Patents

Literature

2730 results about "Process requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process requirements refer to a documented statement of needs a business organization intends to satisfy by identifying methodologies, approaches and techniques to be applied to producing a certain outcome (product or service) that materializes or realizes the initially stated needs.

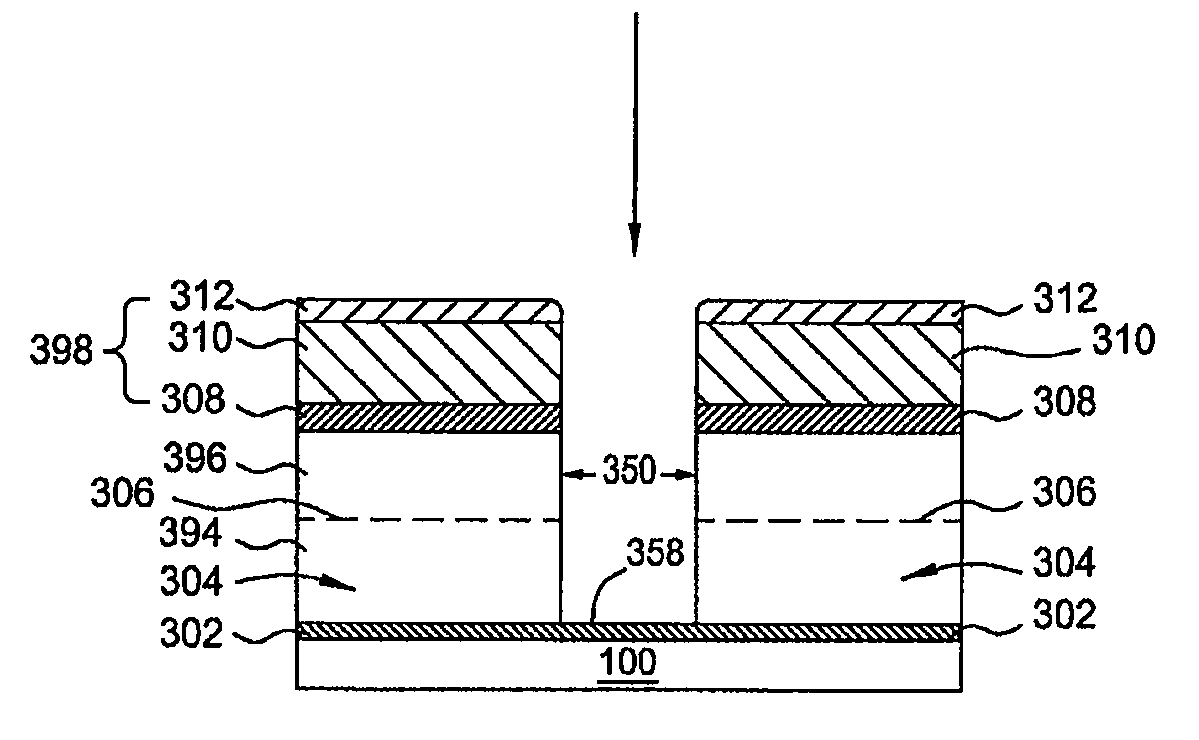

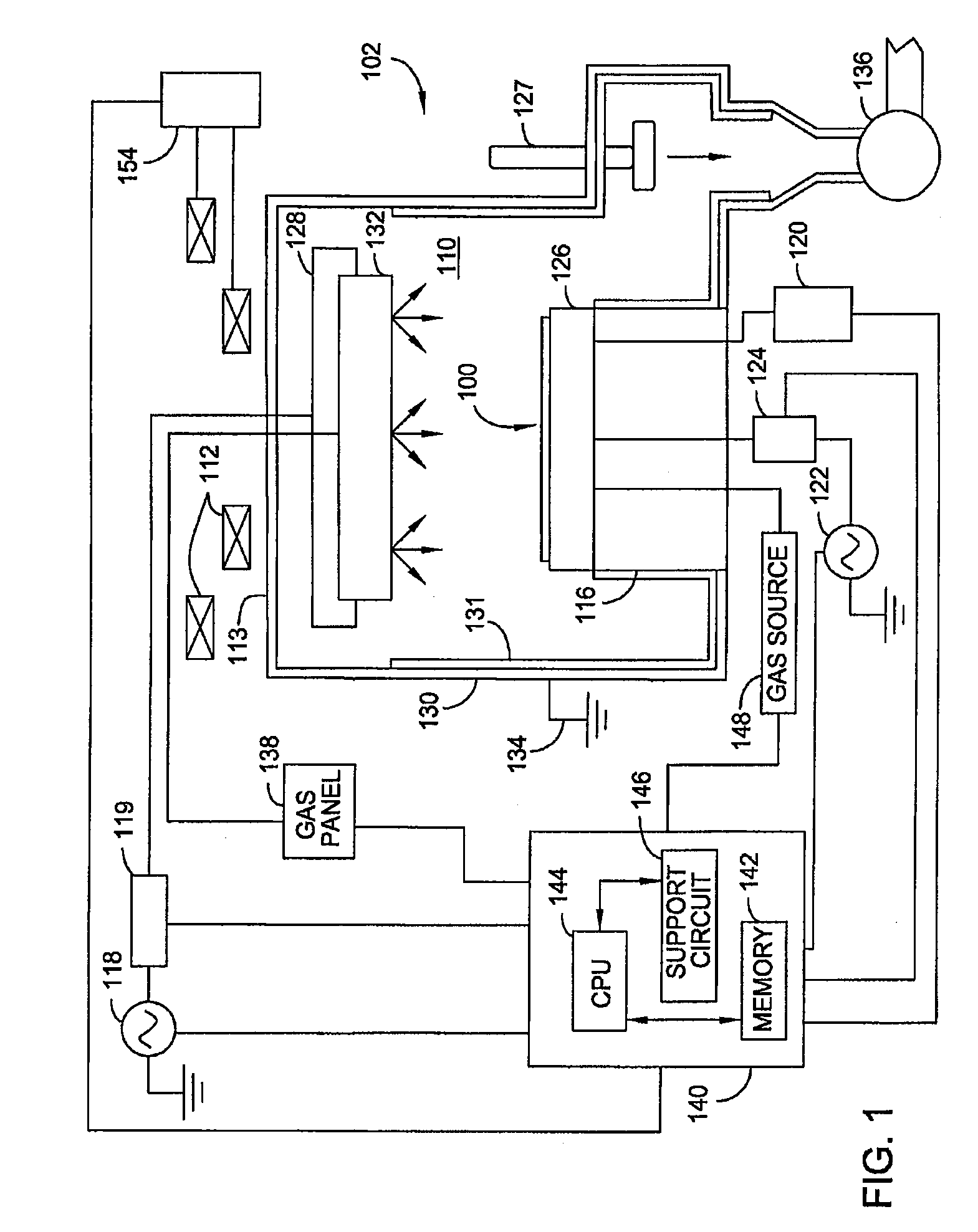

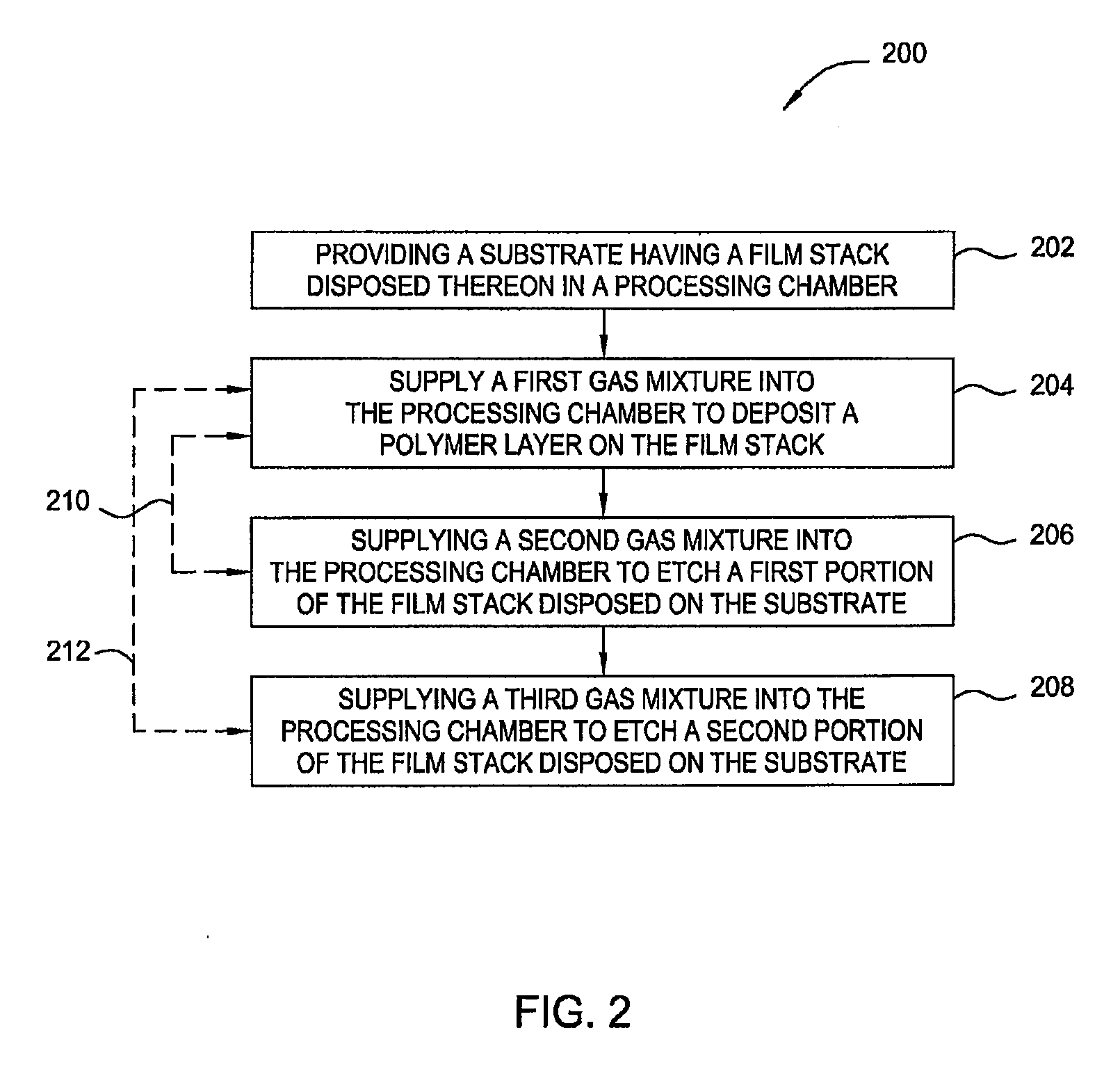

Hardmask open process with enhanced CD space shrink and reduction

InactiveUS20090191711A1Electric discharge tubesSemiconductor/solid-state device manufacturingResistCritical dimension

Methods for forming an ultra thin structure. The method includes a polymer deposition and etching process. In one embodiment, the methods may be utilized to form fabricate submicron structure having a critical dimension less than 30 nm and beyond. The method further includes a multiple etching processes. The processes may be varied to meet different process requirements. In one embodiment, the process gently etches the substrate while shrinking critical dimension of the structures formed within the substrate. The dimension of the structures may be shank by coating a photoresist like polymer to sidewalls of the formed structure, but substantially no polymer accumulation on the bottom surface of the formed structure on the substrate. The embodiments described herein also provide high selectivity in between each layers formed on the substrate during the fabricating process and preserving a good control of profile formed within the structure.

Owner:APPLIED MATERIALS INC

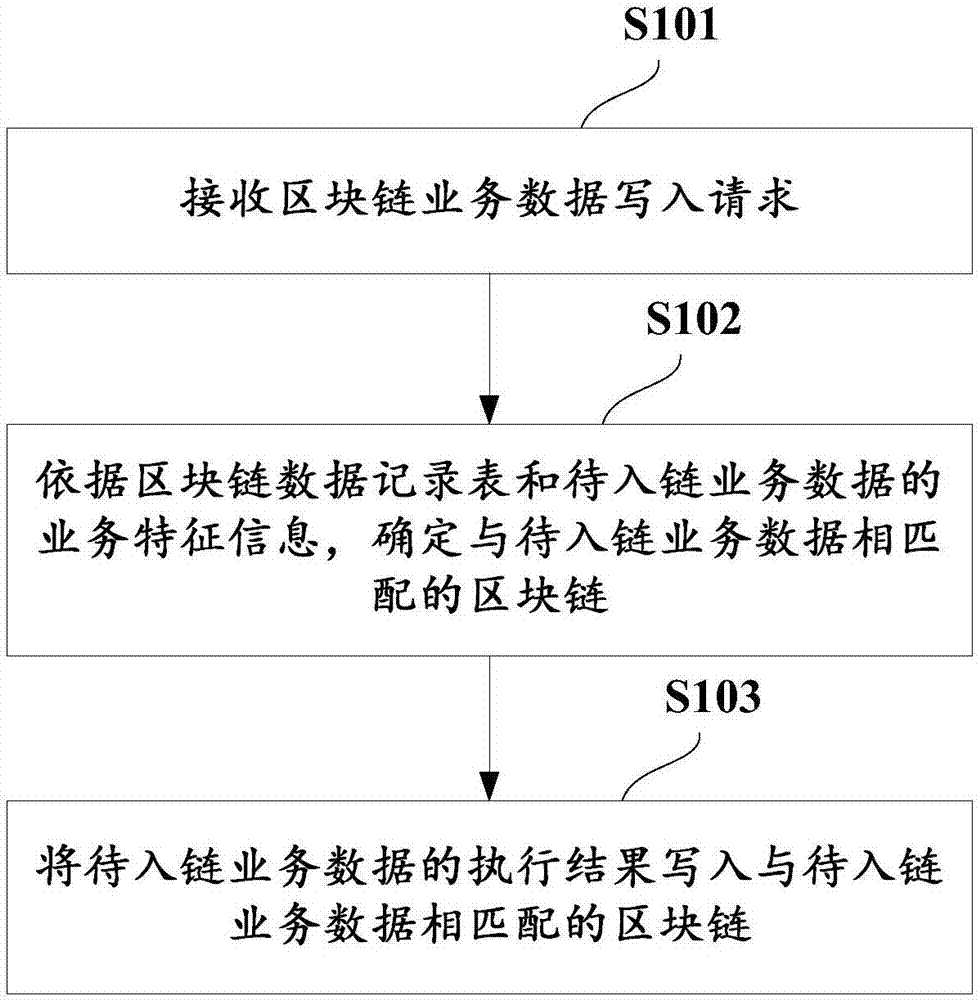

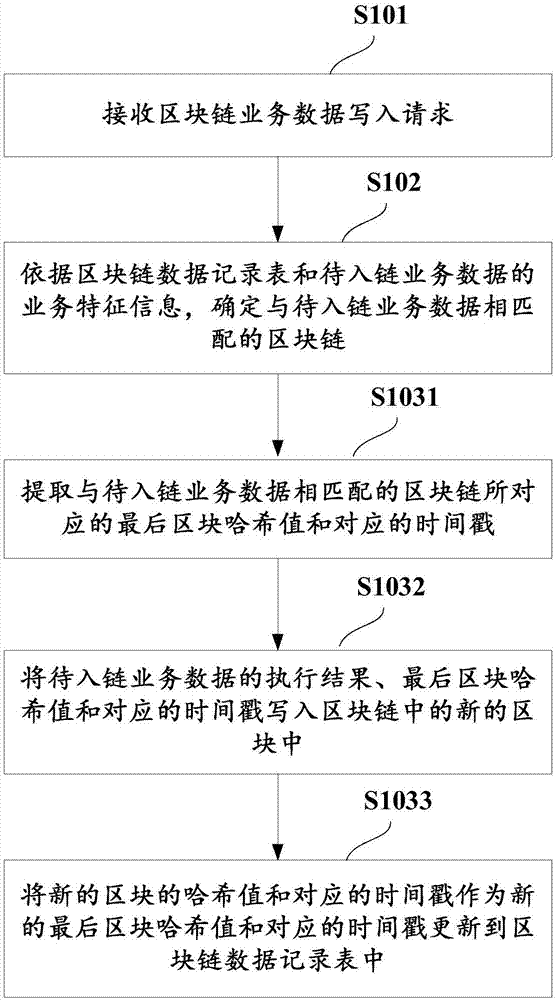

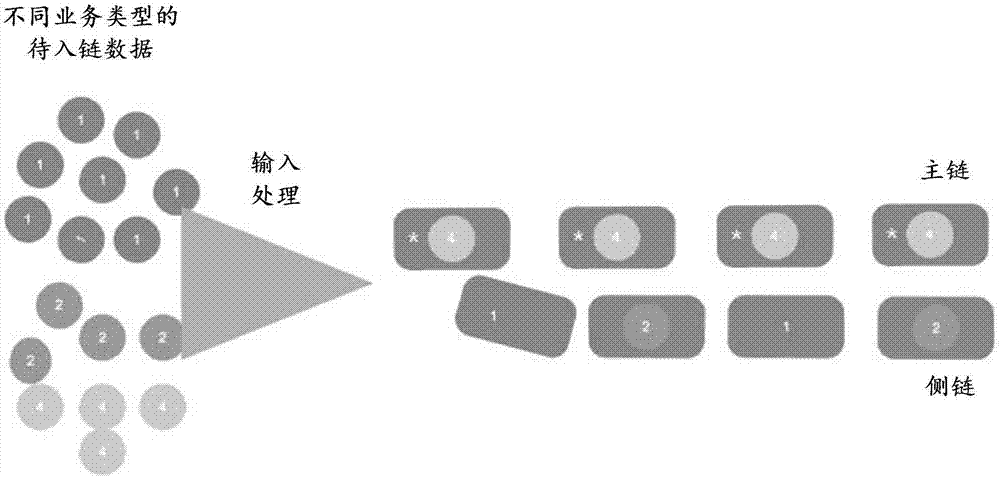

Method and device for writing business data in block chain system

ActiveCN107368259AMeet processing needsInput/output to record carriersDatabase distribution/replicationBusiness dataChain system

The invention discloses a method for writing business data in a block chain system, and the block chain system comprises at least one block chain. The method comprises the following steps of: receiving a block chain business data writing request, wherein the block chain business data writing request comprises business feature information of to-be-chained business data; determining a block chain matched with the to-be-chained business data according to a block chain data record table and the business feature information of the to-be-chained business data, wherein business type identification information of the block chains is recorded in the block chain data record table, and the business type identification information is used for reflecting business feature information of chained business data in the block chains; and writing an execution result of the to-be-chained business data into the block chain matched with the to-be-chained business data. The invention furthermore discloses a corresponding device. By adoption of the method and the device, written block chains can be distinguished according to business types, so that processing requirements of different types of business data in the block chain system can be satisfied.

Owner:ADVANCED NEW TECH CO LTD

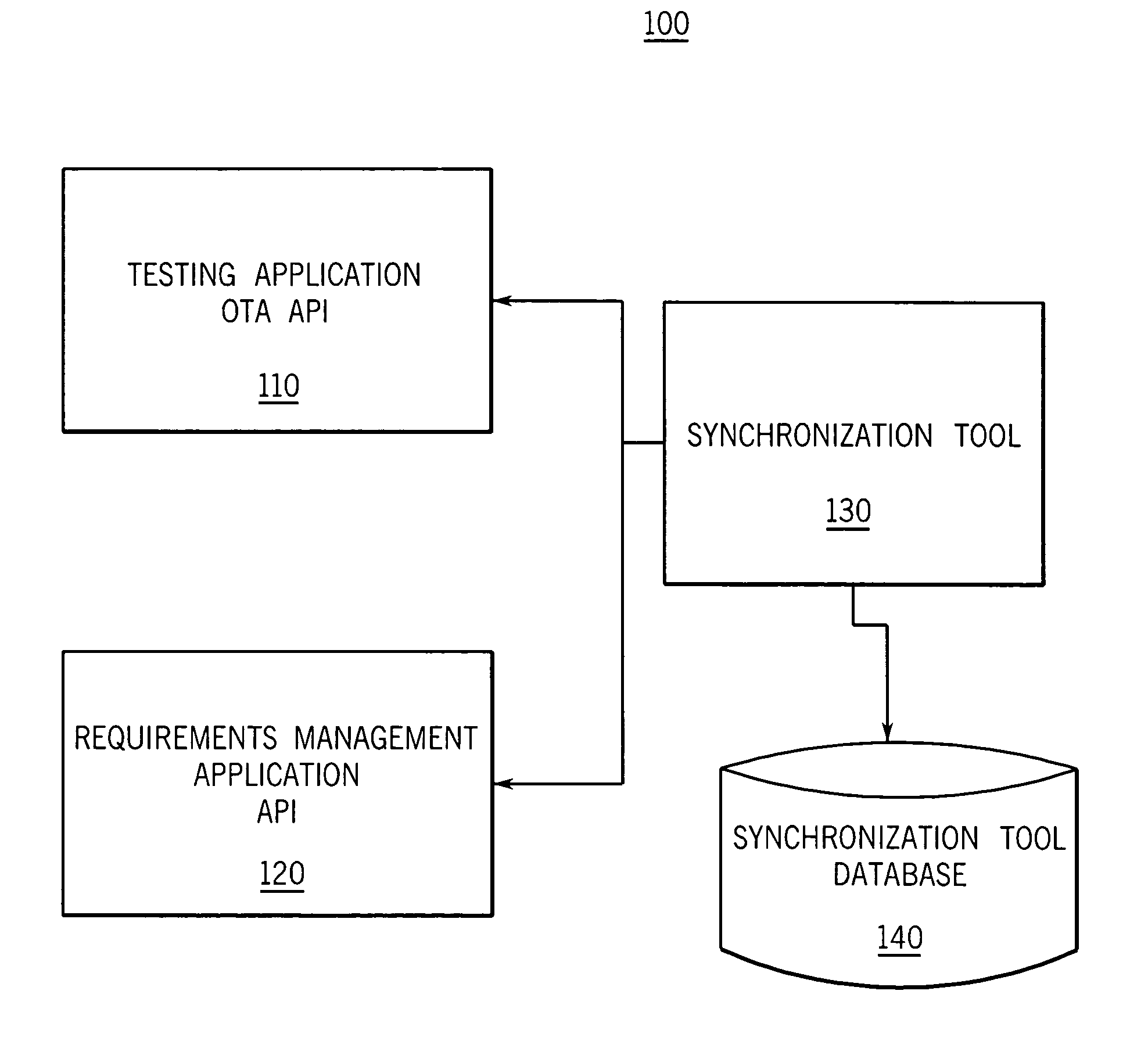

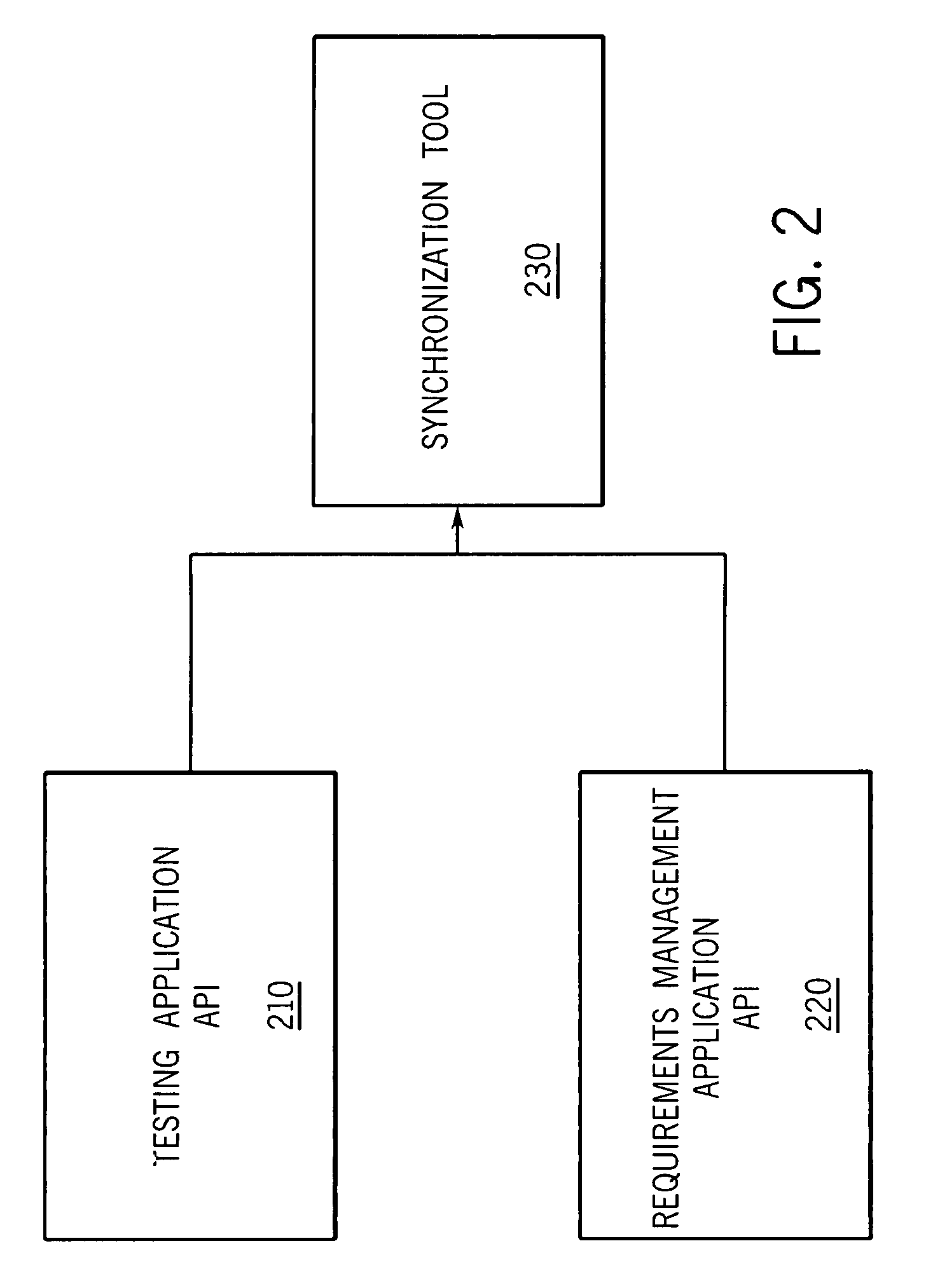

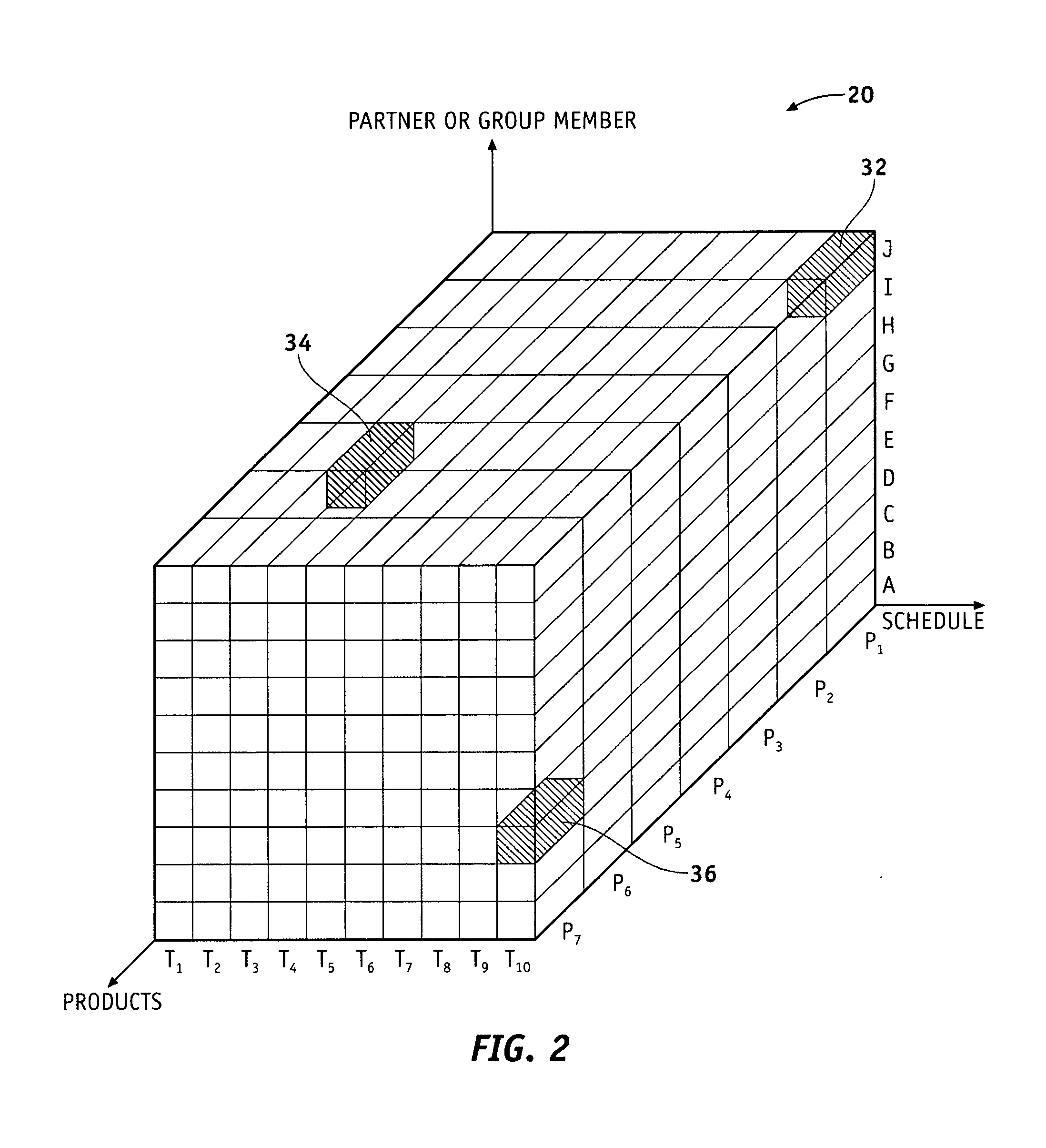

System and method for maintaining requirements traceability

A front end client-server application configured to synchronize requirements between a requirements repository and a testing repository. The front end client-server application validates a requirement, processes at least one filter associated with the requirement, determines a requirement type of the requirement, and processes the requirement. In addition, the method comprises updating a testing application in accordance with the processed requirement. In addition, it can be determined whether a plurality of requirements received by the front end client-server application that need to be synchronized contain traceability relationships. If so, the front end client-server application replicates the traceability relationship between the requirements to be synchronized and any relevant, existing requirements at the testing repository. Furthermore, the front end client-server application allows a user to customize the requirements synchronization process.

Owner:FANNIE MAE

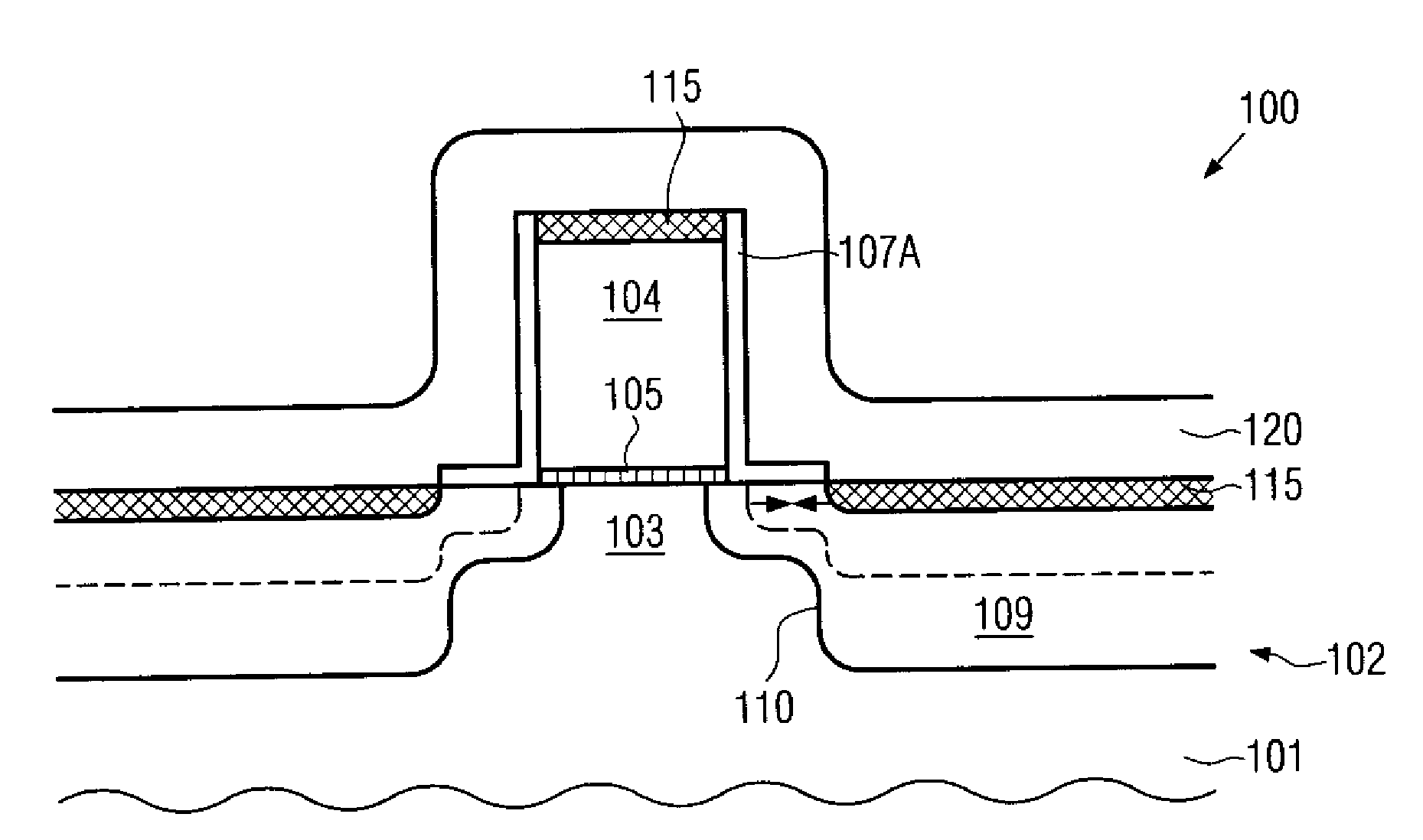

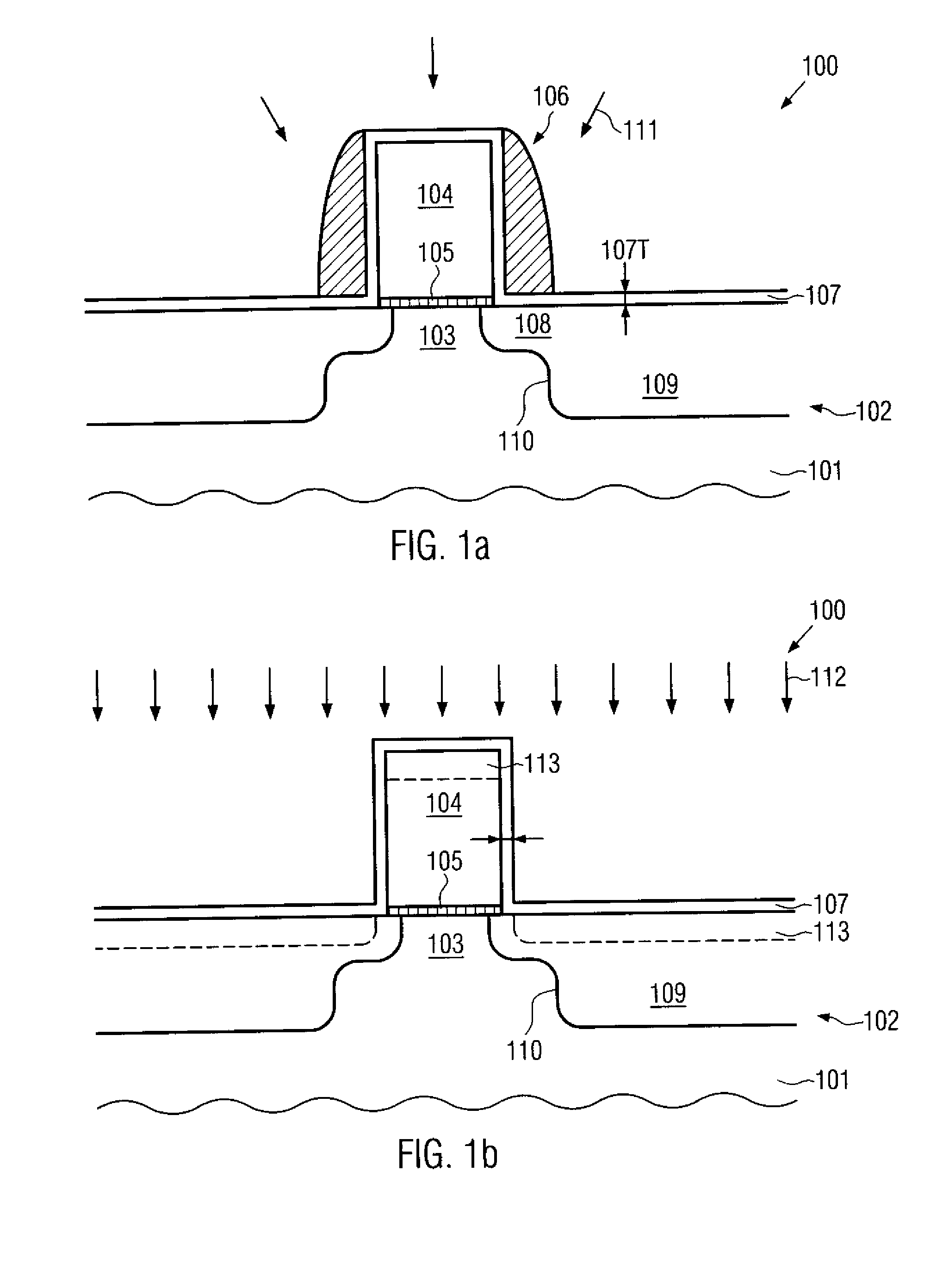

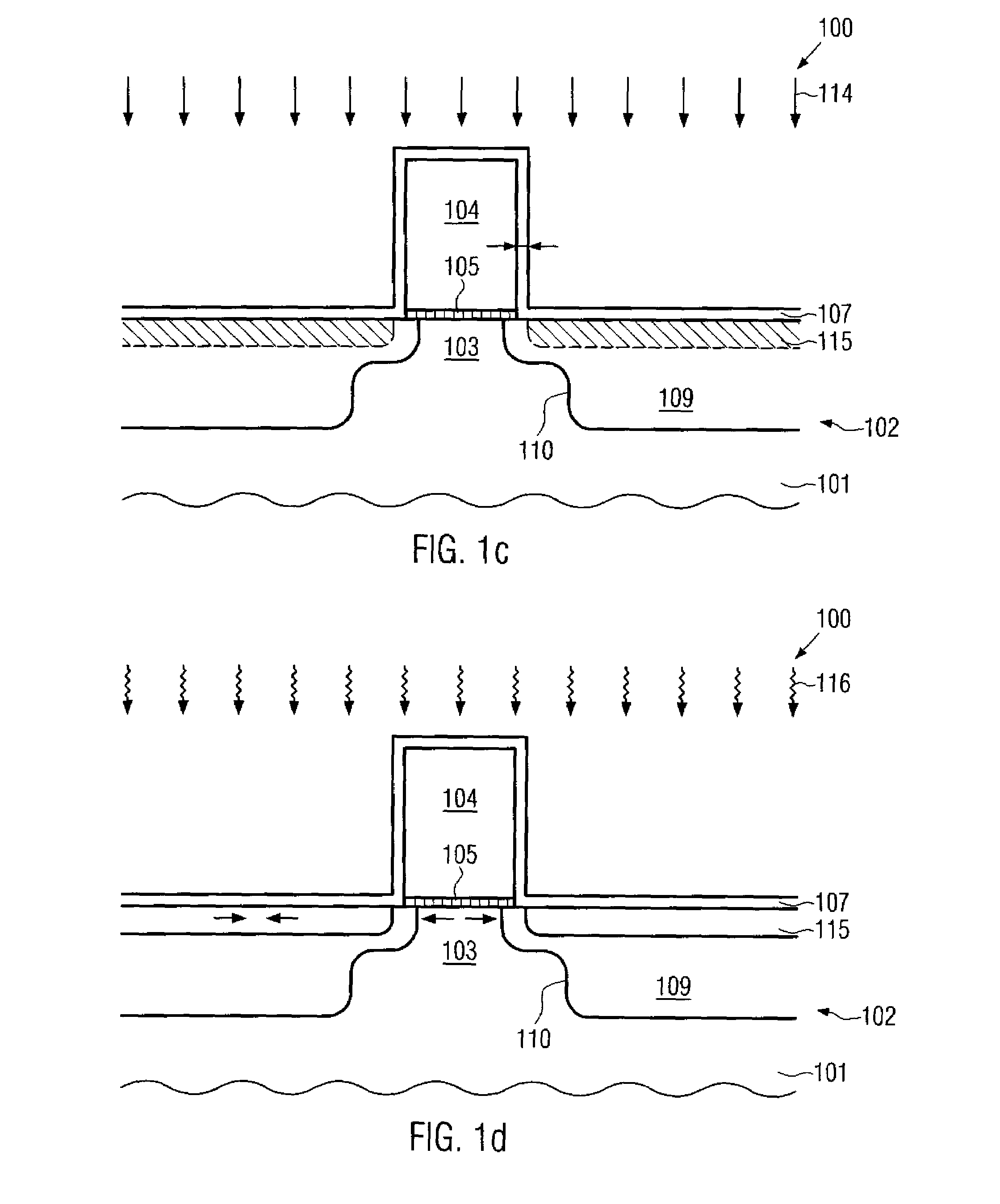

Transistor having an embedded tensile strain layer with reduced offset to the gate electrode and a method for forming the same

ActiveUS20070254461A1Increase strainIncrease flexibilityTransistorSemiconductor/solid-state device manufacturingTensile strainSalicide

By incorporating carbon by means of ion implantation and a subsequent flash-based or laser-based anneal process, strained silicon / carbon material with tensile strain may be positioned in close proximity to the channel region, thereby enhancing the strain-inducing mechanism. The carbon implantation may be preceded by a pre-amorphization implantation, for instance on the basis of silicon. Moreover, by removing a spacer structure used for forming deep drain and source regions, the degree of lateral offset of the strained silicon / carbon material with respect to the gate electrode may be determined substantially independently from other process requirements. Moreover, an additional sidewall spacer used for forming metal silicide regions may be provided with reduced permittivity, thereby additionally contributing to an overall performance enhancement.

Owner:GLOBALFOUNDRIES US INC

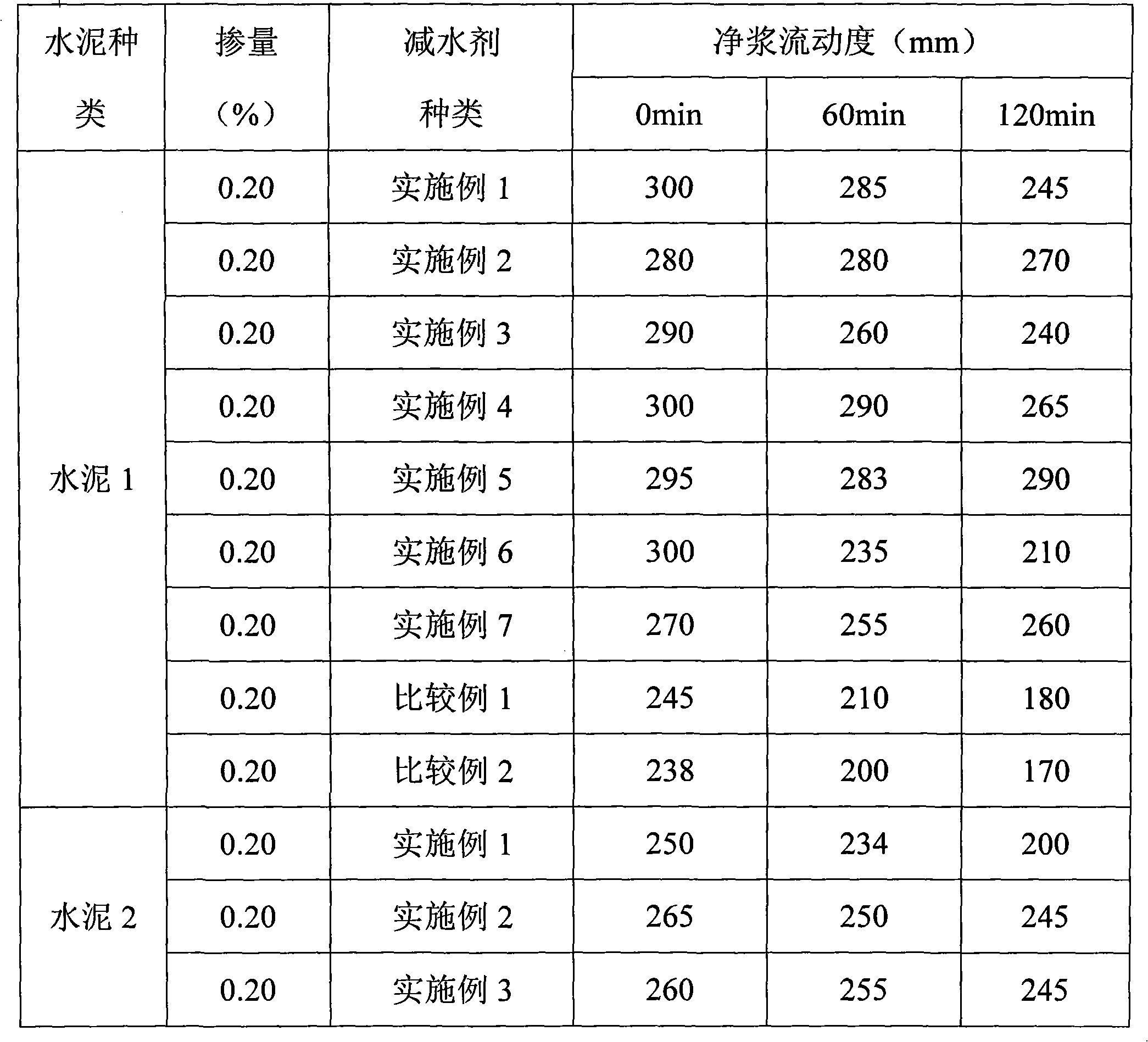

Normal-temperature synthesis method for polycarboxylic acid water-reducing agent

The invention discloses a normal-temperature synthesis method for a polycarboxylic acid water-reducing agent, and belongs to the field of cement concrete water-reducing agents. The water-reducing agent is prepared by the following steps of: copolymerizing polyoxyethylene ether monomer or polyoxyethylene ester monomer a containing unsaturated double bonds, unsaturated monocarboxylic acid and derivative monomer thereof b, unsaturated dicarboxylic acid c and unsaturated sulfonic acid or salt monomer thereof d in aqueous solution under the action of an oxidation reduction initiator, and finally neutralizing the solution by using alkali solution to obtain the water-reducing agent. The reaction can be performed at room temperature by adopting an oxidation reduction initiating system, and the appropriate reaction temperature is between 5 and 30 DEG C; and the synthesis process does not need heating, so energy is saved, and high-temperature side reaction is effectively controlled. The prepared polycarboxylic acid high-performance water-reducing agent has the characteristics of high water-reducing rate and good collapse protecting performance. The water-reducing agent has wide application range, and the method has low production process requirement and is suitable for industrialized large-scale production.

Owner:BEIJING UNIV OF TECH

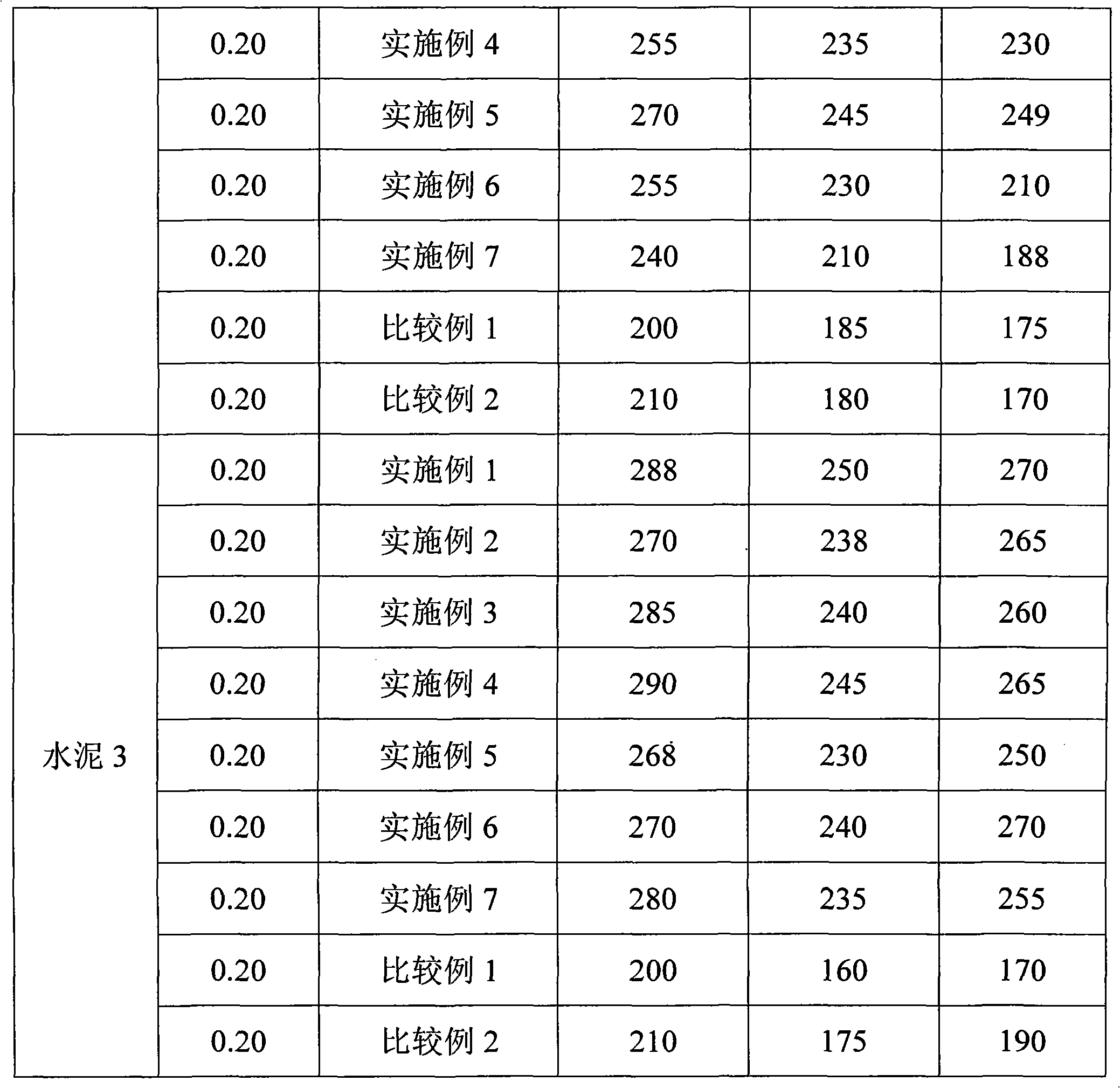

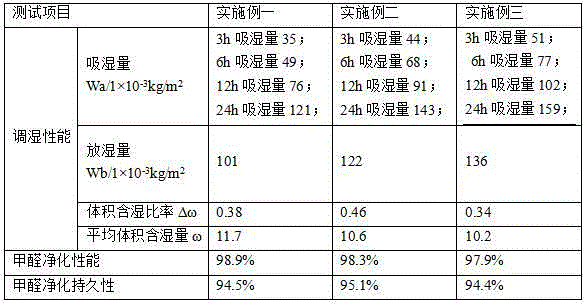

Formaldehyde purification diatom mud decoration material and preparation method thereof

The present invention discloses a formaldehyde purification diatom mud decoration material and a preparation method thereof. Specifically the formaldehyde purification diatom mud decoration material comprises, by mass, 10.0-30.0 parts of refined diatomite, 20.0-50.0 parts of a powdery filler, 2.0-5.0 parts of redispersible glue powder, 20.0-40.0 parts of a gel material, 0.5-1.0 part of a dispersion medium, 3.0-8.0 parts of nanometer titanium dioxide, 1.0-4.0 parts of a modifier, 3.0-5.0 parts of anti-cracking fibers, and 20-80 parts of water. According to the present invention, with the formaldehyde purification diatom mud decoration material, the formaldehyde purification efficiency can be effectively increased, the purification persistence can be significantly improved, the defects of physical adsorption effect losing caused by saturation, and the like are avoided, and the purification speed can be accelerated; and the formaldehyde purification diatom mud decoration material of the present invention further has characteristics of good thixotropy, appropriate modeling, water resistance, alkali resistance, no powdering, no cracking and other beneficial properties, and concurrently meets process requirements of mechanical spraying, brushing coating, roller coating and the like.

Owner:SUZHOU RES INST OF ARCHITECTURE SCI

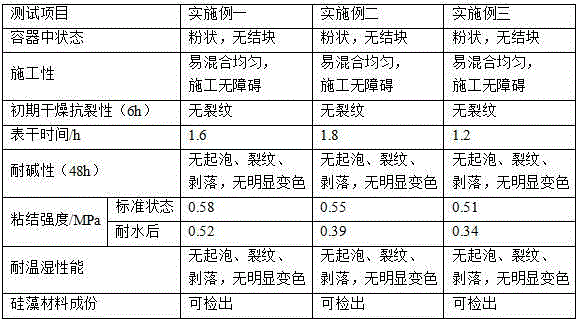

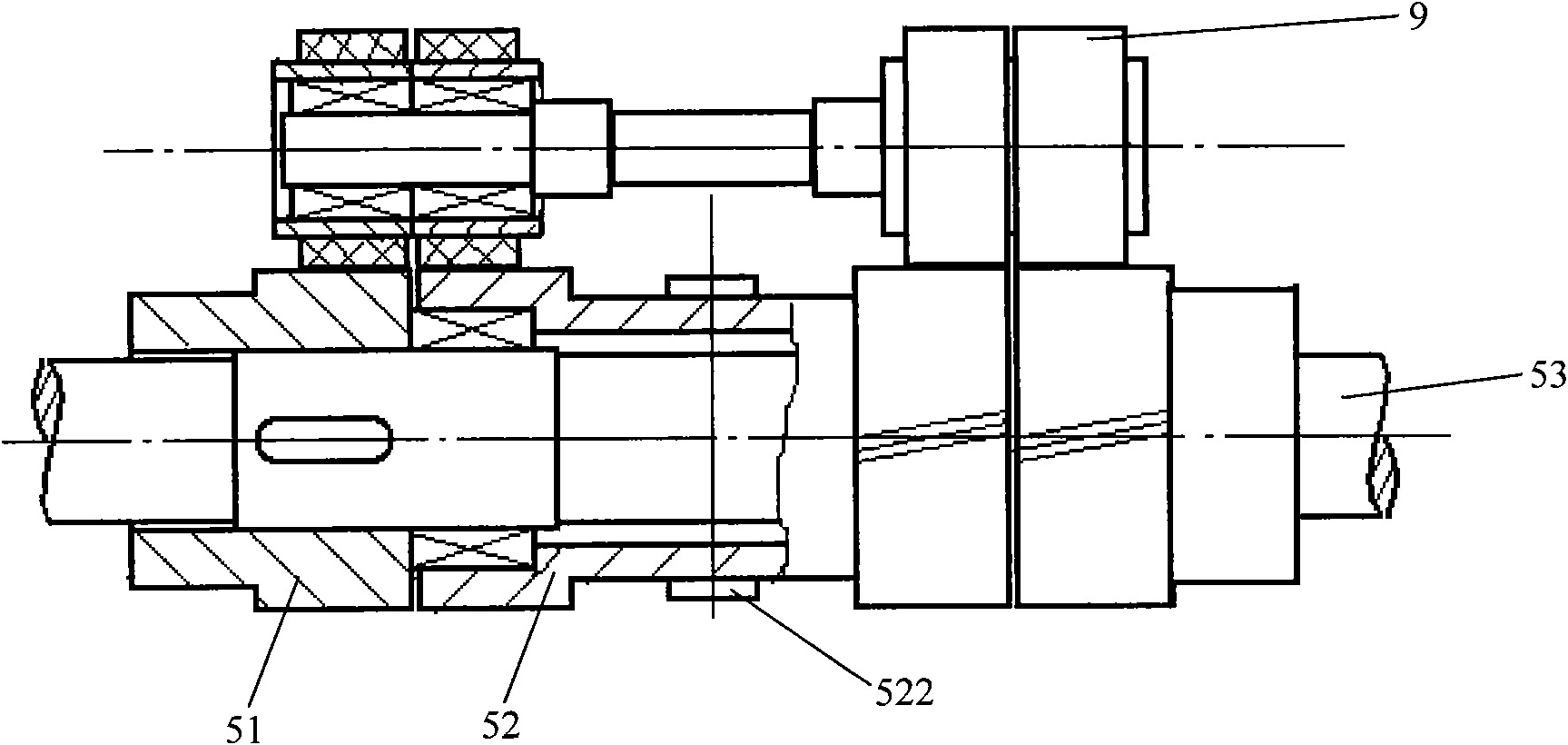

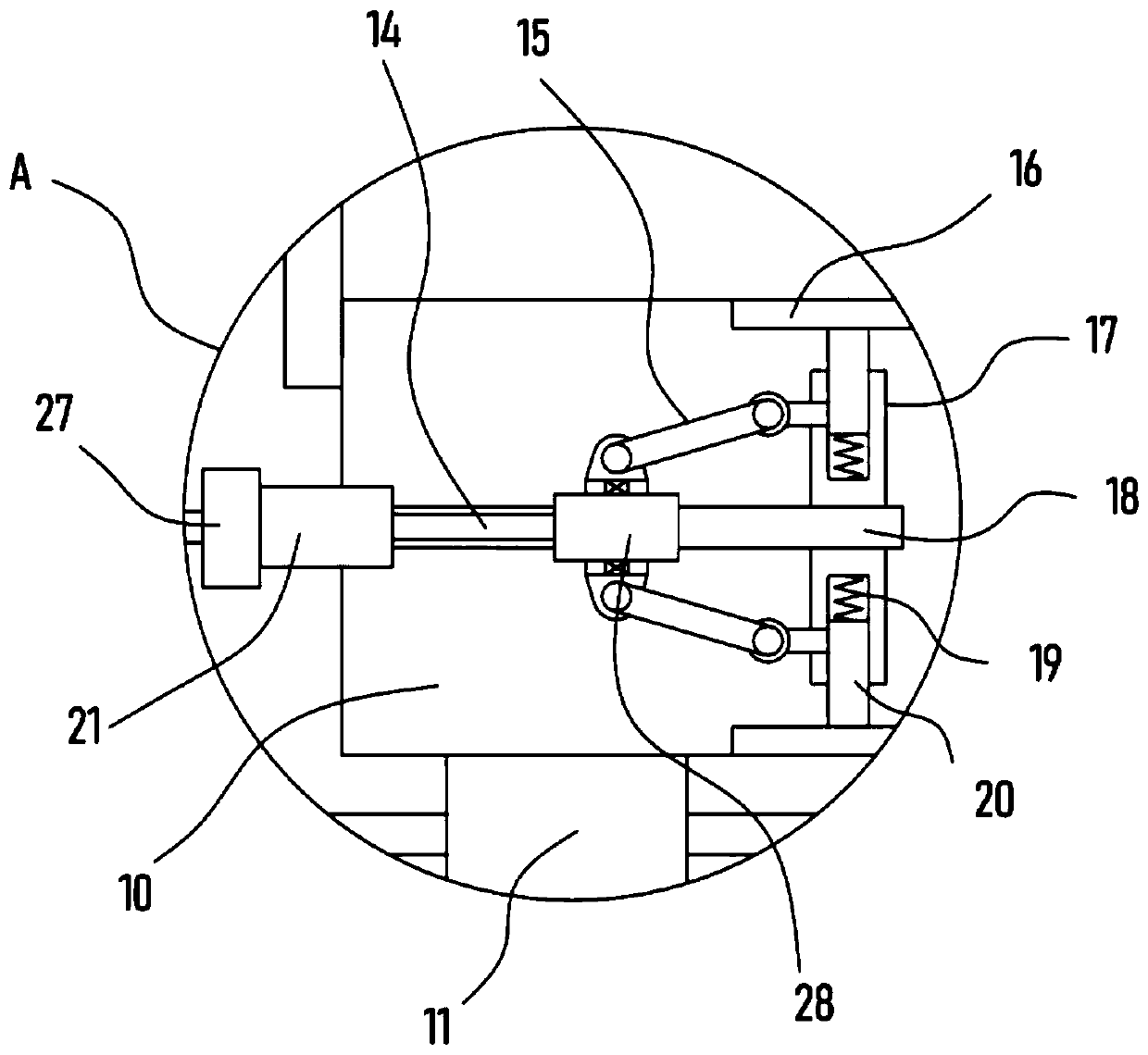

Ring spinning method and device of equi-linear density space dyed yarn

The invention relates to ring spinning method and device of equi-linear density space dyed yarn. The method comprises the following steps of: respectively feeding a fiber strip group (A) with the linear density tex T(A) and a fiber strip group (B) with the linear density tex T(B) into a fixed rear roller and a loop rear roller on a rear roller shaft through yarn guiding rods and grids; and feeding the fiber strip group (A) and the fiber strip group (B) with constant feeding quantity sum into a rear drawing region in any period of time under the process requirement that the feeding speeds of the fiber strip group (A) and the fiber strip group (B) vary with stages by adopting a speed coupling uniform feeding control method. After the strip collection of a strip collector, fiber strips are fed into a middle roller in different drawing ratios, converged in a front drawing region of a spinning machine, drawn and output by a front roller and twisted into equi-linear density space dyed yarn.

Owner:陈伟雄

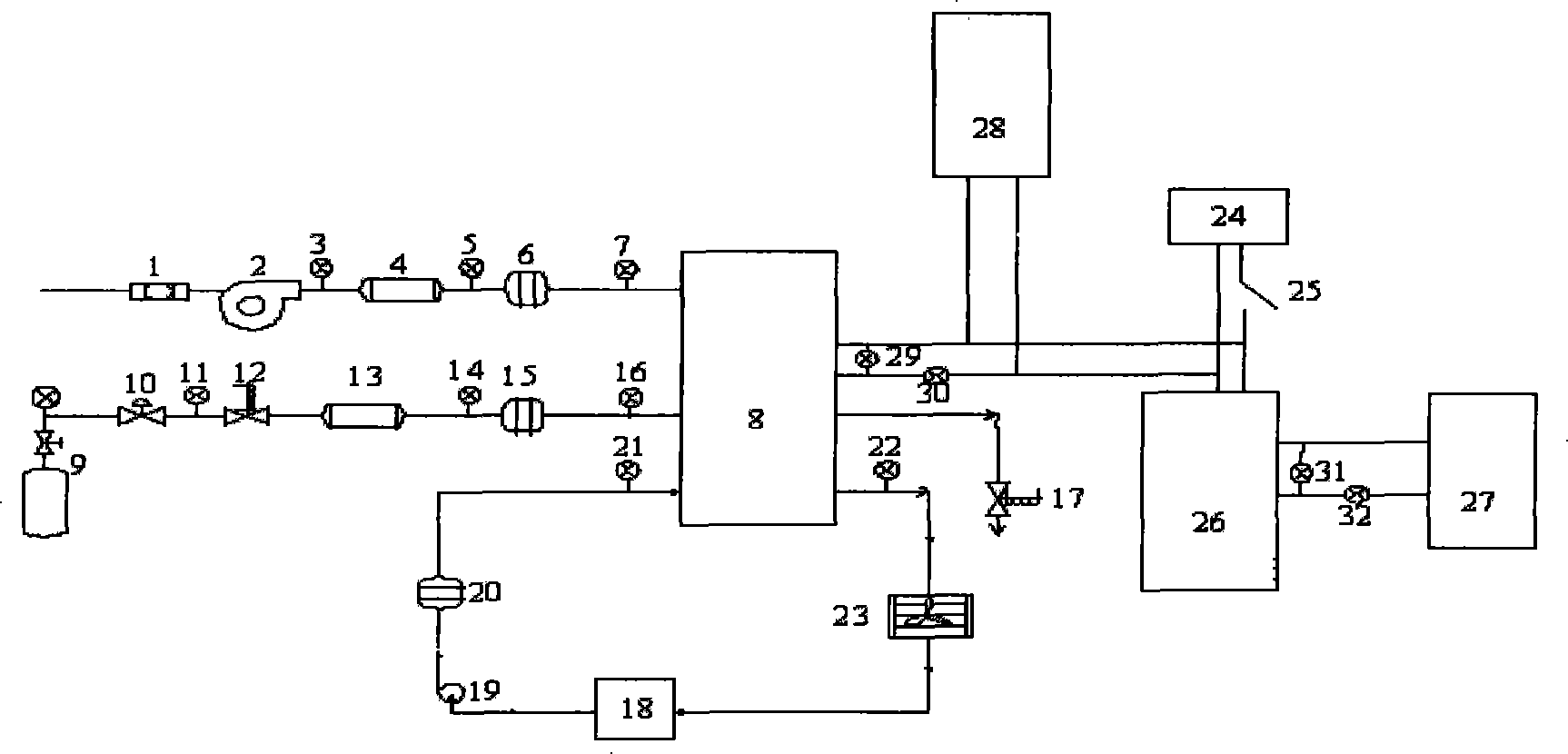

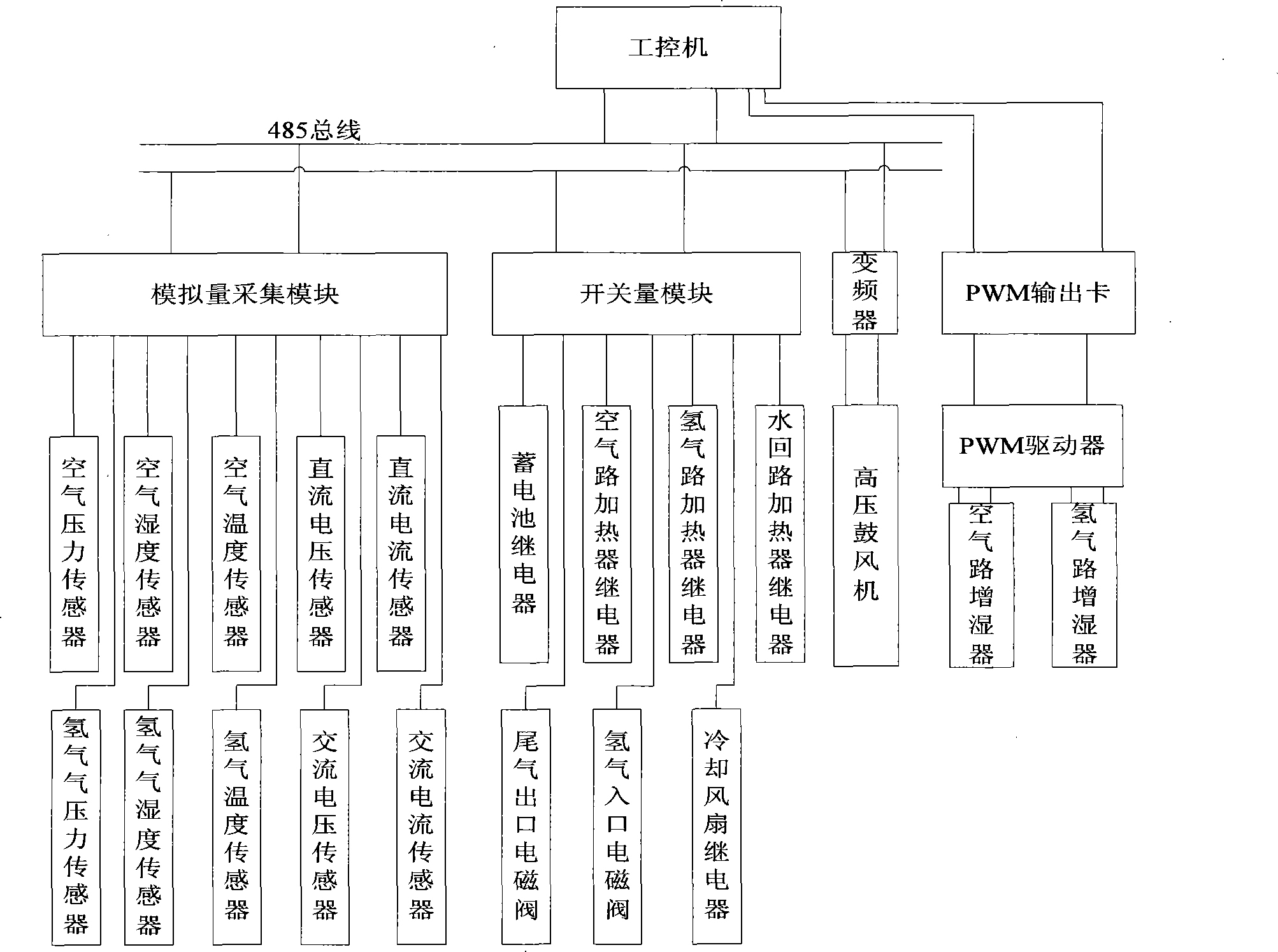

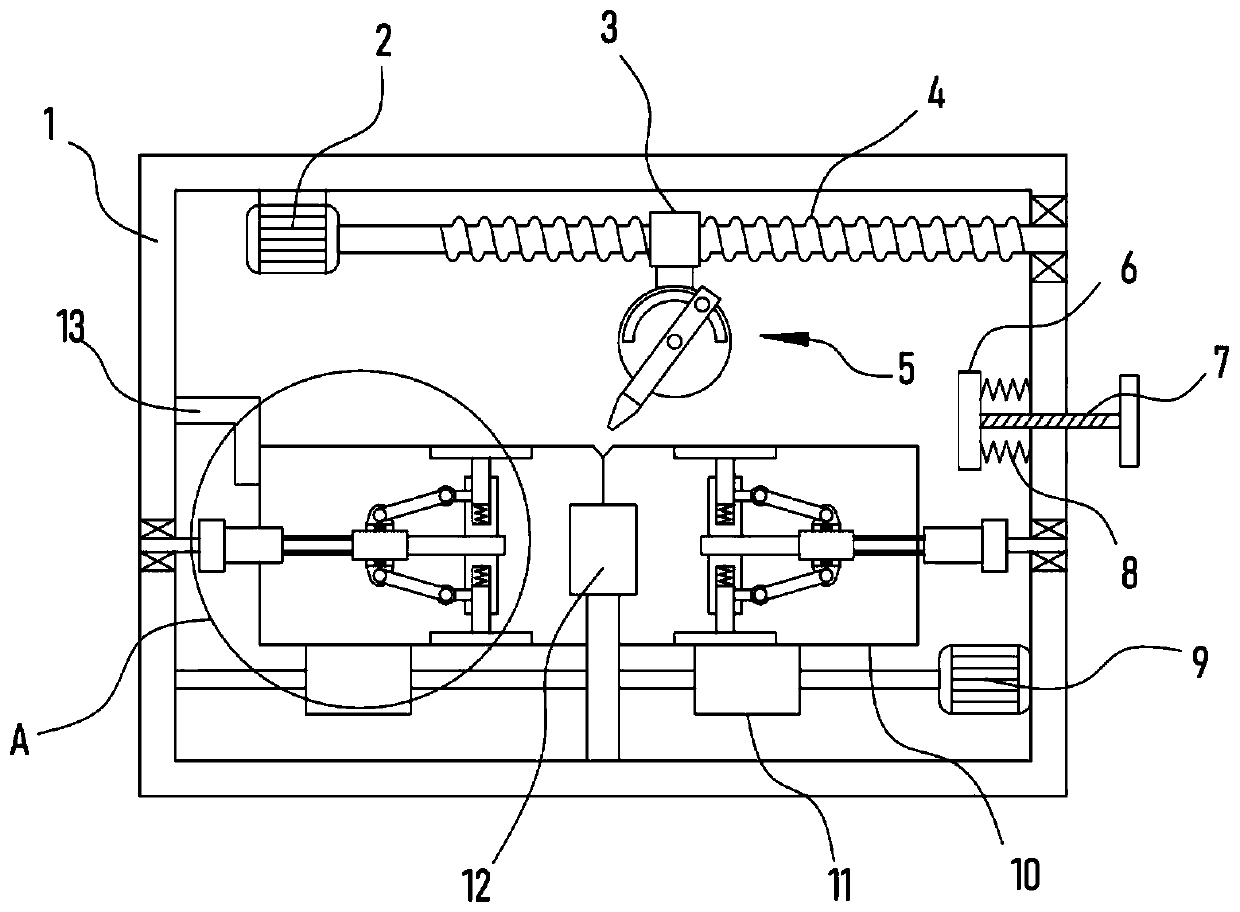

Proton exchanging film fuel battery test platform

The invention provides a testing platform for a proton exchange membrane fuel cell in the fuel cell technical field, comprising an auxiliary system of the fuel cell, a monitoring system and a computer-human interaction part, wherein the auxiliary system of the fuel cell is used to assist a fuel cell set to produce electric power and extract the electric power produced by the fuel cell set; the monitoring system controls the fuel cell set and the auxiliary system of the fuel cell to produce electric power according to the set testing conditions and process requirements of the fuel cell; the computer-human interaction part is used to set the testing conditions and the state of the fuel cell system sent by the monitoring system. The testing platform aims to test the operation status of the fuel cells under different conditions so as to achieve the optimal conditions for the performance and operation of the fuel cells.

Owner:泰州市晟通新能源科技有限公司

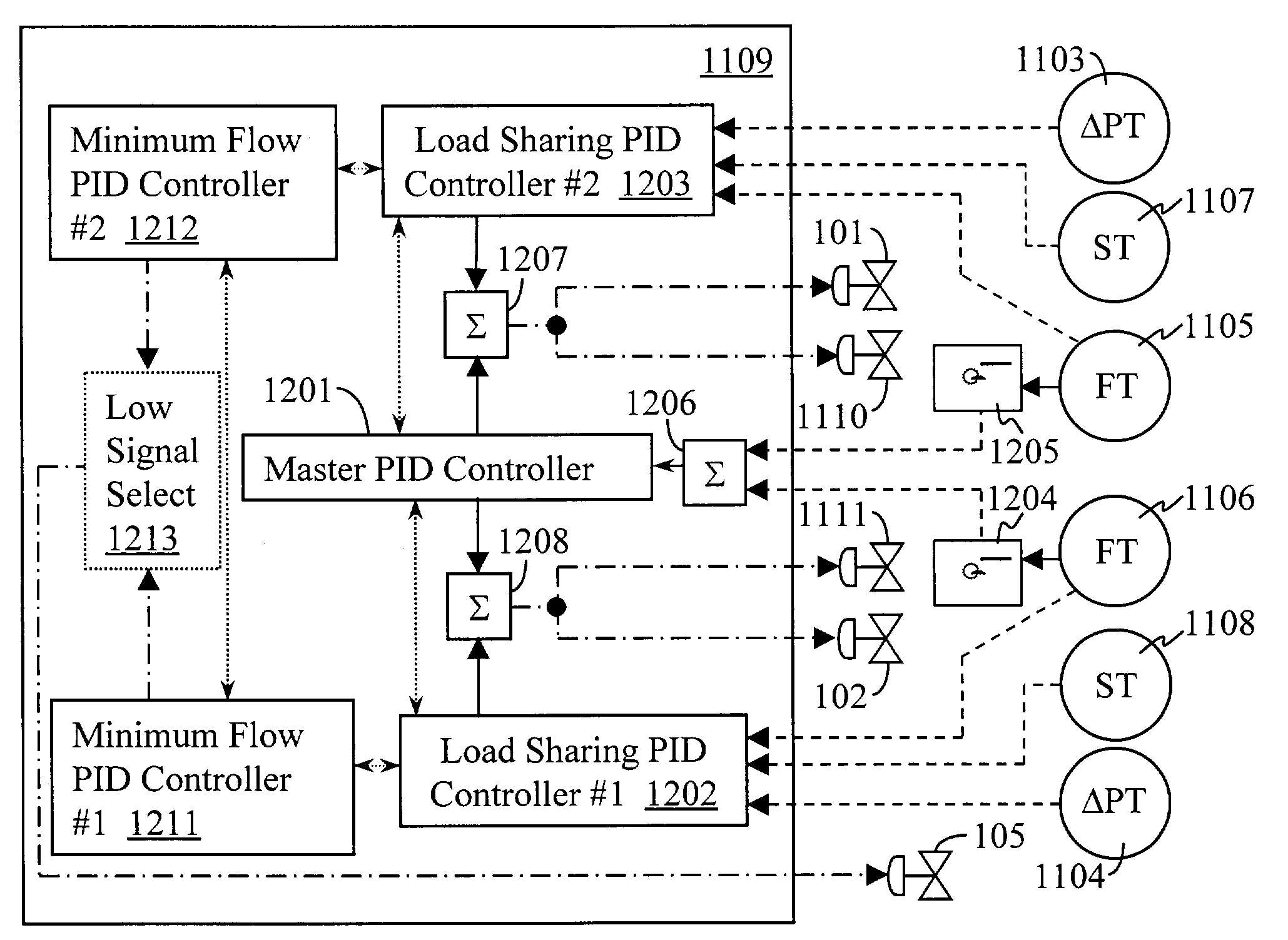

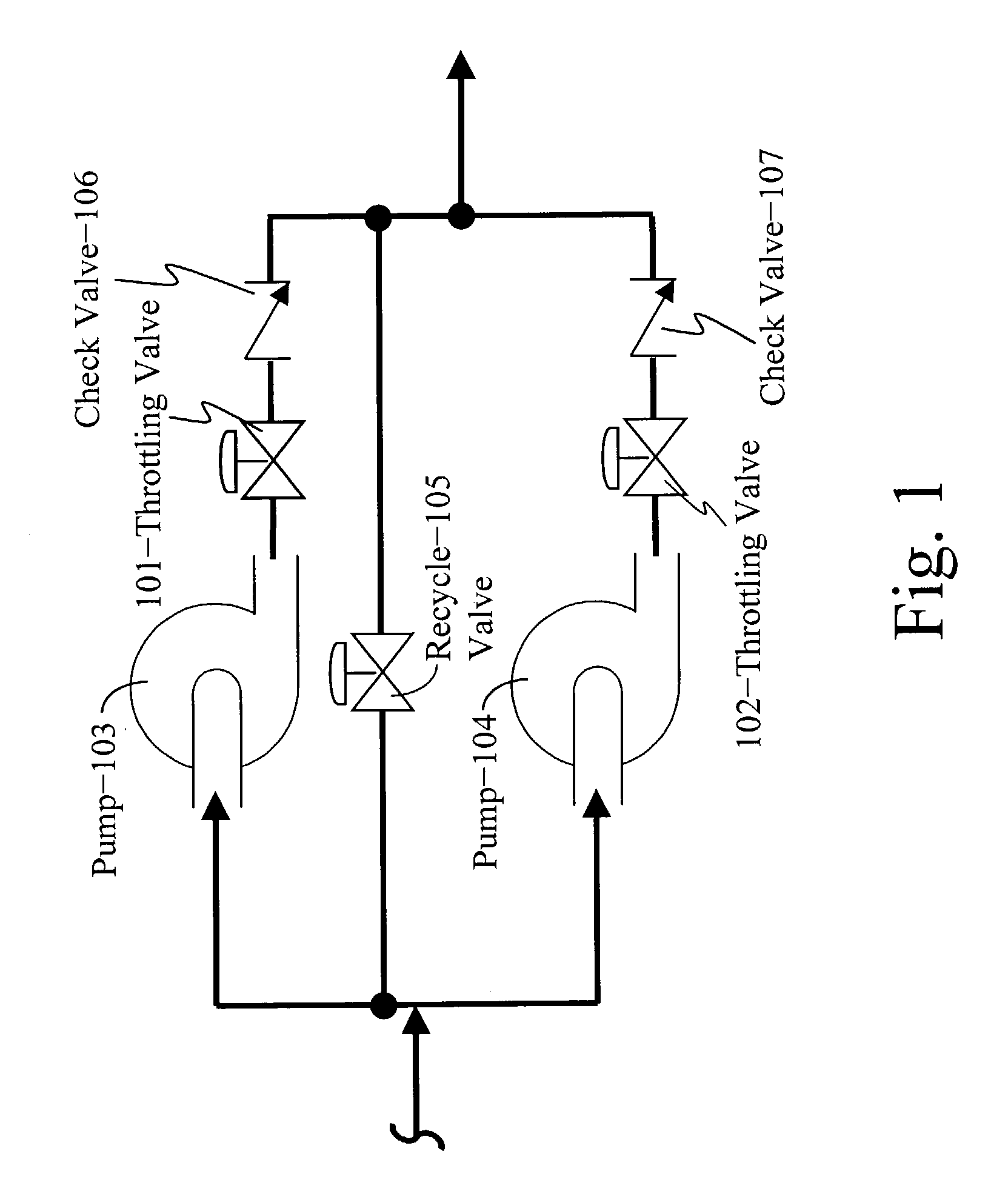

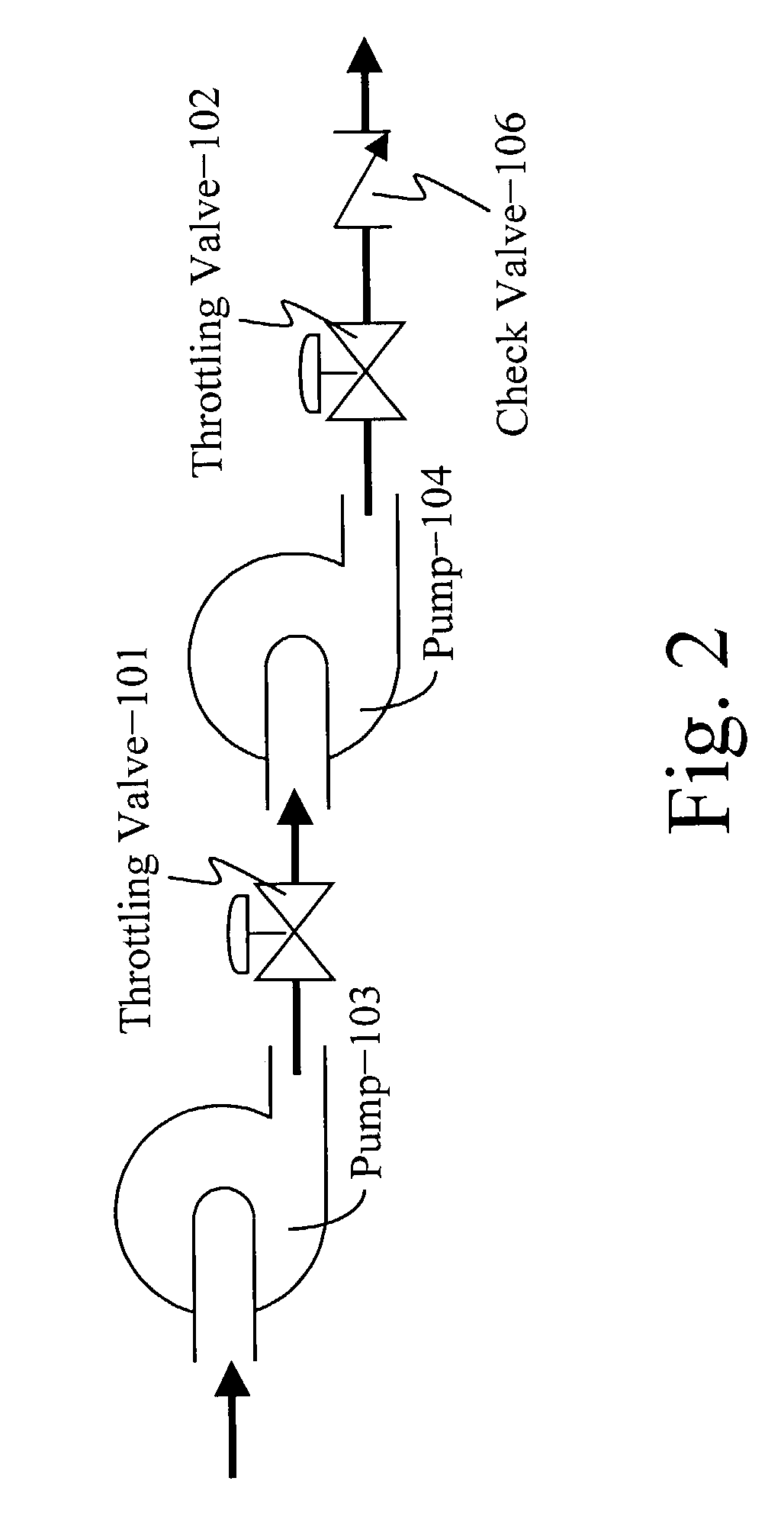

Controlling multiple pumps operating in parallel or series

ActiveUS7010393B2Reduce chanceInefficient recycling or throttling is keptPump controlRatio controlEngineeringProcess requirements

Often, an application or process calls for multiple pumps operating within a piping network. Pump load, such as flow rate or pressure, is shared between these multiple pumps. The present disclosure relates to effective means of distributing the pumping load in a manner that satisfies the process requirements while keeping the pumping machinery safe from functioning in damaging operating regions. It also discloses a method of operating pumps in an efficient or optimal fashion. An additional aspect is a method of using an open-loop response to deal with large transients threatening to force a pump into an operating region that might result in damage or destruction.

Owner:COMPRESSOR CONTROLS LLC

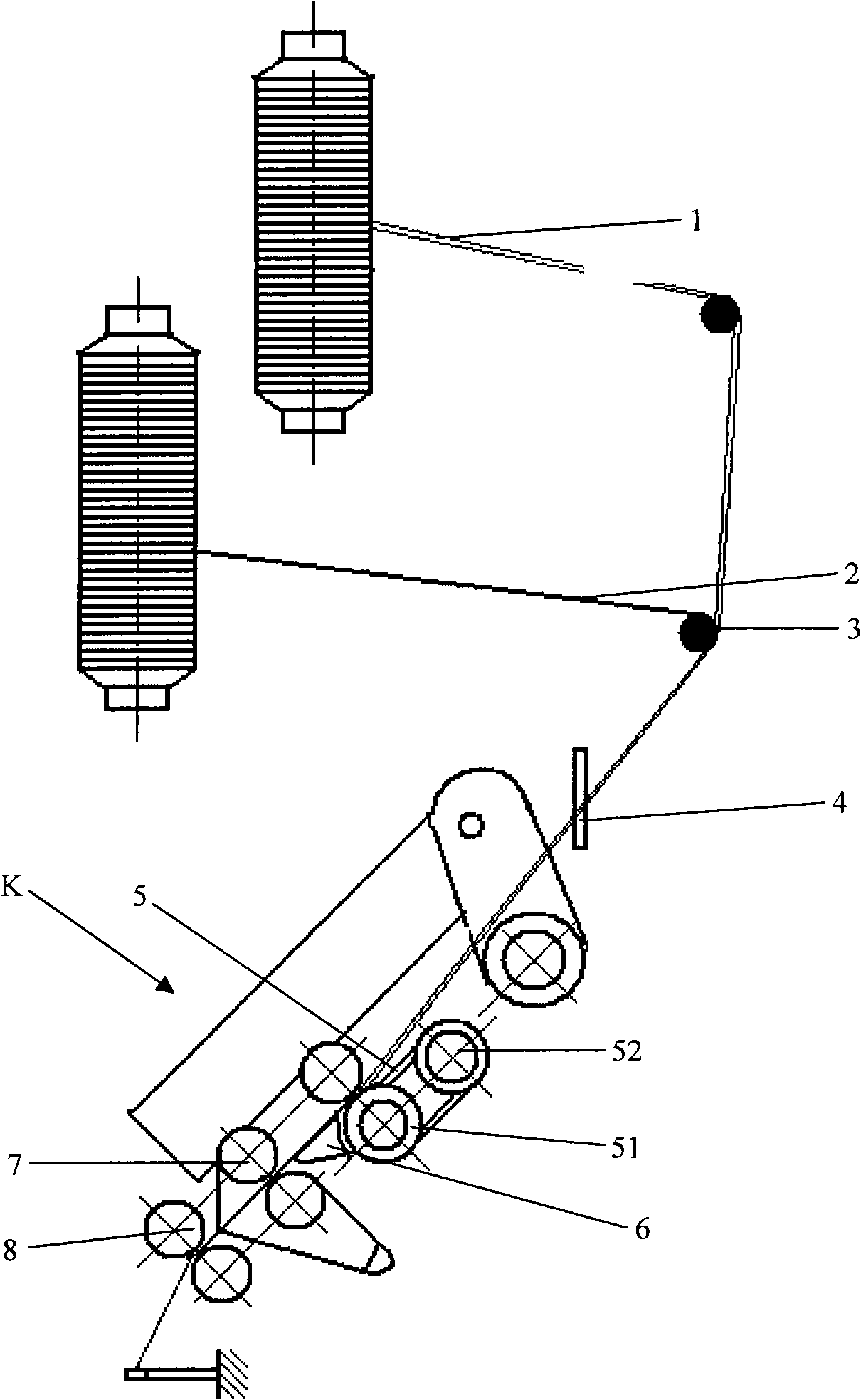

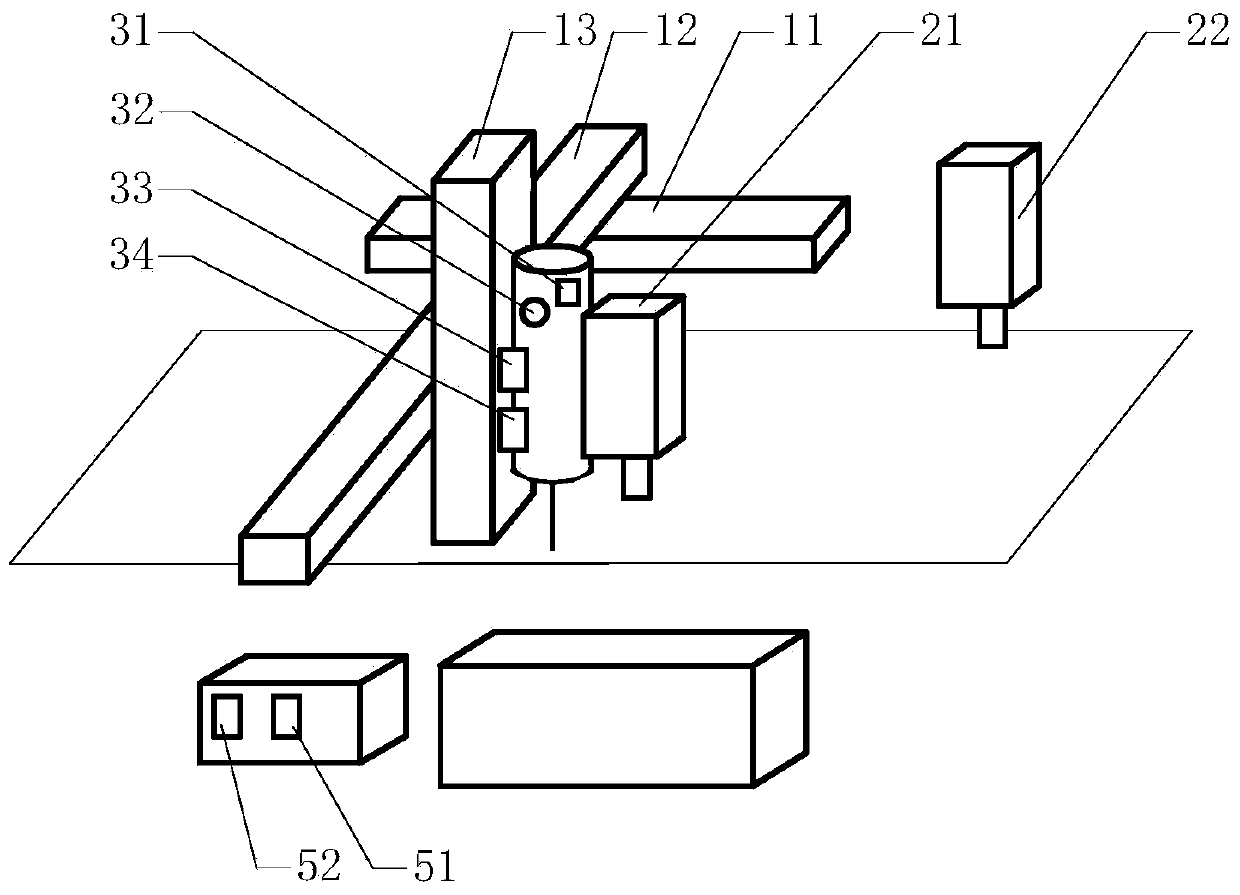

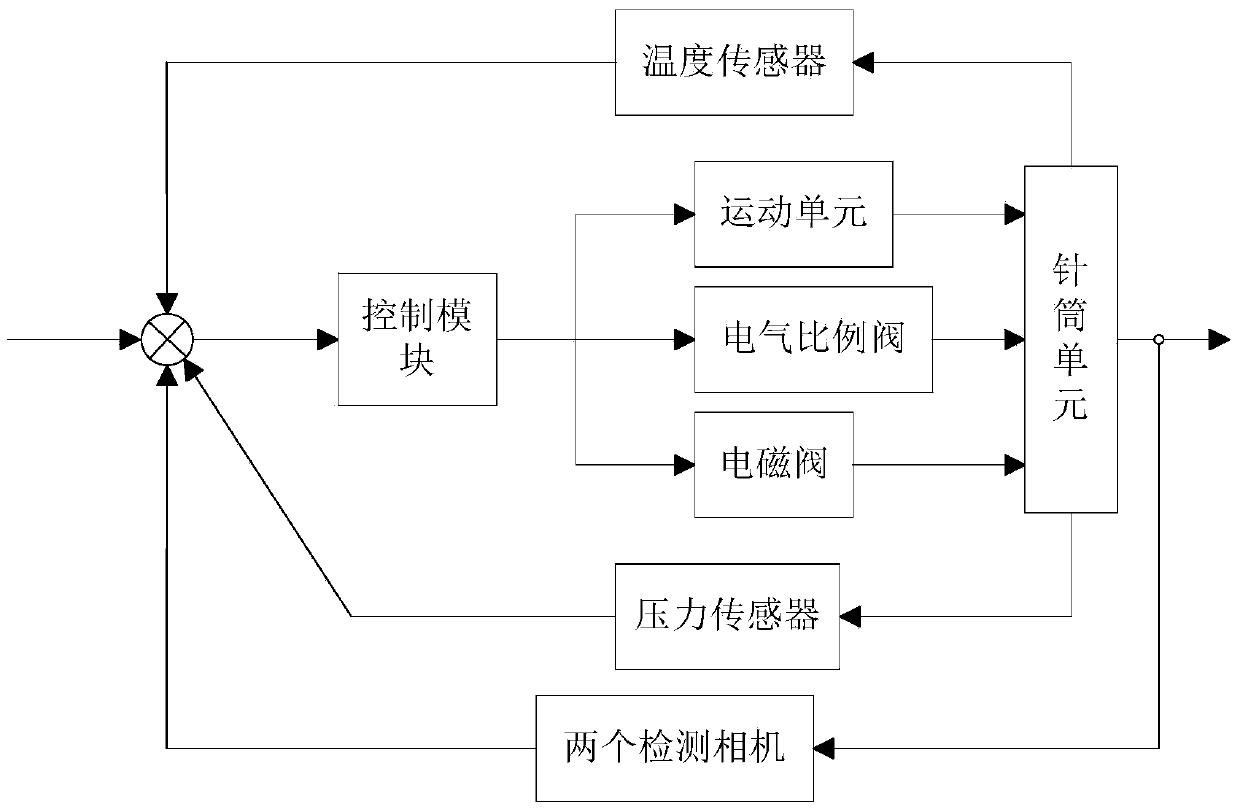

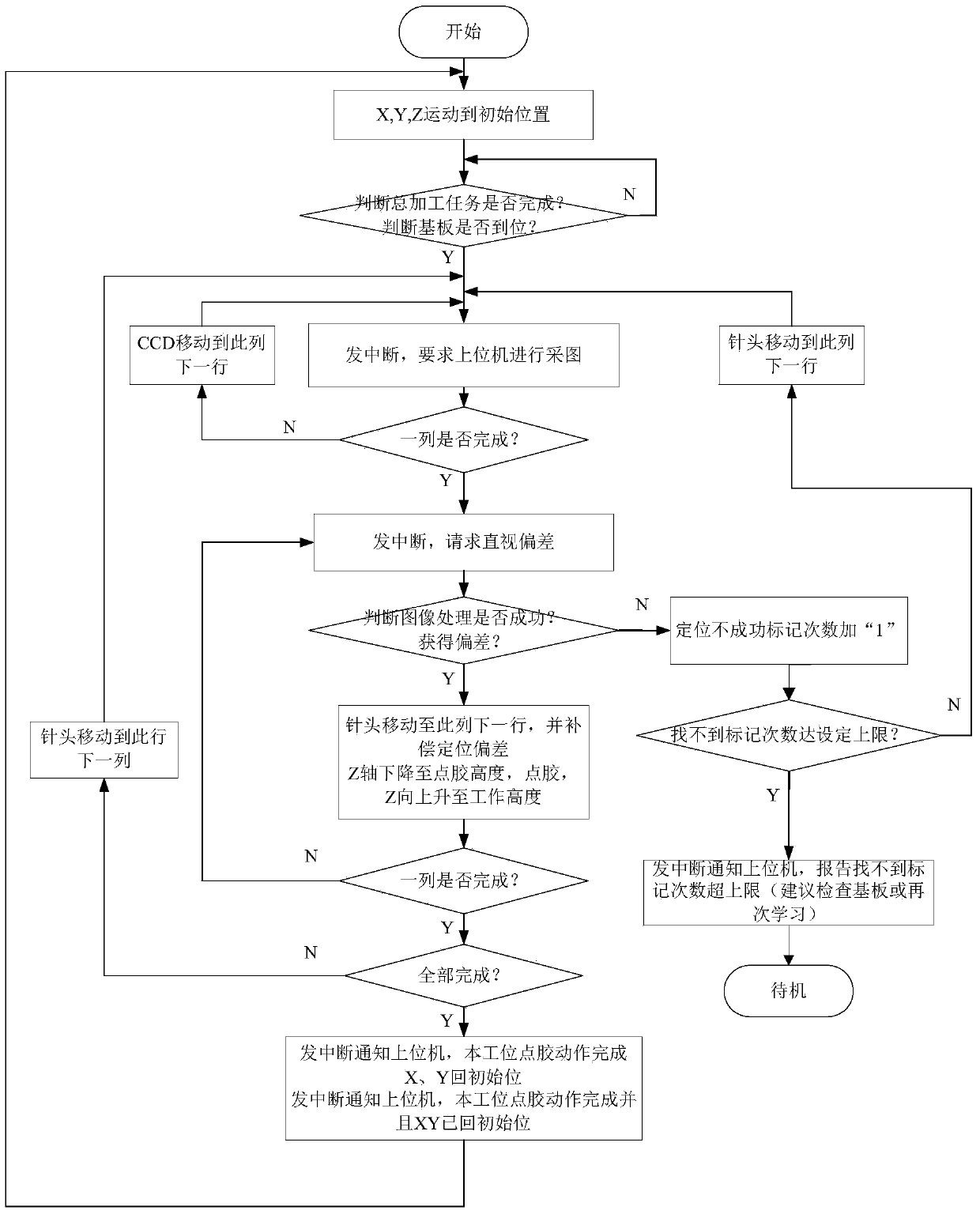

Dispensing control system for production of RFID (radio frequency identification) tag

ActiveCN103721893AAdaptableCompact structureLiquid surface applicatorsCoatingsControl systemClosed loop

The invention discloses a dispensing control system for the production of an RFID (radio frequency identification) tag. The system comprises an XYZ tri-axis movement unit, a needle cylinder unit, an image acquisition unit, a system control unit and an air course regulation unit, wherein key process parameters such as dispensing pressure and dispensing time can be controlled, and meanwhile, a dispensing position and the final shape and size of an adhesive drop can be regulated to meet process requirements by detecting the dispensing position before and after dispensing, the shape and size of the adhesive drop before and after curing, pressure and temperature in a needle cylinder, a dispensing height and the like and correspondingly executing closed loop control processing. According to the system, quality can be rapidly, accurately and comprehensively controlled in the whole packaging process of the RFID tag; in addition, the system has the characteristics of compact structure, convenience for control, high adaptability and the like so as to be suitable for high-quality production processes of various RFID tags.

Owner:HUAZHONG UNIV OF SCI & TECH

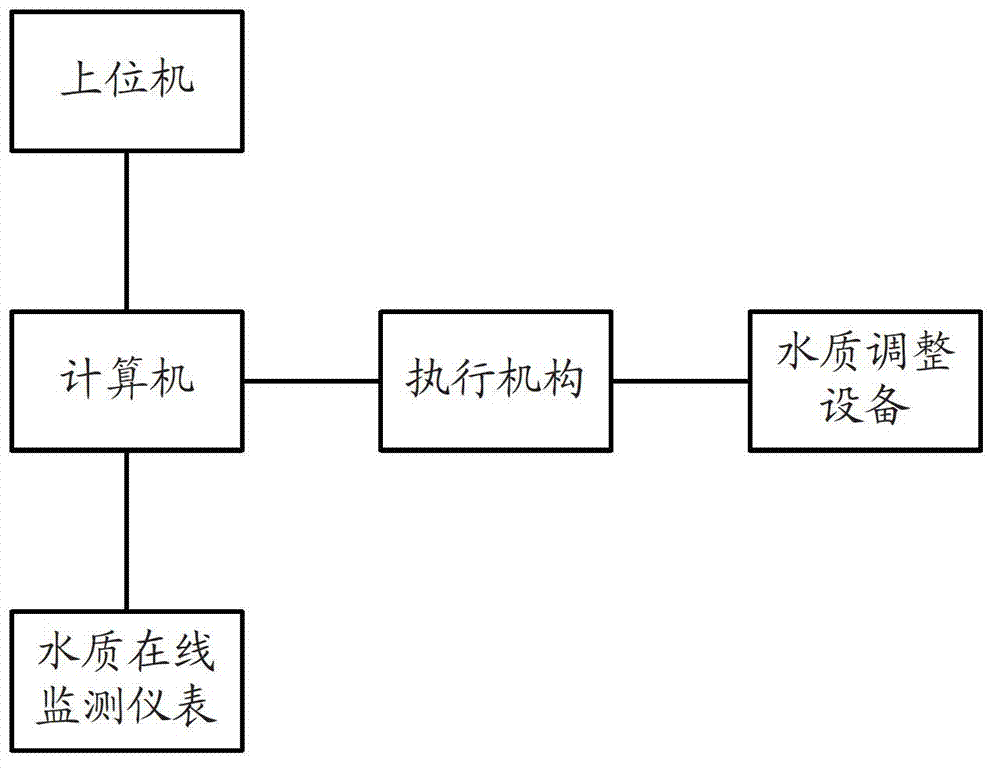

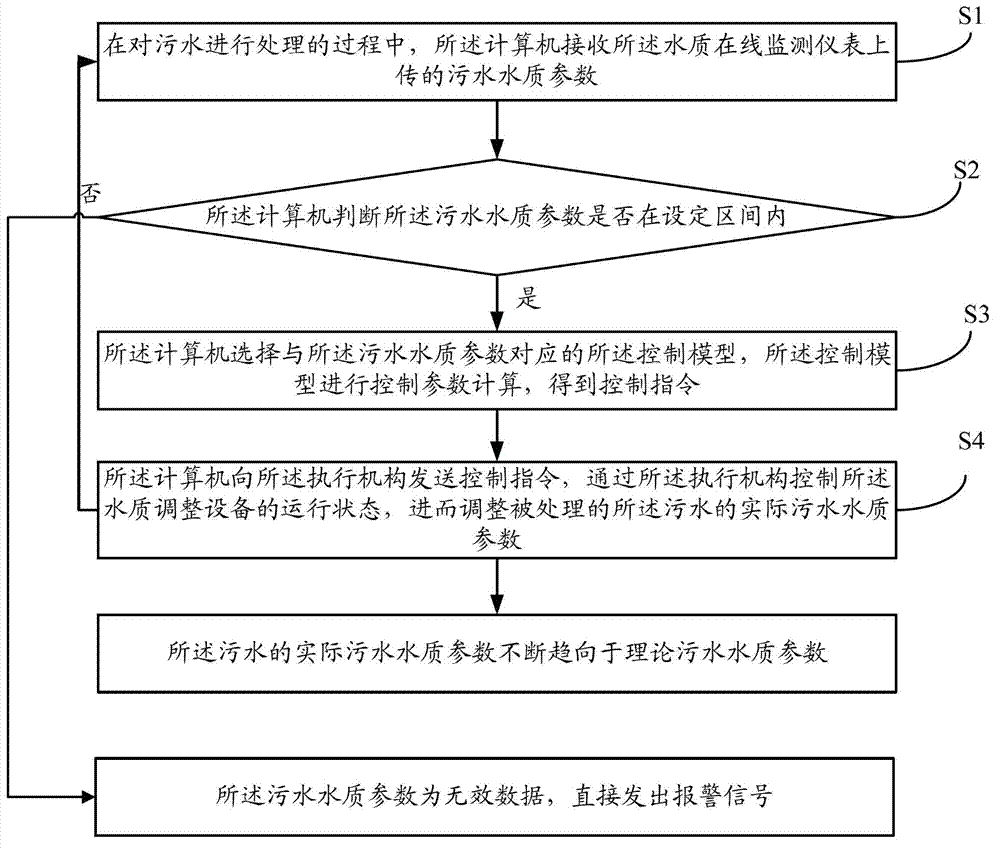

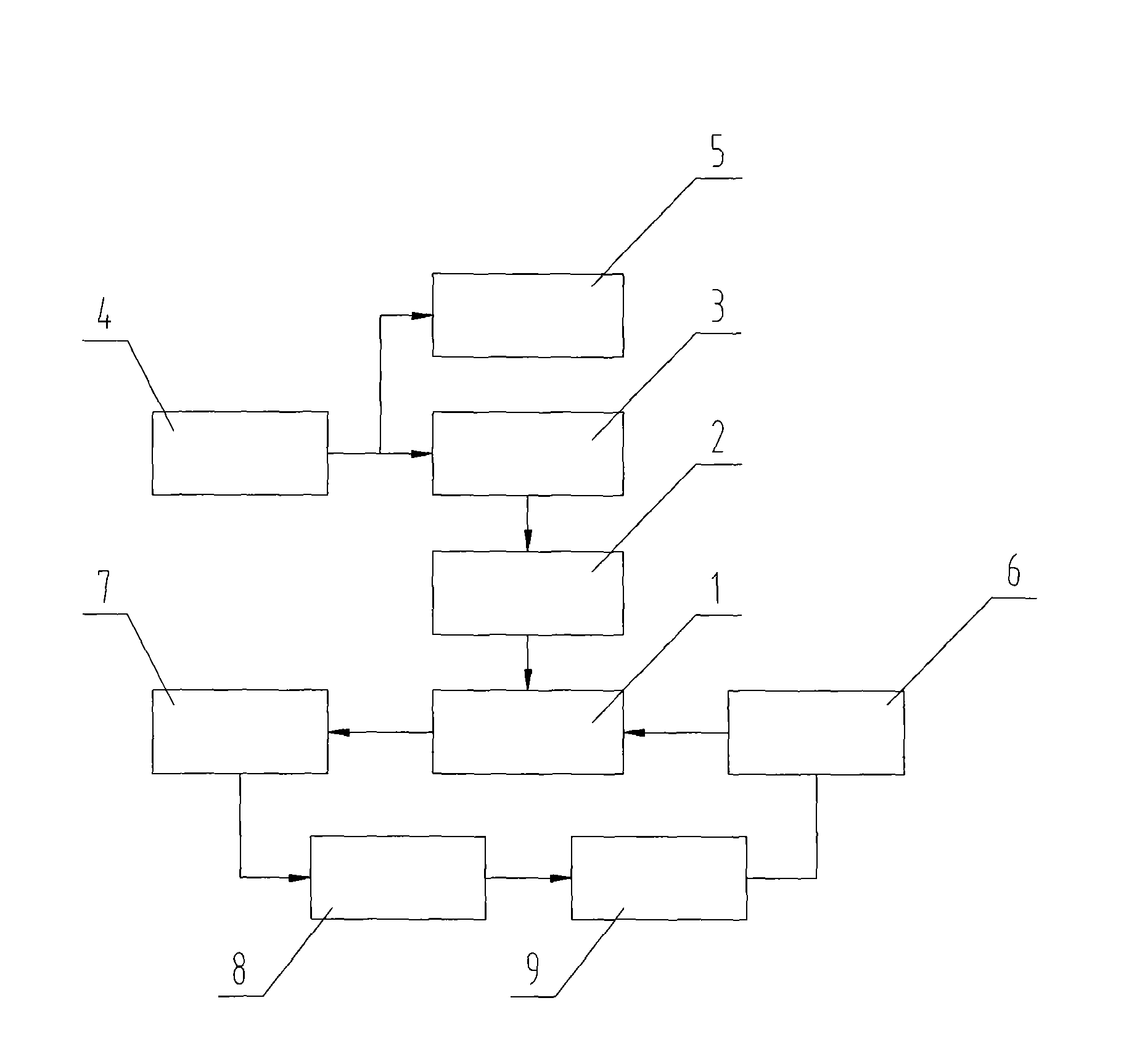

Sewage treatment process optimization and energy-saving control system and method

ActiveCN102902257AEffective regulationOptimal treatment processTreatment using aerobic processesSustainable biological treatmentProcess optimizationControl signal

The invention provides a sewage treatment process optimization and energy-saving control system and a sewage treatment process optimization and energy-saving control method. The sewage treatment process optimization and energy-saving control system comprises a computer, an upper computer, an executing mechanism, more than one on-line monitoring instrument and more than one piece of water quality adjusting equipment, wherein the more than one on-line monitoring instrument is used for acquiring a water quality parameter of treated sewage; and the more than one piece of water quality adjusting equipment is used for adjusting the water quality parameter of the sewage. By acquiring sewage treatment field data, performing simulation treatment on the field data through a simulation model and calculating through a control model, a control signal is obtained to control the operation state of the water quality adjusting equipment so as to form a feed forward-feedback-control model calculation-execution artificial intelligent closed-loop control loop; and the water quality parameter which meets the process requirements can be calculated, and accurate control is performed on the parameter of the sewage water quality process, so that a sewage treatment process optimization and energy-saving effect is achieved.

Owner:W STARTECH BEIJING ENVIRONMENTAL TECH

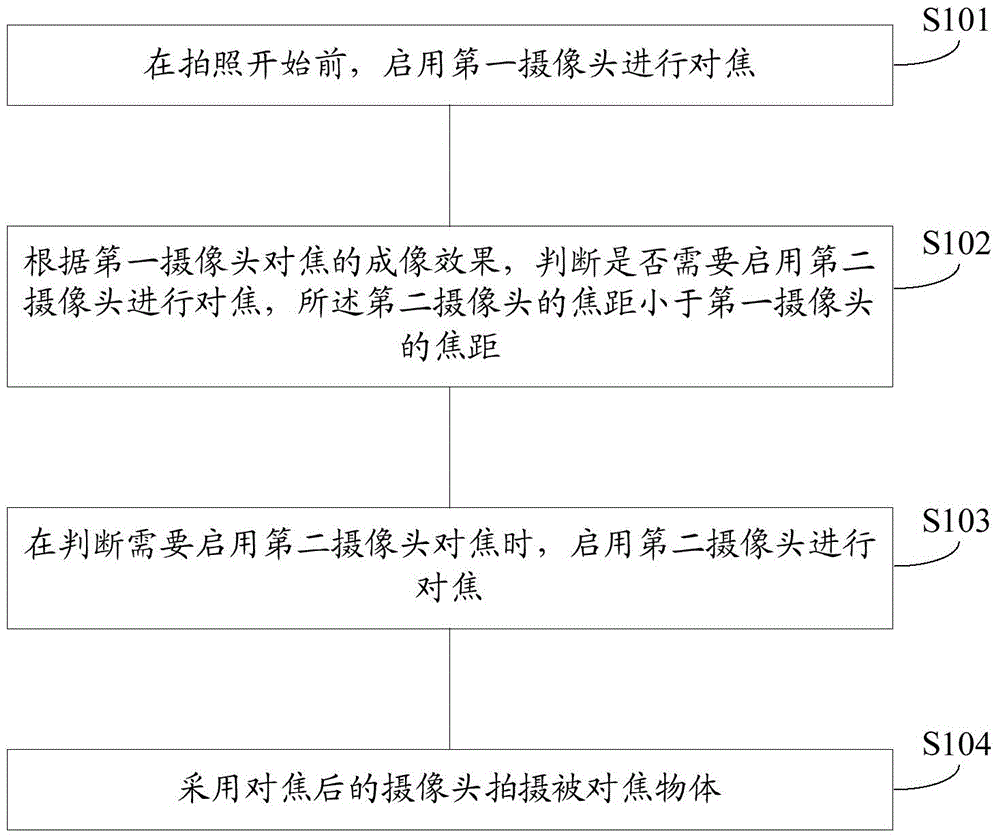

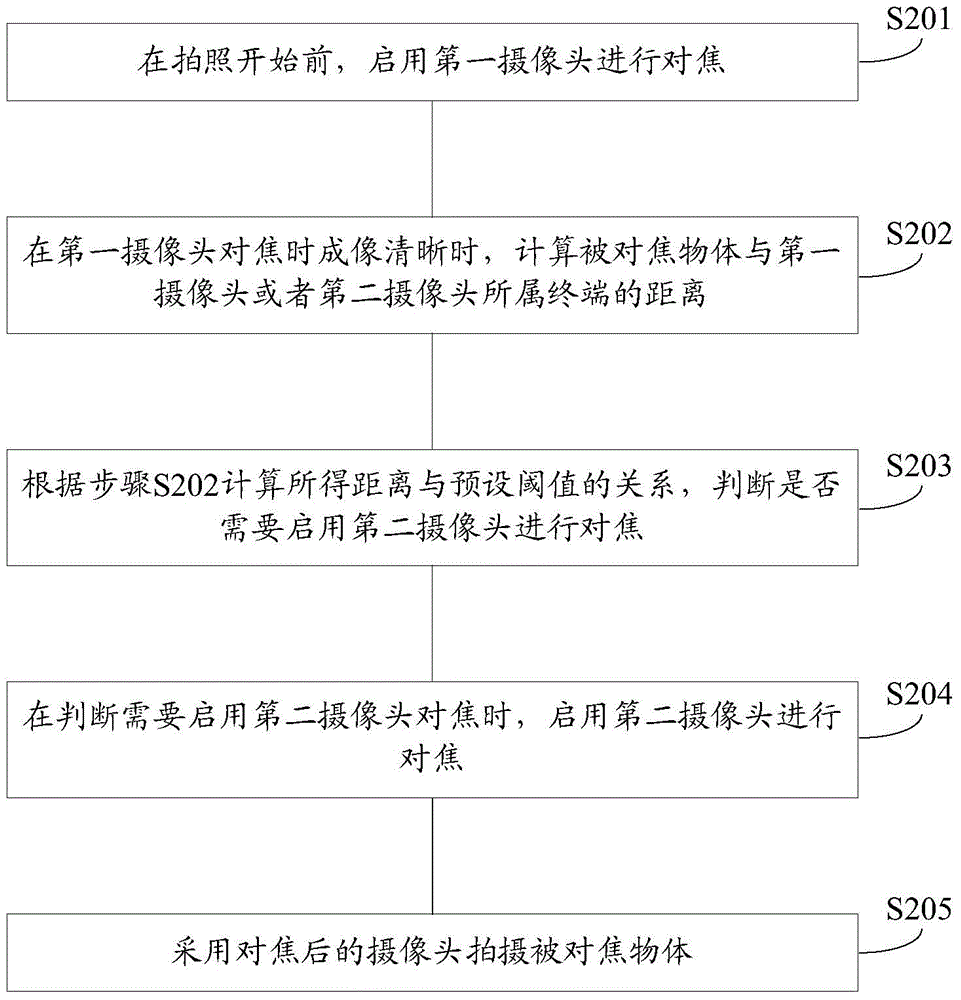

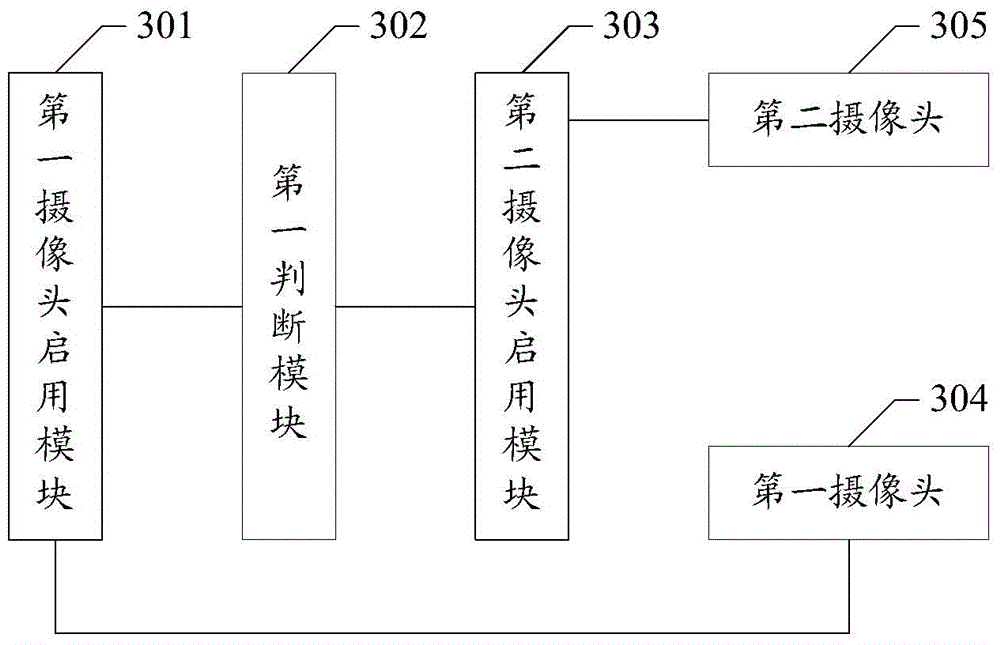

Shooting method by use of cameras with different focal lengths and terminal

ActiveCN104363379AQuality improvementGuaranteed not to stand outTelevision system detailsColor television detailsCamera lensShooting method

The invention discloses a shooting method by use of cameras with different focal lengths and a terminal. A high-quality image can be still acquired under a condition that the lens module is not increased. The method comprises the following steps: starting a first camera for focusing before shooting; judging whether to start a second camera for focusing according to the imaging effect of the first camera after focusing, wherein the focal length of the second camera is less than that of the first camera; if the second camera is judged to be required to be started for focusing, starting the second camera for focusing; and shooting a focused object by the camera after focusing; as the focal length of the second camera is less than that of the first camera, when the object in a close range is shot, the second camera is only started for focusing and shooting, and the high-quality image can be acquired; and besides, the lens is ensured not to protrude out of the terminal, so that the space of the lens module is reduced, the terminal of the camera can be manufactured to be light and small, and the process requirements of a user for the terminal can be met.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

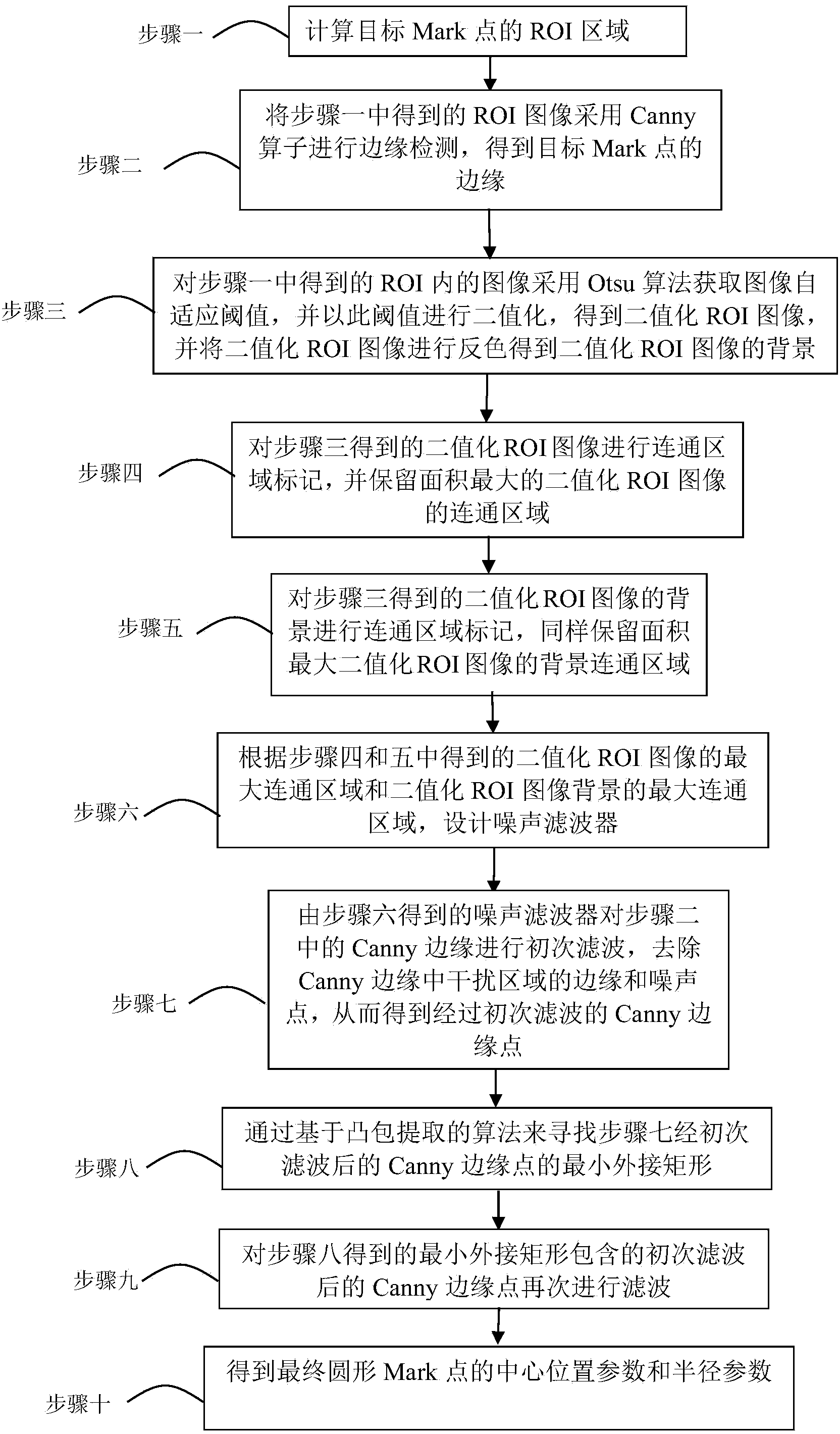

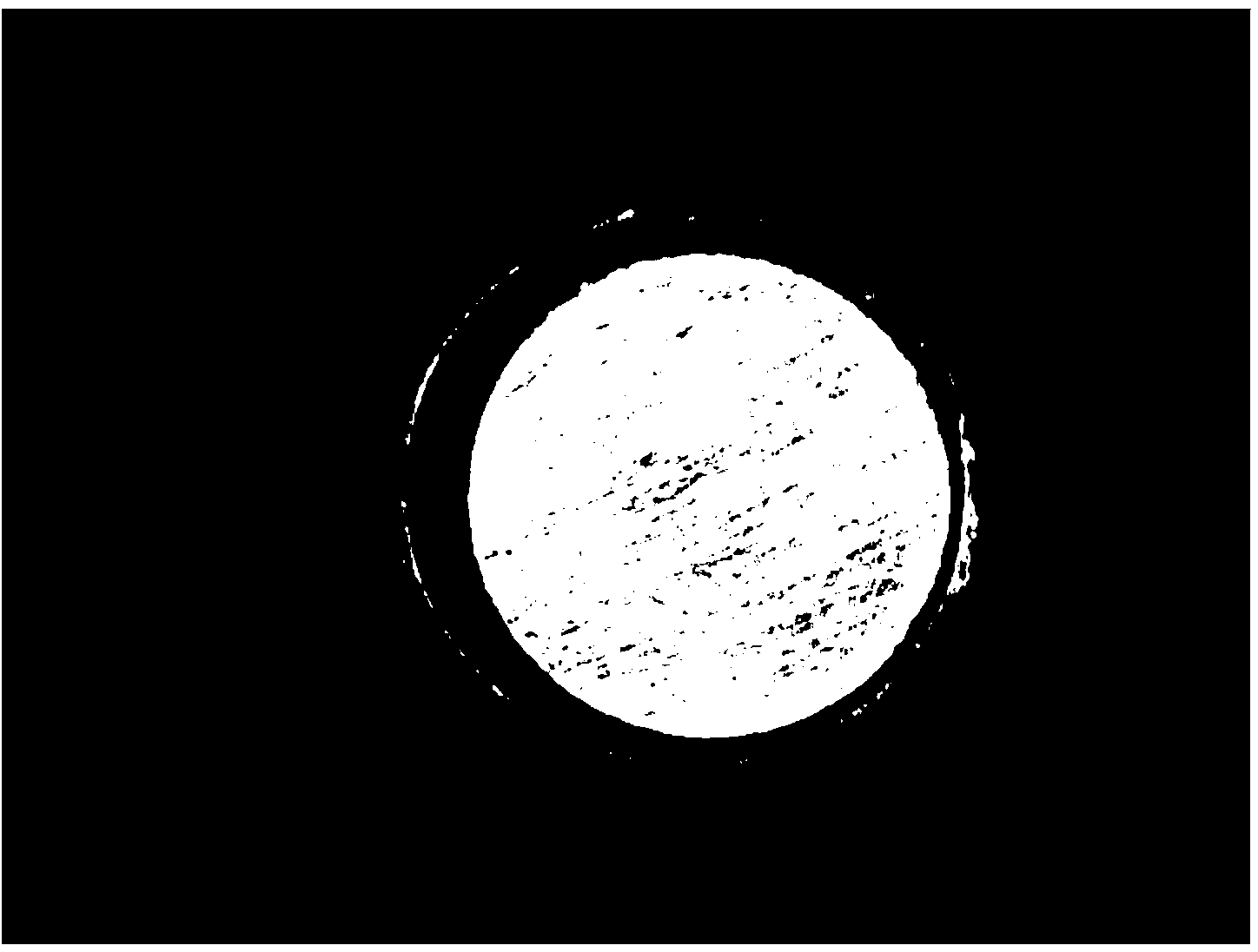

Round Mark point positioning method based on connected region filtering

ActiveCN103729632ARapid positioningPrecise positioningCharacter and pattern recognitionTemplate matchingMinimum bounding rectangle

A round Mark point positioning method based on connected region filtering relates to positioning methods. The round Mark point positioning method based on the connected region filtering mainly solves the problem that traditional round Mark point positioning methods are complex in positioning algorithm, high in computer memory requirements, low in detecting time, low in detecting accuracy and prone to being affected by external environments to lead to template matching failure, meanwhile, have high Mark process requirements and cannot meet the detecting accuracy requirements for deformed round Mark points. The method comprises firstly, calculating the ROI (region of interest) of a target Mark point; secondly, obtaining the edge of the target point; thirdly, obtaining a binary ROI image; fourthly, retaining the ROI connected region with the maximum area; fifthly, retaining the ROI background connected region with the maximum area; sixthly, designing a noise filter; seventhly, obtaining filtering Canny edge points; eighthly, obtaining the minimum enclosing rectangle; ninthly, removing Canny edge defects; lastly, obtaining the central and radial parameters of the round Mark point. The round Mark point positioning method based on the connected region filtering is applied to the field of positioning methods.

Owner:宁波智能装备研究院有限公司

Degradable bio-compatible water treatment filler and preparation method thereof

InactiveCN103408129AImprove hydrophilic abilityHigh affinitySustainable biological treatmentBiological water/sewage treatmentFoaming agentSorbent

The invention discloses a degradable bio-compatible water treatment filler which is prepared from degradable bio-compatible master batch and a foaming agent. The degradable bio-compatible master batch consists of the following components in parts by weight: 40-70 parts of degradable high polymer materials, 10-40 parts of filling materials, 10-25 parts of natural biomass powder, 1-3 parts of adsorbent, 0.5-1 part of nutritional salt, 0.5-1 part of coupling agent, 0.5-1 part of wetting agent and 3-7 parts of other additives. The particle master batch which is obtained in the preparation method of the degradable bio-compatible water treatment filler can be processed into water treatment elastic fillers of various shapes. Besides, the degradable bio-compatible water treatment filler is convenient to process, simple to use, wide in material selection, and can be adjusted differently according to different application process requirements, and therefore, the degradable bio-compatible water treatment filler is extremely wide in adaptability.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

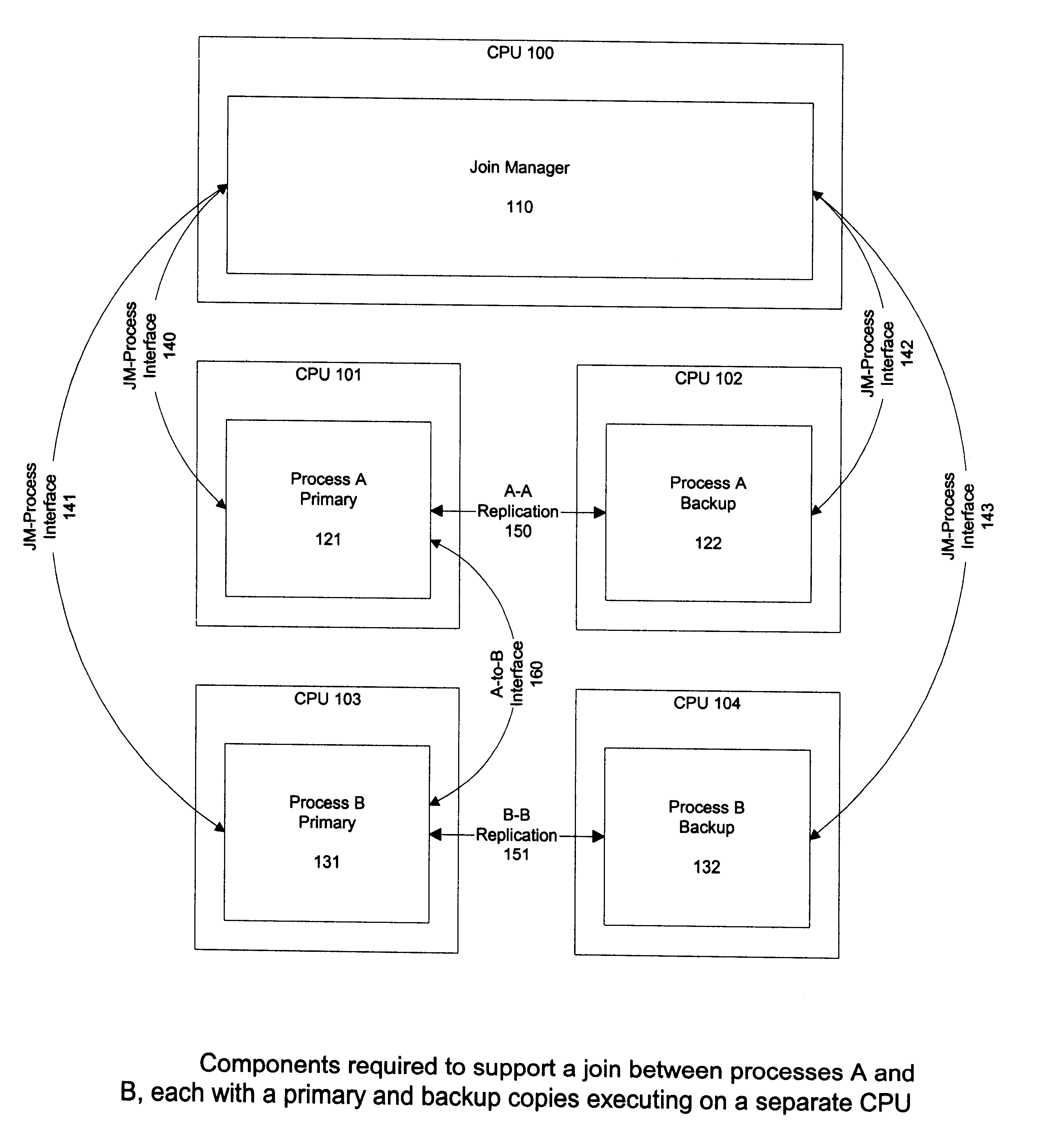

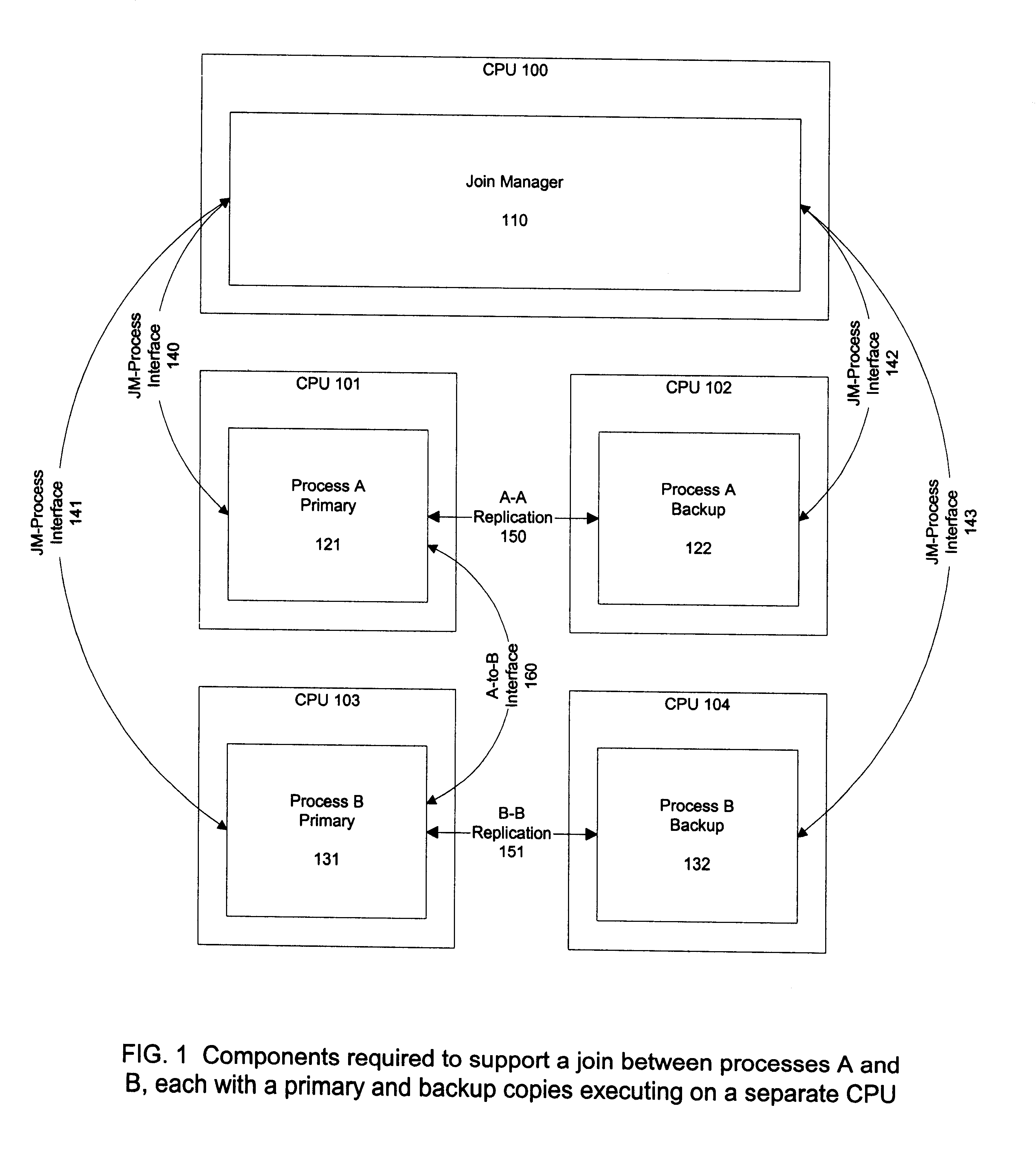

Automatic reconnection of partner software processes in a fault-tolerant computer system

In a fault-tolerant system employing software fault-tolerance techniques, automatic reconnection of partner processes after a failure of one or more of the partner processes requires that the partner processes are aware of the redundancy strategy employed by their partners. The present invention insulates the partner processes from the need for this knowledge, and also enables automatic reconnection between partner processes running in different parts of a heterogeneous distributed system.

Owner:METASWITCH NETWORKS LTD

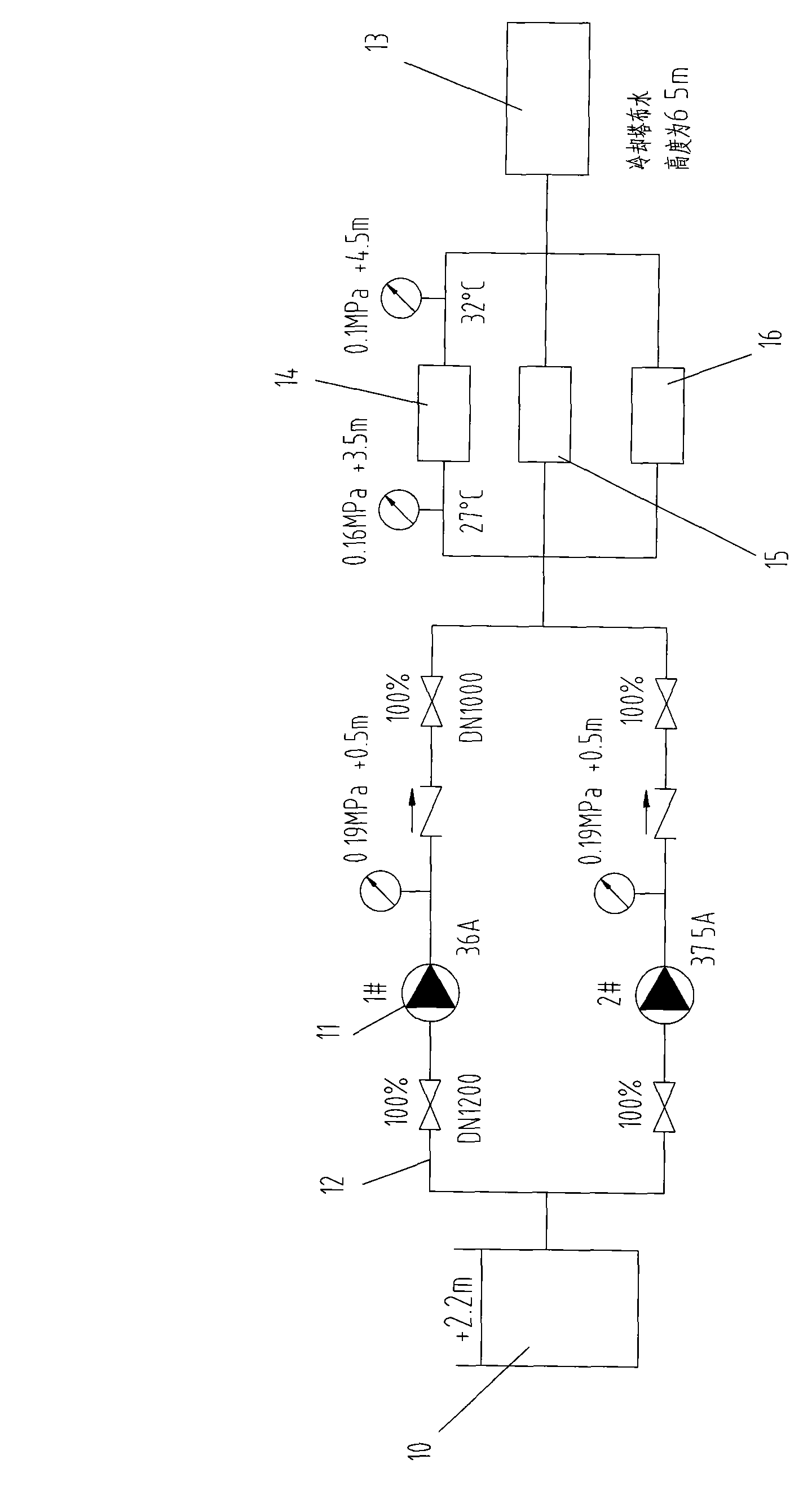

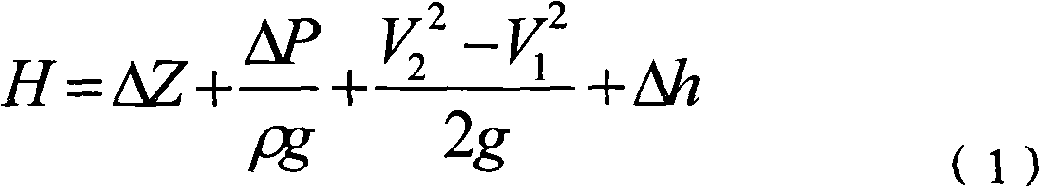

Energy saving method for circulating water system

InactiveCN101666319AImprove efficiencyImprove manufacturing precisionPump installationsNon-positive displacement fluid enginesCooling towerOperating point

The invention discloses an energy saving method for a circulating water system. The method comprises the following steps: firstly, detecting duty parameters of the current operation of the system andparameters of related devices; then, in accordance with the principle of economic operation of the circulating water system, creating a standard for the balance test and the calculation of the systemenergy by starting with a circulating water pump group, a pipe network, a heat-exchange device, a refrigeration device, a cooling tower and the like, analyzing the use efficiency of the system energy,evaluating the current use efficiency index of the system energy, and finding out the cause for the high energy consumption of the system; finally, by combining production process requirements, accurately finding out the optimum operating point where the devices are matched with the liquid transportation, and giving an optimum solution for the process energy of the system so as to achieve the purposes of high efficiency and energy saving. By detecting and analyzing the circulating water system, the invention provides a comprehensive, systemic and thorough energy saving method for the circulating water system.

Owner:长沙翔鹅节能技术有限公司

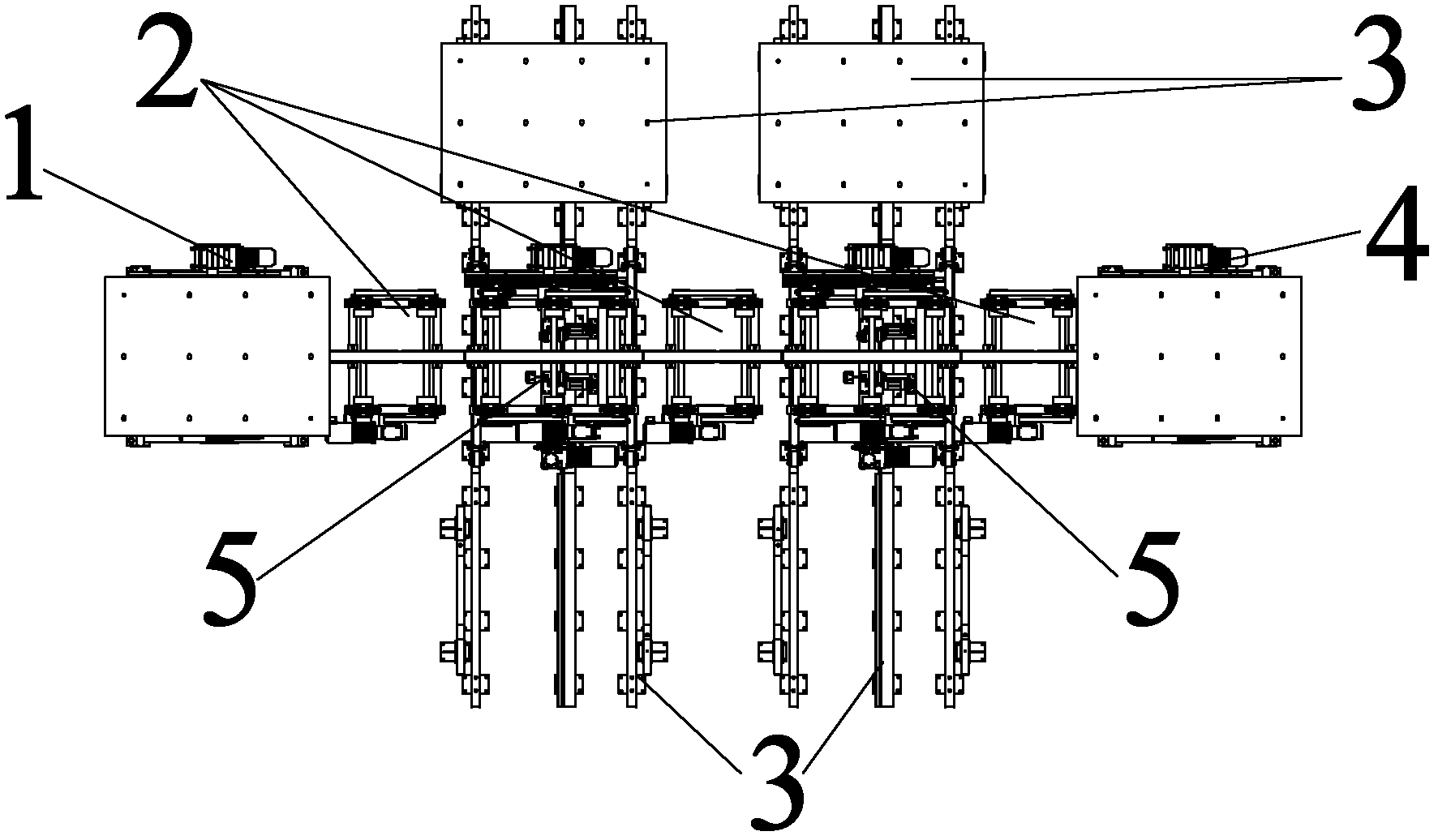

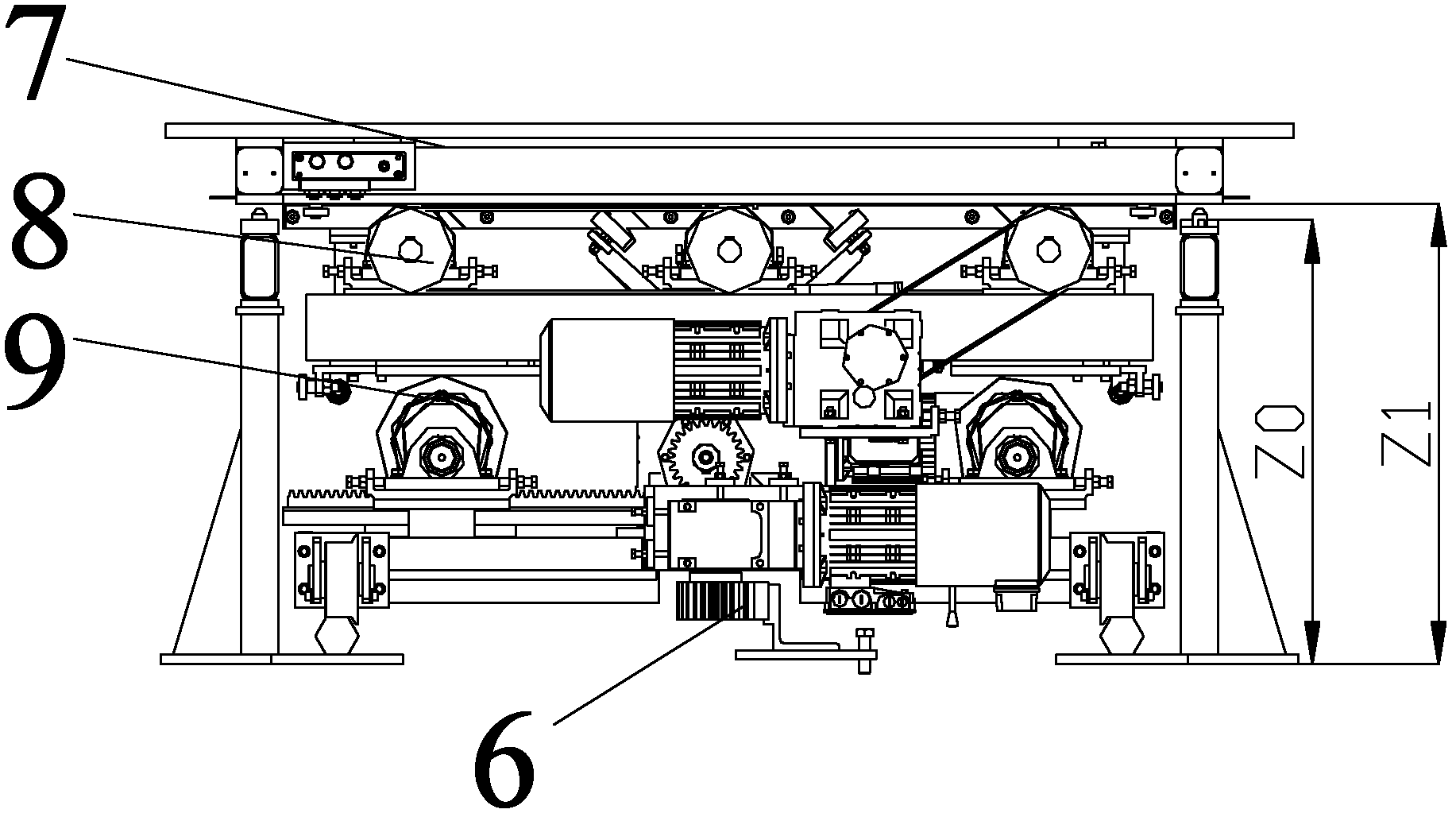

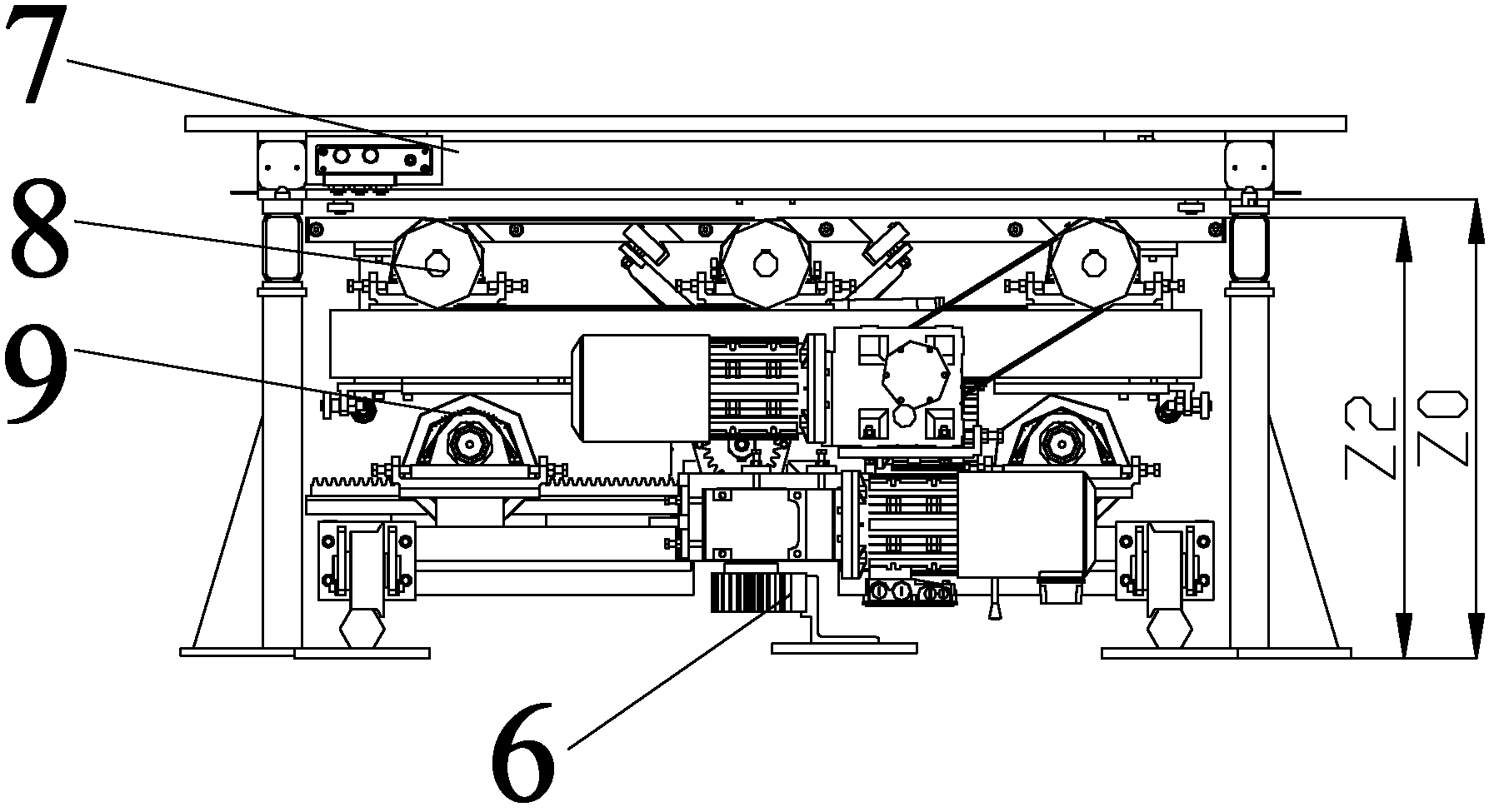

Workpiece conveying system applied to automobile welding line

ActiveCN102407419ARealize uninterrupted cycle switching productionEnsure flexibilityWelding/cutting auxillary devicesAuxillary welding devicesDelivery systemProcess requirements

The invention discloses a workpiece conveying system applied to an automobile welding line. The system comprises a fixture trolley matched with a conveyed workpiece, a workpiece feeding device, a welding transfer device, fixture trolley storage devices and fixture trolley switching devices, wherein the workpiece feeding device and the welding transfer device are arranged in a straight line; the fixture trolley switching devices are arranged in a middle area between the workpiece feeding device and the welding transfer device; the fixture trolley storage devices are arranged on two sides of each fixture trolley switching device; and the fixture trolley switching devices can transfer the workpiece conveyed on the workpiece feeding device and the welding transfer device to the fixture trolley storage devices. Through the technical scheme, secondary delivery warehouse assemblies and front and back bottom plates of various models can be conveyed and produced on the same line according to a process requirement, various models can be produced on the same automobile welding line, different models are quickly and flexibly switched, production efficiency is improved, and the requirement of the operating rate of equipment can be met to the greatest extent.

Owner:CHERY AUTOMOBILE CO LTD

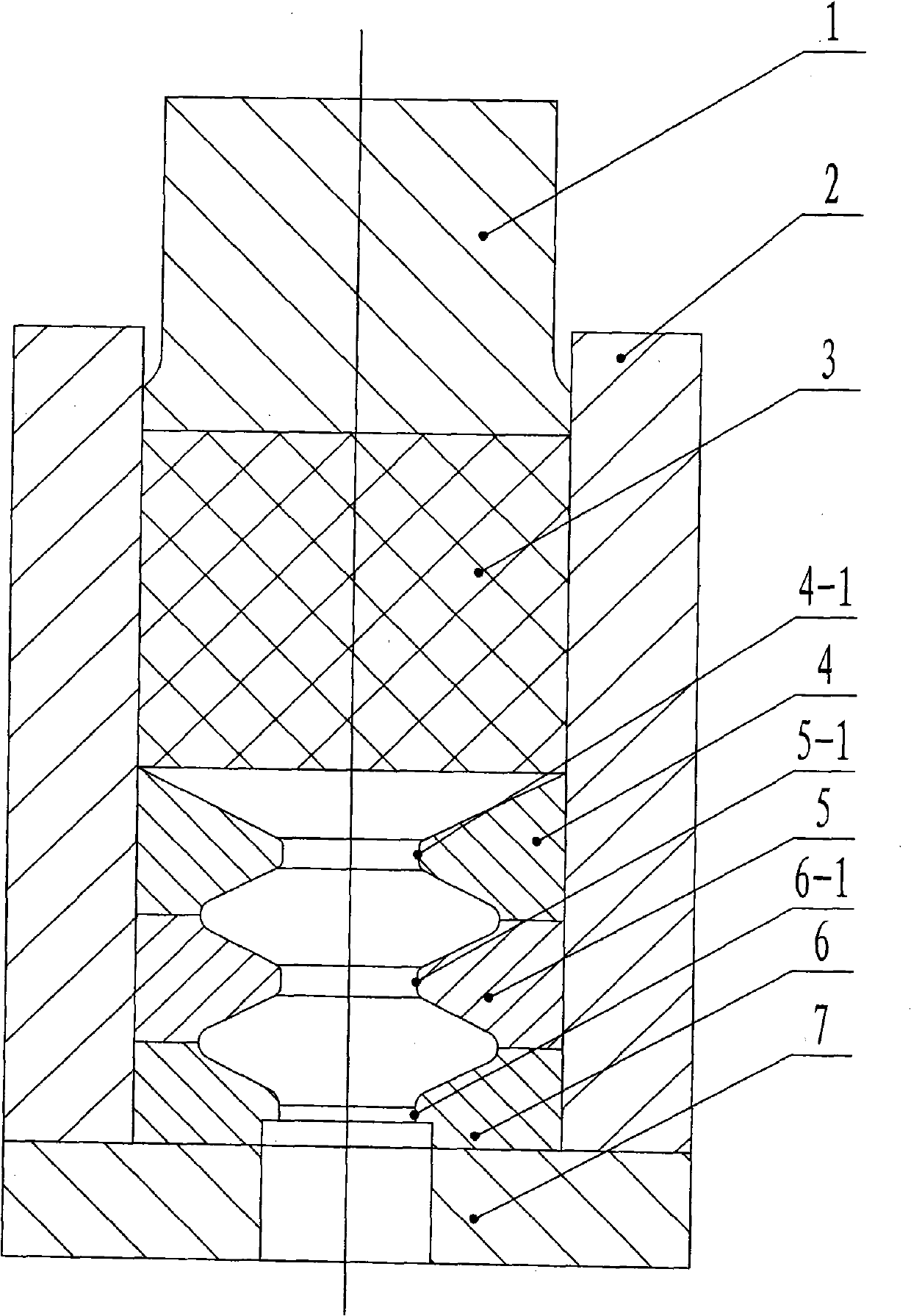

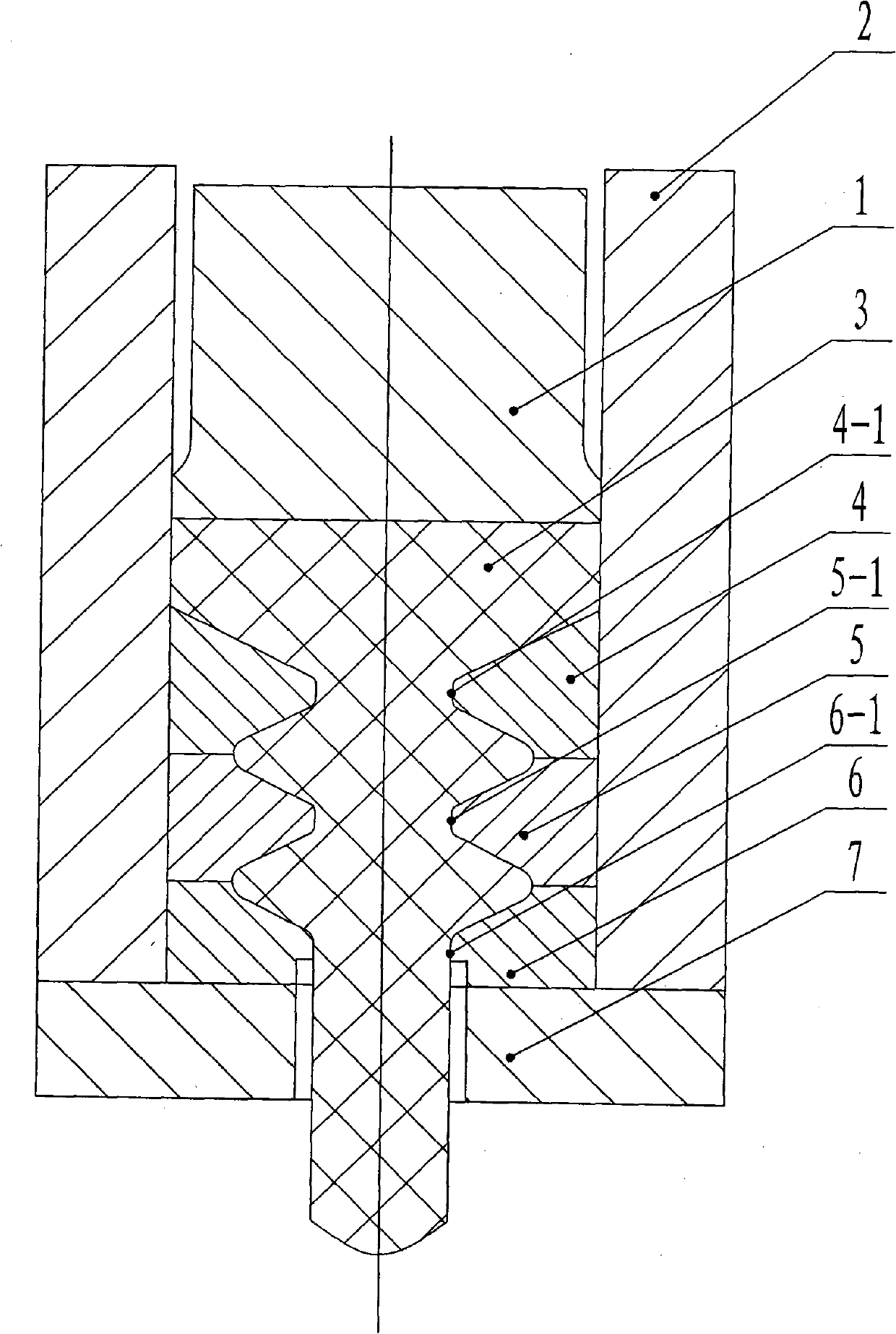

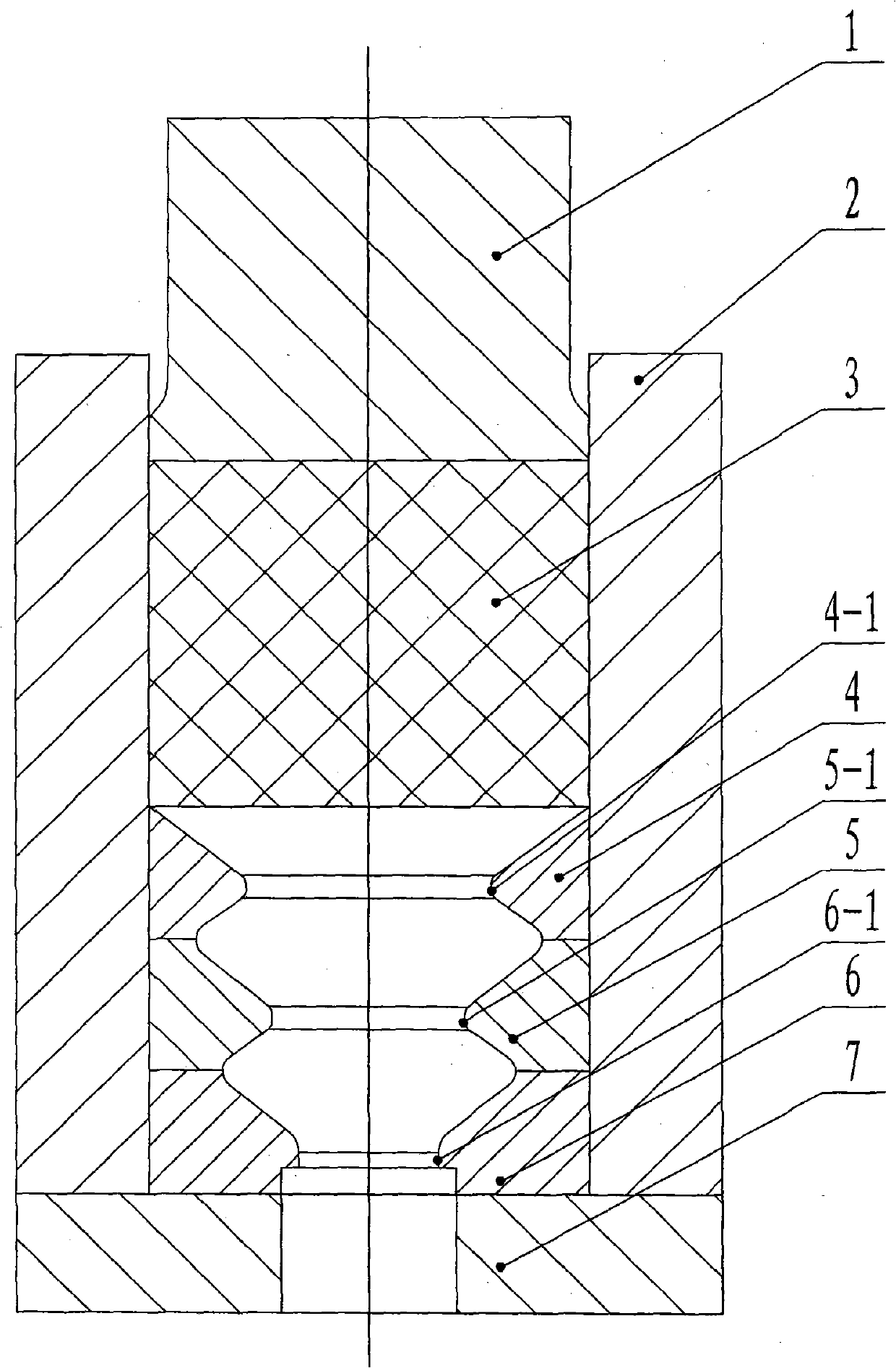

Device and method for preparing fine-grained material by directly extruding continuous variable cross section

InactiveCN101767120AUniform refinementImprove mechanical propertiesExtrusion diesExtrusion mandrelsMaterials preparationIngot

The invention relates to a device and a method for preparing fine-grained material by directly extruding a continuous variable cross section, which relate to a device and a method for preparing fine-grained material. The invention solves the problems of the traditional fine-grained material preparation methods that the procedures are complicated, the process requirements are high, the texture orientation is significant, the defects of folds and material interface superposition are easy to occur in processing and preparation and the preparation methods are difficult to be implemented in production. A primary transition die cavity, a secondary transition die cavity and a core die cavity of the preparation device of the invention are combined to form an axial corrugated extrusion cavity of the continuous variable cross section; the preparation method of the invention comprises the following steps: the preparation device is assembled; an ingot is arranged in a female die, a punch head is put it, a punch head is put in, the die orifice on a core die extrusion end is closed, the punch head descends, the ingot is extruded form a primary transition die orifice and a secondary transition die orifice, the punch head continues to descend, and the ingot is upset and deforms; and the closure is removed, the punch head continues to descend, and the ingot is extruded and formed. The invention requires simple equipment and few production procedures, and is easy to be implemented and popularized in production.

Owner:HARBIN UNIV OF SCI & TECH

Practical method for preparing high thixotropy surface treating nano calcium carbonate

InactiveCN101475759AImprove thixotropyParticle size controllablePigment treatment with non-polymer organic compoundsPolyurethane adhesiveCarbonization

The invention discloses a practical method for preparing high-thixotropy surface treatment nano calcium carbonate, which comprises the following steps: firstly, calcining and digesting preferable limestone, and then controlling carbonization of the limestone in a special reactor to obtain nano calcium carbonate primary slurry; secondly, carrying out surface treatment on the nano calcium carbonate according to practical and special control technology; and finally dehydrating, drying, crushing and grading the coated slurry. The shape of the obtained calcium carbonate is cubic, the particle diameter is 50 to 100 nanometers, and the specific surface area is 20 to 40 m / g. The obtained powder has good dispersion effect and thixotropy, is suitable for occasions needing high thixotropy, such as high-performance silicone adhesive, epoxy adhesive, polysulfide adhesive, polyurethane adhesive, automotive primary coat, floor coating and the like, and has wide market prospect. The method has simple raw materials and process requirement, stabalizes the production and reduces the cost.

Owner:山东海泽纳米材料有限公司

Metal pipeline welding device for water conservancy construction

InactiveCN110216477AGuaranteed smoothImprove welding efficiencyWelding/cutting auxillary devicesOther manufacturing equipments/toolsEngineeringWeld seam

The invention discloses a metal pipeline welding device for water conservancy construction, and relates to the technical field of water conservancy construction machinery. The metal pipeline welding device comprises a supporting frame, wherein a servo motor is fixedly mounted on the top in the supporting frame; two supporting limiting mechanisms for supporting a pipeline are arranged in the supporting frame; a welding assembly which is in drive connection through a translation mechanism is arranged above the pipeline; and the welding assembly comprises a connecting disc, and a welding gun which is connected on the connecting disc through a steering mechanism. According to the metal pipeline welding device disclosed by the invention, the supporting limiting mechanisms are arranged to clampand fix from the inner part of the pipeline, so that the pipeline does not deviate while driven by a rotary roller to rotate, and the pipeline rotates for enabling welding efficiency of the welding gun to be higher; the arranged welding gun can regulate a welding inclination angle through the steering mechanism, and can meet welding operation of different process requirements; and a grinding roller can be arranged to grind a welding seam after the pipeline is welded, so that flatness of the welding seam is guaranteed after the pipeline is welded.

Owner:赵玉研

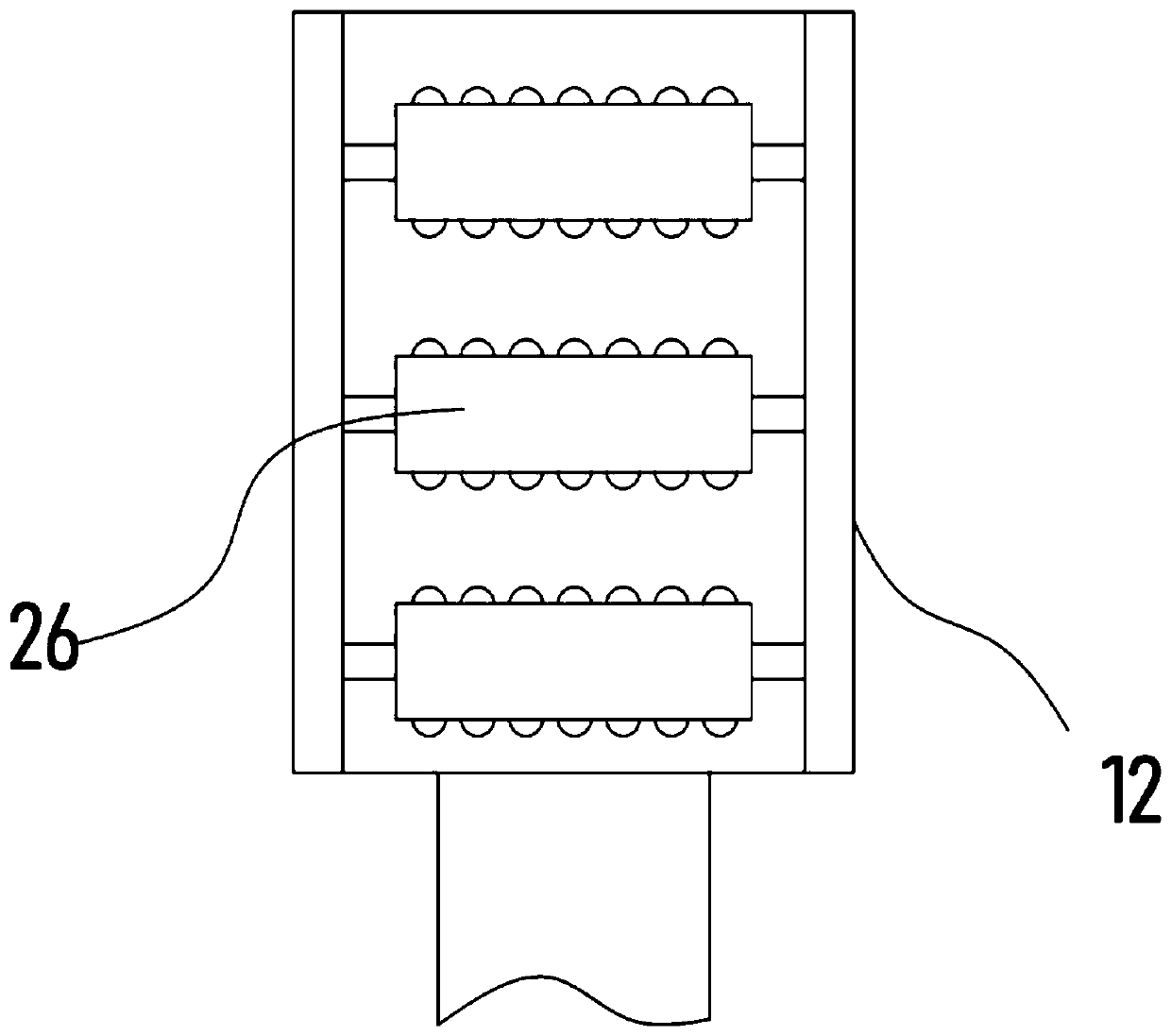

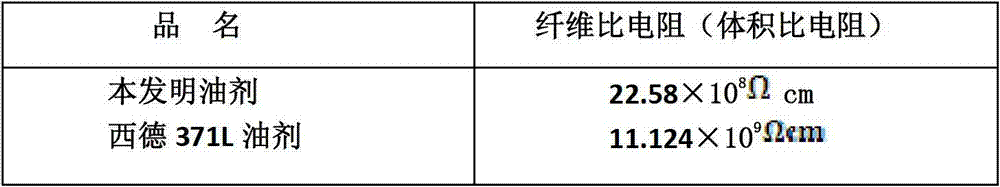

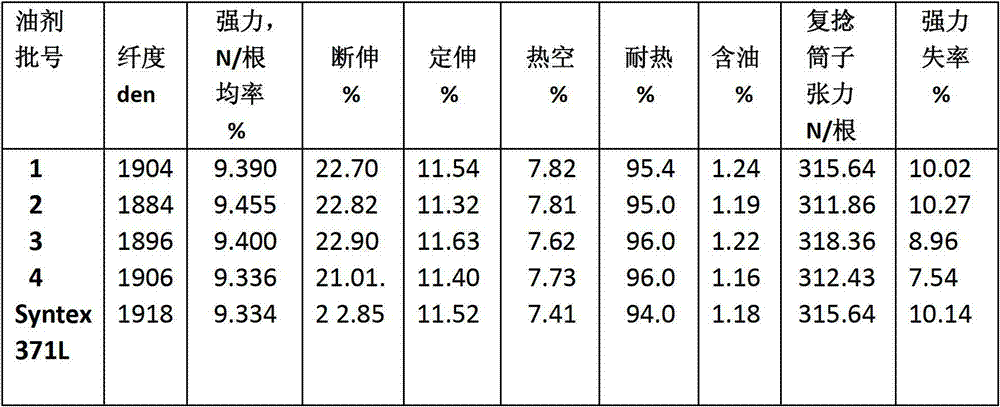

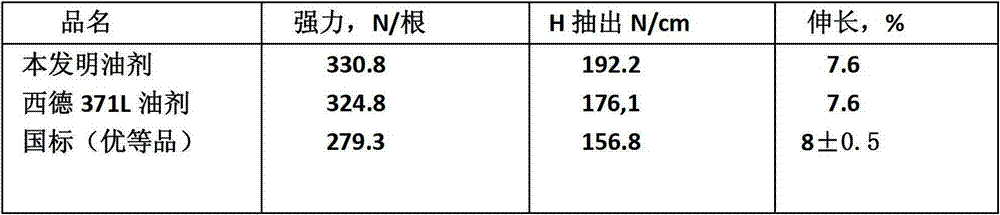

Non-emulsion type pure oiling agent for high speed spinning of polyamide-6 filaments

The invention discloses a non-emulsion type pure oiling agent for the high speed spinning of polyamide-6 filaments, wherein a smoothing agent consists of three polyether type non-ionic surfactants, i.e. fatty alcohol-ethylene oxide-propylene oxide copolyether, fatty alcohol-polyoxyethylene ether and polyxyethylated alkylphenol; a collecting agent is the non-ionic surfactant, i.e. fatty acid polyoxyethylene ether ester; an antistatic agent is fatty alcohol-polyoxyethylene ether phosphate and amine (kali) salt of alkyl phosphate; a binding additive is Ac; and a regulating agent is water. The pure oiling agent for the high speed spinning of the polyamide-6 filaments generates little smoke, does not gel, gather or deposit, and is of good heat stability and chemical properties; and in addition, after a spray nozzle is applied with oil, the process requirements on air bath at the high temperature of 230 DEG C, high speed spinning (3000m / min) and strong drafting can be met. The requirements on the properties of precursors, thrown silk, dipping glue and tyre cords are met, so that the property of a polyamide-6 tyre fabric reaches the high level of national standards.

Owner:SHAANXI HAIAN IND

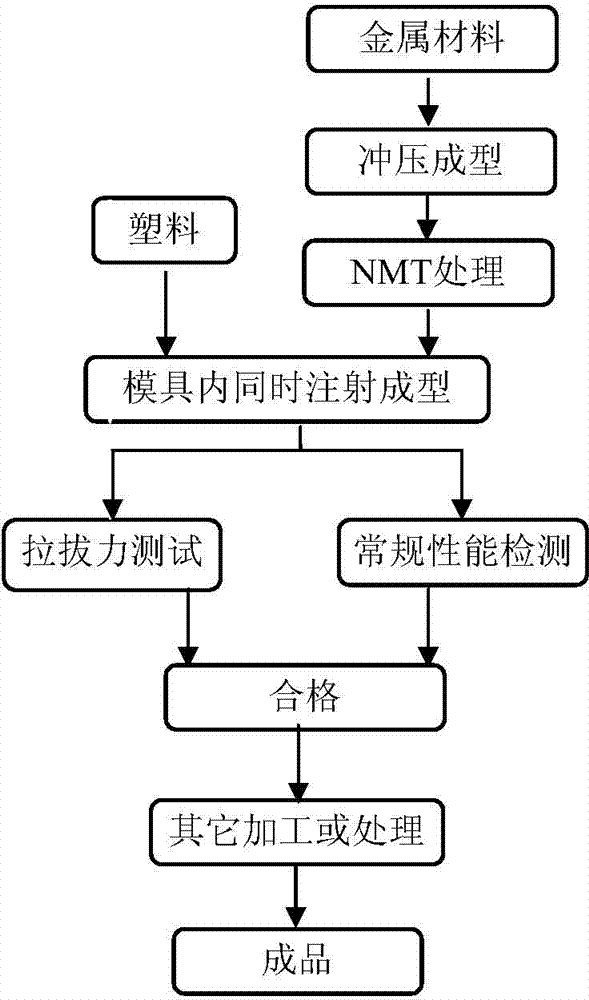

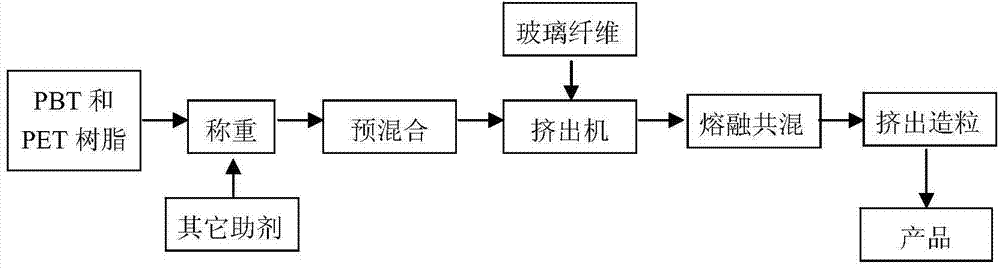

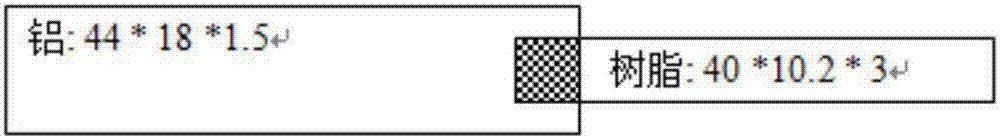

PBT (polybutylece terephthalate) engineering plastic composition used for NMT (Nano Molding Technology)

ActiveCN104845297AImprove mechanical propertiesImprove heat resistanceAntioxidantPolyethylene glycol

The invention provides a PBT (polybutylece terephthalate) engineering plastic composition used for a NMT (Nano Molding Technology) and a preparation method thereof. The PBT engineering plastic composition used for the NMT comprises the following components in parts by mass: 60 parts of PBT resin, 5 to 60 parts of PET (polyethylene glycol terephthalate) resin, 10 to 16 parts of glass fibers, 5 to 15 parts of flexibilizer, 0.3 to 3 parts of antioxidants, 0.3 to 2 parts of heat stabilizers, and 0.5 to 3 parts of lubricants, wherein the flexibilizers are selected from the mixture of at least two of unsaturated carboxylic ester, unsaturated carboxylic ester copolymers, saturated carboxylic acid vinyl ester, saturated carboxylic acid vinyl ester copolymers, unsaturated epoxy compounds, unsaturated epoxy copolymers, unsaturated carboxylic acid, unsaturated carboxylic acid copolymers, unsaturated acid anhydride or unsaturated acid anhydride copolymers. The bond force between the PBT engineering plastic composition and a metal material is excellent, and the NMT process requirements can be met; meanwhile, excellent mechanical performance and heat resistance are realized.

Owner:SHENZHEN HALCYON NEW MATERIALS

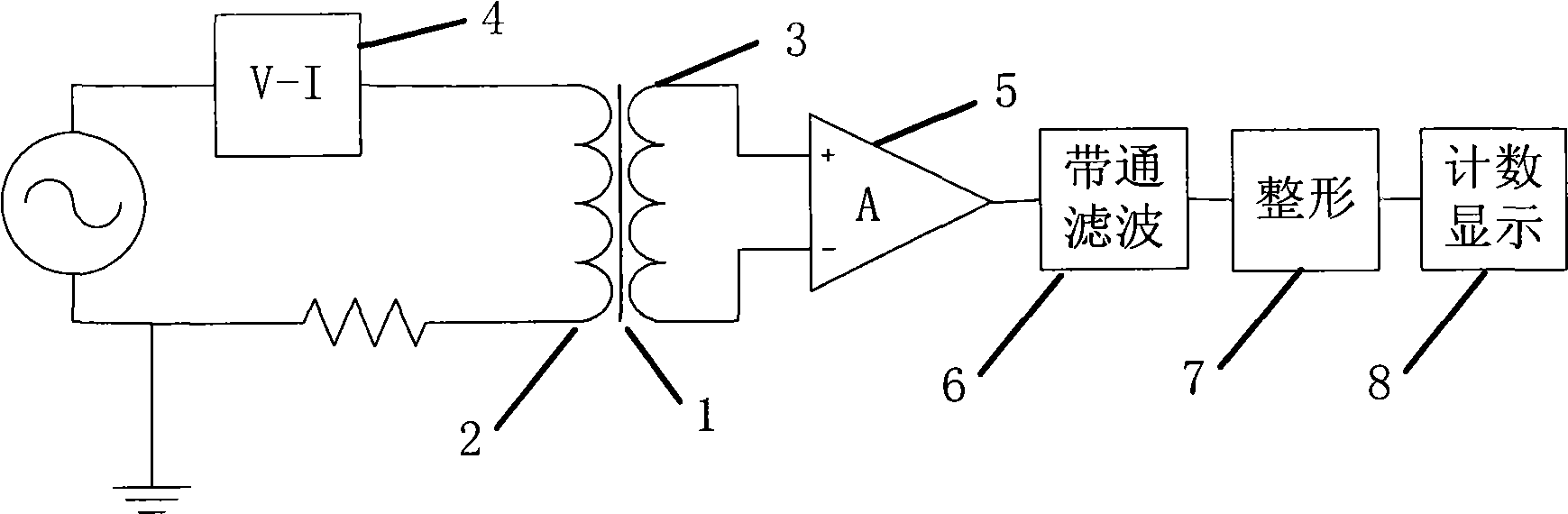

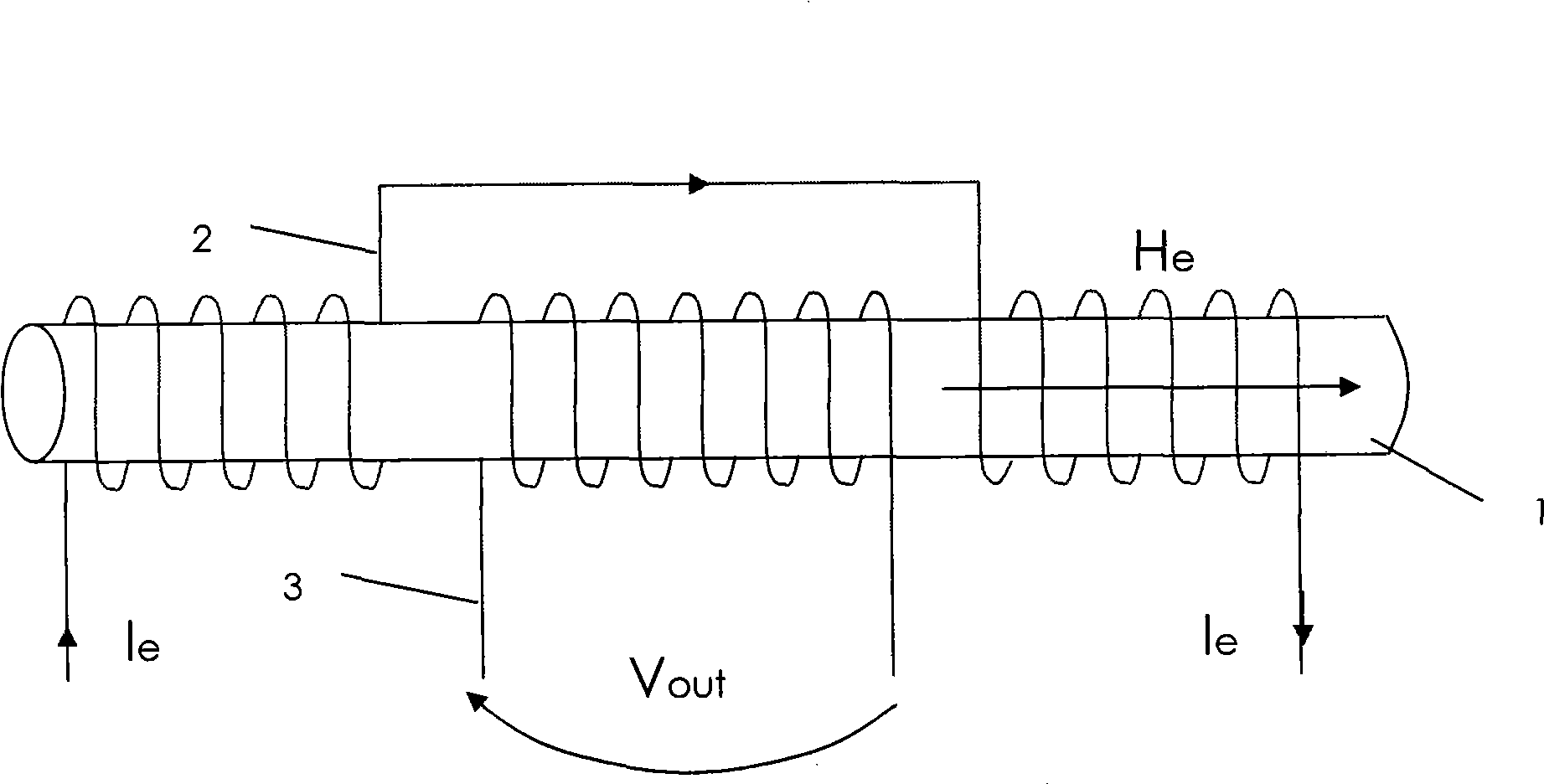

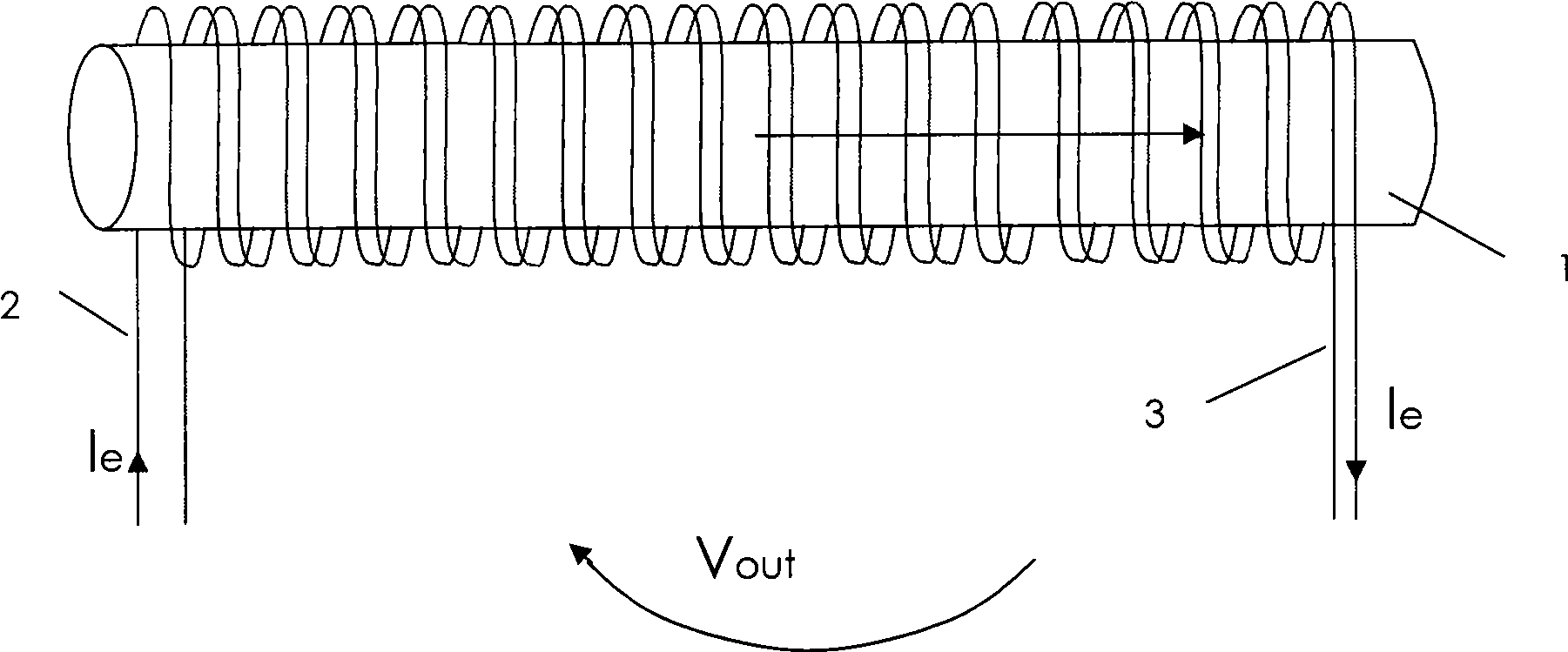

Bidirectional magnetic saturated time difference fluxgate sensor

InactiveCN101545958AReduce power consumptionReduce volumeMagnetic field measurement using flux-gate principleBand-pass filterPhase sensitive

The invention discloses a bidirectional magnetic saturated time difference fluxgate sensor, which is characterized in that two ends of a sensor magnetic core are wound with exciting coils, the middle section of the sensor magnetic core is wound with induction coils, output poles of the induction coils are connected with an amplifying circuit, and the amplifying circuit is connected with a counting display circuit through a band-pass filter circuit and a retardation shaping circuit. By detecting and calculating a positive negative pulse time difference value output by the fluxgate sensor in a time domain, the strength of the measured magnetic field is judged. Compared with the prior fluxgate sensor, the detection circuit is simple, the measurement stability of the system is ensured without a feedback structure, a complex subsequent circuit is not needed, the required excitation current is lower, the data processing is simple, the measured relative quantity is little, the integral volume and power consumption of the sensor are effectively reduced, and the measurement result is acquired quickly. The fluxgate sensor avoids a filter-phase-sensitive demodulation-smooth filter circuit of the prior fluxgate sensor, makes up the defect that the prior fluxgate sensor has harsh process requirement, and achieves the digitized magnetic measurement of the fluxgate sensor.

Owner:JILIN UNIV

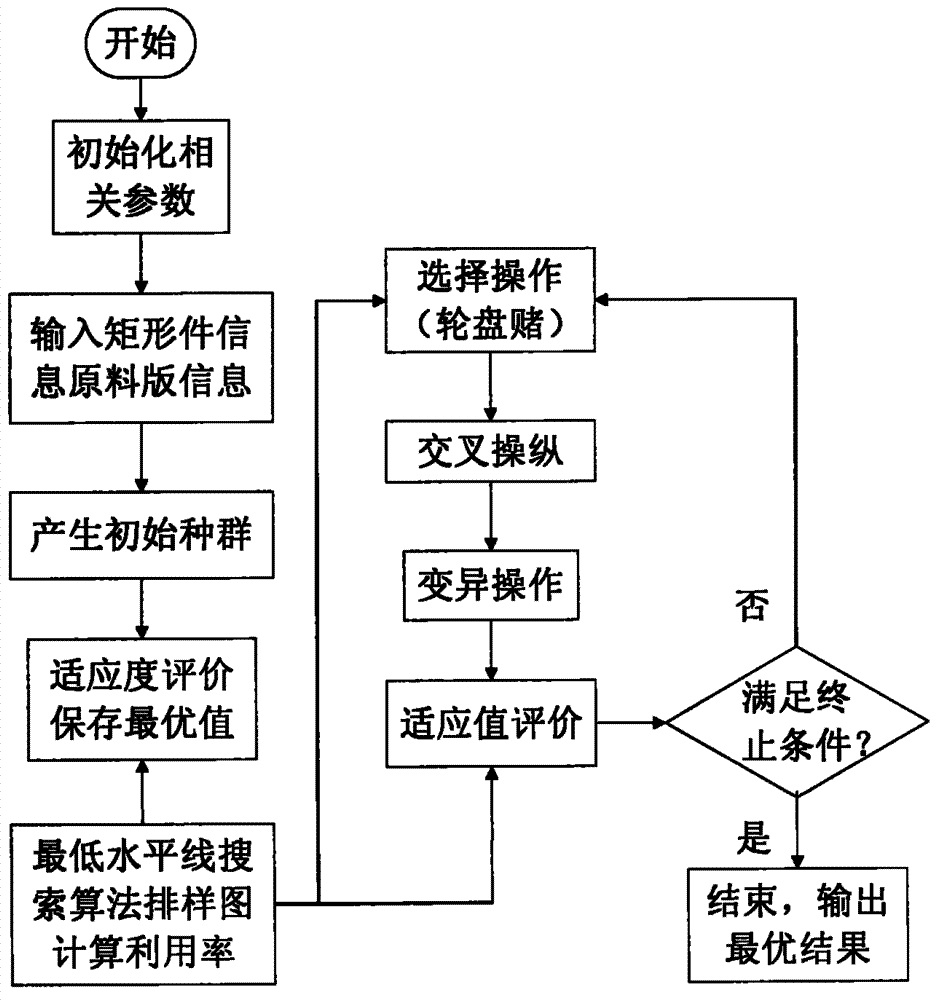

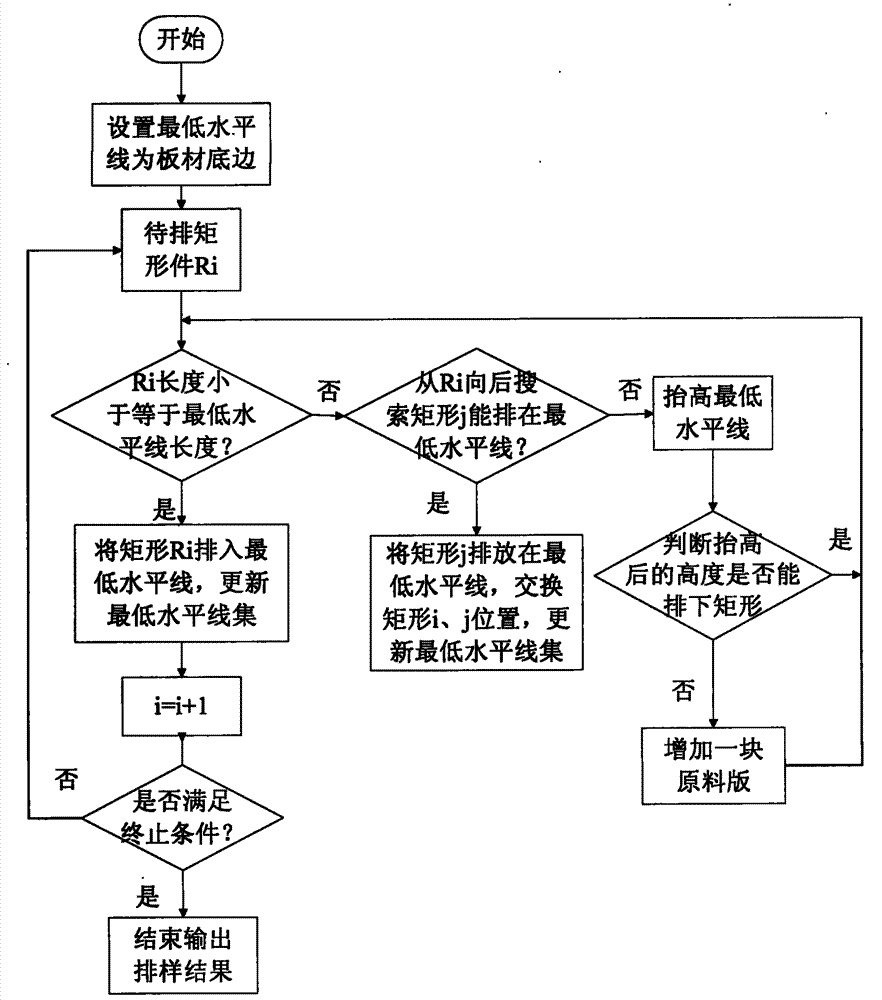

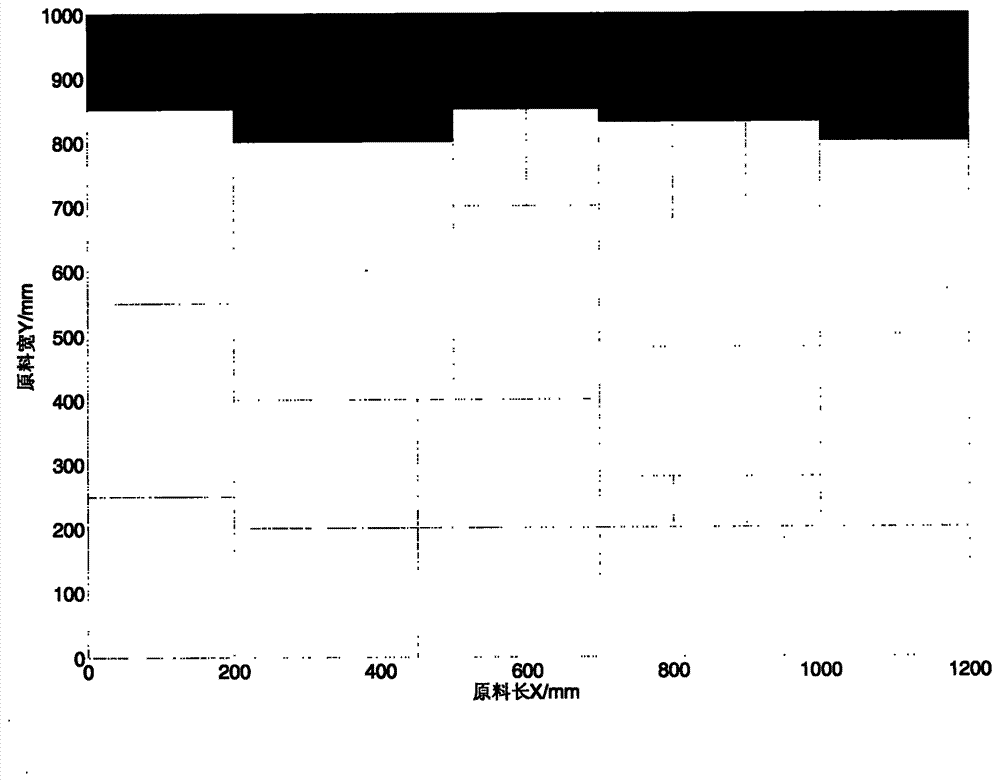

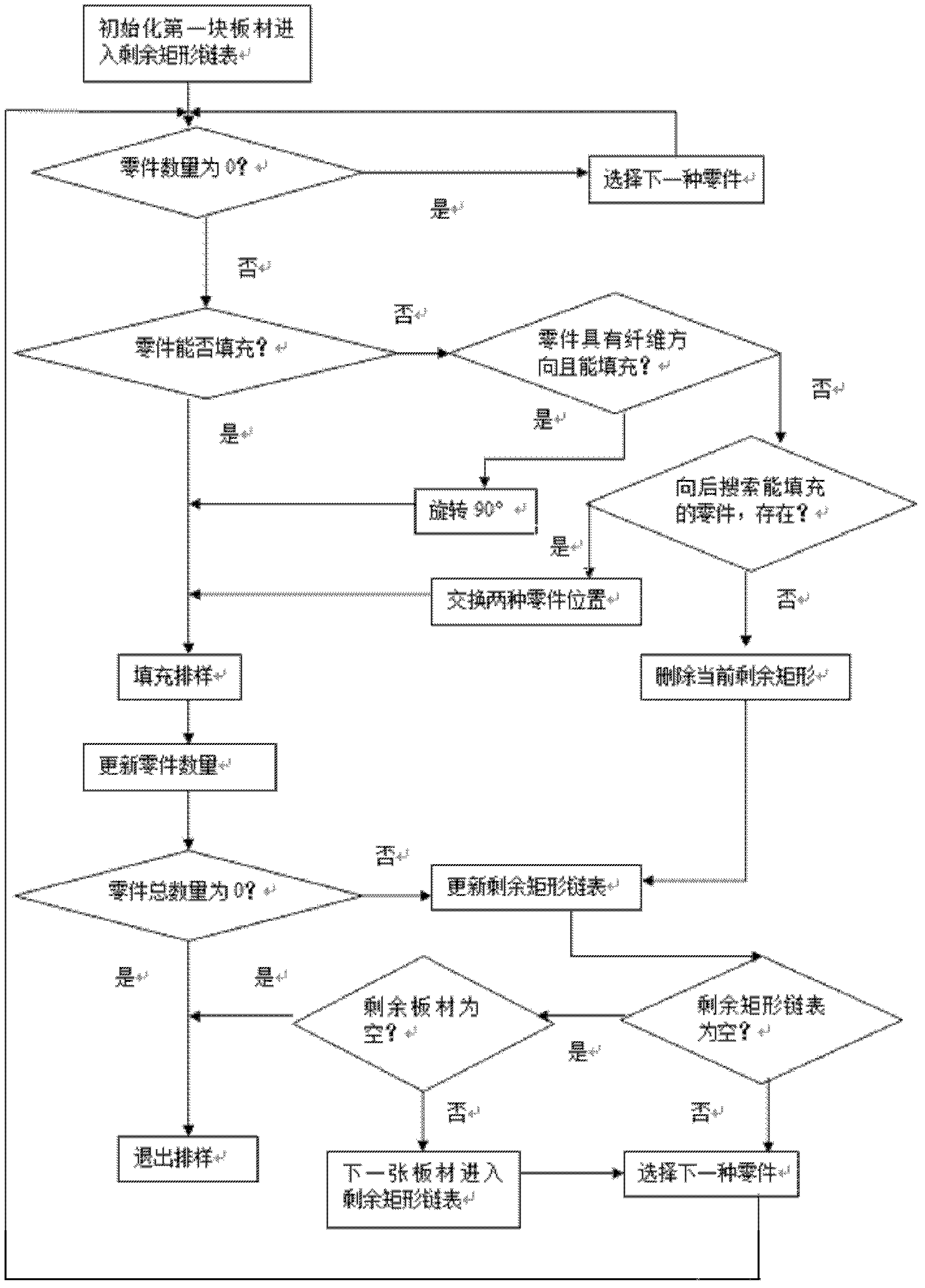

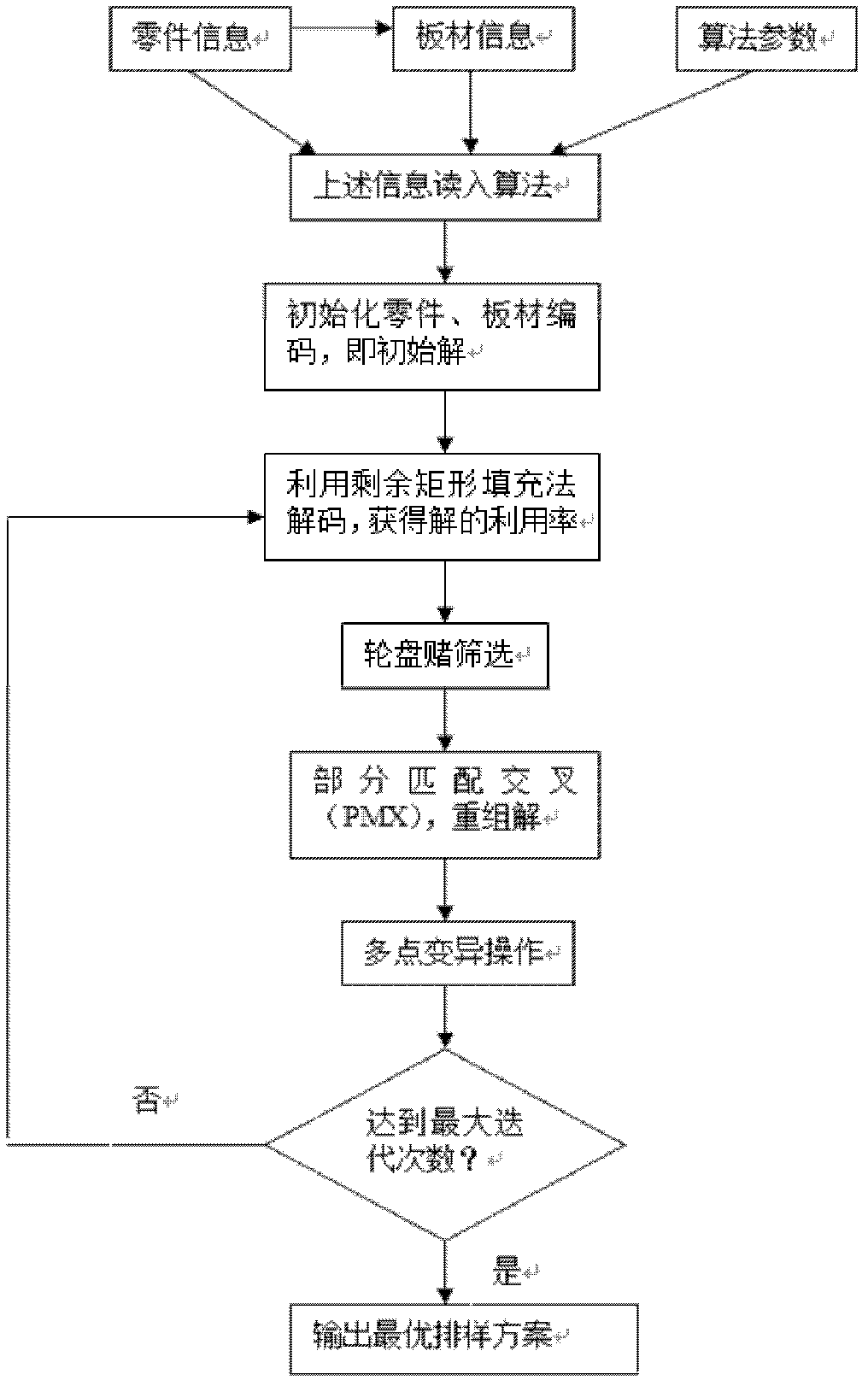

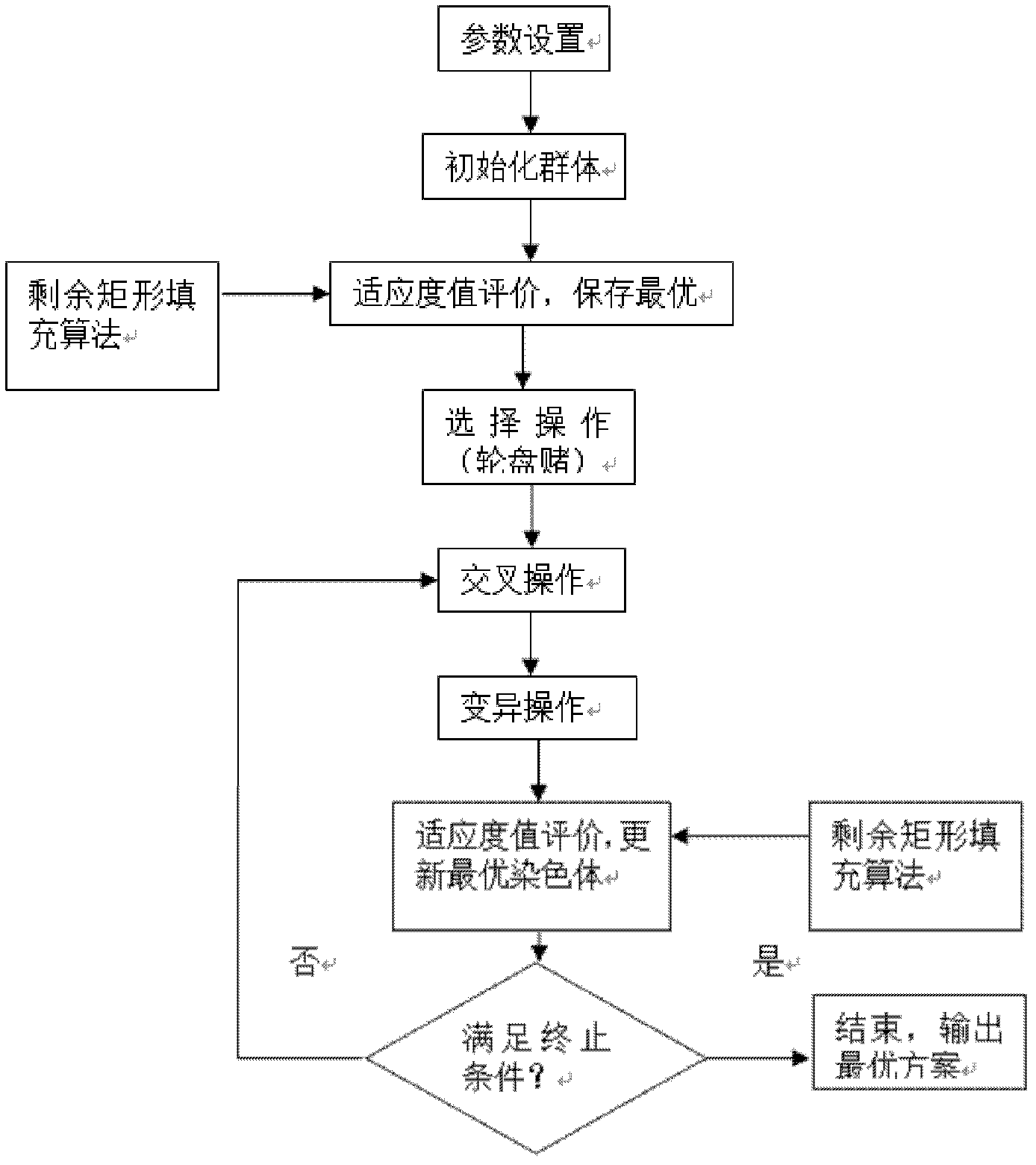

Intelligent layout method used for rectangular part

InactiveCN103500255AMeet the process requirementsEfficient searchSpecial data processing applicationsRelevant informationAlgorithm

The invention discloses an intelligent layout method used for a rectangular part. The method comprises the steps that S1 relative parameters of the genetic algorithm are initialized; S2 relative information of the rectangular part is extracted from a rectangular part bank to be laid out; S3 relative information of raw material boards is extracted from a board tank; S4 the obtained information is coded, and primary species are generated randomly; S5 one-by-one decoding is conducted on the primary species by means of the lowest horizontal line search algorithm to obtain solution using efficiency; S6 selection, crossover and mutation operation is conducted according to the genetic algorithm until iteration is finished, and the optimal layout scheme is output. According to the intelligent layout method, the process requirement of the rectangular part can be met well, the intelligent algorithm and the heuristic algorithm are combined, one optimizing scheme can be found rapidly and efficiently, and therefore the material using rate of an enterprise is greatly improved, layout time can be obviously shortened, and layout efficiency is improved.

Owner:NANTONG UNIVERSITY

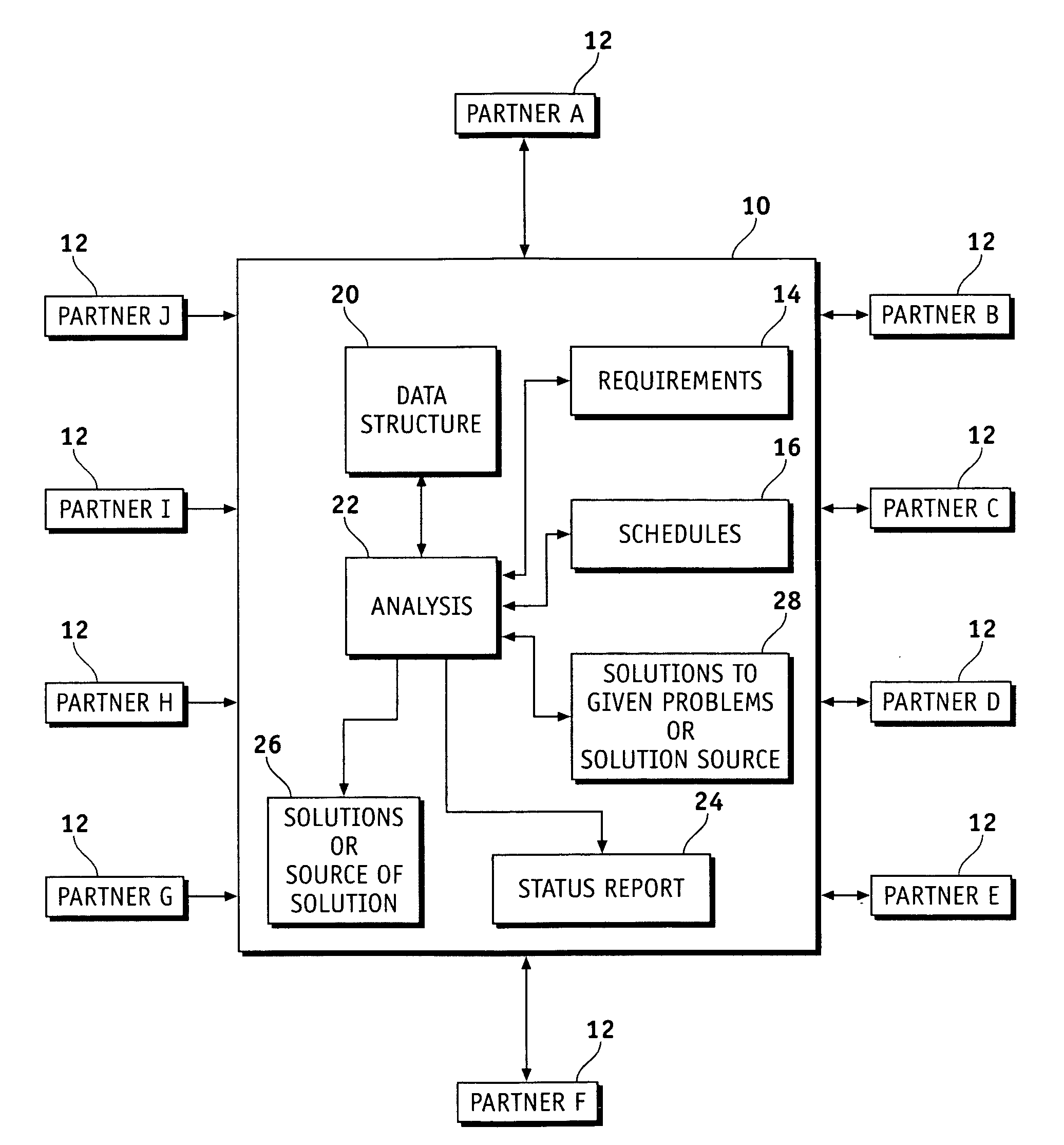

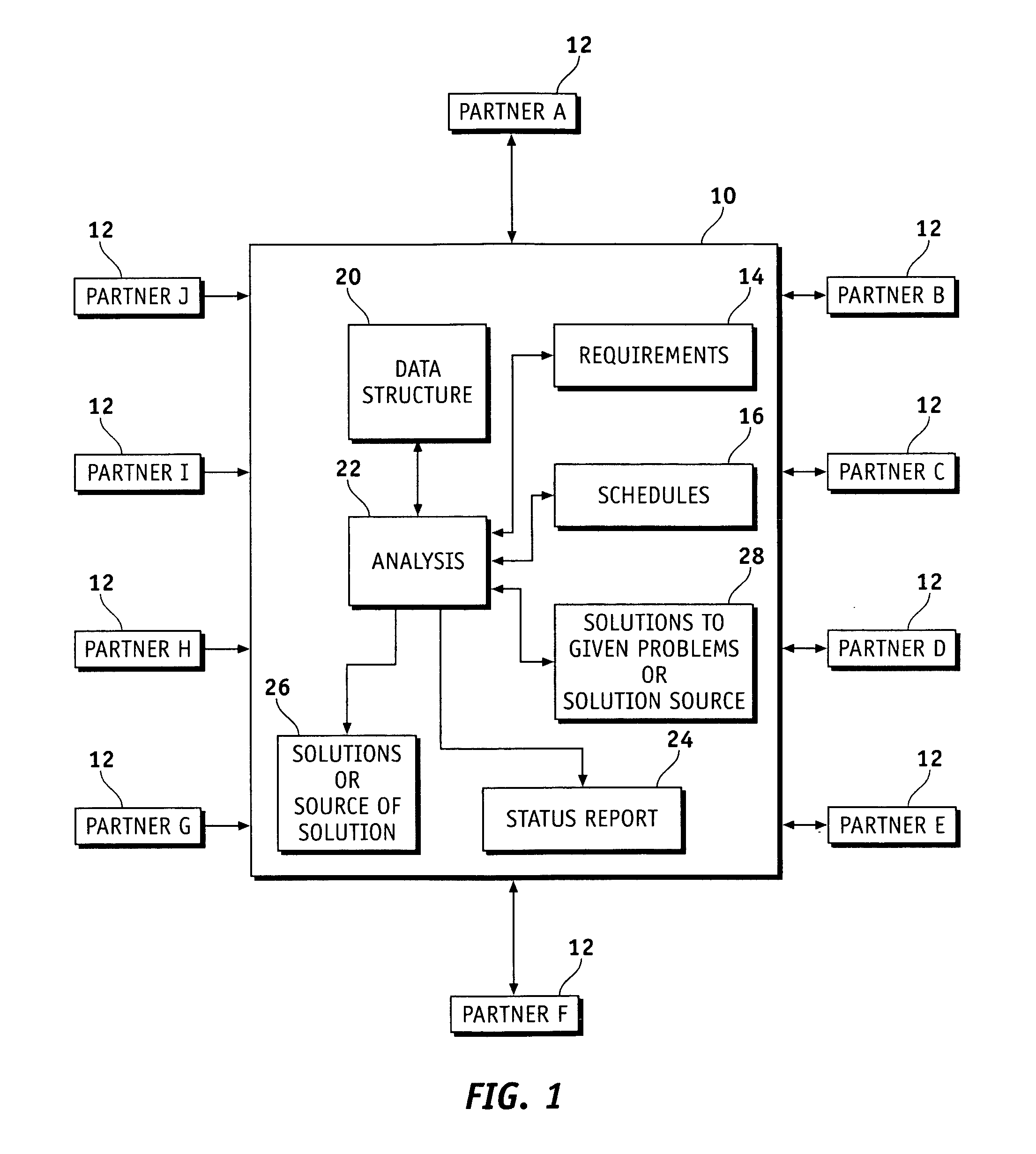

Engineering manufacturing analysis system

InactiveUS20070203912A1Easy to useDigital data information retrievalResourcesInformation typeManagement tool

A network based and automated engineering manufacturing analysis system as described herein is configured to manage producibility characteristics of a project or program throughout the lifecycle of the project or program. The system utilizes a collaborative data relationship and management tool that maintains metadata to create relationships between different information types for the project or program. The system relies upon real-time collaborative status updates that identify whether participants (e.g., vendors, designers, suppliers, and manufacturers) are satisfying requirements related to producibility characteristics. One example system designates a set of specified requirements for each project milestone level, and expects participants to provide electronic files, documents, or artifacts that evidence satisfaction of such requirements. The system processes requirement status updates in substantially real-time such that all participants can view the current project health and status at any time during the lifecycle of the project.

Owner:THE BOEING CO

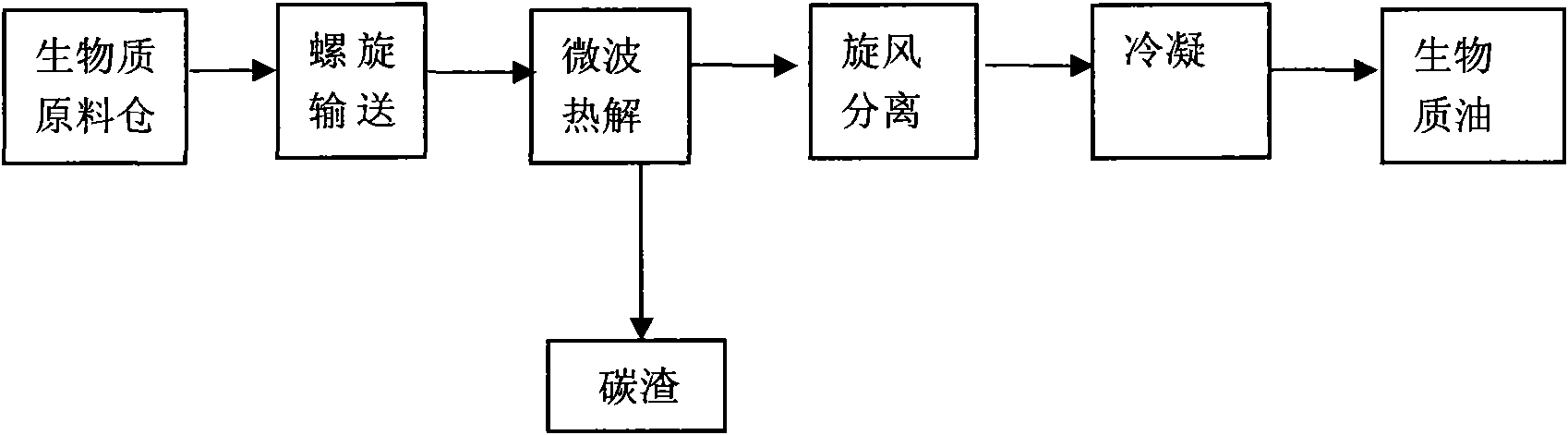

Method for preparing biomass oil in microwave thermal decomposition way

InactiveCN101560404AImprove microwave absorption performanceFast heatingLiquid hydrocarbon mixture productionMicrowave pyrolysisScrew conveyor

The invention discloses a method for preparing biomass oil in a microwave thermal decomposition way, which comprises the following steps: biomass enters a screw conveyer from a storage hopper, the feeding speed of the screw conveyer is 30-60 kilogram / h; the biomass enters a microwave pyrolysis reactor through the screw conveyor, the temperature of the biomass after absorbing microwave rapidly rises to 450-550 DEG C to reach the best temperature 475-500 DEG C of the biomass producing the oil; the biomass is thermally decomposed in the microwave pyrolysis reactor to produce high-temperature organic steam, the organic steam is sent to a cyclone separating device for gas and solid separation to remove carbon grains and sand; the organic steam is discharged through the cyclone separating device, the biomass is sent to a condenser for quenching, a condensable part of the biomass is changed into the biomass oil, and the biomass oil is dropped into an oil tank, thereby the biomass oil is prepared. The invention accords with the best process requirement of the biomass oil extraction without thermal conduction and has low cost, controllable and precise thermal decomposition temperature and no thermal inertia.

Owner:上海鸿泽企业发展有限公司

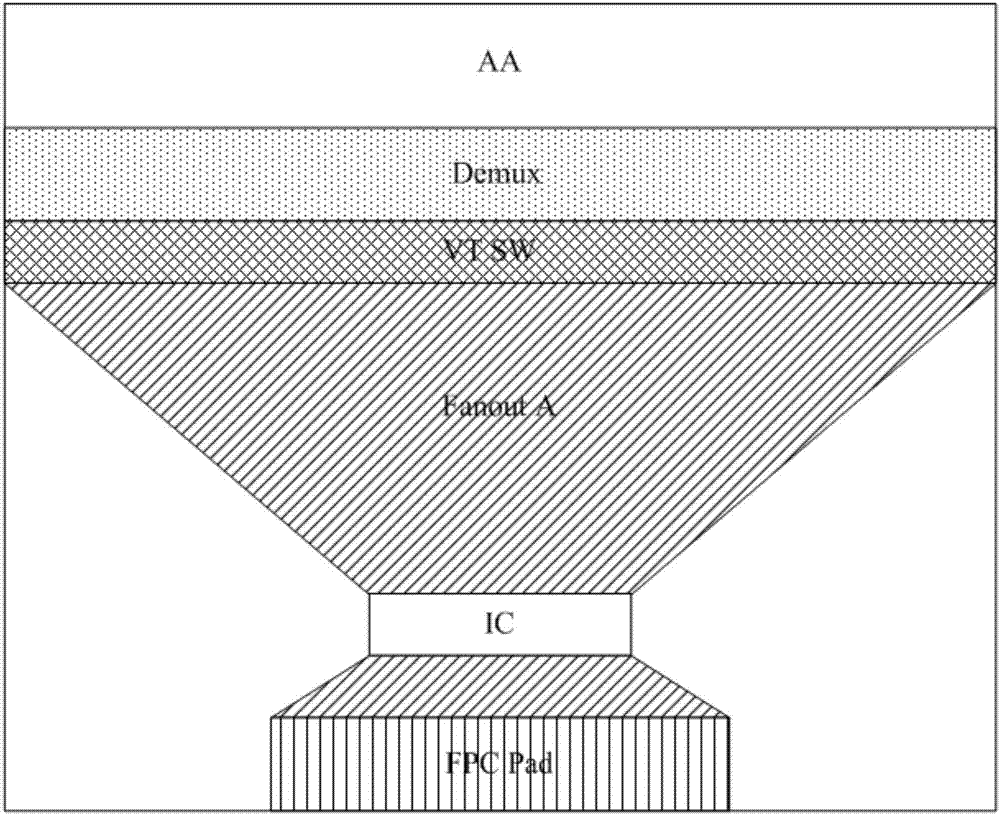

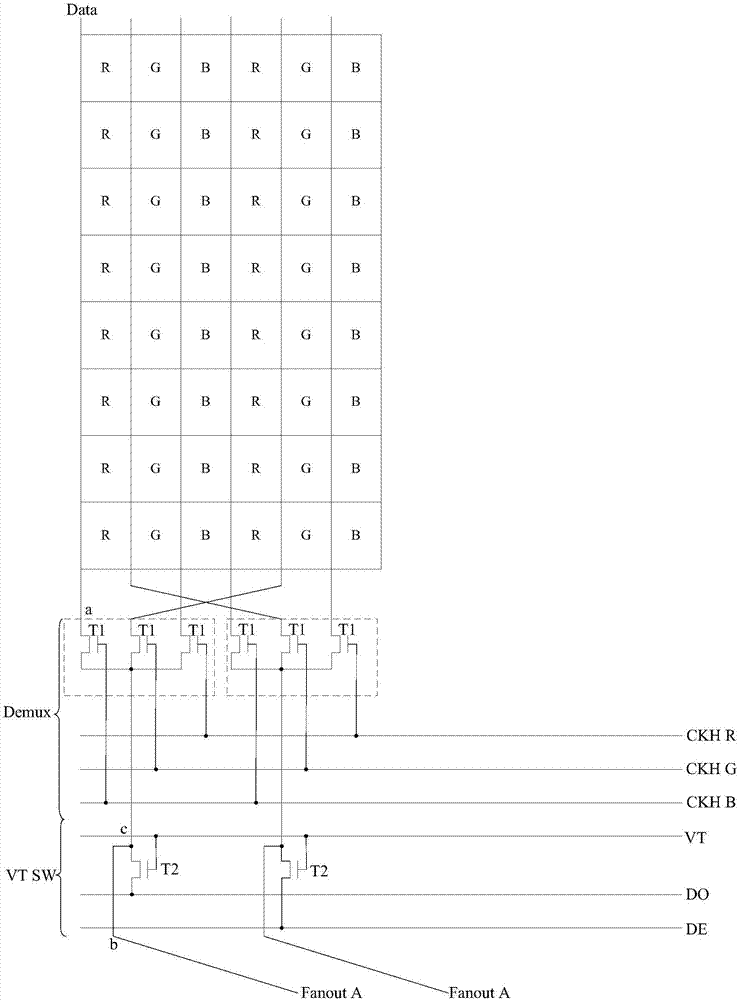

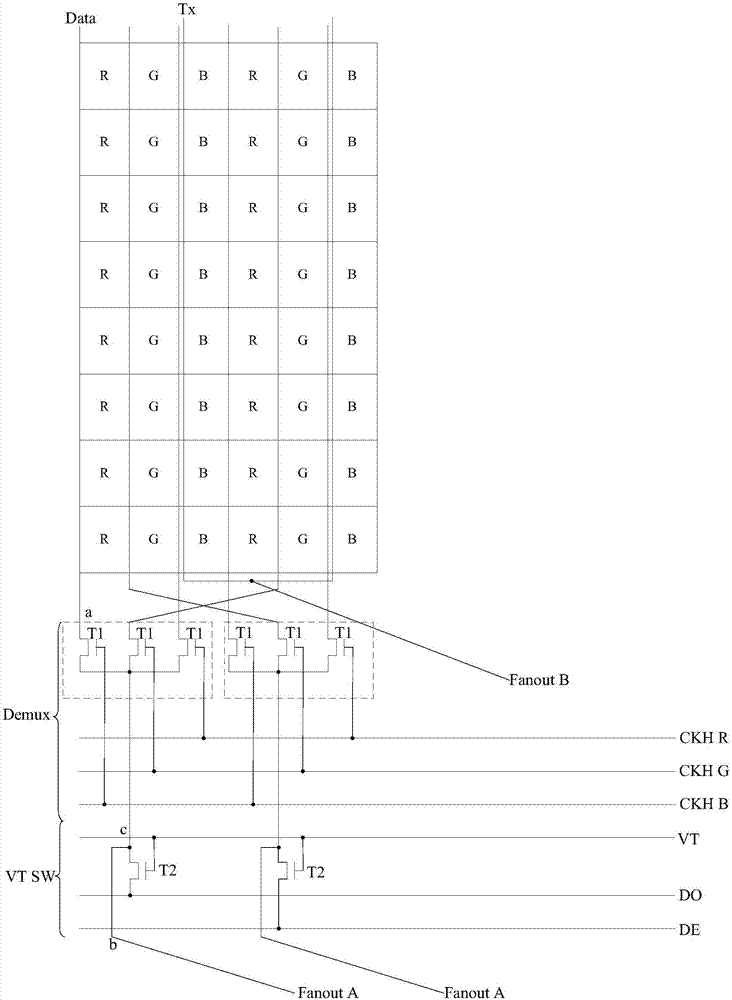

Array substrate, display panel and display device

ActiveCN107039467ATo achieve the effect of narrow borderReduce widthSemiconductor/solid-state device testing/measurementStatic indicating devicesData signalDisplay device

The invention discloses an array substrate, a display panel and a display device. The array substrate comprises a plurality of data lines arranged at a display area, a multi-path distributor assembly, a test switch assembly, and a plurality of data signal section routing units, wherein the multi-path distributor assembly, the test switch assembly, and the plurality of data signal section routing units are arranged at a non-display area. A signal output terminal of the multi-path distributor assembly is connected with the data lines and an input terminal of the multi-path distributor assembly is connected with output terminals of the data signal section routing units and the test switch assembly. The test switch assembly is arranged at one side, far away from the display area, of the multi-path distributor assembly. According to the invention, the plurality of data signal section routing units and the test switch assembly at the non-display area are changed to be arranged at different layers and thus overlapped areas are formed between the data signal section routing units and the test switch assembly, so that the existing continuous arrangement sequence of elements at the non-display area of the array substrate can be changed. Therefore, the width of the non-display area can be reduced under the circumstance that performances and dimensions of all elements at the original lower frame are kept; and thus the narrow frame effect can be realized while the process requirement is not enhanced and the production yield is not reduced.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

Automatic stock layout method of insulated paper board

InactiveCN102592031AMeet the technological requirements of layoutHigh material utilizationGenetic modelsSpecial data processing applicationsCardboardRelevant information

The invention discloses an automatic stock layout method of an insulated paper board, which includes the following steps: (1) selecting a rectangular insulated paper board from a part warehouse and extracting relevant information of parts; (2) selecting rectangular plates from a plate warehouse and extracting relevant information of the plates; (3) encoding obtained information to obtain a plurality of solutions; (4) decoding the plurality of solutions one by one by using remaining rectangle filling algorithm to obtain use rate of the solutions; and (5) performing optimization continuously ona stock layout process by using genetic algorithm and outputting an optimum stock layout scheme correspondingly. By means of the automatic stock layout method, process requirements of stock layout ofthe insulated paper board can be met well, and an optimized stock layout scheme can be found fast and efficiently by combining heuristic algorithm and intelligent algorithm, therefore material use rate of enterprises is greatly improved, stock layout time can be shortened greatly, and stock layout efficiency is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

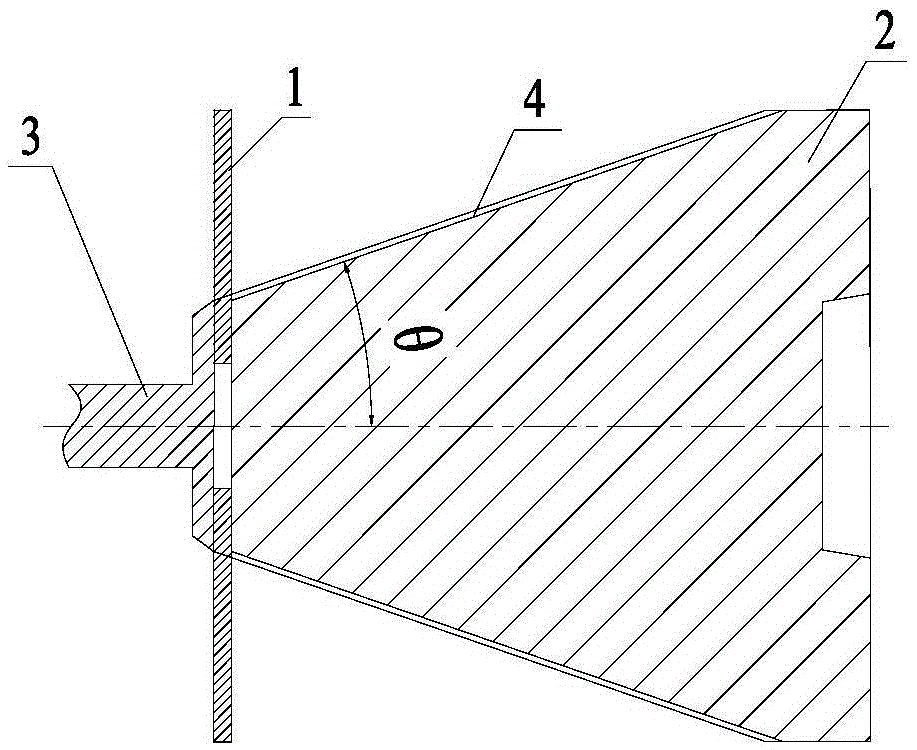

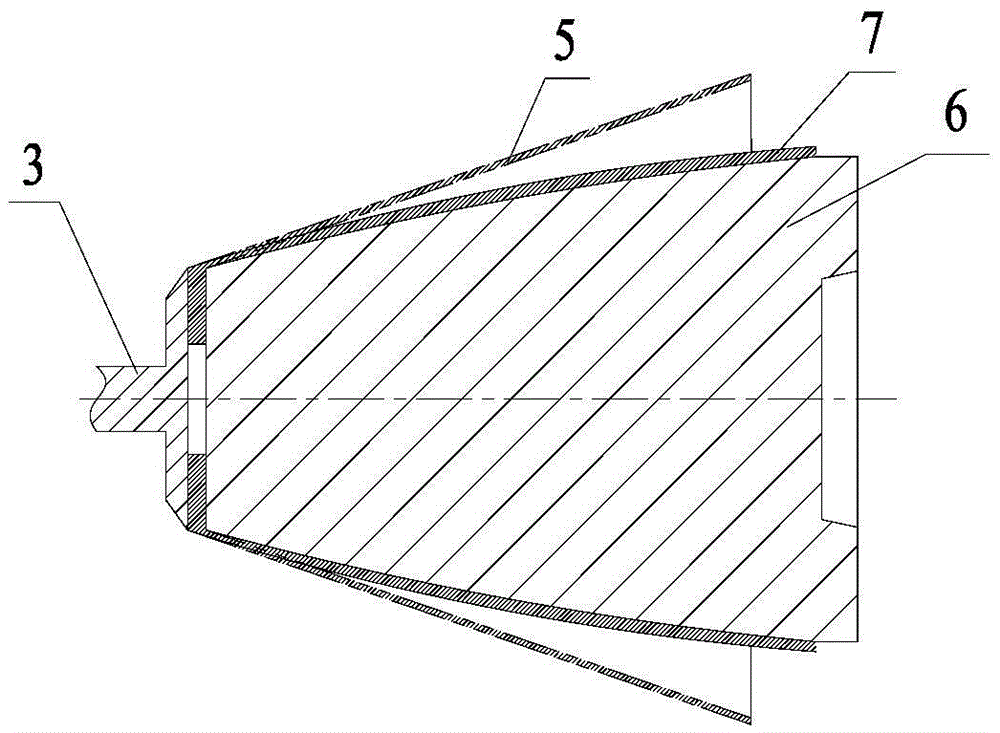

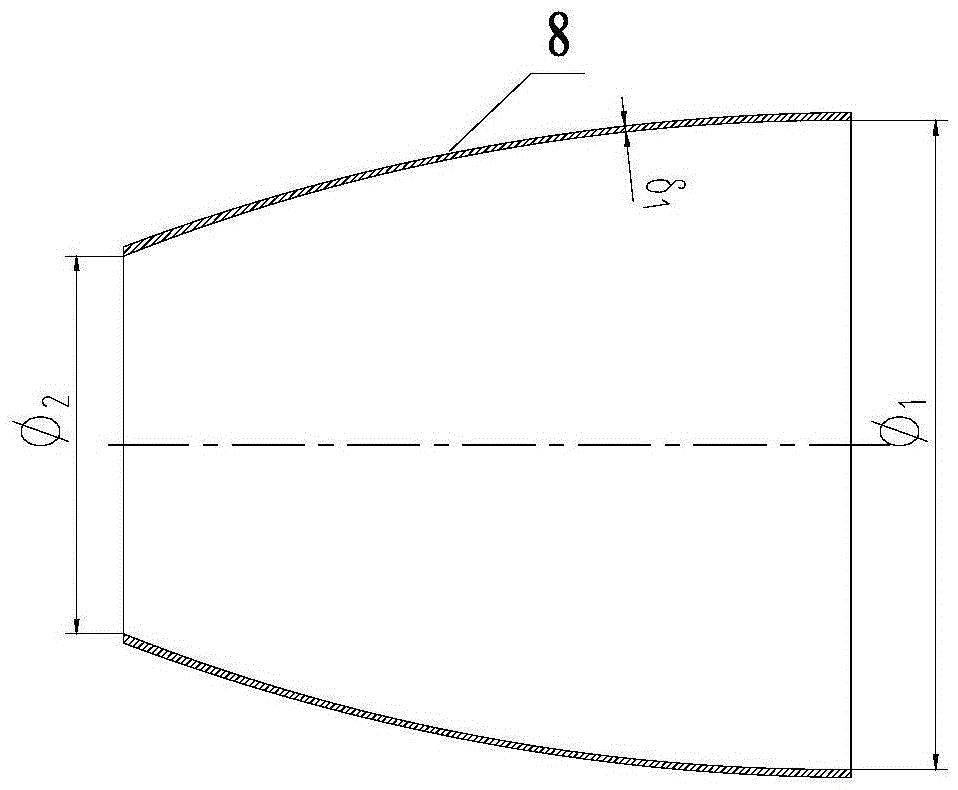

Spinning machining method for aluminium alloy thin-walled revolution body

ActiveCN105537449AMeet sizeFulfil requirementsHollow articles5005 aluminium alloy5052 aluminium alloy

The invention discloses a spinning machining method for an aluminium alloy thin-walled revolution body. The spinning machining method comprises the following steps: producing an aluminium alloy spun blank with required dimensions, and carrying out annealing treatment on the aluminium alloy spun blank; carrying out shearing spinning on the aluminium alloy spun blank to obtain a primary conical barrel; carrying out annealing treatment on the primary conical barrel, and cutting a process allowance at a large end to form a secondary conical barrel; carrying out common spinning on the secondary conical barrel on a spinning machine to obtain a pre-spun aluminium alloy thin-walled revolution body; and carrying out annealing treatment and surface polishing treatment on the pre-spun blank, and then cutting process allowances at the two ends of a spun part by using a plasma cutting machine, so as to obtain the aluminium alloy thin-walled revolution body meeting process requirements. According to the invention, the aluminium alloy thin-walled revolution body is machined by virtue of the technologies of shearing spinning and common spinning; the dimension and structural performance requirements of a bullet shell are met; a machining method and a stamping-welding method can be replaced; and a low-cost and efficient machining method is provided for machining for an aluminium alloy shell of a bullet.

Owner:湖北三江航天江北机械工程有限公司

Conductive silver paste special for circuit of laptop keyboard and preparation method thereof

InactiveCN101645318AReduce volume resistanceHigh hardnessNon-conductive material with dispersed conductive materialCable/conductor manufactureScreen printingSilver paste

The invention relates to a conductive silver paste special for a circuit of a laptop keyboard and a preparation method thereof. The silver paste is prepared from the raw materials of the following components in percentage by weight: 55 to 65 percent of metal silver powder, 10 to 20 percent of macromolecule resin, 1.5 to 5 percent of additive and 10 to 25 percent of solvent. Compared with the priorart, a conductive silver circuit obtained by drying the silver paste has excellent anti-bending performance, the coverage property or associative property of insulation oil or carbon paste on a silver layer is greatly improved, and the performances such as screen printing property, surface rigidity, corrodibility resistance, environmental service life and the like are also improved; and the conductive silver paste enables the silver circuit obtained by screen printing, drying and solidify to be fully suitable for the process requirement of the production of the laptop keyboards.

Owner:SHANGHAI CHANGYIN ELECTRONICS MATERIALS TECHCO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com