Patents

Literature

1906results about How to "Realize resources" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

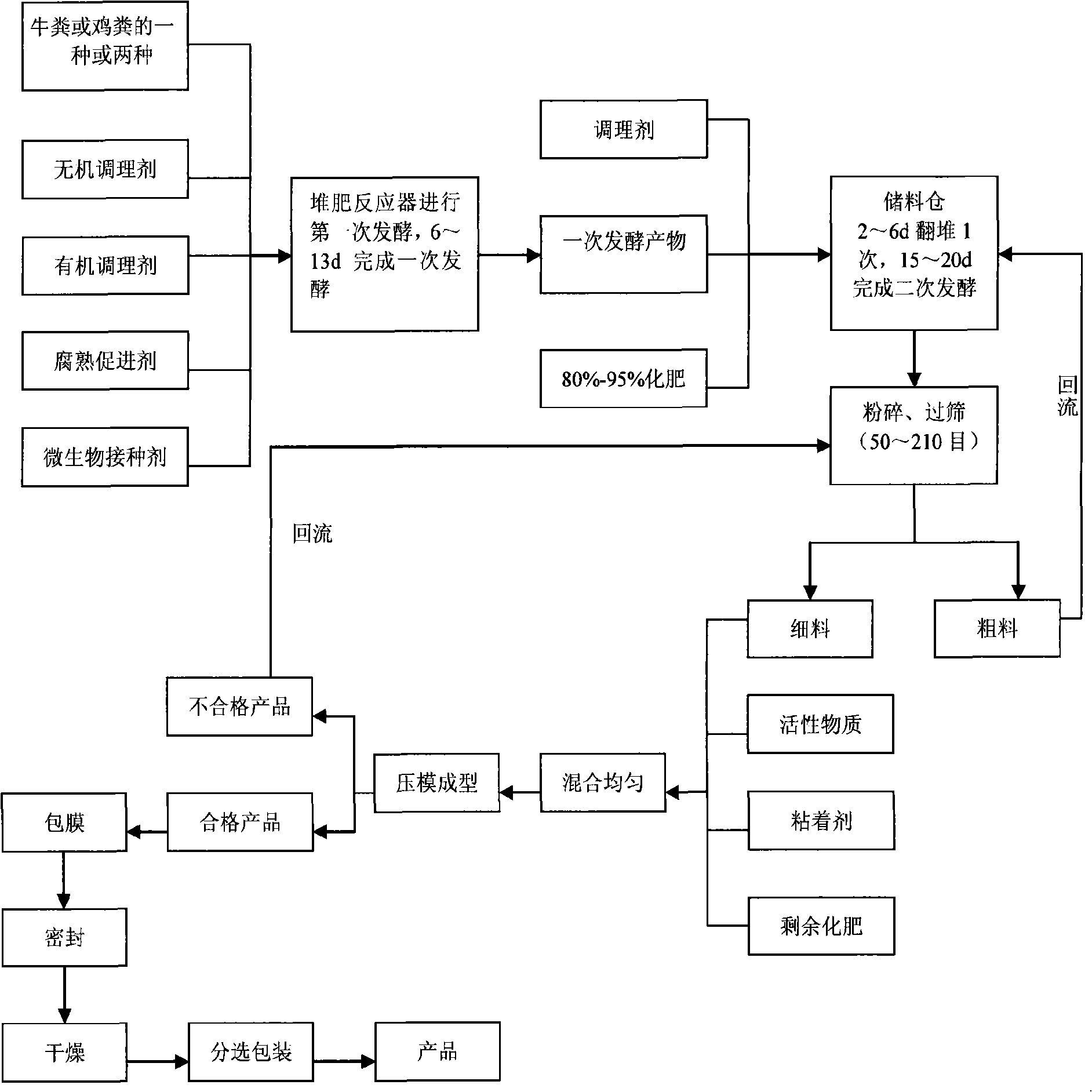

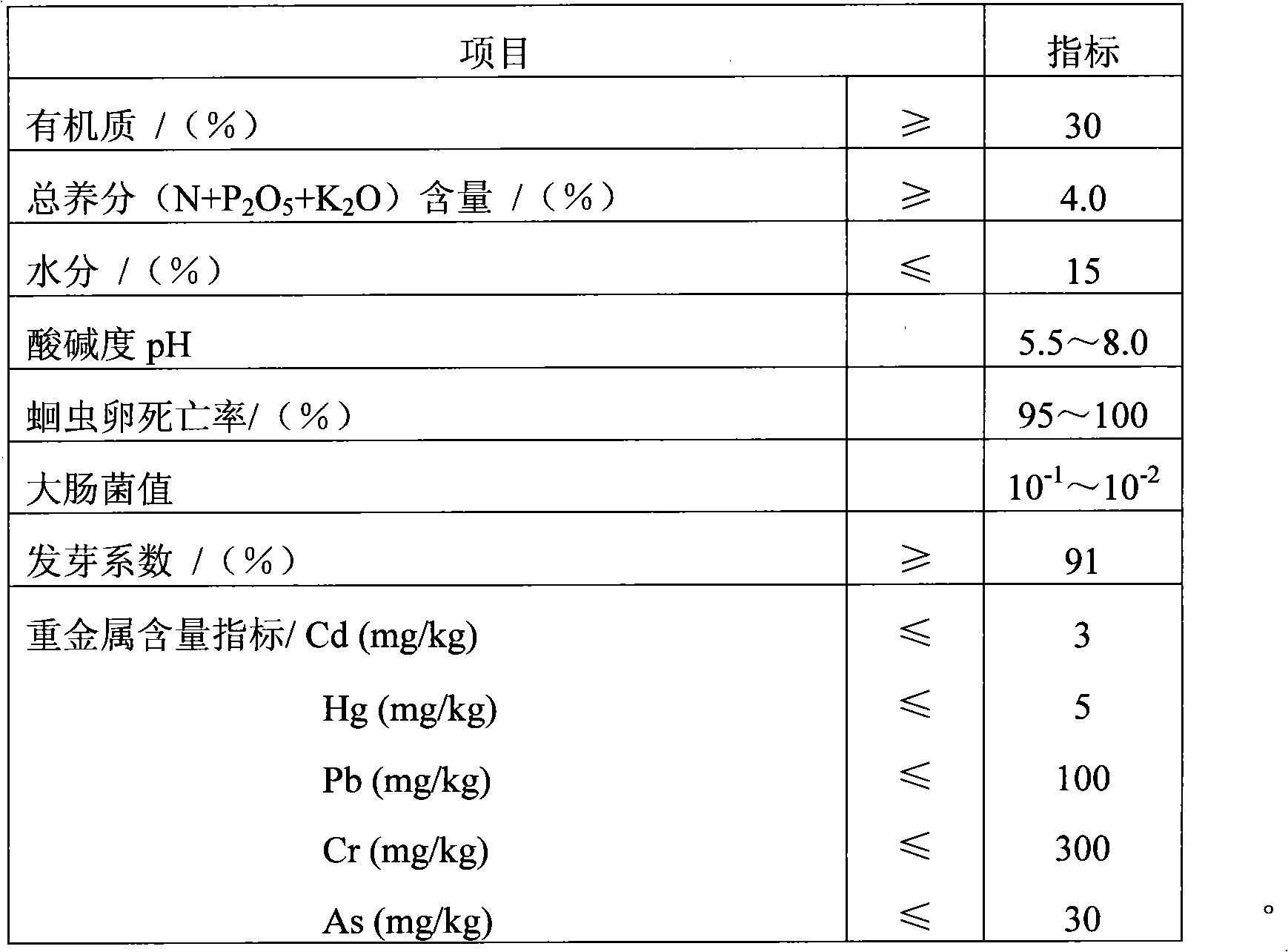

Organic-inorganic slow-released fertilizer and method for preparing same

InactiveCN101284747AHarmlessFastBio-organic fraction processingOrganic fertiliser preparationSealantFermentation

The invention discloses a flower organic-inorganic slow-release fertilizer as well as the preparation method thereof. The slow-release fertilizer contains the following materials by weight: primary fermentation products of 45 to 70 percent, chemical fertilizers of 2 to 35 percent, a conditioner of 5 to 30 percent, coating materials of 3 to 25 percent, an agglutinant of 1 to 10 percent, active materials of 0 to 15 percent and a sealant of 0 to 12 percent; the primary fermentation products, the chemical fertilizers and the conditioner are mixed for carrying out the secondary fermentation of composting, and then the products of the second fermentation are crushed for press molding; finally, compound fertilizer particles formed by the press molding are evenly sprayed with the coating materials and the agglutinant, thereby obtaining the flower organic-inorganic slow-release fertilizer; the flower organic-inorganic slow-release fertilizer of the invention has the advantages that the nutrition is rich, the composting process is fast, the rotten degree is good, the fertilizer is prone to be absorbed by flowers, the manufacturing process is simple, and the use is convenient.

Owner:广东省农业科学院土壤肥料研究所

Resource utilization process of organic hazardous waste

ActiveCN111185460AHarmlessAchieve reductionSolid waste disposalTransportation and packagingFluid phaseSlag

The invention discloses a resource utilization process of organic hazardous waste. The resource utilization process includes the steps that classified storage and treatment of solid-phase, solid-liquid mixing and liquid-phase organic hazardous waste are carried out; solid-phase crushing, grinding and screening treatment is carried out; solid-liquid mixing is carried out after solid-liquid separation, solid-phase grinding and liquid-phase sedimentation separation treatment is carried out; direct liquid-phase sedimentation is carried out; then after solid-liquid mixing, a fluxing agent is addedfor stirring, a stabilizer and a dispersing agent are added for slurrying, the slurry is fed into a gasifier, and the obtained gas is used as fuel gas after being subjected to cooling, dedusting, spraying and desulfuration; slag tapping and vitrification slag discharge are carried out; and waste water is recycled. The resource utilization process has the beneficial effects that solid phase, solid-liquid mixing and liquid-phase comprehensive treatment, harmless treatment and slag discharge are realized.

Owner:杰瑞邦达环保科技有限公司

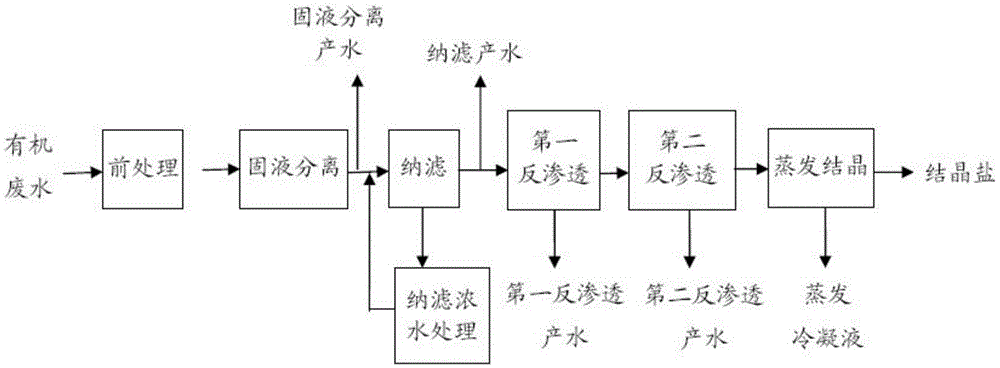

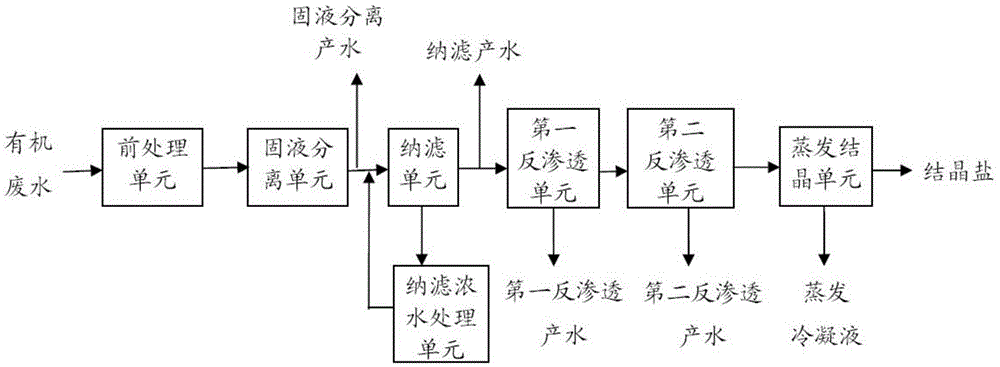

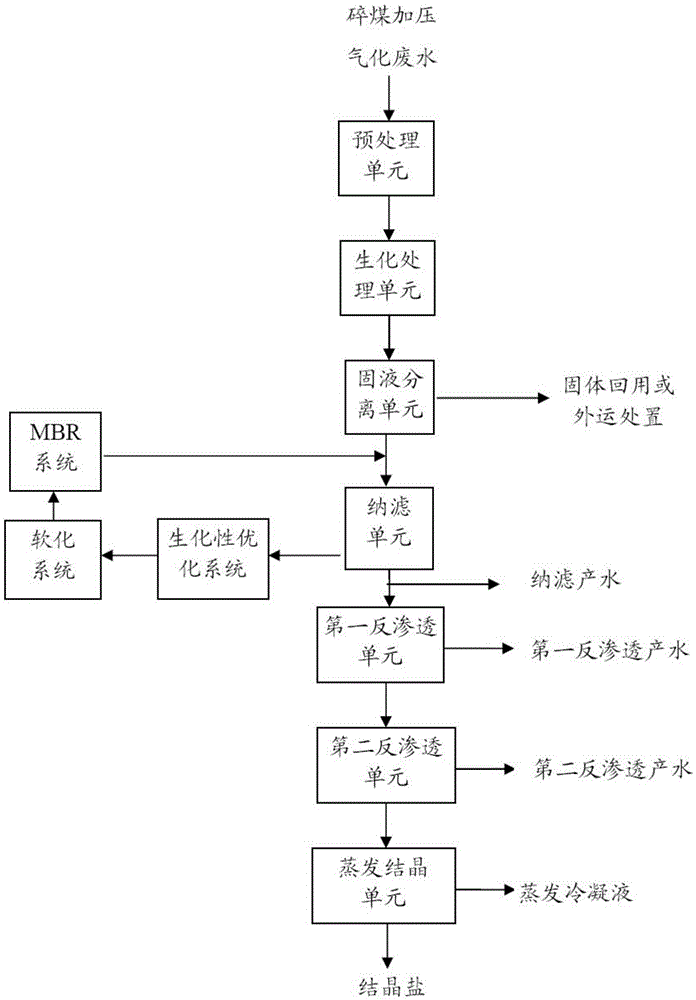

Processing method for reducing and recycling organic waste water and processing system

InactiveCN105540967AReduce foulingReduce the risk of contaminationFatty/oily/floating substances removal devicesWater contaminantsReverse osmosisWastewater

The invention provides a processing method for reducing and recycling organic waste water. The method comprises steps: (1) pre-treating waste water to obtain pre-treated out-water; (2) treating the out-water obtained from the step (1) through solid-liquid separation; (3) nano-filtering the out-water obtained from step (2); (4) treating nano-filtered concentrated water obtained from the step (3) to obtain out-water subjected concentrated water nano-filtering, returning to the step (3) for mixing the out-water subjected to concentrated water nano-filtering with the out-water subjected to solid-liquid separation, and performing nano-filtering; (5) performing first reverse osmosis treatment on out-water obtained from the step (3) through nano-filtering; (6) performing second reverse osmosis treatment on concentrated water obtained from the step (5) through first reverse osmosis treatment; and (7) evaporating and crystallizing a concentrated liquid obtained from the step (6) through second reverse osmosis treatment in order to obtain crystallized salt and evaporated concentrated water. The invention further provides a processing system of the method. Through the method and system, waste water is truly reduced and recycled.

Owner:DATANG INT CHEM TECH RESINST

Wet flue gas denitration technique for nitrite recovery

ActiveCN101352644AHigh economic valueIncrease profitDispersed particle separationAir quality improvementNitriteResource utilization

The invention discloses a wet-method smoke denitration process used for recovering nitrite, comprising the steps as follows: hydrogen peroxide or ozone is taken as oxidant; the oxidant is uniformly sprayed into smoke disposed by pre-dedusting and desulfurizing so as to carry out gas oxidation reaction and lead the NO in the smoke to be oxidated as NO2; subsequently, alkali liquid is taken as absorbent so as to absorb the mixture of the oxidated NO and NO2 and generate the nitrite; the absorbent is concentrated after absorbing the NO and NO2 and cooled and crystallized; after centrifuging separation, the nitrite crystal is gained. The process of the invention can effectively remove the NOx in the smoke, gains the nitrite with high economic values at the same time, and realizes the resource utilization of denitration outgrowth.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

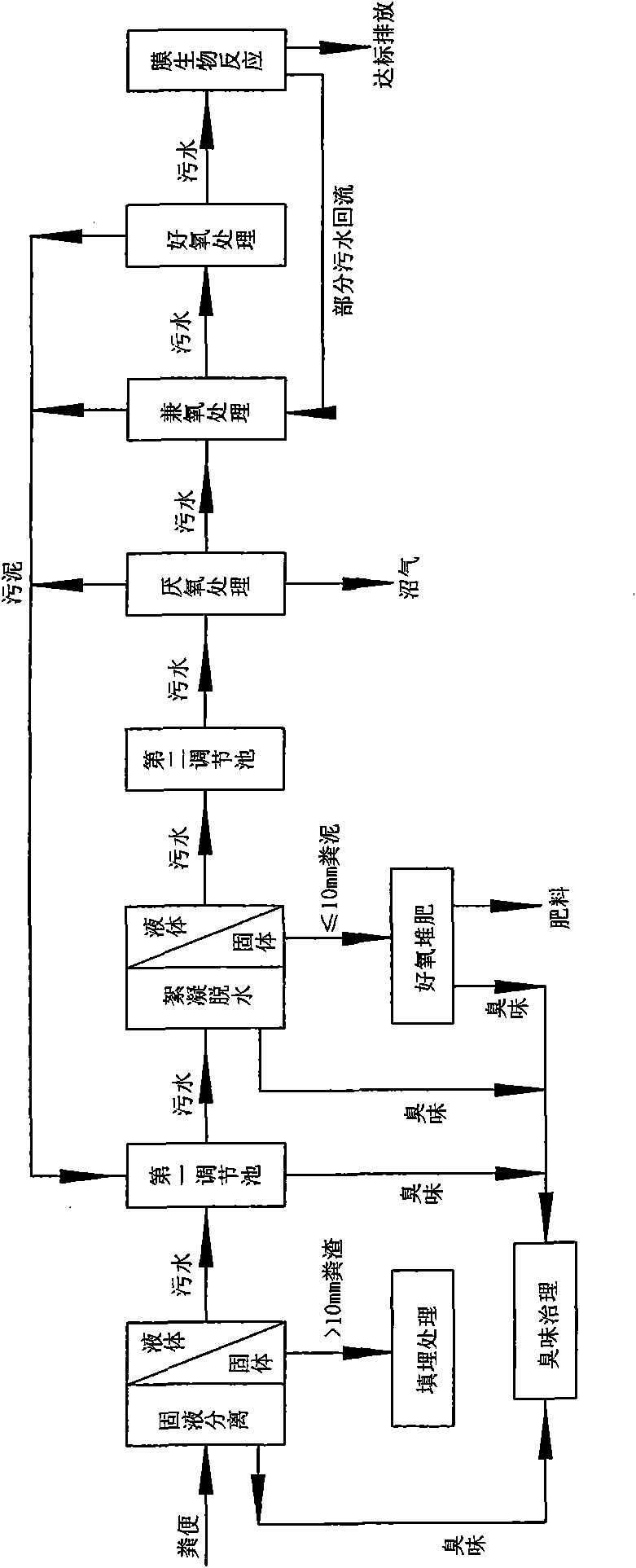

Excrement centralized processing method

ActiveCN101654318AAvoid cloggingCOD removalBio-organic fraction processingSludge treatment by de-watering/drying/thickeningFlocculationFeces

The invention relates to an excrement centralized processing method, comprising the steps of solid-liquid separation, flocculation water removing, aerobic compost treatment, anaerobic sewage treatment, facultative anaerobic sewage treatment, aerobic sewage treatment, membrane anaerobic reacting sewage treatment and odor treatment. Treated with the processing method of the invention, the urban night soil is 100% decontaminated, is 99.7% minimized and the excrement sludge is completely changed into resource.

Owner:北京昊业怡生科技有限公司

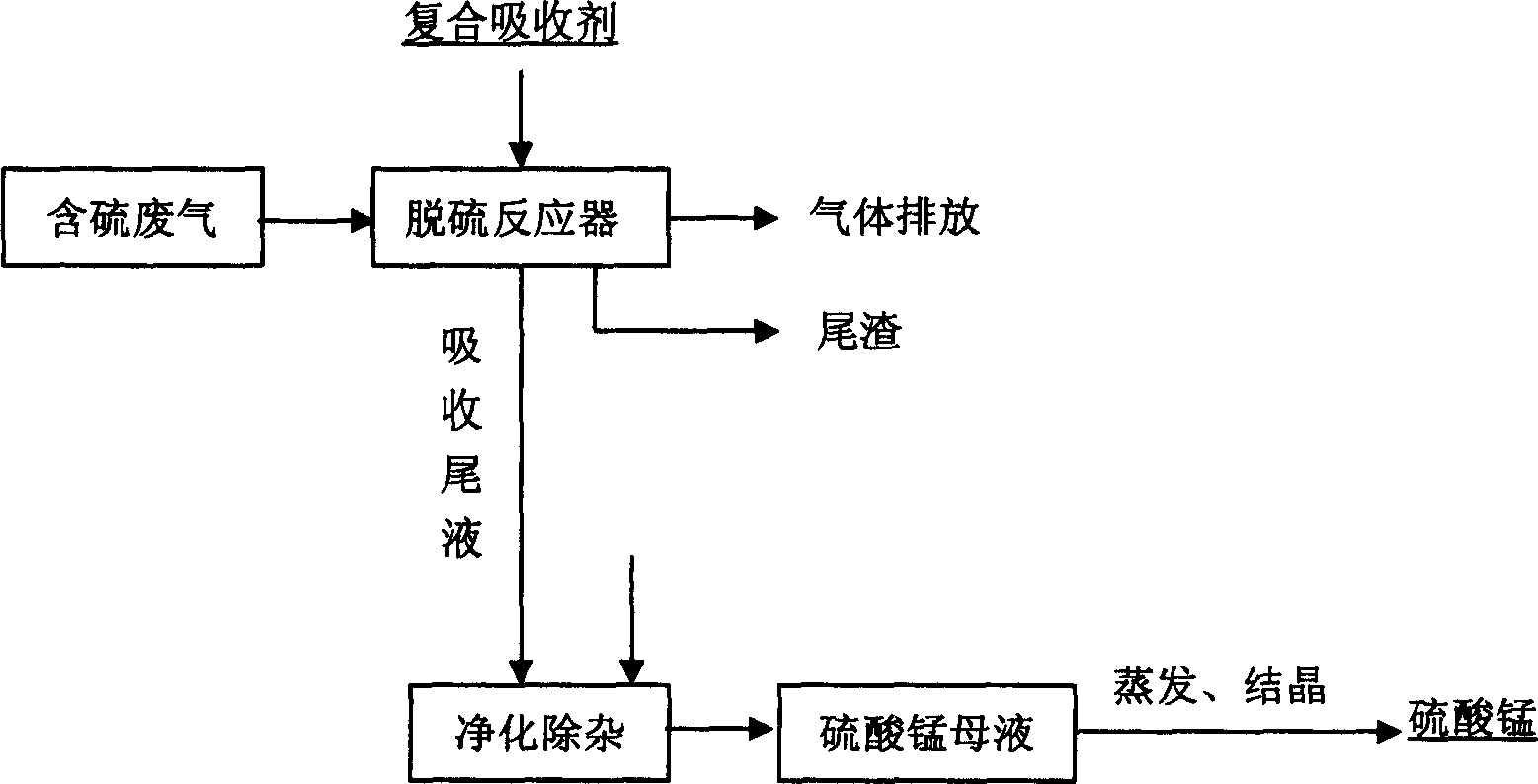

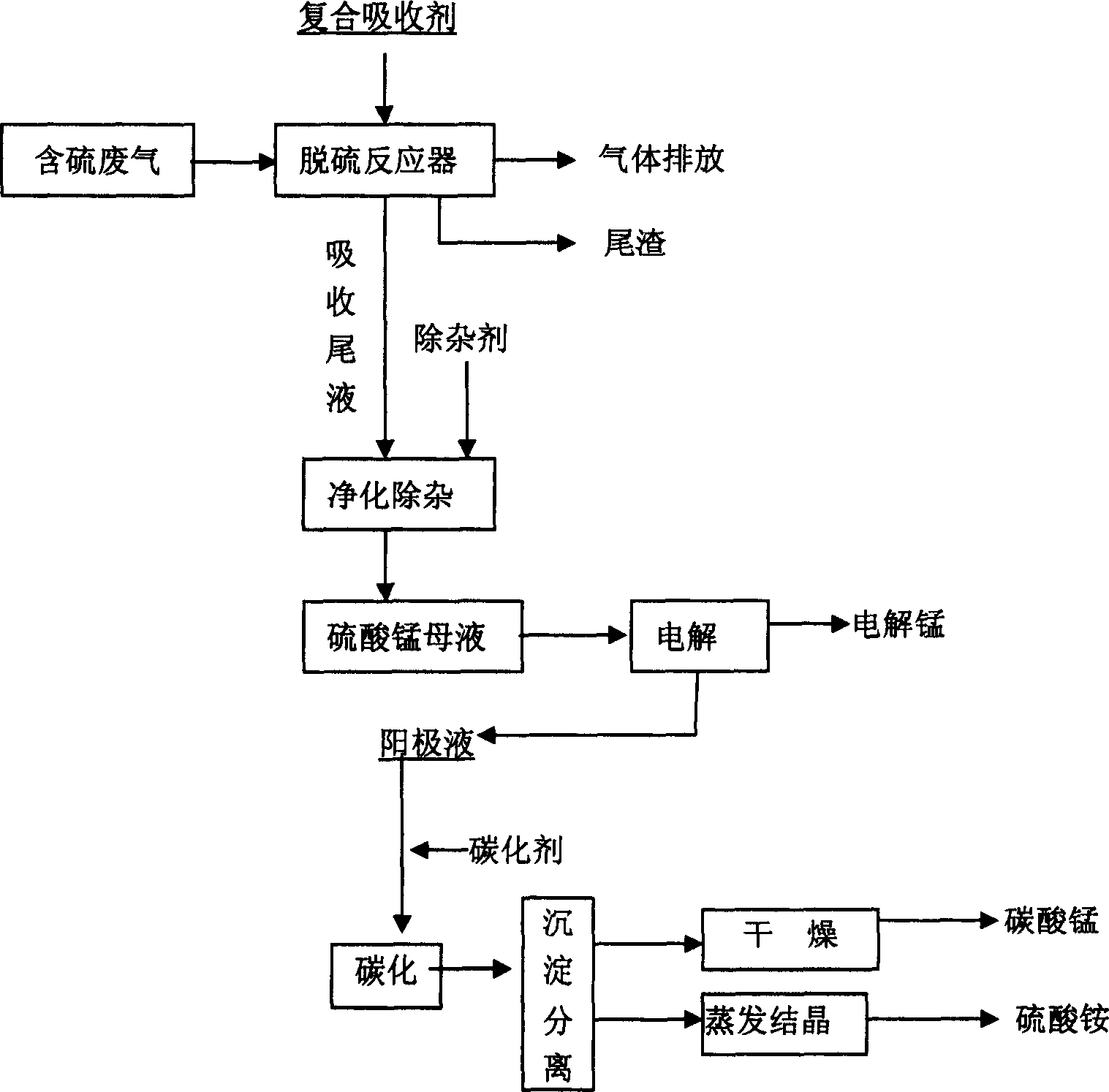

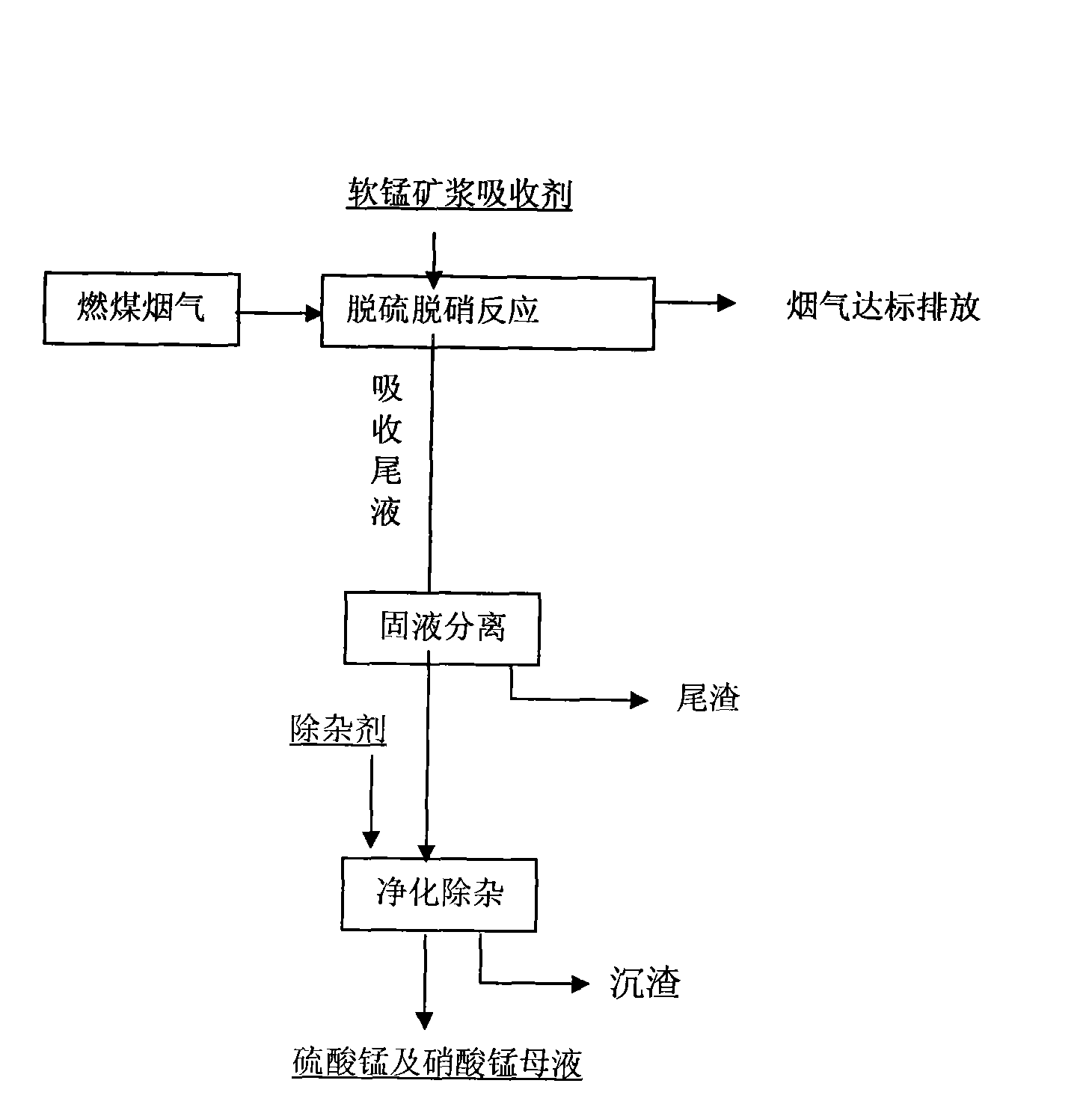

Waste gas desulfurizing method with composite absorbant comprising pyrolusite and pH buffering agent

ActiveCN1772345ARich reservesLow pricePhotography auxillary processesDispersed particle separationPyrolusiteElectrolysis

The present invention is method of comprehensively utilizing waste SO2 gas resource and pyrolusite, and the method includes utilizing the composite absorbent comprising pyrolusite slurry and pH buffering agent to produce oxidation-reduction and neutralizing reaction with waste SO2 gas to eliminate SO2 from the waste gas, purifying the absorbed tail liquid to obtain manganese sulfate product through direct evaporating crystallization or metal manganese product through DC electrolysis, and treating the anode liquid to obtain high purity manganese carbonate product and ammonium sulfate product. The present invention realizes treatment of waste with waste to recover sulfur resource and comprehensively utilize pyrolusite. The method of the present invention is reasonable and has no secondary pollution.

Owner:SICHUAN UNIV

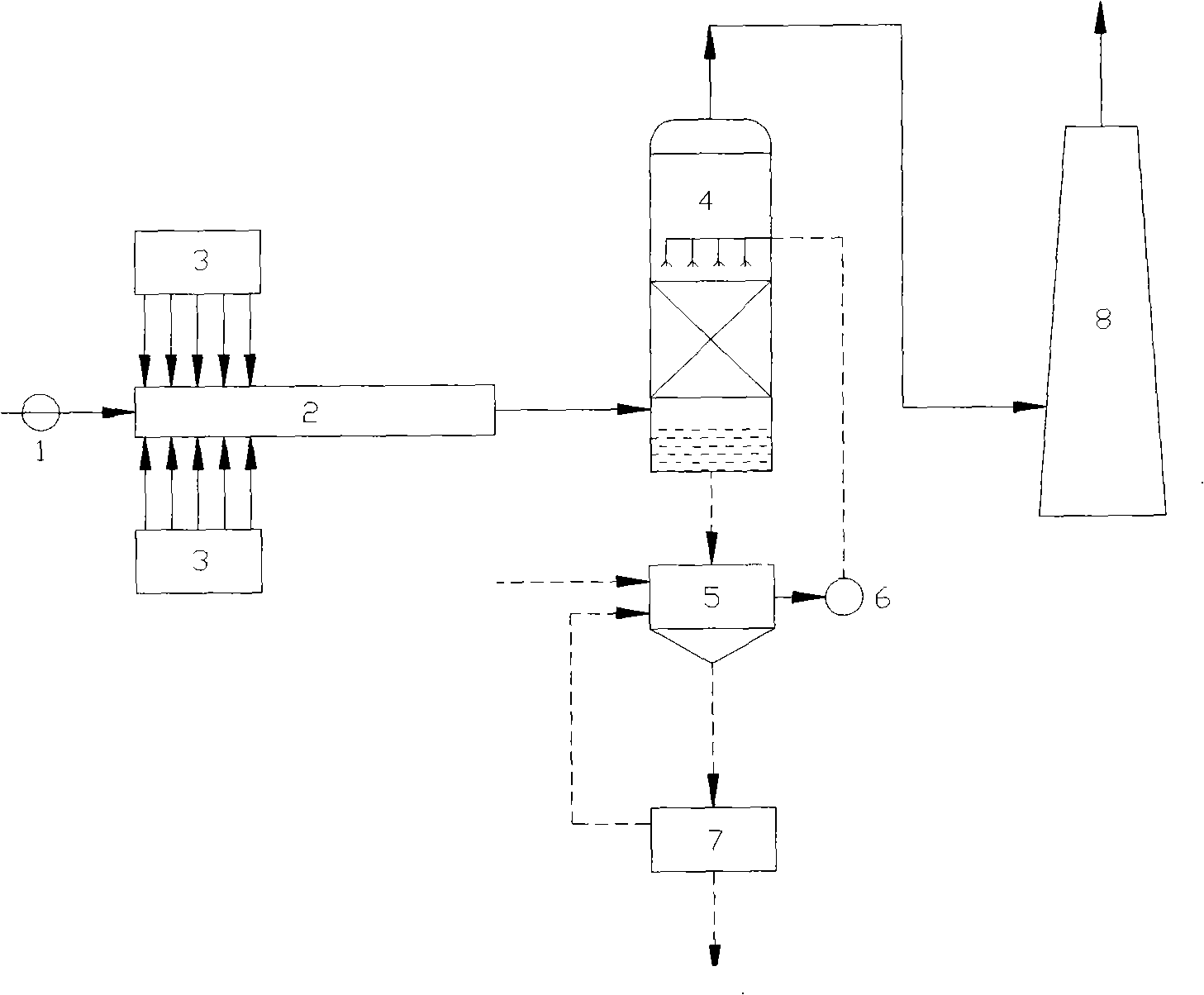

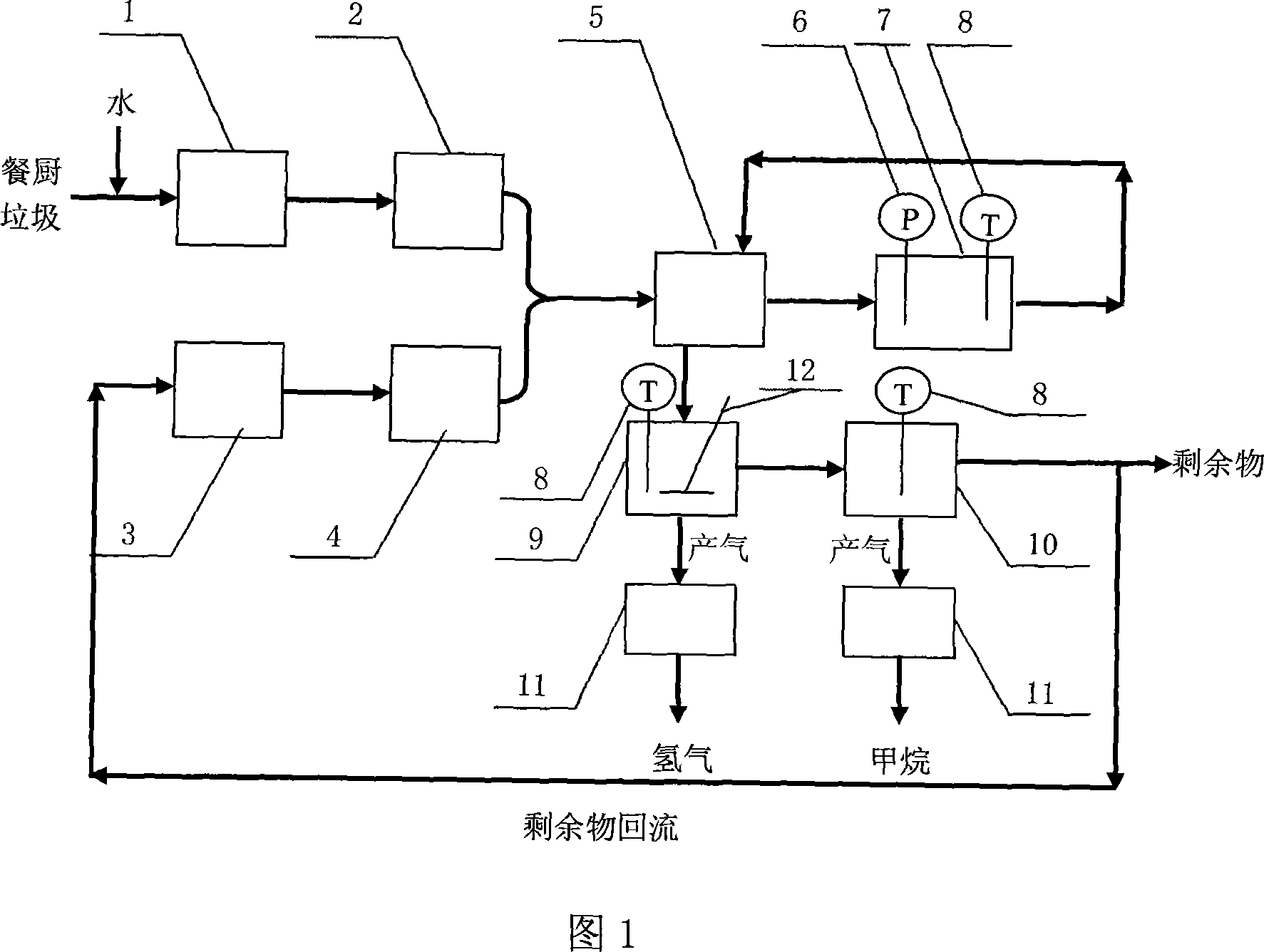

Method for producing hydrogen and methane by kitchen waste diphasic anaerobic fermentation

InactiveCN101134684APH controlLow running costBio-organic fraction processingClimate change adaptationHydrogenSludge

The biphase anaerobic fermentation process of kitchen refuse to produce hydrogen and methane includes the following steps: 1. sorting kitchen refuse and mixing with water in certain amount; 2. mixing with sludge from sewage treating yard and heat treatment; 3. heat exchange between heat treated mixture and mixture without through heat treatment; 4. anaerobic fermentation of the heat treated mixture in the first phase to produce hydrogen; 5. anaerobic fermentation of the residue from the first phase fermentation in the second phase to produce methane; and 6. using the residue from the second phase fermentation as fertilizer or returning to replace sludge serving as hydrogen producing bacteria source. The process is simple, can recover the biomass energy from kitchen refuse effectively, and has no secondary pollution.

Owner:DONGGUAN KECHUANG FUTURE ENERGY SOURCE TECHDEV

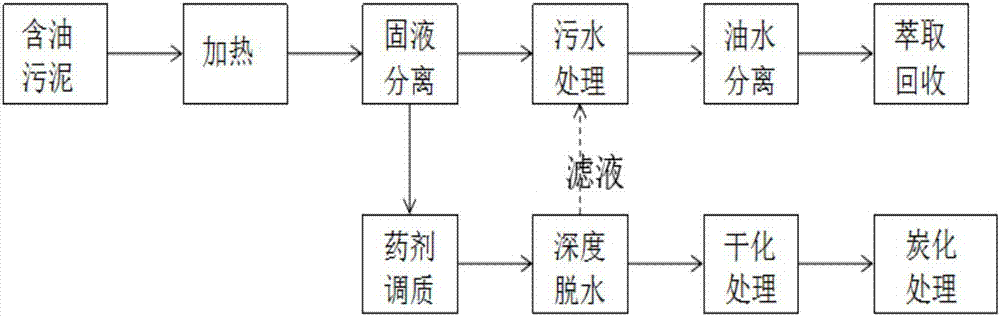

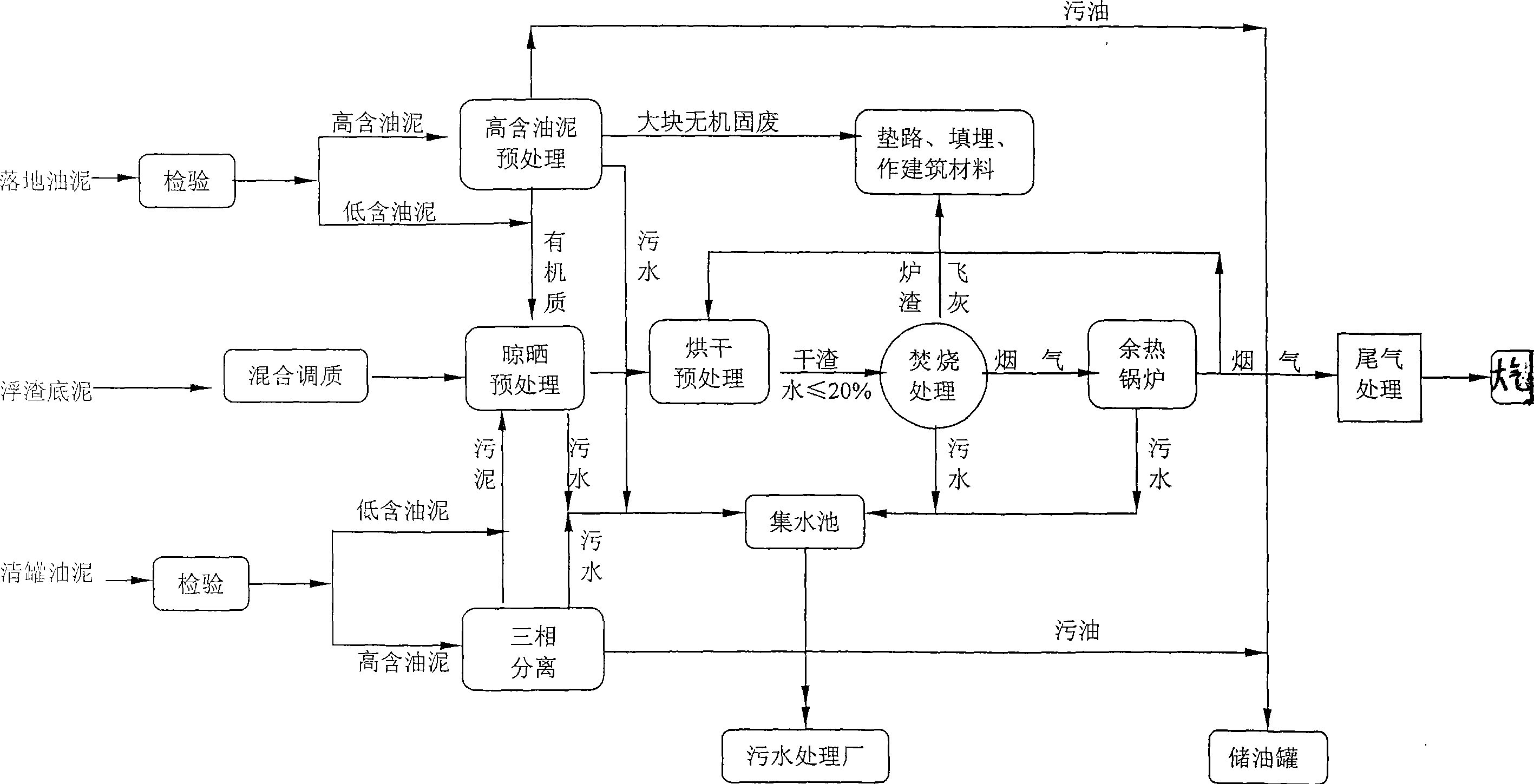

Treating method for oily sludge

InactiveCN106957136AThe treatment method is simple and effectiveSimple processSludge treatment by de-watering/drying/thickeningAgriculture tools and machinesChemistryPyrolysis

The invention provides a treating method for oily sludge and relates to the technical field of oily sludge treatment. The treating method provided by the invention comprises the following steps: heating and stirring oily sludge, standing and then performing solid-liquid separation, thereby acquiring oily mud and oily liquid; introducing the oily liquid into a sewage treatment system for performing oil-water separation, and extracting and purifying the separated oil; adding a reagent into the oily mud for tempering; after tempering, deeply dewatering, thereby acquiring dewatered oily mud and filtrate; performing oil-water separation on the filtrate; performing drying treatment and pyrolysis carbonizing treatment on the dewatered oily mud. The treatment method provided by the invention is simple, convenient and efficient and can realize the reduction, harmless and recycling treatment of the oily sludge, the whole treating process flow operation occupies less area and the investment cost is low.

Owner:安徽省通源环境节能股份有限公司

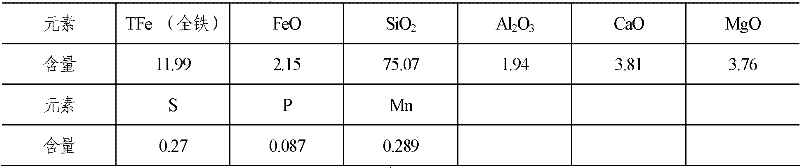

Building hollow brick using industrial tailings and preparation method thereof

InactiveCN102503263AHigh compressive strengthImprove softening effectSolid waste managementBrickAdhesive

The invention relates to the field of building hollow bricks, in particular to a building hollow brick using industrial tailings and a preparation method thereof. The invention especially relates to a burning-free and steaming-free building hollow brick prepared by using industrial iron tailings, copper mine tailings, boric sludge and other industrial wastes and a preparation method thereof. The building hollow brick comprises the following raw materials in percentage by weight: 30-80% of industrial tailings, 5-30% of at least one of cement, fly ash and slag, 0-50% of aggregate, 0-35% of inorganic adhesive and 0-5% of other additives, wherein the water accounts for 3-20% of the total weight of at least one of cement, fly ash and slag and the industrial tailings. The hollow brick is obtained by adding at least one of cement, fly ash and slag to the industrial tailings, vibrating the mixture or molding the mixture under the pressure, releasing the mold after curing the mixture and then continuing to cure the mixture for 28 days or to a strength of more than 5 MPa at room temperature. The hollow brick provided by the invention has the advantages of high strength, good freezing resistance, capability of realizing industrial tailing resources and the like.

Owner:SHENYANG JIANZHU UNIVERSITY

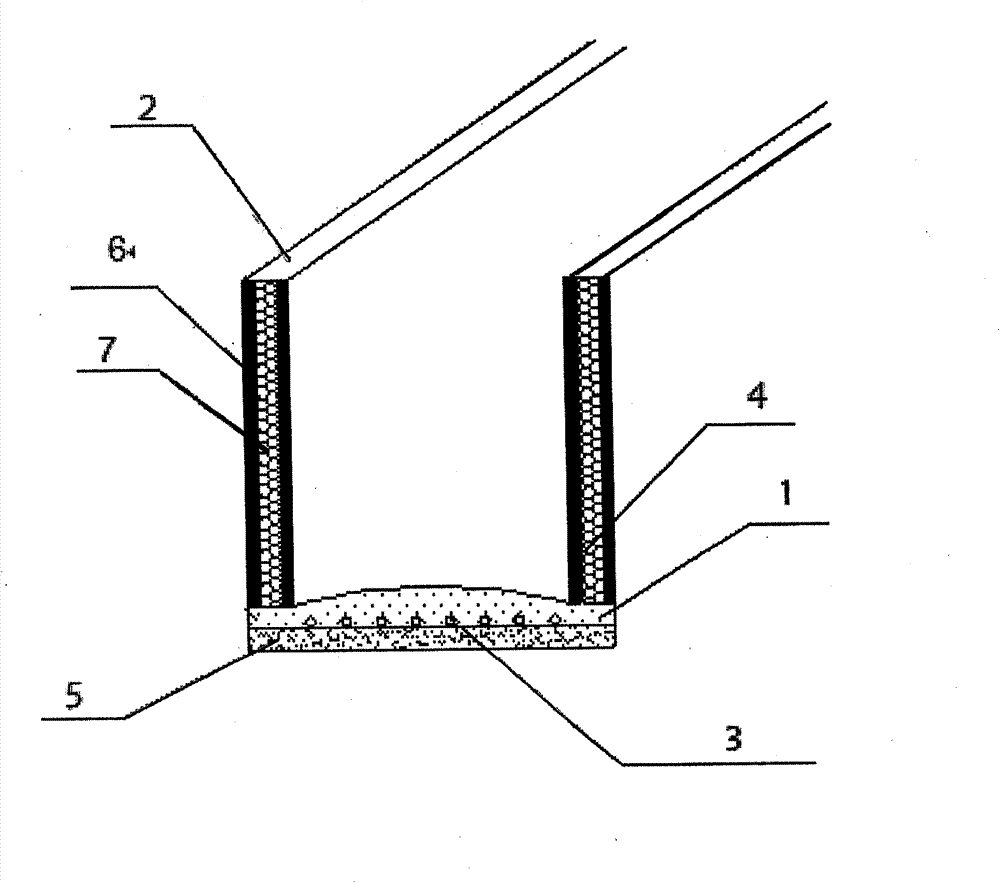

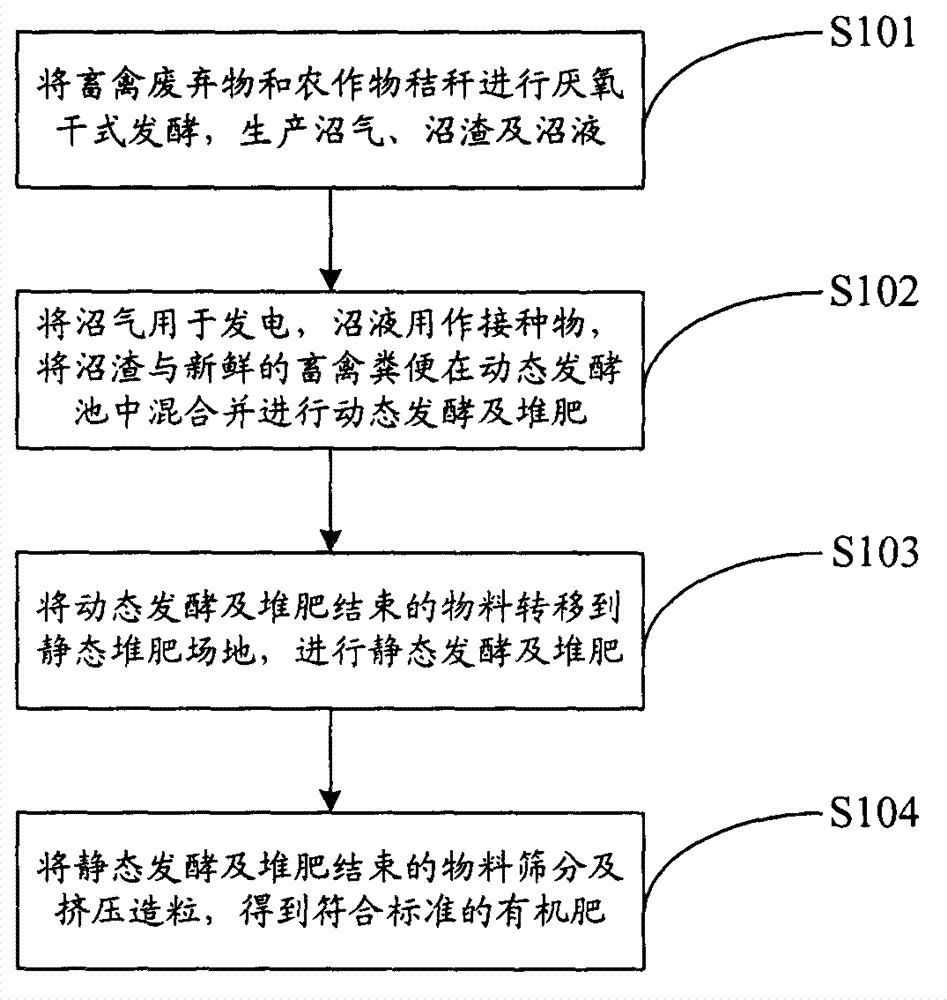

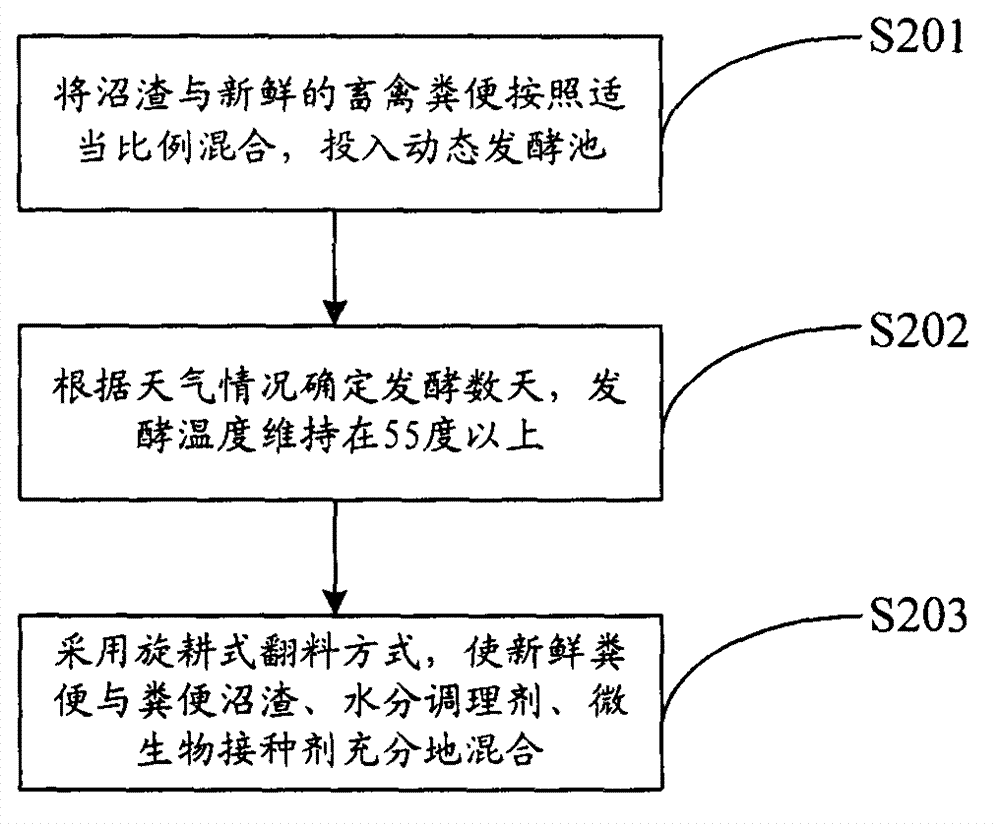

Method for circularly using agricultural wastes and producing organic fertilizers

InactiveCN103288504AFast fermentationShort cycleBio-organic fraction processingGas production bioreactorsNutrientLeavening agent

The invention belongs to the technical field of cyclic utilization of agricultural wastes, and provides a method for circularly using agricultural wastes and producing organic fertilizers. The method comprises the following steps: with the adoption of a dry type anaerobic fermentation technology, generating biogas by livestock wastes and crop straws through anaerobic fermentation; deodorizing and decomposing materials by means of natural microorganisms and inoculated microorganisms, wherein fermentation is fast in speed, short in period and easy to operate mechanically; meanwhile, recovering the biogas slurry for next anaerobic fermentation inoculum; generating electricity by biogas to provide energy sources to heat an anaerobic fermentation tank in low temperature seasons and meanwhile, providing an electric energy to production of organic fertilizers; adjusting nutrients and moisture of biogas residue and adding a leavening agent and converting the biogas residue into the organic fertilizers through a secondary static composting process. In the whole production process, substances and energies are recycled without secondary pollution, so that wastes are recycled, harmless and ecological, and substances and energies are recycled. Huge social, ecological and economical benefits can be generated, so that the method has stronger popularization and application values.

Owner:吴江市农业科技发展有限公司

Manufacture method of environment friendly composite ceramic water-permeable brick

ActiveCN1919564AHigh strengthImprove wear resistanceSolid waste managementMixing operation control apparatusBrickComposite ceramic

The invention discloses a manufacturing method of environment-friend composite ceramic permeable brick, which comprises the following steps: adopting industrial slag with combustible substance as bottom aggregate and waste ceramic particle as layer aggregate, sieving at 10-20 order to obtain 55-65% material, sieving at 20-30 order to obtain 35-45% material, adding high-temperature adhesive and organic adhesive CMC, allocating, aging, moulding, drying, sintering.

Owner:JINGDEZHEN CERAMIC UNIV

Preparation and application of biological carbon immobilized microbial agent

ActiveCN106148318AImprove removal efficiencyKeep aliveContaminated soil reclamationMicroorganism based processesMicroorganismMicrobial agent

The invention relates to preparation and application of a biological carbon immobilized microbial agent. The method comprises the following steps of: sequentially performing seed solution culture and liquid fermentation culture to microorganisms capable of degrading petroleum to obtain fermentation liquid; performing mixed adsorption to the fermentation liquid and biological carbon to prepare the biological carbon immobilized microbial agent. The invention further provides application of the biological carbon immobilized microbial agent to soil polluted by oily sludge and sand and petroleum. By immobilizing the microorganisms having a function of degrading petroleum and then remedying the soil polluted by oily sludge and sand and petroleum, the petroleum removal efficiency is remarkably improved and the removal rate is improved by 20 to 30 percent as compared with remediation by solely using microorganisms. The invention uses agricultural wastes such as corncobs as precursors to prepare carriers, the cost is low, a great amount of microbial agent is easily obtained and simultaneously the reclamation of wastes is realized.

Owner:山东百科利生态科技有限公司

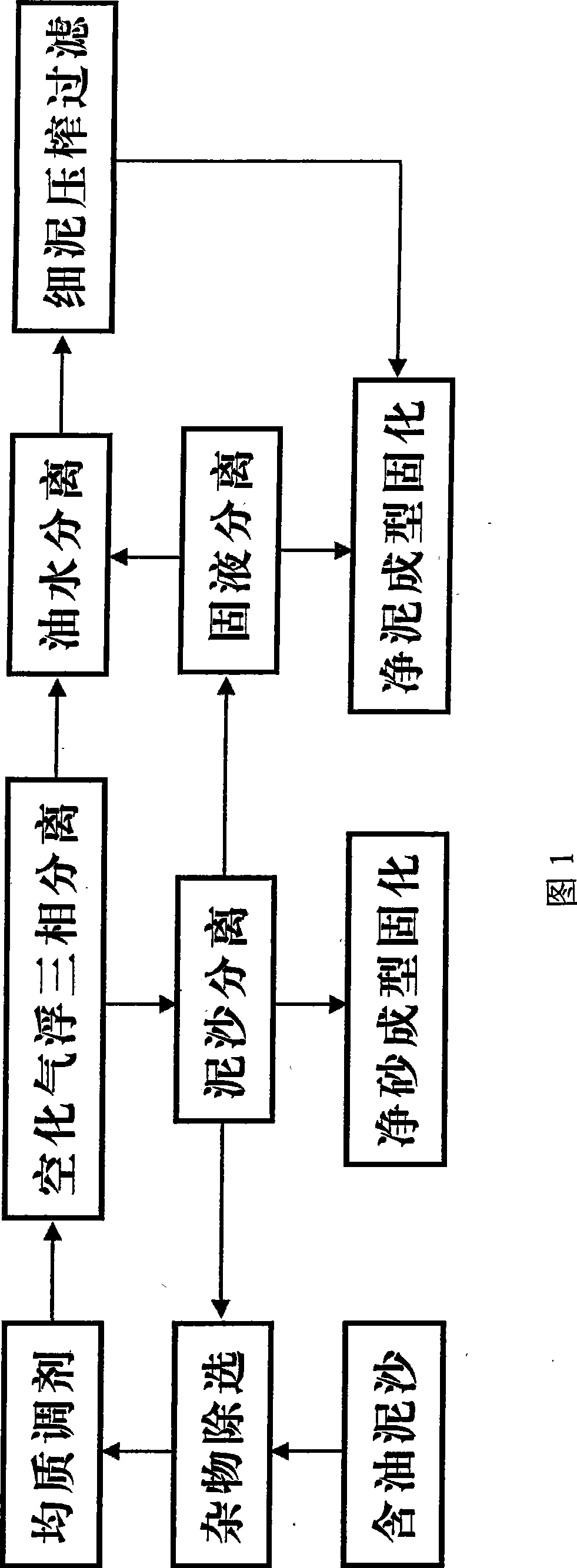

Pollution-free oil-containing mud cleaning treatment method and treatment system thereof

InactiveCN101428247ASolve the problem of secondary pollutionSimple purification processWet separationResource recoverySlurry

The invention relates to a pollution-free oily sediment purification treatment method and a treatment system, and the implementation steps are as follows: adopting a mechanical feeding device for conveying oily sediment to a miscellany removing and sorting device, filtering out and removing the miscellanies therein, perfusing hot water and a reagent into the oily sediment; evenly regulating the oily sediment through mechanical rolling; treating oil, water and sediment in an input tank through a cavitation and air flotation three-phase separator, so as to realize the three-phase separation of the oil, the water and the sediment, and discharging most of the separated oil; separating the sediment through a cyclone separator, and discharging net sand; separating slurry through a centrifuge, discharging net mud; separating fine mud from the water through a pressing filter, discharging net fine mud; separating the oil-water through natural ascending and descending, outputting the oil, and continuously heating water for the cyclic utilization; and curling and molding the discharged net sand and net mud according to routine. The invention realizes the resource recovery of crude oil in oily sediment and reduces the cost for purifying and treating oily sediment effectively, and the purified sediment is made into cured resin used for building materials.

Owner:TIANJIN TAIXING ENG TECH CO LTD

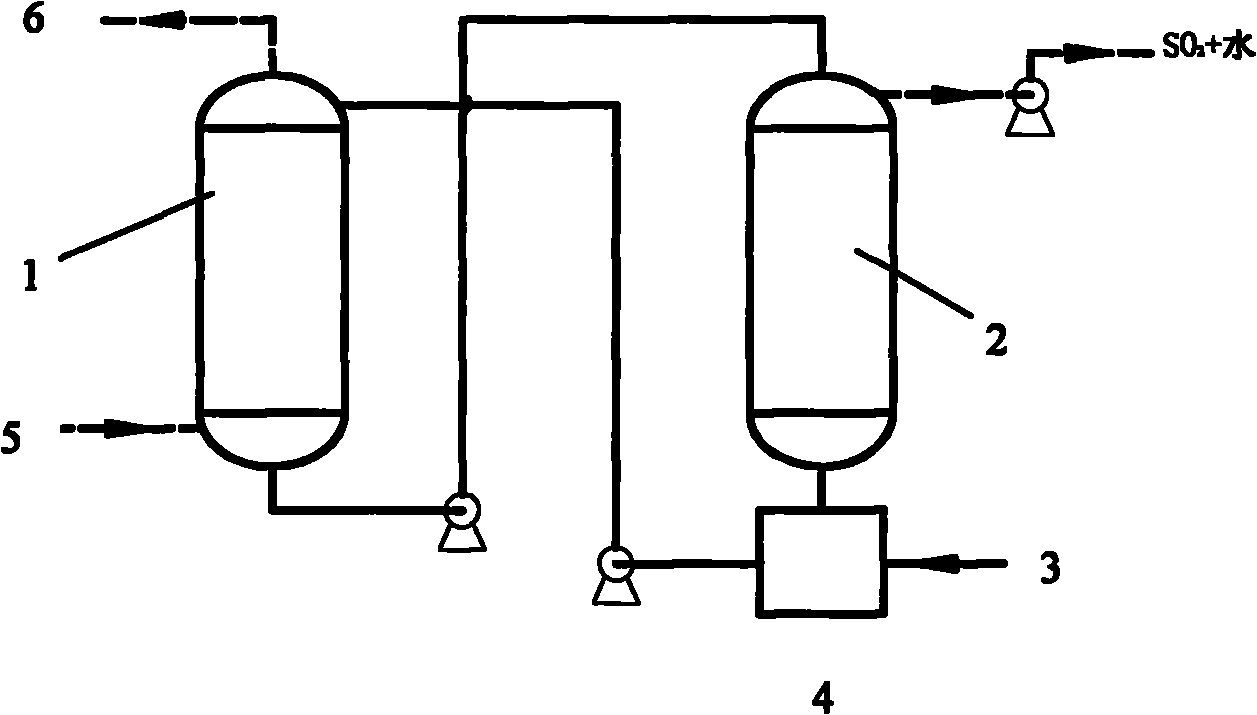

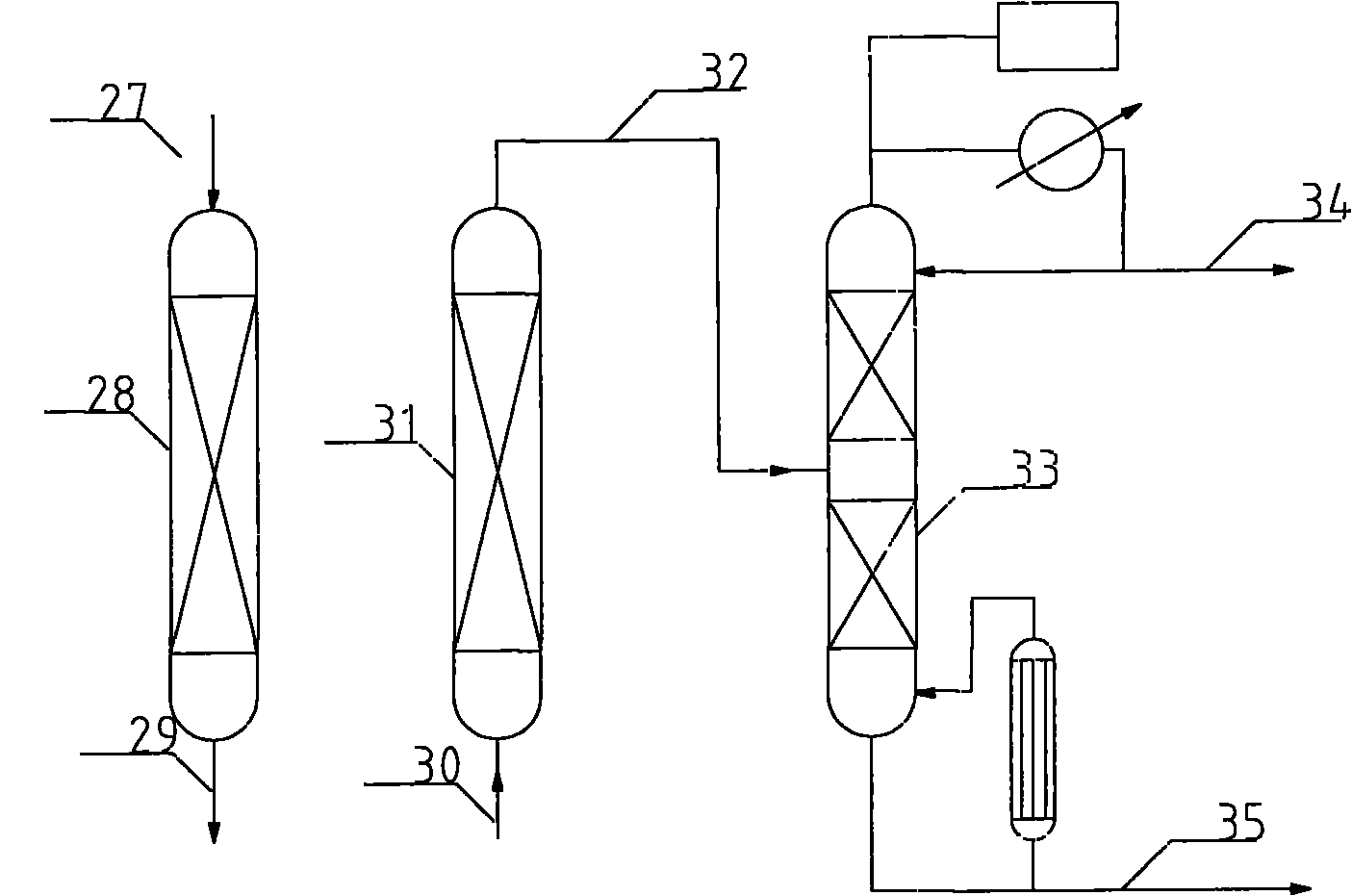

Flue gas desulfurization process

InactiveCN102068876AEasy to recycle and reuseRealize resourcesDispersed particle separationFlue gasTower

The invention provides a flue gas desulfurization process employing an ionic liquid. In the process, the ionic liquid is used as an absorbent, different types of absorption towers are adopted to absorb SO2 in the flue gas at the temperature of 0-200 DEG C under the pressure of 0.09-5.0 MPa, wherein gas-liquid countercurrent contact is adopted, various types of towers are adopted to improve a mass transfer effect so as to realize the emission of flue gas reaching the standard. The ionic liquid after absorbing the SO2 is pumped into a desorber through a pump and is subjected to deabsorption by adopting a heating and / or decompressing method, and SO2 is recovered. The desorbed ionic liquid enters the absorption towers to be reused. The process provided by the invention can be used for effectively removing the SO2 in the flue gas and recovering the SO2.

Owner:BEIJING UNIV OF CHEM TECH

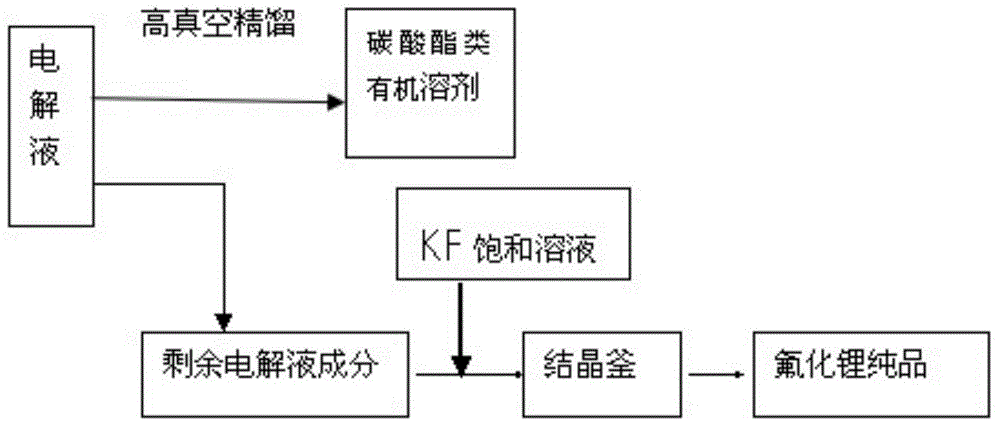

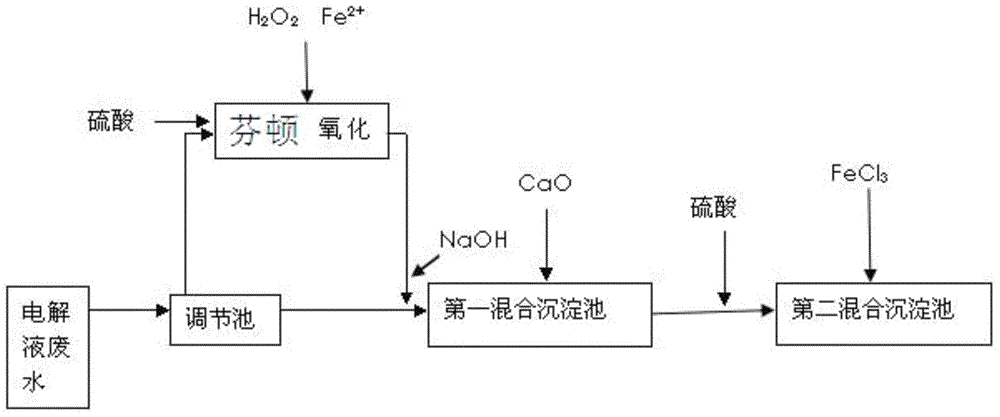

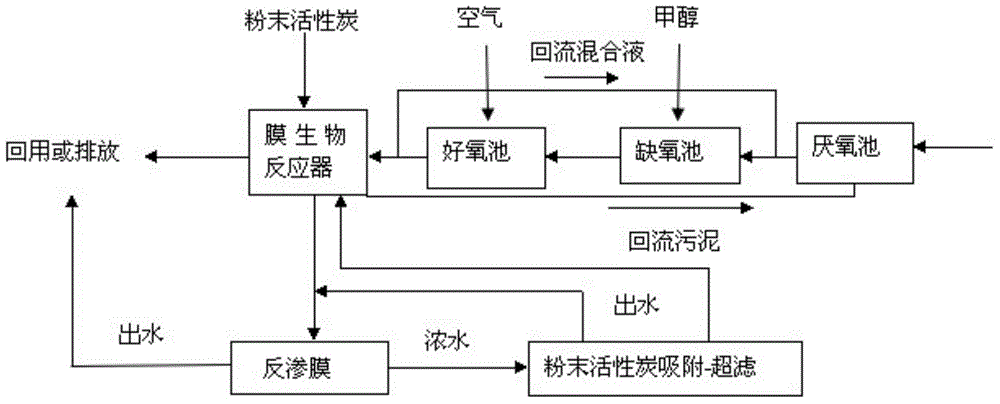

Method for recovery treatment of waste-and-old lithium battery electrolyte and treatment of electrolyte wastewater

InactiveCN104628217AImprove biodegradabilityOvercome incompletenessDispersed particle separationWater/sewage treatmentUltrafiltrationFiltration

The invention discloses a method for recovery treatment of a waste-and-old lithium battery electrolyte and treatment of electrolyte wastewater. Three treatment units are employed for treatment. Firstly, the waste-and-old electrolyte is treated. Then, waste gas resulting from the reaction of the electrolyte is pumped into the waste water for absorption, so that the waste gas can be removed during a waste water treatment process; the lithium battery waste water is treated by a Fenton agent through oxidation to obtain improved biodegradability of the waste water; and reaction precipitates are removed through flocculent sedimentation and the obtained water is treated through combination of A2 / O and MBR membrane separation. Finally, the outlet water goes through a RO reverse osmosis unit to ensure the quality of the outlet water. Combination technology of active carbon powder adsorption and ultra-filtration is employed to remove organic pollutants of the concentrated water resulting from the RO unit, so that the water after treatment can meet the requirements of RO high-quality reuse water. According to the invention, imperfection of an existing technical method of waste-and-old lithium battery recovery and treatment is overcome, and quantitative reduction, harmlessness, and reutilization of waste water treatment of the waste-and-old electrolyte are realized.

Owner:天津卡特化工技术有限公司

Method for producing liquid organic fertilizer by using organic fertilizer

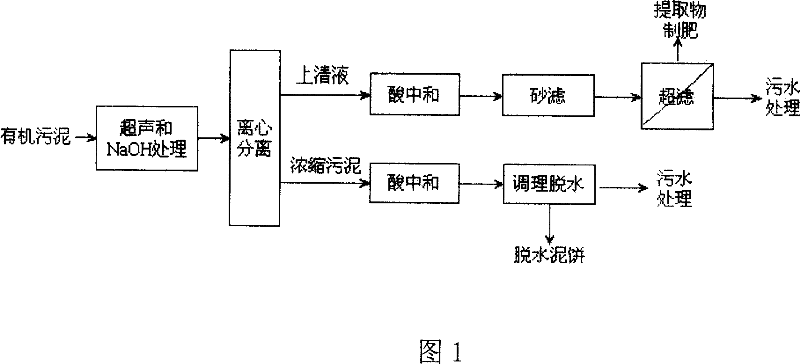

InactiveCN101037354AImprove cracking efficiencyImprove dehydration efficiencySludge treatment by de-watering/drying/thickeningClimate change adaptationUltrafiltrationHumic acid

The invention discloses method of producing liquid organic fertilizer by organic belonging to solid wastes disposal field, including: co-treating the residual sludge with 98 percent moisture content by ultrasound and sodium hydroxide to make the organic matters dissolve out; getting concentrated sludge and supernatant fluid after centrifugation; dehydrating the concentrated sludge after neutralization in a routine method; sand leaching and ultrafiltration treating the supernatant fluid twice after centrifugation to get a concentrated liquid containing macromolecule organic matter such as humic acid and the filtrate containing low molecular organic matter; the filtrate entering into the sewage treating plant for a primary treatment. Disposed dehydrated sludge cake has 70-80 percent moisture content and a reduction of the content of organic matter of 30-50%. The concentrated liquid by ultrafiltration is mainly composed of macromolecule organic matter and with a low content of heavy metal, and can be an organic liquid fertilizer, and complies the rule of using green food fertilizer. The invention is suitable for the sludge with a high organic matter content such as residual sludge and digested sludge.

Owner:TSINGHUA UNIV

Method for processing wastewater produced in saponification cyclization step in epoxy chloropropane production method

ActiveCN101798154ARealize resourcesOptimize process flowWater contaminantsMultistage water/sewage treatmentEpoxyWastewater

The invention relates to a method for processing organic saponification high-salinity wastewater produced in the production processes of epoxy chloropropane and epoxy-propane. The processing method comprises the steps of concentration of organic high-salinity wastewater, crystallization of calcium chloride, purification and recycling, innocent treatment of mother liquid and the like. The method has simple and convenient technical process, easy operation and control, obvious economic benefit, and environmental protection; the recovery rate of calcium chloride can reach 98%, and the recovery rate of glycerine can reach 88%, thereby changing pollutant into resources.

Owner:NINGBO HUANYANG CHEM

Sludge treatment method and sludge treatment system

ActiveCN102153256AHarmlessAchieve reductionCombination devicesSludge treatment by de-watering/drying/thickeningCombustionTreatment system

The invention provides a sludge treatment method which comprises the following steps: drying: drying sludge through a drying device; combusting: feeding the sludge dried in the drying step to a combustion furnace, mixing a combustion improver with the dried sludge, and carrying out mixed combustion; and tail gas treatment: treating the tail gas generated in the combustion step, and discharging. The sludge treatment system comprises the combustion furnace and a tail gas treatment device, wherein the combustion furnace is used for burning the sludge; and the tail gas treatment device is used for treating the tail gas generated after the sludge is burned by the combustion furnace. The sludge treatment system is characterized by further comprising a sludge drying device and a sludge conveyer, wherein the sludge drying device is arranged in front of the combustion furnace and is used for drying the sludge to be burned by the combustion furnace; and the sludge conveyer is convenient for delivery of the sludge in the sludge drying device. The method and system provided by the invention have the advantages that the cost is low, and effect is good.

Owner:JIAXING NEW JIES THERMAL POWER +1

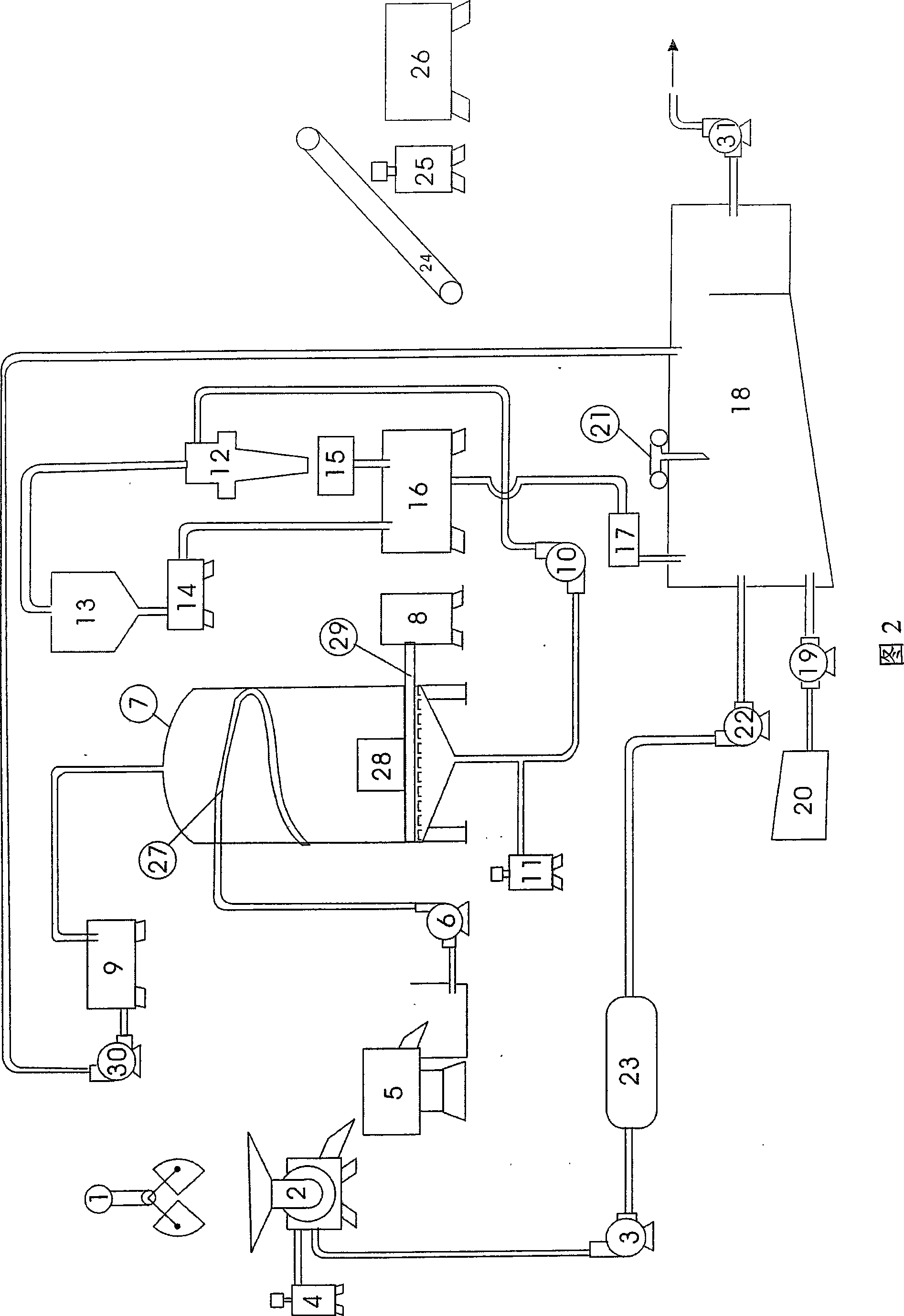

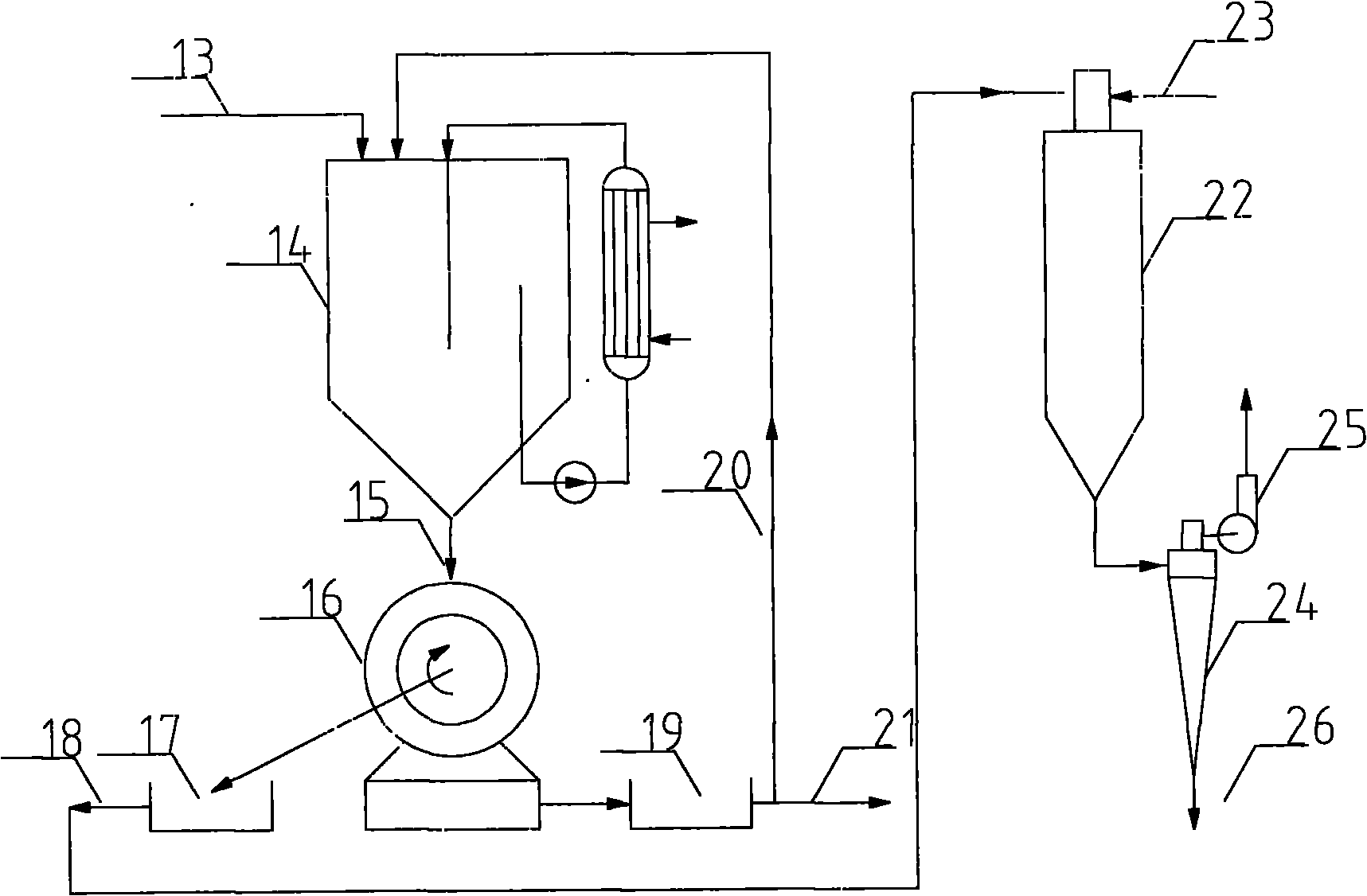

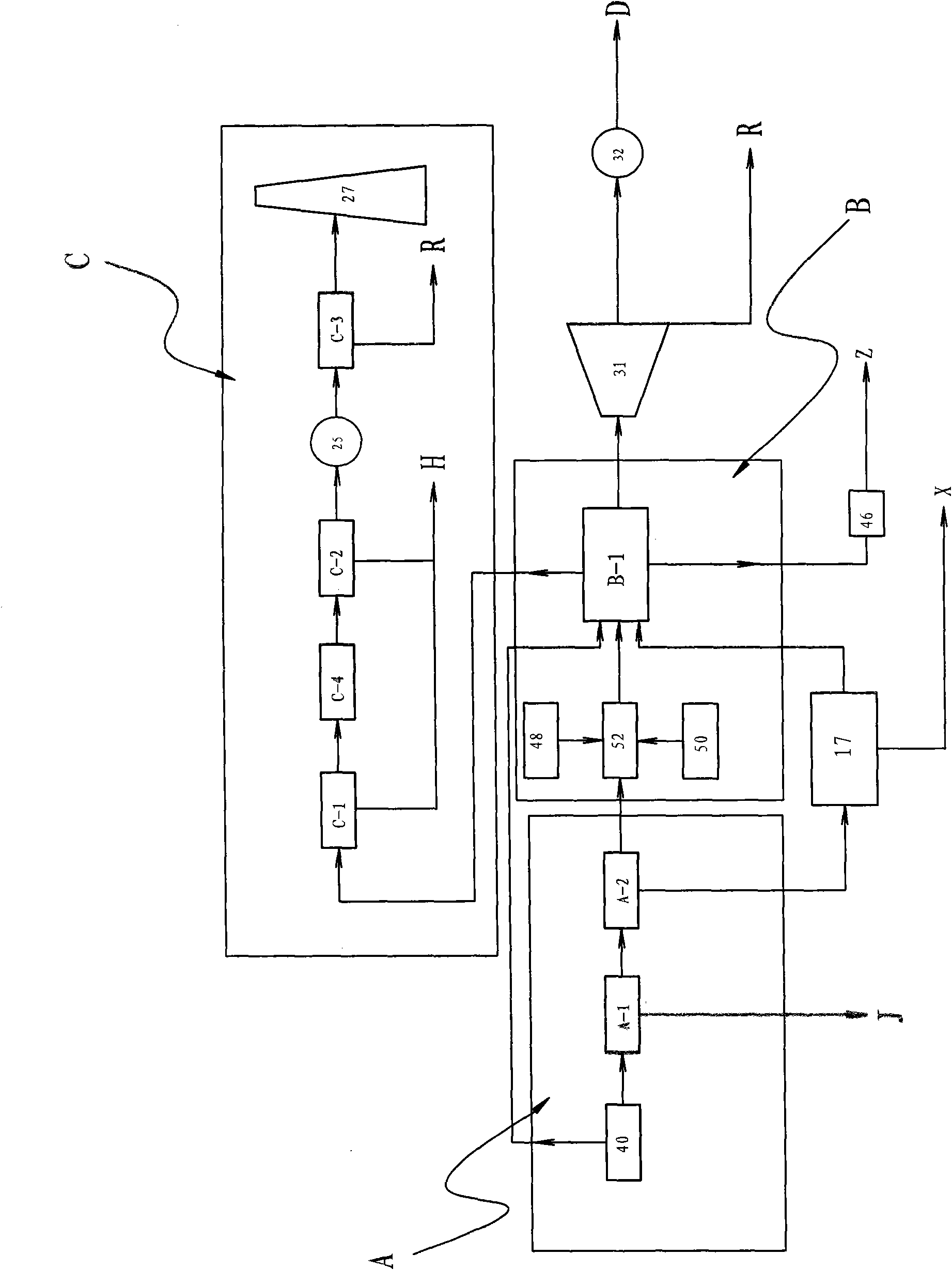

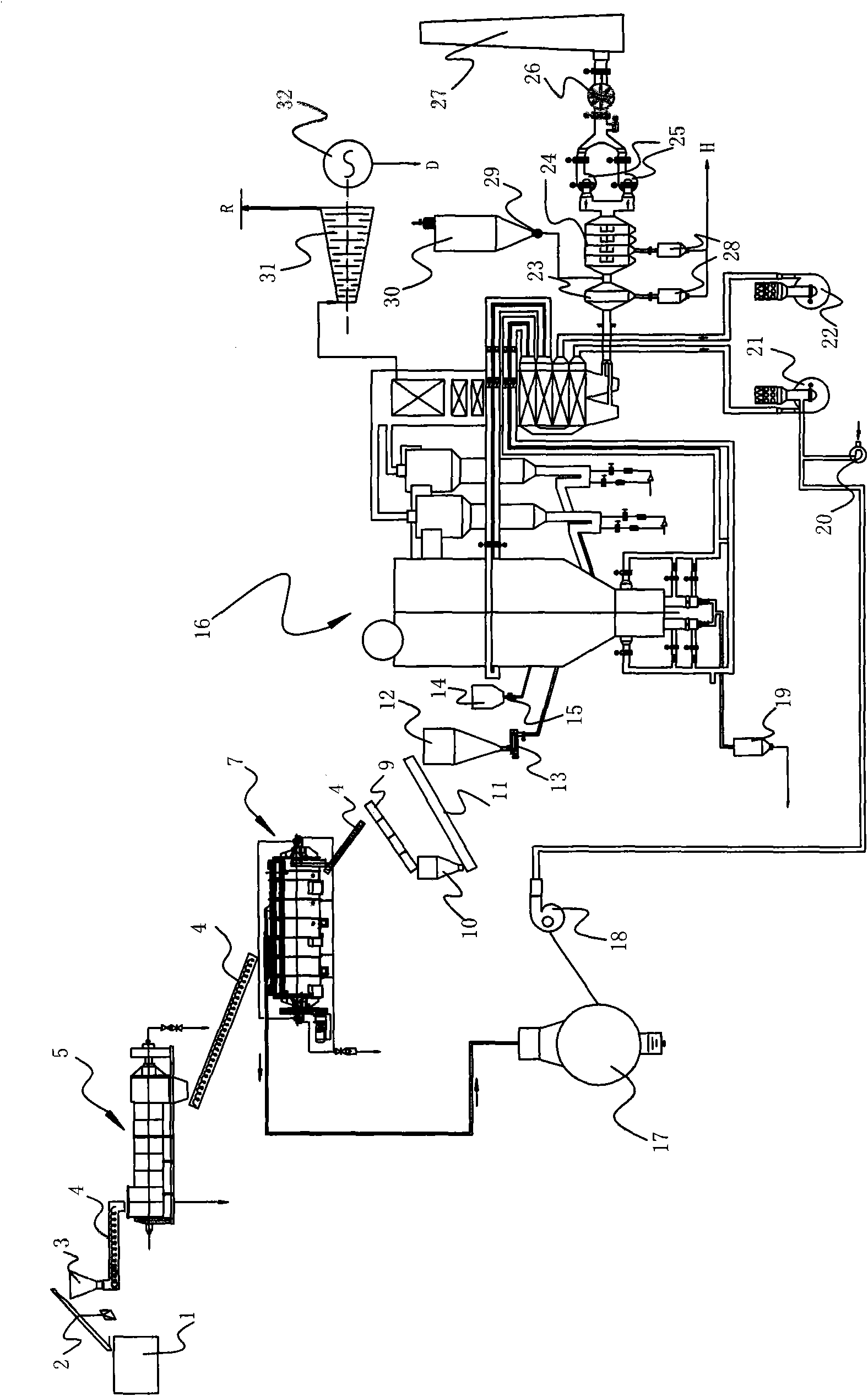

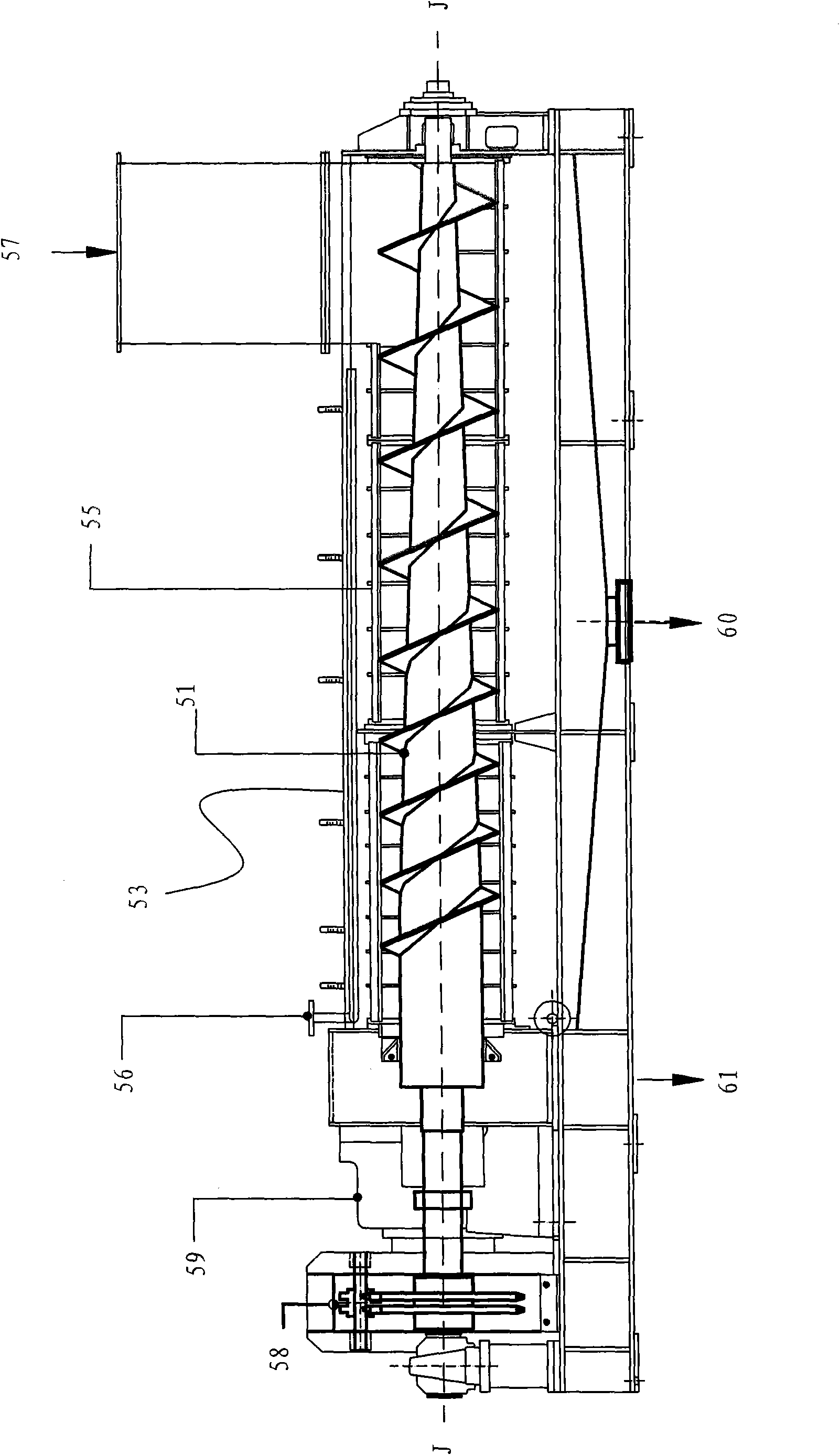

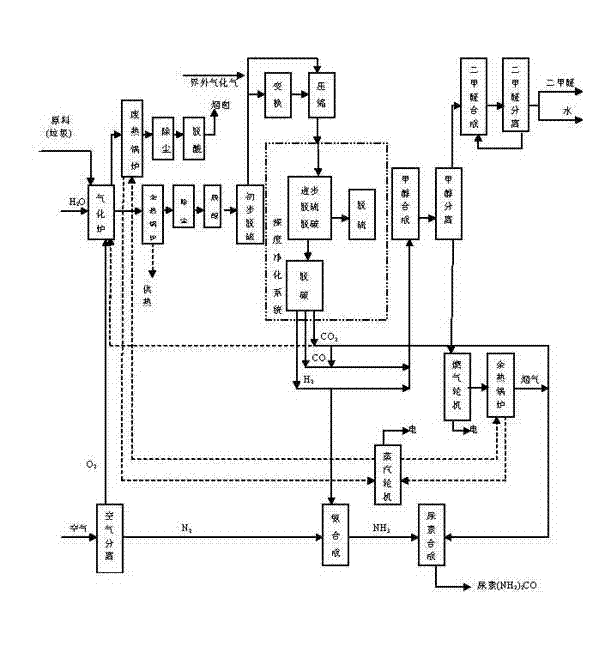

Pyrolysis gasification and purification method of household garbage

InactiveCN103242134ARealize resourcesWill not affect performanceUrea derivatives preparationOrganic compound preparationPurification methodsDimethyl ether

The invention relates to a household garbage treatment method. According to the household garbage treatment method, the household garbage is subjected to thermal cracking to form mixed combustible gases containing carbon monoxide (CO), carbon dioxide (CO2), hydrogen (H2), methane (CH4), nitrogen (N2) and inert argon (Ar) by a full gasification process; and the mixed combustible gas flow is purified and separated and then are used for synthesizing methanol and / or dimethyl ether, generating electricity and synthesizing urea. The household garbage treatment method comprises eight steps of: performing pyrolysis gasification, cooling, removing dust, performing deacidification and desulfuration, performing transformation reaction, adjusting the ratio of components, compressing and synthesizing. By adopting the method, the optimal ratio of the components required by the synthesis reaction can be adjusted, in particular the CO, the CO2, the H2 and the N2 can be comprehensively utilized, the N2 of an air separation device and the H2 of a purification system are synthesized to generate NH3, and the NH3 and the CO2 are synthesized to generate urea; biomass gas is used for generating electricity, so the heat efficiency can reach 30 to 40 percent; and by adopting the method, reclamation and zero emission of the household garbage can be realized.

Owner:SHENZHEN JUNENG BIOMASS GASIFICATION TECH +2

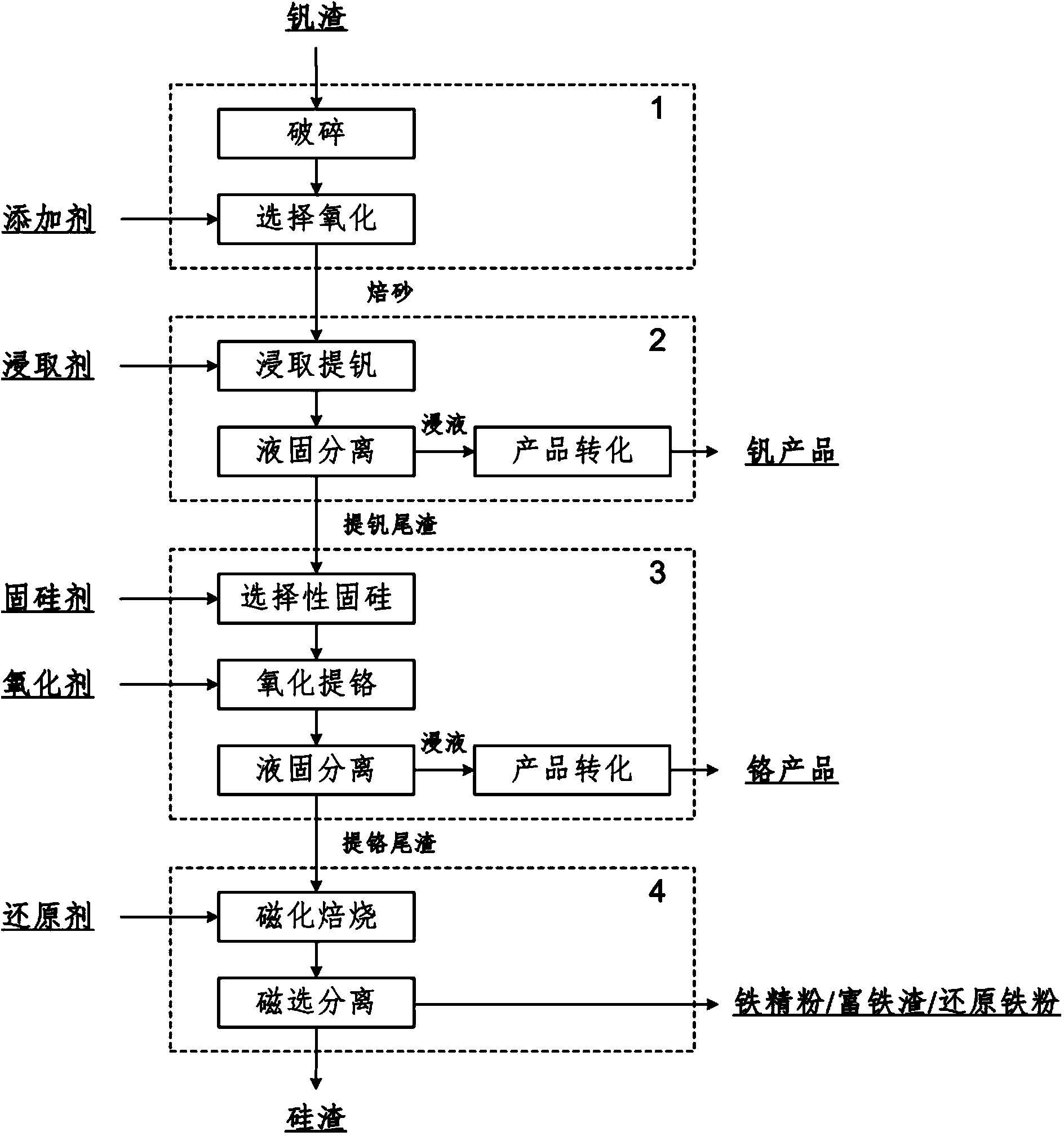

Clean process method for extracting vanadium, chromium and iron from vanadium slag step by step

The invention relates to a clean process method for extracting vanadium, chromium and iron from vanadium slag step by step. The clean process method comprises the following steps of: selectively oxidizing the vanadium slag to obtain a roasted product; leaching the obtained roasted product by using a leaching agent to extract vanadium, carrying out liquid-solid separation to obtain vanadium-containing leach liquor and vanadium-extracted tailings, and carrying out product transformation on the vanadium-containing leach liquor to prepare vanadium series products; adding the obtained vanadium-extracted tailings and a silicon fixing agent to a sodium hydroxide solution, selectively fixing silicon, then oxidizing to extract chromium, then carrying out liquid-solid separation to obtain chromium-containing leach liquor and chromium-extracted tailings, and carrying out product transformation on the chromium-containing leach liquor to prepare chromium series products; mixing the chromium-extracted tailings with a reducing agent, and carrying out magnetizing roasting and magnetic separation to obtain silicon slag and ion concentrate powder / iron-enriched slag / reduced iron powder. The clean process method disclosed by the invention realizes the step-by-step extraction and high-efficiency separation of valuable components such as vanadium, chromium and iron which are contained in the vanadium slag, prevents the mutual entrainment of vanadium, chromium and iron products; in addition, the clean process method disclosed by the invention realizes the near zero discharge of waste water and the recycling of final slag and is clean and pollution-free.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

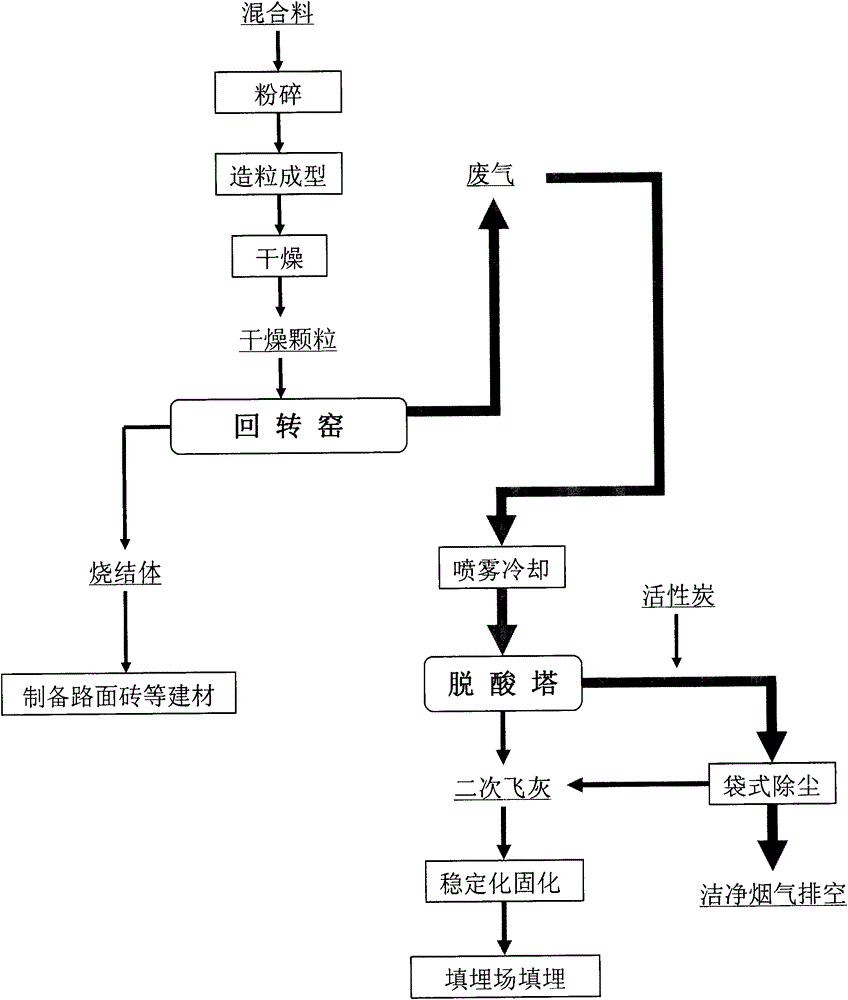

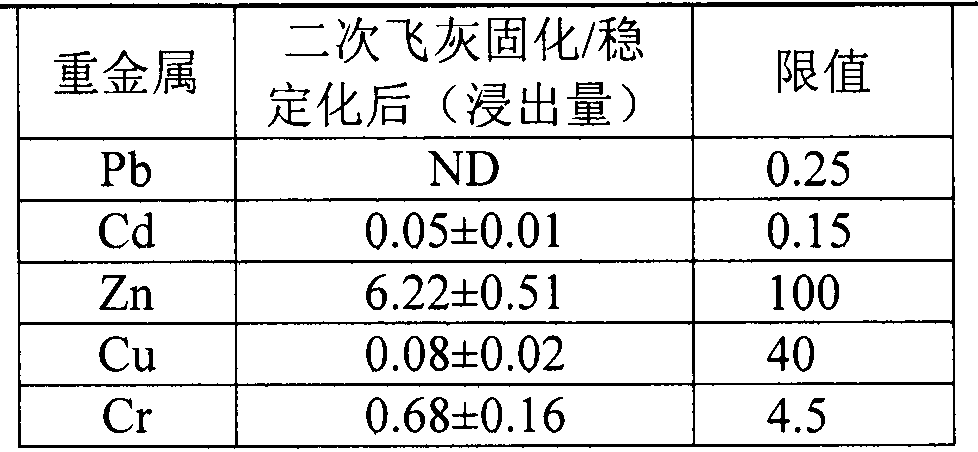

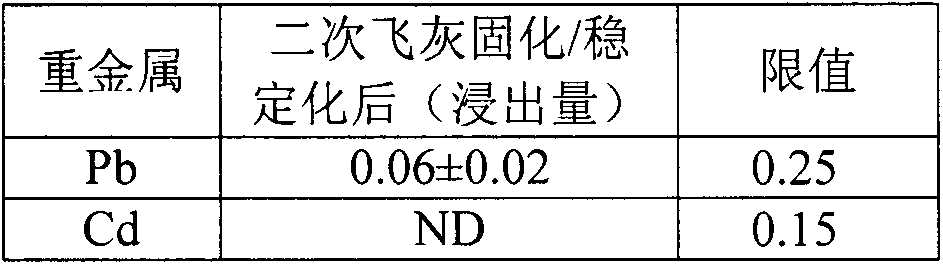

Garbage burning fly ash sintering harm-eliminating resource-utilization treatment system

The invention relates to a garbage burning fly ash sintering harm-eliminating resource-utilization treatment technology. According to the invention, garbage burning fly ash is mixed with premixed coal and auxiliary materials; the mixture is granulated and shaped; and the material is dried and is sintered in a rotary kiln. During the sintering process, when the temperature is increased and a coal ignition point is reached, the premixed coal is spontaneously combusted. Therefore, external coal dose can be reduced. Initial combustion of the premixed coal can provide a reductive atmosphere, such that dechlorination and detoxification of dioxin in fly ash can be benefited. Large amount of gas is produced by subsequent combustion, such that dust pores and holes are produced on inner and outer parts of the sintered body, and heavy metal volatilization can be promoted, and fly ash sintered body with low heavy metal content and leaching amount can be obtained. The sintered body has no potential harm to the environment, such that fly ash harm-eliminating and resource-utilization are sufficiently realized. During the processing process, smoke and secondary fly ash production amounts are low, and heavy metal and acidic component contents are high. In deacidification and heavy metal stabilization processes, agent utilization rate is improved. Compared with a traditional original fly ash curing / stabilizing process, a landfill amount can be reduced by 80-90%, such that pressure caused by serious landfill space shortage can be effectively relieved.

Owner:TIANJIN YIMING ENVIRONMENTAL TECH CO LTD

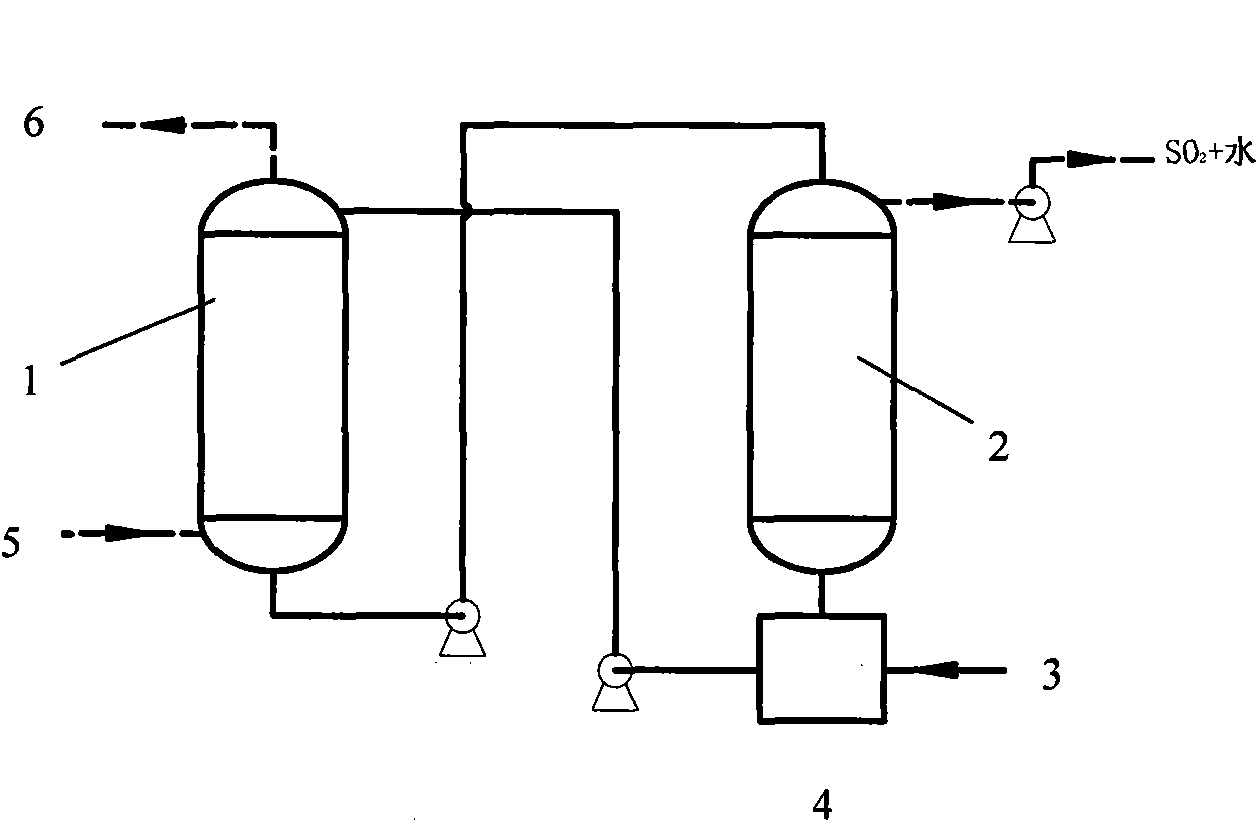

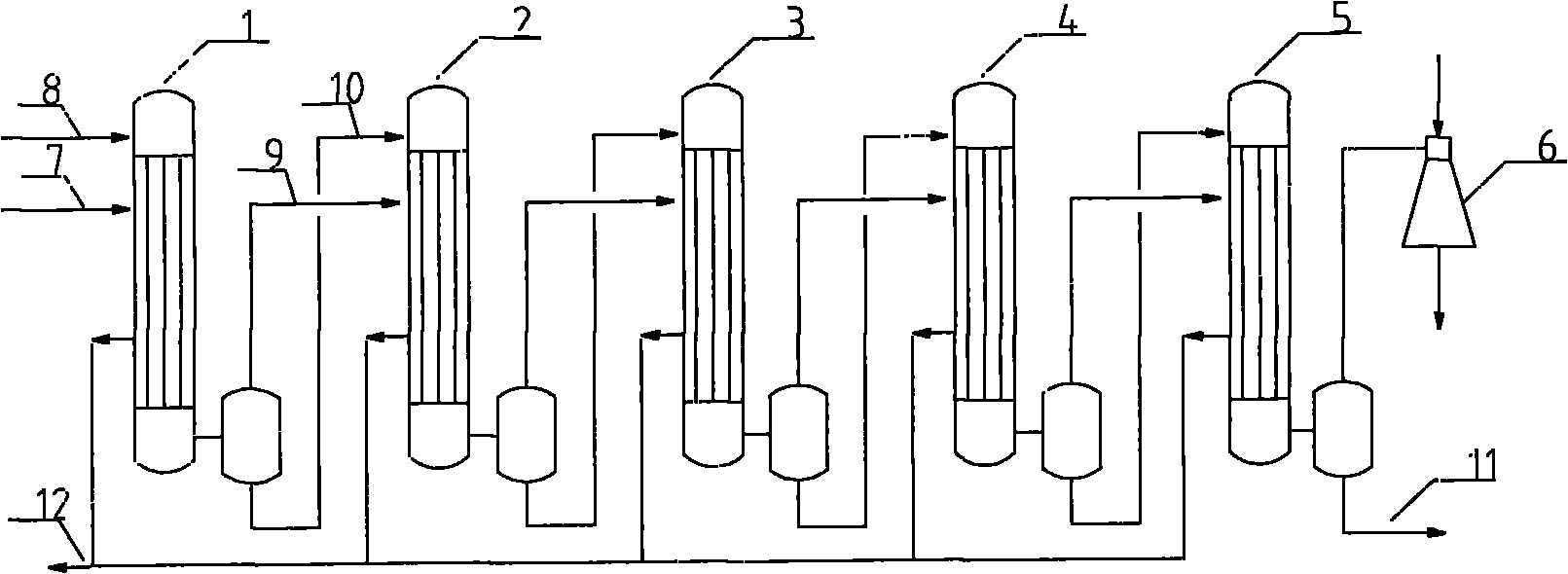

Closed-loop processing integrated process for high-efficiency air stripping and tail-gas ammonia recycling of ammonia-nitrogen wastewater

ActiveCN102060406AImprove ammonia removal efficiencyReduce the gas-liquid volume ratioChemical industryMultistage water/sewage treatmentExhaust gasProcess engineering

The invention relates to a closed-loop processing integrated process for the high-efficiency air stripping and the tail-gas ammonia recycling of ammonia-nitrogen wastewater, which is characterized in that: by selecting the types of fillers, tower internals and the like of an ammonia-nitrogen air-stripping tower and strengthening a gas-liquid mass transferring process, the ammonia removing efficiency is improved, and meanwhile, the gas-liquid volume ratio is reduced, thereby the energy consumption is markedly reduced; the invention provides a renewable ammonia-absorbing solution which can be used for efficiently absorbing the ammonia in air-stripping gas, and the ammonia is regenerated and desorbed to obtain strong ammonia water with the concentration of 10-25wt%, therefore, the high-efficiency recovery and the recycling of the ammonia in the air-stripping gas is realized, and the absorbing solution is recycled after being regenerated; the purified gas after absorption is used as the air-stripping gas for closed-loop circulating by adopting a closed-loop circulating technology, thereby the reaction heat in the absorbing process is effectively recovered, the energy consumption is further reduced, and meanwhile, the secondary pollution is eliminated; and the ammonia-removing and recycling processes of the wastewater are developed into a set of modularized process technologies by applying an integrated technology, thereby the technical requirements of industrial enterprises on processing the ammonia-nitrogen wastewater with different concentrations are satisfied.

Owner:NANJING UNIV OF TECH

Method and special device for treating organic wastewater by combination of microbial fuel cell and microalgae culture

InactiveCN102674529AIncrease transfer rateHigh power outputBiological water/sewage treatmentMicrobial fuel cellFuel cells

The invention relates to a wastewater treatment technology, in particular to a method for treating organic wastewater by the combination of a microbial fuel cell and microalgae culture. The method comprises the following steps of: generating electric energy while organic substances, nitrogen and phosphorus in wastewater are removed through the microbial fuel cell, introducing the wastewater treated by the microbial fuel cell into a photobioreactor and culturing microalgae, and performing further continuous treatment by using the microalgae until the wastewater obtained after treatment meets the discharge standard. The method can be widely used for the treatment of the organic wastewater, improves the treatment effect of the wastewater, ensures that the electric energy and biomass energy which are obtained can compensate the cost of wastewater treatment, provides a novel way for the effective treatment of the organic wastewater, and has an important significance for saving energy, reducing emission and protecting environments.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

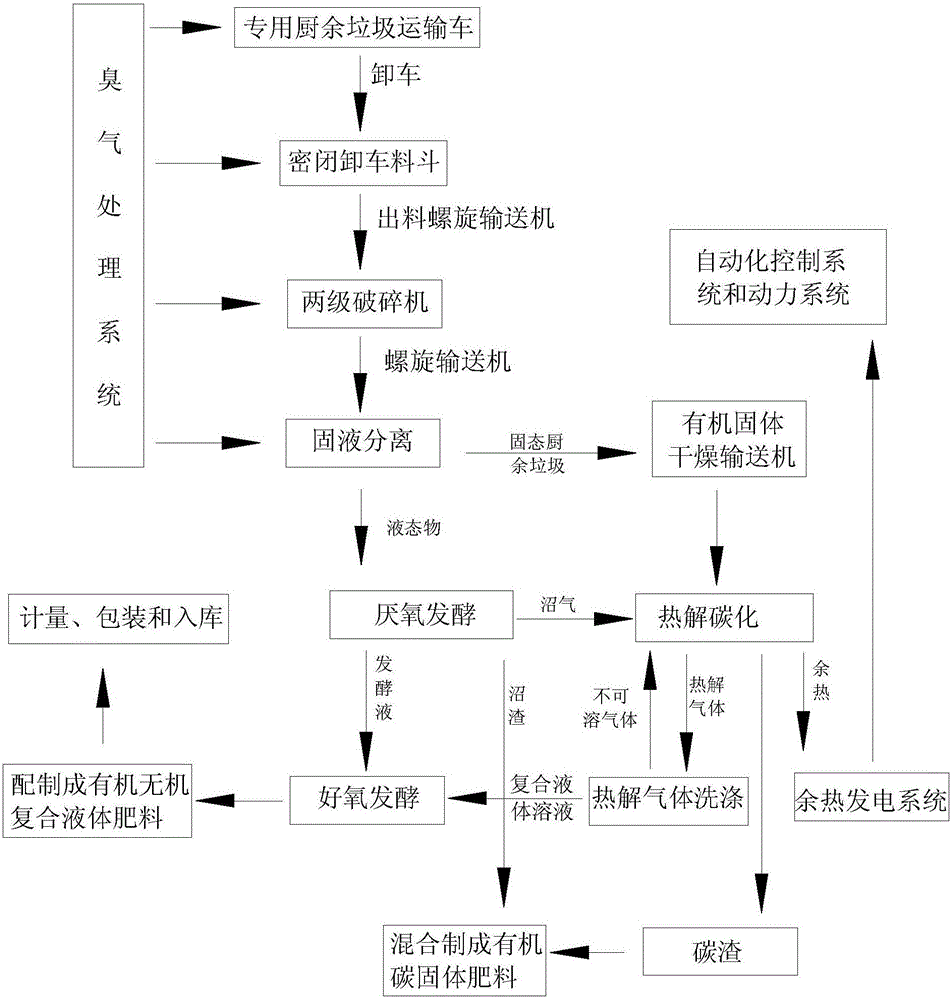

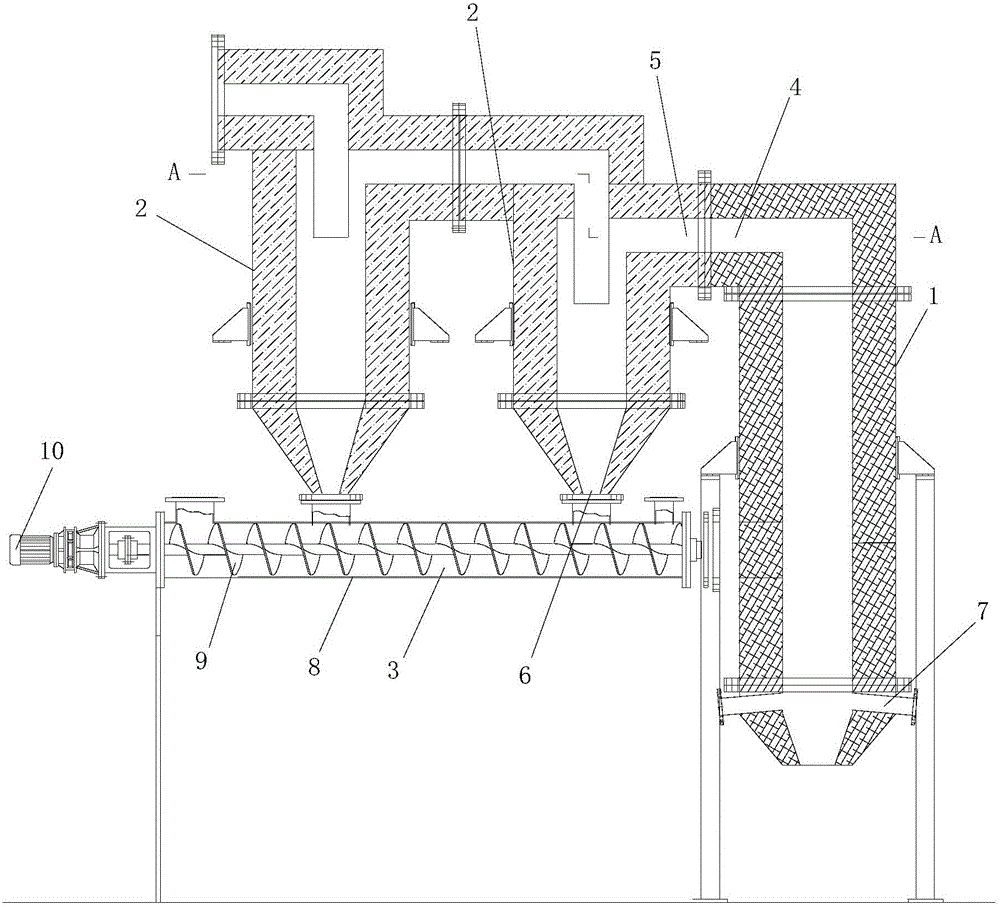

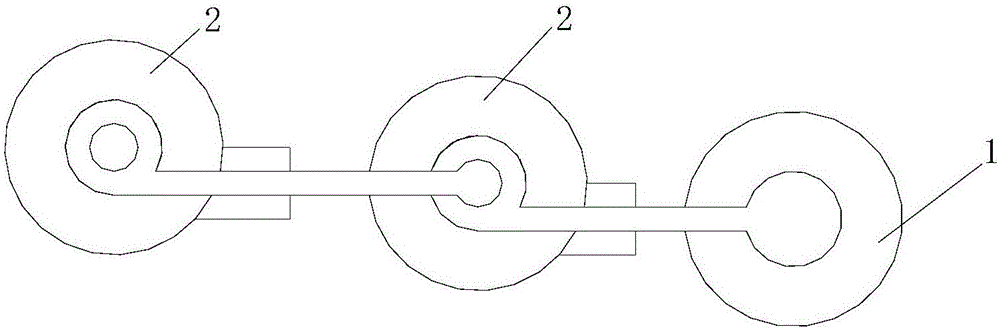

Method and device for preparing fertilizer from kitchen garbage

ActiveCN105060946AImprove efficiencySave spaceBio-organic fraction processingClimate change adaptationLitterOrganic liquids

The invention discloses a method and device for preparing fertilizer from kitchen garbage. The method comprises crushing kitchen garbage, carrying out solid-liquid separation, carrying out pyrolysis carbonization on the separated solid kitchen garbage to obtain pyrolysis gas and carbon residue, washing the pyrolysis gas, carrying out anaerobic fermentation on the separated liquid to obtain a broth, biogas residue and biogas, carrying out aerobic fermentation on the broth, then preparing organic-inorganic composite liquid fertilizer from the obtained liquid, mixing the biogas residue and the biogas residue obtained by the pyrolysis carbonization, adding composite microbe engineering bacteria into the mixture, and carrying out solid state fermentation to obtain the organic carbon solid fertilizer. The method and device respectively carry out resourceful treatment on the solid kitchen garbage and the organic liquid, the organic liquid is treated by a biotechnology so that the organic-inorganic composite liquid fertilizer is produced, and solid kitchen garbage is subjected to pyrolysis carbonization so that energy and biochar are produced.

Owner:GUANGZHOU YINGHAO ENVIRONMENTAL PROTECTION TECH CO LTD

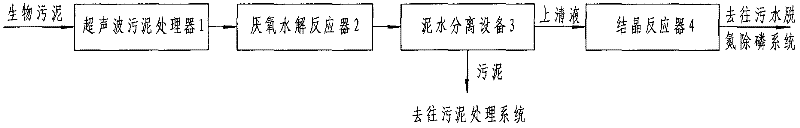

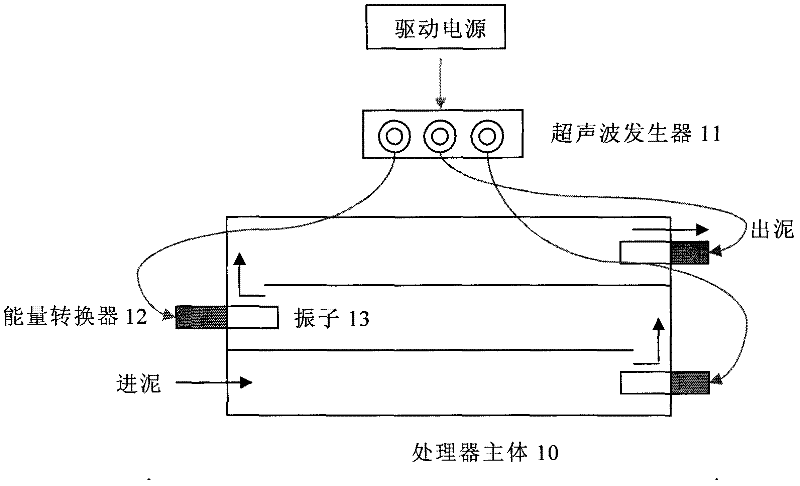

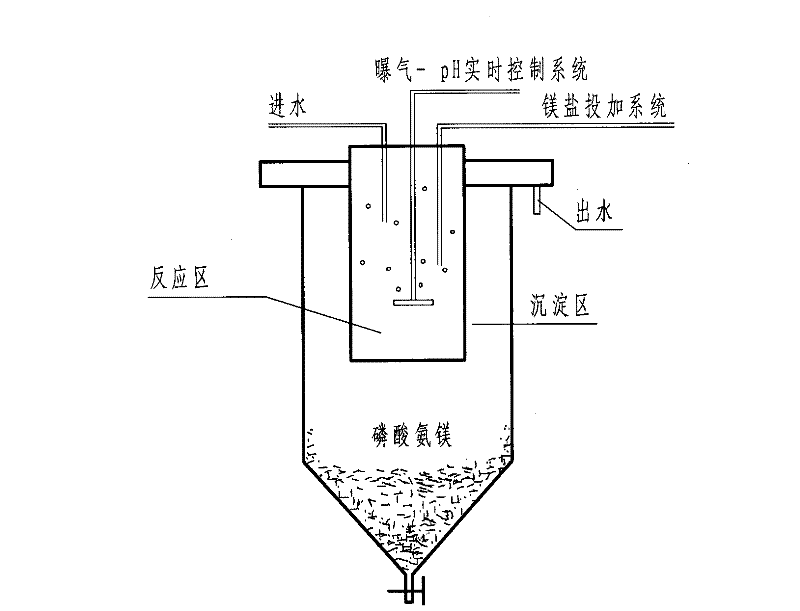

System and method for obtaining carbon source by utilizing ultrasonic enhanced sludge hydrolysis

InactiveCN102229463AImprove efficiencyIncrease speedBiological sludge treatmentBiological water/sewage treatmentPropanoic acidUltrasonic cavitation

The invention relates to a system and method for obtaining a carbon source by utilizing ultrasonic enhanced sludge hydrolysis. The biological sludge in a municipal sewage plant is used as a raw material; the flocculation structure and cell wall of the sludge are firstly damaged by utilizing a waterpower shear force generated by an ultrasonic cavitation effect; the sludge after ultrasonic preprocessing is added to an anaerobic hydrolysis reactor; and under anaerobic conditions, macromolecular solid organic matters are finally converted into volatile fatty acids (VFAs) such as acetic acid, propionic acid, butyric acid and the like through a series of biological hydrolytic action. In the invention, the efficiency and velocity for a sludge to release a carbon source are improved by utilizing the coupling of ultrasonic processing and anaerobic hydrolysis processes, and the N (nitrogen) and P (phosphorus) which are released by hydrolysis are effectively eliminated and recovered by utilizing a crystallization method. The invention can solve the problem of carbon source insufficiency of the existing denitrification and dephosphorization process and realizes the stabilization and resource of the sludge to some extent. Simultaneously, because the hydrolysis velocity of the sludge is enhanced, the hydrolysis time of the sludge is greatly shortened and the investment and operating cost of engineering are lowered.

Owner:BEIJING MUNICIPAL RES INST OF ENVIRONMENT PROTECTION

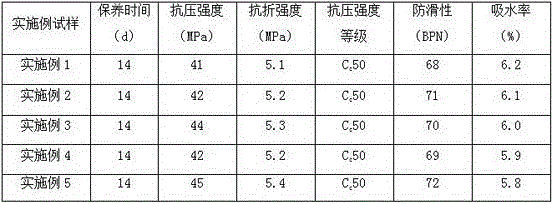

Method for preparing concrete pavement brick by using recycled aggregate of construction waste

InactiveCN106673592ARealize resourcesQuality improvementSolid waste managementEcological environmentBrick

The invention relates to a method for preparing a concrete pavement brick by using recycled aggregate of construction waste. The method is characterized in that a concrete pavement is prepared from the following raw materials in parts by weight: 60-80 parts of recycled aggregate of the construction waste, 25-35 parts of superfine 52.5 Portland cement, 10-15 parts of a gelatinizing agent, 0.5-2 parts of a superplasticizer, 0.5-2 parts of a reinforcing agent, 0.1-0.5 part of a dispersing agent and 0.1-1 part of a retarder. The quality of the concrete pavement brick is ensured by adopting the construction waste as the aggregate and adjusting the ingredients and quality of the cement and an additive; the prepared concrete pavement brick has the characteristics of high strength, good abrasive resistance, stable quality, long service life, low cost and the like; and the concrete pavement brick is prepared by adopting the construction waste as the aggregate, so that the construction waste is comprehensively utilized to turn the waste into treasure, reclamation of the construction waste is achieved, the ecological environment is improved, and the aims of protecting the environment, saving resources and achieving low-carbon economy are achieved.

Owner:盛丹

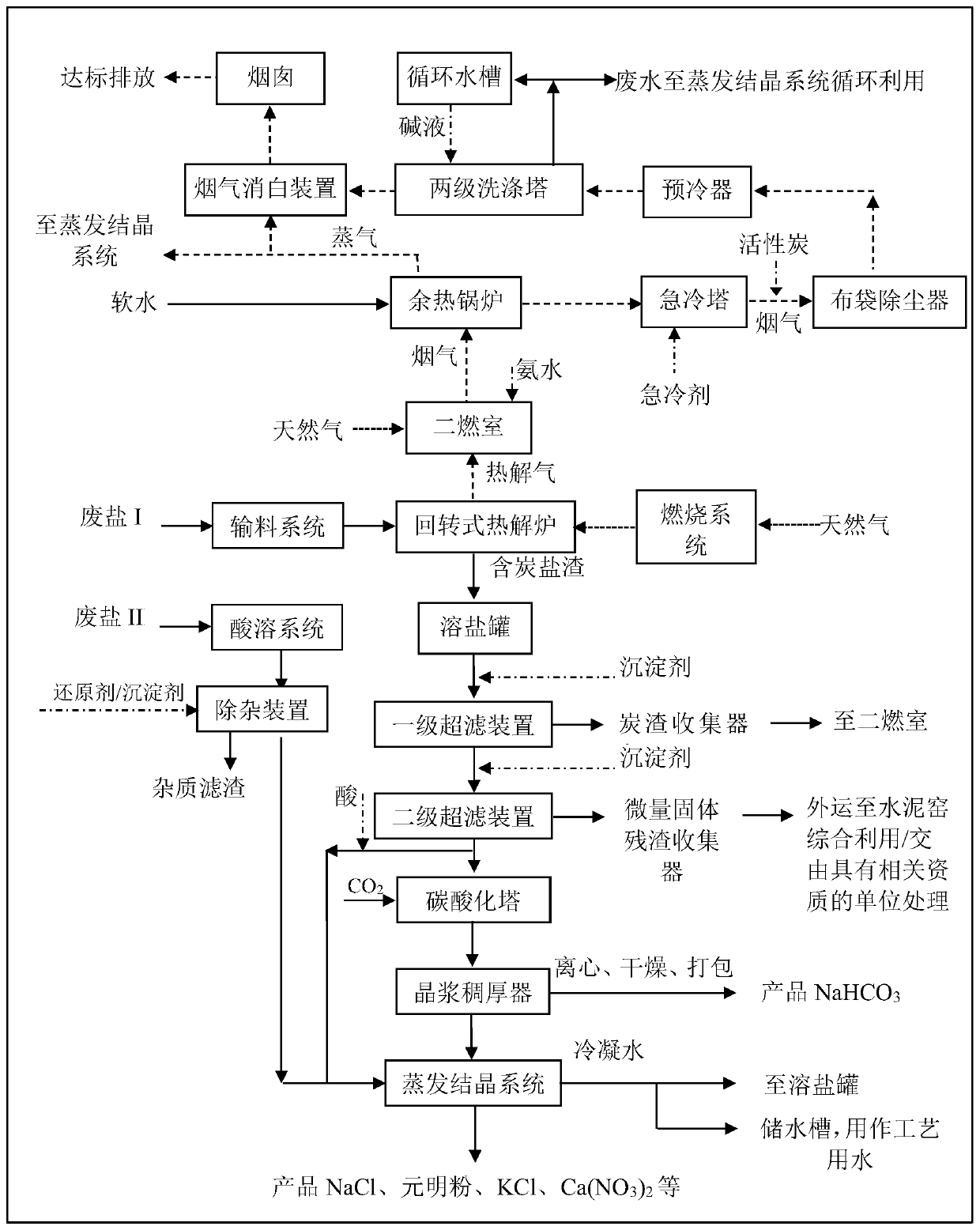

Waste salt resourceful treatment system and application

PendingCN110201975ARealize resourcesAchieve emission standardsSolid waste disposalTransportation and packagingSlagEvaporation

The invention relates to a waste salt resourceful treatment system which comprises a waste salt carbonization and pyrolysis system, a carbon-containing salt slag dissolving and filtering system and anevaporating and salt separating system in sequential connection, wherein the waste salt carbonization and pyrolysis system can carry out carbonization and pyrolysis treatment on waste salt I composedof sodium chloride, and sodium sulfate monomer salt or mixed waste salt and also can treat tail gas; the carbon-containing salt slag dissolving and filtering system can dissolve and filter the carbon-containing salt slag treated by the waste salt carbonization and pyrolysis system; and the evaporating and salt separating system can carry out evaporation and concentration, fractional crystallization and drying treatment on the strong brine treated by the carbon-containing salt slag dissolving and filtering system to obtain product salt. The waste salt resourceful treatment system takes industrial waste salt as the raw material, removes organic pollutant from waste salt and separates mixed inorganic salt to finally obtain an industrial second-grade salt product, so that recycling of waste salt is realized, and the flue gas generated during the production process is discharged after reaching the standard.

Owner:北京航天环境工程有限公司

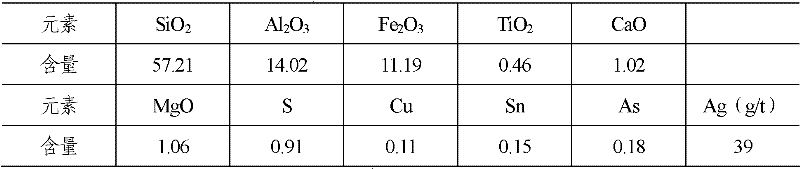

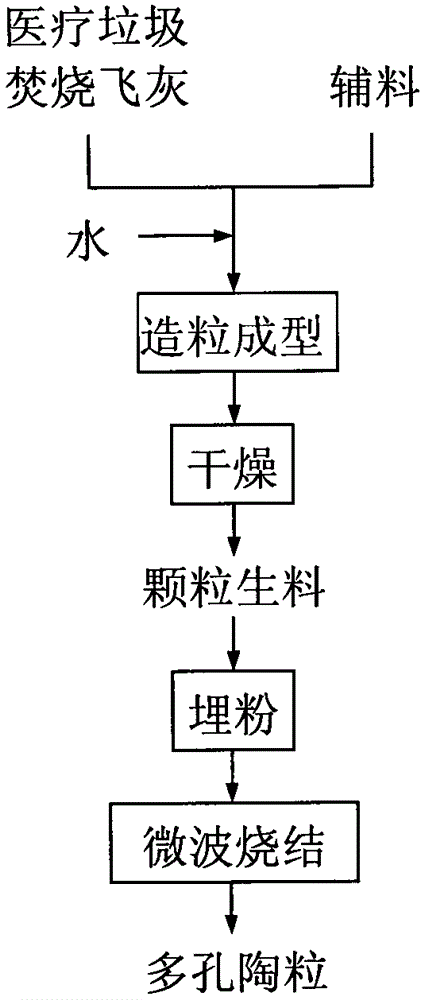

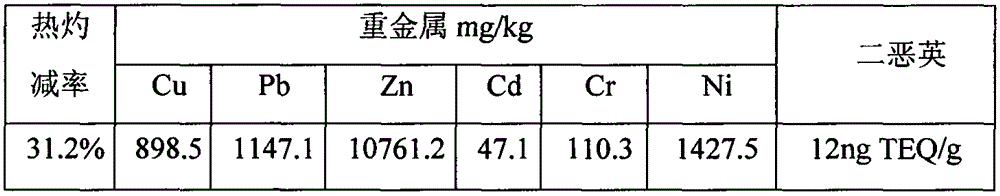

Method for microwave firing of porous ceramsites by adopting medical waste incineration fly ash

The invention discloses a method for microwave sintering of porous ceramsites by adopting medical waste incineration fly ash. The method comprises the following steps: (1) fully mixing the medical waste incineration fly ash with an auxiliary material, adding a small amount of water into the mixture, and carrying out granulation molding by a molding machine; (2) carrying out granulation molding, drying to obtain a particle raw material, filling the periphery of the particle raw material with a microwave coupling agent powder; and (3) carrying out microwave sintering of the particle raw material filled with the powder, and after sintering, cooling to the room temperature to obtain the porous ceramsites. The method can utilize a 'hot spot' effect of fly ash high-content active carbon in a microwave field to instantly completely decompose dioxins in the fly ash, at the same time, allows most heavy metals to be wrapped and cured in grids of the sintered product, and rapidly sinters the fly ash into the porous ceramsites; and the ceramsites can be used for building aggregates or wastewater filter materials, achieves further resource utilization while achieving harmlessness treatment of the medical waste incineration fly ash, and achieves many things at one stroke.

Owner:TIANJIN CHENGJIAN UNIV

Method for synthesizing and using oil sludge falling to the ground

InactiveCN101050049AEfficient recyclingEliminate pollutionSludge treatment by de-watering/drying/thickeningFatty/oily/floating substances removal devicesOil sludgeMineral oil

This invention relates to a method for utilizing the mixtures of crude oil and soil. The method adopts thermochemical washing, dehydration / drying treatment, and incineration on different kinds of mixtures of crude oil and soil. Recovered mineral oil and wastewater can be utilized. Petroleum sludge is sent to an incinerator for incineration, and the flue gas generated during incineration is used to heat waste heat boiler to produce steam, which is a heat source for production and living. The method has such advantages as simple process, easy application, low running cost, effective recovery and utilization of mineral oil, no environmental pollution, clean production, and high profit.

Owner:LIAOHE GASOLINEEUM EXPLORATION BUREAU

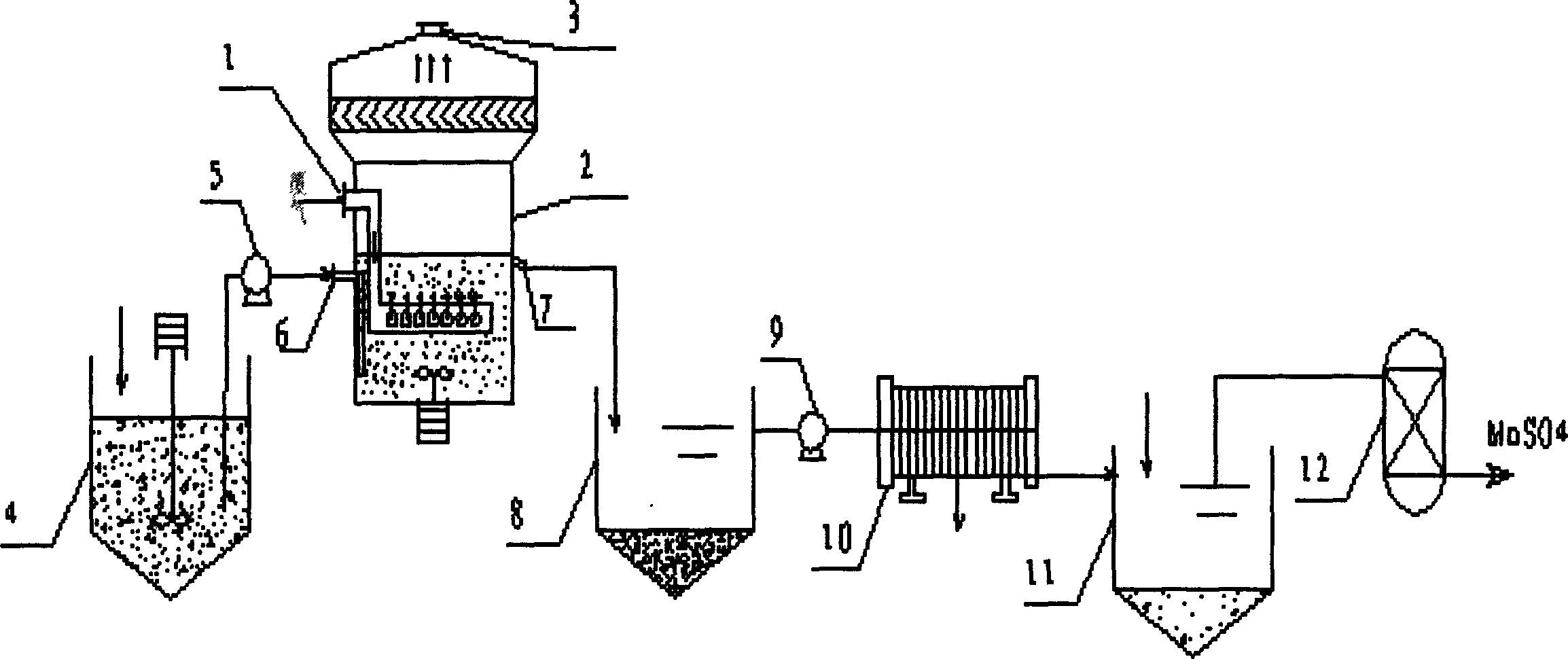

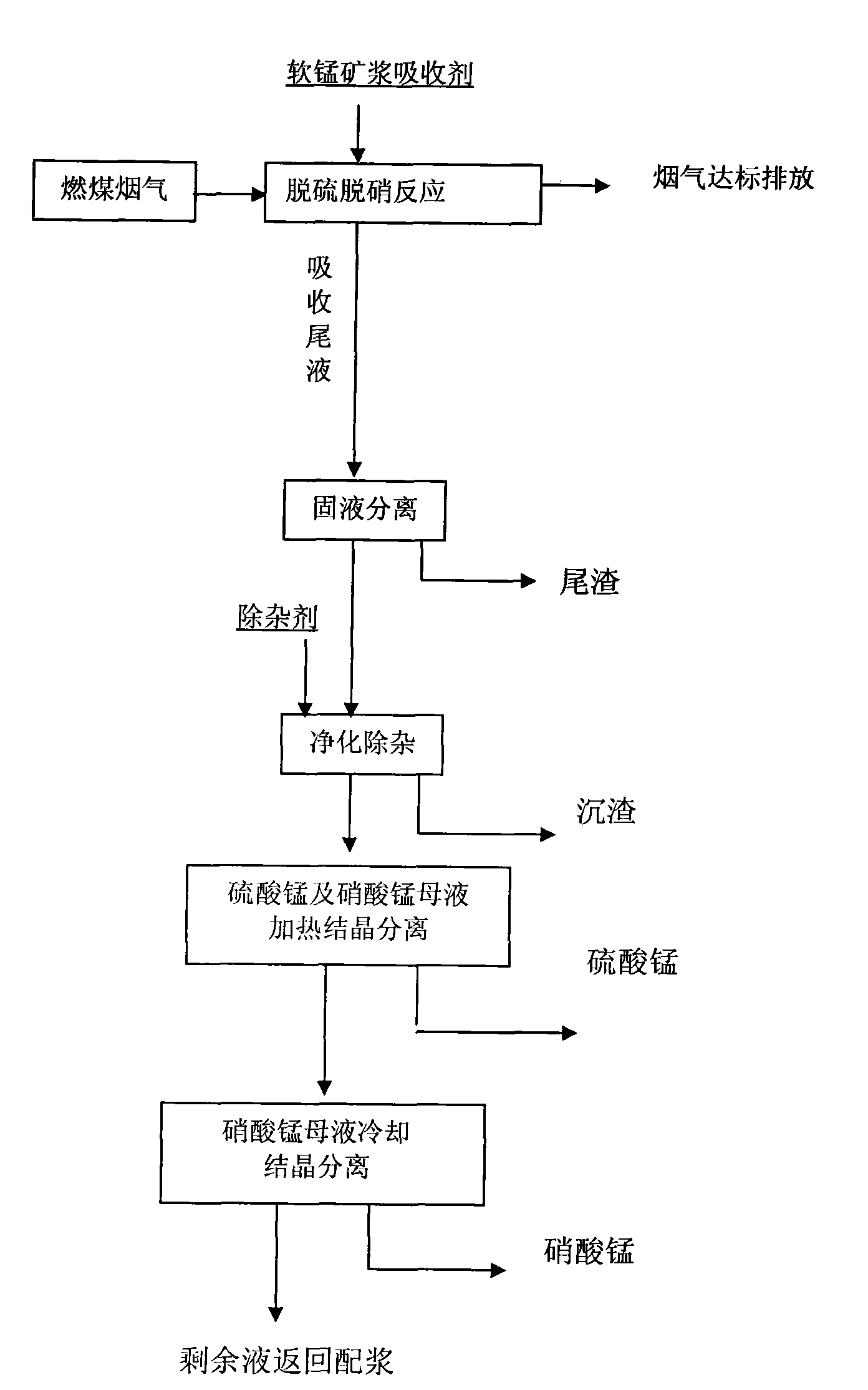

Synchronous desulphrization and denitration method of flue gas pyrolusite pulp for reclamation

ActiveCN101574617ARich reservesLow priceDispersed particle separationProcess efficiency improvementSolubilityPyrolusite

The invention discloses a synchronous desulphrization and denitration method of flue gas pyrolusite pulp for reclamation. The method mainly comprises the following steps: pyrolusite, water and metal-chelator are prepared into pulp which is taken as an absorbing agent; sulfur dioxide and nitrogen oxides in the flue gas are synchronously absorbed and removed by the absorbing agent; the flue gas is discharged when the purification reaches a standard; the primary product of the mixed mother solution of manganese sulfate and manganese nitrate is obtained after absorbing tail solution is purified; and by utilizing the different solubility of manganese sulfate and manganese nitrate at same temperature, the mixed mother solution is heated firstly to cause the manganese sulfate therein to be crystallized and separated, next, the left mother solution is cooled to cause the manganese nitrate therein to be crystallized and separated, and the left solution is returned to preparation pulp for recycling. No waster water is discharged in the whole process, thereby achieving the purposes of controlling waste by waste, recycling sulfur resources and improving the comprehensive utilization value of pyrolusite. The method is characterized by high desulphrization and denitration efficiency and manganese utilization rate, little secondary pollution, obvious economic benefit and the like.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com