Anaerobic fermentation-incineration combined treatment method for organic wastes

A technology of organic waste and anaerobic fermentation, which is applied in the treatment of organic waste and the combined treatment of anaerobic fermentation and incineration of organic waste. The effect of recycling and development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

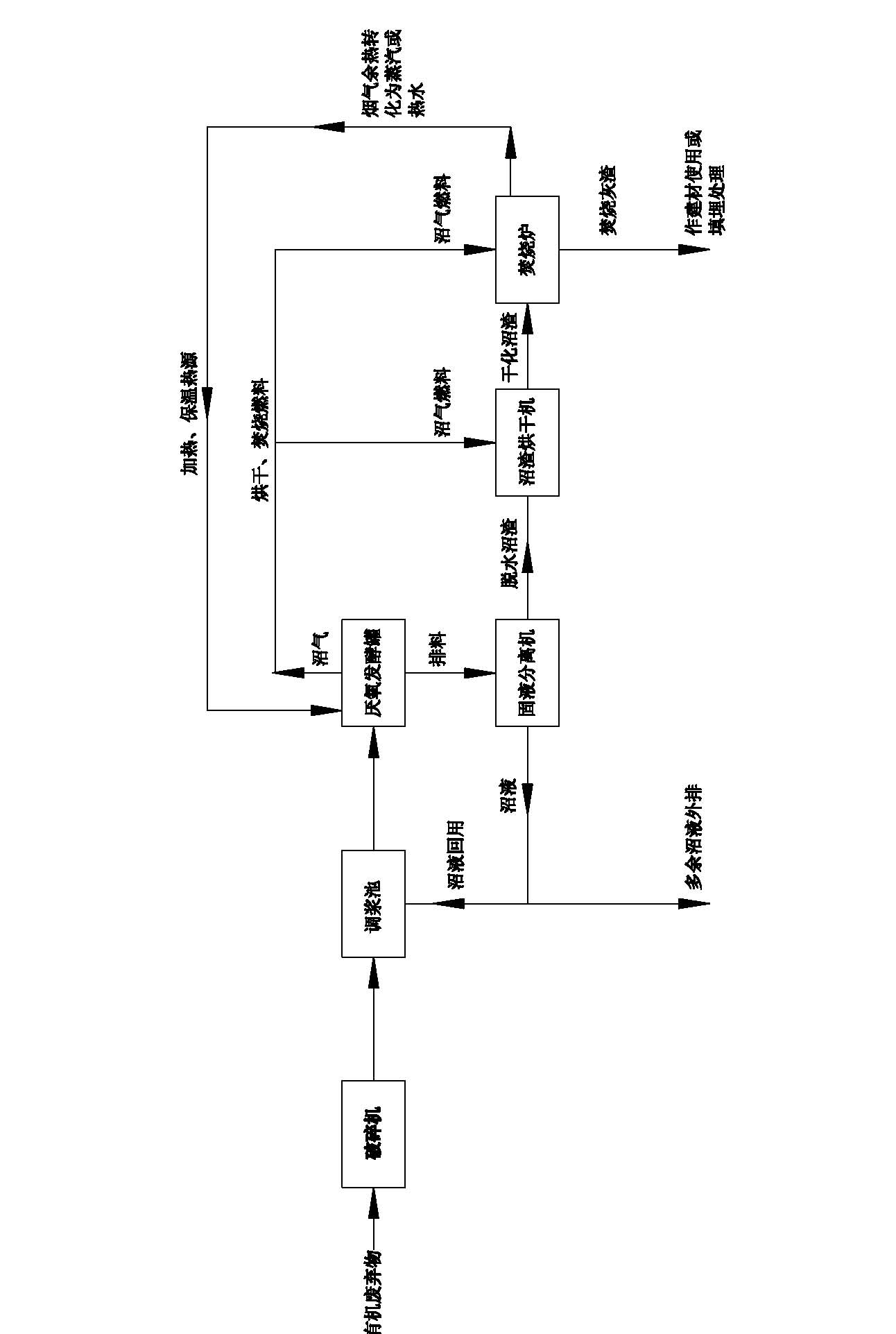

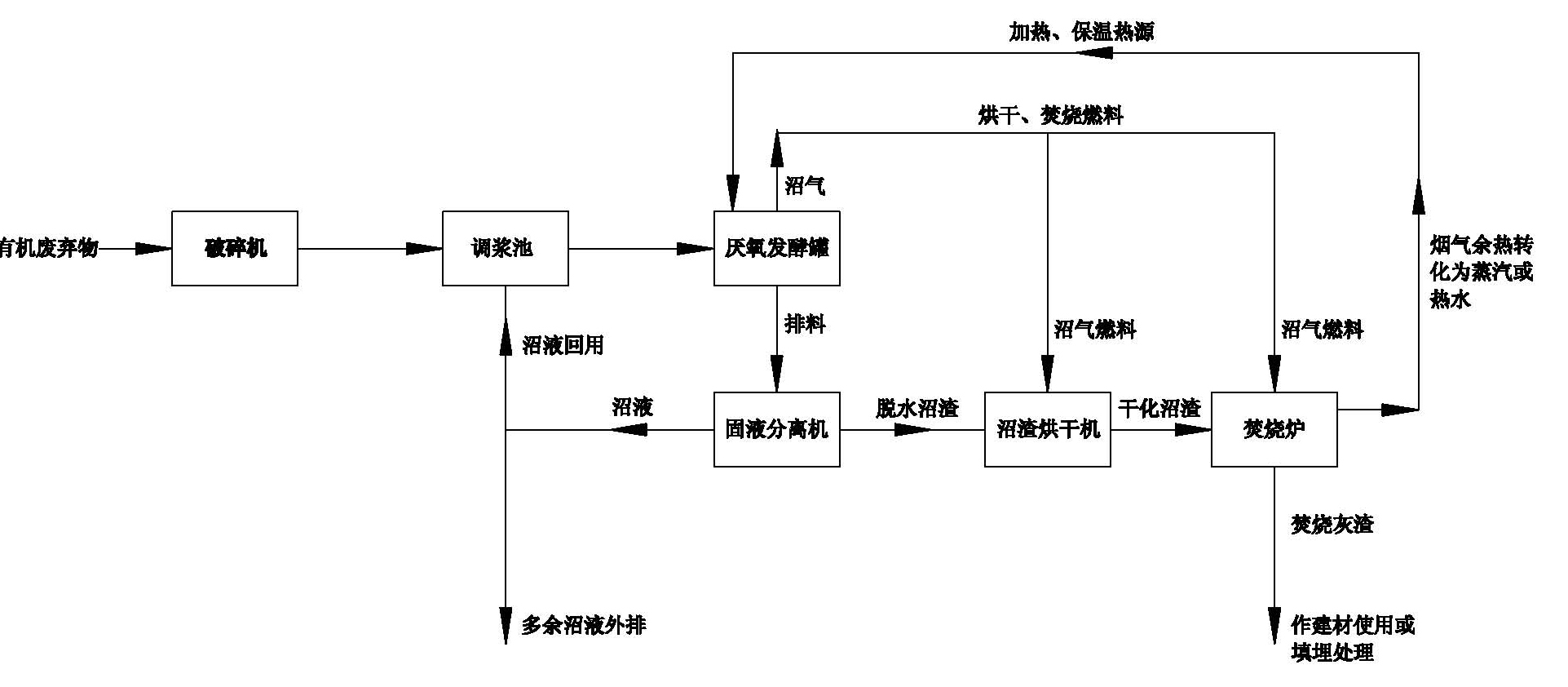

[0022] Such as figure 1 shown.

[0023] A kind of anaerobic fermentation-incineration combined treatment method of organic waste, it comprises the following steps:

[0024] 1. First of all, for organic waste (including kitchen waste, kitchen waste, urban sludge, farmer’s market waste, poultry manure and other waste with degradable organic matter as the main component, it can be a single component from the same source, or It can be a mixture of different sources) for crushing treatment, crushing its particle size to less than 30mm, entering the slurry mixing tank and mixing with water or biogas slurry to form fermentation raw materials, entering anaerobic fermentation tank for anaerobic fermentation treatment, generating biogas, in order to provide Subsequent dryers and incinerators provide fuel; the biogas produced can be collected or automaticall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com