Patents

Literature

8961results about How to "Efficient recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

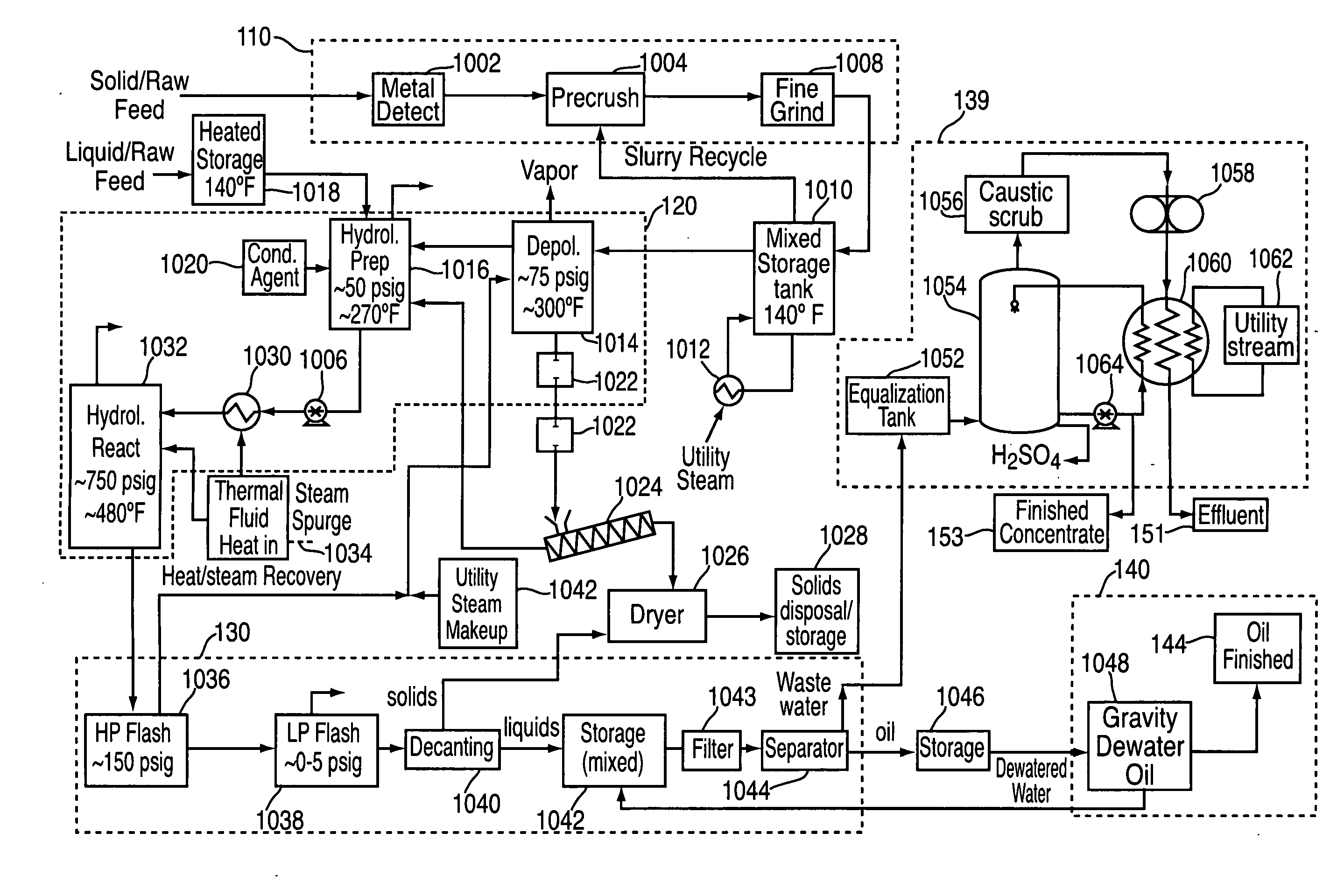

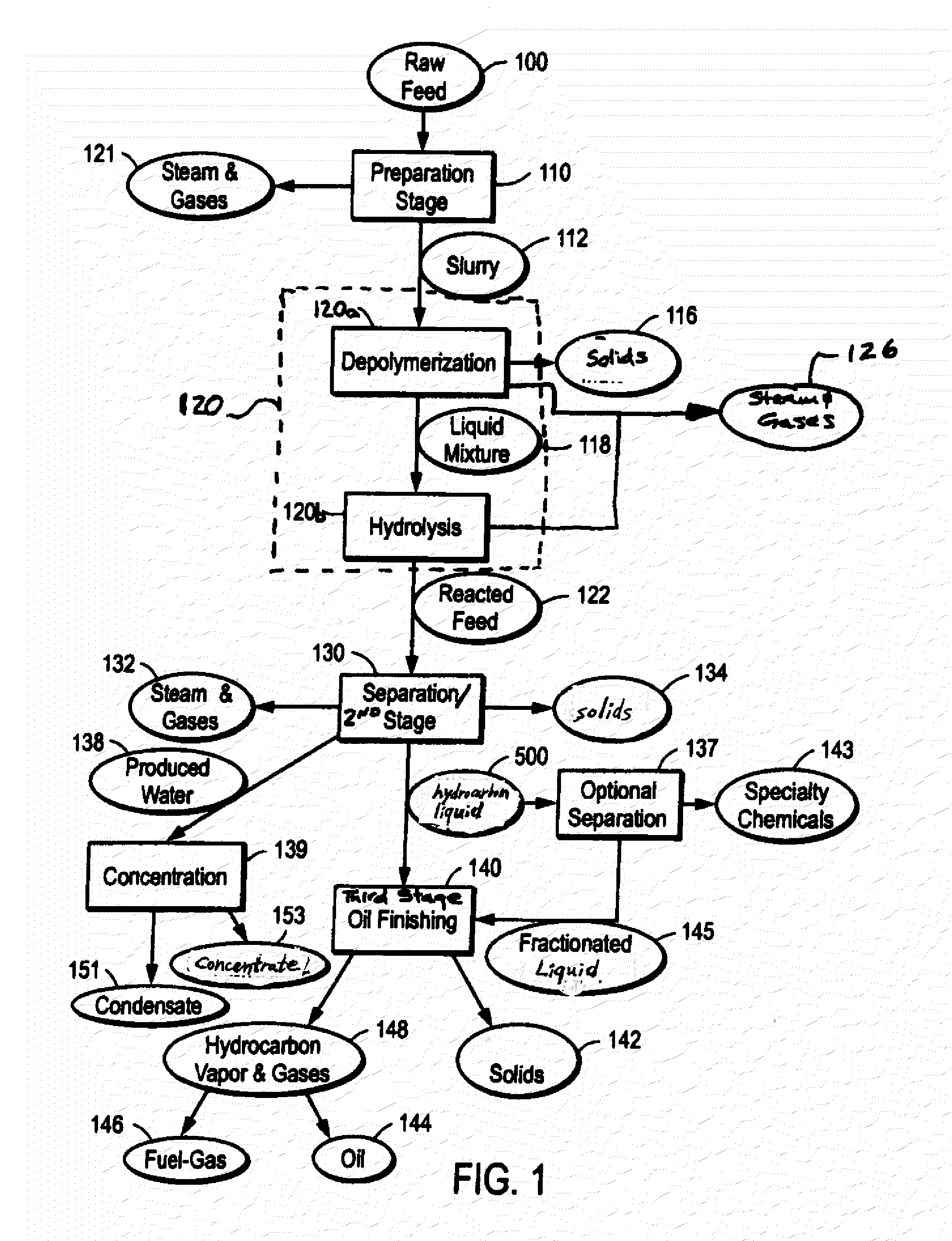

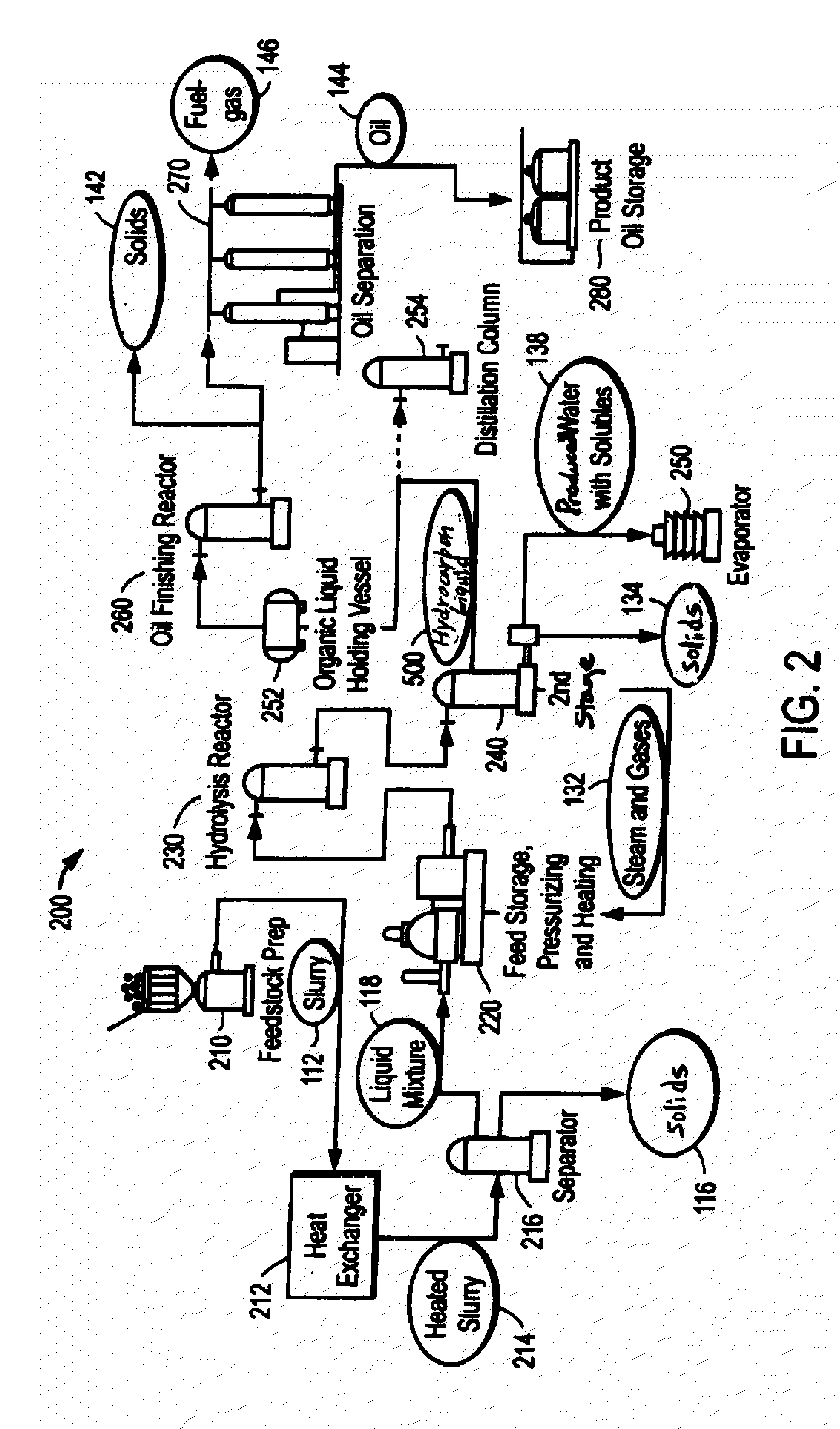

Methods and apparatus for converting waste materials into fuels and other useful products

ActiveUS20090062581A1Effectively handle problematic wasteFree of contaminantsTransportation and packagingSolid waste disposalSpeciality chemicalsBiological waste

Conversion of waste and other organic feedstock into sustainable energy, feed, fertilizer, and other useful products of reliable purities is accomplished using water, heat, and pressure. More specifically, the invention provides methods and apparatus that handle mixed streams of various feedstocks, e.g. agricultural waste, biological waste, municipal solid waste, municipal sewage sludge, and shredder residue, to yield gas, oil, specialty chemicals, and carbon solids that can be used as is or are further processed. Useful products can be diverted at various points of the process or internalized to enhance the efficiency of the system.

Owner:SYNPET TEKNOLOJI GELISTIRME

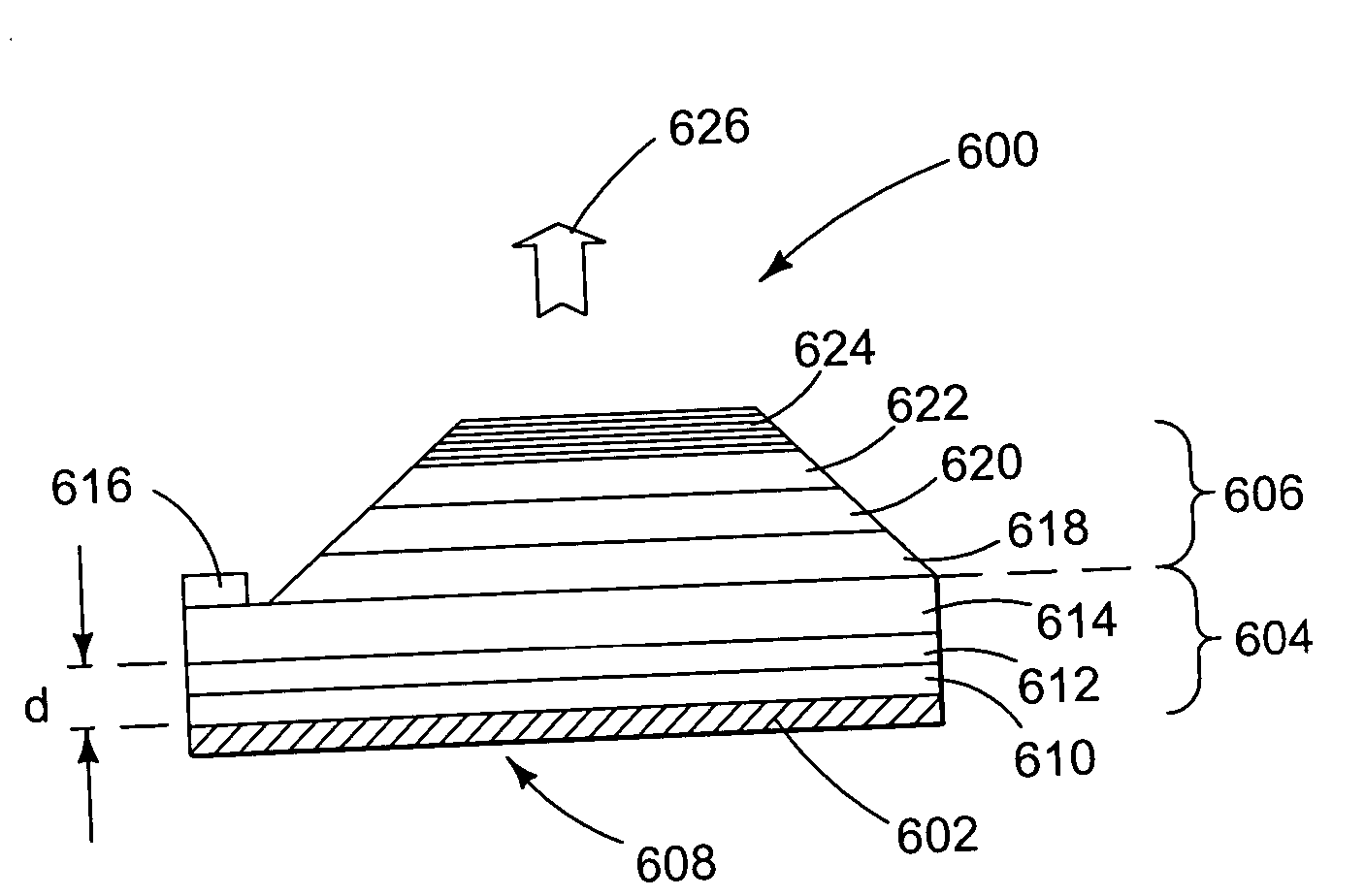

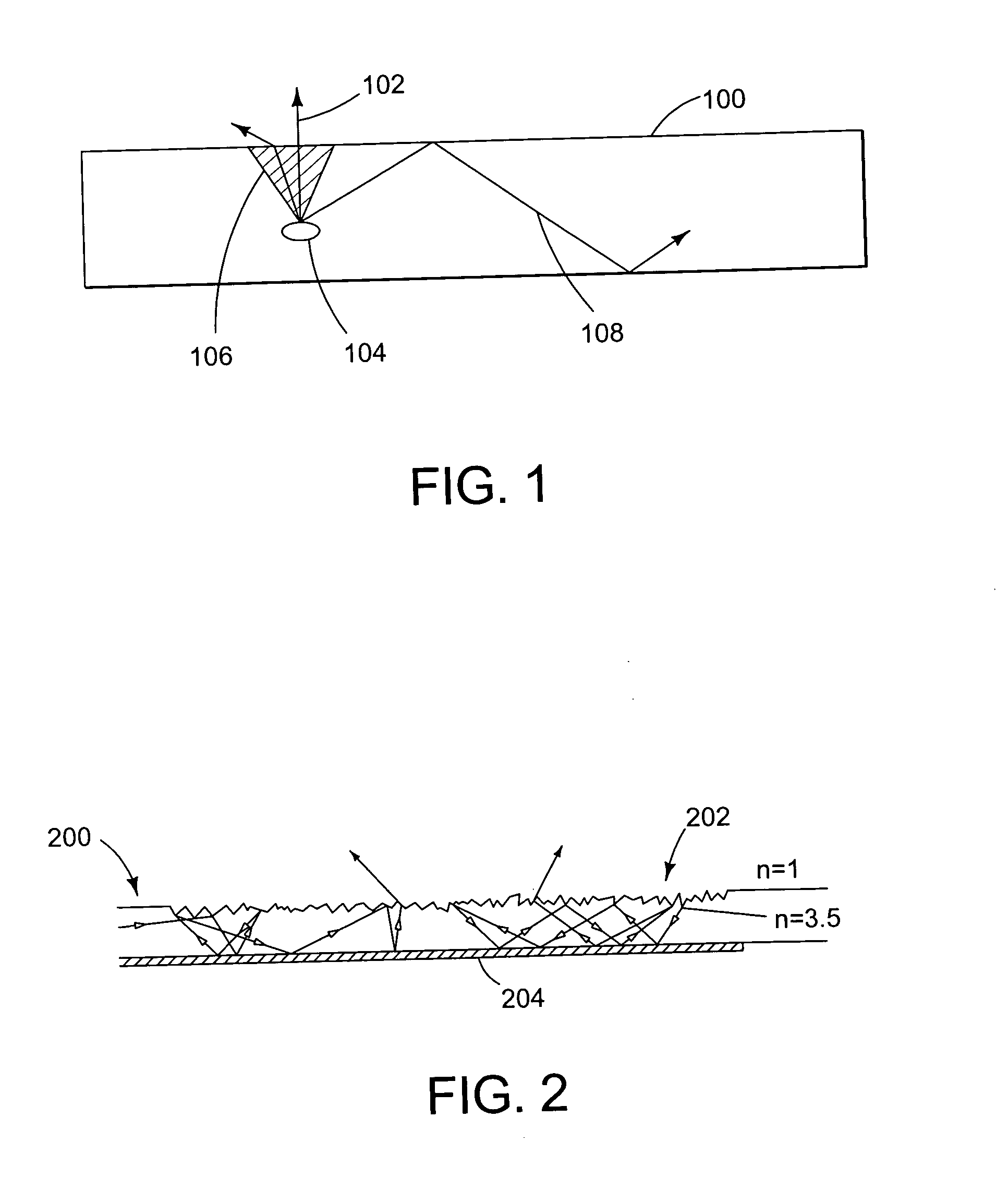

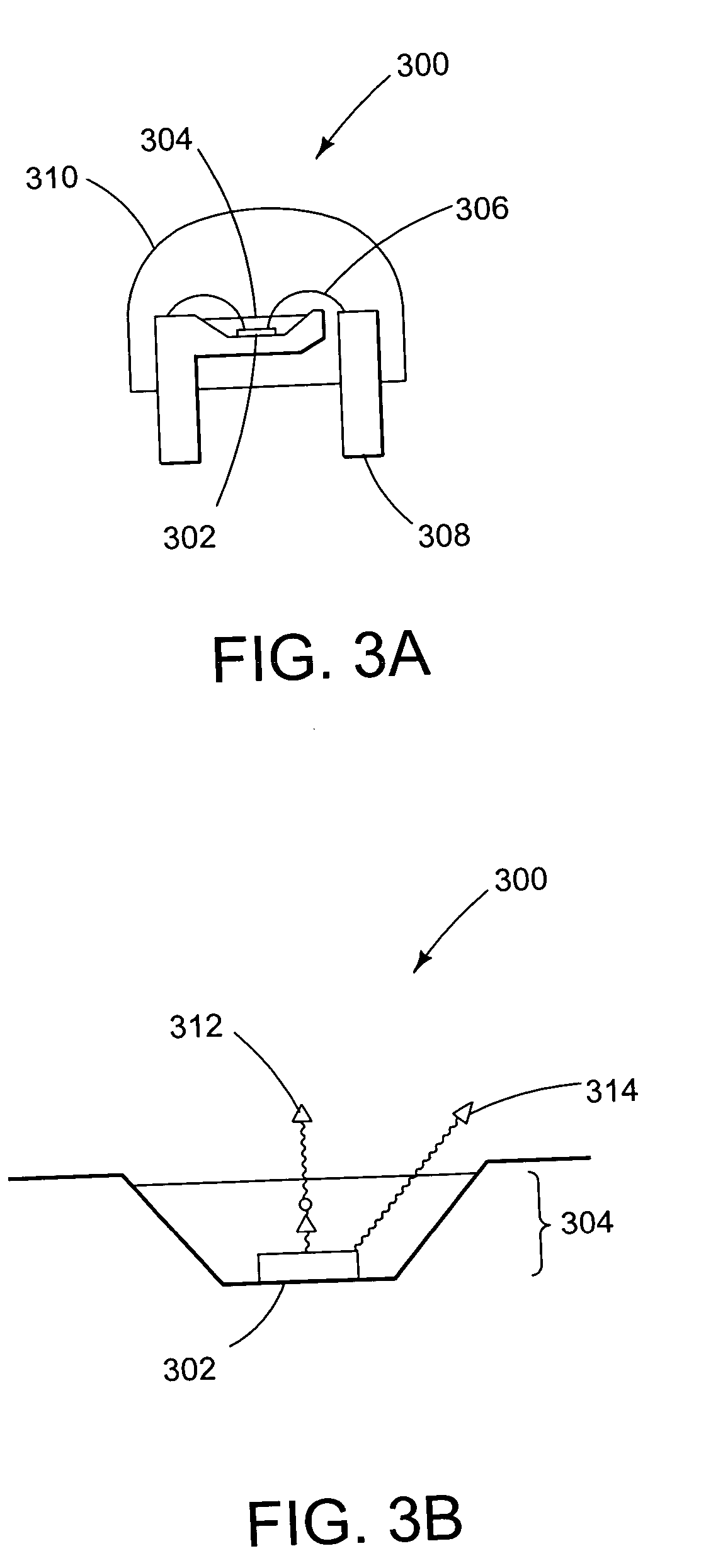

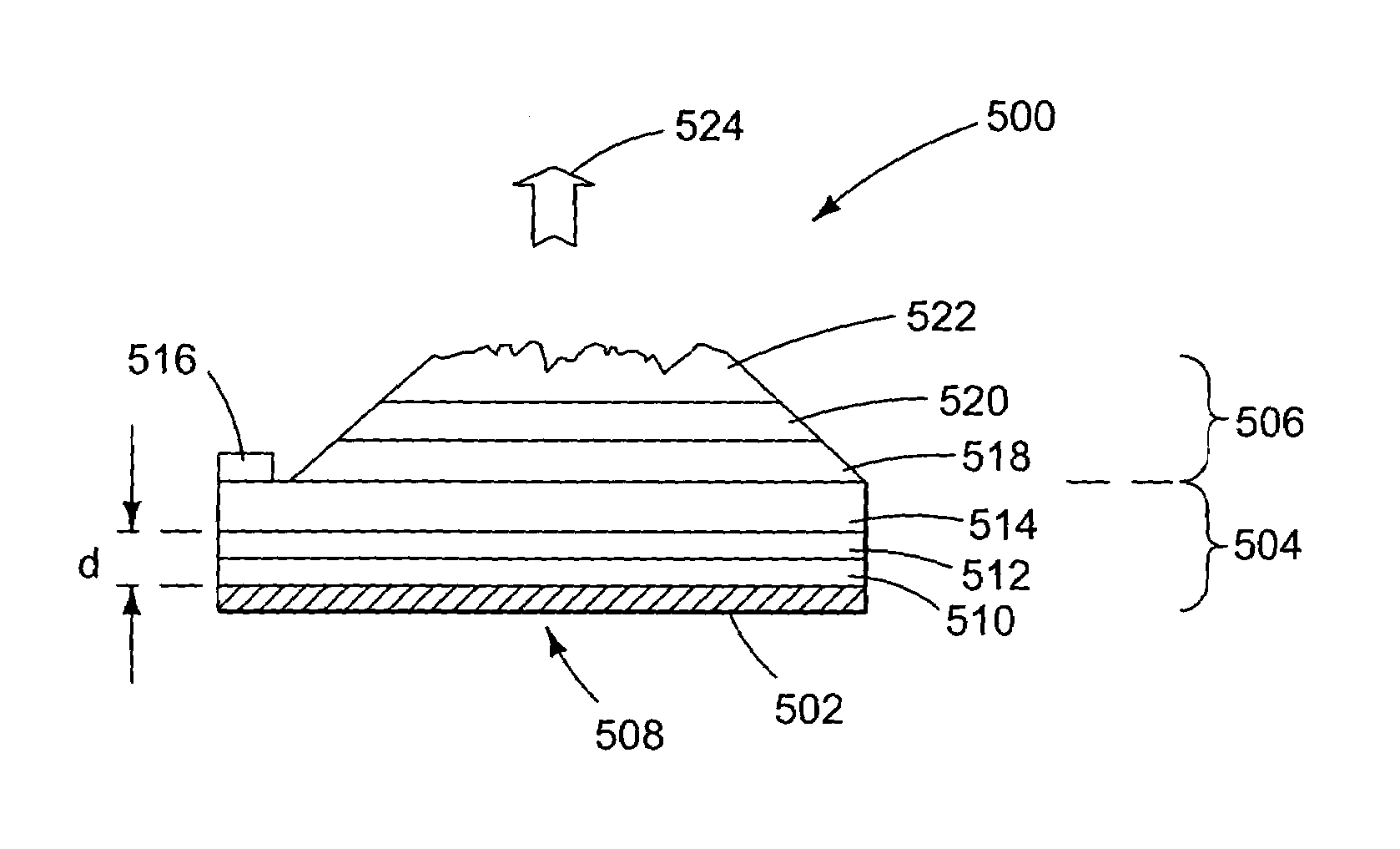

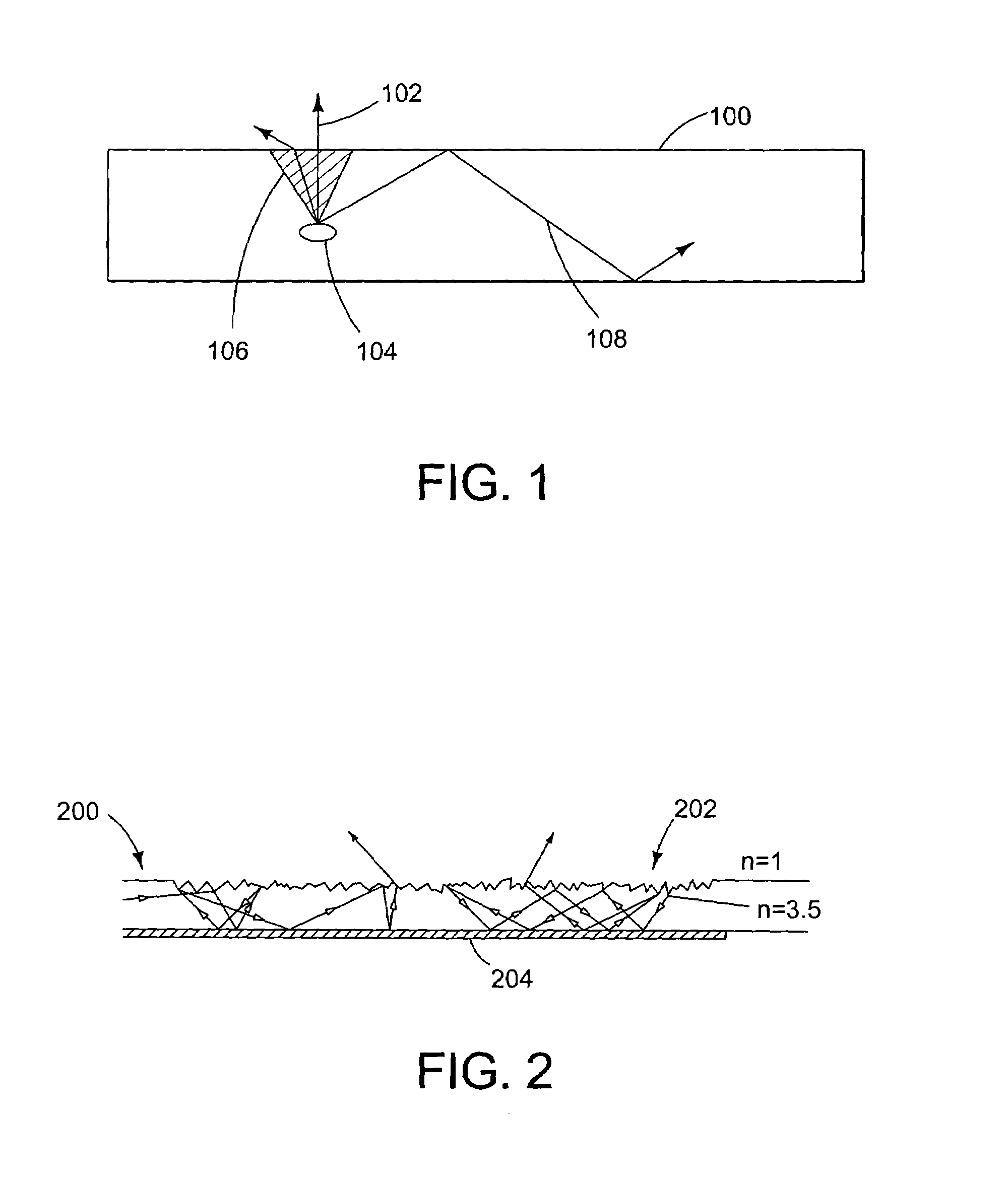

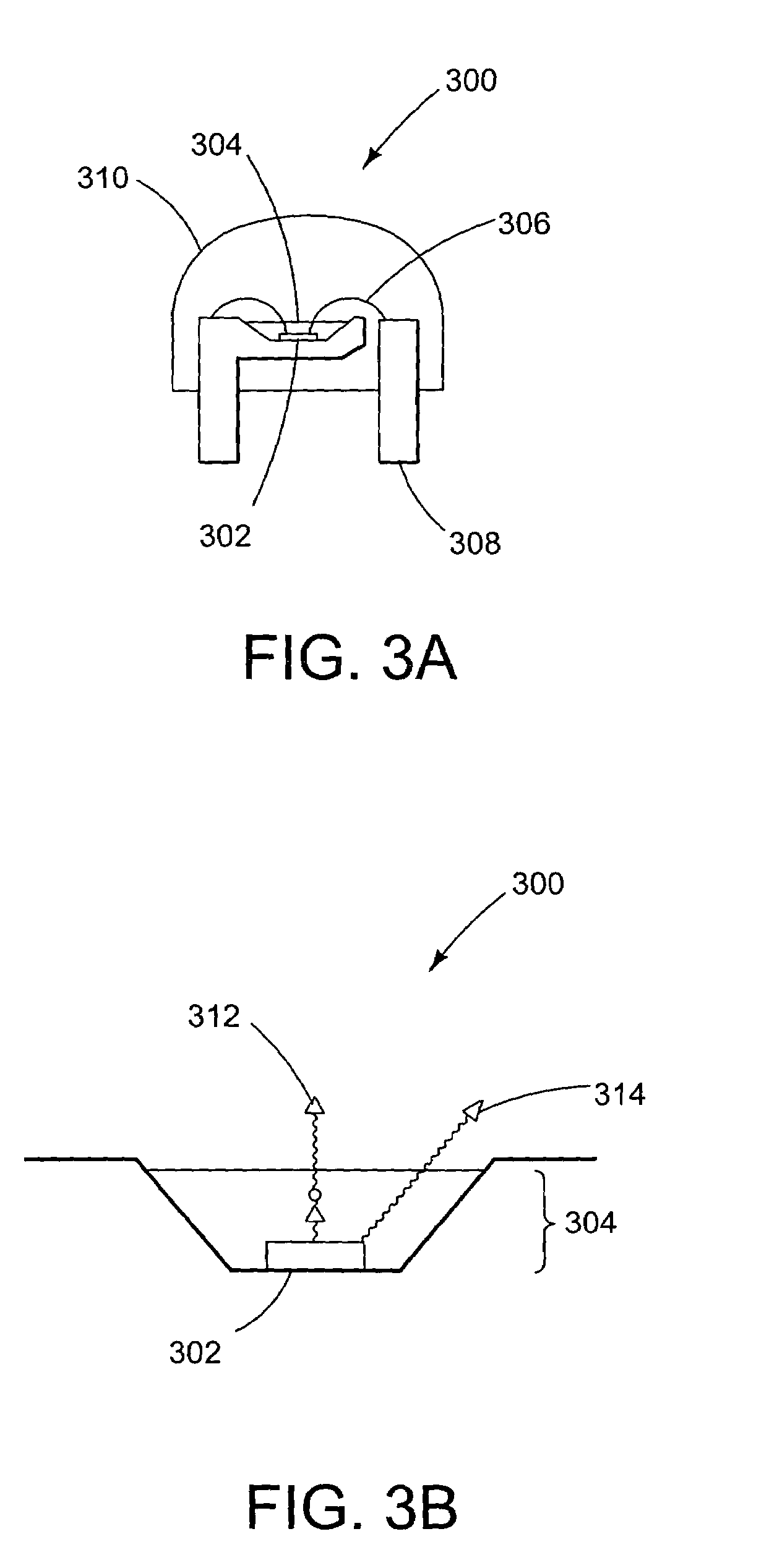

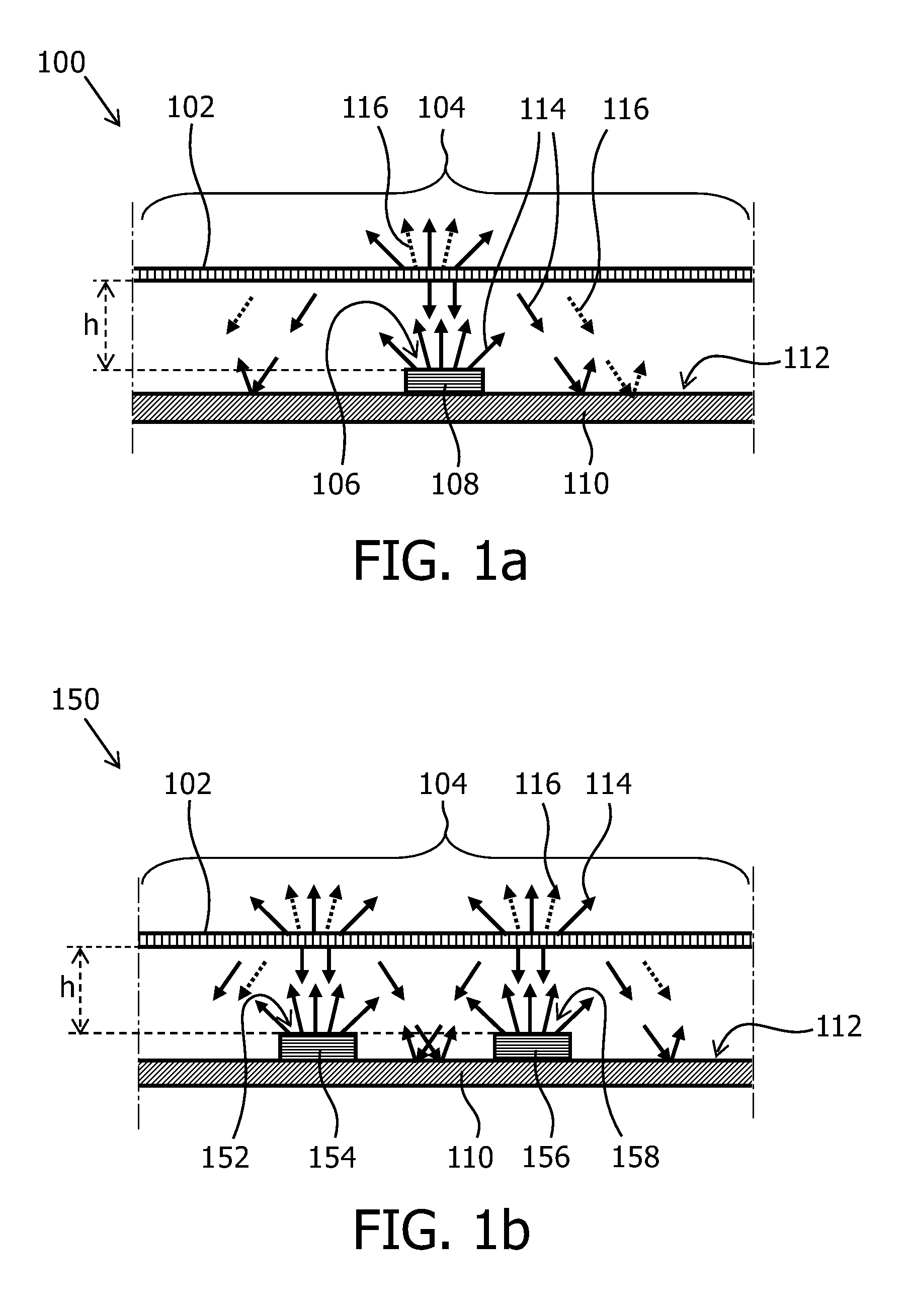

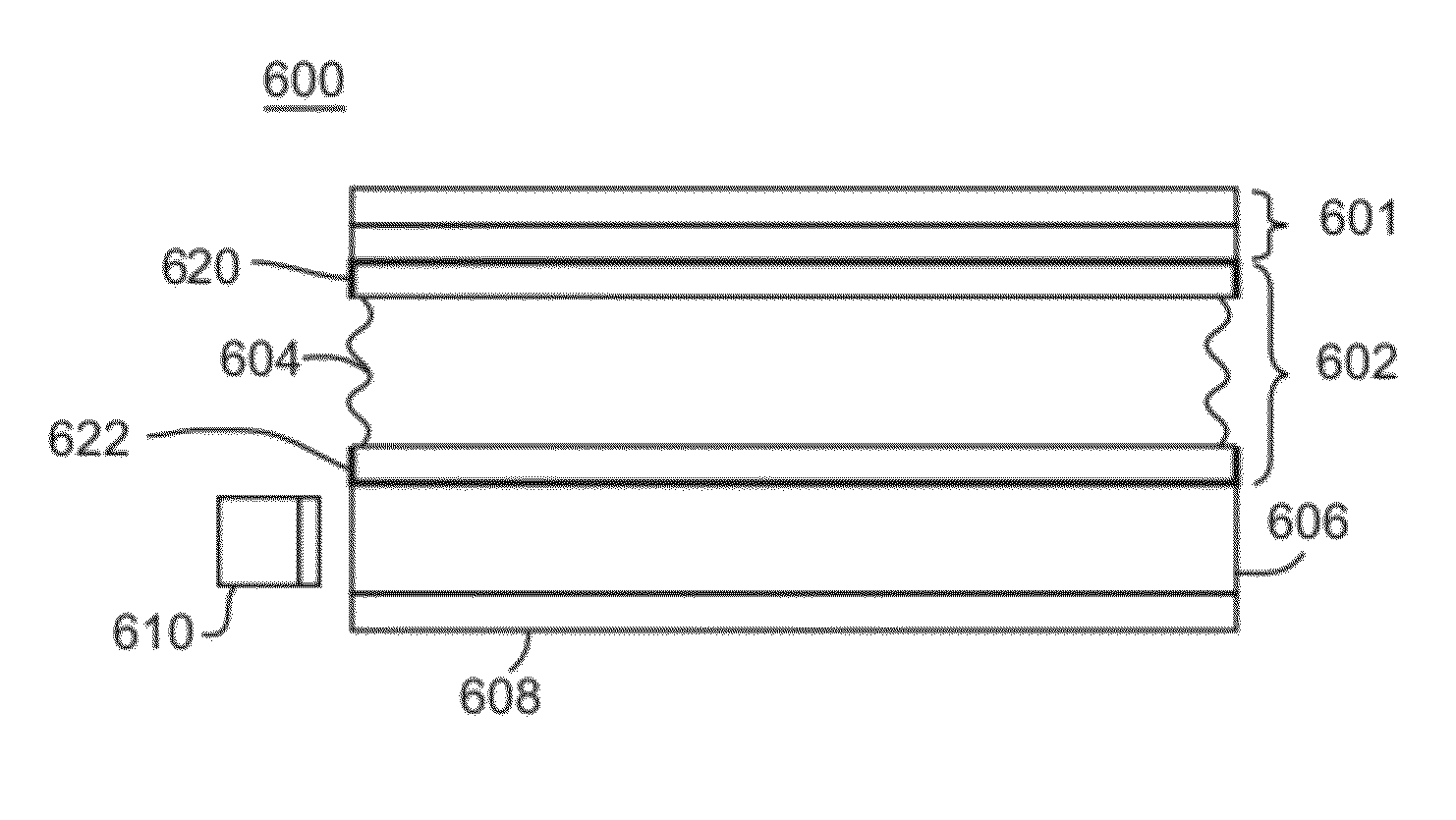

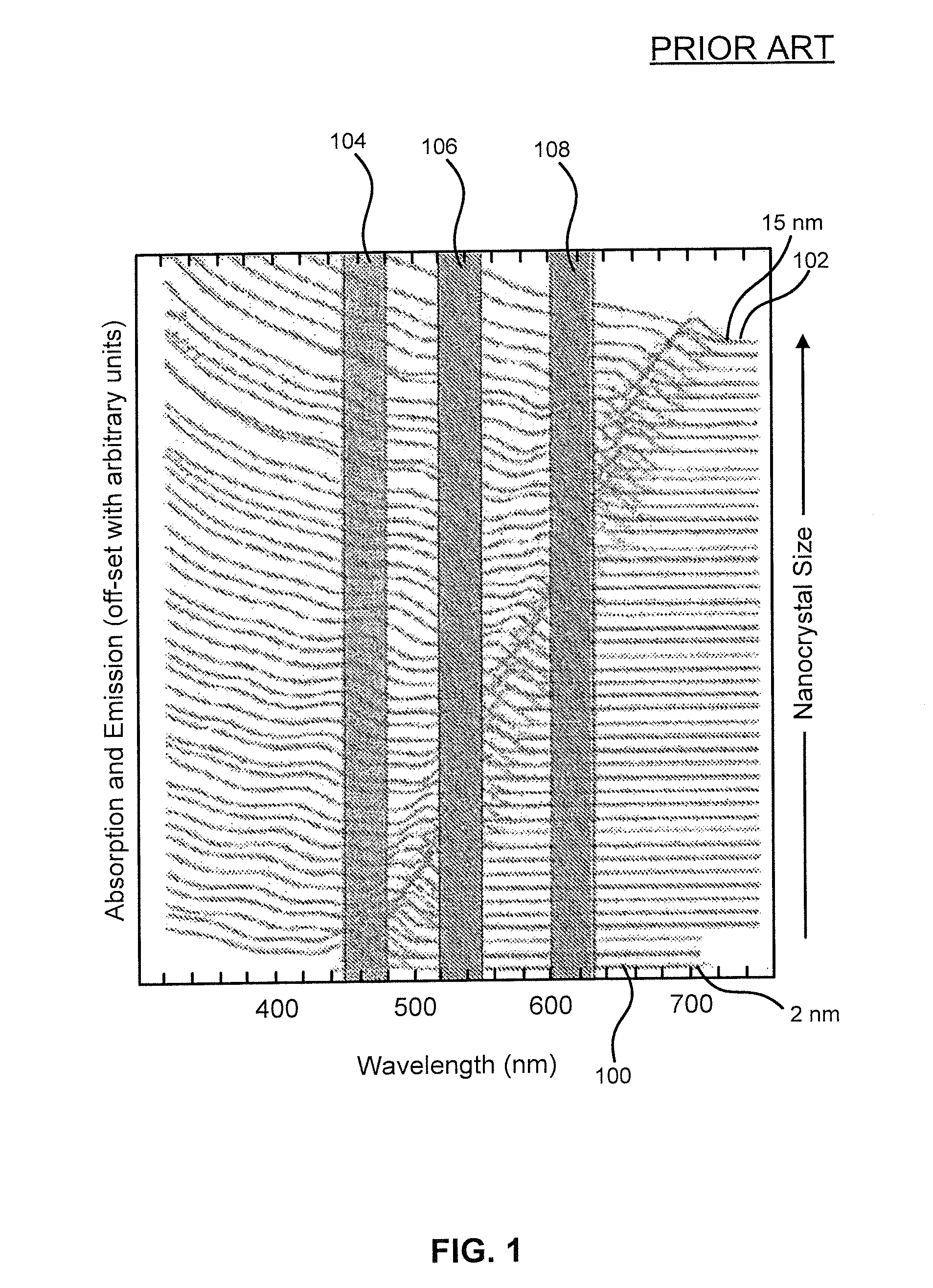

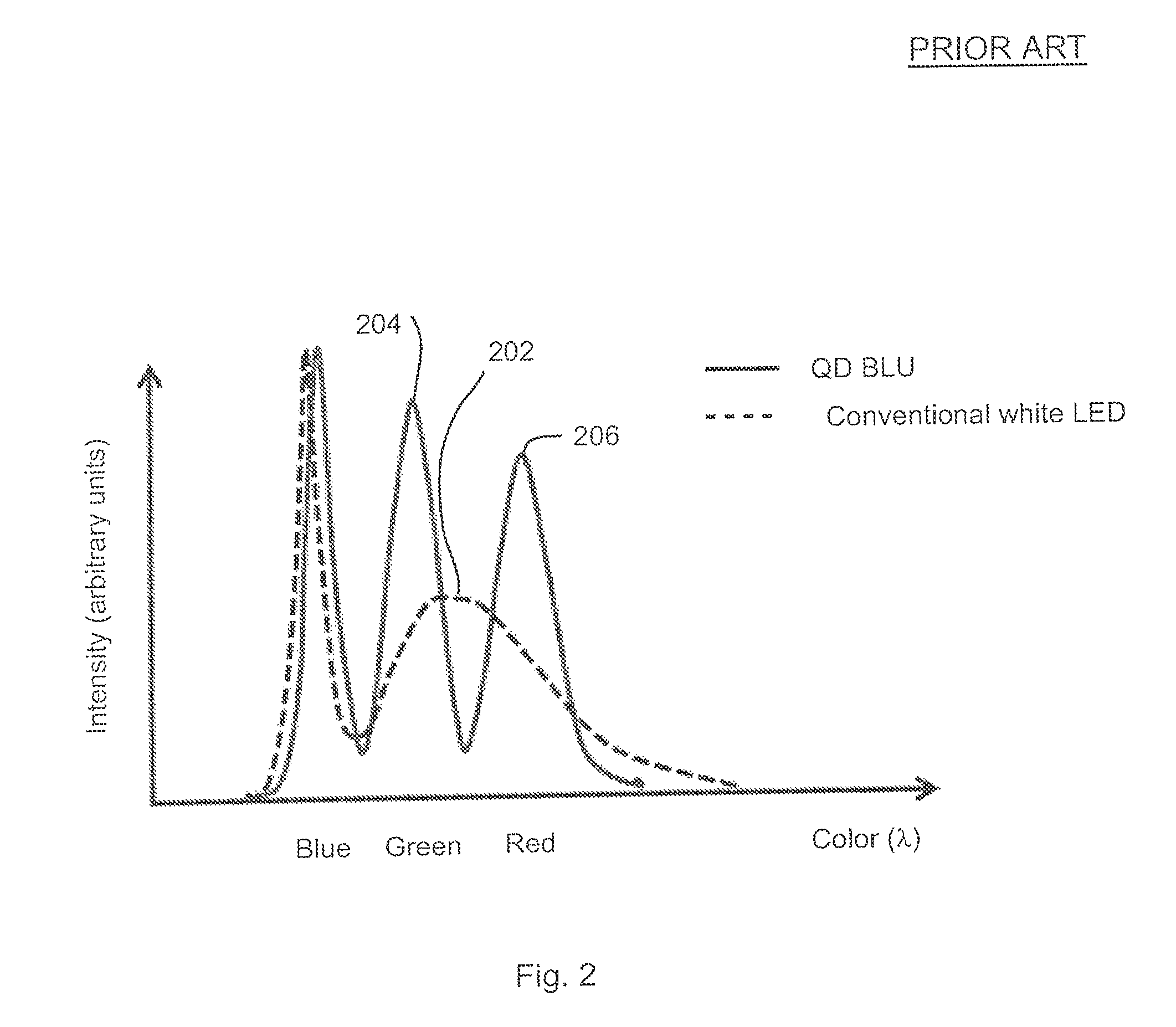

White, single or multi-color light emitting diodes by recycling guided modes

InactiveUS20060054905A1Improve the coupling effectEfficient recyclingSolid-state devicesSemiconductor/solid-state device manufacturingMonochromatic colorLight-emitting diode

A white, single or multi-color light emitting diode (LED) includes a mirror for reflecting photons within the LED; a first active region, adjacent the mirror, including one or more current-injected layers for emitting photons when electrically biased in a forward direction; a second active region, adjacent the first active region, including one or more optically-pumped layers for emitting photons, wherein the optically-pumped layers are optically excited by the photons emitted by the current-injected layers, thereby recycling guided modes; and an output interface, adjacent the second active region, for allowing the photons emitted by the optically-pumped layers to escape the LED as emitted light.

Owner:RGT UNIV OF CALIFORNIA

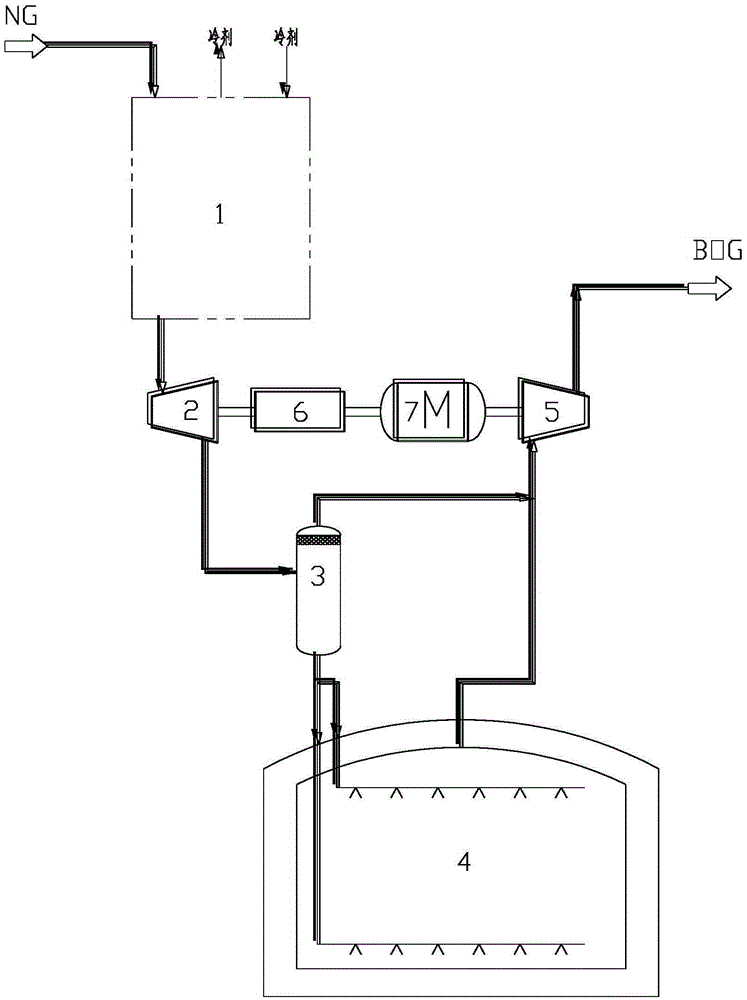

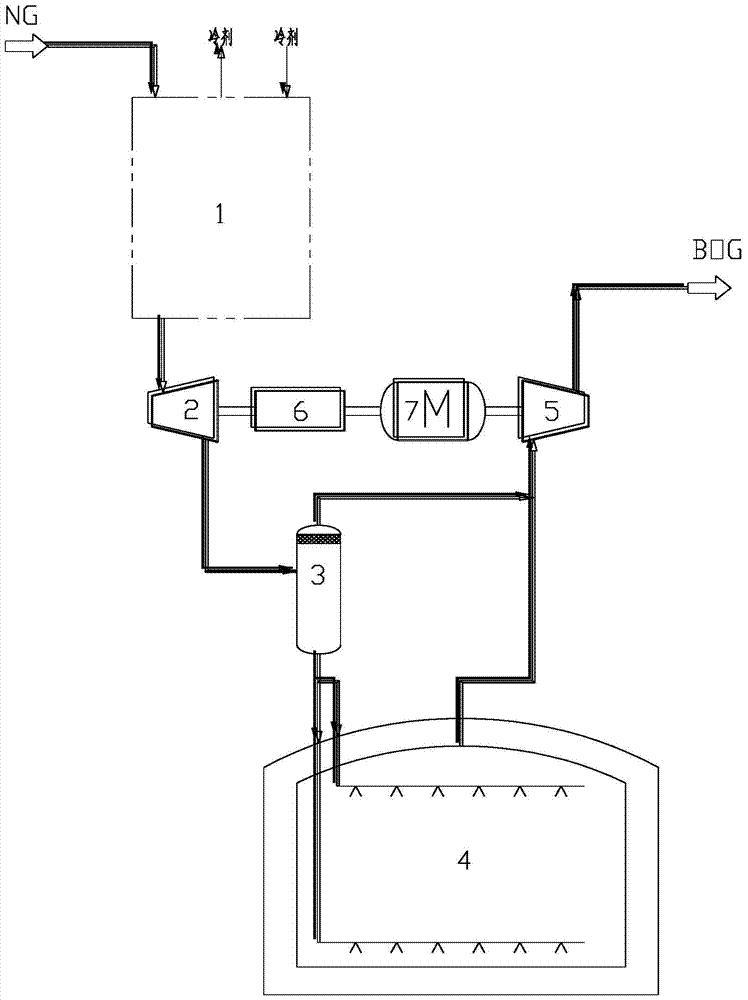

LNG (Liquefied Natural Gas) energy recovery process

ActiveCN105240064AIncreased LNG productionBOG volume reductionSteam engine plantsProcess engineeringEngineering

The invention relates to the technical field of natural gas low temperature equipment, in particular to an LNG energy recovery process. By an LNG hydraulic turbine device (or expanding machinery in other forms), high pressure and low temperature LNG converts pressure energy to mechanical energy which is output by a supercharging end of the LNG hydraulic turbine device. Depressurized LNG is further cooled, a gas phase and a liquid phase generated in a depressurizing process are separated by a gas-liquid separation tank, the liquid LNG is charged to an LNG storage tank, and the gas phase BOG and BOG of the LNG storage tank are supercharged together by the supercharging end, namely, a BOG supercharger, of the LNG hydraulic turbine device. The LNG hydraulic turbine device replaces a J-T valve of the LNG product for expanding throttling, as the LNG is lower in temperature, output of the BOG is reduced, LNG yield is improved, and mechanical energy can be recovered by BOG supercharging of the BOG supercharging end.

Owner:JEREH OIL & GAS ENG

A kind of lng energy recovery process

ActiveCN105240064BReduce the temperatureIncrease productionSteam engine plantsGas phaseMechanical energy

The invention relates to the technical field of natural gas low temperature equipment, in particular to an LNG energy recovery process. By an LNG hydraulic turbine device (or expanding machinery in other forms), high pressure and low temperature LNG converts pressure energy to mechanical energy which is output by a supercharging end of the LNG hydraulic turbine device. Depressurized LNG is further cooled, a gas phase and a liquid phase generated in a depressurizing process are separated by a gas-liquid separation tank, the liquid LNG is charged to an LNG storage tank, and the gas phase BOG and BOG of the LNG storage tank are supercharged together by the supercharging end, namely, a BOG supercharger, of the LNG hydraulic turbine device. The LNG hydraulic turbine device replaces a J-T valve of the LNG product for expanding throttling, as the LNG is lower in temperature, output of the BOG is reduced, LNG yield is improved, and mechanical energy can be recovered by BOG supercharging of the BOG supercharging end.

Owner:SICHUAN HENGRI GAS ENG CO LTD

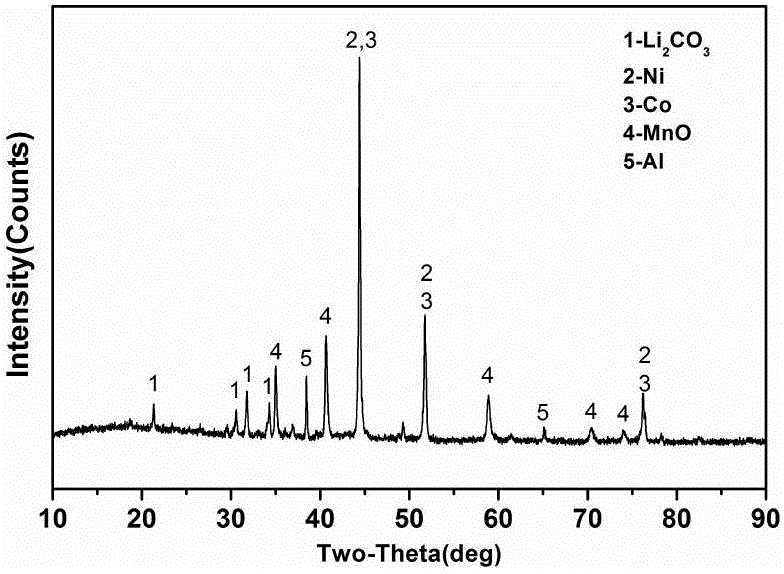

Method for comprehensively recovering valuable metals from waste lithium-ion battery material

ActiveCN106129511AEfficient recyclingHigh recovery rateWaste accumulators reclaimingProcess efficiency improvementManganeseAmmonia

The invention discloses a method for comprehensively recovering valuable metals from a waste lithium-ion battery material. The method is characterized by comprising the steps of mixing a waste lithium-ion battery positive electrode material with a reducing agent, or mixing simply crushed whole battery with a carbon reducing agent; carrying out reducing roasting treatment at the temperature of 500-750 DEG C; firstly carbonizing and leaching a roasted product through CO2 to obtain a lithium bicarbonate water solution for preparing an Li2CO3 product; and leaching valuable elements of cobalt, nickel, manganese and the like from liquid leached residues through oxidation acid leaching or oxidation ammonia leaching, carrying out extracting and purifying and then preparing the corresponding compound product. The method is simple in technology and short in flow; the reagent cost is low; and valuable metal elements of lithium, the cobalt, the nickel, the manganese and the like in the waste lithium-ion battery material can be efficiently recovered.

Owner:GUANGDONG GUANGHUA SCI TECH

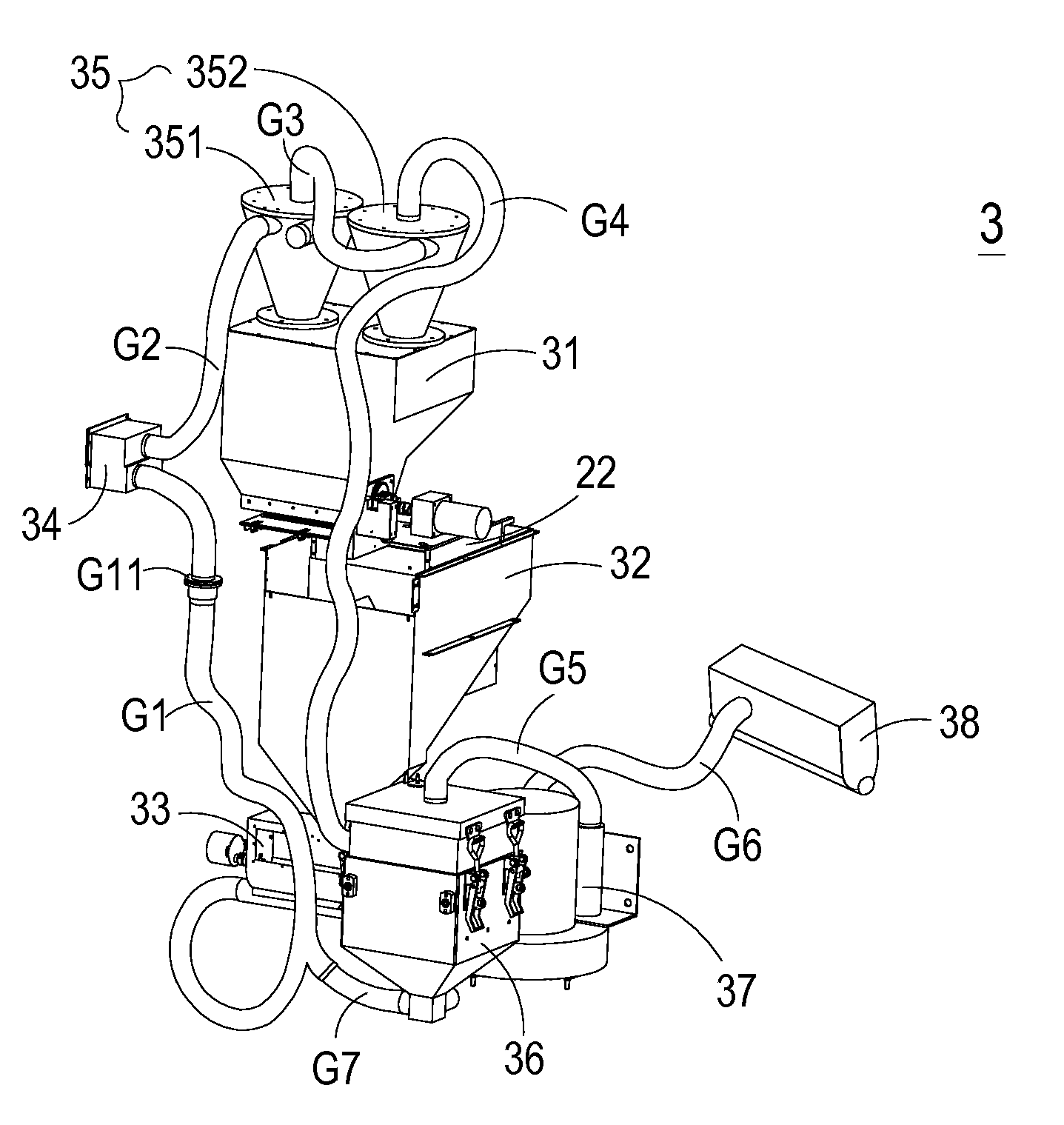

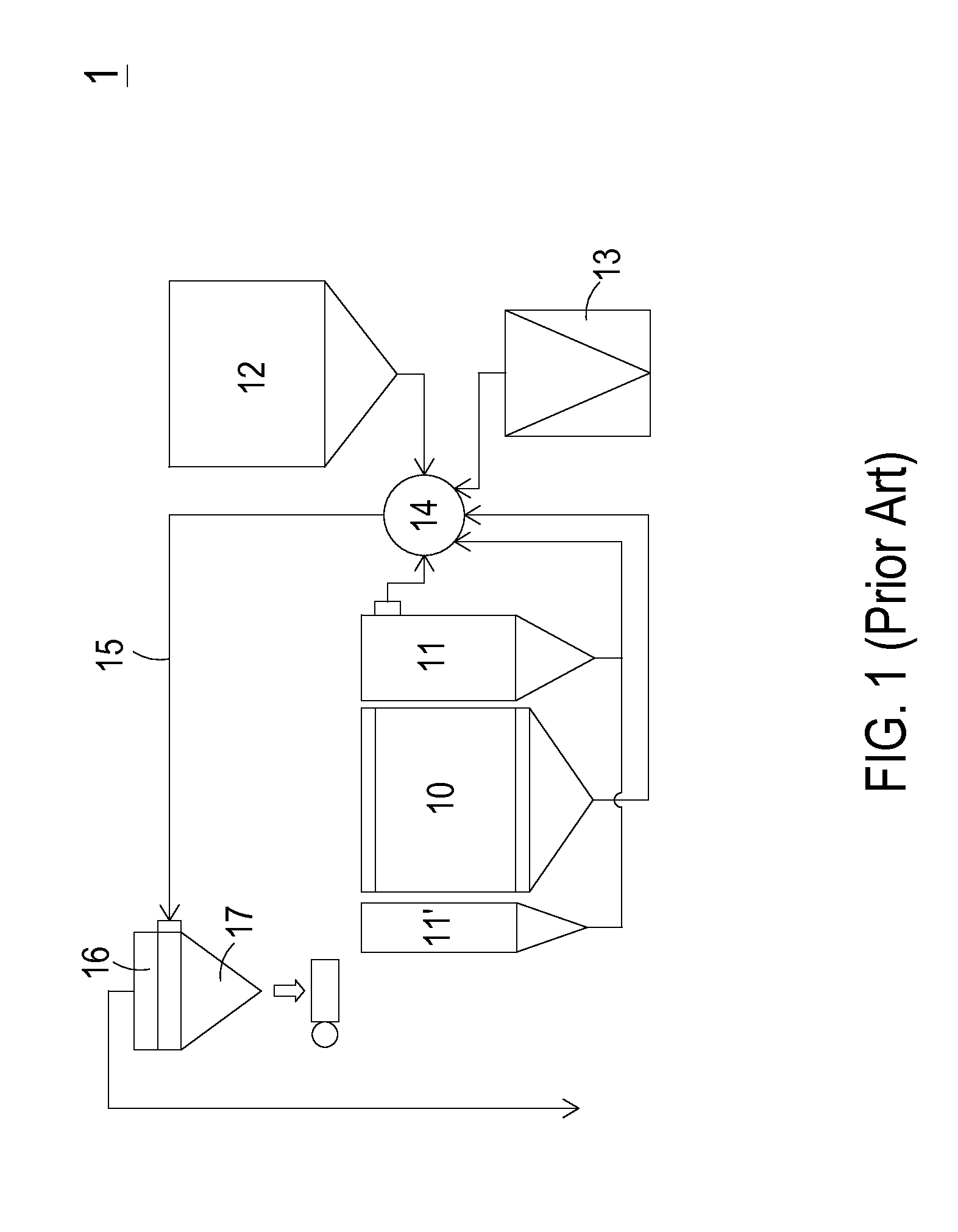

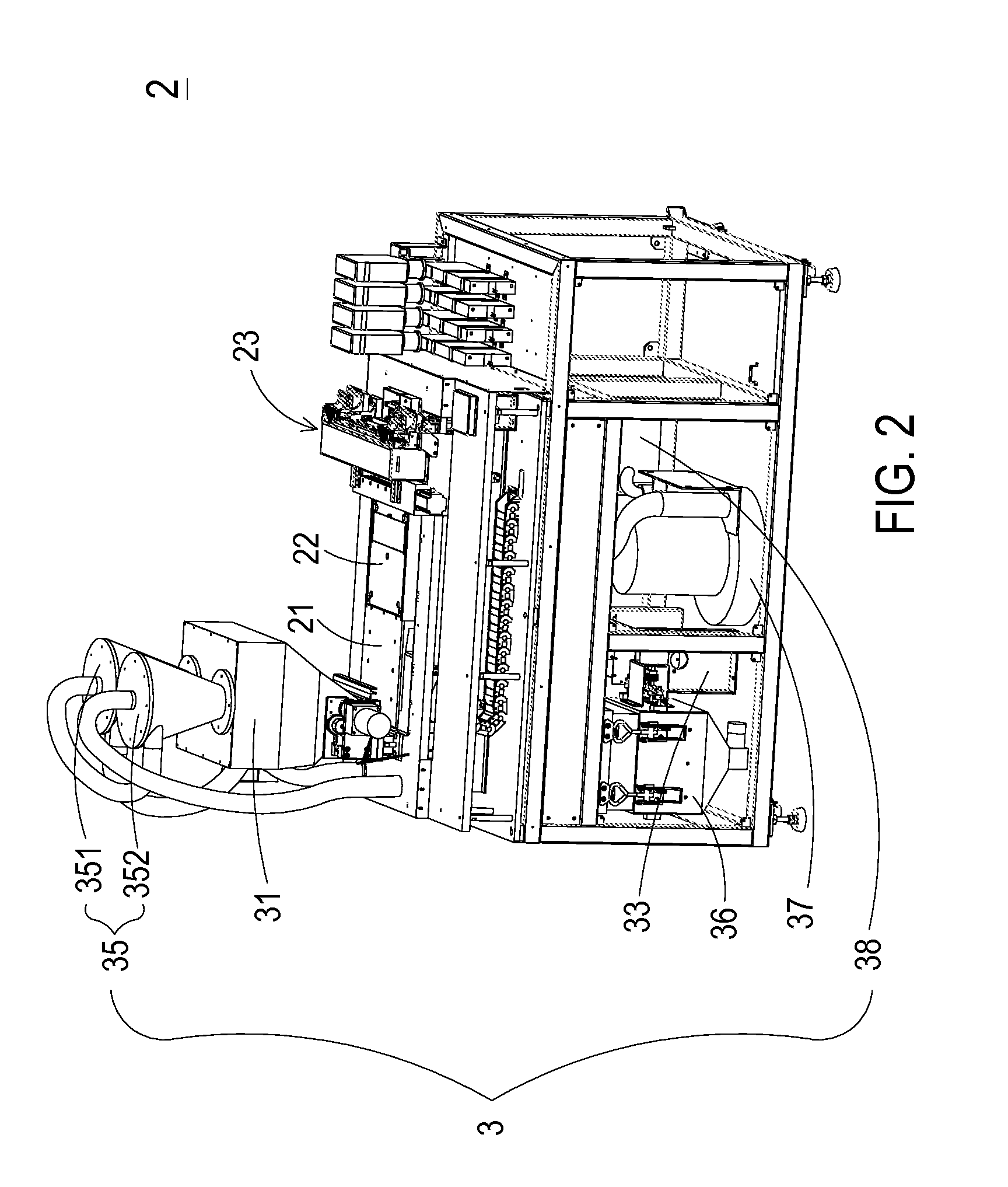

Powder recycling system

ActiveUS20150298397A1More user-friendlyCost-effectiveAdditive manufacturing apparatusGas current separationParticulatesPressure generation

A powder recycling system includes a powder feeder, a remaining powder collector, a bridge breaker, a block powder filter, a cyclone separator, a particulate filter cleaner, an air pressure generation device and an electrostatic precipitator. The powder feeder provides a construction powder to a construction platform. The remaining powder collector for collects the remaining powder. The cyclone separator is used to separate the large-size powdery particles and the small-size powdery particles of the remaining powder from each other through a rotating gaseous stream. The large-size powdery particles fall down to the powder feeder due to gravity, and the small-size powdery particles of the remaining powder is removed from the rotating gaseous stream and transmitted to the particulate filter cleaner. After the small-size powdery particles of the remaining powder are filtered by the particulate filter cleaner, the suspended small-size powdery particles are transmitted to the electrostatic precipitator.

Owner:MICROJET TECH

Transparent, oxygen-scavenging compositions containing polyesters comprising a cyclobutanediol and articles prepared therefrom

ActiveUS20060247388A1Easy to passGood active barrier propertyEnvelopes/bags making machinerySynthetic resin layered productsPolyesterPolymer science

Disclosed are oxygen-scavenging polymer compositions having high transparency and low haze comprising immiscible blends of at least one polyester comprising 2,2,4,4-tetramethyl-1,3-cyclobutanediol, a copolyamide or a transamidized, homogeneous blend of a least two polyamides, and a metal catalyst. The components of the immiscible blend which have refractive indices which differ by about 0.006 to about −0.0006. The small difference in the refractive indices enable the incorporation of regrind into the polymer composition to produce transparent shaped articles. The blends of the present invention are useful in producing shaped articles such as, for example, sheeting, films, tubes, bottles, preforms and profiles. These articles may have one or more layers and can exhibit improved excellent barrier properties and good melt processability while retaining excellent mechanical properties.

Owner:EASTMAN CHEM CO

White, single or multi-color light emitting diodes by recycling guided modes

InactiveUS7223998B2Improve the coupling effectEfficient recyclingSolid-state devicesSemiconductor/solid-state device manufacturingLight-emitting diodeMonochrome

Owner:RGT UNIV OF CALIFORNIA

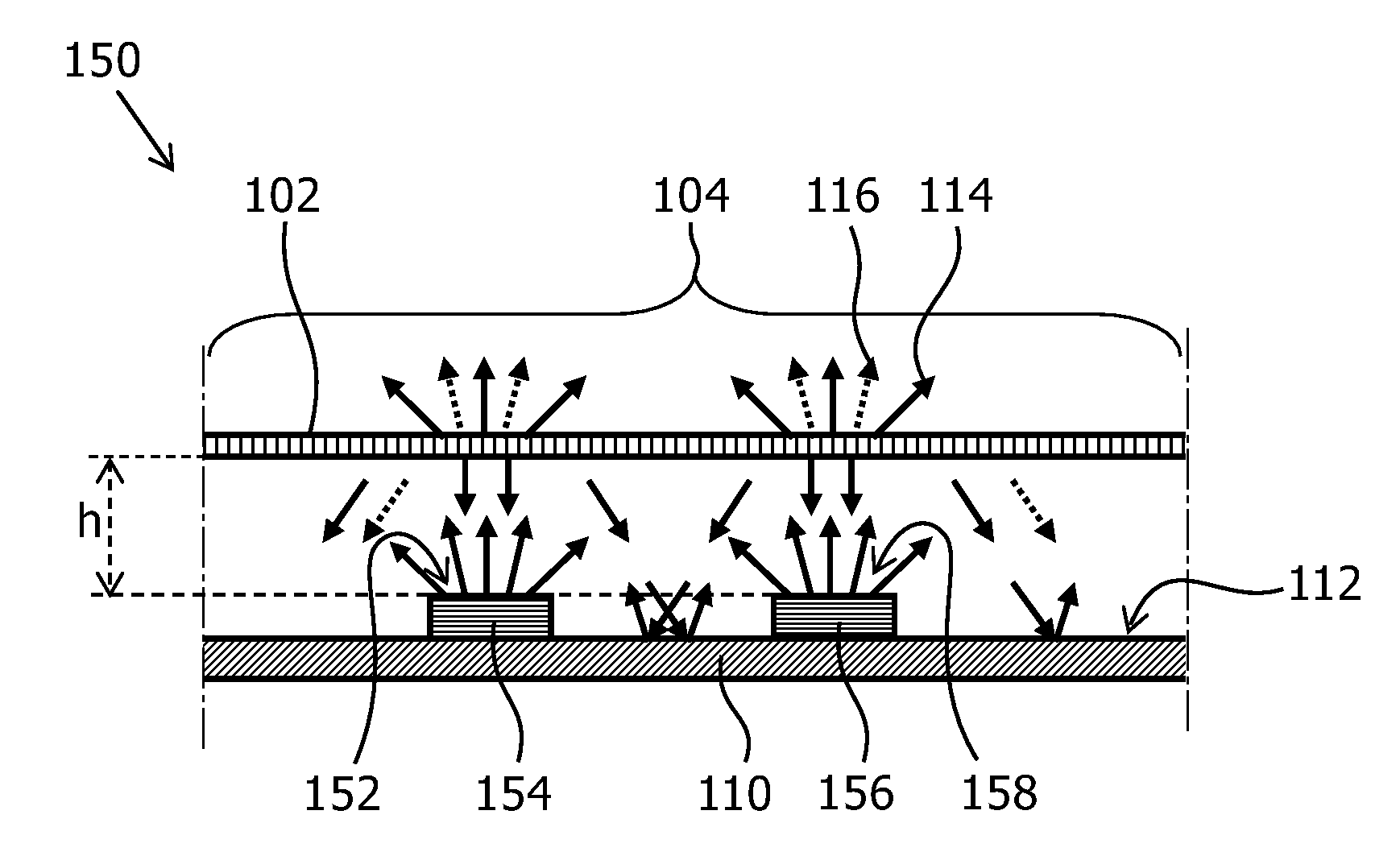

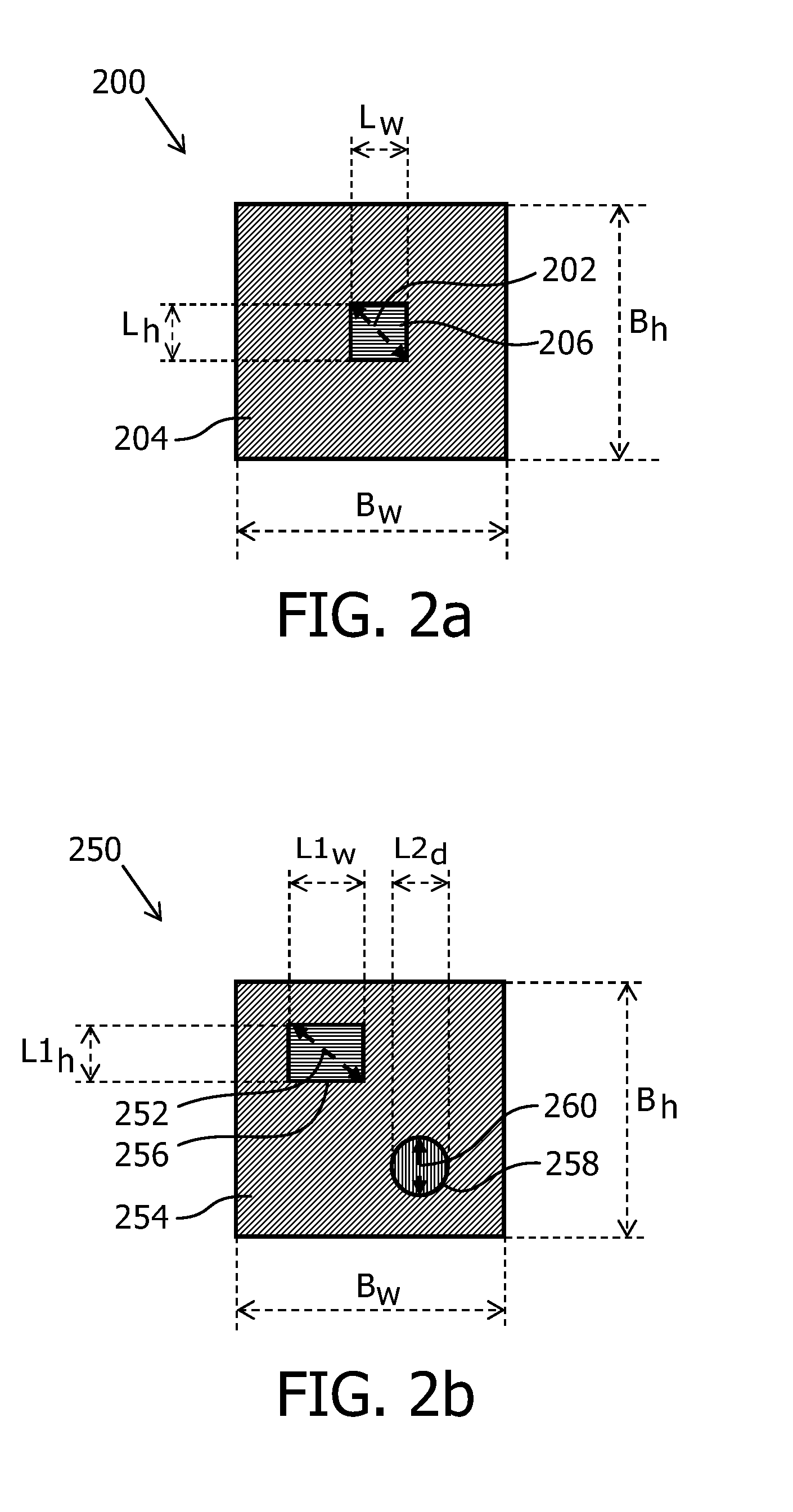

Light emitting module, a lamp, a luminaire and a display device

ActiveUS20130334559A1Cost reductionLess lightSolid-state devicesSemiconductor devicesReflection coefficientSolid-state

A light emitting module 150 emits light through a light exit window 104 and comprises a base 110, a solid state light emitter 154, 156 and a partially diffusive reflective layer 102. The base 110 has a light reflective surface 112 which faces towards the light exit window 104. The light reflective surface 112 has a base reflection coefficient Rbase which i defined by a ratio between the amount of light that is reflected by the light reflective surface and the amount of light that impinges on the light reflective surface. The solid state light emitter 154, 156 emits light of a first color range 114, comprises a top surface 152, 158 and has a solid state light emitter reflection coefficient R_SSL which is defined by a ratio between the amount of light that is reflected by the solid state emitter 154, 156 and the amount of light that impinges on the top surface 152, 158 of the solid state light emitter 154, 156. The light exit window 104 comprises at least a part of the partially diffusive reflective layer 102. A solid state light emitter area ratio ρSSL is defined as the ratio between the area of the top surface of the at least one solid state light emitter and the area of the light reflective surface of the base. A relatively efficient light emitting module is obtained if Rbase>R_SSL+c*(1−R_SSL) and the factor c is 0.2≦c≦1 for 0<ρSSL<0.1, 0.3≦c≦1 for 0.1≦ρSSL≦0.25, and 0.4≦c≦1 for ρSSL>0.25.

Owner:LUMILEDS

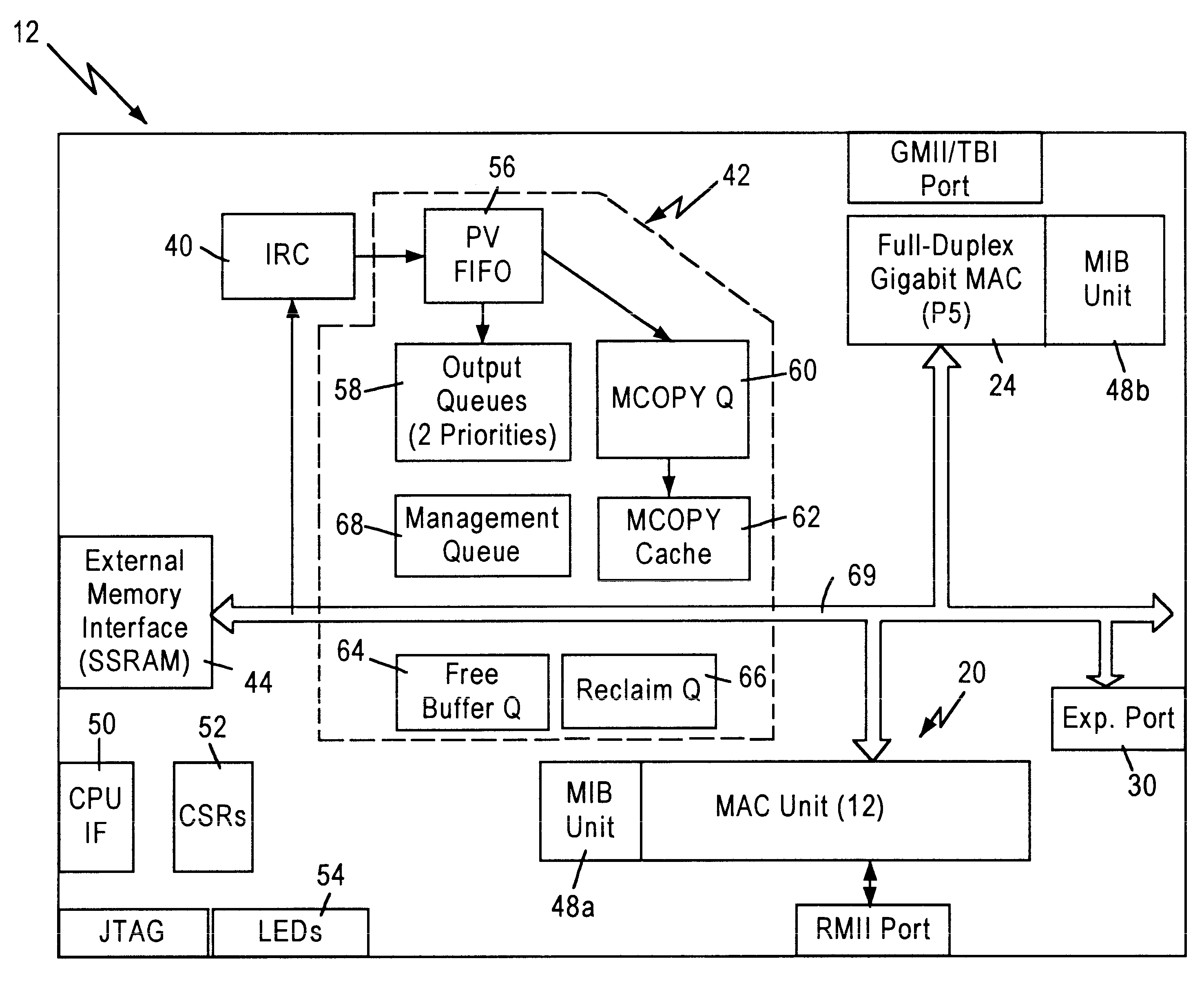

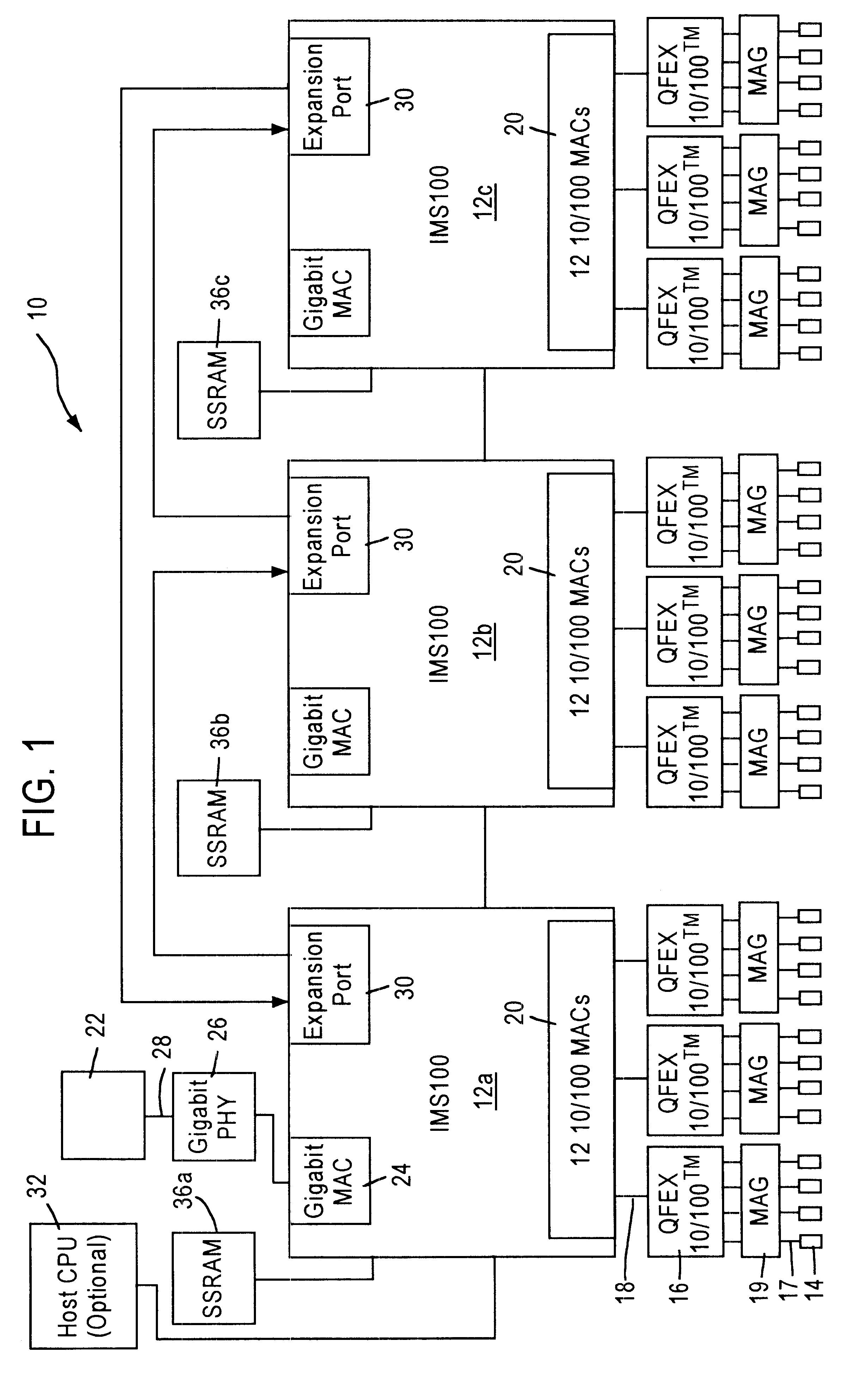

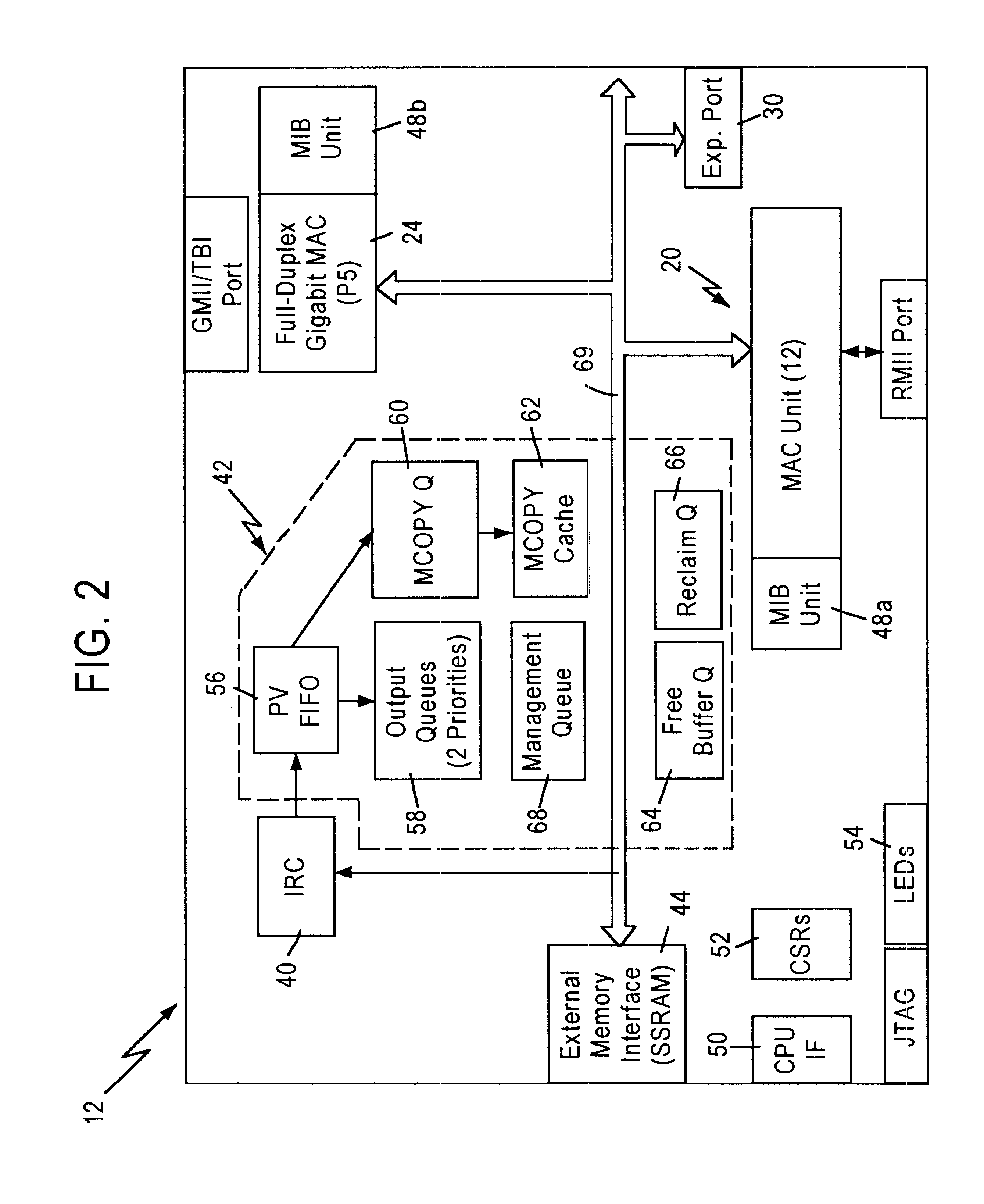

Method and apparatus for reclaiming buffers using a single buffer bit

InactiveUS6504846B1Efficient recyclingSpecial service provision for substationNetworks interconnectionExternal storageMultiple frame

A method and apparatus are disclosed for reclaiming frame buffers used to store data frames received by a network switch. The apparatus includes a multicopy queue for queuing entries corresponding to received data frames which must be transmitted by multiple output ports of the network switch, a free buffer queue for queuing frame pointers that identify locations in an external memory where reclaimed frame buffers are located, and a multicopy circuit that retrieves entries from the multicopy queue and determines if all copies of a received data frame have been transmitted by the specified output ports. The multicopy circuit also reclaims one or more frame buffers, based on the size of the received data frame. The present invention allows efficient reclaiming of frame buffers regardless of whether the received data frame is stored in a single frame buffer or multiple frame buffers.

Owner:GLOBALFOUNDRIES INC

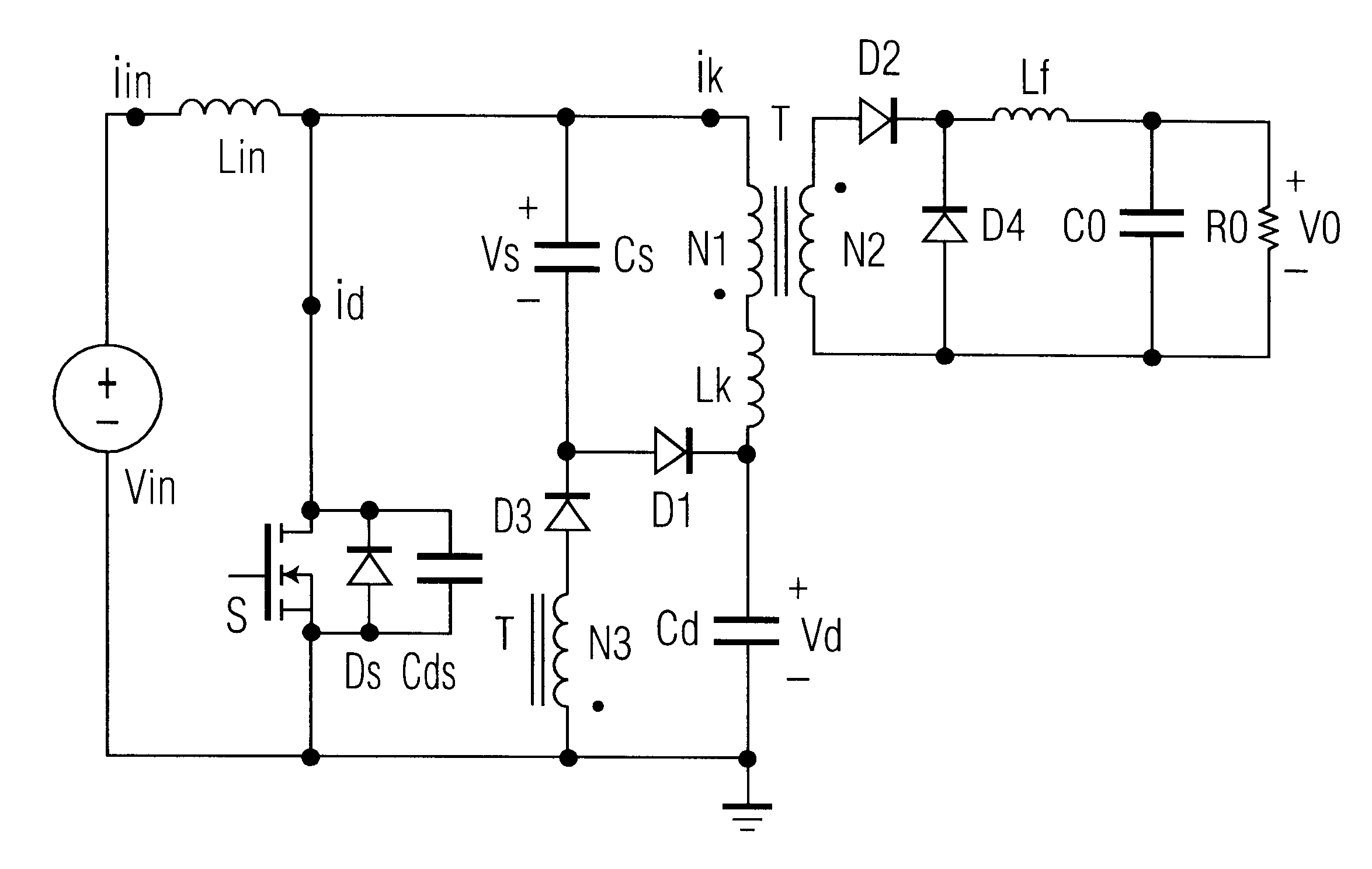

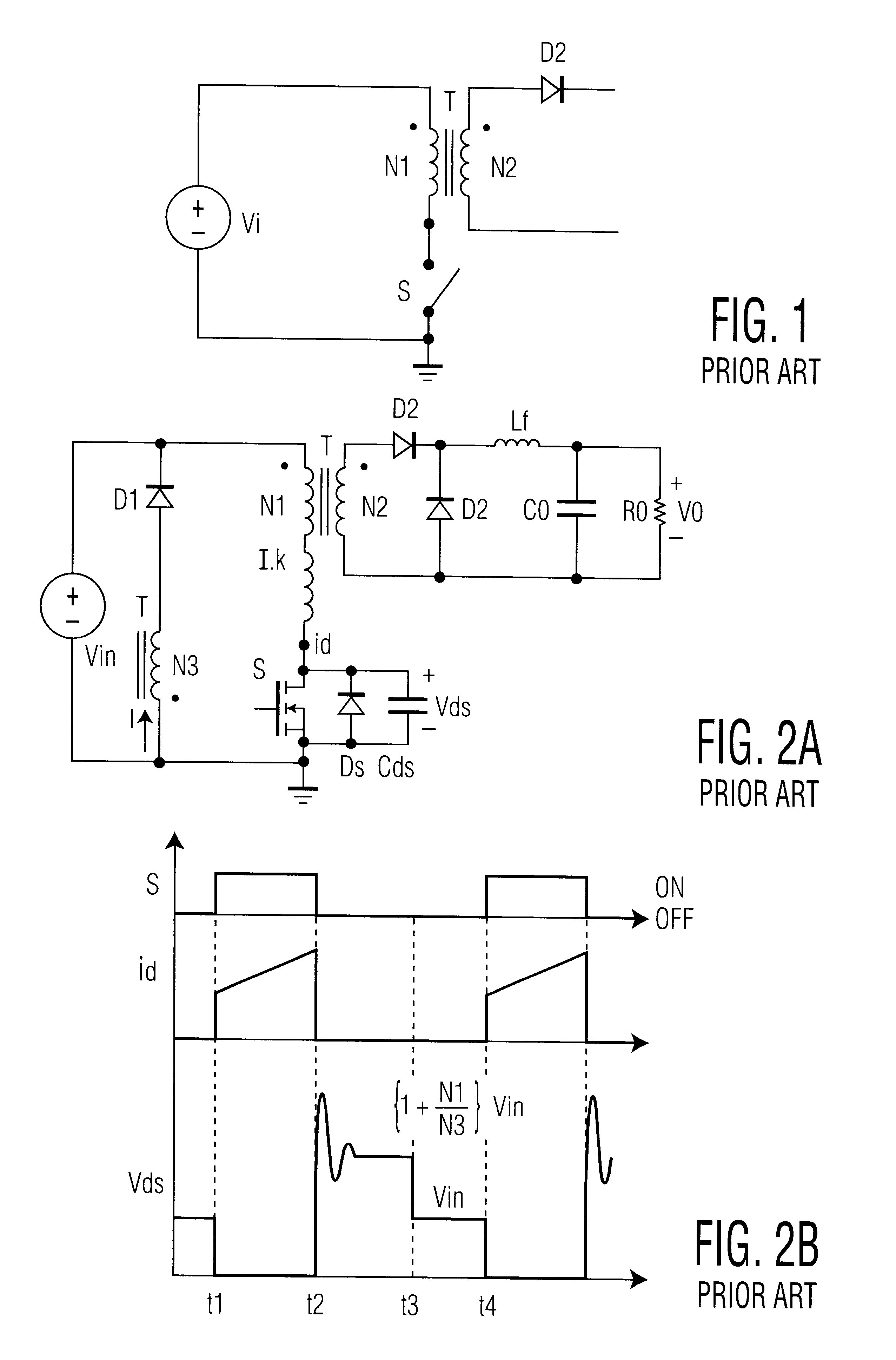

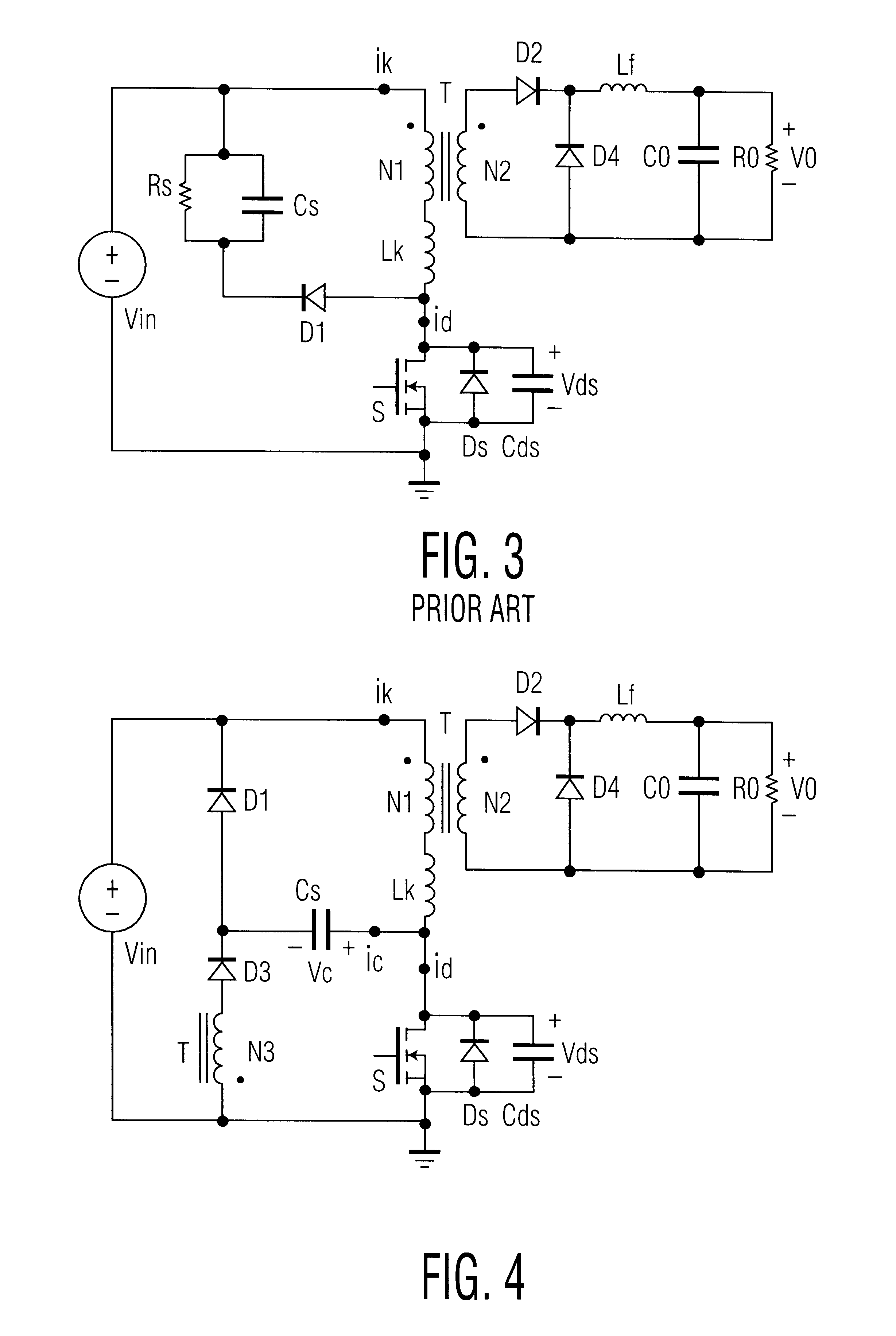

Voltage clamping system and method for a DC/DC power converter

InactiveUS6314002B1Efficient recyclingReduce switchingEfficient power electronics conversionEmergency protective circuit arrangementsCapacitanceClamp capacitor

A voltage boost power converter circuit, having an input inductor, active switch, and a transformer having primary, secondary and auxiliary windings. A clamping capacitor and a first passive switch are in series across the primary winding. The auxiliary winding and a second passive switch are in series, connected to the node between the clamping capacitor and first passive switch. The active switch is connected between ground the primary winding. A bulk capacitor forms a series loop including the active switch and primary winding. The method efficiently resets a the transformer, by transferring power to a load through the primary winding, and discharging a clamping capacitor through a separate inductively linked winding of the transformer during an ON state; and clamping the active switch voltage with the clamping capacitor, charging the clamping capacitor with a leakage inductance of the transformer, and charging the bulk capacitor during an OFF state.

Owner:PHILIPS ELECTRONICS NORTH AMERICA

Nano-filtration method for separating magnesium and enriching lithium from salt lake brine

InactiveCN1542147AEfficient recyclingSimple processSemi-permeable membranesLithium compoundsIon contentLithium chloride

The nanofiltration process is suitable for Mg-Li separation and Li enriching of Li containing bittern or Li containing solution from salt lake to prepare lithium carbonate or lithium chloride with the Li enriching bittern. Nanofiltration membrane is used in separating and enriching lithium from lithium containing bittern, which contains Mg, Ca and other cations and sulfate radical and other anions and has Li ion concentration of 0.1-11.5 g / L and Mg / Li ion weight ratio 1-200, to obtain lithium enriched bittern suitable for preparing lithium carbonate or lithium chloride. The said process is effective, and can obtain lithium enriched bittern with Mg / Li ion weight ratio 0.6-5 and Li ion content of 0.6-20 g / L.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Method of preparing aluminum oxide from fly ash

ActiveCN1923695AHigh dissolution rateFewer separation stepsAluminium oxide/hydroxide preparationAluminium oxides/hydroxidesAluminium sulfateSlag

The invention discloses a preparing method of alumina through fly ash, which comprises the following steps: grinding fly ash; sintering; activating; stirring with H2SO4 evenly to sinter into dried slag; immersing through hot water; stripping aluminum sulfate; condensing; cooling to evolve aluminum sulfate; crystallizing; heating; dehydrating to obtain anhydrous aluminum sulfate; heating; decomposing to obtain gamma-Al2O3.

Owner:PINGSHUO INDAL

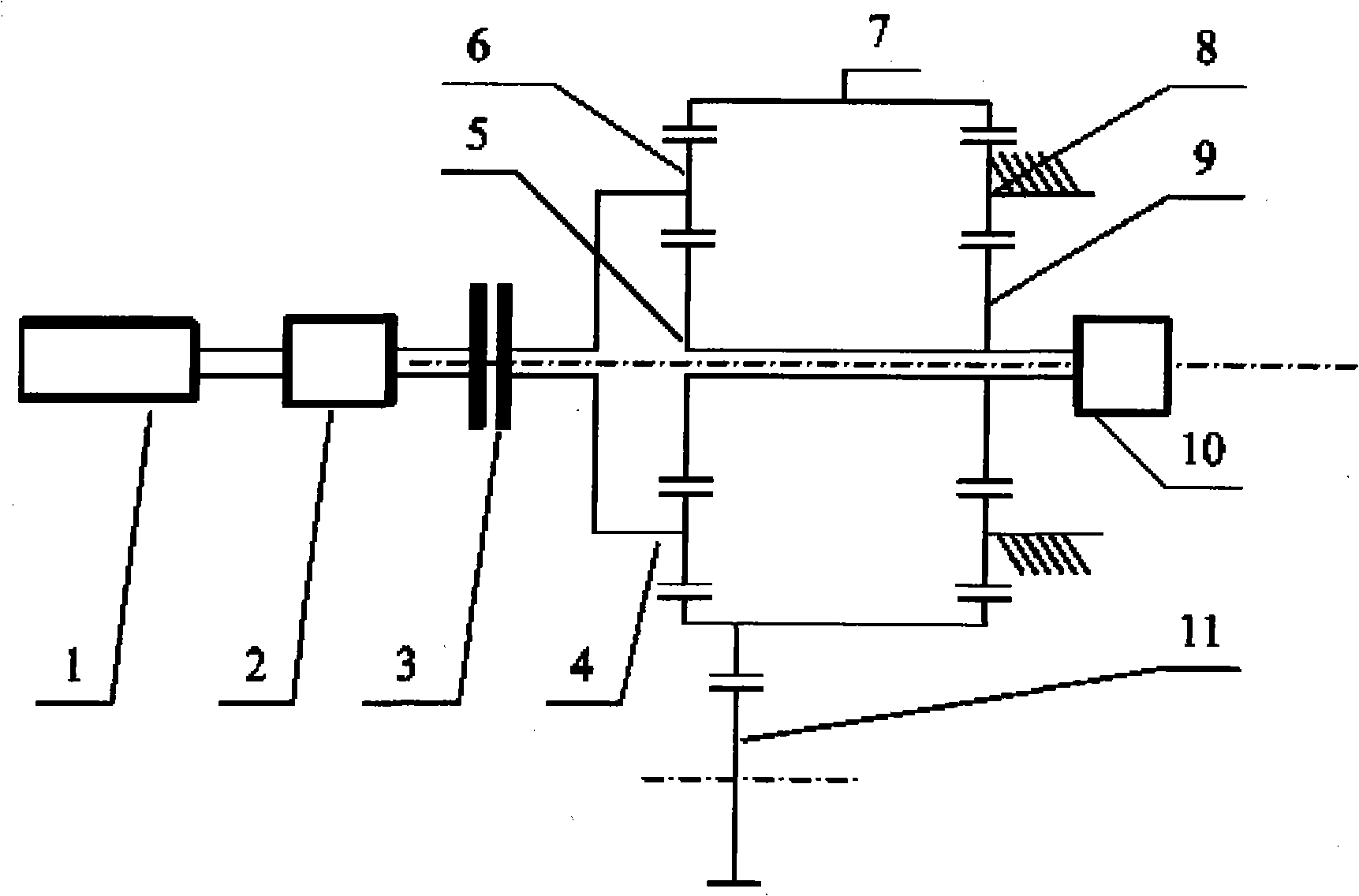

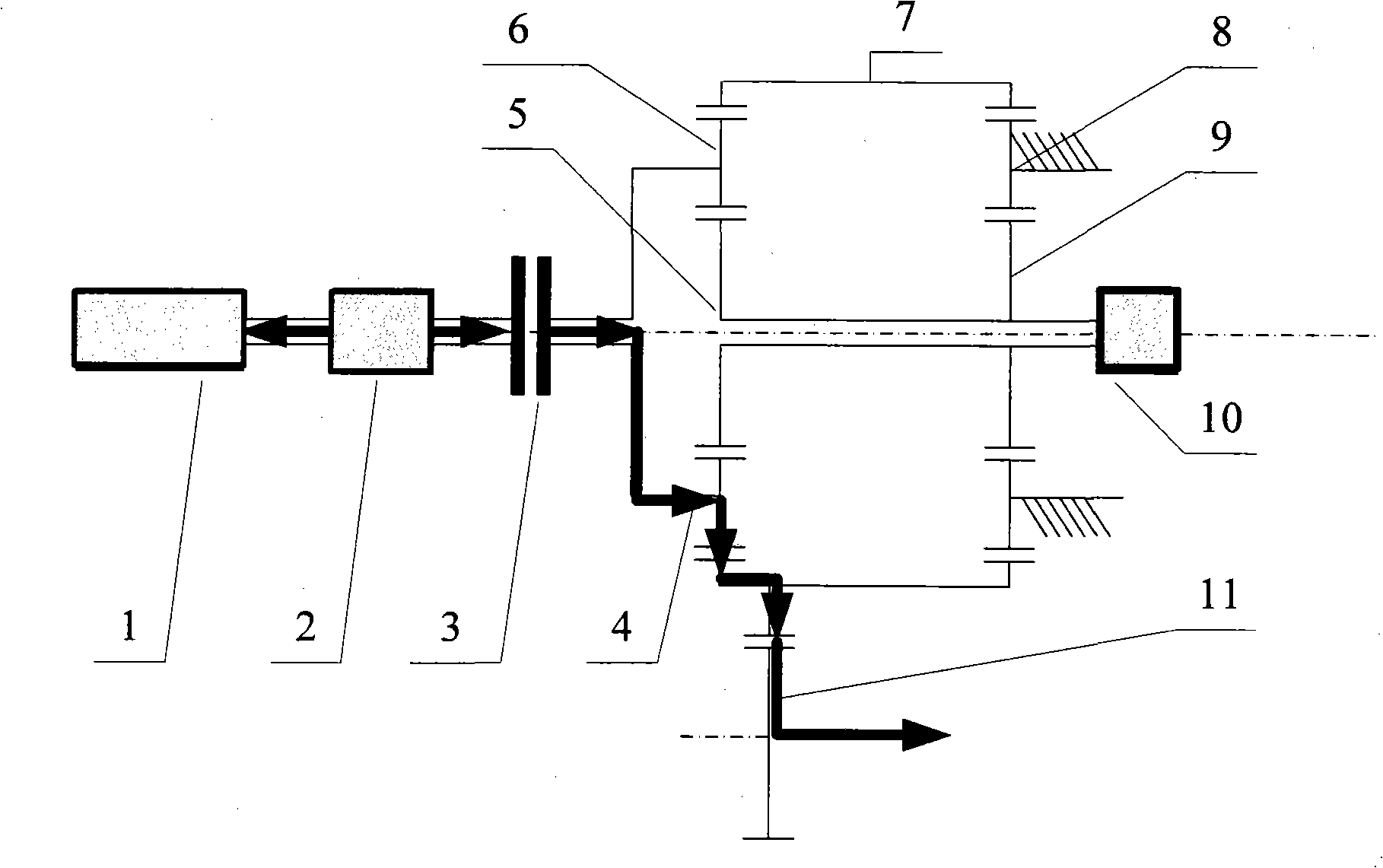

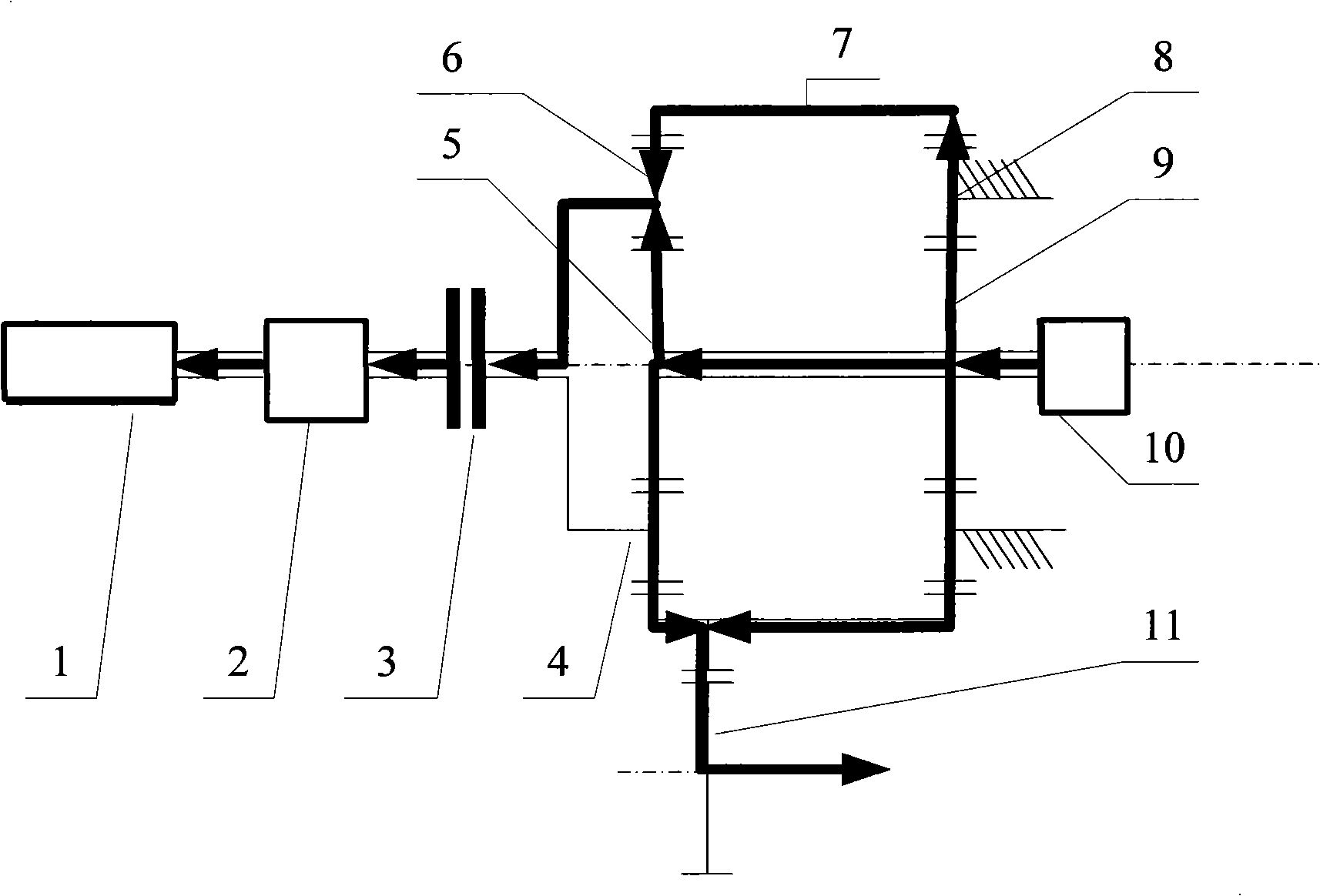

Hybrid power vehicle double electric machine double row planetary gear single clutch drive apparatus

InactiveCN101323243ALower requirementIncrease profitHybrid vehiclesGas pressure propulsion mountingStarter generatorVehicle frame

The invention discloses a twin-motor two-planet-row and single clutch driving device of a hybrid vehicle in the technical field of machinery. The device is provided with a front planet row and a back planet row; the front planet row is provided with a front planet row planet wheel and a front planet row sun gear; the back planet row is provided with a back planet row planet wheel and a back planet row sun gear; the front planet row and the back planet row share a gear ring. The output shaft of an engine is connected with the input end of an integrated starter generator; the output end of the integrated starter generator is connected with the driving disk of the clutch; the driven disk of the clutch is connected with the planet wheel of the front planet row through a planet carrier; the sun gear of the front planet row is connected with a drive motor; the planet carrier of the planet wheel of the back planet row is arranged fixedly on a car frame; the sun gear of the back planet row is also connected with the drive motor; the outside gear of the gear ring is normally engaged with a power take-off gear. The twin-motor two-planet-row and single clutch driving device of the hybrid vehicle has the advantages of compact structure, large transmission ratio, large load support capability, stable driving, and high transmission efficiency, thereby realizing power dividing and infinite variable speed at the same time.

Owner:SHANGHAI JIAO TONG UNIV

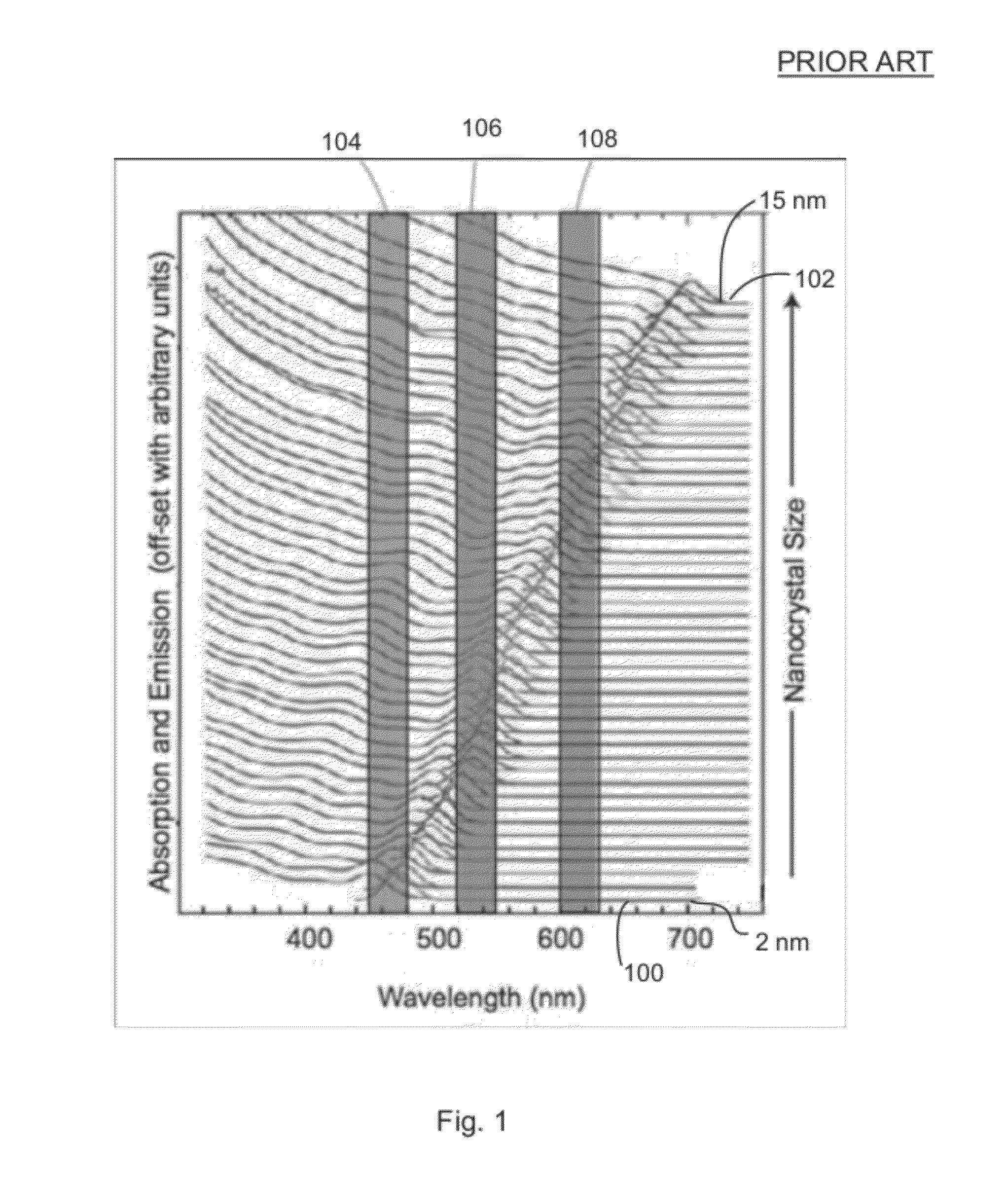

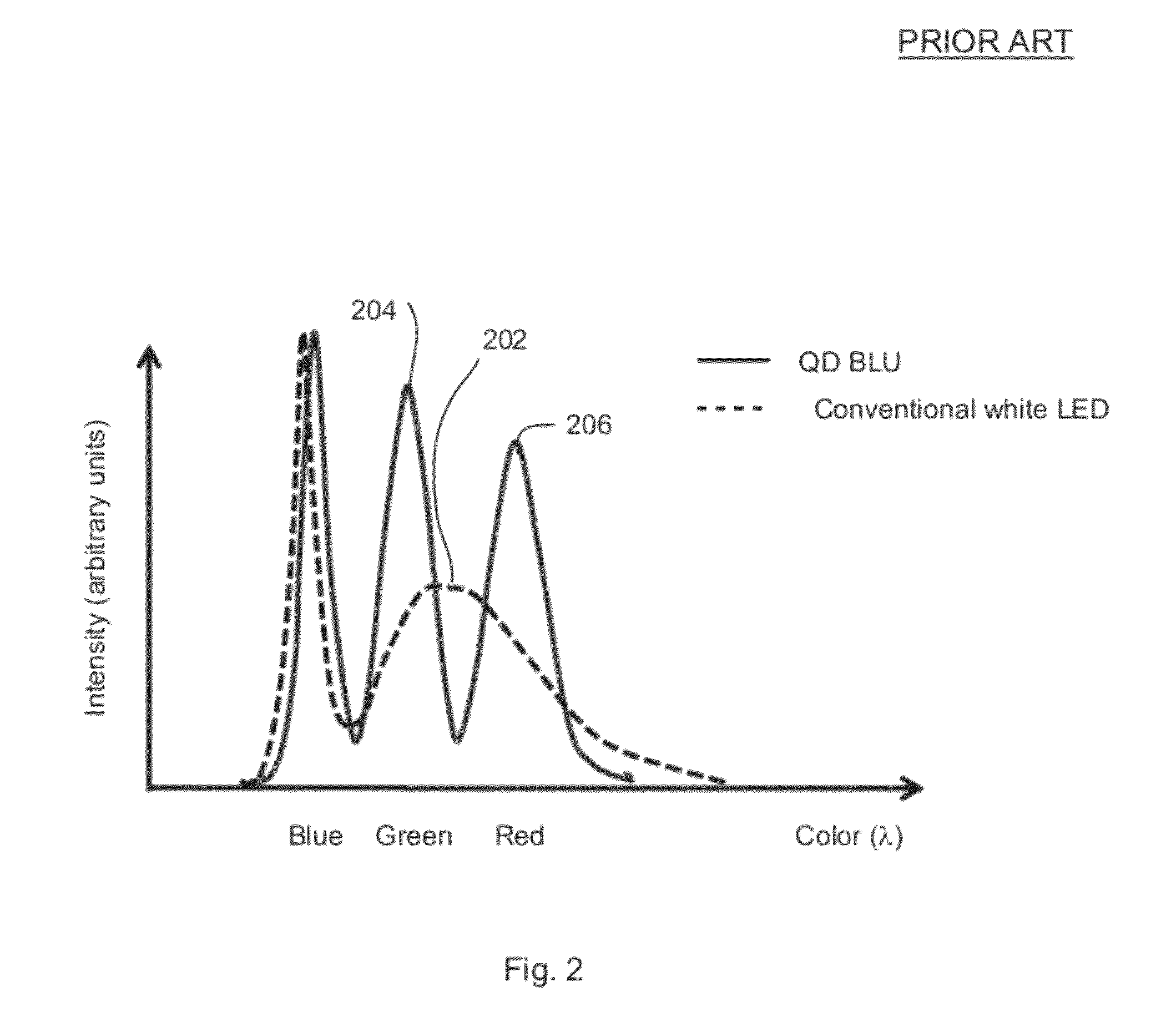

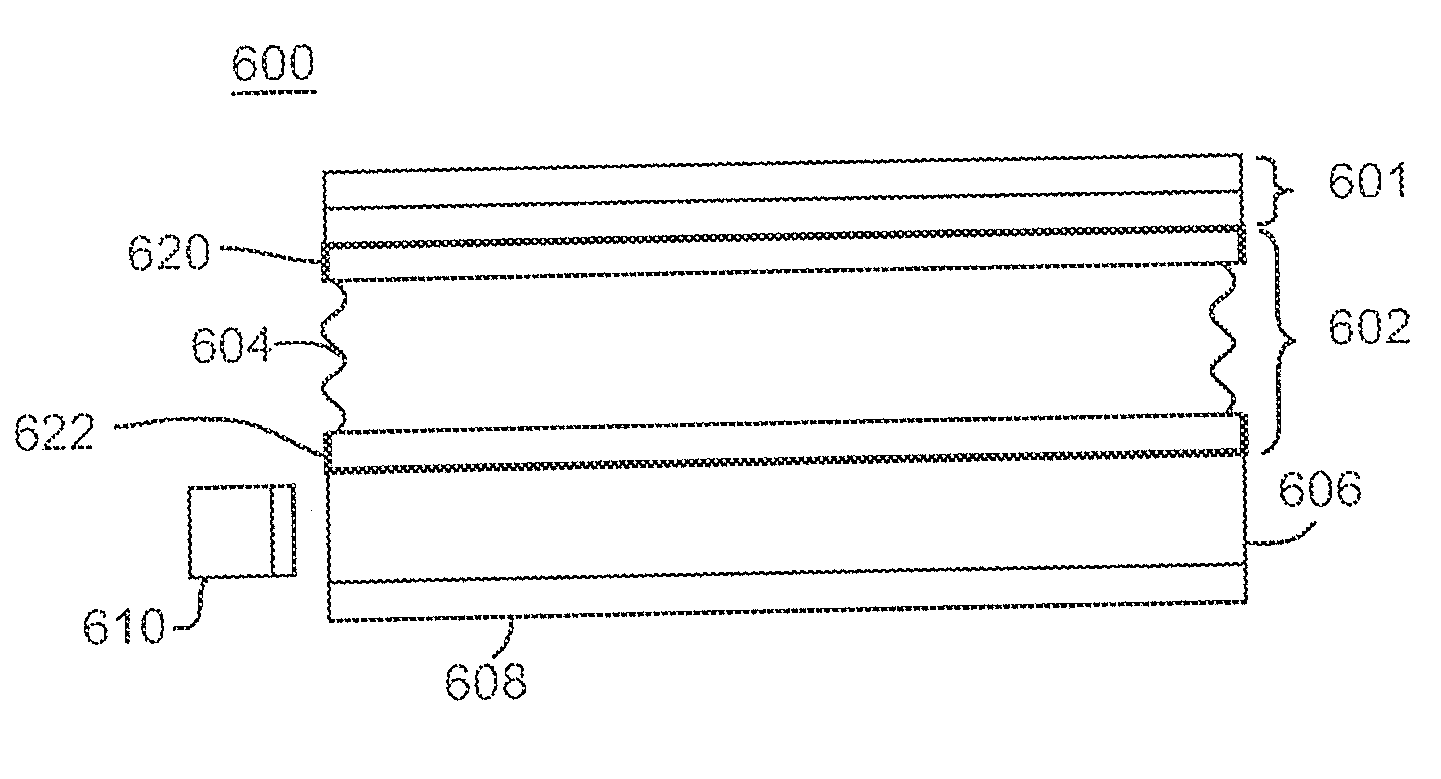

Quantum dot films, lighting devices, and lighting methods

ActiveUS9199842B2Improve solar conversion efficiencyEfficient recyclingMechanical apparatusLayered productsLight equipmentQuantum dot

Light-emitting quantum dot films, quantum dot lighting devices, and quantum dot-based backlight units are provided. Related compositions, components, and methods are also described. Improved quantum dot encapsulation and matrix materials are provided. Quantum dot films with protective barriers are described. High-efficiency, high brightness, and high-color purity quantum dot-based lighting devices are also included, as well as methods for improving efficiency and optical characteristics in quantum dot-based lighting devices.

Owner:SHOEI CHEM IND CO LTD

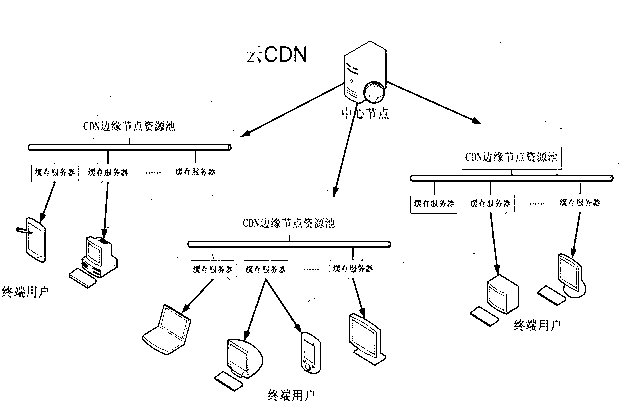

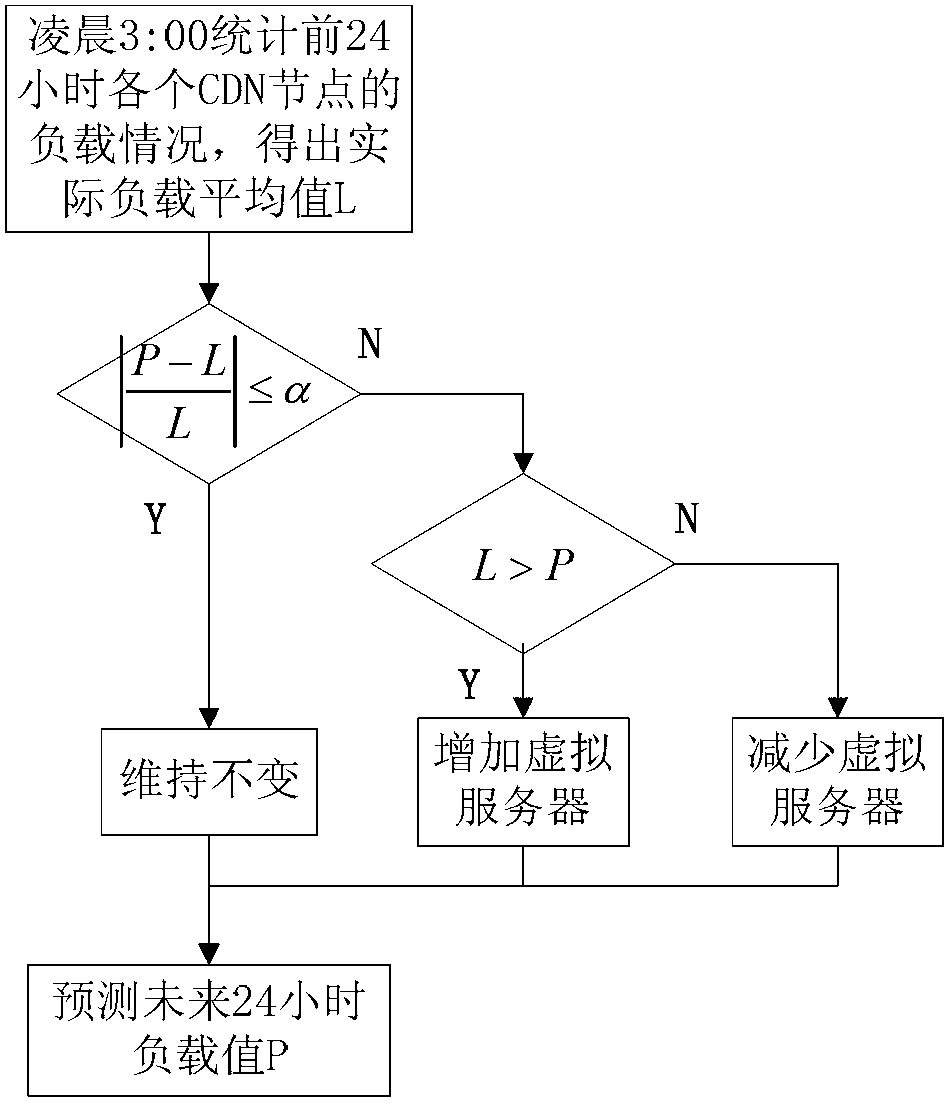

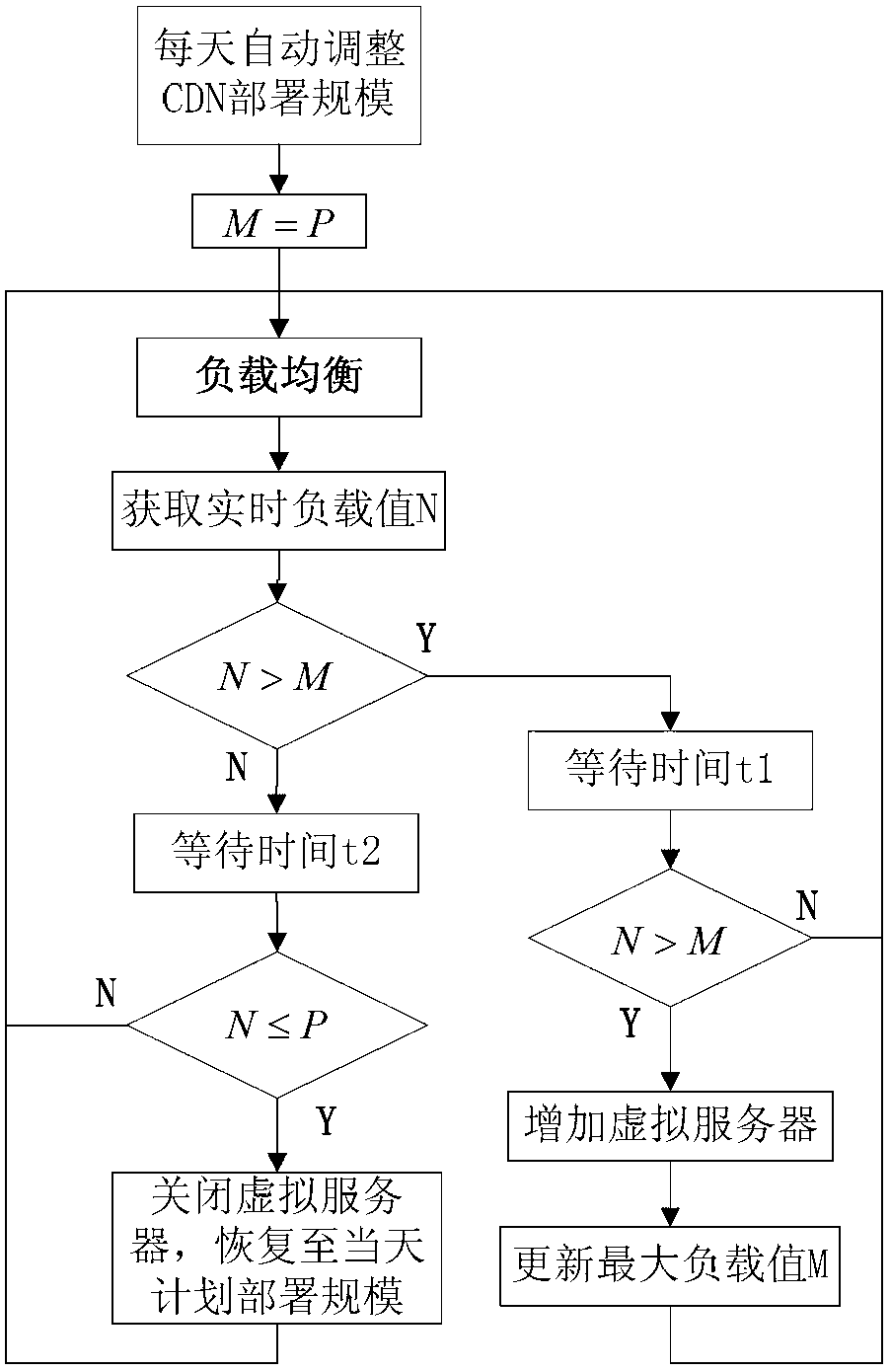

Statistical-prediction-based automatic cloud CDN (Content Delivery Network) resource automatic deployment method

InactiveCN102801792AImprove resource utilizationReduce energy consumption and operation and maintenance costsEnergy efficient ICTTransmissionData predictionProgram planning

The invention discloses a statistical-prediction-based automatic cloud CDN (Content Delivery Network) resource deployment method which comprises the steps of: predicting a load prediction value in a next 24h according to history data of a load of each edge node of a CDN, formulating a virtual server resource deployment plan of a corresponding edge node, carrying out virtual server resource deployment on each edge node of a cloud CDN; monitoring a load condition of each edge node of the cloud CDN in real time, when the cloud CDN is in a user visit rush time, mounting mirror images configured with relevant businesses to virtual servers by a cloud platform, and starting so as to be added in each edge node of the cloud CDN for sharing burst visit pressure; and when the cloud CDN is in a non-visit rush time, only preserving the virtual server which can keep business operate at a normal level, and recovering idle virtual server resources to a resource pool. According to the statistical-prediction-based cloud CDN resource automatic deployment method, the burst business rush time can be effectively dealt, the resource utilization rate of the CDN is increased, and the energy consumption and the maintenance and operation cost of the CDN are lowered.

Owner:SOUTH CHINA UNIV OF TECH

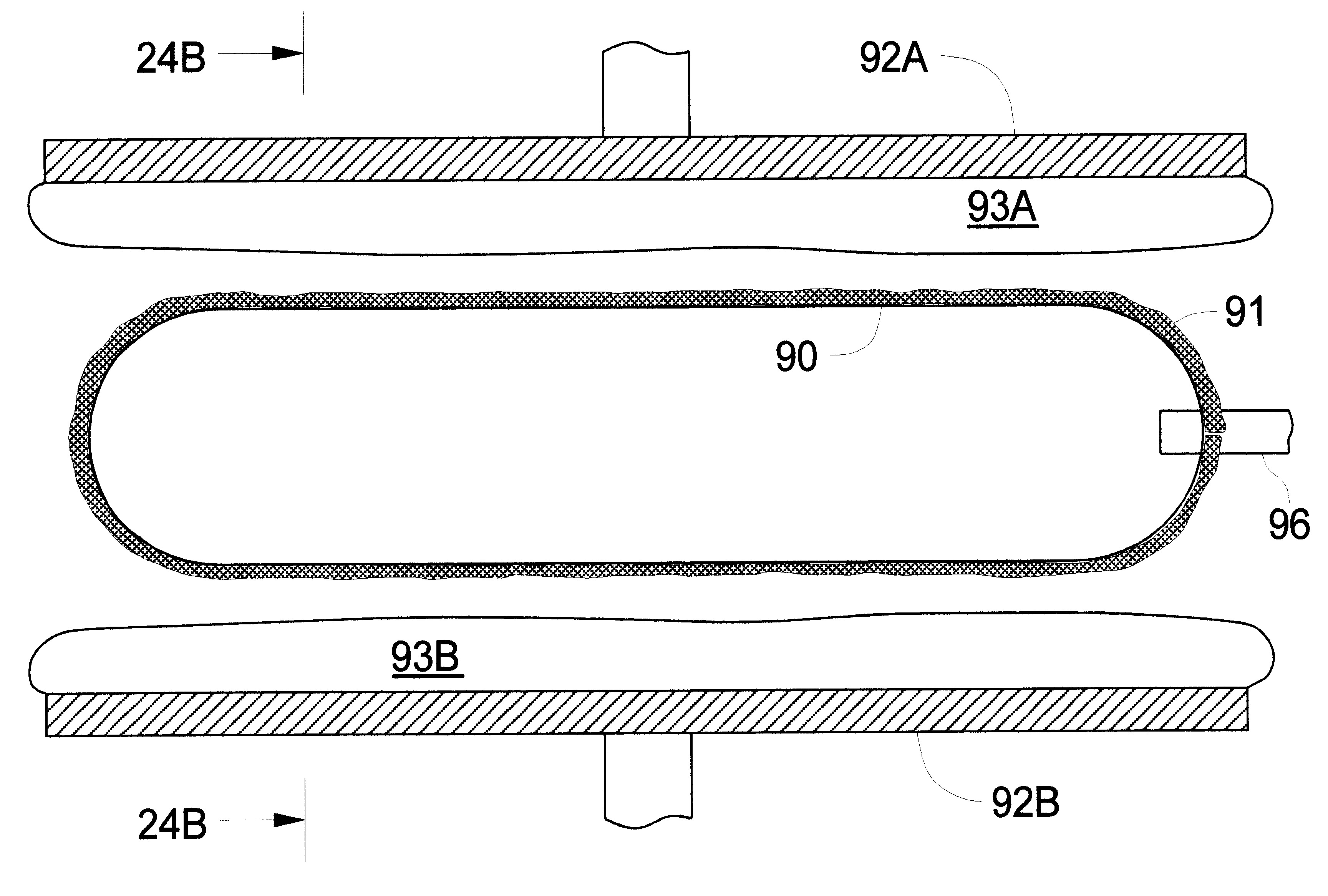

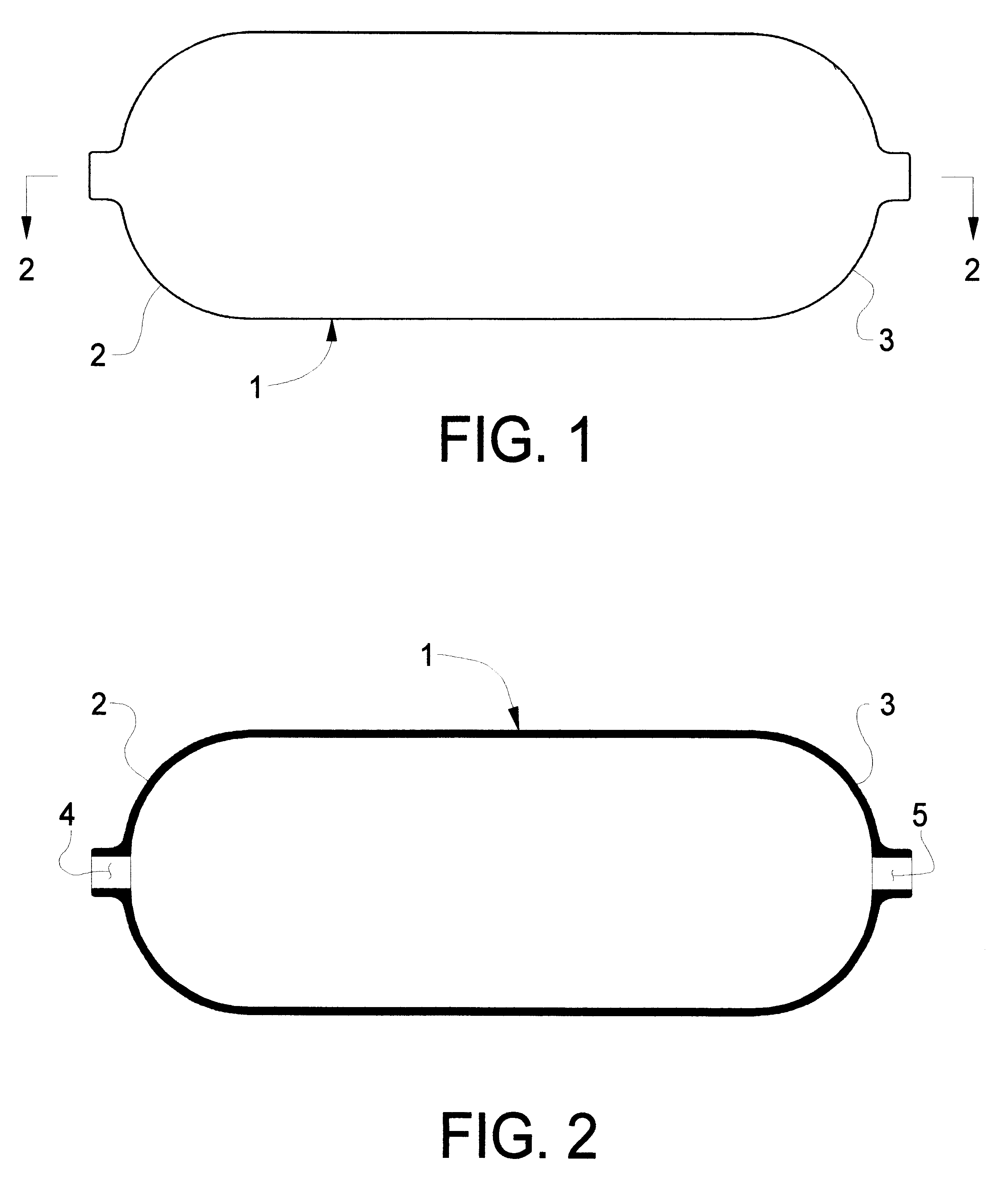

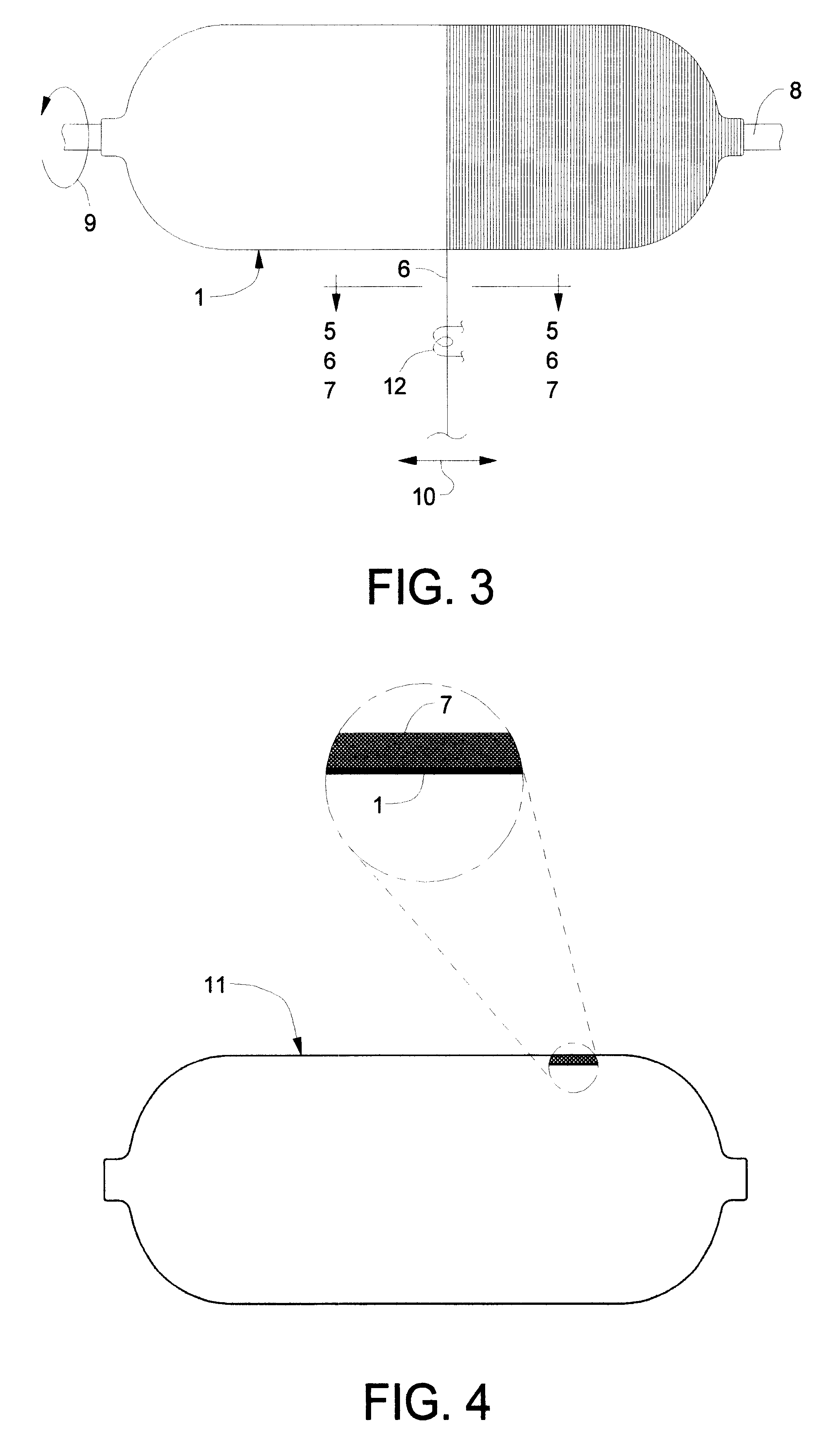

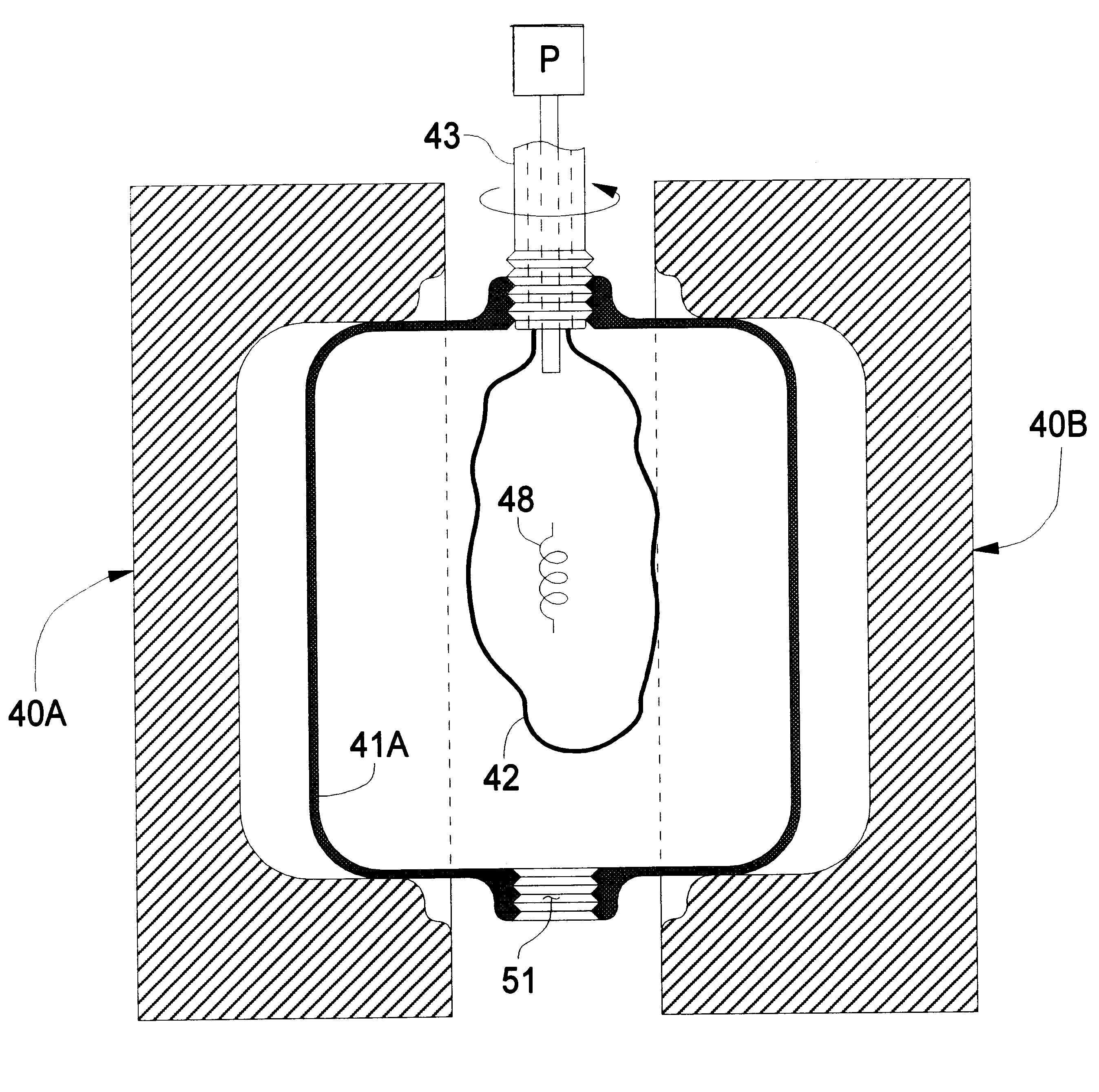

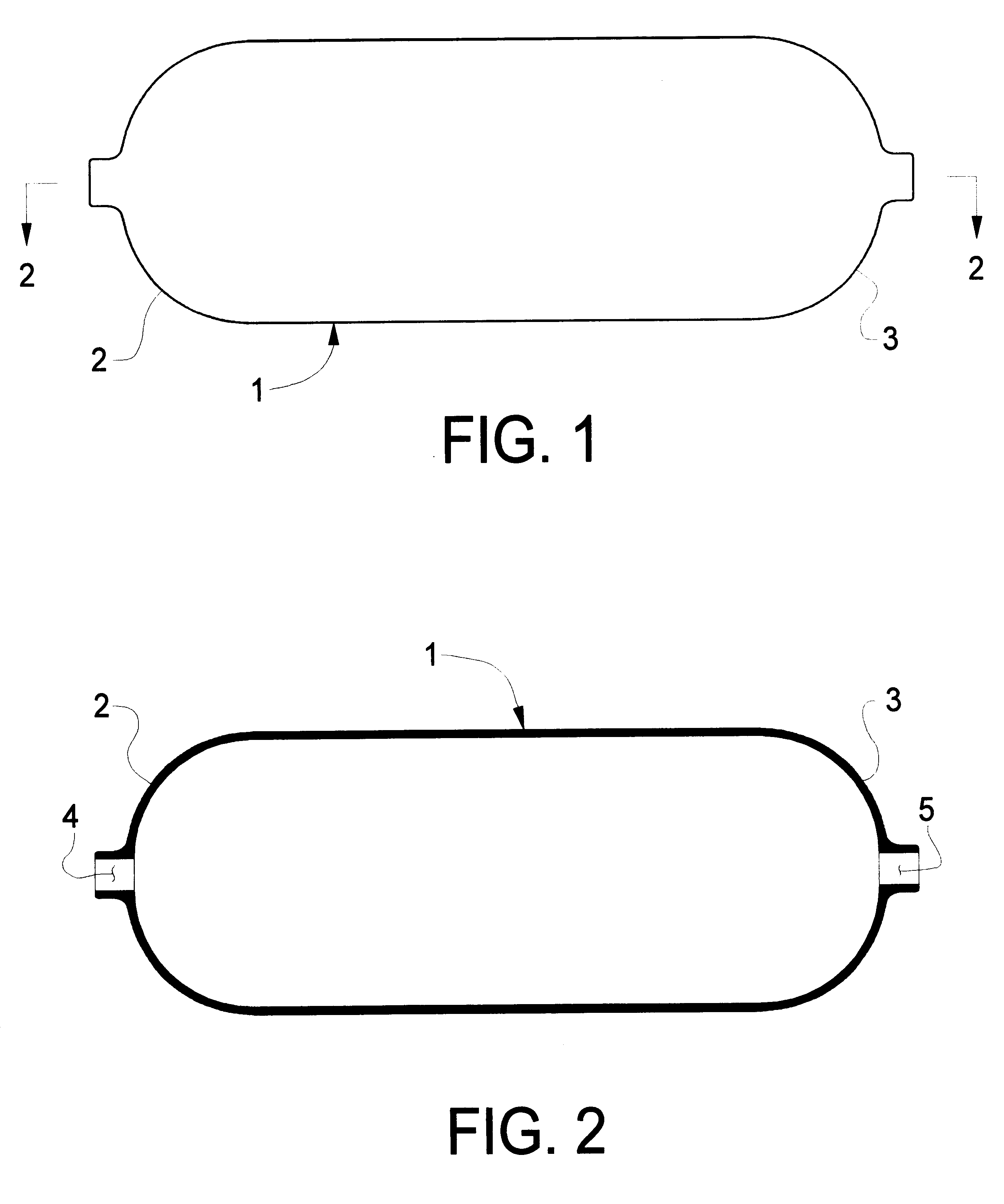

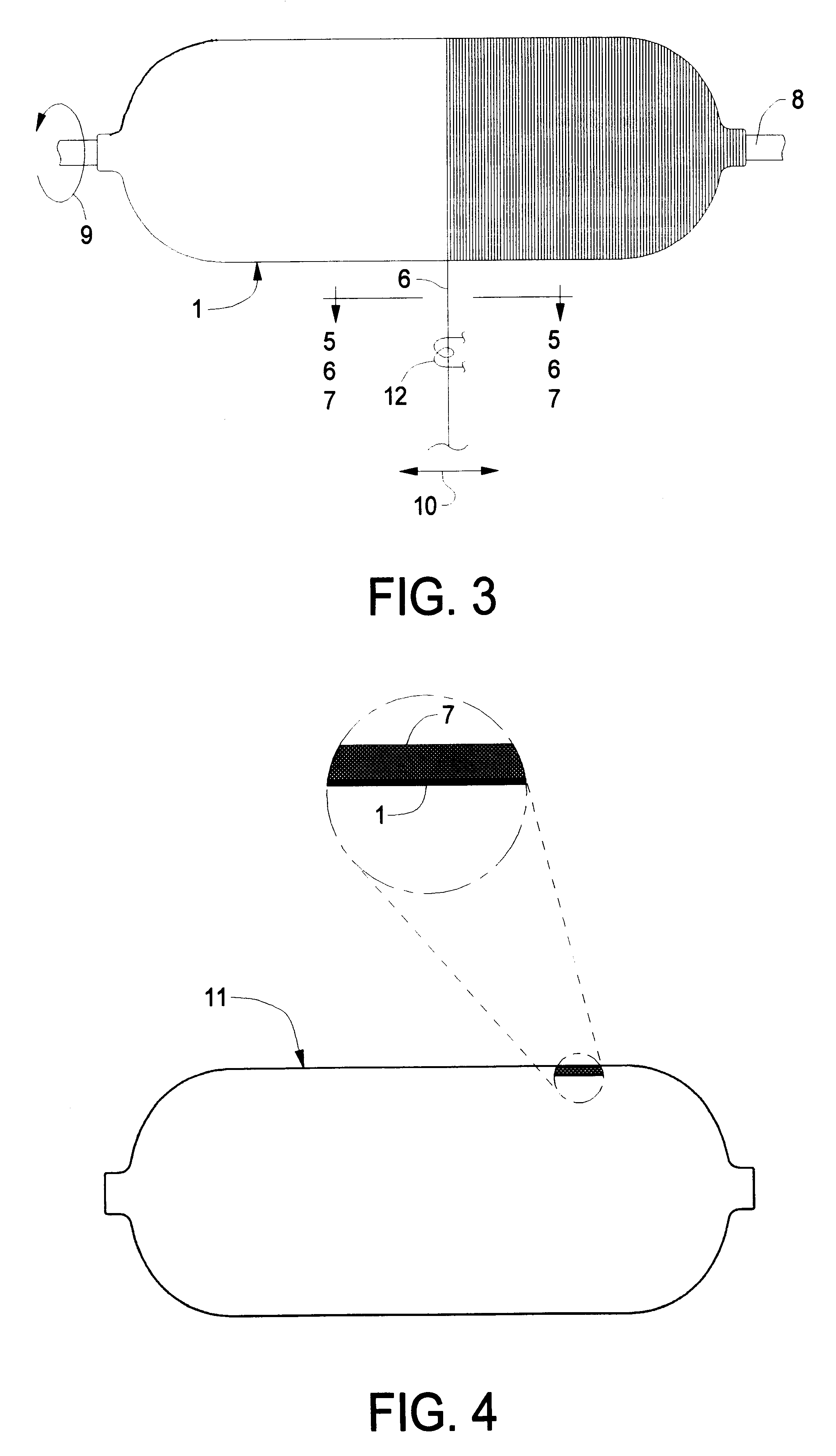

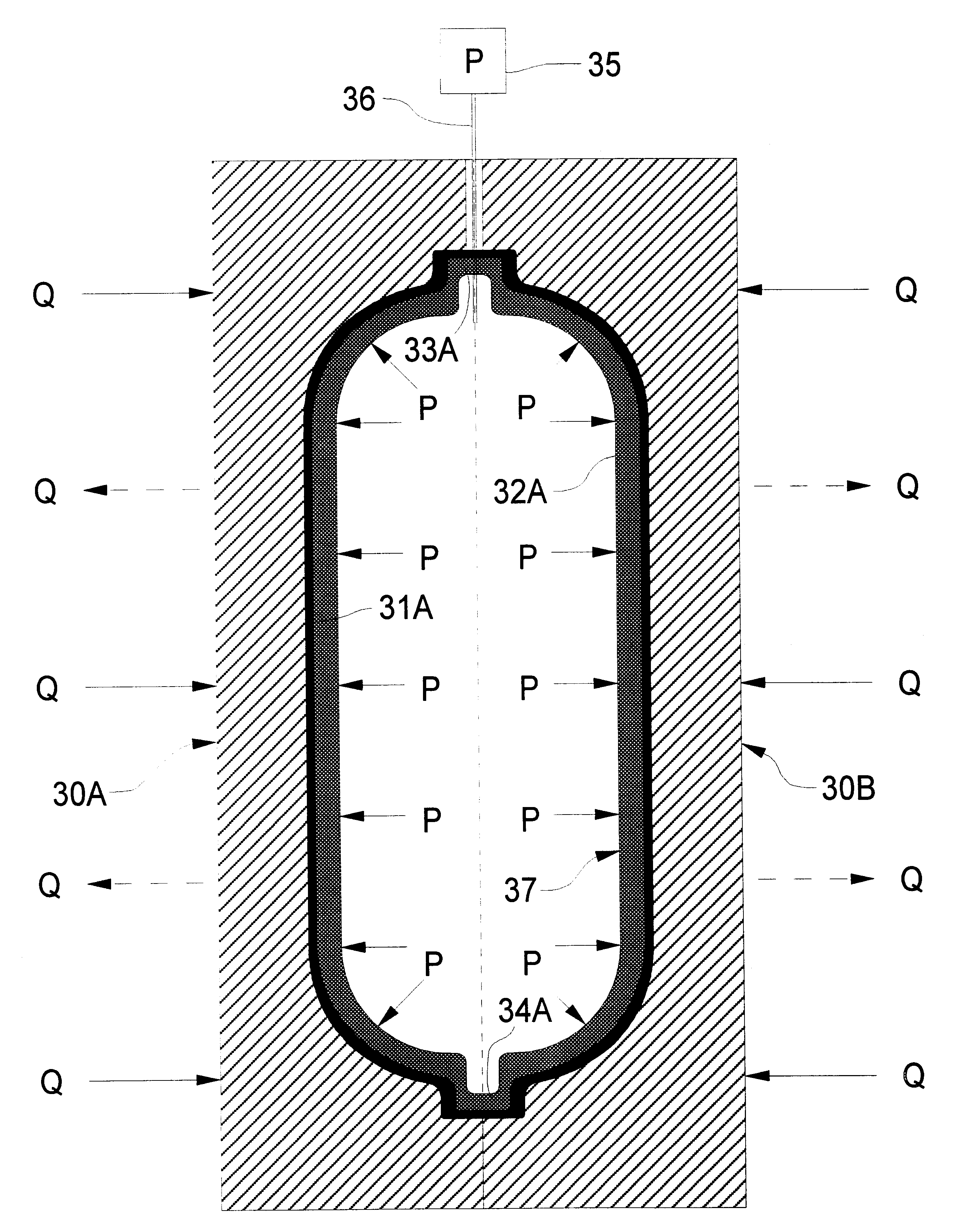

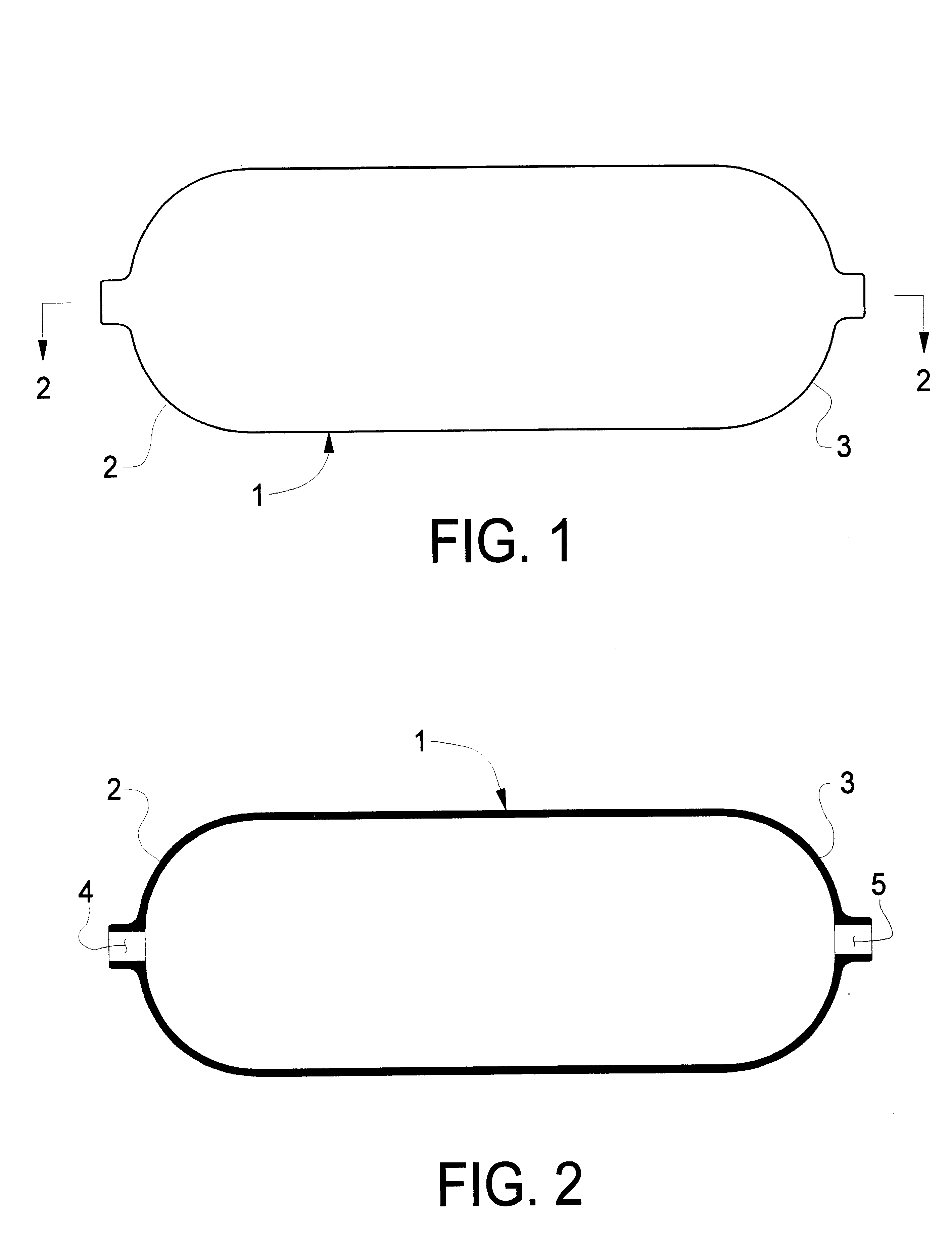

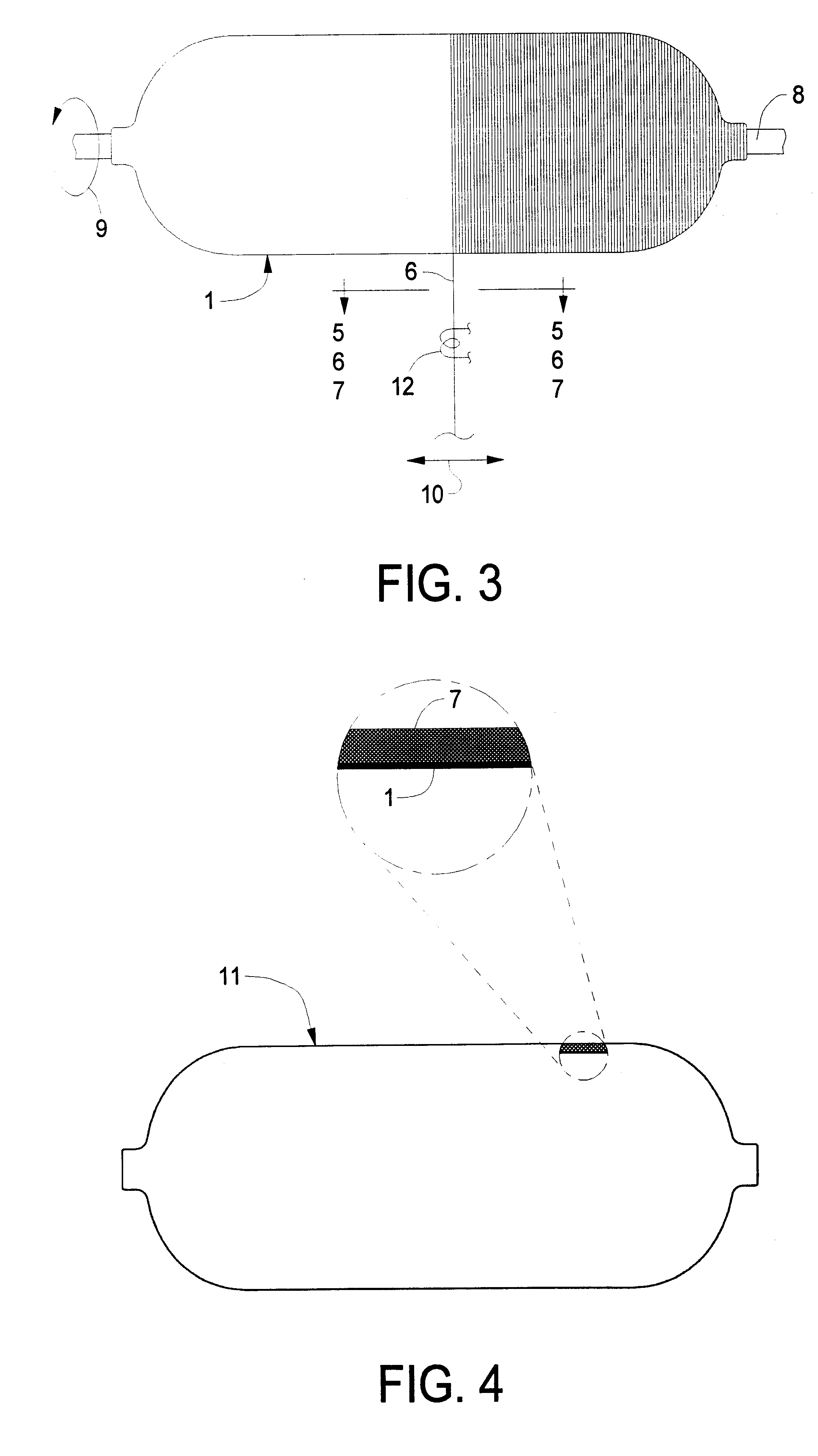

Method for fabricating composite pressure vessels and products fabricated by the method

InactiveUS6485668B1Speed up the processRatio is limitedLabelling non-rigid containersConfectioneryFiberSilicon rubber

A process, and the product thereof, for making a composite vessel having at least one closed end, the process including the steps of: fabricating a thermoplastic liner for the vessel; overlaying onto the liner a layer of commingled fiber and thermoplastic material to obtain a composite intermediate structure; pressing and heating the composite intermediate structure to effect at least partial consolidation in apparatus which includes upper and lower silicon rubber bags, the bags having dimensions such that, during operation, their facing peripheral regions abut to encompass the composite intermediate structure; then placing the composite intermediate structure in a mold; heating the composite intermediate structure in the mold while applying a force, such as internal gas pressure, tending to urge the composite intermediate structure against and into the shape of the interior walls of the mold until the thermoplastic liner and the overlaid layer fully consolidate; cooling the mold and composite vessel until the composite vessel is solidified; and removing the formed composite vessel from the mold. The commingled fiber and thermoplastic material may either be wound onto the liner or laid on the liner in the form of fabric woven from the fiber and threads of the thermoplastic material.

Owner:ESSEF CORP +1

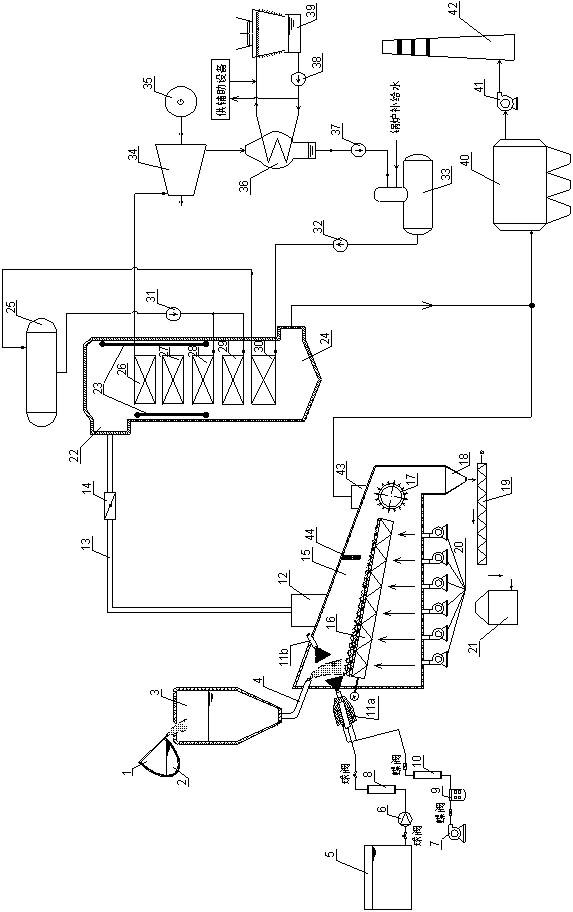

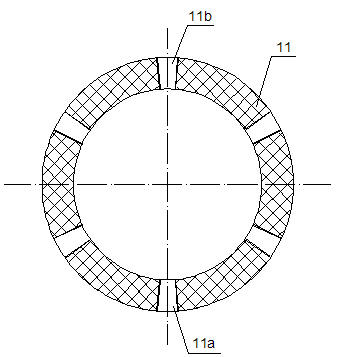

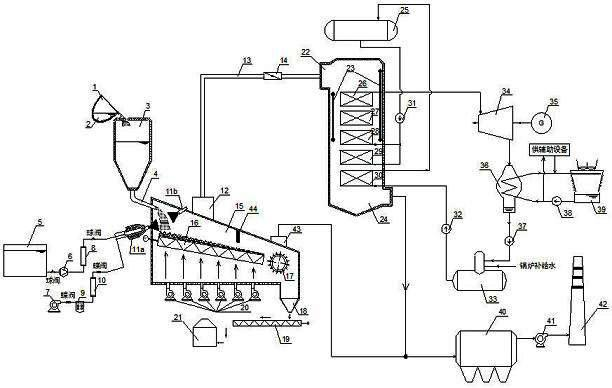

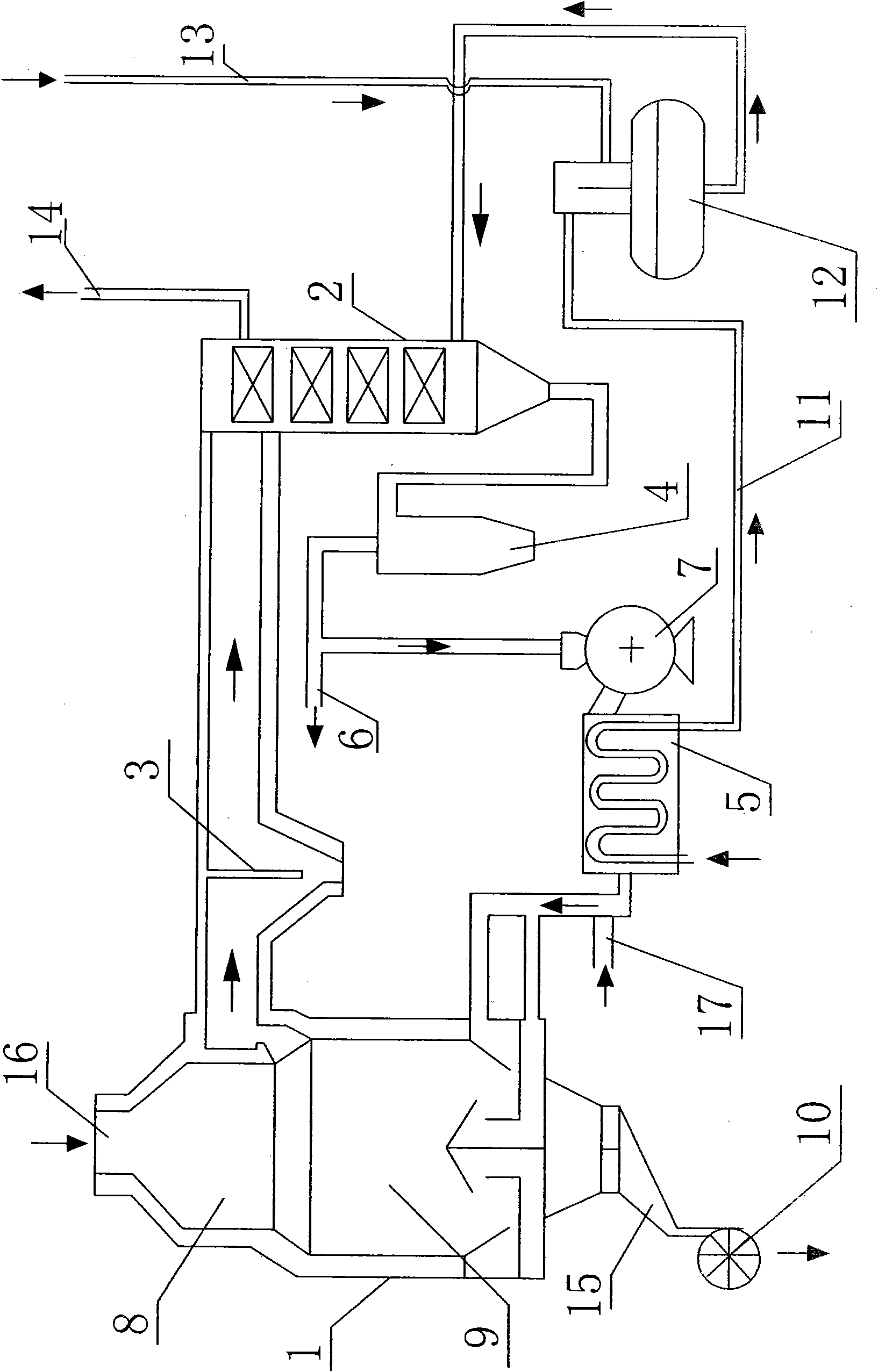

Melting furnace slag quenching dry type granulation and sensible heat recovery generating system and method using same

ActiveCN102433401AReduce cooling air volumeReduce power consumptionIncreasing energy efficiencyRecycling and recovery technologiesSlagHigh pressure water

The invention provides a melting furnace slag quenching dry type granulation and sensible heat recovery generating system and a method using the same and belongs to the technical field of steel metallurgy furnace slag treatment and complementary energy recovery. The melting furnace slag quenching dry type granulation and sensible heat recovery generating system provided by the invention comprisesa slag-receiving device, a high-pressure water-air pulverization furnace slag quenching and granulating device, a furnace slag slow-cooling device, a sensible heat recovery generating device and a waste gas purification treatment device. According to the invention, the melting furnace slag is quenched and granulated by utilizing the high-pressure water-air pulverization device, so that the melting furnace slag is rapidly cooled to be in a glassy state; and then through a water-cooled type vibration grid plate, the melting furnace slag in the glassy state is further subjected to heat exchange with cold air so as to facilitate the subsequent recovery of the sensible heat. By the system provided by the invention, the melting furnace slag is quenched and granulated, and the high-temperature sensible heat resource of the furnace slag is sufficiently recovered and is used for generation on the basis that the water activity quality of the furnace slag is not influenced.

Owner:NANJING KESEN KENEN ENVIRONMENT & ENERGY

Method for making thermoplastic composite pressure vessels

InactiveUS6190598B1Speed up the processRatio is limitedLayered productsDomestic articlesGlass fiberEngineering

A process of making a composite vessel with superior mechanical and aesthetic characteristics includes the steps of: A) preforming a composite thermoplastic shell (e.g., by winding a commingled roving of fiberglass and a thermoplastic material onto a thermoplastic liner) having an opening for access to the interior; B) placing the shell (which may optionally be preheated) into a mold (which itself may optionally be preheated); C) introducing an inflatable bag containing a heater into the shell through the opening; D) heating the inflatable bag to a temperature which is sufficient to render the shell fluid while pressurizing the interior of the inflatable bag; E) continuing step D) until the shell forms against the interior walls of the mold; F) allowing the formed composite vessel to cool; G) removing the inflatable bag; and H) removing the formed composite vessel from the mold. Prior to step C), an insert having an opening may be juxtaposed in alignment with the opening in the shell such that, during step C), the inflatable bag is inserted through the opening in the insert. If desired for the intended purpose of the composite vessel, a portion of the exterior surface of the insert may be threaded such that threads are formed in the opening of the shell whereby the insert can be unscrewed leaving a threaded port into the vessel.

Owner:FLECK CONTROLS +1

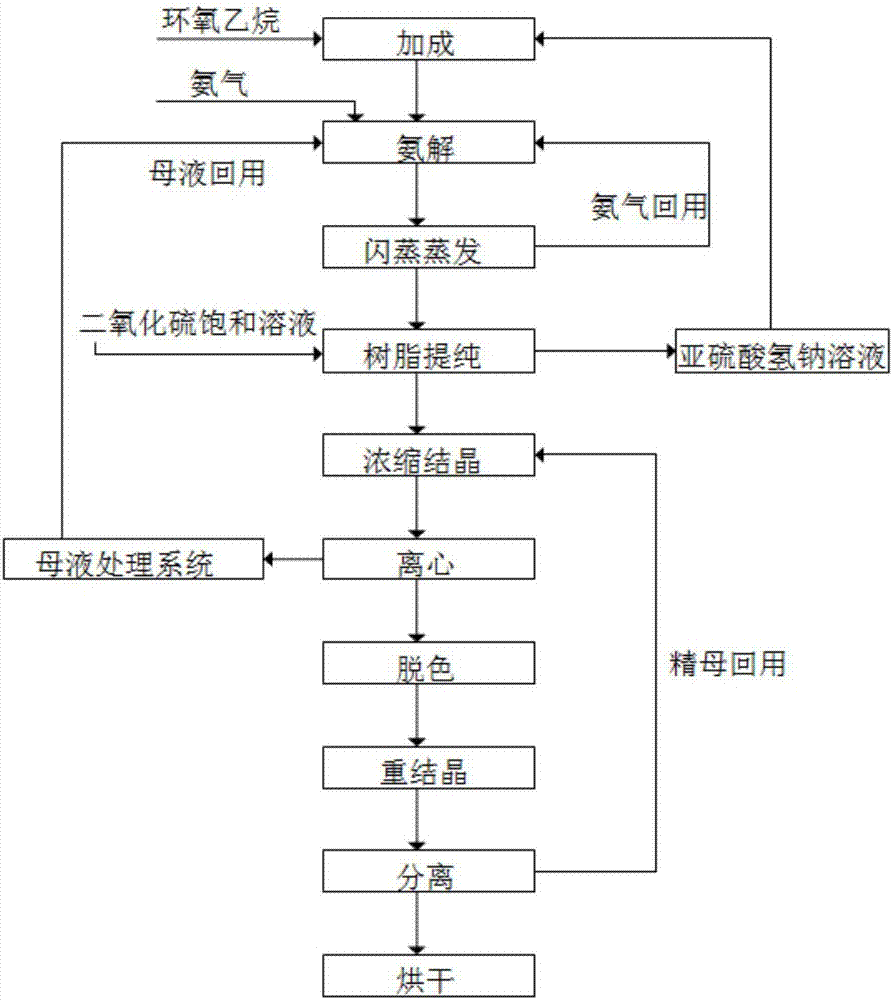

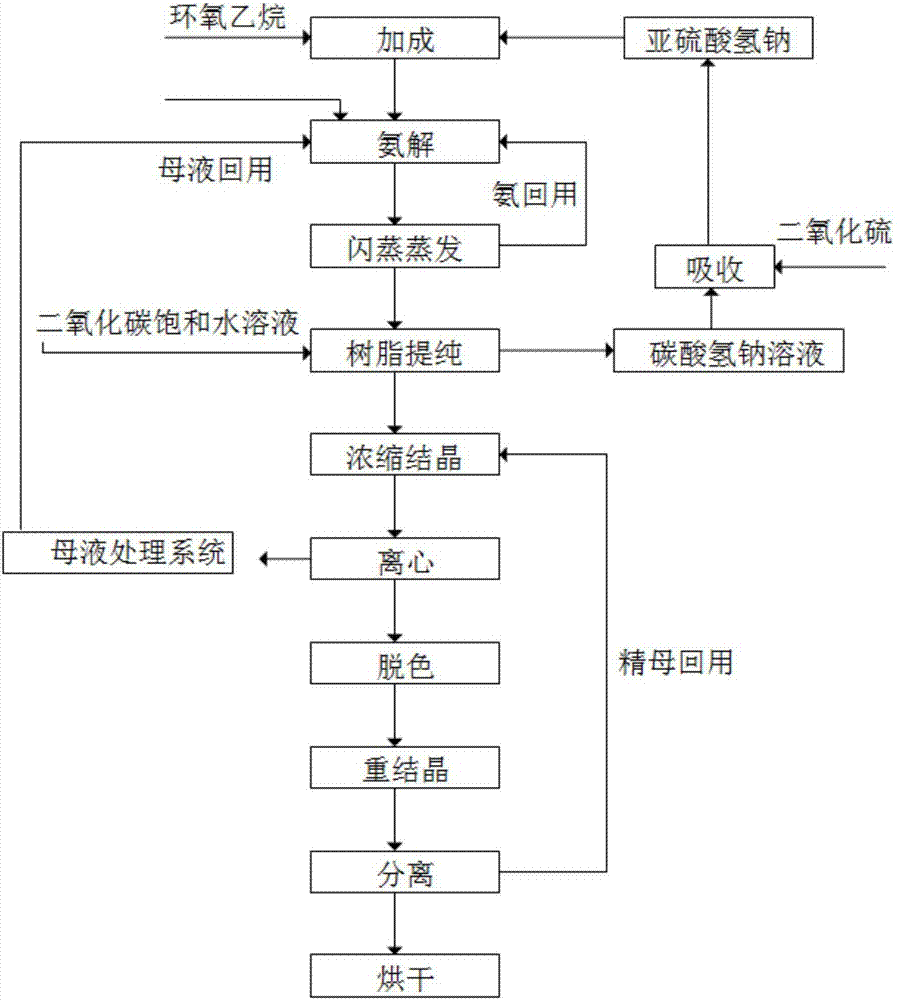

Method for cyclically producing taurine at high yield

ActiveCN107056659AReduce productionEfficient recyclingPhysical/chemical process catalystsOrganic compound preparationAfter treatmentHydrogen

The invention relates to a method for cyclically producing taurine at a high yield. The method includes the following steps that S1, ethylene oxide reacts with a sodium hydrogen sulfite solution to generate sodium hydroxyethyl sulfonate; S2, sodium hydroxyethyl sulfonate obtained in S1 is subjected to an ammonolysis reaction in ammonium hydroxide, flashing is carried out after the reaction is completed, and ammonia gas is recycled; S3, taurine-containing feed liquid of reaction liquid obtained after flashing in S2 is collected through an acid cation exchange resin column, the resin column is regenerated with a sulfur dioxide or carbon dioxide water solution after being inactivated, and eluant obtained during regeneration can be directly reused or reused after being treated with sulfur dioxide; S4, the feed liquid collected in S3 is subjected to after-treatment, and taurine is obtained. The method has the advantages that the generation amount of waste liquid in the whole process is small, part of substances are effectively and cyclically utilized in the process, the cost is reduced, the yield of taurine can reach 90% or above, meanwhile, the production process is relatively simple, and large-scale production is easy.

Owner:QIANGJIANG YONGAN PHARMA

Grading recycling and cascade utilization method of residual heat resources in sintering process and device thereof

ActiveCN101655320AOvercome congenital deficienciesSolve the problem of air leakageLiquid degasificationIncreasing energy efficiencyThermodynamicsEngineering

The invention relates to a method for effectively recycling and utilizing residual heat resources in a sintering process and a device thereof. The invention has the main contents that a fiery sinter ore is filled in a vertical and sealed tank body, air is led from the tank body so as to cool the sinter ore, sensible heat of the sinter ore is almost totally carried by the air and is exhausted fromthe top of the tank body at the same time; and hot air is led into a residual heat boiler to generate steam to synchronously generate power. Compared with the prior sintering residual heat recycling and utilization technology, the invention has higher residual heat recycling utilization ratio, effectively reduces the energy consumption of the sintering procedure with reasonable and effective method, simple apparatus and easy operation, and is relatively favorable for popularization and application in the technical field of residual heat resource recycling and utilization in a metallurgy process.

Owner:NORTHEASTERN UNIV

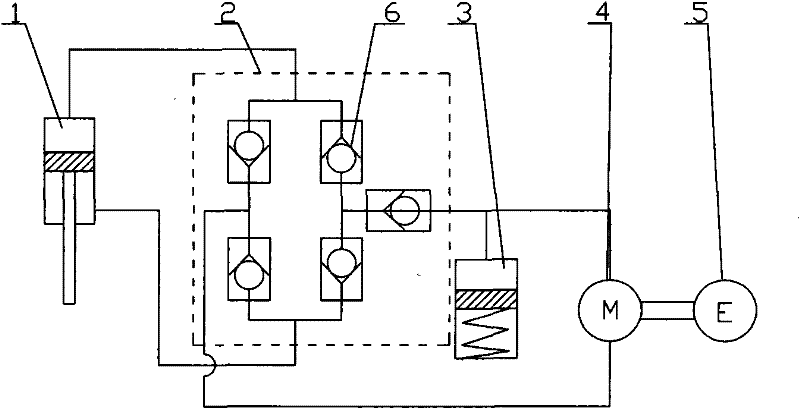

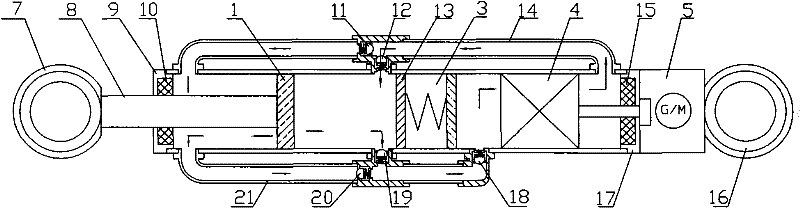

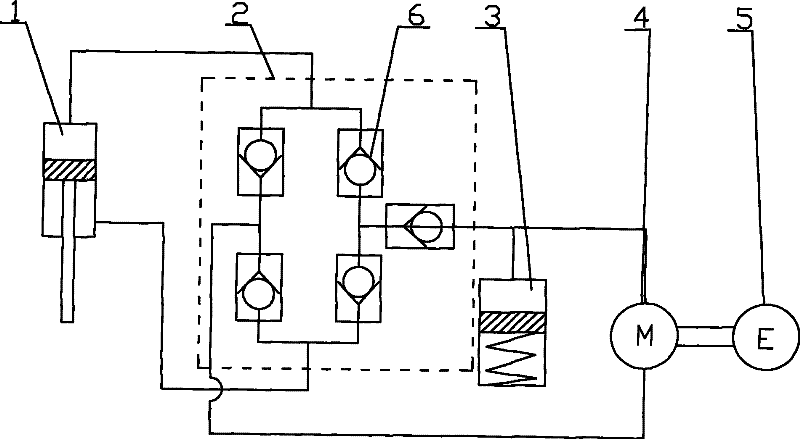

Electrohydraulic energy-regenerative type shock absorber

ActiveCN101749353APrevent reversalExtend your lifeLiquid based dampersMechanical energy handlingHydraulic motorDrive shaft

The invention relates to an electrohydraulic energy-regenerative type shock absorber, which comprises a hydraulic circuit, a working chamber and a piston, wherein the working chamber is divided into a piston working cavity and an accumulating power-generating cavity by a partition plate (13), and the piston is positioned in the piston working cavity and is connected with an external upper mounting base (7) through a piston push rod (8); a hydraulic motor (4) is positioned in the energy storage power-generating cavity and is connected with an external rotary generator (5) through a driving shaft, and an accumulator (3) is positioned in the accumulating power-generating cavity and is positioned below the partition plate (13); and the hydraulic circuit and a plurality of one-way valves (6) form a hydraulic rectifier bridge, and the hydraulic circuit adopts the method that an external pipeline is arranged outside the piston or the piston is designed to form internal and external cavities. The invention has simple structure, fewer components and small volume, can allow the energy generated by vehicle vibration to be fully used for doing work, can effectively recover vibration energy, has better shock absorbing effect than the existing shock absorber, and also prolongs the service life of the generator.

Owner:武汉经开科创运营有限公司

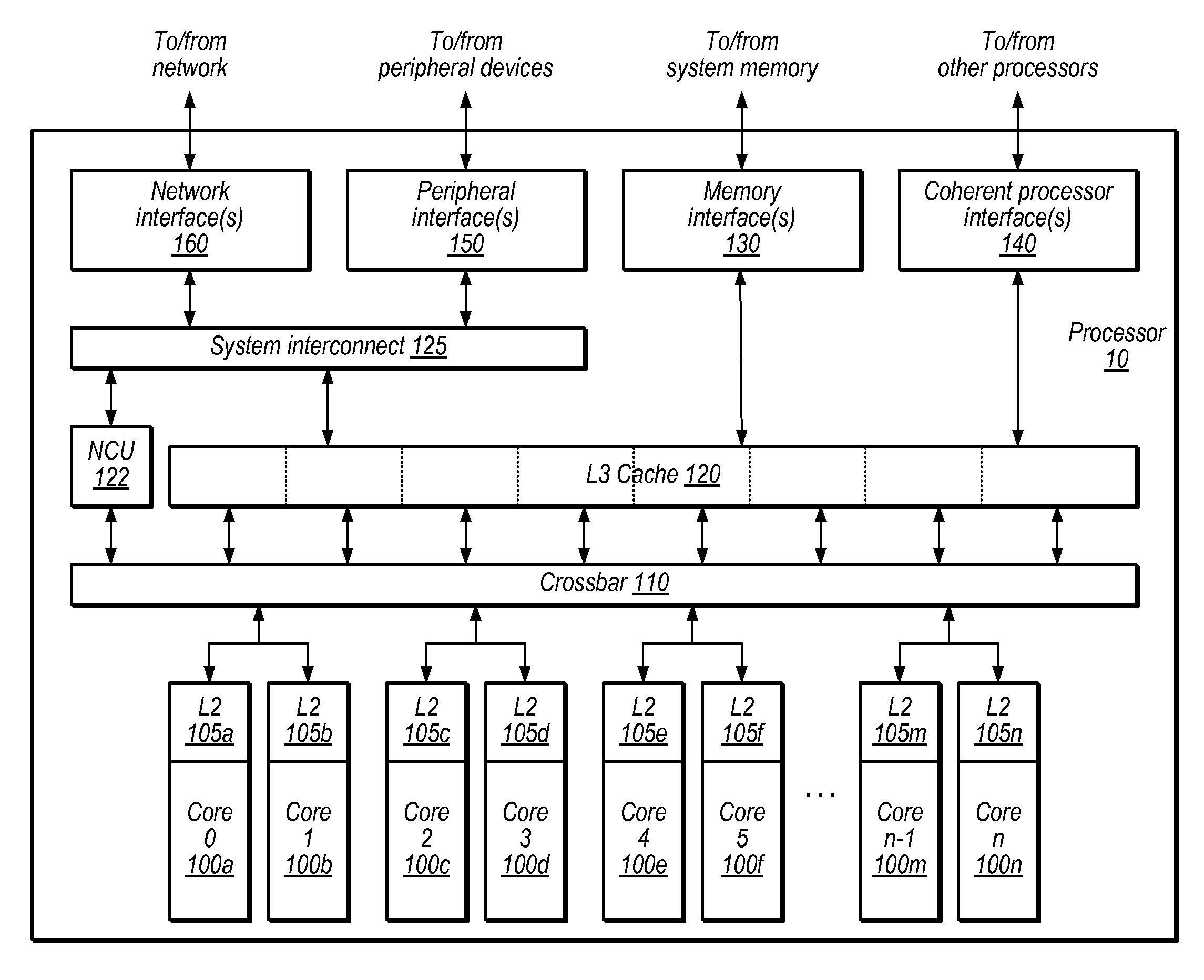

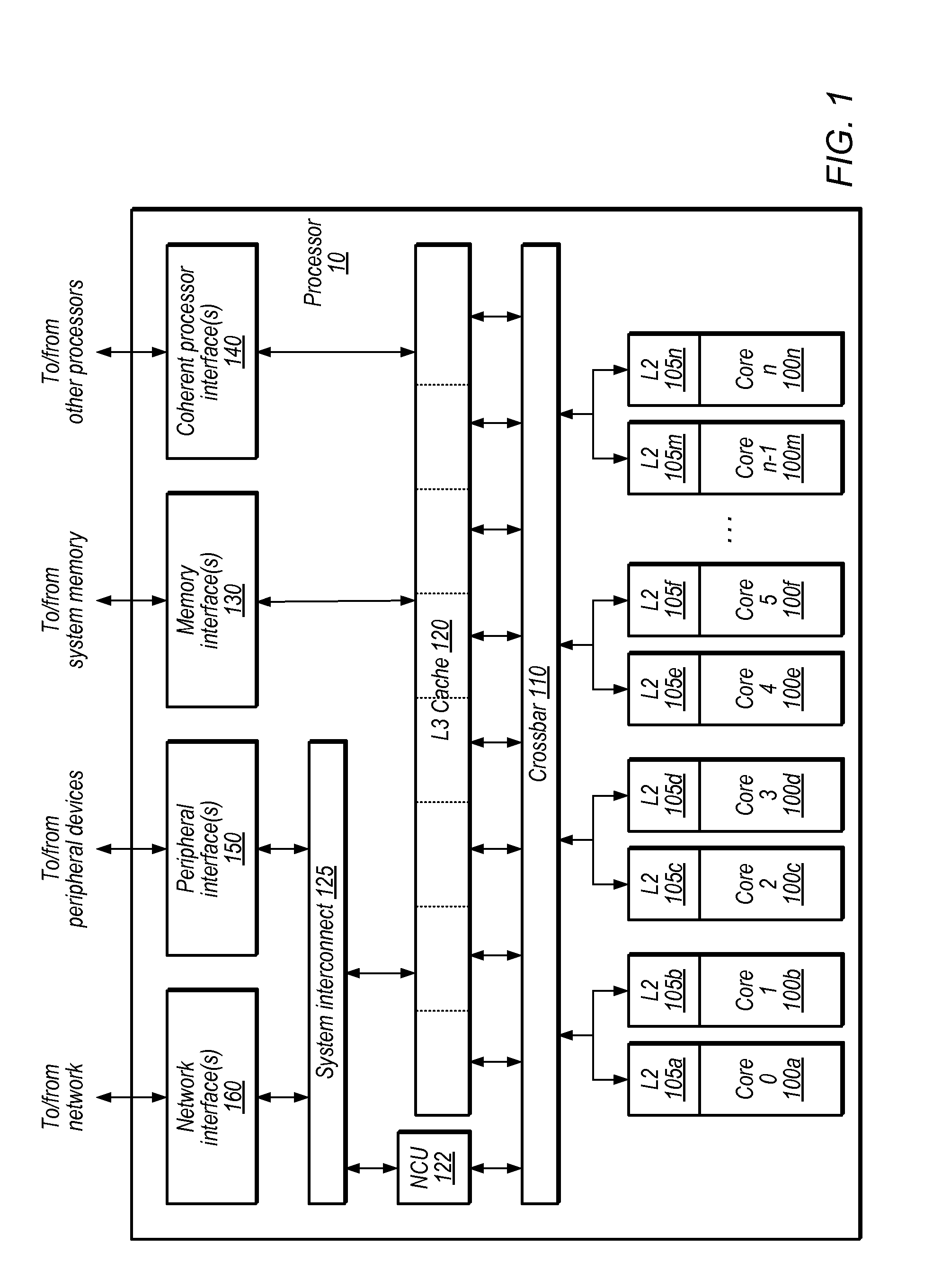

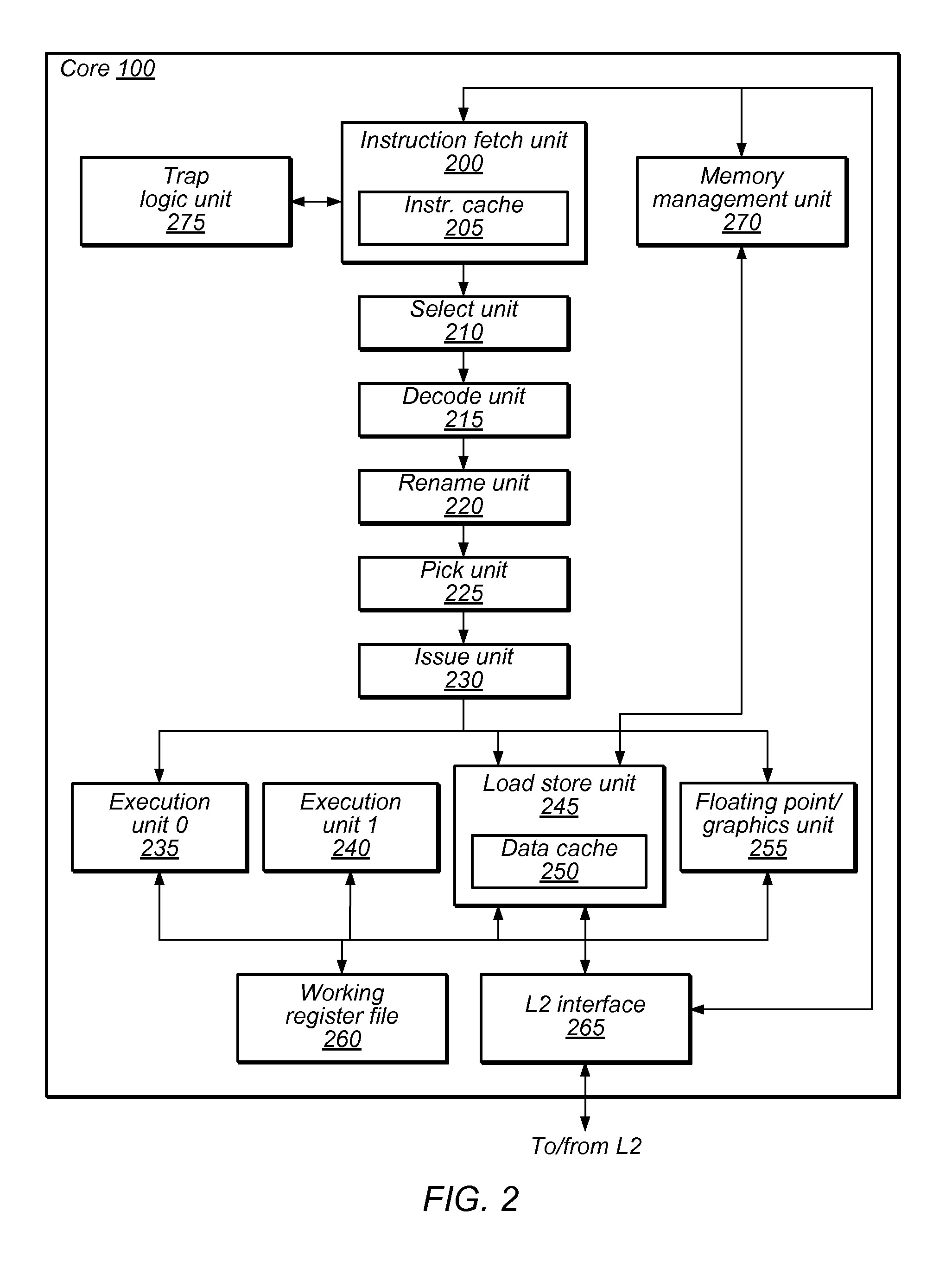

System and Method to Manage Address Translation Requests

ActiveUS20100332787A1Efficient managementEfficient recyclingMemory architecture accessing/allocationMemory adressing/allocation/relocationManagement unitTranslation table

A system and method for servicing translation lookaside buffer (TLB) misses may manage separate input and output pipelines within a memory management unit. A pending request queue (PRQ) in the input pipeline may include an instruction-related portion storing entries for instruction TLB (ITLB) misses and a data-related portion storing entries for potential or actual data TLB (DTLB) misses. A DTLB PRQ entry may be allocated to each load / store instruction selected from the pick queue. The system may select an ITLB- or DTLB-related entry for servicing dependent on prior PRQ entry selection(s). A corresponding entry may be held in a translation table entry return queue (TTERQ) in the output pipeline until a matching address translation is received from system memory. PRQ and / or TTERQ entries may be deallocated when a corresponding TLB miss is serviced. PRQ and / or TTERQ entries associated with a thread may be deallocated in response to a thread flush.

Owner:ORACLE INT CORP

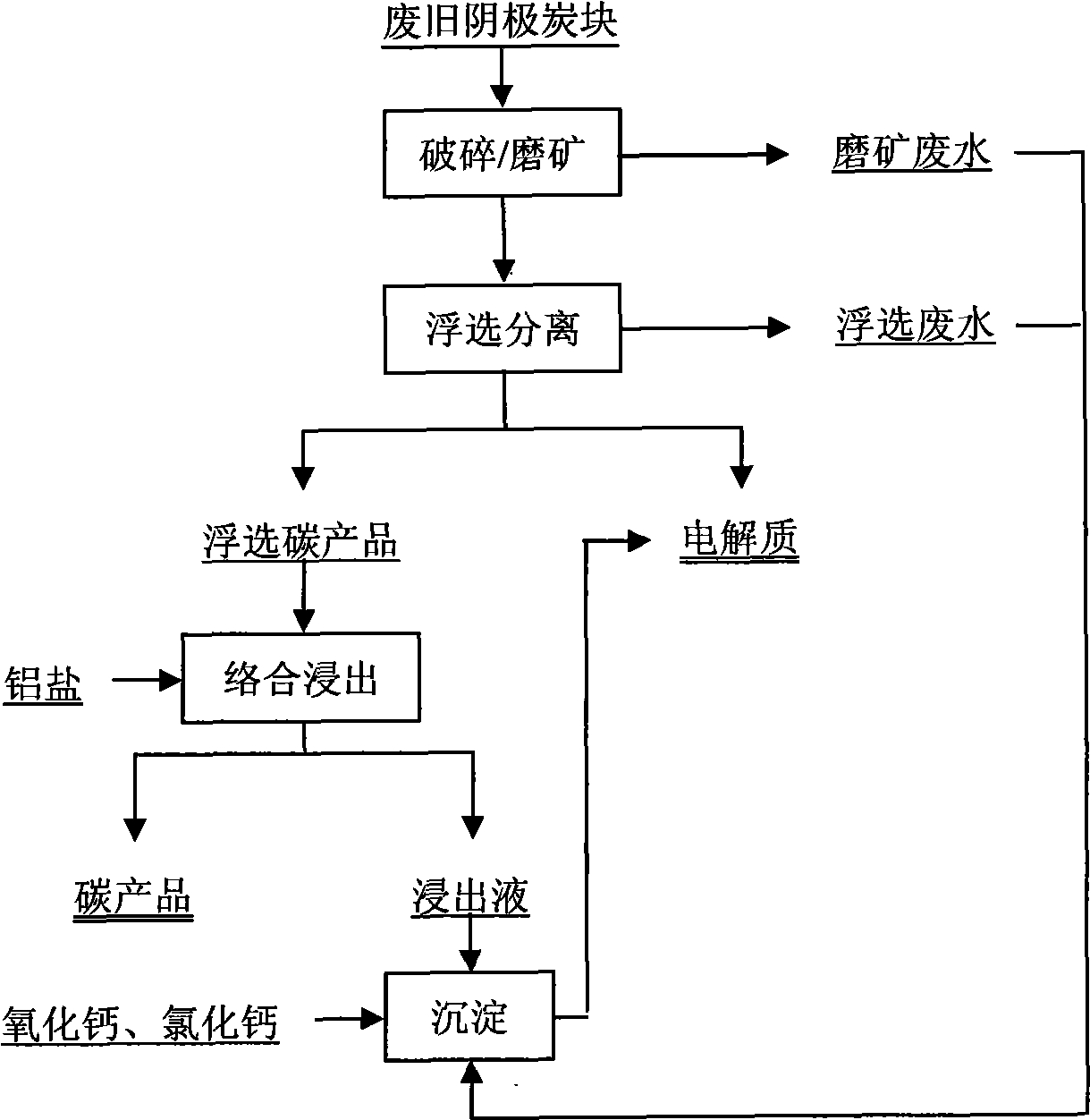

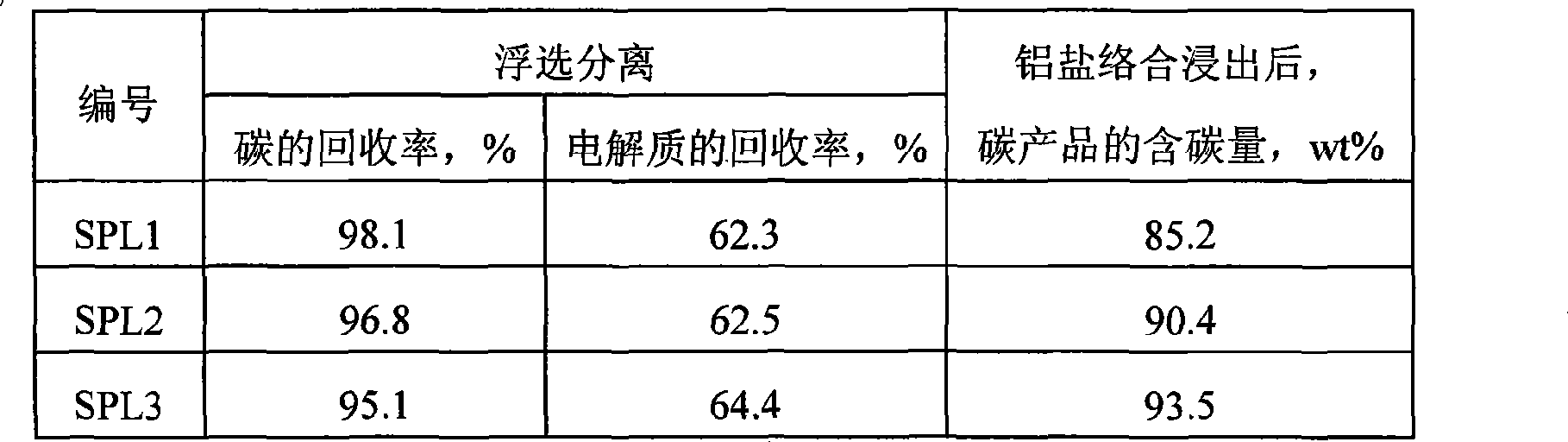

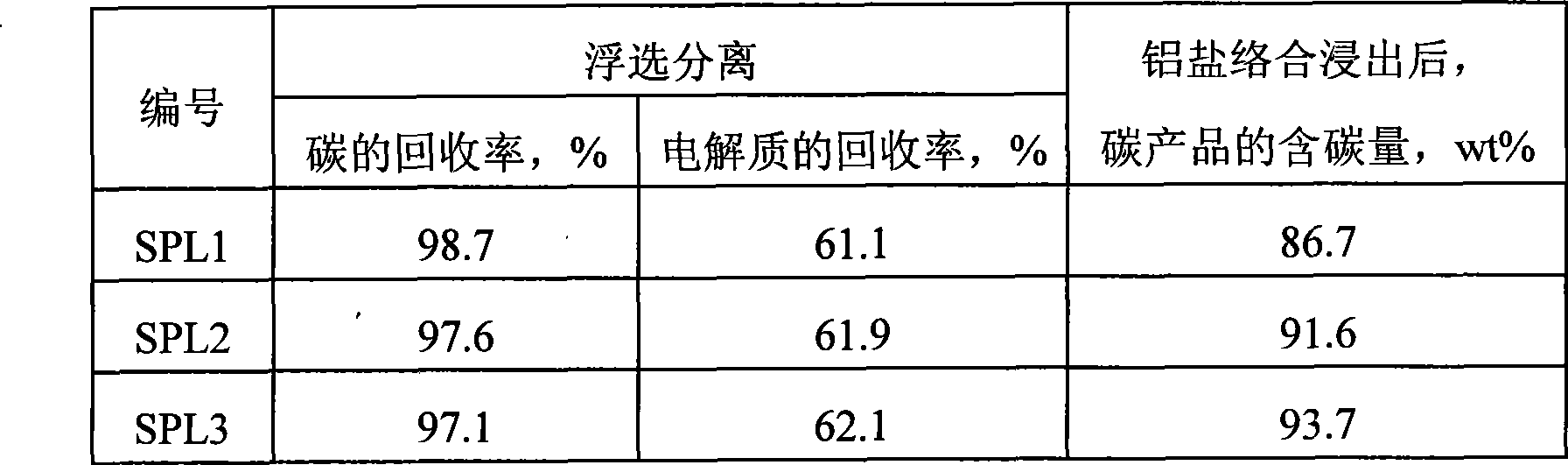

Method for electrolyzing waste and old cathode carbon block by comprehensive utilization of aluminum

ActiveCN101480658ARealize flotation separationHigh carbon contentFluoride preparationWaste processingPregnant leach solutionHigh carbon

The invention relates to a method for comprehensively using aluminium to electrolyze a waste cathode carbon block, which belongs to the technical field of environment protection and comprises the following steps: crushing and grinding the waste cathode carbon block; adjusting the concentration and the PH value of ore slurry after the grinding, then using floatation equipment to carry out floatation treatment, and separating electrolyte and carbon which are contained in the waste cathode carbon block; using an aluminium salt solution to soak for extracting the electrolyte contained in a carbon product obtained from the floatation, and further improving the grade of a high-carbon product; mixing the grinding waste water, the floatation waste water and the soaking solution, and adding CaO and CaCl2 to precipitate and recover aluminium and fluothane in the mixture. The method for comprehensively using aluminium to electrolyze a waste cathode carbon block has simple operating condition, low energy consumption, high recovery ratio of valuable substances and good application prospect.

Owner:NORTHEASTERN UNIV

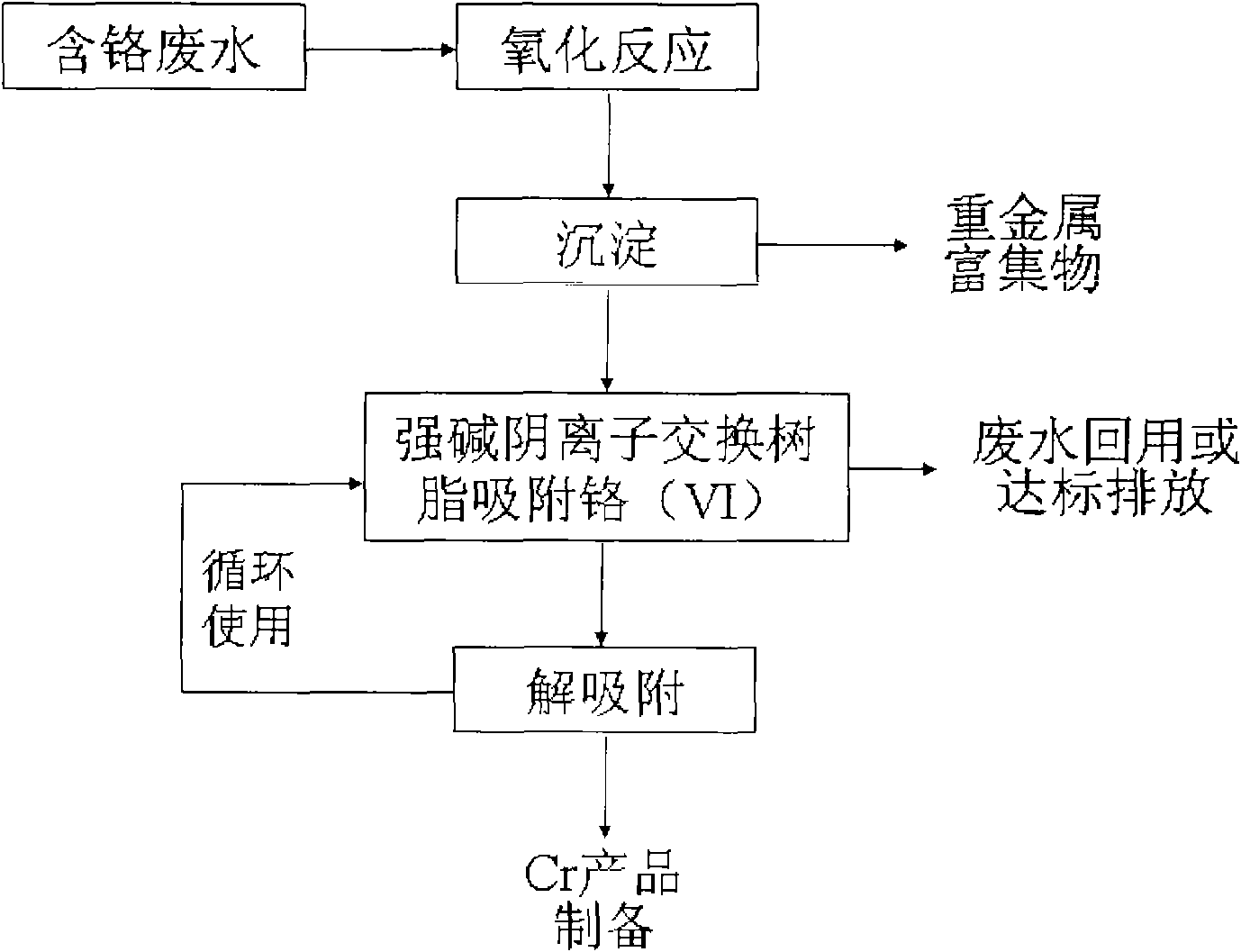

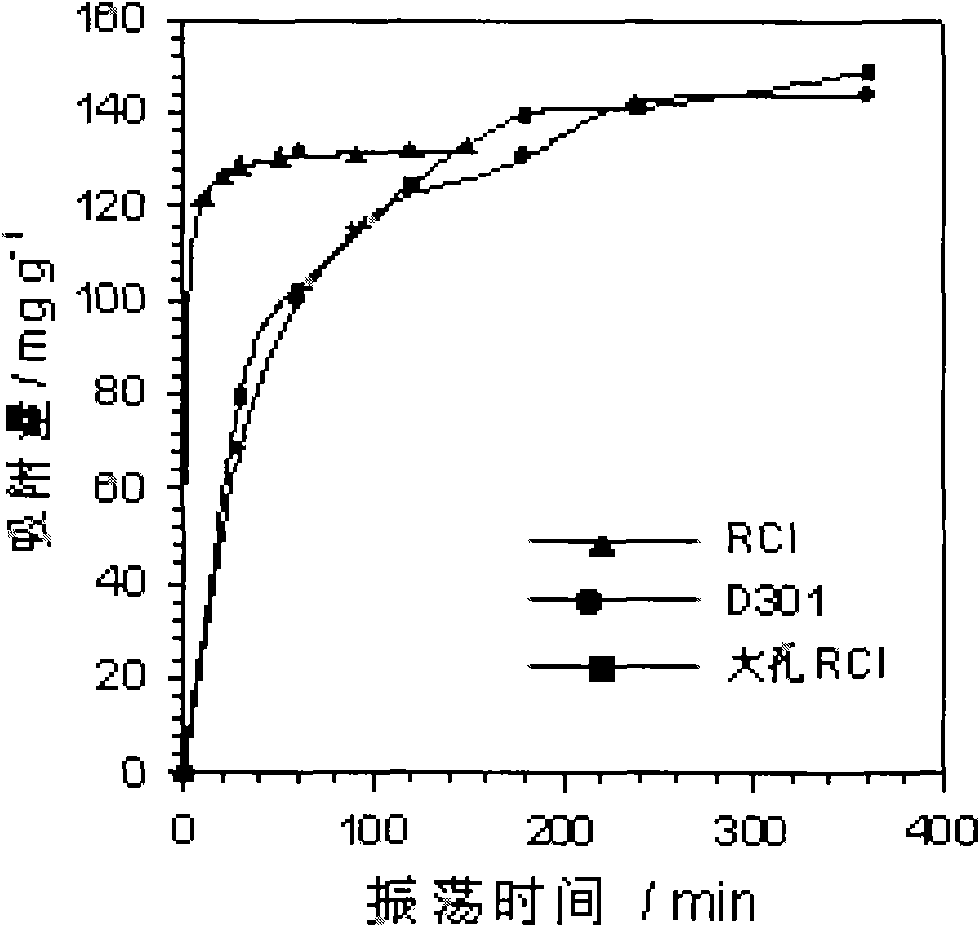

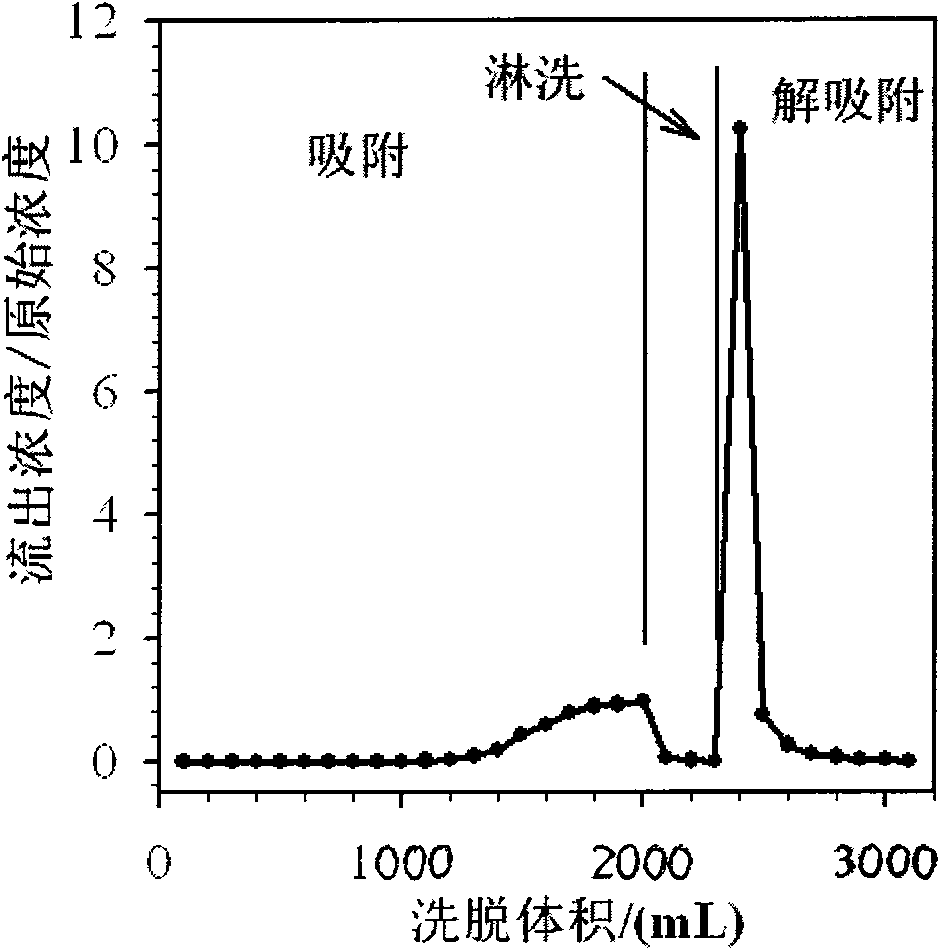

Method for purifying electroplating wastewater and comprehensively utilizing resources

ActiveCN101570372AImprove adsorption capacityEasy to separateWater contaminantsWater/sewage treatment by ion-exchangeChemical reactionWater quality

The invention relates to a method for purifying electroplating wastewater and comprehensively utilizing resources, which is to adopt low-cost strong basic anion-exchange resin containing macropores and imidazole structure to reclaim valuable resources in the electroplating wastewater by coupling technology based on a chemical oxidation-reduction method, a precipitation method and an ion exchange method. The method comprises the following steps: firstly, Cr(III) is oxidized into Cr(VI) under basic condition through a chemical reaction; then, Zn, Cu, Ni and other heavy metal elements in the wastewater are transformed into precipitation of hydroxide; and finally, the Cr(VI) in the wastewater is adsorbed by the strong basic anion-exchange resin, the purified water quality achieves the requirement of electroplating pollutant discharge standard and recycle, and the Cr and other heavy metal resources in the electroplating wastewater can be comprehensively reclaimed and utilized. The method overcomes the defects that the prior regenerating process of porous weak-basic resin requires acidification, and the method has the advantages of simple process, low treatment cost, large treatment quantity and acid and base consumption conservation, and is the electroplating wastewater treatment method with green environmental protection and efficient utilization of resources.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Method for fabricating composite pressure vessels

InactiveUS6171423B1Speed up the processRatio is limitedVessel manufacturingCylinder headsPolytetramethylene terephthalateFiber

A process for fabricating a composite vessel includes the steps of: A) preforming (e.g., by winding fiber and at least one thermoplastic substance onto a thermoplastic liner) a thermoplastic shell which has at least one opening for access to the interior; B) extruding a circular cross section of a fluid parison of thermoplastic material (which preferably is chosen to have a melting point lower than that of the thermoplastic shell) into the interior of the thermoplastic shell through the opening; C) in a mold, applying at least one force (such as gas under pressure) which tends to urge the fluid parison toward the interior walls of the thermoplastic shell (which may be preheated prior to introduction into the mold) such that the fluid parison imparts heat to the thermoplastic shell; D) continuing step C) until the thermoplastic shell and the fluid parison consolidate to form a composite vessel; E) cooling the vessel until it is solidified; and F) removing the vessel from the mold. For some composite vessels, prior to step C), an insert may be introduced into the interior of the parison and positioned in alignment with the opening in the thermoplastic shell such that the insert is rendered integral with the composite vessel during step D). Suitable thermoplastic materials include polyethylene, polypropylene, polybutylene terephthalate and polyethylene terephthalate. The resulting composite vessel exhibits superior mechanical and aesthetic properties.

Owner:FLECK CONTROLS +1

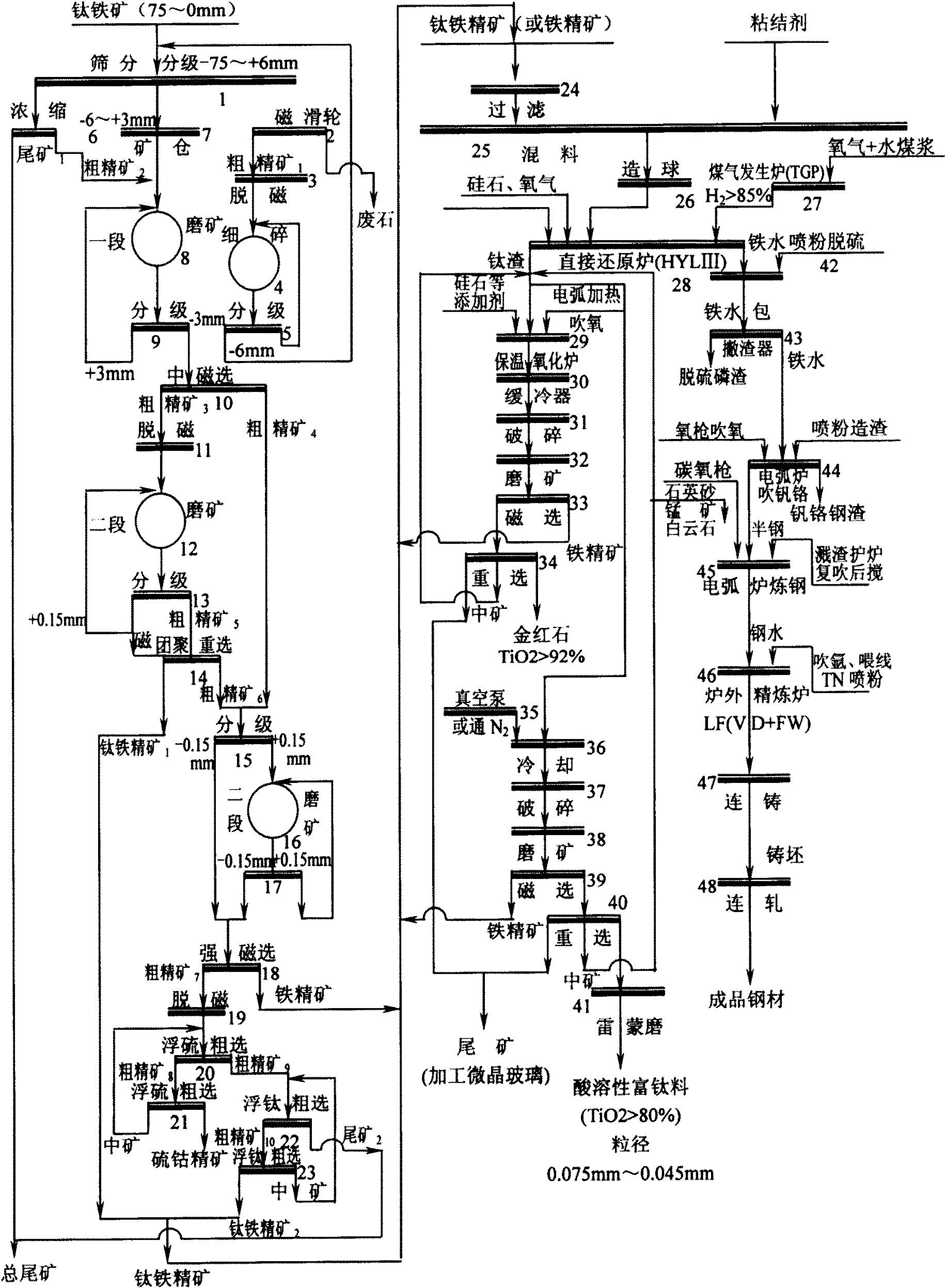

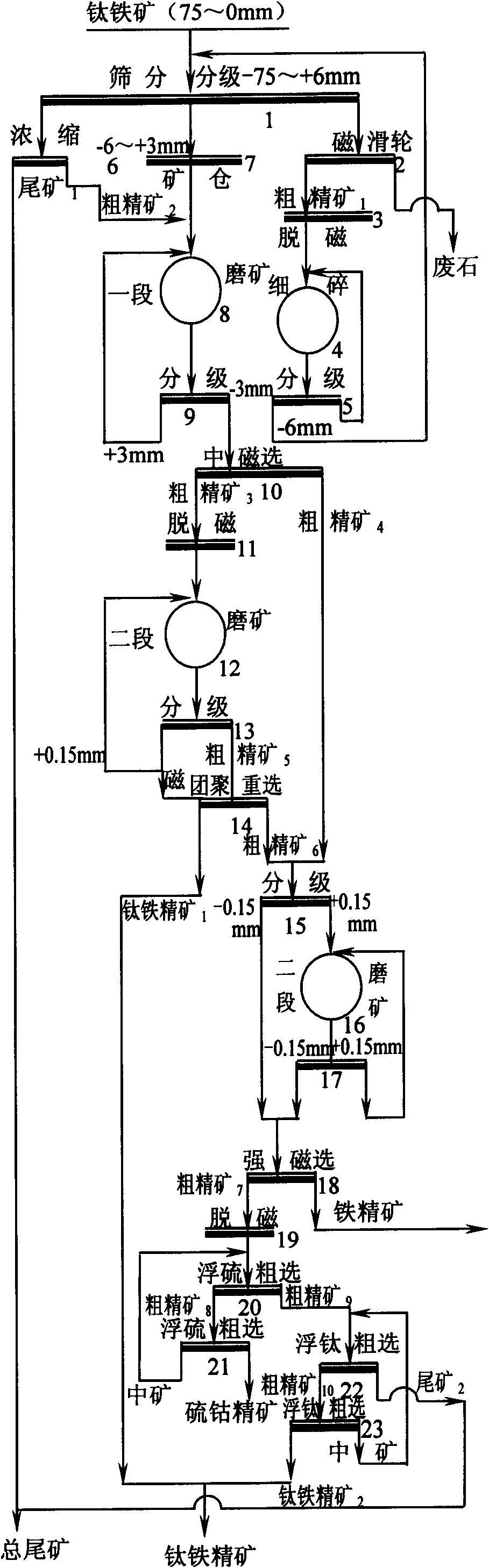

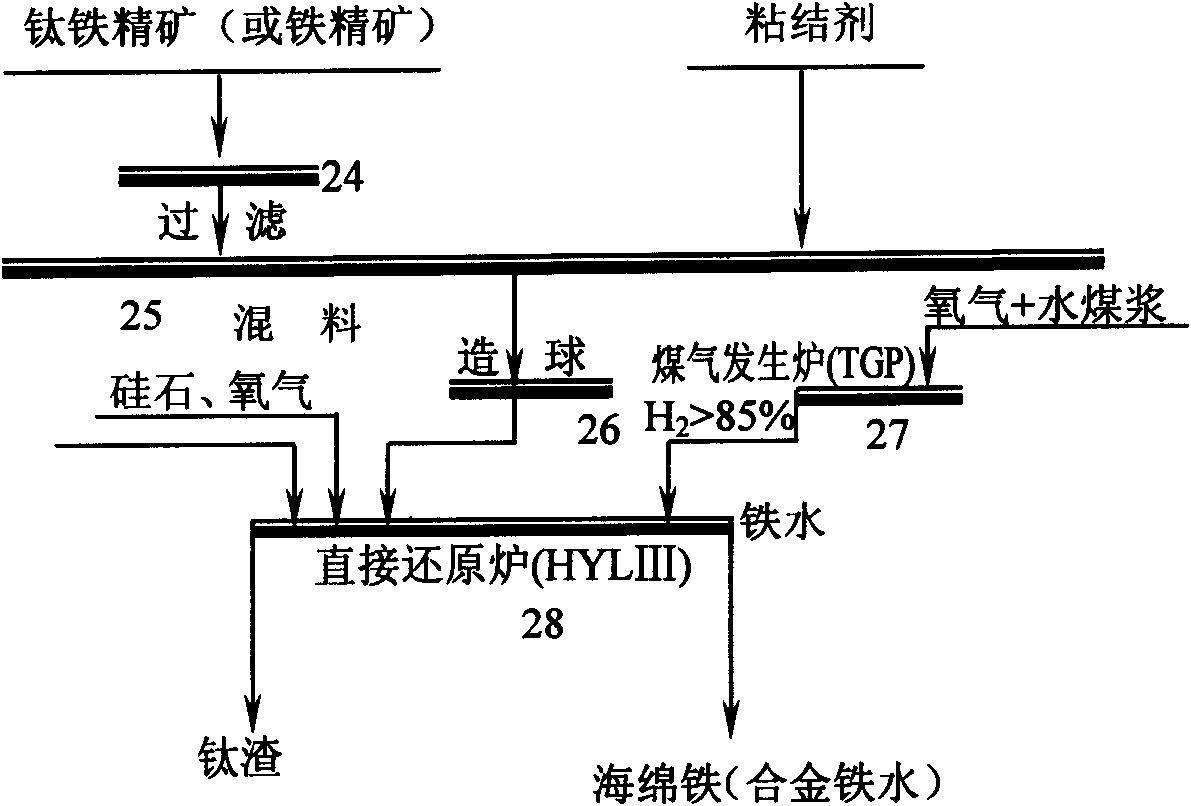

Method for producing titanium and steel products by utilizing titanium and iron ores

InactiveCN101613825AIncrease profitHigh recovery rateProcess efficiency improvementElectric furnaceRutileContinuous rolling

The invention discloses a method for producing titanium and steel products by utilizing titanium and iron ores, which belongs to the field of technical innovation of mining, dressing and smelting full process flow of the titanium and iron ores. Ordinary blast furnaces are not suitable for the smelting of high-titanium and medium-titanium schreyerite; and schreyerite mining, dressing and smelting enterprises in Panxi region extract rich parts and discard poor parts, and discard weathered ore of submarginal ore which accounts for over 95 percent of that of raw ore and is taken as mining mullock. The method comprises the following step: directly reducing titaniferous iron concentrate dressed from the mining mullock (TiO2 is over 5 percent, and TFe is over 13 percent) of the schreyerite, electric furnace melt producing titanium slag and molten water with electric furnace melt components, and producing a titanium-rich material and rutile with the titanium slag through mineral dressing by a fire method; producing alloy molten iron with the molten iron through electric smelting and vanadium-chrome steel slag blowing; and producing various alloy steel products the alloy molten iron in a continuous casting and continuous rolling mode through the electric smelting. The recovery rates of titanium, iron and vanadium are improved to 80 percent from 3.86 percent, improved to 70 percent from 34.5 percent and improved to 70 percent from 20.90 percent respectively.

Owner:PANZHIHUA JINTAI HI TECH

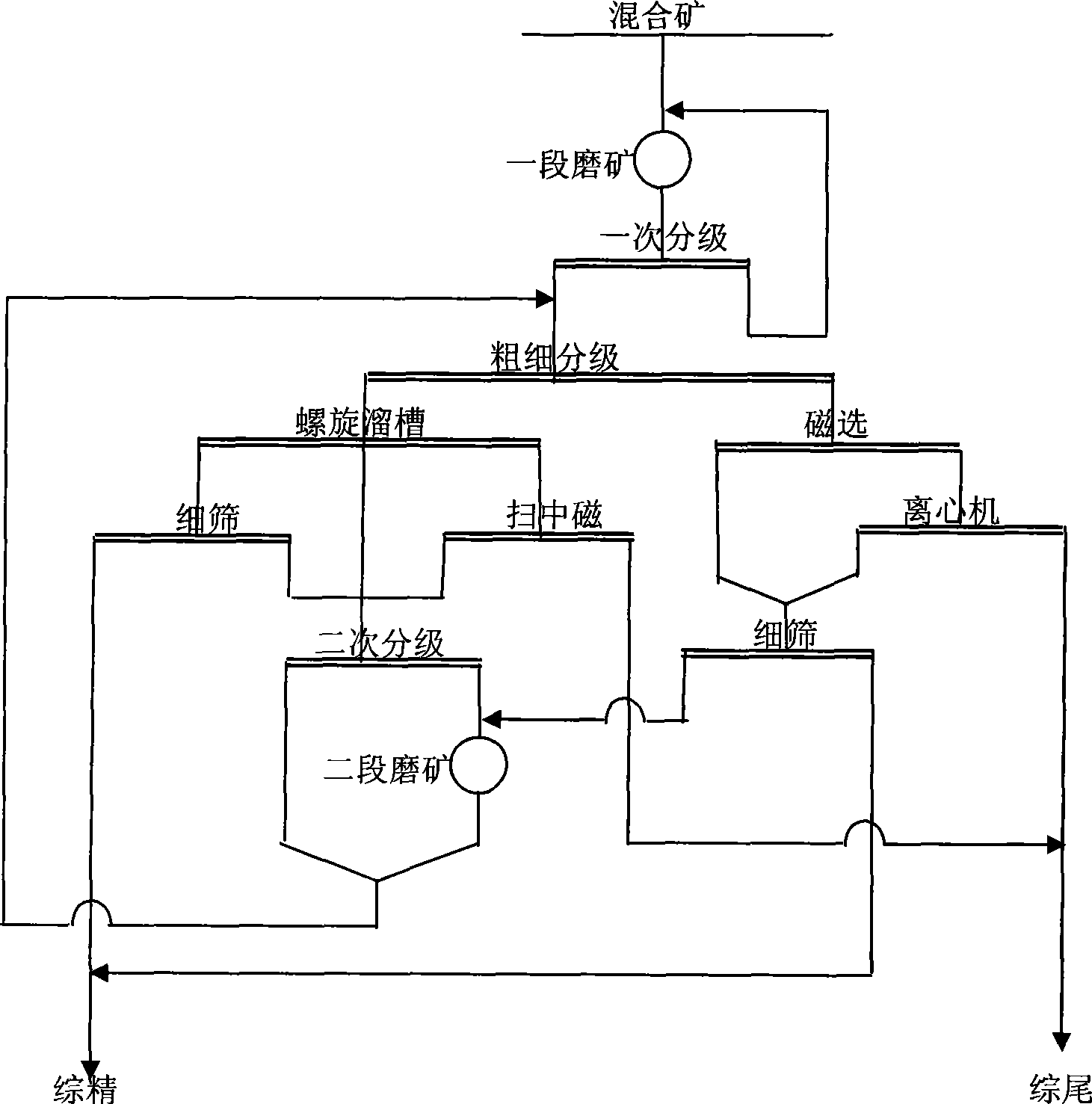

Technique for processing mixed type iron ore

ActiveCN101468330AEfficient recyclingOvercome the complex system and the shortcomings of being easily interfered by other mineralsSievingScreeningHybrid typeGravity separation

The invention discloses a process for treating mixed-type iron ore. The process comprises the following steps: raw ore is crushed and then subjected to primary grinding and primary grading which form closed circuit grinding; after primary overflow is subjected to crudeness / fineness grading and coarse grains are sorted through a gravity separation device, spiral chute concentrate is fed into a fine screen with large mesh size, and undersize products are coarse-grain concentrate; after gravity separation tailings are subjected to tailings discarding through intermediate-magnetism sweeping, intermediate-magnetism sweeping concentrate, gravity separation middlings and oversize products are merged into coarse-grain middlings; the middlings are fed into an open-circuit grinding system consisting of secondary grading and secondary grinding and reground, and then return to crudeness / fineness grading; fine grains after crudeness / fineness grading are sorted through a magnetic separation device; magnetic separation concentrate is fed into the fine screen with small mesh size, and the undersize products are fine-grain concentrate, while the oversize products are fine-grain middlings which are directly fed into two-stage grinding so as to be reground; fine-grain concentrate and the coarse-grain concentrate are merged into final concentrate; and intermediate-magnetism sweeping tailings and the magnetic separation tailings are merged into final tailings. The process has the advantages of good flow stability, easy operation and capability of effectively recovering the mixed-type ore and fully utilizing mixed-type ore resources.

Owner:鞍钢集团矿业设计研究院有限公司

Three-dimensional fiber-based aerogel catalyst carrier and preparation method thereof

ActiveCN103285920AGood flexibilitySufficient reactive sitesCatalyst carriersOrganic-compounds/hydrides/coordination-complexes catalystsFiberPliability

The invention relates to a preparation method of a three-dimensional fiber-based aerogel catalyst carrier and a product thereof. The preparation method comprises the following steps of: firstly dispersing fibers in solvents to form turbid liquid; secondly curing the turbid liquid to form cured pieces; thirdly removing cured solvents to form non-crosslinked fiber-based aerogel; finally carrying out crosslinking stabilization treatment and then carrying out activation treatment, thus obtaining the three-dimensional fiber-based aerogel catalyst carrier. The product is a three-dimensional network-shaped material formed through mutual penetration and stagger of fibers. The fiber crossing points are effectively interconnected through non-hydrogen-bond bonding. The three-dimensional fiber-based aerogel catalyst carrier has volume density of 0.1-500mg / cm<3>, average pore size of 0.01-2000mu m and specific surface area of 0.2-2000m<2> / g. The preparation method and the product have the advantages that the preparation process is simple; the raw material limitations are less; and the aerogel catalyst carrier product has good flexibility, connectivity and catalyst supporting capacity and has broad application prospects in the catalytic application field.

Owner:DONGHUA UNIV

Quantum Dot Films, Lighting Devices, and Lighting Methods

ActiveUS20150300600A1Increase the optical path lengthImprove efficiencyRadiation applicationsLayered productsLight equipmentQuantum dot display

Light-emitting quantum dot films, quantum dot lighting devices, and quantum dot-based backlight units are provided. Related compositions, components, and methods are also described. Improved quantum dot encapsulation and matrix materials are provided. Quantum dot films with protective barriers are described. High-efficiency, high brightness, and high-color purity quantum dot-based lighting devices are also included, as well as methods for improving efficiency and optical characteristics in quantum dot-based lighting devices.

Owner:NANOSYS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com