Patents

Literature

7574results about How to "Improve welding efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

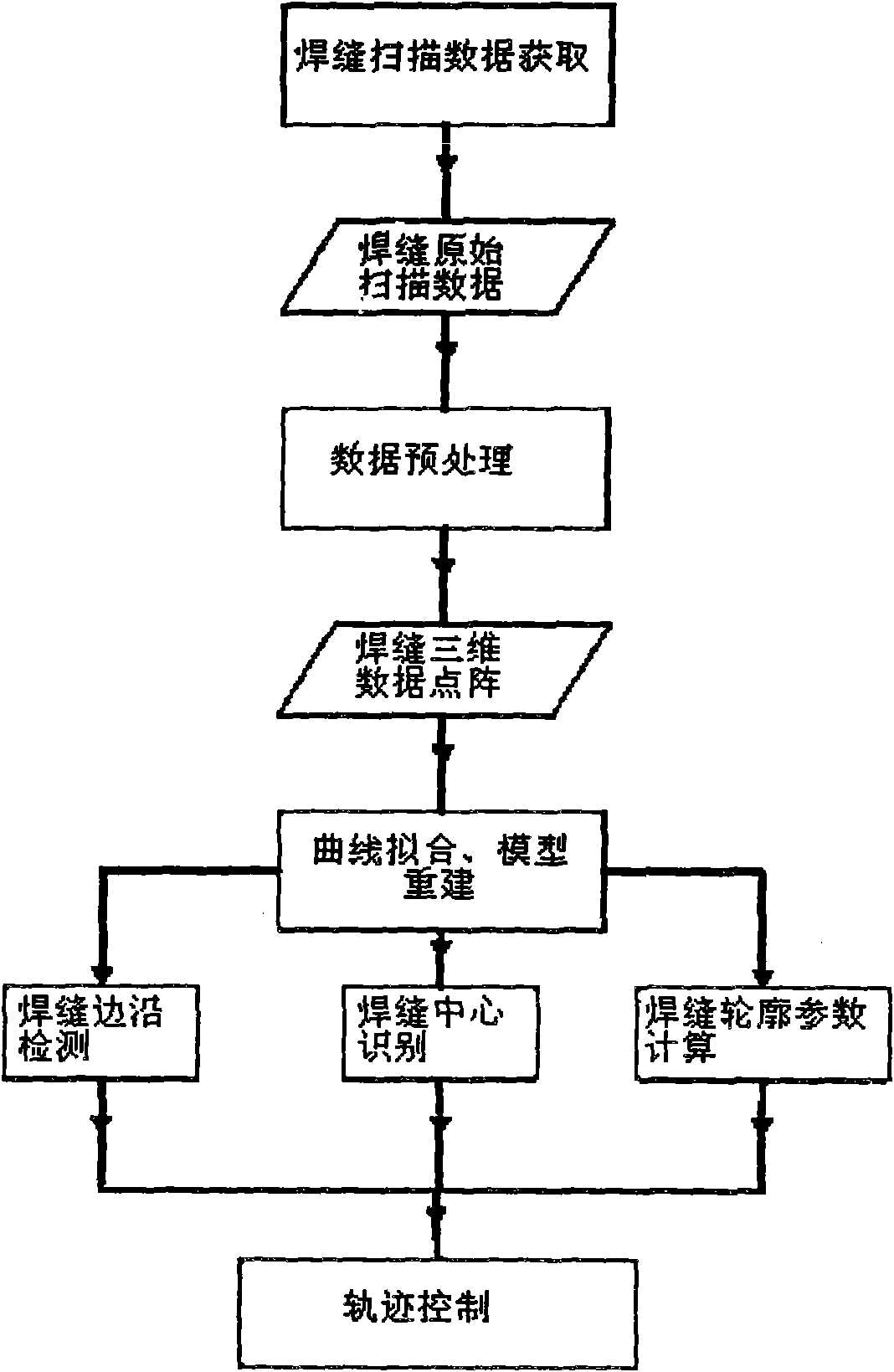

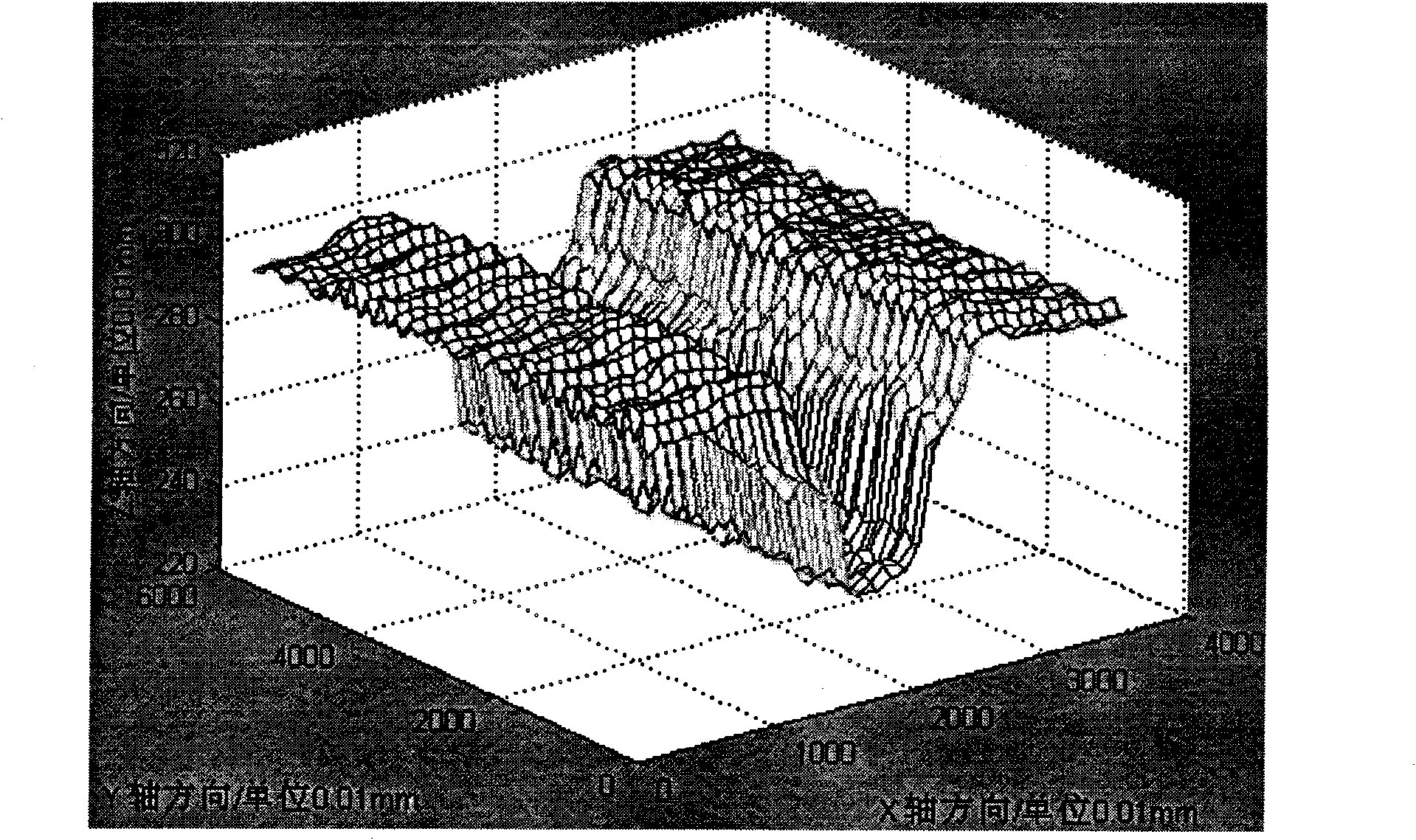

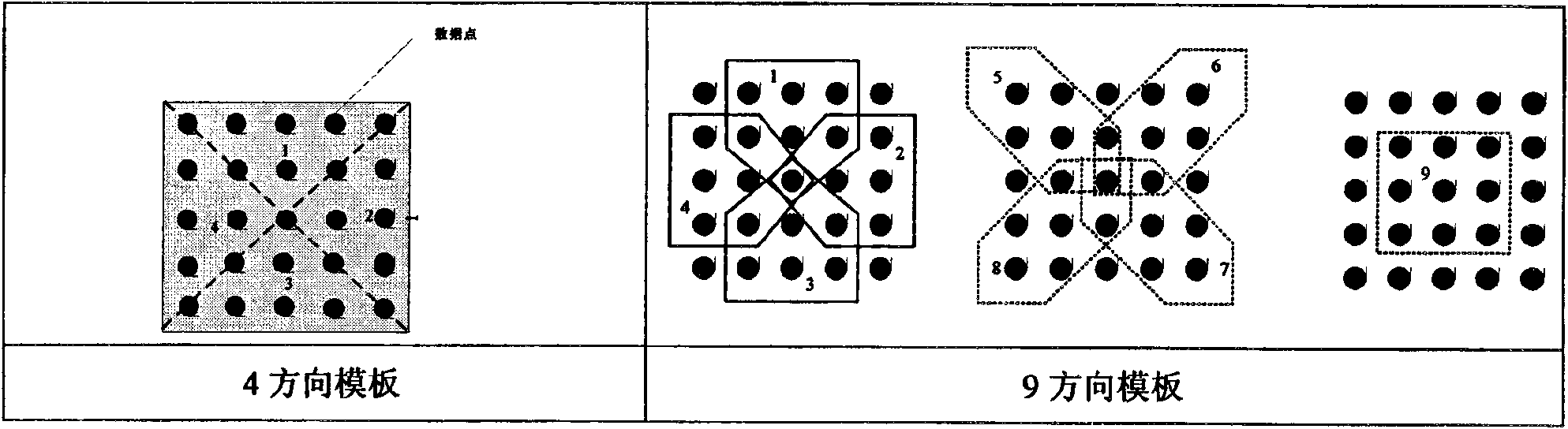

Welding track detection and control method of plate butt weld based on laser ranging

InactiveCN101559512ATo achieve the purpose of seam trackingTo achieve the purpose of trackingArc welding apparatusNumerical controlLaser rangingField tests

The invention relates to a welding track detection and control method of plate butt weld based on laser ranging, including the following steps: A. track detection is carried out; B. track identification and extraction are carried out; C. track control is carried out; D. the relative position relation between a welding gun and a welding seam is adjusted at last by performing mechanism actions. In the invention, the information of welding seam profile is obtained by transverse scanning of a laser sensor, and welding seam is rebuilt after effective wave filtering treatment to realize three-dimensional detection of the welding seam; simultaneously, the welding track curve is obtained by fit while detecting welding seam by using dynamic B spline fit algorithm, and the track control is carried out in combination with constant speed B spline track interpolation algorithm, thereby fundamentally solving the problem of track detection and control in automatic welding of plate butt weld. By using the method in the invention, the field test welding has welding profile identification precision of 0.15mm and welding track identification precision of 0.2mm, and the welding speed is more than four times of common manual welding.

Owner:SHANDONG UNIV

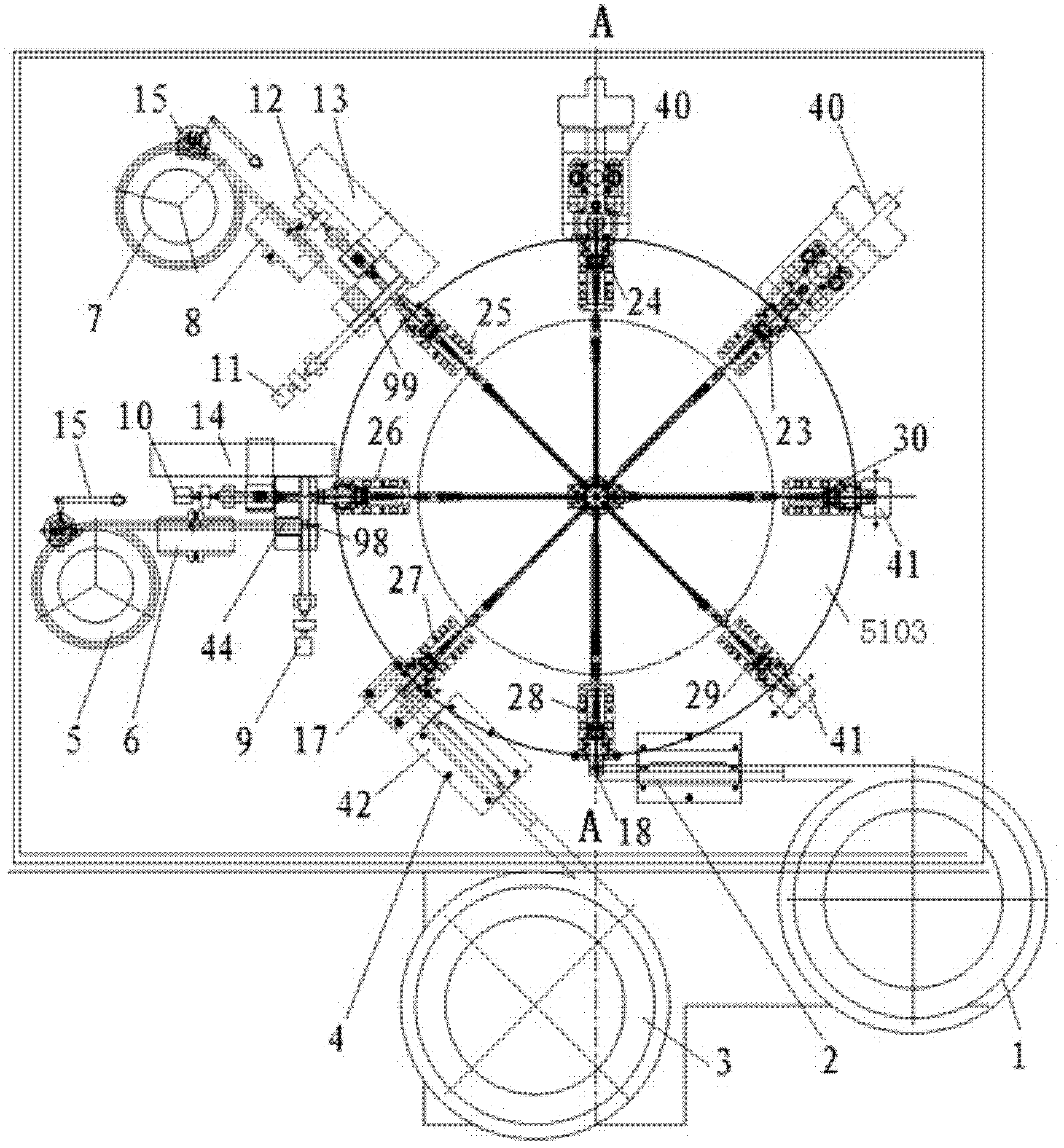

Full-automatic multi-station welding system

ActiveCN102528353AAchieve separationAchieve storageWelding/cutting auxillary devicesAuxillary welding devicesManipulatorContactor

The invention discloses a full-automatic multi-station welding system which mainly comprises a rotary table and driving device, contact bridge storage and feeding devices, contactor feeding and conveying devices, welding machine heads and a discharge component, wherein the rotary table and driving device is internally and externally divided in the shape of a ring in the such way of equal and concentric eight parts and four stations, and the positions are set to be an even number according to the welding positions of welded pieces; eight mechanical arm assemblies are uniformly distributed in the circumferential direction on the upper surface of an outer rotary table; two contact bridge storage and feeding devices, two contactor feeding and conveying devices, two welding machine heads and two discharge devices are correspondingly arranged in sequence on the outer side of eight positions; each contact bridge storage and feeding device is engaged with a lower mechanical arm in the present position; each contactor feeding and conveying device comprises a device for identifying front / back faces and sorting during contactor feeding, a solder dropping device and a contactor cross-pushing device. The full-automatic multi-position welding system achieves synchronization of fully automatically welding, assembling and forming multiple sets of equipment in multiple positions at the same time.

Owner:ZHEJIANG CHINT ELECTRIC CO LTD

High-performance refractory weather-resisting building steel and its production method

InactiveCN1354273AImprove fire resistanceHigh yield strengthManufacturing cost reductionHeat-affected zone

The present invention relates to a high-performance fire-resistant weather-resisting building steel and its production method. Said invention steel contains C, Si, Mn, P, S, Mo, Ti, Al, N, O, Cr, Ni, Cu, Ca, B and one or more than one kind of Nb, V and RE and the rest is Fe. After having been undergone the processes of smelting, rolling and heat treatment, said building steel possesses high strenght, high toughness and excellent fire-resisting and weather-resisting properties. The building steel can be used for providing various steel structural members whose thickness is 4-100 mm in the fields of building, civil engineering and marine structure. Under the large linear energy (50-100 kJ / cm) welding condition of gas-arc welding, electroslag welding and high-frequency resistance welding, its heat affected zone (HAZ) still possesses excellent toughness so as to greatly raise welding efficiency of engineering structure and reduce its manufacture cost.

Owner:武钢集团有限公司

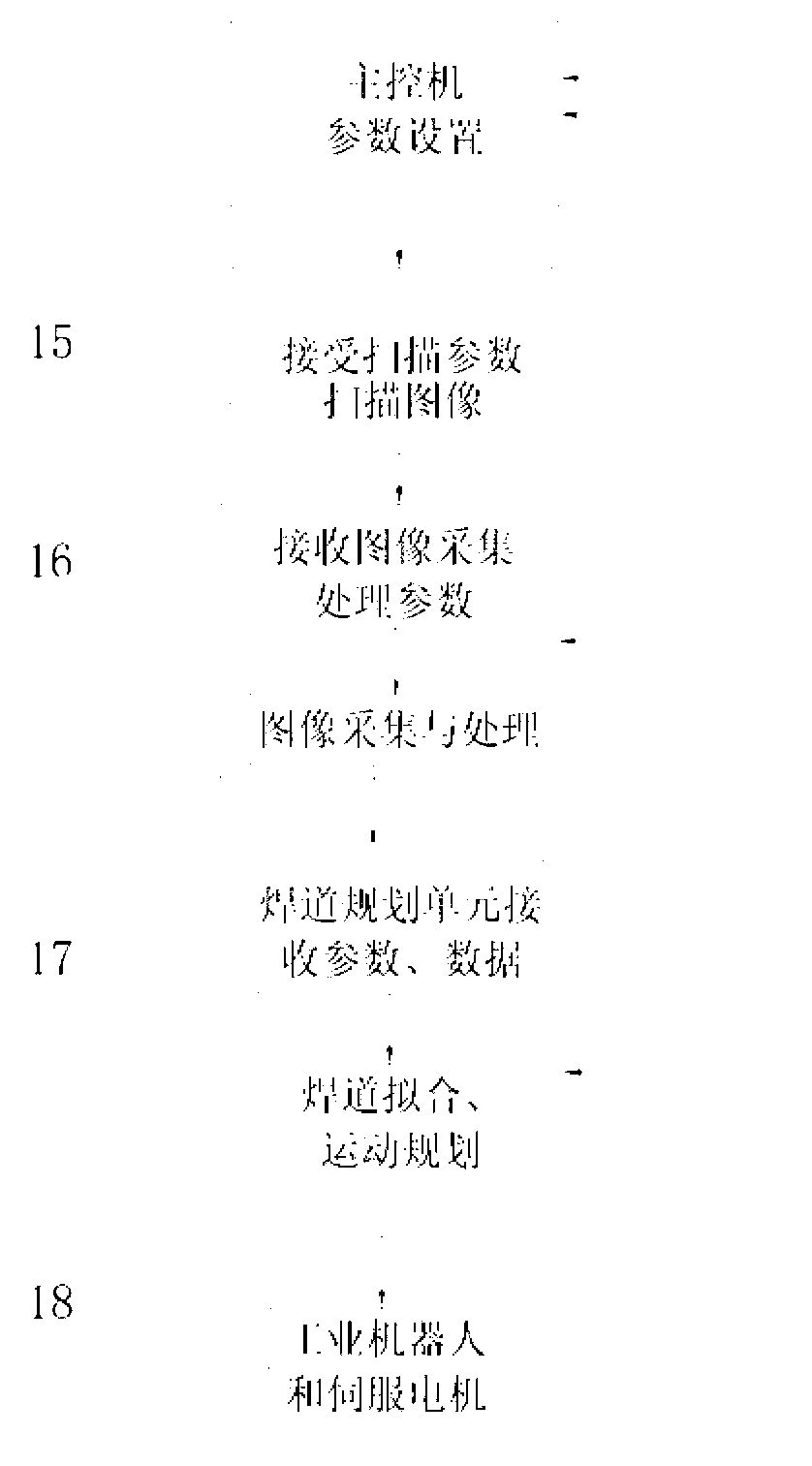

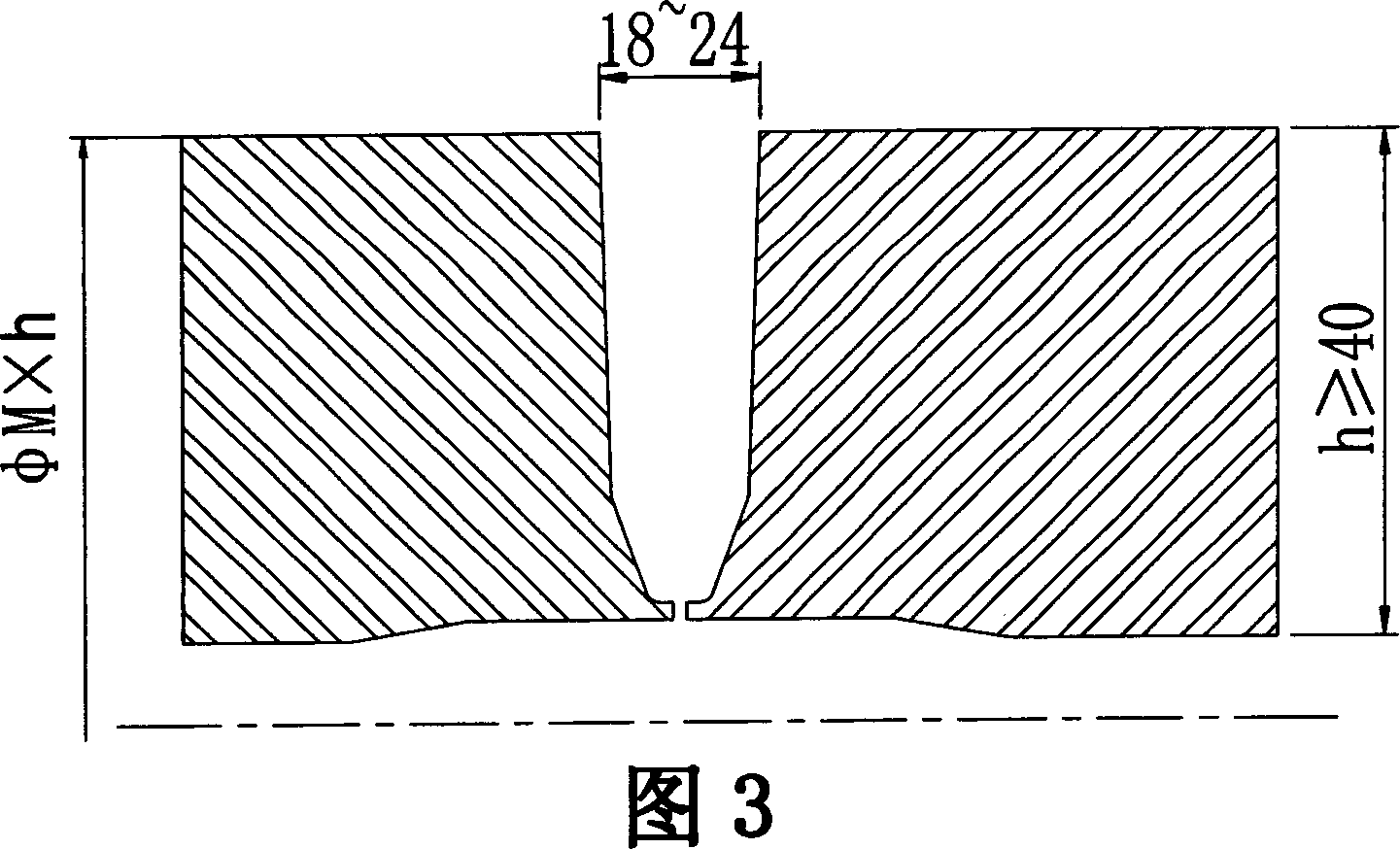

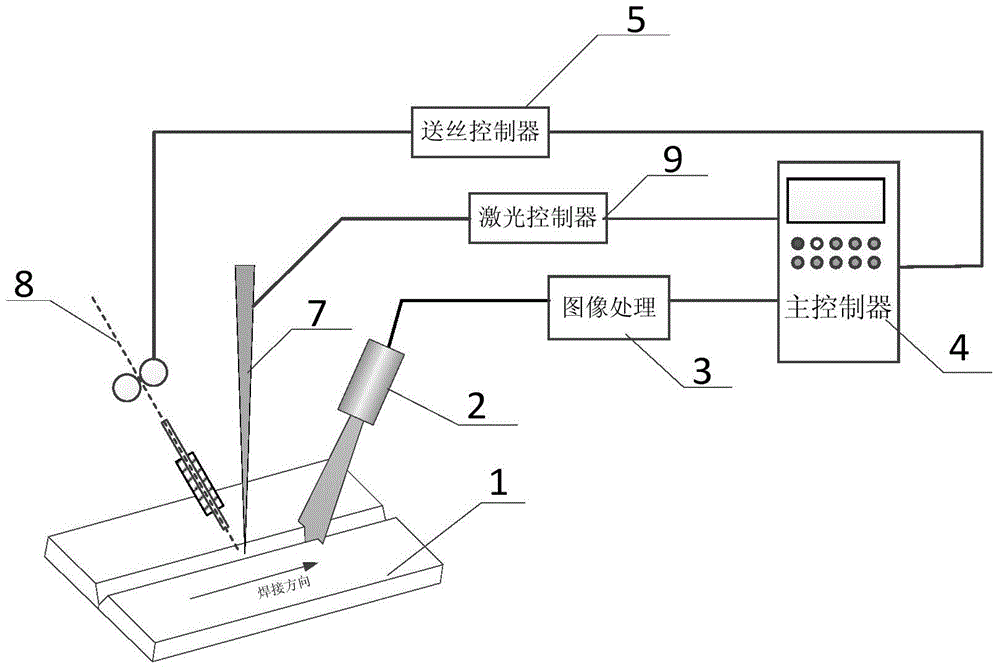

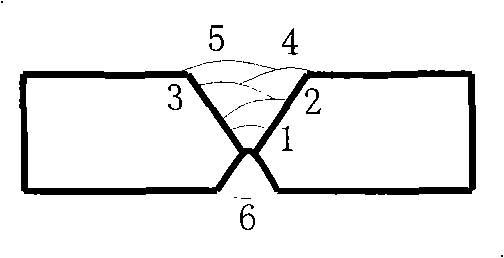

Scanning type laser vision sensing-based narrow-gap deep-groove automatic laser multilayer welding method for thick plate

InactiveCN102699534AImprove portabilityIncrease flexibilityLaser beam welding apparatusThick plateImaging algorithm

The invention discloses a scanning type laser vision sensing-based narrow-gap deep-groove automatic laser multilayer welding method for a thick plate, relates to a welding method, and aims to solve the problems that the conventional structured light vision sensing-based welding method can only be used for a simple shallow-groove laser weld seam tracking task and that when the conventional structured light vision sensing-based welding method is used for the narrow-gap deep-groove weld seam welding of the thick plate, a covering phenomenon is easily produced, the groove identification accuracy is lower, only real-time weld seam alignment calibration can be realized and narrow-gap deep-groove laser multilayer welding bead planning and welding cannot be realized. The method specifically comprises the following steps of: 1, selecting a groove form; 2, scanning a groove section image of a thick plate workpiece to be welded by using an image scanning unit; 3, processing the acquired groove section image by using an image algorithm to obtain weld seam image data; 4, performing fitting calculation; and 5, finishing the welding of welding beads layer by layer. The method is used for the deep-groove weld seam welding of the thick plate.

Owner:HARBIN INST OF TECH

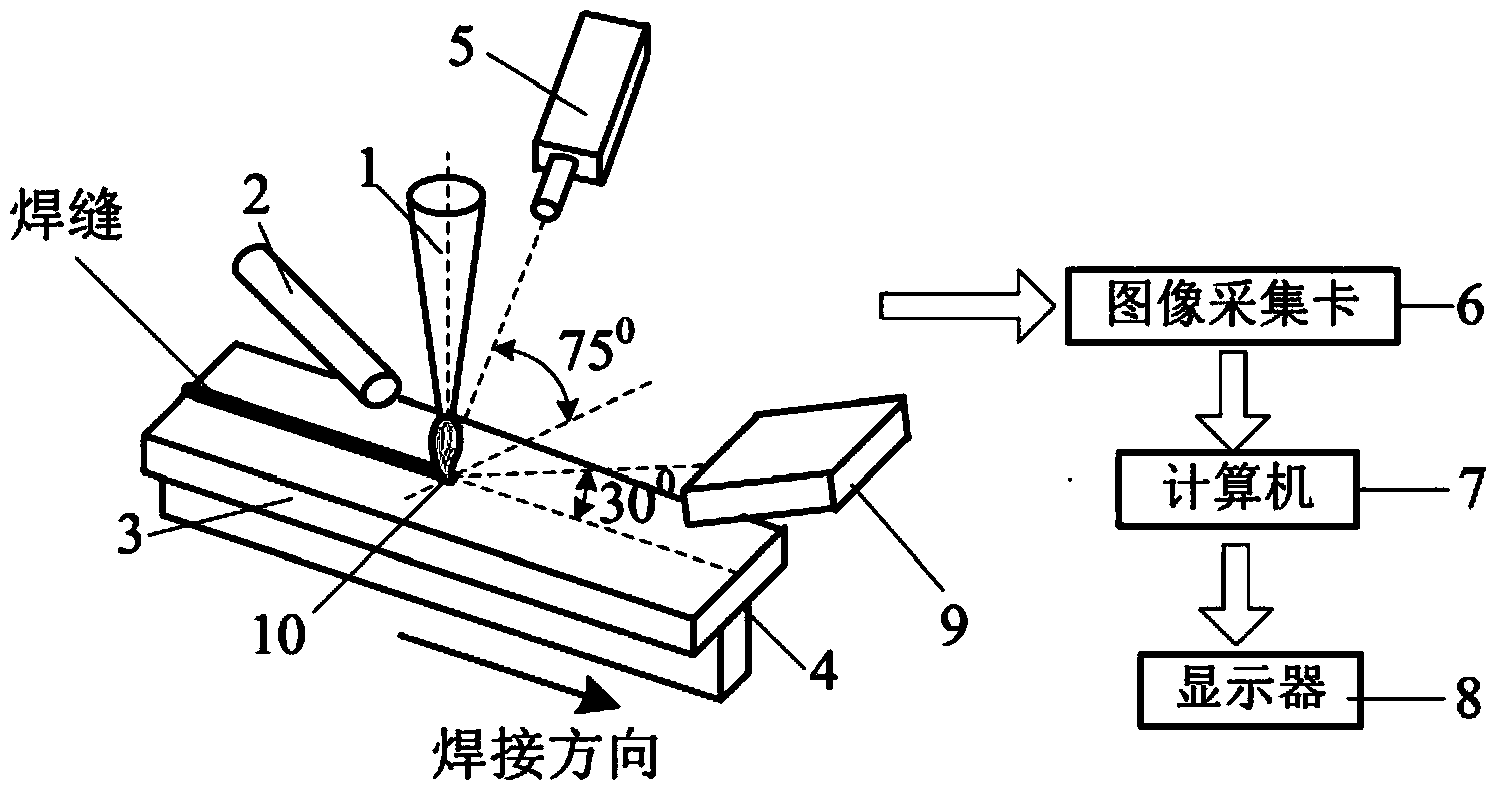

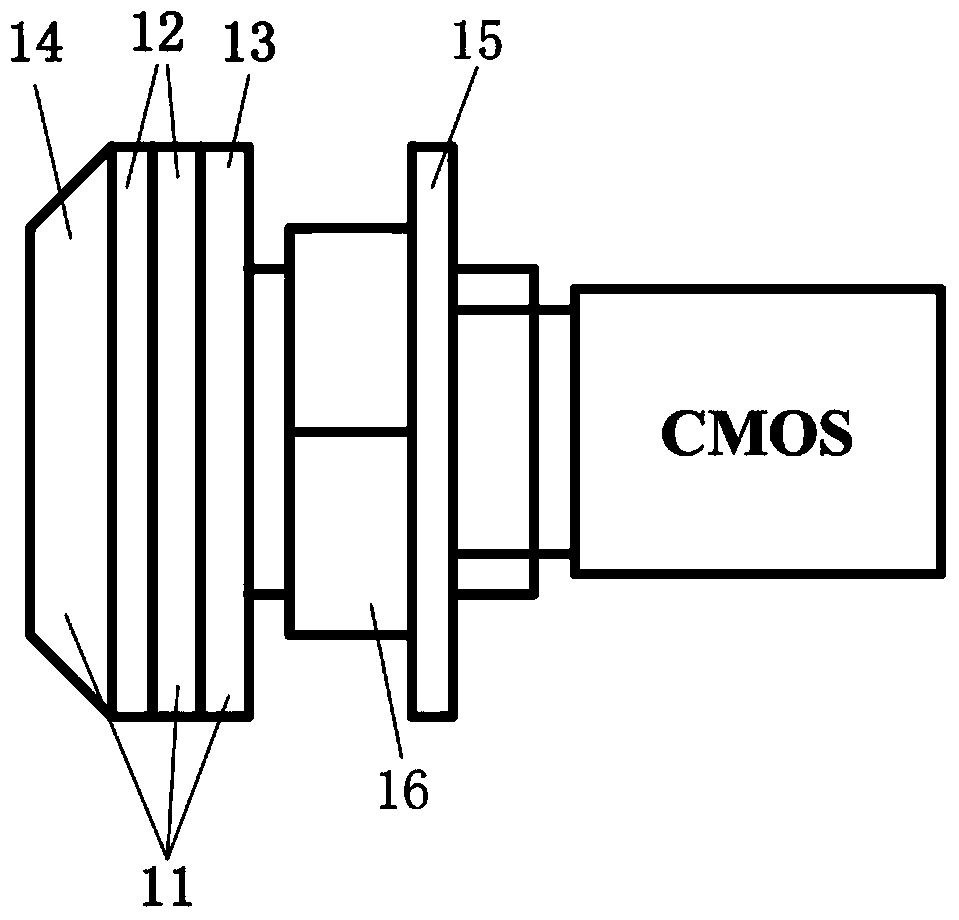

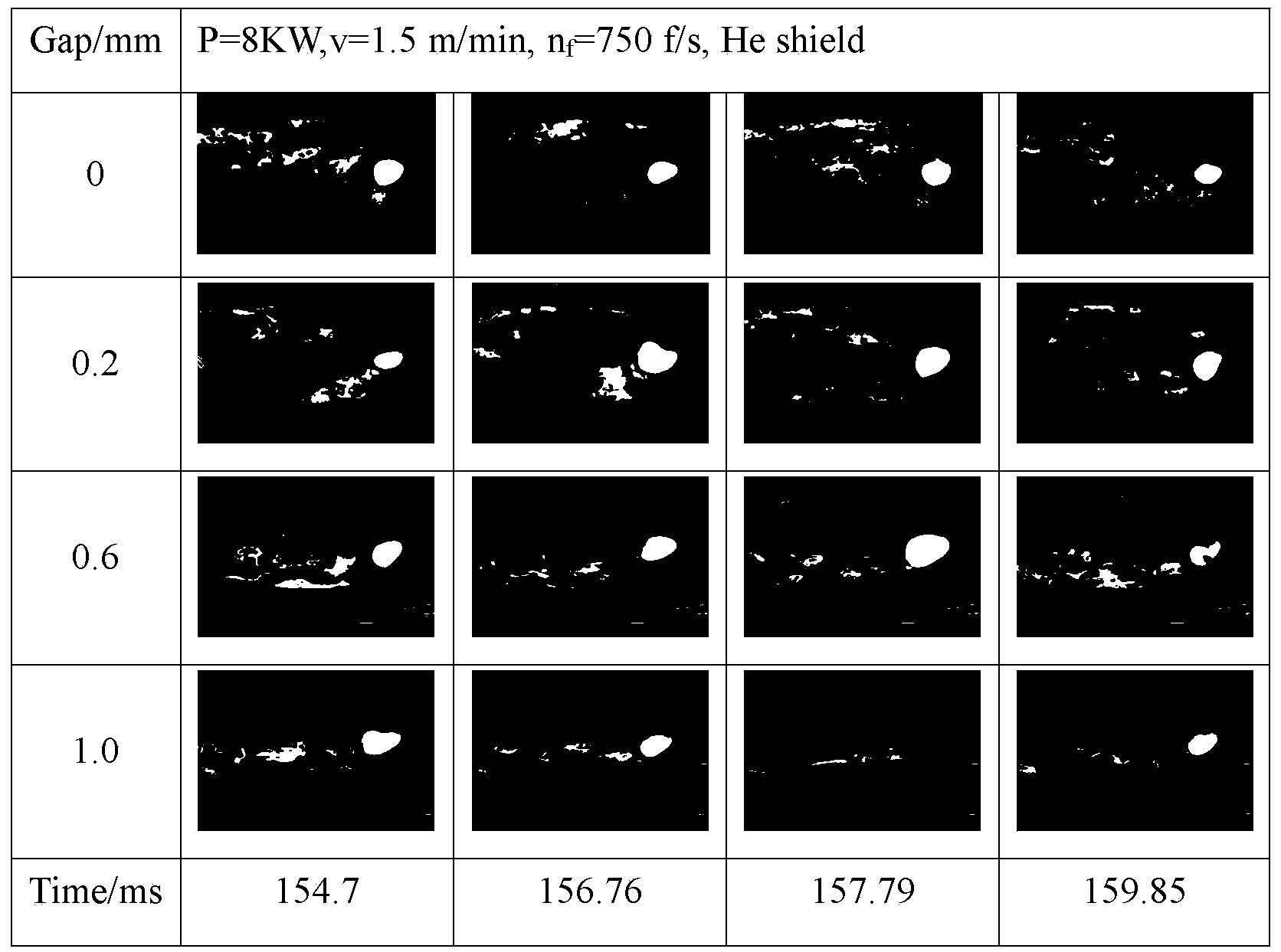

Laser lap welding gap detecting system and laser lap welding gap detecting method based on molten pool image visual sensing

ActiveCN103506756AMeet the requirements of seam trackingImprove quality and efficiencyLaser beam welding apparatusAnti jammingDisplay device

The invention discloses a laser lap welding gap detecting system and a laser lap welding gap detecting method based on molten pool image visual sensing. The detecting system is a visual sensing system and comprises a CMOS camera, a light filtering system, a secondary light source, an image capture card, a computer, a display and the like, wherein the CMOS camera has a LinLog photosensory technology. According to the detecting method, the secondary light source and emitted light of molten pools are used as light sources; plasma is filtered out by utilizing the light filtering system, and light intensity is adjusted; the computer is used for collecting and displaying molten pool images in real time, wherein the molten pool images are obtained by the CMOS camera; molten pool image edges and areas and orifice image edges and areas are extracted and calculated by utilizing a Labview image processing platform, and the quantitative relations between molten pool sizes and orifice areas and between the molten pool sizes and orifice gaps are obtained. The detecting system is simple in structure, clear in monitoring image, high in light signal detecting accuracy, strong in anti-jamming capacity, good in engineering practicability and capable of monitoring laser welding of T-type overlap joint gaps in real time.

Owner:SHANGHAI JIAO TONG UNIV

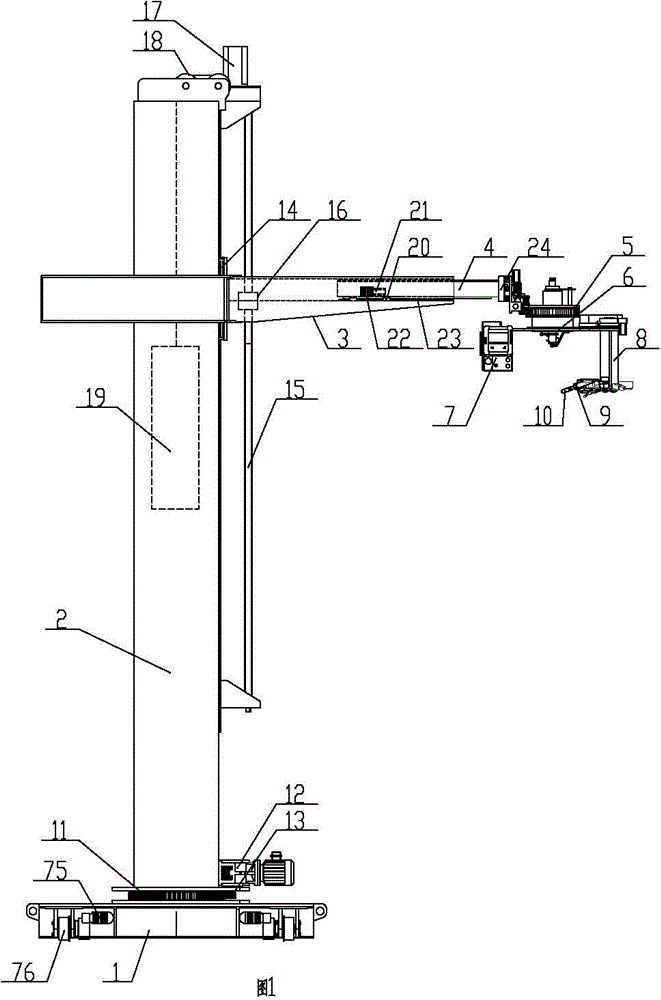

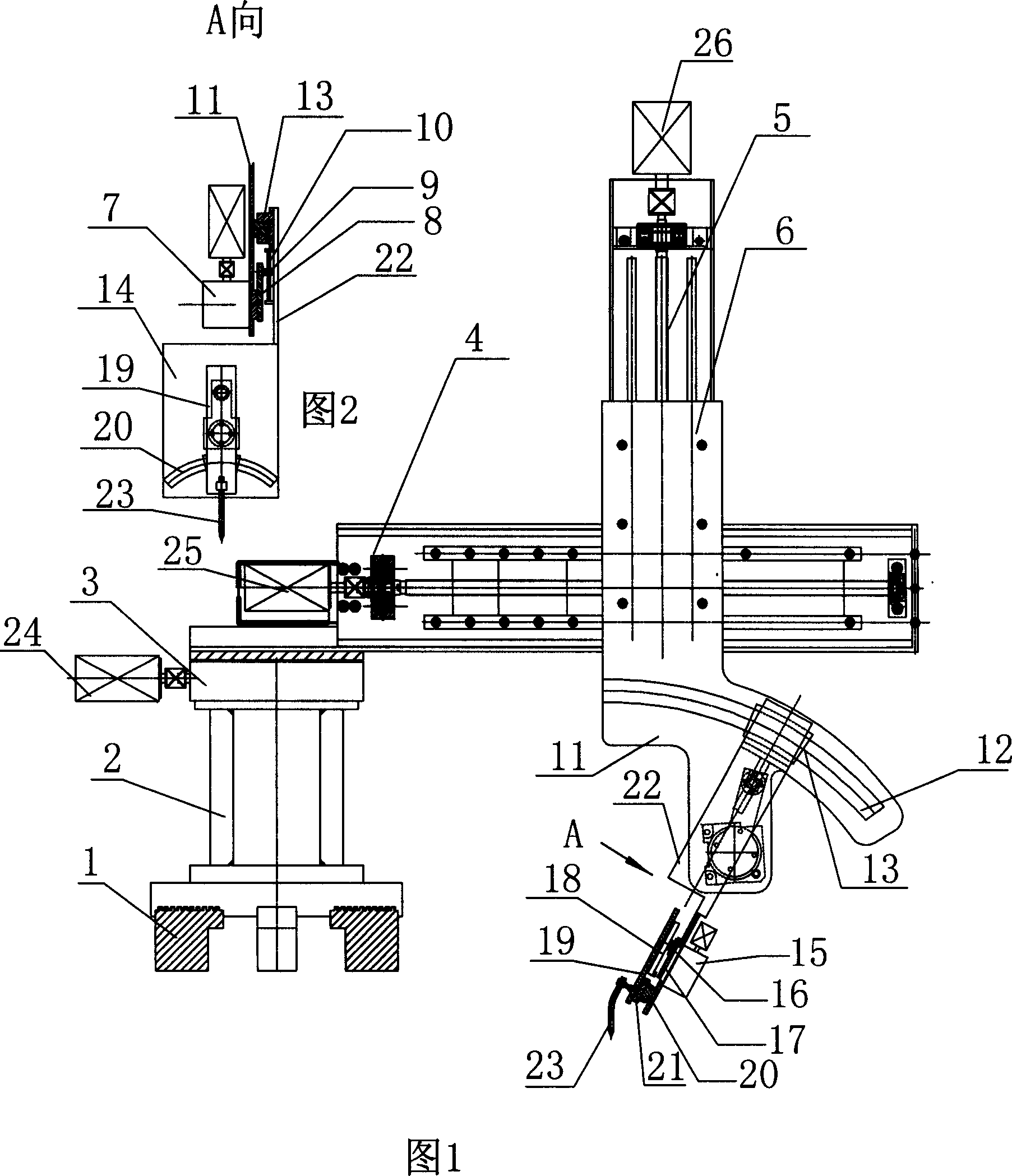

Multifunctional single-cantilever cutting and welding integrated machine

InactiveCN104308333AAvoid frequent movementReduce the number of card positioningWelding/cutting auxillary devicesAuxillary welding devicesFillet weldEngineering

The invention relates to the technical field of automated cutting and welding, and discloses a multifunctional single-cantilever cutting and welding integrated machine. The integrated machine comprises a machine frame base, a machine frame stand column, a stand column rotary device, a vertical lifting device, a machine frame transverse arm, a left-right translation device, a telescopic arm, a front-rear transverse moving device and a multi-joint machine head, wherein the machine frame stand column is mounted on the machine frame base through the stand column rotary device, and the machine frame transverse arm is mounted at the upper part of the machine frame stand column through the vertical lifting device. The integrated machine is reasonable and compact in structure and convenient to use; the welding of longitudinal, circumferential and fillet weld seams, cutting of an intersecting line hole and automatic welding of a saddle-shaped weld seam between a barrel body and a connecting pipe can be finished in a relatively fixed station through the stand column rotary device, the vertical lifting device, the left-right translation device, the front-rear transverse moving device and the multi-joint machine head, the frequent motion of a workpiece can be avoided, the clamping and positioning frequency of the workpiece is greatly reduced, the welding efficiency and quality are remarkably improved, and the labor intensity of welding workers is reduced.

Owner:新疆威奥科技股份有限公司

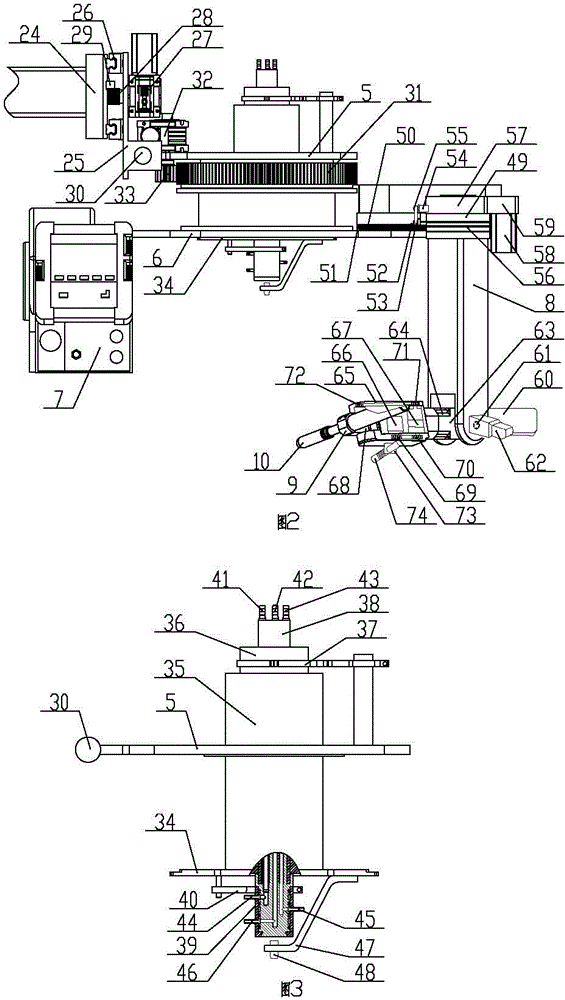

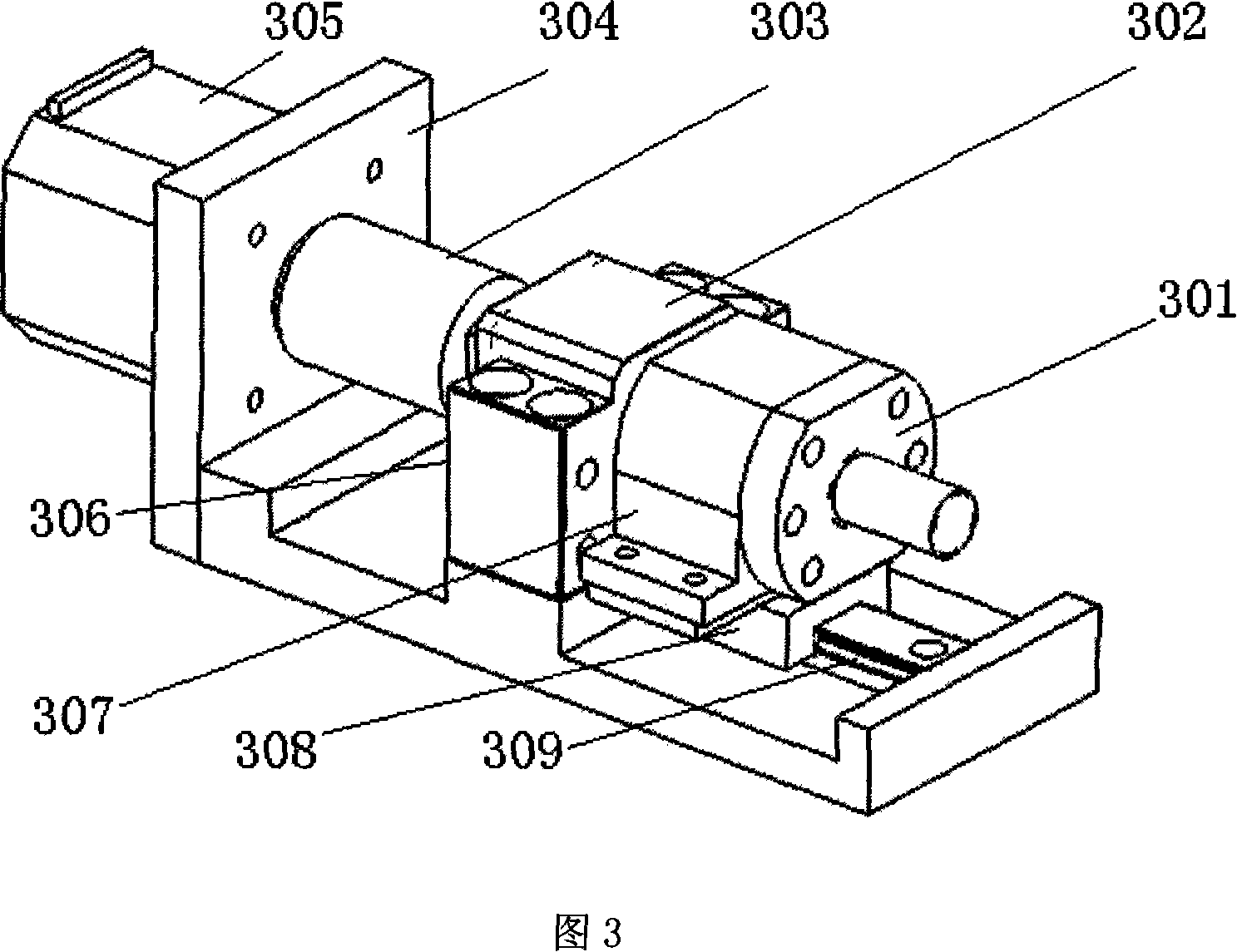

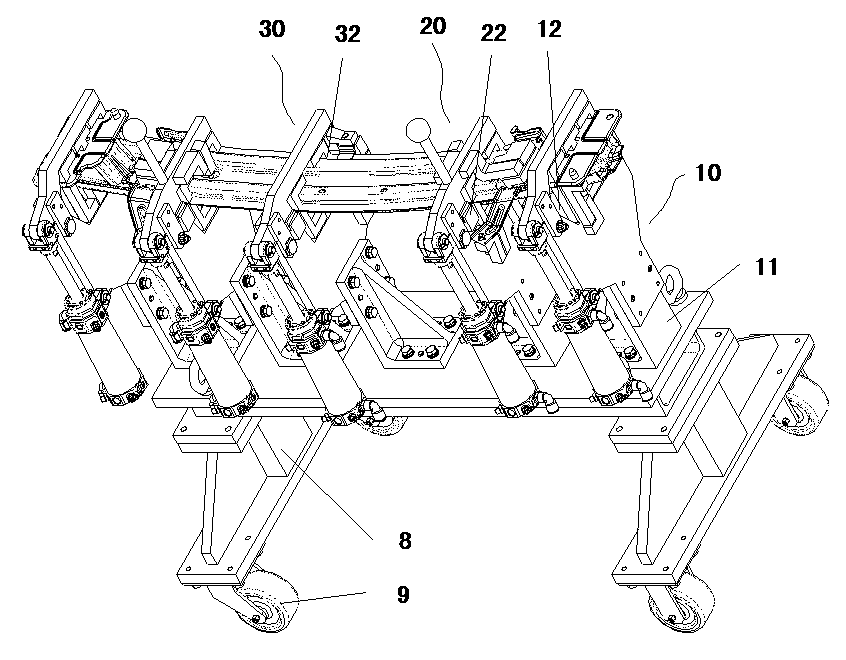

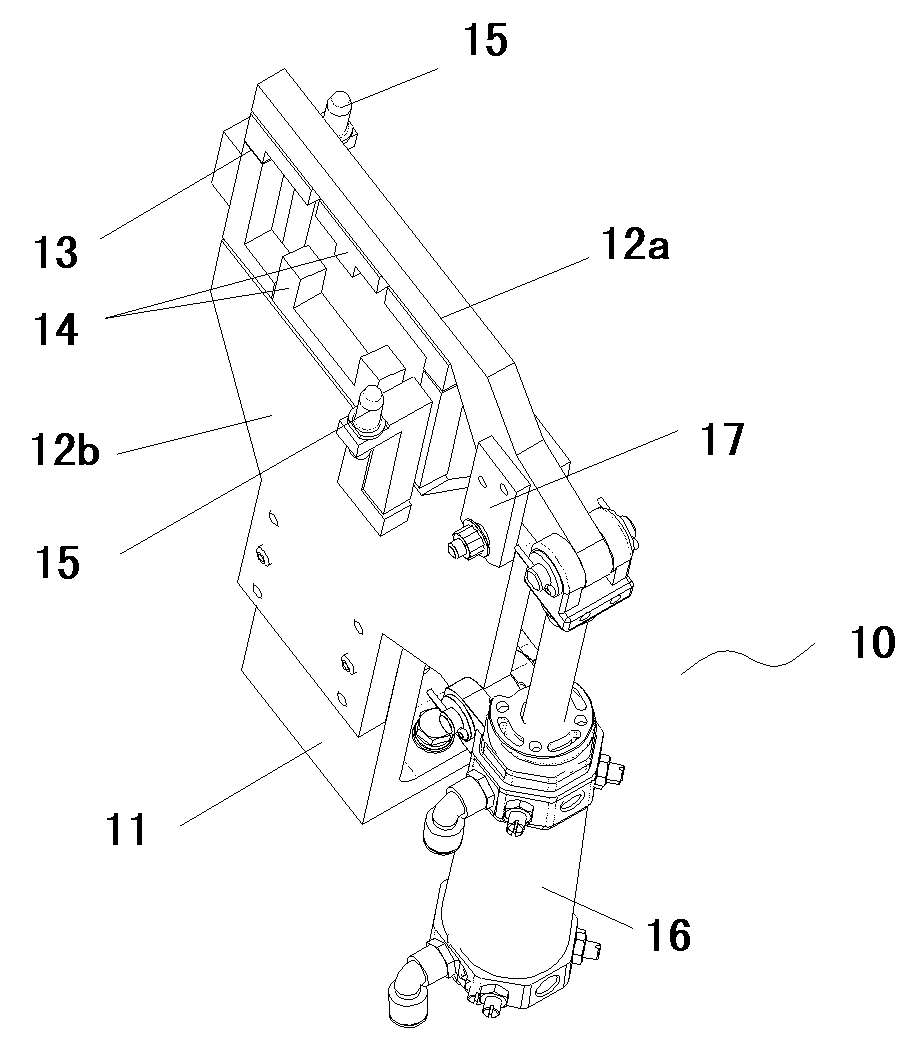

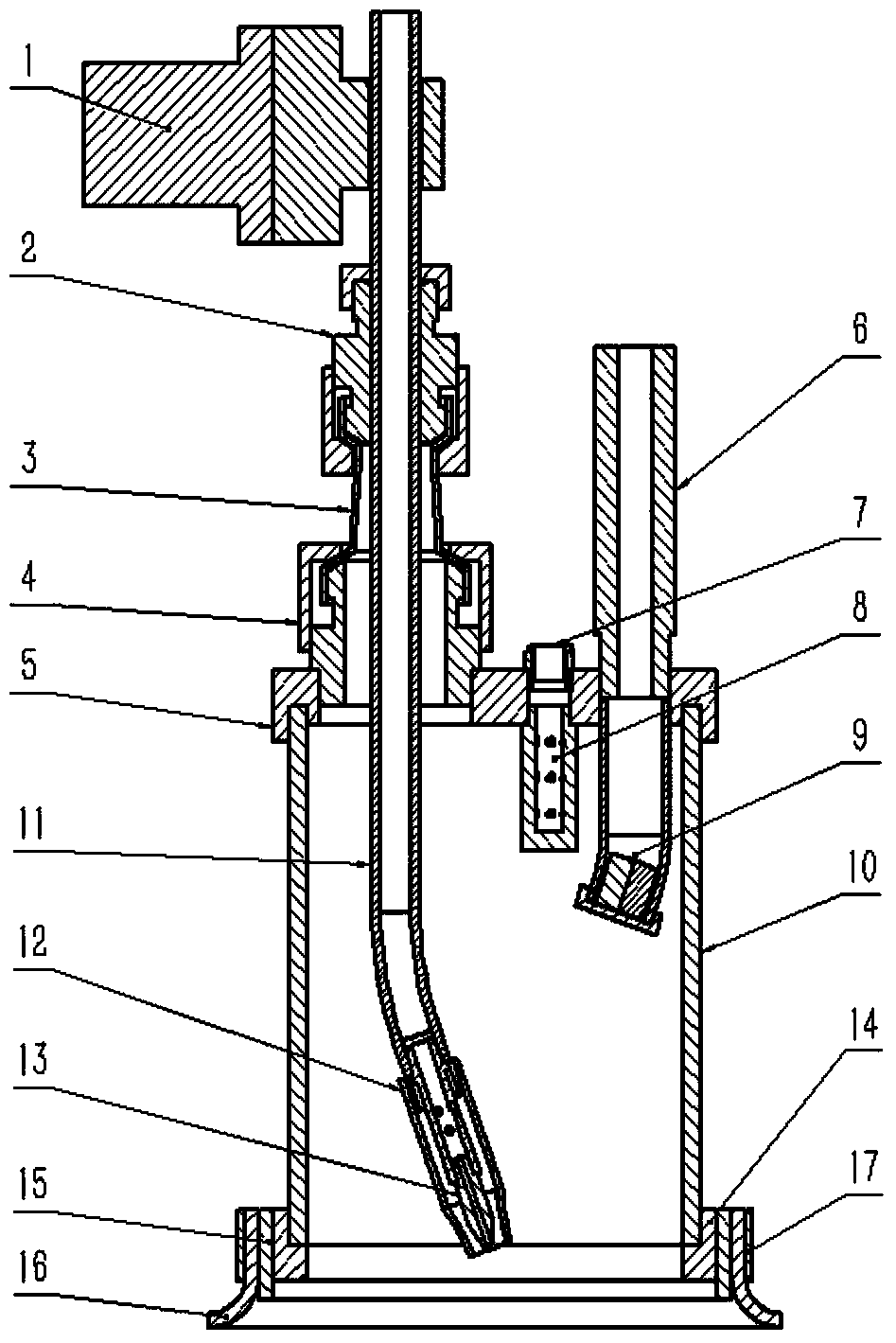

Modular self-adaptive regulation clamp to weld car and its regulating method

InactiveCN101104233AEasy to connectImprove flexibilityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSelf adaptive

The invention relates to a modularizing self-adaptation adjusting clamp used in the automobile welding, comprising a based station(1), a clamping mechanism(100) fixed on the based station(1) , an independent principal positioning mechanism(200), and an online real-time detecting and self-adaptation adjusting device(300). The online real-time detecting and self-adaptation adjusting device (300) is composed of a stepping motor (305), a slider (308), a straight-line guiding rail (309) and a transmission device. The transmission device, which is driven by the stepping motor (305), pushes a pushing rod (301) and the slider to slide along the straight-line guiding rail (309). The invention is more flexible and is convenient for the connection and combination of every component by means of modularized, standardized and serialized clamp elements, can be adapted to various work within a certain range and type, can effectively reduce the manufacturing cost, effectively controls the precision of the key points of workpieces and improves the welding quality and efficiency.

Owner:DONGHUA UNIV

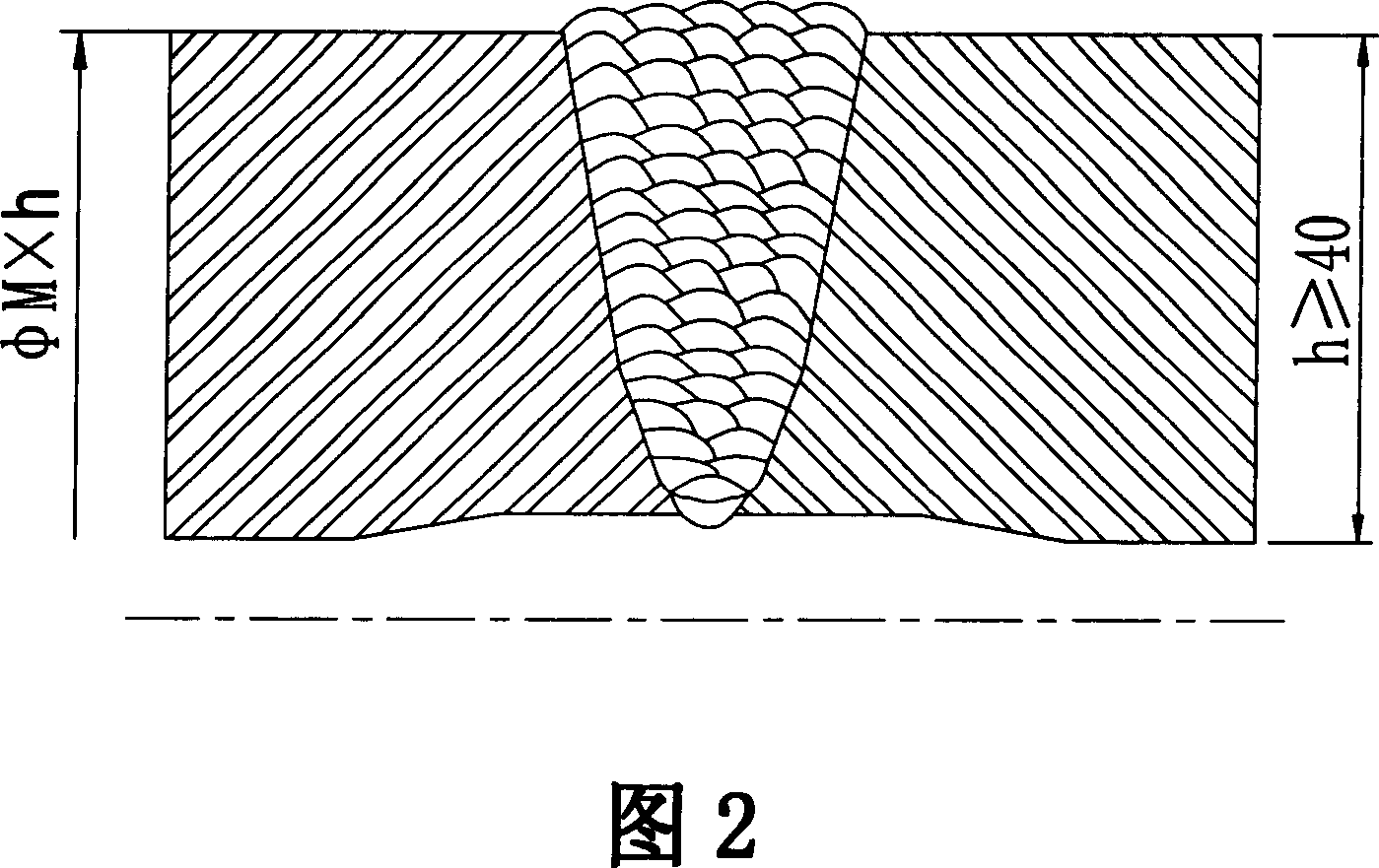

Large posted sides pipeline narrow gap tungsten electrode noble gas protecting all-position automatic soldering method

ActiveCN101077547AReduce fillingReduce welding costsArc welding apparatusWelding/cutting media/materialsNoble gasEngineering

The present invention relates to inert gas protected automatic narrow gap tungsten electrode welding process for large thick pipe with diameter over 325 mm and thickness over 40 mm. The automatic welding process includes forming combining chamfer in the opposite ends to be welded before welding, bottoming welding, single layer filling welding, and covering welding in linear or swinging weld pass. The process has less filled deposited metal, low welding cost, high welding efficiency and other advantages.

Owner:CHINA NUCLEAR IND 23 CONSTR

Yield strength 700MPa grade atmospheric corrosion resistant steel and method for manufacturing same

ActiveCN101135029AImprove mechanical propertiesSuitable for thin designTemperature control deviceHeat treatment process controlSheet steelWeather resistance

The atmospheric corrosion resistant steel with yield strength of 700 MPa level has the chemical composition comprising C 0.05-0.10 wt%, Si not more than 0.50 wt%, Mn 0.8-1.6 wt%, P not more than 0.020 wt%, S not more than 0.010 wt%, Al 0.01-0.05 wt%, Cu 0.20-0.55 wt%, Cr 0.40-0.80 wt%, Ni 0.12-0.40 wt%, Ca 0.001-0.006 wt%, N 0.001-0.006 wt% and Fe and inevitable impurity for the rest. Its production process includes the following steps: 1. smelting and casting to form steel billet; 2. heating the steel billet to over 1200 deg.c, finish rolling at 950 deg.c in the final temperature lower than 910 deg.c and lowered with the increased plate thickness; and 3. cooling in the rate of 5-15 deg / s to 450-650 deg.c, winding and air cooling to room temperature. The atmospheric corrosion resistant steel has excellent comprehensive mechanical performance, yield strength over 700 MPa, high weather resistance and other advantages.

Owner:BAOSHAN IRON & STEEL CO LTD

Unmodified high-toughness low-temp steel for high-energy line welding and its production method

A high-toughness low-temp steel for high-energy linear welding contains C, Si, Mn, P, S, Al, Ti, N, B, Fe, and one or more of Cu, Ni, Nb, V, Mo and RE. The compound Ti-B oxide is used to obtain high welding performance under high linear energy (greater than 50 KJ / cm). Its low content of C and impurities can improve its toughness. Its advantags are high weld performance and low-temp toughness, andlow cost. It is suitable for low-temp spherical tank and large containers.

Owner:武钢集团有限公司

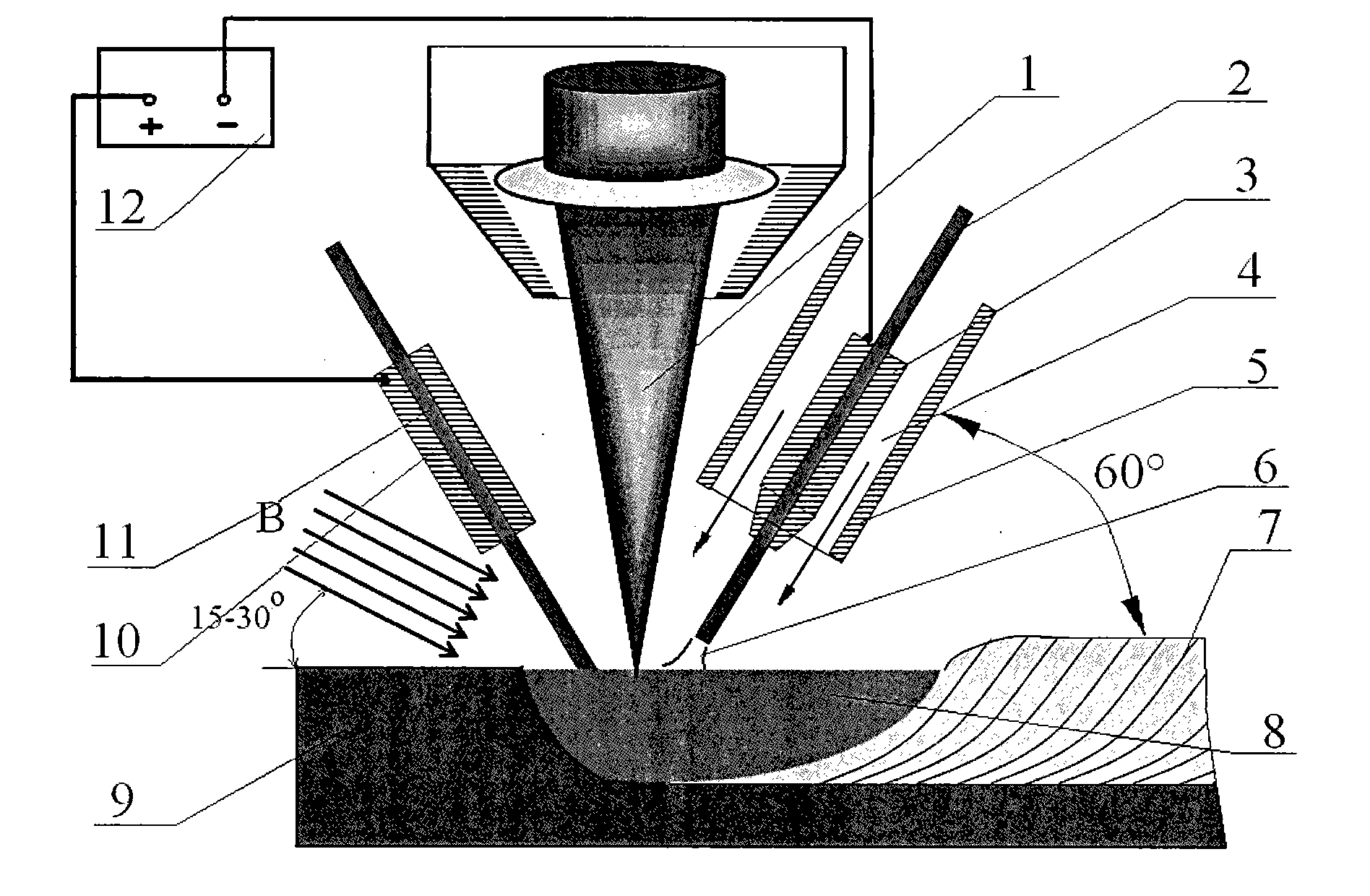

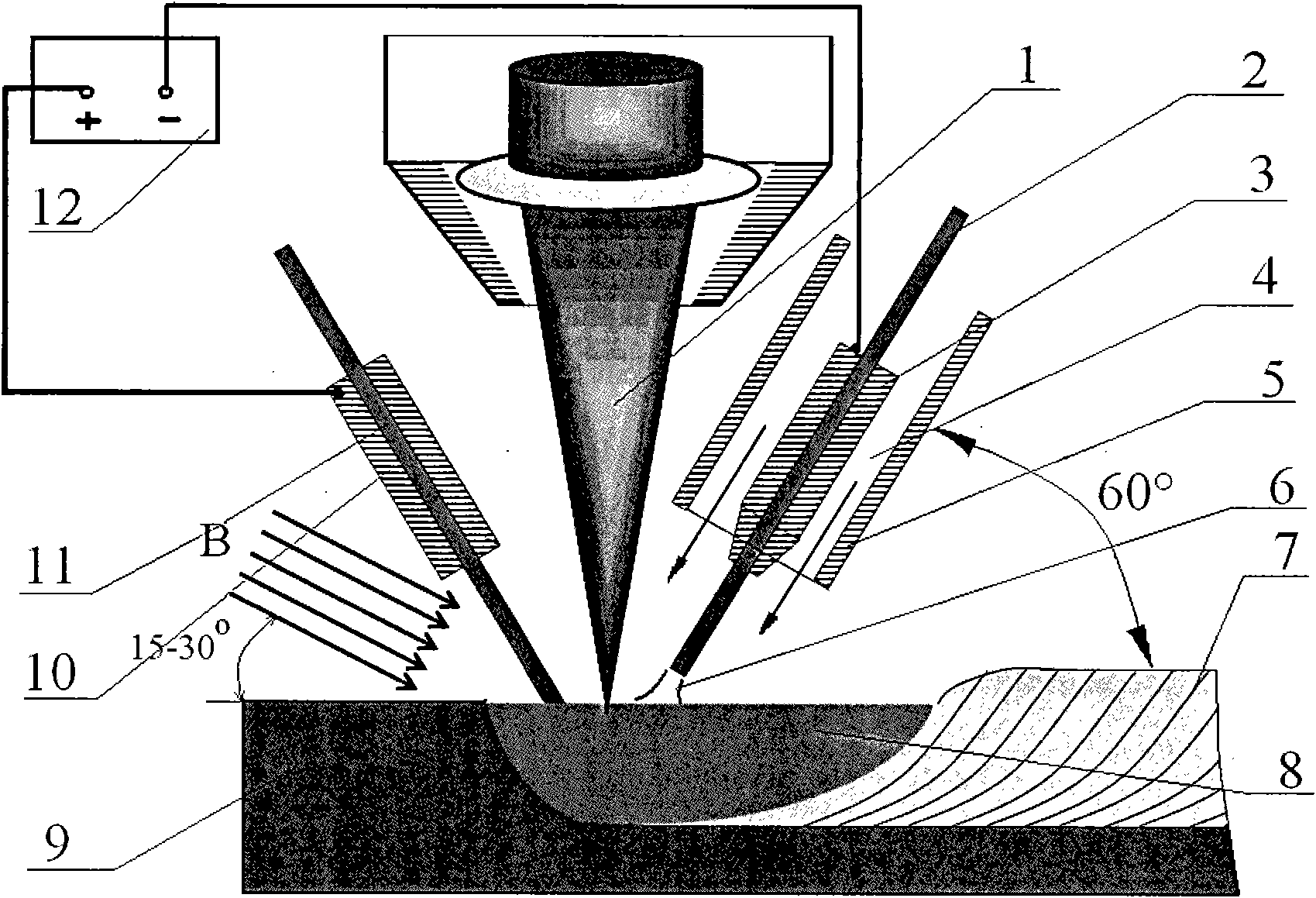

Electromagnetic current coupling field assisted hybrid melting-brazing method for laser-TIG arc and equipment

InactiveCN101862913AImprove connection qualityInhibition formationSoldering apparatusWelding apparatusMetallic materialsWelding defect

The invention discloses an electromagnetic current coupling field assisted hybrid melting-brazing method for a laser-TIG arc and equipment. In addition to the use of the welding zone, an alternating magnetic field is added to control properties of plasma formed through ionization of laser, arc and a raw material metal, thereby improving the laser utilization rate. Under the electric field assisted comprehensive effect, the weld melting depth is increased, and the assistant effect on the melting bath of the liquid-state brazing filler metal for laser-arc melting-brazing is realized through electromagnetic stirring and excitation and enhancement, thereby promoting the orderly flow of the liquid-state brazing filler metal and the rupture, wetting, spreading and proliferation of the liquid-state brazing filler metal on the surface of the high metal material, improving the full mixing of the liquid-state brazing filler metal and the base metal formed by melting the low-melting-point metal material, improving the uniformity of the components of the brazed weld, stabilizing the welding process, reducing welding defects, increasing the welding speed, improving the weld formation, optimizing the structure and performance of the brazed weld, and improving the quality of the brazed joint. Moreover, the equipment has the advantages of simple structure, flexible application, low cost, good effect and easy realization.

Owner:CHONGQING UNIV

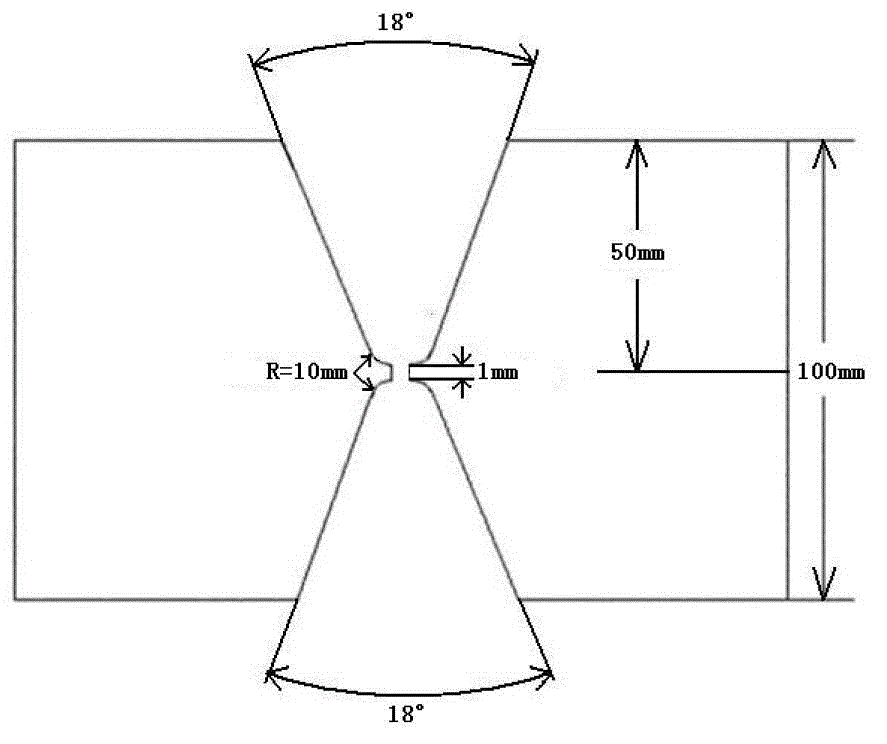

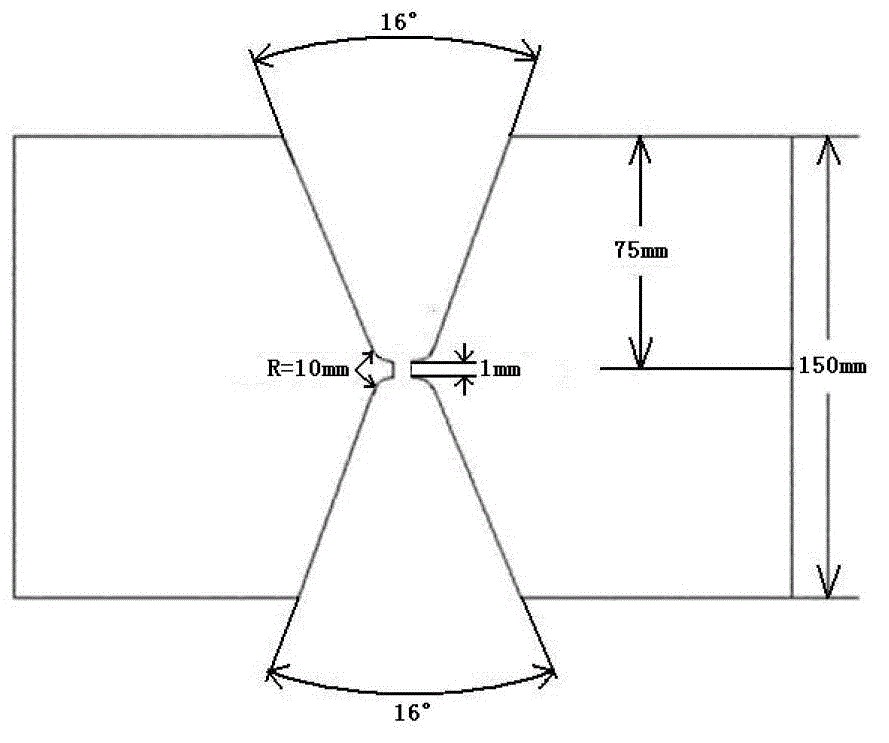

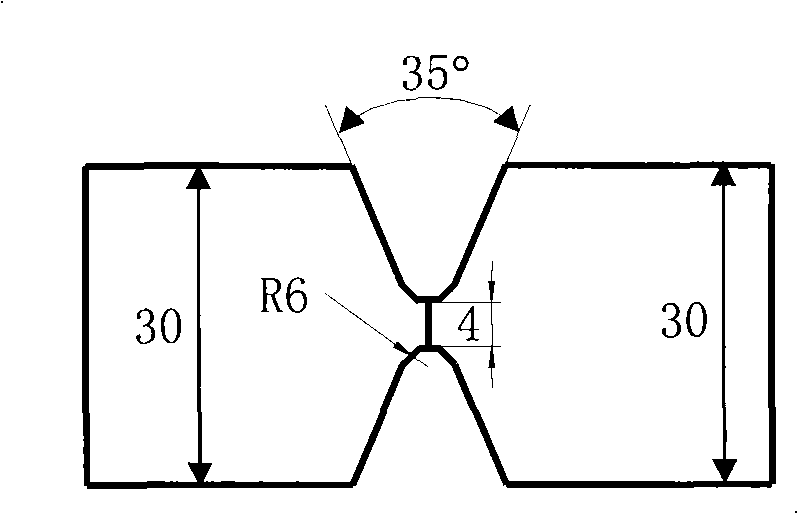

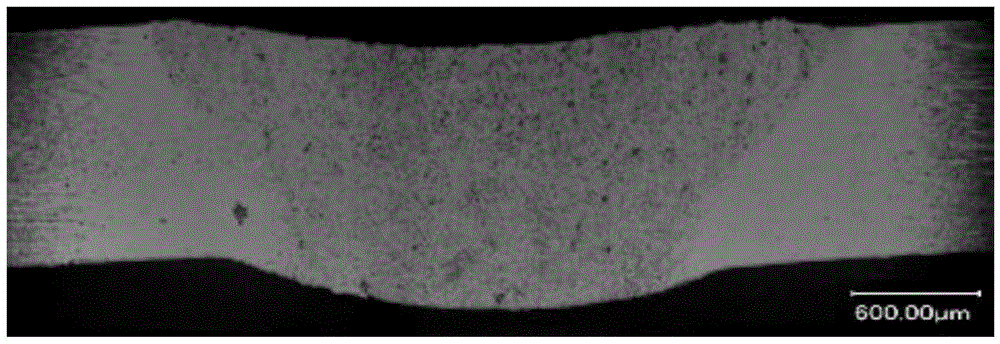

Method for welding specially-thick high-strength bridge steel plate

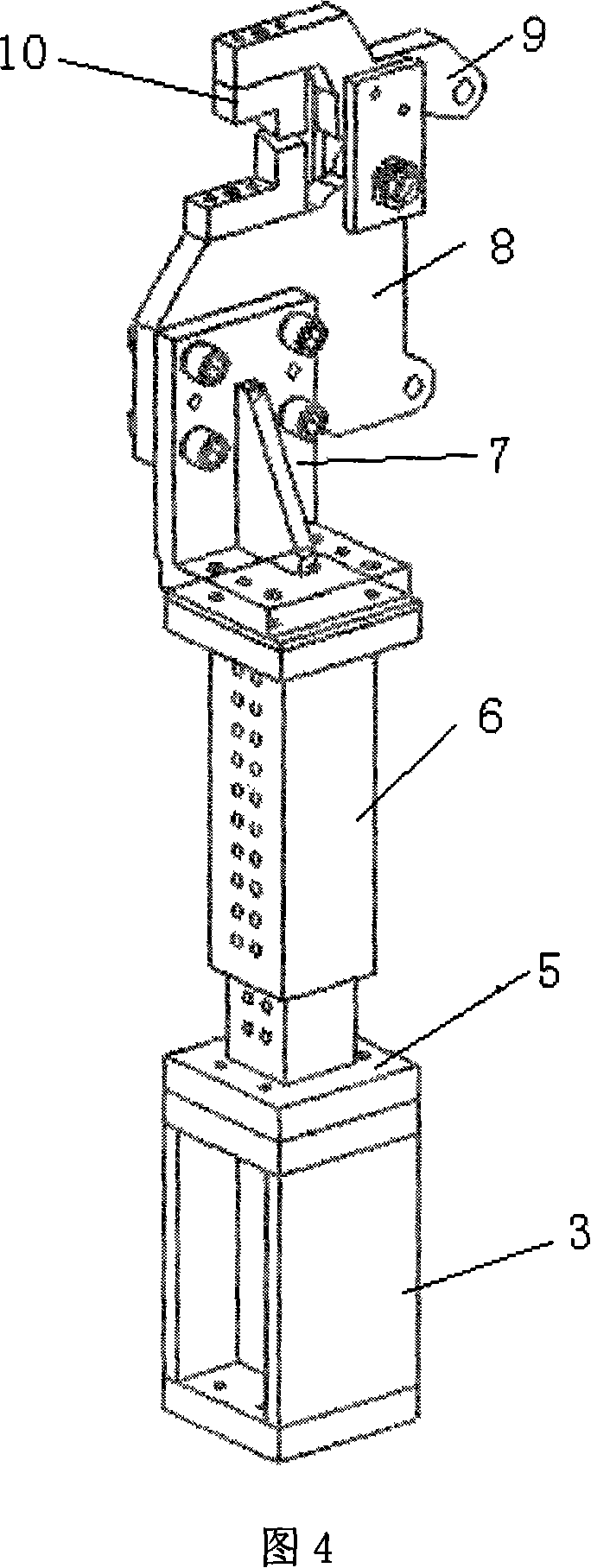

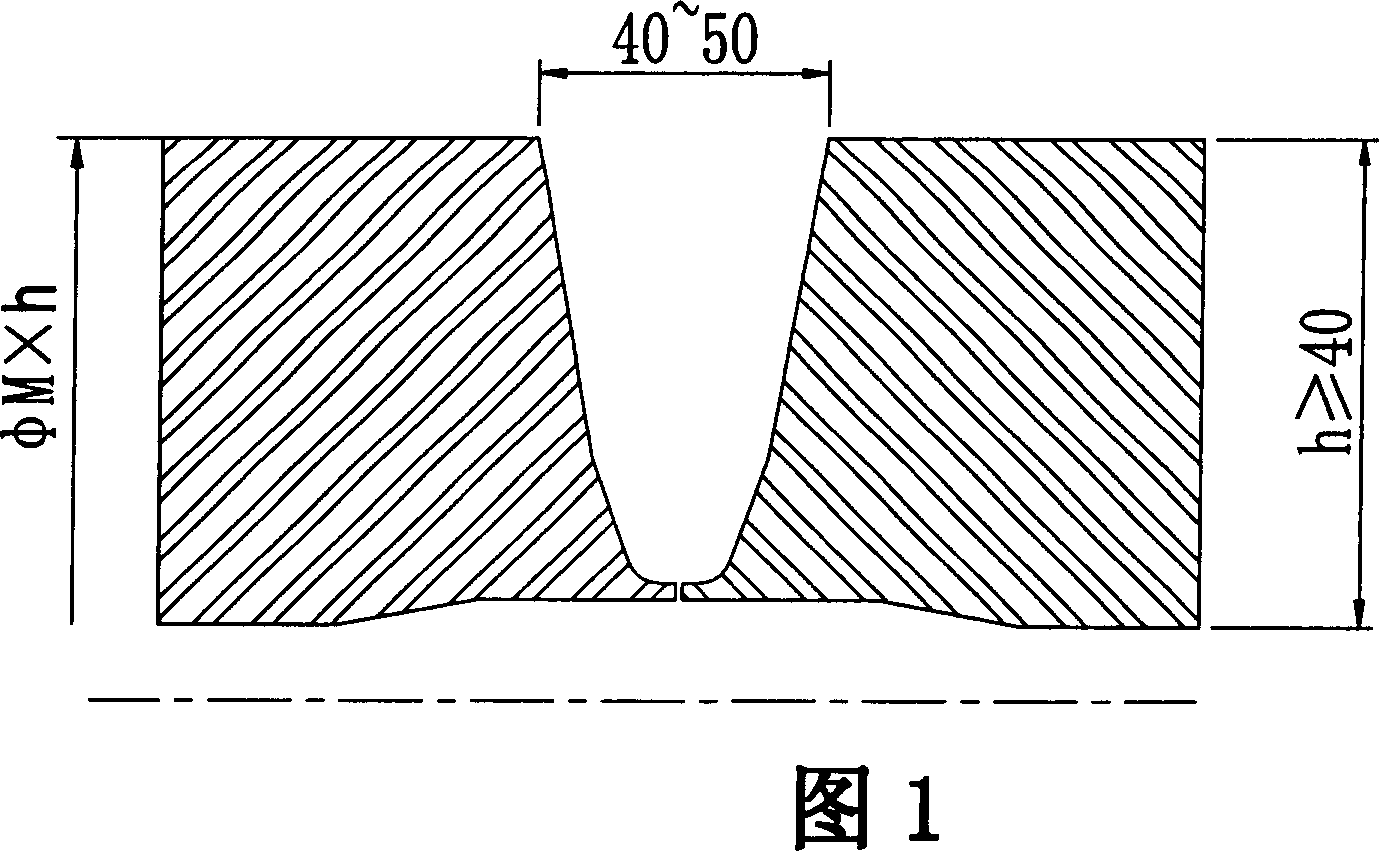

InactiveCN102744498AImprove welding efficiencyReduce manufacturing costArc welding apparatusWorkpiece edge portionsSteel platesSubmerged arc welding

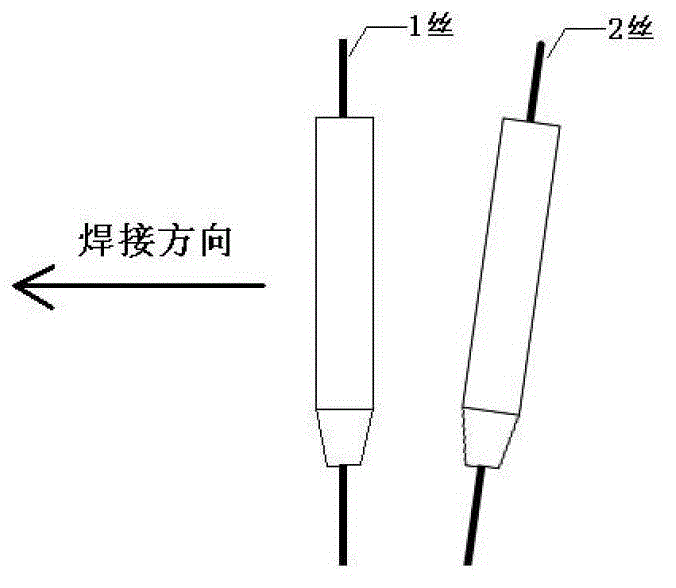

The invention provides a method for welding a specially-thick high-strength bridge steel plate and belongs to the technical field of specially-thick plate welding. The test plate of the method adopts a symmetric narrow gap U-shaped groove form, is combinedly welded by using two efficient welding methods, namely gas shielded welding for priming and bottom filling, and double-wire submerged arc welding for continuous filling and finishing, so as to achieve the purposes of reducing filling level and giving full play to the efficient double-wire submerged arc welding and high automation degree. The method has strong operability, greatly improves the welding efficiency of the specially-thick bridge steel plate, and significantly reduces manpower cost. Furthermore, by selecting a proper welding sequence, the method solves the problem that the welding deformation of the specially-thick steel plate is hard to control.

Owner:SHOUGANG CORPORATION

Air corrosion resisting high strength low alloy metal and its production process

ActiveCN1986864AImprove mechanical propertiesIncreased load-bearing capacityTemperature control deviceRoom temperatureHigh intensity

The present invention relates to high strength air corrosion resisting steel and its production process. The low alloy air corrosion resisting steel consists of C 0.05-0.10 wt%, Si not more than 0.75 wt%, Mn 1.0-1.6 wt%, P not more than 0.020 wt%, S not more than 0.010 wt%, Al 0.01-0.05 wt%, Cu 0.20-0.55 wt%, Cr 0.20-0.45 wt%, Ni 0.12-0.40 wt%, Ca 0.001-0.006 wt%, N 0.001-0.006 wt%, Nb not more than 0.07 wt%, Ti not more than 0.025 wt%, Mo not more than 0.35 wt%, and Fe and inevitable impurity for the rest. It is produced through conventional smelting and two stage rolling after being heated to over 1200 deg.c, and the rolling includes finish rolling with initial temperature of 950 deg.c, accumulated reduction degree not lower than 80 % and final temperature lower than 880 deg.c, cooling in the rate of 5-15 deg.c / s to 400-700 deg.c, coiling and air cooling to room temperature. It is used for vehicle, container, bridge, etc.

Owner:BAOSHAN IRON & STEEL CO LTD

Friction stir welding machine and friction stir welding tool

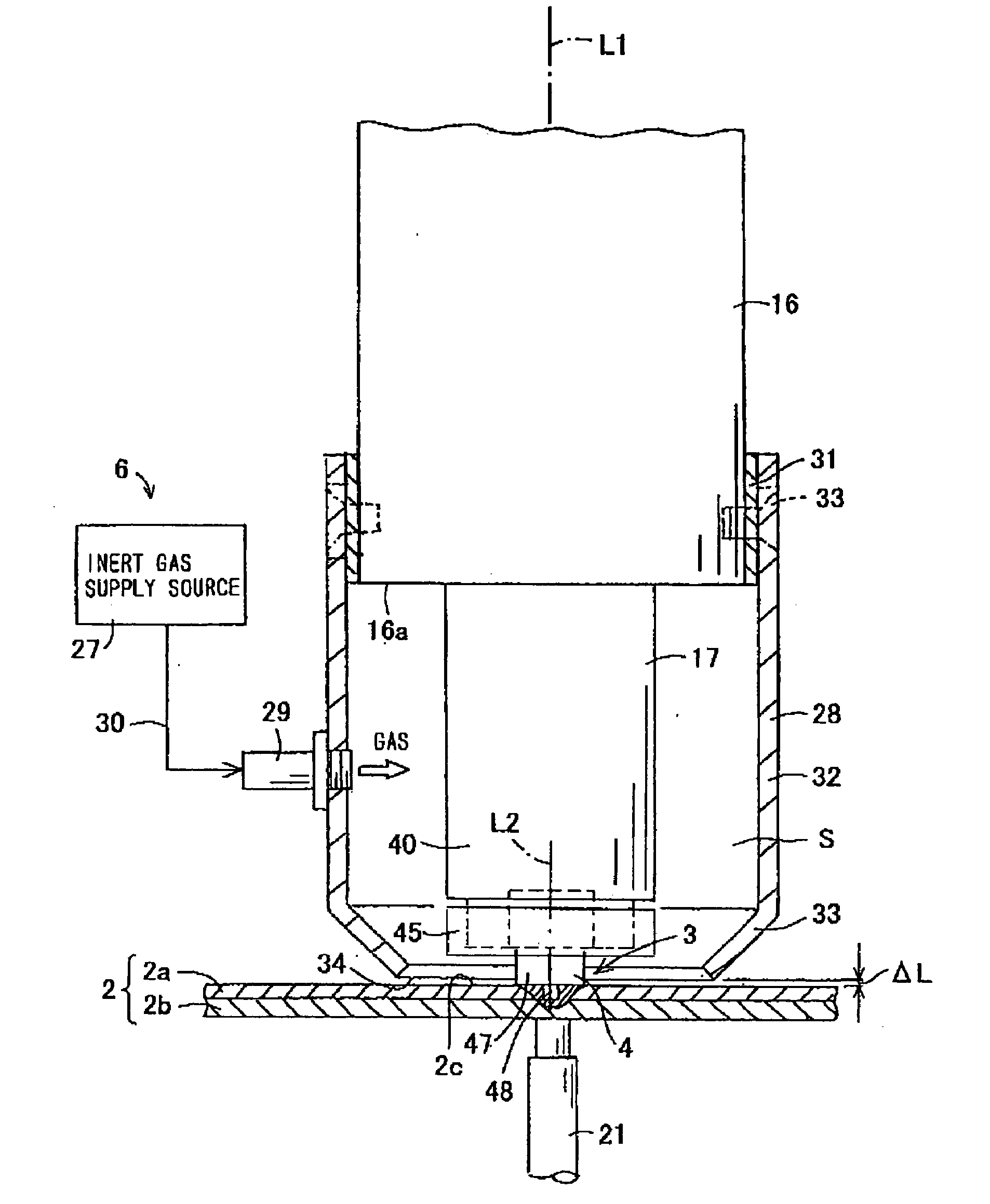

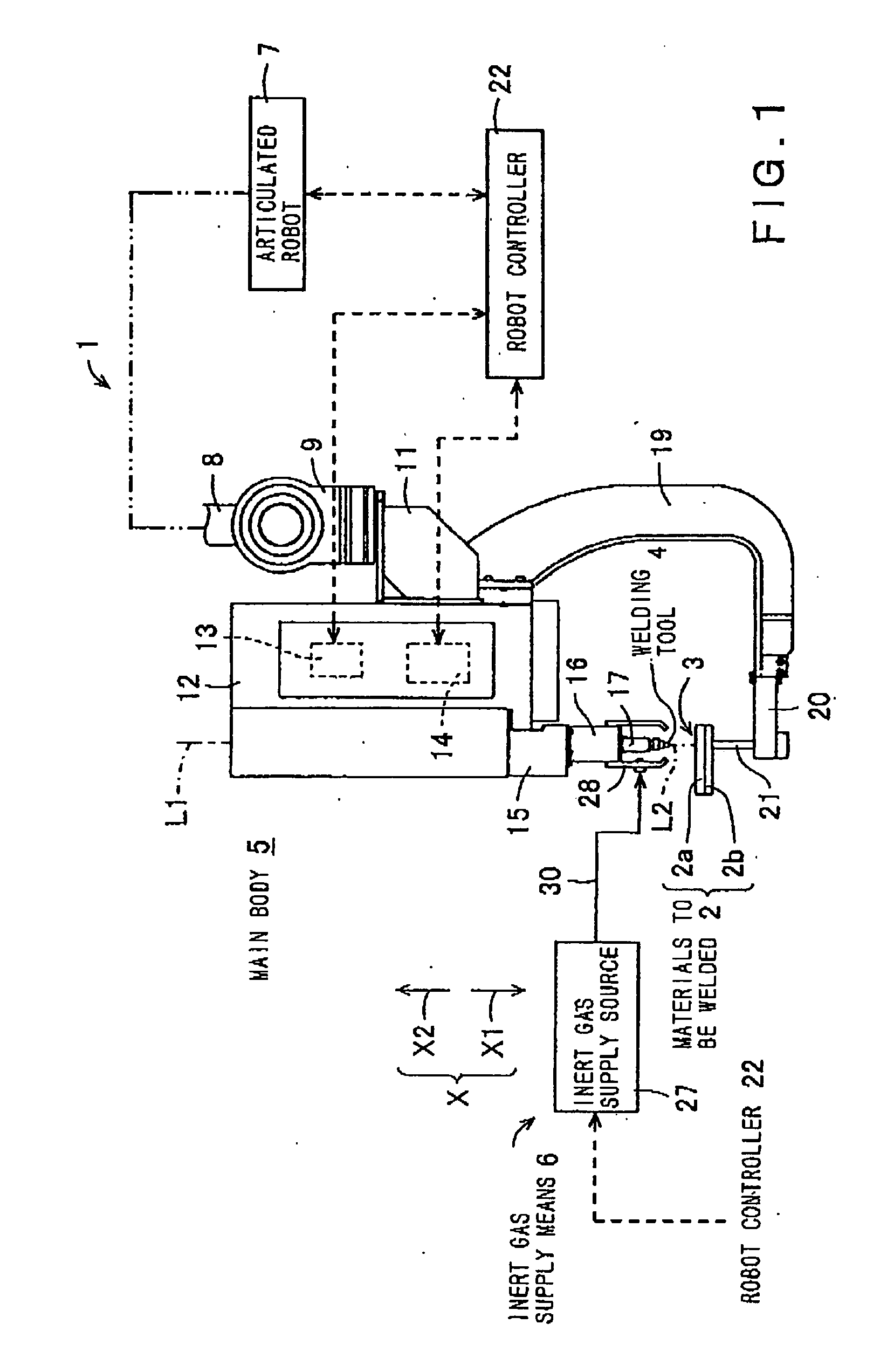

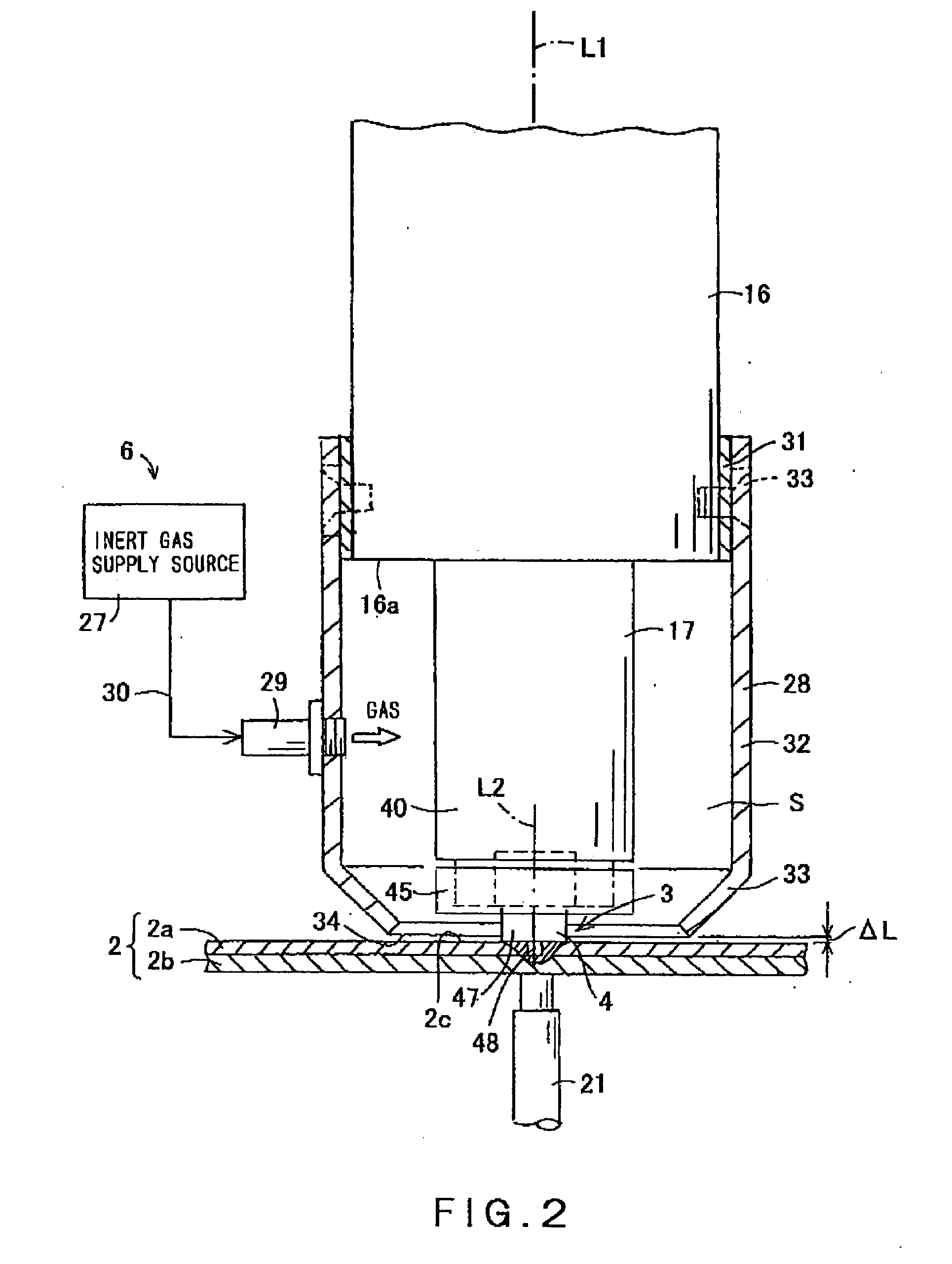

ActiveUS20080023524A1Prolong lifeInhibit wearWelding/cutting auxillary devicesAuxillary welding devicesEngineeringNitride

The present invention is a friction stir welding machine adapted to perform solid phase welding on a welding portion of materials to be welded, by pressing a welding tool against the welding portion of the materials to be welded while rotating the welding tool, and forcing the welding tool to be advanced into a softened portion which is softened by a frictional heat while stirring the softened portion, wherein a coating made of aluminum nitride is formed on at least a region of the welding tool to be in contact with the materials to be welded.

Owner:KAWASAKI HEAVY IND LTD

Lithium-ion battery with high rate discharge performance

ActiveCN103730625AImprove rate discharge performanceImprove securitySecondary cellsCell component detailsHigh rateEngineering

The invention discloses a lithium-ion battery with high rate discharge performance. The lithium-ion battery comprises a cover, a battery core in the cover, an upper cover plate, and a lower cover plate, wherein the battery core is prepared either by winding or laminating a positive pole piece with a positive pole ear, a negative pole piece with a negative pole ear and a diaphragm. The lithium-ion battery is characterized in that a positive pole piece clamping mechanism and a negative pole piece clamping mechanism are also arranged; the positive pole ear is packed and fixed inside of the positive pole piece clamping mechanism and a positive pole stud is arranged on the outside of the positive pole piece clamping mechanism and is in detachable connection with the upper cover plate; the negative pole ear is packed and fixed inside of the negative pole piece clamping mechanism and a negative pole stud is arranged on the outside of the negative pole piece clamping mechanism and is in detachable connection with the lower cover plate. The lithium-ion battery is particularly applicable to the fields of electrical motorcycles, electrical taxies and electrical buses, and the like, and can meet the requirements for high rate discharge performance of batteries when the vehicles are in the bad circumstances such as climbing, instantaneous starting and instantaneous accelerating.

Owner:安徽金鑫宏运新能源科技有限公司

Steel series with high linear energy and low weld crack sensitivity and its preparing process

InactiveCN1396294ALow weld crack susceptibilityGood welding performanceUltimate tensile strengthPhase point

A high-strength steel as low-alloy steel contains low-C, Ti, Nb, B and two or more of Ni, V, Cu, Mo, Zr and RE, and is prepared through rolling and modifying heat-treatment to obtain high-toughness tempered sorbite texture and the high-smelting-point second-phase points and compound educed phase to suppress growth of welding coarse crystal region. Its advantages are high linear energy (60-70 kg) and low sensitivity to weld cracking.

Owner:武钢集团有限公司

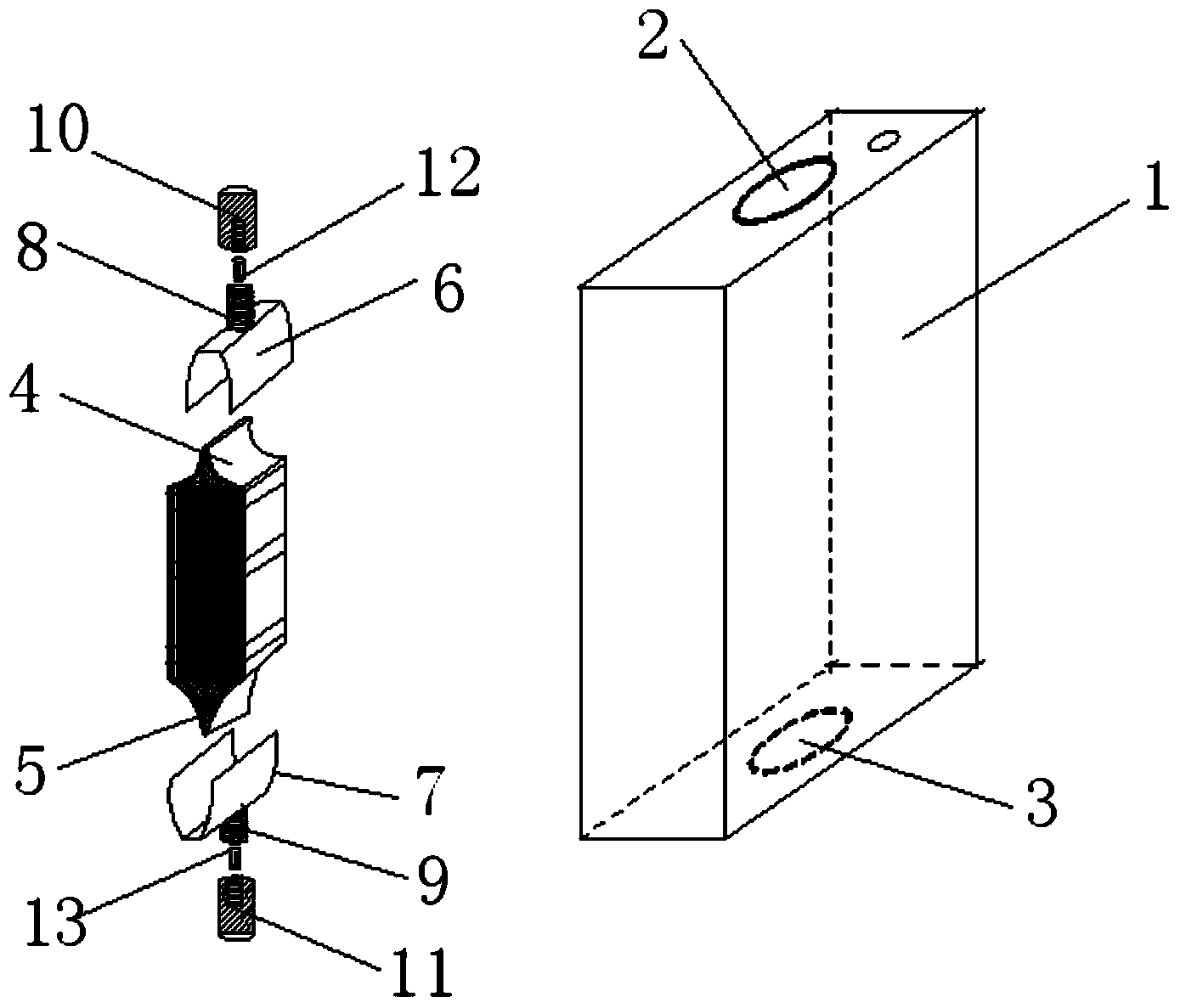

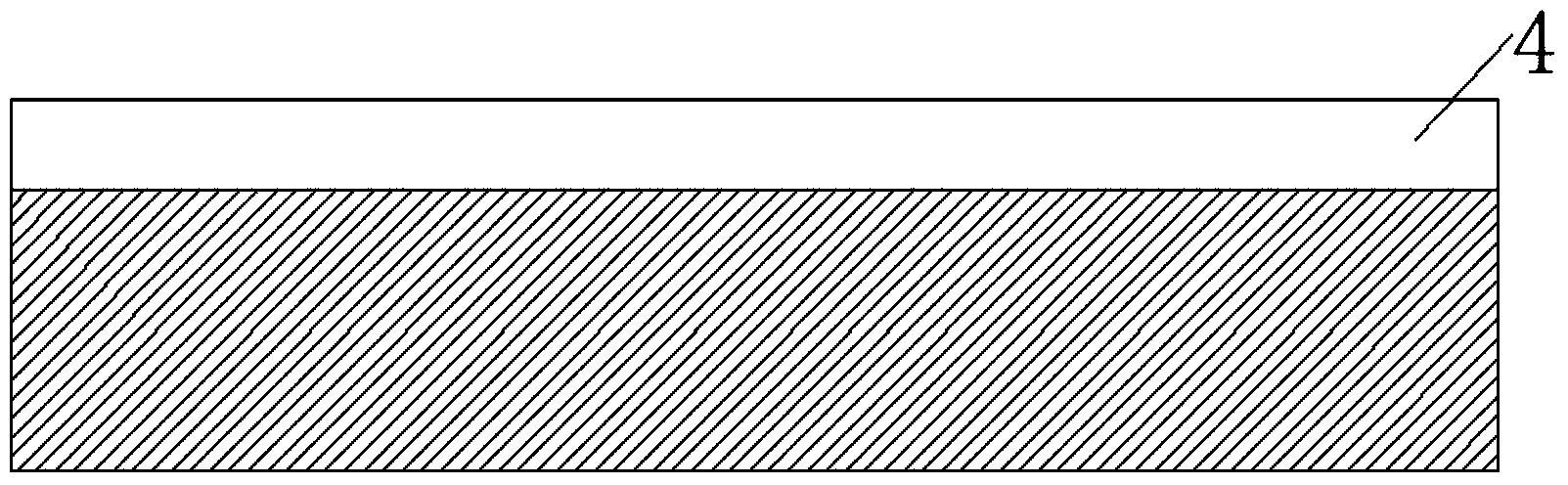

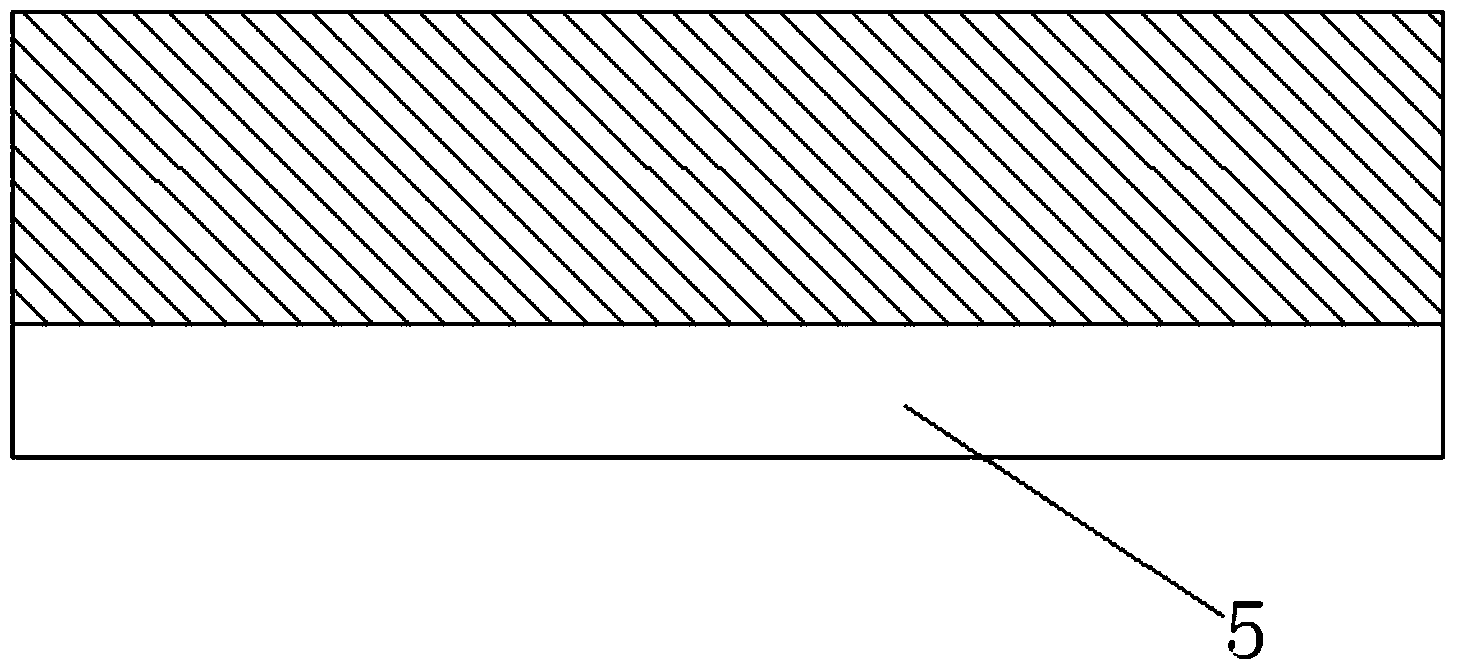

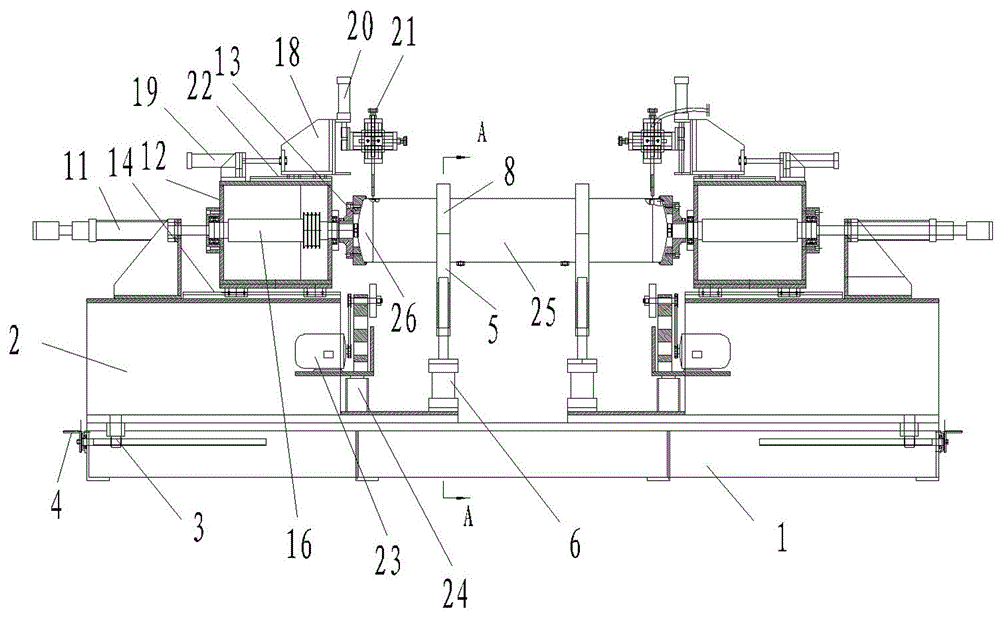

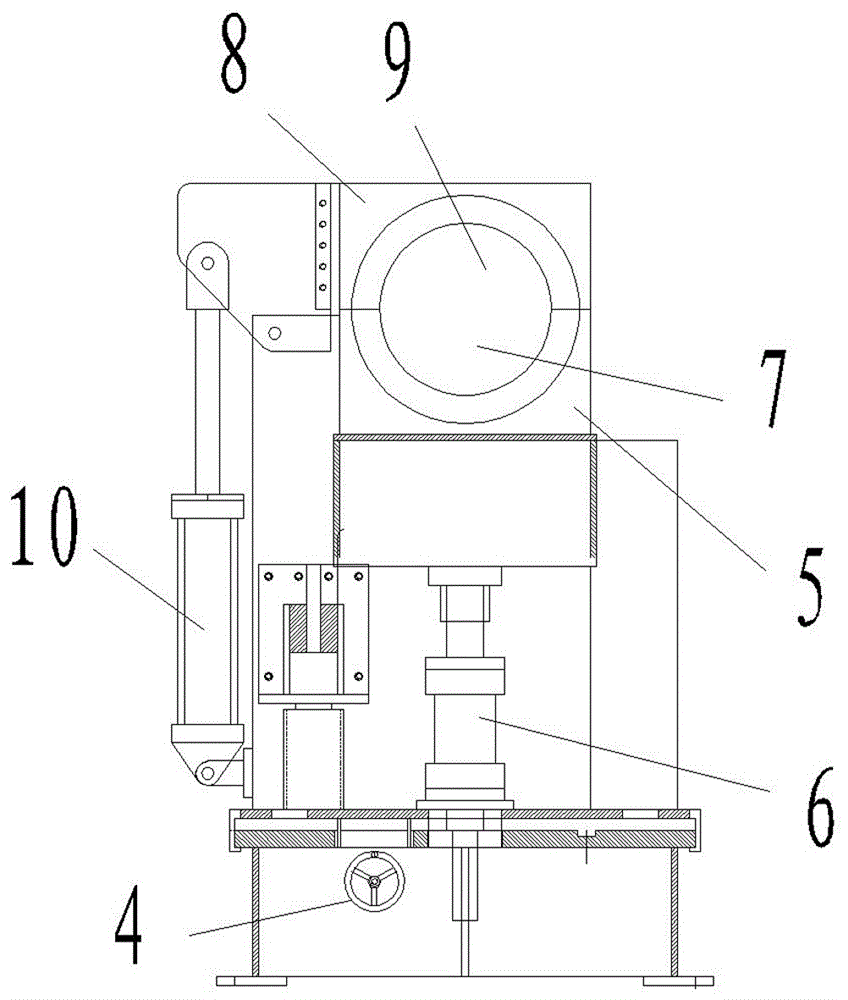

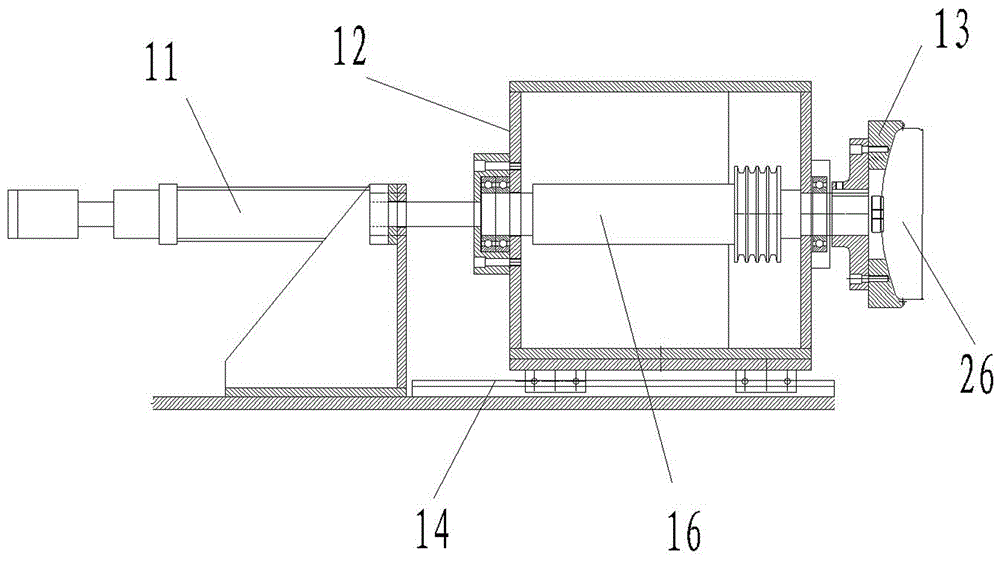

Automatic girth welding device for air cylinder for automobile

InactiveCN106736084AImprove welding efficiencyImprove grinding efficiencyWelding/cutting auxillary devicesOther manufacturing equipments/toolsThrough transmissionPiston rod

The invention discloses an automatic girth welding device for an air cylinder for an automobile. The automatic girth welding device comprises a base, wherein two symmetric machine seats on the base, an air cylinder bracket located between the two machine seats, and clamping mechanisms separately arranged on the two machine seats, wherein each clamping mechanism comprises a clamping cylinder, a mobile box seat and an air cylinder end cover clamp; piston rods of the clamping cylinders are connected with the outer sides of the mobile box seats; the air cylinder end cover clamps are arranged on the inner sides of the mobile box seats; the mobile box seats are further provided with servo motors; the servo motors are connected with rotating shafts arranged along the axial direction of the air cylinder through transmission devices; the rotating shafts are connected with the air cylinder end cover clamps; a cylinder body of the air cylinder is arranged on the air cylinder bracket; the clamping cylinders push the air cylinder end cover clamps to move towards the direction of the cylinder body of the air cylinder, so that air cylinder end covers are clamped with the cylinder body of the air cylinder; the servo motors are started to enable the air cylinder end cover clamps to drive the whole air cylinder to rotate and be subjected to welding; after the air cylinder rotates a circle, girth welding is completed; and furthermore, the automatic girth welding device is high in efficiency and high in quality.

Owner:BENGBU TONGDA AUTO PARTS

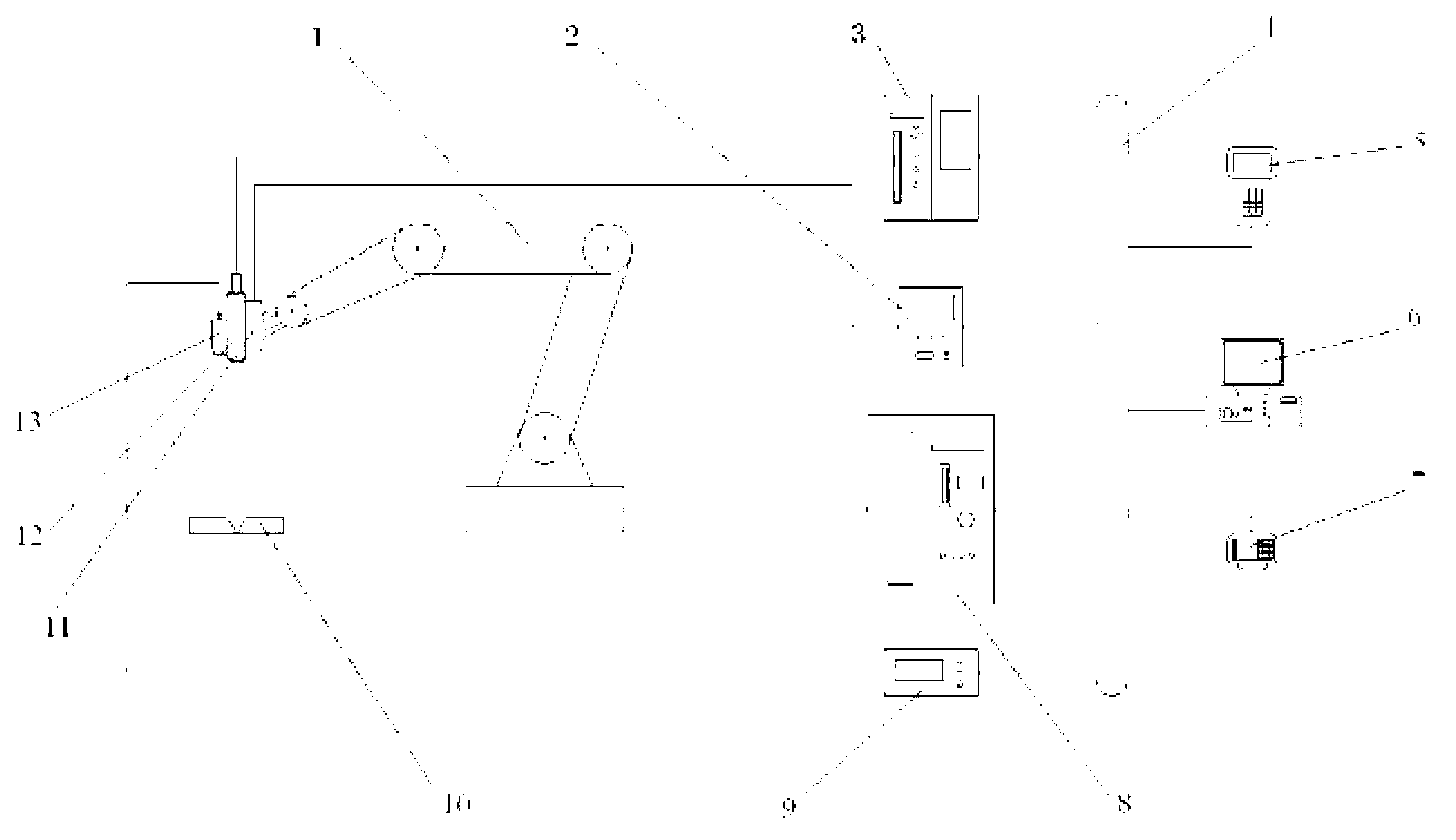

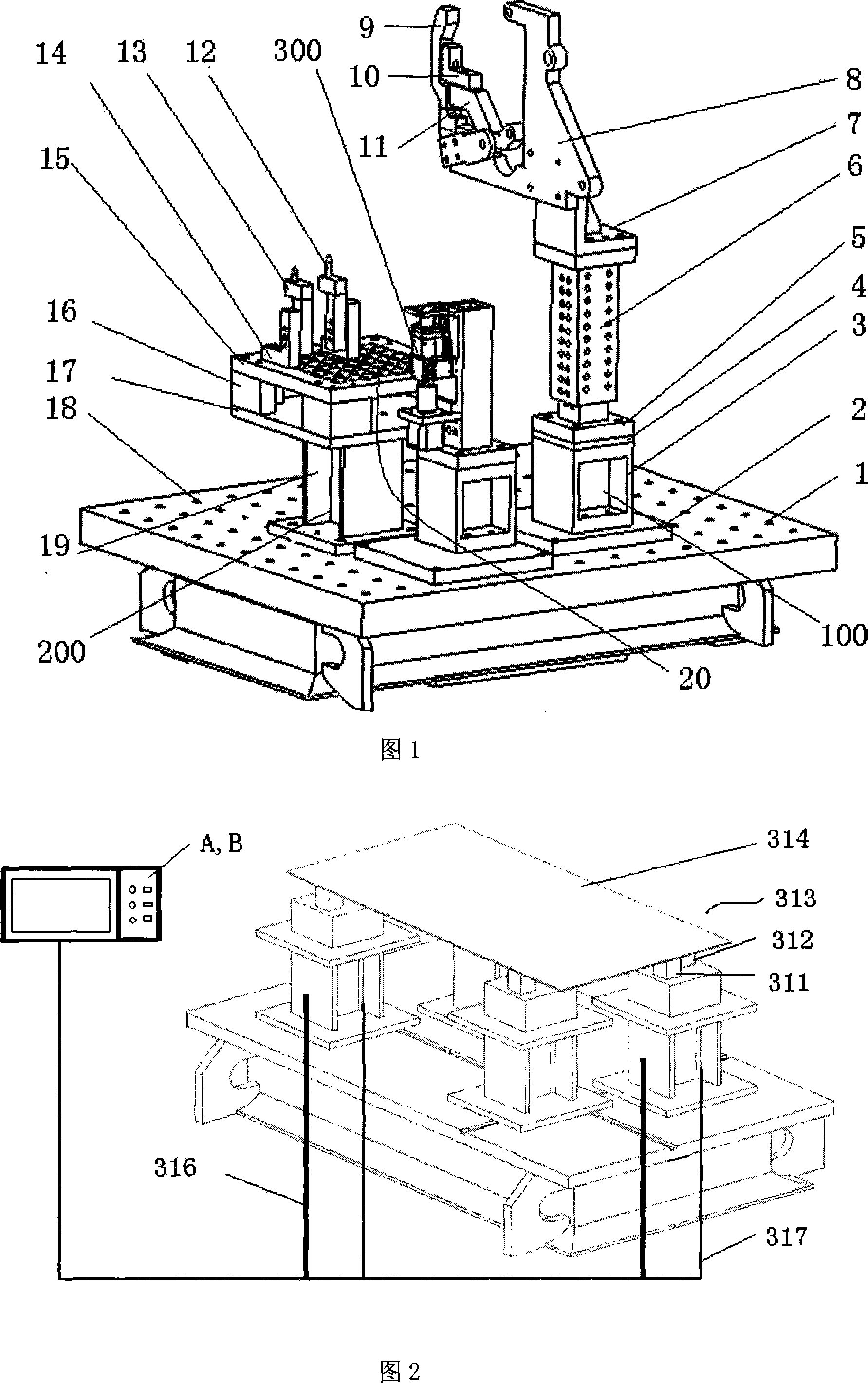

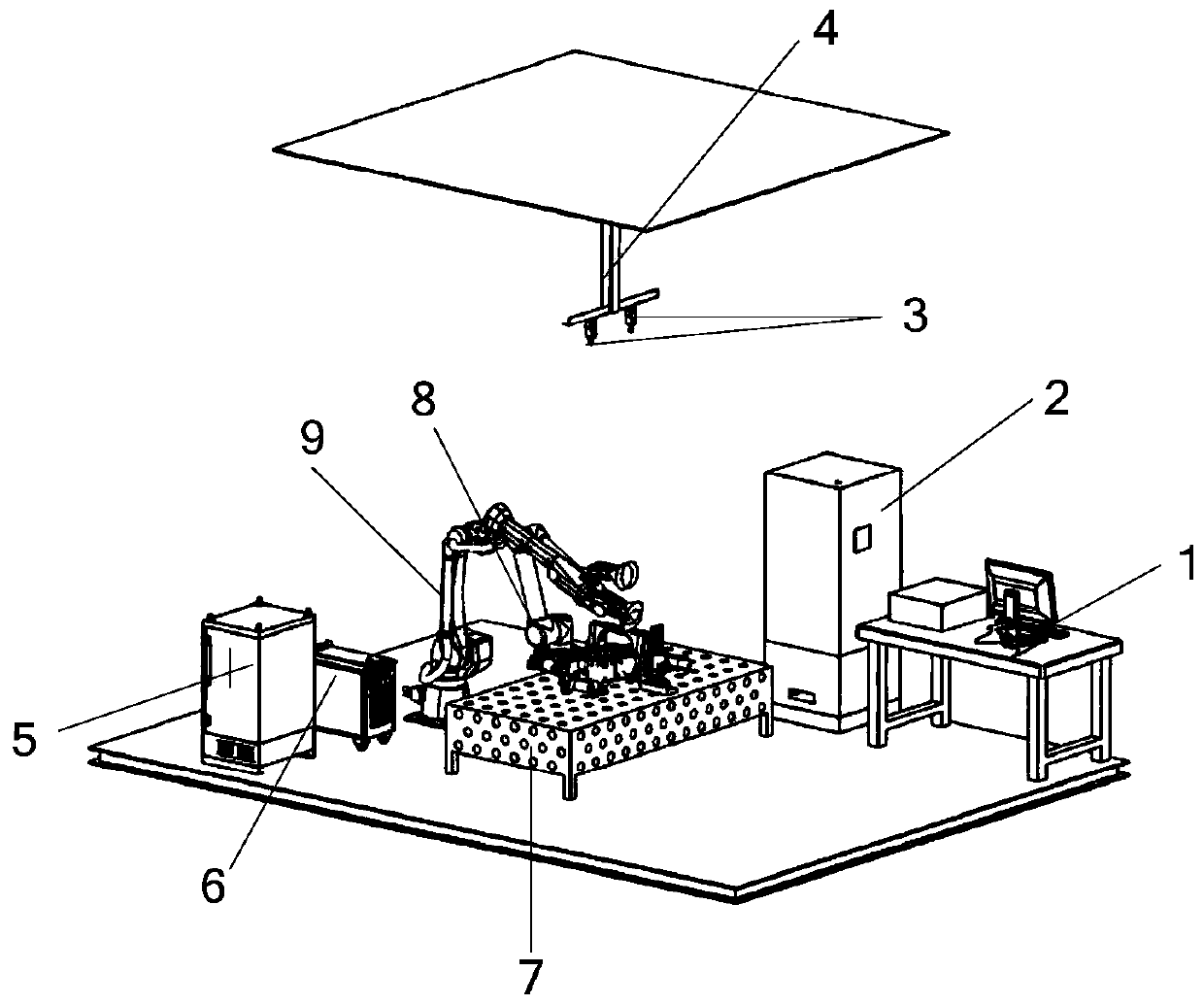

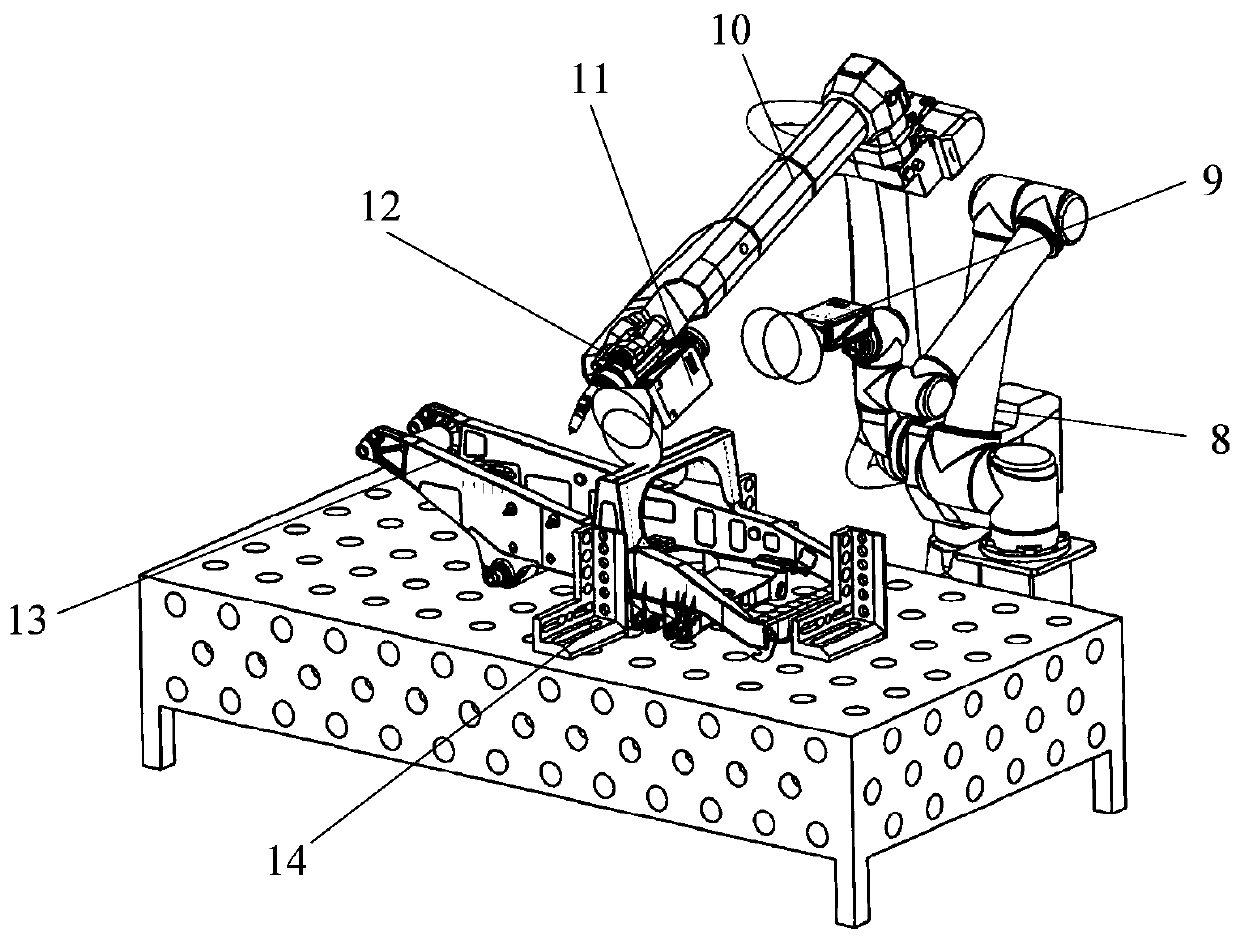

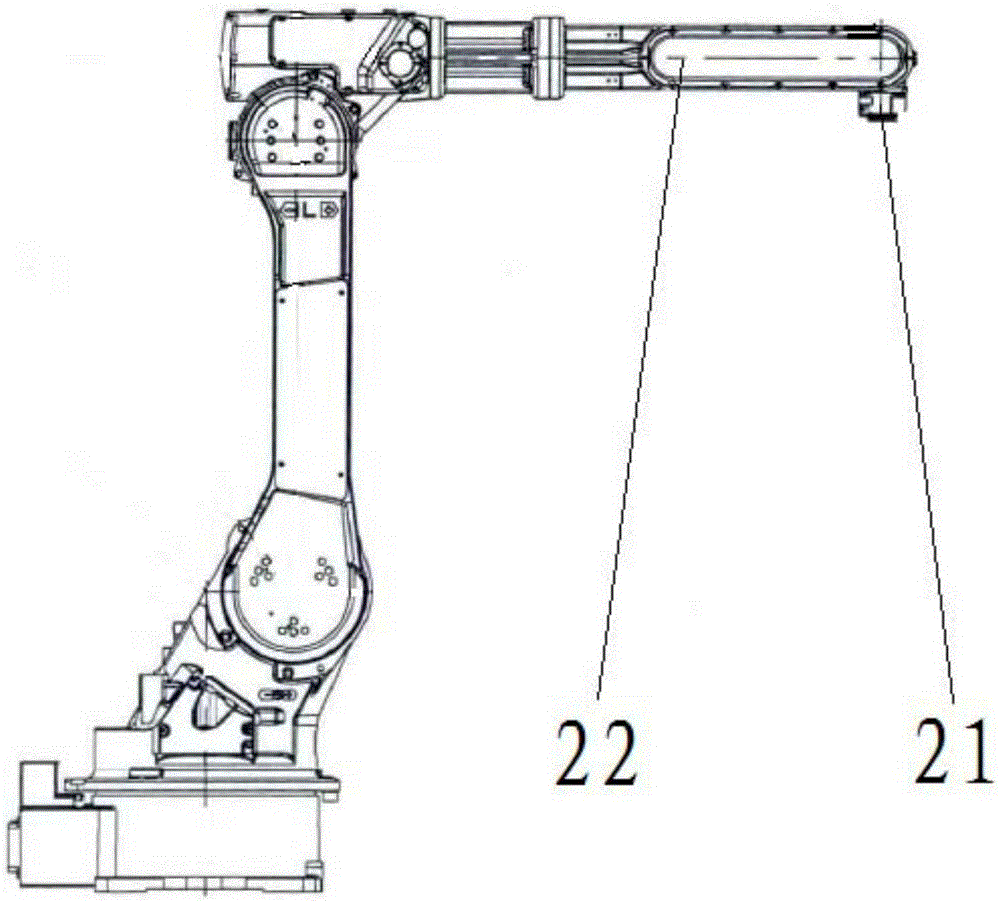

Flexible welding robot system and welding method thereof

ActiveCN110524581AAvoid harmAchieve high flexibilityProgramme-controlled manipulatorTotal factory controlImaging processingSimulation

The invention discloses a flexible welding robot system and a welding method thereof. The welding method comprises the following steps: a global vision unit recognizes image information of a to-be-welded workpiece and locates the position of the to-be-welded workpiece; a flexible welding robot unit precisely recognizes the position of a to-be-welded workpiece through a precise positioning visual assembly, an image processing control machine solves a welding path, and the flexible welding robot conducts welding operation. A flexible detection robot unit recognizes the geometric dimension and quality of the appearance of a welded workpiece through a stereoscopic vision detection assembly, generates a welding quality report according to parameter information set by a user, and transmits a position with the welding deviation exceeding a threshold value and deviation value information to the flexible welding robot for repair welding. A master control unit executes image processing, data communication and motion control of the welding robot and the detection robot; and a workbench unit is used for quickly clamping different types of welding workpieces. The harm of welding operation to the body of a worker is avoided, and high flexibility and intelligence of the flexible welding robot system are achieved.

Owner:XIAN ZHONGKE PHOTOELECTRIC PRECISION ENG CO LTD

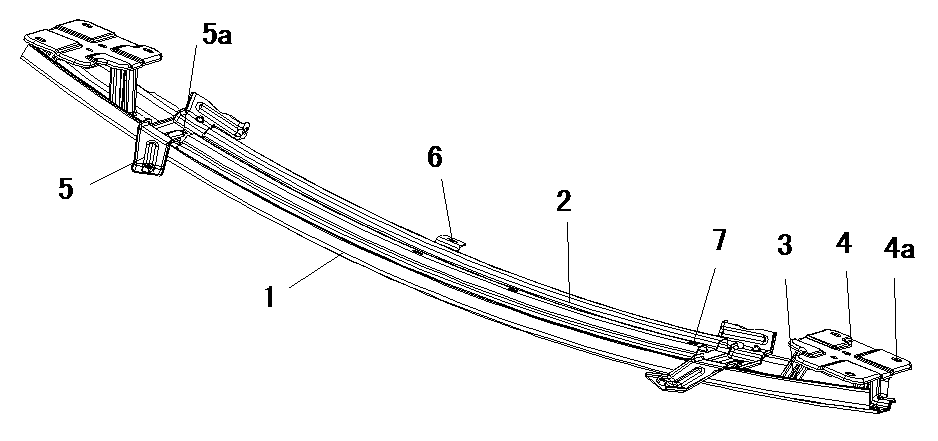

Welding tool for front collision transverse beam of automobile

InactiveCN103008953AEasy to weld productionEasy to fixWelding/cutting auxillary devicesAuxillary welding devicesEngineeringTransverse beam

The invention discloses a welding tool for a front collision transverse beam of an automobile. The welding tool comprises a base, wherein the base is provided with two clamping devices I which correspond to front collision box welding assemblies one by one, clamping devices II which correspond to side locking plates one by one, and clamping devices III for clamping and positioning lug plates. Through the clamping devices I which are arranged corresponding to the front collision box welding assemblies one by one, the front collision box welding assemblies can be compressed and fixed at the two ends of an outer plate, and the front collision box welding assemblies are convenient to weld and fix on the outer plate; through the clamping devices II which are arranged corresponding to the side locking plates one by one, the side locking plates can be compressed and fixed on the outer plate, and are convenient to weld and fix on the outer plate; due to the arrangement of positioning rods I, the clamping position accuracy of the outer plate and an inner plate can be ensured; and through the clamping devices III which are arranged corresponding to the lug plates, the lug plates can be clamped and positioned at design positions, and are convenient to weld and fix on the inner plate.

Owner:CHONGQING DADONG AUTO PARTS

Special portable miniature drainage cover for automatic underwater local dry-method welding

InactiveCN103433606ARealize free adjustmentAvoid unfusedElectrode supporting devicesWelding accessoriesEngineeringCopper

The invention provides a special portable miniature drainage cover for automatic underwater local dry-method welding. A drainage cover body of the drainage cover comprises an upper end cover, an organic glass cover and a lower end cover. A clamping rod, an air inlet quick plug connector, a lower locking sleeve, a cooling air chamber and an underwater camera component are fixed to the upper side of the upper end cover and the lower side of the upper end cover through threaded connection respectively, and the upper end cover and lower end cover are connected with the organic glass cover through threads. A welding oscillator is clamped on the upper portion of a copper welding torch of a welding gun. According to the structure of a drainage sealing device, drainage felt and a felt skirt are arranged on the periphery of the lower end cover, and the drainage felt and the felt skirt are fastened on the lower end cover through hose clamps; the copper welding torch of the welding gun is fastened through an upper locking sleeve and the lower locking sleeve, the welding gun is inserted into the organic glass cover, and an elastic rubber leather sheath is arranged between the upper locking sleeve and the lower locking sleeve. The special portable miniature drainage cover for automatic underwater local dry-method welding has the advantages of being simple in structure, exquisite, convenient and fast to use, low in cost, obvious in drainage effect, and stable and reliable in welding process. Moreover, a connector with the quality of on-land welding is formed, the welding efficiency is improved and the special portable miniature drainage cover is easy to popularize.

Owner:TIANJIN UNIV

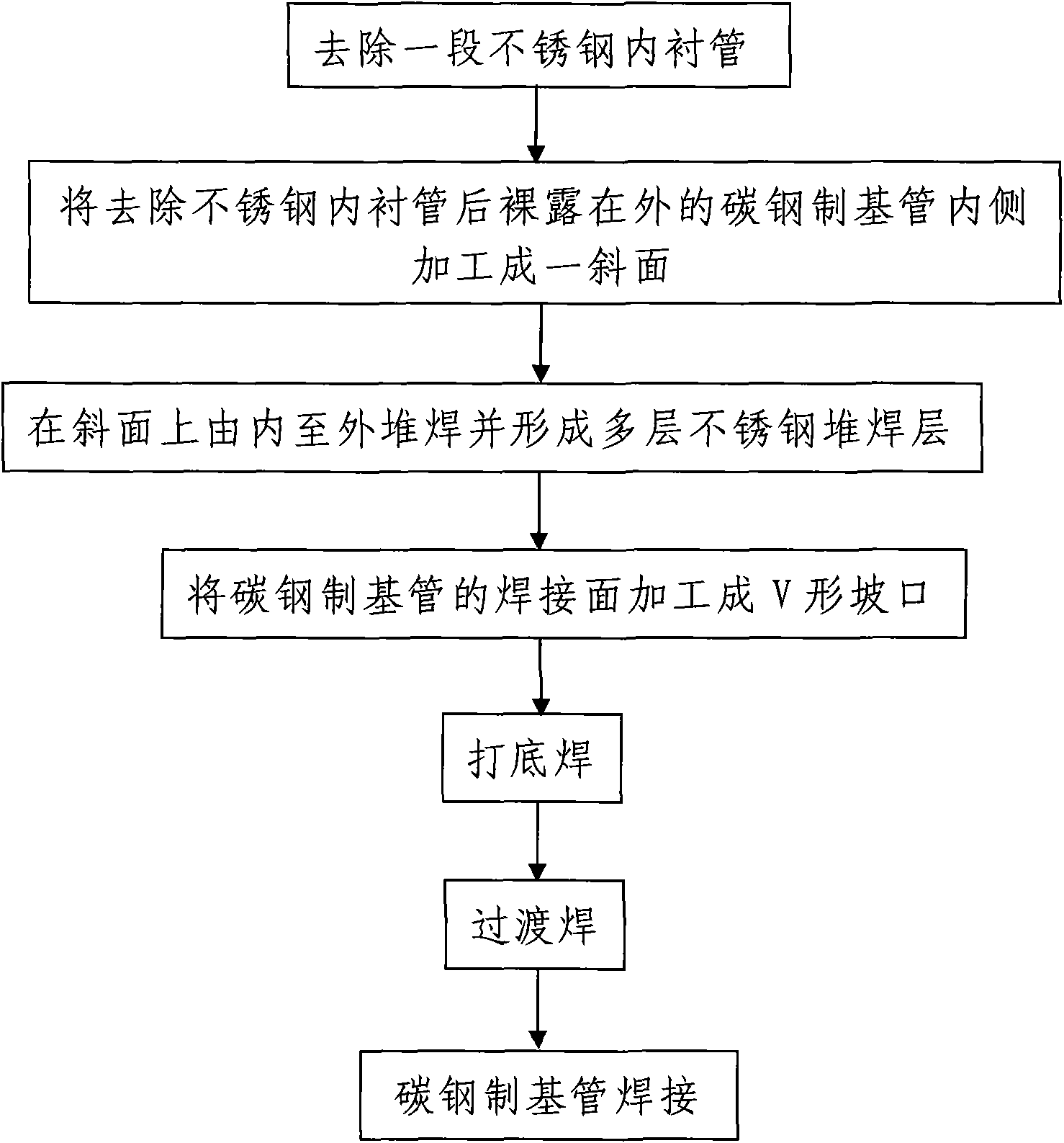

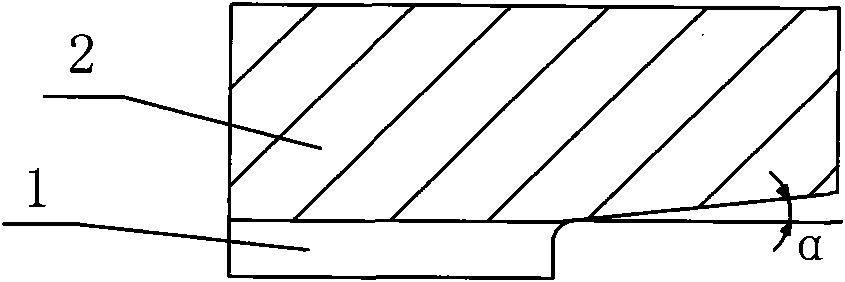

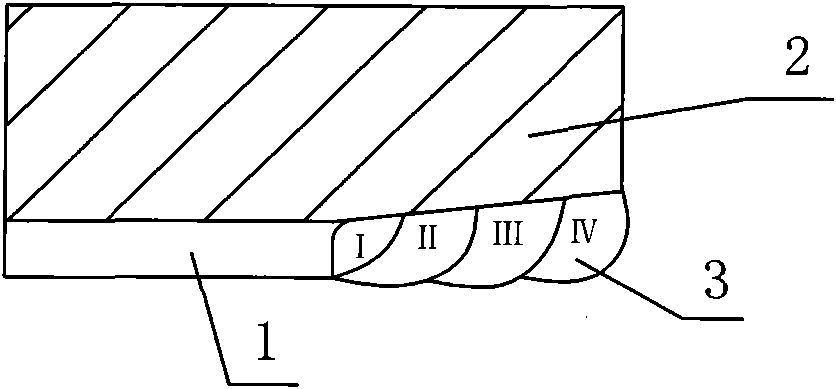

Method for welding composited tube at bonding interface of carbon steel/stainless steel machinery

ActiveCN101653855ASimple welding processExcellent weld mechanical properties and corrosion resistanceArc welding apparatusWelding/cutting media/materialsCarbon steelArc welding

The invention discloses a method for welding composited tube at the bonding interface of carbon steel / stainless steel machinery, comprising the following steps: 1. welding groove treatment as follows:removing a section of stainless steel lined tube; processing the interior of the carbon steel parent tube exposed outside after removing the stainless steel lined tube into an inclined plane inclinedinwards from exterior to interior; using a tungsten electrode argon arc welding machine to carry out bead weld on the inclined plane from interior to exterior and forming multiple stainless steel bead weld layers; processing the weld surface of the carbon steel parent tube into a V-shaped groove; 2. backing weld: when fitting up the stainless steel bead weld layers before backing weld, adopting the tungsten electrode argon arc welding machine to carry out fitting-up and fixing in a manner of spot welding; 3. transition weld; and 4. carbon steel parent tube weld. The invention features simpleprocedure steps, less used weld materials, high weld pass percentage, good welding line mechanical property, high weld quality and improved production efficiency simultaneously.

Owner:XIAN SUNWARD AEROSPACE MATERIAL

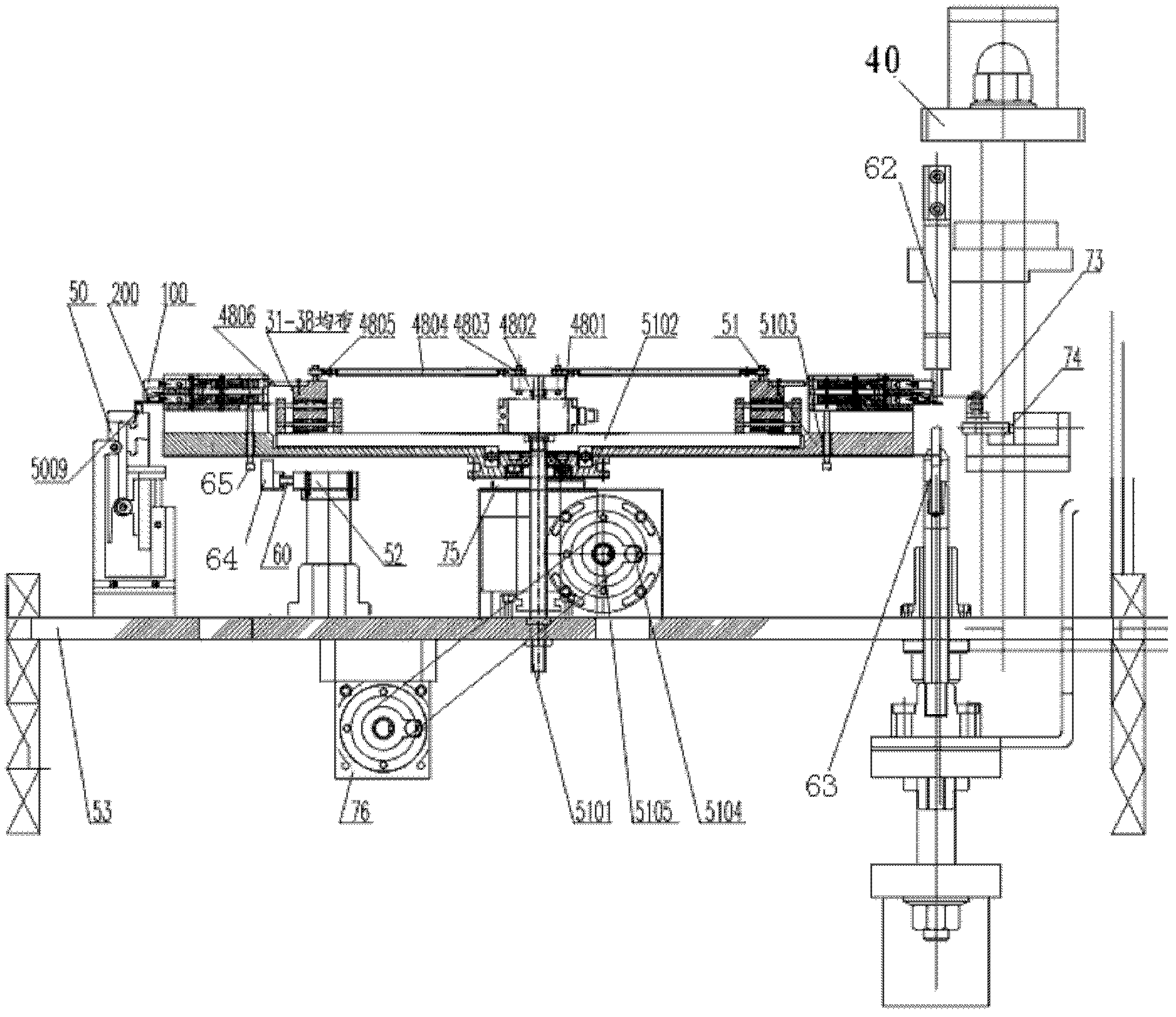

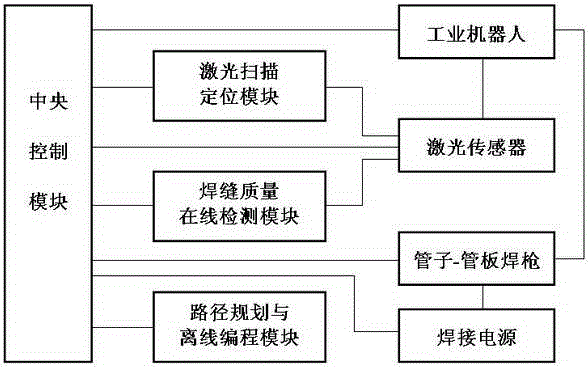

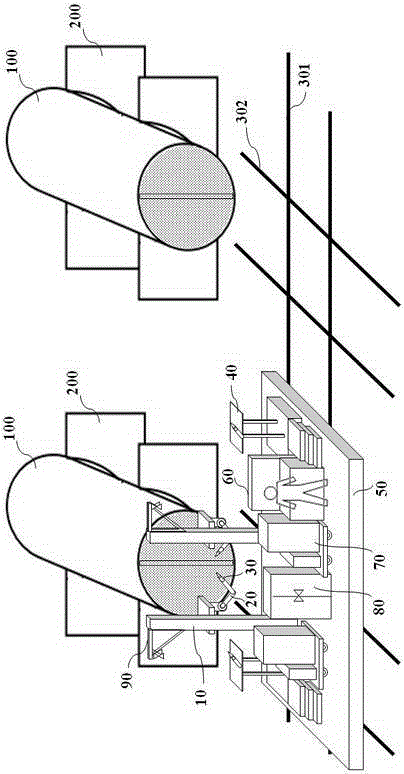

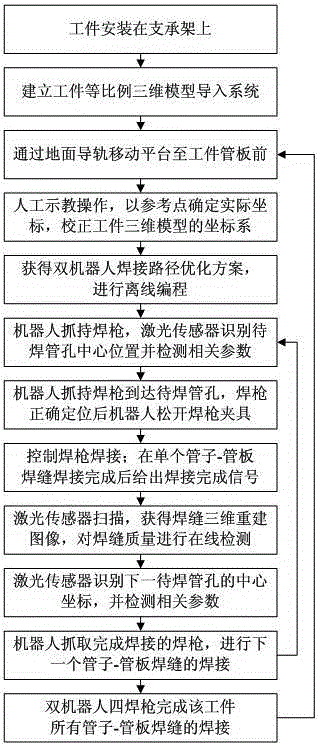

Robot welding system and welding method thereof

ActiveCN105195868AImprove work efficiencyHigh repeatabilityProgramme-controlled manipulatorHeat exchange apparatusLaser scanningVapor generator

The invention provides a robot welding system and a welding method thereof and suitable for pipe-pipe plate welding for a vapor generator of a main device in a nuclear island. According to the invention, a path planning and off-line programming module is used for planning an anti-collision welding path for an industrial robot and performing off-line programming on a planned scheme; a laser scanning positioning module obtains the circle centre coordinate of a pipe hole according to scanning results and performing initial welding position identification and autonomous guiding; the two industrial robots controlled by a central control module are matched with four pipe-pipe plate welding guns to perform welding on all pipe-pipe plate welding lines on a pipe plate; and an on-line welding line quality detection module obtains a three-dimensional reconstruction image according to welding line laser scanning results and performing on-line detection on welding line quality according to morphologies of the welding lines. Due to adoption of the system and the method disclosed by the invention, the pipe-pipe plate welding efficiency is improved, and the stability of the welding line quality is ensured.

Owner:SHANGHAI ELECTRIC NUCLEAR POWER EQUIP CO LTD

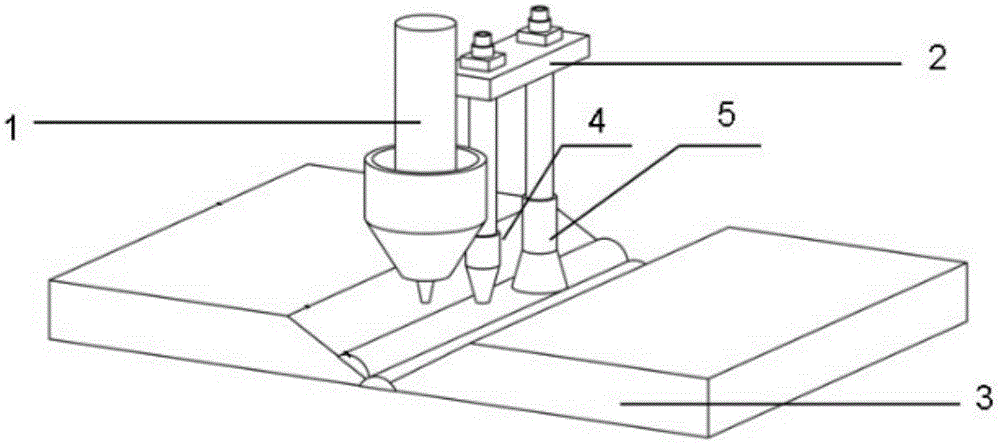

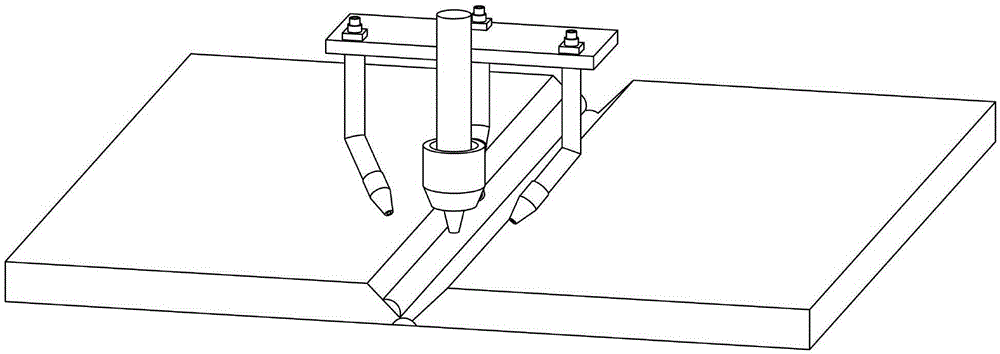

Adaptive welding method for laser filler wire welding of high-strength steel sheet

ActiveCN104057204ARealize adaptive adjustmentGuaranteed stabilityMetal working apparatusLaser beam welding apparatusNuclear powerMathematical model

The invention provides an adaptive welding method for laser filler wire welding of a high-strength steel sheet. The method comprises: step 1, performing process experiment on the high-strength steel sheet, and building a process parameter model of welding wire filling area and upper-groove width; step 2, during welding, acquiring the welding wire filling area and the groove width of a current groove in real time based on a laser vision sensor; step 3, according to the filling area and the groove width of the current groove and the process parameter model, adjusting process parameters in real time, so as to realize adaptive control during welding. Through an expert database or a process mathematical model built in specific materials and groove forms, and the groove filling area acquired in real time based on the laser vision sensor, adaptive adjustment on the process parameters during welding is realized, the stability and uniformity of the welding quality are ensured, the welding efficiency is improved, welding defects are reduced, and the method has very high practical values during welding large sheet elements in the fields such as aviation, spaceflight and nuclear power.

Owner:SHANGHAI JIAO TONG UNIV +1

Quake-proof construction steel with lamellar tearing resistance and excellent performance and production method thereof

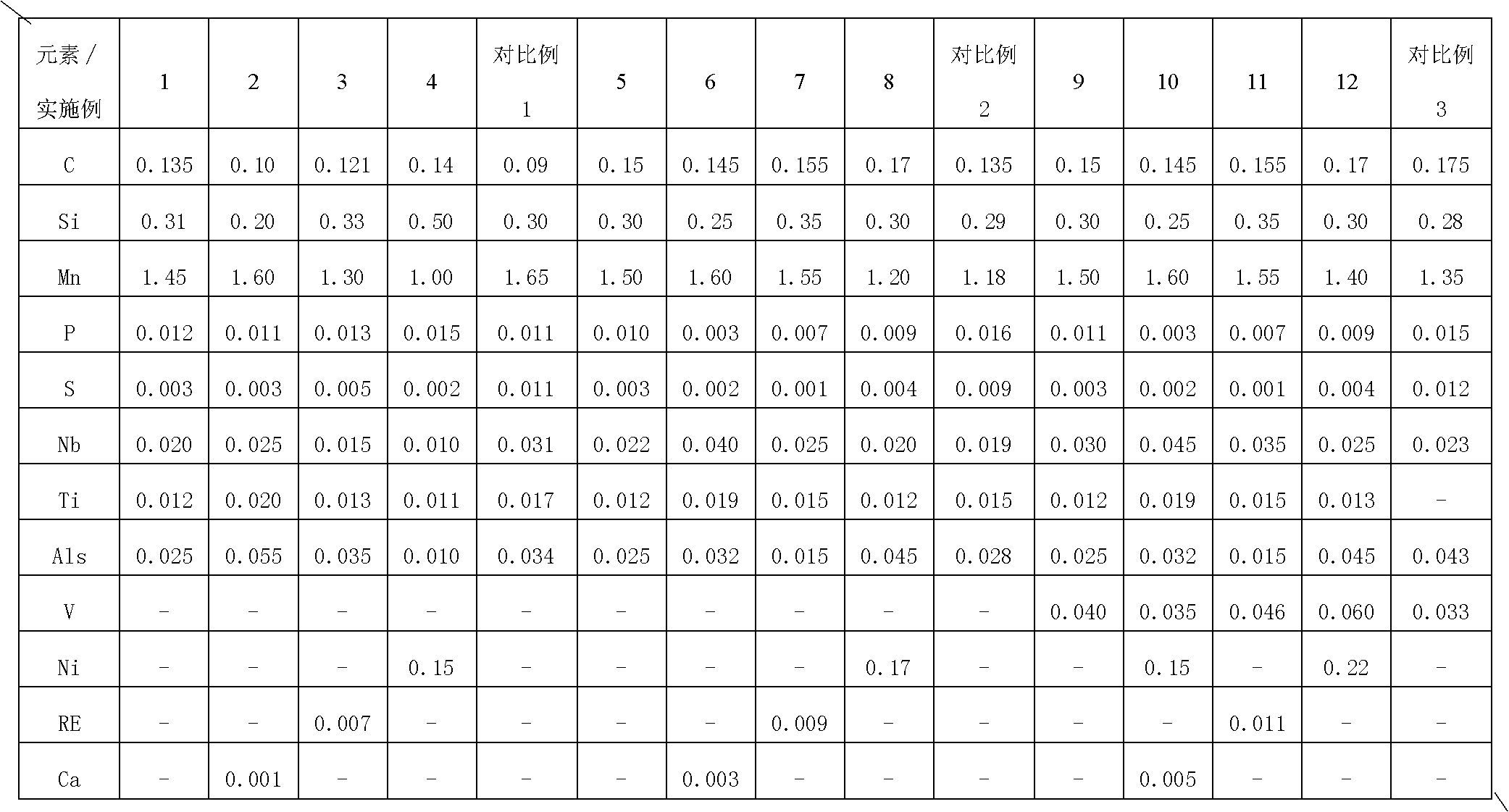

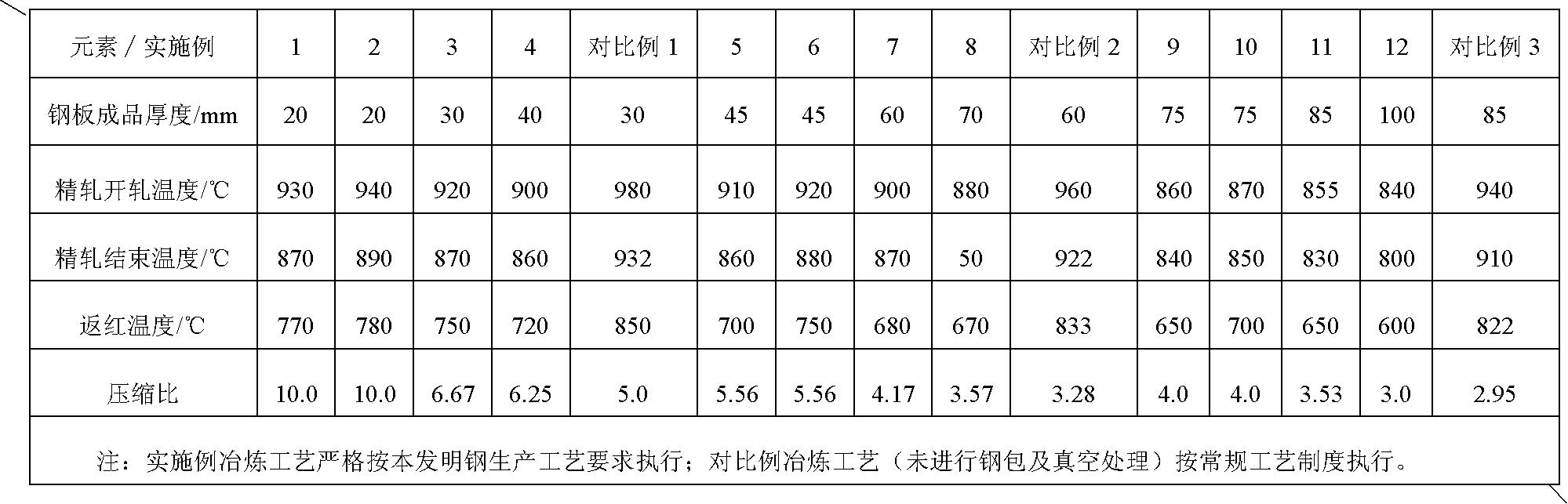

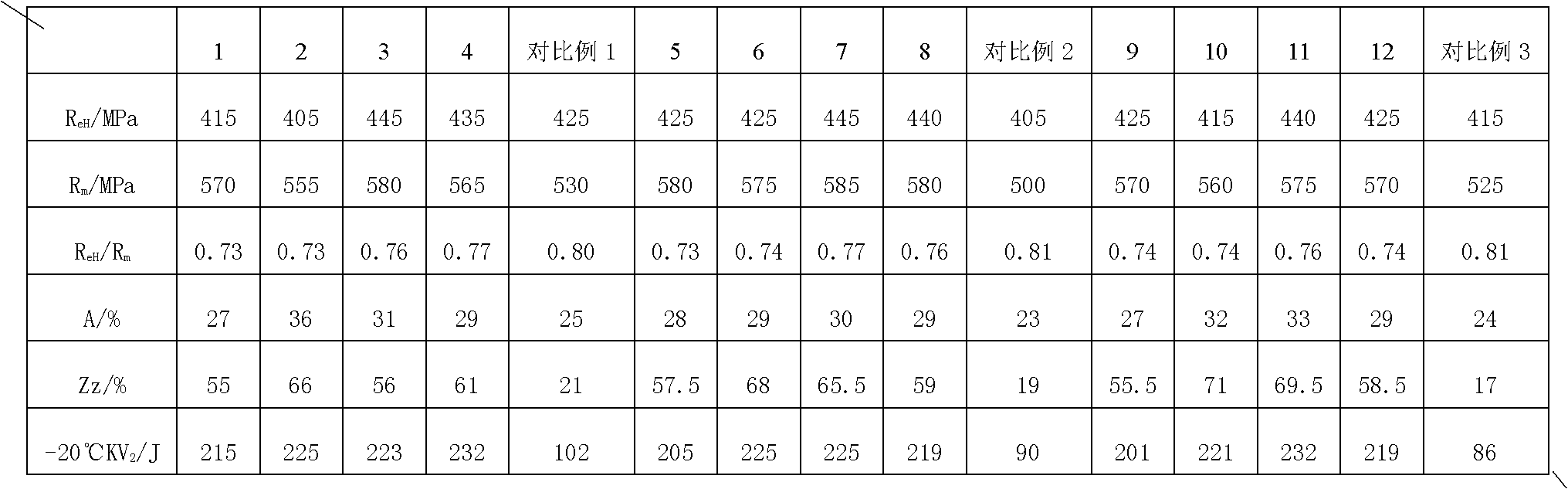

InactiveCN101994058AGood welding performanceSimplify welding production processProof constructionSheet steel

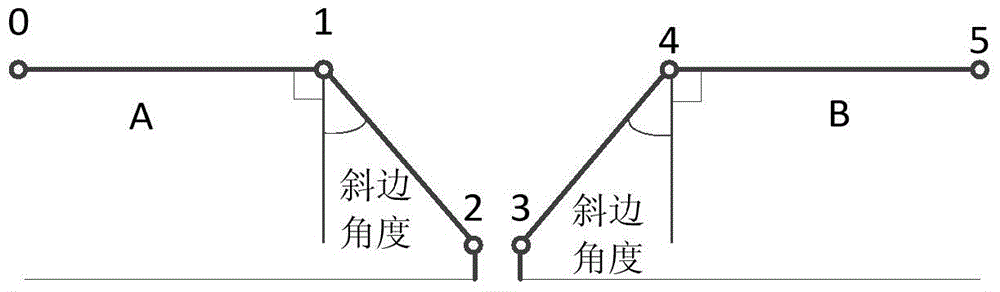

The invention relates to quake-proof construction steel with lamellar tearing resistance and excellent performance and a production method thereof. The steel is suitable for steel plates of which the thicknesses are between 20 and 100 millimeters and comprises the following chemical components: less than or equal to 0.015 percent of C, less than or equal to 0.015 percent of Si, less than or equal to 0.015 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.005 percent of S, 0.02 to 0.04 percent of Nb, 0.005 to 0.020 percent of Ti, 0.010 to 0.060 percent of Als and the balance of Fe. The method comprises the following steps of: performing the pretreatment of molten iron; performing desulfuration treatment; controlling target components of a smelting terminal point, wherein the target components comprise 0.05 to 0.07 percent of [C] and less than or equal to 0.015 percent of [P]; refining through a ladle furnace, and feeding aluminum wires and blasting argon; performing relative humidity (RH) vacuum treatment, and introducing the argon before the treatment; adding SiCa wires; casting continuously and performing the pouring of full-process protection; heating casting blanks; performing rough rolling; performing precision rolling; and cooling. The steel of the invention has the excellent quake-proof performance (ReH / Rm is less than or equal to 0.77); and the contractibility rate of a cross section in the full-thickness direction is between 40 and 70 percent, so the steel meets the requirements of key stressed points of major constructions such as steel structure work and the like fully.

Owner:武钢集团有限公司

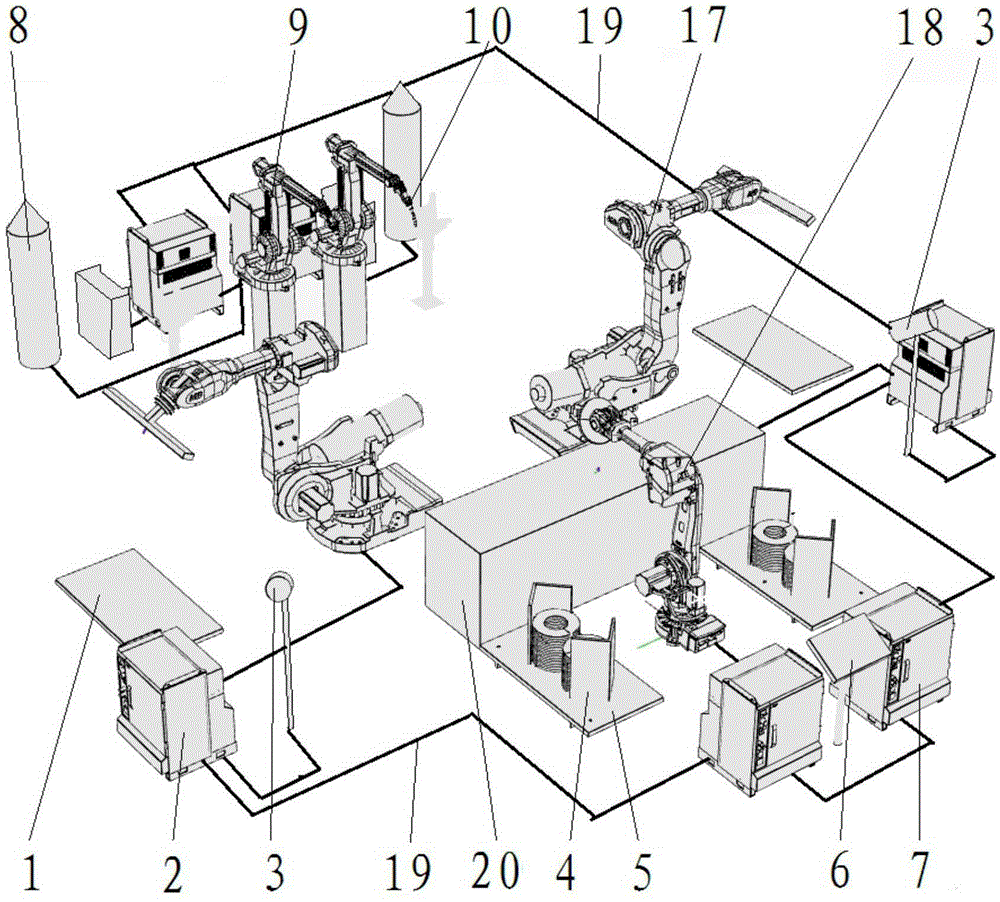

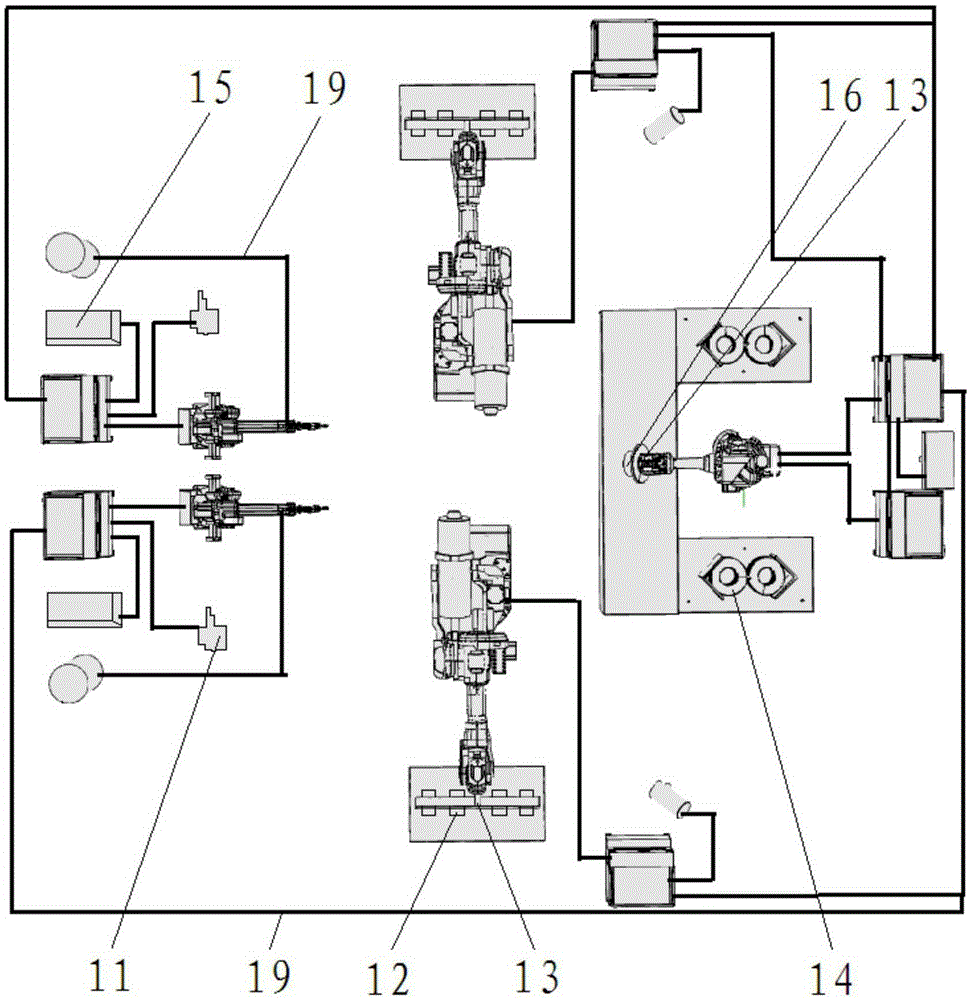

Multi-station robot intelligent welding system for pipe piling sheets

InactiveCN105397244ARealize the intelligentization of automatic identification of weld seam informationRealize intelligenceManipulatorWelding accessoriesRobotic systemsHuman–machine interface

The invention discloses a multi-station robot intelligent welding system for pipe piling sheets. The multi-station robot intelligent welding system comprises a control system, a clamp system, a machine vision system, a robot system, a welding system and a safety protection system, wherein the control system comprises a robot control cabinet, a PLC control cabinet, a machine vision system and a man-machine interface; the robot system comprises two supplying robots, two welding robots and a feeding robot; the two supplying robots are placed in a back-to-back manner; the two welding robots are placed at front middle positions of the two supplying robots side by side; the PLC control cabinet is in communication with the robot control cabinet; the robot control cabinet controls movement of a robot body; the welding system is connected with a welding robot control cabinet; and a welding robot body controls a welding gun to finish welding. By the multi-station robot intelligent welding system, positions and widths of welded joints can be recognized accurately, and information of the welded joints is recognized automatically; and the feeding robot feeds materials automatically, the labor intensity is reduced, and high automation of a whole process of feeding, supplying and welding is realized.

Owner:DALIAN UNIV OF TECH

Intersecting line welding robot

InactiveCN1935444AEasy to controlReduce labor intensityWelding/cutting auxillary devicesArc welding apparatusEngineeringRobot

The present invention relates to an intersecting line welding robot for welding cylinder body. Said welding robot includes welding gun, and is formed from the following several portions: machine body, clamp, rotation mechanism, X-axis movement device, Y-axis movement device, large radial arm and small radial arm. Said invention also provides its working principle and concrete operation method.

Owner:BEIHANG UNIV +1

Refractory anti-seismic construction steel for high-toughness welding structures, and production method thereof

InactiveCN101691643AImprove fire resistanceImprove seismic performanceChemical compositionRefractory

The invention discloses refractory anti-seismic construction steel for high-toughness welding structures, and a production method thereof, and solves the problem that the traditional construction steel is high in Mo that is a noble alloying element, high in producing-processing cost, low in refractory property and poor in anti-seismic performance. Based on the chemical composition of steel in percentage by weight, the steel comprises 0.05 to 0.13 percent of C, 0.10 to 0.60 percent of Si, 0.80 to 1.80 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.010 percent of S, 0.15 to 0.50 percent of Mo, 0.15 to 0.50 percent of Cr, 0.015 to 0.050 percent of Nb, and 0.010 to 0.050 percent of Als, at least one of 0.01 to 0.10 percent of V, 0.005 to 0.020 percent of Ti, 0.05 to 0.50 percent of Ni, 0.0010 to 0.020 percent of RE and 0.0010 to 0.010 percent of Ca, and the balance of Fe and inevitable impurities. The steel has the advantages of low content of Mo that is a noble alloying element, short production process and cycle, excellent refractory and anti-seismic performance, good cold-hot machining performance and excellent low-temperature toughness and welding performance.

Owner:武钢集团有限公司

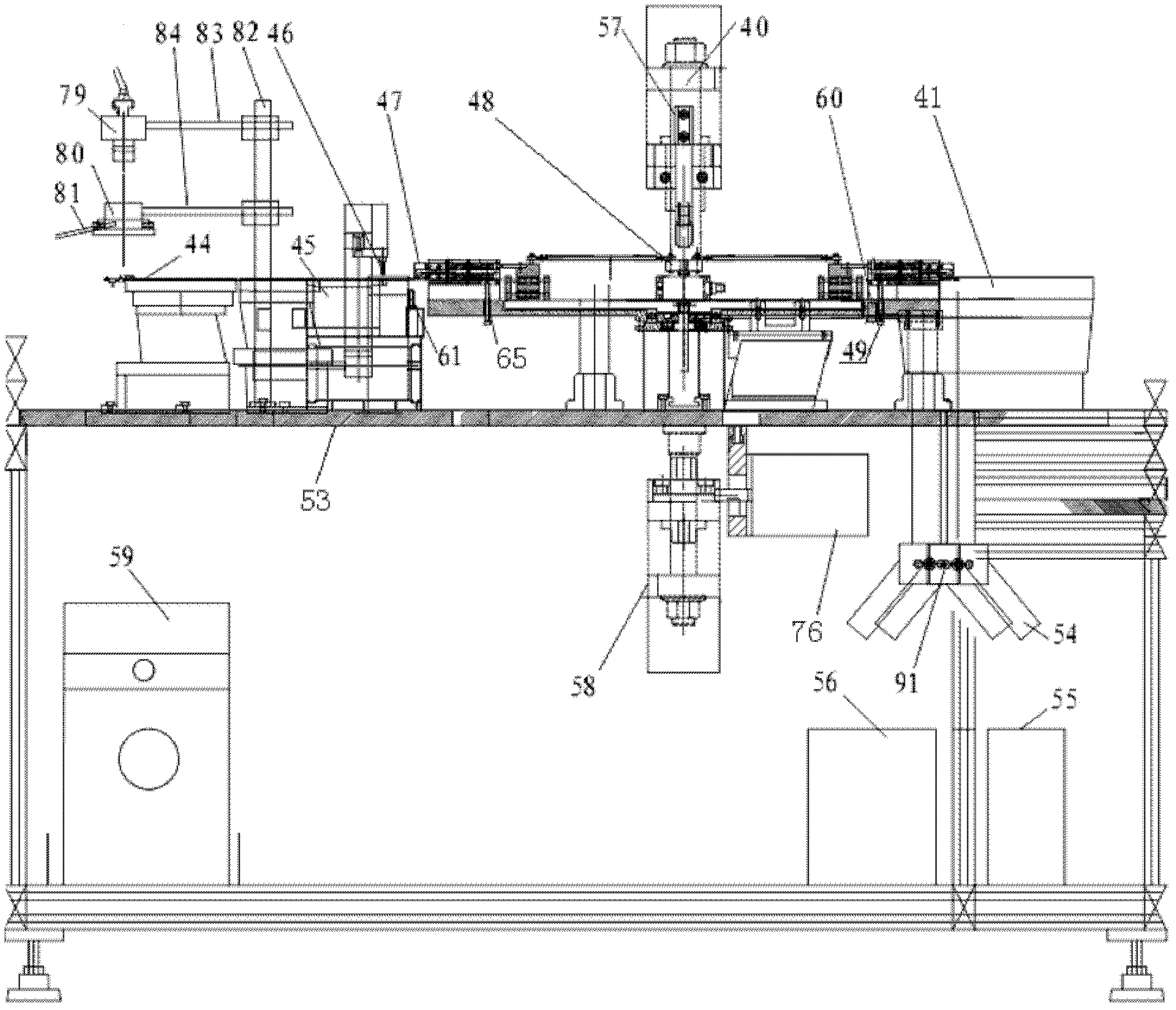

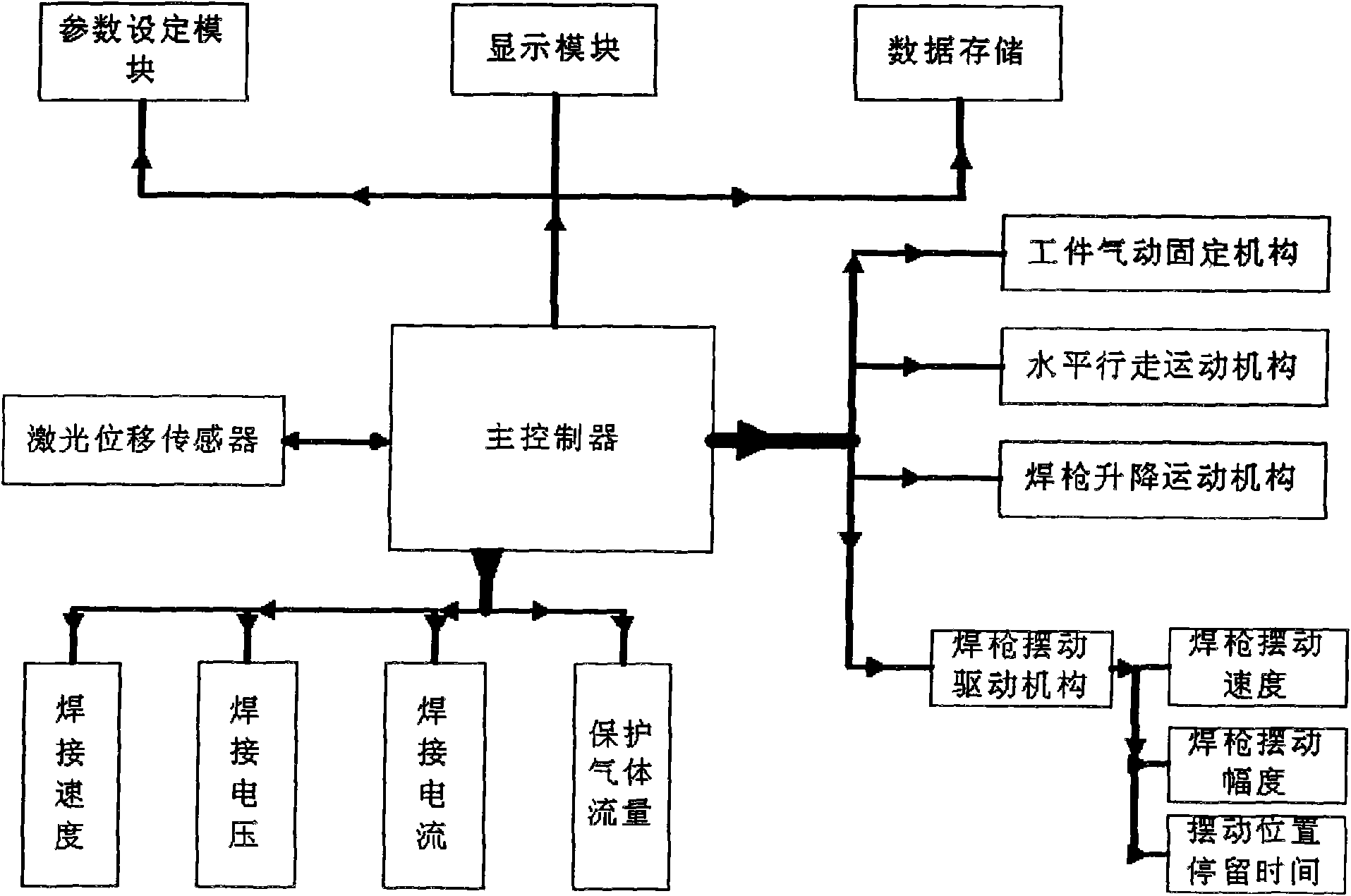

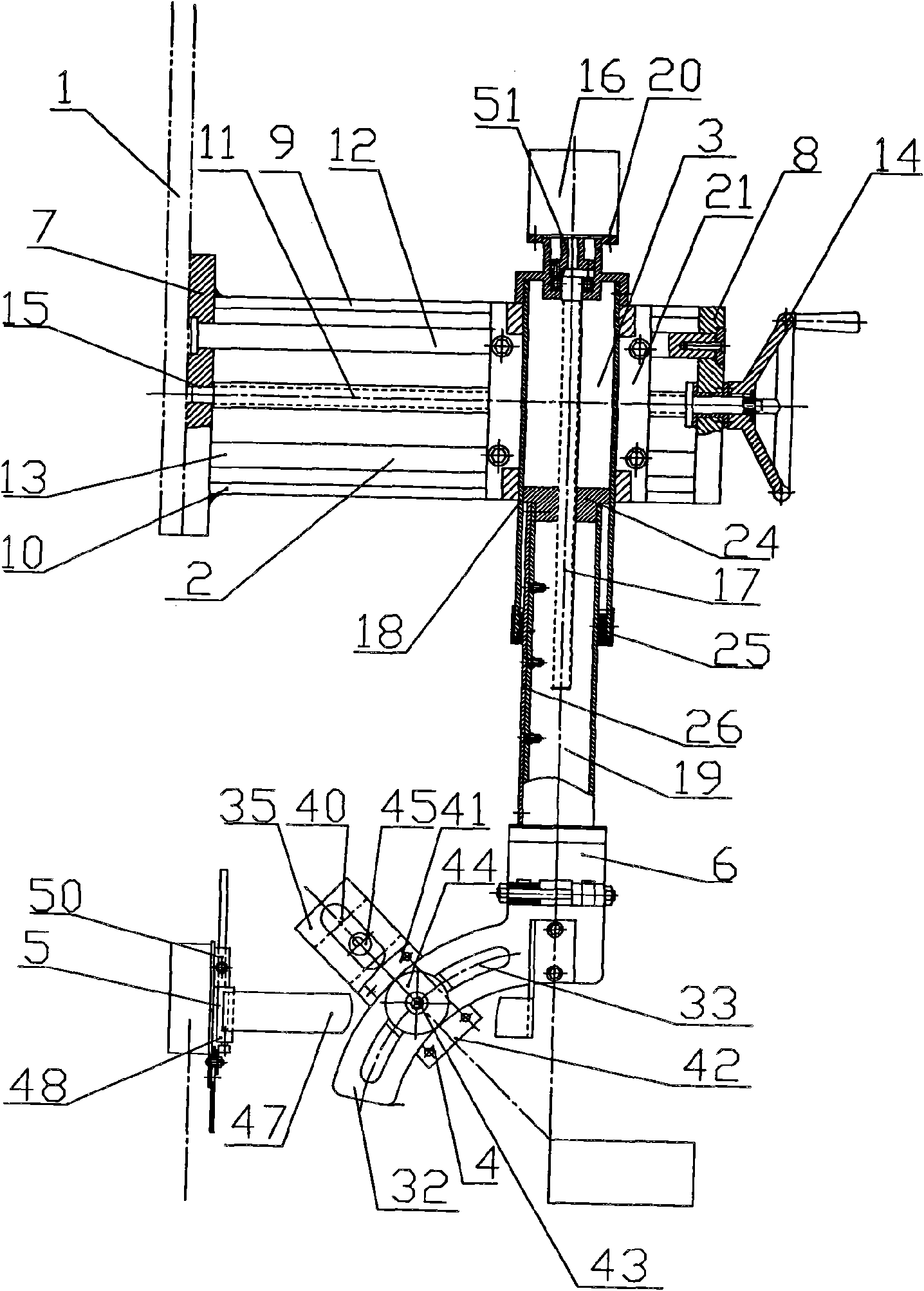

Detection and control system for container corrugated plate welding track based on laser ranging

InactiveCN101554672ARealize detectionImprove quality and efficiencyComputer controlArc welding apparatusLaser rangingAutomatic control

The invention relates to a detection and control system for a container corrugated plate welding track based on laser ranging, comprising a laser displacement sensor, a welding torch pose adjusting device and a circuit control device. The laser displacement sensor and the welding torch pose adjusting device are connected with the circuit control device through a circuit; one end of a welding torch space position and pose adjusting mechanism is fixed on a stand; and the laser displacement sensor is arranged at the lower end of the welding torch space position and pose adjusting mechanism. Through the diction of the corrugated plate welding line, the control of the welding torch pose and the automatic control of the welding process, the invention achieves the effect that the thickness of welding lines of a downslope welding section from a wave crest to a wave trough, a upslope welding section from a wave trough to a wave crest, a wave crest tangential path and a wave trough are consistent, remarkably improves the uniformity of welding lines of each welding section, greatly reduces the labor intensity of workers, reduces the manual expense of production and is fast and convenient to adjust parameters. The welding speed is more than three times of general manual welding or profile modeling welding, and automatic control is available in the whole process.

Owner:SHANDONG UNIV

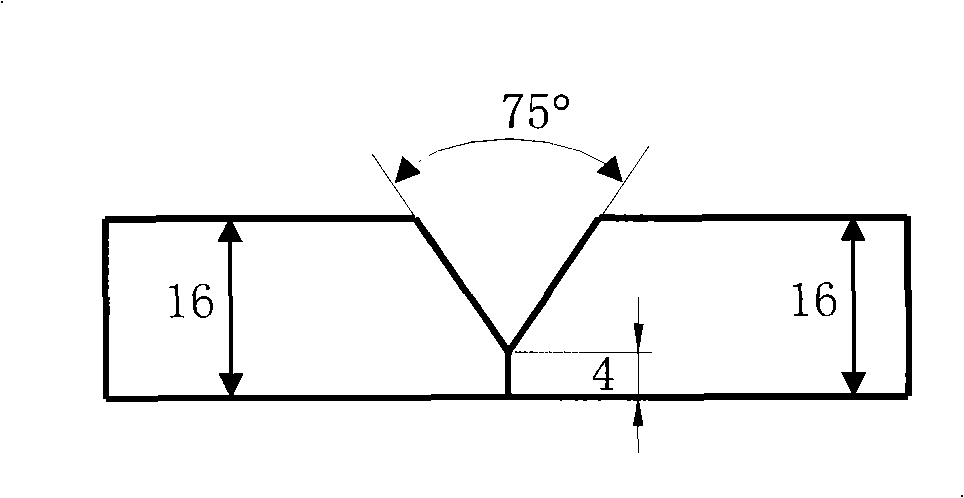

Welding method of Q420qE grade ultra-low-carbon bainite steel for bridges

InactiveCN101513695AImprove mechanical propertiesImprove welding efficiencyWelding/soldering/cutting articlesMetal working apparatusChemical IngredientsWeld line

The invention discloses a welding method of Q420qE grade ultra-low-carbon bainite steel for bridges, comprising the following steps: 1. the special chemical ingredients and technical conditions of Q420qE grade ultra-low-carbon bainite steel for bridges related to the welding method; 2. the pre-heating temperature before welding related to the steel and thickness specification of the steel; 3. welding line energy related to the steel; 4, the groove form and welding method related to the joint form and the plate thickness of the steel; 5. welding materials related to the steel, the joint form, groove form and welding method of the steel; and 6. welding process parameters related to the steel, the joint form, groove form, welding method and welding materials of the steel. The welding method covers the typical joint forms and thickness specifications of the bridge structure, and is simple and practical, the implementation effect of which complies with the related standards of the present bridge steel and the bridge structure, thus being practically applied to welding of the bridge steel structure.

Owner:YANSHAN UNIV +1

Simultaneous cooling assisted connection method based on laser additive manufacturing

InactiveCN105414746AGrain refinementImprove welding efficiencyLaser beam welding apparatusMetallurgyMartensitic stainless steel

The invention relates to a simultaneous cooling assisted connection method based on laser additive manufacturing, and aims to solve the problems of an increase in the crystal grain size, a decrease in the connector performance, and the like caused by the fact that heat cannot be effectively dissipated when titanium alloy, carbon stainless steel, martensitic stainless steel and other materials being relatively low in heat conductivity are involved in connection processes based on a laser additive manufacturing method. According to the method, a cooling device is arranged for being combined with a laser welding machine and a welding powder feeder, so as to achieving a cooling process; heat accumulated in the welding process can be effectively dissipated, so as to refine crystal grains; the welding efficiency and the connector performance are improved; in order to solve the problem that an oxidation phenomenon is likely to occur in the welding process, the cooling process is performed according to a cooling method adopting liquid nitrogen, inert gas or the like, so that connector oxidation can be effectively avoided when a cooling effect is exerted.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com