Patents

Literature

216 results about "Relative thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

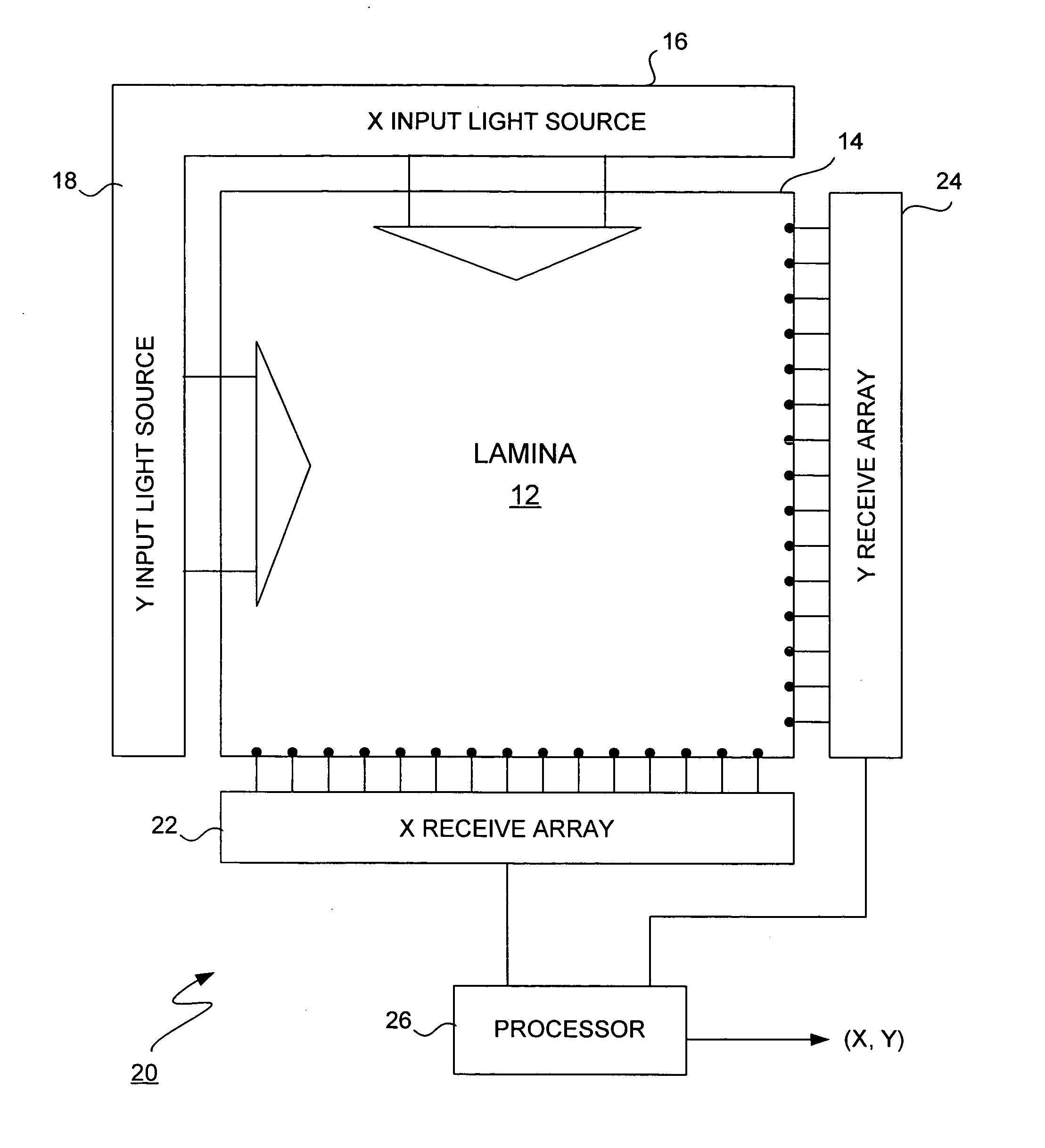

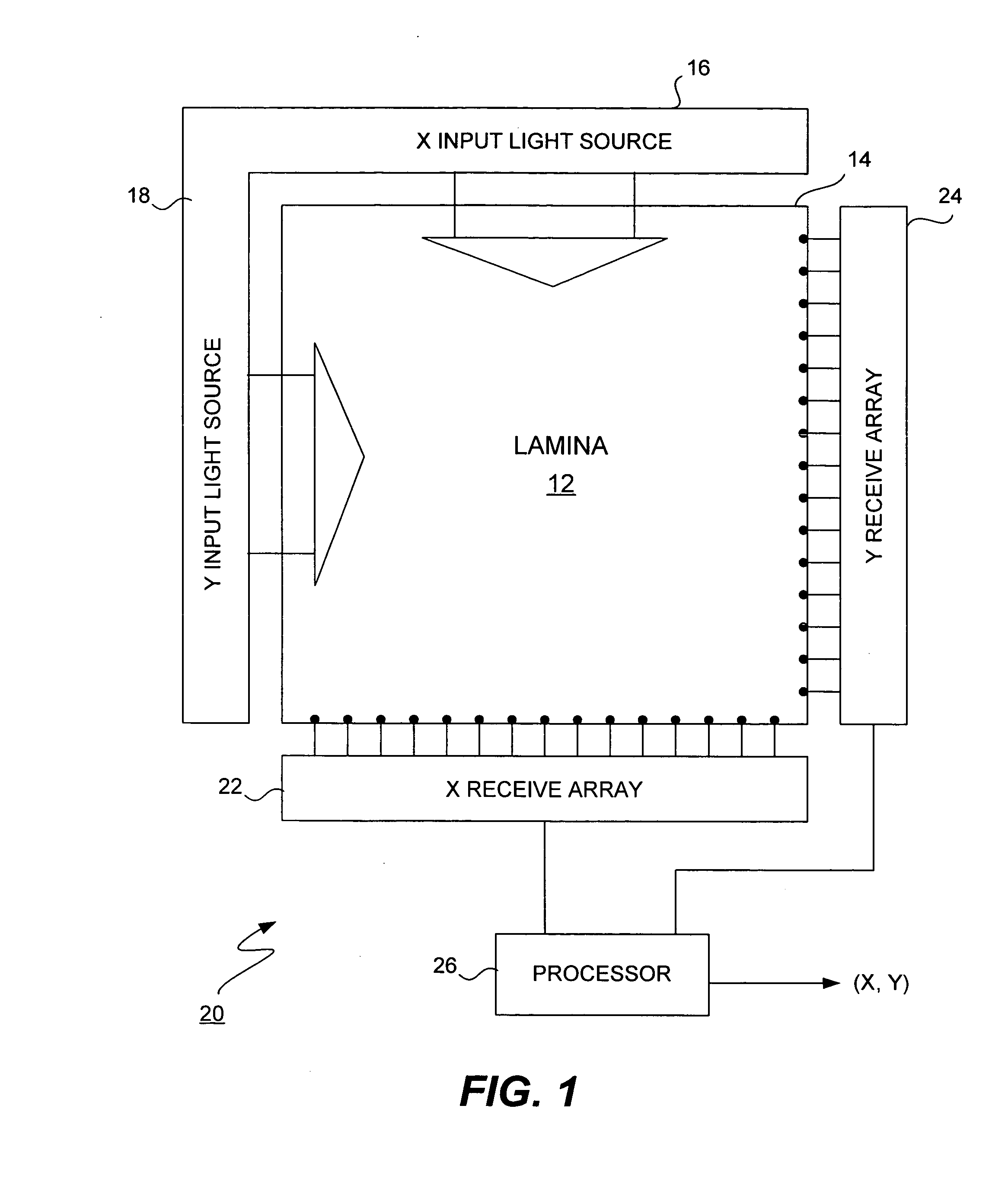

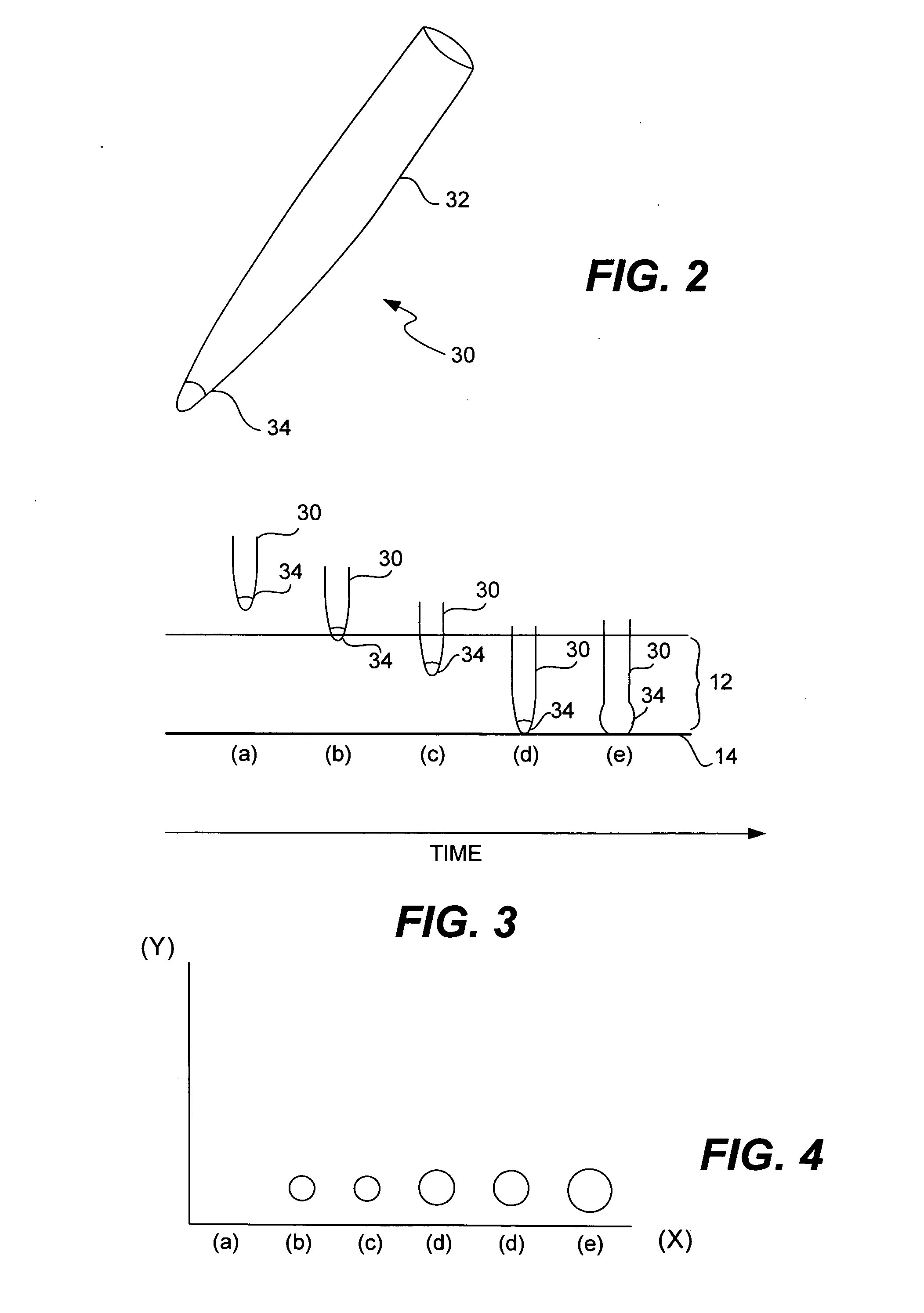

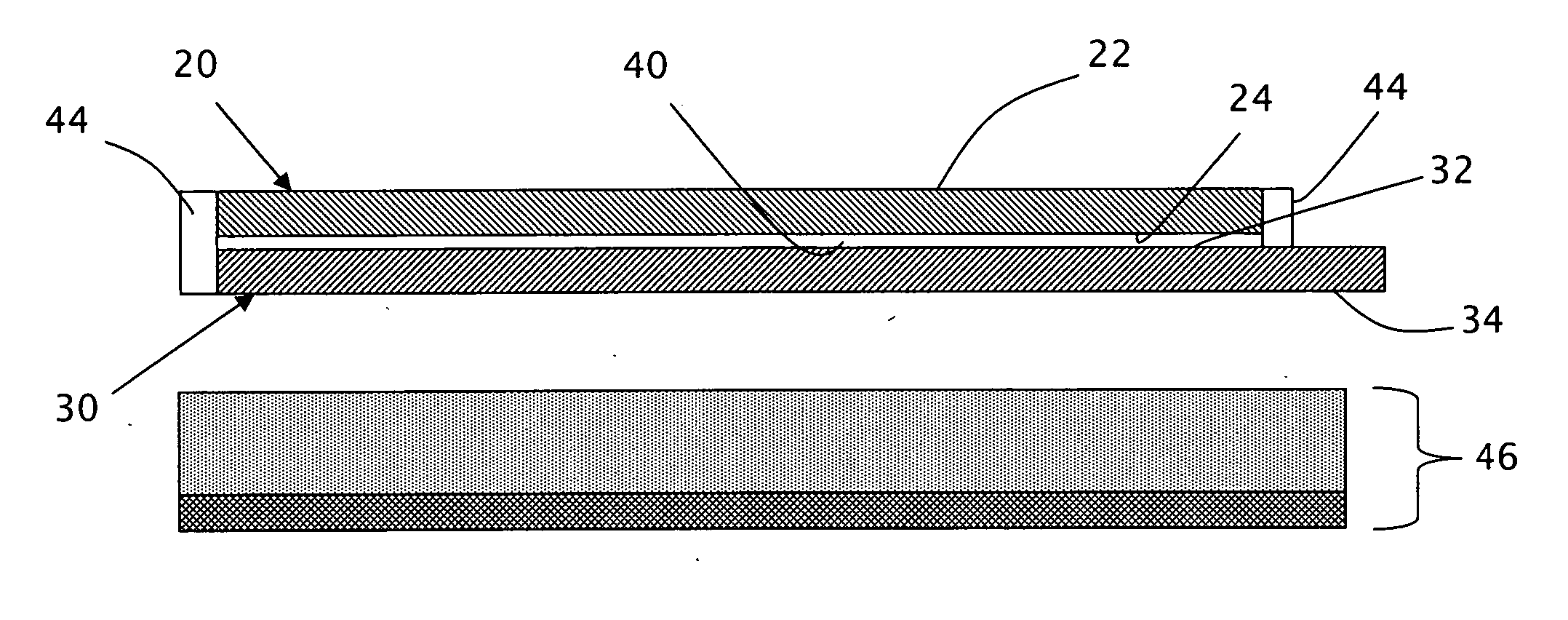

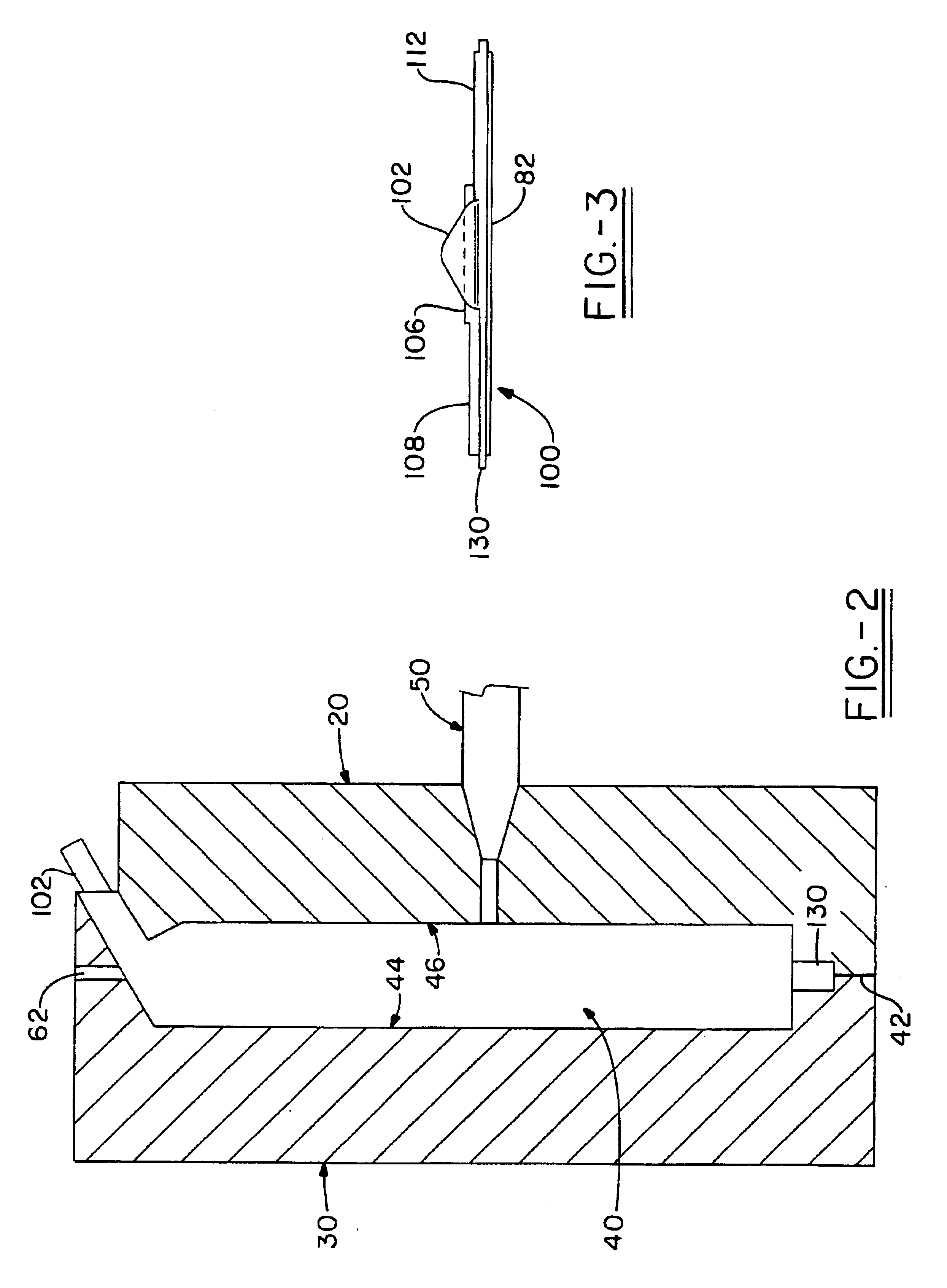

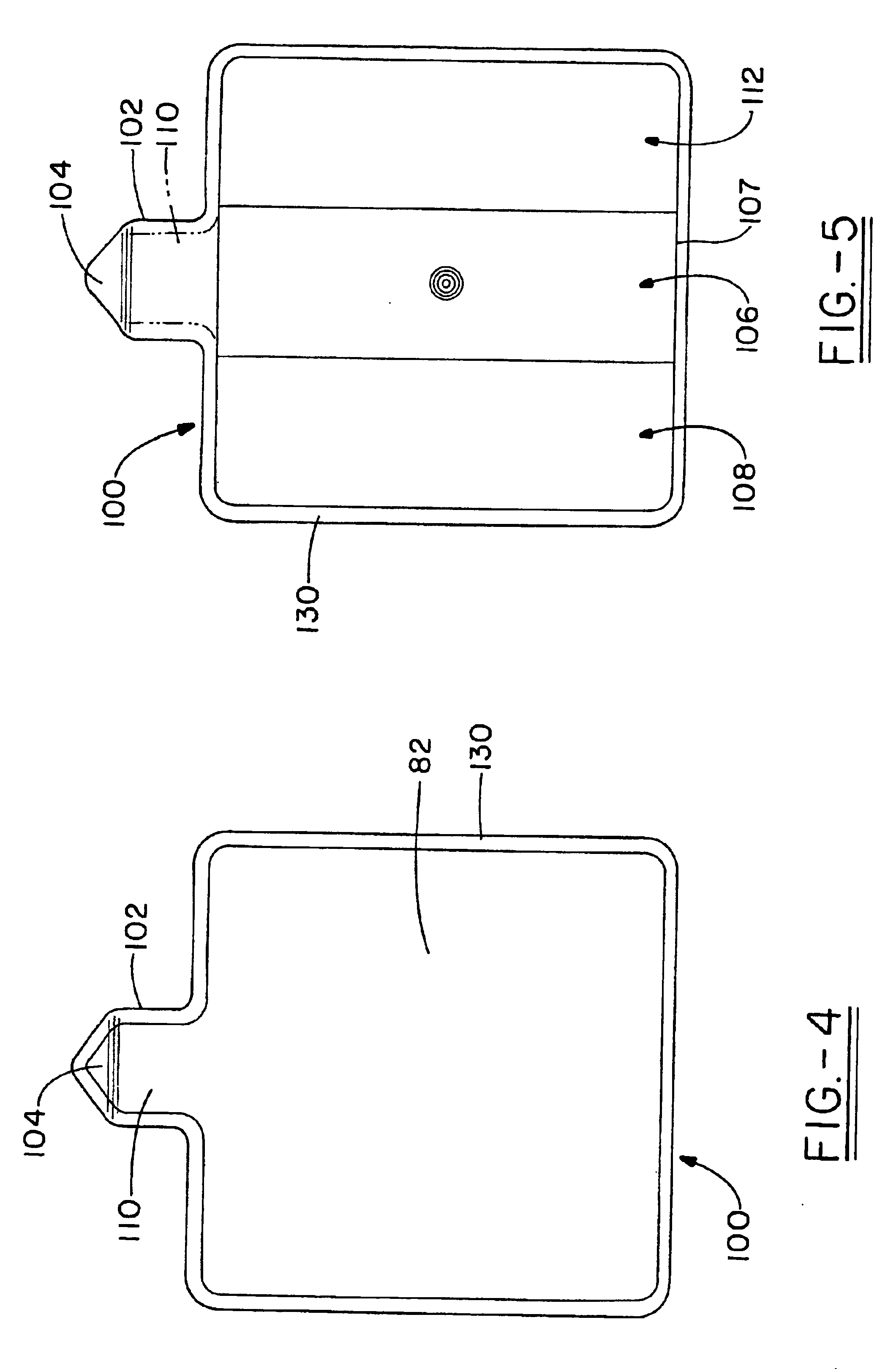

Apparatus and method for performing data entry with light based touch screen displays

InactiveUS20060001654A1Cathode-ray tube indicatorsInput/output processes for data processingDisplay deviceTouchscreen

An apparatus and method for performing data entry with light based touch screen displays and that is capable of implementing the functions of inking, pressure sensitive data entries, the rate of descent and angle of entry of the pen or stylus, the ability to rotate objects, double-clicking objects, fast clicking, etc. The apparatus and method includes a touch screen and a stylus having a tip that compresses depending on the amount of force is applied to the stylus when placed in contact with the touch screen during a data entry operation. A processor is provided to generate a display on the touch screen that traces the movements of the stylus on the touch screen. To implement the inking function, the processor is configured to extrapolate the relative thickness of the display generated on the touch screen to be commensurate with the amount of compression of the tip caused by the amount of writing force applied to the stylus. The amount of compression of the tip also enables pressure sensitive data entries.

Owner:POA SANA LIQUIDATING TRUST

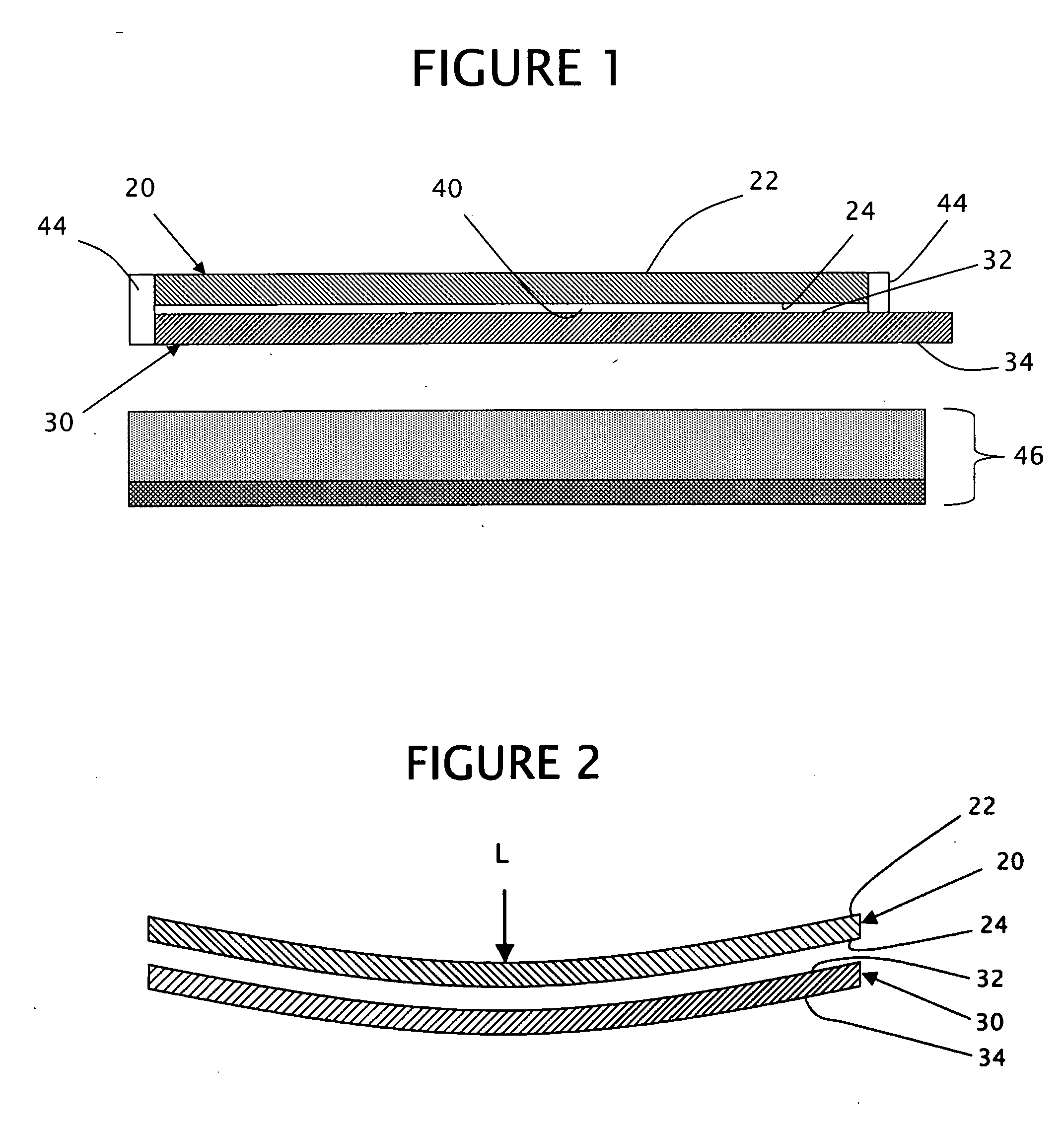

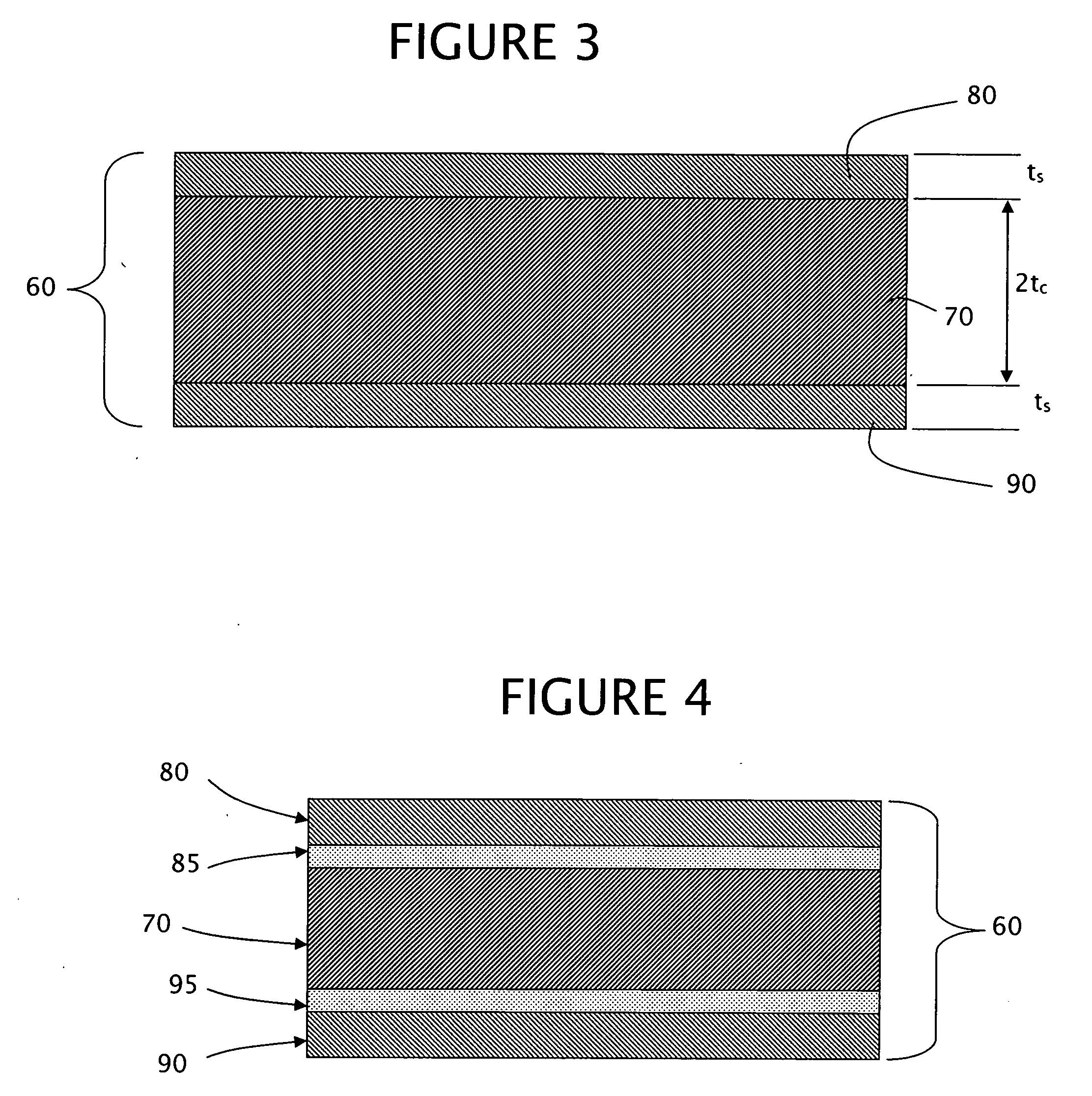

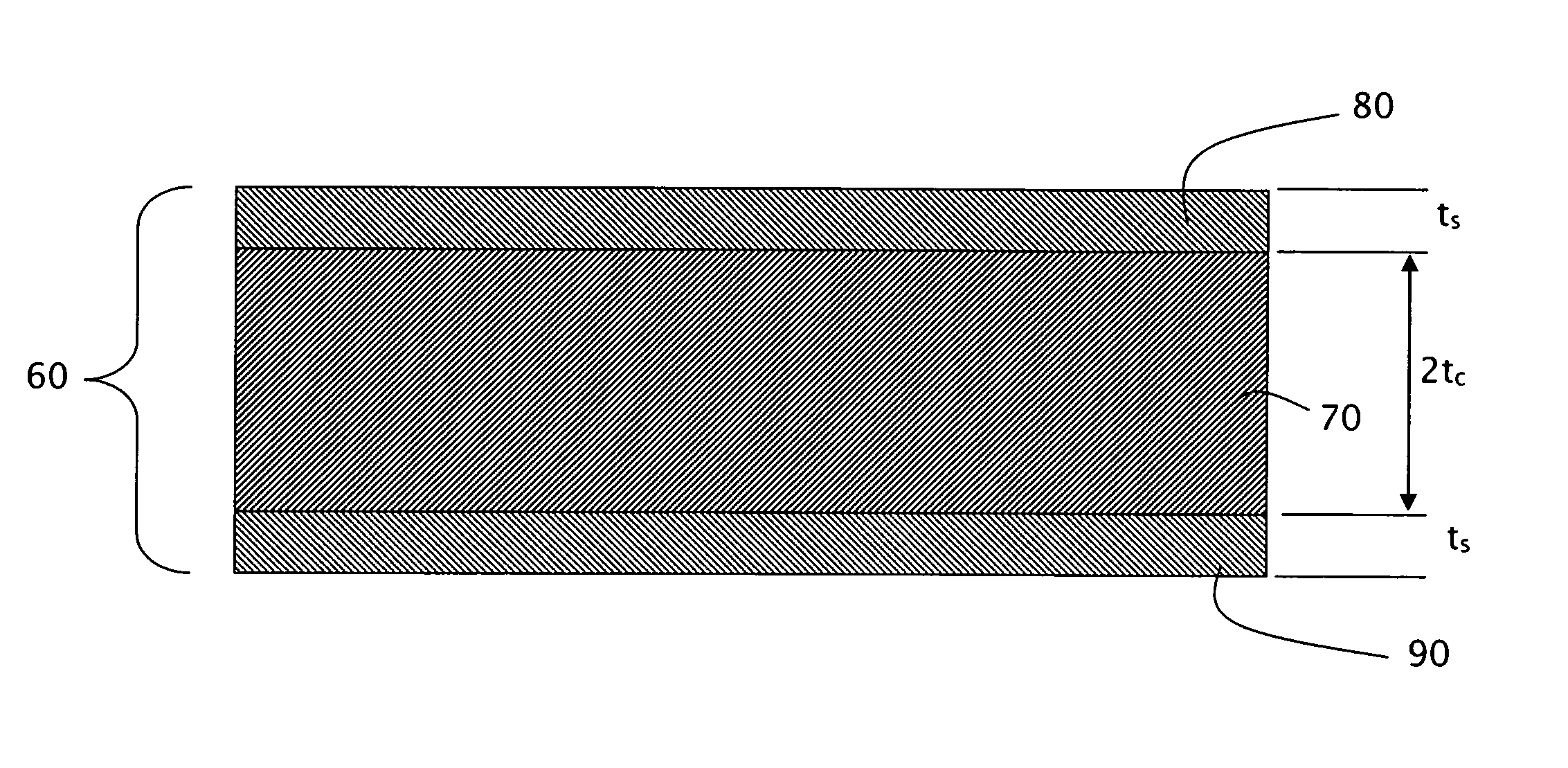

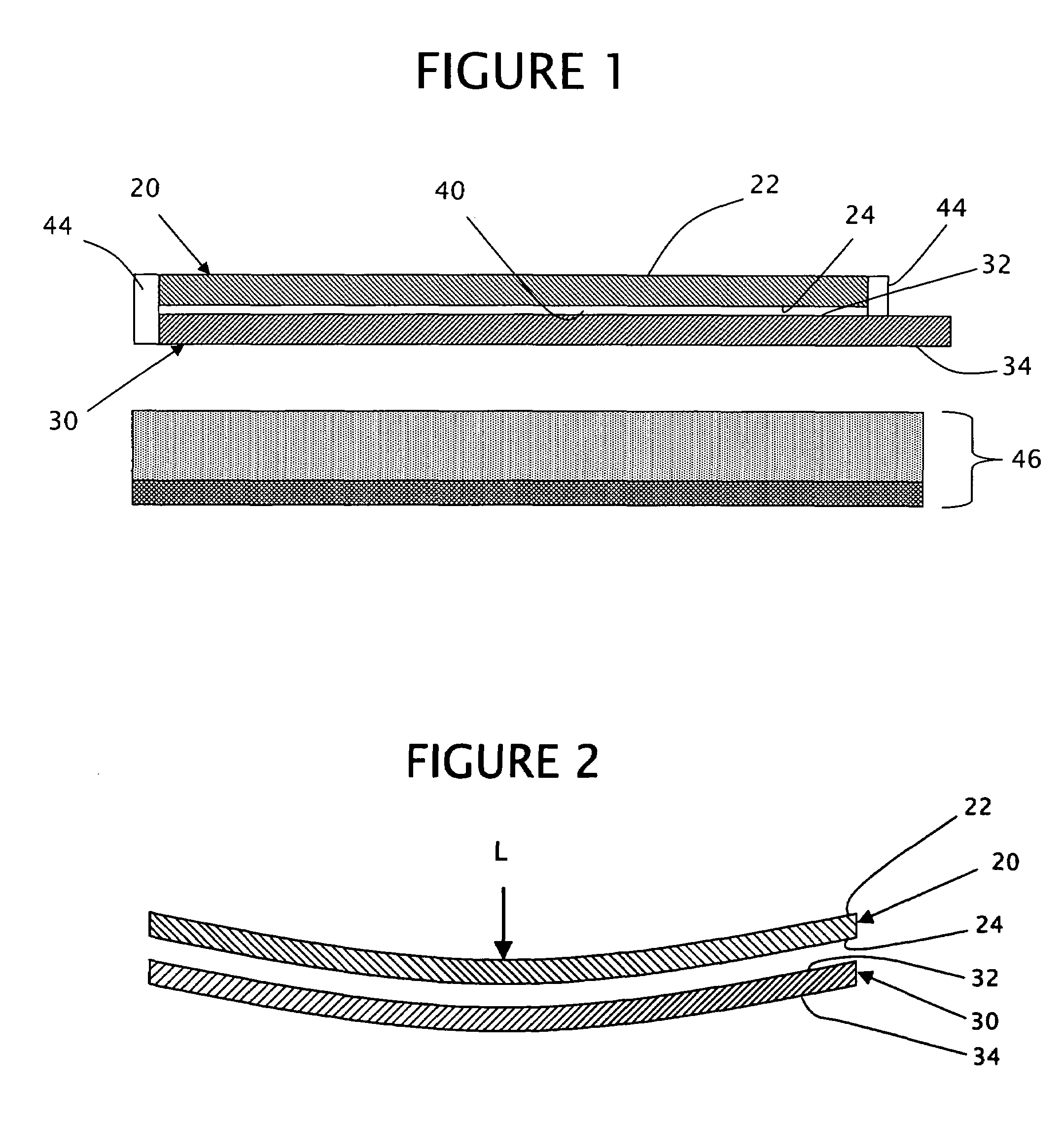

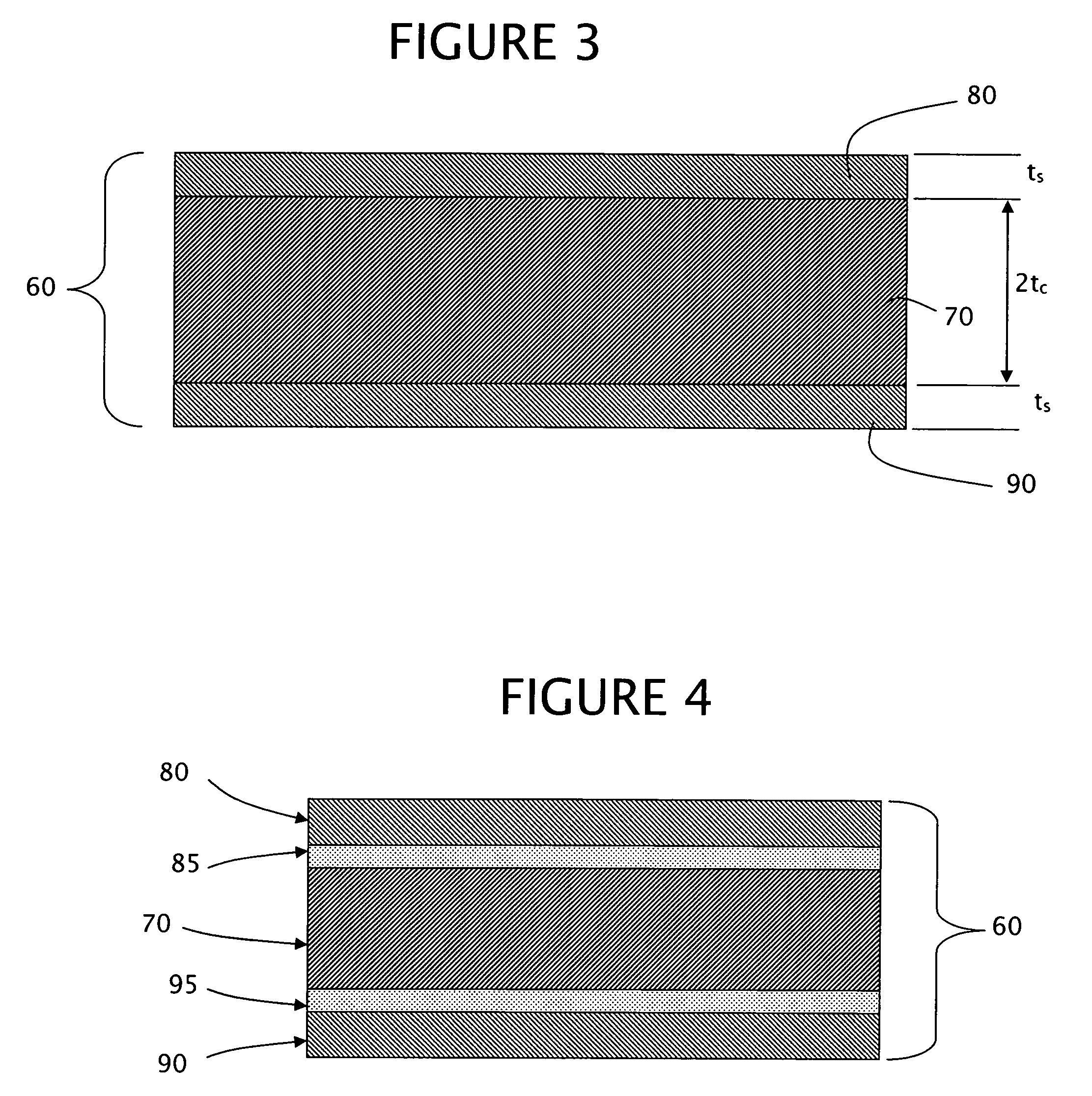

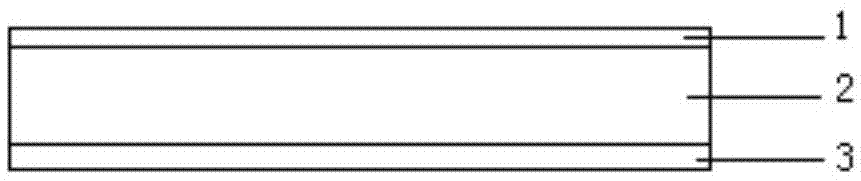

Glass laminate substrate having enhanced impact and static loading resistance

ActiveUS20060127679A1Increased resistance to impactIncrease static loadLiquid crystal compositionsGas-filled discharge tubesDisplay deviceThermal expansion

A glass laminate substrate for electronic substrates, such as flat panel displays, includes a transparent glass core bounded by transparent glass skin layers, wherein the coefficient of thermal expansion of the core is greater than the coefficient of thermal expansion of the skin layers thereby forming a residual compressive stress in the skin layers and a residual tensile stress in the core. The relative thickness of the skin layers can be selected to enhance the strength of the glass laminate substrate while maintaining a sufficiently low residual tensile stress in the core to allow scribing and separating of the substrate to size. Interlayers can be located between the core and the skin layers, wherein the interlayers include a residual compressive stress, and produce a reduced residual tensile stress in the core.

Owner:CORNING INC

Glass laminate substrate having enhanced impact and static loading resistance

ActiveUS7201965B2Increased resistance to impact and static loadingImprove load resistanceLiquid crystal compositionsGas-filled discharge tubesThermal expansionFlat panel display

A glass laminate substrate for electronic substrates, such as flat panel displays, includes a transparent glass core bounded by transparent glass skin layers, wherein the coefficient of thermal expansion of the core is greater than the coefficient of thermal expansion of the skin layers thereby forming a residual compressive stress in the skin layers and a residual tensile stress in the core. The relative thickness of the skin layers can be selected to enhance the strength of the glass laminate substrate while maintaining a sufficiently low residual tensile stress in the core to allow scribing and separating of the substrate to size. Interlayers can be located between the core and the skin layers, wherein the interlayers include a residual compressive stress, and produce a reduced residual tensile stress in the core.

Owner:CORNING INC

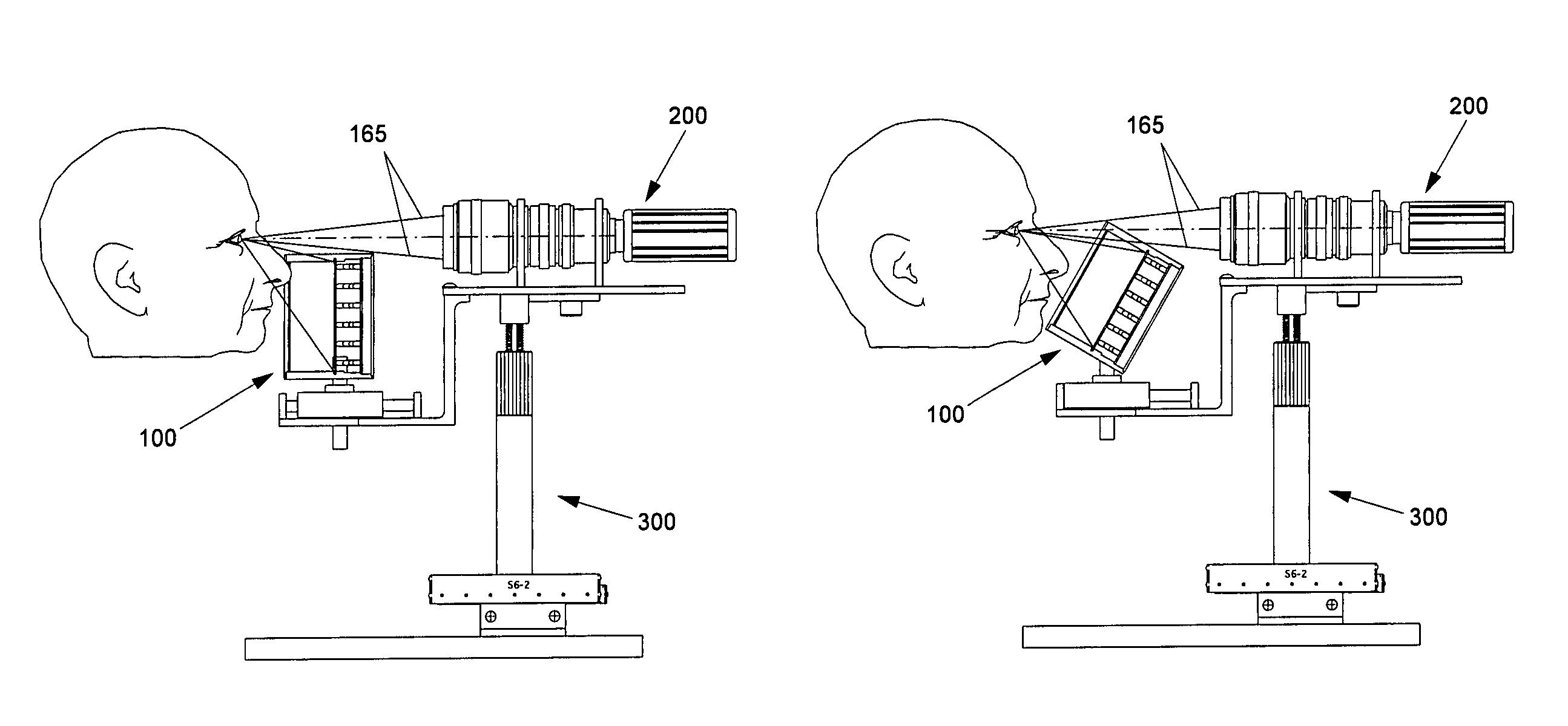

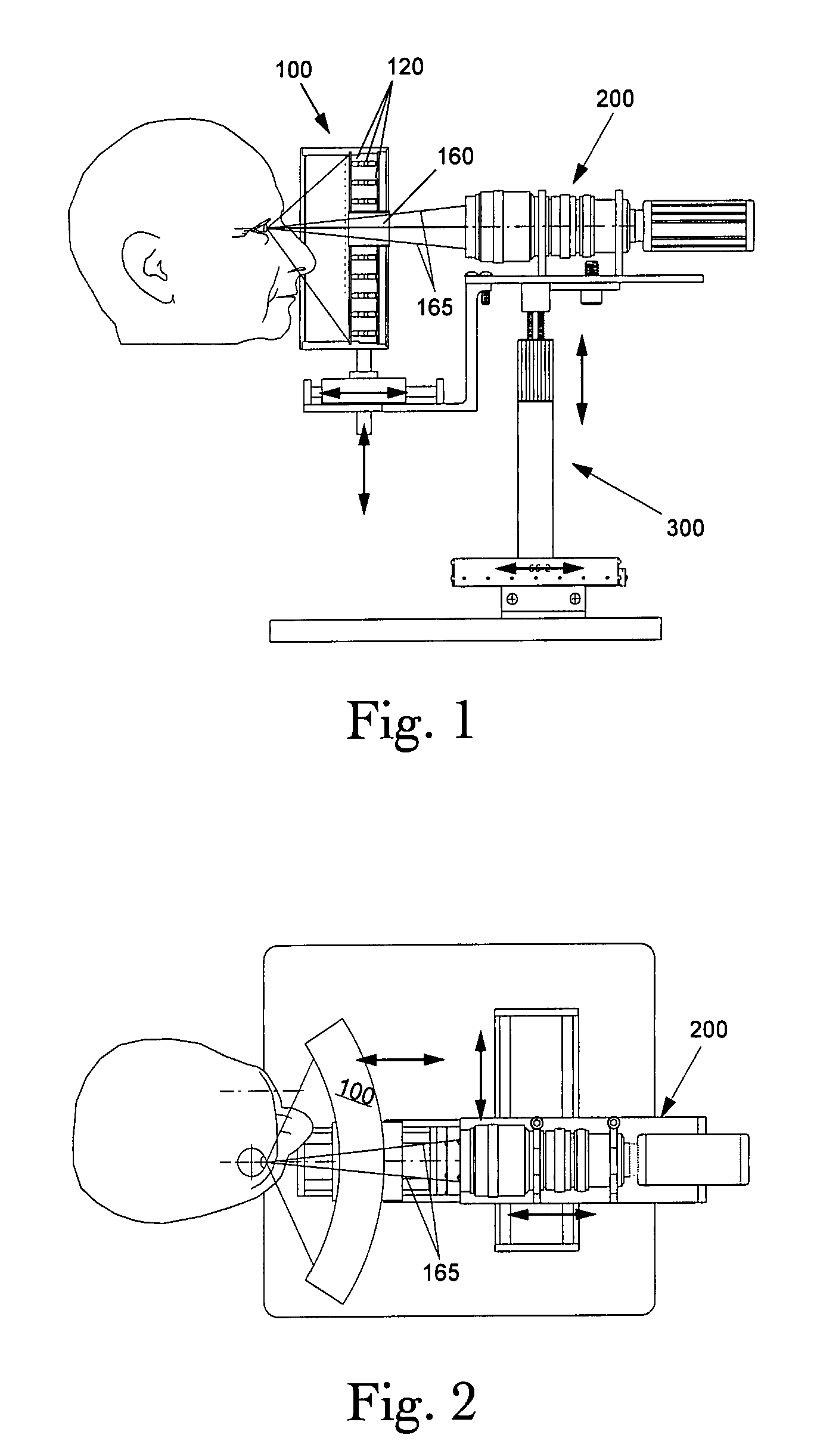

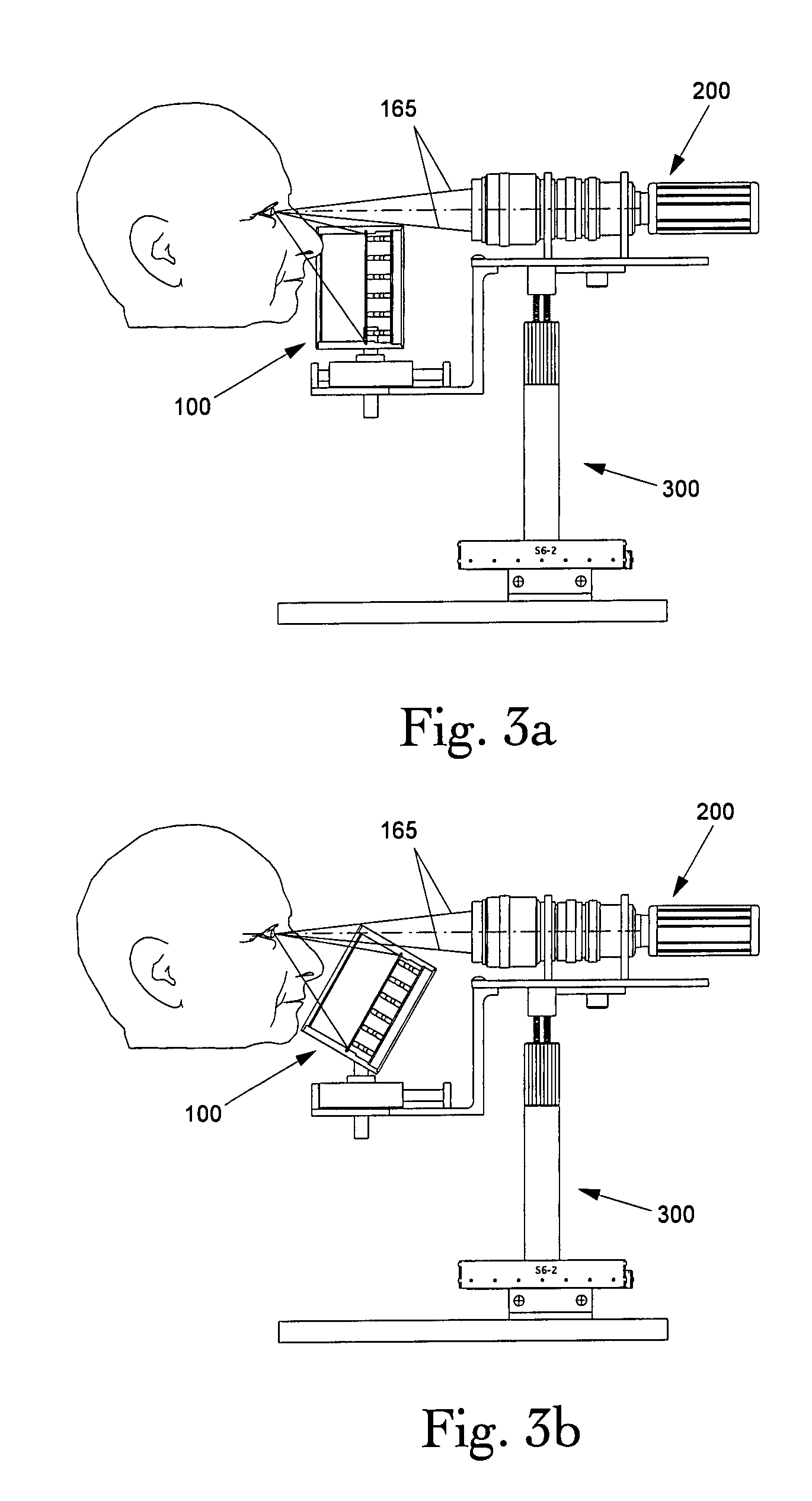

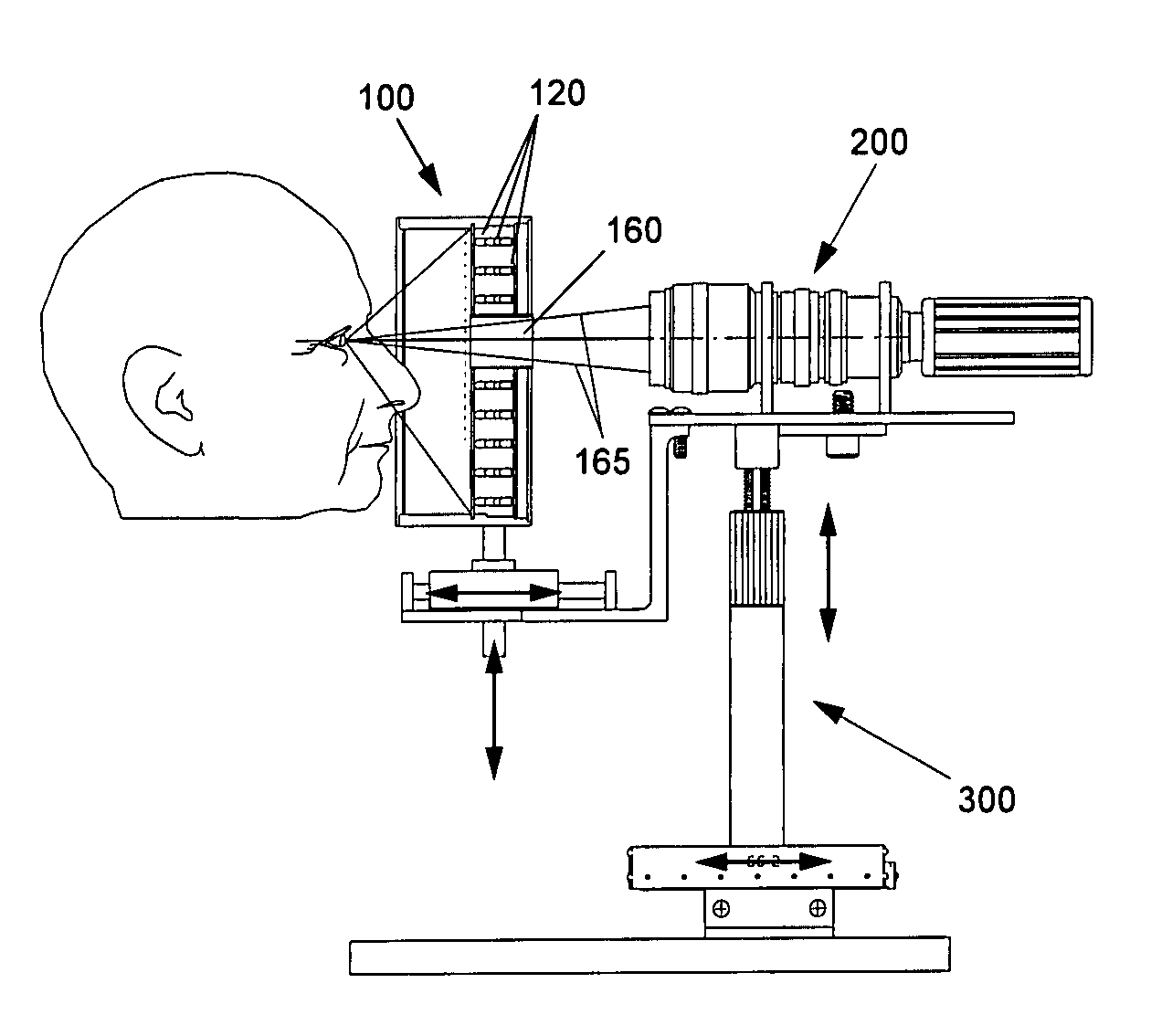

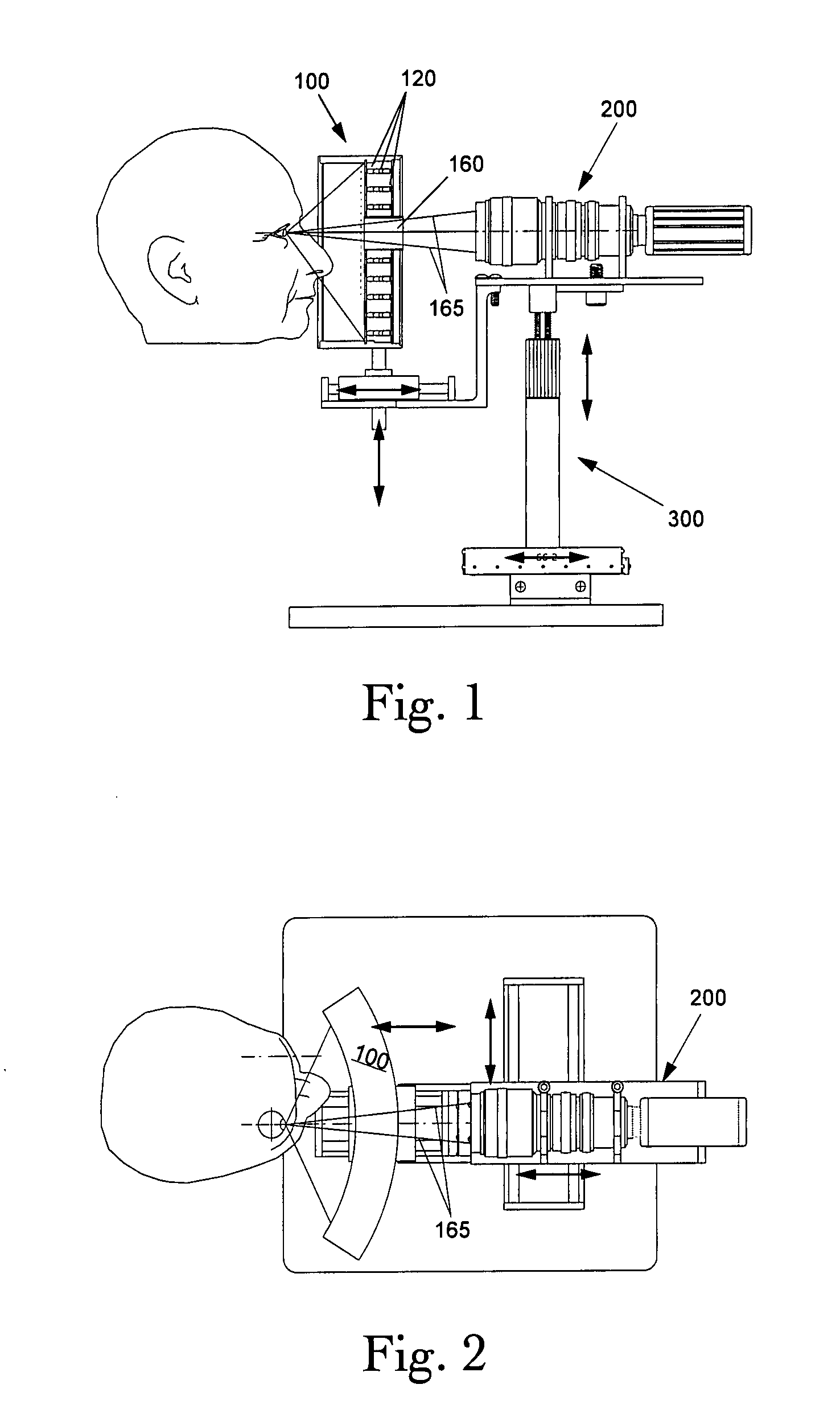

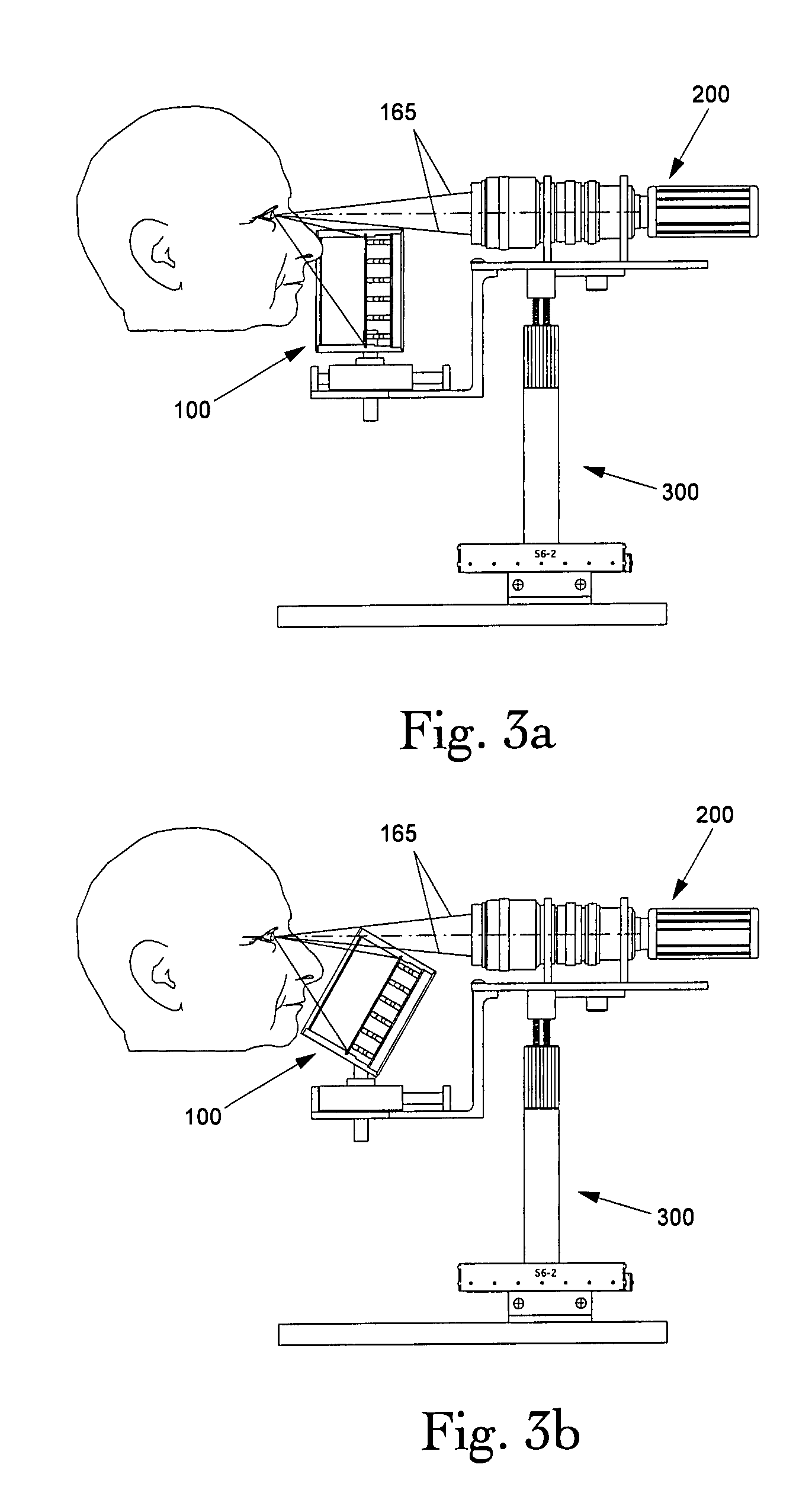

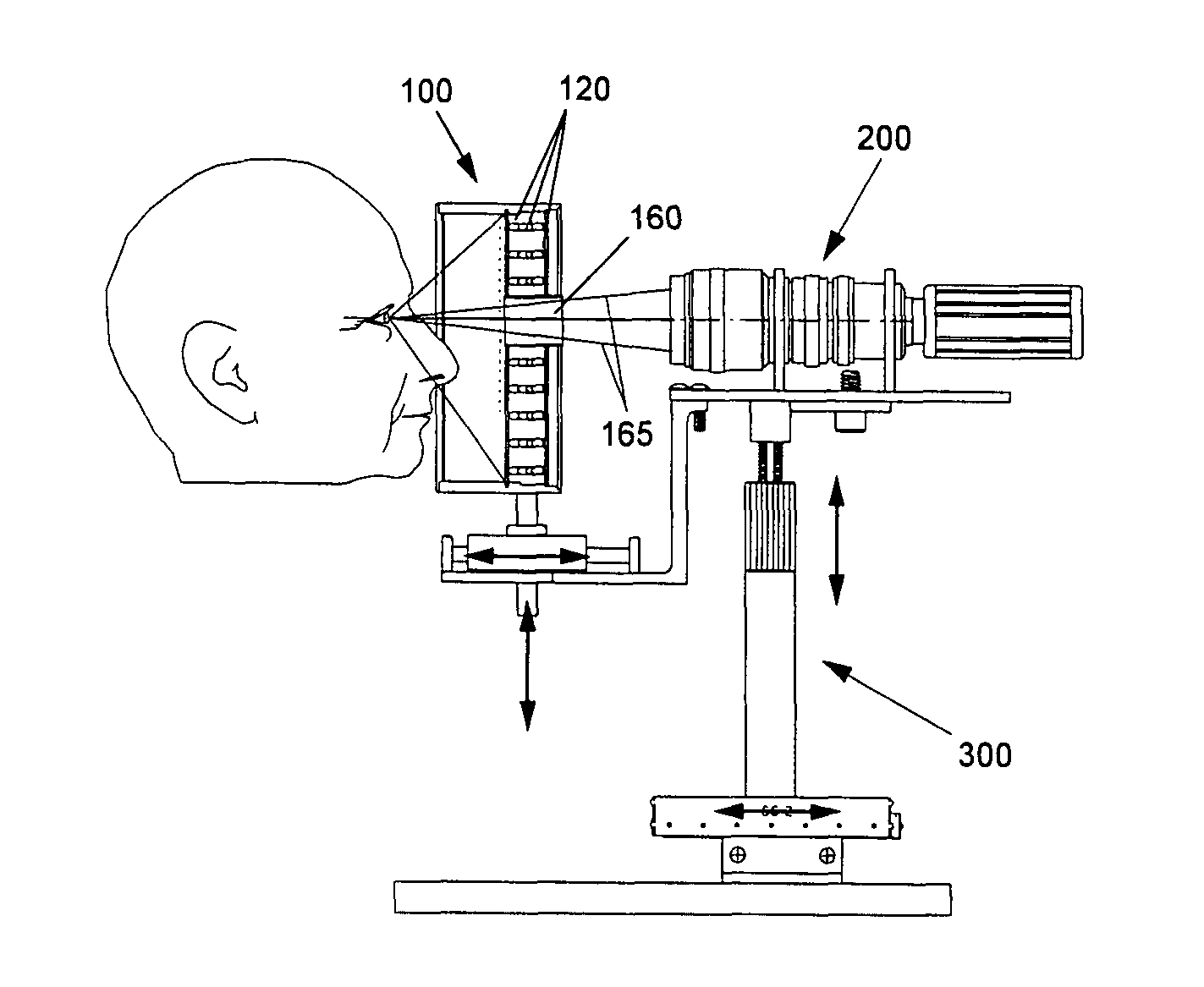

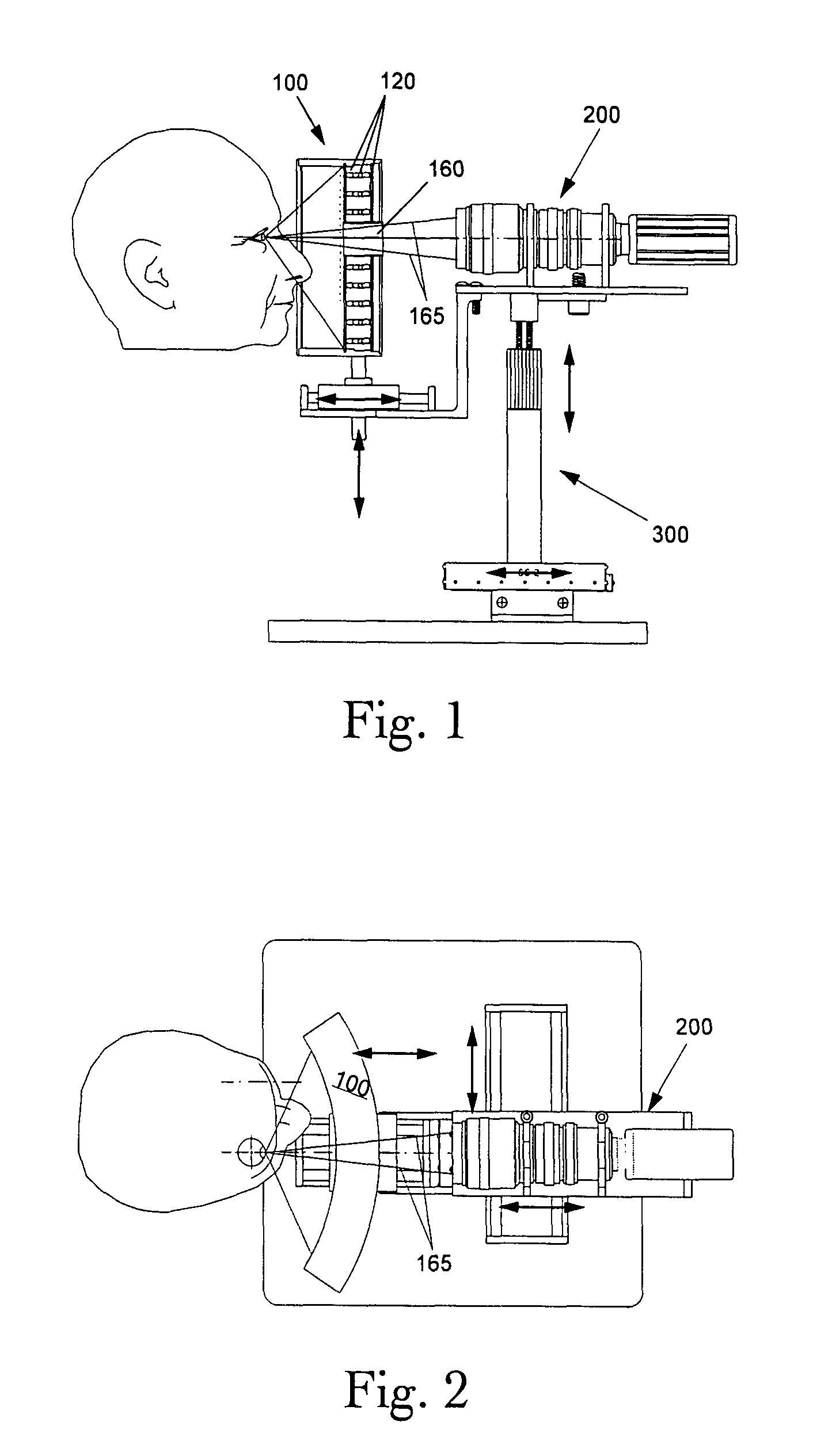

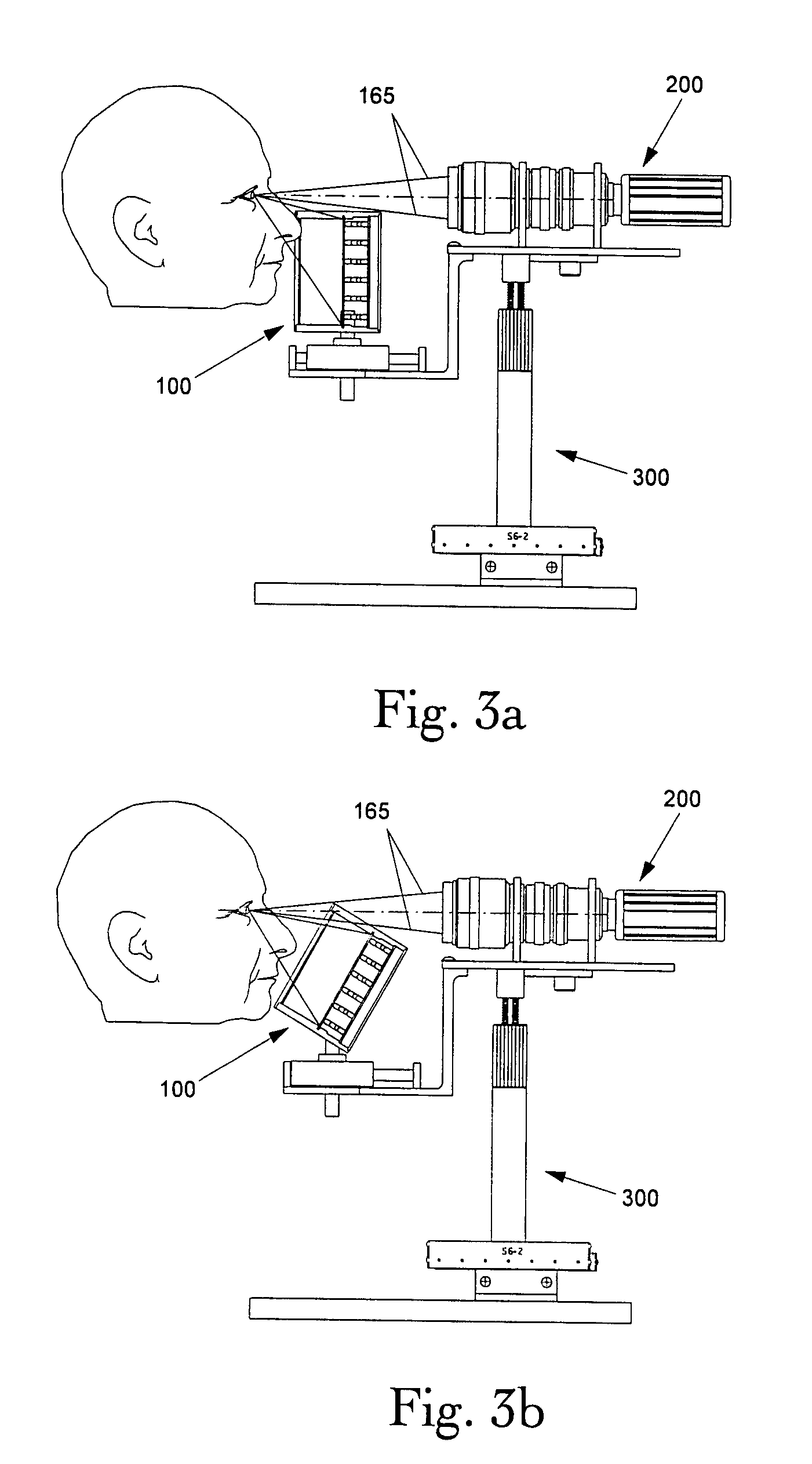

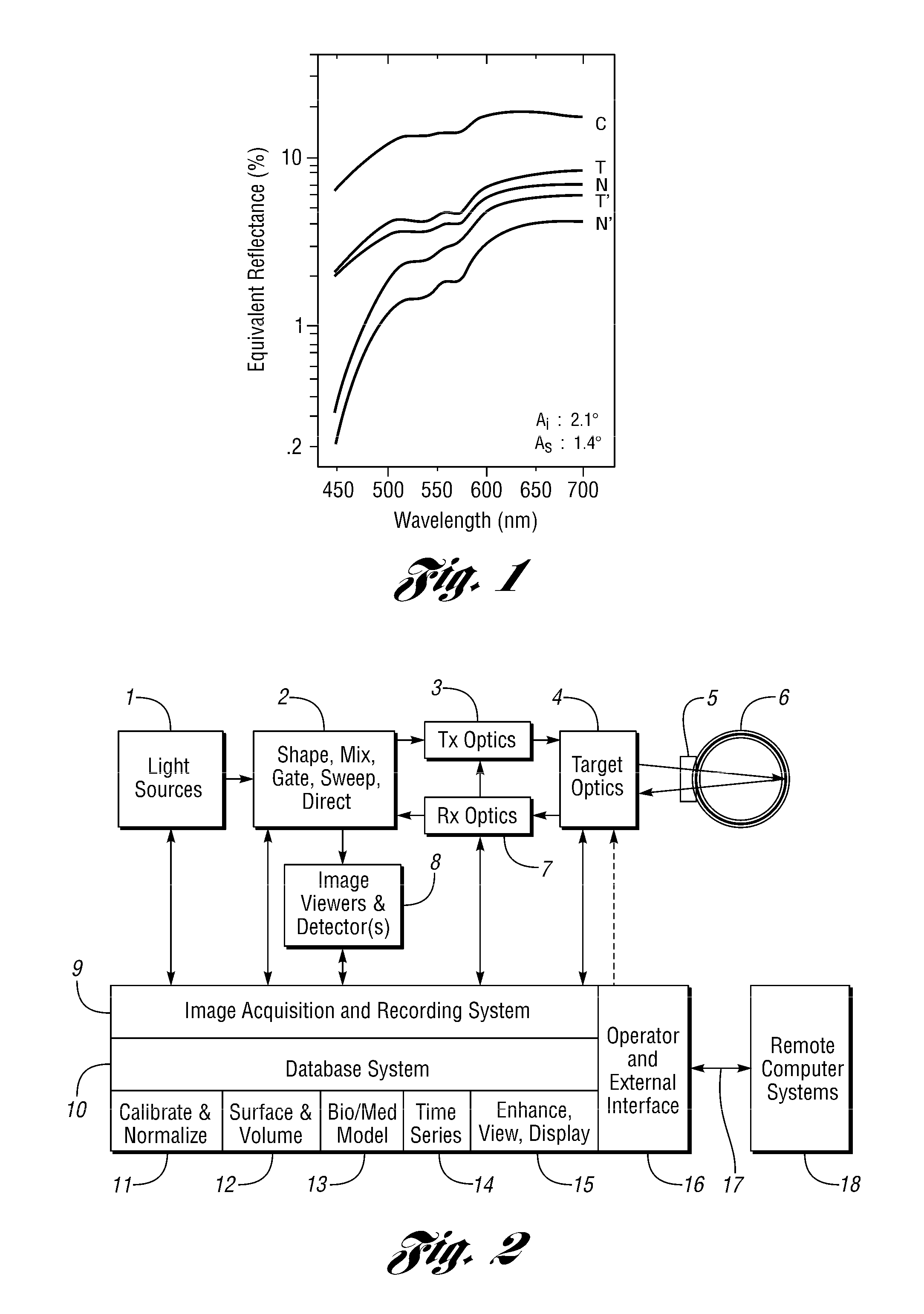

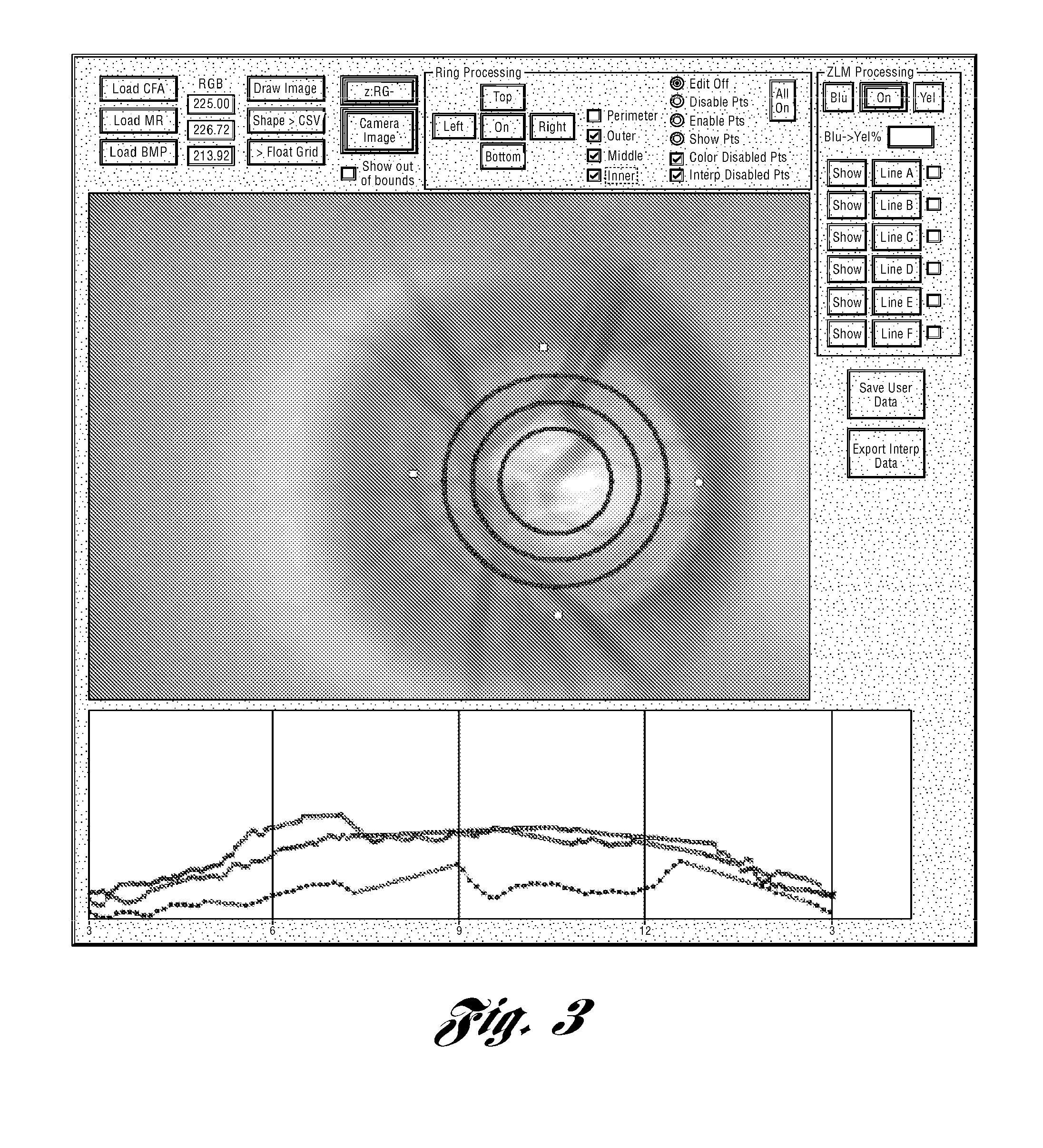

Tear film measurement

ActiveUS7758190B2Avoid introducingReduce light intensityUsing optical meansEye diagnosticsTearsFARR assay

Owner:TEARSCIENCE INC

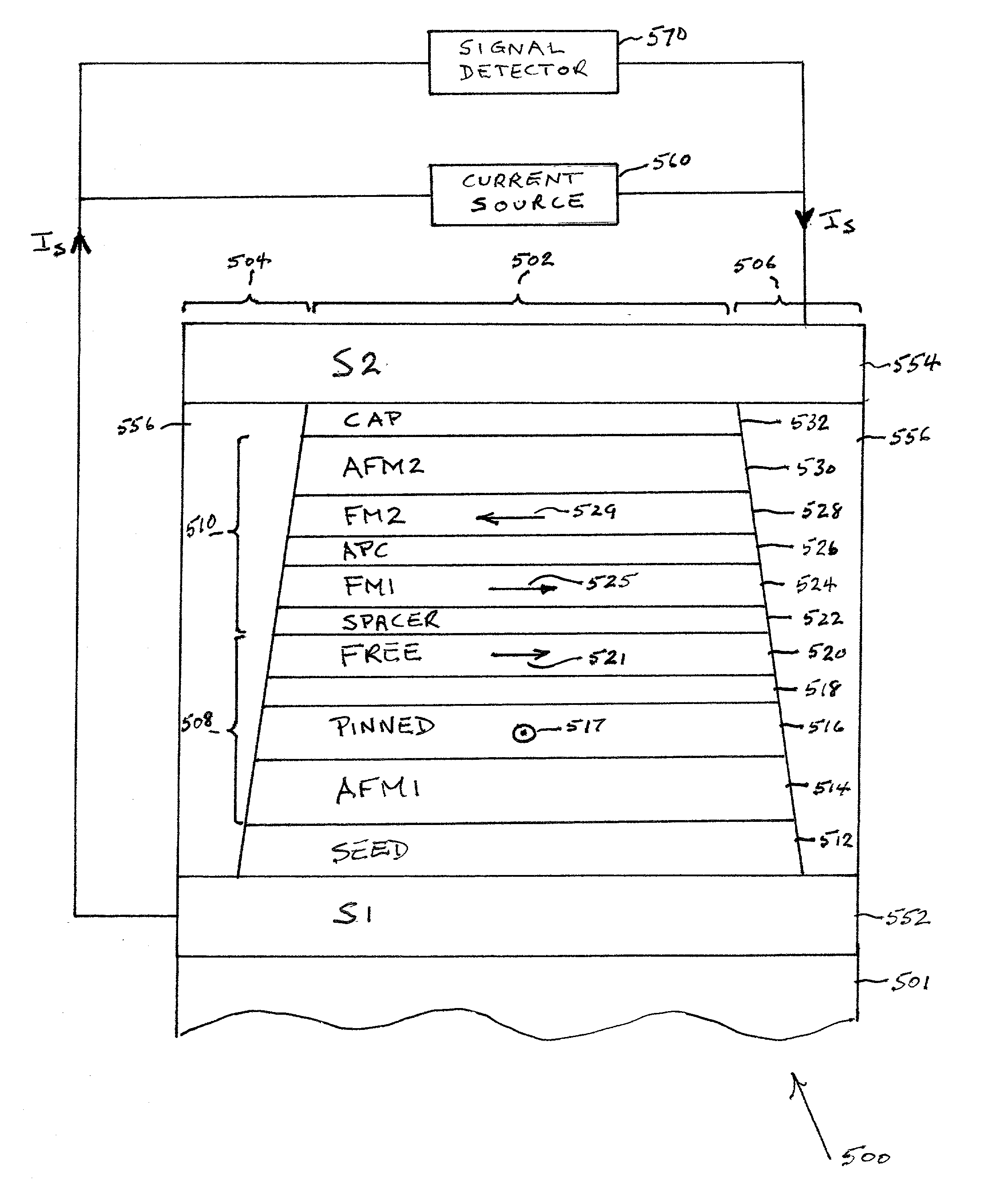

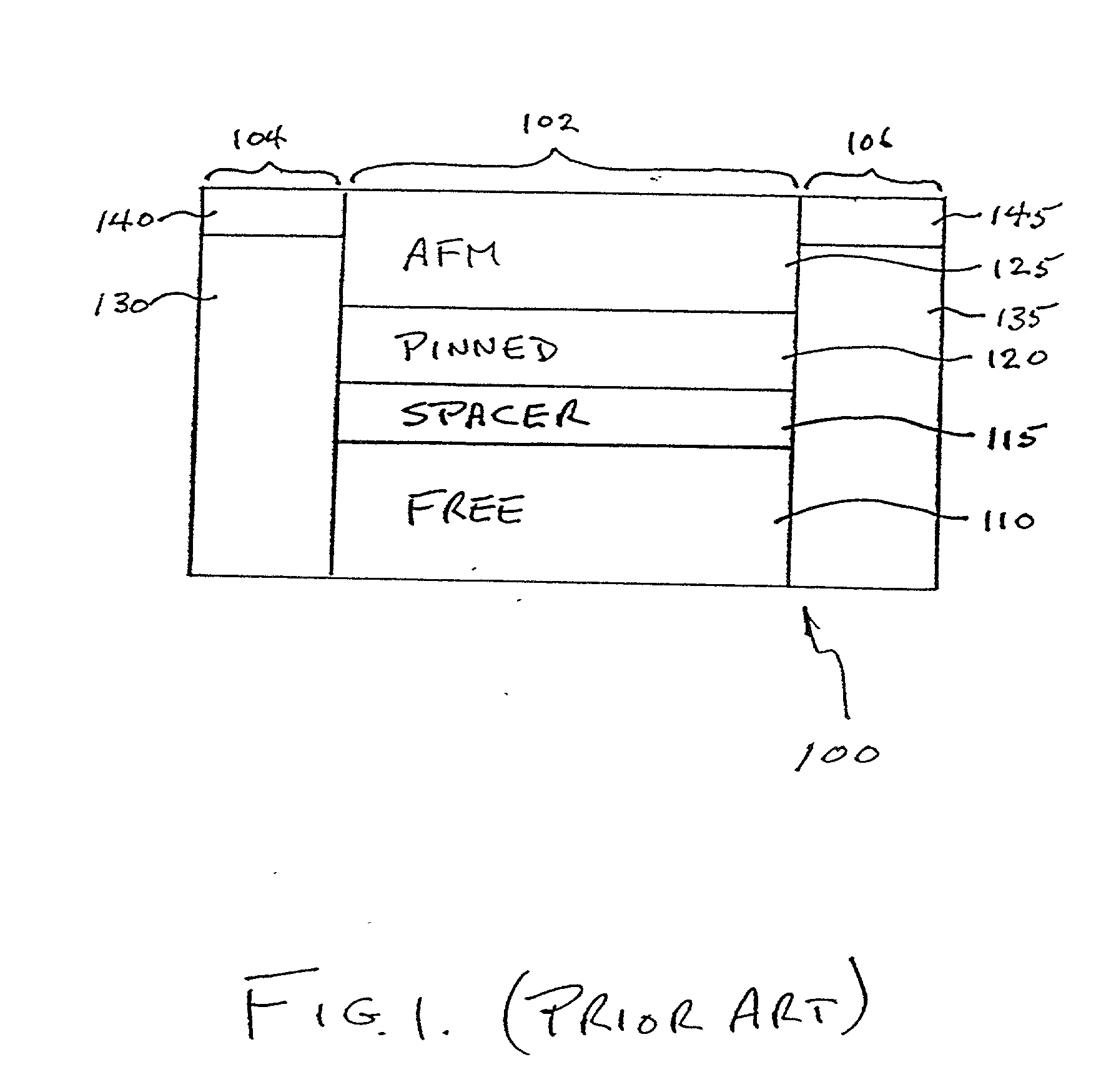

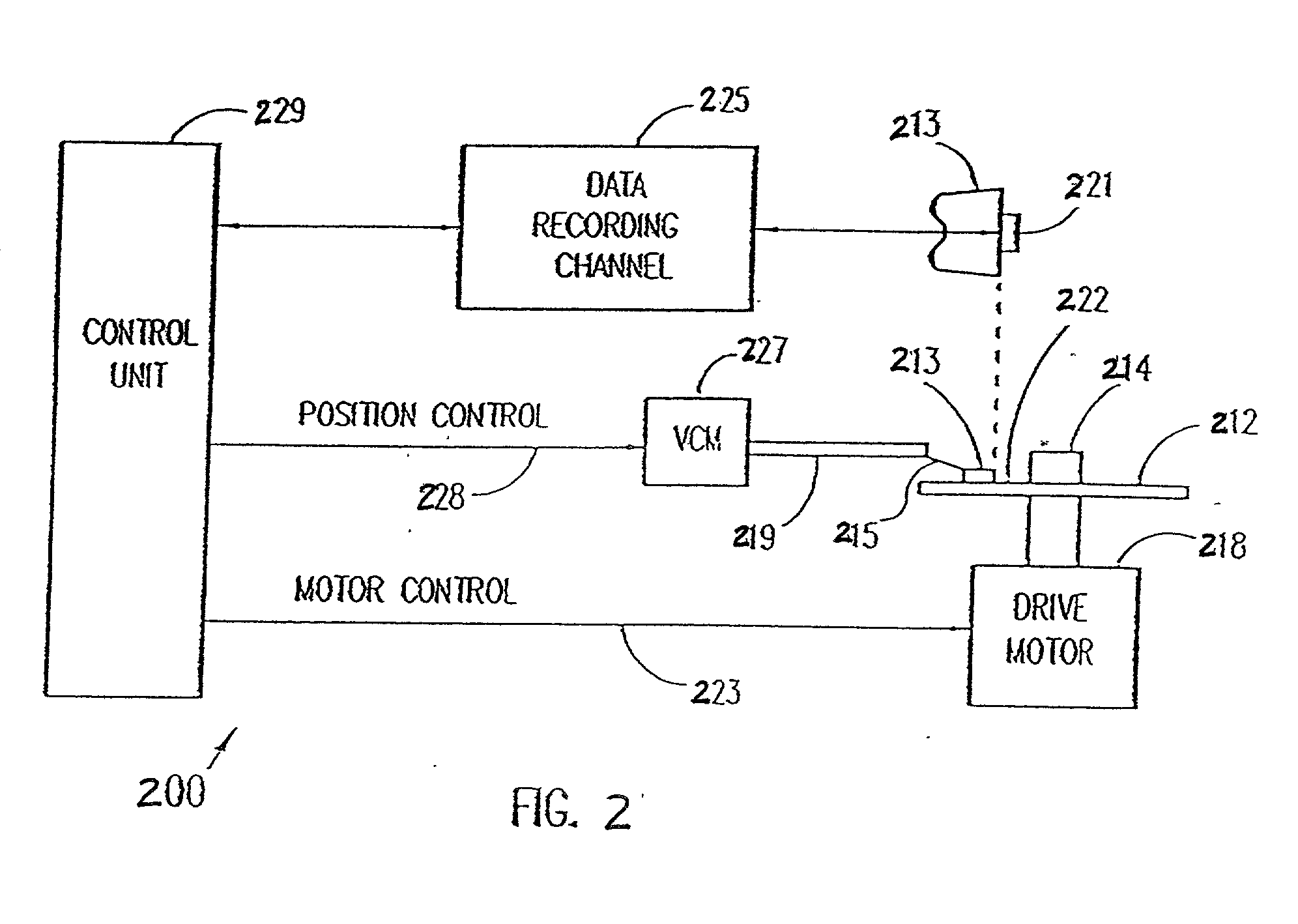

Stabilization structures for CPP sensor

Current-perpendicular-to-plane (CPP) spin valve (SV) and magnetic tunnel junction (MTJ) sensors are provided having an antiparallel (AP)-coupled longitudinal bias stack for instack biasing to stabilize the free layer. A CPP sensor comprises a longitudinal bias stack adjacent to and in contact with a free (sense) layer of the sensor. The bias stack comprises an antiparallel (AP)-pinned layer including FM1 and FM2 layers separated by an antiparallel coupling (APC) layer. The FM1 layer is separated from the free layer of the sensor by a nonmagnetic spacer layer. By choosing the relative thicknesses of the FM1 and FM2 layers, the bias field HB from the AP-pinned layer and the ferromagnetic coupling field HFC between the FM1 layer and the free layer is made additive at the free layer for either positive or negative coupling. By ensuring that the bias field adds to the coupling field, the stability of the free layer by in-stack longitudinal biasing is improved.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

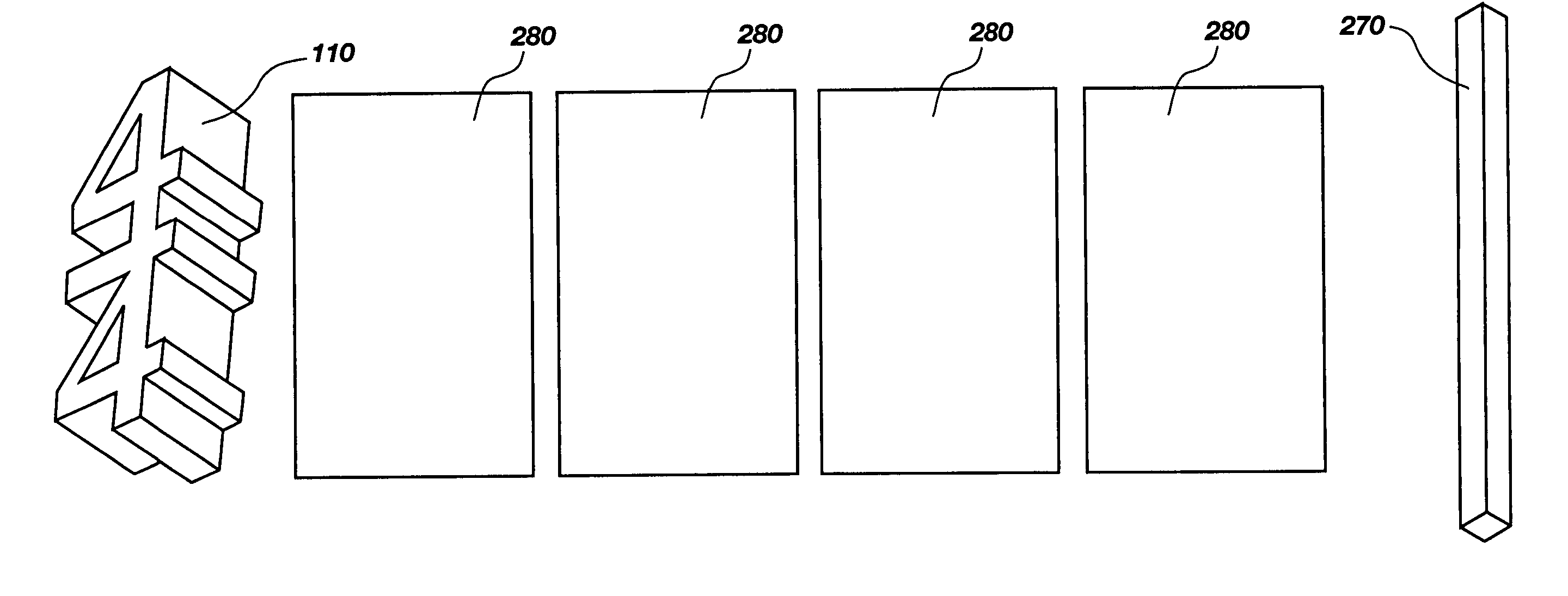

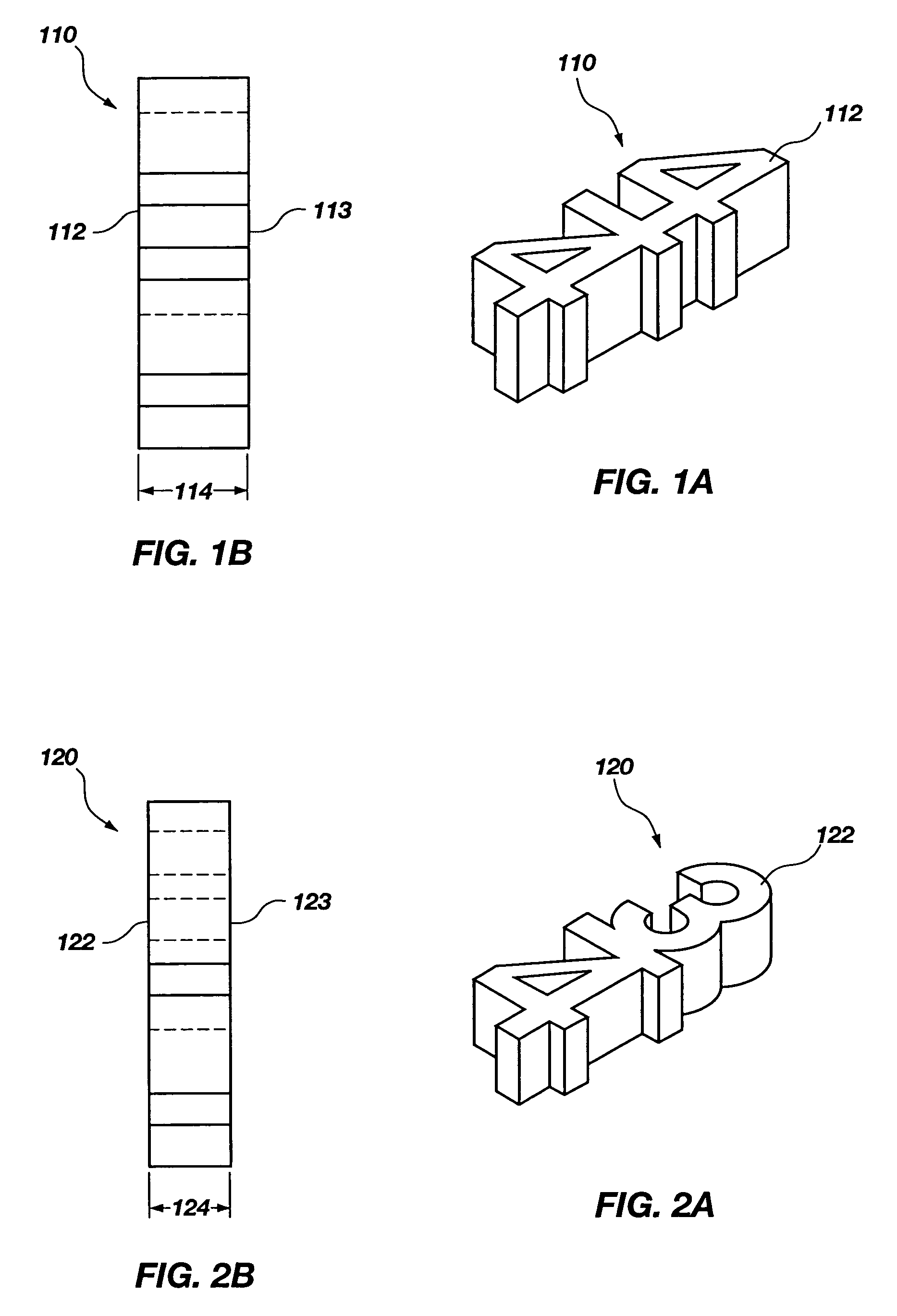

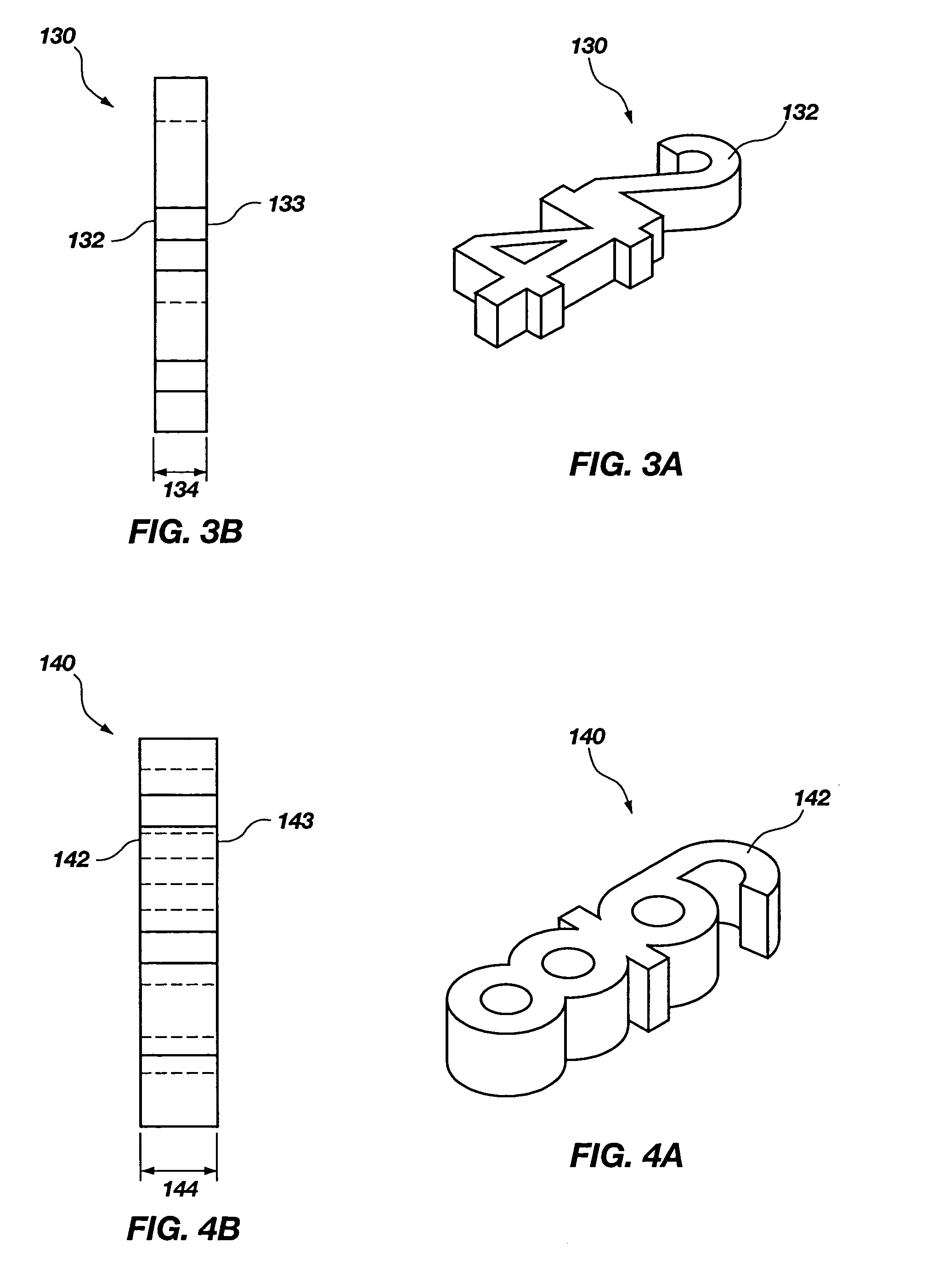

System and method for teaching music

A system and method for teaching music both visually and tactilely. In one embodiment, the invention comprises blocks shaped to resemble musical symbols used to compose music, including time signatures, notes, rests, and dots. Each of the blocks are relative in thickness such that for a given time signature, the correct rhythm for a given measure can be determined by laying one or more of the notes, rests and dots one over the other to see if their combined thickness is equal to that of a preselected time signature. The thickness of the block shaped to resemble the time signature is such that it only allows the correct number of blocks shaped as notes, rests or dots to be of equal thickness to thereby determine the correct rhythm. In addition, the correct rhythm can be determined by simply reading the shaped blocks as one would read music. The use of the shaped blocks having relative thicknesses allows a student to learn rhythm by trial and error and does not necessarily require that the student understand complex music theory. In addition, the blocks can be used by the student when clapping the correct rhythms. Other musical notation can be represented by blocks as well such as bar lines and slurs.

Owner:STEPHANIE ROSS

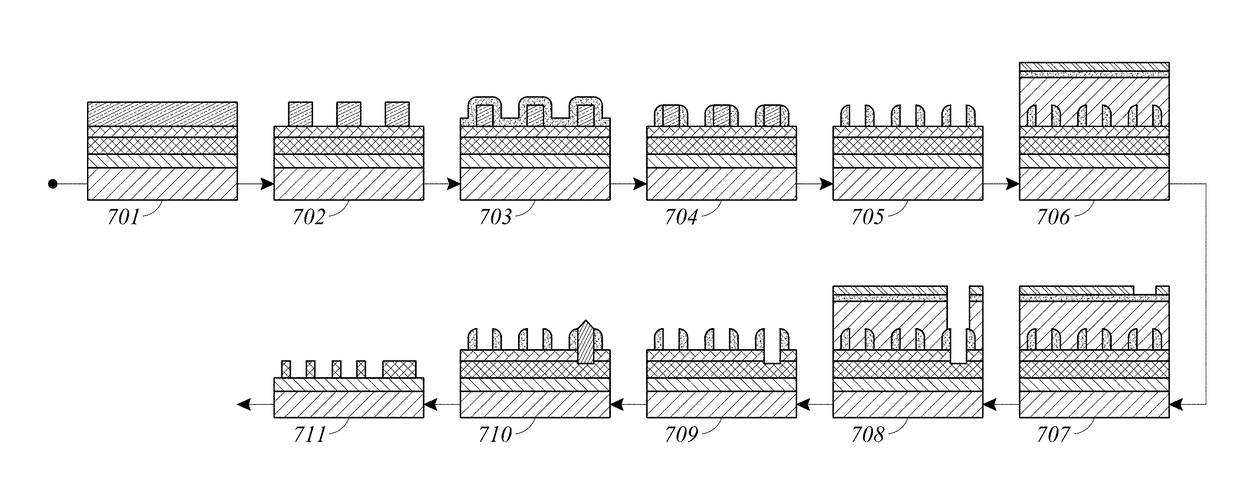

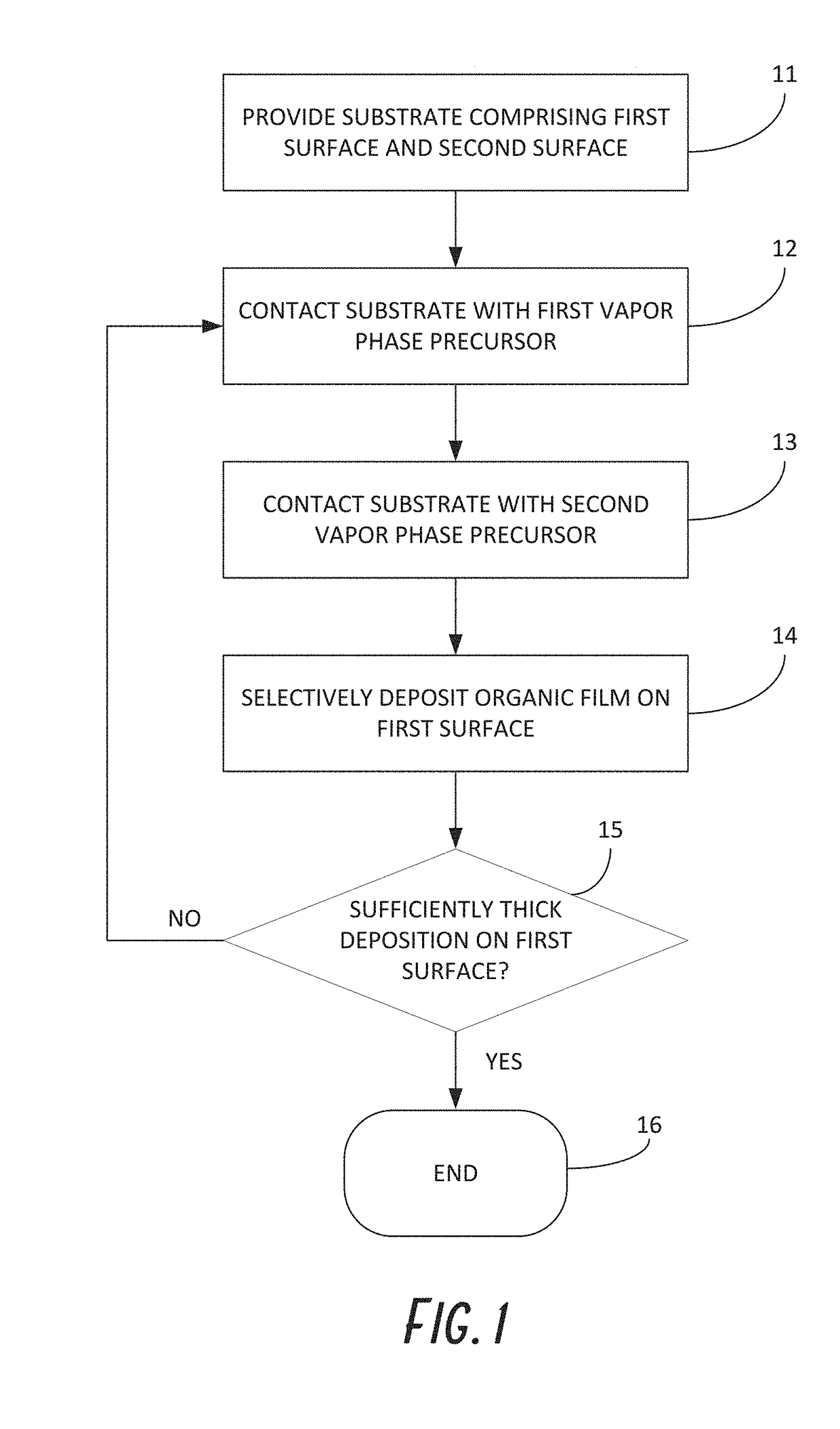

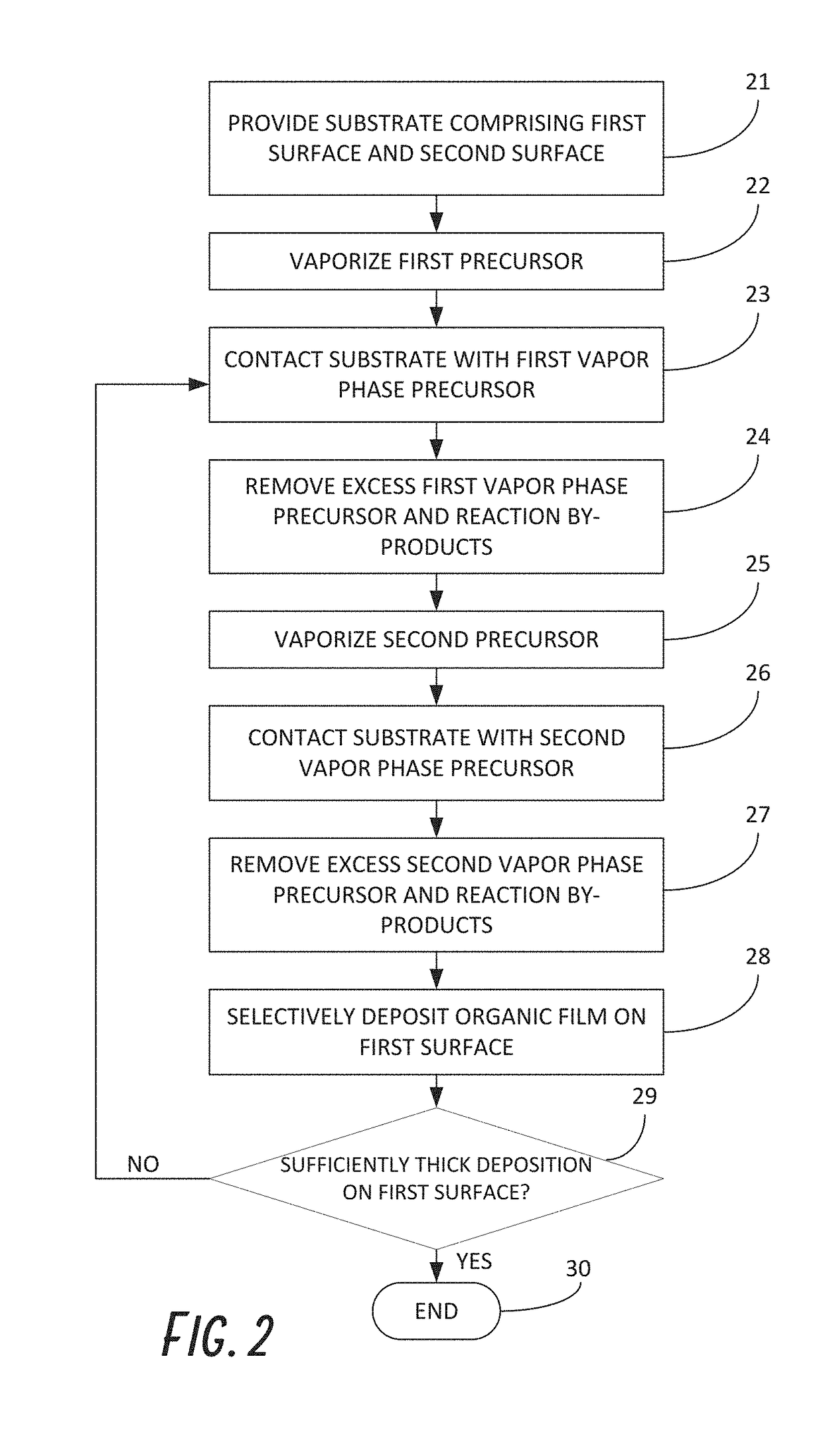

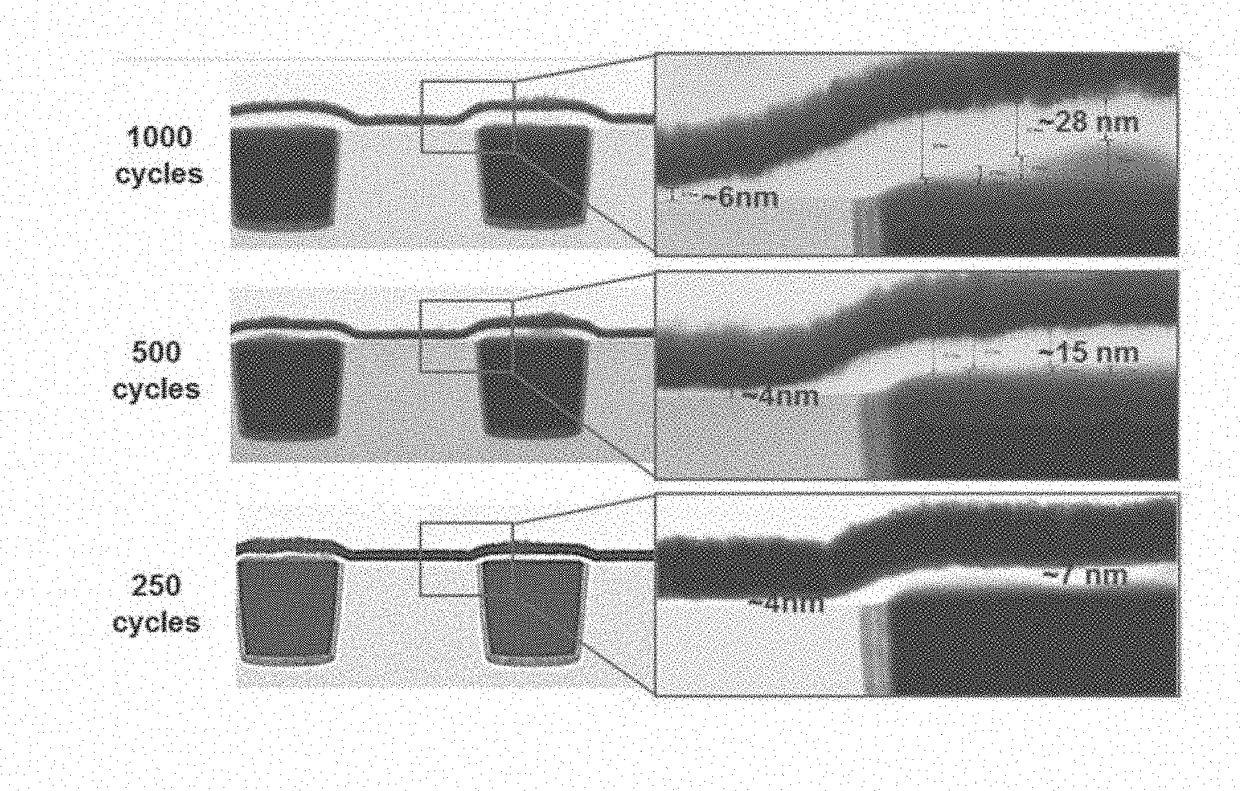

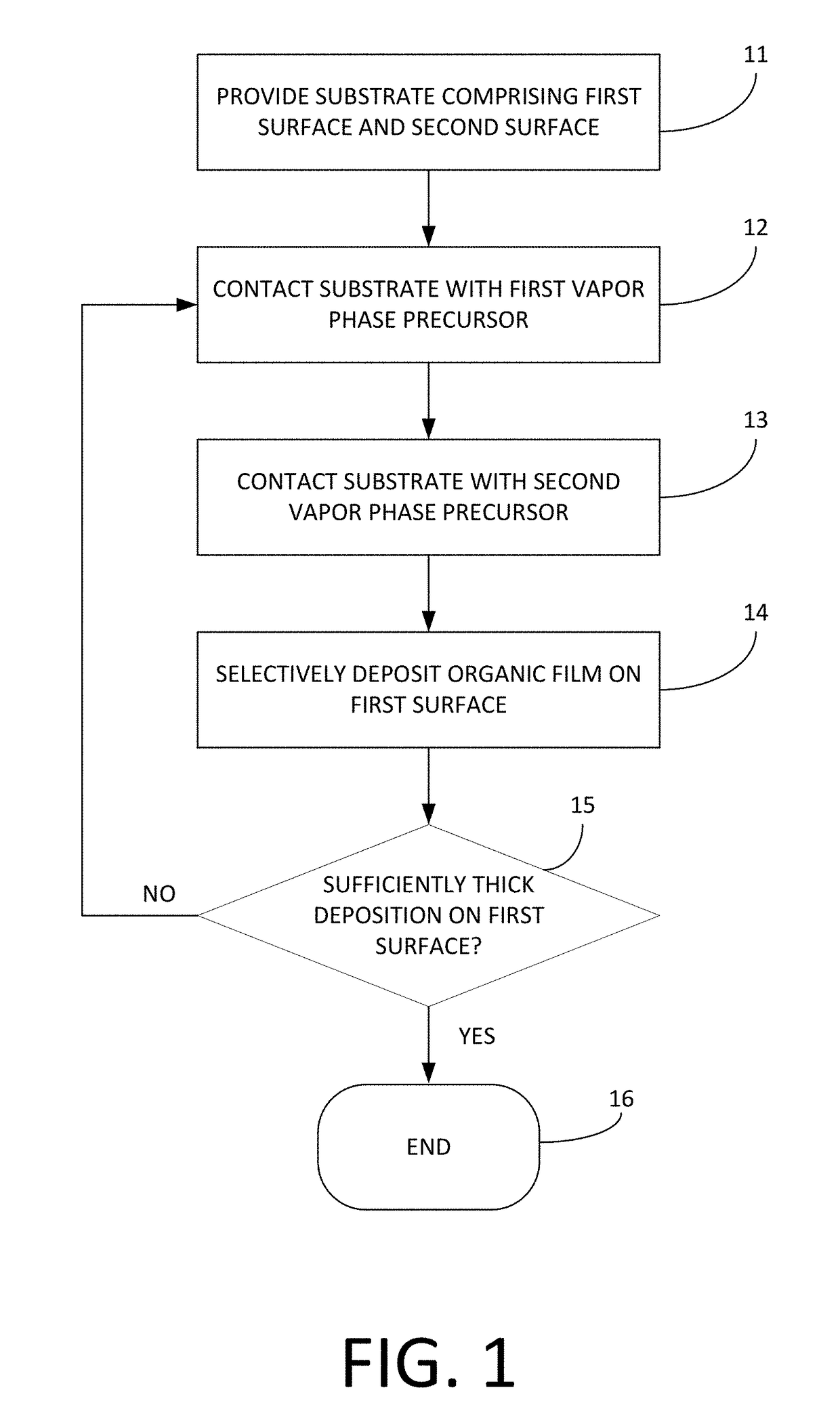

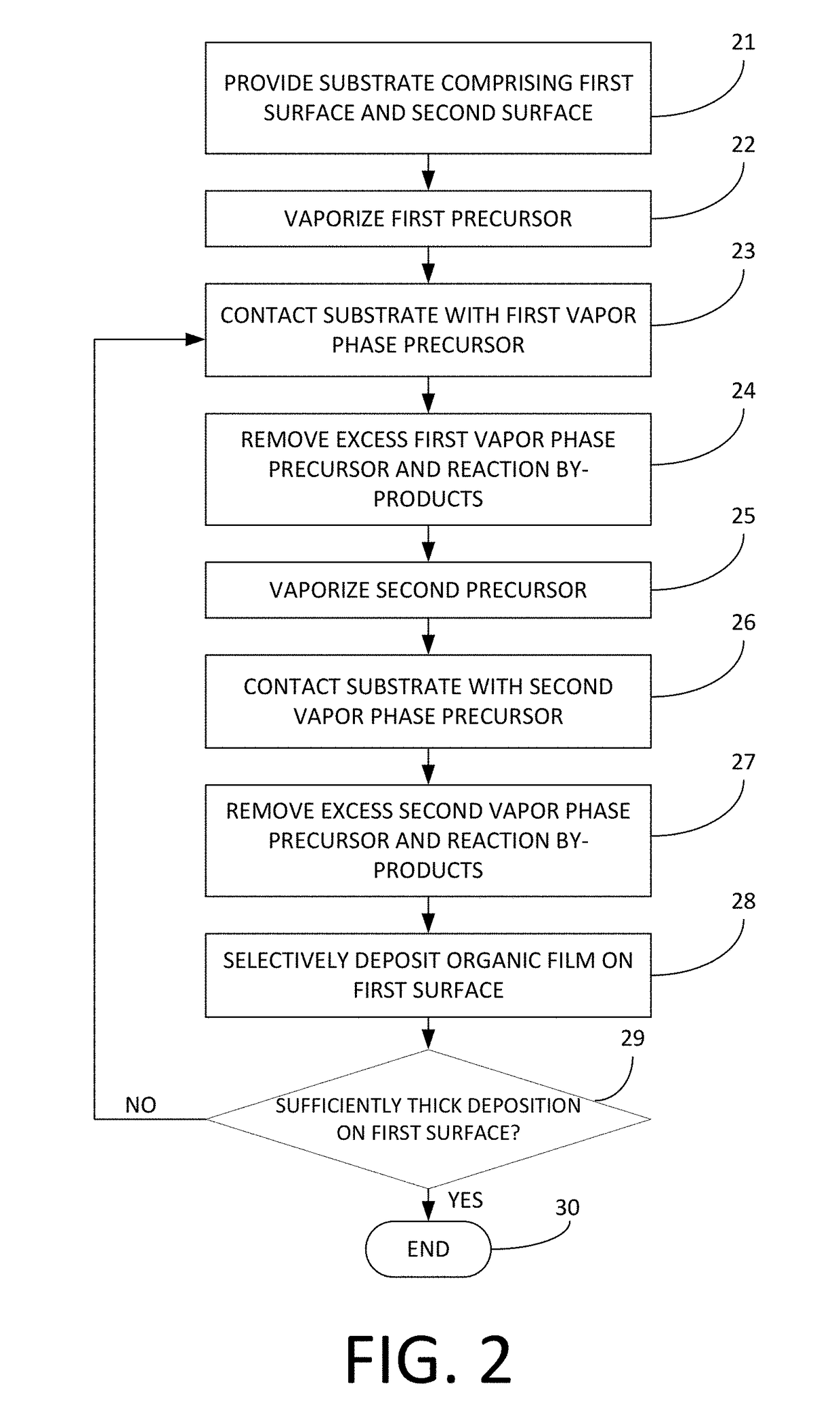

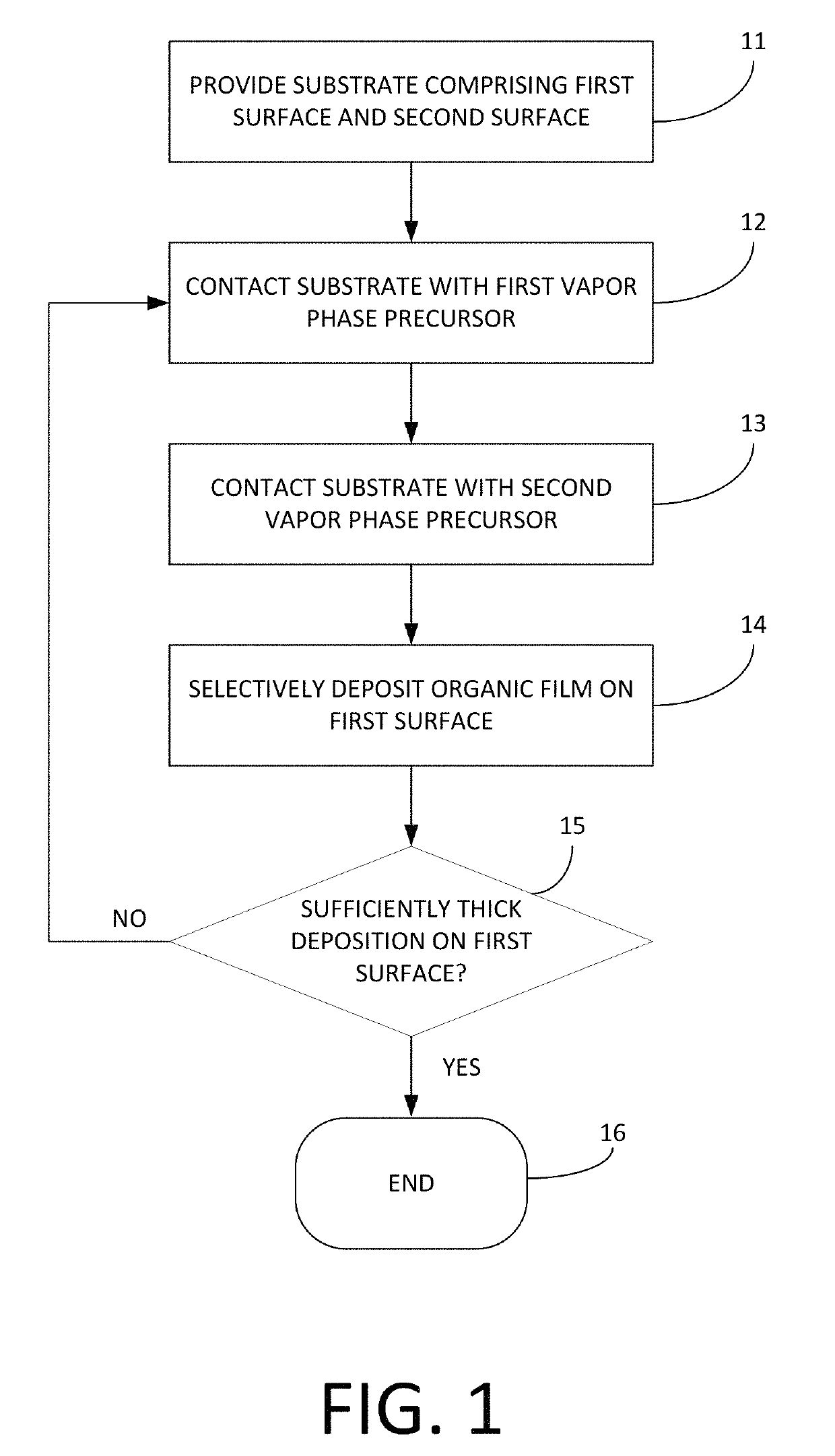

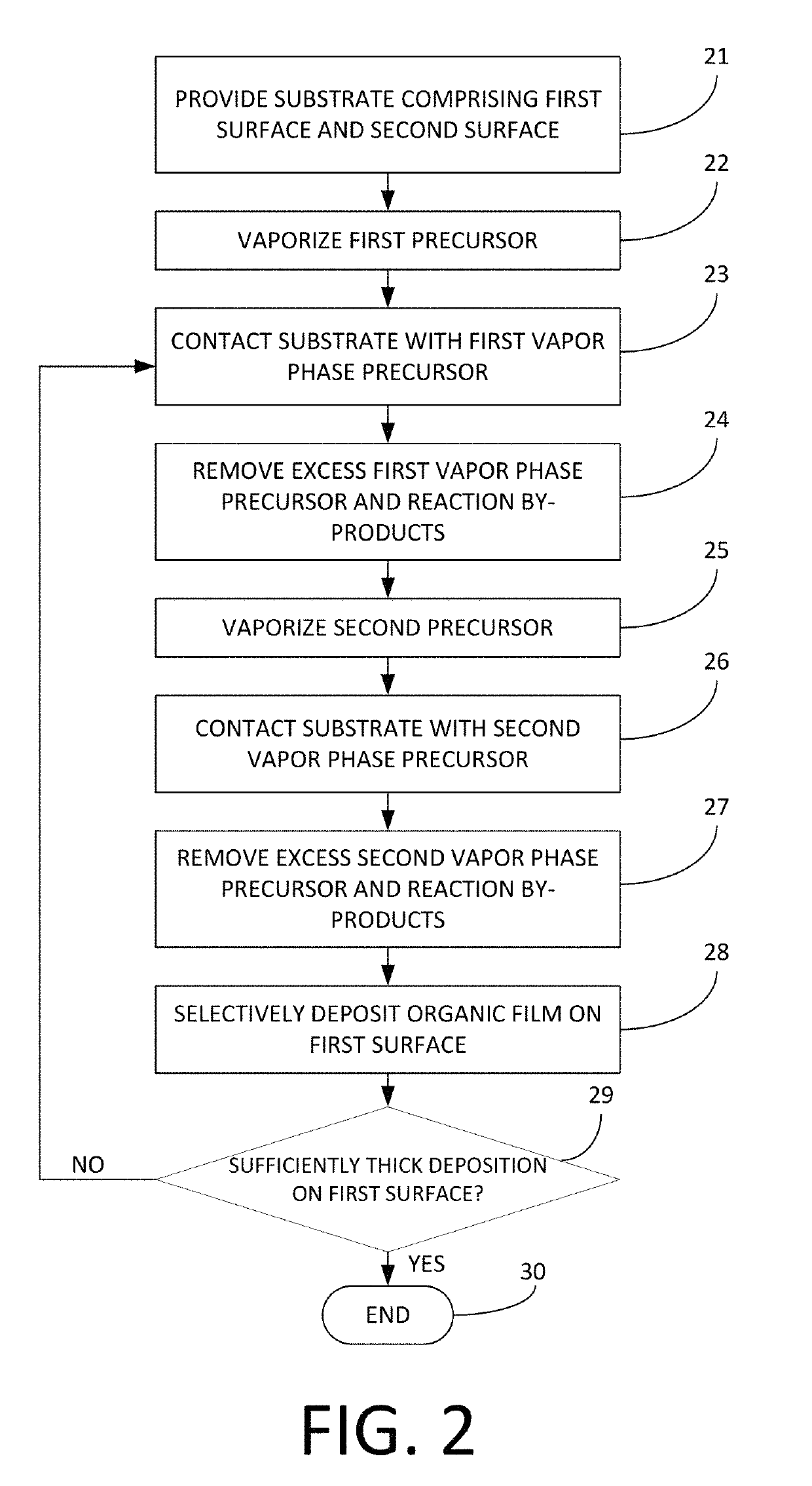

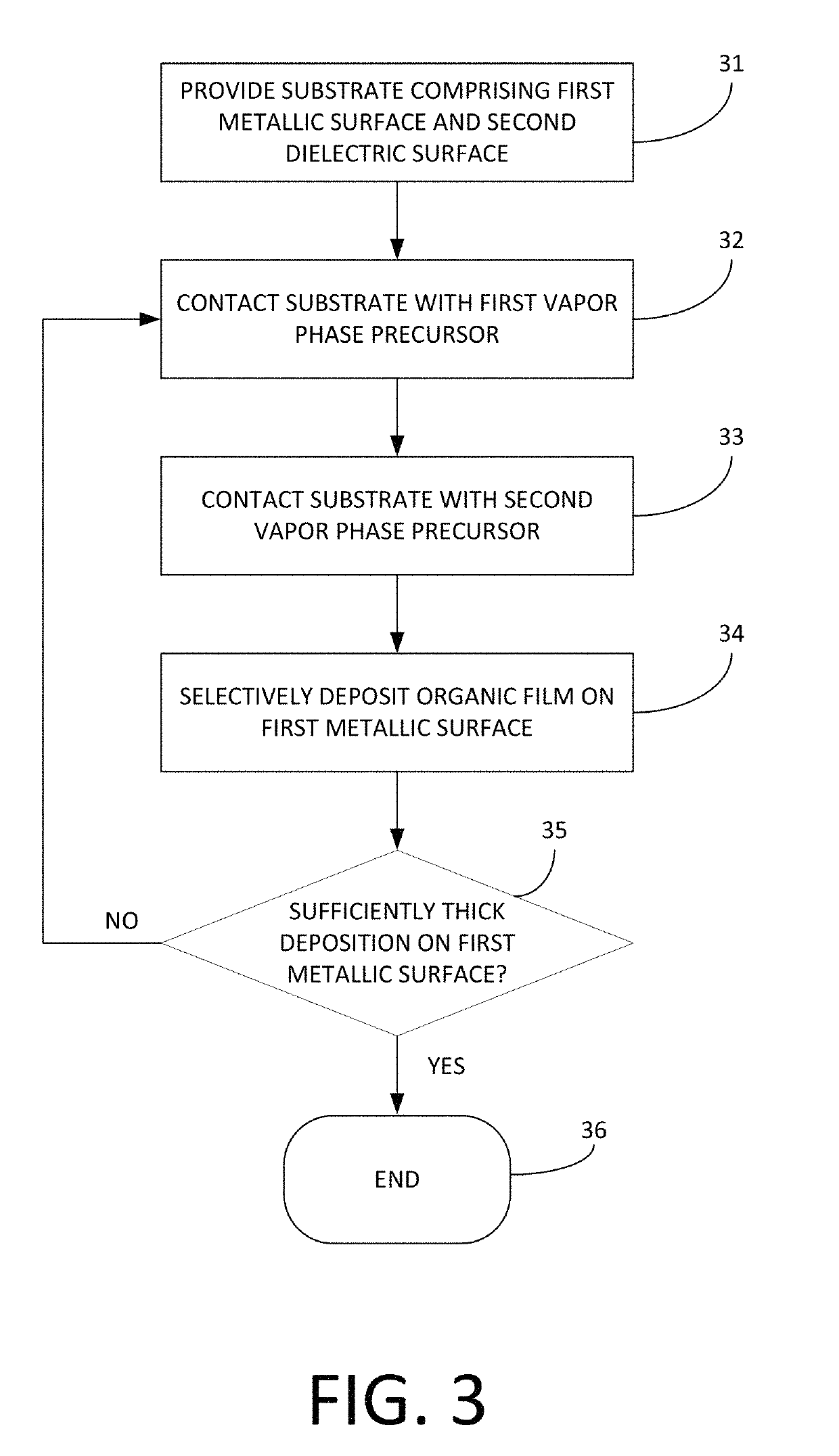

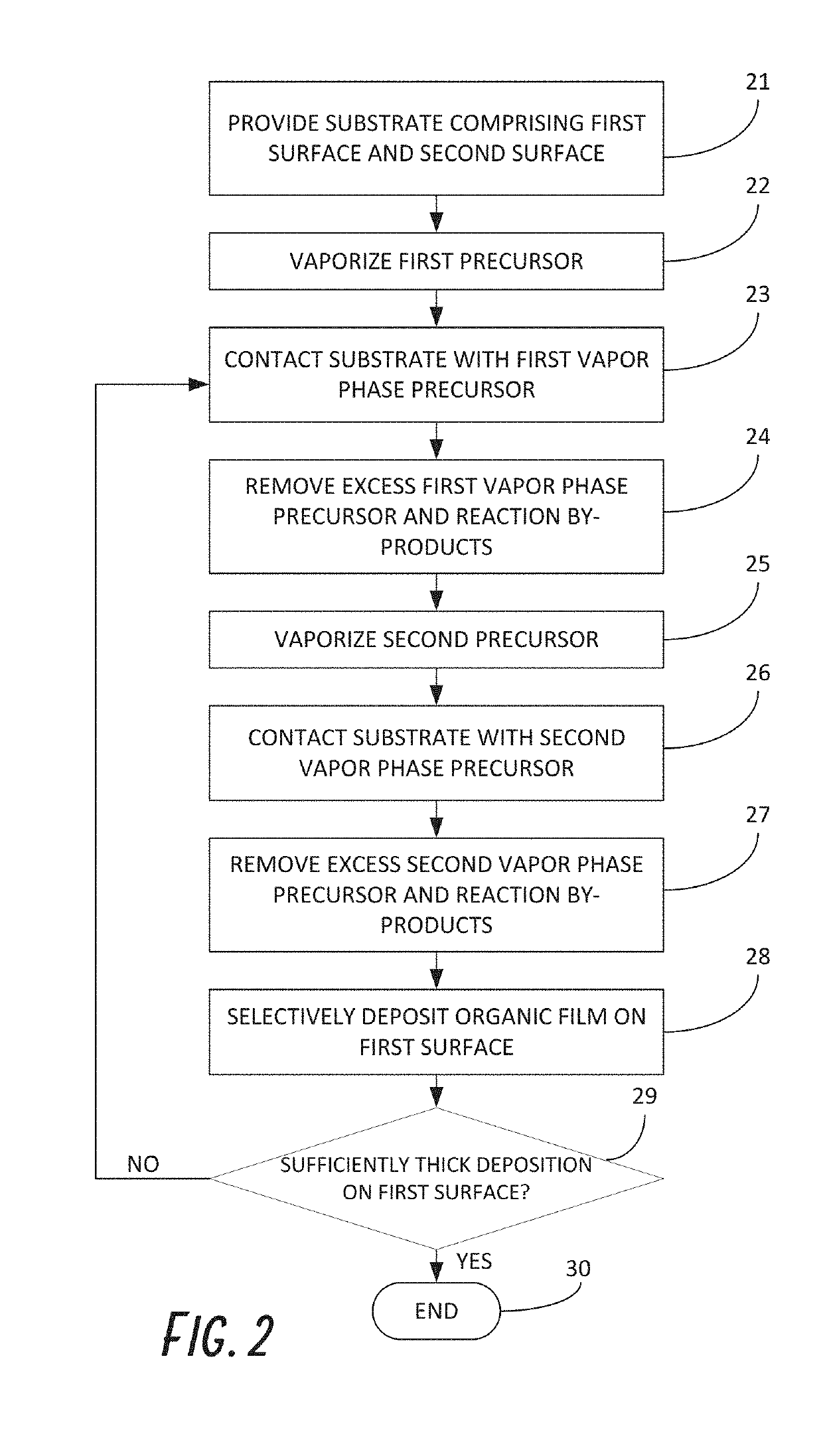

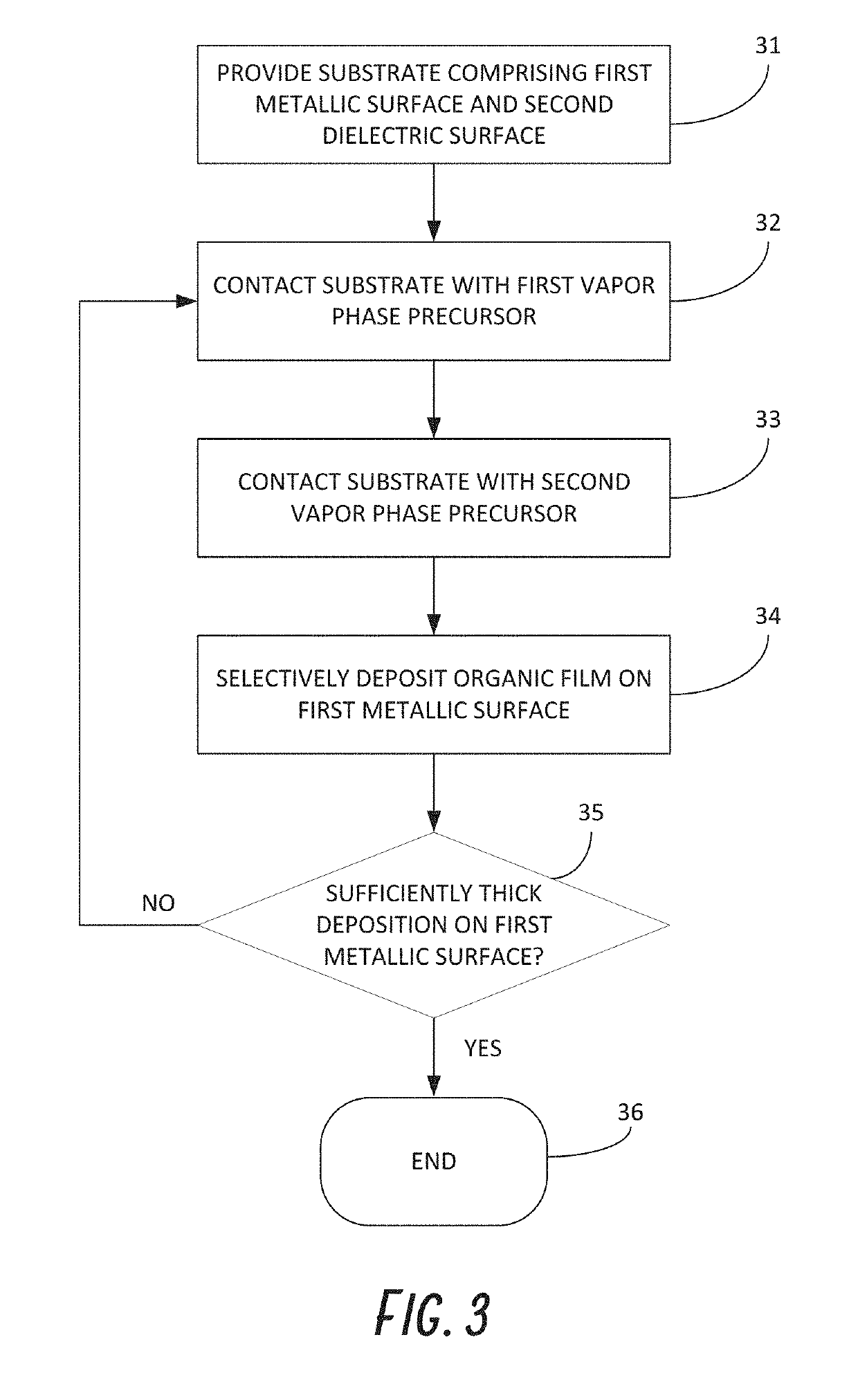

Deposition of organic films

ActiveUS20170352550A1Increased resistance to HFSemiconductor/solid-state device manufacturingChemical vapor deposition coatingOrganic filmDielectric surface

Processes are provided herein for deposition of organic films. Organic films can be deposited, including selective deposition on one surface of a substrate relative to a second surface of the substrate. For example, polymer films may be selectively deposited on a first metallic surface relative to a second dielectric surface. Selectivity, as measured by relative thicknesses on the different layers, of above about 50% or even about 90% is achieved. The selectively deposited organic film may be subjected to an etch process to render the process completely selective. Processes are also provided for particular organic film materials, independent of selectivity. Masking applications employing selective organic films are provided. Post-deposition modification of the organic films, such as metallic infiltration and / or carbon removal, is also disclosed.

Owner:ASM IP HLDG BV

Deposition of organic films

ActiveUS20170352533A1Liquid surface applicatorsSemiconductor/solid-state device manufacturingOrganic filmDielectric surface

Processes are provided herein for deposition of organic films. Organic films can be deposited, including selective deposition on one surface of a substrate relative to a second surface of the substrate. For example, polymer films may be selectively deposited on a first metallic surface relative to a second dielectric surface. Selectivity, as measured by relative thicknesses on the different layers, of above about 50% or even about 90% is achieved. The selectively deposited organic film may be subjected to an etch process to render the process completely selective. Processes are also provided for particular organic film materials, independent of selectivity.

Owner:ASM IP HLDG BV

Tear film measurement

ActiveUS20080316499A1Avoid introducingReduce intensityUsing optical meansEye diagnosticsRelative thicknessBroad spectrum

The invention comprises an apparatus for measuring the relative thickness of the lipid layer component of the precorneal tear film on the surface of an eye after distribution of the lipid layer subsequent to blinking is disclosed. An illuminator directs light to the lipid layer of a patient's eye. The illuminator is a broad spectrum light source covering the visible region and is a lambertion light emitter such that the light source is specularly reflected from the lipid layer and undergoes constructive and destructive interference in the lipid layer. A collector collects and focuses the specularly reflected light such that the interference patterns on the tear film lipid layer are observable. The collector also produces an output signal representative of the specularly reflected light which is suitable for further analysis, such as projection on to a high resolution video monitor or analysis by or storage in a computer. In order to facilitate ease of measurement, the patient's head may be positioned on an observation platform when the illuminator directs light to the lipid layer of the patient's eye.

Owner:TEARSCIENCE INC

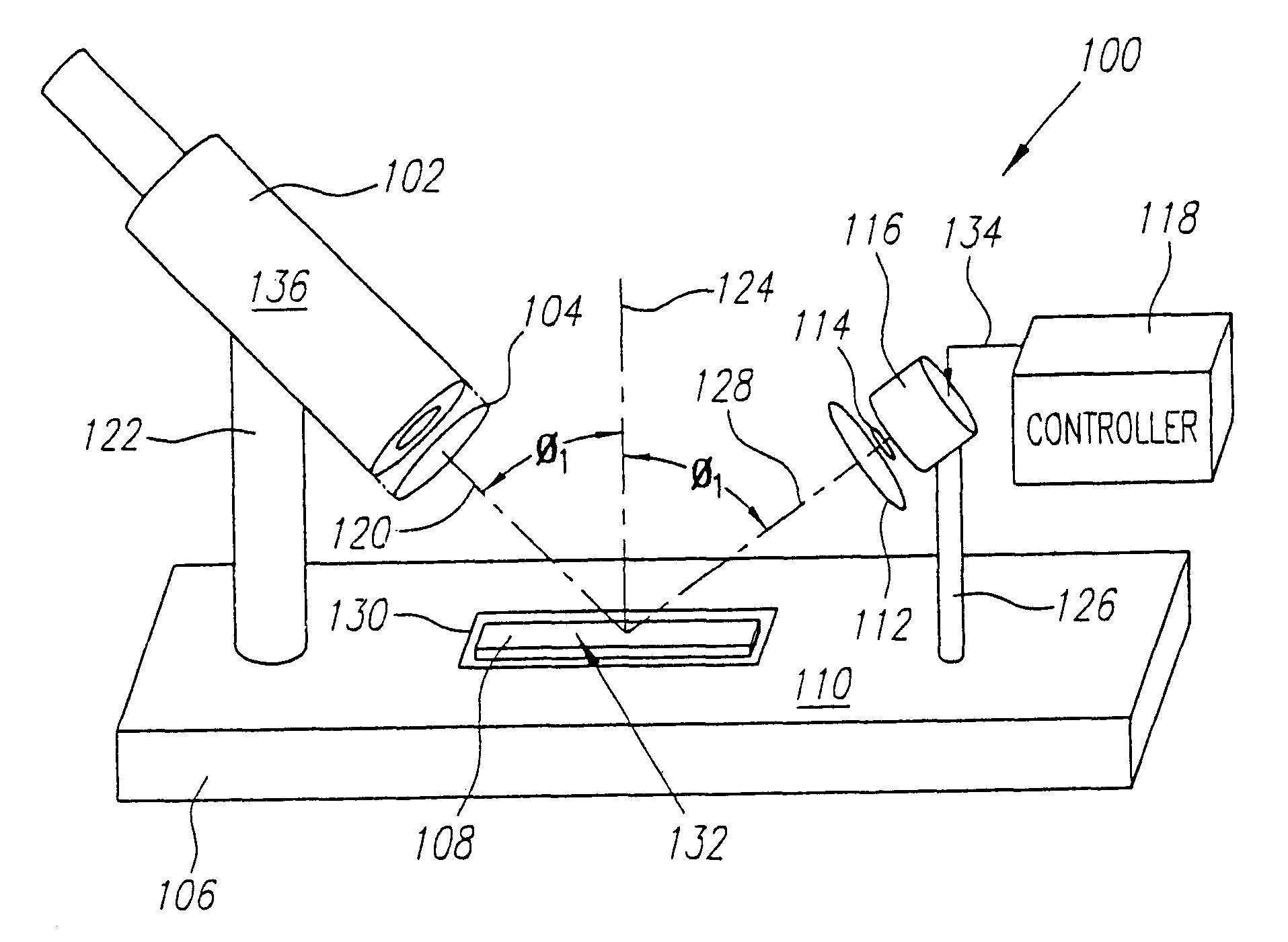

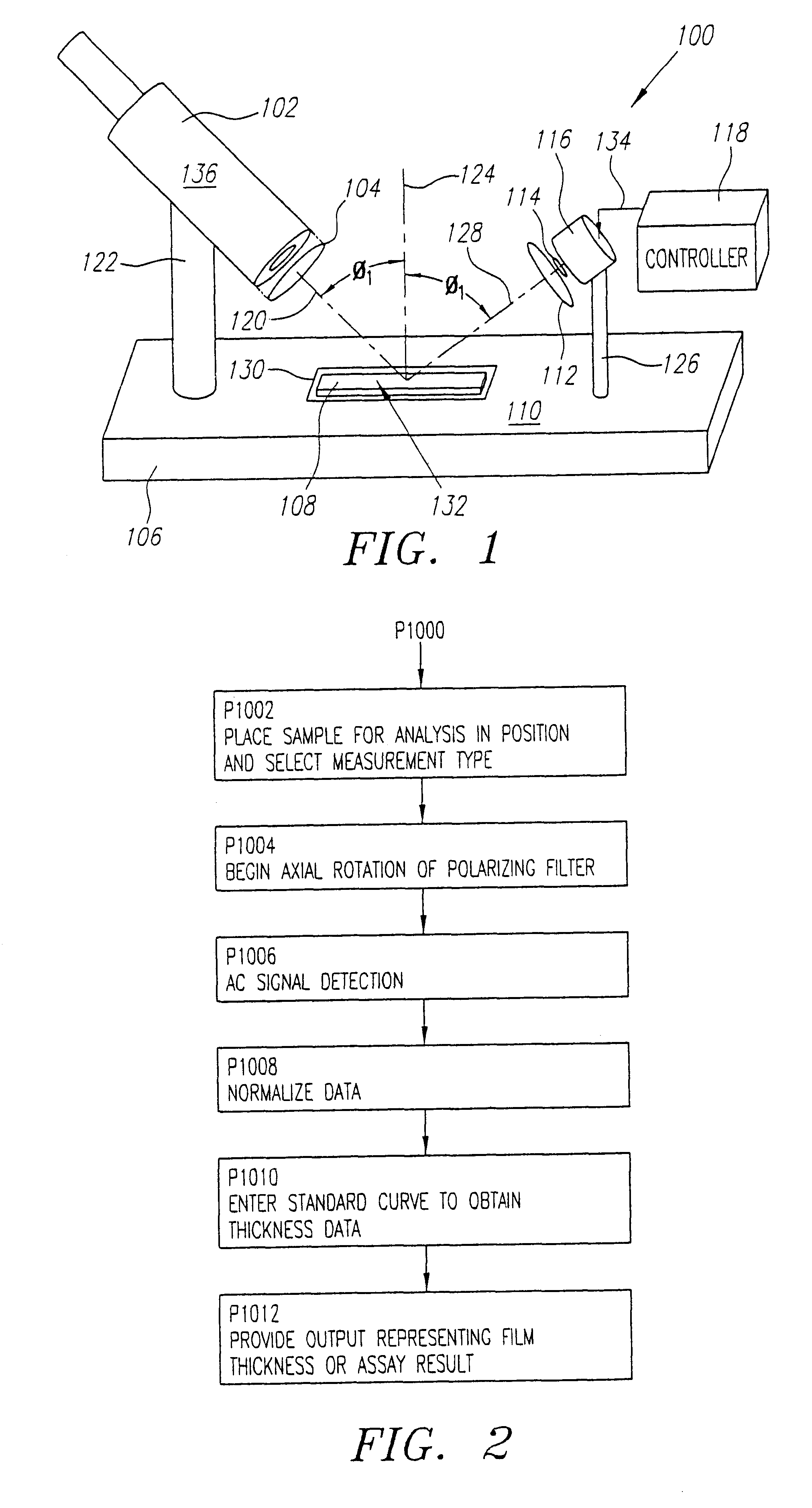

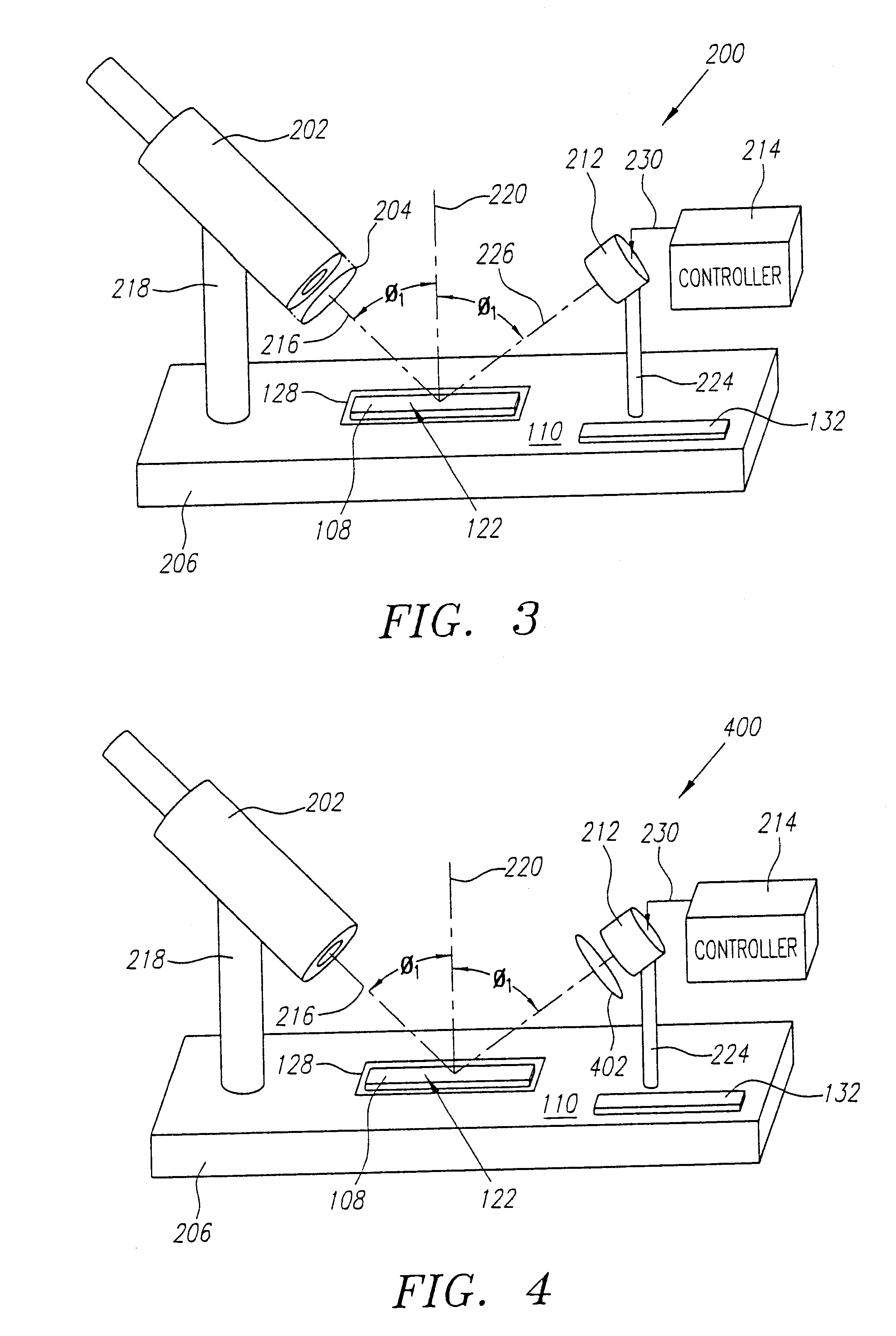

Instruments for analyzing binding assays based on attenuation of light by thin films

InactiveUS6483585B1Increase the amount of lightIncreasing the thicknessPolarisation-affecting propertiesAnalysis by subjecting material to chemical reactionUltrasound attenuationSignal quality

A modified and improved polarizier ellipsometer allows for improved signal quality and signal to noise performance. This improvement is based on rotating one polarizer relative to the other fixed polarizer to generate AC mode signals related to a thin film under analysis. The AC mode signal may be compared to a background signal and the ratio of sample signal to background signal used to provide a more accurate assessment of film thickness. The normalized AC signal for an unknown thickness may be compared to a standard curve generated for a film of similar optical properties for an exact thickness determination or may be used directly to report a relative thickness value. Other modifications of the improved polarizer ellipsometer of the invention are also described where one or both of the fixed polarizers are removed to improve the signal intensity through reduction of the number of optical components. These modifications are designed to address specific thin film and substrate combinations.

Owner:INVERNESS MEDICAL - BIOSTAR

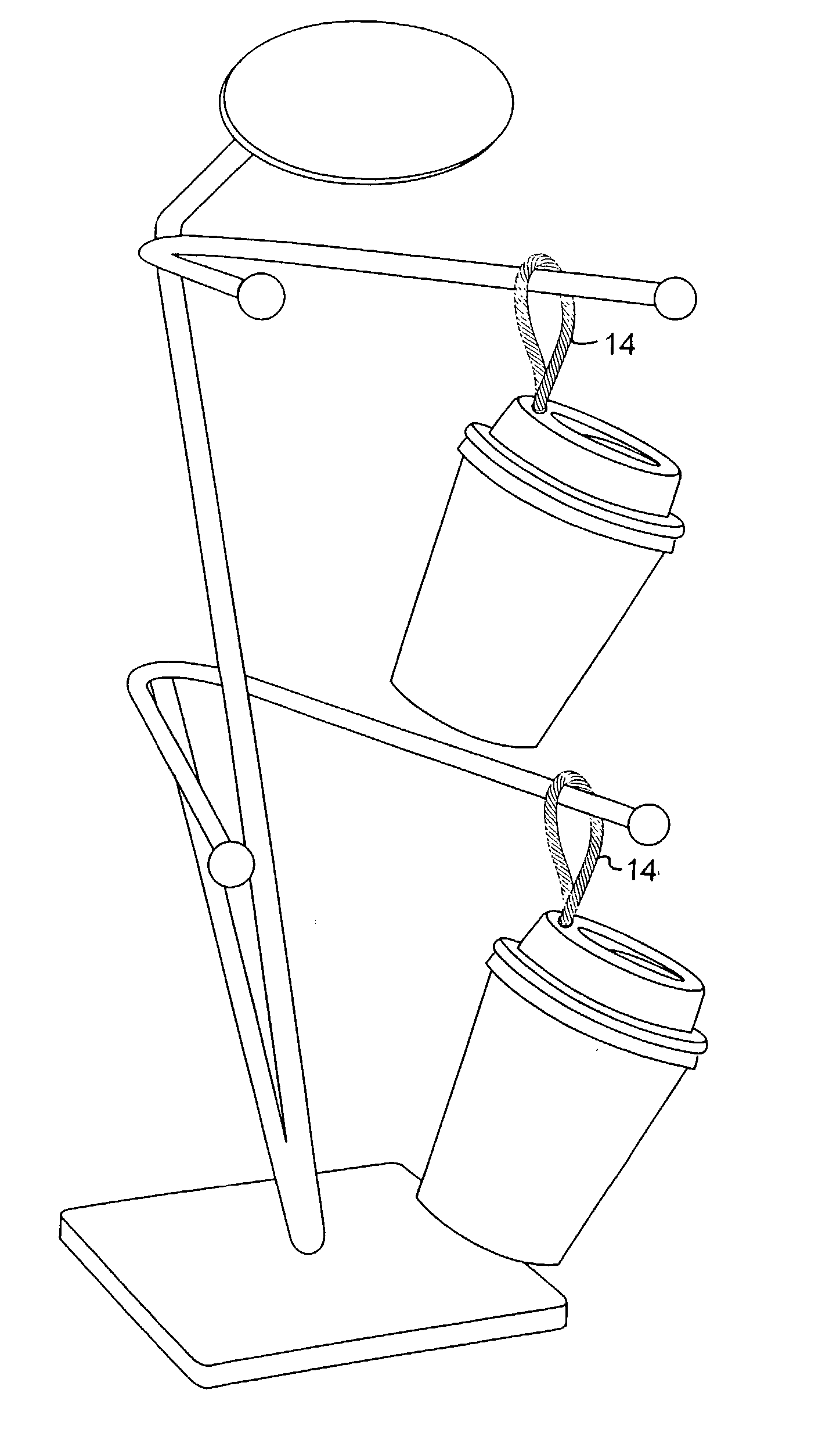

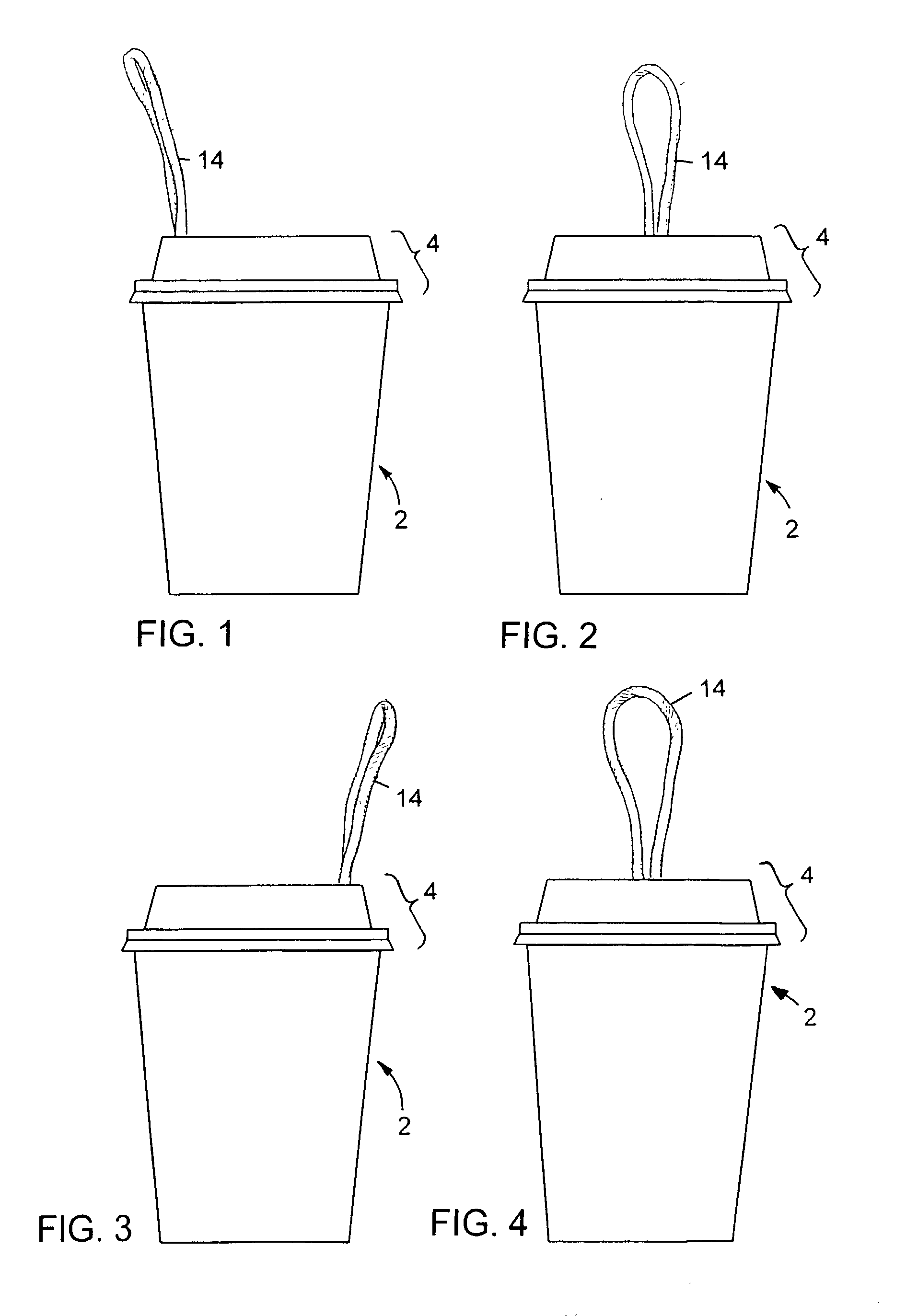

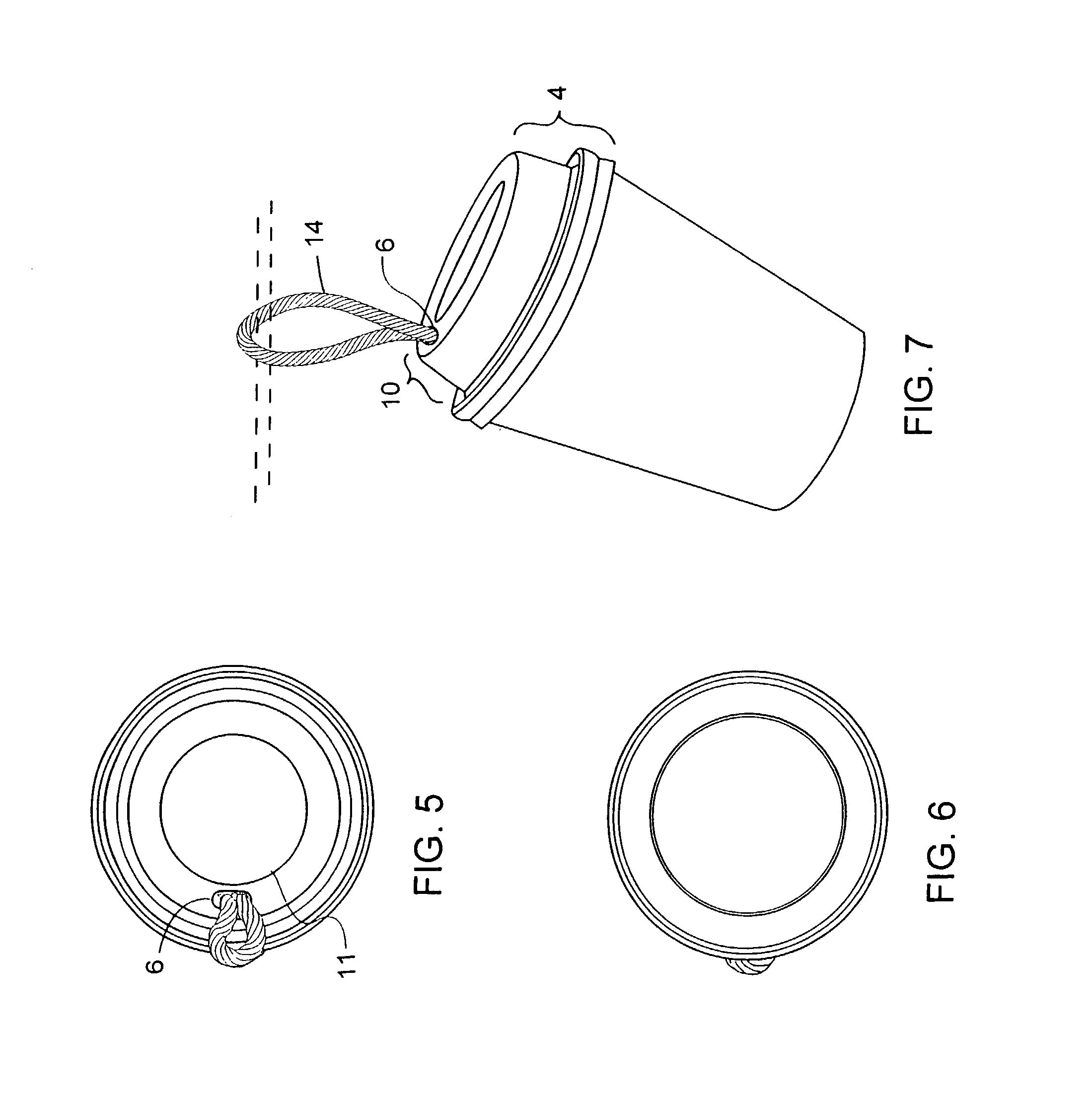

Suspended containers

InactiveUS20020121456A1Effective displayDomestic cooling apparatusLighting and heating apparatusWide mouthRelative thickness

A disposable package for consumable contents includes a container having a surrounding wall of upstanding, generally flexible material extending from a container bottom to a wide mouth defined by a rim formation of greater relative thickness than said surrounding wall, said mouth being of greater than two inch minimum horizontal dimension and being about as wide as the horizontal cross-section of a top of the container. The disposable package further includes a removable lid at least partially closing the mouth, the lid having a rim portion extending over and removably engaged with the rim formation to form at least part of an attachment of the lid to the container, the attachment being constructed to support the container and its contents when suspended by the lid, and a flexible suspending element extending from the lid and arranged to be engaged by a thin support element, the suspending element being sized and arranged, with a length less than about 5 inches, such that when engaged by said support element, the suspending element suspends the container by its lid in a position below the support, for at least one of display and transport. In some embodiments, a single suspending element extends from a rim region of the container, the element being located to suspend the package at a tilted orientation, such that the lid of the container, so suspended, extends at a greater angle to horizontal than does the lid of the container when rested upon said bottom. Also, a display rack is provided for displaying such disposable packages.

Owner:LID LASSO

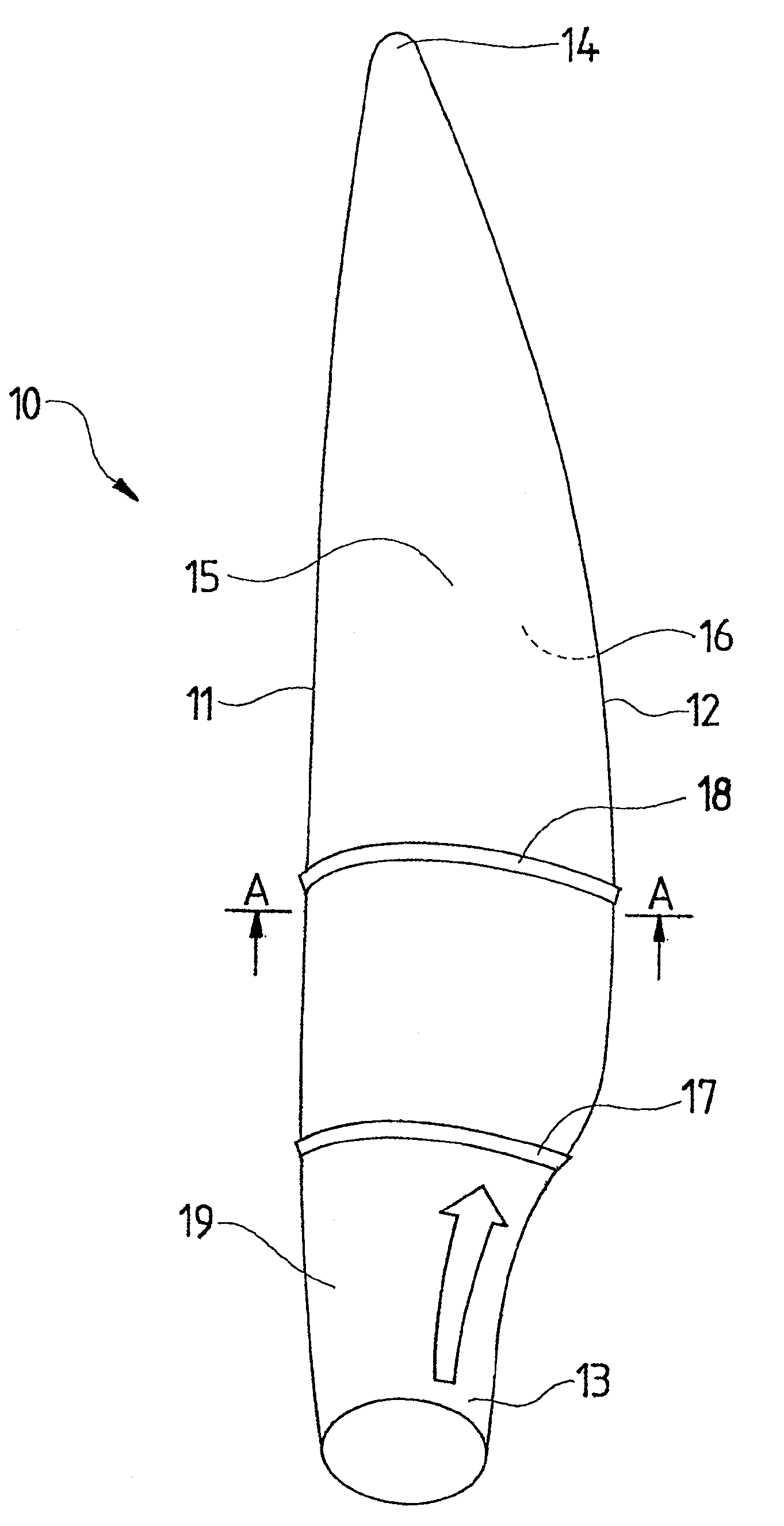

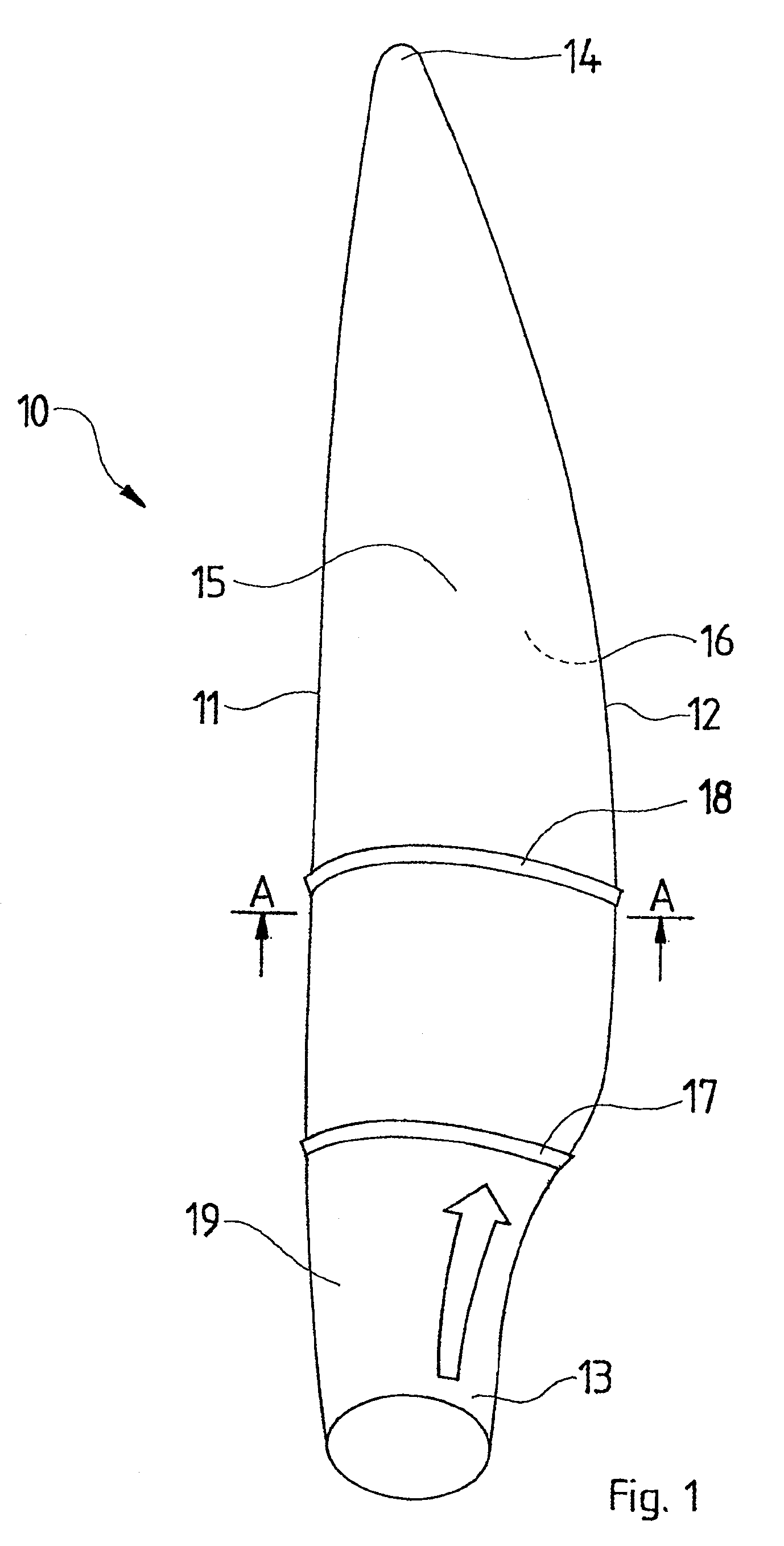

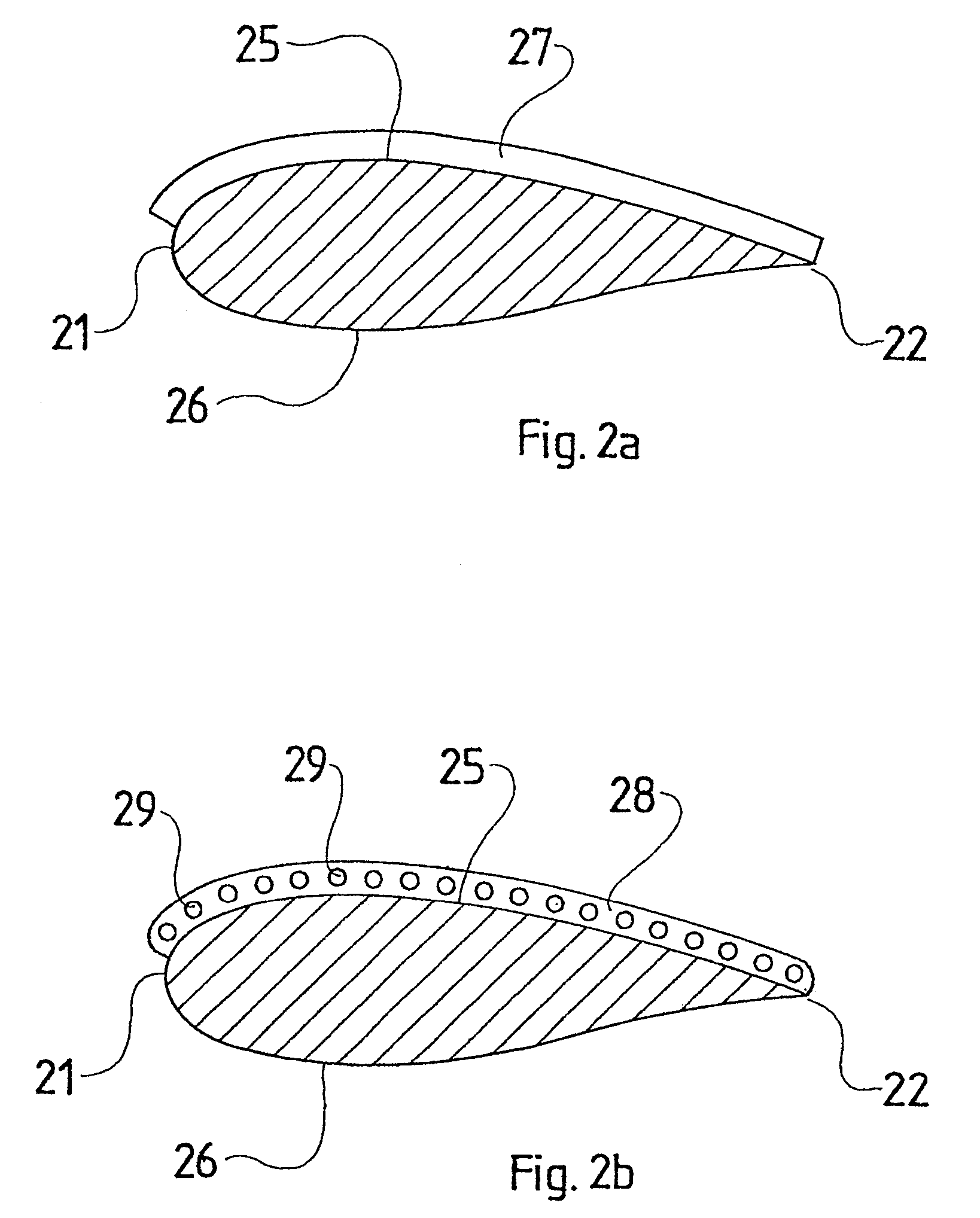

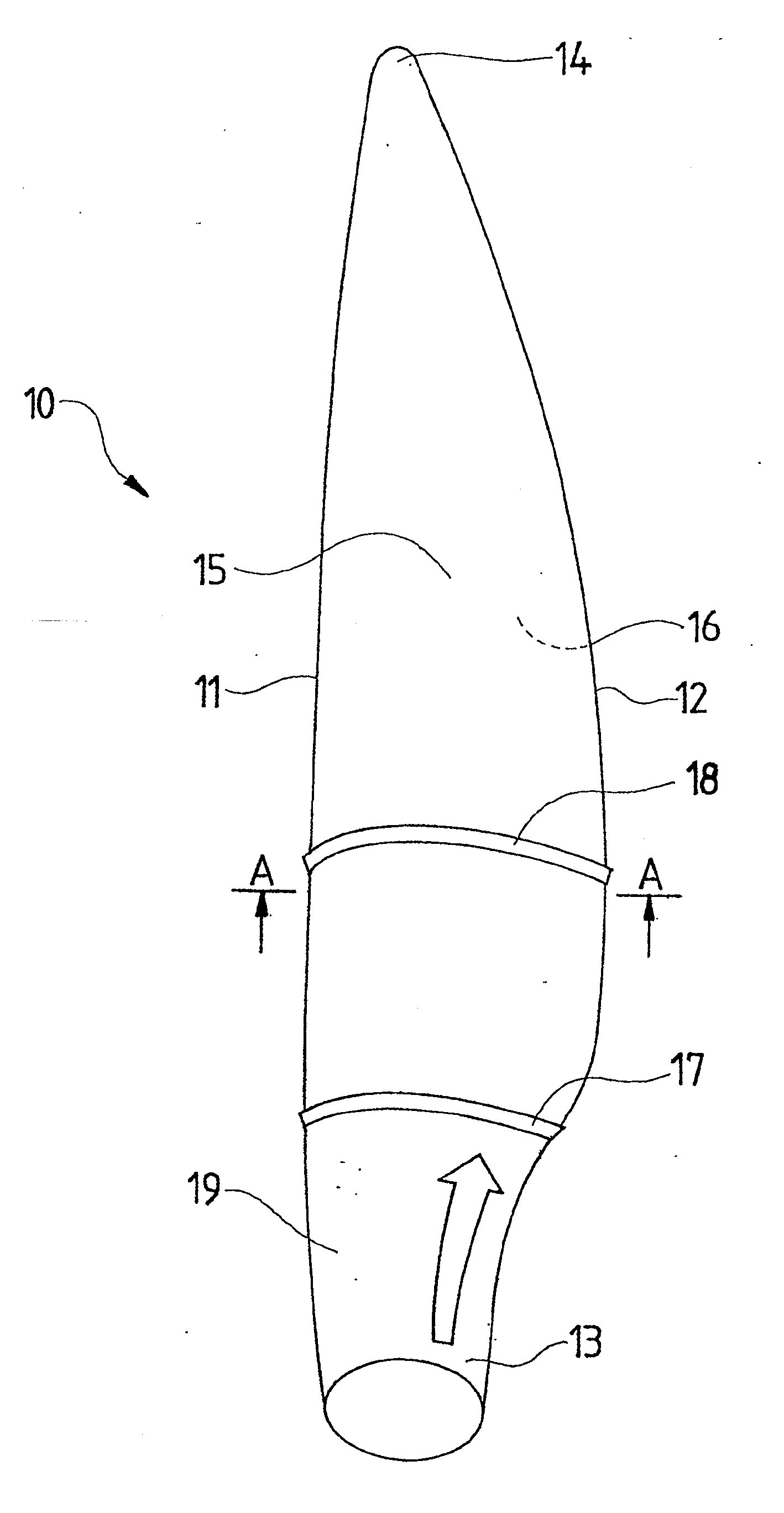

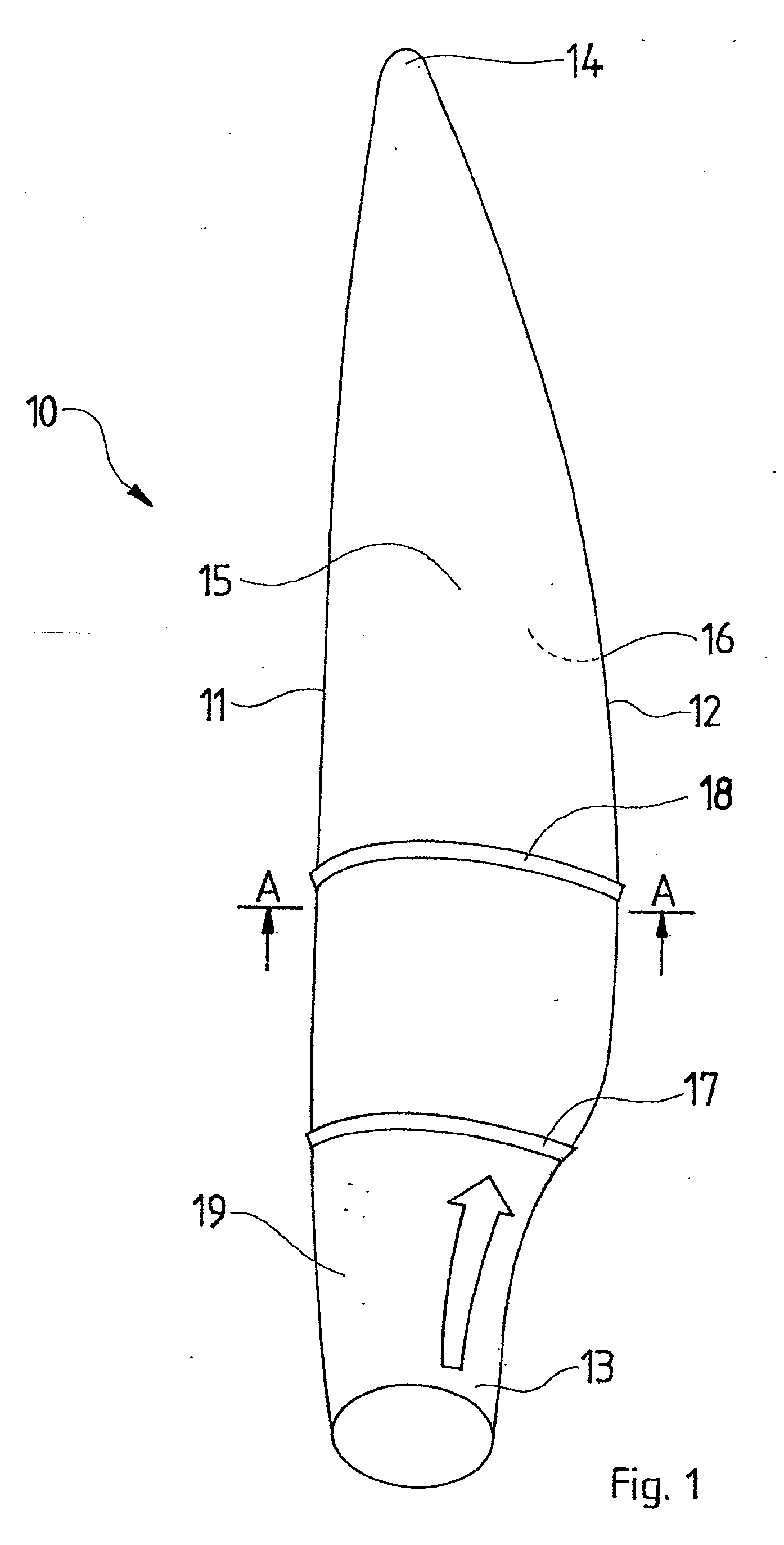

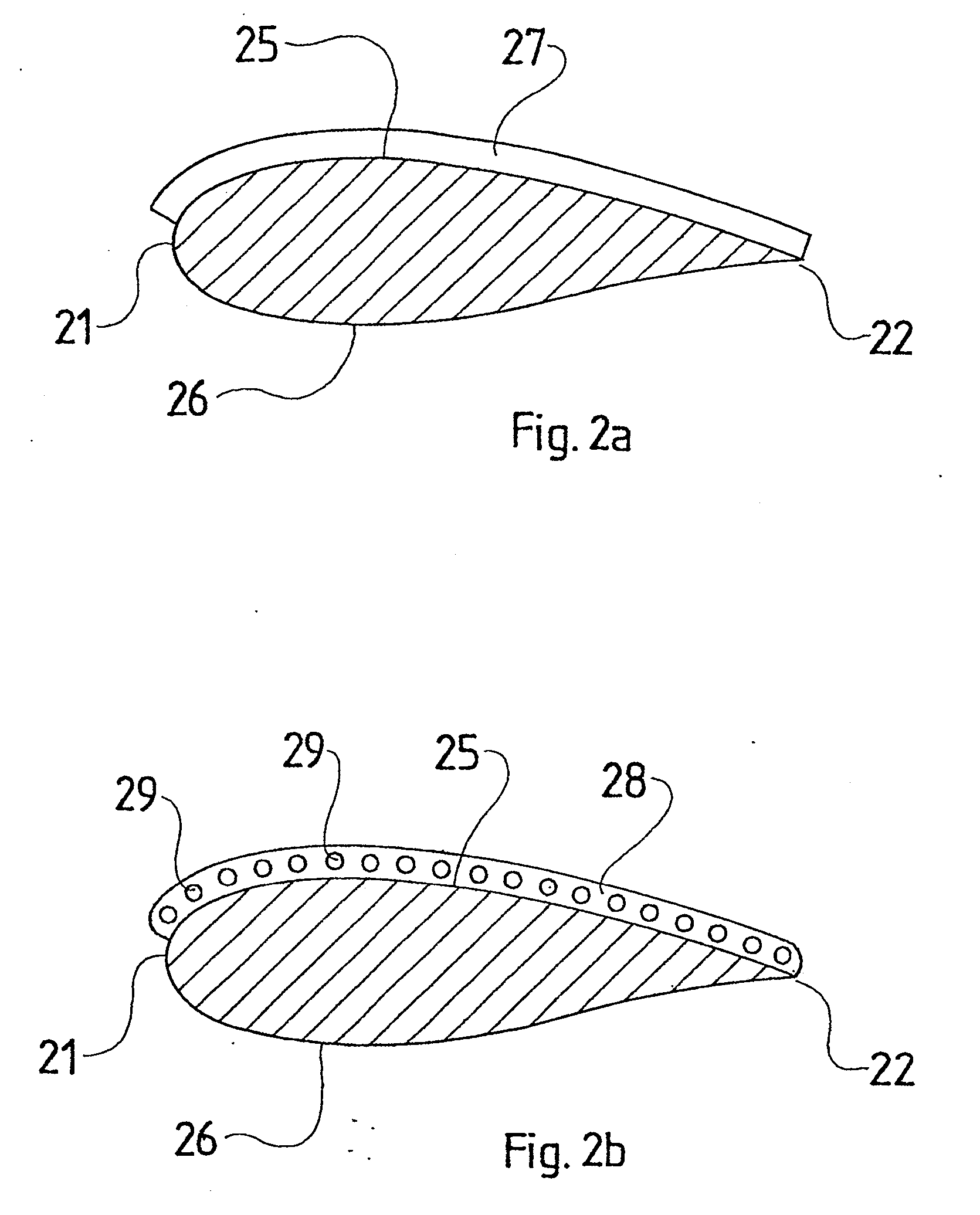

Rotor blade for a wind power station

A rotor blade for a wind power station includes a profiled member that is provided with a relative thickness which decreases towards the outside from a root to a tip of the blade. The profiled member has a leading edge and a trailing edge as well as a suction side and a pressure side while generating a negative pressure relative to the pressure side on the suction side when being flown against by moved air, the negative pressure resulting in buoyancy. The suction side of the rotor blade encompasses a device for optimizing flow around the profiled member. The device is provided with at least one planar element that extends substantially in the direction of flow, protrudes from the suction side, and is arranged in the zone of a transversal flow which runs from the root to the tip of the blade on the suction side of the profiled member.

Owner:SENVION GMBH

Tear film measurement

ActiveUS8192026B2Avoid introducingReduce light intensityEye diagnosticsRadiation diagnosticsSpecular reflectionTears

The disclosure comprises a method for measuring the relative thickness of the lipid layer component of the precorneal tear film on the surface of an eye after distribution of the lipid layer subsequent to blinking. Light is directed to the lipid layer of a patient's eye with an illuminator. The illuminator is a broad spectrum light source covering the visible region and is a lambertion light emitter such that the light source is specularly reflected from the lipid layer and undergoes constructive and destructive interference in the lipid layer. The specularly reflected light is collected and focused using a collector such that the interference patterns on the tear film lipid layer are observable. The collector also produces an output signal representative of the specularly reflected light suitable for further analysis, such as projection on to a high resolution video monitor or analysis by or storage in a computer.

Owner:TEARSCIENCE INC

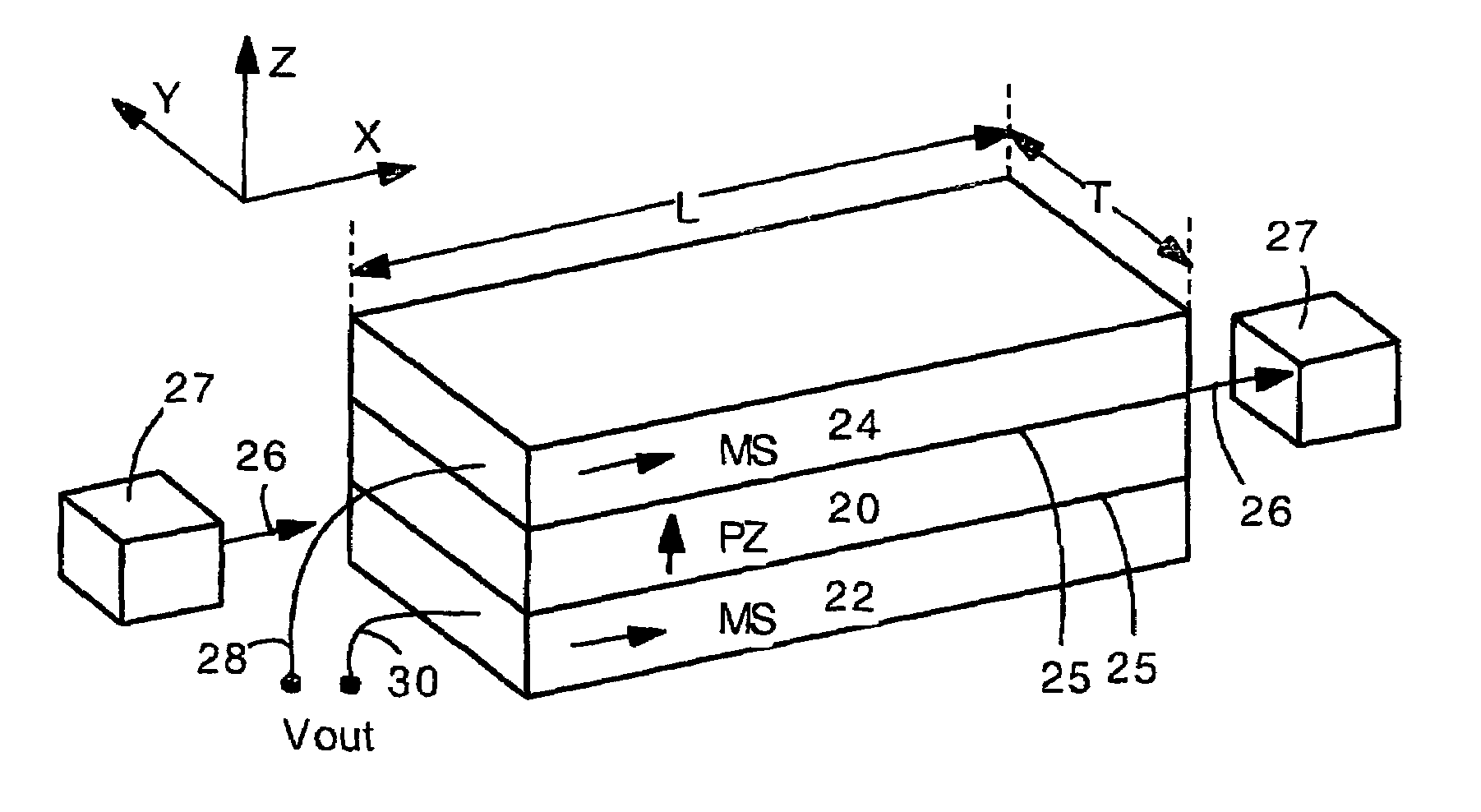

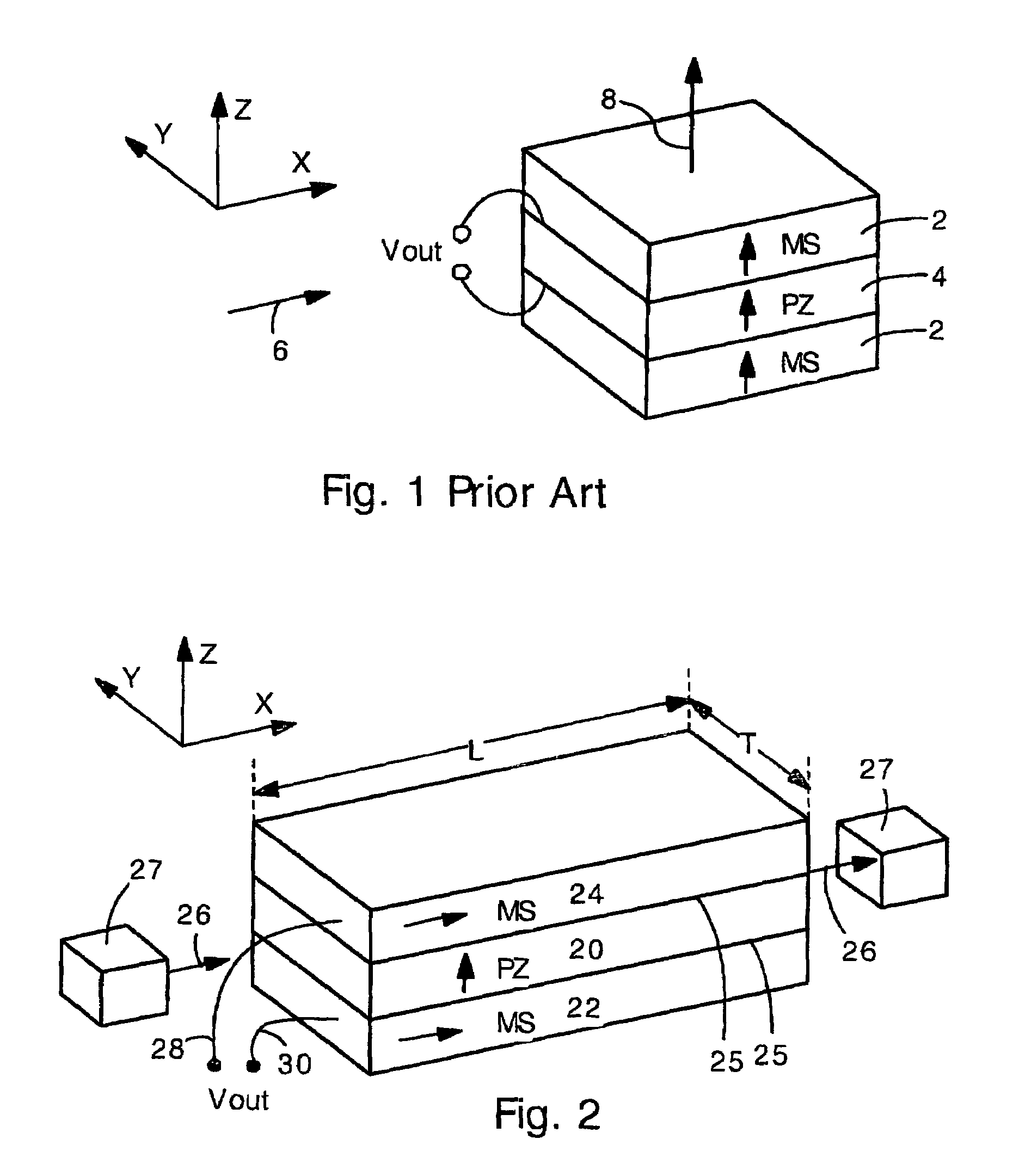

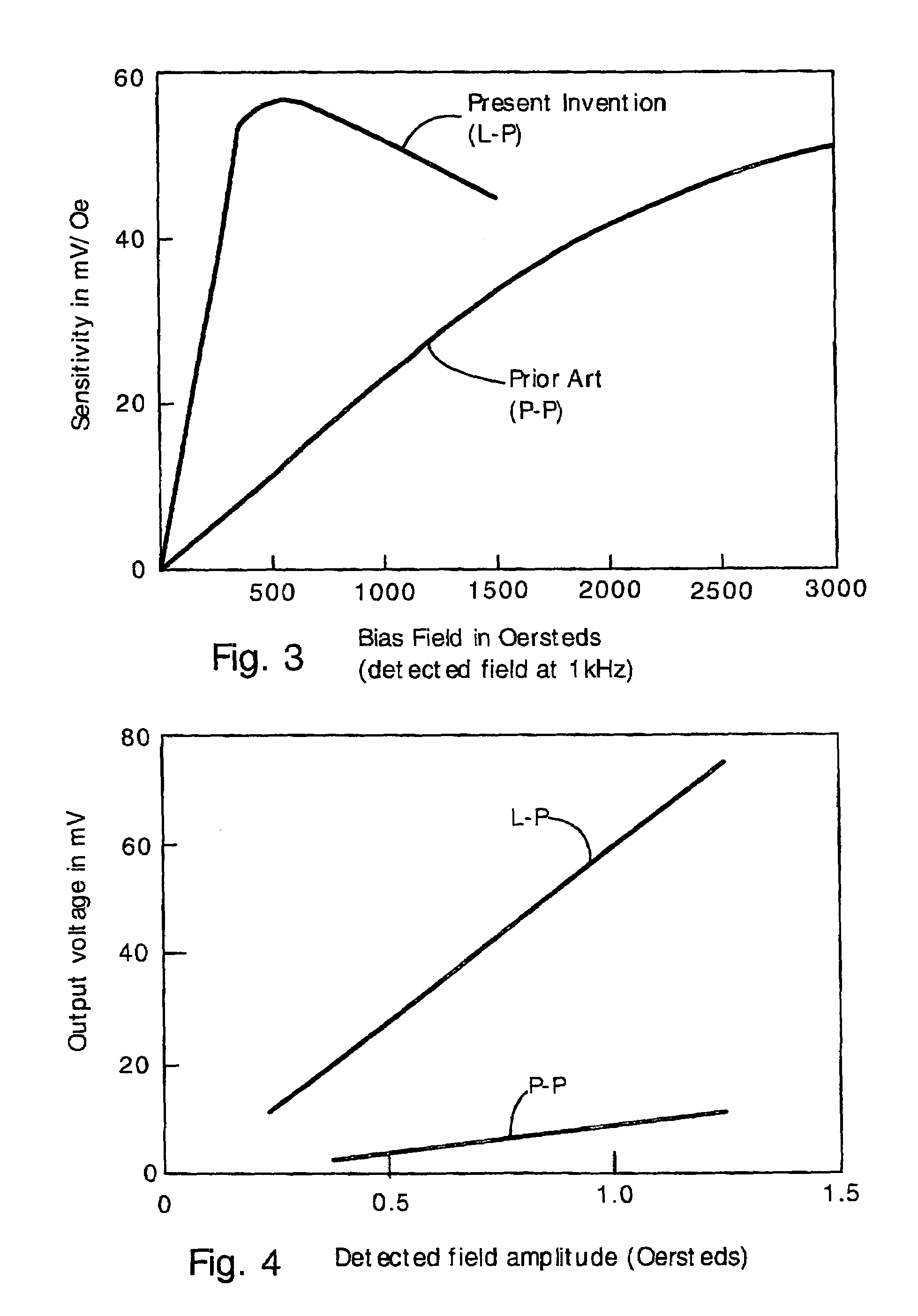

Magnetoelectric magnetic field sensor with longitudinally biased magnetostrictive layer

A magnetoelectric magnetic field sensor has one or more laminated magnetostrictive layers and piezoelectric layers. The magnetostrictive layers are magnetized by a bias magnetic field in a longitudinal, in-plane direction. The piezoelectric layers can be poled in the longitudinal direction or perpendicular direction. The longitudinal magnetization of the magnetostrictive layers provides greatly increased sensitivity at lower bias fields compared to other magnetoelectric sensors. Perpendicular poling of the piezoelectric layers tends to provide higher sensitivity at lower detection frequency (e.g. less than 1 Hz). Longitudinal poling tends to provide higher sensitivity at high detection frequency (e.g. above 10 Hz). Also included are embodiments having relative thicknesses for the magnetostrictive layers that are optimized for sensitivity. Equations are provided for calculating the best relative thickness for the magnetostrictive layer for maximum sensitivity.

Owner:VIRGINIA TECH INTPROP INC

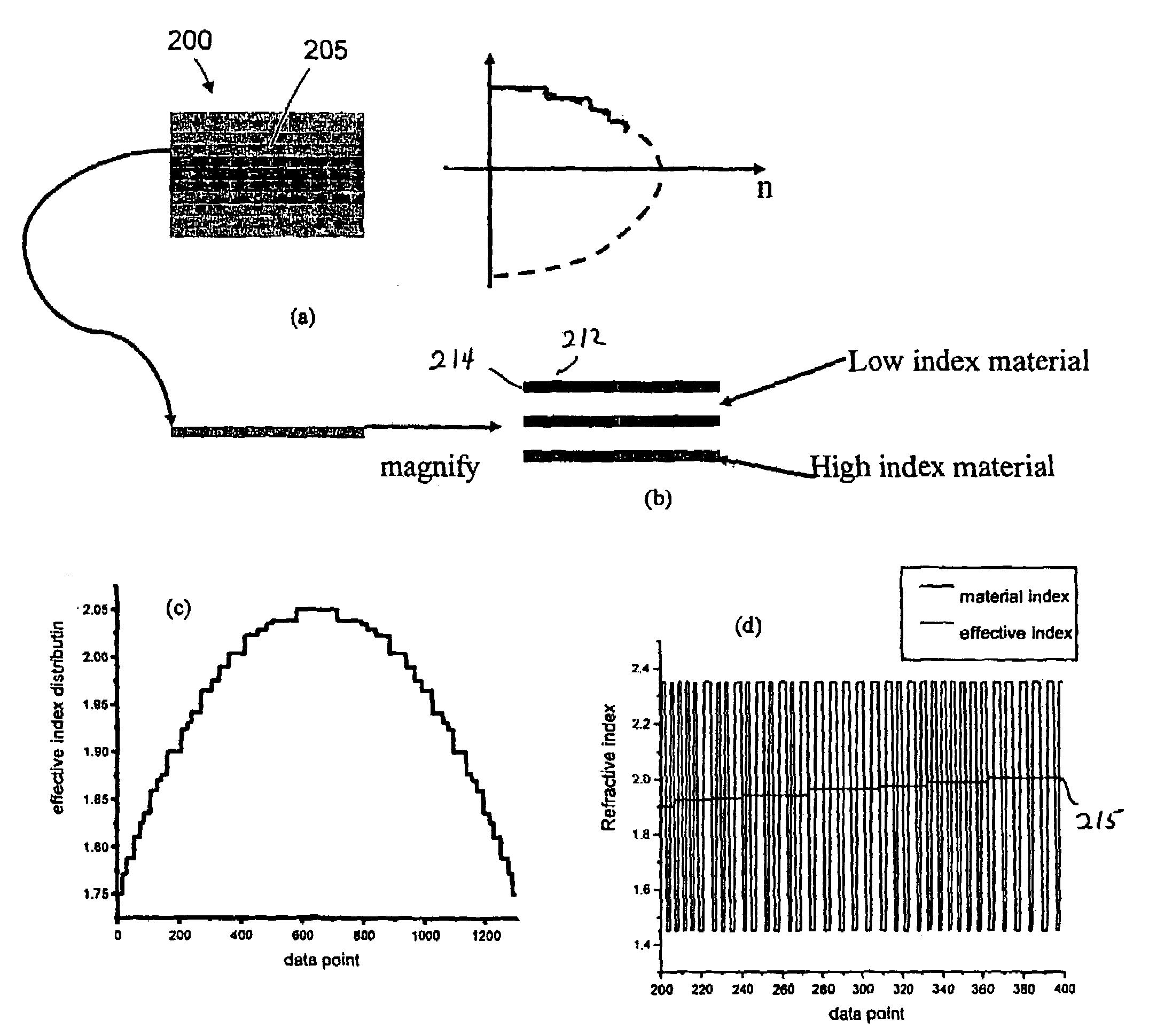

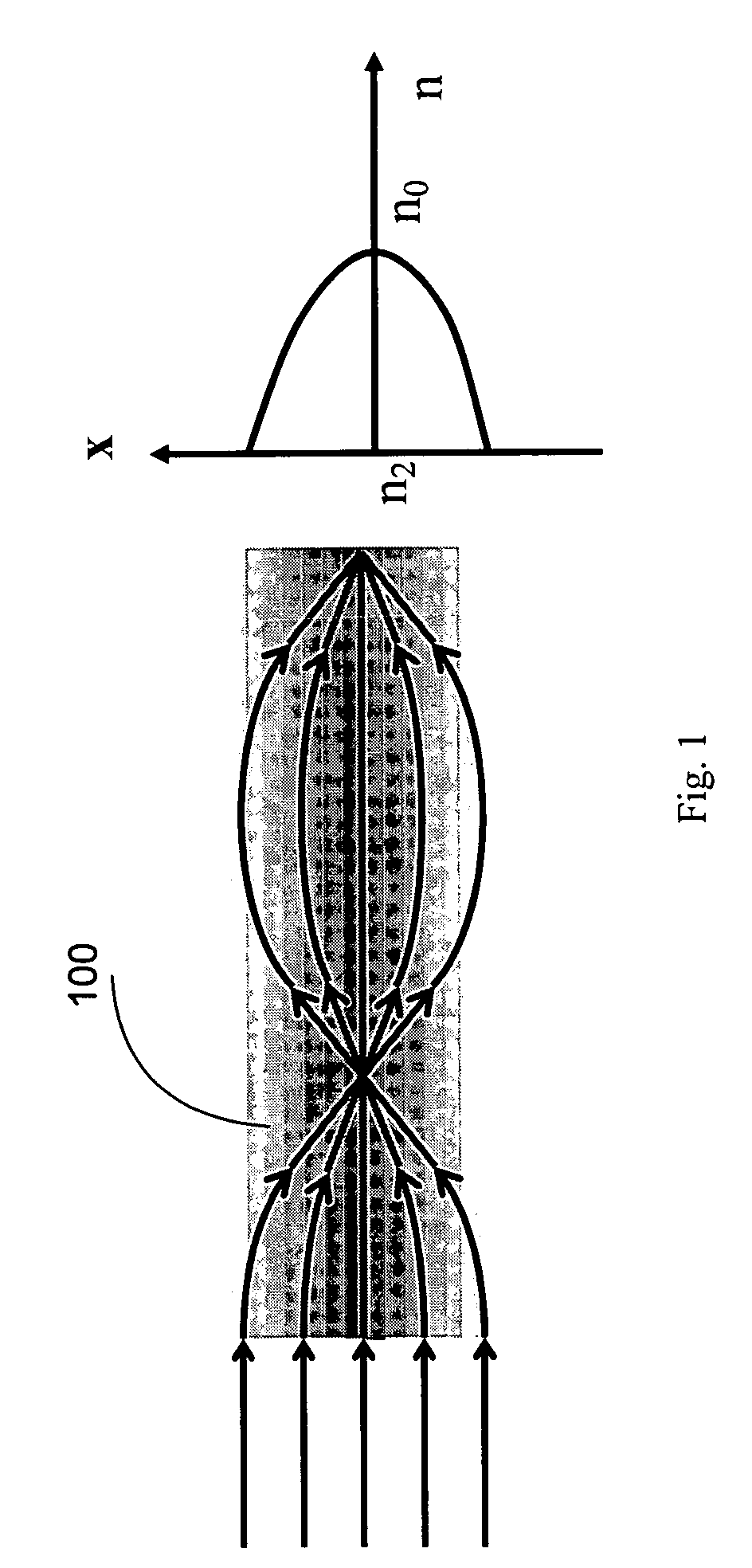

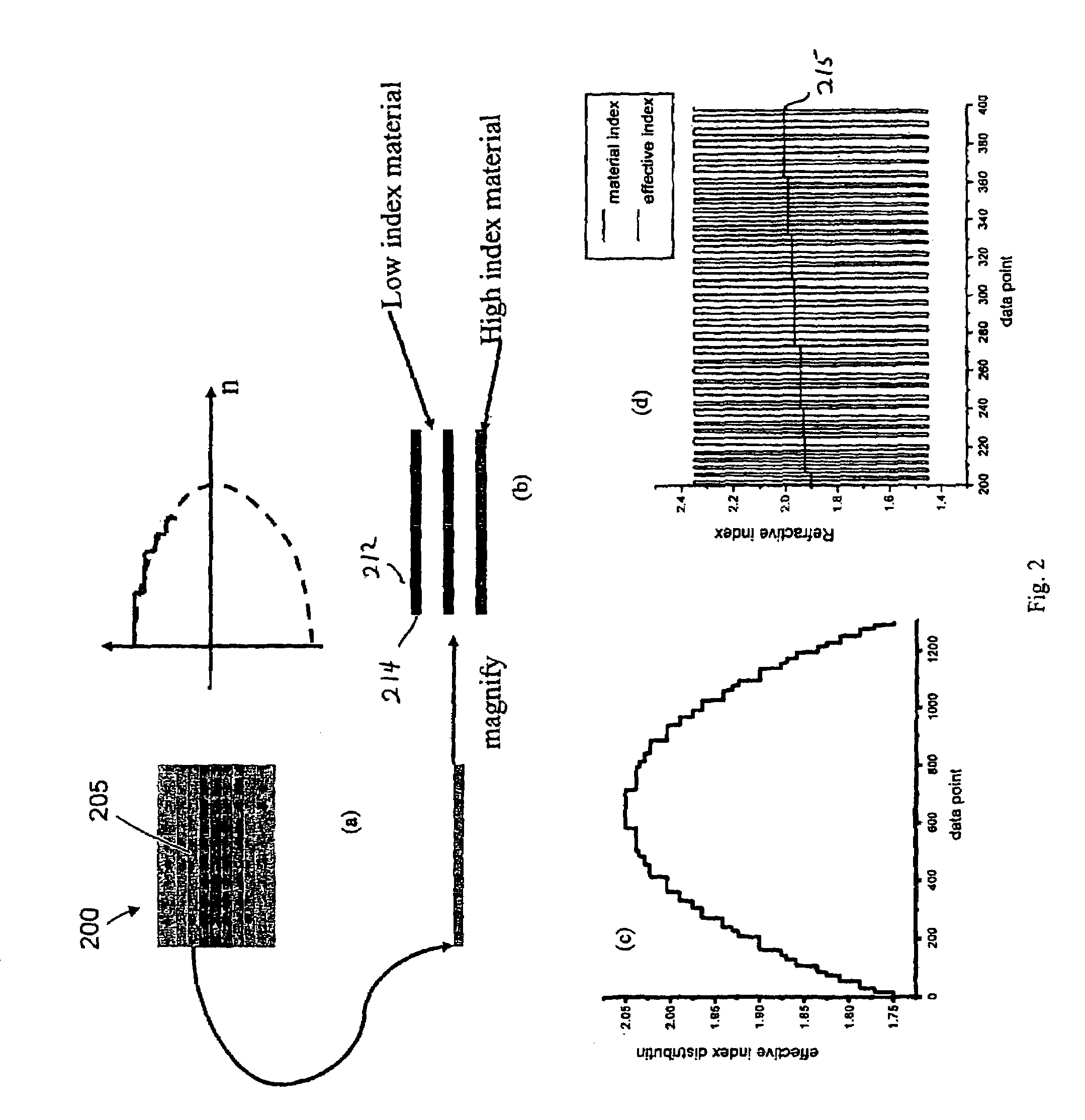

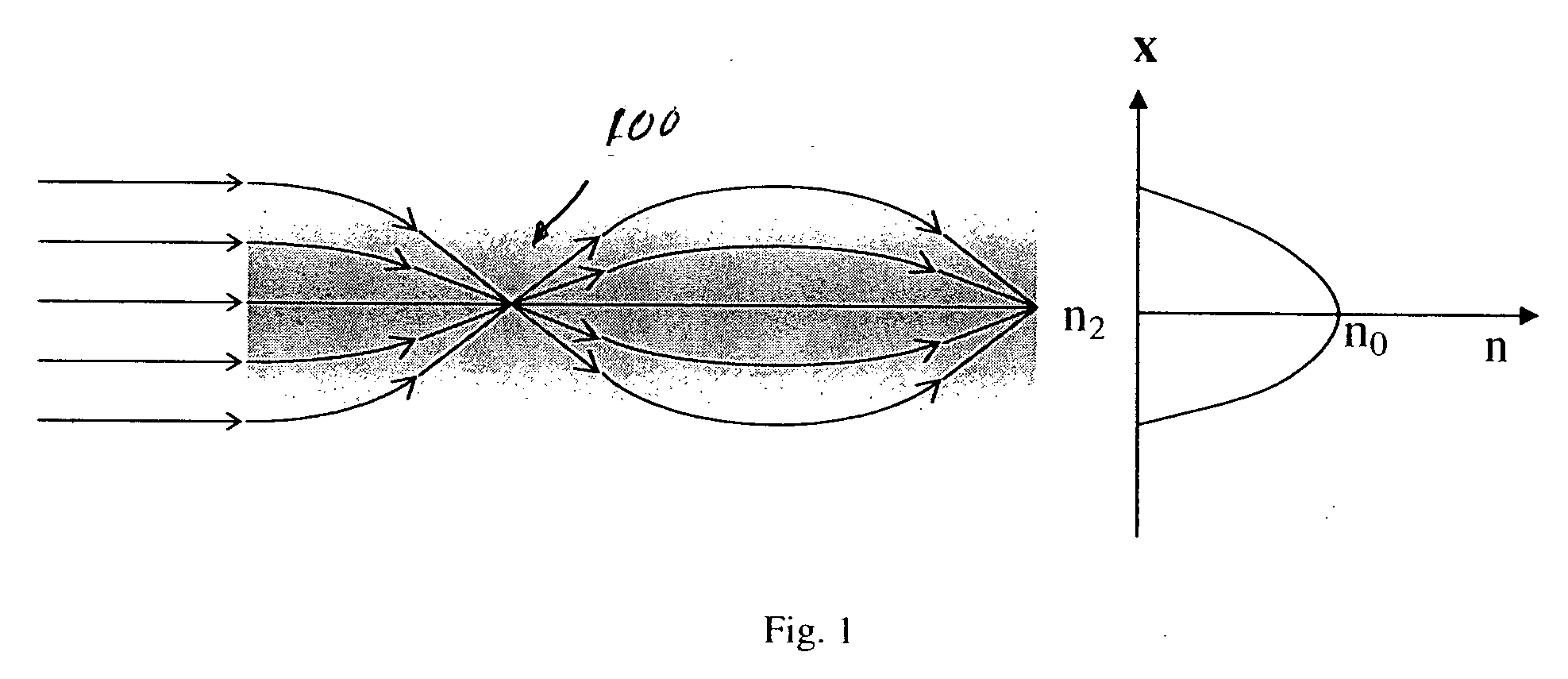

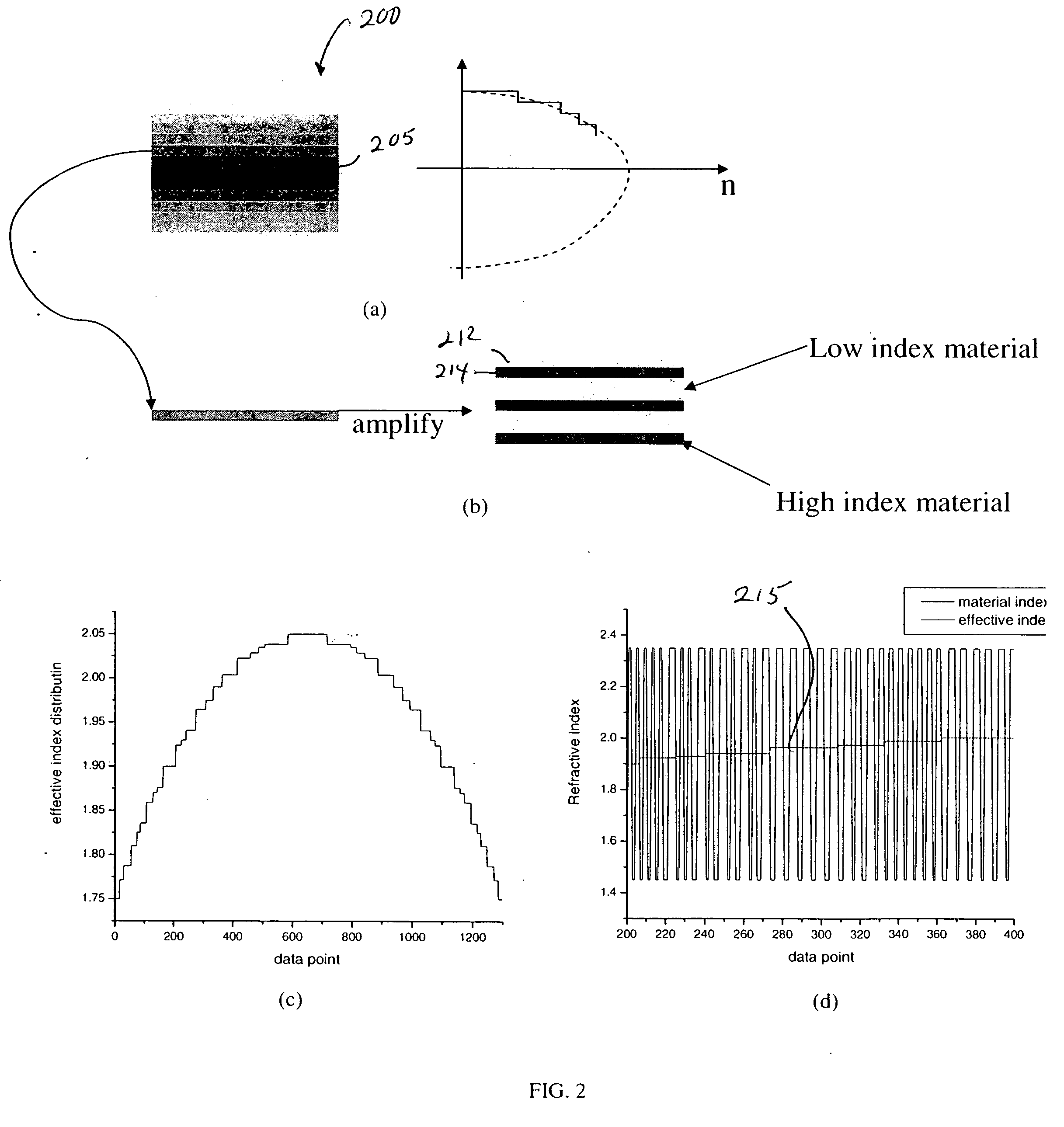

Varying refractive index optical medium using at least two materials with thicknesses less than a wavelength

InactiveUS7426328B2High maximum refractive index changeDifferent refractive indexOptical fibre with graded refractive index core/claddingCoupling light guidesMulti materialLength wave

An optical medium has a graded effective refractive index with a high maximum refractive index change. The medium is formed using alternating layers of two or more materials having significantly different refractive indices. The thickness of the layers of at least one of the materials is substantially less than the effective light wavelength of interest. The effective index of refraction in a local region within the medium depends on the ratio of the average volumes of the two materials in the local region. A graded index of refraction is provided by varying the relative thicknesses of the two materials.

Owner:HO SENG TIONG

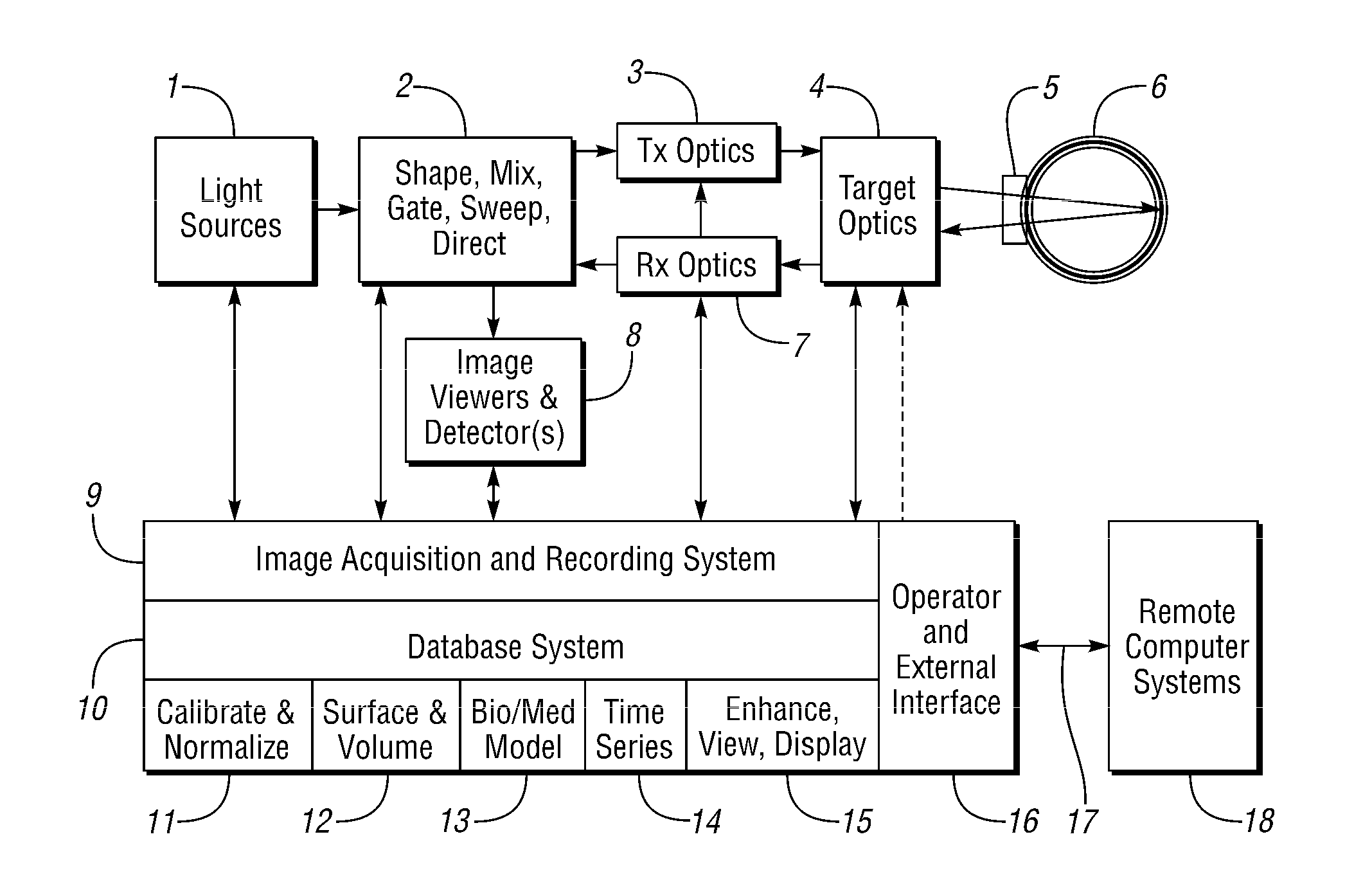

System and Method for Determining Volume-Related Parameters of Ocular and Other Biological Tissues

A system and method for determining volume-related parameters of a biological tissue, such as ocular tissue, include a light source for projecting light towards the biological tissue, a receiver for receiving light reflected from the biological tissue at two spectral wavelengths, and an image acquisition system in communication with the receiver for forming an image from the reflected light at each wavelength. A processor applies a mathematical model to the image which compares the absorption of light by the biological tissue at a selected image point at each of the two spectral wavelengths to determine the volume-related parameters, such as the relative thickness and material properties, of the biological tissue at that location.

Owner:EYELAB GROUP

Deposition of organic films

ActiveUS10373820B2Liquid surface applicatorsSemiconductor/solid-state device manufacturingOrganic filmDielectric surface

Processes are provided herein for deposition of organic films. Organic films can be deposited, including selective deposition on one surface of a substrate relative to a second surface of the substrate. For example, polymer films may be selectively deposited on a first metallic surface relative to a second dielectric surface. Selectivity, as measured by relative thicknesses on the different layers, of above about 50% or even about 90% is achieved. The selectively deposited organic film may be subjected to an etch process to render the process completely selective. Processes are also provided for particular organic film materials, independent of selectivity.

Owner:ASM IP HLDG BV

Deposition of organic films

ActiveUS10453701B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingOrganic filmDielectric surface

Processes are provided herein for deposition of organic films. Organic films can be deposited, including selective deposition on one surface of a substrate relative to a second surface of the substrate. For example, polymer films may be selectively deposited on a first metallic surface relative to a second dielectric surface. Selectivity, as measured by relative thicknesses on the different layers, of above about 50% or even about 90% is achieved. The selectively deposited organic film may be subjected to an etch process to render the process completely selective. Processes are also provided for particular organic film materials, independent of selectivity. Masking applications employing selective organic films are provided. Post-deposition modification of the organic films, such as metallic infiltration and / or carbon removal, is also disclosed.

Owner:ASM IP HLDG BV

Rotor blade for a wind power station

InactiveUS20060280614A1Improved aerodynamic airflowPropellersPump componentsLeading edgePower station

A rotor blade for a wind power station includes a profiled member that is provided with a relative thickness which decreases towards the outside from a root to a tip of the blade. The profiled member has a leading edge and a trailing edge as well as a suction side and a pressure side while generating a negative pressure relative to the pressure side on the suction side when being flown against by moved air, the negative pressure resulting in buoyancy. The suction side of the rotor blade encompasses a device for optimizing flow around the profiled member. The device is provided with at least one planar element that extends substantially in the direction of flow, protrudes from the suction side, and is arranged in the zone of a transversal flow which runs from the root to the tip of the blade on the suction side of the profiled member.

Owner:SENVION GMBH

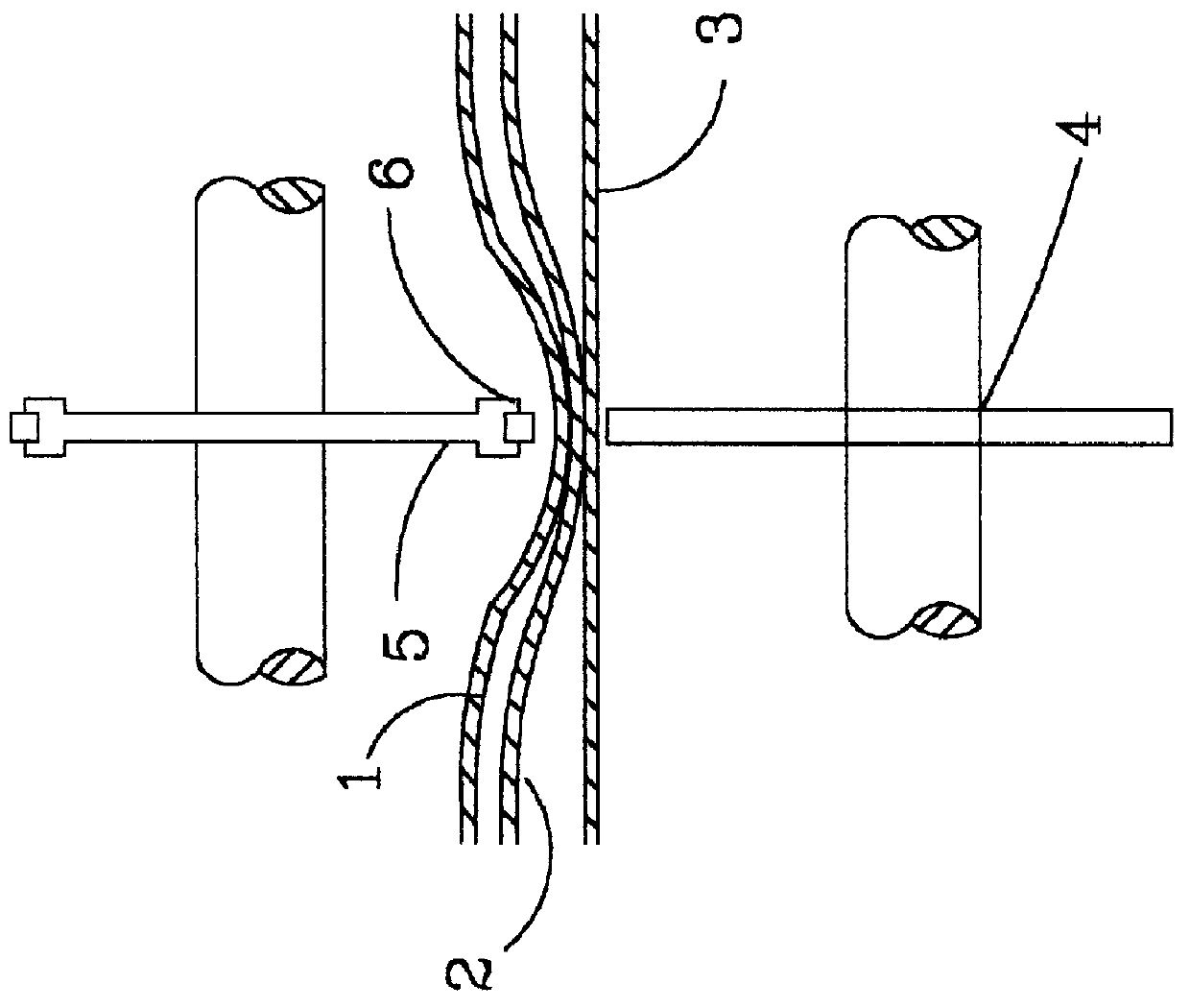

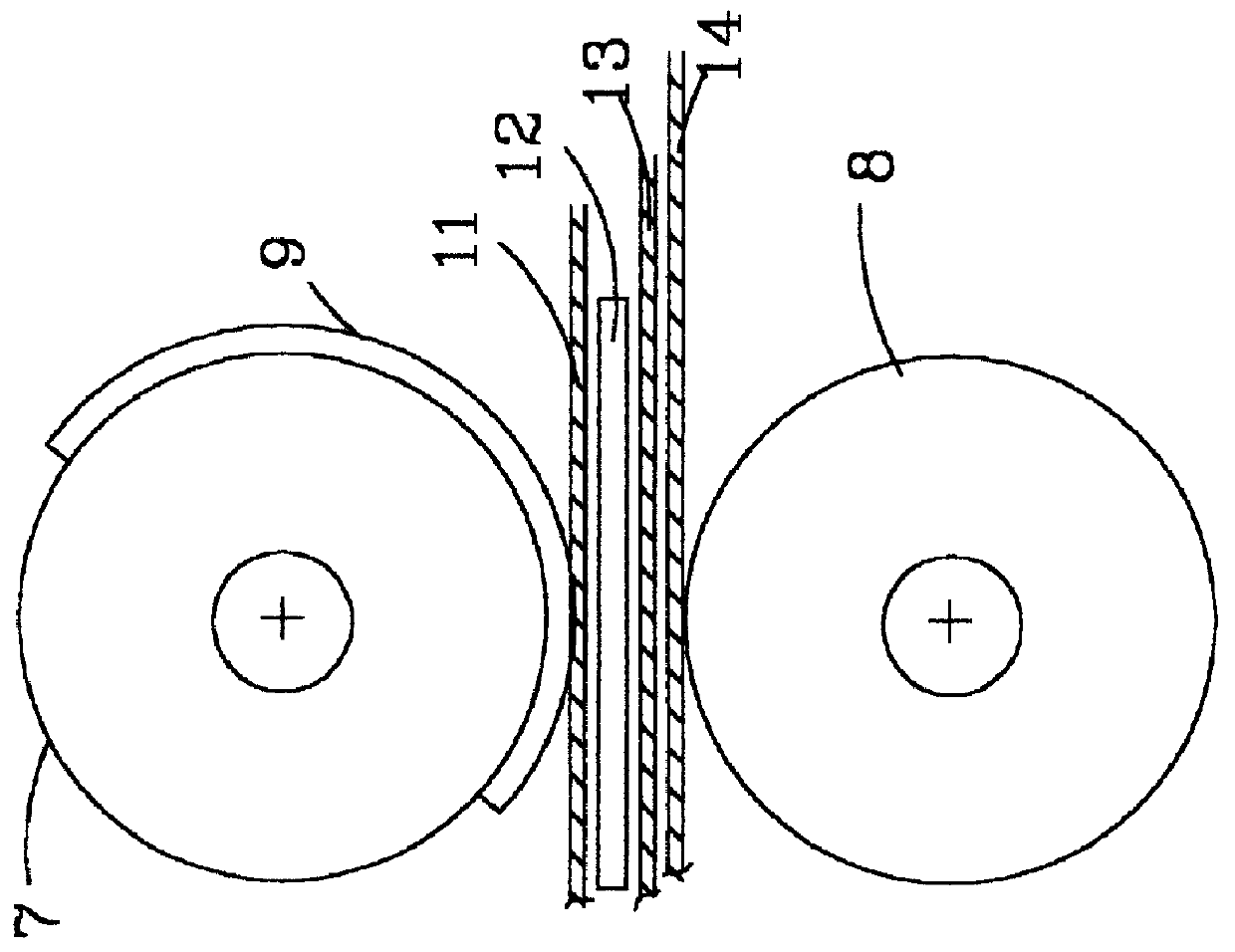

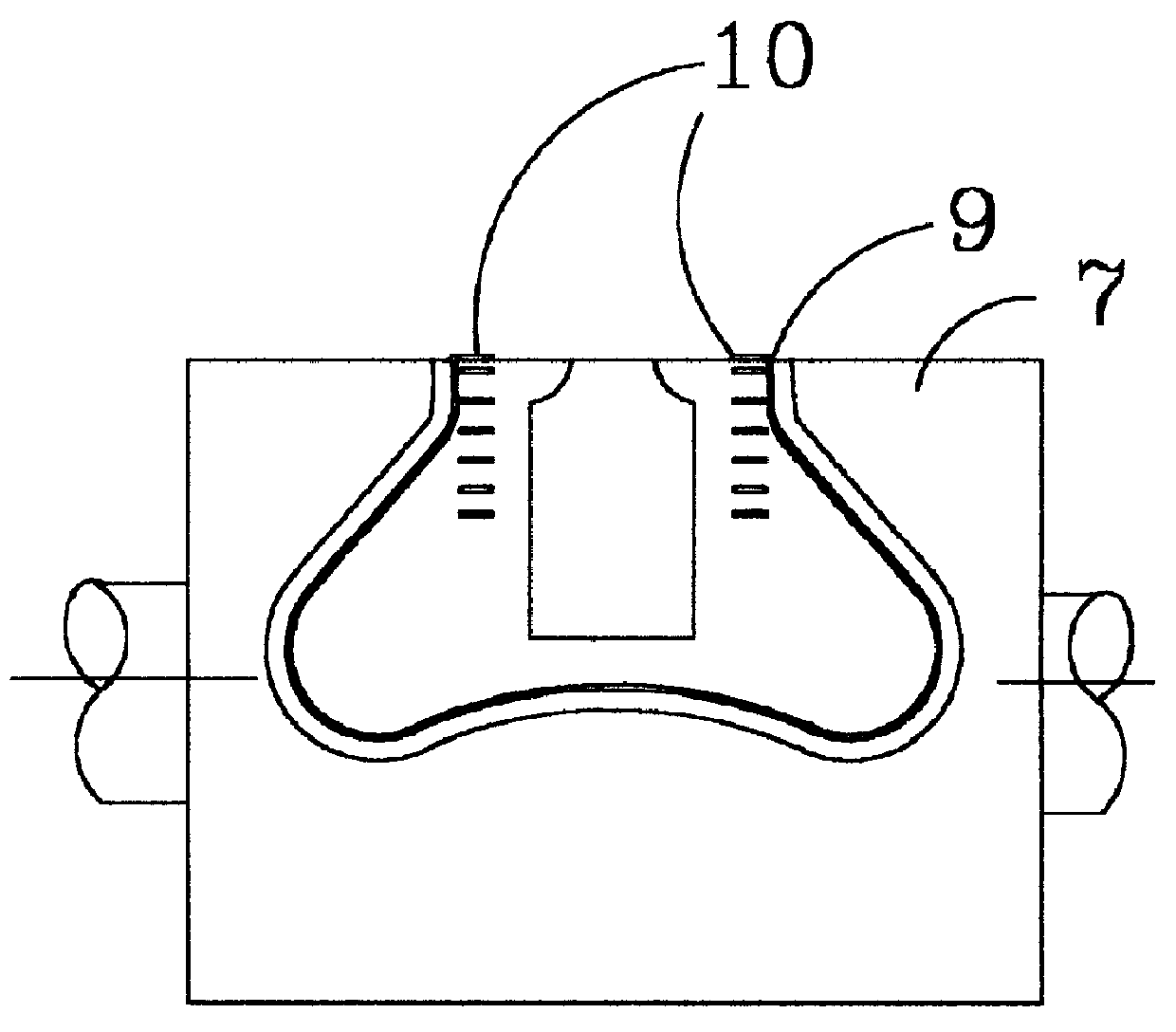

Process for the fabrication of disposable diapers and other disposable products and a disposable diaper

The present invention relates to a rapid and low cost procedure for joining webs and films containing dissimilar polymers. It is especially applicable but not limited to the construction and assembly of disposable products such as infant and adult incontinent products, feminine hygiene products, and other low-cost, high volume disposable products. The process involves producing a high rate of heat flux through the dissimilar materials where the material with the higher plastic point is at the influx point and the lower plastic point material is adjacent and further from the heat source. In addition to this constraint and as a necessary component the application of the high rate of heat flux must be accompanied by a pressure of appropriate to the difference in plastic points and to the relative thickness of the dissimilar materials to be joined.

Owner:LUNT AUDREY +1

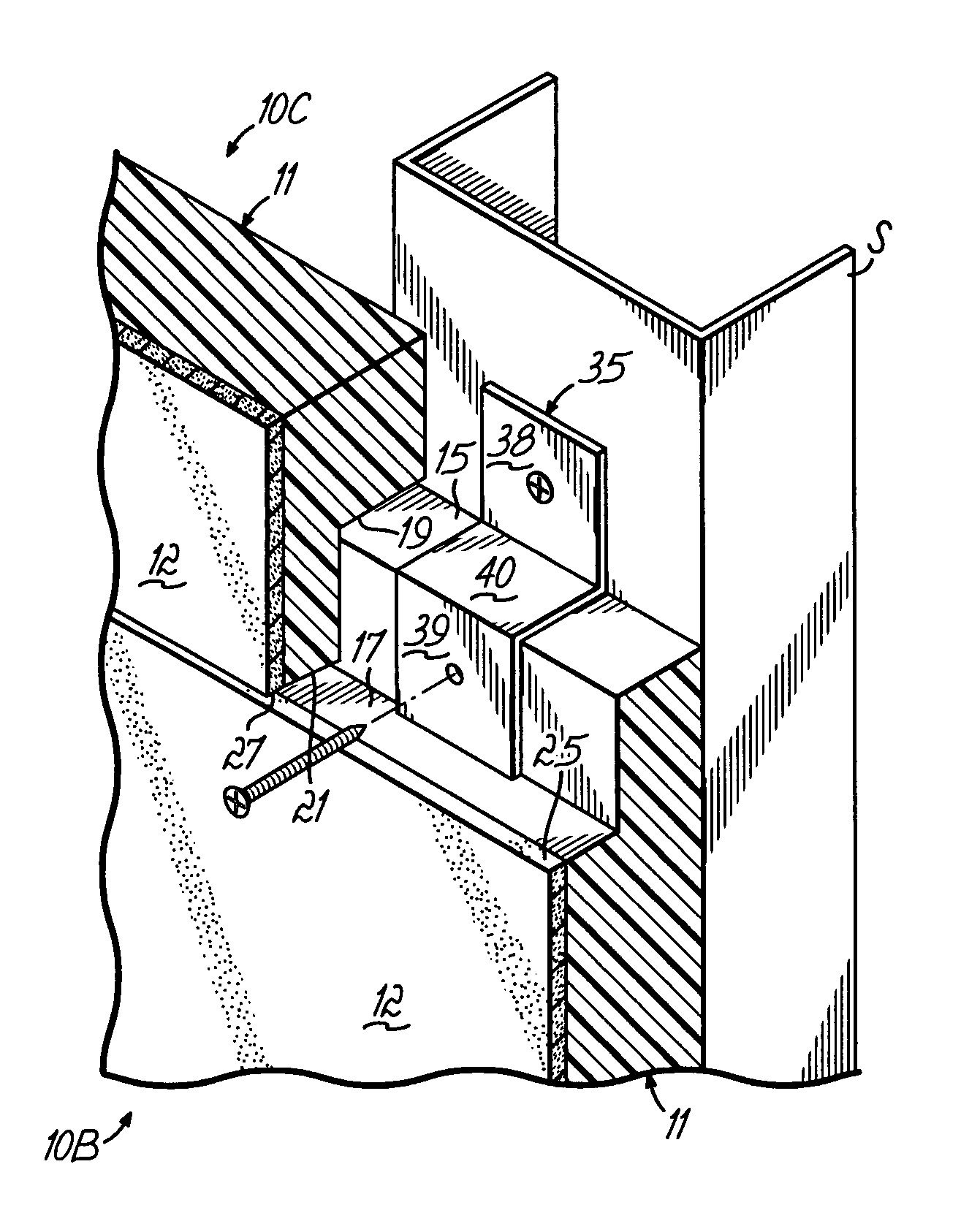

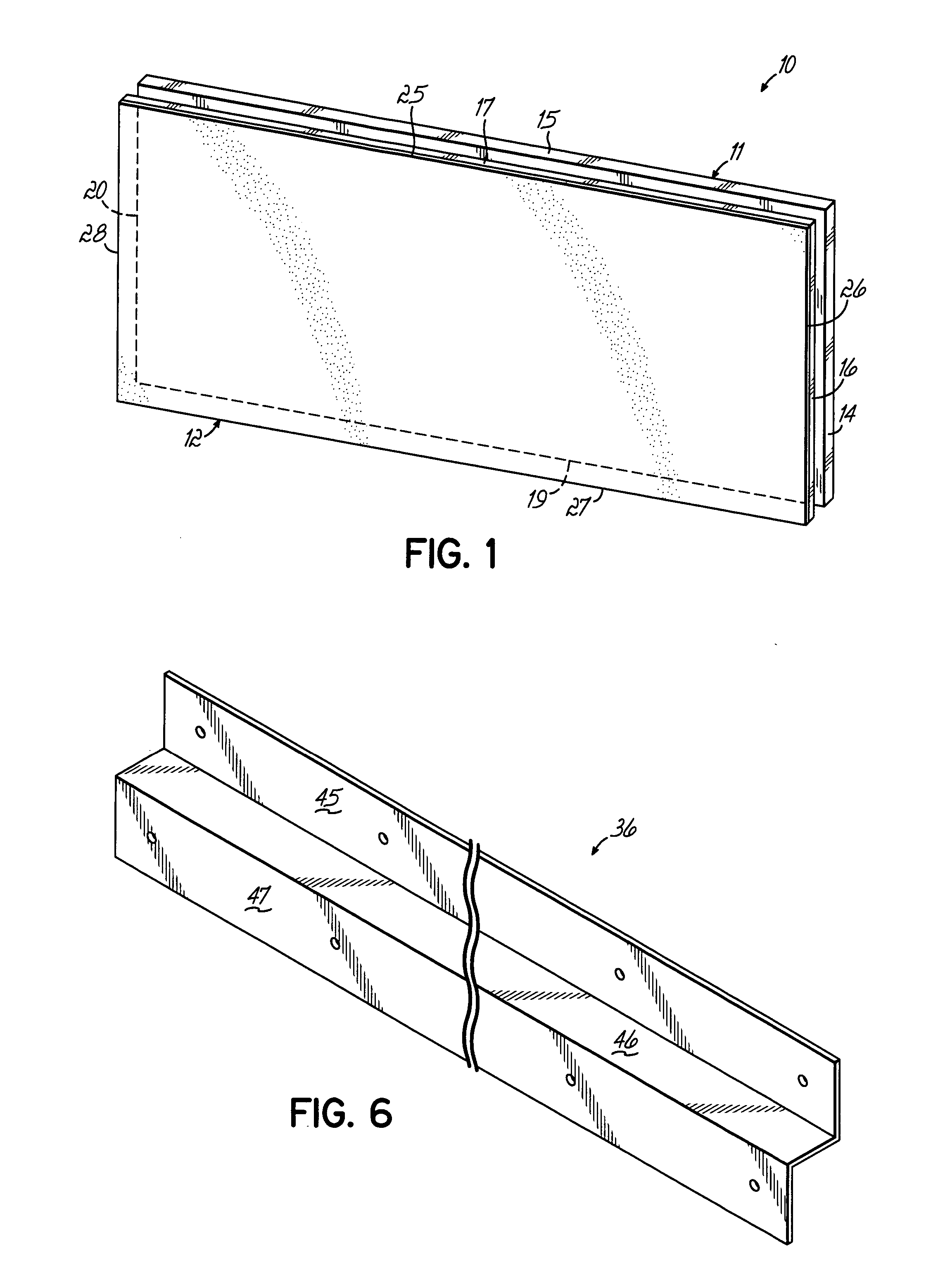

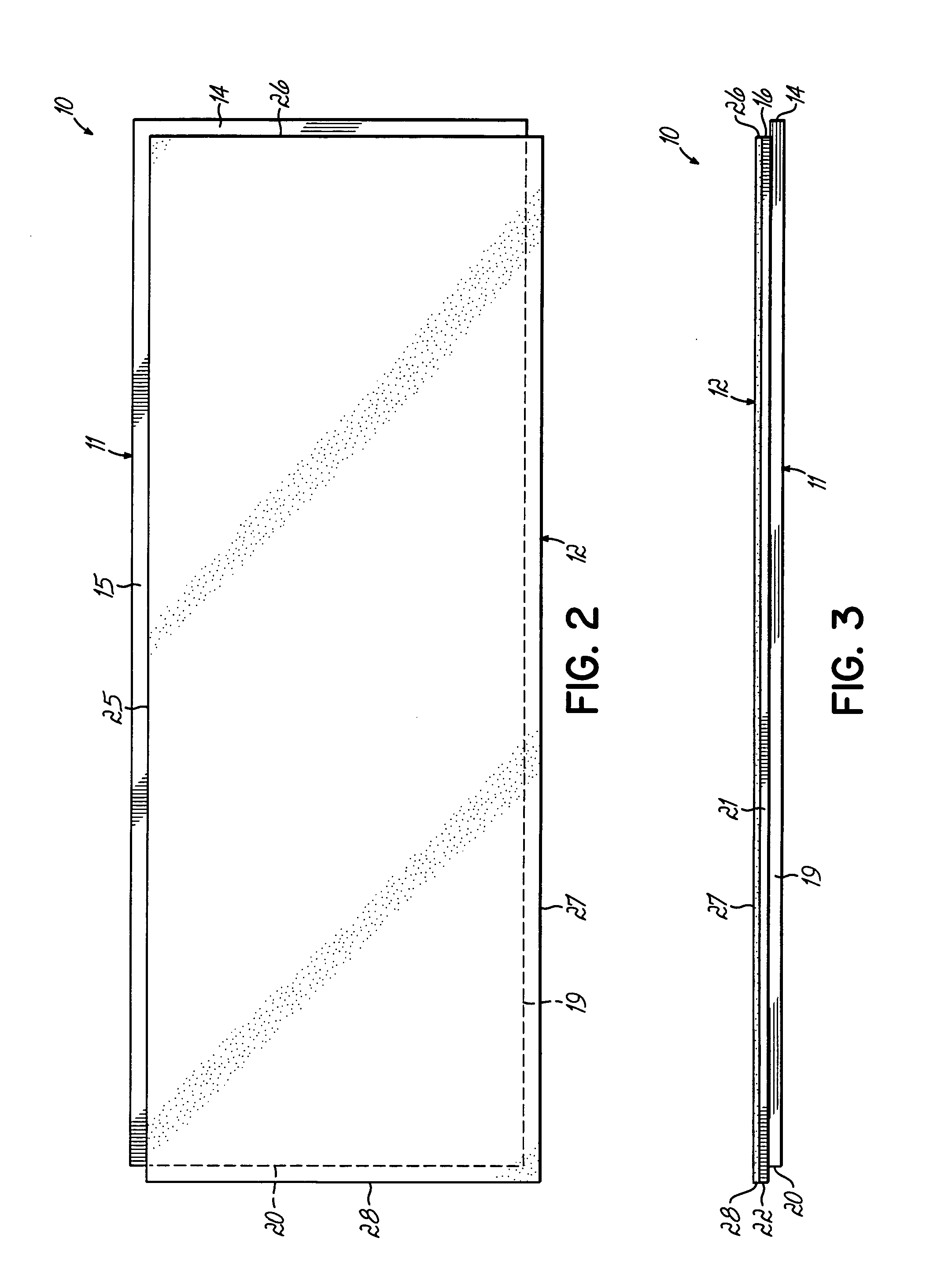

Insulated sheathing panels

An insulated sheathing panel comprises an insulating member and a facing. The insulating member has two adjacent edges formed by a portion of its thickness extending beyond two corresponding adjacent edges of said facing. Two other adjacent edges of said insulating member in the said relative thickness portion are recessed within two corresponding edges of said facing. When the panels are applied to a stud wall, their edges are ship-lapped, with edges of the facings in abutted relation so there is not thermal break at the panel seam. “Z”-shaped clips or elongated bars are used to secure panels to the stud wall. The panel facings are finished and no vapor barrier is required. Methods are included.

Owner:CRAWFORD RICHARDS H

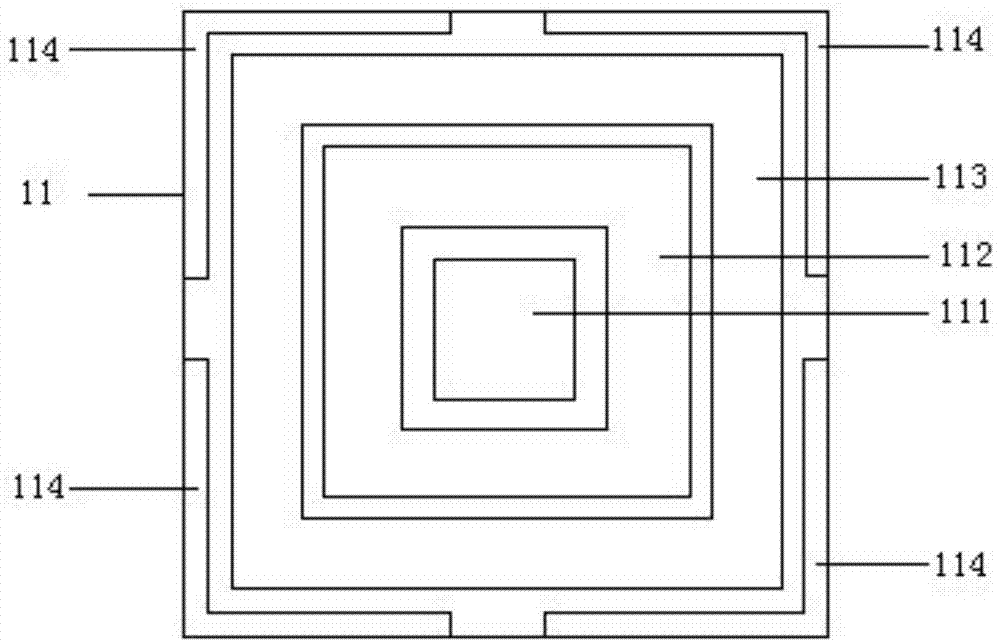

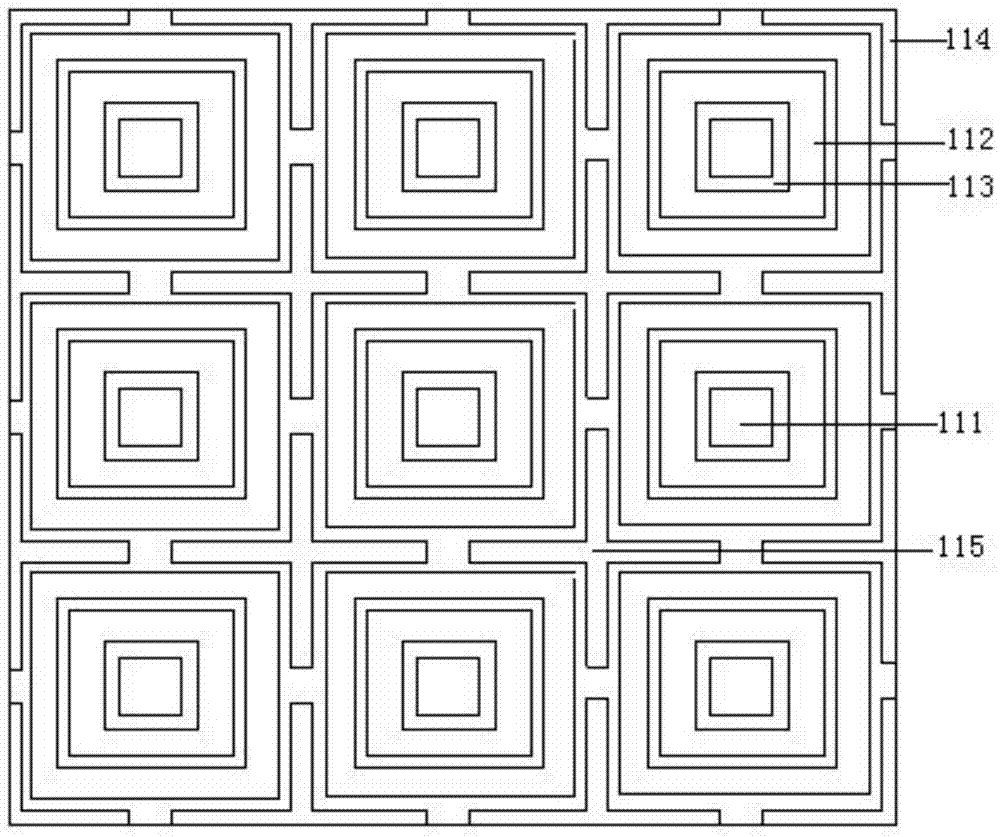

Ultrathin metallic resistance composite multi-frequency wave-absorbing material

ActiveCN103943967ASimple structureEasy to processAntennasElectrical resistance and conductanceFrequency wave

The invention relates to an ultrahigh metallic resistance composite multi-frequency wave-absorbing material and belongs to the technical field of wave-absorbing materials. The technical problems that in the prior art, a circuit simulation wave-absorbing structure is narrow in wave-absorbing bandwidth, single in wave-absorbing frequency band and large in relative thickness are solved. The wave-absorbing material comprises a frequency selecting surface, a medium layer and a metal bottom plate. The frequency selecting surface is composed of patch units arrayed periodically, and each patch unit comprises a square patch, a first square surrounding patch and a second square surrounding patch, wherein the square patch, the first square surrounding patch and the second square surround patch are sequentially arrayed from inside to outside according to the length of sides. The wave-absorbing material further comprises four L-shaped patches which are symmetrically arranged outside four right angles of the second square surrounding patch. The double-frequency or triple frequency wave-absorbing characteristic that the reflection coefficient, below -10dB, of the wave-absorbing material is adjusted within the 4 GHz-18 GHz range can be achieved, the reflection coefficient of about -20 dB can be achieved nearby a wave-absorbing harmonic peak, and therefore a higher wave-absorbing effect is achieved.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

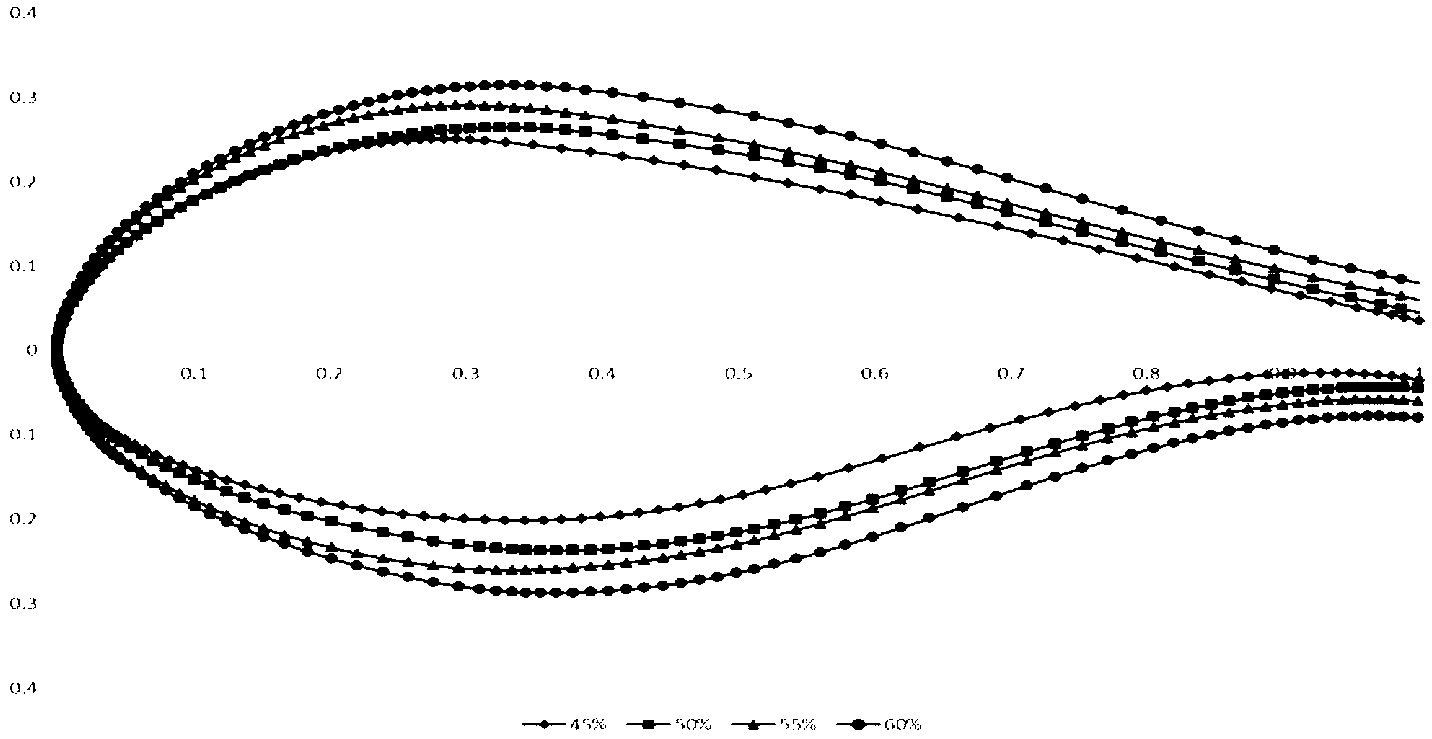

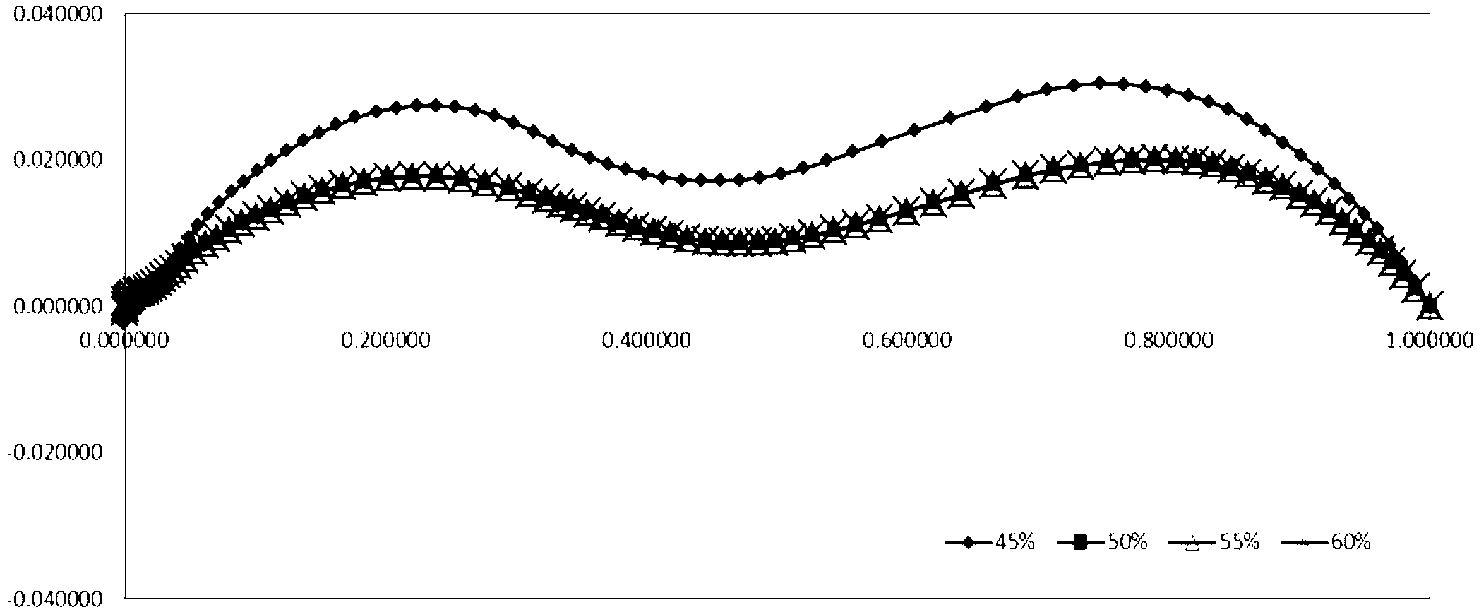

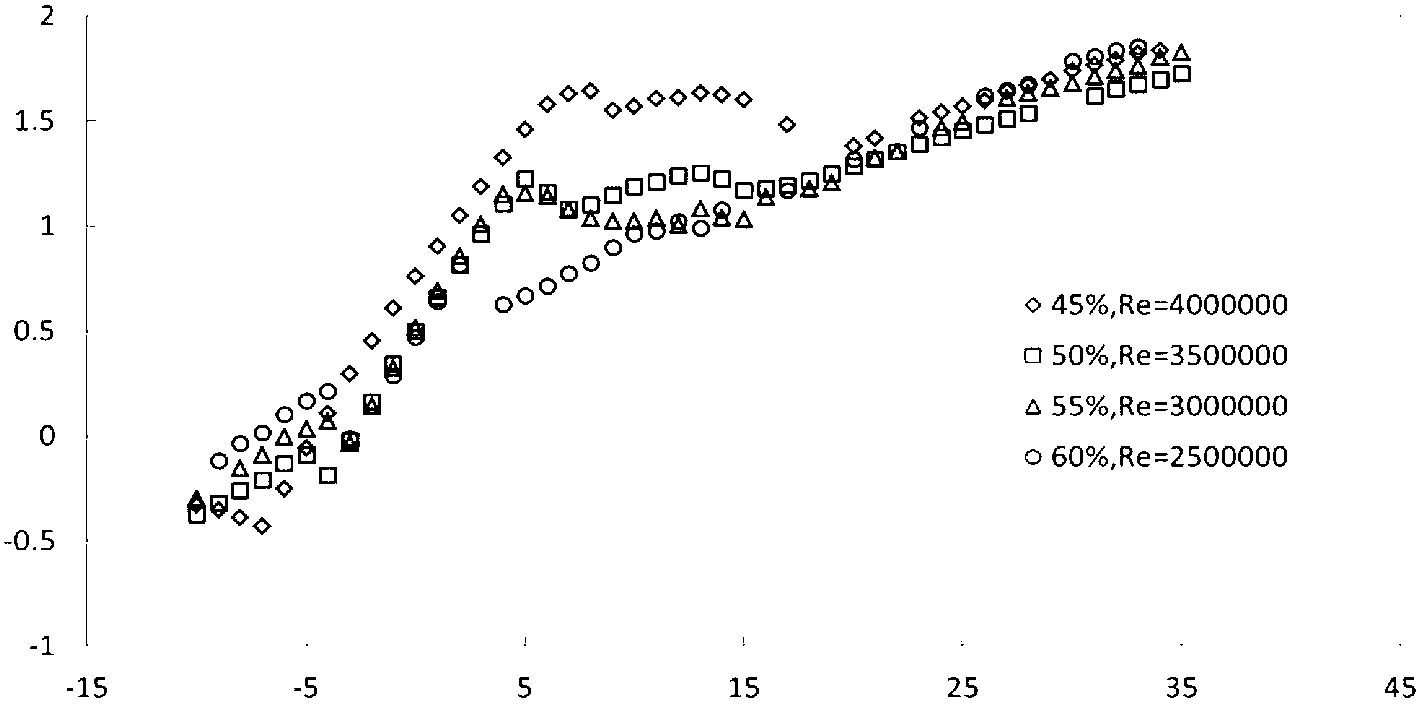

Large-thickness blunt-trailing-edge wind-power airfoil profiles and a design method thereof

ActiveCN103277245AImprove structural propertiesClose to performance requirementsMachines/enginesWind energy generationHigh liftTrailing edge

The invention discloses a group of large-thickness blunt-trailing-edge wind-power airfoil profiles and a design method thereof. The airfoil profiles have high lift coefficients under operation angles of attack. The airfoil profile group includes four airfoil profiles with relative thicknesses of 45%, 50%, 55% and 60% in sequence and with trailing edge thicknesses of 7%, 9%, 12% and 16% in sequence. Variable working condition design is adopted by the airfoil profile group, design Reynolds numbers of the four airfoil profiles are 4.0*106, 3.5*106, 3.0*106 and 2.5*106 in sequence according to the relative thicknesses, and the design objective mainly aims to take stability, changed along with the Reynolds numbers, of the lift coefficients as main constraint according to change features of the lifting coefficients within the range of large angles of attack in vane root areas. Numerical prediction results indicate that when the four large-thickness blunt-trailing-edge airfoil profiles are in the range of large angles of attack, the lift coefficients ascend continuously and stably and are in a high level. By the airfoil profile group, vane structural strength and stiffness can be improved, and a wind turbine can have high-efficient and stable output.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Degradable lamellar Zn-Mg composite material and preparation method thereof

ActiveCN108237214AGood biocompatibilityPromote degradationSurgeryMetallic material coating processesMg compositeMaterial Design

The invention discloses a degradable lamellar Zn-Mg composite material and a preparation method thereof. The outer layer of a lamellar medical metal composite material is made of pure zinc or zinc alloy, and the core part of the lamellar medical metal composite material is made of pure magnesium or magnesium alloy; the ratio of zinc or zinc alloy and magnesium or magnesium alloy is calculated according to volume percentage, zinc or zinc alloy accounts for 20%-50% of the total volume of the material, and the balance is magnesium or magnesium alloy. The lamellar composite material is prepared bycombining layered casting with nested extruding. The degradable lamellar Zn-Mg composite material has the advantages that: the selected magnesium alloy and the selected zinc alloy have good biocompatibility and degradability; mechanical properties and a degradation rate of the integral composite material are controlled by controlling a relative thickness of a Zn layer to a Mg layer, so that the composite material adapts to a service environment, and therefore, a condition that single metal is too quick or too slow in degradation is solved. The material design and the preparation method are simple and convenient, and the cost is low, so that industrial production is facilitated.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Varying refractive index optical medium using at least two materials with thicknesses less than a wavelength

ActiveUS20050036738A1High maximum refractive index changeDifferent refractive indexOptical fibre with graded refractive index core/claddingCoupling light guidesMulti materialLength wave

An optical medium has a graded effective refractive index with a high maximum refractive index change. The medium is formed using alternating layers of two or more materials having significantly different refractive indices. The thickness of the layers of at least one of the materials is substantially less than the effective light wavelength of interest. The effective index of refraction in a local region within the medium depends on the ratio of the average volumes of the two materials in the local region. A graded index of refraction is provided by varying the relative thicknesses of the two materials.

Owner:HO SENG TIONG

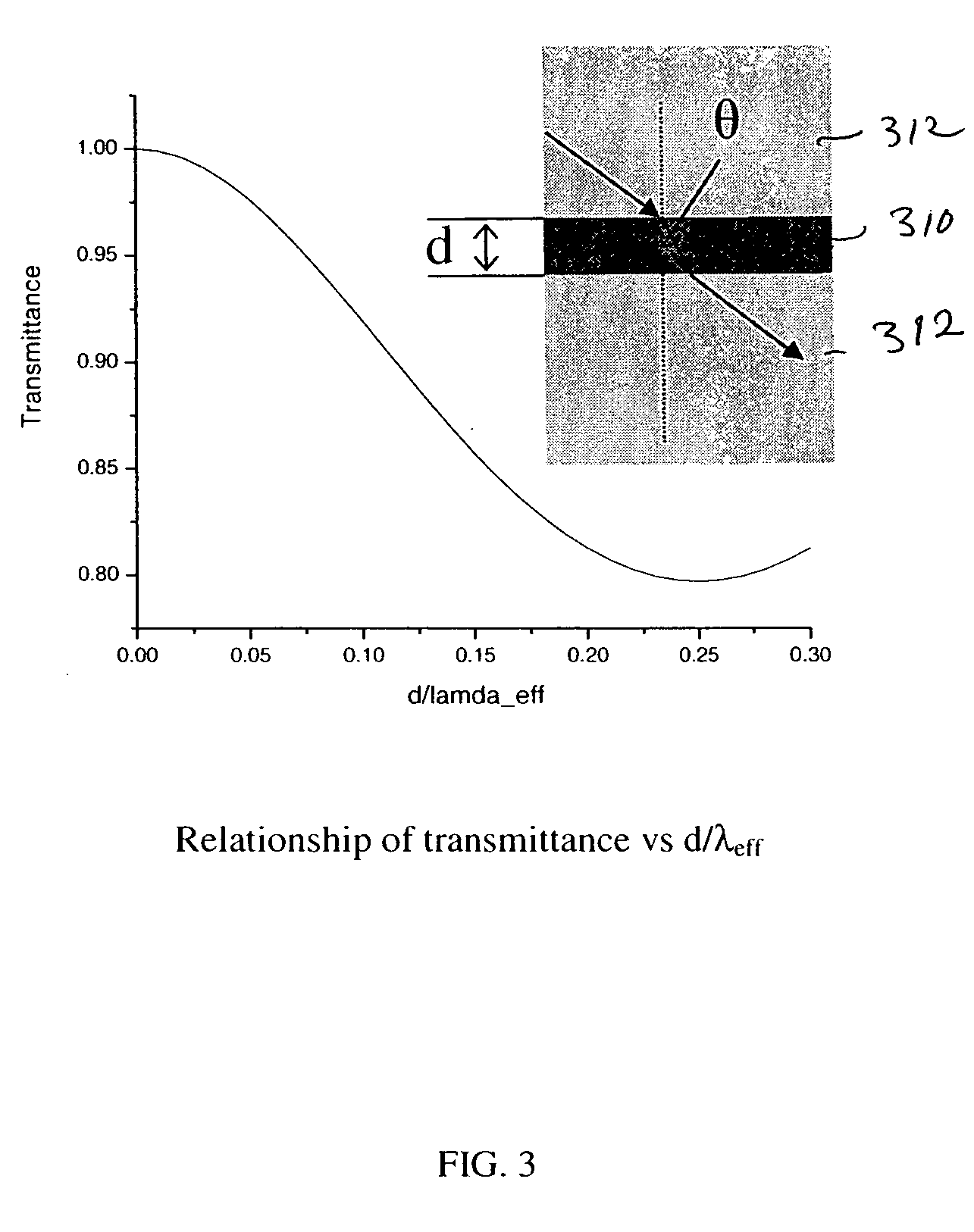

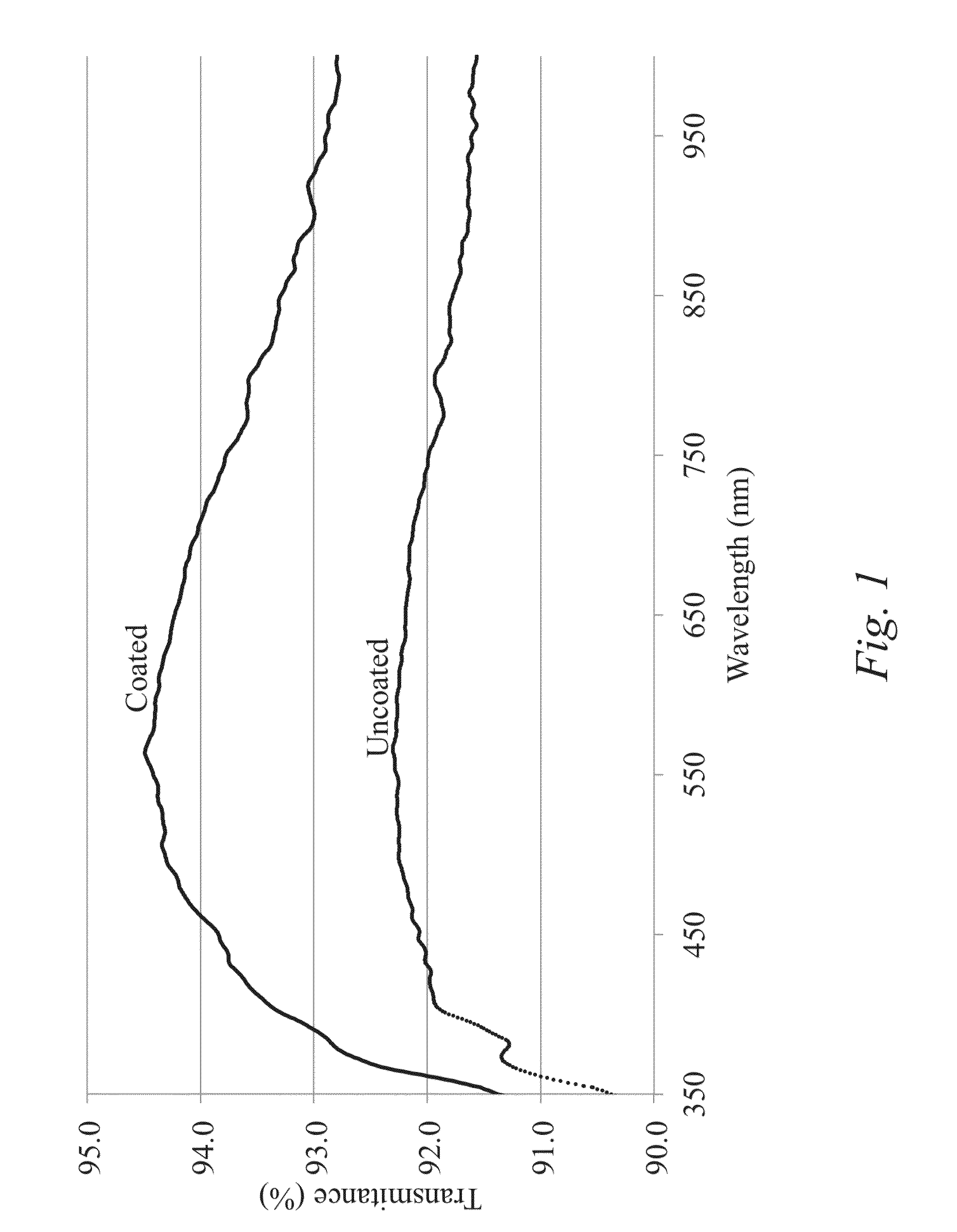

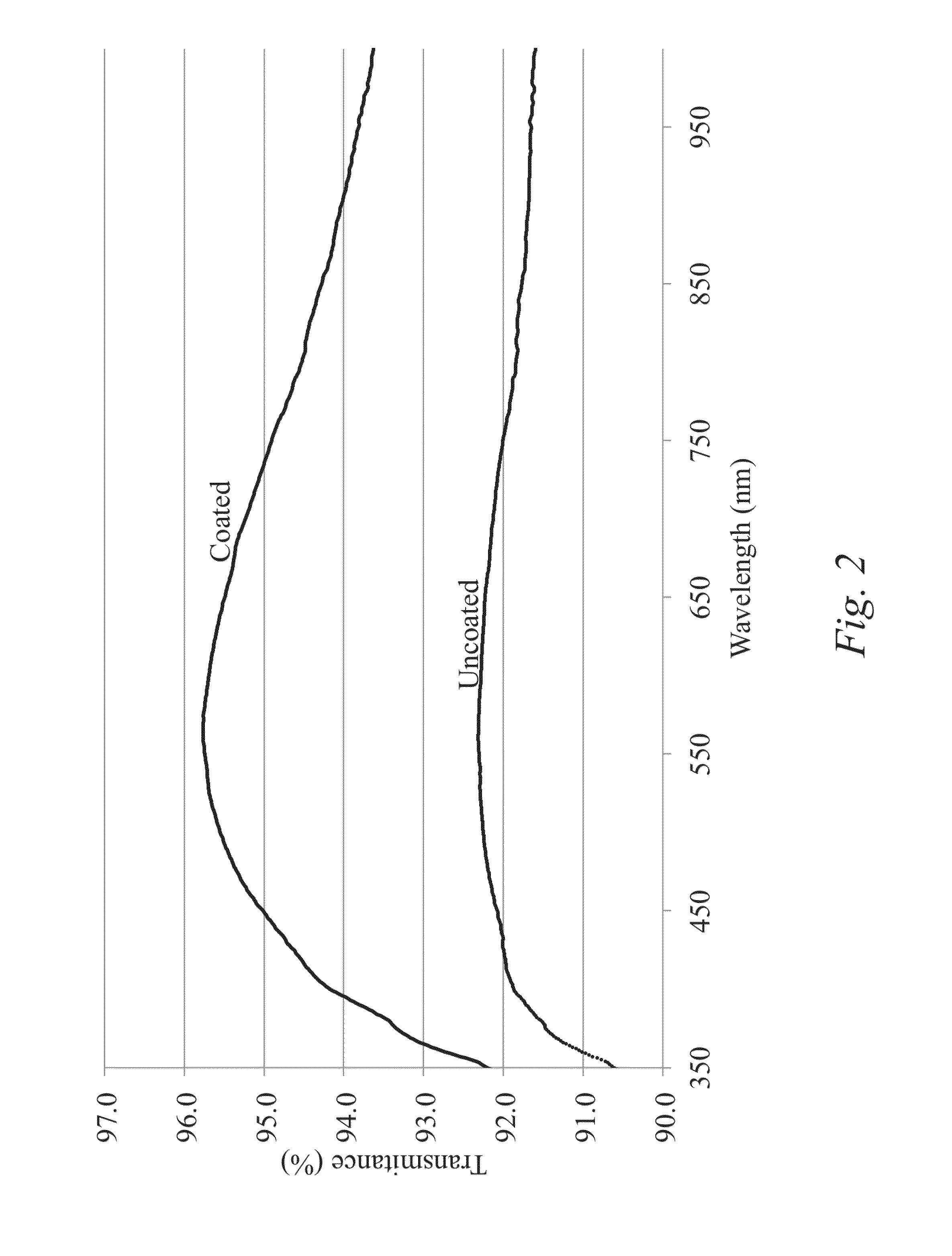

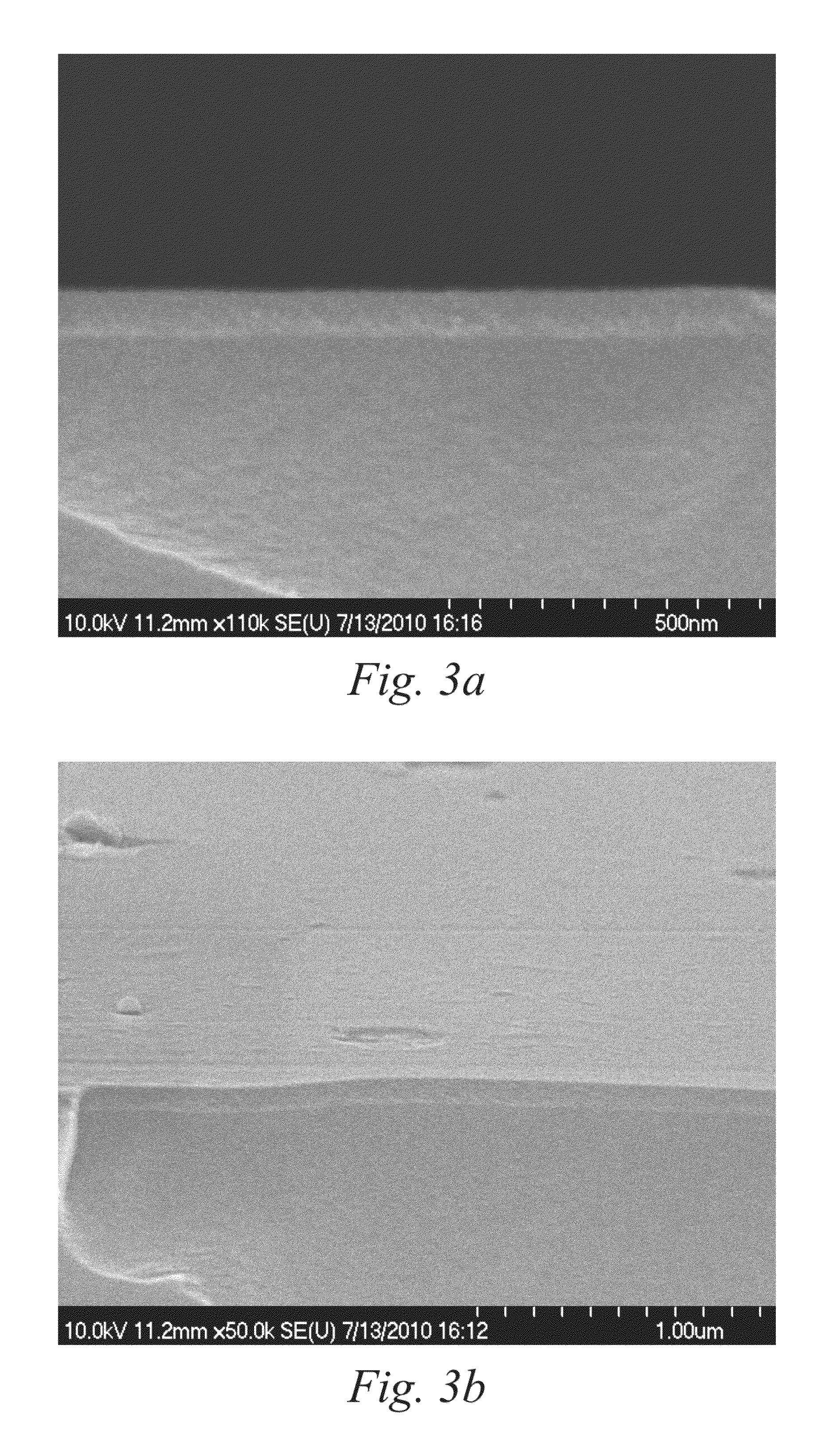

Multi-layer coatings

ActiveUS20160002498A1Good weather resistanceProtection protectionSynthetic resin layered productsAnti-reflective coatingsAnti-reflective coatingLayer thickness

Disclosed herein are coating materials and methods for applying a top-layer coating that is durable, abrasion resistant, highly transparent, hydrophobic, low-friction, moisture-sealing, anti-soiling, and self-cleaning to an existing conventional high temperature anti-reflective coating. The top coat imparts superior durability performance and new properties to the under-laying conventional high temperature anti-reflective coating without reducing the anti-reflectiveness of the coating. Methods and data for optimizing the relative thickness of the under-layer high temperature anti-reflective coating and the top-layer thickness for optimizing optical performance are also disclosed.

Owner:FIRST SOLAR INC (US)

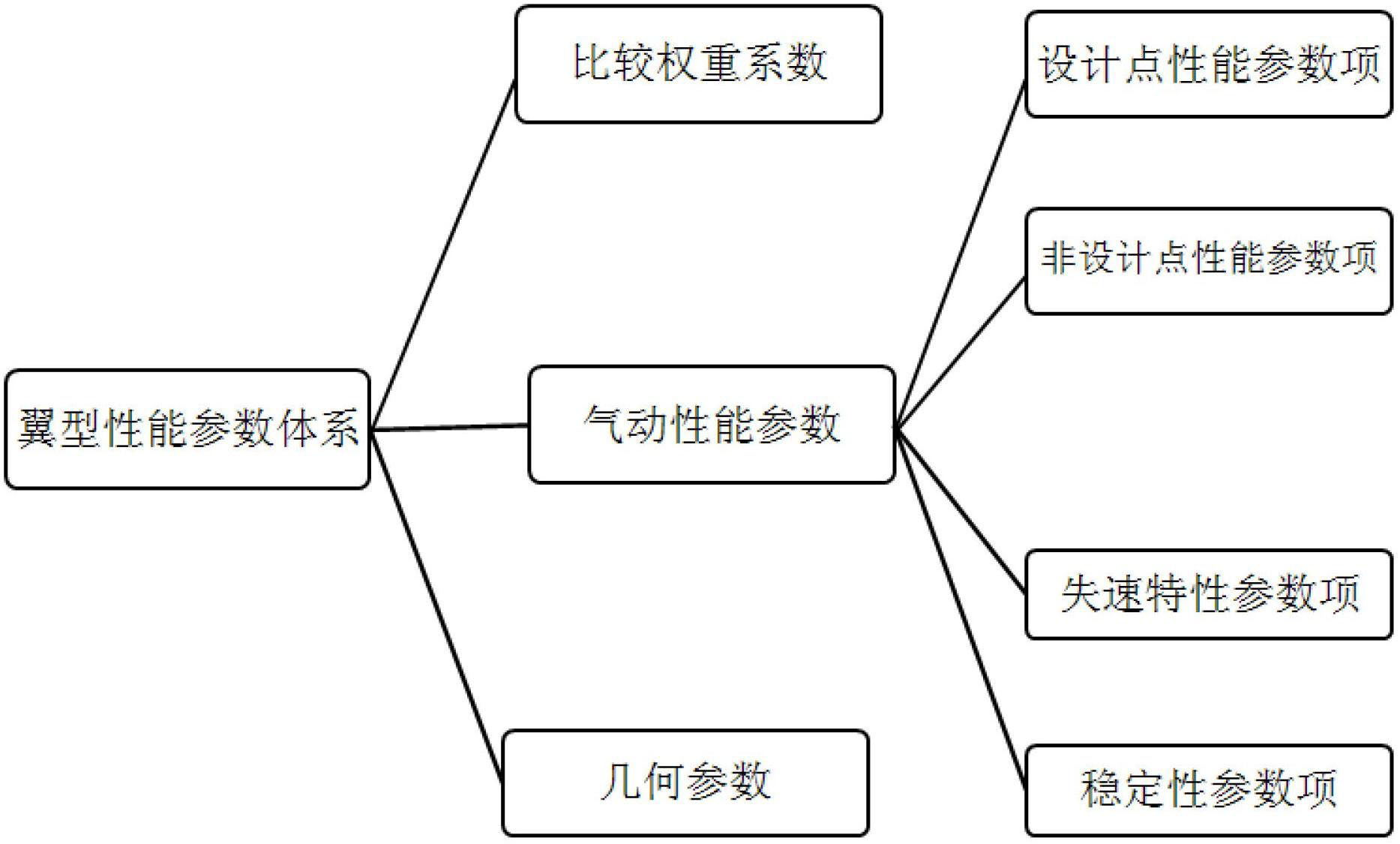

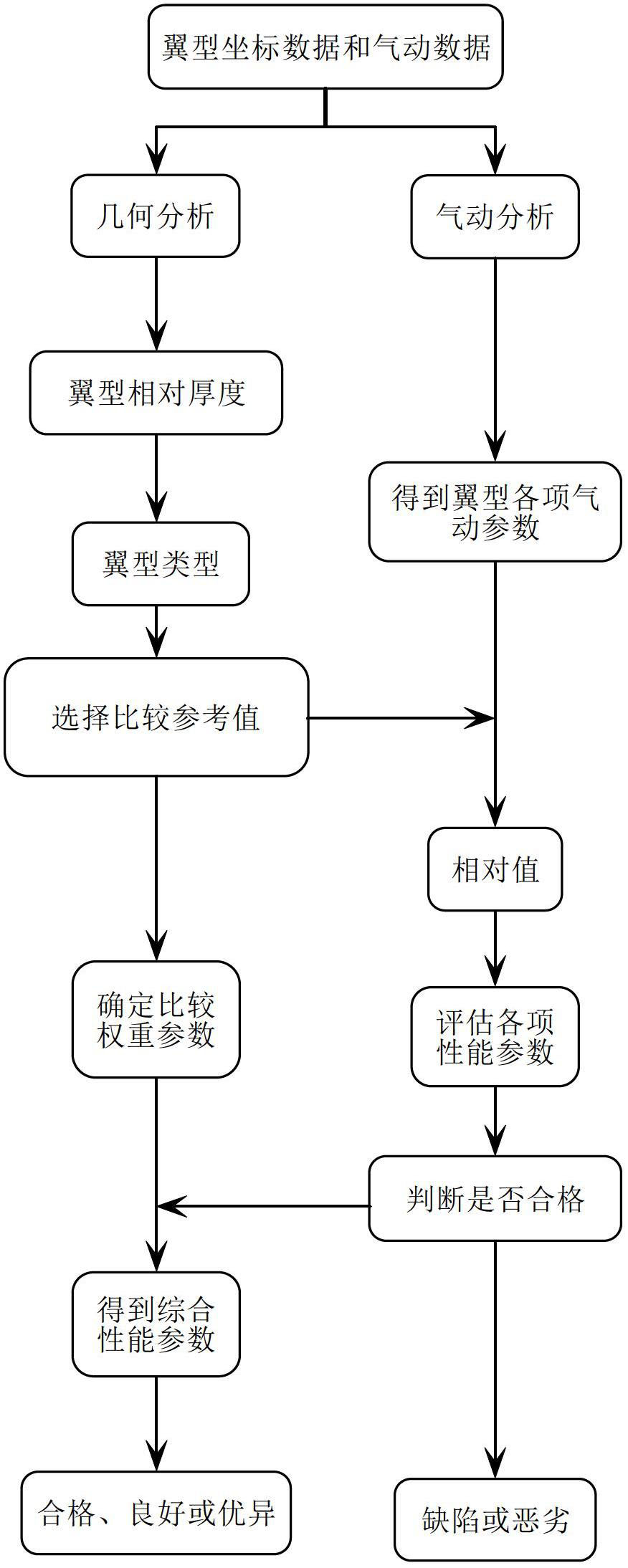

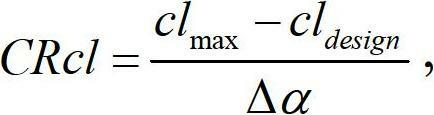

Method for evaluating performance of wing profile special for horizontal axis wind turbine

The invention discloses a method for parameter testing the performance of a wing profile special for a horizontal axis wind turbine. The method comprises the following steps of: firstly, acquiring the wing profile and aerodynamic data thereof; secondly, analyzing the geometry parameter of the wing profile and dividing the wing profile into a thin type and a thick type according to different relative thicknesses; thirdly, obtaining a design point performance parameter item, a non-design point performance parameter item, a stalling characteristic parameter item and a stability parameter item of the wing profile; fourthly, comparing with the performance reference index of the wing profile to obtain a relative value and judging the performance level of the wing profile; and finally, endowing the wing profile with different weight coefficients according to different types of the wing profiles, and calculating an overall performance evaluation value of the wing profile based on the relative value to judge the performance level of the wing profile of the wind turbine. The invention can provide a judging basis and a method for selecting different wing profiles on different parts when wind turbine blades are designed or can be used for evaluating the performance of an intermediate wing profile during design and optimization of new wing profiles.

Owner:中科国风科技有限公司

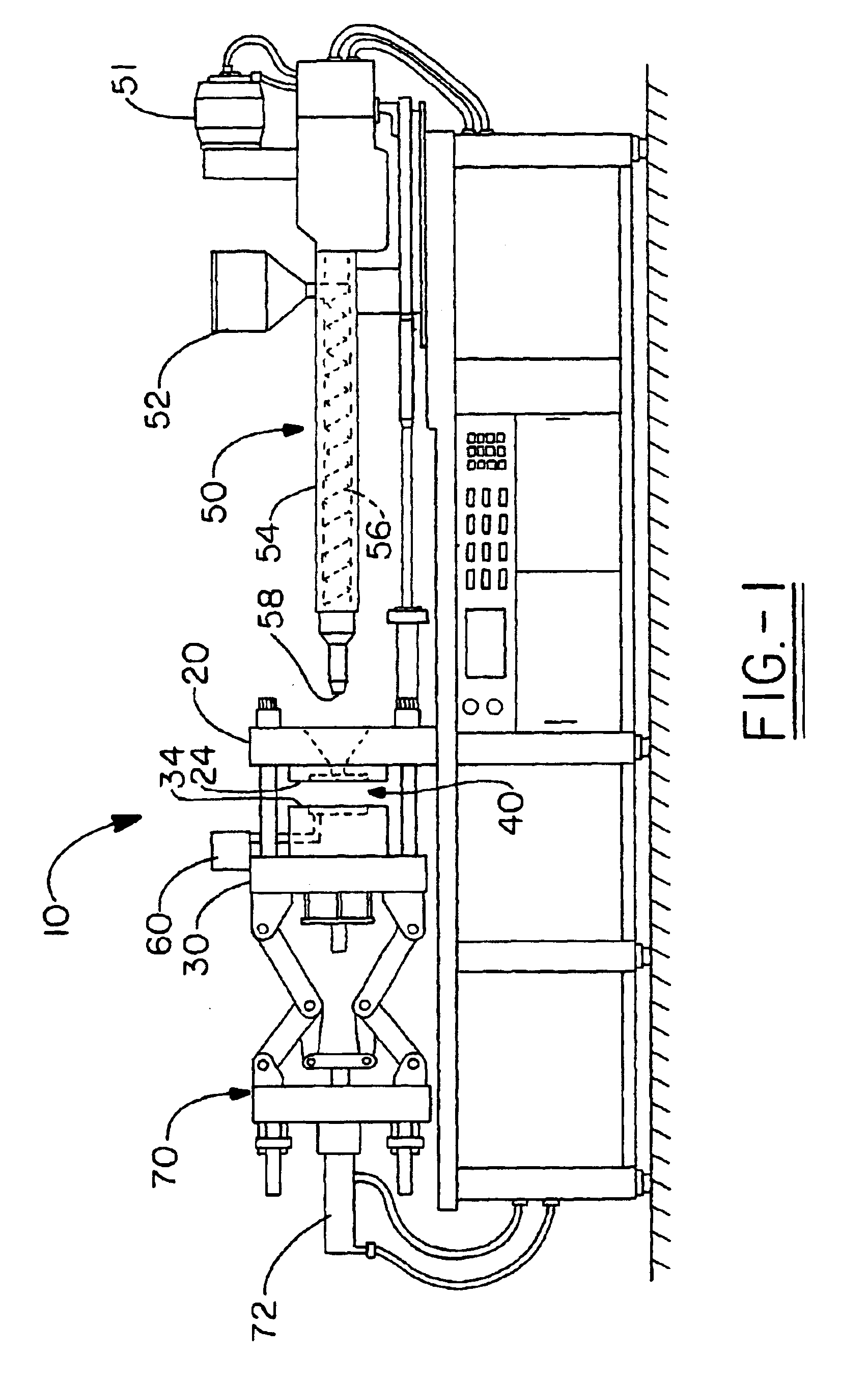

In-mold coating injection inlet flow control

InactiveUS7045213B2Eliminate needGood weather resistanceLiquid surface applicatorsSynthetic resin layered productsPolymer scienceShell molding

Molded articles or substrates having an in-mold coating thereon are disclosed. The in-mold coated substrates are produced by a method wherein the flow of the in-mold composition onto the substrate can be selectively controlled. The molded articles can be preferentially coated in desired or predetermined areas with in-mold coating compositions by controlling the thickness or depth of various sections of the substrate. The present invention provides a molded article with an area of increased relative thickness at the location of in-mold coating injection to encourage or promote in-mold coating flow.

Owner:OMNOVA SOLUTIONS INC

Production technique for ceramic title having semitransparent reflecting decorative surface

ActiveCN101157542AIncreasing the thicknessLively and unique decorative effectPlane surface grinding machinesClaywaresBrickLight effects

The invention discloses a production technique of ceramic tile with translucent reflection decorating surface , which includes such working procedures as biscuit formation, above glazing, silk screen rotary printing, firing process and overglaze polish. The biscuit, being dried, is spurted with the surface glaze that is fired but does not reflect light, and then the dye printing procedure is carried with 180 of multi-channel silk screens. The last channel of silk screen adopts the 80 of silk screen dye printing with the relative thickness of white translucent ceramic glaze, and then is heated to 1,170 DEG C in a kiln stove for 50 to 60 minutes. After the firing, the flexible polishing unit is used to do micro polishing on the tile glaze, thereby ensuring that the bulges of the white translucent glaze is positioned at the most outer surface flat and ensuring that the sunken part is unchanged. The craft enables the face of the tile to have light and shade, and partly visible changes under the light effect, thereby greatly enriching the decoration effect of the grain pattern of the face of brick.

Owner:GUANGDONG KITO CERAMICS GROUP CO LTD

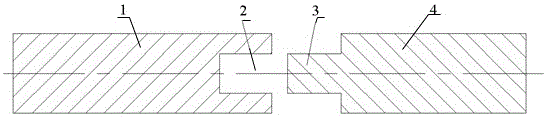

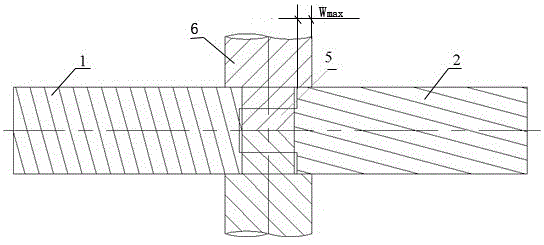

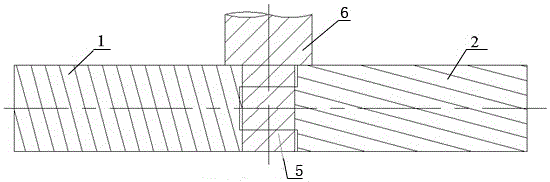

Friction stir welding method for different metal plates

ActiveCN105965150AAvoid it happening againEasy to shapeWelding/soldering/cutting articlesMetal working apparatusStress conditionsTransition layer

The invention provides a friction stir welding method for different metal plates. The friction stir welding method for different metal plates comprises the following steps that (1) the relative thicknesses of two metal plates are determined; (2) connector structures are machined at the welding end of the two metal plates, specifically, a rectangular groove is machined in the welding end of the low-melting point metal plate, and a rectangular boss is machined at the welding end of the high-melting point metal plate, and the height and thickness of the rectangular boss are matched with the depth and width of the rectangular groove correspondingly; (3) whether a transition layer capable of avoiding or reducing generated intermetallic compounds needs to be additionally arranged or nor is determined, specifically, the transition layer is arranged on the surface of the rectangular boss if the ductility of the intermetalic compounds between the two metal plates is not larger than 2%, otherwise, the next step is executed directly; (4) the two metal plates are fixed through clamps; (5) welding technological parameters are set; and (6) welding of the two metal plates is completed through a stirring head according to the set welding technological parameters. According to the friction stir welding method for different metal plates, the welding quality is high, and the stress condition of connectors can be improved.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com