Patents

Literature

919results about "Extrusion control devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

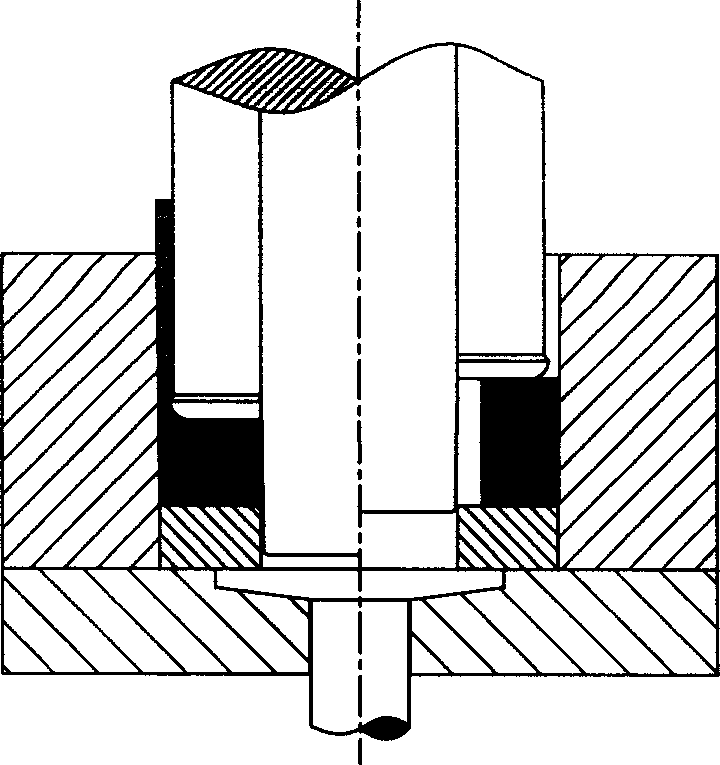

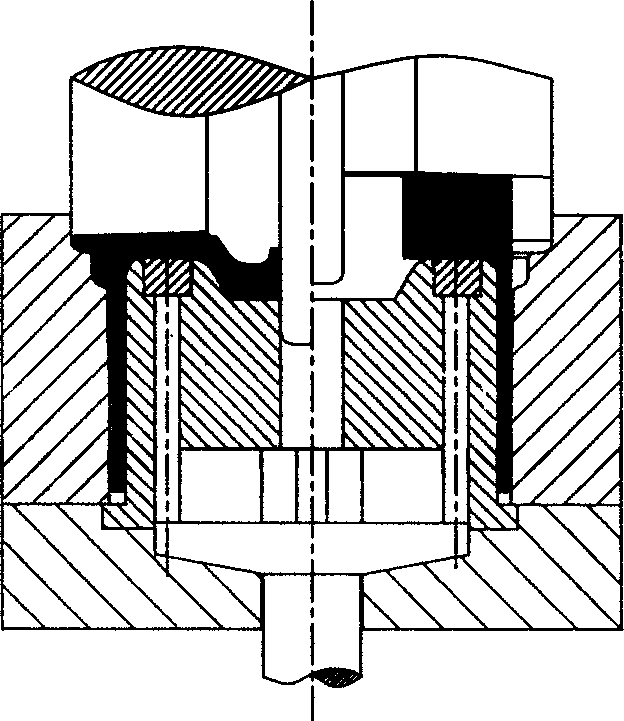

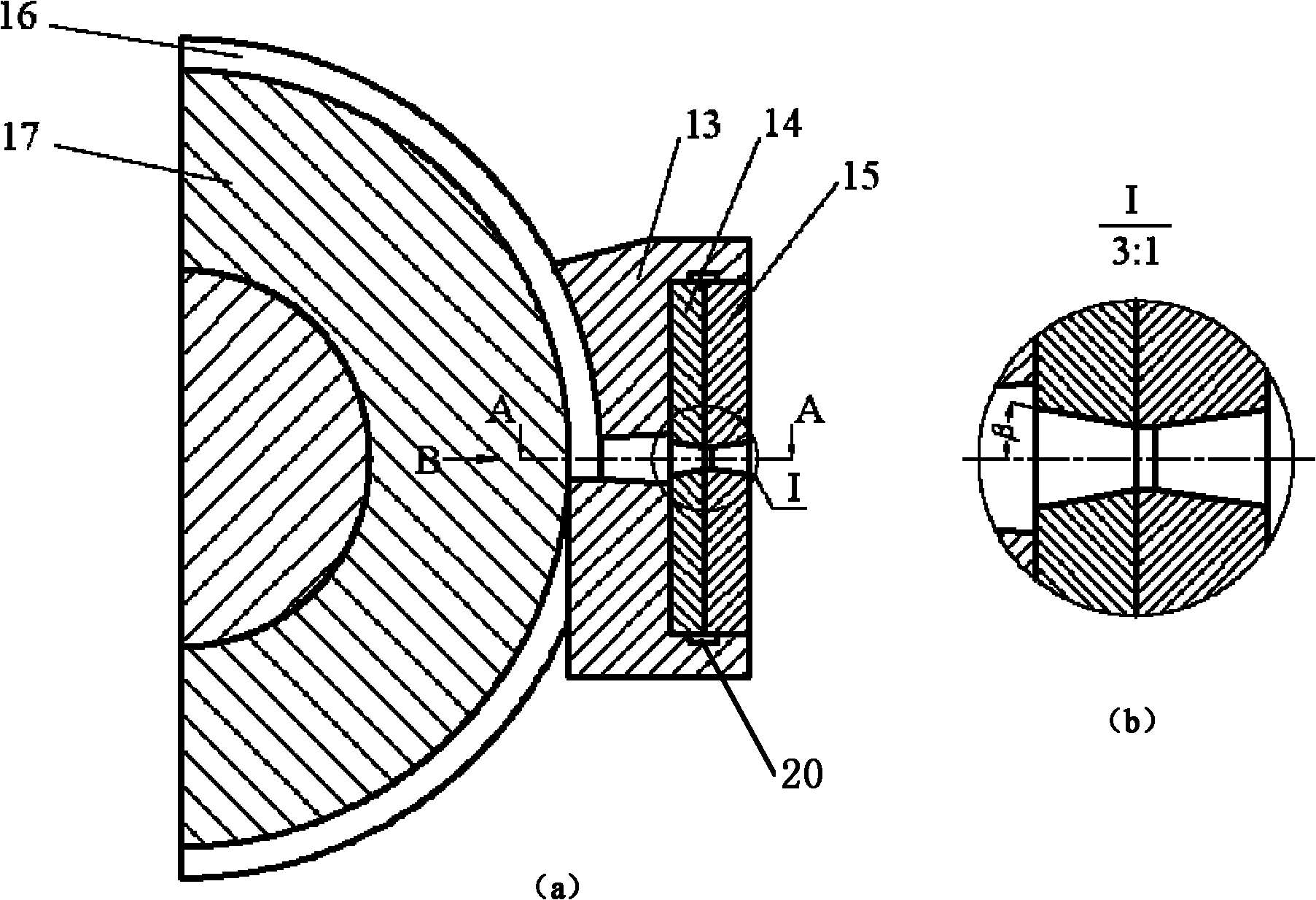

A labor-saving automobile hub forming method and device

InactiveCN1864915AWith substantive technologyReduction toolExtrusion diesExtrusion control devicesEngineeringMechanical engineering

The invention relates to a method for shaping the vehicle hub and relative device. Wherein, it comprises following steps that casting blank; uniform processing; pre-shaping blank; compressing; compressing the front rim; expanding opening and folding the edge at the back rim. The invention is characterized in that: the casting blank via pre-shaping is made into hollow blank; the concave and convex moulds in the compressing step and the compressing front rim step are integrated, while the convex mound contains core axle; the compressing step compresses the hollow blank in the mould via core axle to obtain the cylinder element whose bottom has holes; the step that compressing front rim uses metal diversion to stuff and shape; the step that expanding opening and folding the edge of back rim uses integrated convex mould and separated concave mould to expand opening, fold edge an shape the back rim. The invention can simplify the process, reduce device number, reduce the shaping force, reduce the energy consumption, and reduce the producing cost. The invention is mainly used to produce aluminum and magnesium alloy hub.

Owner:ZHONGBEI UNIV

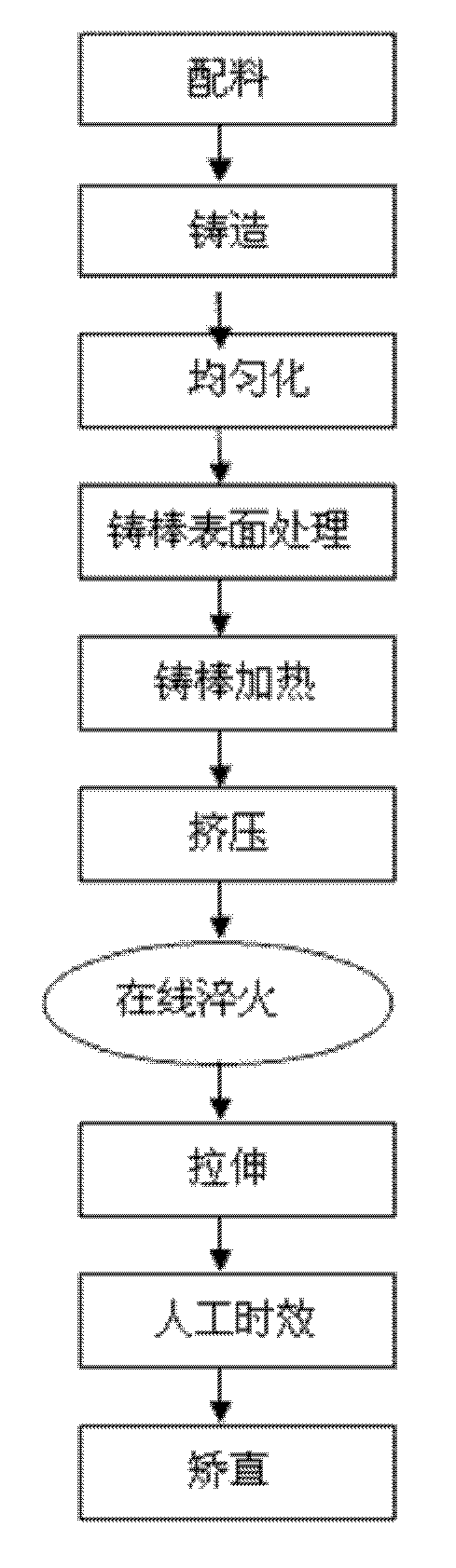

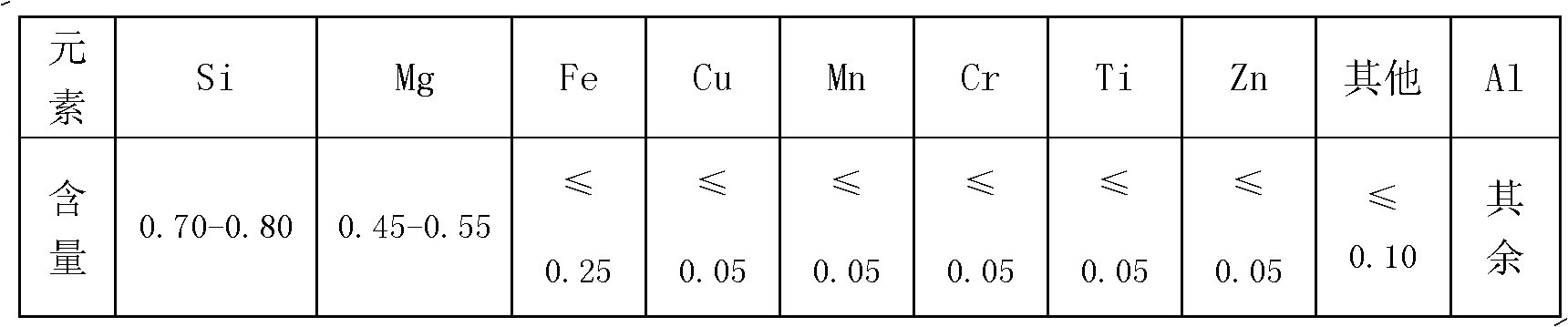

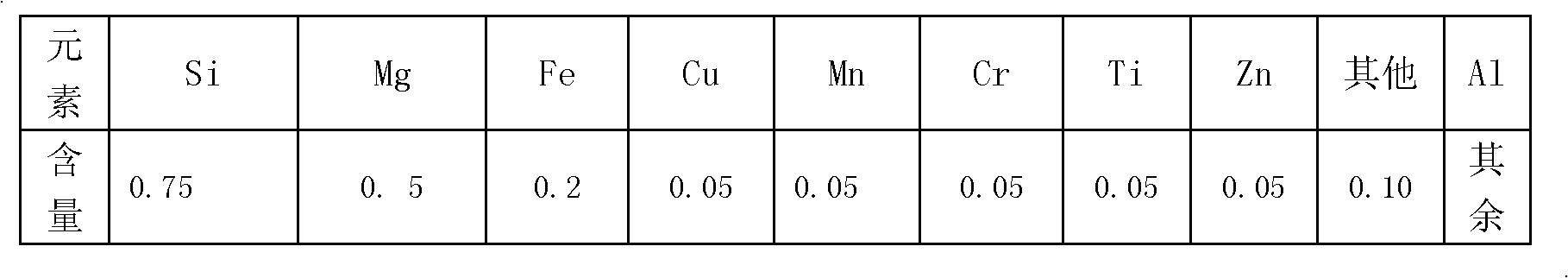

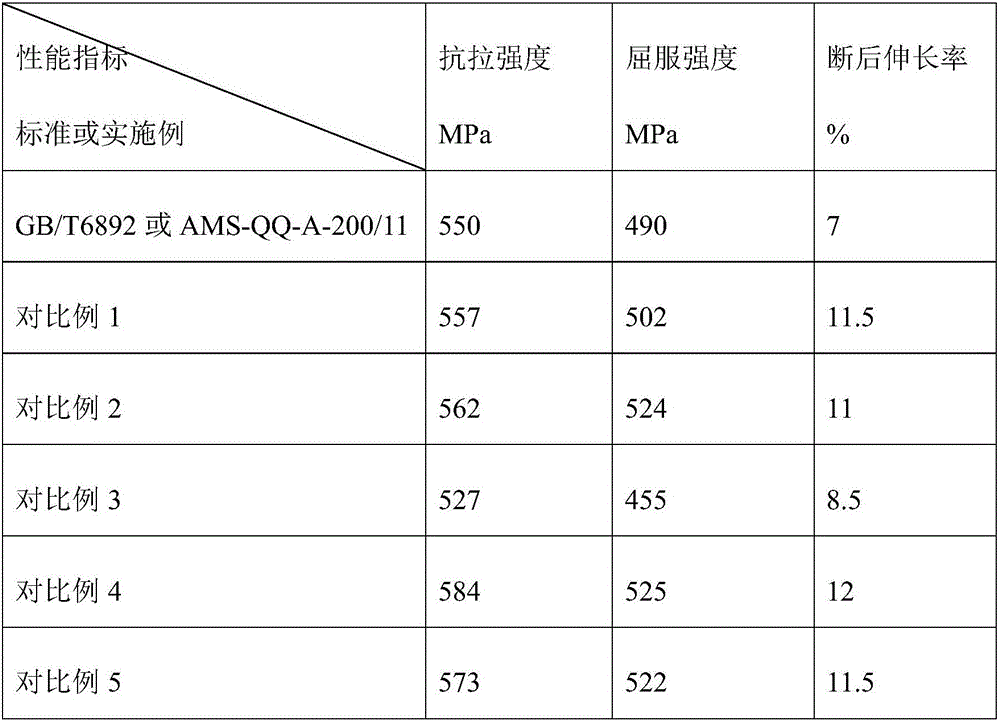

Extruding processing technology of aluminium alloy tubing with large diameter

InactiveCN102492877AReduce residual stressHigh strength propertiesExtrusion control devicesFailure rateHigh energy

The invention discloses an extruding processing technology of an aluminium alloy tubing with large diameter. The method comprises steps of a. proportioning, b. casting, c. uniformization, d. surface treatment on casting rod, e. casting rod heating, f. extrution, g. on-line quenching, h. stretching, i. artificial aging and j. straightening, etc. Strict control on each parameter can solve problems of extruding production of tubing with large diameter, eliminate disadvantages of long production period, low production efficiency, high energy consumption, huge environmental pollution and expensiveauxiliary equipment of rolling and drawing, save cost, simplify arrangement of auxiliary equipment and further reduce failure rate of an apparatus. The energy consumption of the present invention is merely 1 / 4 that of rolling and drawing, and water consumption is 1 / 8 that of a steam jet pump set; therefore, the invention brings obvious economic effects.

Owner:CHINA ZHONGWANG

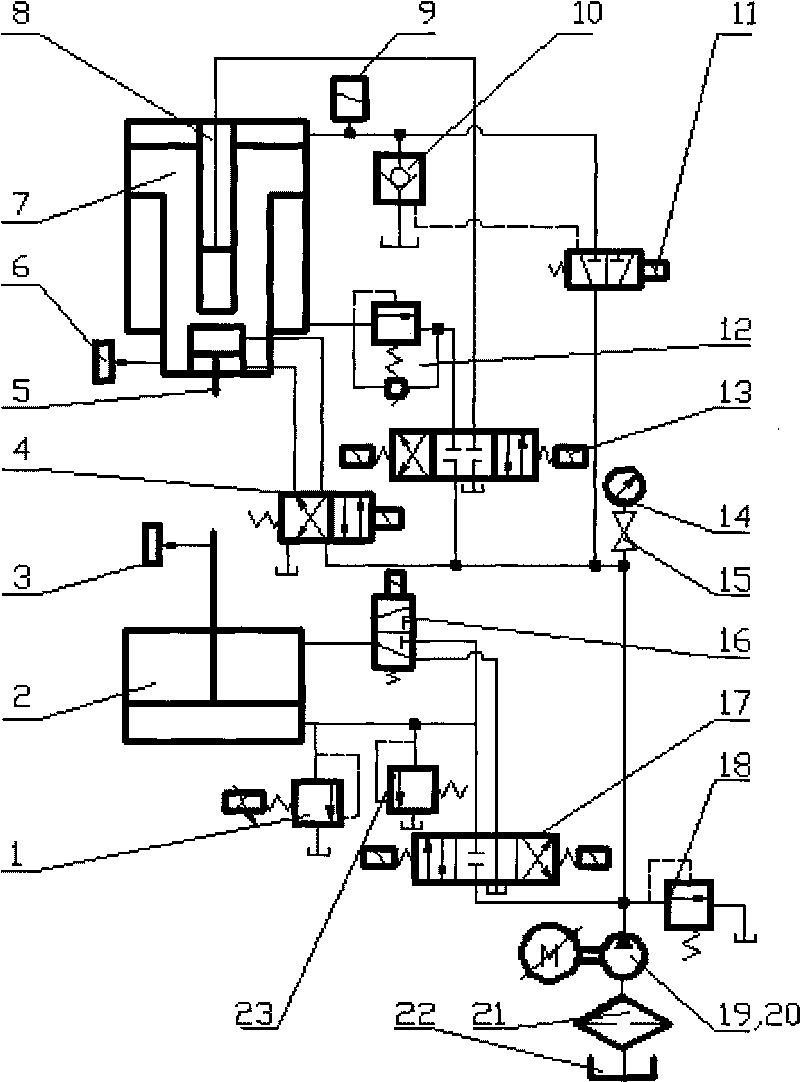

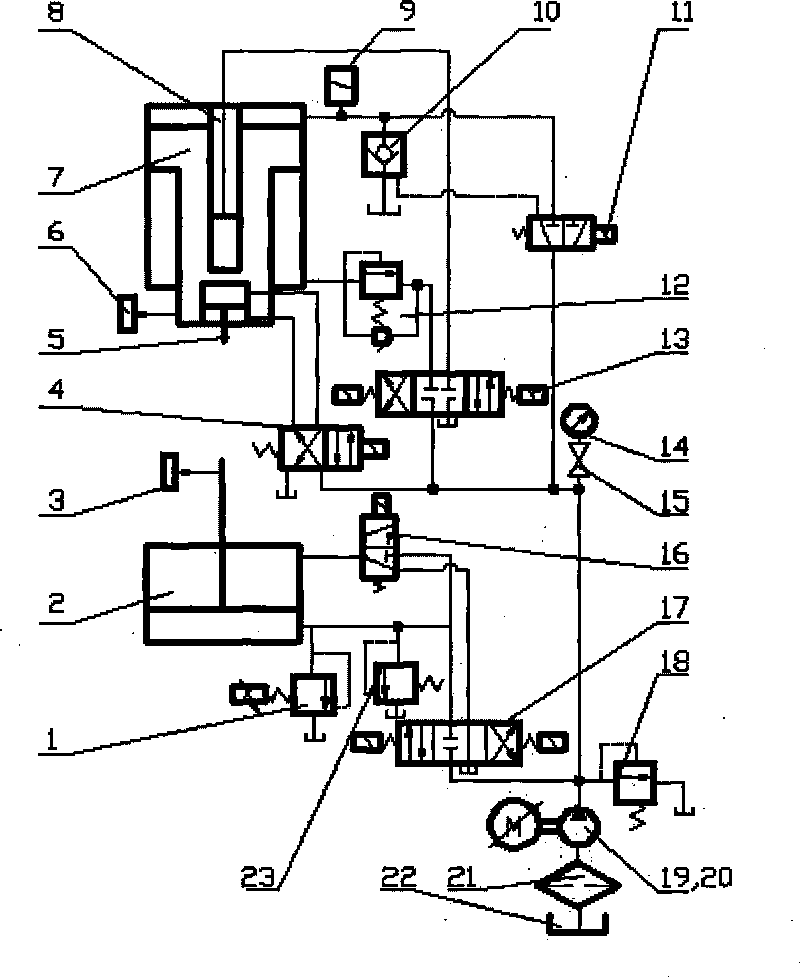

High performance and energy-saving double-acting hydrostatic press driven by servo motor

InactiveCN101712207AImprove performanceOvercome a series of disadvantagesExtrusion control devicesForging press detailsClosed loopHydrostatic pressure

The invention relates to a high performance and energy-saving double-acting hydrostatic press driven by a servo motor. The invention retains the rapid liquid-filling and direction control circuits in the common hydrostatic press, but uses a controllable hydraulic source composed of an AC servo motor and a quantitative oil pump to replace an uncontrollable hydraulic source driven by a common induction motor and combine with various sensors, and realizes the energy-saving pressure, position and speed control of the system under the control and regulation of the electrical motor; displacement sensors are added in a main cylinder and an auxiliary cylinder, a pressure sensor is added in the oil inlet line of the main cylinder, thus realizing the closed-loop control of position, speed and pressure; and a proportional relief valve is added at the oil outlet of the auxiliary cylinder, thus realizing variable blank holder force floating blank-holding of the auxiliary cylinder, wherein the electrical motor is the high-power AC servo motor, the electrical motor is connected with a controller, and the flow control and the volume velocity-governing and pressure-regulating of the main oil line can be realized by controlling the speed of the electrical motor. The invention completely uses the advantages of the high-power AC servo motor such as high efficiency, controllable performance, adjustable performance and good reliability to realize the optimization of process parameters, improve the hydrostatic press performance and reduce the energy consumption.

Owner:GUANGDONG UNIV OF TECH

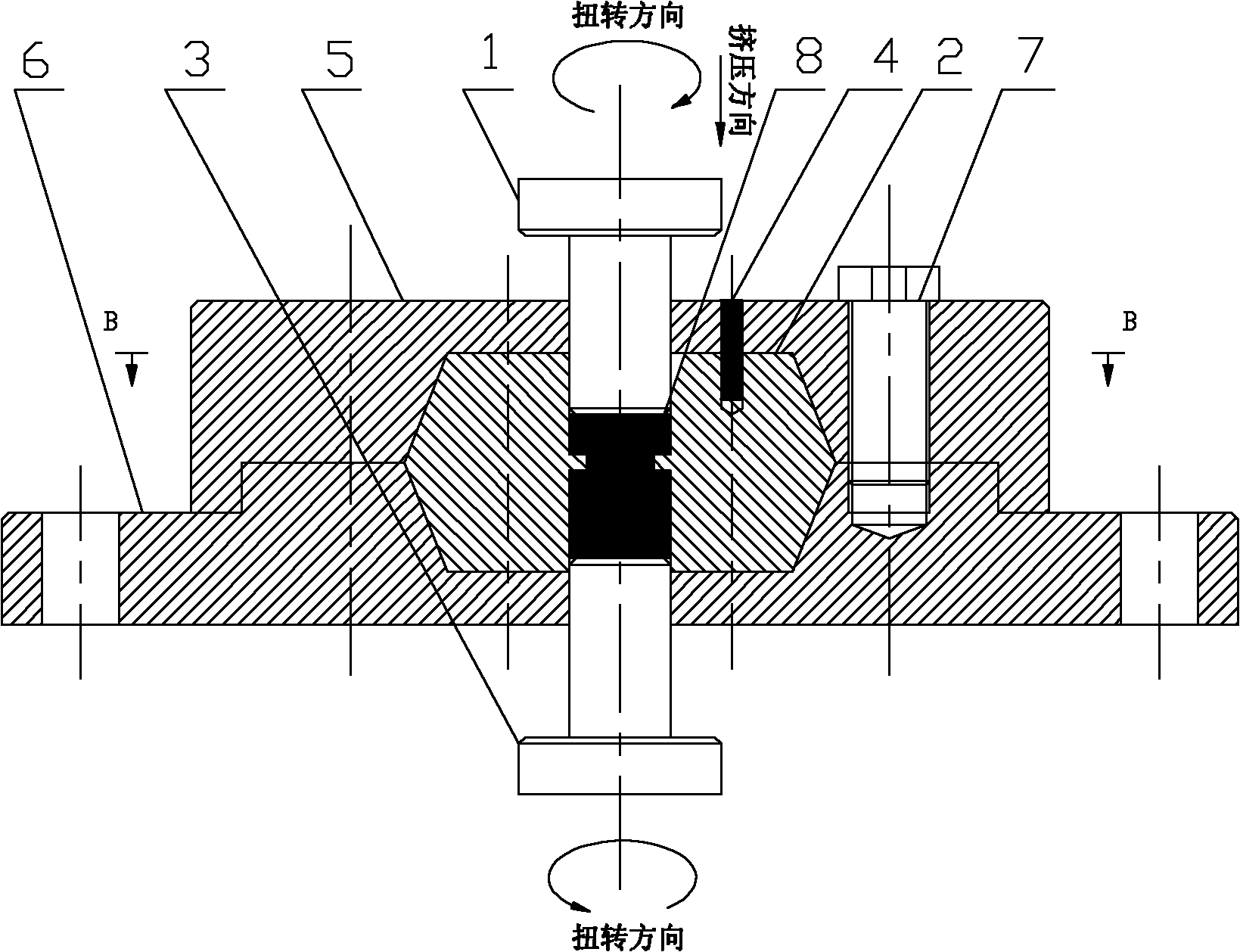

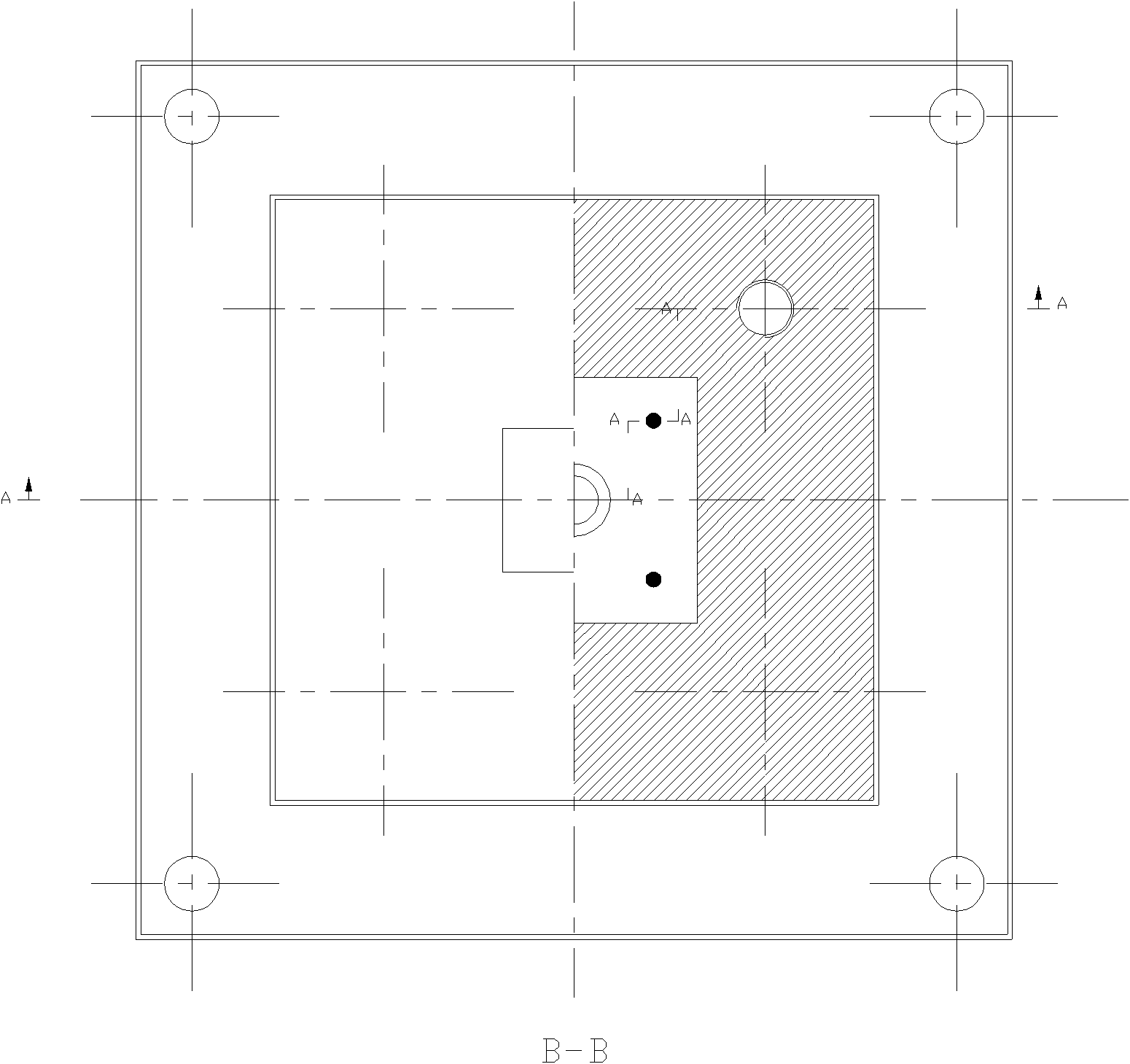

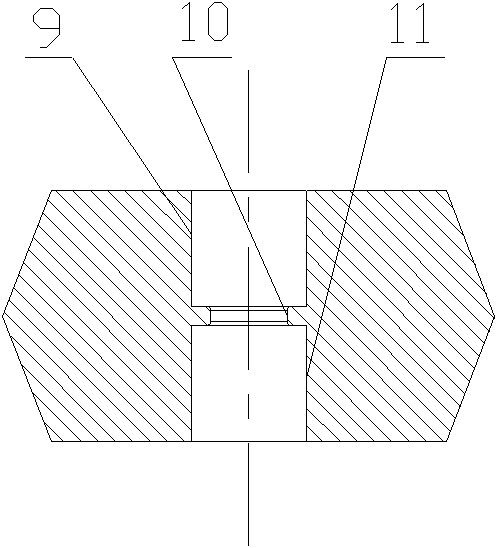

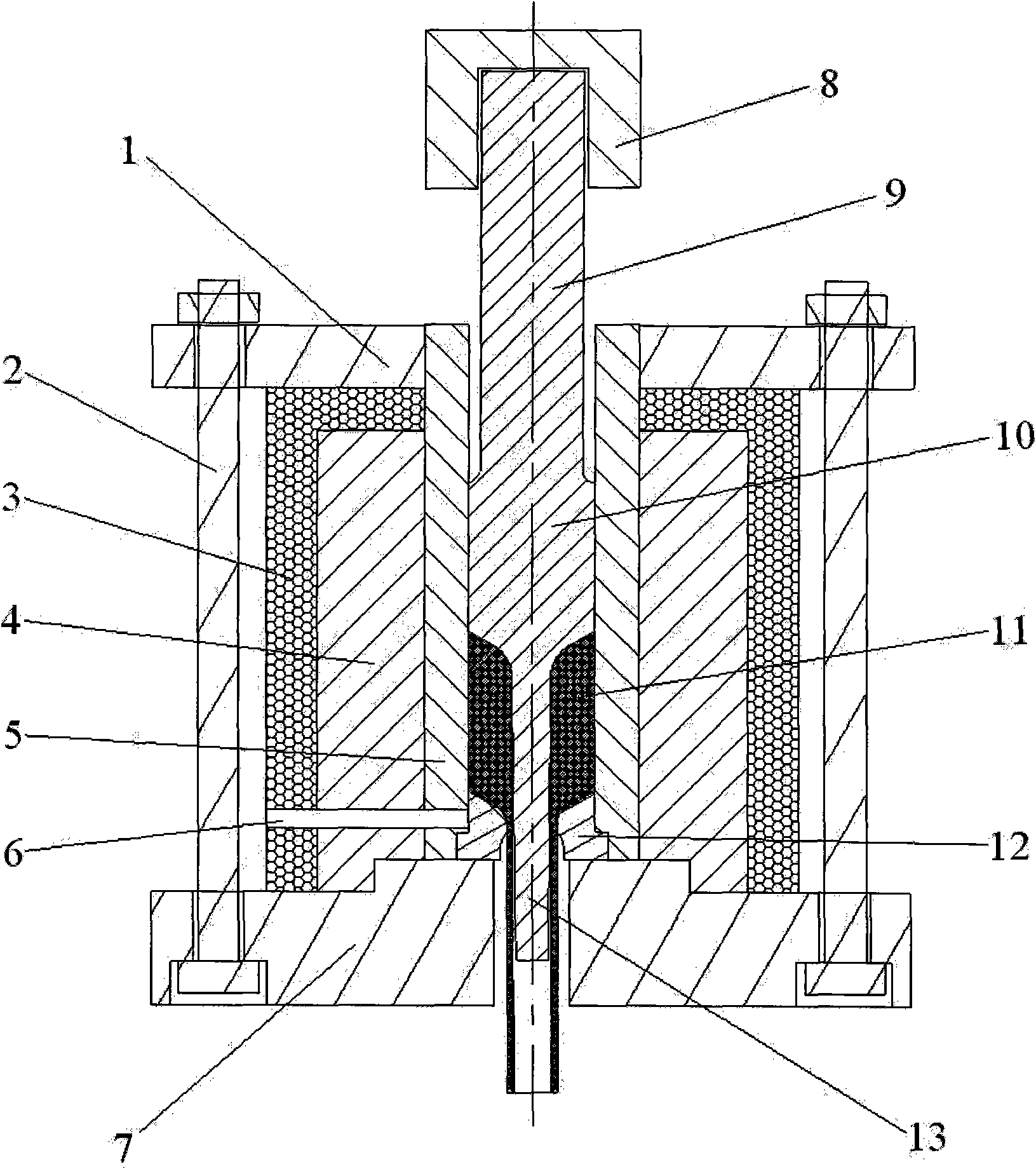

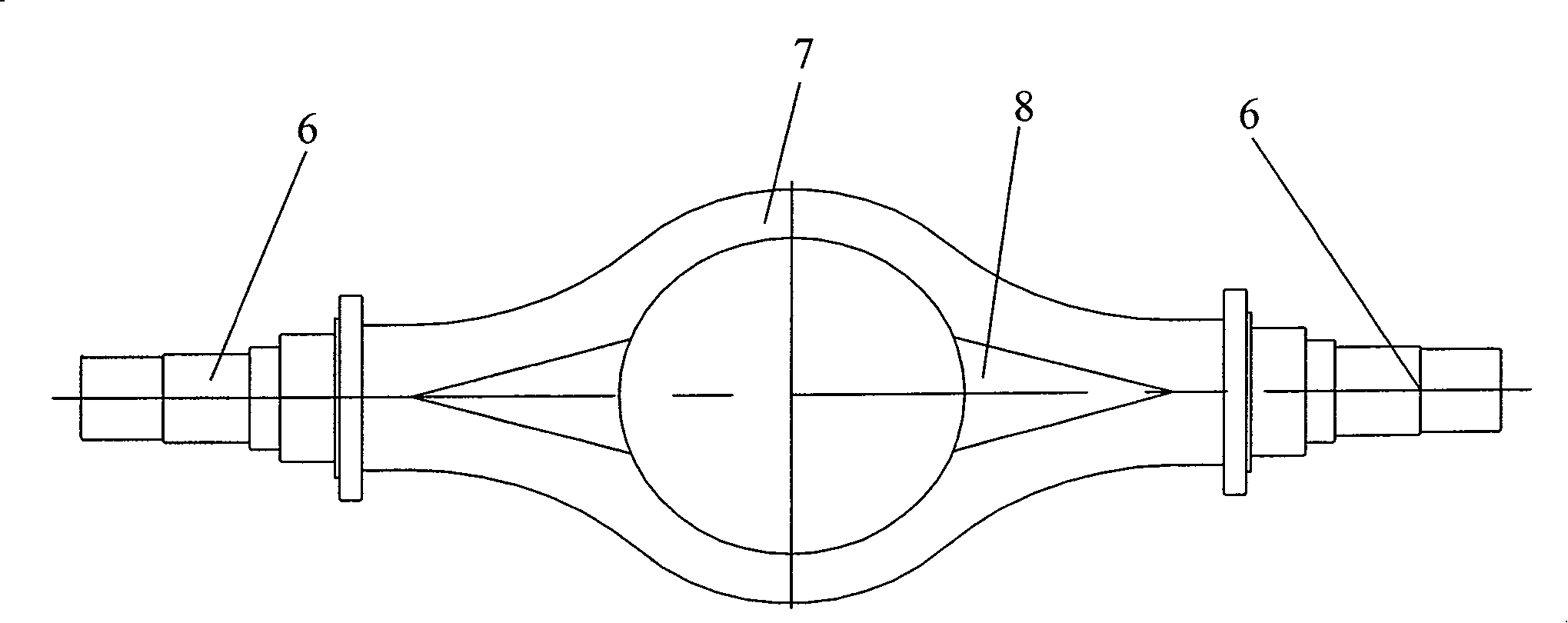

Torsion type reciprocating extrusion device and process method thereof

ActiveCN101966536AAddressing Smaller Size LimitationsImprove toughnessExtrusion profiling toolsExtrusion control devicesEngineeringUltra fine

The invention discloses a torsion type reciprocating extrusion device and a process method thereof, belonging to the technical field of plastic formation. The device comprises a cavity die, a cavity die cover plate and a cavity die fixing plate, wherein the cavity die fixing plate is fixed on a work table, and the cavity die with a variable section spindle structure is arranged between the cavity die fixing plate and the cavity die cover plate. The process method makes materials generate the compound formation of reciprocating extrusion and torsion shearing so as to prepare ultra-fine grained materials with larger volume and uniform tissue.

Owner:SHANGHAI JIAO TONG UNIV

Rare-earth magnesium alloy seamless thin wall tubule hot-extrusion method and its specialized mold

InactiveCN101549361AIncrease profitReduce extrusion pressureExtrusion diesExtrusion containersThermal insulationRare earth

The invention relates to a rare-earth magnesium alloy seamless thin wall tubule hot-extrusion method and its specialized mold. The method includes: machine-tooling after casting ingot homogenization treatment into a hollow blank, performing pre-extrusion in the mold, extrusion molding after die change, and performing solid dissolving aging treatment for further improving the tube dynamics performance. The invention relates to a special mold, including an upper and a lower die holders, a thermal insulation sleeve, a squeezing barrel, a male die and a concave die, wherein, the concave die is composed of a pre-extrusion concave die and a shaping concave die, one of the pre-extrusion concave die and the shaping concave die is selected and interchangeable with the other, and is fixed on the lower die holder through a squeezing barrel. The invention can extrude a rare-earth magnesium alloy seamless thin wall tubule with the external diameter of 5-10mm and internal diameter of 4-8mm, which has features of high material utilization, small extruding force, high products dimensional precision, good surface accuracy, good dynamics performance and the like features. The inventive mold simultaneously has advantages of simple structure, easy operation, low cost, long life and so on.

Owner:CHONGQING UNIV

Method for preparing magnesium alloy section bar by continuous corner shearing and squeezing shaping and mold

InactiveCN101406906AImprove material plasticityImprove plasticityExtrusion diesExtrusion control devicesGrain structureHigh strain

The invention relates to a method for preparing a magnesium alloy section through continuous angle rotation shearing, extrusion and shaping and a mould. The method comprises the following steps: (1) a magnesium alloy blank material is subjected to homogenization treatment; (2) a mould of an extrusion mould with a plurality of angle rotation and molding is preheated; and the inside of a mould passage is evenly coated with lube; (3) an extrusion cylinder is heated to a temperature of between 175 and 325 DEG C; and (4) the homogenized blank material is heated to a temperature of between 200 and 350 DEG C; the extrusion ratio of the extrusion mould is between 4 and 100; and the magnesium alloy blank material is subjected to unidirectional extrusion at an extrusion speed of between 3 and 6 m / min so that the magnesium alloy blank material is subjected to compression and extrusion with high extrusion ratio and equal passage extrusion with a plurality of angle rotation. The magnesium alloy material prepared through the method has an ultrafine crystal grain structure, has the advantages of substantially improving the plasticity, low temperature superplasticity and high strain speed of the magnesium alloy material and has high yield stress.

Owner:CHONGQING UNIV

Short-flow preparation method of minor-caliber nickel-based alloy thin-wall tubes

InactiveCN102463272AIncrease productivityShort labor intensityExtrusion control devicesAlloyMaterials science

The invention relates to a short-flow preparation method of minor-caliber nickel-based alloy thin-wall tubes, belonging to the technical field of processing non-ferrous metal material tubes, mainly comprising the following steps that: (1) centrifugal casting technology is carried out to prepare nickel-based alloy tube billets, wherein, the ratio of outer diameters and inner diameters of the tube billets is 0.4-0.6; (2) the hot extrusion temperature of nickel-based alloy tubes is 1000-1250 DEG C, and the extrusion ratio is 5-16; (3) LG / LD and other series of cold pilger mills or drawing machines are used for carrying out multi-pass cold processing to reduce the tube diameter and reduce the wall thickness, so as to obtain thin-wall tubes; and (4) intermediate annealing, final annealing and final tube straightening are carried out. The method has the advantages of short flow, low labor intensity, laborsaving shaping, low cost, and high production efficiency. The prepared minor-caliber nickel-based alloy thin-wall tubes have high additional values. The method is suitable for large scale production, and has remarkable economic benefits and social benefits.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

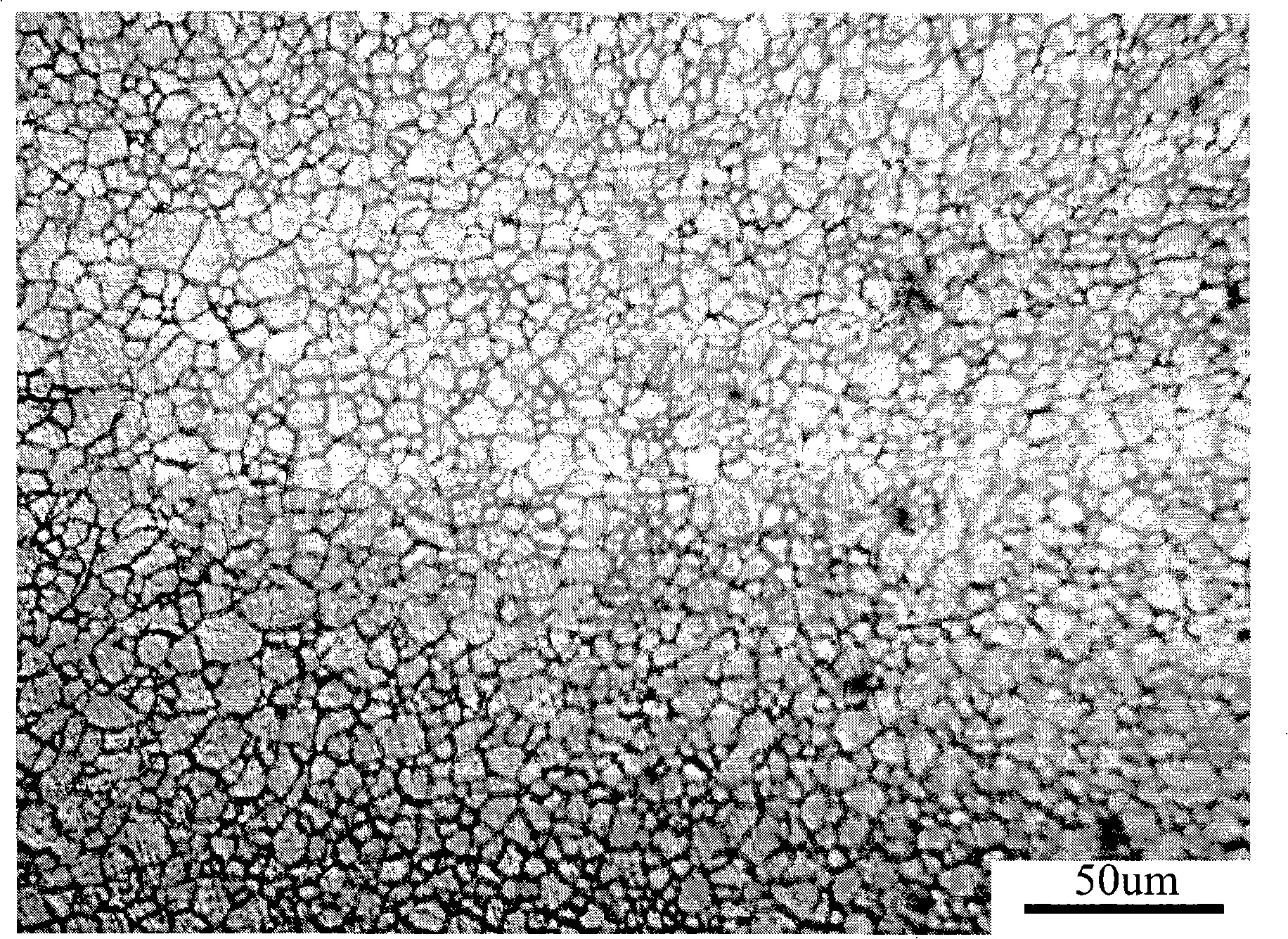

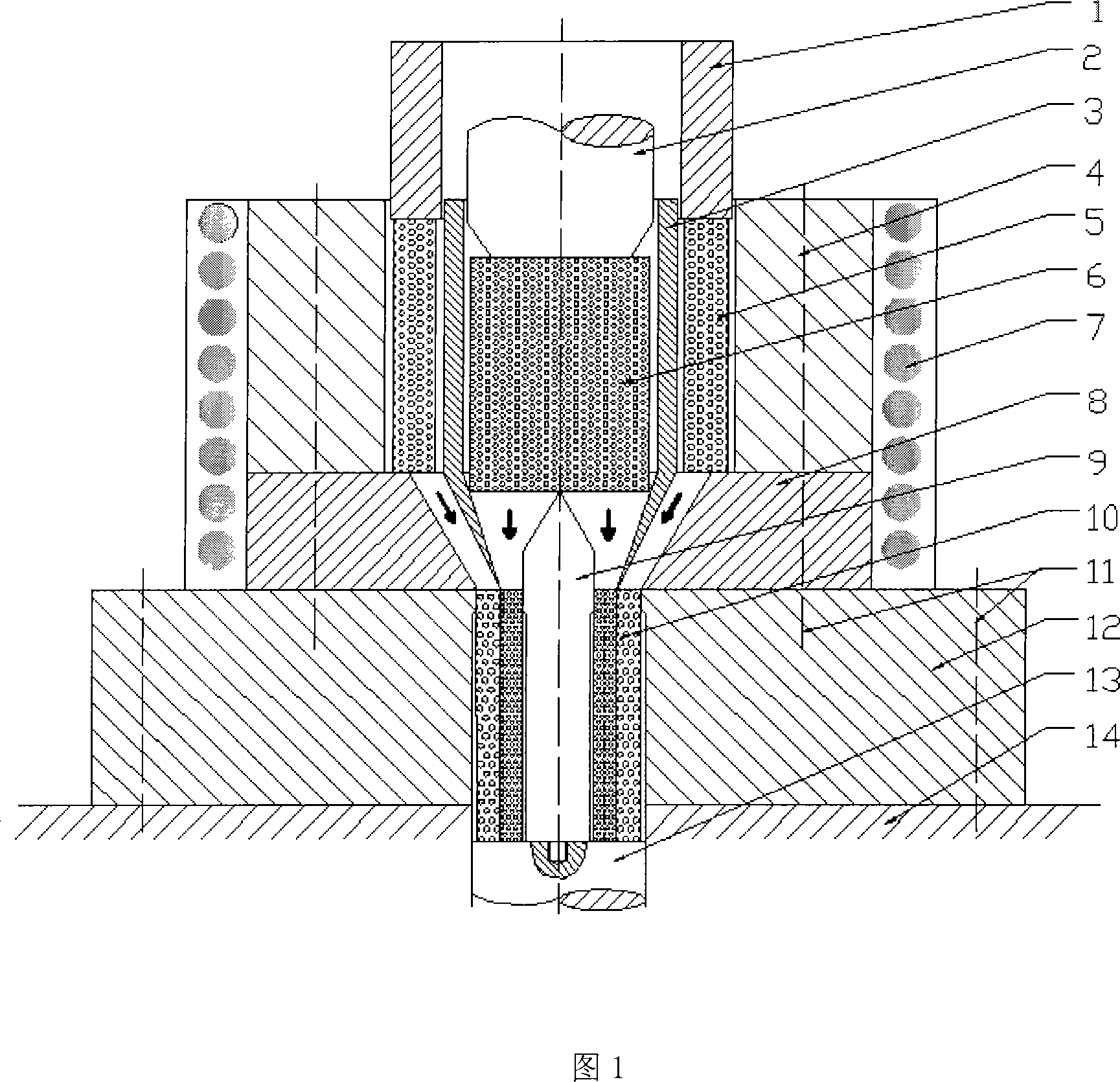

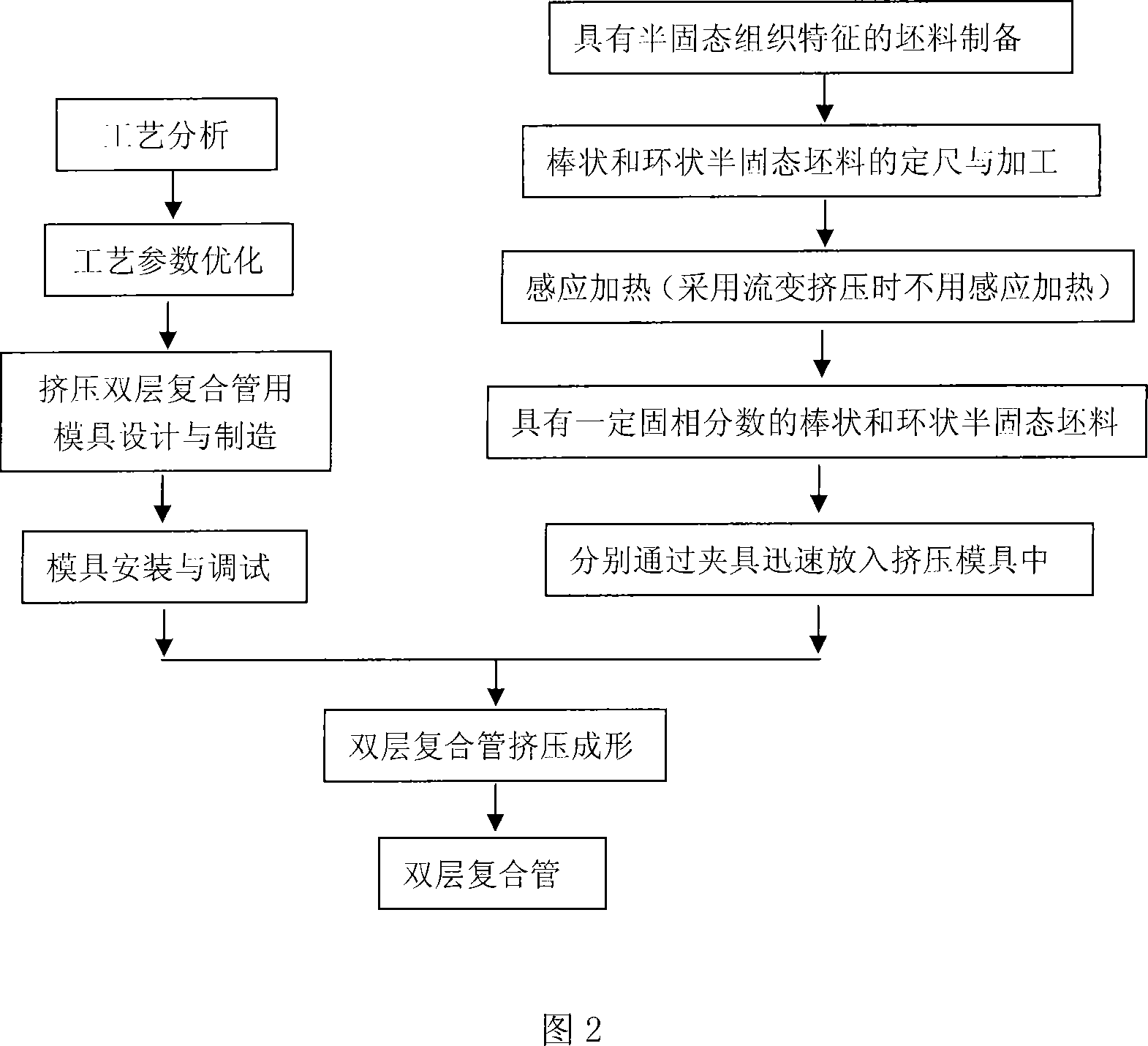

Semi-solid multi-blank extruding process and apparatus for forming double-layer composite pipe

InactiveCN101020201AReduce consumptionImprove product qualityExtrusion diesExtrusion control devicesTemperature controlControl system

The present invention relates to semi-solid forming technology, and is especially semi-solid multi-blank extruding process and apparatus for forming double-layer composite pipe. The technological process includes the following steps: pre-heating the mold to 200-300 deg.c and establishing temperature control system, setting the induction heated blank into the extruding mold, and extruding at regulated speed and stroke to obtain the required composite pipe. The new extruding process for making composite pipe has short procedure, low power consumption and high product quality.

Owner:TSINGHUA UNIV

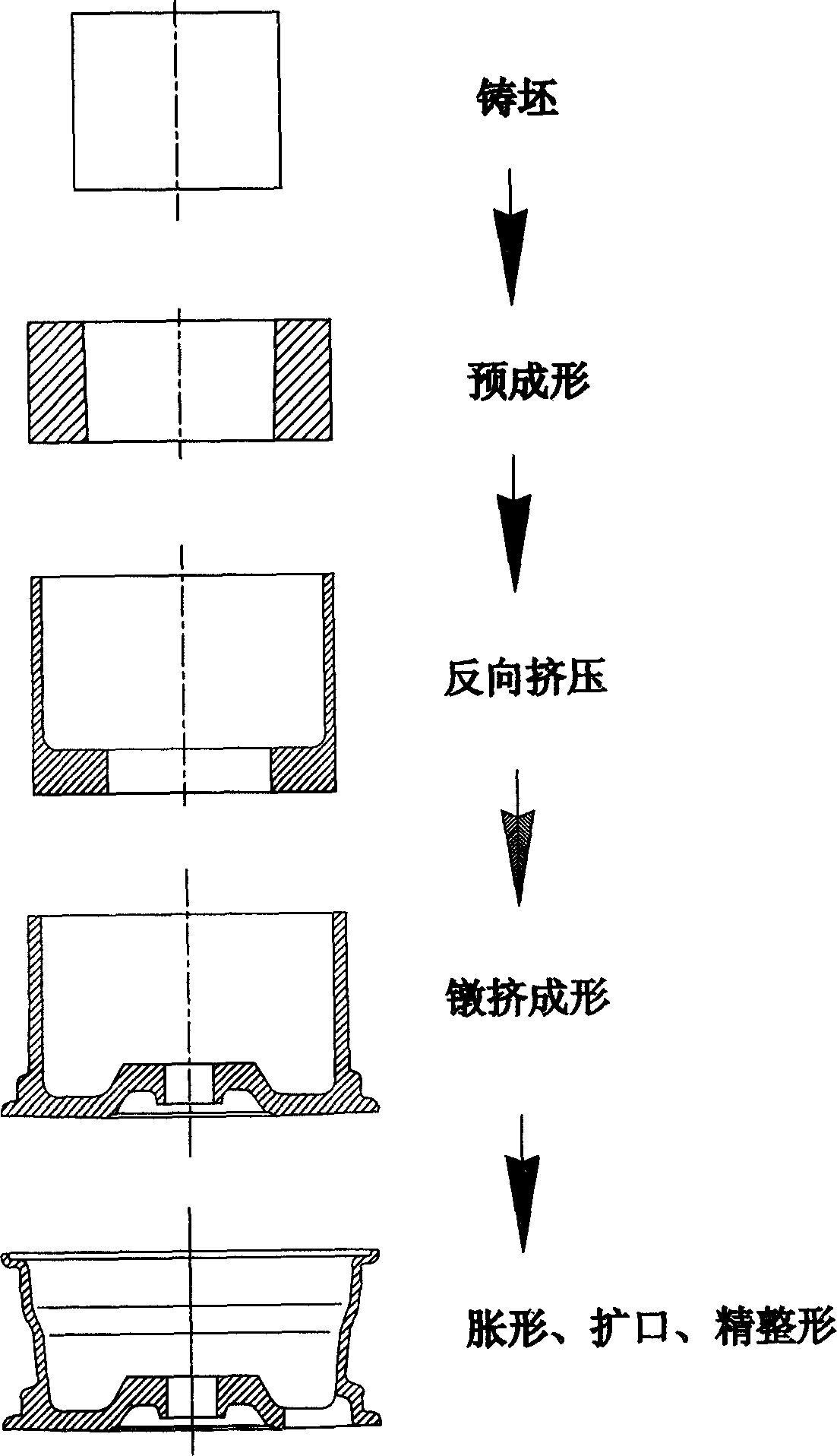

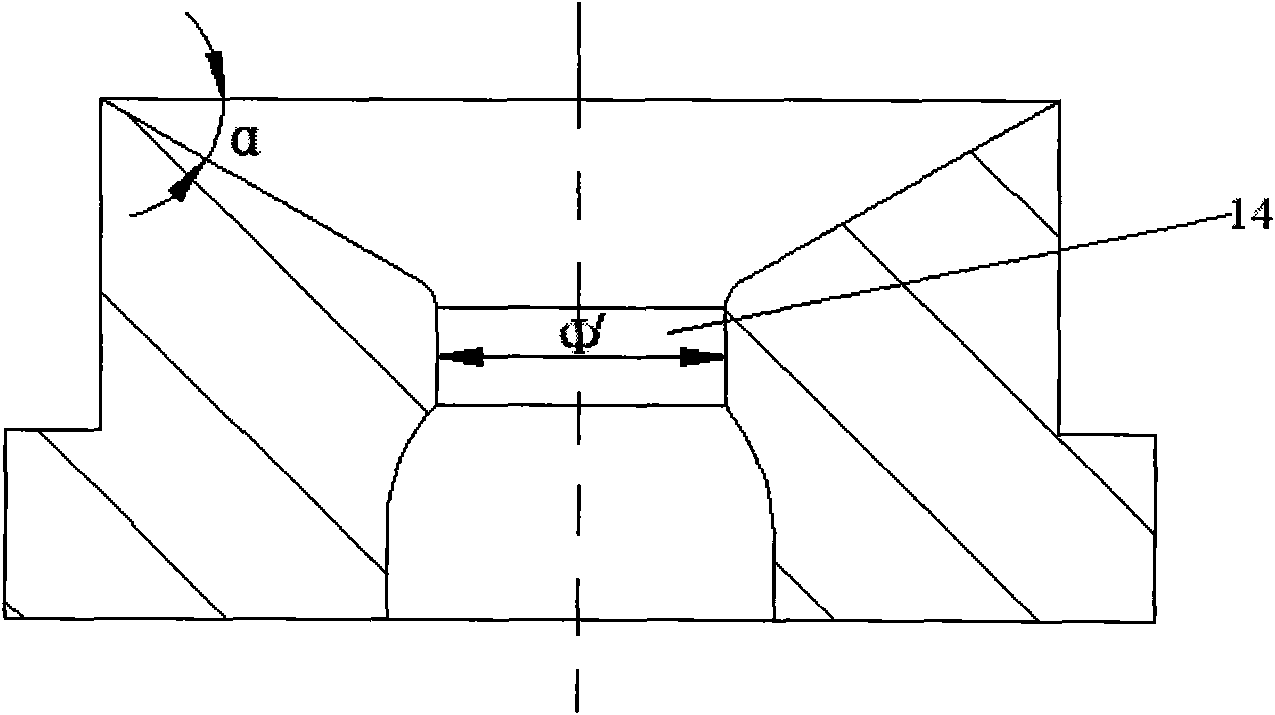

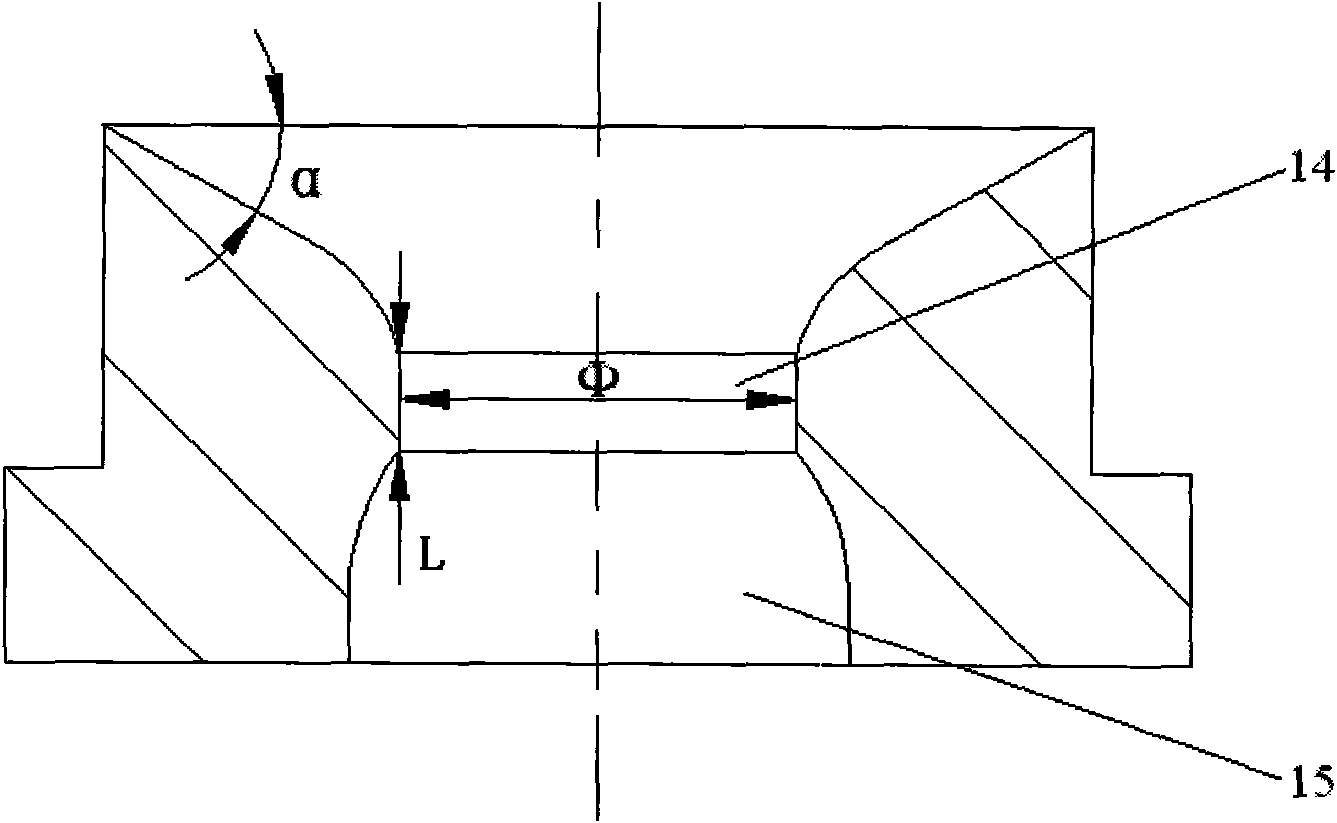

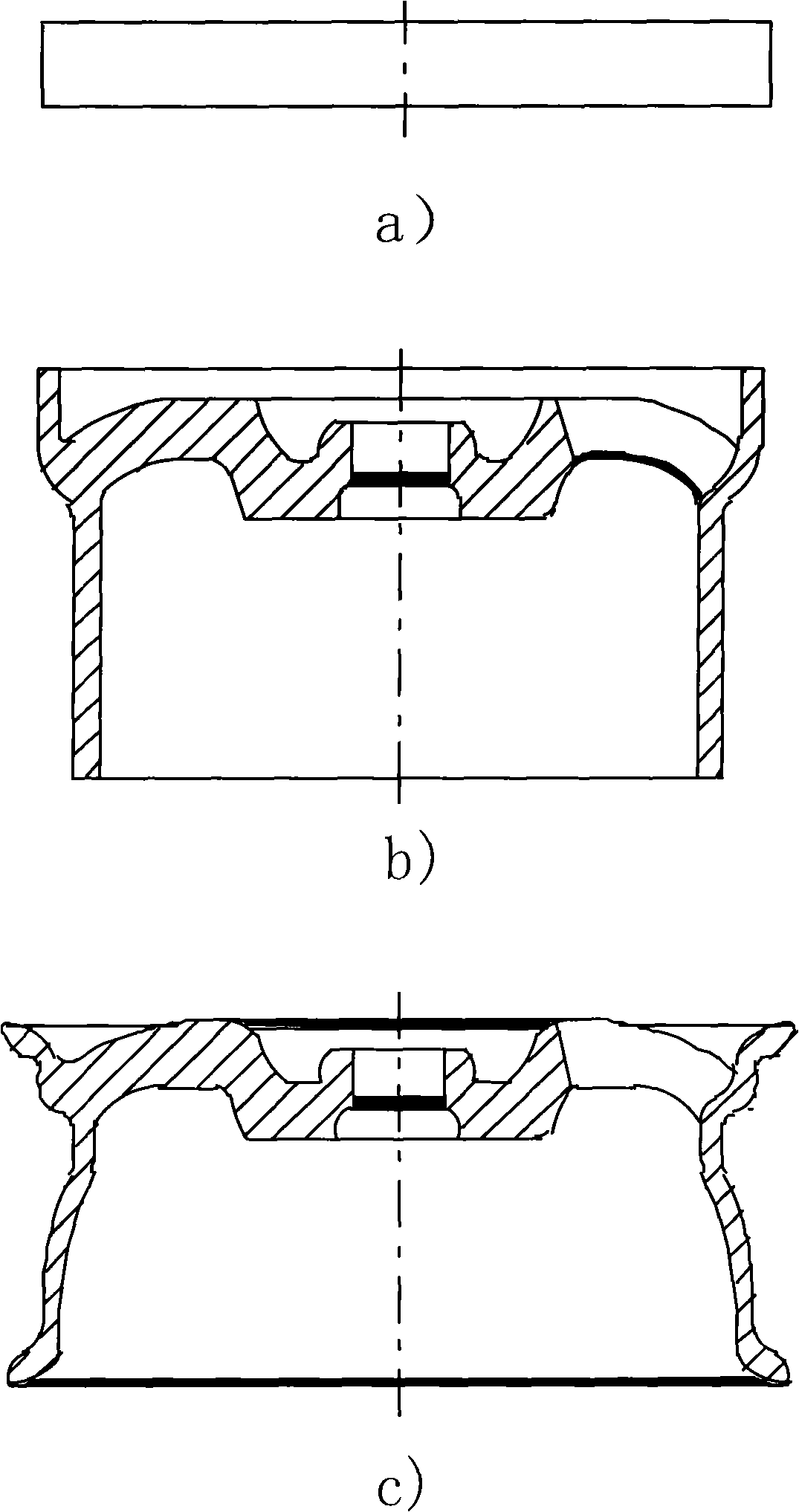

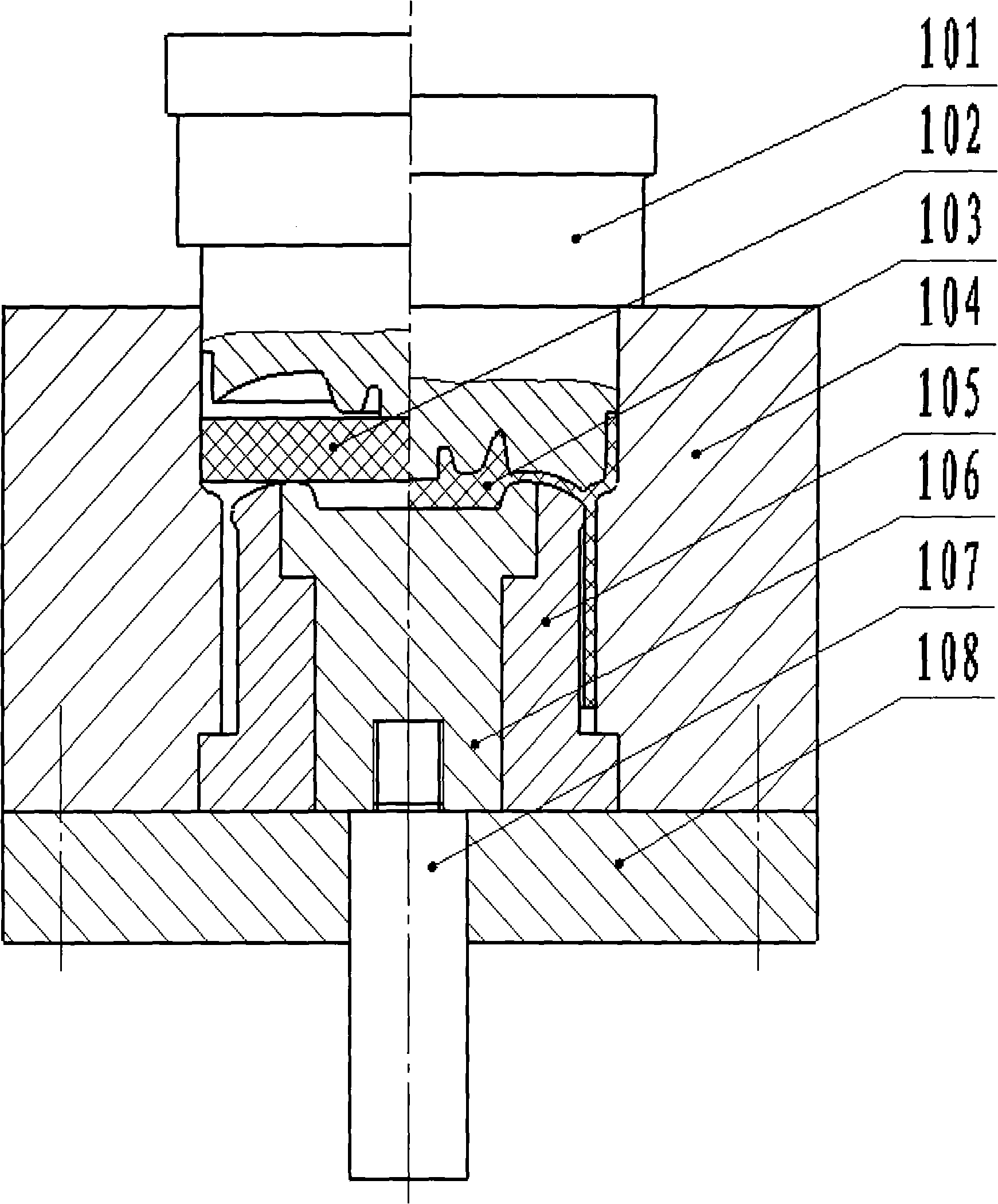

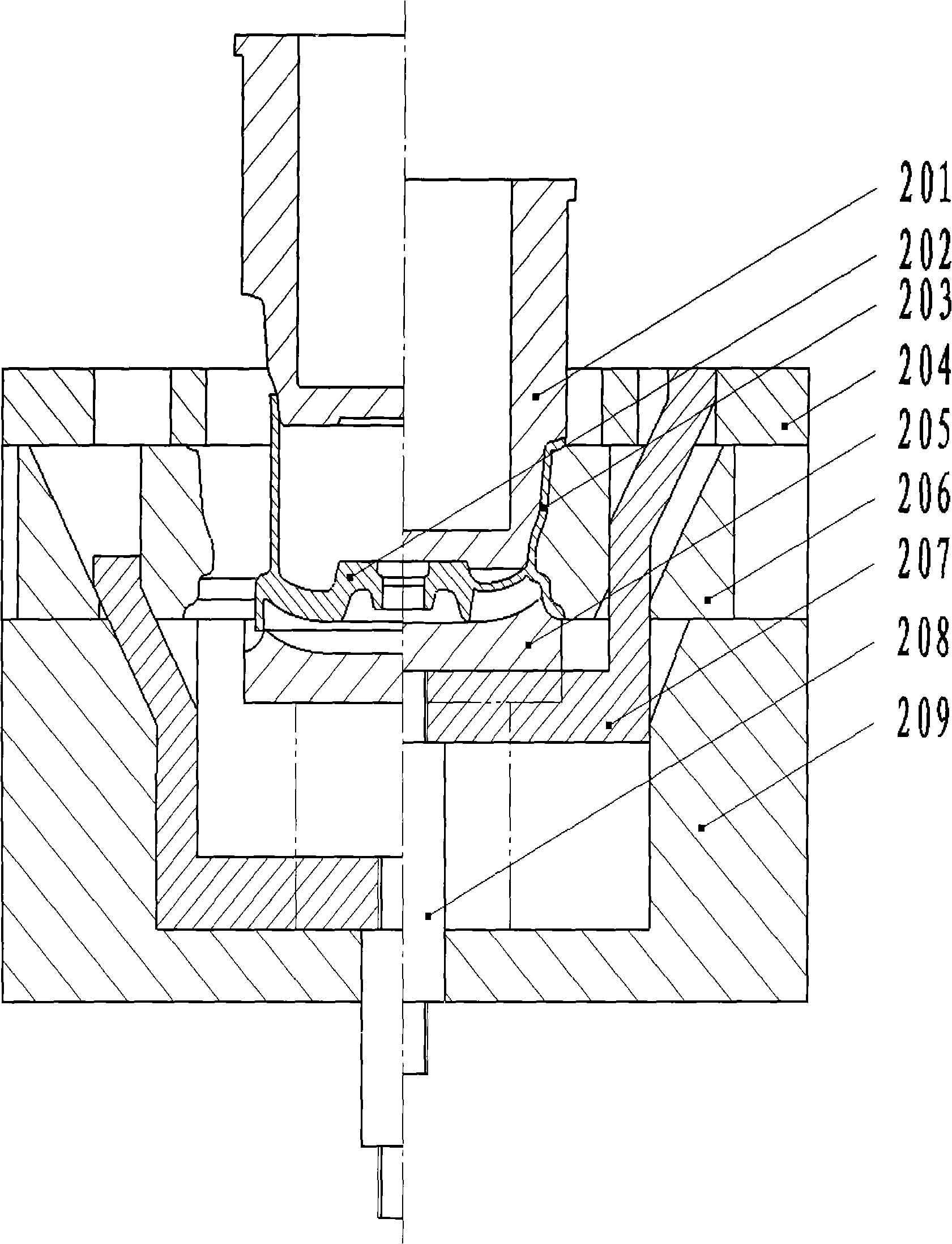

Two-step plasticity forming method of vehicle wheel hub and mated forming die

InactiveCN101491873AReduce investmentOptimizing the forming processExtrusion diesExtrusion control devicesEngineeringMechanical engineering

The invention discloses a two-step plastic forming method for a wheel hub of an automobile. The method adopts two sets of molds to perform extrusion forming on a blank in two steps under isothermal conditions, and comprises the following steps: 1, placing the blank into a extrusion forming mold, and forming a wheel spoke part firstly and pre-forming front and rear wheel rim parts of a wheel felloe at the same time by adopting an extrusion mode; and 2, placing a preformed part into a flaring mold to perform one-time flaring forming on the front and rear wheel rim parts of the wheel felloe. Compared with the prior art, the method has the characteristics of low forming force, less equipment investment, low production cost, high forming quality, and the like. At the same time, the invention also discloses the extrusion forming mold and the flaring mold which are matched with the method.

Owner:HENAN UNIV OF SCI & TECH

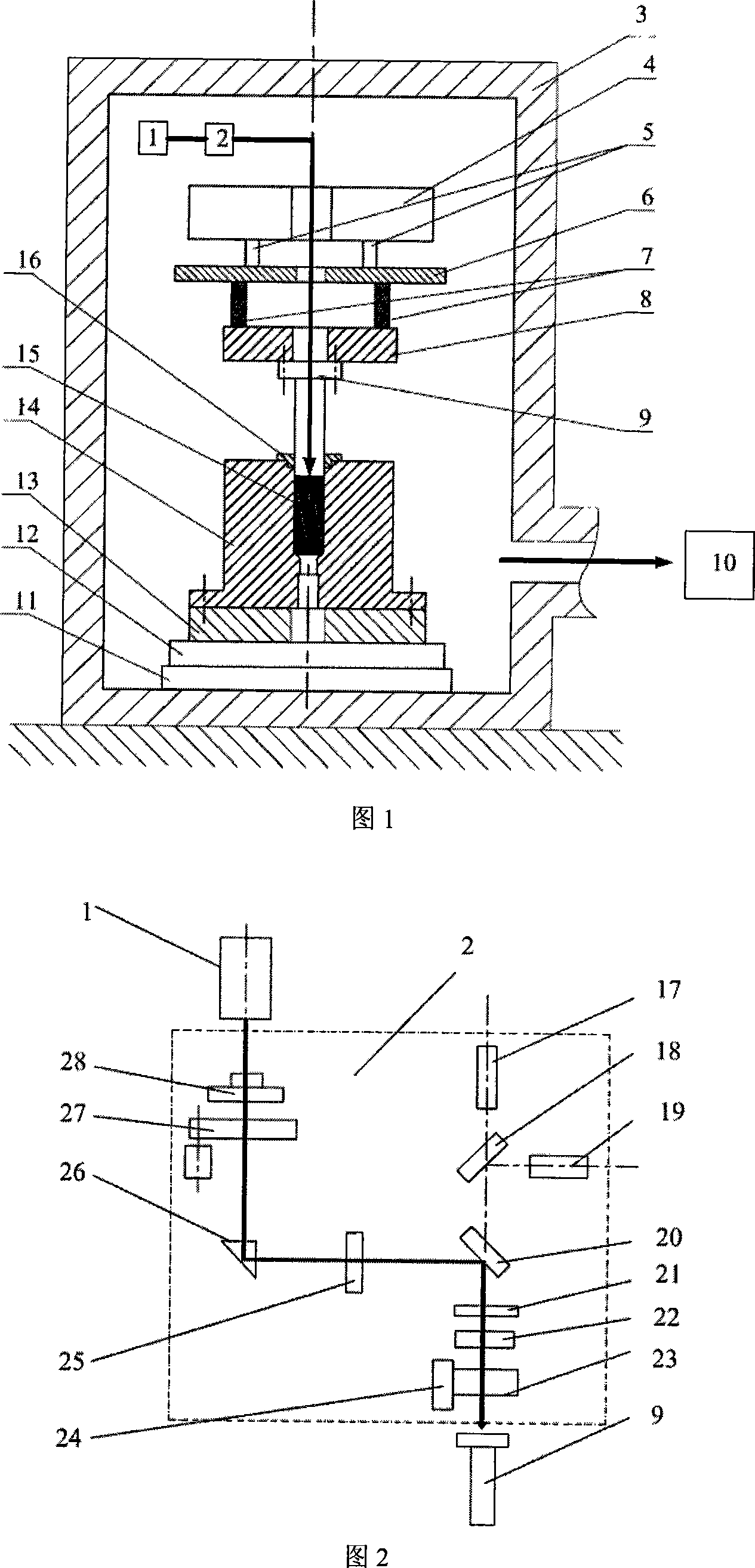

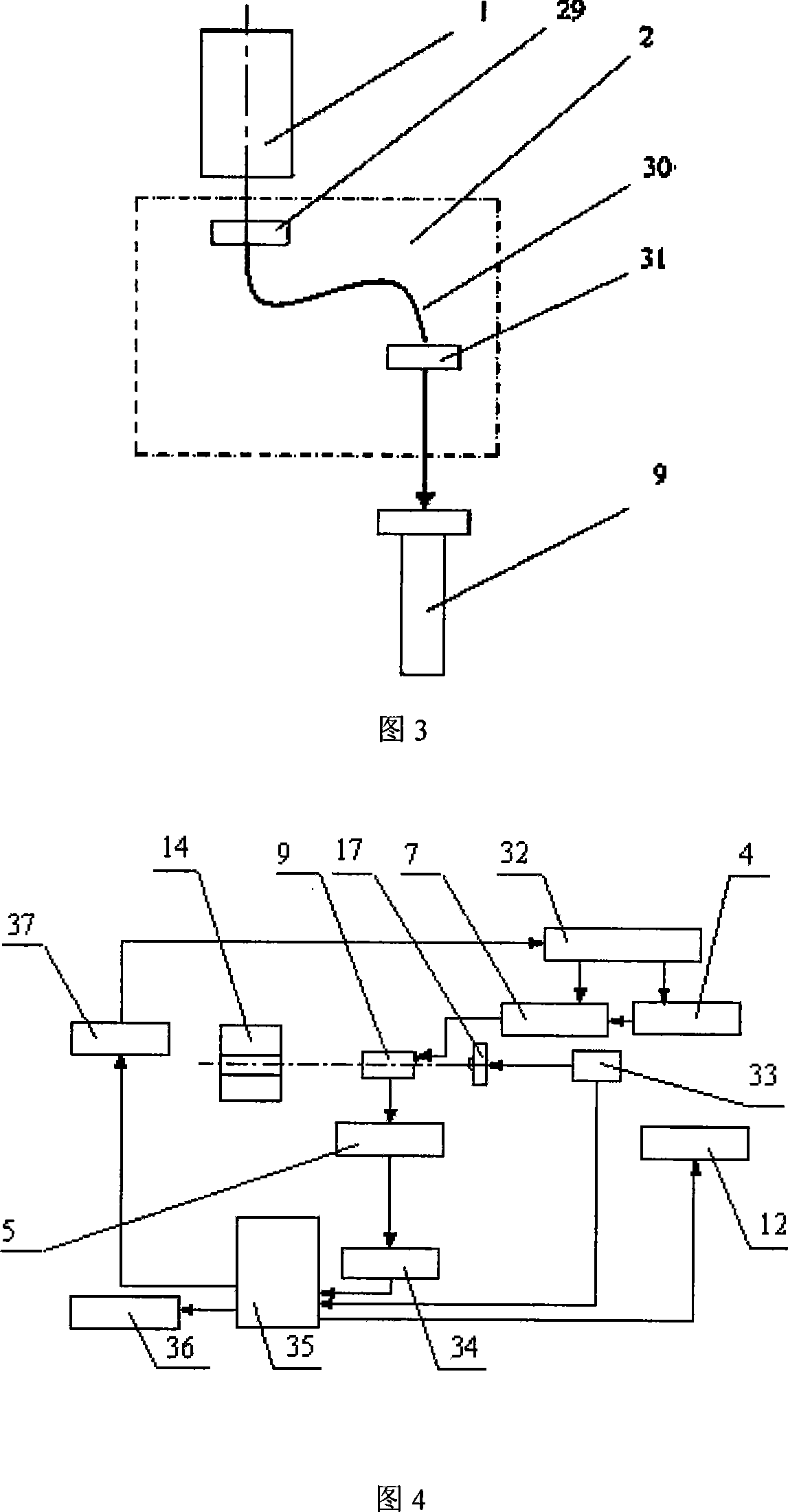

Micro-plastic molding method and apparatus for micro-device

InactiveCN101130196AAccurate temperatureReduce deformation resistanceShaping toolsExtrusion diesControl systemLaser heating

The invention discloses a microplastic shaping method and device of microelement in the microplastic piece preparing and shaping technical domain, which comprises the following parts: laser heating system, microshaping system, loading system, control system and assembling platform, wherein the flat-top laser beam emitted by laser is loaded on the surface of microelement surface through transmittable terrace die, which utilizes laser to do non-contact heating of working piece and heat conductivity; the heat work piece material is below recrystallizing temperature for shaping temperature scale; the terrace die does feeding movement towards female die through microdriving system; the loading system combines the microdriving system to realize loading action for microblank to finish microplastic shaping. The invention reduces the deformation resistance of material at non-contact heating on the upper surface of working piece through laser, which increases the evenness of material fluidity for batching manufacturing of microelement to realize automation manufacturing easily.

Owner:JIANGSU UNIV

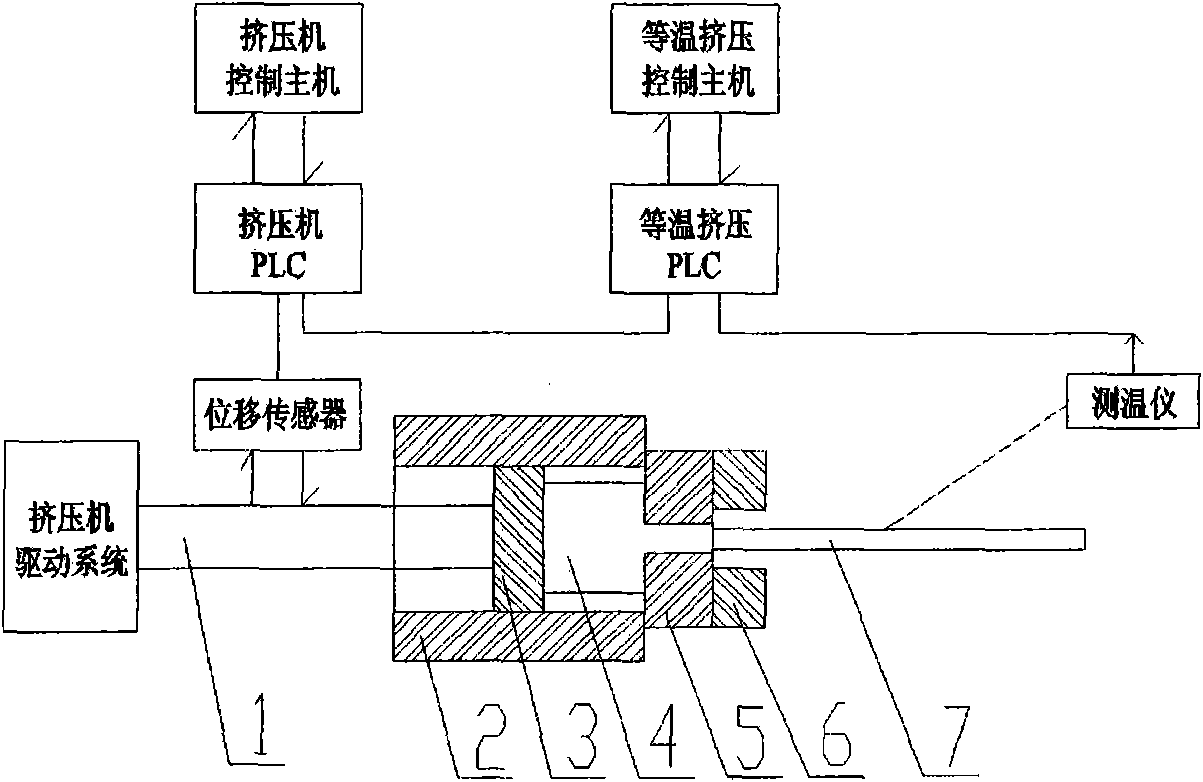

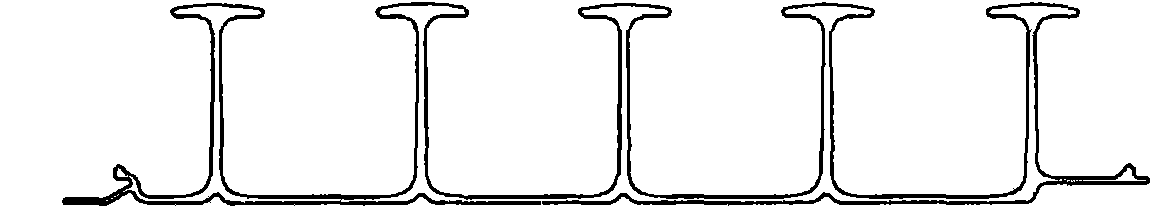

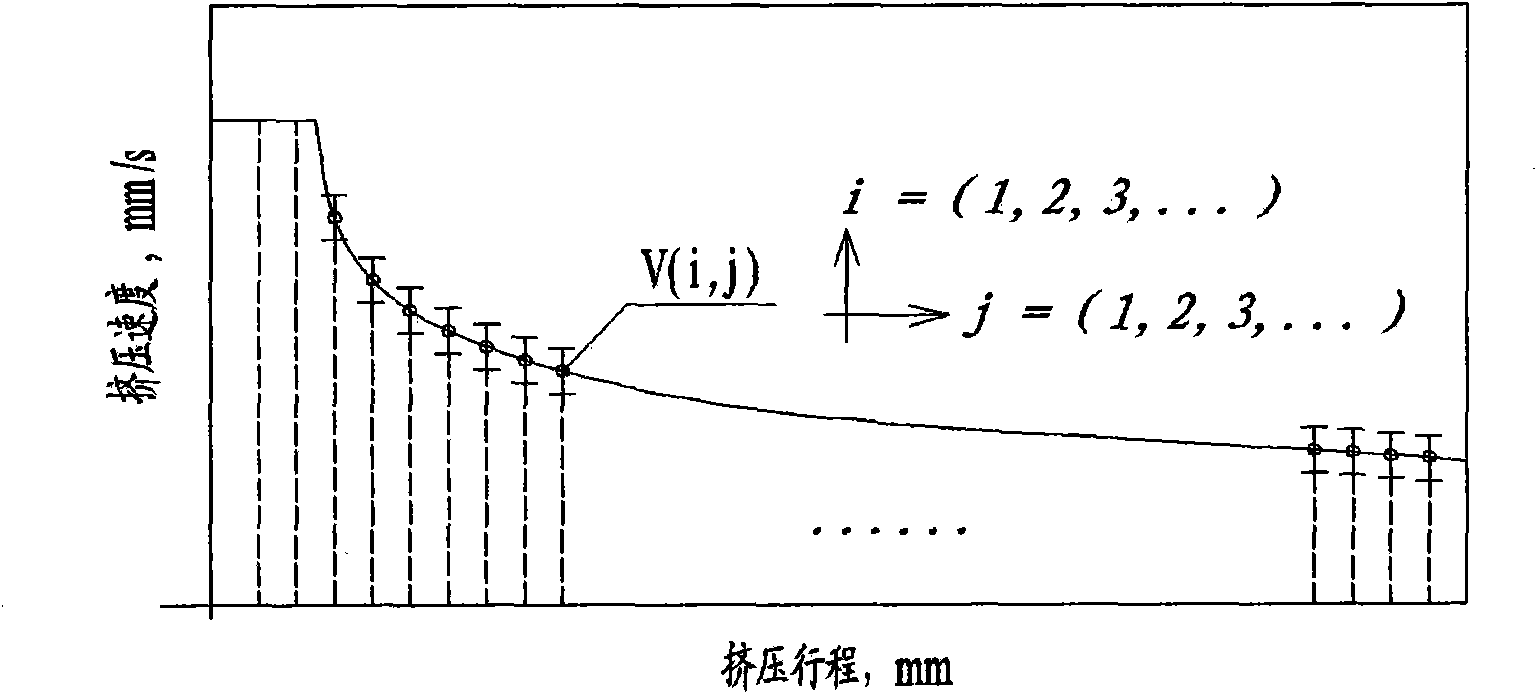

Method for controlling speed regulation of isothermal extrusion of industrial aluminum profiles for transportation

InactiveCN102049426AShort measurement response timeUniform microstructureExtrusion control devicesTemperature controlControl system

The invention discloses a method for controlling the speed regulation of the isothermal extrusion of industrial aluminum profiles for transportation, wherein a control system host machine, an isothermal extrusion PLC (Programmable Logic Controller) and an industrial aluminum profile outlet temperature thermodetector are used. The isothermal extrusion curves of the industrial aluminum profiles and profile outlet temperature control information are saved in the control system host machine. The method comprises the steps of: continuously monitoring and acquiring extruded profile outlet temperature by the thermodetector, importing temperature data into the isothermal extrusion PLC, issuing an extrusion speed regulation instruction by the isothermal extrusion PLC and a control system according to the detected temperature, transmitting the extrusion speed regulation instruction to an extruder PLC through the isothermal extrusion PLC, and regulating the increment / decrement of the extrusion speed of an extruder; and meanwhile, feeding back the real-time extrusion speed of the extruder to the isothermal extrusion PLC by the extruder PLC, and carrying out the processes in cycle. The method disclosed by the invention obviously improves the automation degree and production and manufacture efficiency of the extrusion production procedure of the industrial aluminum profiles and solves the technical problems of huge quality fluctuation and low production efficiency caused by controlling on the basis of manual experience for a long time.

Owner:GUANGDONG XINGFA ALUMINUM

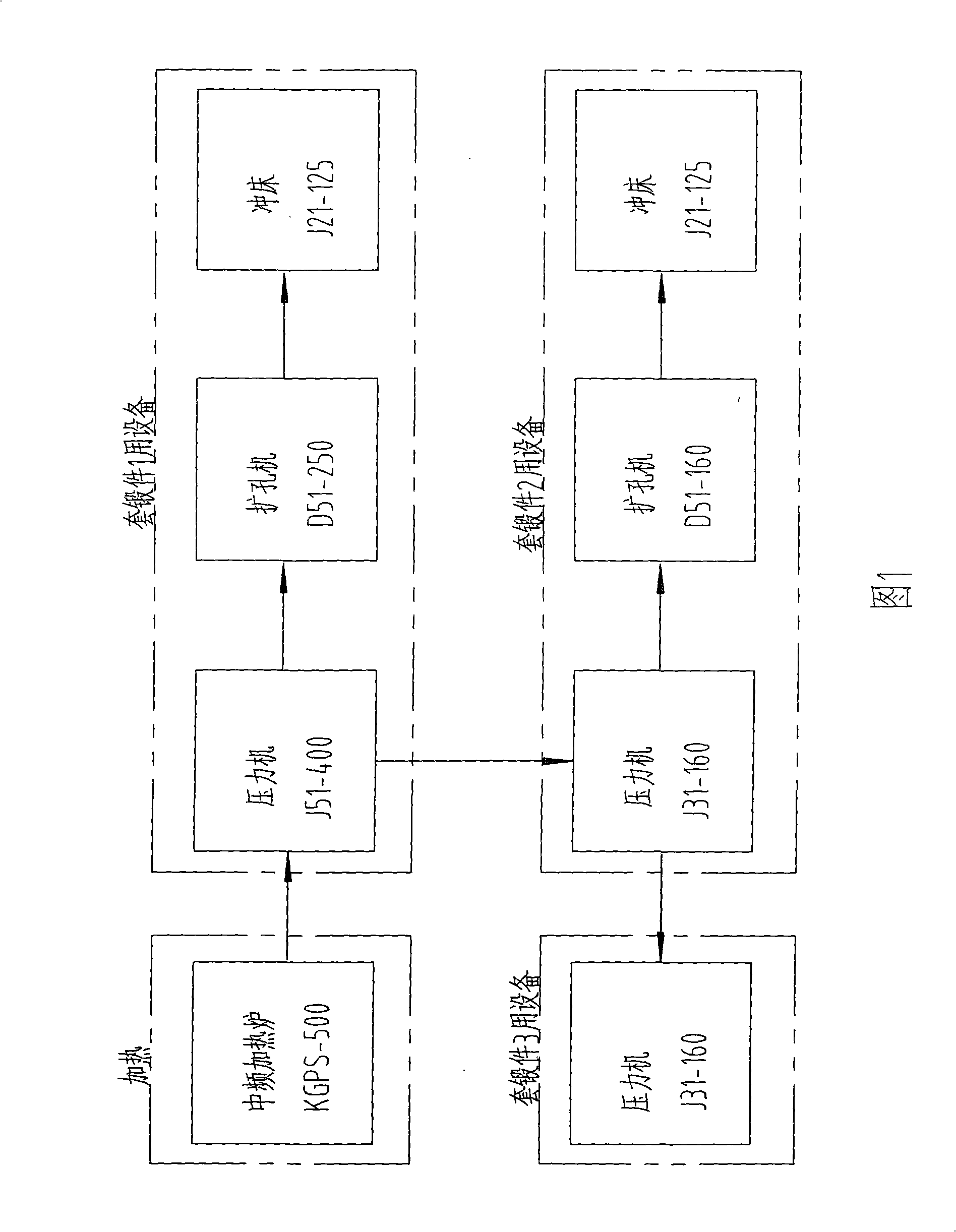

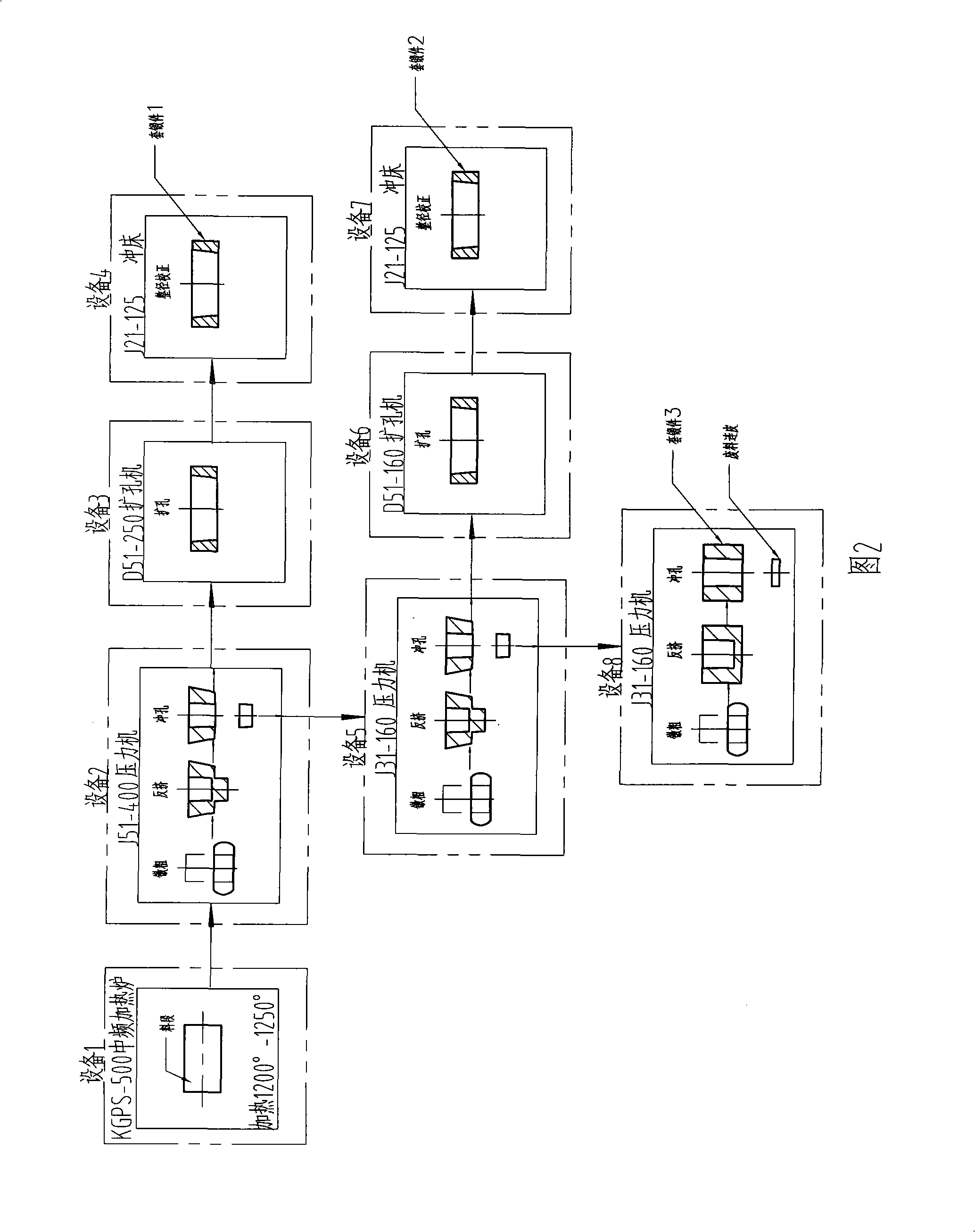

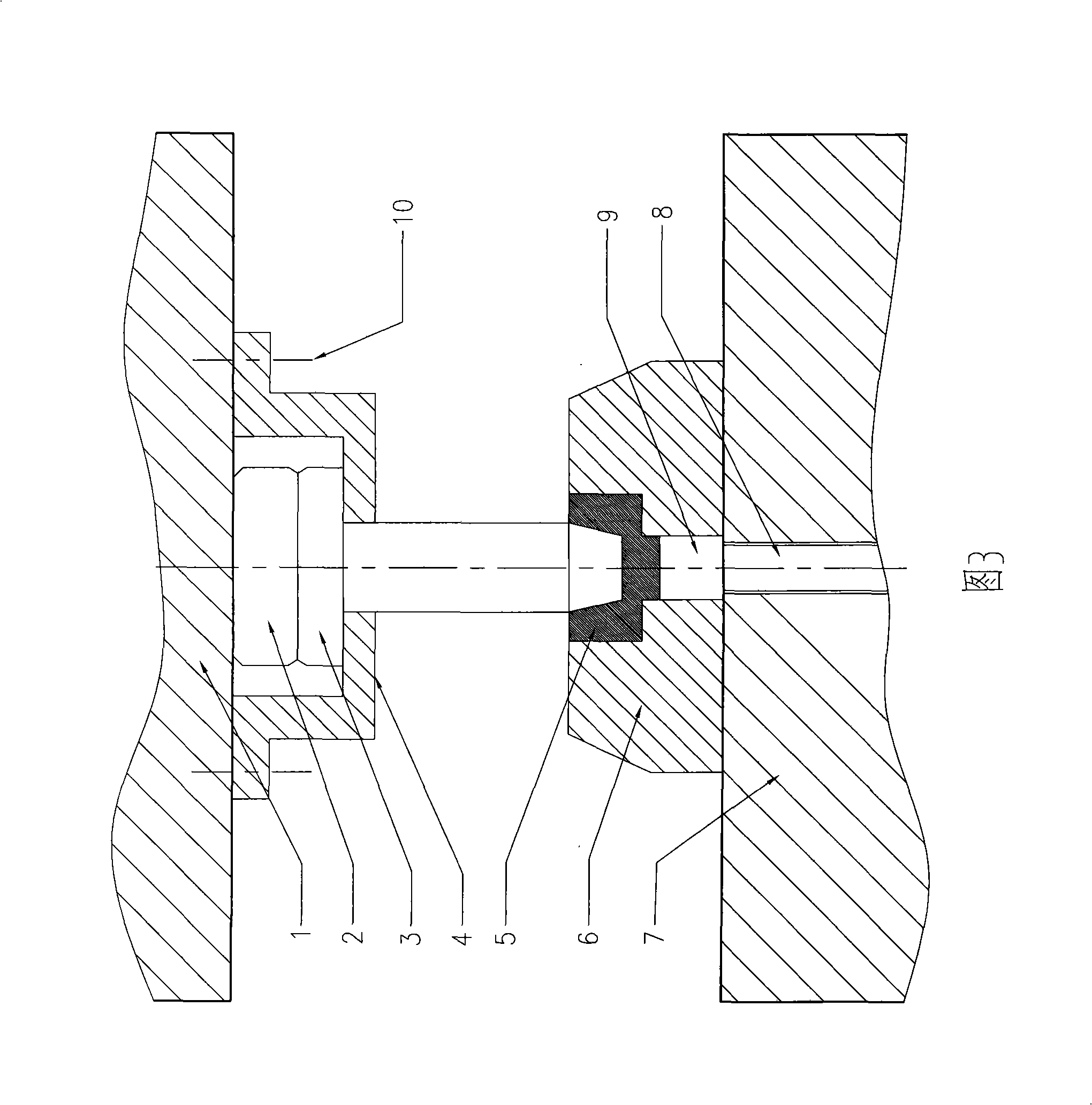

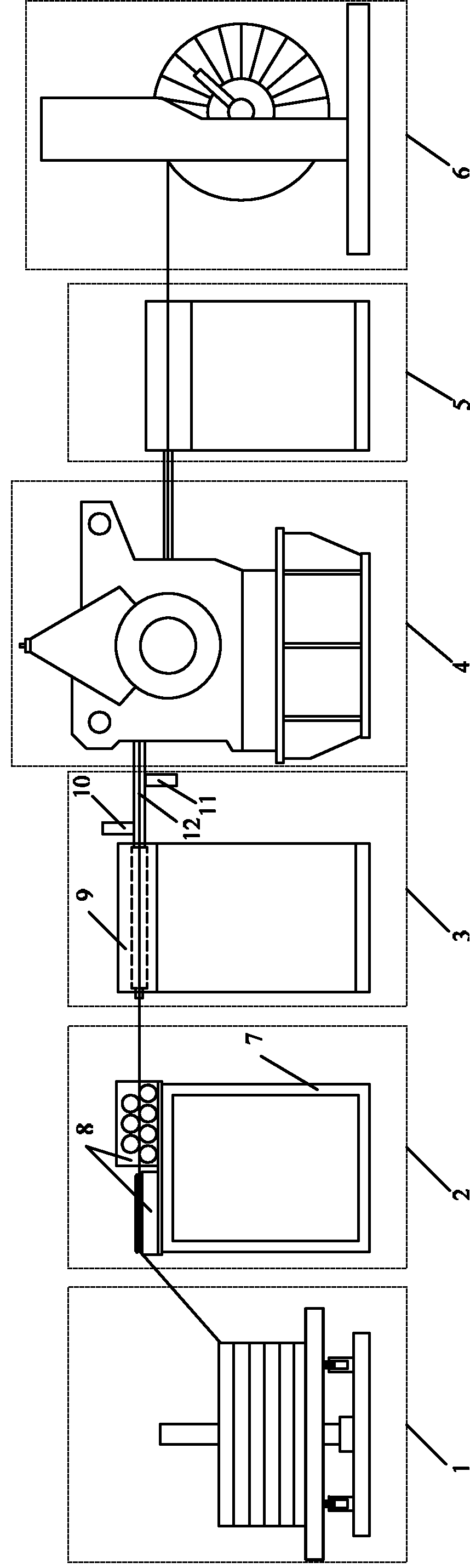

Bearing ferrule workblank triple external member smithing and molding process

InactiveCN101402163ASimple production processImprove productivityExtrusion control devicesMetal rollingIntermediate frequencyRoughcast

The invention discloses a process for forging and molding three connecting kits of a bearing ring roughcast. On equipment which is put in an I-shaped arrangement, a metal material section is sent to an intermediate frequency heating furnace of equipment 1; after the heating temperature of the metal material section reaches between 1,200 and 1,250 DEG C, the metal material section is sent to the equipment, is subjected to continuous upsetting, back extrusion, punching and ring rolling; and the bearing ring roughcast after chambering is subjected to finishing and correction to complete the processing of the first kit, the second kit and the third kit (the ring roughcasts). The process for forging and molding three connecting kits of the bearing ring roughcast can fully utilize residual materials, achieve effective conservation of the materials, simplify the production process, improve production efficiency and complete the production of a plurality of forging pieces of the bearing ring roughcast on one production line under the condition of not increasing the consumption of the raw materials.

Owner:XIANGYANG YUQING FORGING CO LTD

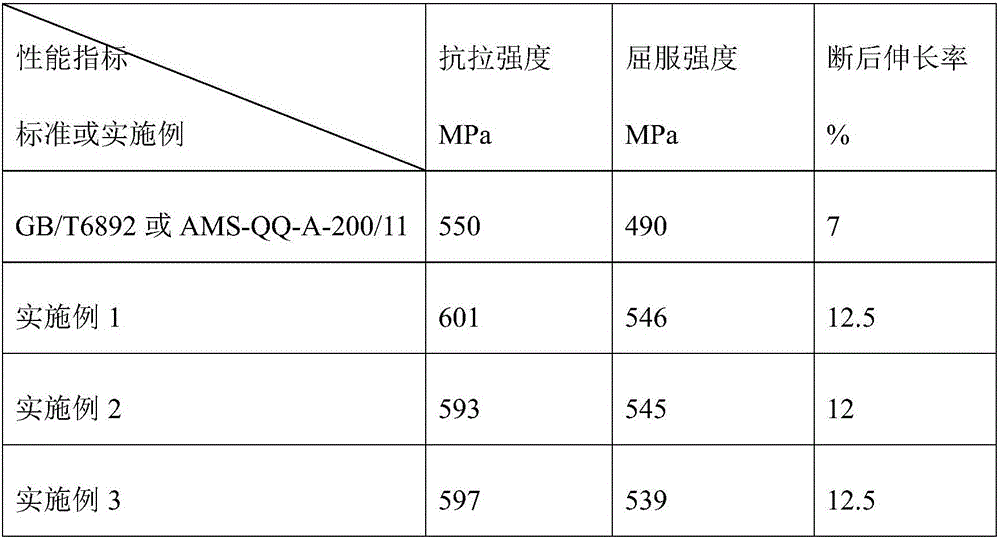

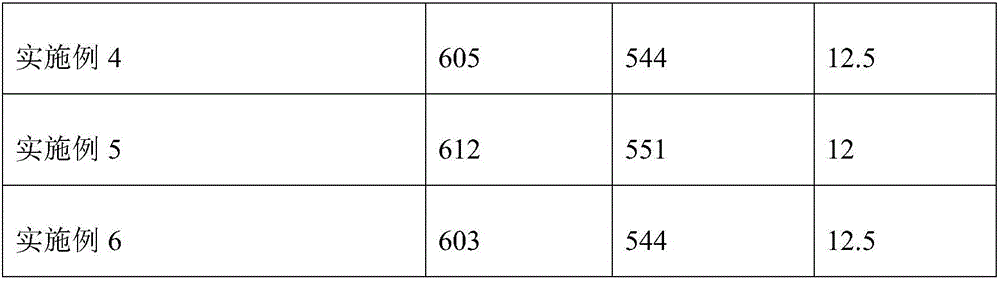

Technique for improving performances of 7075 aluminum alloy extruded material

InactiveCN106399881AShorten aging timeRaise the ratioExtrusion control devicesSolution treatmentIngot

The invention provides a technique for improving the performances of a 7075 aluminum alloy extruding material. The technique comprises the following concrete technological steps: heating an alloy ingot manufactured from the 7075 alloy material; heating a mold and an extruding cylinder; putting the heated mold and ingot into an extruder and extruding; performing solution treatment on the extruded extruding material; quenching the extruding material which is subjected to the solution treatment; stretching the quenched extruding material; ageing the stretched extruding material. The invention also provides the alloy ingot used in the method, and the ingot comprises the following components in percentage by weight: smaller than or equal to 0.40% of Si, smaller than or equal to 0.50% of Fe, 1.5% to 2.0% of Cu, smaller than or equal to 0.3% of Mn, 2.5% to 2.9% of Mg, 0.20% to 0.28% of Cr, 5.5% to 5.9% of Zn, smaller than or equal to 0.2% of Ti, smaller than or equal to 0.05% of other single elements, other impurity elements and the balance Al, wherein the total amount of other impurity elements is smaller than or equal to 0.15%.

Owner:SHANDONG NANSHAN ALUMINUM +1

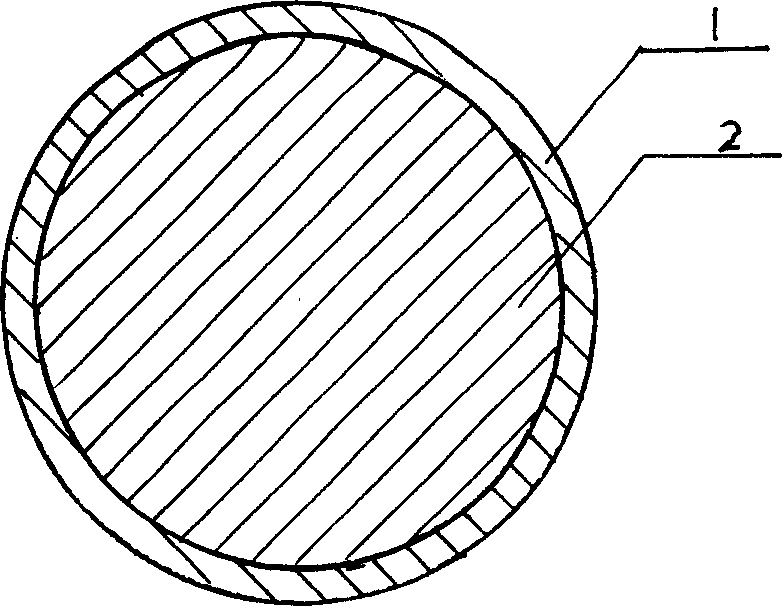

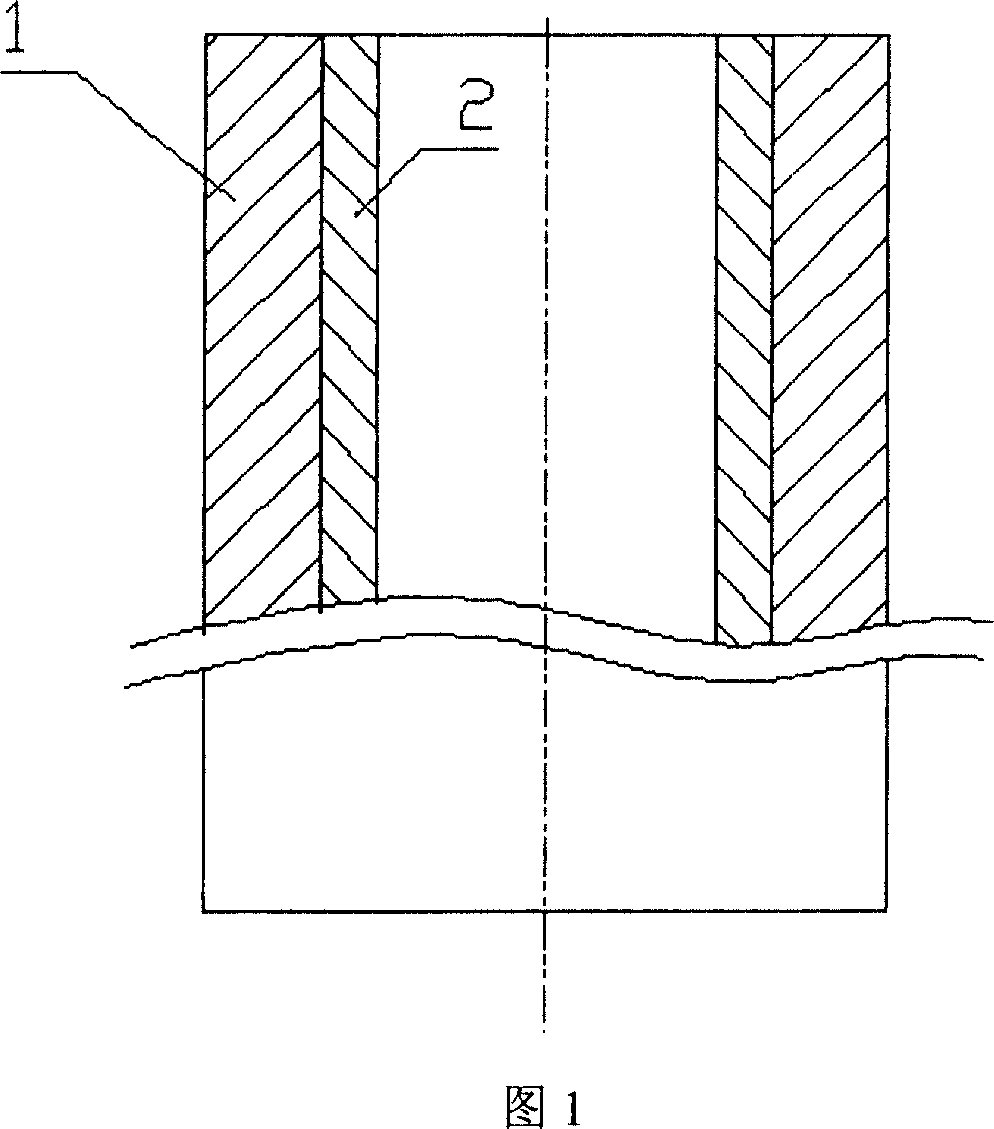

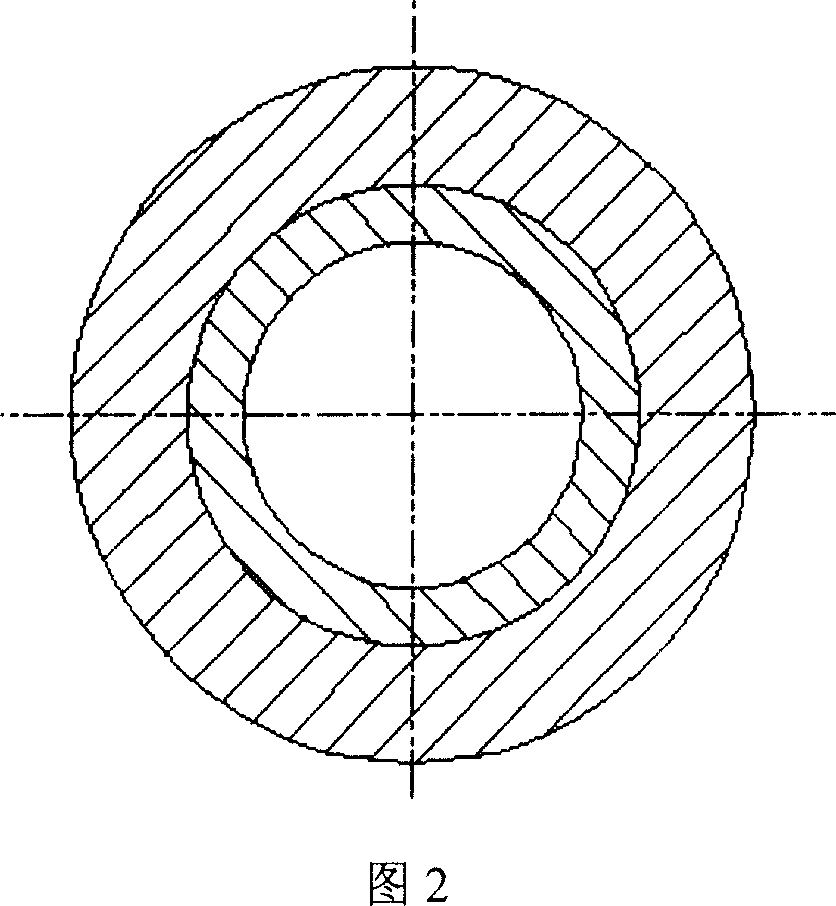

Magnesium-aluminium bimetal composite pipe/bar

InactiveCN1850383ALow densityHigh specific strengthExtrusion diesExtrusion control devicesIngotHeating temperature

The present invention relates to a kind of magnesium aluminium bimetal composite pipe / rod material. It is formed from interior magnesium alloy pipe / rod material and aluminium alloy layer covering surface of said interior magnesium alloy pipe / rod material. Its processing process includes the following steps: utilizing aluminium alloy and magnesium alloy to prepare combined ingot, heating said combined ingot and heat-insulating, extruding and straightening so as to obtain the invented product. Its extruding ratio is greater than 10, heating temperature is 300-400 deg.C, heat-insulating time is 1-5h and extruding speed is 0.5-3m / min.

Owner:CHONGQING UNIV

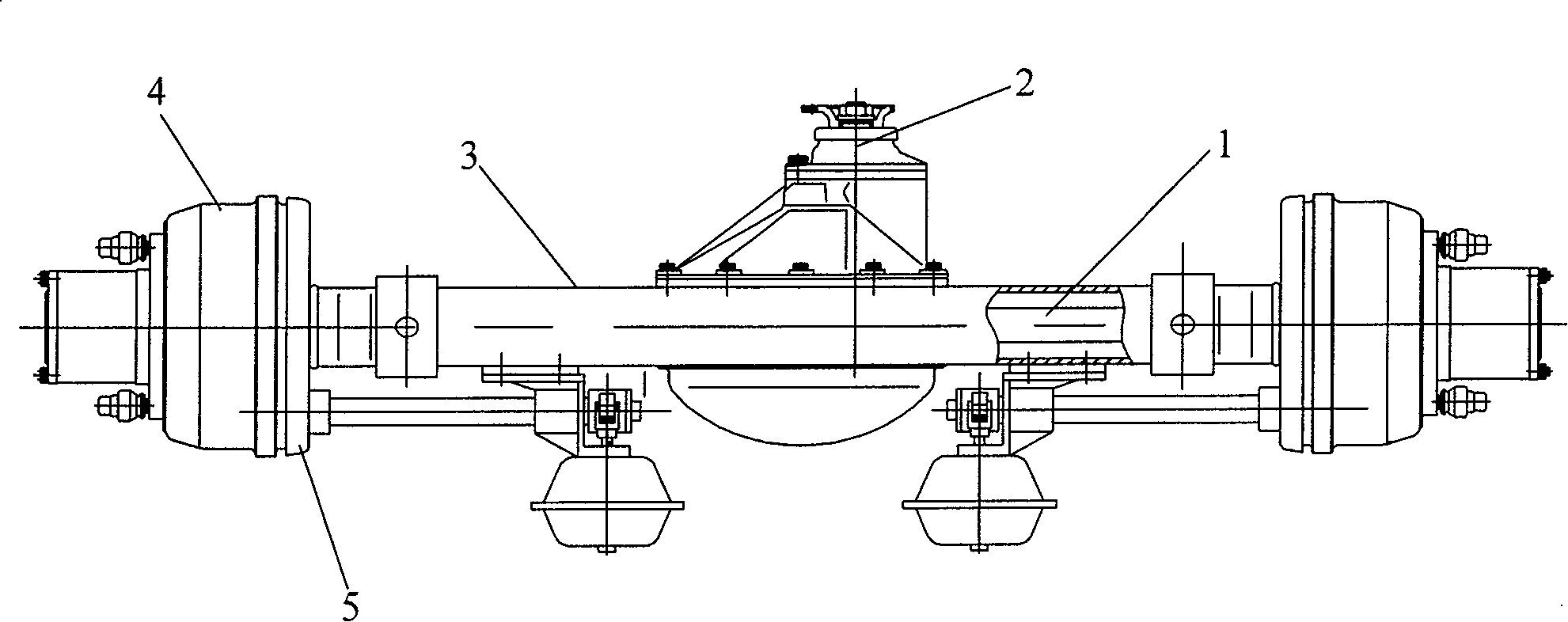

Roll type cold pressing processing method and device for vehicle driving axle housing

InactiveCN101185946ASimple structureHigh mechanical strengthExtrusion control devicesRams/plungersAxial pressureEngineering

Owner:梅利红

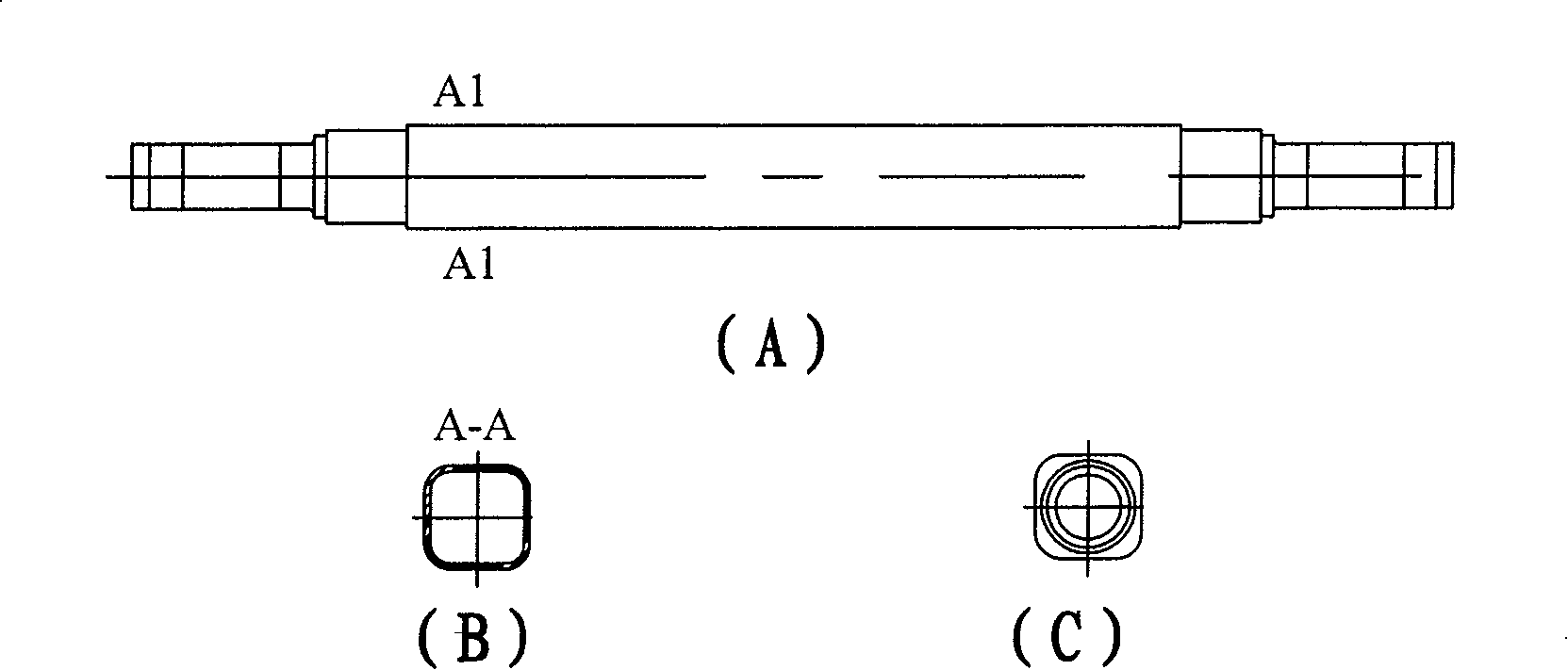

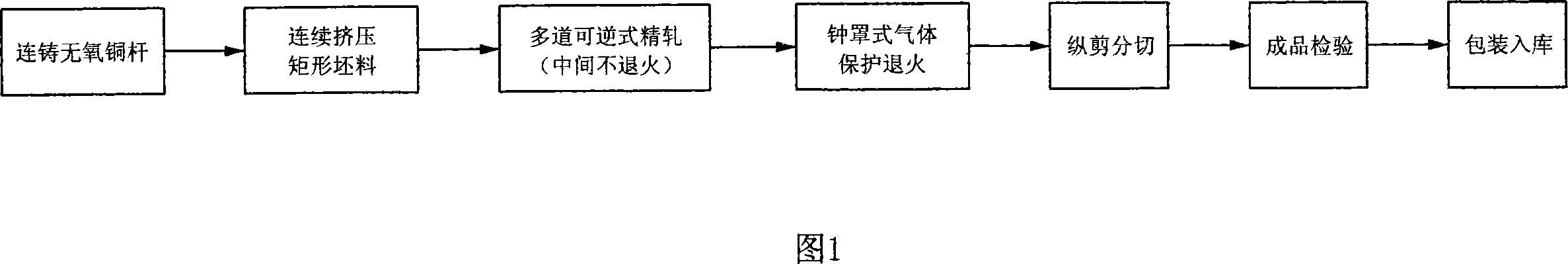

Production technology of big-length oxygen-free copper stripe

InactiveCN101134276AHigh purityHigh anaerobicRoll mill control devicesExtrusion control devicesOxidation resistantImpurity

The present invention discloses great length oxygen-free copper belt producing process, which includes continuously casting oxygen-free copper rod, continuously extruding rectangular blank, several gates of reversible finish rolling, annealing, longitudinally shearing, inspection, packing and other steps. By means of using oxygen-free copper rod as initial blank, continuous extrusion, continuous finish rolling, anti-oxidizing treatment, light gas protection and complete annealing, the present invention obtain great length oxygen-free copper belt product with high performance and good color.

Owner:浙江力博实业股份有限公司

Method for processing metallic lithium belt

ActiveCN101497088BHigh dimensional accuracyBright surfaceExtrusion control devicesMetallic lithiumEngineering

The invention provides a method for a novel lithium ribbon by vacuum extrusion forming. The lithium ribbon produced by the method has high dimensional precision and bright surface, and a lithium battery made of the lithium ribbon produced by the method has uniform and stable performance.

Owner:CHINA ENERGY LITHIUM

Wire hydrostatic extrusion device and method for extruding superfine grain wire using the device

InactiveCN101279331AGuaranteed qualityWill not oxidizeExtrusion diesExtrusion control devicesWire rodEngineering

The invention discloses a linear material static liquid extruding device which comprises an external extruding cylinder; an internal extruding cylinder is sheathed in the external extruding cylinder; the empty cavity of the internal extruding cylinder is filled with a hydraulic medium; the upper end of the empty cavity of the internal extruding cylinder is connected with an extruding rod; a sealing device is arranged between the extruding rod and the internal extruding cylinder. The lower end surface of the empty cavity of the internal extruding cylinder is provided with a discharge channel along the axes direction; the inner side of the lower end surface of the empty cavity of the internal extruding cylinder is provided with an extruding mould; the sealing device is arranged between the extruding mould and the internal extruding cylinder; the extruding mould is provided with an leading-in hole and an extruding hole along the axes direction; the leading-in hole, the extruding hole and the discharge channel are arranged on the same axes and are permeable. The invention also discloses a method for preparing super-thining crystal grain linear materials by the extruding device; the whole device has the advantages of compact structure, simple technique and easy operation, which is suitable for static liquid extruding to prepare aluminum alloy linear materials with thin diameters and is applied to continuously extruding other light alloys or brittle alloy linear materials that are hard to be extruded.

Owner:XIAN UNIV OF TECH

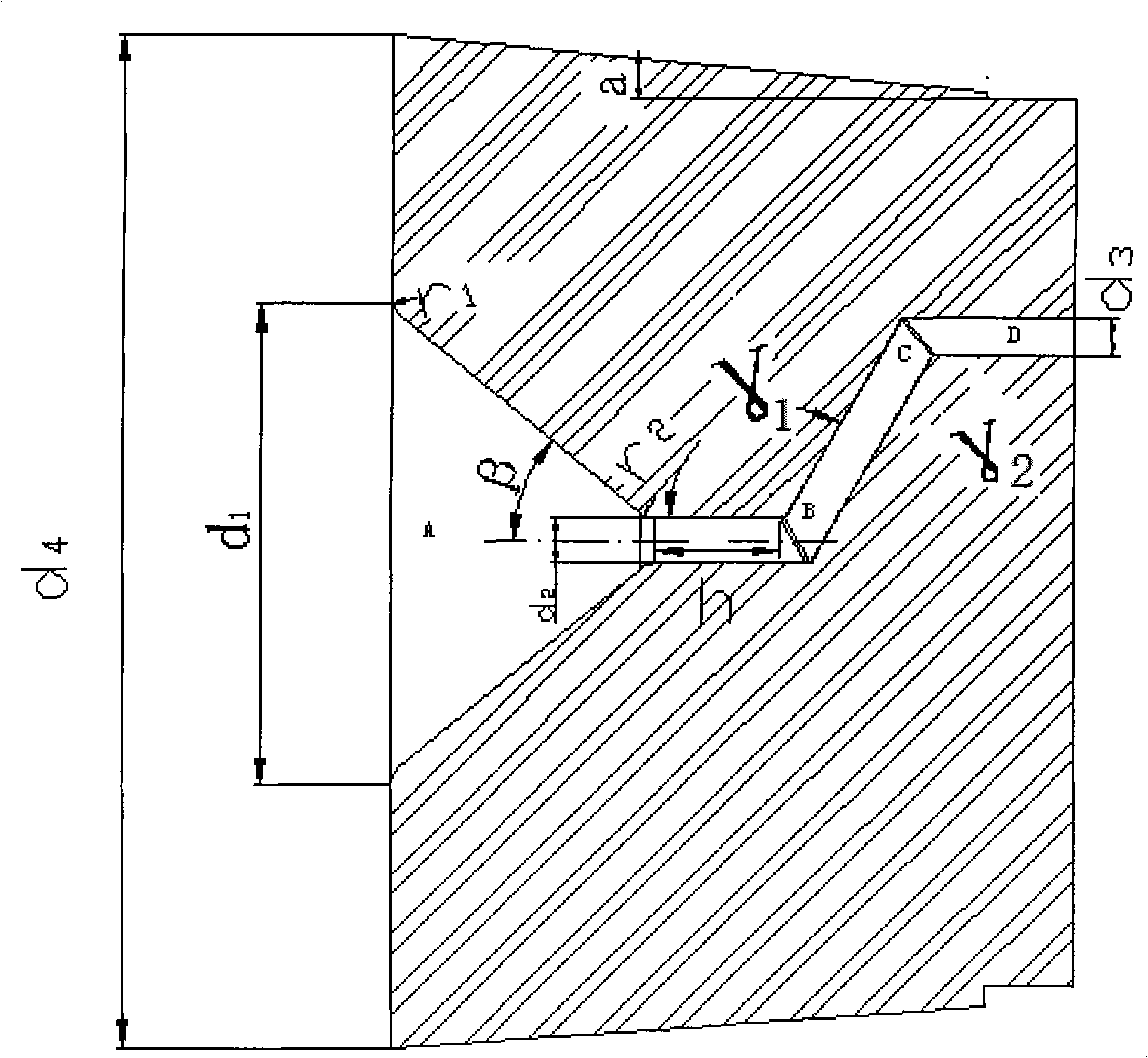

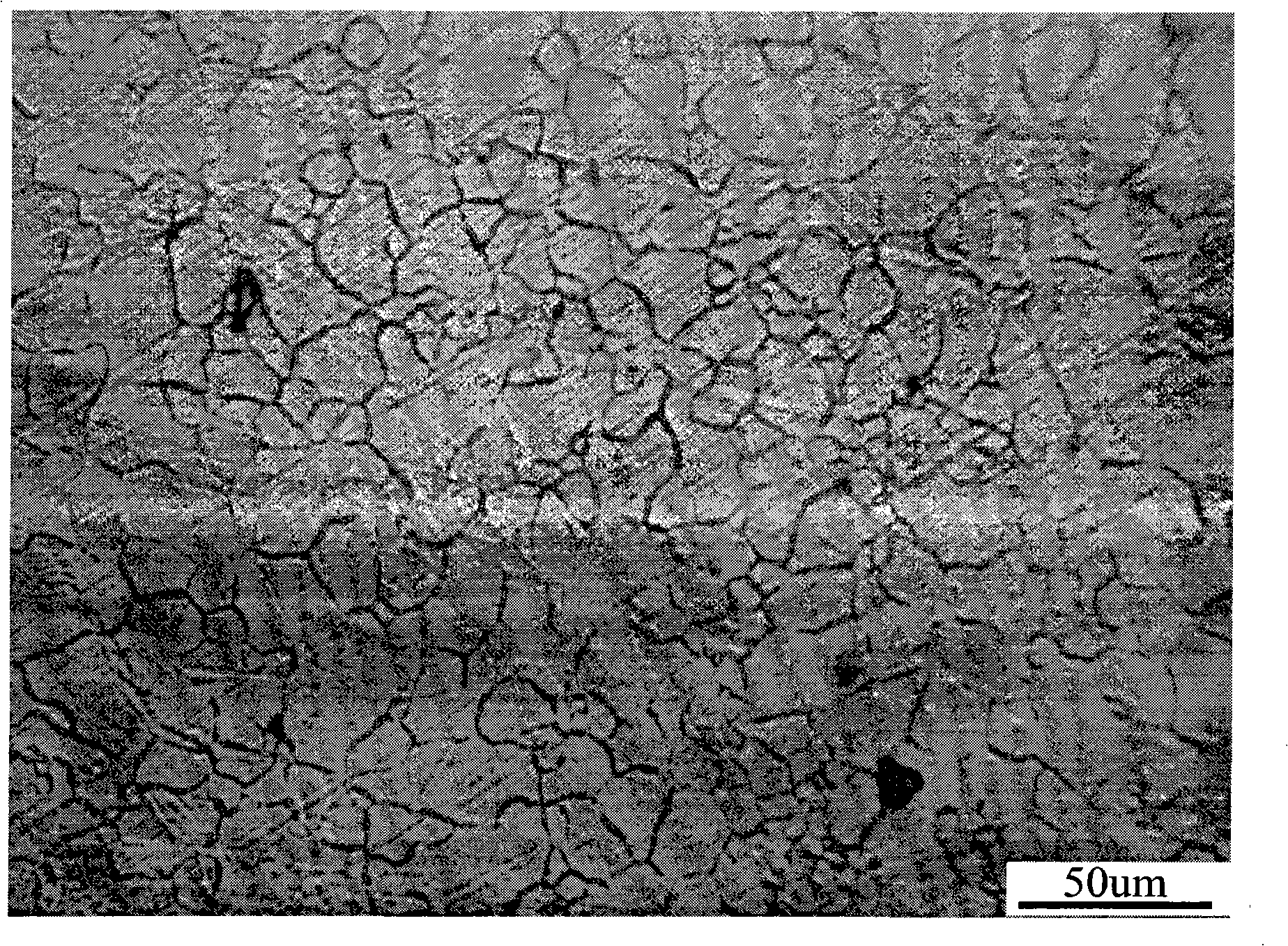

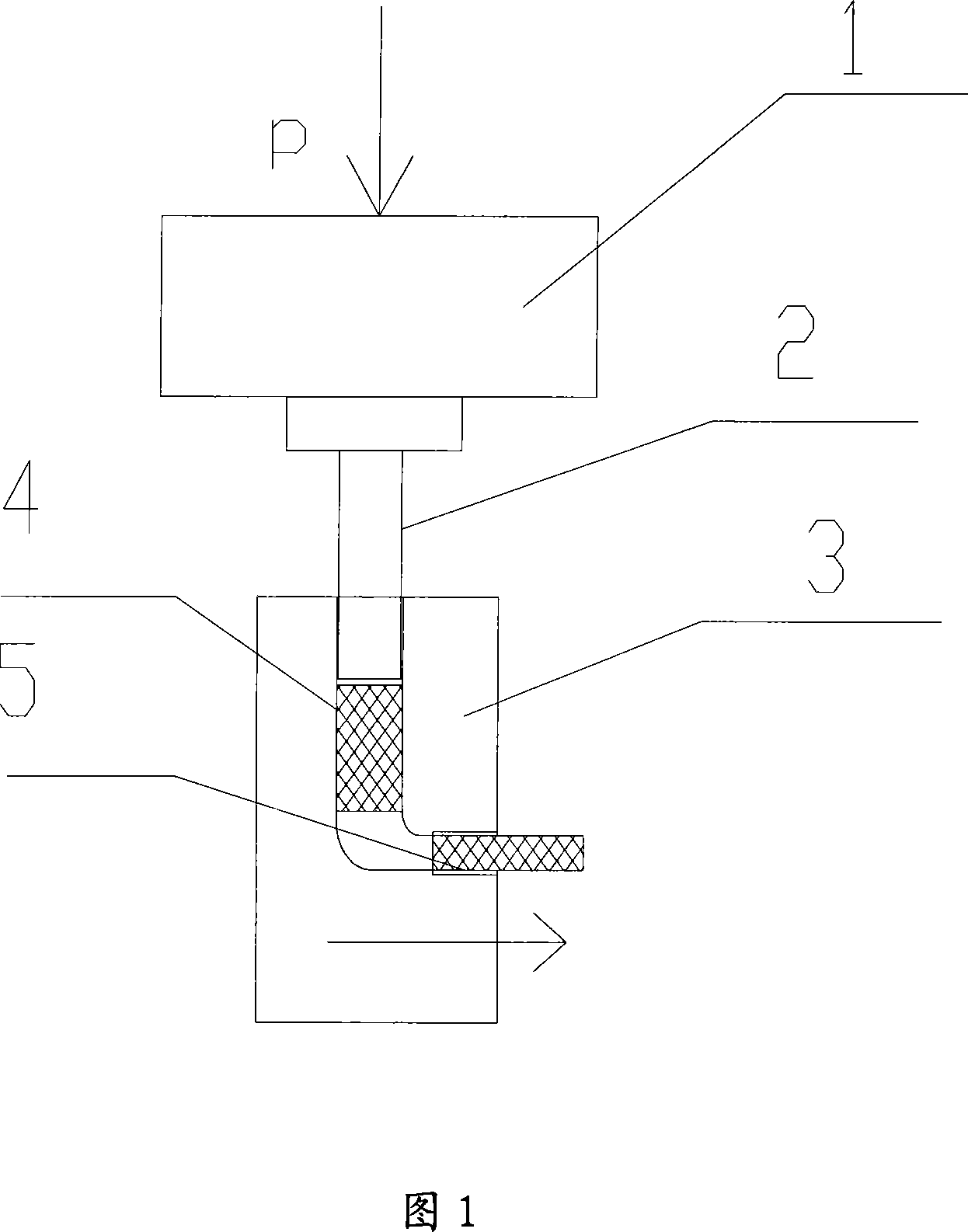

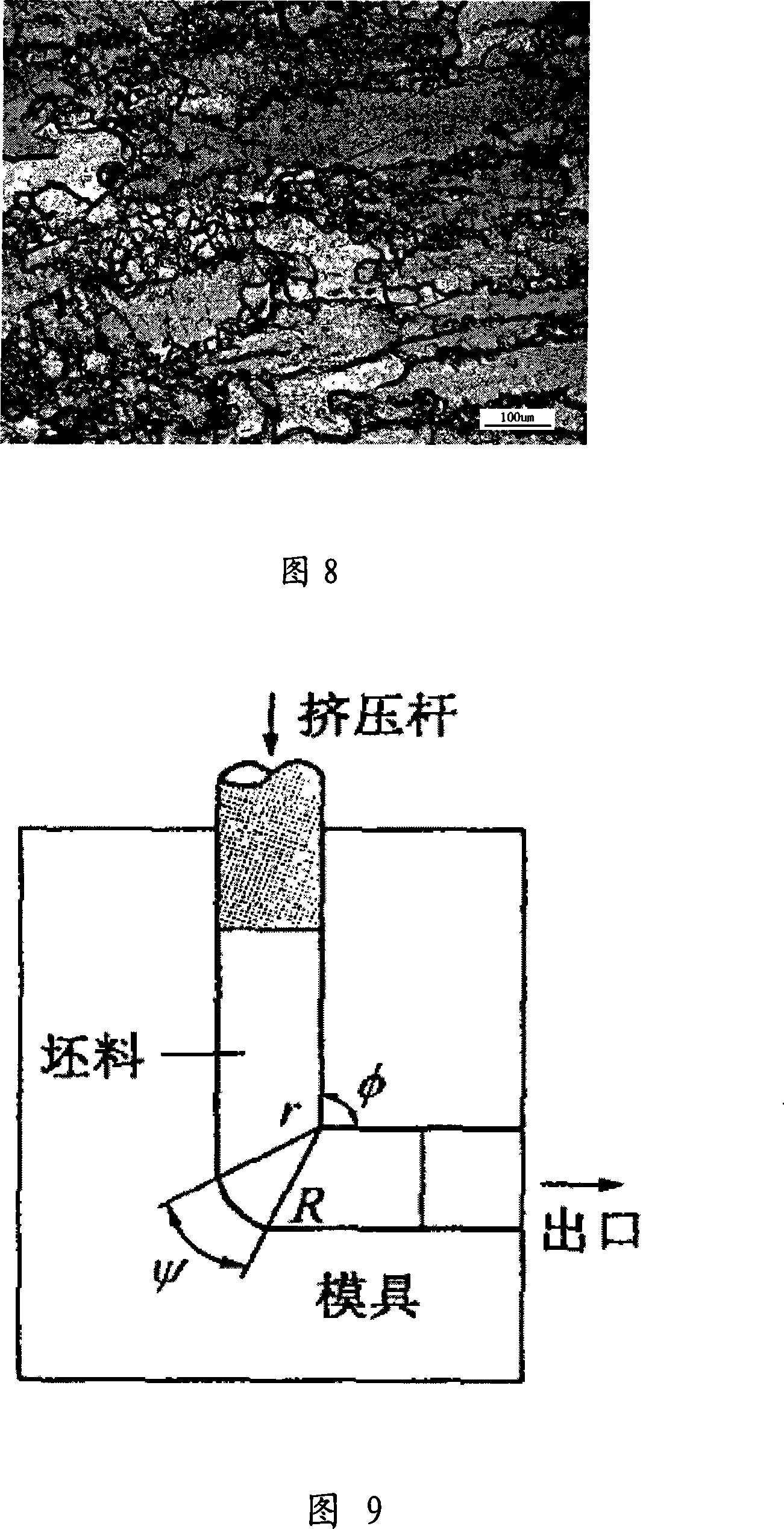

Processing method of magnesium alloy compressional deformation and mold

The invention discloses a processing method and a die for the extruding deformation of the magnesium alloy, and adopts an extrusion die which unilaterally extrudes, radially flows and molds through a diameter changing angle, the extrusion ratio is four to sixty, antifriction material is uniformly coated in an extruding channel cavity of the die after the die is heated, then the semi finished metal of the magnesium alloy which is processed in uniformization is heated and put in the extrusion cavity of the heated die, and then passed through the downwards moved terne die of the extrusion die, with the extrusion speed of 0.5 m / min to 3 m / min and the extruding force of 3 MPa to 35 MPa at the same time, the die extrudes from the top end of the semi finished metal of the magnesium alloy in a constant speed, to lead the semi finished metal of the magnesium alloy to flow to the diameter changing cavity channel of the die extrusion cavity to be radially deformed. The invention adopts the unilateral extrusion die which extrudes, radially flows the diameter changing angle to deform, to not only hugely improve the refined effect of the magnesium alloy crystal grain, to lead the synthetic mechanical property of the magnesium alloy material to be improved, but also to achieve the extrusion speed to keep under the state of low temperature extrusion, to keep the quality of the shaped sample piece, thereby improving the production efficiency of the extrusion deformation process of the magnesium alloy.

Owner:CHONGQING UNIV

Preparation method of light high-intensity aluminum base home-position composite material for cable bridge frame

InactiveCN101417388ASimple processConstitute controllableExtrusion control devicesMaterials scienceHeat treating

The invention relates to a preparation technology of aluminum-matrix in-situ composites, in particular to a preparation method of light-weight high-strength aluminum-matrix in-situ composites used in cable testing bridges. The method includes the following specific steps: alloy is melted according to requirements of mixture ratios of components of aluminium alloy 6061, 6063 or 6070; mischmetal with the mass of 0.2 to 0.4 percent of that of the aluminium alloy is added and reaction materials of the composites are added through a dusting device for reaction synthesis of particle reinforced aluminum-matrix composites; chemical constituents are adjusted on grounds of demand; Al-5Ti-1B wires with the mass of 0.15 to 0.20 percent of that of the aluminium alloy are added for refining treatment and then semicontinuous casting; ingots are carried out homogenization treatment; and the testing bridges are obtained through the technologies of hot extrusion and hot treatment. The invention is simple and convenient in technology and controllable in constitution of the composites and the combination property of the bridges of the particle reinforced aluminum-matrix composites is obviously improved, thus meeting requirements of more high-standard construction.

Owner:JIANGSU UNIV

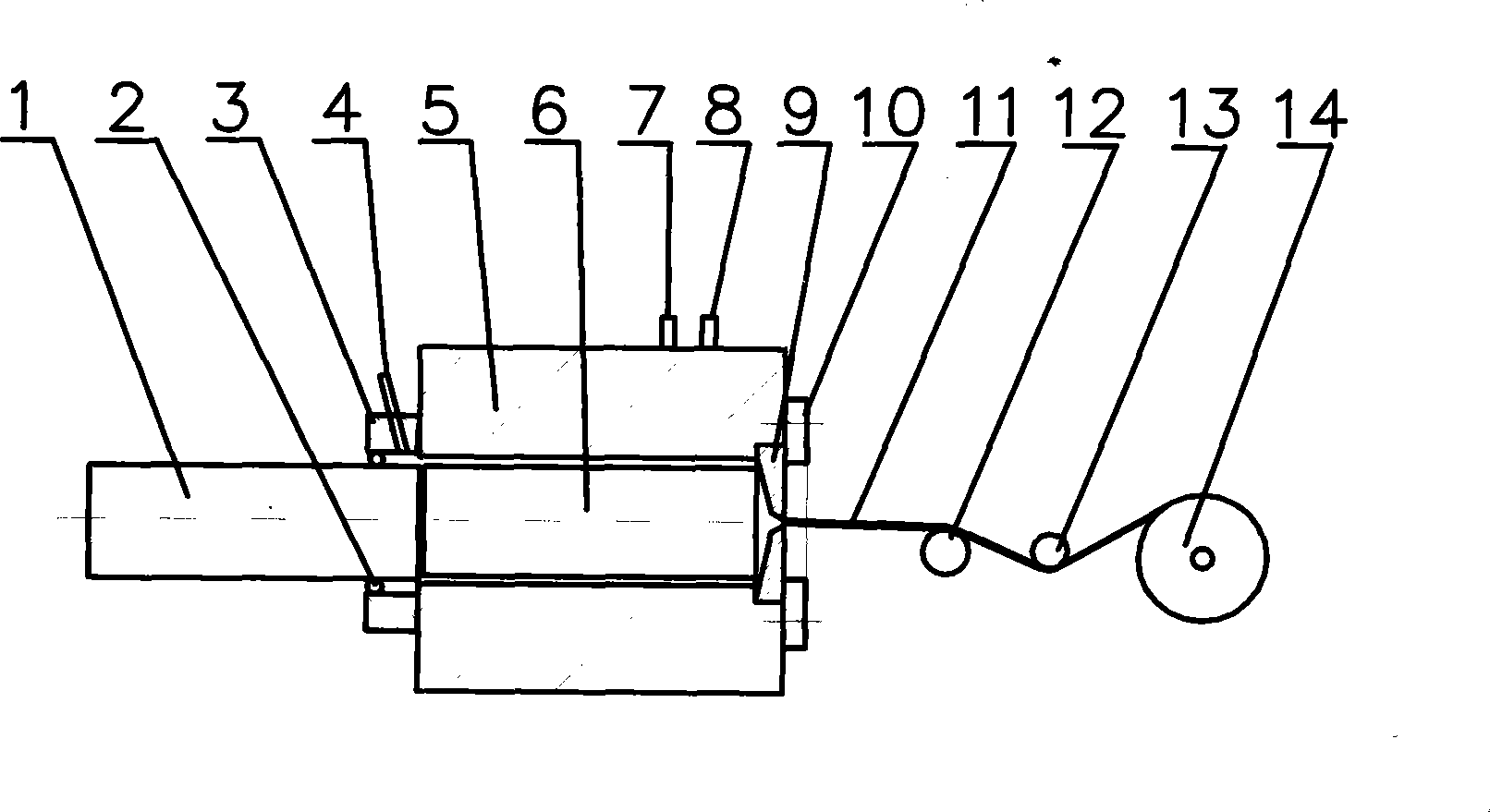

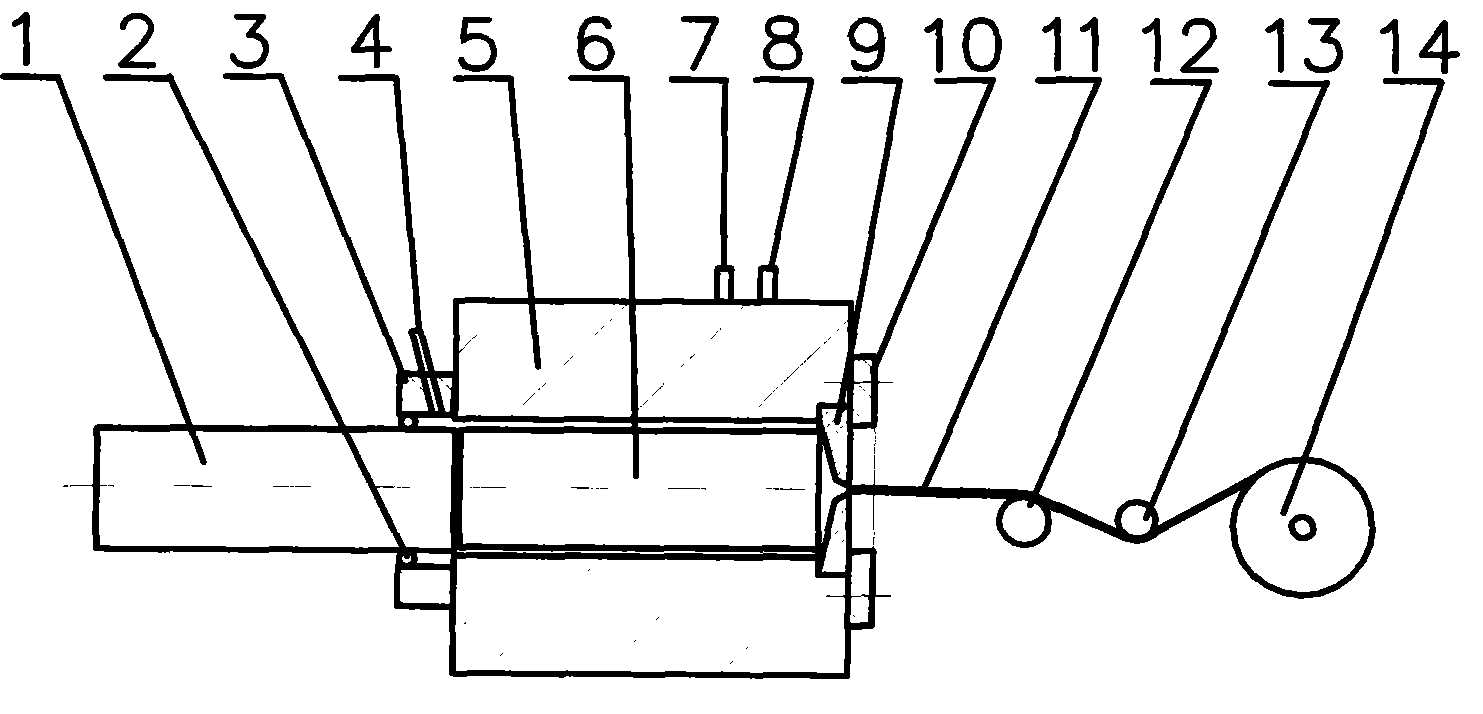

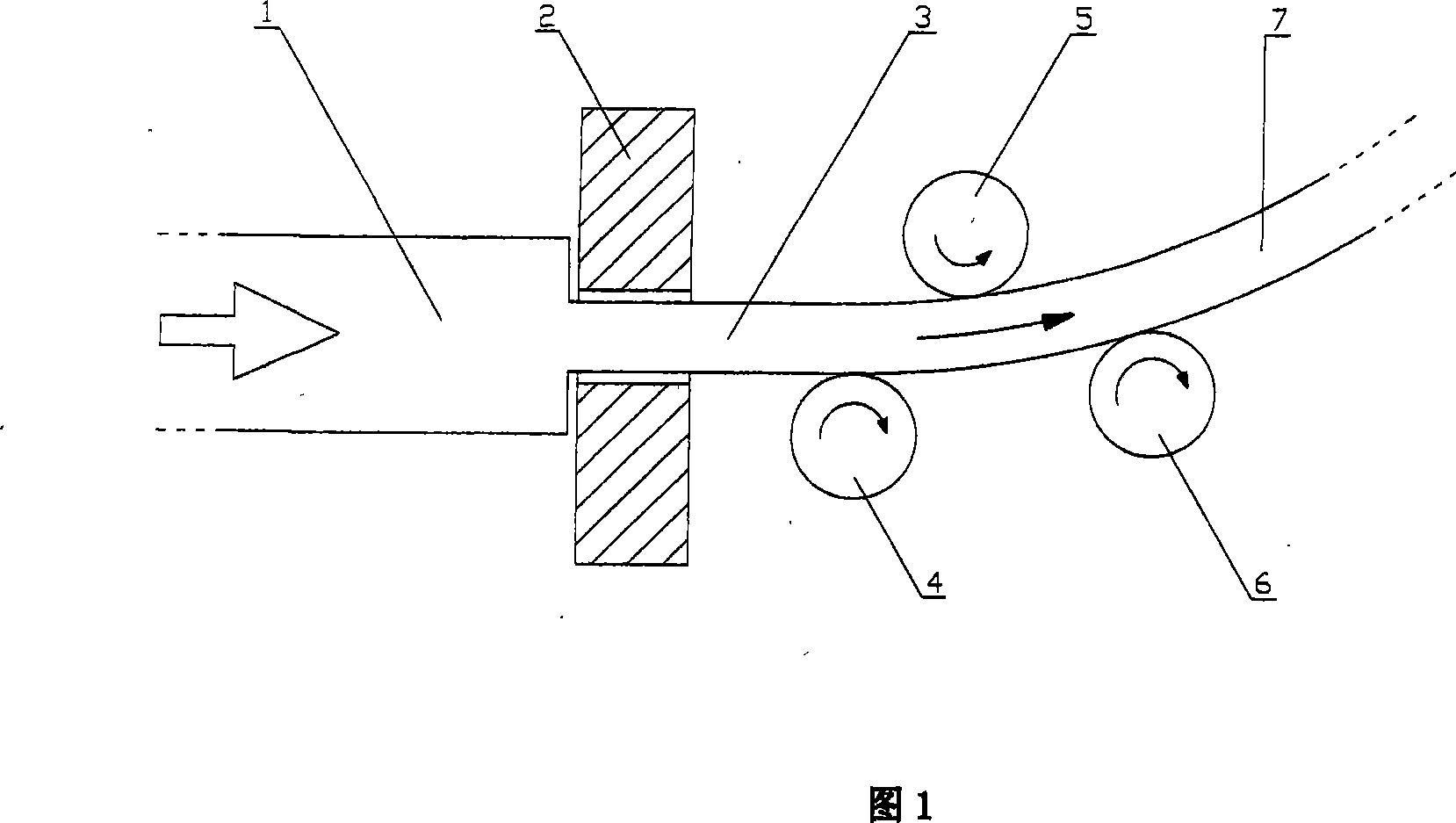

Extruding-bending integral forming method for magnesium alloy profiles

The invention relates to a technical method used for extruding-bending-integral forming of a magnesium alloy sectional material, pertaining to the technical field of plasticity processing. A set of three-wheel roll bending device is arranged near a discharge port of the original horizontal extruding machine, magnesium alloy ingot blanks are molded into the sectional material through hot extrusion, the sectional material is put into the roll bending mechanism directly before being cooled, bending moment is carried out to the sectional materials by the three roll wheels that are arranged on a same surface so as to achieve bending and molding, and the movement and position of the roll wheels are controlled to gain a bending angle and a bending radius that are required. The invention can realize the extrusion, bending and continuous molding of the magnesium alloy sectional material under the condition of only heating original ingot blanks, thereby having high production efficiency and low cost.

Owner:SHANGHAI JIAO TONG UNIV

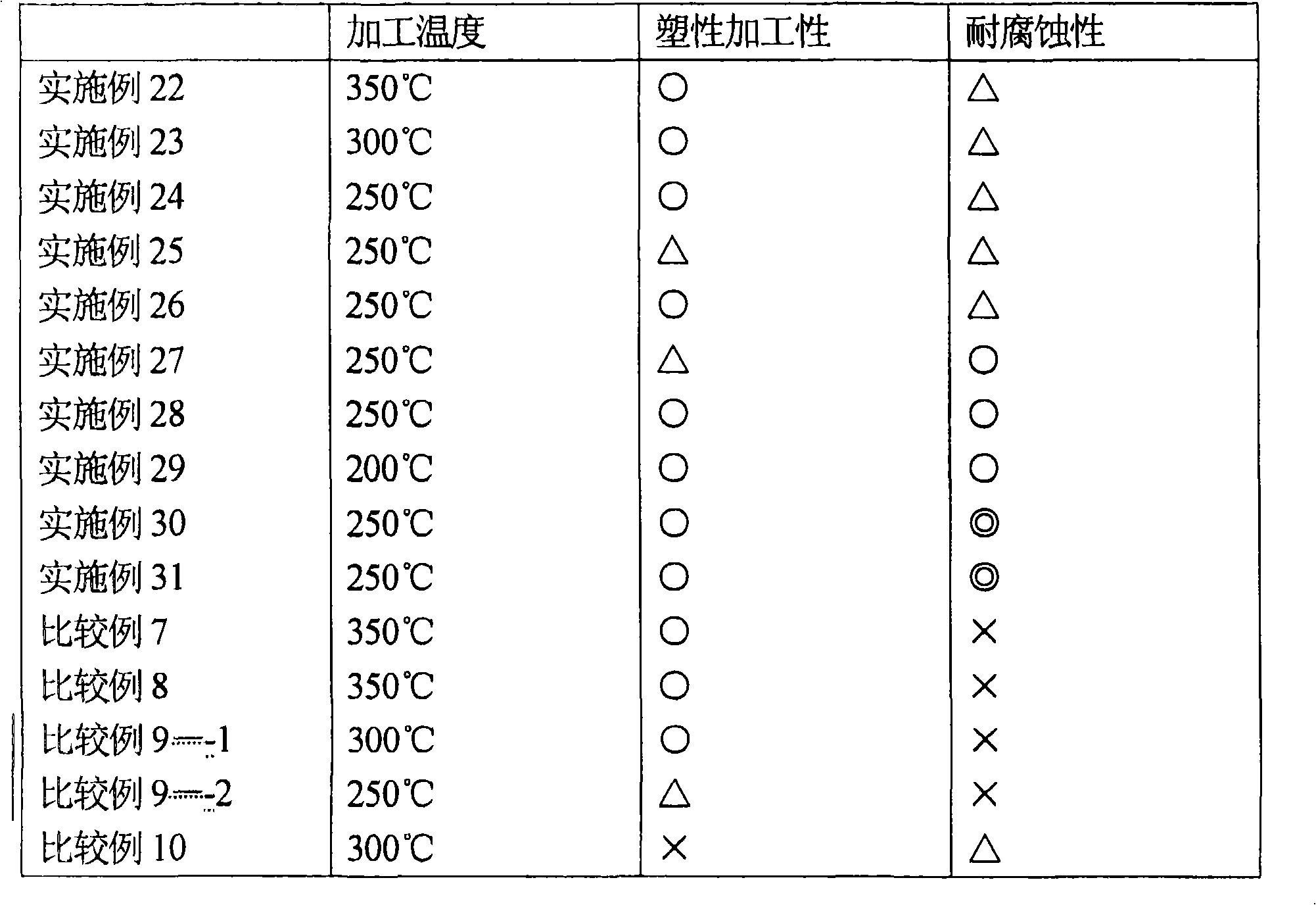

Magnesium alloy plastic process product and manufacture method thereof

InactiveCN101269386AGuaranteed mechanical strengthEnsure plastic workabilityExtrusion control devicesMetal rolling arrangementsDie castingHigh intensity

The invention provides the production of plastic processing products ensuring forgeability, preventing from fracture, blackening and burning surface, realizing formability of complex shape of die casting, high reliability and high intensity performance of forging products, and production of cheep and high-quality plastic processing products, as well as producing magnesium alloy plates cheaply according to requirements, further comprising production of magnesium alloy plastic processing products plastically processing the magnesium alloy plates produced cheaply.

Owner:三井金属压铸株式会社

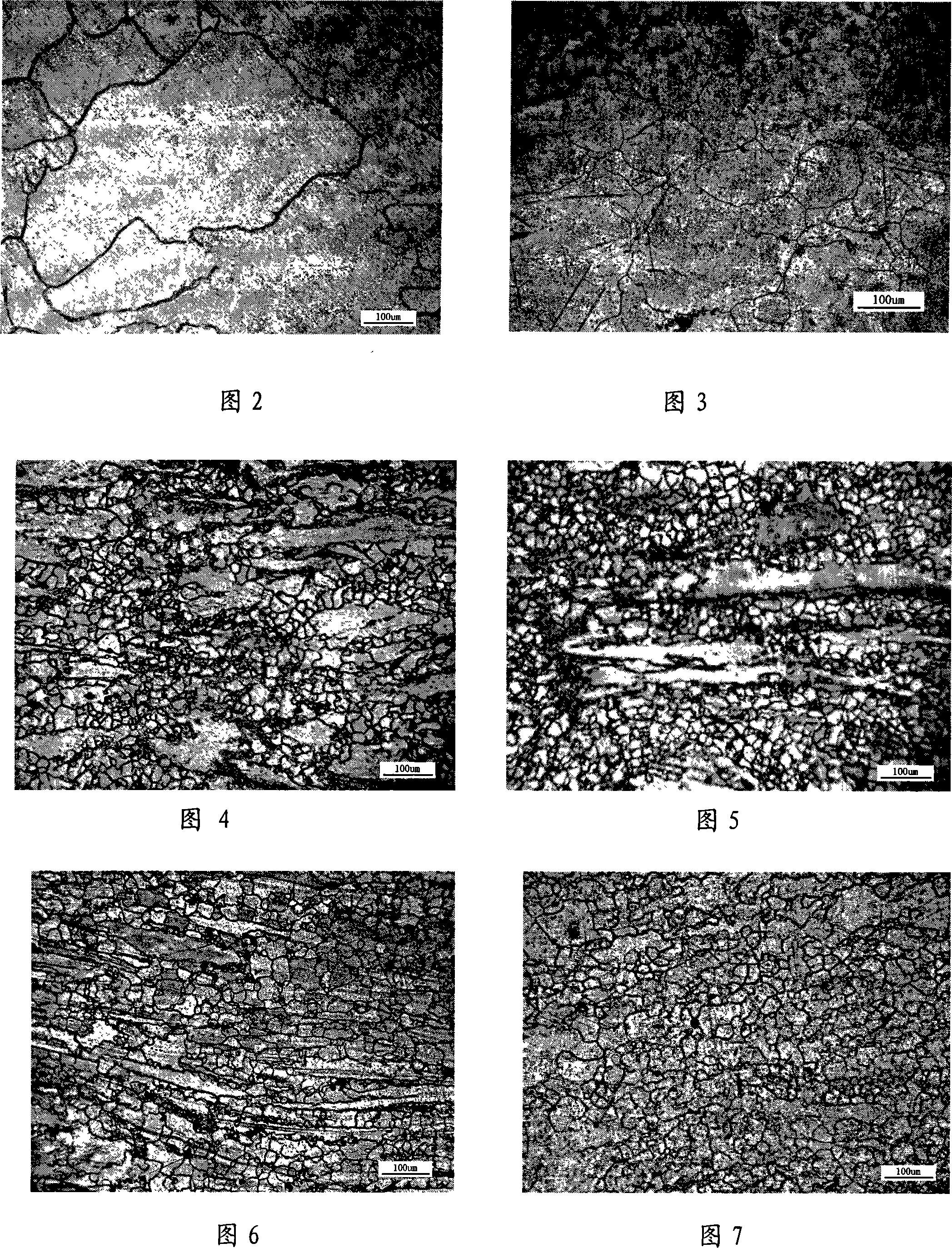

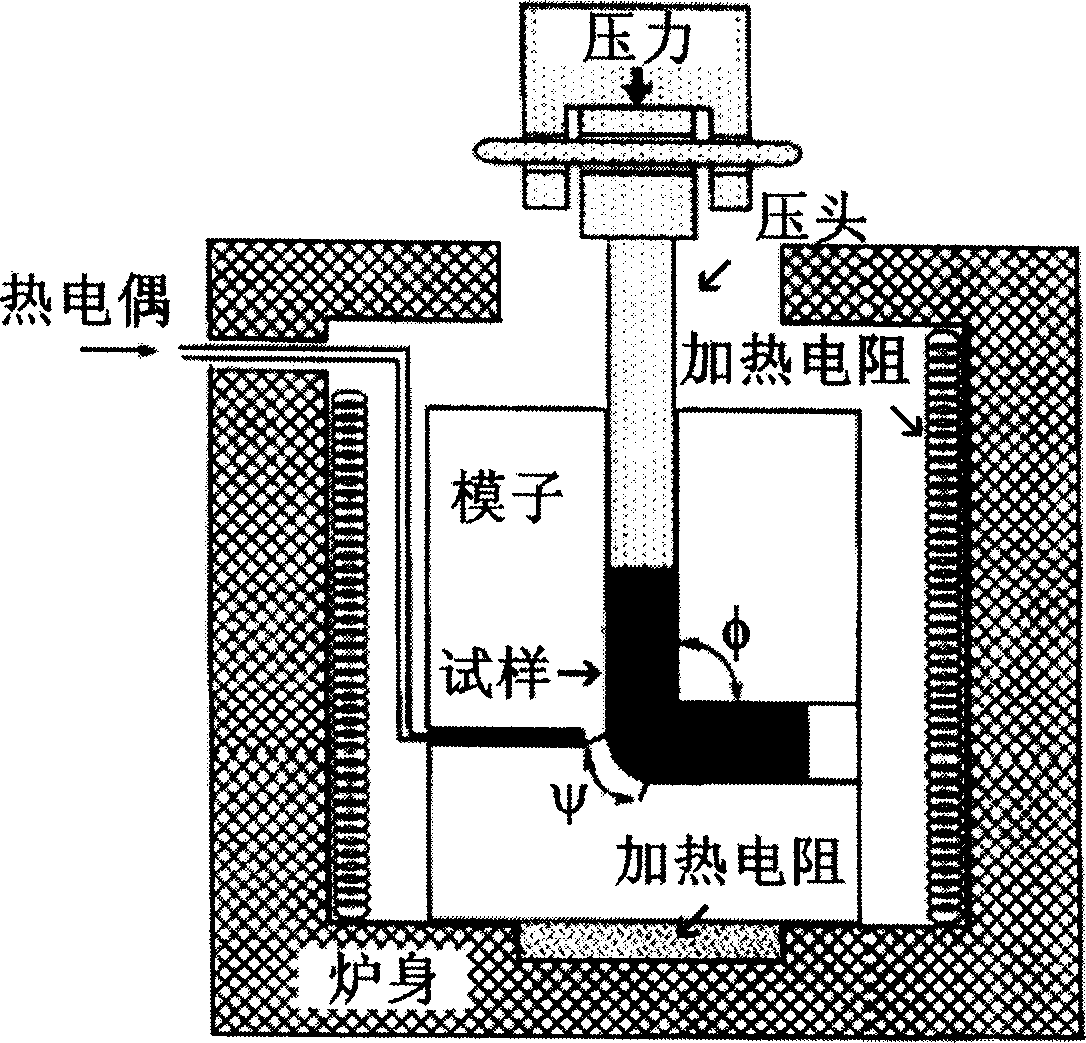

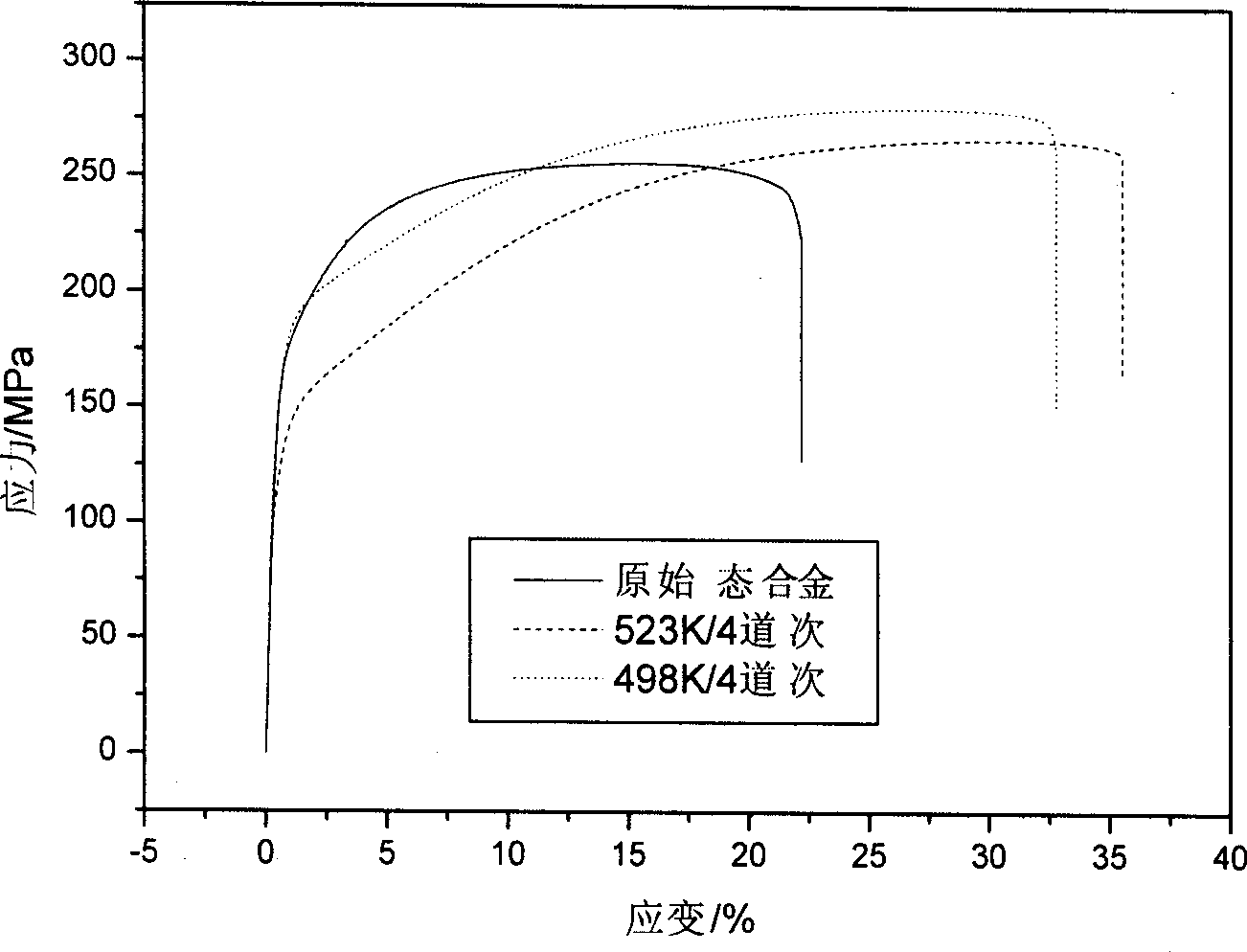

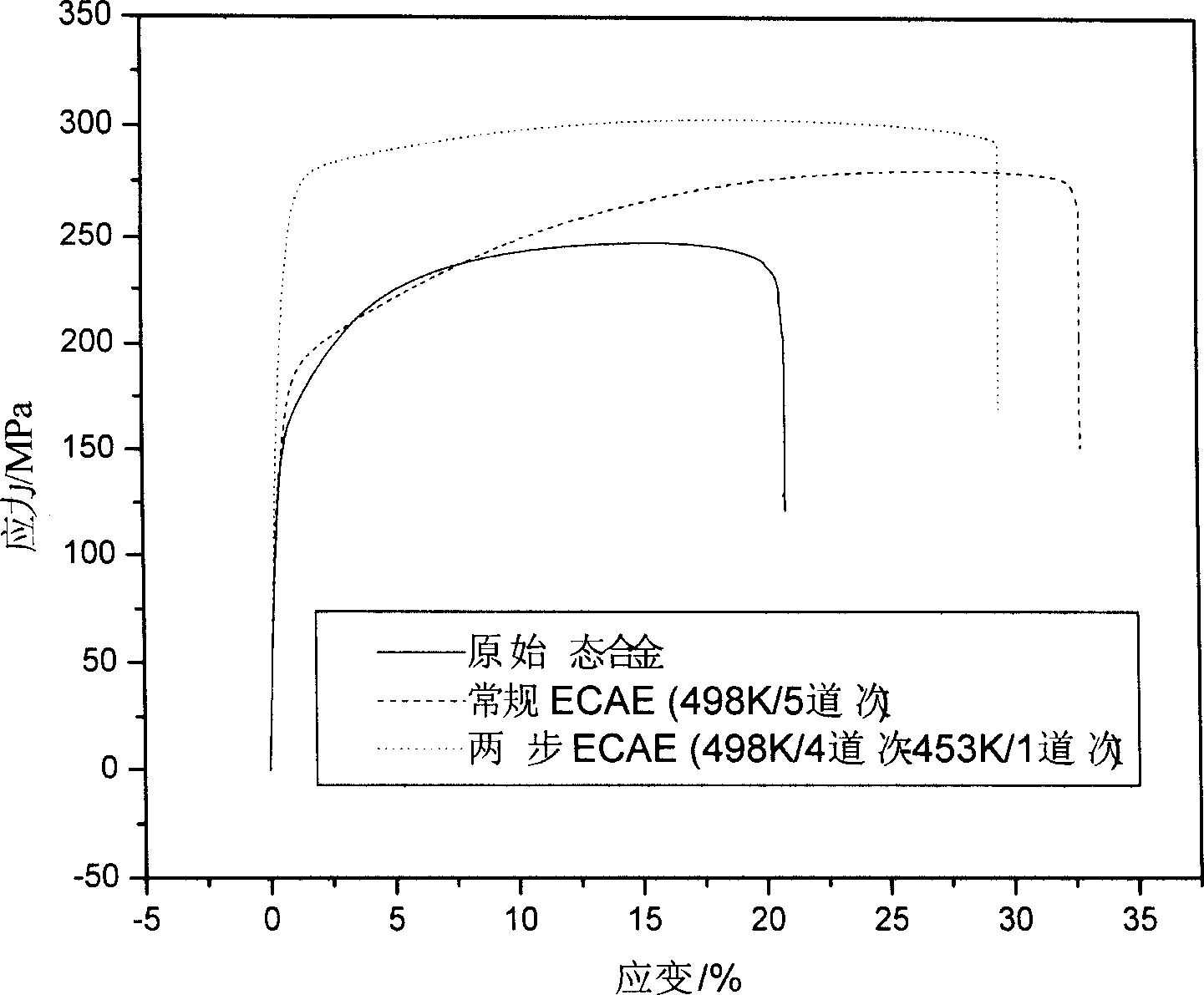

Method for extrusion two-step equal channel angle of magnesium alloy

InactiveCN1792487AGrain refinementImprove organizational structureExtrusion control devicesEqual channel angular extrusionMaterials processing

A two-step squeeze method with equal channel angle for Mg-alloy includes such steps as designing equi-channel squeezing die set, regulating deformation speed and temp to find out the lowest temp for non-crack deformation, equichannel squeezing by 2-4 passes, lowering the deformation temp, and squeezing by 4-8 passes. Its advantage is high strength and toughness.

Owner:FENGYANG L S NET FORMING CO LTD

Method for preparing semi-solid metal slurry and rheologic molding

InactiveCN101130203AImprove liquidityEliminates the difficulty of pouringExtrusion control devicesVertical tubeCrucible

The invention discloses a preparing technique of semi-solid metal slurry and rheologic moulding equipment in the preparing technical domain of semi-solid metal slurry, which comprises the following steps: pouring the overheat metal liquid into straight-in composite tube path with an inclined tube and a vertical tube; moving the semi-solid metal slurry and preparing copper into the temperature controller after flowing the overheat metal liquid into the copper along the inner wall of the straight-in composite tube path; doing subsequent cooling or temperature field control for the semi-solid metal slurry; pouring the semi-solid metal slurry into pressing chamber with squeeze moulding machine or squeeze caster or forger to mould; opening or fetching the cast piece or squeeze cast or forge from mould. The invention simplifies the preparing technique, reduces energy consumption and shortens the technical flow path, which reduces the manufacturing cost of the semi-solid metal rheopectic casting die or rheopectic squeeze casting die or rheopectic forge.

Owner:UNIV OF SCI & TECH BEIJING

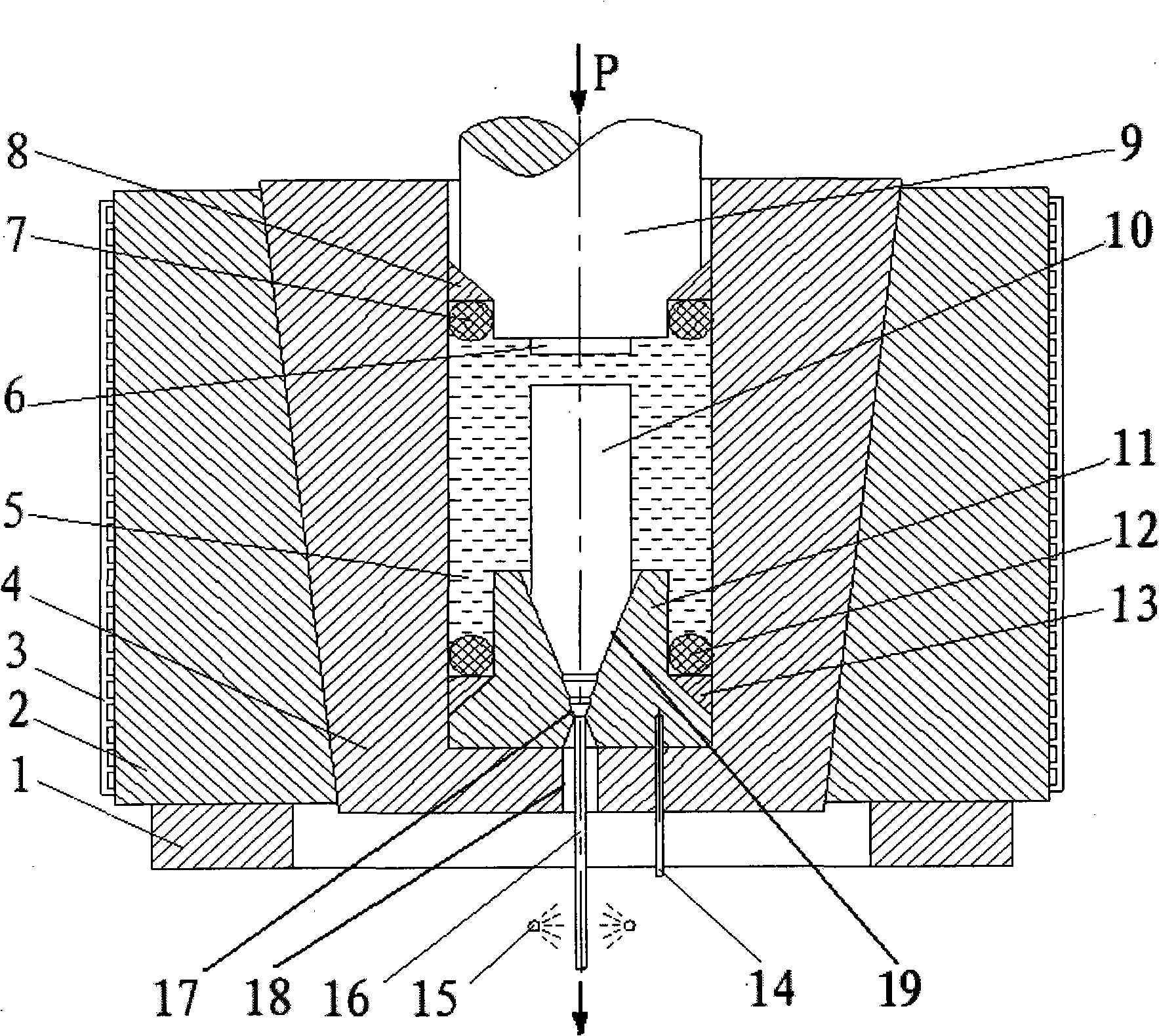

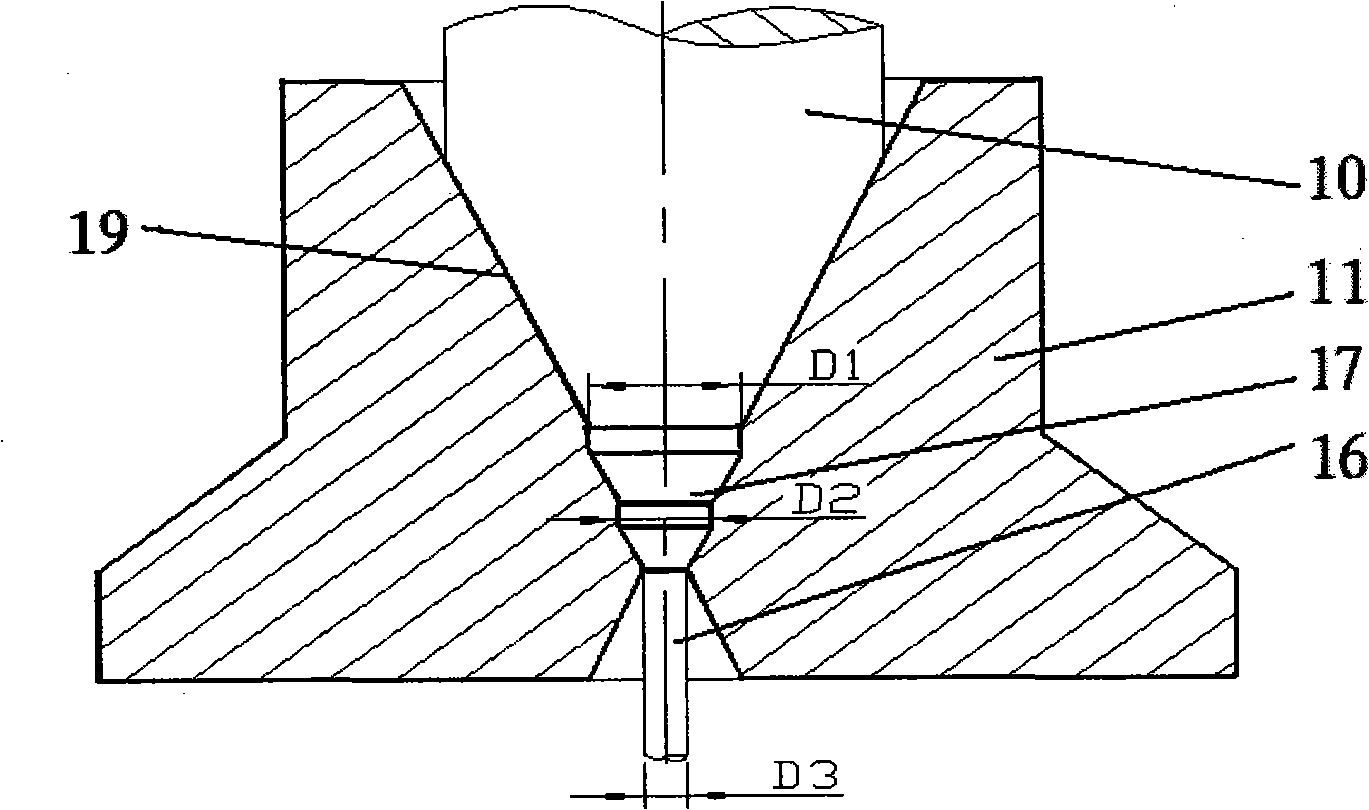

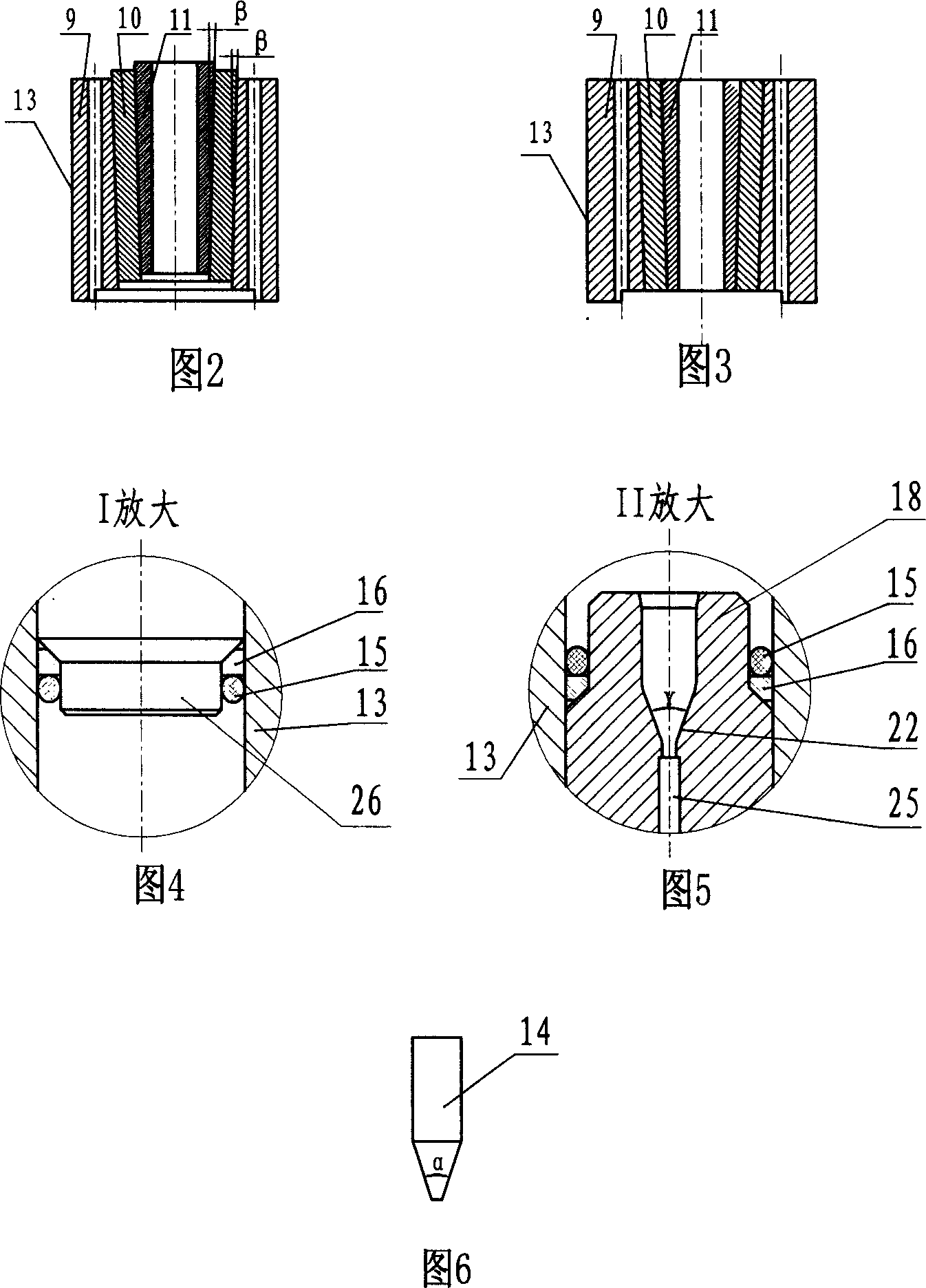

Warm static liquid extrusion method and mould for producing magnesium alloy wire or bar

InactiveCN101015841ASpeed up heat dissipationSlow down heat dissipationExtrusion diesExtrusion control devicesTemperature controlPhysical property

The invention relates to a hydraulic extruding method for producing magnesium alloy wire or rod, and relative specific extruding mould, which can avoid crack and high cost or the like. The inventive method comprises that processing magnesium alloy blank, coating lubricant, and heating with era oil, heating hydraulic extruding mould and controlling temperature, arranging magnesium alloy blank, filling era oil, arranging movable convex mould, pressurizing and extruding. The inventive mould comprises a movable convex mould (26), under a convex mould (6) and coaxial with the convex mould (6), wherein the lower end of the convex mould (26) is through a convex mould through hole (8) at the middle of a convex mould press plate (17) to be mounted on the upper part of an extruding barrel (13), and the extruding barrel (13) is a multilayer cold press extruding one. The invention can obtain better physical property and surface quality, or the like.

Owner:HARBIN INST OF TECH

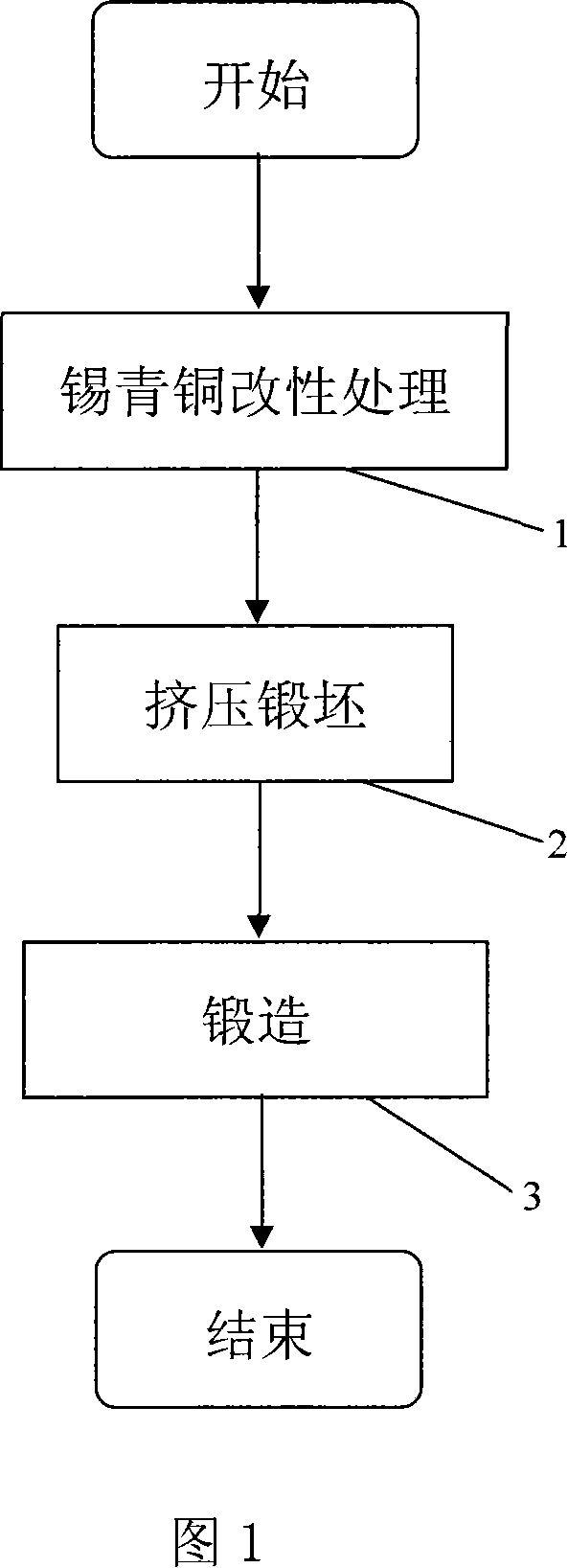

Technique for processing tin bronze valve body and tube union

InactiveCN101152692AImprove ductilitySolve the problem of airtightnessExtrusion control devicesRare earthAlloy composite

The present invention discloses a processing technique of a tin bronze valve body and a pipe joint which comprises a modification processing of tin bronze, extruding and forging of the unburnt earthenware, forging and so on. The tin bronze is metamorphosed and modified by the present invention by adding rare earth to purify and RE-Li-Bi alloy composite modifier to refine the crystal grain and improves the scalability of bronze and addresses the tin bronze sealing problem. The forging of an unburnt earthenware piece is a technique which is light and fast at the beginning, heavy and slow in the middle and is formed by tapping in the brittle region. The processes of forging the original unburnt earthenware, extruding the unburnt earthenware, forging the tin bronze valve body and producing a pipe joint are integrated; the work which needed a plurality of months at the beginning is capable of being integrated and finished in a production cycle, so the processing accuracy is increased; the process is simplified; the production efficiency is improved and the production cost is reduced. The present invention is mainly used for the bronze valve which is provided with the dimension of 3 / 8 inches to 4 inches and the series components for forging the pipe joint.

Owner:王仁辉

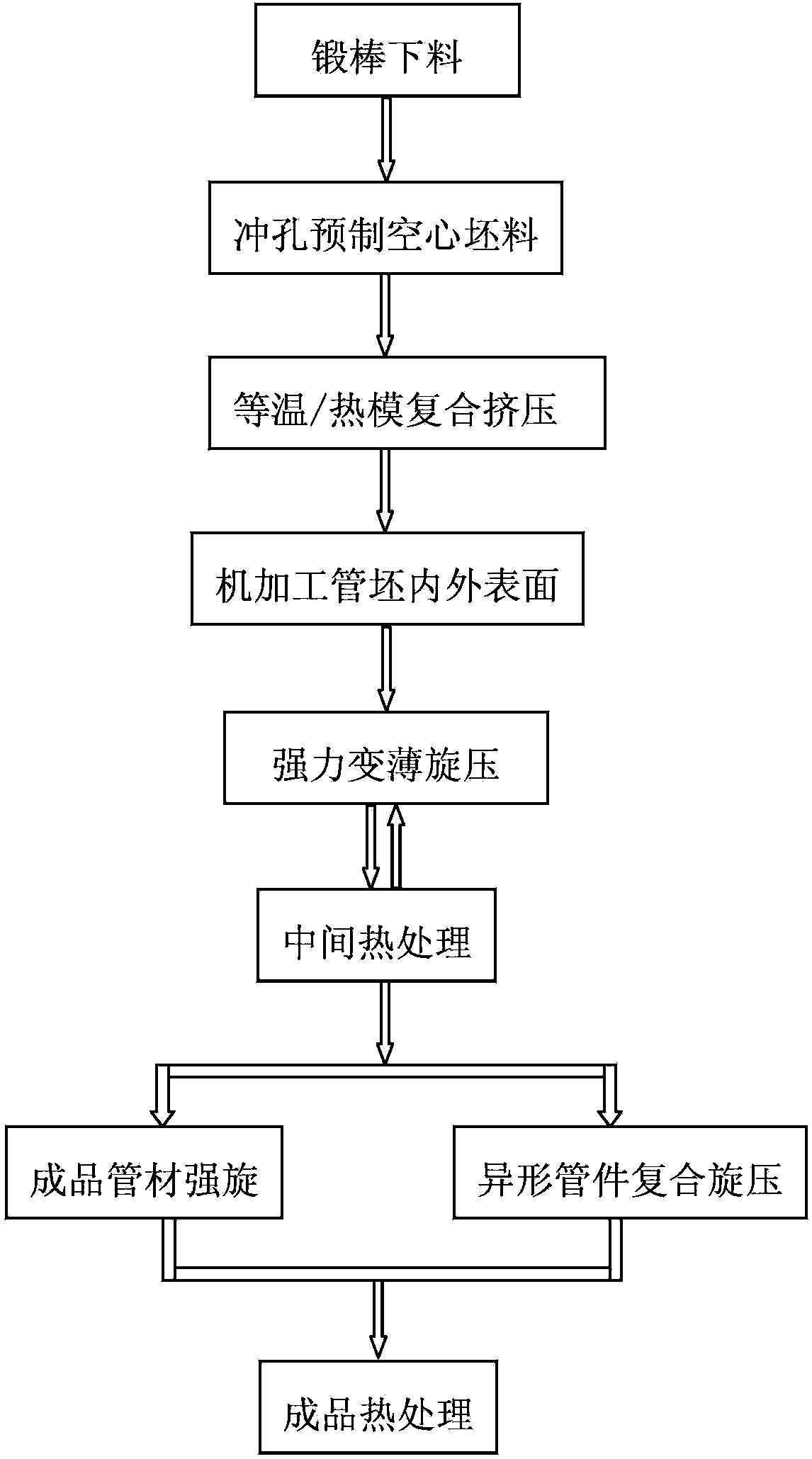

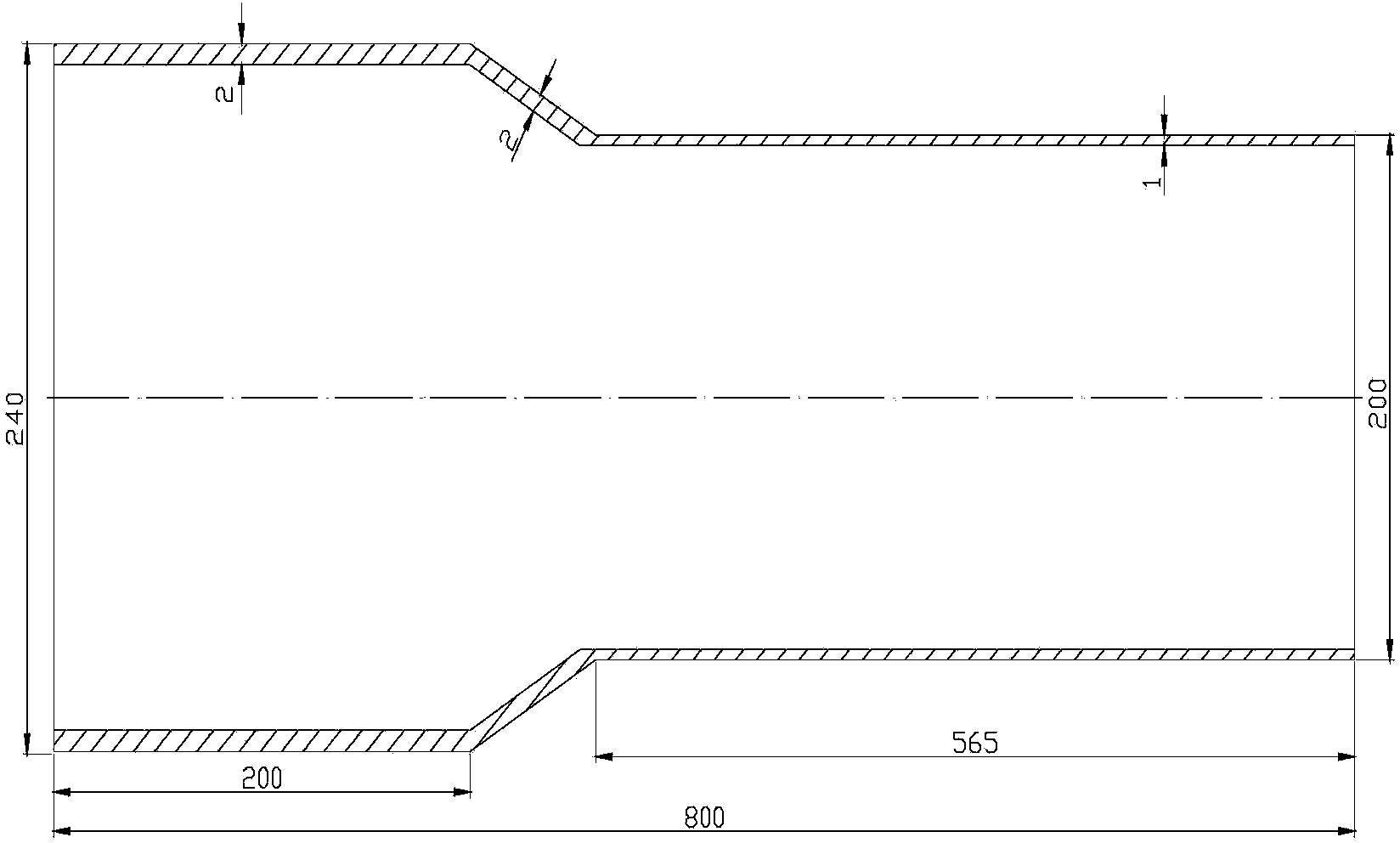

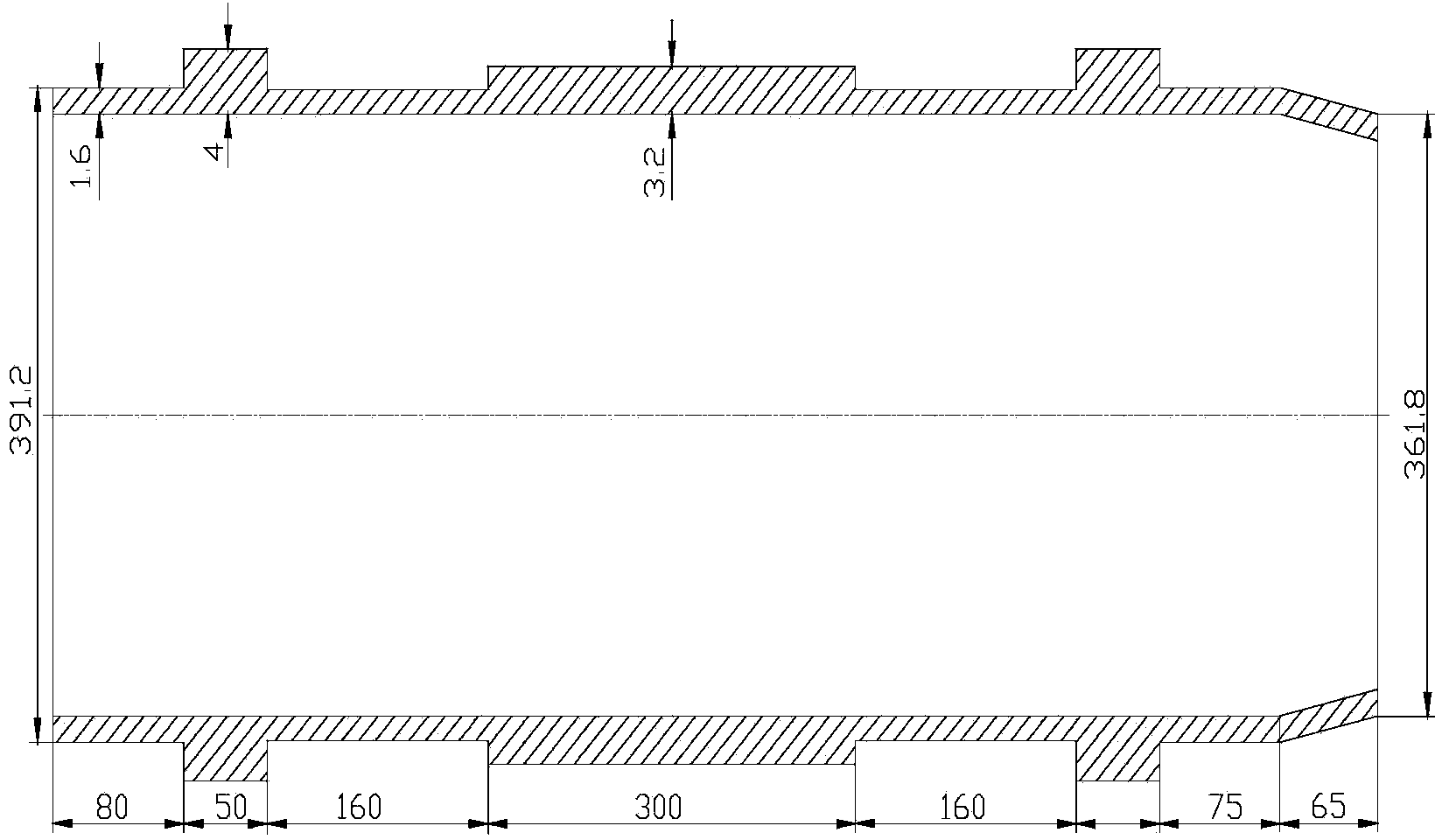

Preparation machining method of large-diameter pipe material and special-shaped pipe fitting

ActiveCN103846305AFormabilityForming labor-savingExtrusion control devicesSocial benefitsSolution treatment

The invention belongs to the technical field of metal machining, and particularly relates to a preparation machining method of a large-diameter pipe material and a special-shaped pipe fitting. The preparation machining method comprises the following steps of prefabricating a hollow blank by punching, carrying out isothermy or hot mould combined extrusion on the hollow blank, machining the inner and outer surfaces of an extruding tube blank, and carrying out multi-pass cold or hot power cone spinning on the machined tube blank; carrying out intermediate heat treatment (which can be annealing or solution treatment) on a semi-finished pipe material product; repeatedly and alternately carrying out multi-pass power cone spinning and the intermediate heat treatment, and carrying out power spinning on the finished pipe material product; carrying out multi-pass composite spinning forming on the semi-finished pipe material product after heat treatment so as to obtain the special-shaped pipe fitting; and carrying out acid pickling and cleaning on the obtained pipe fitting and special-shaped pipe fitting and then carrying out thermal treatment on the finished product. The preparation machining method of the large-diameter pipe material and the special-shaped pipe fitting provided by the invention has the advantages that the large-diameter pipe material and the special-shaped pipe fitting are prepared and machined, the product organization is uniform, the combination property is high, the forming is effort-saving, the additional value is high, and a product has good popularization and application prospect and definite economic benefits and social benefits.

Owner:GRIMAT ENG INST CO LTD

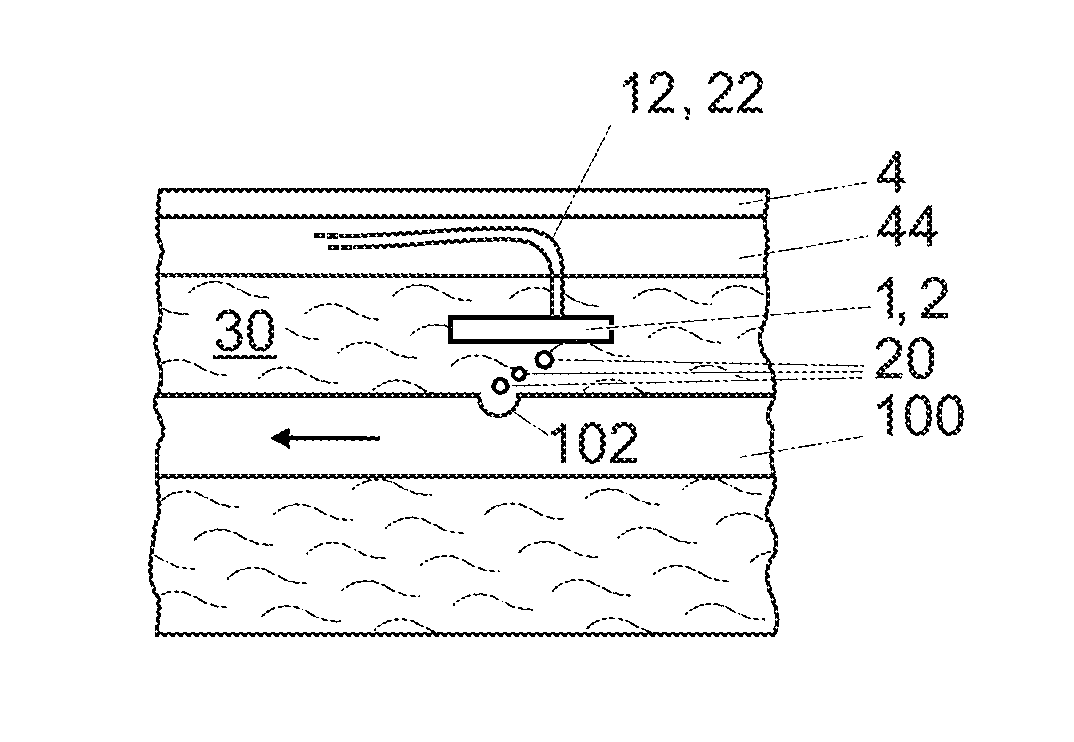

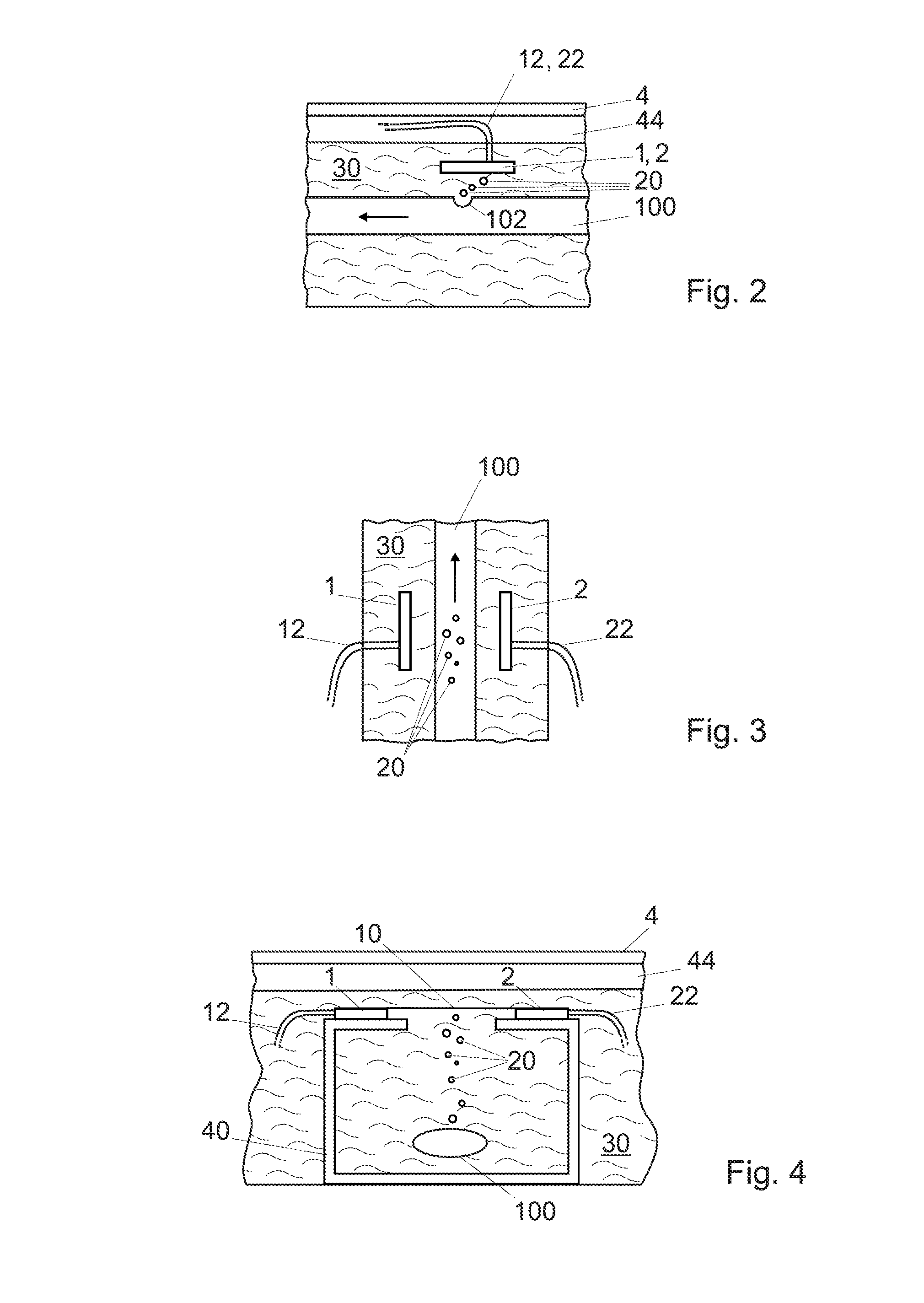

System for manufacturing an irrigation pipe and a device and method for detecting holes in the wall of an irrigation pipe

InactiveUS9022764B2Less expensiveImproving transmission and receptionTurning machine accessoriesWatering devicesEngineeringOptical transmitter

A system for manufacturing an irrigation pipe comprises an extrusion unit, a calibrator unit, a cooling unit for cooling the irrigation pipe in a cooling liquid, and a traction unit for drawing the irrigation pipe in the cooling unit. The cooling unit comprises a device for detecting holes in the wall of the irrigation pipe and arranged for being immersed in the cooling liquid. The device for detecting holes comprises at least one optical transmitter and at least one optical receiver which define an optical barrier. The device is arranged so that the holes in the irrigation pipe located below the device produce gas bubbles which modify the optical barrier.

Owner:MAILLEFER SA MAILLEFER SA

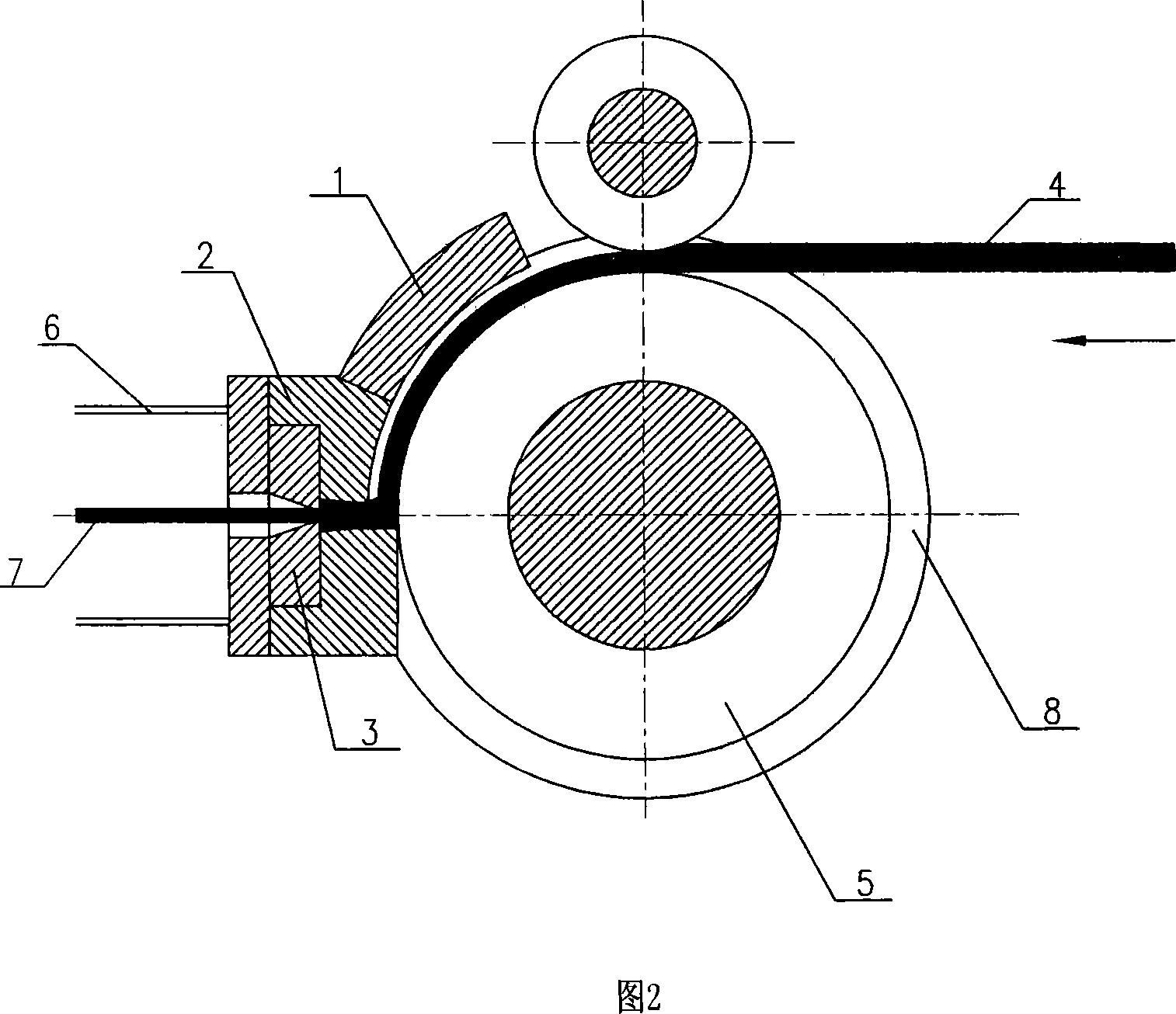

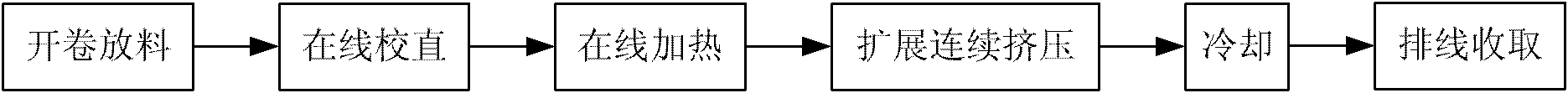

System and method for continuous extrusion production of fine-grain magnesium alloy strip

ActiveCN102688907AShort processIncrease productivityExtrusion control devicesProduction lineLine heating

The invention discloses a system and a method for continuous extrusion production of a fine-grain magnesium alloy strip. The system comprises a decoiling emptying device, an on-line straightening device, an on-line heating device, a continuous extrusion device, a cooling device and a winding displacement collection device. Through control of a temperature of a rod, a good extrusion driving force is produced between the rod and an extrusion wheel groove. Through an expansion mold cavity and a flow-blocking mold, magnesium alloy expansion flowing in a width direction is realized. In order to extrude a plate having larger width, the system adopts a two / three rod feeding-type extrusion mode so that joining and intermetallic welding of multiple rods in a corresponding multi-rod mold cavity are realized. The system and the method have the advantages that a process route is short; production efficiency is high; a grain refinement degree of a product microstructure is high; plate formability is good; and a continuous production line provided by the invention is suitable for industrial application.

Owner:DALIAN JIAOTONG UNIVERSITY

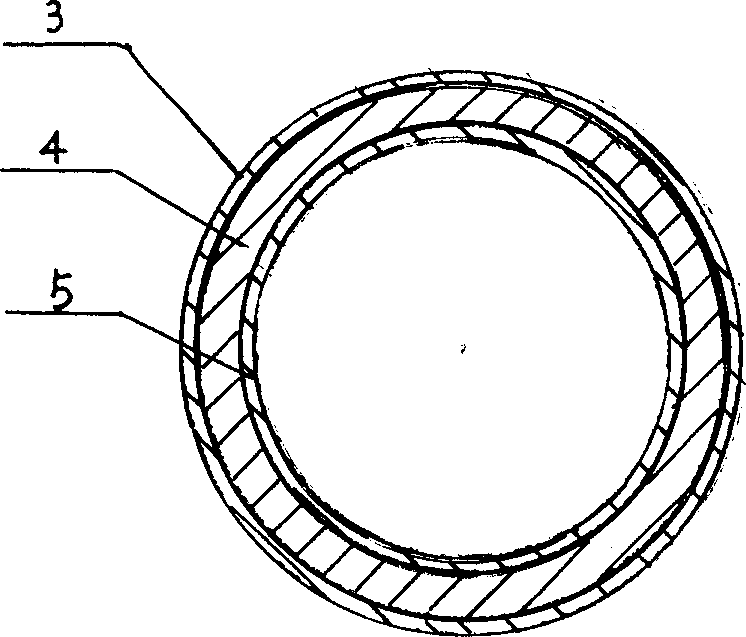

Method for producing metal composite seamless pipe with metallurgical binding

InactiveCN1943979ARefined grain structureImprove performanceExtrusion control devicesFurnace typesMetalInduction heating

The present invention belongs to the field of seamless steel pipe producing technology, and is especially production process of seamless composite metal pipe with metallurgical binding. The production process includes the following steps: heating the composite pipe blank in an induction heating furnace, hot extruding the composite pipe blank in an extruder for different metal layers to deform synchronously and homogeneously and to form the metallurgical binding between the different layers, annealing in an annealing furnace, straightening, end cutting and lengthing, and packing. The seamless composite metal pipe with metallurgical binding has low production cost.

Owner:PANGANG GROUP SICHUAN CHANGCHENG SPECIAL STEEL +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com