Adhesion agent and method of manufacturing the same

An adhesive and rubber technology, applied in the direction of adhesives, adhesive types, epoxy resin adhesives, etc., can solve the problems of poor high temperature decomposition resistance, etc., and achieve the effect of excellent high temperature decomposition resistance and metal migration resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of the adhesive of the present invention comprises dissolving epoxy resin, toughening agent and catalyst in a solvent, then raising the temperature to 60-100°C, keeping the temperature for 5-40 hours, and then mixing the above product with curing agent, accelerator and inorganic filler Or mix uniformly with curing agent, accelerator, coupling agent and inorganic filler to prepare the adhesive for flexible printed circuit board of the present invention. Wherein, relative to 100 parts by weight of the epoxy resin, the addition of the toughening agent is preferably 30-80 parts by weight, the addition of the catalyst is preferably 0.1-2 parts by weight, and the addition of the curing agent is preferably 2-20 parts by weight , the add-on of accelerator is preferably 0.1-5 parts by weight, the add-on of inorganic filler is preferably 2-15 parts by weight, the add-on of solvent is preferably 100-600 parts by weight, the add-on of coupling agent is prefera...

Embodiment 1

[0028] This example illustrates the adhesive provided by the present invention and its preparation method.

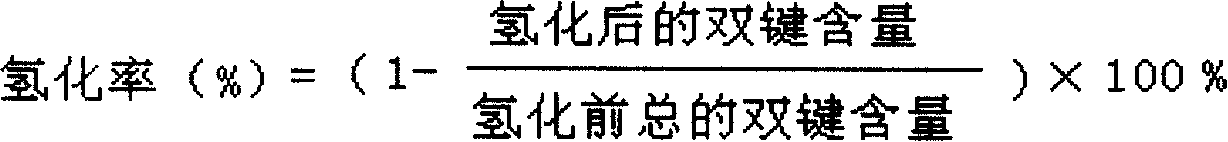

[0029] The carboxyl-terminated hydrogenated nitrile rubber of 55 parts by weight (the number average molecular weight is 3000, the content of acrylonitrile unit is 10% by weight, the hydrogenation rate is 96%, produced by Bayer China Co., Ltd.), the E-12 epoxy resin of 35 parts by weight Resin, 80 parts by weight of EX-48 brominated epoxy resin and 0.2 parts by weight of catalyst N-methylpyrrolidone were dissolved in 416 parts by weight of methyl ethyl ketone under stirring, and kept at 80° C. for 20 hours. Then add the curing agent DDM of 6.54 parts by weight, the promotor 2-methylimidazole of 1.40 parts by weight, the coupling agent gamma-aminopropyltriethoxysilane of 6 parts by weight, the inorganic filler aluminum hydroxide of 8 parts by weight, Stir and mix evenly to obtain the adhesive A1 provided by the present invention.

Embodiment 2

[0034] This example illustrates the adhesive provided by the present invention and its preparation method.

[0035] Adhesives are prepared according to the method of Example 1, except that 60 parts by weight of carboxyl-terminated hydrogenated nitrile rubber (number-average molecular weight 1200, the content of acrylonitrile units is 20% by weight, and the hydrogenation rate is 65%, produced by Bayer China Co., Ltd. ) and 15 parts by weight of solid nitrile rubber to replace 55 parts by weight of the carboxyl-terminated hydrogenated nitrile rubber to obtain the adhesive A2 provided by the invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com