Patents

Literature

9557 results about "Acrylonitrile" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acrylonitrile is an organic compound with the formula CH₂CHCN. It is a colorless volatile liquid, although commercial samples can be yellow due to impurities. In terms of its molecular structure, it consists of a vinyl group linked to a nitrile. It is an important monomer for the manufacture of useful plastics such as polyacrylonitrile. It is reactive and toxic at low doses. Acrylonitrile was first synthesized by the French chemist Charles Moureu (1863–1929) in 1893.

Bi-component epoxide-resin adhesive and preparation method thereof

InactiveCN101397486AImprove heat resistanceImproved tensile shear strengthEpoxynovolac adhesivesEpoxyBenzene

The invention relates to a two-component epoxy resin adhesive, including the following components: novolac epoxy resin, lipid ring type epoxy resin and terminal carboxylic acrylonitrile butadiene rubber in component A, and 1, 4-di-benzene (2, 4-diaminobenzene oxygen) in component B, wherein, the mass percentage of the lipid ring type epoxy resin is 20-35 percent of the novolac epoxy resin, the mass percentage of the terminal carboxylic acrylonitrile butadiene rubber CTBN is 12 percent of the novolac epoxy resin and the mass percentage of the 1, 4-di-benzene (2, 4-diaminobenzene oxygen) is 15-20 percent of the novolac epoxy resin; and the preparation of the two-component epoxy resin adhesive includes the step of evenly mixing the component A and the component B for use. The two-component epoxy resin adhesive used for conductive adhesive has good heat resistance, average stretching and shearing strength of 21.28MPa, simple preparation process and operation without solvent, and plays the role of protecting environment.

Owner:DONGHUA UNIV +1

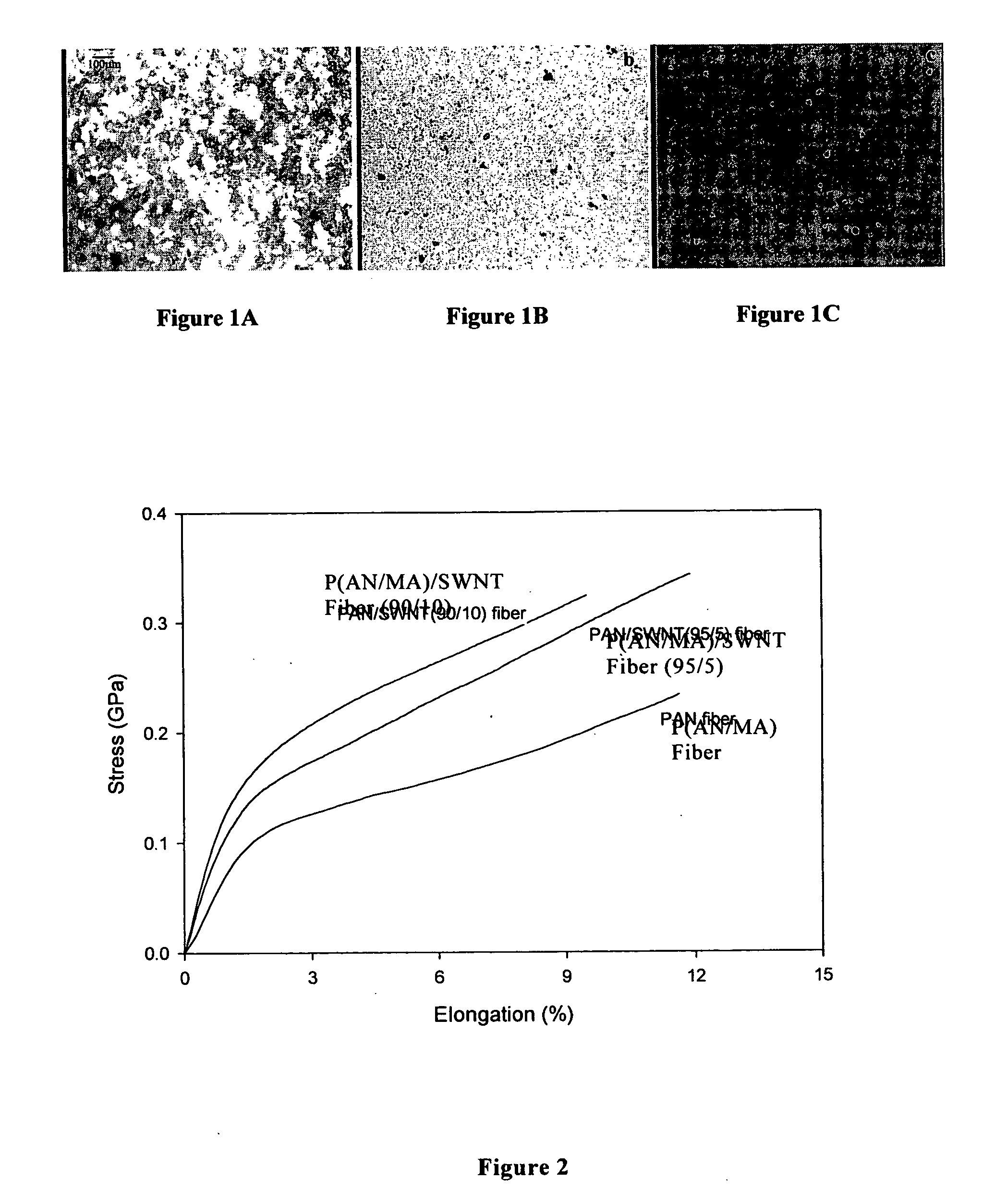

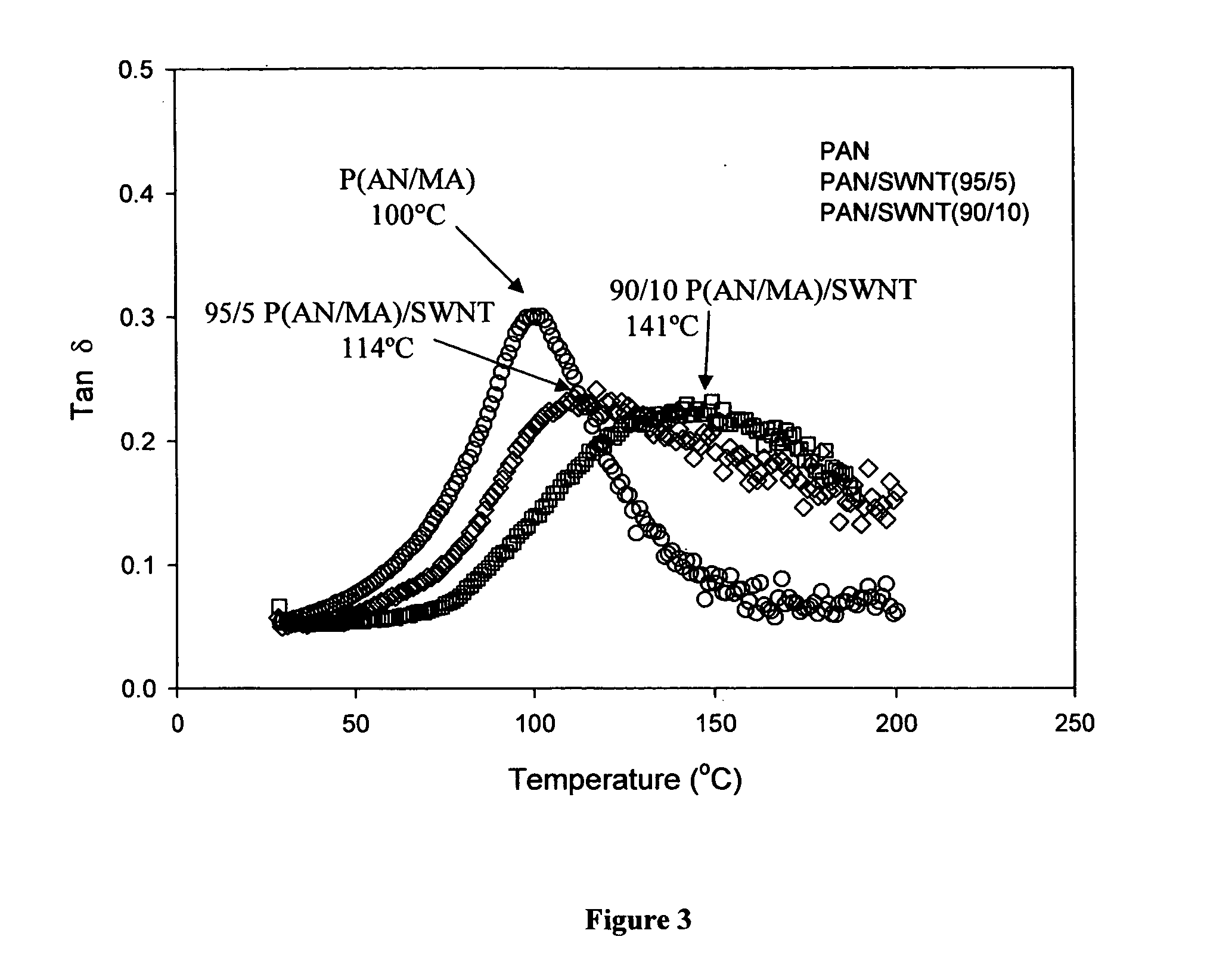

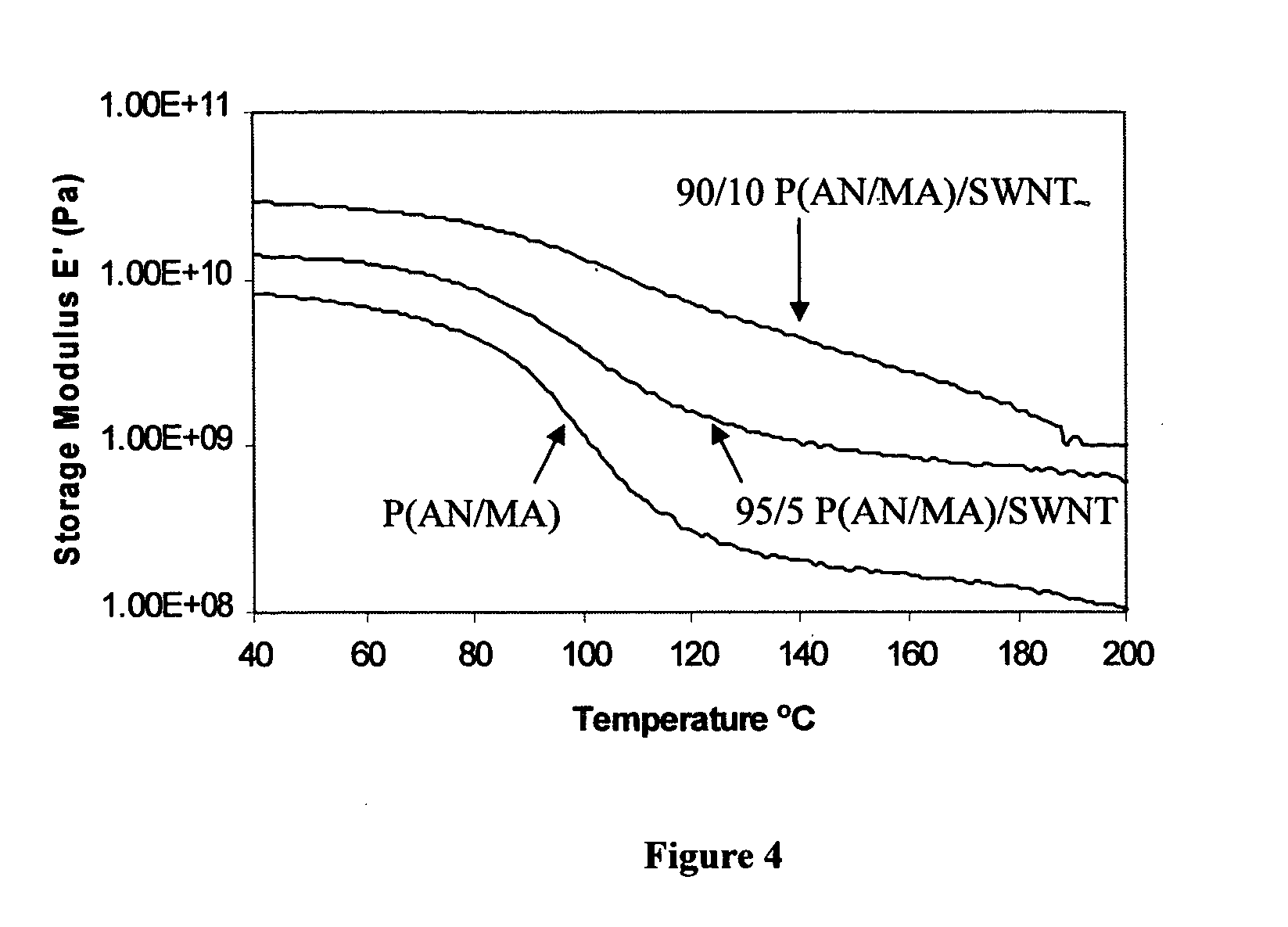

Macroscopic fiber comprising single-wall carbon nanotubes and acrylonitrile-based polymer and process for making the same

InactiveUS6852410B2Increased tensile modulusReduced thermal shrinkageMaterial nanotechnologyElectroconductive/antistatic filament manufactureVitrificationPolymer science

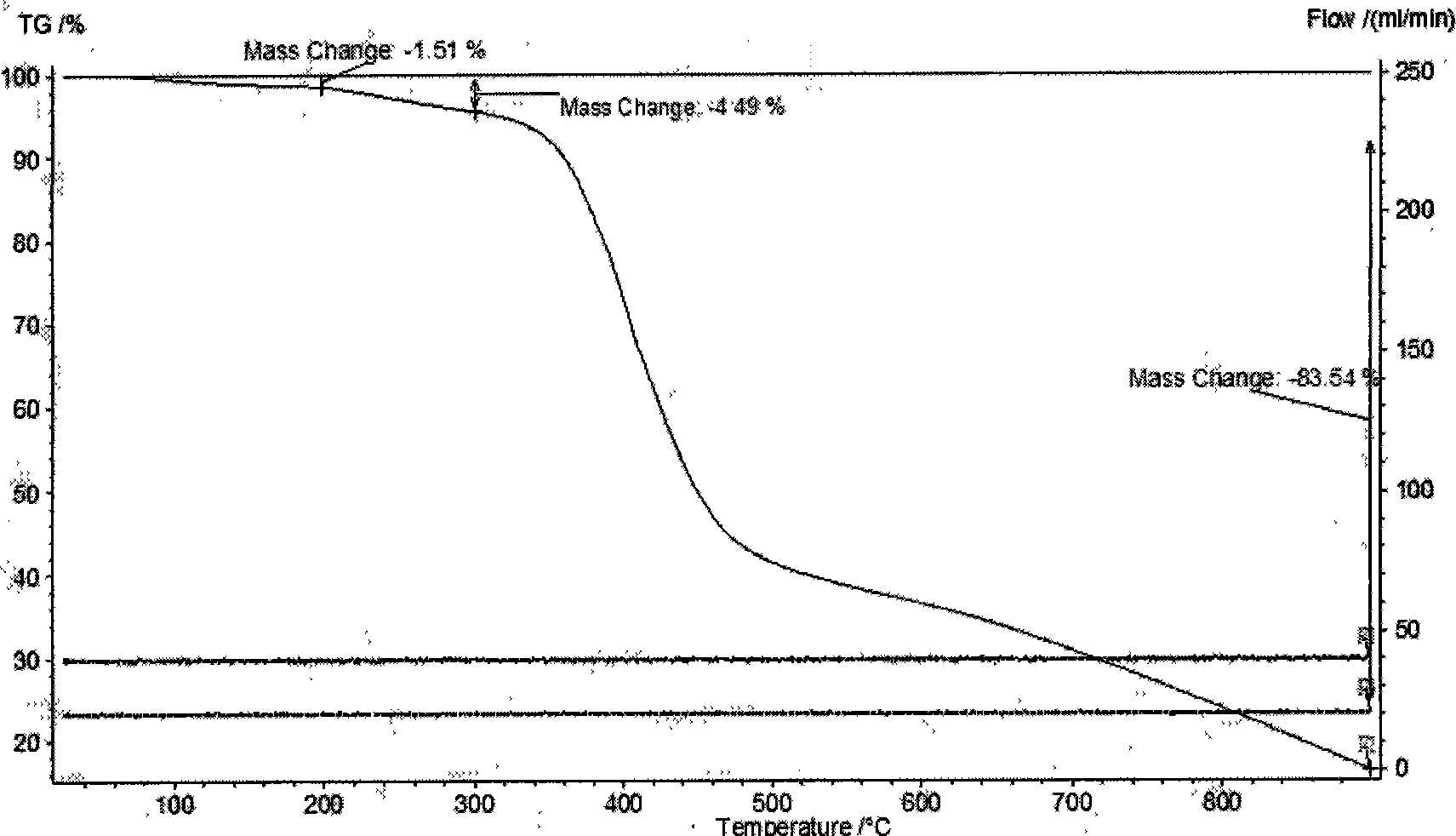

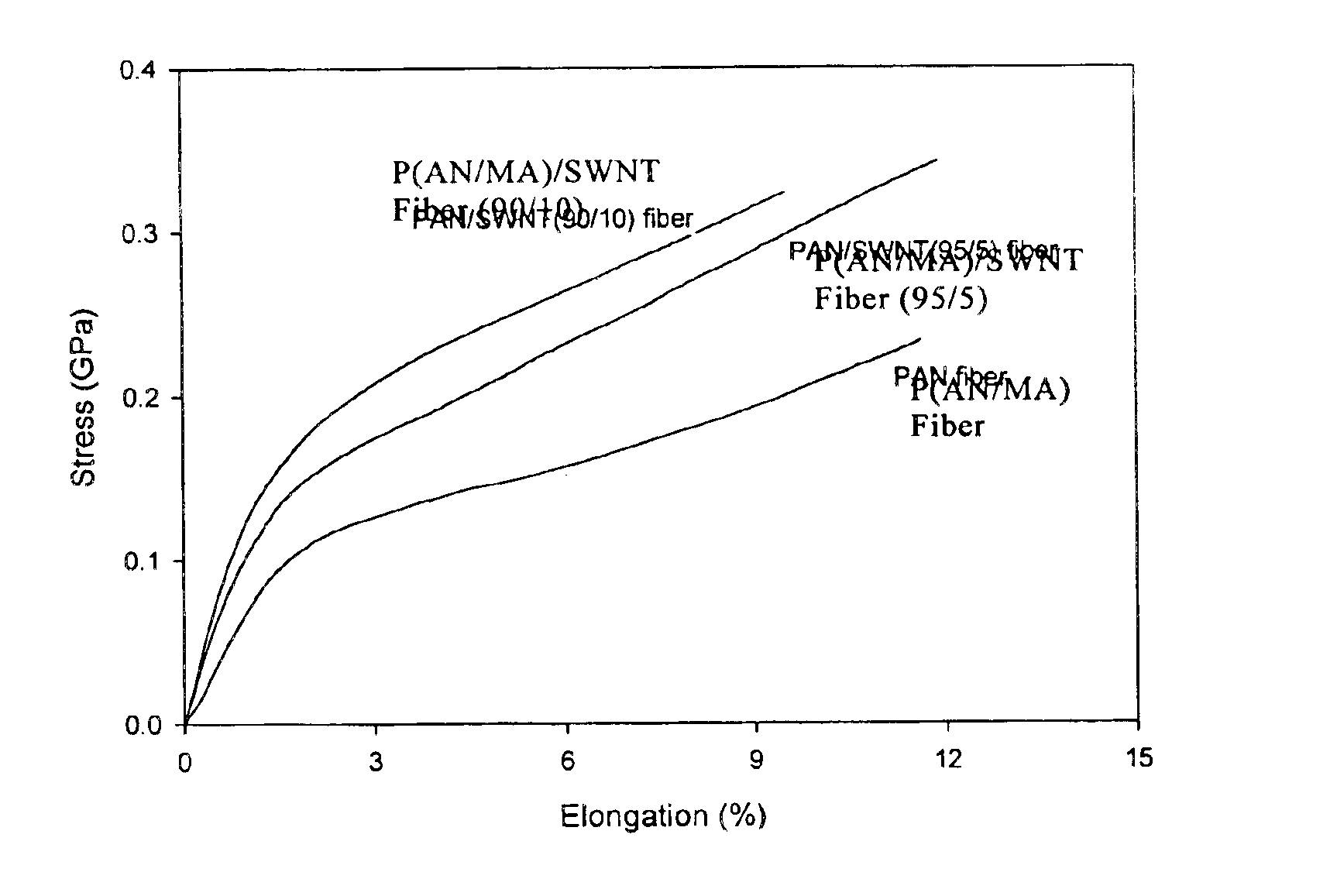

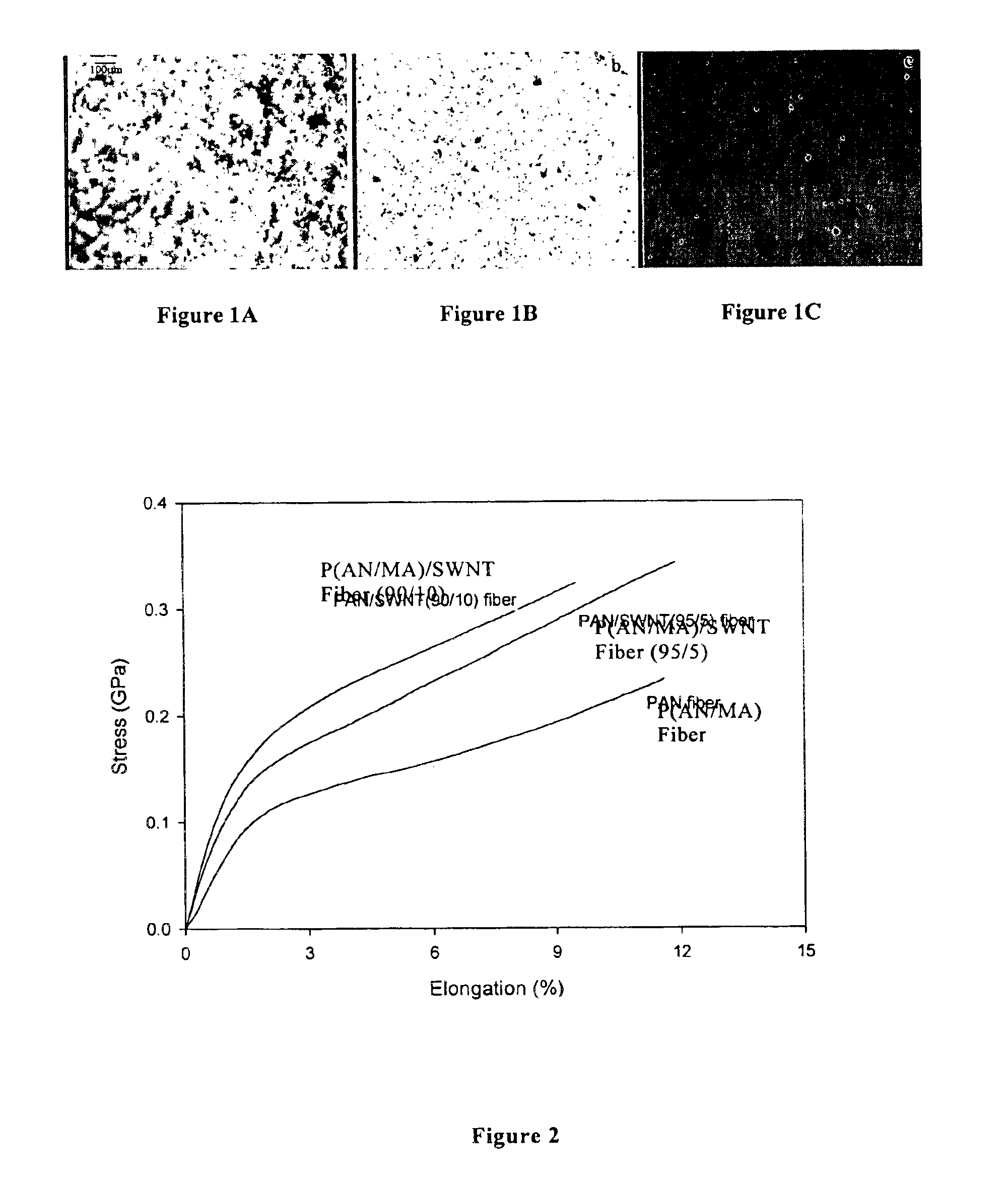

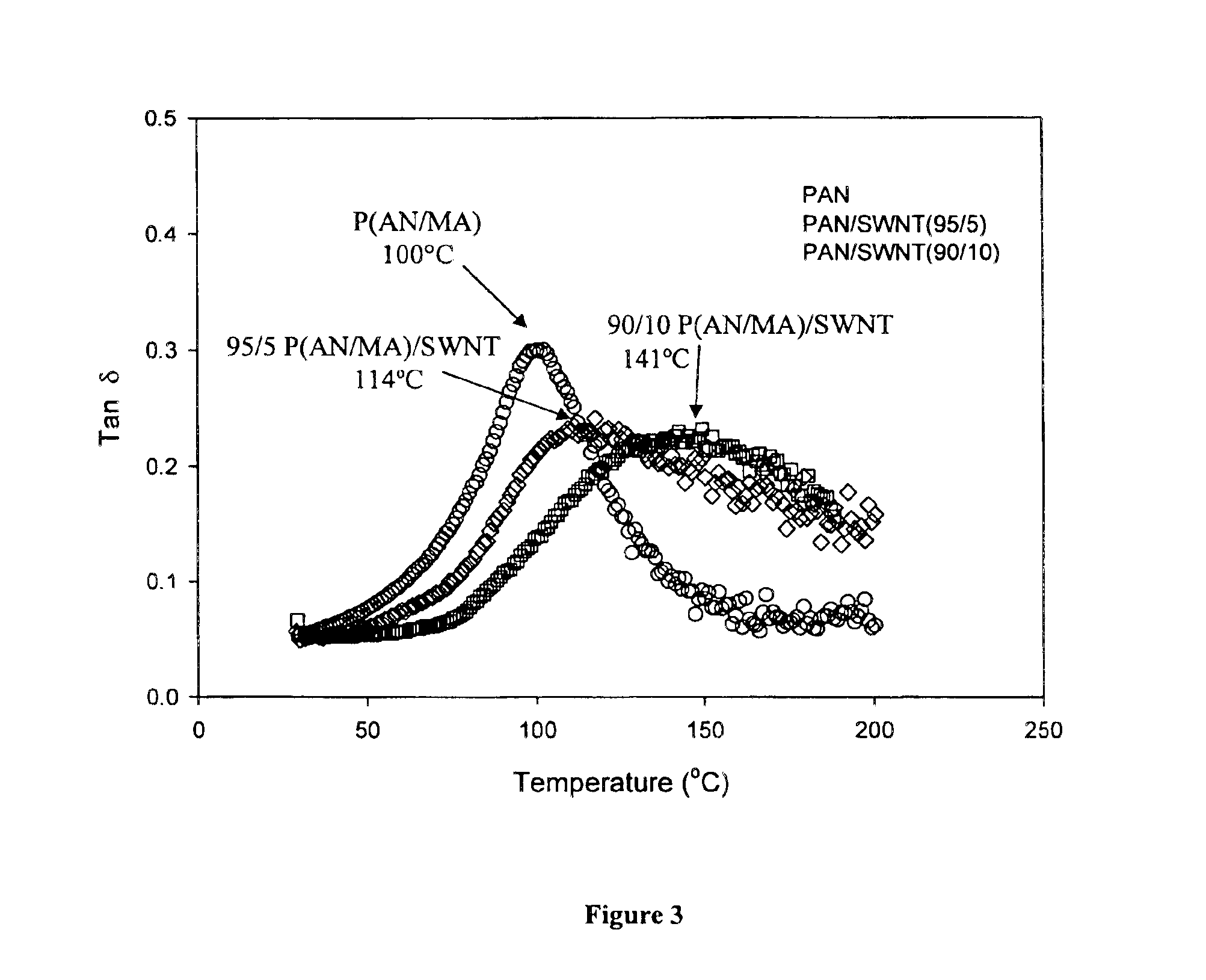

The present invention relates to a high modulus macroscopic fiber comprising single-wall carbon nanotubes (SWNT) and an acrylonitrile-containing polymer. In one embodiment, the macroscopic fiber is a drawn fiber having a cross-sectional dimension of at least 1 micron. In another embodiment, the acrylonitrile polymer-SWNT composite fiber is made by dispersing SWNT in a solvent, such as dimethyl formamide or dimethyl acetamide, admixing an acrylonitrile-based polymer to form a generally optically homogeneous polyacrylonitrile polymer-SWNT dope, spinning the dope into a fiber, drawing and drying the fiber. Polyacrylonitrile / SWNT composite macroscopic fibers have substantially higher modulus and reduced shrinkage versus a polymer fiber without SWNT. A polyacrylonitrile / SWNT fiber containing 10 wt % SWNT showed over 100% increase in tensile modulus and significantly reduced thermal shrinkage compared to a control fiber without SWNT. With 10 wt % SWNT, the glass transition temperature of the polymer increased by more than 40° C.

Owner:GEORGIA TECH RES CORP

Heat-expandable microcapsules, process for producing the same, and method of utilizing the same

InactiveUS6235394B1High TgHigh heat-resistanceSynthetic resin layered productsCellulosic plastic layered productsPolymer scienceHeat resistance

A heat-expandable microcapsule comprising a polymer shell formed by polymerizing (I) acrylonitrile, a main monomer component, (II) a monomer having carboxyl and (III) a monomer having groups reactive with the carboxyl of the monomer (II) and of a liquid having a boiling point lower than the softening point of the polymer and being encapsulated in the polymer shell. The heat-expandable microcapsules expand within high temperature range, 240° C. or above, and have heat-resistance.

Owner:MATSUMOTO YUSHI SEIYAKU

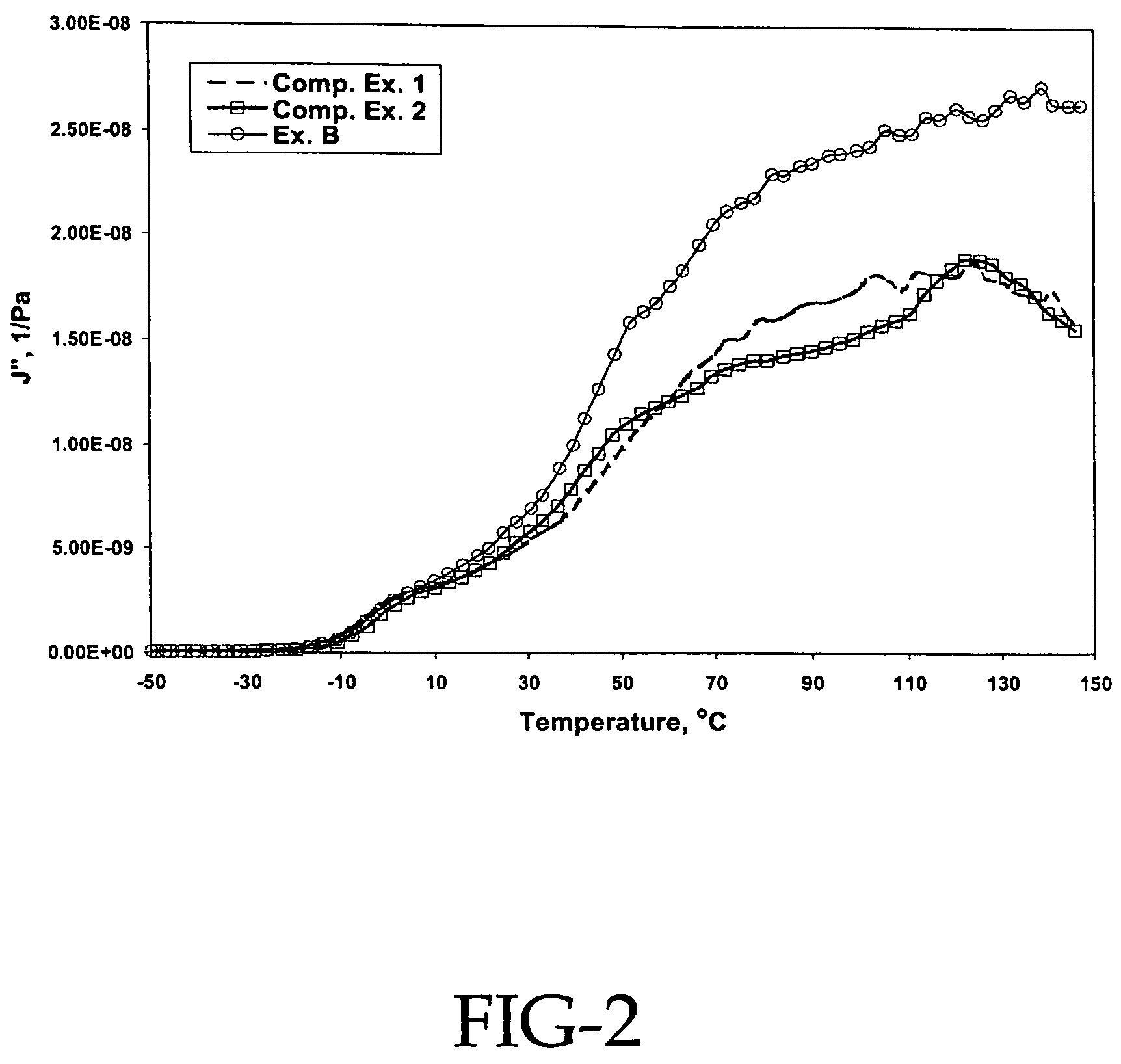

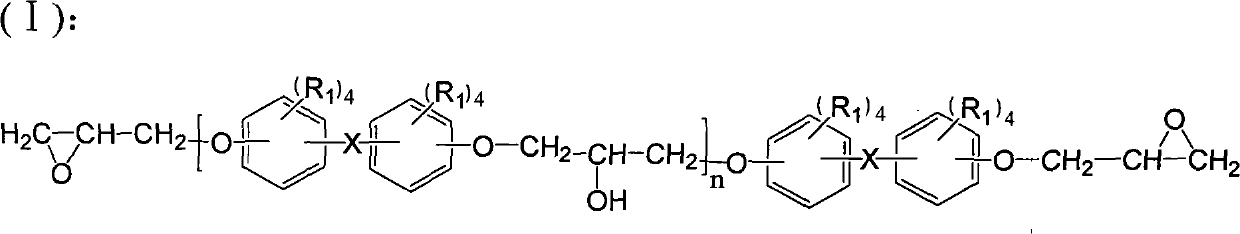

Toughened epoxy adhesive composition

ActiveUS20050209401A1High impact strengthImprove crash resistanceMacromolecular adhesive additivesEpoxy resin adhesivesAcrylonitrileEpoxy adhesive

The invention relates to an epoxy adhesive composition comprising a) a first epoxy resin, b) a second epoxy resin modified with an acrylonitrile-butadiene rubber, the latter comprising on average less than about 25 weight percent acrylonitrile, and c) a toughener. The total amount of component b) and component c) is higher than about 30 percent based on the total weight of the composition, and the weight ratio of component c) to component b) is greater than about 1:1. The invention further relates to the use of said epoxy adhesive composition for the assembly of parts of a vehicle. It also relates to a vehicle, parts of which are assembled by said epoxy adhesive composition.

Owner:DOW GLOBAL TECH LLC

Ionomer/rubber/polyolefin blend and uses thereof

A thermoplastic ionomer blend or alloy exhibiting advantageous properties upon molding or extrusion and / or thermoforming, consisting essentially of the following components:A. about 15 to 85 parts by weight of a thermoplastic copolymer containing about 91 to 80 weight percent of alpha-olefin units and about 9 to 20 weight percent of alpha, beta-ethylenically unsaturated carboxylic acid units said carboxylic acid units being about 20 to 90 percent neutralized with metal ions, preferably zinc,B. about 10 to 80 parts by weight of a rubber, preferably a thermoplastic elastomer selected from the group consisting of (a) crosslinked ethylene-propylene-diene copolymers and equivalent polyolefin copolymers such as ethylene-butene, hexene, or octene, (b) acrylonitrile-butadiene copolymers, (c) styrene-butadiene copolymers, and (d) styrene acrylonitrile graft-crosslinked butadiene rubbers, andC. about 5 to 40 parts by weight of a thermoplastic polymer selected from the group consisting of polyethylene and polypropylene copolymers and homopolymers, the total number of parts being 100,and molded or extruded and / or thermoformed products produced from the same.

Owner:LYONDELLBASELL ADVANCED POLYMERS INC

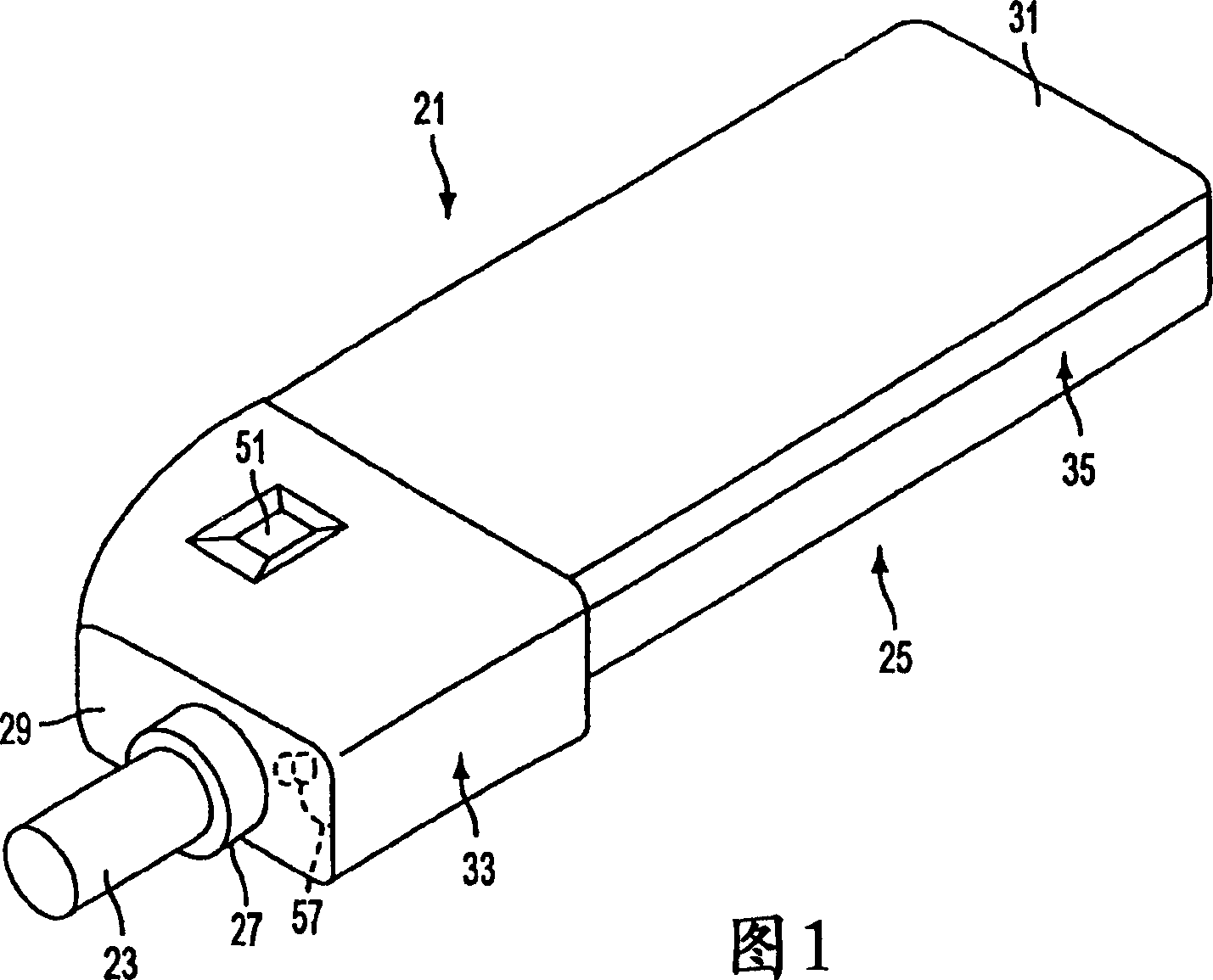

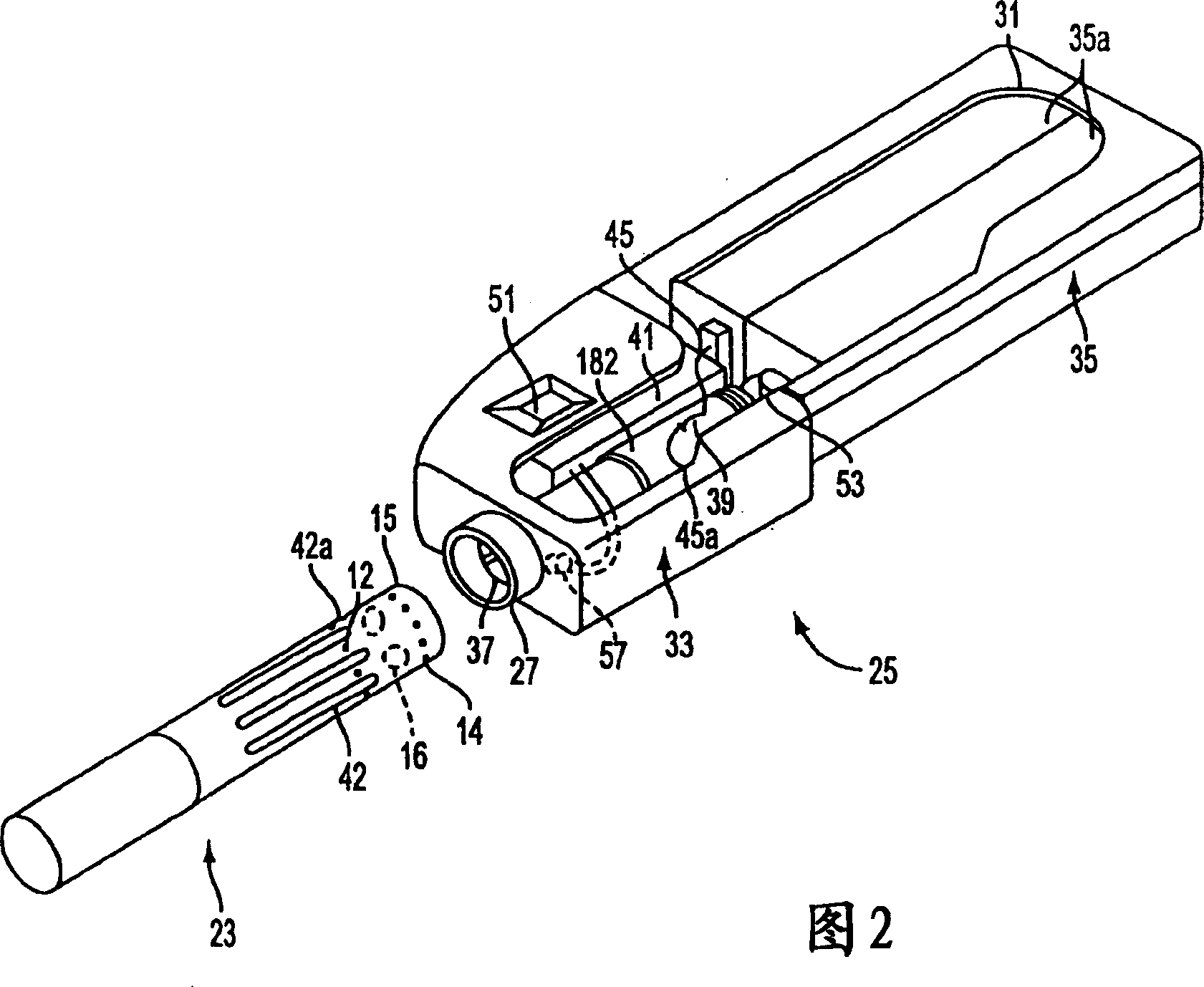

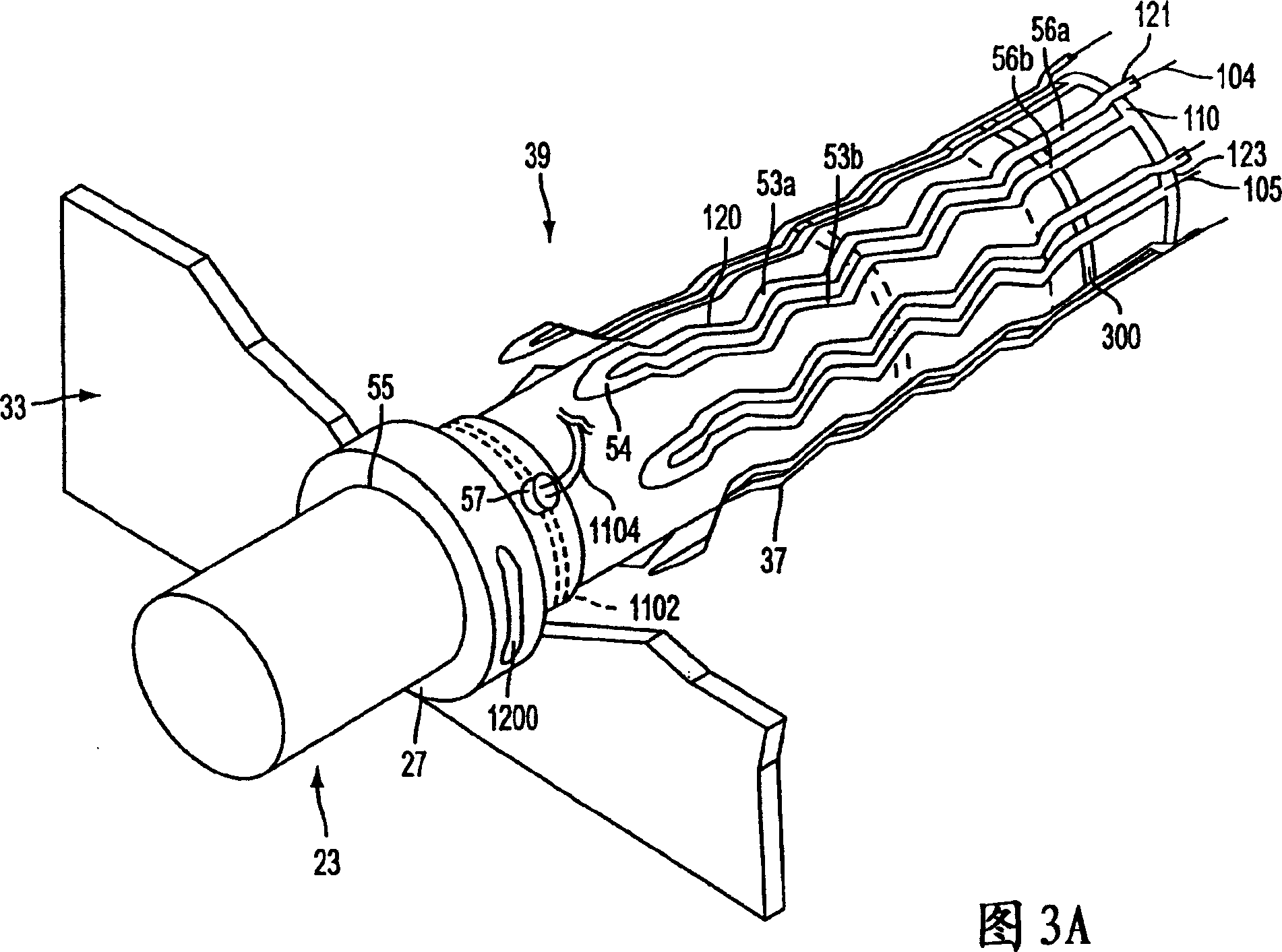

Electrical smoking system and method

InactiveCN1633247AReduce gaseous componentsIncandescent ignitionCigar manufactureIntegratorAcrylonitrile

An electric smoking system includes a cigarette including a cylindrical tobacco web partially filled with tobacco material to define a filled tobacco rod portion and an unfilled tobacco rod portion, and an electric lighter. The wrapper includes a filler of ammonium-containing compounds effective to reduce the gaseous constituents of the smoke produced during smoking. The system includes a pilot burner including at least one heating vane and a controller adapted to control heating of the heating vane. The lighter is configured to at least partially contain the cigarette such that the heater blade heats the heating region of the cigarette. Manipulating the controller to limit the heating of the heater blades to a predetermined temperature range which allows the delivery of the smoke generated when the portion of the tobacco rod is heated while at least reducing the amount of smoke present in the smoke as compared to smoking a cigarette having only calcium carbonate as filler. A gaseous component. The gaseous components that can be reduced include carbon monoxide, 1,3 butadiene, isoprene, acrolein, acrylonitrile, hydrogen cyanide, 0-toluidine, 2-naphthylamine, nitrogen oxide, benzene, NNN, Phenol, catechol, benzanthracene and benzopyrene.

Owner:PHILIP MORRIS PROD SA

Macroscopic fiber comprising single-wall carbon nanotubes and acrylonitrile-based polymer and process for making the same

InactiveUS20050100501A1Good orientationIncrease modulusMaterial nanotechnologyElectroconductive/antistatic filament manufactureVitrificationPolymer science

The present invention relates to a high modulus macroscopic fiber comprising single-wall carbon nanotubes (SWNT) and an acrylonitrile-containing polymer. In one embodiment, the macroscopic fiber is a drawn fiber having a cross-sectional dimension of at least 1 micron. In another embodiment, the acrylonitrile polymer-SWNT composite fiber is made by dispersing SWNT in a solvent, such as dimethyl formamide or dimethyl acetamide, admixing an acrylonitrile-based polymer to form a generally optically homogeneous polyacrylonitrile polymer-SWNT dope, spinning the dope into a fiber, drawing and drying the fiber. Polyacrylonitrile / SWNT composite macroscopic fibers have substantially higher modulus and reduced shrinkage versus a polymer fiber without SWNT. A polyacrylonitrile / SWNT fiber containing 10 wt % SWNT showed over 100% increase in tensile modulus and significantly reduced thermal shrinkage compared to a control fiber without SWNT. With 10 wt % SWNT, the glass transition temperature of the polymer increased by more than 40° C.

Owner:GEORGIA TECH RES CORP

Cement compositions containing flexible, compressible beads and methods of cementing in subterranean formations

Cement compositions comprising flexible, compressible beads, processes for preparing such cement compositions, and methods of cementing in subterranean formations using such cement compositions. One or more flexible, compressible beads are mixed with the cement before pumping the cement into a well bore. The flexible, compressible beads are preferably composed of an elastomeric material such as a copolymer of methylmethacrylate and acrylonitrile; a terpolymer of methylmethacrylate, acrylonitrile, and dichloroethane; a styrene-divinylbenzene copolymer; and polystyrene. The flexible, compressible beads may be heated to expand the beads before mixing with the cement such that the ensuing cement composition will have a desired density. Non-flexible beads such as spherulites may also be added to the cement compositions.

Owner:REDDY B RAGHAVA +2

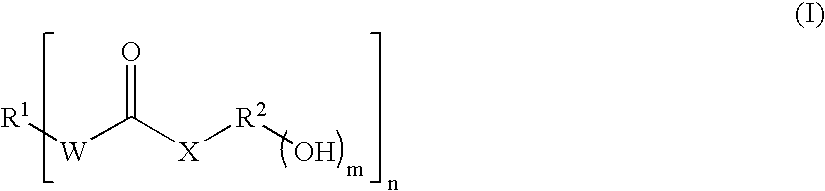

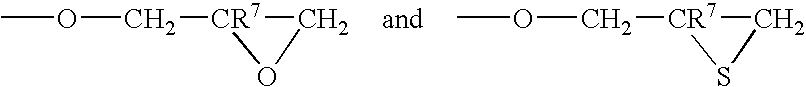

High-toughness photosensitive resin for 3D printing and preparation method thereof.

The invention provides a high-toughness photosensitive resin for 3D printing and a preparation method thereof. The photosensitive resin comprises a photosensitive resin (maleable photosensitive resin and rigid photosensitive resin), an active diluent, a light initiator and an additive. The method first synthesizes the toughness photosensitive resin (maleable polyurethane acrylate and epoxy modified polyurethane), and then the maleable photosensitive resin is mixed with the rigid photosensitive resin, active diluent, light initiator and additive. The maleable photosensitive resin is prepared from a polymer soft segment, which is a mixture of one or more selected from of polypropyleneoxide glycol ether, PTMG, hydroxyl-terminated polybutadiene, hydroxyl-terminated styrene butadiene rubber, hydroxyl-terminated butadiene acrylonitrile rubber and hydroxyl-terminated polysiloxane, and a polymer hard segment of toluene diisocyanate or isophorone diisocyanate, through hydroxyethyl acrylate or epoxypropanol termination. The photosensitive resin is applicable to DLP or SLA type 3D printers for modification of the existing 3D printing photosensitive resin, has excellent bending strength, and can directly print out elastic models.

Owner:QINGDAO UNIV OF SCI & TECH

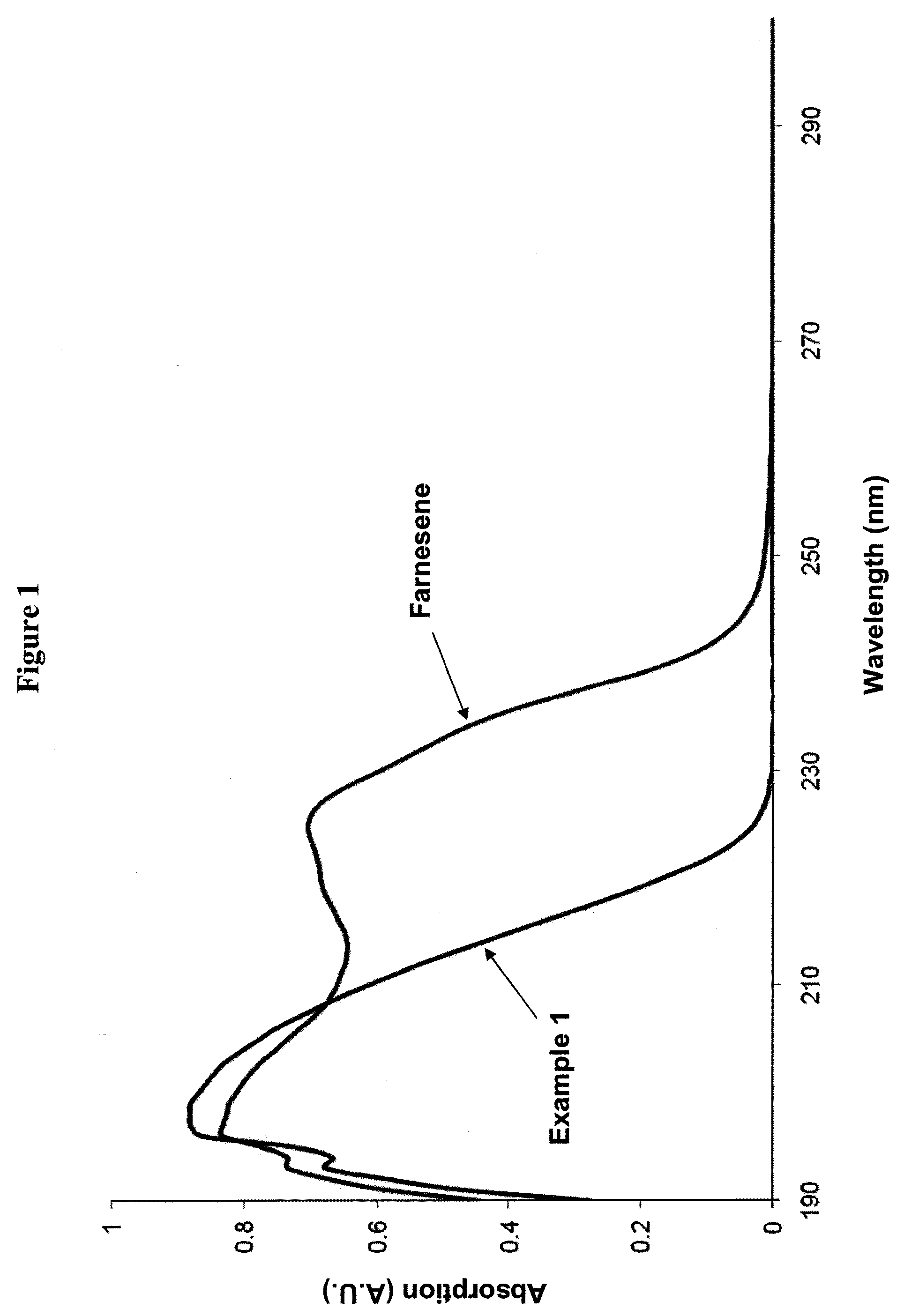

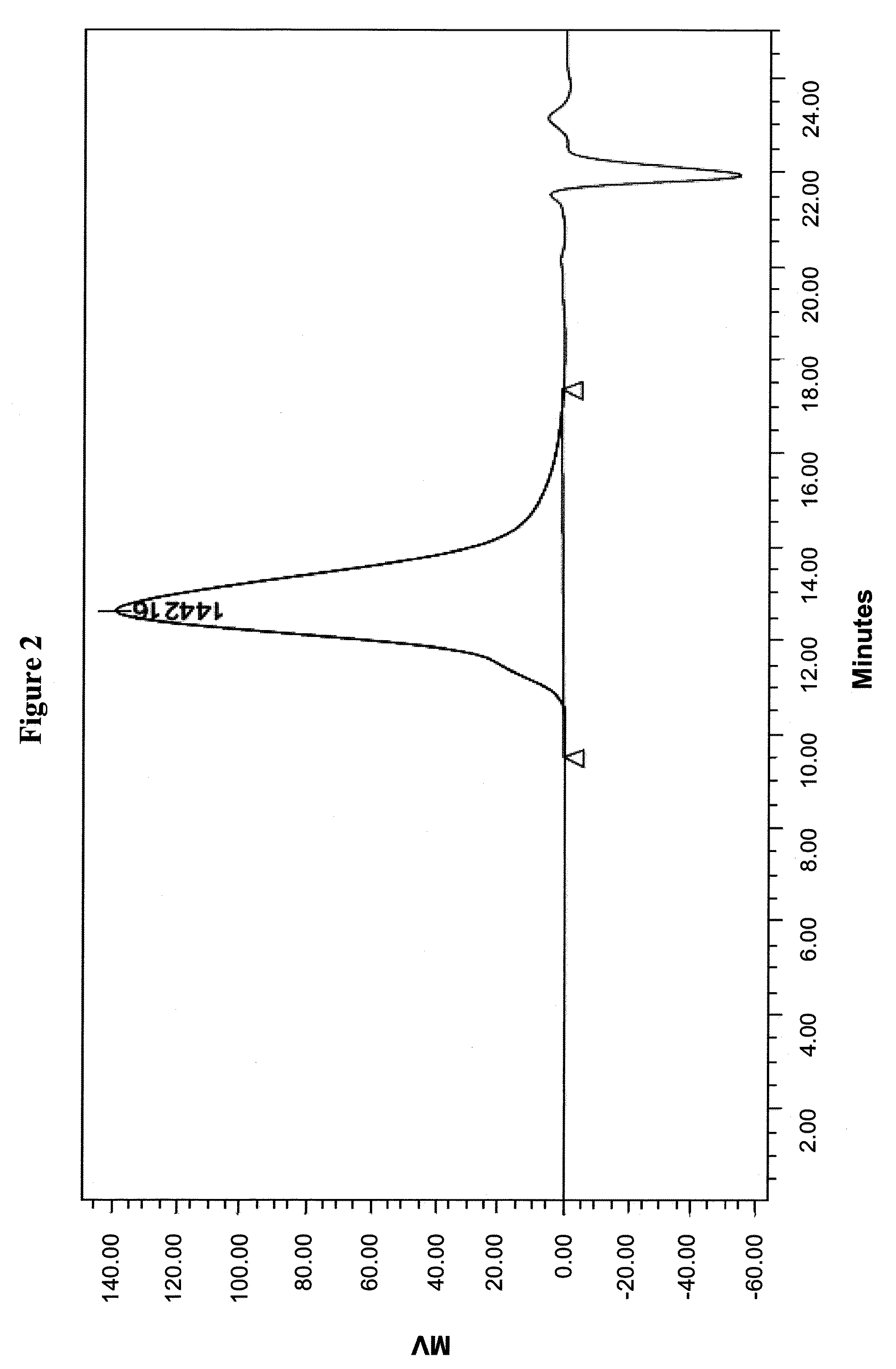

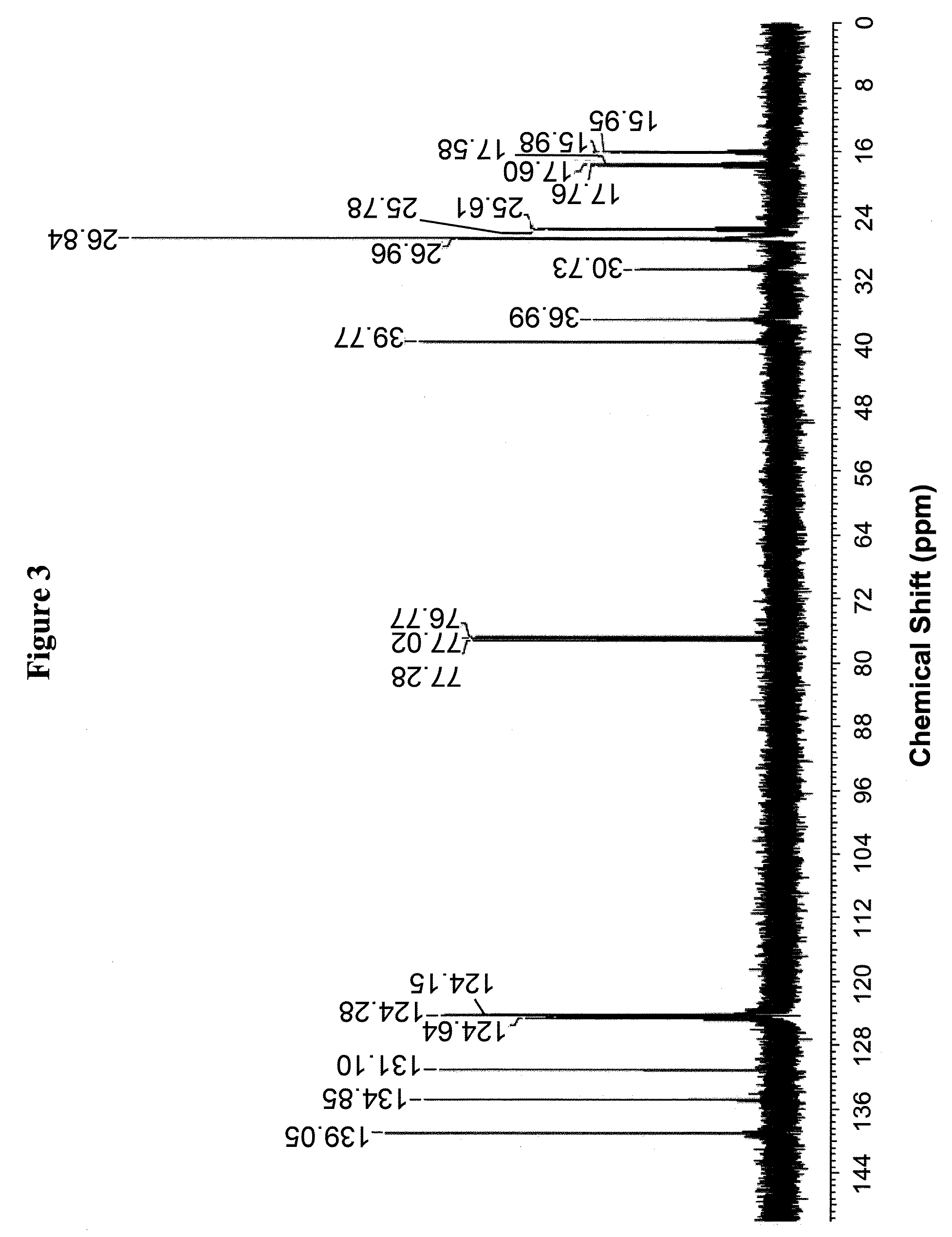

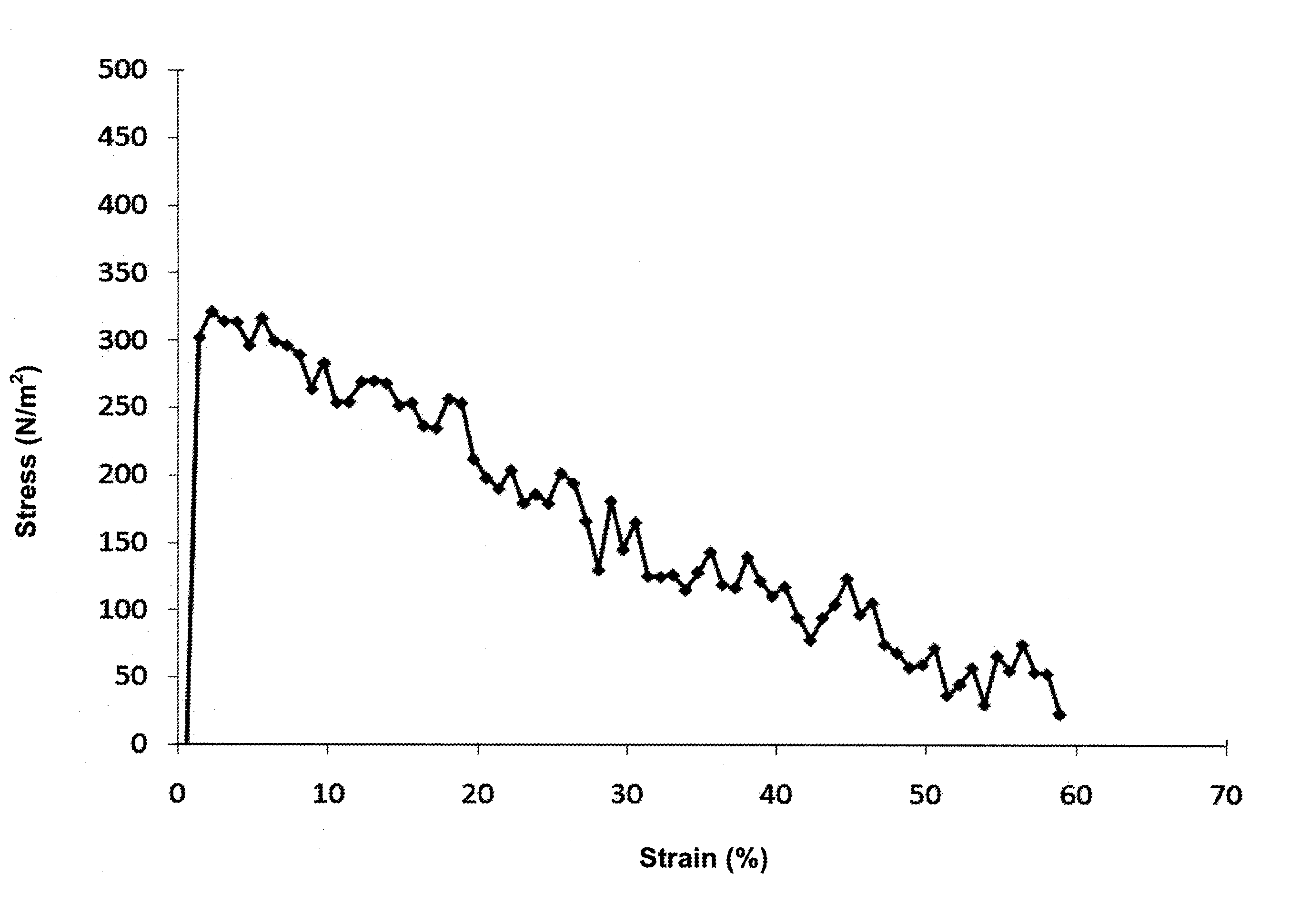

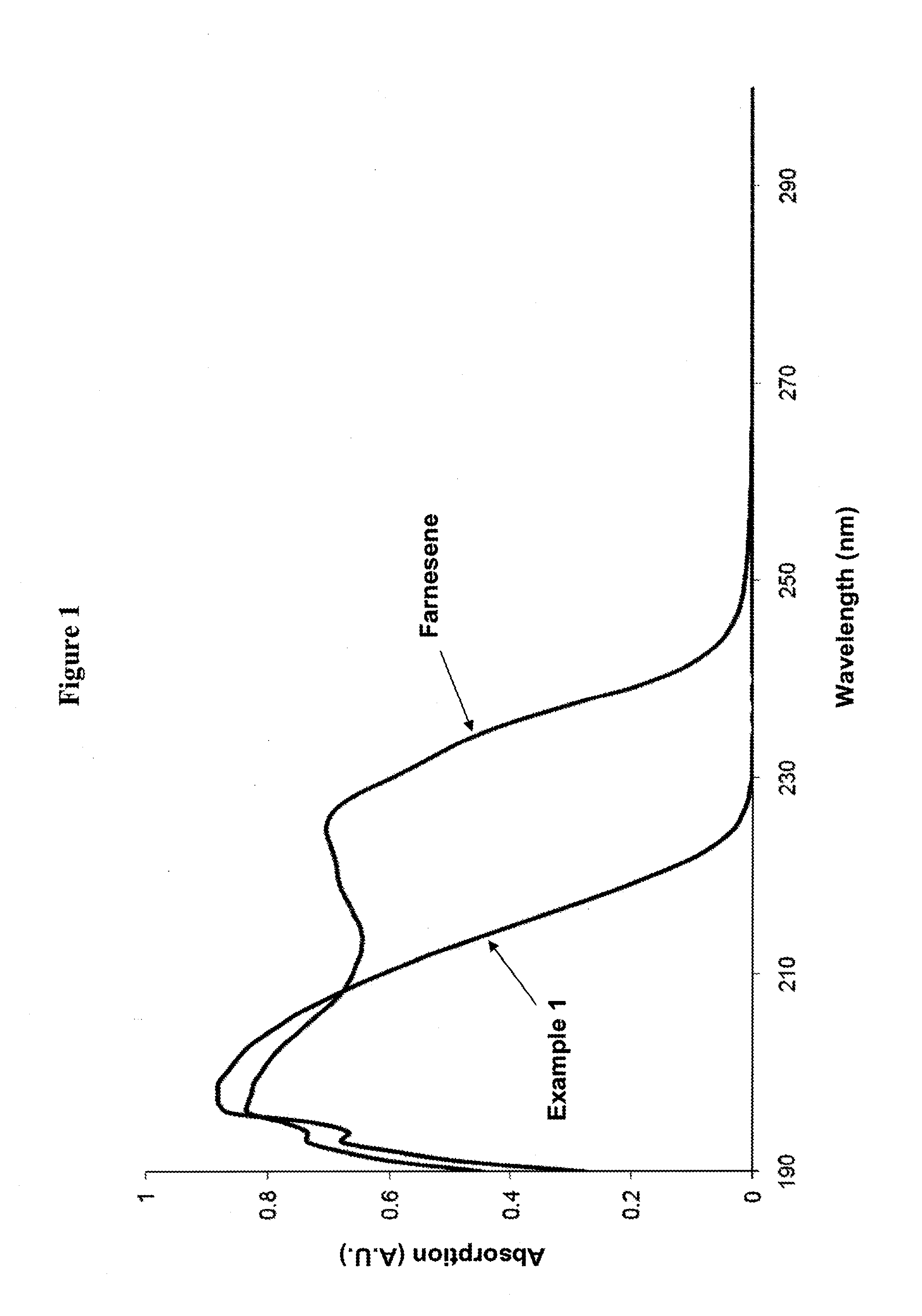

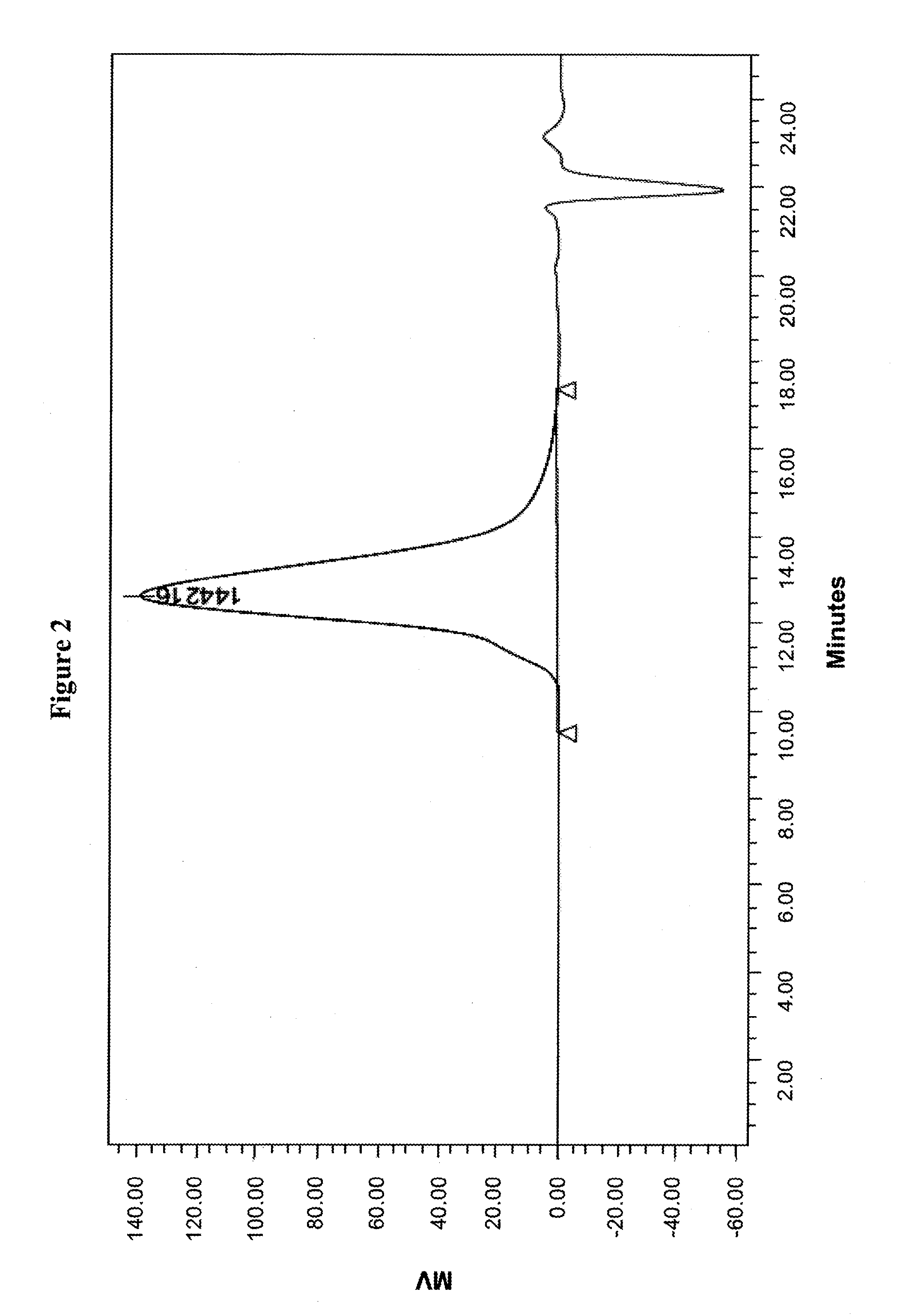

Farnesene interpolymers

Farnesene interpolymer comprises units derived from a farnesene (e.g., α-farnesene or β-farnesene) and units derived from at least one vinyl monomer. The farnesene interpolymer can be prepared by copolymerizing the farnesene and at least one vinyl monomer in the presence of a catalyst. In some embodiments, the farnesene is prepared from a sugar by using a microorganism. In other embodiments, the at least one vinyl monomer is ethylene, an α-olefin, or a substituted or unsubstituted vinyl halide, vinyl ether, acrylonitrile, acrylic ester, methacrylic ester, acrylamide or methacrylamide, or a combination thereof.

Owner:AMYRIS INC

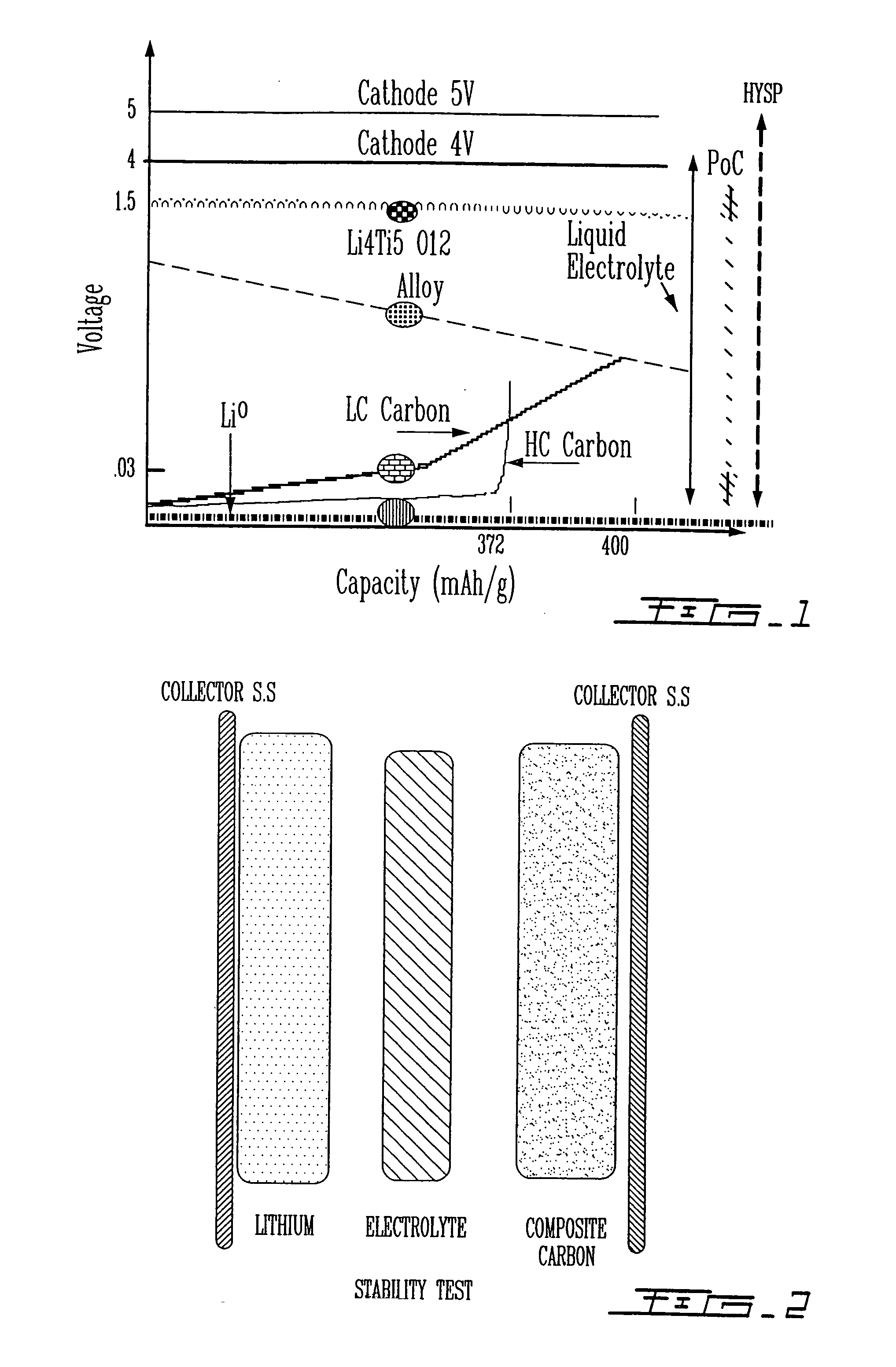

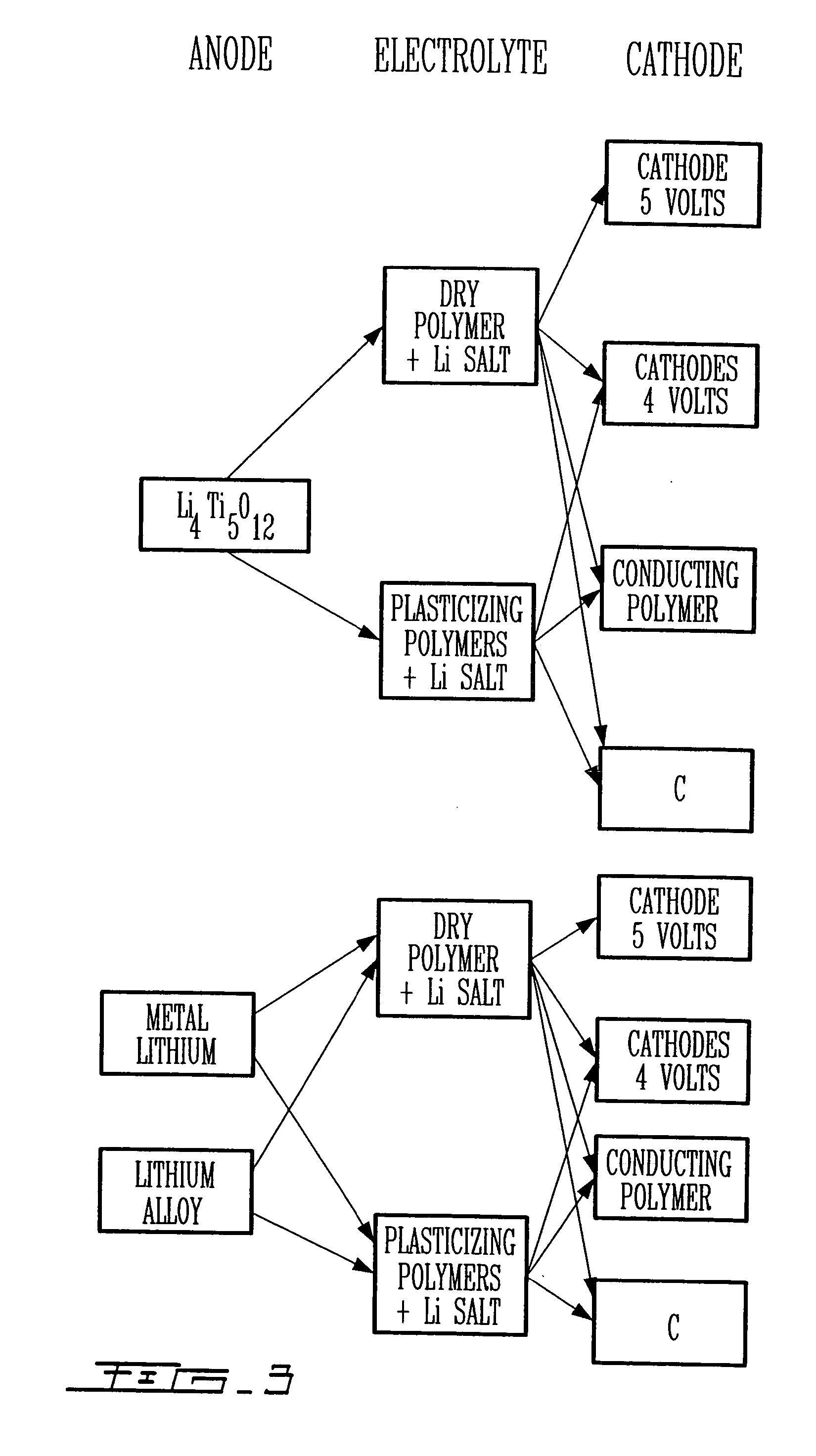

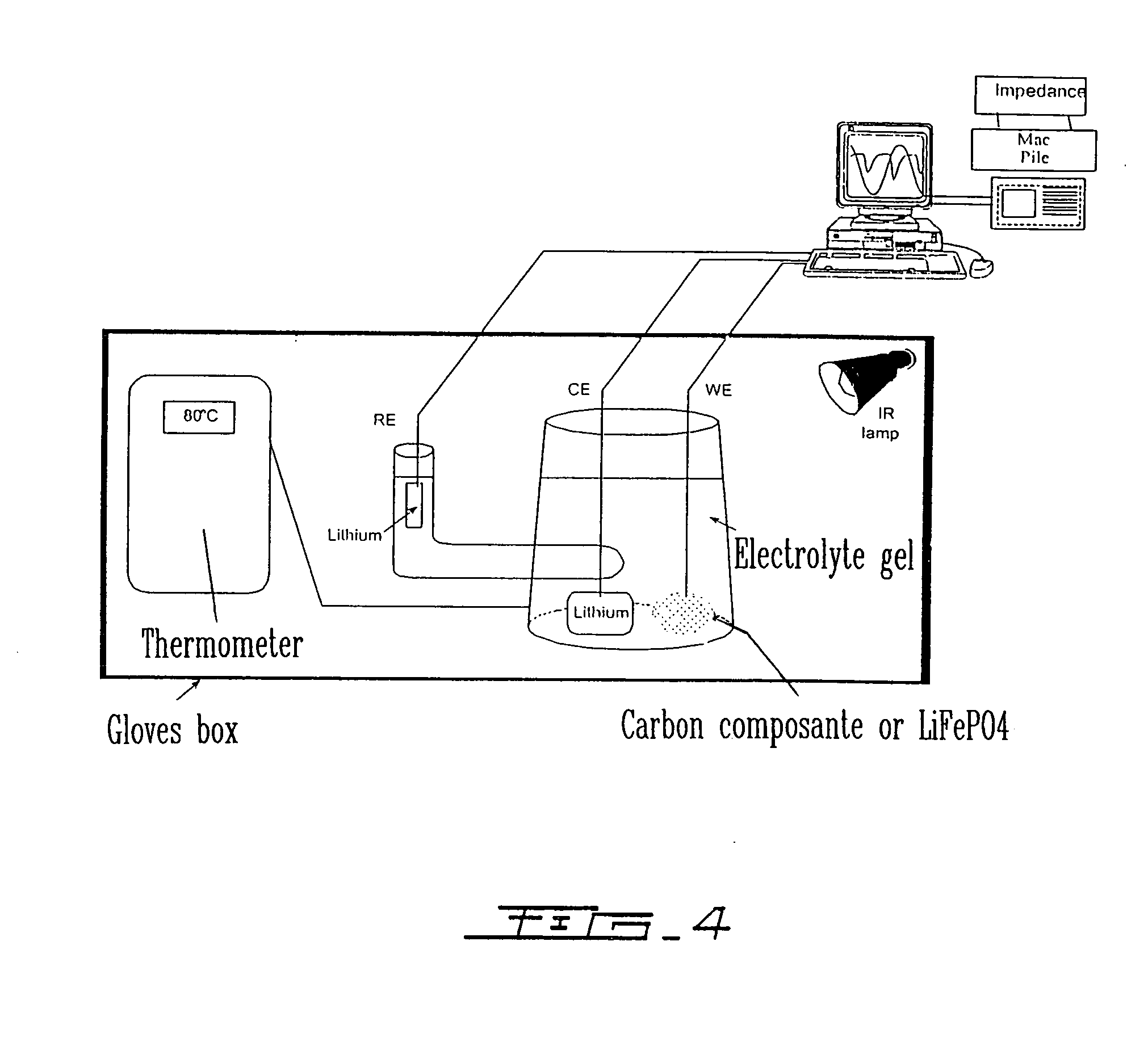

Highly-stable polymeric electrolyte and use thereof in electrochemical systems

ActiveUS20050234177A1Hybrid capacitor electrolytesHybrid capacitor electrodesPolymer electrolytesElectrolysis

Polymer electrolyte for an electrochemical generator based on at least a four branched polymer, at least a poly(vinylyldienefluoride), a poly(vinyldiene fluoro-co-hexafluoropropene copolymer), a poly(tetrafluoroethylene), a poly(ethylene-co-propylene-co-5-methylene-2-norbornene) or an ethylene propylene-diene copolymer, a polyol, a poly(methylmethacrylate, a poly(acrylonitrile), SiO2Al2O3, or nano TiO2 non coated or coated with an organic material. This electrolyte allows to prepare electrolytic compositions that can be used in high performance electrochemical devices.

Owner:HYDRO QUEBEC CORP

Coating composition, process for preparing coating composition and process for preparing dispersing component of inorganic oxide sol

InactiveUS6022919AGood weather resistanceLow appearance requirementsSpecial tyresMixingMeth-Acrylonitrile

A coating composition which comprises (A) a resin having a glass transition temperature of 50 to 120 DEG C., a number average molecular weight of 2,000 to 100,000, a hydroxyl value of 50 to 150 mgKOH / g and an acid value of 1 to 25 mgKOH / g, which is produced by copolymerizing 10 to 90 percent by weight of (a) a (meth)acrylic acid ester of a C1 to C12 alkyl alcohol, 10 to 50 weight % of (b) a first polymerizable double bond-containing and hydroxyl group-containing monomer, 0.1 to 10 weight % of (c) a polymerizable double bond-containing and carboxyl group-containing monomer, 0 to 20 weight % of (d) styrene, 0 to 20 weight % of (e) acrylonitrile and 0 to 10 weight of (f) a second polymerizable double bond-containing monomer, (B) at least one compound selected from the group consisting of a polyisocyanate compound having two or more unblocked isocyanate groups and / or blocked isocyanate groups in the molecule and an aminoplast resin, (C) a dispersing component of at least one inorganic oxide sol selected from the group consisting of an aluminum oxide sol, a silica sol, a zirconium oxide sol and an antimony oxide sol, wherein an amount of a nonvolatile matter of component (C) is 5 to 60 percent by weight based on a total amount of nonvolatile matter of resin (A), compound (B) and component (C). The coating composition provides cured films having excellent weathering resistance, light resistance, stain resistance, stain-removing property, chemical resistance, moisture resistance and appearance and is environmentally friendly and safe.

Owner:BASF NOF COATINGS CO LTD

Non-halogen flame-retardant polypropylene composite material and preparation thereof

InactiveCN101412830AImprove flame retardant performanceImprove mechanical propertiesFlexural modulusAcrylonitrile

The invention provides a halogen-free flame-retardant polypropylene composite material, which is characterized by consisting of the following raw materials in weight portion: 82.5 to 12 portions of polypropylene, 0.3 to 2 portions of heat stabilizer, 0.2 to 1 portion of processing aid, 1 to 10 portions of toughening agent, 10 to 40 portions of flame retardant, 1 to 5 portions of glass fiber compatibilizer and 5 to 30 portions of glass fiber. The invention also provides a method for preparing the material. The material has the flame retardancy up to 1.6mm V0, the tensile strength higher than or equal to 50 MPa, the flexural modulus higher than or equal to 3,000 MPa, the notched impact strength more than or equal to 8KJ / m<2>, the shrinkage between 4 and 6 per thousand, the heat distortion temperature higher than or equal to 140 DEG C, as well as the other technical indexes up to or exceeding the standard of flame-retardant acrylonitrile-butadiene-styrene copolymer materials. As the material uses the phosphorus-nitrogen flame retardant containing no halogen, the flame-retardant effect of the material completely reaches UL94-V0 grade.

Owner:SHANGHAI KINGFA SCI & TECH +1

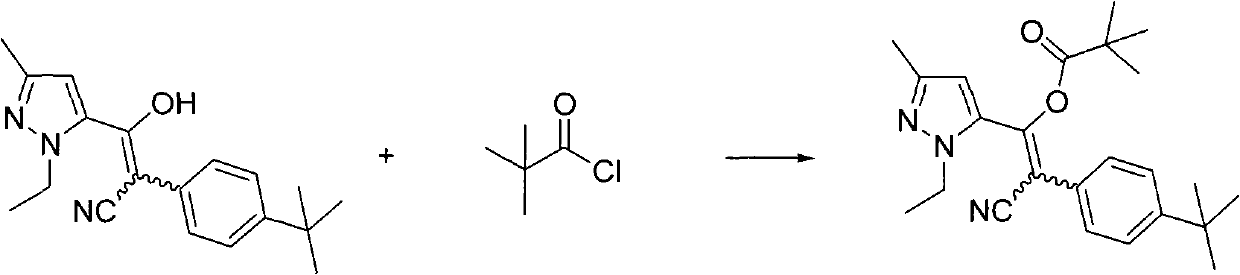

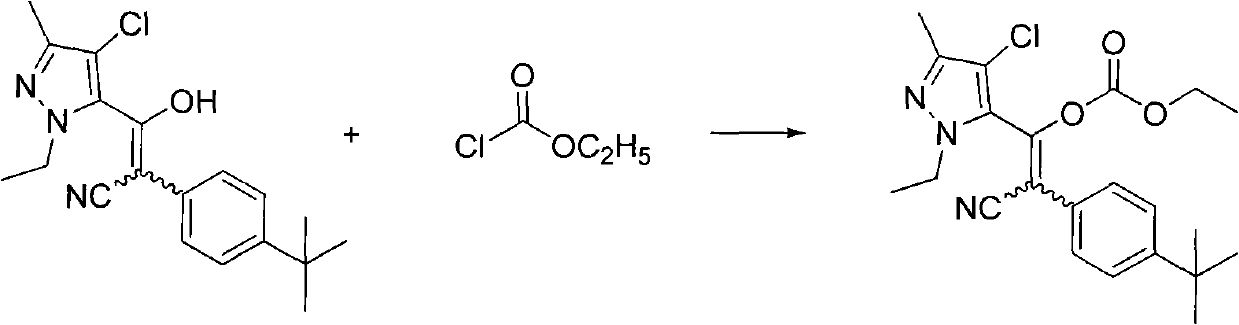

Pyrazolyl acrylonitrile compound and application thereof

The invention discloses a pyrazolyl acrylonitrile compound with a novel structure. The structure of the compound is shown as the general formula I, and in the formula, the definitions of substituent groups are specified in the specification. The compound with the general formula I has excellent activity for killing insects and mites and can be used for preventing insect pest and mites.

Owner:SHENYANG SINOCHEM AGROCHEMICALS R&D CO LTD

Adhesive compositions comprising a polyfarnesene

Adhesive composition comprises a polyfarnesene and a tackifier. The polyfarnesene can be a farnesene homopolymer derived from a farnesene (e.g., α-farnesene or β-farnesene) or a farnesene interpolymer derived from a farnesene and at least a vinyl monomer. In some embodiments, the at least one vinyl monomer is ethylene, an α-olefin such as styrene, or a substituted or unsubstituted vinyl halide, vinyl ether, acrylonitrile, acrylic ester, methacrylic ester, acrylamide or methacrylamide, or a combination thereof. The composition disclosed herein can be used as a hot melt adhesive, a pressure sensitive adhesive or the like.

Owner:AMYRIS INC

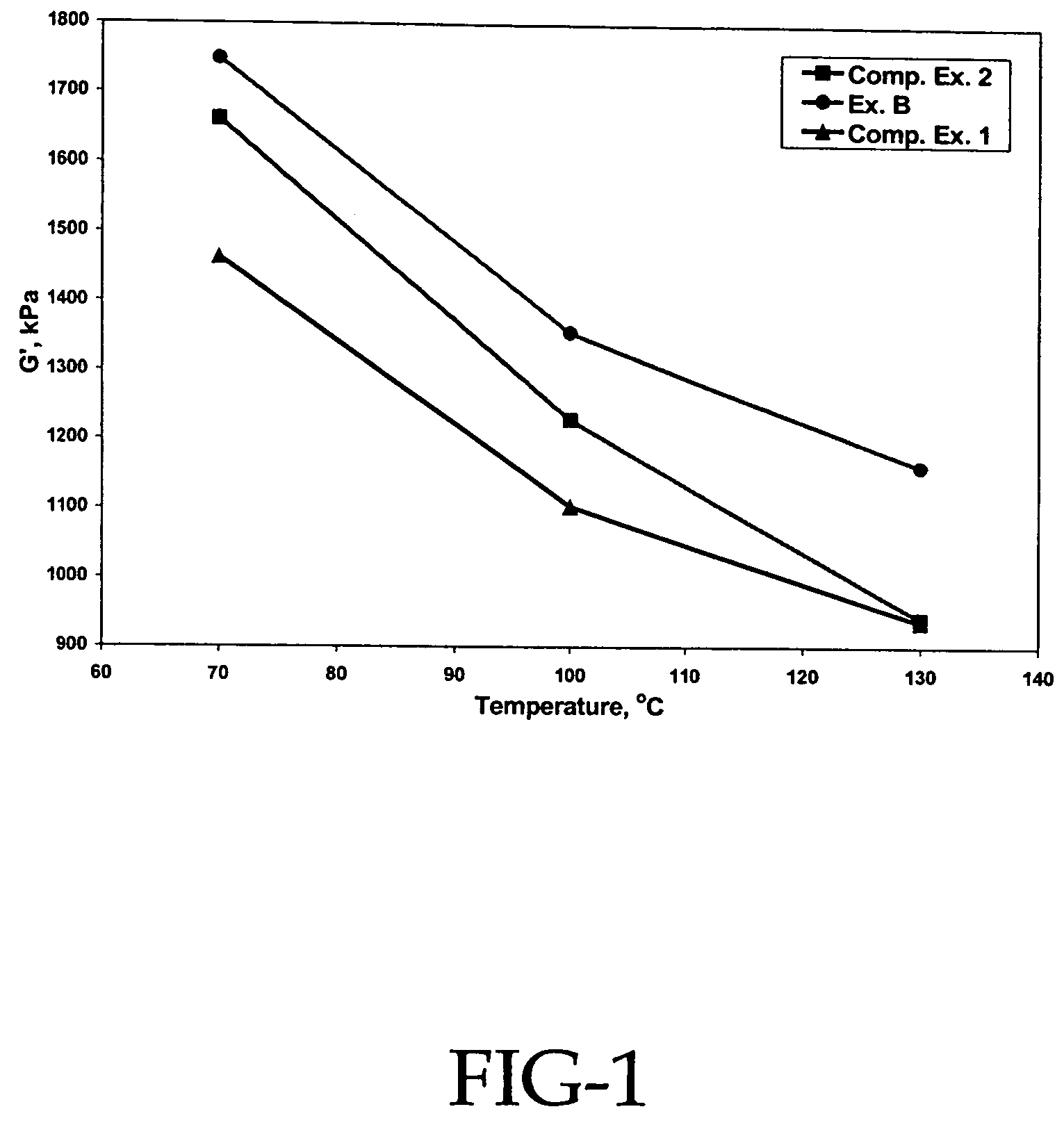

Rubber composition containing resinous nanoparticle

InactiveUS7347237B2Deteriorate controllabilityDeteriorate stabilitySpecial tyresInflatable tyresElastomerEngineering

Owner:THE GOODYEAR TIRE & RUBBER CO

Modified rubber powder and its prepn and use

InactiveCN1974621ALow costReduce noiseNon-macromolecular adhesive additivesOther chemical processesRubber materialChemical reaction

The present invention relates to modified rubber powder and its preparation process and use. Structurally, the modified rubber powder has alkyl group, alkenyl group, hydroxyl group, carboxyl group, nitrile group or amino group in the side chain or has side chain connected via double bond reaction to butadiene, polystyrene, vinyl acetate, acrylate, acrylonitrile or other compound. The modified rubber powder has the structural features of rubber retained and thus excellent mechanical performance, physical and chemical performance and machining performance. The introduction of functional group to the side chain results in obviously raised compatibility with other rubber material, plastic and other polymer material, easy grafting reaction and functional group chemical reaction for further modification. In addition, the performances may be regulated via altering the sort and amount of the introduced functional groups.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

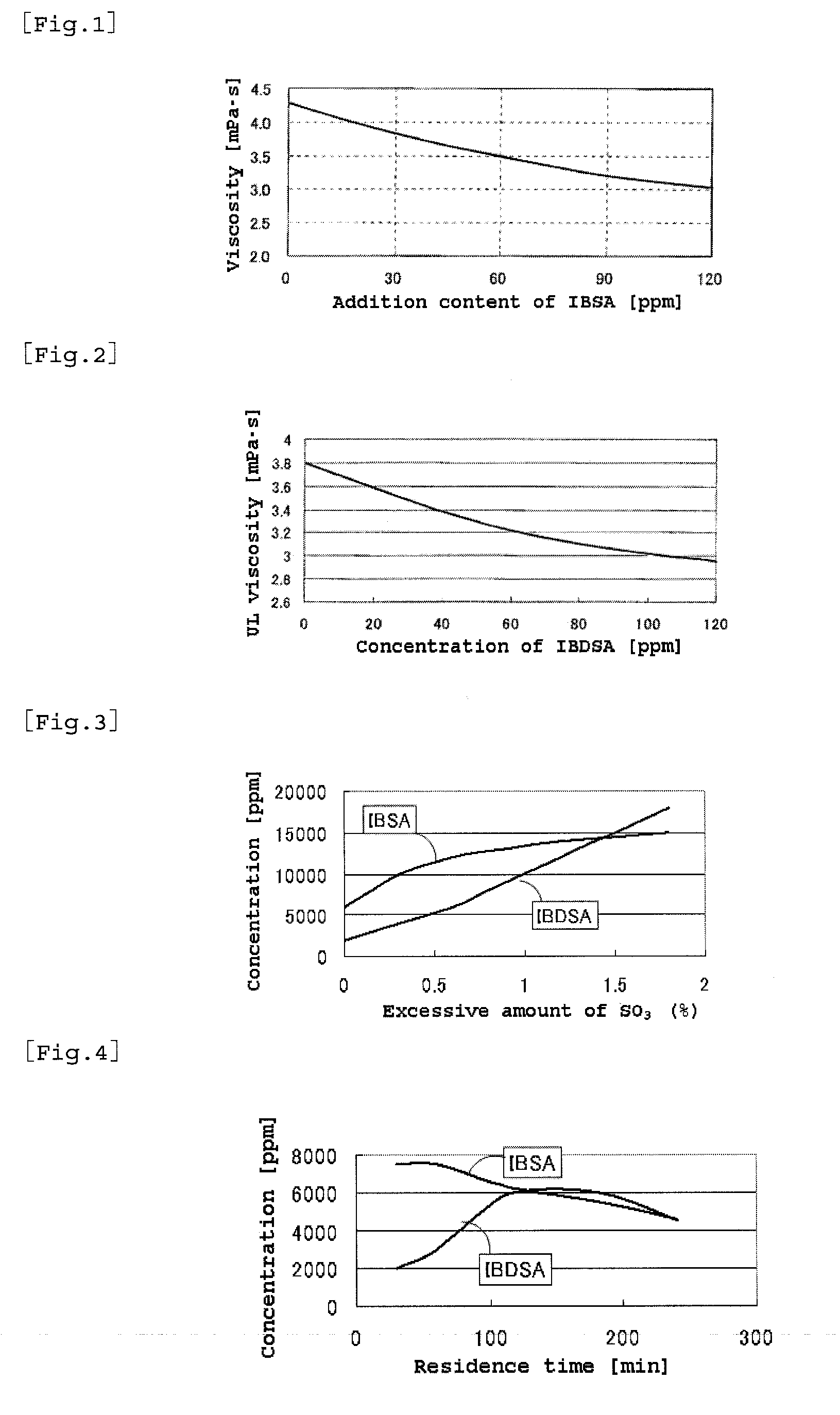

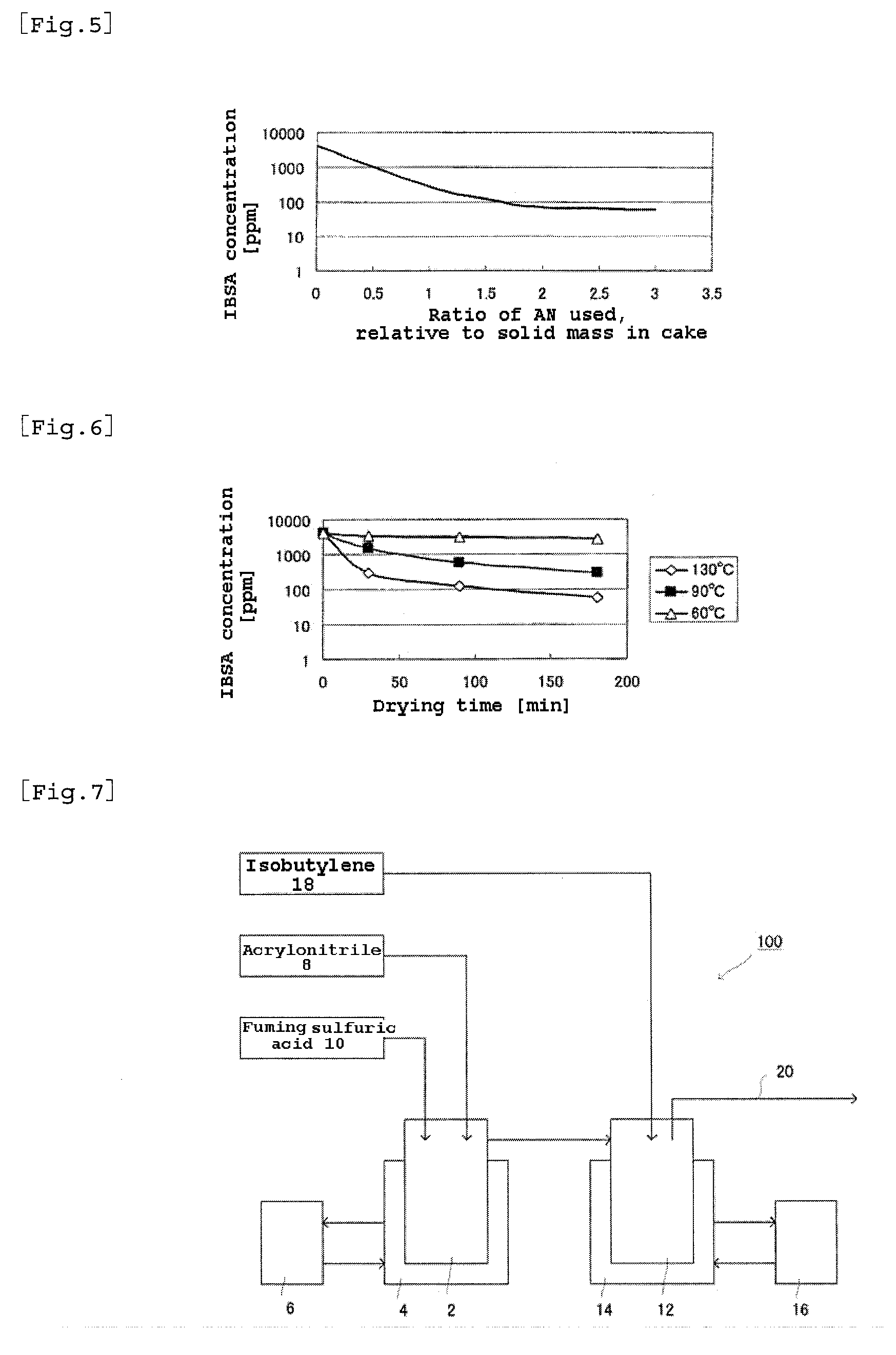

2-acrylamide-2-methylpropanesulfonic acid and process for producing the same

ActiveUS20100274048A1Large molecular weightHigh purityOrganic compound preparationSulfonic acid preparationSulfur trioxideMethyl group

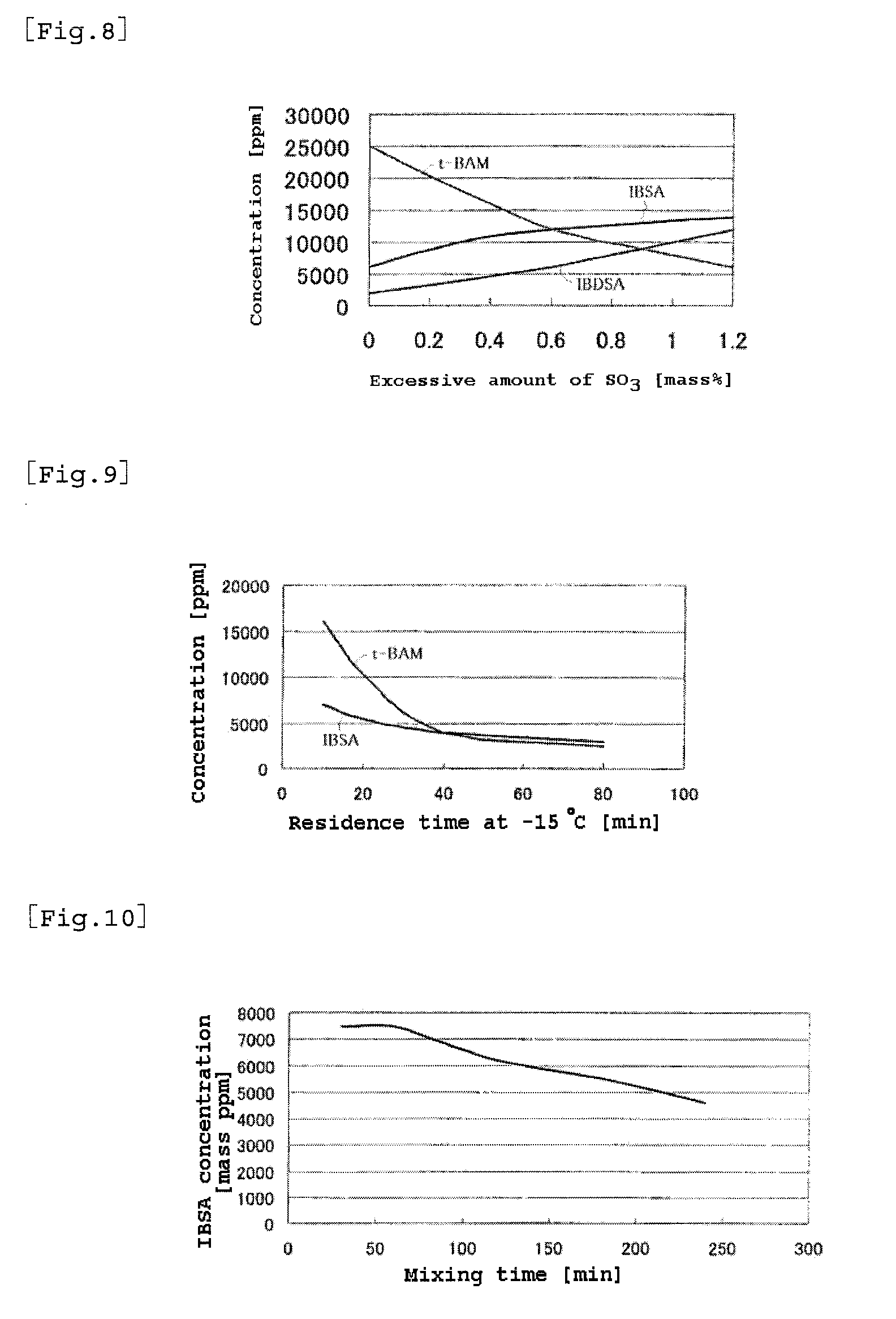

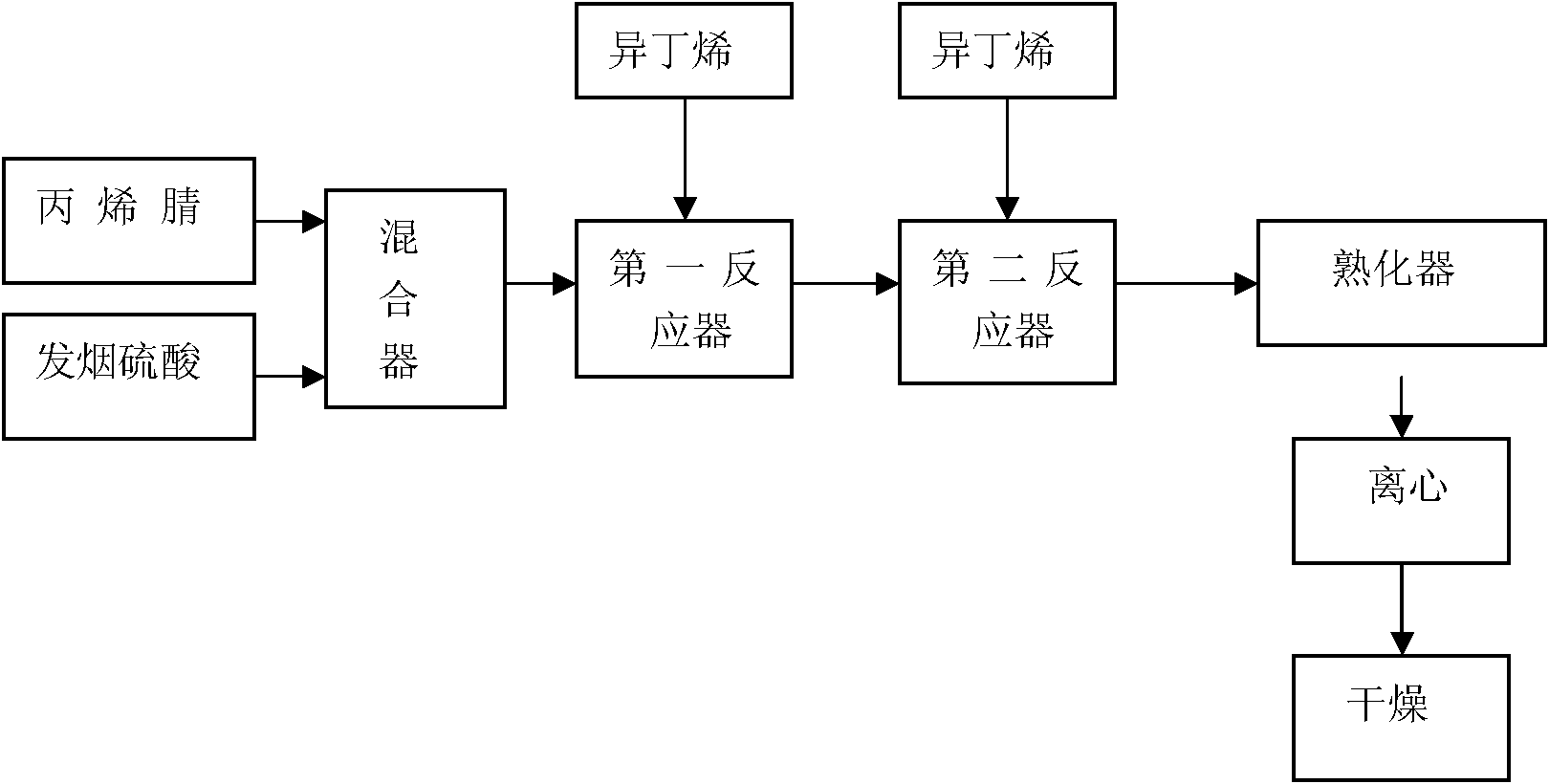

A process for producing 2-acrylamide-2-methyl propane sulfonic acid (ATBS) which comprises reacting acrylonitrile, fuming sulfuric acid, and isobutylene. During the reaction, the concentration of 2-methyl-2-propenyl-1-sulfonic acid (IBSA) and / or that of 2-methylidene-1,3-propylenedisulfonic acid (IBDSA) in the reaction system are determined. When the IBSA concentration exceeds 12,000 mass ppm and / or the IBDSA concentration exceeds 6,000 mass ppm, then the concentration of sulfur trioxide in the reaction system is reduced. Thus, ATBS having an IBSA content of 100 mass ppm or lower and an IBDSA content of 100 mass ppm or lower is produced.

Owner:TOAGOSEI CO LTD

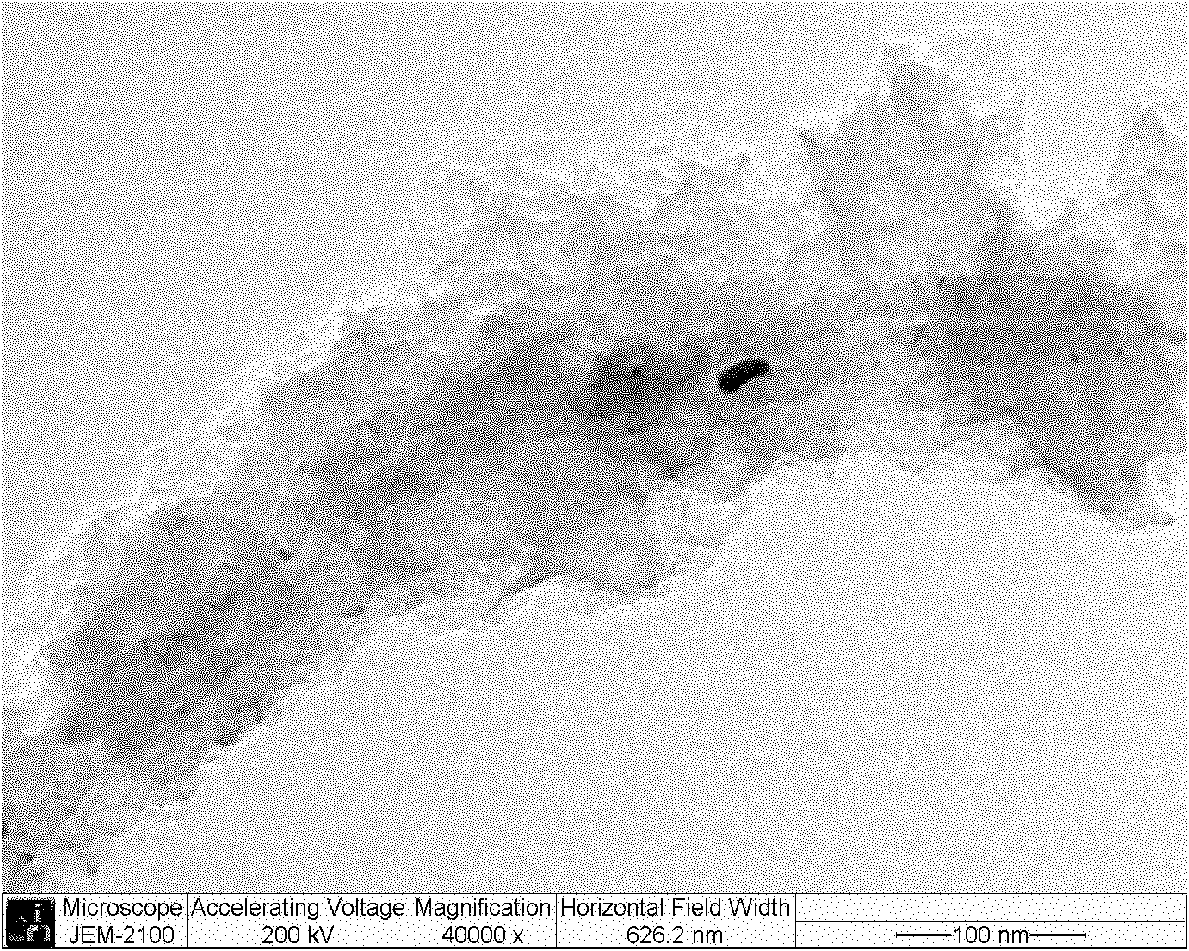

Synthesis process for 2-acrylamido-2-methyl propane sulfonic acid through continuous method

InactiveCN102351744AStable ratioStrong reaction stabilitySulfonic acid preparationFirst-order reactionAcrylonitrile

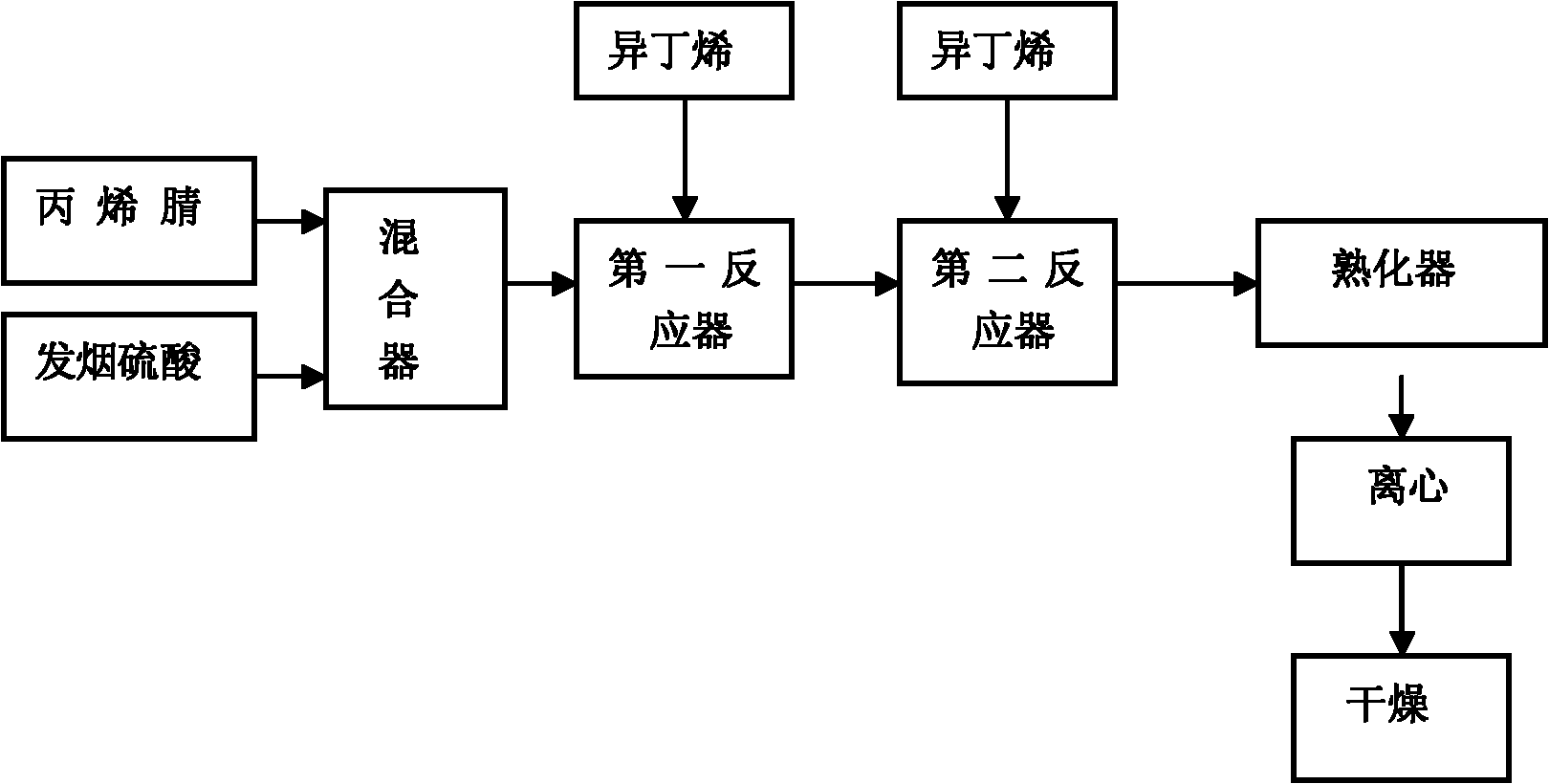

The invention discloses a synthesis process for 2-acrylamido-2-methyl propane sulfonic acid through a continuous method. The synthesis process comprises the following steps of: continuously and uniformly mixing acrylonitrile and fuming sulfuric acid at the temperature of 10-12 DEG C; performing first order reaction and second order reaction at the temperature of 20-45 DEG C under a condition of introducing vaporized isobutene; and slaking, centrifuging and drying to continuously produce the 2-acrylamido-2-methyl propane sulfonic acid product. By designing unique first order reaction, second order reaction and slaking flow, completeness degree of reaction of the material is guaranteed, the product yield and the quality stability are improved, and the reaction period is greatly shortened. The synthesis process has the advantages of scientific and rational flow design, practicability, product yield of over 96 percent and liquid phase detection purity of over 96 percent.

Owner:WEIFANG QUANXIN CHEM

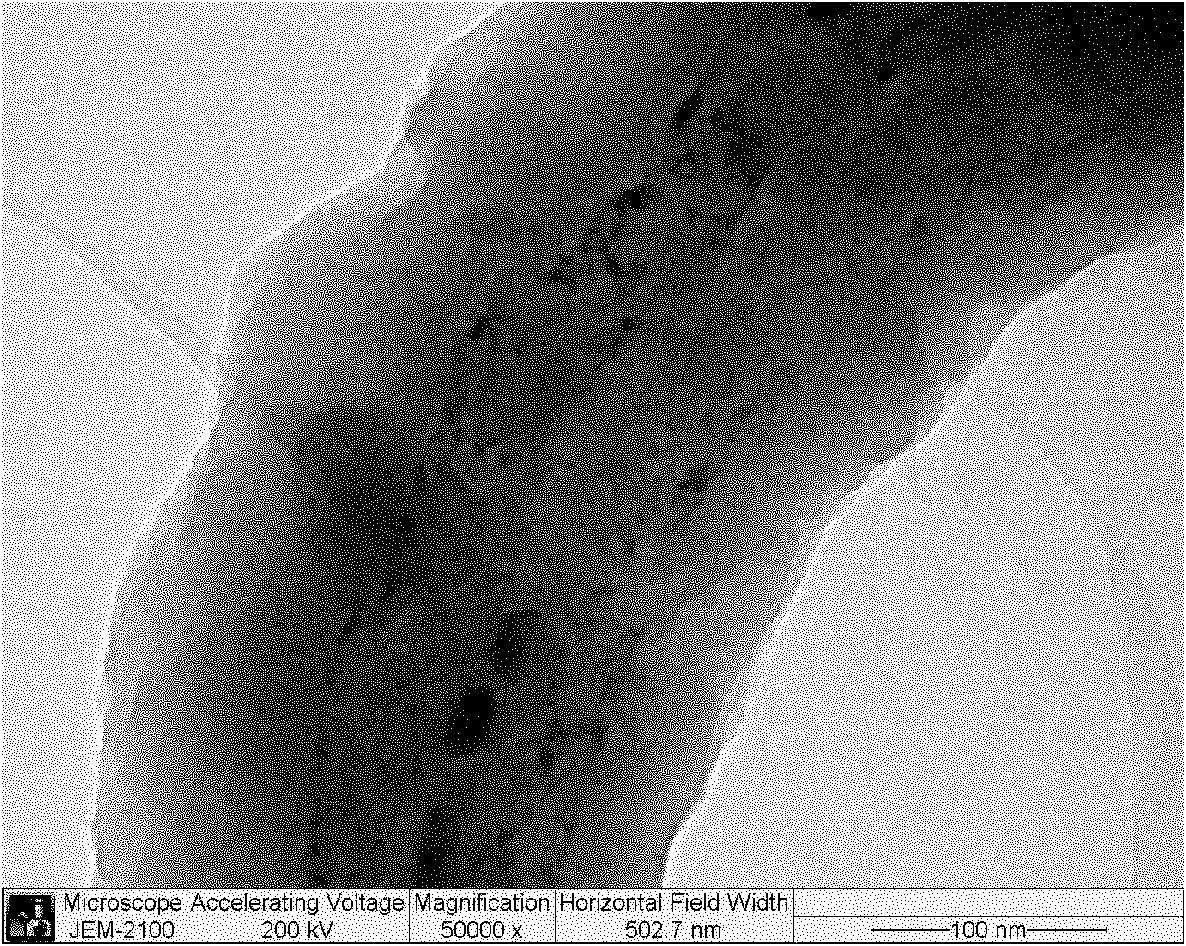

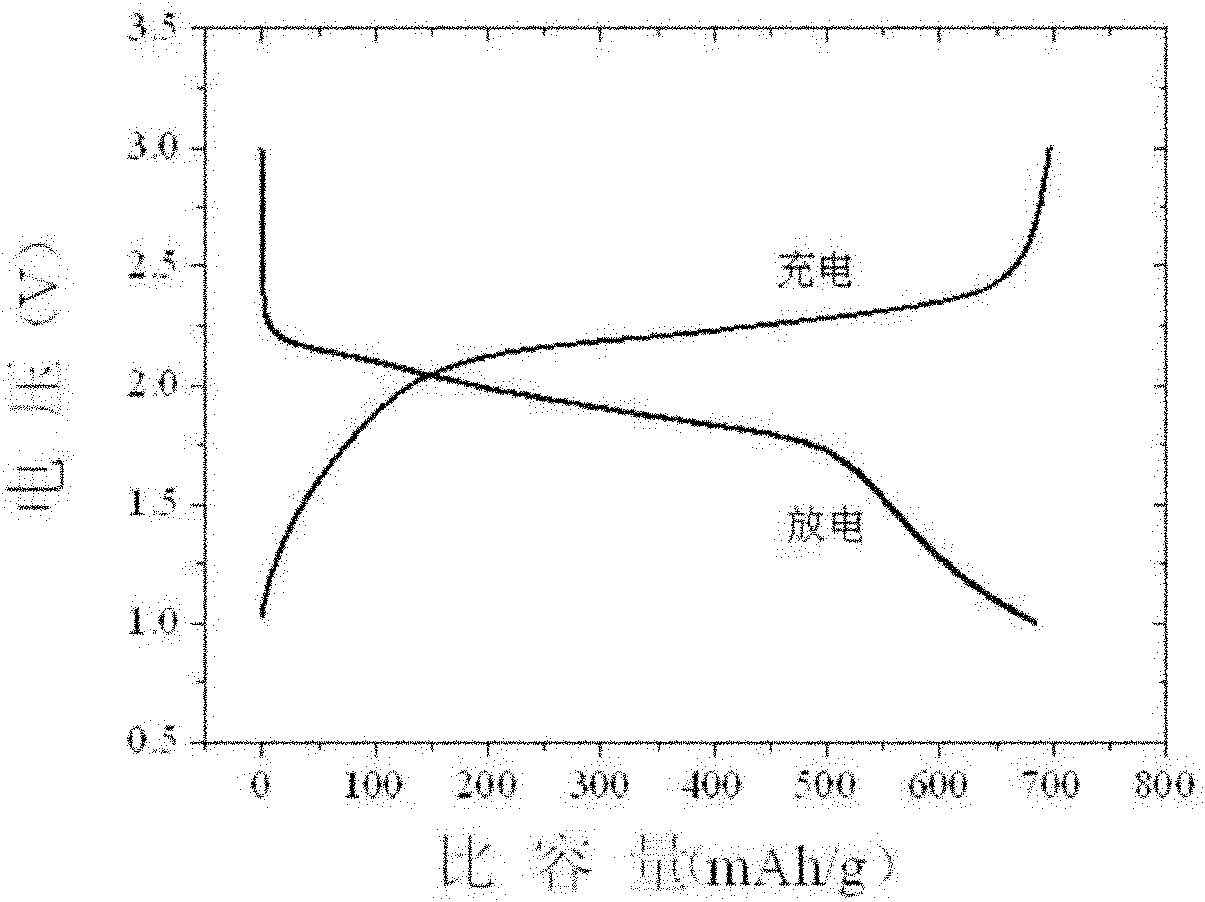

Carbon nano tube-containing sulfur-based composite cathode material and preparation method thereof

ActiveCN101891930AIncrease contentImprove power characteristicsNon-aqueous electrolyte accumulator electrodesIn situ polymerizationAcrylonitrile

The invention discloses a carbon nano tube-containing sulfur-based composite cathode material and a preparation method thereof. The sulfur-based composite cathode material is a ternary composite material AxByCz, wherein A is a dehydrocyclization product of an acrylonitrile-itaconic acid copolymer; B is elemental sulfur; C is a carbon nano tube; x is more than or equal to 30 weight percent and less than or equal to 60 weight percent; y is more than or equal to 30 weight percent and less than or equal to 60 weight percent; and z is more than or equal to 1 weight percent and less than or equal to 20 weight percent. The preparation method comprises the following steps of: in-situ polymerizing an acrylonitrile-itaconic acid monomer on the surface of the multi-wall carbon nano tube, and performing thermal treatment on both of the acrylonitrile-itaconic acid copolymer and the elemental sulfur, so that the sulfur is uniformly dispersed in a substrate formed by the dehydrocyclization of the acrylonitrile-itaconic acid copolymer. The carbon nano tube-containing sulfur-based composite cathode material and a lithium cathode form a secondary lithium-sulfur battery which is charged and discharged at the room temperature. The carbon nano tube-containing sulfur-based composite cathode material has the reversible specific capacity of 697 mAh / g and high cyclical stability.

Owner:SHANGHAI JIAO TONG UNIV

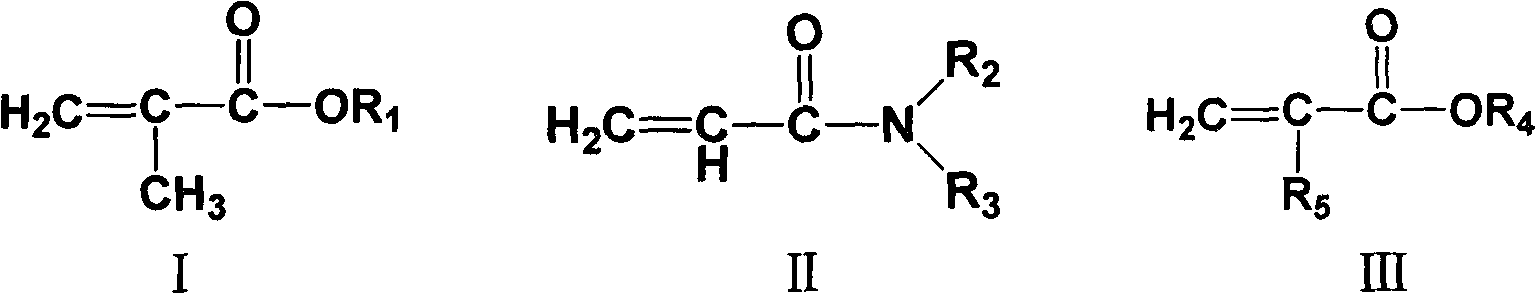

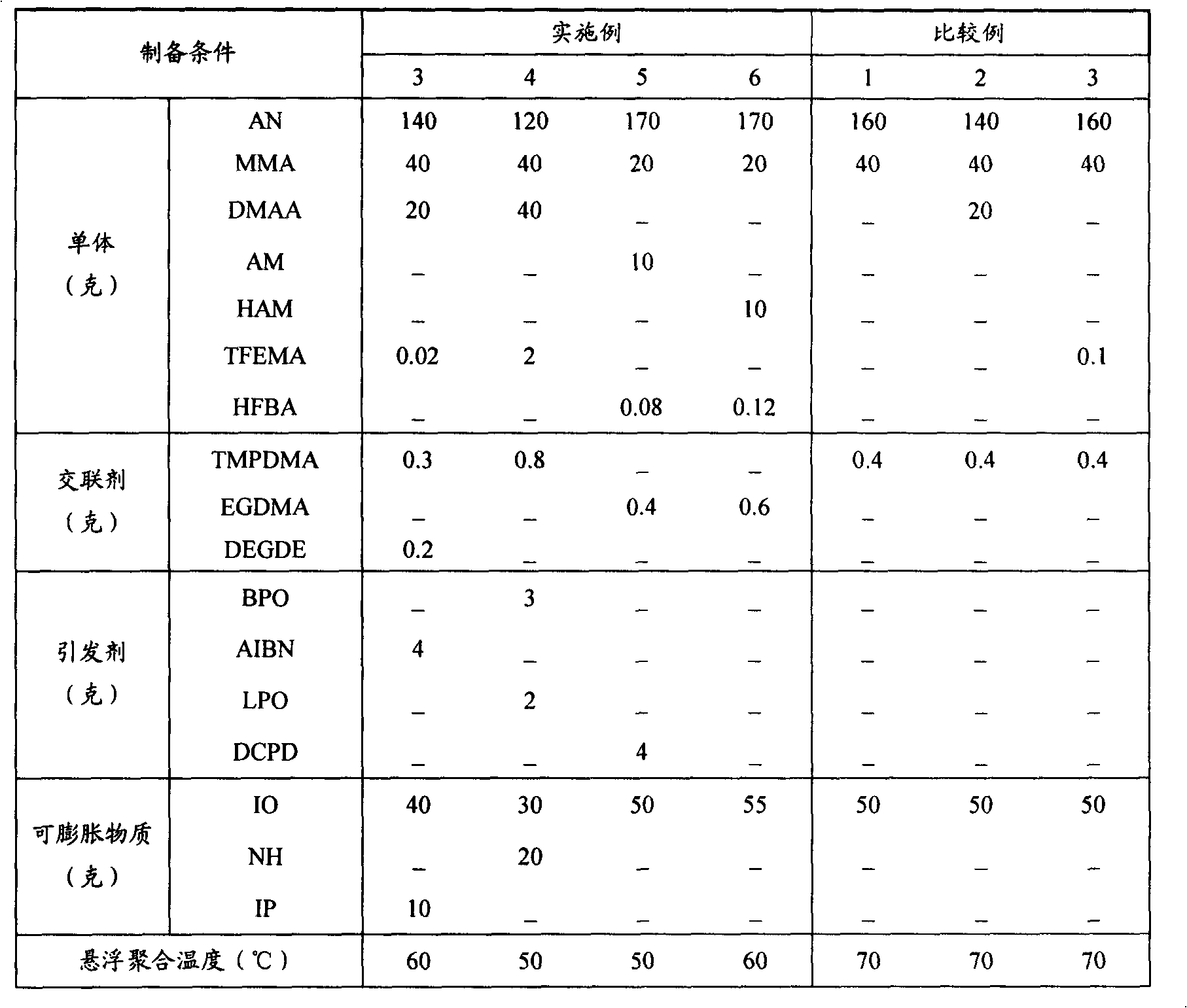

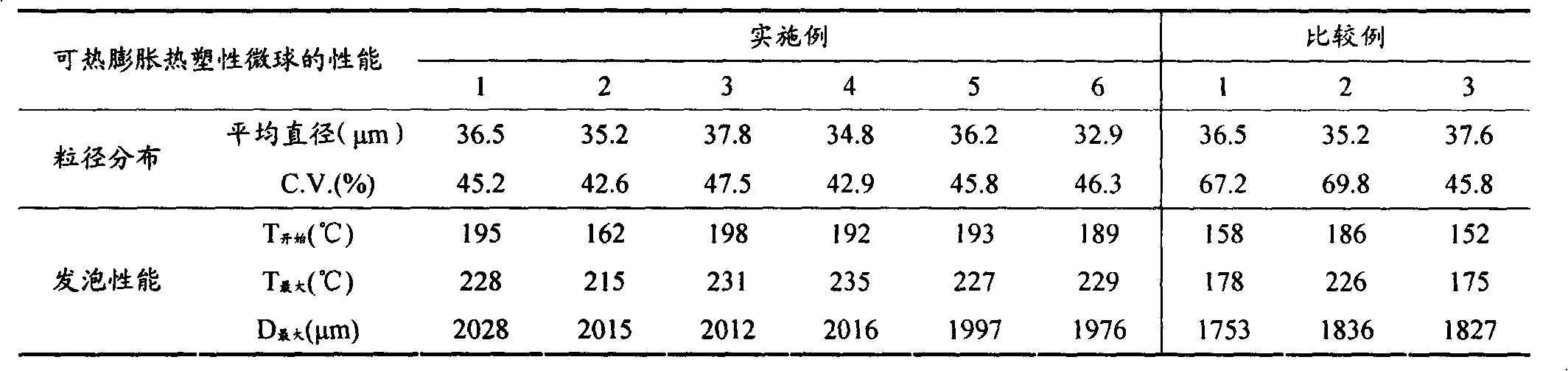

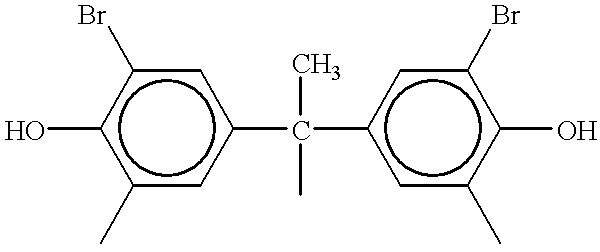

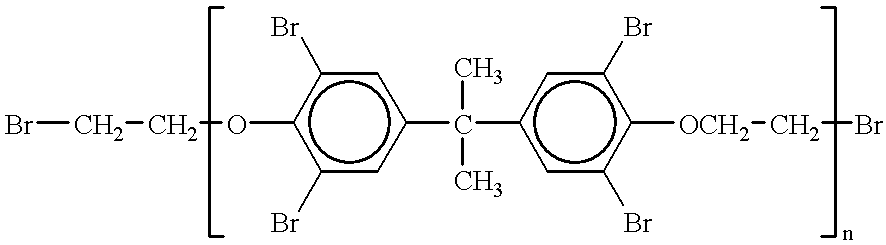

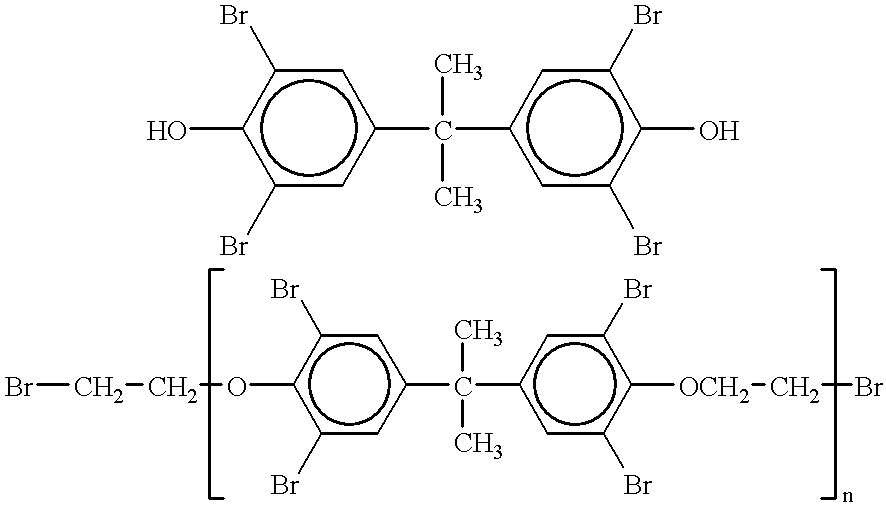

Thermoexpandable thermoplastic microspheres

The invention relates to thermoexpandable thermoplastic microspheres which are mainly prepared by carrying out suspension polymerization on olefine polymerizable monomers and expandable substances. The thermoexpandable thermoplastic microspheres have a core-shell structure which uses the thermoplastic polymers as the shell and the expandable substances as the cure. The invention is characterized in that on the basis of 100 wt% as the total weight of the olefine polymerizable monomers, the olefine polymerizable monomers are composed of 30-90 wt% of acrylonitrile, 5-50 wt% of methacrylate monomers, 1-20 wt% of acrylamide monomers, 0.01-1.0 wt% of fluorine-containing acrylate monomers and 0-40 wt% of acrylic monomers. The start T of the thermoexpandable thermoplastic microspheres is 160-200 DEG C.

Owner:NANOSPHERE SHANGHAI

Electrically conductive adhesive composition, electrically conductive adhesive sheet and use thereof

InactiveUS6344155B1Improve rendering capabilitiesImprove conductivityCross-talk/noise/interference reductionSynthetic resin layered productsEpoxyFolding endurance

An electrically conductive adhesive composition which has flexibility and folding endurance and is feasible for use as a shield against electromagnetic waves from a flexible printed circuit, comprises 100 parts by weight of (a) an acrylonitrile-butadiene copolymer, 20 to 500 parts by weight of (b) a phenolic resin and / or an epoxy resin, 1 to 100 parts by weight, per 100 parts by weight of the components (a) and (b) in total, of (c) an electrically conductive filler and 1 to 50 parts by weight, per 100 parts by weight of the components (a) and (b) in total, of (d) a bromine-containing flame retardant.

Owner:TOMOEGAWA PAPER CO LTD

Method for preparing polyacrylonitrile carbon fiber protofilament by dry and wet methods

InactiveCN102146595AGive full play to the advantages of dry and wet methodsGive full play to the advantagesArtificial filament washing/dryingFilament/thread formingPolymer scienceCarbon fibers

The invention discloses a method for preparing polyacrylonitrile carbon fiber protofilament by dry and wet methods. The method comprises the steps of polymerization, demonomerization and defoaming, filtration, coagulation, washing and drafting, oiling densification, steam drafting, heat setting and drying. Three-level coagulating baths at the temperature of between 10 DEG C below zero and 70 DEG C and with dimethyl sulfoxide with concentration of 10 to 60 mass percent are adopted in the coagulation step, and the first coagulating bath contains aqueous ammonia accounting for 0.05 to 1 percent of the mass of the first coagulating bath; and a spinning head is subjected to 1.5 to 5 times positive drafting in the first coagulating bath, and the drafting is 0 in the second and third coagulatingbathes. According to the method for preparing the polyacrylonitrile carbon fiber protofilament, the spinning process is stable, the broken filament is little, the spinning speed is high, the spinningis stable, the prepared protofilament has few defects, the density is not less than 1.180g / cm<3>, and the tensile strength is not less than 7cN / dtex. The protofilament can be prepared into a high-performance carbon fiber with tensile strength of more than 4.9GPa and elastic modulus of between 260 and 280GPa by high-temperature carbonization.

Owner:KINGFA SCI & TECH CO LTD +1

Adhesion agent and method of manufacturing the same

The invention discloses an adhesive, which comprises the following parts: epoxy resin, flexibilizer, catalyst, hardener, accelerant, mineral filler and solvent, wherein the flexibilizer consists of 10-100wt% hydrogenated acrylonitrile butadiene and 0-90wt% acrylonitrile butadiene with hydrogenated rate of hydrogenated acrylonitrile butadiene at 50-100%. The invention has good expression in peel strength of flexible printing circuit, flexibility, size stability, chemical-resisting and electric insulativity, which also possesses superior thermostable decomposability and anti-metal mobility.

Owner:BYD CO LTD

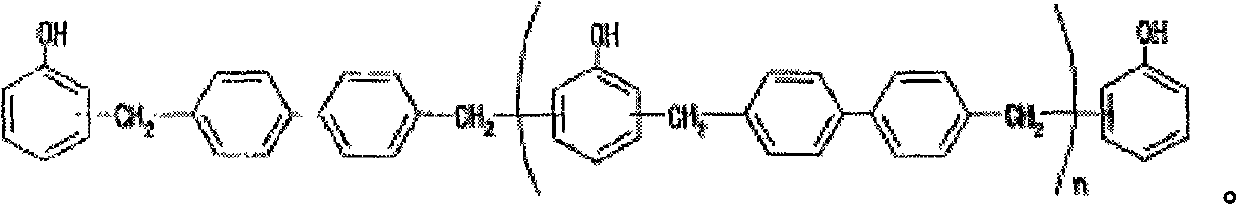

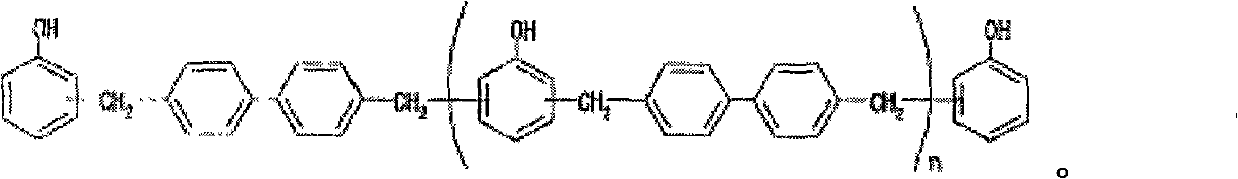

High thermal conductivity resin composition and high thermal conductivity coated metal foil board manufactured by using same

ActiveCN101974208AImprove thermal conductivityImprove heat resistanceMetal layered productsPolyesterEpoxy

The invention relates to a high thermal conductivity resin composition and a high thermal conductivity coated metal foil board manufactured by using the same. The high thermal conductivity resin composition comprises the following components of: epoxy resin, at least one phenoxy resin or carboxy terminal butadiene acrylonitrile, biphenyl phenolic resin and a high thermal conductivity packing material, wherein the biphenyl phenolic resin has the structure shown in the specification. The high thermal conductivity coated metal foil board manufactured by using the high thermal conductivity resin composition comprises a high thermal conductivity adhesive film and metal foils coated on both sides of the high thermal conductivity adhesive film, wherein the high thermal conductivity adhesive film comprises a carrier film and the high thermal conductivity resin composition coated on the carrier film, and the carrier film is a polyester film or a polyimide film. The high thermal conductivity coated metal foil board comprises a resin composite metal foil and a metal foil or another resin composite metal foil coated on the previous resin composite metal foil, and the resin composite metal foil comprises a metal foil and the high thermal conductivity resin composition coated on the metal foil.

Owner:GUANGDONG SHENGYI SCI TECH

Low-smoke halogen-free flame retardant PC/ABS alloy and preparation method thereof

InactiveCN101591468AImprove flame retardant performanceImprove mechanical propertiesAcrylonitrileAlloy

The invention relates to a low-smoke halogen-free flame retardant PC / ABS alloy and a preparation method thereof. 40-75 polycarbonate (PC), 10-40 acrylonitrile-butadiene-styrol copolymer (ABS), 10-15 compound flame retardant, 0.2-2 compound smoke suppression agent, 2-16 compatilizer, 1-6 low-smoke promoter, 0.1-0.5 stabilizer and 0.1-0.6 lubricant are taken in percentage by weight and are put in a high-speed mixer for mixing for 1-15min, and then the mixture is put in a screw extruder for extrusion granulation. Compared with the prior art, the invention has the advantages of low smoke, halogen-free flaming retardation, excellent comprehensive performance, and the like.

Owner:SHANGHAI KELING INDS

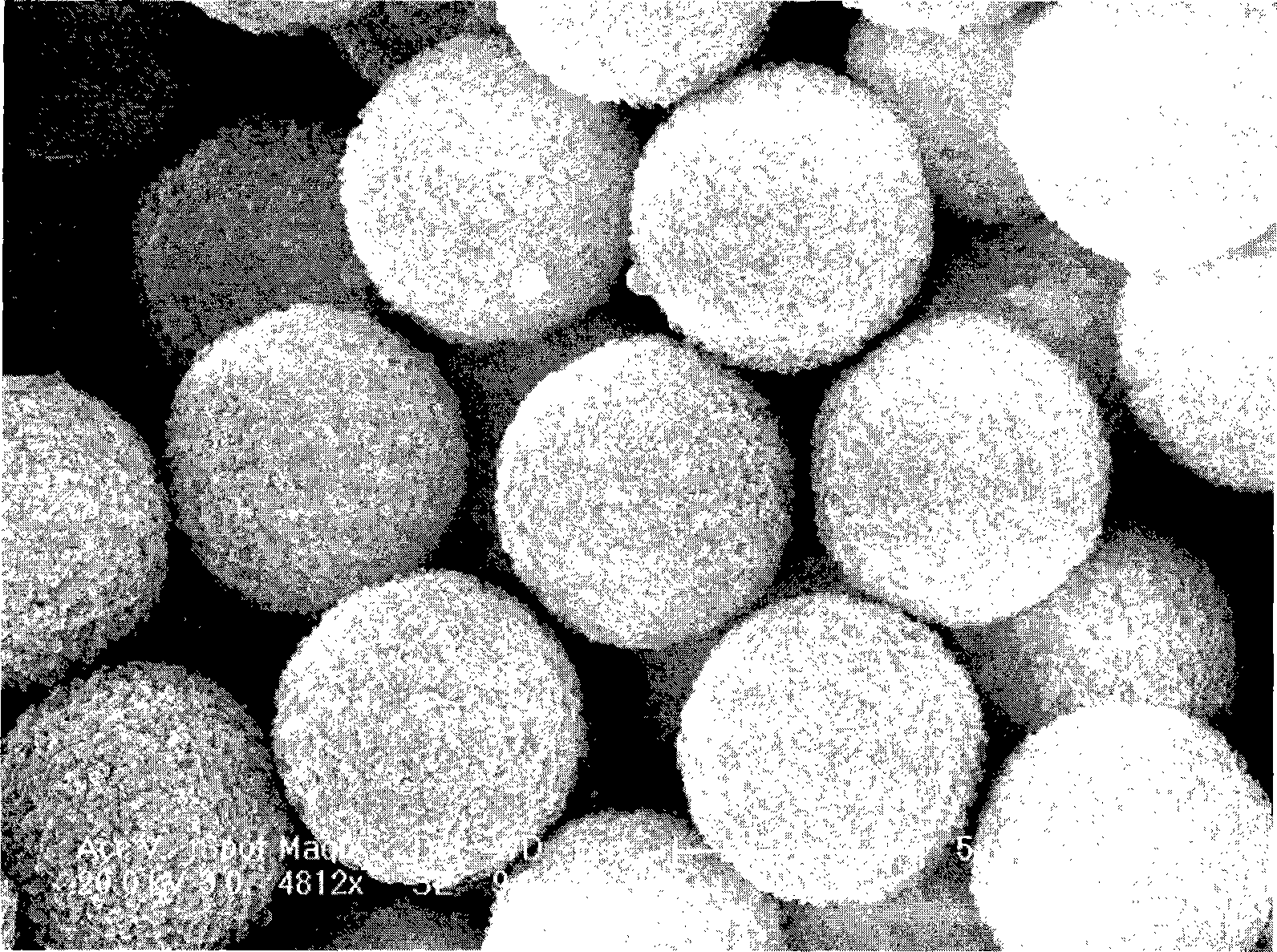

Preparation of monodisperse porous polymer microsphere

The invention provides a preparation method of a monodisperse porous polymer microsphere. After a second stage of swelling of two-stage seed swelling polymerization, remnant monomer separation technology is adopted to avoid the aggregation of the microspheres and the generation of secondary particles, thereby greatly improving the stability of preparing monodisperse porous polymer microsphere through the two-stage seed swelling polymerization. The two-stage seed swelling polymerization can stably prepare the following monodisperse porous polymer microspheres: P(St-co-DVB) (PSD for short) and P(St-co-DVB-co-MMA) (PSDA for short), wherein, St is referred to as styrene, DVB as divinybenzene, MMA as methyl methacrylate, AN as acrylonitrile and co as copolymerization. The monodisperse porous polymer microsphere PSDA prepared by the method can be seen in an attached drawing.

Owner:芜湖万隆新材料有限公司

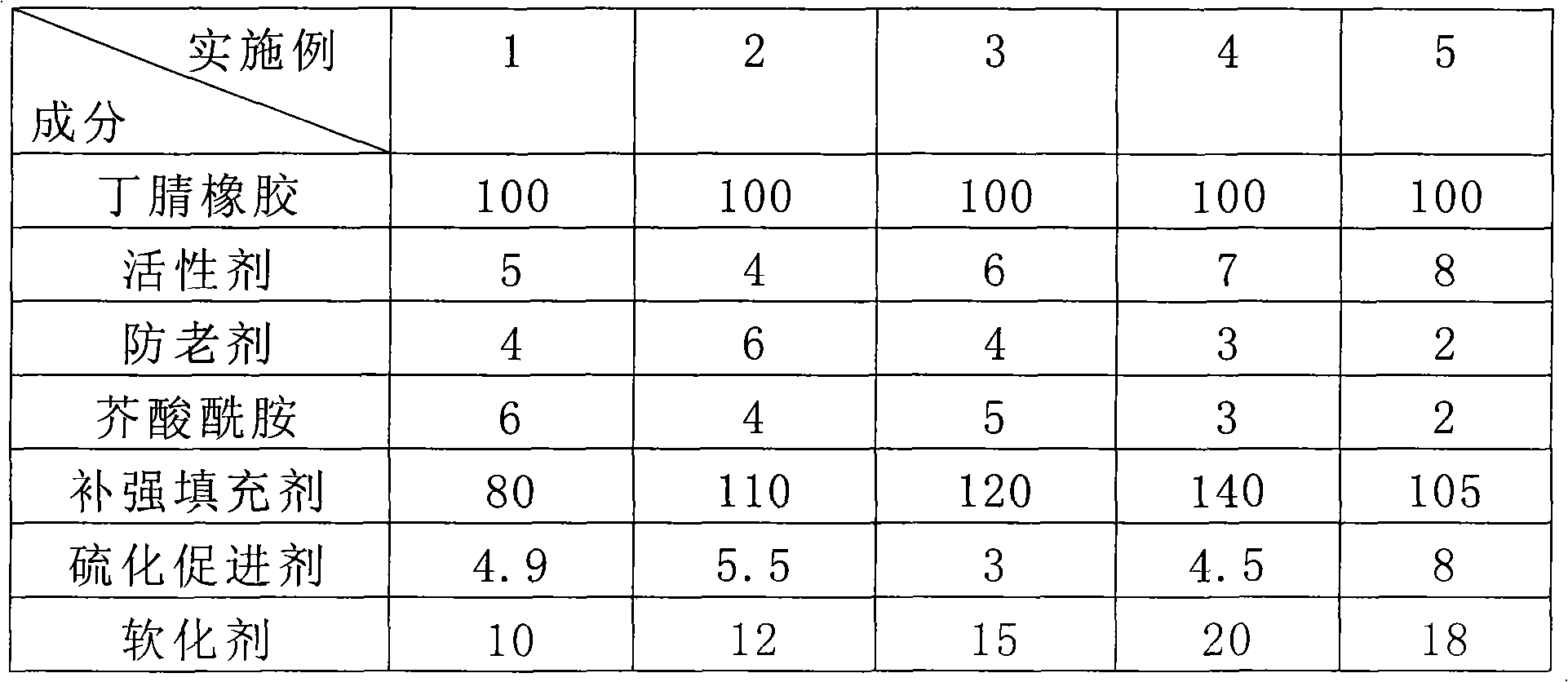

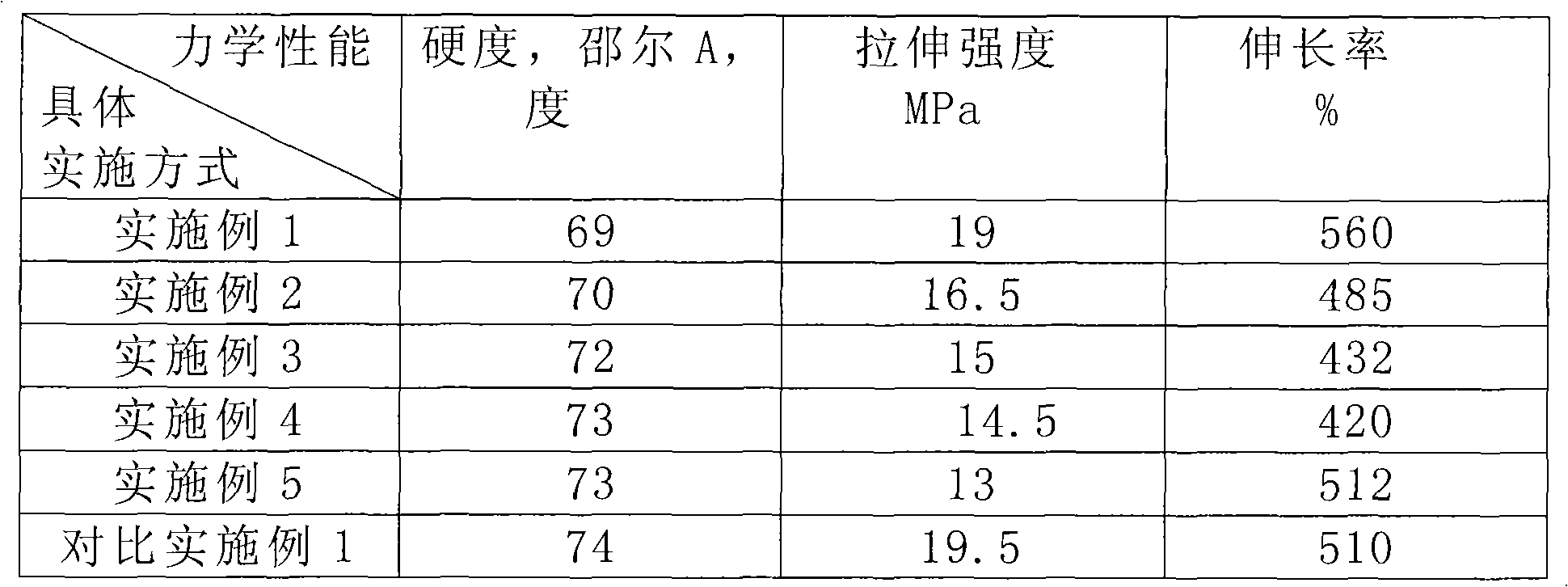

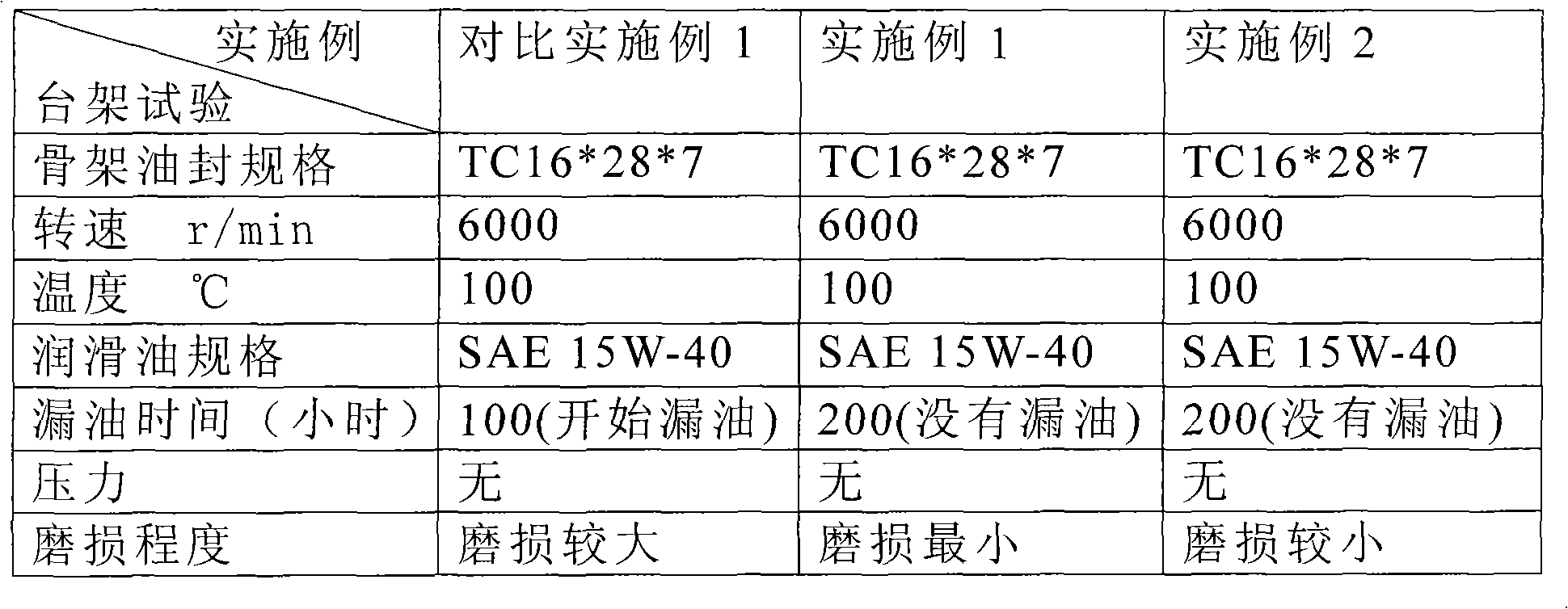

Highly-abrasion-resistant butadiene-acrylonitrile-rubber vulcanized rubber and preparation method thereof

InactiveCN101597391AThe ingredients are well matchedReduce coefficient of frictionNitrile rubberVulcanization

The invention provides a highly-abrasion-resistant butadiene-acrylonitrile-rubber vulcanized rubber and a preparation method thereof. The highly-abrasion-resistant butadiene-acrylonitrile-rubber vulcanized rubber comprises the following components according to parts by weight: 100 parts of butadiene-acrylonitrile rubber, 3-8 parts of active agent, 1-6 parts of antiager, 2-6 parts of erucamide, 50-150 parts of reinforcing filler and 3-8 parts of vulcanizing accelerator, wherein acrylonitrile content in the butadiene-acrylonitrile rubber is 34-41 percent by weight, and Mooney viscosity (ML[1+4] of the butadiene-acrylonitrile rubber is 45-70. The preparation method of the butadiene-acrylonitrile-rubber vulcanized rubber comprises the steps of A. mixing and processing and B. recycled processing and vulcanization. The butadiene-acrylonitrile-rubber vulcanized rubber has reasonable component mixing and higher abrasion resistance. The highly-abrasion-resistant butadiene-acrylonitrile-rubber vulcanized rubber prepared according to the method has high elongation and long service life.

Owner:ANHUI RUNKANG RUBBER & PLASTIC TECH CO LTD

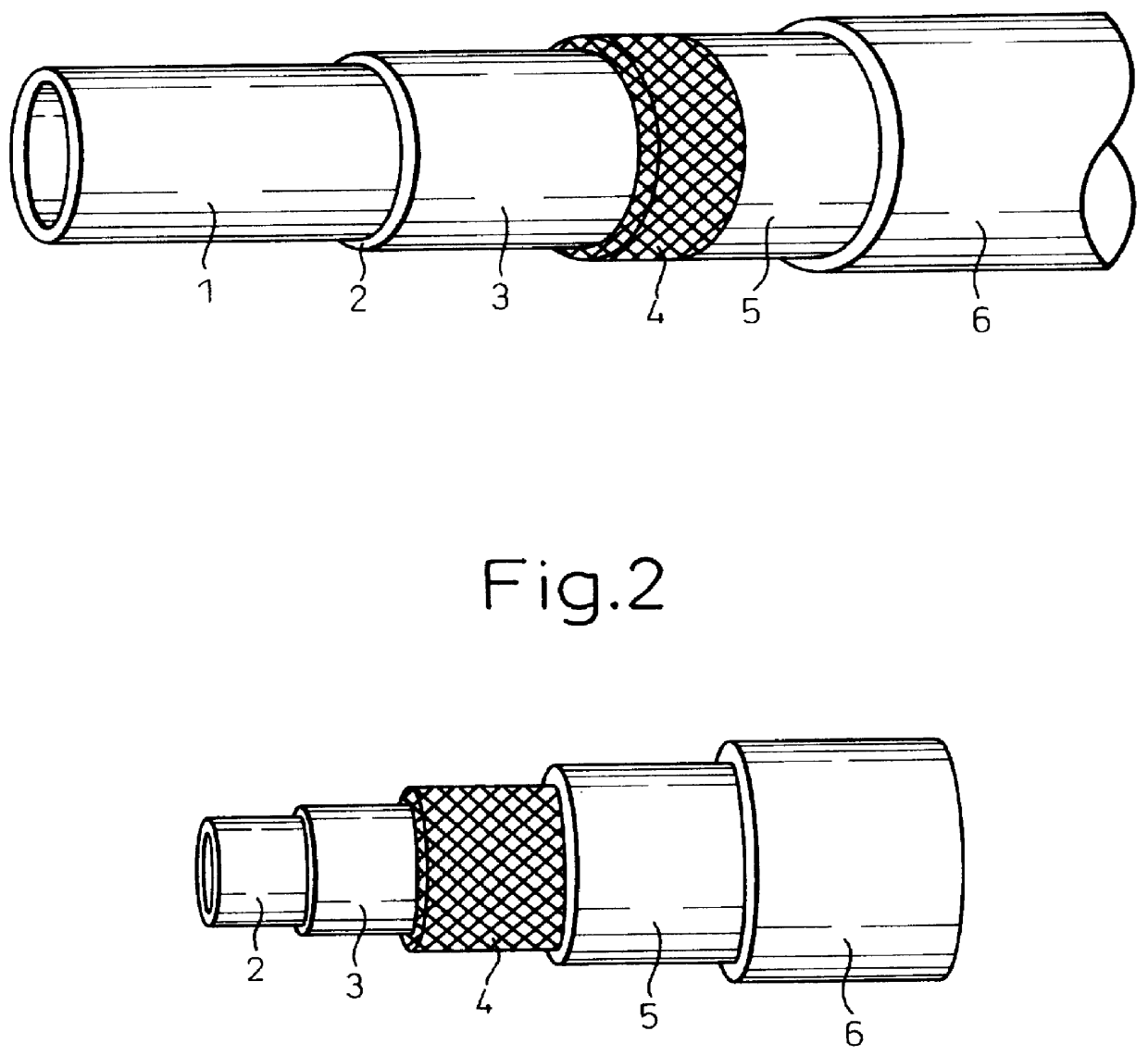

Thermoplastic elastomer composition, hose comprising thermoplastic elastomer composition and process of production thereof

InactiveUS6166143AImprove compatibilitySolve the lack of flexibilityClosuresClosure using stoppersThermoplasticCross-link

PCT No. PCT / JP97 / 03987 Sec. 371 Date Jul. 2, 1998 Sec. 102(e) Date Jul. 2, 1998 PCT Filed Oct. 31, 1997 PCT Pub. No. WO98 / 20068 PCT Pub. Date May 14, 1998A thermoplastic elastomer composition containing a component (A) (thermoplastic polyolefin resin), component (B) (epoxy-group-containing ethylene acrylic ester copolymer rubber), and component (C) (acid-modified polyolefin resin) comprising a continuous phase of the component (A) in which the component (B) is dispersed as a dispersed phase and is cross-linked by a peroxide; a thermoplastic elastomer composition comprising a continuous phase of a thermoplastic polyolefin resin (A) and a dispersed phase of an epoxy-group-containing ethylene-acrylic ester copolymer rubber component (B) and acrylonitrile butadiene rubber component (C), which is dynamically cross-linked; and a hose having an inner tube, at least one reinforcing layer, and an outer cover, wherein the inner tube and the outer cover contain a thermoplastic elastomer composition comprised of a thermoplastic resin in which is blended an at least partially cross-linked elastomer component, the reinforcing layer is a brass-plated wire, and the reinforcing layer and inner tube and the reinforcing layer and outer cover have between them a maleic-acid-modified polyolefin thermoplastic resin.

Owner:YOKOHAMA RUBBER CO LTD

Rubber composition containing resinous nanopractice

InactiveUS7071246B2Deteriorate controllabilityDeteriorate stabilitySpecial tyresCoatingsElastomerPolymer science

This invention relates to a tread rubber composition for tires with the addition of crosslinked resinous nanoparticles having a high glass transition temperature (Tg) into elastomeric base polymers. The invention demonstrates greatly improved handling performance without deteriorating controllability and stability during high-speed running. The present invention discloses a rubber composition comprising: (1) a rubbery polymer and (2) from 1 to 30 parts per hundred parts of rubber by weight (phr) of pre-crosslinked polymer particles, wherein the pre-crosslinked polymer particles have a particle size which is within the range of 30 nm to 500 nm, wherein the pre-crosslinked polymer is comprised of repeat units that are derived from at least one monomer selected from the group consisting of acrylate monomers, vinyl aromatic monomers, acrylonitrile monomer, and vinyl halide monomers, and wherein the pre-crosslinked polymer has a glass transition temperature which is within the range of 30° C. to 200° C.

Owner:THE GOODYEAR TIRE & RUBBER CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com