Thermal-conductive antistatic PC/ABS (polycarbonate/acrylonitrile butadiene styrene) material and preparation method thereof

An ABS material, antistatic technology, applied in the field of thermal conductivity and antistatic PC/ABS material and its preparation, can solve the problems of high volume resistivity, electric shock, dust collection, etc., and achieve the effect of excellent physical and mechanical properties and high filling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

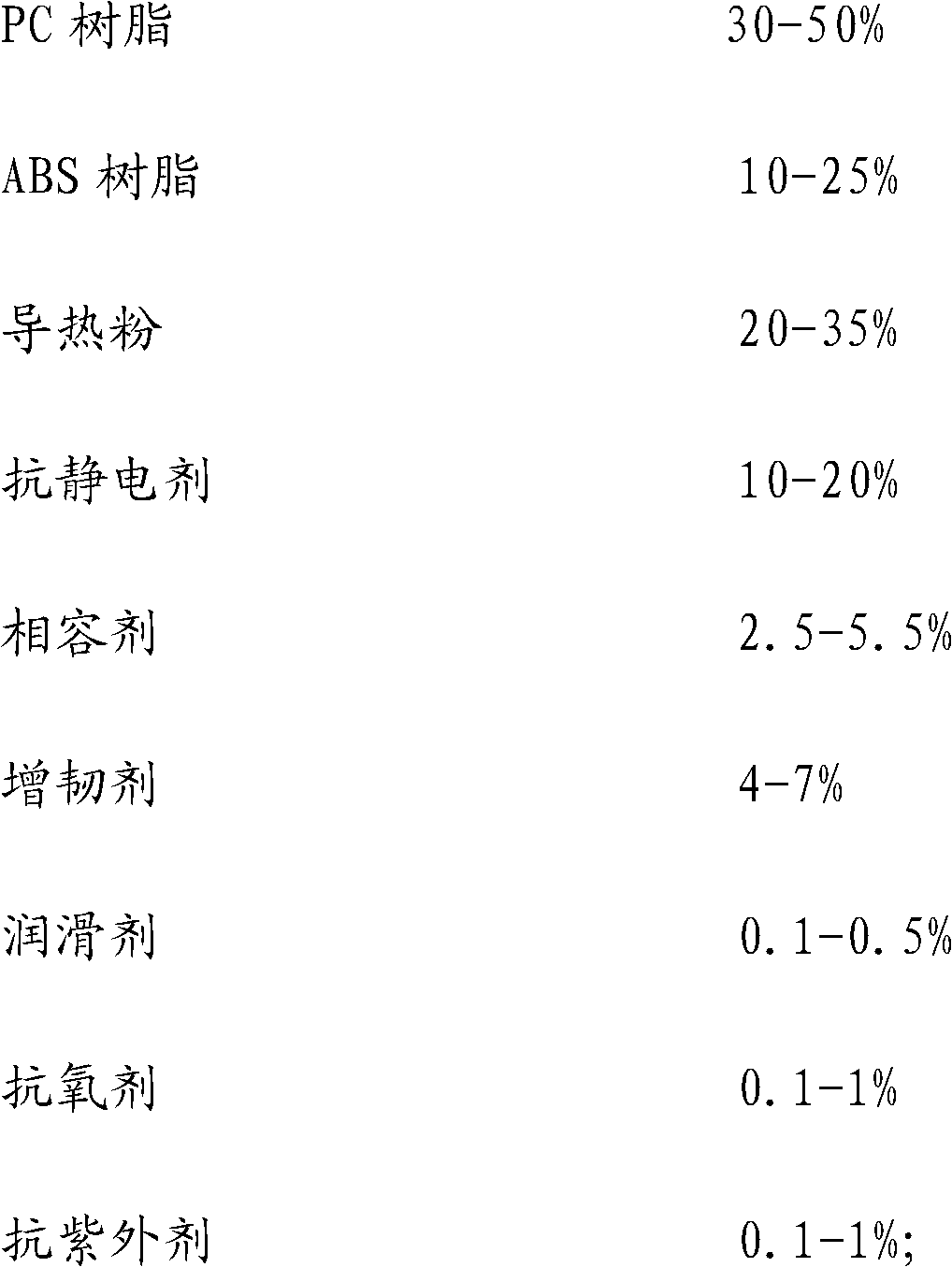

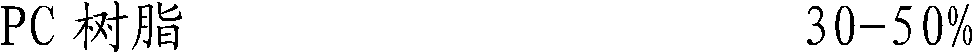

[0024] The thermally conductive and antistatic PC / ABS material in this embodiment, by weight percentage, consists of the following components:

[0025] 40% of PC resin, 15.8% of ABS resin, 20% of aluminum oxide or silicon carbide treated with coupling agent (or a mixture of the two by weight 1:1), 15% of graphite, 3% of compatibilizer, and toughening agent 5%, lubricant 0.5%, antioxidant 0.4%, anti-ultraviolet agent 0.3%.

[0026] Its preparation method is as follows:

[0027] Step 1. Weigh each component according to the above-mentioned weight percentage; wherein, the thermally conductive powder is treated with a coupling agent;

[0028] Step 2. Pour the weighed components into the mixing bucket and stir for 8min, and the stirring speed is 400r / min;

[0029] Step 3: Put the mixed material into the twin-screw extruder, and then extrude and granulate through the melting reaction; the technological conditions of the twin-screw extruder are: the temperature of the first zone is...

Embodiment 2

[0031] The thermally conductive and antistatic PC / ABS material in this embodiment, by weight percentage, consists of the following components:

[0032] PC resin 30%, ABS resin 25%, aluminum oxide or silicon carbide treated with coupling agent (or a mixture of the two by weight 1:1) 25.8%, graphite 10%, compatibilizer 4%, toughening agent 4%, lubricant 0.3%, antioxidant 0.6%, anti-ultraviolet agent 0.3%.

[0033] Its preparation method is as follows:

[0034] Step 1. Weigh each component according to the above-mentioned weight percentage; wherein, the thermally conductive powder is treated with a coupling agent;

[0035] Step 2: Pour the weighed components into the mixing bucket and stir for 5min, and the stirring speed is 450r / min;

[0036] Step 3: Put the mixed material into the twin-screw extruder, and then extrude and granulate through the melting reaction; the technological conditions of the twin-screw extruder are: the temperature of the first zone is 220°C, the tempera...

Embodiment 3

[0038] The thermally conductive and antistatic PC / ABS material in this embodiment, by weight percentage, consists of the following components:

[0039] PC resin 50%, ABS resin 10%, aluminum oxide or silicon carbide treated with coupling agent (or a mixture of the two by weight 1:1) 20.8%, graphite 11%, compatibilizer 3%, toughening agent 4%, lubricant 0.3%, antioxidant 0.6%, anti-ultraviolet agent 0.3%.

[0040] Its preparation method is as follows:

[0041] Step 1. Weigh each component according to the above-mentioned weight percentage; wherein, the thermally conductive powder is treated with a coupling agent;

[0042] Step 2. Pour the weighed components into the mixing bucket and stir for 10min, and the stirring speed is 350r / min;

[0043] Step 3: Put the mixed material into the twin-screw extruder, and then extrude and granulate through the melting reaction; the technological conditions of the twin-screw extruder are: the temperature of the first zone is 220°C, the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com