Patents

Literature

179 results about "Surface tooth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

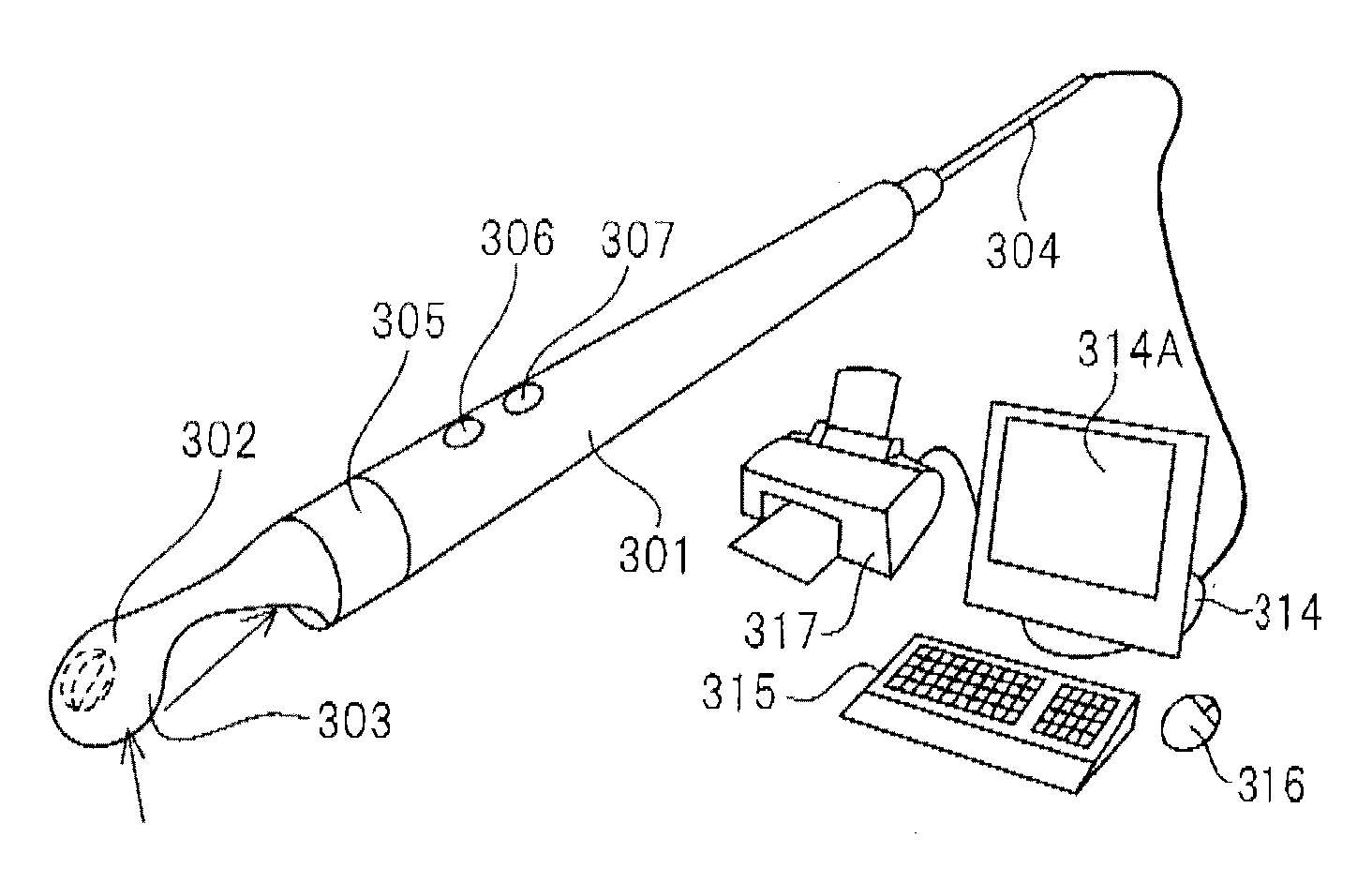

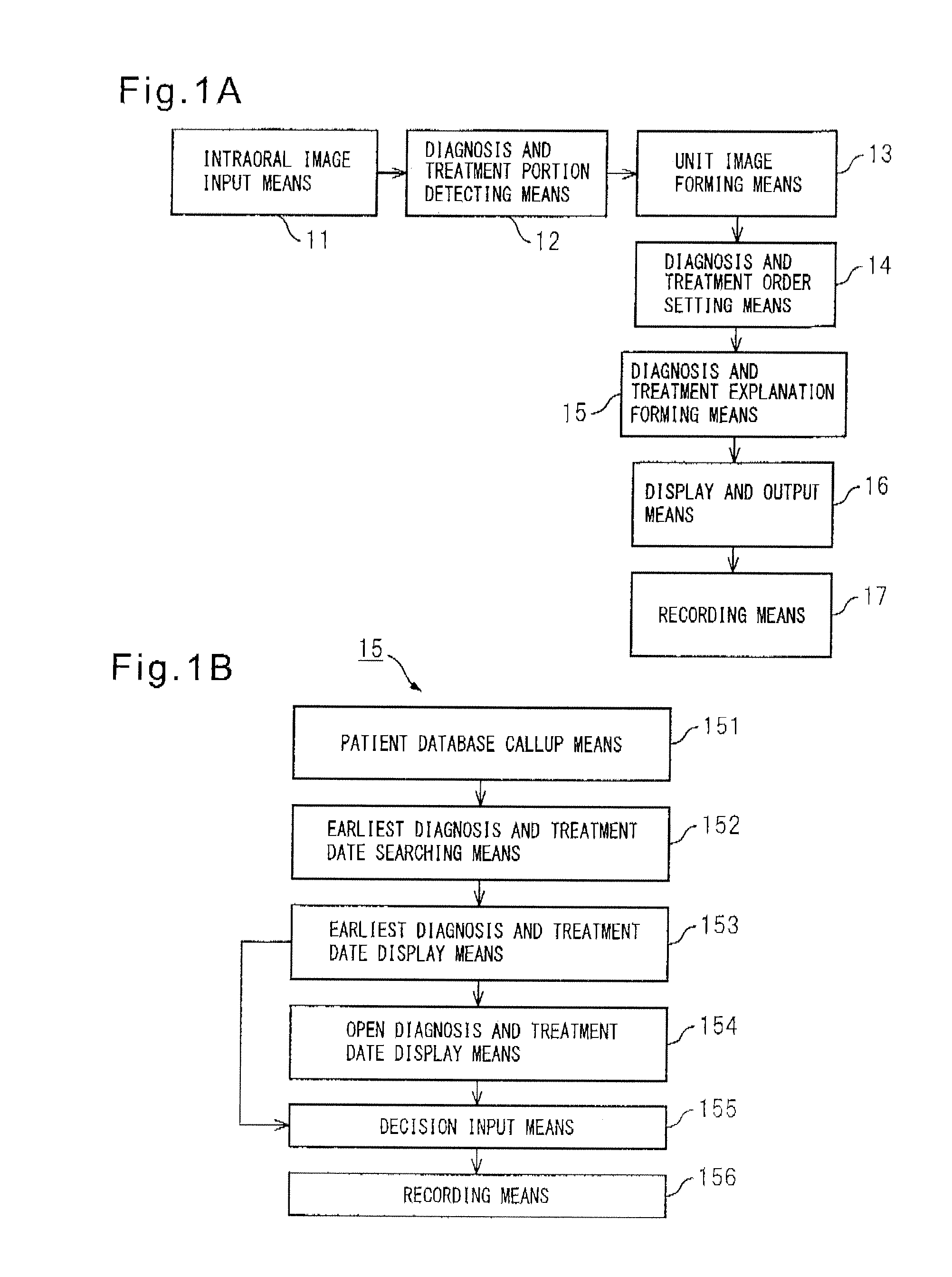

Intraoral video camera and display system

InactiveUS20130286174A1Accurate displayEasy to watchImpression capsSurgeryComputer monitorSurface tooth

A system configured provided with a continuously captured image sequence forming means for continuously capturing side surfaces of rows of teeth to form an image sequence, a side surface tooth row image forming means for combining sequences of images which were formed by the continuously captured image sequence forming means as partial tooth row images from an image forming the center of the overall composite so as to form a plurality of partial tooth row images, and a side surface tooth row image combining means for linking and combining a plurality of partial tooth row images which were formed by the side surface tooth row image forming means based on images farming the centers of the overall composite so as to form overall rows of teeth. By configuring the system in this way, it is possible to use a handheld type intraoral video camera to form a panoramic image of the side surface tooth rows for display on a computer monitor and propose a broad range of dental diagnosis and treatment to a patient and to secure participation of the patient in proactive dental diagnosis and treatment.

Owner:ADVANCE CO LTD

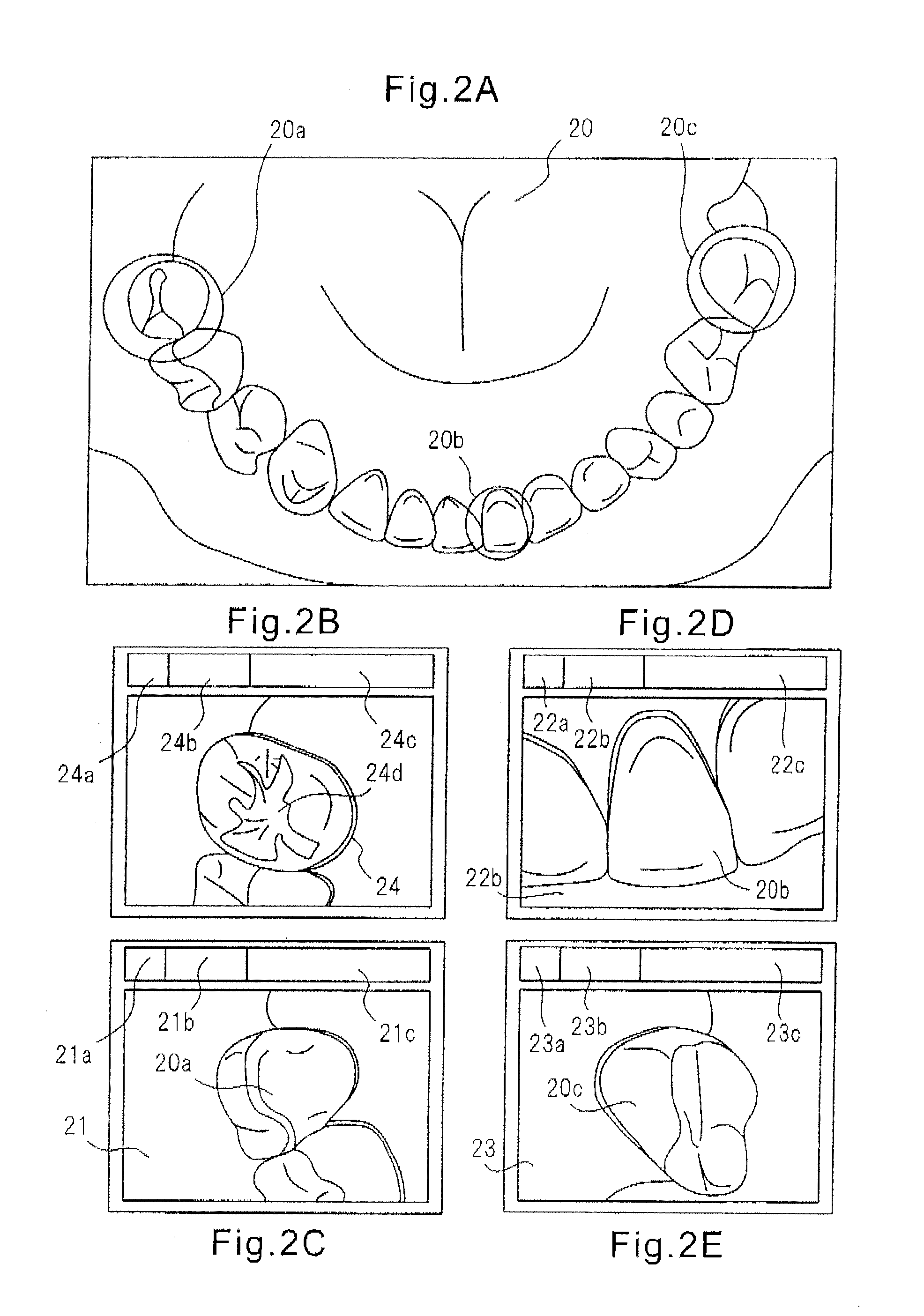

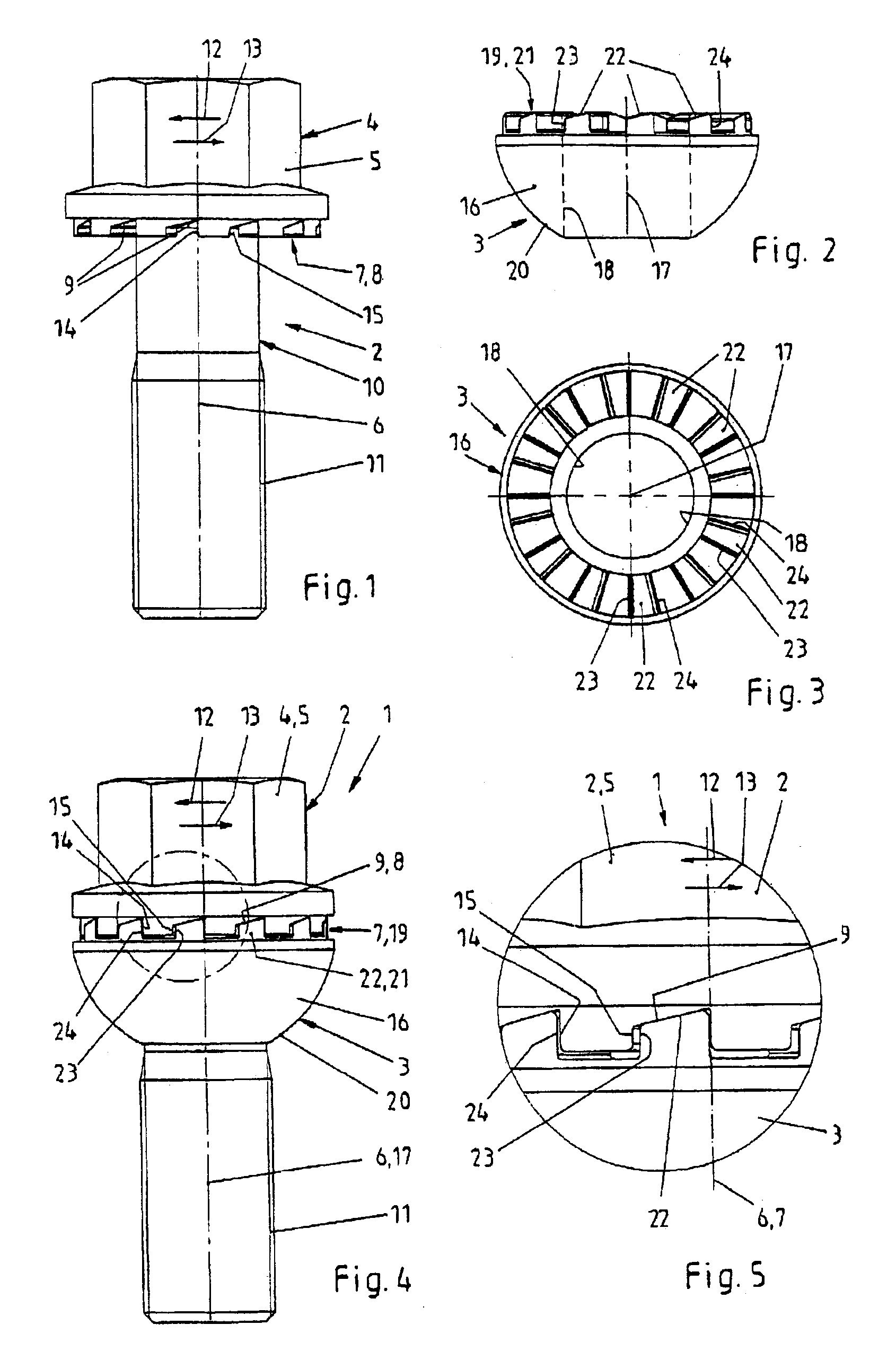

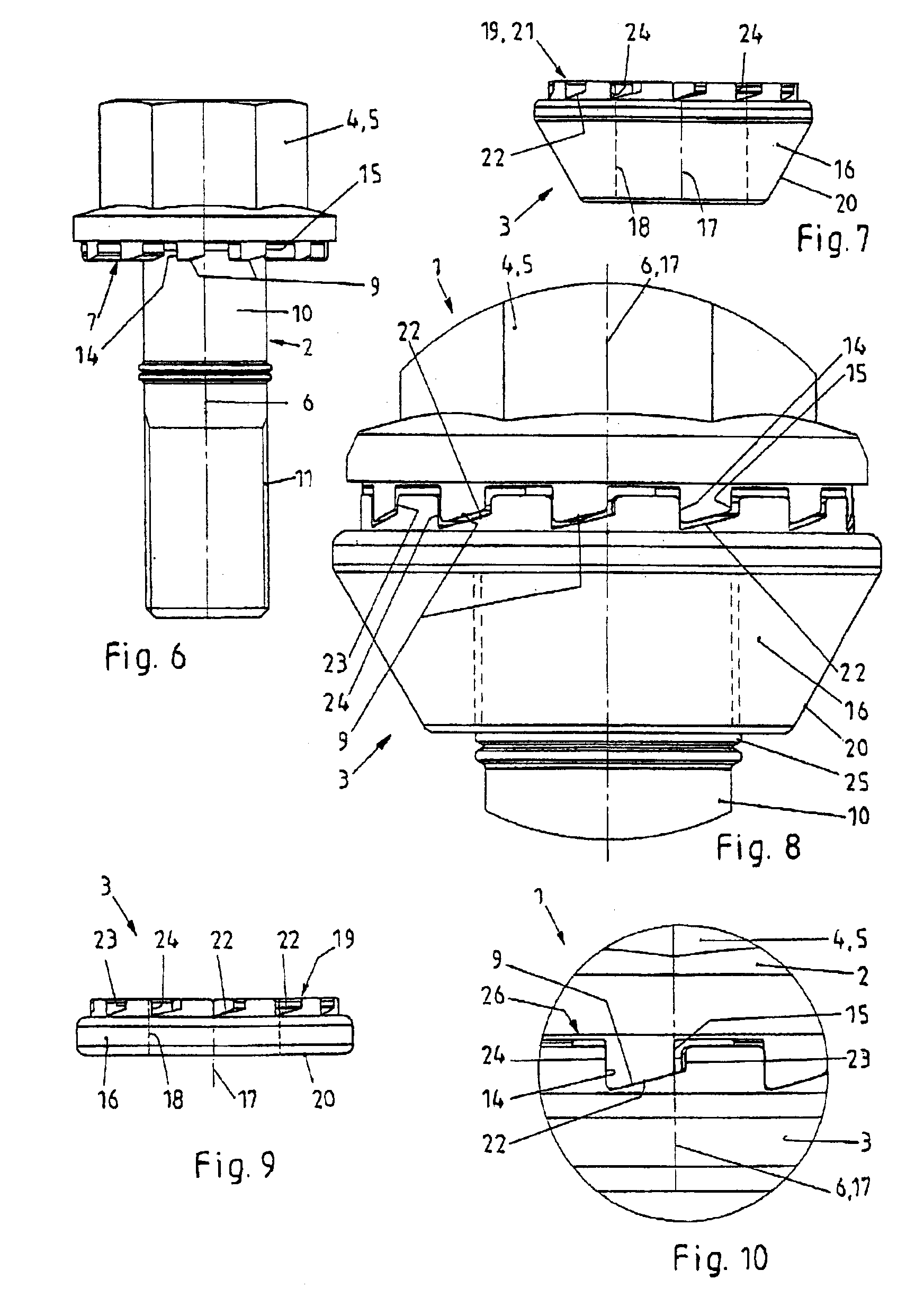

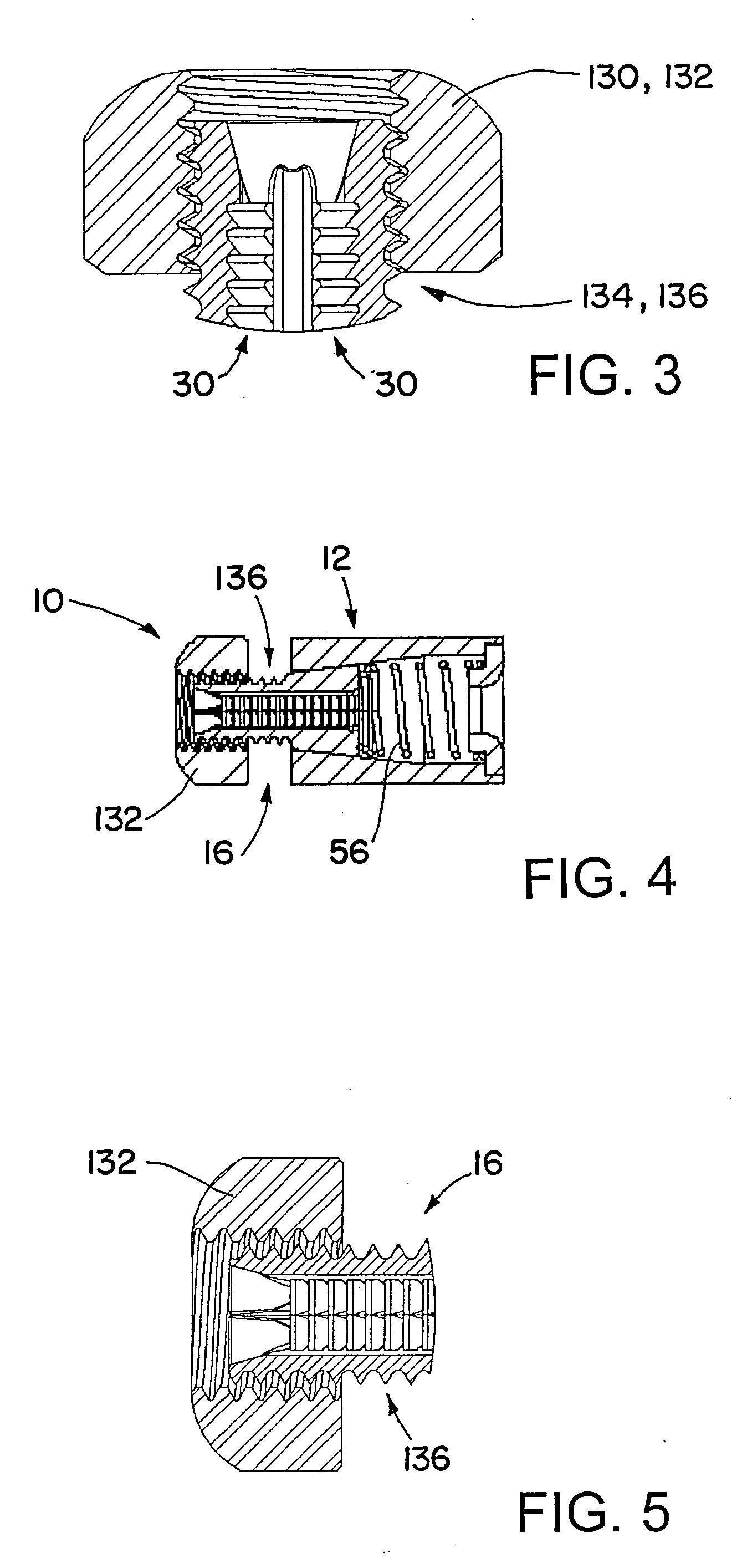

Detachable fastener including a screw element and a securing ring

A detachable fastener includes a screw element and a securing ring. The screw element and the securing ring each include cooperating wedge-shaped surface tooth arrangements and two different pairs of stop surfaces. The wedge-shaped surface tooth arrangements face one another and form sliding surfaces sliding upon one another in a loosening direction of rotation resulting in an increase of the axial force. The first pair of stop surfaces transmits torque in a tightening direction of rotation. The second pair of stop surfaces transmits torque in a loosening direction of rotation. The stop surfaces are arranged with a clearance existing between one another such that the wedge-shaped surface tooth arrangements can slide upon one another without skipping.

Owner:KAMAX HLDG

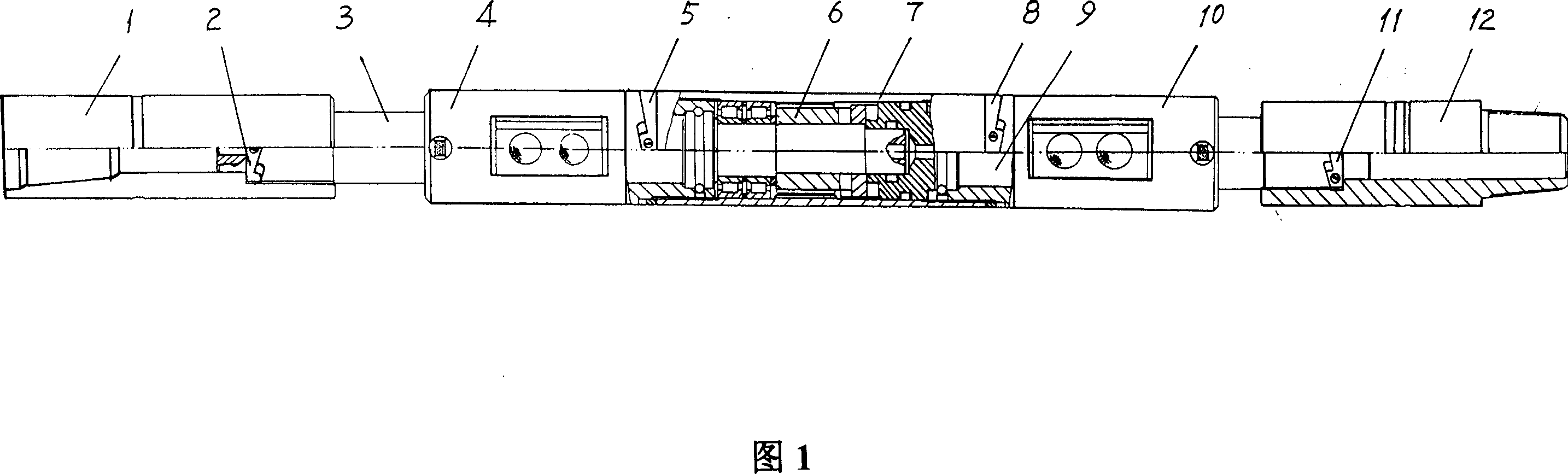

Cable locking device and method

InactiveUS20100037554A1Higher cable load ratingRopes and cables for vehicles/pulleyNutsSurface toothEngineering

A locking device includes a main housing with one or more plunger sets therein for gripping a cable. The plunger sets each have two or more pieces, for example plunger pieces, that are partially within a bore in the main housing. The plunger halves or pieces have teeth on inner surfaces, for gripping a cable that runs through the bore, between the plunger halves or pieces. A spring within the bore biases the plunger set to one side of the bore, a location in which the plunger halves or pieces are pressed together, causing the inner surface teeth to bite into the cable to secure the cable. A nut is threadedly connected to a threaded outer surface of the plunger halves, outside of the bore, to allow the plunger set to be moved within the bore, to allow disengagement of the cable from the teeth.

Owner:ERICO INT

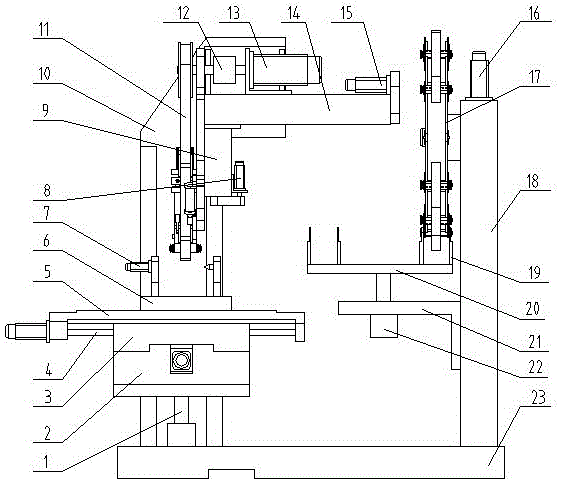

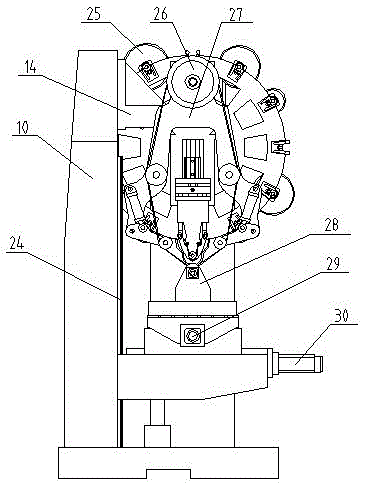

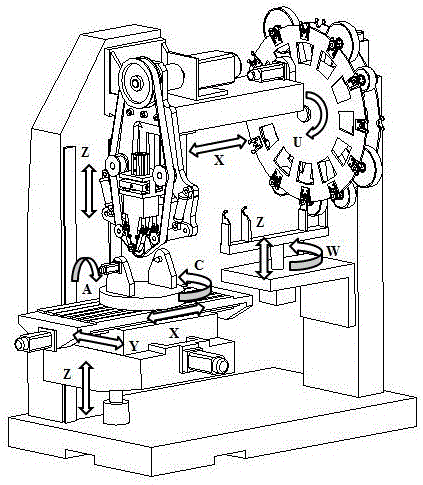

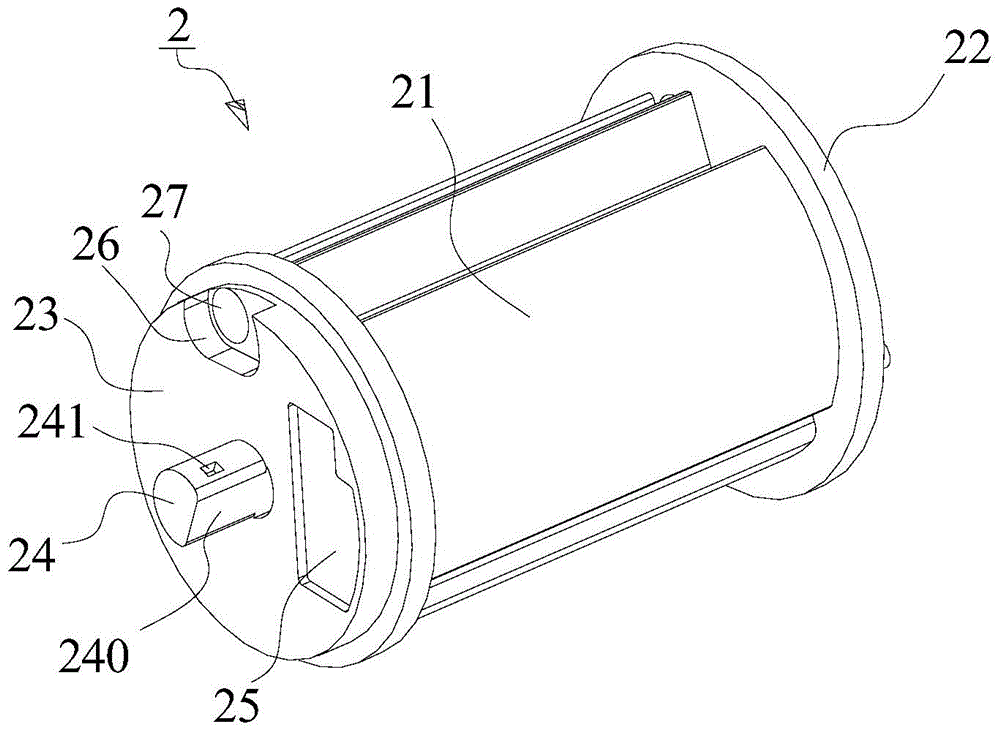

Abrasive belt grinding machining device with contact wheel depot

InactiveCN105058207AAxis position unchangedNo tape dropGrinding drivesBelt grinding machinesRotary stageSurface tooth

The invention discloses an abrasive belt grinding machining center with a contact wheel depot. The abrasive belt grinding machining center comprises a base, a stand column, a five-degree-of-freedom workbench, a power device, an abrasive belt supporting tensioning device, a grinding head device, the contact wheel depot and an automatic wheel replacing device. The five-degree-of-freedom workbench is composed of an X-direction saddle, a Y-direction saddle, a Z-direction saddle, a rotating table, a centre and a servo motor, and grinding machining of planes, revolution bodies and free curve faces can be achieved; an abrasive belt and a tensioning device are arranged on an abrasive belt supporting plate, and the abrasive belt is in the tensioning state all the time under the constant pressure effect of a tensioning air cylinder; the grinding head device can move in the X direction and the Z direction, so that the movement requirements in the grinding machining process and the wheel replacing process are met; contact wheels with different diameters, hardness degrees and surface tooth shapes are distributed on a rotary disc of the contact wheel depot in a circumferential manner; and an automatic wheel replacing mechanical arm is provided with four mechanical arm claws, and every two paired mechanical arm claws are used for clamping a contact wheel component to achieve the wheel replacing function. The abrasive belt grinding machining device is suitable for grinding machining of the planes, the revolution bodies and the free curve faces, and grinding machining with different surface quality requirements and different process requirements. The machining accuracy and the stability of parts are remarkably improved, the production period is shortened, and economic benefits are improved.

Owner:JILIN UNIV

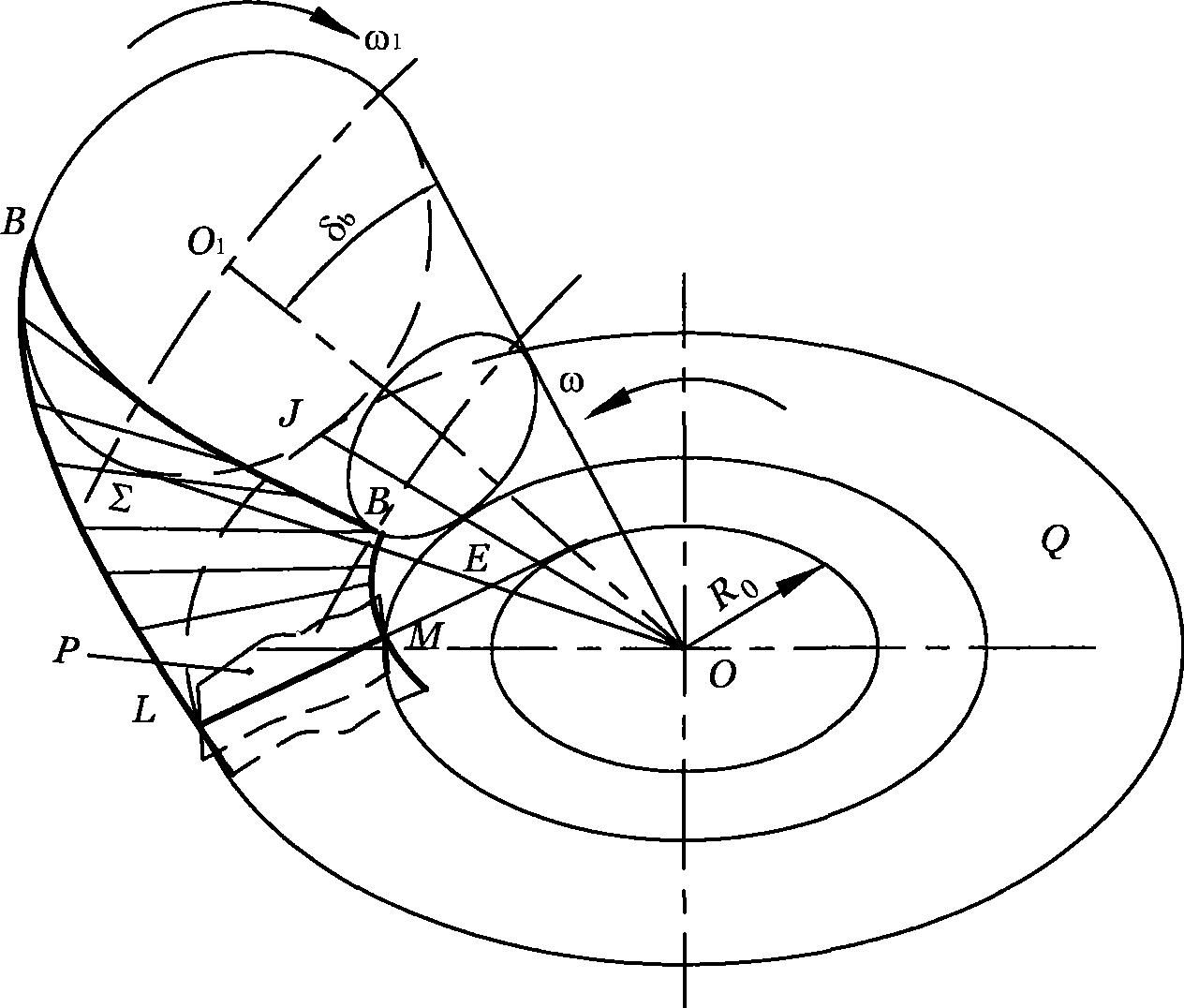

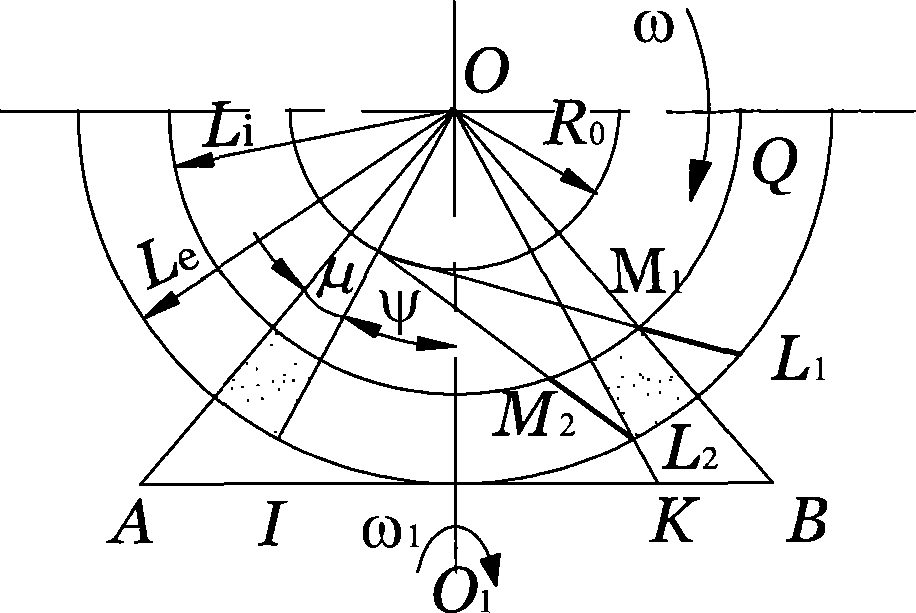

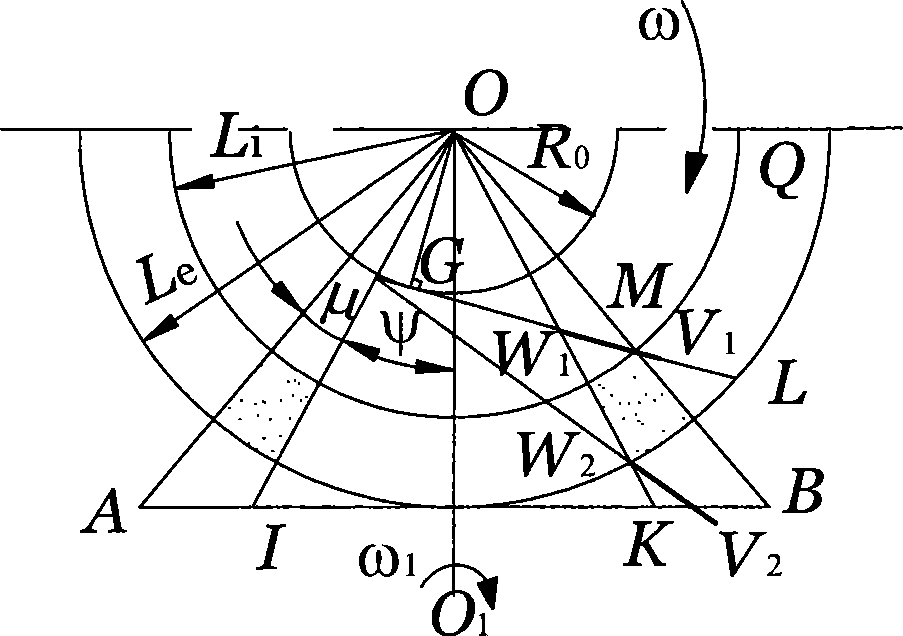

Processing method of tapered tooth spherical-involute tooth-form slant straight bevel gear

InactiveCN101391323AIncreased durabilityExtend your lifeGear-cutting machinesGear teethSurface toothEngineering

The invention discloses a machining method for a spherical involute toothed oblique straight bevel gear made by taped teeth. The machining method for a bevel gear adopts methods of gear skiving, gear milling and gear grinding. The methods of gear skiving, gear milling and gear grinding have the common technical characteristics that an oblique straight line ML on the big circular plane (Q) of a spherical surface, which is tangent to a toothed portion tangent circle with the radius of R0, represents a skiving cutter edge on an imaginary gear or uses a tangent plane which contains the ML and is perpendicular to the big circular plane (Q) of a spherical surface as the rotating plane of a single angle milling cutter end edge or the end surface of a grinding wheel, so a gear blank base cone with the base cone angle Delta b is tangent to the big circular plane (Q) of a spherical surface and the relative pure rolling is completed, the involute surface tooth cutting of the base cone is carried out to obtain the oblique straight bevel gear flank with the spherical involute teeth. In order to avoiding overcutting, the ML line for representing a skiving gear cutter edge or a straight line along the gear root cuts out along a straight line of the gear root with the speed of vW which is equal to R0 Omega sinaOmega t / cos<2> t or along the ML self straight line with the speed of vW which is equal to R0 Omega / cos<2> Omega t. One side flank of a gear is cut according to single tooth division. The machining of two side flanks is completed by adopting double cutter heads and double stations to cut teeth. A new machine tool is designed according to the method.

Owner:JILIN UNIV

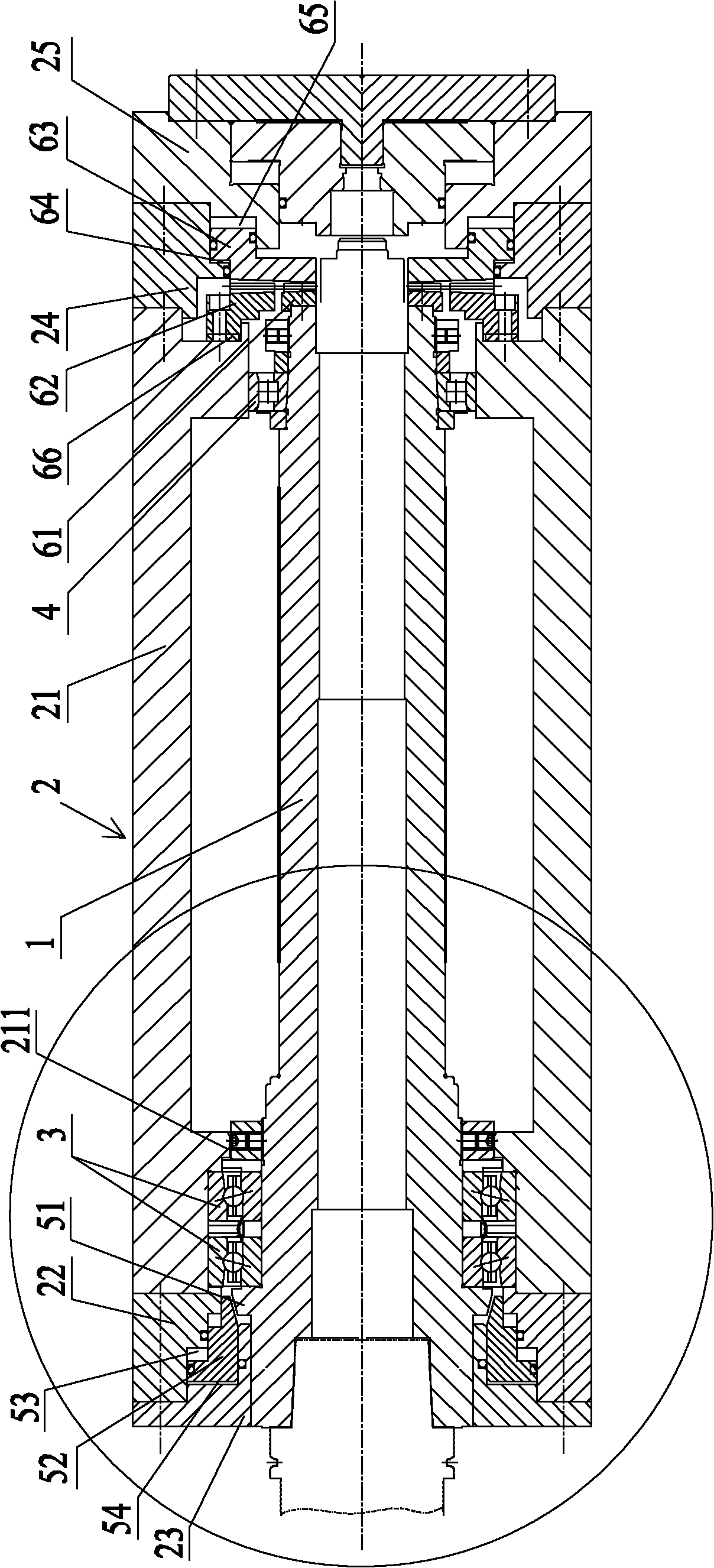

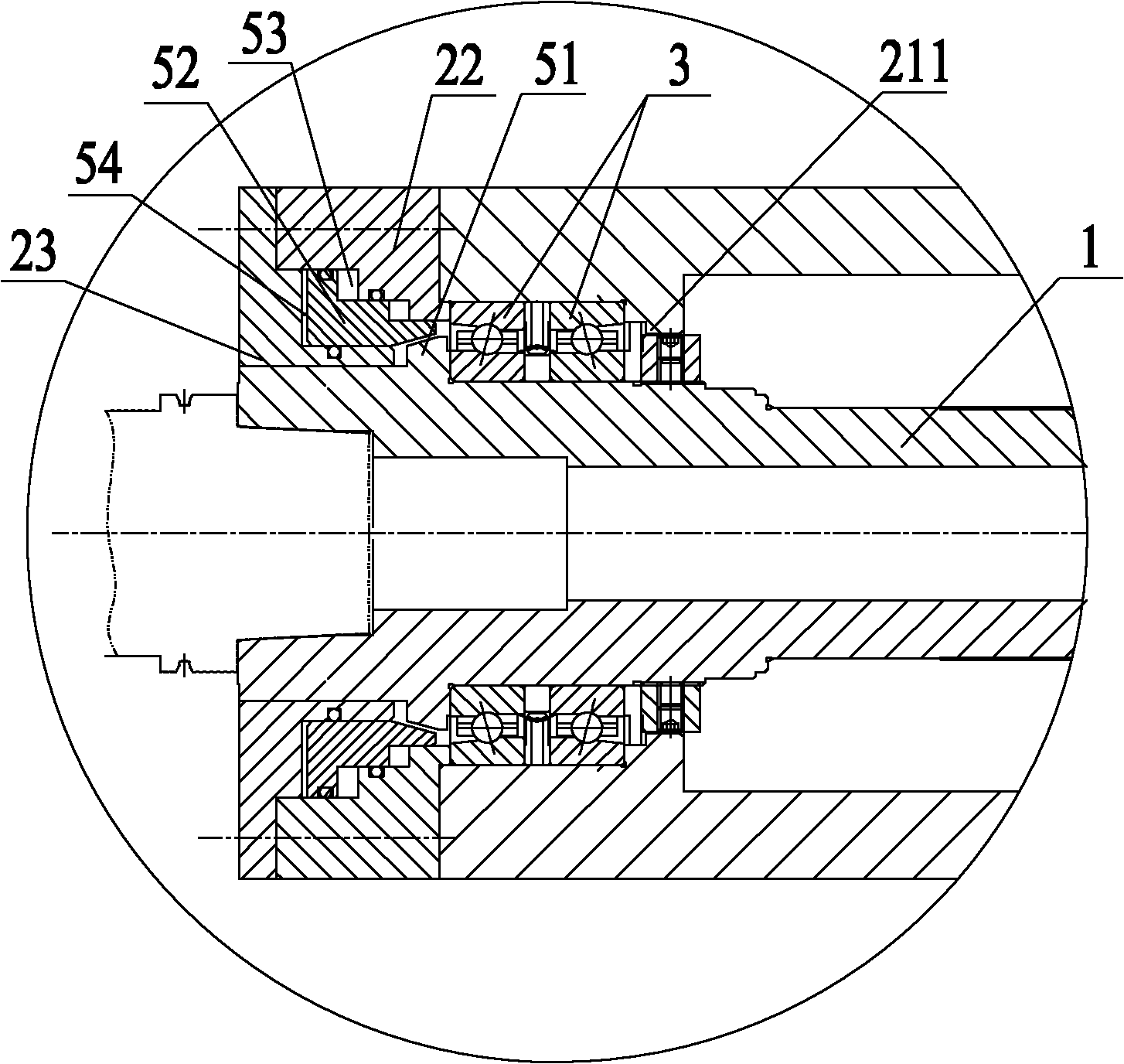

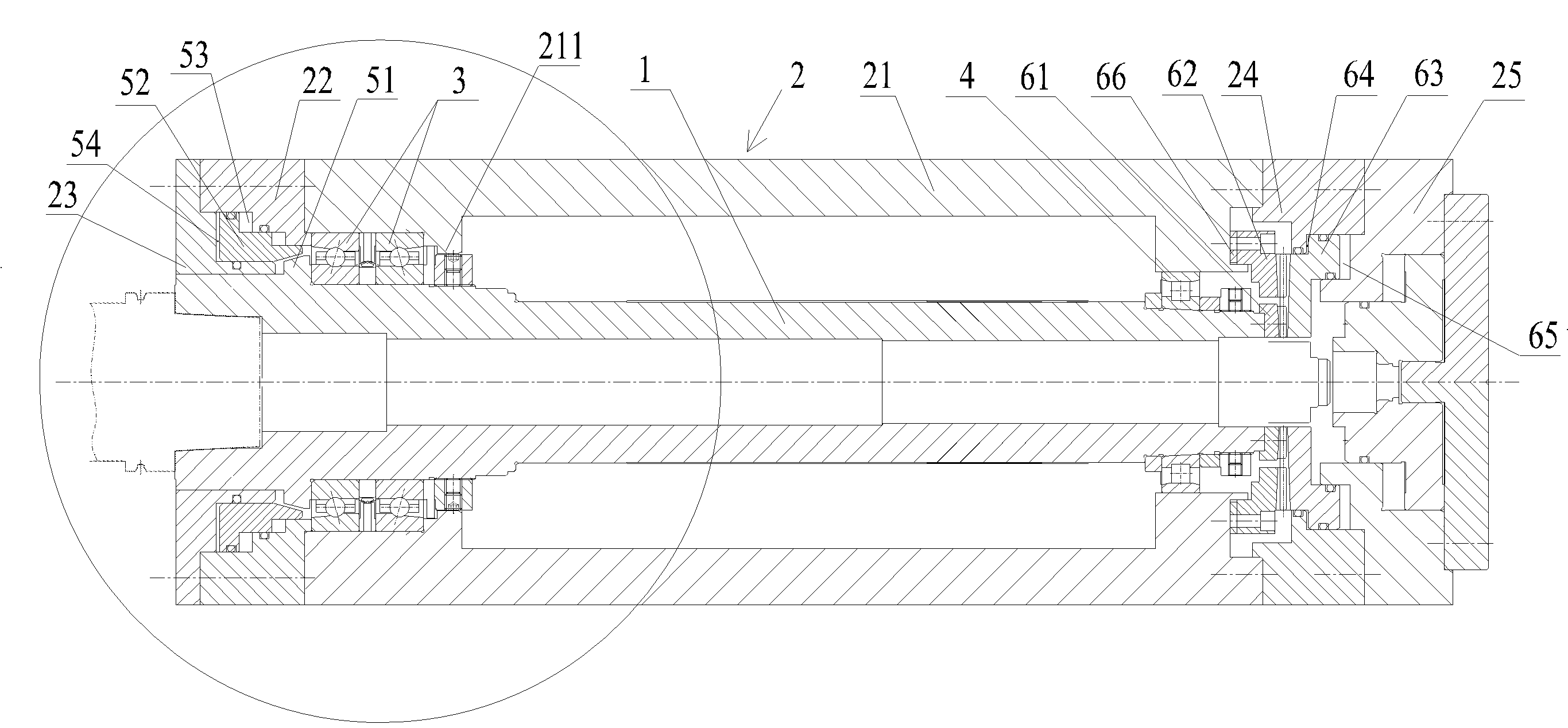

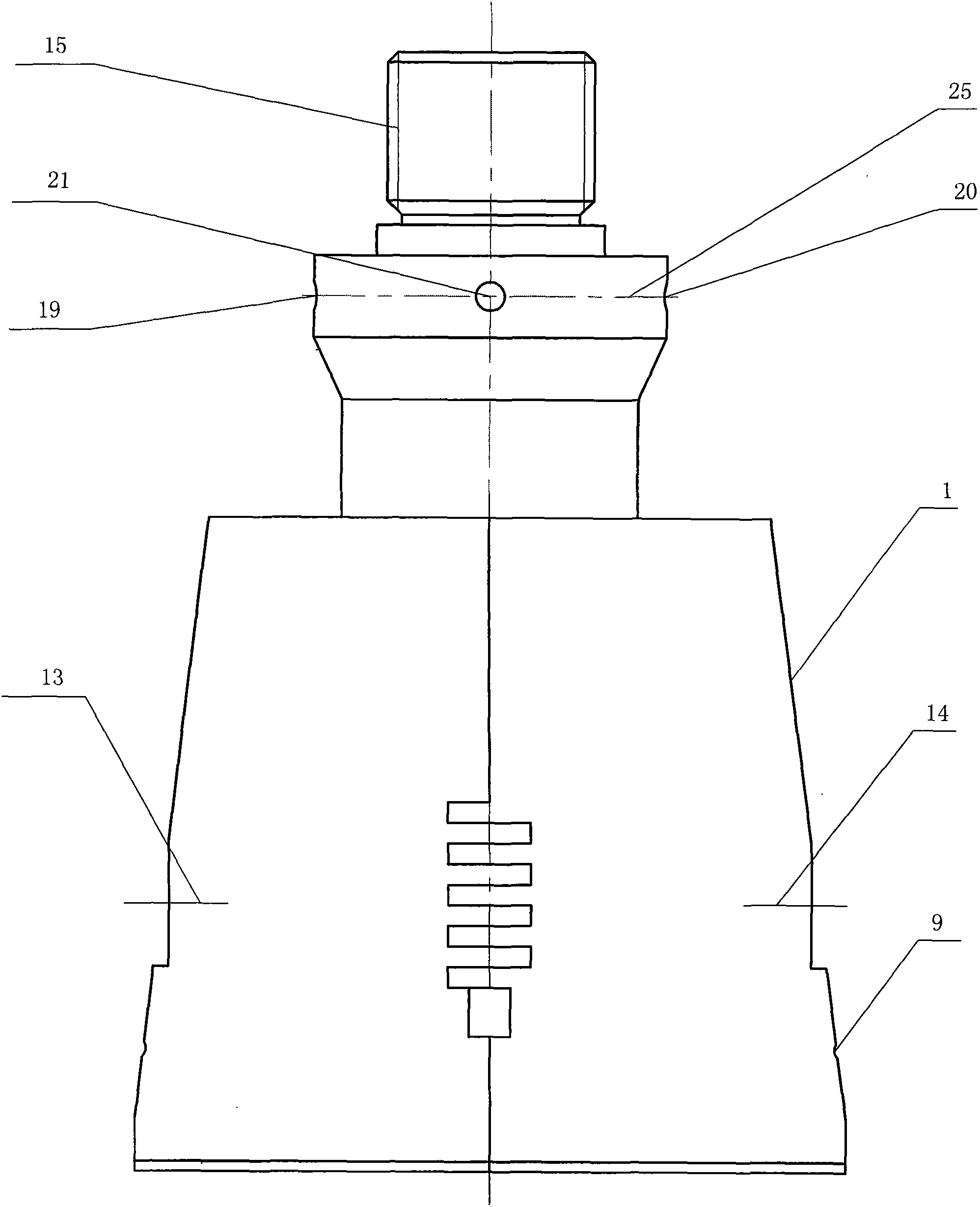

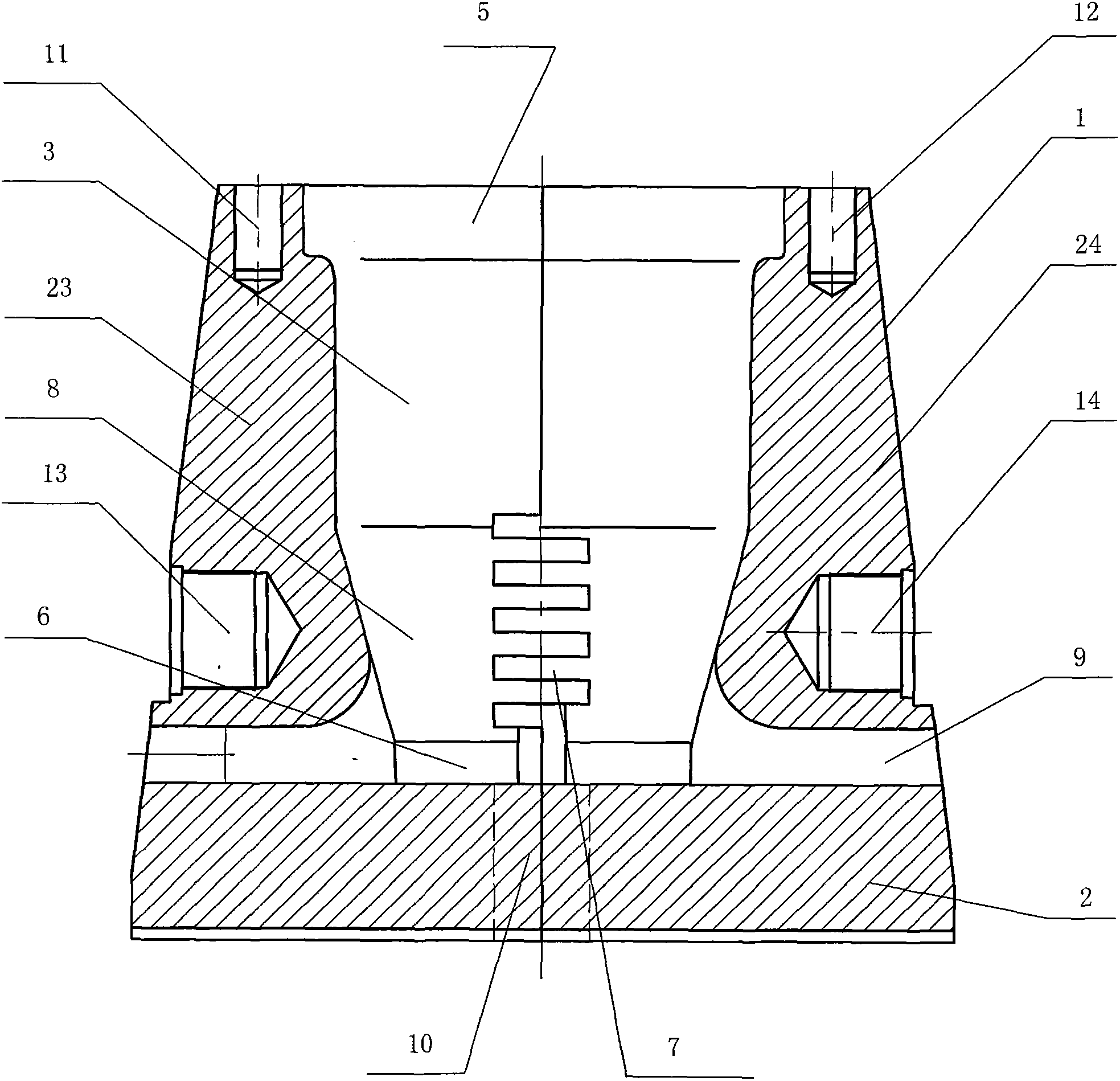

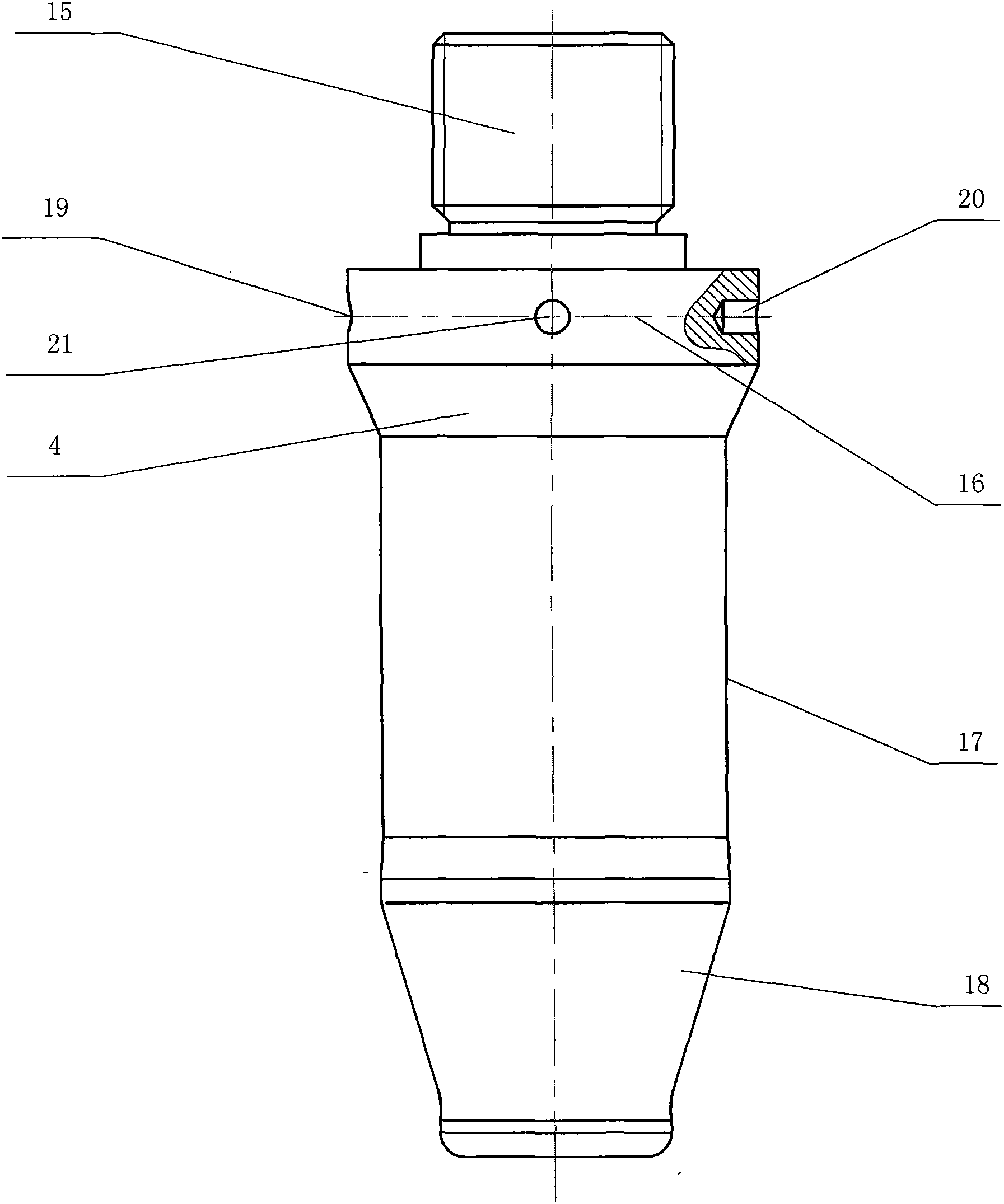

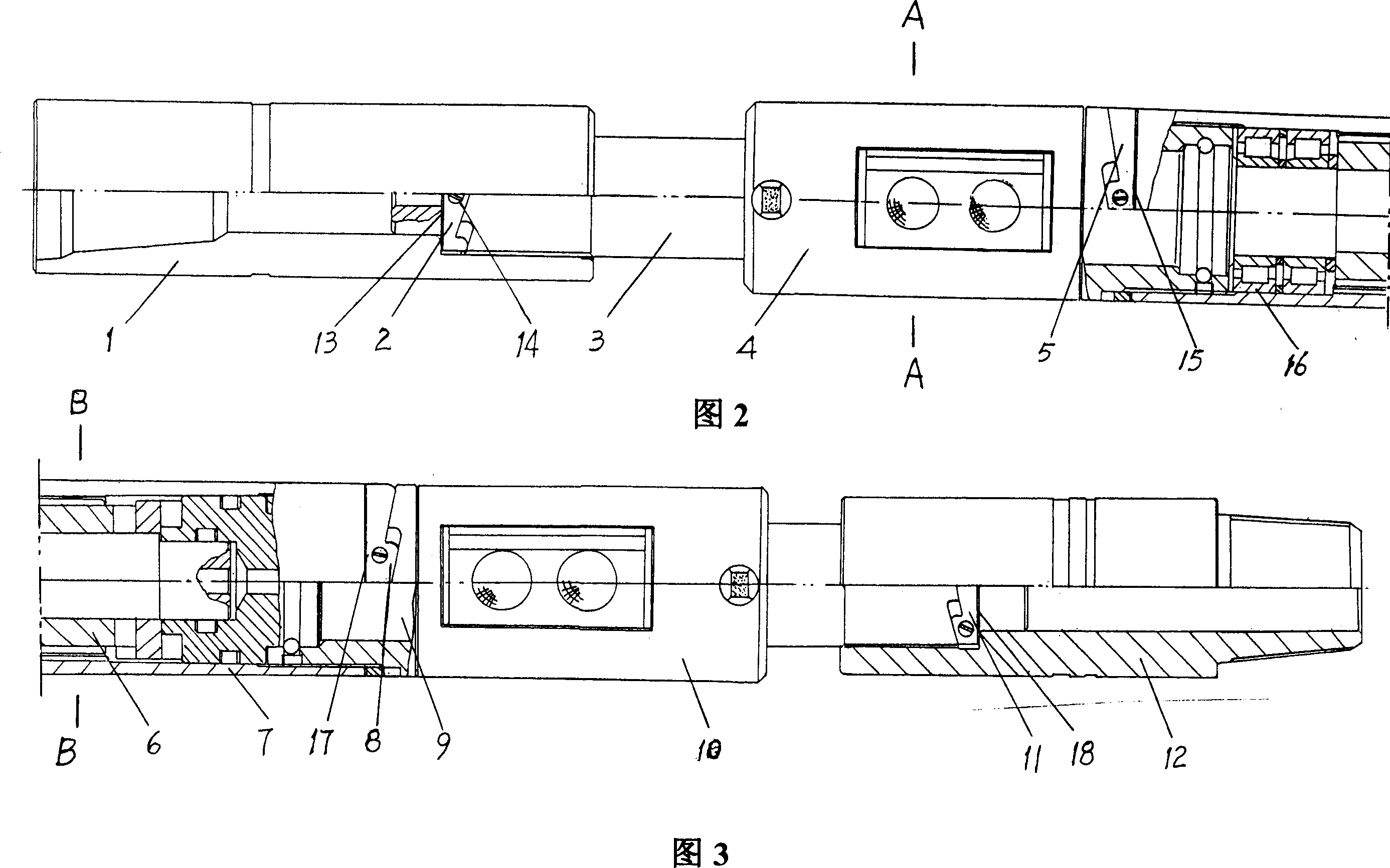

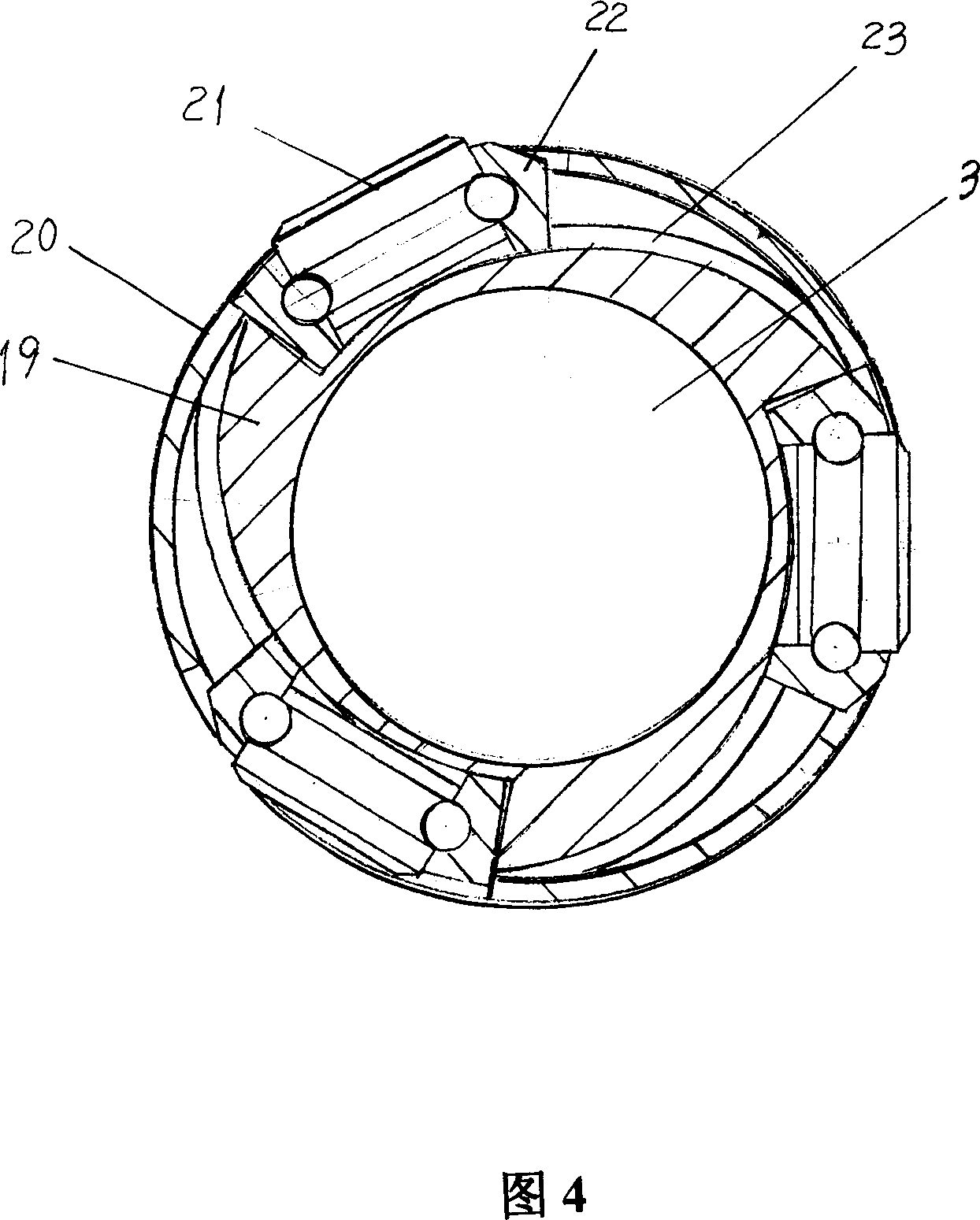

Turning-milling combined machine tool and spindle locking device thereof

InactiveCN102513554ALocking directly effectiveSmall structure sizeOther manufacturing equipments/toolsLocking mechanismSurface tooth

The invention provides a turning-milling combined machine tool and a spindle locking device thereof. The spindle locking device comprises end face tooth locking devices arranged in a spindle box and close to the outer side of a second bearing and a conical surface locking device arranged in the spindle box and close to a first bearing, the conical surface locking device comprises a fixed locking annular block fixed on a spindle and a movable locking annular block capable of sliding axially along the spindle, the periphery of the fixed locking annular block is a conical surface, and an inner hole at one end of the movable locking annular block toward the fixed locking annular block is a conical surface. When the turning-milling combined machine tool is in a turning state, the end surface tooth locking devices are engaged mutually, so that the conical surface locking device achieves locking, and locking of the spindle is ensured through the two locking mechanisms. When the spindle is in a milling state, the two locking mechanisms relax simultaneously, and rotation of the spindle can be achieved. The spindle locking device is high in accuracy, good in manufacturability and simple in structure.

Owner:SANY GRP

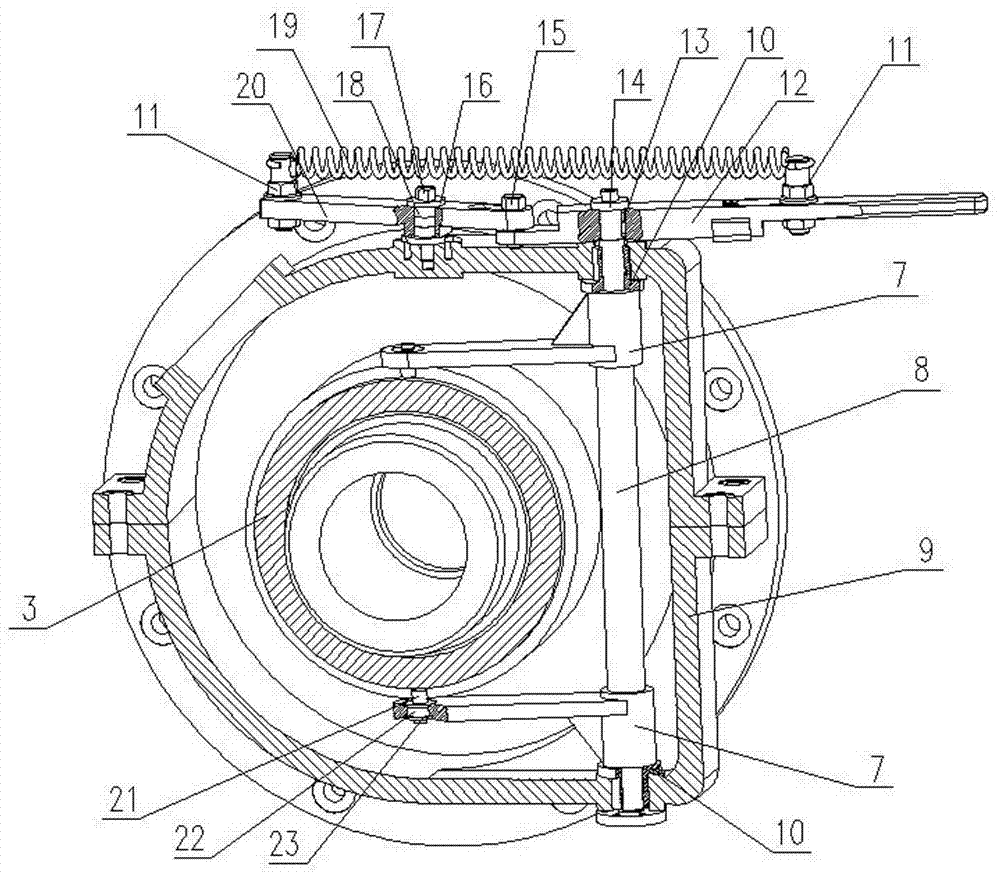

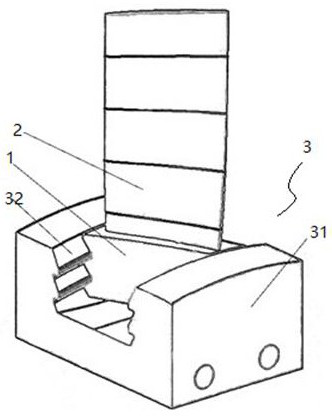

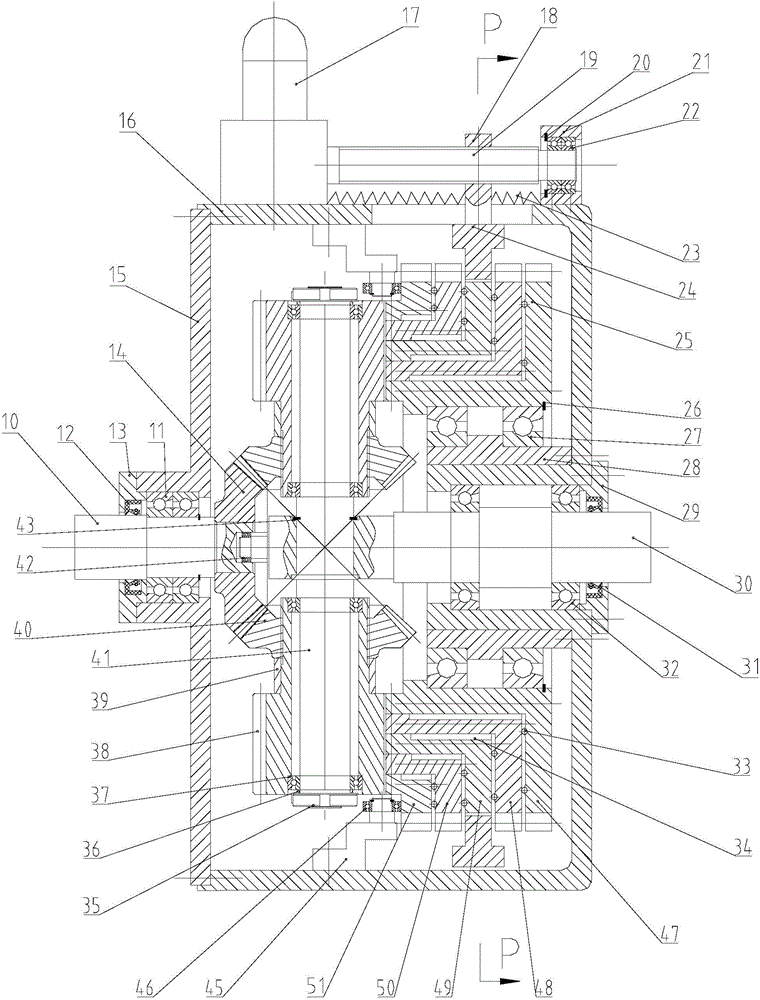

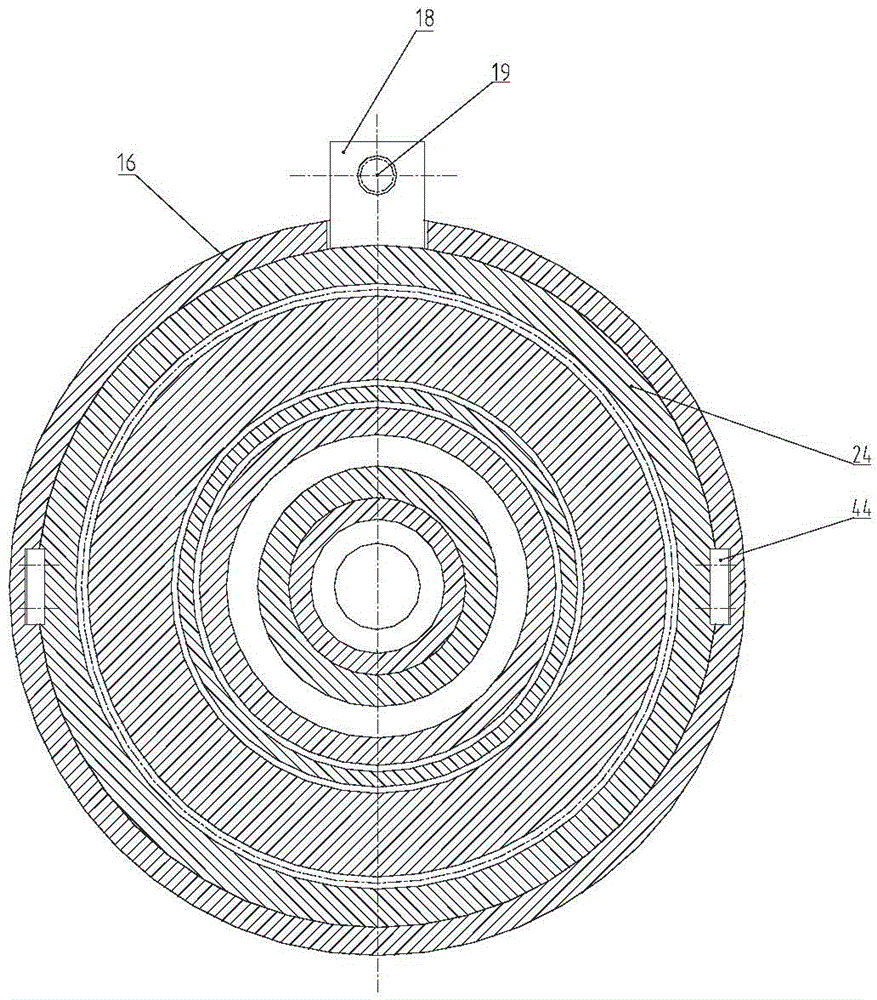

Intelligent anti-counterfeiting seal with information tracing, authority controlling and seal impression authenticity verifying functions

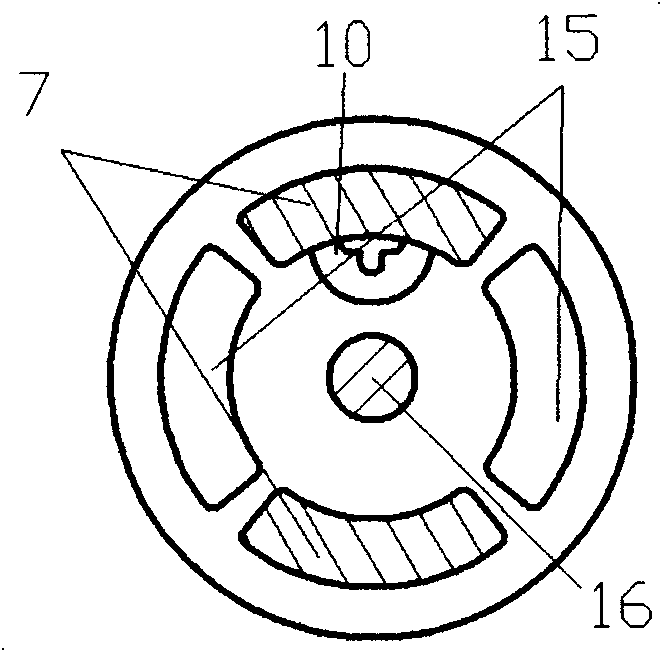

InactiveCN103465649ASolve anti-counterfeitingAnti-abuseDigital data authenticationResourcesSurface toothRotation - action

The invention relates to the field of anti-counterfeiting techniques for seals, in particular to an intelligent seal. A service protection mechanism of the intelligent seal in an embodiment of the invention comprises a service protection barrier column 12, service protection limiting seats 15, a guide column 16, a displacement sensor 9 and a return spring 17; a protection relief mechanism of the intelligent seal comprises rotating coils 7, a fixed coil 19 and an angular displacement sensor 6; end-surface teeth are staggered from one another or are aligned with one another under the rotation actions of the rotating coils 7, so that protection or protection relief can be implemented. The intelligent seal has the advantages that service information of the intelligent seal can be traced, the intelligent seal only can be used by authorized operators, authenticity of seal impression on files can be verified, and abuse, embezzlement and counterfeiting of the intelligent seal are prevented; sealing information is recorded at first by an electronic information technique, and then sealing only can be performed after legitimacy of the sealing information is confirmed; authority authentication constraints are set, so that a seal holder is prevented from performing sealing against true will of the seal holder to a certain extent; the sealing information is stored in a management database, so that a file holder can apply for verifying the authenticity of the seal impression on the files.

Owner:刘文化

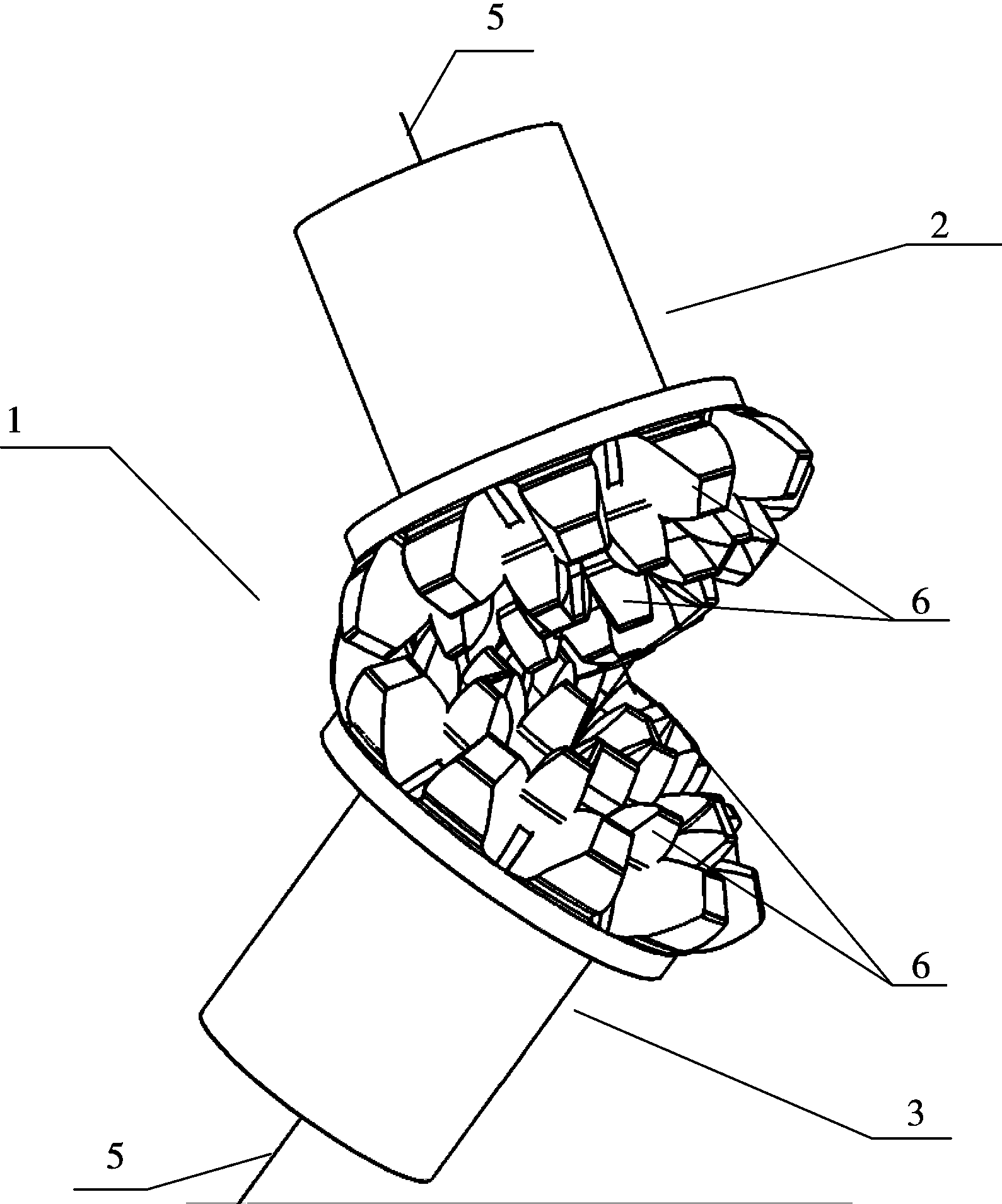

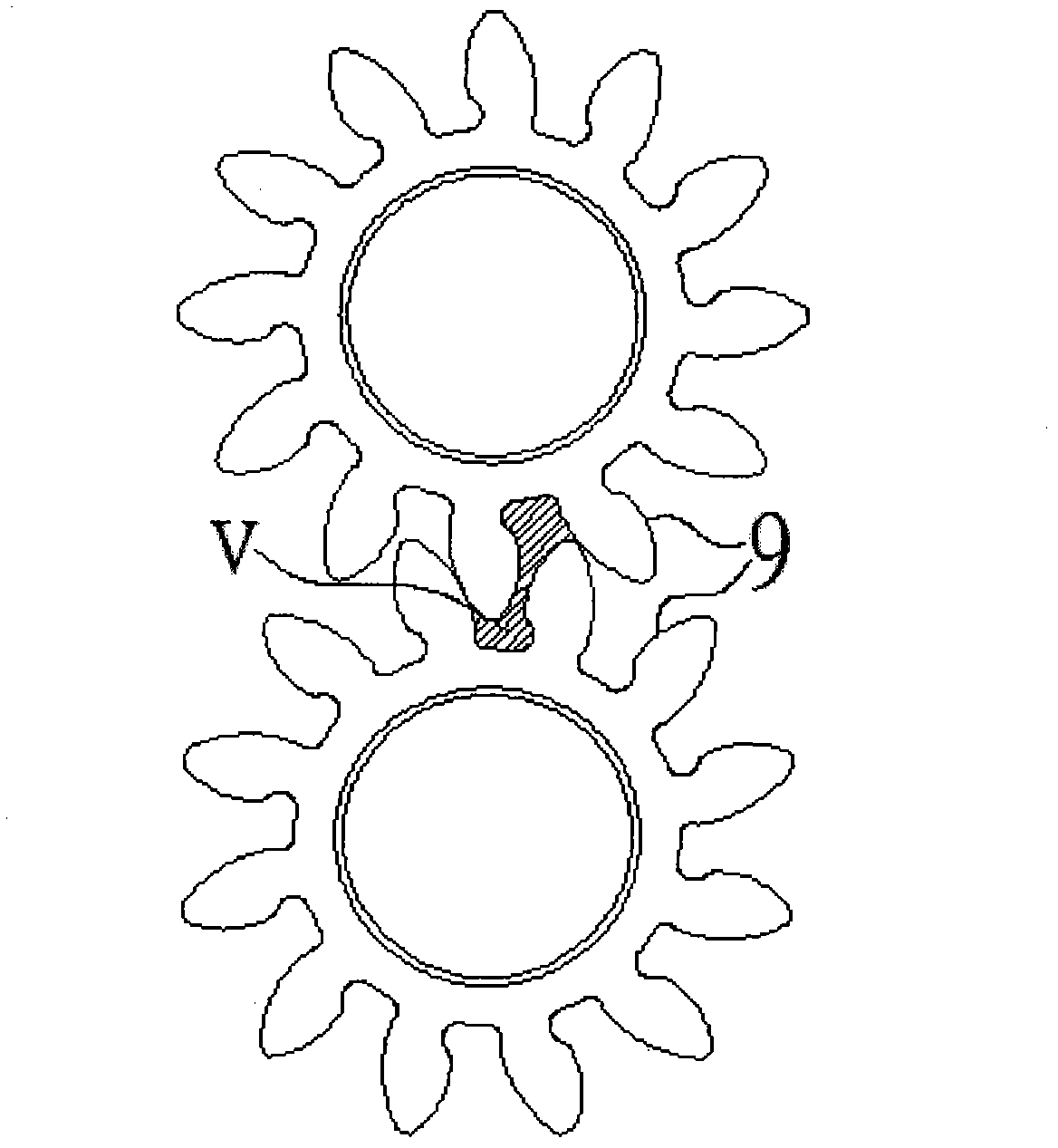

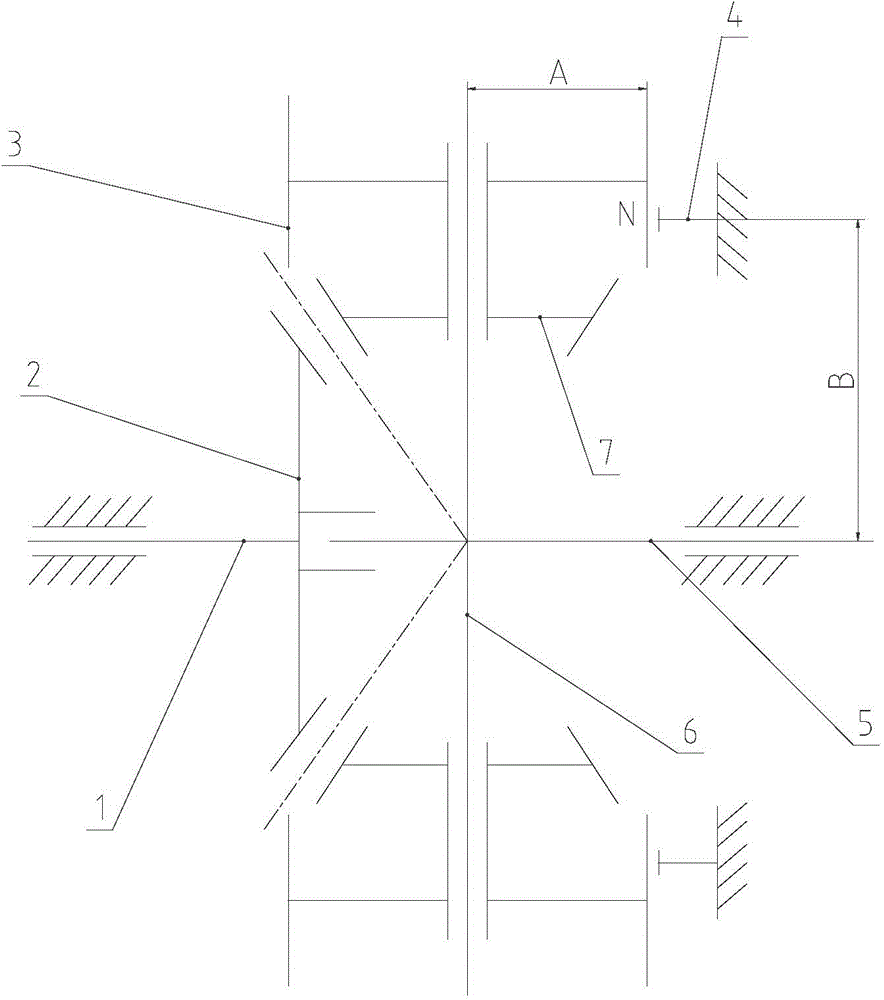

Involute spherical gear transmission pair

The invention discloses an involute spherical gear transmission pair. The involute spherical gear transmission pair comprises two spherical gears, wherein involute gear teeth are uniformly distributed on the circumferences in the weft directions of the spherical surfaces of spherical cap sections on spherical caps; the tooth thickness directions are along the weft directions of the spherical caps; the numbers of the teeth on the wefts at different heights are variable; the number of the teeth on low-latitude parts is large; the number of the teeth on high-latitude parts is small; a plurality of tooth rings from the high latitude to the low latitude are formed. The spherical gears are sectioned over the axis; the outer contours of the sections of the tooth rings form the outer contours of the involute spherical gear teeth along the meridians in the tooth thickness directions; the outer counters of the gear teeth formed by the sections of the tooth rings are divided into two groups; odd-number groups and even-number groups are respectively the same as the shapes of the end surface teeth of two straight gears of which the gear teeth are placed in a staggered way.

Owner:杨兆奎

Method for restoring inner bore of gear coupling

InactiveCN102747364AExtended service lifeImprove wear resistanceMetallic material coating processesLaser coatingHigh power lasers

A method for restoring the inner bore of a gear coupling is disclosed. Dimensions of all parts of the gear coupling are measured to check whether all the dimensions satisfy laser coating restoration standards, the surface fatigue layer of the inner bore of the gear coupling is removed, Ni55 and nanometer WC powder which are prepared in proportion are fully mixed in a mechanical powder mixer through adopting a mechanical mixing method, the Ni55 and the nanometer WC powder are coated on the surface of the inner bore of the gear coupling through adopting a coaxial powder sending method and through scanning by adopting a large-power CO2 laser, and the gear coupling undergoes heat treatment and then is slowly cooled with a furnace; and the inner bore of the cooled gear coupling is machined to obtain the gear coupling with the dimensions and the surface process which satisfy requirements, the gear coupling undergoes processing precision detection, and finally the gear coupling is packaged. Compared with the prior art, the method disclosed in the invention has the advantages of continuous use, better performances and long service life of the gear coupling, simple technology, strong controllability, less energy consumption and the like.

Owner:YANSHAN UNIV

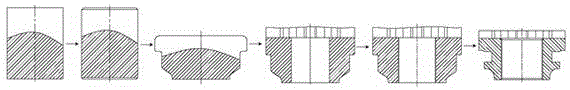

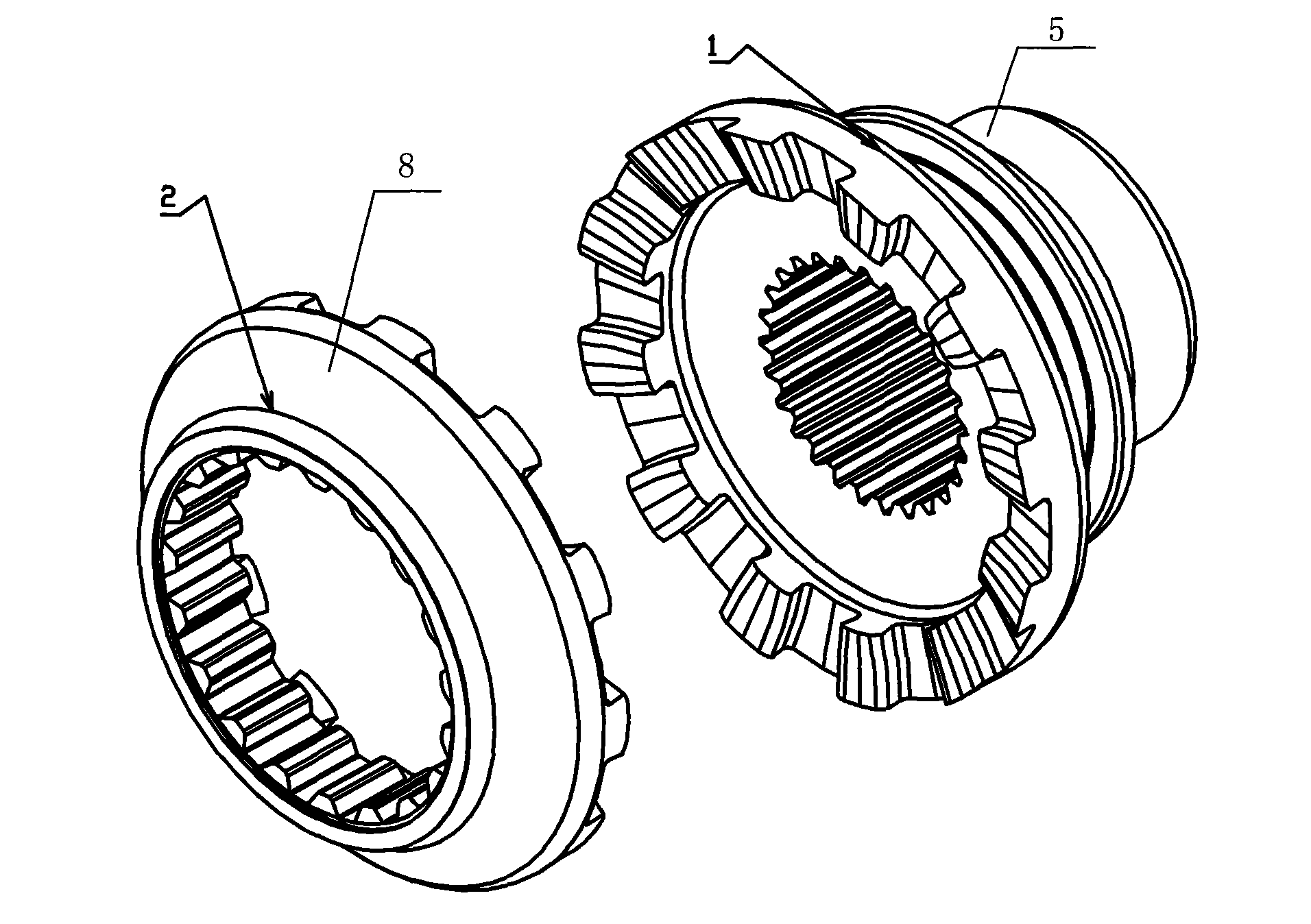

Production process of automotive middle-rear axle transmission meshing sleeve

The invention discloses a production process of an automotive middle-rear axle transmission meshing sleeve. The production process comprises the following steps of step 1, feeding; step 2, blank forming; step 3, shot blasting; step 4, coating heating; step 5, heating and upsetting; step 6, warm forging extrusion and residual heat annealing; step 7, cold extrusion on a straight tooth spline arranged on the inner wall of a middle hole; step 8, shot blasting and turning according to design drawings; step 9, carburizing and quenching and step 10, sandblasting and oil coating packaging. According to the production process of the automotive middle-rear axle transmission meshing sleeve, the warm extrusion is combined with the cold extrusion to forge the end surface tooth shape and the straight tooth spline which is arranged on the inner wall of the middle hole, the milling machining on the end surface tooth shape and the straight tooth spline which is arranged on the inner wall of the middle hole does not need to be performed after forging, and accordingly the production processes are less, the cutting quantities are less, the tooth shape forging extrusion forming is high in accuracy and high in density, the impact resistance is good, the quality is good, and accordingly the technical requirements of the automotive middle-rear axle transmission meshing sleeve are fully met and meanwhile the production process conforms to the development trend of the current automotive manufacturing.

Owner:江苏威鹰机械有限公司

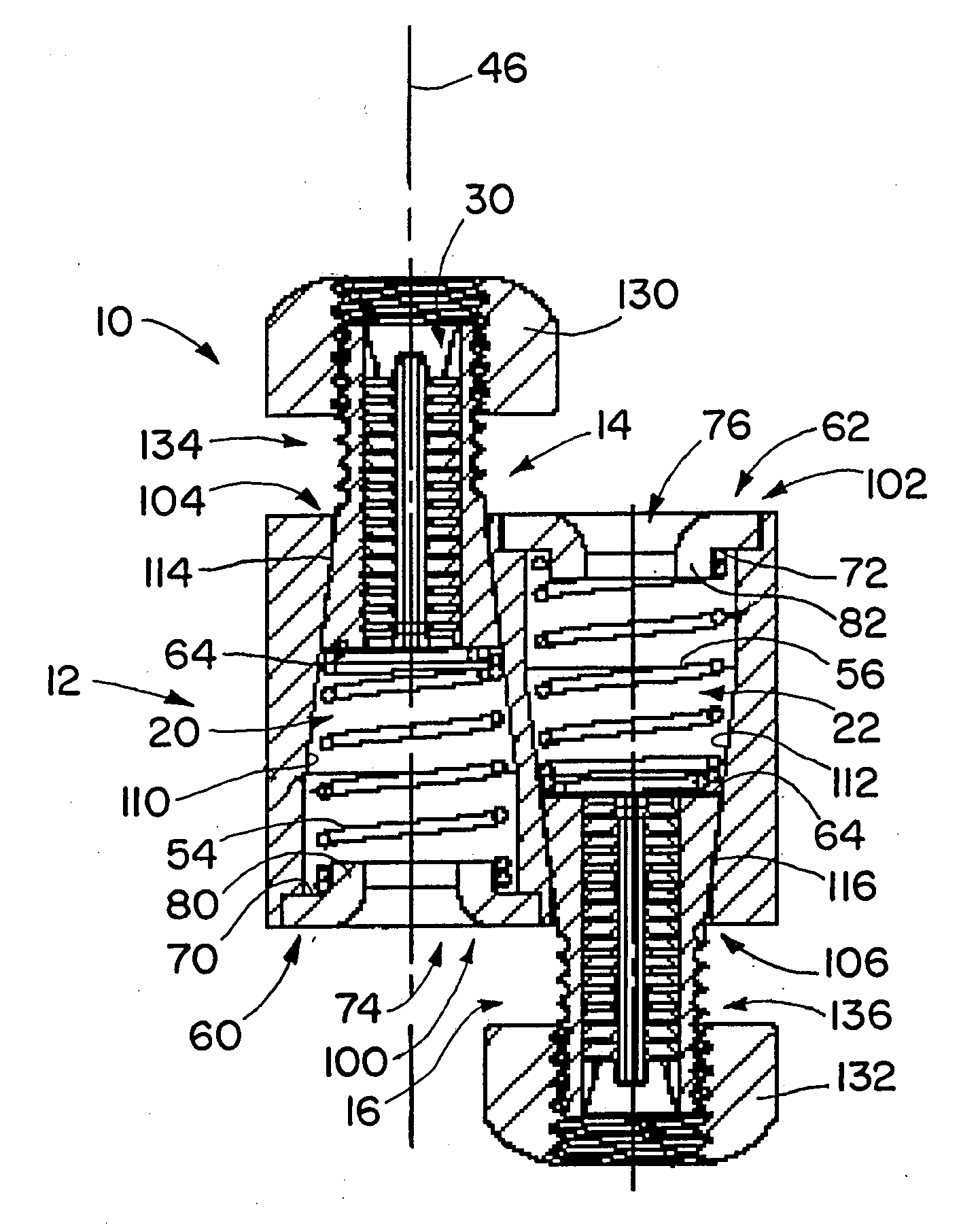

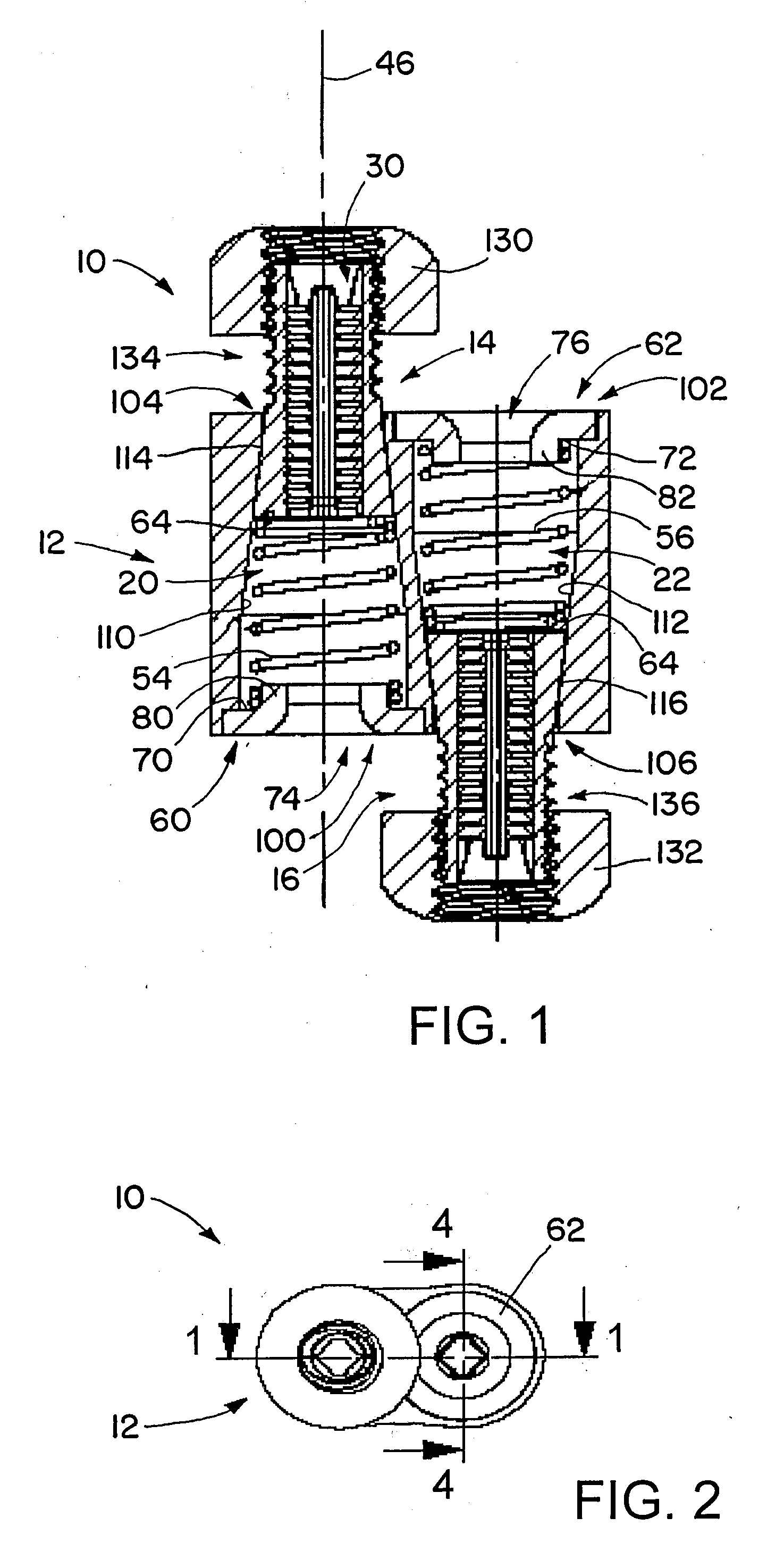

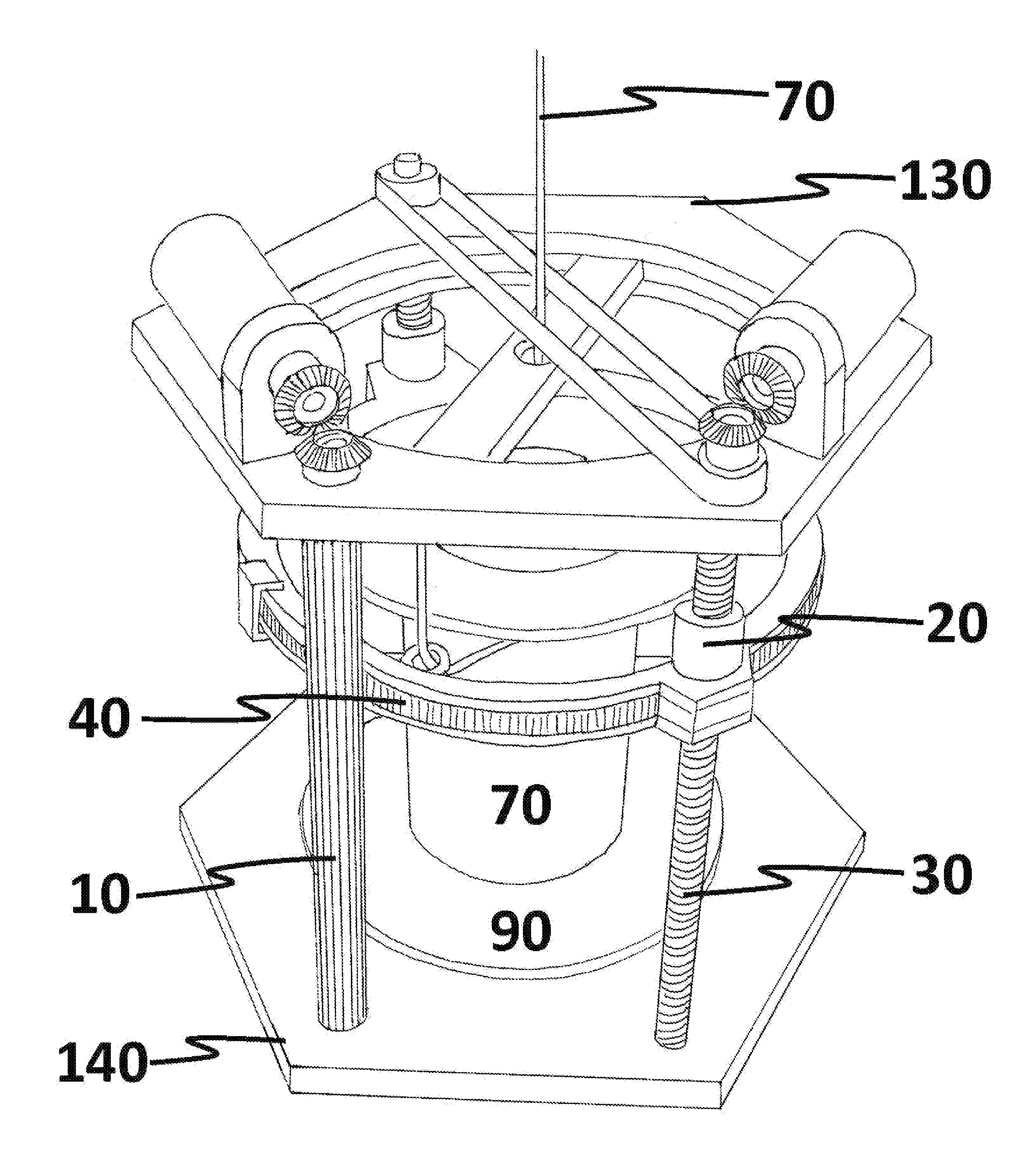

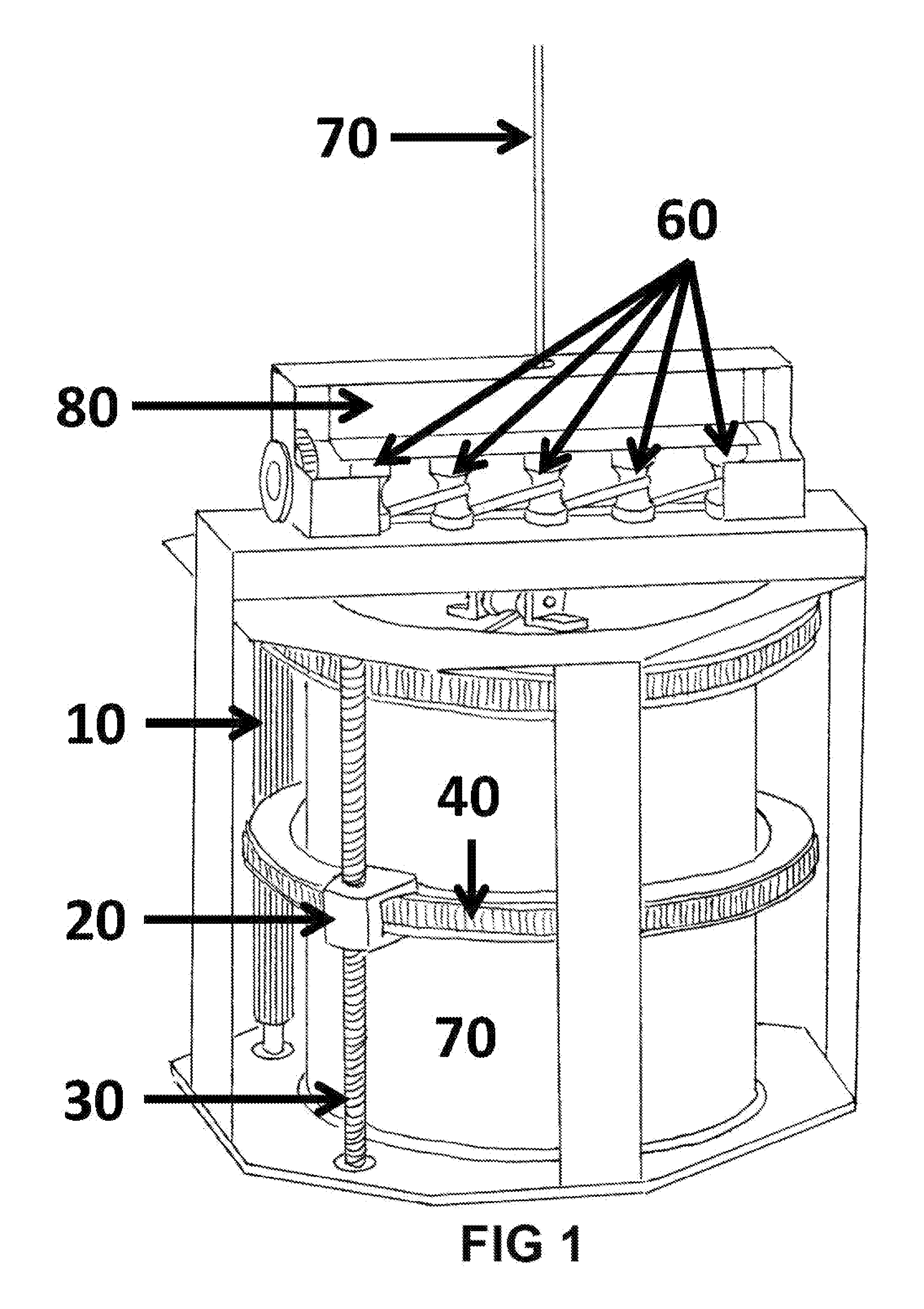

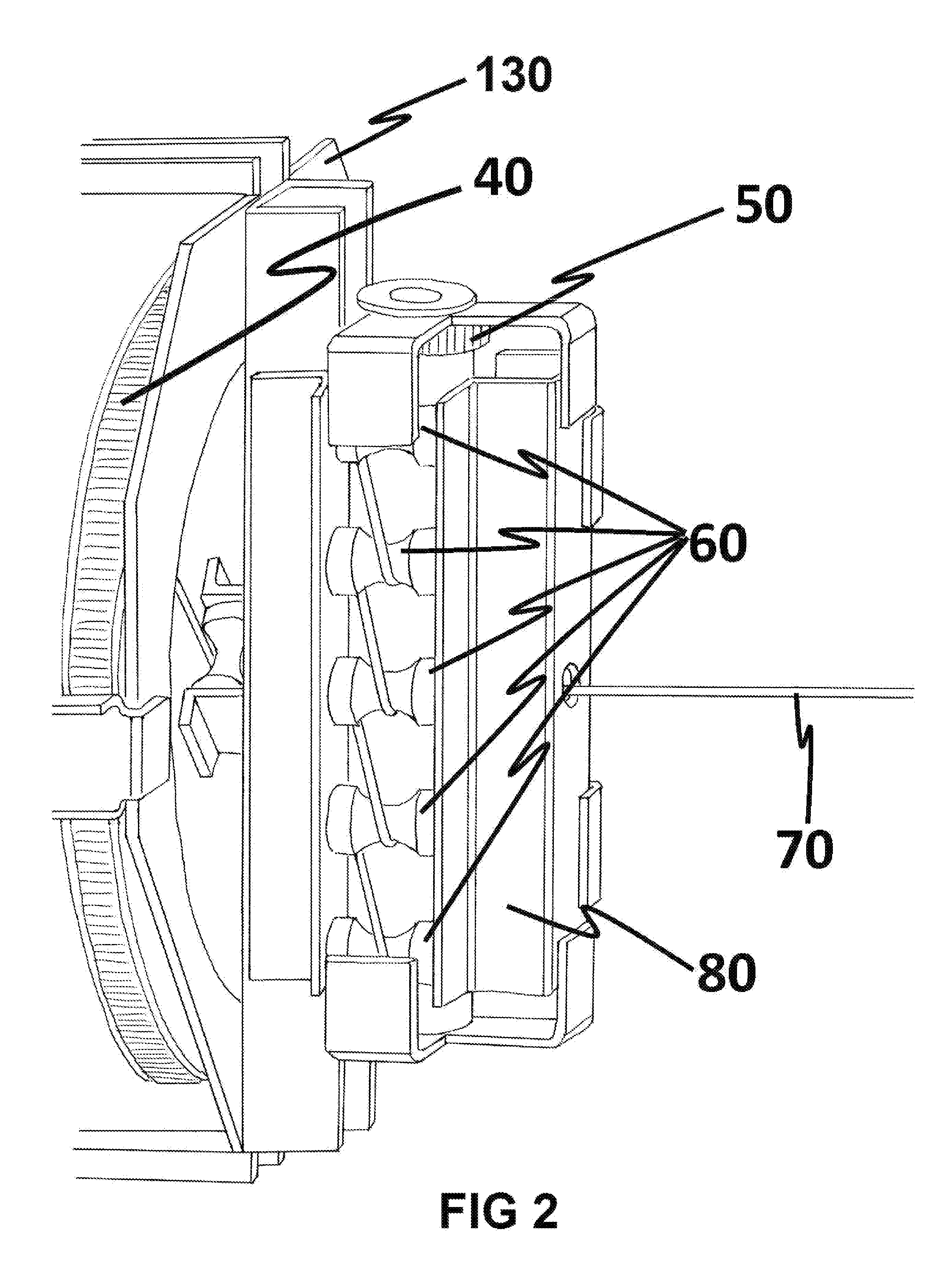

Orbital Winch

ActiveUS20140284531A1Regulate tensionReduce wearLifting devicesWinding mechanismsSurface toothPinion

Orbital winch having: lower and upper frames; spool having upper and lower flanges with lower flange attached to lower frame; axial tether guide mounted to upper frame; secondary slewing ring coaxial with spool and rotatably mounted to upper frame, wherein secondary slewing ring's outer surface has gearing; upper tether guide mounted to inner surface of secondary slewing ring; linear translation means having upper end mounted to upper frame and lower end mounted on lower frame; primary slewing ring rotatably mounted within linear translation means allowing translation axially between flanges, wherein primary slewing ring's outer surface has gearing; lower tether guide mounted on primary slewing ring's inner surface; pinion rod having upper end mounted to upper frame and lower end mounted to lower frame, wherein pinion rod's teeth engage primary and secondary slewing rings' outer surface teeth; and tether passing through axial, upper, and lower tether guides and winding around spool.

Owner:TETHERS UNLTD

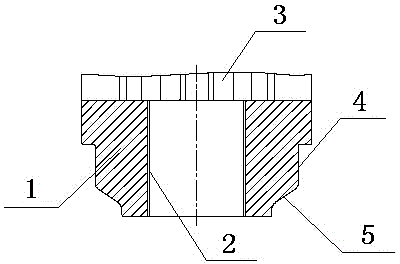

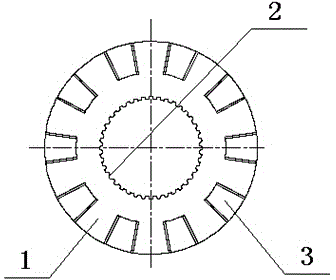

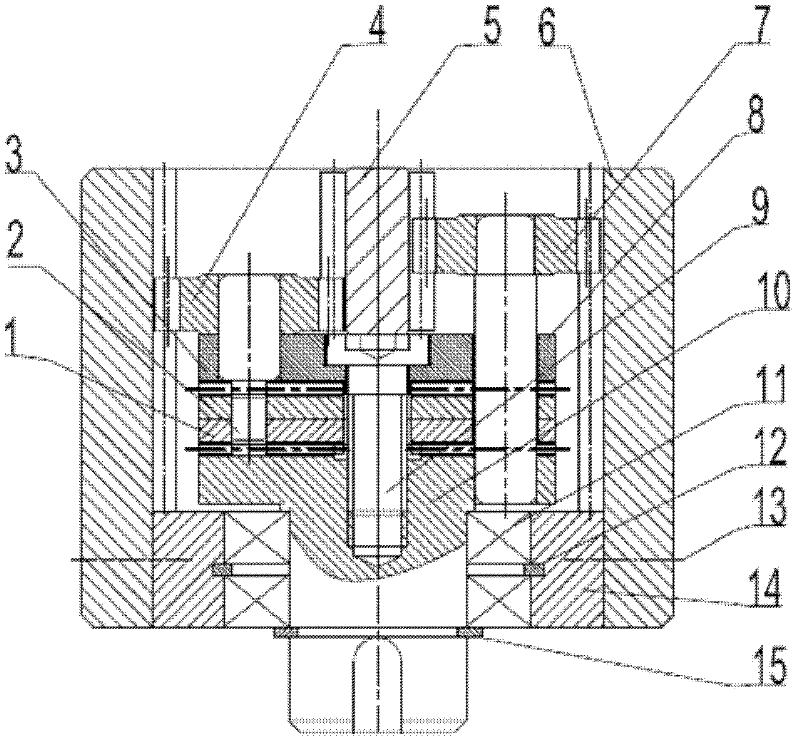

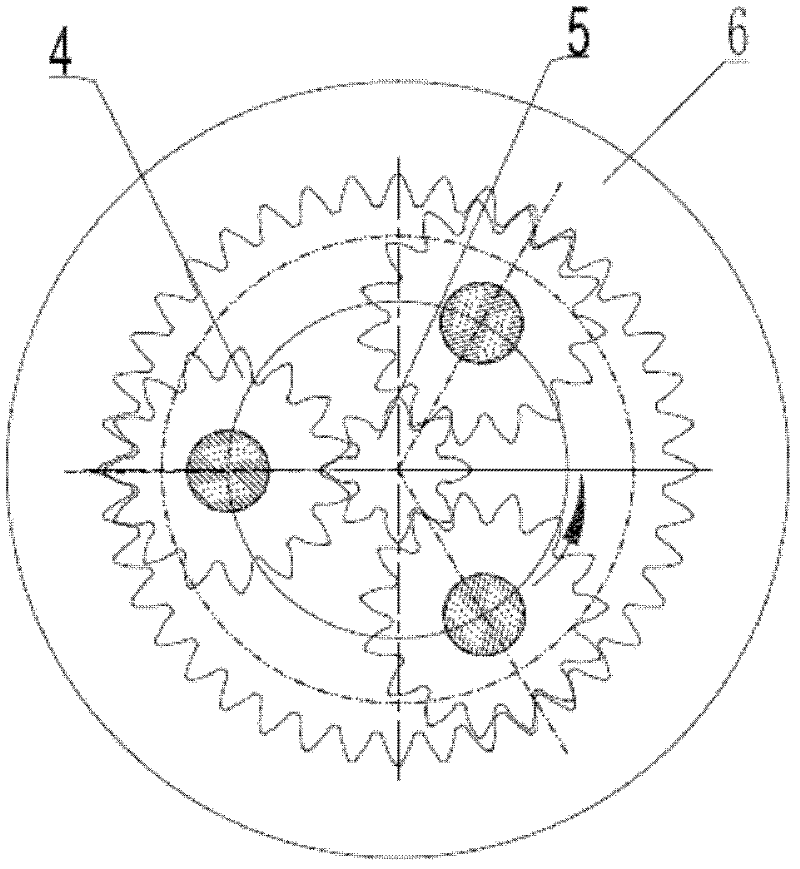

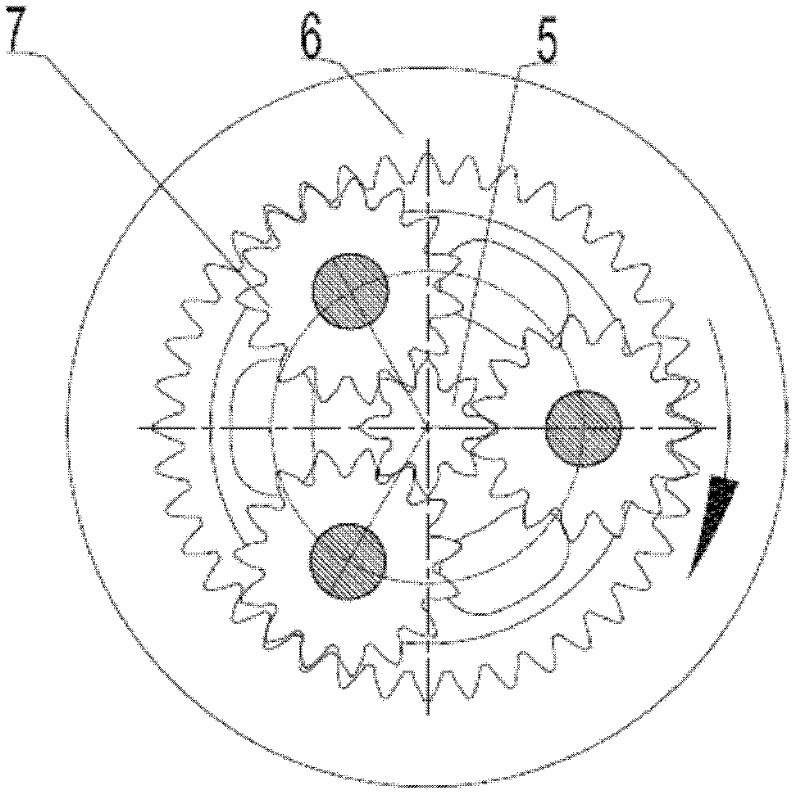

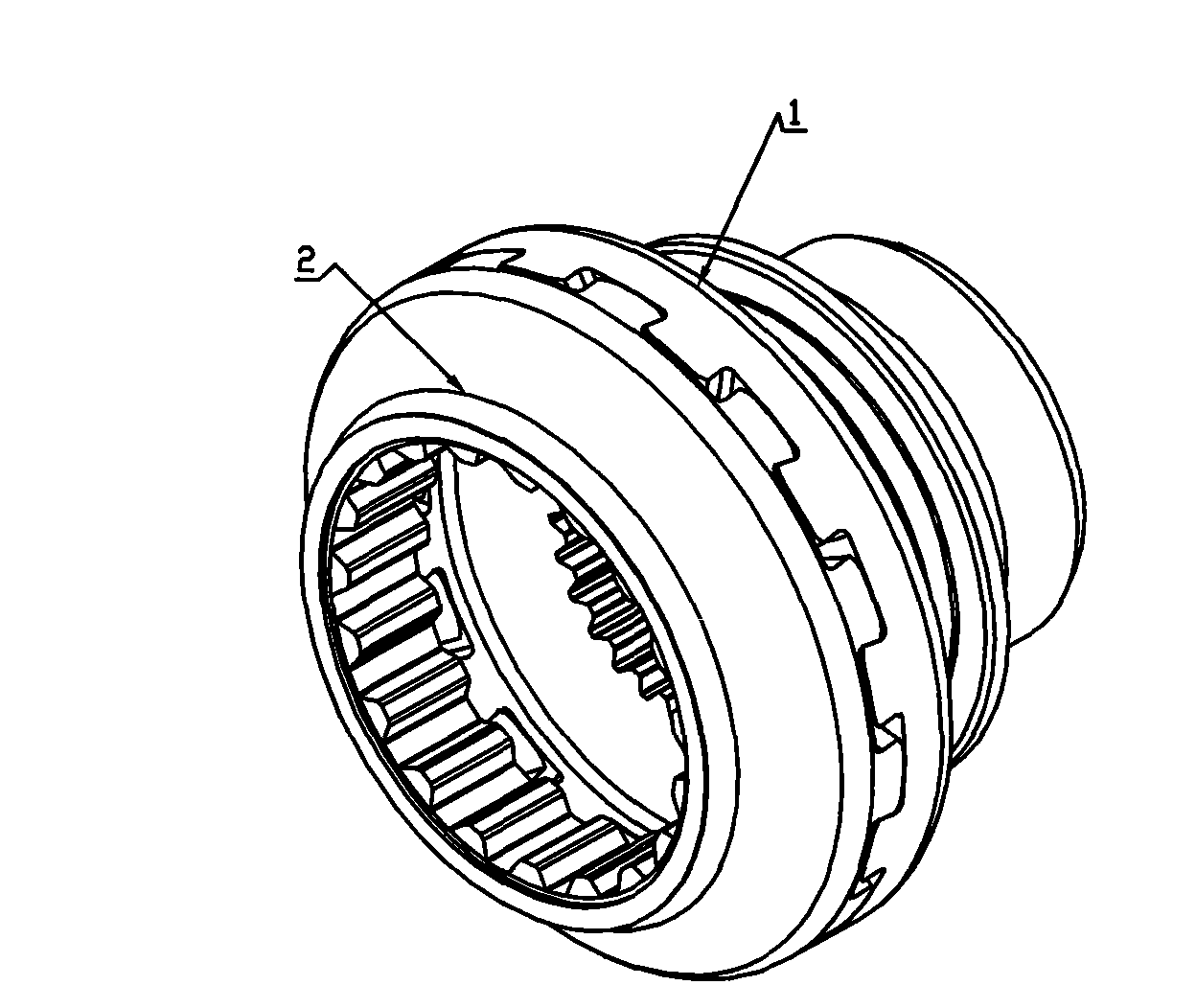

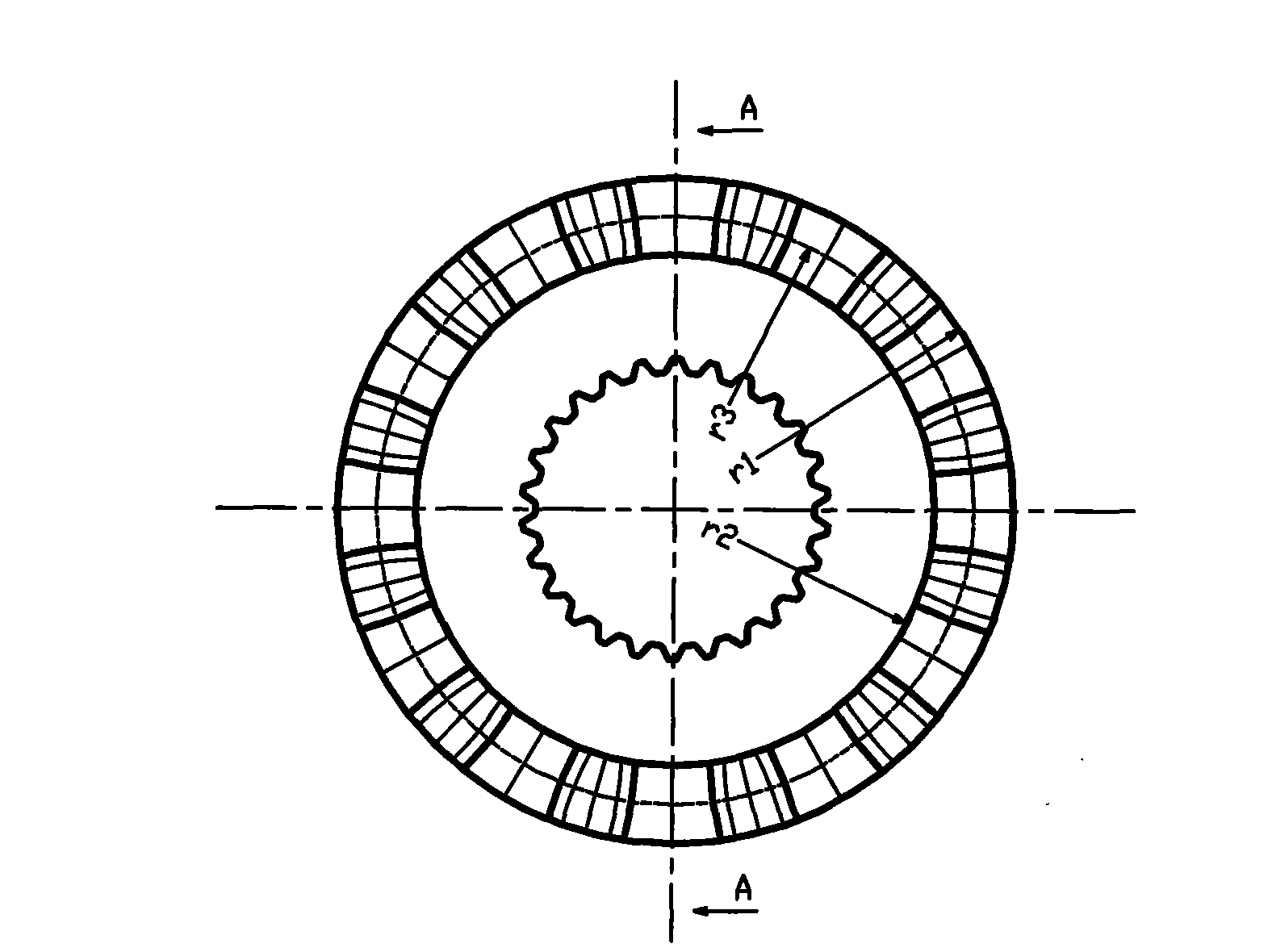

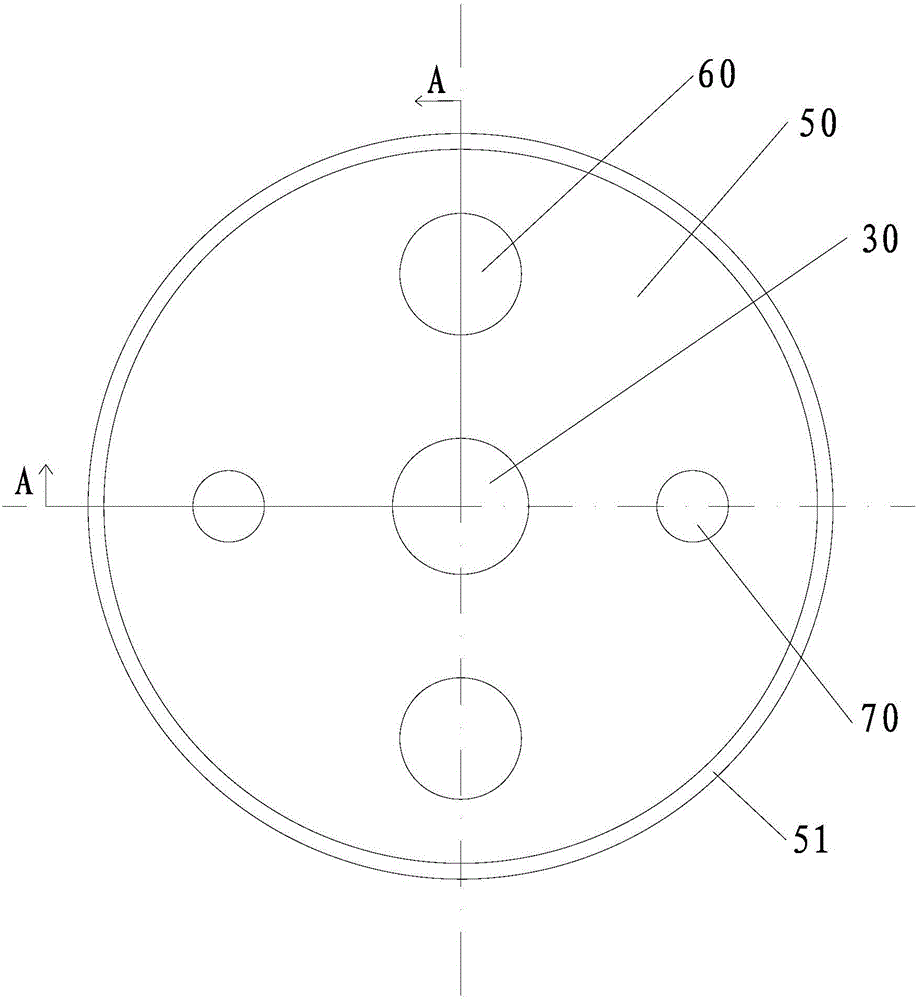

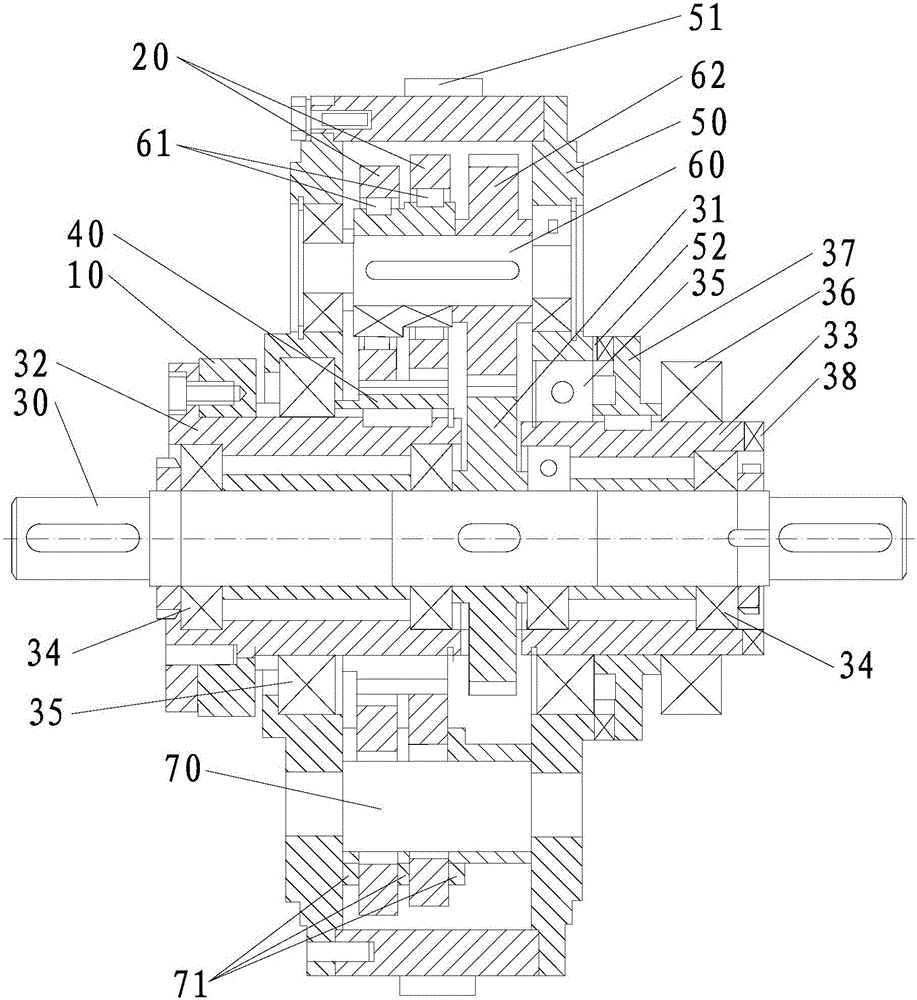

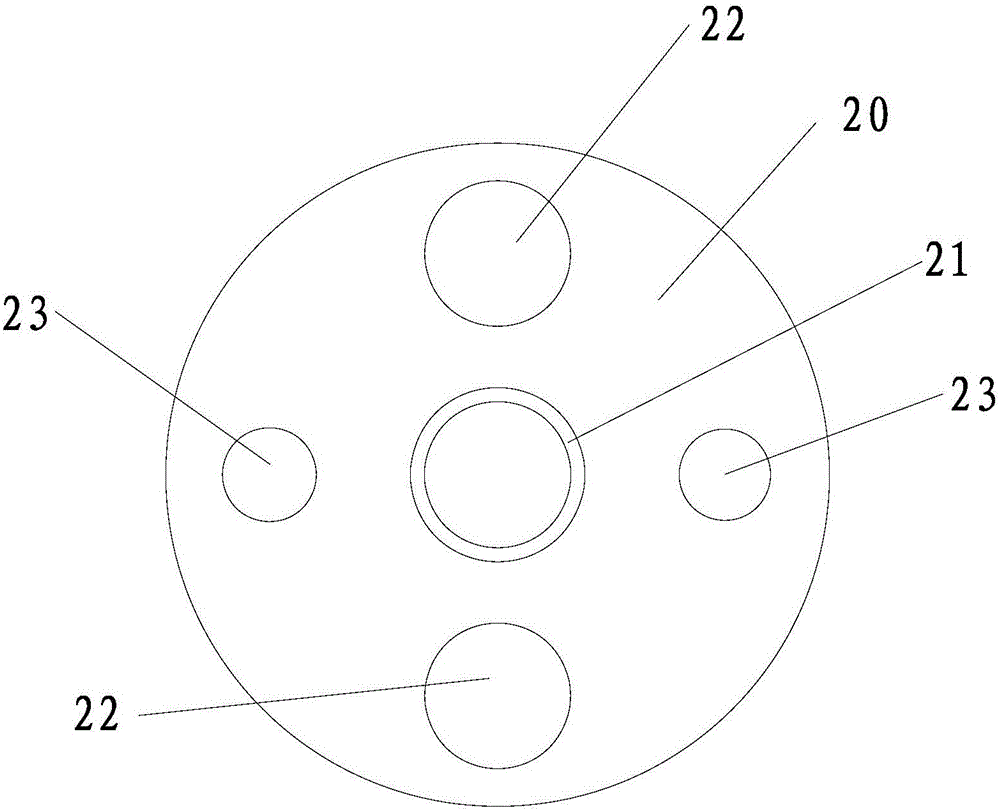

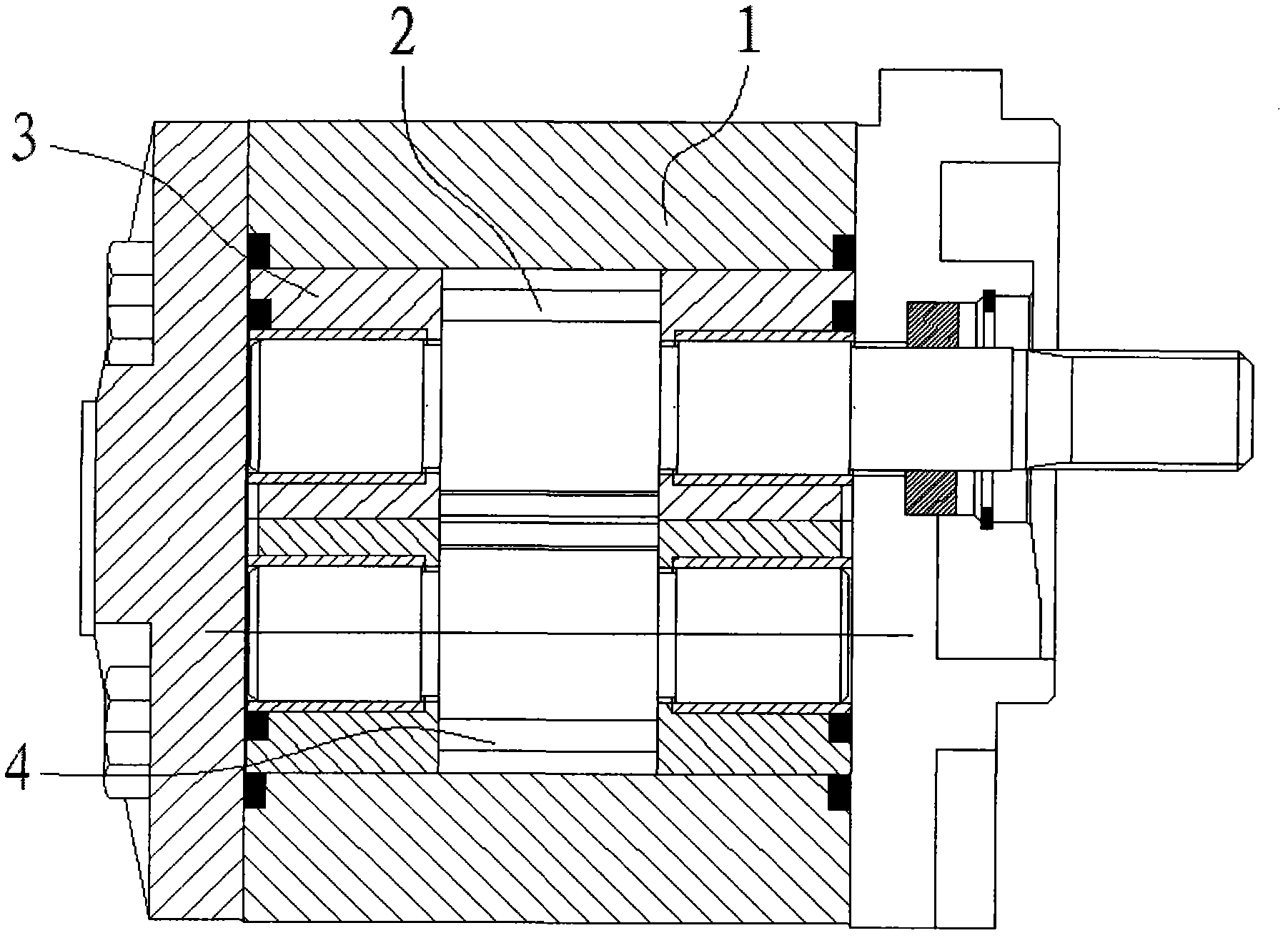

A planetary gear reducer with adjustable backlash

ActiveCN102297257AEliminate meshing backlashSmall backlashGearing detailsSurface toothReduction drive

The invention discloses a planetary gear reducer with an adjustable back lash; an inner gear ring in the reducer is fixed and cannot rotate; the teeth of the planetary gear are respectively meshed with the outer teeth of a sun gear and the inner teeth of the inner gear ring; the planetary gear reducer with the adjustable back lash is characterized in that: a first planetary gear group and a second planetary gear group are respectively arranged in a transmission level; and end surface teeth which are mutually occluded are respectively arranged on a contact surface between a first planetary gear frame component and a lower lock block and the contact surface between a second planetary gear frame component and an upper lock block. According to the invention, the back lash required by the reducer is obtained through differential gear adjustment by simultaneously eliminating gear side spacing as well as the spacing between a shaft and an inner hole of a planetary gear in a clockwise direction and a counterclockwise direction.

Owner:合肥波林新材料股份有限公司

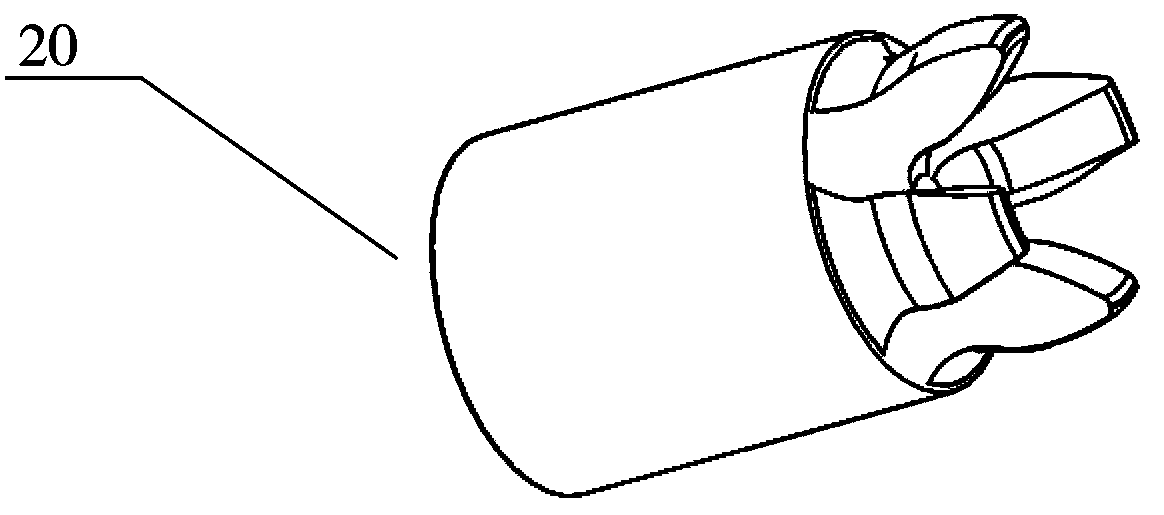

Negative pressure angle conical working tooth surface differential lock

InactiveCN101666375AImprove cross-country passing abilityWith self-locking featureDifferential gearingsControl devicesSurface toothEngineering

The invention relates to a negative pressure angle conical working tooth surface differential lock. A slidable joint sleeve and a stationary joint sleeve are connected together via the joint between an end surface tooth of the slidable joint sleeve formed on the end surface of the slidable joint sleeve and an end surface tooth of the stationary joint sleeve formed on the end surface of the stationary joint sleeve. The slidable joint sleeve is provided with an end surface tooth of the slidable joint sleeve and a slidable joint sleeve body; the tooth top surface and tooth groove surface of the end surface tooth of the slidable joint sleeve are parallel to each other in the axial section and are higher outside and lower inside; the acute angel between the tooth top surface and the tooth groove surface and a rotation axis is beta; a bore of the slidable joint sleeve body is an internal spline of the slidable joint sleeve; the stationary joint sleeve is provided with an end surface tooth ofthe stationary joint sleeve and an integrally-formed stationary joint sleeve body; the tooth top surface and tooth groove surface of the end surface tooth of the slidable joint sleeve are parallel toeach other in the axial section and are lower outside and higher inside; the acute angel between the tooth top surface and the tooth groove surface and a rotation axis is also beta; and a bore of thestationary joint sleeve body is an internal spline of the stationary joint sleeve. In the invention, slide wheels or axles are temporarily and rigidly stopped so as to improve the cross-country capability.

Owner:MILITARY TRANSPORTATION UNIV PLA

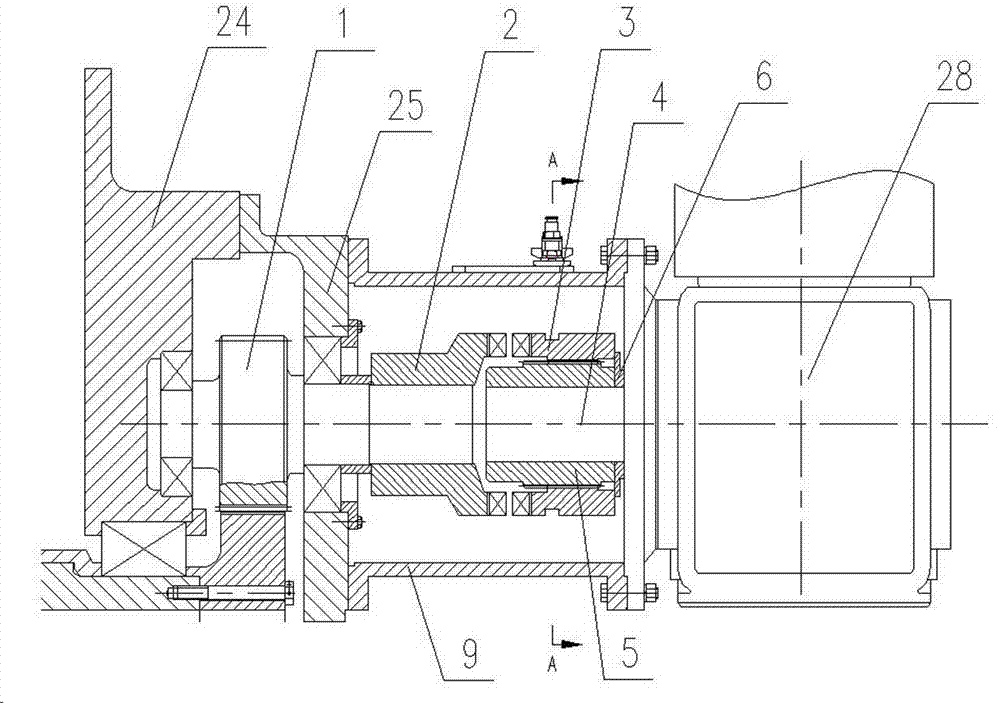

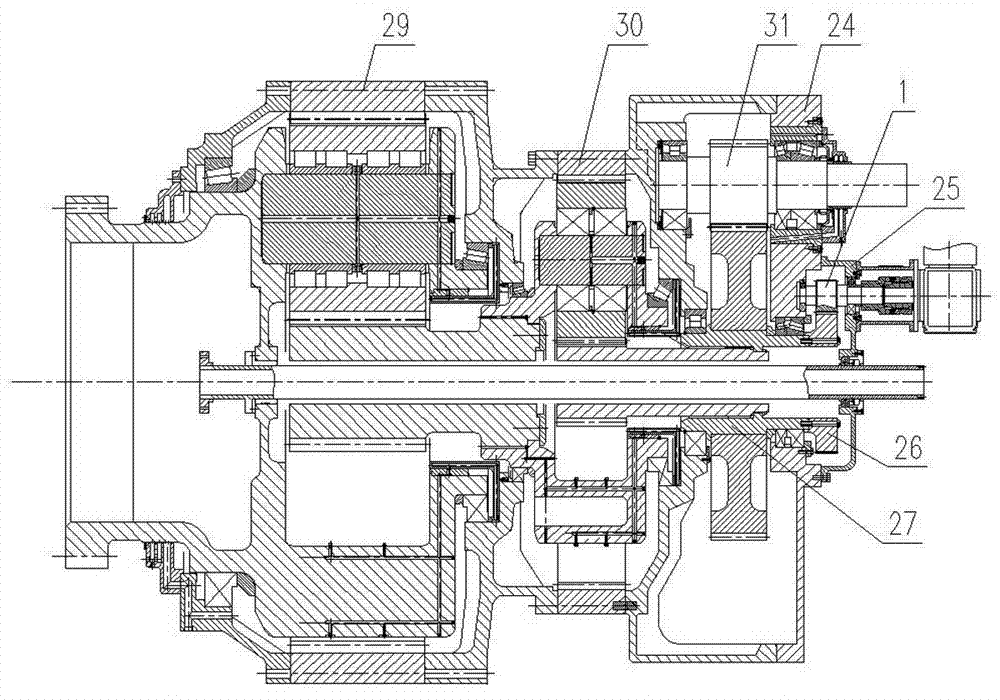

Large-power wind driven generator step-up gearbox with electric barring device

ActiveCN104500353AWork reliablyStable and reliable working conditionToothed gearingsInterengaging clutchesWind drivenSurface tooth

The invention relates to a large-power wind driven generator step-up gearbox with an electric barring device. The large-power wind driven generator step-up gearbox comprises a large-power wind driven generator step-up gearbox, wherein a large barring gear, a small barring gear shaft and a box body of a clutch device are arranged on a high-speed end bearing seat; a driving motor is fixedly mounted on the box body of the clutch device; the large barring gear is meshed with the small barring gear on a small barring gear shaft; a clutch mechanism is fixedly mounted on the small barring gear shaft and the output shaft of the driving motor; the clutch mechanism comprises an outer spline shaft sleeve, an inner sliding spline combination shaft sleeve, a combination shaft sleeve, shifting fork rods and a shifting rod shaft; the combination shaft sleeve sleeves the small barring gear shaft; the inner sliding spline combination shaft sleeve is matched with the outer spline shaft sleeve; end surface teeth are formed in match on opposite sides of the combination shaft sleeve and the inner sliding spline combination shaft sleeve in the clutch mechanism; the end surface teeth matched with the inner sliding spline combination shaft sleeve are driven by the shifting fork rods to be separated or meshed in a tooth embedding manner.

Owner:NANJING HIGH SPEED GEAR MFG

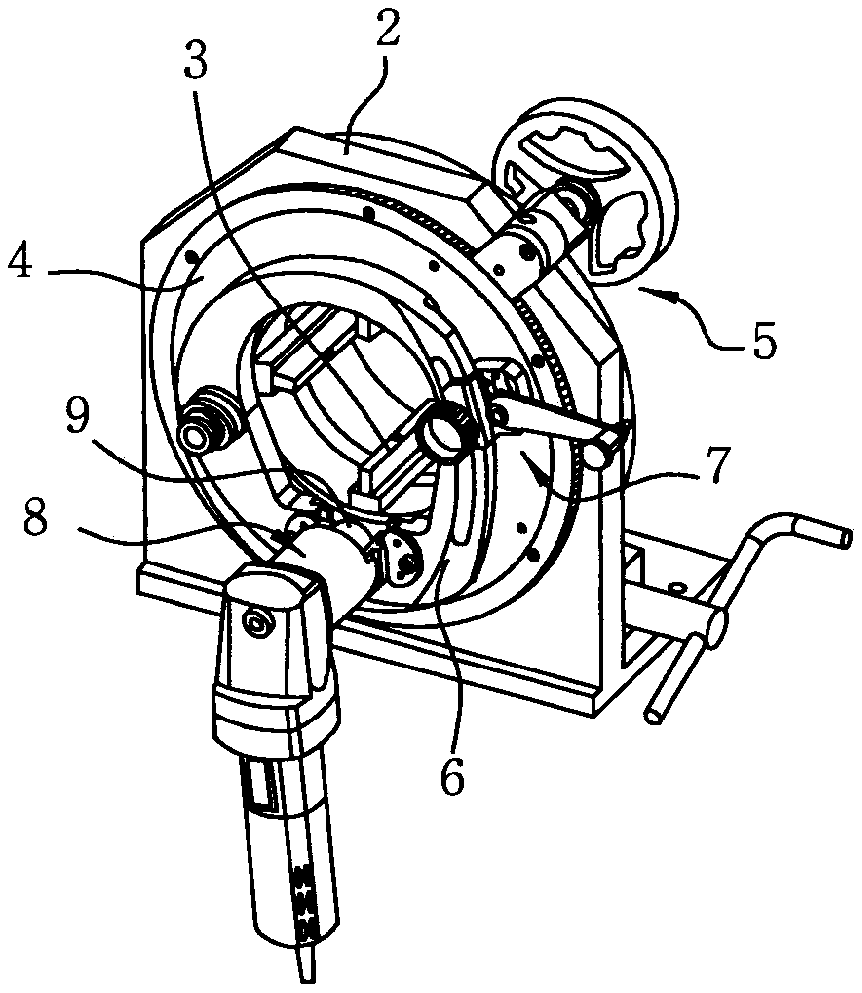

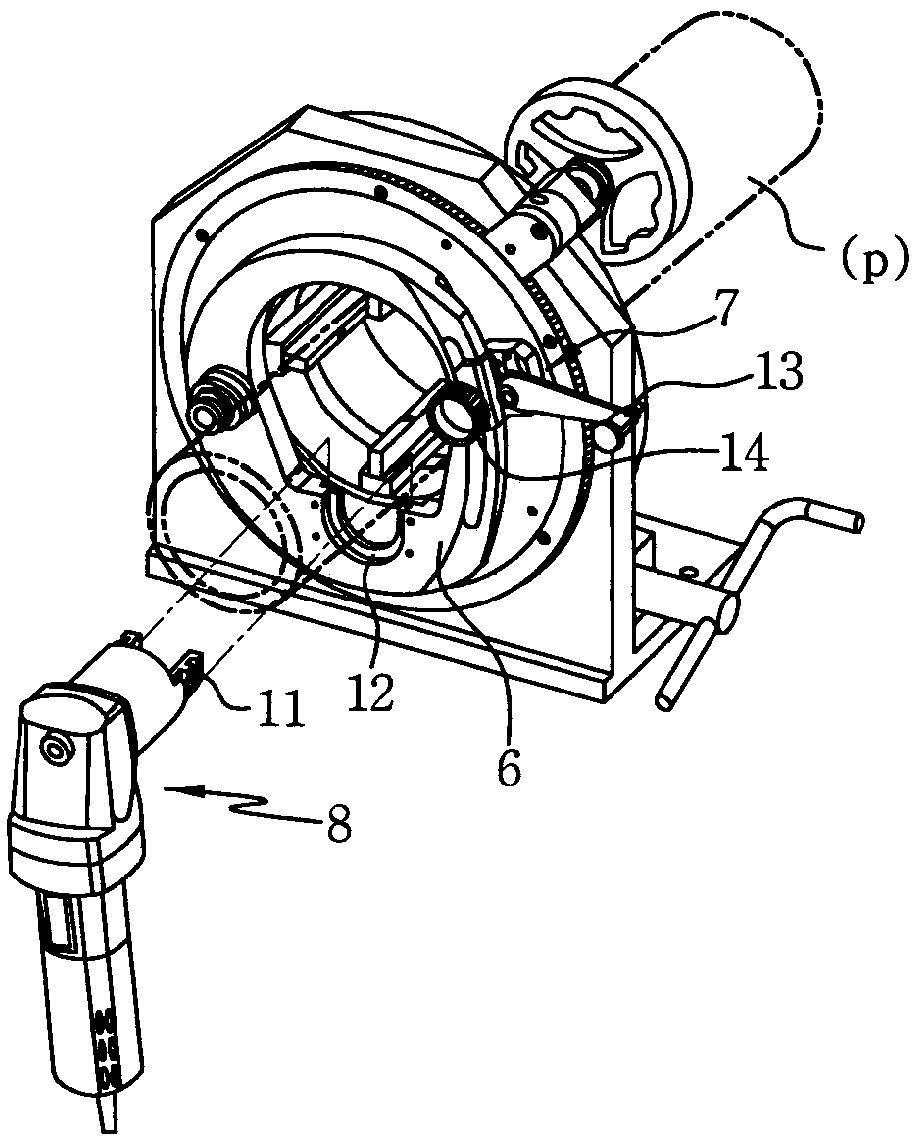

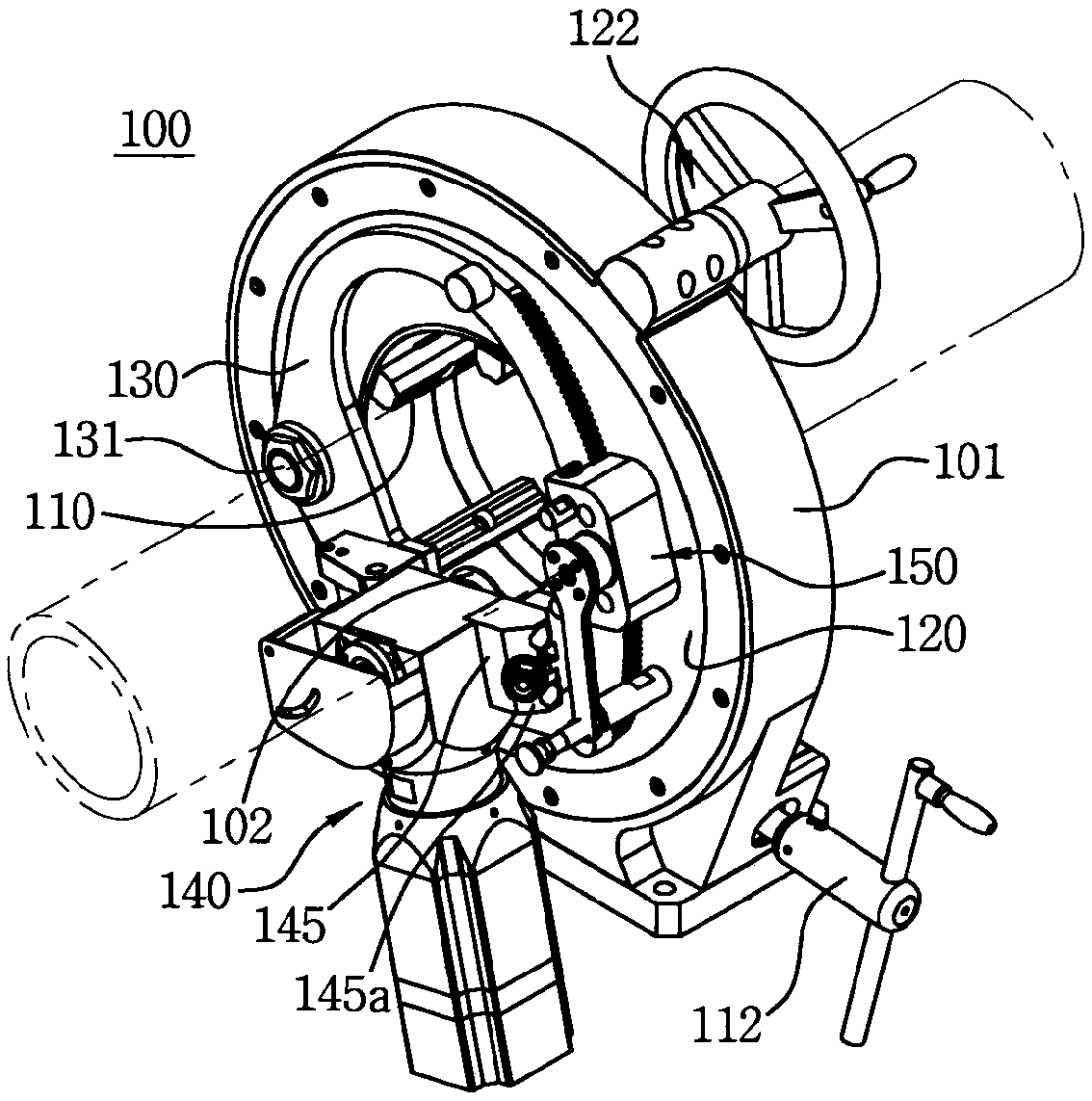

Pipe cutting and beveling machine

ActiveCN108698245AWon't interfereWill not be disturbedTurning machine accessoriesWorkpiecesRotational axisGear wheel

Disclosed is a dedicated machine capable of cutting or beveling a pipe, such as a circular pipe or bar, in such a manner that a cutter unit rotates around the pipe while cutting any one surface of thepipe after gripping and fixing the pipe. A pipe cutting and beveling machine, according to the present invention, comprises: a main body unit in which a pipe passes through the center portion thereofso as to be fixed; and a cutter unit which is coupled to the main body unit so as to cut or bevel the pipe by means of a cutting blade while rotating around the fixed pipe, wherein the cutter unit may be provided with a rotating unit on one side thereof so as to pull the cutter unit aside and a locking unit on the other side thereof so as to restrain or release the cutter unit from being pulled aside. In addition, an entry control unit, which operates the cutter unit to move forward or backward, may comprise: a lever which is gear-engaged with an outer side surface of an entry control plate;and a clutch which is formed on a rotation shaft of the lever such that the restraint thereof is released when the lever is lifted or pressed in the axial direction.

Owner:DCSENG CO LTD

Single-input double-output transmission device

ActiveCN105782355AReduce volumeNot easy to jumpToothed gearingsGearing detailsGear wheelSurface tooth

The invention provides a single-input double-output transmission device. The single-input double-output transmission device comprises a base, and further comprises planet wheels, an input shaft, a fixed gear, a rotary supporting frame and transmission shafts rotationally connected with the rotary supporting frame. The input shaft is provided with a central gear. The transmission shaft is provided with eccentric bearings and a transmission gear engaged with the central gear. The planet wheels are provided with inner gear rings and bearing holes, the tooth number of the inner gear rings is 1-4 larger than that of the fixed gear, and the fixed gear is fixedly connected with the base. The eccentric bearings are installed in the bearing holes. The rotary supporting frame is provided with an outer gear ring and a first end surface tooth, the outer gear ring is coaxial with the input shaft, and the plane where the first end surface tooth is located is perpendicular to the input shaft. The two ends of each transmission shaft are rotationally connected with the rotary supporting frame, the rotary supporting frame is used for supporting the transmission shafts, other supporting parts are not needed, and thus the size of the whole transmission device is relatively small.

Owner:安徽邮谷快递智能科技有限公司

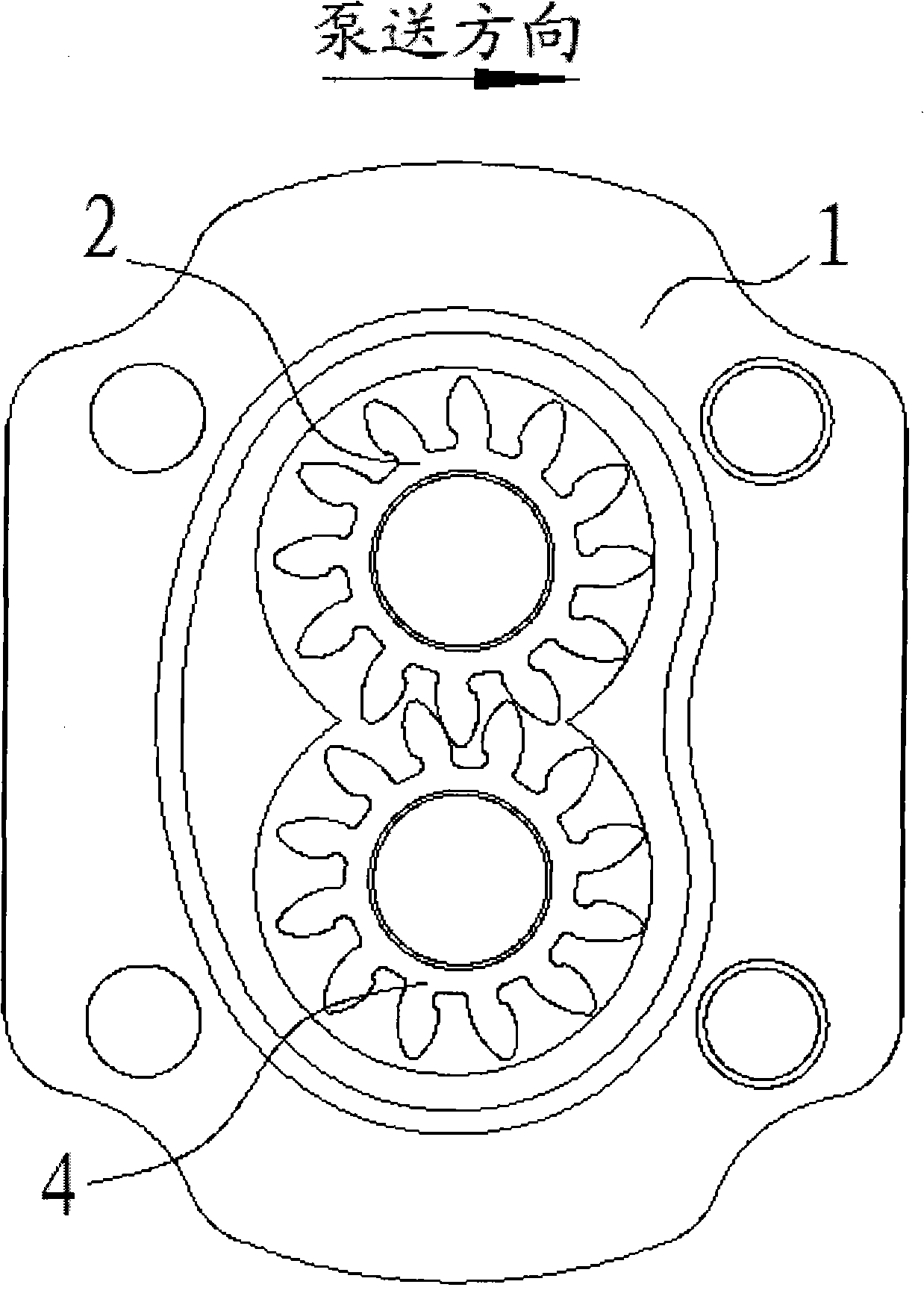

Gear pump with asymmetric combined curved surface tooth form

InactiveCN102094813AGuaranteed single pumping volumeReduce stress concentrationRotary piston pumpsRotary piston liquid enginesGear pumpSurface tooth

The invention discloses a gear pump with an asymmetric combined curved surface tooth form. The gear pump comprises a hollow pump body; a driving gear and a driven gear which are meshed mutually are arranged in the pump body; a tooth surface on one side where the driving gear and the driven gear are contacted and stressed is a working surface, and the tooth surface on the other side is a non-working surface; a pressure angle of the working surface is 20.5 to 22.8 degrees; the gear pump is characterized in that: a pressure angle of the non-working surface is 14 to 19 degrees; and the non-working surface is formed through smooth transition of an evolvent curved surface and a circular arc camber. The gear pump has large single pump output, a large overlap coefficient, small noise, low gear collapsing probability, and transmits stably, and the chamber sweeping phenomenon is avoided.

Owner:浙江凯斯特液压有限公司 +1

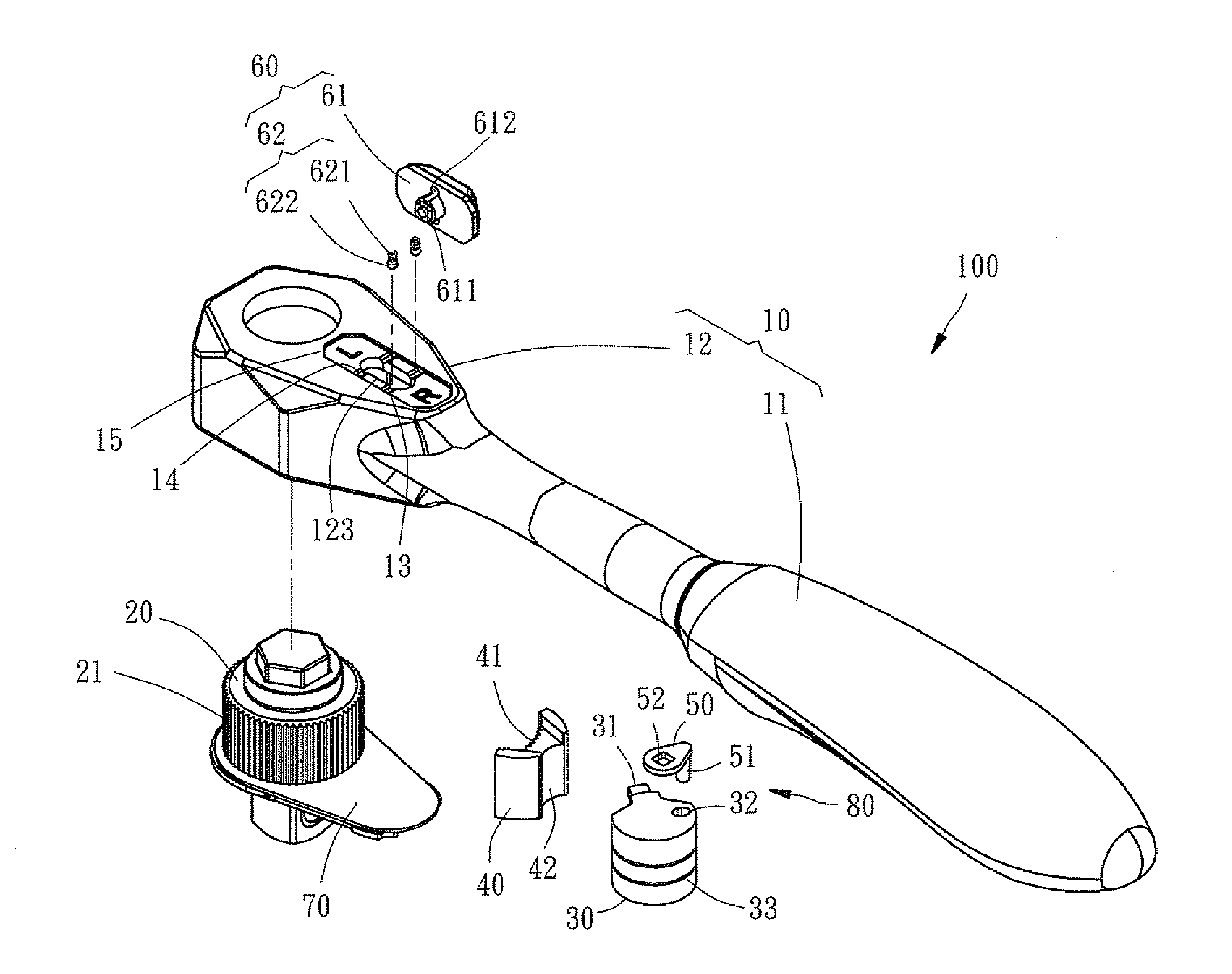

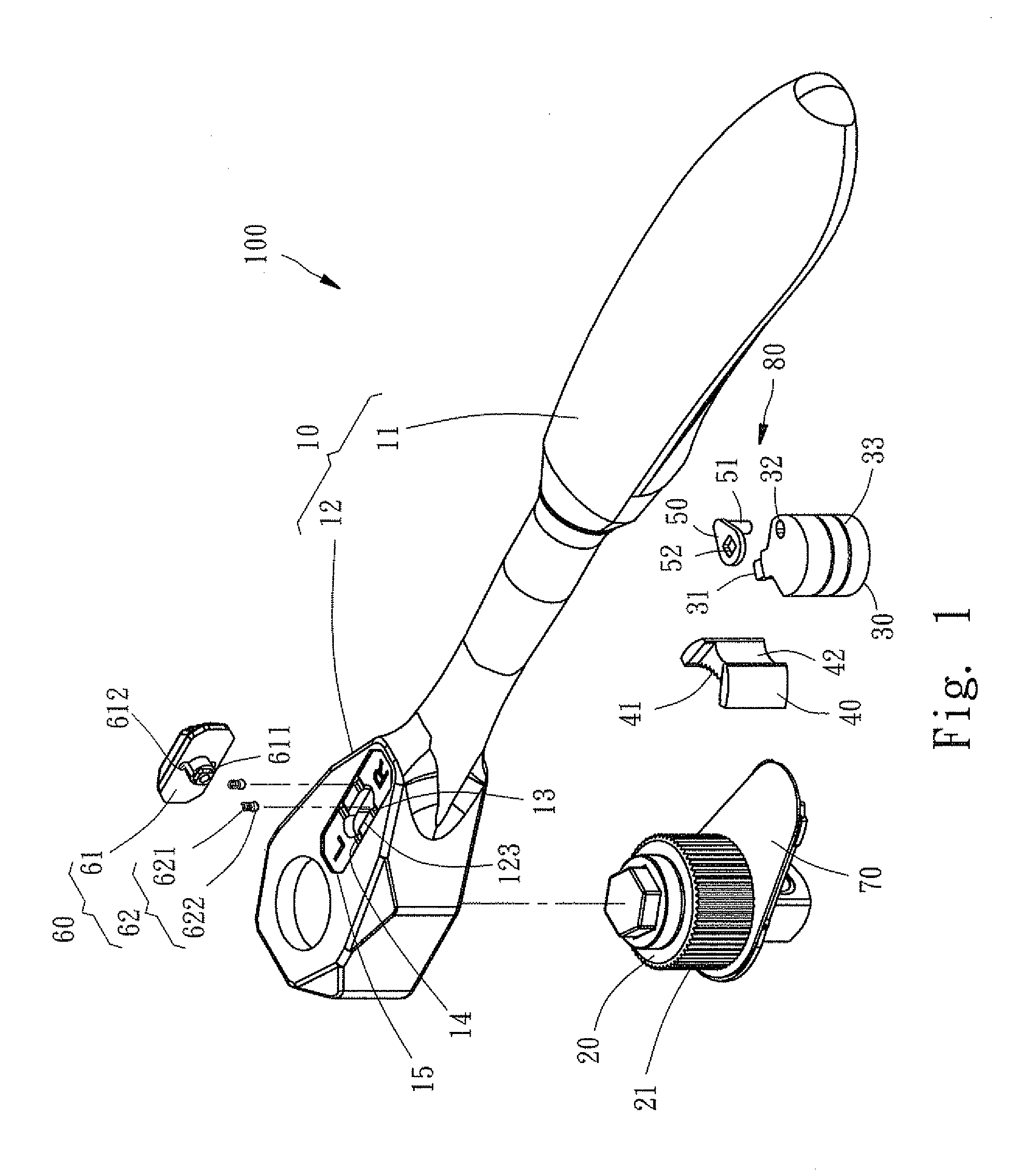

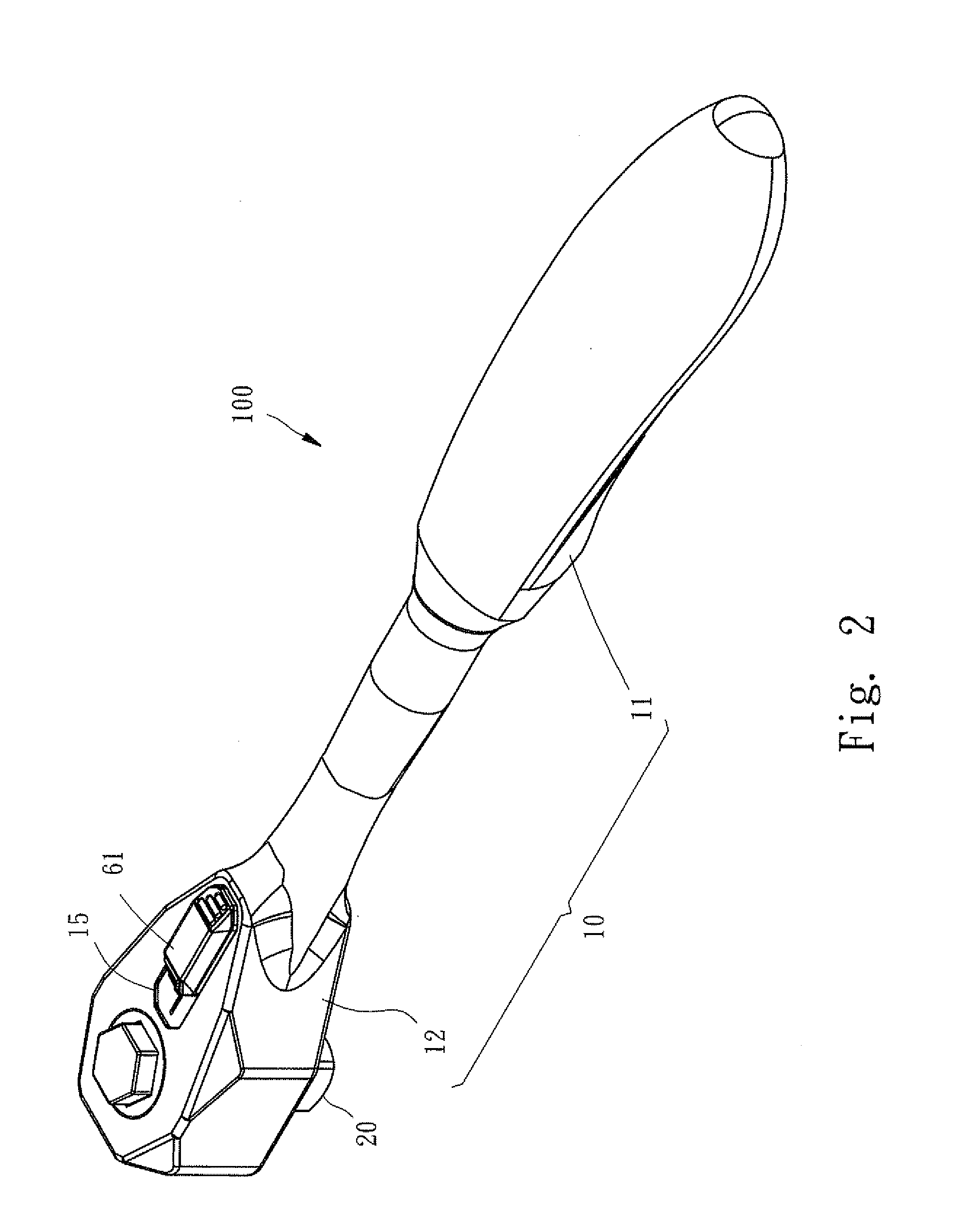

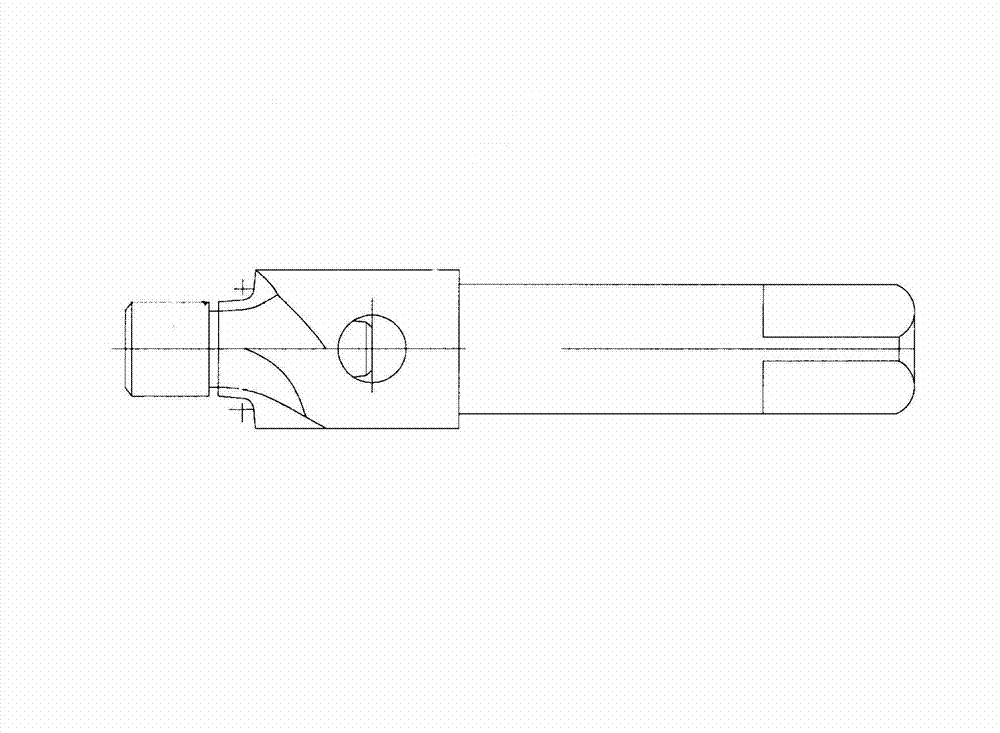

Ratchet wrench

A ratchet wrench includes a handle; a wrench head comprising a first cavity and a second cavity communicating therewith; a drive gear and socket combination rotatably disposed in the first cavity and comprising surface teeth; a reversing pawl comprising pawl teeth on one surface, the pawl teeth meshed with the teeth of the drive gear and socket; a pivotal unit pivotably disposed in the second cavity, the pivotal unit urging against the other surface of the reversing pawl and being adapted to reciprocally pivot about the reversing pawl; and a reversing button assembly moveably disposed on the wrench hand and aligned with an axial direction of the handle. The reversing button assembly is adapted to manually move along a straight line to activate the pivotal unit which pivots the reversing pawl so as to permit the drive gear and socket combination to rotate clockwise or counterclockwise.

Owner:LIN YI HUNG

Machining method for profile countersink drill

The invention provides a machining method for a profile countersink drill. The machining method includes the following steps: a cutter body blank with an edge part and a tail shank is fixed correctly, a 1:50 tapered bore is drilled and reamed to a dimension, and with the 1:50 tapered bore as a reference, a tail central bore is made; the top is turned to be shaped, the remainder of grinding of the outer circle of the edge part is 0.4mm to 0.5mm, the remainder of grinding of the outer circle of the tail shank is 0.4mm to 0.5mm, and 0.2mm to 0.3mm of profile uniformly remains by adopting a template; according to the requirement of a drawing, an angled surface tooth profile is milled, and the remainder of relief grinding K is equal to 2.1; a profile grinding wheel is used for roughly profile-grinding a profile and a clearance angle, and the remainder of grinding is 0.4mm to 0.5mm; the profile grinding wheel is used for roughly profile-grinding the profile and the clearance angle to required dimensions, and 0.5mm of margin remains to guarantee equal division; a front edge is ground; the machined cutter body part is mounted on a guide shaft, and thereby the whole machining process is finished. The machining method guarantees the machining precision of the profile grinding wheel, so that the profile countersink drill has higher precision and can better meet requirements.

Owner:SHENYANG AIRCRAFT CORP

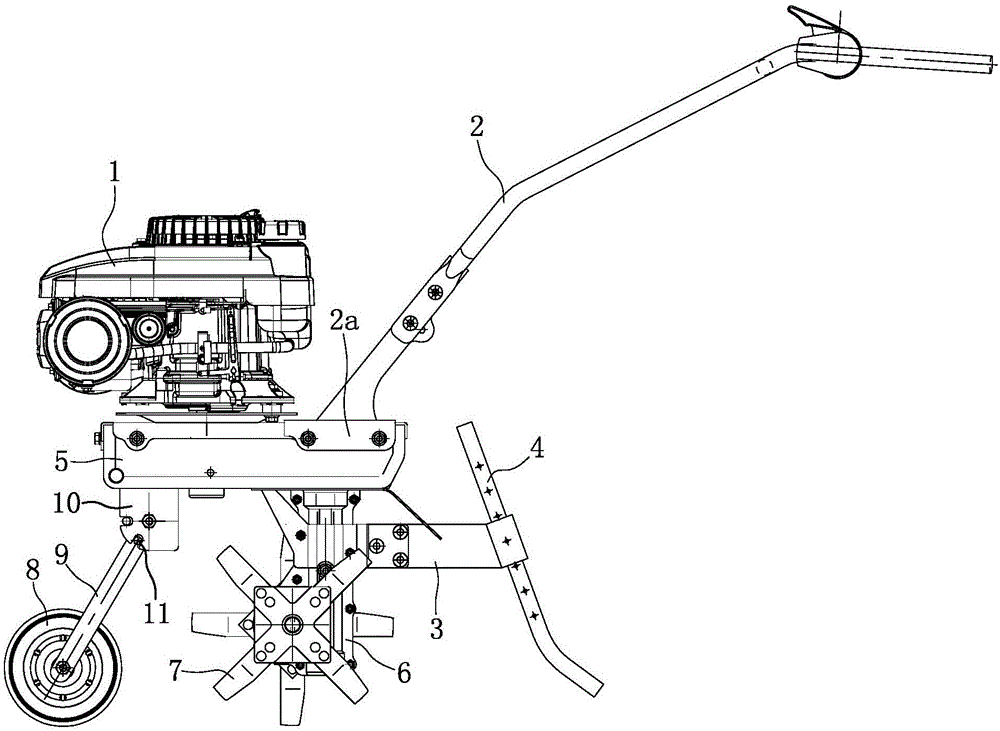

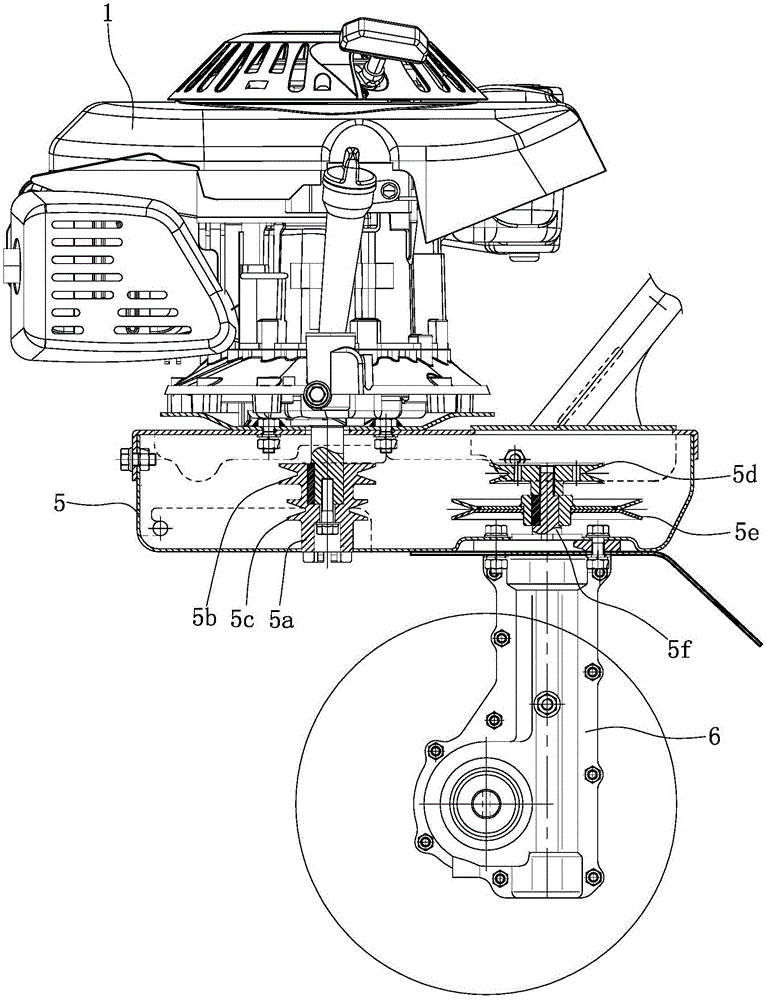

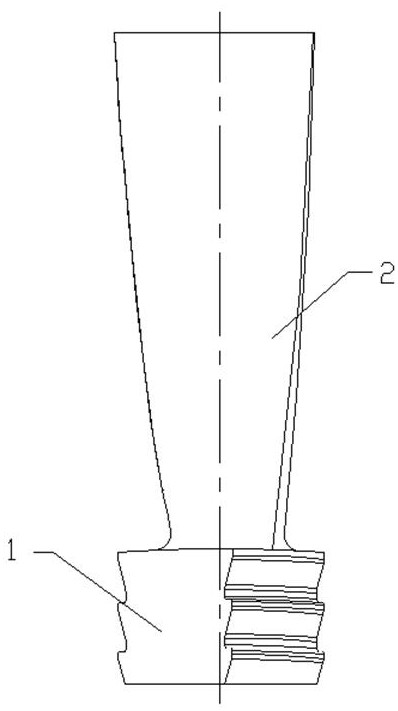

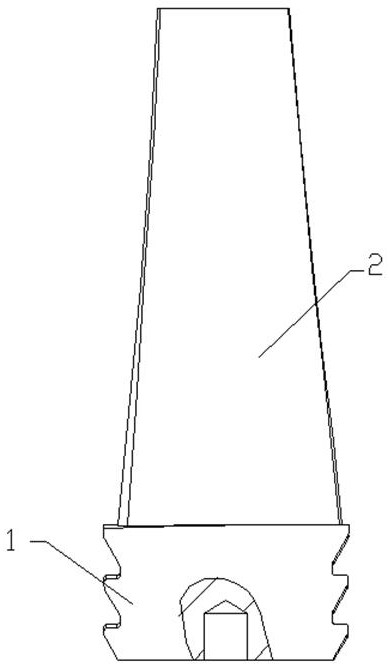

Transmission system of portable mini tiller

Owner:CHONGQING JIAMU MACHINERY

Machining process of rhombic-surface tooth-shaped blade root shroud-free moving blade for steam turbine

The invention relates to a machining process of a rhombic-surface tooth-shaped blade root shroud-free moving blade for a steam turbine. The machining process is characterized by comprising the following specific machining steps of S1, blanking; S2, taking out a hexagon; S3, milling; and S4, cutting a process clamping end face. According to the machining process of the rhombic-surface tooth-shapedblade root shroud-free moving blade for the steam turbine provided by the invention, a center hole is drilled first and then positioning holes are drilled symmetrically, so that a clamping step on a process clamping head is machined conveniently, the subsequent clamping standard on a machining center is guaranteed, the machining precision is improved, the problem that positioning and clamping arenot easy due to the fact that no positioning standard exists is solved, subsequent machining is detected by the assistance of a blade root ring gauge, and machining qualification is guaranteed; and single-head pliers can be positioned and clamped in the center, so that the positioning standard is guaranteed, the machining precision is improved, and the machining efficiency is greatly improved.

Owner:NANTONG ZHONGNENG MACHINERY

Efficient and safe oral cavity supporting device with automatic sterilization function

InactiveCN106388760AReduce volumeSimple structureDentistryMedical devicesOral treatmentSurface tooth

The invention discloses an efficient and safe oral cavity supporting device with an automatic sterilization function. The efficient and safe oral cavity supporting device comprises a supporting device main body, atomization holes, a pressure ball, a base, a telescopic joint, an air inlet pipe, an air jetting pipe, a control valve, a connecting threaded pipe, an air bag, an atomization pipe, a nozzle, a fixed seat and a liquid storage bottle; the atomization holes are formed in the outer side of the supporting device main body; the pressure ball is installed at the tail end of the supporting device main body; and the base is arranged on the upper side of the pressure ball. The efficient and safe oral cavity supporting device with the automatic sterilization function is small and exquisite in size, simple in structure and convenient to regulate aiming at the sizes of oral cavities of different patients; after the efficient and safe oral cavity supporting device is put in the oral cavity, the supporting device main body is occluded by utilizing side surface teeth, a cavity space is not occupied basically, and no influence on oral treatment operation performed by a doctor exists basically; the supporting height can be lifted through air injection of the air bag, and treatment is convenient; and by being manufactured by adopting a non-soft silica gel material, the efficient and safe oral cavity supporting device does not damage teeth, is comfortable to occlude, also has the automatic sterilization function and is diversified in functions and convenient to use.

Owner:陈建栋

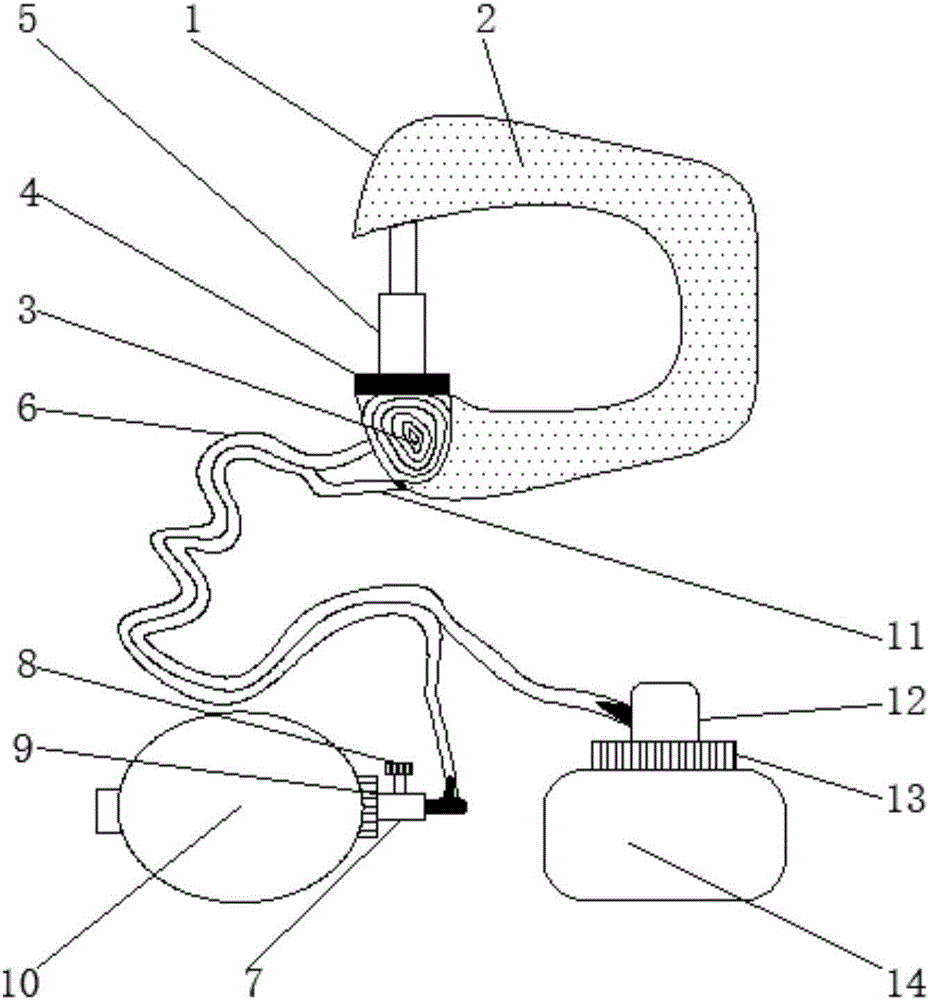

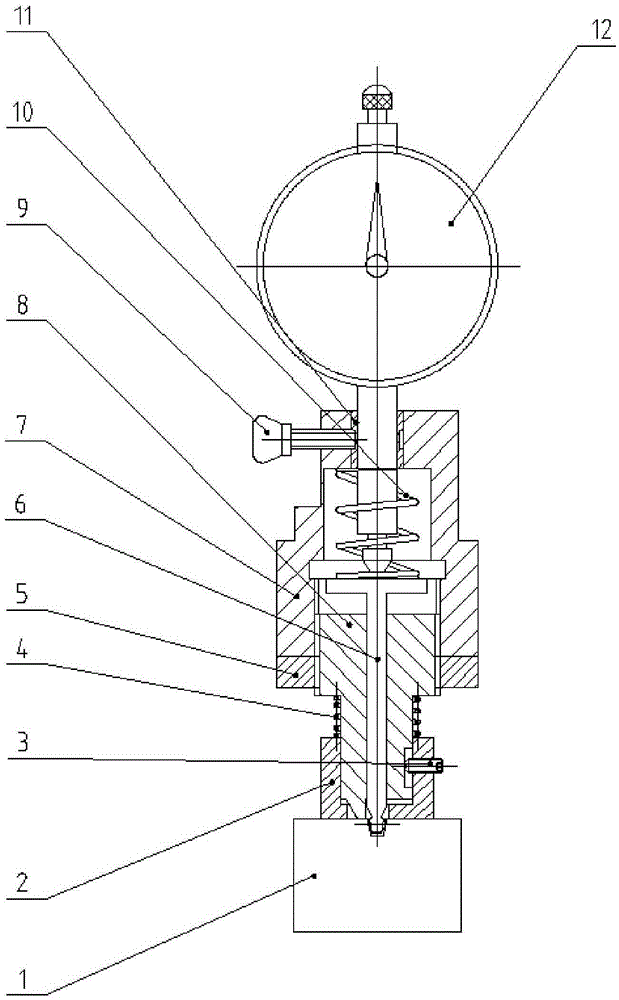

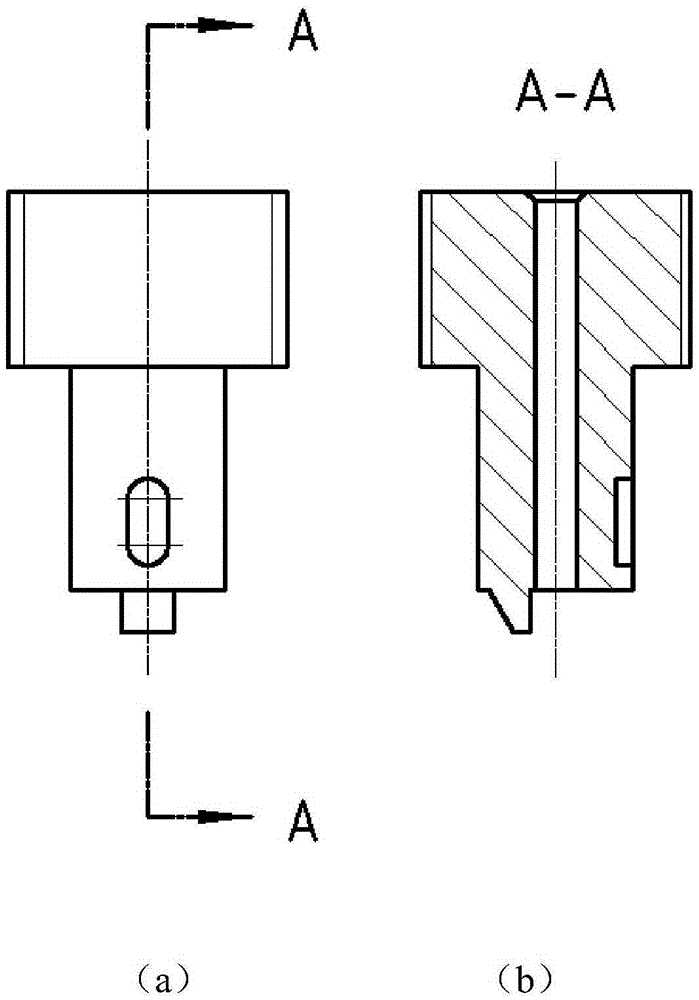

Checking tool capable of measuring 0.7-dimension end surface teeth

InactiveCN105371722AGuaranteed to be verticalSolve measurement problemsMechanical measuring arrangementsSurface toothEngineering

Owner:SHAANXI FAST GEAR CO

Planetary multi-speed transmission method and device

InactiveCN104633022AWith the principle of speed regulationHas rangeToothed gearingsSurface toothEngineering

The invention discloses a planetary multi-speed transmission method and device. According to the device, a driving taper gear is connected with an input shaft, and the driving taper gear is engaged with a driven taper gear; the driven taper gear is fixedly connected with a cylinder gear and rotates around a rotary arm; the end surface gear assembly comprises multiple ferrule end surface gears, each ferrule end surface gear comprises end surface teeth and straight teeth, the end surface teeth are arranged on the end surface of each circular ferrule, the straight teeth are arranged along the outer cylinder surface periphery of the circular ferrule of each ferrule end surface gear, the end surface teeth of each ferrule end surface gear are engaged with the cylinder gear, and the straight teeth of each ferrule end surface gear are selectively fixed to an inner tooth ring of a speed regulating mechanism in an engaged mode; the rotary arm is perpendicular and orthogonal to the input shaft and is fixed to the input shaft, so that an integral part is formed. According to the planetary multi-speed transmission method and device, a non-stage transmission range is changed into multiple optional fixed speed ratios, the performance of a stage transmission is achieved, the whole device is simple in structure, small in size and light in weight, and gear transmission serves as the transmission mode so that the transmission efficiency is high.

Owner:SOUTH CHINA UNIV OF TECH

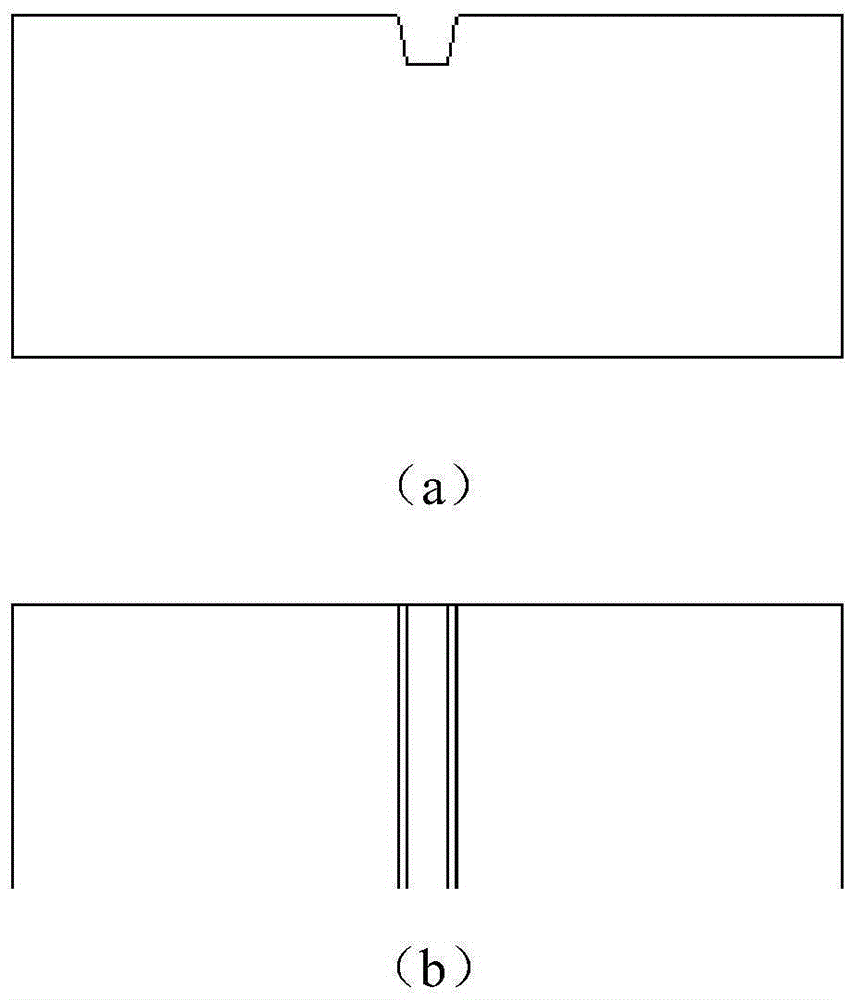

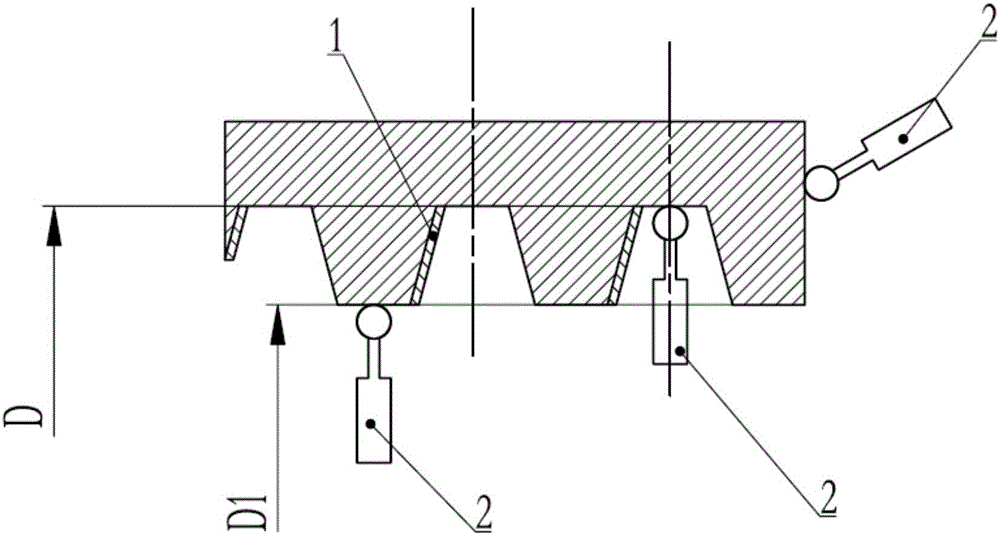

Non-flash die for extruding aluminum alloy shell parts

The invention relates to a non-flash die for extruding aluminum alloy shell parts. The non-flash die mainly comprises a female die, a male die, a cavity, curved surface teeth, a left female die, a right female die, positioning holes, screw holes, a threaded connection part and pin holes and is improvement on an extrusion forming die aiming at the condition that flashes are easily generated in the process of extruding the aluminum alloy branched shell parts. According to the non-flash die, the curved surface teeth are formed additionally on the conical part of the female die, so that oddments and flowing metal which are generated in the extrusion process are restrained and blocked, and the flashes are prevented from being generated; through introduction of the male die, mutually meshed curved teeth are increased, and the residual free space in which the flowing metal can flow is reduced, so that the probability of forming the flashes is reduced; and therefore, the flashes are not generated when the branched shell parts are extruded, the extrusion forming quality and efficiency are improved, metal materials are saved, and the non-flash die is very ideal and can be applied to extrusion forming of various similar parts.

Owner:ZHONGBEI UNIV

Reverse buckling equipment

InactiveCN1920240AReversing, unlocking and salvage is normalIncrease success rateConstructionsBorehole/well accessoriesSurface toothEngineering

The invention relates to a reversed clamper, which comprises: upper connector, eccentric axle, upper and lower anchor devices, inner gear, and rotation gear, bearing element, output axle and lower connector, wherein between the lower part of upper connector and the upper end of eccentric axle, between the upper and lower ends of inner gear, between upper and lower anchor devices, and between the lower end of output axle and the upper part of lower connector, there are torque rings whose circumferences contacted with the eccentric axle, upper and lower anchor devices and output axle have slope sliding channels; said slope sliding channels are reversed to the slope sliding channels of said elements; and their circumferences contacted with the lower part of upper connector, upper and lower ends of inner gear, and the upper part of lower connector have mesh end surface teeth. The invention can replace reversed clamp rod, to increase the torque after speed reduction, to reduce the cost and improve the efficiency.

Owner:周德育

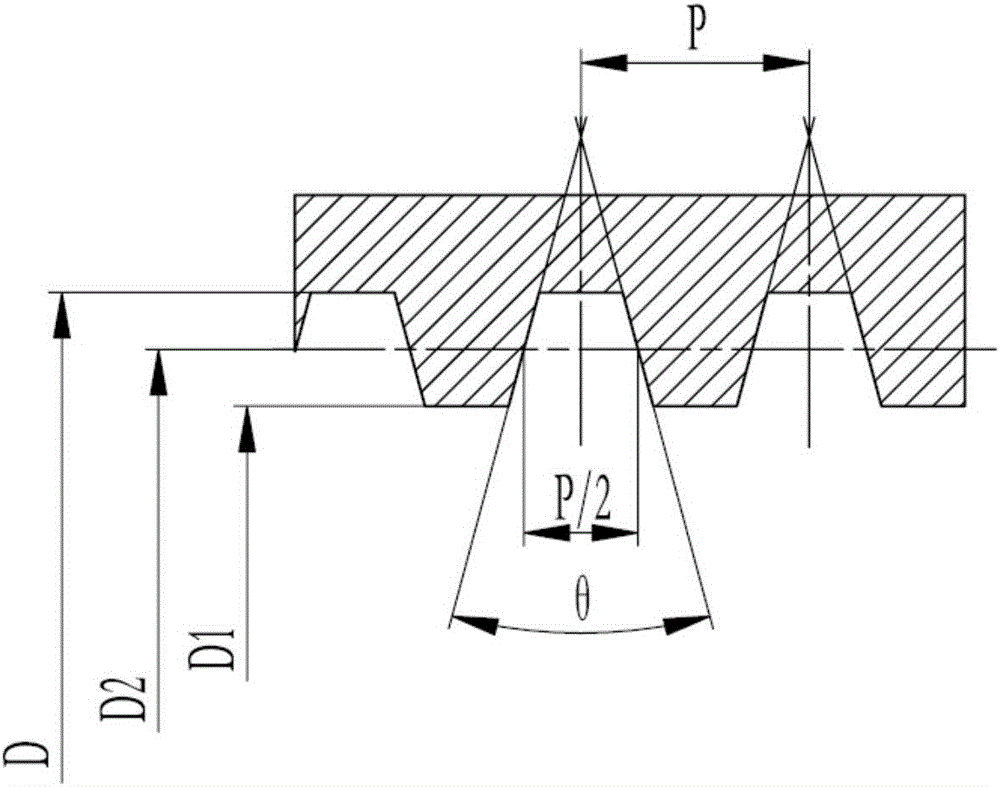

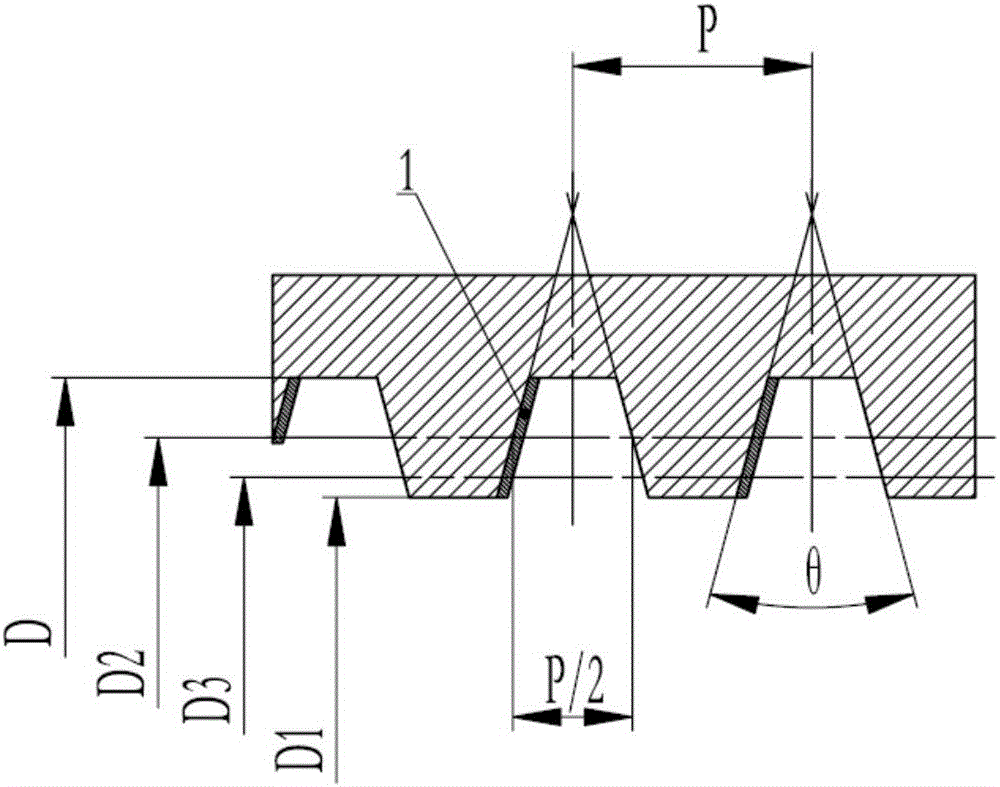

Tooth form geometrical parameter measurement method for online machining of large-diameter multi-thread ring gauge

ActiveCN106392206AImprove detection accuracyThread cutting machinesMeasurement/indication equipmentsMicrometerSurface tooth

The invention provides a tooth form geometrical parameter measurement method for online machining of a large-diameter multi-thread ring gauge. The tooth form geometrical parameter measurement method for online machining of the large-diameter multi-thread ring gauge comprises the steps that machining equipment is locked, and a part measurement basis is adjusted; the thread minor diameter D1 measurement dimension is re-checked through an inside micrometer, and the thread minor diameter D1 is determined (measured); thread surface tooth form data are collected through laser scanning; the measurement value P of the thread pitch, and the measurement value theta of the tooth form angle theta are determined (measured) through fitting calculation; a steel ball calibration measurement head with the proper diameter is selected through calculation based on the theoretical thread tooth form dimension; dotting is conducted for thread measurement, the machining allowance d is determined, and the machining quantity is calculated and determined; and dotting is conducted for measuring the actual thread pitch diameter, all geometrical parameters of the tooth form of the large-diameter multi-internal-thread ring gauge are obtained. By adoption of the measurement method, the parameters of the tooth form of the ring gauge can be checked on the ring gauge machining site and are provided for machining personnel for high-precision machining, and the rate of finished ring gauges is guaranteed; and the detection precision is high, and the tooth form geometrical parameter measurement method is suitable for large-diameter multi-internal-thread ring gauges of various specifications.

Owner:CSIC NO 12 RES INST

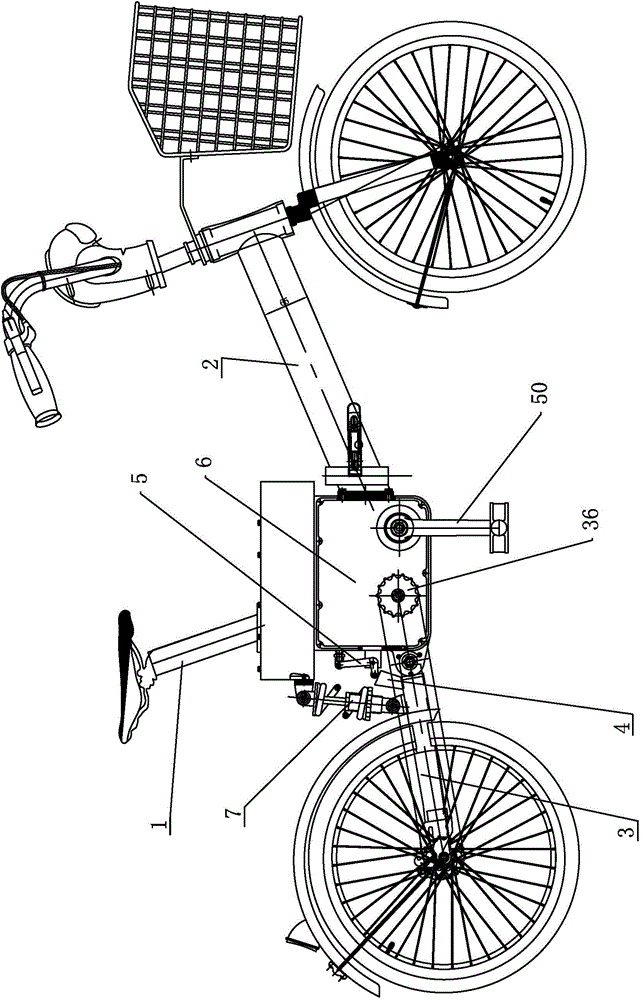

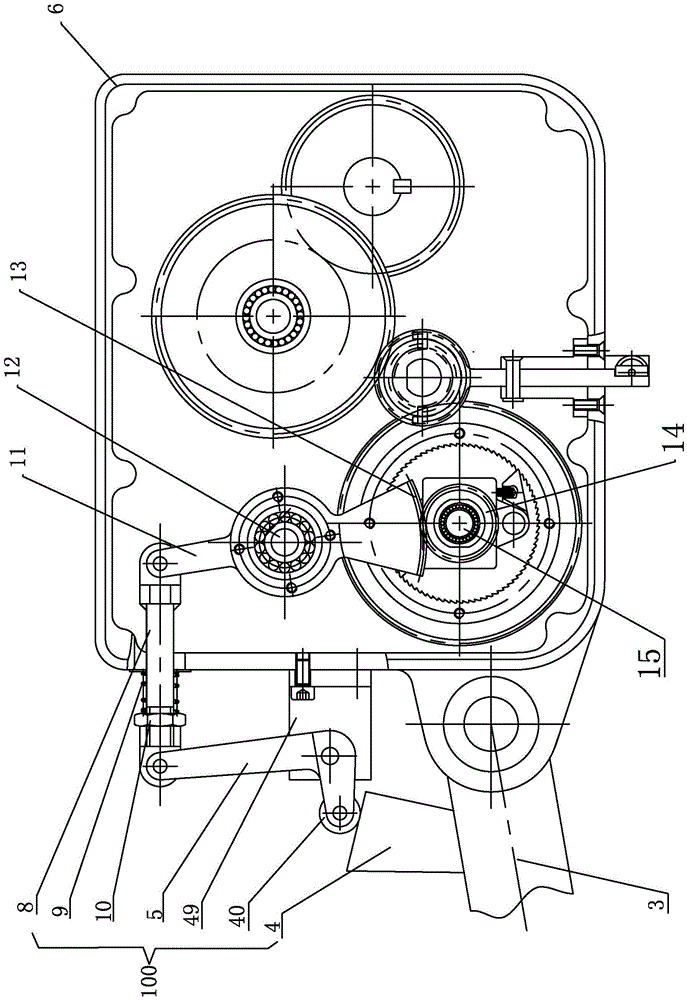

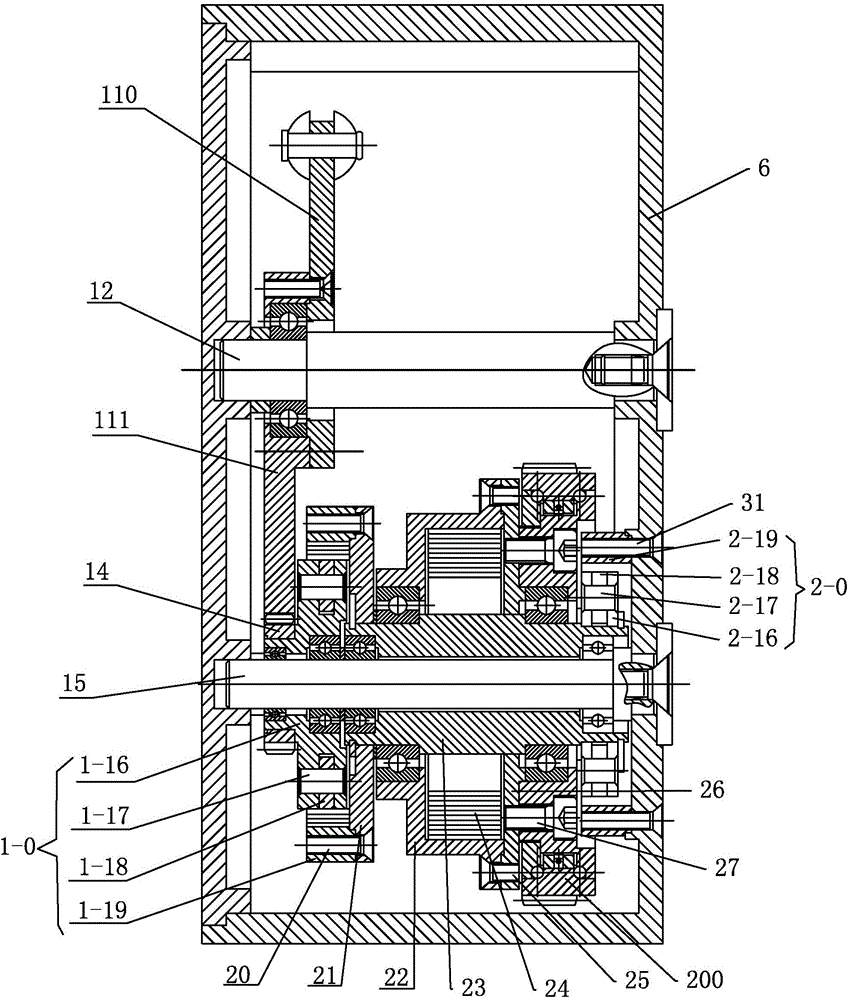

Bicycle vibration energy conversion mechanism and bicycle adopting same

ActiveCN104787212AImprove driving comfort performanceSave energyWheel based transmissionRider propulsionDrive wheelVehicle frame

The invention relates to a bicycle vibration energy conversion mechanism and a bicycle adopting the same. The bicycle vibration energy conversion mechanism comprises a force transfer mechanism and a shell used for being arranged on a fixed frame of the bicycle, wherein one end of the force transfer mechanism is in transmission connection with a swing frame, capable of vertically swinging, of the bicycle; the other end of the force transfer mechanism is in transmission connection with a swing arm which is rotatably matched with the inner wall of the shell and is suitable for the swing arm to carry out reciprocating swinging; an arc-shaped surface tooth at the lower end of the swing arm is in transmission connection with an input gear which is located on the lower part and is rotatably matched with a fixed shaft; the input gear is in transmission connection with the inner end of a clockwork spring at the rear side by a ratchet wheel mechanism; the outer end of the clockwork spring is in transmission connection with a driven gear on a rotating shaft in a matching way by utilizing a bearing and a one-way clutch provided with gear teeth on the outer side face; the driven gear is suitable for being in transmission connection with the rotating shaft; and the end part, stretching out of the shell, on the rotating shaft is suitable for being fixedly connected with a chain wheel used for driving a driving wheel of the bicycle. The bicycle vibration energy conversion mechanism is capable of accumulating vibration energy and then outputting the vibration energy to wheels so as to drive the bicycle to advance.

Owner:龚天波

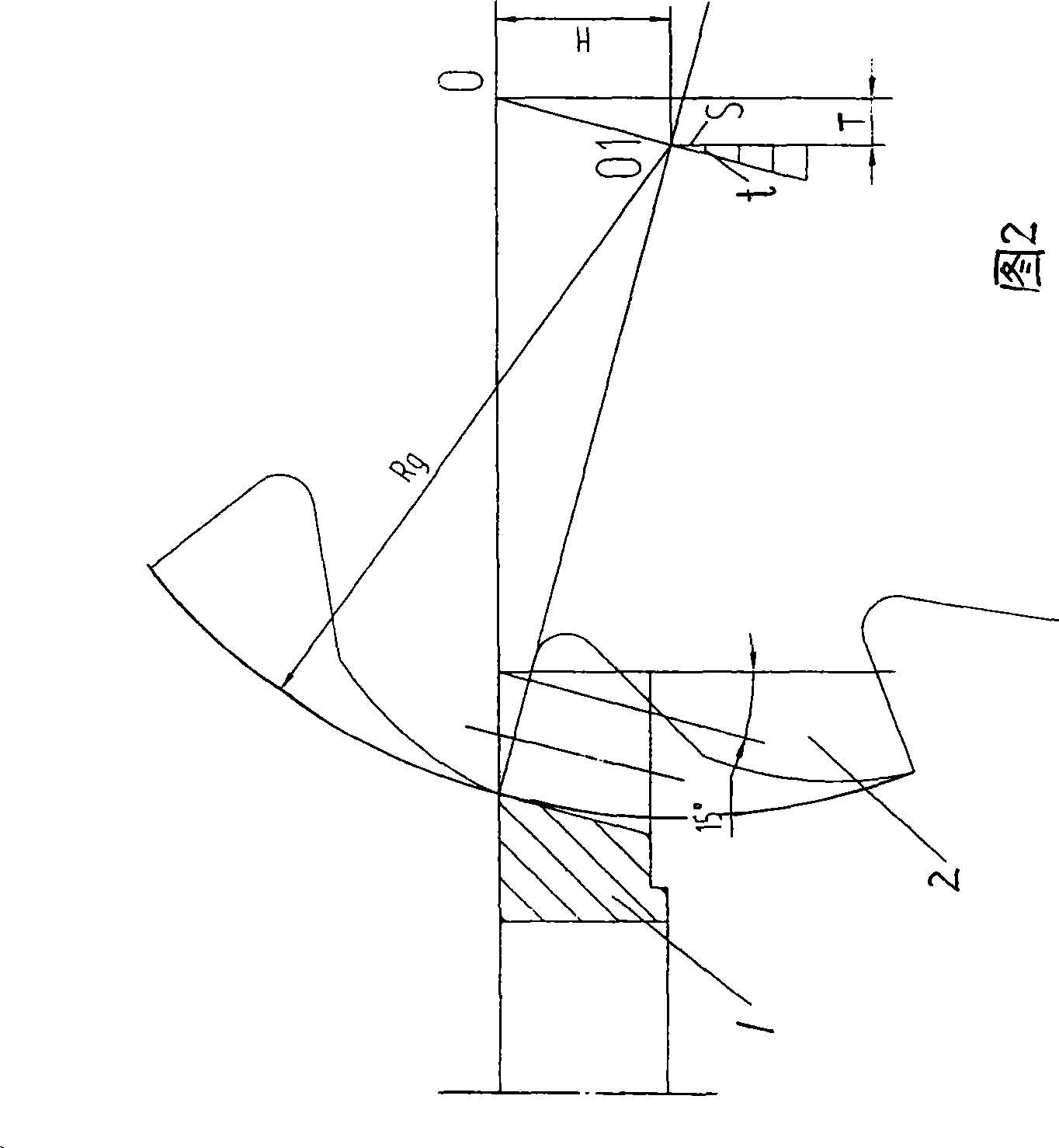

Technique for producing and processing chamfering tool for cylindrical gear double-side tooth profile

InactiveCN101439461AReduce usageSimple methodGear teeth manufacturing toolsGear teethHobbingSurface tooth

The invention relates to a production processing technology of dual-surface tooth profile chamfering cutter used for a cylindrical gear, belonging to the technical field of tool processing for chamfering gears, the process technology solves the problem that the processing technology of the dual-surface chamfering cutter in the prior art is complex. The production processing technology of dual-surface tooth profile chamfering cutter used for a cylindrical gear comprises the following steps of the hobbling processes: 1. the helical tooth is hobbed on a hobbing machine by a gear hob; 2. a back taper angle Alphai is hobbed, the starting position of hobbing of the gear hob is that H is equal to Rgsin Alphai and T is equal to Htg Alphai; 3. the tooth thickness of the large end is kept unchanged, the left tooth surface of the reverse tapered teeth is hobbed by a first tooth at the right end of the hob; 4. the right tooth surface of the reverse tapered teeth is hobbed by a first tooth of the left end of the hob. The process has the beneficial effects that operations completed originally by a plurality of processes and a plurality of cutters of the chamfering cutter can be completed by a single hob and special cutters are not required, the method is simple, the precision is reliable, secondary cutter is less used and the cost is low.

Owner:SHANXI DATONG GEAR GROUP

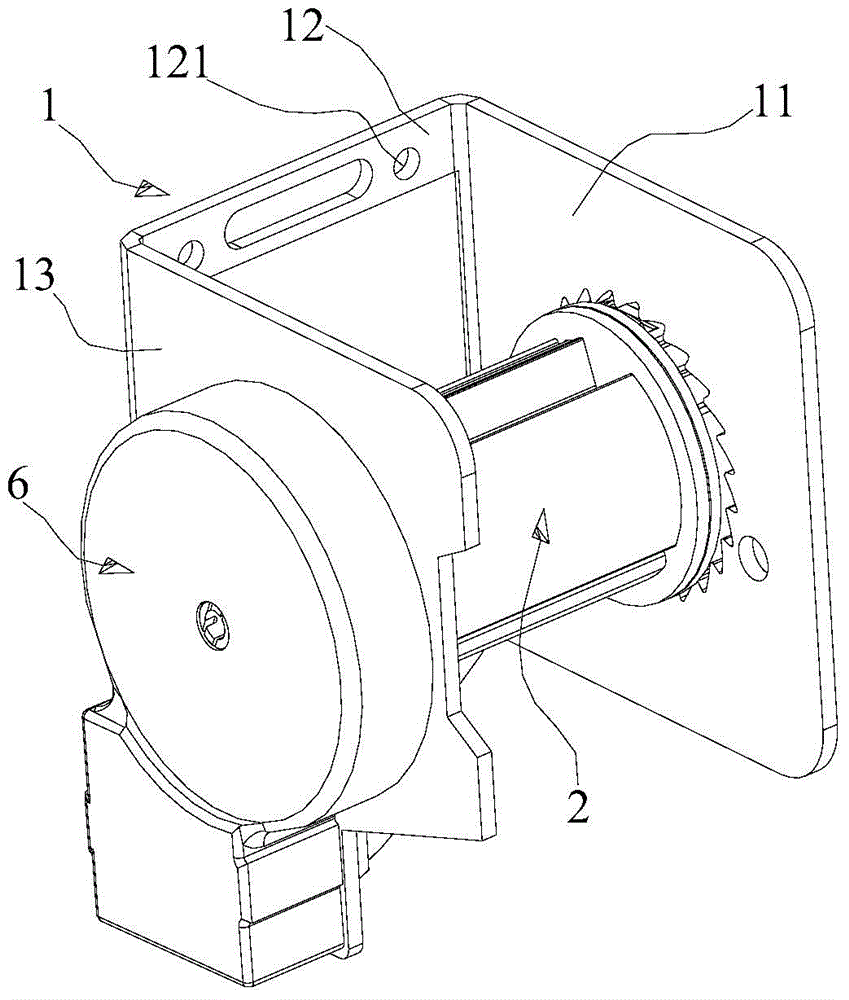

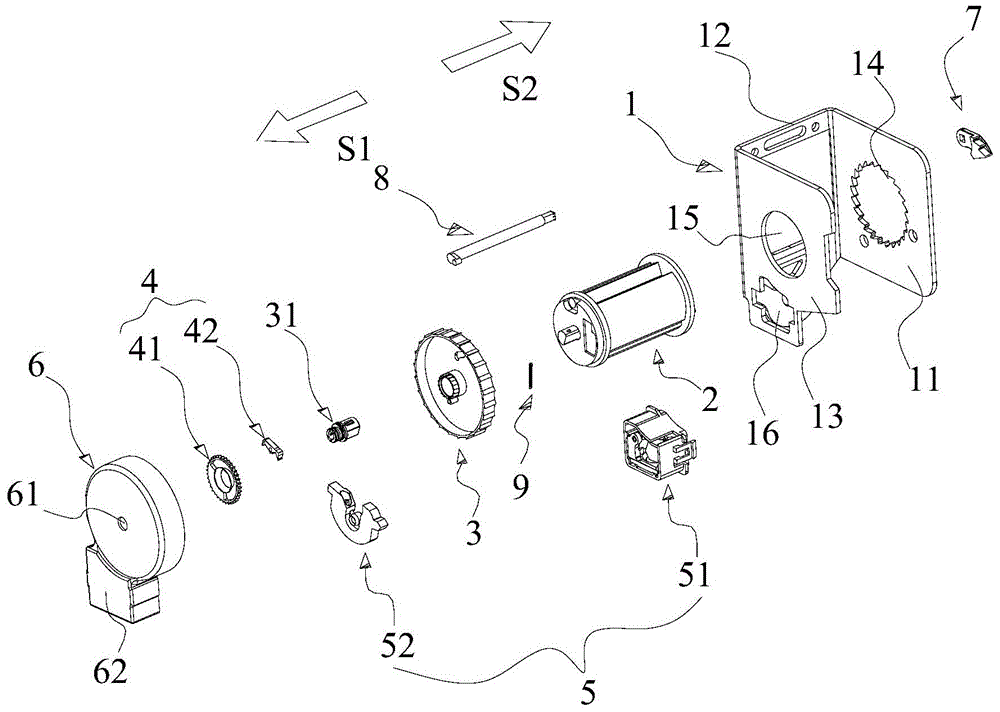

Safety belt device and safety belt winder

In order to solve the problem of complex structure of a traditional safety belt winder, the invention provides a safety belt winder and a safety belt device thereof. The safety belt winder comprises a winding shaft, a frame, a ratchet wheel, a locking device and a switching device, wherein the switching device comprises a transmission wheel and an automatic locking rod; as the transmission wheel is eccentrically connected with a pin column, when the winding shaft rotates, the winding shaft can drive the transmission wheel to eccentrically rotate; a first switching pin and a second switching pin are arranged on the transmission wheel; the automatic locking rod comprises a locking jaw, an induction groove and an induction jaw; the locking jaw fits an end surface tooth; and the engagement or the separation of the locking jaw and the end surface tooth is realized through the fit between the first switching pin and the induction groove and the fit between the second switching pin and the induction jaw. The safety belt winder, disclosed by the invention, effectively realizes the switching between an ALR mode and an ELR mode, and has the advantages of simpler structure, small part number, low cost, small occupied space and lower material cost and assembly cost.

Owner:BYD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com