Method for producing titanium and steel products by utilizing titanium and iron ores

A technology for ilmenite and steel products, applied in chemical instruments and methods, wet separation, improvement of process efficiency, etc., can solve problems such as waste, unsatisfactory theoretical explanation, high iron loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0128] specific implementation plan

[0129] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

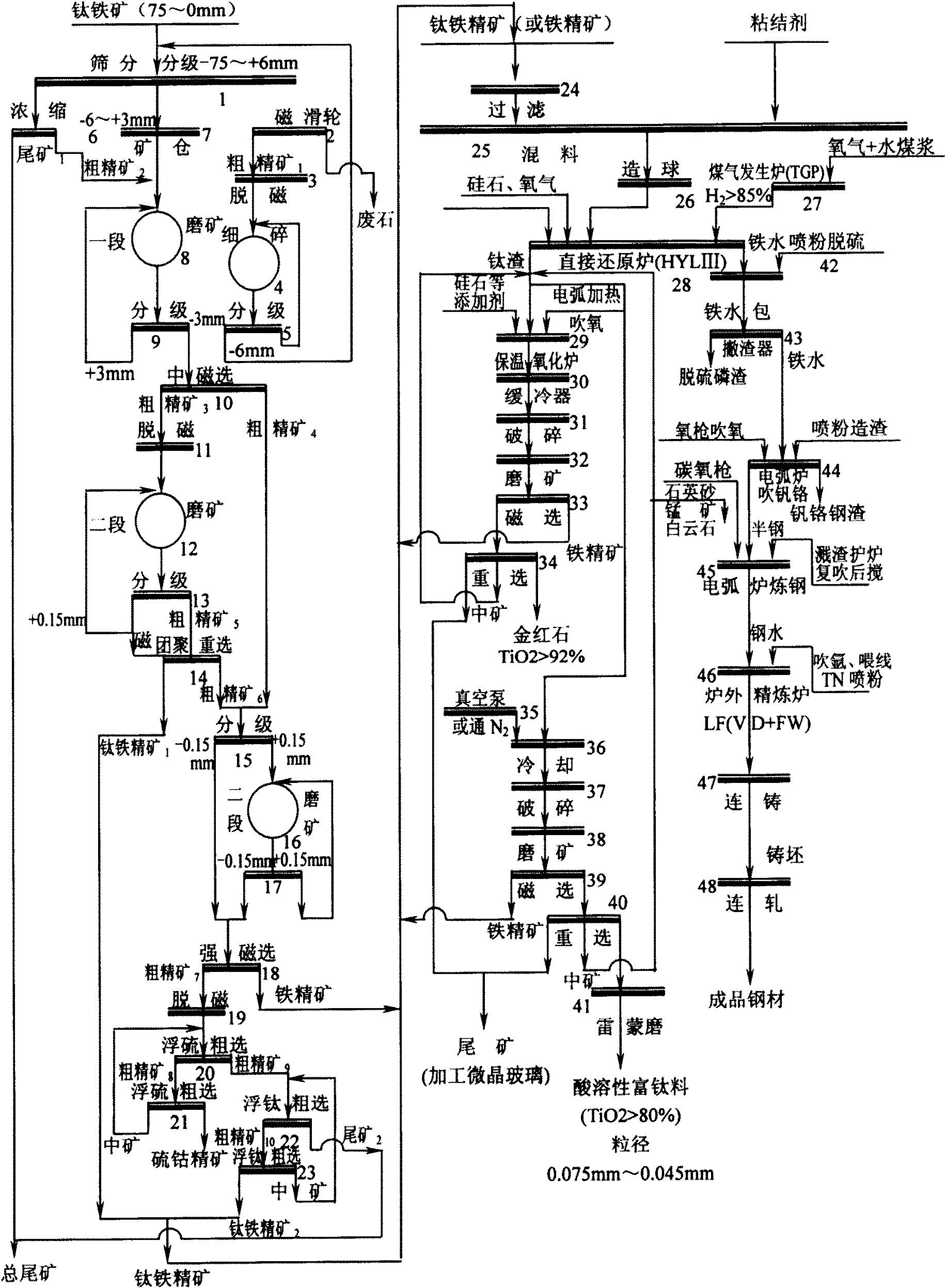

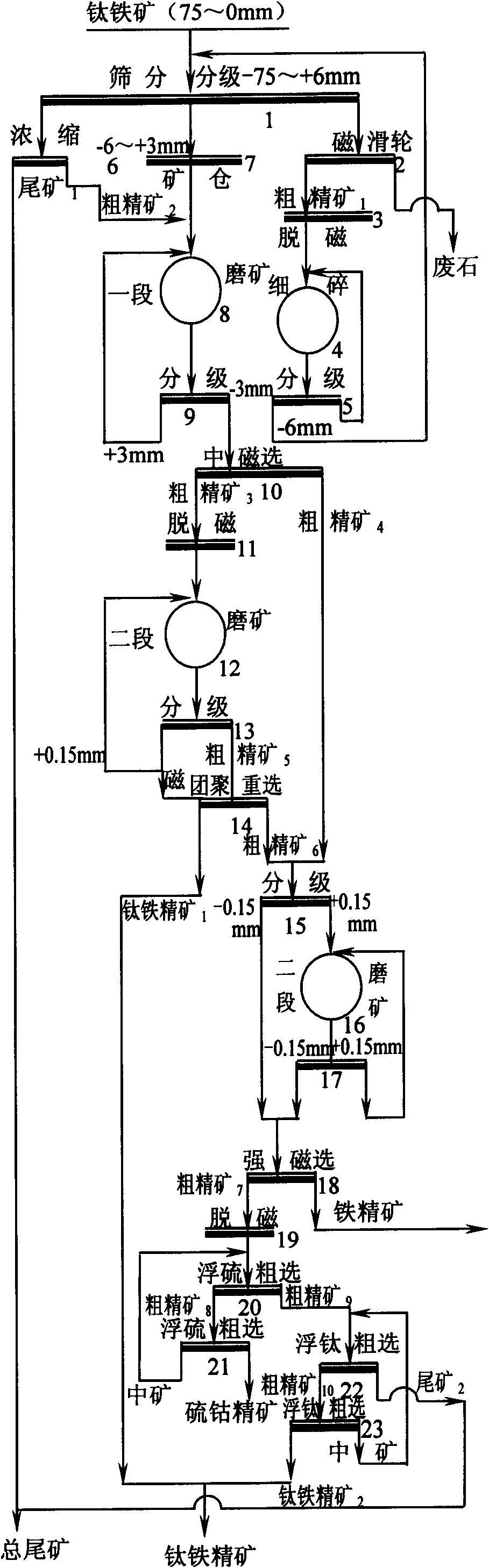

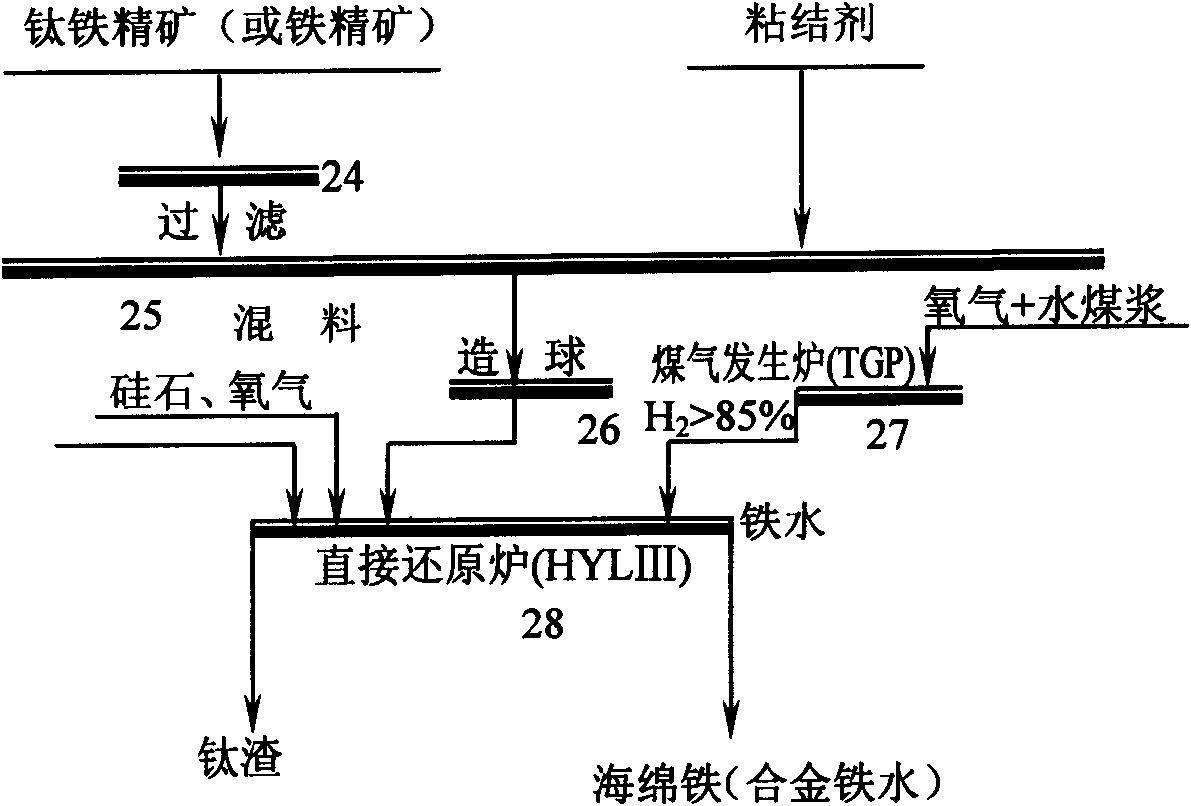

[0130] Such as figure 1 As shown, -1000mm ilmenite (magnetite or hematite ilmenite, or titanium placer or magnetite and other iron-containing minerals) after coarse crushing, medium crushing and screening (1), -75mm+ 6mm ore is discharged by magnetic pulley (2) to discharge gangue minerals (waste rock), rough concentrate 1 Demagnetization (3), into the fine crusher (4) for fine crushing, ore discharge and classification (5), +6mm ore returns to the fine crusher (4) for fine crushing, -6mm ore enters the screening machine (1), -3mm ore or weathered ore After screening (1), the tailings are discharged by concentrated washing (6) 1 , crude concentrate 2 -6mm~+3mm ore in the ore bin (7) enters the first stage mill (8), the mill discharges ore and classifies (9), +3mm ore returns to the mill (8) for regrind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com