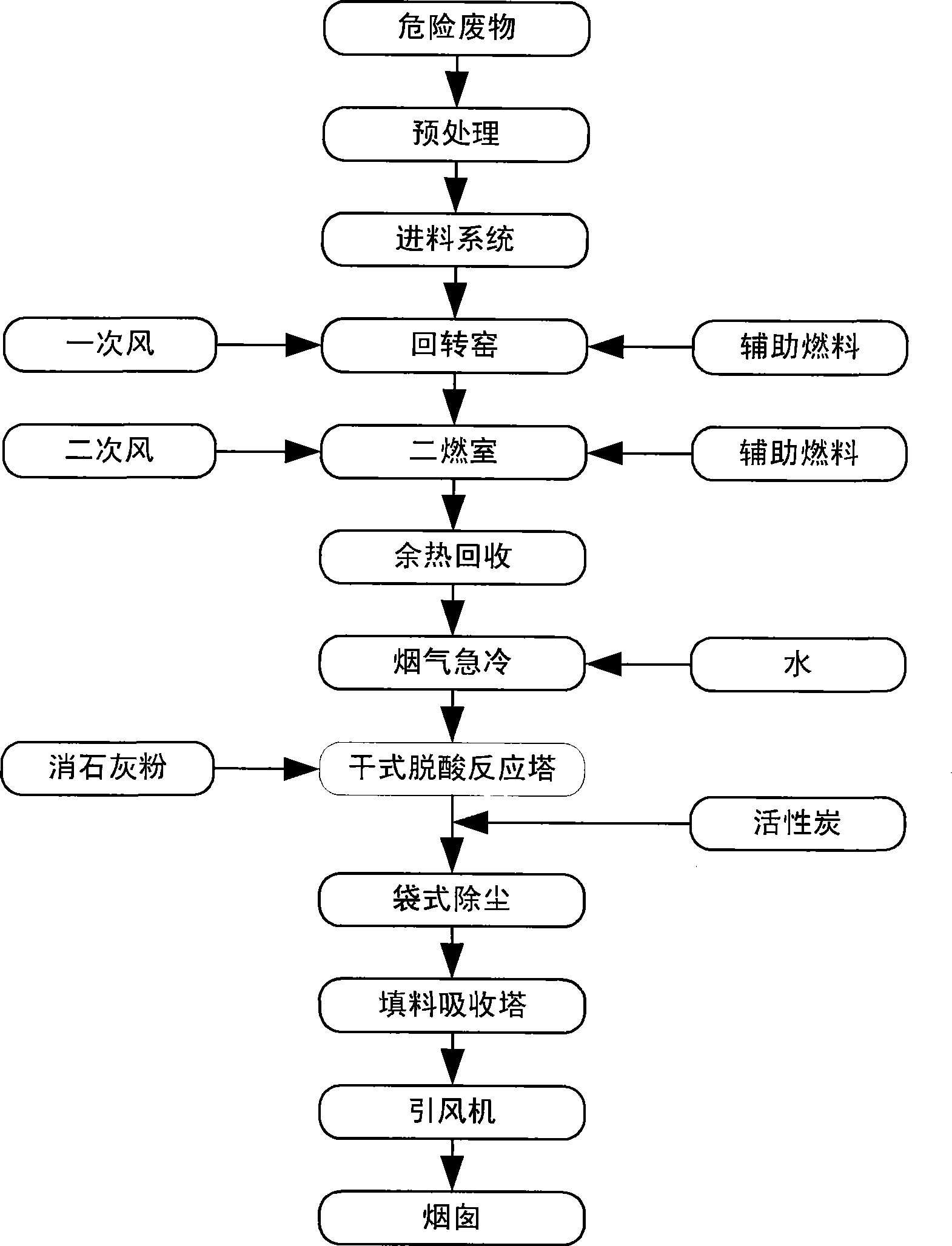

Industrial dangerous waste incineration processing system for realizing multiple physical states

A system for implementing multiple-physical state industry dangerous waste incineration and disposal relates to the garbage disposal technology of the environment protection technical field. Two seal doors are arranged at a bulk waste material feed port or a barreled waste material feed port on a rotary kiln feed hopper. The rotary kiln and a second combustion chamber frame all adopt carbon steel materials, refractory materials a working layer of the rotary kiln select chromium fused alumina abrasion-proof plastic materials, refractory materials of the second combustion chamber select abrasion-proof pouring materials. The rotary kiln is provided with a primary fan and a combustion-supporting combustor 1 which are connected with the rotary kiln, the second combustion chamber is provided with a second fan and a combustion-supporting combustor 2 which are connected with the second combustion chamber, a stuffing absorbing tower and a flue gas heater are connected in turn between the bag-type dust remover and a draught fan. Compared to the prior art, the invention can effectively destroy large quantities of toxic and noxious high molecule organic matters, can effectively avoid phenomenon of the collapse fall of the rotary kiln incineration furnace wall and the burning ring of the steel body, and can avoid high-temperature corrosion and low-temperature corrosion, the invention has advantages of good operation economical performance, fluent slag system and low pollution discharge index.

Owner:TONGFANG ENVIRONMENT

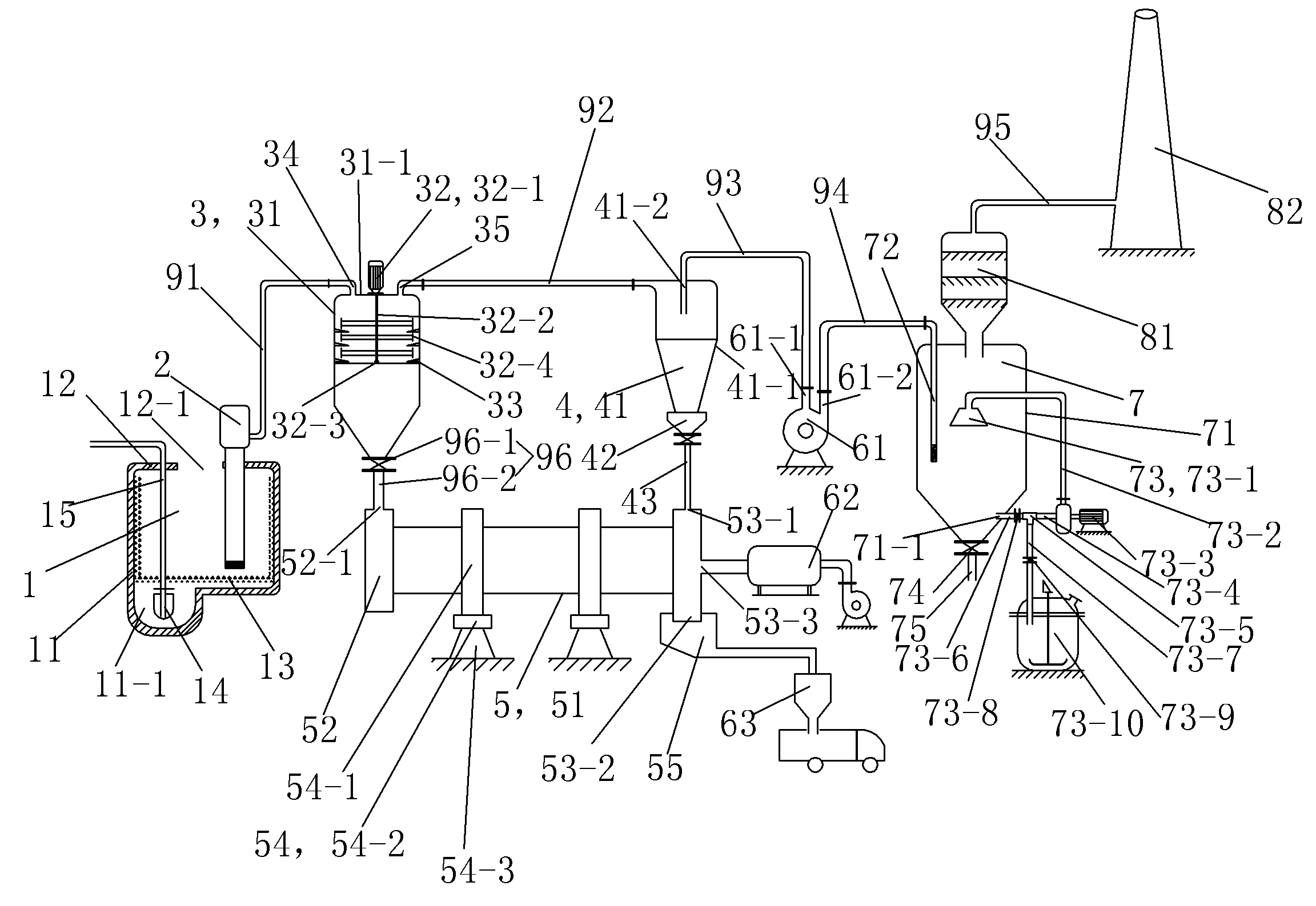

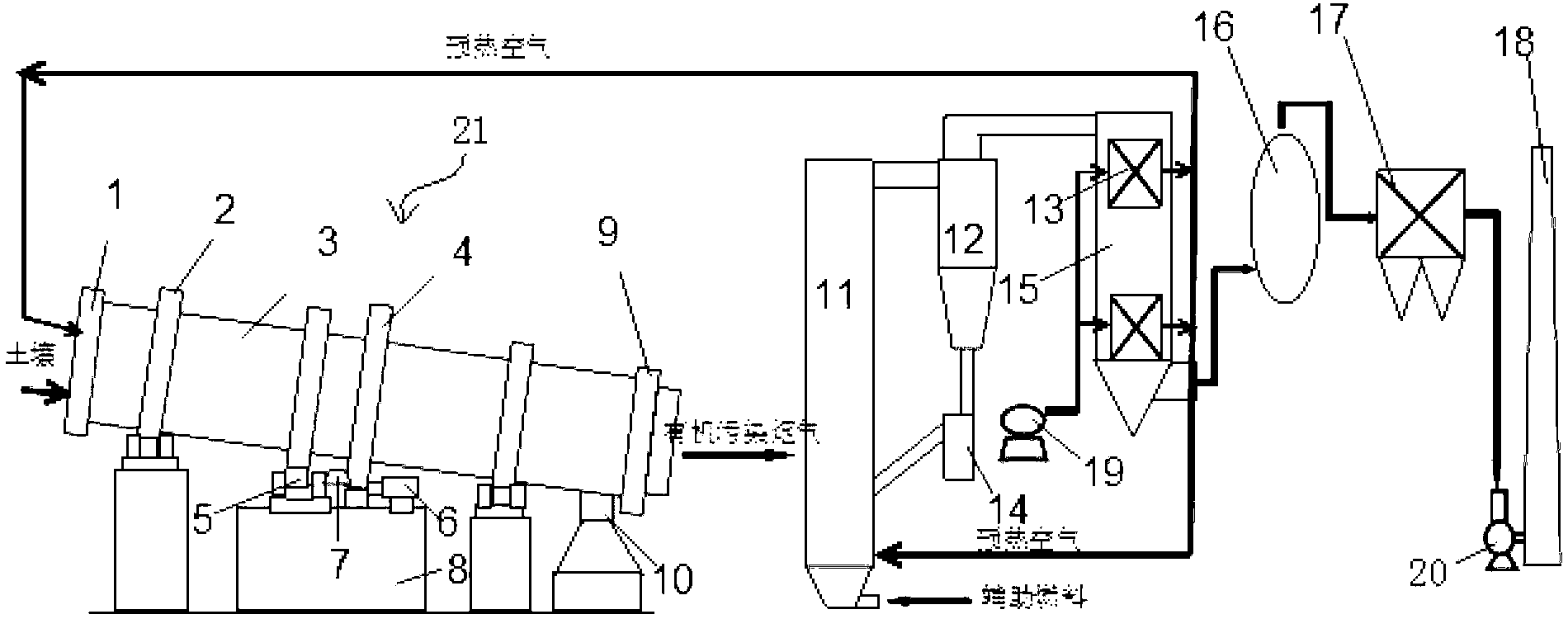

System and method for repairing organic material polluted soil

ActiveCN103008337AClear division of laborGive full play to the advantages of technologyContaminated soil reclamationAir preheaterEngineering

The invention discloses a system for repairing organic material polluted soil, which comprises a chimney and a rotary kiln reactor, wherein the smoke exhaust port of the rotary kiln reactor is connected with a furnace chamber; the furnace chamber is connected with a cyclone separator; one end of the cyclone separator is connected with a preheating passage; the other end of the cyclone separator is connected with a refeeder; the refeeder is connected with the furnace chamber; the preheating passage is connected with the chimney after passing through a flue gas desulfurization denitration purifier and a bag-type dust remover; an air preheating device is arranged in the preheating passage; one end of the air preheating device is connected with a first blower; the other end of the air preheating device is connected with the rotary kiln reactor and the furnace chamber respectively; and a rotary kiln repaired soil outlet is arranged on the rotary kiln reactor. The invention further discloses a method for repairing organic material polluted soil. According to the invention, the advantages of the thermal desorption technology in the organic material polluted soil repairing process are fully played; and organic material polluted soil, which is difficult to repair, can be repaired fast through the combination of new rotary kiln thermal desorption technology and the circulatory fluidized bed incineration technology.

Owner:HUAZHONG AGRI UNIV

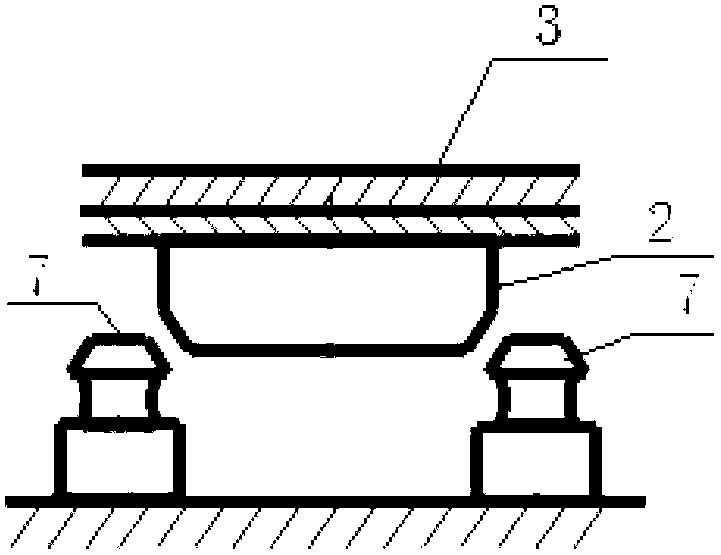

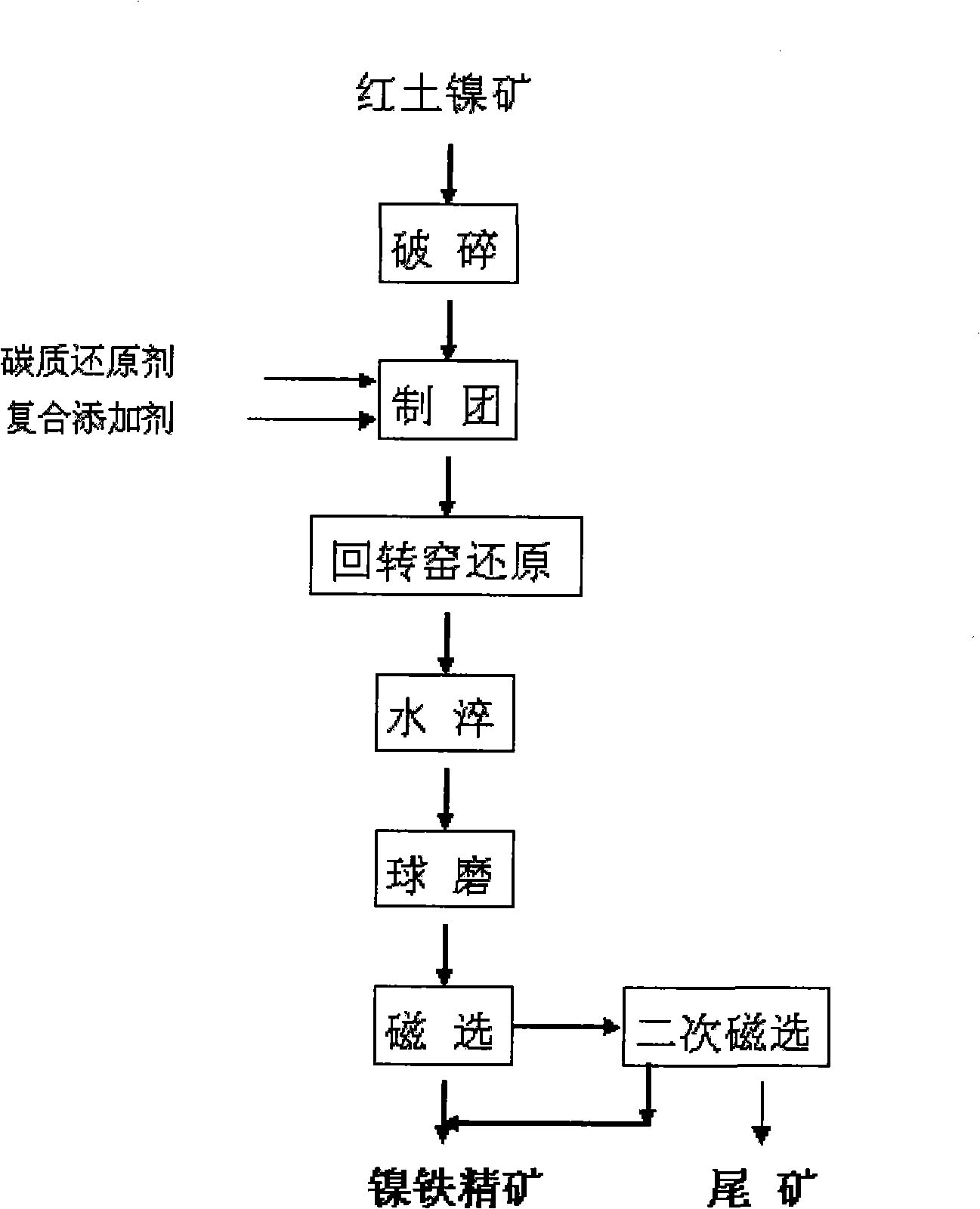

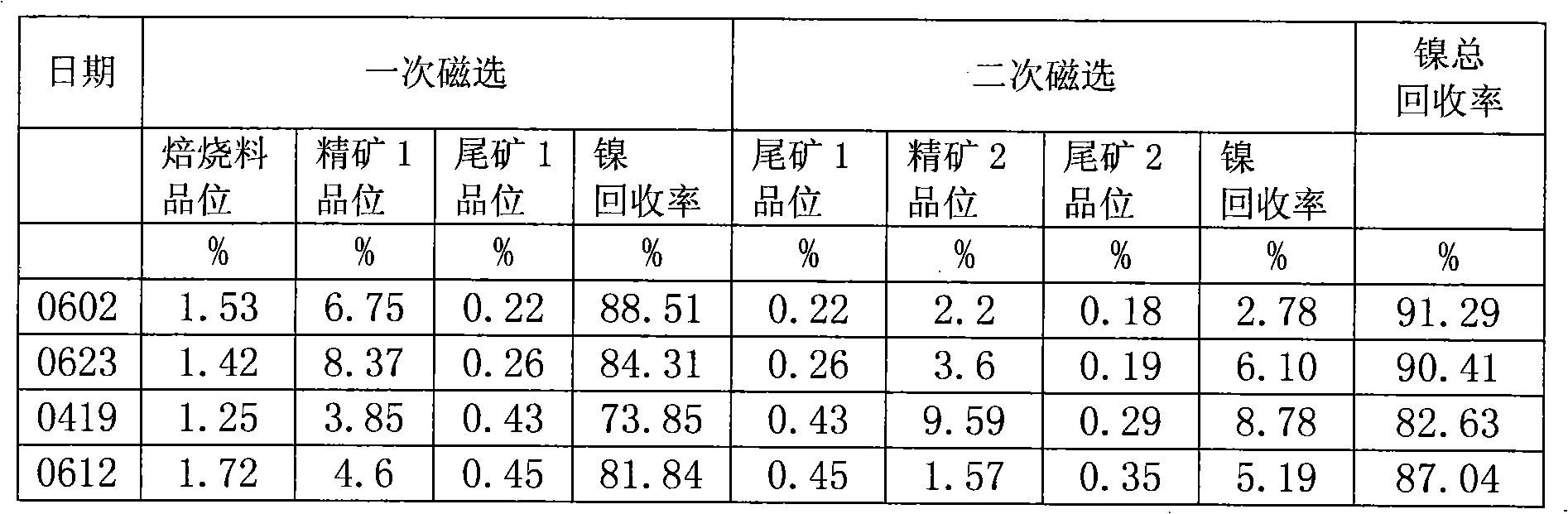

Method for enriching nickel iron ore concentrate from laterite type nickel ore by means of rotary kiln

InactiveCN101323904ANo pollution in the processSimple processRotary drum furnacesMagnetic separatorLaterite

The invention relates to a method for collecting ferronickel concentrate from lateritic nickel ores by a rotary kiln. The lateritic nickel ores are crushed, stirred and mixed with a carbonaceous reducing agent and a compound additive, made into pellets by a ball press or a marble machine and put into the rotary kiln for reducing and roasting; waste heat at the front part of the rotary kiln is used for carrying out the drying and preheating of the pellets; the high-temperature area of the rotary kiln is 9 to 10 meters away from a kiln outlet; the temperature of the high-temperature area is controlled to be 1000 to 1300 DEG C; roasting time is 0.5 to 2 hours; the dried pellets enter the high-temperature area of the rotary kiln for reducing and roasting; a magnetic separator with a magnetic field intensity of 3000 to 5000 gauss is adopted to sort roasted material obtained after water quenching and wet ball milling, thus obtaining high-content ferronickel concentrate; the method can realize the simultaneous recycling of nickel and iron and obtain the high-content ferronickel concentrate; the content of nickel is 5 to 13 percent and the recycling rate of nickel is 85 to 93 percent; the content of iron is 30 to 75 percent and the recycling rate of nickel is 60 to 85 percent; the reasonable utilization of the waste heat during process procedure achieves the purposes of saving energy and reducing discharge and greatly reduces pollution to the environment.

Owner:HONGHE HENGHAO MINING

Siliceous mullite structure-insulating integrated composite brick and preparation method thereof

The invention discloses a siliceous mullite structure-insulating integrated composite brick and a preparation method thereof. The brick consists of a heavy working layer and a high-strength light insulating layer, wherein the main materials of the heavy working layer are dense bauxite and silicon carbide material, the aggregate of the high-strength light insulating layer is one or the mixture of alumina hollow balls, alumina-magnesia hollow balls, corundum hollow balls, hollow microspheres and light ceramisite, the heavy working layer and the light insulating layer are combined together by adopting vibratory pressing or mechanical pressing, and the length proportion between the heavy working layer and a light insulating layer is 1 to 5:2 to 1. The invention overcomes the defect of the abrasion-resistant siliceous mullite brick for rotary kilns, i.e. high coefficient of heat conductivity, and the defects of the light part of the conventional siliceous mullite composite brick, i.e. low strength and low refractoriness, and the structure-insulating integrated composite brick has the advantages of high abrasion resistance, high refractoriness, high structure strength and high insulating property.

Owner:浙江盛旺耐火材料股份有限公司

Method for producing high-performance haydite from red mud

The invention discloses a method for producing high-performance haydite from red mud, which comprises the following steps: taking 40-70 parts by weight of Bayer-process red mud, 0-30 parts by weight of sintering-process red mud, 5-20 parts by weight of fly ash and 5-30 parts by weight of clay material on dry basis as raw materials; evenly mixing the raw materials with 5-20 parts by weight of water, and putting the mixture on a pelletization plate to carry out pelletization, thereby obtaining the haydite fresh pellets; sintering the haydite fresh pellets, of which the diameters are 0.5-20mm, in a rotary kiln or sintering machine at 1050-1200 DEG C for 15-60 minutes; and quenching the sintered haydite to obtain the high-performance haydite product, of which the density level is 600-900, the water absorptivity is lower than 12%, the cylindrical compressive strength is higher than 7.5MPa and the strength grade is higher than 50MPa. The invention can effectively and massively utilize red mud as the raw material to produce the high-performance haydite, has the advantages of simple manufacturing technique and high product quality, and changes wastes into valuable substances.

Owner:贵州省建筑材料科学研究设计院有限责任公司 +1

Reduction and utilization method of dedusting ash of stainless steel

InactiveCN101705333AReduce pollutionHigh recovery rateRotary drum furnacesProcess efficiency improvementMixed materialsMolten steel

The invention relates to a reduction and utilization method of dedusting ash of stainless steel, comprising the following steps of: (1) preparing materials: uniformly stirring and mixing raw materials into a mixed material according to following proportions: 90-95 dedusting ash, 2-4 reducing agent and 3-6 bonding agent; (2) extrusion formation: pressing the mixed material into dedusting ash pressure balls; (3) maintaining: naturally drying and maintaining the dedusting ash pressure balls, wherein the measured intensity of the pressure balls is 2420N / each ball-2820N / each ball; (4) sintering: adding the dedusting ash pressure balls into a rotary kiln, sintering at 650+ / -50 DEG C for no less than 20 minutes, and discharging; (5) preparing materials for an electric furnace according to the following proportions: 70-80 stainless steel waste steel, 35-40 high-carbonferrochrome, 40-45 pig iron containing chromium and nickel, 3-5 dedusting ash pressure balls, 6-8 slag former and 0.3-0.5 reducing agent; and (6) melting: adding the prepared materials into the electric furnace for melting, and tapping when the temperature and the components of the molten steel meet the requirement. The reduction and utilization method of the dedusting ash of stainless steel has the advantages of low cost and little pollution to the environment.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Method for deep reduction and magnetic separation of nickel and iron in lateritic nickel ore carbon-containing pellets

The invention discloses a method for deep reduction and magnetic separation of nickel and iron in lateritic nickel ore carbon-containing pellets. The method aims at realizing deep reduction calcination and magnetic separation, and has obvious nickel and iron enrichment effects. The method comprises the following steps of carrying out crushing and abrasive cleaning of lateritic nickel ores by a jaw crusher and a ball mill, removing soil, carrying out dehydration and drying by an oven, adding a reducing agent, CaO as a flux and a composite binder into the dried lateritic nickel ore particles, feeding the mixture into a damp mill to obtain the uniform mixture, feeding the uniform mixture from the damp mill into a disc-shaped pelletizer for pelletizing, respectively carrying out drying, preheating and calcination by a grate and a rotary kiln, throwing the calcined pellets into a sealed channel of a cooling water tank, wherein an annular air cooler is arranged around the sealed channel, feeding heat carried by the calcined pellets back to the grate for use by the annular air cooler, carrying out water quenching of the calcined pellets falling into the cooling water tank so that the calcined pellets are crushed automatically, dragging nickel, iron and slag in the cooling water tank by a slag dragging machine and feeding them into the ball mill for fine grinding, directly feeding theobtained nickel and iron ore powder into a magnetic separator for separation, drying the separated nickel and iron ore powder by an oven, packaging the dried nickel and iron ore powder, warehousing the packaged nickel and iron ore powder, drying the separated nonmagnetics by an oven, and warehousing the dried nonmagnetics as magnesium raw materials.

Owner:王号德

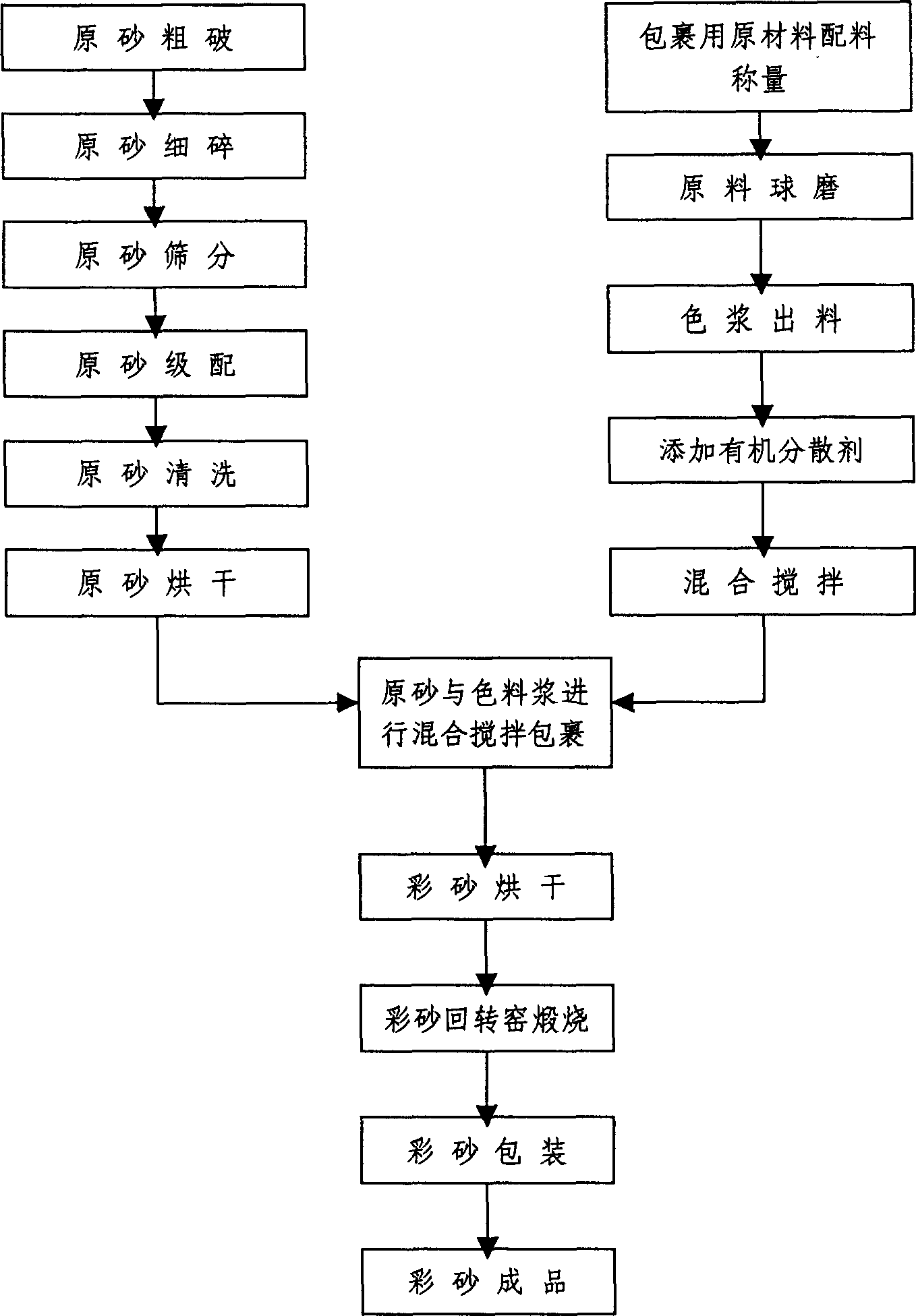

Color sand and production thereof

A surface decorative material color sand and its production are disclosed. The color sand consists of basic material and surface coated chromatograph, the basic material consists of quartz, mineral particle or waste slag particle, the chromatograph coating formula consists of emulsified frit, inorganic pigment, swelled ground, Suzhou ground and inorganic binder. The production is carried out by: 1) breaking, screening, washing and drying basic material, and obtaining particle with certain grain size; 2) mixing water with emulsified frit, inorganic pigment, swelled ground, Suzhou ground and inorganic binder by proportioning, ball grinding, and obtaining coating mill base; 3) adding organic disperser, mixing organic disperser with mill base, chromatographic coating mineral particle with certain grain size; 4) drying particle with mill base coat, putting into external heating rotary kiln, and calcining with calcining temperature 500-950deg.C and heating time 0.5-1hr. It achieves simple production, low calcining temperature and good color.

Owner:CAILIN COLOR SAND PRODS JIANGYIN CITY

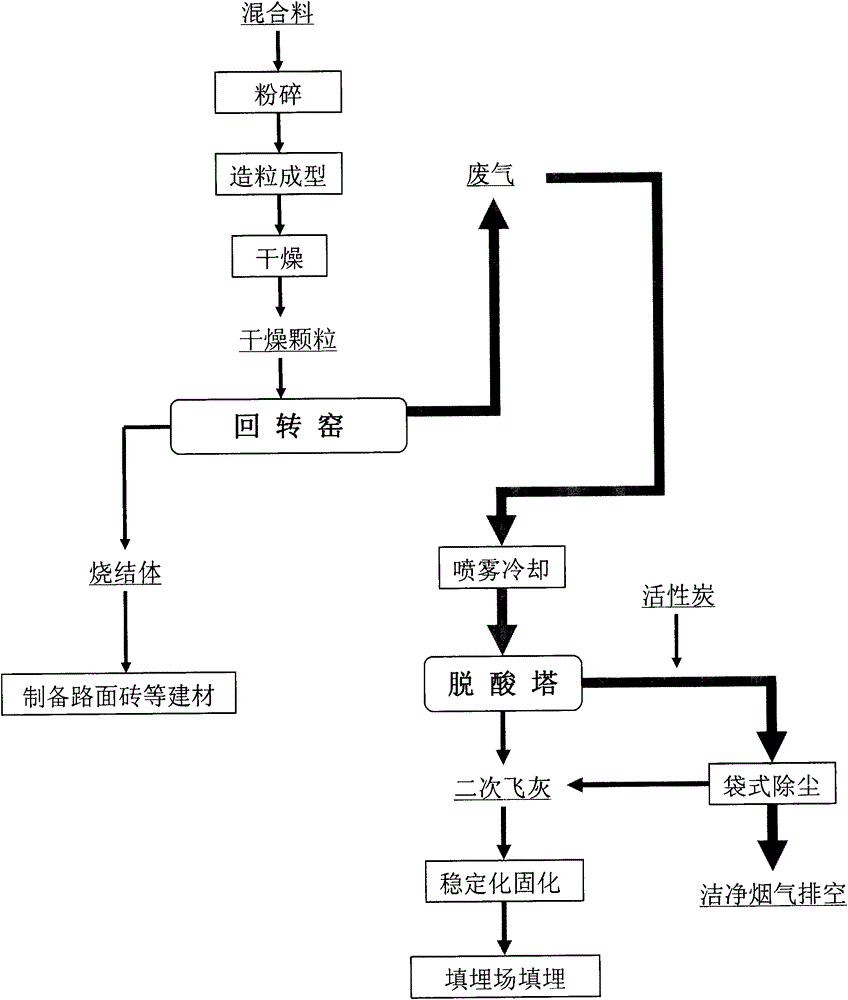

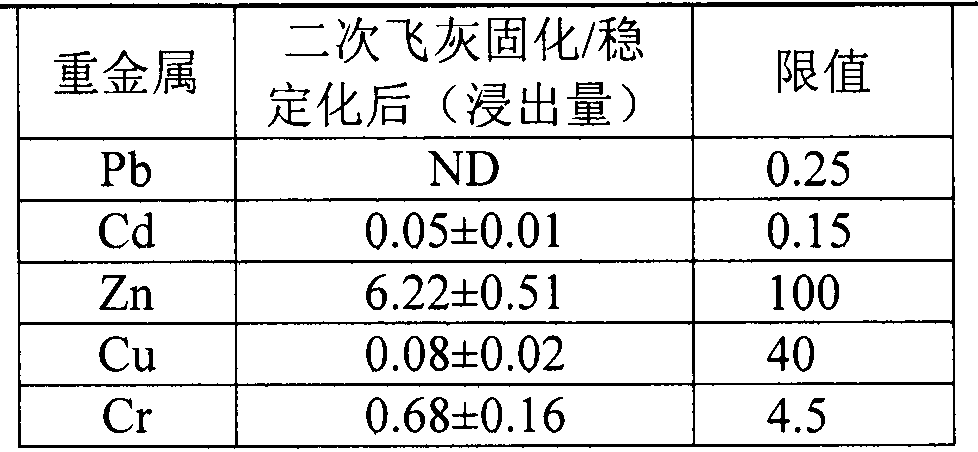

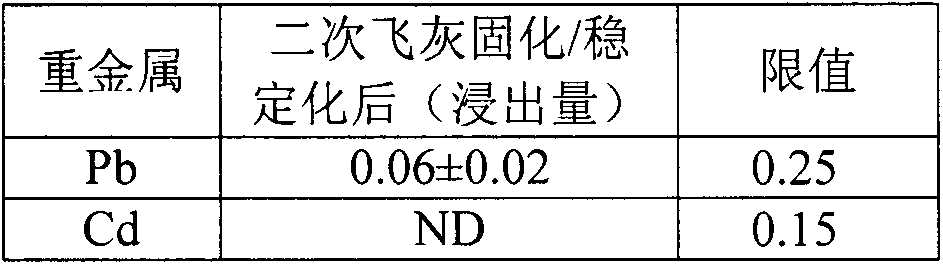

Garbage burning fly ash sintering harm-eliminating resource-utilization treatment system

The invention relates to a garbage burning fly ash sintering harm-eliminating resource-utilization treatment technology. According to the invention, garbage burning fly ash is mixed with premixed coal and auxiliary materials; the mixture is granulated and shaped; and the material is dried and is sintered in a rotary kiln. During the sintering process, when the temperature is increased and a coal ignition point is reached, the premixed coal is spontaneously combusted. Therefore, external coal dose can be reduced. Initial combustion of the premixed coal can provide a reductive atmosphere, such that dechlorination and detoxification of dioxin in fly ash can be benefited. Large amount of gas is produced by subsequent combustion, such that dust pores and holes are produced on inner and outer parts of the sintered body, and heavy metal volatilization can be promoted, and fly ash sintered body with low heavy metal content and leaching amount can be obtained. The sintered body has no potential harm to the environment, such that fly ash harm-eliminating and resource-utilization are sufficiently realized. During the processing process, smoke and secondary fly ash production amounts are low, and heavy metal and acidic component contents are high. In deacidification and heavy metal stabilization processes, agent utilization rate is improved. Compared with a traditional original fly ash curing / stabilizing process, a landfill amount can be reduced by 80-90%, such that pressure caused by serious landfill space shortage can be effectively relieved.

Owner:TIANJIN YIMING ENVIRONMENTAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com