Patents

Literature

12744 results about "Magnesium alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnesium alloys are mixtures of magnesium with other metals (called an alloy), often aluminum, zinc, manganese, silicon, copper, rare earths and zirconium. Magnesium is the lightest structural metal. Magnesium alloys have a hexagonal lattice structure, which affects the fundamental properties of these alloys. Plastic deformation of the hexagonal lattice is more complicated than in cubic latticed metals like aluminium, copper and steel; therefore, magnesium alloys are typically used as cast alloys, but research of wrought alloys has been more extensive since 2003. Cast magnesium alloys are used for many components of modern automobiles and have been used in some high-performance vehicles; die-cast magnesium is also used for camera bodies and components in lenses.

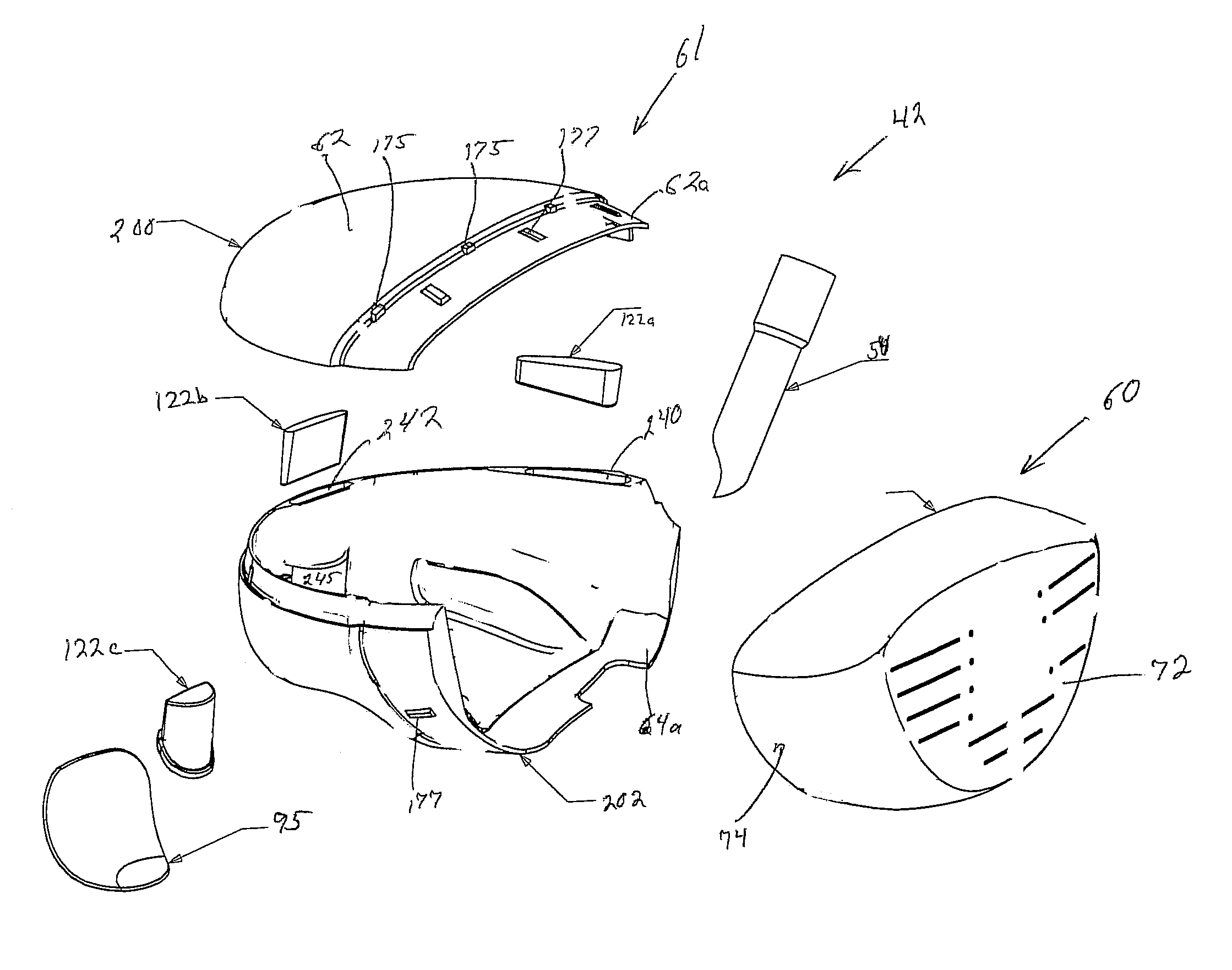

Multiple material golf club head

Owner:TOPGOLF CALLAWAY BRANDS CORP

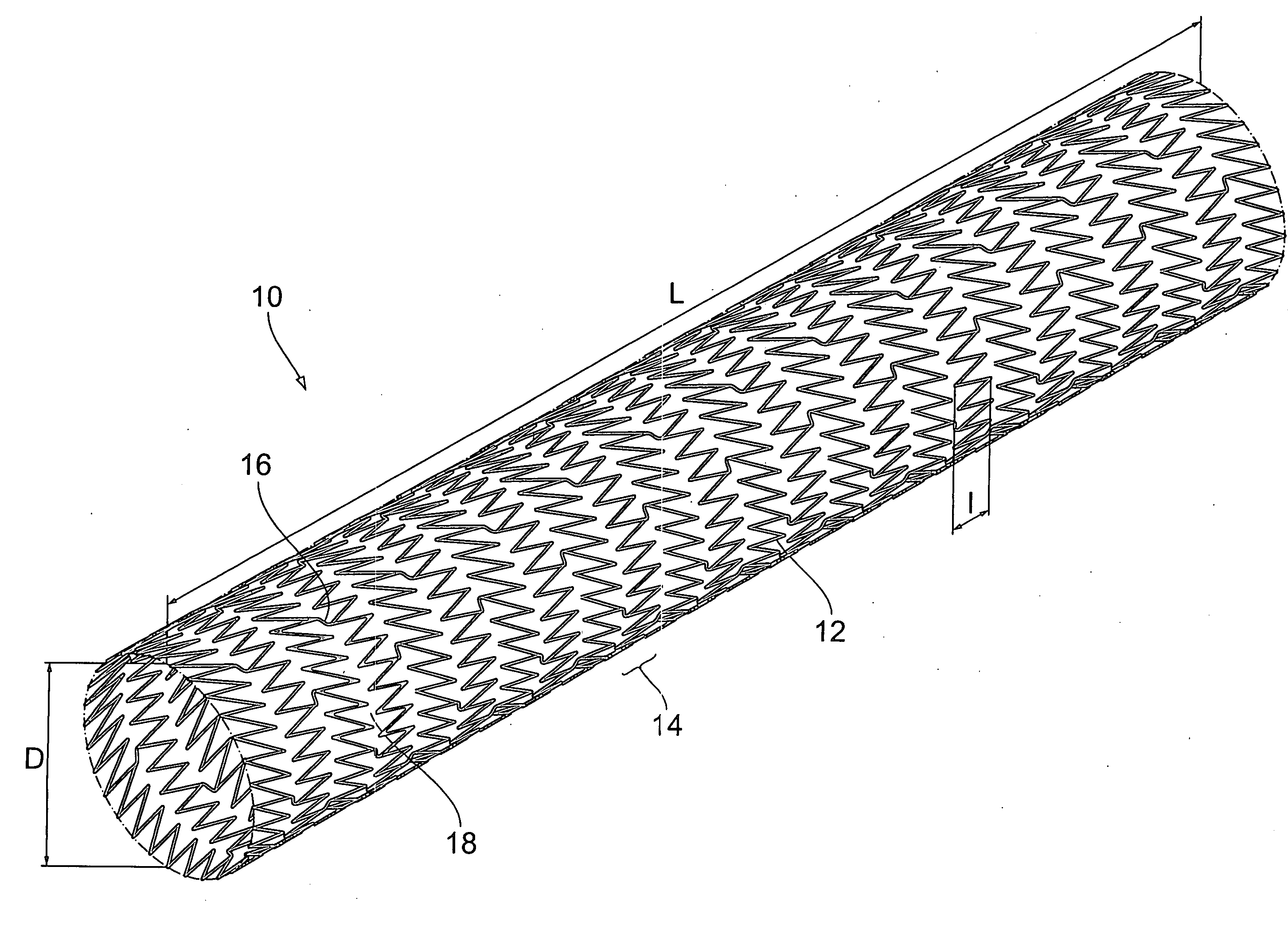

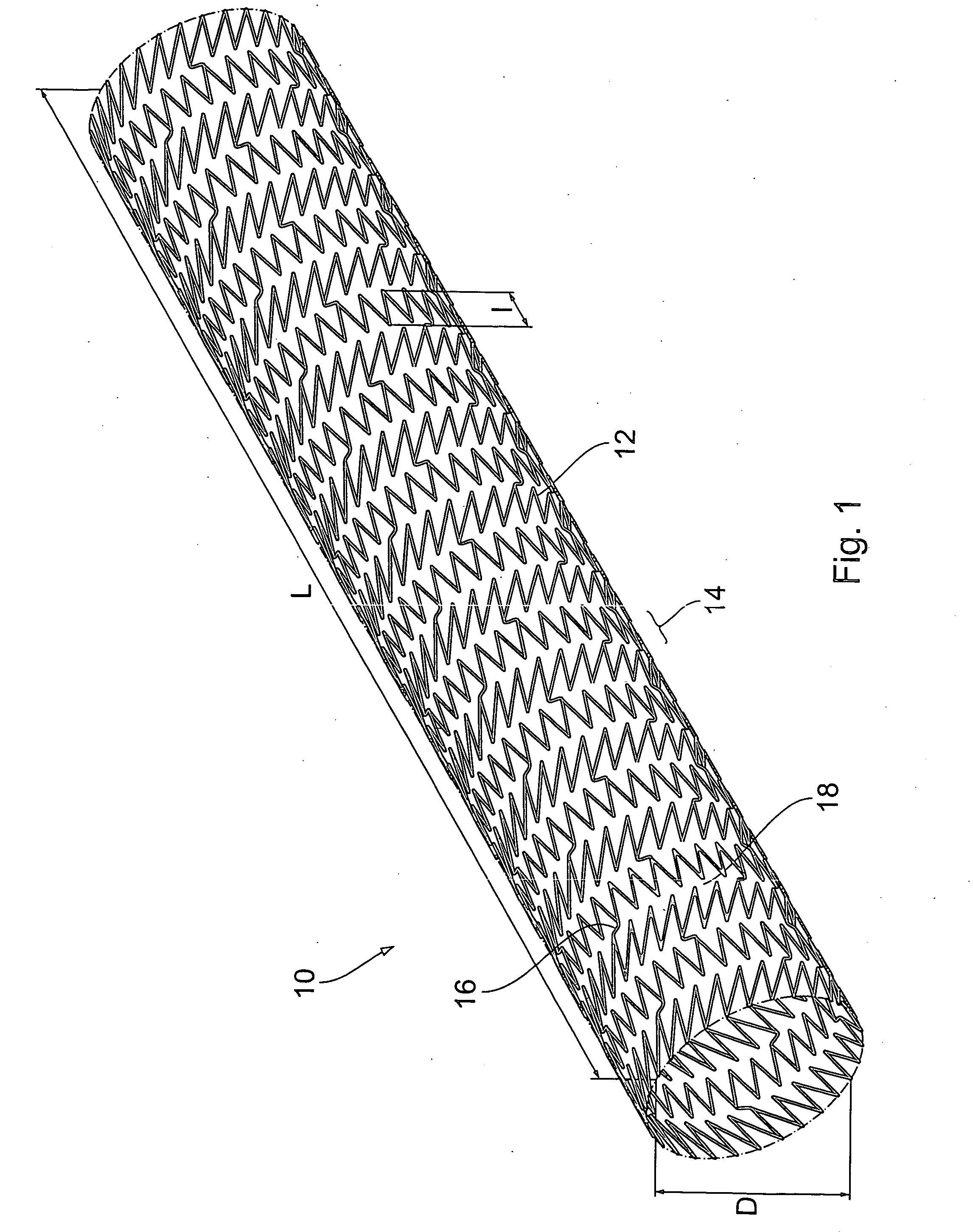

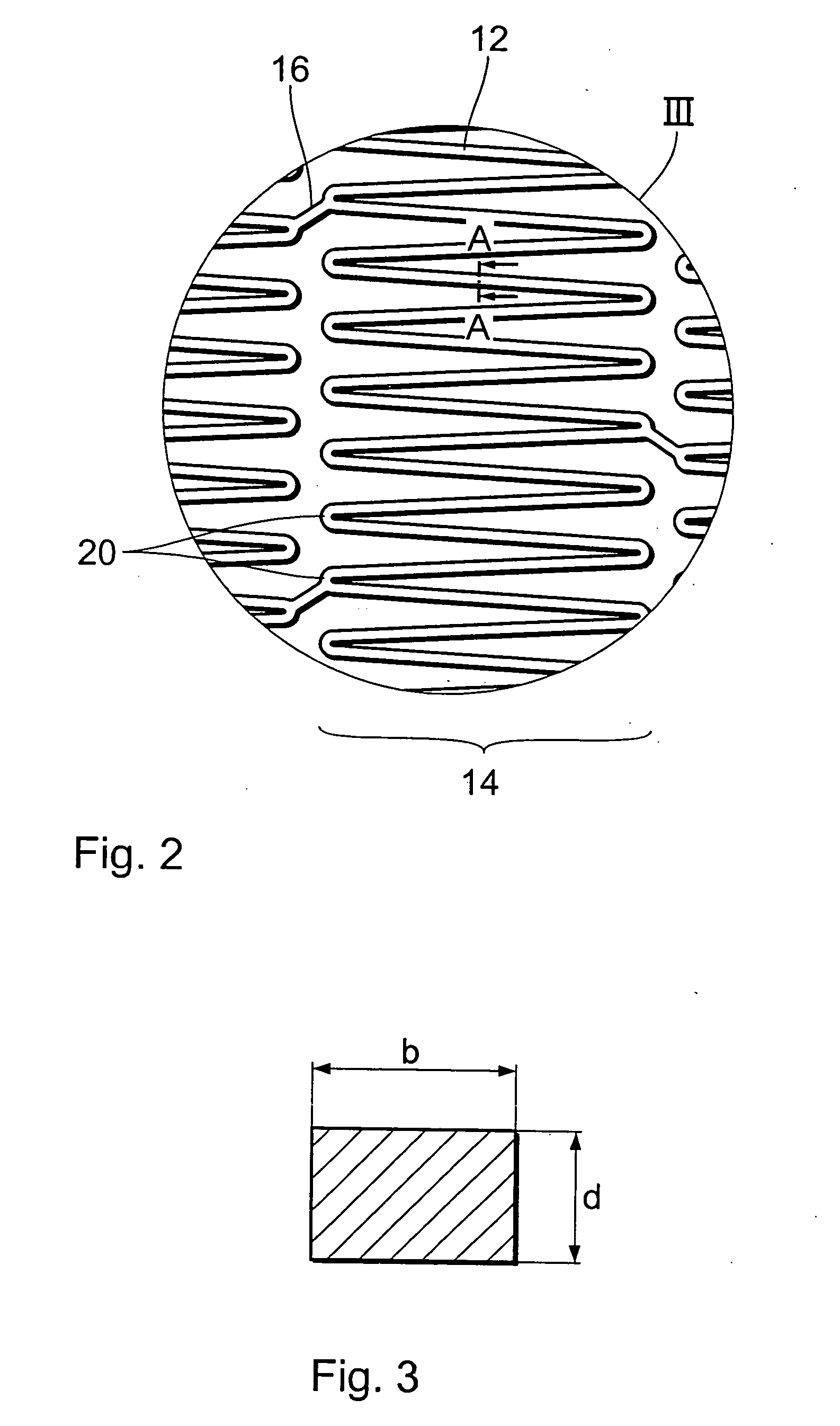

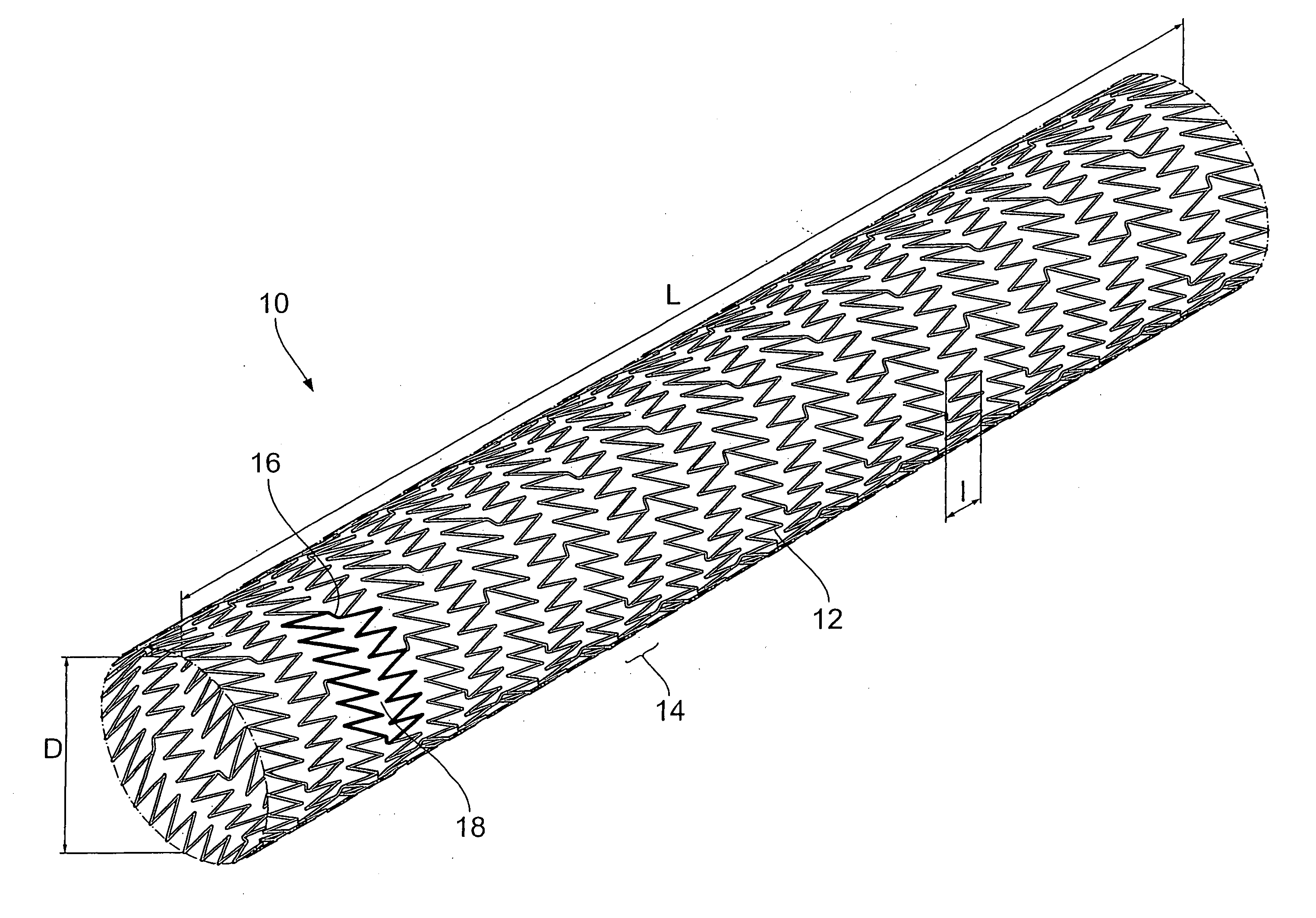

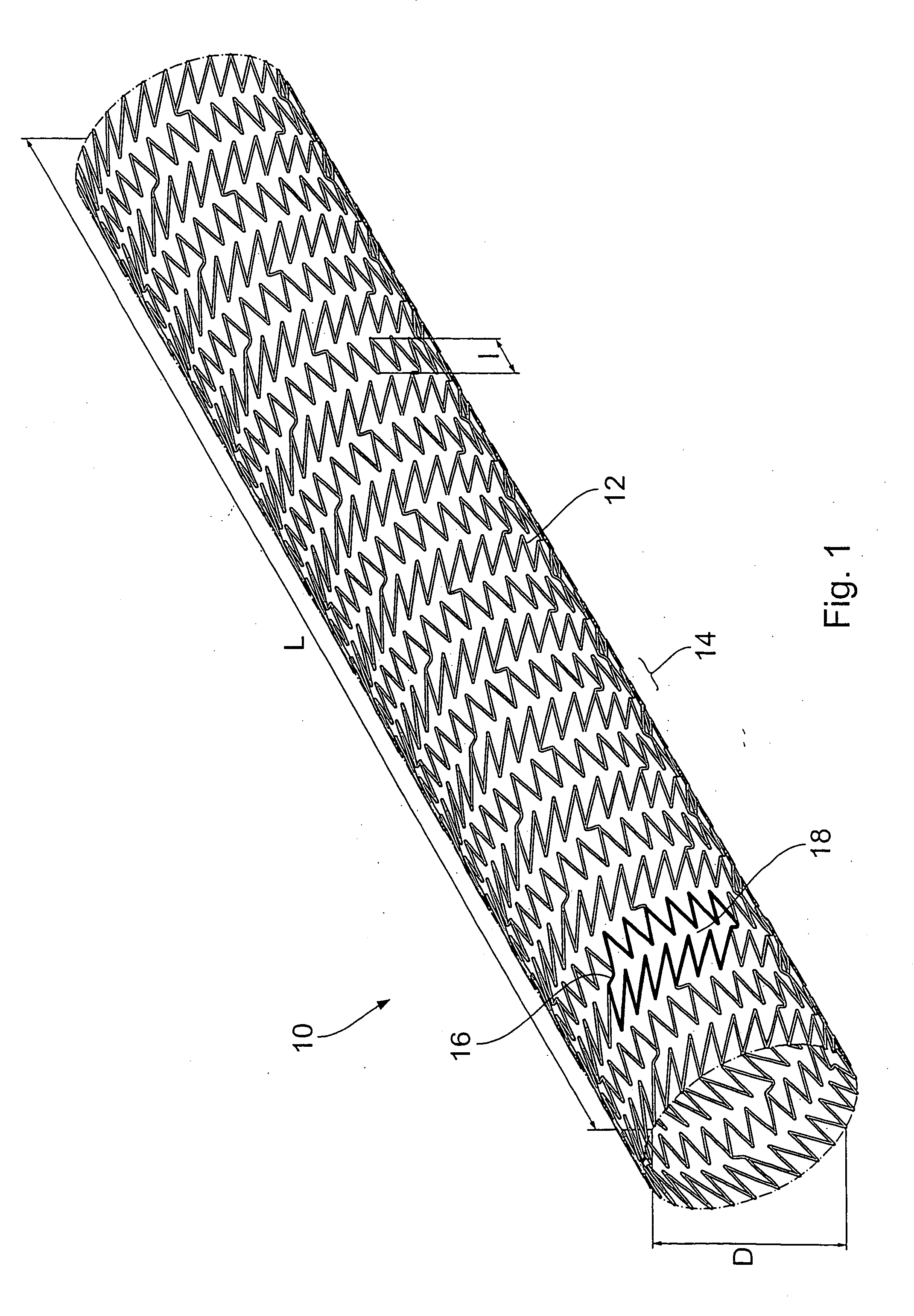

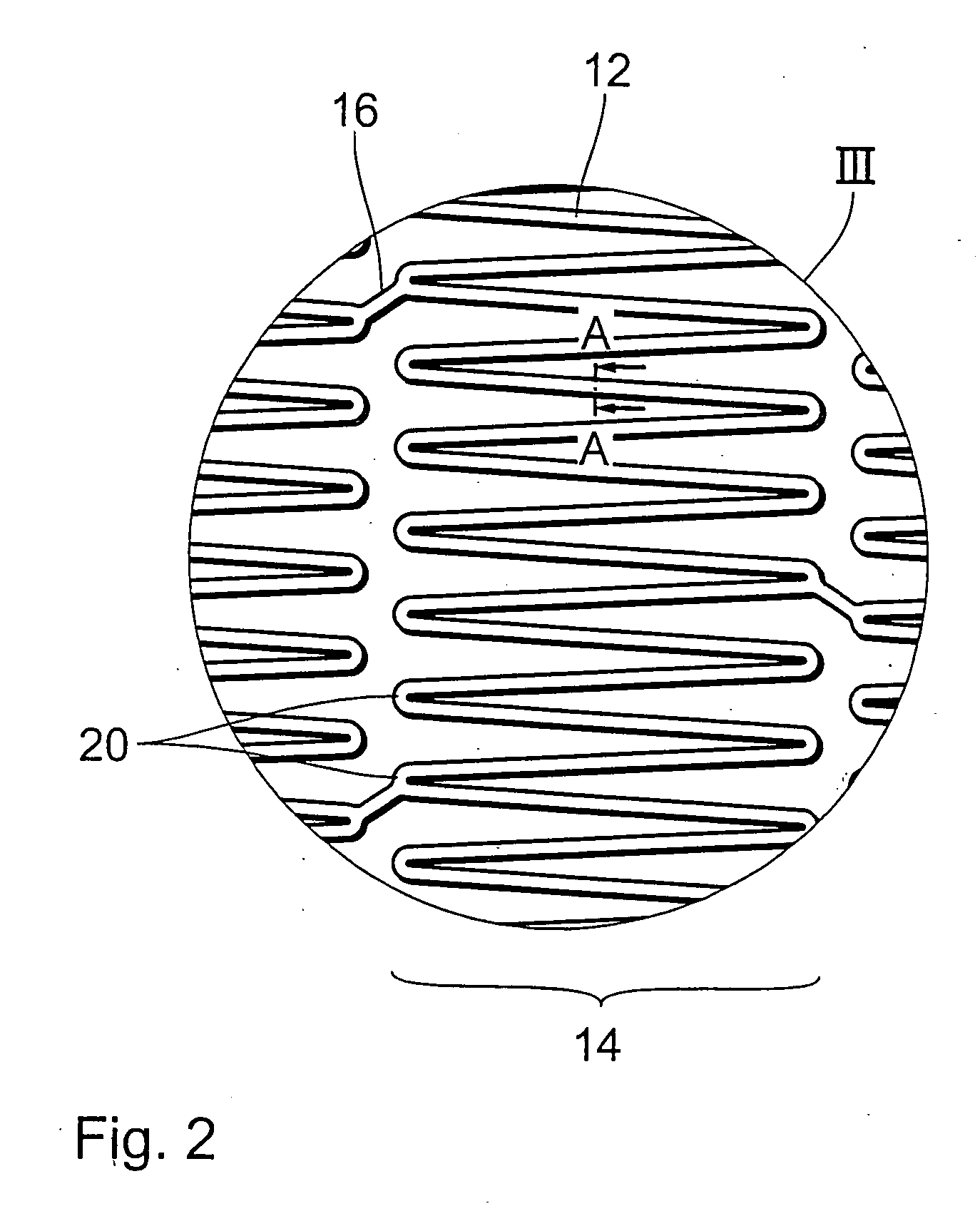

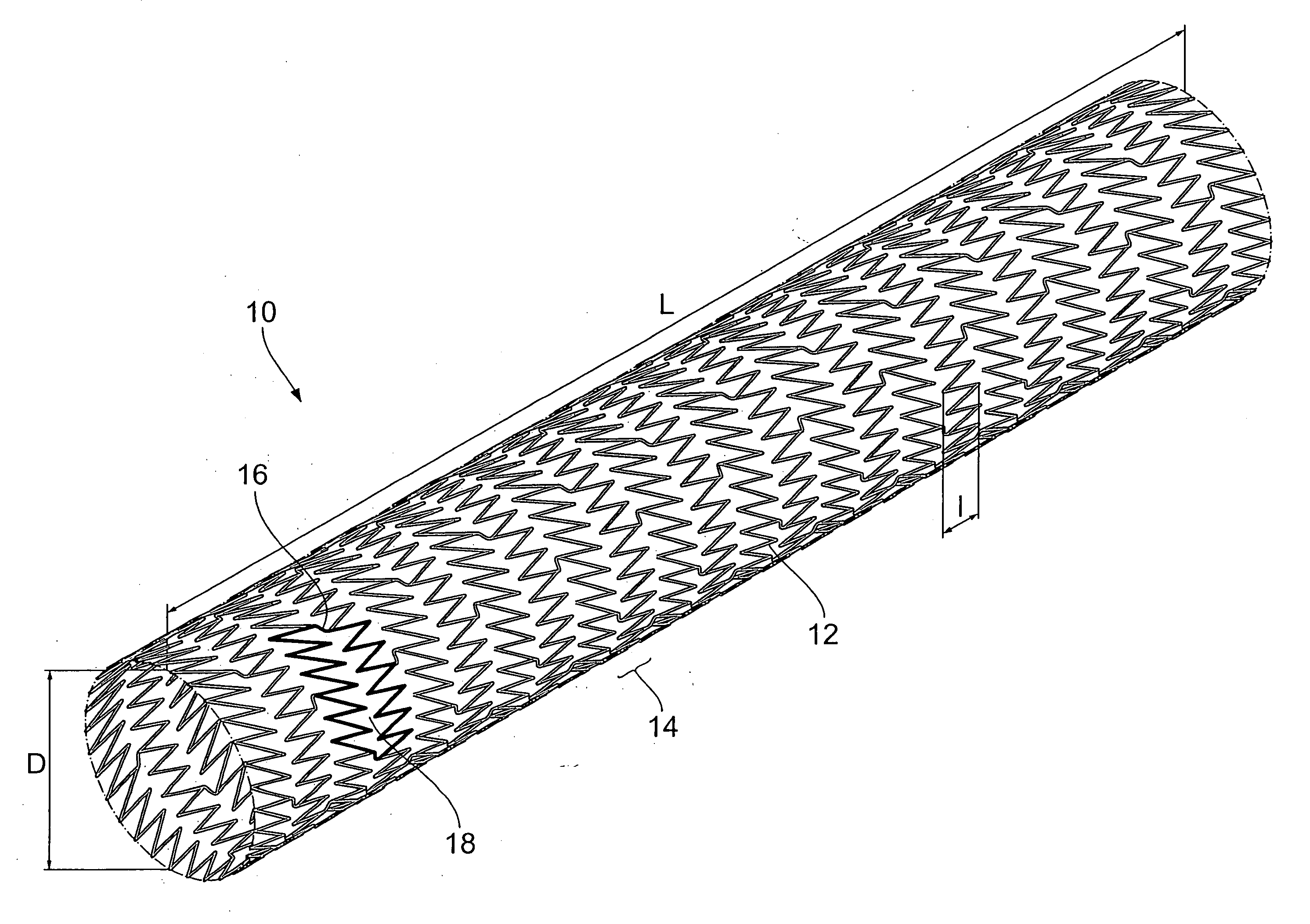

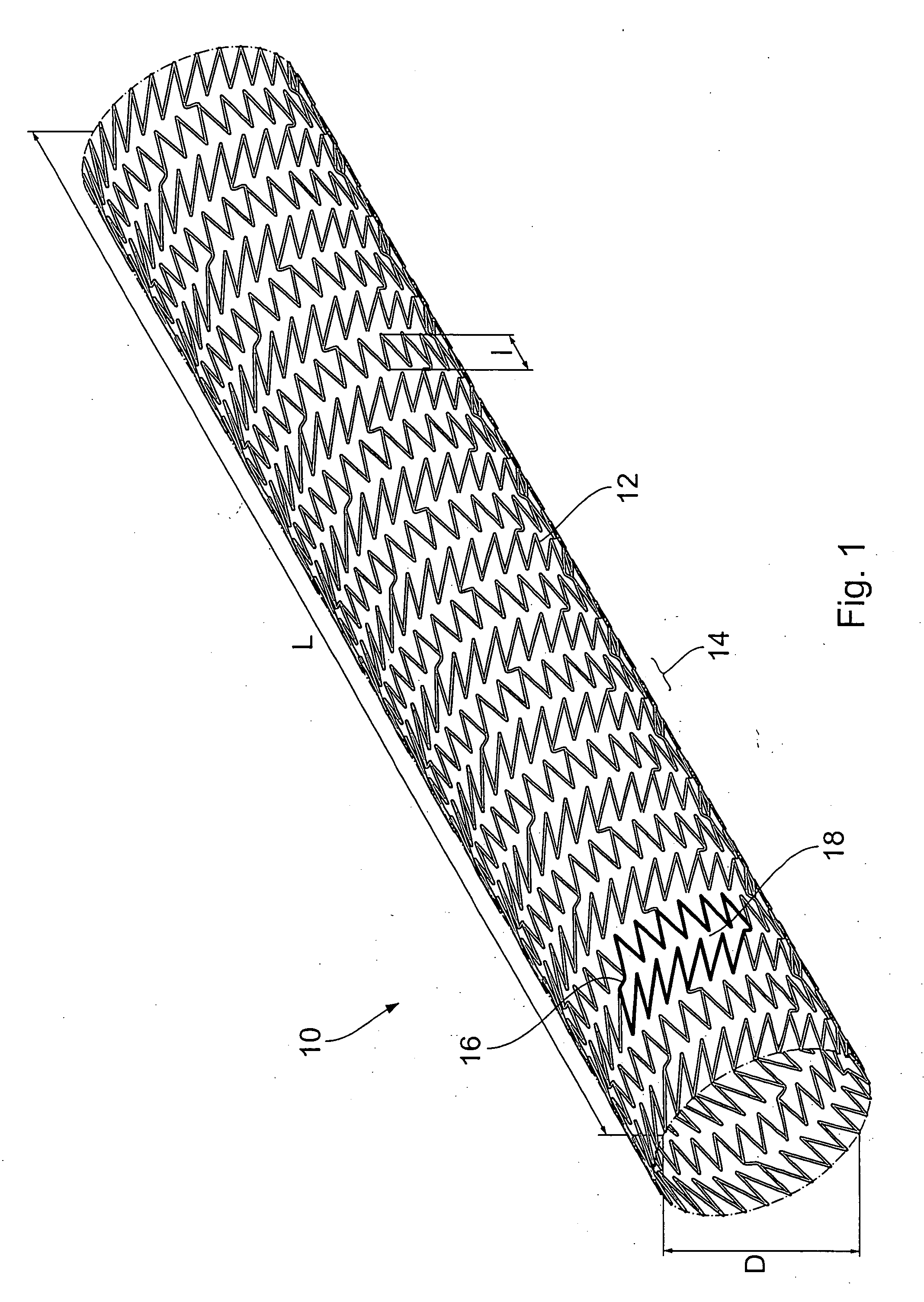

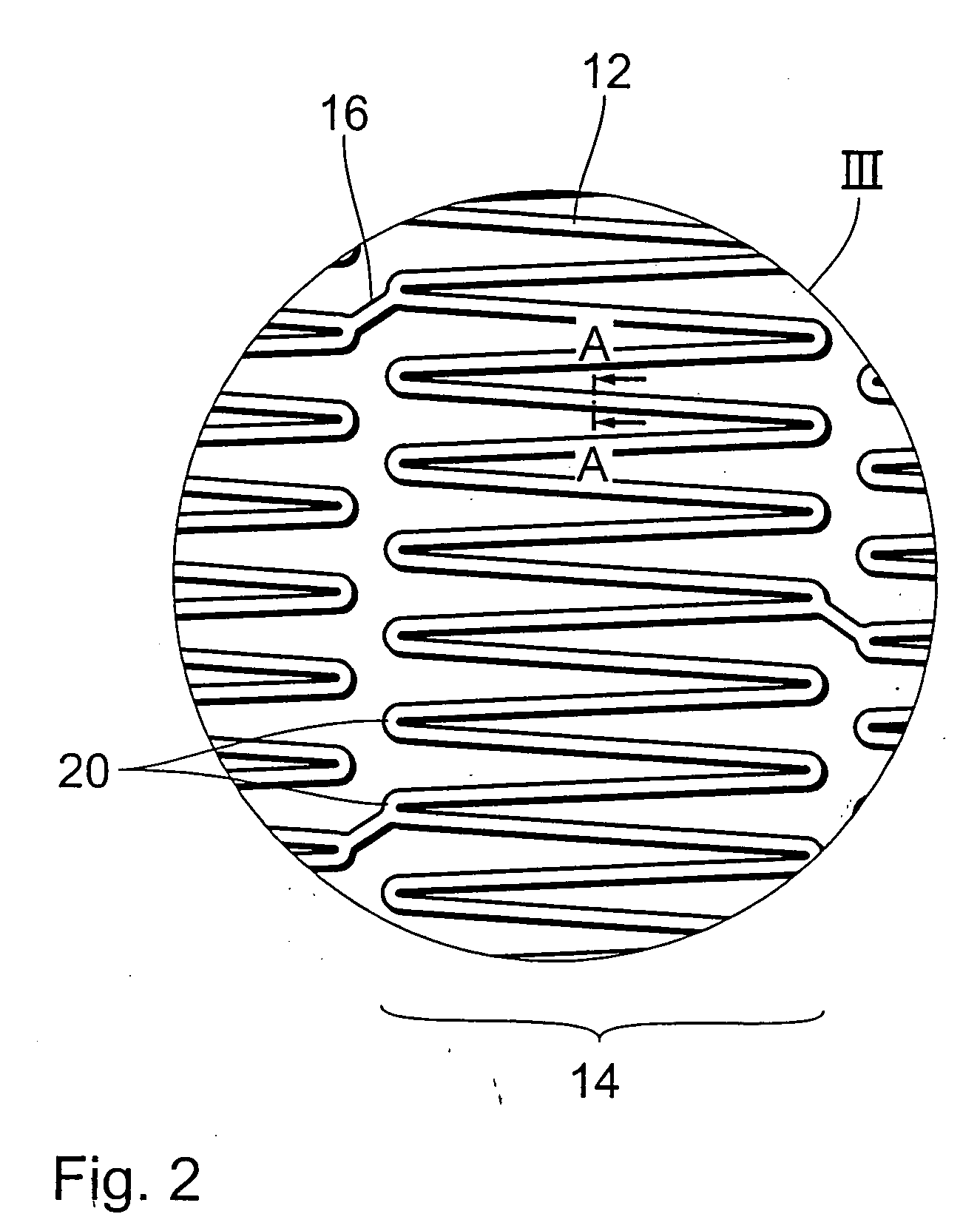

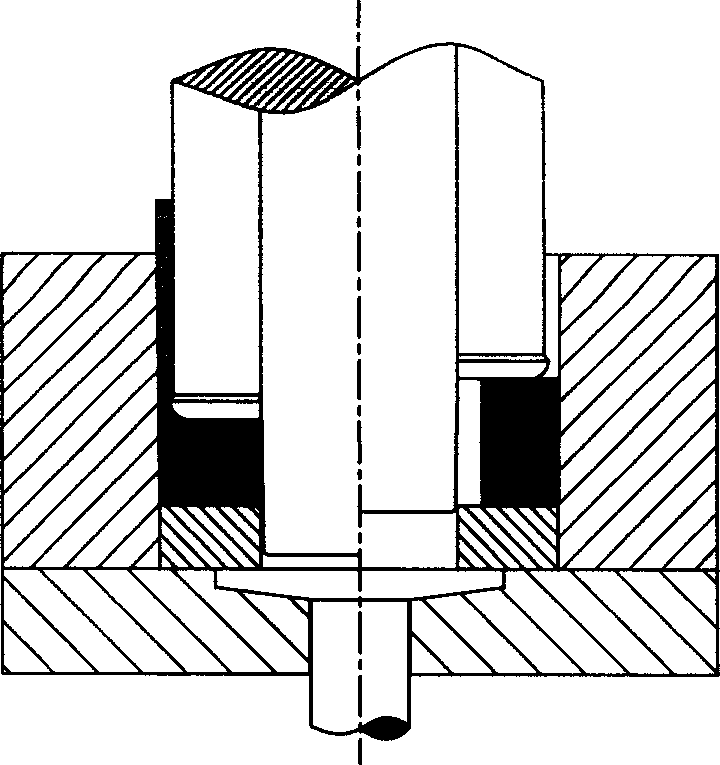

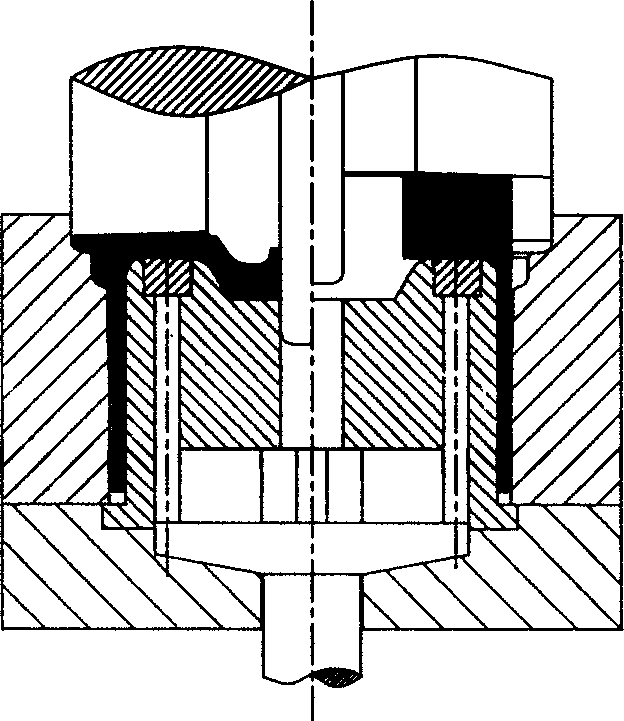

Endoprosthesis comprising a magnesium alloy

InactiveUS20060052863A1Improve mechanical stabilityLong degradation timeStentsSurgeryMischmetalInsertion stent

An endoprosthesis, in particular an intraluminal endoprosthesis such as a stent, comprises a carrier structure, which includes at least one component comprising a magnesium alloy of the following composition: Magnesium: between about 60.0 and about 88.0% by weight Rare earth metals: between about 2.0 and about 30.0% by weight Yttrium: between about 2.0% and about 20.0% by weight Zirconium: between about 0.5% and about 5.0% by weight Balance: between 0 and about 10.0% by weight wherein the alloy components add up to 100% by weight.

Owner:BIOTRONIK AG

Endoprosthesis comprising a magnesium alloy

An endoprosthesis, in particular an intraluminal endoprosthesis such as a stent, comprises a carrier structure, which includes at least one component comprising a magnesium alloy of the following composition: Rare earth metals: between about 2.0 and about 5.0% by weight, with neodymium between about 1.5 and about 3.0% by weight Yttrium: between about 3.5% and about 4.5% by weight Zirconium: between about 0.3% and about 1.0% by weight Balance: between 0 and about 0.5% by weight wherein magnesium occupies the proportion by weight that remains to 100% by weight in the alloy.

Owner:BIOTRONIK VI PATENT

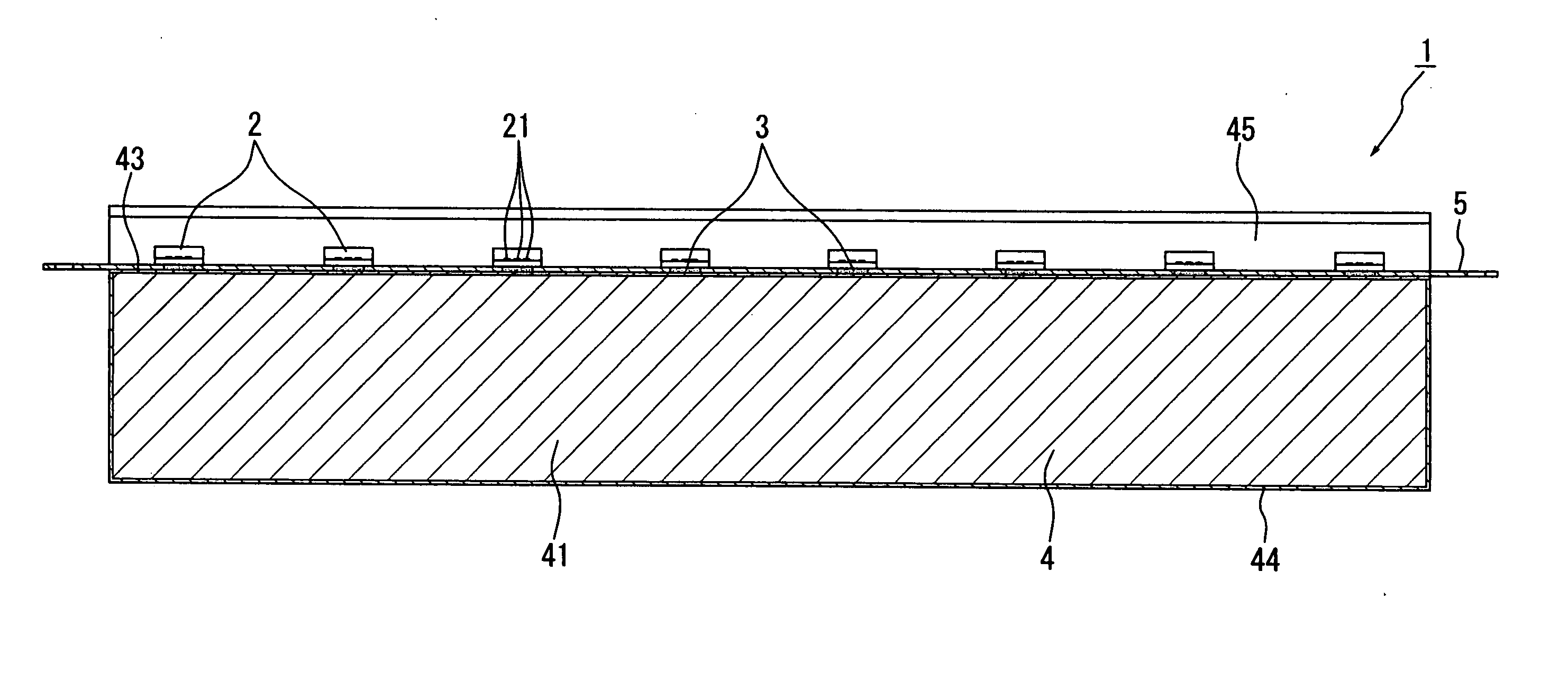

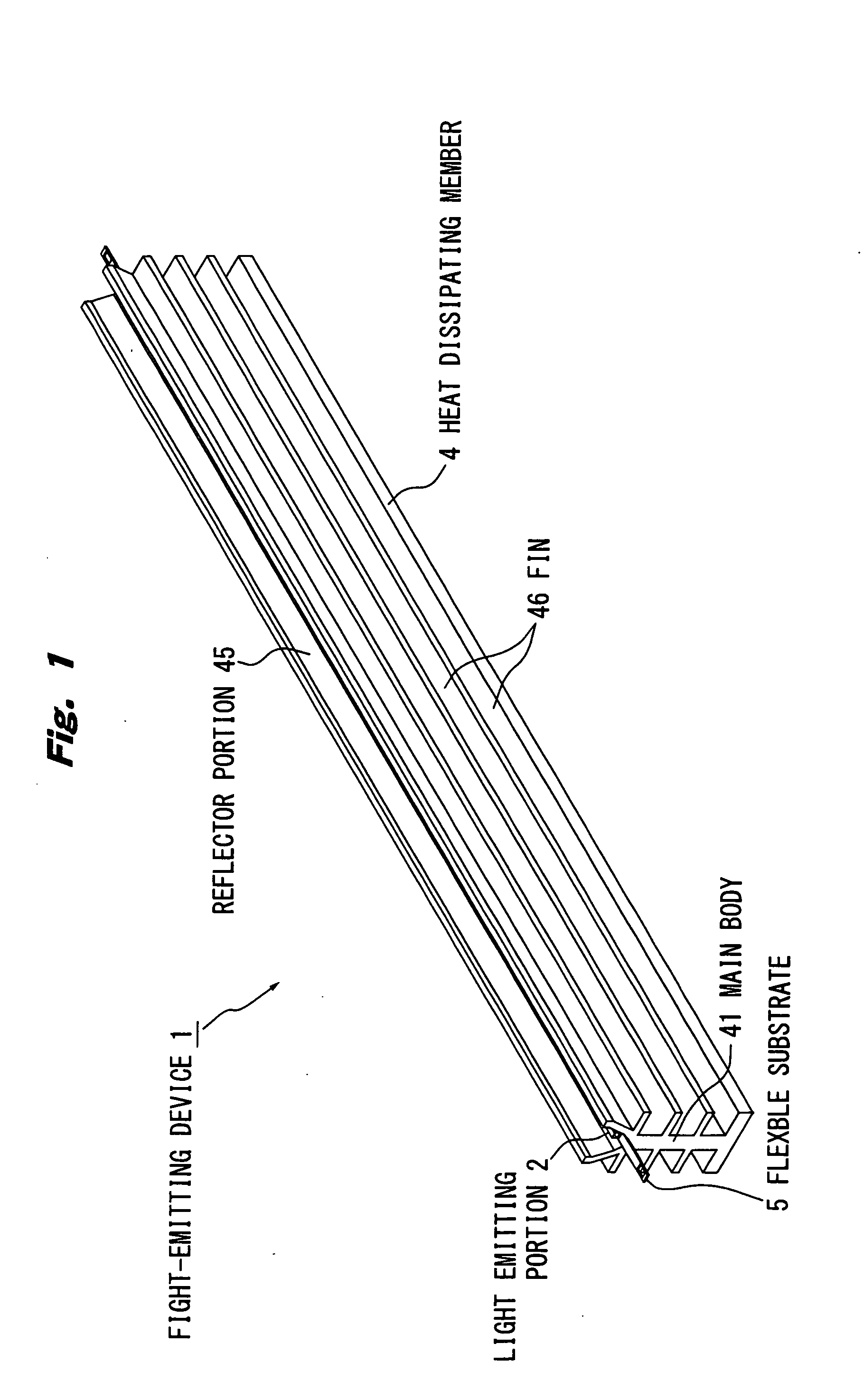

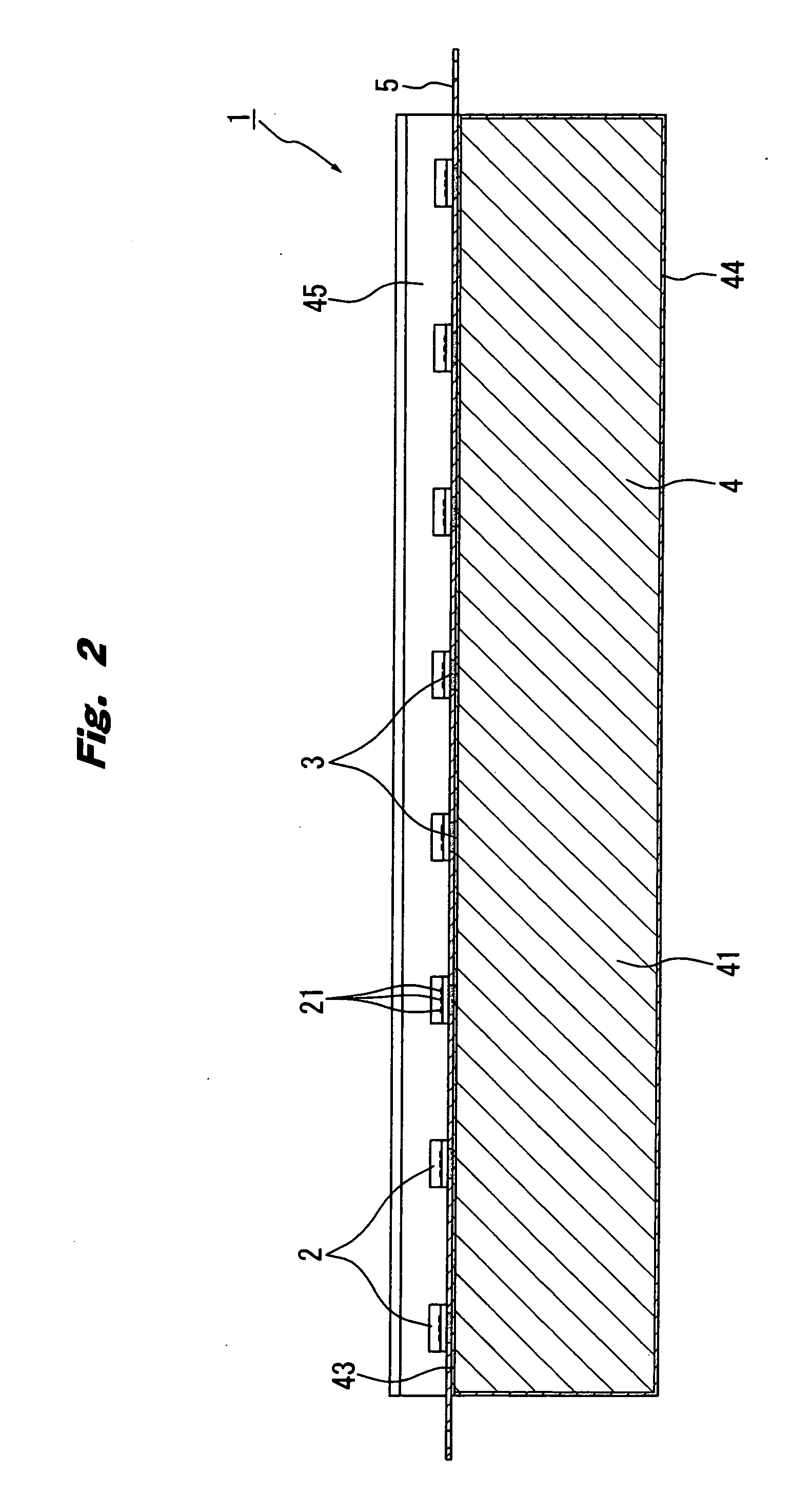

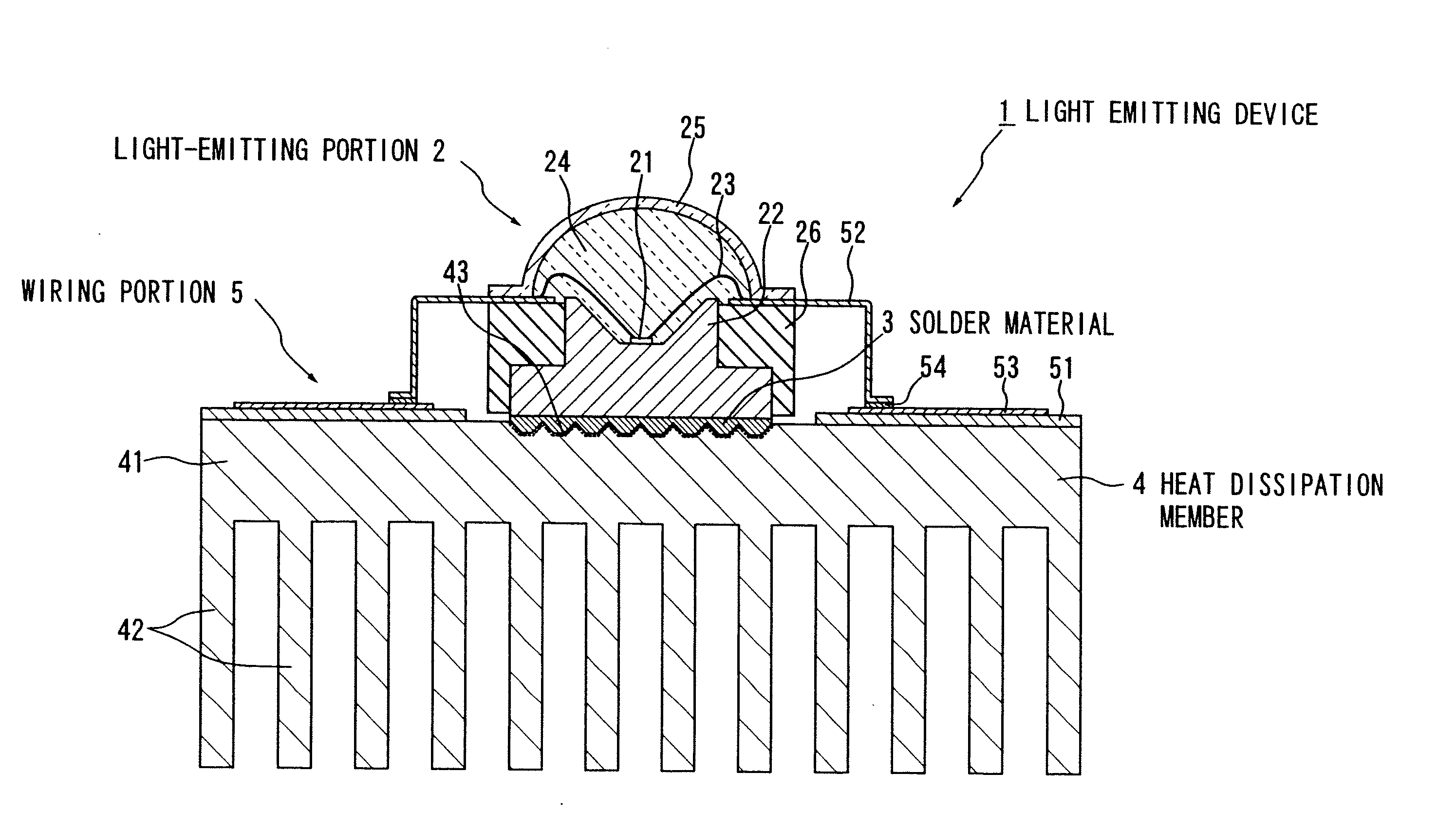

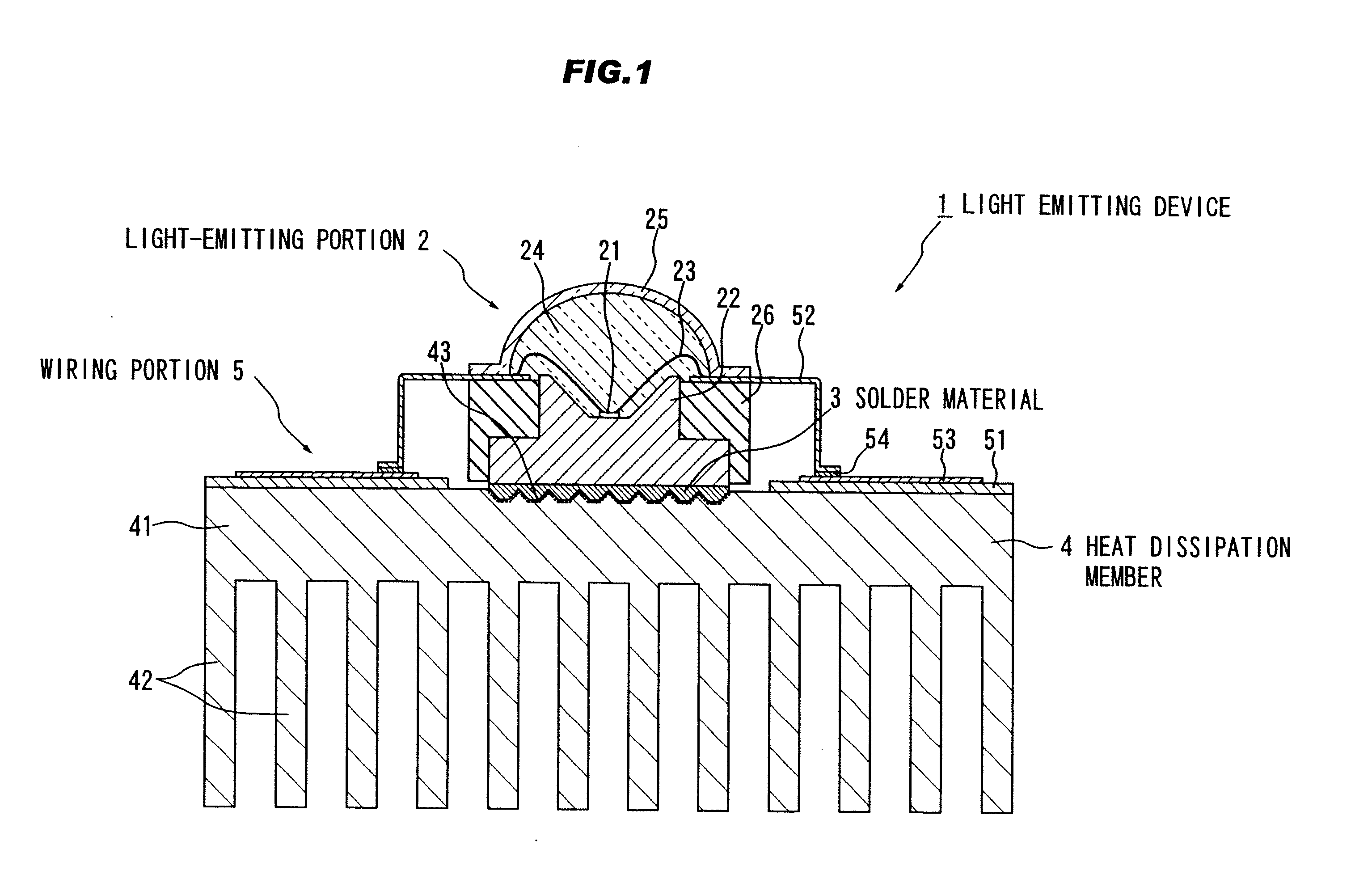

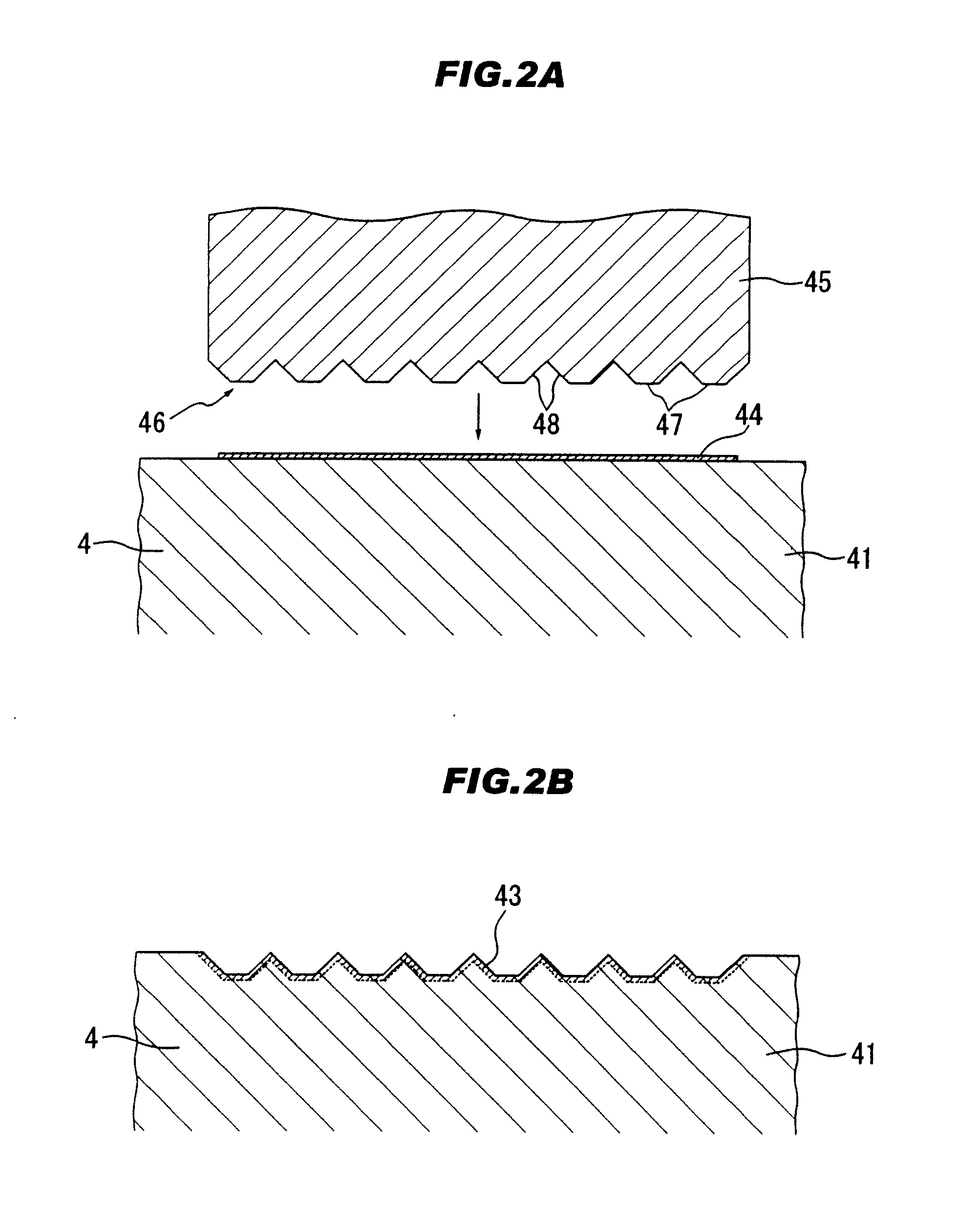

Light-emitting device and method of manufacturing the same

InactiveUS20100214777A1Increase the number ofImprove cooling efficiencyLighting support devicesPoint-like light sourceLight emitting deviceSemiconductor

A light-emitting device includes a light emitting portion comprising a substrate having a mounting surface for mounting a LED element and a metal portion formed on a surface of the substrate opposite to the mounting surface, the substrate comprising ceramic or a semiconductor and the metal portion being bondable to a solder material and a heat dissipating member comprising aluminum, aluminum alloy, magnesium or magnesium alloy, and having, on a surface thereof, a junction treated so as to be bondable to the solder material and a heat dissipating film formed in a periphery of the junction, wherein the metal portion of the light emitting portion is bonded to the junction of the heat dissipating member by the solder material.

Owner:TOYODA GOSEI CO LTD

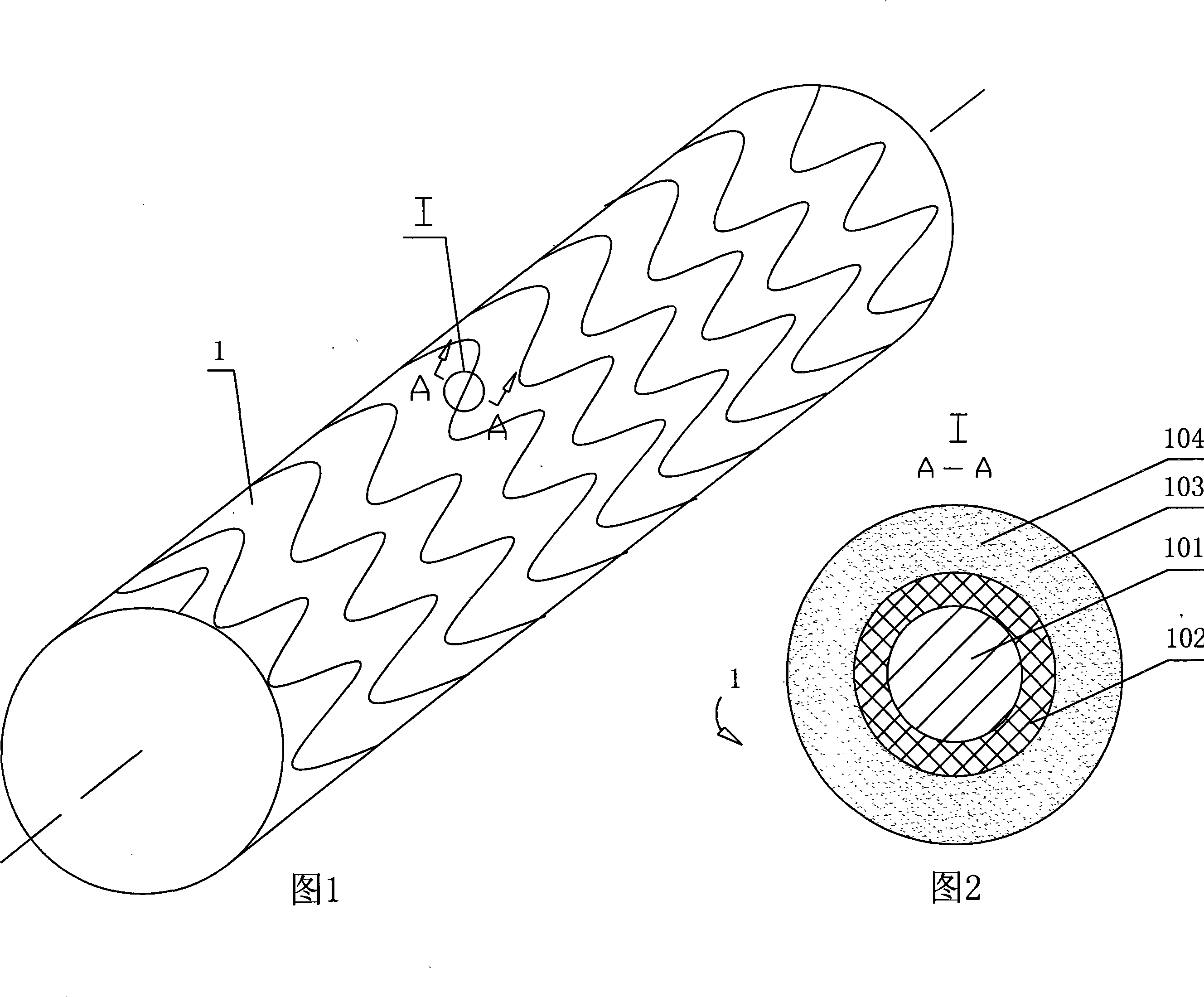

Absorbable stent comprising coating for controlling degradation and maintaining pH neutrality

InactiveUS20070135908A1Simple designImprove the environmentSurgeryCoatingsMedicineMetallic materials

A biocompatible metallic material may be configured into any number of implantable medical devices, including intraluminal stents. The biocompatible metallic material may comprise a magnesium alloy. The magnesium alloy implantable medical device may be designed to degrade over a given period of time. In order to control the degradation time, the device may be coated or otherwise have affixed thereto one or more coatings, one of which comprises a material for controlling the degradation time and maintain a pH neutral environment proximate the device. Additionally, therapeutic agents may be incorporated into one or more of the coatings on the implantable medical device.

Owner:WYETH LLC

Easily-soluble magnesium alloy material as well as production method and application thereof

The invention discloses an easily-soluble magnesium alloy material which comprises the following elements such as Al, Li, Ca, Zn, In, Ga, Si, Zr, and the like. The invention further discloses a preparation method of the easily-soluble magnesium alloy material. The easily-soluble magnesium alloy material is used for producing products such as a ball sealer, a target, and the like, has technical characteristic of being easy to dissolve or quick to degrade, and can be designed into an oil exploitation underground component or an underground component which is used for performing a temporary function or is temporarily needed. Compared with the prior art, the easily-soluble magnesium alloy material has the advantages as follows: a high operation cost problem for secondary drilling or milling is solved or avoided, and technical and economic effects with low cost and high efficiency are obtained. Meanwhile, the magnesium alloy density is proper, molten slag or corrosion products of the magnesium alloy satisfy flow-back operation technical requirements, and technical effects with multiple advantages of being simple, efficient, environment-friendly, energy-saving, and the like, can be obtained.

Owner:NINGBO HIGH NEW DISTRICT RONGCHUANG NEW MATERIAL SCI & TECH

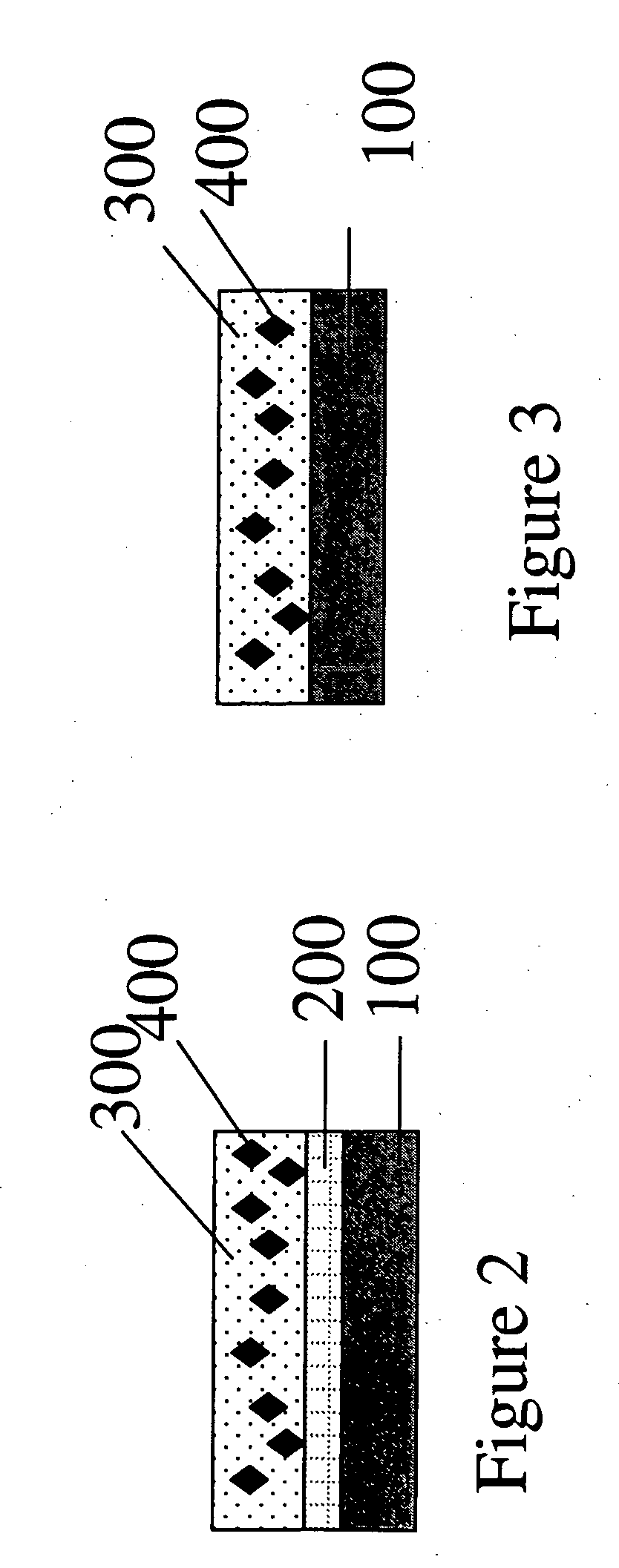

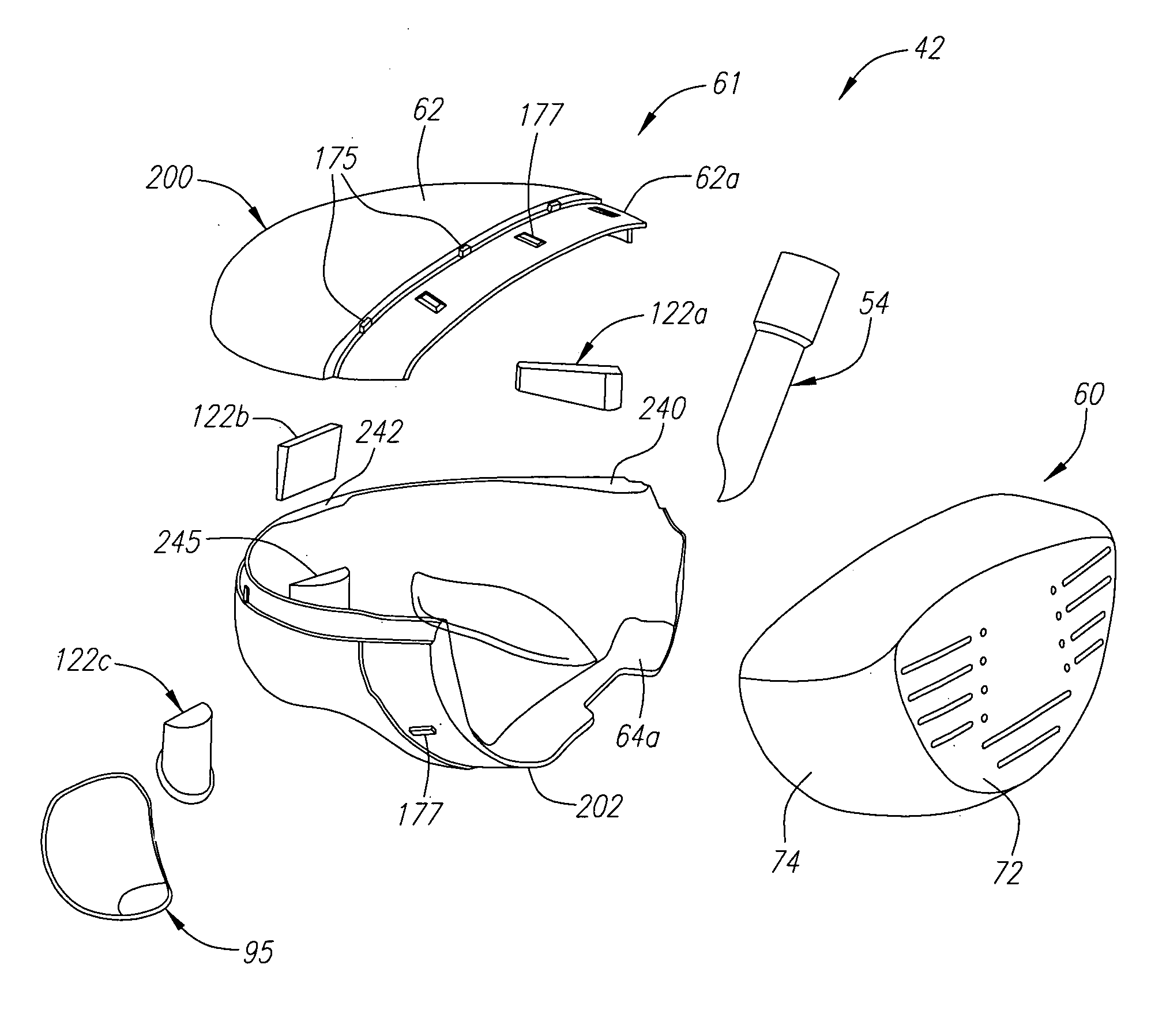

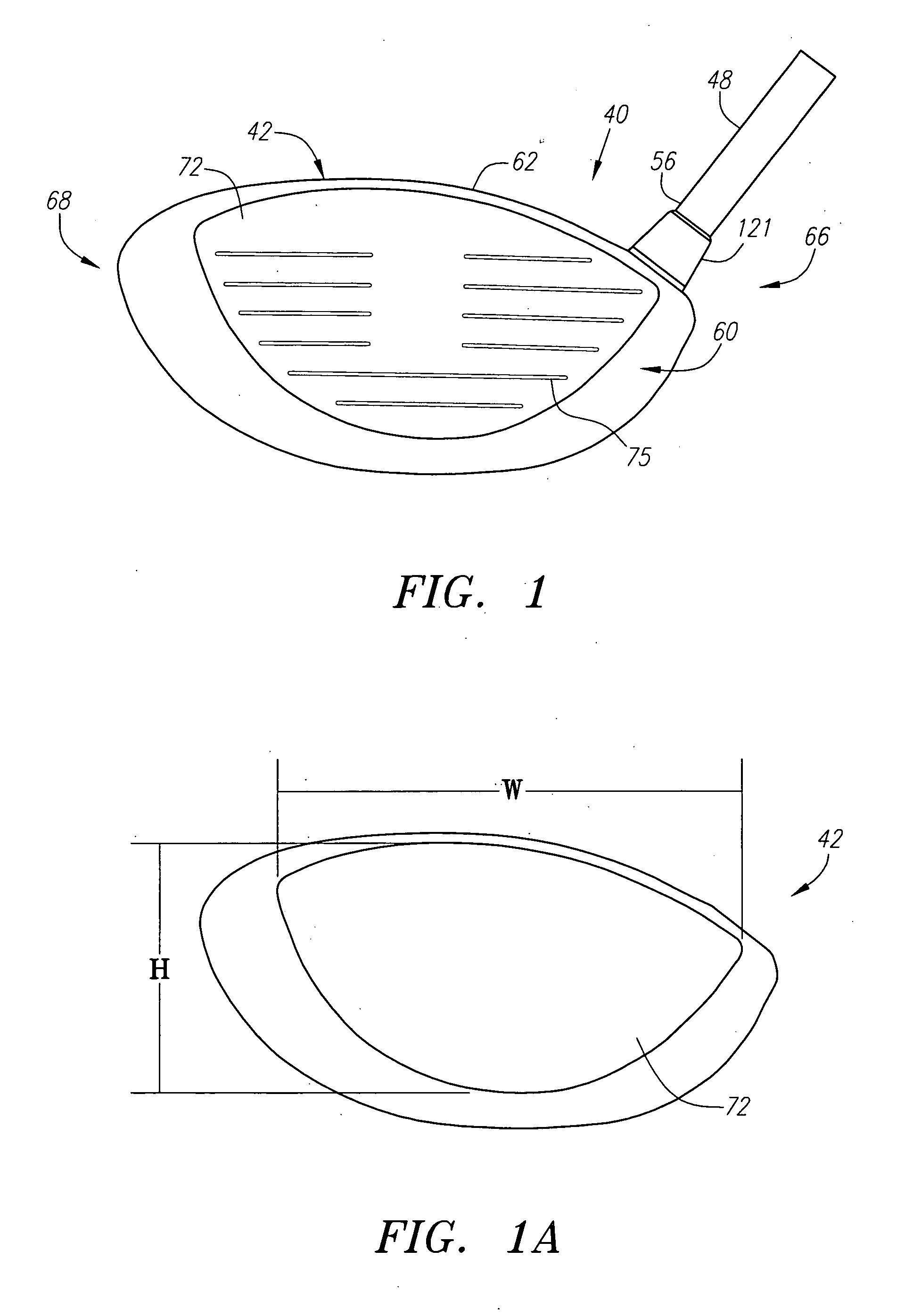

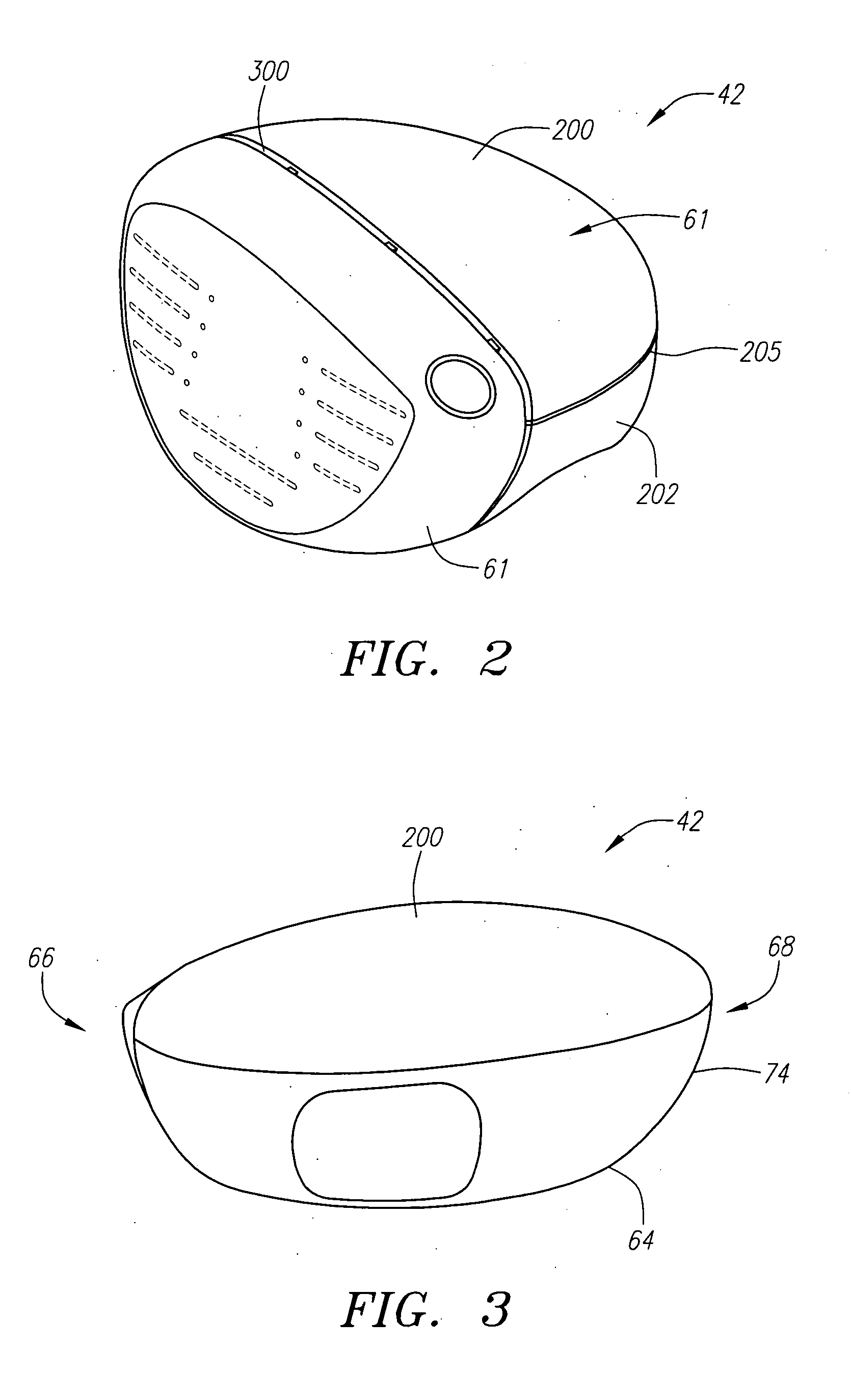

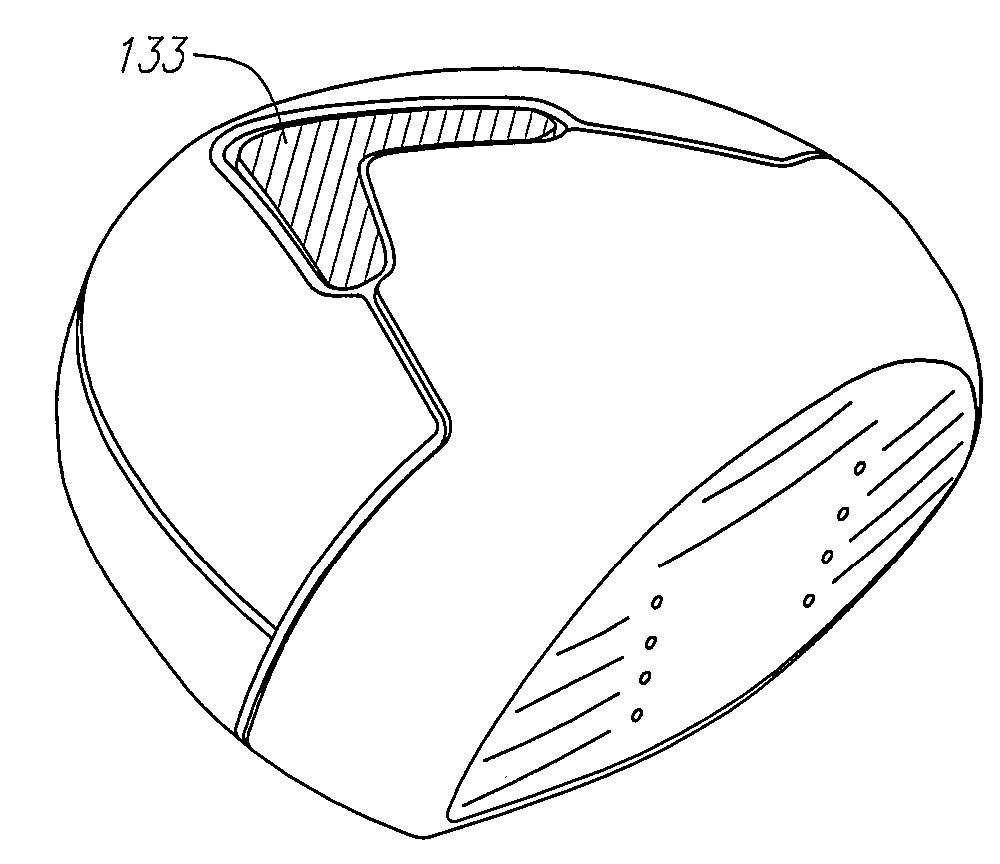

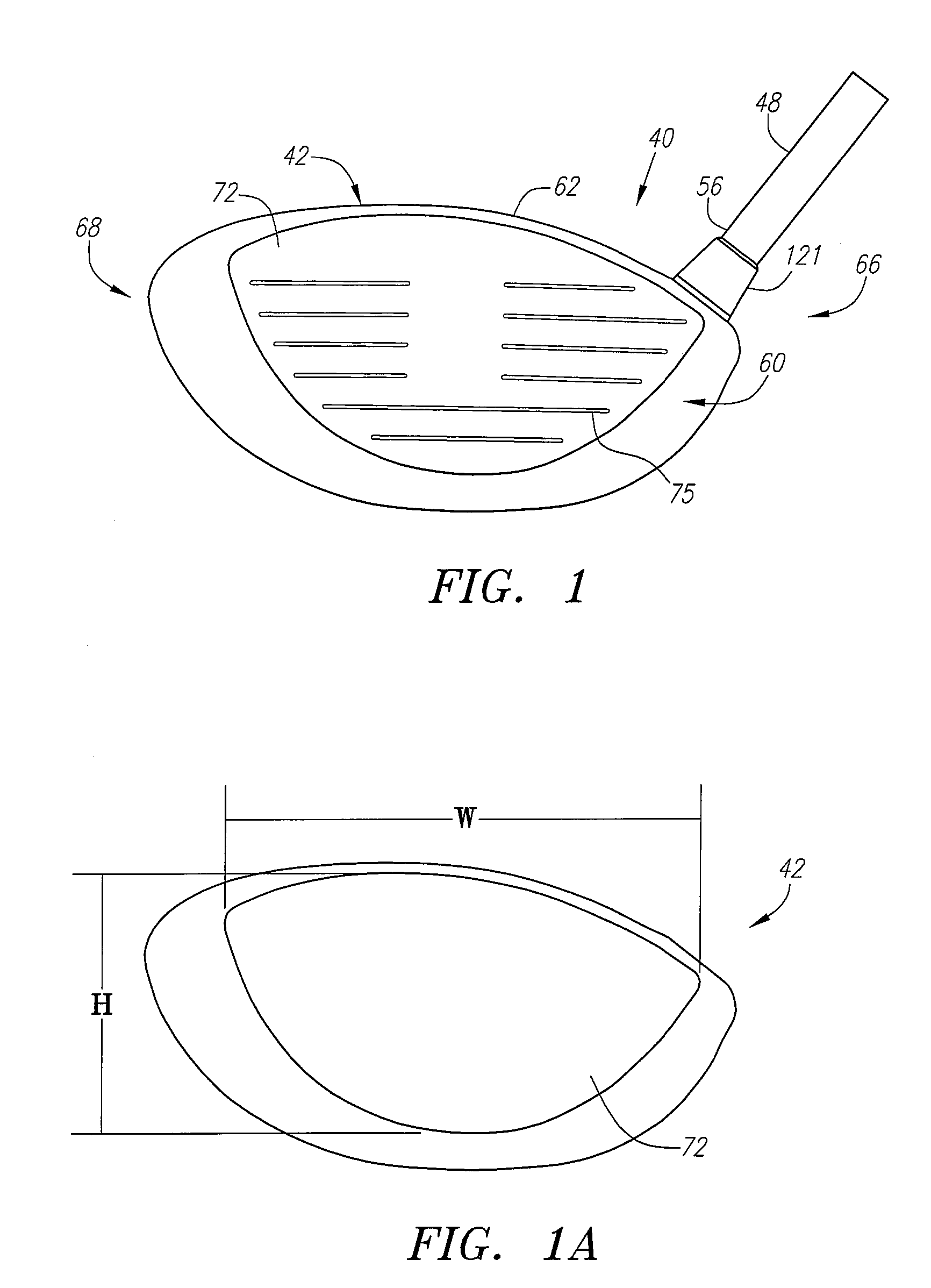

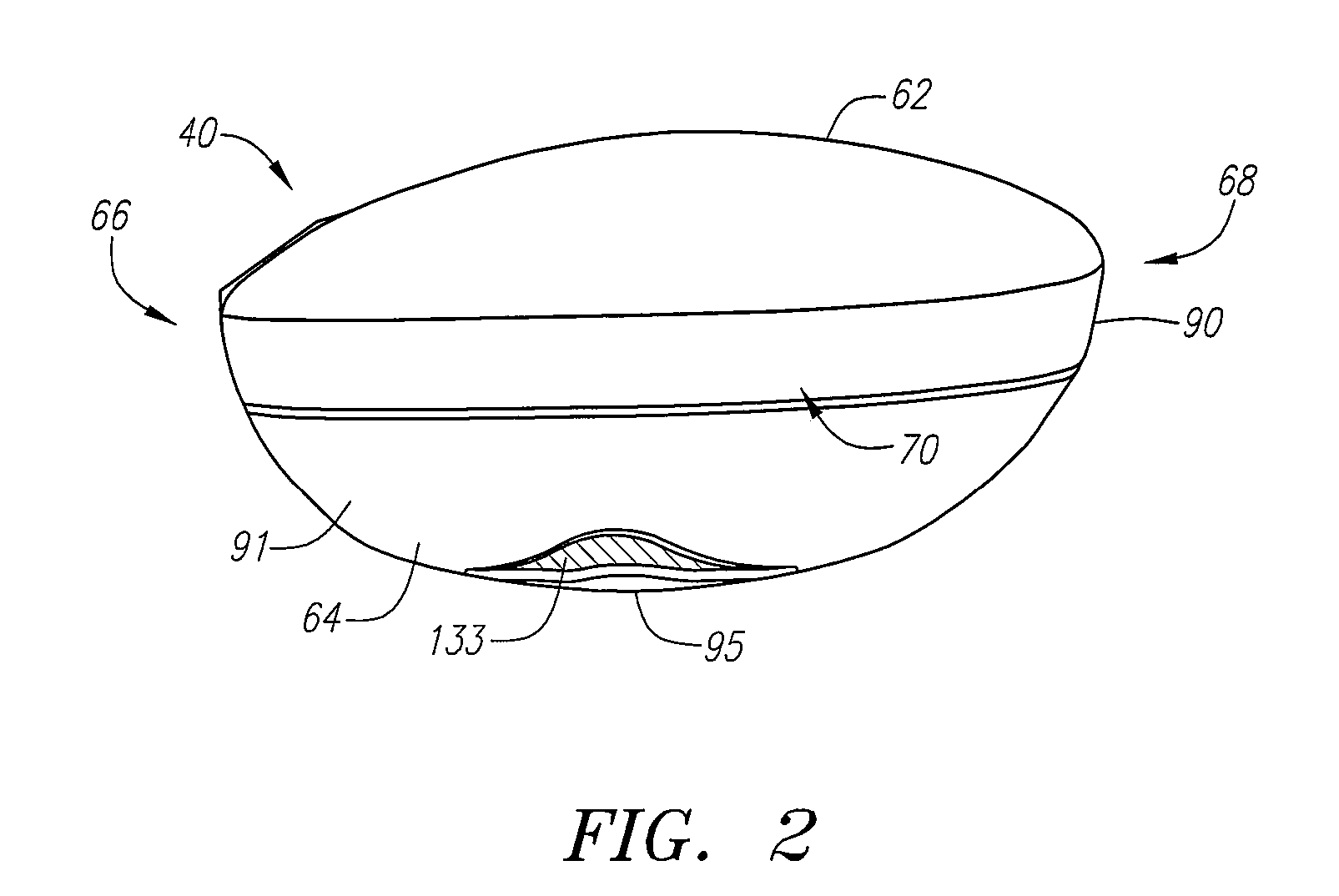

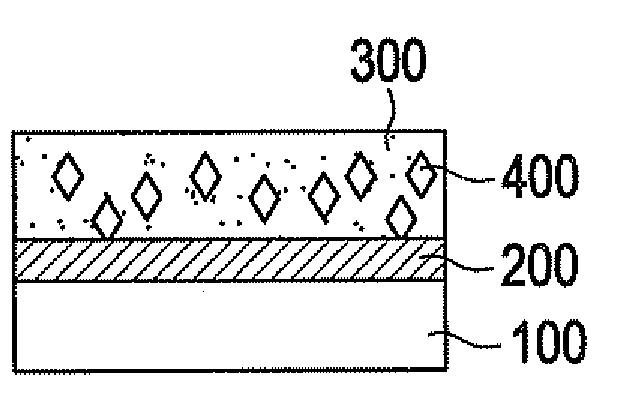

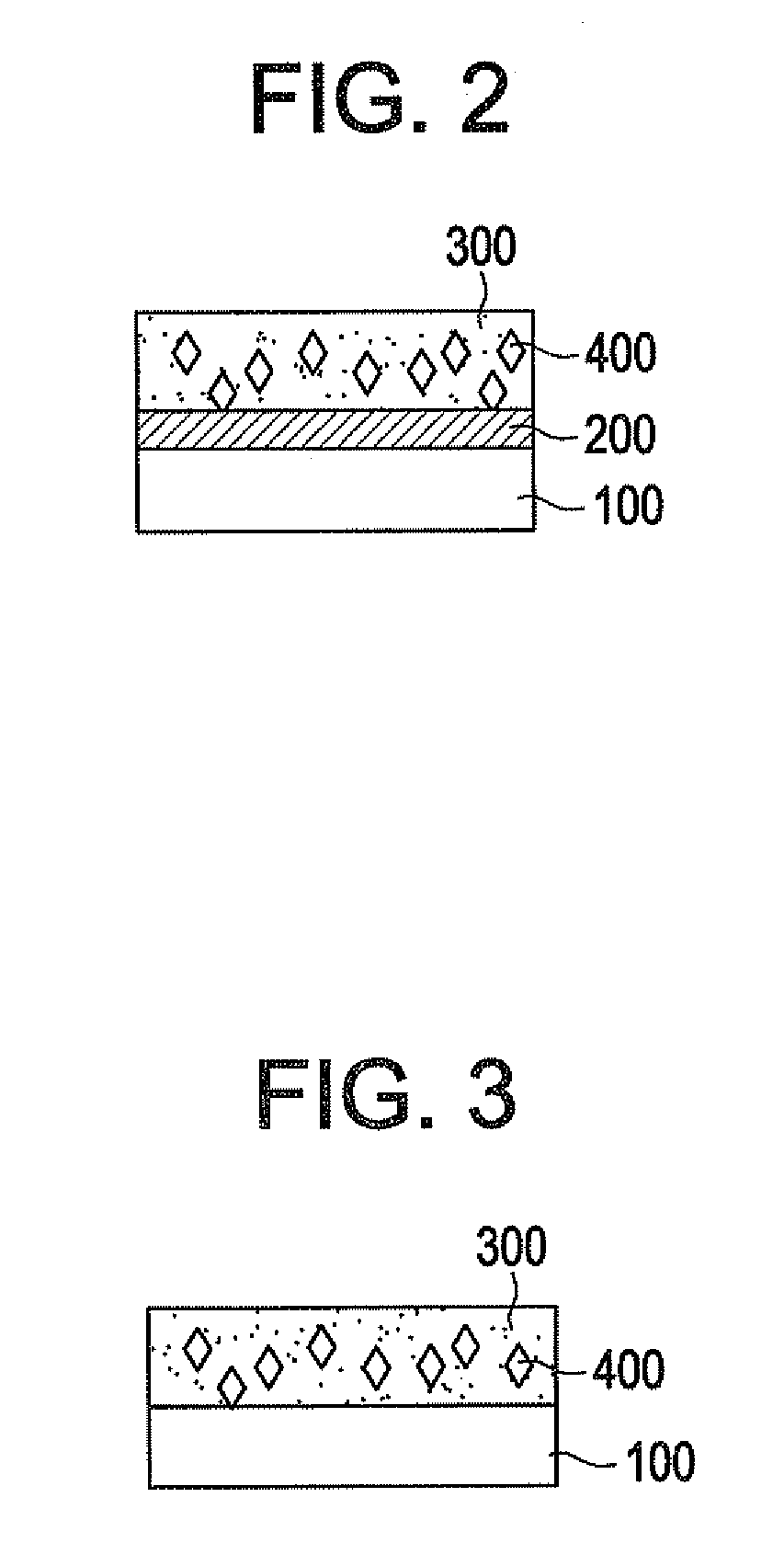

Plated magnesium golf club head

A golf club (40) having a club head (42) with a face component (60) and an aft-body (61) is disclosed herein. The face component (60) has a striking plate portion (72) and a return portion (74). The aft-body (61) is composed of a crown portion (62), a sole portion (64) and optionally a ribbon section (90). The face component (60) is composed of a metal material, and the aft-body (61) is composed of a metal material selected from the group consisting of magnesium alloys, aluminum alloys, magnesium and aluminum. A plating layer (300) is disposed on at least a portion of the aft-body (61). The plating layer (300) preferably comprises a nickel or nickel-based alloy material. The club head (42) preferably has a volume in the range of 290 cubic centimeters to 600 cubic centimeters.

Owner:TOPGOLF CALLAWAY BRANDS CORP

Process for producing bioresorbable implants

A process for producing implants made of a bioresorbable metal, particularly magnesium alloys or zinc alloys, in which the material properties of the magnesium or the zinc are changed and the processing and utilization properties are improved by combining process steps for adjusting the properties of the material and subsequent machining. In this way it is possible to produce thin-walled tubular implants, particularly blood vessel support stents, from bioresorbable magnesium or zinc alloys, which are readily deformable without the risk of fracture during implantation.

Owner:UNIVERSITY OF HANOVER

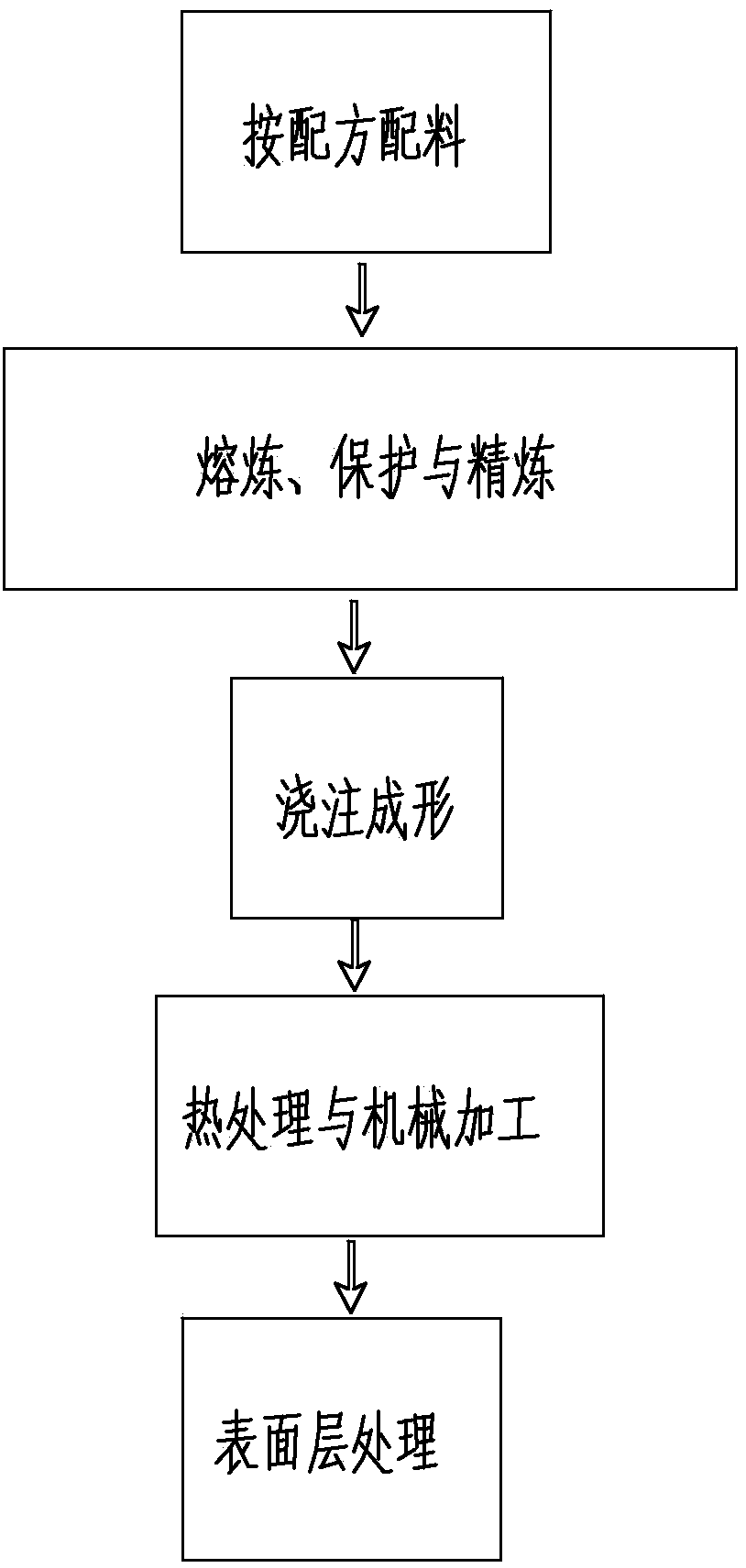

High-strength heat-resisting magnesium alloy and its preparing method

This invention is a high-intensive heat-fast magnesium alloy and its preparation method, and the magnesium alloy has the following components with their weight percentages: 6-15%Gd, 1-6%Y, 0.35-0.8%Zr, 0-1.5%Ca, and impurity elements Si, Fe, Cu and Ni with their gross less than 0.02%, and the rest percentage is Mg. while melting, add Gd, Y, Zr in the Mg melt in Mg-Gd, Mg-Y, Mg-Zr forms, then carry out solution treatment to the magnesium alloy under 450-500deg.C for 6-12 hours, squeeze in in 350-450deg.C, treat in time the squeezing stick for 10-16 hours in 225deg.C to improve its strength.

Owner:SHANGHAI JIAO TONG UNIV

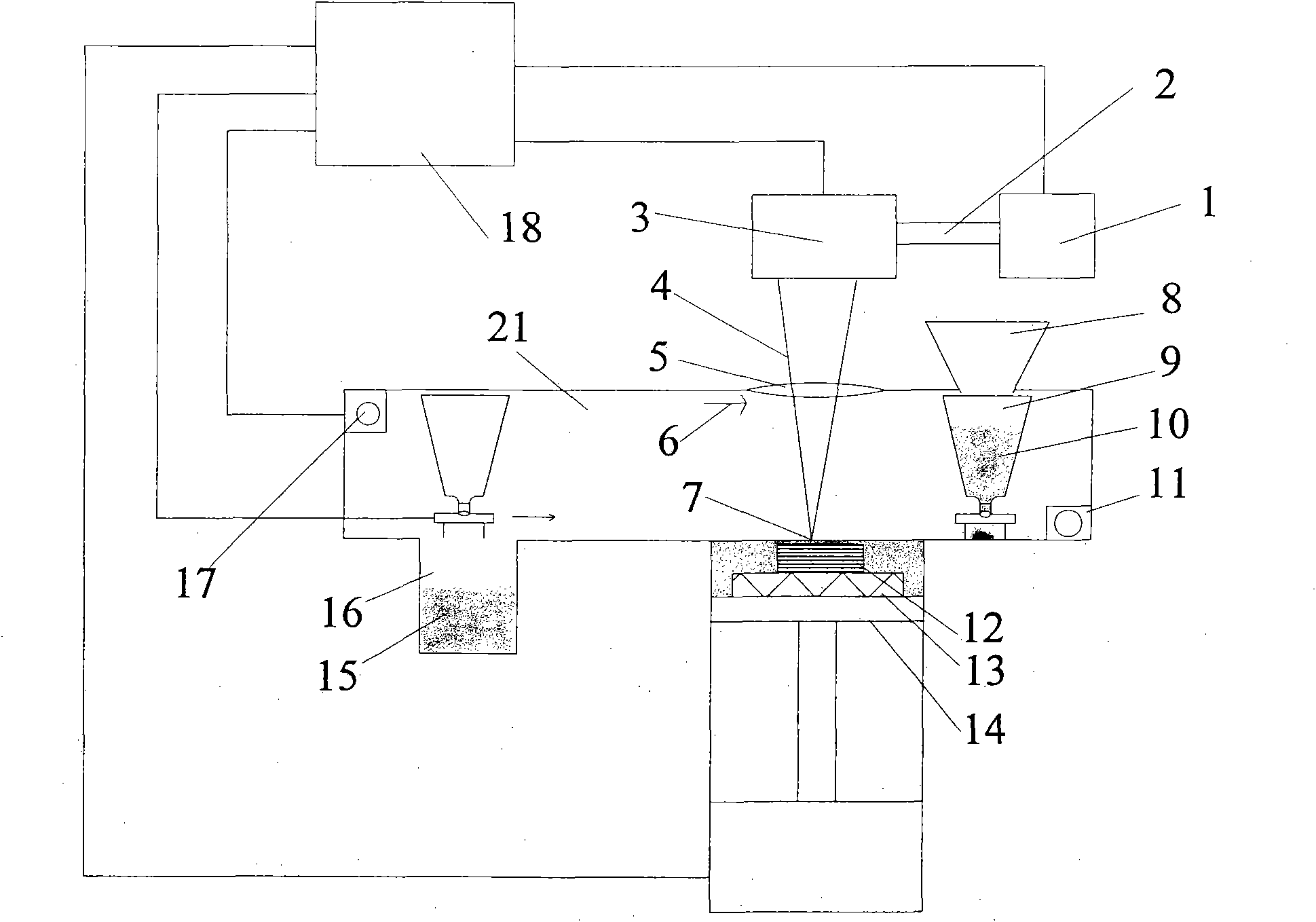

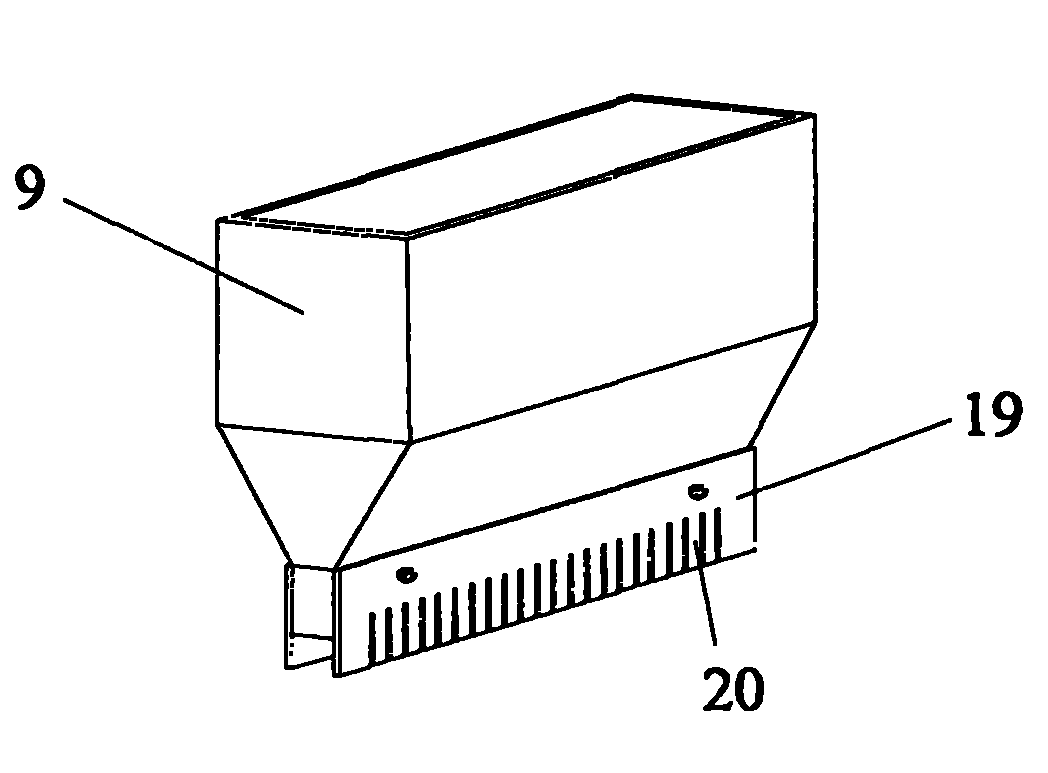

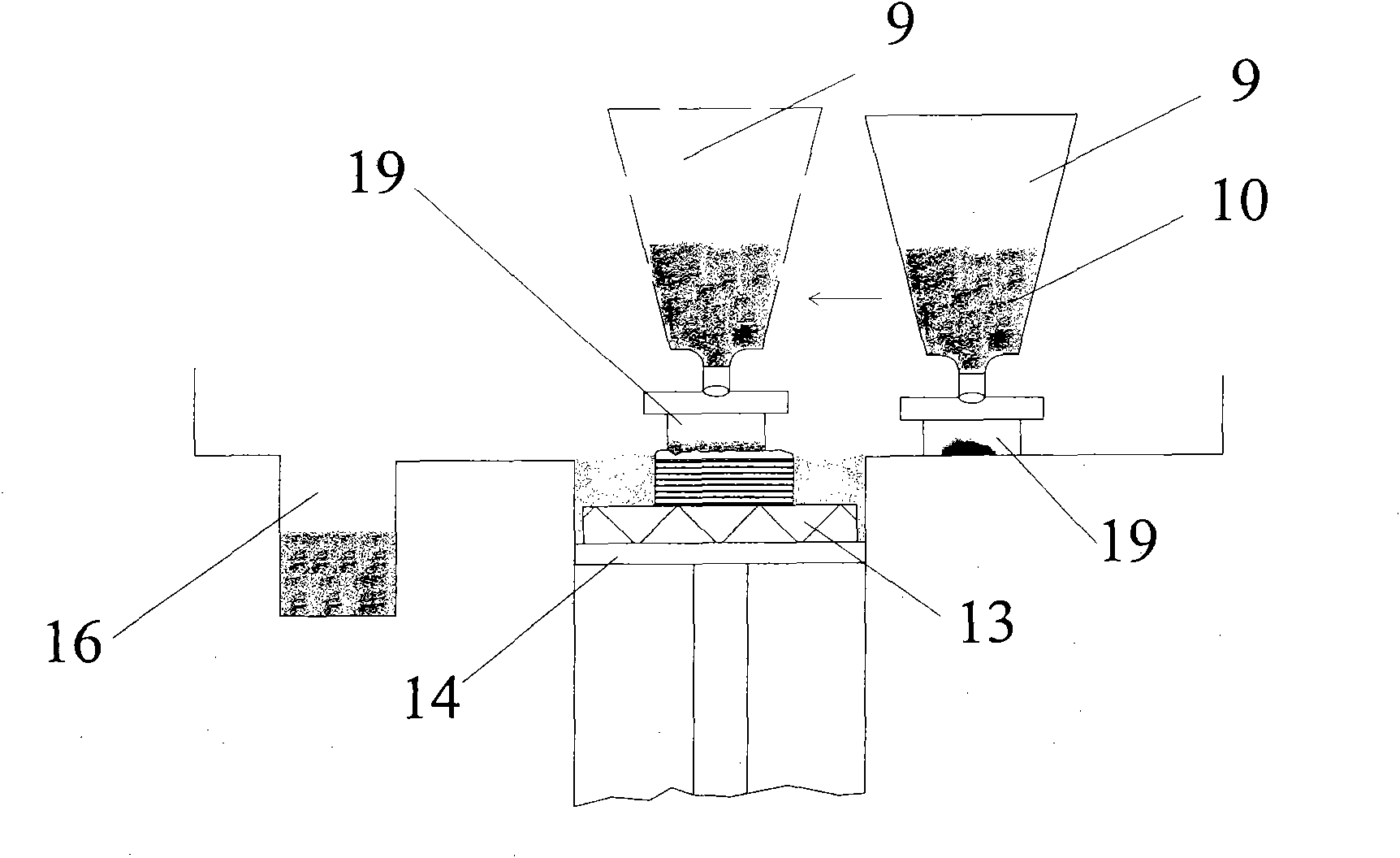

Selective laser melting forming device and method of medical magnesium alloy metal part

ActiveCN101856724ASatisfies complex spatial shape requirements with high degrees of freedomMeet complex space shape requirementsSelective laser meltingOptoelectronics

The invention provides a selective laser melting forming device of a medical magnesium alloy metal part, which comprises a control device, a powder delivering and spreading device, a laser transmission mechanism, an air purification device and a closed forming chamber, wherein the powder delivering and spreading device comprises a hopper and powder spreading brushes arranged on two sides below the hopper, the upper part of the hopper is arranged in a way of corresponding to a feeding opening on the upper part of the forming chamber, and the lower parts of the powder spreading brushes horizontally correspond to the upper surface of a forming cylinder; the laser transmission mechanism is arranged outside and above the forming chamber and is arranged in a way of corresponding to the forming cylinder; the side wall of the forming chamber is provided with an air inlet and an air outlet, and the air purification device is connected with the air inlet and the air outlet respectively; and the control device is connected with the powder delivering and spreading device, the laser transmission mechanism, the forming cylinder and the air purification device respectively. The invention also provides a selective laser melting forming method of the medical magnesium alloy metal part. The device and the method can manufacture parts which have complex shapes required in the medical field directly, and have the advantages of high forming efficiency and the like.

Owner:SOUTH CHINA UNIV OF TECH

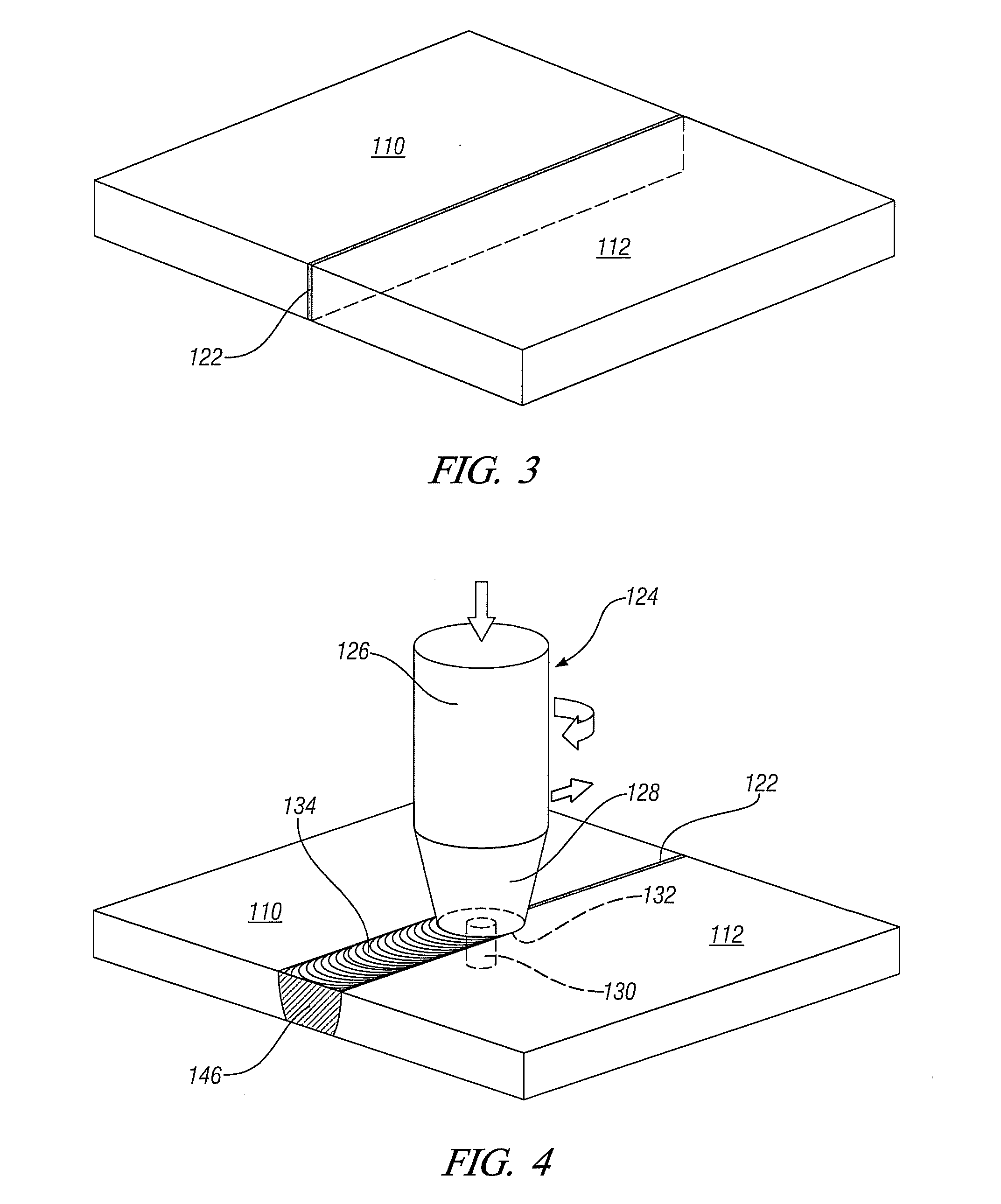

Light emiting device and method of making same

ActiveUS20100123164A1Low production costReduce the number of partsPoint-like light sourceElongate light sourcesThermal expansionLight emitting device

A light emitting device includes a light-emitting portion including a metal part including a metal able to be bonded to a solder material, and a heat dissipation member that includes aluminum, aluminum alloy, magnesium or magnesium alloy and a bonding portion processed to be bonded to the solder material. The metal part of the light-emitting portion is bonded via the solder material to the bonding portion of the heat dissipation member. The solder material includes a material unable to be directly bonded to the heat dissipation member, the metal part of the light-emitting portion is formed by metalizing an insulation of ceramic or semiconductor, and the bonding portion includes a thermal expansion coefficient between that of the heat dissipation member and that of the insulation.

Owner:TOYODA GOSEI CO LTD

Controlled degradation magnesium alloy coating bracket and preparation thereof

InactiveCN101214396AImprove mechanical propertiesExcellent pharmacological propertiesAnodisationStentsSurface cleaningPolymer chemistry

The invention relates to a controlled degradation magnesium alloy coating stent and a preparation method. The stent body is made of medical high purity magnesium or magnesium alloy by mechanical processing or laser carving; the stent body is provided with a drug-loading coating which bears curative drug; the surface of the stent body is provided with an anti-corrosive coating; the surface of the anti-corrosive coating is provided with a degradable polymer film drug-loading coating; the preparation method includes surface cleaning, preparation of the degradable polymer film drug-loading coating, and application of curative drug; through (1)surface cleaning, (2)preparation of the degradable polymer film drug-loading coating, and (3)application of curative drug, an oxide film is formed on the surface; different drugs and dosage can be fixed by regulating the molecular weight and the thickness of the polymer layer, the drug-loading quantity is more than 30 percent, which improves the fixed stability of the drug, greatly reduces the degradation speed of the magnesium alloy and controls release of the drug, delays corrosion of the magnesium alloy, extends the service life of the stent, is safe in use, and meets the clinical requirement.

Owner:LEPU MEDICAL TECH (BEIJING) CO LTD

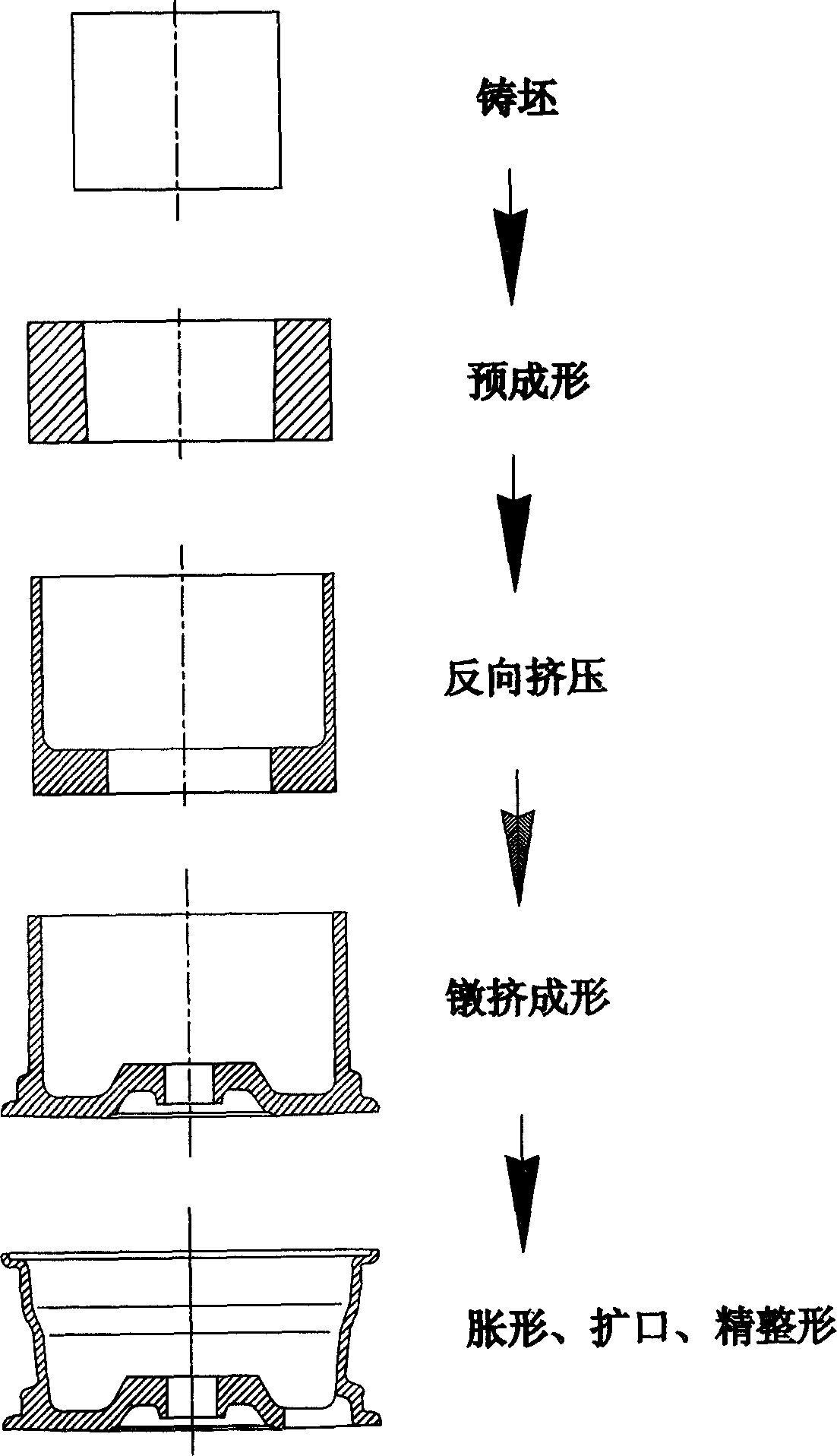

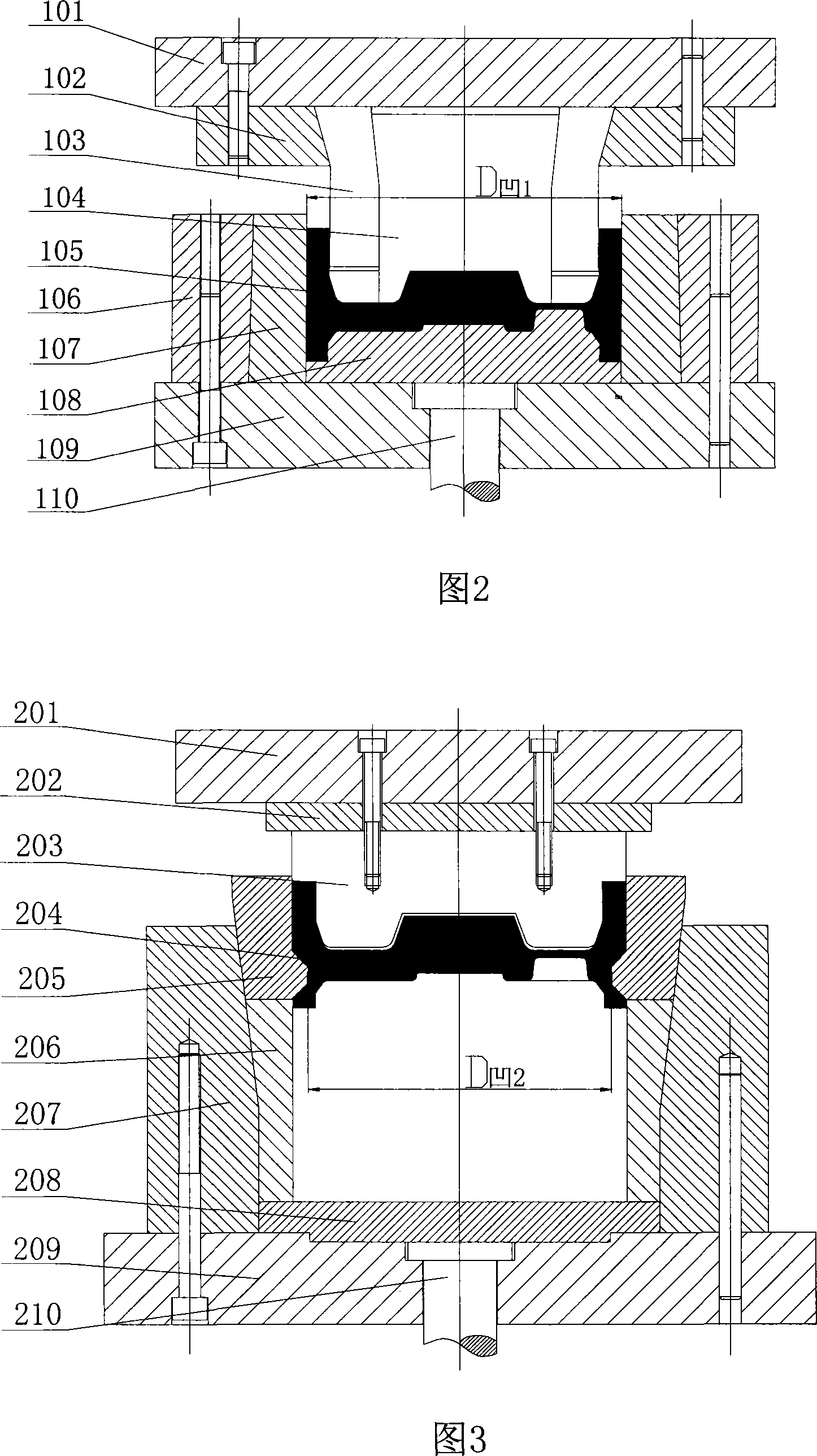

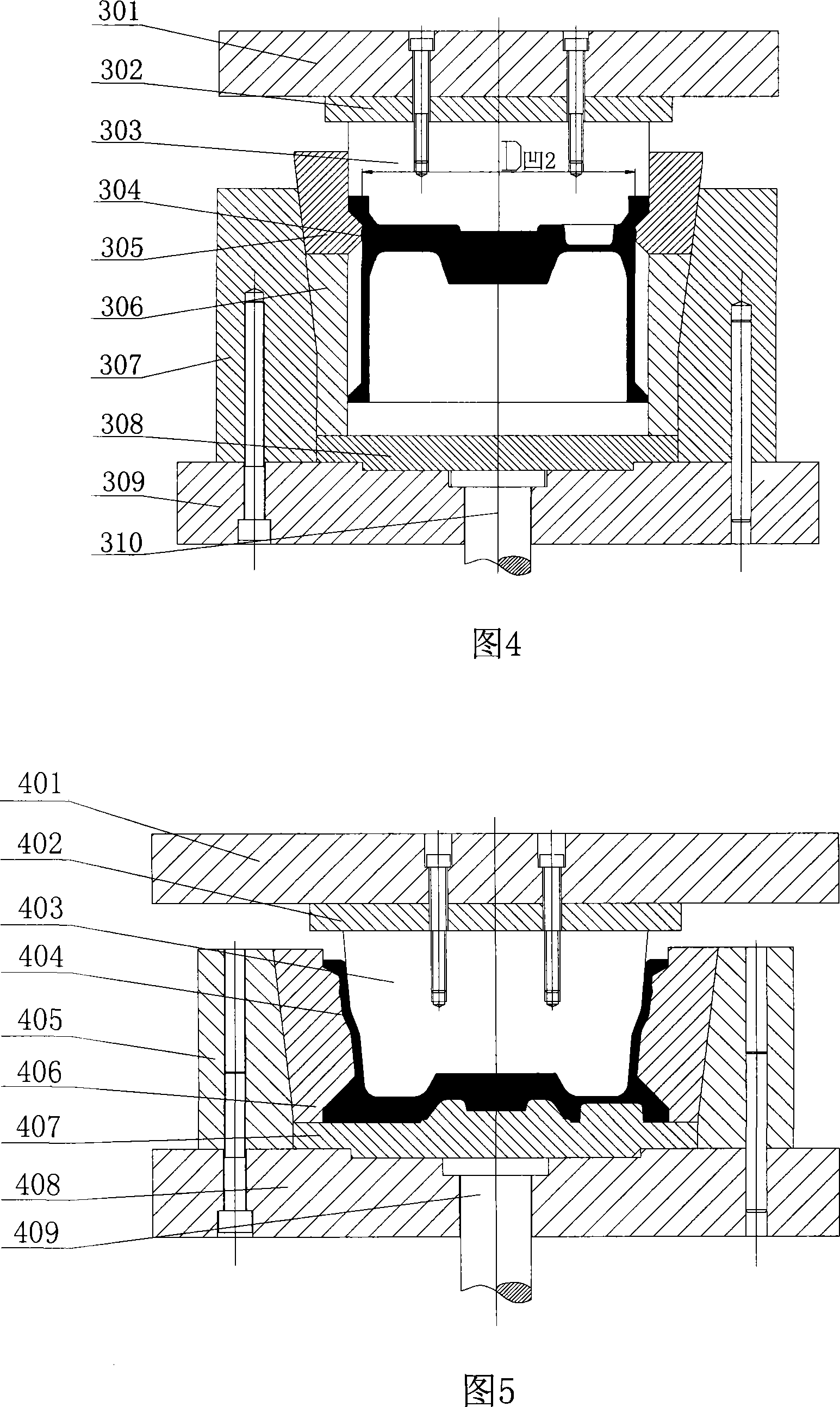

A labor-saving automobile hub forming method and device

InactiveCN1864915AWith substantive technologyReduction toolExtrusion diesExtrusion control devicesEngineeringMechanical engineering

The invention relates to a method for shaping the vehicle hub and relative device. Wherein, it comprises following steps that casting blank; uniform processing; pre-shaping blank; compressing; compressing the front rim; expanding opening and folding the edge at the back rim. The invention is characterized in that: the casting blank via pre-shaping is made into hollow blank; the concave and convex moulds in the compressing step and the compressing front rim step are integrated, while the convex mound contains core axle; the compressing step compresses the hollow blank in the mould via core axle to obtain the cylinder element whose bottom has holes; the step that compressing front rim uses metal diversion to stuff and shape; the step that expanding opening and folding the edge of back rim uses integrated convex mould and separated concave mould to expand opening, fold edge an shape the back rim. The invention can simplify the process, reduce device number, reduce the shaping force, reduce the energy consumption, and reduce the producing cost. The invention is mainly used to produce aluminum and magnesium alloy hub.

Owner:ZHONGBEI UNIV

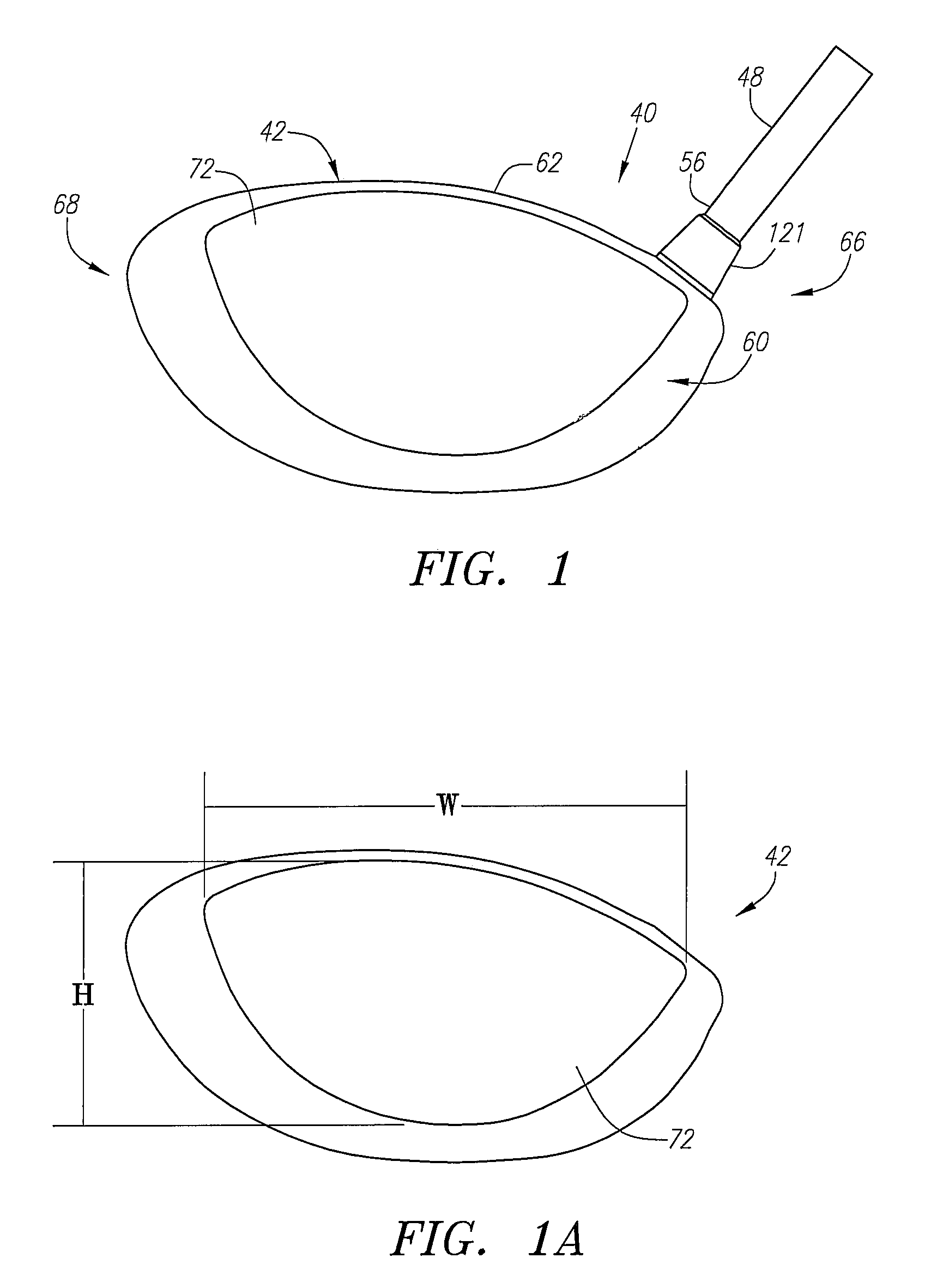

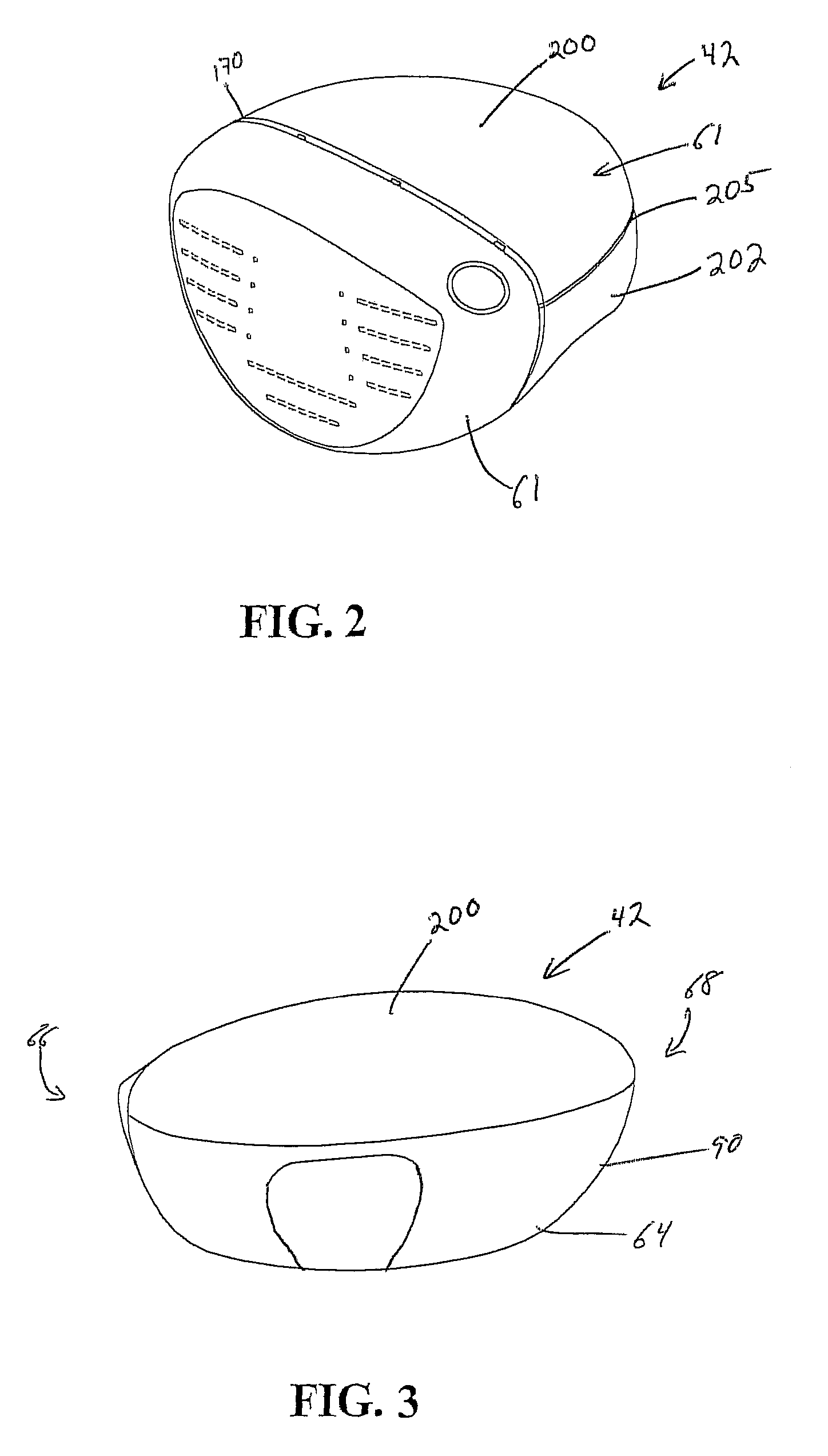

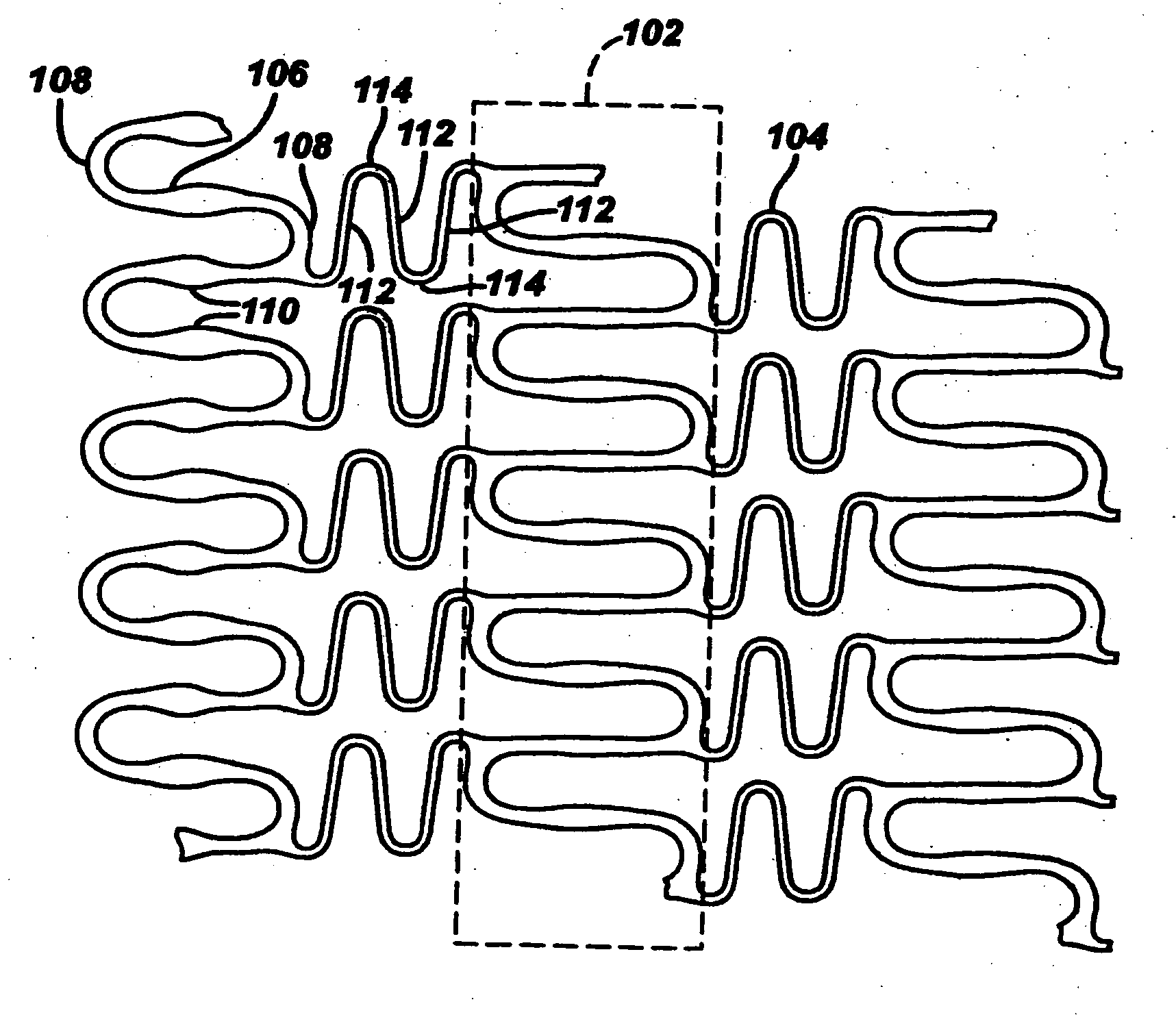

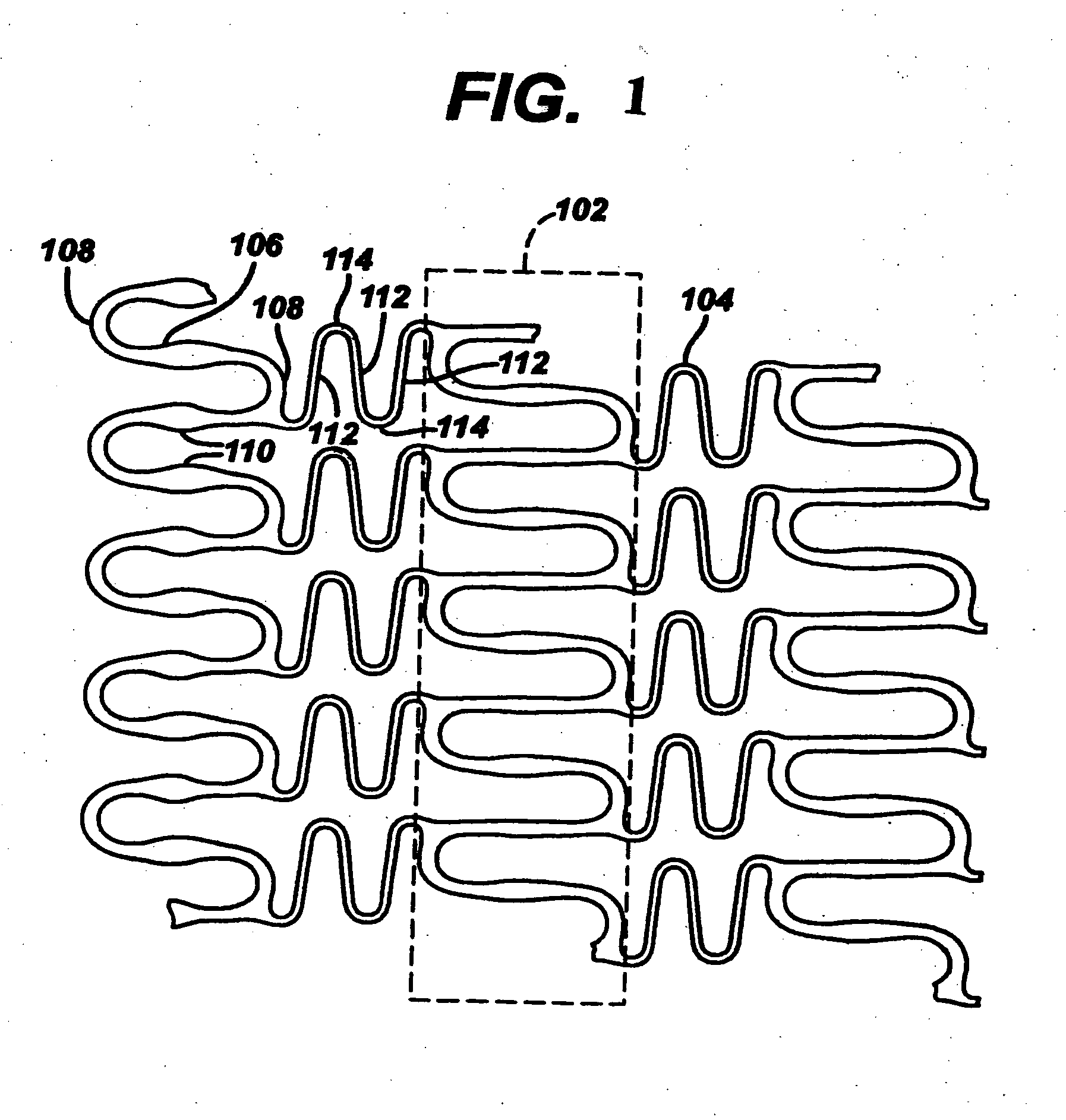

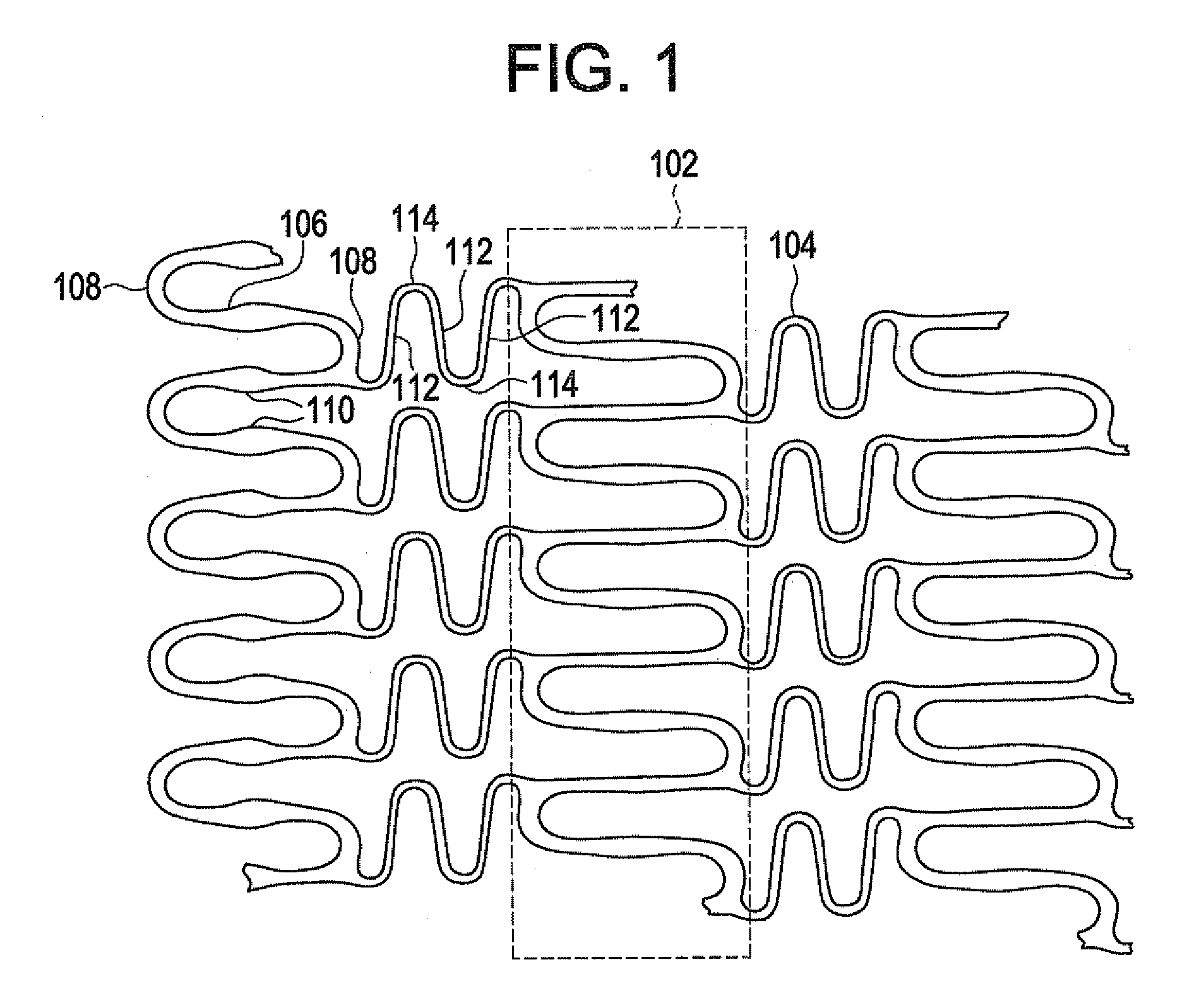

Multiple material golf club head

A golf club (40) having a club head (42) with a face component (60) and an aft body (61) is disclosed herein. The face component (60) has a striking plate portion (72) and a return portion (74). The aft-body (61) is composed of a crown portion (62), a sole portion (64) and optionally a ribbon section (90). The face component (60) is composed of a metal material, and the aft-body (61) is composed of a metal material selected from the group consisting of magnesium alloys, aluminum alloys, magnesium and aluminum. The striking plate portion (72) preferably has an aspect ratio less than 1.7. The striking plate portion (72) preferably has concentric regions of thickness with the thickness portion in the center (102). The club head (42) has a volume in the range of 290 cubic centimeters to 600 cubic centimeters, a weight in the range of 165 grams to 300 grams, and a striking plate portion (72) surface area in the range of 4.00 square inches to 7.50 square inches. The golf club head (42) has a coefficient of restitution greater than 0.81 under test conditions such as the USGA test conditions specified pursuant to Rule 4-1e, Appendix II, of the Rules of Golf for 1998–1999.

Owner:TOPGOLF CALLAWAY BRANDS CORP

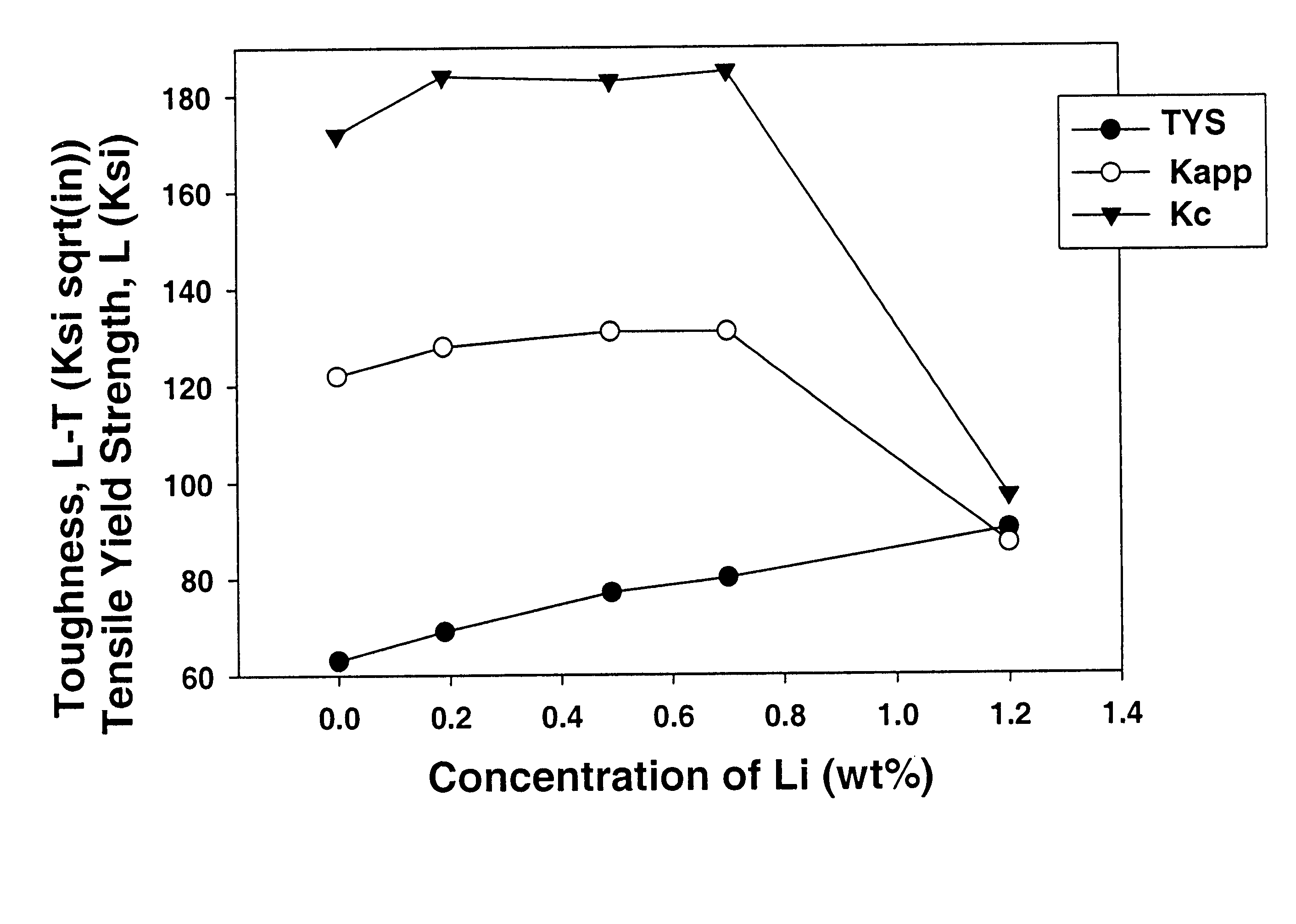

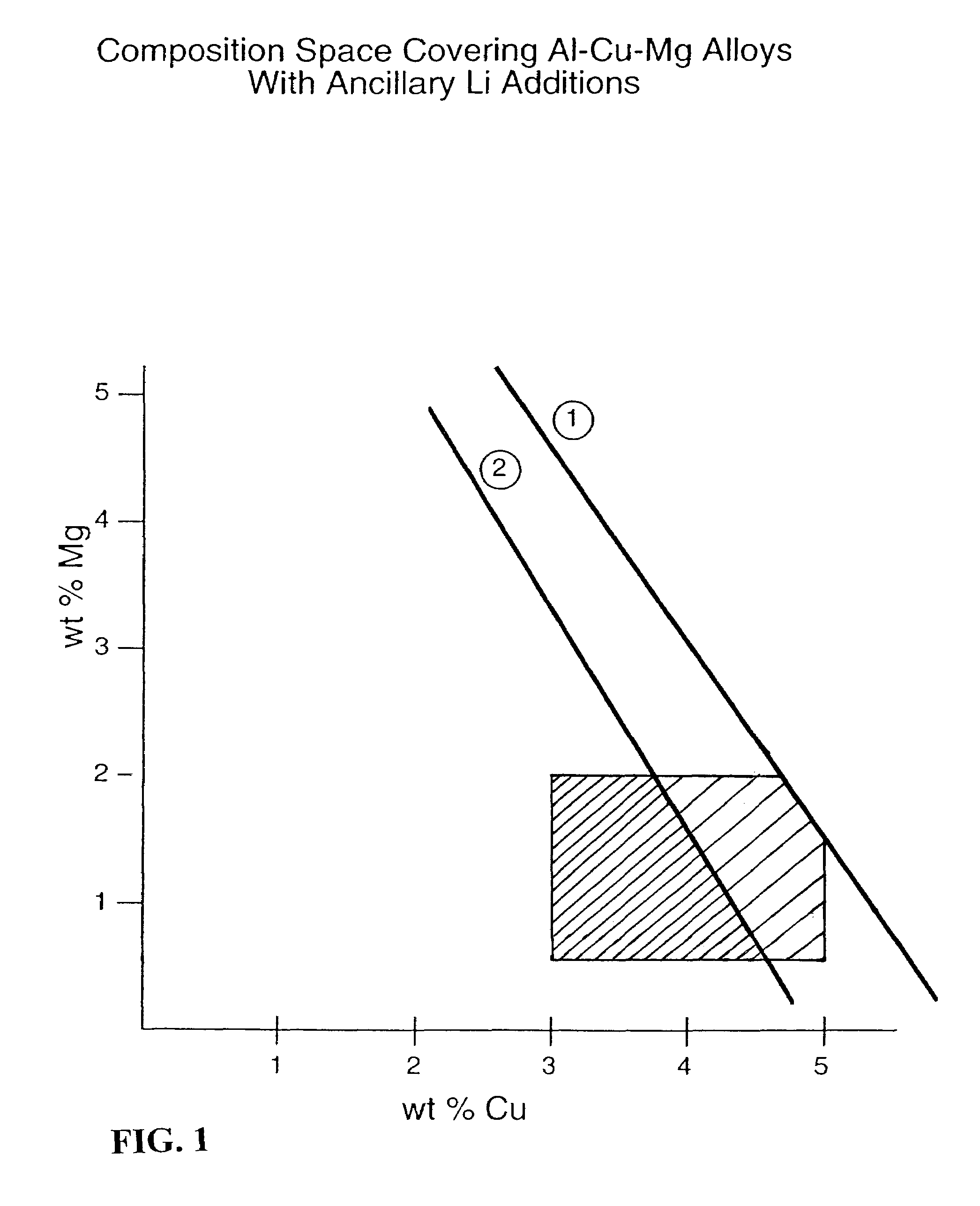

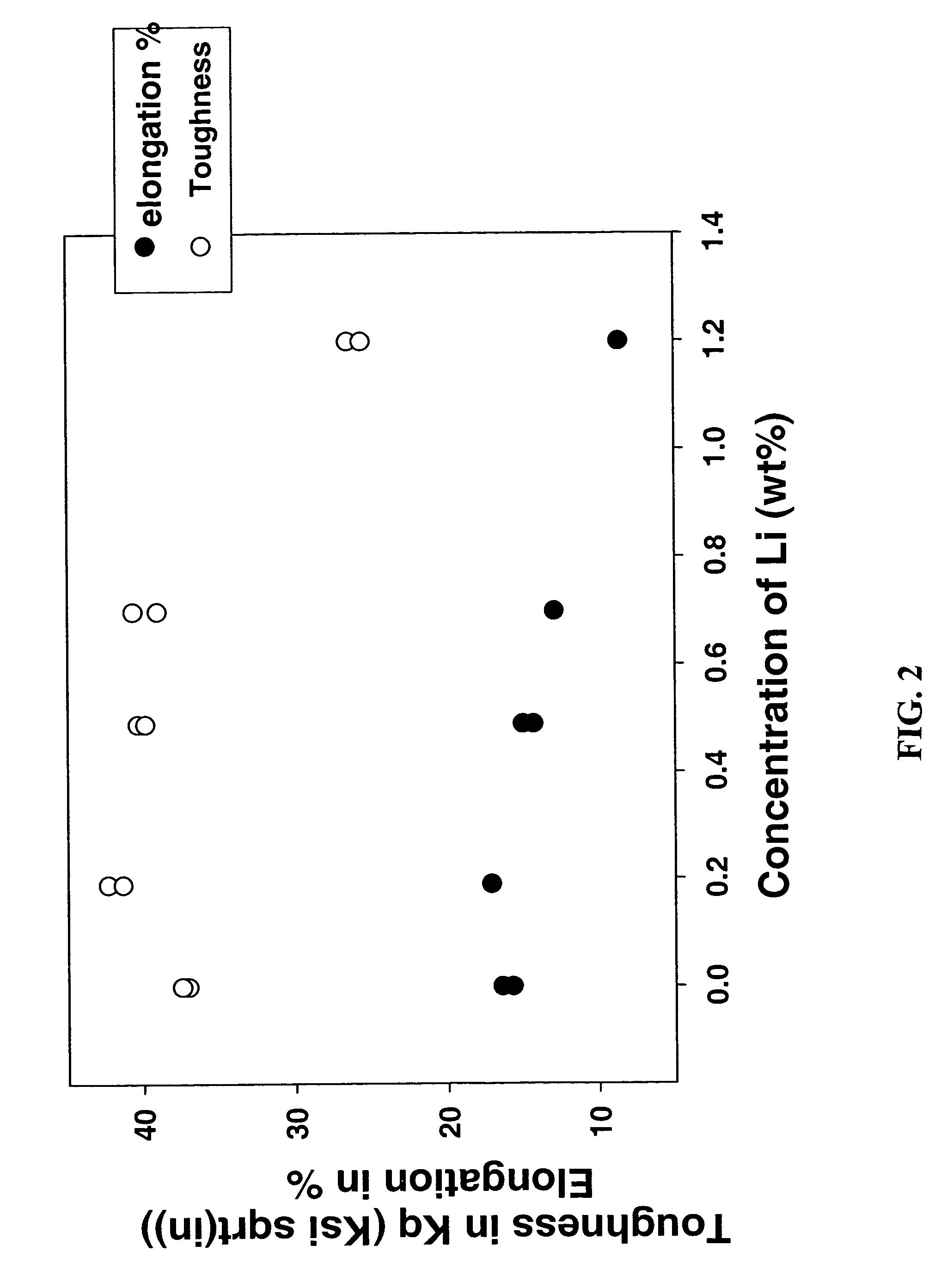

Aluminum-copper-magnesium alloys having ancillary additions of lithium

InactiveUS7438772B2Improve fracture toughnessEquivalent and improved fatigue crack growth resistanceSolubilityLithium

An aluminum-copper-magnesium alloy having ancillary additions of lithium. The alloy composition includes from about 3 to about 5 weight percent Cu, from about 0.5 to about 2 weight percent Mg, and from about 0.01 to about 0.9 weight percent Li. The combined amount of Cu and Mg is maintained below a solubility limit of the aluminum alloy. The alloys possess improved combinations of fracture toughness and strength, and also exhibit good fatigue crack growth resistance.

Owner:ARCONIC INC

Acidic solution for treating surface of magnesium alloy and processing method

InactiveCN101285193AFully activatedHigh activityMetallic material coating processesGlutaric acidBinding force

The invention relates to acid solution used for processing the magnesium alloy surface. The acid solution is water solution which contains acids, inhibitor and wetting agent, wherein, the acids are first acids or mixture of first acids and second acids; the first acids are selected from one type or a plurality of types among citric acids, oxalic acids, tartaric acids, methanoic acids, acetic acids, metacetonic acids, butyric acids, glutaric acids, phenylformic acids, benzene dicarboxylic acids, lactic acids, glycolic acids, glyoxylic acids and amino acids; and the second acids are hydrochloric acids and / or nitric acids. By adoption of the acid solution, the magnesium alloy surface can be fully activated; the membranous layer of a converting film which is formed on the magnesium alloy surface after chemical conversion process is compact, has erosion resistance and good binding force with a paint film. Moreover, the method is a environment-friendly method for processing the magnesium alloy surface.

Owner:BYD CO LTD

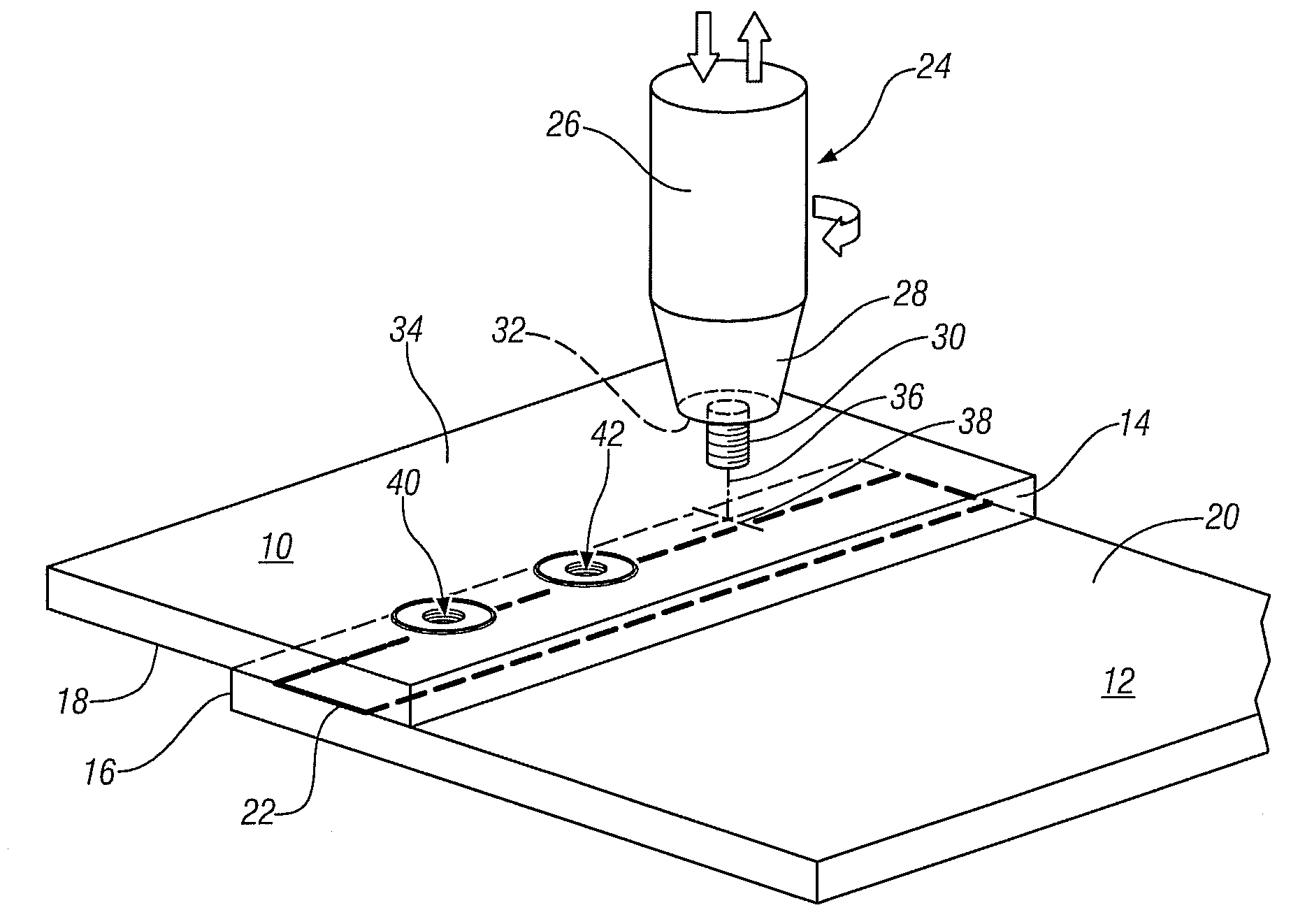

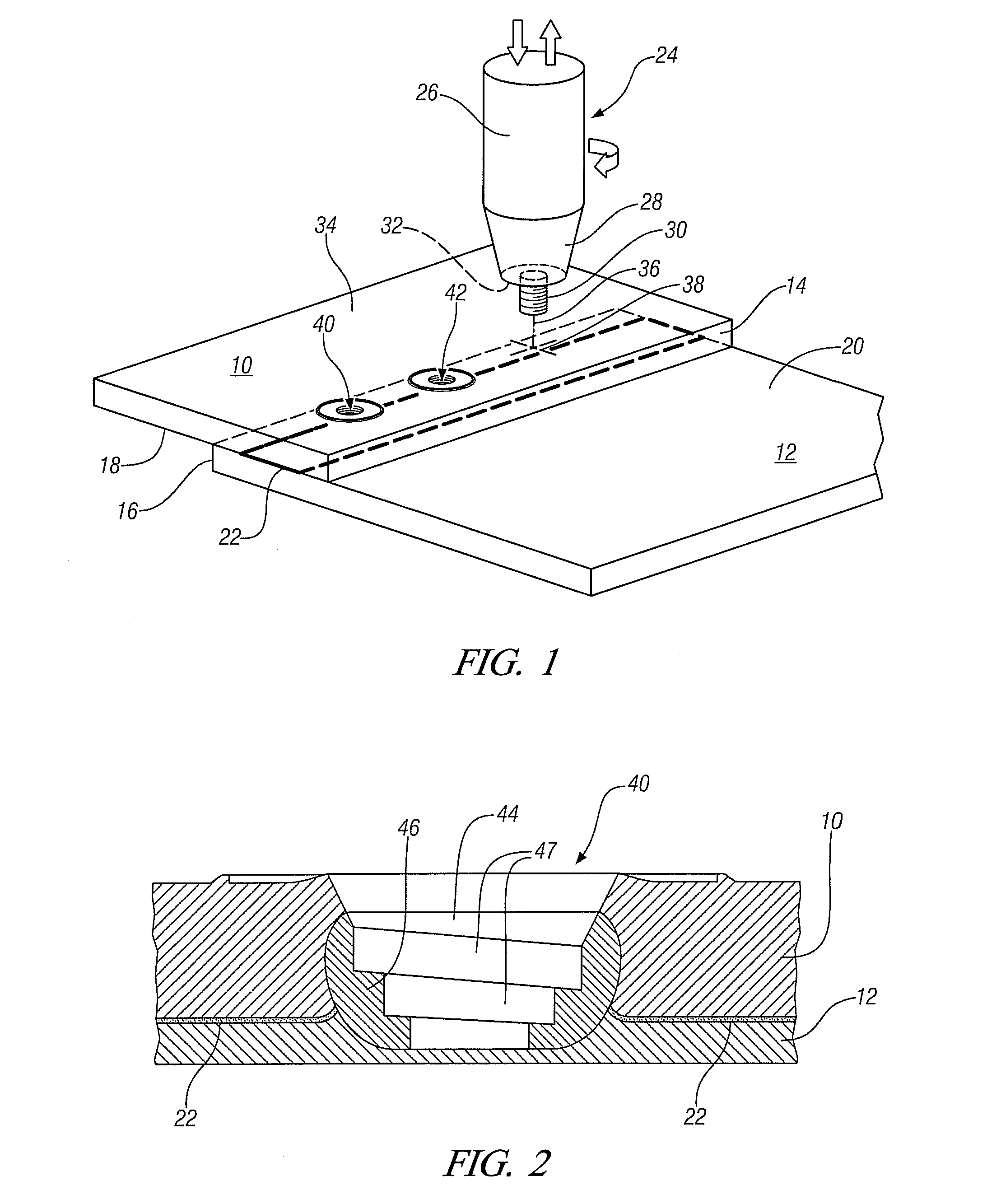

Friction stir welding of dissimilar metals

InactiveUS20100089977A1Improve mechanical propertiesHigh viscosityWelding/soldering/cutting articlesNon-electric welding apparatusFriction stir weldingTin

When a friction stir weld tool penetrates the interface of two workpieces of dissimilar metal alloy materials, the resultant weld of the different alloy materials may produce a weak weld joint. Such weak joints are often experienced, for example, when attempting to form spot welds or other friction stir welds between a magnesium alloy sheet or strip and an aluminum alloy sheet or strip. It is discovered that suitable coating compositions placed at the interface of assembled workpieces can alter the composition of the friction stir weld material and strengthen the resulting bond. In the example of friction stir welds between magnesium alloy and aluminum alloy workpieces, it is found that combinations of copper, tin, and zinc, and other powders can strengthen the magnesium-containing and aluminum-containing friction stir weld material.

Owner:GM GLOBAL TECH OPERATIONS LLC

Rare earth-containing high strength heat resisting magnesium alloy and preparation thereof

The invention relates to a high strength heat-resistant magnesium alloy containing rare earths of the technical field of metallic materials and a preparation method thereof. The magnesium alloy comprises the following components according to the mass percent: Y with more than or equal to 3% and less than or equal to 16%, Gd with more than or equal to 0% and less than or equal to 10%, Ca with more than or equal to 0.3% and less than or equal to 5%, Zr with more than or equal to 0.1% and less than or equal to 1.5%, and one or a plurality of Nd, Si, Sb, Ti, Sn, Sr, Bi, Cd, Nd with more than or equal to 0% and less than or equal to 5%, Si with more than or equal to 0% and less than or equal to 5%, Sb with more than or equal to 0% and less than or equal to 5%, Ti with more than or equal to 0% and less than or equal to 5%, Sn with more than or equal to 0% and less than or equal to 5%, Sr with more than or equal to 0% and less than or equal to 5%, Bi with more than or equal to 0% and less than or equal to 5%, Cd with with more than or equal to 0% and less than or equal to 5%, and the rest is Mg and impurities. The magnesium alloy is obtained by using melting and the subsequent heat treatment. The magnesium alloy not only can serve as casting magnesium alloy but also can serve as the deformation magnesium alloy and has better predominant mechanical property compared with the WE series commercial magnesium alloy.

Owner:SHANGHAI JIAO TONG UNIV

Wear-resisting alloy steel with high boron, high chrome and low carbon and preparation method thereof

ActiveCN101660097AReduce manufacturing costElectric furnaceProcess efficiency improvementSilicon alloyCerium

The invention discloses a wear-resisting alloy steel with high boron, high chrome and low carbon and a preparation method thereof, which comprises the following chemical constituents in weight percent: 0.1-0.5% of C, 3-26% of Cr, 0.5-1.2% of Si, 0.5-1.5% of Mn, 0.3-2.8% of B, 0.3-2.6% of Cu, 0.2-0.6% of Ti, 0.02-0.15% of Ca, 0.03-0.25% of Ce, 0.02-0.18% of N, 0.05-0.3% of Nb, 0.04-0.09% of Al, 0.02-0.15% of Mg, 0.04-0.13% of K, less than 0.03% of S, less than 0.04% of P and the balance Fe and unavoidable impurity elements. The method comprises the following steps: melting steel scrap and chromium iron in an electric furnace; adding copper plates, ferrosilicon, ferromanganese into the melted steel scrap and chromium iron, heating the melt to 1560-1620 DEG C after the constituents are adjusted to be qualified in stokehold; adding calcium-silicon alloy and aluminium deoxidation into the melt; and then adding ferrotitanium and ferroboron in sequence, melting and discharging; roasting the compound inoculant composed of granular rare earth magnesium alloy with the diameter being less than 12mm and cerium metal, Si3N4, VN, Nb and K; placing the roasted compound inoculant at the bottom ofa steel ladle; carrying out modification and inoculation processes on the smelted liquid steel by pour-over method in the steel ladle, wherein, the pouring temperature of the liquid steel is 1400-1450DEG C; heating castings to 920-1150 DEG C and preserving heat for 2-4 hours; and air cooling the castings to room temperature to obtain the alloy steel in the invention. The alloy steel of the invention has the advantages of high strength, rigidity and toughness, good thermal fatigue resistance property, wear resistance, and low manufacture cost.

Owner:泰州海天机械配件有限公司

Magnesium alloy and preparation method thereof

The invention discloses a magnesium alloy and a method for preparing the same. The weight percentage compositions of the magnesium alloy as follows: 7 to11 percent by weight of Gd, 2 to 5 percent by weight of Y, 0.3 to 0.6 percent by weight of Zr, 0 to 1.0 percent by weight of Zn, the balance Mg and incidental impurity elements. The method for preparing the alloy comprises alloy melting, refining, casting, solid solution, extrusion deformation and two artificial aging methods, to produce heat resistant magnesium alloy extruded bar with high strength and high toughness. The tensile properties of the magnesium alloy at room temperature manufactured by adopting direct artificial aging is: tensile strength sigma b is between 450 and 480 MPa, sigma 0.2 is between 390 and 425 MPa, delta 5 is between 3 and 5 percent; when test specimen is heated to 250 DEG C for 10 min, the tensile strength sigma b is more than or equal to 300 MPa. The tensile properties of the magnesium alloy at room temperature manufactured by adopting dual artificial aging is: tensile strength sigma b is between 380 and 395 MPa, sigma 0.2 is between 280 and 290 MPa, delta 5 is between 15 and 21 percent; when test specimen is heated to 250 DEG C for 10 min, the tensile strength sigma b is more than or equal to 260 MPa. The invention produces the heat resistant magnesium alloy of high strength and high toughness with the density of no more than 1.93g / cm3, which can satisfy the demands of density, strength and toughness, and heat resistance of metal materials in specific fields.

Owner:GRIMAT ENG INST CO LTD

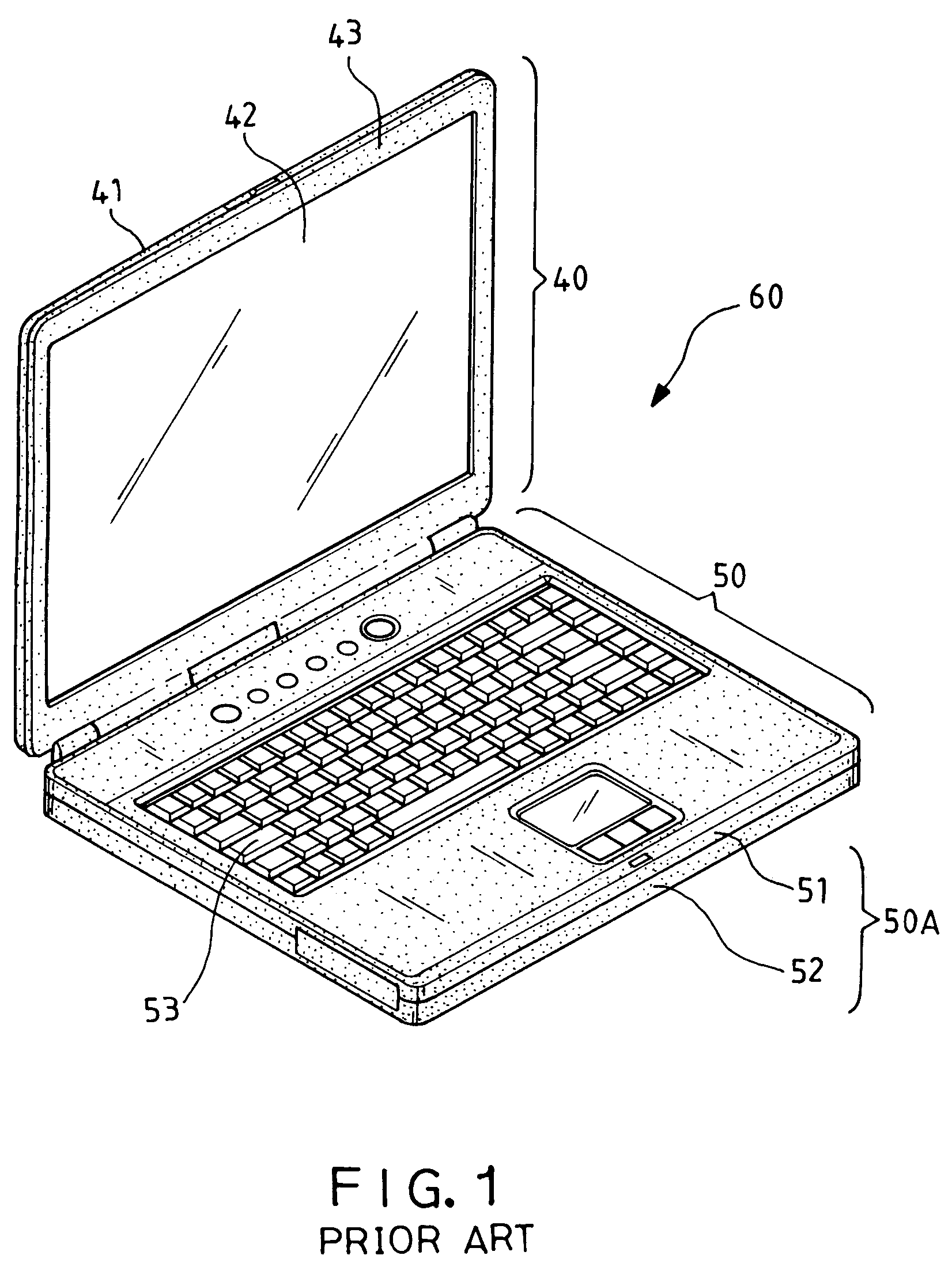

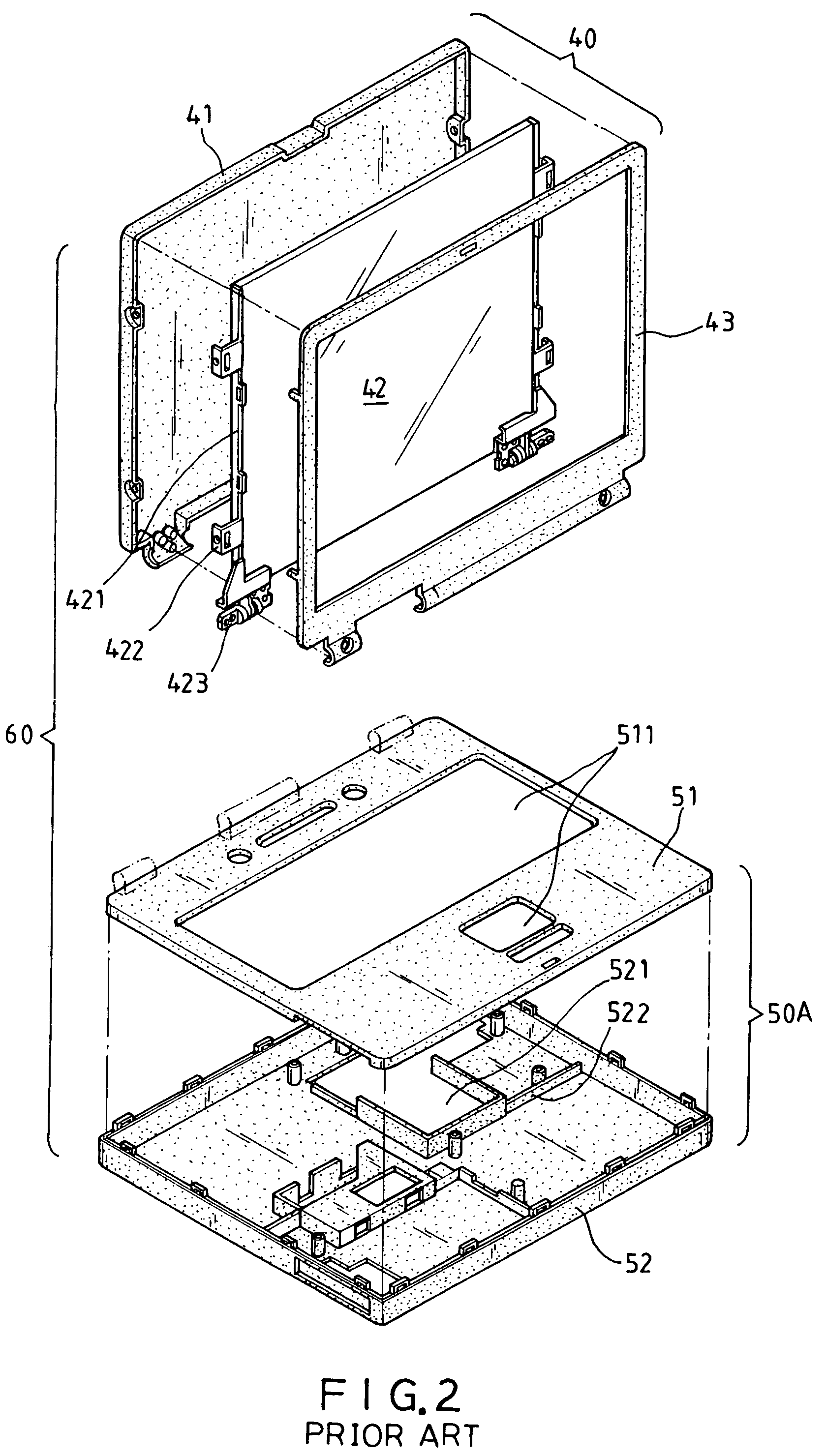

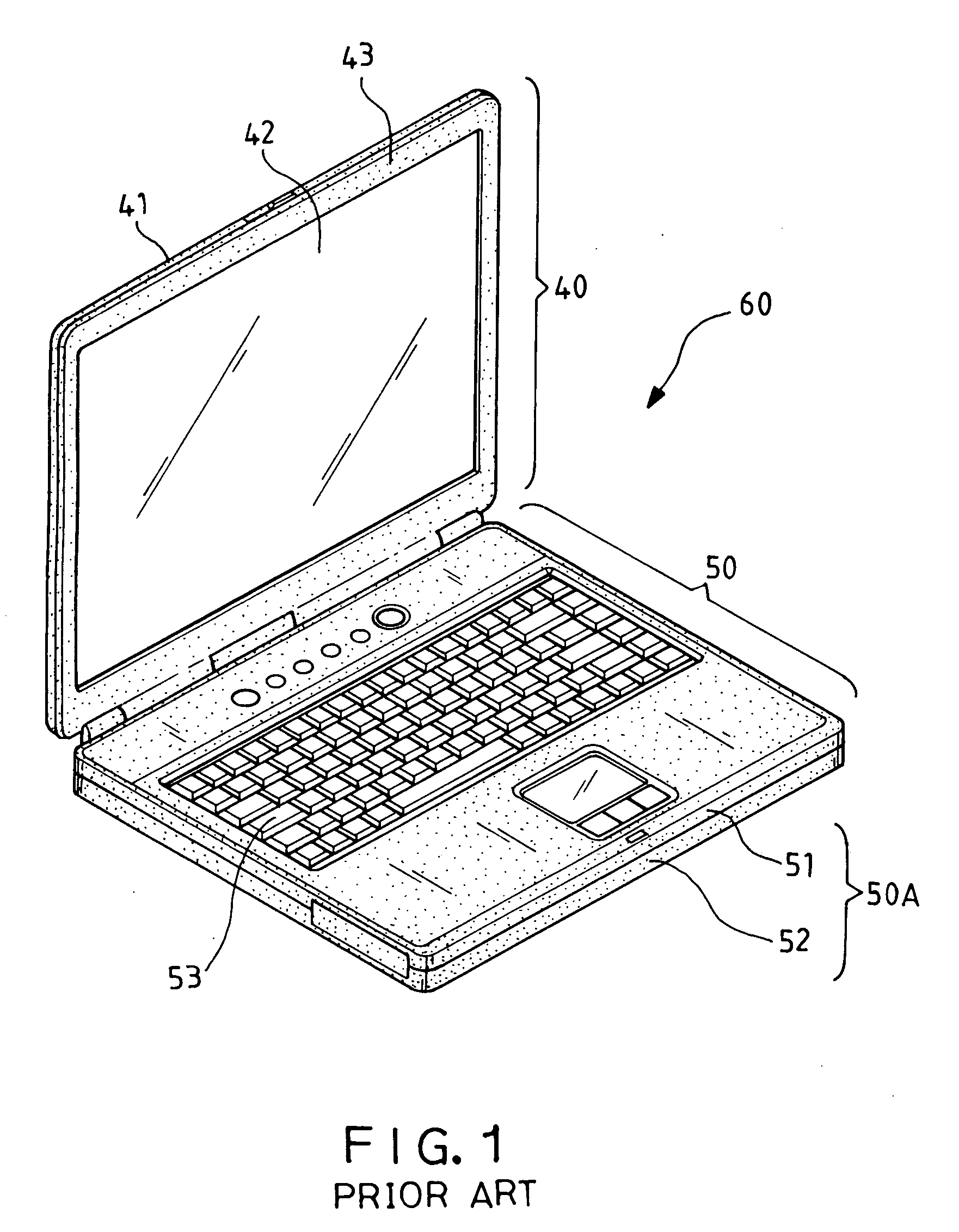

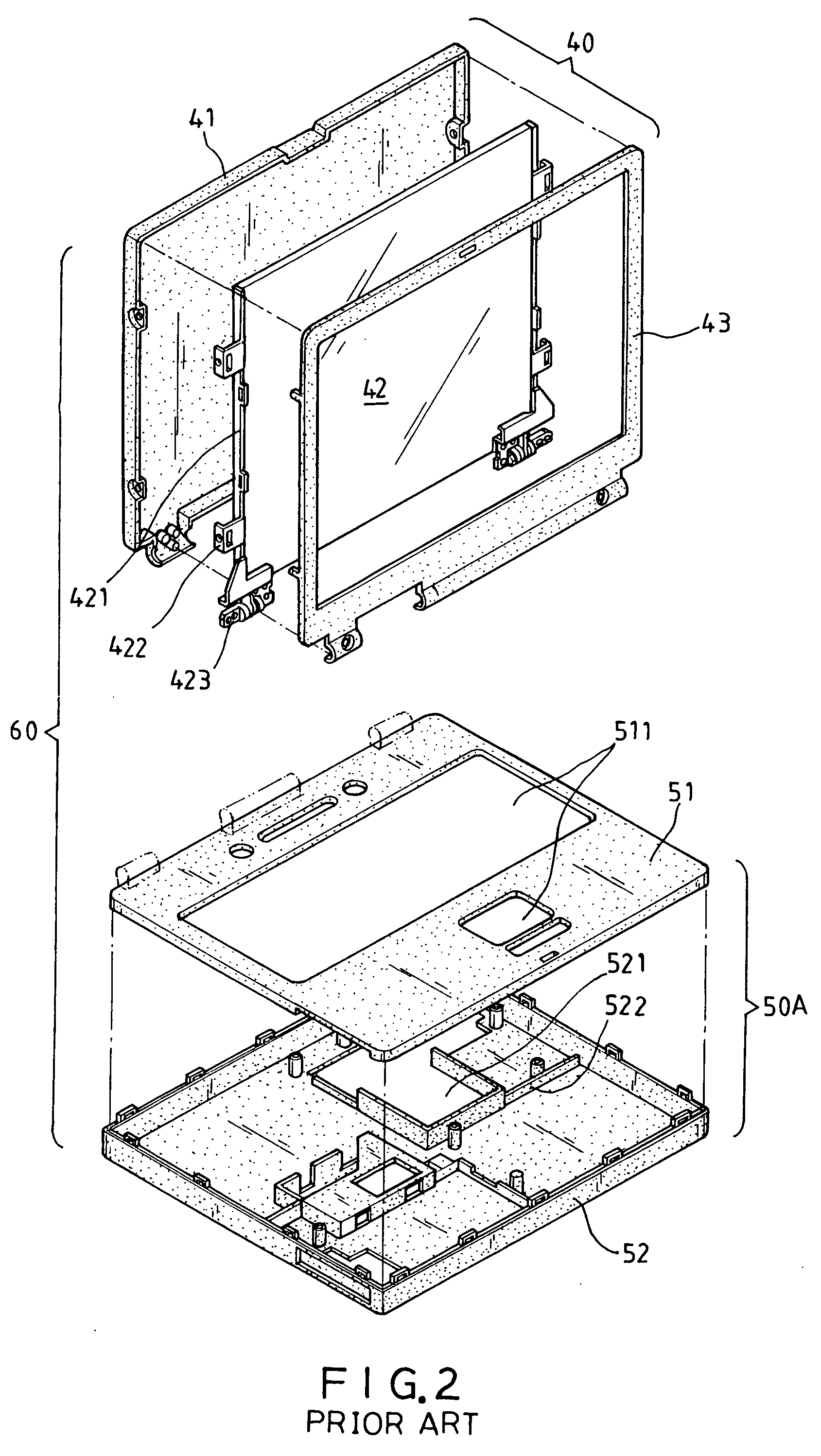

Combination housing of a notebook computer

InactiveUS7385806B2Improve textureMinimize the numberFurniture partsCabinetsDisplay deviceEngineering

A combination housing of a notebook computer having a display housing and a main frame housing. The main frame housing including a top metal cover, a first middle plastic frame, and a bottom metal cover three of which are combined to form a sandwich structure. Meanwhile, the main frame housing including a front metal cover, a second middle plastic frame, and a rear metal cover three of which are combined to form a sandwich structure. Besides, an engagement of engaging parts of the metal covers in corresponding arched cavities of the middle plastic frames is utilized to permit a rapid fastening. In this way, the main housing portion of the notebook computer can be made of aluminum ally or aluminum magnesium alloy.

Owner:ELITEGROUP COMPUTER SYSTEMS

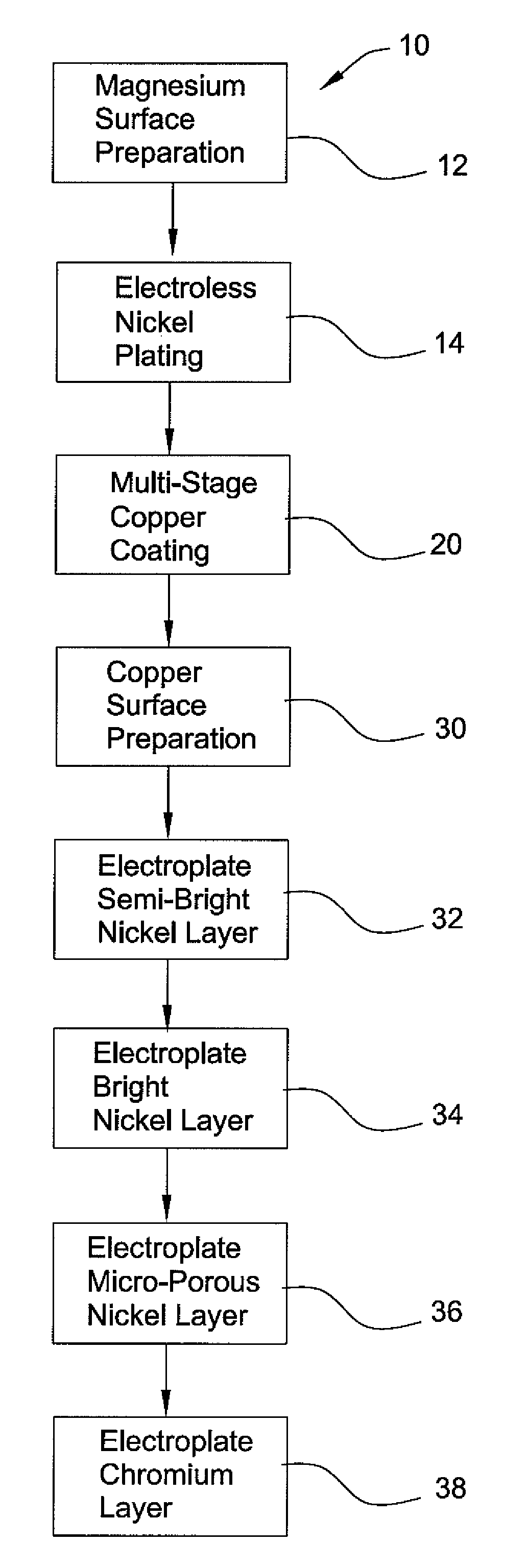

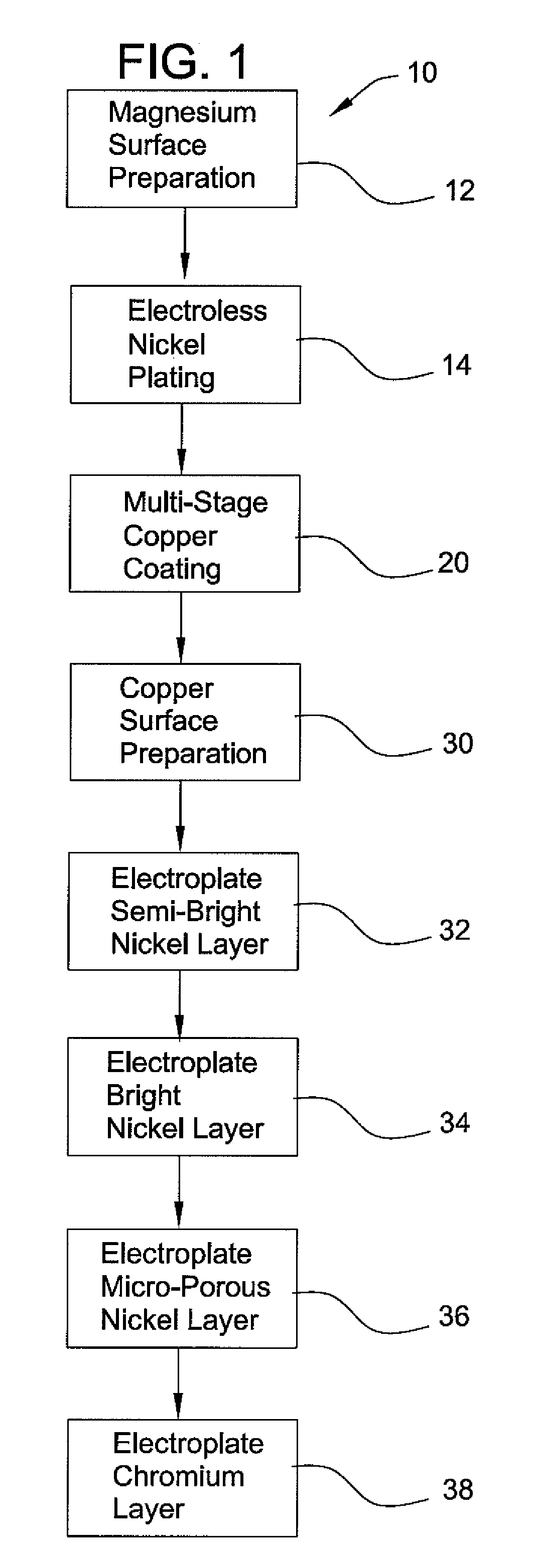

Method of Chrome Plating Magnesium and Magnesium Alloys

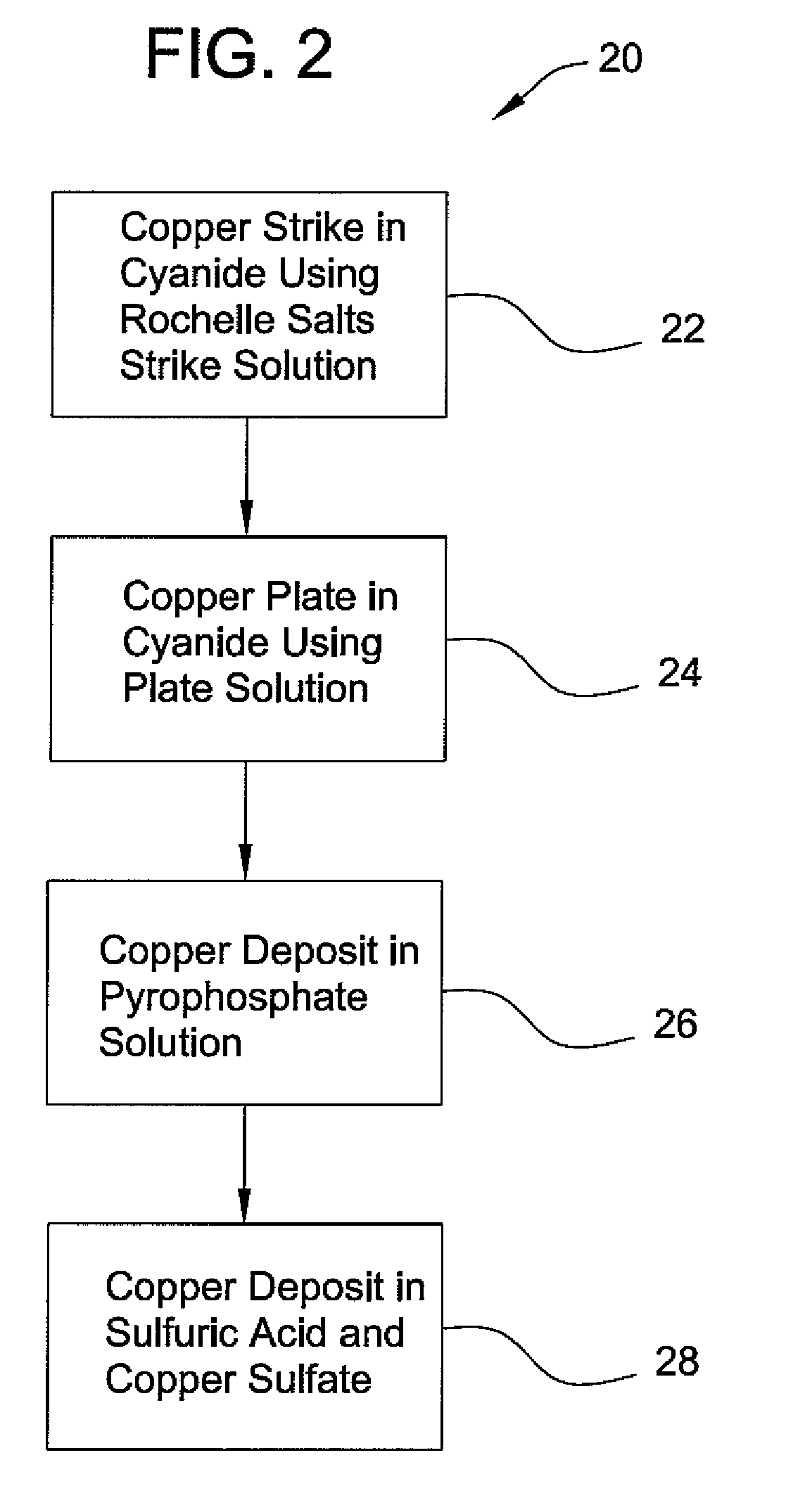

ActiveUS20090317556A1Liquid surface applicatorsLiquid/solution decomposition chemical coatingCopper coatingChrome plating

A process for chrome plating magnesium and its alloys. The process uses a combination of electroless nickel plating, a multi-stage copper coating transition system and multiple layers of electrodeposited nickel to form a corrosion resistant system of substantial impermeability and interlayer adherence suitable for direct chromium electroplating.

Owner:ARLINGTON PLATING

ABSORBABLE STENT HAVING A COATING FOR CONTROLLING DEGRADATION OF THE STENT AND MAINTAINING pH NEUTRALITY

ActiveUS20100131050A1Simple designImprove the environmentStentsSurgeryMetallic materialsMedical device

A biocompatible metallic material may be configured into any number of implantable medical devices, including intraluminal stents. The biocompatible metallic material may comprise a magnesium alloy. The magnesium alloy implantable medical device may be designed to degrade over a given period of time. In order to control the degradation time, the device may be coated or otherwise have affixed thereto one or more coatings, one of which comprises a material for controlling the degradation time and maintain a pH neutral environment proximate the device. Additionally, therapeutic agents may be incorporated into one or more of the coatings on the implantable medical device.

Owner:CARDINAL HEALTH SWITZERLAND 515 GMBH

Combination housing of a notebook computer

InactiveUS20070025072A1Improve textureMinimize the numberFurniture partsCabinetsDisplay deviceEngineering

A combination housing of a notebook computer having a display housing and a main frame housing. The main frame housing including a top metal cover, a first middle plastic frame, and a bottom metal cover three of which are combined to form a sandwich structure. Meanwhile, the main frame housing including a front metal cover, a second middle plastic frame, and a rear metal cover three of which are combined to form a sandwich structure. Besides, an engagement of engaging parts of the metal covers in corresponding arched cavities of the middle plastic frames is utilized to permit a rapid fastening. In this way, the main housing portion of the notebook computer can be made of aluminum ally or aluminum magnesium alloy.

Owner:ELITEGROUP COMPUTER SYSTEMS

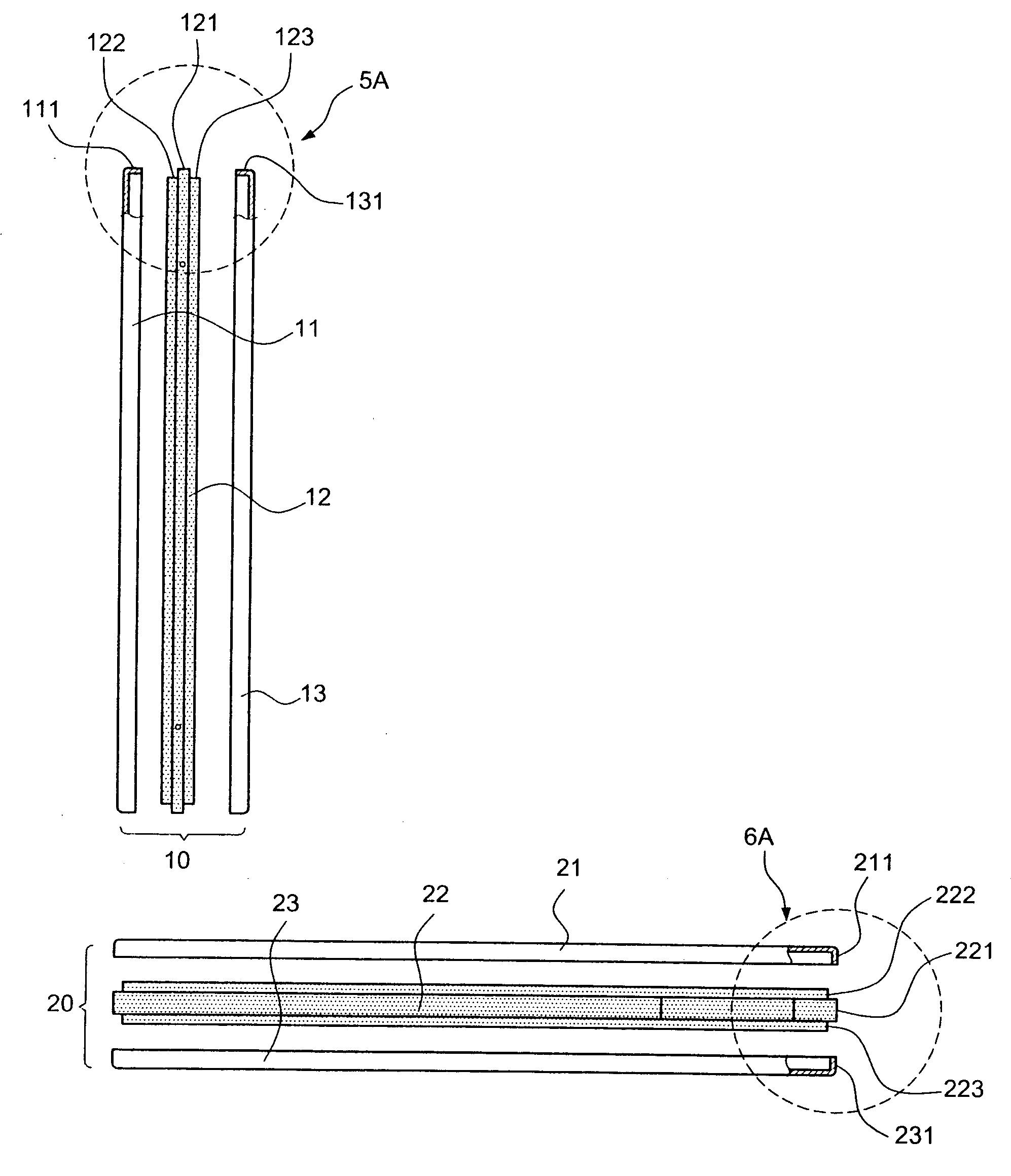

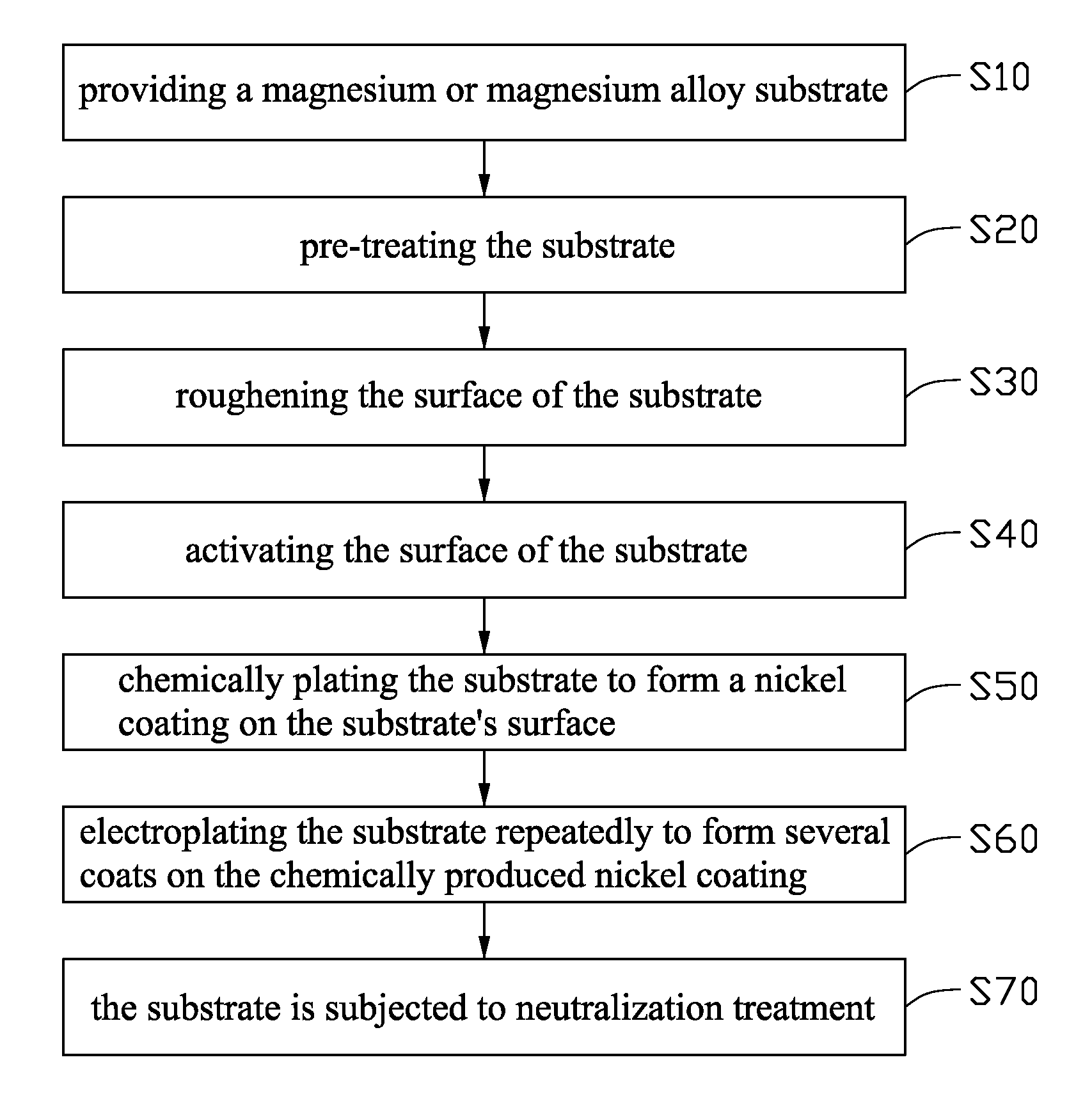

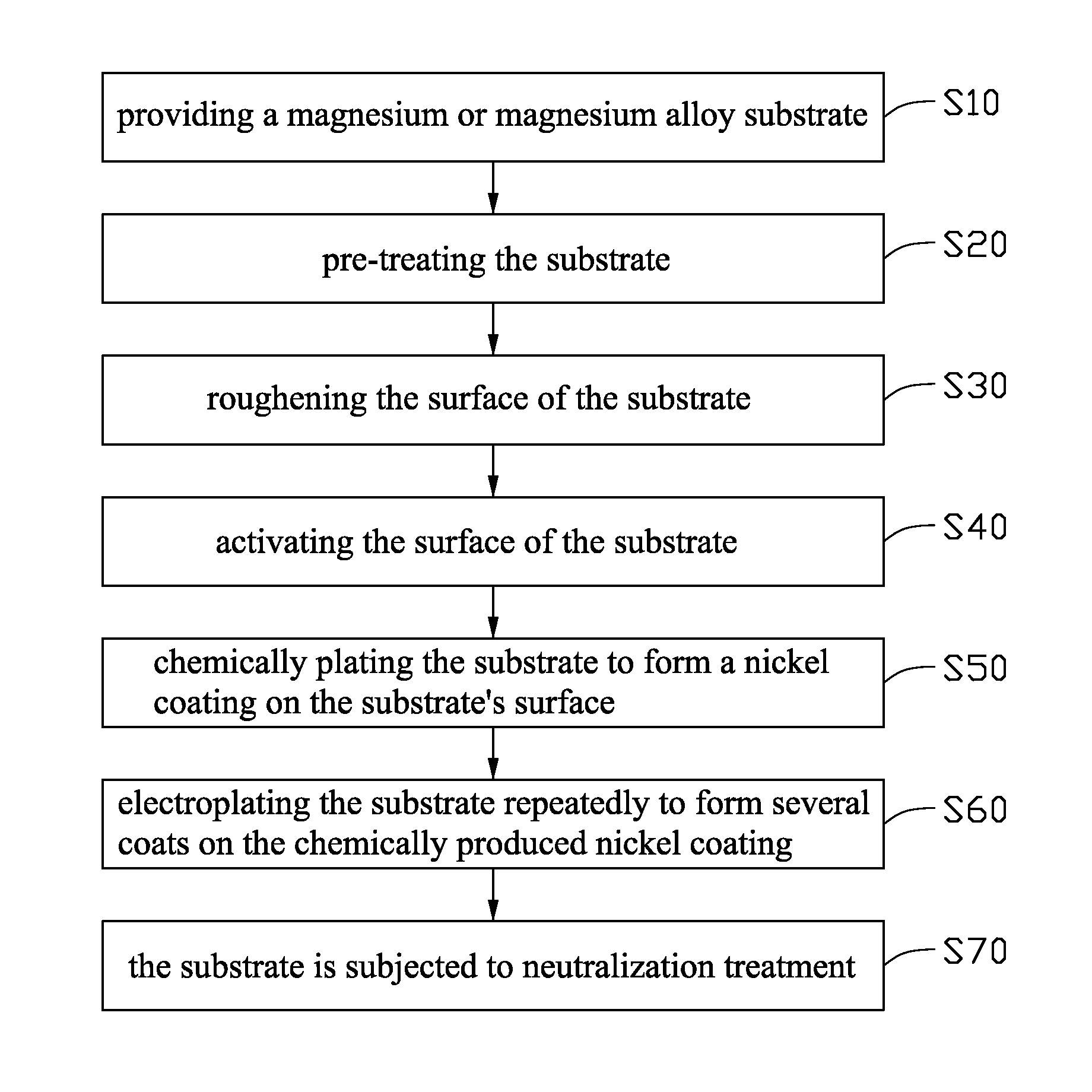

Electroplating method for magnesium and magnesium alloy

An electroplating method for magnesium and magnesium alloys, comprising: providing a magnesium or magnesium alloy substrate and pre-treating it to be cleaned; roughening the surface of the substrate; activating the surface of the substrate; chemically plating the substrate to form a nickel coating on its surface; and electroplating the substrate to form, in order, a first nickel coating, a copper coating, a second nickel coating, and a chromium coating on the chemically produced nickel coating.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD +1

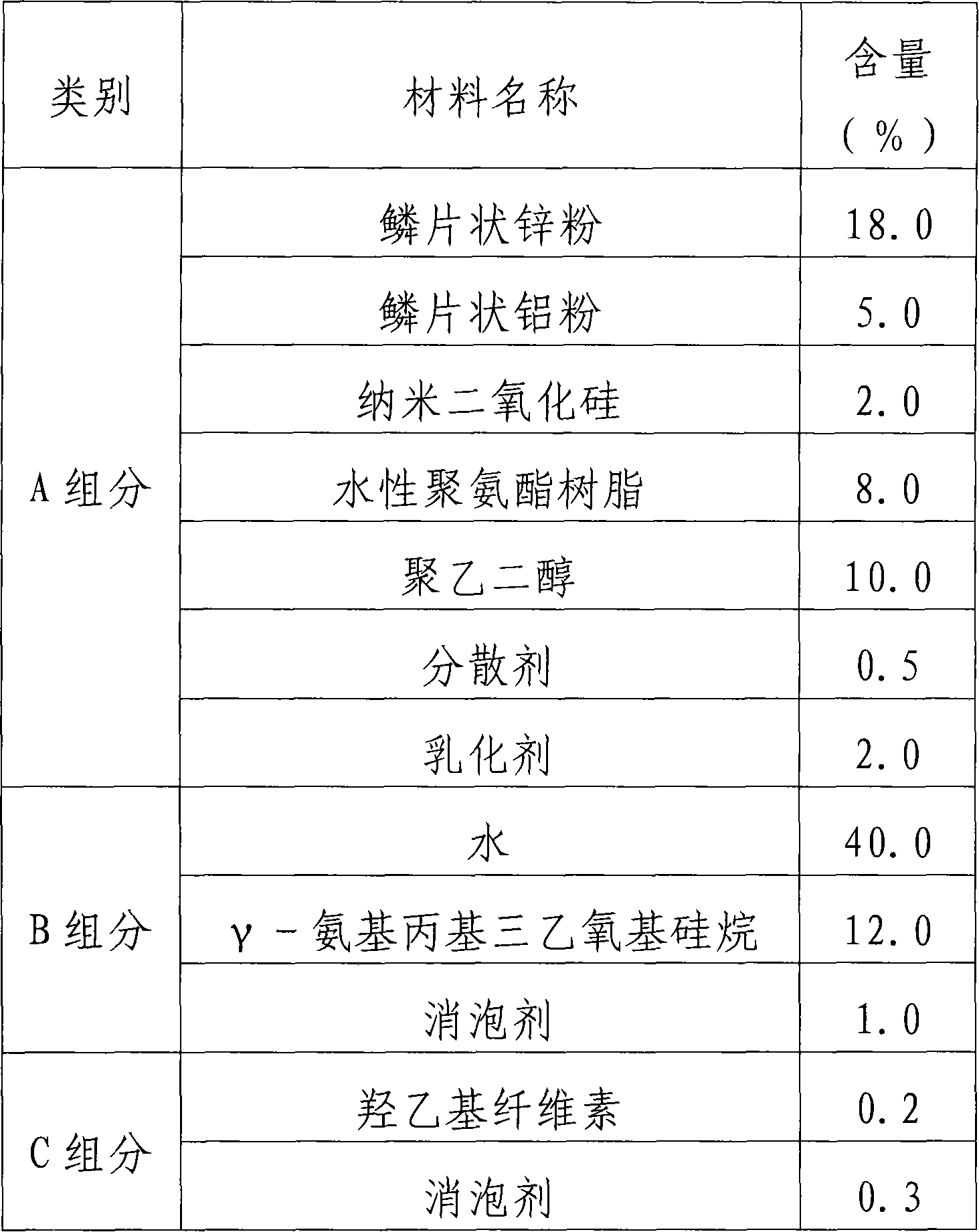

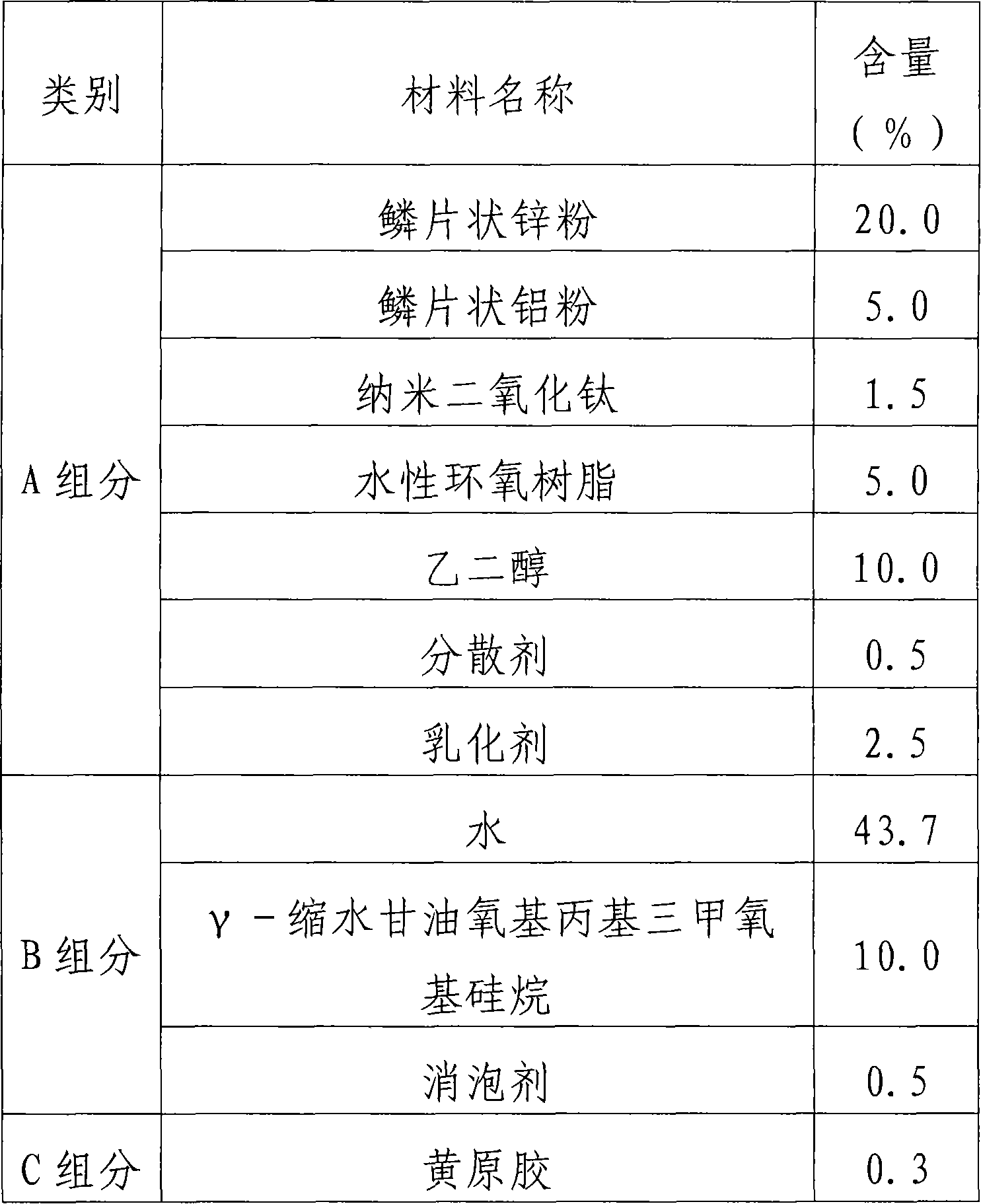

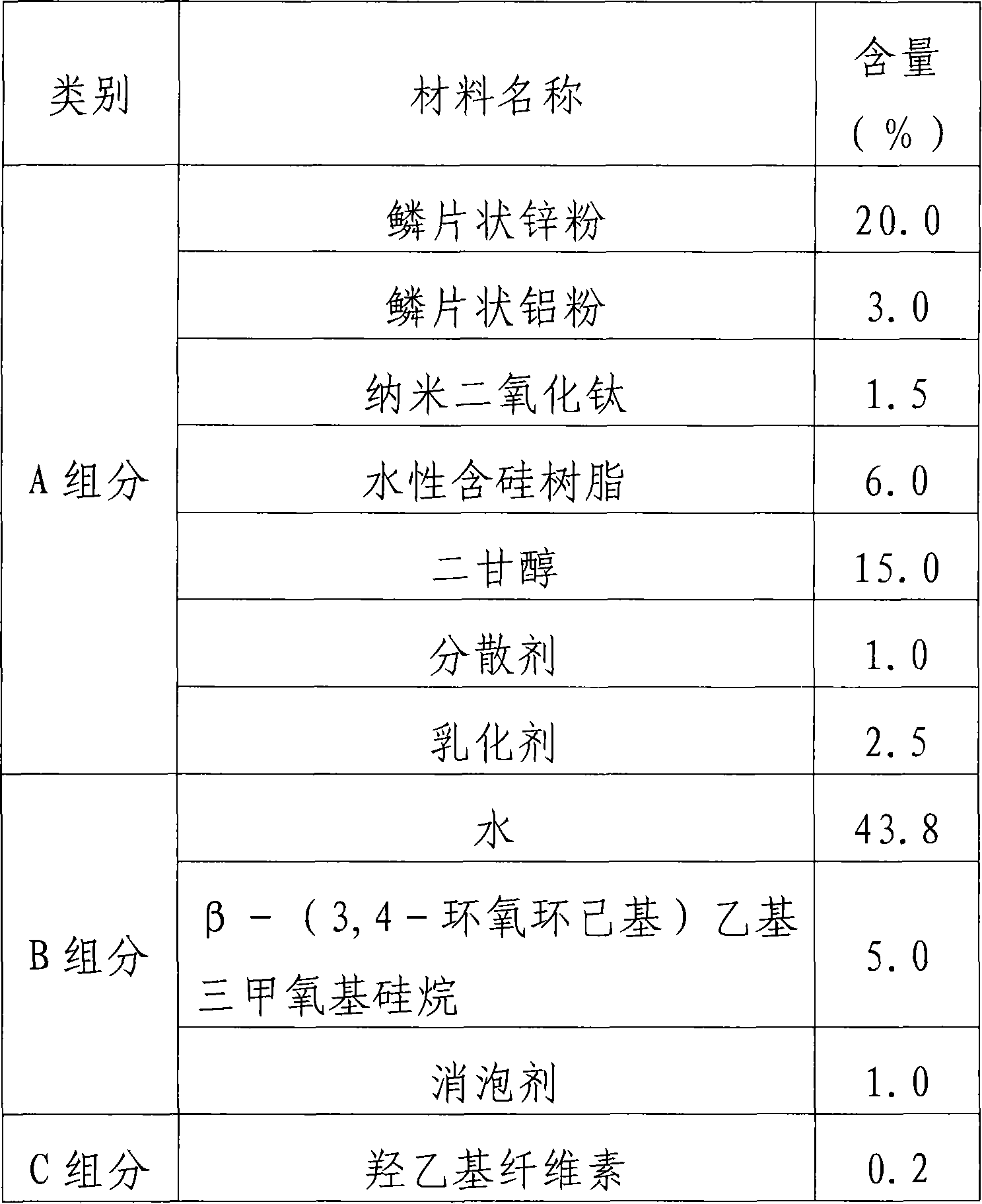

Hydrophilic nano zinc based composite coating

InactiveCN101613559AStrong weather resistanceNo pollution in the processAnti-corrosive paintsPolyurea/polyurethane coatingsSilanesSolvent

The invention belongs to the technical field of chemical engineering coatings and particularly relates to a hydrophilic nano zinc based composite coating used for preventing corrosion on the surfaces of the metal parts. The coating comprises an emulsifier, a dispersant, an antifoaming agent, scaly metallic powder, nano oxides, a silane coupler, an alcohol-type solvent, a high-molecule organic material, a thickener and 30.0 to 60.0 percent of water serving as a disperse medium. The coating can be coated by spraying, brushing, soaking and soaking-centrifugal coating and other methods, and the coating can be formed by being roasted at a temperature of about 200 DEG C for 20 minutes. Neutral salt spray corrosion resistant tests show that the neutral salt spray corrosion resistant time is more than 800h, the binding force is proved to be above level 4 (by an adhesive band test). The coating has the advantages of environmental pollution prevention, excellent metallic corrosion resistant property, economy and practicability and convenient use; and moreover, the coating can be widely used for the corrosion resistant treatment of the surface of metal parts made of iron, aluminum, copper and magnesium alloy and the like, particularly the corrosion resistant treatment of metal parts with complex geometric shapes.

Owner:YUNNAN GREAT IND DEV

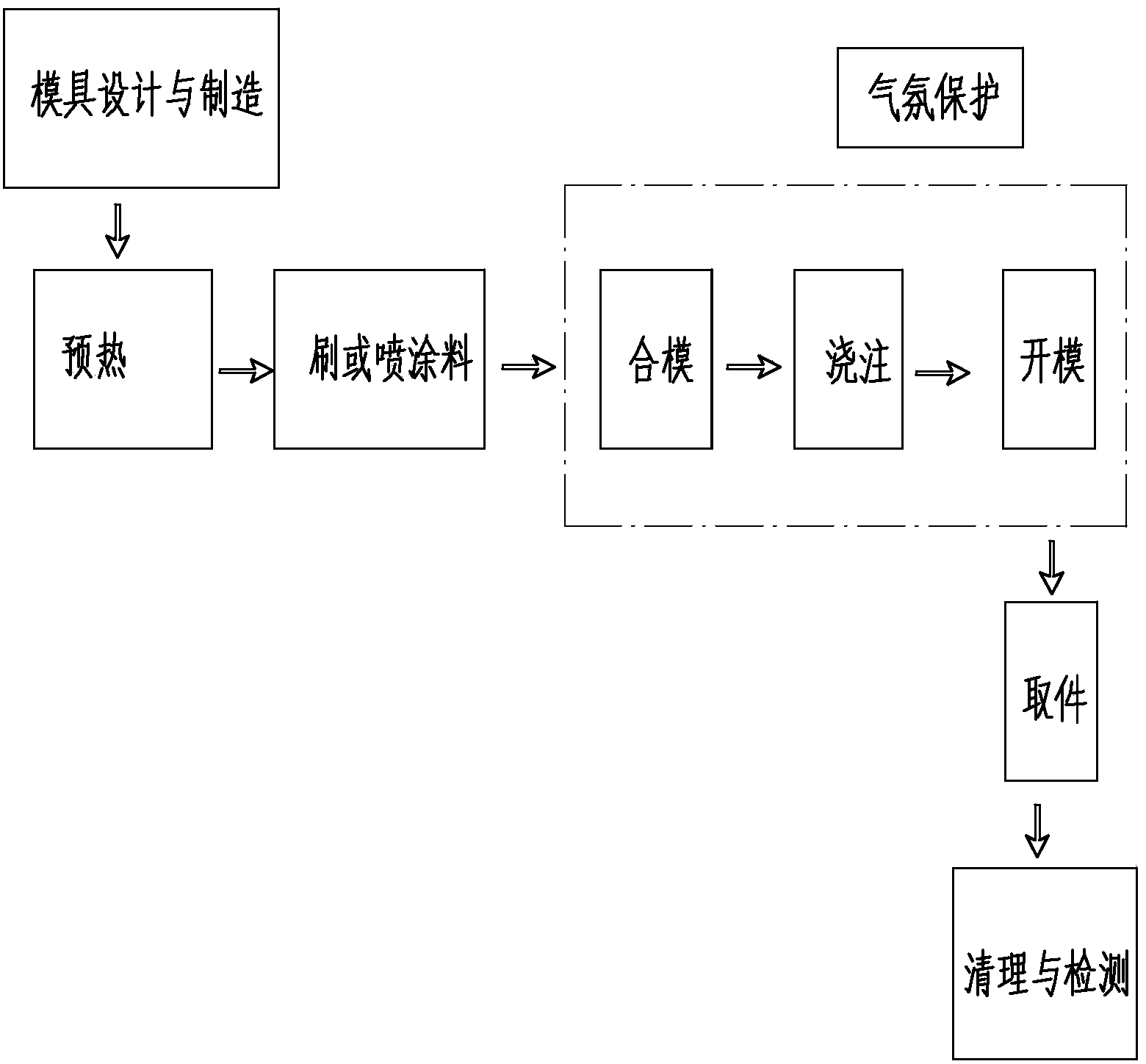

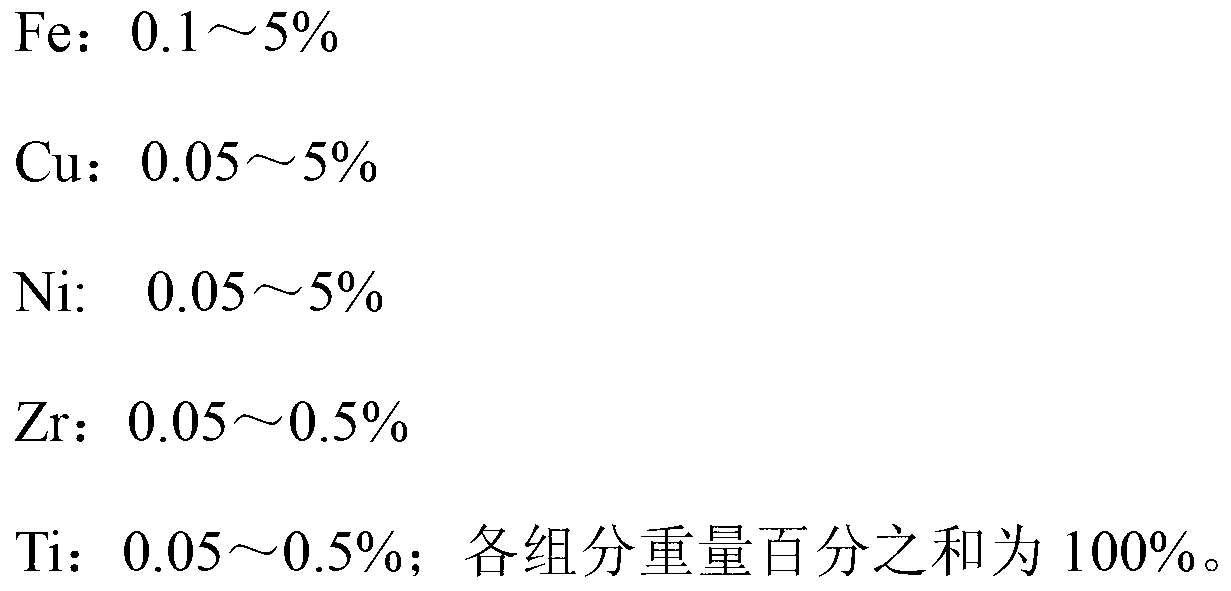

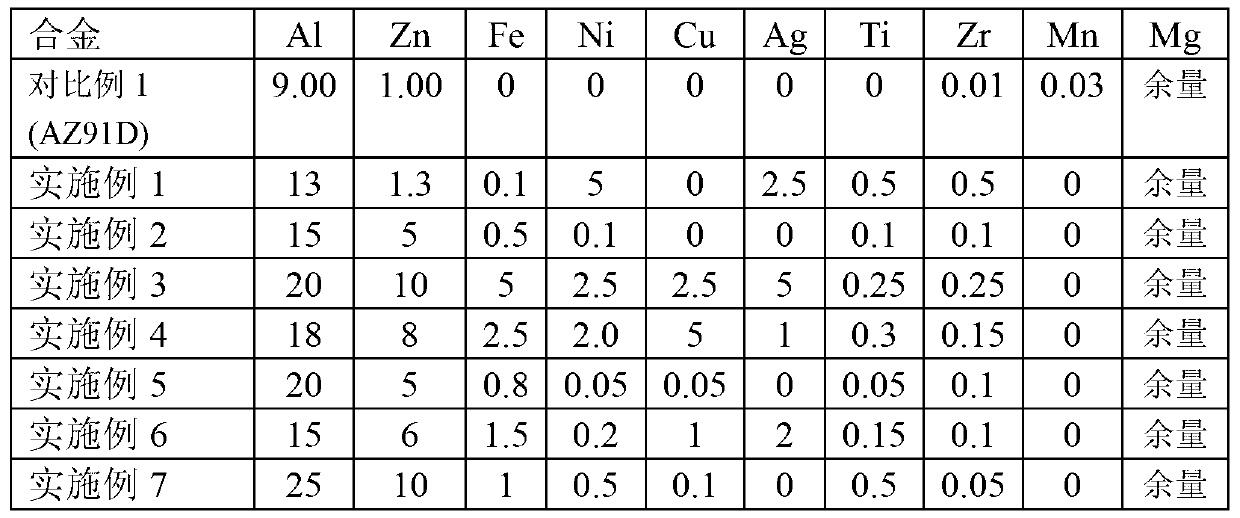

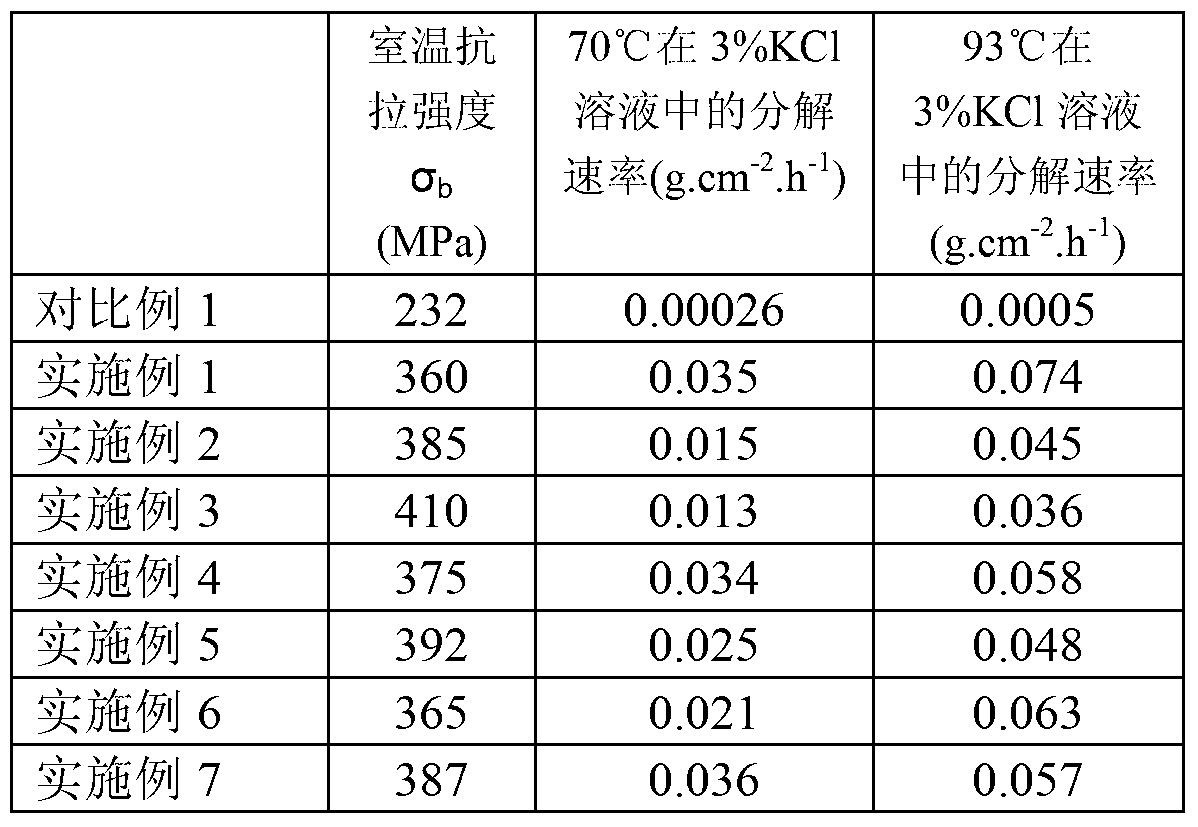

Light and pressure-proof fast-decomposed cast magnesium alloy

The invention discloses light and pressure-proof fast-decomposed cast magnesium alloy which can be used as a tripping ball material for a multi-stage sliding sleeve staged-fracturing technique. The light and pressure-proof fast-decomposed cast magnesium alloy is prepared from the following components: 13-25% of Al, 2-15% of Zn, 0.1-5% of Fe, 0.05-5% of Cu, 0.05-5% of Ni, 0-5% of Ag, 0.05-0.5% of Zr, 0.05-0.5% of Ti, and the balance of Mg. The preparation method comprises the following steps of: weighing the components according to the designed component ratio of the magnesium alloy; firstly, putting pure magnesium and pure aluminum into a smelting furnace, putting pure zinc and intermediate alloy of other components into magnesium-aluminum alloy melt after melting; refining, degassing, and stewing after warming to melt; then casting in a protective atmosphere. The light and pressure-proof fast-decomposed cast magnesium alloy is reasonable in component ratio, and simple in craft process; the light and pressure-proof fast-decomposed cast magnesium alloy can be obtained by controlling the ingredients of the alloy; the alloy decomposition performance exceeds that of the traditional cast magnesium alloy; the demands of the multi-stage sliding sleeve staged-fracturing technique on the decomposition performance of the tripping ball material can be met; industrialized application can be achieved; application of the magnesium alloy in the field of exploitation of petroleum and gas is expanded.

Owner:中山市宏镁科技有限公司

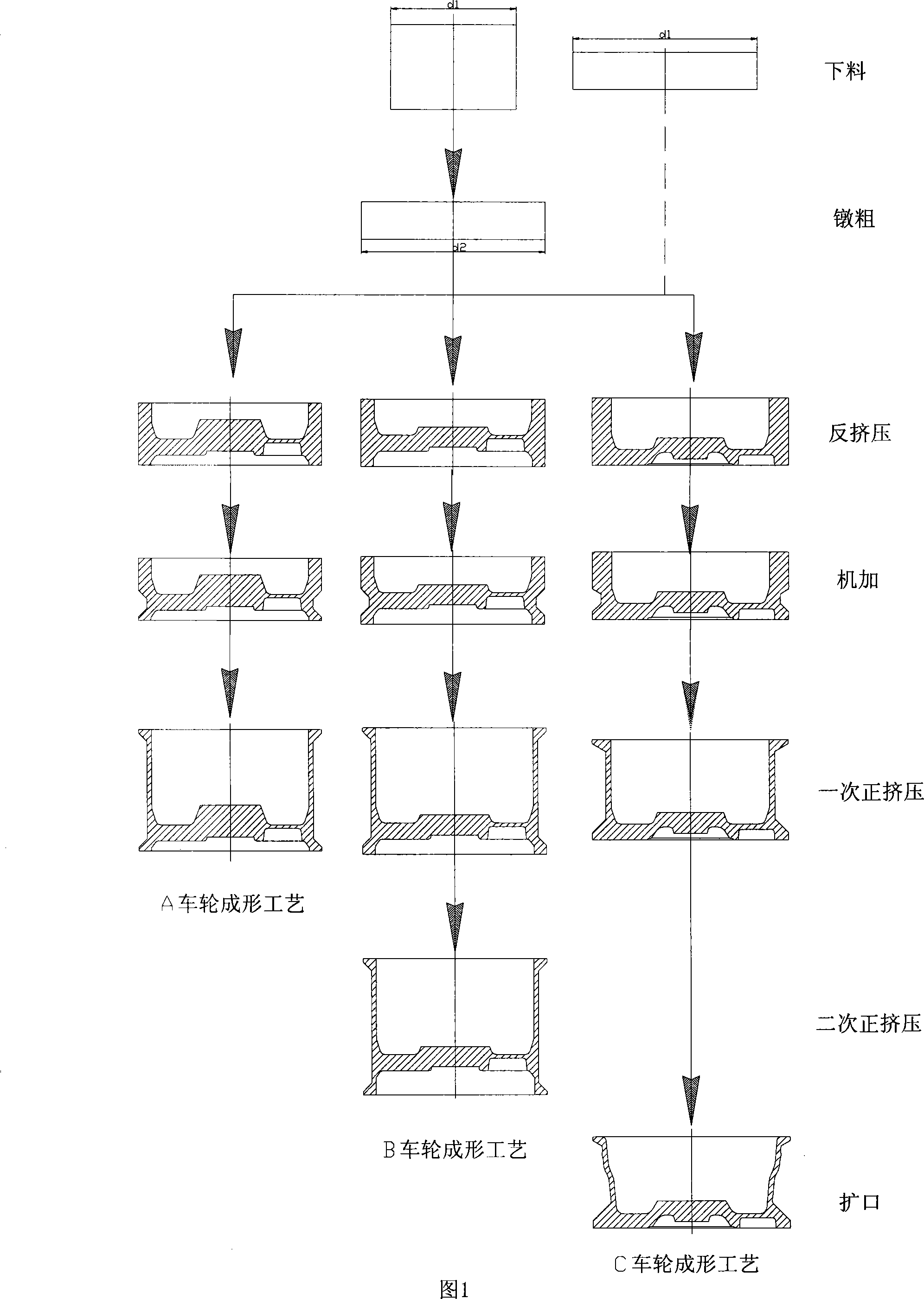

Magnesium alloy automobile wheel extrusion molding method and mold

The invention relates to a press forming method of magnesium alloy automobile wheels and a die thereof, the working procedures of the press forming method comprise: blanking-continuous upsetting-backward extrusion-machinery adding-forward extrusion-flaring-thermal treatment-ultimate machinery adding-superficial treatment; the press forming die comprises: a backward extrusion die, a forward extrusion die and a flaring die; the method of the invention can directly form magnesium alloy or aluminium alloy automobile wheels of various shapes, which solves the problem of hard forming of flanges of wheels and reduces the forming force, which particularly suitable for the magnesium alloy of low plasticity with hexagonal close packed lattice, three-direction compressive stress acquired from forward extrusion is beneficial to improve the plasticity of the material; the formed wheel has the advantages of high size precision and surface precision, good comprehensive mechanical property and simple die structure, which improves the quality of the product, simplifies technical process, decreases die frock and equipment and reduces production cost.

Owner:ZHONGBEI UNIV

Magnesium alloy non cyanogen plating copper chemical plating nickle and its plating process

InactiveCN1598059AImprove bindingUniform coating thicknessSuperimposed coating processCopper platingChemical plating

The invention discloses a method of plating Nickel with magnalium alloy without cyanogen and the plating technique. The direction for the plating solution is: 20 to 80g.dm-3 of copper charred phosphate; one or several of the 60 to 320g.dm-3 of sodium charred phosphate or Potassium charred phosphate or 60 to 250g.dm-3 of sodium citric acid, 5 to 20g.dm-3 of Potassium sodium tartaric acid, 60 to 250g.dm-3 of HEDP and 60 to 250g.dm-3 of amine ethylene; one or several of the 5 to 20g.dm-3 of hydrogen amine di-fluorin or 5 to20 g.dm-3 sodium fluoride or 5 to 20g.dm-3 of Potassium fluoride or 5 to 20g.dm-3 of lithium fluoride. The plating solution chooses the nickel sulfate or alkali type nickel carbonate or nickel acetic acid as the main salt and adds the reducing agent, combination agent and stabilization agent. The plating technique adopts the acid plating copper-plating three nickel-plating chromium. The invention has little pollution to the environment, high binding power and erosion-proof property.

Owner:GCI SCI & TECH +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com