Patents

Literature

78036 results about "Ceramic materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ceramic materials are inorganic, non-metallic materials made from compounds of a metal and a non metal. Ceramic materials may be crystalline or partly crystalline. They are formed by the action of heat and subsequent cooling. Clay was one of the earliest materials used to produce ceramics, as pottery, but many different ceramic materials are now used in domestic, industrial and building products. Ceramic materials tend to be strong, stiff, brittle, chemically inert, and non-conductors of heat and electricity, but their properties vary widely. For example, porcelain is widely used to make electrical insulators, but some ceramic compounds are superconductors.

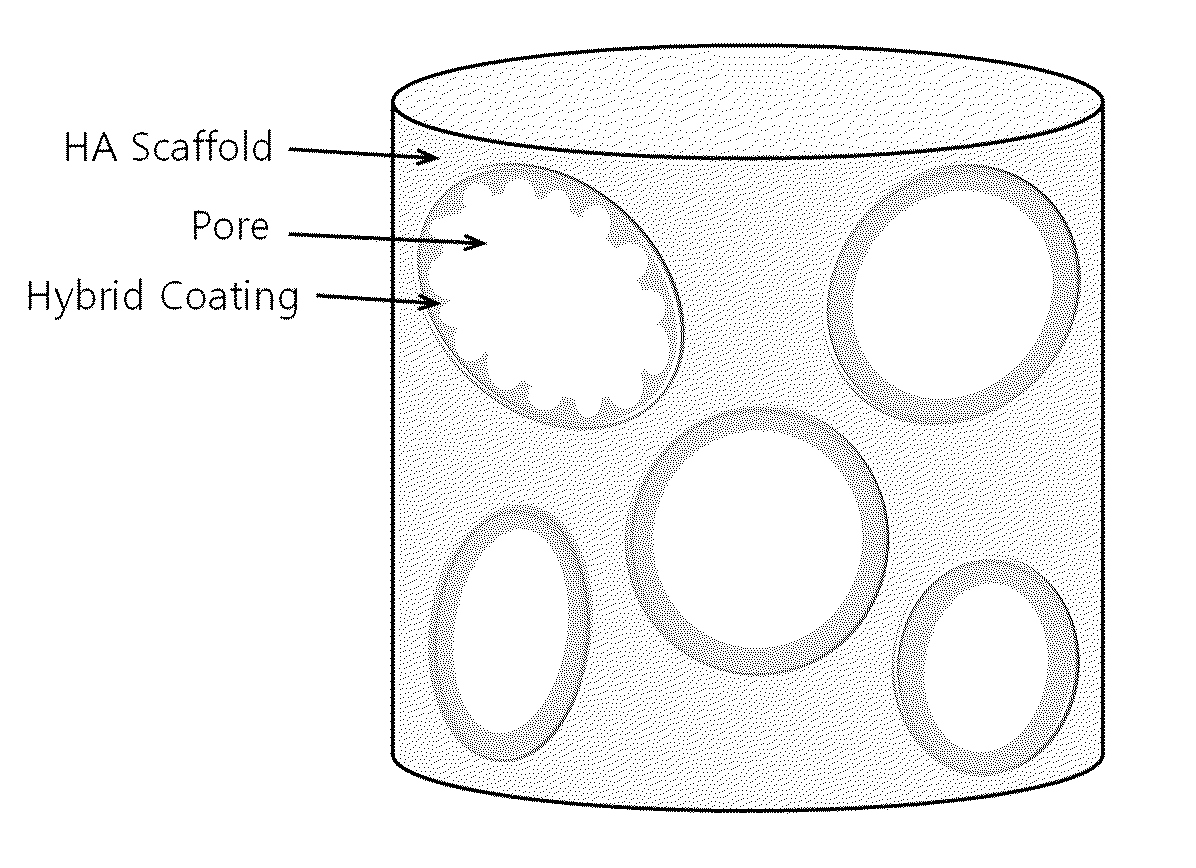

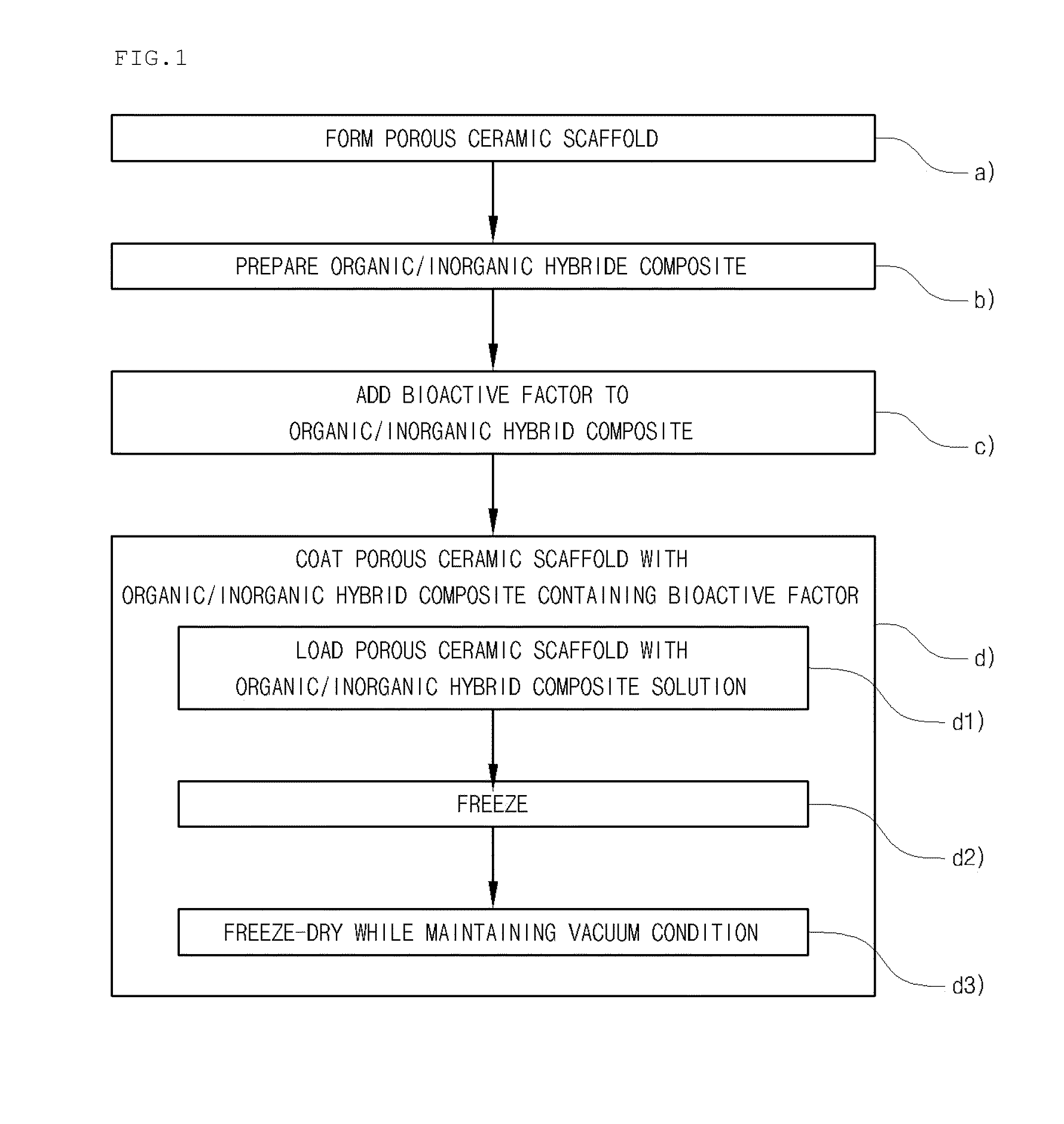

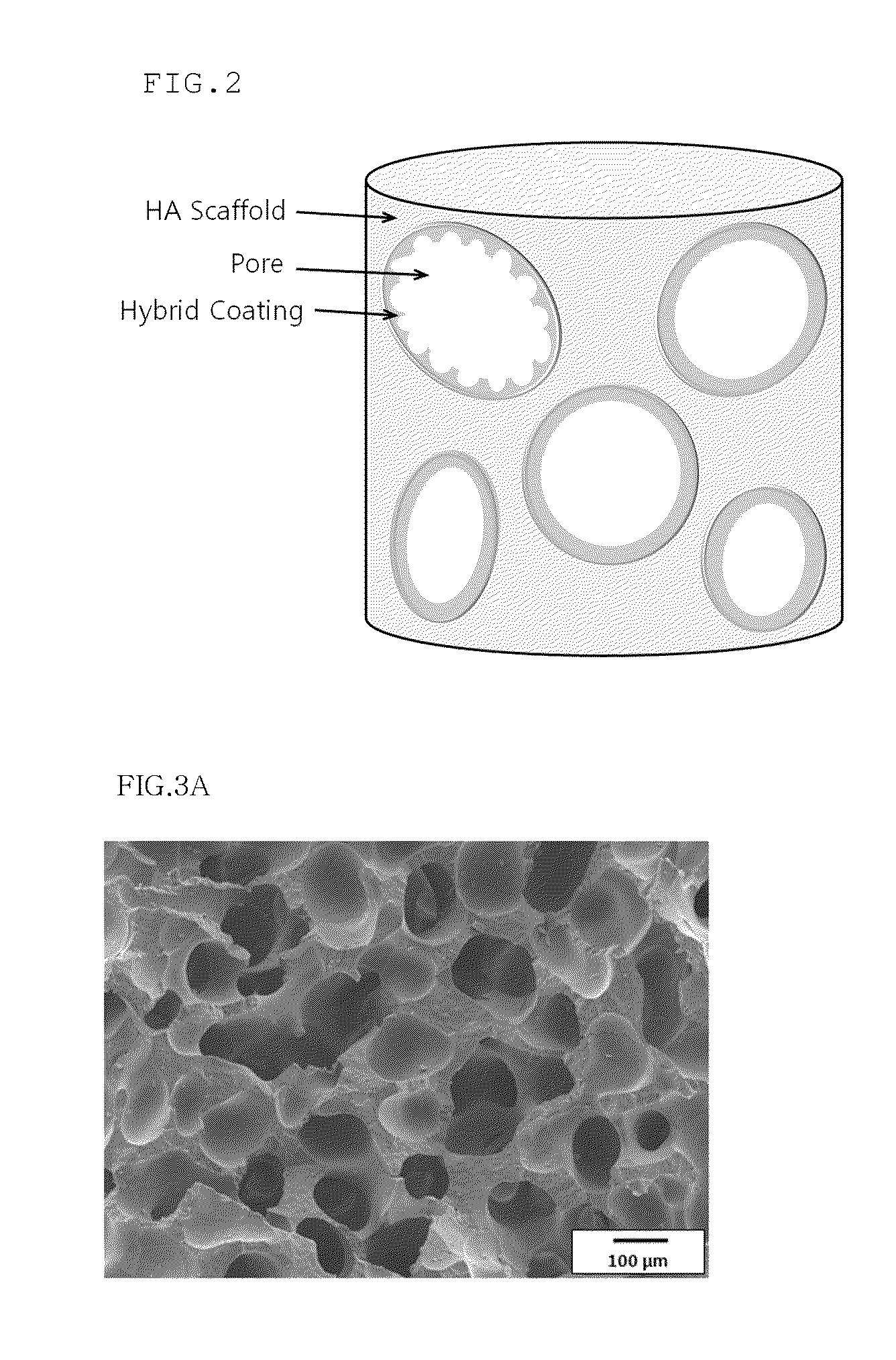

Method for manufacturing a porous ceramic scaffold having an organic/inorganic hybrid coating layer containing a bioactive factor

ActiveUS8734831B2Good biocompatibilityEasy to controlBiocideSurgical adhesivesOrganic matterPorous ceramics

A method for manufacturing a porous ceramic scaffold having an organic / inorganic hybrid coating layer containing a bioactive factor includes (a) forming a porous ceramic scaffold; (b) mixing a silica xerogel and a physiologically active organic substance in a volumetric ratio ranging from 30:70 to 90:10 and treating by a sol gel method to prepare an organic / inorganic hybrid composite solution; (c) adding a bioactive factor to the organic / inorganic hybrid composite solution and agitating until gelation occurs; and (d) coating the porous ceramic scaffold with the organic / inorganic composite containing the bioactive factor added thereto. In accordance with the method, the porous ceramic scaffold may be uniformly coated with the organic / inorganic hybrid composite while maintaining an open pore structure, and stably discharge the bioactive factor over a long period of time.

Owner:SEOUL NAT UNIV R&DB FOUND

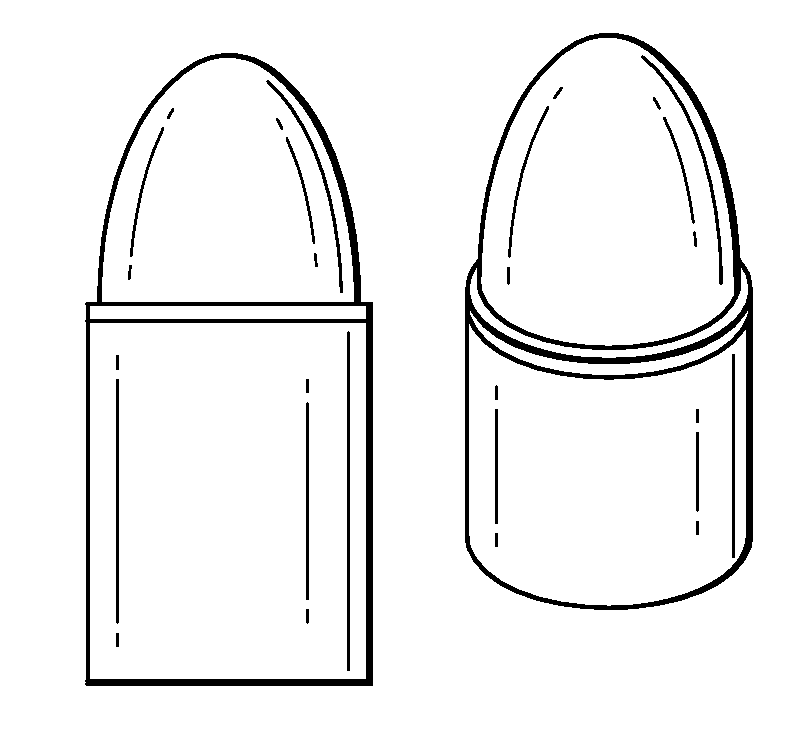

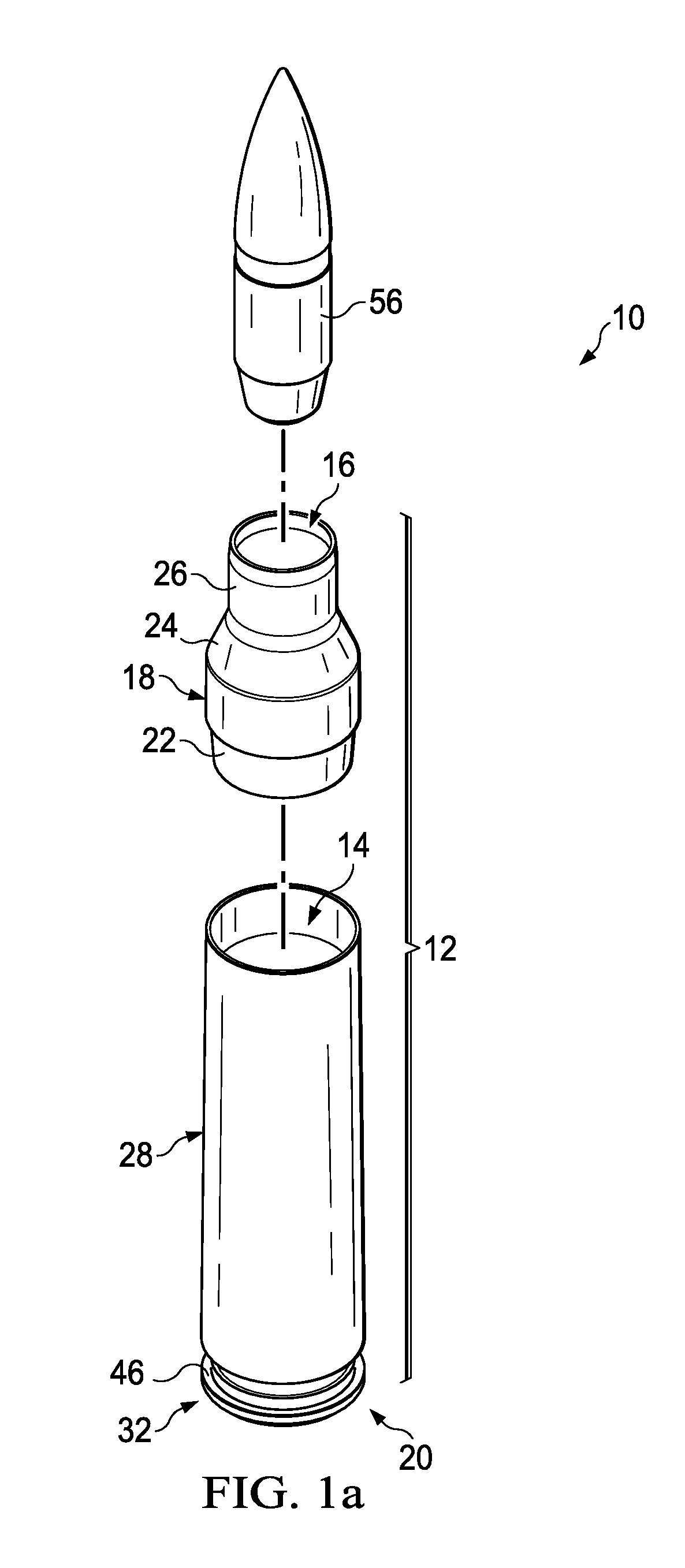

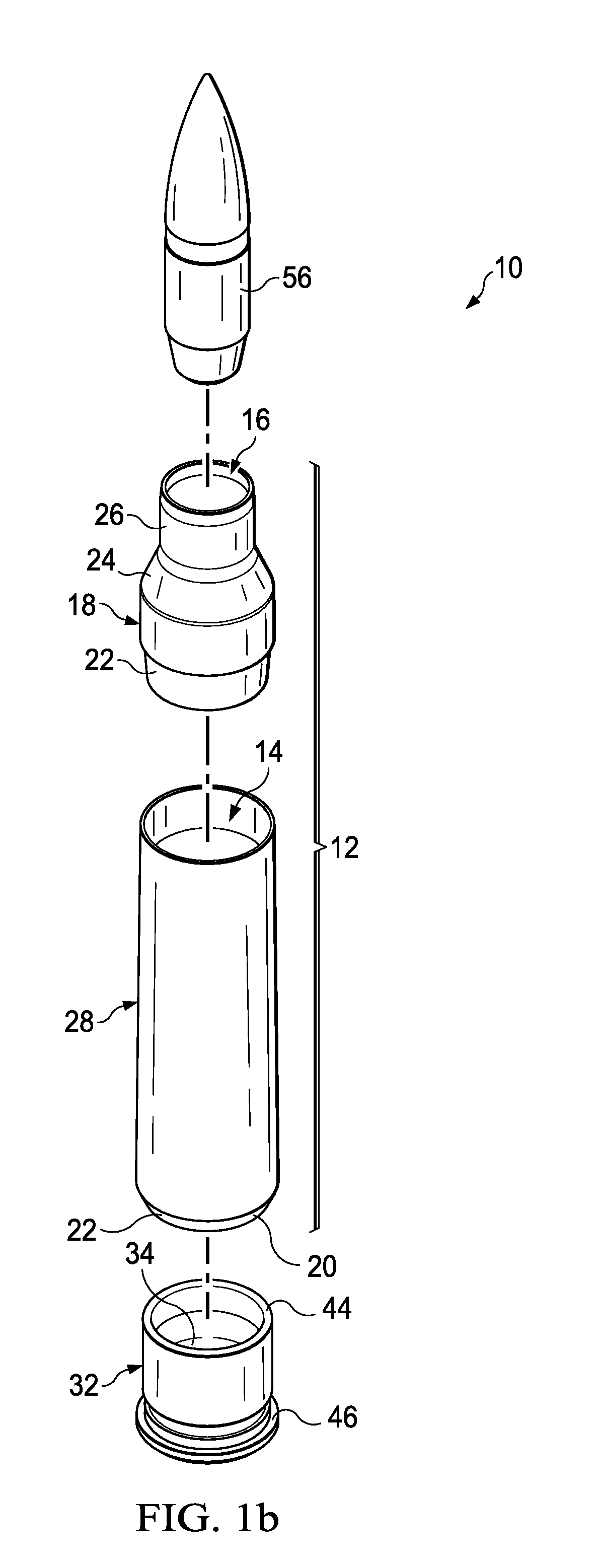

Method of making a projectile by metal injection molding

The present invention provides a method of making a metal ammunition projectile by metal injection molding comprising the steps of: providing a projectile mold to form a nose extending essentially symmetrically to a shoulder; and an essentially cylindrical bearing surface extending from the shoulder to a base; providing a metal injection molding feedstock comprising a powdered metal and a first binding agent and a second binding agent; injection molding the metal injection molding feedstock into the projectile mold to form a first projectile having a first size; debinding the first projectile to remove the first binding agent; and sintering the first projectile to remove the second binding agent and form a projectile having a second size.

Owner:TRUE VELOCITY IP HLDG LLC

Two-dimensional fiber cloth reinforced composite material and preparation method thereof

InactiveCN101224989AImprove fracture toughnessImprove use reliabilityMetal powderStructural stability

The invention discloses a two-dimensional fiber cloth reinforced ceramics based composite material and the preparation technique, which adopts the two-dimensional fiber cloth as the reinforcing phase and the ceramic powder or the refractory metal powder as the stuffing, and the carbon and the carborundum as the base. The process steps are following: first the sizing agent with different ceramic powder and metal powder is coated on the two-dimensional fiber cloth, and then overlapping, puncturing and repeated densification are carried out. The preparation method has the advantages of lowering preparation cost and shortening preparation cycle, and the two-dimensional fiber cloth reinforced ceramics based composite material has the advantages of high shear strength between layers, structural stability and high reliability. The types of fiber cloth and the base can be adjusted and optimized in a wider range according to the applications, so as to be applicable for different fields.

Owner:NAT UNIV OF DEFENSE TECH

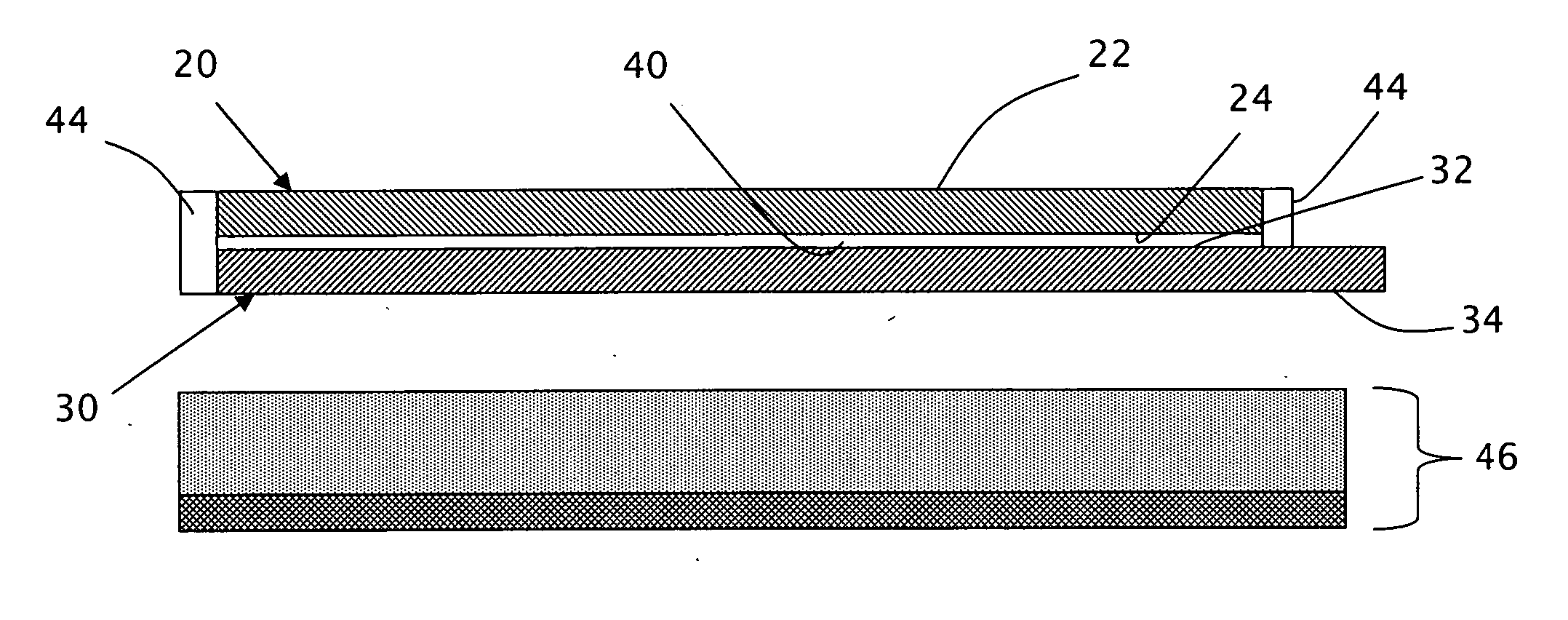

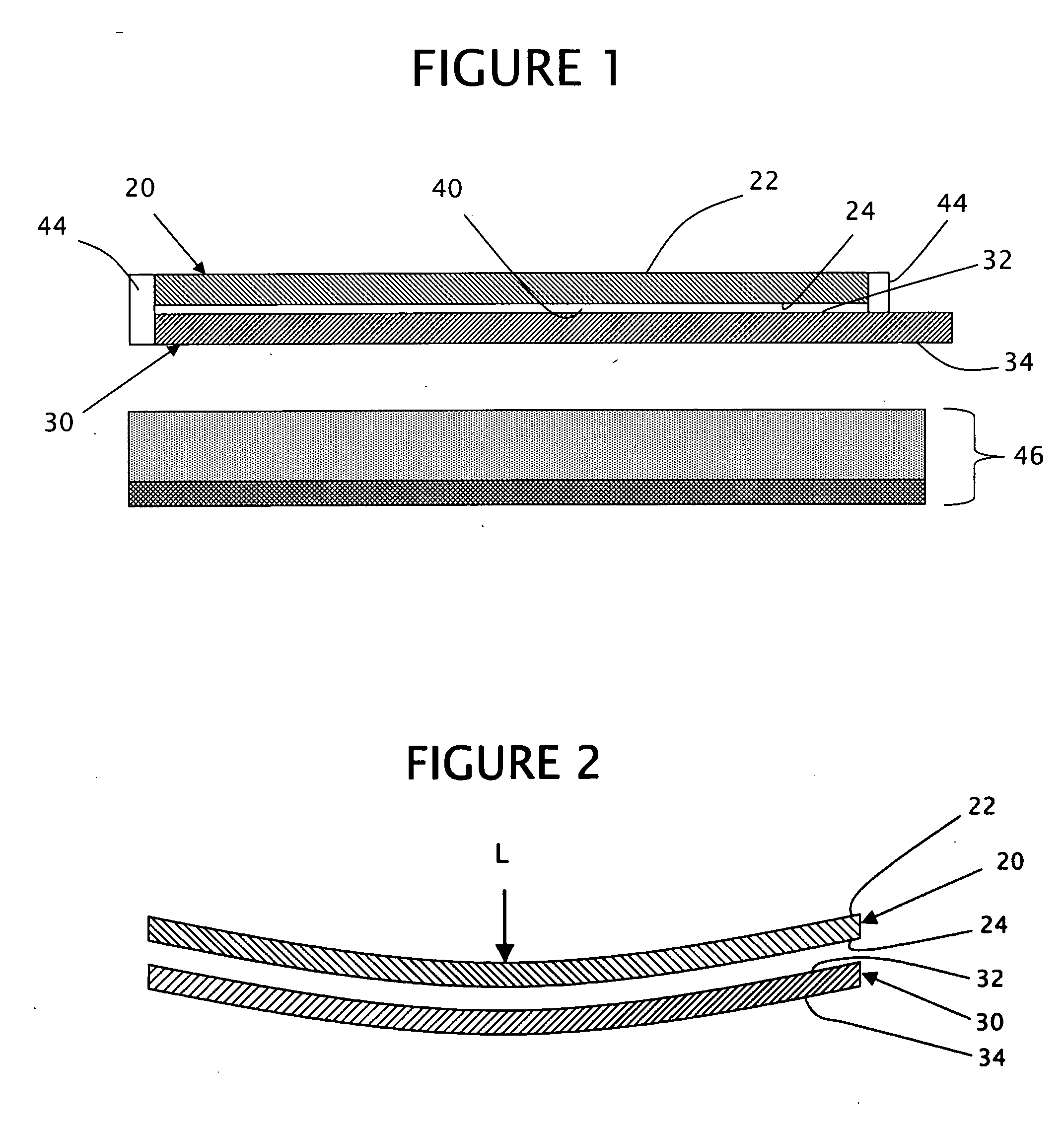

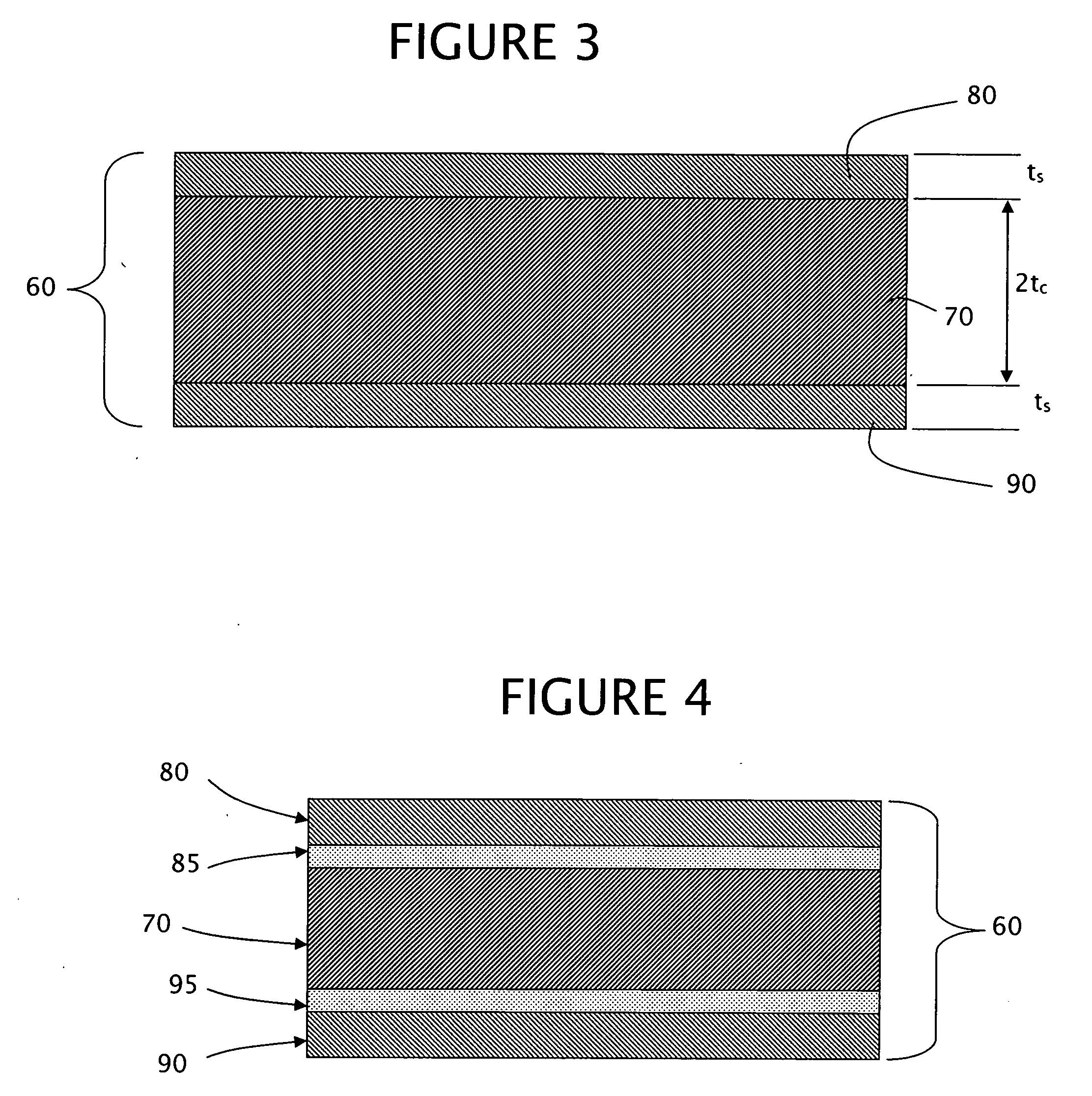

Glass laminate substrate having enhanced impact and static loading resistance

ActiveUS20060127679A1Increased resistance to impactIncrease static loadLiquid crystal compositionsGas-filled discharge tubesDisplay deviceThermal expansion

A glass laminate substrate for electronic substrates, such as flat panel displays, includes a transparent glass core bounded by transparent glass skin layers, wherein the coefficient of thermal expansion of the core is greater than the coefficient of thermal expansion of the skin layers thereby forming a residual compressive stress in the skin layers and a residual tensile stress in the core. The relative thickness of the skin layers can be selected to enhance the strength of the glass laminate substrate while maintaining a sufficiently low residual tensile stress in the core to allow scribing and separating of the substrate to size. Interlayers can be located between the core and the skin layers, wherein the interlayers include a residual compressive stress, and produce a reduced residual tensile stress in the core.

Owner:CORNING INC

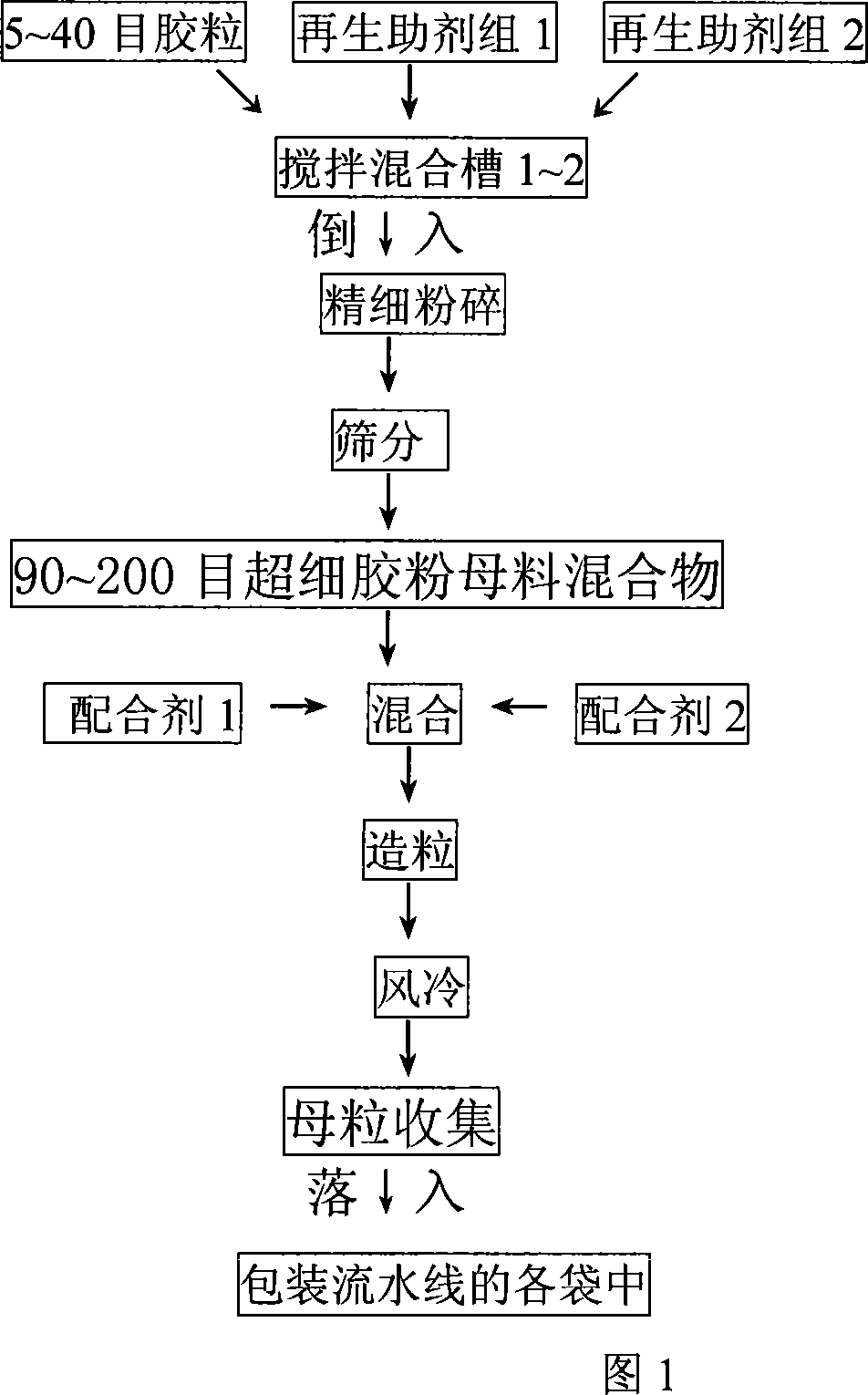

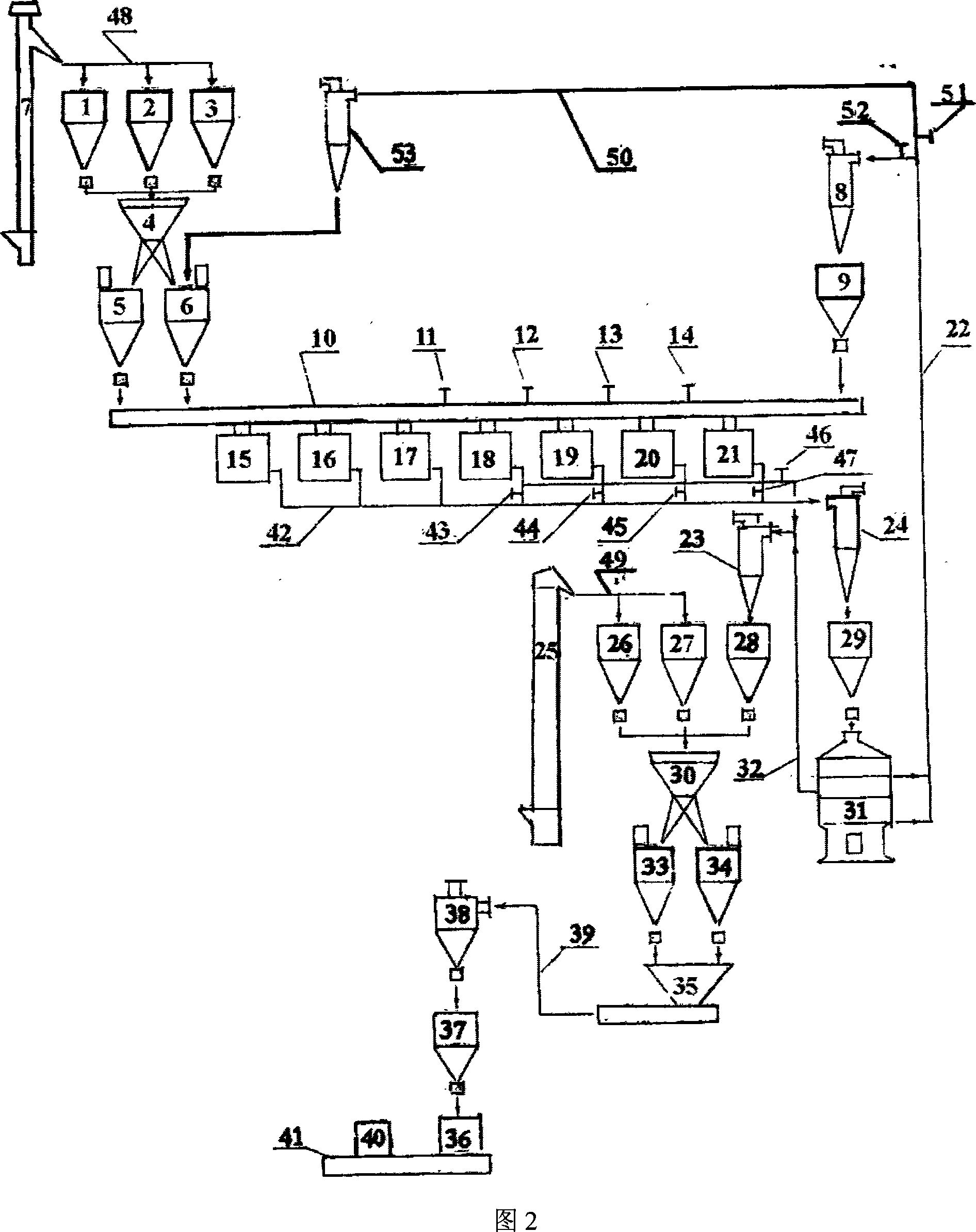

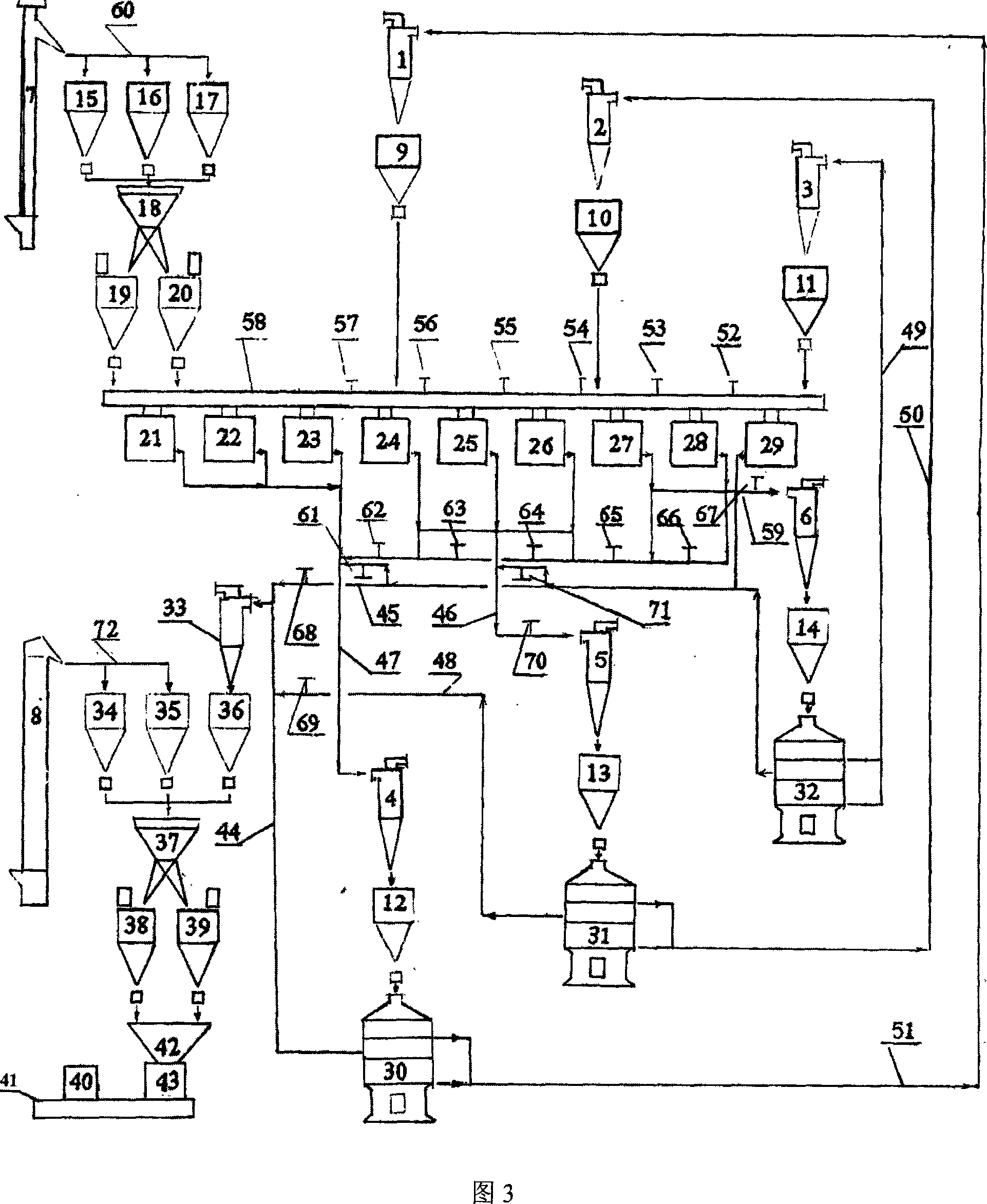

Reproduction new method for waste elastomer and plastic

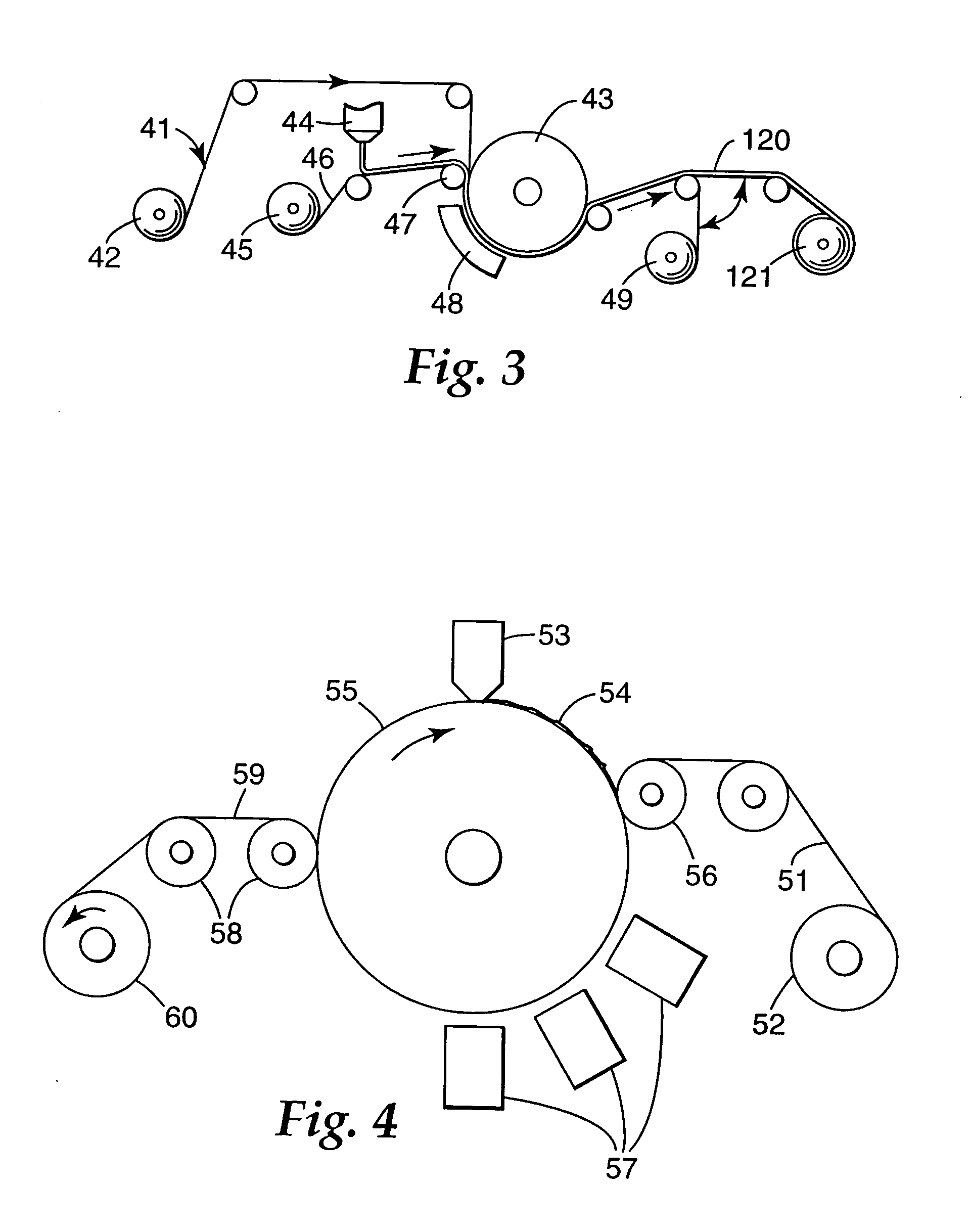

InactiveCN101041725AThe ratio is roughly constantReduce or eliminate the impact of flow fluctuationsPlastic recyclingElastomerEngineering

The invention discloses a new regenerating method of waste elastics and plastic, which comprises the following steps: 1. blending waste elastics or / and plastic with grain size between 5 and 80 order and non-polluted regenerative adjuvant according to proportion; placing into the manufacturing machine; grinding; sieving; heating to desulfurize; bulking; soaping; emulsifying; kneading; pressing; graining; obtaining composite product 1 with mother material or mother particle or mother gel of plastic elastic powder; 2. weighing product 1 and non-polluted mating agent into mixing machine according to proportion; kneading; blending evenly; pressing; graining; obtaining the product 2 of mother material or mother particle or mother gel with 5-95% waste elastic or / and plastic.

Owner:陈书怡 +1

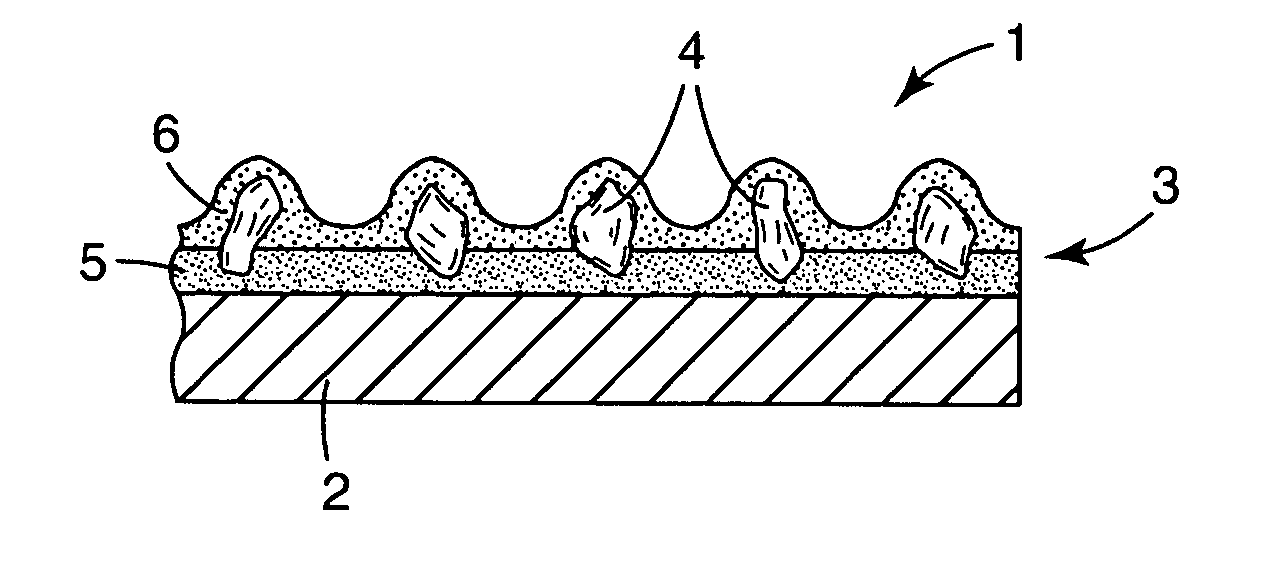

Abrasive grain, abrasive articles, and methods of making and using the same

InactiveUS6287353B1Easy accessImprove grinding efficiencyPigmenting treatmentOther chemical processesComposite materialCeramic materials

Owner:3M INNOVATIVE PROPERTIES CO

Dust filter bag including a highly porous backing material ply

InactiveUS6706086B2Simple and cost-effective productionCleaning filter meansCombination devicesBursting strengthCellulose fiber

A dust filter bag having a highly porous backing material ply and a method for producing the dust filter bag. The dust filter bag includes at least one filter material ply and at least one backing material ply, the backing material ply possessing an air permeability of at least 900 l / m<2 >x s, a burst strength of at least 70 kPa, a rupture strength longitudinally better than 10 and transversely better than 3 N, a flexural rigidity longitudinally better than 0.5 cN cm<2 >and transversely better than 0.25 cN cm<2>, a basis weight of 30-80 g / m<2 >and a droplet sink-in time of less than 10 minimum. The dust filter bag can be produced by the following steps: mixing fibers including cellulose fibers and fusible fibers into a homogenous fiber mix, processing the fiber mix into a fiber web by wet laying, drying the fiber web, curing the dried fiber web by thermofusion into a backing material ply, processing the backing material ply with a filter material ply into a raw bag, and finishing the raw bag into a dust filter bag.

Owner:NEENAH GESSNER GMBH

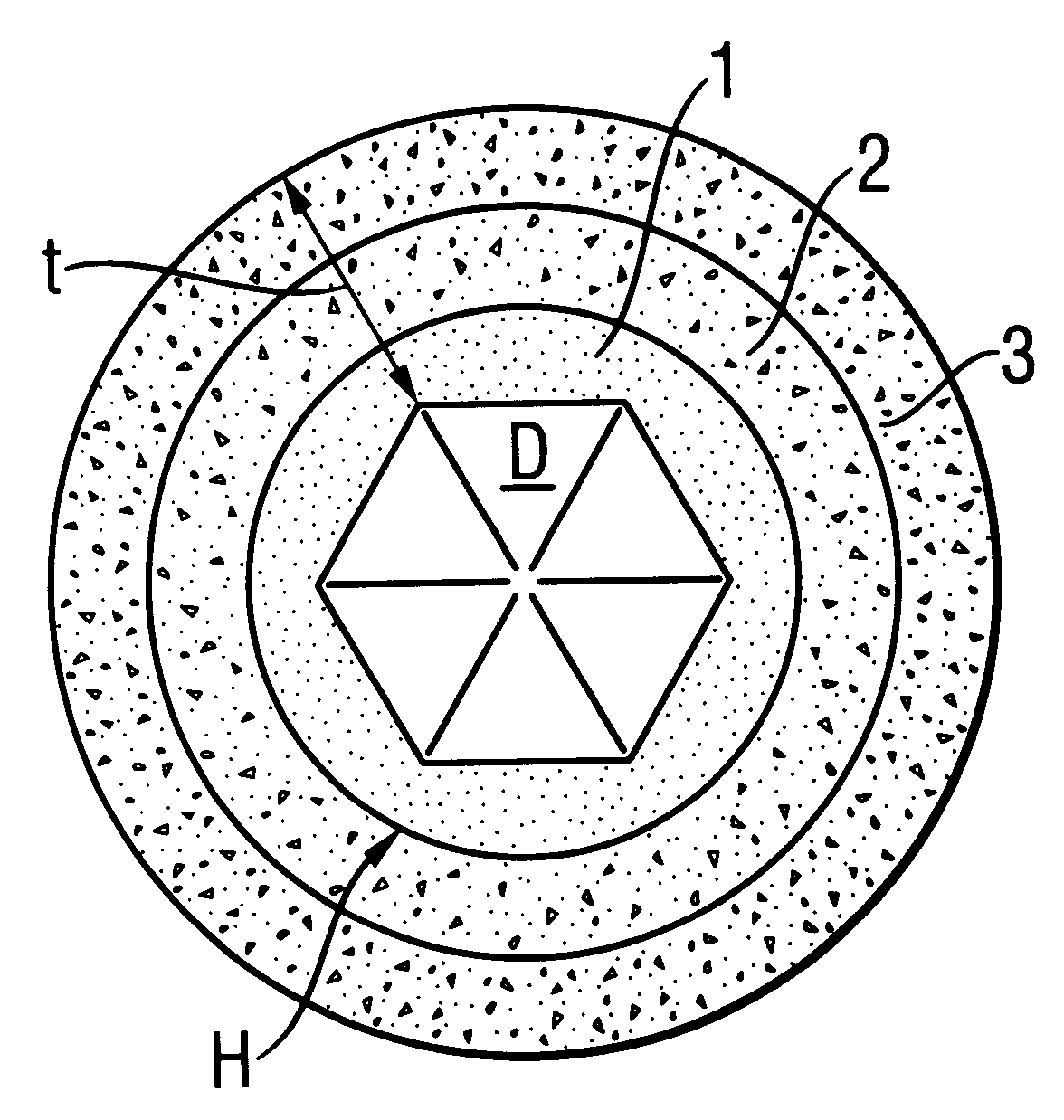

Abrasive cutter containing diamond particles and a method for producing the cutter

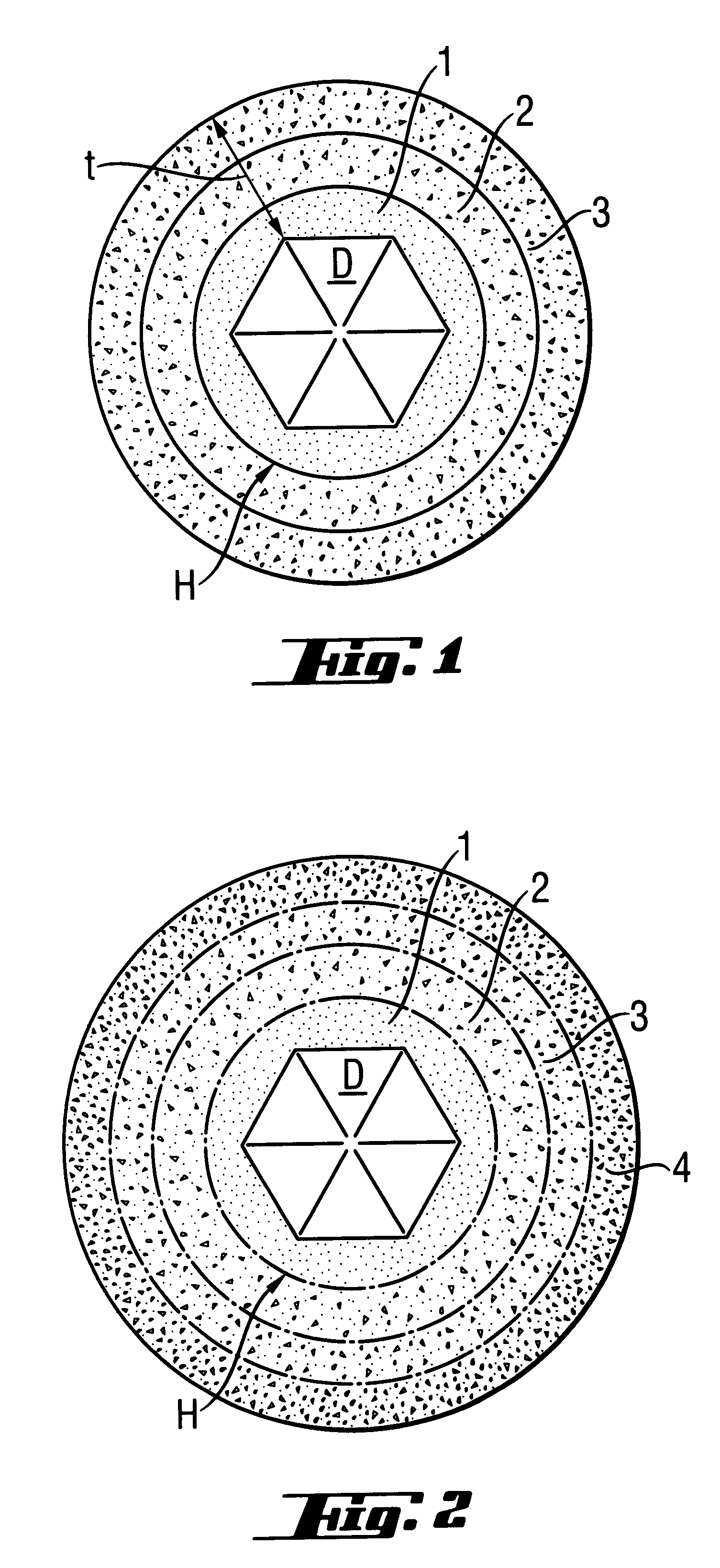

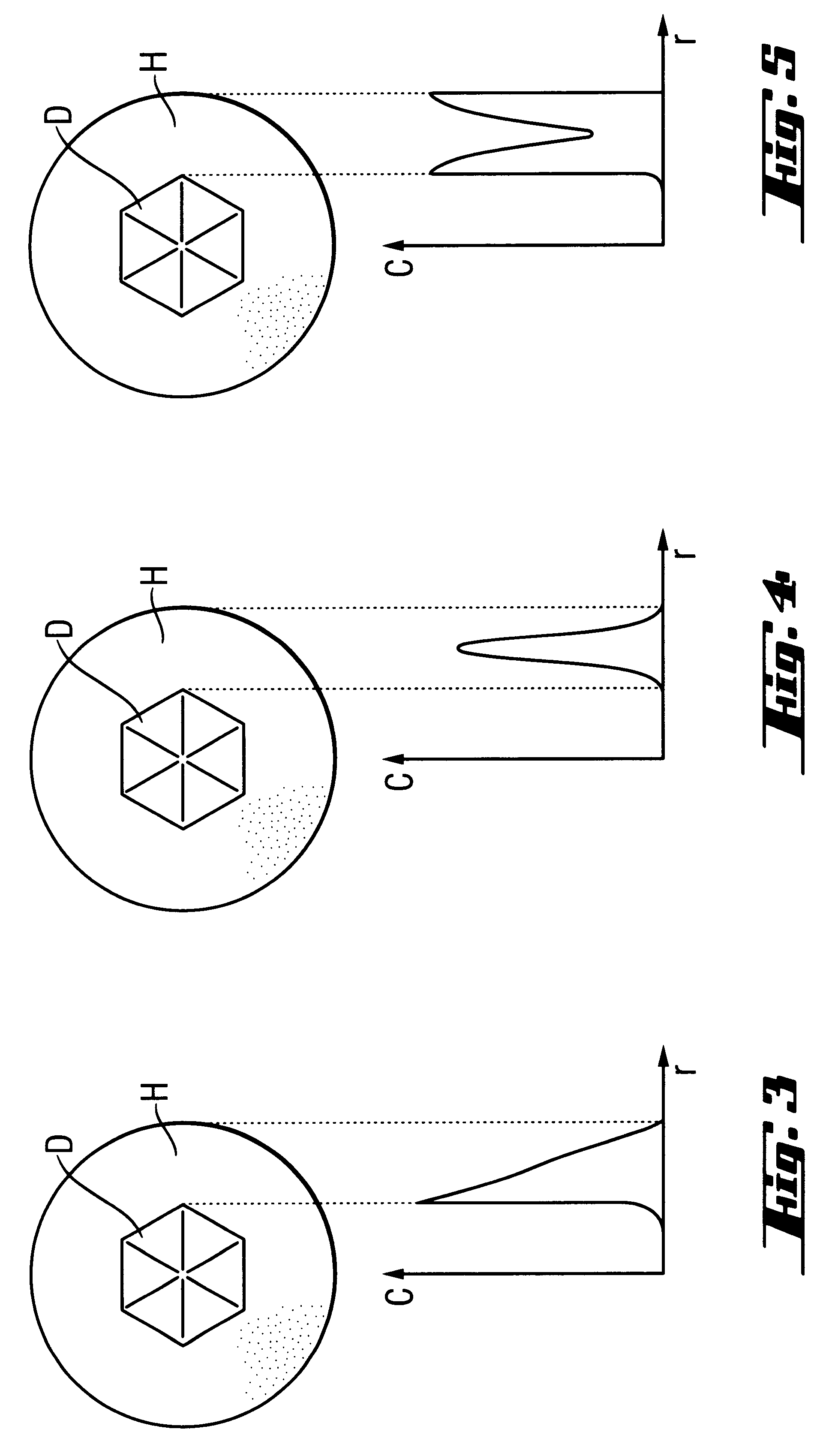

InactiveUS6238280B1Eliminate disadvantagesAvoid attenuationRevolution surface grinding machinesBonded abrasive wheelsMetal coatingDiamond crystal

An abrasive cutter formed of at least one diamond particle, preferably at least one mono-diamond crystal and metallic binder material distinguished by the fact that the diamond particle (D) has a size of about 50 mum to about 500 mum and each diamond particle (D) is enclosed by a coating (H) produced in a fluidized bed with the coating having a wall thickness of about 10 mum to about 200 mum. The volume of the coating (H) constitutes at least 30% of the volume of the diamond particles (D) in the fully consolidated state following individual sintering of the coated diamond particles (D, H). The abrasive cutters can be applied directly onto an abrasive tool. Further they can be processed to form composite cutters or cutting segments. In the method of forming the abrasive cutter, the diamond particle (D) is brought into a fluidized bed reactor and enclosed in a metallic coating (H). Coated diamond particle (D, H) can be processed into larger cutters or segments in each case individually sintered and fixed directly on an abrasive tool.

Owner:HILTI AG

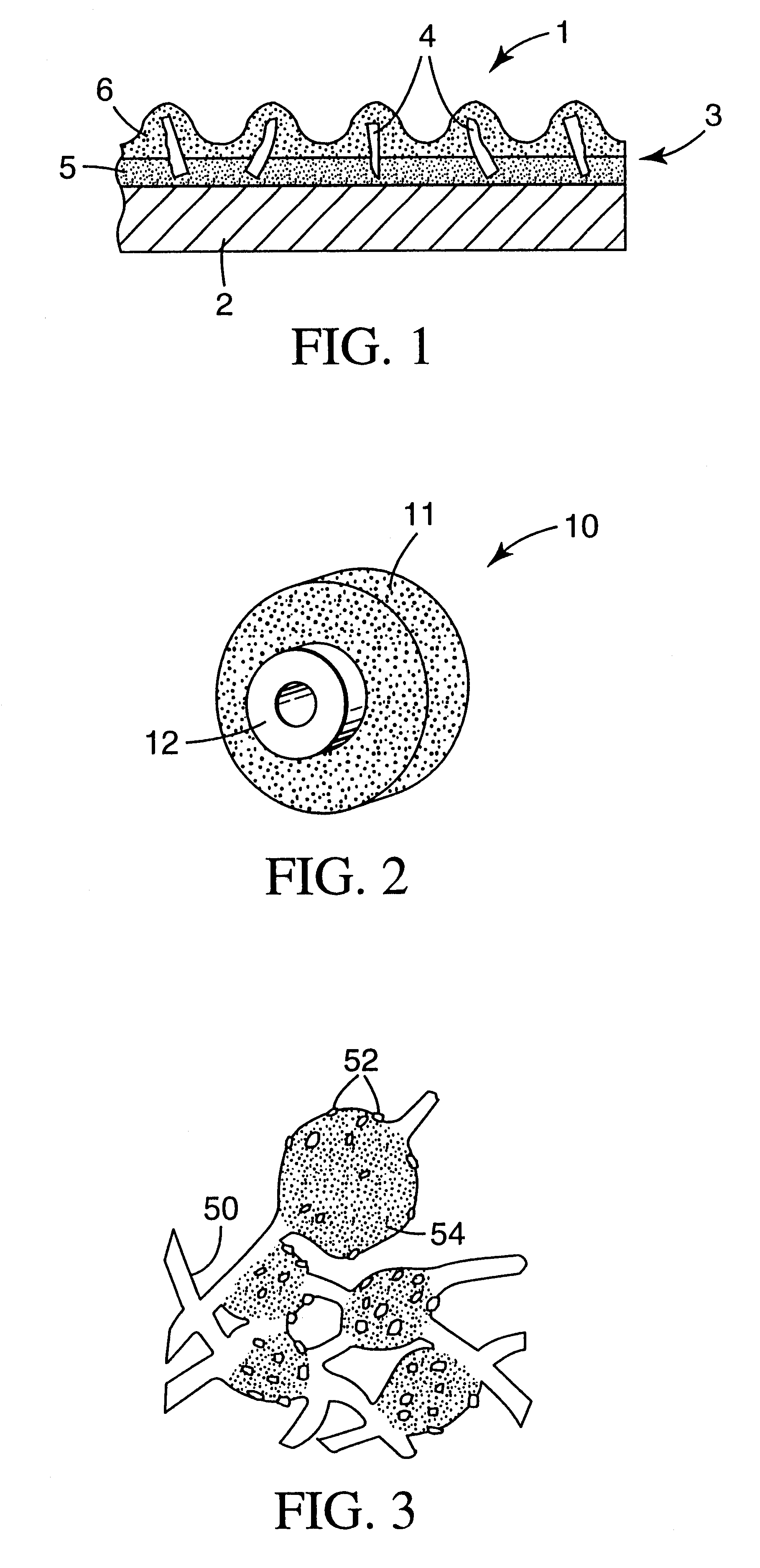

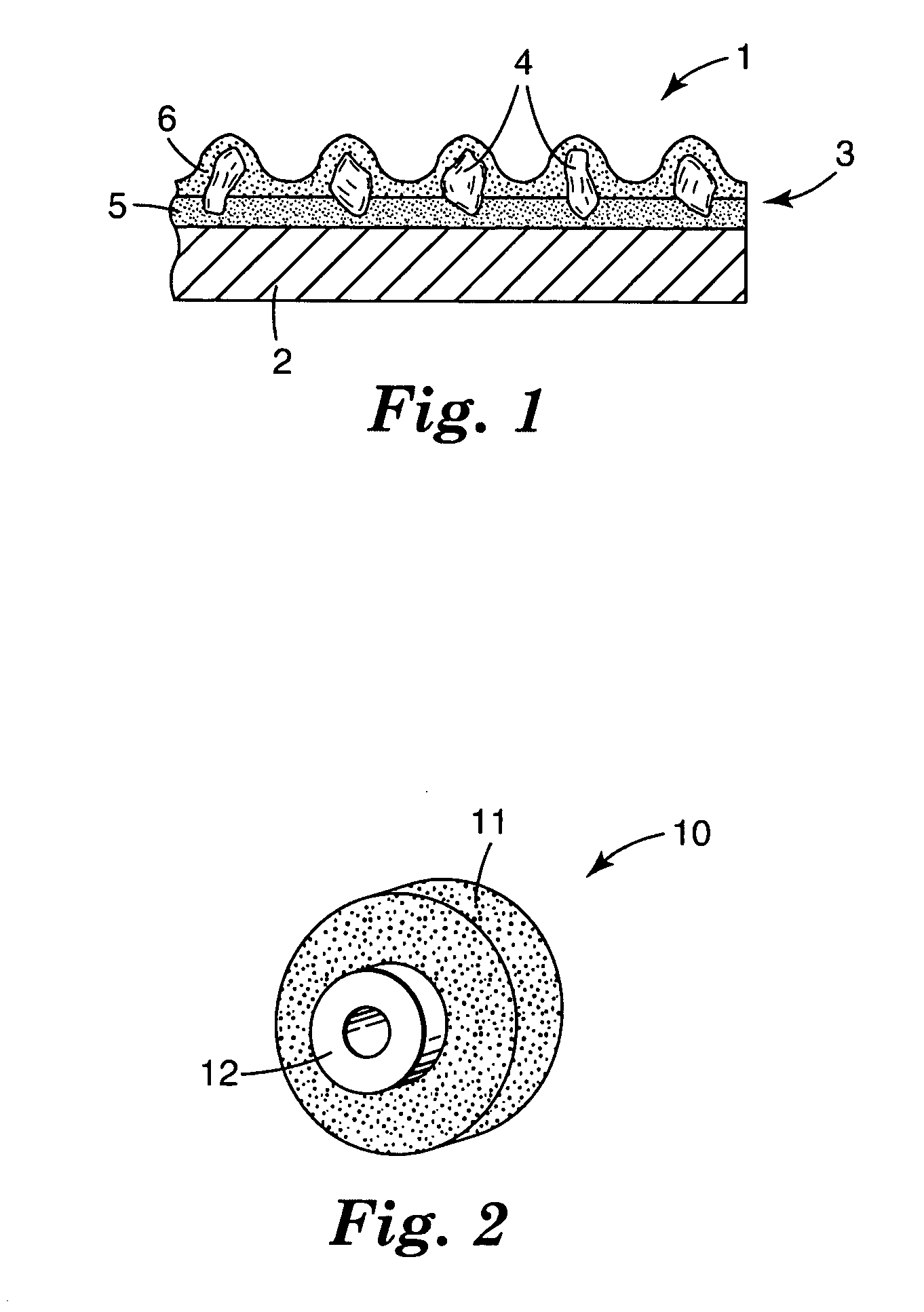

Flexible abrasive product and method of making and using the same

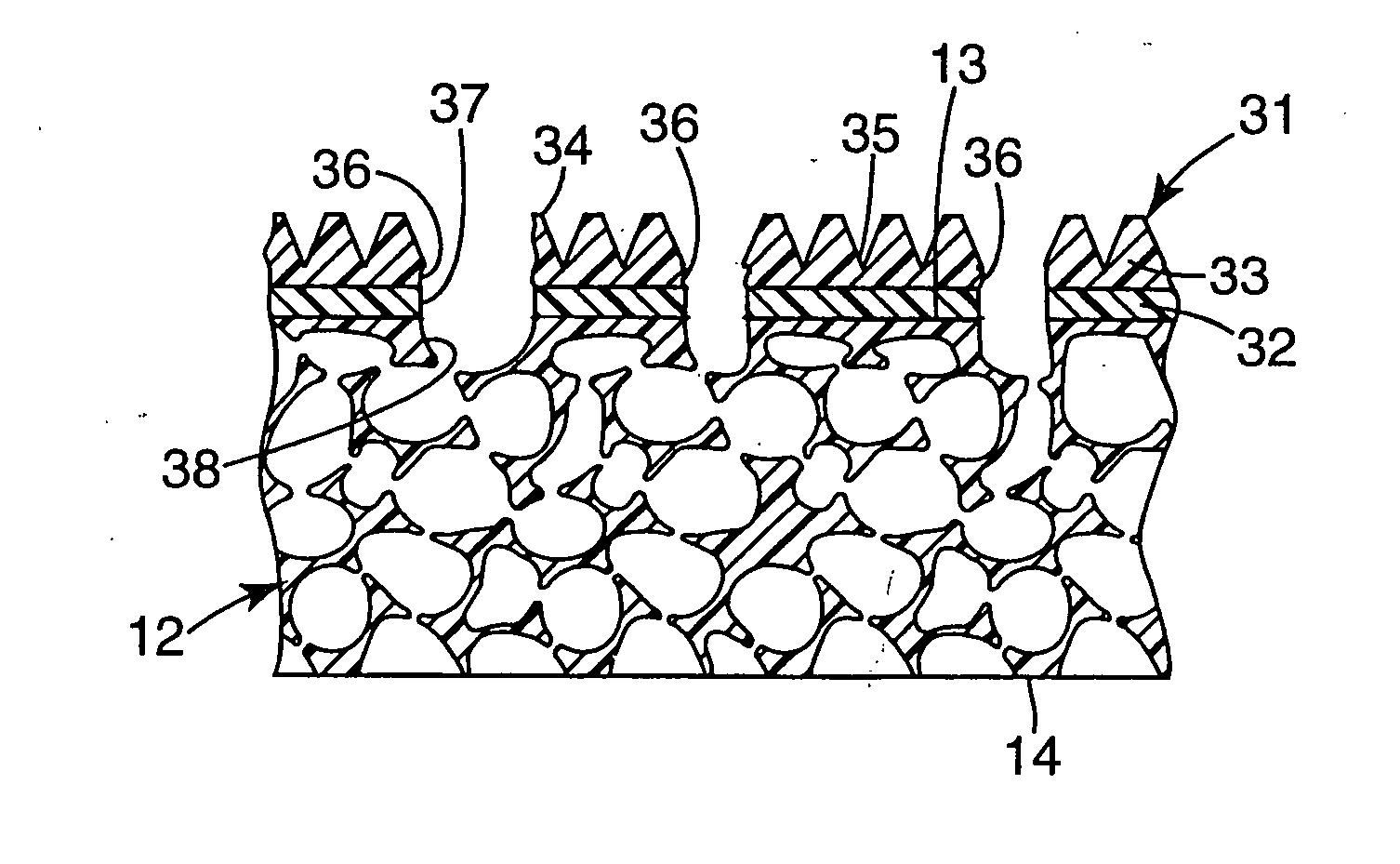

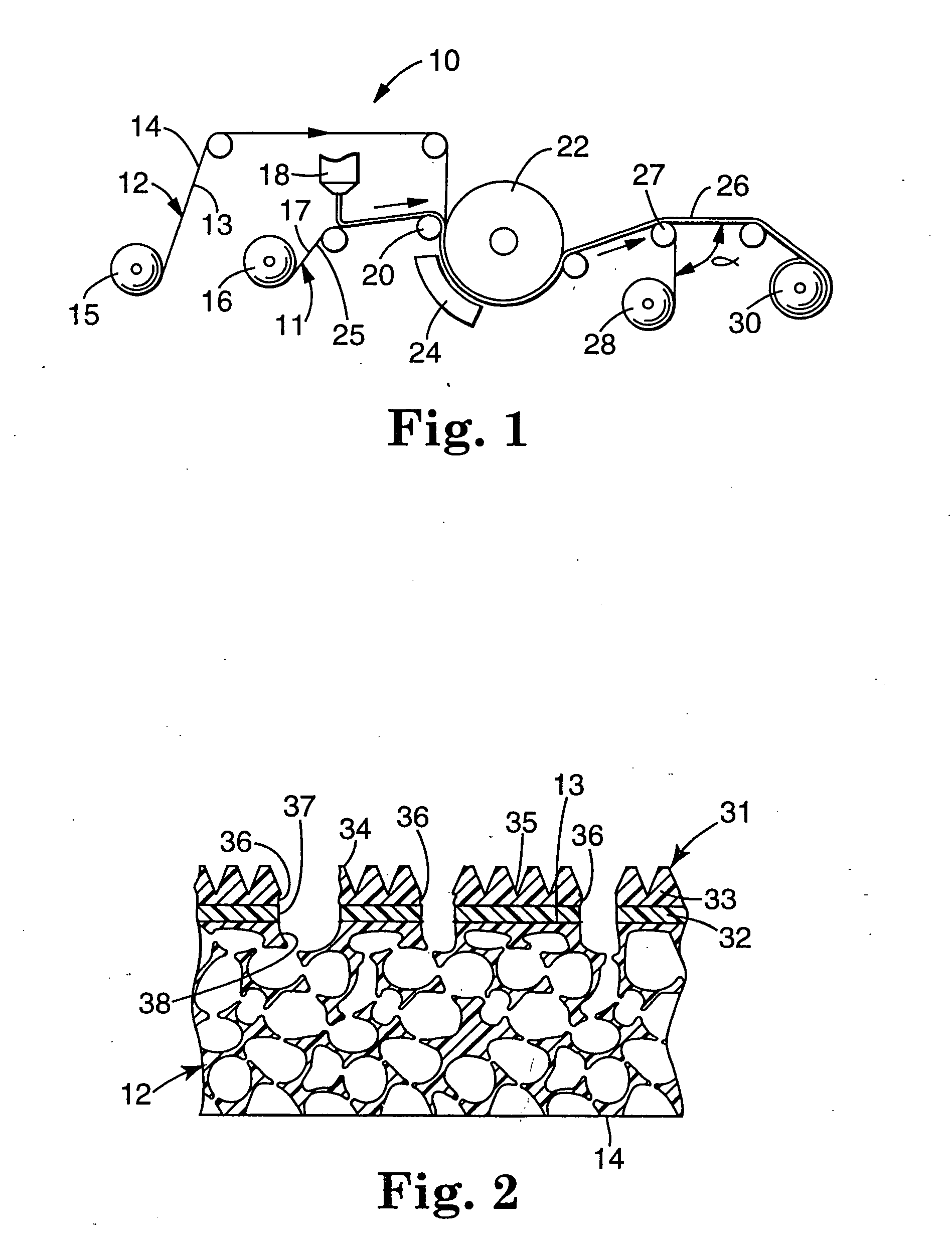

InactiveUS20050020190A1Provide dimensional stabilityFlexible-parts wheelsPlane surface grinding machinesOpen cellCoating

The present invention provides a flexible abrasive product comprised of an open cell foam backing, a foraminous barrier coating and a shaped foraminous abrasive coating. The flexible abrasive article of the invention is made by applying a curable barrier coating over an open cell foam backing, curing the curable barrier coating to provide a foraminous barrier coating having openings therethrough corresponding to openings in the open cell foam, applying a coating composition comprising a curable binder and abrasive particles over the foraminous barrier coating, imparting a textured surface to the coating composition with a production tool which has a textured surface which is the inverse of the textured surface of the abrasive coating and to which production tool textured surface any coating composition coated over an opening of the first major surface may adhere, at least partially curing the binder, and separating the production tool from the textured surface to provide the shaped foraminous abrasive coating.

Owner:3M INNOVATIVE PROPERTIES CO

Aerogel heat insulation composite material and its preparing method

The heat insulating composite aerogel material consists of silica aerogel, titania as infrared opacifier and reinforcing fiber in the weight ratio of 1 to 0.1-0.7 to 0.7-3. Its preparation process includes compounding sol with silanolate, surface modifier, titanolate, alcohol solvent, acid catalyst and alkaline catalyst in certain proportion; soaking fiber felt or prefabricated fiber part in the sol; and supercritical fluid drying. The material of the present invention has high blocking effect on solid heat transfer, air heat transfer and infrared radiation heat transfer, excellent hydrophobicity, simple preparation process, low cost, mechanical strength over 2 MPa, and wide application range, and may be used in strict heat protection condition in aeronautics, astronautics, military and civil uses.

Owner:NAT UNIV OF DEFENSE TECH

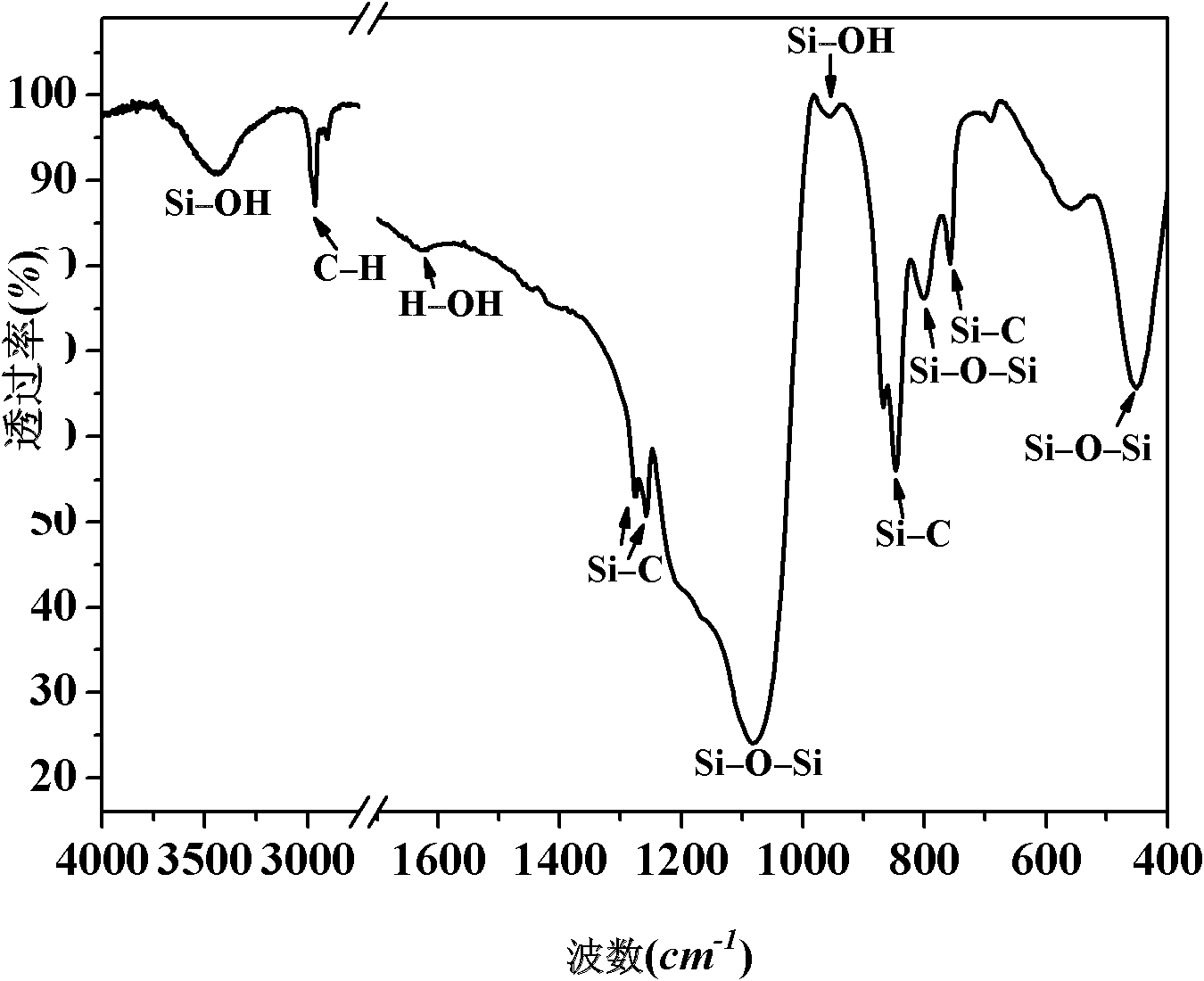

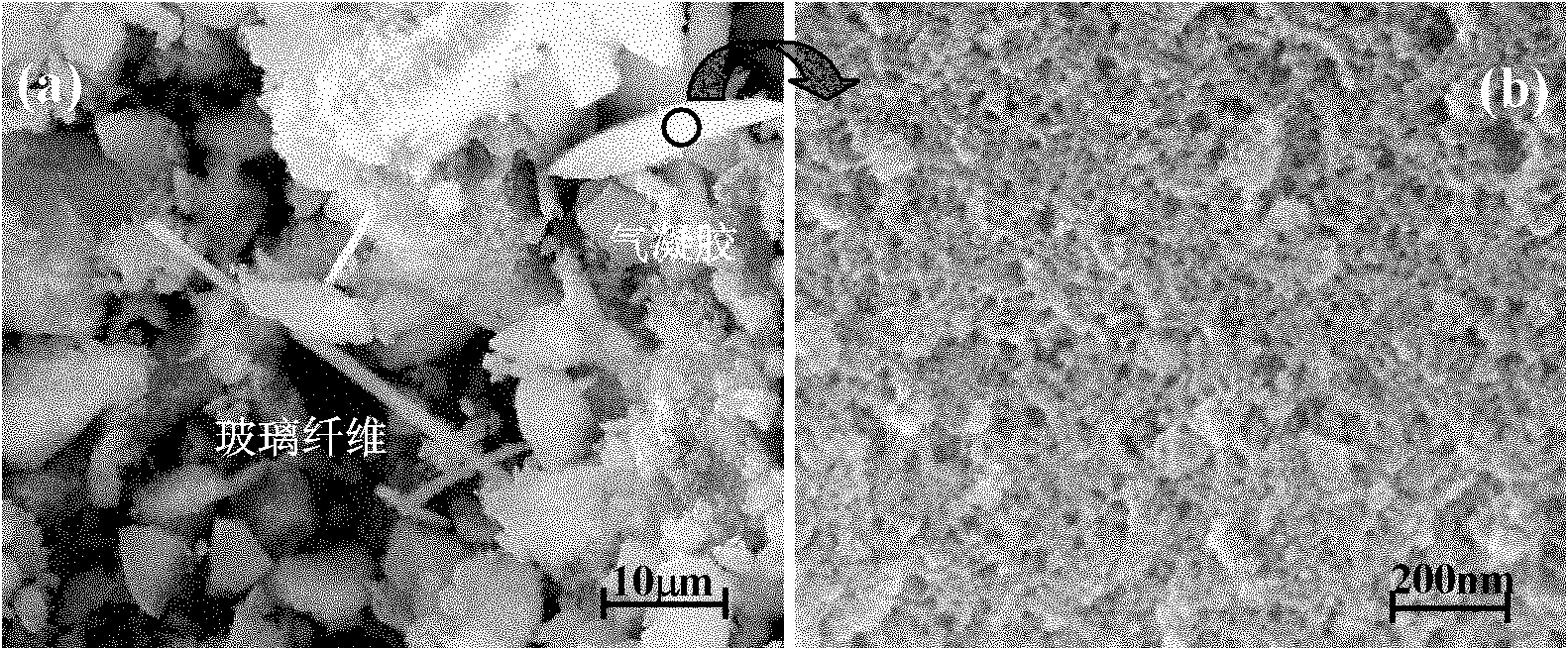

Glass fiber reinforced silicon dioxide aerogel composite material and preparation method thereof

The invention relates to an aerogel composite material, in particular to a glass fiber reinforced silicon dioxide aerogel composite material and a preparation method thereof. The excellent properties of aerogel are maintained, the mechanical properties of the aerogel are reinforced, and the glass fiber reinforced silicon dioxide aerogel composite material has good integrity and certain strength. The glass fiber reinforced silicon dioxide aerogel composite material is prepared by compounding glass fiber and silicon dioxide aerogel, wherein the glass fiber is a reinforcement, and the content ofthe glass fiber accounts for 1-15% total mass of a sample; the silicon dioxide aerogel is a matrix, tetraethoxysilane is a silicon source material, and methyltrimethoxysilane or methyltriethoxysilaneis used as a silicon source co-precursor. The preparation method comprises the following steps of: firstly, pretreating the glass fiber; then, preparing glass fiber reinforced silicon dioxide composite wet gel; and finally, aging, secondarily modifying and drying the silicon dioxide composite wet gel.

Owner:ZHONGKE RUNZI (CHONGQING) ENERGY SAVING TECH CO LTD

Prosthetic bone filler and process for the production of the same

InactiveUS6203574B1Preventing good bio-compatibilityPromote resultsIon-exchange process apparatusImpression capsCeramic particleLiving body

A prosthetic bone filler including ceramic granules for use in a living body, the ceramic granules being bonded to each other with a polymeric substance, and having ventilation pores produced as a result of the presence of gaps between the adjacent granules. The prosthetic bone filler is produced by adding the polymeric substance in two portions to the ceramic granules. In addition to good flexibility, the prosthetic bone filler exhibits excellent bio-compatibility.

Owner:ASAHI KOGAKU KOGYO KK

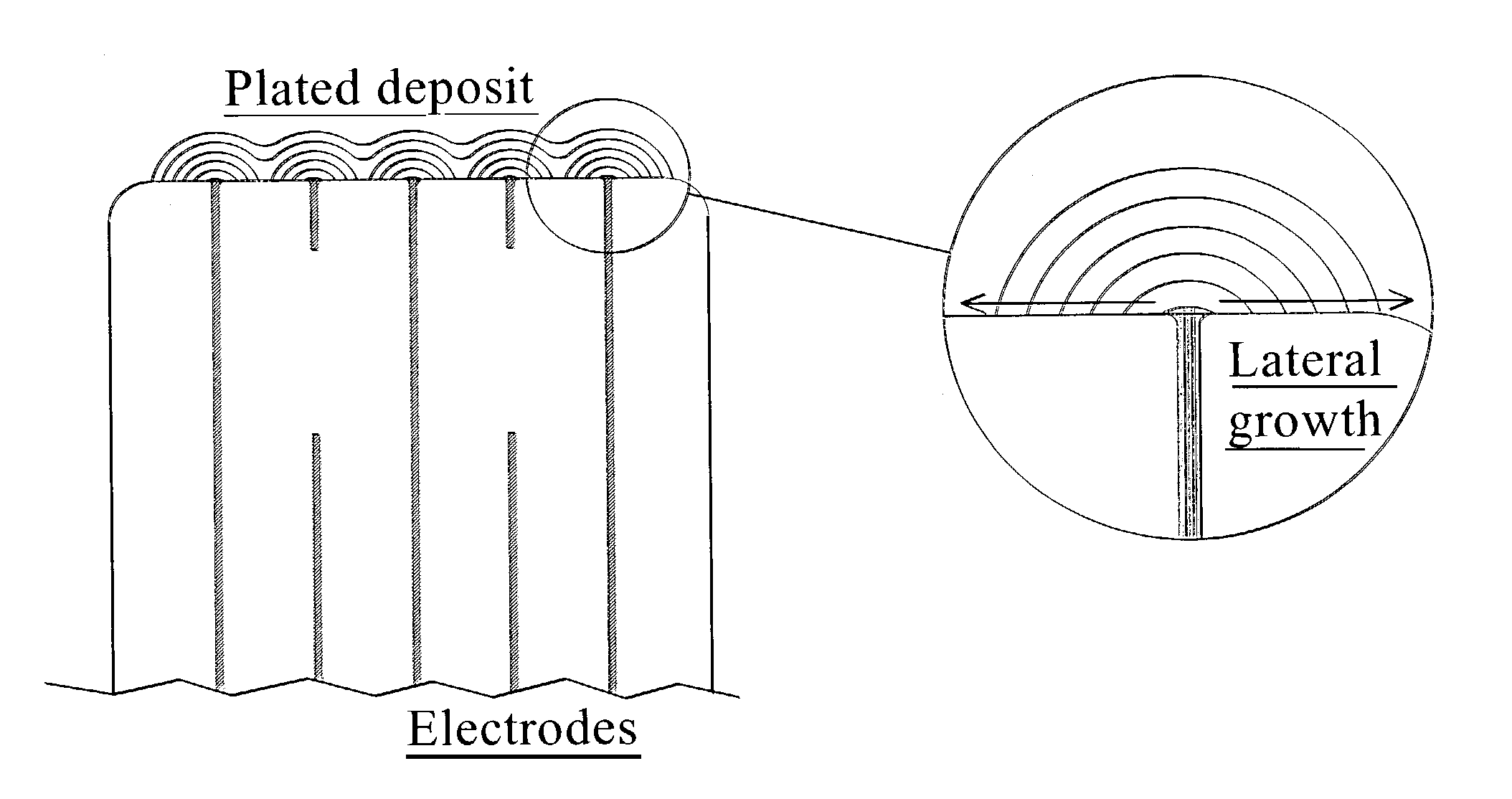

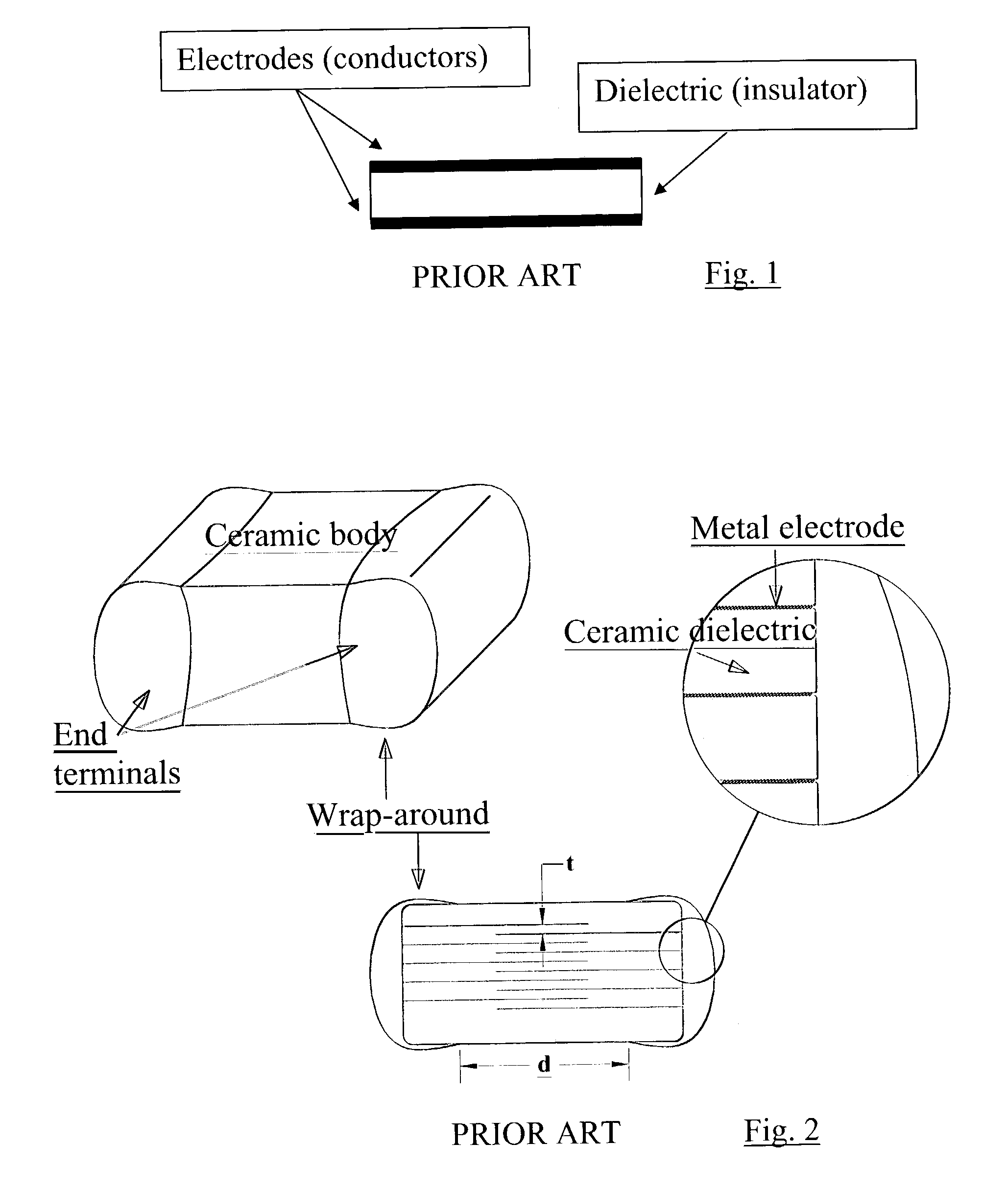

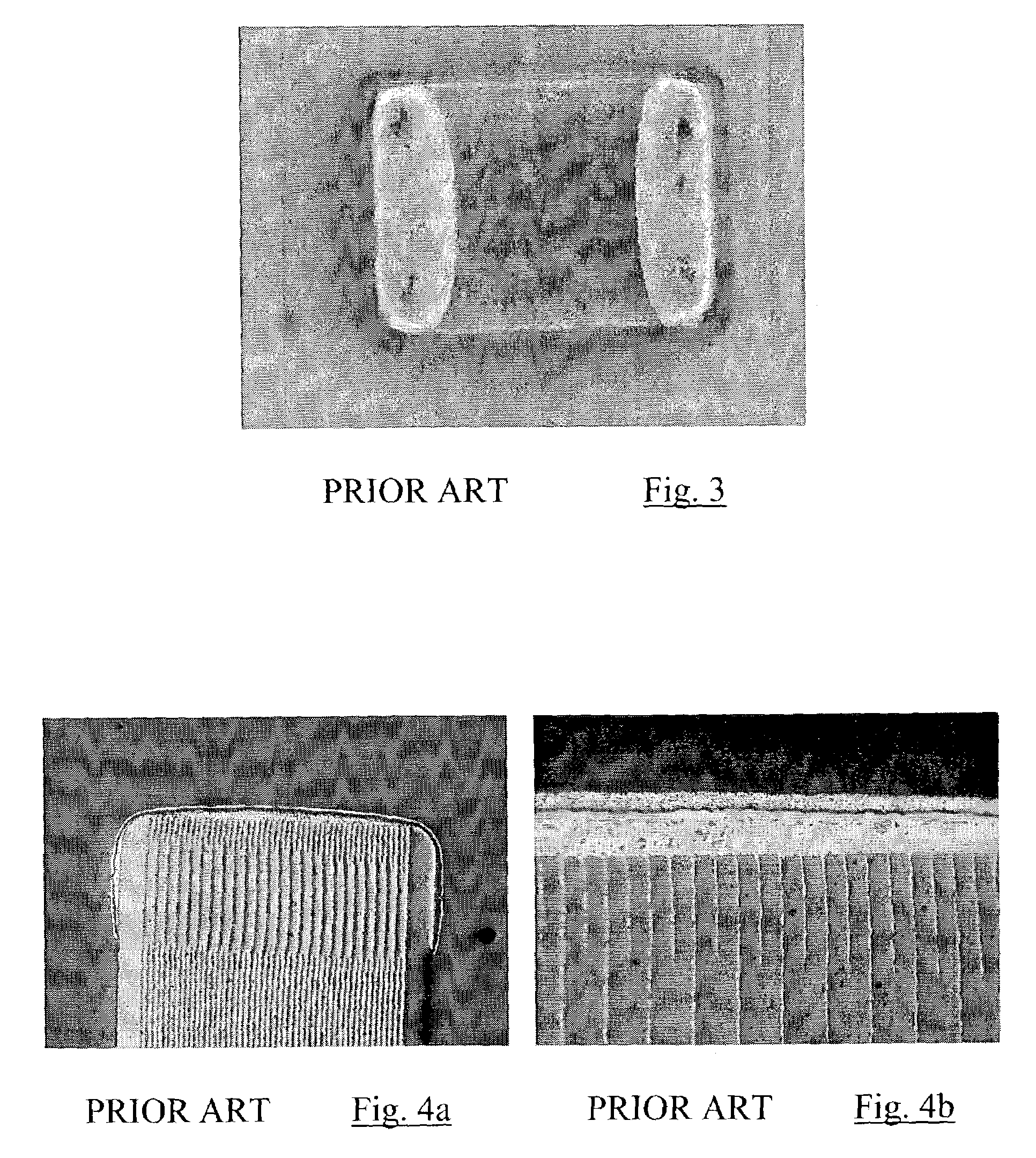

Multilayer ceramic capacitor with terminal formed by electroless plating

InactiveUS7345868B2High strengthFixed capacitor electrodesFixed capacitor dielectricElectrolysisCeramic capacitor

A terminal to, most commonly, a ceramic capacitor, most commonly a multilayer ceramic capacitor (MLCC), is formed by electroless plating, also known as electroless deposition or simply as electrodeposition. In the MLCC having a multiple parallel interior plates brought to, and exposed at, at least one, first, surface, an electrically-conductive first-metal layer, preferably Cu, is electrolessly deposited upon this first surface directly in contact with, mechanically connected to, and electrically connected to, the edges of these interior plates. Lateral growth of the electrolessly-deposited first-metal is sufficient to span from exposed plate to exposed plate, electrically connecting the plates. One or more top layers, preferably one of Ni and one of Sn and Pb, are deposited, preferably by plating and more preferably by electrolytic plating, on top of the electrolessly-deposited Cu.

Owner:PRESIDIO COMPONENTS

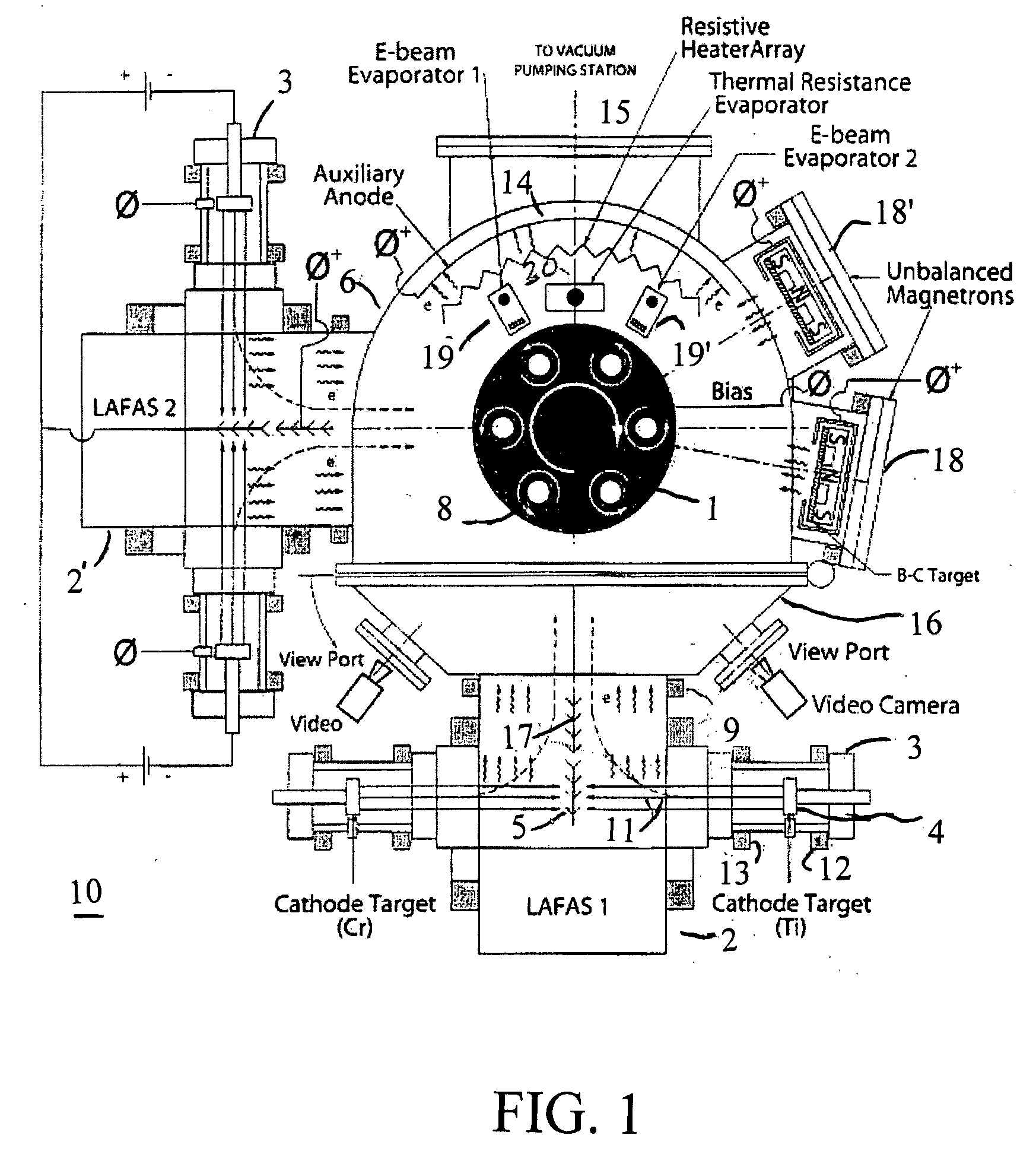

Multi-layered radiant thermal evaporator and method of use

InactiveUS20050072361A1Stable and reliableHigh quality usefulnessVacuum evaporation coatingSputtering coatingCrucibleVacuum chamber

The present invention provides a system and method for uniform coating of a substrate at high deposition rates by evaporating a coating material in a vacuum chamber. The system includes an evaporator having a heating crucible for containing a coating material to be evaporated and a generally planar heat source disposed so as to heat a surface of a coating material contained in the heating crucible. Preferably, the heat source is manufactured from a ceramic or intermetallic material and includes a first layer defining a first set of openings and a second layer defining a second set of openings wherein the second layer overlies the first layer and is spaced apart therefrom. The first and second sets of openings allow the evaporated coating material to pass therethrough for dispersion of the coating material in a deposition zone defined by a containment shield disposed above the heat source.

Owner:DARLY CUSTOM TECH

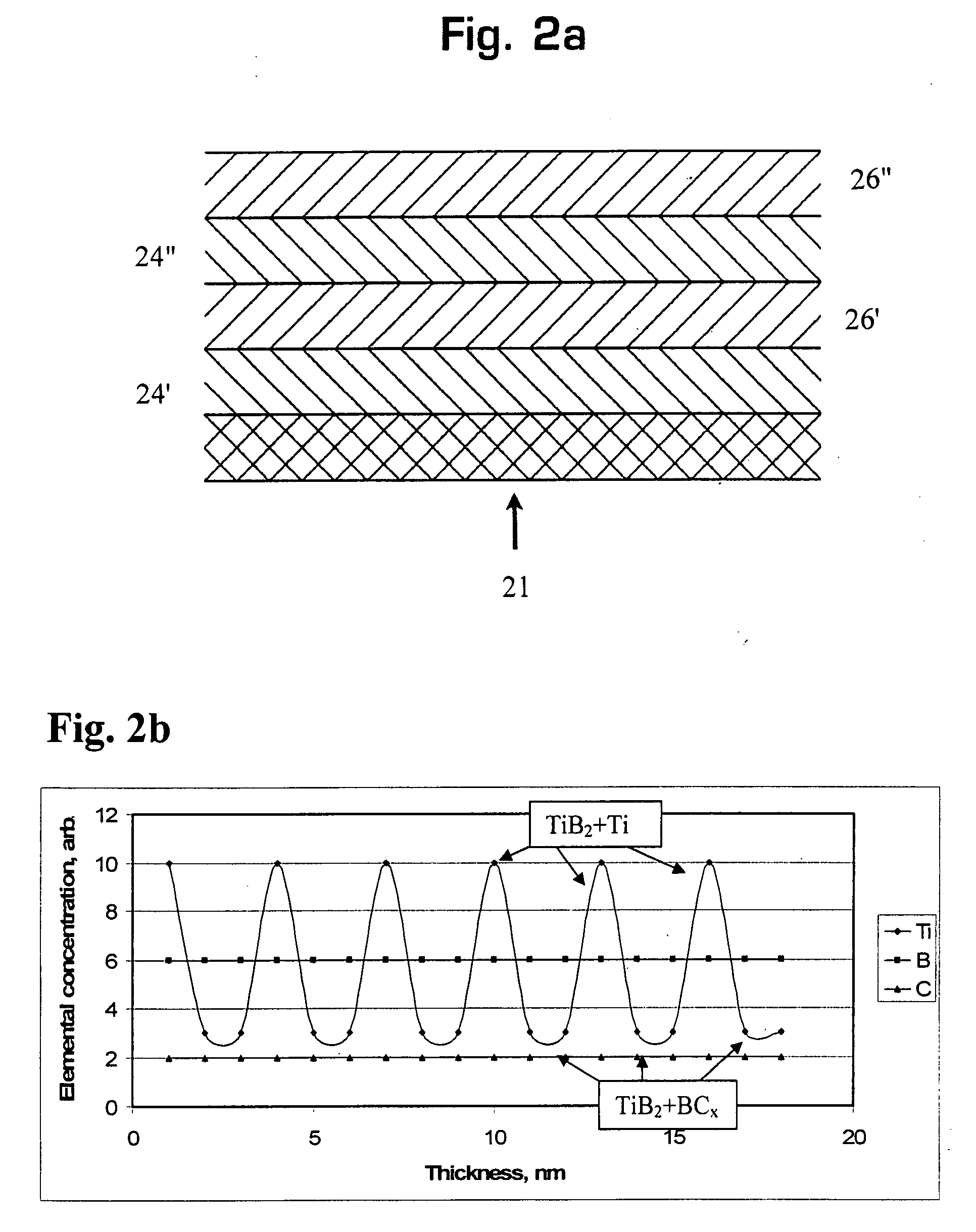

Wear resistant vapor deposited coating, method of coating deposition and applications therefor

ActiveUS20070284255A1Stable cutting edgeReduce torsion fatiguePigmenting treatmentSurgeryWear resistantShape-memory alloy

A low friction top coat over a multilayer metal / ceramic bondcoat provides a conductive substrate, such as a rotary tool, with wear resistance and corrosion resistance. The top coat further provides low friction and anti-stickiness as well as high compressive stress. The high compressive stress provided by the top coat protects against degradation of the tool due to abrasion and torsional and cyclic fatigue. Substrate temperature is strictly controlled during the coating process to preserve the bulk properties of the substrate and the coating. The described coating process is particularly useful when applied to shape memory alloys.

Owner:G&H TECH LLC

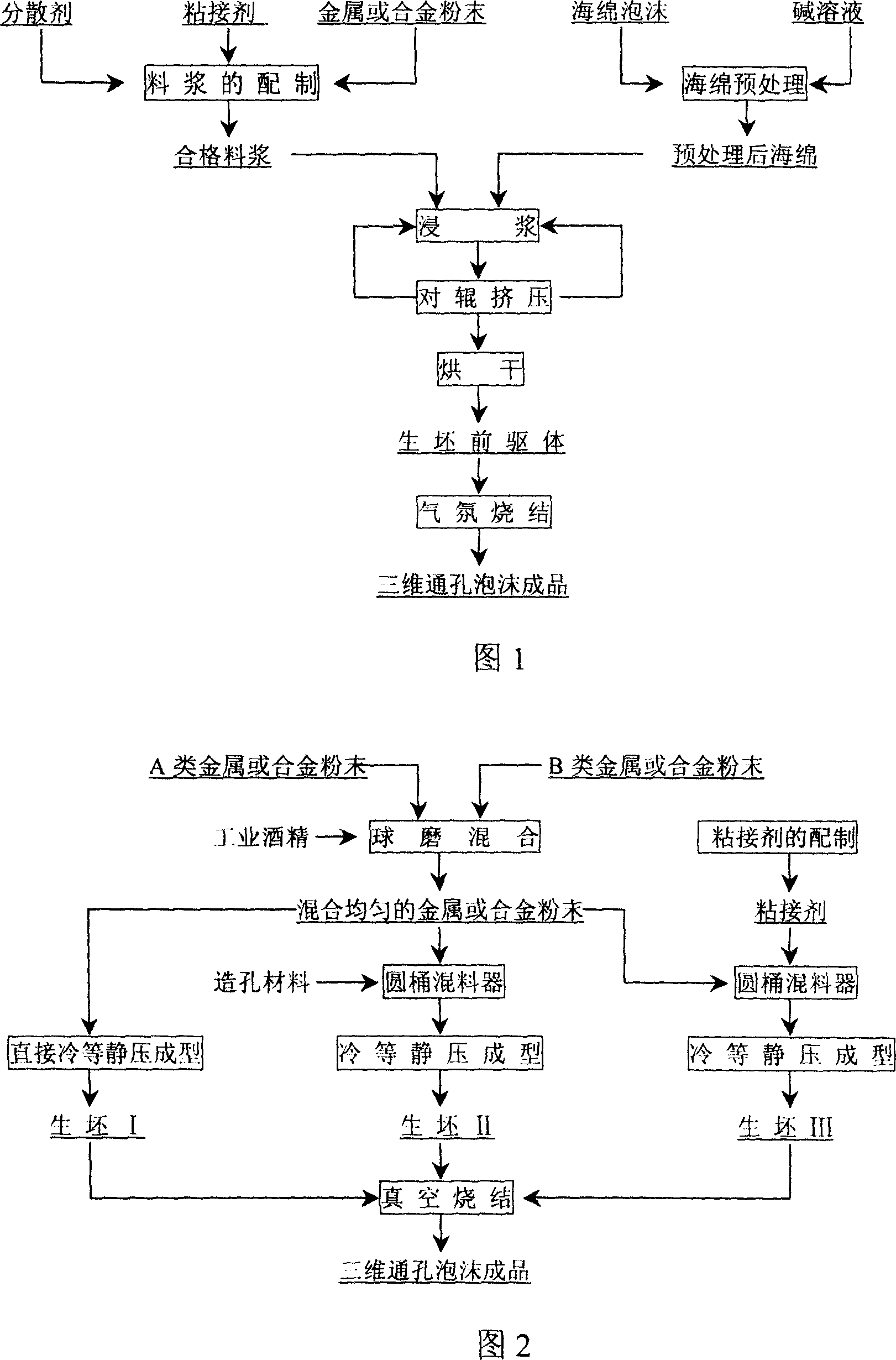

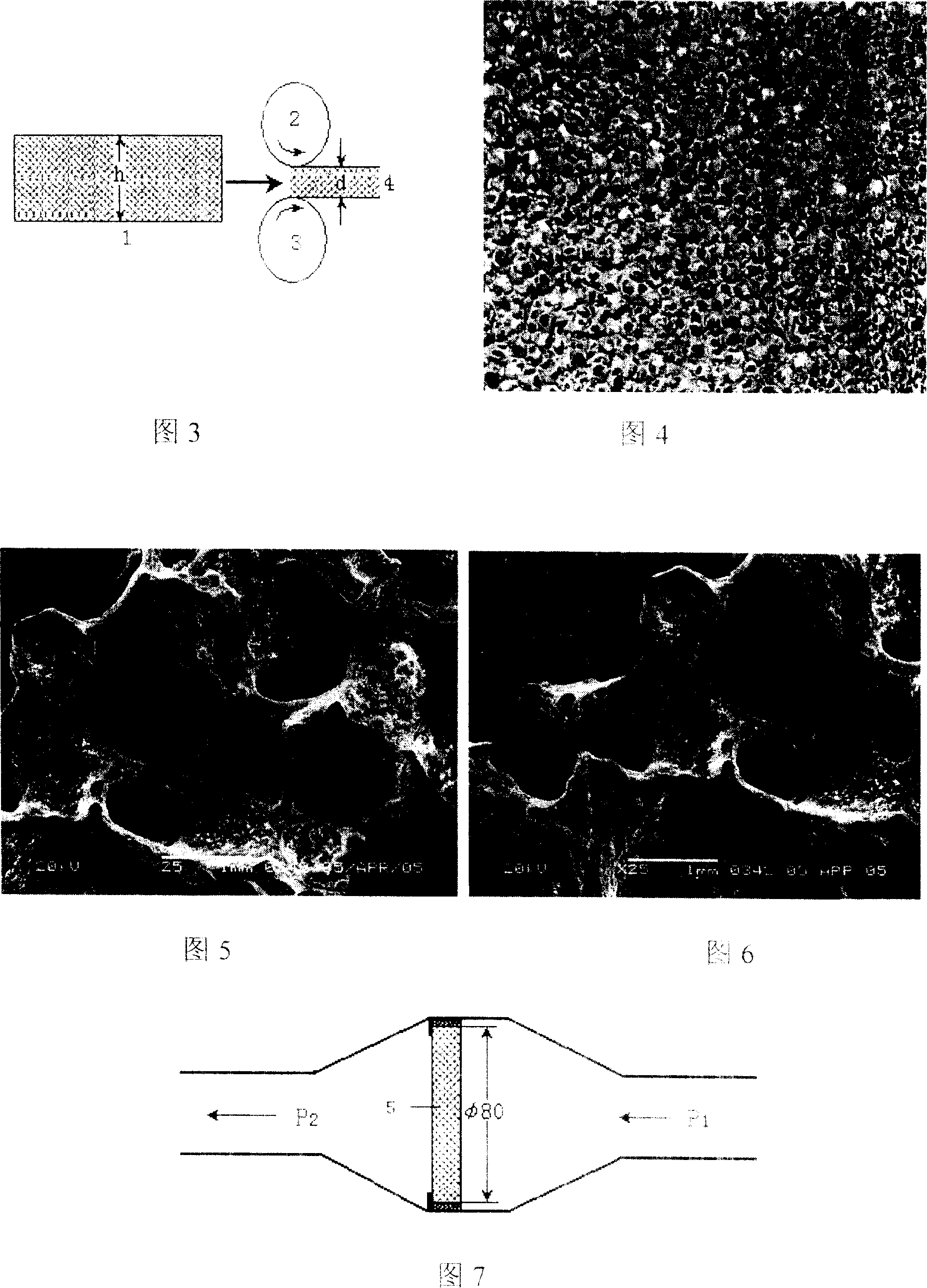

Three-dimensional through-hole or part-hole interconnecting porous metal foam and its preparing method

The invention relates to a multi-hole foamed metal material and the manufacturing method. It includes the following steps: equally dispersing metal or alloy powder that has the particle diameter at 1-100um into solution contains adhesive agent to make slime, pouring the slime into through-hole polyurethane sponge foam, after taking drying and sintering, the material would be gained. It also could be make by the method of directly isostatic cool pressing one or more metal or alloy powder, isostatic cool pressing after mixing with pore forming material or isostatic cool pressing after mixing with adhesive agent solution to gain green pressing that would be sintered in vacuum furnace to make the material. The invention could be used to process vehicle tail gas and could also be used to filter the smoke form thermal power station or metallurgical furnace.

Owner:CENT SOUTH UNIV

Lightweight proppant and method of making same

InactiveUS20060016598A1Manufactured usingSuitable viscosityFluid removalDrilling compositionPrillHigh intensity

A lightweight, high-strength proppant is disclosed, comprising the formation of finely dispersed ceramic precursors and sintering at low temperatures, causing the formation and retention of mesopores and micropores in pelletized ceramic. A method of manufacturing such a proppant is also disclosed, comprising the steps of manufacturing finely divided ceramic precursors and additives using grinding, milling, and preferably sol-gel processes, and dispersing the finely divided ceramic precursors and additives in a liquid, preferably water. The dispersion has a viscosity profile, which permits the shaping of spheres using conventional pelletizing techniques. Drying of the pellets and sintering at temperatures below 1,400.degrees. C. forms and retains mesopores and micropores in the ceramic. Preferred total pore volumes range from 0.05 to 0.7 cm.sup.3 / g. The pelletized and porous ceramic is useful as lightweight and high-strength proppants.

Owner:URBANEK THOMAS WILHELM

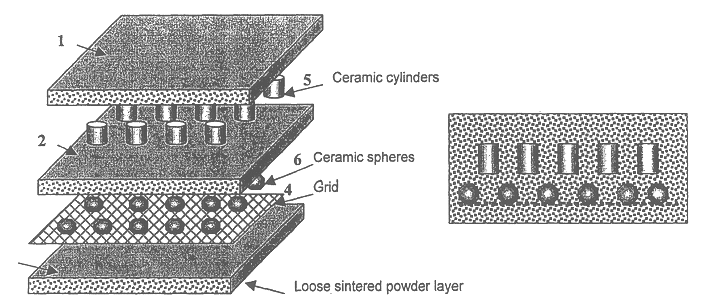

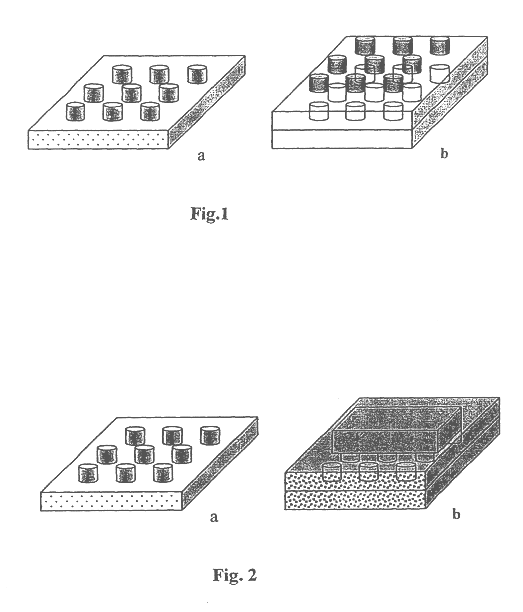

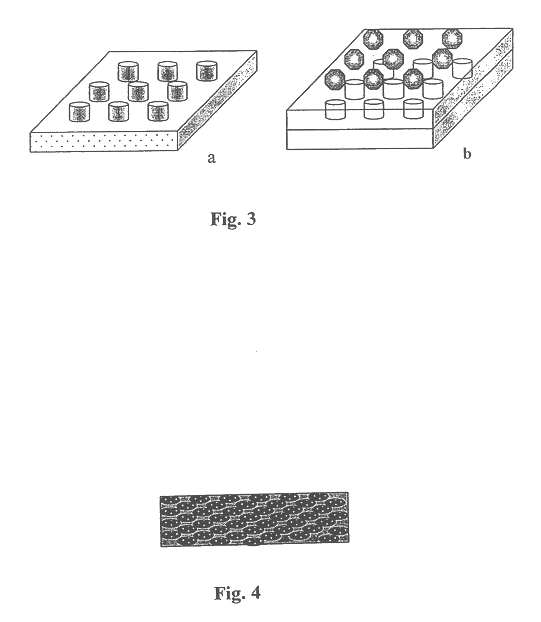

Bulletproof lightweight metal matrix macrocomposites with controlled structure and manufacture the same

InactiveUS6635357B2Stop crack propagation after bullet orPromote reproductionMilitary adjustmentWelding/cutting media/materialsPorosityMetal insert

The lightweight bulletproof metal matrix macrocomposites (MMMC) contain (a) 10-99 vol. % of permeable skeleton structure of titanium, titanium aluminide, Ti-based alloys, and / or mixtures thereof infiltrated with low-melting metal selected from Al, Mg, or their alloys, and (b) 1-90 vol. % of ceramic and / or metal inserts positioned within said skeleton, whereby a normal projection area of each of said inserts is equal to or larger than the cross-section area of a bullet or a projectile body. The MMMC are manufactured as flat or solid-shaped, double-layer, or multi-layer articles containing the same inserts or different inserts in each layer, whereby insert projections of each layer cover spaces between inserts of the underlying layer. The infiltrated metal contains 1-70 wt. % of Al and Mg in the balance, optionally, alloyed with Ti, Si, Zr, Nb, V, as well as with 0-3 wt. % of TiB2, SiC, or Si3N4 sub-micron powders, to promote infiltrating and wetting by Al-containing alloys. The manufacture includes (a) forming the permeable metal powder and inserts into the skeleton-structured preform by positioning inserts in the powder followed by loose sintering in vacuum to provide the average porosity of 20-70%, (b) heating and infiltrating the porous preform with molten infiltrating metal for 10-40 min at 450-750° C., (c) hot isostatic pressing of the infiltrated composite, and (d) re-sintering or diffusion annealing.

Owner:ADVANCED MATERIALS PRODS

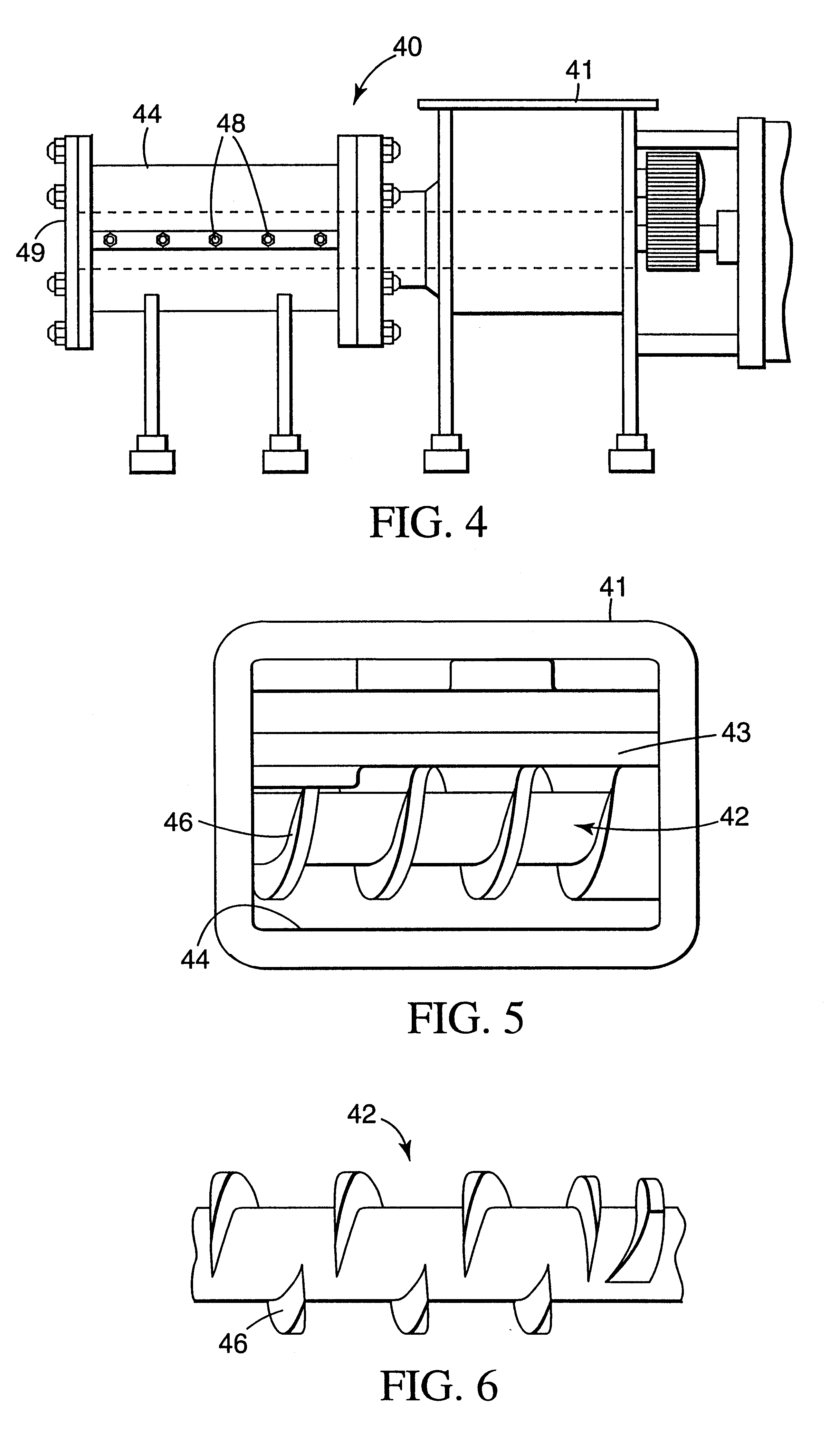

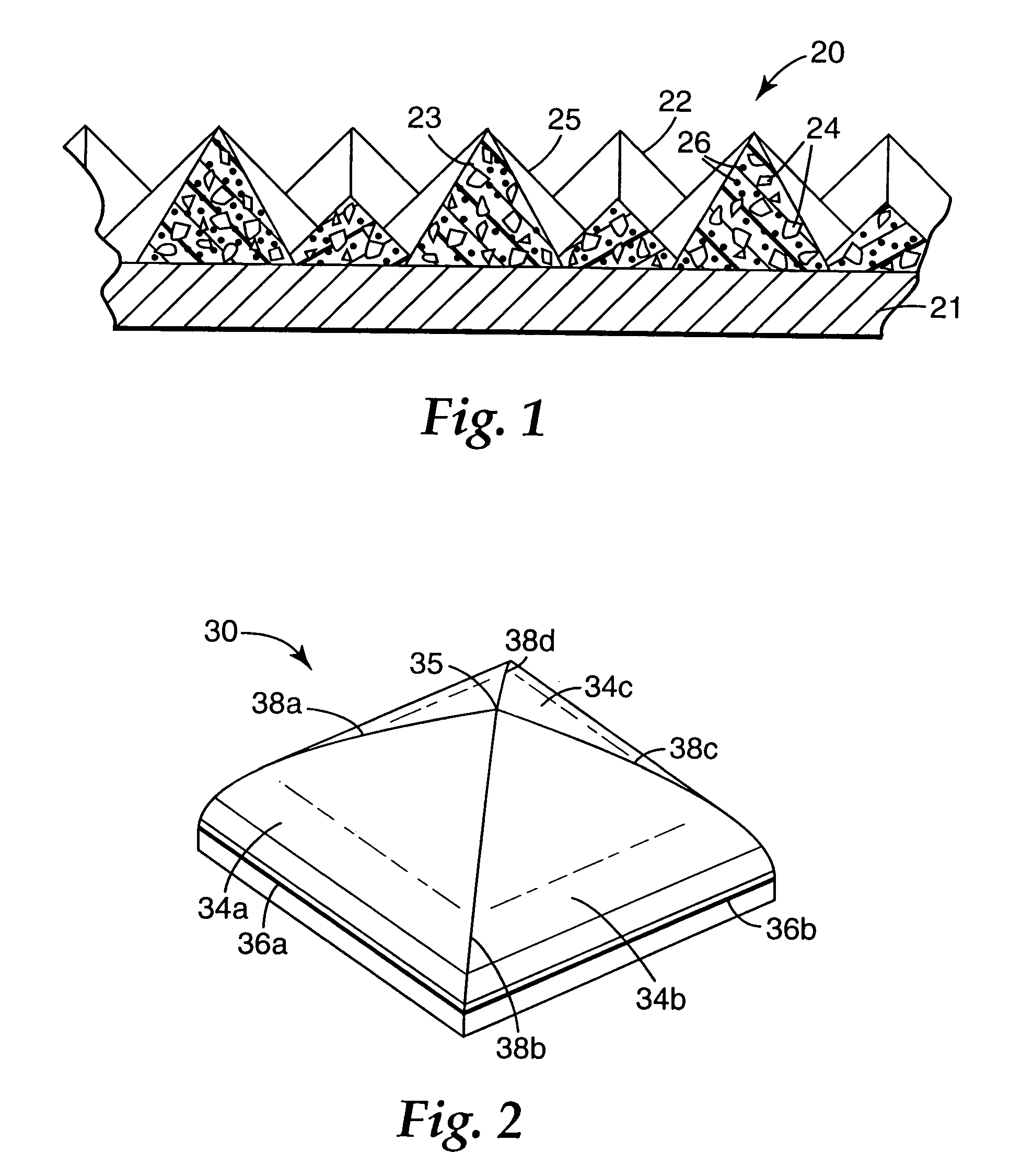

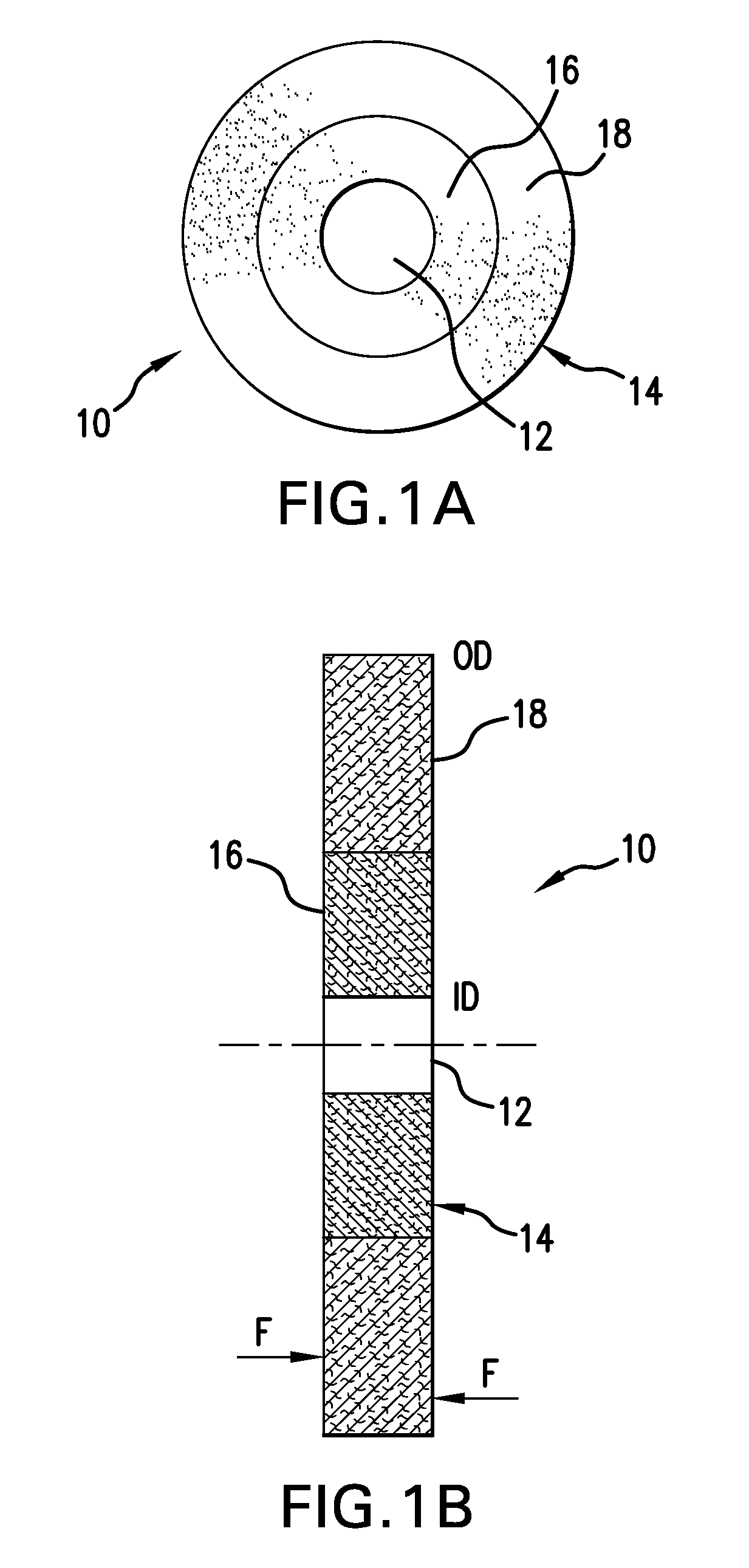

Compositions for abrasive articles

ActiveUS20050060947A1Attenuation consistentImprove cutting lifePigmenting treatmentOther chemical processesSurface finishMicrometer

A structured abrasive article, methods of making an abrasive article, and methods of using an abrasive article. The abrasive composites forming the abrasive article have a height of at least 500 micrometers, and the abrasive particles in the composites have an average particle size of at least 40 micrometers, in some embodiments, at least about 85 micrometers. The large topography composites, together with the large ceramic abrasive particles, provides an abrasive article that has a more consistent cut, a longer cutting life, and a more consistent surface finish than conventional make / coat abrasive articles with the same size and type of abrasive particles. Additionally, the large topography composites, together with the large ceramic abrasive particles, provide an abrasive article that has a more consistent cut, a longer cutting life, and a more consistent surface finish than structured abrasive articles having a smaller topography, even with the same abrasive particles.

Owner:3M INNOVATIVE PROPERTIES CO

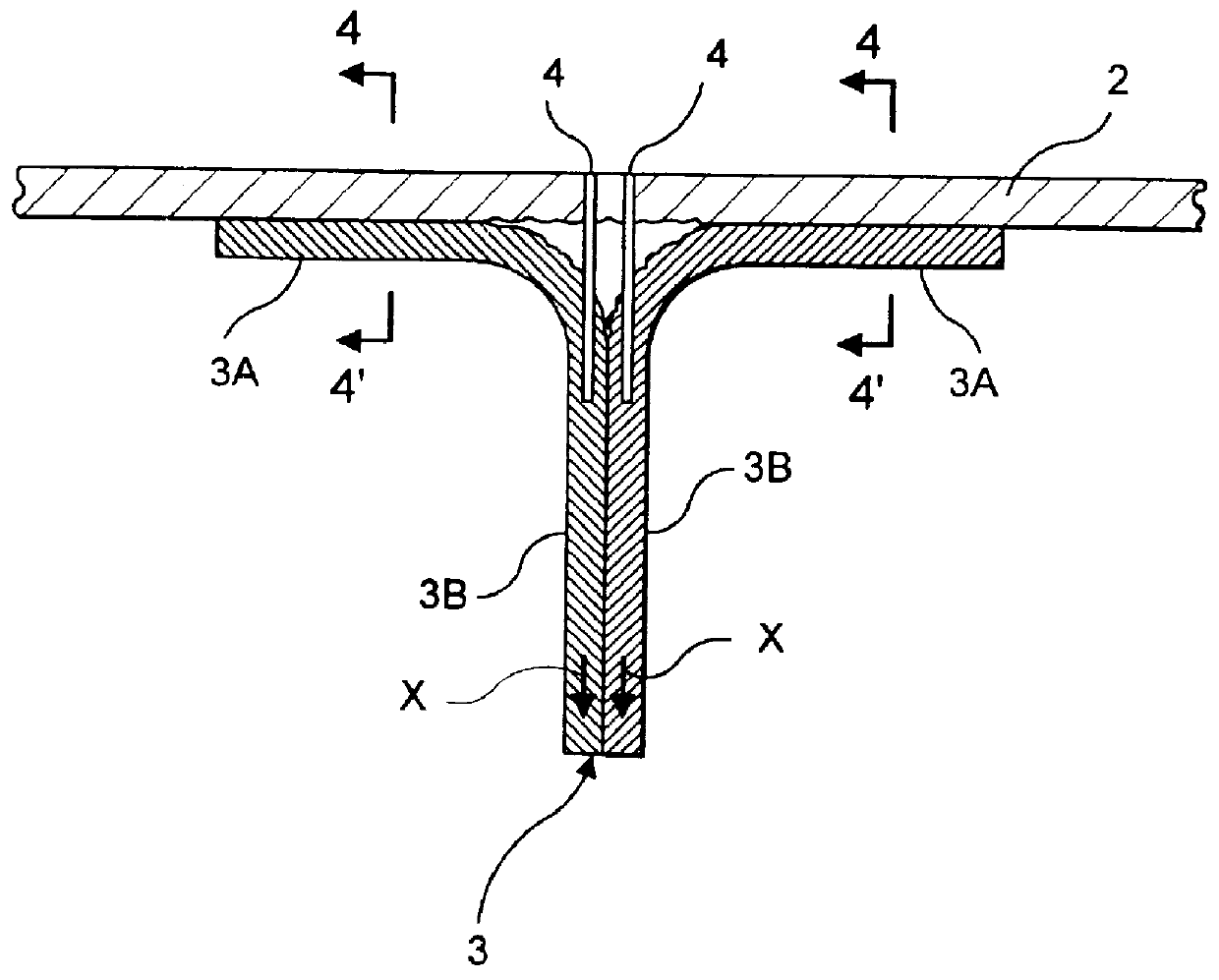

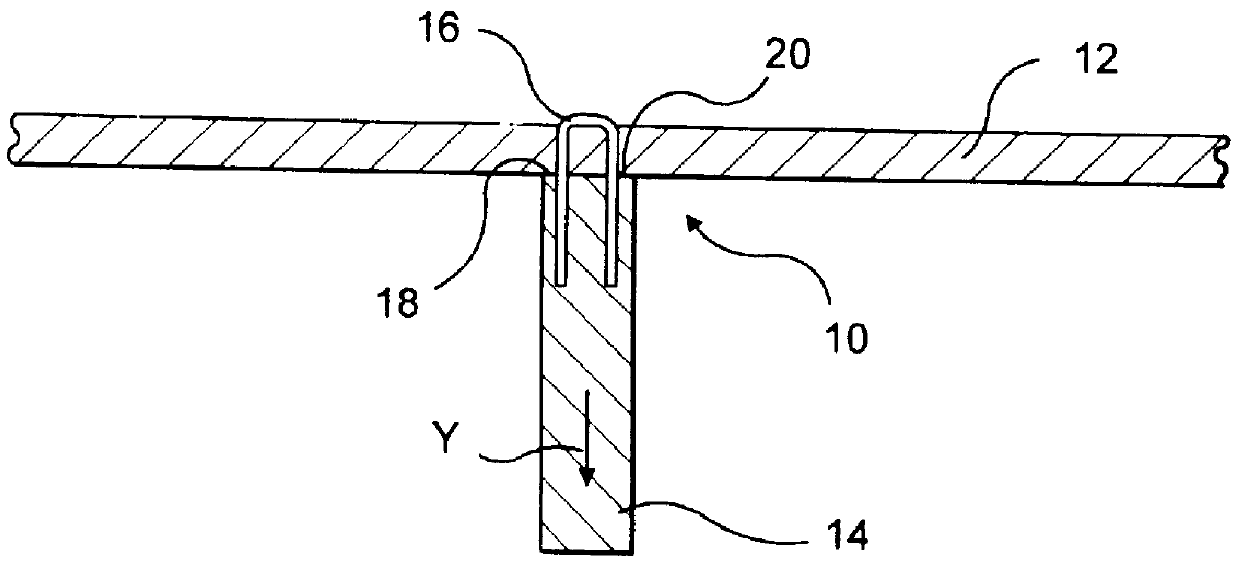

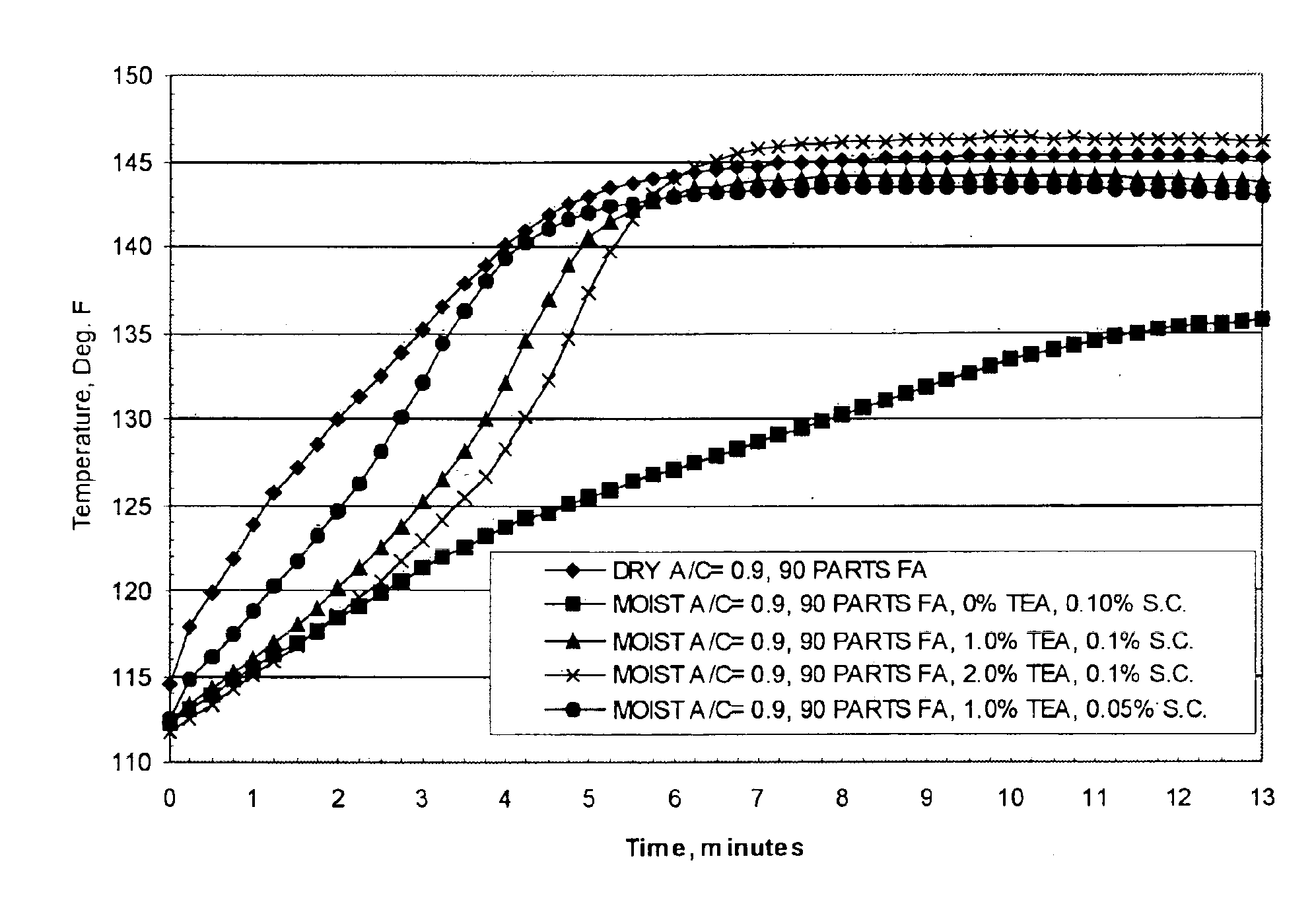

Fiber-reinforced composite materials structures and methods of making same

Reinforcement preforms and methods for making same for use in fiber-reinforced composite materials structures are disclosed, in which the reinforcement preforms comprise first and second reinforcement preform elements which include strength reinforcement fibers that are in desired directional orientation. The first element has a cross-fiber surface which extends transverse of its constituent strength reinforcement fibers and is in contacting juxtaposition to a selected surface region of the second element, forming an abutment therebetween. Abutment strength reinforcing fibers, which may optionally be introduced in situ by a continuum of fibers, such as a yarn or thread, extend through at least a portion of said second element and its said selected surface region, the abutment, said cross-fiber edge surface, and into the first element substantially in the direction of orientation to its constituent strength fibers to which its cross-fiber surface is transverse.

Owner:ALBANY ENGINEERED COMPOSITES

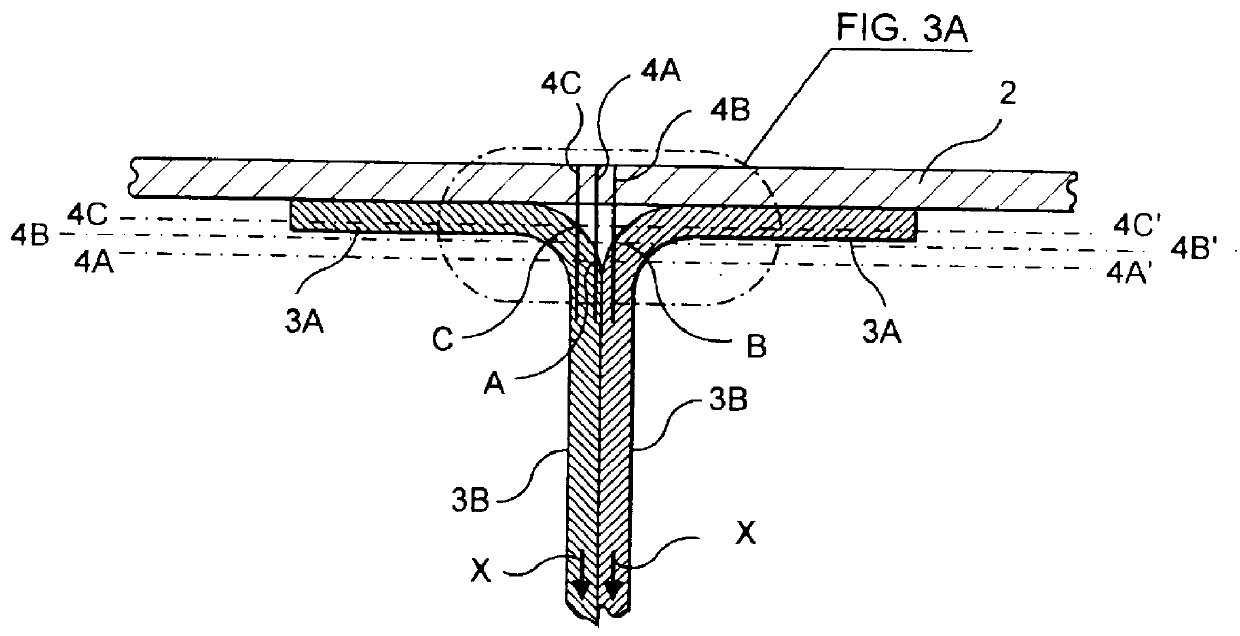

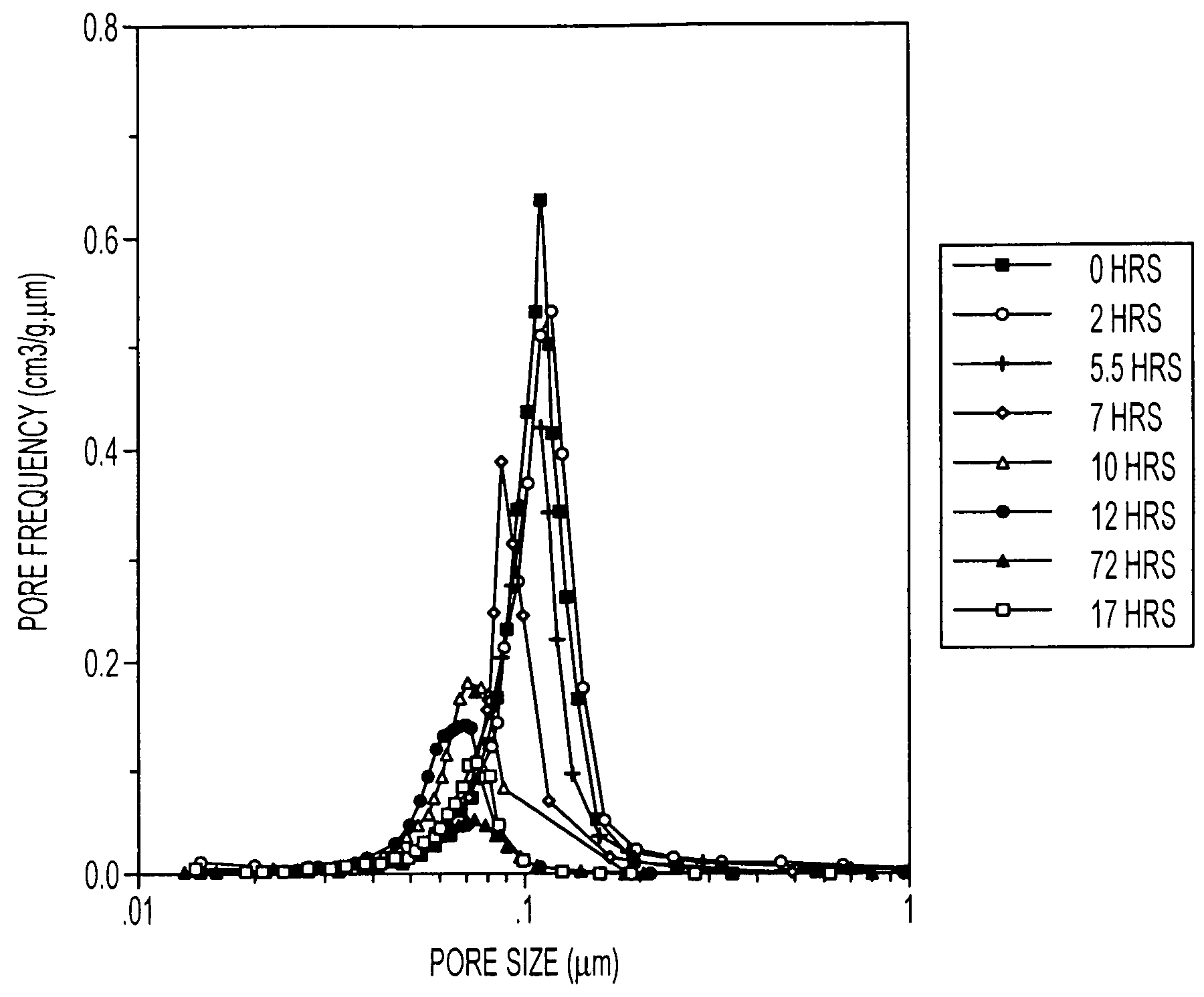

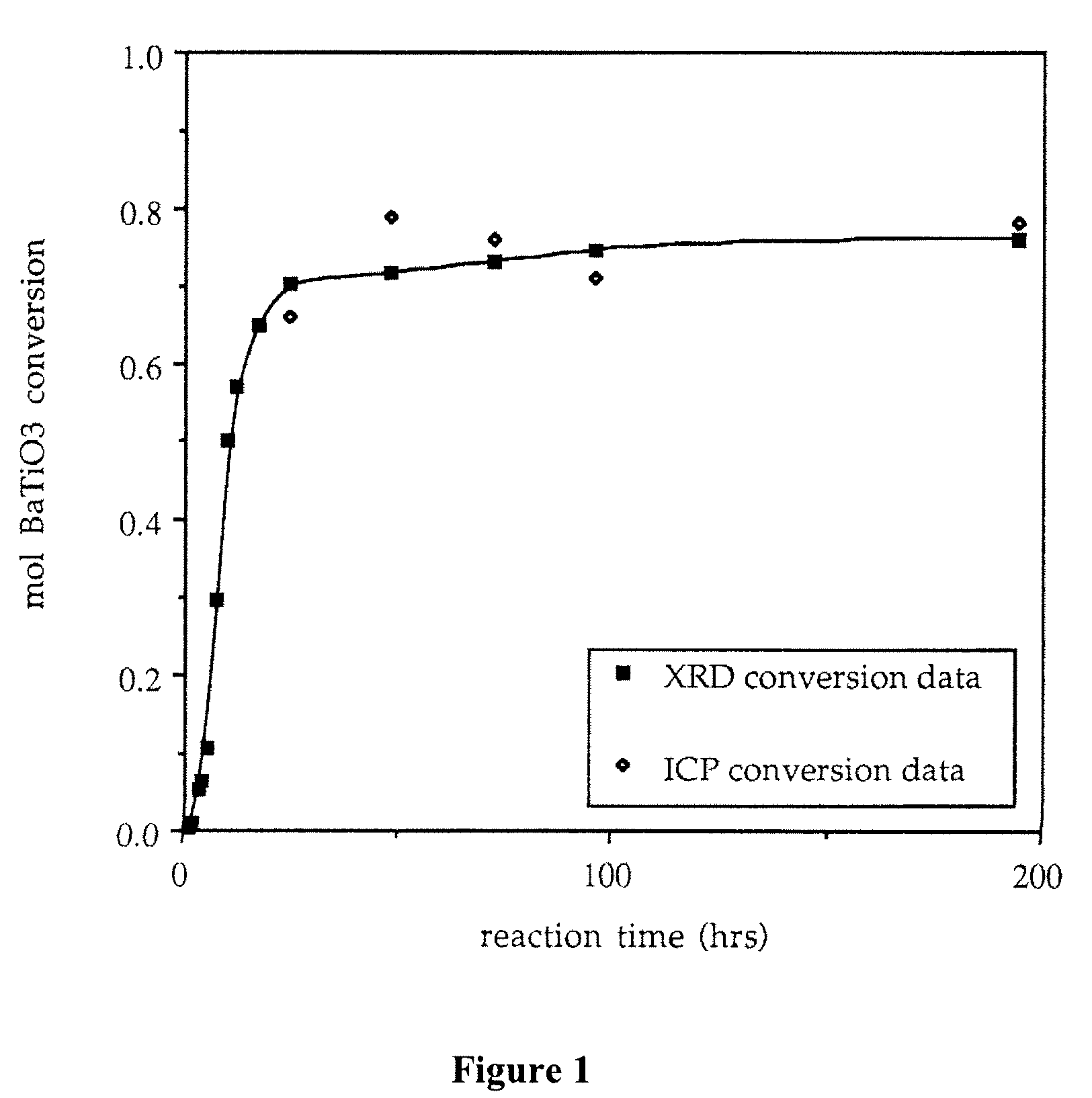

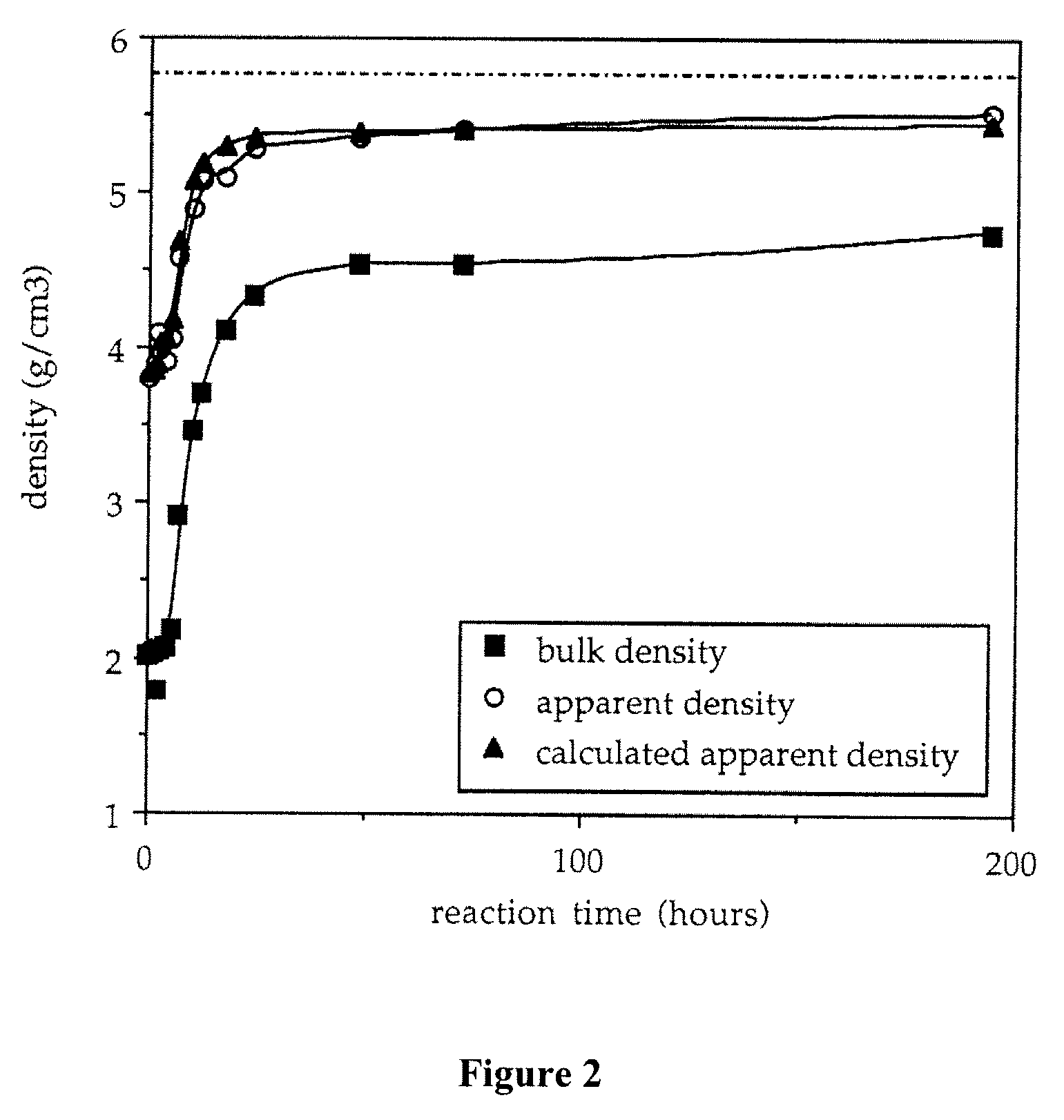

Method of hydrothermal liquid phase sintering of ceramic materials and products derived therefrom

ActiveUS20090142578A1Improve responseLayered productsPretreated surfacesBarium titanateCeramic materials

Provided here is a method of producing a monolithic body from a porous matrix, comprising: (i) providing a porous matrix having interstitial spaces and comprising at least a first reactant; (ii) contacting the porous matrix with an infiltrating medium that carries at least a second reactant; (iii) allowing the infiltrating medium to infiltrate at least a portion of the interstitial spaces of the porous matrix under conditions that promote a reaction between the at least first reactant and the at least second reactant to provide at least a first product; and (iv) allowing the at least first product to form and fill at least a portion of the interstitial spaces of the porous matrix, thereby producing a monolithic body, wherein the monolithic body does not comprise barium titanate.

Owner:RUTGERS THE STATE UNIV

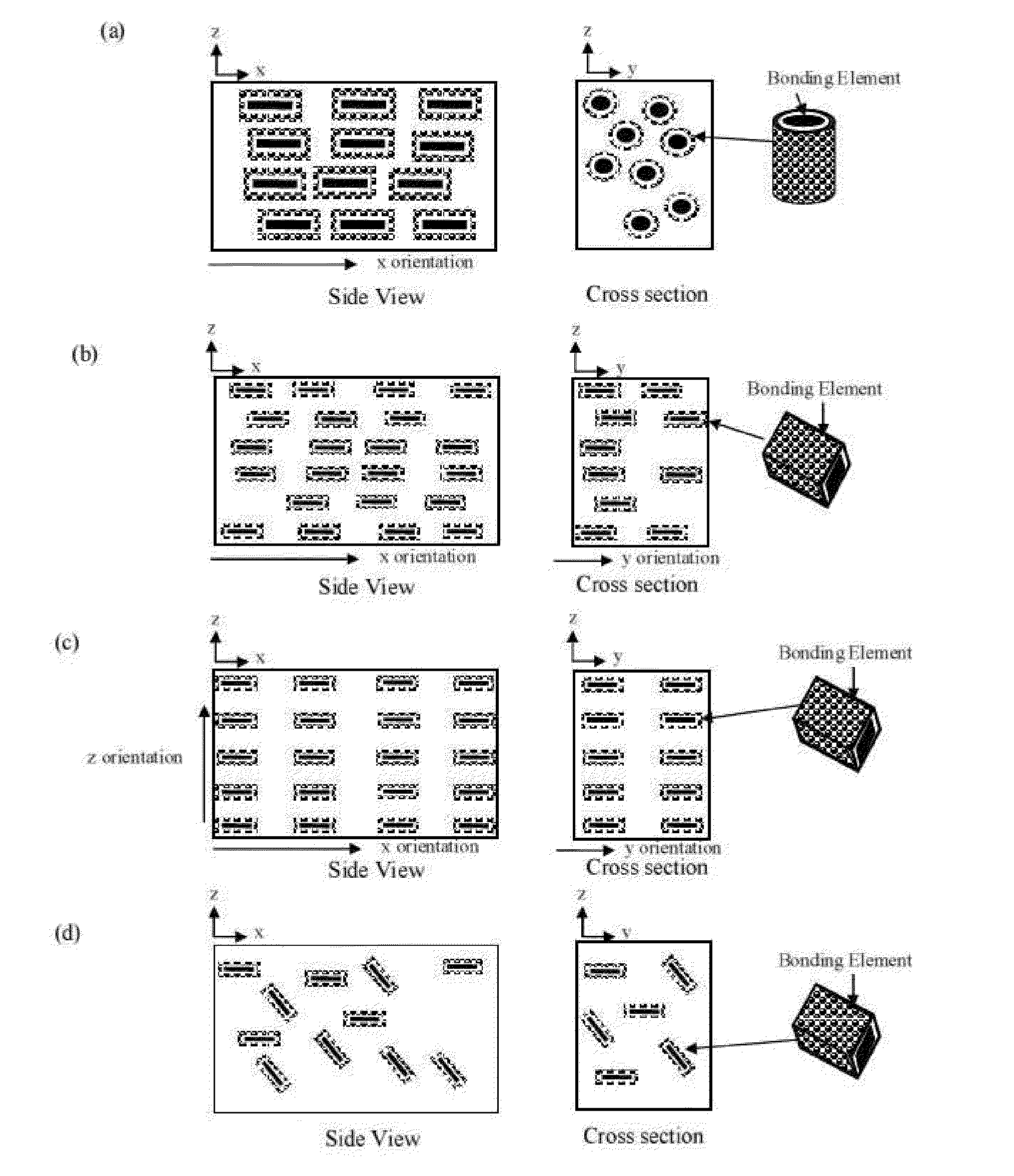

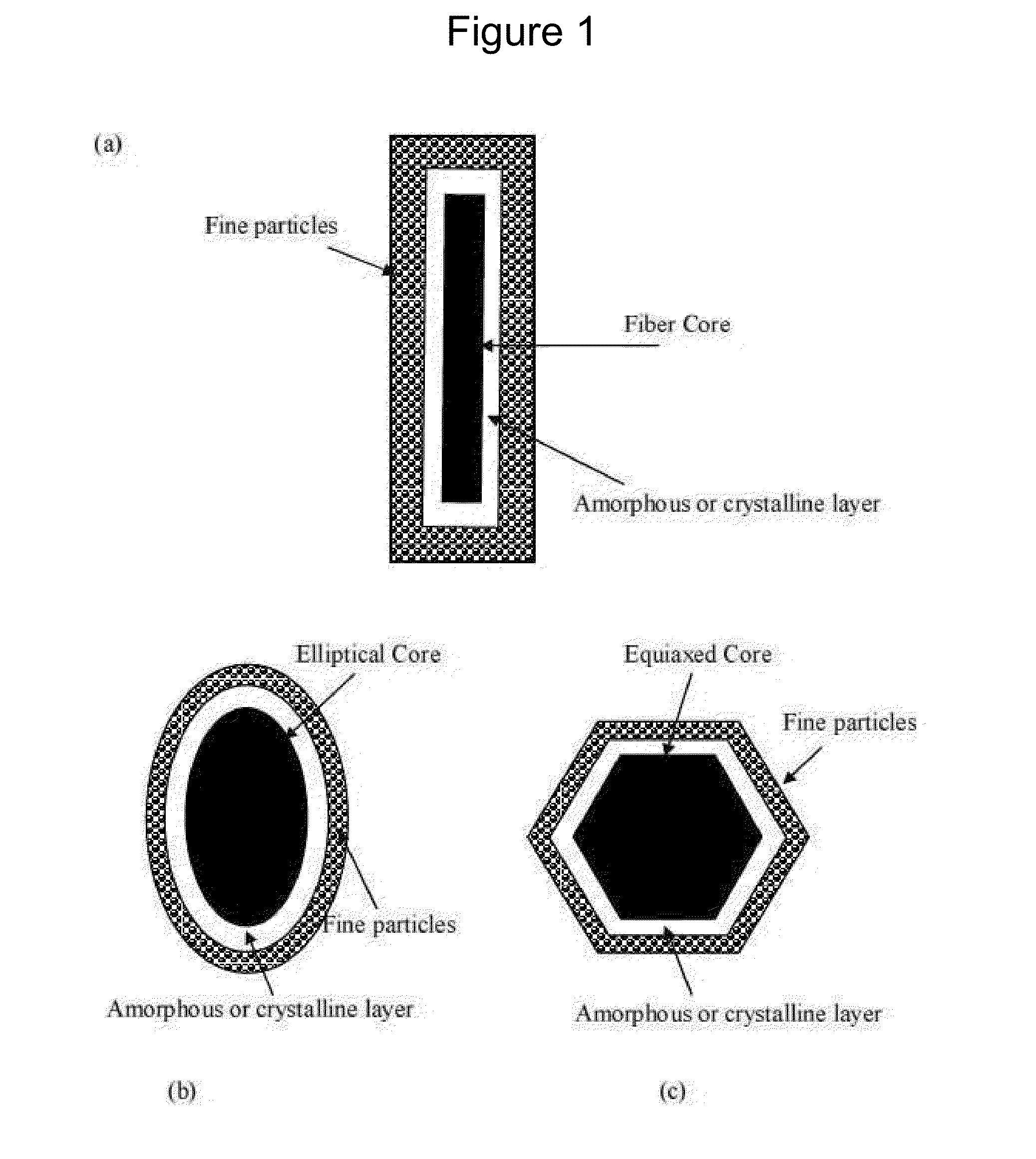

Bonding element, bonding matrix and composite material having the bonding element, and method of manufacturing thereof

A bonding element, a bonding element matrix and composite materials with a wide range of attractive properties that may be optimized, including, but not limited to, mechanical properties, thermal properties, magnetic properties, optical properties and nuclear properties, as a result of a first layer and second layer structure or core, first layer, and second layer structure of the bonding elements, as well as methods for making the bonding elements and the corresponding ceramic and / or composite materials.

Owner:RUTGERS THE STATE UNIV

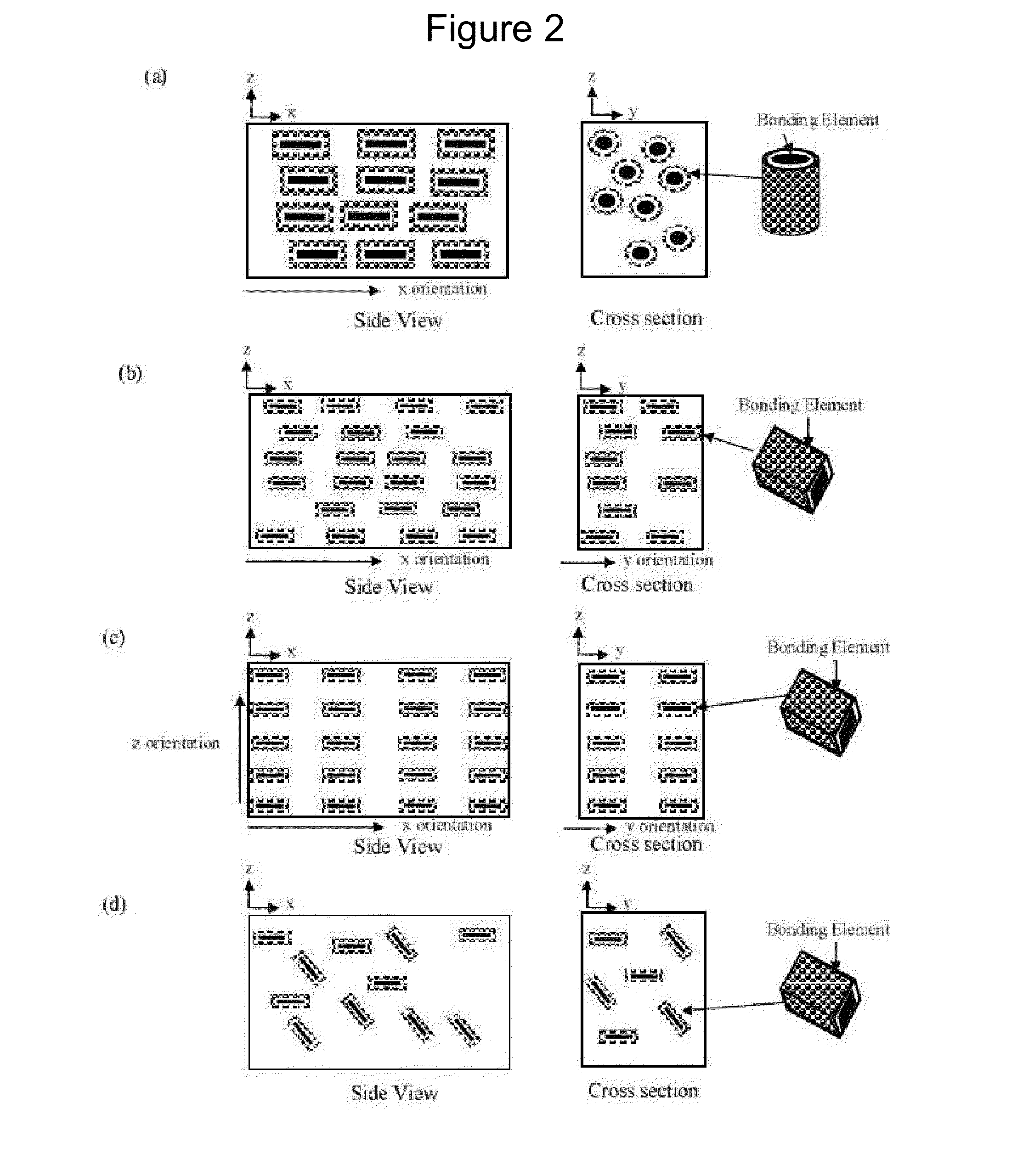

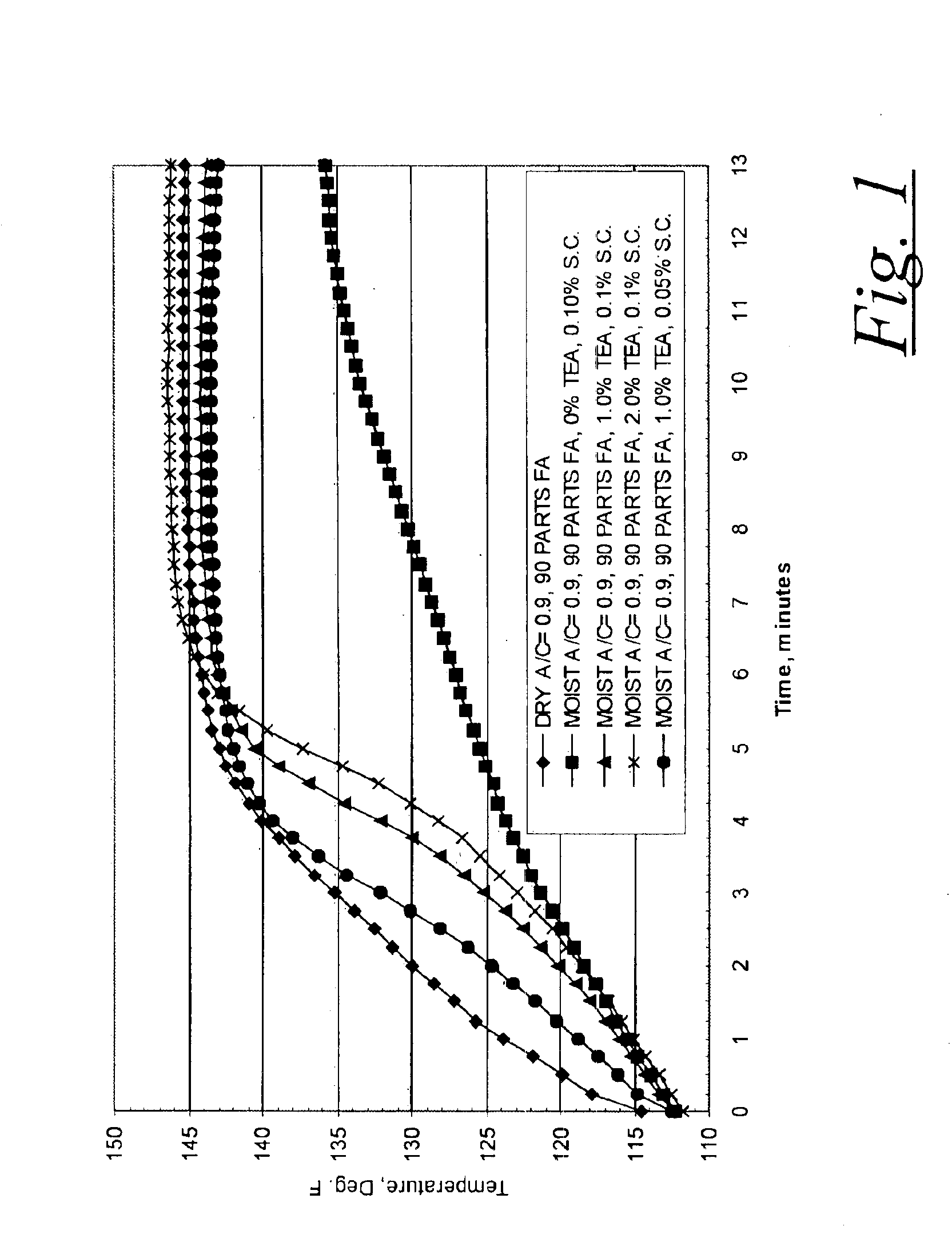

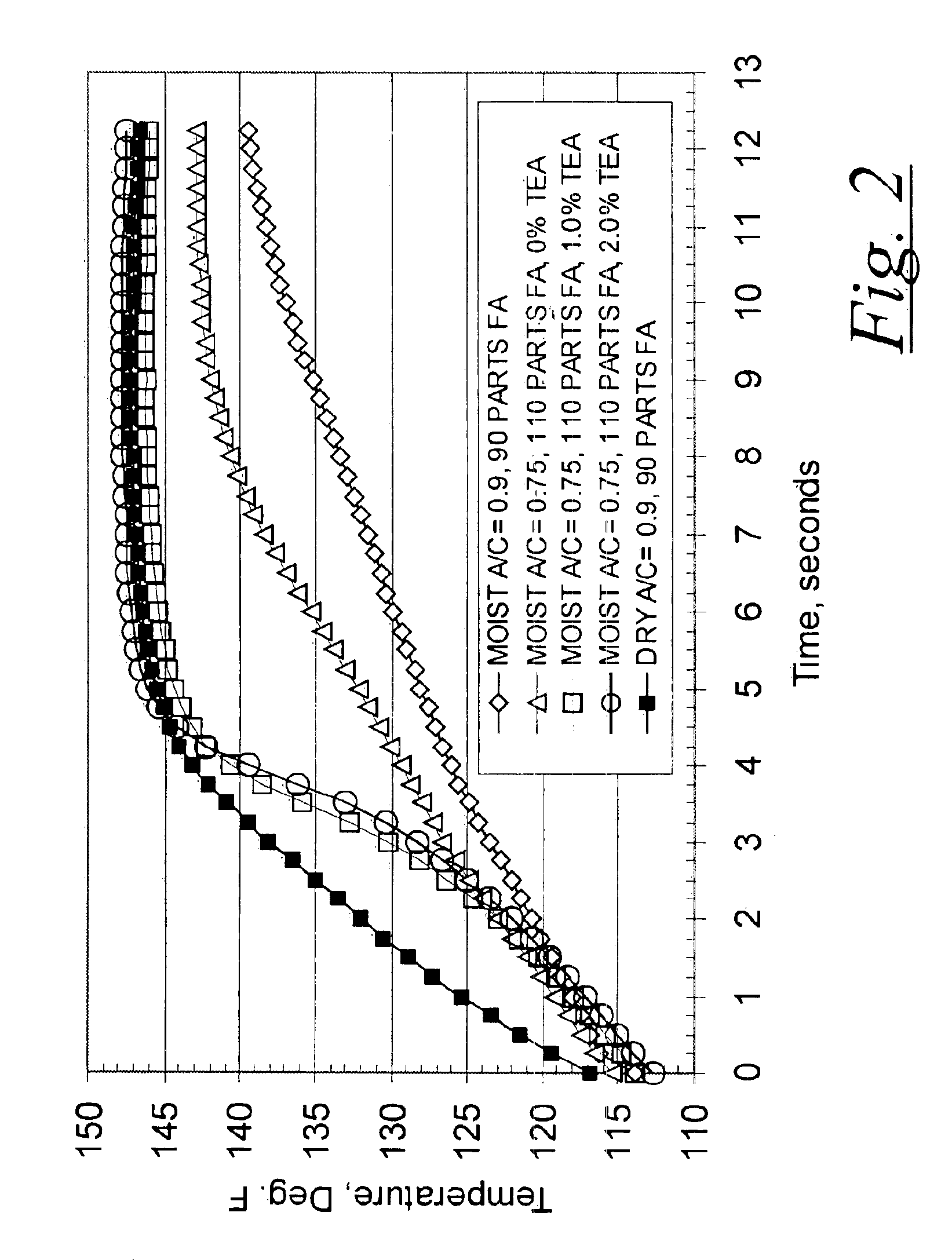

Very fast setting cementitious composition

Extremely fast setting of cementitious compositions for producing cement-based products such as cement boards is made possible by adding an alkanolamine to a hydraulic cement such as portland cement, and forming a slurry with water under conditions that provide an initial slurry temperature of at least 90° F. Use of alkanolamine under conditions disclosed herein allows an extremely rapid setting of the cementitious composition. Additional reactive materials may be included such as high alumina cement, calcium sulfate and a pozzolanic material such as fly ash. The extremely fast rapid set permits rapid production of cementitious products.

Owner:UNITED STATES GYPSUM CO

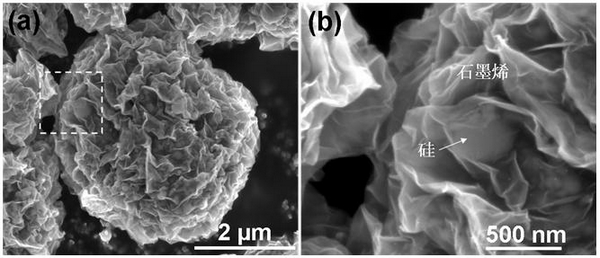

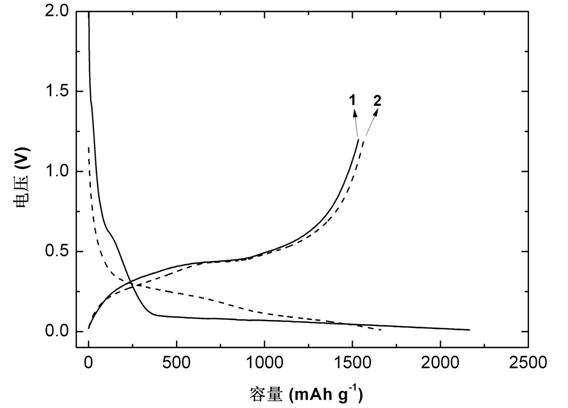

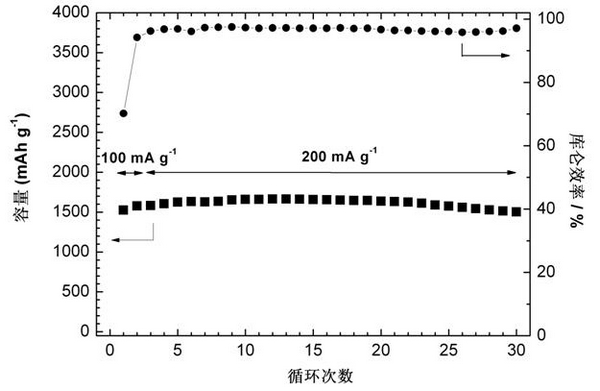

Silicon graphene composite anode material of lithium ion battery and preparation method of silicon graphene composite anode material

The invention discloses a silicon graphene composite anode material of a lithium ion battery and a preparation method of the silicon graphene composite anode material. The material consists of the following components in percentage by weight: 10 to 99 percent of silicon powder with the particle size of between 20 nanometers and 5 micrometers, 1 to 90 percent of graphene and 0 to 40 percent of amorphous carbon, wherein the graphene forms a three-dimensional conducting network with an internal cavity, and wraps the silicon powder in the internal cavity to form spherical or sphere-like composite particles with the particle size of between 500 nanometers and 15 micrometers. The preparation method of the material comprises the following steps of: uniformly dispersing the silicon powder and graphene oxide in a solvent; and performing spray drying, reducing, and cladding by using the amorphous carbon. Compared with the prior art, the invention has the advantages that: the material has high capacity and high cycle performance and is subjected to a constant-current charge-discharge test at the current density of 200mA / g, the reversible capacity of the material after 30-times circulation is still 1502mA / g, and the capacity retention rate of the material is up to 98 percent; and the preparation method is simple and practicable, high in yield and suitable for mass industrial production.

Owner:浙江钠创新能源有限公司

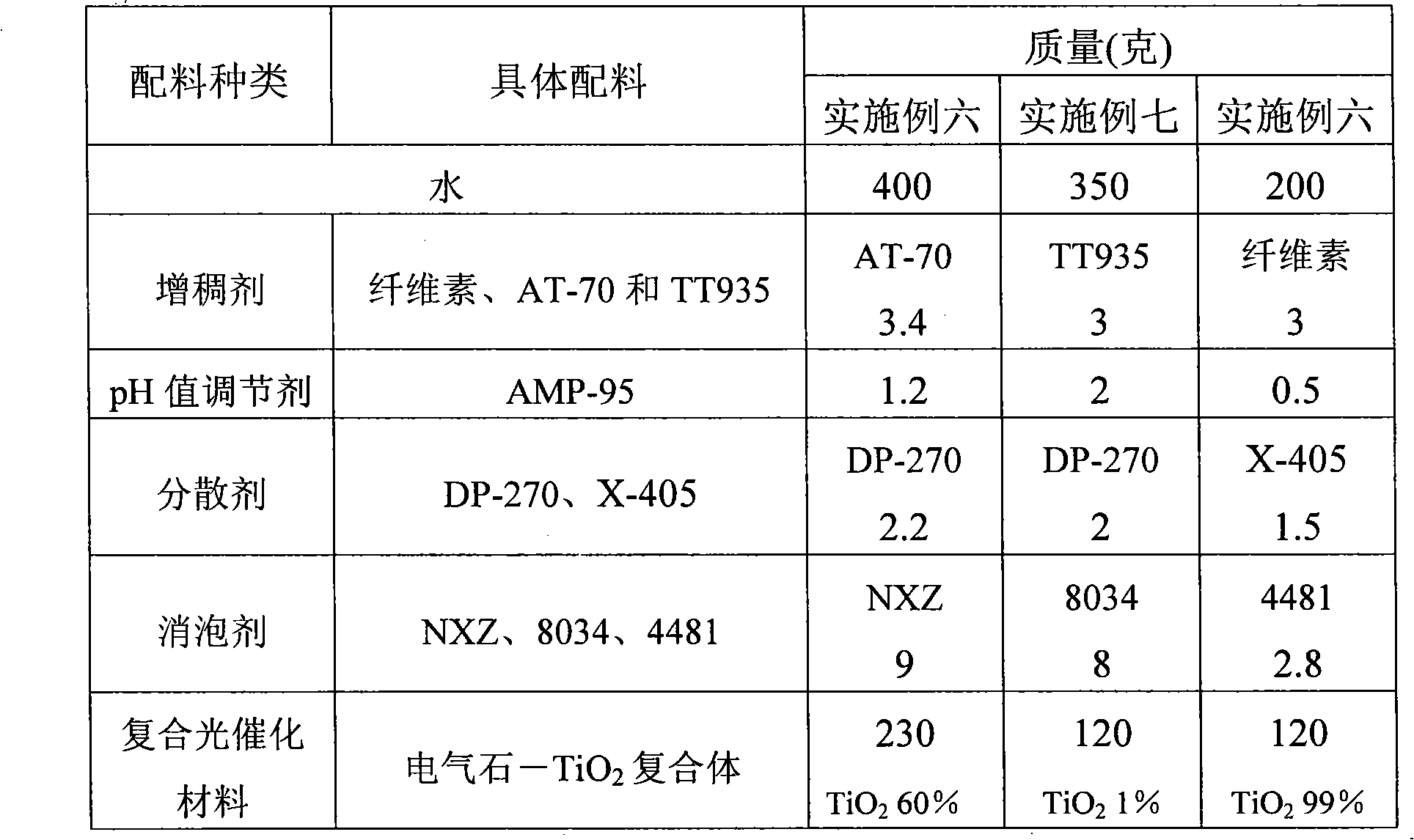

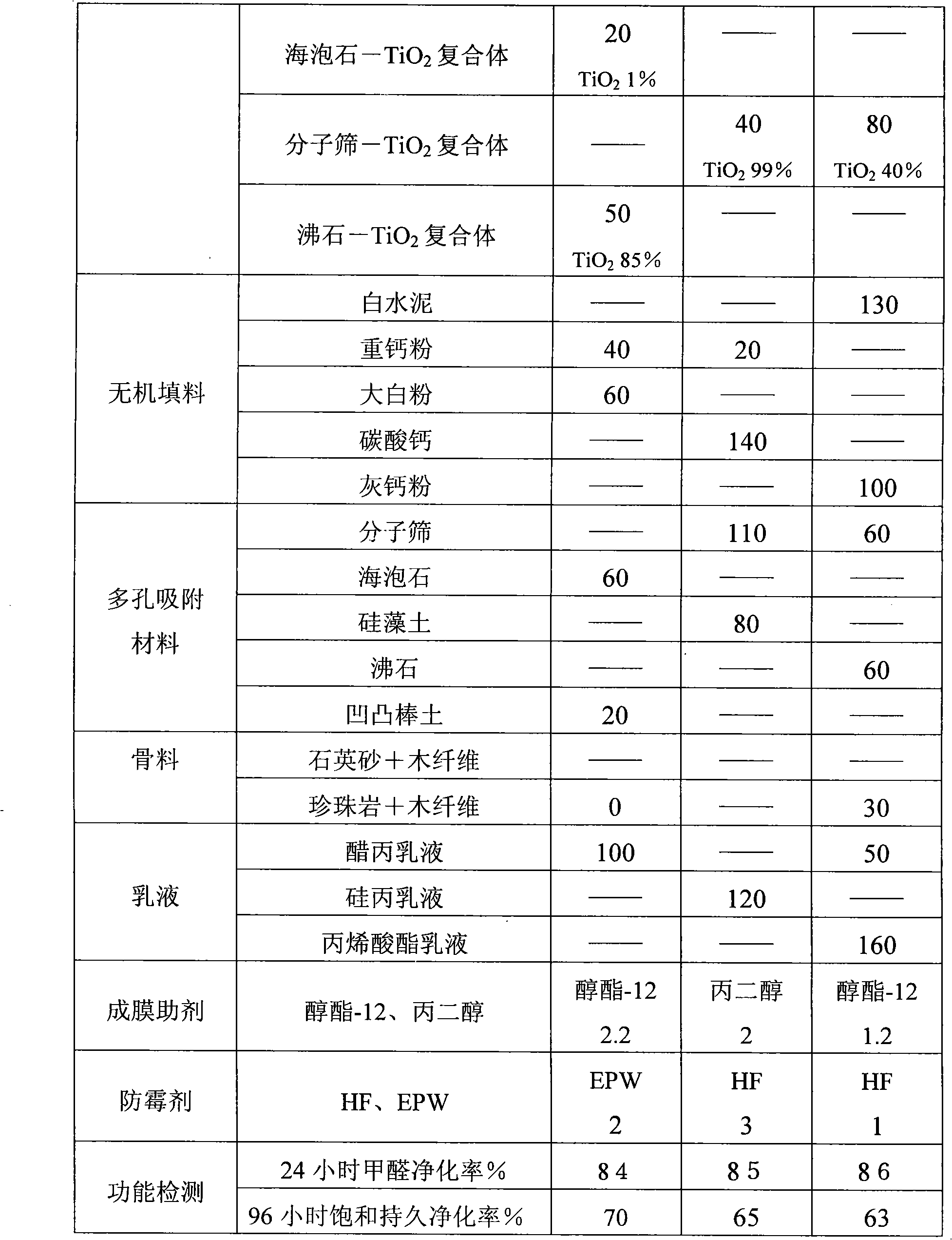

Thick coating material purifying air and preparing method thereof

ActiveCN101348628AGood purification effectImprove purification effectDispersed particle separationDeodrantsCompound aAir cleaning

The invention provides a thick coating material capable of purifying air and a preparation method thereof, belonging to the building material field. An internal wall coating decorative material comprises 5 to 40 weight portions of a porous absorbing material and 10 to 40 weight portions of a composite photocatalysis material in every 100 weight portion of the paint. In the preparation method, the coating material, is formed by compounding a mineral material with the nanometer photocatalysis material to obtain a high activity purifying material, matching the high activity purifying material with other nanometer materials and the porous absorbing material, and then adding an inorganic filling material, a skeletal material and other addition agents, can remove harmful gases such as formaldehyde and toluol in air and has the environmental protection function. The paint has good effect for removing formaldehyde, is effective continuously, has certain thickness when the coating layer is used, has simple construction, and beautiful and elegant patterns, is well-bedded, is strong in the three-dimension effect and has good decorative effect.

Owner:CHINA BUILDING MATERIALS ACAD

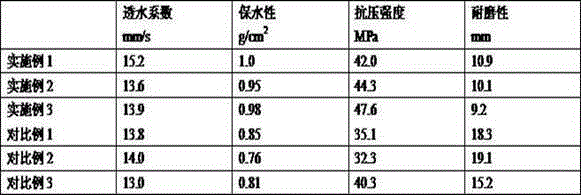

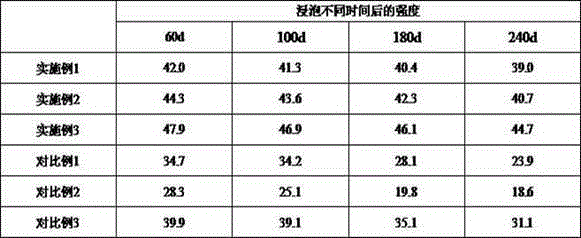

Corrosion resistant water permeable brick

ActiveCN105016765AHigh permeability coefficientHigh compressive strengthCeramicwareCompressive resistanceBrick

The present invention relates to a corrosion resistant water permeable brick, and belongs to the technical field of building materials. The corrosion corrosion resistant water permeable brick comprises 20-25wt% of Portland cement, 1.0-1.2wt% of anhydrite powder, 15.0-20.0wt% of slag pellets, 10-12wt % of cenospheres, 1.5-2.1wt% of admixtures, and the balance of quartz sand. Under the premise that the porosity and water permeability coefficient of the corrosion resistant water permeable brick are significantly higher than that of a water permeable brick, the compressive strength of the corrosion resistant water permeable brick is still higher than that of the conventional water permeable brick, the corrosion resistant water permeable brick has good corrosion resistance, and service life is significantly increased.

Owner:江苏溧阳建设集团有限公司

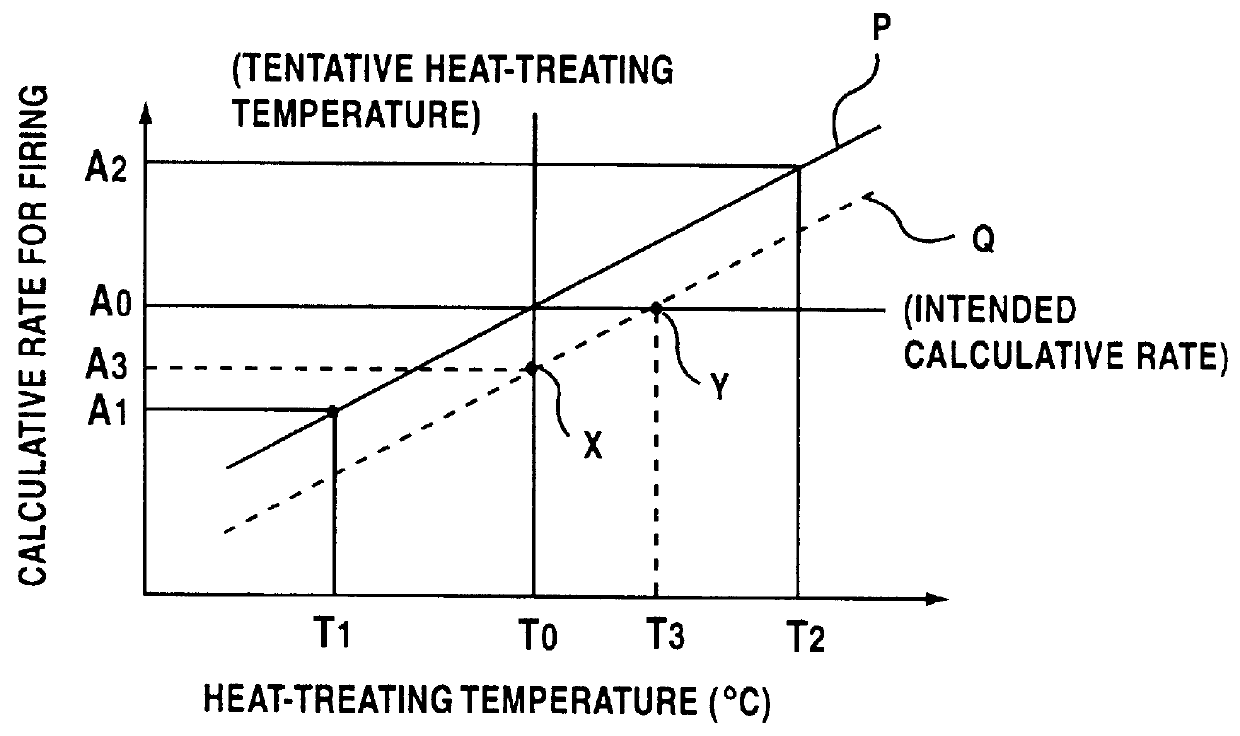

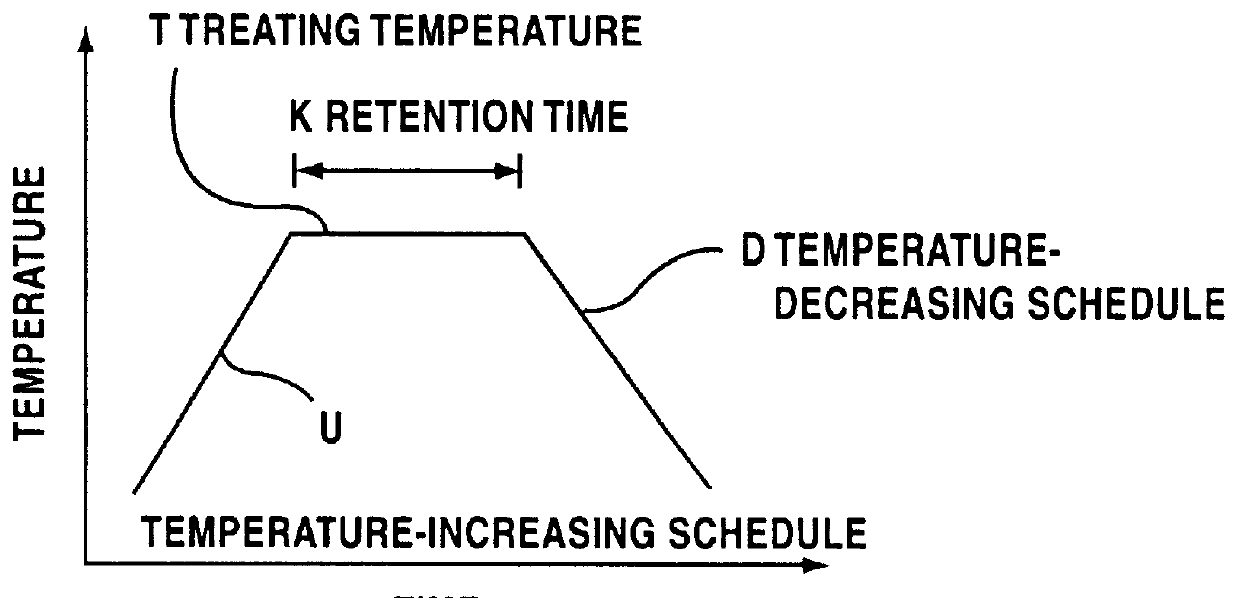

Method for controlling firing shrinkage of ceramic green body

A method of controlling the amount of firing shrinkage of a ceramic green body prepared by molding a ceramic powder (A) to a desired value A1 by heat treating the powder at a temperature T1 that provides the firing shrinkage A1 at a predetermined firing temperature. The temperature T1 is determined based on an established correlation between an amount of firing shrinkage at the predetermined firing temperature and a heat-treatment temperature of a powder (B) having a composition similar to that of the powder (A) in such an extent that a total amount of a greatest common content of an individual component common between the powders (A) and (B) in terms of percent is 90% by weight or more, and satisfying such a relation that the spherical diameter of powder (A) is within a range of + / - 30% relative to the spherical diameter (Rs) of the powder (B) and that its average degree of aggregation (+E,uns x+EE ) is within the range from +E,fra 1 / 2+EE fold to 2 fold relative to the average degree of aggregation (+E,uns x+EE ) of the powder (B).

Owner:NGK INSULATORS LTD

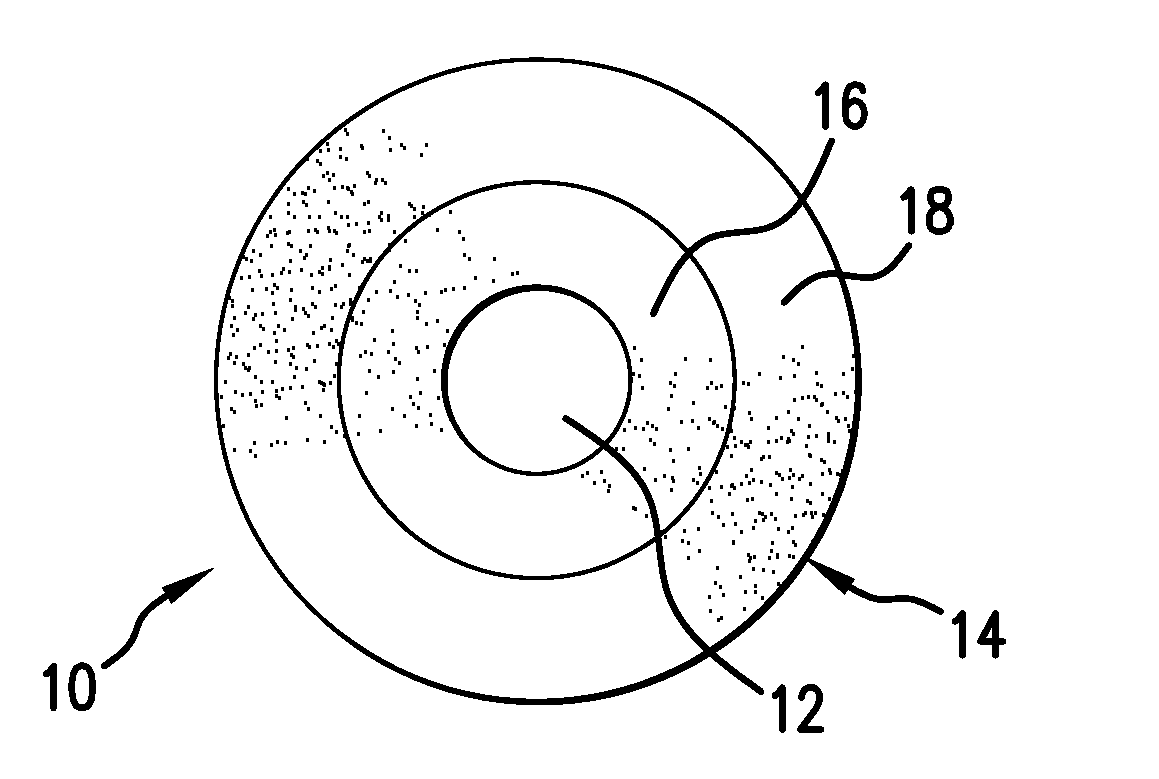

Composite particle comprising an abrasive grit

InactiveUS20070020457A1Delay premature failureProlong lifePigmenting treatmentOther chemical processesAbrasiveComposite pellet

Owner:3M INNOVATIVE PROPERTIES CO

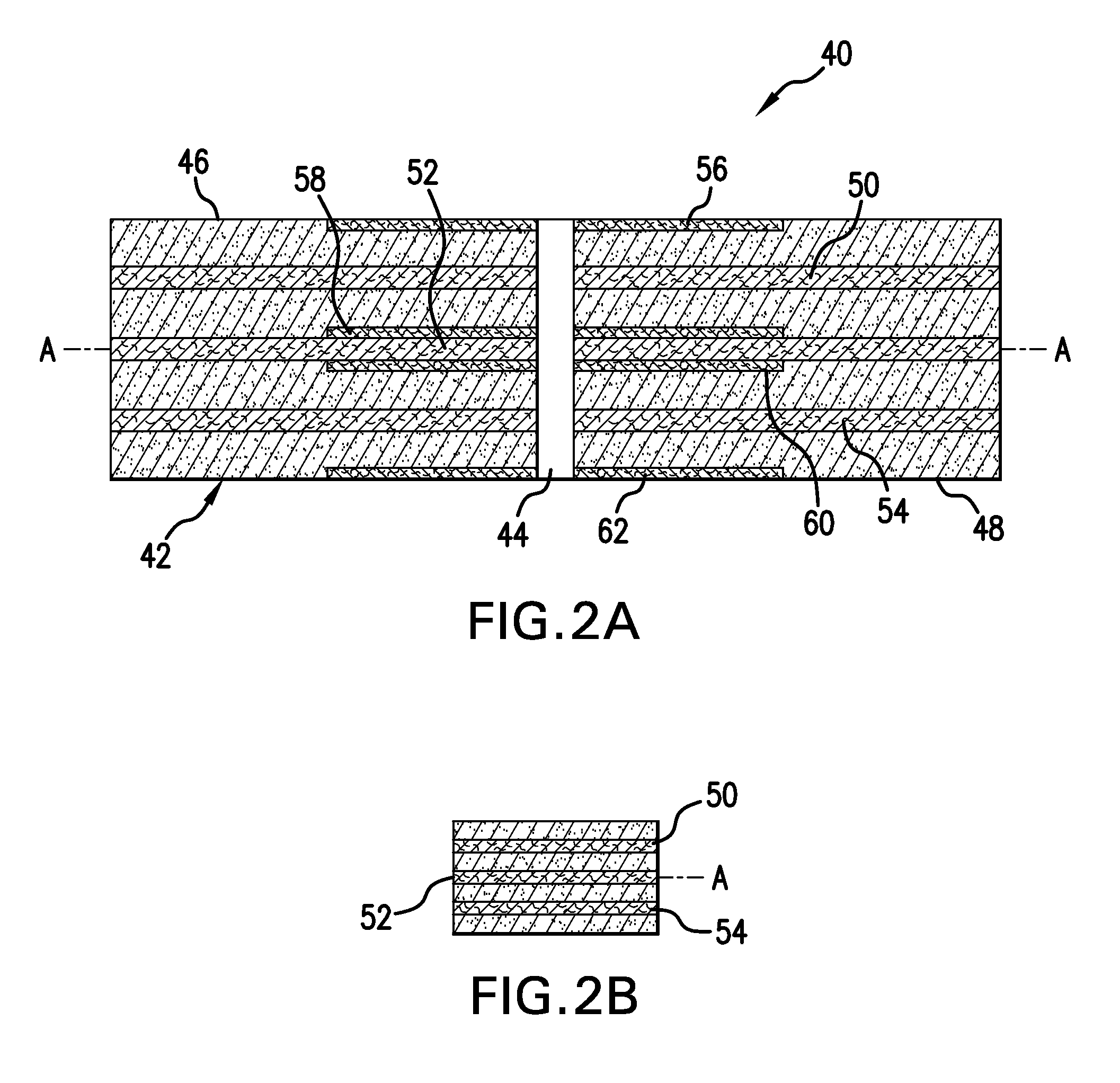

Reinforced Bonded Abrasive Tools

InactiveUS20100190424A1Improve performanceReduce the amount requiredPigmenting treatmentRevolution surface grinding machinesFiberFiberglass mesh

Bonded abrasive tools, e.g., grinding wheels, can be reinforced using, for instance, one or more fibreglass web(s) having a surface of glass per unit of at least 0.2. Alternatively or in addition, the fibreglass web has a thickness of 2 mm or less. The web can be designed to provide improved adhesion between the fibreglass reinforcement and the mixture employed to form the bonded abrasive tool. In some examples, the middle reinforcement at the neutral zone of the wheel can be eliminated or minimized.

Owner:SAINT GOBAIN ABRASIVES INC +1

Abrasive tools having a permeable structure

ActiveUS20070074456A1Compromising surface-finish qualityCompromising structural opennessPigmenting treatmentOther chemical processesThree dimensional shapeAgglomerate

A bonded abrasive tool comprises a blend of abrasive grains and a bond component. The blend of abrasive grains comprises a filamentary sol-gel alumina abrasive grain and agglomerated abrasive grain granules. A bonded abrasive tool comprising an agglomerate of filamentary sol-gel alumina abrasive and non-filamentary abrasive grains, and a bond component is also disclosed. The filamentary sol-gel alumina abrasive grain has a length-to-cross-sectional-width aspect ratio of greater than 1.0. The agglomerated abrasive grain granules comprise a plurality of abrasive grains held in a three-dimensional shape by a binding material. A method of making such a bonded abrasive tool as described above is also disclosed.

Owner:SAINT GOBAIN ABRASIVES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com