Patents

Literature

1033 results about "Specific strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The specific strength is a material's strength (force per unit area at failure) divided by its density. It is also known as the strength-to-weight ratio or strength/weight ratio or strength-to-mass ratio. In fiber or textile applications, tenacity is the usual measure of specific strength. The SI unit for specific strength is Pa m³/kg, or N·m/kg, which is dimensionally equivalent to m²/s², though the latter form is rarely used. Specific strength has the same units as specific energy, and is related to the maximum specific energy of rotation that an object can have without flying apart due to centrifugal force.

Wood plastic foamed material and machine-shaping process thereof

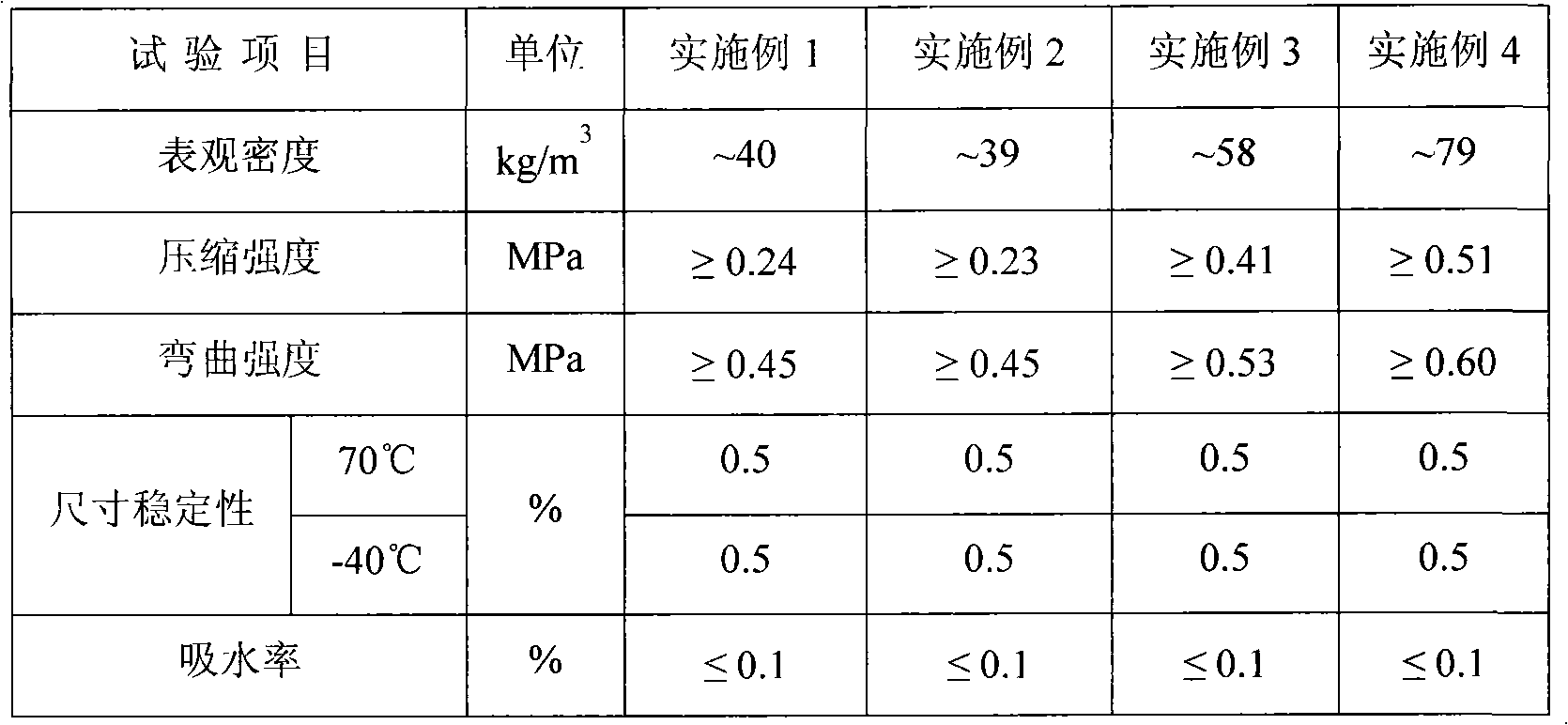

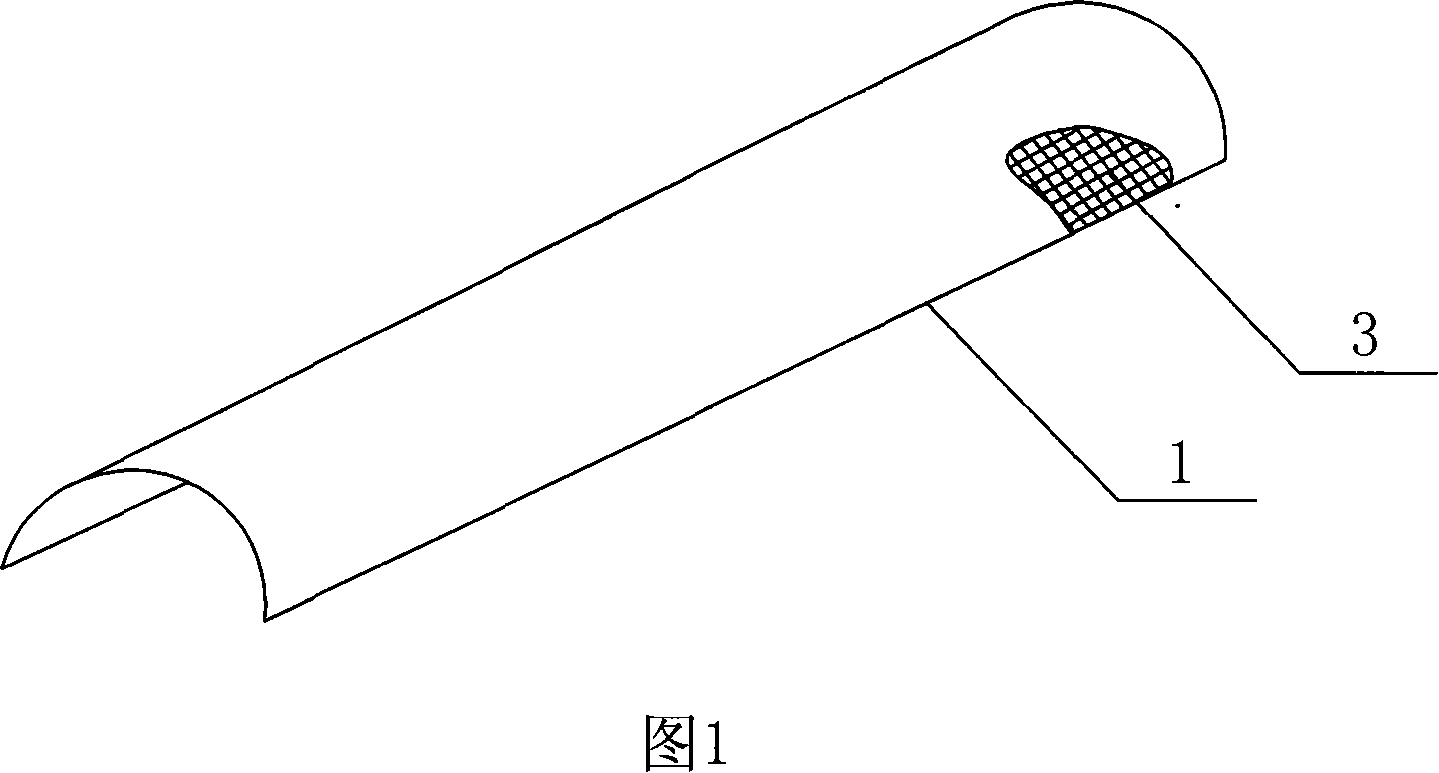

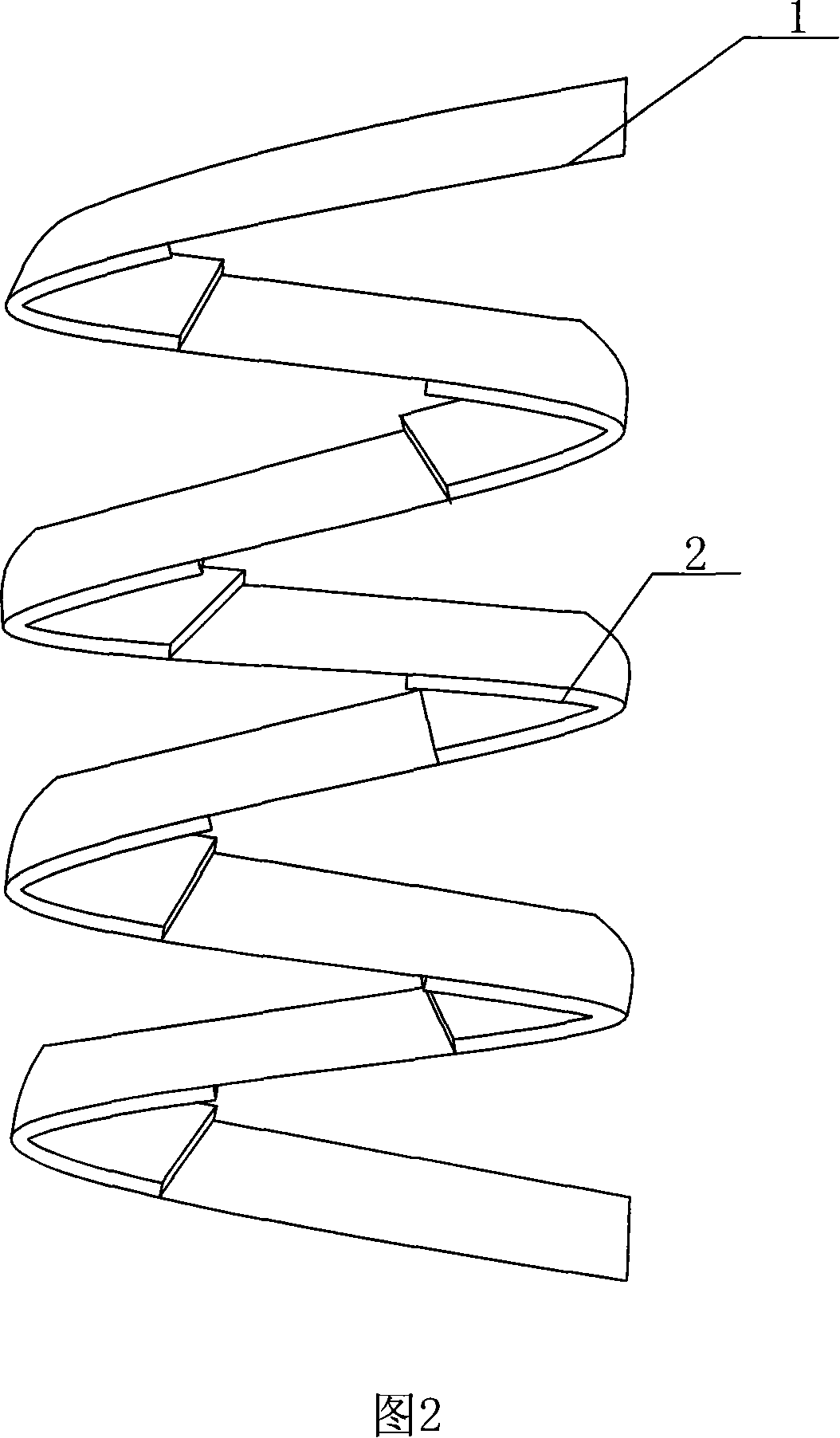

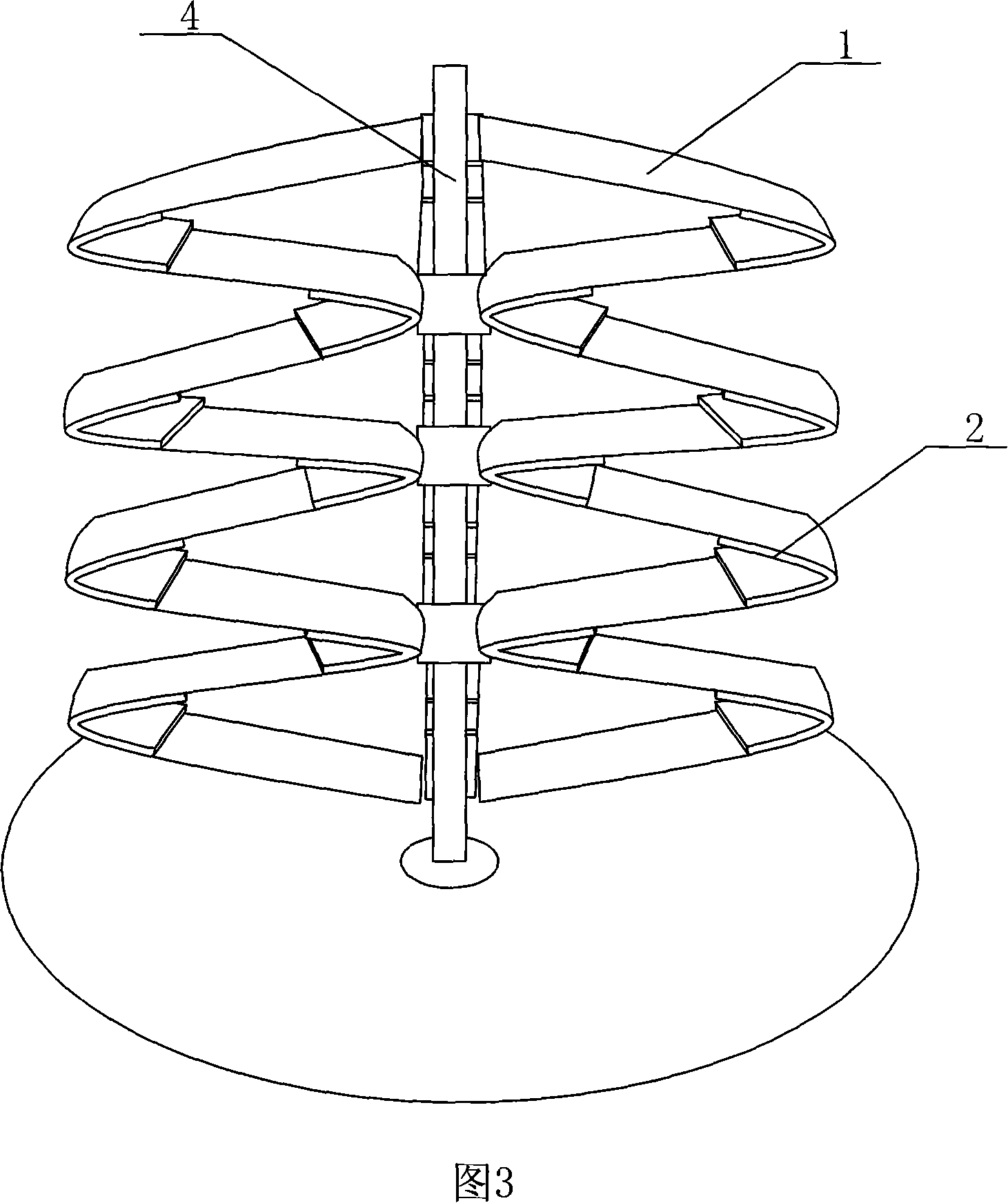

The foamed wood-plastic material is produced with plastic, wood dust, mineral stuffing, assistant, modifier, foaming agent, etc. in certain proportion and through mixing, heating to fusion, foaming and forming in a heat forming apparatus. It has continuous homogeneous pores, and is light, high in specific strength, waterproof, anticorrosive and heat insulating, and may be nailed, sawn and planed, so that it may be used widely in building, transportation, packing, household decoration and daily use articles.

Owner:北京欧尼克新型材料有限公司

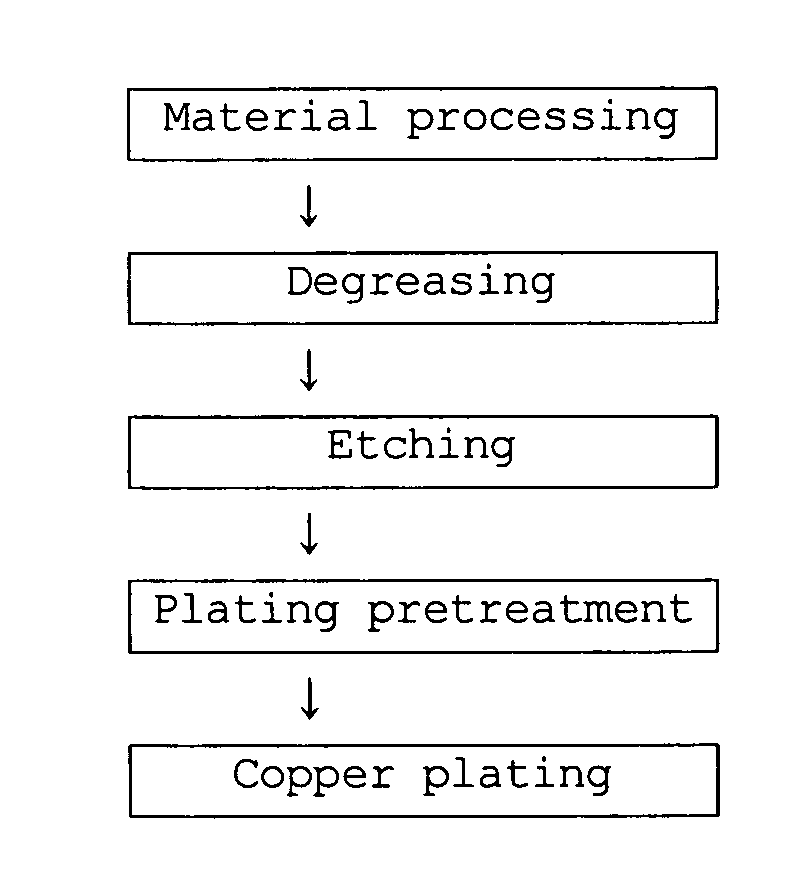

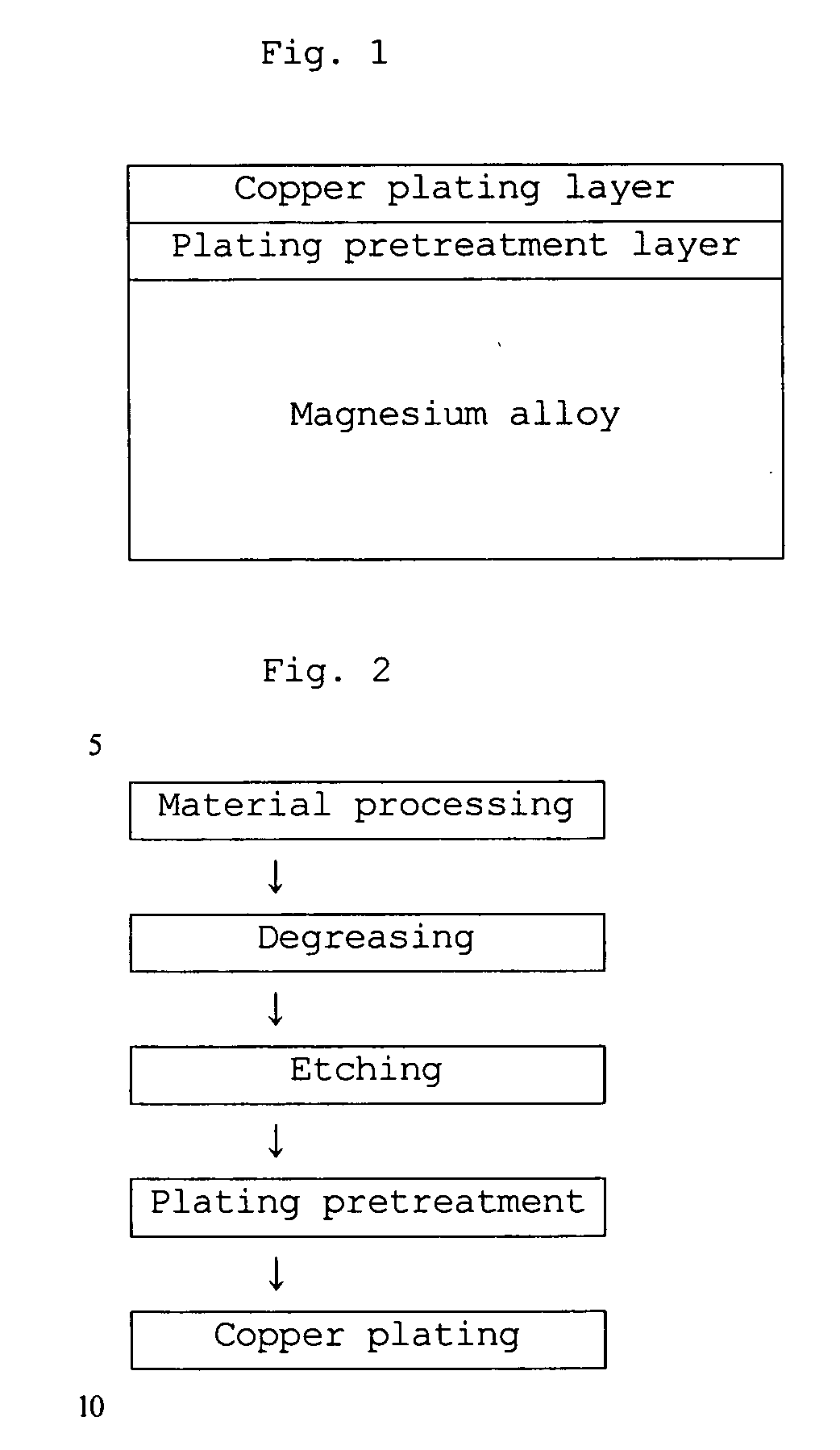

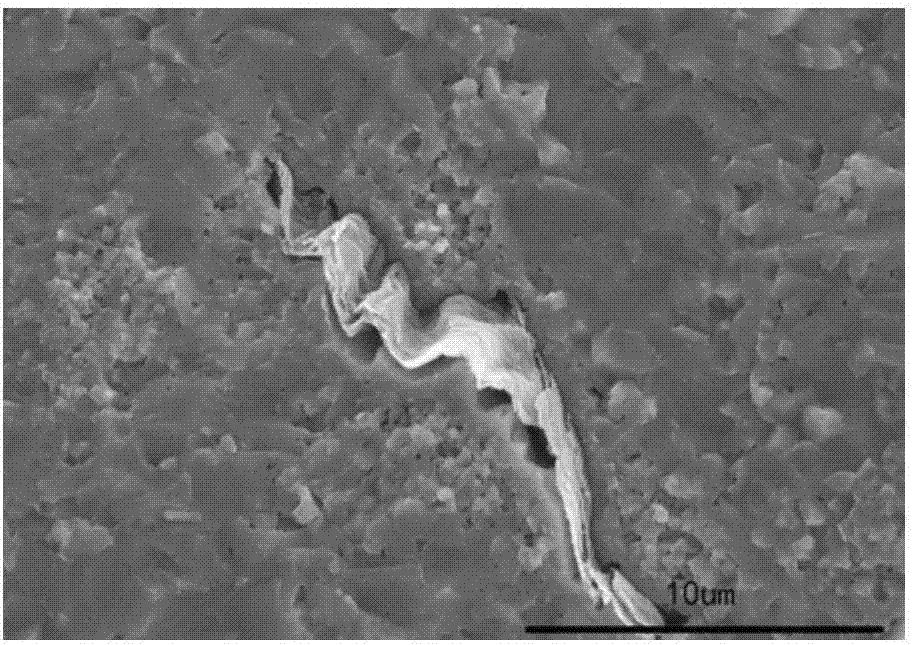

Method of preparing copper plating layer having high adhesion to magnesium alloy using electroplating

InactiveUS20070108060A1Improve adhesionImprove corrosion resistanceSuperimposed coating processCopper platingCurrent distribution

Disclosed is a method of preparing a copper electroplating layer having high adhesion to a magnesium alloy, which is advantageous because the usability of the magnesium alloy, having the highest specific strength among actually usable metals, can be increased through the development of a process of forming a uniform copper plating layer upon electroplating of the magnesium alloy. The method of preparing a copper electroplating layer having high adhesion to a magnesium alloy of this invention is characterized in that the magnesium alloy is pretreated with a plating pretreatment solution to form a film for electroplating, serving as a magnesium alloy pretreatment layer, exhibiting a uniform current distribution, which is then electroplated with copper to form the copper plating layer. According to this invention, through the pretreatment of the magnesium alloy, the adhesion of the copper plating layer to the film for electroplating formed on the magnesium alloy can be increased.

Owner:PANGRIM

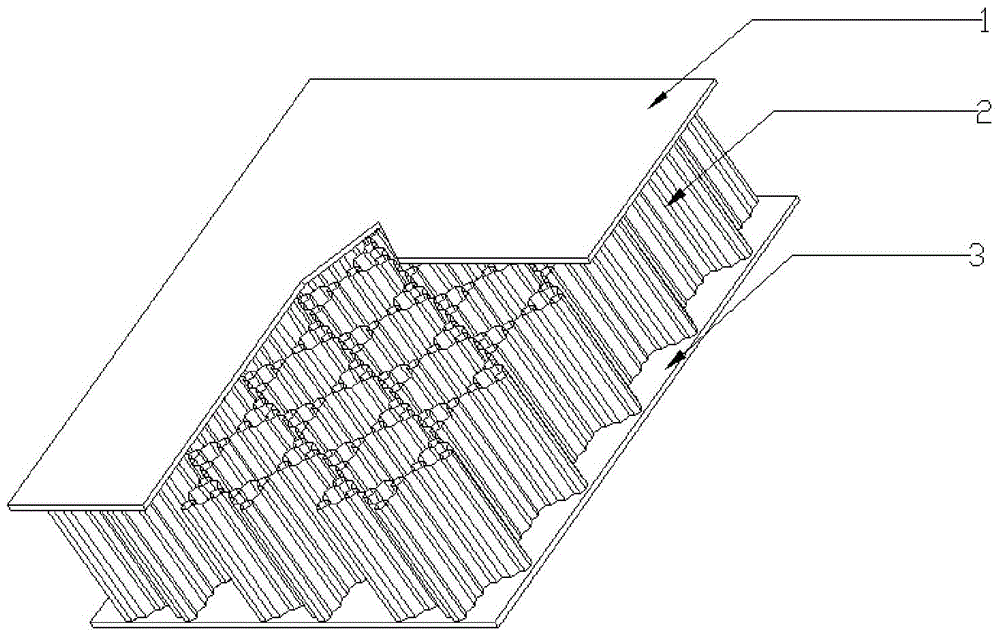

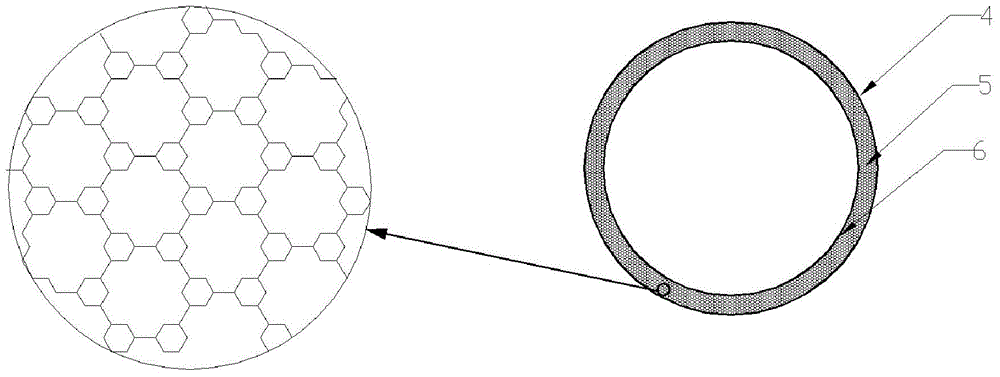

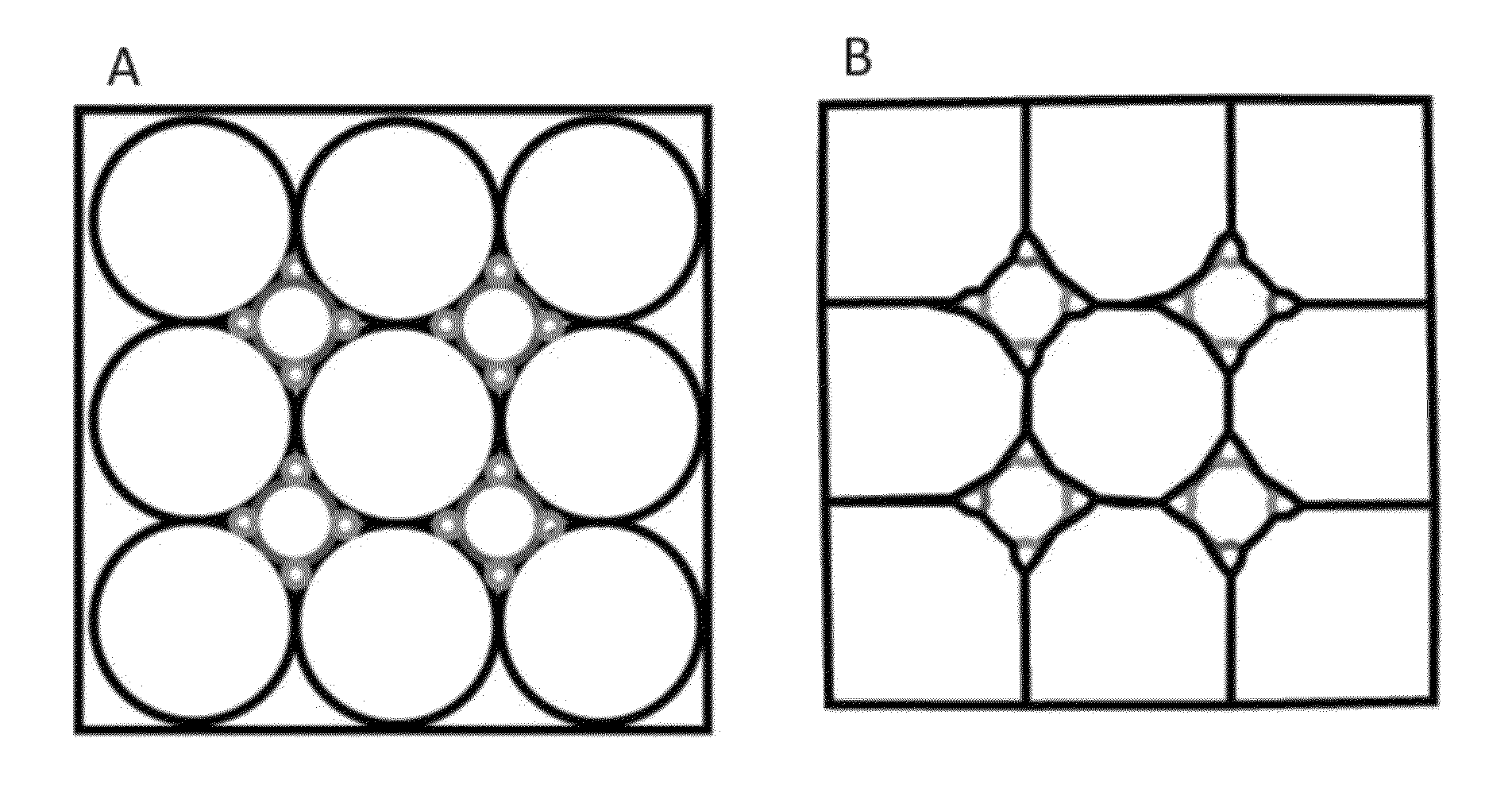

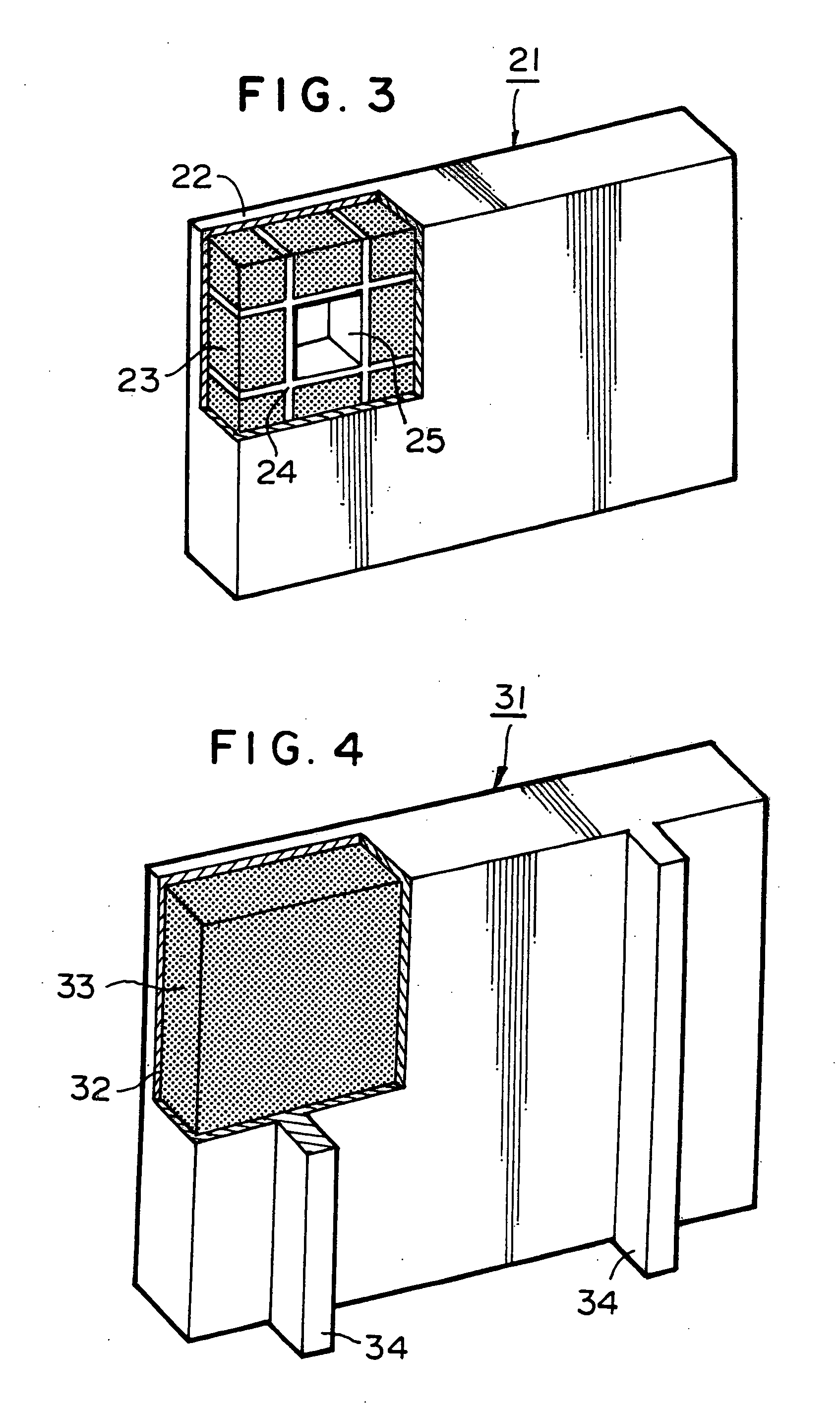

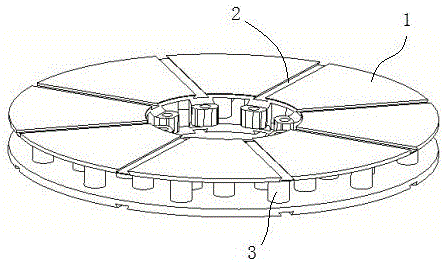

Sandwich structure and honeycomb structure core

The invention provides a sandwich structure, comprising a first interlayer, a second interlayer and a core located between the first interlayer and the second interlayer. The core is in a multilevel honeycomb structure. In the multilevel honeycomb structure, intersections of every two or three sides of a current-level honeycomb structure having cell-element side length L<0> are replaced with polygons with side length L<1> to form a next-level honeycomb structure, wherein L<1> is less than L<0>. The sandwich structure is light in weight, high in specific strength, high in energy absorption efficiency, good in thermal insulation and acoustic insulation, and high in multifunctional comprehensive performance; compared with the traditional honeycomb structures in in-plane (X-Y) and out-plane (Z) directions, the sandwich structure is evidently higher in various performances such as mechanical properties, mechanical strength, energy absorption efficiency and impact resistance; the higher the honeycomb level, the better the performances; thus, the honeycomb structure is of greater advantages in the engineering field than the traditional honeycomb structures.

Owner:HUNAN UNIV

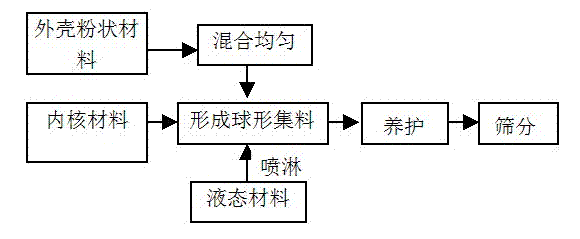

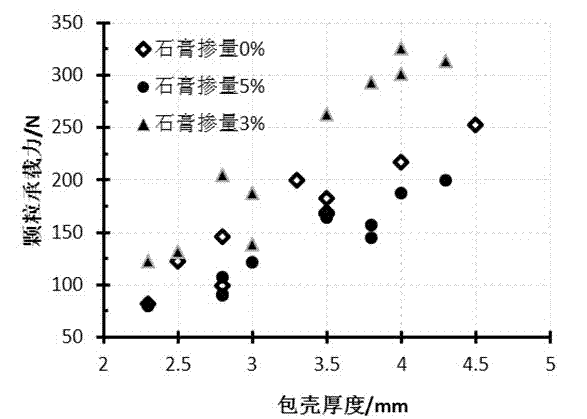

Preparation method of novel core-shell type cement-based high-strength lightweight aggregate

ActiveCN103496866AConducive to the protection of non-renewable resourcesSimple processSolid waste managementSpecific functionPollution

The invention provides a preparation method of novel core-shell type cement-based high-strength lightweight aggregate. A cement-based composite material (cement and an admixture) is used as a main cementing material of a shell material, a pelletizing process is adopted for surrounding a shell outside a lightweight core material, and the high-strength lightweight aggregate can be successfully prepared after curing is performed for a certain period of time. The prepared light aggregate has the advantages of high specific strength, good grain shape and good heat preservation and heat insulation, and can realize certain specific functions, such as heat storage, sound insulation and wave absorption. A production process of the high-strength light aggregate comprises the steps of mixing powder, uniformly stirring, spraying liquid to form pellets, curing (steam curing and moisturizing) and screening. According to the preparation method, the problems of great production energy consumption, complex process and serious pollution of the aggregate produced by a traditional sintering process or the problems of relatively large packing density, insufficiently high strength and insufficiently high product quality of unburned ceramsite products are solved.

Owner:SOUTHEAST UNIV

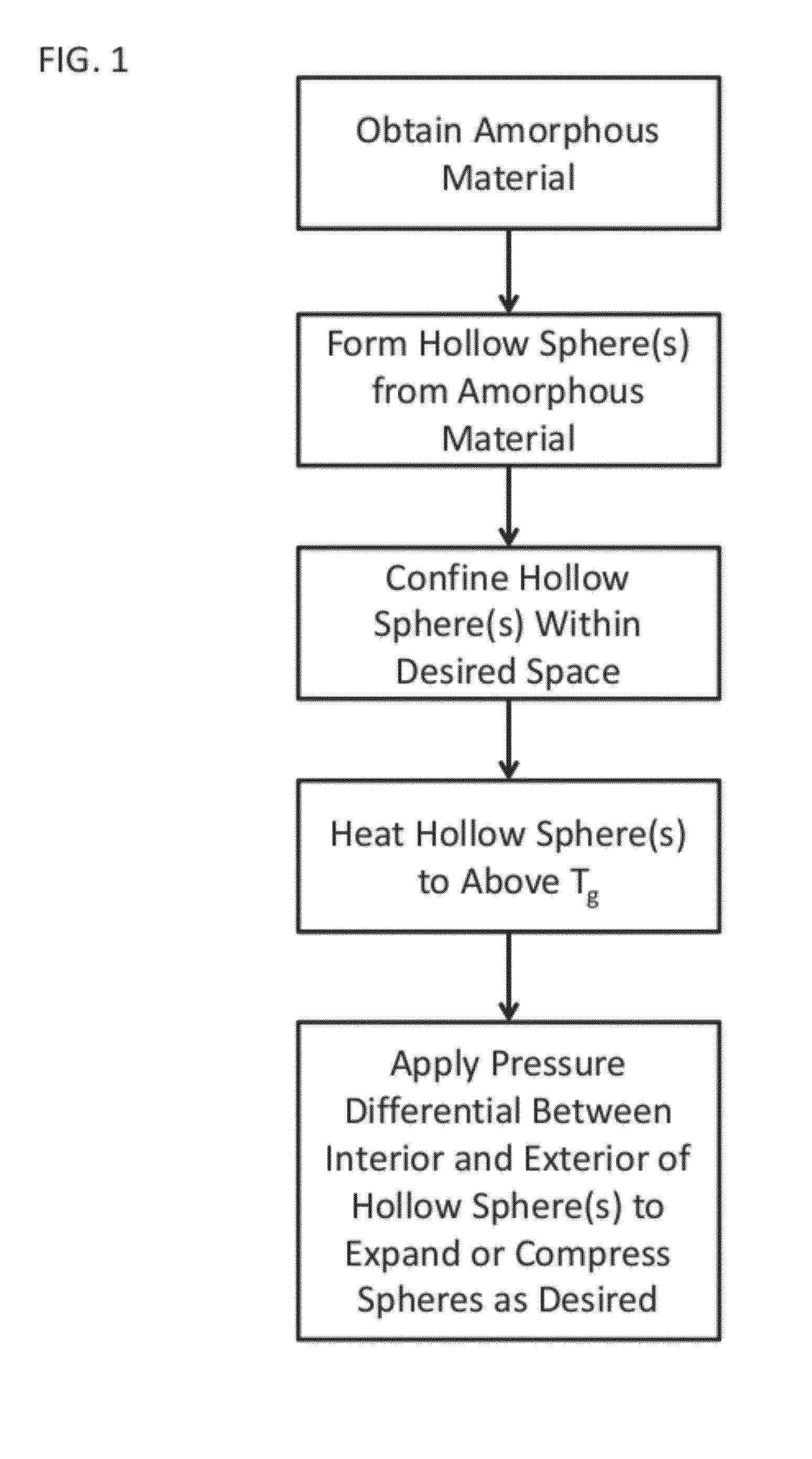

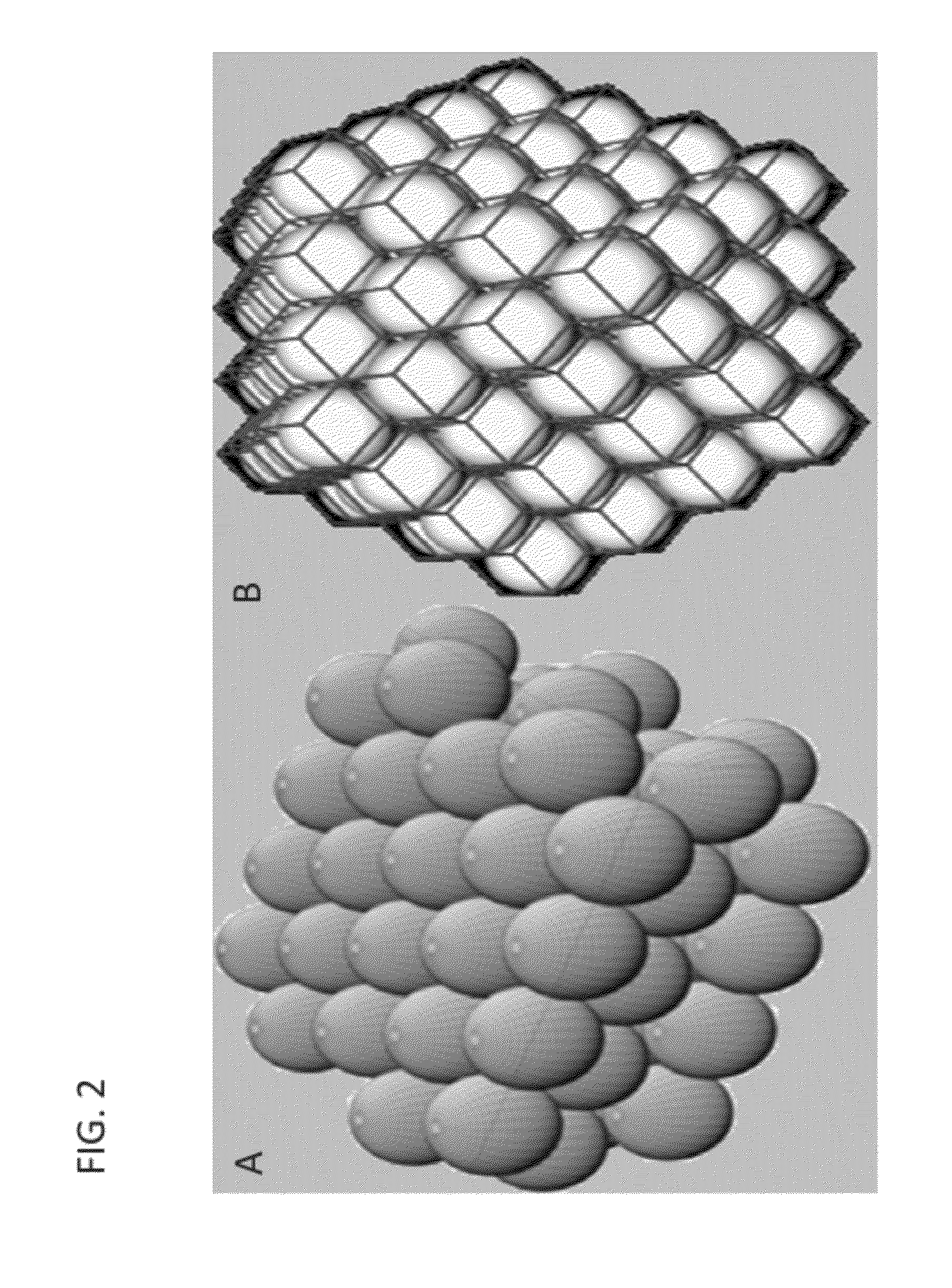

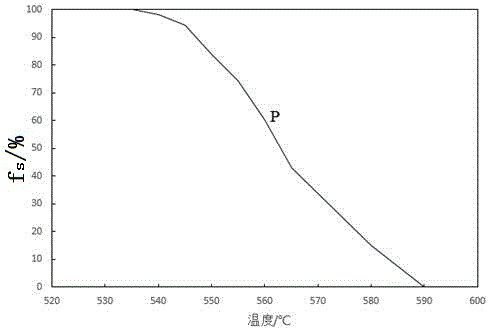

Foams Made of Amorphous Hollow Spheres and Methods of Manufacture Thereof

ActiveUS20120241073A1Minimizes pressure differentialImprove bindingDecorative surface effectsWood working apparatusVitrificationConfined space

Novel cellular solids and foams from amorphous materials with a glass transition temperature (Tg) and methods of forming such materials are provided. In particular, foams are formed by expanding or compressing hollow spheres made of a high strength amorphous material, which is defined as a material having high strength characteristics, but also possessing a glass transition within a confined space. Using such a method, it has been unexpectedly found that it is possible to make cellular structures, including both open and closed cell foams, with customizable properties from materials that have been inaccessible with conventional methods. Moreover, based on calculations high specific strengths and stiffnesses are expected.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

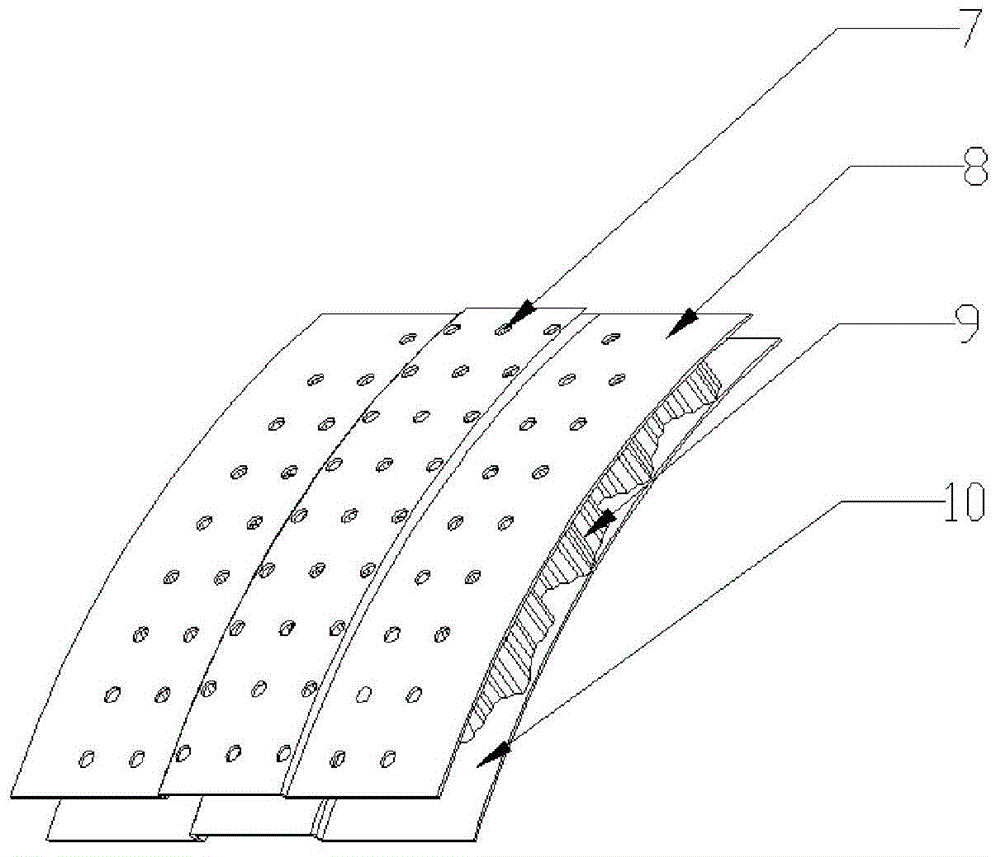

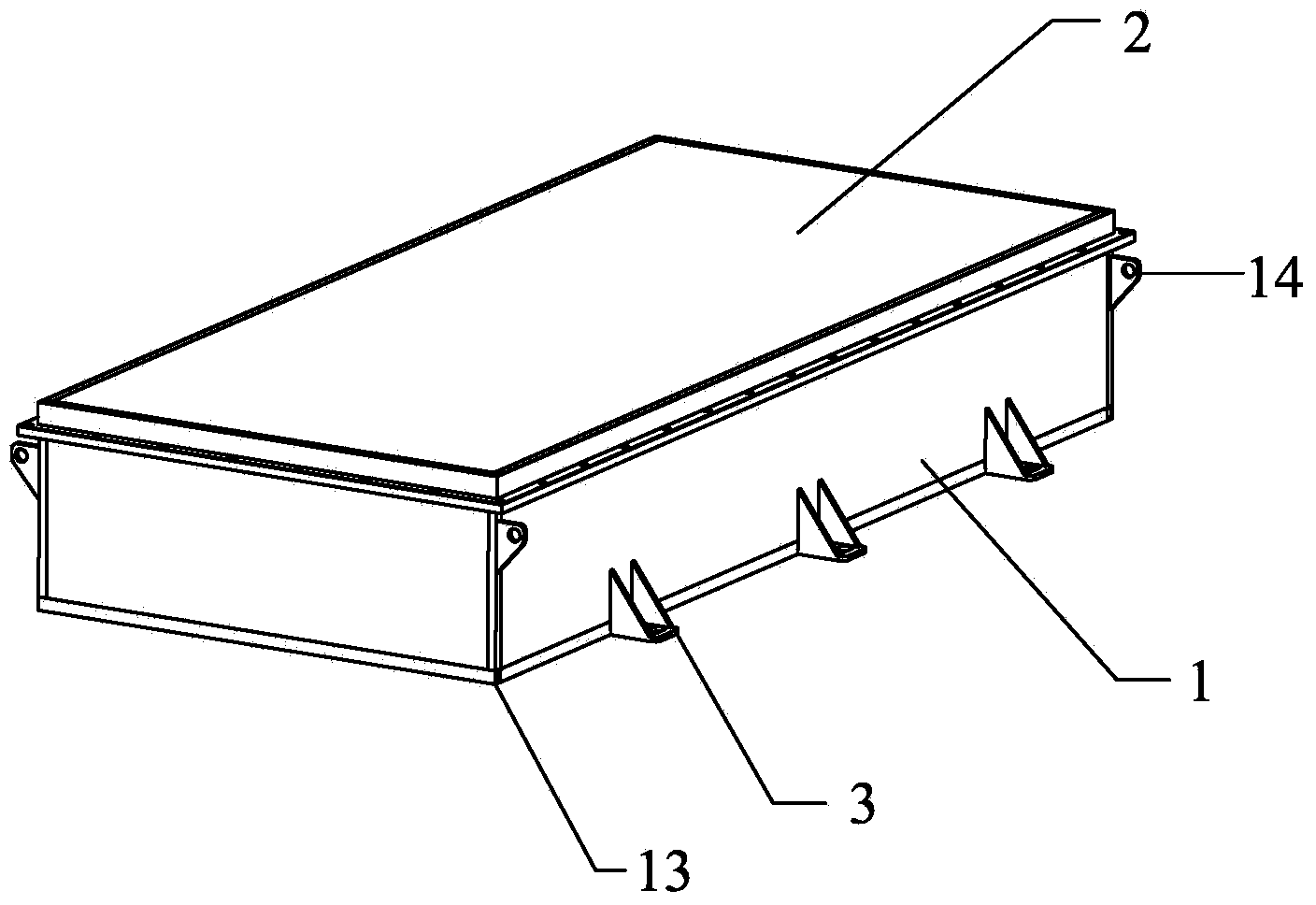

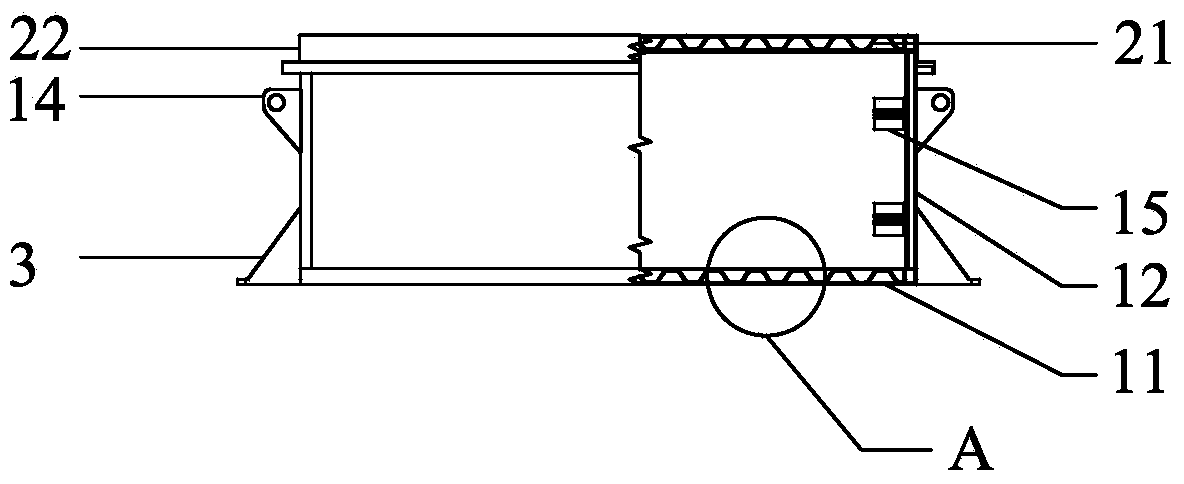

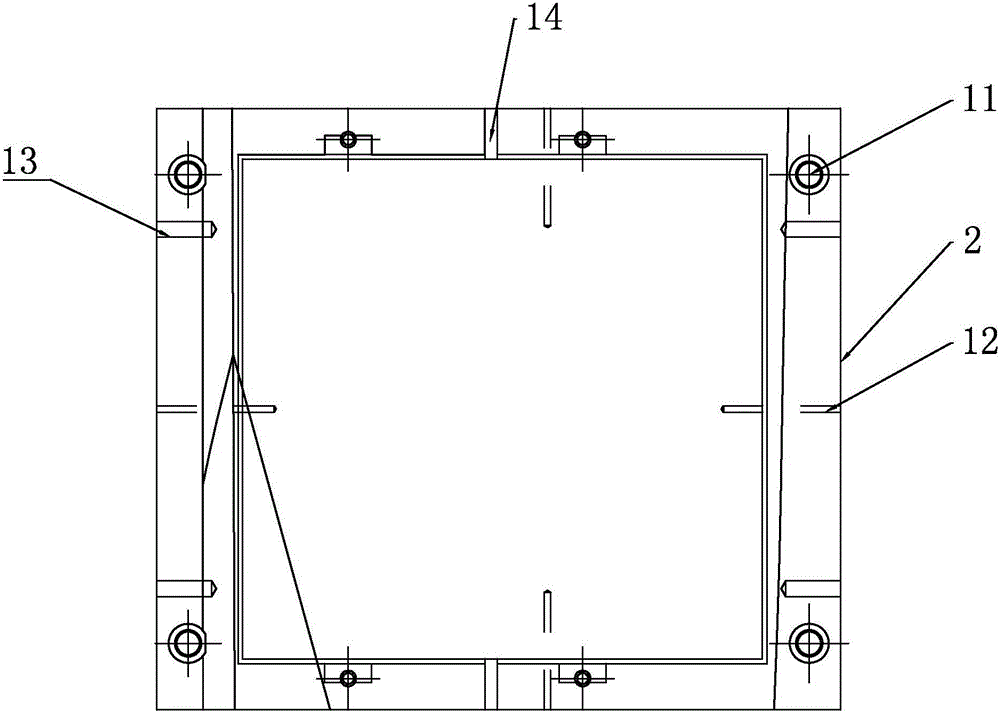

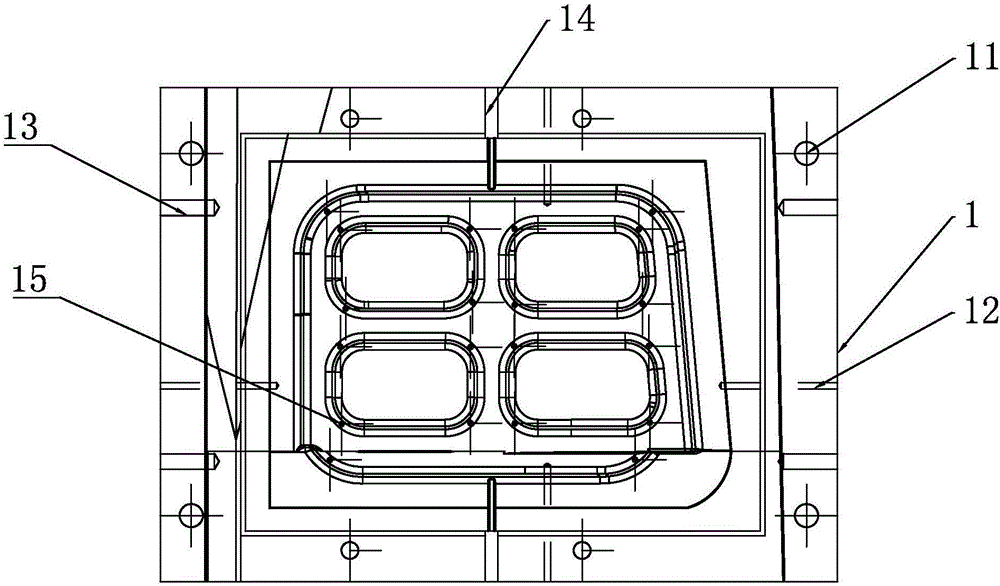

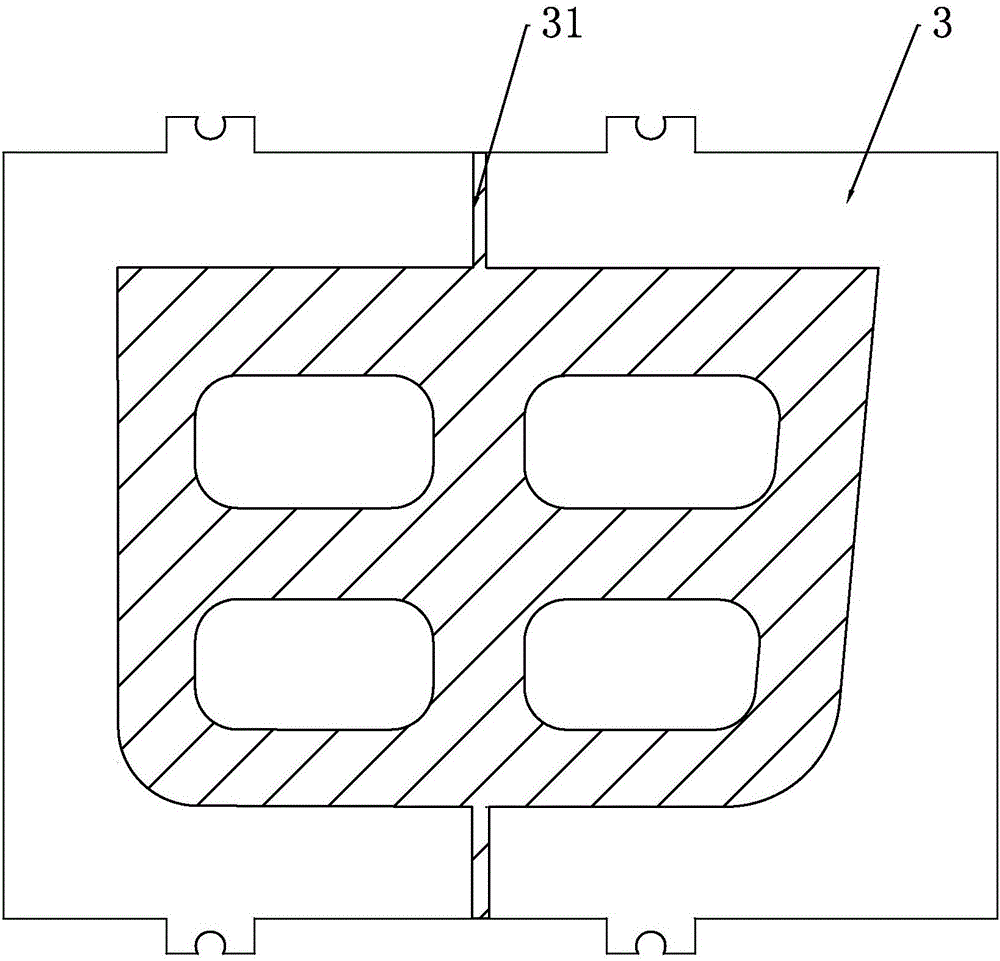

Corrugated sandwich protective structure of battery box of electric vehicle

InactiveCN103730616AUndamagedFree from destructionElectric propulsion mountingVehicle sub-unit featuresAutomotive batteryEngineering

The invention discloses a corrugated sandwich protective structure of a battery box of an electric vehicle. The protective structure comprises a box body and a box cover, wherein the box body is not closed at top, is composed of a baseplate and a baseplate wallboard fixed around the baseplate and is used for accommodating batteries; the box cover comprises a top plate and a top-plate wallboard fixed around the top plate, and the box cover and the box body are buckled so as to form a closed space. The protective structure is characterized in that the baseplate and the baseplate wallboard are respectively made of a corrugated sandwich protective plate. According to the invention, the box body and the box cover are made of the corrugated sandwich protective plates, so that the batteries can be prevented from being damaged; the corrugated sandwich protective structure has the advantages of high specific stiffness, high specific strength, high fatigue life, strong impact resistance and shock resistance, good impacting energy absorption property, light weight, and the like, thereby facilitating the promotion and application of electric vehicles and passenger cars.

Owner:DALIAN UNIV OF TECH

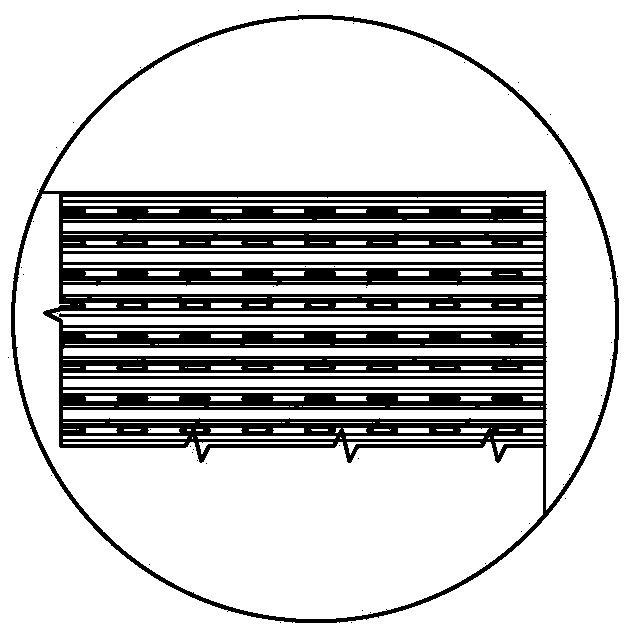

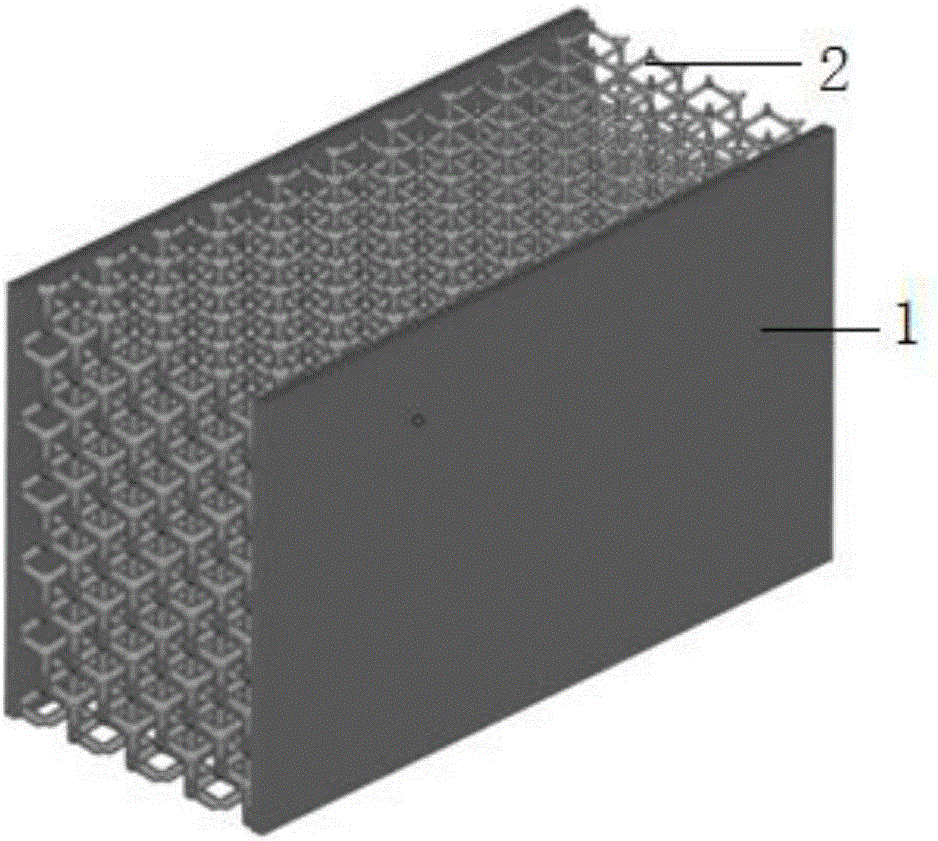

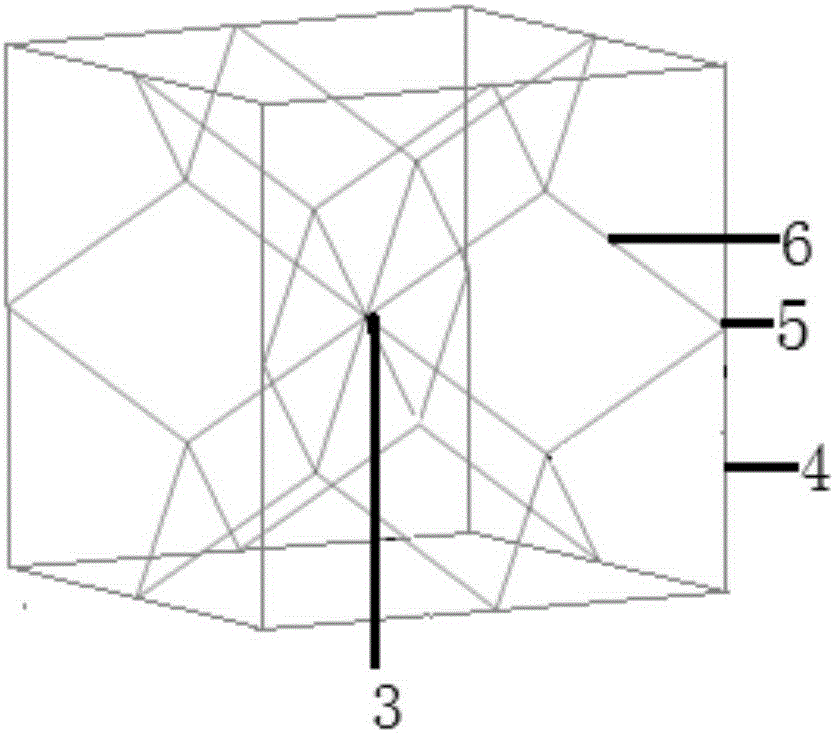

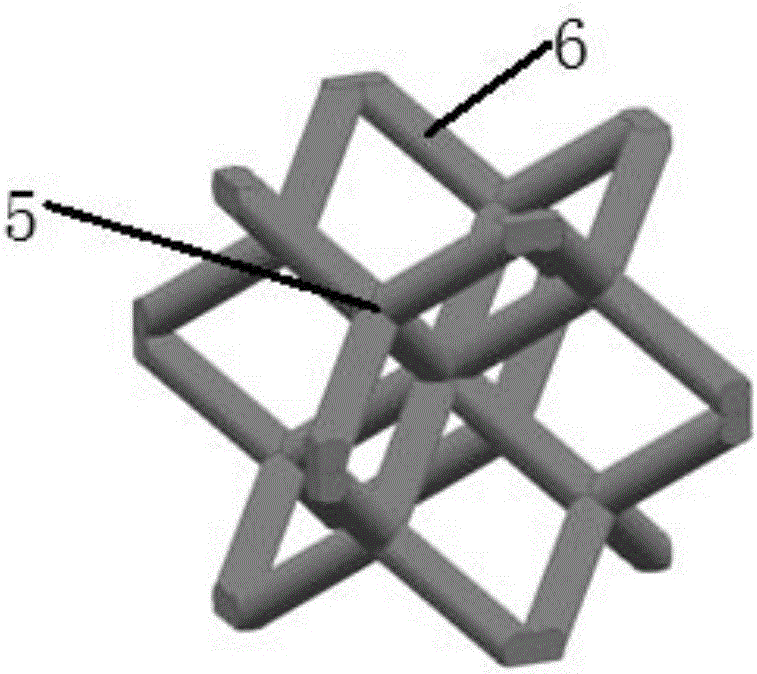

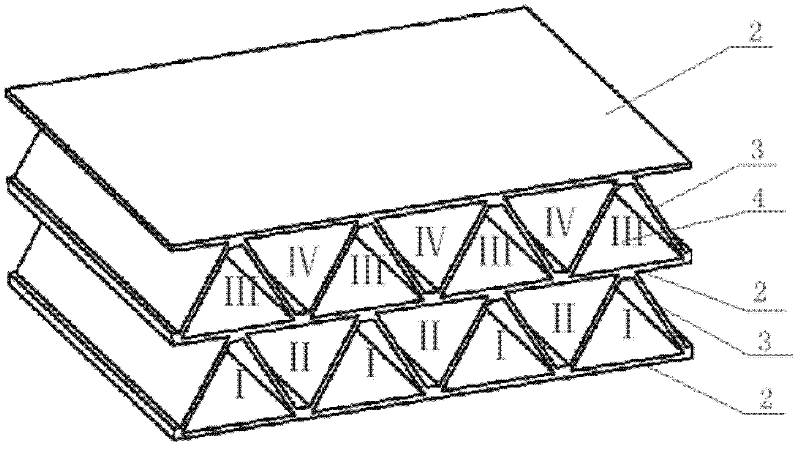

Hollowed-out lattice sandwich layer with gradient functionality and manufacturing method of hollowed-out lattice sandwich layer

ActiveCN106694884ALightweight structureHigh specific strengthAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingSandwich board

The invention discloses a hollowed-out lattice sandwich layer with gradient functionality. The hollowed-out lattice sandwich layer with gradient functionality comprises two cladding plates, wherein a core sandwich layer is arranged between the cladding plates and comprises a plurality of hollowed-out lattice filling units which are connected with one another; and each hollowed-out lattice filling unit consists of a plurality of tiny dense hollowed-out base cells. The hollowed-out sandwich layer is formed by the hollowed-out lattice filling units, and is light in structure weight and high in specific strength, the maximum weight reduction benefit can reach 85% or above, and meanwhile, the hollowed-out lattice sandwich layer has functional benefits such as heat insulation and sound insulation; comprehensive benefits of structure light weight and functionalization are improved, property mismatching of a sandwich board with the single structure in the application field under various working conditions is avoided, and finally, the gradient function is fulfilled; and meanwhile, a selective laser melting technology is adopted, the risk of reduction of strength of a connecting region between a traditional sandwich layer and an outer cladding plate and complicated multi-process flow can be avoided, and therefore, the use value is quite high.

Owner:XIAN BRIGHT ADDTIVE TECH CO LTD

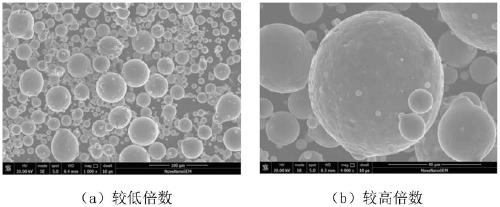

Graphene-reinforced titanium-based composite and preparation method thereof

The invention discloses a graphene-reinforced titanium-based composite and a preparation method thereof. The preparation method comprises the following steps: S1, weighing titanium powder and graphene nanoflake and carrying out ultrasonic dispersion; S2, subjecting the titanium powder and graphene nanoflake having undergone mixing and dispersion to ball milling; S3, drying and grinding mixed powder formed after ball milling; S4, putting the mixed powder obtained in the step S3 into a graphite die and placing the graphite die in a spark plasma sintering system; S5, carrying out spark plasma sintering on a compacted powder material in the graphite die; and S6, after completion of sintering, cooling a sintered sample to room temperature in a furnace and taking out the sample. The preparation method prepares the graphene-reinforced titanium-based composite with lightweight and high strength and toughness; and according to the method, ultrasonic dispersion and ball milling technologies are employed for powder mixing, then the composite is prepared from the uniformly mixed powder through spark plasma sintering technology, so the advanced composite with lightweight and high specific strength is obtained.

Owner:SUZHOU UNIV

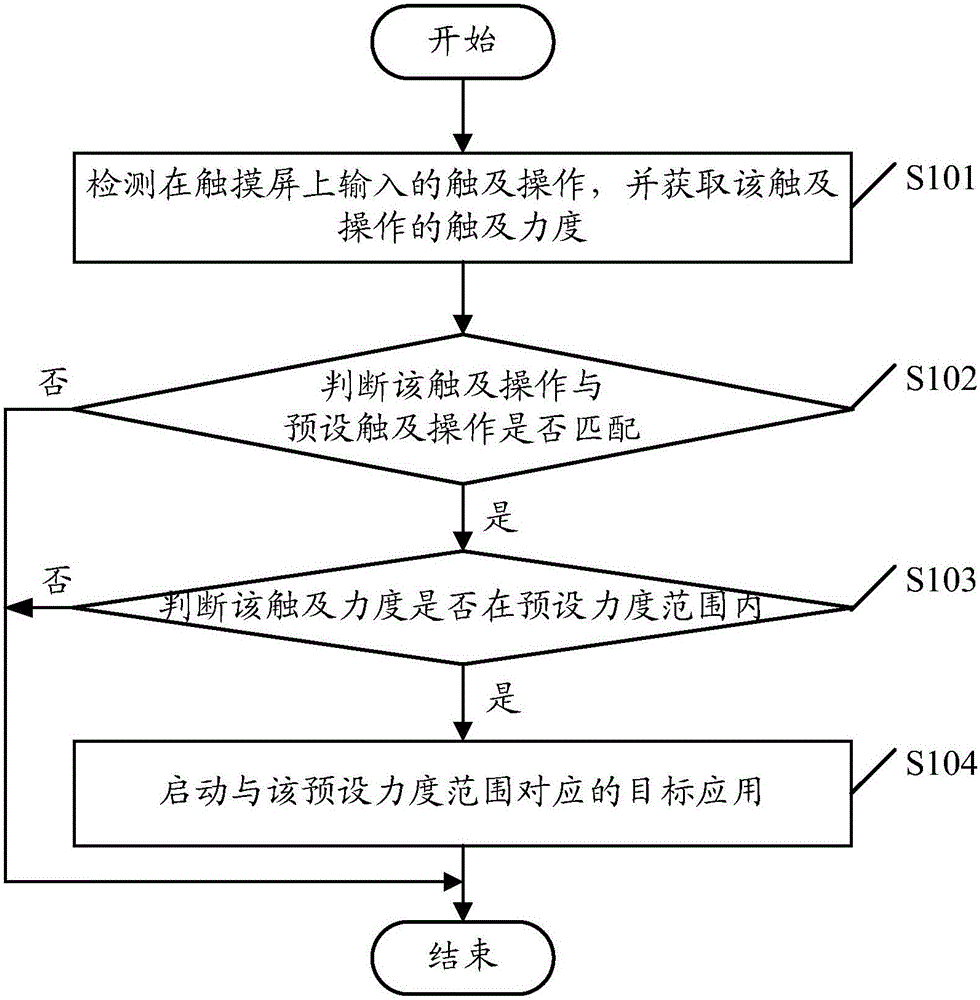

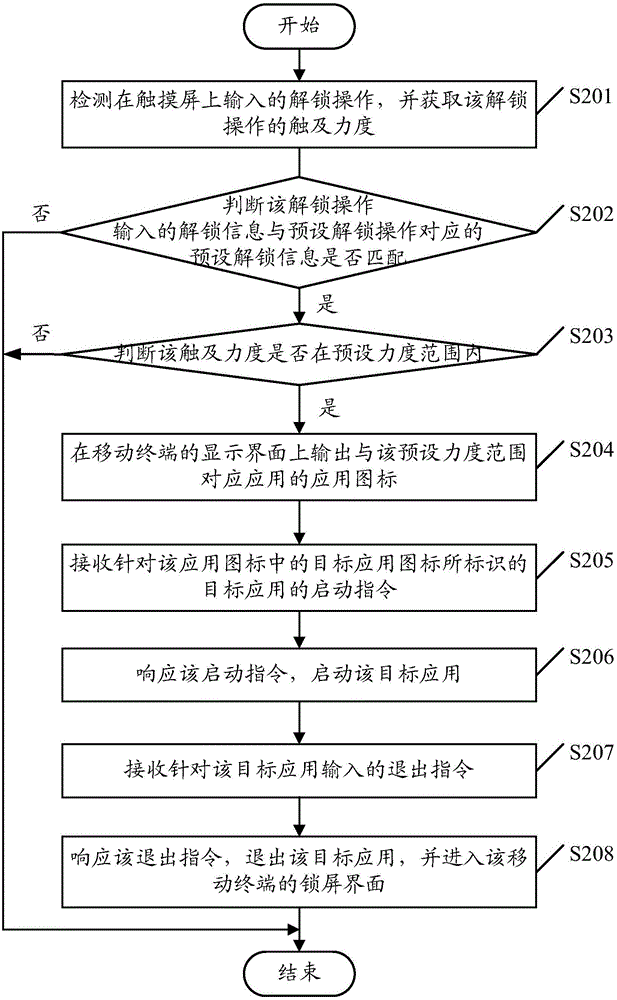

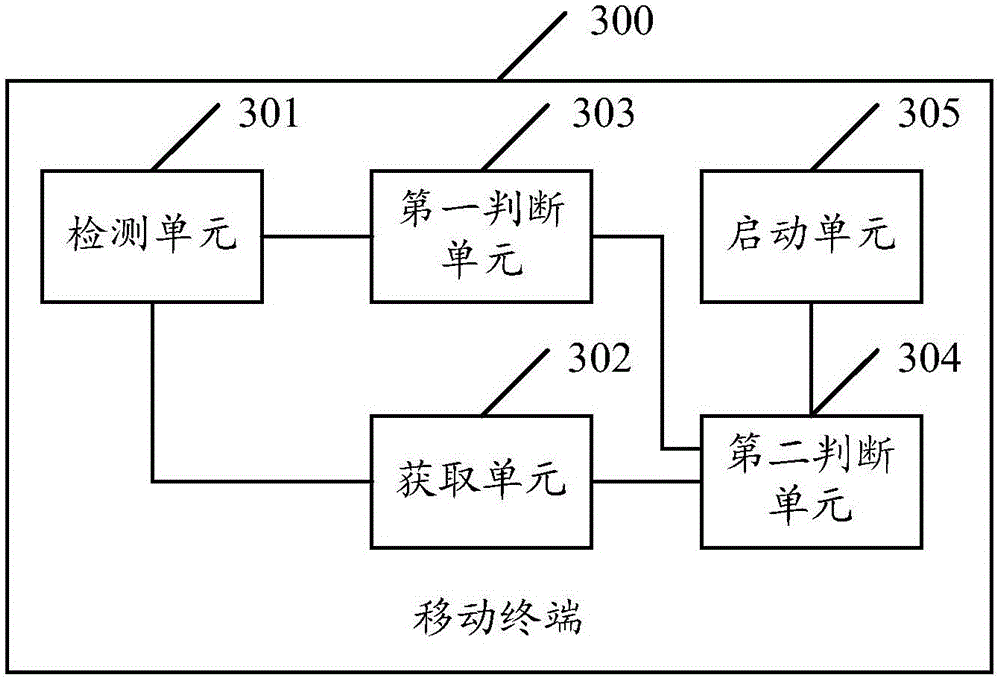

Application starting method and mobile terminal

InactiveCN105159531AImprove application startup efficiencyAvoid misuseProgram loading/initiatingInput/output processes for data processingUser inputComputer terminal

The embodiment of the invention relates to the field of the electronic technology, and discloses an application starting method and a mobile terminal. The method comprises the following steps: a mobile terminal can detect a touch operation input on the touch screen of the mobile terminal, and obtain the touch strength of the touch operation; and when the touch operation is judged to be consistent with a preset touch operation, judging whether the touch strength of the touch operation is within a preset strength range or not, and starting a target application corresponding to the preset strength range if the touch strength of the touch operation is within the preset strength range. Through the embodiment of the invention, when a user inputs the touch operation used for starting the target application on the touch screen, the mobile terminal can start the target application only when the touch strength of the touch operation achieves a specific strength range, so that the application starting efficiency of the mobile terminal can be improved, and the misoperation of the user can be avoided so as to improve user experience.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

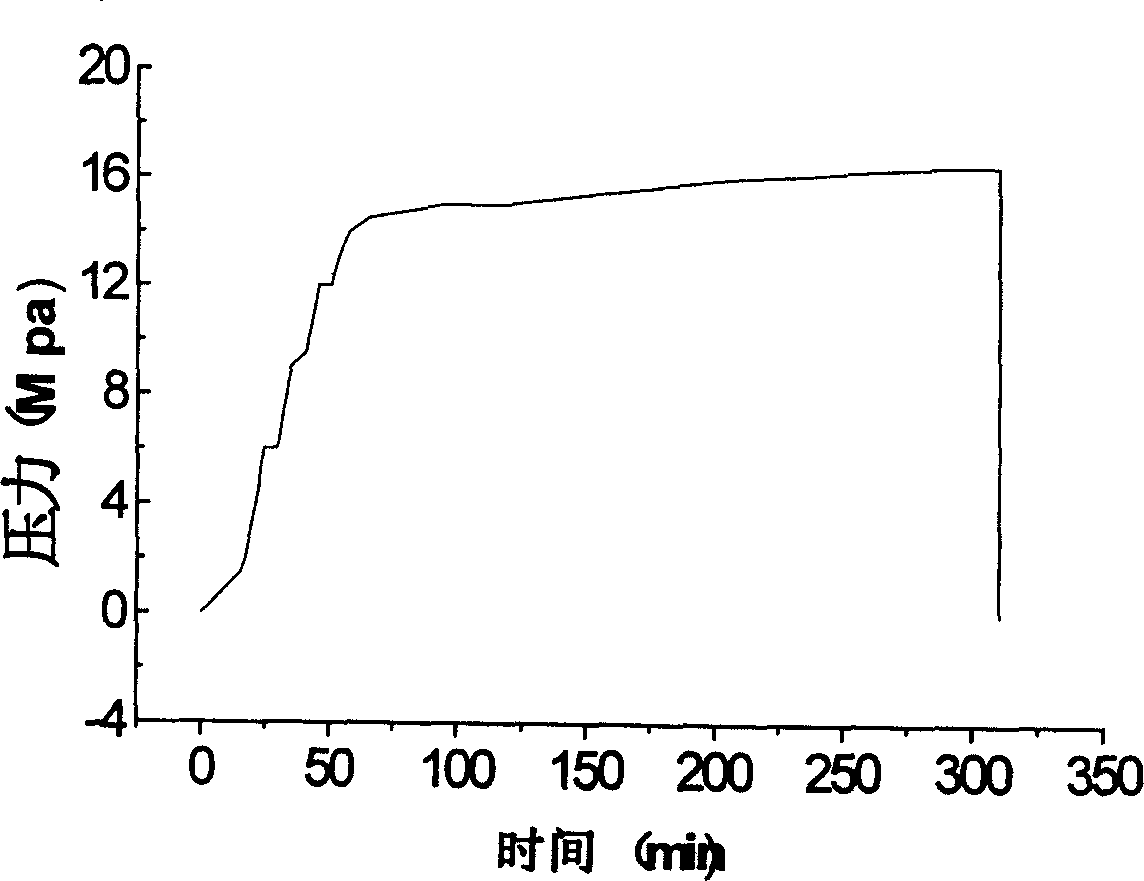

Superplastic forming/diffusion bonding forming method for heat-resistant titanium alloy envelope

ActiveCN106271439AHigh strengthIncrease stiffnessWelding apparatusTitanium alloyUltimate tensile strength

The invention belongs to the technical field of metal plastic processing, and aims at providing a superplastic forming / diffusion bonding forming method for a heat-resistant titanium alloy envelope with high material utilization ratio, high dimension control precision and high product performance. As a mould is adopted to control the appearance and dimension of a workpiece, the forming of a titanium alloy workpiece provided with a complex profile is completed, the production process of the heat-resistant envelope workpiece is shortened, and production cost is lowered; as the process of diffusion bonding followed by superplastic forming is adopted, the diffusion bonding is realized at the contact part of an inner envelope and an outer envelope, and the superplastic forming is realized at a separated part, the once-formed heat-resistant envelope with the complex profile and a hollow structure has the advantages of greatly improved structural integrity of a component, enhanced specific strength and specific stiffness of the component and increased welding rate of the diffusion bonding; the processed workpiece has the advantages of high dimension accuracy, high integral performance, light weight and the like; and the method disclosed by the invention has the advantages of shortened processing period, high material utilization ratio and lowered production cost.

Owner:北京普惠三航科技有限公司

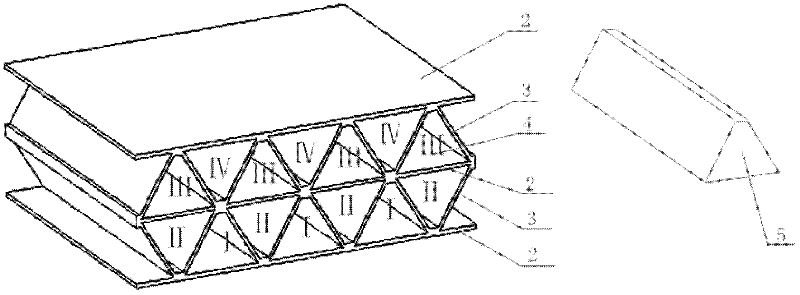

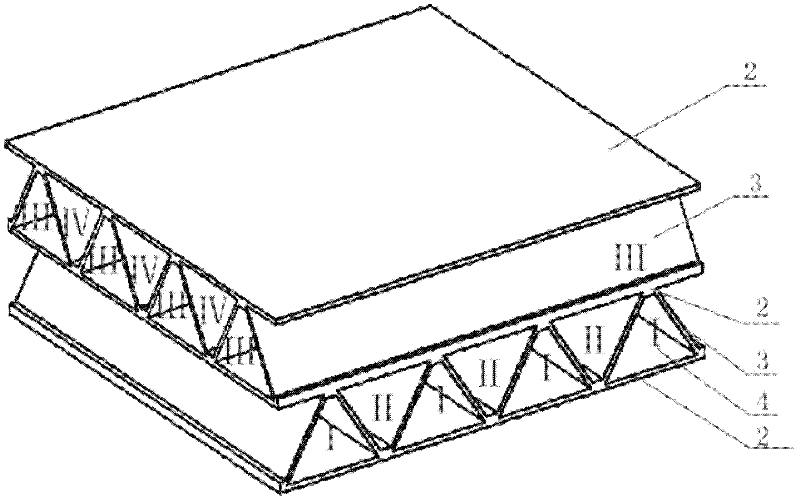

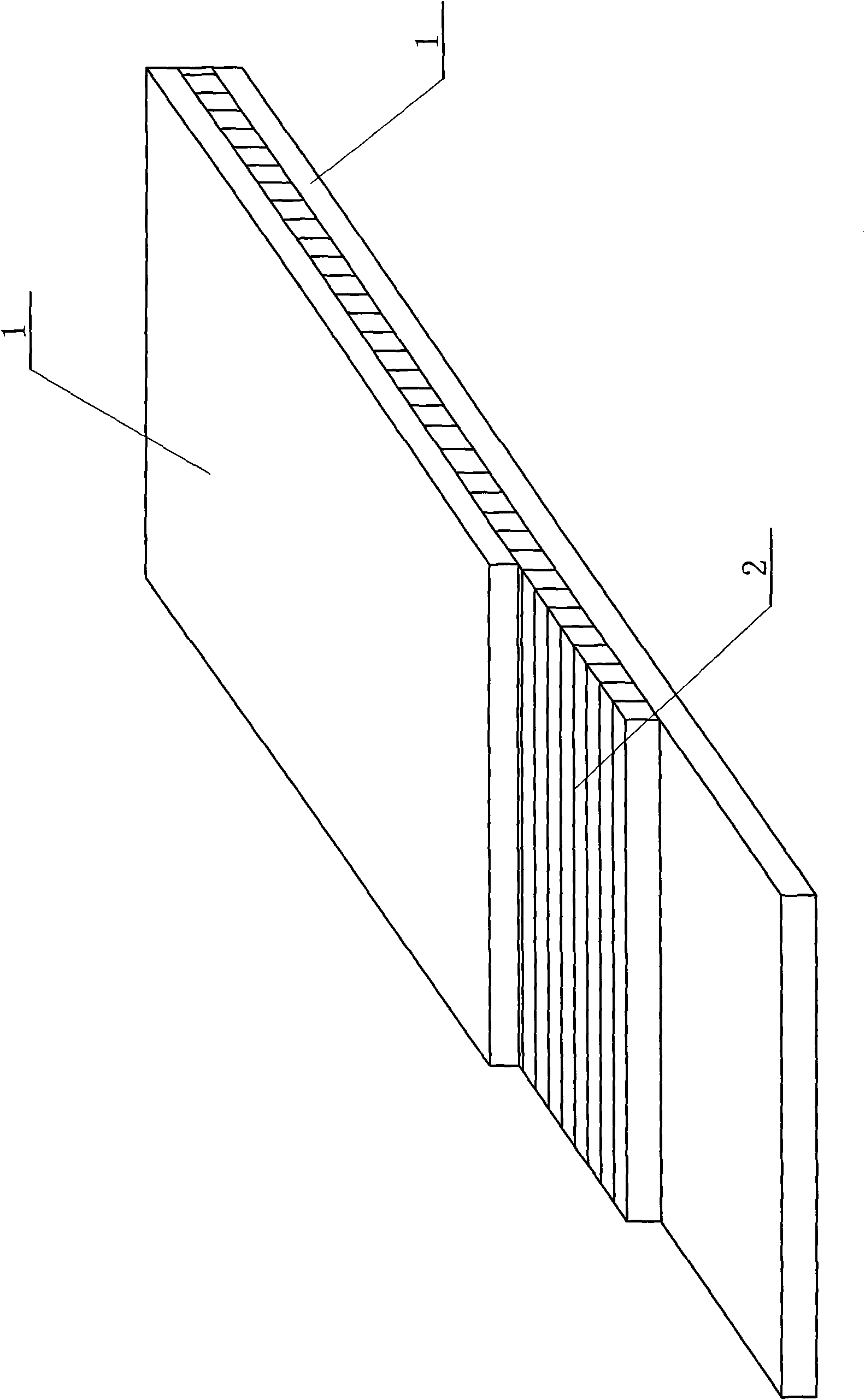

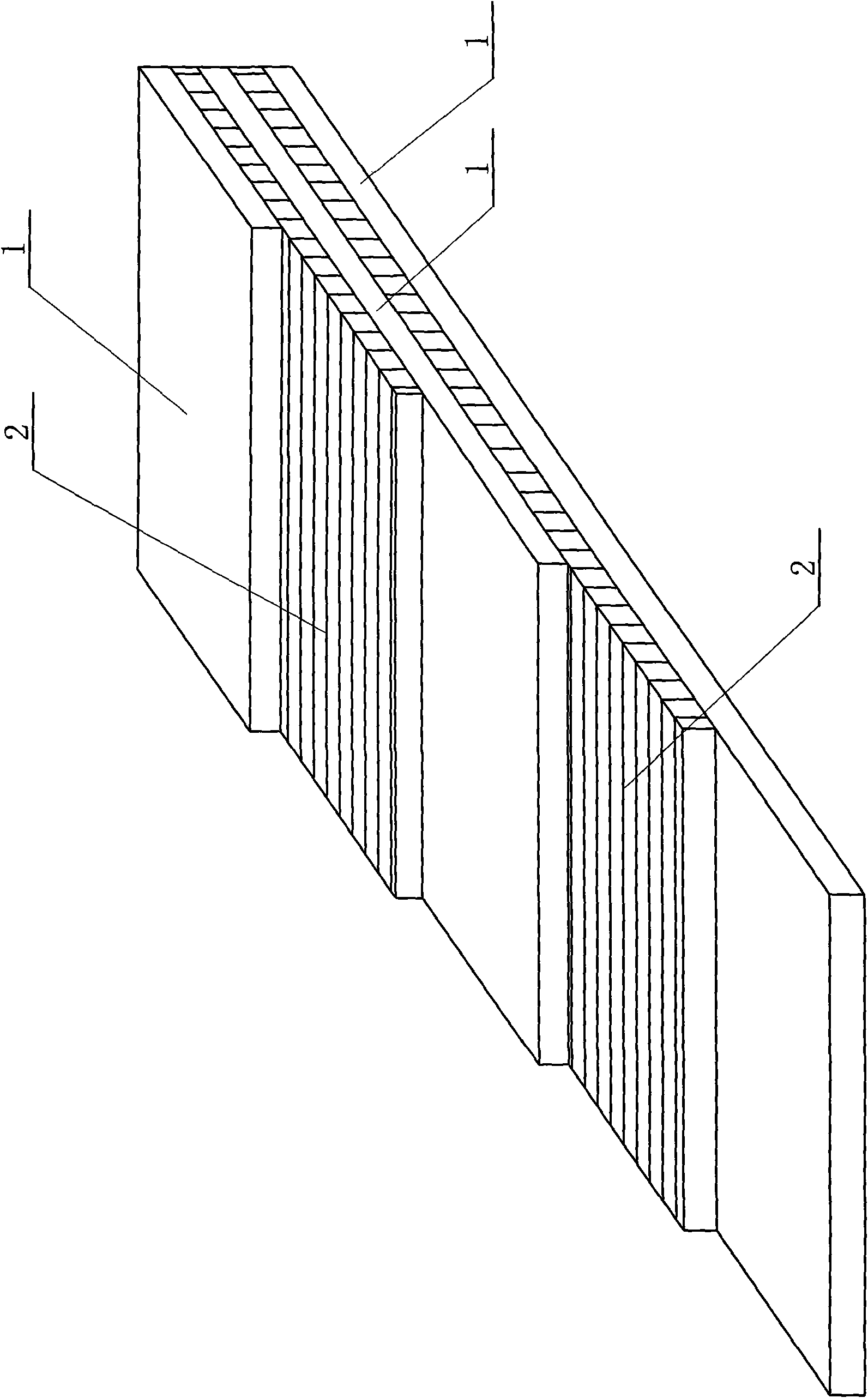

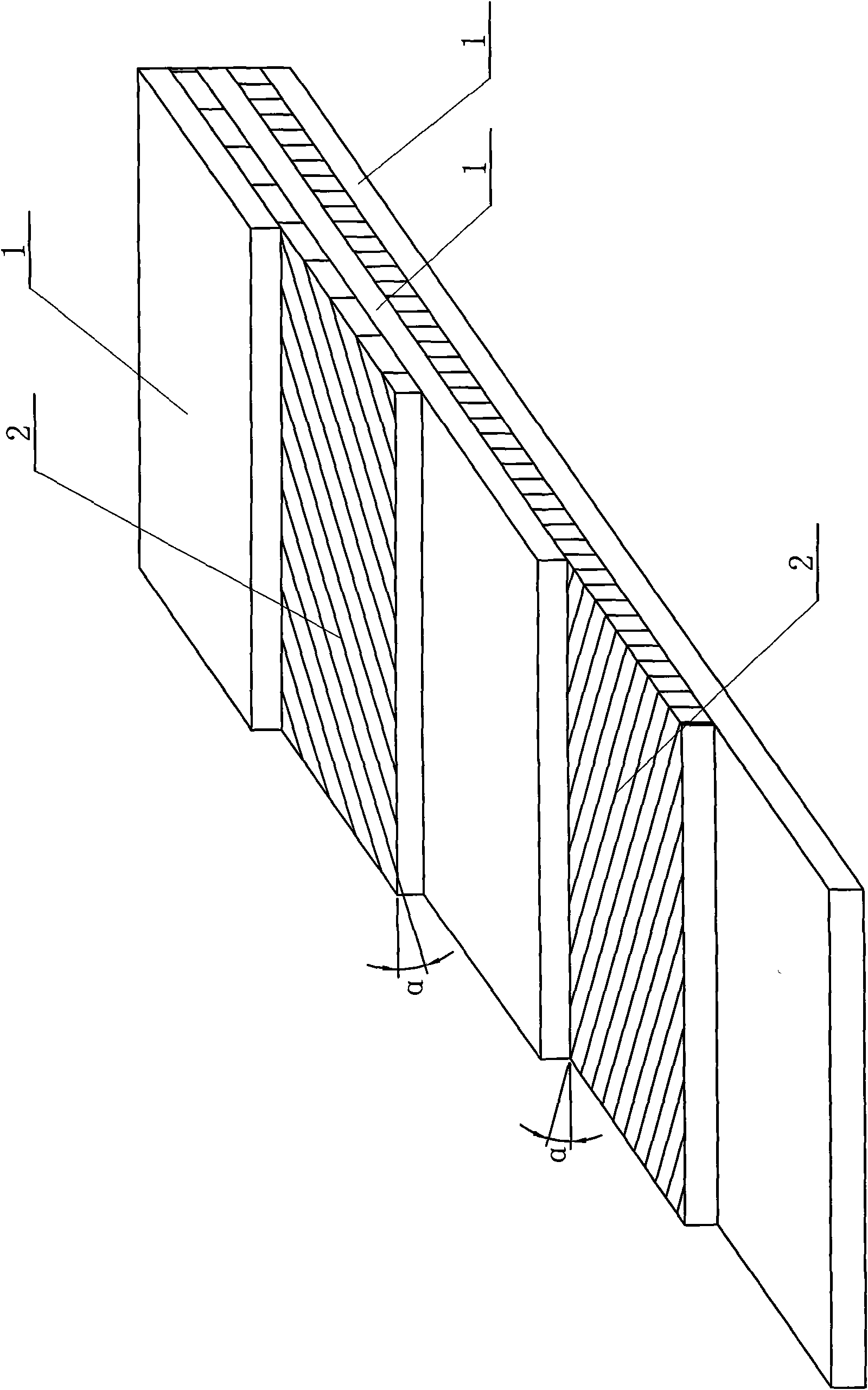

Method for preparing multilayered lattice metal and foamed aluminium composite material

InactiveCN102390136AGood mechanical propertiesImprove performanceMetal layered productsAluminum compositesLayer wise

A method for preparing multilayered lattice metal and foamed aluminium composite material comprises the steps of welding a lattice metal core body (comprising corrugated structures and pyramid structures) and a steel plates one layer after another to get the multilayered lattice metal interlayered plate, and getting the multilayered lattice metal and foamed aluminium composite material after compounding with cut foamed aluminium in a gluing manner. The invention realizes the preparation of the multilayered lattice metal material and the compounding of the multilayered lattice metal and the foamed aluminium, and can get the multilayered lattice metal and foamed aluminium composite material interlayered plate. The multilayered lattice metal and foamed aluminium composite material interlayered plate has a broad application prospect in security safeguard, military, and other fields, can effectively reduce construction weight, improves impact deformability, has excellent buffering energy-absorber effect and low intensity when being used in personnel and equipment security safeguard particularly, has obvious edges compared with solid material on specific strength and specific stiffness, and has a lower manufacturing cost.

Owner:XI AN JIAOTONG UNIV

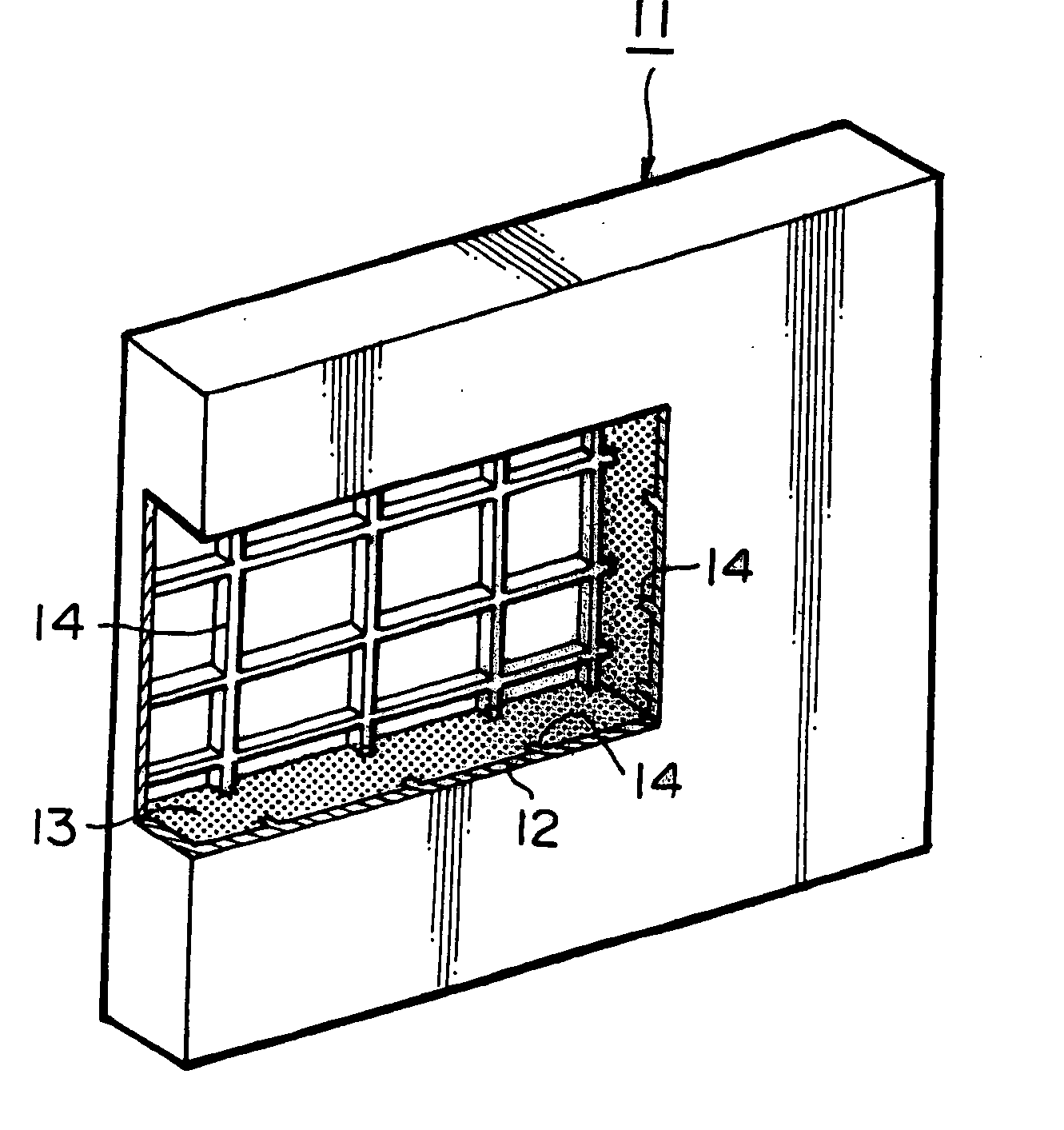

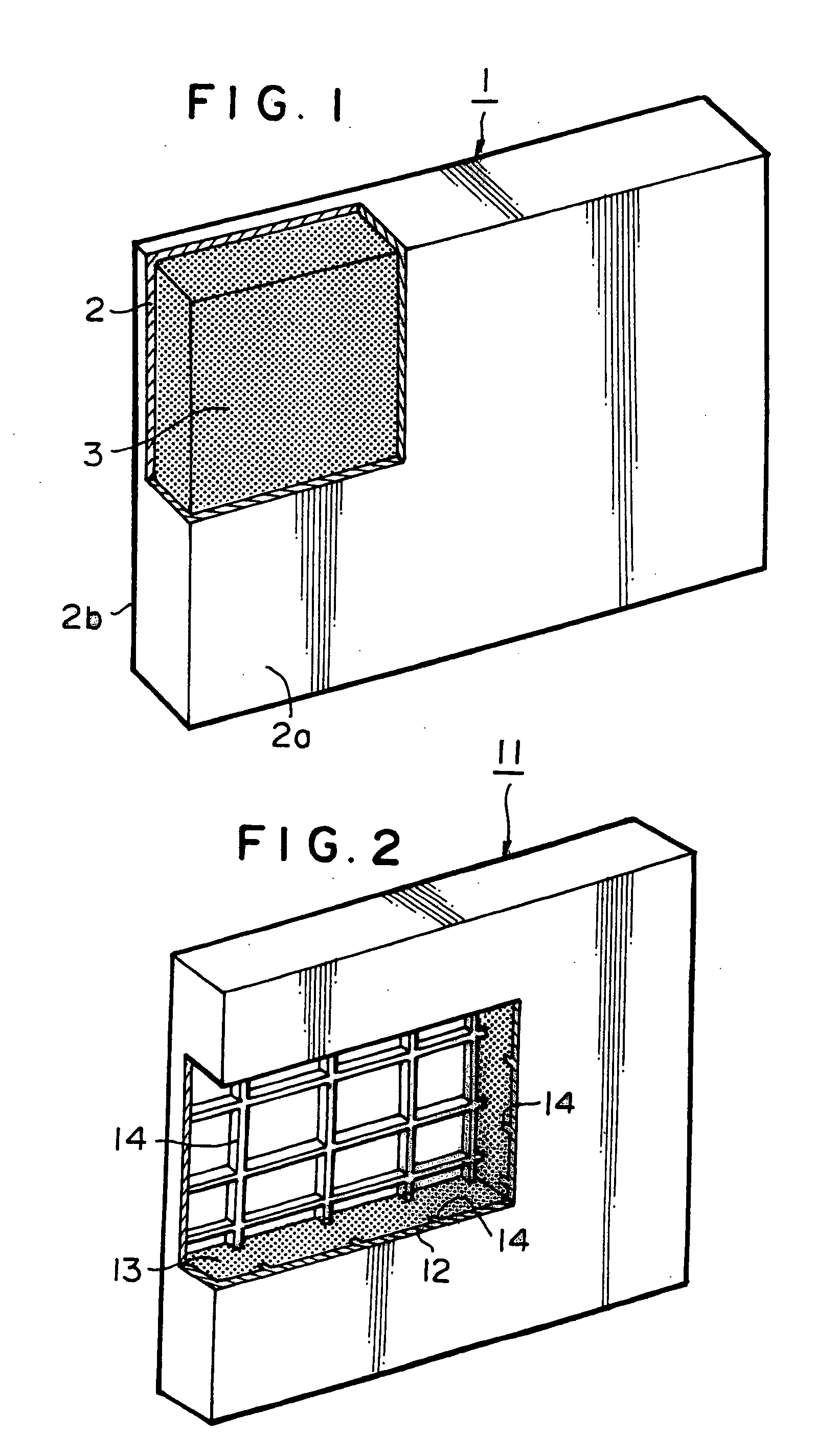

Sound-proof wall made of frp, and method of producing the same

InactiveUS20040128947A1Avoid noisePreferable sound-proof effectWallsLayered productsEngineeringDegrees of freedom

A sound-proof wall made of FRP in the form of a sound-proof wall panel that comprises a core and skin members made of FRP positioned on both sides of the core and whose weight per nit area is within the range of 10-60 kg / m<2>; and a method of producing the same. This sound-proof wall, though light in weight, has a superior sound insulation property and will never corrode because it is made of FRP. Further, it has a high degree of freedom of engineering design including sound-proof property, design, and shape, capable of producing a desired sound-proof wall with case. Further, since it has a high specific strength, it is possible to attain a drastic weight reduction while retaining the necessary strength, and facilitate working, shorten construction time, and reduce construction cost.

Owner:TORAY IND INC

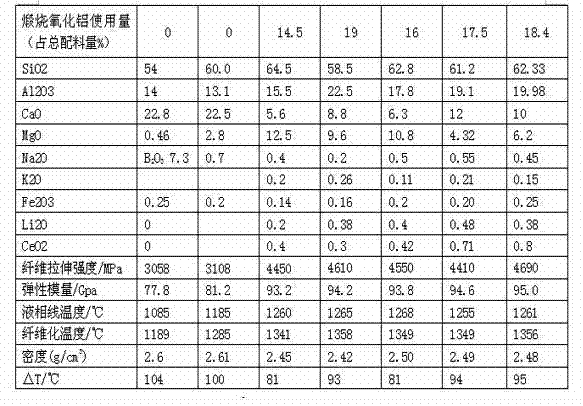

High-strength glass fiber composition

InactiveCN102786223ARelieve pressureLower fiberization temperatureGlass making apparatusFiberMechanical property

The invention relates to a high-strength glass fiber which has an excellent mechanical property and a product of the glass fiber. The high-strength glass fiber can serve as an ideal enhancing base material of a high-performance composite material and is applied widely in the fields of windmill blades, space shuttles and the like, which have high requirements for the specific strength and the specific elasticity modulus. The system is characterized in that calcinated aluminum oxide serves as on of the raw materials, impurities in glass compositions are reduced, the diathermancy of molten glass is improved, the energy consumption is reduced, and the stability of glass fiber drawing operation is improved greatly. The glass fiber with the compositions is required to be produced by direct drawing on a specific tank furnace, the electric boosting input energy of the tank furnace accounts for more than 20% of the total energy input, and more than 60% of the electric boosting energy is applied to raw material melting areas. The fiber mainly comprises 56-65 wt.% of SiO2, 18.5-25.8 wt.% of Al2O3, 11.5-23.0 wt.% of RO (RO is sum of CaO, MgO, SrO and BaO), 0.1-1.0 wt.% of CeO2 and 0.1-0.8 wt.% of Li2O.

Owner:TAISHAN FIBERGLASS INC

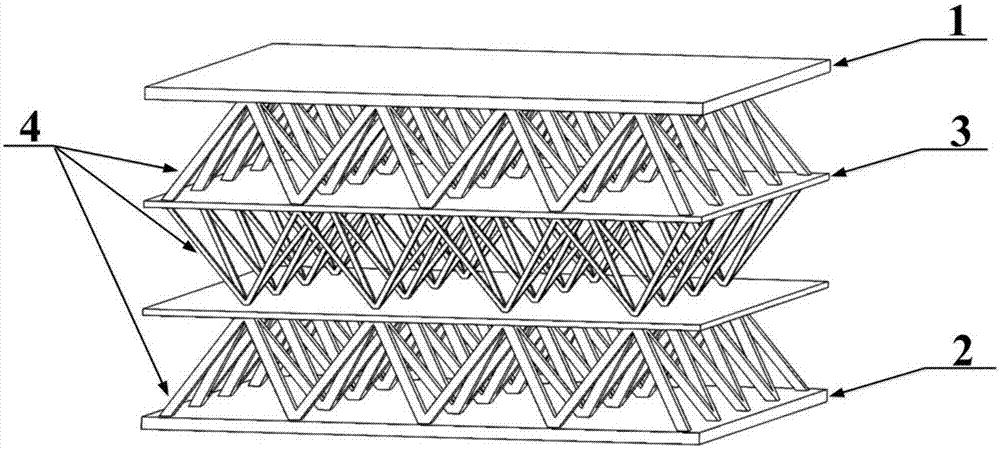

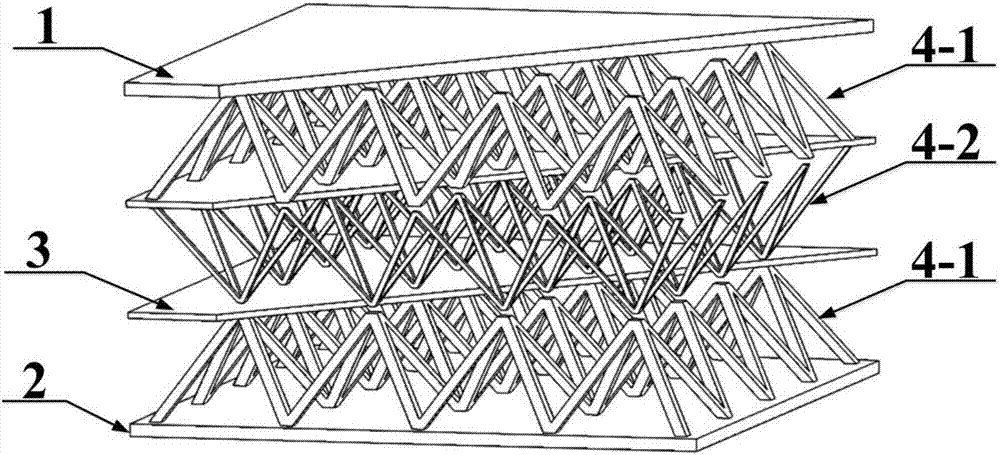

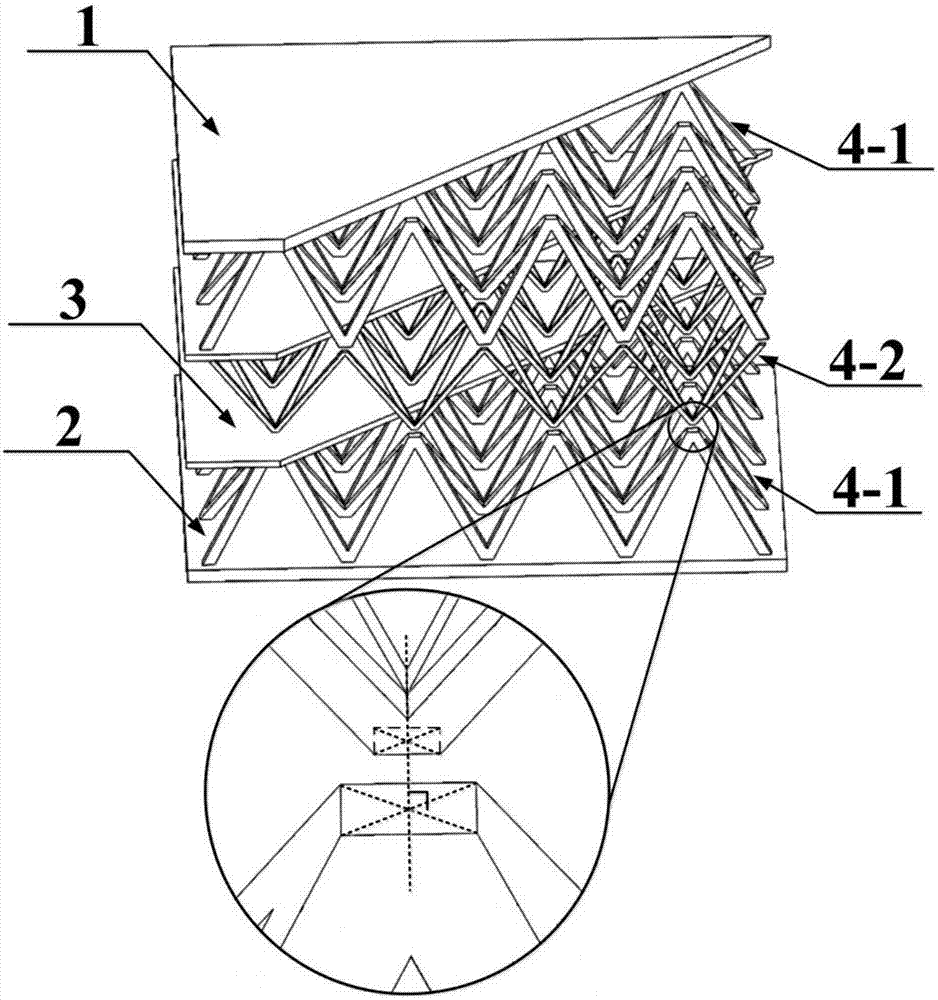

Multilayer gradient lattice sandwich panel and preparation method thereof

The invention discloses a multilayer gradient lattice sandwich panel and a preparation method thereof. Two punched diamond plates with different thicknesses are treated with mold pressing and folding technologies, two pyramid lattice core layers with different core rod part side lengths are prepared, the two core layers are welded with metal panels or partition boards in a circularly interphase distribution form, and the multilayer gradient lattice sandwich panel is obtained. Compared with a non-gradient multilayer lattice structure, the multilayer gradient lattice structure has the advantages that deformation difference among different core layers under the explosion load is greatly reduced, buckling deformation of the core layers are sufficiently utilized, influence of the rear panel by explosion shock is reduced by 50%, and a better protection function is realized. Besides, the characteristic of high porosity of the lattice structure is reserved, and further function composite is facilitated. The sandwich panel has broad application prospects in the fields of safety protection, military and the like by means of the excellent energy adsorption mechanism, low density, high specific strength and specific stiffness and multifunctional composite potentials.

Owner:三亚哈尔滨工程大学南海创新发展基地

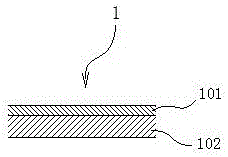

Carbon fiber metal laminate

InactiveCN101524903AImpact resistantImprove fatigue performanceSynthetic resin layered productsMetal layered productsHigh fractureFiber metal laminate

The invention relates to a carbon fiber metal laminate. The invention aims at the problem that, so far, flight vehicle structure materials, which not only has high specific strength and high specific stiffness, but also has high fracture toughness and processability, are non-existent. The inventive laminate is composed of at least two metal plates and at least one carbon fiber composite material layer; at least two metal plates are superposed together, a carbon fiber composite material layer which is adhesively bonded with the two adjacent metal plates are laid between the two adjacent metal plates; the thickness of the metal plate is 0.2m-0.4m and the thickness of the carbon fiber composite material layer is 0.15mm. The inventive laminate has high specific strength and specific stiffness, high fracture toughness and processability, and is also excellent in fatigue property and loss tolerance property. The invention can be used as a structure material for aerospace flights, such as a skin material of large civil planes, and can also be used as alternative material of metal auto panels, magnetically levitated train, light bulletproof armor and ship, etc.

Owner:HARBIN INST OF TECH

Aluminum-based composite brake disc and manufacturing method

ActiveCN106812837AImprove toughnessImprove reliabilityBraking discsFriction liningThermal expansionLow density

The invention discloses an aluminum-based composite brake disc, comprising a disc body, wherein the disc body comprises a composite structure formed by a disc core and a friction layer covering the disc core, the disc core is made of aluminum alloy, and the friction layer is made of a particle reinforced aluminum-based composite material. The non-friction surface (disc core) of the brake disc is casted by using the aluminum alloy with good ductility and toughness, the friction surface (friction layer) is casted by using the particle reinforced aluminum-based composite material based on the disc core, and the brake disc having the interior made of the aluminum alloy and the surface made of the particle reinforced aluminum-based composite material is finally formed. The brake disc has the advantages of low density, high specific strength and specific rigidity, small thermal expansion coefficient, good heat conductivity, excellent wearability and the like, besides, the toughness of the brake disc during assembly is improved, the machining cost is reduced, and the service reliability of the brake disc is improved.

Owner:徐骏 +1

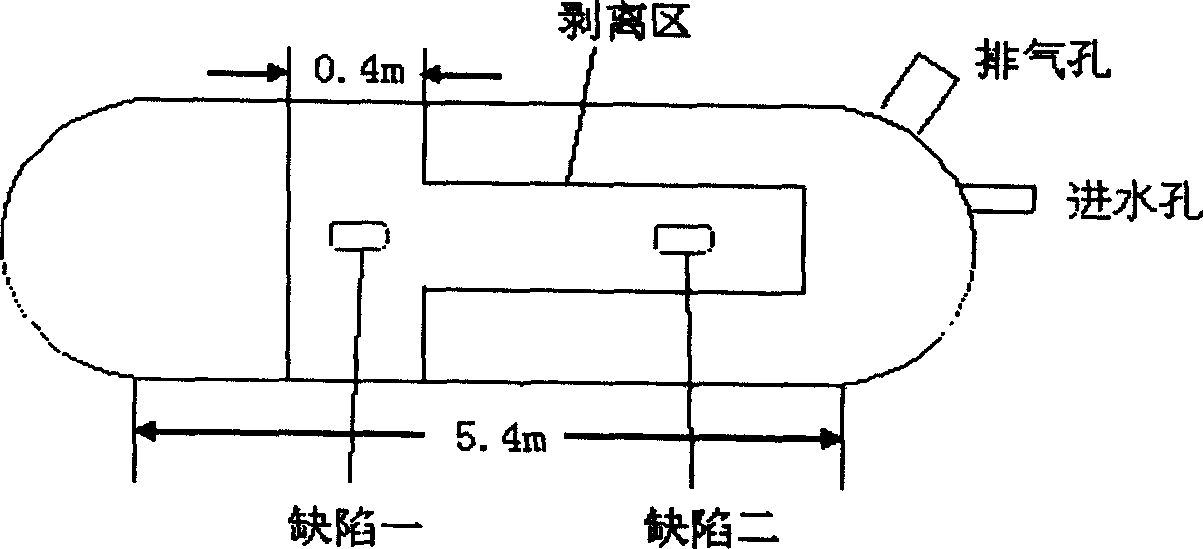

Strengthening carbon fiber composite material and method for repairing defective pipeline

The pipeline repairing and reinforcing material includes repairing glue layer for repairing and leveling the outer pipeline fault; carbon fiber sheet painted or dipped with glue for restoring and raising the bearing strength of the fault part; and anticorrosive material layer for the outer surface. The repairing and reinforcing material of the present invention has specific strength and specific module near that of the metal pipe material, can bear the pressure inside the pipe together with the pipe and reach or even exceed the bearing capacity of the pipe. The present invention may be used in repairing pipeline without stopping conveyance.

Owner:UNIV OF SCI & TECH BEIJING +1

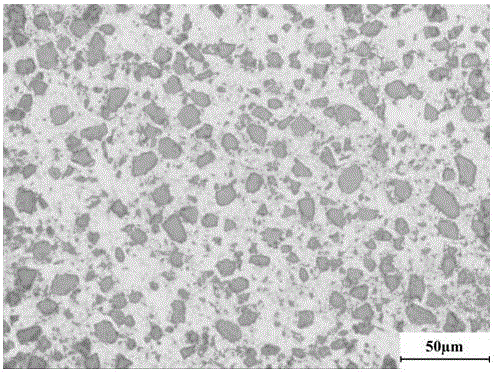

Carborundum-added particle-reinforced silicon aluminum alloy matrix composite for brake disc and preparation method thereof

The invention relates to the technical field of brake disks, in particular to a carborundum-added particle-reinforced silicon aluminum alloy matrix composite for a brake disc and a preparation method of the composite. The technical scheme adopted by the invention is as follows: the raw material of the composite takes an alloy of silicon and aluminum as a basal body and is reinforced via immersing silicon carbide particles; the alloy of the silicon and the aluminum takes a Al-26Si aluminum alloy blank material, and a ZAlSi9Mg aluminum alloy blank material as the main body, and modest elements such as Cu, Ni, Ti, Mn and the like are added and melted to form the alloy; and chemical copper plating treatment is required to carry out before immersing the silicon carbide particles. The aluminum matrix composite prepared by the preparation method is light in weight, high in specific strength and specific stiffness, and low in thermal expansion coefficient, and has good thermal conduction performance and abrasion resistance.

Owner:SHANDONG ZHENGNUO GRP

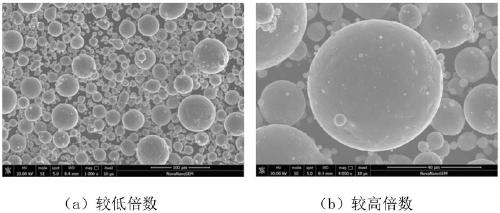

High-strength aluminum alloy for additive manufacturing and preparation method of high-strength aluminum alloy powder

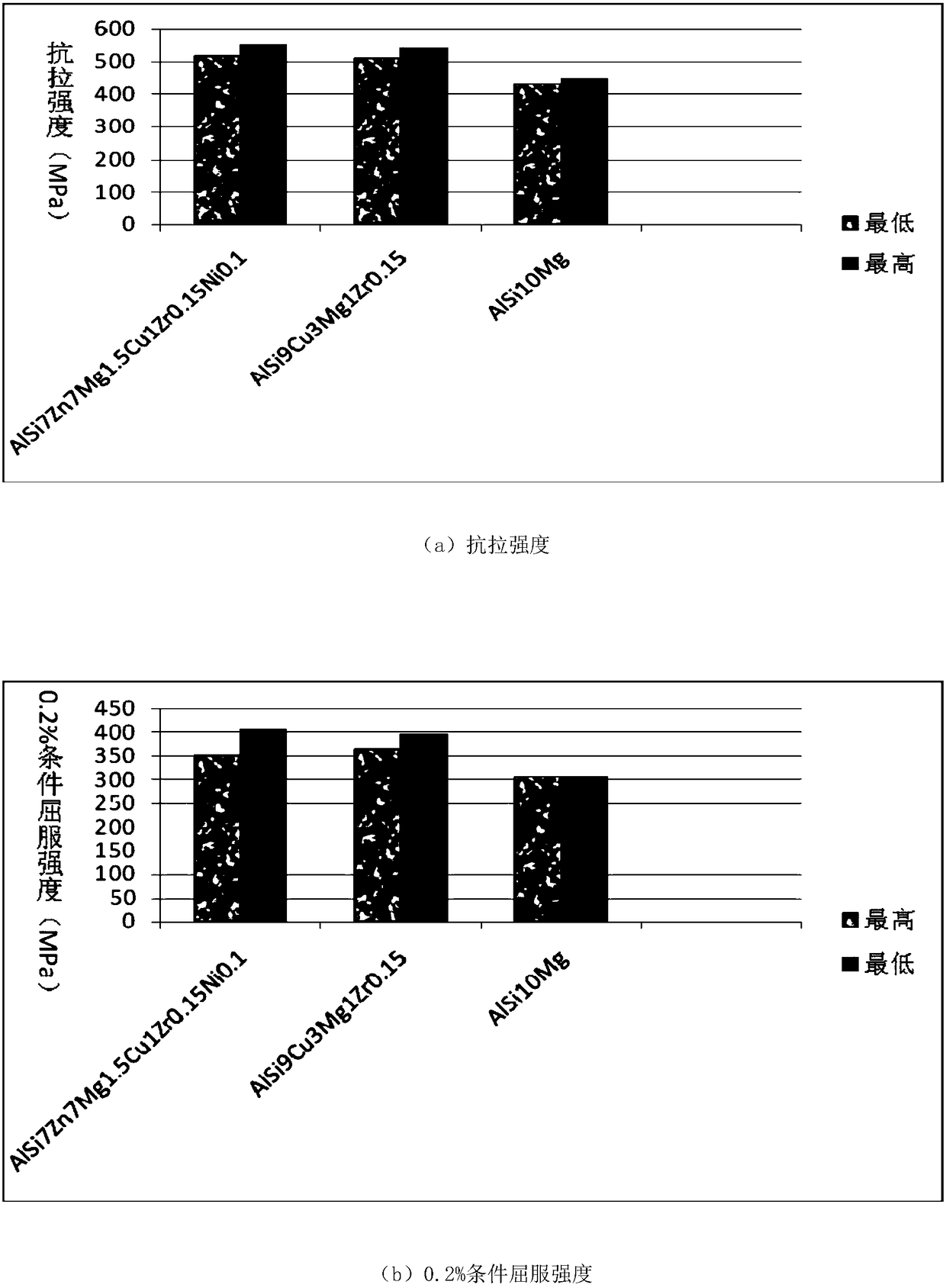

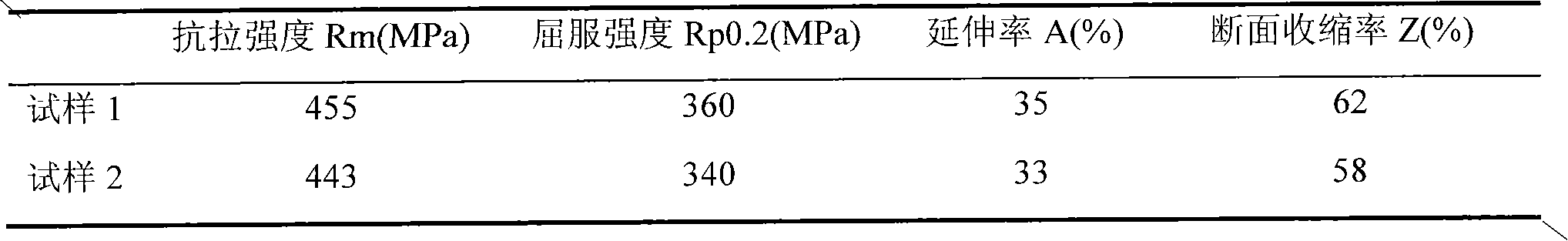

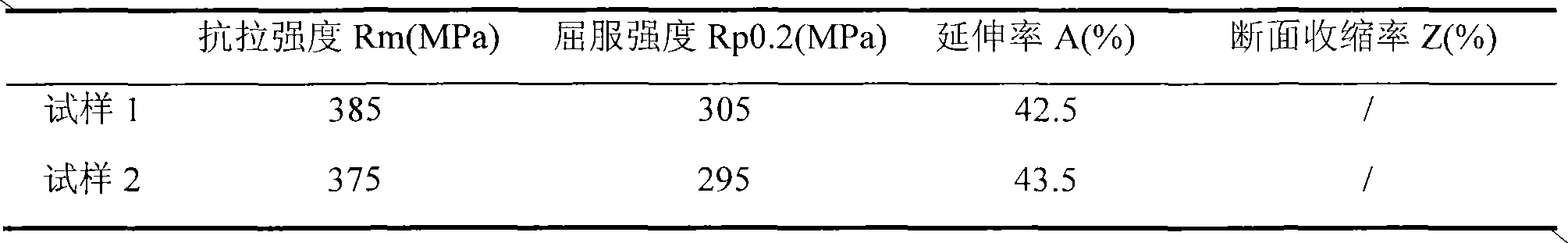

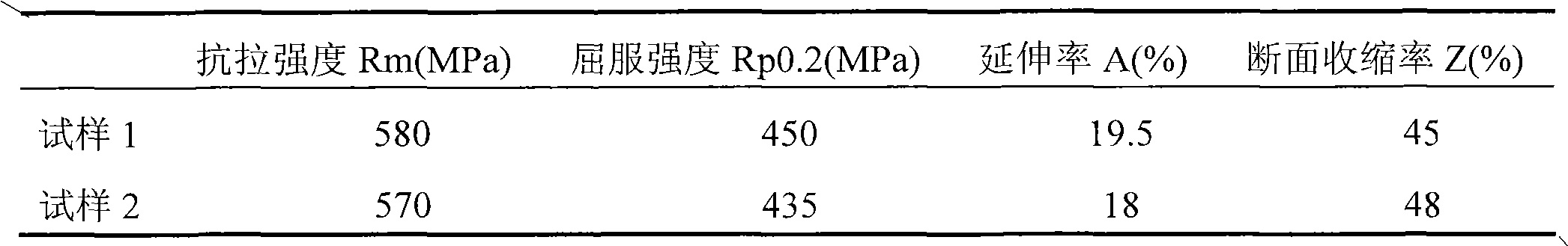

ActiveCN109280820AGuaranteed yieldAvoid oxidation burnAdditive manufacturing apparatusTransportation and packagingTest sampleMedium frequency

The invention provides a high-strength aluminum alloy for additive manufacturing and a preparation method of high-strength aluminum alloy powder. The high-strength aluminum alloy powder is prepared byadopting a gas atomization process. The preparation method comprises the following steps of: firstly, melting an Al-Si-Zn-Cu-Mg-X alloy prefabricated ingot by adopting a medium frequency induction furnace, then powdering by adopting a supersonic speed gas atomization process, sieving and preparing powder of different specifications for additive manufacturing. A test sample obtained by adopting the high-strength aluminum alloy powder through additive manufacturing has compact texture without crack defects, the strength of extension exceeding 500MPa and the elongation exceeding 3%; the strengthperformance of the test sample is obviously superior to the strength performance of additive manufacturing test samples of AlSi10Mg, AlSi7Mg and AlSi12; and the performances of the test sample are also superior to the performances of additive manufacturing test samples of conventional 2000 series and 7000 series alloys. The alloy powder can be used for preparing aluminum alloy parts with compacttexture, complicated shapes and high strength in an additive manufacturing method to meet the requirements of use occasions on high specific strength and complicated shapes in the fields of aviation,spaceflight and automobiles.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

High temperature furnace-grade curing carbon fiber thermal insulating material and production technology thereof

ActiveCN101550017AImprove insulation effectSimple process, energy saving and environmental protectionCarbon fibresFurnace liningsFiberCarbon fibers

The invention discloses a high temperature furnace-grade curing carbon fiber thermal insulating material having simple technology and small coefficient of heat conductivity, and a production technology thereof, characterized in that the material is made of the carbon fiber by the steps of the preparation of a preform, densification, hot-vibration purification and machine processing; the invention is free from the processes of bonding, immersion, curing and charring in the preparation of the preform and has simple technology, great energy-saving property and environmental protection ability, the carbon fibers inside the preform are distributed in a crisscross pattern, strong in cohesive force, stable in structure and free from delamination, the coefficient of heat conductivity is not larger than 0.8 W / mK and the thermal insulating property is excellent; the product consists of the high-strength carbon fiber and carbon matrix and has outstanding performances such as high specific strength, good high temperature resistance, corrosion resistance and thermal insulating property, in addition, the product integrates the fire resistance and the thermal insulating property, can bear certain loads, and is an ideal upgraded product in taking the place of related high temperature furnace-grade graphite products and soft carbon felt.

Owner:HUNAN KINGBO CARBON CARBON COMPOSITES CO LTD

PVC (Poly Vinyl Chloride) wood-plastic foaming composite and preparation method thereof

ActiveCN102501506AGood weather resistanceReduce formulation costsSynthetic resin layered productsASA-polymerWeather resistance

The invention discloses a PVC (Poly Vinyl Chloride) wood-plastic foaming composite and a preparation method of the wood-plastic foaming composite. The PVC wood-plastic foaming composite comprises a PVC wood-plastic foaming base material layer and an ASA (Acrylonitrile Styrene Acrylate) layer which is co-extruded and formed on at least one side of the PVC wood-plastic foaming base material layer, wherein the PVC wood-plastic foaming base material layer comprises the following components in parts by weight: 100 parts of PVC, 50-100 parts of paddings, 1-1.5 parts of coupling agents, 5-7 parts of compound stabilizers, 1.0-1.5 parts of compound foaming agents and 6-8 parts of blowing promoters. The PVC wood-plastic foaming composite disclosed by the invention has the characteristics of light weight, high specific strength, water prevention, corrosion prevention, heat preservation, good weather resistance, low formula cost and low material density, and can be widely used in outdoor product markets such as exterior decoration of buildings, garden landscapes, fences, plank ways and the like.

Owner:北京欧尼克新型材料有限公司

Pure titanium wire for spectacle frame and manufacturing method thereof

The invention discloses a pure titanium wire for a spectacle frame and a manufacturing method thereof. 0 to 0.20 weight percent of O element and 0 to 0.26 weight percent of Fe element are added in the pure titanium cast ingot smelting process. The amount of Fe and O elements needed to be added during reinforcement is obtained according to the strength theta 0 of original spongy titanium, and the adding amount of Fe and TiO2 in the pure titanium material smelting process is determined further. Through forging, rolling, drawing and annealing processes, the strength controllable pure titanium wire is prepared and meets requirements on titanium wire properties of different parts of the spectacle frame. In the smelting process for preparing the pure titanium material, accurate amount of Fe element and O element are added, and chemical composition content in the pure titanium wire is controlled, so that the strength of the pure titanium wire is accurately controlled, the strength deviation of TA2 pure titanium wires produced in different batches is controlled within 40MPa, and the pure titanium wires meeting specific strength requirements are produced.

Owner:XIAN AEROSPACE NEW MATERIAL

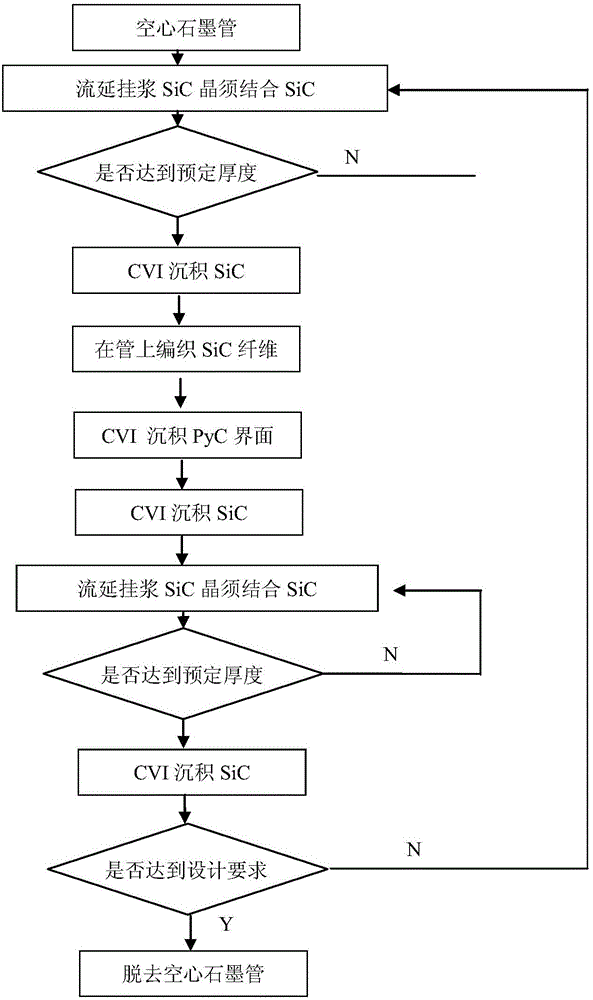

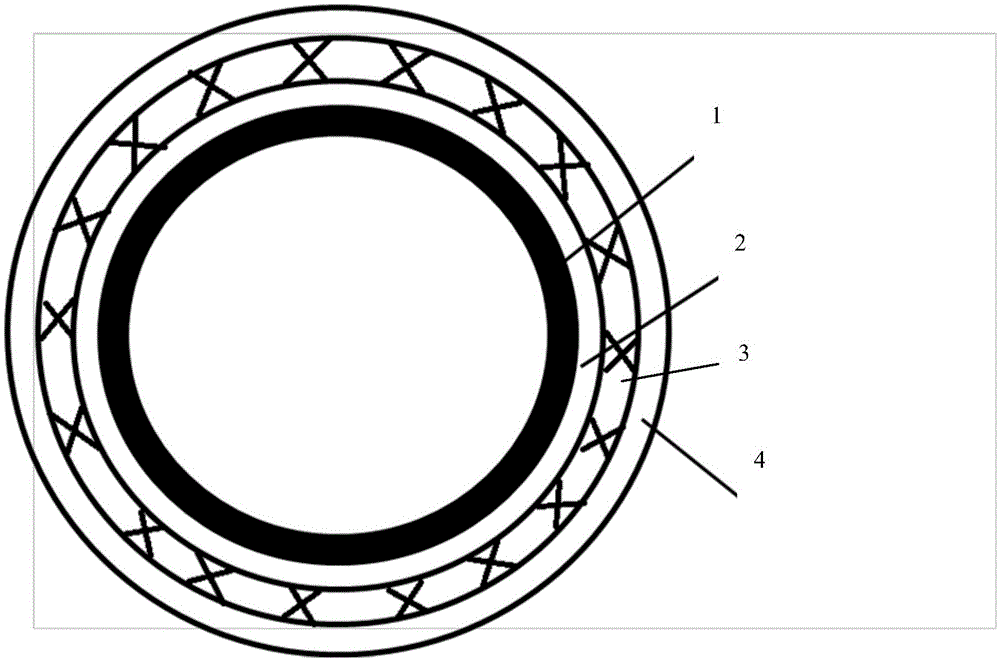

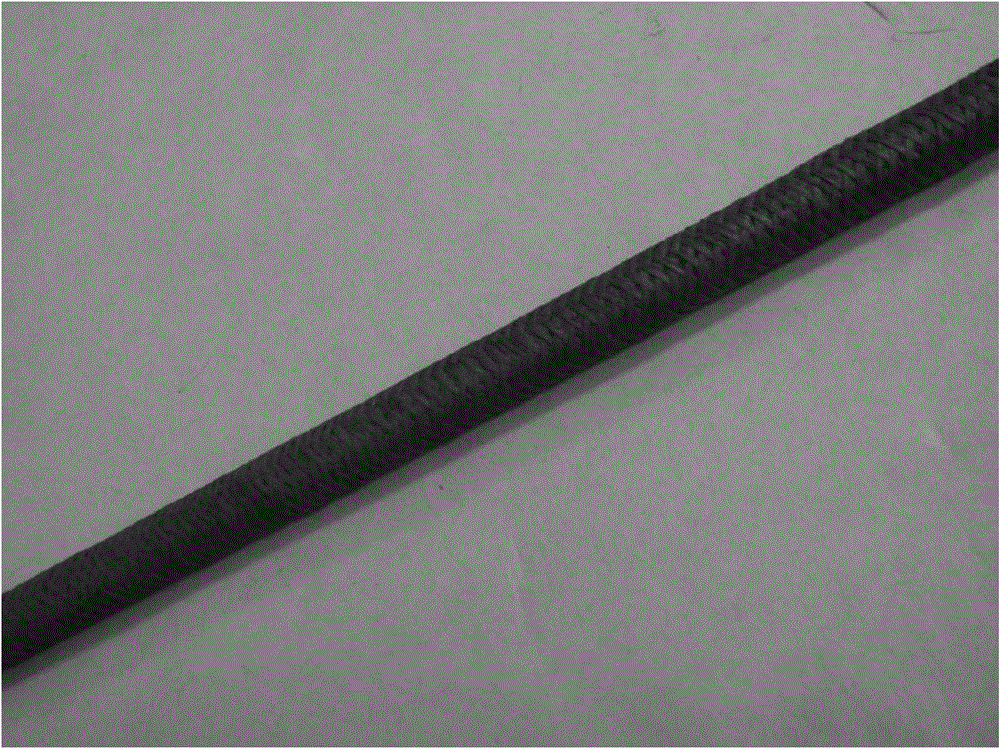

Multilayer structure of SiC/SiC (silicon carbide) composite cladding tube and preparation method thereof

ActiveCN103818056AHigh strengthHigh thermal conductivityCeramic layered productsCrack resistanceWhiskers

The invention discloses a multilayer structure of an SiC / SiC (silicon carbide) composite cladding tube and a preparation method of the multilayer structure. The multilayer structure of the SiC / SiC composite cladding tube is formed by alternately overlapping an SiC whisker toughening SiC composite layer and a continuous SiC fiber toughening SiC composite layer according to design needs. A three-layer overlapping structure takes the SiC whisker toughening SiC composite layer as an inner layer, a continuous SiC fiber toughening SiC composite material as a middle layer and a SiC whisker toughening SiC composite material as an outer layer; the multilayer structure can be formed by continuous alternate overlapping according to the design needs. The SiC whisker toughening SiC composite layer in the multilayer structure mainly plays a role of seal leakage prevention, meanwhile, the SiC whisker toughening SiC composite layer has high strength and toughness, the continuous SiC fiber toughening SiC composite layer plays a role of strength supporting, the multilayer structure of the SiC / SiC composite cladding tube has high crack resistance, high heat conductivity, high specific stiffness, high specific strength, excellent thermal shock and the like.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Preparation method for short carbon fiber/silicon carbide composites

The invention discloses a preparation method for short carbon fiber / silicon carbide composites by means of spark plasma sintering (SPS). The preparation method includes the steps: (1), pre-treating the short carbon fiber by placing the same in a heat-treatment furnace for heat preservation for 30 minutes under the temperature of 400 DEG C prior to soaking and coarsening the short carbon fibers in coarsening liquid composed of nitric acid, potassium dichromate, hydrogen peroxide and ammonium persulfate to be washed with deionized water and dried for standby; (2), placing the short carbon fiber, silicon carbide powder and sintering aids in a ball-milling pot to be ball-milled; (3), drying the materials in the step (2) through rotary evaporation prior to grinding the same to sieve the mixed powder; and (4), placing the mixed powder into a graphite mould and subjecting the mixed powder to the spark plasma sintering. The short carbon fiber / silicon carbide composites prepared by the method are good in performance, and volume content of the short carbon fibers can be controllable; and the short carbon fiber / silicon carbide composites have high specific modulus, high specific strength and excellent toughness, and can hopefully be applied to light weight armor field.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

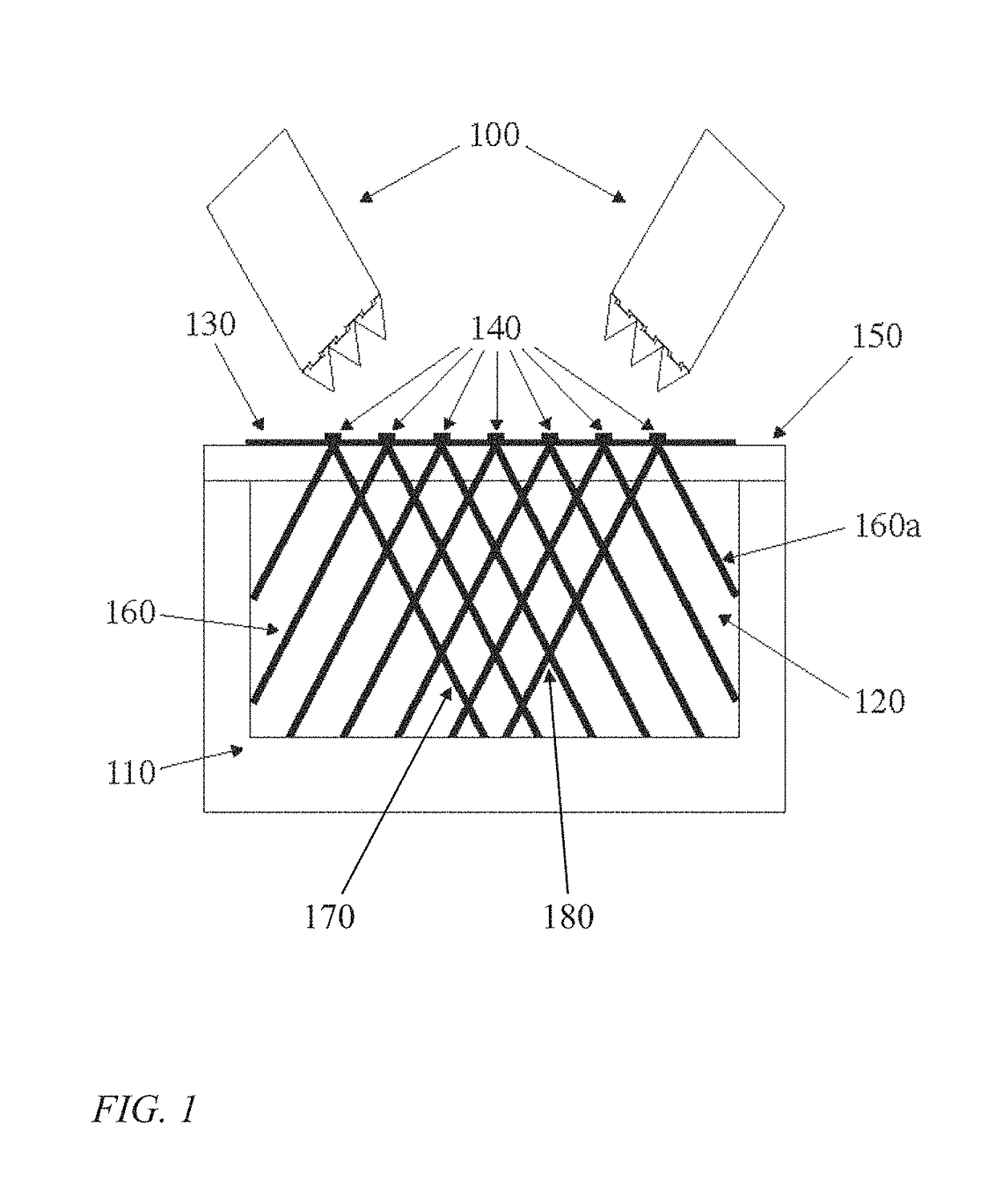

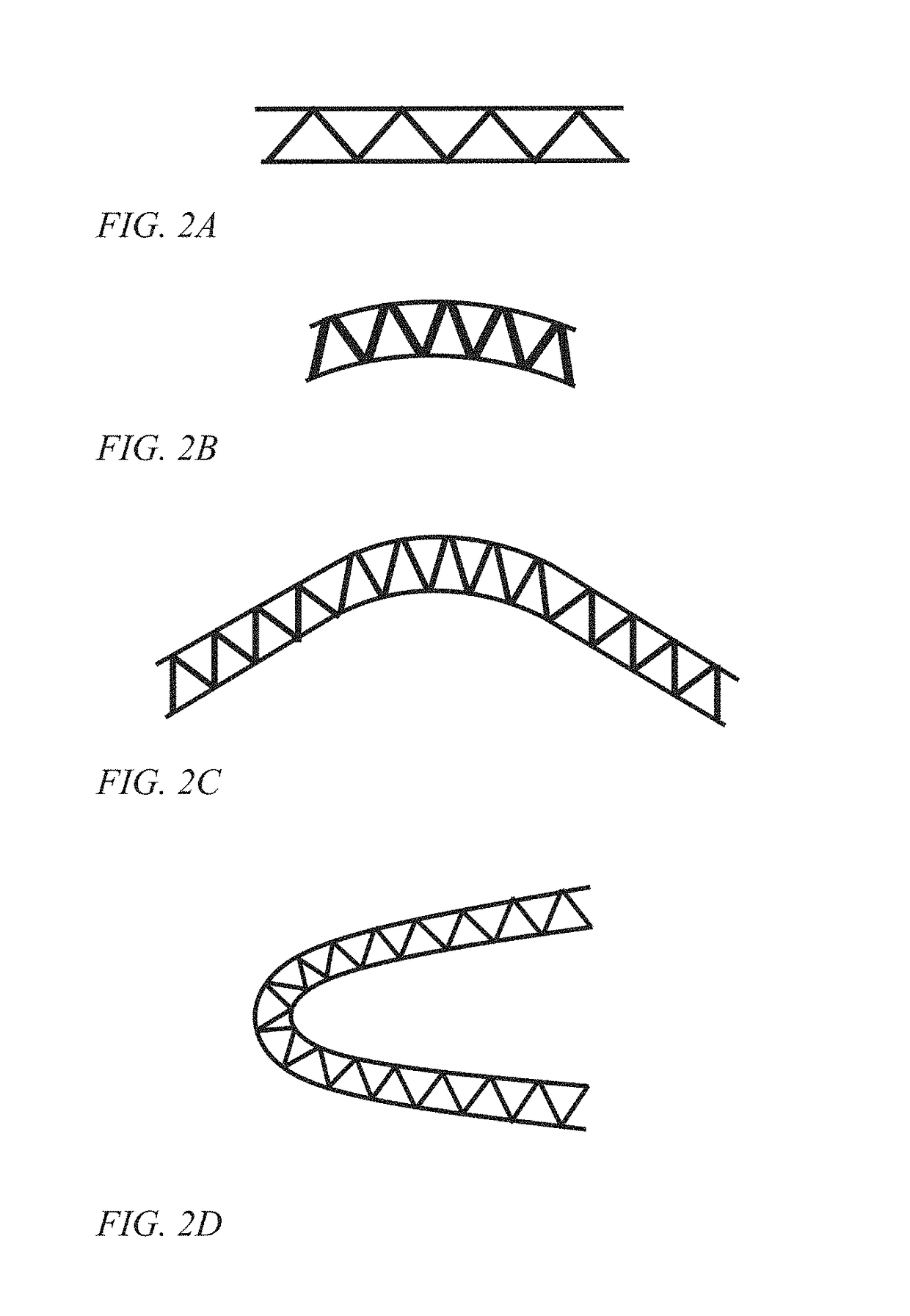

Curved high temperature alloy sandwich panel with a truss core and fabrication method

ActiveUS9731471B2High specific strength and stiffnessMinimize and reduce weak pointEngine manufactureVacuum evaporation coatingSuperalloyUltimate tensile strength

A lightweight sandwich panel structure with a complex shape and curvature, and a method to fabricate such a panel out of high temperature alloys. Embodiments of a micro-truss core structure that offer high specific strength and stiffness while allowing for curvature, and methods for depositing multiple layers of metals that can be interdiffused into complex alloys, are provided. A core of a panel may be fabricated from a polymer template, which may be shaped, e.g., curved, and coated with metal layers, which may then be heat treated to cause the layers of metal to interdiffuse, to form an alloy.

Owner:HRL LAB

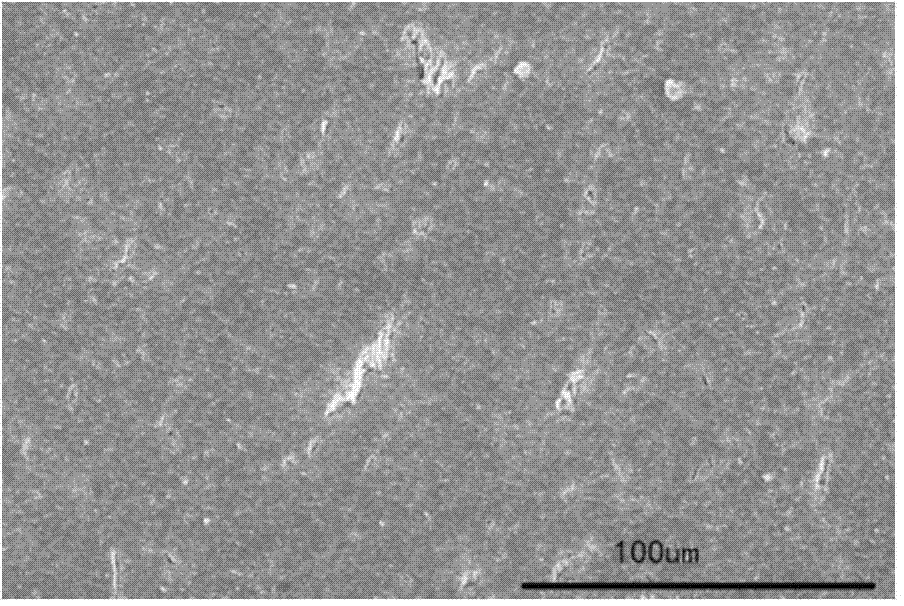

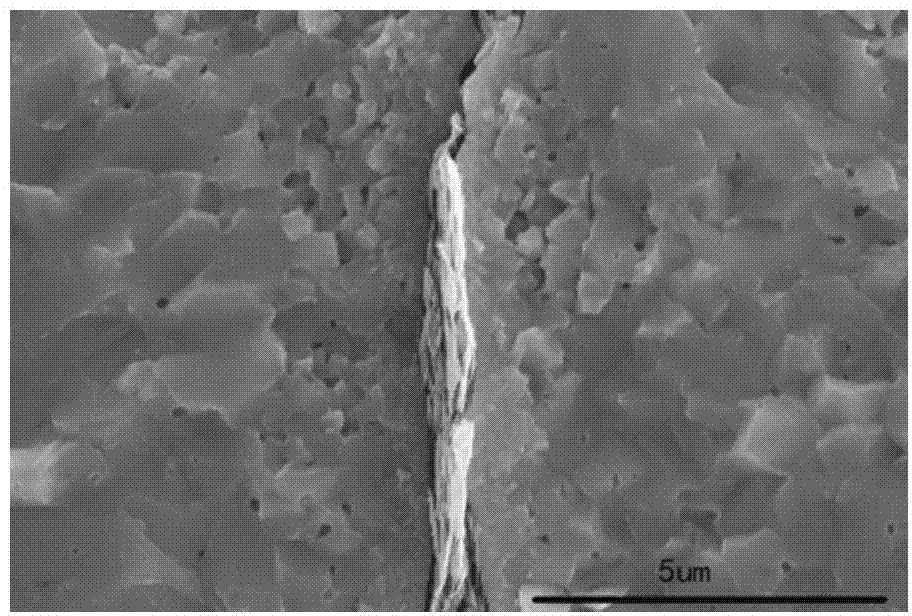

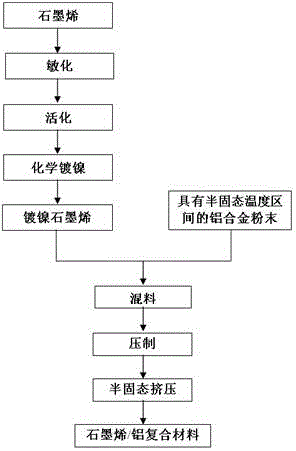

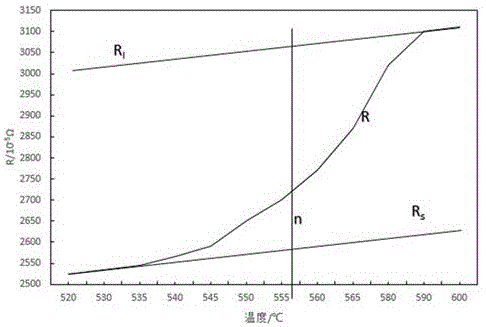

Production method of graphene-aluminum composite

ActiveCN106513621AOvercome the disadvantage of being easy to pull out from the aluminum alloy matrixTake full advantage of enhanced capabilitiesLiquid/solution decomposition chemical coatingElectricityMetal matrix composite

The invention discloses a production method of a graphene-aluminum composite, and belongs to the field of metal-matrix composites. Aluminum alloy powder with the semisolid temperature interval and graphene are adopted as raw materials. The method mainly includes the steps of 1, chemical nickel plating of the graphene; 2, mixing; 3, pressing; and 4, semisolid extruding. According to the graphene-aluminum composite produced through the method, the wettability and the metallurgical bonding strength of the nickel-plated graphene and aluminum alloy are high, the nickel-plated graphene is uniformly distributed in the matrix aluminum alloy, the microstructure is compact, the specific strength and the specific stiffness are high, and the thermal conductivity and the electrical conductivity are good. Thus, the graphene-aluminum composite has wide application prospects in the fields of the national defense and military industry, aerospace, electricity and heat exchange.

Owner:KUNMING UNIV OF SCI & TECH

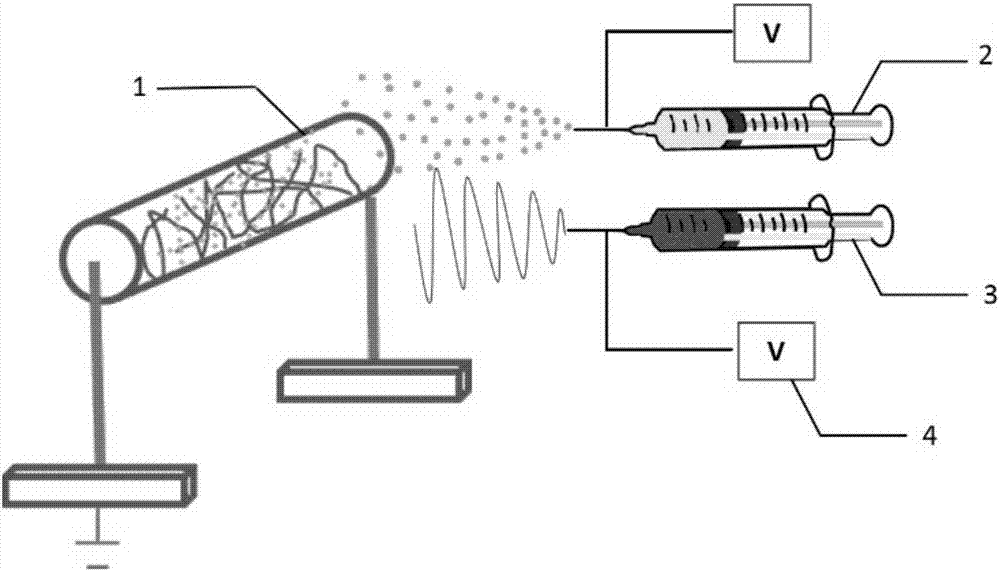

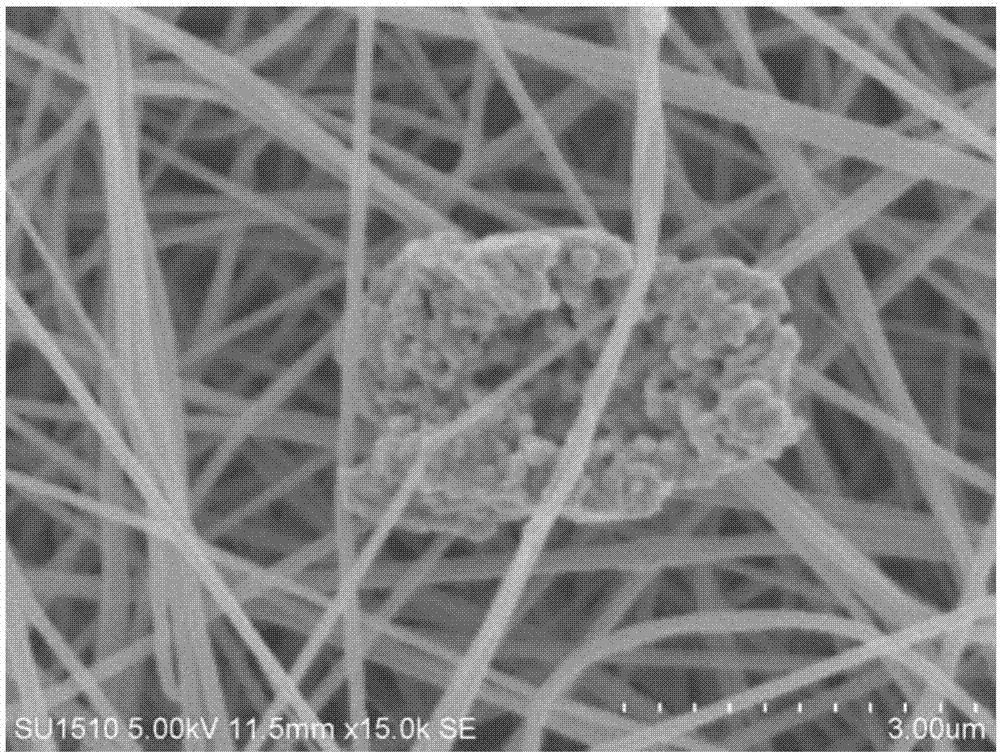

Composite nanofiber membrane and preparation method and application thereof

InactiveCN107299456AHigh porosityImprove breathabilityElectro-spinningNon-woven fabricsFiberPorosity

The invention discloses a composite nanofiber membrane and a preparation method and application thereof. The composite nanofiber membrane is prepared from electrostatic nanofiber deposition foam material. Compared with the prior art, the composite nanofiber membrane has the advantages that by the utilization of an electrostatic spraying technology, foaming particles or foaming short fibers are prepared and deposit on the surface of electrostatic nanofibers, so that the composite nanofiber membrane with controllable thickness is obtained, and the porosity, air permeability and filling power of the nanofiber membrane are improved. By the utilization of the method, the resistance to impact load, heat insulation, sound insulation, specific strength and other physical and mechanism properties of the nanofiber membrane are improved. With the method, the pressure drop and resistance of the nanofiber membrane are reduced, the preparation technology is simple, and cost is low.

Owner:JIANGNAN UNIV

Biodegradation expanded plastic and method for manufacturing same

InactiveCN101245175ANo difficult recycling issuesNo atmosphere damage problemThermal insulationCopolymer

The invention relates to a biological degradation foamed plastic which comprises the following components and contents: polylactic acid resin: 100 portions; polylactic acid plasticizer: 10 to 20 portions; polyhydroxy alkanoates multipolymer: 10 to 50 portions; corn starch: 20 to 60 portions; foaming agent: 8 to 17 portions; blowing promoter: 2 to 4 portions; lubricant: 0.8 to 1.2 portions; antiager: 0.45 to 0.70 portion, and the amount is calculated by weight. The biological degradation foamed plastic of the invention also provides a manufacturing method for manufacturing the biological degradation foamed plastic. The biological degradation foamed plastic is characterized by low density, high specific strength, good shock absorption performance and complete biological degradation, can be applied not only in the shock absorption packages of industrial products, such as domestic appliances, electron, instruments, industrial fittings and glass / ceramic etc., but also in a field that needs heat preservation and thermal insulation, thus the biological degradation foamed plastic of the invention is a new environmental-friendly packaging material.

Owner:陈俭秋

Shape memory polymer composite body with spatially-expanded three-wing beam and its preparation method

InactiveCN101055344AHigh specific strengthHigh specific modulusLamination ancillary operationsSynthetic resin layered productsElectrical resistance and conductancePolymer science

A space expanded three-wing-beam shaped remember polymer compound and the preparation thereof relates to a space expanded three-wing-beam shaped remember polymer and the preparation thereof, and to solve the problems of large material weight, complicated expanded mechanical performance, unsteady controlling of the expanding-telescoping procedure, and complicated fabrication technology in the existing space expanded beam structure design procedure. The compound material layer of the shaped remember polymer compound is shaped as superposition and the electric resistance silk screen is located therein. The inner of the compound material layer bending part of the shaped remember polymer compound is connected with a yalloy material layer, the preparation of which comprises the steps of: sorting, confect material, curing. The invention has the advantages of: high specific strength, small material weight, strong controlling ability for beam expanding, simple mechanical performance of the space beam expanding. Moreover, the invention has the characteristic of shaped remember and simple technological operation of the preparation.

Owner:HARBIN INST OF TECH

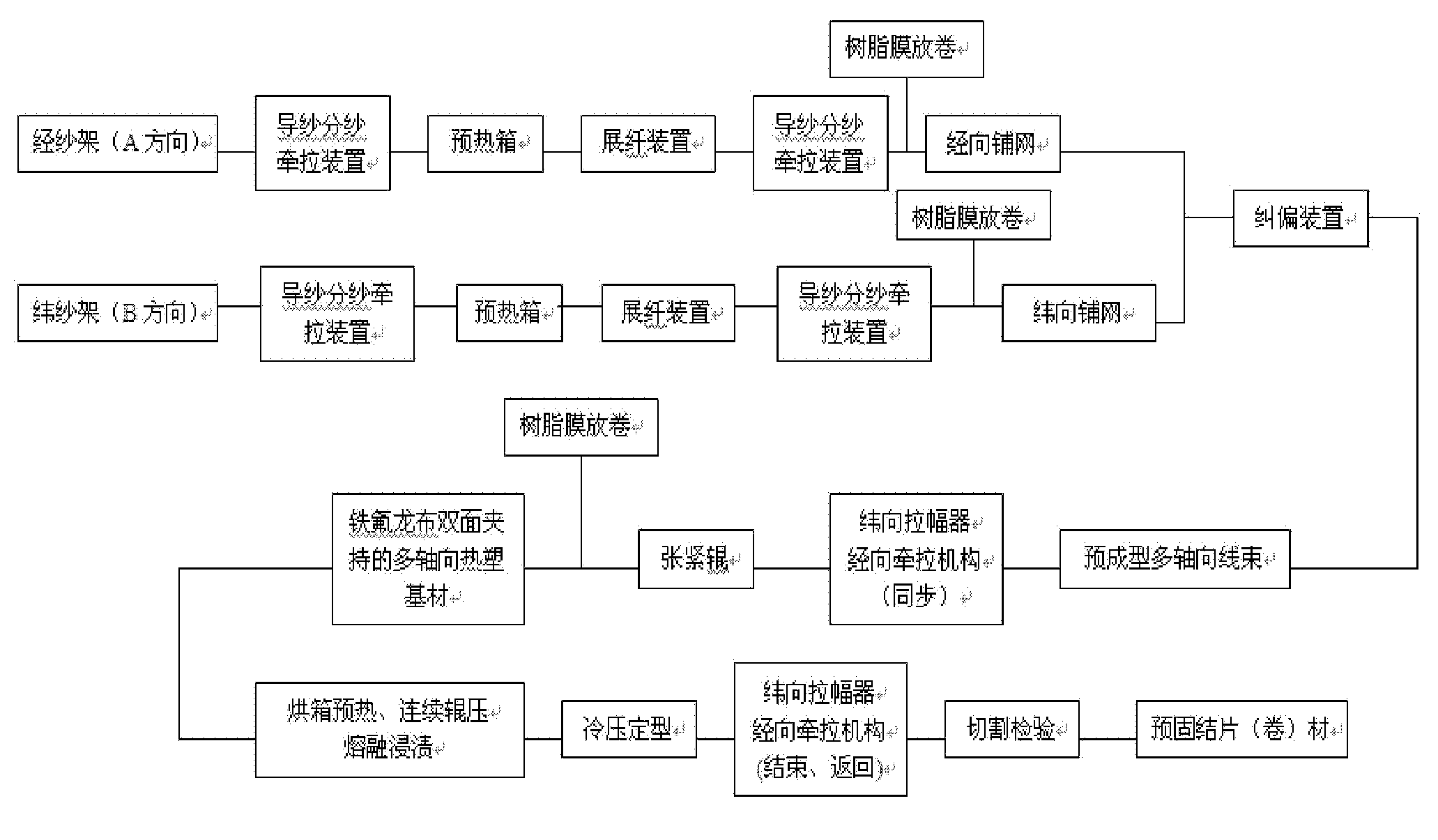

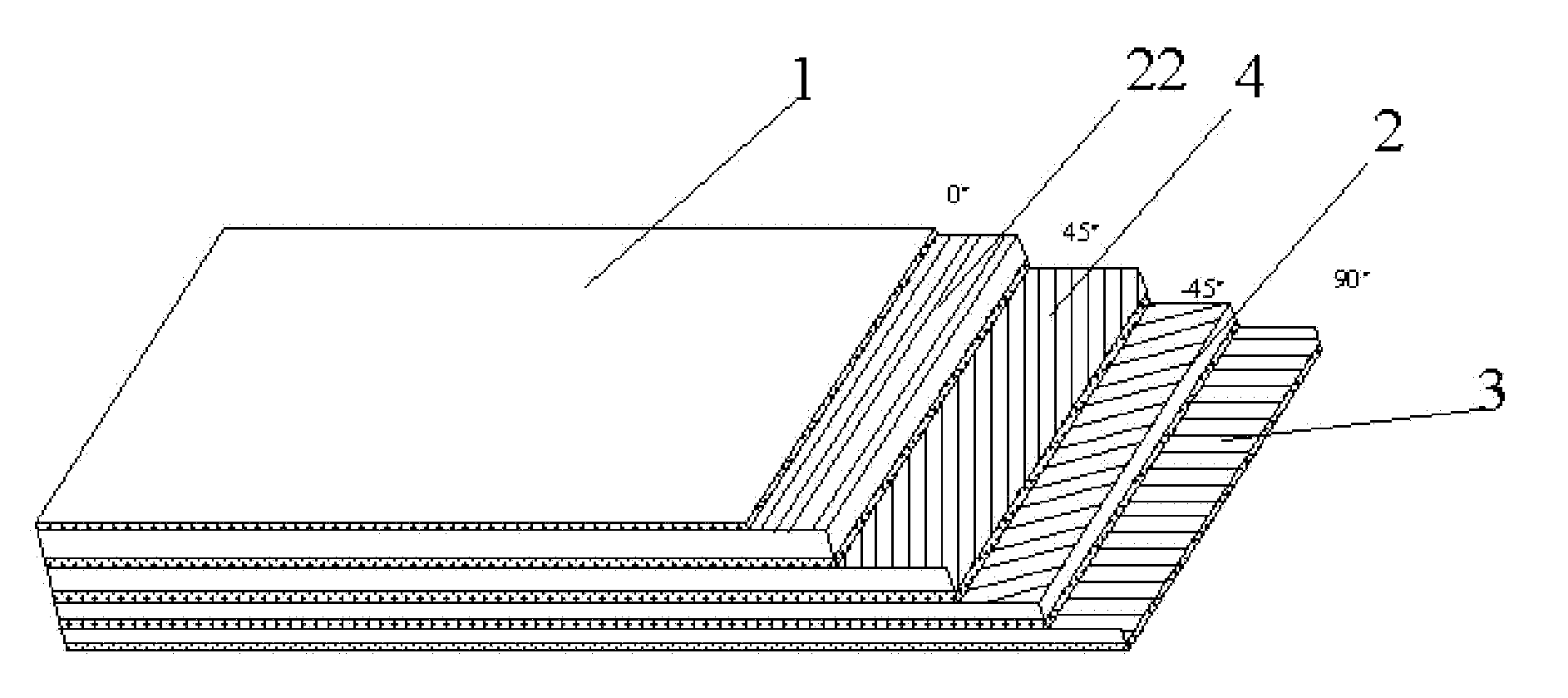

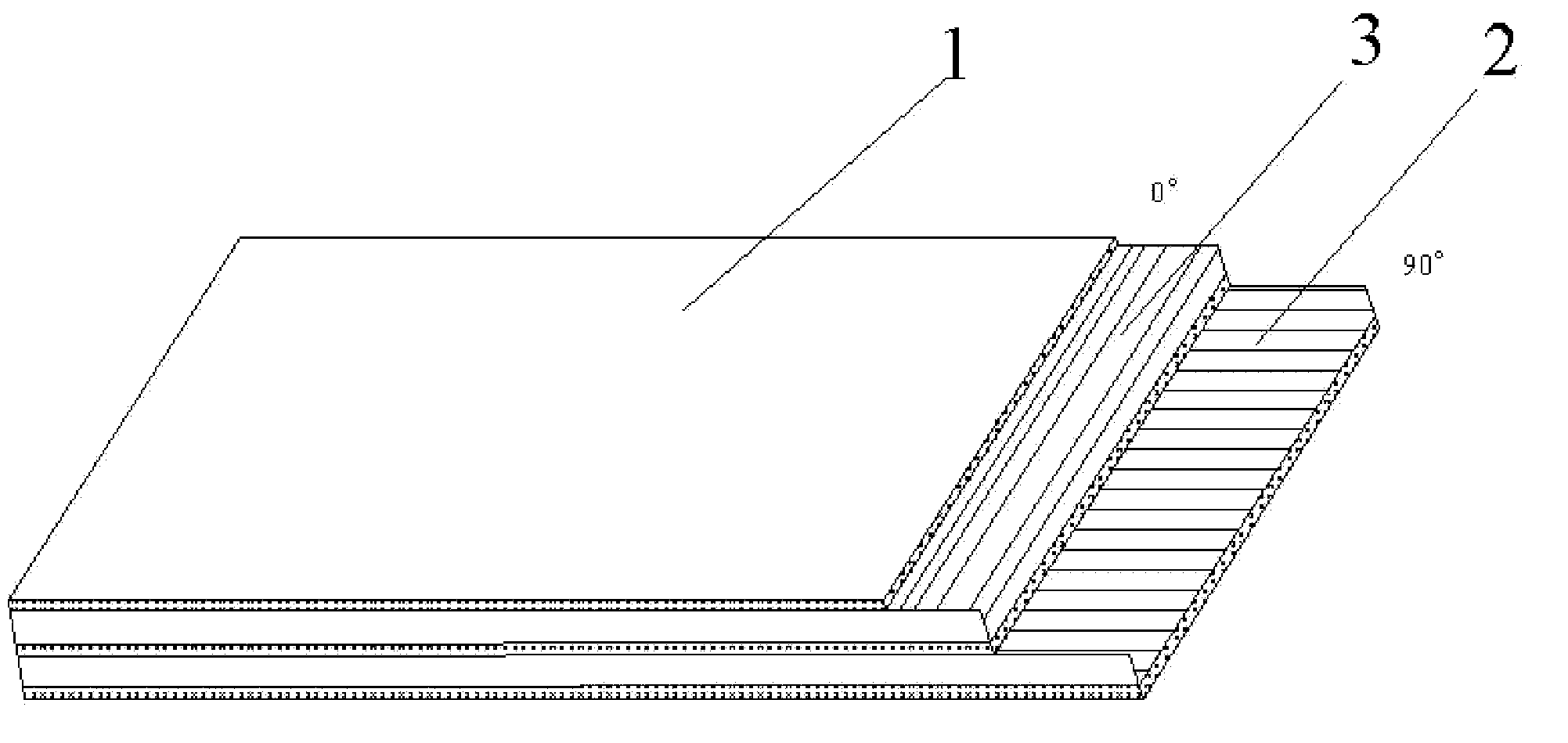

Continuous fiber multi-axial enhanced thermoplasticity preconsolidation sheet and preparation method thereof

InactiveCN102218831AGuaranteed to be straightAvoid breakingSynthetic resin layered productsLaminationPorosityEngineering

The invention discloses a preparation method of a continuous fiber multi-axial enhanced thermoplasticity preconsolidation sheet. Warp direction and weft direction yarns are respectively led out from a creel to be expanded after being preheated by a drying oven, and then the yarns are conveyed to a weaving and overlaying net system by a traction roller. Under the control of a tension system, nets are overlaid in a cross mode to prepare multi-axial wiring harness sheets. The upper layer, the lower layer and the middle layer of the fabric sheet are respectively overlaid with the modified thermoplasticity resin film to prepare preformed thermoplasticity base material. The base material is introduced into the drying oven to be plastified at high temperature, and the sheet is subjected to cold pressing and shaping after continuous roll-in melting dipping to prepare the multi-axial enhanced preconsolidation sheet. According to the warp knitting wiring harness and the tentering dipping technology disclosed by the invention, the fabric wiring harness structure is kept, the dry fiber zone in material is eliminated, the compactness of the material is improved, and the porosity of the material is lowered; the fabric fibers of different directions construct higher specific strength of the thermoplasticity composite material; and the new technology breaks through the technical bottleneck that high-performance fiber fabric is difficult to dip.

Owner:CHANGZHOU HONGFA ZONGHENG ADVANCED MATERIAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com