Processing method of magnesium alloy compressional deformation and mold

A technology of extrusion deformation and processing method, applied in metal extrusion dies, metal extrusion control equipment, metal extrusion, etc., can solve the problems of high energy consumption of equipment, insufficient ECAE technology, and many processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

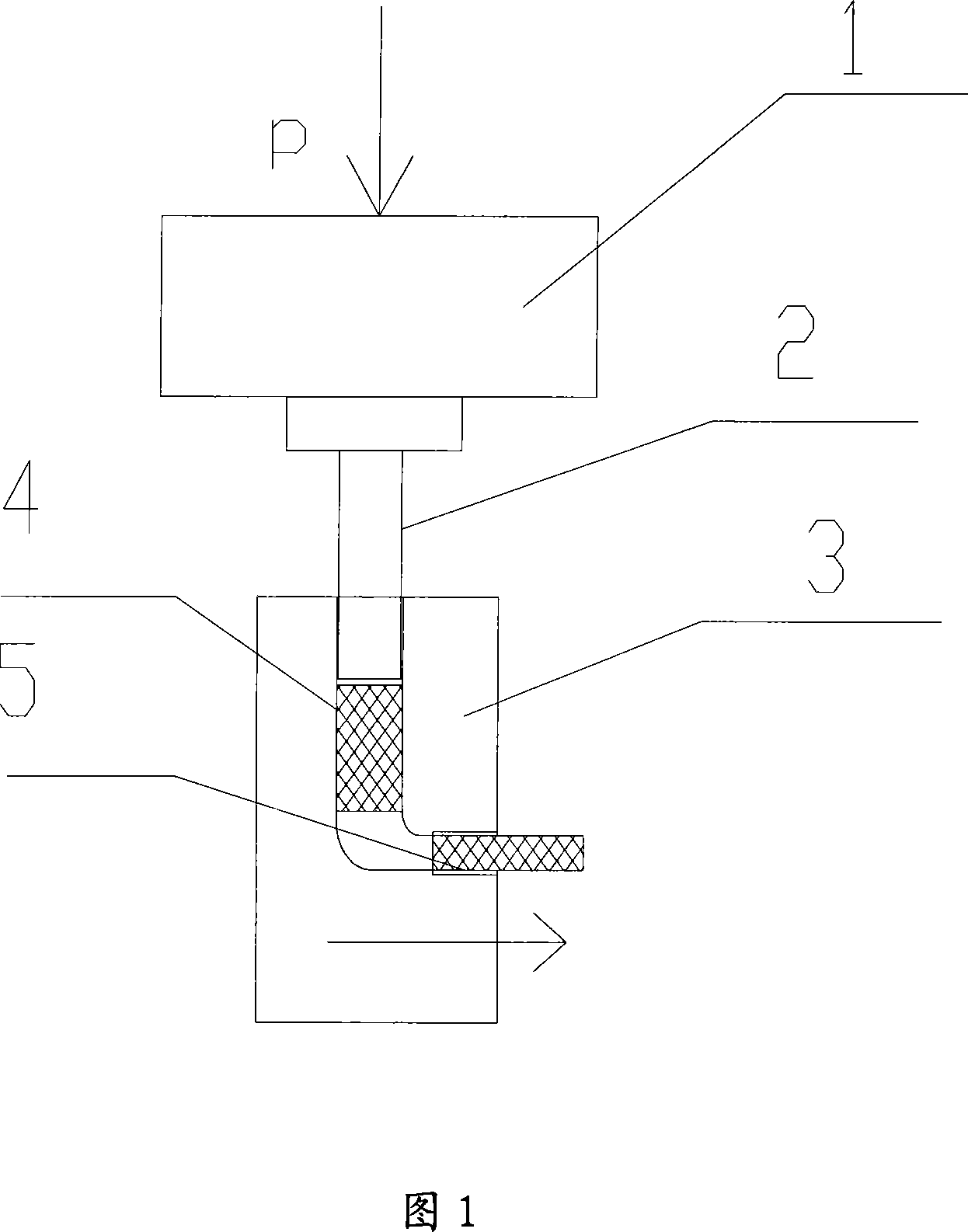

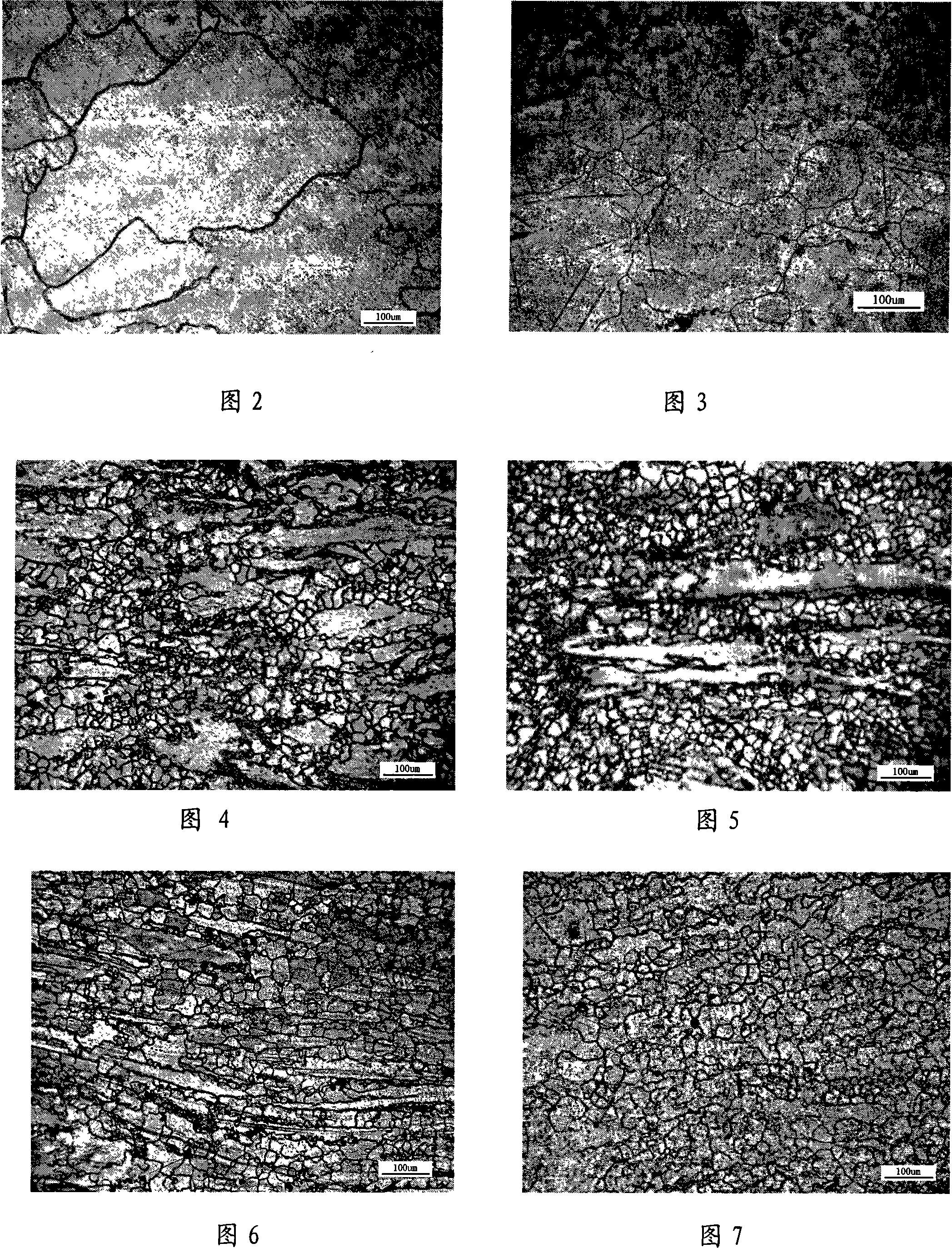

[0036] Referring to FIG. 1 , in this embodiment, an extrusion die formed by unidirectional extrusion, radial flow, and angle-changing angle is used, and AZ31 magnesium alloy rods are extruded and deformed on a vertical extruder. First, heat the magnesium alloy billet to 400°C for 15 hours for homogenization treatment. After homogenization treatment, the coarse dendrites disappear, making the chemical composition and structure of the ingot more uniform (as shown in Figure 3). Before extrusion, heat the mold to 220°C-430°C, evenly apply lubricant in the cavity of the extrusion channel of the mold, the lubricant is a glass lubricant with a particle size of glass powder: 109um-190um, and then fix the mold 3 On the workbench of the vertical extruder, heat the homogenized magnesium alloy billet to 250°C-450°C, the extrusion ratio is 4-60, and put it into the extrusion cavity 4 of the heated mold, The pressure rod 1 of the vertical extruder drives the upper punch 2 to perform constan...

Embodiment 2

[0038] Referring to Fig. 1, the present embodiment adopts the same type of variable channel angle extrusion die as the above embodiment, and the extrusion ratio is 20, that is, the diameter ratio of the transverse variable diameter cavity and the vertical cavity channel is: 1: 4.5, Before extrusion, the billet should be homogenized at 400°C for 15 hours to eliminate various dendrites and intermetallic compounds left during casting. The mold heating temperature range is 180°C, the lubricant used is glass powder with a particle size of 109um, the extrusion temperature is 200°C, the extrusion speed is 2m / min, and the extrusion force ranges from 10 to 12MPa Among them, the specific implementation process is: put the homogenized billet into the extrusion chamber 4, apply pressure from the pressing rod of the extruder to drive the punch 2 to move downward, and squeeze the billet by the punch 2 to make the magnesium The alloy billet flows, extrudes and deforms to the variable-diamete...

Embodiment 3

[0040] Referring to Figure 1, the extrusion ratio is 60, that is, the diameter ratio of the transverse variable diameter cavity channel to the vertical cavity channel is about 1:8, and the extrusion temperature is 250°C. The extrusion speed becomes: 1m / min, the extrusion force range is: 20-25MPa, and other conditions and implementation processes are the same as the previous two embodiments. The lower the temperature, the smaller the extrusion speed. For example, at 150°C, the extrusion speed should be controlled at about 0.5-1m / min.

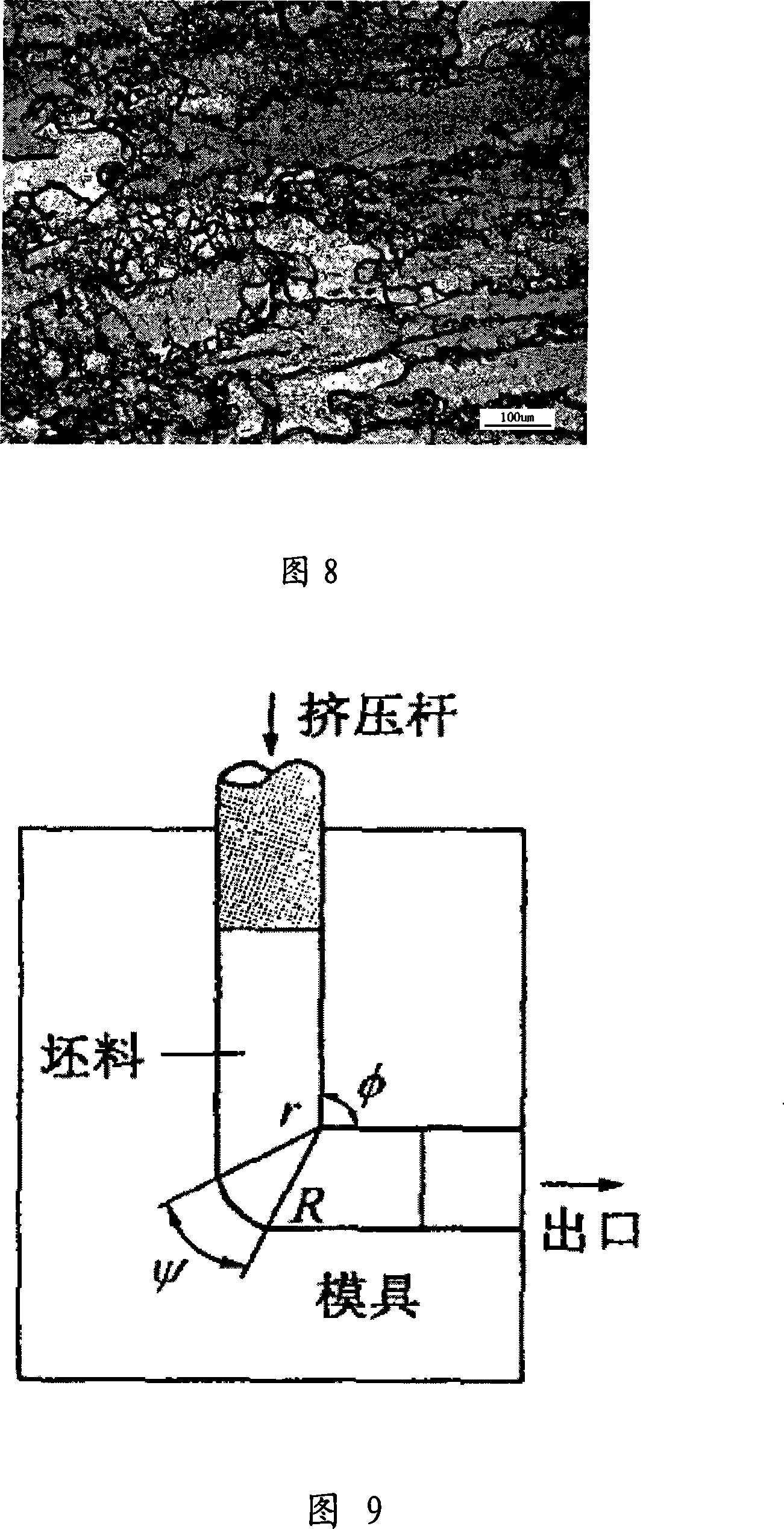

[0041] The corner and fillet radius of the mold cavity of the present invention can be modified, and the fillet radius should be 2 mm to 5 mm within an appropriate range for better results.

[0042] The present invention is not only limited to processing various magnesium alloy bars, but also can extrude special magnesium alloy profiles in various forms by adopting an appropriate mold structure according to the structure of the radial variable-di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com