Patents

Literature

3072results about How to "Guaranteed smooth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

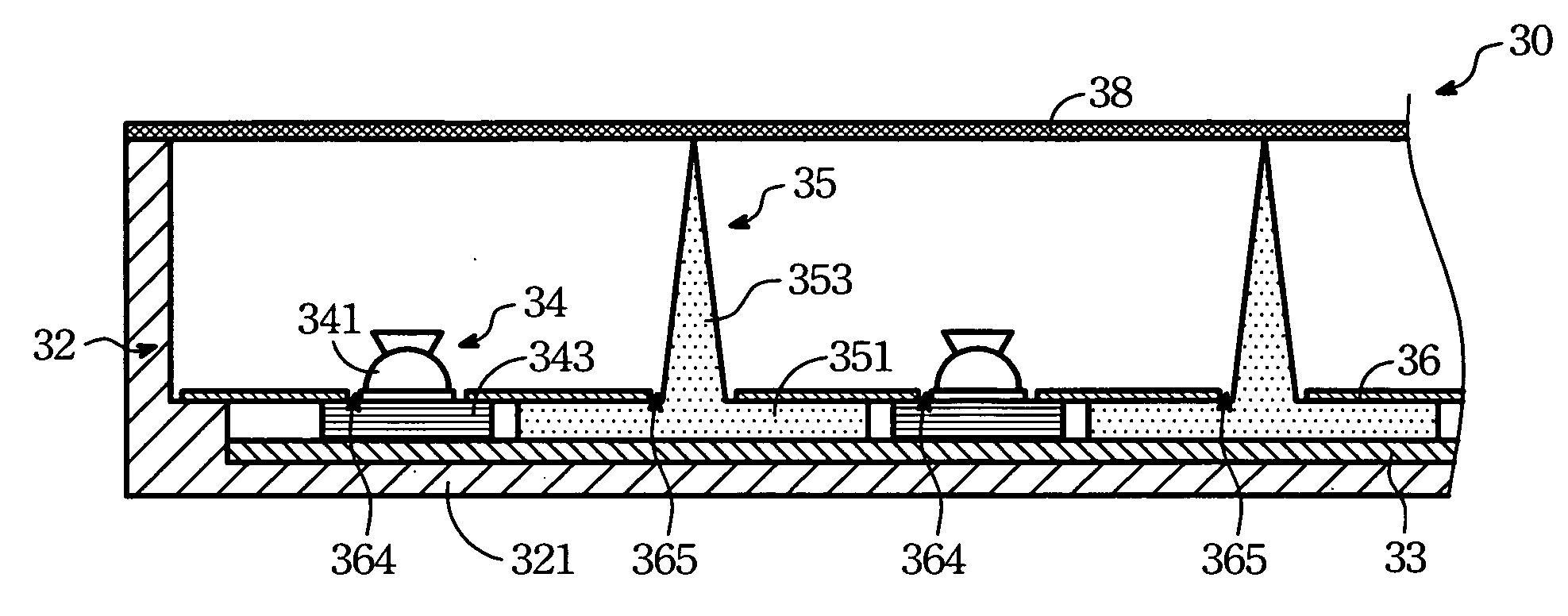

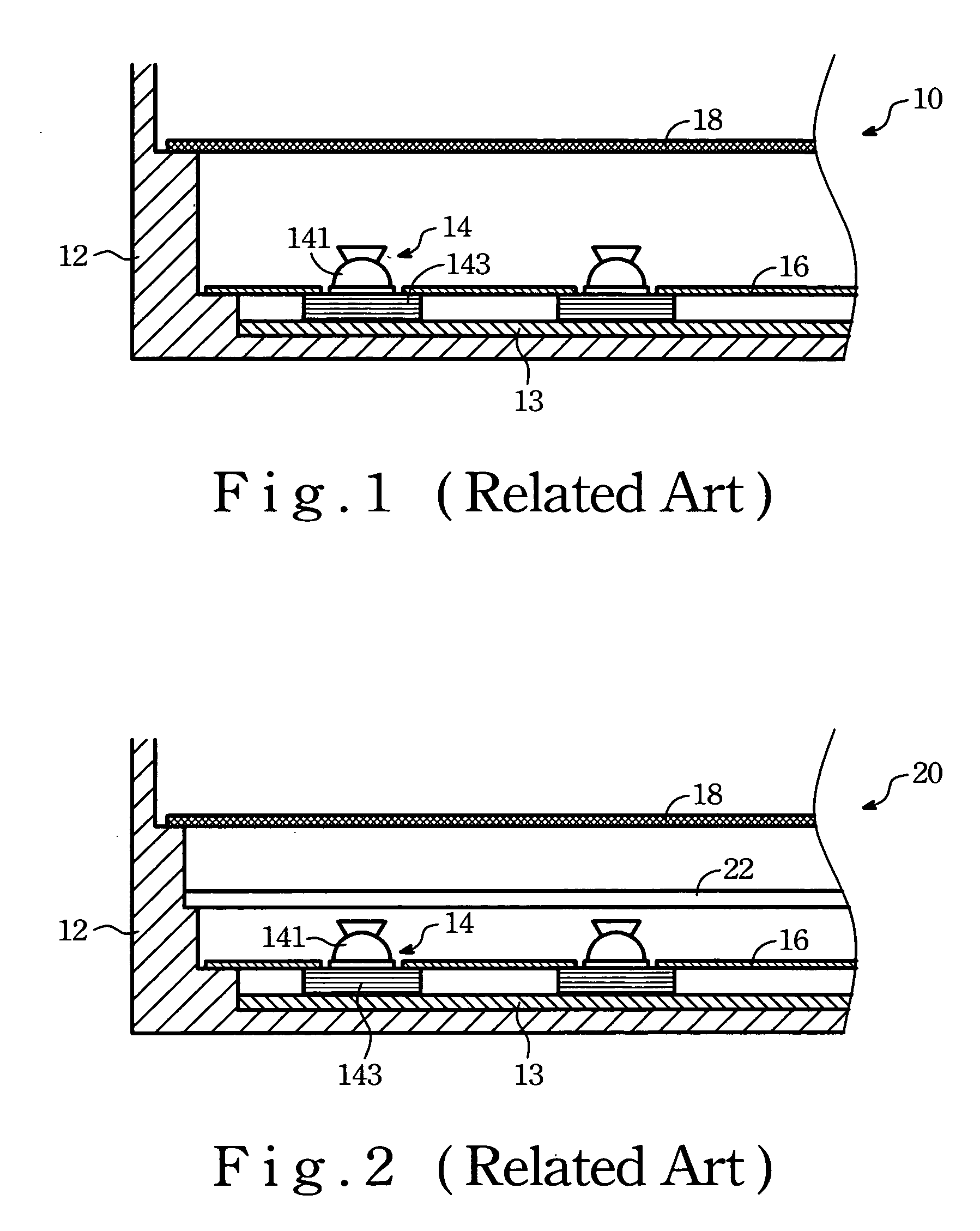

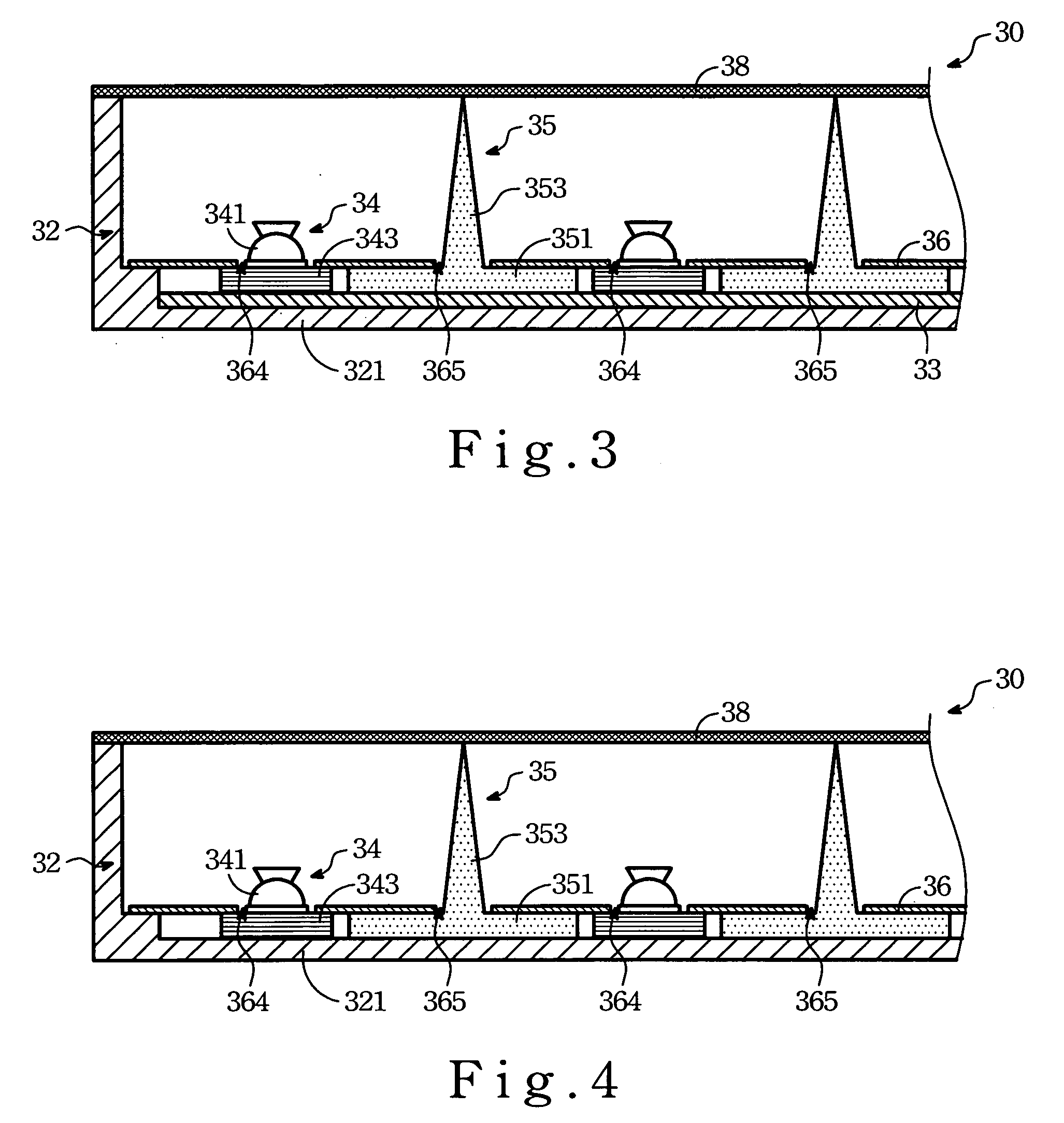

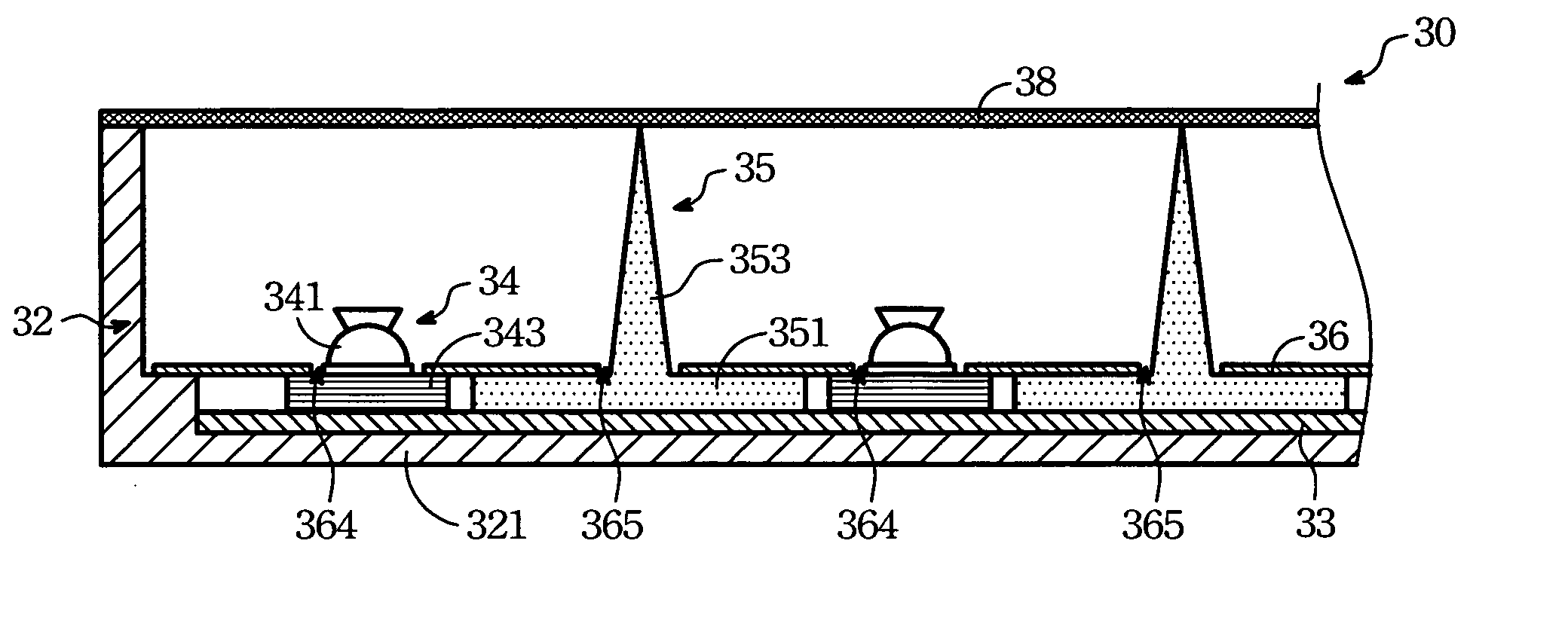

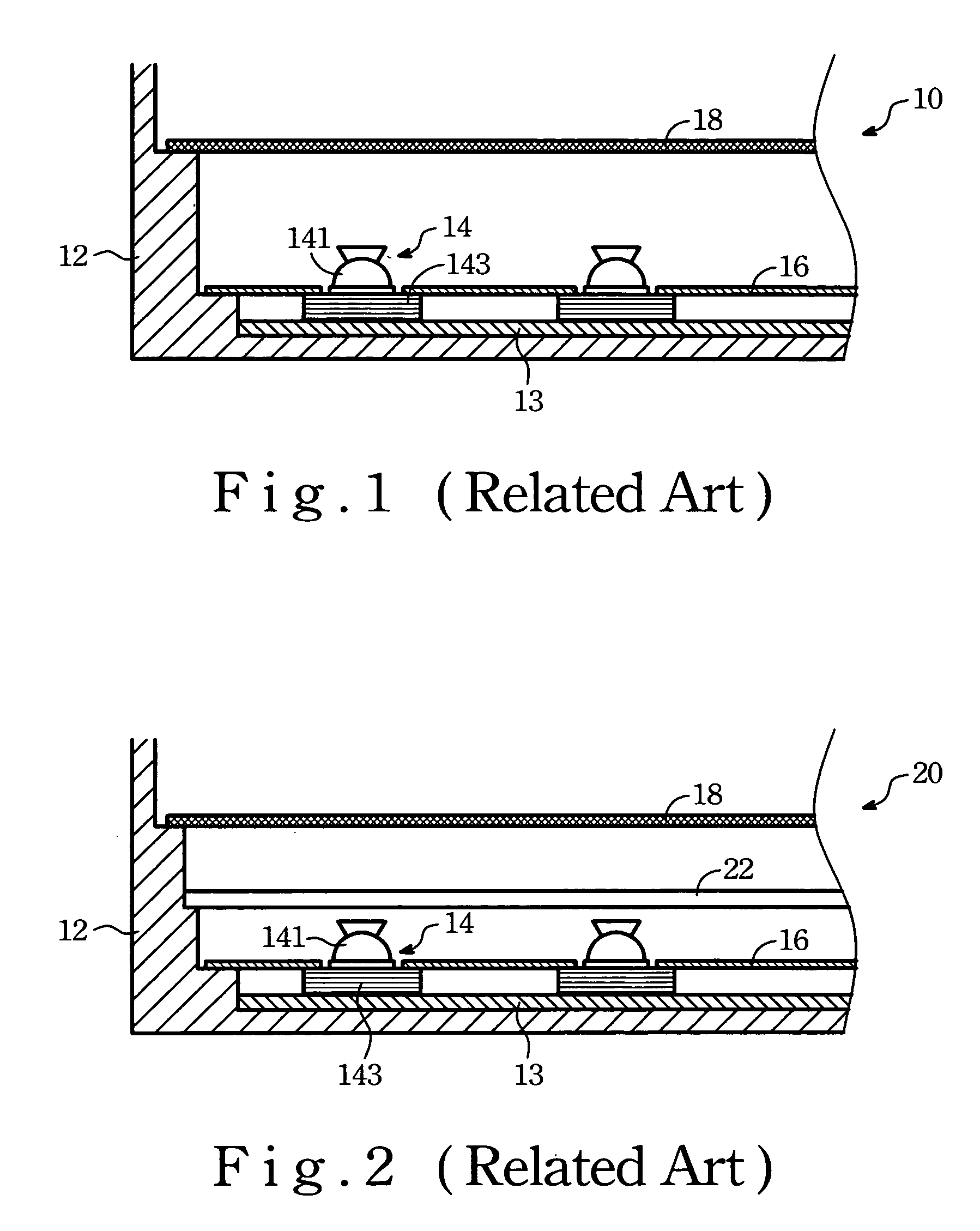

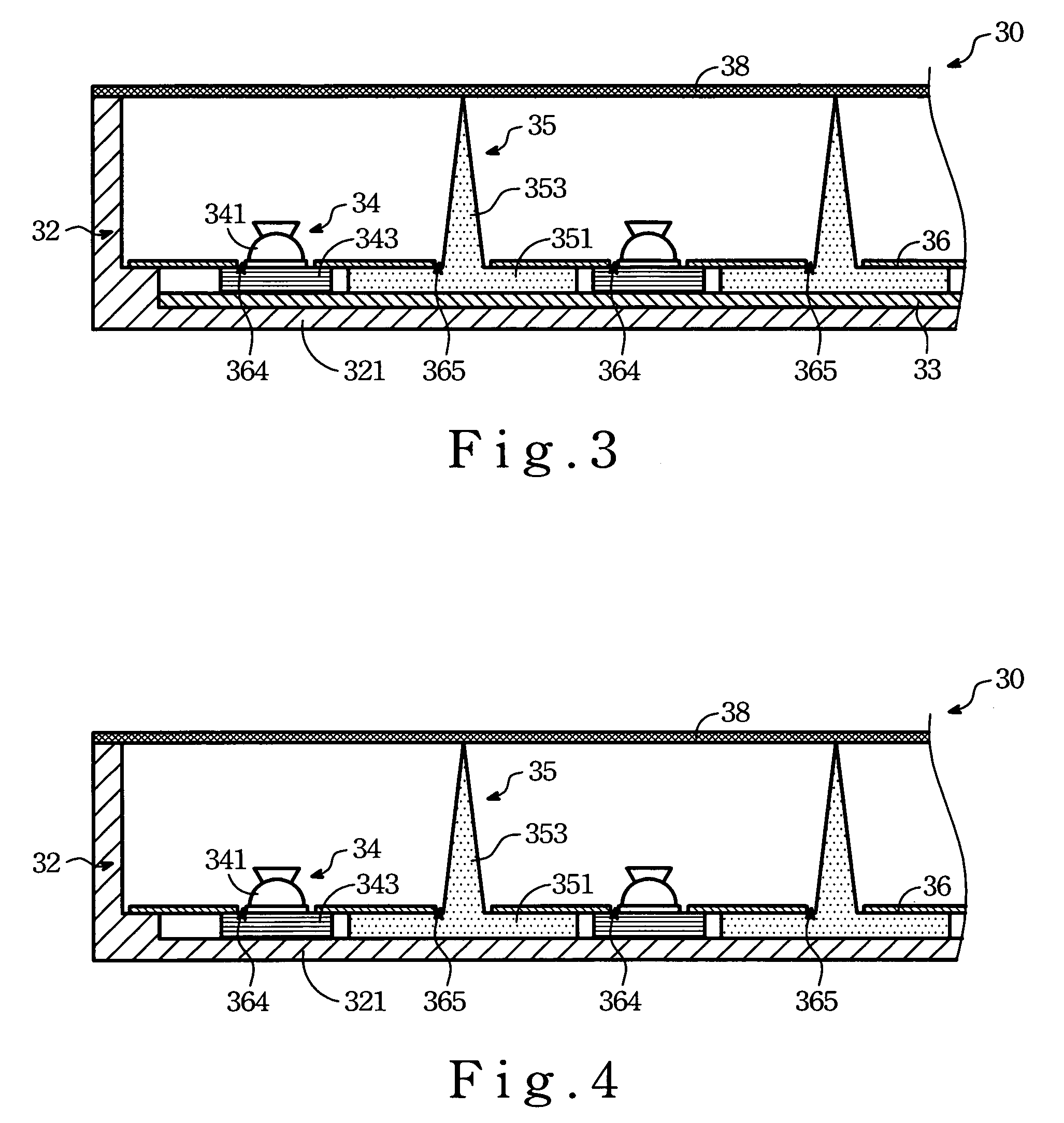

Support member and light emitting diode module using the same

ActiveUS20050281050A1Avoid it happening againReduce distractionsPoint-like light sourceOptical signallingEngineeringLight-emitting diode

Owner:AU OPTRONICS CORP

Thermoplastic light-duty composite plate and preparing method thereof

The invention discloses a thermoplastic light compound plate and the manufacturing method, characterized in that it comprises acupuncture fiber carpet dipped in double faced foam of thermoplastic glue liquid and thermoplastic glue liquid layer coated on the surface, the density of compound plate is 0.35-0.90g / cm3, the weight of fiber scattered in bunchiness is 15-45% of acupuncture fiber carpet. The merit of invention is very remarkable. Special super long fiber and bunchiness fiber with certain proportion are maintained in the material so that the mechanical performance of material can be improved. In addition, the material is provided with foam structure, very good effect of heat and sound insulation. The invention is also provided with environmental protection and recovery.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

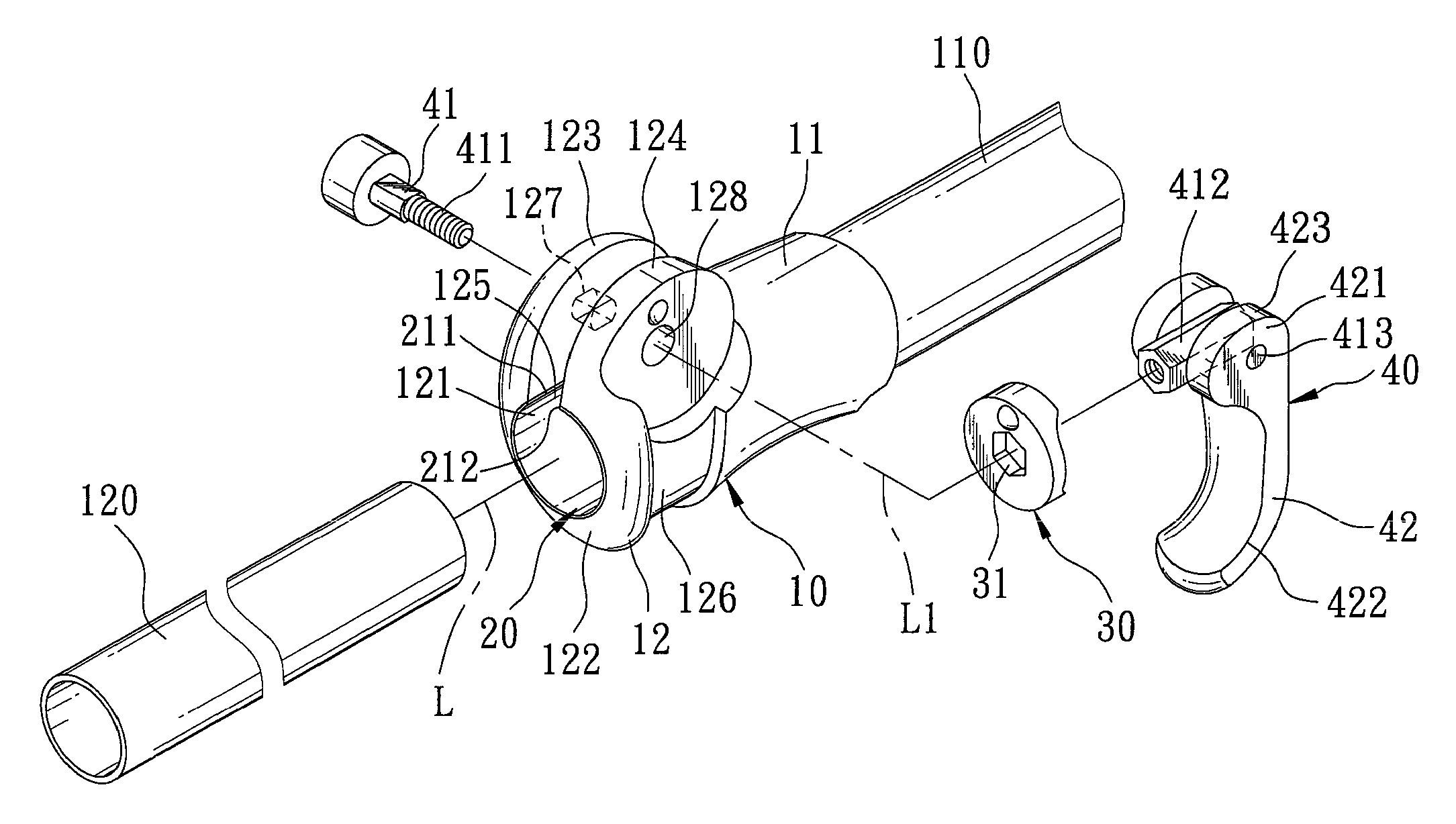

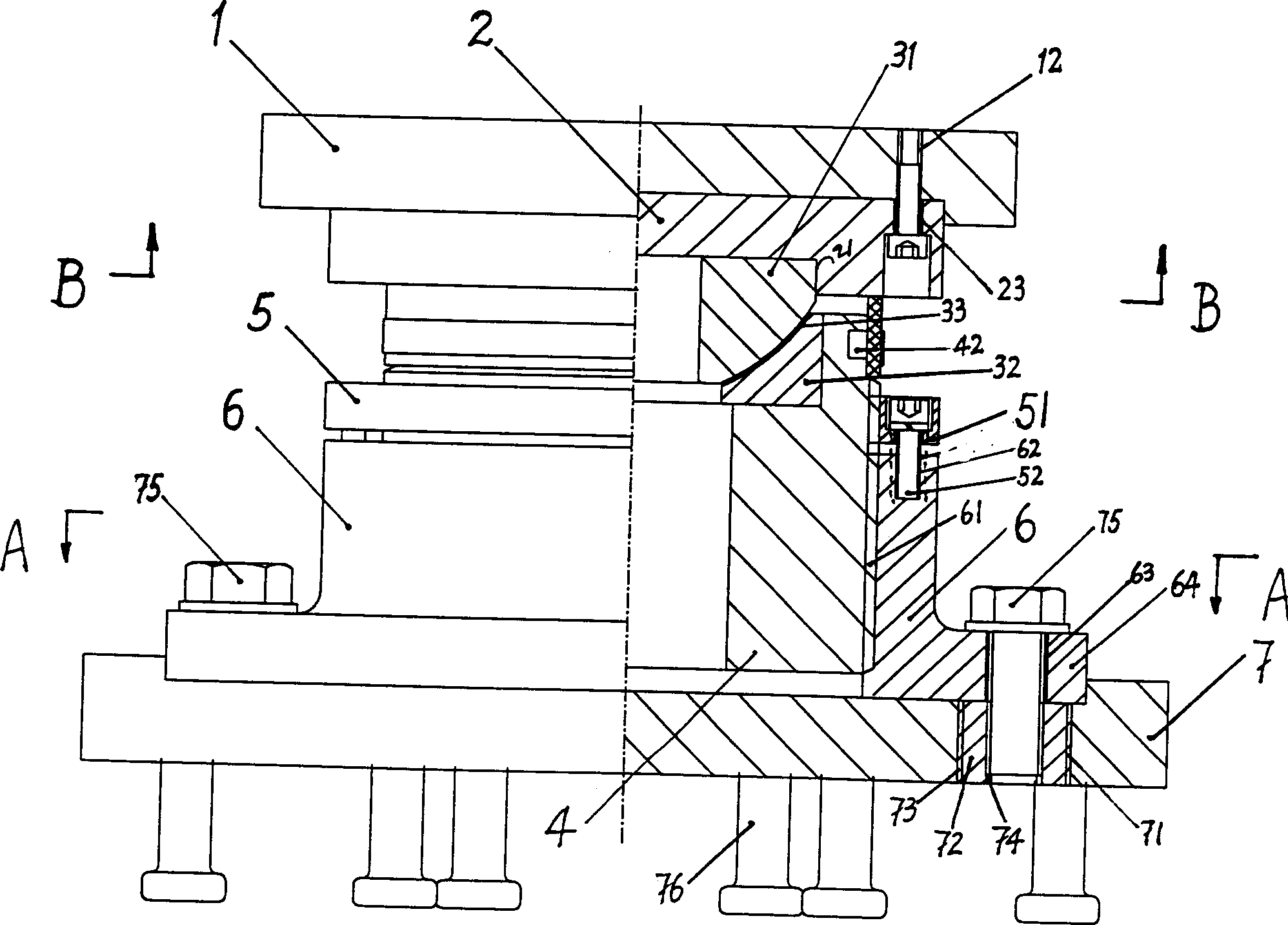

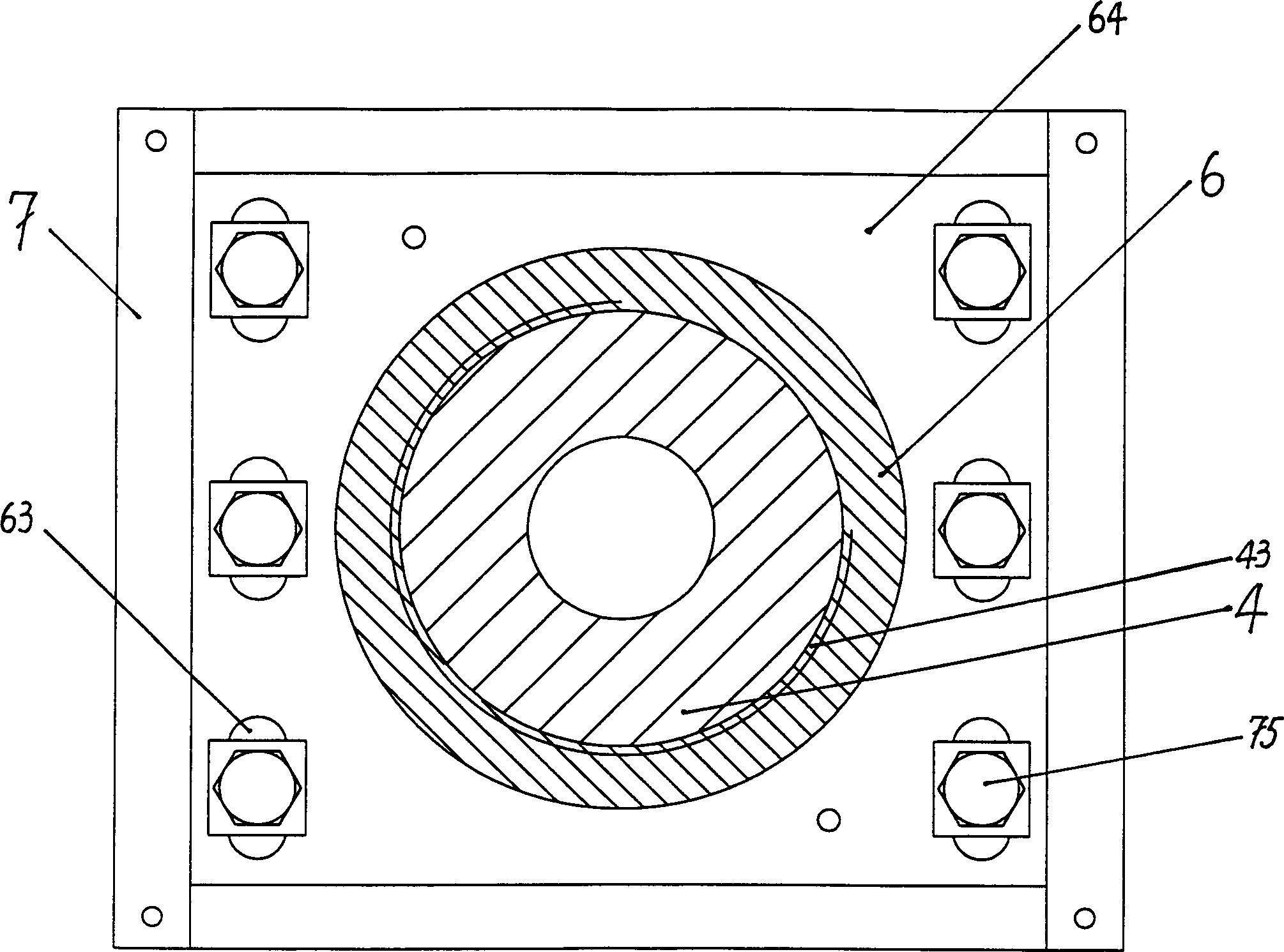

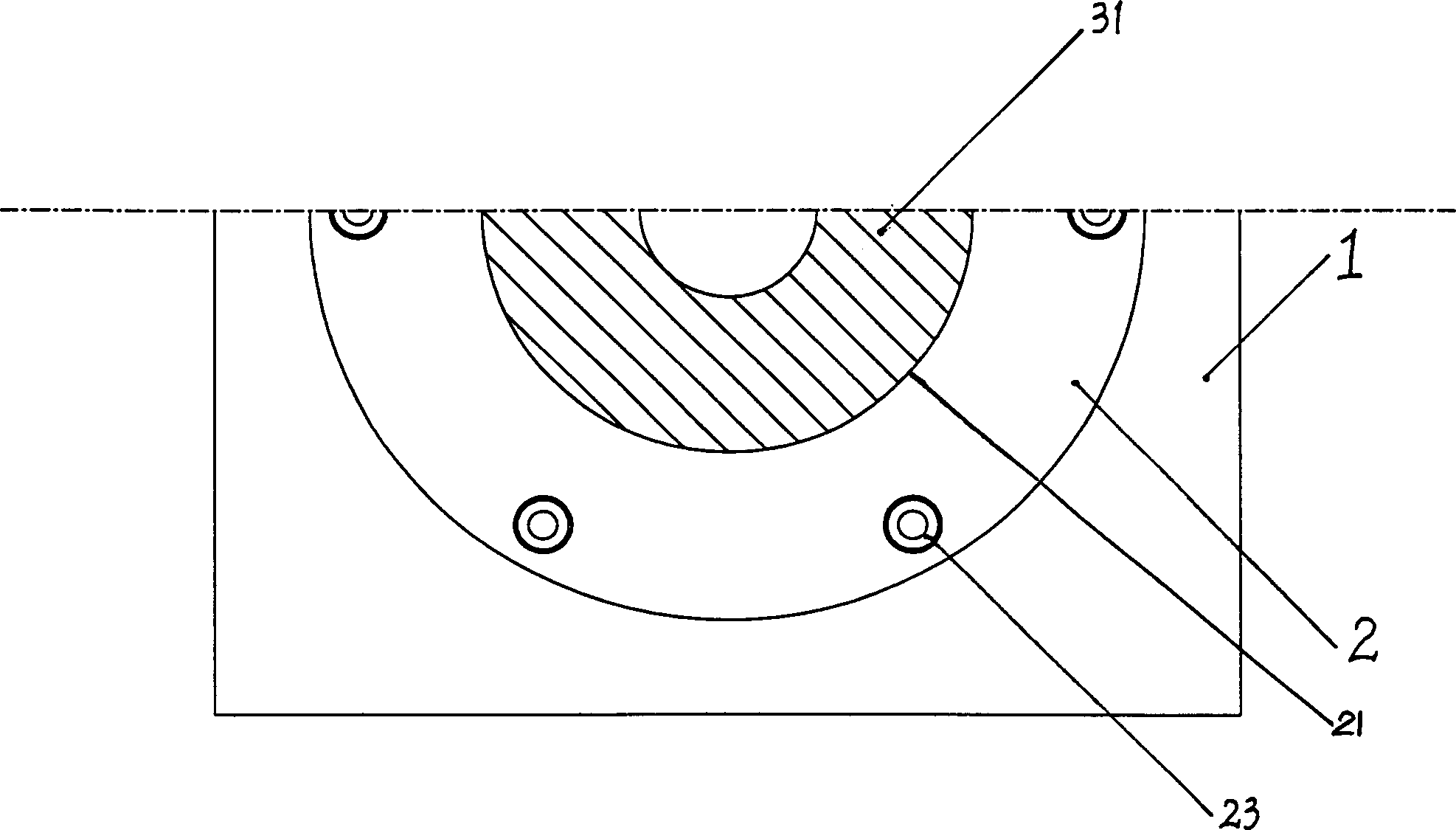

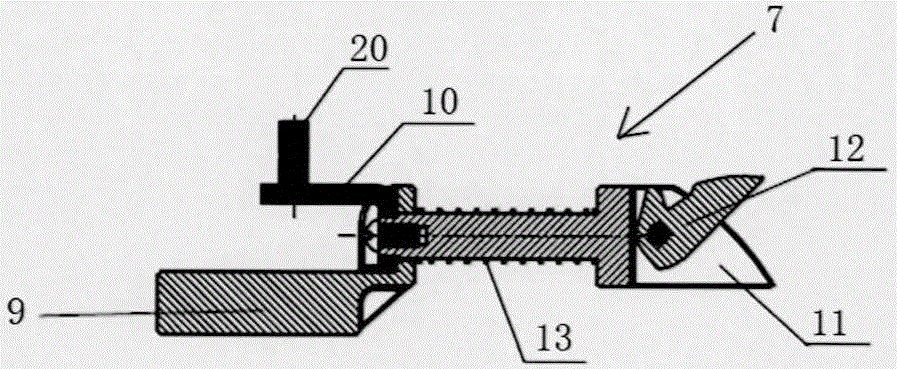

Clamping device for a telescopic rod

ActiveUS8608118B2Avoid failureGuaranteed smoothSnap fastenersStands/trestlesEngineeringMechanical engineering

Owner:HSIN YUAN LAI

Prefabricated thermal insulating composite panel, assembly thereof, moulded panel and concrete slab comprising same, method and mould profile for prefabricating same

ActiveUS20140059961A1Not easy can be inflamedConvenient to assembleCovering/liningsWallsMechanical engineeringComposite plate

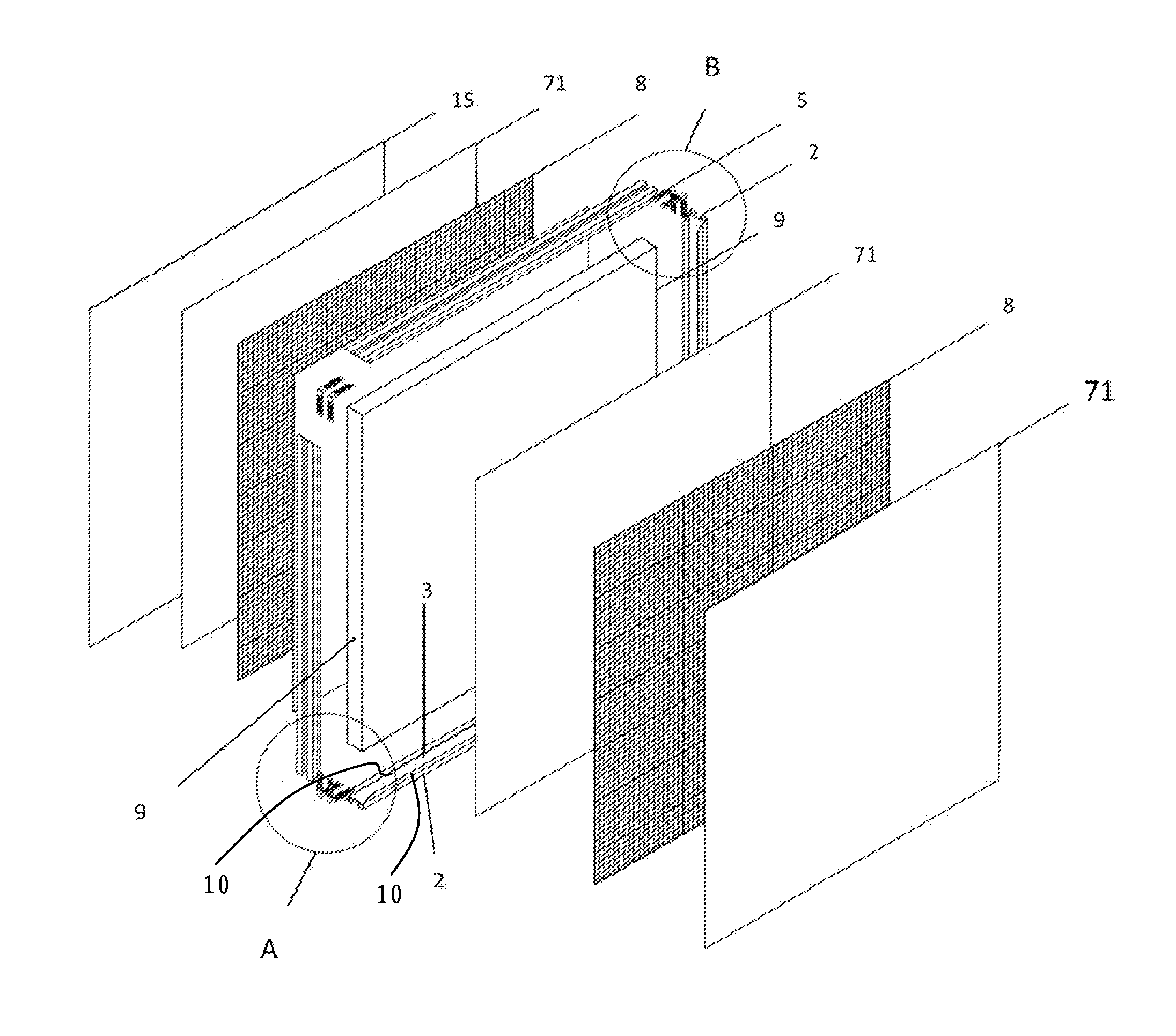

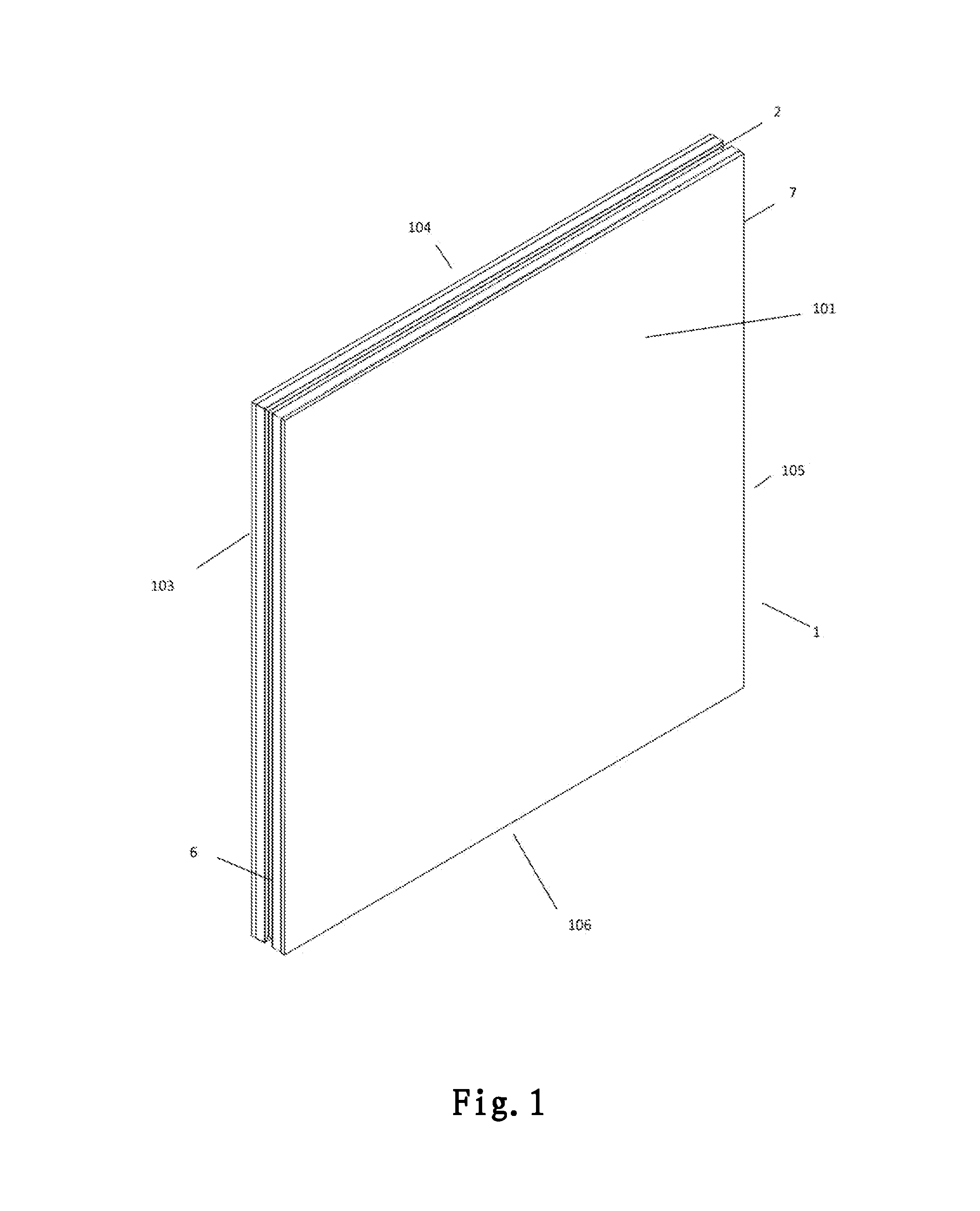

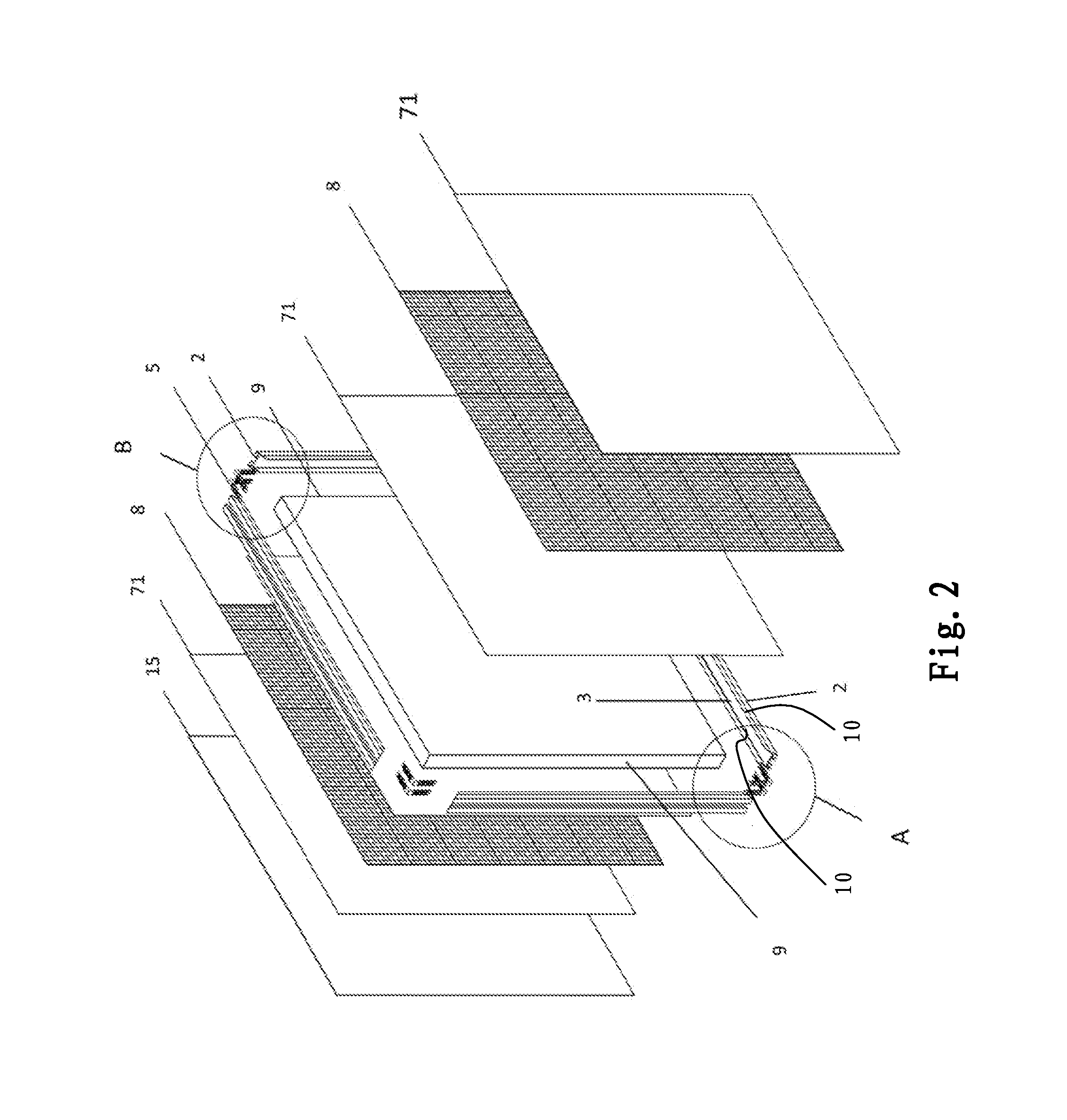

Disclosed are a prefabricated thermal insulating composite panel (1), an assembly thereof, a moulded panel and a concrete slab comprising the same, and a method and a mould profile (50) for prefabricating the same. The prefabricated composite thermal insulating panel (1) comprises: two reinforcing protective layers (7) of an inorganic noncombustible material, a core (9) formed by a thermal insulating material, a frame (2) with installation grooves (13) surrounding the core (9) and being secured onto the core (9), with the core (9) being placed between the two reinforcing protective layers (7). The prefabricated thermal insulating composite panel (1) has the inorganic noncombustible material incorporated onto the outside of the core (9) of the thermal insulating material to have it covered, so as to solve the problem of the tendency of causing a fire, during the placement of the thermal insulating panels at a construction site or other places, or during the transportation or installation of the same, due to the combustible material thereof being exposed.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

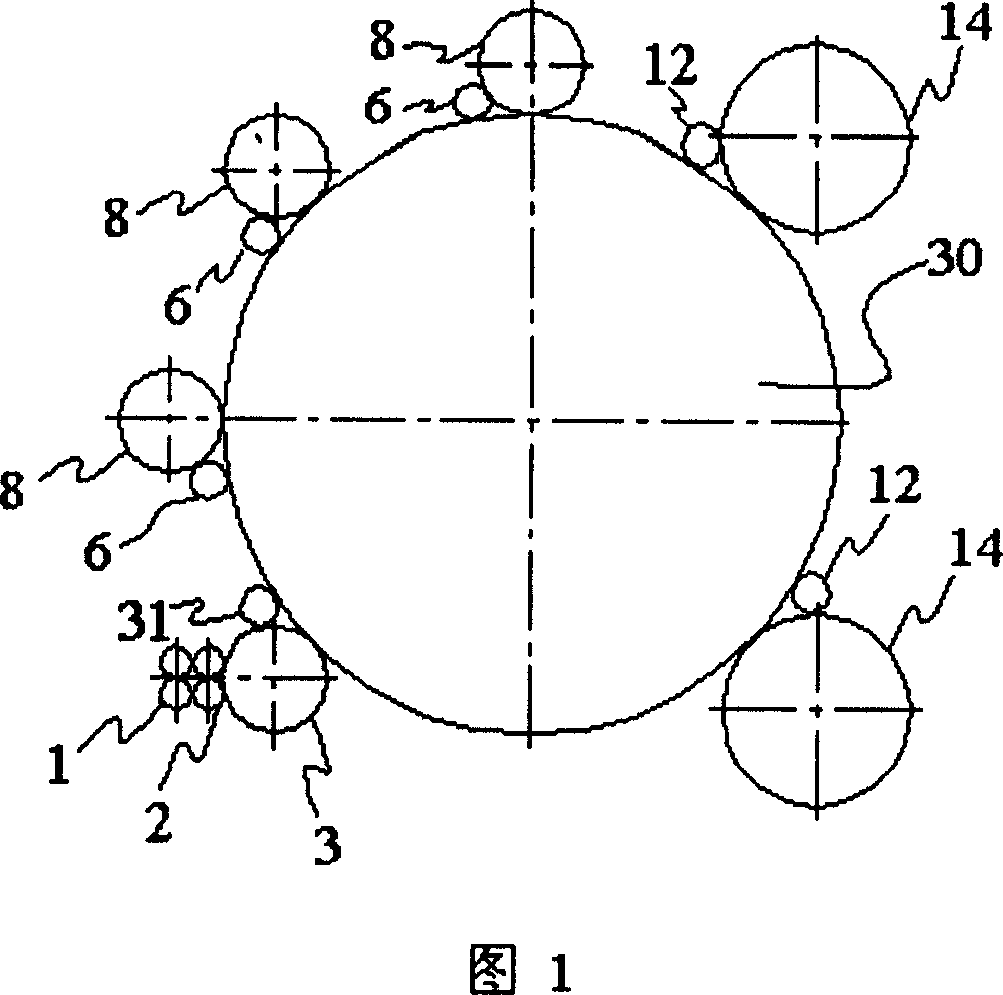

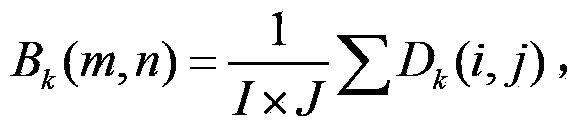

Electronic image stabilization method based on visual attention mechanism

ActiveCN103426182AHigh precisionImprove real-time performanceTelevision system detailsImage analysisVision basedImage stabilization

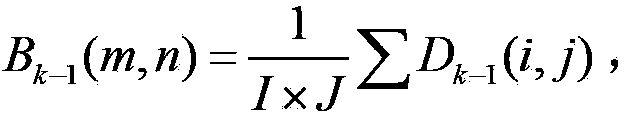

An electronic image stabilization method based on a visual attention mechanism includes the following steps: conducting foreground moving area detection on a reference frame, marking foreground moving sub blocks, extracting overall situation remarkable characteristic points in the reference frame, matching characteristic point pairs, removing error-matched characteristic point pairs, acquiring moving parameters, conducting moving filtering, conducting rapid moving compensation, and rebuilding undefined boundary information to acquire a panoramic image. By means of the method, compensation parameters are acquired through extraction, matching, checking and moving parameter calculation of the overall situation remarkable characteristic point pairs and self-adaptation filtering smooth movement, vision stability and definition between video frames are improved, instability of video sequences is removed or reduced, and observation effects of a video monitoring or tracking system is improved.

Owner:西交思创智能科技研究院(西安)有限公司

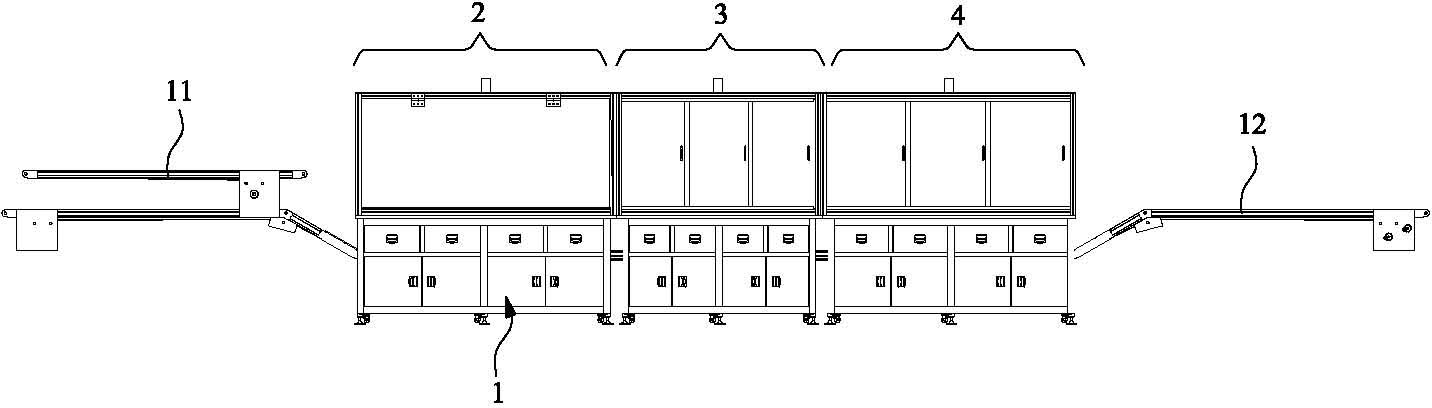

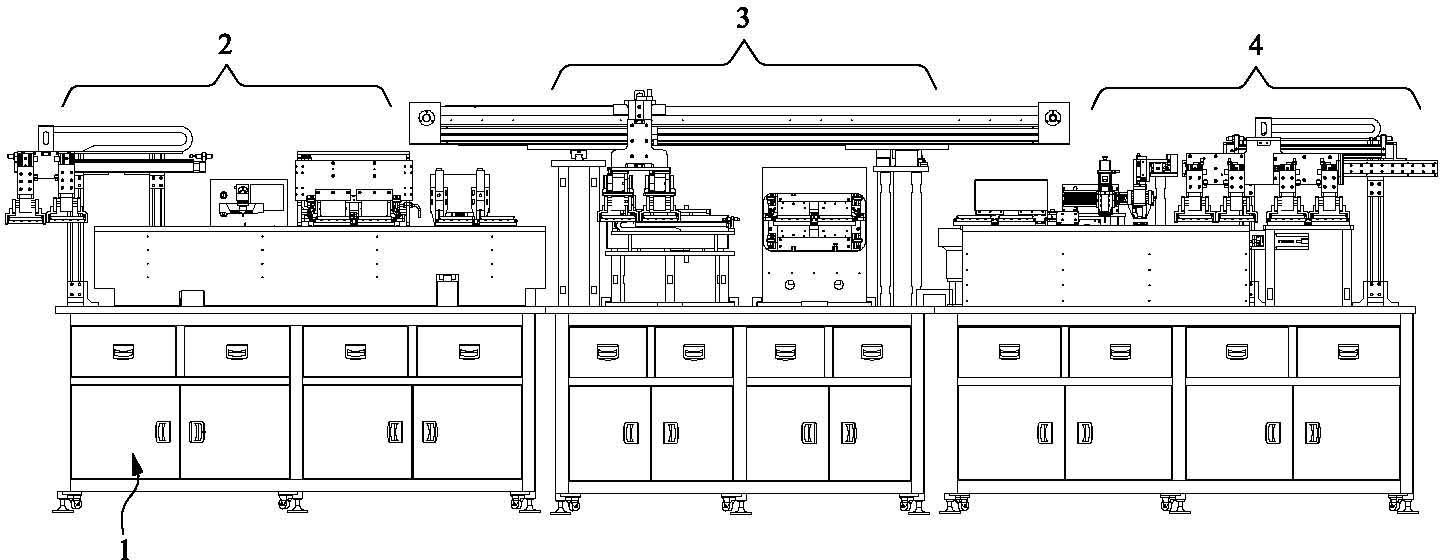

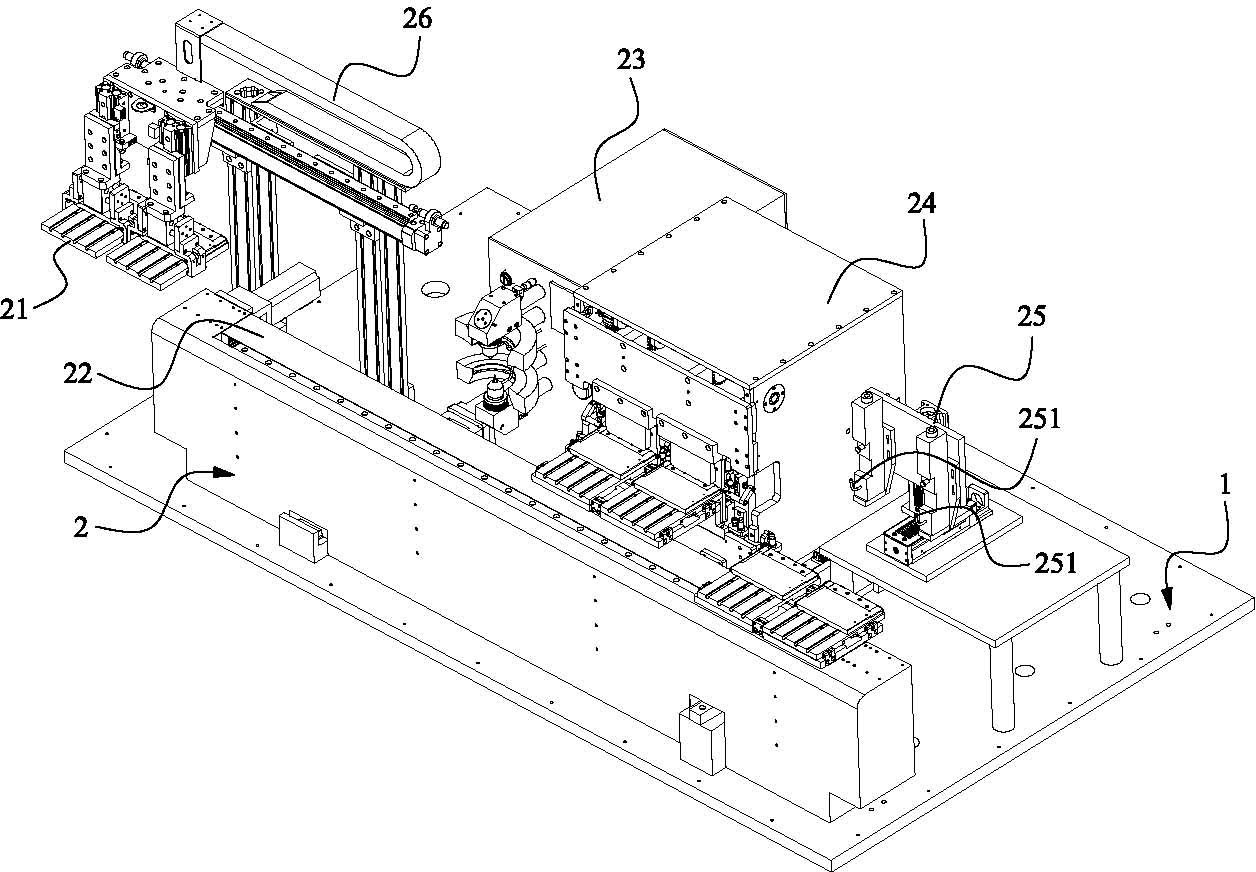

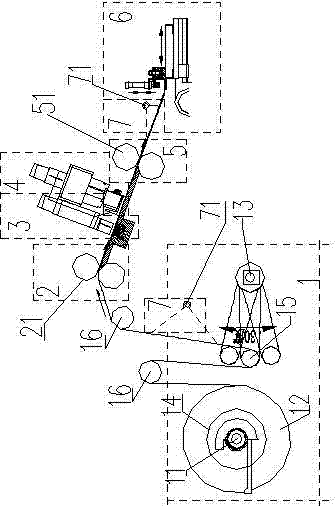

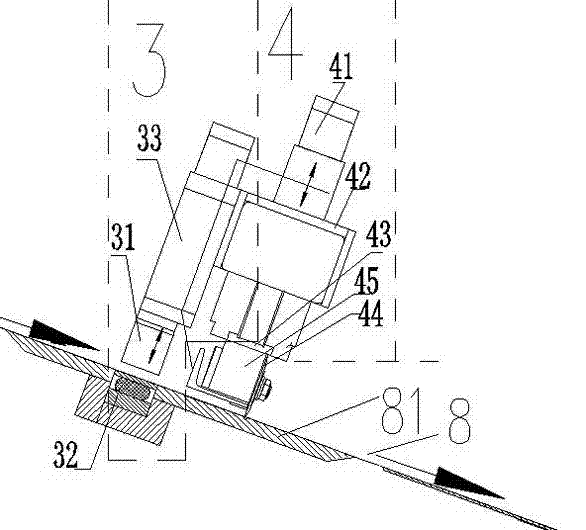

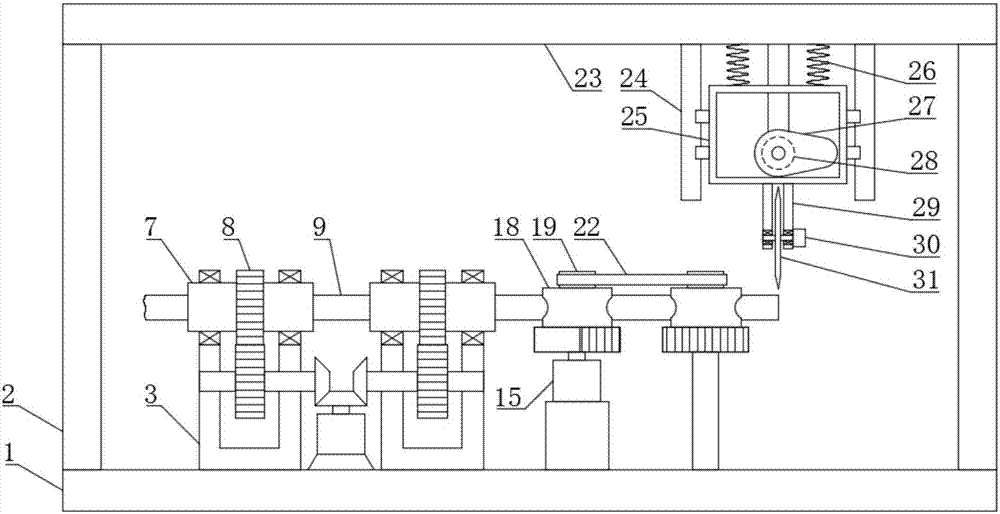

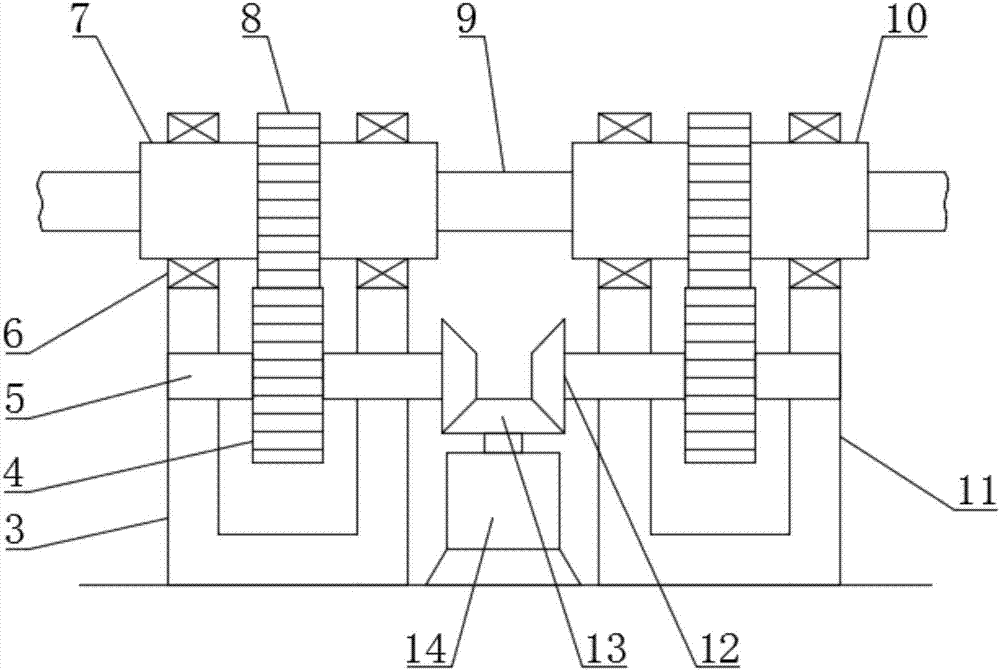

Automatic cable and connector processing, welding and assembling machine

InactiveCN102637988AEliminate weldsEliminate quality problemsLine/current collector detailsEconomic benefitsEngineering

The invention discloses an automatic cable and connector processing, welding and assembling machine, comprising a rack as well as a laser peeling module, an adhered tin trimming module and a plug welding module sequentially arranged on the rack, wherein the laser peeling module comprises a jig, a first transmission device, a laser device, a peeling device and a flux spraying device; the adhered tin trimming module comprises a clamping-jaw feeding device, a tin pot and a trimming device; and the plug welding module comprises a soldering device, a plugging device, a welding device and a clamping-jaw laying-off device. Therefore, the automatic machining on a cable is finished by virtue of the laser peeling module and the adhered tin trimming module, the laser peeling module, the adhered tin trimming module and the plug welding module are matched to weld and connect a connector and the cable together, and a core wire of the cable is kept to be straight in processes of processing and welding the core wire, so that the quality problems of insufficient soldering, leaving out of welding, short circuit and the like during the connection between the cable and the connector are eliminated, and the unmanned automatic processing, welding and assembling procedures are realized to effectively improve the production efficiency of products and to bring more economic benefits to enterprises.

Owner:DONGGUAN SANXIN PRECISION MACHINERY

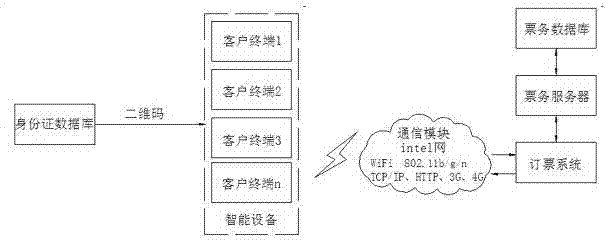

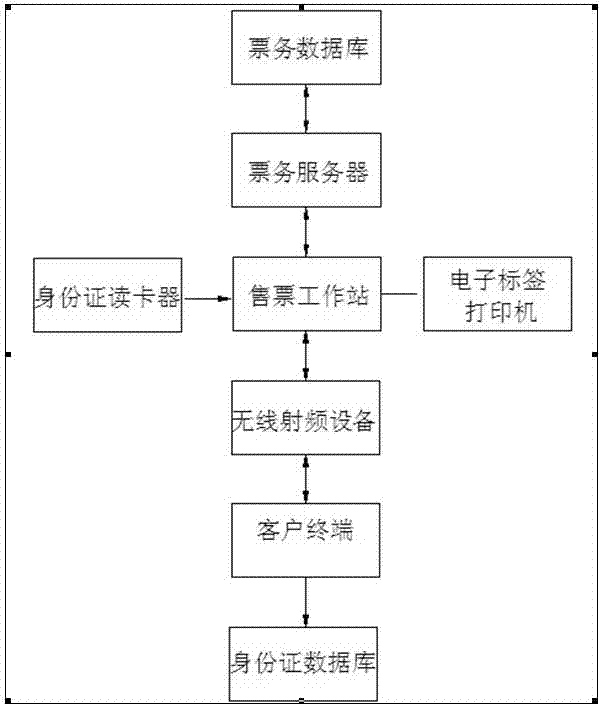

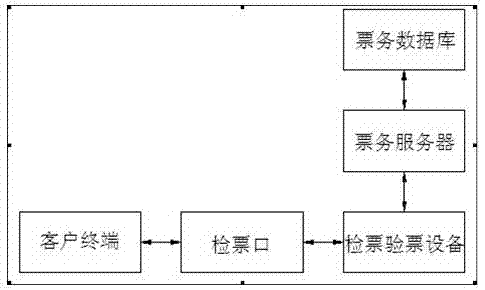

Method for carrying out electronic identity recognition by utilizing two-dimensional code

InactiveCN103177297ARealize online managementConducive to the efficiency of pit stopsTicket-issuing apparatusReservationsElectronic taggingTerminal equipment

The invention relates to the field of identification, and particularly relates to a method for carrying out electronic identity recognition by utilizing two-dimensional codes. The method is characterized in that at least one client terminal, a ticket reservation system, a ticket business server, a ticket business database, a ticket selling workstation, an electronic tag printer, an identity card reader, a ticket checking entrance, wireless radio-frequency equipment and an identity card database are adopted in the method, wherein the client terminal refers to a passenger, namely a person who needs to purchase a ticket for taking a bus and acquires a two-dimensional code electronic tag through intelligent terminal equipment during ticket purchasing; the ticket reservation system refers to a network ticket reservation system; and the ticket selling workstation refers to the existing station ticket window and various agent ticket offices. The method for fast and conveniently carrying out the electronic identity recognition, which is provided by the invention, mainly aims at overcoming the defects of the existing paper ticket and solving the problem of difficult queuing during the ticket purchasing and can reduce the labor intensity of ticket checking personnel, improve the incoming efficiency of the passengers and realize the high security and the high antifalsification through the uniqueness of a second-generation identity card.

Owner:JINHUA INFORMATION DIGITAL TECH

Support member and light emitting diode module using the same

ActiveUS7204604B2Avoid it happening againReduce distractionsPoint-like light sourceOptical signallingEngineeringLight-emitting diode

Owner:AU OPTRONICS CORP

Regulatable supporter

InactiveCN1382873ASmooth rotationPrevent looseningBridge structural detailsConnectionsMechanical engineeringLocknut

A regulatable supporter is composed of top plate, top seat, ball hinge, screw piles, locking nuts, base of screw pile, locking screw and base, and can be regulated vertically and horizontally in stepless mode. Its advantages are less compression and high precision.

Owner:SHANGHAI MAGLEV TRANSPORTATION DEVELOPMENT CO LTD

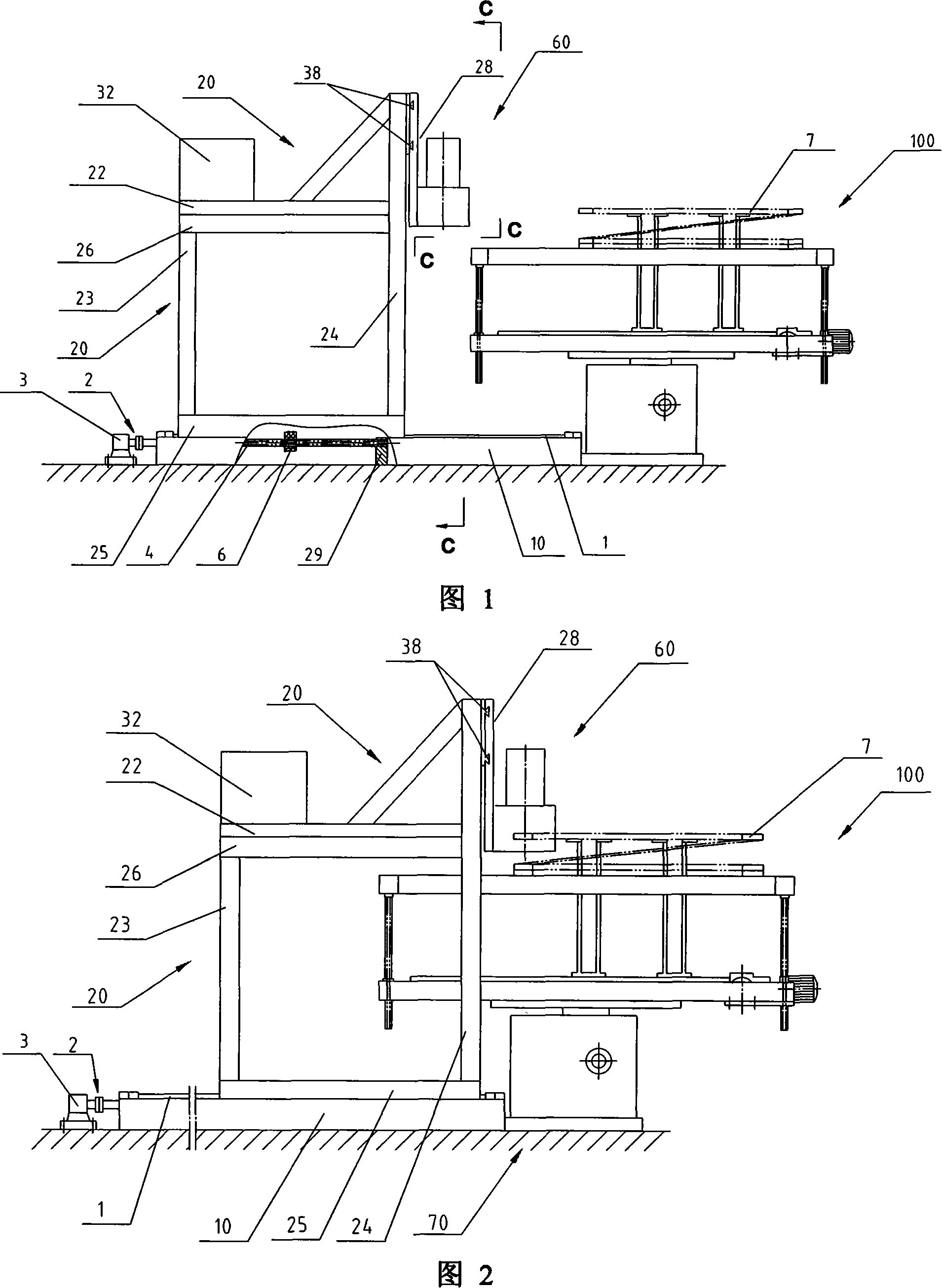

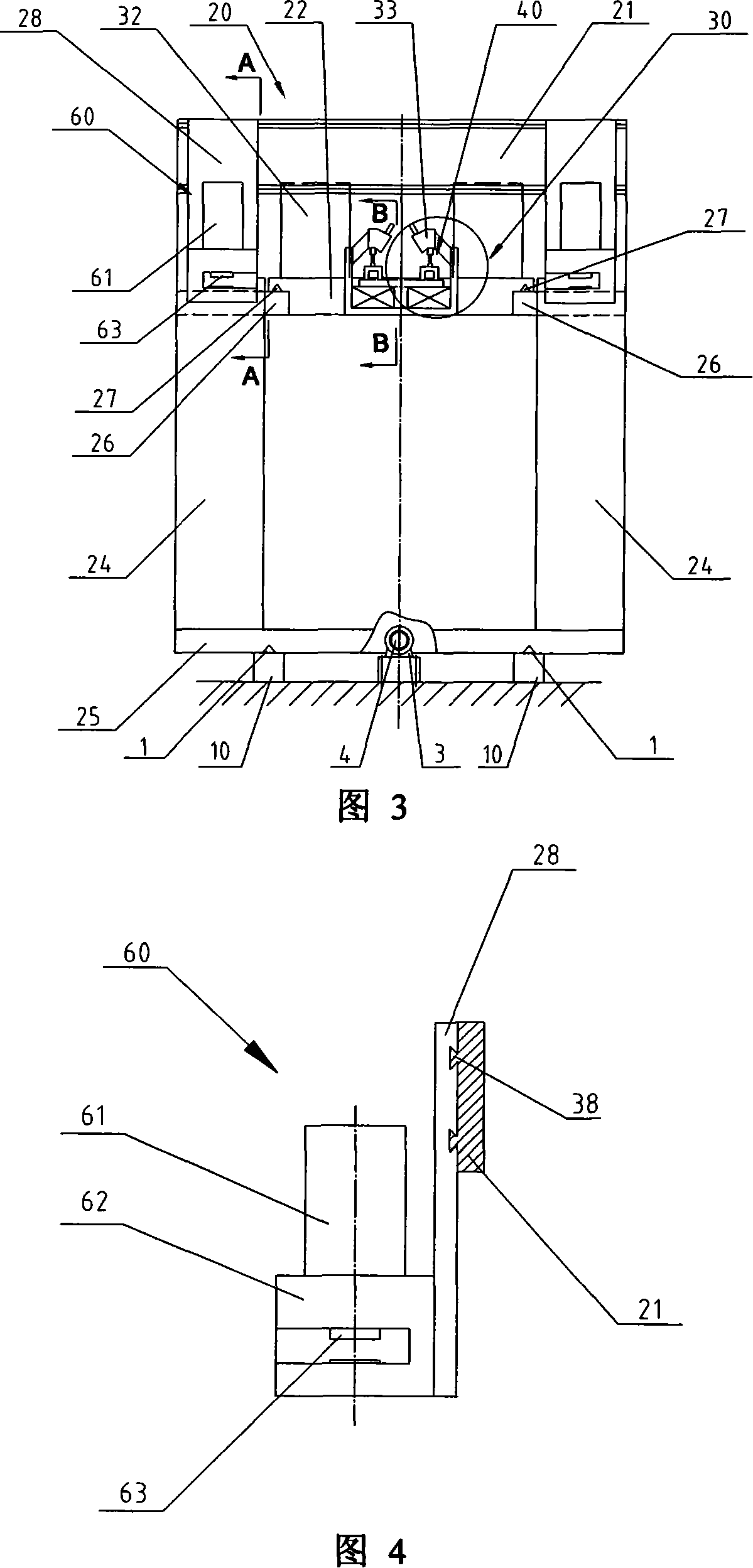

Automatic cutting equipment

InactiveCN102259774AEasy to controlGuaranteed smoothArticle deliveryWebs handlingProduction lineAutomatic control

The invention relates to full-automatic cutting equipment, comprising a main control computer arranged in a chassis and an automatic tension control discharging mechanism, a transporting and metering mechanism, an automatic punching mechanism, an automatic pressing and cutting mechanism, an automatic feeding mechanism and an automatic material receiving and folding mechanism which are arranged in turn according to a process production line. The transporting and metering mechanism, the automatic punching mechanism, the automatic pressing and cutting mechanism and the automatic feeding mechanism are installed on a transmission platform. Therefore, all functions of control discharging, metering, transporting, cutting, punching, receiving and folding materials are carried out on equipment simultaneously. Compared with the prior art, the equipment disclosed by the invention is applicable to fully-automatic cut of soft texture materials, such as an EVA (Ethylene Vinyl Acetate) film.

Owner:上海博显实业有限公司

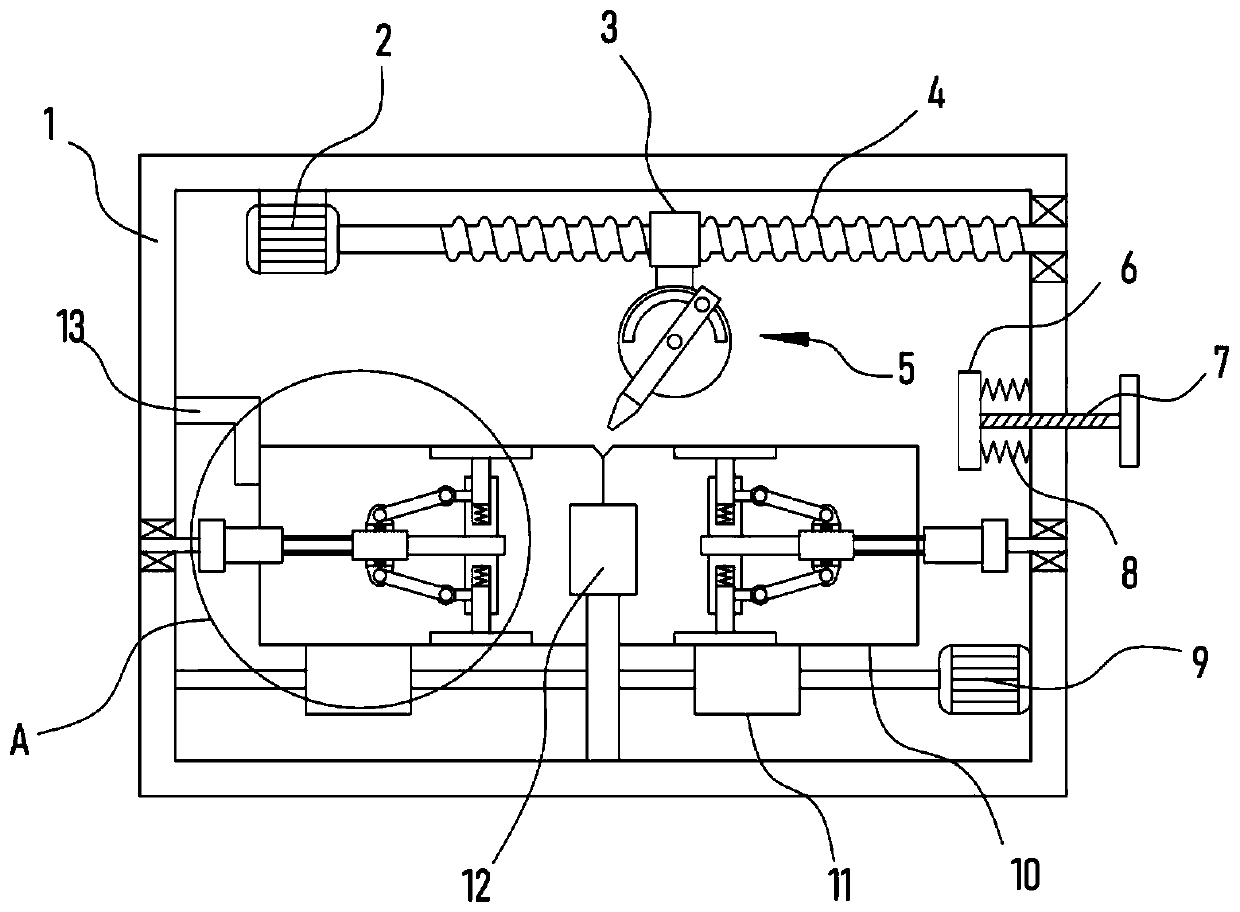

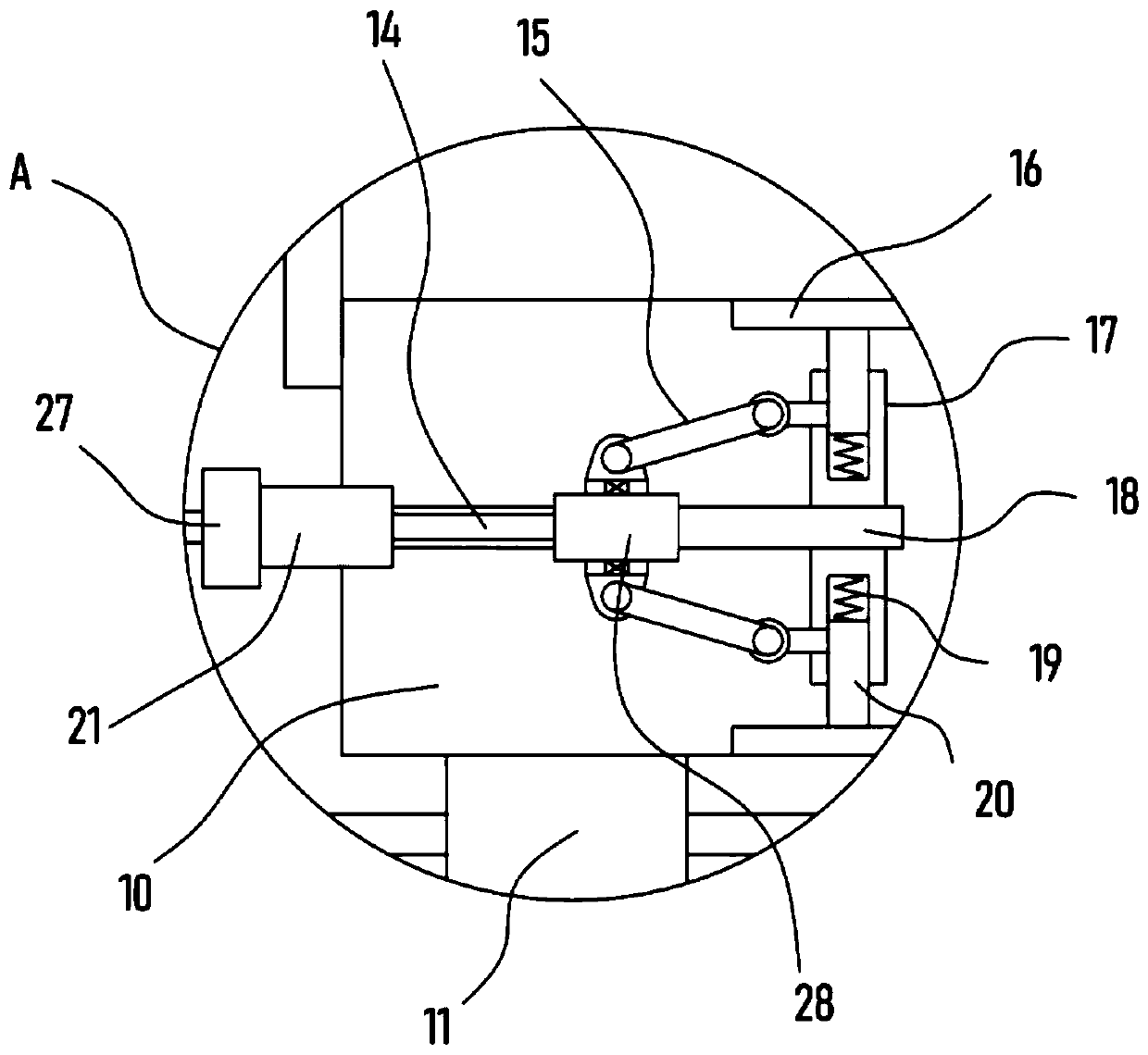

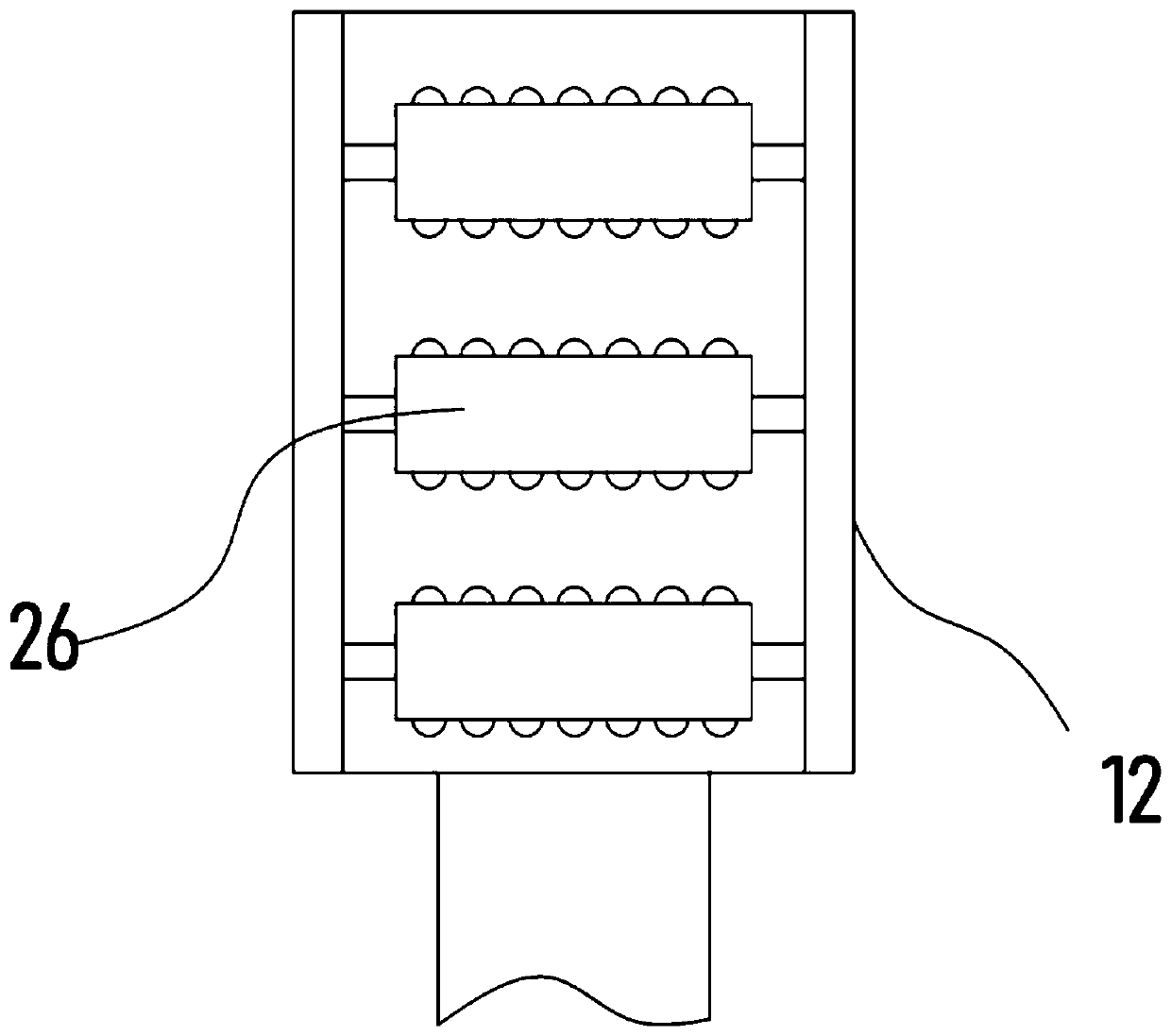

Metal pipeline welding device for water conservancy construction

InactiveCN110216477AGuaranteed smoothImprove welding efficiencyWelding/cutting auxillary devicesOther manufacturing equipments/toolsEngineeringWeld seam

The invention discloses a metal pipeline welding device for water conservancy construction, and relates to the technical field of water conservancy construction machinery. The metal pipeline welding device comprises a supporting frame, wherein a servo motor is fixedly mounted on the top in the supporting frame; two supporting limiting mechanisms for supporting a pipeline are arranged in the supporting frame; a welding assembly which is in drive connection through a translation mechanism is arranged above the pipeline; and the welding assembly comprises a connecting disc, and a welding gun which is connected on the connecting disc through a steering mechanism. According to the metal pipeline welding device disclosed by the invention, the supporting limiting mechanisms are arranged to clampand fix from the inner part of the pipeline, so that the pipeline does not deviate while driven by a rotary roller to rotate, and the pipeline rotates for enabling welding efficiency of the welding gun to be higher; the arranged welding gun can regulate a welding inclination angle through the steering mechanism, and can meet welding operation of different process requirements; and a grinding roller can be arranged to grind a welding seam after the pipeline is welded, so that flatness of the welding seam is guaranteed after the pipeline is welded.

Owner:赵玉研

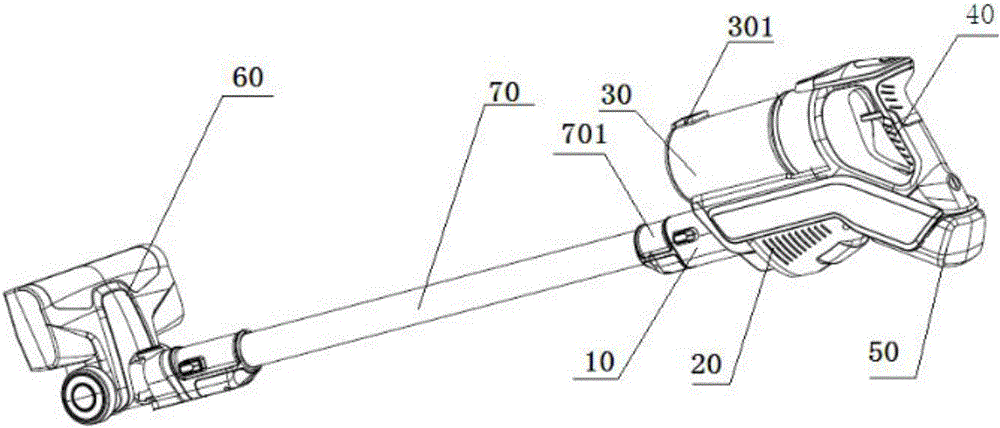

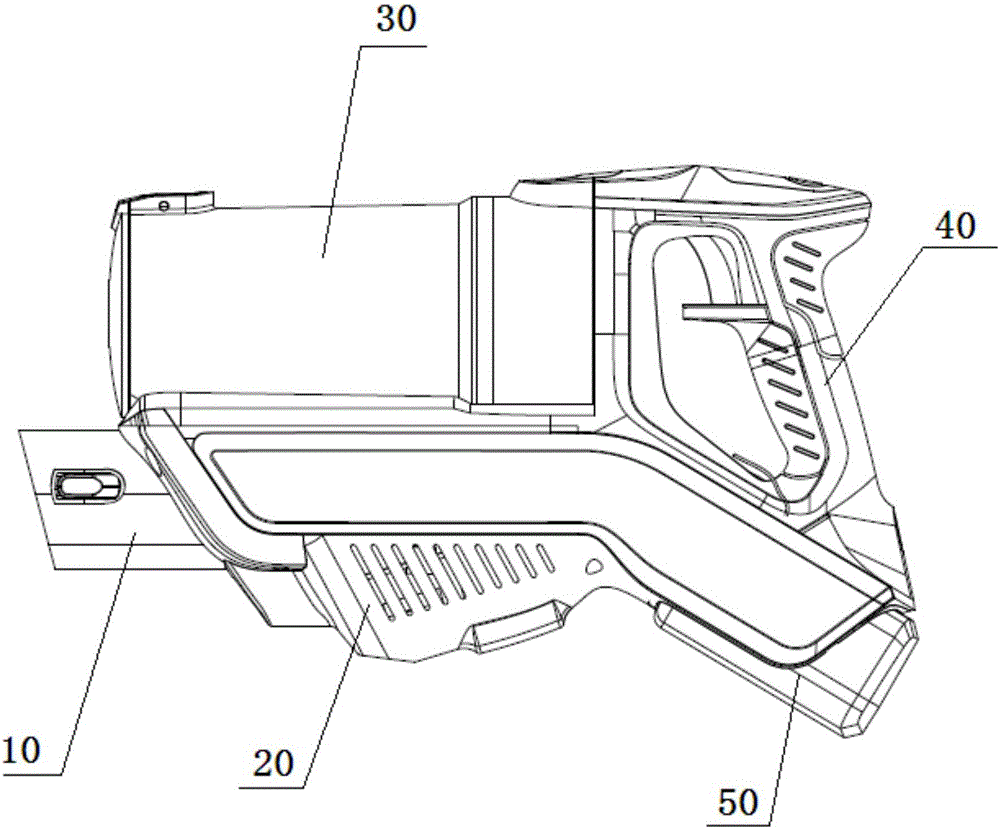

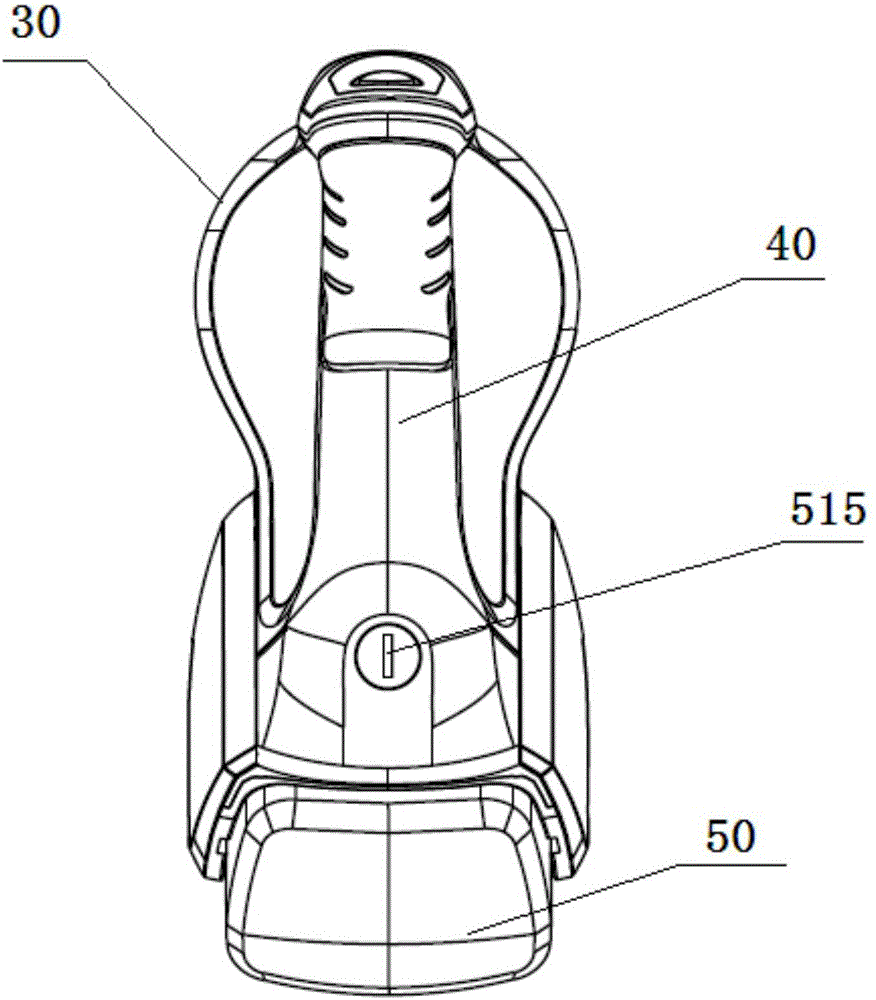

Handheld vacuum cleaner host

The invention discloses a handheld vacuum cleaner host, which comprises a dust cup, an air duct connecting pipe, a motor and a handle, wherein one end of the air duct connecting pipe is connected to a floor brush and the other end of the air duct connecting pipe is connected to an air inlet of the dust cup, and an air outlet of the dust cup is connected to an exhaust duct of the motor; the motor is arranged on one side of the air outlet of the air duct connecting pipe; an included angle between the motor and the center line of the dust cup is 0-69 degrees; the handle is arranged on one side of the dust cup; the handle and the dust cup are detachably connected; and through suction force generated from negative pressure formed due to rotation of the motor, dust is sucked by the floor brush and enters into the dust cup along the air duct connecting pipe, the dust is separated and filtered by virtue of a cyclone in the dust cup, the dust is accumulated in the dust cup, and clean air, obtained through filtration, is discharged from the motor. According to the vacuum cleaner host disclosed by the invention, the dust cup is arranged at the upper part of the air duct connecting pipe in a transverse mode, so that the entire host is compact in structure; optimally, the included angle between the motor and the center line of the dust cup is 0-30 degrees, so that smooth operation of an air duct is guaranteed and the size of the host is diminished.

Owner:SUZHOU TENGPU ELECTRICAL TECH CO LTD

Steel pipe rust removing and cutting integrated machine for building

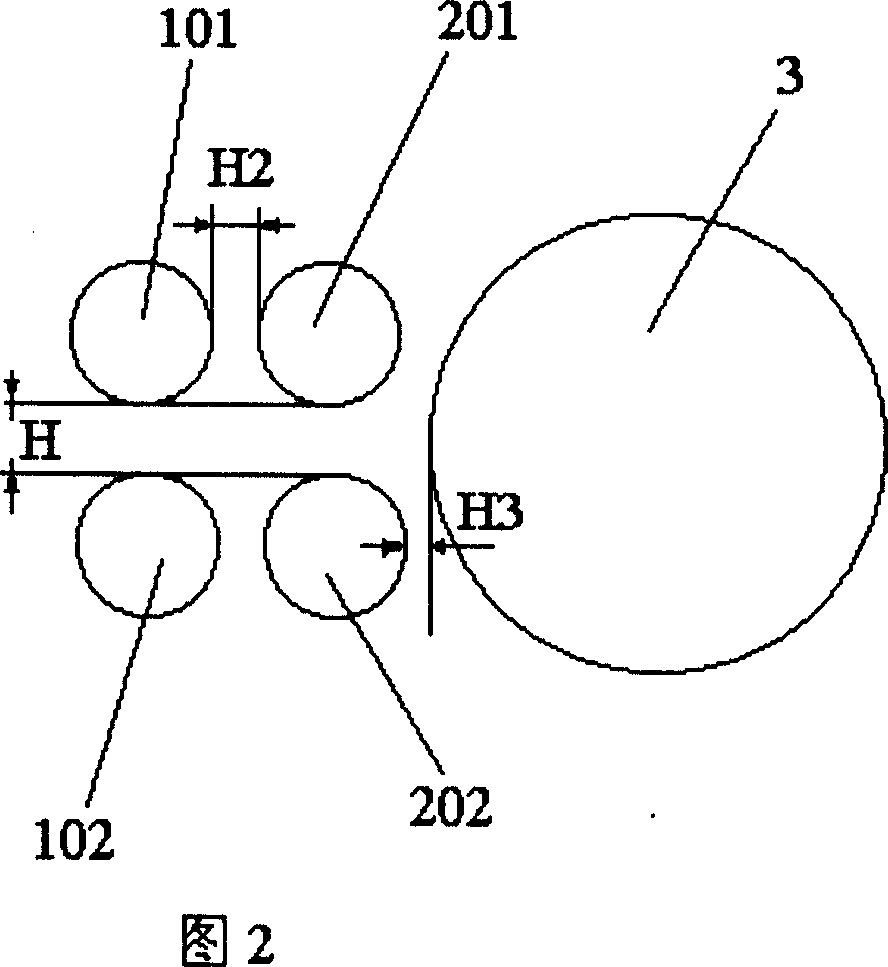

InactiveCN107234293AImprove processing efficiencyGuaranteed smoothGrinding machinesTube shearing machinesGear wheelArchitectural engineering

The invention discloses an integrated machine for derusting and cutting steel pipes for construction, which comprises a base and a steel pipe. The base is provided with a first U-shaped seat and a second U-shaped seat, and the tops of the first U-shaped seat and the second U-shaped seat respectively pass through the The bearing with seat is rotatably connected with a first derusting cylinder and a second derusting cylinder, and second gears are fixedly installed on the first derusting cylinder and the second derusting cylinder; the first U-shaped seat and the second U-shaped seat also have Rotationally connected with a rotating shaft, the first gear is installed on the rotating shaft, the first gear meshes with the second gear, the right end of the rotating shaft connected with the first U-shaped seat and the left end of the rotating shaft connected with the second U-shaped seat are equipped with the second bevel gear , the base is also provided with a first motor, the motor shaft at the top of the first motor is connected with a first bevel gear, and the first bevel gear meshes with the second bevel gear. The invention rotates the derusting cylinder, and a derusting brush is arranged on the inner wall of the derusting cylinder to derust the steel pipe, and the scope of derusting is wide; there are two derusting cylinders with opposite rotation directions, so that the derusting is more thorough.

Owner:肖进兴

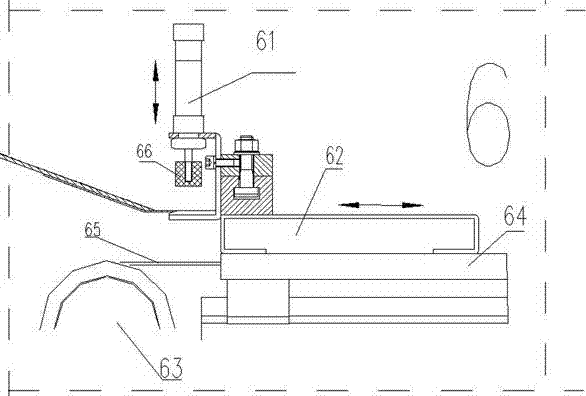

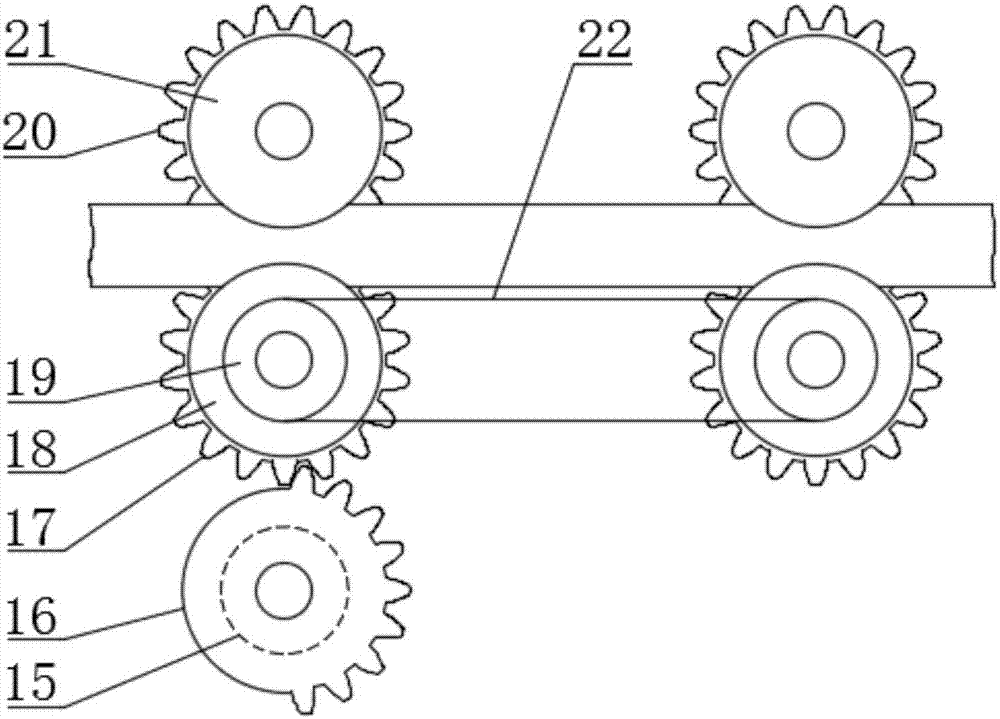

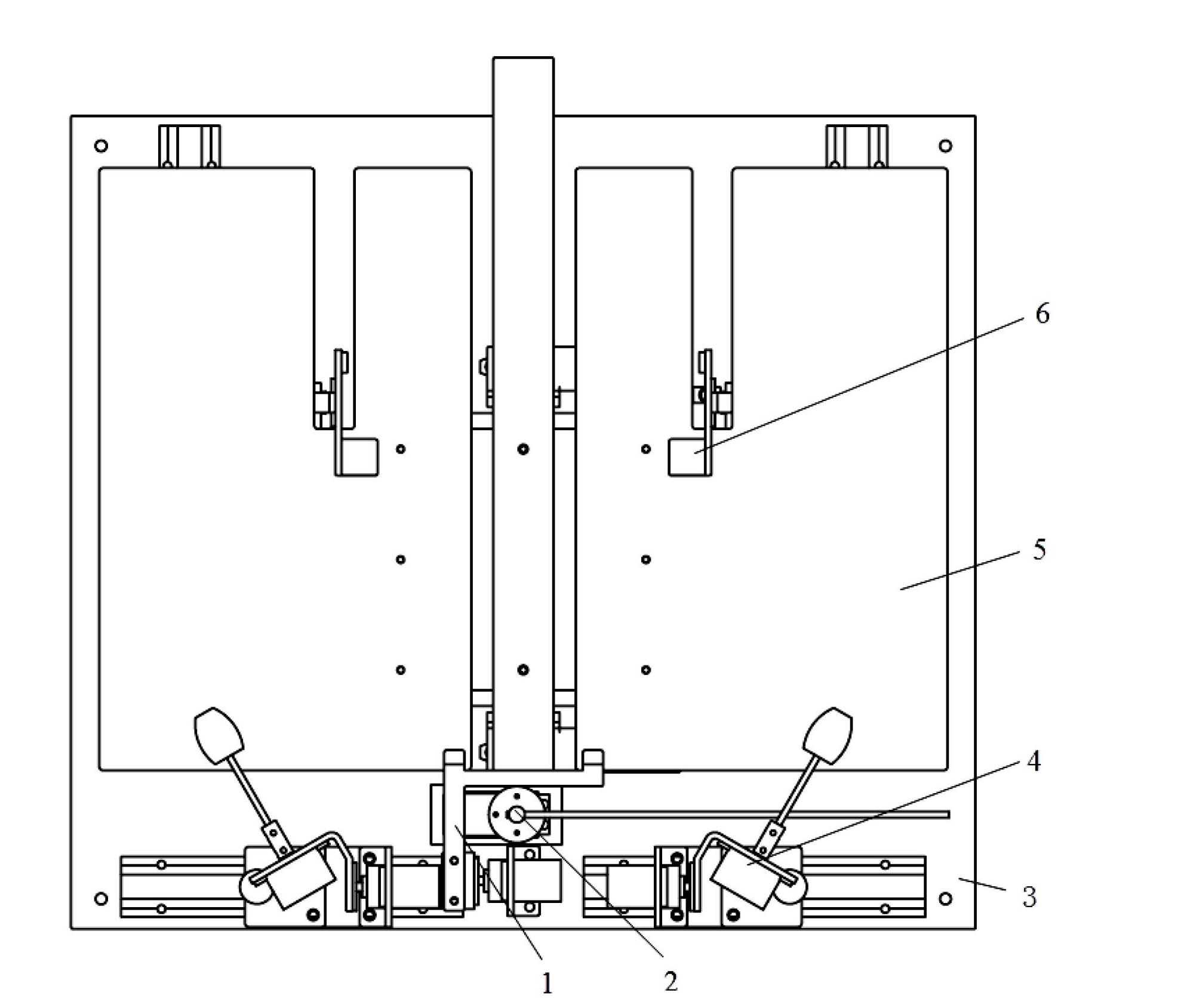

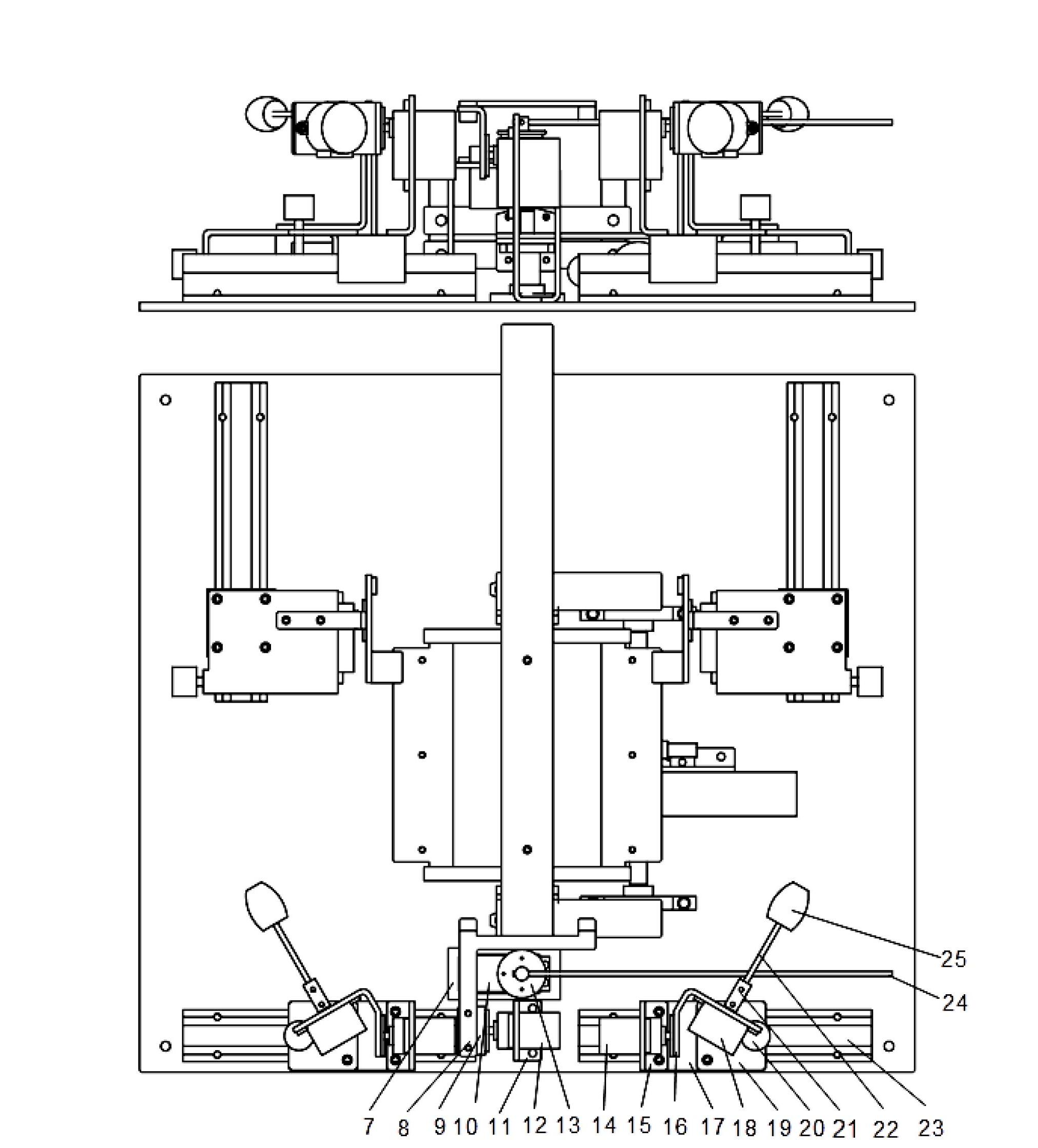

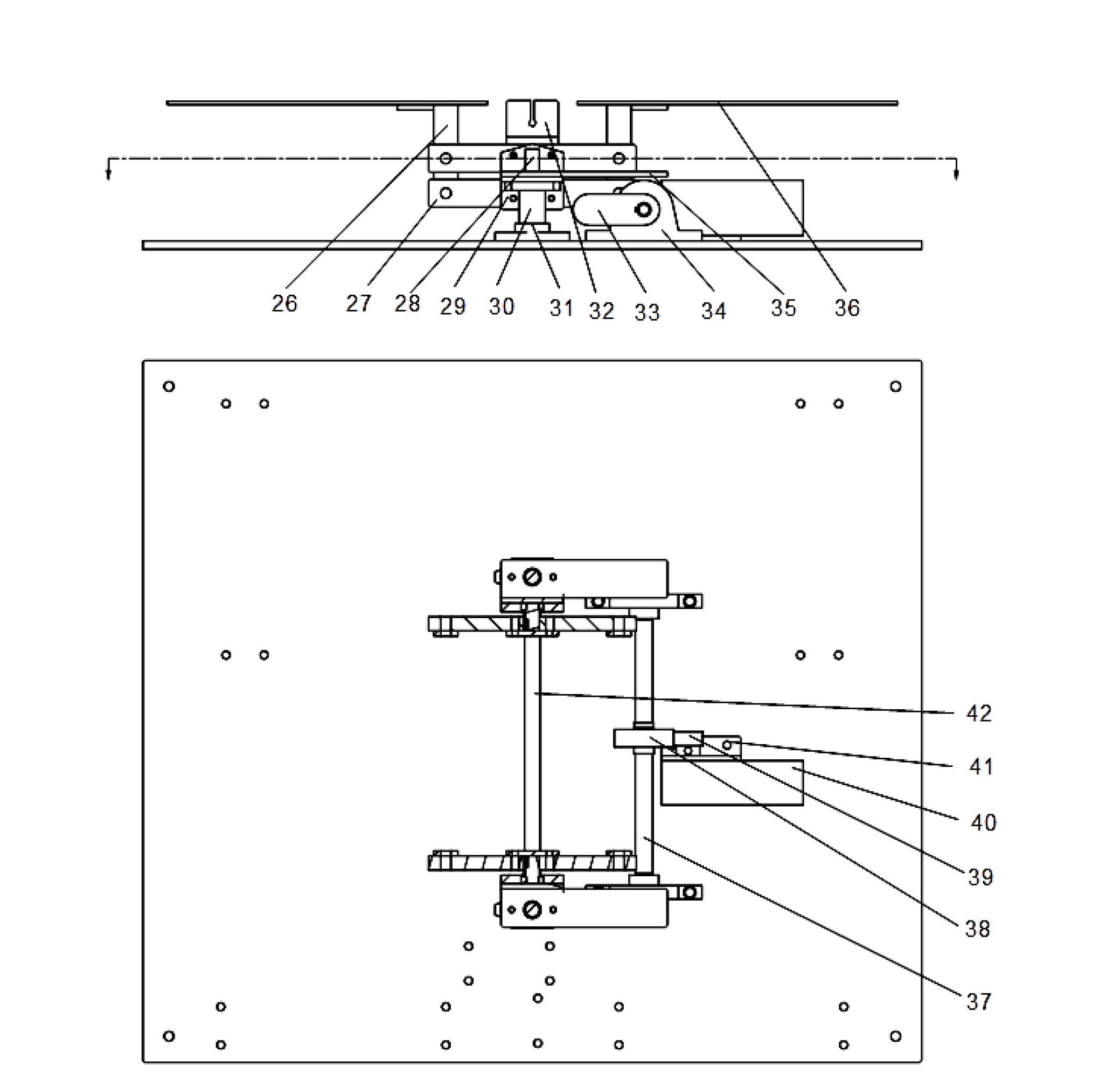

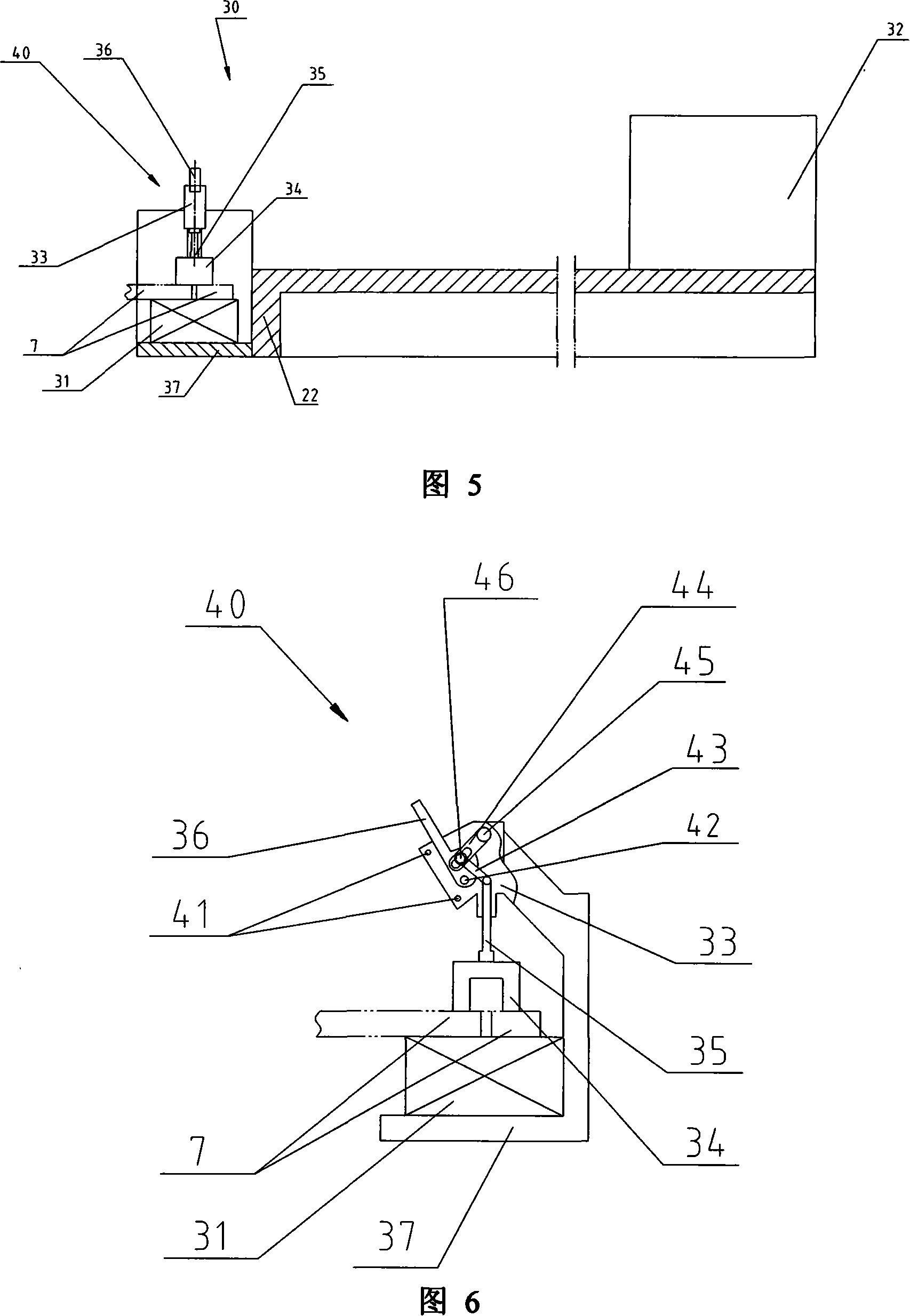

Automatic page turning machine

InactiveCN102673219AGuaranteed smoothImprove adjustabilityBook markersHand movementsComputer science

The invention relates to an automatic page turning machine. The automatic page turning machine comprises a bottom plate, page rubbing mechanisms, a page supporting mechanism, a page turning mechanism, a page down-pressing mechanism and a page up-pressing mechanism. The connecting method is as follows: the page supporting mechanism is fixed at the center of the bottom plate; the page turning mechanism is positioned at the middle part of the lower side of the page supporting mechanism and just connected with the bottom plate; the page rubbing mechanisms are positioned on the two sides of the lower side of the page supporting mechanism; the page down-pressing mechanism is just connected with the bottom plate and positioned between the two groups of page rubbing mechanisms; and the page up-pressing mechanism is positioned on the upper side of the page supporting mechanism and penetrates through a rectangular groove of a page supporting plate. The automatic page turning machine provided by the invention has the advantages of good adjustability, strong adaptability, capability of conveniently turning pages forward and backward as well as capability of guaranteeing flatness of the page, can be used for character scanning and character optical identification equipment, so that these equipments have automatic page turning functions, and can be also used as assisting equipment for disabled so as to help the disabled with inconvenient hand movements in reading; and by using rubbing heads, the pages can be turned.

Owner:SHANGHAI JIAO TONG UNIV

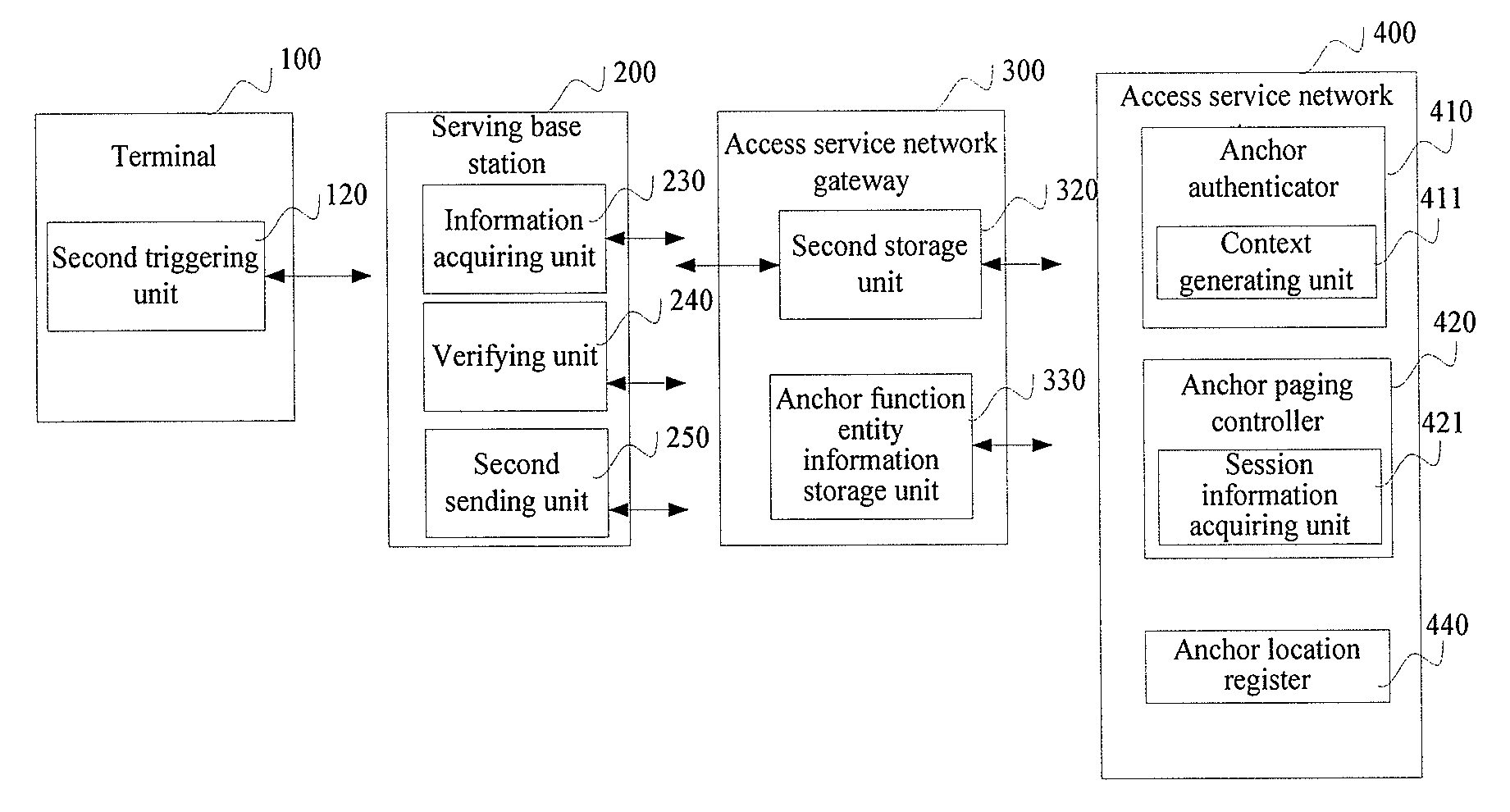

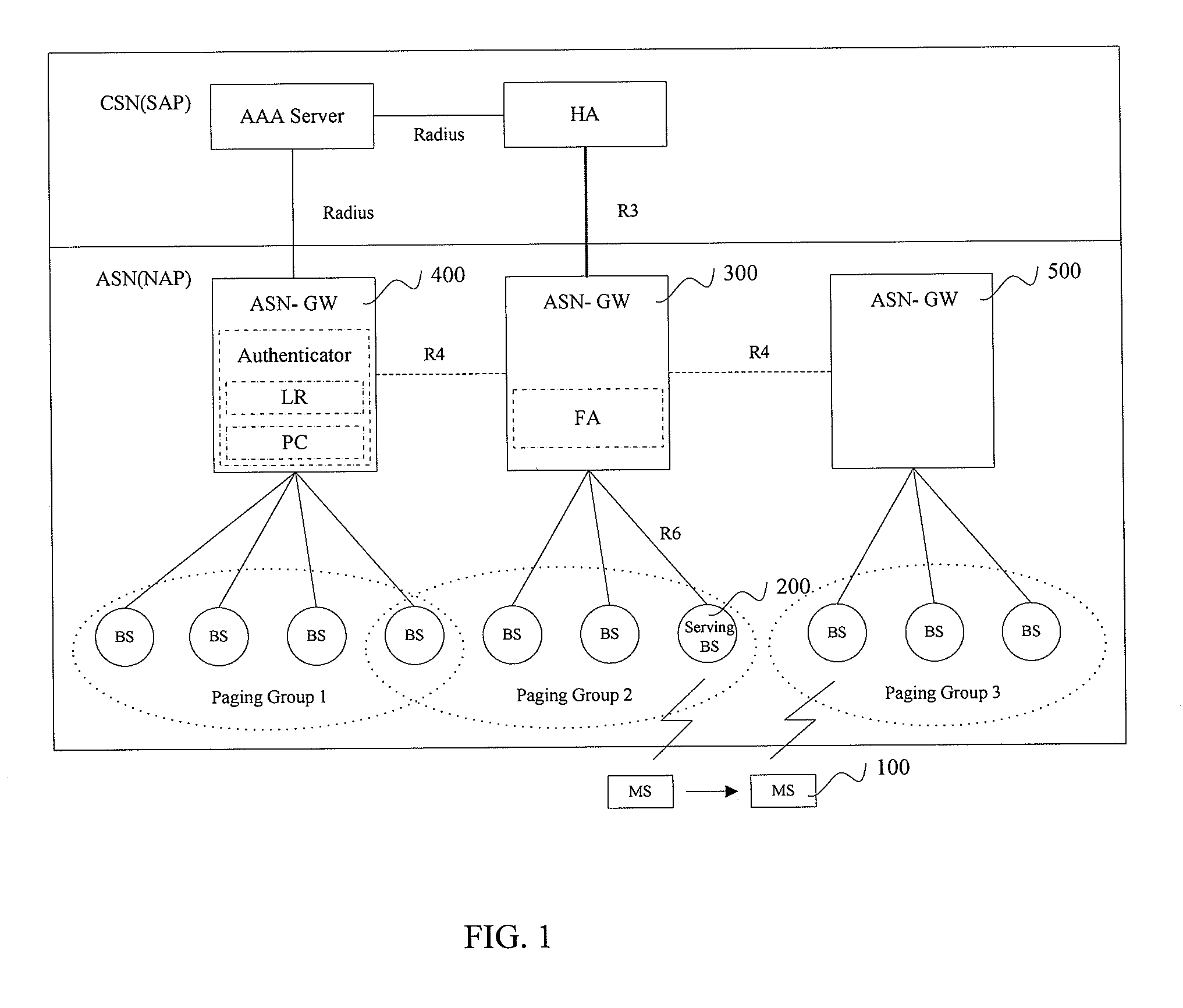

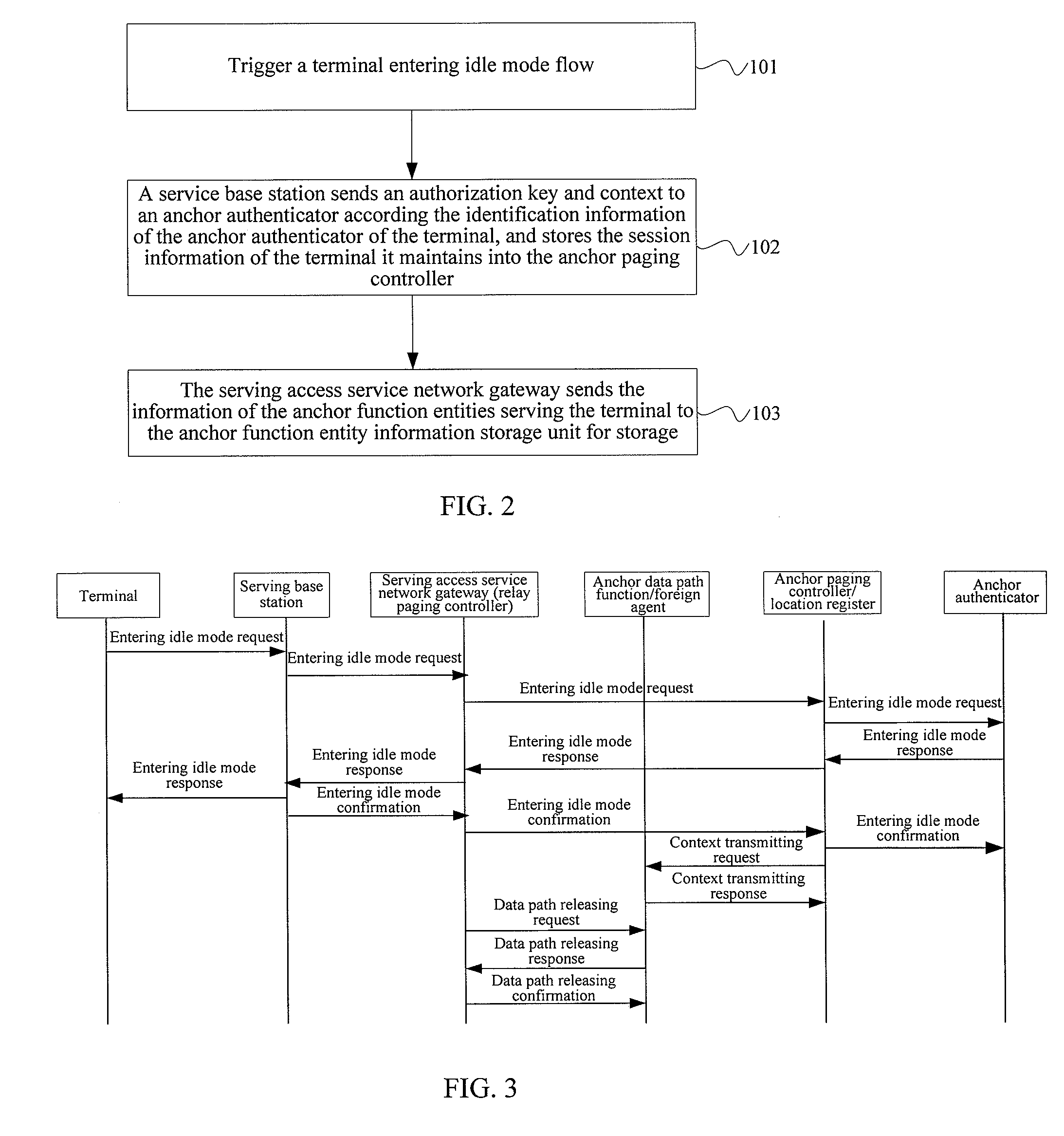

Communication method and system for terminal entering and leaving idle mode

InactiveUS20080259889A1Guaranteed smoothTransmission systemsEncryption apparatus with shift registers/memoriesTelecommunicationsPhysical entity

A communication method and system for terminal entering and leaving idle mode in a mobile communication system are disclosed. The communication method for a terminal entering an idle mode includes: triggering a flow of entering the idle mode for the terminal; and a serving access service network gateway sending the information of anchor function entities serving the terminal to an anchor function entity information storing unit, so as to store the information. With the technical scheme of the invention, when the anchor function entities serving the terminal are not located at the same physical entity, the addressing process can be accomplished correctly, and the smoothness of the network service flow can be guaranteed.

Owner:HUAWEI TECH CO LTD

Process for production of radioresistant worsted face fabric

InactiveCN101012591ASolve the difficulty of uneven final surface in shrinking productionSolve the difficulty of unevennessWoven fabricsYarnPolyesterWorsted

The invention relates to a manufacturing method for anti-radiation spinning fabric. At first, wool and polyester are combed in double and spun into the wool yarn; then the wool yarn and fine stainless steel wire are combined into fine stainless steel yarn; finally anti-radiation spinning fabric is generated by the wool yarn and fine stainless steel yarn through weaving and dyeing. The fabric manufacturing method makes that the fabric is not only provided with anti-radiation performance but also high-grade fabric and good wearability by folding and stranding, weaving and dyeing. It can satisfy demands of office white collar class to the fabric of business wear.

Owner:杨毅方

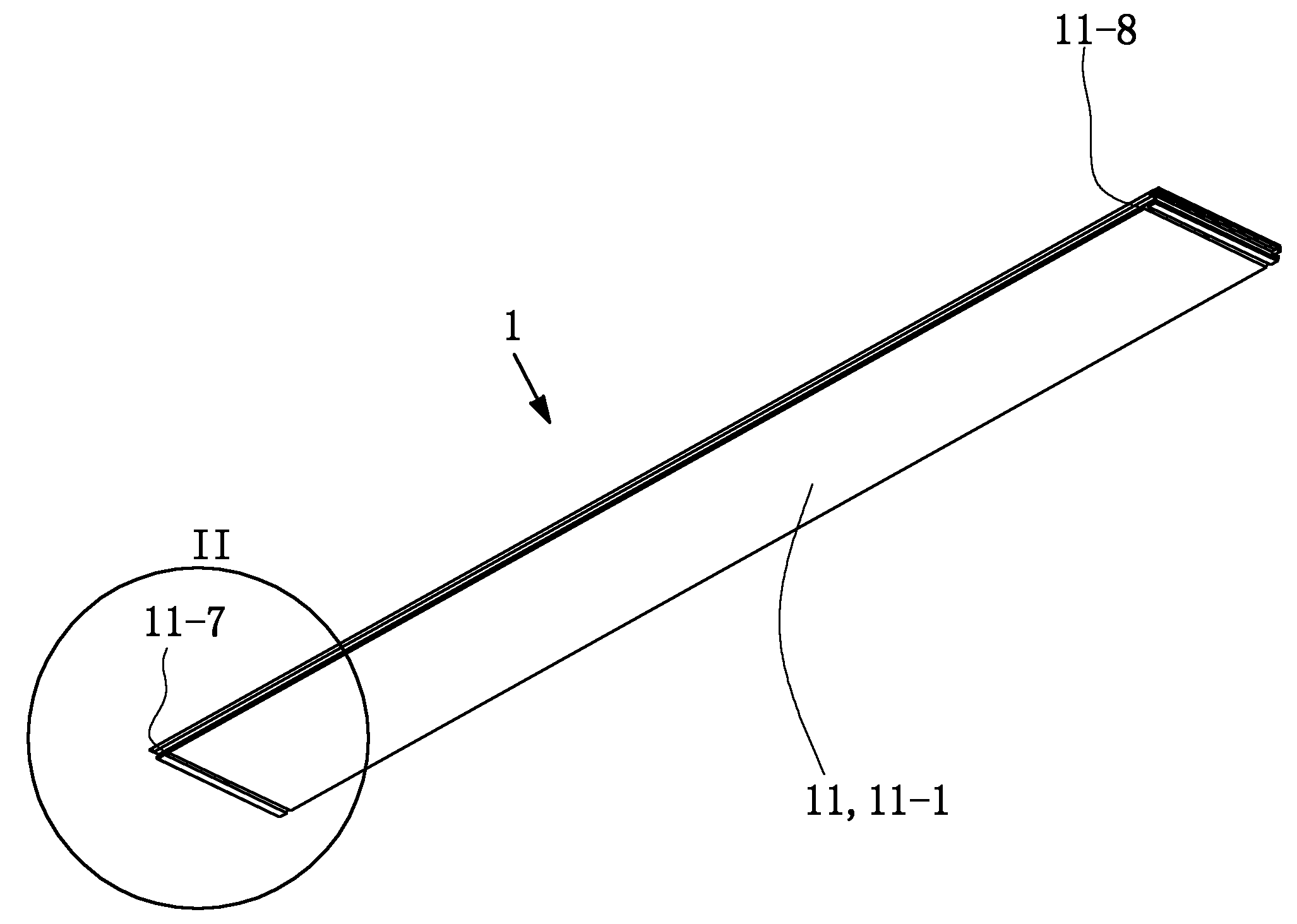

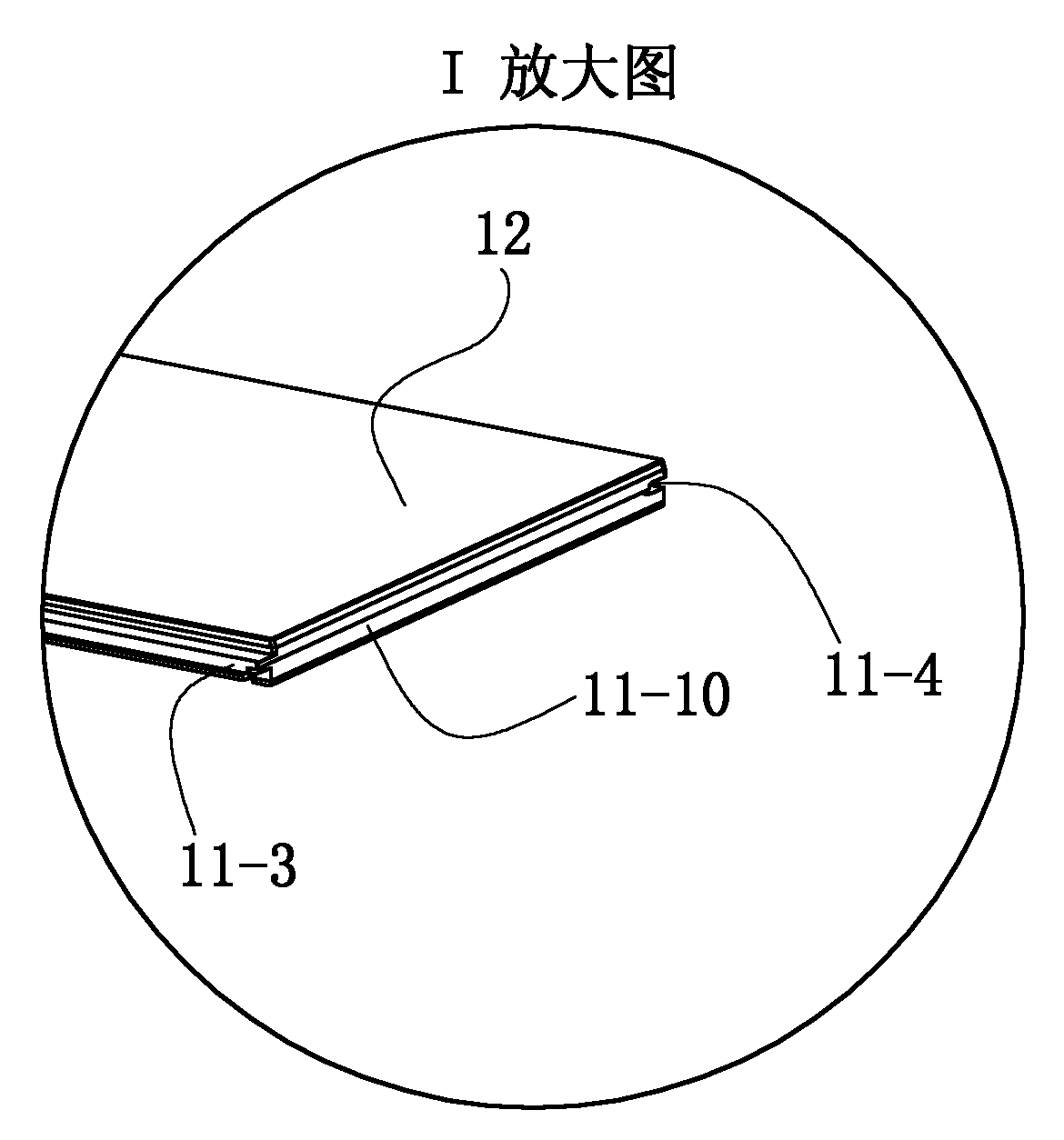

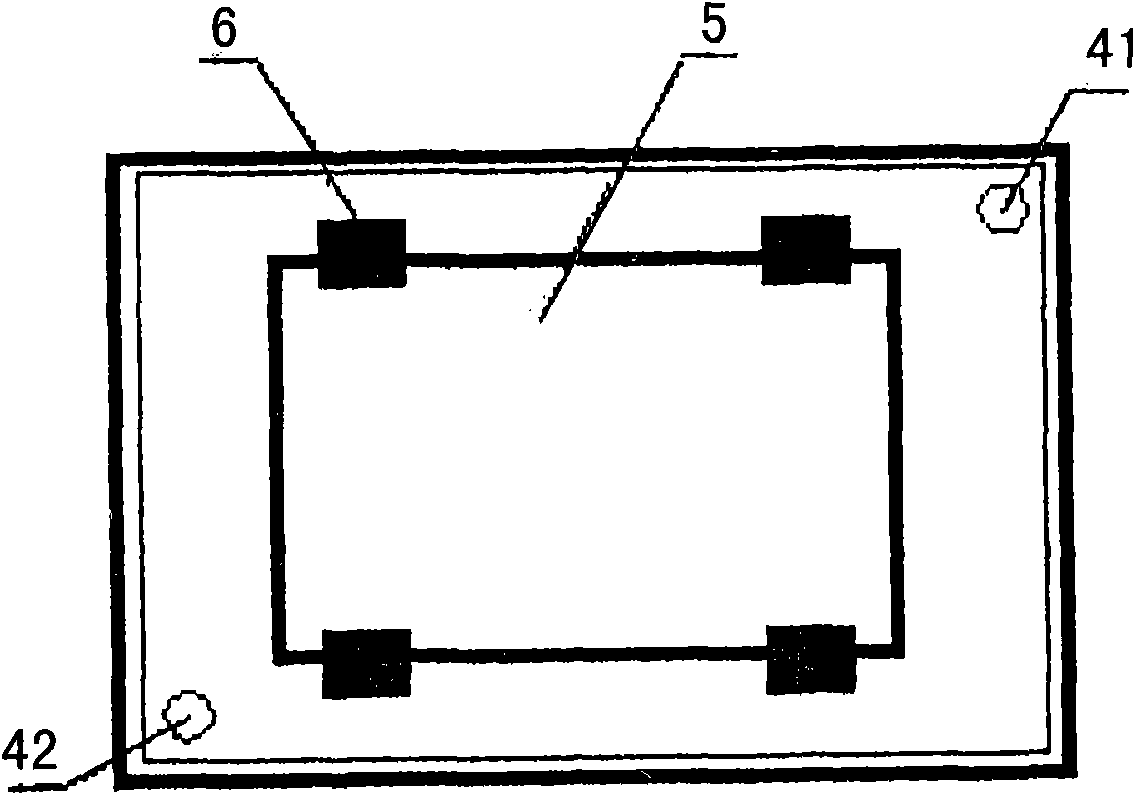

Non-nail clamped electric heating floor system and electric heating floors thereof

InactiveCN102042633AQuality improvementEasy to removeLighting and heating apparatusElectric heating systemCopper conductorKeel

The invention discloses a non-nail clamped electric heating floor system which is characterized by comprising electric heating floors, mounting bases, power supply keels, inserting piece clips, copper conductors, connecting pieces and connecting wires. The installation method of the non-nail clamped electric heating floor system comprises the following steps: firstly the power supply keels are laid on the floor along the side of the rear wall of the laid room in the length direction; the mounting bases are laid on the floor in the mode that the length direction of the mounting bases are perpendicular to that of the power supply keels, the mounting bases are parallel to one another, and plate-end transverse clamping parts and middle transverse locating parts of two neighboring mounting bases are correspondingly arranged at front and back positions; the electric heating floors are vertically fixed on the mounting bases; and finally the electric heating floors work in parallel, i.e. all the electric heating floors emit heat for warming purpose while switching on a power supply, and other electric heating floors are not affected even though certain floor is damaged.

Owner:葛跃进

Soldering machine with movable rotating function

InactiveCN101108437AGuaranteed smoothAvoid collisionWelding/cutting auxillary devicesAuxillary welding devicesWater wheelRotation function

The invention provides a mill welding machine with moving and rotating function, which comprises a base, a main frame, a moving frame, an induction mill welding structure, a worktable and a clamp; a drive structure is arranged at the bottom of the main frame, which is composed of a screw rod connected with a motor and a nut at the bottom of the main frame; a sliding way which is parallel to a lead rail is arranged on the main frame; the moving frame is supported on the sliding way, an induction mill welding structure is provided at one side of the worktable close to the moving frame; the worktable and the clamp are fixed two lead rails at one side of the base, which comprises a worktable of the supporting work piece and a clamp of the clamp work piece. The beneficial effect of the invention is that: the invention has simple structure and advanced technology, which is suitable for symmetric work piece at the position of welding opening. The forming structure can ensure the welding opening flat, which is especially suitable for large and middle size water wheel dynamo rotor coil with adopting four corner welded purple copper bar. After one side of the work piece is finished welding, the main frame returns, the worktable drives the coil rotate by 180 degree, and proceed welding to the other side of the work piece.

Owner:TIANJIN TIRNFR HEAVY HYDROELECTRIC FRCILITY CO LTD

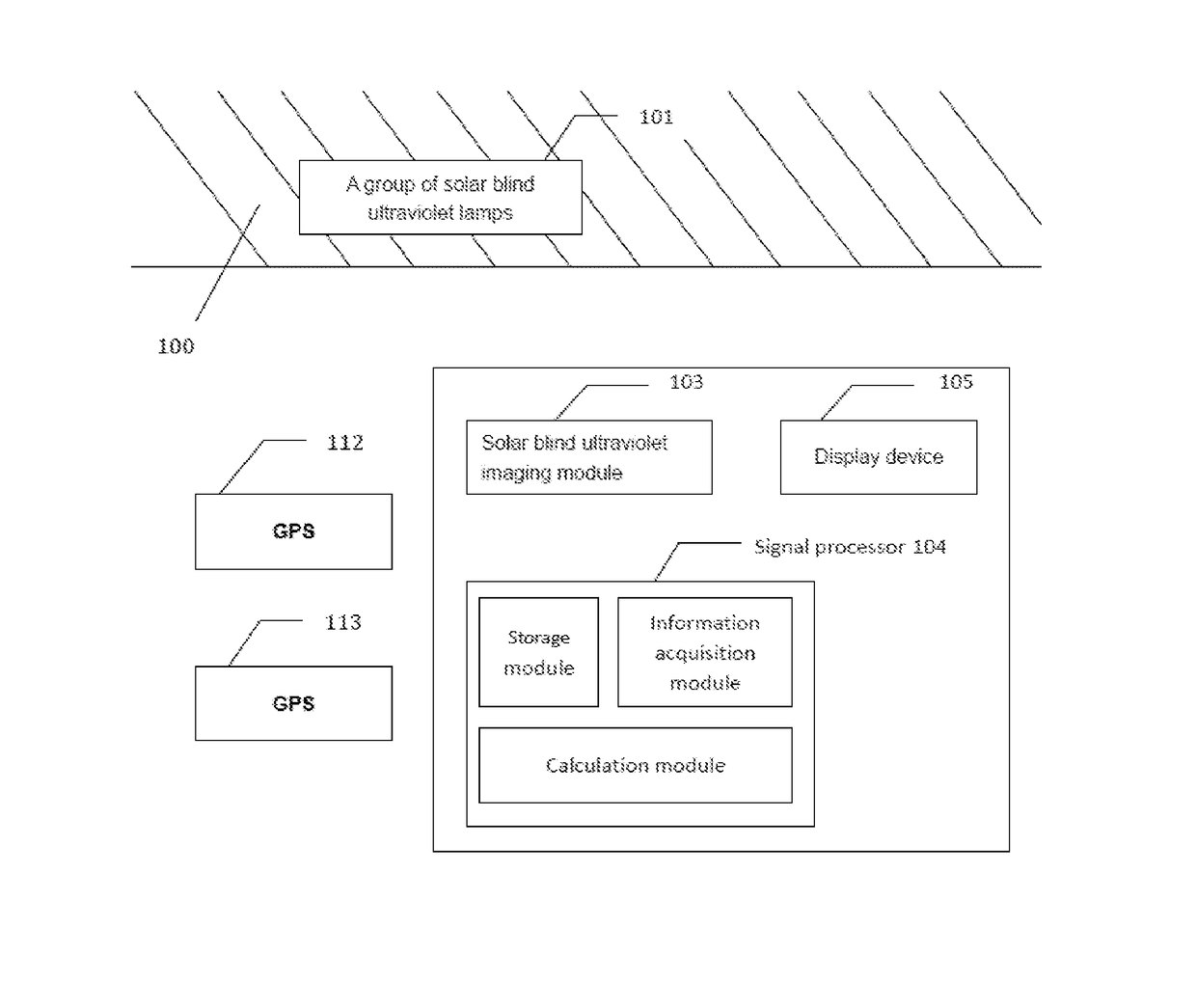

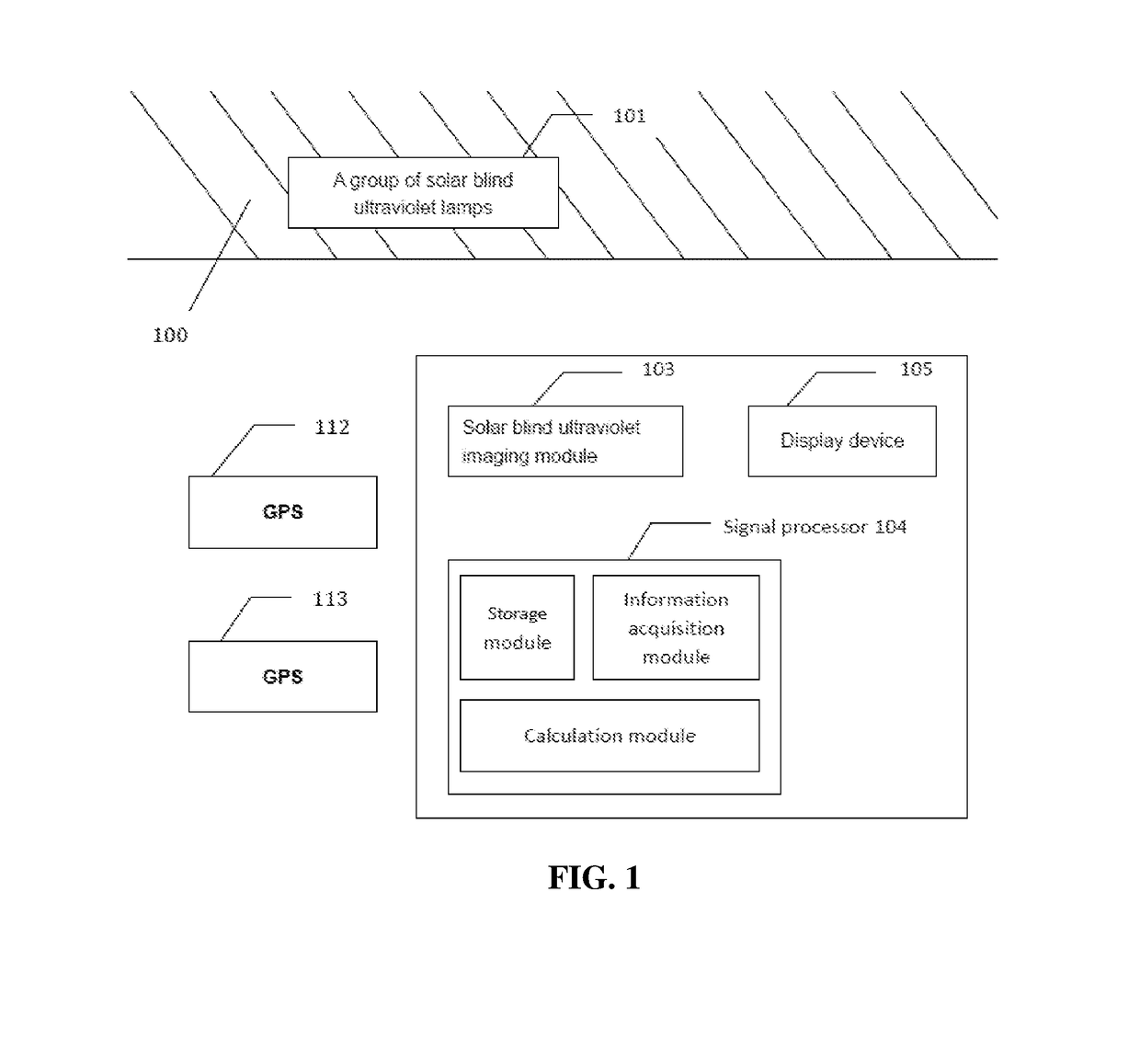

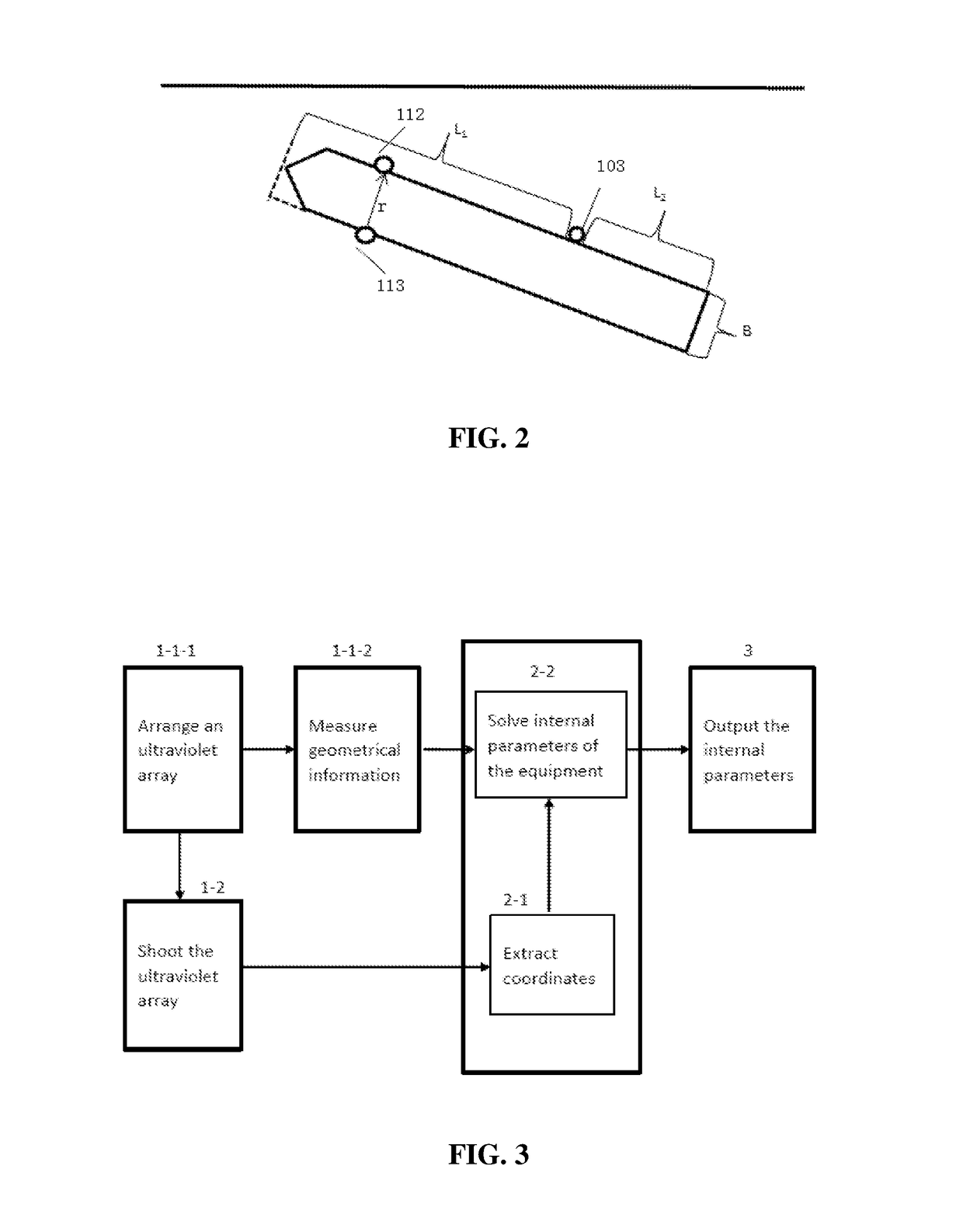

Auxiliary berthing method and system for vessel

ActiveUS20180012498A1High positioning accuracyGuaranteed smoothImage enhancementImage analysisVisibilityGps receiver

The present invention provides an auxiliary berthing method and system for a vessel. Position information of a vessel relative to a berth is determined by a solar blind ultraviolet imaging method; meanwhile, by a GPS method, an attitude angle of the vessel relative to the berth is determined by at least two GPS receivers. Thus, the vessel can be berthed safely when getting close to the shore at low visibility. Further, in the method and device of the present invention, it can be preferable to integrate coordinate data and angle data received by a solar blind ultraviolet imaging module and GPS signal receiving modules by a normalized correlation algorithm and a data fusion algorithm, so as to improve the positioning accuracy.

Owner:NANJING UNIV 5D TECH

Metal-plastic composite mobile phone shell and forming method thereof

InactiveCN103722668AUniform wall thicknessBeautiful surfaceDomestic articlesCoatingsConvex structureUltimate tensile strength

The invention provides a metal-plastic composite mobile phone shell and a forming method thereof. The provided mobile phone shell has a metal surface and a plastic structure feature, wherein the external surface of the mobile phone shell is made of a sheet metal and is small in wall thickness, high in strength and beautiful in appearance; a convex structure feature of the internal surface of the mobile phone shell is made of plastics, so that the formation of a complex installation structure is facilitated, and the functional requirements on assembling and shock absorption and the like are satisfied. According to the forming method, structure features of the sheet metal and the plastic are firmly combined together and form an integral structure. Meanwhile, according to the forming method, the combination strength of plastics and metals is high, so that the mobile phone shell satisfies the assembling and application requirements of mobile phones, and also can be applied to the shell production fields of household appliances, computers and other industrial products.

Owner:ZHEJIANG NORMAL UNIVERSITY

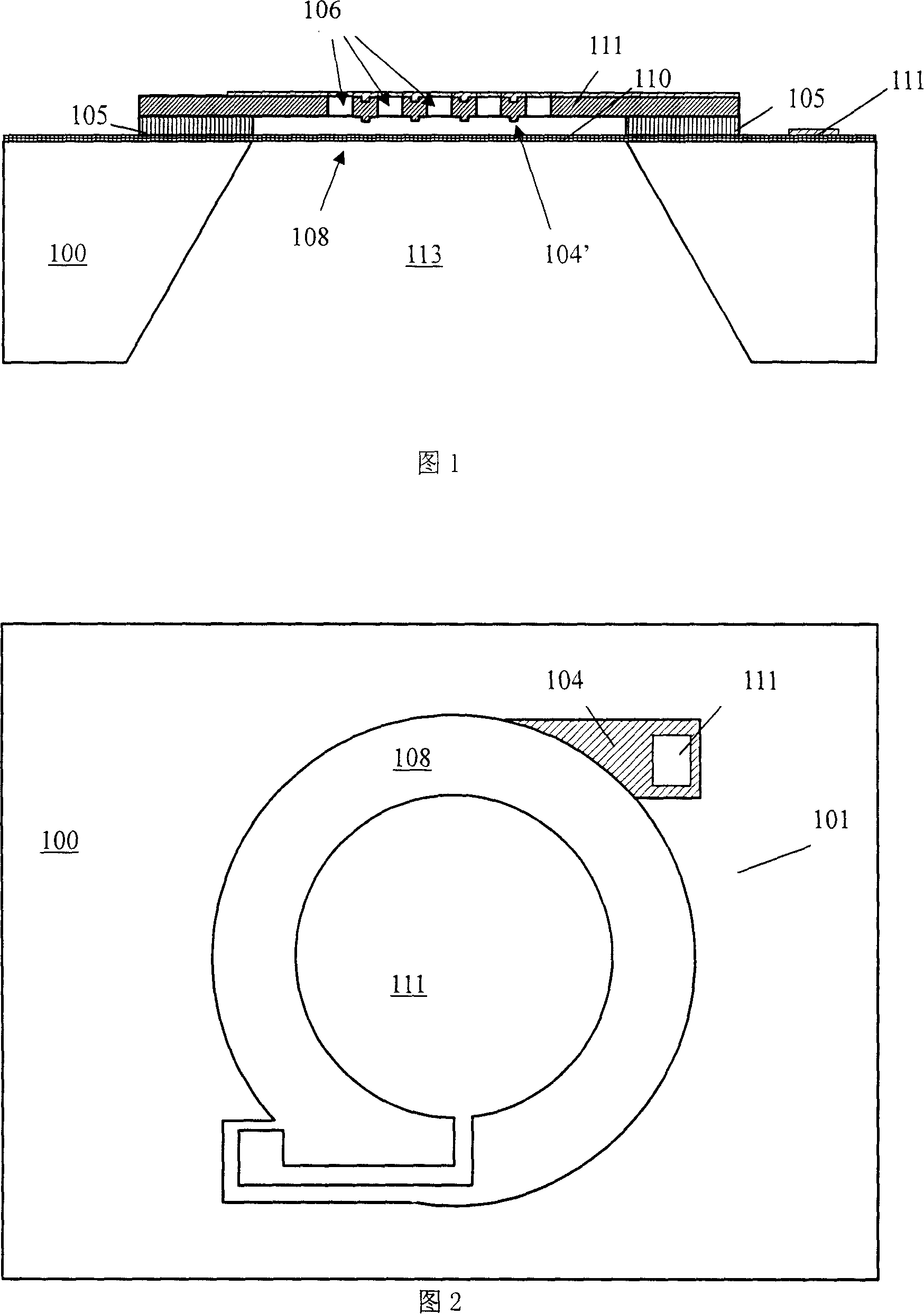

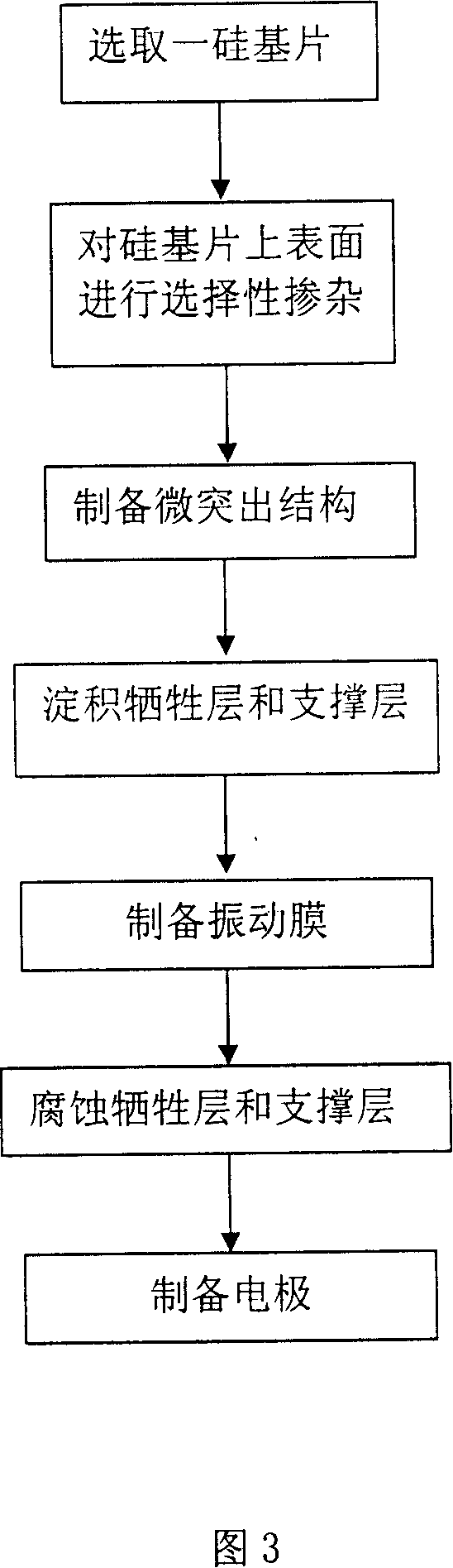

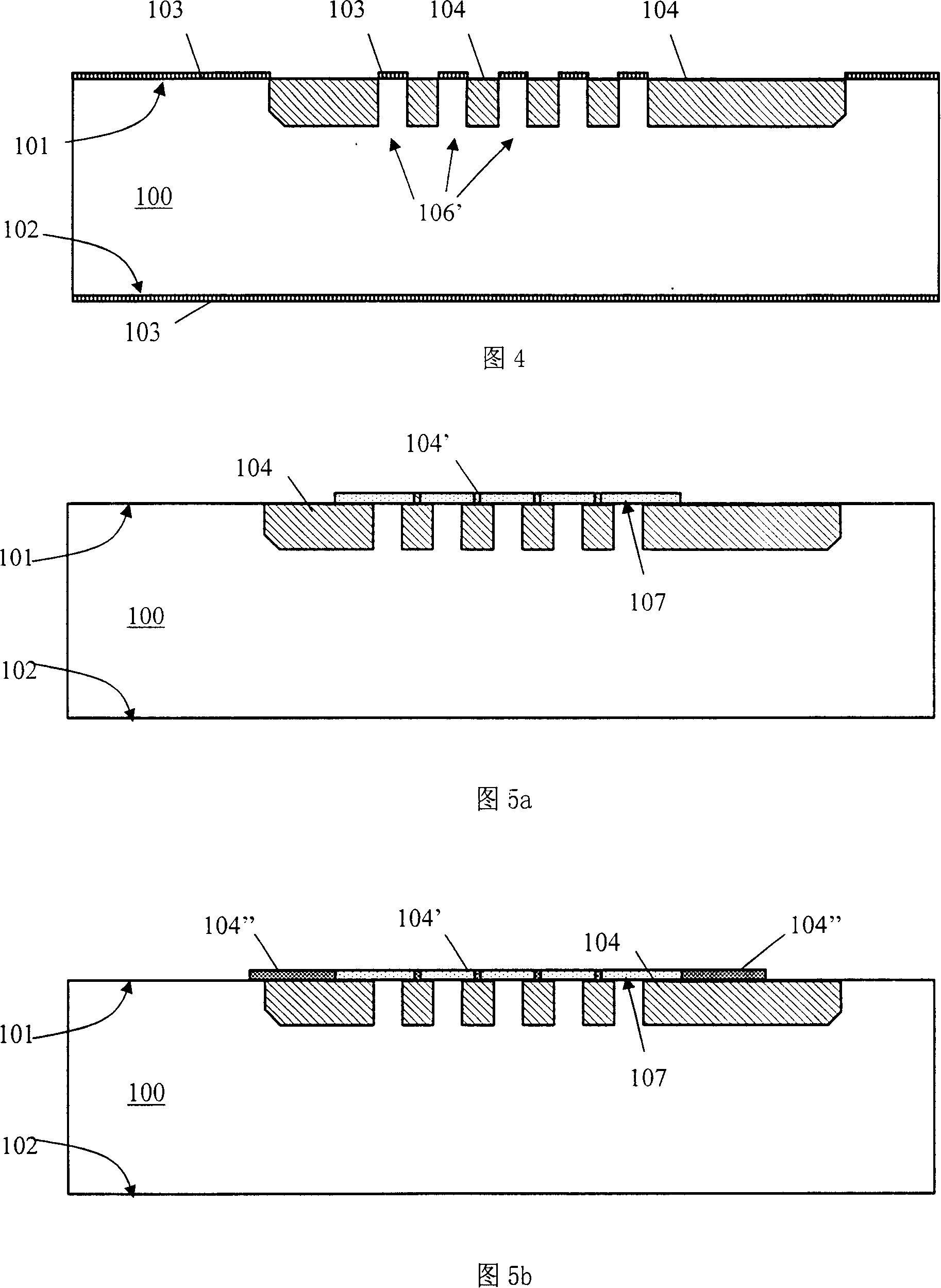

Adhesion preventive silicon capacitance sound transmitter chip and its making method

InactiveCN101123827AImprove performanceOvercome deficienciesElectrets selectrostatic transducerElectrostatic transducer microphonesCapacitanceConvex structure

The invention relates to an anti-conglutination silicon micro-condenser microphone chip and a preparation method of the chip including a silicon chip, a perforation backboard, a diaphragm and an electrode. The invention is characterized in that the perforation backboard is arranged on the upward side of the hollow area of the silicon chip. The diaphragm is arranged on the upward side of the perforation backboard and supported by an annular isolating-supporting layer. An air-gap is formed between the diaphragm and the perforation backboard. The upper surface of the perforation backboard is provided with a convex structure. The preparation method comprises the steps of adulterating and preparing the convex structure, depositing a sacrificial layer and a supporting layer, eroding and preparing the diaphragm and the electrode. As the invention has an anti-conglutination and micro-convex structure, the invention avoids conglutinations mainly occurring in a sublimation drying technical process and working process when the sacrificial layer is releasing and greatly improves the qualified rate of apparatus. Simultaneously the convex structure scheme prepared under the lower backboard can prepare to get a thicker backboard which can effectively avoid the problem of soft backboard existed in the preparation of anti-conglutination micro-convex scheme in a former upper backboard structure.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

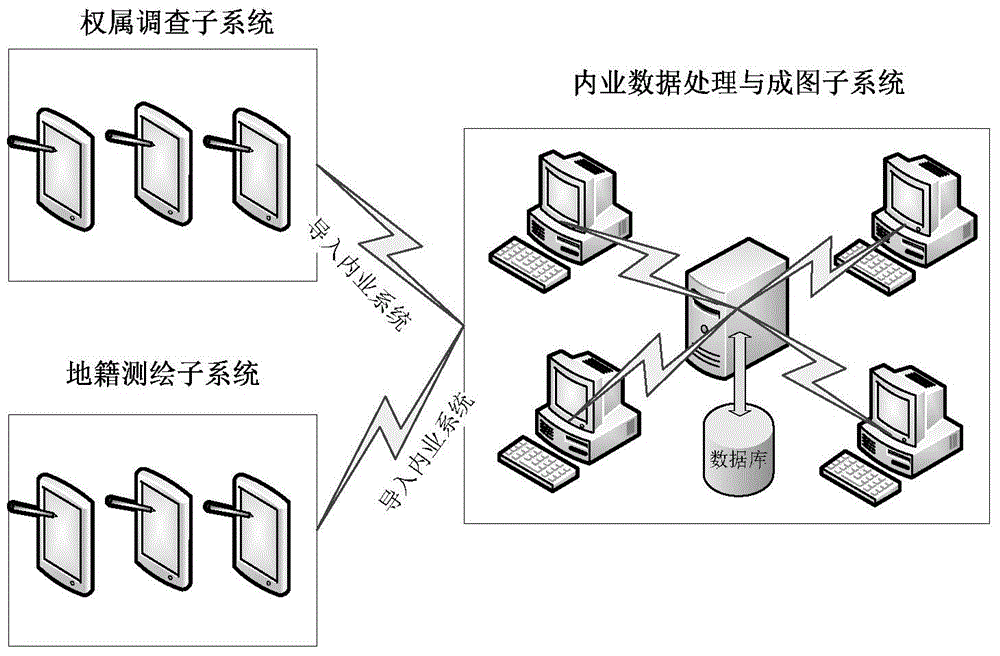

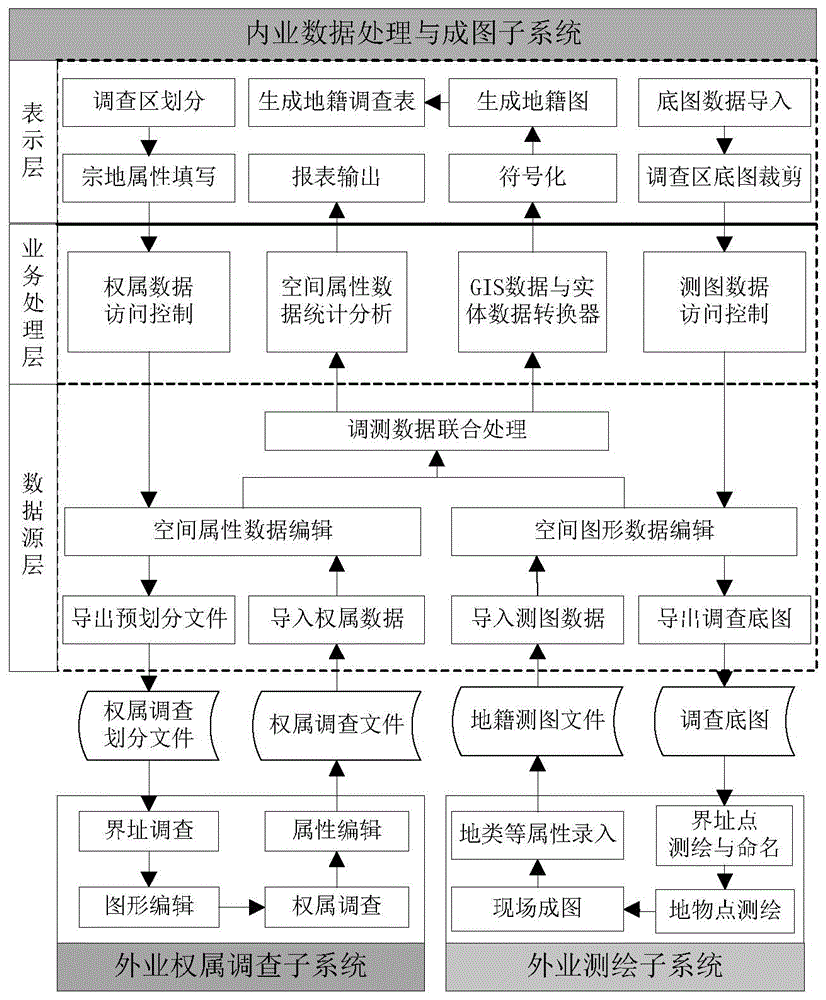

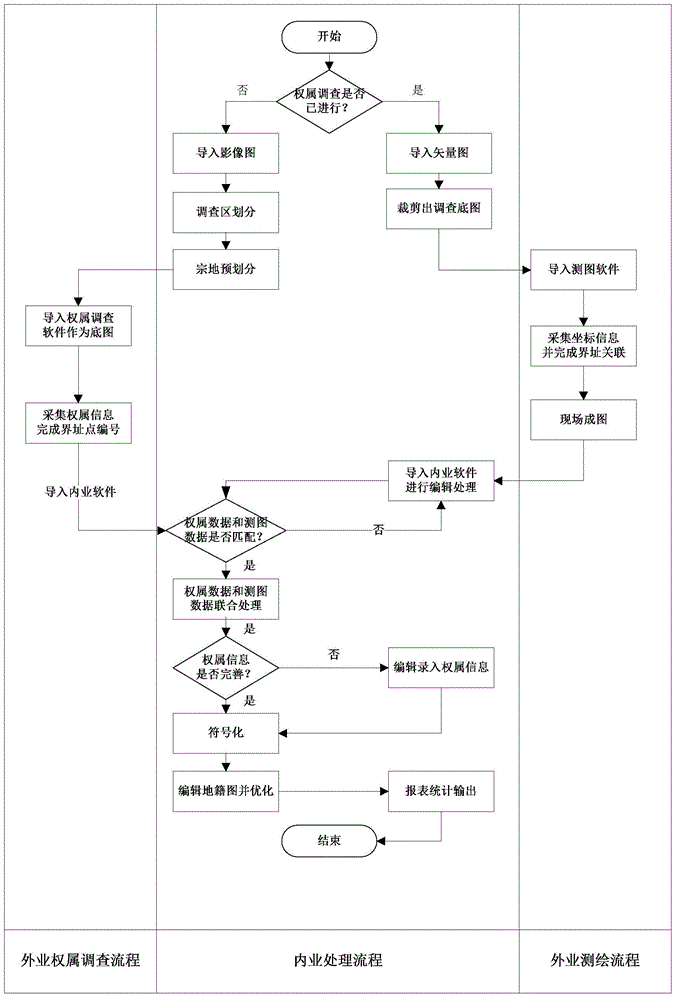

Cadastral surveying system and method achieving automatic cadastral mapping

InactiveCN104462298AResponsibilities are clearStrong targetingGeographical information databasesSpecial data processing applicationsBusiness PersonnelSurvey methodology

The invention discloses a cadastral surveying system and method achieving automatic cadastral mapping. The system comprises an office work data processing and mapping subsystem, a field work ownership surveying subsystem and a field work cadastral plotting subsystem, wherein the field work ownership surveying subsystem and the field work cadastral plotting subsystem are communicated with the office work data processing and mapping subsystem; the field work cadastral plotting subsystem carries out field work plotting on the surveying result of the field work ownership surveying subsystem, the plotting result and the ownership surveying result are guided into the office work data processing and mapping subsystem for making a cadastral map, and automation of cadastral mapping is achieved according to field results. The data management is enhanced, surveying data, the field surveying results and cadastral results are managed in a unified mode, automation of cadastral mapping is achieved, maps, data and on-site situations are coincident, the method is clear in division, the system operation is easy, and servicers can operate the system conveniently.

Owner:SOUTHEAST UNIV

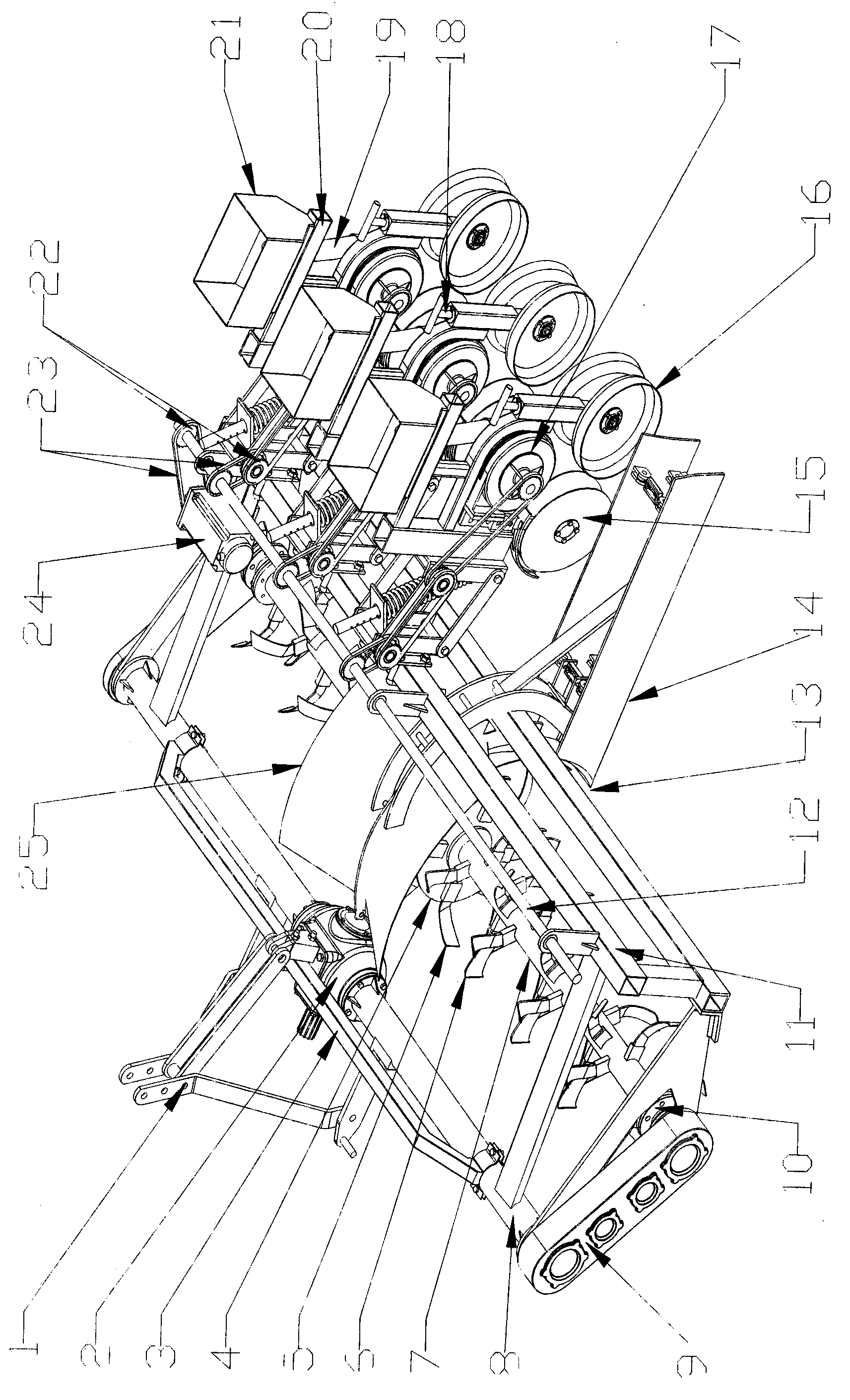

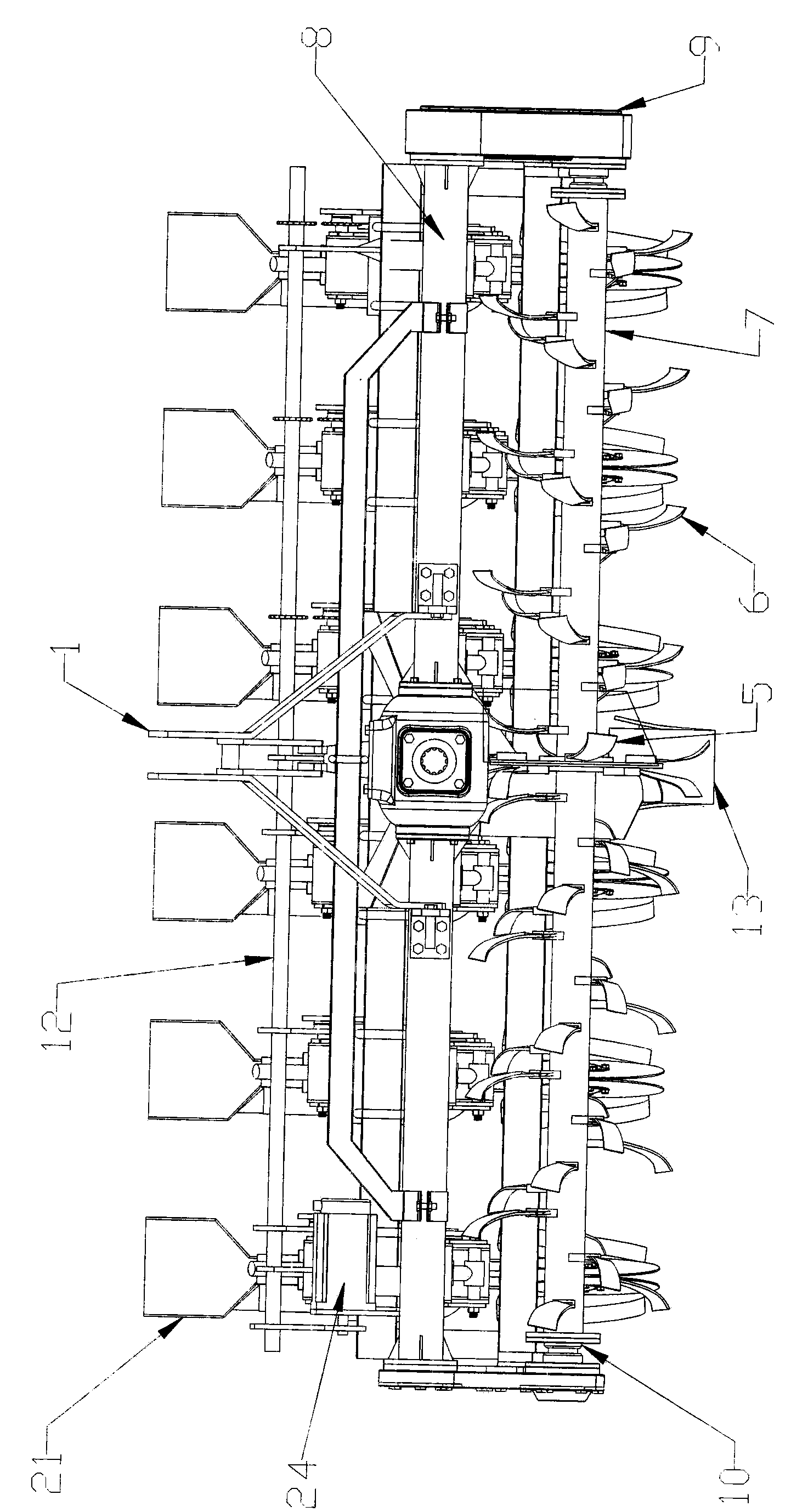

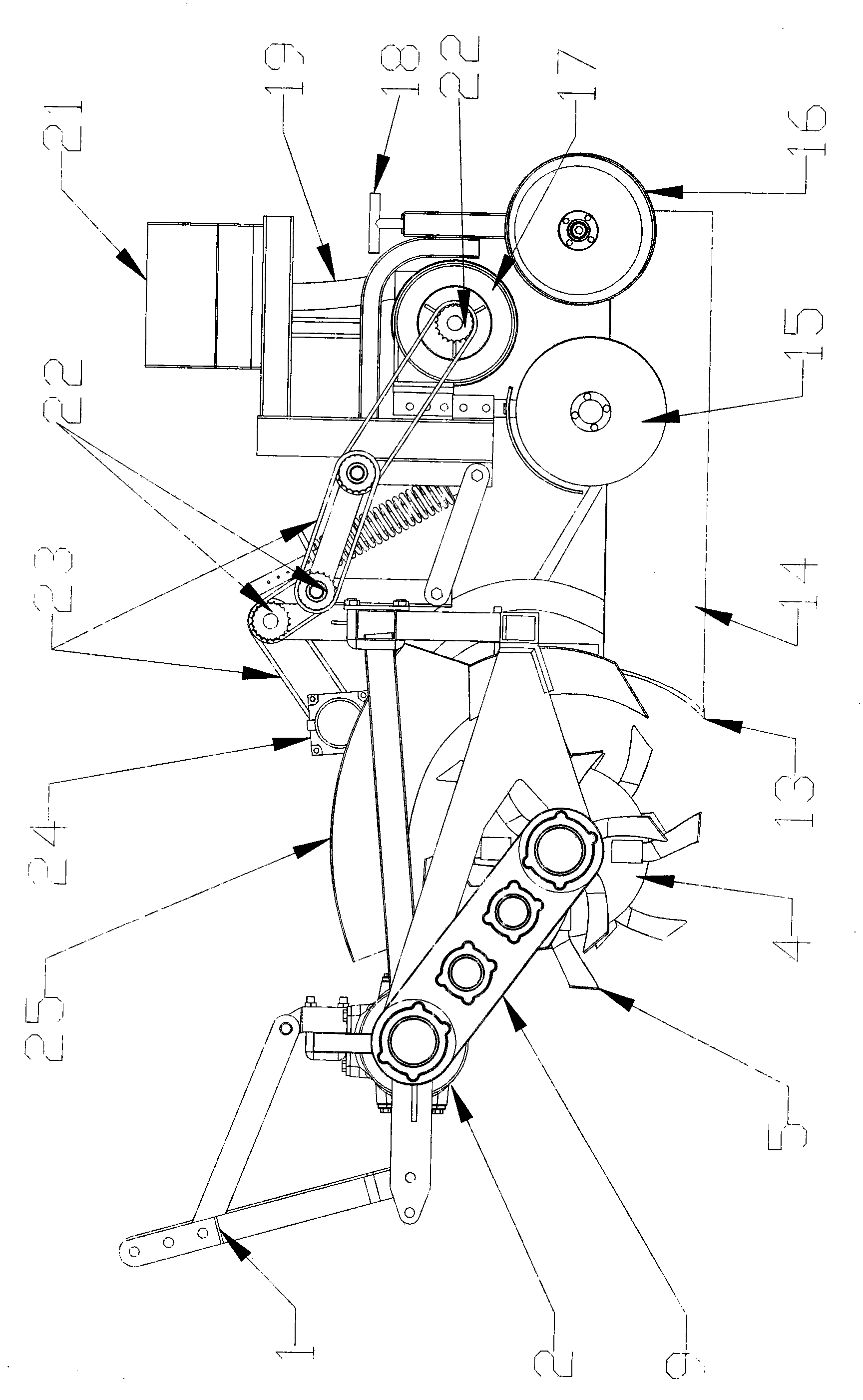

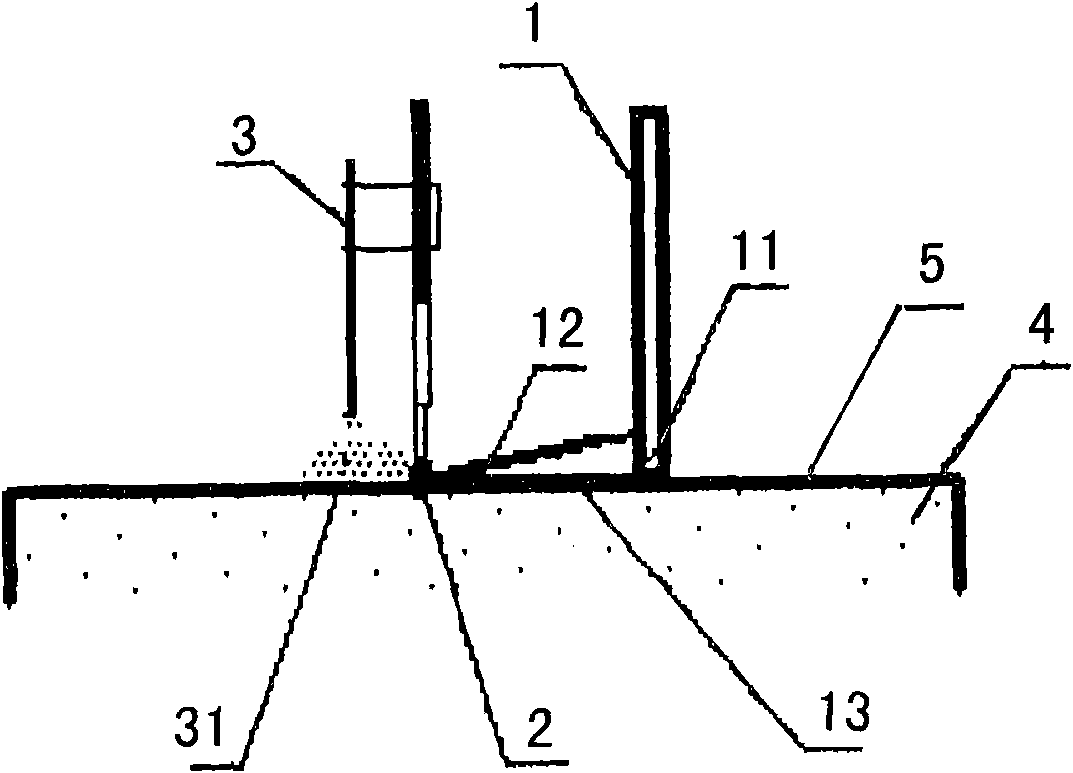

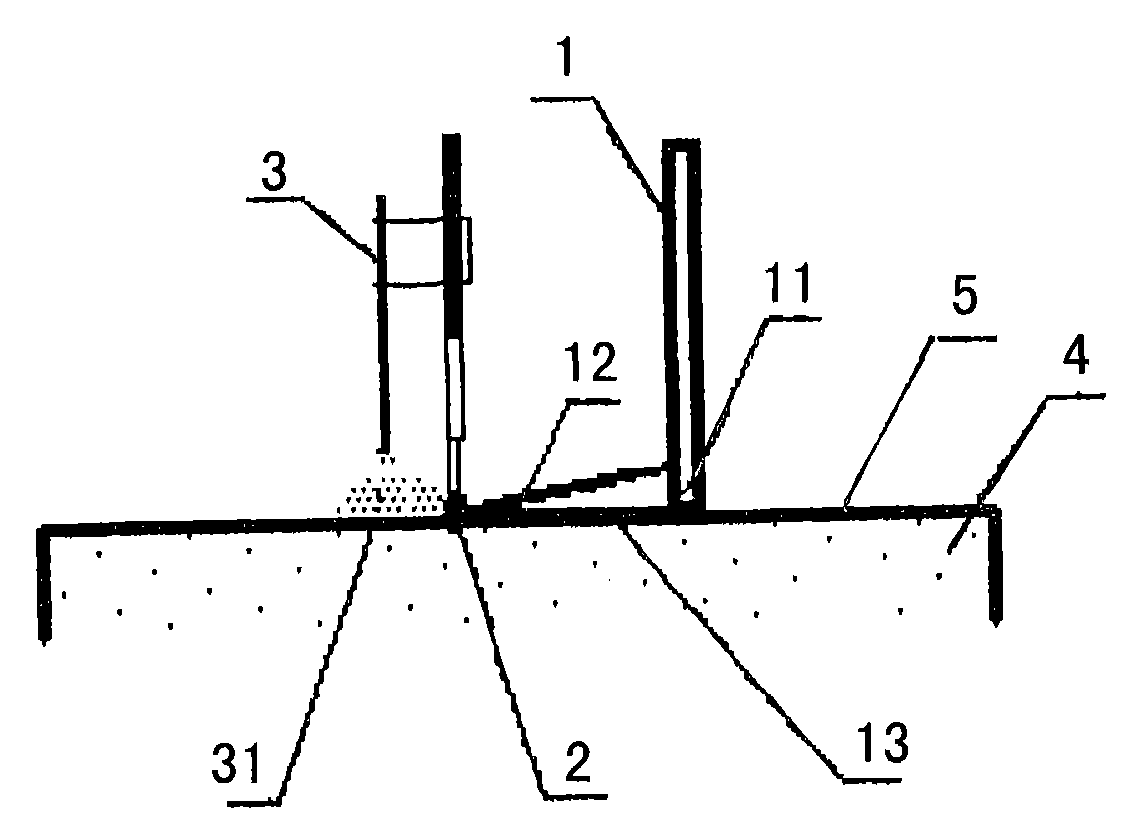

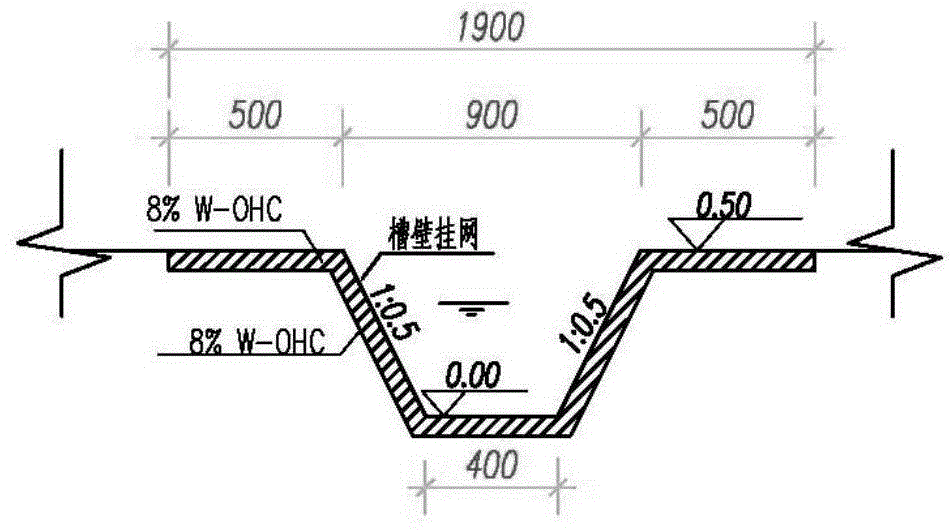

Seeder with middle ditching, unit profile modeling and seeding depth adjusting functions

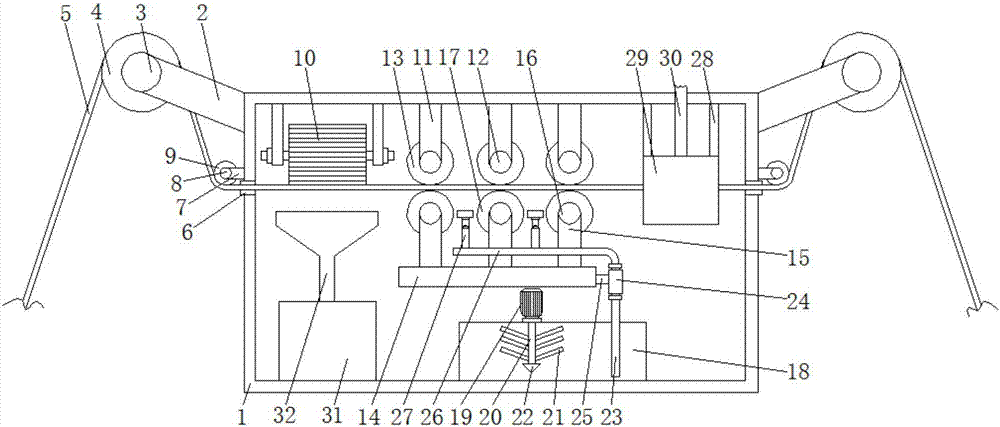

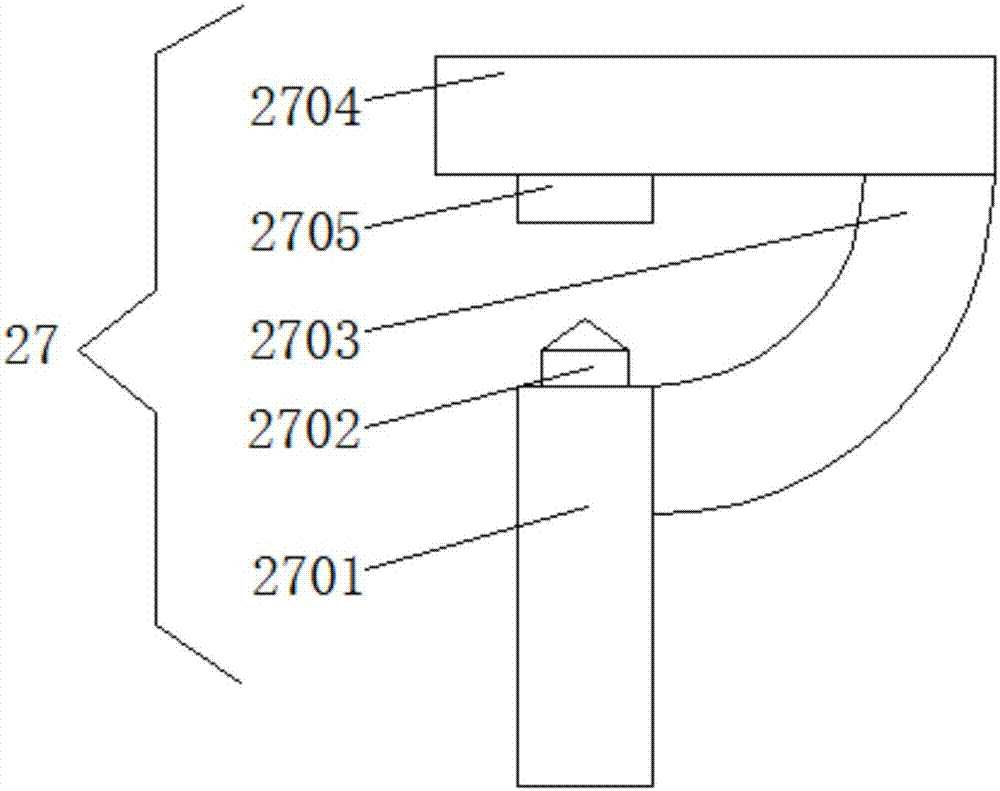

InactiveCN104025775AGuaranteed smoothUniform sowing depthPlantingFurrow making/coveringSeederUniversal joint

The invention discloses a seeder with middle ditching, unit profile modeling and seeding depth adjusting functions, belonging to the field of rotary tillage seeders. The seeder mainly comprises a frame, a rotary tillage transmission device, a rotary tillage mechanism, a middle ditching mechanism, a seed-metering transmission mechanism, a seeding unit and a seeding amount electric control system. The operations of rotary tillage, middle ditching and seeding can be finished at a time. During operation, power of a tractor is transmitted to a rotary tillage cutter shaft and a ditching cutter shaft through a universal joint, a gearbox, a rotary tillage transmission shaft and a gear case, rotary tillage and ditching are performed, and the ditch wall is smooth through a breast board, a ditch cleaning shovel and a ditch strengthening device; the included angle between ditch strengthening plates is adjusted through a lead screw mechanism so as to change the ditch shape; the tractor hub rotating speed acquired by a speed measuring probe is processed by a programmable logic controller (PLC), the processed signal is transmitted to a driver, the rotating speed of a stepping motor is controlled to be matched with the speed of the tractor, a bucket wheel tray of the seed-metering device is driven through chain drive, so that precision drilling is realized; the line spacing can be adjusted by loosening a U-shaped bolt and moving the seeding unit; moreover, uniform and consistent seeding depth of each line can be guaranteed through parallel four-rod unit profile modeling and V-shaped wheel depth limiting.

Owner:NANJING AGRICULTURAL UNIVERSITY

Method for manufacturing high-chromium alloy overlaying composite abrasion resistant plate

The invention discloses a method for manufacturing a high-chromium alloy overlaying composite abrasion resistant plate and relates to an abrasion resistant plate technology. The front of a contact tube of a self-protecting flux-cored wire is provided with a powder feeding device; while swinging and overlaying, the self-protecting flux-cored wire, a spray cooling device and a scraping plate synchronously swing; when visible arc swing overlaying is carried out, the spray cooling device sprays cooling water, a powder feeding pipe conveys alloy powder out, and the alloy powder is uniformly distributed on the upper surface of the abrasion resistant base plate by the scraping plate; and the self-protecting flux-cored wire is mixed with the alloy powder, the ratio of the mass of the alloy powder to the mass of the welding wire is larger than 0.8, the mixture is distributed on the surface of the abrasion resistant base plate by visible arc overlaying to form an abrasion resistant layer, thus the composite abrasion resistant plate is obtained. The method of the invention has simplicity, easy operation, low cost, good water-cooling effect, guarantee of oriented growth of carbide and even as well as fine cracks, and the product has dual performances of a high-hardness material and a ductile material and long service life.

Owner:CHINA JINGYE ENG TECH CO LTD +1

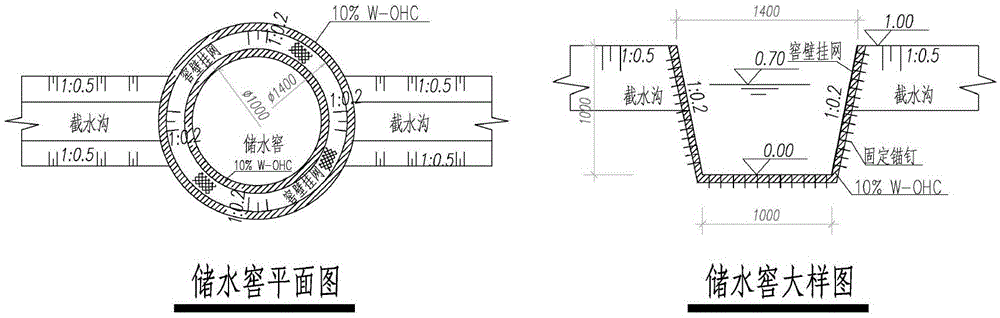

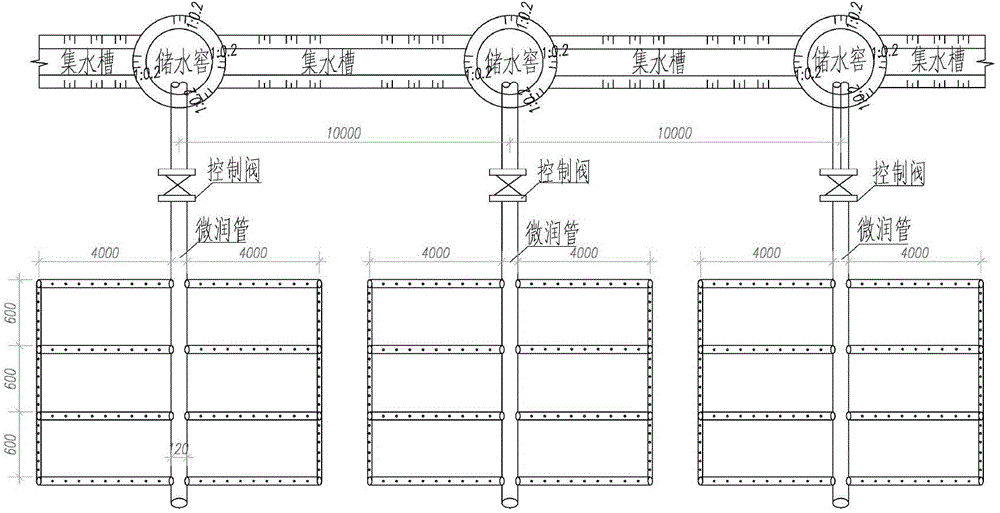

Flexible slope protection method for soft sandstone natural side slope

InactiveCN104805845AReduce penetrationImprove survival rateExcavationsHorticultureFreeze thawingVegetation

The invention provides a flexible slope protection method for a soft sandstone natural side slope. The method comprises the following steps of (1) slope surface early-stage cleaning; (2) net hanging; (3) micro lubricating system building; (4) spray coating; (5) plant planting and greening; (6) operation and maintenance. The method has the advantages that through a series of measures of the flexible slope protection method, a processed side slope surface layer soft sandstone composite body has the comprehensive performance such as excellent mechanical performance, ultraviolet degradation resistance performance, wind etching resistance performance, water etching resistance performance, gravity etching resistant performance, freeze thawing resistance, water preservation, heat insulation and fertilizer preservation, the soft sandstone can be fixed, meanwhile, the method is combined with plant-growing methods such as a seed spraying method, the vegetation recovery is promoted, and the water and soil maintaining effect is effectively improved. The flexible slope protection method is suitable for ecological control and restoration engineering of the soft sandstone natural side slope and is particularly suitable for soft sandstone regions with the serious water and soil loss.

Owner:ANHUI AGRICULTURAL UNIVERSITY

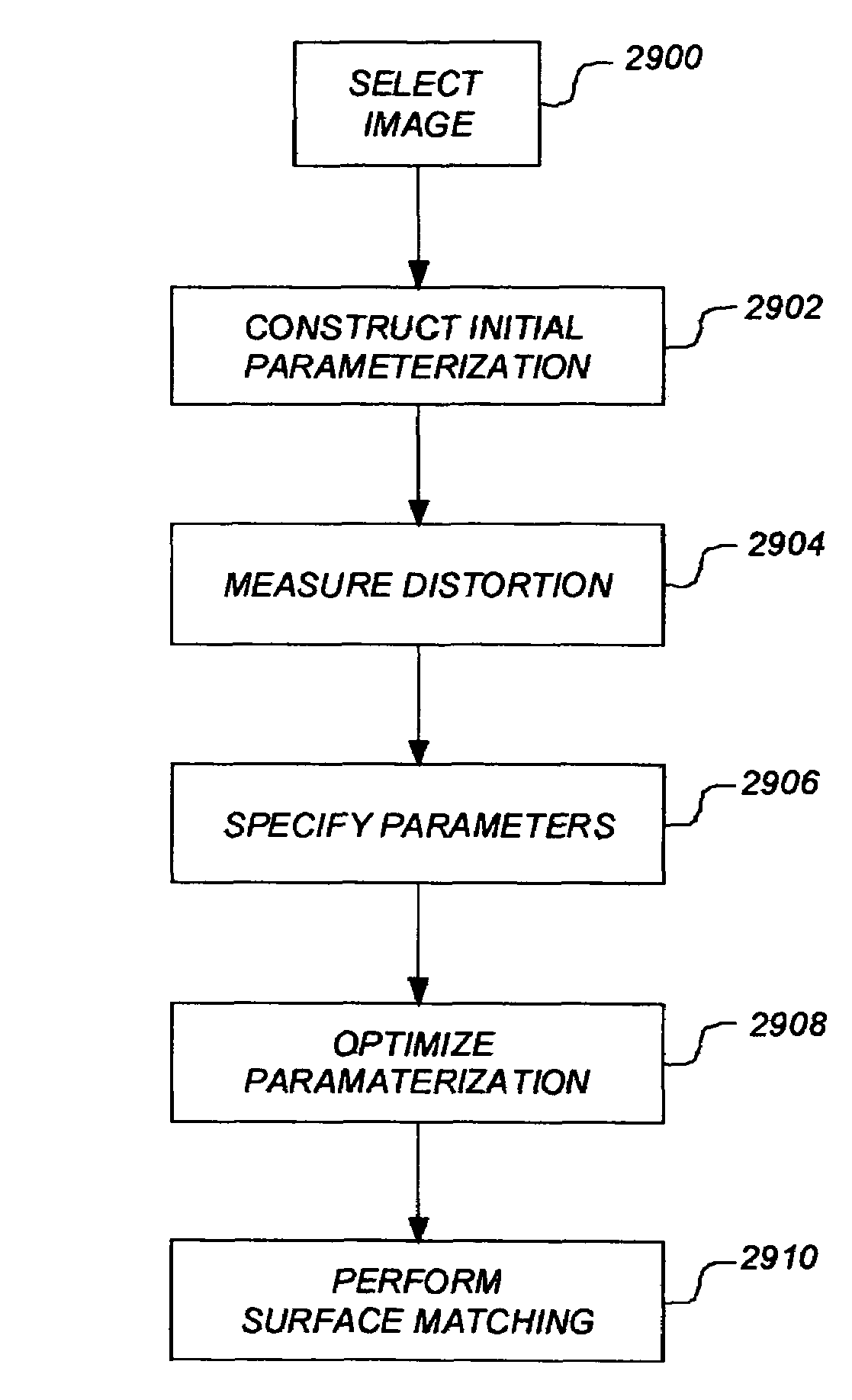

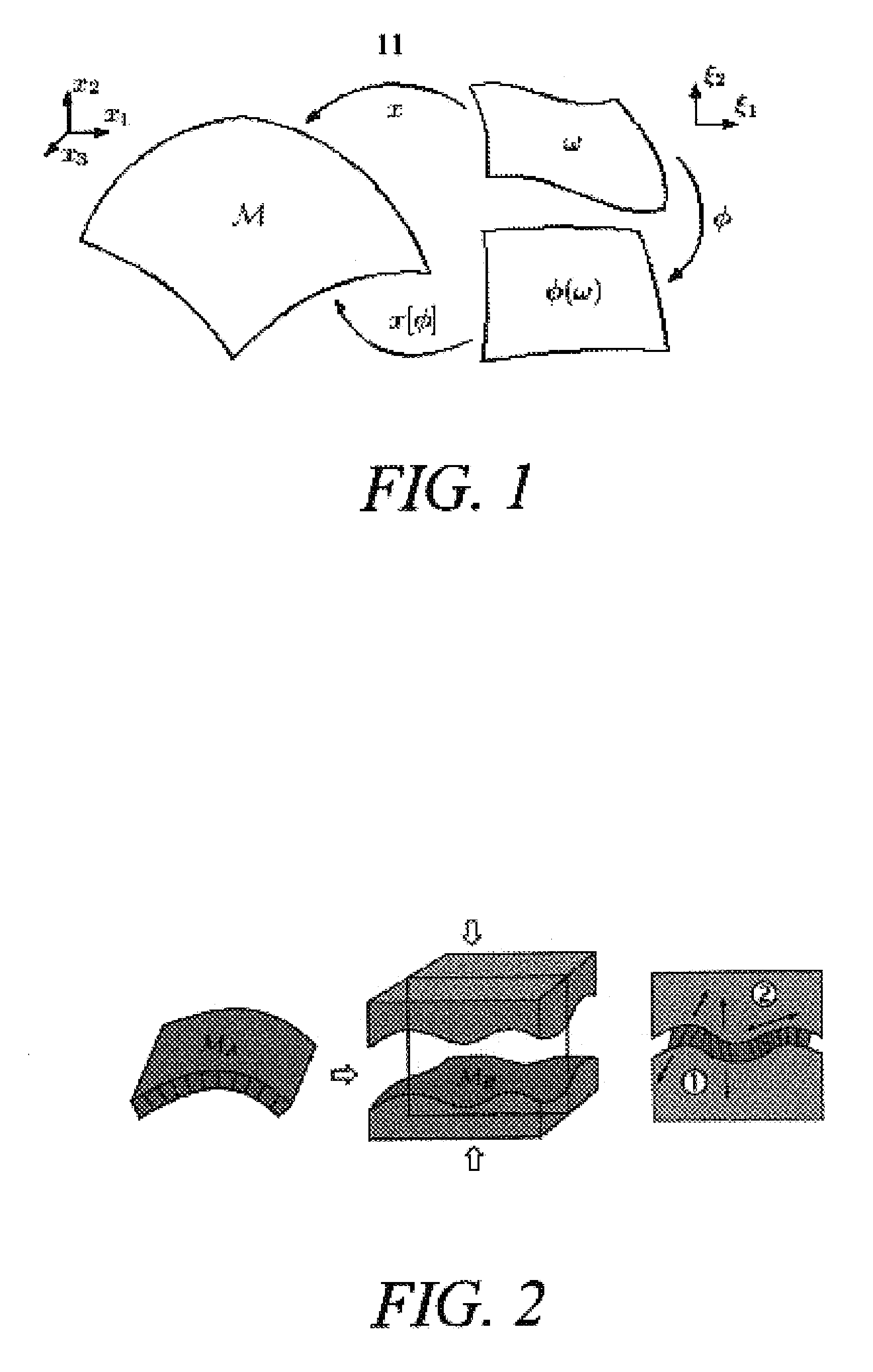

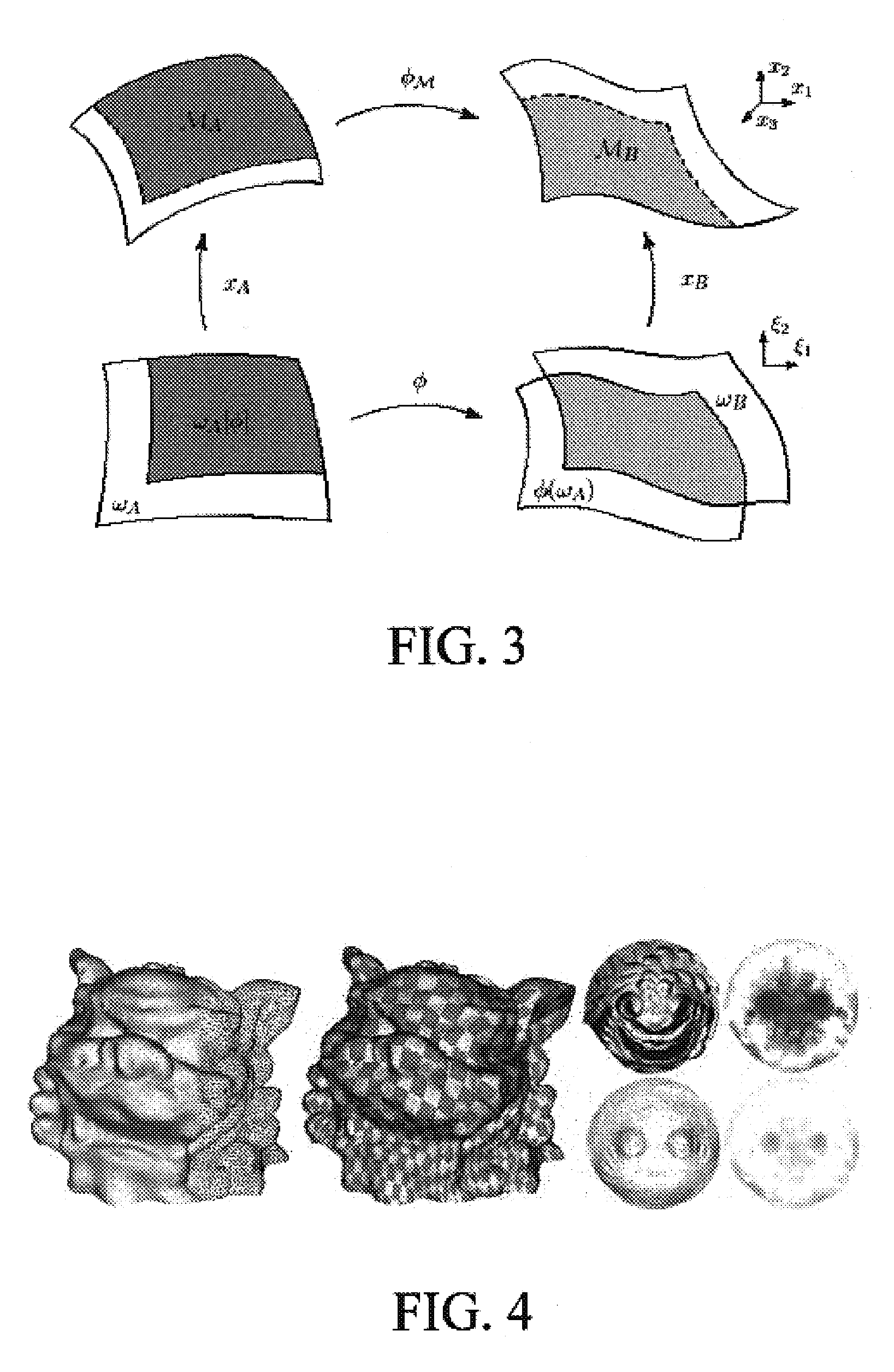

Method for constructing surface parameterizations

InactiveUS7576738B2Execution time can be reasonableHighlight flexibility and varietyDrawing from basic elementsCharacter and pattern recognitionComputer graphics (images)Distortion minimization

A method, apparatus, and article of manufacture provide the ability to construct an optimal parameterization for a discrete surface patch. A three-dimensional image having a surface is selected. An initial parameterization of the surface onto a two-dimensional plane is constructed. A distortion of the initial parameterization is measured. A length parameter, an area parameter, and an angle parameter are specified. The initial parameterization is then optimized through a discrete deformation of a parameter domain that minimizes the distortion based on the length, area, and angle parameter.

Owner:CALIFORNIA INST OF TECH

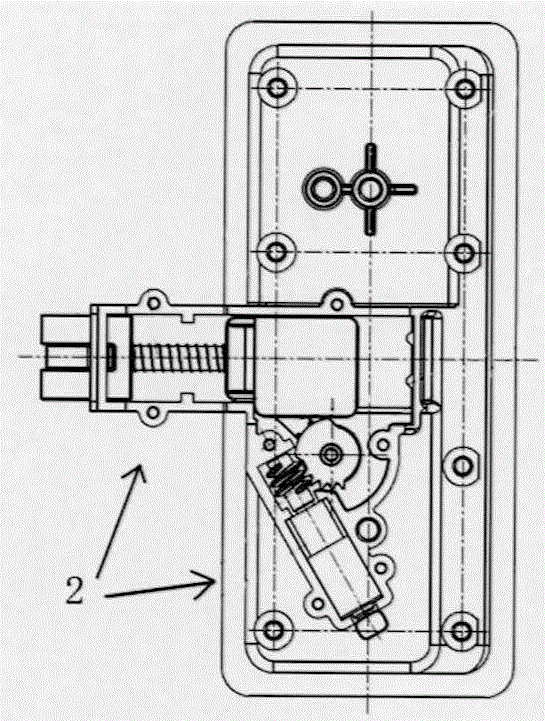

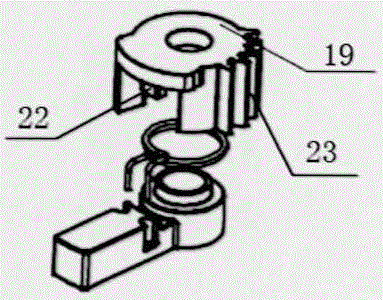

Intelligent lock based on storage cabinet of Internet of Things and operation method of intelligent lock

ActiveCN105275278AGuarantee the safety of usePlay a role of security protectionNon-mechanical controlsElectric permutation locksThe InternetMotherboard

The invention discloses an intelligent lock based on a storage cabinet of the Internet of Things and an operation method of the intelligent lock. The intelligent lock comprises a shell, a panel, a lock body, a motor module, a mechanical unlocking module, a main board module and a fingerprint recognition module. The intelligent lock has the functions of electronic unlocking and automatic locking and also has the functions of manual unlocking and locking. The using safety and operation convenience of the intelligent lock are improved, and the installing cost is reduced.

Owner:深圳市顺易通信息技术有限公司

Decarburization annealing process for cold-rolled non-oriented silicon steel with high carbon content and low grade

ActiveCN102268516AGuaranteed smoothSimple decarburization annealing processFurnace typesHeat treatment process controlHigh carbonShielding gas

The invention provides a decarburization and annealing process of high-carbon middle-and-low-grade cold rolling orientation-free silicon steel. In the process, a horizontal type continuous decarburization and annealing coating unit is adopted, the thickness of a steel belt is 0.35-0.65mm, the operation speed of the steel belt is controlled to 70-100m / min, the tension of the steel belt in a continuous decarburization and annealing furnace is 1800-2200N; the temperatures of various furnace sections are controlled as follows: the furnace temperature of a preheating / oxidation-free heating section is 1000-1100 DEG C, the furnace temperature of a radiant tube heating section is 900-920 DEG C, and the furnace temperature of a soaking section is 850-910 DGE C; apertures of a fan at a cooling section are 25-99% in turn; the pressures in the furnace are as follows: the pressure of an inlet is 25-30Pa, and the pressure of an outlet is 45-50Pa; and H2 and N2 are adopted as protective gas in the furnace, wherein the content of H2 is 25%-35%, the dew point value of the protective gas is 35+ / -5 DEG C, and the flux of the protective gas is 350-420m<3> / h. In the invention, the process is adopted so as to not only ensure that the steel belt is smooth, the magnetic property, magnetic ageing and the like of the steel belt meet technical requirements, the qualified rate of a finished product is improved and waste quantity is reduced but also ensure that production is smoothly carried out.

Owner:ANGANG STEEL CO LTD

Dedusting and drying integrated printing-and-dyeing drying equipment

InactiveCN107339871AGuaranteed smoothImprove cleanlinessDrying gas arrangementsDrying machines with progressive movementsWorking environmentEngineering

The invention discloses a printing and dyeing drying equipment integrating dust removal and drying. A rotating shaft, the outer surface of the first rotating shaft is sleeved with unwinding rollers. The printing and dyeing drying equipment integrating dust removal and drying can effectively ensure the cleanliness of the fabric, effectively maintain the working environment of the equipment, avoid dust falling into the fabric again, and cause the fabric to be polluted again, effectively making the fabric quality better. Effectively spray the dye evenly onto the second electric printing and dyeing roller, which ensures the automation of the equipment, ensures the stable flow of the dye liquid, and avoids the excessive impact of the dye during stirring, which causes the equipment to shake, effectively It ensures the drying of the fabric, solves the problem of the fabrics sticking together, improves the quality of the fabric, and saves the drying time.

Owner:姚飞

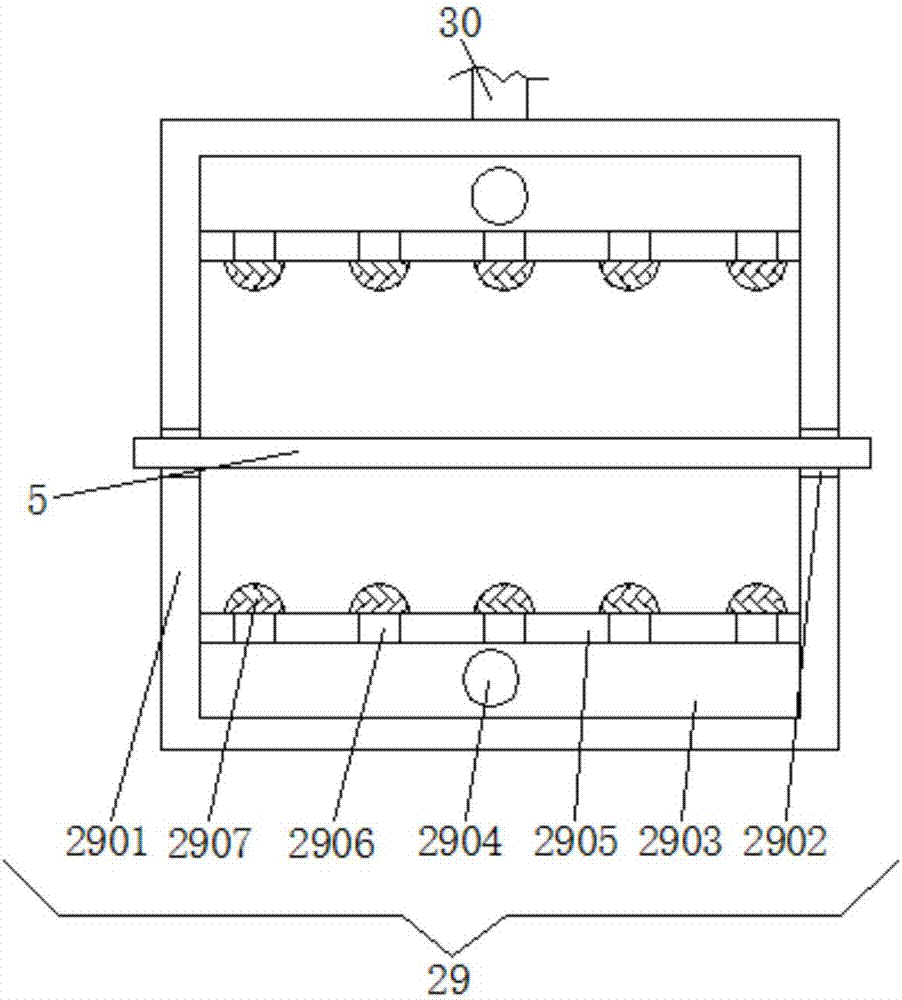

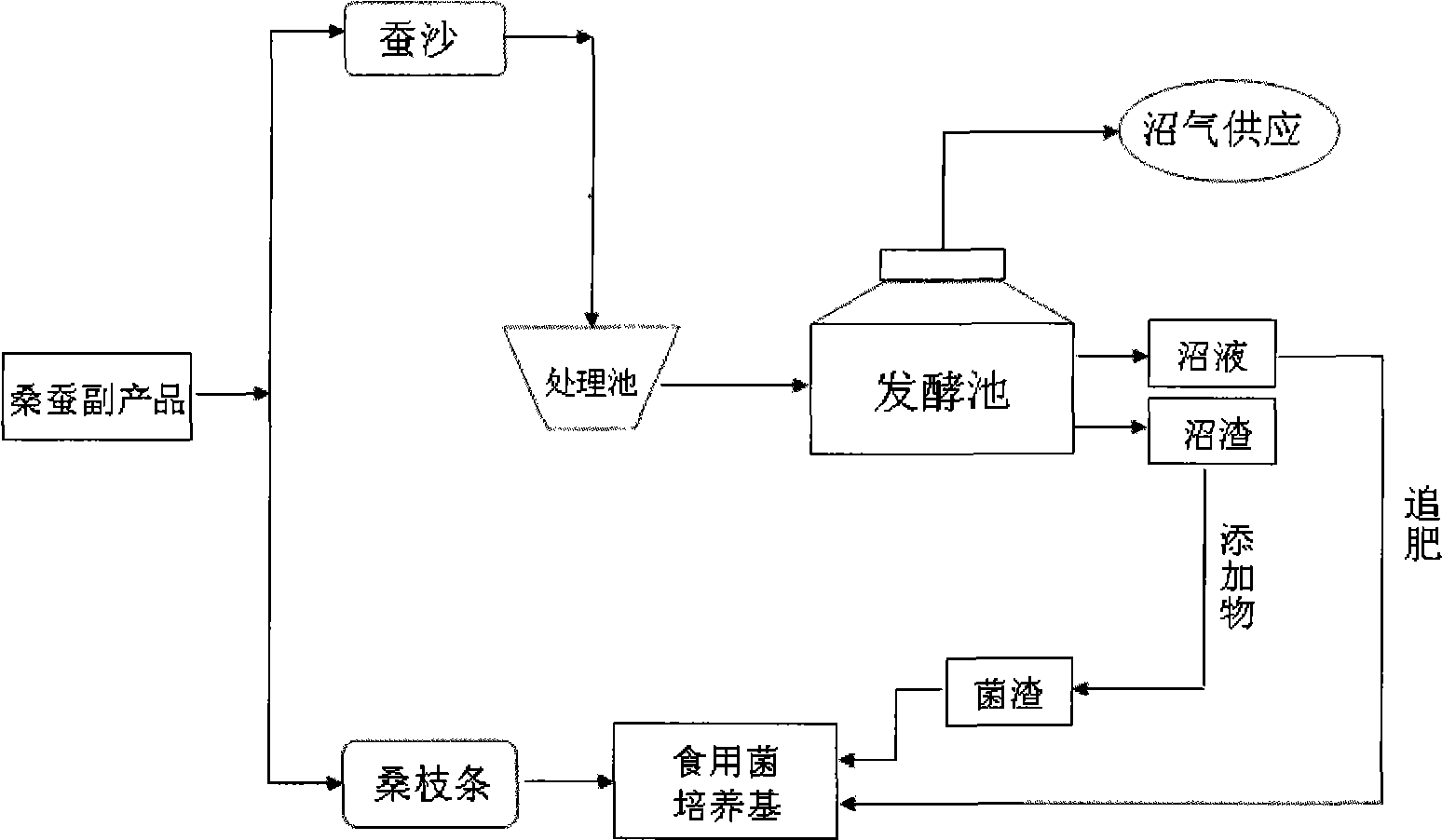

Application of silkworm and mulberry by-product silkworm excrement fermentation wastes in edible fungus cultivation

InactiveCN101496485AReduce manufacturing costIncrease the added value of agricultureBio-organic fraction processingClimate change adaptationBiogasFertilizer

The invention provides the application of a silkworm raising byproduct of a silkworm excrement fermentation waste to the edible fungus culture. The silkworm excrement is taken as the biogas fermentation raw material; and the marsh liquid and marsh refuse after the biogas fermentation can be further reutilized. The marsh liquid can be taken as the liquid fertilizer for the earthing edible fungus culture after being processed; and the marsh refuse can be taken as the fungus culture material after being processed. Therefore, the edible fungus culture cost can be reduced. While another silkworm raising byproduct of mulberry twigs can be prepared into fungus rods for the production of the edible fungus after clipping, crushing, sterilization and inoculation. The invention can improve the comprehensive utilization of the silkworm raising byproducts, reduce the environmental pollution, realize the cyclic production of the edible fungus, and reduce the production cost of the edible fungus.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com