Patents

Literature

11506 results about "Incineration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Incineration is a waste treatment process that involves the combustion of organic substances contained in waste materials. Incineration and other high-temperature waste treatment systems are described as "thermal treatment". Incineration of waste materials converts the waste into ash, flue gas and heat. The ash is mostly formed by the inorganic constituents of the waste and may take the form of solid lumps or particulates carried by the flue gas. The flue gases must be cleaned of gaseous and particulate pollutants before they are dispersed into the atmosphere. In some cases, the heat generated by incineration can be used to generate electric power.

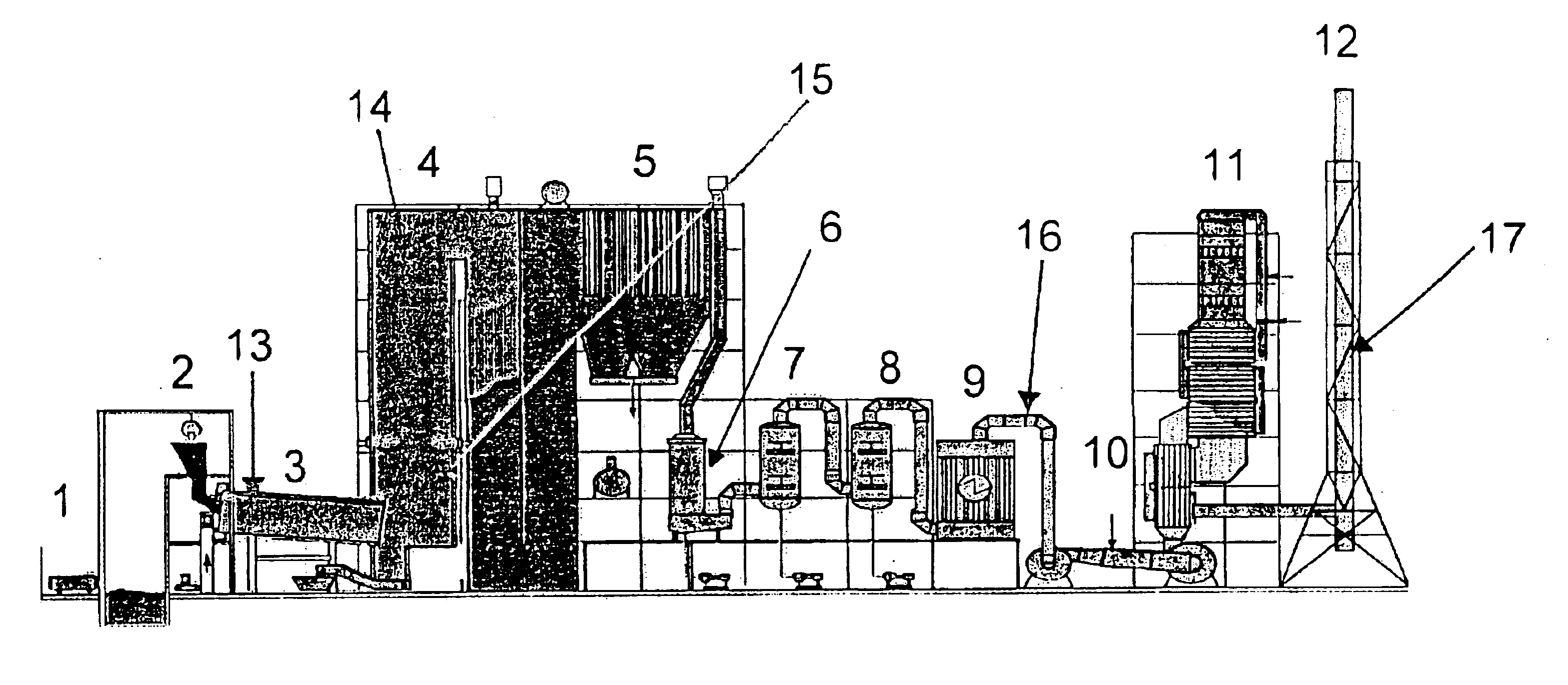

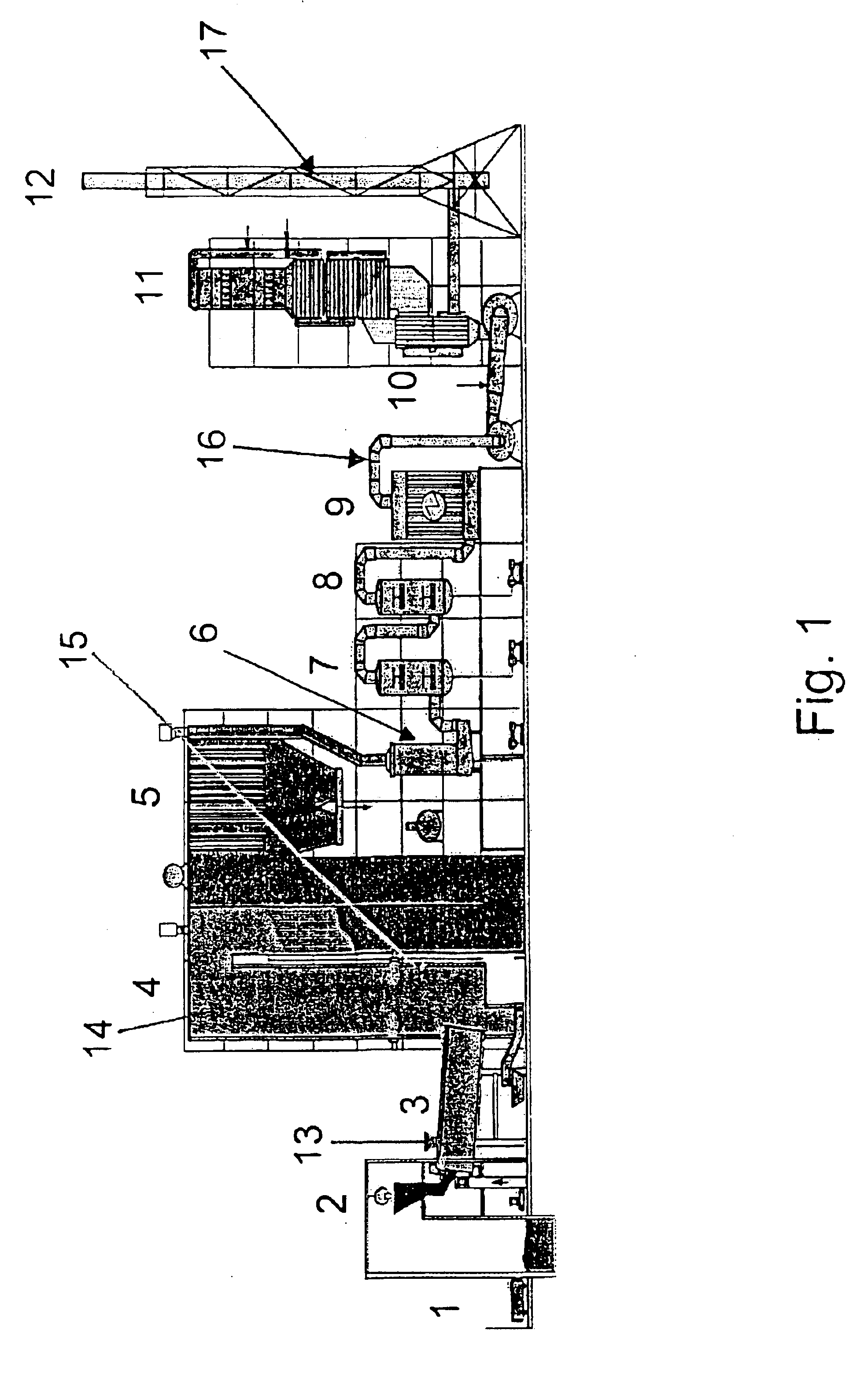

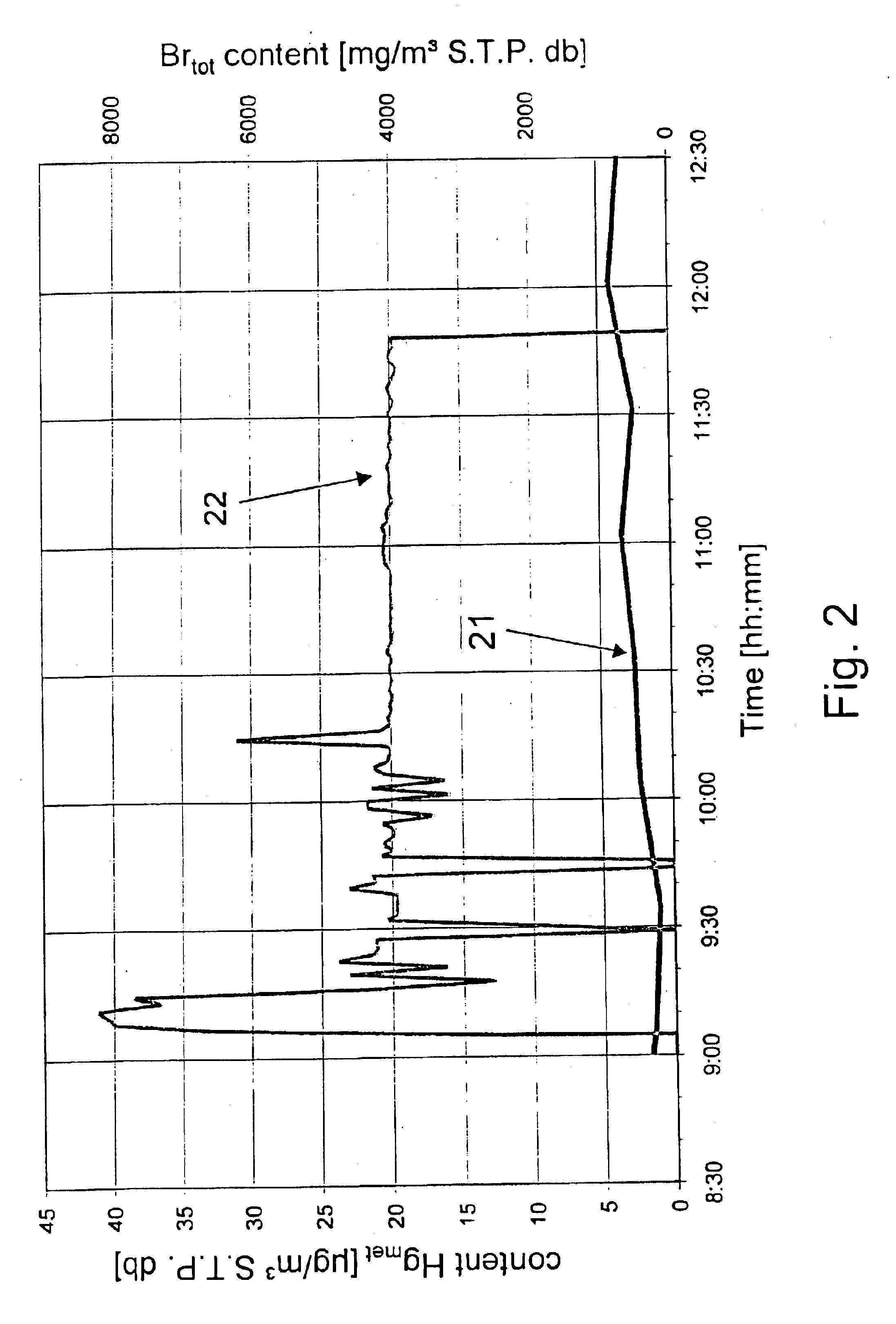

Process for removing mercury from flue gases

InactiveUS6878358B2Reduce operating costsSmall amountUsing liquid separation agentChemical/physical processesPower stationCombustion

Process for removing mercury from flue gases of high-temperature plants, in particular power stations and waste incineration plants in which a bromine compound is fed to the multistage furnace and / or the flue gas in a plant section downstream of the furnace, the temperature during contact of the bromine compound with the flue gas being at least 500° C., preferably at least 800° C. The combustion is carried out in the presence of a sulphur compound, in particular sulphur dioxide. Subsequently to the furnace, the flue gas is subjected to an optional multistage cleanup for removing mercury from the flue gas, which cleanup comprises a wet scrubber and / or a dry cleanup.

Owner:BROMERC

Heat energy recapture and recycle and its new applications

InactiveUS20050120715A1Increase the atmosphereGood sunshineEngine fuctionsEfficient propulsion technologiesThermal energyDistillation

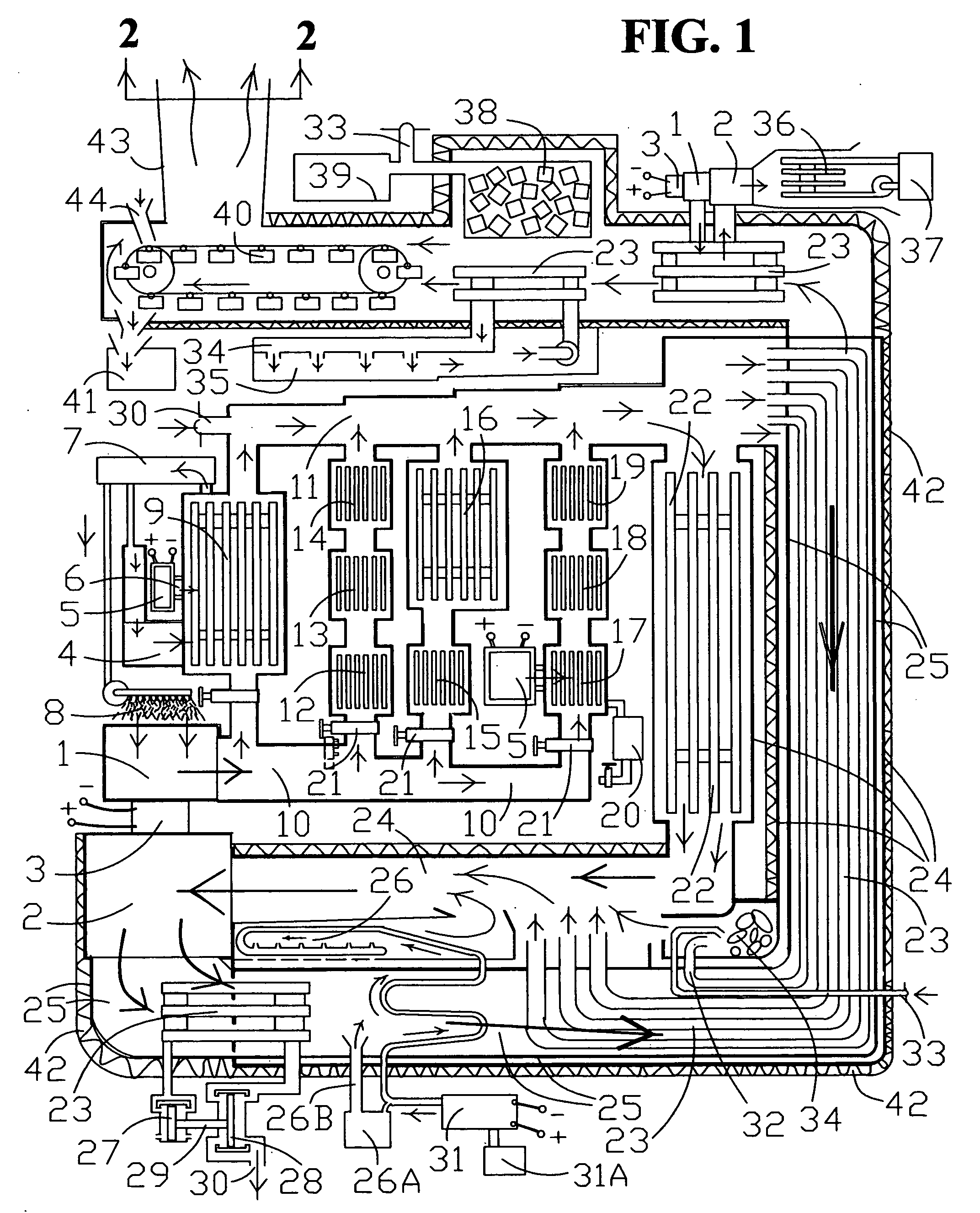

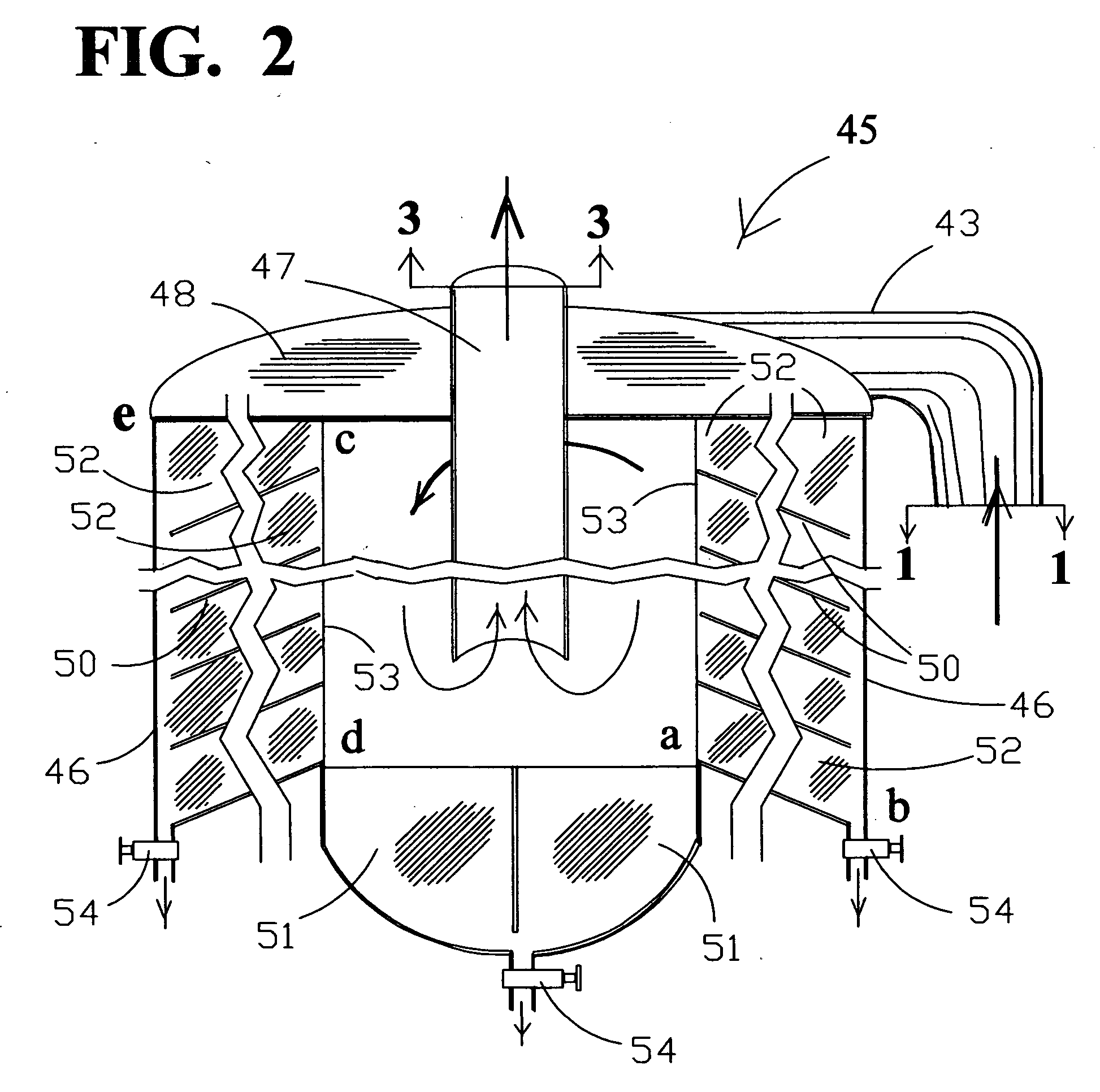

What has been created is a plurality and a variety of processes and a variety of devices correspondingly supportive to each process, wherein, a new partnership between; (1) a heat absorbing radiator compressed air pipes / tubes and (2) a gas turbine engine or a reciprocating piston engine,—is used to recapture and reconvert the, otherwise wasted, heat energies expelled by engines, by factories, by smelting plants, by distillation plants, by chillers / coolers / freezers, by cooking ovens, by lamps / stoves, by trash burners, and the heat energies created by the solar heat on the desert / ocean water,—into electric power and finally into hydrogen-deuterium fuel,—by having the engine's tailpipes submerged in cold compressed air inside the heat absorbing radiator pipes in reverse air flow, to further drive and re-drive the same engine; wherein, in order to capture fusion heat energy the hydrogen bomb is detonated in the deep ocean to catch the flames by the water and the hot water is used to energize the compressed air inside the heat absorbing radiator pipes; wherein, in order to produce fusion energy, an abundant electric arc is passed across liquid deuterium or across gaseous deuterium by the electro-plasma torch and sparkplug in the internal combustion engine, and by detonating a dynamite inside a liquid deuterium; wherein diamond is produced by placing carbon inside the hydrogen bomb; and wherein, deuterium fusion flame is used first in smelting glass to large sizes before running an engine.

Owner:CHRISTIAN SCHOOL OF TECH CHARITABLE FOUND TRUST

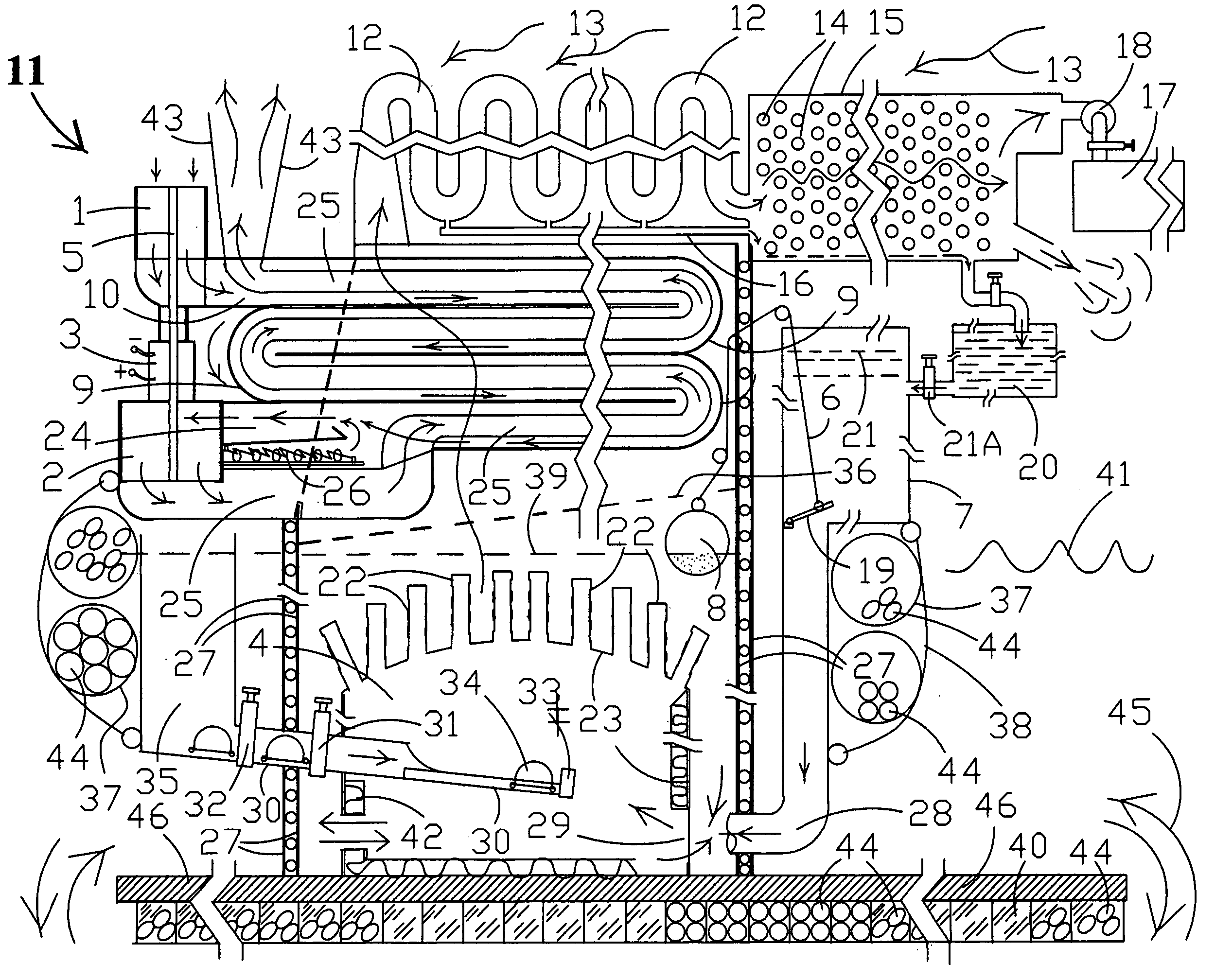

Method for removing mercury from flue gas after combustion

InactiveUS7727307B2Simple and economical methodGas treatmentUsing liquid separation agentPower stationCombustion

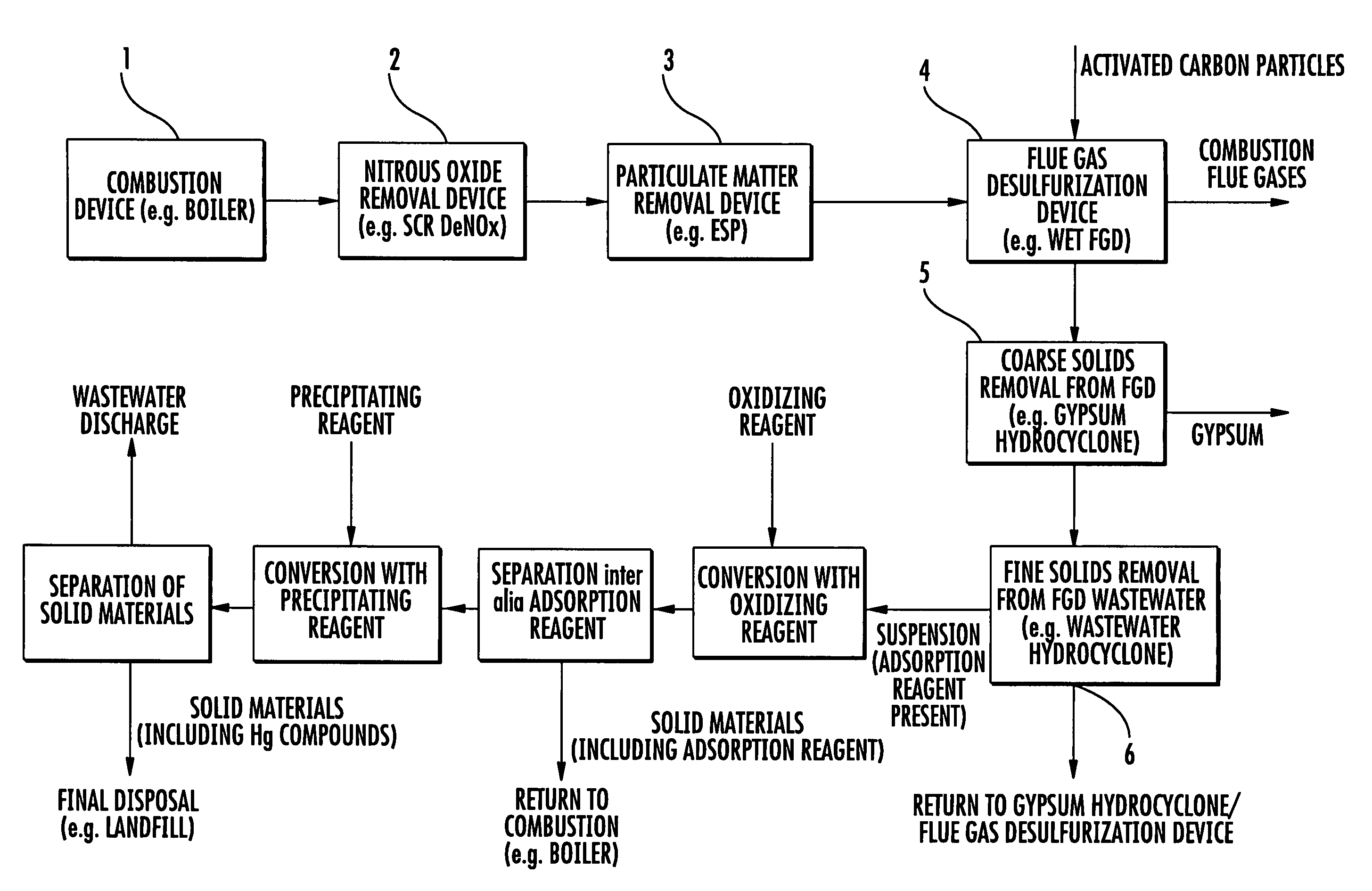

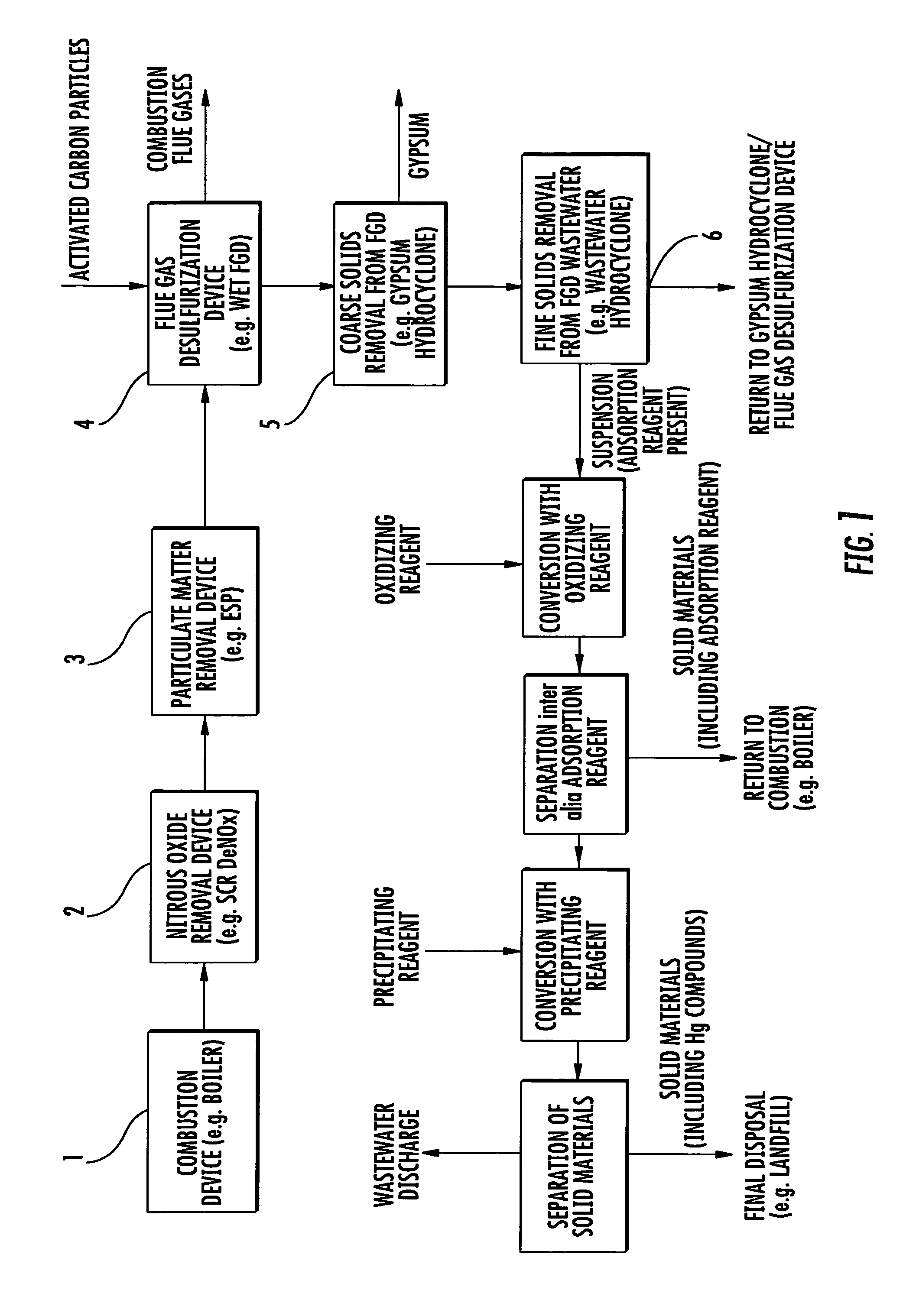

A method of removing mercury from flue gases from combustion plants, such as for example power plants or waste incineration plants, is achieved in which mercury-containing flue gases are brought into contact with an adsorption reagent either directly or indirectly by being contained in an absorption reagent, whereby mercury is substantially adsorbed by the adsorption reagent during this contact. After adsorption has occurred the adsorption reagent is separated from the flue gases and subsequently from the absorption reagent and added to an aqueous solution containing an oxidizing agent, whereby the adsorbed mercury dissolves as Hg2+. The Hg2+-containing solution is subsequently separated from the adsorption agent and the Hg2+ then is removed from the solution. This method enables the mercury to be removed from flue gas in a simple and economical manner.

Owner:STEAG ENERGY SERVICES

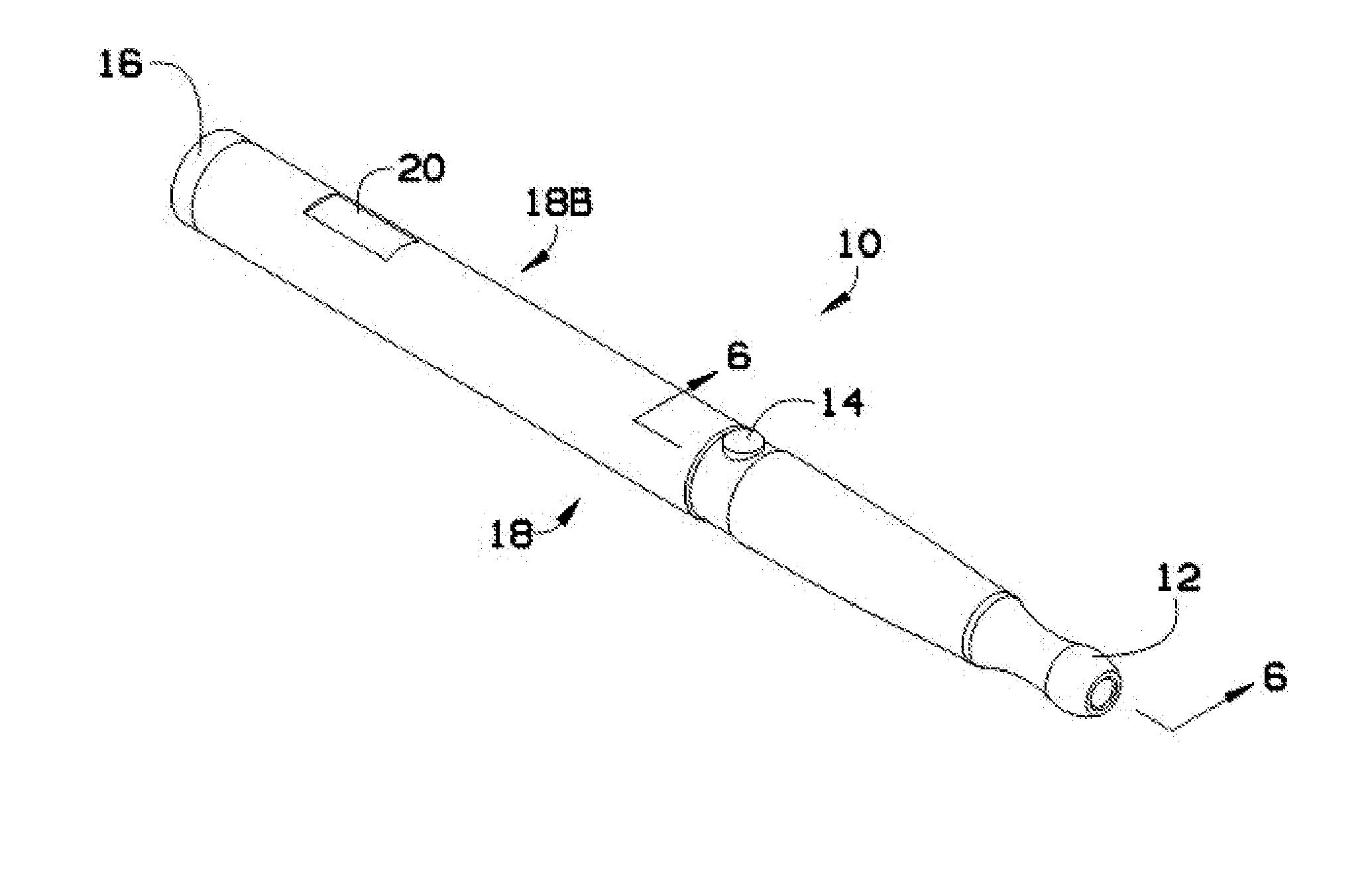

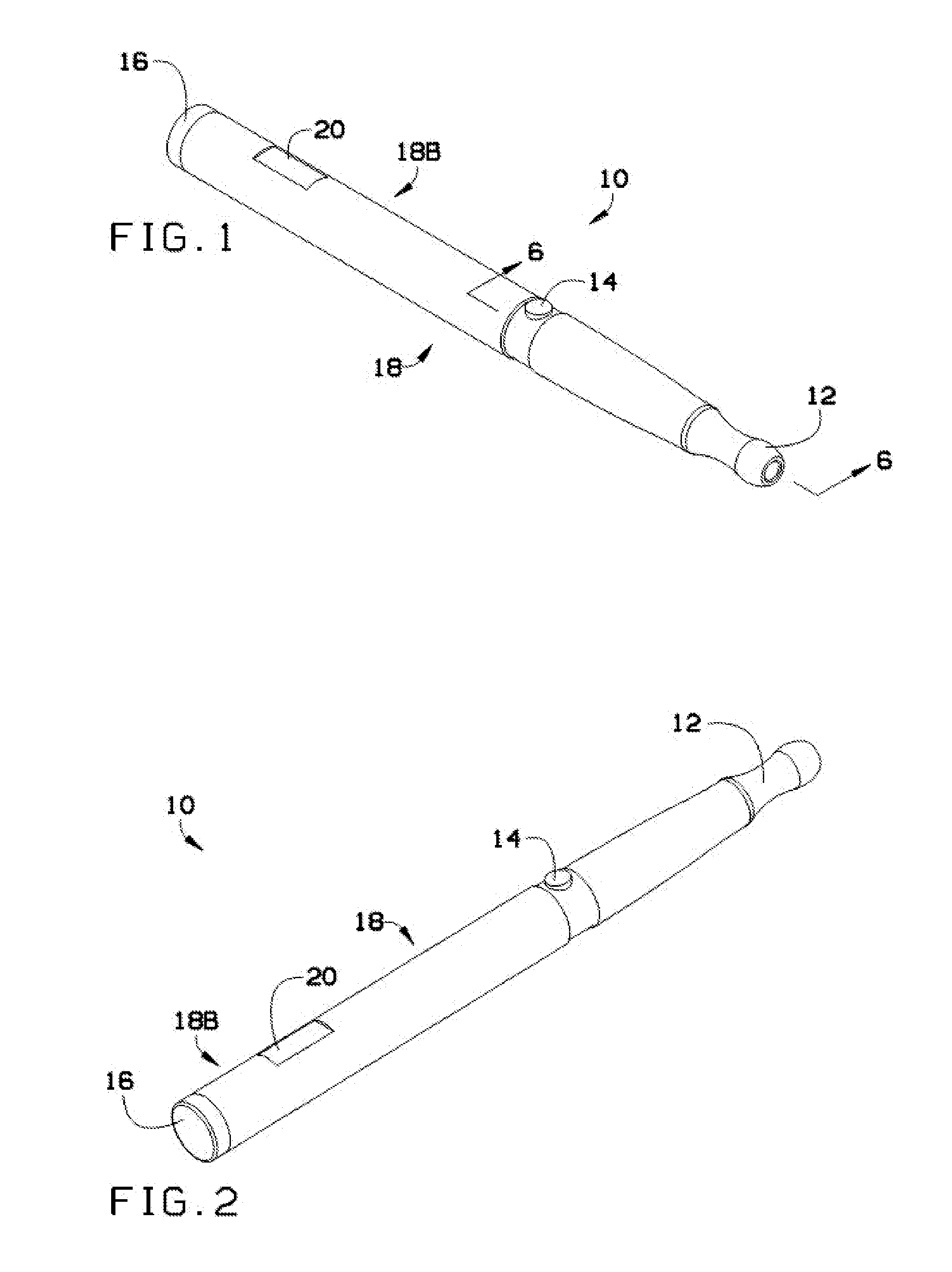

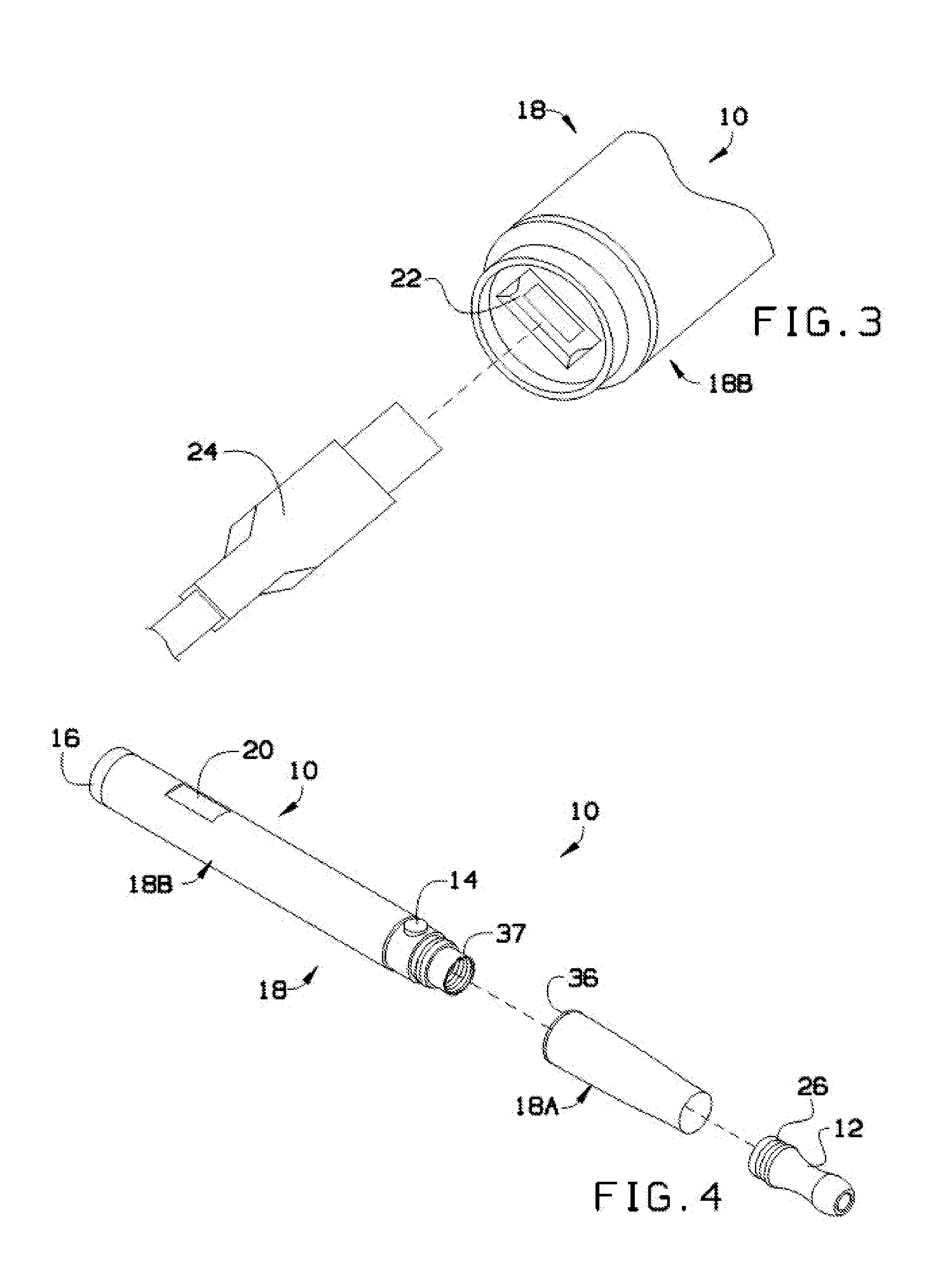

Self-contained electronic smoking device that produces smoke and ash by incineration

Embodiments include an electronic smoking device that produces authentic smoke and ash by incinerating smoking material placed directly onto a heating source that obtains a high temperature. This heat could also be harnessed for warmth or lighting cigars and cigarettes. The device may be an electronic pipe with a housing compartment, a power source, an atomizer heating source, a mouthpiece, a power trigger, a charger, and airflow ducts. The heating source may include one or more filaments that get heated in the burnable material compartment. The device may be conical in shape as to be a compatible water-pipe accessory. The housing may include several separable sections, including a battery housing and a burn housing that may separate from each other. The device may include adapters including plugged bifurcated adapters, to mitigate leaking from burn housing into the battery adapter, a ceramic dish, and insulation.

Owner:KATZ SAMUEL AARON

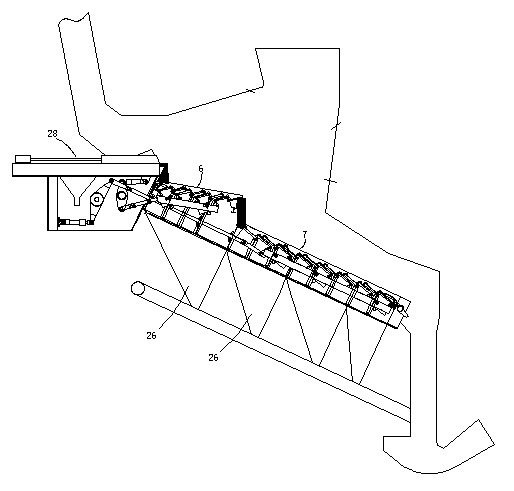

Two-stage garbage incinerator

ActiveCN101922715AGuaranteed incineration effectFully dryInclined grateIncinerator apparatusLoss rateCombustion

A two-stage garbage incinerator is characterized in that secondary air supply holes are arranged on front and rear arches of a furnace body and an ignition combustion-supporting hole is arranged on the rear arch; a grate in the furnace body is divided into two stages from top to bottom; the upper stage is a forward pushing stage and the lower stage is a backward pushing stage; an independent primary air chamber is arranged below each stage; the heads of the grates on the forward pushing stage face the low point direction of the grates; the heads of the grates on the backward pushing stage face the high point direction of the grates; moving beams of the grates on the same stage are equipped with left and right draw bars arranged side by side; the left and right draw bars are supported by supporting roller devices and are connected with the moving beams to form draw bar frames; and the ends of the draw bar frames are connected with front rocker arm driving mechanisms, lateral rocker arm driving mechanisms or front straight driving mechanisms. The incinerator can realize full drying of the whole garbage material, ensure complete combustion and ensure the garbage incineration effect and hot ignition loss rate. At the same time, the incinerator has less spare parts and spare part specifications, good quick-wear part interchangeability and low manufacture and maintenance costs.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP

Ozone oxidation and denitration method of boiler flue gas

The invention provides a method for processing de-nitration on the boiler smoke, belonging to the environmental protective technique. The method comprises: ejecting ozone O3 into the low-temperature section of smoke channel of boiler whose temperature ranges from 110-150Deg. C; oxygenizing the nitric oxide NO into high-state nitrogen oxide as NO2, NO3 or N2O5; washing the smoke with alkali liquor to remove the nitrogen oxide in the smoke. Compared to other de-nitration method, said invention has higher efficiency, lower cost, and non-secondary pollution, while the absorption effect combined with alkali liquor can reach more than 80%. In addition, the invention can apply variable boiler devices, which is not relative to the burning condition of boiler.

Owner:ZHEJIANG UNIV

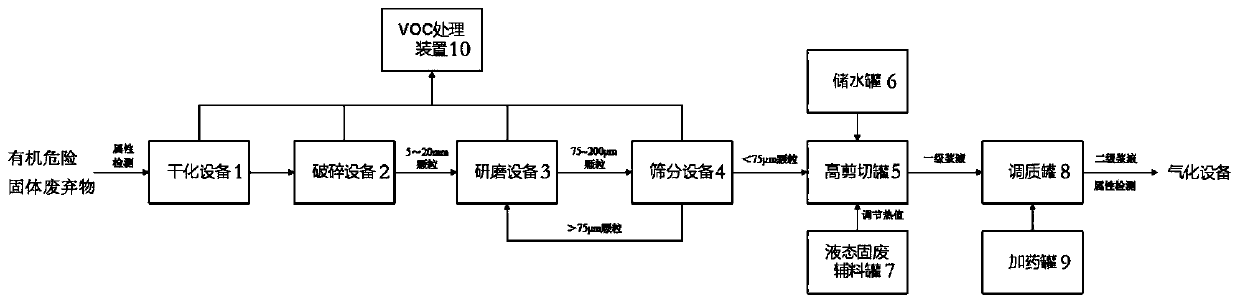

Slurrying method of organic dangerous solid waste

ActiveCN111185461AImplement resourcesSolid waste disposalTransportation and packagingWaste treatmentIncineration

The invention discloses a slurrying method of organic dangerous solid waste. The slurrying method of the organic dangerous solid waste can be used for preparing up-to-standard slurry for gasificationequipment feeding in a high-temperature gasification technology so as to realize the purpose of treating the organic dangerous solid waste by utilizing the high-temperature gasification technology, existing organic dangerous solid waste treatment methods including incineration, landfill, fermentation and the like are replaced, and after the prepared slurry is treated by the gasification equipment,treatment recycling and harmlessness of the organic dangerous solid waste can be realized.

Owner:杰瑞邦达环保科技有限公司

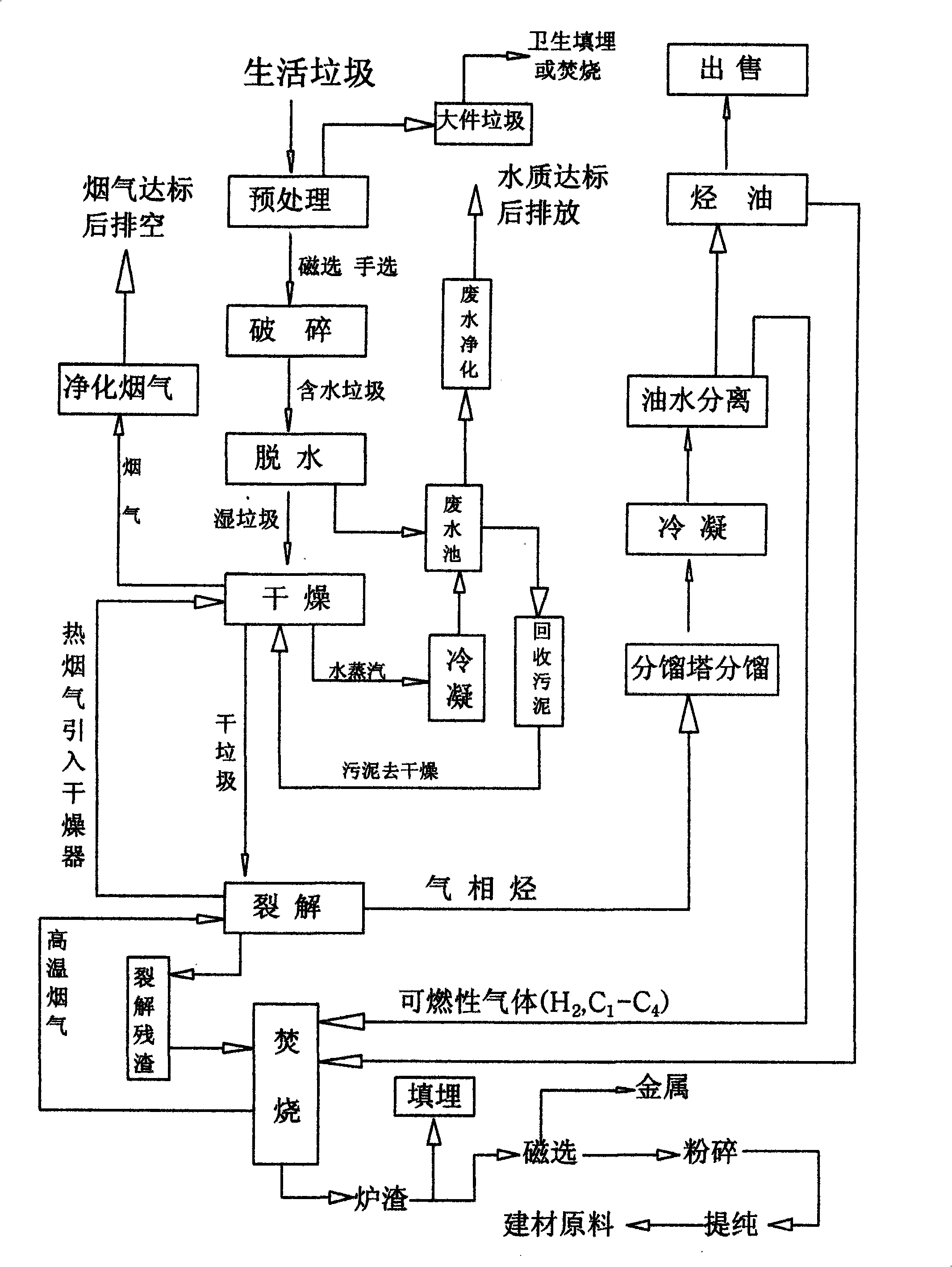

Method for sequentially processing consumer waste

ActiveCN101352721AHarmless treatmentIncrease throughputSludge treatment by de-watering/drying/thickeningSolid waste disposalLitterMature technology

The invention discloses a method for continuously treating domestic garbage, more specifically belongs to a method for continuously treating domestic garbage according to the process flows of pretreatment, crushing, dehydration, drying, cracking, incineration, etc. Dioxin C2H4O2 is not produced in the garbage treatment process; and the method can realize various requirements of massive and continuous treatment, reclamation (the energy in the garbage is stored in a manner of collecting hydrocarbon oil), energy saving, environmental protection, high efficiency, and the like, in domestic garbage treatment. The devices adopted in the method belong to standardized commodities for industrial use, and have the advantages of reliable operation, mature technology, simple structure and low investment. The method of the invention belongs to the continuous garbage treatment process, can completely and thoroughly implement reduction, harmless treatment and reclamation of mountains of domestic garbage, and is characterized by good novelty, creativity and industrial applicability.

Owner:北京康乔世纪环境科技有限公司 +1

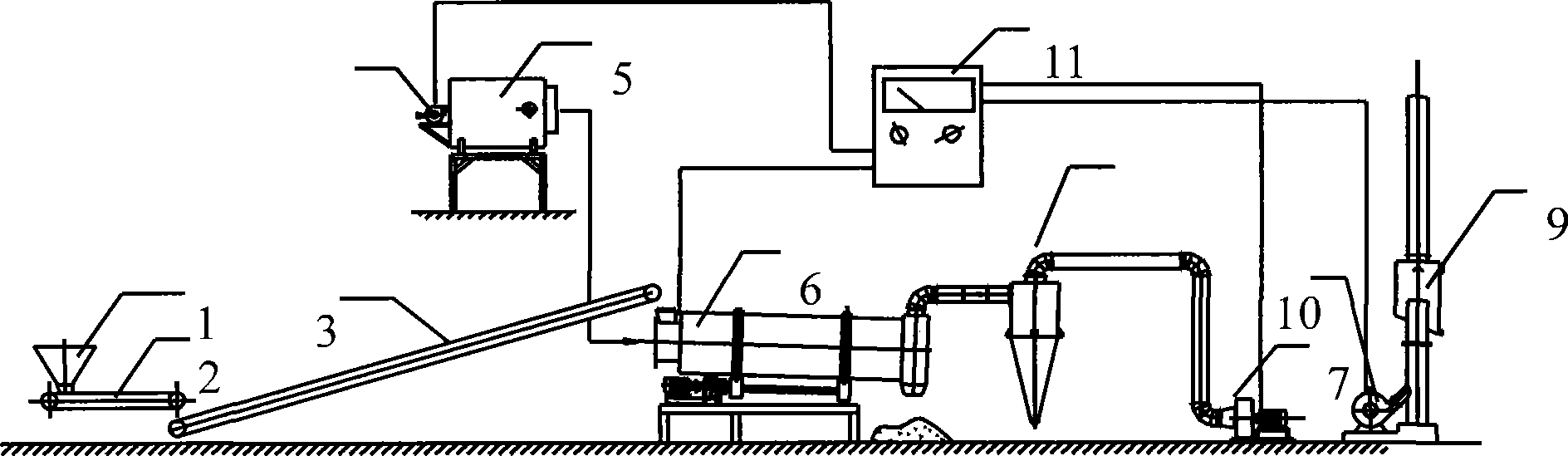

Soil pollution thermal desorption restoration processing system

InactiveCN101530858AAvoid secondary pollutionImprove applicabilityContaminated soil reclamationEngineeringProcessing cost

The invention relates to a soil pollution thermal desorption restoration processing system, which belongs to a soil restoration processing system. The system comprises a feed system, a heat source system and a control system, and is characterized by further comprising a thermal desorption system and a tail gas processing device, wherein the thermal desorption system consists of a draught fan and a thermal extraction converter, and the tail gas processing device consists of a dust remover and an absorption tower. When the system is applied to processing polluted soil with main pollutants of volatile / semi-volatile organic compounds, compared with the like products in other countries, the equipment cost is only 1 / 3 to 1 / 5 of the same; the problem of secondary pollution probably brought about in the process of processing the polluted soil is thoroughly avoided; a temperature control system has better practicability; the running cost for each ton of the polluted soil is between 300 and 500 RMB, which is far low than the processing cost for hazardous landfilling and incineration of the polluted soil; and half of the purification effect of processing the polluted soil with the main pollutants of the volatile / semi-volatile organic compounds can reach between 70 and 80 percent.

Owner:NANJING INST OF ENVIRONMENTAL SCI MINIST OF ECOLOGY & ENVIRONMENT OF THE PEOPLES REPUBLIC OF CHINA

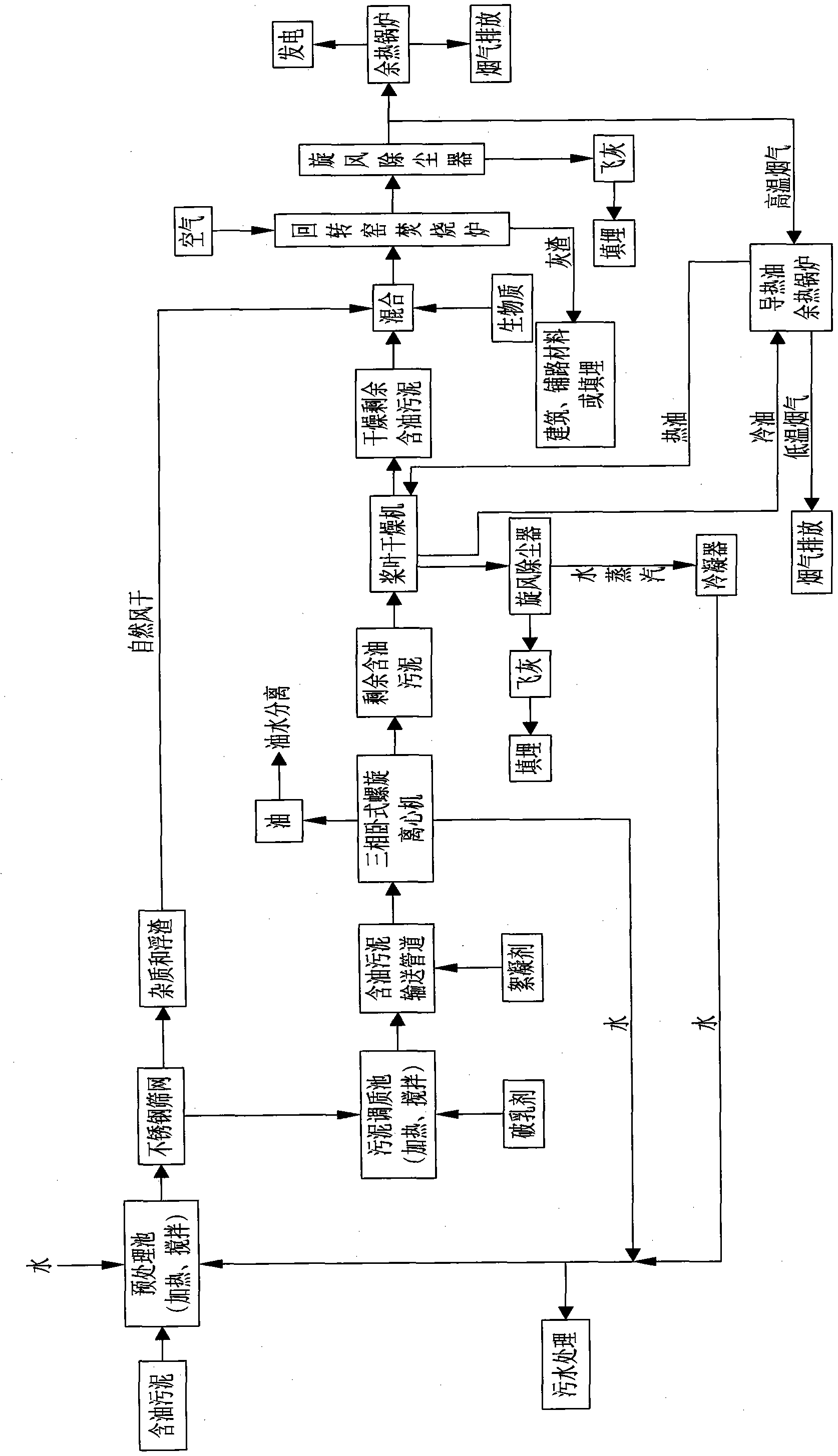

Oily sludge recycling and innocent comprehensive treatment process

InactiveCN102039301APromote resource utilizationEliminate secondary pollutionSolid waste disposalTreatment with plural serial refining stagesSlagOil sludge

The invention provides an oily sludge recycling and innocent comprehensive treatment process, which comprises the following four steps of: 1, pretreating oily sludge: adding water into the oil sludge, heating and stirring to form fluidized sludge, and separating in a stainless steel screen; 2, conditioning the oily sludge, adding a demulsifier and a flocculant into the separated fluidized sludge for conditioning the oily sludge; 3, performing centrifugal separation on three phases of the oily sludge: introducing separated oil into an oil-water separation system for recovering crude oil, conveying separated water to the oily sludge pretreatment step for recycling, drying the separated residual oily sludge, and solid impurities and floating slag which are separated in the oily sludge pretreatment, and introducing the dried substances into a rotary kiln incinerator; and 4, performing mixed combustion on the residual oily sludge and biomass, performing high temperature incineration treatment after the residual oily sludge, the separated solid impurities and floating slag, and the biomass are mixed in a rotary kiln to remove the secondary pollution of the oily sludge, and recovering afterheat from high temperature flue gas.

Owner:KUNMING UNIV OF SCI & TECH

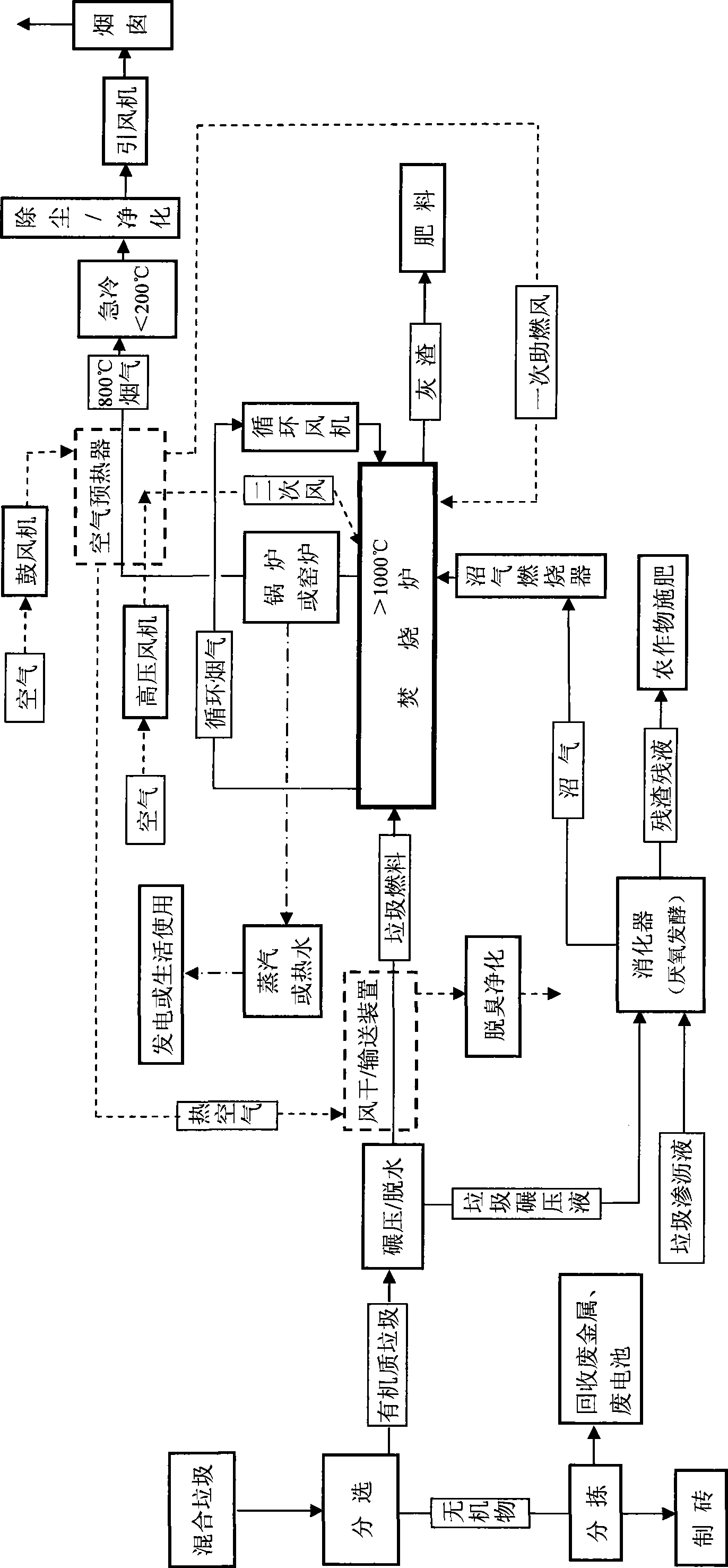

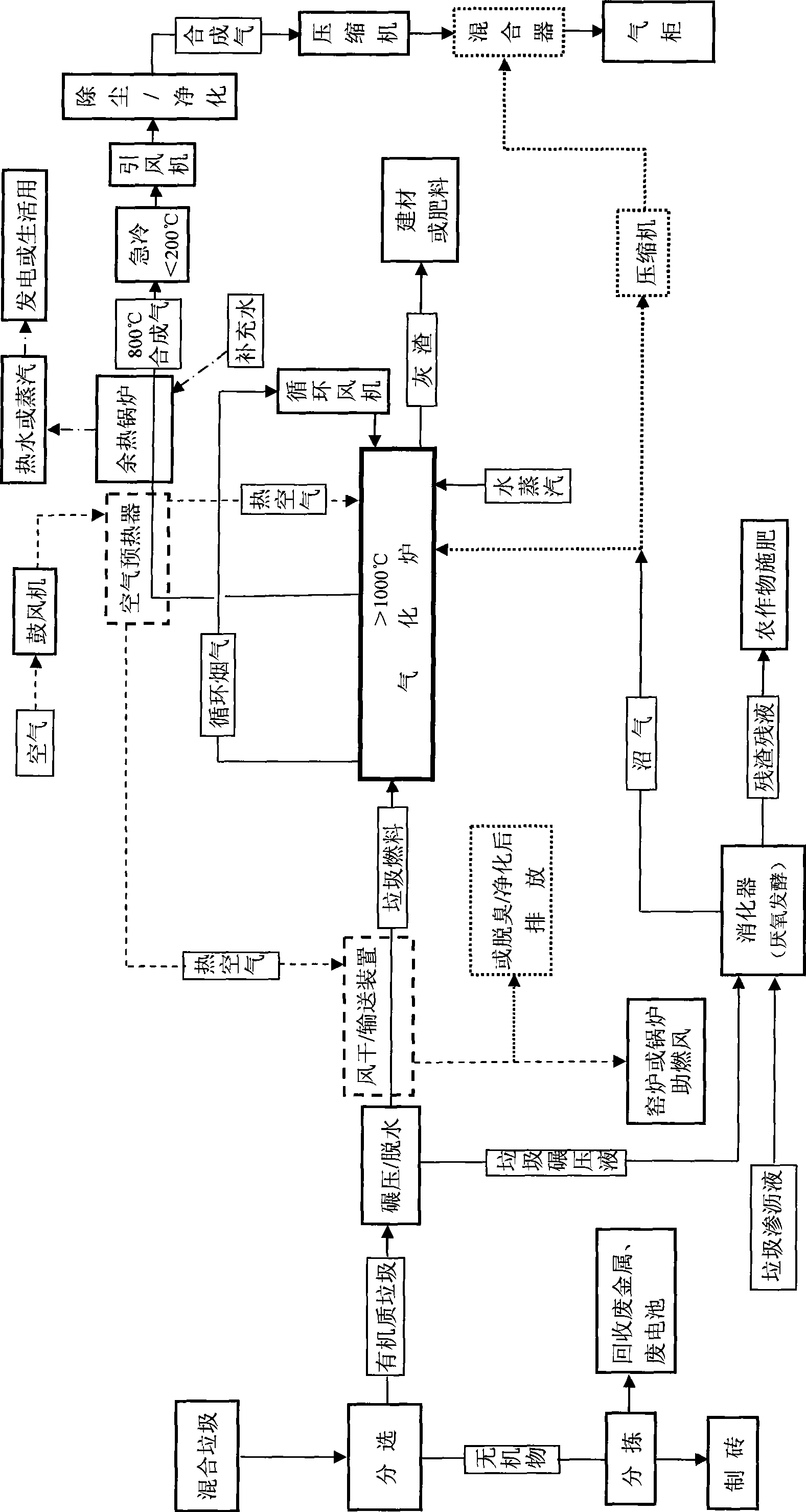

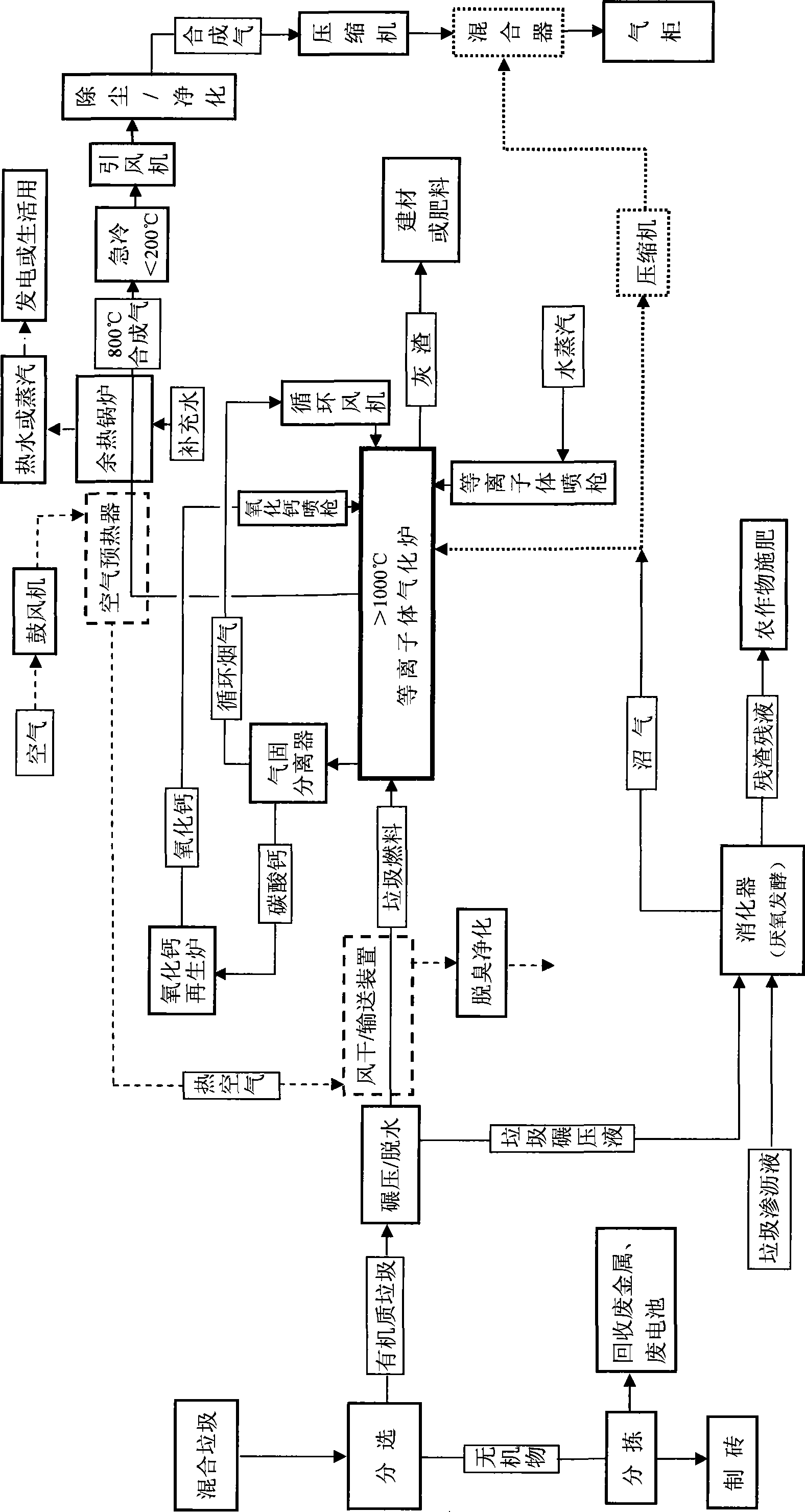

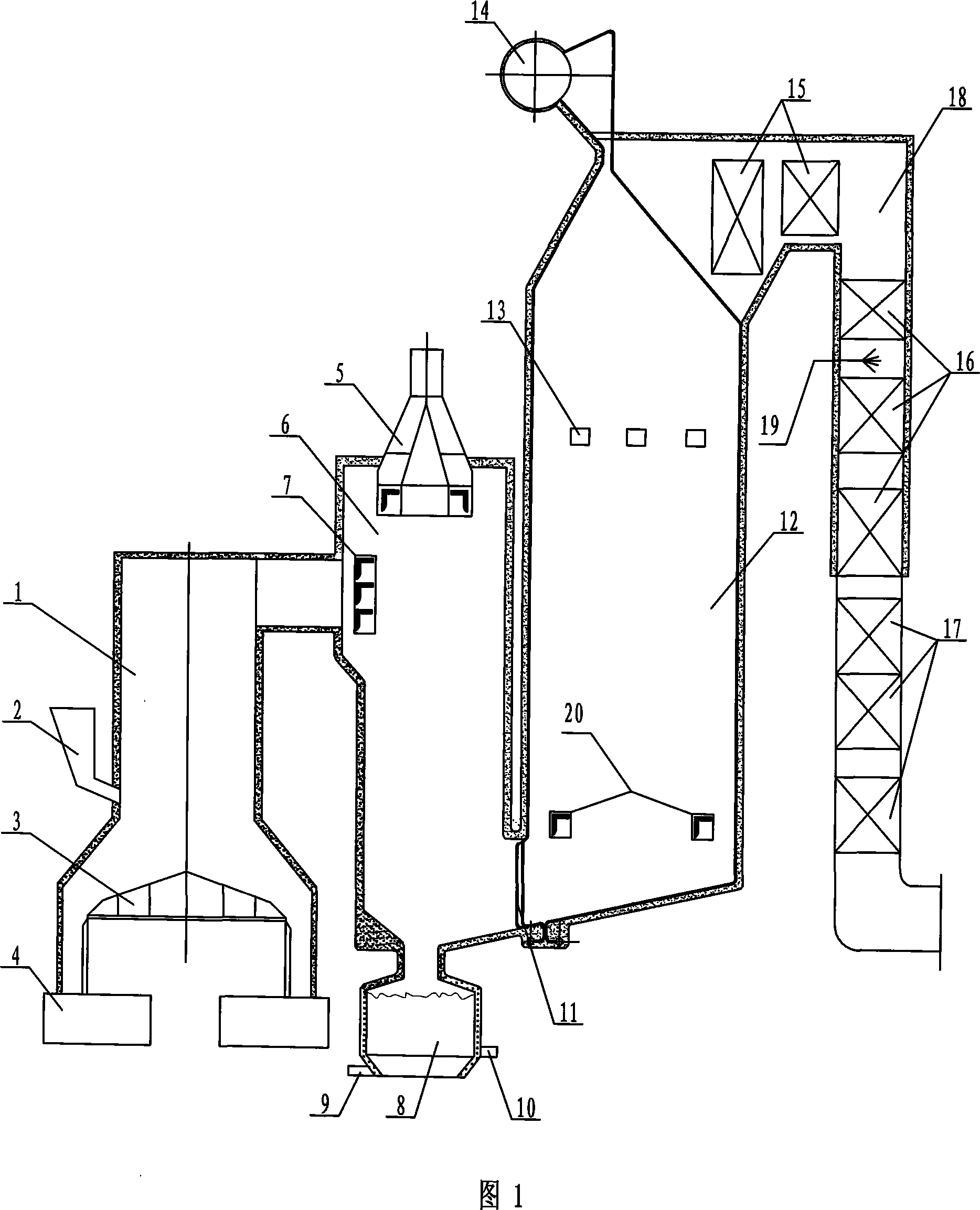

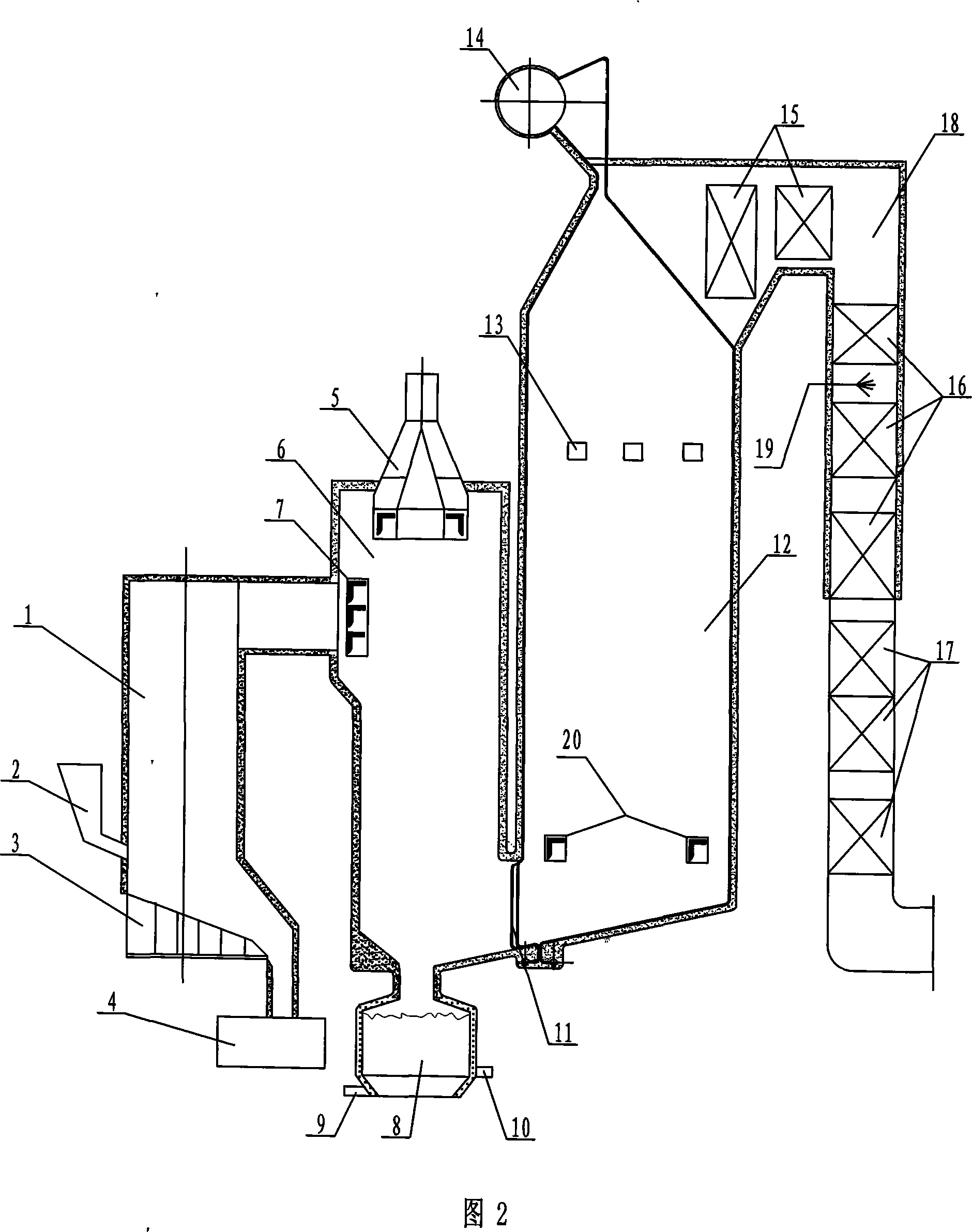

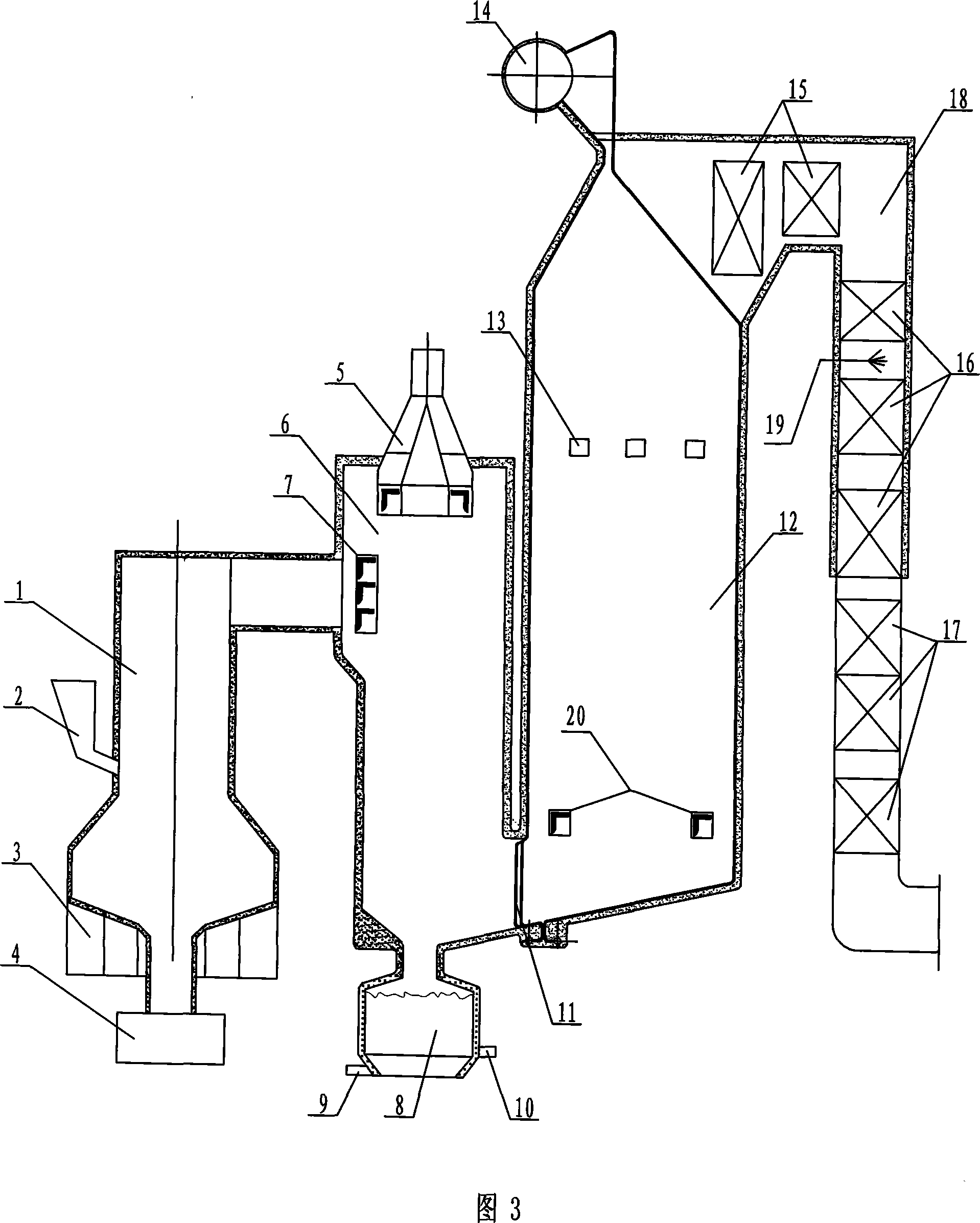

Domestic garbage transformation technique, system and apparatus without conventional fuel for combustion supporting

InactiveCN101468789AReduce pollutant contentLow investment costBio-organic fraction processingSolid waste disposalBrickClean energy

The invention provides a process, a system and equipment for converting household garbage without support combustion of the prior fuels, which relates to a process and equipment for processing garbage. The process is characterized in that the household garbage is sent into a gasification furnace or an incinerator after separating, dehydrating by rolling compaction and air-drying treatment; garbage fuel is converted in the furnace by a mode of gasification or incineration, and is subjected to baking, pyrogenation, gasification and carbon residue burn-out in the furnace; the converted synthesis gas is used for cleaning energy; waste heat of incineration is absorbed by heat-exchange equipment for reclamation; garbage rolling liquid is sent into a digesting machine for anaerobic fermentation so as to produce biogas, the biogas is used as auxiliary fuel of the incinerator, and the digested residue and residual liquid are used for fertilizing crops; and inorganic substances separated from the garbage are used as raw materials to manufacture bricks, and clinker discharged from the incinerator or the gasification furnace is used for producing cement or fertilizer. The process, the system and the equipment comprehensively utilize the garbage so as to achieve complete dissolving treatment, and the equipment has a simple structure and low investment cost, and is easy to popularize..

Owner:周开根

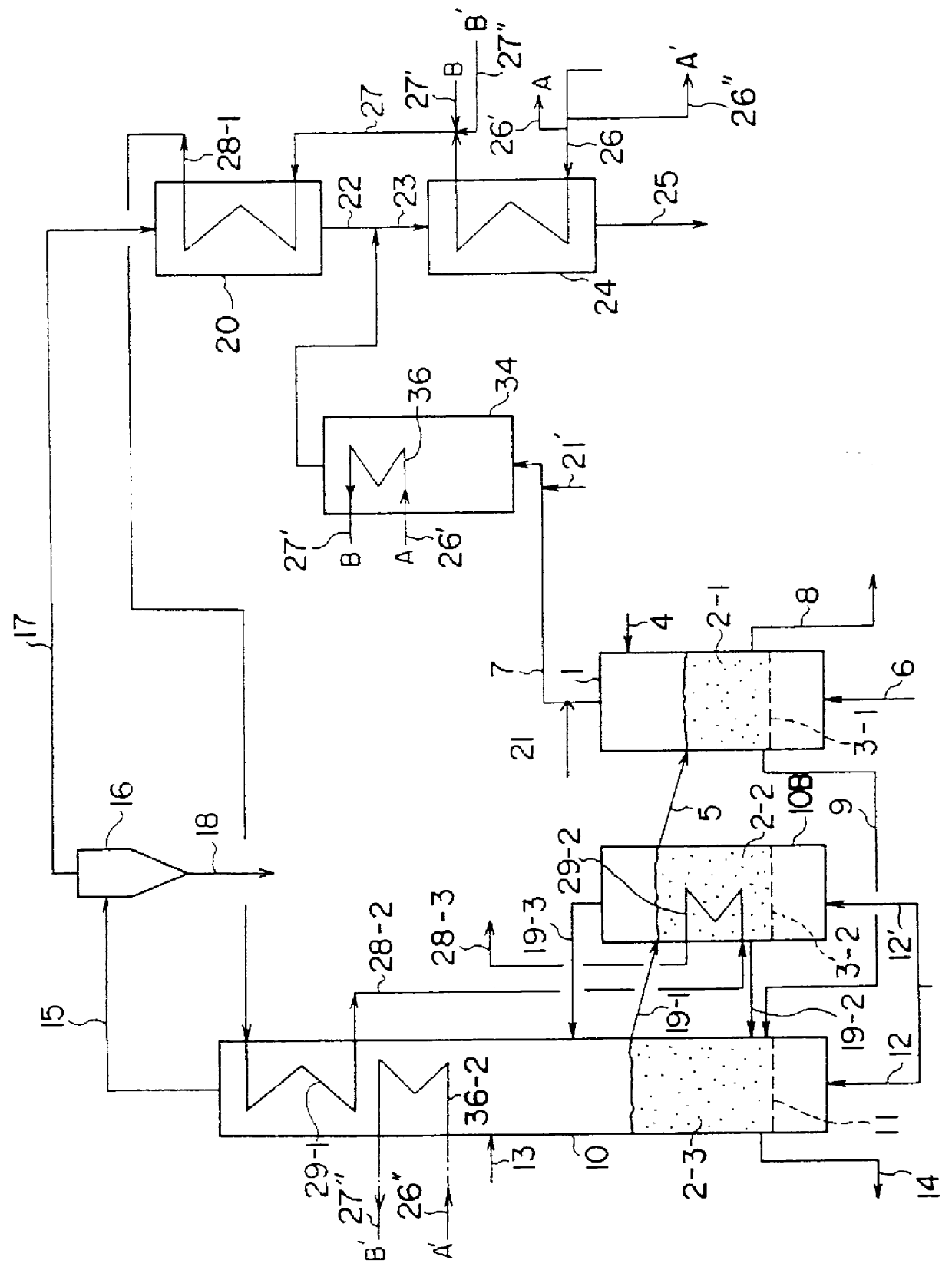

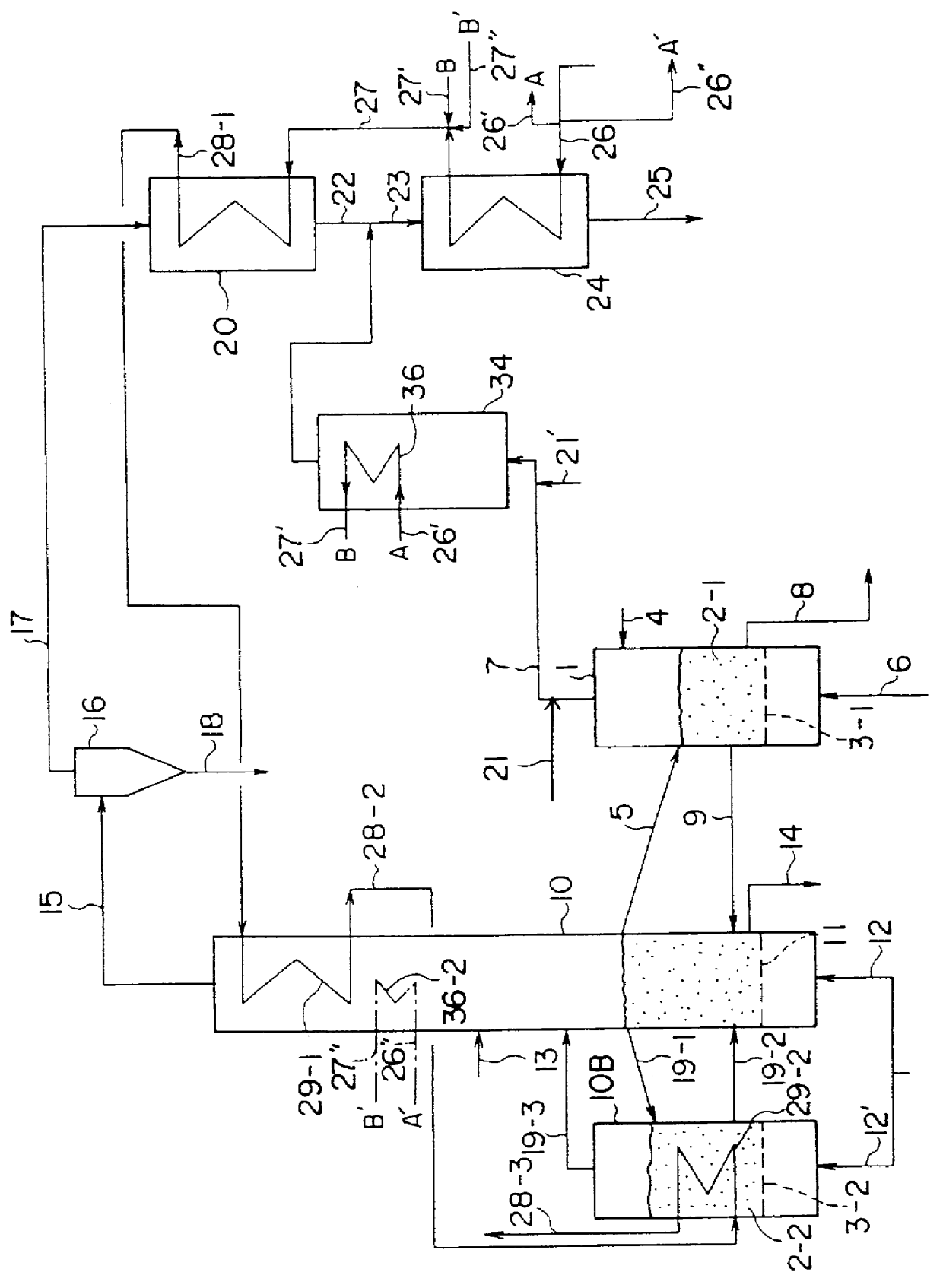

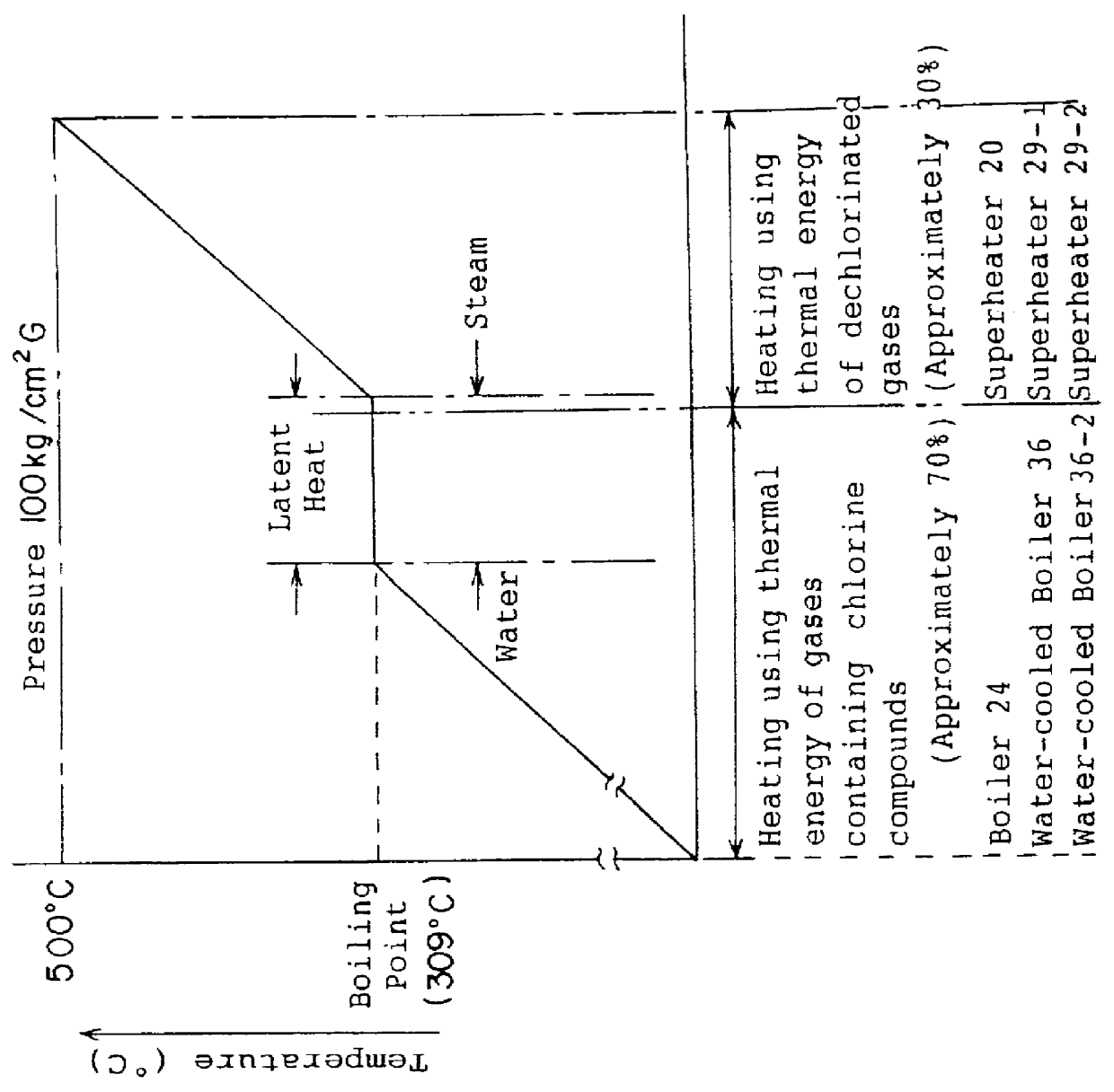

Method and apparatus for producing superheated steam using heat from the incineration of waste material

PCT No. PCT / JP97 / 00573 Sec. 371 Date Jan. 12, 1998 Sec. 102(e) Date Jan. 12, 1998 PCT Filed Feb. 27, 1997 PCT Pub. No. WO97 / 32161 PCT Pub. Date Sep. 4, 1997According to the present invention, boiler water is pressurized so that its boiling point is set at approximately 200 DEG C. to 320 DEG C. The boiler water is heated in at least two stages. Thermal energy of gases containing chlorine compounds is used to heat the water to its boiling point. Thermal energy of gases which do not contain chlorine compounds is used to heat the water from its boiling point until superheated steam of a given temperature is generated. The heating which uses the thermal energy of gases containing chlorine compounds is accomplished using the thermal energy from the combustion of pyrolysis gases obtained from a pyrolysis means in which waste material is supplied into a chamber containing a fluidized bed medium which has been heated to at least 300 DEG C., and a pyrolytic reaction is induced. The heating which uses the thermal energy of gases which do not contain chlorine compounds is accomplished using the thermal energy obtained from a char combustion means to combust char in which a char mixture consisting of unpyrolyzed residue and fluidized bed medium removed from the pyrolysis means is fluidized by a stream of air, and the unpyrolyzed residue is combusted.

Owner:MITSUBISHI HEAVY IND LTD

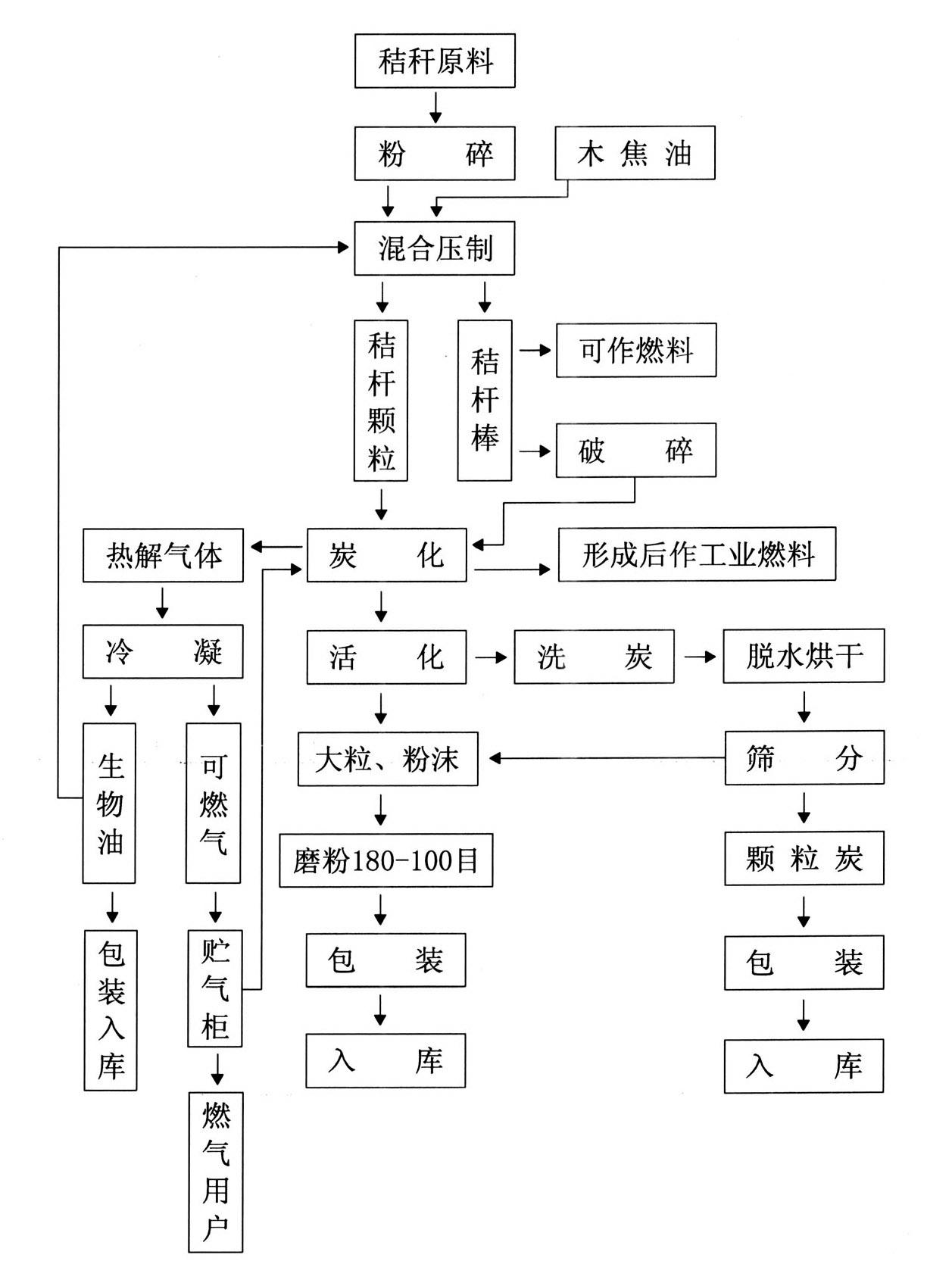

Method for preparing charcoal activated carbon flammable gas biological oil by utilizing crop straws

InactiveCN102161897AReduce investment in fixed assetsCarbon compoundsBiofuelsProduction lineActivated carbon

The invention discloses a method for preparing charcoal activated carbon flammable gas biological oil by utilizing crop straws. In the method, a co-production process technique integrated with comprehensive processing of multiple varieties is adopted. The method comprises the following steps: smashing the collected crop straws by a smash machine so as to form straw powder with the particle size of 8-30 meshes; pressing and forming the straw powder material for pyrolysis; and in the process of pyrolysis, preparing straw charcoal and activated carbon on one production line through carbonization and activation processes, and simultaneously, recovering flammable gas and extracting biological oil. By using the method, fixed investment is greatly reduced, economic and social benefits are effectively increased, the problems of stack and incineration of the straws are solved, waste straw resources are further developed and utilized, and the blank in the same industry in China is filled.

Owner:卞奎友

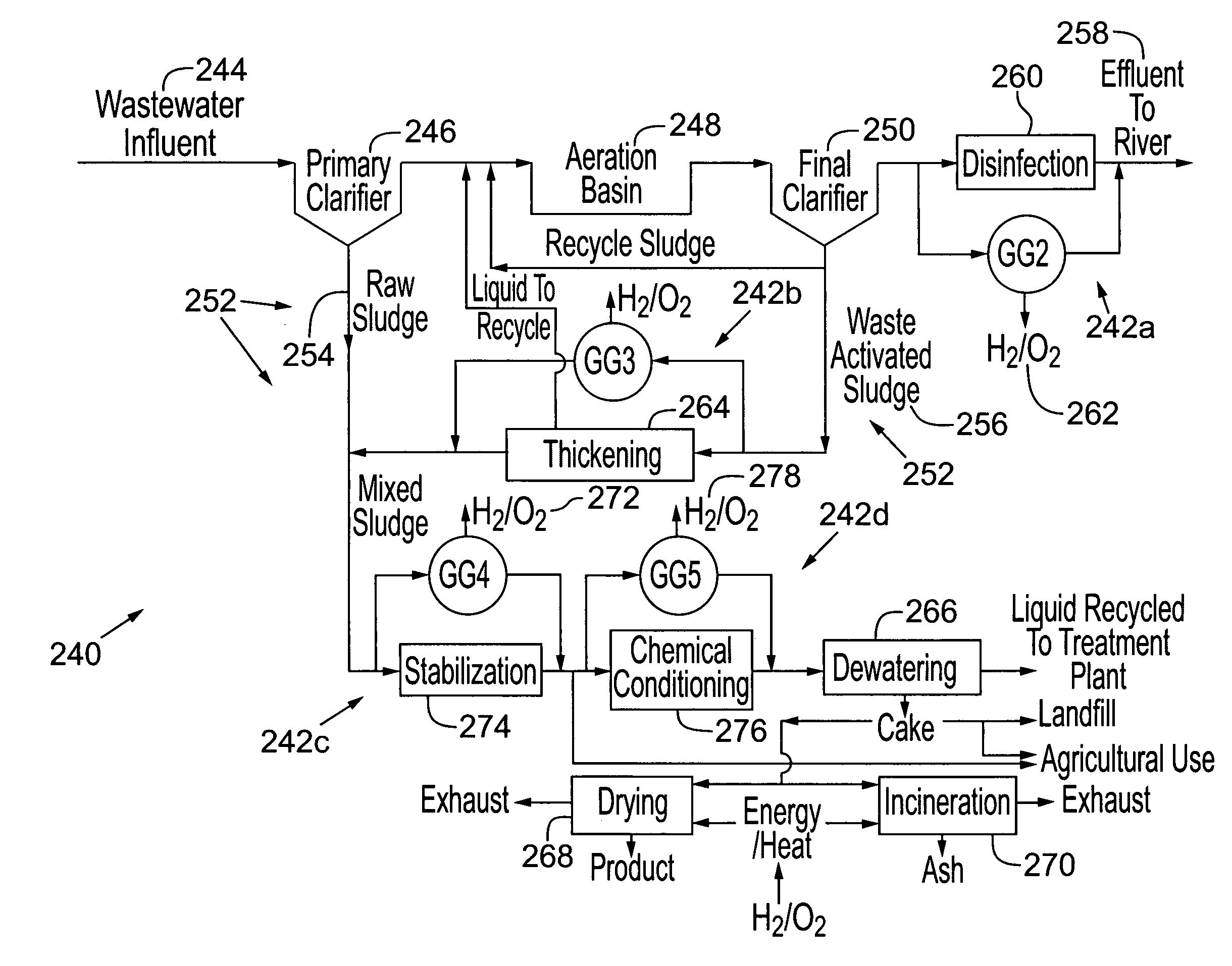

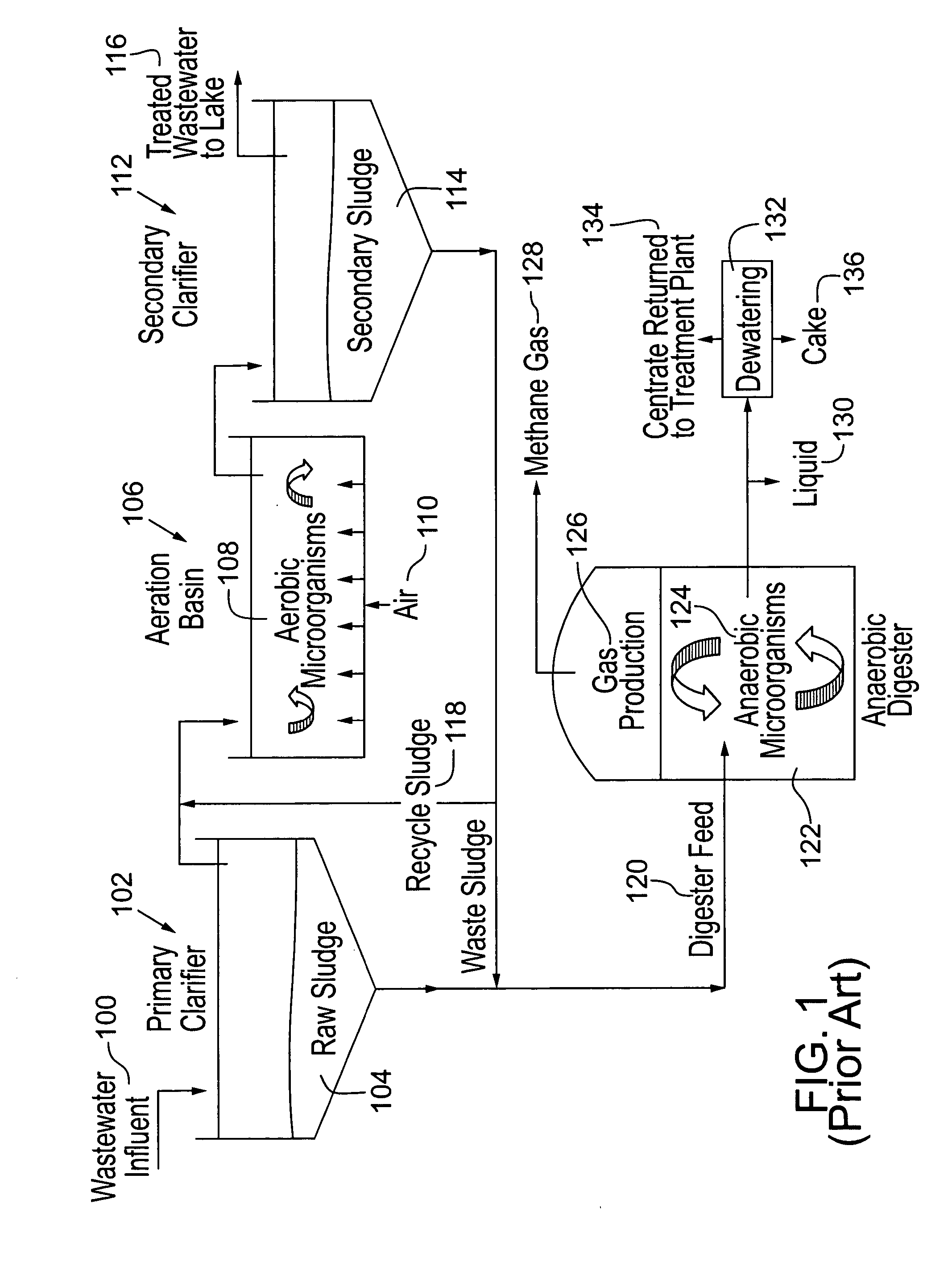

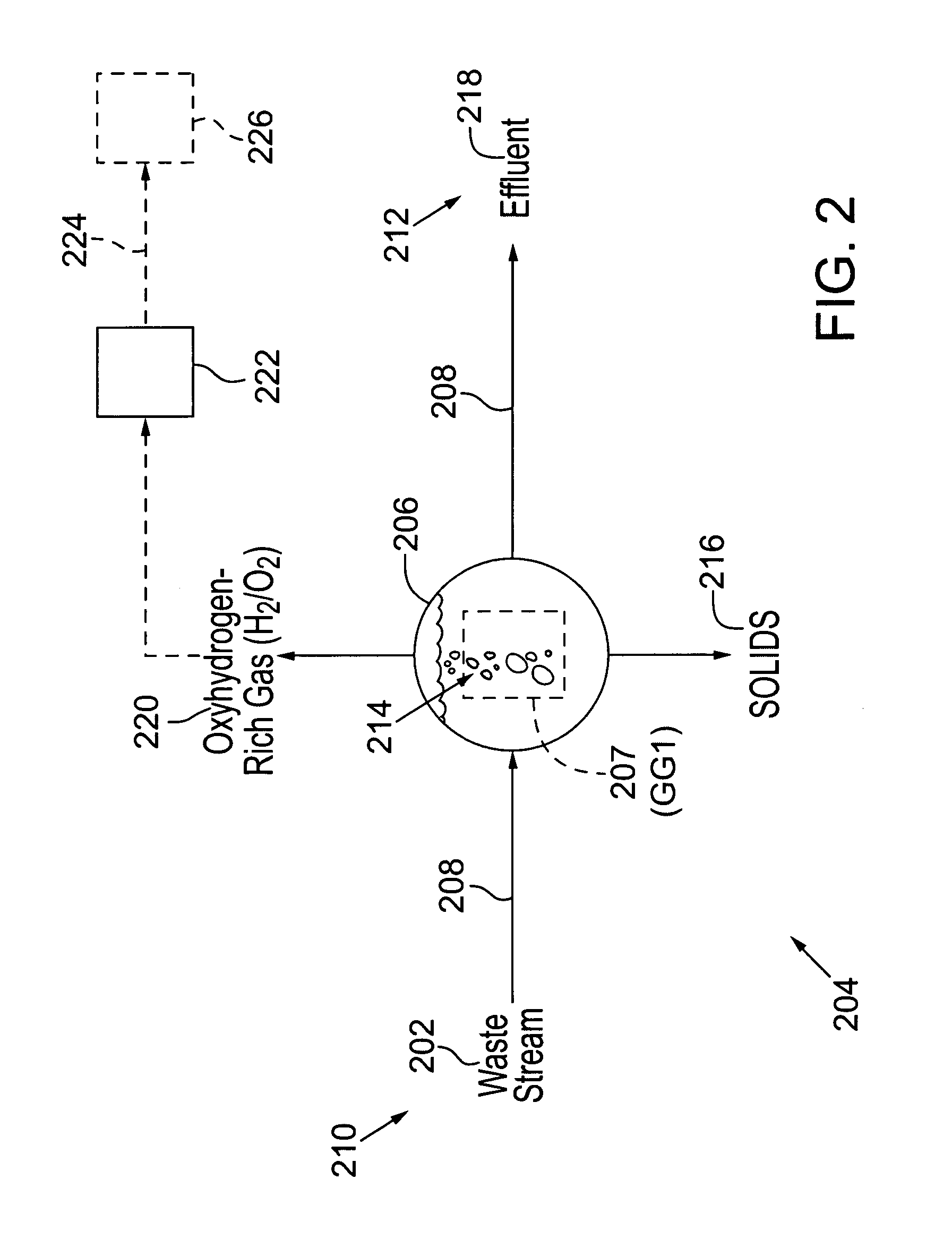

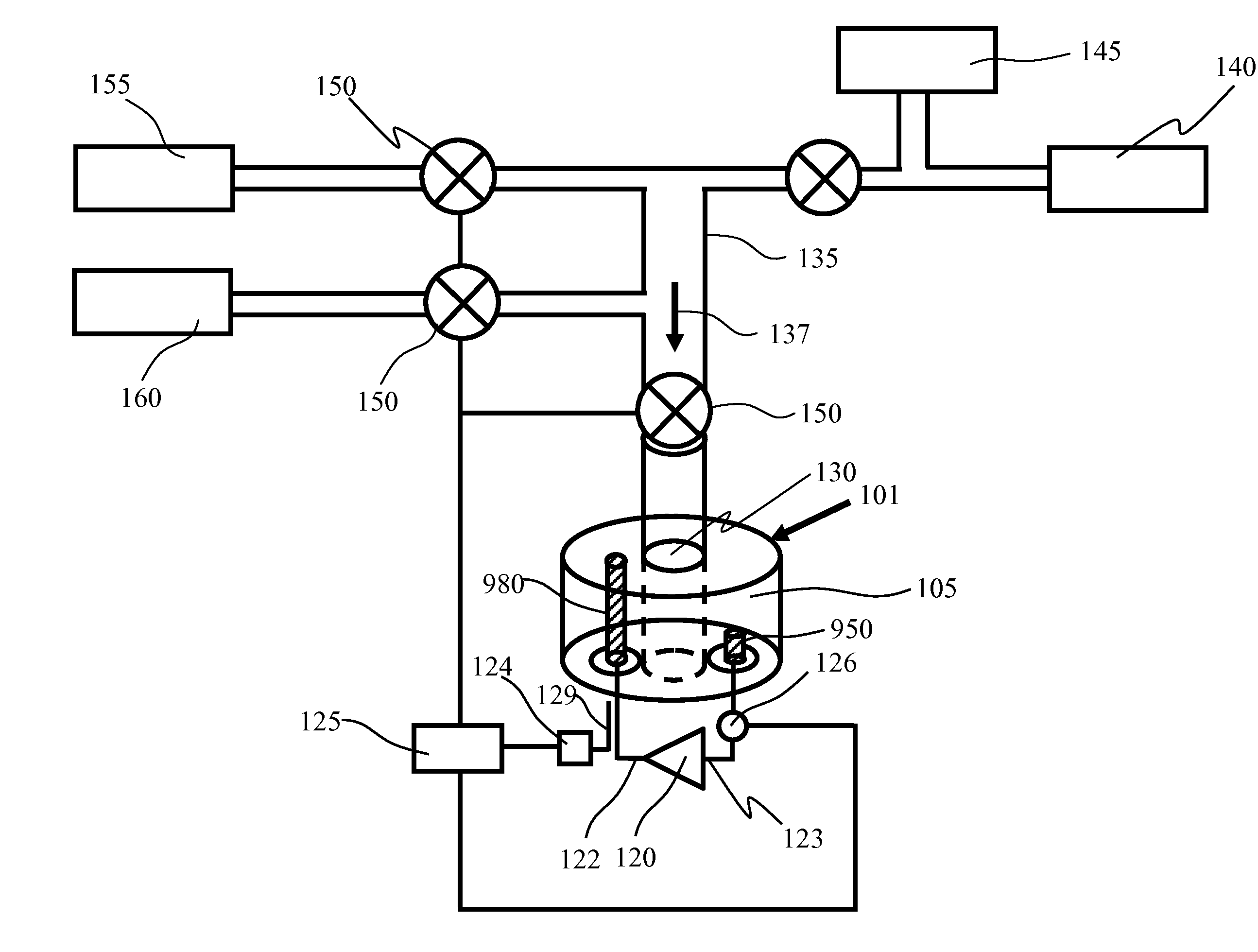

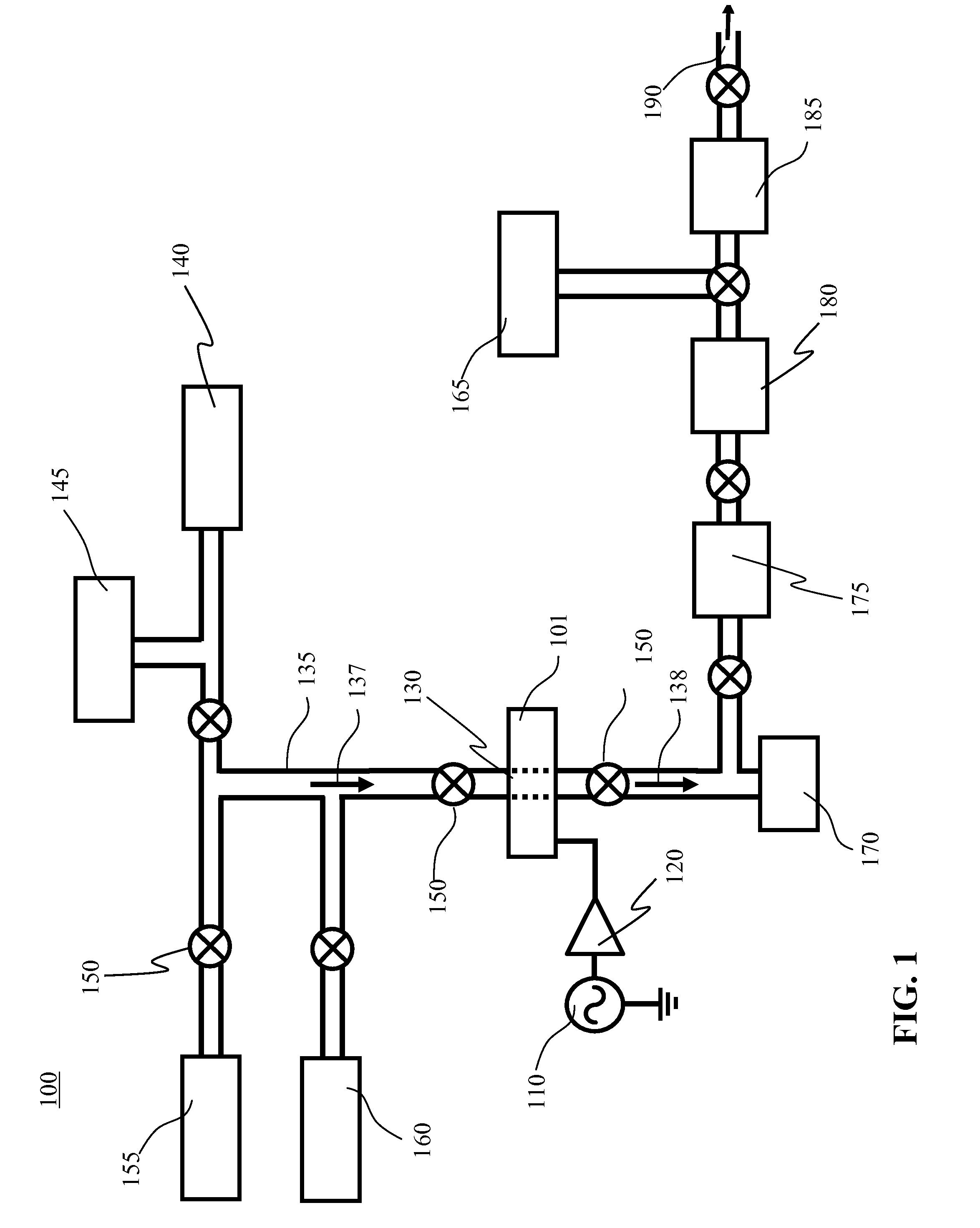

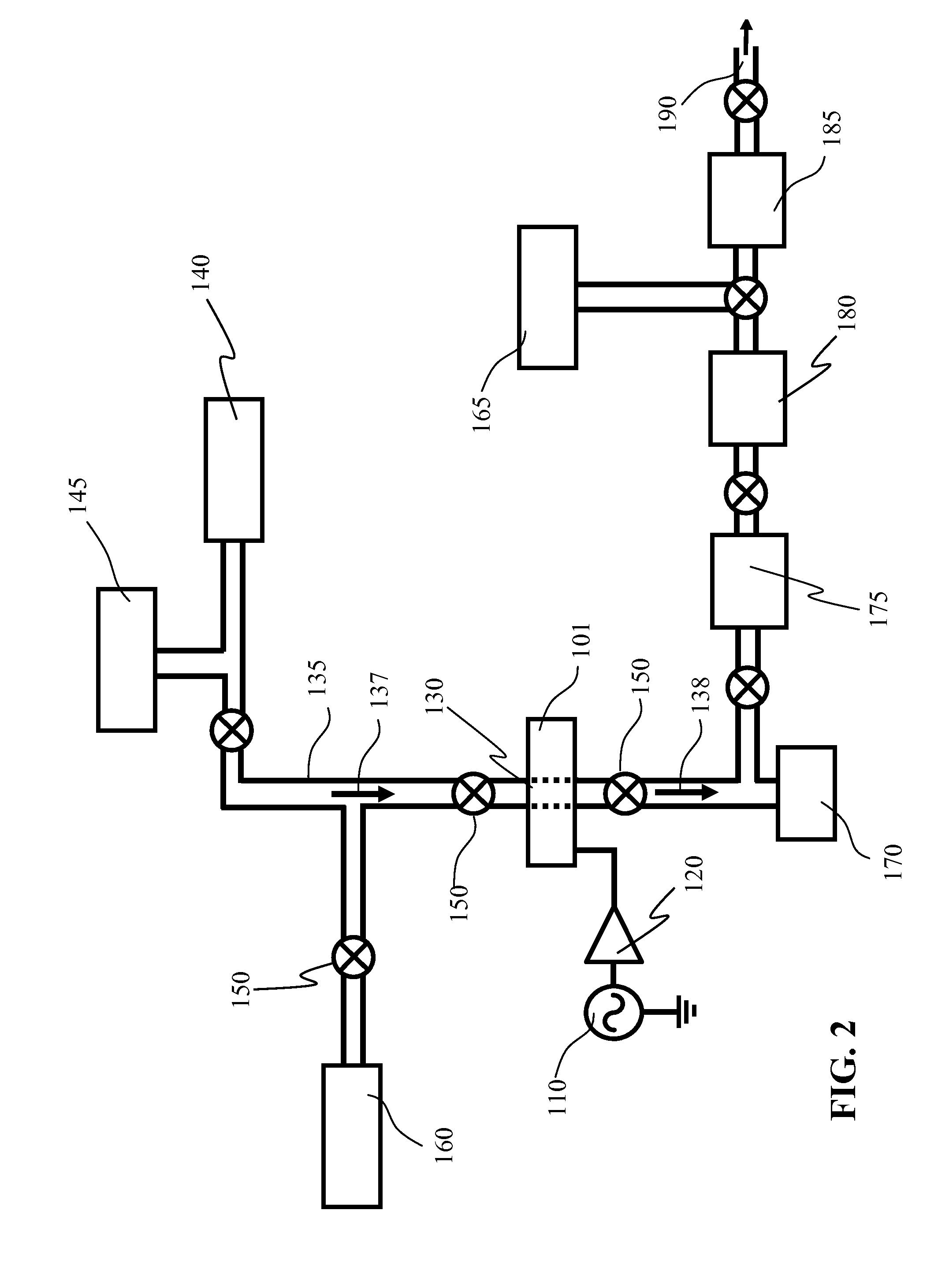

Treatment of a waste stream through production and utilization of oxyhydrogen gas

Methods and systems for treating a waste stream in a waste treatment system involve performing a unit process of the waste treatment system by contacting the waste stream with oxyhydrogen-rich gas generated on-site by an oxyhydrogen gas generator that implements water dissociation technology. In a preferred embodiment, the oxyhydrogen gas generator involves applying a pulsed electrical signal to a series of closely-spaced electrodes that are submerged in the waste stream to produce oxyhydrogen-rich gas from a water component of the waste stream. Operation of the oxyhydrogen gas generator in the waste stream may accomplish one or more unit processes for waste treatment, such as conditioning, stabilization, thickening, and dewatering, among others. At least a portion of the oxyhydrogen-rich gas can be conveyed for a second use in the waste treatment system, such as a source of combustible fuel for incineration or power generation, for example.

Owner:XOGEN TECH

Process for reclaiming combustion residues

InactiveUS6039787AEmission reductionImprove heat transfer performanceManufacturing convertersProcess efficiency improvementCombustionWater vapor

PCT No. PCT / AT97 / 00201 Sec. 371 Date May 15, 1998 Sec. 102(e) Date May 15, 1998 PCT Filed Sep. 12, 1997 PCT Pub. No. WO98 / 12359 PCT Pub. Date Mar. 26, 1998In a process for working up combustion residues and slags from waste incineration plants or steel works slags, the slag is charged at a slag layer height of above 1.2 m into a converter (1), in which the molten slag is reacted with a metal bath (4) through which oxygen is blown. The oxygen is introduced into the bath (4) for cooling the submerged tuyeres (7, 8) in the form of air or along with CO2 or water vapor.

Owner:HOLCIM

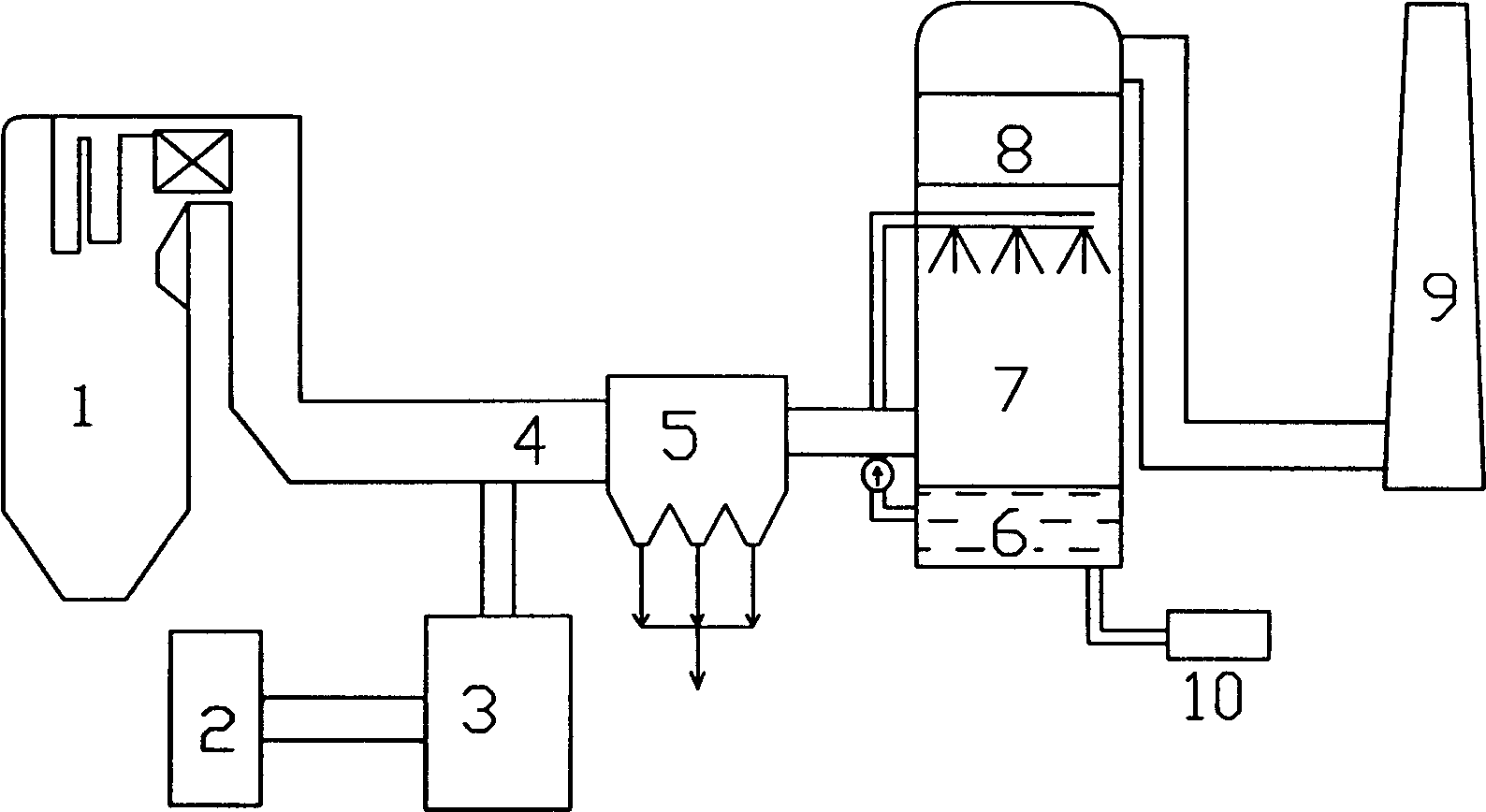

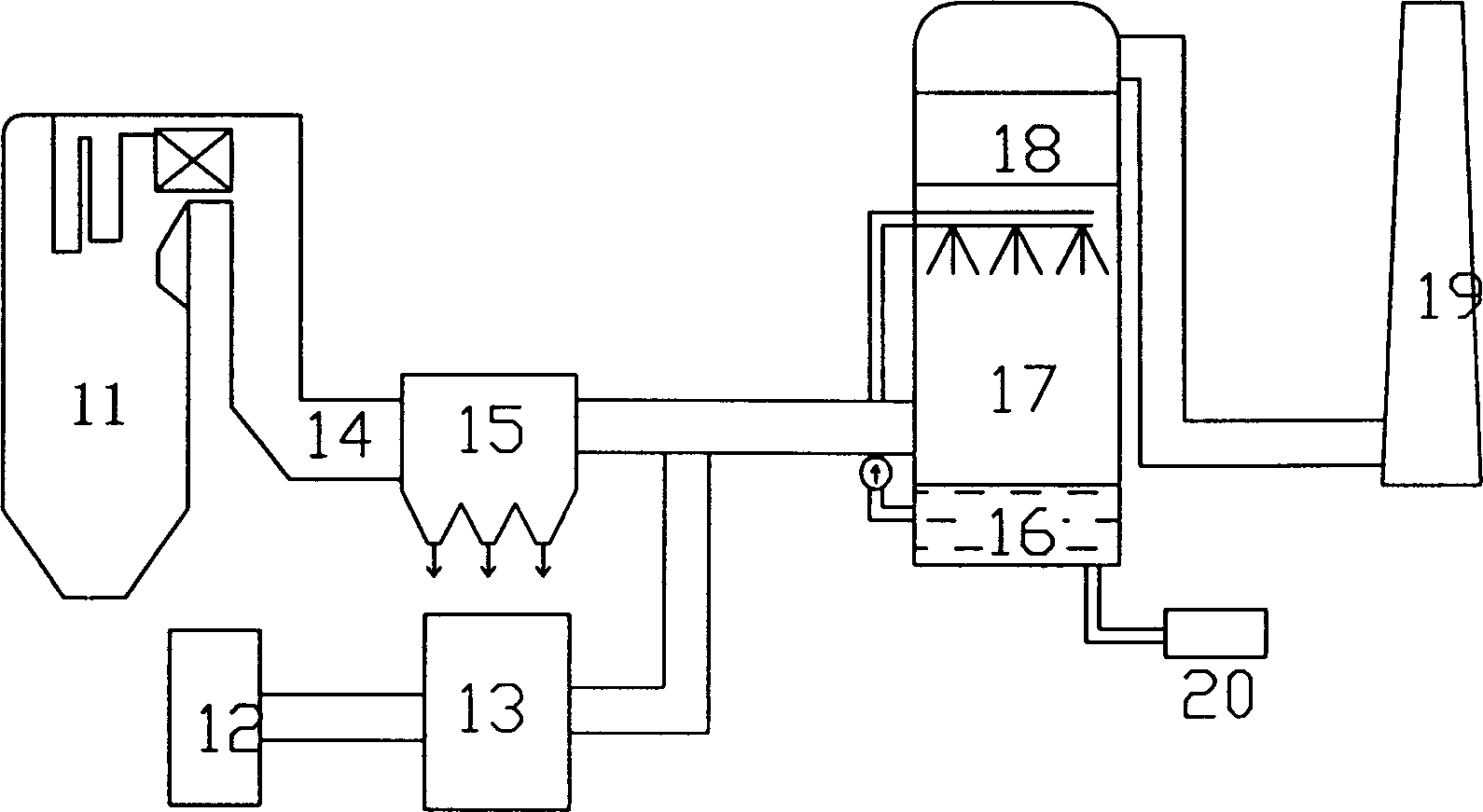

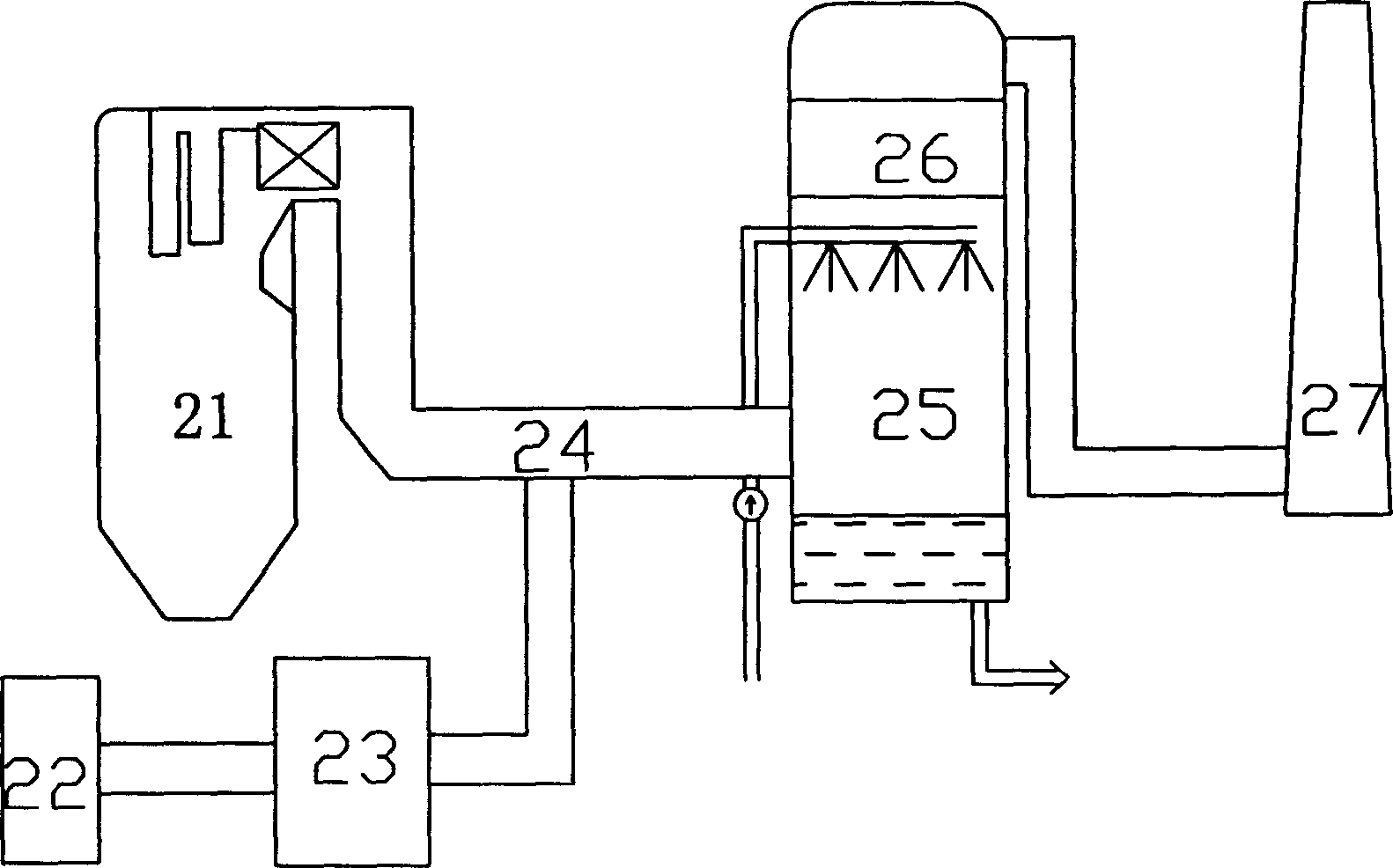

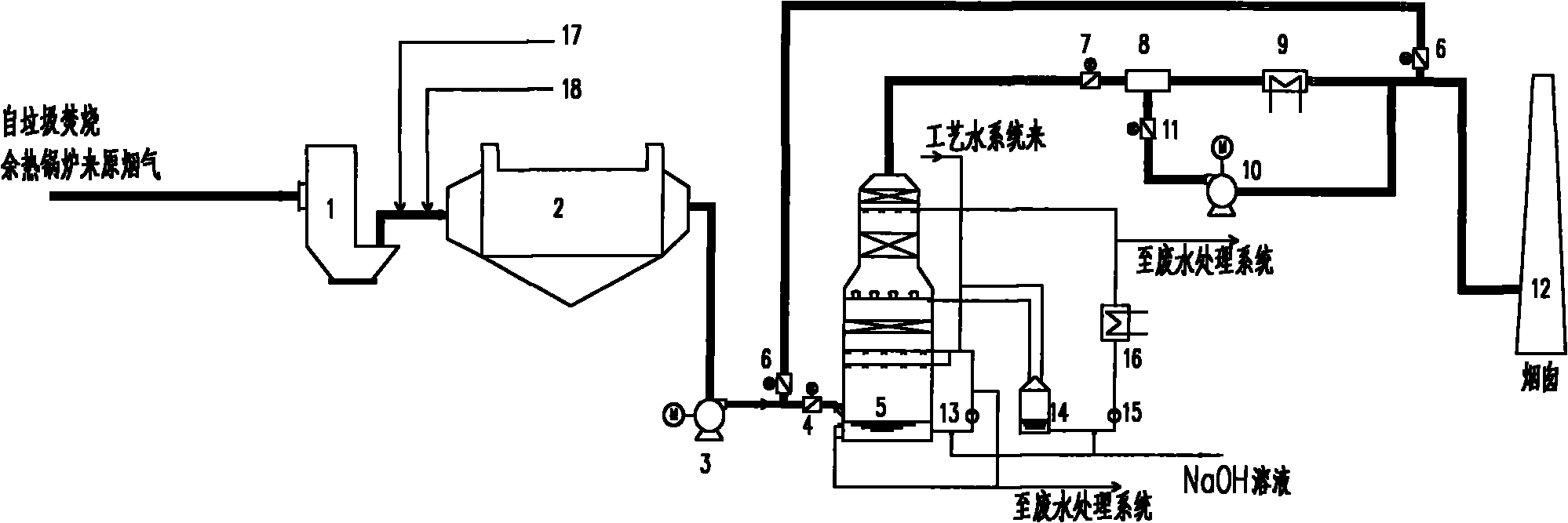

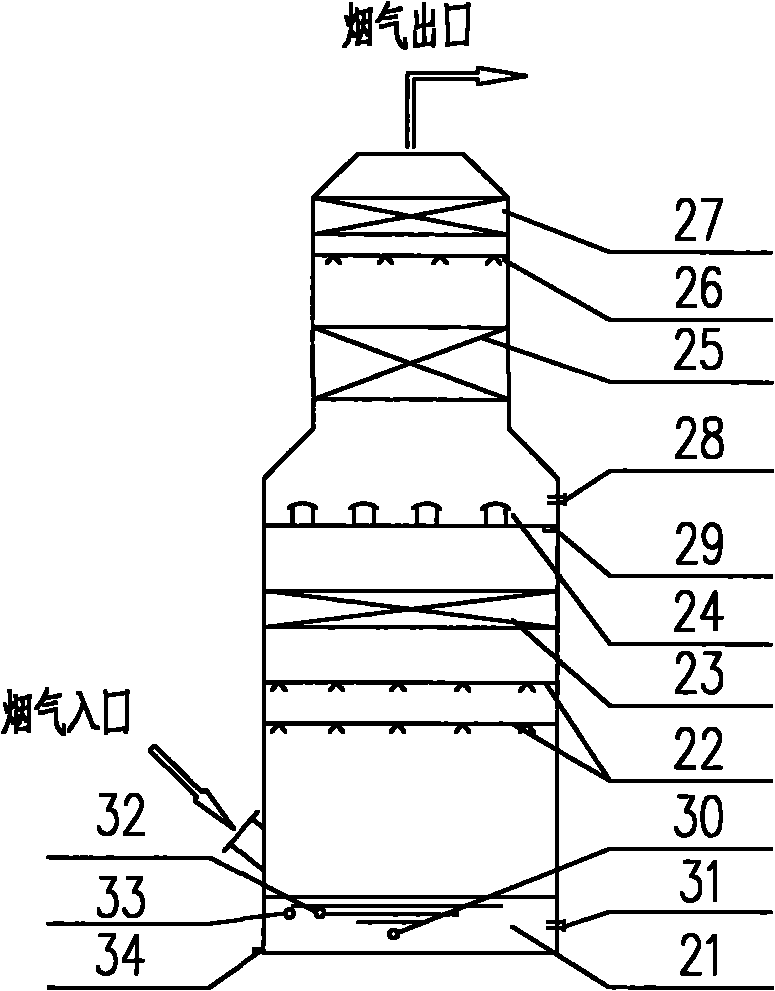

Flue-gas cleaning method and system for waste incineration

InactiveCN101829468AImprove removal efficiencyLarge load concentrationCombination devicesLighting and heating apparatusCooling towerHazardous substance

The invention discloses a flue-gas cleaning method for waste incineration, which comprises a dry process and a wet process. In the dry process, harmful substance in the flue gas is adsorbed by utilizing an adsorbent, and acid gas is neutralized by utilizing an alkaline absorbent, and in the wet process, a wet spray scrubber is utilized to purify the flu gas with higher efficiency. In addition, the invention also discloses a flue-gas cleaning system for waste incineration, which comprises a cooling tower, a bag-type dust collector, a wet washing tower and a glue-gas reheater. Flue gas from an exhaust-heat boiler enters the bag-type dust collector after being cooled by the cooling tower. Activated carbon and slaked lime powder are sprayed into the flue gas before the flue gas enters the bag-type dust collector to carry out preliminary purification on the flue gas; the purified flue gas is introduced to the wet washing tower through a draught fan for further processing; and the purified flue gas is discharged into the atomosphere by a chimney after the two-stage heating. The invention can effectively remove pollutant in flue gas and the quality of the purified flue gas can achieve the EU 2000 effluent standard.

Owner:山东三融环保工程有限公司

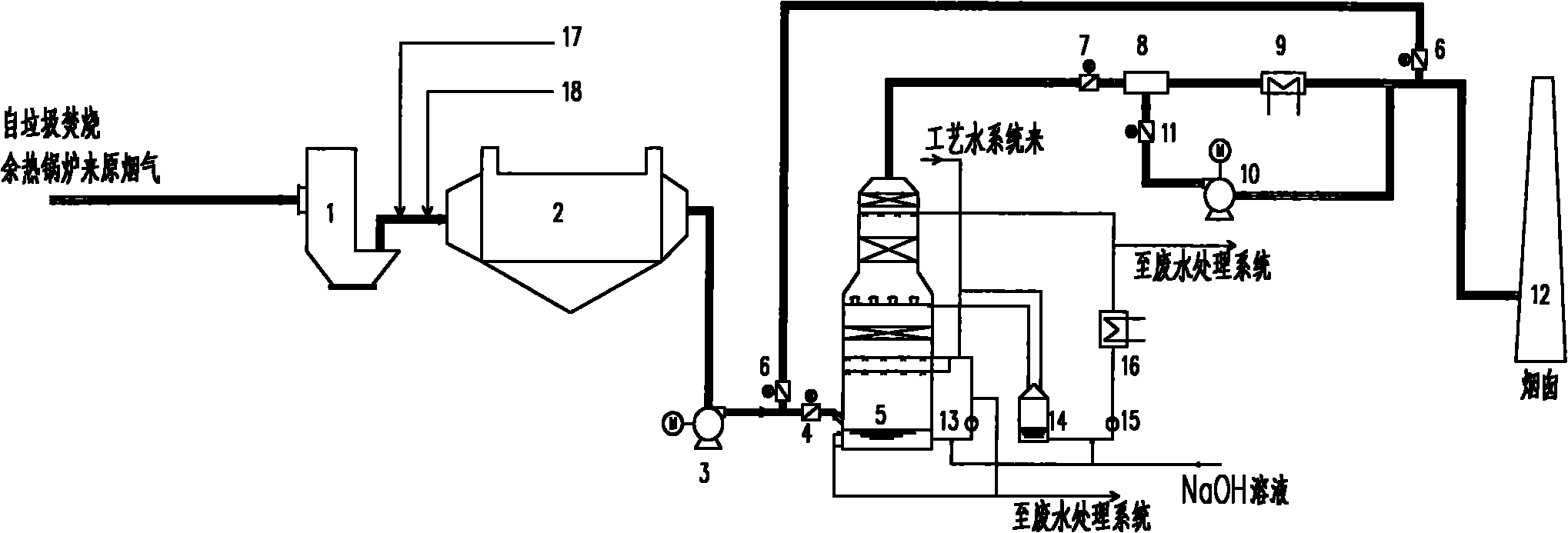

Sludge drying and resource disposal process

InactiveCN1762863AImprove processing efficiencyReduce energy consumptionSludge treatment by de-watering/drying/thickeningSolid waste disposalEutrophicationSludge

The present invention relates to environment protecting technology, and is especially one kind of sludge drying treatment process. The present invention is one low-cost combined sludge drying and utilizing process integrating microwave technology, aerobic fermentation technology and heat pump drying technology. The present invention is suitable for treatment of different kinds of sludge, and the sludge product has wide applications, including use as organic fertilizer, use as the material for composite organic fertilizer and building material, use as fuel for incinerating garbage and heating boiler, etc.

Owner:吴为中 +1

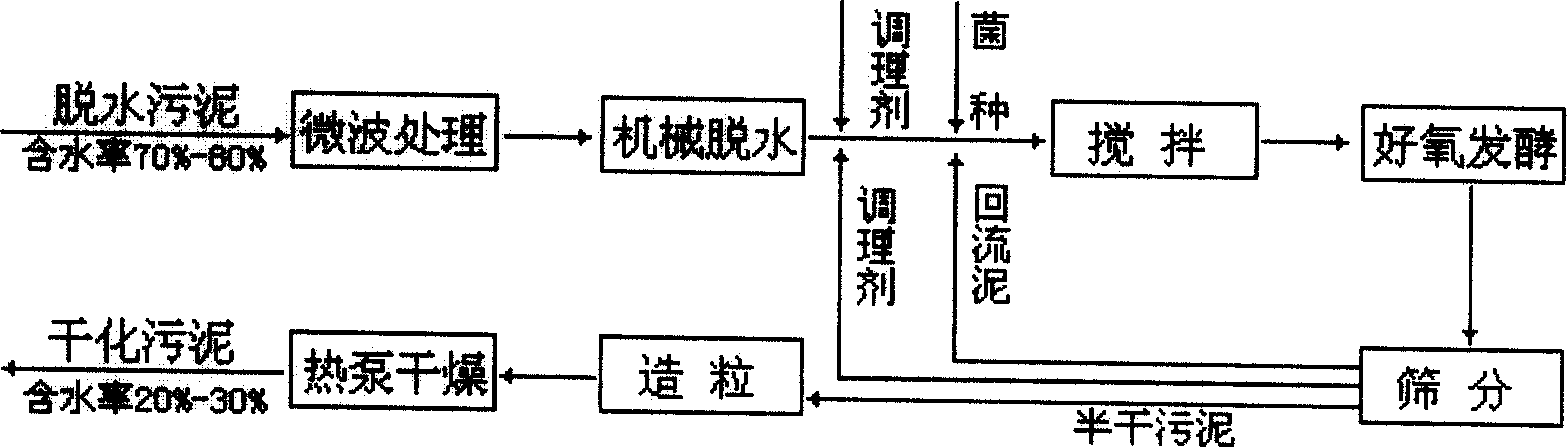

Low temperature Claus sulfur recovery process and device therefor

InactiveCN101519192AAchieve regenerationImprove conversion rateEnergy inputSulfur preparation/purificationReaction temperatureOxygen

Owner:CHENGDU SEPMEM SCI & TECH

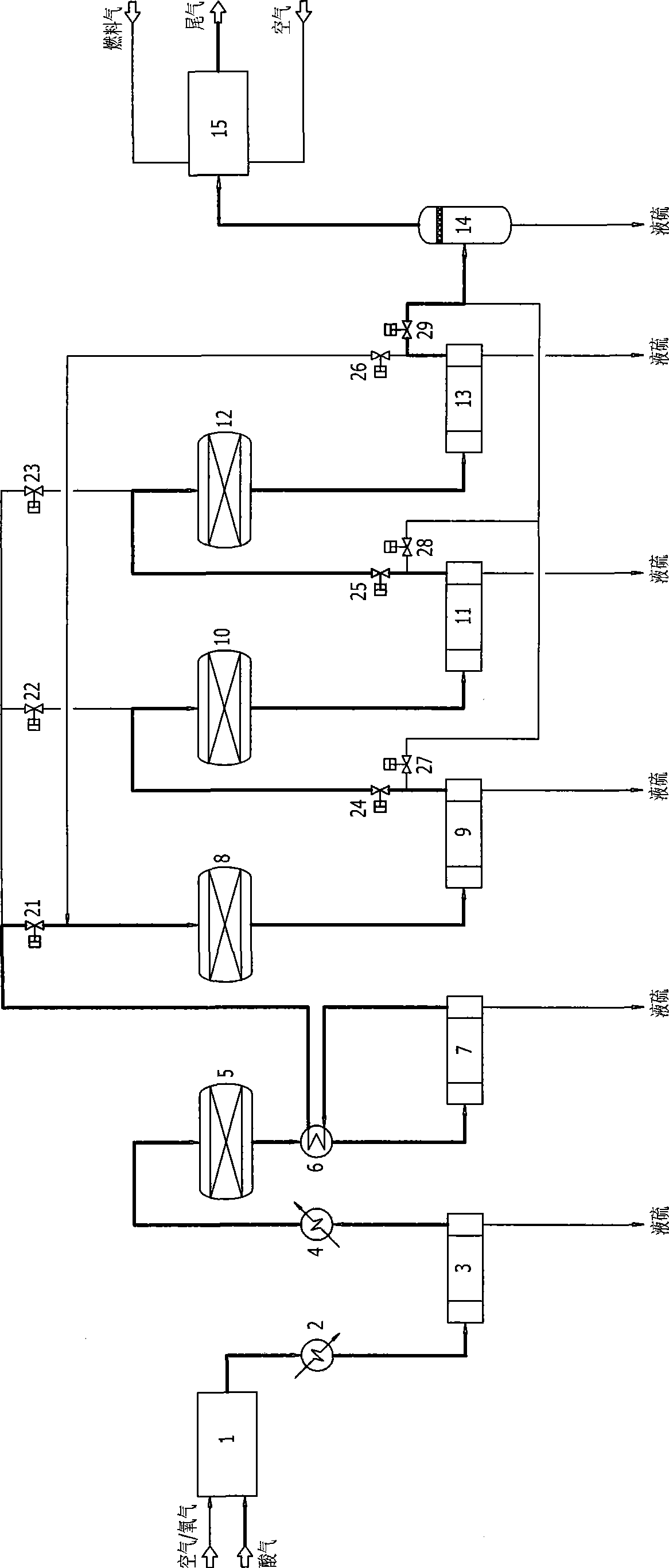

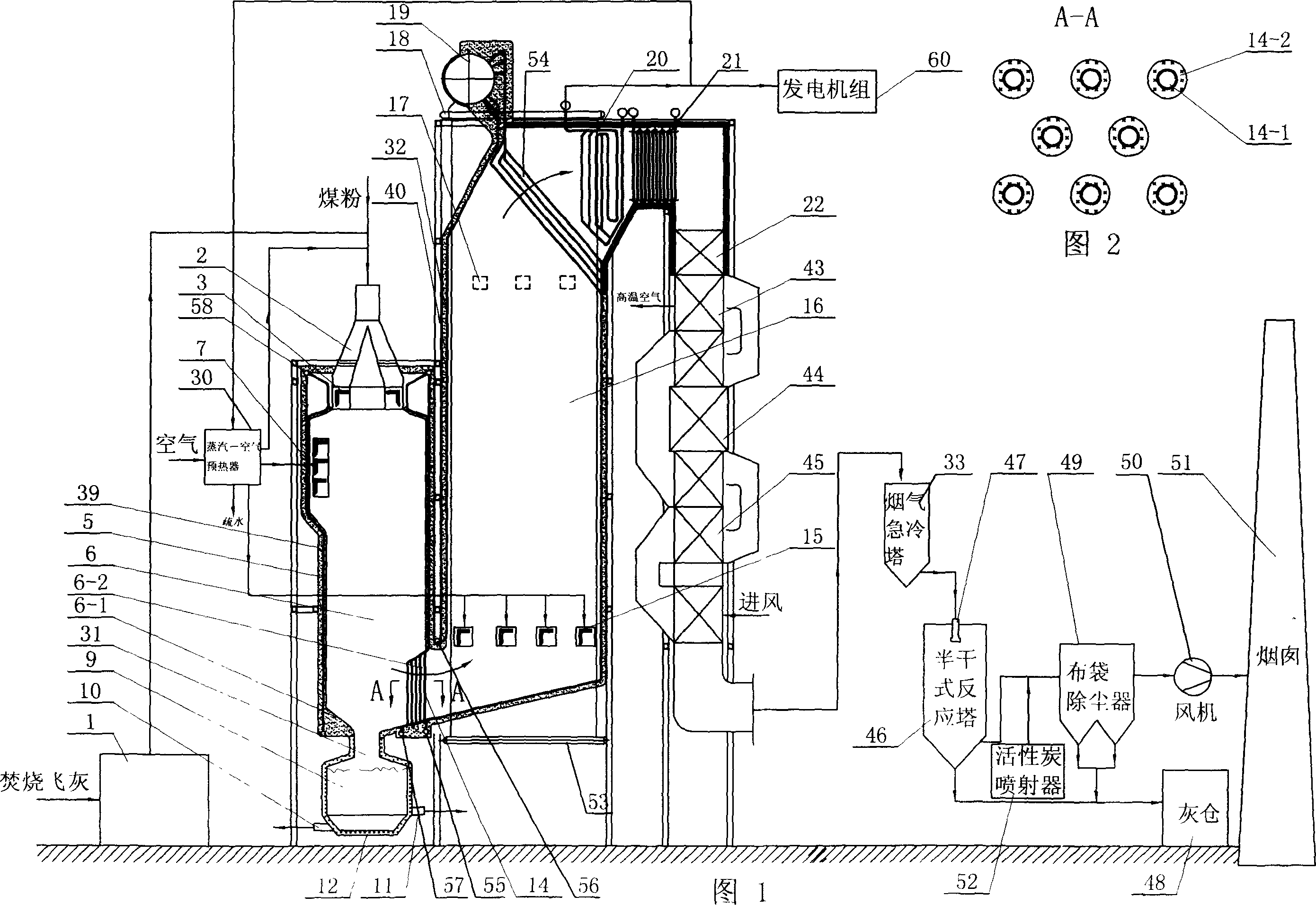

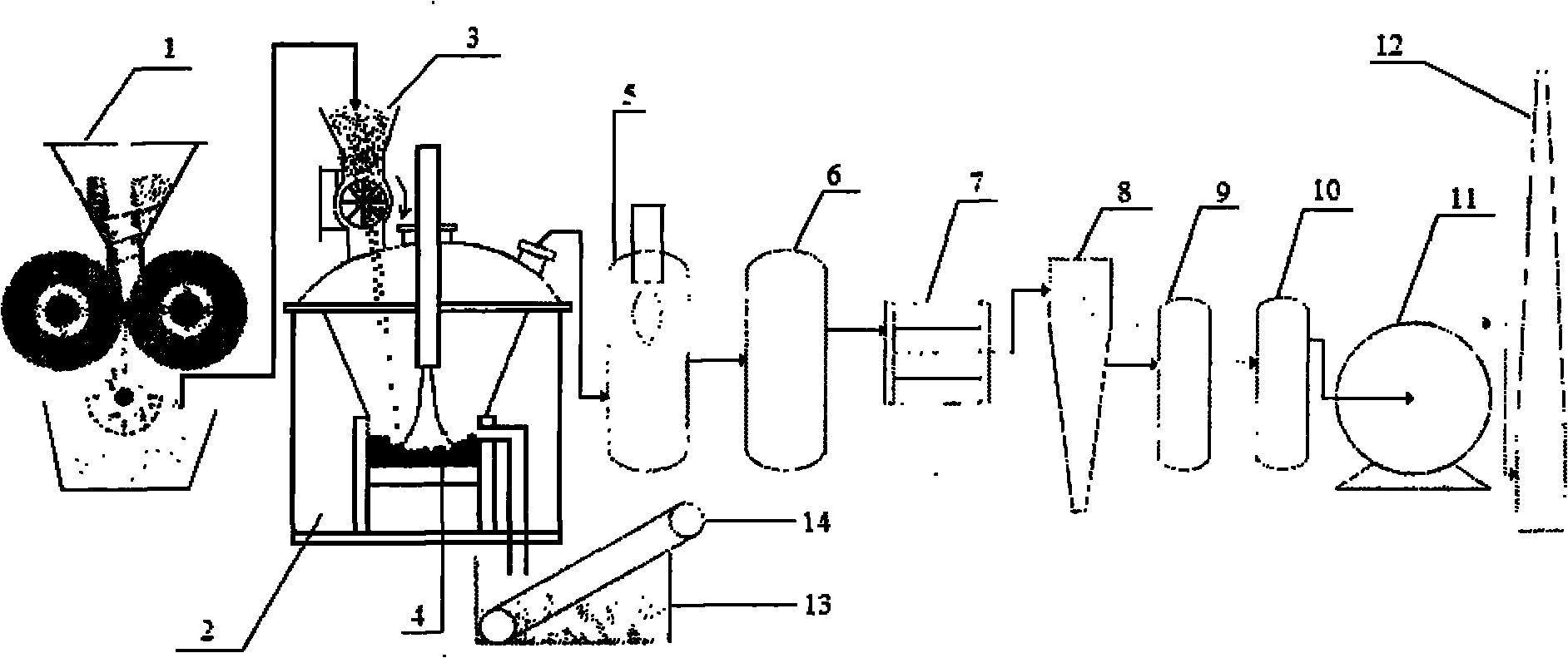

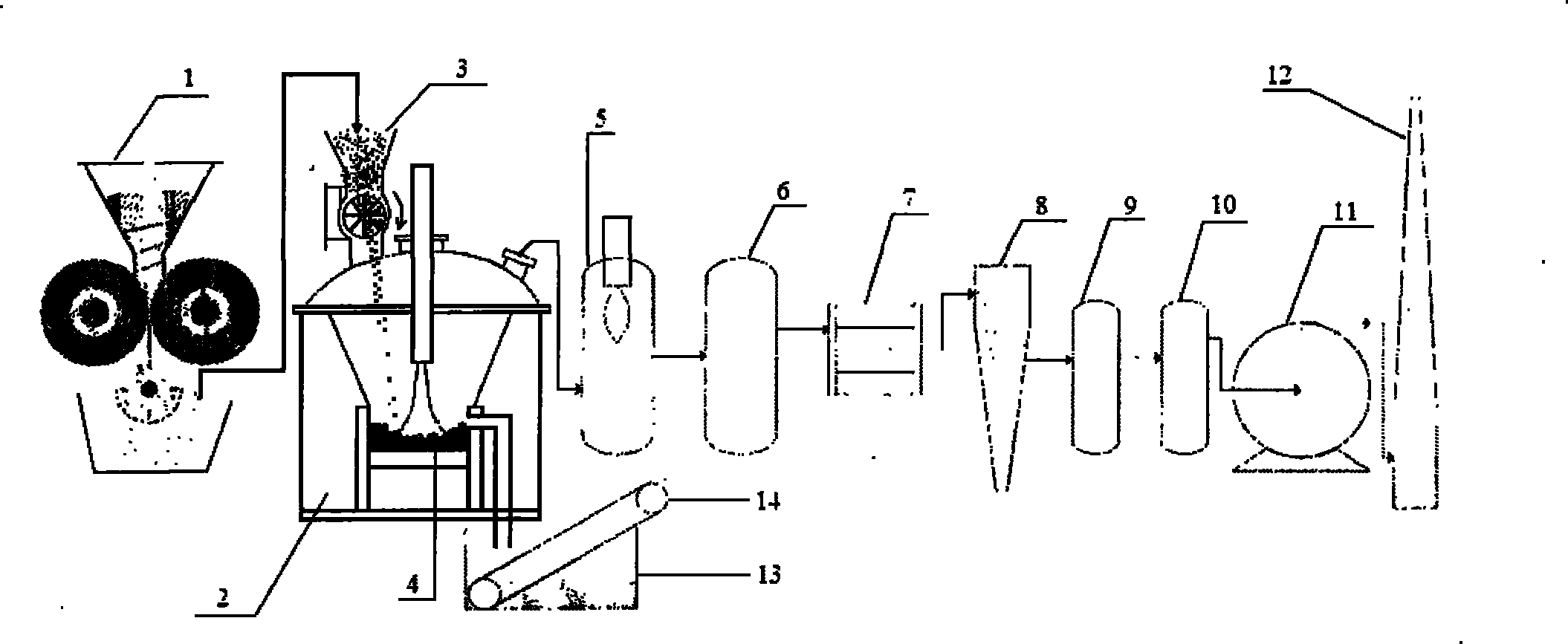

Apparatus and method for gasification of refuse and hyperthermia melt processing of flying ash

ActiveCN101201167AWith waste heat utilizationHigh heat intensity of combustionDamper arrangementIndirect carbon-dioxide mitigationAir preheaterEngineering

A device and method for garbage gasification and flying ash high temperature melting treatment relates to an integrated technology for garbage gasification and flying ash high temperature melting. The invention aims at solving the problem that the heavy metals and dioxins in the ash collected by a hop-pocket in an incinerator for garbage gasification exceeds the standard limits greatly. The device is formed in the way that a fluidized bed gasifier is communicated with a cyclone furnace; the cyclone furnace is communicated with a burnt chamber and the burnt chamber is communicated with a flue. The method includes that the smoke and gas generated by the gasification of the garbage in the fluidized bed gasifier enters the cyclone furnace and burns with the help of coal powder; the heavy metals in the flying ash are reduced to metals and recycled; the dioxins in the flying ash are decomposed; the exhaust smoke and gas enters a tail gas treatment device after entering the burnt chamber, a superheater, a coal saving device and an air preheater. The invention leads the smoke and gas generated by the gasification and burning of the garbage in the fluidized bed gasifier to enter the cyclone furnace for high temperature melting treatment so as to lead the dioxins in the tail gas collecting ash and in the tail gas to be respectively lower than 50ng-TEQ / kg, 0.1ng-TEQ / m{3}.

Owner:HARBIN INST OF TECH

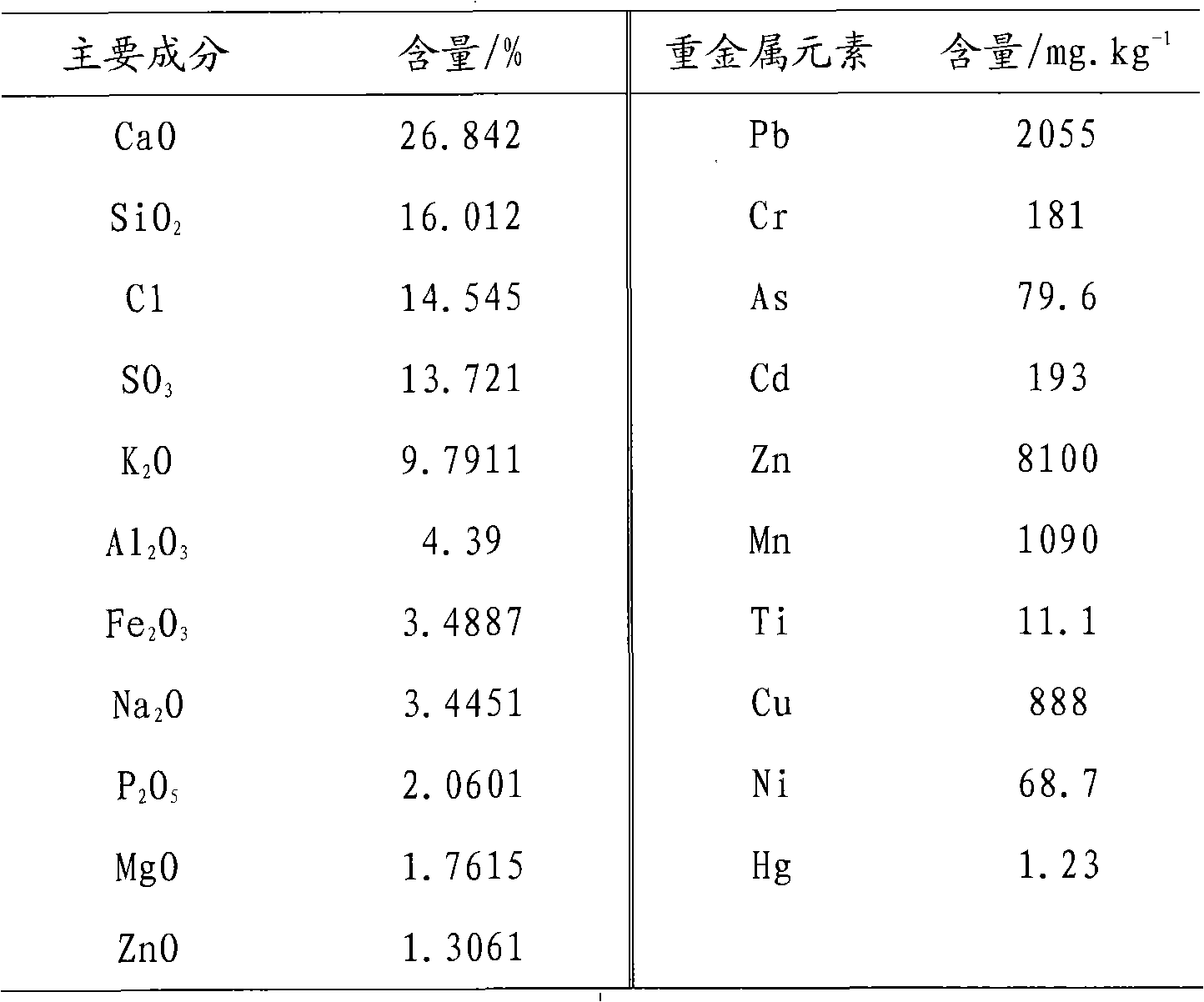

Refuse incineration fly ash solidification/stabilization treatment method

The invention discloses a refuse incineration fly ash solidification / stabilization treatment method comprising the following steps of: firstly, sufficiently mixing a heavy metal stabilizer and water into a solution; mixing the solution, refuse incineration fly ashes and a little amount of cement, stirring and curing so that fly ashes has double-effect stabilization and certain intensity at the same time; finally, landfilling the fly ashes in a domestic refuse landfill site. The refuse incineration fly ash solidification / stabilization treatment method realizes fly ash decontamination and achieves the purpose of slightly increasing volume at the same time, thereby increasing the overall efficiency and the economical efficiency of a fly ash treating and disposing system and solving the problem of large increasing volume after the traditional cement solidification treatment.

Owner:天津渤海环保工程有限公司

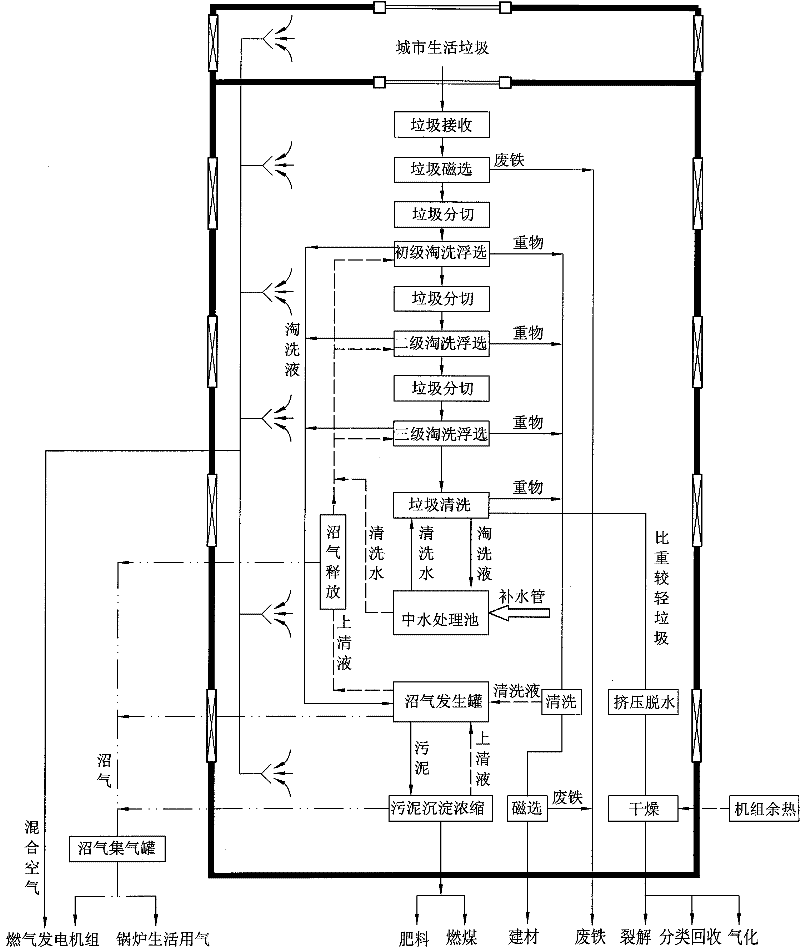

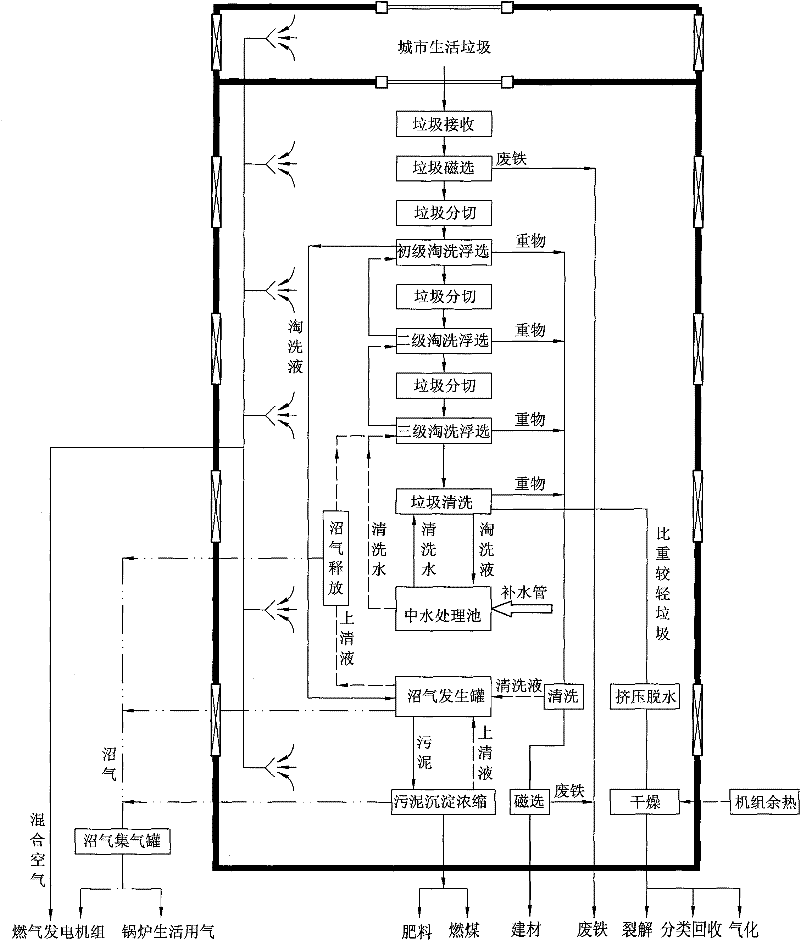

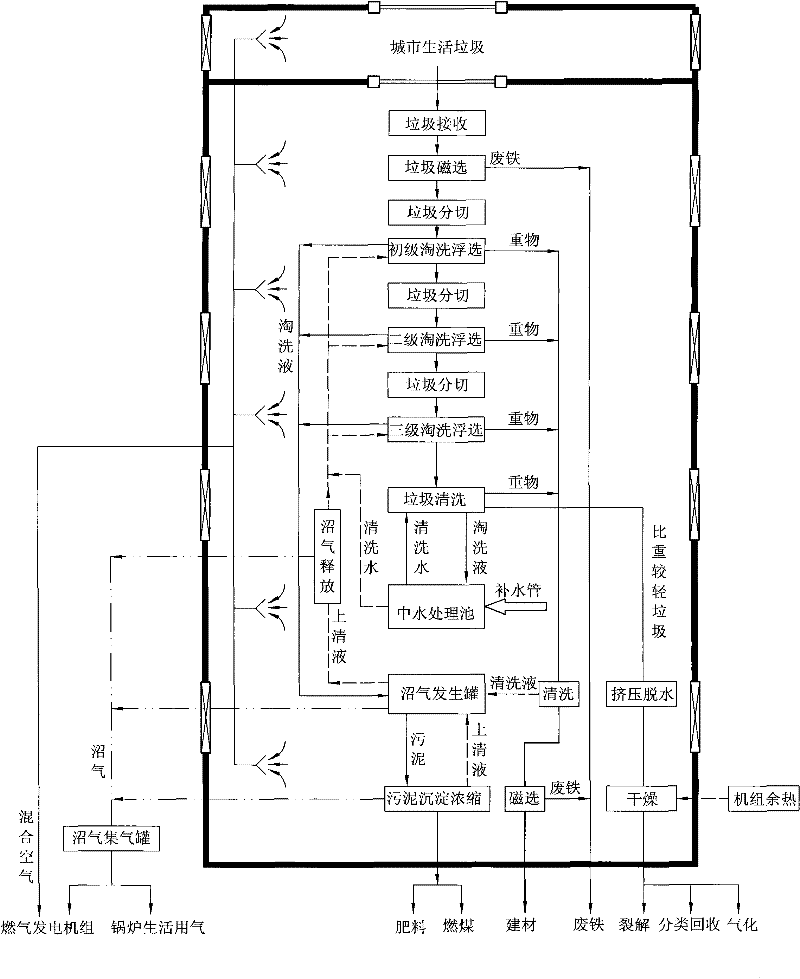

Method for resource recovery and classification utilization of urban domestic waste

ActiveCN102247969AHigh thermal efficiencyEasy to wash and separateSolid waste disposalFurniture waste recoveryEngineeringFuel oil

The invention discloses a method for resource recovery and classification utilization of urban domestic wastes, which at least comprises the following steps of: a magnetic separation step, a waste cutting step, a elutriation flotation step, a waste extrusion dehydration step, an anaerobic treatment step and a sludge deposition concentration step; scrap iron is separated by the magnetic separationstep for the recovery and utilization of the scrap iron; anaerobic organic matter is crushed by the waste cutting step; pasty organic matter and block non-anaerobic wastes are thoroughly separated bythe elutriation flotation step so as to allow the pasty anaerobic organic matter to enter a biogas generation pool or tank for an anaerobic reaction and to allow the clean non-anaerobic wastes to be extruded, dehydrated and dried for individual treatment, and the waste decrement is above 90%; after elutriation, the left 10% non-anaerobic wastes are prepared into fuel oil by a cracking reaction; or are recycled through screening with no screening difficulty being caused by dust and organic matter containing in the wastes; or are delivered into a gasifier for fuel gas production, which preventsthe energy consumption of water-containing organic matter during waste incineration treatment, and greatly increases the thermal efficiency of waste treatment.

Owner:刘振亮

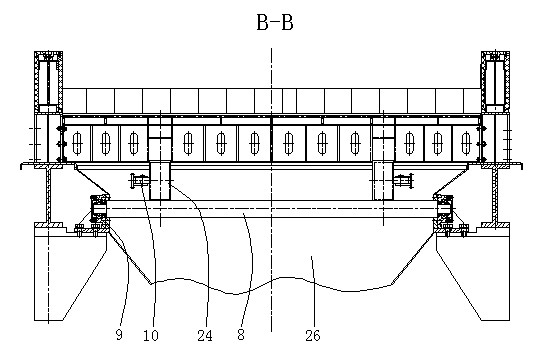

Method of processing refuse burning fly ash through cyclone furnace high temperature melting

The invention relates to a method for processing fly ash after incineration of domestic waste. The high-temperature melting treatment method of fly ash in a garbage incineration is completed by the following steps: 1. The fly ash produced after garbage incineration is mixed with coal powder at a ratio of 15 to 25: 75-85 mixed in a ratio of 75 to 85 and sent to the cyclone furnace 6 for combustion until high-temperature melting; 2. The combustion in the cyclone furnace 6 is in a reduced state; 3. The heavy metals in the fly ash sink to the bottom of the slag pool 9 and are discharged and recovered , and the slag floating on the liquid metal flows out of the slag pool from the slag recovery outlet 11, and is then rapidly cooled by water as cement raw material or building material recycling. The method can not only recover valuable metals in fly ash, decompose dioxin, recover waste heat to generate electricity, but also recycle molten ash as cement raw material or building material after being quenched with water, and has low operating cost. Or the combustion in the cyclone furnace 6 is in an oxidized state, the air excess coefficient is kept at 1.1 to 1.2, and only the quenched glass body is recovered.

Owner:HARBIN INST OF TECH

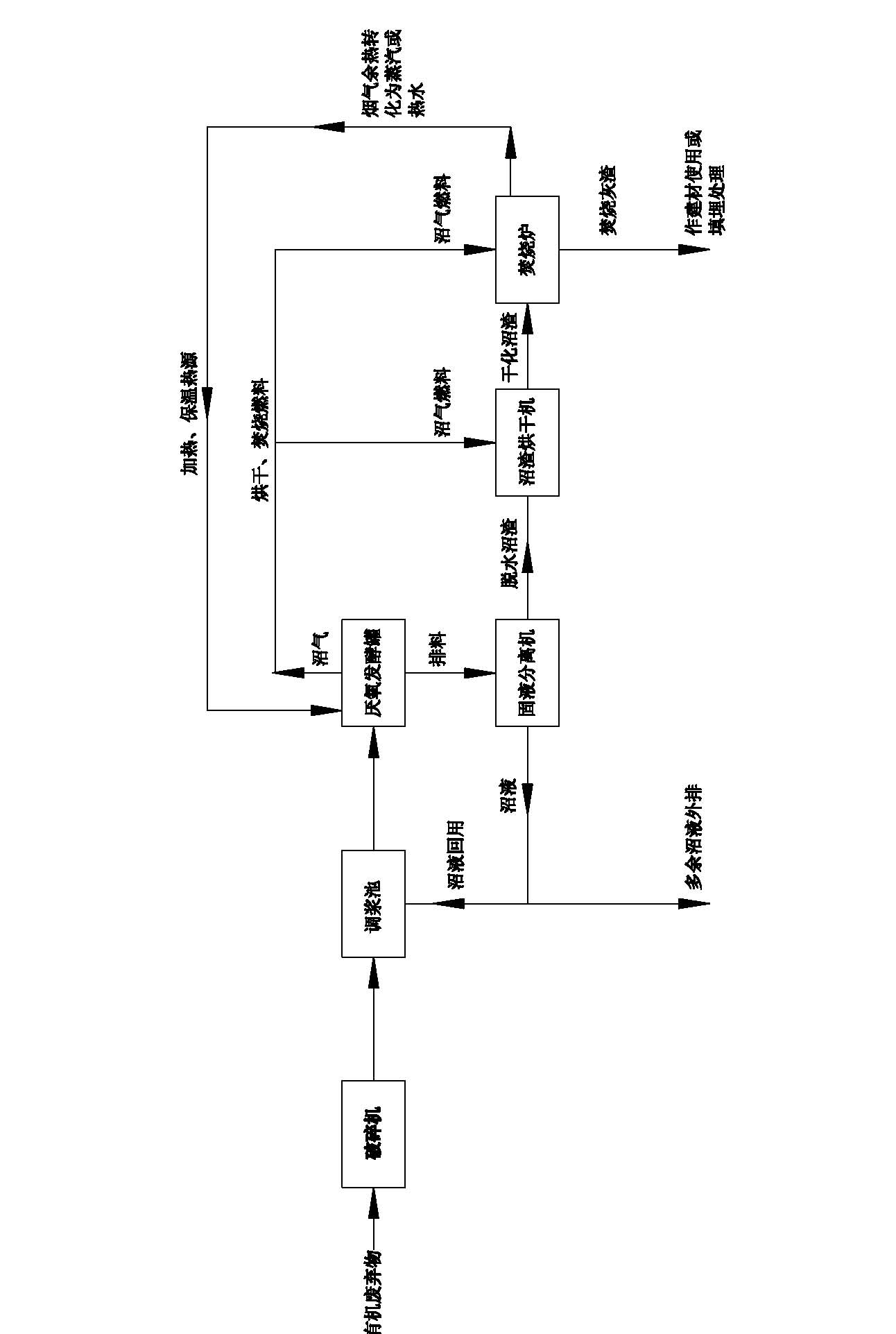

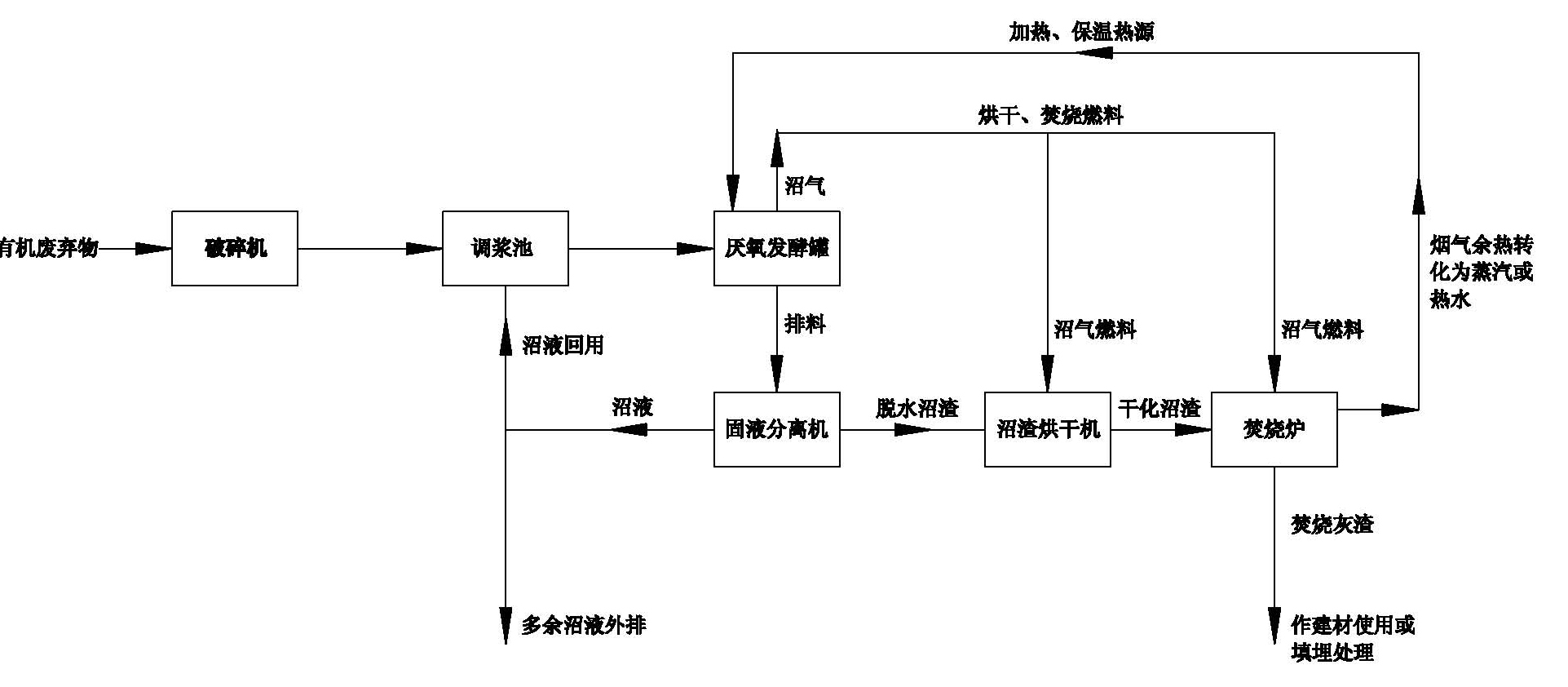

Anaerobic fermentation-incineration combined treatment method for organic wastes

InactiveCN102374543AAchieve reductionHarmlessGas production bioreactorsLiquid production bioreactorsSlagSlurry

The invention discloses an anaerobic fermentation-incineration combined treatment method for organic wastes. The anaerobic fermentation-incineration combined treatment method is characterized by comprising the following steps of: firstly, crushing the organic wastes, feeding the crushed organic wastes into a slurry mixing pool to be mixed with water or a methane solution to form a fermentation raw material, and feeding the fermentation raw material into an anaerobic fermentation tank for anaerobic fermentation treatment; secondly, performing solid-liquid separation treatment on residual slurry to form the methane solution and dehydrated methane slag; thirdly, making partial methane solution flow back to the slurry mixing pool, discharging surplus methane solution outwards to a sewage treatment facility; fourthly, feeding the dehydrated methane slag into a methane slag drying machine by taking methane generated by the anaerobic fermentation tank as fuel for heating, wherein the moisture content of the dried methane slag is made lower than 40%; fifthly, incinerating the dried methane slag subjected to drying treatment by using the methane collected from the anaerobic fermentation tank as auxiliary fuel for methane slag combustion; and sixthly, producing steam or hot water by a waste heat boiler by using high-temperature flue gas discharged from a methane slag incineration furnace, and supplying the steam or the hot water to the fermentation tank to serve as a hot source for heating or heat insulating. According to the invention, the anaerobic fermentation and the incineration treatment are organically combined, the advantages of the anaerobic fermentation and the incineration treatment are fully exerted, and the reduction, harmlessness and the recycling of rubbish are facilitated.

Owner:NANJING UNIV

Method for preparation of polytetrafluorethylene microporous film for the processing of high-temperature fume and flour dust

InactiveCN101081356ASimple processReduce manufacturing costSemi-permeable membranesDispersed particle separationPolymer scienceBurn treatment

The present invention discloses one kind of microporous teflon film for treating high temperature fume and dust and its preparation process. The preparation process includes mixing powdered teflon resin and powdered catalyst, adding liquid lubricant to the mixture, extruding, rolling, longitudinally stretching, transversely stretching, heat setting and other steps. The microporous teflon film for treating high temperature fume and dust has simple preparation process and low cost. It has pore size of 0.5-5 micron and dioxins eliminating rate at 200 deg.c as high as 95-98 %. It may be applied widely for high temperature tail gas treatment in refuse burning treatment plant, refuse burning power plant, coal burning power plant, cement mill, etc.

Owner:ZHEJIANG SCI-TECH UNIV

Heavy metal treating agent and heavy metal pollutants treating method

ActiveCN101947381AGood storage stabilityInhibitionSludge treatmentWater contaminantsHigh concentrationSludge

Provided is a heavy metal treating agent and a heavy metal pollutants treating method. The invention provides a medicament and a treating method thereof. The medicament is used for treating heavy metal pollutants, like burning ash and fly ash discharged from a garbage burning field, soil polluted by heavy metal, sludge generated from waste water treatment, and heavy metal contained in the waste water discharged by factories. Heavy metal treating agent comprising piperazine dithiocarboxylic acids salt and reductible composition is used. In terms of reductible composition, water soluble bivalent iron compound and aliphatics Alpha - hydroxycarboxylic acid and / or salt, or sulfurated bi-alkali metal salt are preferably used. With the heavy metal treating agent, harmful cation species heavy metal like lead, zincum, cadmium, mercury, arsenic, selenium, and hexavalent chromium can be treated by encapsulation in a high concentration, and harmful anion species heavy metal like hexavalent chromium, arsenic and selenium can be treated by encapsulation in a high concentration.

Owner:TOSOH CORP

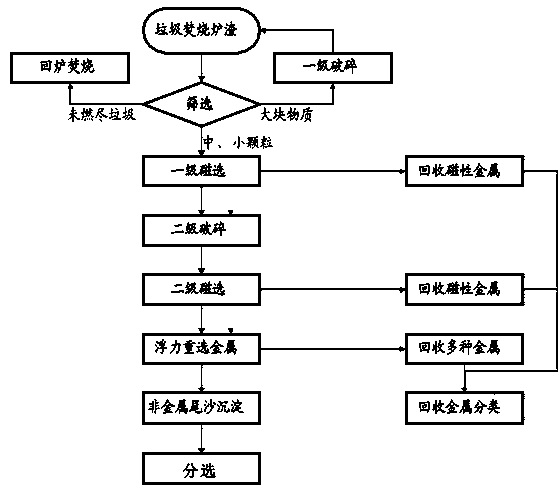

Method for comprehensively treating and utilizing household garbage incineration slag

The invention discloses a method for comprehensively treating and utilizing household garbage incineration slag.. The method comprises the following steps: A. screening and primary crushing of slag; B. primary magnetic separation; C. secondary crushing: the slag subjected to the primary magnetic separation is conveyed into a flushing water continuous injection type sanding machine through a conveying belt, the slag is crushed in the sanding machine, and the crushed slag granules flow out of the sanding machine together with the flushing water; D. secondary magnetic separation: the mixture of the slag and the flushing water flowing out of the outlet of the sanding machine flows by a drum magnetic iron remover, and magnetic metals contained in the slag are picked out by secondary magnetic separation; E. buoyancy gravity concentration on other metals; and F. precipitation of non-metallic tailings. Since other metals are picked up by secondary magnetic separation and buoyancy gravity concentration, the metal content in the slag is effectively decreased, the quality of bricks or cement is guaranteed when the treated slag is used to make bricks or cement; and since the flushing water is continuously injected into the sanding machine, most of disgusting odor can be removed and dust is eliminated, and the water circulation manner is adopted, the advantages of saving energy and protecting the environment are achieved.

Owner:山东环兴再生资源科技有限公司

Method for treating waste incineration fly ash by using plasmas

InactiveCN101797572APromote vitrificationSolve the "bridge" problemSolid waste disposalMelting tankVitrification

Owner:安徽中科华炬环保科技有限公司

Apparatus and method for reaction of materials using electromagnetic resonators

An electromagnetic resonator may be used for efficient heating and / or reaction of materials. More particularly, resonator-based systems may be used for efficient pyrolysis, gasification, incineration (or other similar processes) of feedstock including but not limited to biomass, petroleum, industrial chemicals and waste materials using RF resonators and adaptively tunable RF resonators. A processing architecture based on the use of resonators is presented.

Owner:UNIVERSAL PHASE

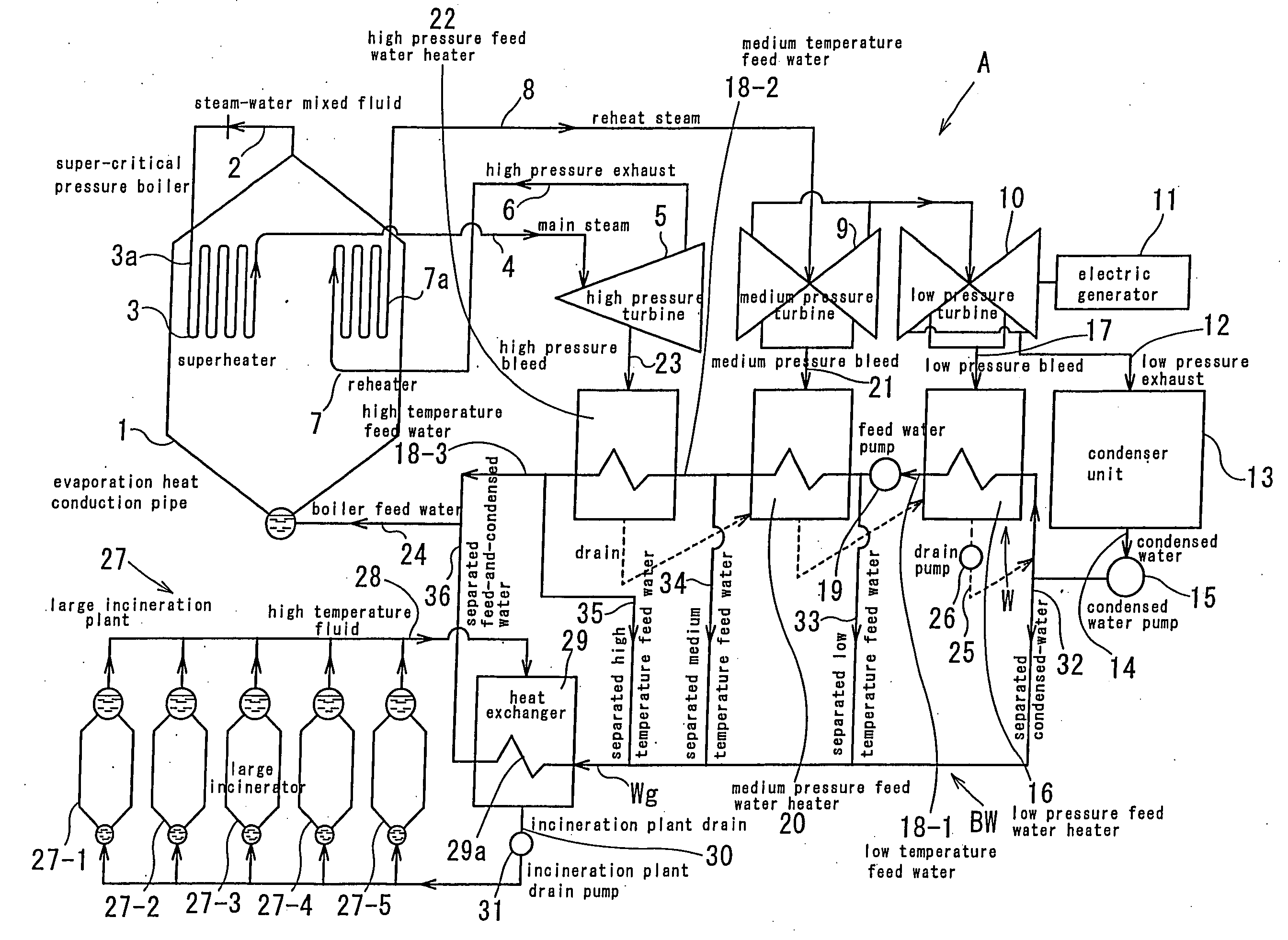

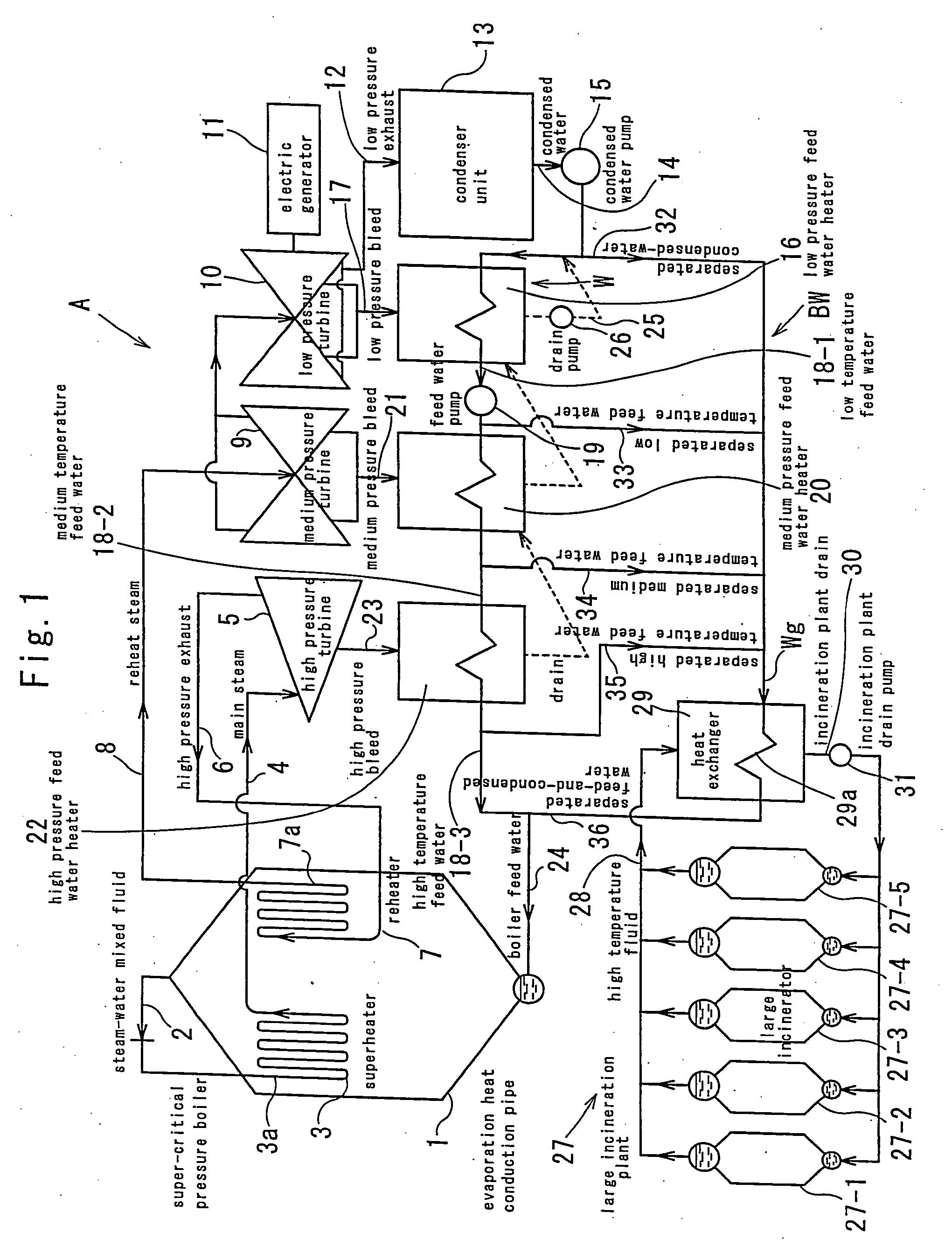

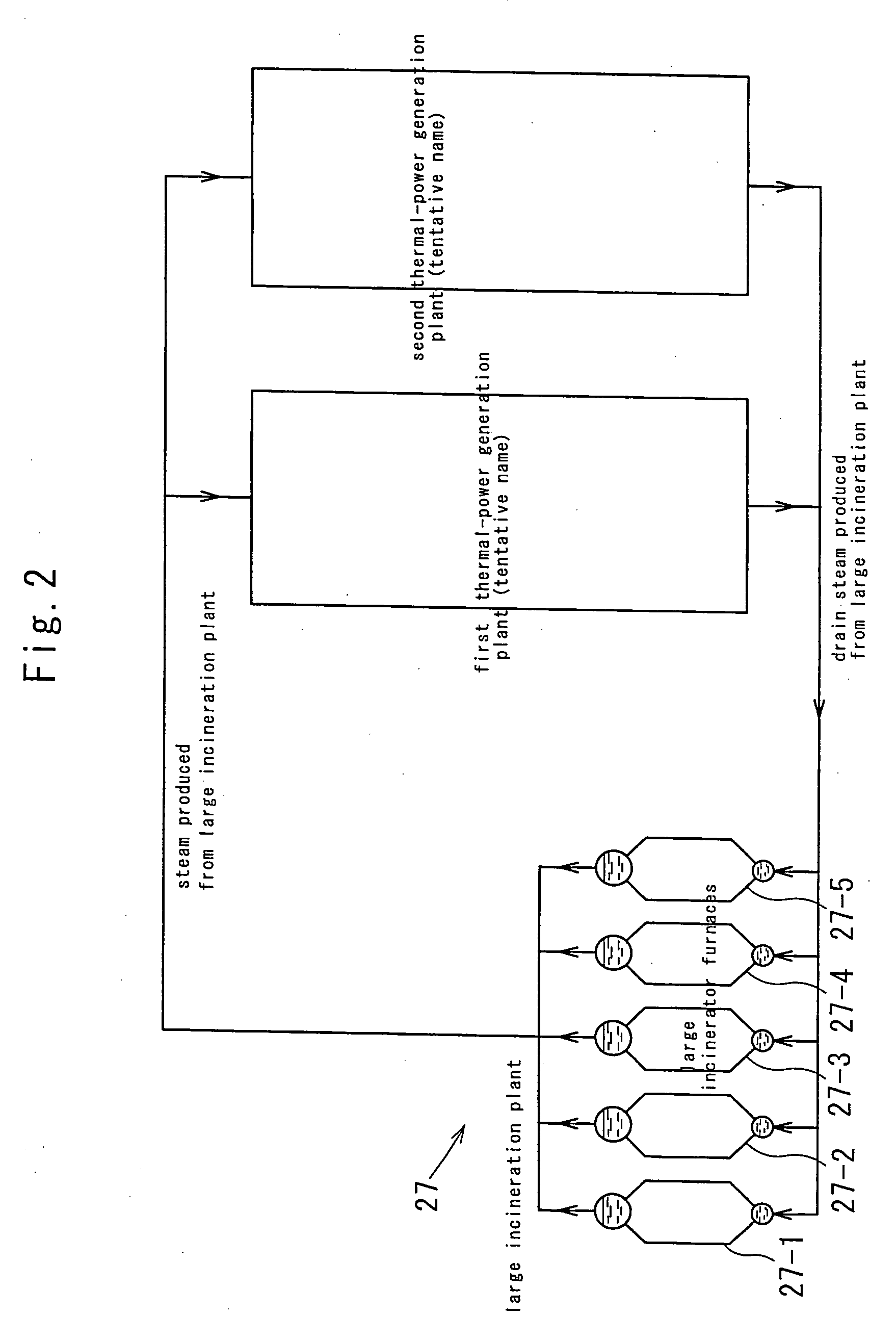

Reheat/regenerative type thermal power plant using rankine cycle

InactiveUS20060254251A1Reducing thermic efficiencyEasy to useEnergy industryGas turbine plantsIncinerationThermoelectric Power Plants

A reheat-and-regenerating type thermal power plant (A) using Rankine cycle has a water feed bypass (BW) which suppies high temperature fluid (28) produced in a large incineration plant (27) to a heat exchanger (29) and by which confluent feed water (Wg) resulting from the confluence of separated condensed-water (32), separated low temperature feed water (33), separated medium temperature feed water (34) and separated high temperature feed water (35) is supplied to a superheat conduction pipe (3a) through a heat exchanger conduction pipe (29a). The water feed bypass (BW) is installed separately from a feed water path (W), thus insuring an efficient use of the high temperature fluid (28) produced upon incinerating a huge amount of combustible wastes in the large incineration plant (27).

Owner:OGAWA KIICHIRO

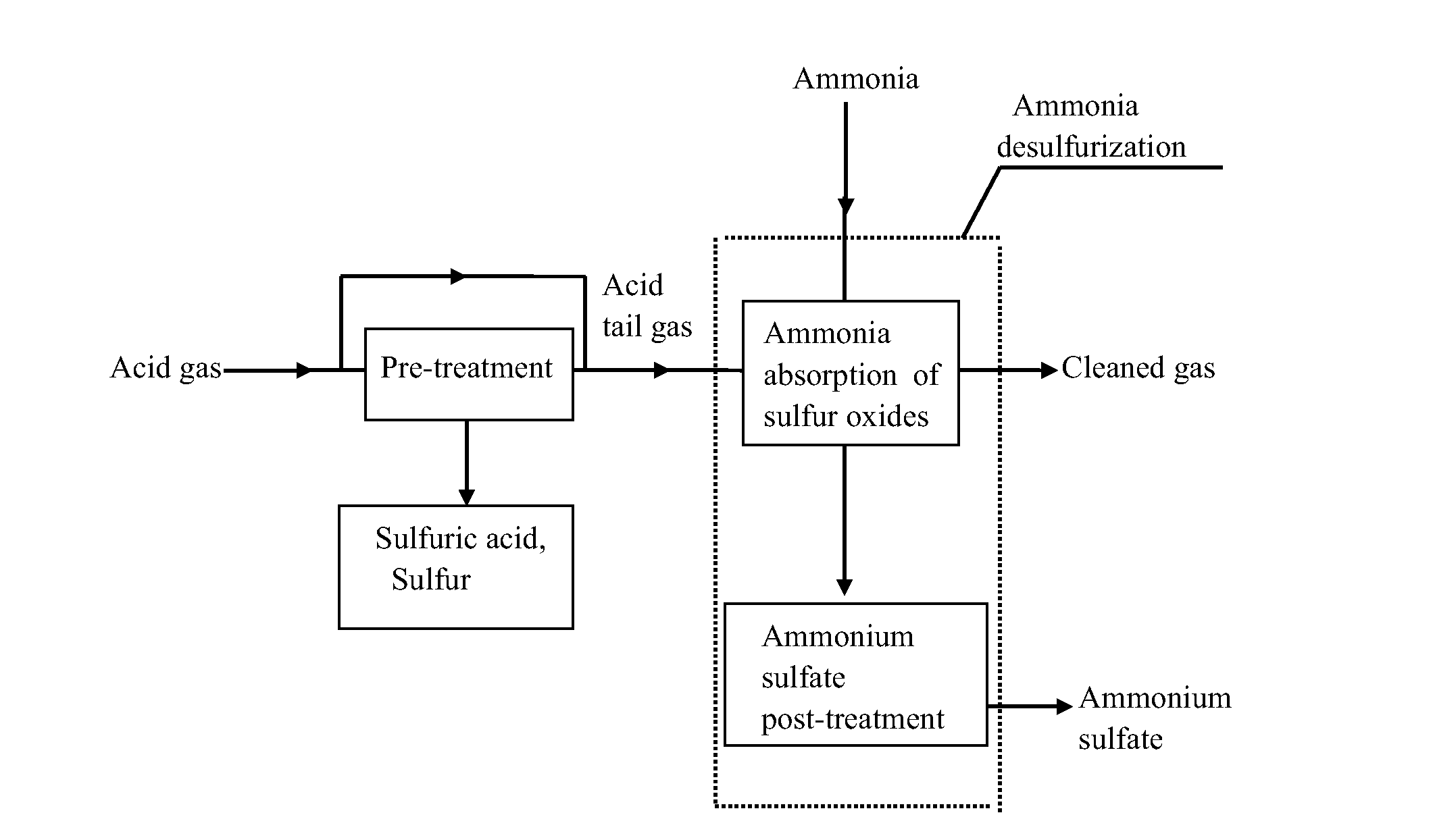

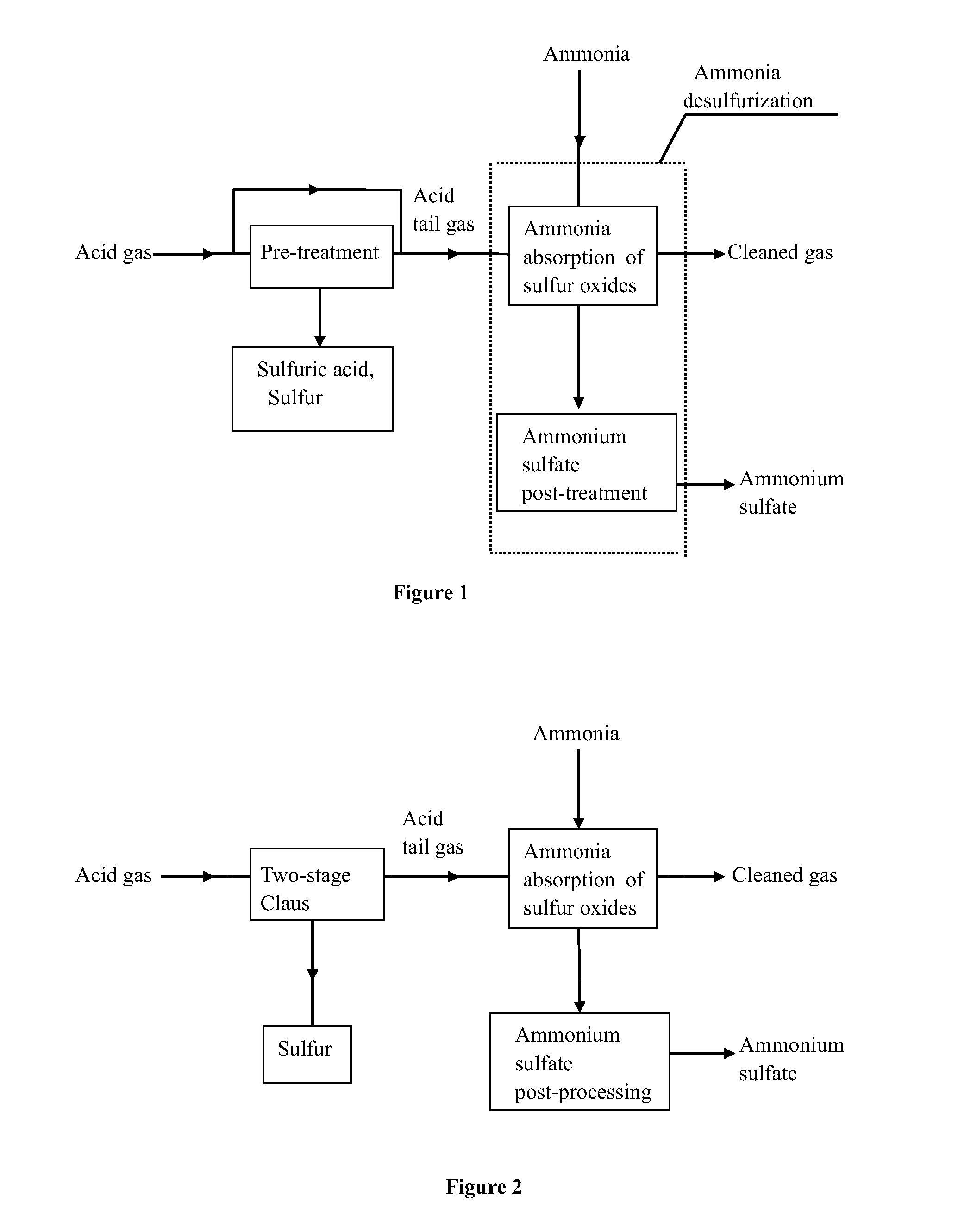

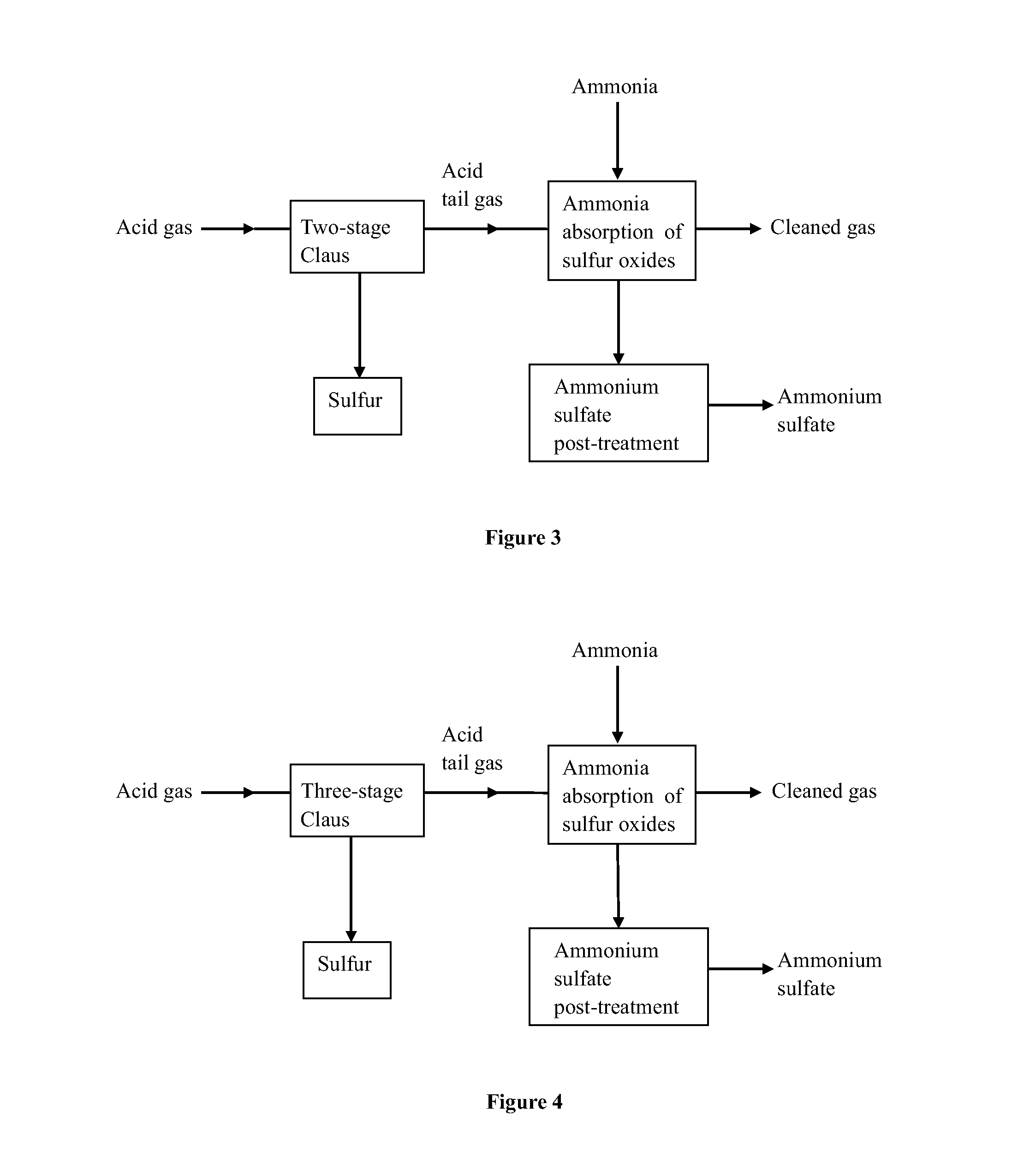

Effective removal of acidic sulfide gas using ammonia-based desulfurization

InactiveUS20150352489A1Efficient removalPromote recoveryGas treatmentDispersed particle separationChemical industryPretreatment method

A method for effectively removing acidic sulfide gas using ammonia-based desulfurization includes the following steps of: 1) pre-treatment, wherein sulfide in acid gas undergoes through pre-treatment methods of sulfur recovery, acid making or / and incineration to convert remaining sulfur in the acid gas into sulfur oxides, and the acid tail gas with sulfur oxides is obtained; and the acid gas is derived from petrochemical industry, natural gas chemical industry, coal chemical industry, etc.; 2) ammonia absorption of sulfur oxides, wherein the acid tail gas with sulfur oxides is allowed to flow into an ammonia absorption apparatus, and a cyclic absorption solution is used to absorb sulfur oxides; and 3) post-treatment of ammonium sulfate, wherein a saturated or nearly saturated absorption solution undergoes concentration, crystallization, solid-liquid separation, and drying to obtain a solid product of ammonium sulfate. Sulfur oxides (including sulfur dioxide, sulfur trioxide and hydrates thereof) in the acid tail gas are removed and sulfuric acid, sulfur and ammonium sulfate are byproduced, and the cleaned gas is discharged upon meeting the emission standard.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com