Patents

Literature

508results about How to "Reduce filling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

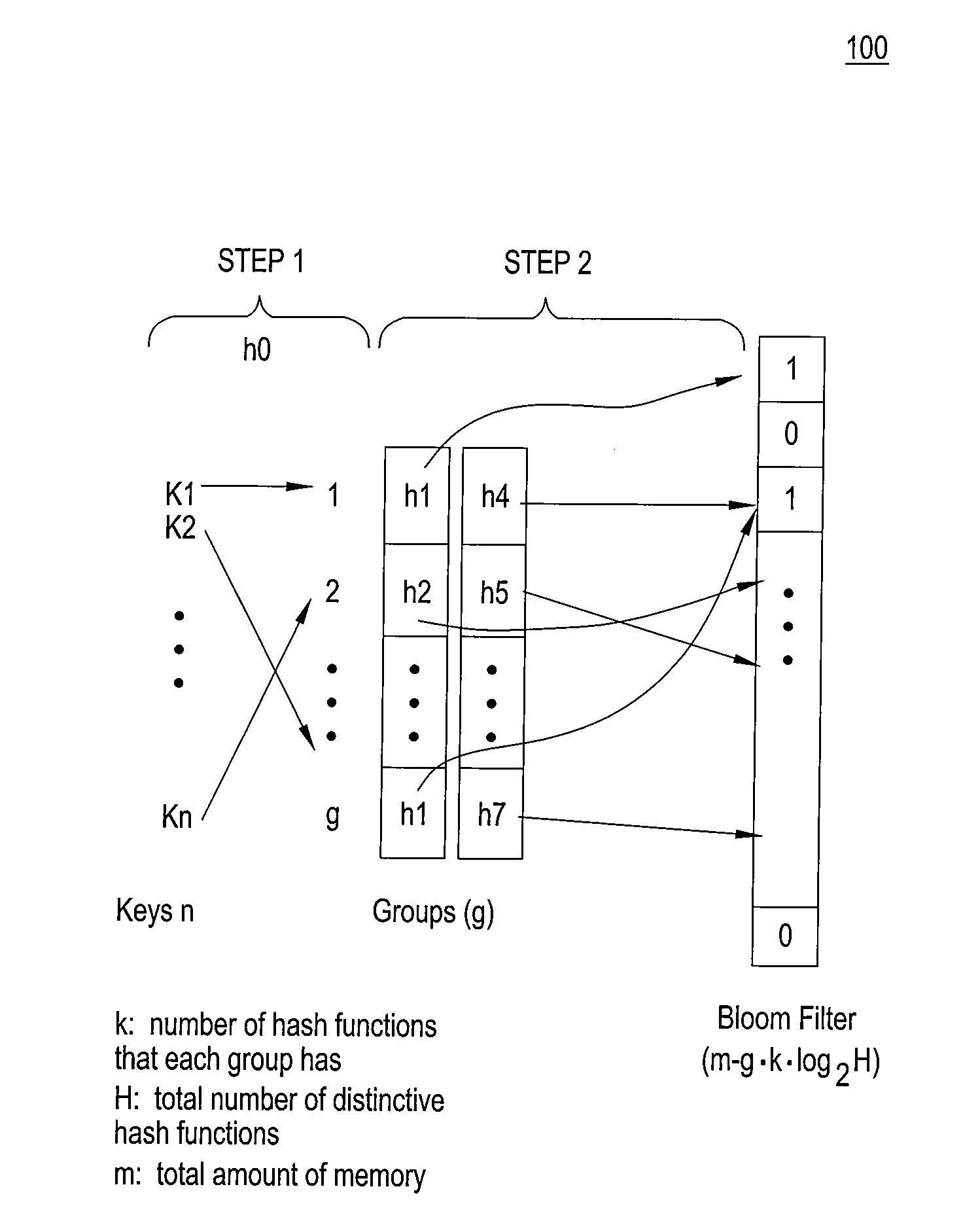

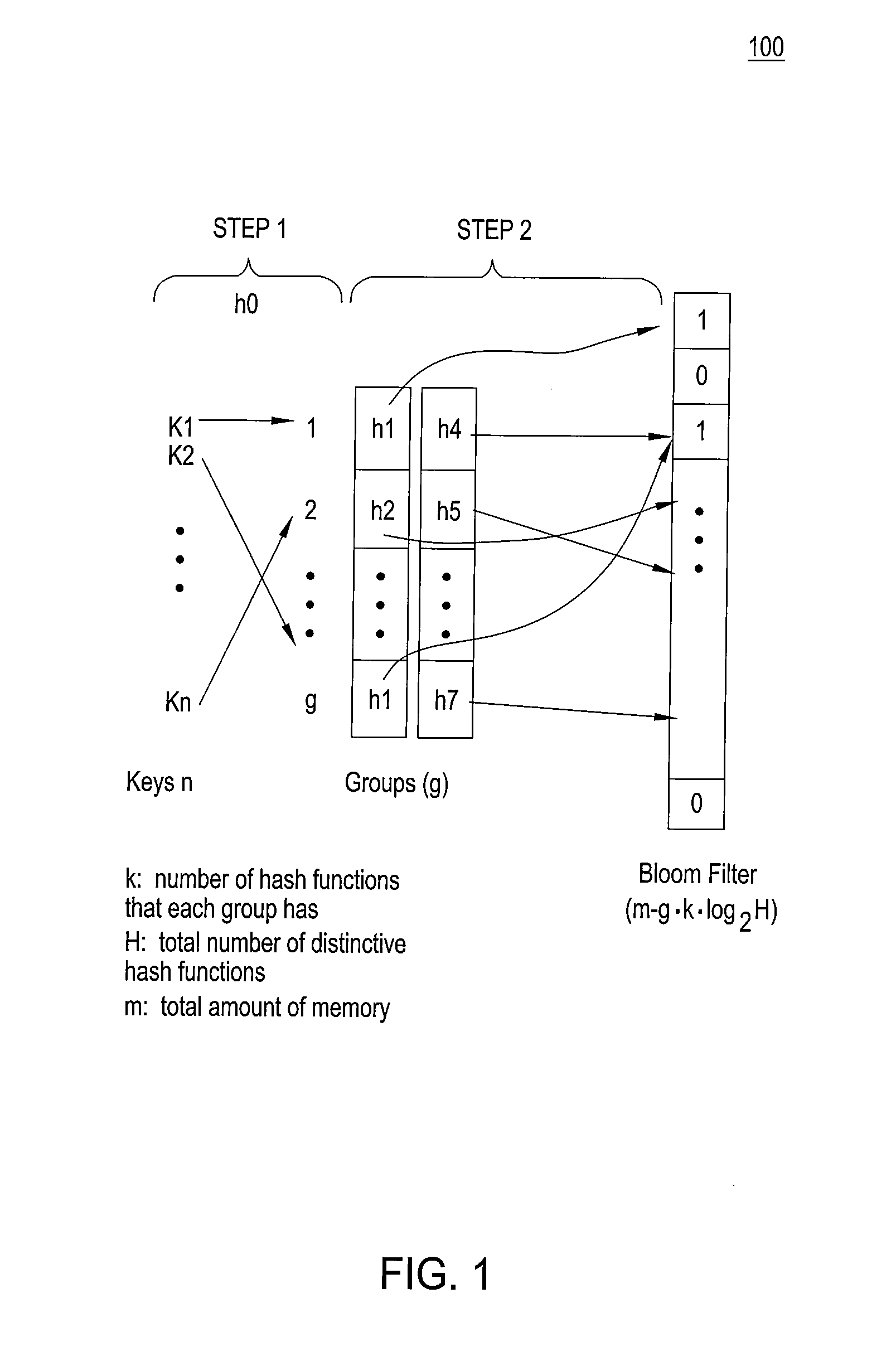

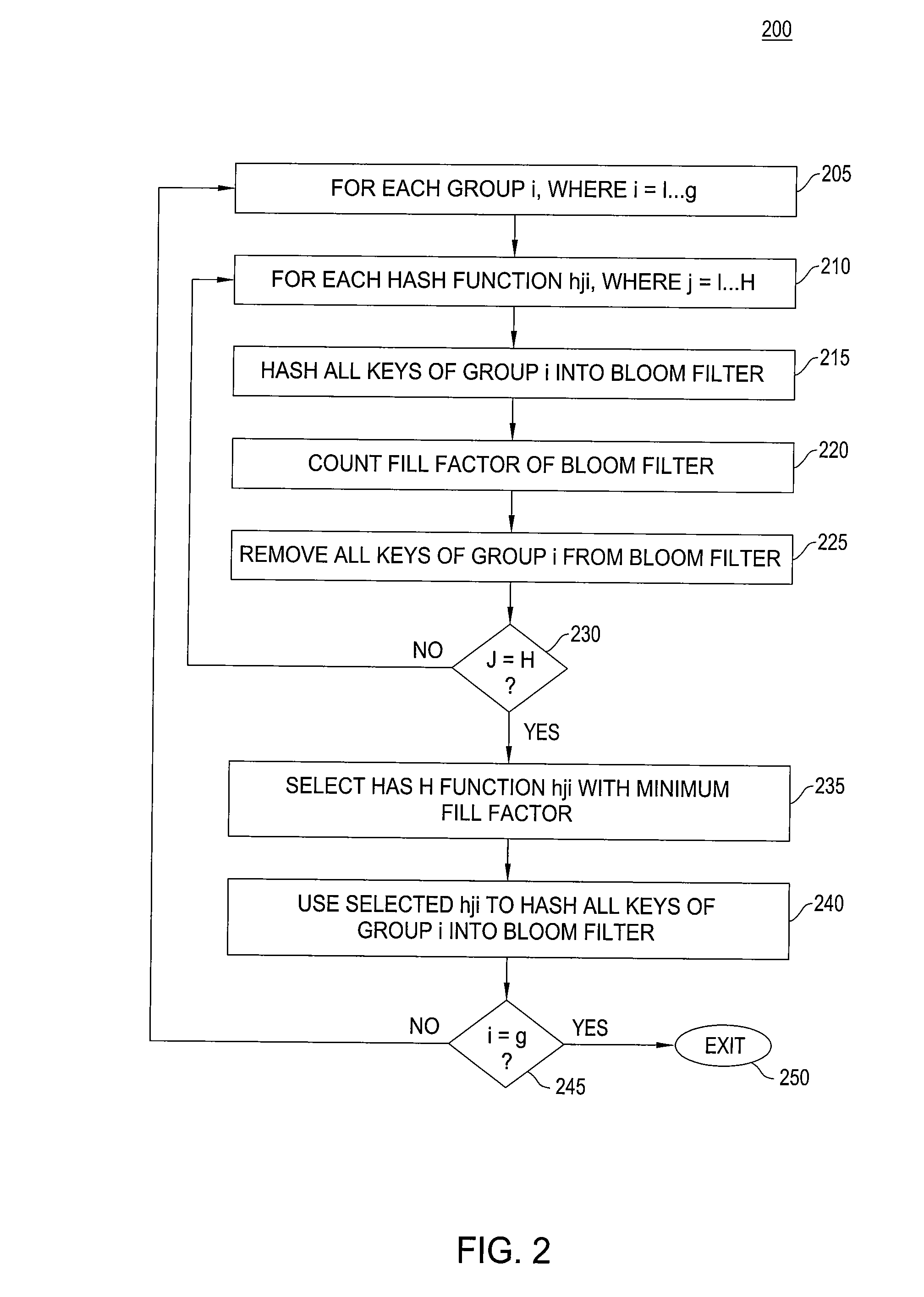

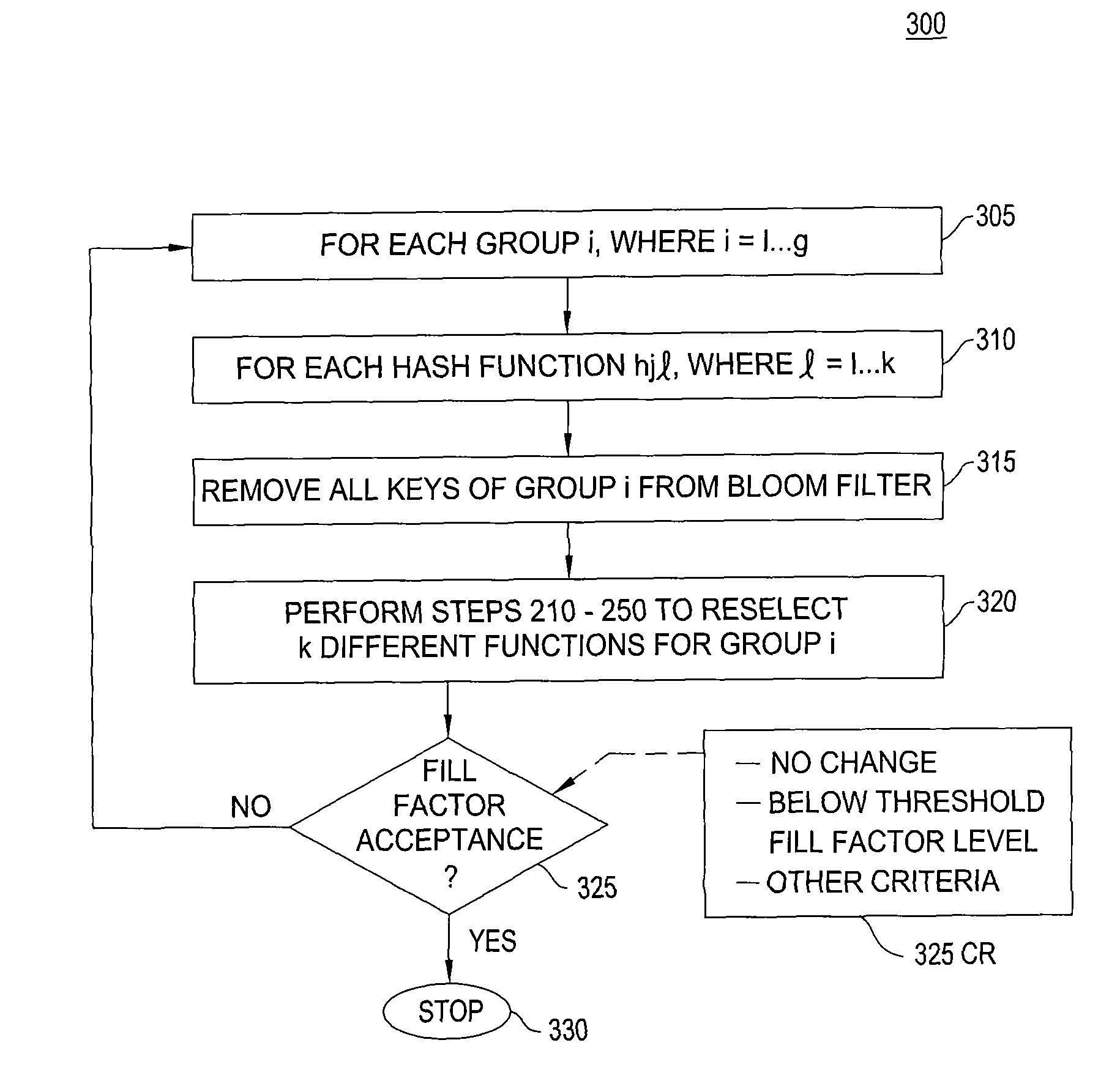

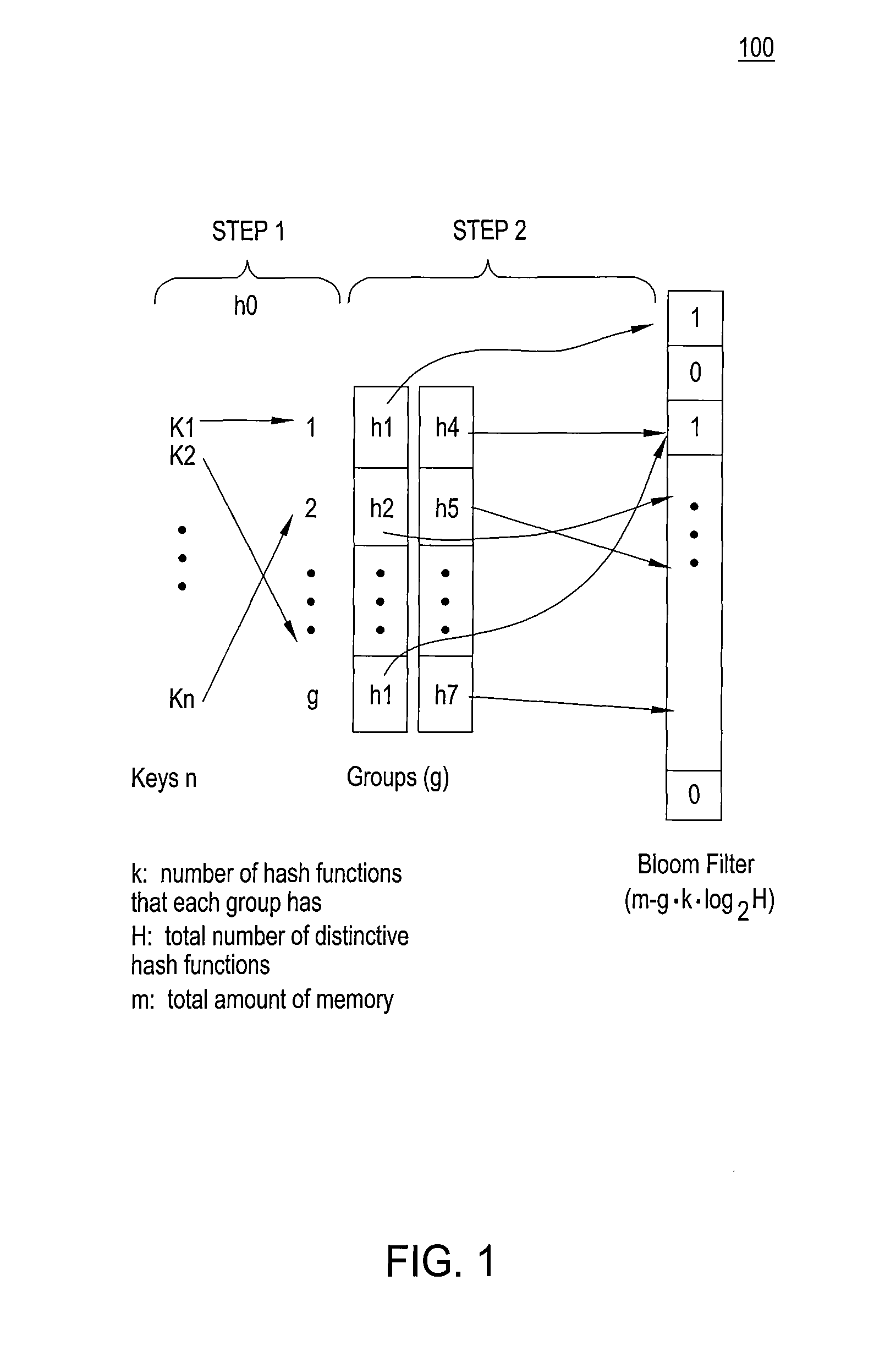

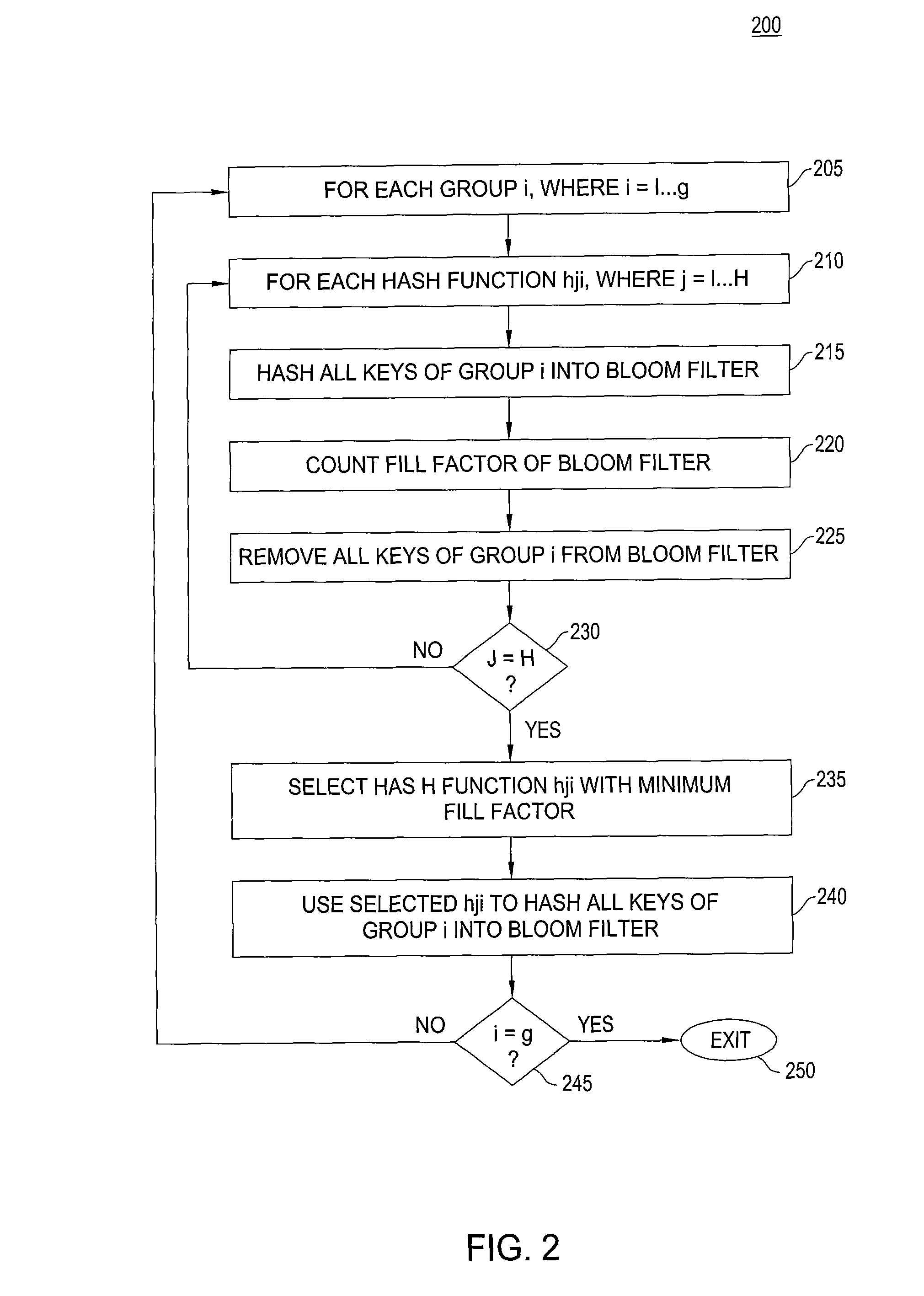

High accuracy bloom filter using partitioned hashing

ActiveUS20080313132A1Reduce false alarm rateReduce the probability of false positivesTransmissionSpecial data processing applicationsHash functionTheoretical computer science

A method and system for generating a bloom filter by mapping into respective groups each of a plurality of initial keys according to a first hash function and mapping each group hashed key into a bloom filter using k respective hash functions.

Owner:ALCATEL-LUCENT USA INC

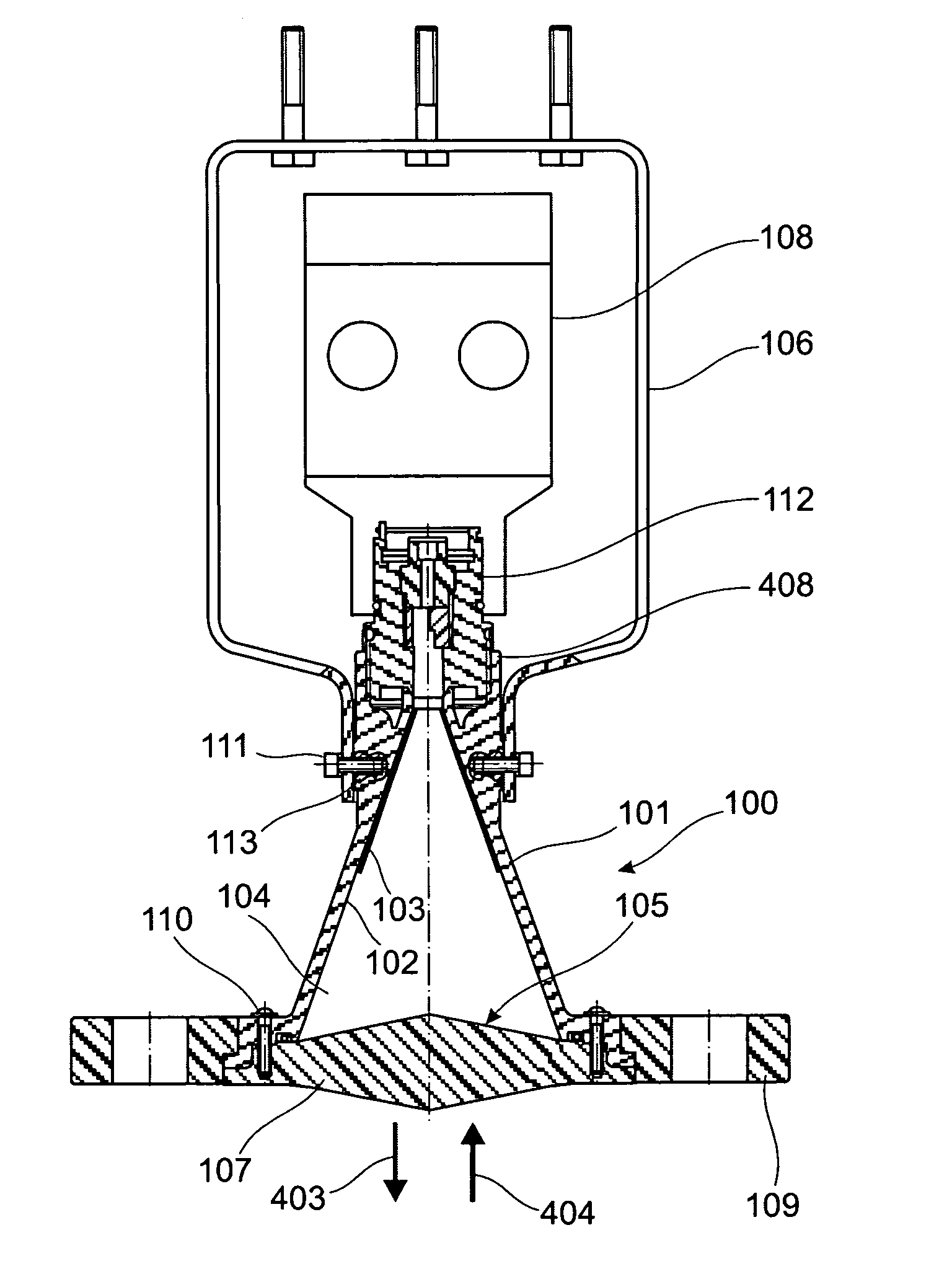

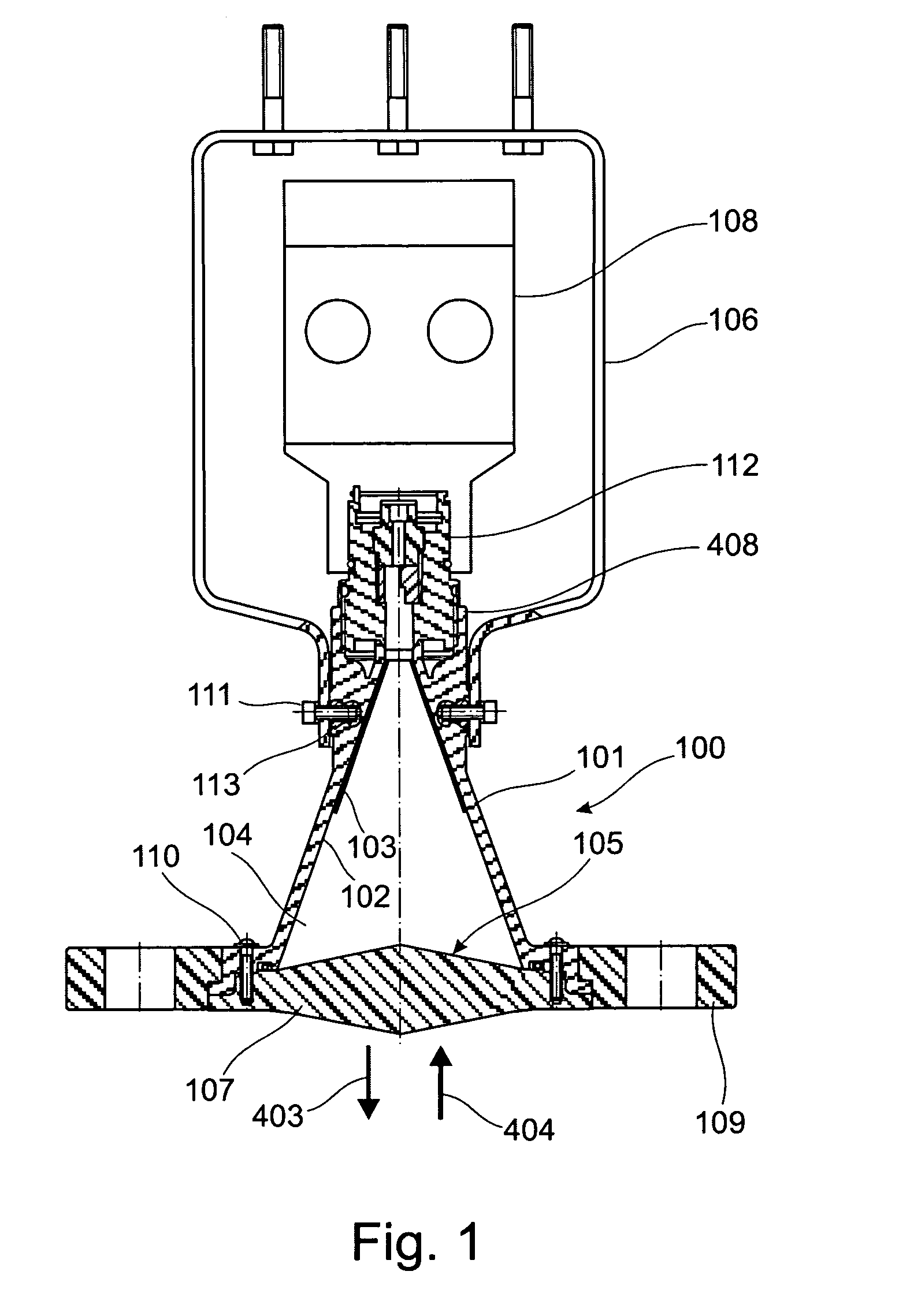

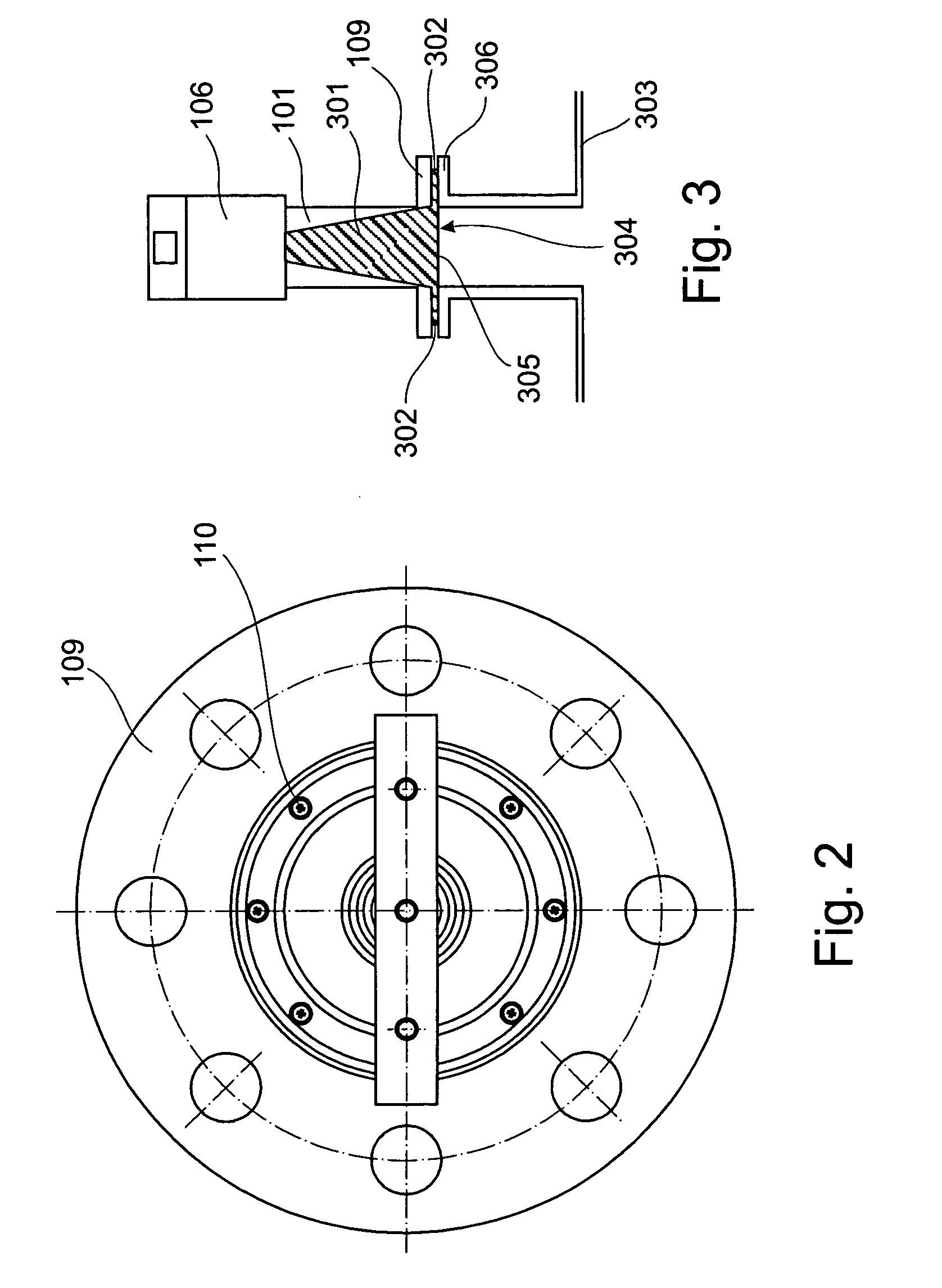

Metallised plastic antenna funnel for a fill level radar

A metalized plastic antenna includes a plastic antenna body with metallization on the inside. In this arrangement metallization is used for conducting electromagnetic waves. Furthermore, metallization may be implemented as a protective coating so that chemical resistance of the plastic antenna may be ensured even in the case of corrosive environmental conditions.

Owner:VEGA GRIESHABER GMBH & CO

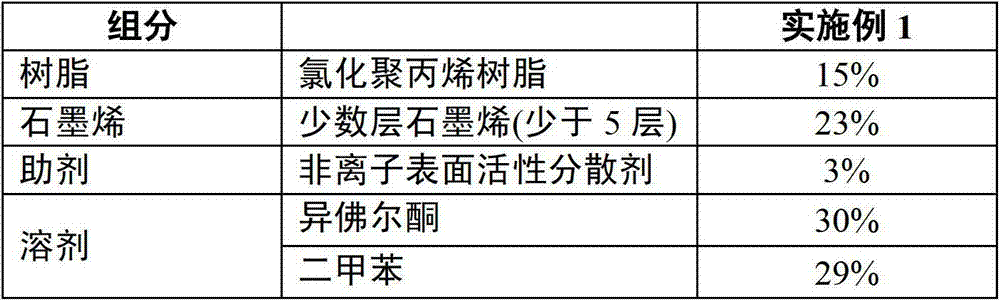

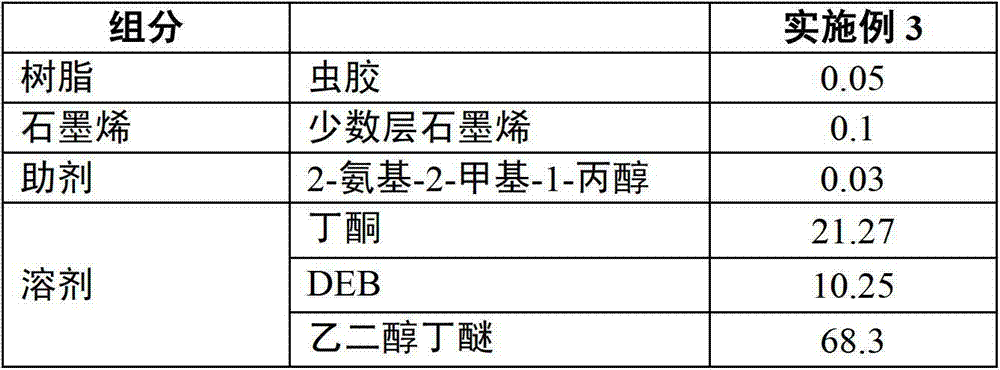

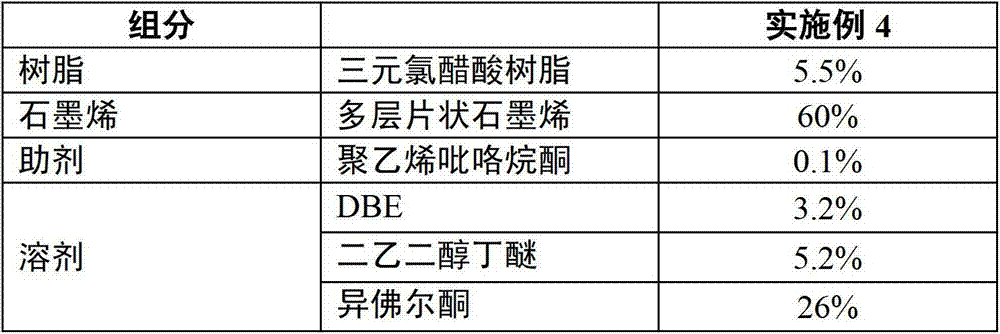

Graphene conductive ink and preparation method thereof

ActiveCN103113786AImprove thermal conductivityImprove mechanical propertiesInksConductive materialsSolvent

The invention relates to graphene conductive ink comprising the following components by weight percent: 0.01-25% of resin, 0.1-95% of graphene, 0.1-30.0% of assistant, and 5.0-99.79% of solvent. The two-dimensional conductive material graphene is used for the conductive ink; the graphene with special ratio is adopted as a conductive phase; the resin is taken as a binder; the assistant and the solvent are used for assisting; the prepared ink is good in anti-sedimentation property, and adjustable in viscosity and rheological behavior, and can be used for flexibly printing on the surfaces of a plurality of substrates; and the ink is stable in mechanical property, stable in electrical properties, oxidation resistance, acid resistance, alkali resistance and resistance to a chemical solvent after being cured.

Owner:SUZHOU NIUJIAN NEW MATERIAL

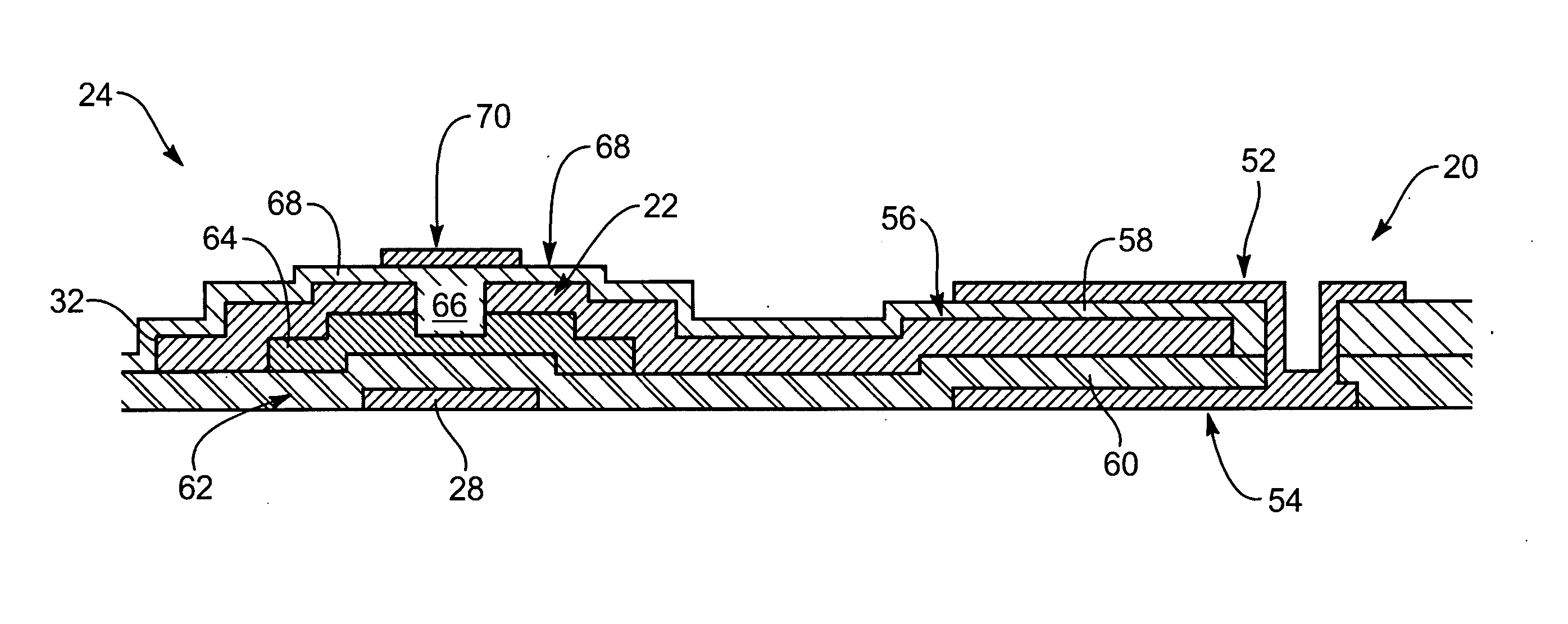

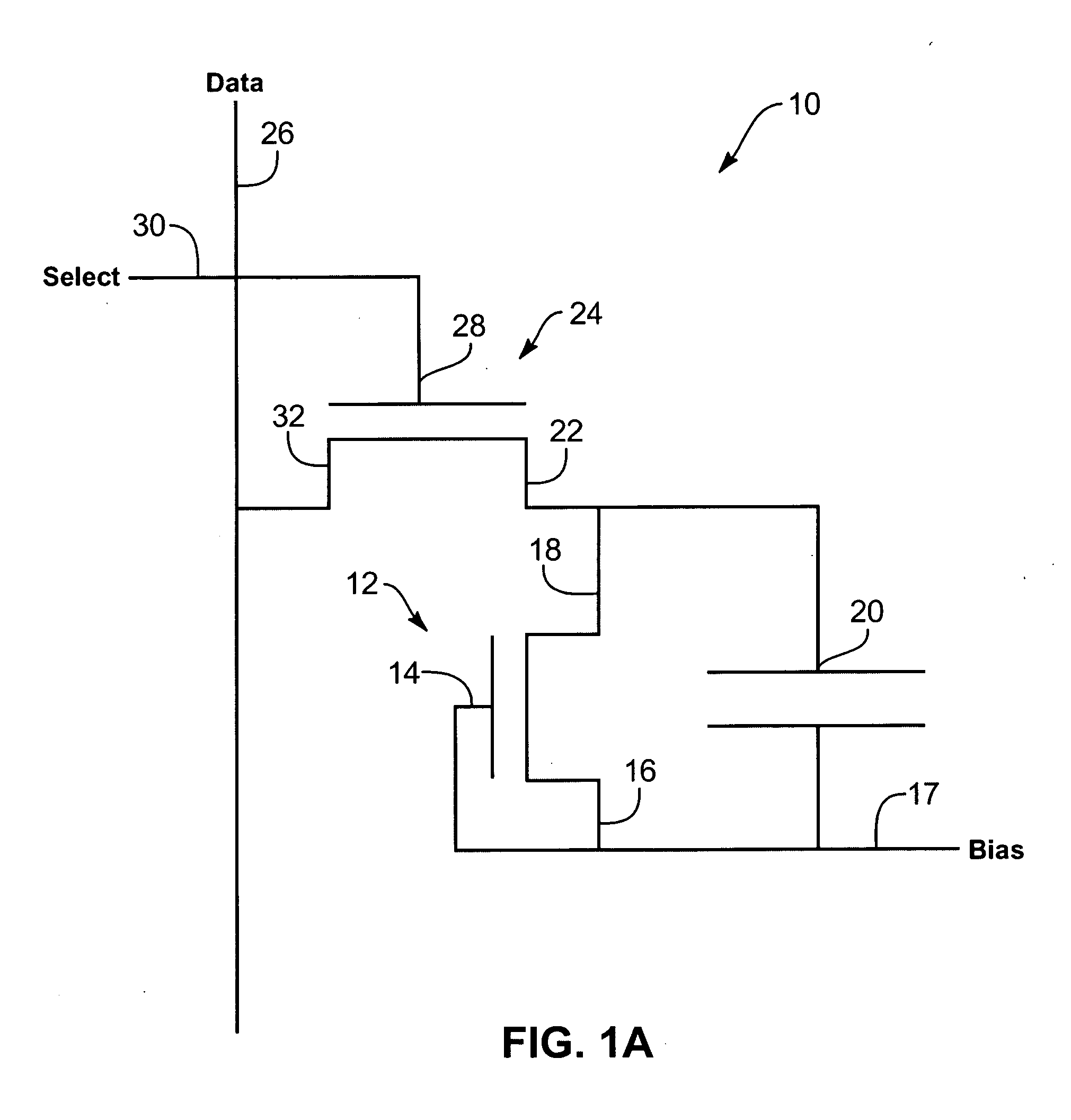

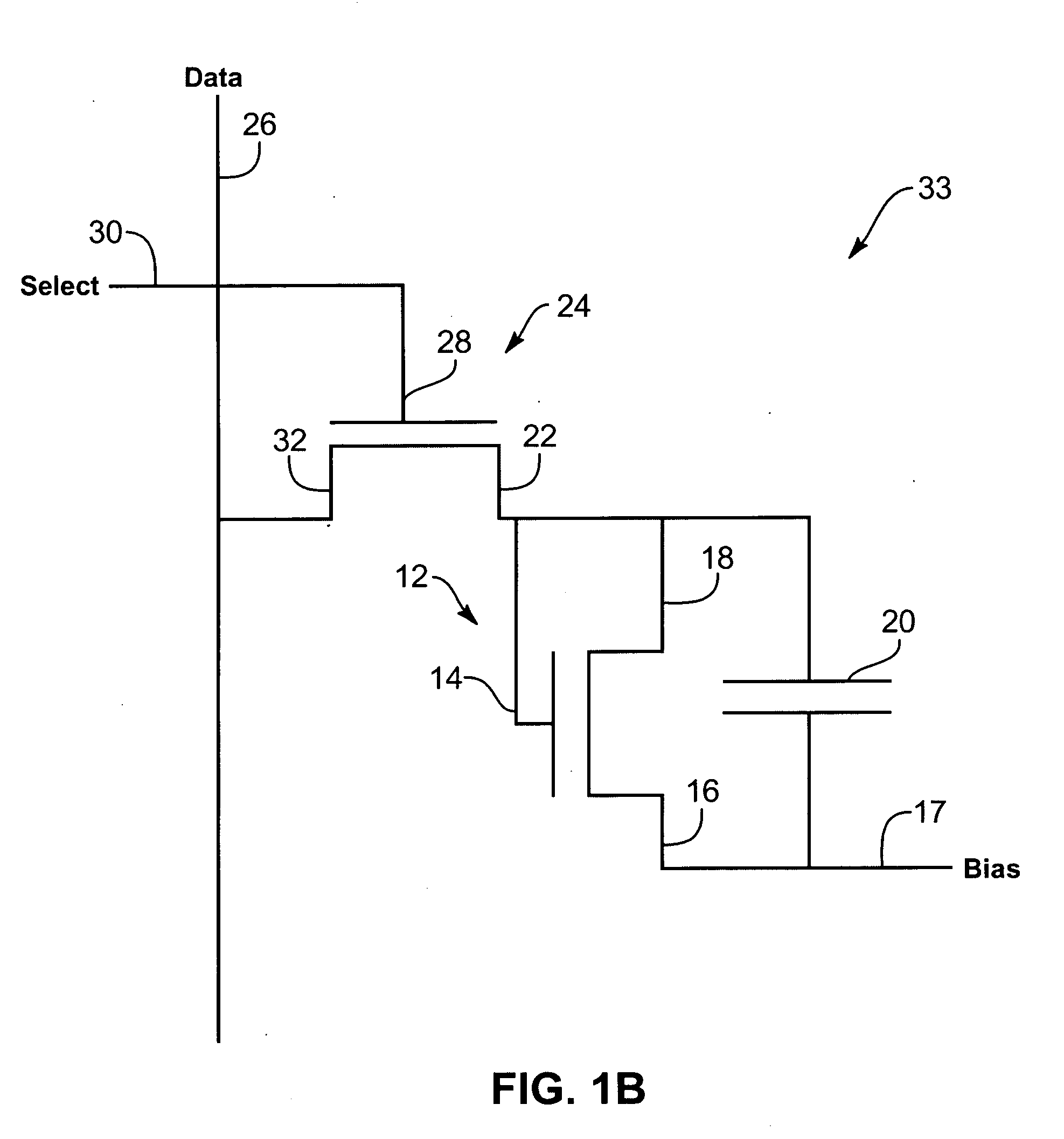

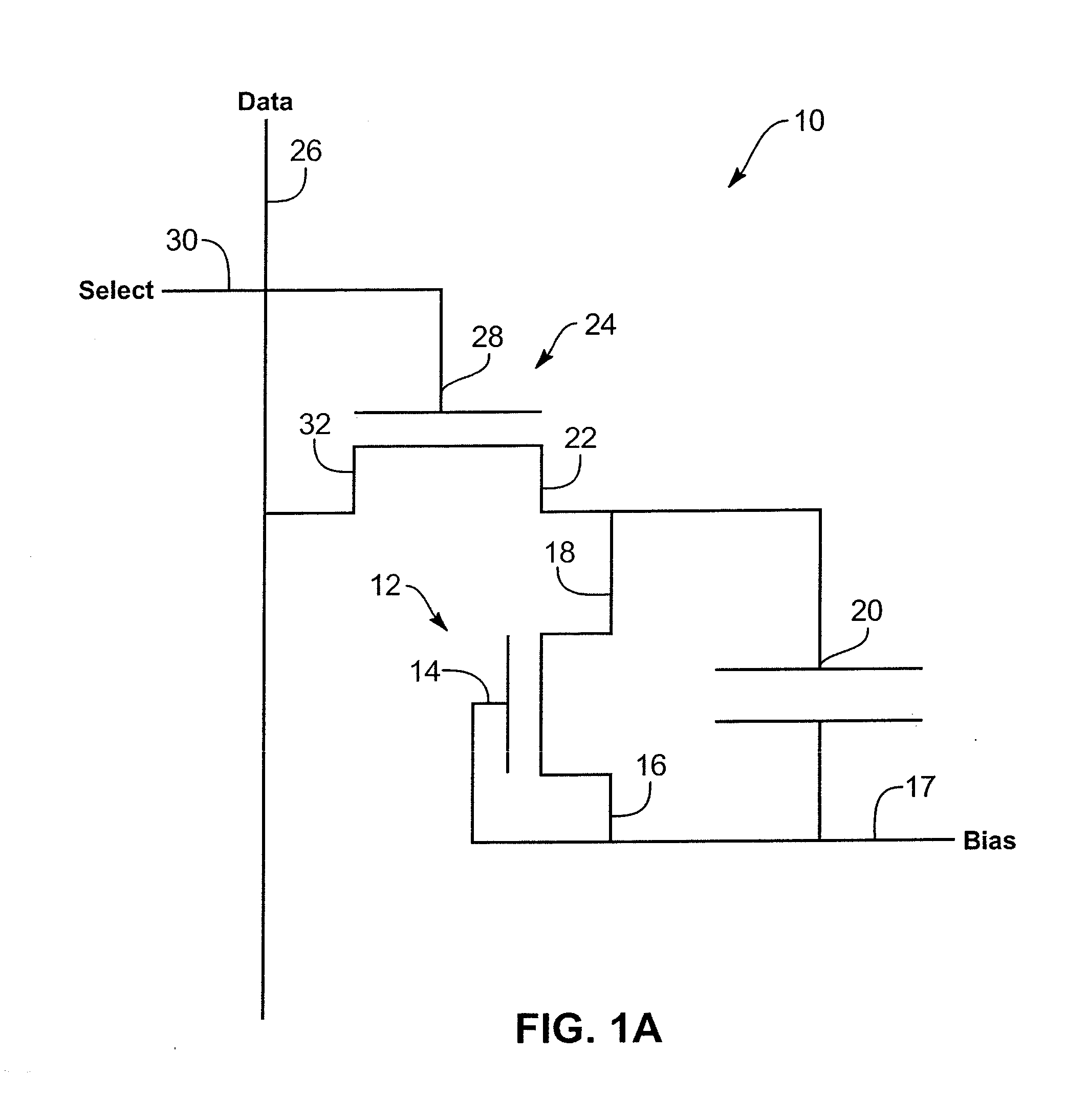

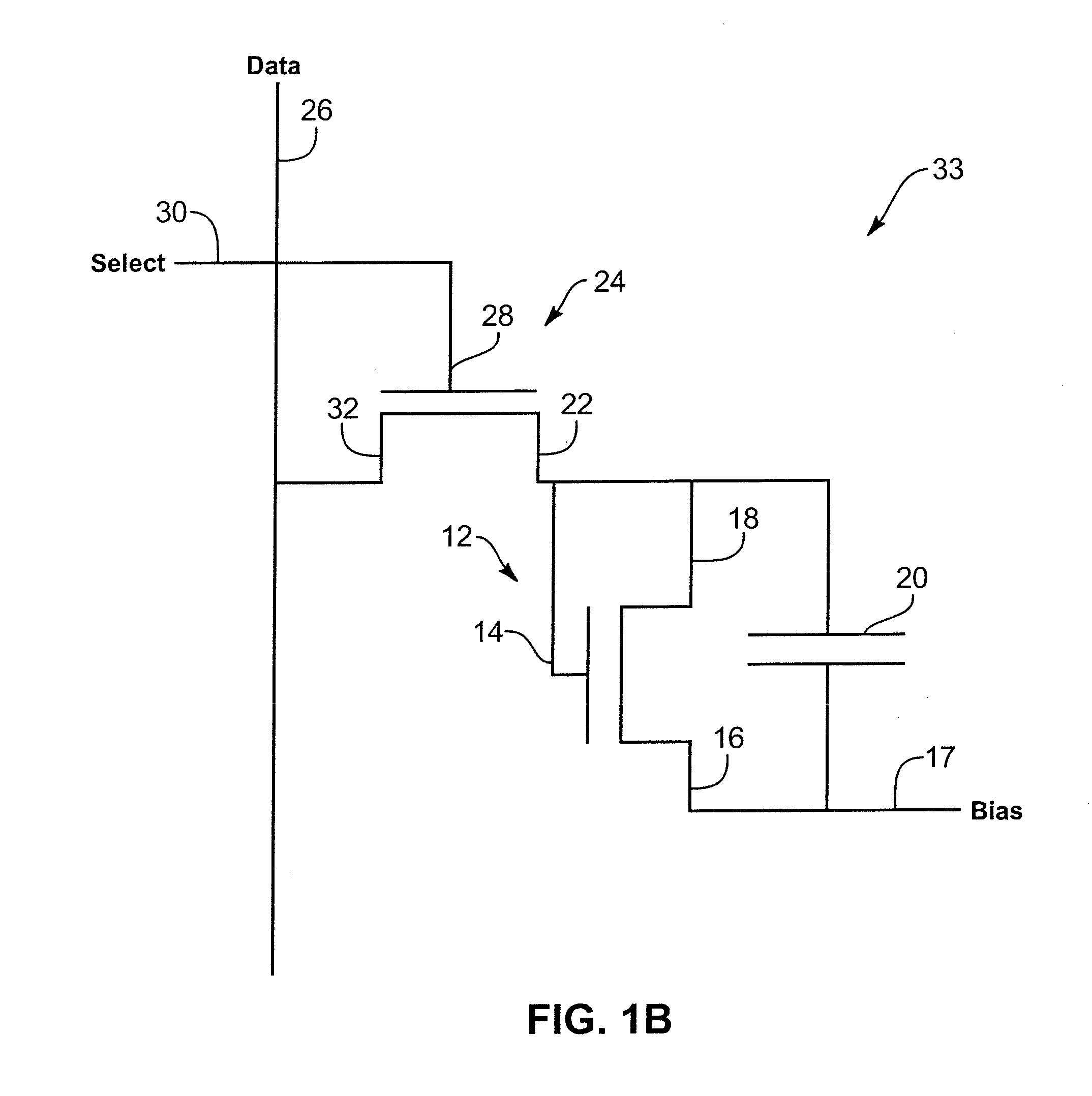

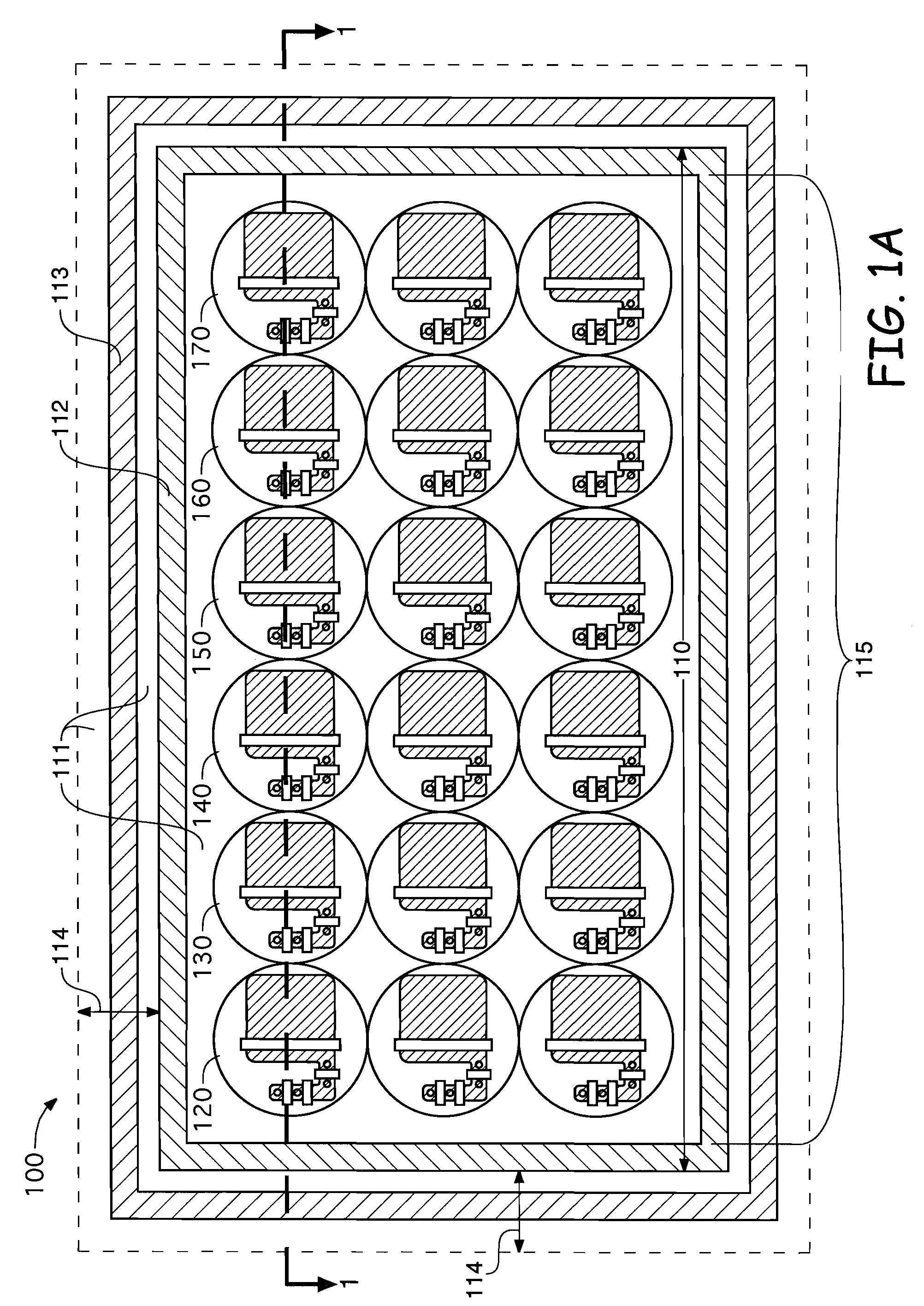

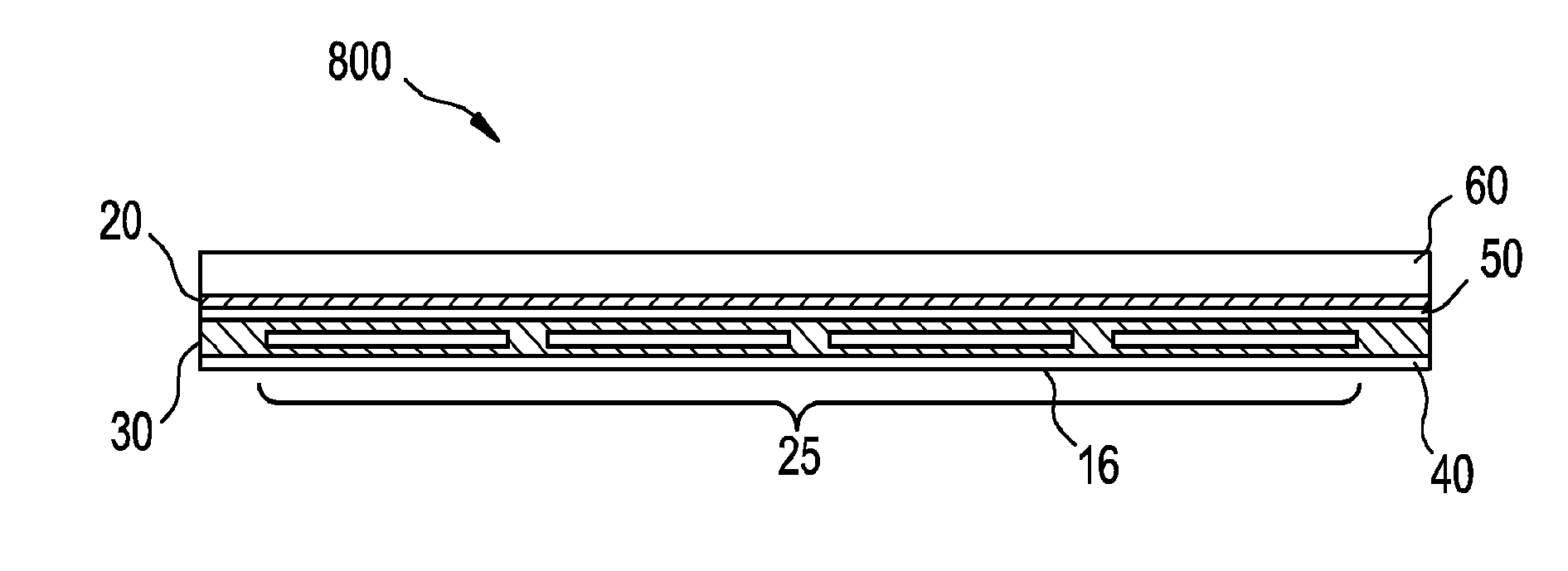

Image sensor with photosensitive thin film transistors and dark current compensation

InactiveUS20050231656A1Increase photosensitivityReduce impactTelevision system detailsTelevision system scanning detailsPhotocurrentCapacitor

An image sensor array includes image sensors having photo TFTs to generate photocurrent in response to received images. The photo TFTs each have their respective gate electrodes and source electrodes independently biased to reduce the effects of dark current. Storage capacitors are coupled to each photo TFT and discharged upon generation of a photocurrent. Each storage capacitor is coupled to a readout TFT that passes a current from the storage capacitor to a data line. The photo TFT may be disposed above the storage capacitor to increase the exposed surface area of the photo TFT.

Owner:APPLE INC

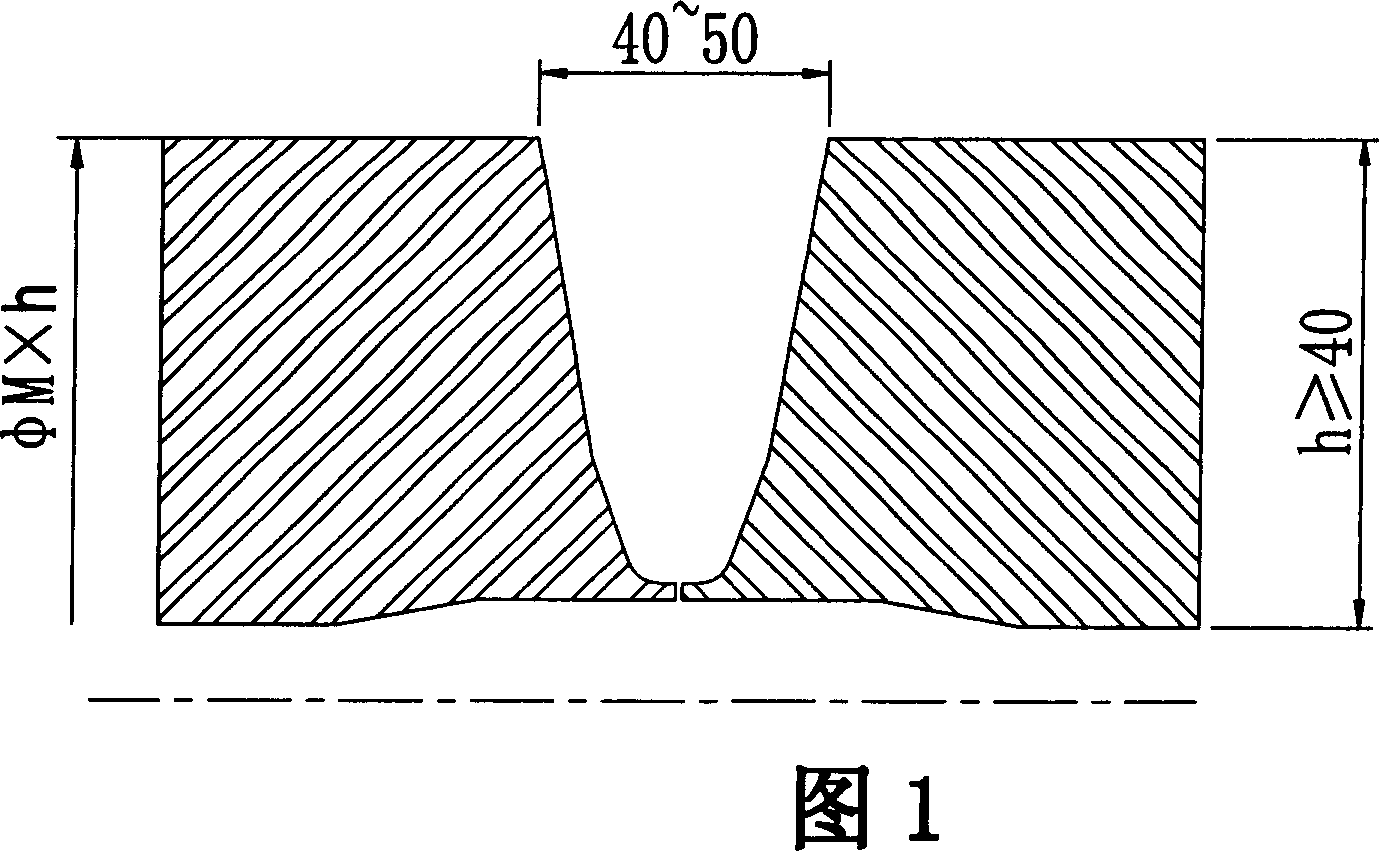

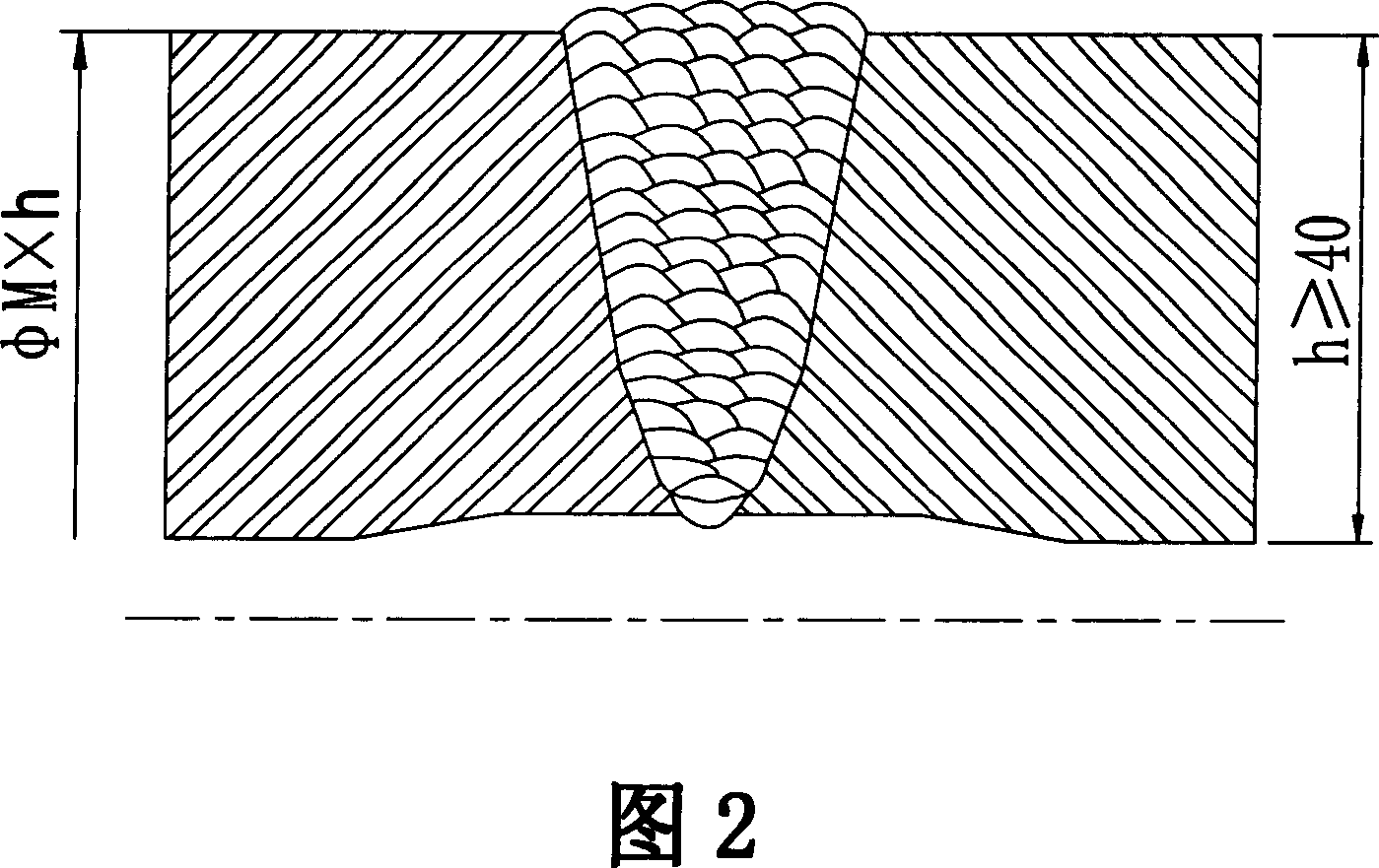

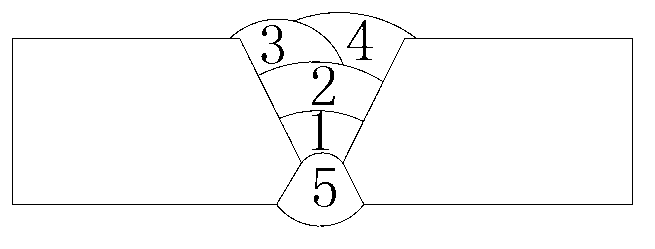

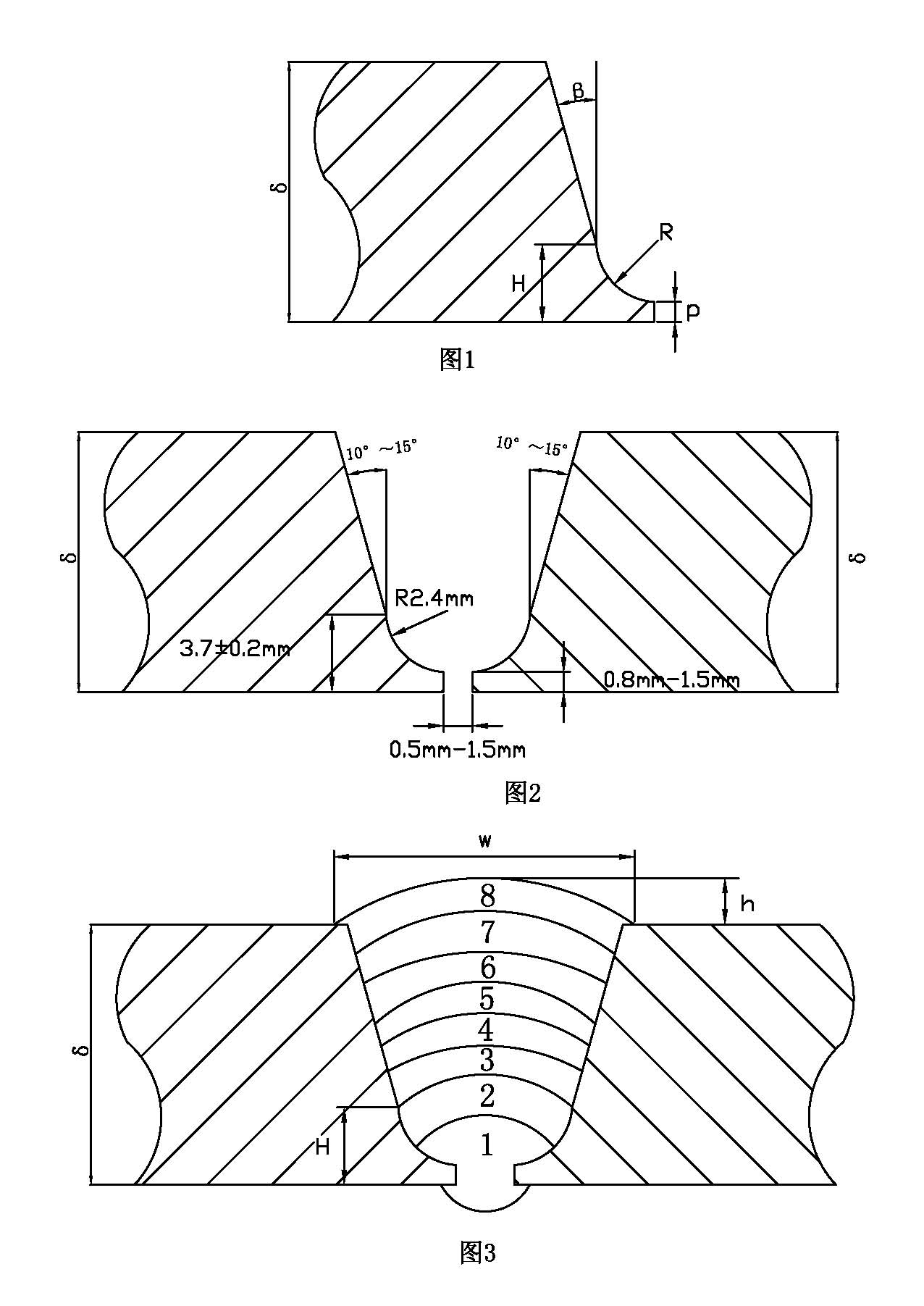

Large posted sides pipeline narrow gap tungsten electrode noble gas protecting all-position automatic soldering method

ActiveCN101077547AReduce fillingReduce welding costsArc welding apparatusWelding/cutting media/materialsNoble gasEngineering

The present invention relates to inert gas protected automatic narrow gap tungsten electrode welding process for large thick pipe with diameter over 325 mm and thickness over 40 mm. The automatic welding process includes forming combining chamfer in the opposite ends to be welded before welding, bottoming welding, single layer filling welding, and covering welding in linear or swinging weld pass. The process has less filled deposited metal, low welding cost, high welding efficiency and other advantages.

Owner:CHINA NUCLEAR IND 23 CONSTR

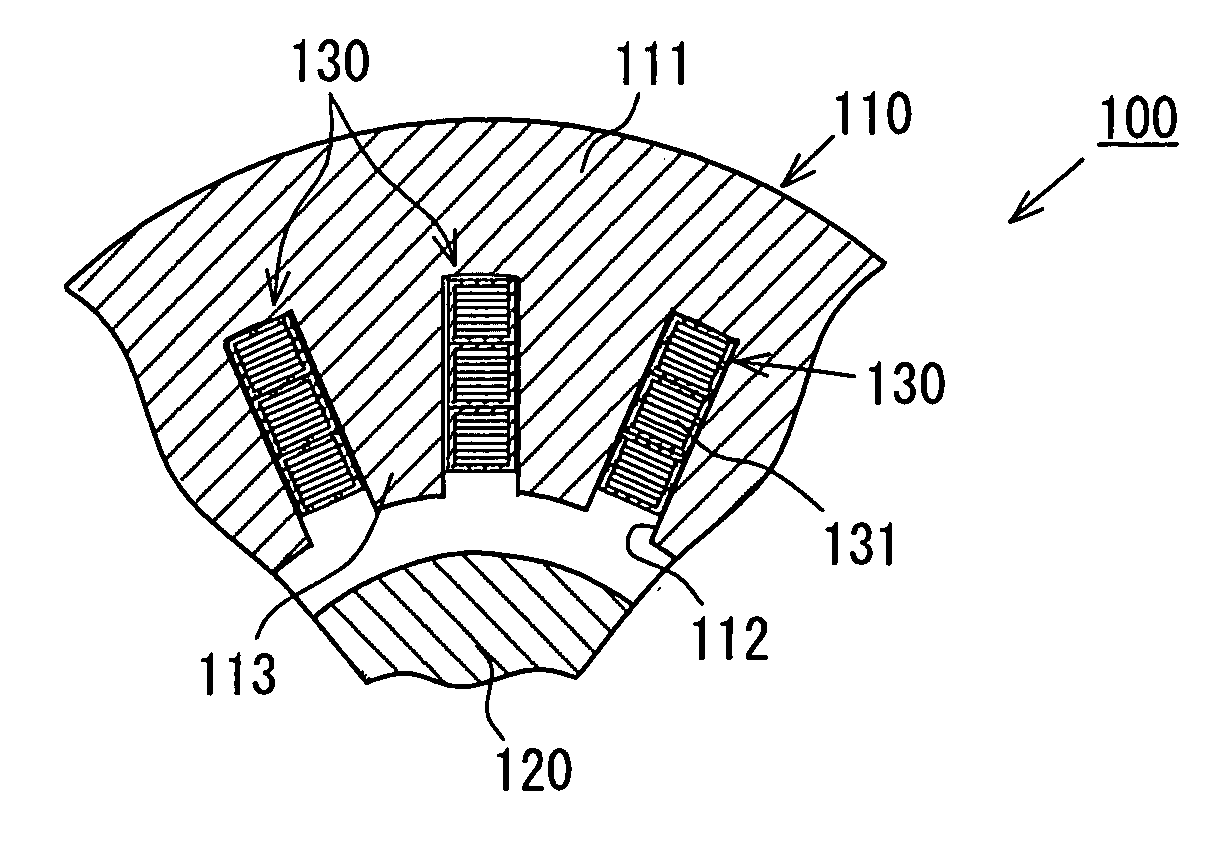

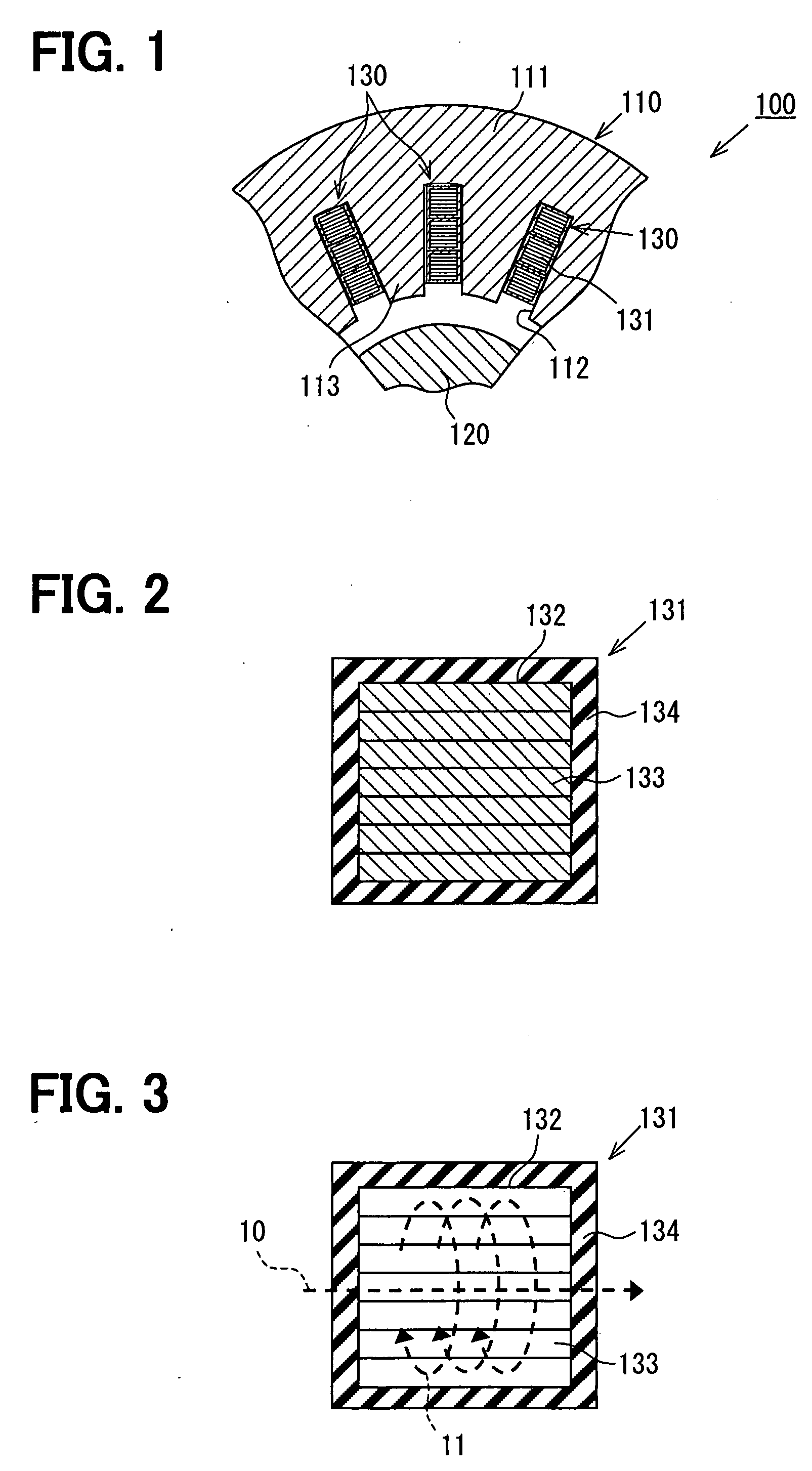

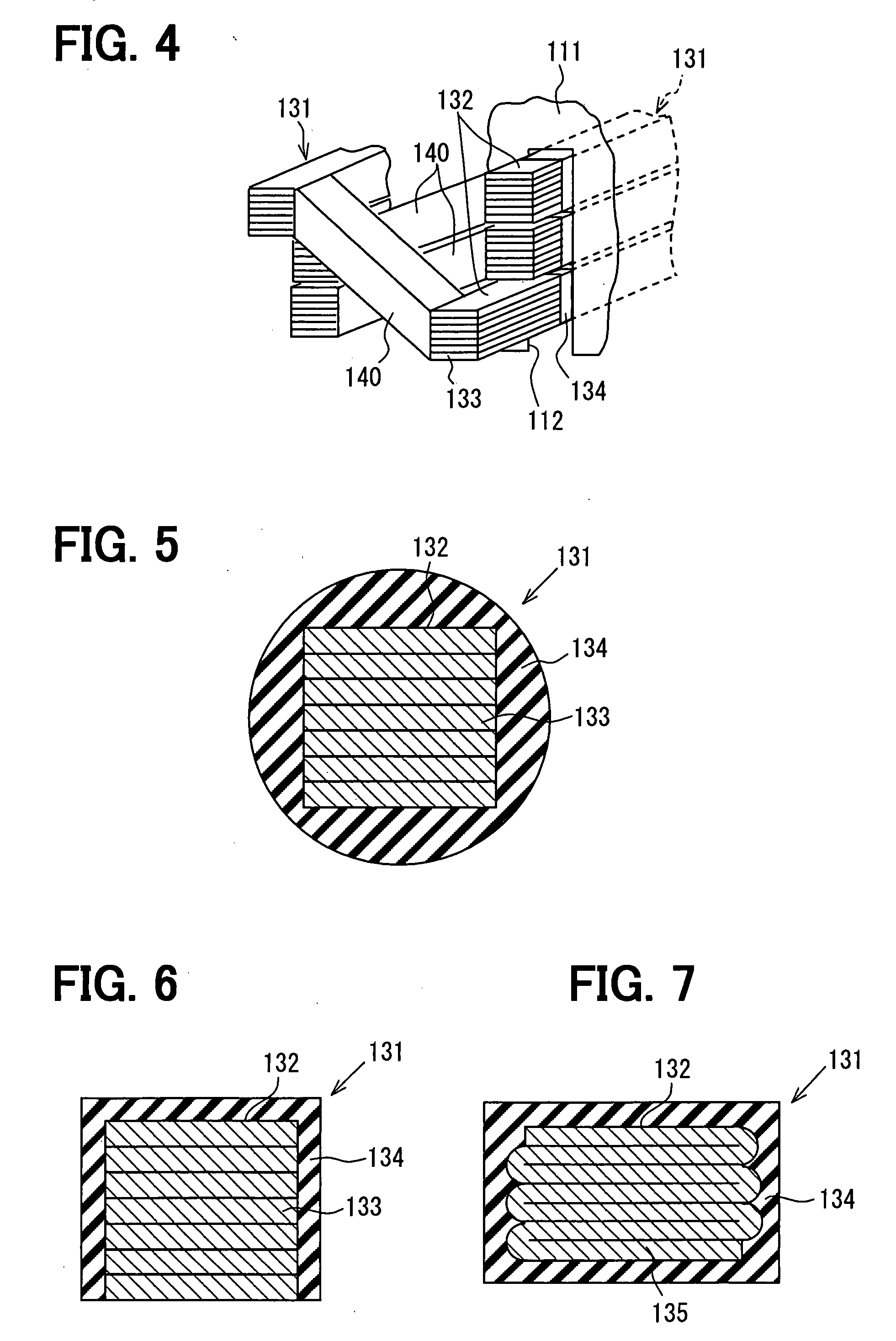

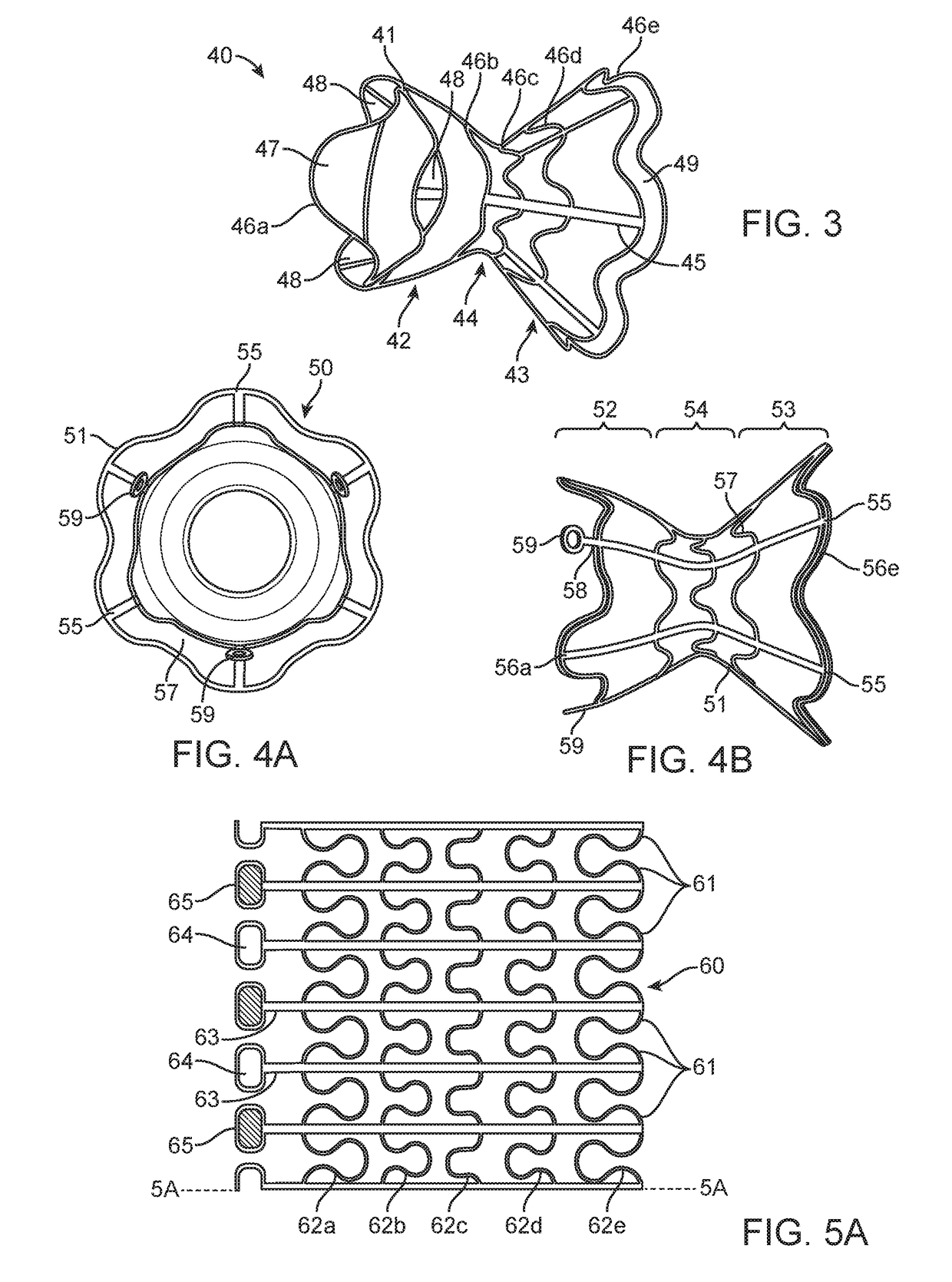

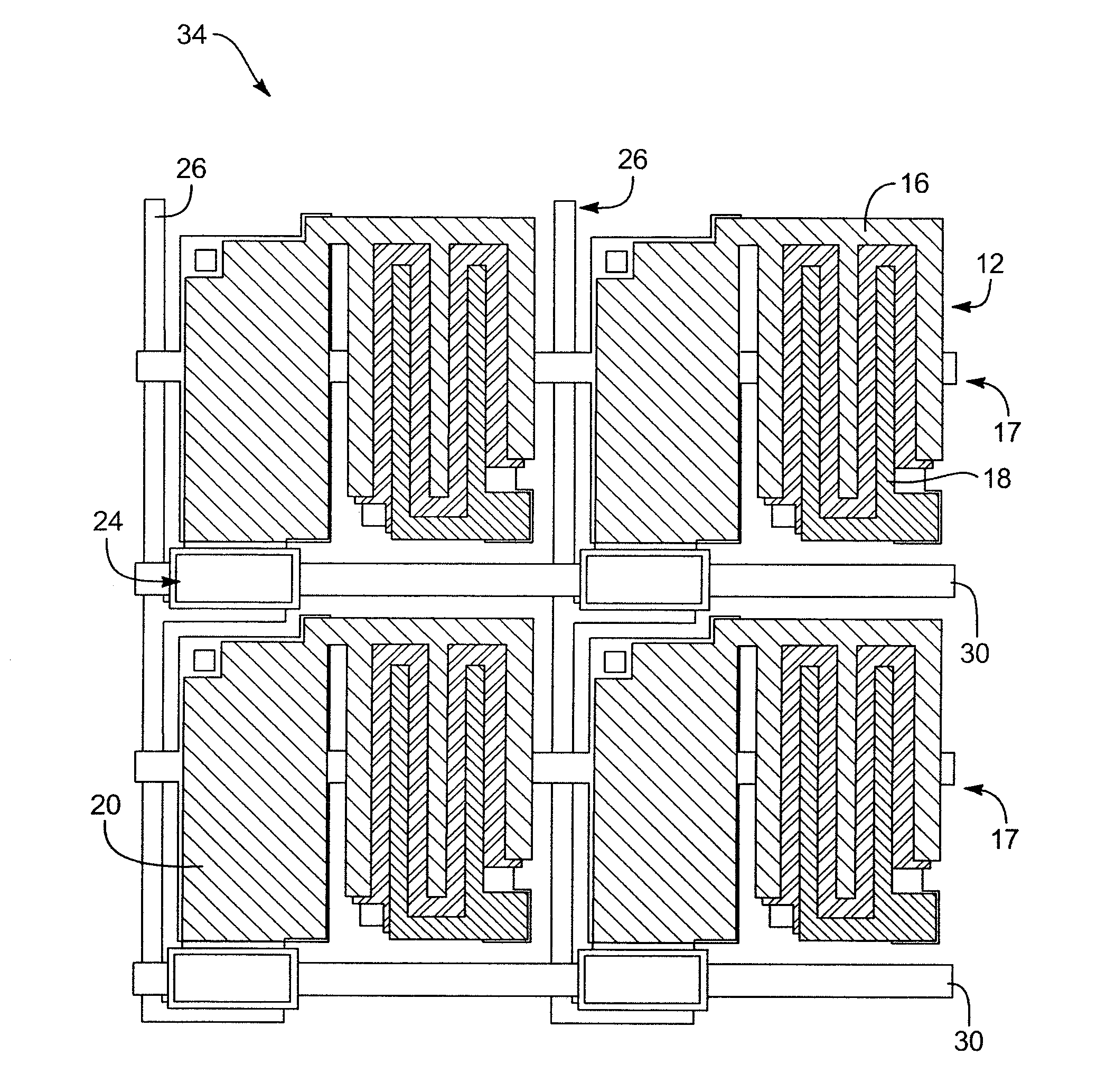

Electromagnetic device

ActiveUS20080007133A1Reduce fillingEddy-current loss is reducedWindings insulation shape/form/constructionMagnetic circuitElectrical conductorEngineering

An electromagnetic device includes a plurality of coils formed by winding conductors. At least some of the conductors are constructed by stacking conductor constructional elements so that an eddy current generated by a leakage flux linked to the conductor is divided. An outer insulating member is disposed on an outer circumferential surface of the conductor stack for electrically insulating the conductor stack from another member. An inner insulating member whose thickness is smaller than a thickness of the outer insulating member is disposed between the conductor constructional elements adjoining to each other in the same conductor stack.

Owner:DENSO CORP

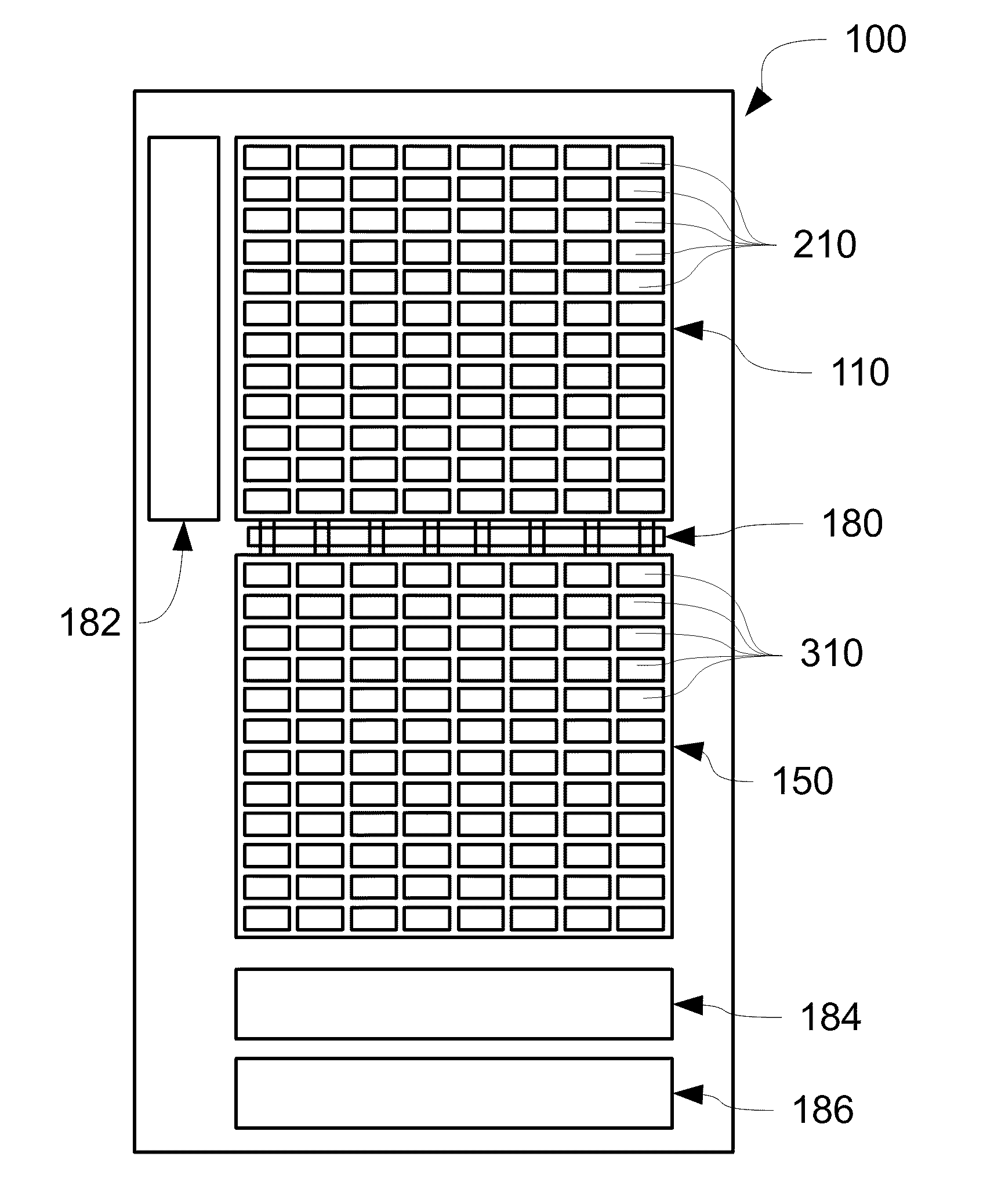

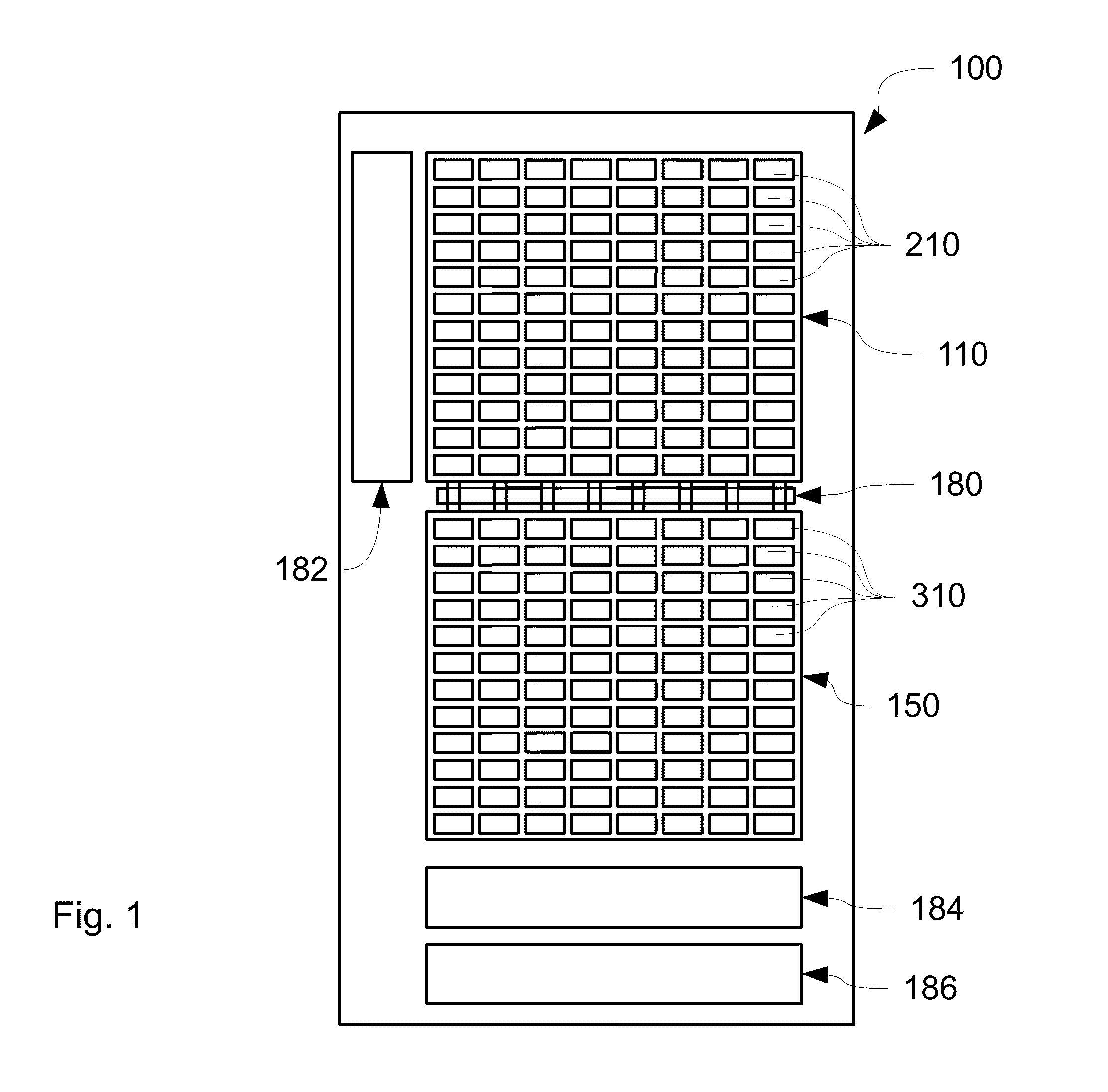

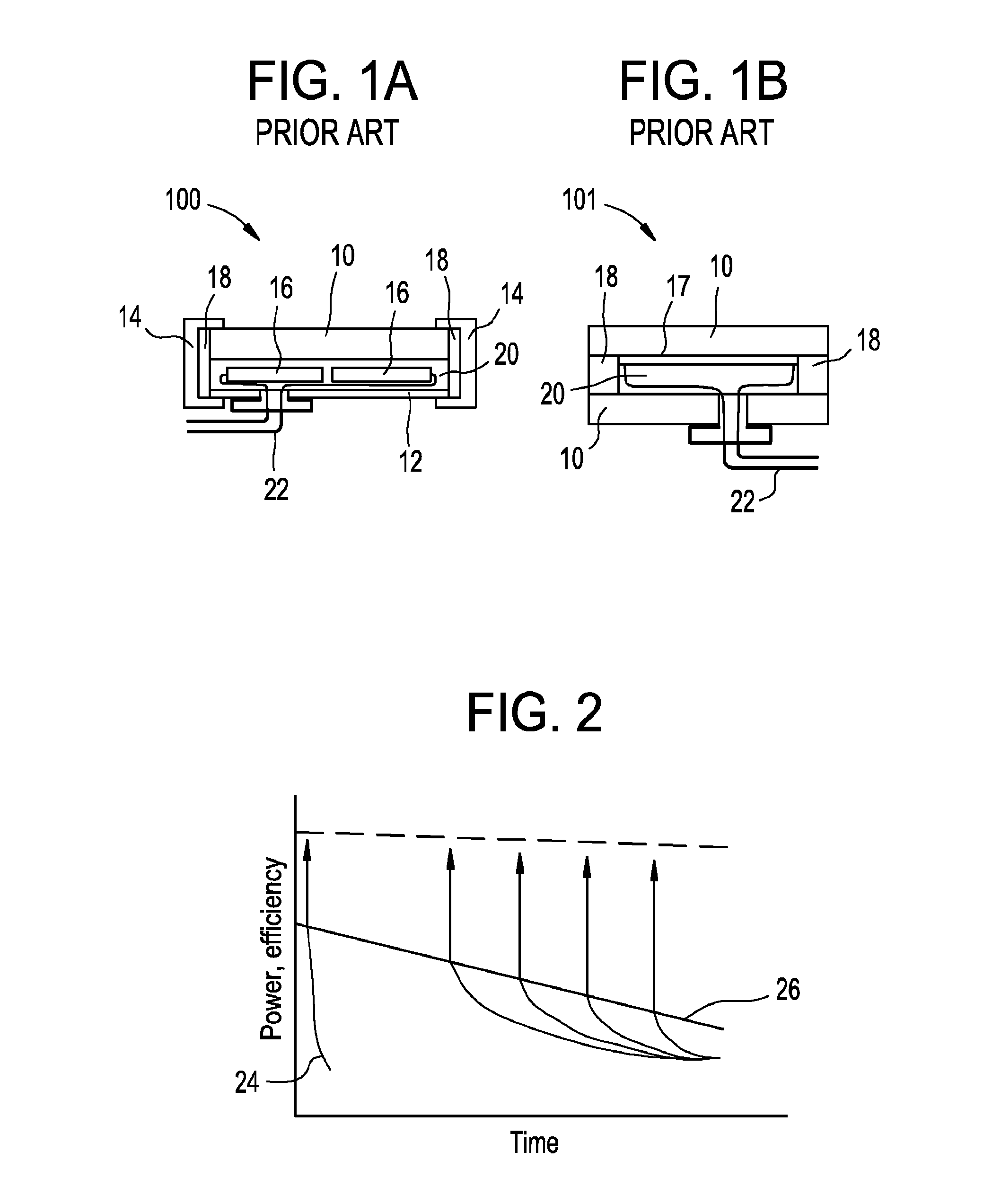

Demodulation Sensor with Separate Pixel and Storage Arrays

ActiveUS20110164132A1Improve image qualityReduce Motion ArtifactsSolid-state devicesMaterial analysis by optical meansCapacitanceDown scaling

A demodulation image sensor, such as used in time of flight (TOF) cameras, extracts all storage- and post-processing-related steps from the pixels to another array of storage and processing elements (proxels) on the chip. The pixel array has the task of photo-detection, first processing and intermediate storage, while the array of storage and processing elements provides further processing and enhanced storage capabilities for each pixel individually. The architecture can be used to address problems due to the down-scaling of the pixel size. Typically, either the photo-sensitivity or the signal storage capacitance suffers significantly. Both a lower sensitivity and smaller storage capacitances have negative influence on the image quality. The disclosed architecture allows for keeping the storage capacitance unaffected by the pixel down-scaling. In addition to that, it provides a high degree of flexibility in integrating more intelligence into the image sensor design already on the level of the pixel array. In particular, if applied to demodulation pixels, the flexibility of the architecture allows for integrating on sensor-level concepts for multi-tap sampling, mismatch compensation, background suppression and so on, without any requirement to adjust the particular demodulation pixel architecture.

Owner:AMS SENSORS SINGAPORE PTE LTD

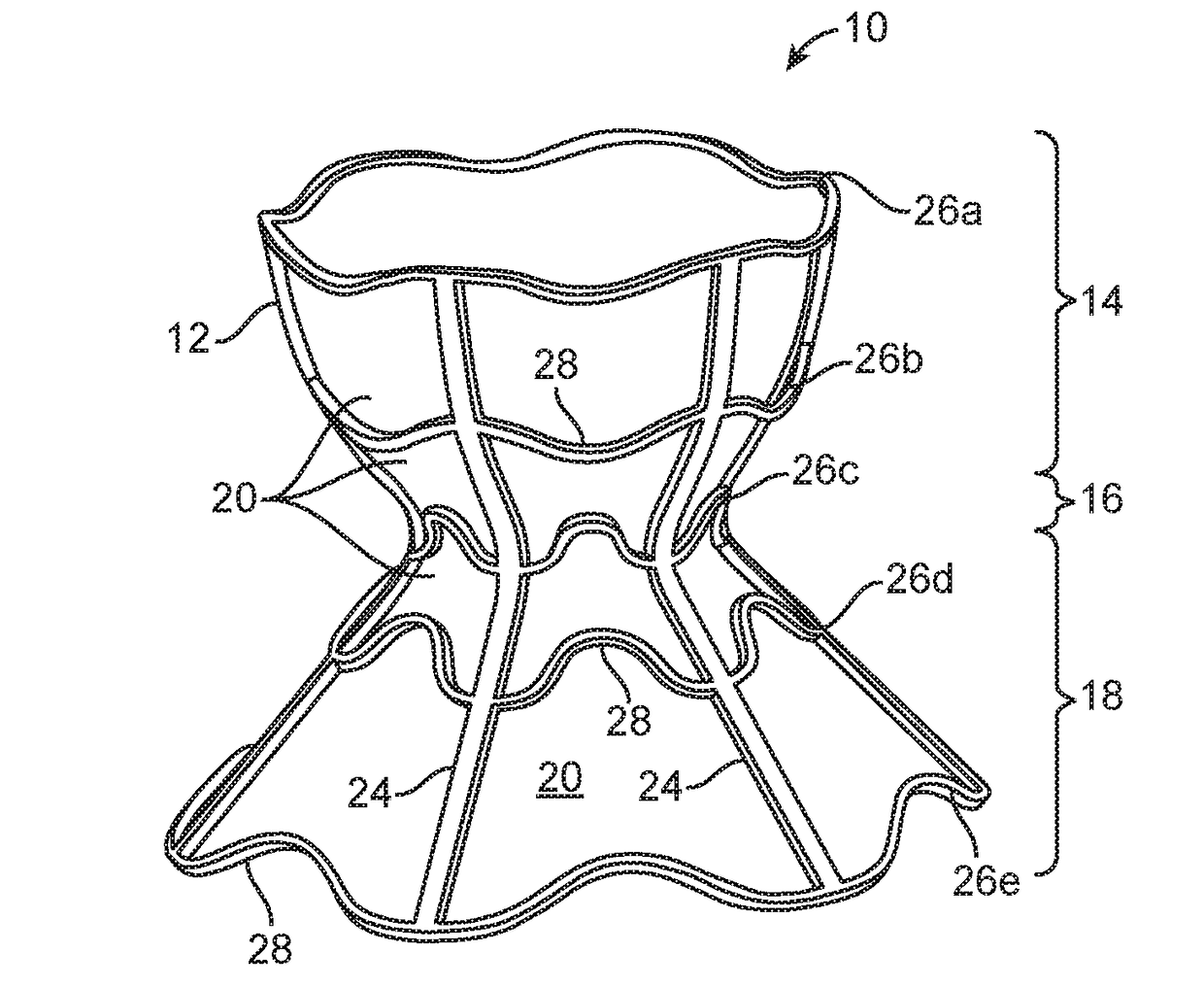

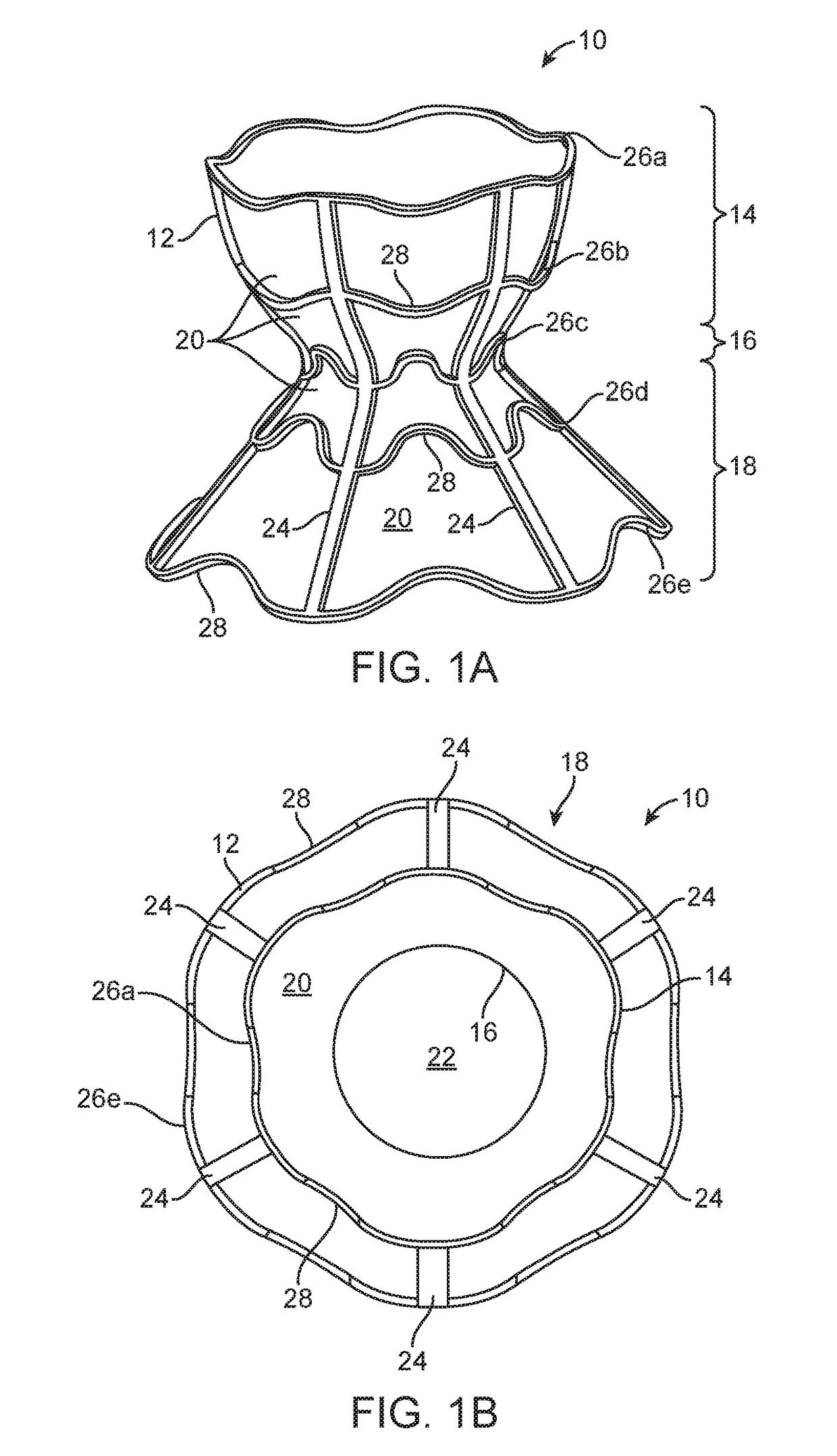

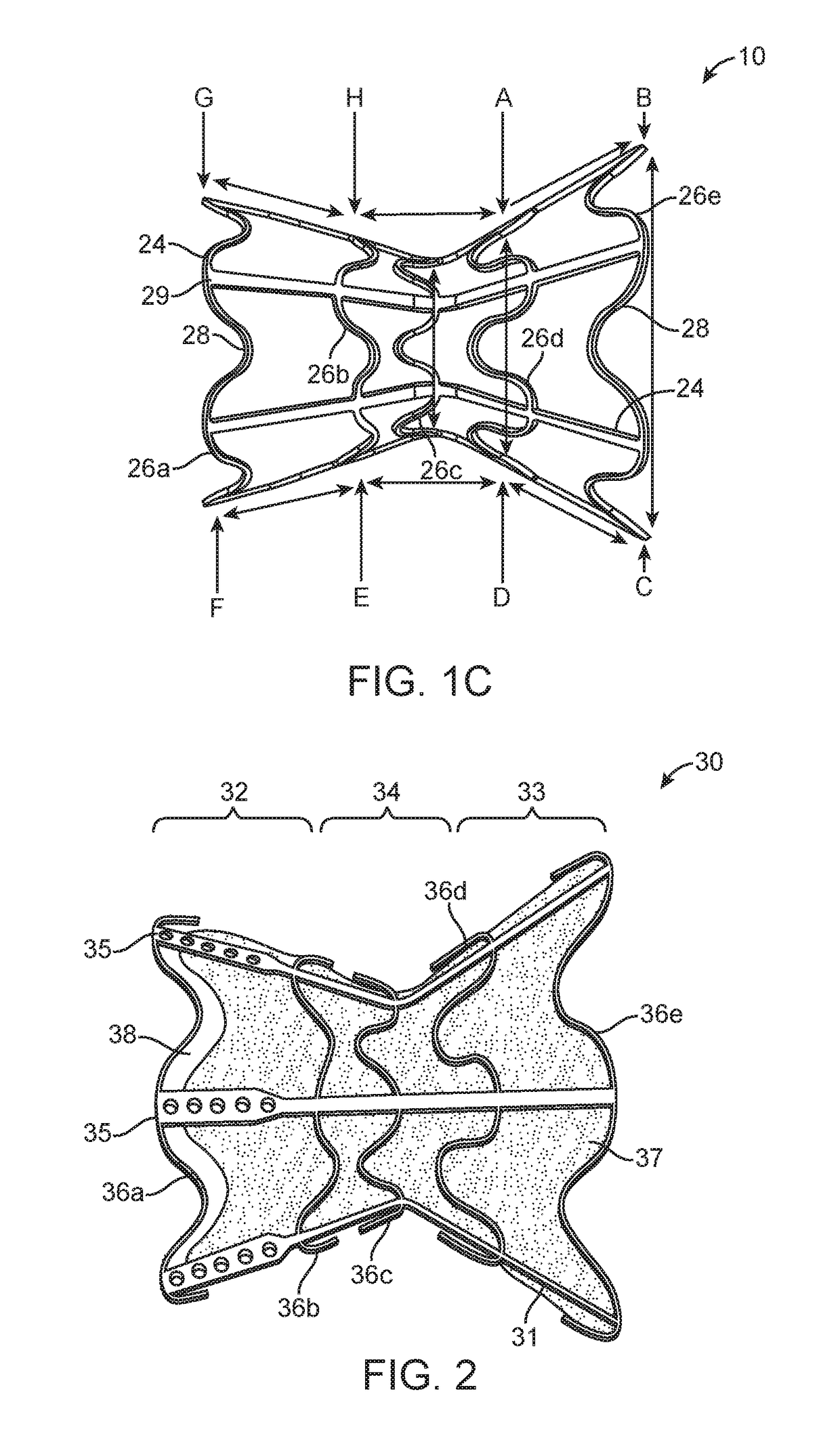

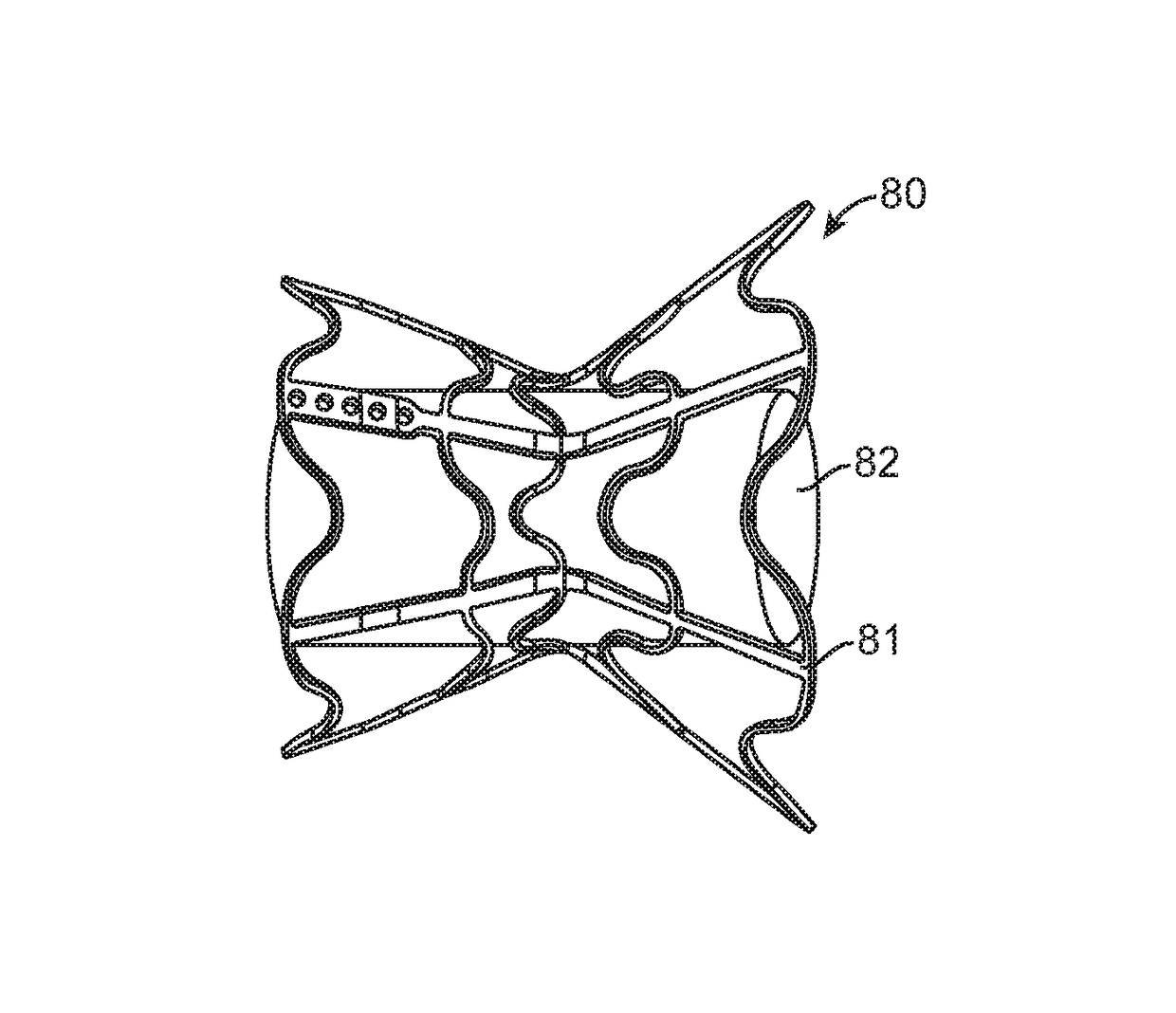

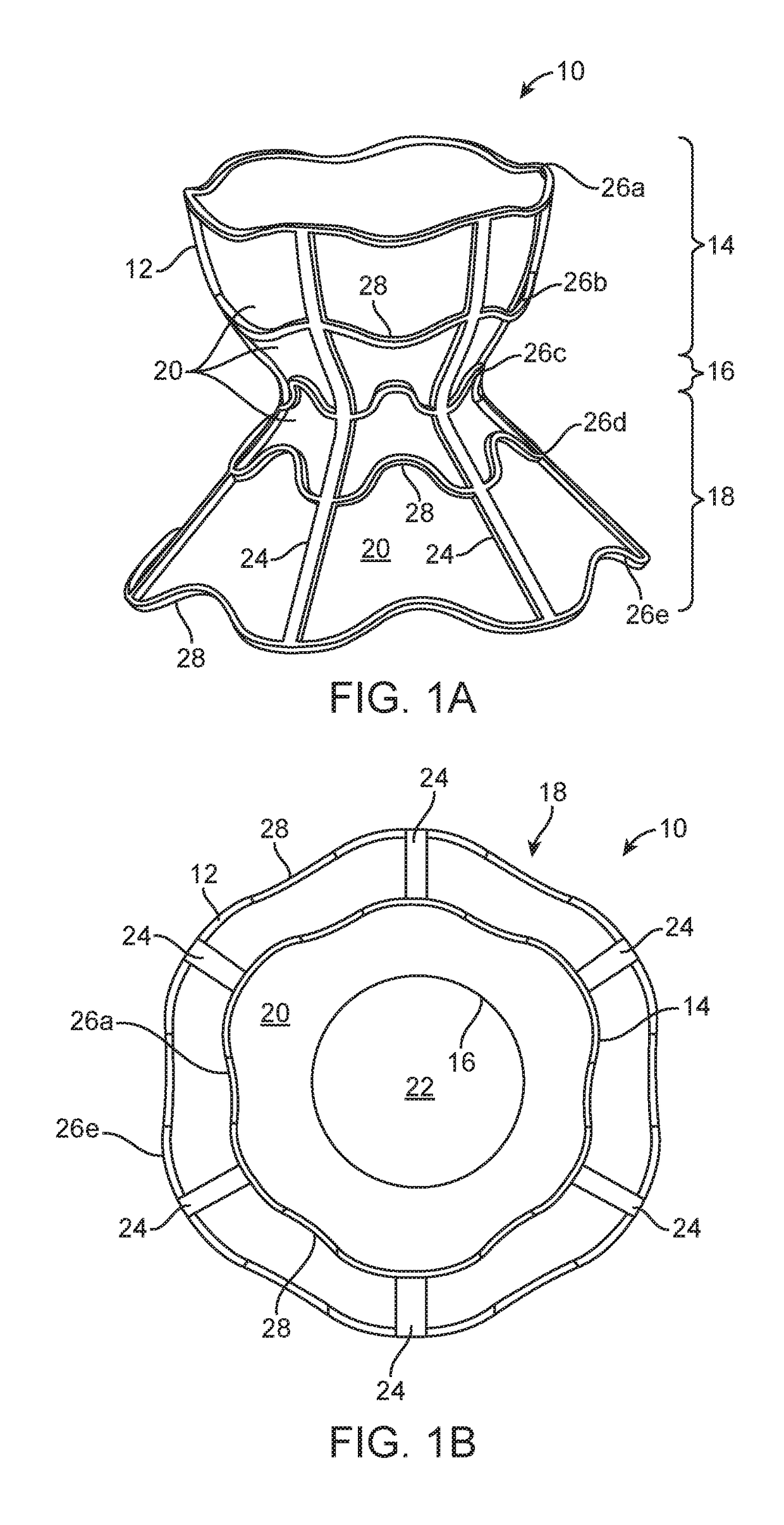

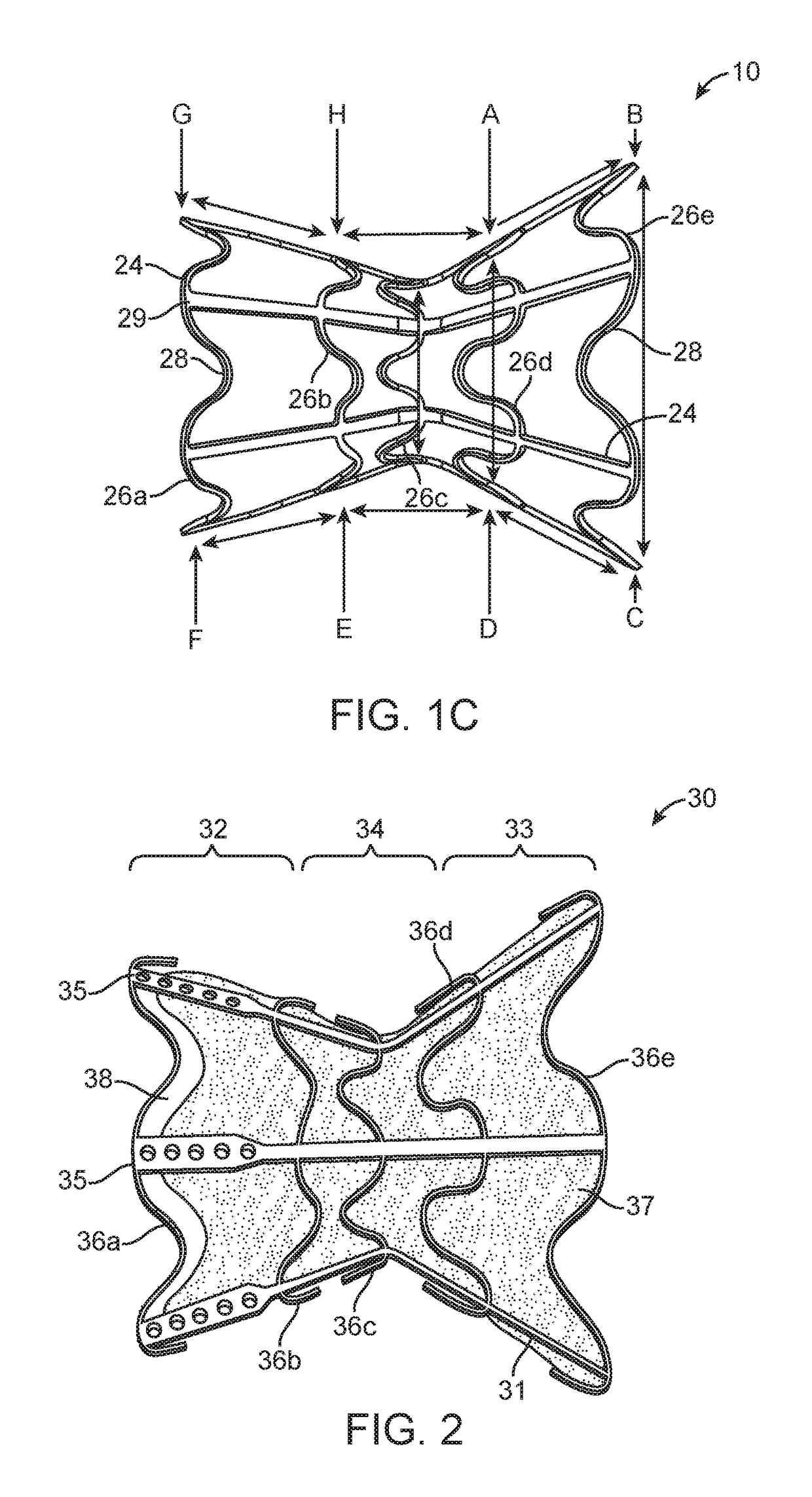

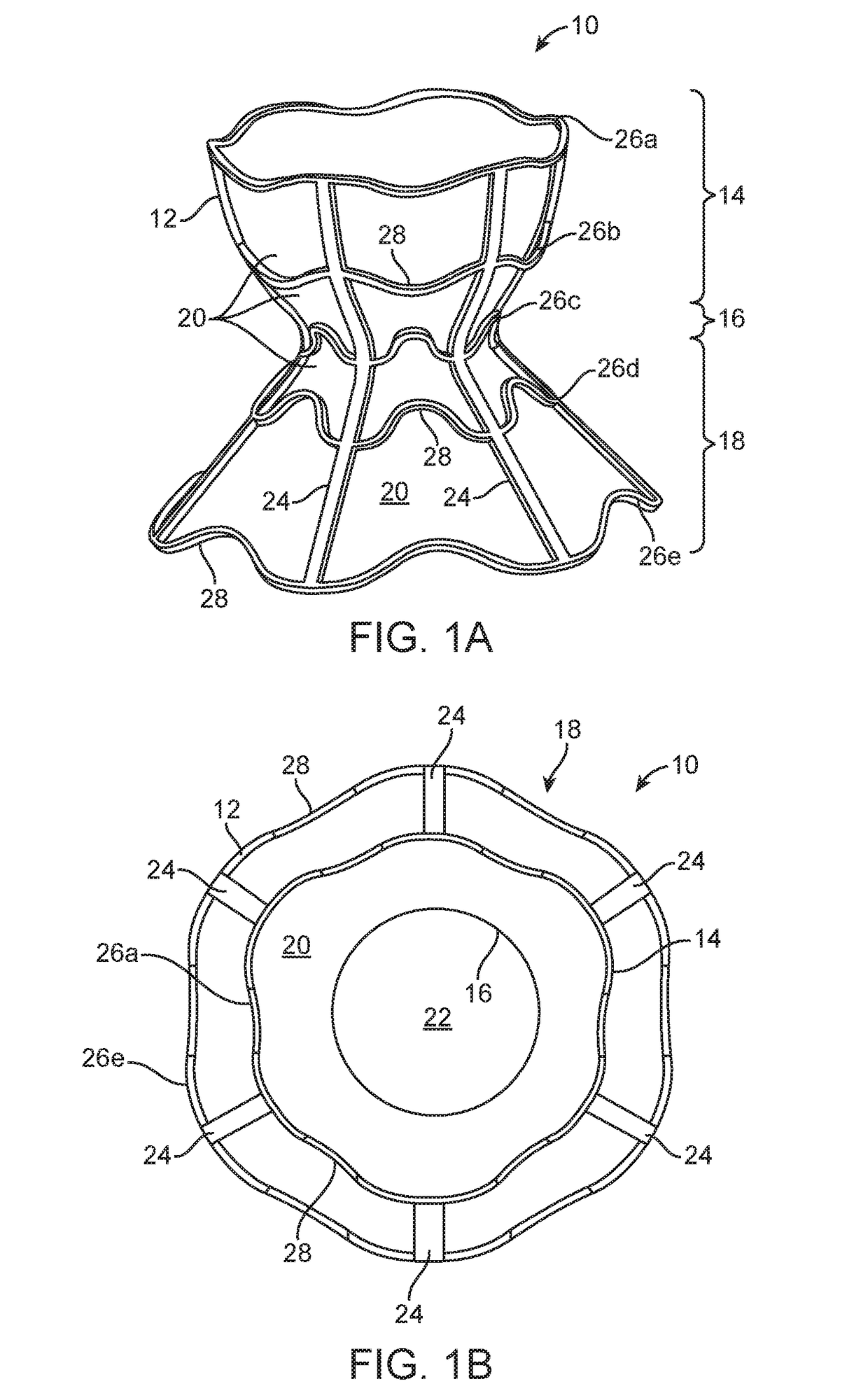

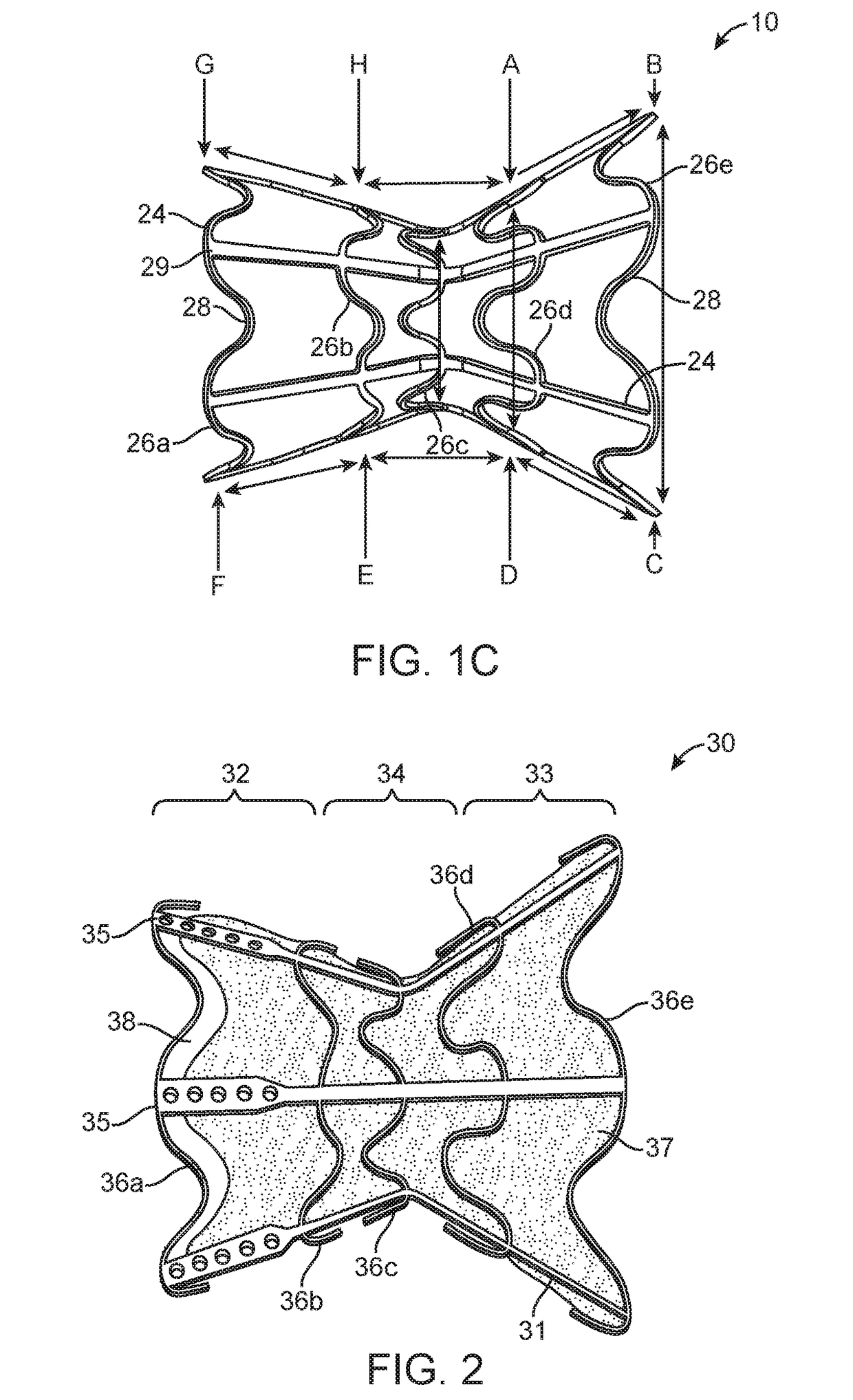

Shunt for redistributing atrial blood volume

ActiveUS20180243071A1Maintains luminal patencyReduce riskHeart valvesWound drainsNormal blood volumeBlood pressure

A shunt for regulating blood pressure between a patient's left atrium and right atrium comprises an anchor comprising a neck region, first and second end regions, and a conduit affixed with the anchor that formed of a biocompatible material that is resistant to transmural and translation tissue ingrowth and that reduces a risk of paradoxical embolism.

Owner:WAVE LTD V

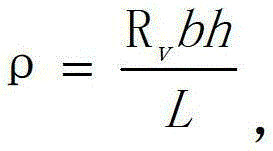

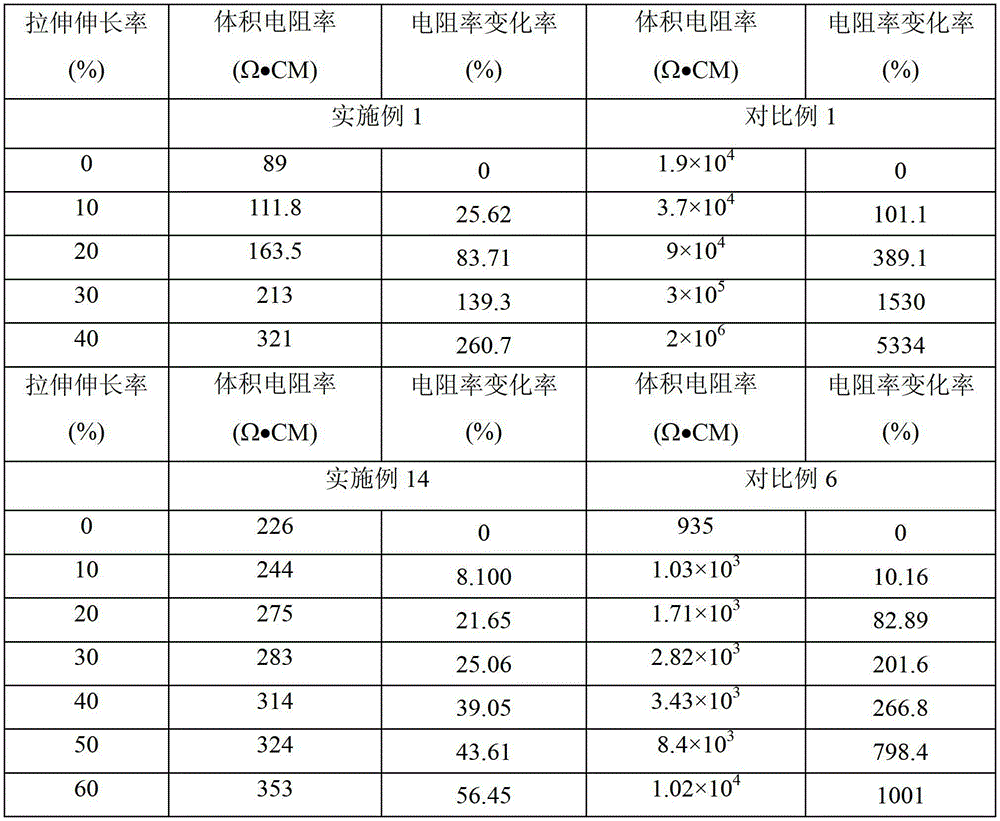

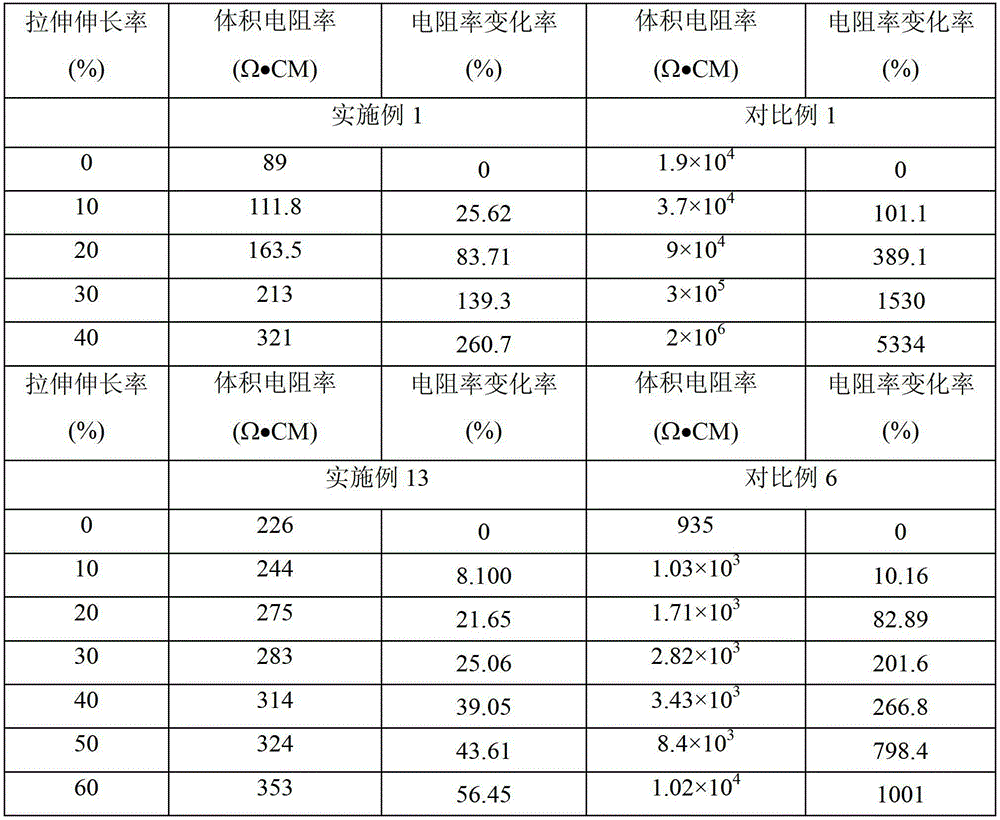

Conductive polymer composite material and preparation method thereof

The invention provides a conductive polymer composite material and a preparation method thereof. The composite material includes following blended components: a. thermoplastic resin; b. rubber particles having crosslinking structures; c. a conductive filling material; and d. low-melting-point metal. Gel content in the component b is, by weight, 60% or more than 60%. An average particle size of the rubber particles is 0.02-1 [mu]m. The component c is not melted at a processing temperature of the thermoplastic resin. The component d is at least one of a single-component metal and a metal alloy. A melting point of the component d ranges from 20-480 DEG C and is lower than the processing temperature of the thermoplastic resin. The conductive polymer composite material is low in filling amount of the conductive filling material and the low-melting-point metal, is more excellent in conductive performance, can be prepared through a conventional melt blending method, can be used for manufacturing electronic production devices and tools which have an anti-static function and an electromagnetic wave interference resistant function and is of a dust-free requirement, can be used for manufacturing shells of electronic instruments and meters, can be used as a decoration material in a dust-free production workshop and can be used as shells and circuit boards of various flexible electronic products.

Owner:CHINA PETROLEUM & CHEM CORP +1

Shunt for redistributing atrial blood volume

A shunt for regulating blood pressure between a patient's left atrium and right atrium comprises an anchor comprising a neck region, first and second end regions, and a conduit affixed with the anchor that formed of a biocompatible material that is resistant to transmural and translation tissue ingrowth and that reduces a risk of paradoxical embolism.

Owner:WAVE LTD V

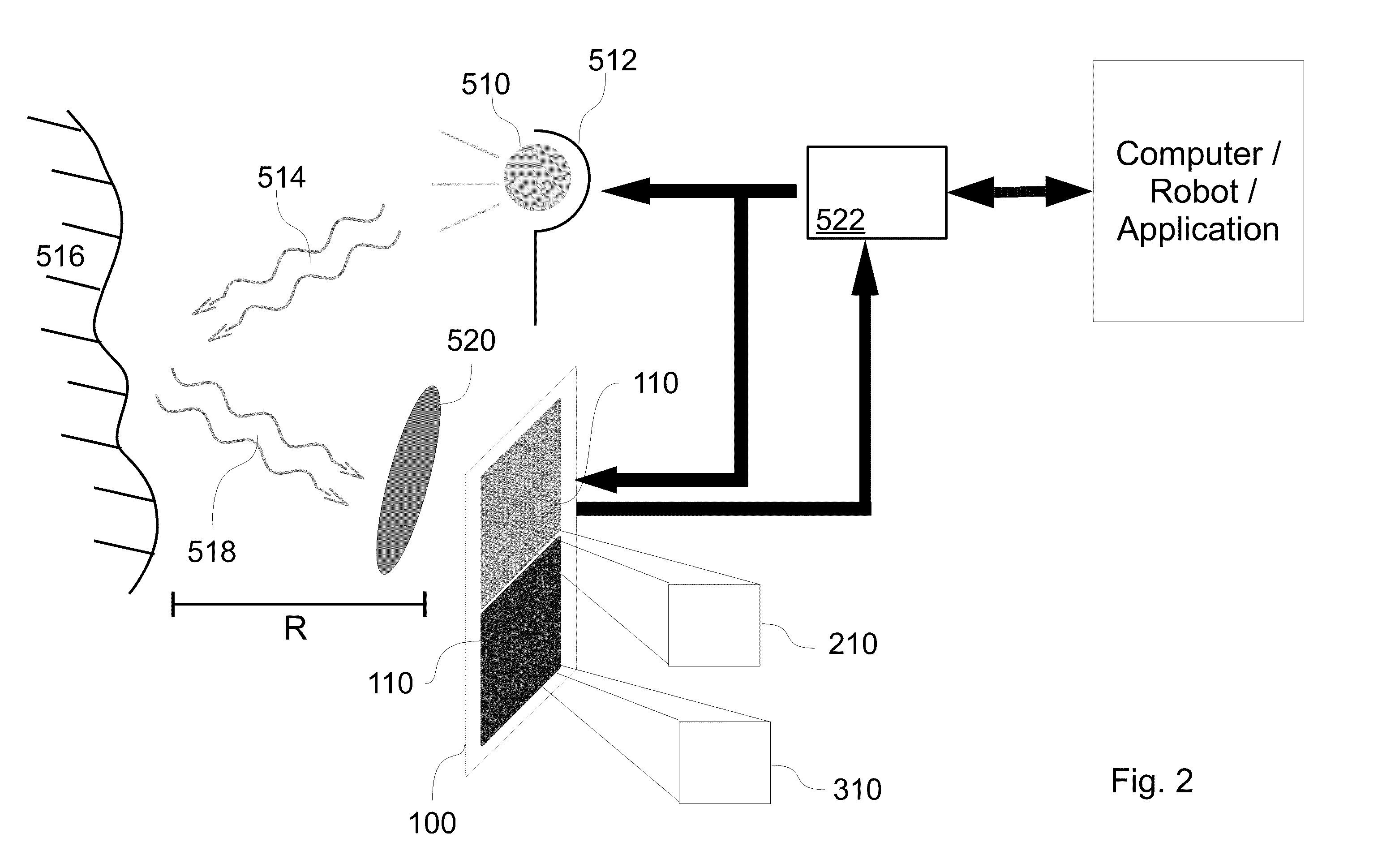

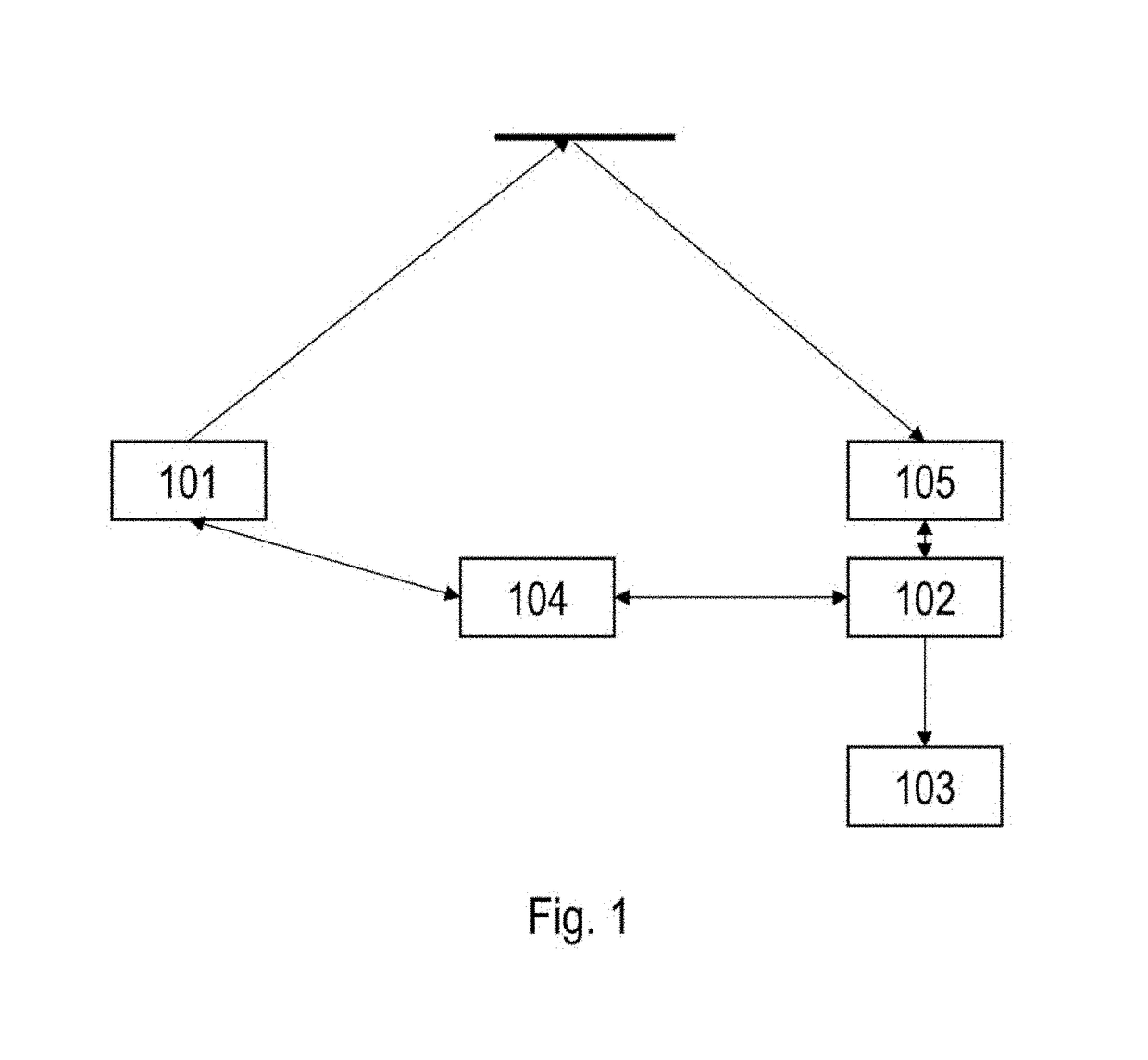

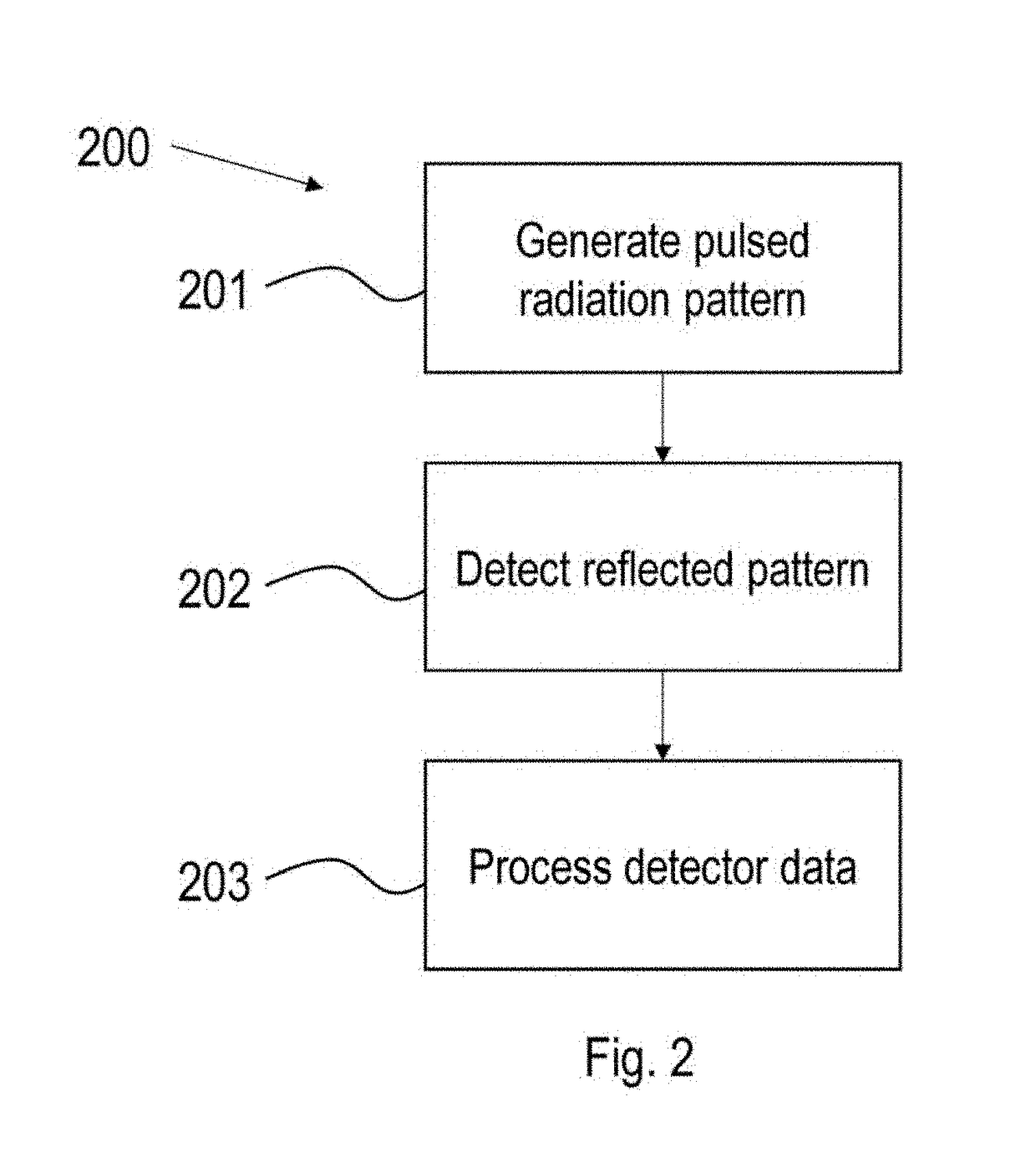

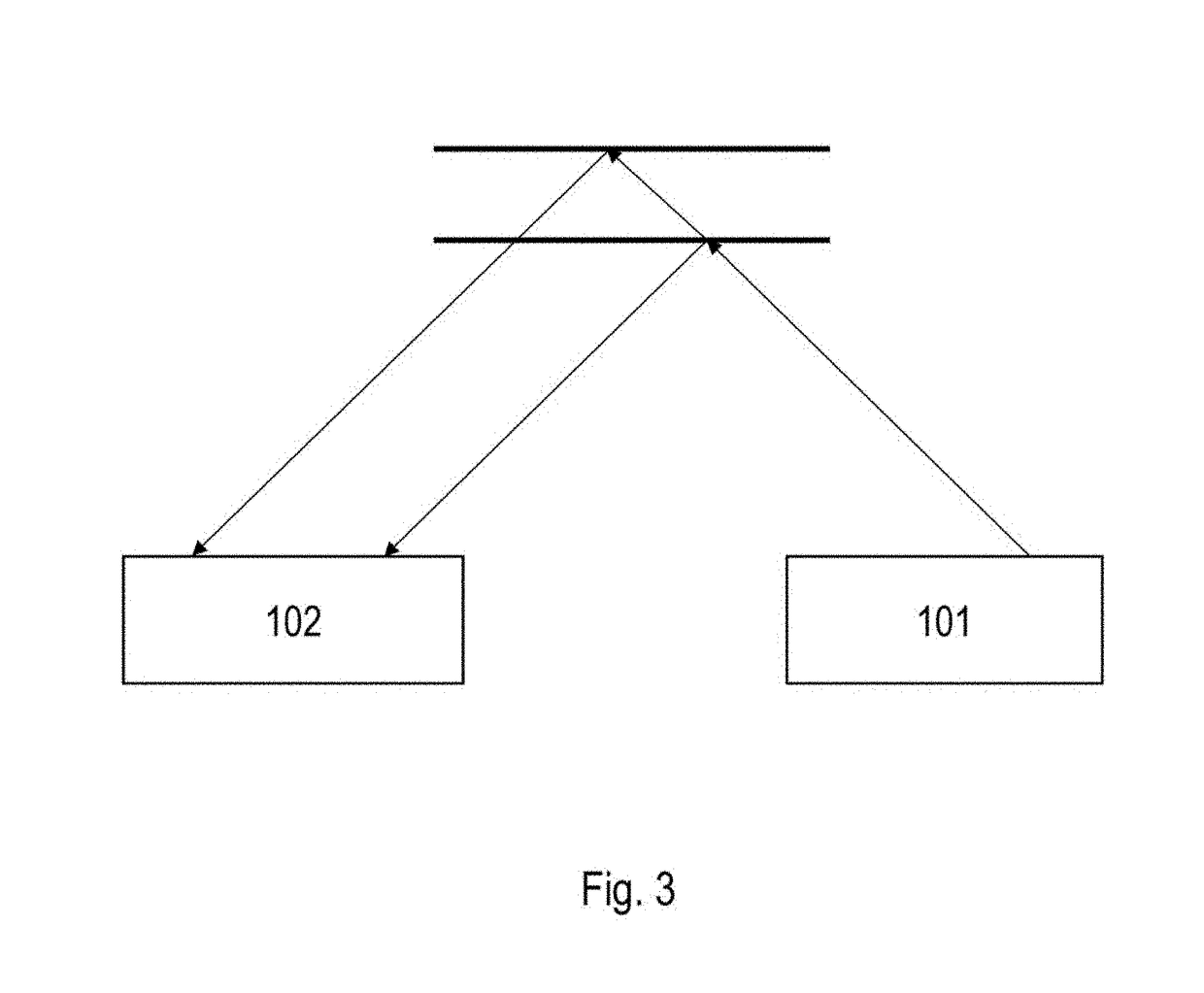

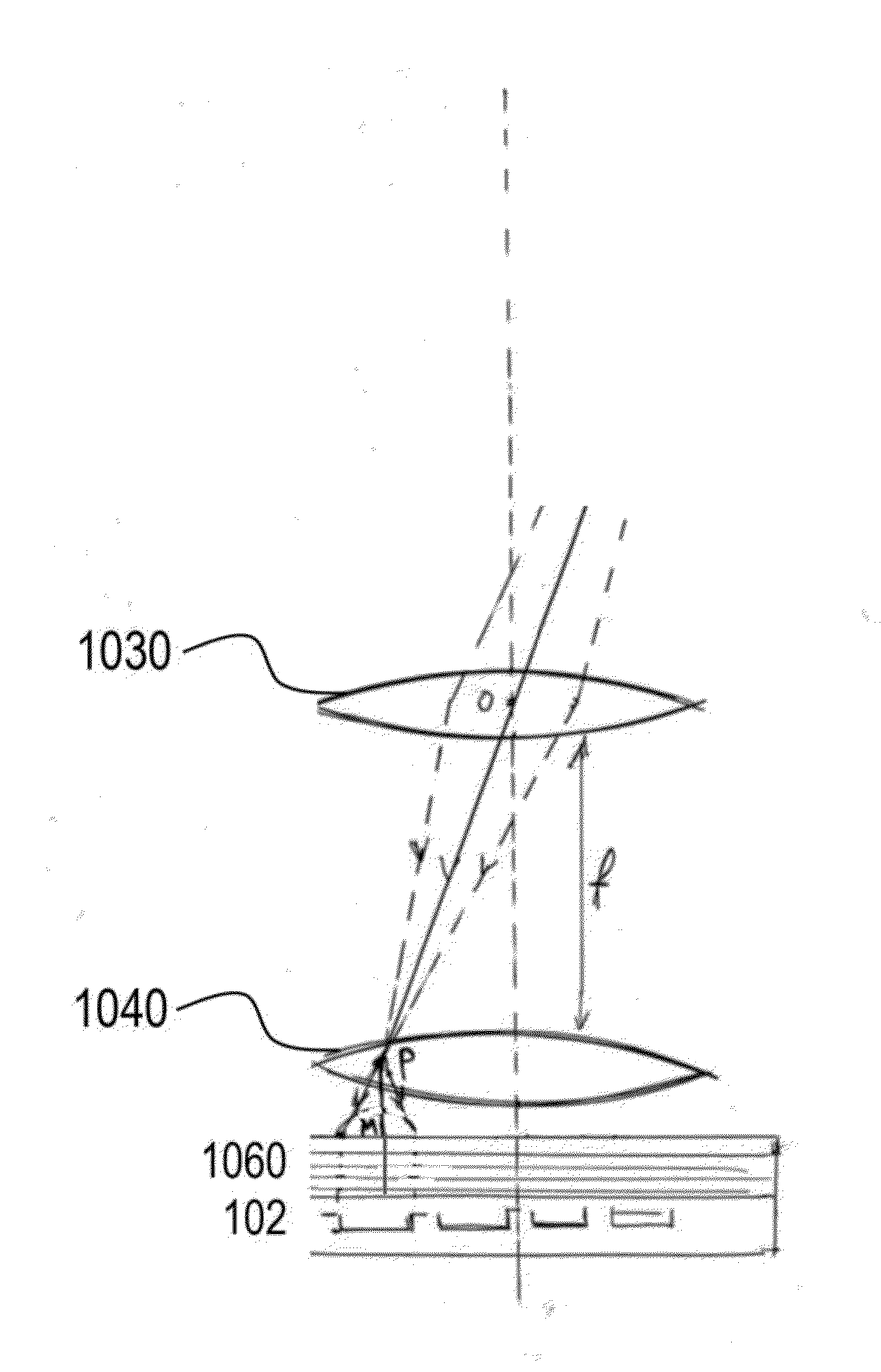

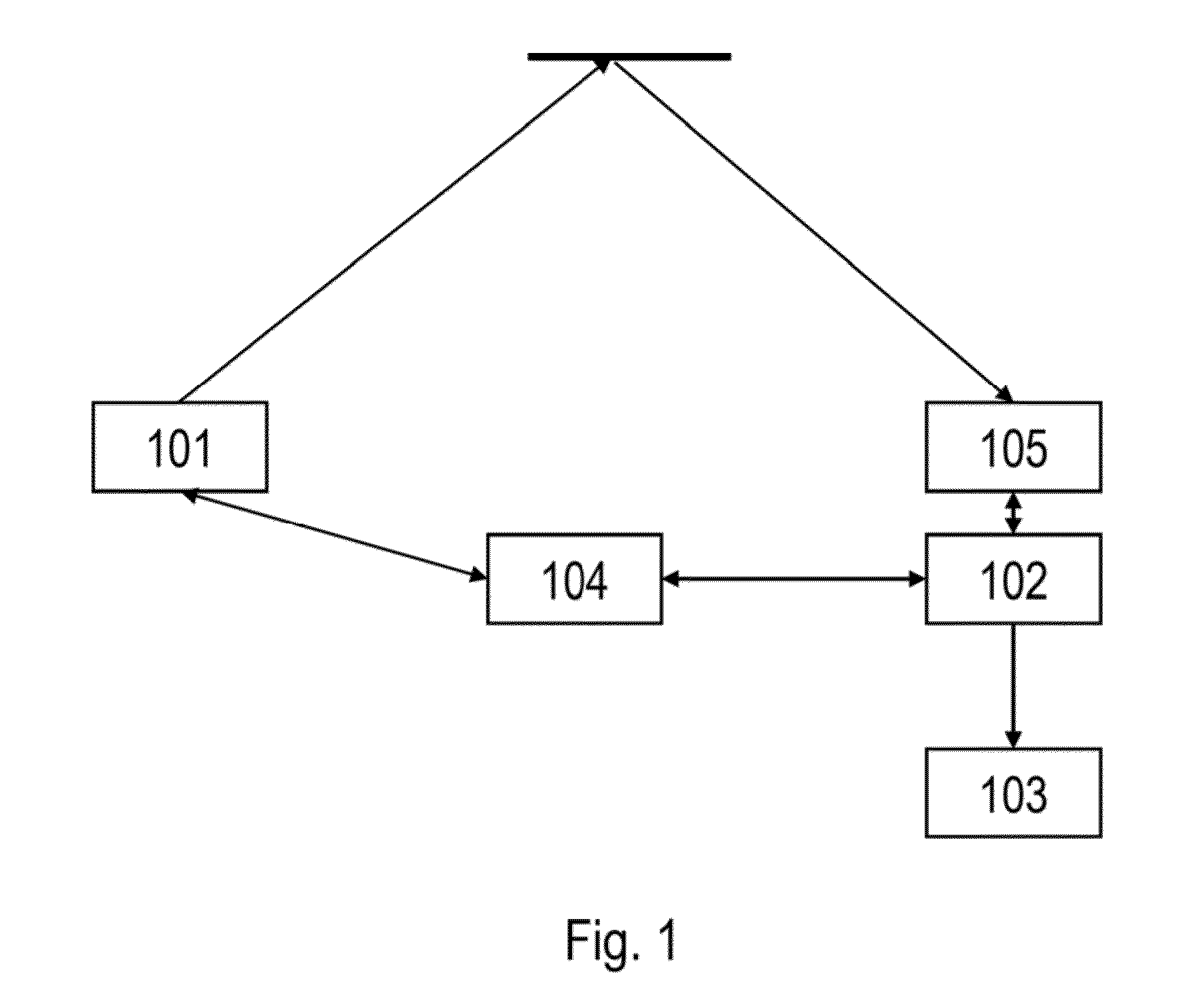

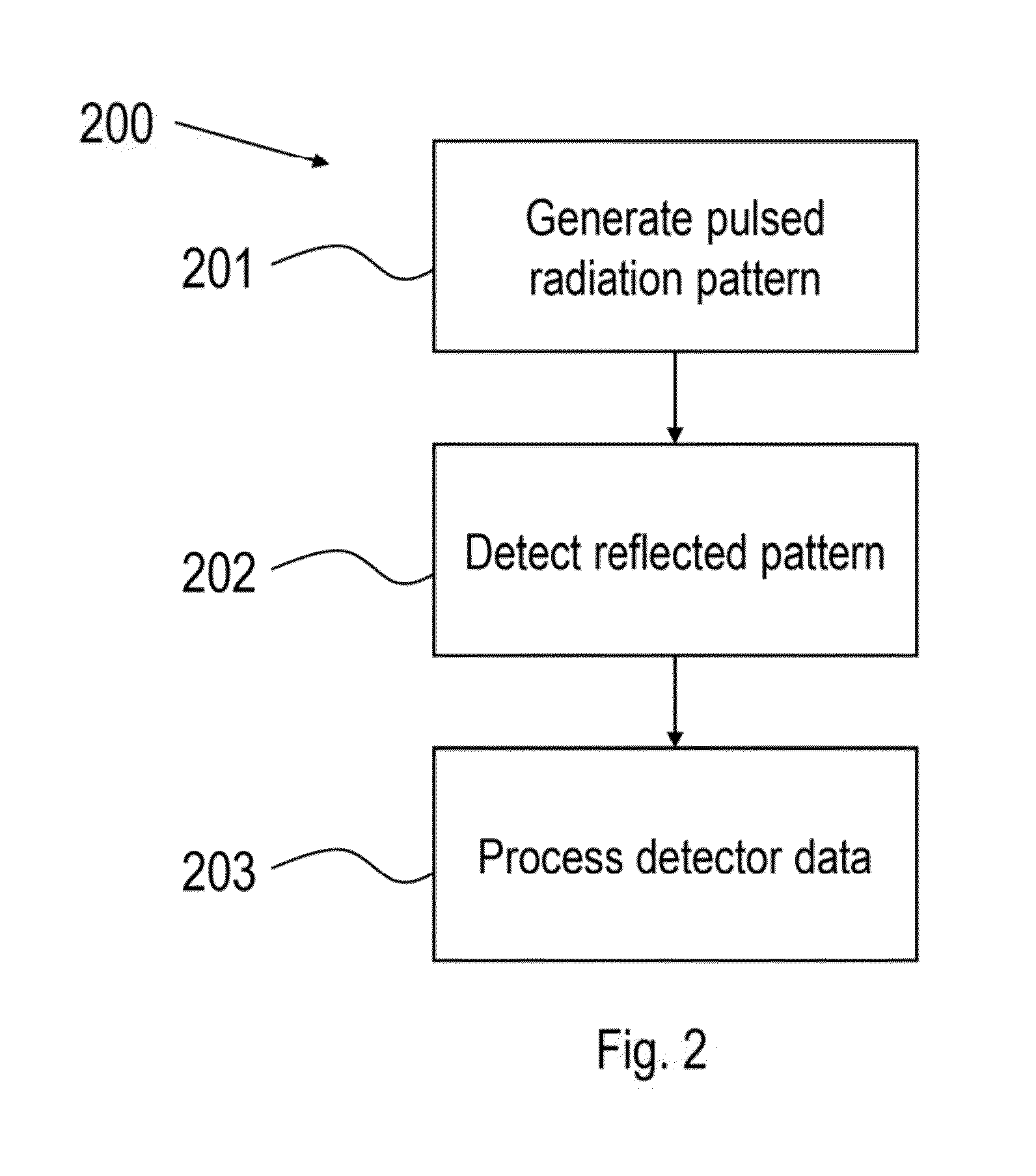

Surround sensing system with telecentric optics

ActiveUS10183541B2Reduce the amount requiredAccurate detectionUsing optical meansResilient suspensionsBandpass filteringAngle of incidence

The invention pertains to a system comprising: a source to generate a pulsed radiation pattern; a detector; a processor to process data from the detector when radiation is reflected by an object; a synchronization means interfacing between the detector and the source; wherein: the detector is synchronized with the source so that radiation to be processed is detected only during the pulses, the processor determines a characteristic of the object by determining displacement of detected spots with reference to predetermined positions, the source emits monochromatic light and the detector is equipped with a bandpass filter and optics arranged so as to modify an angle of incidence onto said filter to confine light to a predetermined range around a normal of said filter, said optics comprising an image-space telecentric lens.

Owner:XENOMATIX NV

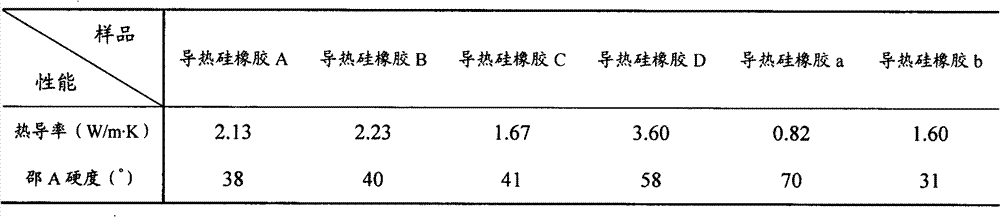

Method for preparing high-heat-conducting silicon rubber compound material

ActiveCN102827480AImprove thermal conductivityReduce fillingHeat-exchange elementsFiberVulcanization

The invention relates to a method for preparing a high-heat-conducting silicon rubber compound material. The method comprises the following steps of: (1) mixing a substrate, a heat conducing filler and a sufficient amount of vulcanizing agent under the room temperature condition to obtain a mixed sizing material; and (2) performing two-stage vulcanization on the mixed sizing material obtained in the step (1) to obtain a target product, wherein the substrate is a crude silicon rubber or a mixture consisting of silicon rubber and silicon oil; the crude silicon rubber is siloxane containing vinyl of which the molecular weight is 100,000-1,000,000; the heat conducting filler is a carbon-series filler, which is expansion graphite or a mixture mainly comprising expansion graphite, carbon black, graphite, a carbon nanotube, grapheme, fullerene, or / and carbon fibers; and the heat conducting filler is required to be subjected to dispersing pretreatment. Due to the adoption of the method, the heat conductivity of the silicon rubber can be increased effectively, the filling amount of the heat conducting filler can be reduced, and the hardness of an obtained material is lowered.

Owner:EAST CHINA UNIV OF SCI & TECH

Surround sensing system with telecentric optics

ActiveUS20160200161A1Decrease the filling factorReduce lossesDigital data processing detailsAnimal undercarriagesBandpass filteringAngle of incidence

The invention pertains to a system comprising: a source to generate a pulsed radiation pattern; a detector; a processor to process data from the detector when radiation is reflected by an object; a synchronization means interfacing between the detector and the source; wherein: the detector is synchronized with the source so that radiation to be processed is detected only during the pulses, the processor determines a characteristic of the object by determining displacement of detected spots with reference to predetermined positions, the source emits monochromatic light and the detector is equipped with a bandpass filter and optics arranged so as to modify an angle of incidence onto said filter to confine light to a predetermined range around a normal of said filter, said optics comprising an image-space telecentric lens.

Owner:XENOMATIX NV

Shunt for redistributing atrial blood volume

A shunt for regulating blood pressure between a patient's left atrium and right atrium comprises an anchor comprising a neck region, first and second end regions, and a conduit affixed with the anchor that formed of a biocompatible material that is resistant to transmural and translation tissue ingrowth and that reduces a risk of paradoxical embolism.

Owner:WAVE LTD V

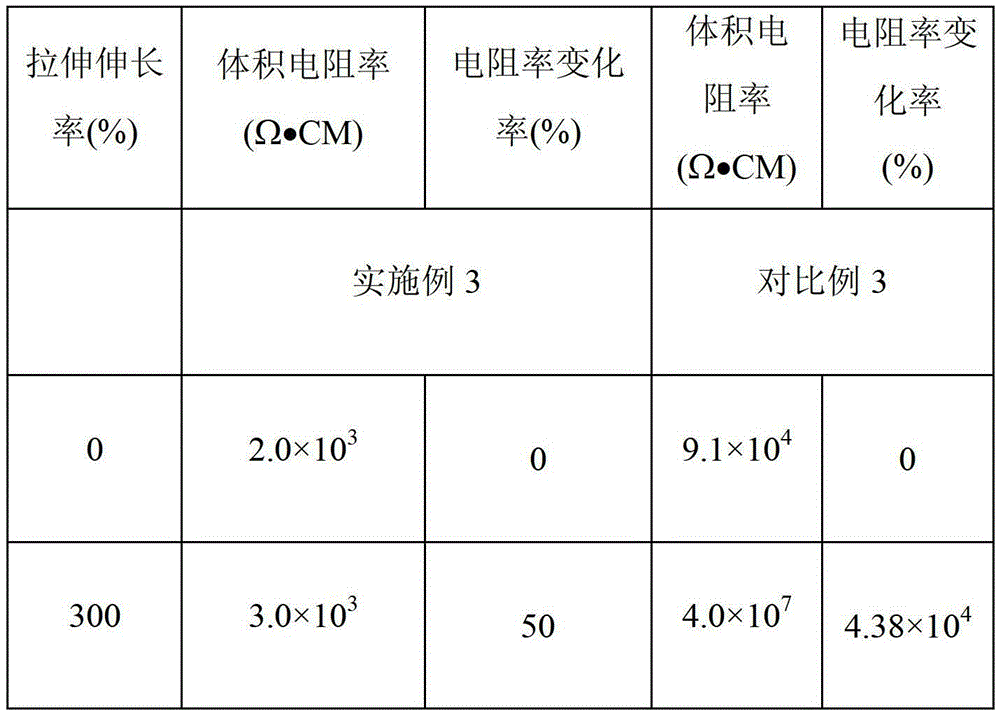

Conductive thermoplastic elastomer and preparation method thereof

ActiveCN104098795AConductiveEvenly dispersedNon-conductive material with dispersed conductive materialThermoplasticConductive polymer composite

The invention provides a conductive thermoplastic elastomer and a preparation method thereof. The thermoplastic elastomer includes following blended components: a. thermoplastic resin; b. rubber particles having crosslinking structures; c. a conductive filling material; and d. low-melting-point metal. Gel content in the component b is, by weight, 60% or more than 60%. An average particle size of the rubber particles is 0.02-1 [mu]m. The component c is not melted at a processing temperature of the thermoplastic resin. The component d is at least one of a single-component metal and a metal alloy. A melting point of the component d ranges from 20-480 DEG C and is lower than the processing temperature of the thermoplastic resin. A weight ratio of the component b to the component a is more than 30:70 and is lower than 75:25. The conductive polymer composite material is low in filling amount of the conductive filling material and the low-melting-point metal, is excellent in conductive performance, can be prepared through a melt blending method, can be used for manufacturing electronic production devices and tools which have an anti-static function and an electromagnetic wave interference resistant function and is of a dust-free requirement, can be used for manufacturing shells of electronic instruments and meters, can be used as a decoration material in a dust-free production workshop and can be used as shells and circuit boards of various flexible electronic products.

Owner:CHINA PETROLEUM & CHEM CORP +1

High accuracy bloom filter using partitioned hashing

ActiveUS7930547B2Reduce false alarm rateReduce probabilityUser identity/authority verificationHash functionTheoretical computer science

Owner:ALCATEL-LUCENT USA INC

Image sensor with photosensitive thin film transistors and dark current compensation

InactiveUS20100302419A1Increase photosensitivityReduce impactTelevision system detailsTelevision system scanning detailsPhotocurrentCapacitor

An image sensor array includes image sensors having photo TFTs to generate photocurrent in response to received images. The photo TFTs each have their respective gate electrodes and source electrodes independently biased to reduce the effects of dark current. Storage capacitors are coupled to each photo TFT and discharged upon generation of a photocurrent. Each storage capacitor is coupled to a readout TFT that passes a current from the storage capacitor to a data line. The photo TFT may be disposed above the storage capacitor to increase the exposed surface area of the photo TFT.

Owner:APPLE INC

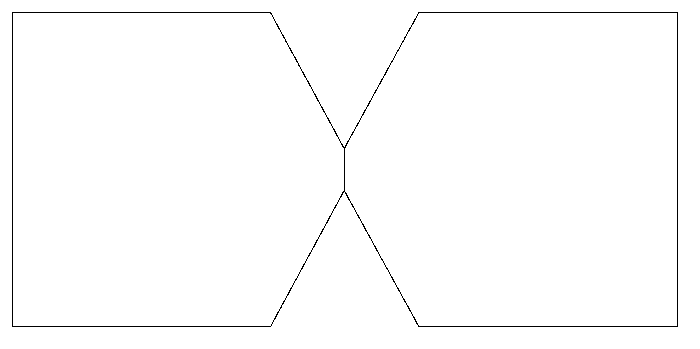

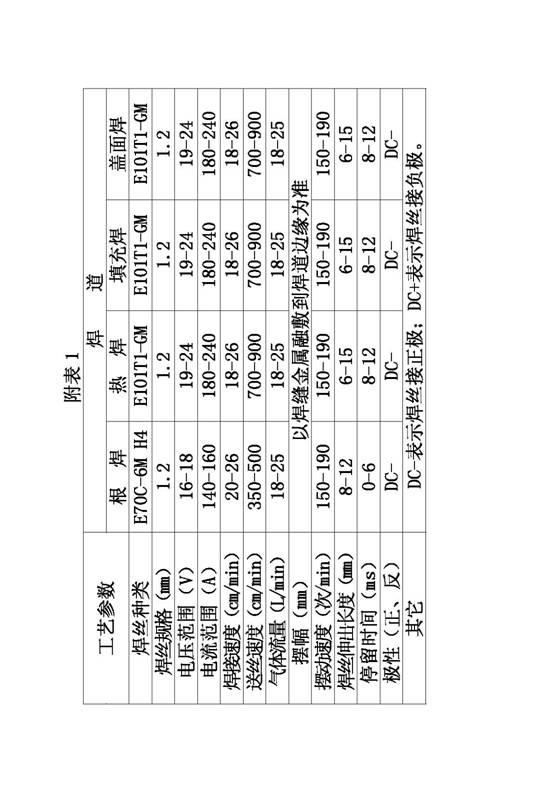

Method for welding Q500qE ultralow-carbon bainite steel for bridge

ActiveCN103286427ASolve welding process problemsAvoid cold cracksArc welding apparatusWelding/cutting media/materialsShielded metal arc weldingChemical composition

The invention provides a method for welding Q500qE ultralow-carbon bainite steel for a bridge. The method is excellent in joint mechanical performance and high in welding efficiency and specifically includes that aiming at specific chemical components, applicable technical conditions and different plate thicknesses of the Q500qE ultralow-carbon bainite steel for the bridge, preheating temperature before welding, groove types and welding process parameters are determined; a welding joint type adopts butt joint, penetration angle joint or ship position T-shaped angle joint; a welding method adopts submerged arc welding, CO2 gas shielded semiautomatic welding or shielded metal arc welding. By the welding method, the joint type and thickness specifications of a bridge structure are comprehensively covered, the technical scheme is simple, convenient and high in adaptivity, all implementing effects meet technical requirements of standards related to building of bridge steel and the bridge structure, and the method is of great significance in promoting upgrading of the bridge steel and development of large-span steel bridge building technology. The method can be applied to building of the bridge structure, can also be applied to welding of other ultrathin-carbon bainite steel and is high in adaptivity.

Owner:CHINA RAILWAY SHANQIAO GRP CO LTD

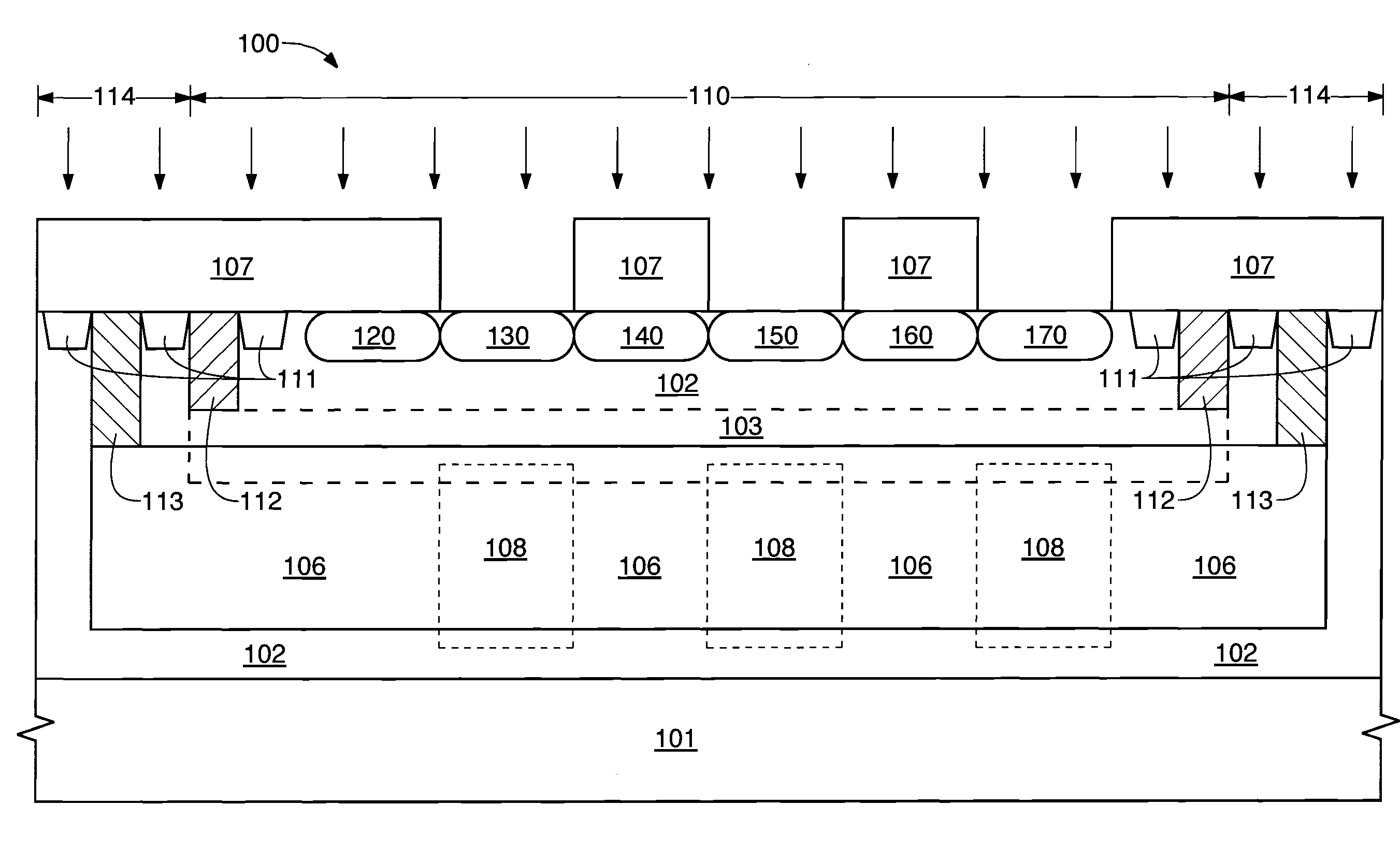

Methods, structures and sytems for an image sensor device for improving quantum efficiency of red pixels

ActiveUS20080265295A1Reduction of floating body effectReduced quantum efficiencySolid-state devicesSemiconductor/solid-state device manufacturingCMOSQuantum efficiency

A method and structure for providing a high energy implant in only the red pixel location of a CMOS image sensor. The implant increases the photon collection depth for the red pixels, which in turn increases the quantum efficiency for the red pixels. In one embodiment, a CMOS image sensor is formed on an p-type substrate and the high energy implant is a p-type implant that creates a p-type ground contact under the red pixel, thus reducing dark non-uniformity effects. In another embodiment, a CMOS image sensor is formed on an n-type substrate and a high energy p-type implant creates a p-type region under only the red pixel to increase photon collection depth, which in turn increases the quantum efficiency for the red pixels.

Owner:APTINA IMAGING CORP

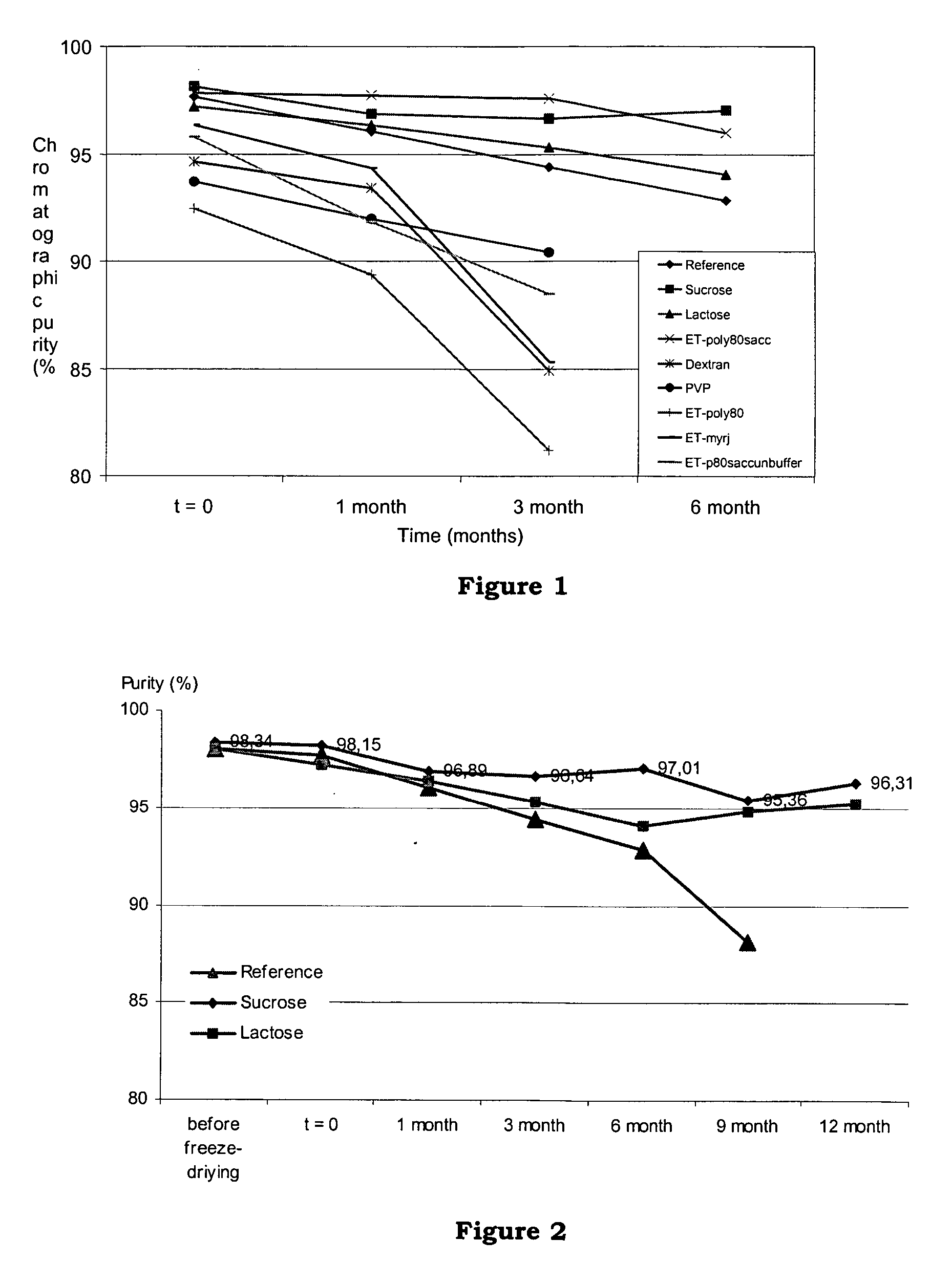

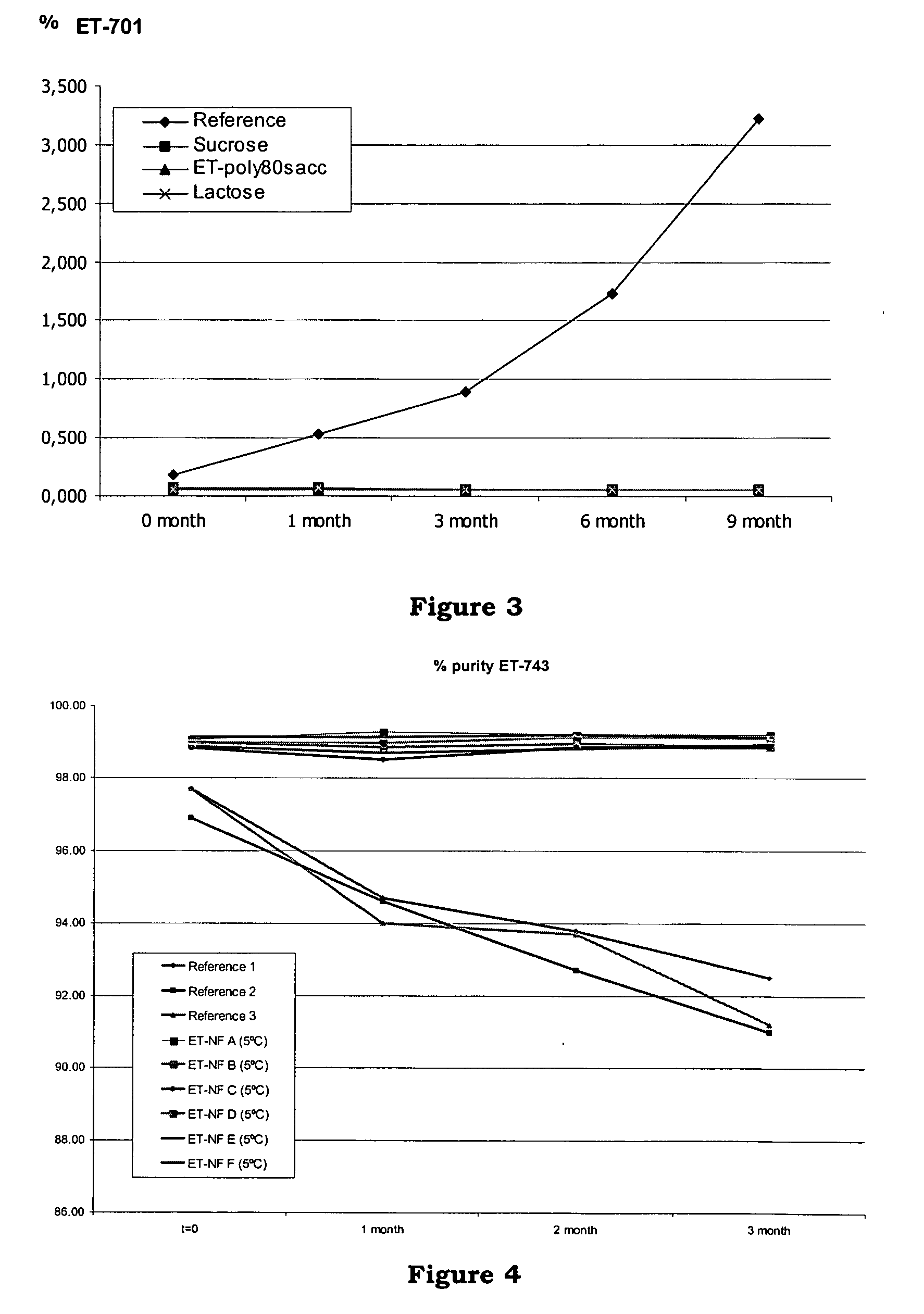

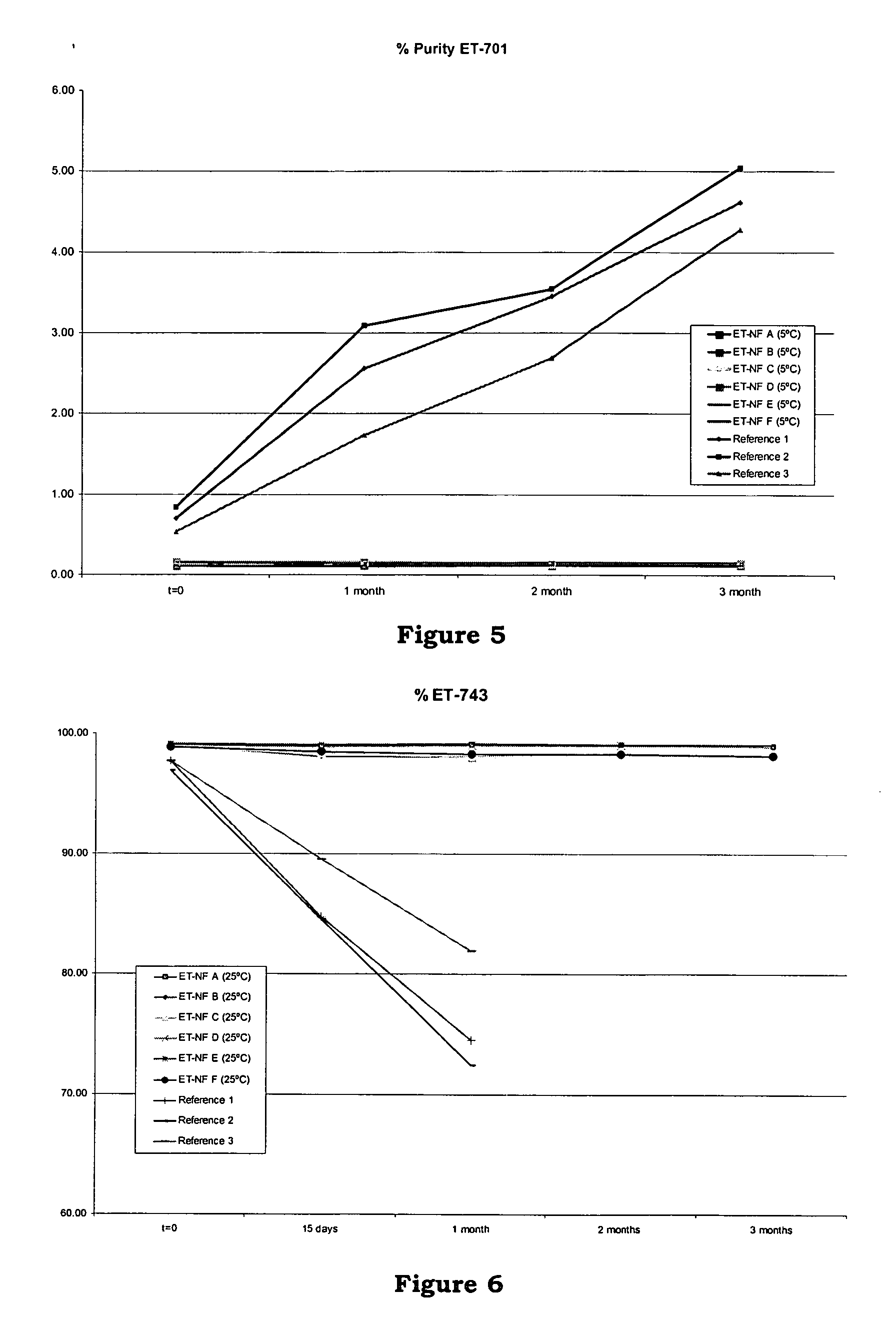

Formulations

ActiveUS20060094687A1Improve solubilityIncreasing ET-74 concentrationBiocideInorganic non-active ingredientsMedicineProliferative disease

Owner:PHARMA MAR U

Conductive plastic and preparation method thereof

The invention provides a conductive plastic and a preparation method thereof. The conductive plastic comprises the following blended compositions: a, thermoplastic resin; b, rubber particle with a crosslinking structure; c, a conductive filter; and d, a low-melting-point metal. The gel content of the composition b is 60% by weight or more, and the average particle size of the composition b is 0.02-1 mu m; the composition c is not fused at a thermoplastic-resin processing temperature; the composition d is at least one of a single-composition metal or metal alloy, the melting point of the composition d is 20-480 DEG C and is lower than the thermoplastic-resin processing temperature; and the weight ratio of the composition b to the composition a is 0.1:99.9-30:70. The conductive plastic is low in filling content of the conductive filler and the metal, is relatively low in conductive performance, can be prepared by using a common melt blending method, and can be used to prepare antistatic electromagnetic-wave-interference-resisting electron production equipment and tools with dust-free requirements, and electronic apparatuses, instrument housings and decoration materials of dust-free production workshops.

Owner:CHINA PETROLEUM & CHEM CORP +1

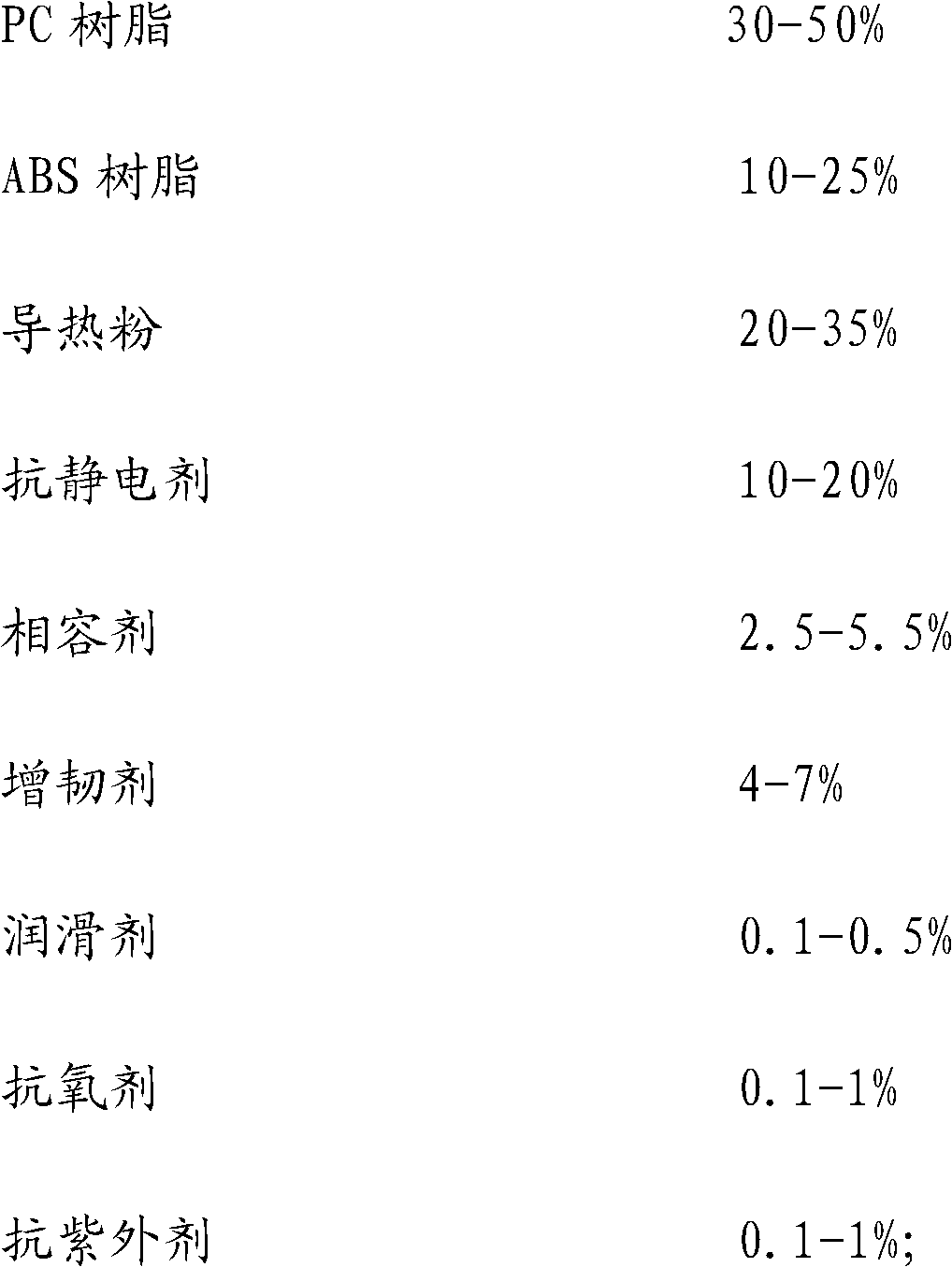

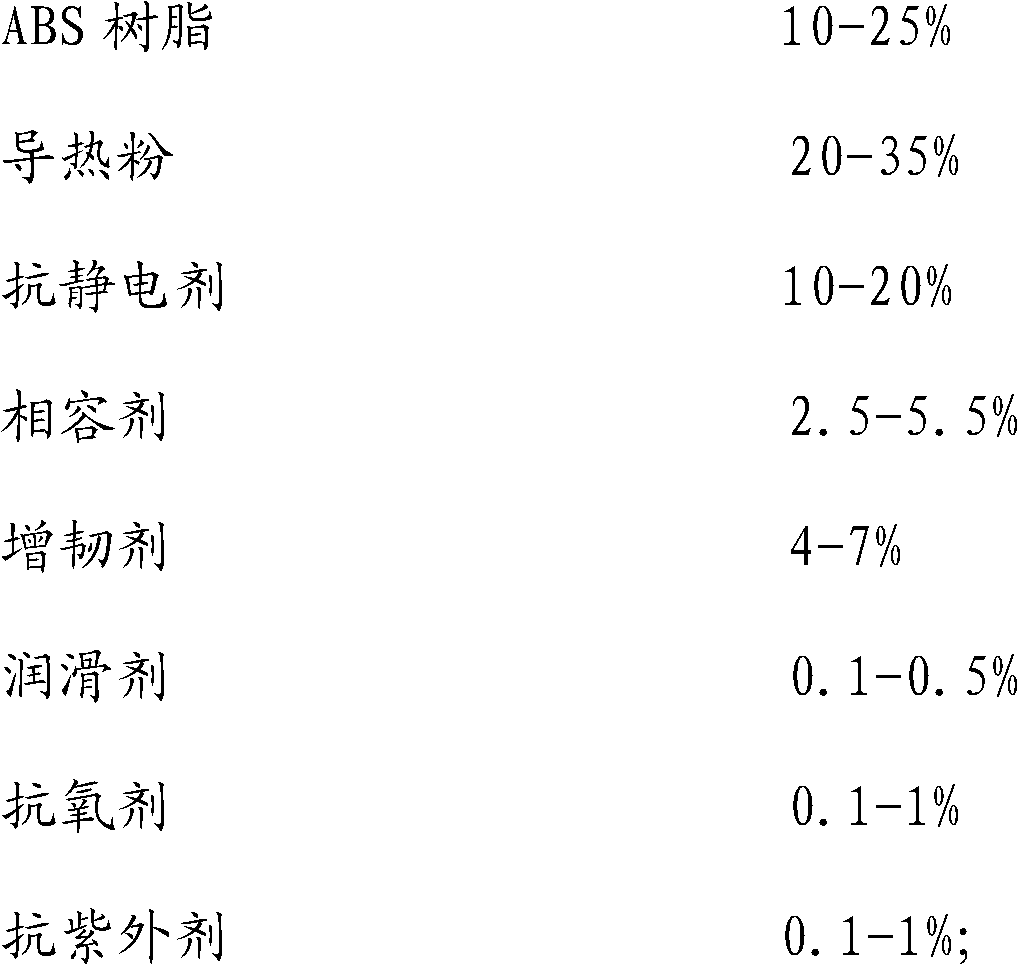

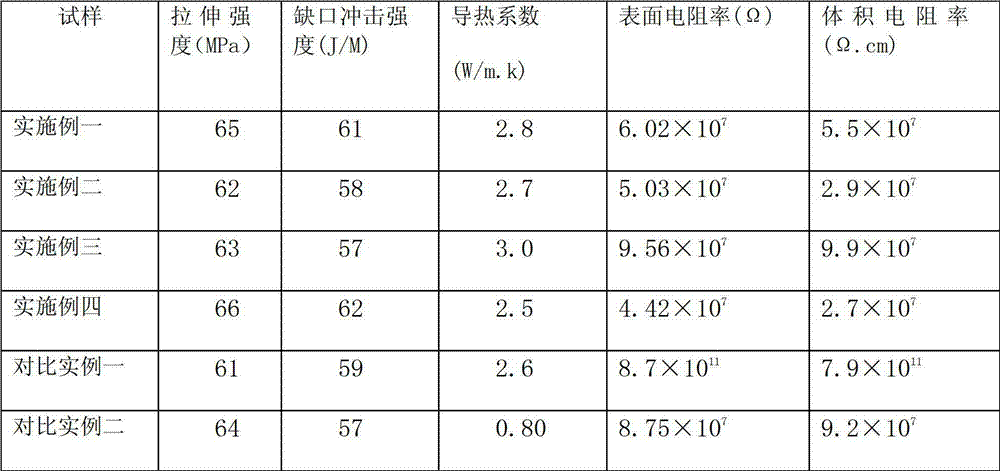

Thermal-conductive antistatic PC/ABS (polycarbonate/acrylonitrile butadiene styrene) material and preparation method thereof

InactiveCN102604358AGood physical and mechanical propertiesReduce fillingAntistatic agentAntioxidant

The invention discloses a thermal-conductive antistatic PC / ABS (polycarbonate / acrylonitrile butadiene styrene) material and a preparation method thereof. The PC / ABS material comprises the following compositions in percentage by weight: 30-50% of PC resin, 10-25% of ABS resin, 20-35% of thermal conductive powder, 10-20% of antistatic agent, 2.5-5.5% of a compatilizer, 4-7% of toughening agent, 0.1-0.5% of lubricant, 0.1-1% of antioxidant, and 0.1-1% of anti-ultraviolet agent, wherein the thermal conductive powder is treated by using a coupling agent. According to the PC / ABS material prepared in the invention, the thermal conductive powder is treated by using the coupling agent, and due to the mutually cooperated and coordinated action of the two fillers (namely, the thermal conductive powder and the antistatic agent), the high-performance thermal conductivity and antistatic property can be realized with less filling quantity; and the physical and mechanical properties of the prepared PC / ABS material are excellent.

Owner:ANHUI KEJU NEW MATERIALS

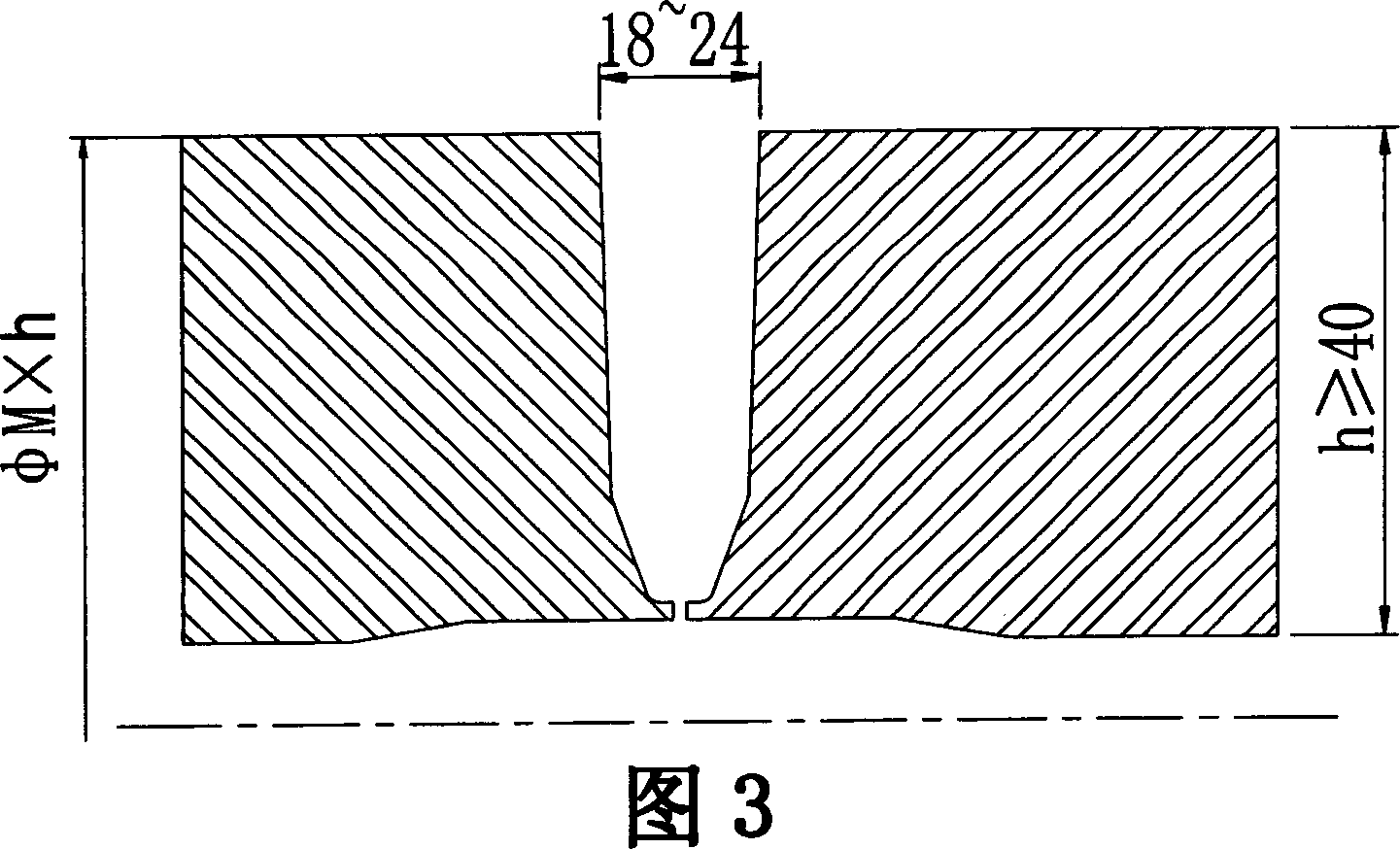

Full-position welding method for pipeline by full-automatic external welding machine

ActiveCN102009251AImprove efficiencyReduce weld metal fillerArc welding apparatusWeld seamProcess engineering

The invention discloses a full-position welding method for a pipeline by a full-automatic external welding machine, which comprises the following steps of: pretreating a pipe orifice end face of the pipeline; conventionally checking a welded pipeline, and performing environmental protection and equipment debugging; inputting and saving welding technical parameters into a tractor controller of an automatic external welding machine; machining the pipe orifice end face of the pipeline to be welded to form the needed groove by using a groove processing machine, and clearing and assembling the pipe orifice end face with the machined groove; checking welding rails and loading a welding tractor; and performing pre-welding preheating on the pipeline to be welded according to regulation requirement in welding technology, and welding according to the specified welding technical parameters. The method realizes real full-automatic pipeline welding, guarantees stable control of the welding process, ensures effective protection on electric arcs and molten baths, guarantees impact toughness of welded joints and welding quality, solves the bottleneck problems which restrict semi-automatic welding flow construction work, and improves the working efficiency.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

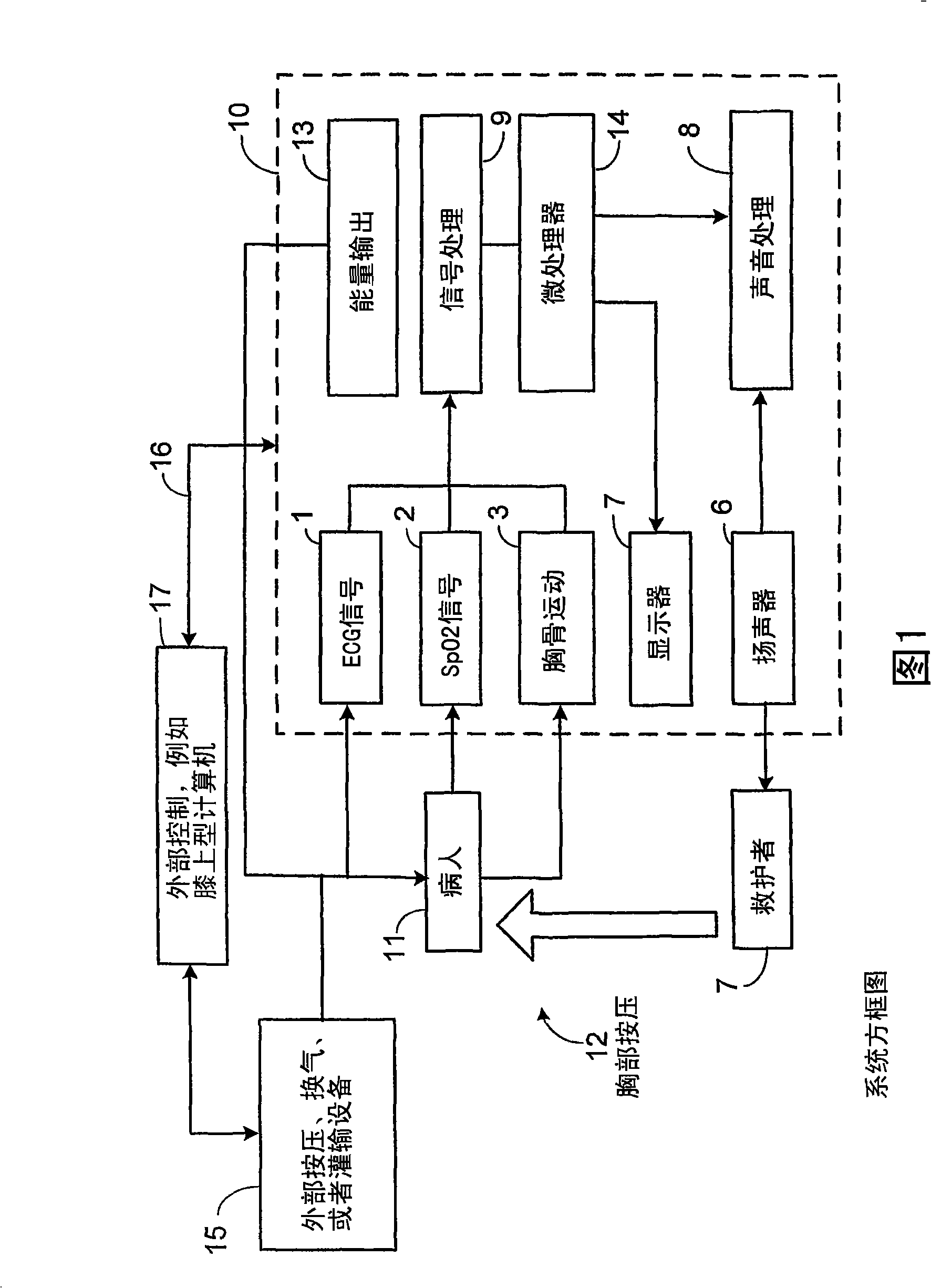

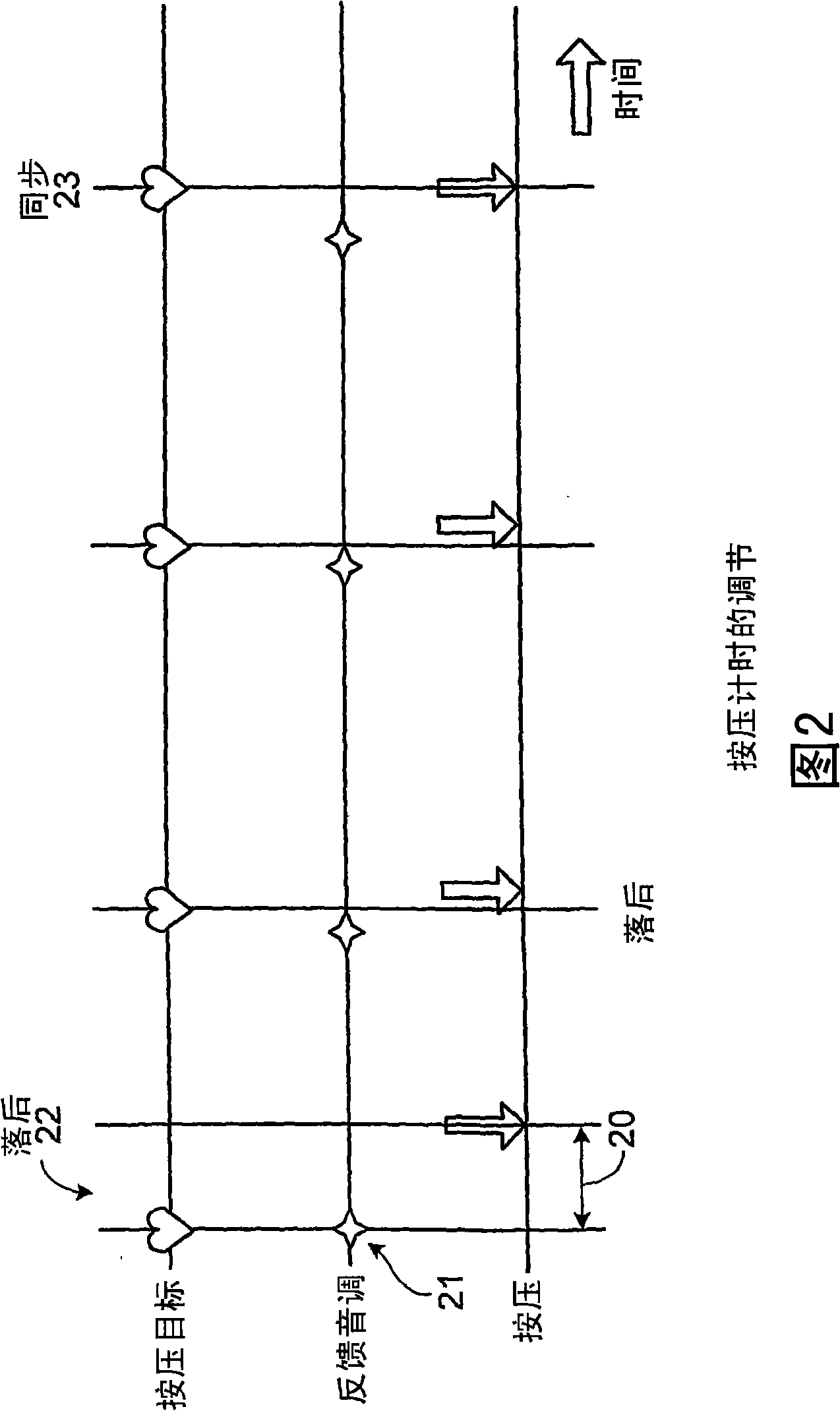

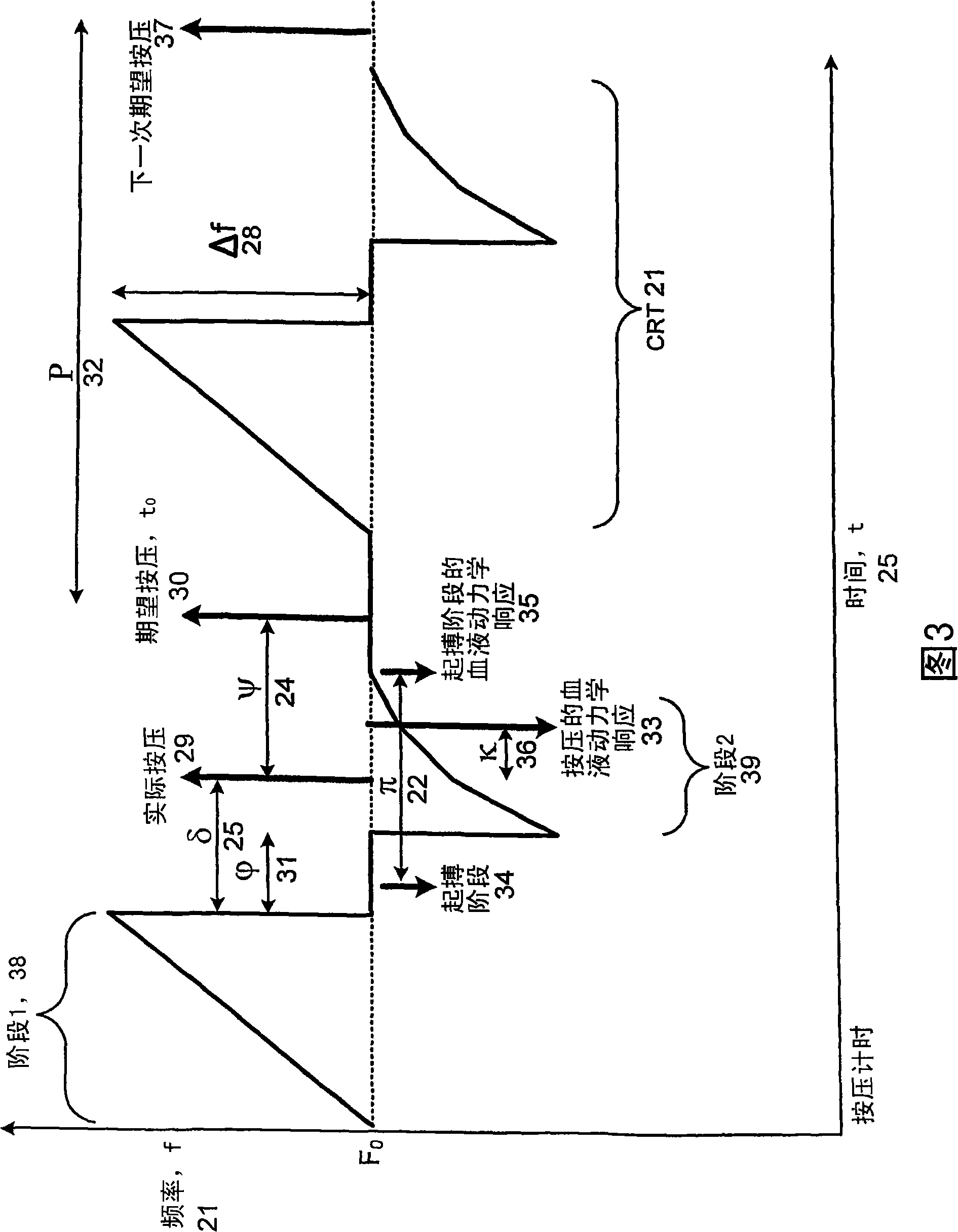

Synchronization of repetitive therapeutic interventions

ActiveCN101309722APromote recoveryReduced mechanical outputUltrasound therapyHeart defibrillatorsCardiac resuscitationPhysical therapy

A medical device of the type used for assisting a user in manually delivering repetitive therapy to a patient (e.g., chest compressions or ventilations in cardiac resuscitation), the device comprising a feedback device configured to generate feedback cues to assist the user in timing the delivery of the repetitive therapy, at least one sensor or circuit element configured to detect actual delivery times, at which the user actually delivers the repetitive therapy, and a processor, memory, and associated circuitry configured to compare the actual delivery times to information representative of desired delivery times to determine cue times at which the feedback cues are generated by the feedback device.

Owner:ZOLL MEDICAL CORPORATION

Conductive silicon rubber material with ultralow compressive deformation and low hardness and preparation method thereof

ActiveCN103160128AReduce fillingIncrease elasticityNon-conductive material with dispersed conductive materialRubber materialCarbon nanotube

The invention relates to a conductive silicon rubber material with ultralow compressive deformation and low hardness and a preparation method thereof and belongs to the technical field of conductive silicon rubber materials. The rubber material is prepared by filling conductive fillers with different shape factors so as to ensure that a network passage is formed under the condition of low-usage conductive filler. The rubber material comprises the following ingredients in parts by mass: 100 parts of silicon rubber, 1-15 parts of vulcanizing agent, 0 or 1-8 parts of vulcanizing assistant, 5-15 parts of carbon black and 0.5-5 parts of carbon nanotubes. According to the material, the material is endowed with higher conductivity under the condition that lower compression permanent deformation and lower hardness are guaranteed; the preparation process is simple, and the cost is low; and through testing the electrical and mechanical properties of the material, the conductive silicon rubber material has the following properties: the Shore A hardness is not higher than 50, the 25% constant compression permanent deformation is not higher than 10% (100 DEG C * 24 h), the instantaneous resilience performance is not lower than 60%, and the volume resistivity is not higher than 50 omega.cm.

Owner:BEIJING UNIV OF CHEM TECH

Nylon 66 composite material, preparation method thereof and electronic device

The invention is suitable for the technical field of high polymer materials and provides a nylon 66 composite material, a preparation method thereof and an electronic device. the nylon 66 composite material comprises the raw materials in percentage by weight as follows: 40%-65% of PA 66 resins, 8%-12% of a roughening agent, 20%-35% of heat conduction powder; 10%-15% of an antistatic agent, 2.5%-5.5% of a compatilizer, 0.1%-0.5% of a lubricating agent, 0.1%-1% of an antioxidant agent, 0.1%-2% of a coupling agent and 0.2%-0.5% of a nucleating agent, wherein the heat conduction powder is processed by the coupling agent. According to the invention, when the nylon 66 composite material is prepared, the coupling agent is used for processing the heat conduction powder, and two fillers of the heat conduction powder and a conductive agent are mutually matched and coordinated, so that the excellent heat conductivity and antistatic property can be obtained with low filler consumption, and simultaneously the prepared nylon 66 composite material has excellent physical and mechanical properties.

Owner:SHENZHEN YATAIXING IND

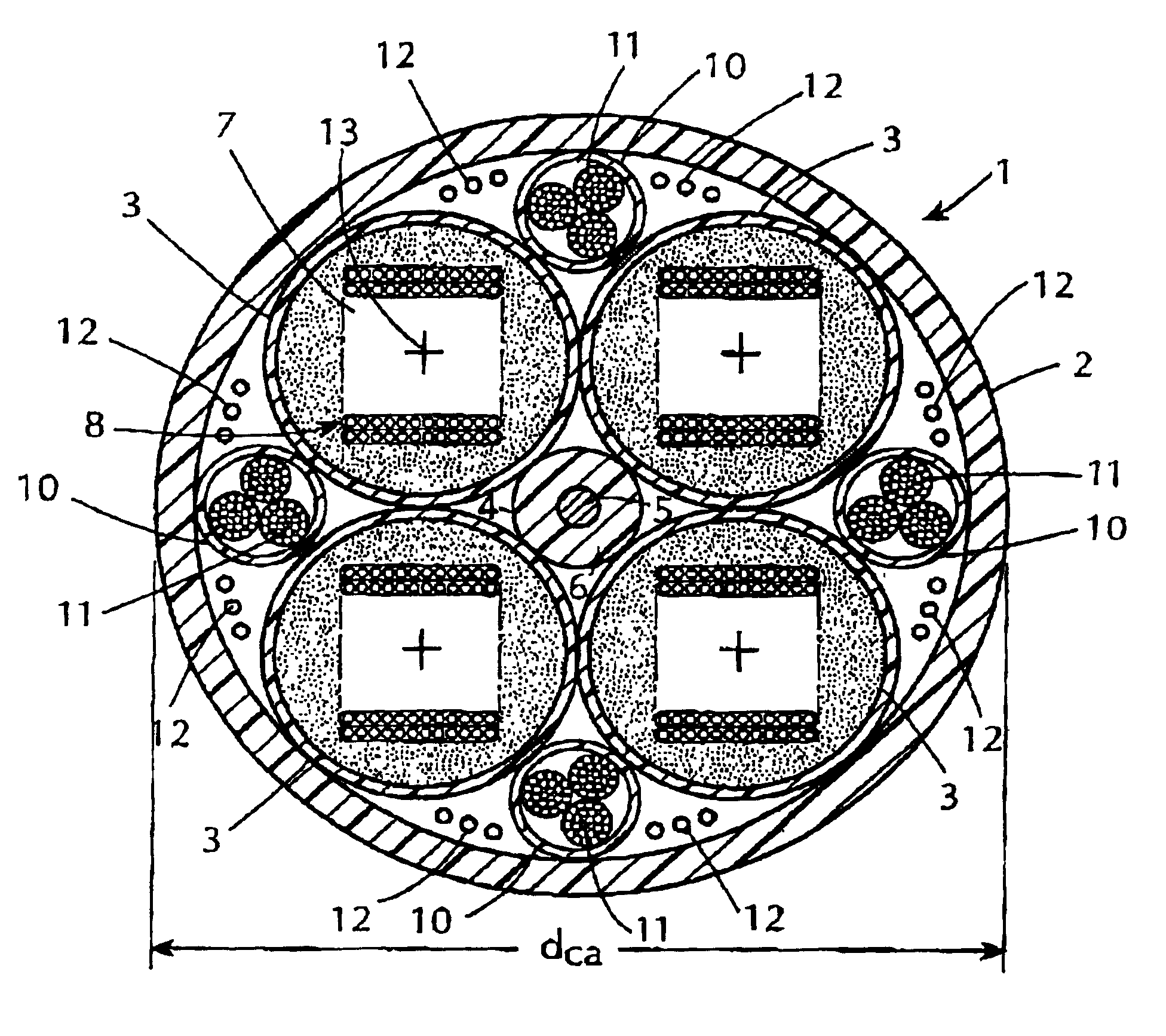

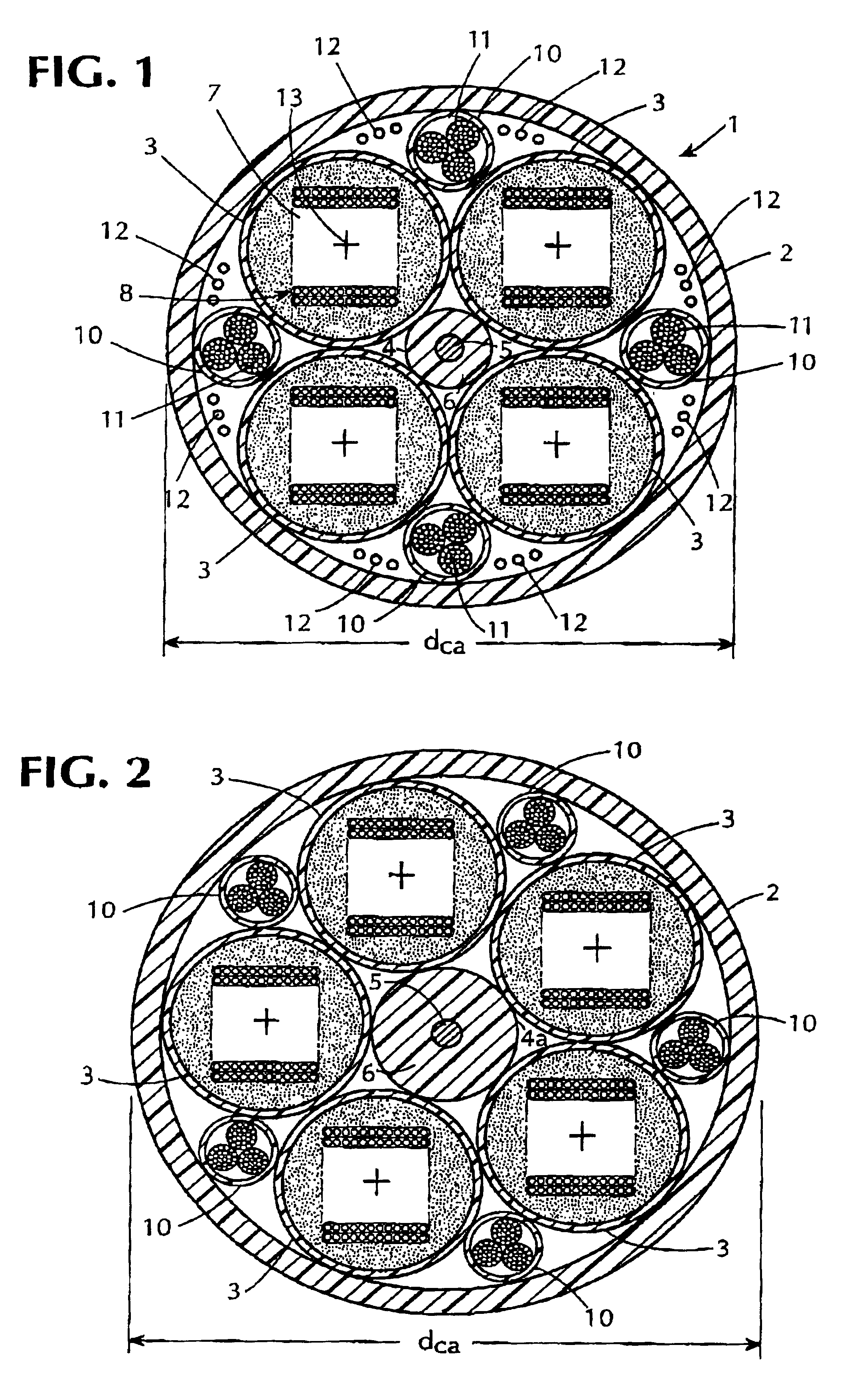

High fiber count optical fiber cable with buffer tubes around central strength member

InactiveUS6870995B2Increase the number ofReduce the overall diameterFibre mechanical structuresFiberFill factor

Optical fiber cable with a central strength member structure and with four or five buffer tubes each loosely receiving optical fiber ribbons in a stack and is disposed around and contacting the strength member. The optical fiber count is in excess of 1000 and the fill factor is not greater than 85% in a two inch duct. Each buffer tube contacts adjacent buffer tubes, and the buffer tubes are encircled by a jacket. Optionally, spaces bounded by pairs of buffer tubes and the jacket have optical fibers therein and can also include flexible longitudinal strength members and / or water blocking filaments. Preferably, the strength member structure and / or the buffer tubes are encircled by a water blocking tape. The optical fiber ribbons in the stacks can include different numbers of fibers, and hence, can have different width.

Owner:PRYSMIAN COMM CABLES & SYST USA LLC

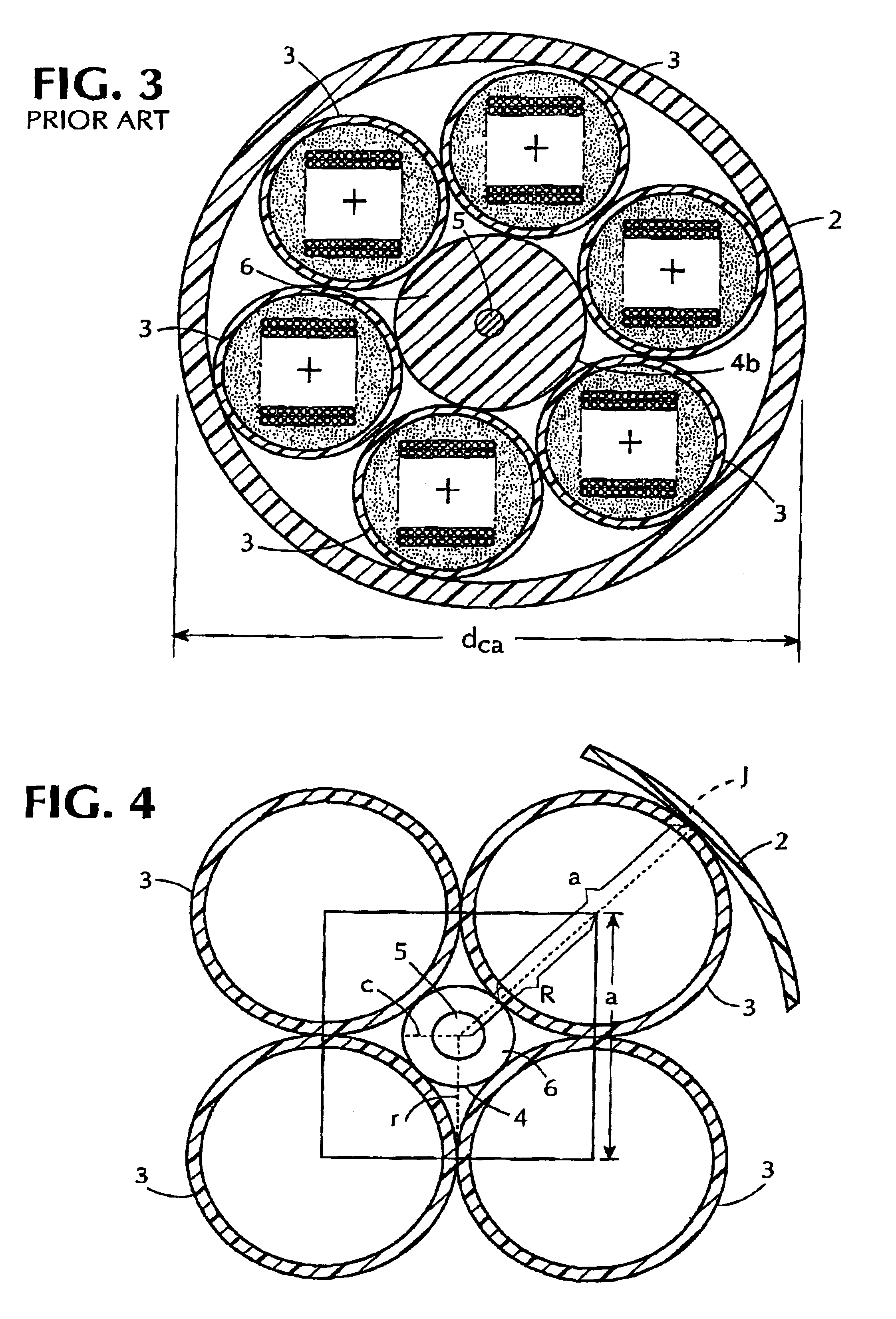

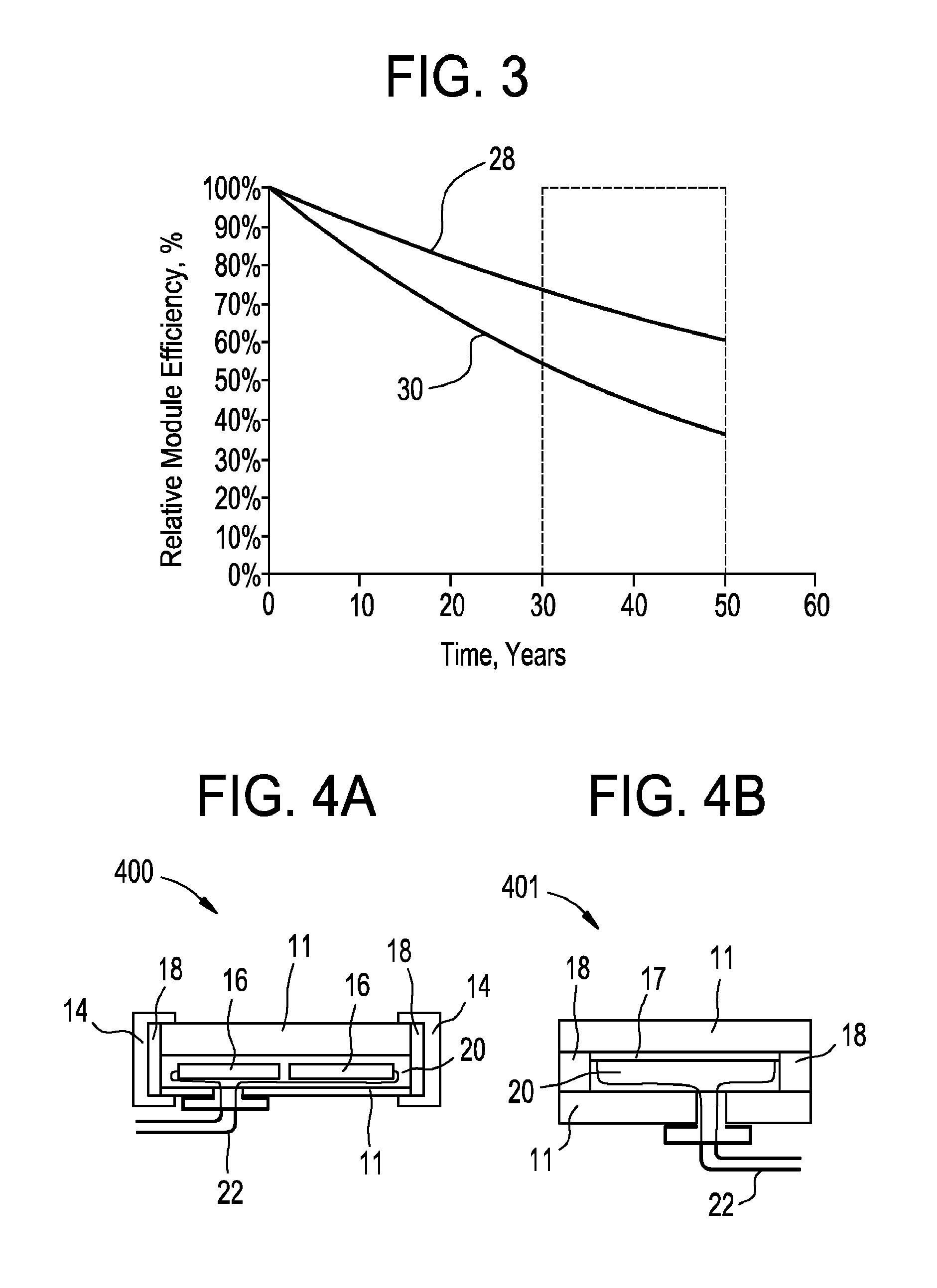

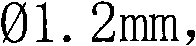

Photovoltaic module package

ActiveUS20140158201A1High efficiencyDegradation rateGlass/slag layered productsPhotovoltaic energy generationIonEngineering

A silicon wafer-based photovoltaic module is described, which includes a first outer protective layer and a second outer protective layer, wherein both outer protective layers comprise a low- or no-sodium glass or low- or no-alkali compositions. The photovoltaic modules show resistance to water ingress, no or reduced potential-induced sodium ion drift, and reduced potential induced degradation.

Owner:CORNING INC

Welding method of ultra-thick and high-strength water-power steel

ActiveCN101905365ATo achieve the welding effectReduce fillingArc welding apparatusWorkpiece edge portionsEngineeringWelding defect

The invention relates to a welding method of ultra-thick and high-strength water-power steel, belonging to the welding field. Welding is realized by adopting a mixed welding mode, i.e. hand welding is adopted as a basis for filling the bottom, and gas shielded welding is adopted for a middle layer and a cover part, multilayer and multi-pass welding are adopted, a carbon arc is cropped out after a single side is filled, and the input of welding heat is controlled within 65 kJ / cm. A welding bevel adopts an asymmetric U-shaped bevel, a thick steel plate of 145-155 mm is preheated to 100 DEG C before welding, the inter-layer temperature is kept between 100 DEG C to 160 DEG C, and heat treatment stress is not carried out after welding, and the problem of reheat embrittlement of a welding joint of the high-strength water-power steel is solved. The invention needs simple welding equipment, realizes welding through a combined welding process on the basis of the traditional equipment, reduces the filling amount of welding metal, and achieves the welding effect of a narrow gap. Compared with the hand arc welding, the invention greatly improves the welding efficiency of the thick steel plate and lowers the possibility of welding defects easily generated on the hand arc welding of an ultra-thick steel plate, such as cold cracks, incomplete fusion, crisp fusion, and the like.

Owner:SHOUGANG CORPORATION +1

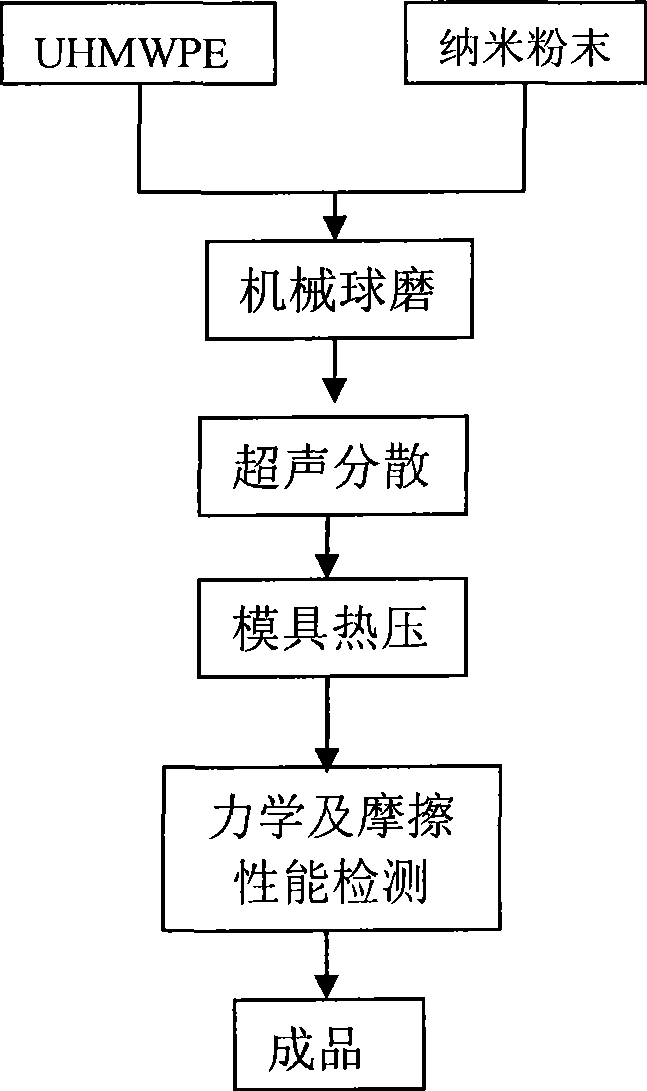

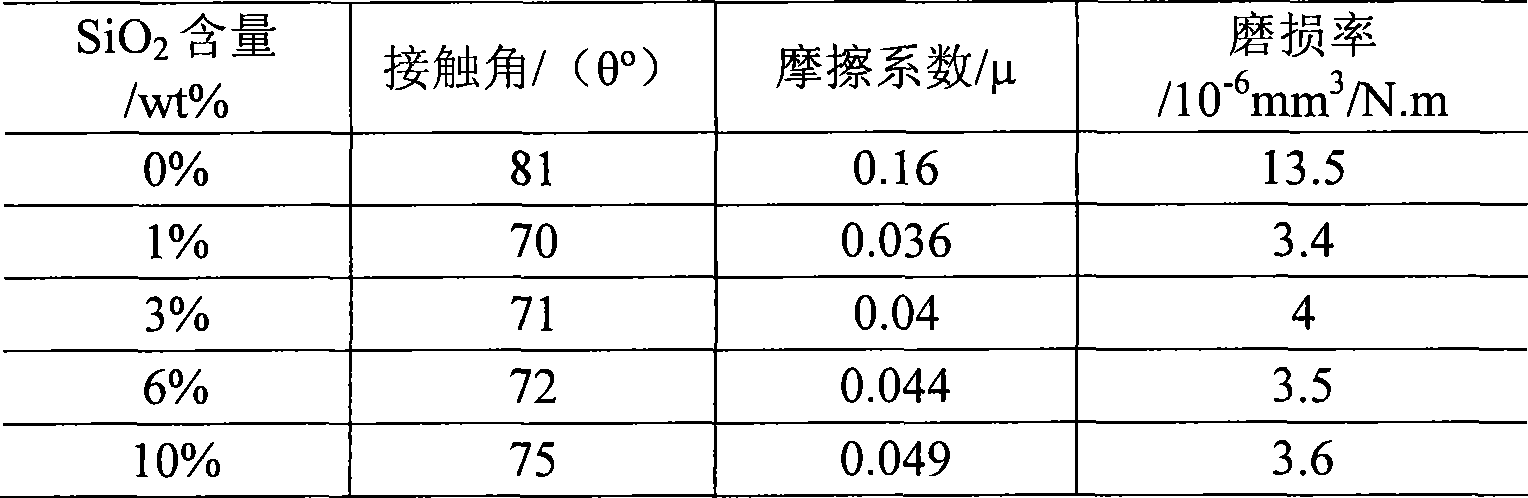

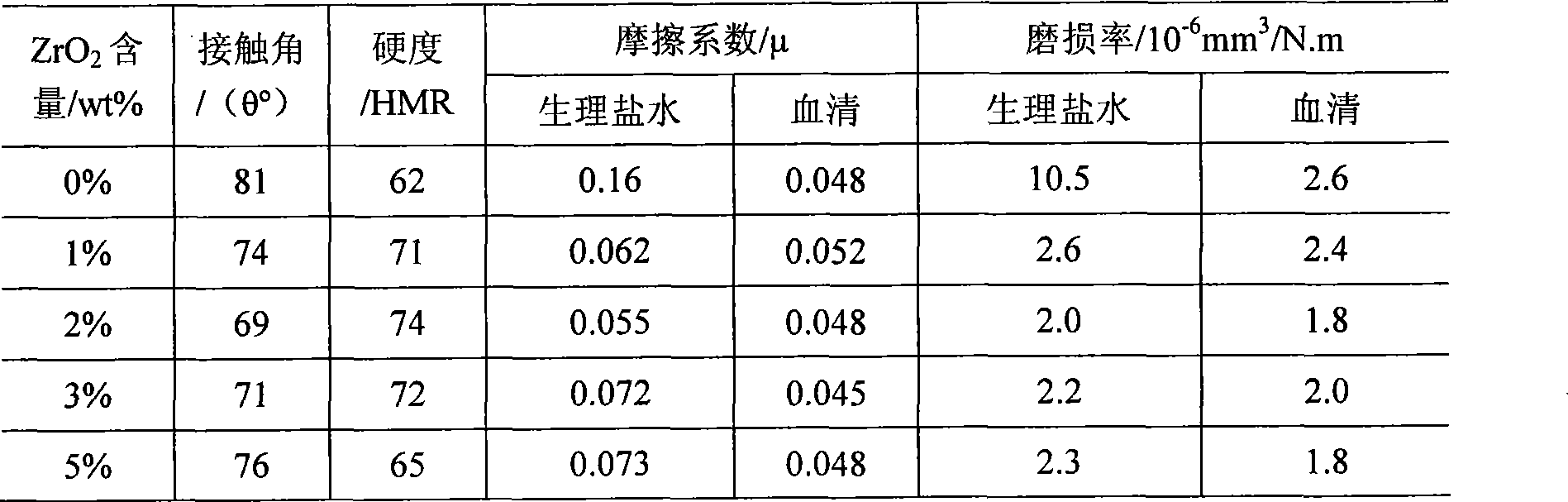

Nano-granules reinforced ultra-high molecular weight polyethylene artificial joint material and production method thereof

InactiveCN101396571AReduce fillingMaintain shock absorptionJoint implantsNanoparticlePolymer composites

The invention discloses a nanoparticle reinforced ultra high molecular weight polyethylene artificial joint material and a preparation method thereof. The nanoparticle reinforced ultra high molecular weight polyethylene artificial joint material takes nanoparticles which are filled in the ultra high molecular weight polyethylene as cross-linking points, thereby forming a polymer composite material with a network cross-linking structure. The method comprises the following steps: ultra high molecular weight polyethylene powder is subdivided and screened; ethanol solution containing a coupling agent is used for modifying the nanoparticles; the nanoparticles are fully mixed with the ultra high molecular weight polyethylene powder; the powder after the mixing is dispersed; the mixed powder is added in a mold, and the block composite material is prepared by hot-pressing forming. The filling amount of nanoparticles in the nanoparticle / UHMWPE composite material is low, which is less than 10 percent by weight; the wear rate of the composite material is decreased to one half to one fifth of pure UHMWPE, the friction coefficient is decreased to one half to one fourth of the pure UHMWPE, and the experimental results on a knee joint wear test machine particularly prove that the wear resistance thereof is significantly improved.

Owner:NANJING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com