Reflux type temperature controllable sludge drying device and method

A sludge drying and sludge technology, applied in the direction of dewatering/drying/concentrating sludge treatment, can solve the problems of large energy consumption, high operating costs, complex sludge composition, etc., and achieve obvious economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

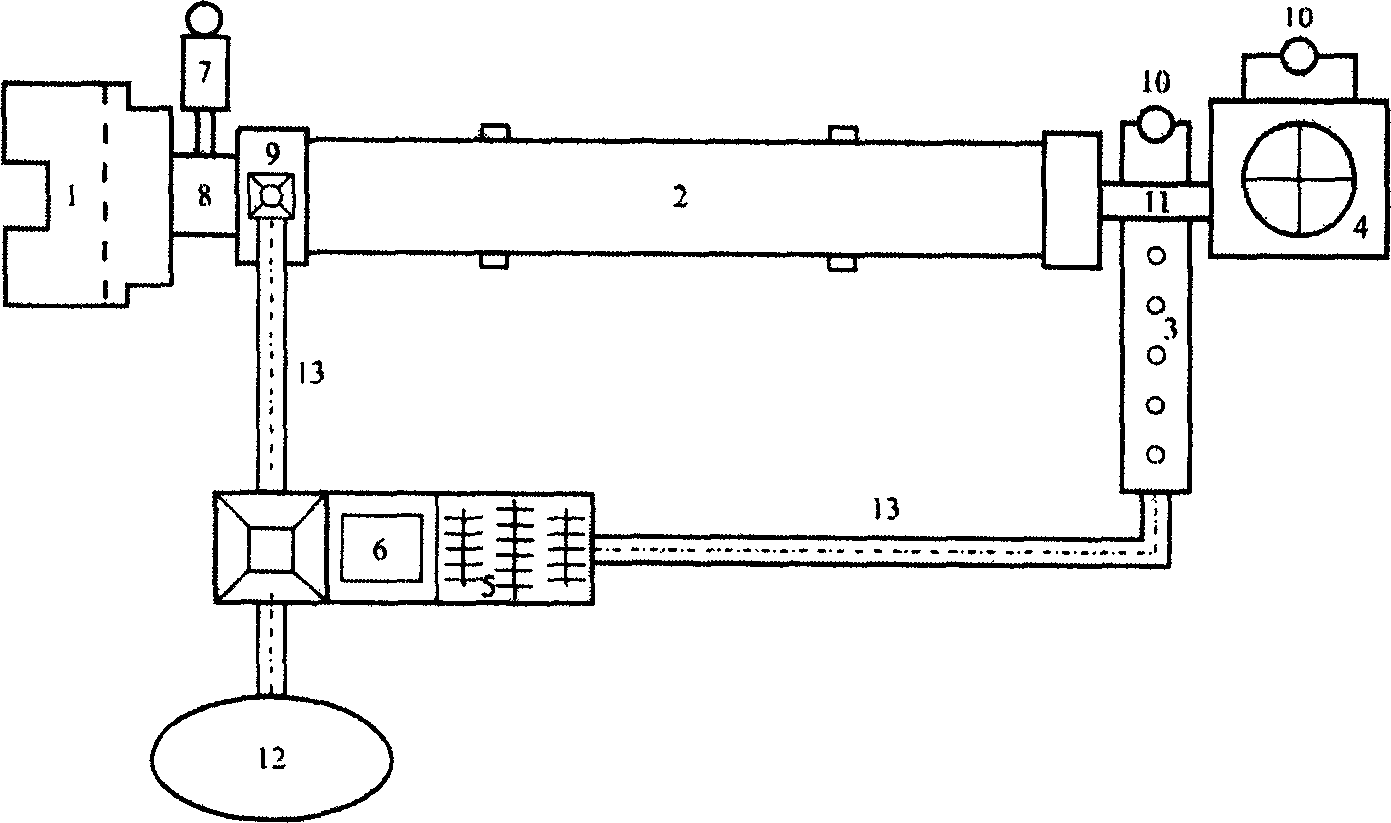

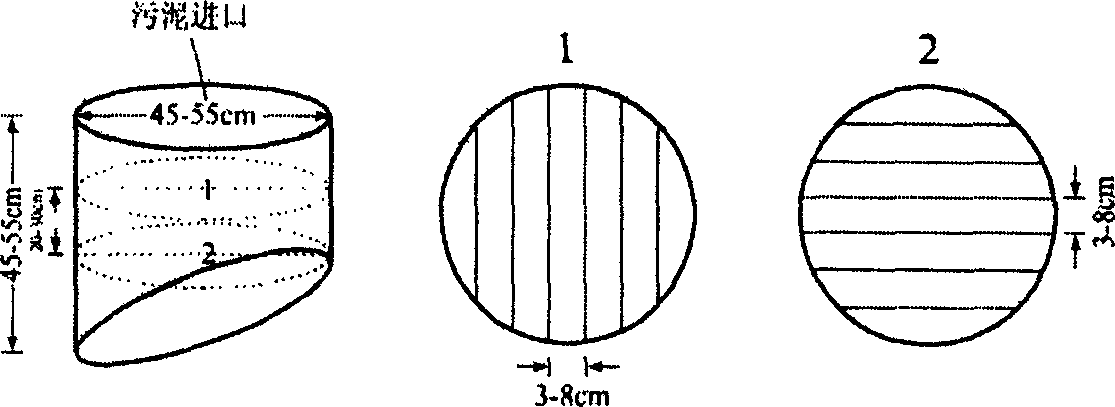

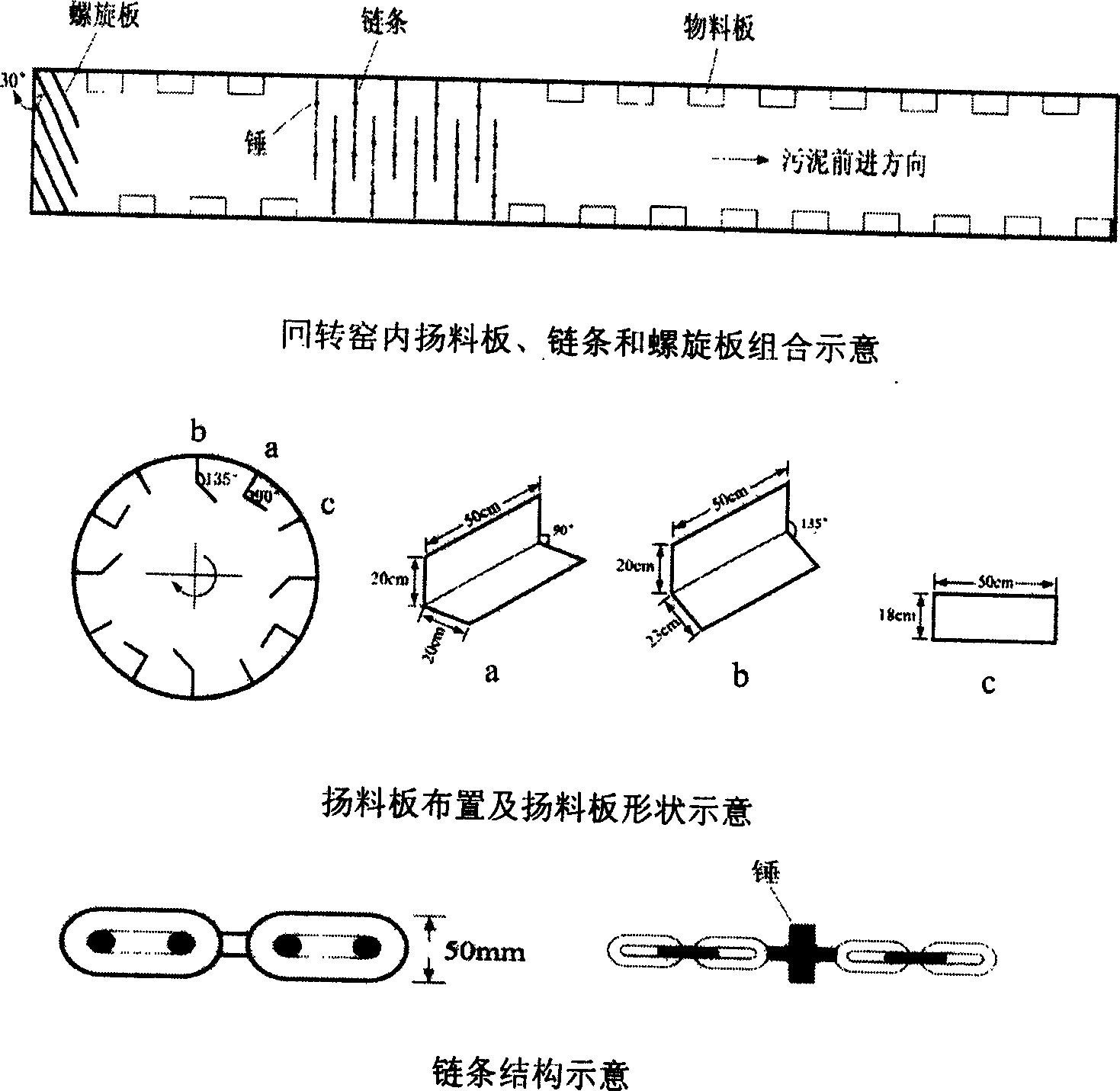

[0019] The return-type temperature-controllable sludge drying device has sequentially connected heating furnace 1, heat pipe 8, rotary kiln 2, cold air blowing off equipment 3, conveyor belt 13, pulverizer 5, material distribution screen 6, granulator 12, A jet air inducer 7 is provided on the side of the heat pipe 8, and the rotary kiln 2 and the cold air blowing off equipment 3 are connected to the dust removal and degassing equipment 4 through the ventilation pipe 11. The fan 10 and the top of the front end of the rotary kiln 2 are provided with a sludge inlet 9), and the material distribution screen 6 is connected with the sludge inlet 9 through a conveyor belt 13. See attached figure 1 .

[0020] In this device, the heat provided by the heating furnace can be generated by burning coal or by gas. The jet induced air device is used to control the heat provided for sludge drying, and the temperature during sludge drying is adjusted according to the properties of sludge and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com