Patents

Literature

15825 results about "Pyrolysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pyrolysis is the thermal decomposition of materials at elevated temperatures in an inert atmosphere. It involves a change of chemical composition and is irreversible. The word is coined from the Greek-derived elements pyro "fire" and lysis "separating".

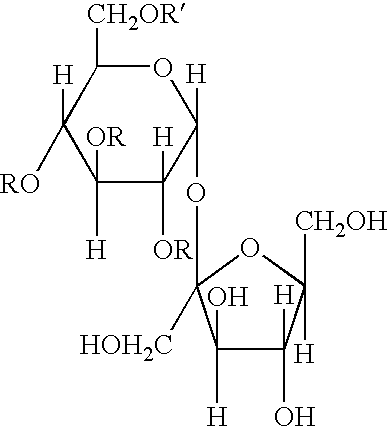

Method of reducing the sucrose ester concentration of a tobacco mixture

InactiveUS7025066B2Altering flavorAltering aroma characteristicTobacco preparationTobacco treatmentFlavor3-methylbutyric acid

The flavor and aroma characteristics of the smoke of a tobacco blend incorporating Oriental tobacco are improved by subjecting that blend to heat treatment. Oriental tobacco having a relatively high sucrose ester content is combined with a second dissimilar Oriental tobacco material and / or a non-Oriental tobacco material to form a tobacco mixture, and that mixture is heated for a time and under conditions sufficient to reduce the concentration of sucrose esters in the Oriental tobacco. Tobacco blends having reduced levels of sucrose esters yield smoke that does not possess undesirable off-notes provided by pyrolysis products of those sucrose esters; namely, 2-methylpropionic acid, 3-methylbutyric acid and 3-methylpentanoic acid.

Owner:R J REYNOLDS TOBACCO COMPANY

Thermal cracking of crude oil and crude oil fractions containing pitch in an ethylene furnace

InactiveUS6632351B1Cheap sourceMinimizing coke formationThermal non-catalytic crackingHydrocarbonsEthyleneChemistry

Owner:SHELL OIL CO

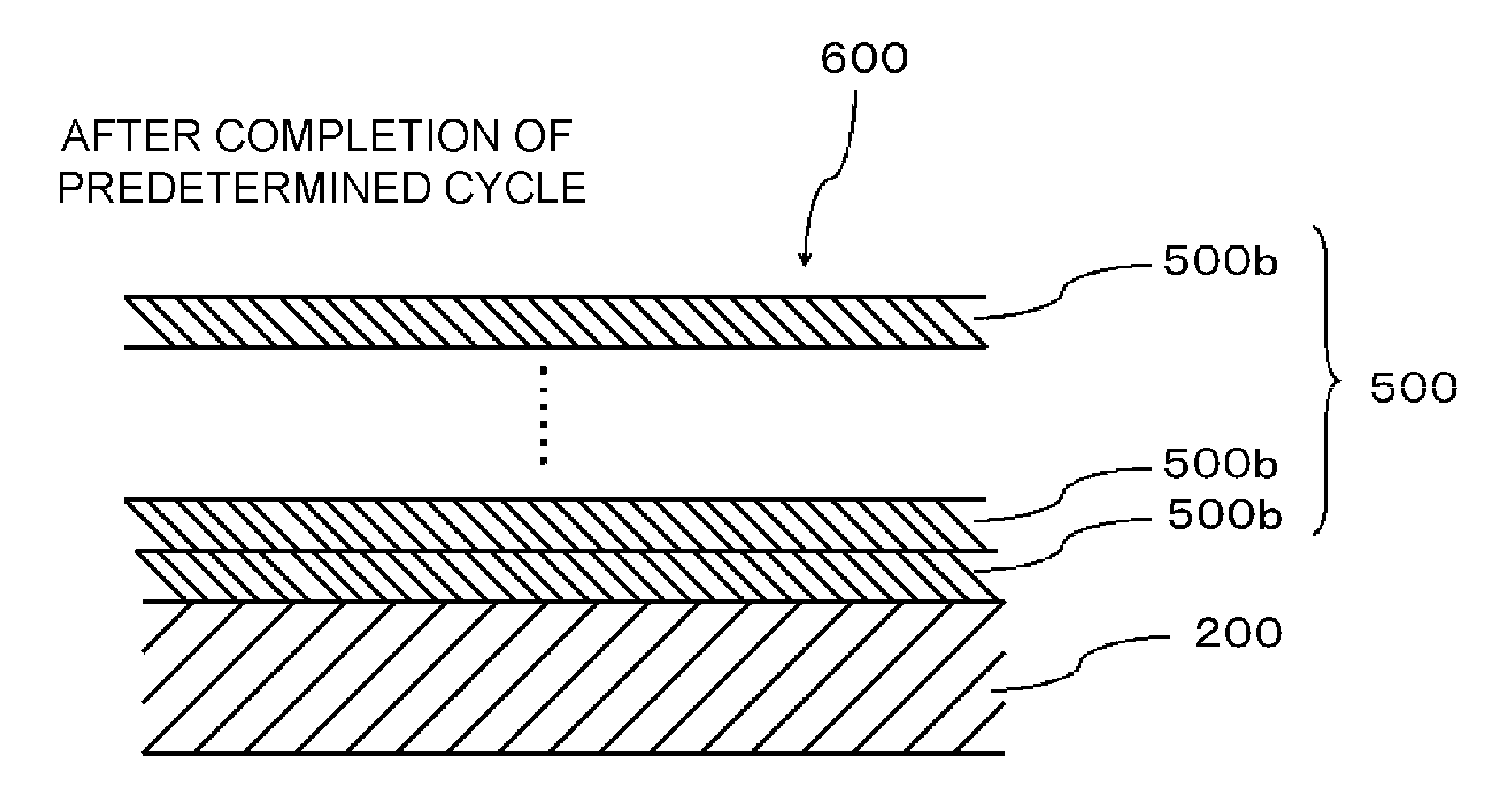

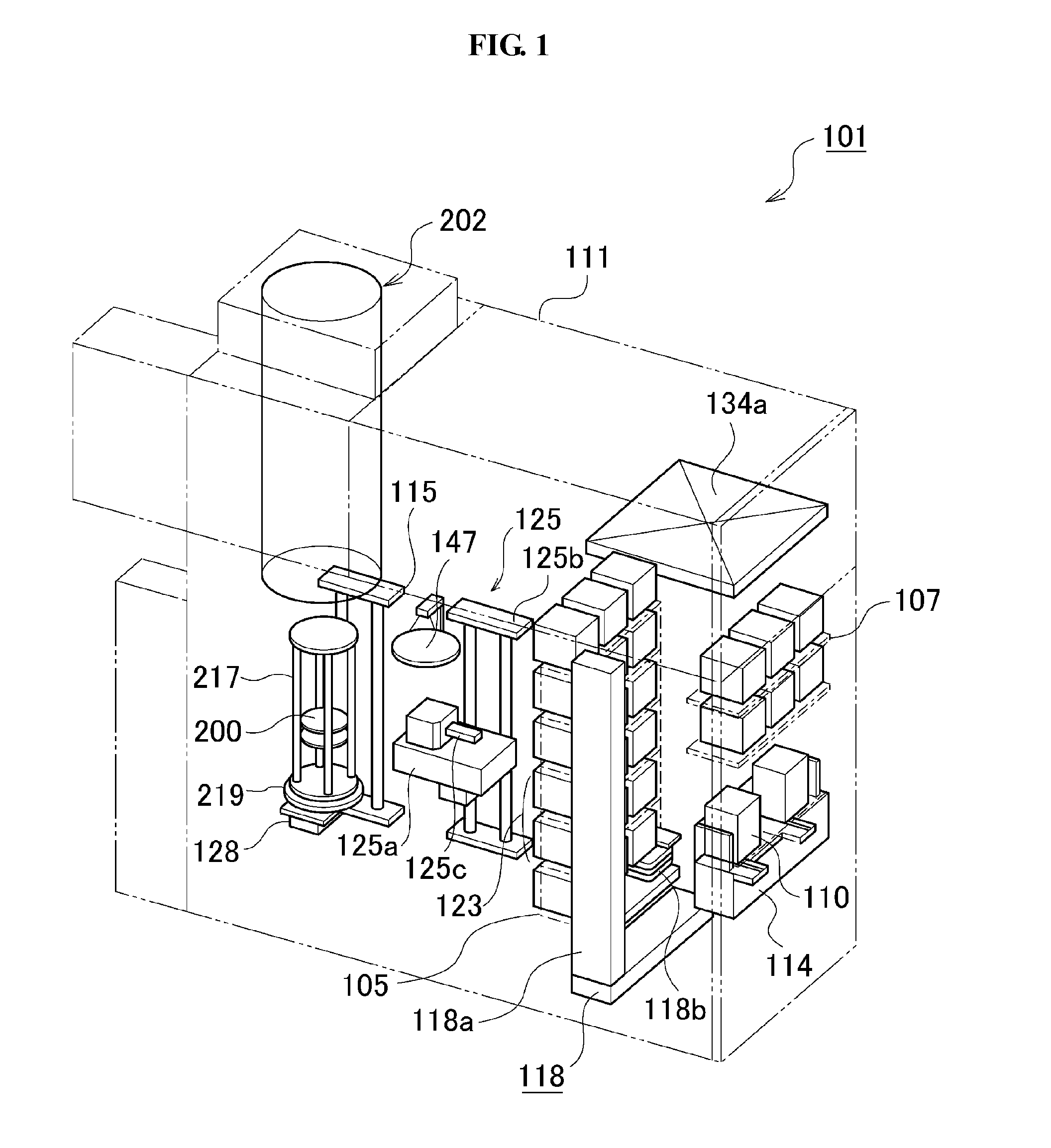

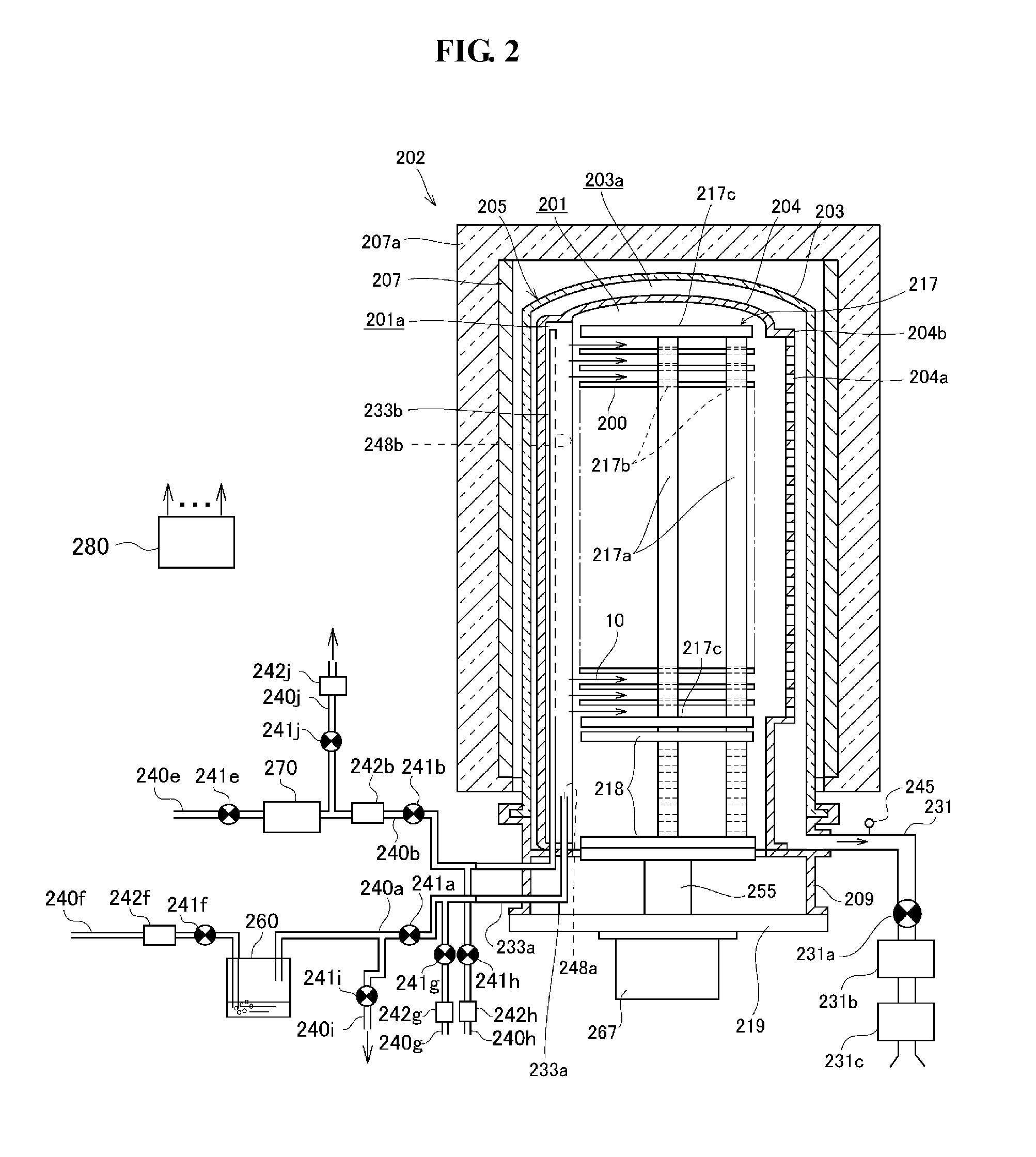

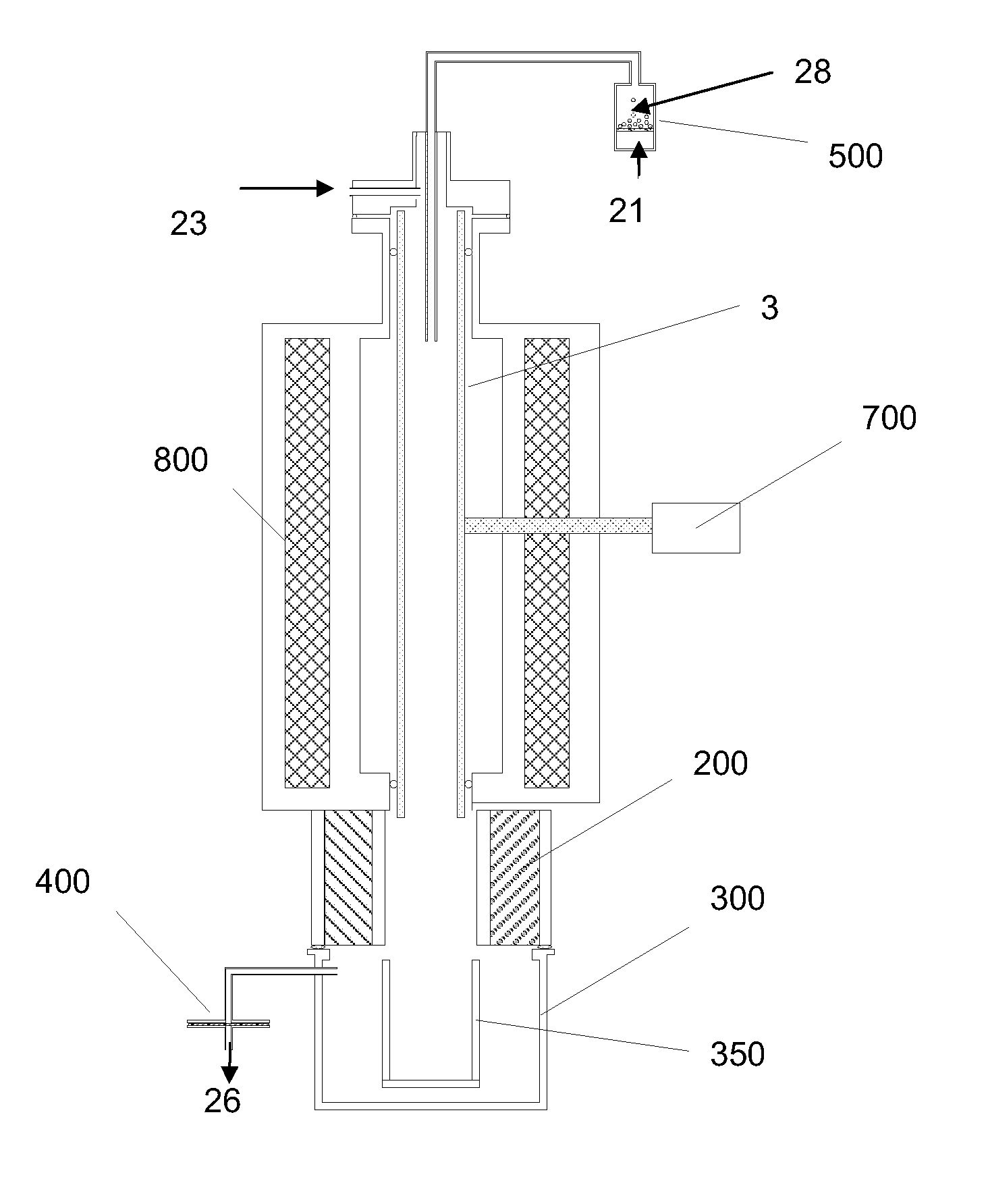

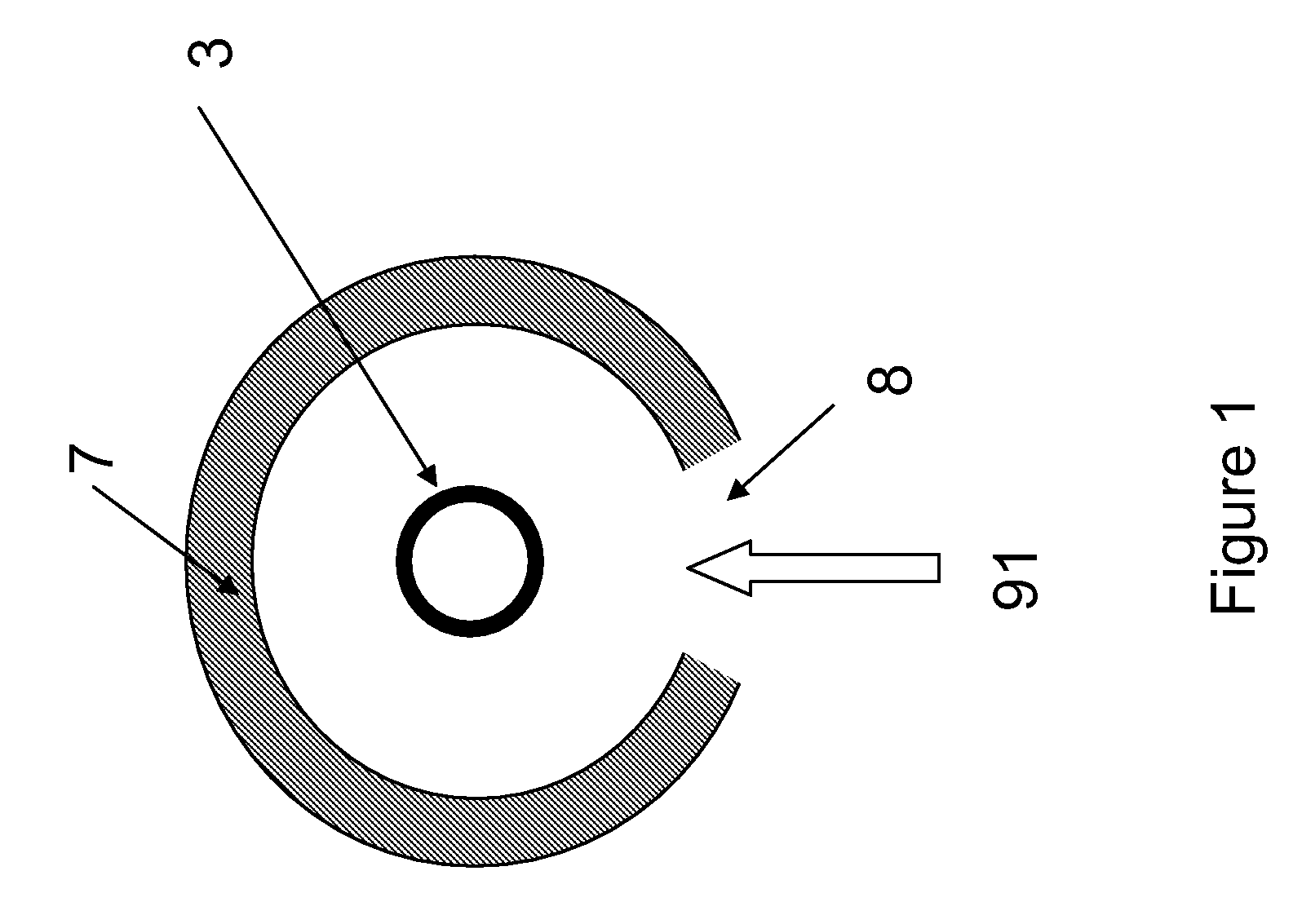

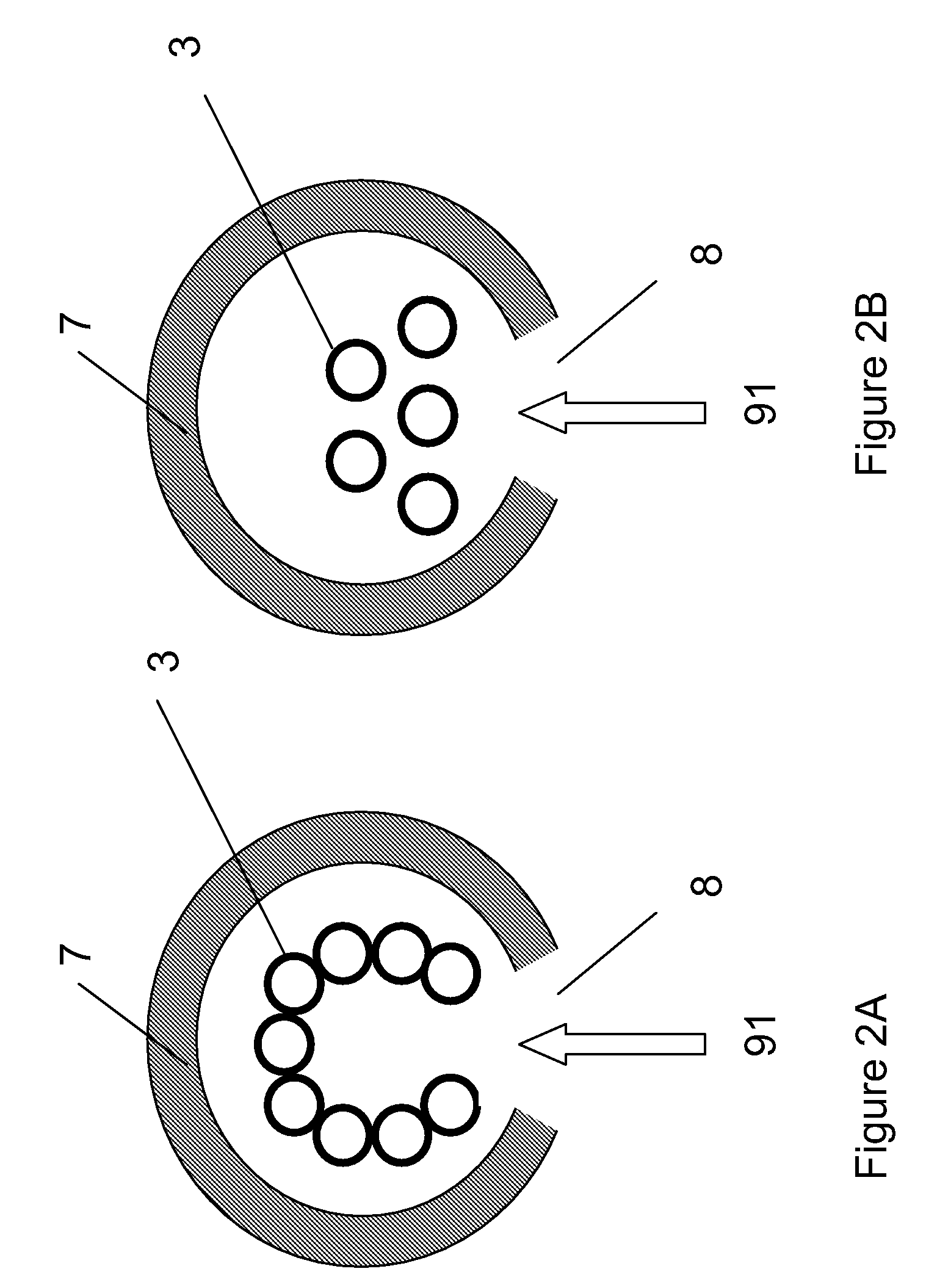

Substrate processing apparatus, method of manufacturing semiconductor device and semiconductor device

ActiveUS20120119337A1Avoid processing qualitySuppress scatterLiquid surface applicatorsSemiconductor/solid-state device detailsForeign matterThermodynamics

Provided is a substrate processing apparatus capable of suppressing accumulation of reaction products or decomposed matters on an inner wall of a nozzle and suppressing scattering of foreign substances in a process chamber. The substrate processing apparatus includes a process chamber, a heating unit, a source gas supply unit, a source gas nozzle, an exhaust unit, and a control unit configured to control at least the heating unit, the source gas supply unit and the exhaust unit. The source gas nozzle is disposed at a region in the process chamber, in which a first process gas is not decomposed even under a temperature in the process chamber higher than a pyrolysis temperature of the first process gas, and the control unit supplies the first process gas into the process chamber two or more times at different flow velocities to prevent the first process gas from being mixed.

Owner:KOKUSA ELECTRIC CO LTD

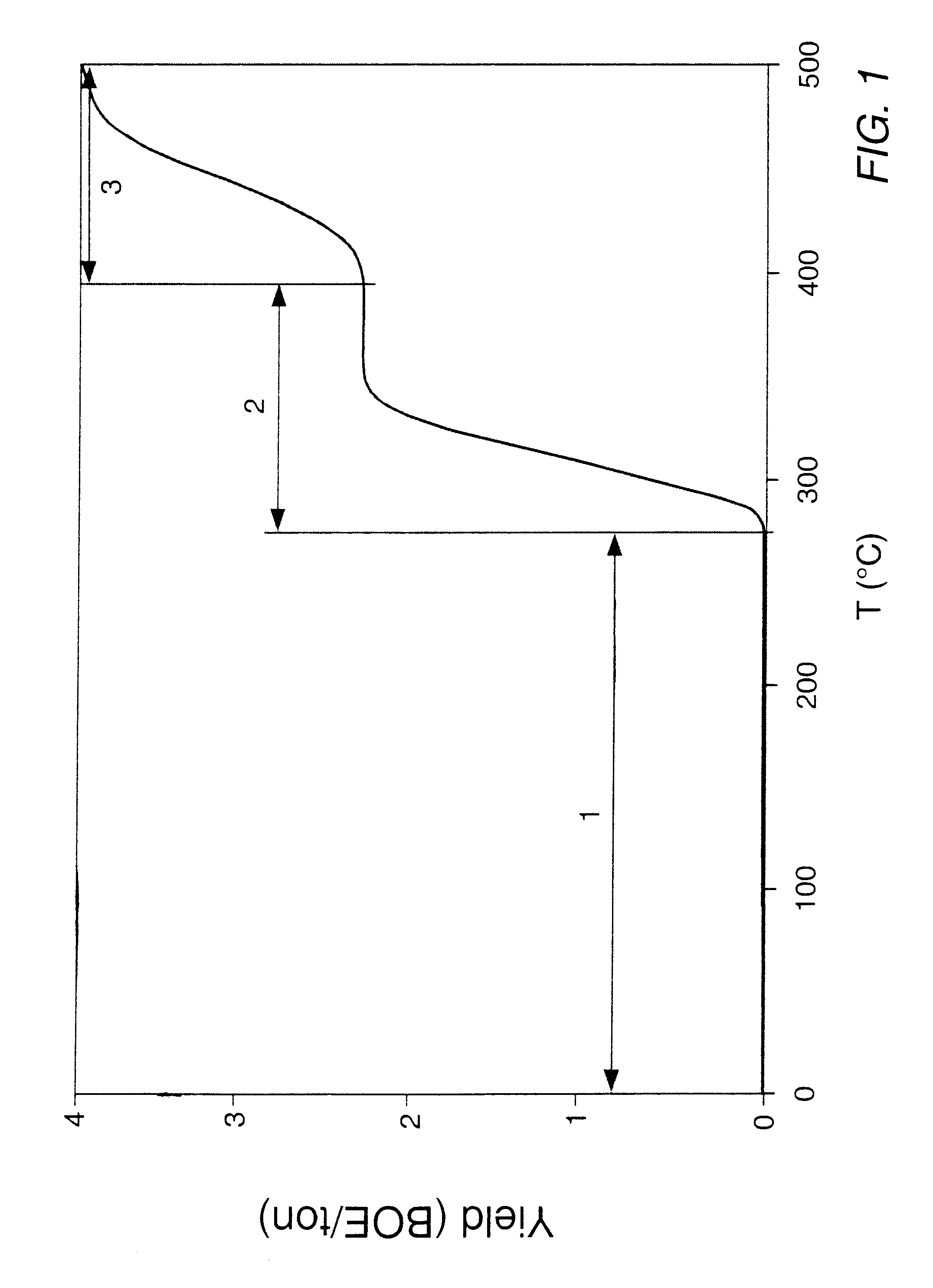

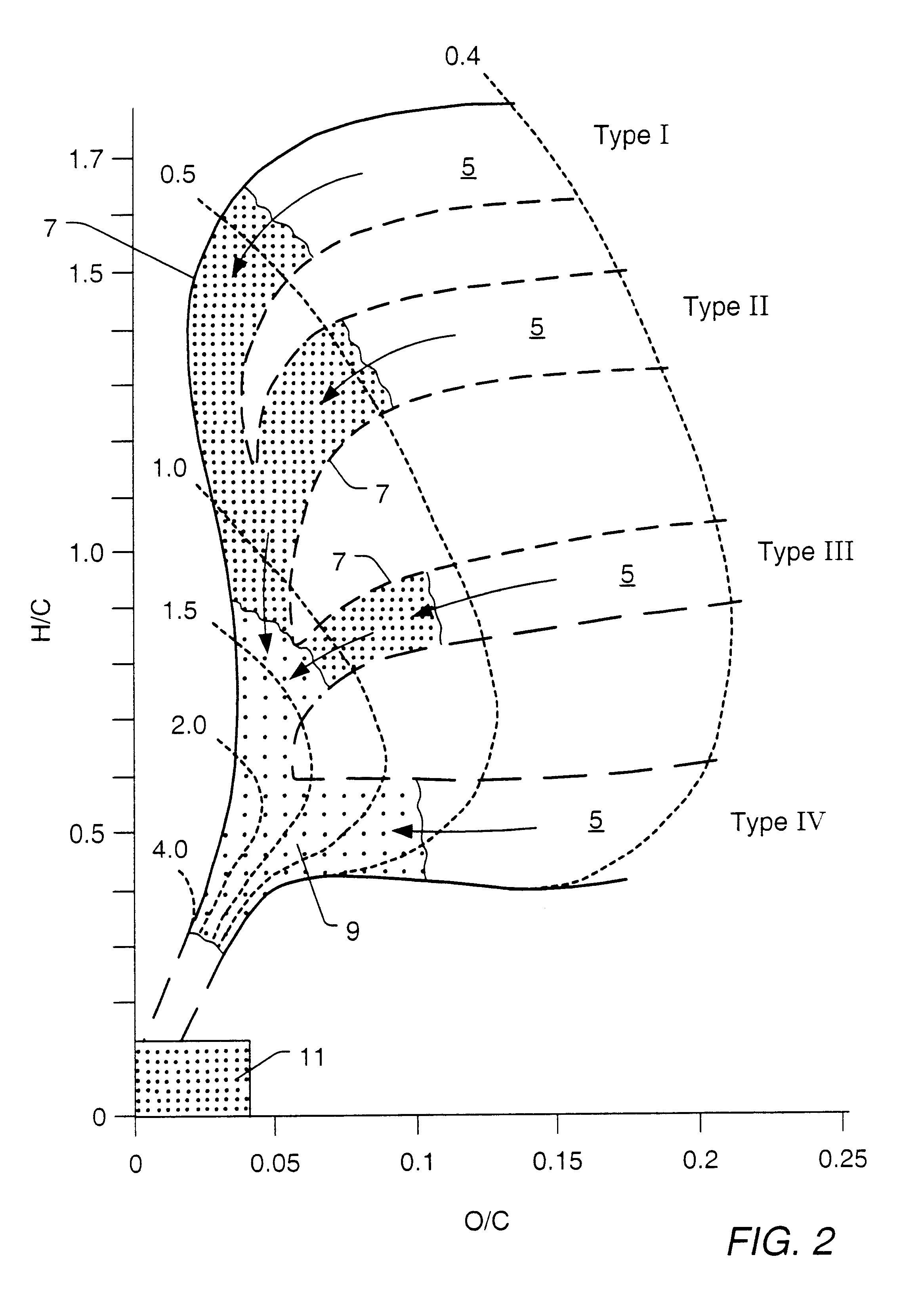

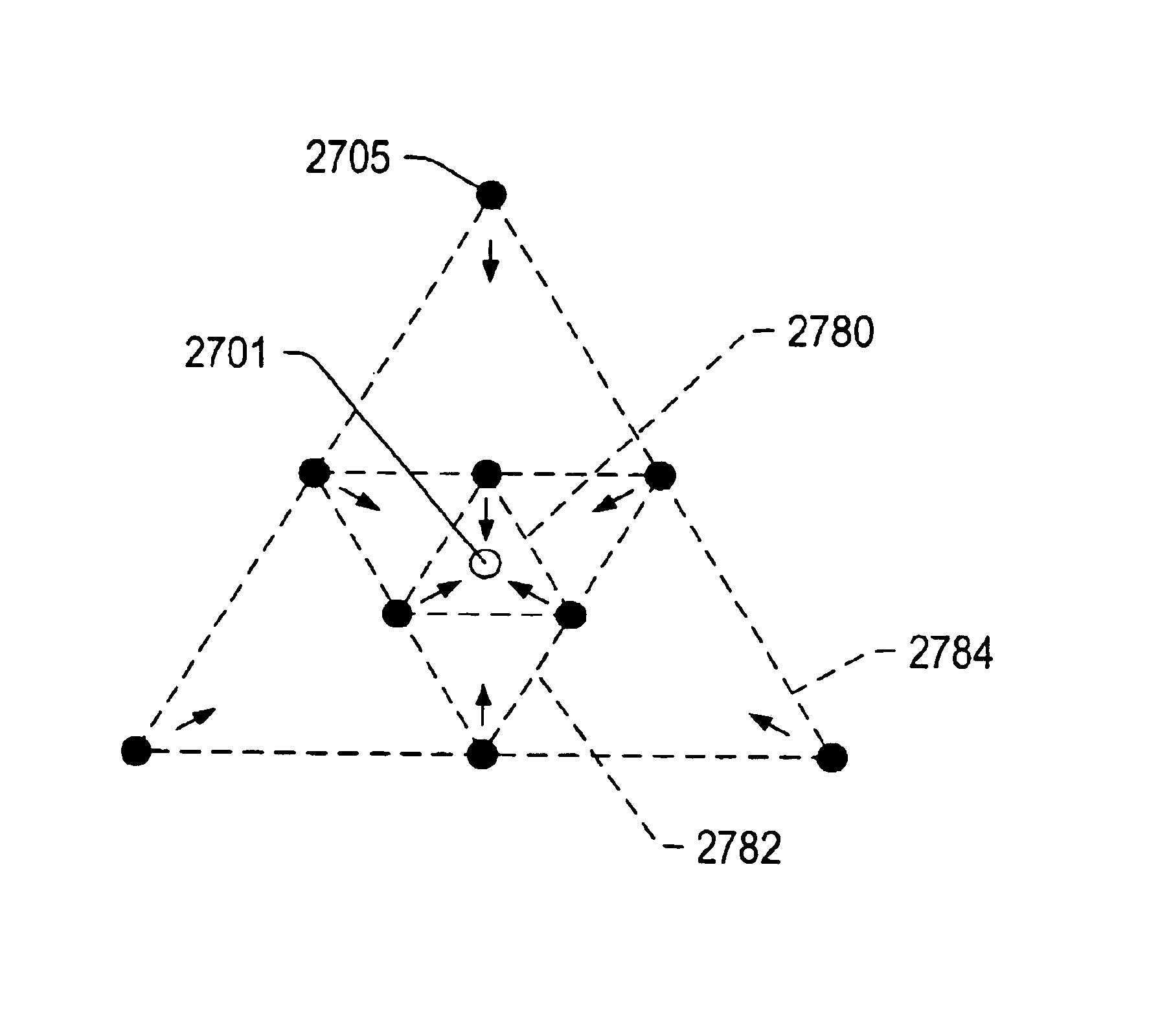

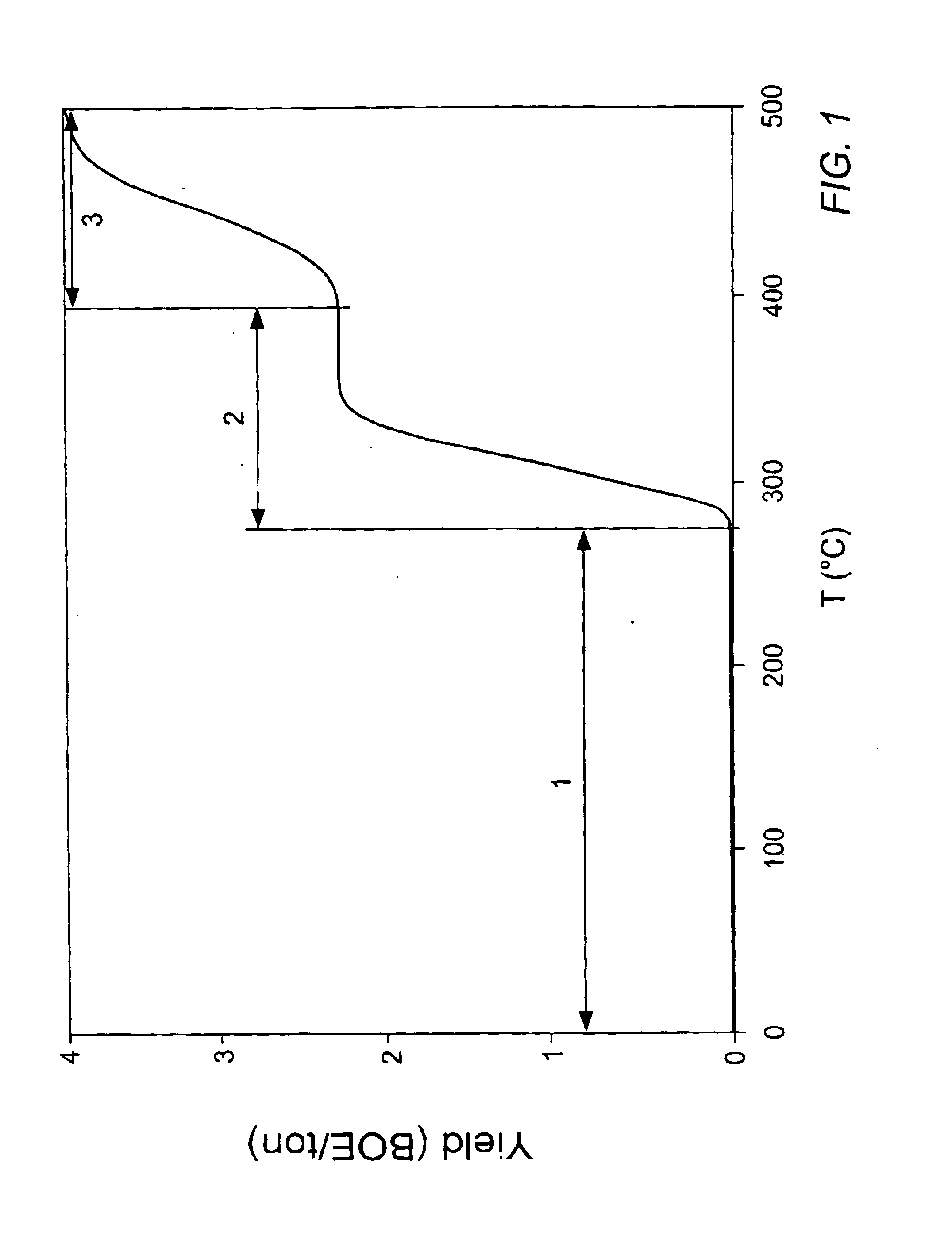

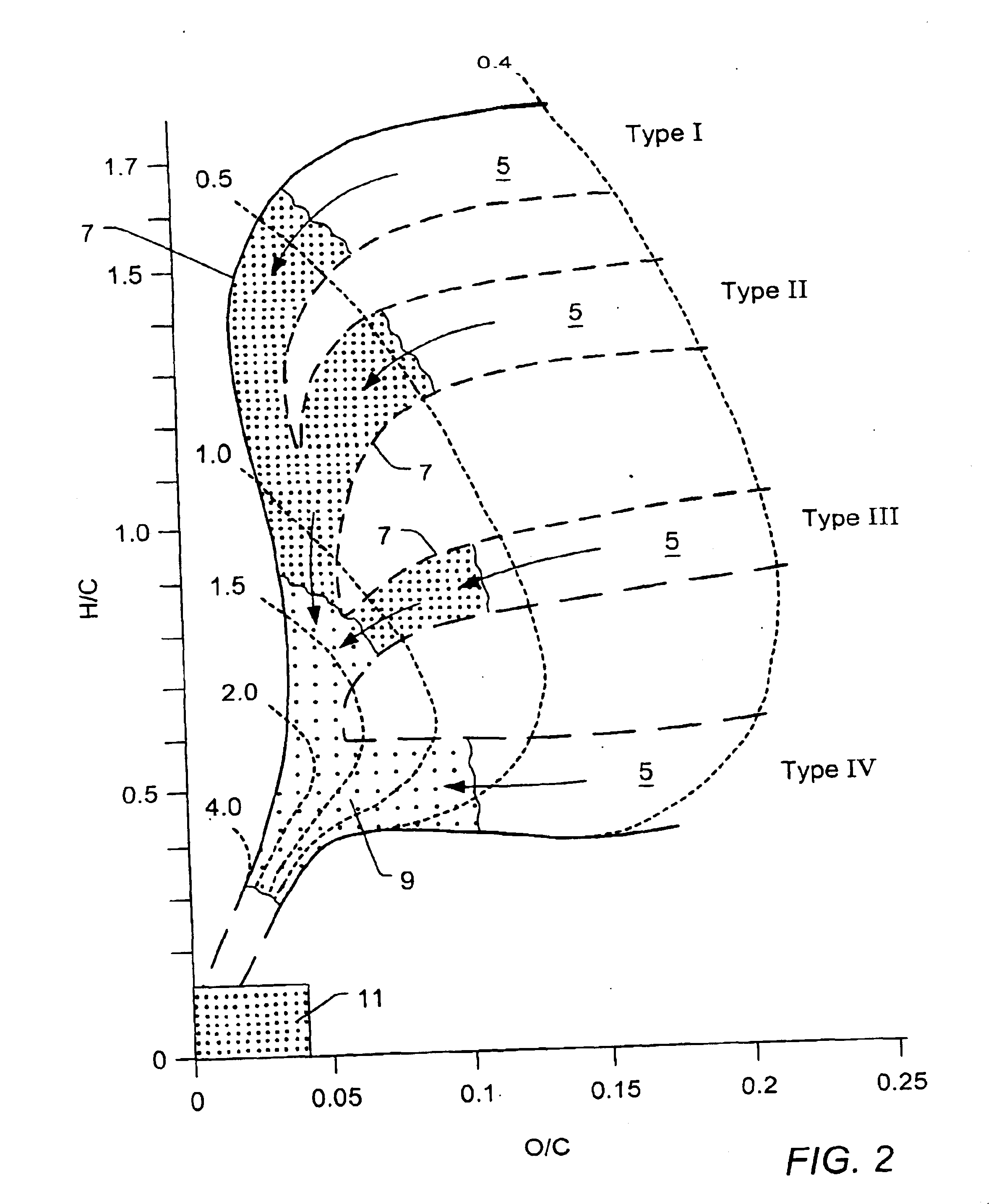

In situ thermal processing of a hydrocarbon containing formation using a controlled heating rate

InactiveUS6745837B2High calorific valueImprove the heating effectSurveyCombustion processFormation fluidHeat energy

A hydrocarbon containing formation may be treated using an in situ thermal process. A mixture of hydrocarbons, H.sub.2, and / or other formation fluids may be produced from the formation. Heat may be applied to the formation to raise a temperature of a portion of the formation to a pyrolysis temperature. A heating rate to a selected volume of the formation may be controlled by altering an amount of heating energy per day that is provided to the selected volume.

Owner:SALAMANDER SOLUTIONS INC

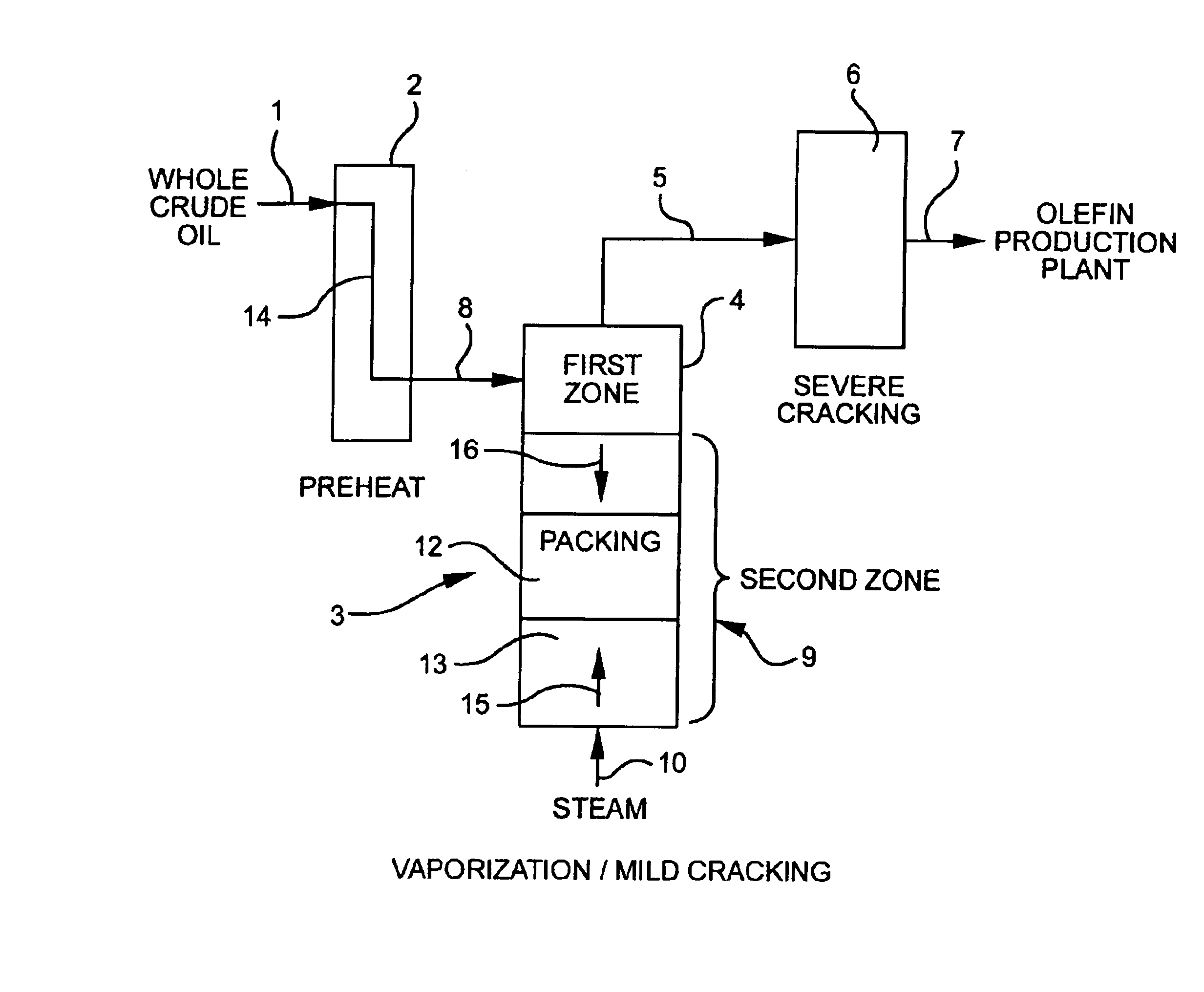

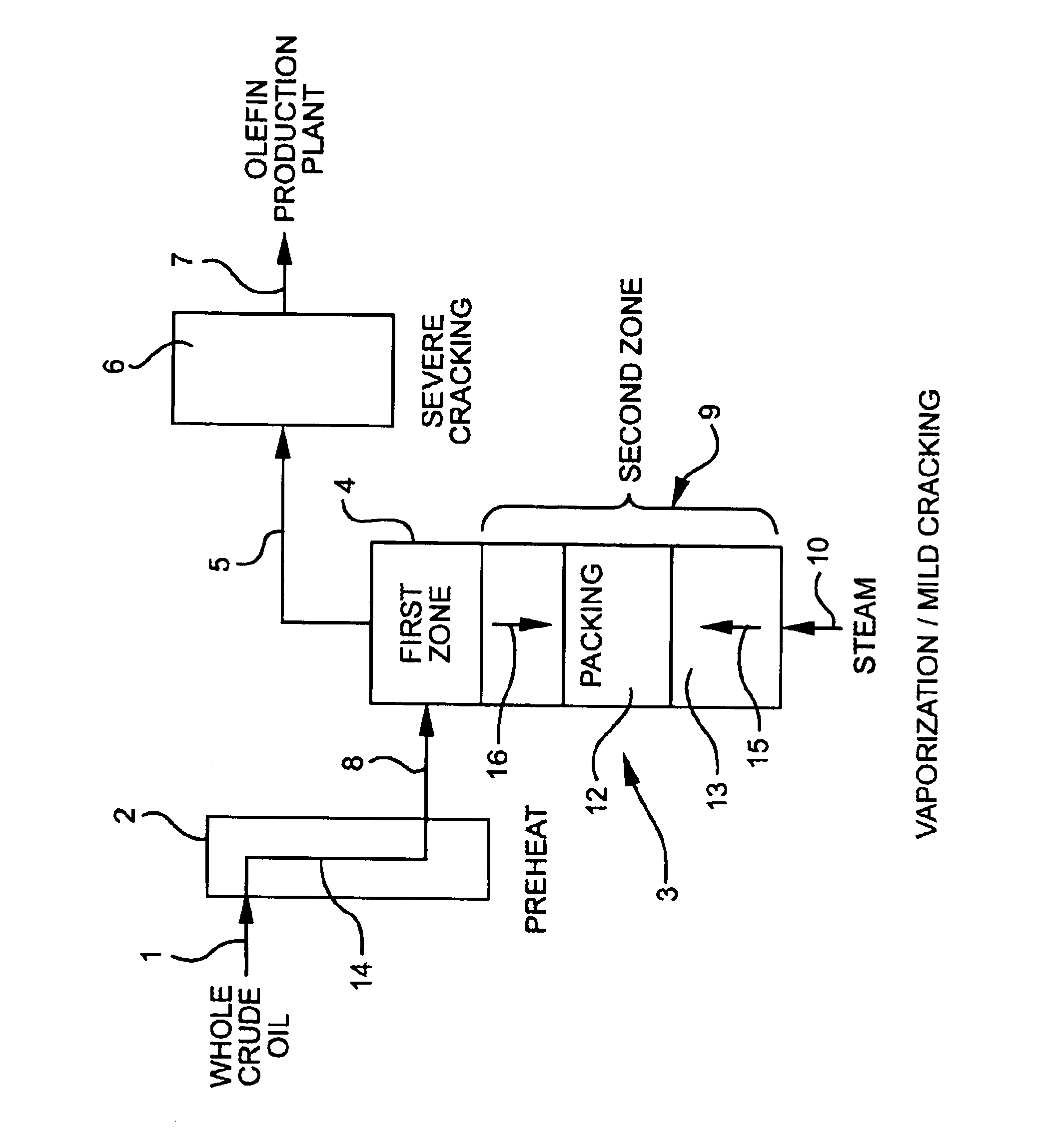

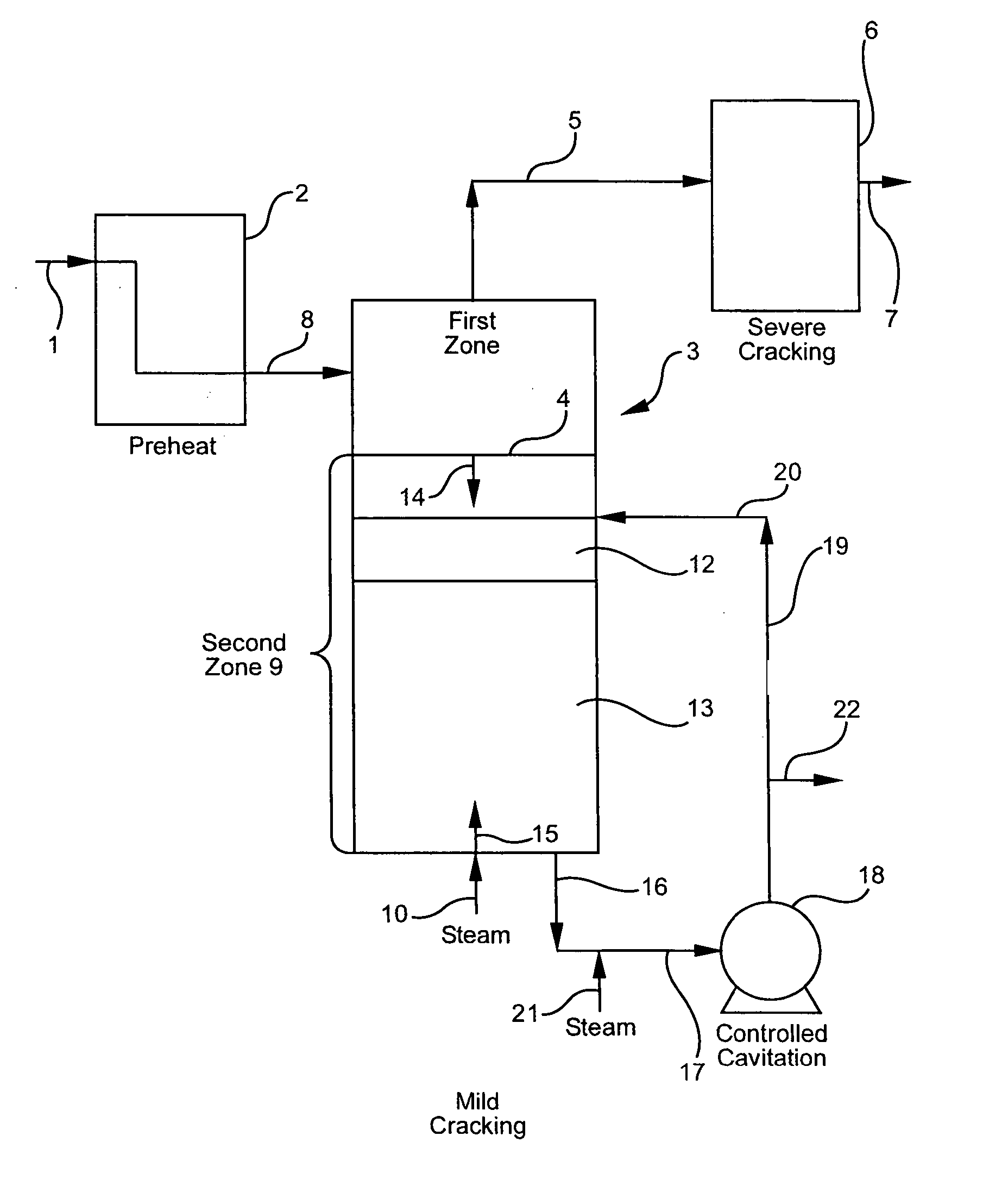

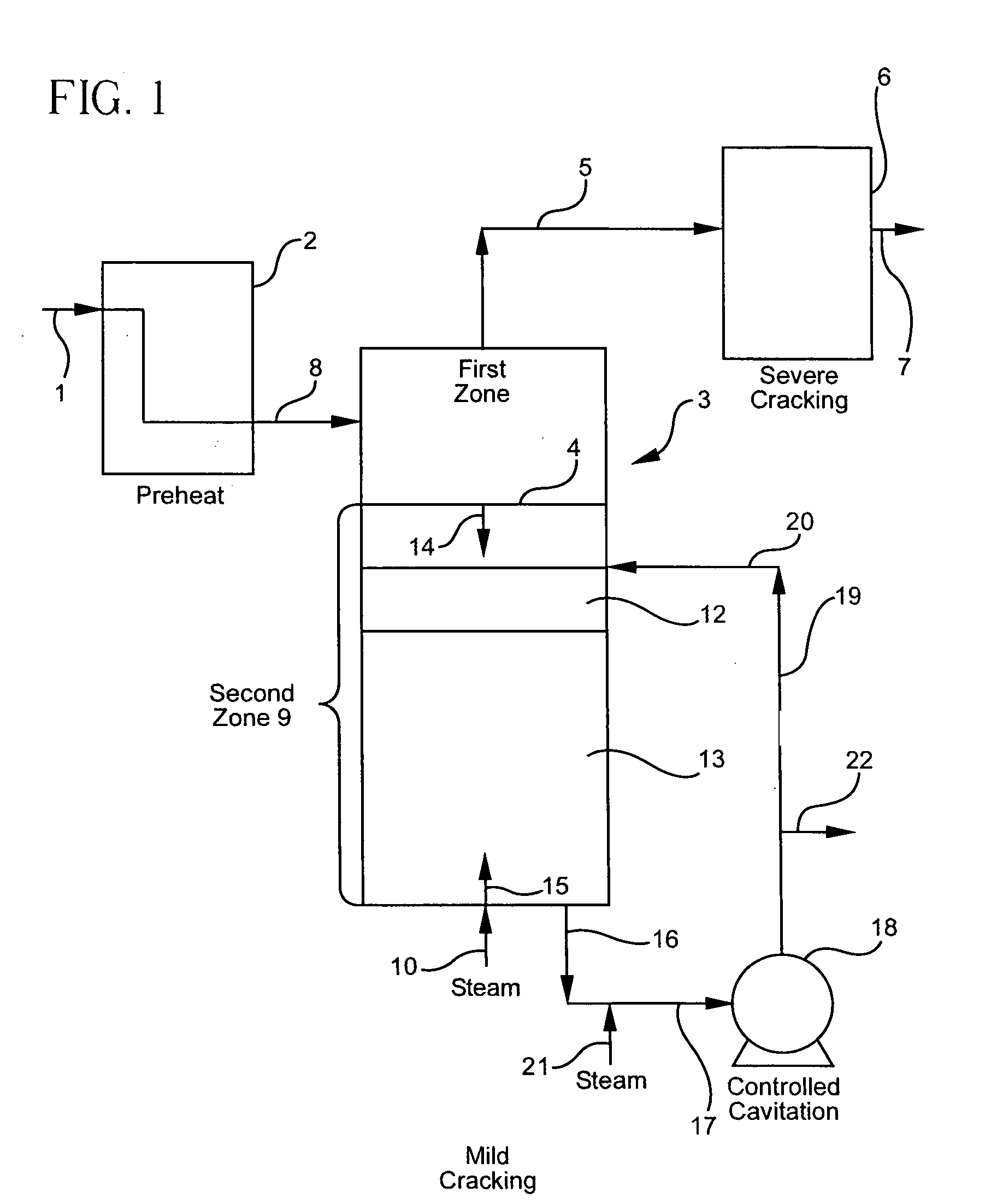

Olefin production utilizing whole crude oil

InactiveUS6743961B2Lower temperature rangeReduce molecular weightThermal non-catalytic crackingHydrocarbonsOil productionAlkene

A method for utilizing whole crude oil as a feedstock for the pyrolysis furnace of an olefin production plant wherein the feedstock after preheating is subjected to mild cracking conditions until substantially vaporized, the vapors from mild cracking being subjected to severe cracking in the radiant section of the furnace.

Owner:EQUSR CHEM LP

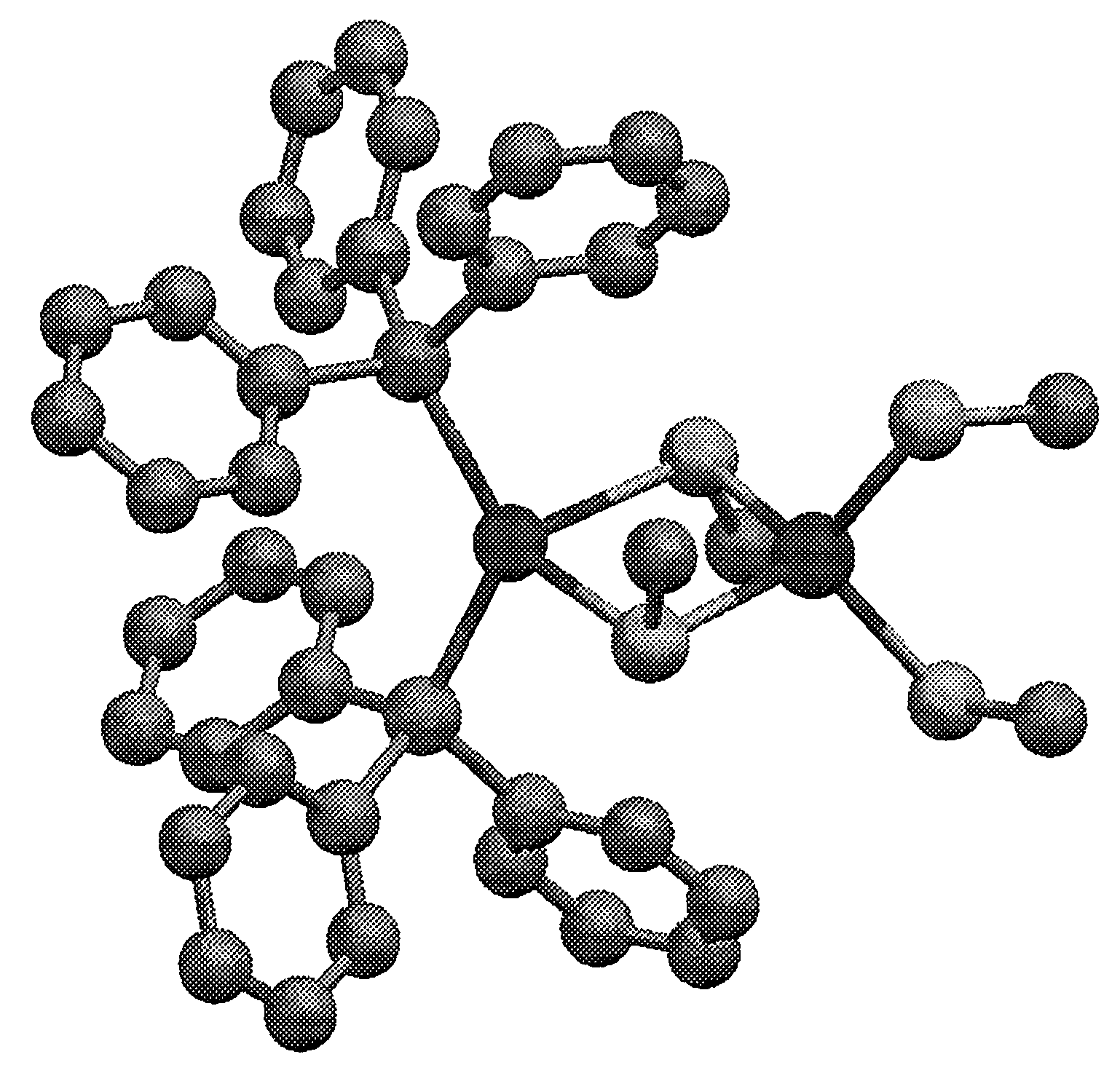

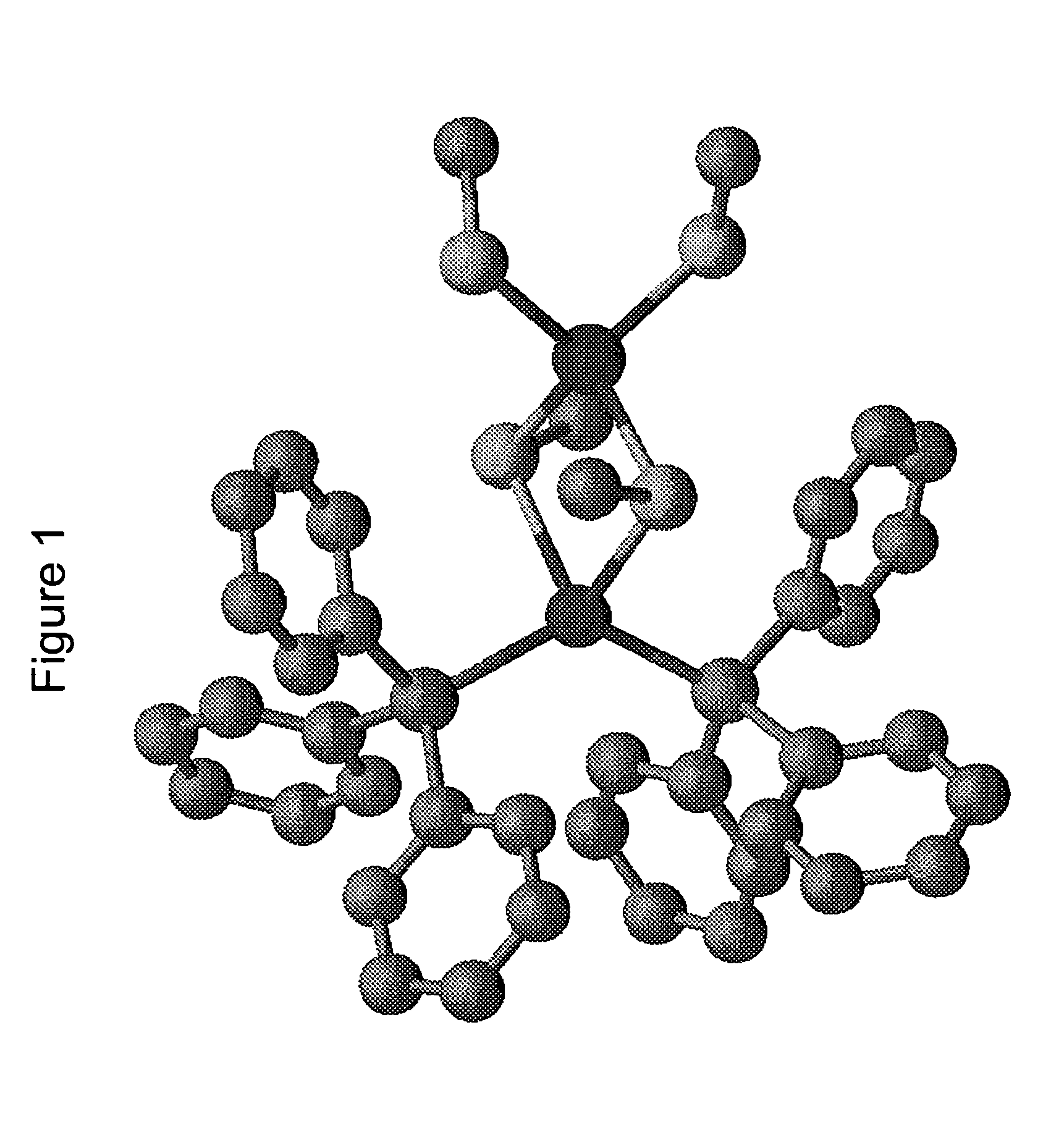

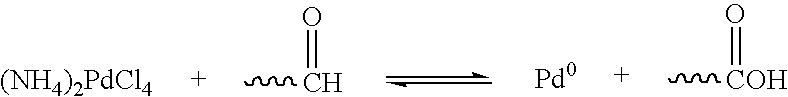

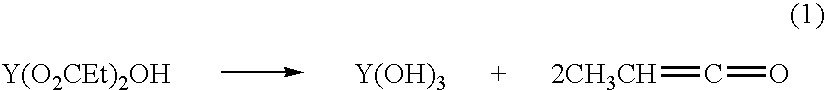

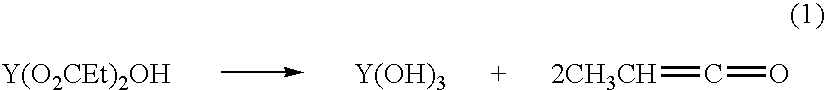

Single-source precursors for ternary chalcopyrite materials, and methods of making and using the same

InactiveUS6992202B1Effective yieldFurnaces without endless coreMaterial nanotechnologyChalcopyriteQuantum dot

A single source precursor for depositing ternary I-III-VI2 chalcopyrite materials useful as semiconductors. The single source precursor has the I-III-VI2 stoichiometry “built into” a single precursor molecular structure which degrades on heating or pyrolysis to yield the desired I-III-VI2 ternary chalcopyrite. The single source precursors effectively degrade to yield the ternary chalcopyrite at low temperature, e.g. below 500° C., and are useful to deposit thin film ternary chalcopyrite layers via a spray CVD technique. The ternary single source precursors according to the invention can be used to provide nanocrystallite structures useful as quantum dots. A method of making the ternary single source precursors is also provided.

Owner:OHIO AEROSPACE INST +1

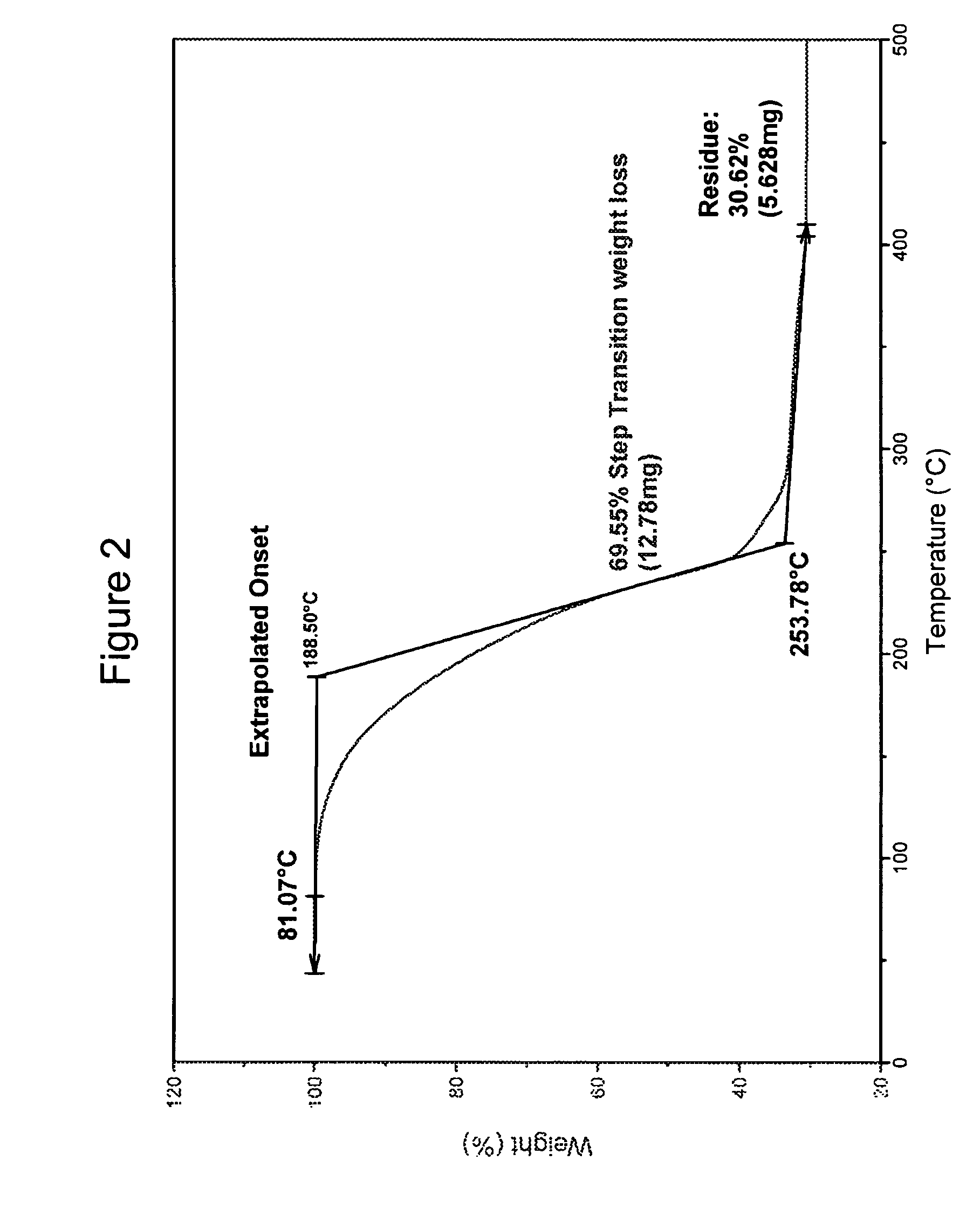

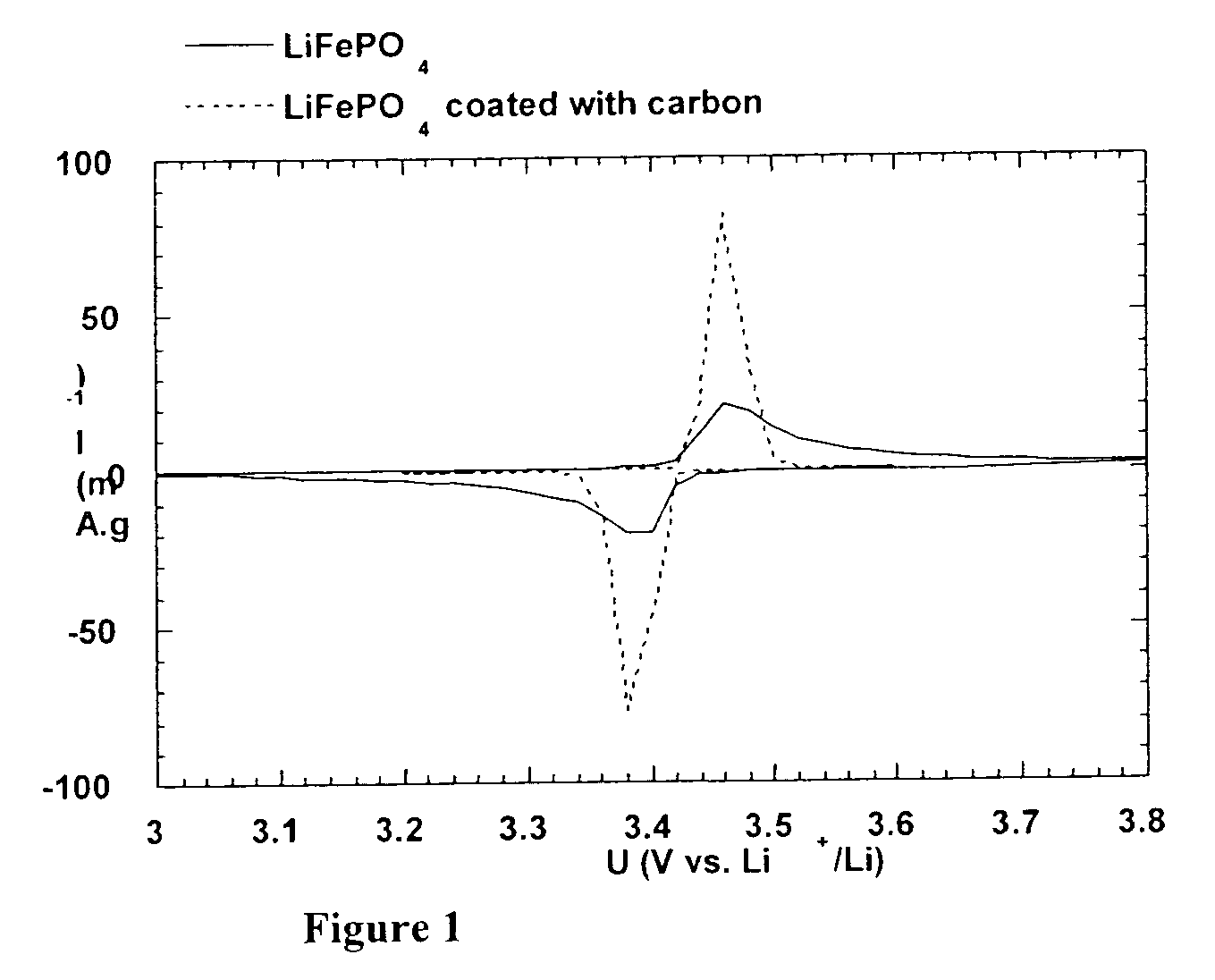

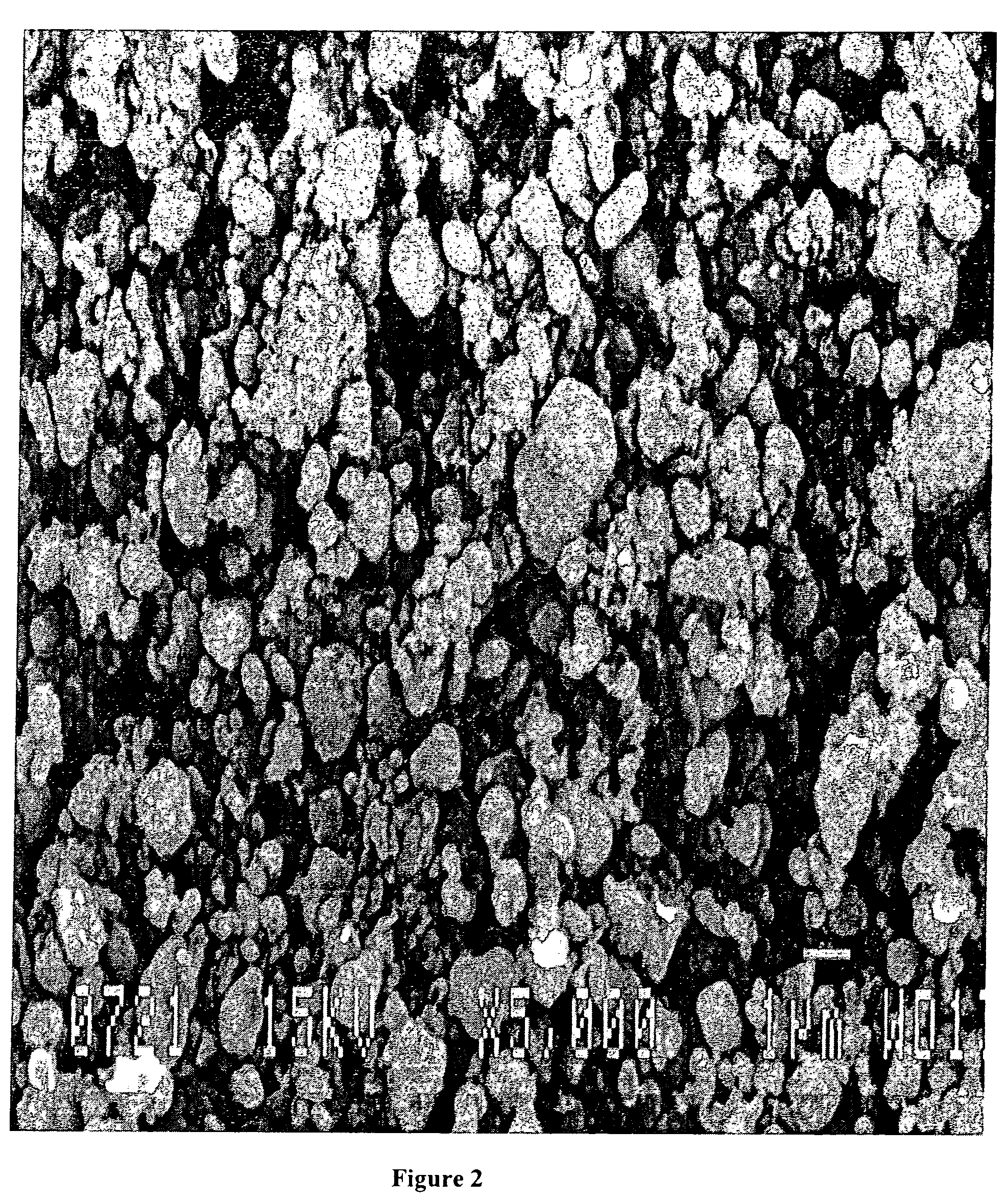

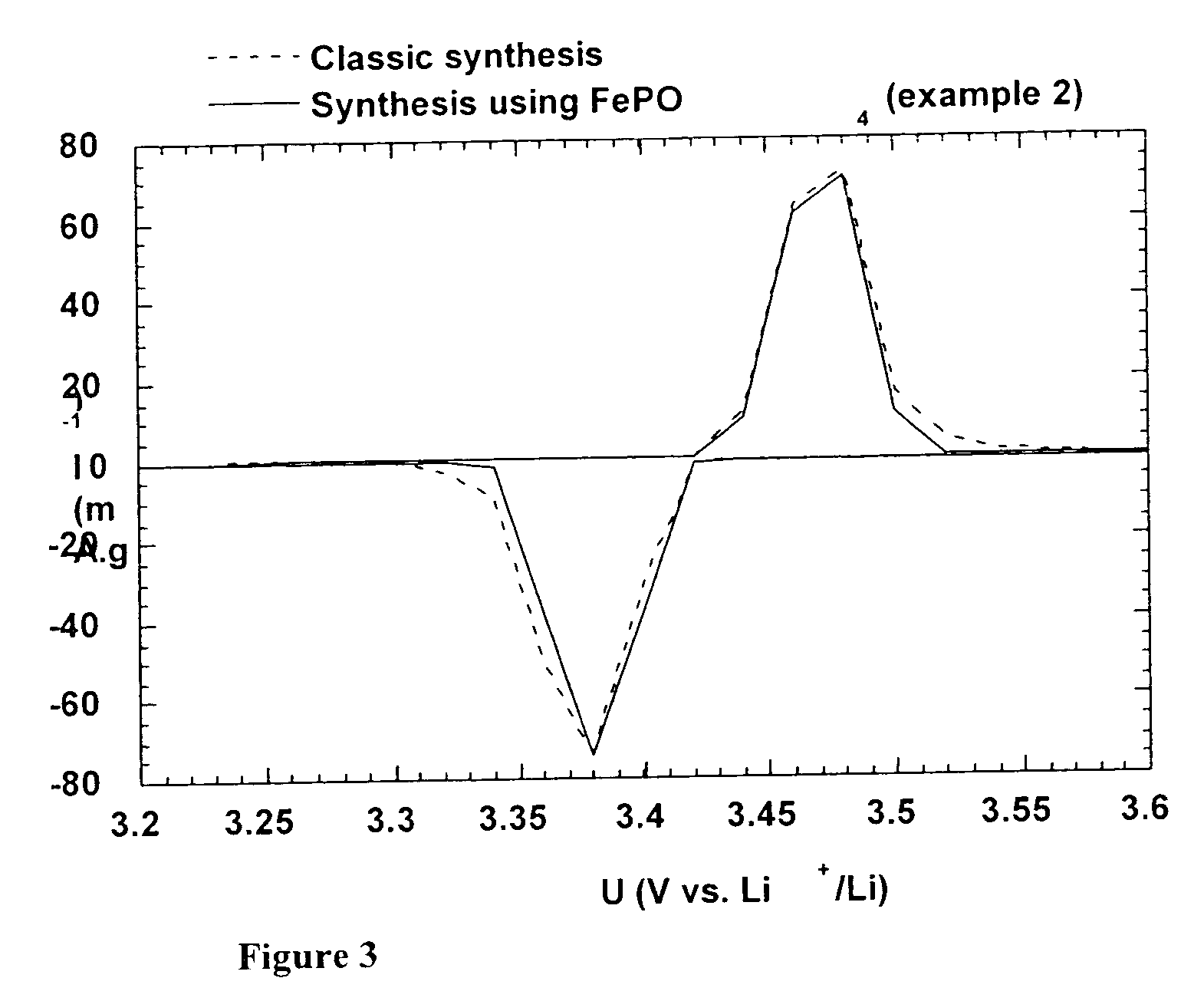

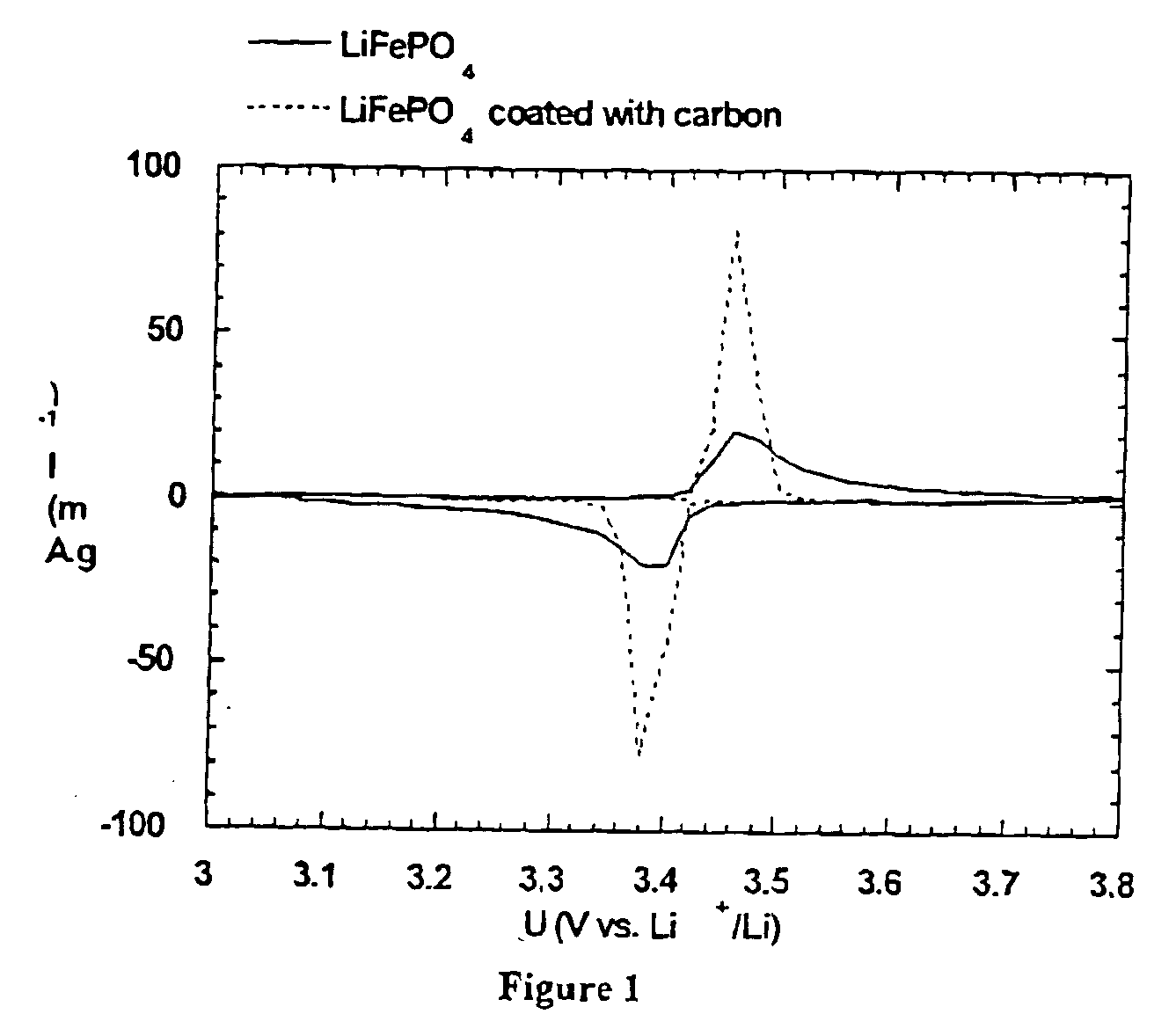

Method for synthesis of carbon-coated redox materials with controlled size

ActiveUS20040033360A1Low costReduce the numberMaterial nanotechnologyHybrid capacitorsCross-linkRedox

A method for the synthesis of compounds of the formula C-LixM1-yM'y(XO4)n, where C represents carbon cross-linked with the compound LixM1-yM'y(XO4)n, in which x, y and n are numbers such as 0<=x<=2, 0<=y<=0.6, and 1<=n<=1.5, M is a transition metal or a mixture of transition metals from the first period of the periodic table, M' is an element with fixed valency selected among Mg<2+>, Ca<2+>, Al<3+>, Zn<2+> or a combination of these same elements and X is chosen among S, P and Si, by bringing into equilibrium, in the required proportions, the mixture of precursors, with a gaseous atmosphere, the synthesis taking place by reaction and bringing into equilibrium, in the required proportions, the mixture of the precursors, the procedure comprising at least one pyrolysis step of the carbon source compound in such a way as to obtain a compound in which the electronic conductivity measured on a sample of powder compressed at a pressure of 3750 Kg.cm<-2 >is greater than 10<-8 >S.cm<-1>. The materials obtained have excellent electrical conductivity, as well a very improved chemical activity.

Owner:CENT NAT DE LA RECHERCHE SCI +2

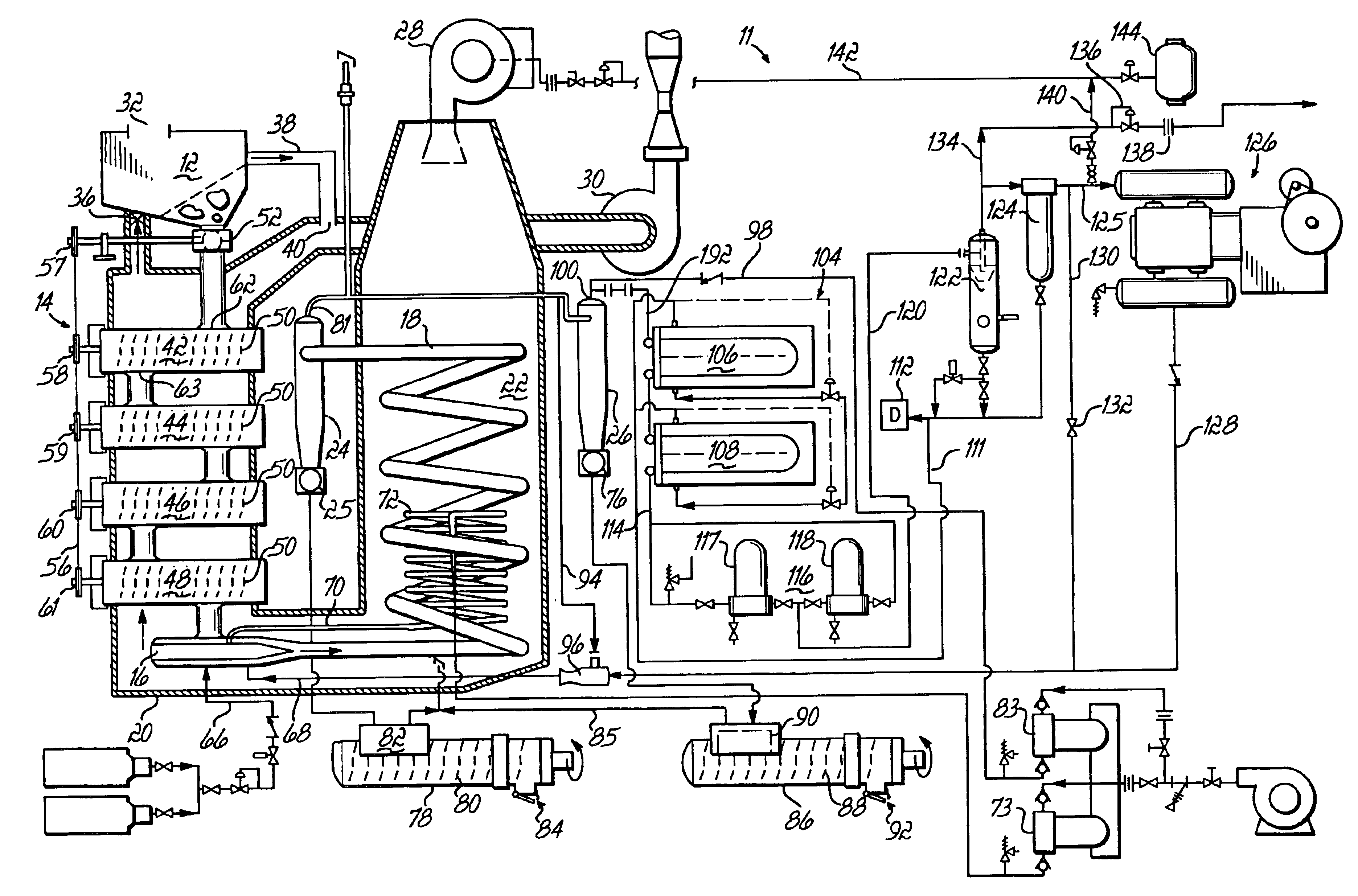

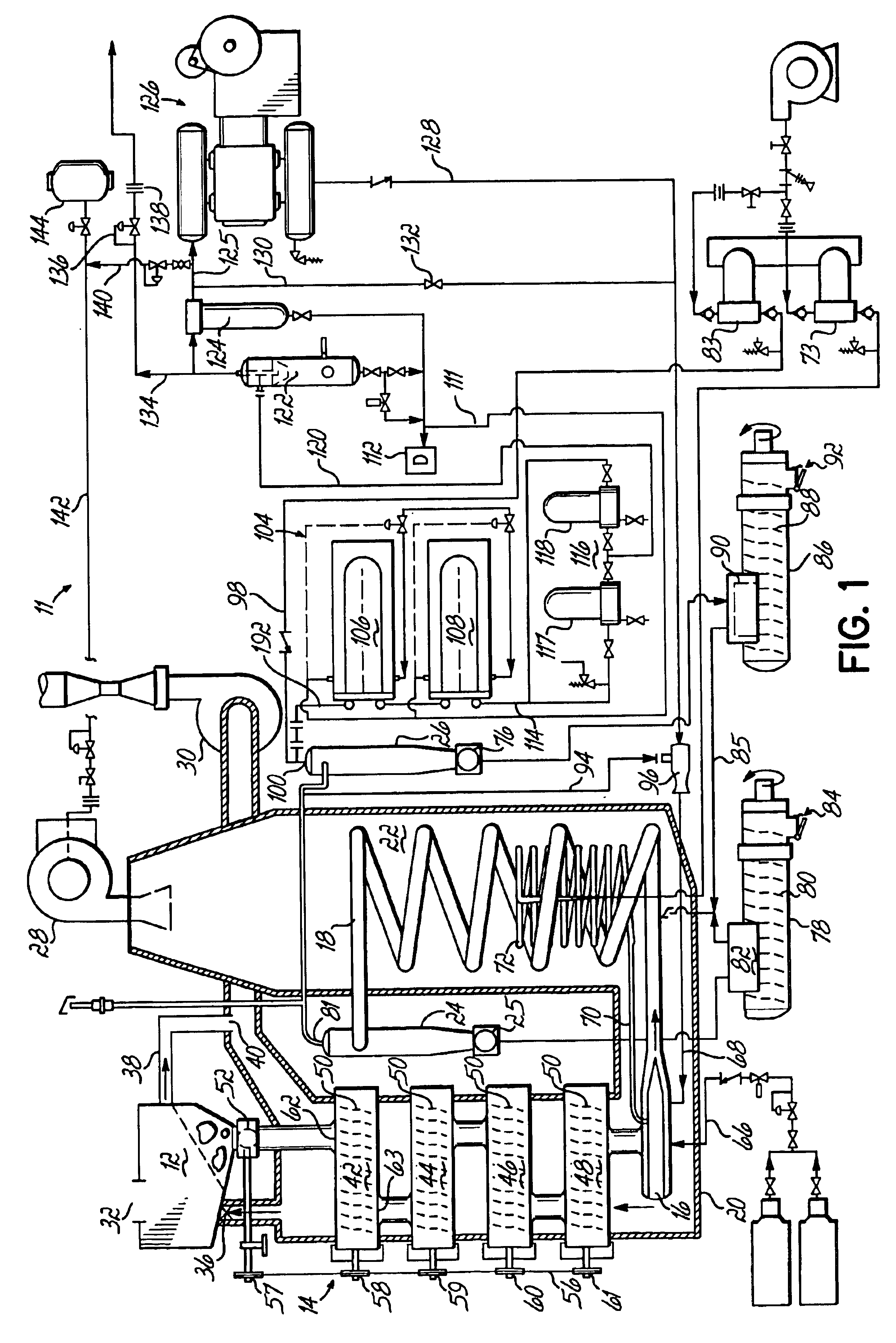

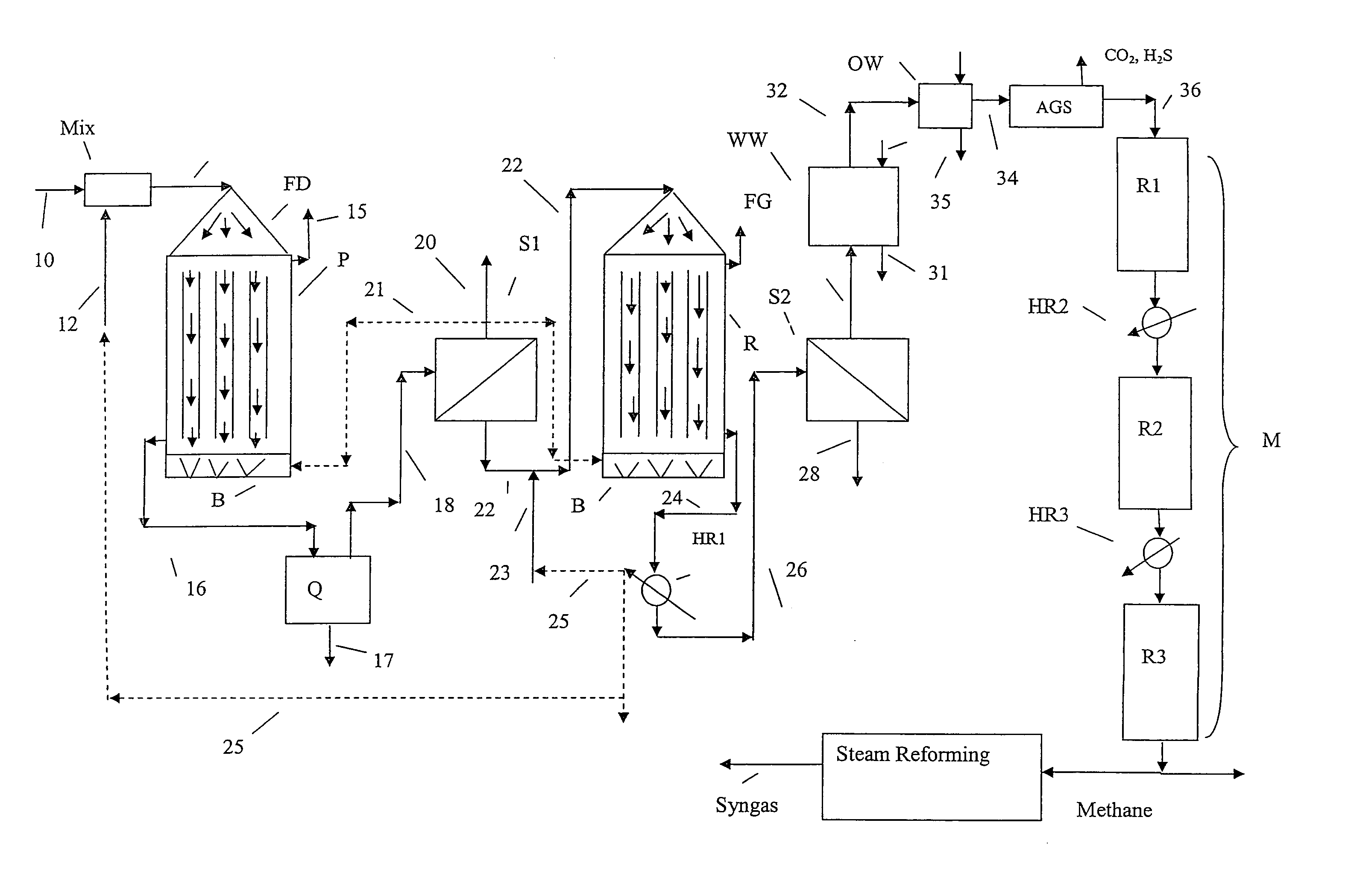

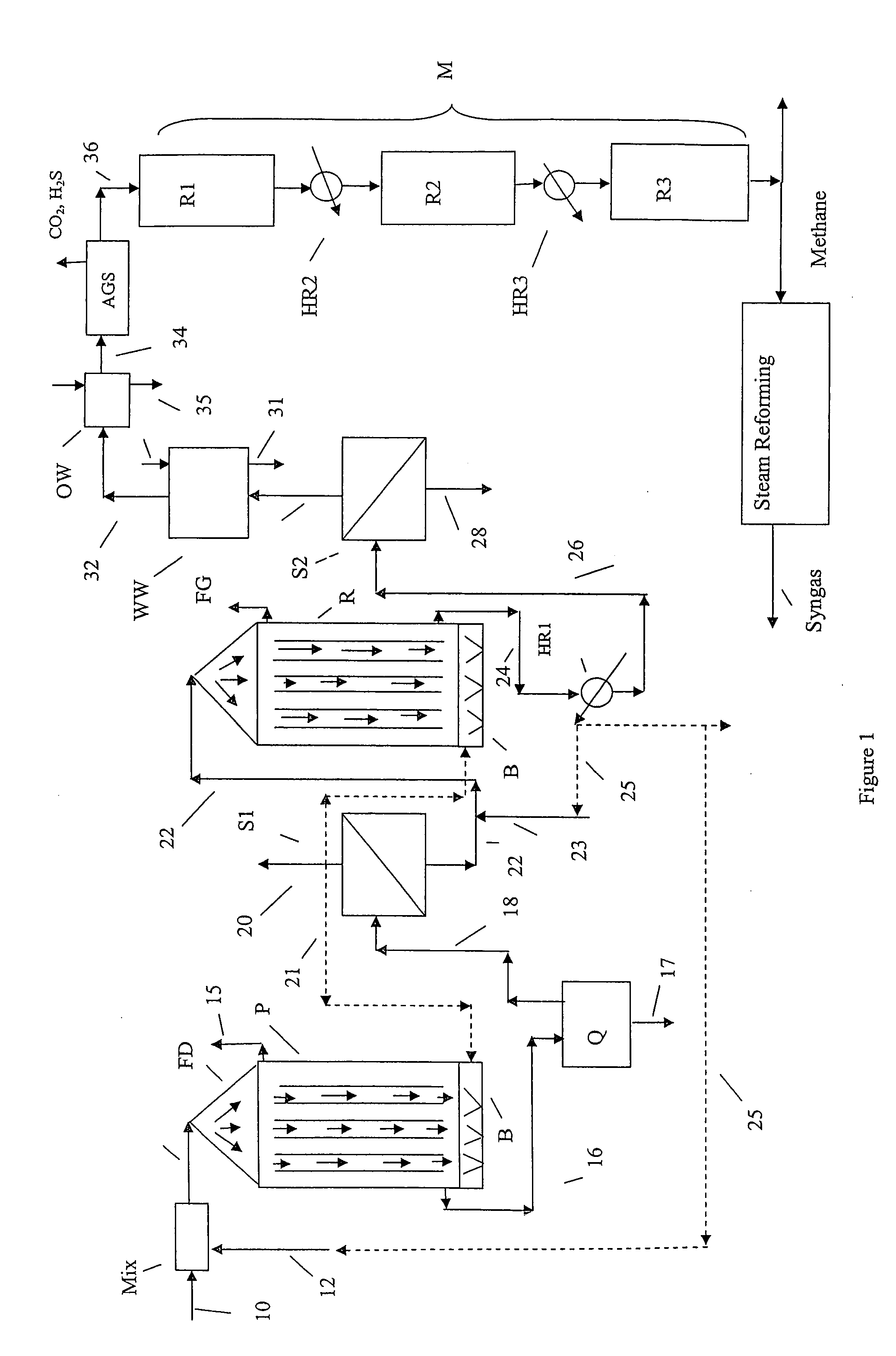

Method and apparatus for producing synthesis gas from carbonaceous materials

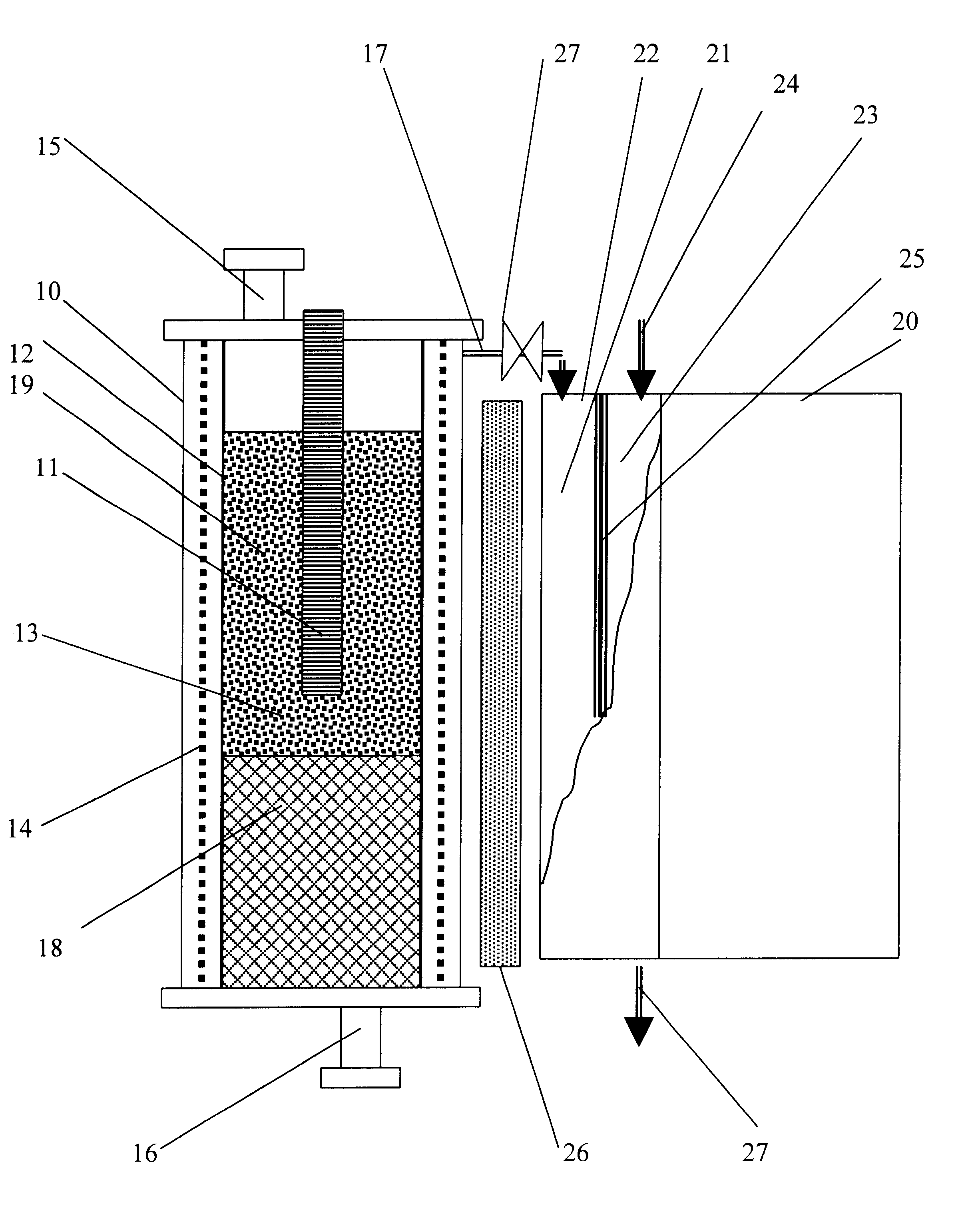

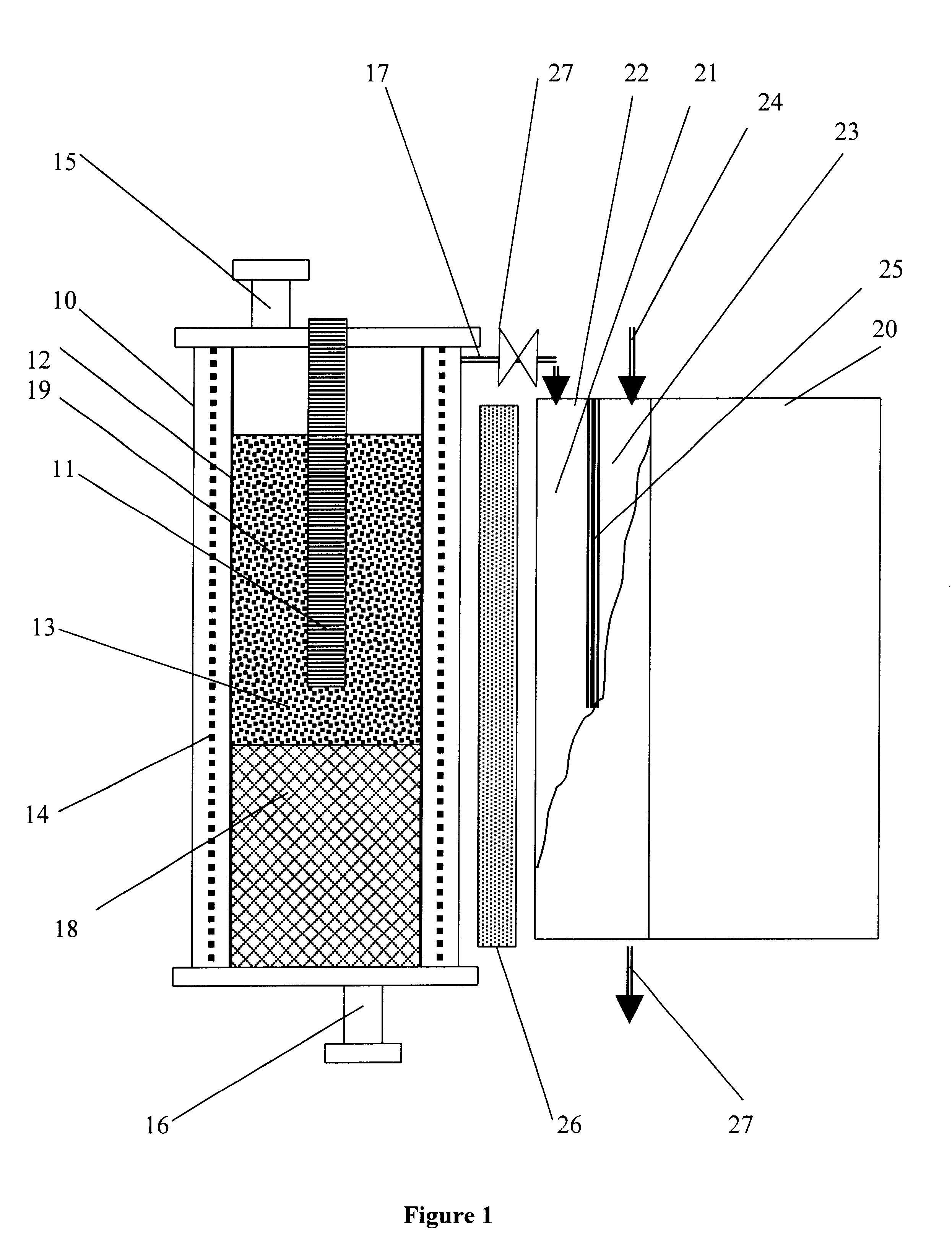

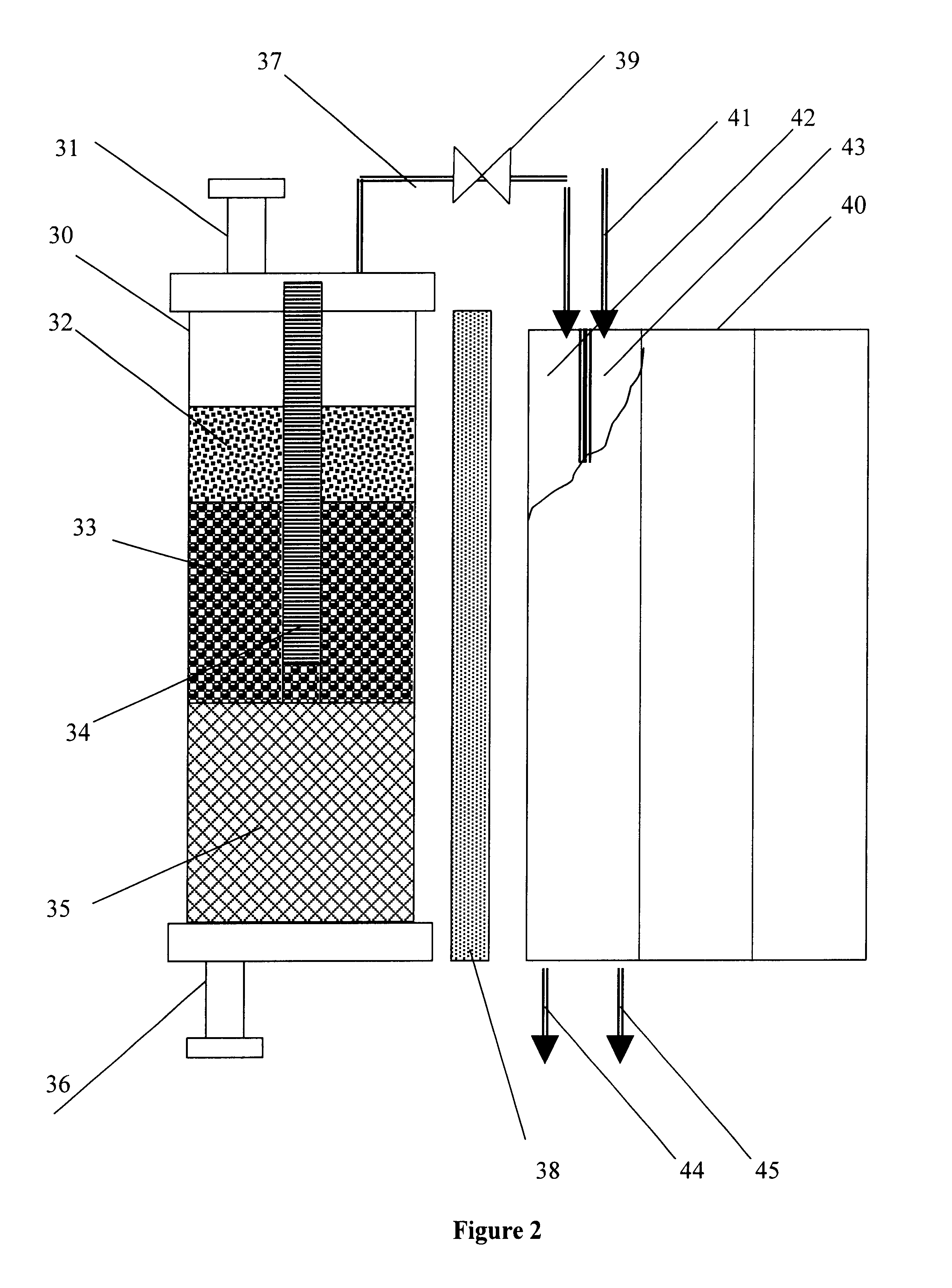

A method of producing syn gas from biomass or other carbonaceous material utilizes a controlled devolatilization reaction in which the temperature of the feed material is maintained at less than 450° F. until most available oxygen is consumed. This minimizes pyrolysis of the feed material. The method and apparatus utilizes the formed synthesis gas to provide the energy for the necessary gasification. This provides for a high purity syn gas and avoids production of slag.

Owner:JBK EXTRACTIONS

In situ thermal processing of a coal formation to increase a permeability/porosity of the formation

InactiveUS6866097B2Reduce the temperatureHigh strengthSurveyCombustion processPorosityInitial permeability

Owner:SHELL OIL CO

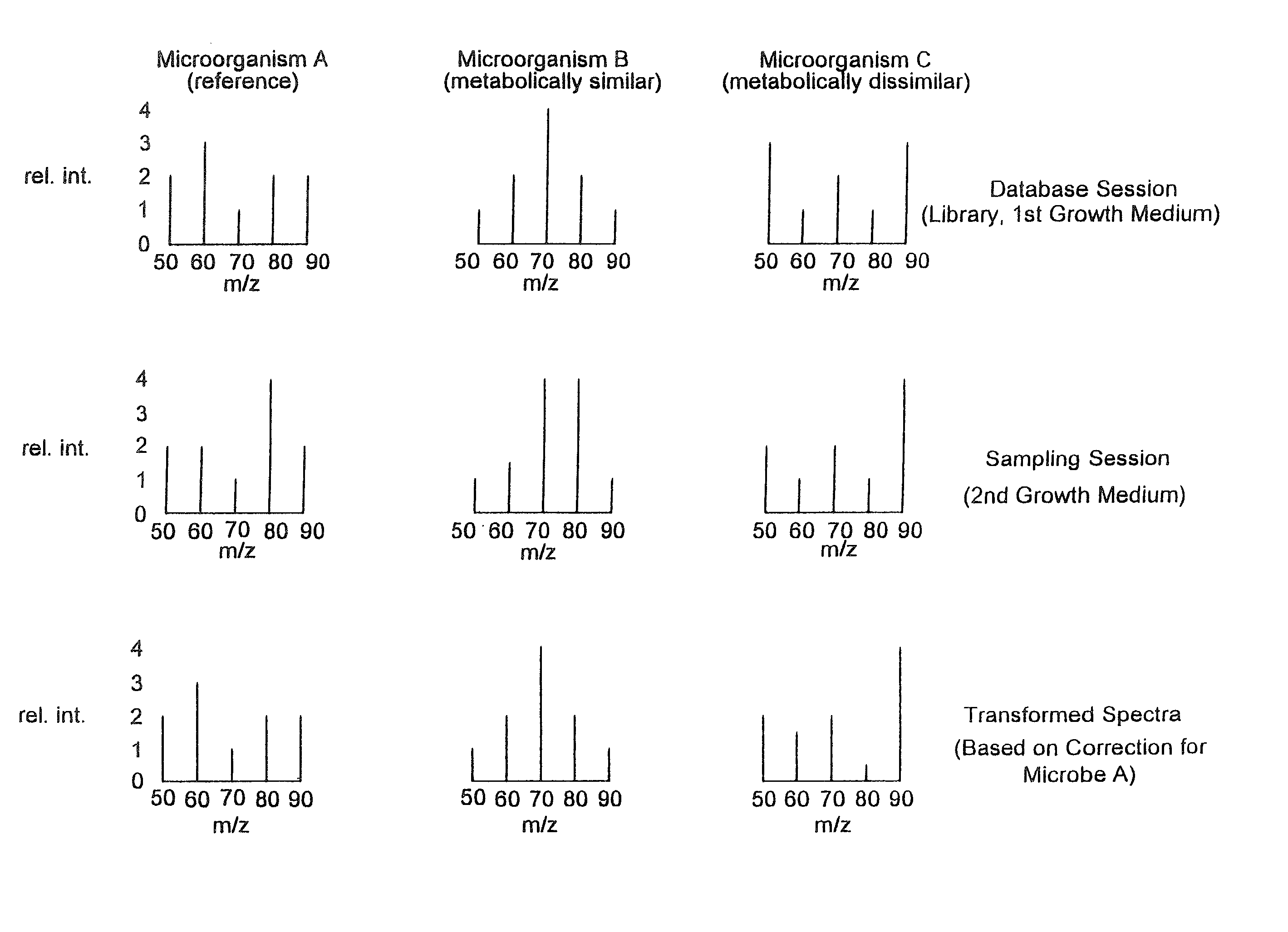

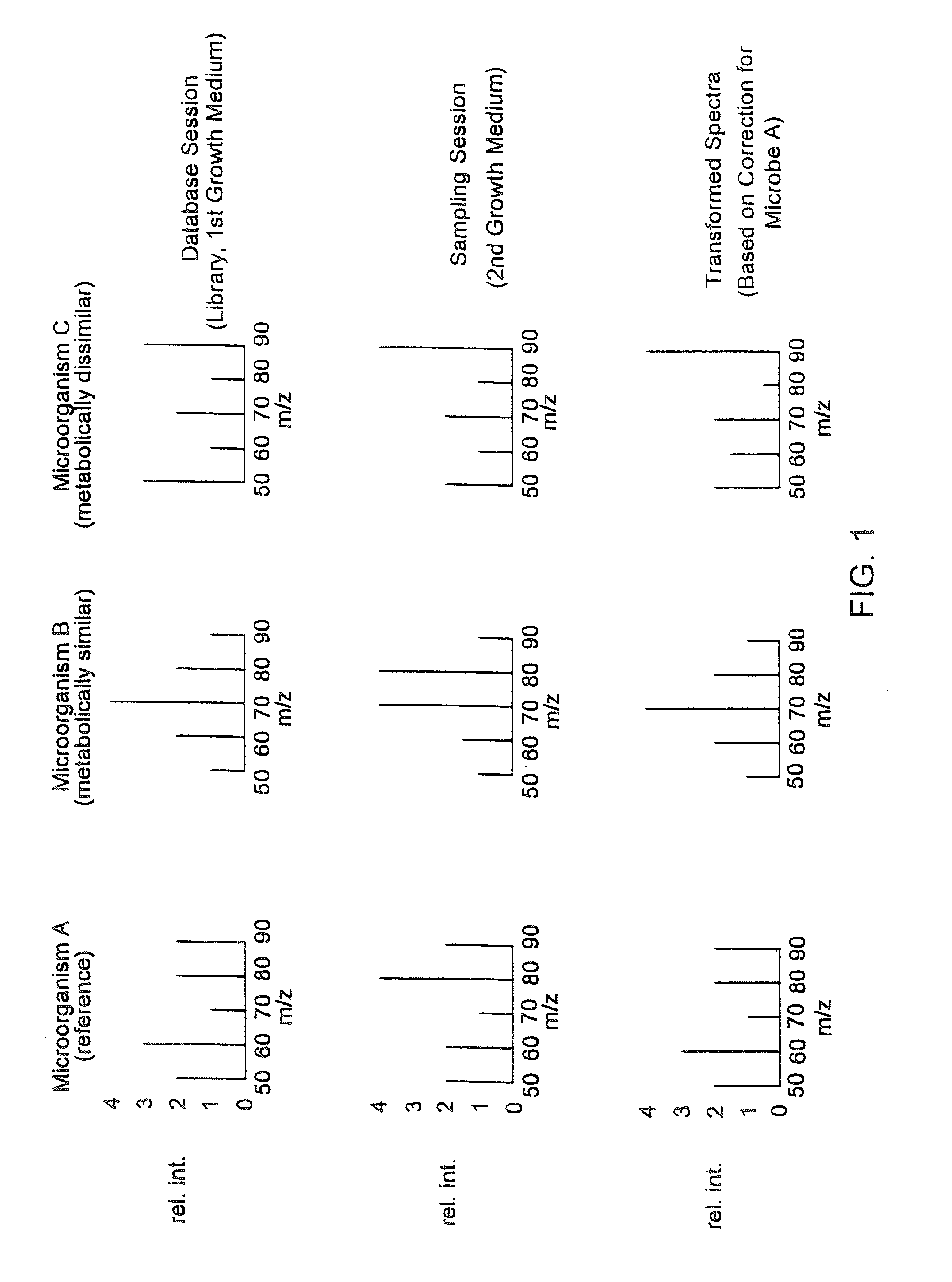

Microbial identification databases

InactiveUS20020138210A1Easy mappingComponent separationBiological testingMicroorganismMass spectral database

Methods of compensating for drift in fingerprint spectra of microorganisms caused by changes in their environment are disclosed. These methods of compensating for drift permit identification of microorganisms from their fingerprint spectra regardless of the environment from which the microorganisms are obtained. Furthermore, the disclosed methods may be used to construct coherent databases of fingerprint spectra that may be expanded even though the standard database conditions are no longer experimentally achievable. In particular embodiments, methods of compensating for drift in pyrolysis mass spectra, constructing coherent pyrolysis mass spectral databases, and identifying bacteria from their pyrolysis mass spectra are disclosed.

Owner:HEALTH & HUMAN SERVICES THE GOVERNMENT OF THE US SEC THE DEPT

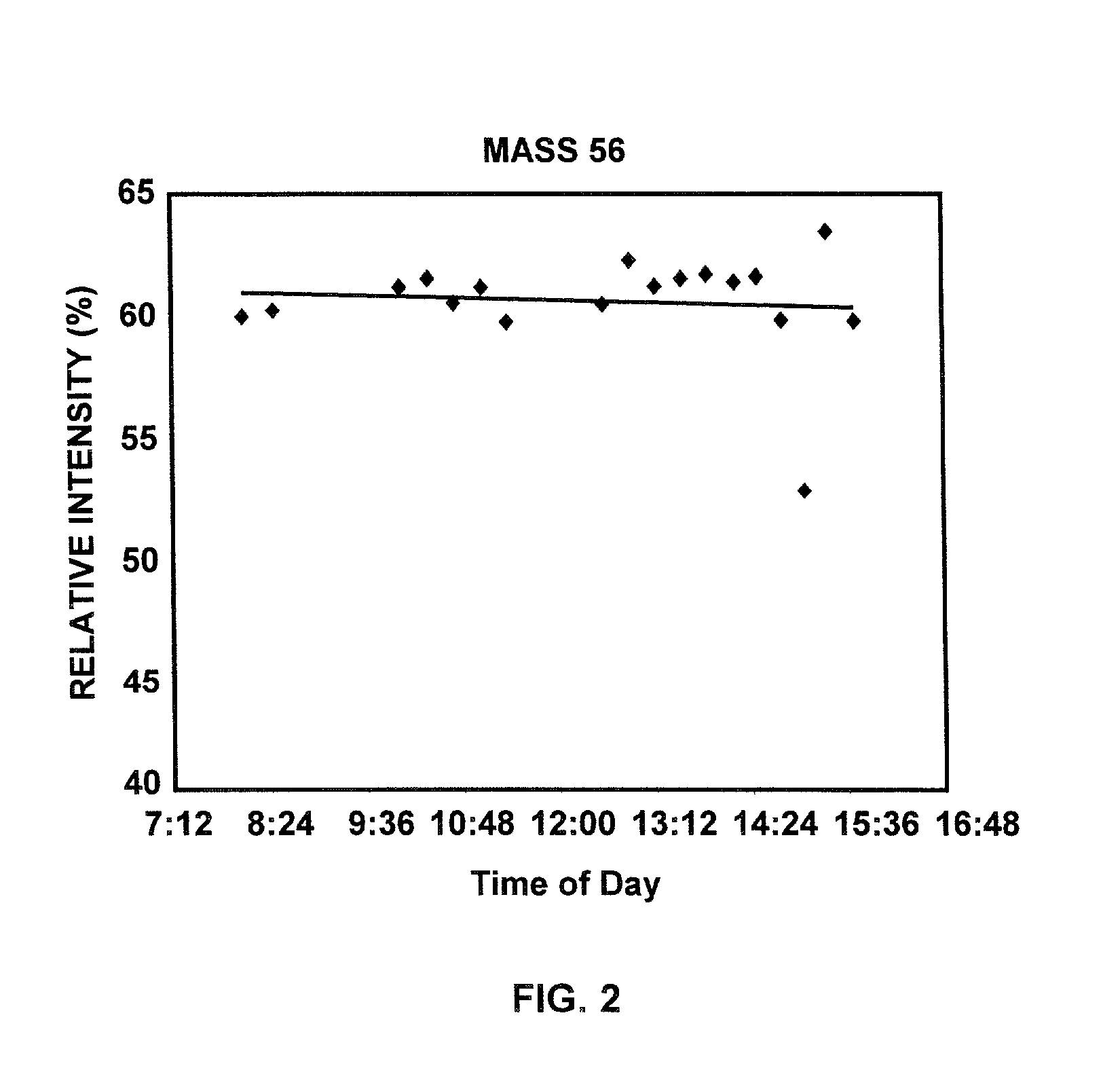

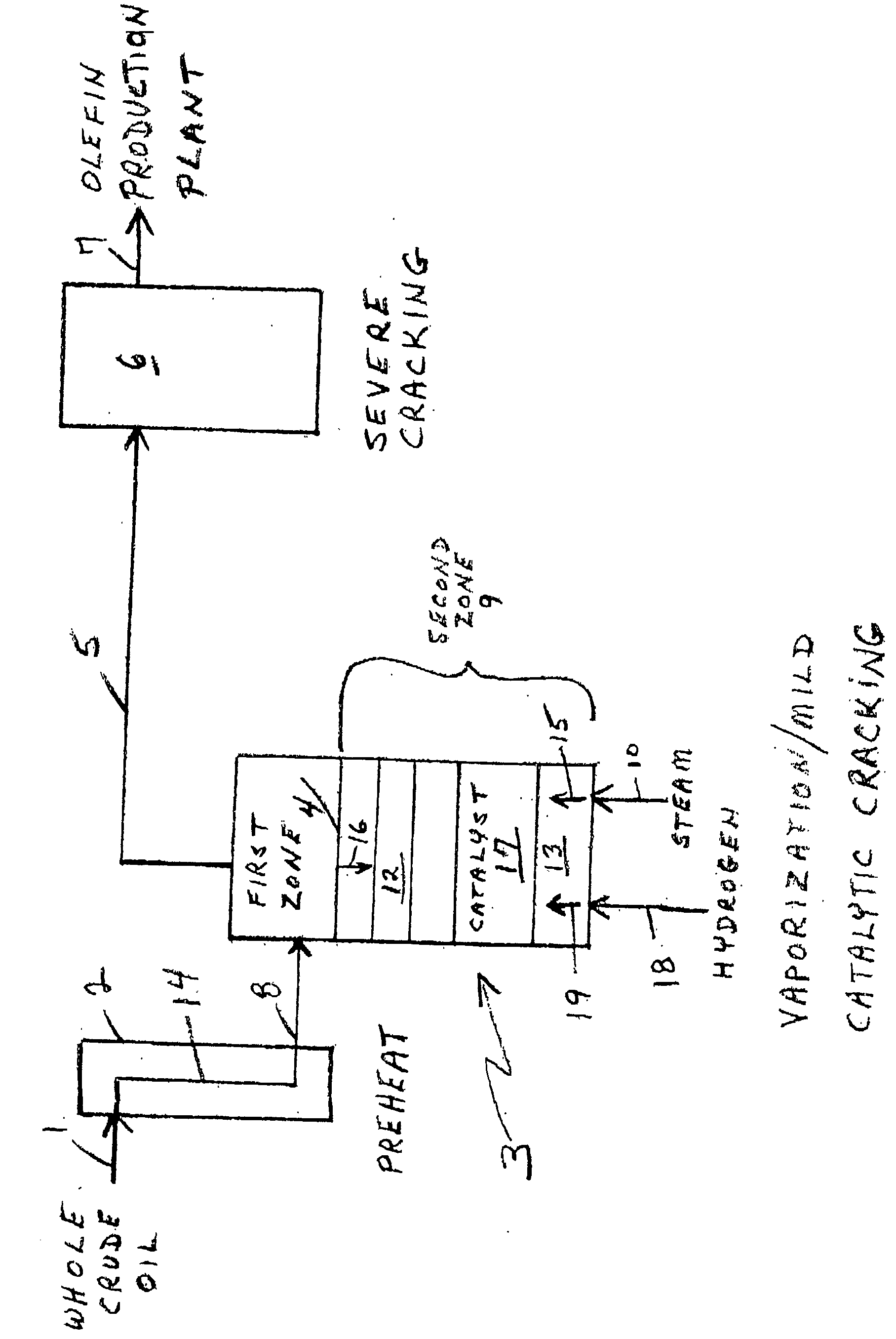

Olefin production utilizing whole crude oil and mild catalytic cracking

InactiveUS20040054247A1Lower temperature rangeImproved vaporizationThermal non-catalytic crackingCatalytic crackingChemistryPyrolysis

A method for utilizing whole crude oil as a feedstock for the pyrolysis furnace of an olefin production plant wherein the feedstock after preheating is subjected to mild catalytic cracking conditions until substantially vaporized, the vapors from the mild catalytic cracking being subjected to severe cracking in the radiant section of the furnace.

Owner:EQUSR CHEM LP

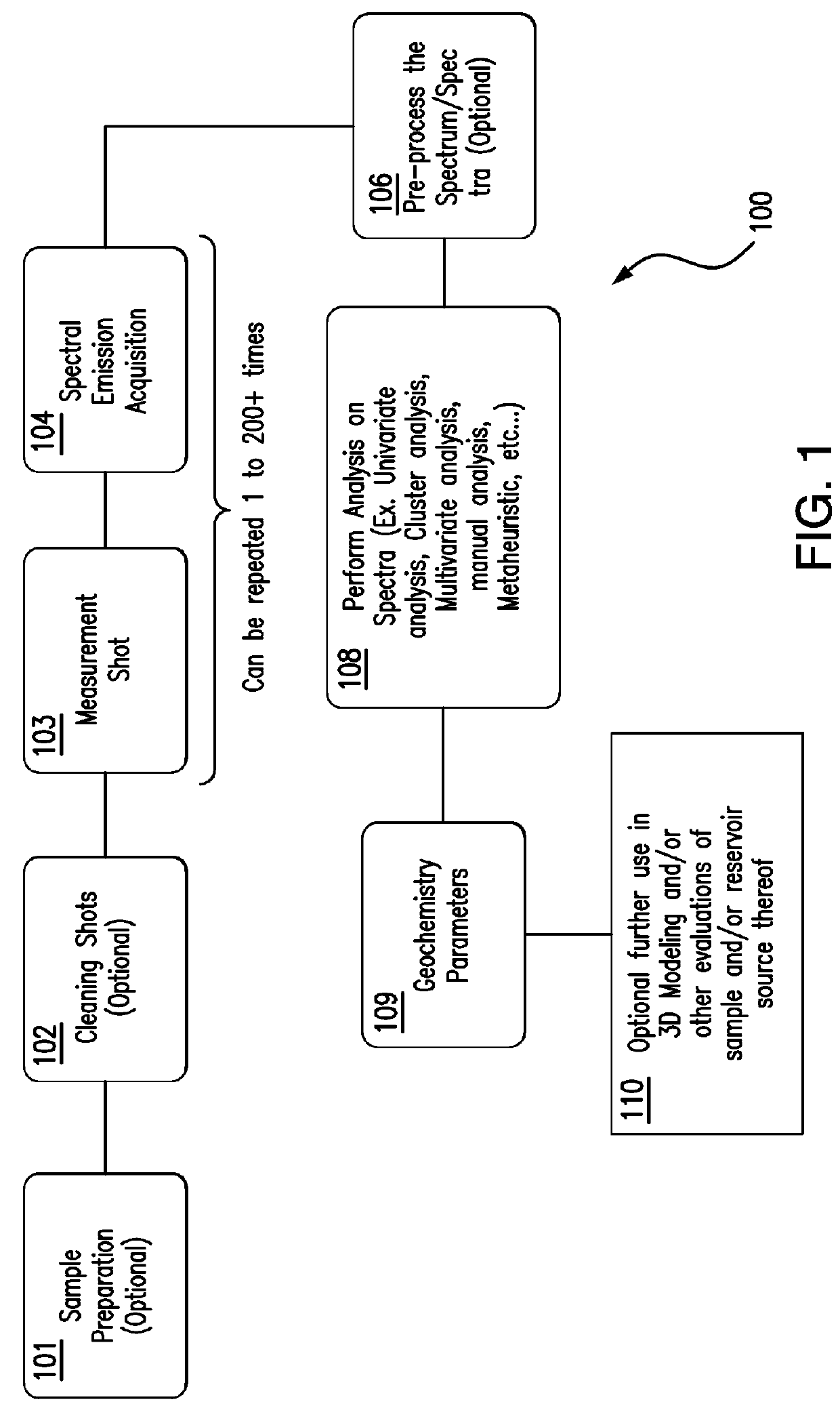

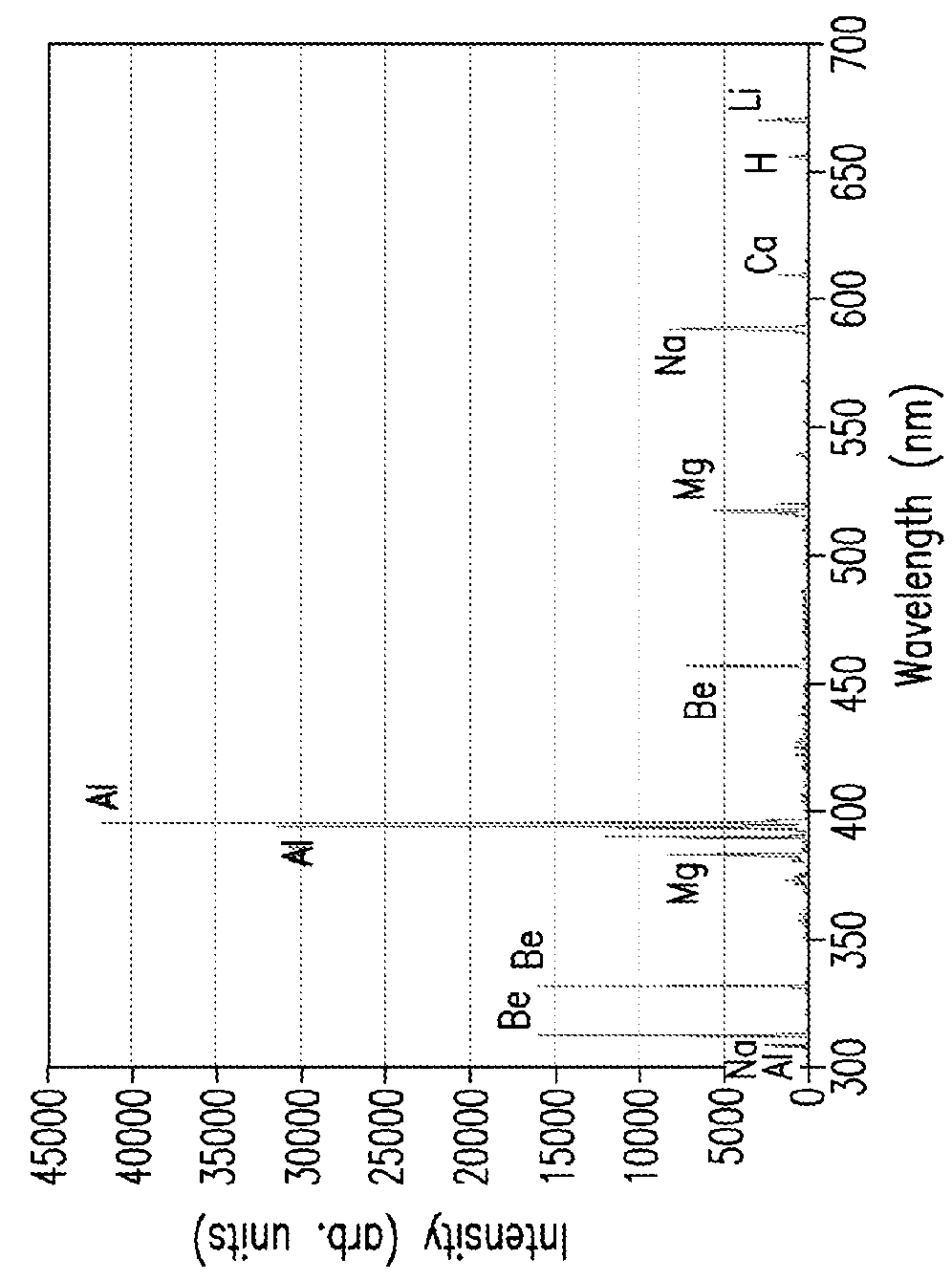

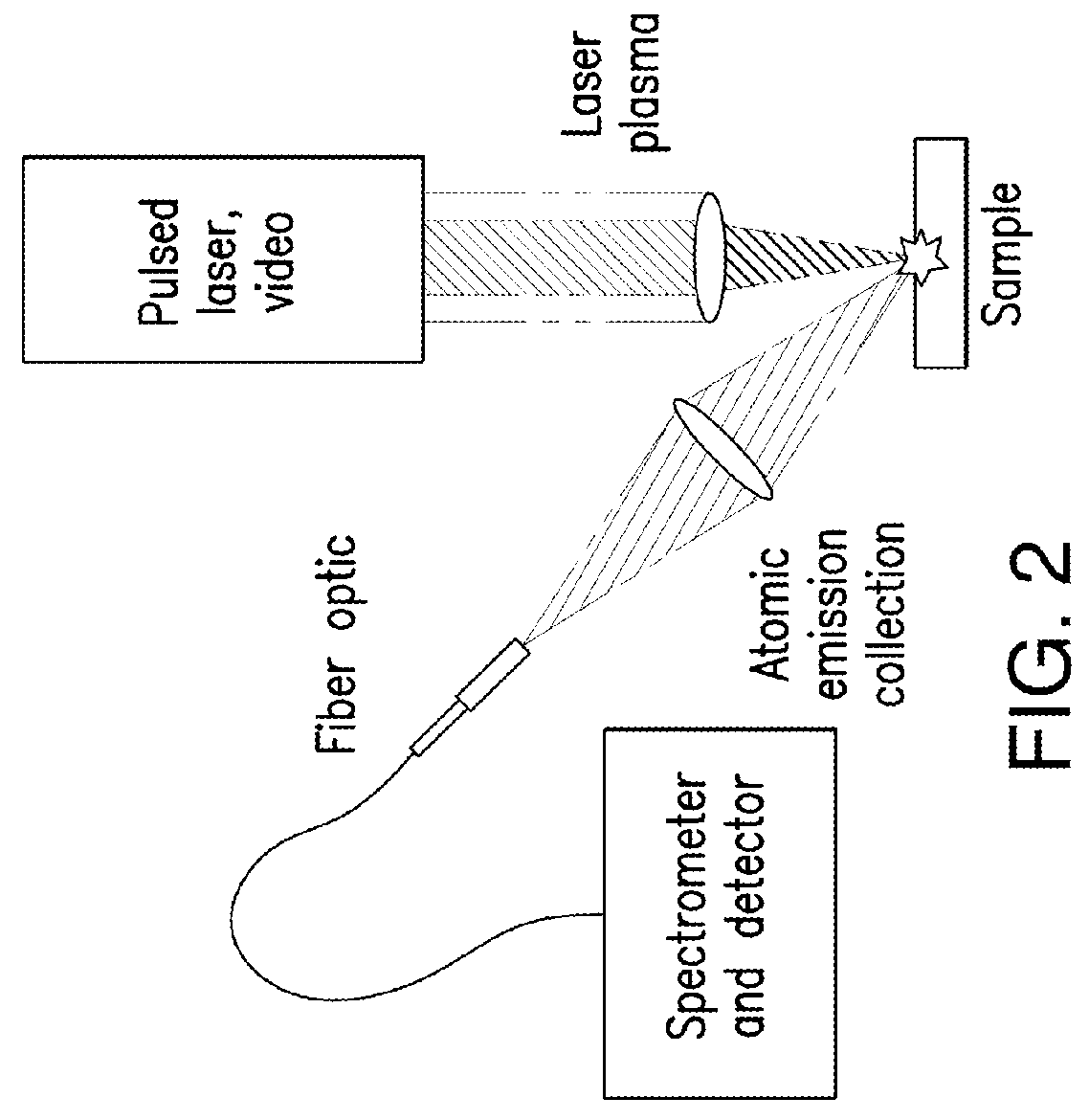

Method And System For Obtaining Geochemistry Information From Pyrolysis Induced By Laser Induced Breakdown Spectroscopy

ActiveUS20160054284A1Simple methodEmission spectroscopyEarth material testingNon destructiveLaser-induced breakdown spectroscopy

A method for determining geochemistry of at least one geological sample with laser-induced breakdown spectral measurements performed on the geological sample in a time variant manner with spectral acquisitions made after each of a plurality of measurement shots, spectral pre-processing performed as necessary, and subsequent analysis is applied to the collected data to determine at least one geochemistry parameter of the sample. The method can provide a rapid method to estimate thermal maturity of a sample, which does not require sample preparation, and which can be non-destructive with respect to portions of the sample. A system for performing the method also is provided.

Owner:HALLIBURTON ENERGY SERVICES INC

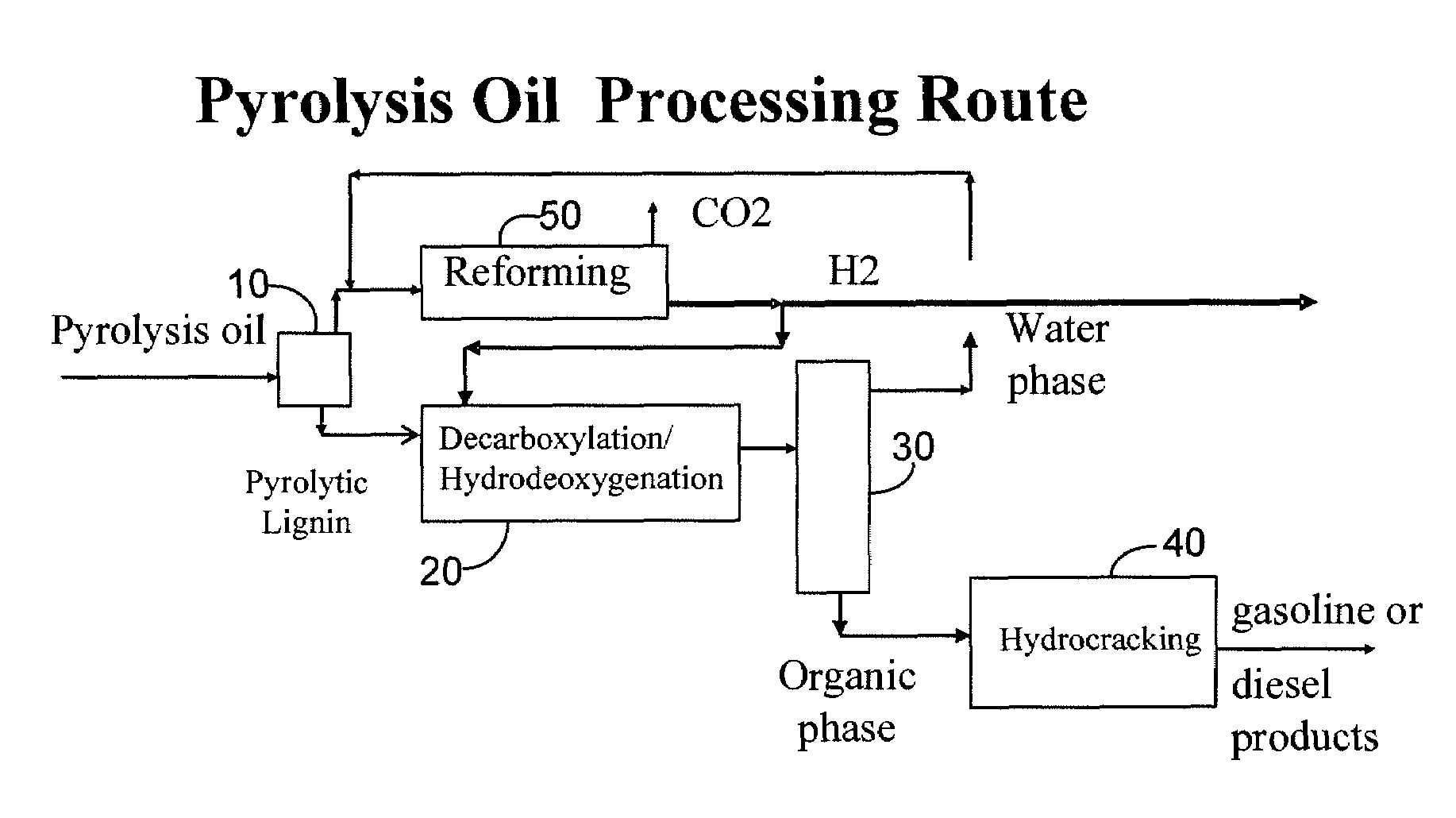

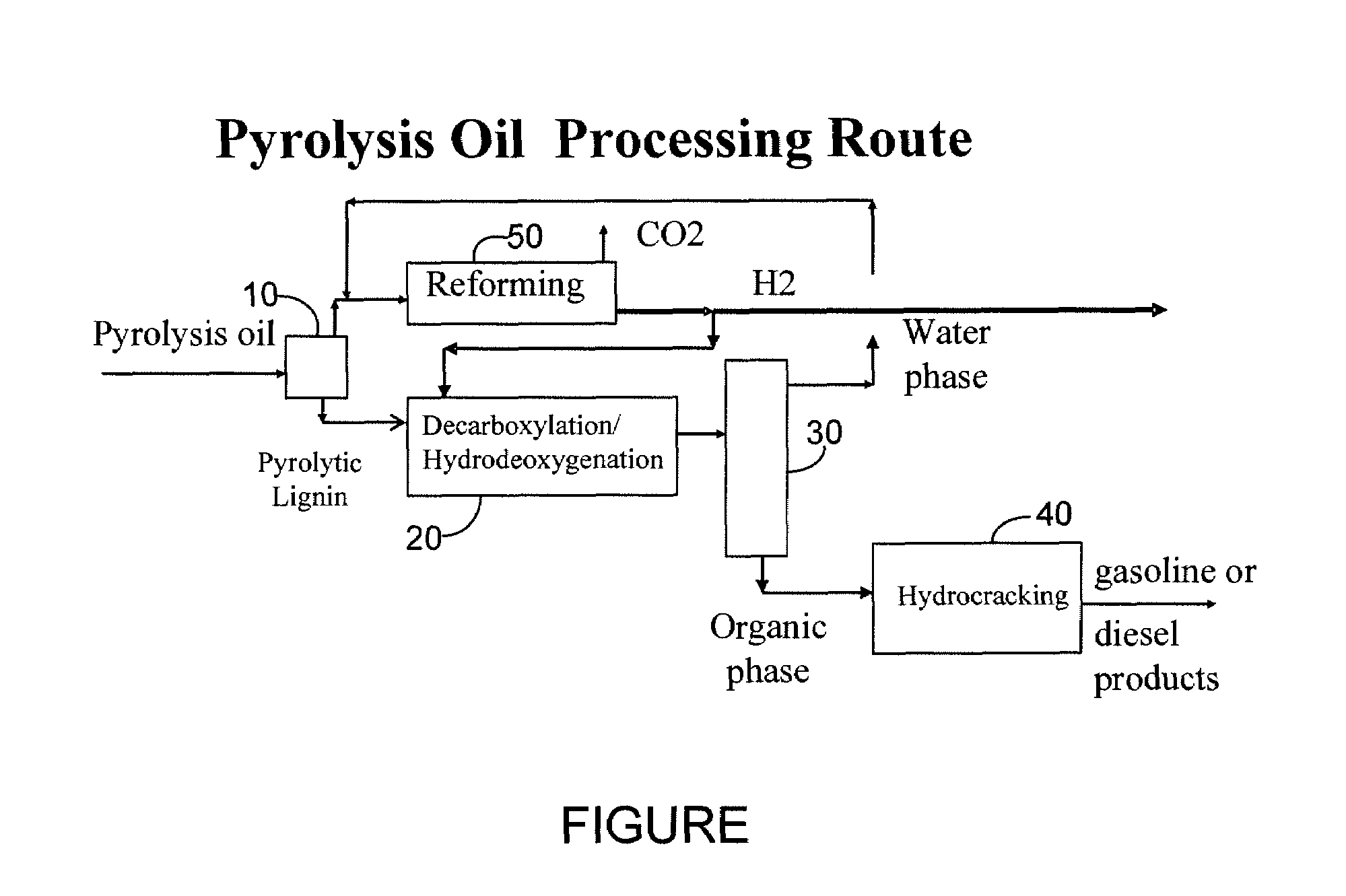

Gasoline and diesel production from pyrolytic lignin produced from pyrolysis of cellulosic waste

InactiveUS7578927B2Treatment with plural serial cracking stages onlyTreatment with plural serial stages onlyCelluloseNaphtha

A process for the conversion of biomass to a liquid fuel is presented. The process includes the production of diesel and naphtha boiling point range fuels by hydrocracking of pyrolysis lignin extracted from biomass.

Owner:UOP LLC

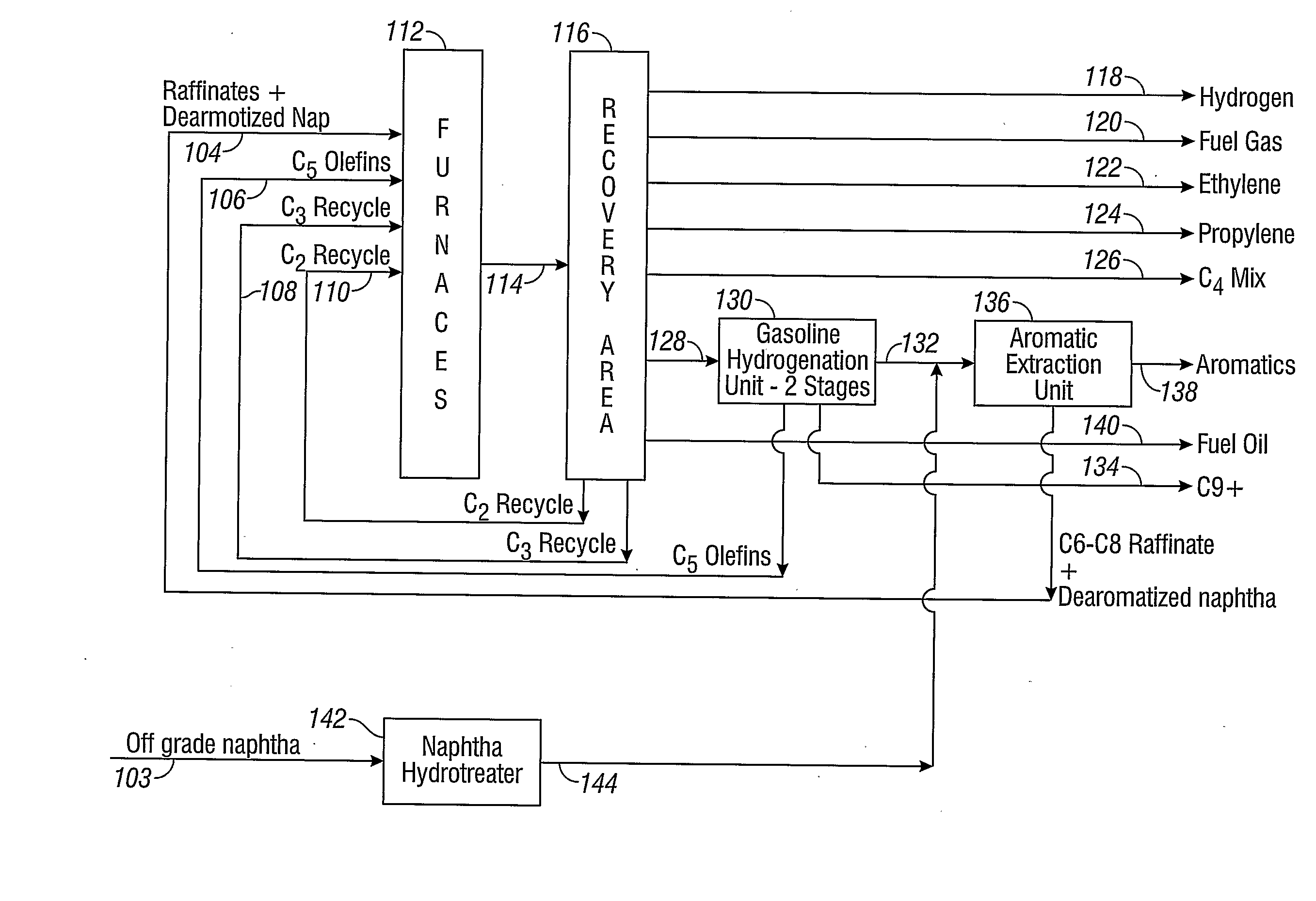

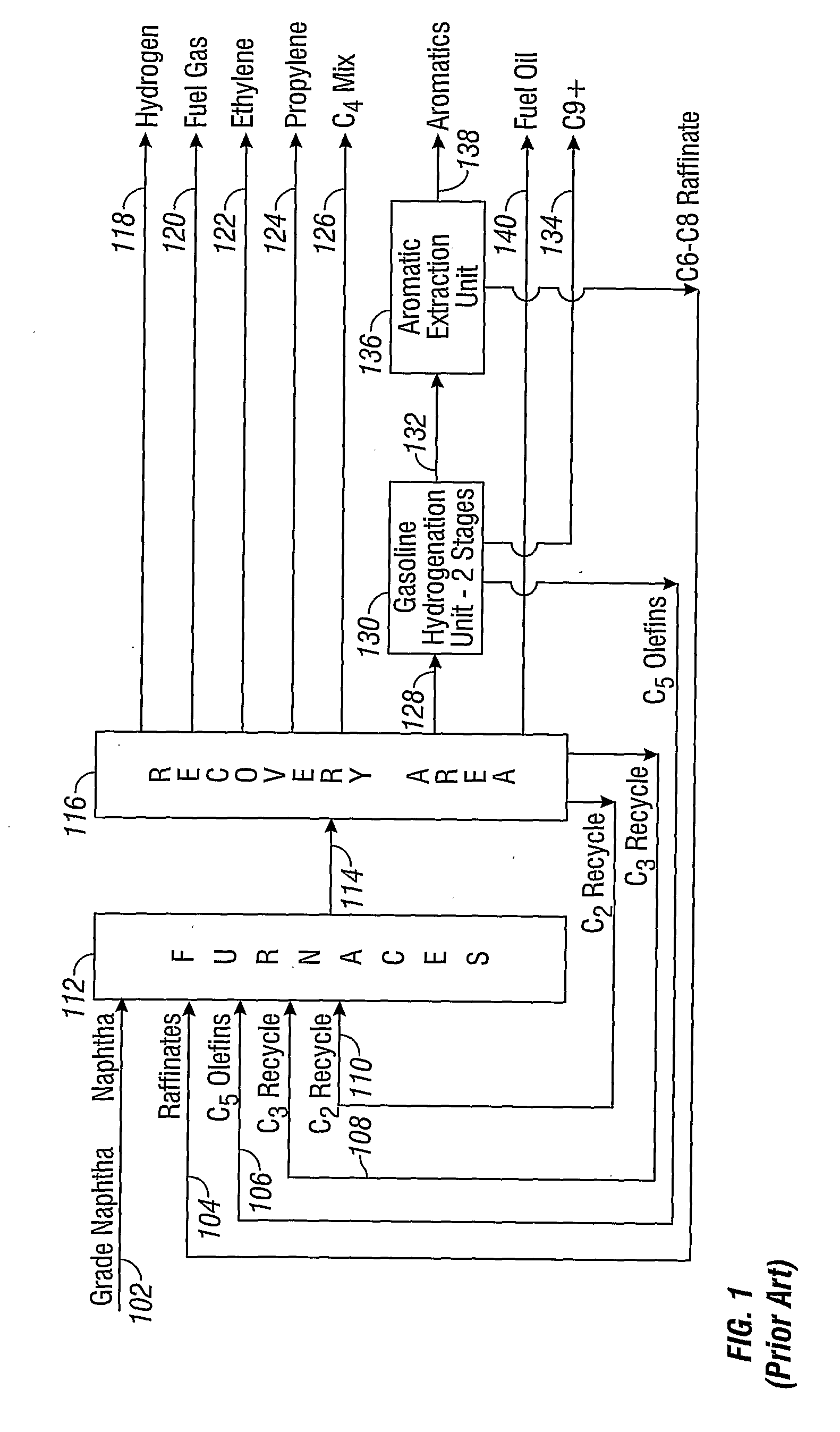

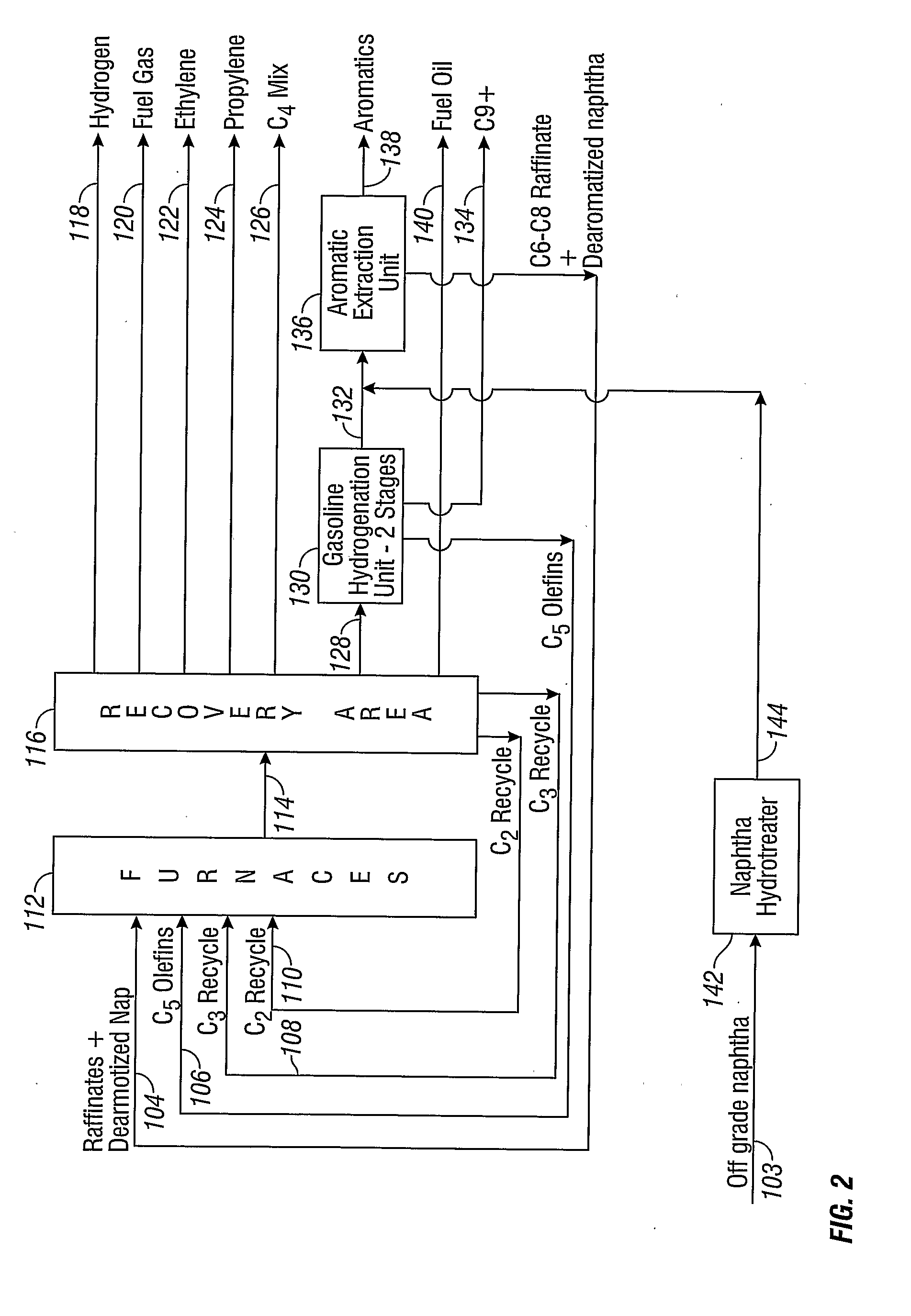

Steam Cracking with Naphtha Dearomatization

Disclosed is a process for upgrading a naphtha feed stream comprising light naphtha, heavy naphtha, or a combination thereof, for supplying to a cracking process. A naphtha feed stream can be supplied to a hydrotreater 142 to remove impurities, followed by dearomatization in an aromatics extraction unit 136. A dearomatized naphtha stream 104 can be supplied to a cracking process 112 and a recovery process 116 to produce various streams including ethylene 122 and propylene 124 for collection, ethane 110 and propane 108 for recycle to the cracking process 112, and a pyrolysis gas stream 128 which can be further treated to produce a C5 olefins stream 106, a C6-C8 stream 104, a C9+ stream 134, and a fuel oil stream 140.

Owner:BHIRUD VASANT L

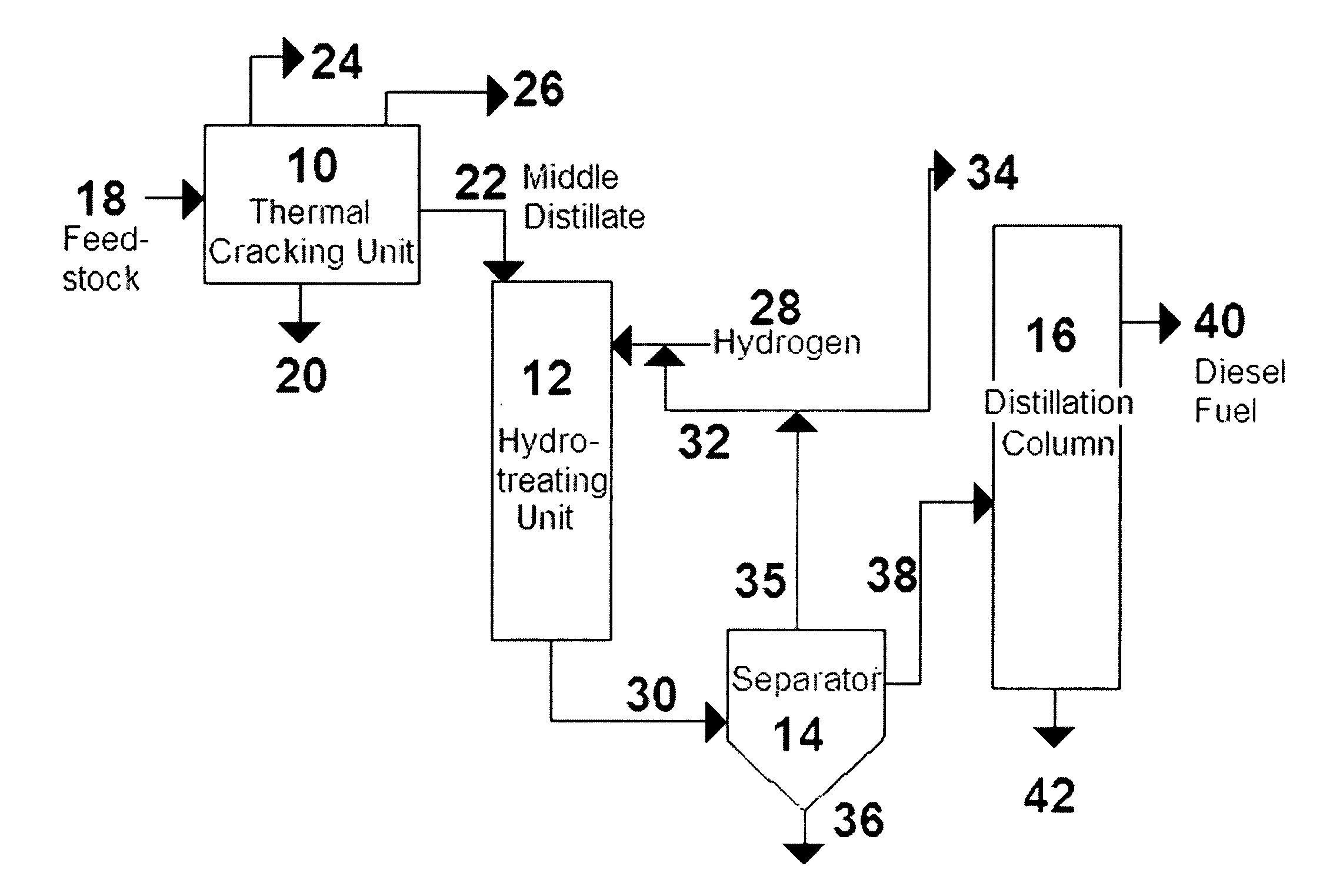

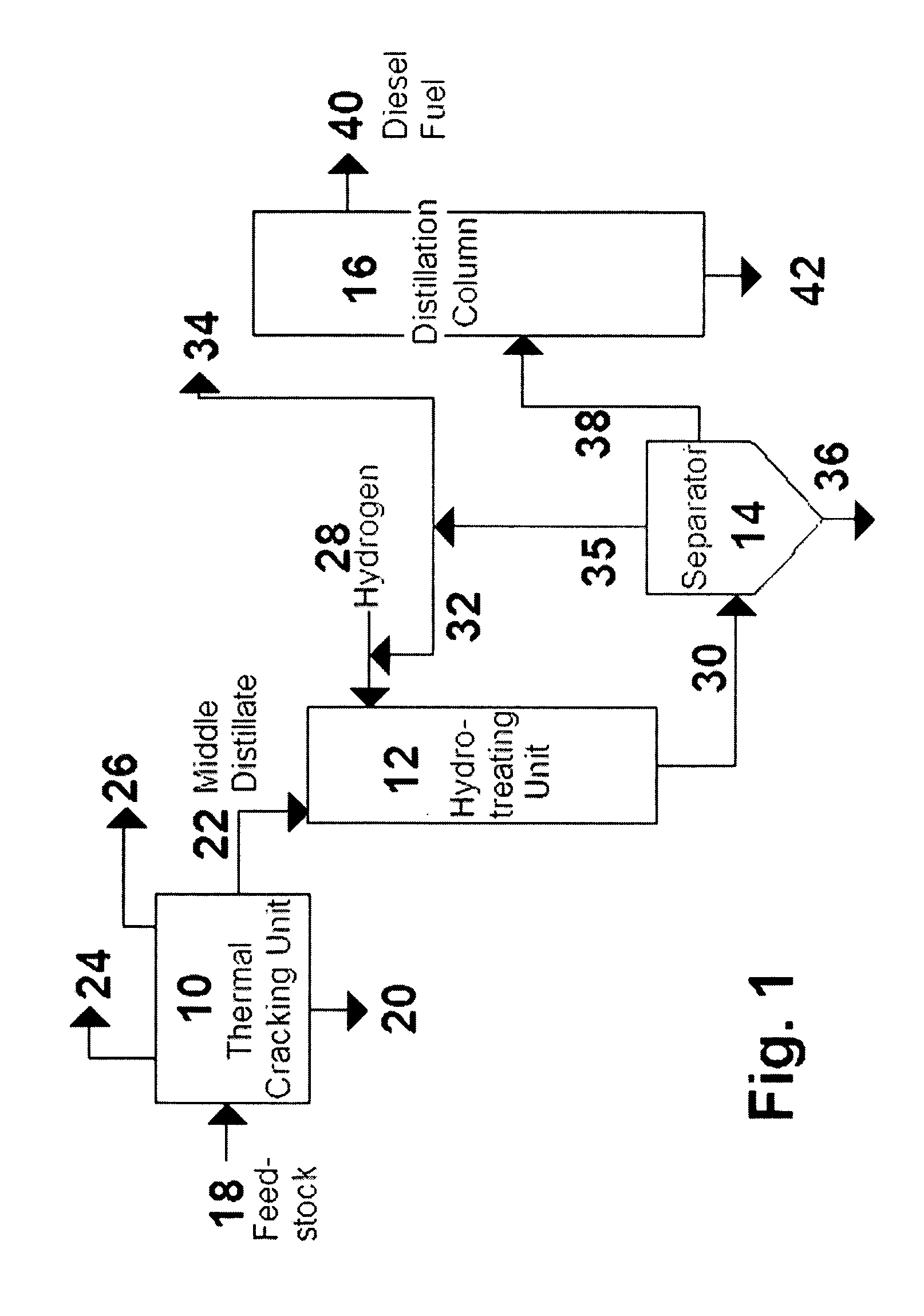

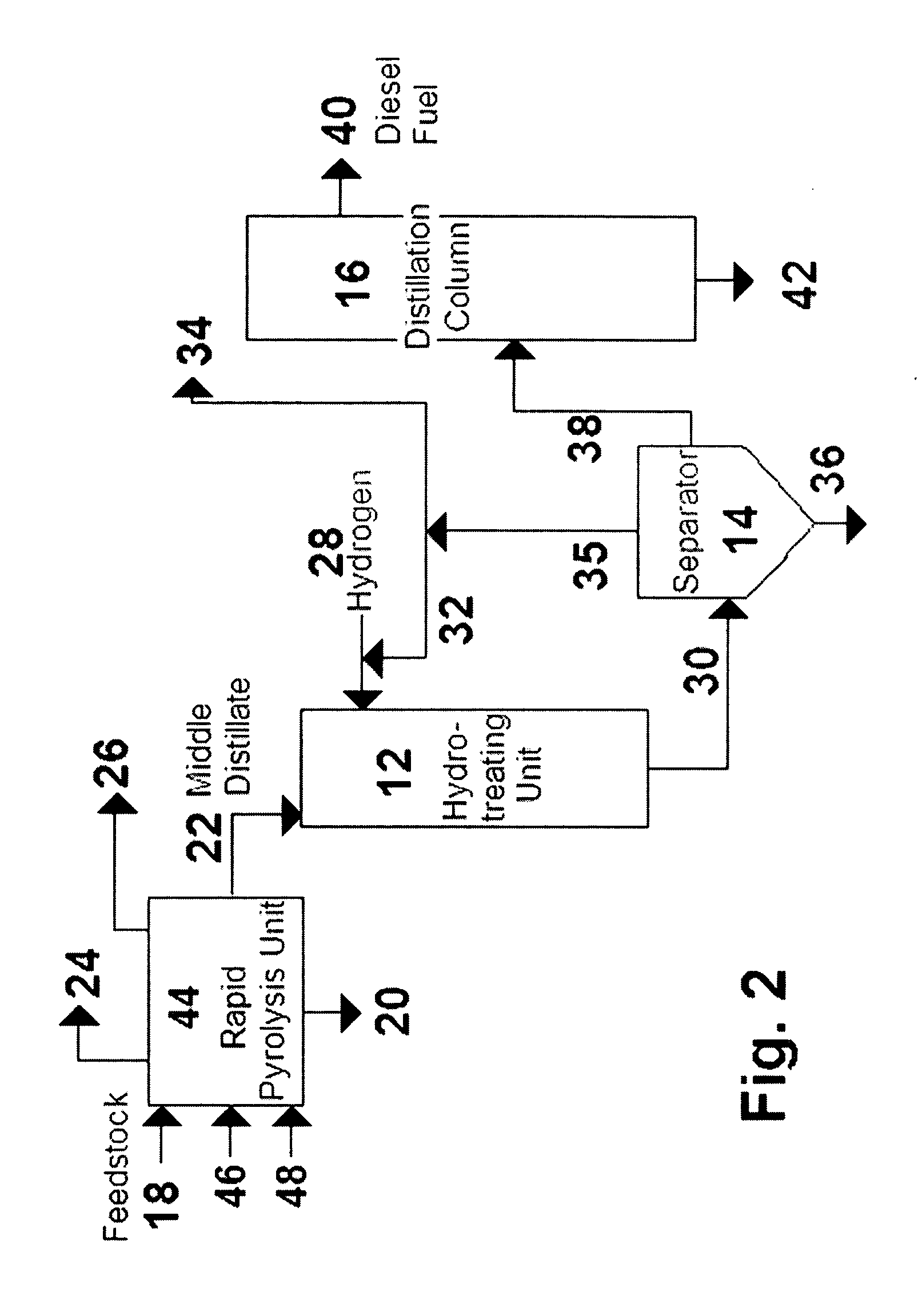

Production of high-cetane diesel fuel from low-quality biomass-derived feedstocks

A method is taught for producing diesel fuels of high cetane value from a triglyceride feedstock, comprising pretreating the triglyceride feedstock by thermal cracking or rapid pyrolysis to partially convert the triglycerides and produce a middle distillates stream, and catalytically hydrotreating the middle distillate fraction to produce high cetane value diesel fuels. A biomass-derived diesel fuel is also taught having sulphur content below 10 ppm, a cetane-value of at least 70, a cloud point below 0° C. and a pour point of less than −4° C. A blended diesel fuel is also taught comprising 5 to 20 vol. % of the biomass-derived diesel fuel of the present invention and 80 to 95 vol. % of a petroleum diesel, based on total volume of the blended diesel fuel.

Owner:HER MAJESTY THE QUEEN & RIGHT OF CANADA REPRESENTED BY THE MIN OF NATURAL RESOURCES

Rapid solar-thermal conversion of biomass to syngas

ActiveUS20080086946A1Improve reaction kineticsWide rangeElectrical coke oven heatingSolar heating energySyngasReactor design

Methods for carrying out high temperature reactions such as biomass pyrolysis or gasification using solar energy. The biomass particles are rapidly heated in a solar thermal entrainment reactor. The residence time of the particles in the reactor can be 5 seconds or less. The biomass particles may be directly or indirectly heated depending on the reactor design. Metal oxide particles can be fed into the reactor concurrently with the biomass particles, allowing carbothermic reduction of the metal oxide particles by biomass pyrolysis products. The reduced metal oxide particles can be reacted with steam to produce hydrogen in a subsequent process step.

Owner:UNIV OF COLORADO THE REGENTS OF

Mixed-metal oxide particles by liquid feed flame spray pyrolysis of oxide precursors in oxygenated solvents

Liquid feed flame spray pyrolysis of solutions of a metal oxide precursor which is an alkoxide or C1-6 carboxylate and at least one second metal oxide precursor and / or second metal compound dissolved in oxygenated solvent by combustion with oxygen lead to the formation of sub-micron mixed-metal oxide powders not accessible by other processes or by the pyrolysis of metal chlorides or nitrates. The powders have numerous uses in advanced materials applications including particulate solid state lasers, advanced ceramic materials, and as catalysts in organic synthesis and automobile exhaust systems.

Owner:TAL MATERIALS +1

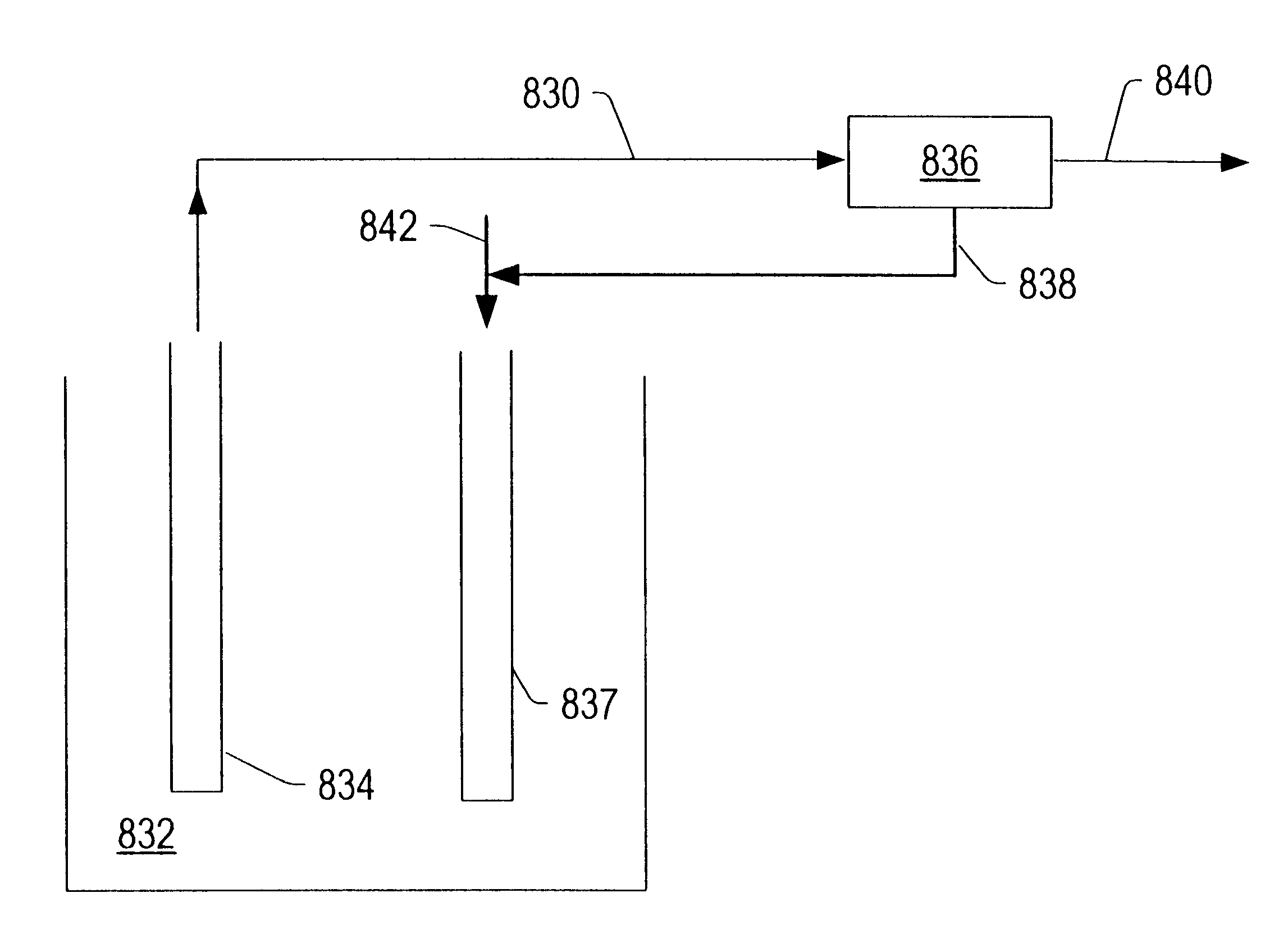

Portable hydrogen generator-fuel cell apparatus

InactiveUS6653005B1Increase specific energy and overall energy efficiencyHydrogenFuel cell auxillariesKeroseneImpurity

A compact hydrogen generator is coupled to or integrated with a fuel cell for portable power applications. Hydrogen is produced via thermocatalytic decomposition (cracking, pyrolysis) of hydrocarbon fuels in oxidant-free environment. The apparatus can utilize a variety of hydrocarbon fuels, including natural gas, propane, gasoline, kerosene, diesel fuel, crude oil (including sulfurous fuels). The hydrogen-rich gas produced is free of carbon oxides or other reactive impurities, so it could be directly fed to any type of a fuel cell. The catalysts for hydrogen production in the apparatus are carbon-based or metal-based materials and doped, if necessary, with a sulfur-capturing agent. Additionally disclosed are two novel processes for the production of two types of carbon filaments, and a novel filamentous carbon product. The hydrogen generator can be conveniently integrated with high temperature fuel cells to produce an efficient and self-contained source of electrical power.

Owner:UNIV OF CENT FLORIDA RES FOUND INC +1

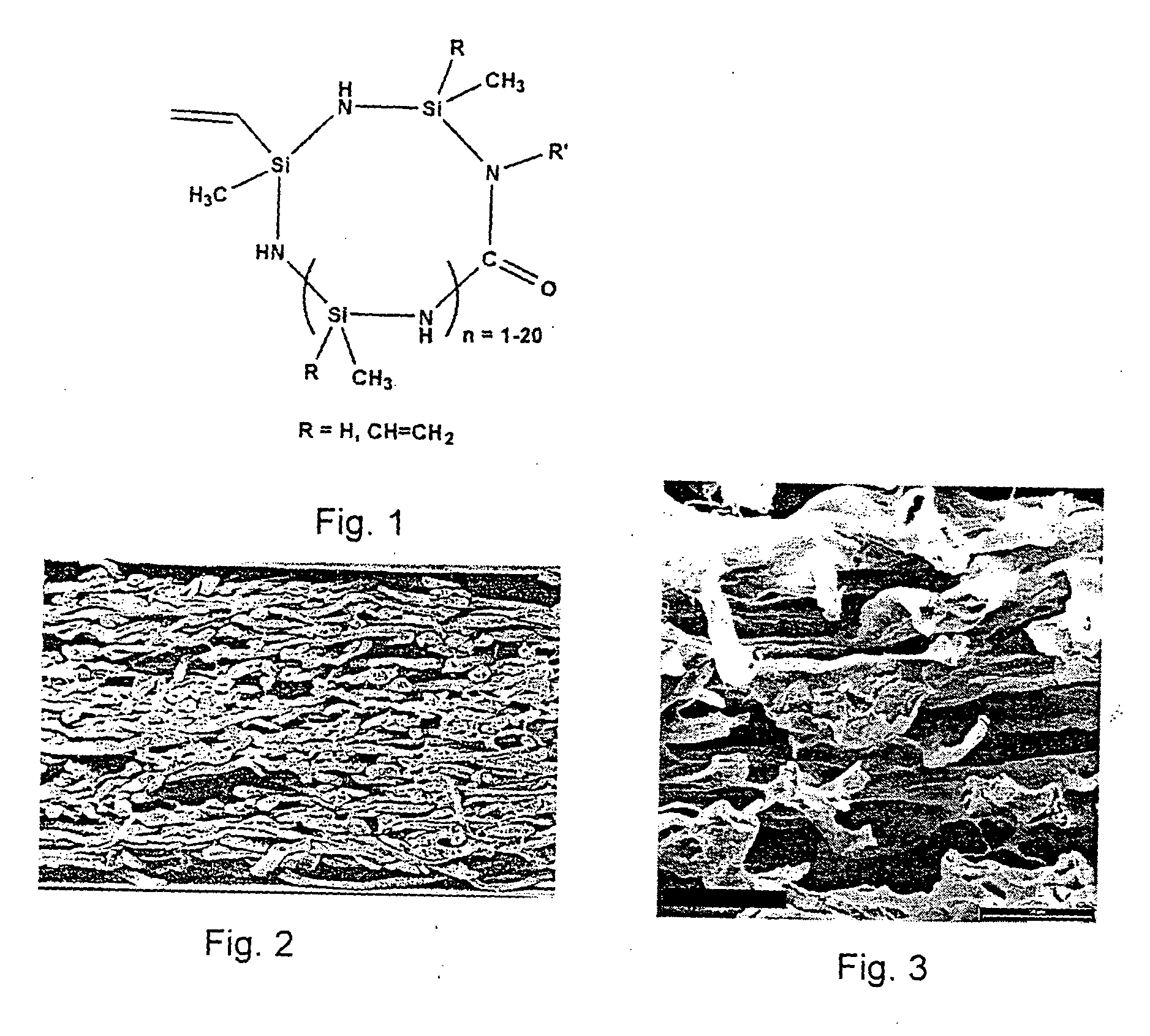

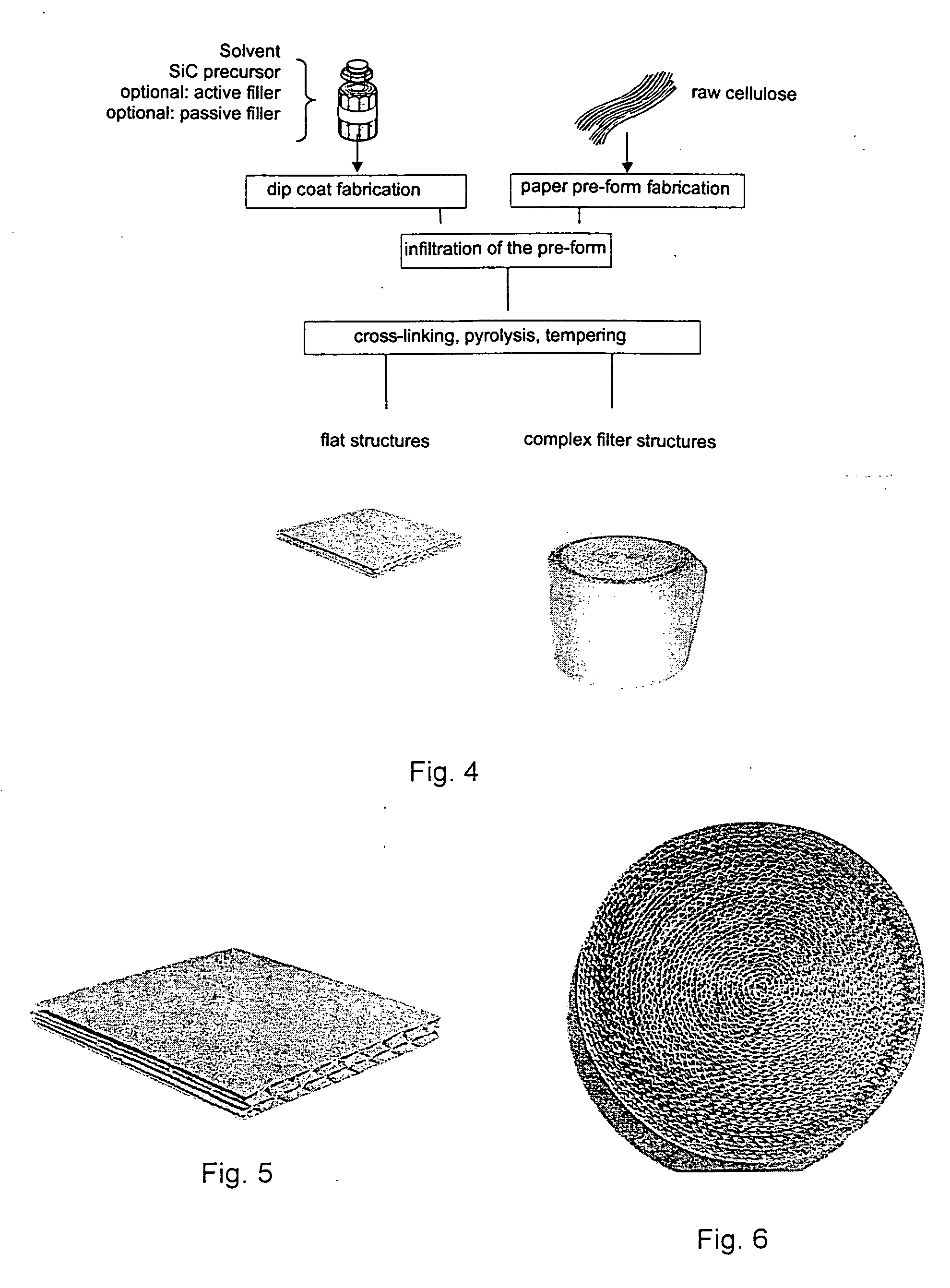

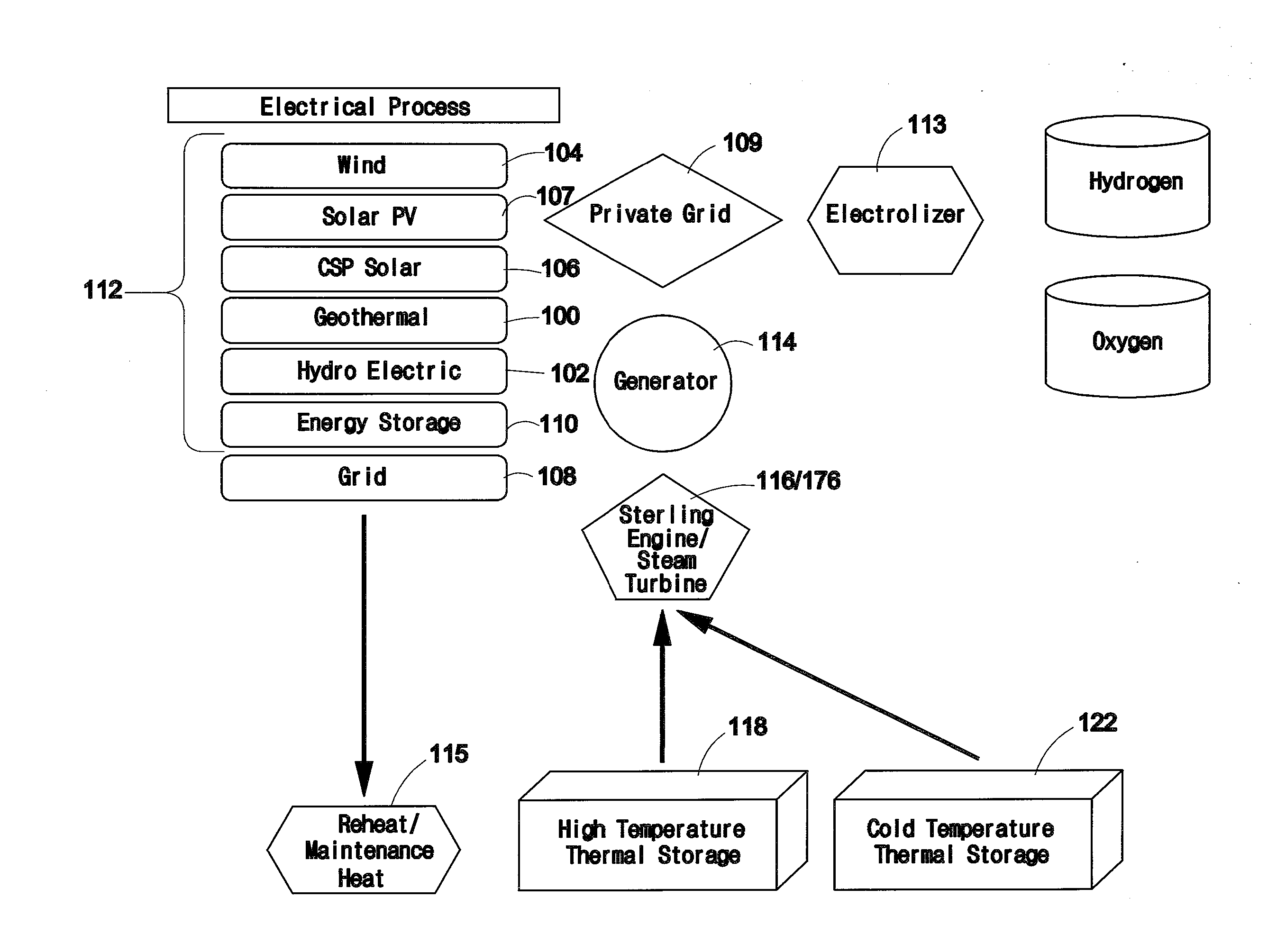

Porous SiC-bodies with micro-channels and process for their fabrication

InactiveUS20060121266A1Large effective internal surface areaImprove filtering effectInternal combustion piston enginesLayered productsParticulatesCellulose

Process for the fabrication of porous bodies mainly constituted by SiC containing ceramic with a microstructure which is interfused with micro-channels which consists of the process steps a) Provision of a pre-body made from cellulose or pulp b) Fabrication of an infiltration solution or a slurry consisting of (A) solvent, polysilazane, polysilane and / or polycarbosilane or (B) solvent, polysilazane and / or polysilane as well as active metallic fillers and / or passive ceramic fillers. c) Infiltrating the body with infiltration solution or slurry d) Cross-linking of the polysilazane, polycarbosilane and / or polysilane while generating a solid green body e) Ceramization through pyrolysis of the green body in an inert-gas atmosphere. f) Removal of residual carbon with an oxidizing thermal process, thereof producible catalyst carriers or carbon particulate filters as well as Porous ceramic which is made from at least 80% SiC in which the porous ceramic features a microstructure with micro-channels consisting mainly of SiC coated micro-channels featuring an average diameter between 1 and 25 μm and webs of SiC located between the micro-channels as well as additional ceramic materials with a content below 20 wt %.

Owner:DAIMLER AG

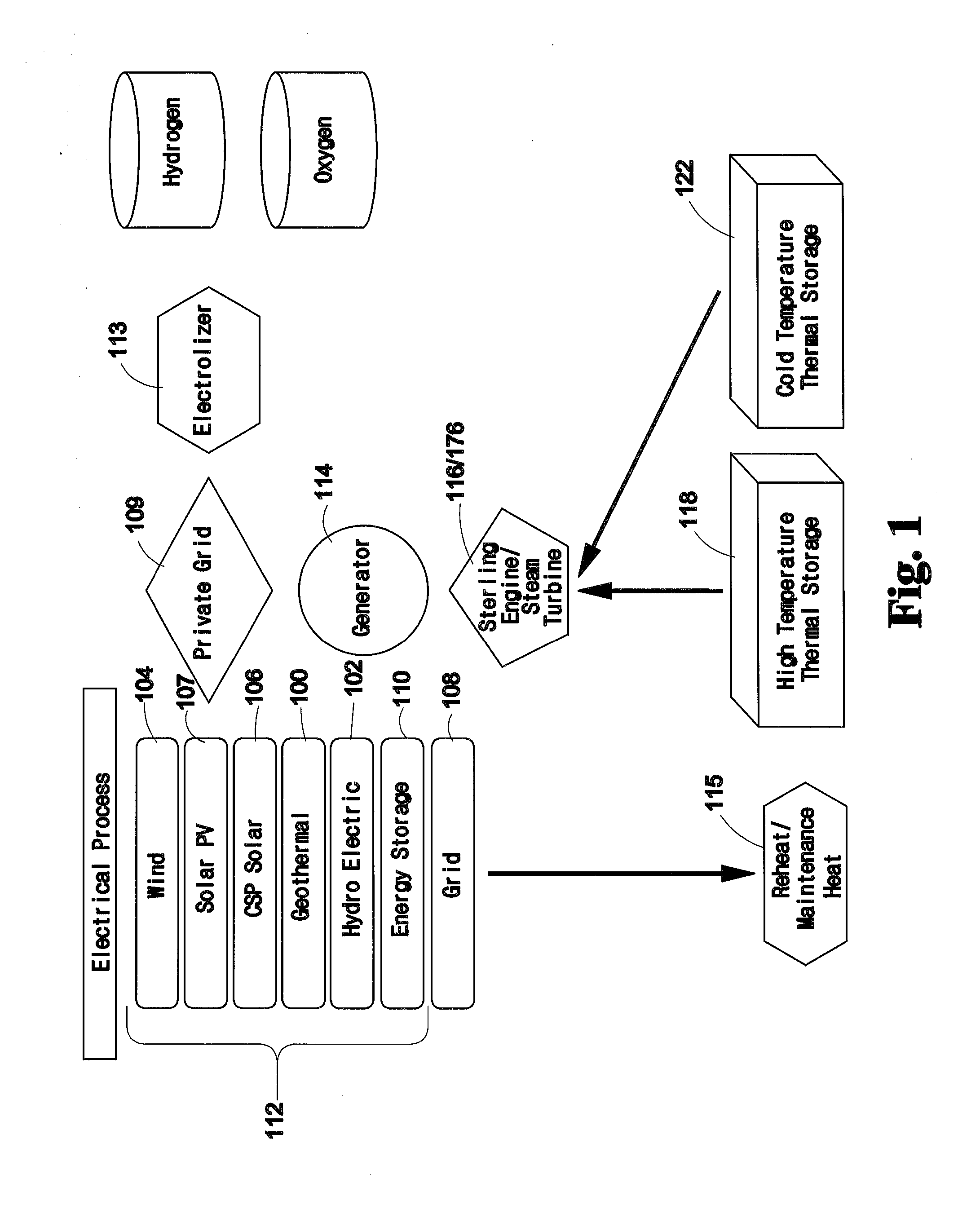

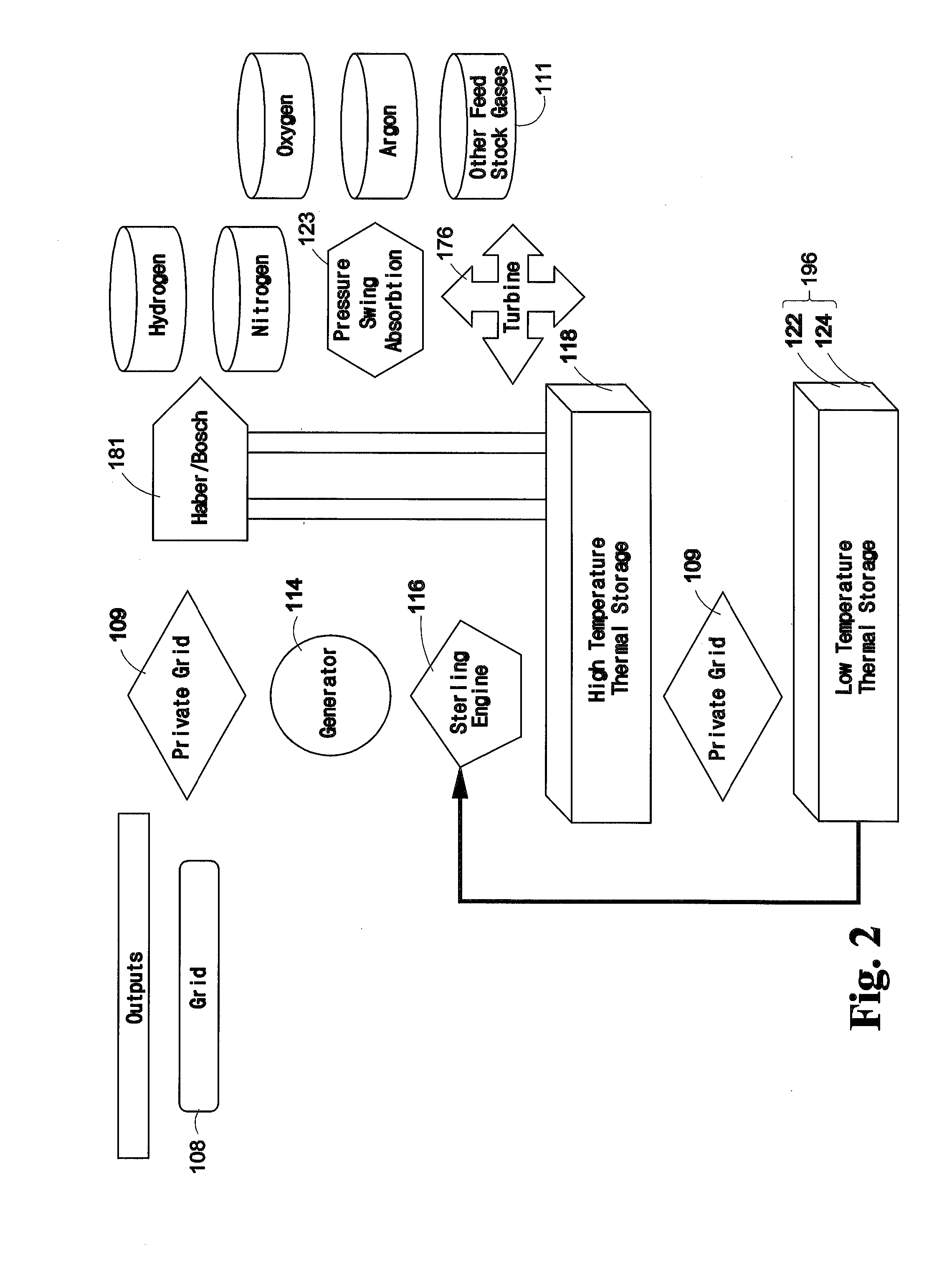

Quintuple-Effect Generation Multi-Cycle Hybrid Renewable Energy System with Integrated Energy Provisioning, Storage Facilities and Amalgamated Control System Cross-Reference to Related Applications

InactiveUS20150143806A1Lowering expensiveIncrease energy generatedSolar heating energyInternal combustion piston enginesEnergy recoveryOpen architecture

Provided is a consumer to industrial scale renewable energy based quintuple-generation systems and energy storage facility. The present invention has both mobile and stationary embodiments. The present invention includes energy recovery, energy production, energy processing, pyrolysis, byproduct process utilization systems, separation process systems and handling and storage systems, as well as an open architecture for integration and development of additional processes, systems and applications. The system of the present invention primarily uses adaptive metrics, biometrics and thermal imaging sensory analysis (including additional input sensors for analysis) for monitoring and control with the utilization of an integrated artificial intelligence and automation control system, thus providing a balanced, environmentally-friendly ecosystem.

Owner:FRIESTH KEVIN LEE

Mixed-metal oxide particles by liquid feed flame spray pyrolysis of oxide precursors in oxygenated solvents

Liquid feed flame spray pyrolysis of solutions of a metal oxide precursor which is an alkoxide or C1-6 carboxylate and at least one second metal oxide precursor and / or second metal compound dissolved in oxygenated solvent by combustion with oxygen lead to the formation of sub-micron mixed-metal oxide powders not accessible by other processes or by the pyrolysis of metal chlorides or nitrates. The powders have numerous uses in advanced materials applications including particulate solid state lasers, advanced ceramic materials, and as catalysts in organic synthesis and automobile exhaust systems.

Owner:TAL MATERIALS +1

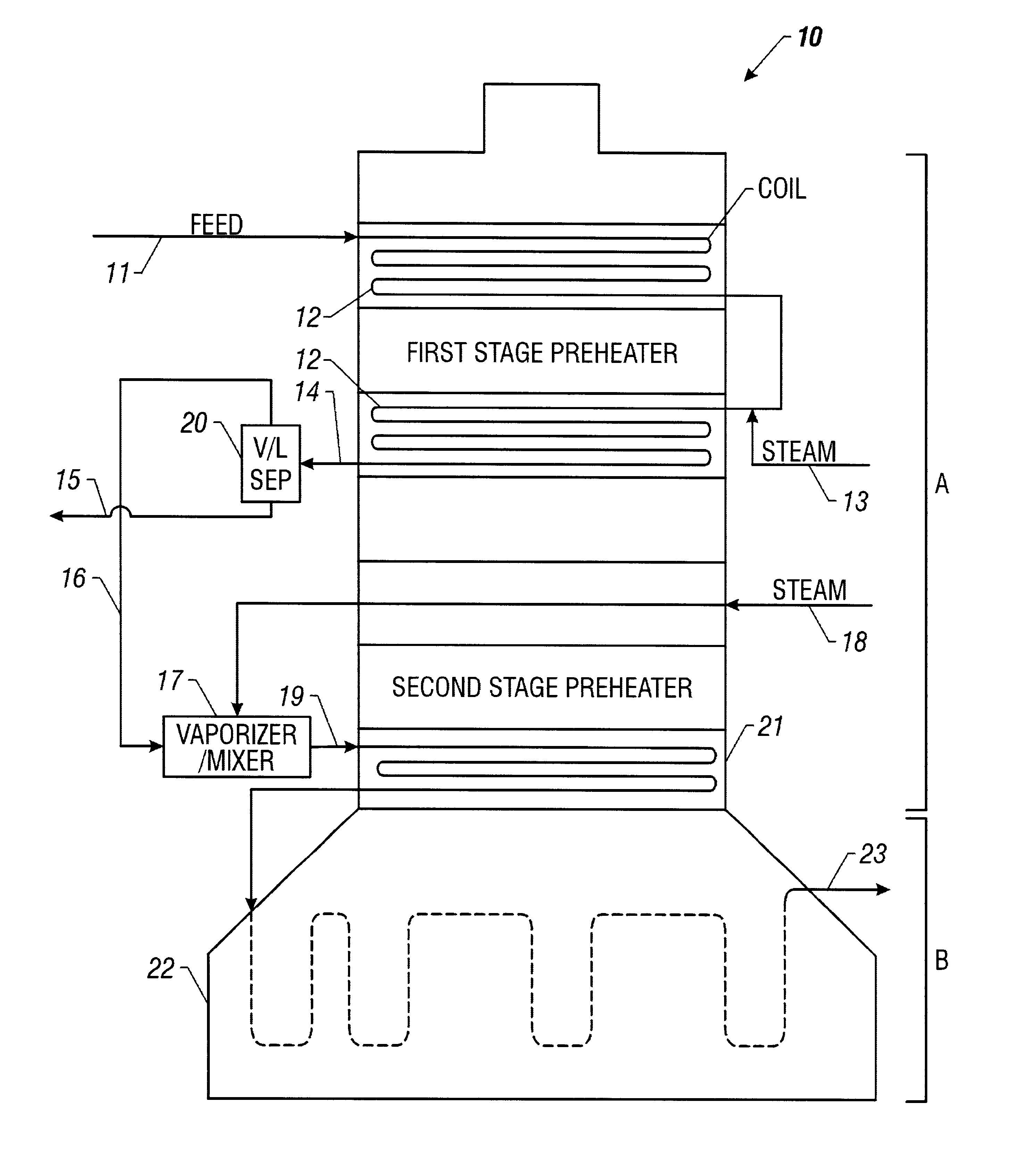

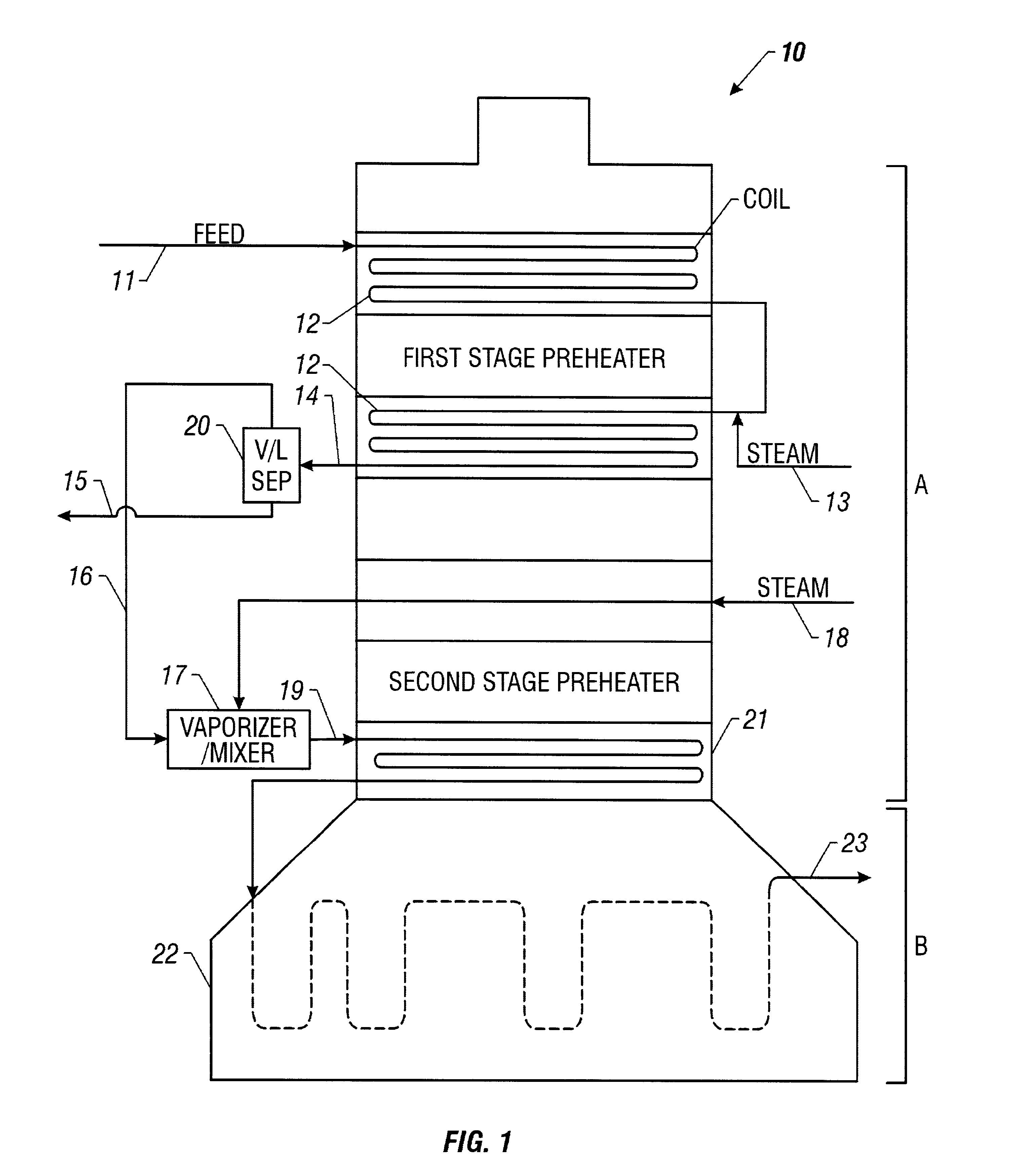

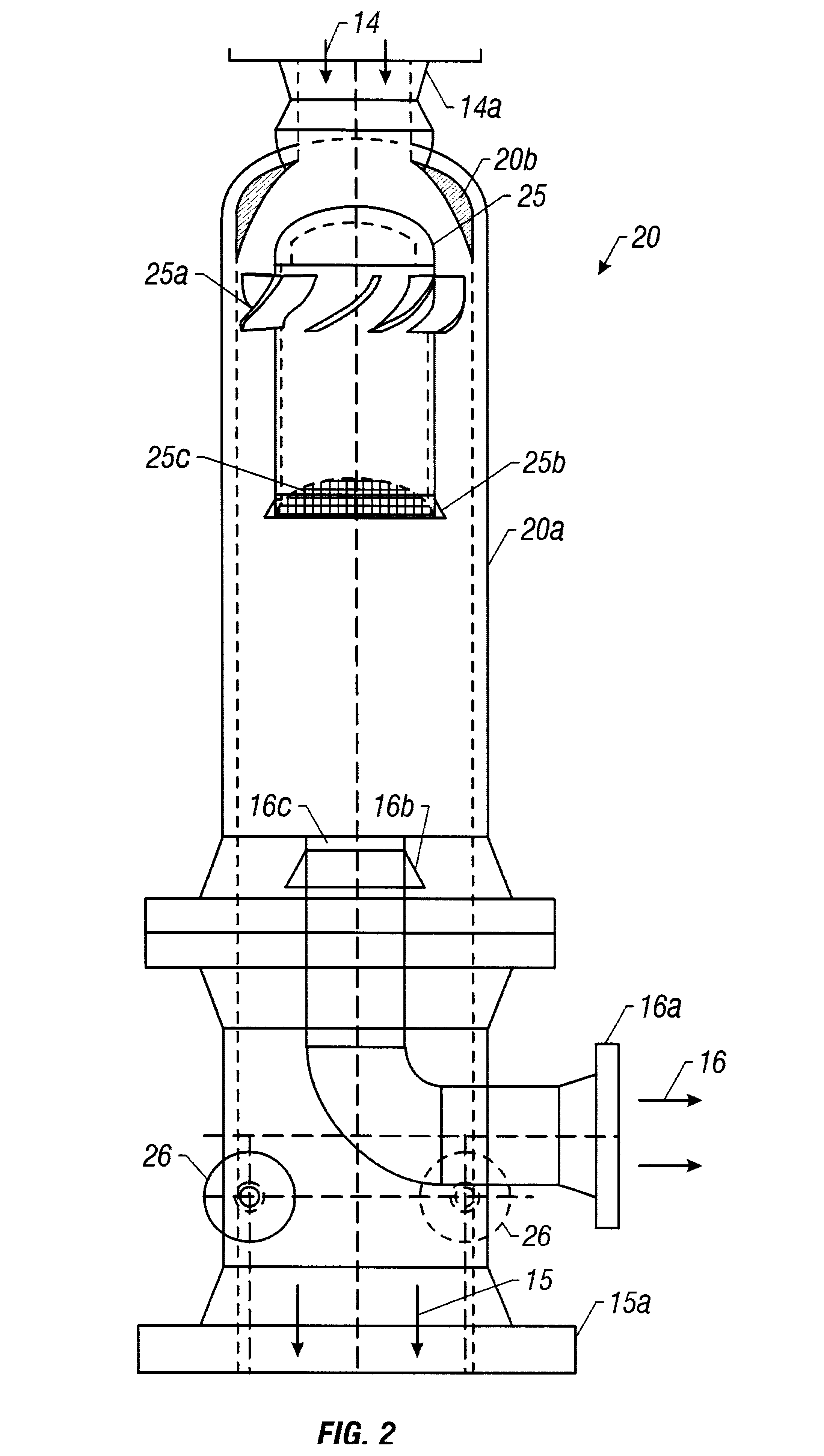

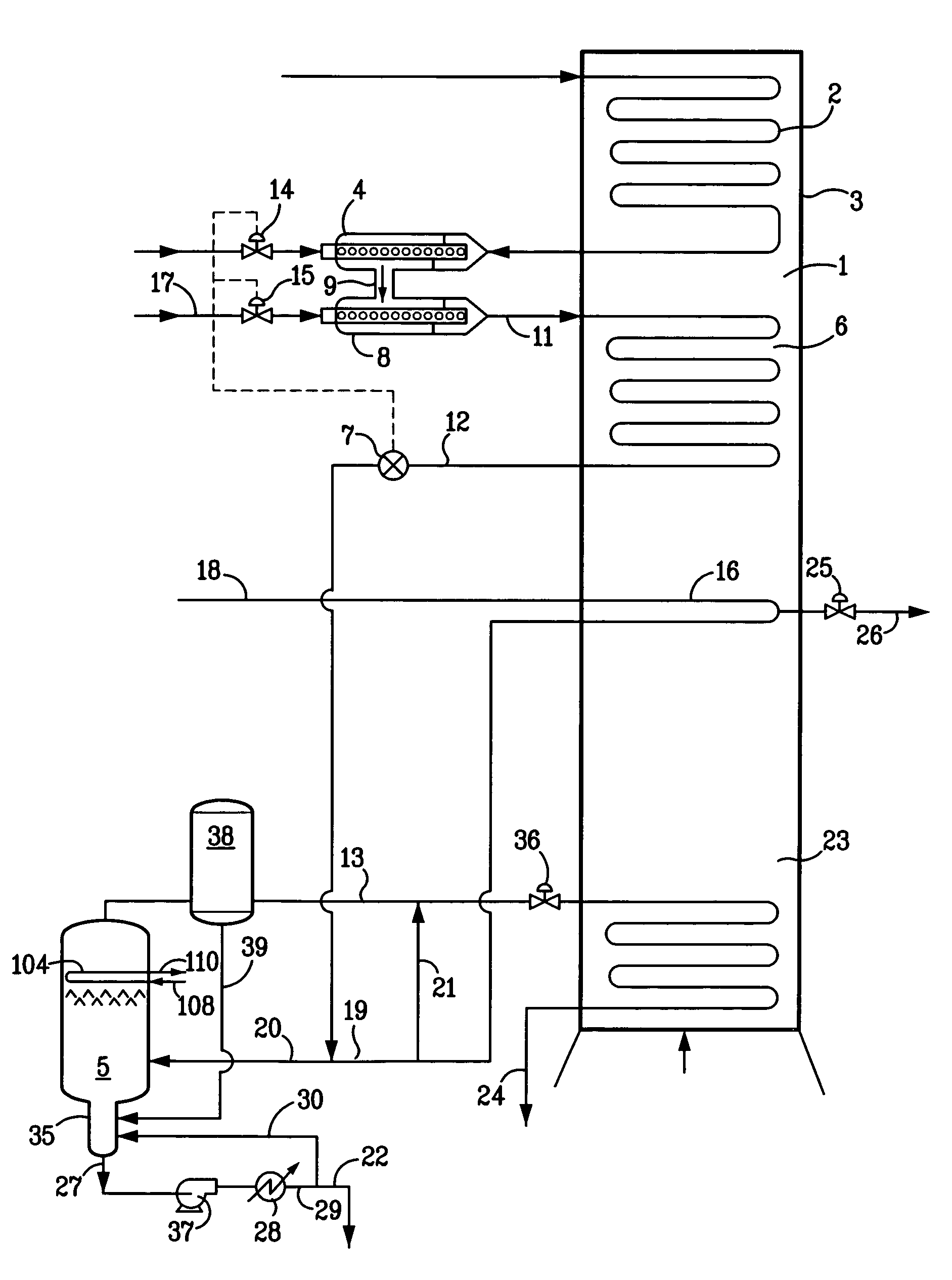

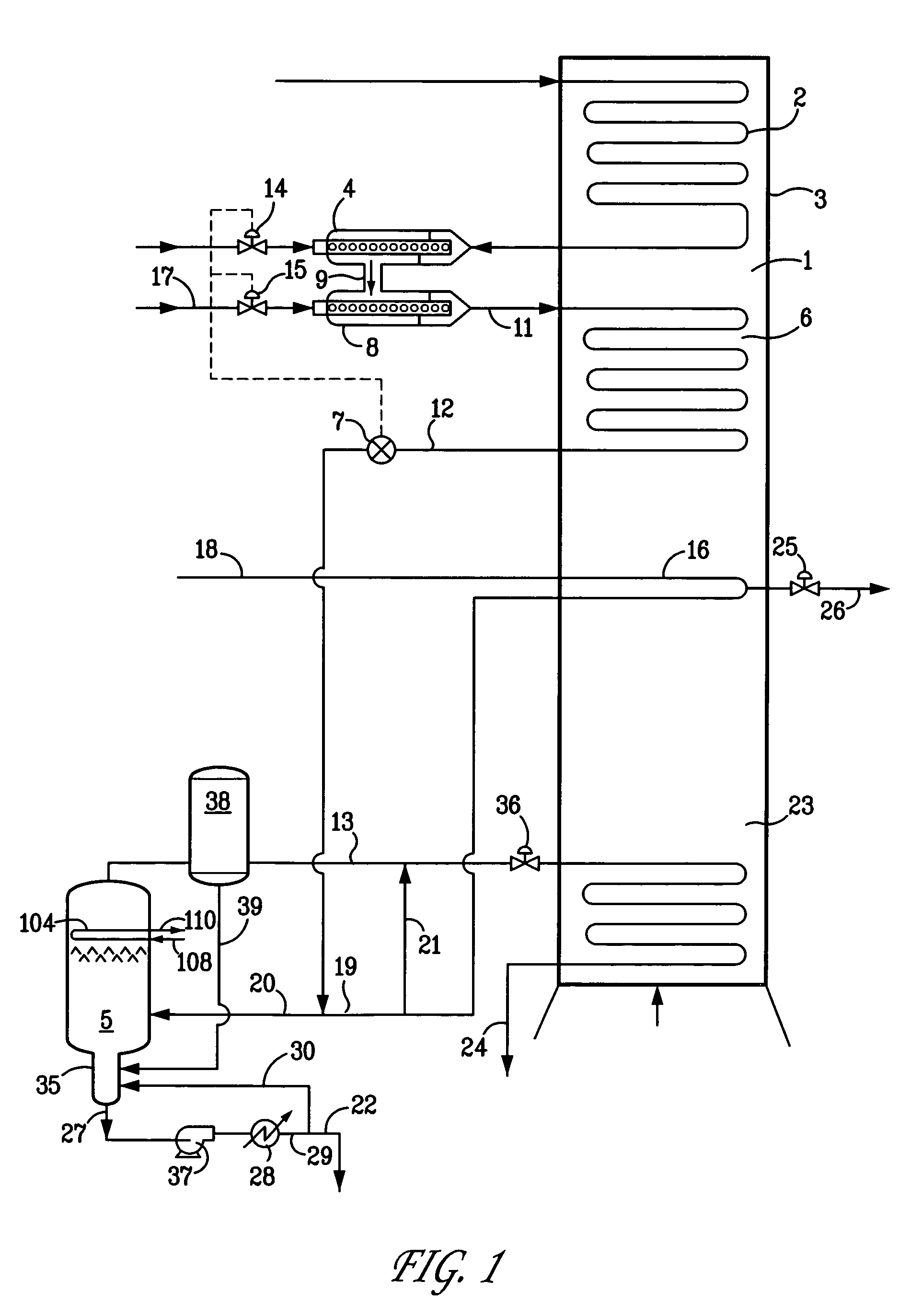

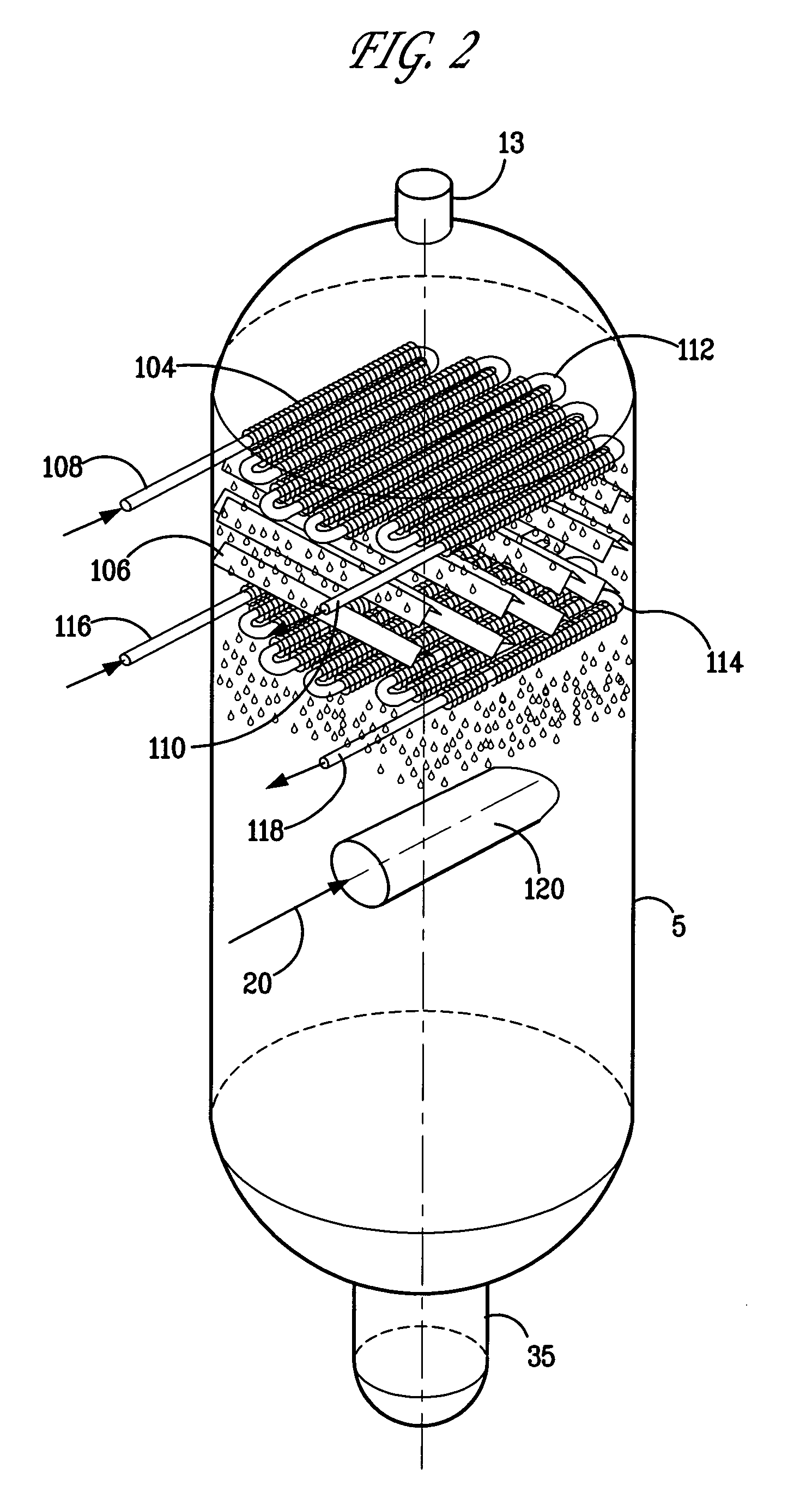

Cracking hydrocarbon feedstock containing resid utilizing partial condensation of vapor phase from vapor/liquid separation to mitigate fouling in a flash/separation vessel

A process is provided for cracking hydrocarbon feedstock containing resid comprising: heating the feedstock, mixing the heated feedstock with a fluid and / or a primary dilution steam stream to form a mixture, optionally further heating the mixture, flashing the mixture within a flash / separation vessel to form a vapor phase and a liquid phase, partially condensing the vapor phase by contacting with a condenser within the vessel, to condense at least some coke precursors within the vapor while providing condensates which add to the liquid phase, removing the vapor phase of reduced coke precursors content as overhead and the liquid phase as bottoms, heating the vapor phase, cracking the vapor phase in a radiant section of a pyrolysis furnace to produce an effluent comprising olefins, and quenching the effluent and recovering cracked product therefrom. An apparatus for carrying out the process is also provided.

Owner:EXXONMOBIL CHEM PAT INC

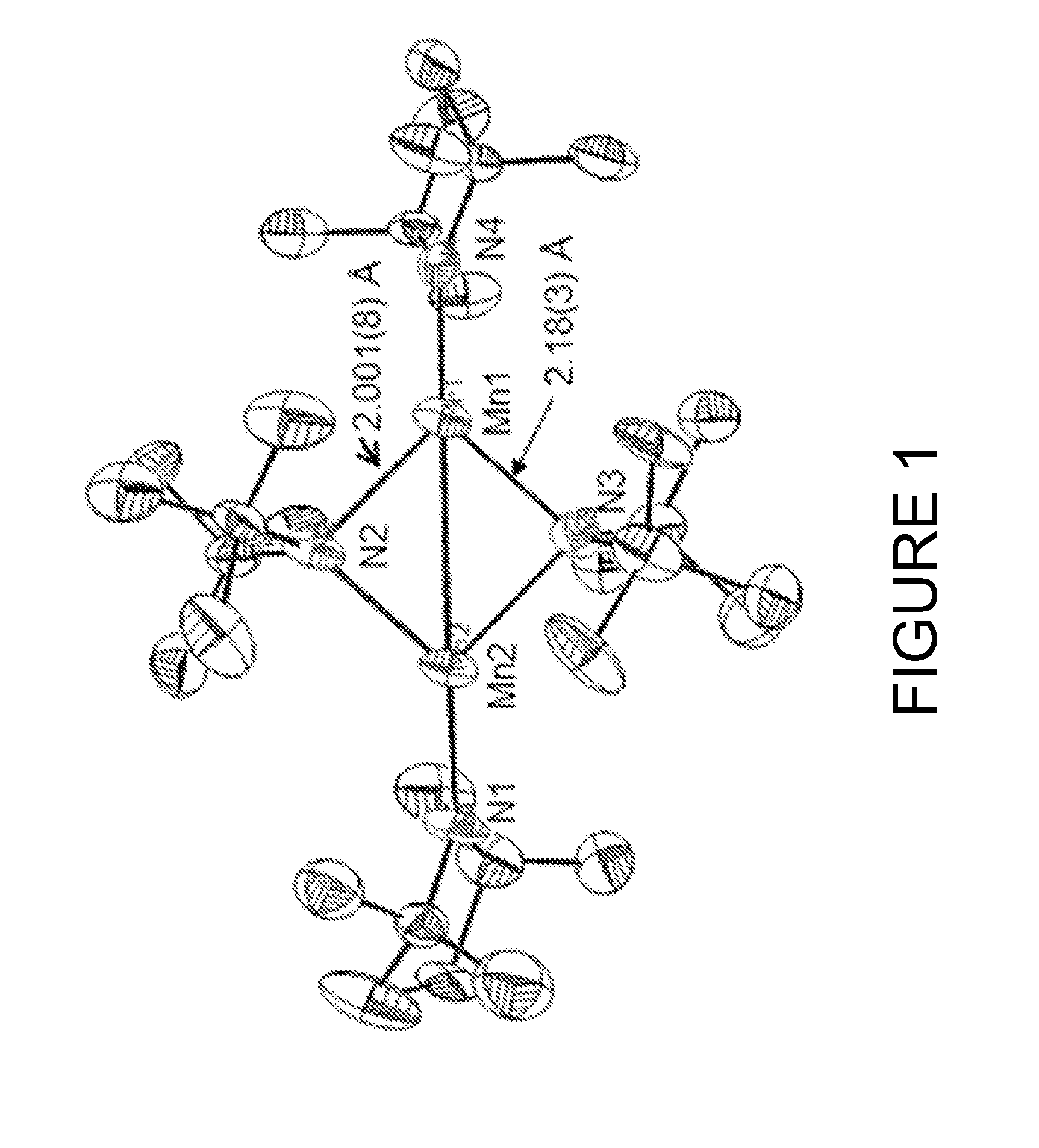

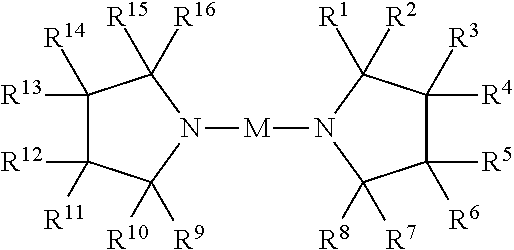

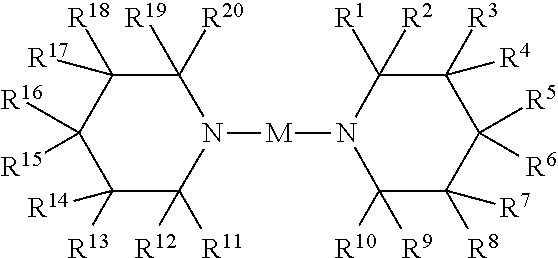

Metal amides of cyclic amines

ActiveUS20160152649A1Improve thermal stabilityImprove conductivityIron group organic compounds without C-metal linkagesNickel organic compoundsGermanideMetal silicide

Compounds, and oligomers of the compounds, are synthesized with cyclic amine ligands attached to a metal atom. These compounds are useful for the synthesis of materials containing metals. Examples include pure metals, metal alloys, metal oxides, metal nitrides, metal phosphides, metal sulfides, metal selenides, metal tellurides, metal borides, metal carbides, metal silicides and metal germanides. Techniques for materials synthesis include vapor deposition (chemical vapor deposition and atomic layer deposition), liquid solution methods (sol-gel and precipitation) and solid-state pyrolysis. Suitable applications include electrical interconnects in microelectronics and magnetoresistant layers in magnetic information storage devices. The films have very uniform thickness and high step coverage in narrow holes.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

Olefin production utilizing whole crude oil and mild controlled cavitation assisted cracking

InactiveUS20050010075A1Thermal non-catalytic crackingTreatment with plural serial cracking stages onlyCavitationAlkene

A method for utilizing whole crude oil as a feedstock for the pyrolysis furnace of an olefin production plant wherein the feedstock after preheating is subjected to mild thermal cracking assisted with controlled cavitation conditions until substantially vaporized, the vapors being subjected to severe cracking in the radiant section of the furnace.

Owner:EQUSR CHEM LP

Nanometer doped zinc oxide and its prepn and application in photocatalysis to degrade organic matter and kill bacteria

InactiveCN1772375AImprove photocatalytic activityImprove performanceCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsFiberRare earth

The present invention relates to Ag and RE doped nanometer zinc oxide and its preparation process and application in photocatalysis to degrade organic matter and killing bacteria. Ag, RE metals La, Ce, Pr, Nd, Sm, etc. are doped into nanometer zinc oxide to raise its photocatalytic activity in degrading harmful chemical matter and resisting bacteria. Under lighting, the doped nanometer zinc oxide has higher photocatalytic activity and higher antibacterial capacity; and in case of no lighting, it has relatively high antibacterial effect owing to the antibacterial effect one Ag, Zn, RE and other antibacterial ions. The preparation process may be an organic matter complexing process or a sprying pyrolysis process. The doped nanometer zinc oxide may be used through mixing with other material, or used as additive added into plastic, ceramic, fiber, timber, rubber, glass, cement, metal and other material to form various kinds of photocatalytic antibacterial material and product.

Owner:NANJING UNIV

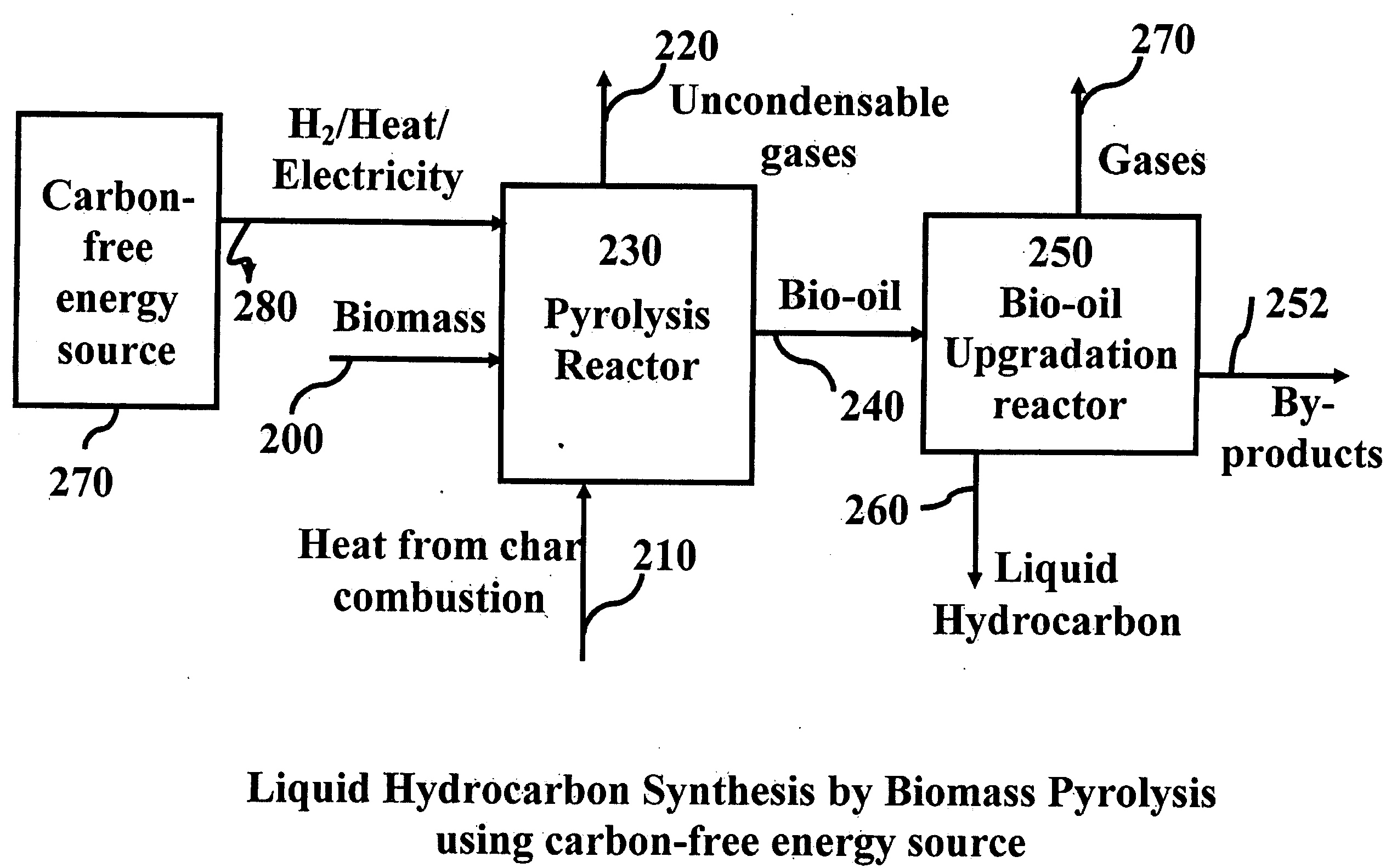

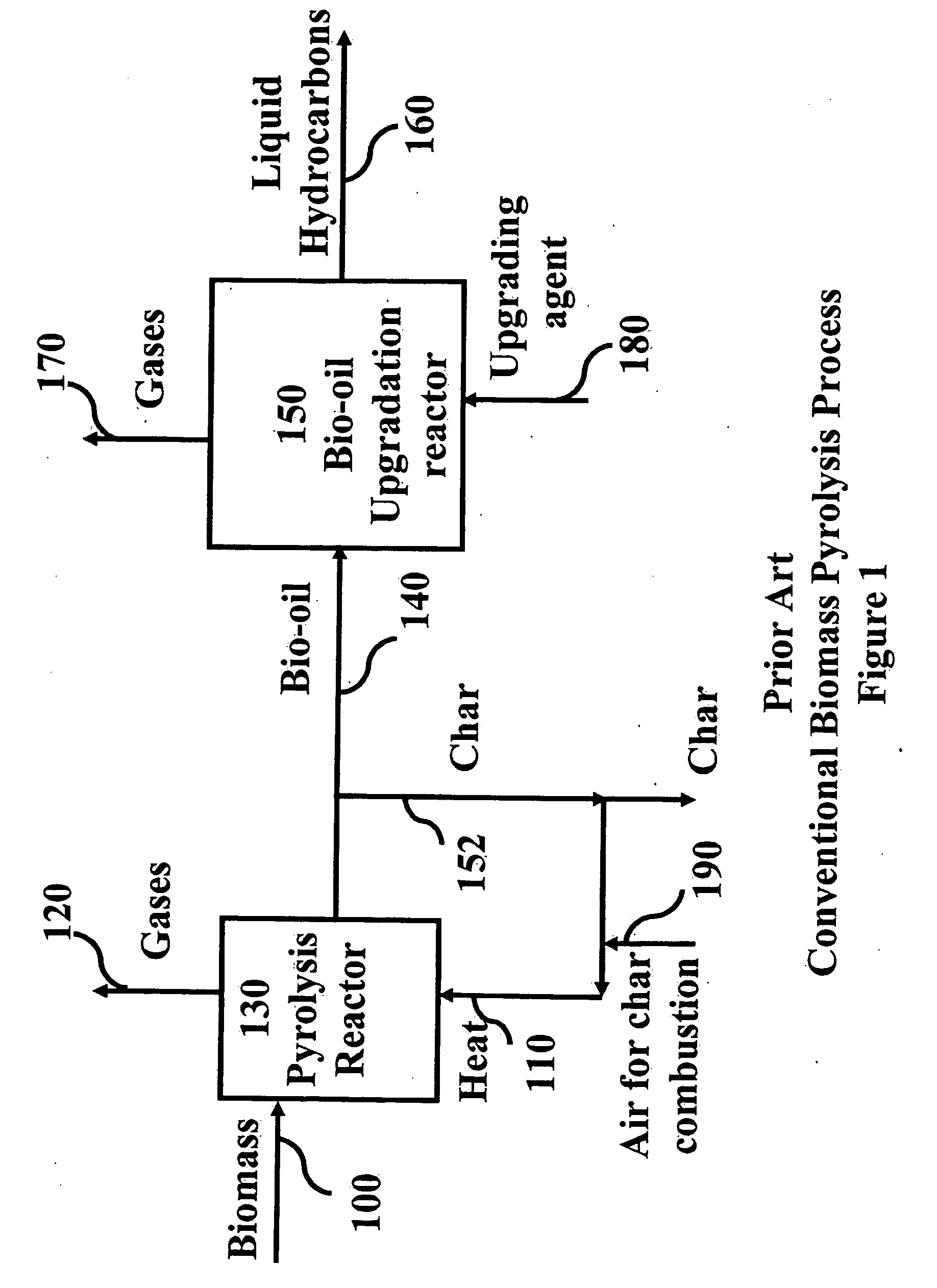

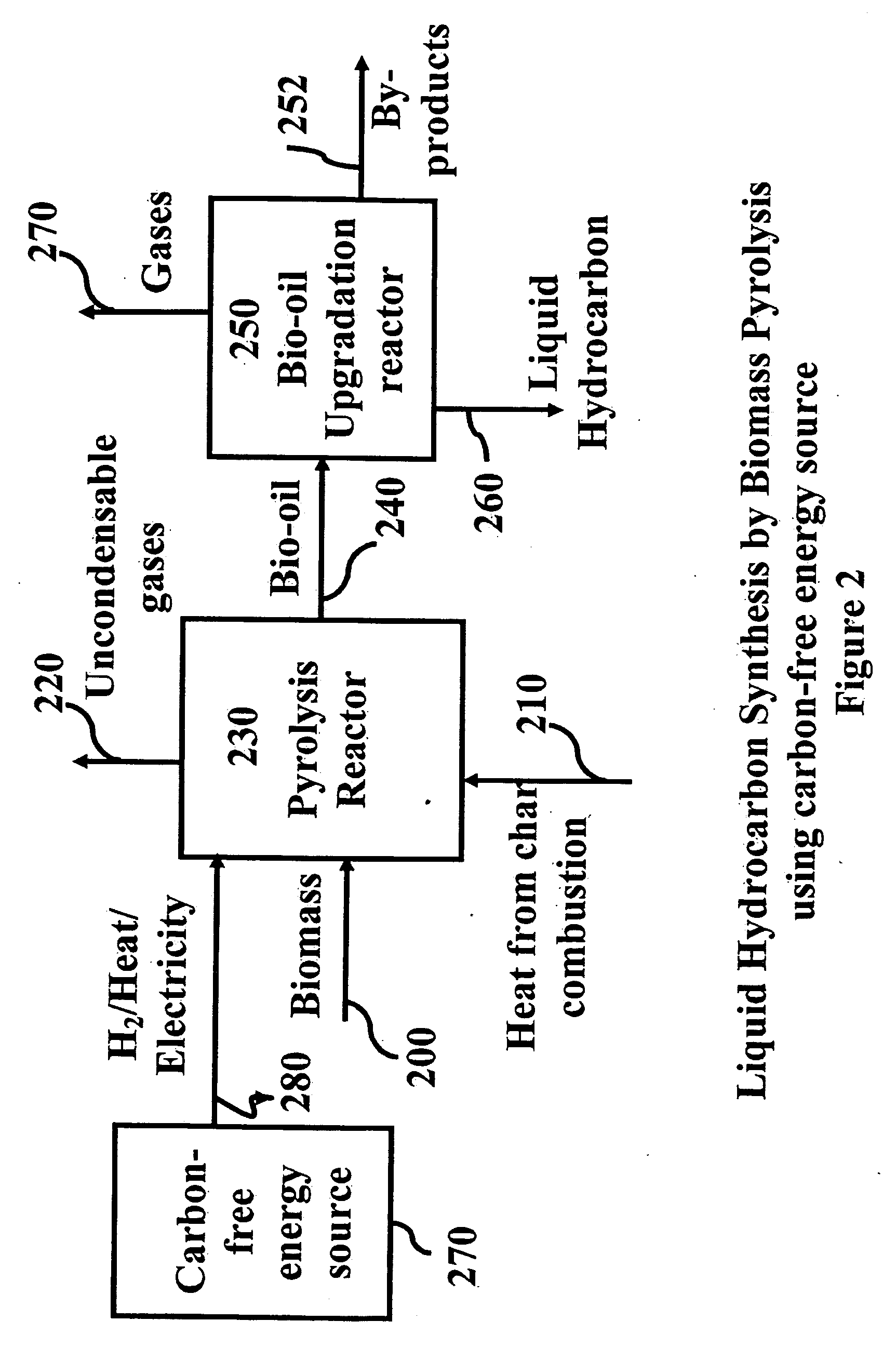

Novel process for producing liquid hydrocarbon by pyrolysis of biomass in presence of hydrogen from a carbon-free energy source

ActiveUS20090082604A1Process stabilityIncrease energy contentBioreactor/fermenter combinationsBiological substance pretreatmentsAlkaneHydrogen

In at least one embodiment of the present invention, a method for producing liquid hydrocarbons from biomass is provided. The method comprises pyrolizing the biomass with hydrogen (H2) to form bio-oil. The bio-oil comprises alkanes, alkenes, alcohols, aldehydes, ketones, aromatics, hydrocarbons or mixtures thereof. The H2 is formed from a carbon-free energy source.

Owner:PURDUE RES FOUND INC

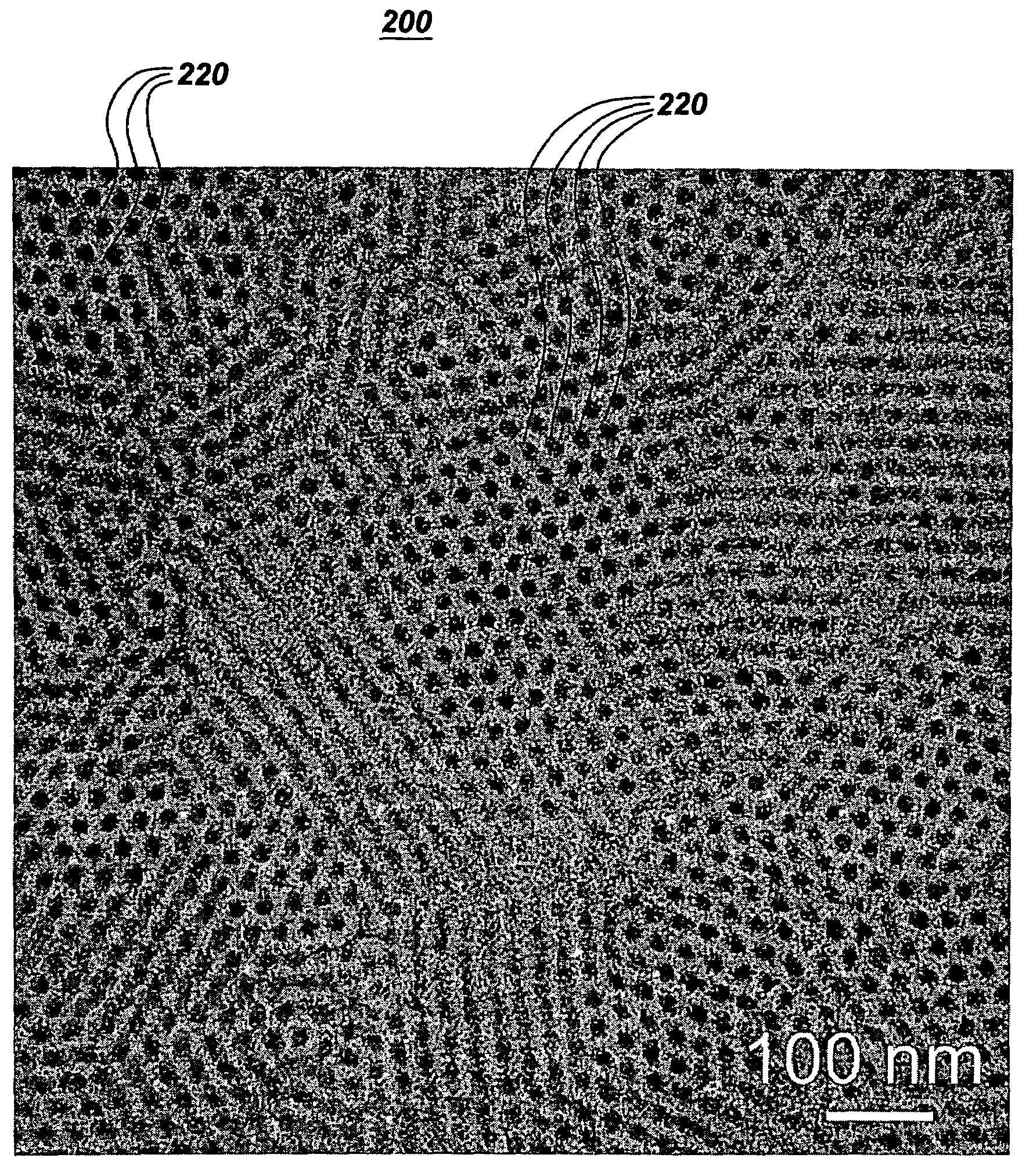

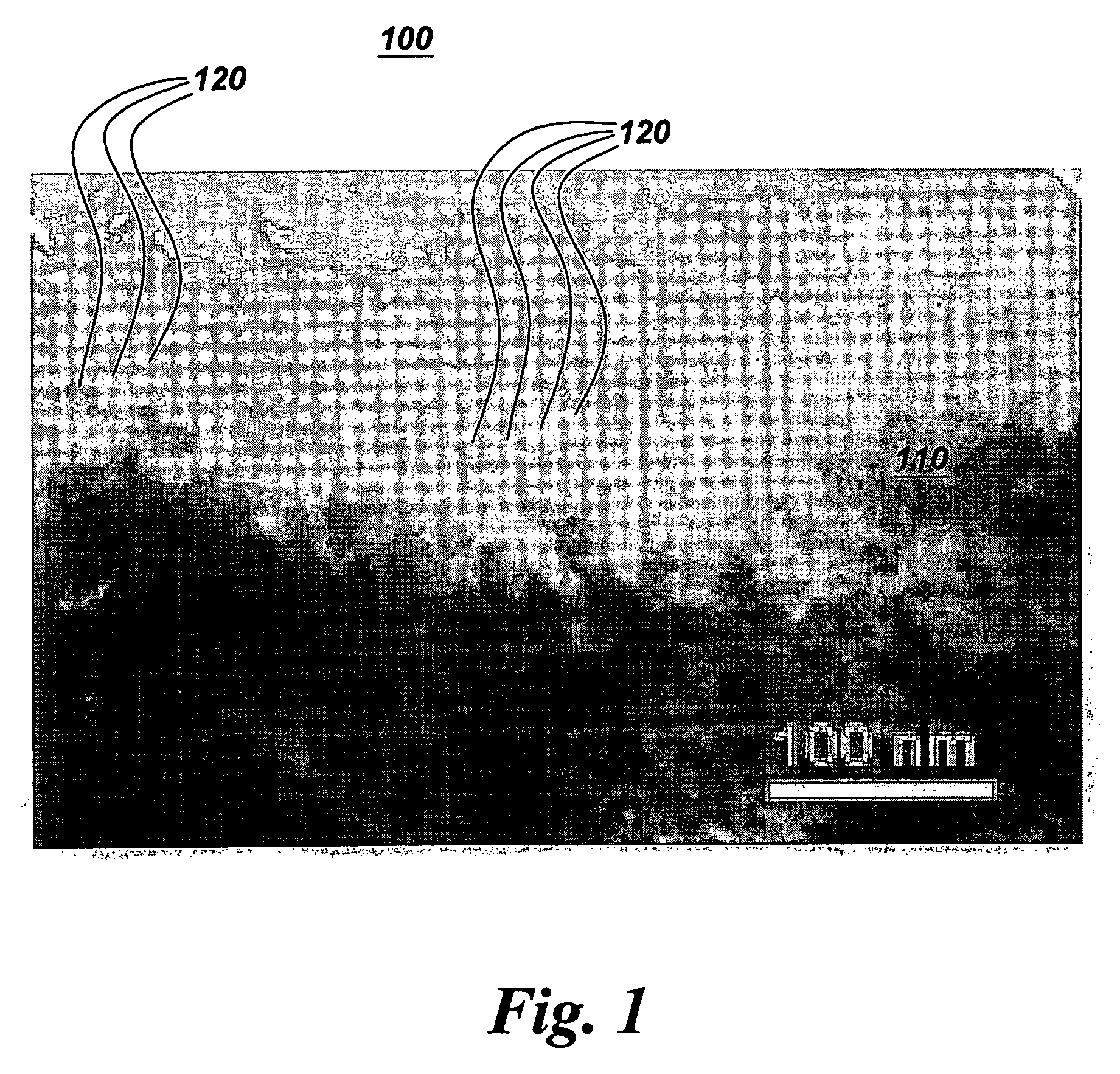

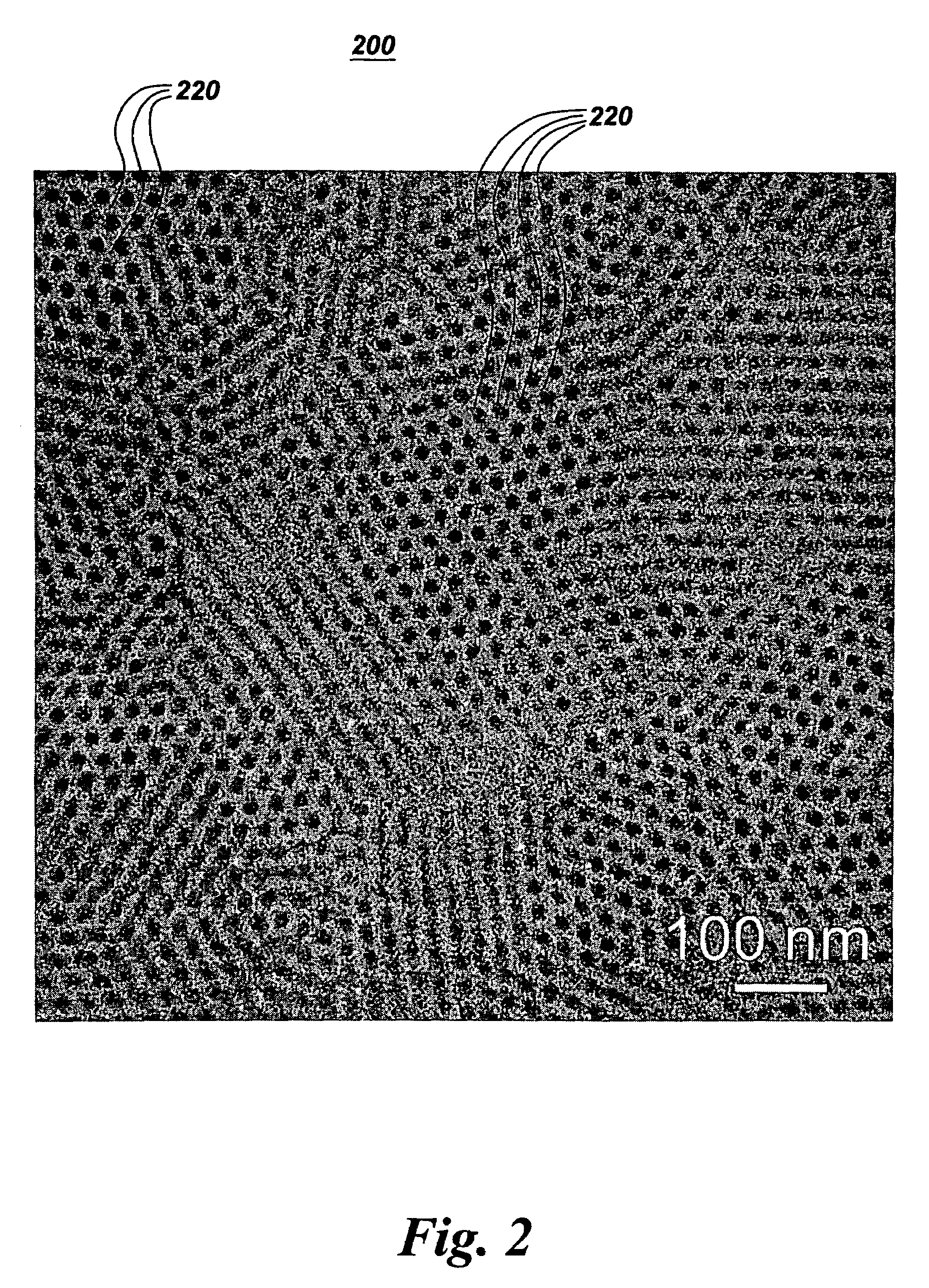

Nanoscale ordered composites of covalent ceramics for high-temperature structural applications via block-copolymer-assisted assembly and method of making

A method of making nanoscale ordered composites of covalent ceramics through block copolymer-assisted assembly. At least one polymeric precursor is mixed with a block copolymer, and self-assembly of the mixture proceeds through an annealing process. During the annealing step, the polymeric precursor cross-links to form a structure robust enough to survive both the order-disorder transition temperature the block copolymer and the pyrolysis process, yielding ordered nanocomposites of high temperature ceramic materials. The method yields a variety of structures and morphologies. A ceramic material having at least one ceramic phase that has an ordered structure on a nanoscale and thermally stable up to a temperature of at least about 800° C. is also disclosed. The ceramic material is suitable for use in hot gas path assemblies, such as turbine assemblies, boilers, combustors, and the like.

Owner:GENERAL ELECTRIC CO

Conversion of carbonaceous materials to synthetic natural gas by pyrolysis, reforming, and methanation

InactiveUS20080016769A1Reduce the temperatureCombustible gas chemical modificationProductsSyngasSteam reforming

The production of synthetic natural gas from a carbonaceous material, preferably a biomass material, such as wood. The carbonaceous material is first pyrolyzed, then subjected to steam reforming to produce a syngas, which is then passed to several clean-up steps then to a methanation zone to produce synthetic natural gas.

Owner:CLEAN ENERGY LLC

Synthesis method for carbon material based on lixm1-ym'(xo4)n

InactiveUS20040086445A1Improve performanceLow costHybrid capacitorsElectrolytic capacitorsElectrical conductorSynthesis methods

Method of synthesis for a material made of particles having a core and a coating and / or being connected to each other by carbon cross-linking, the core of these particles containing at least one compound of formula LixM1-yM'y(XO4)n, in which x,y and n are numbers such as 0<=x<=2, 0<=y<=0.6 and 1<=n<=1.5, M is a transition metal, M' is an element with fixed valency, and the synthesis is carried out by reaction and bringing into equilibrium the mixture of precursors, with a reducing gaseous atmosphere, in such a way as to bring the transition metal or metals to the desired valency level, the synthesis being carried out in the presence of a source of carbon called carbon conductor, which is subjected to pyrolysis. The materials obtained have excellent electrical conductivity as well as very improved chemical activity.

Owner:CENT NAT DE LA RECHERCHE SCI +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com