Patents

Literature

2855results about "Carbon fibres" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

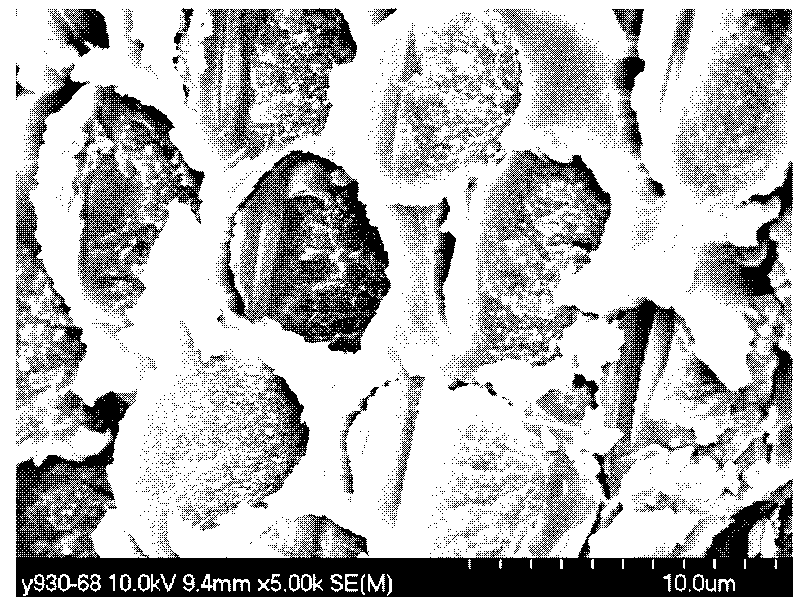

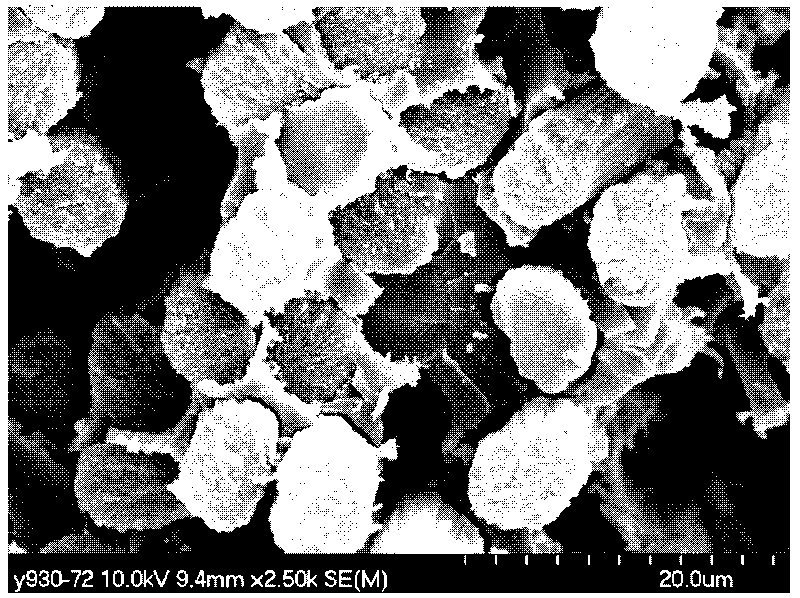

Hybrid nano-filament anode compositions for lithium ion batteries

ActiveUS20090169996A1Superior multiple-cycle behaviorImprove cycle lifeElectrochemical processing of electrodesElectrode thermal treatmentLithium-ion batteryNanometre

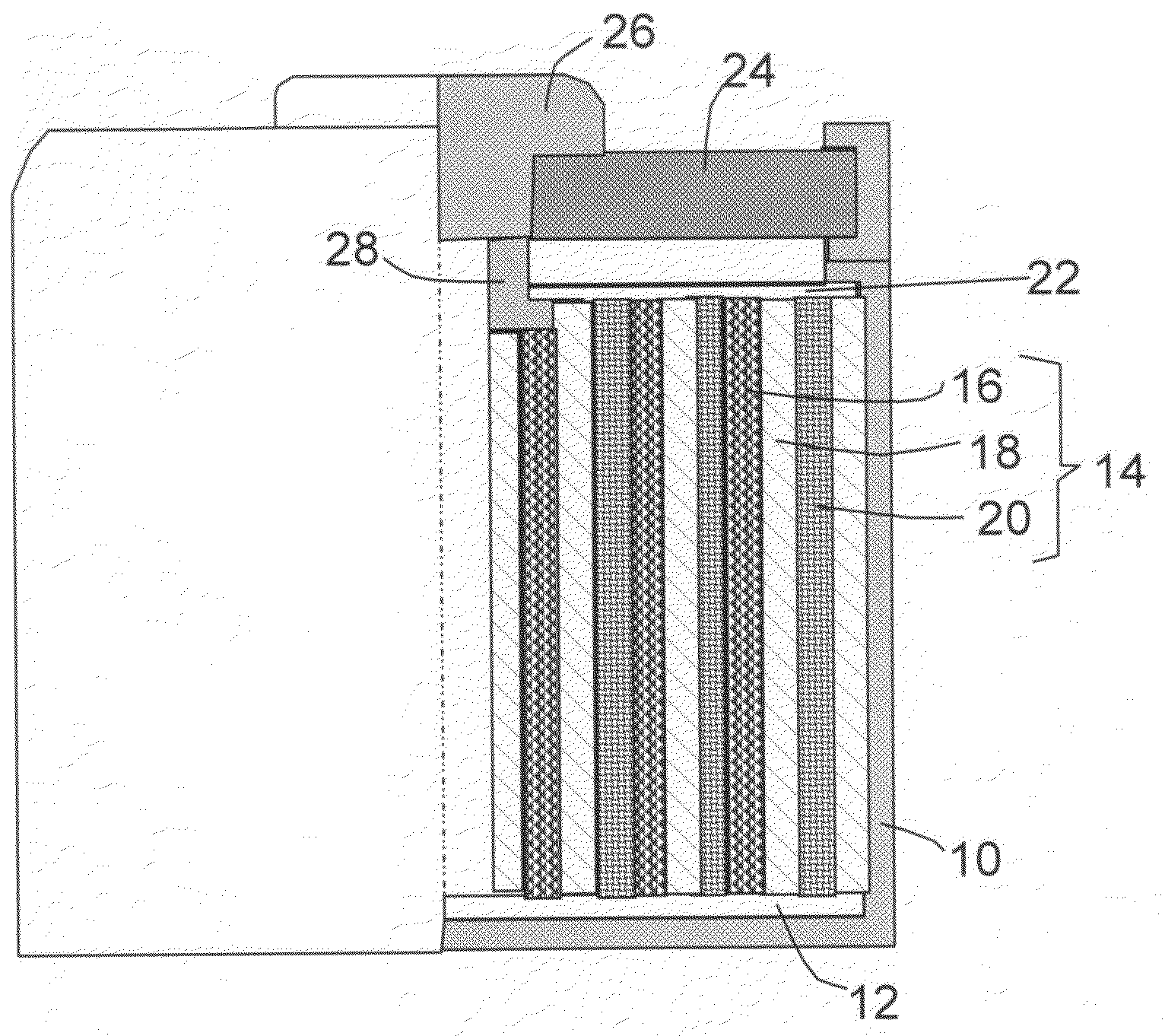

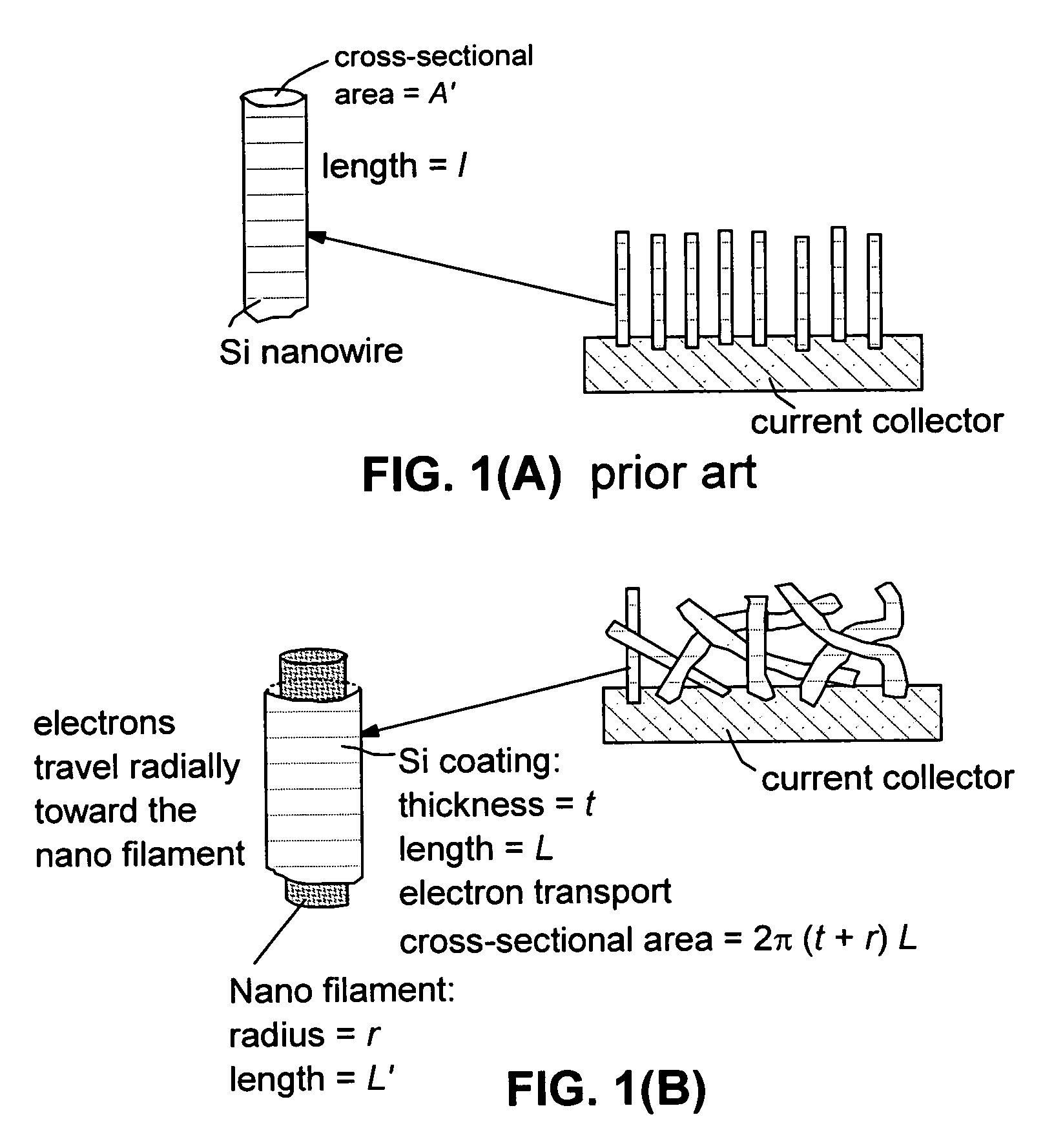

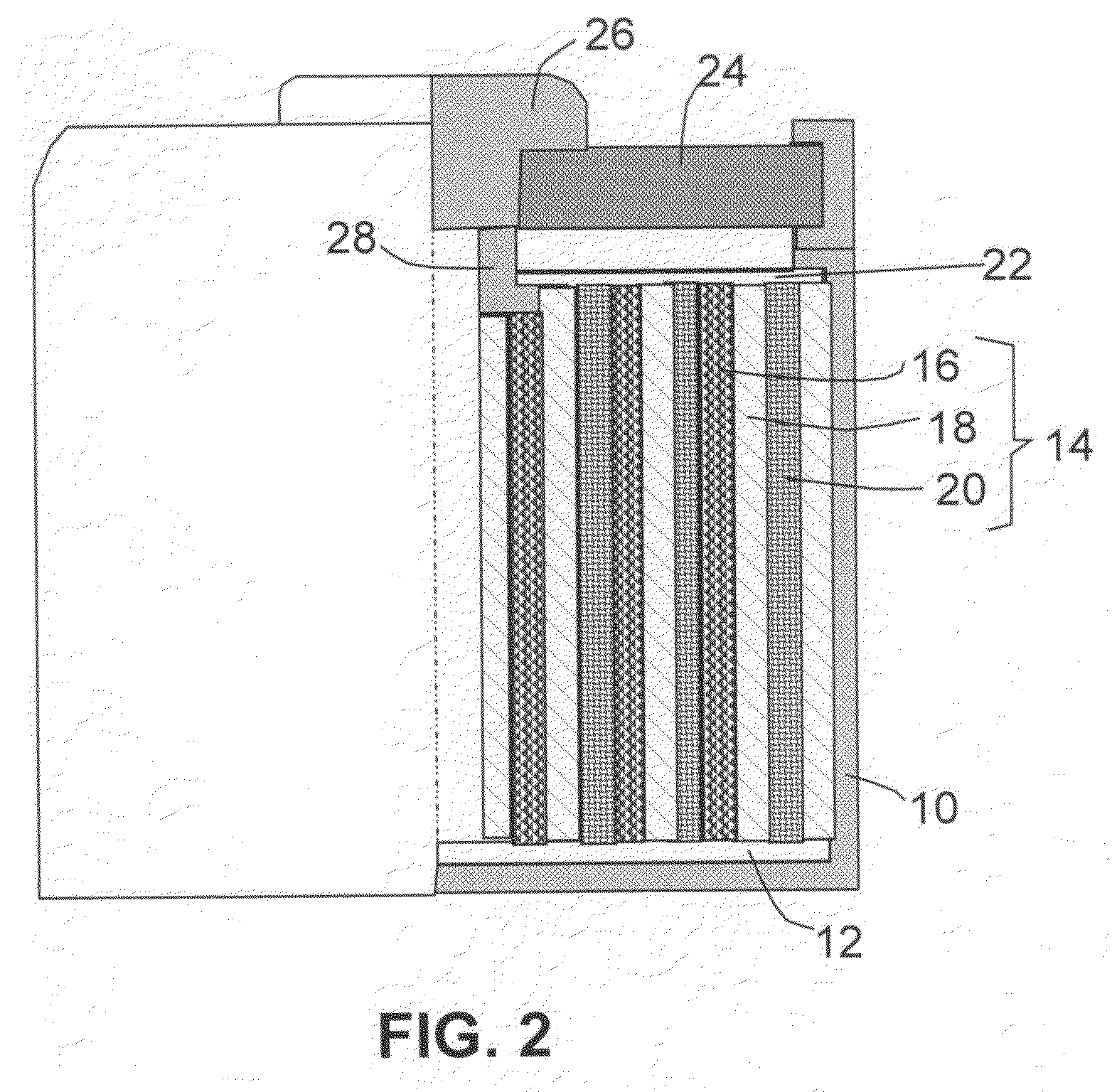

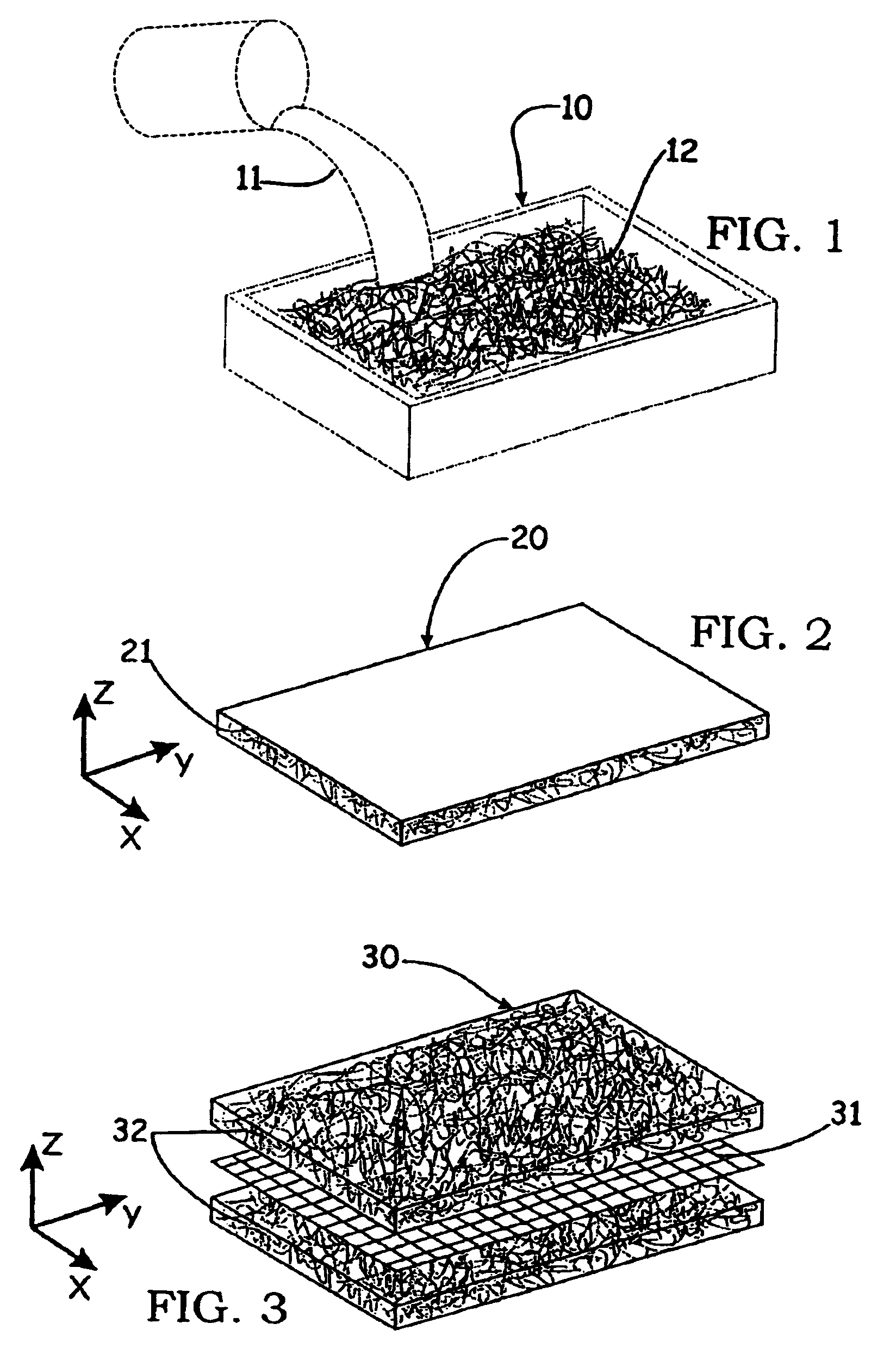

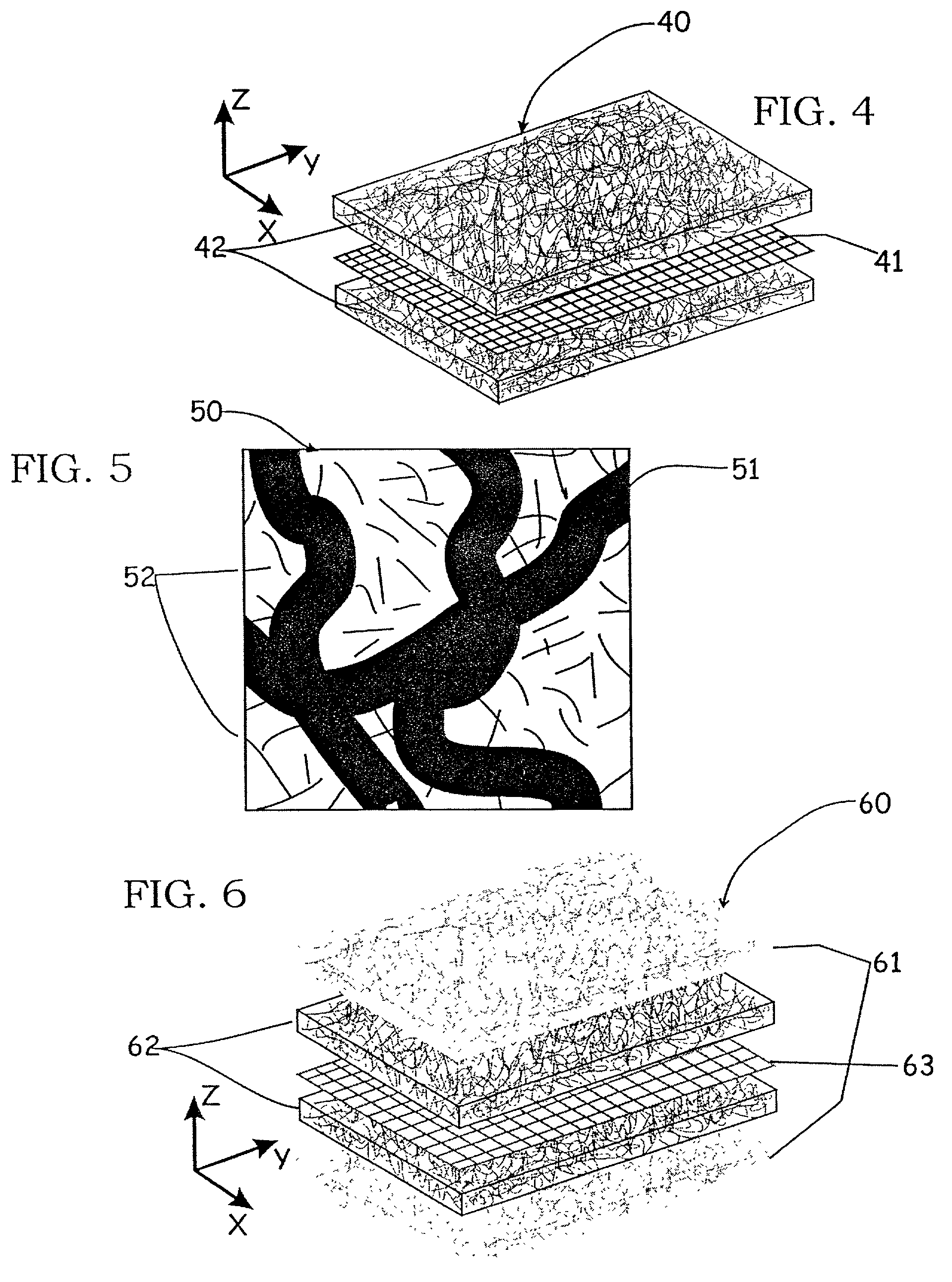

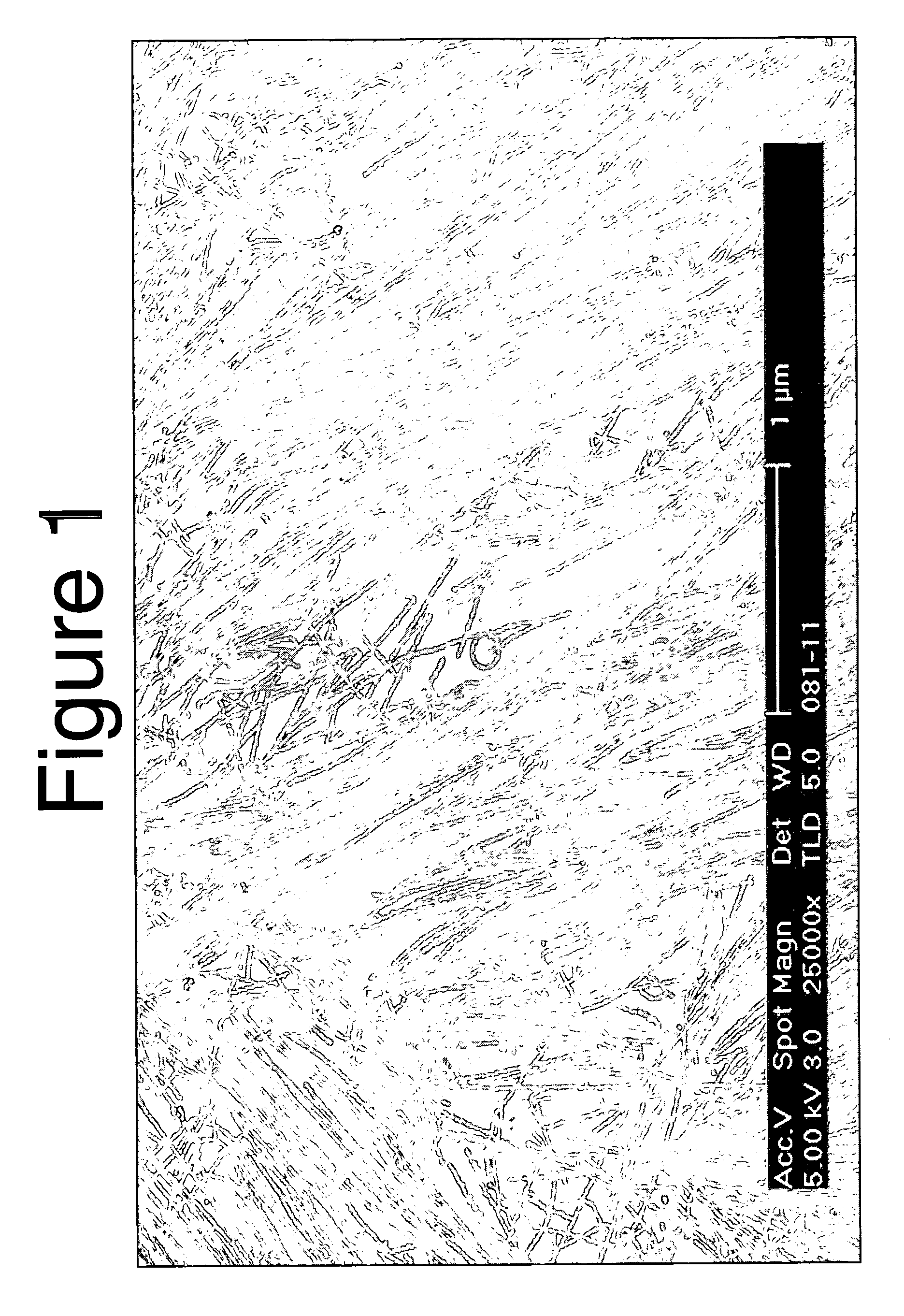

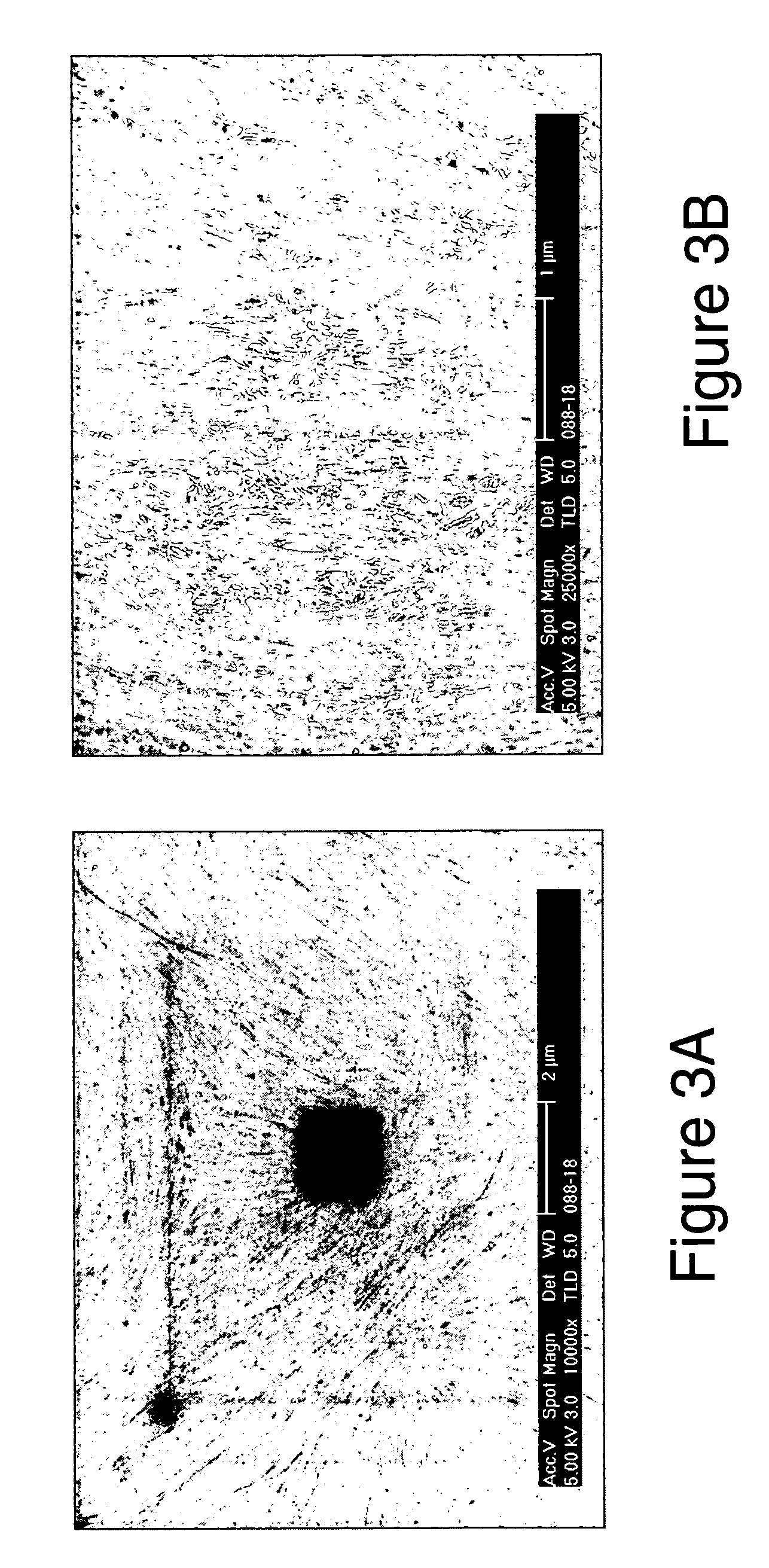

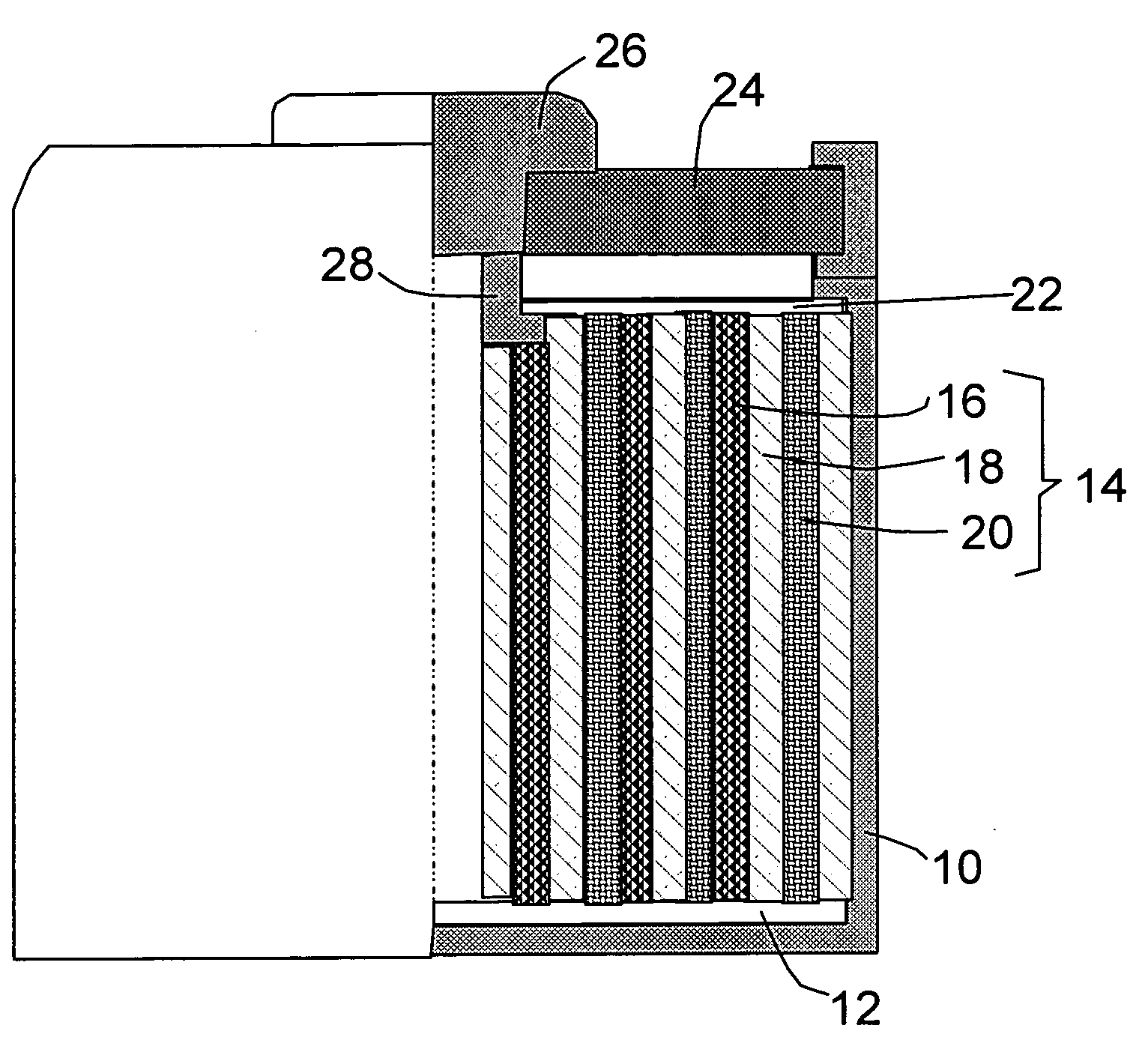

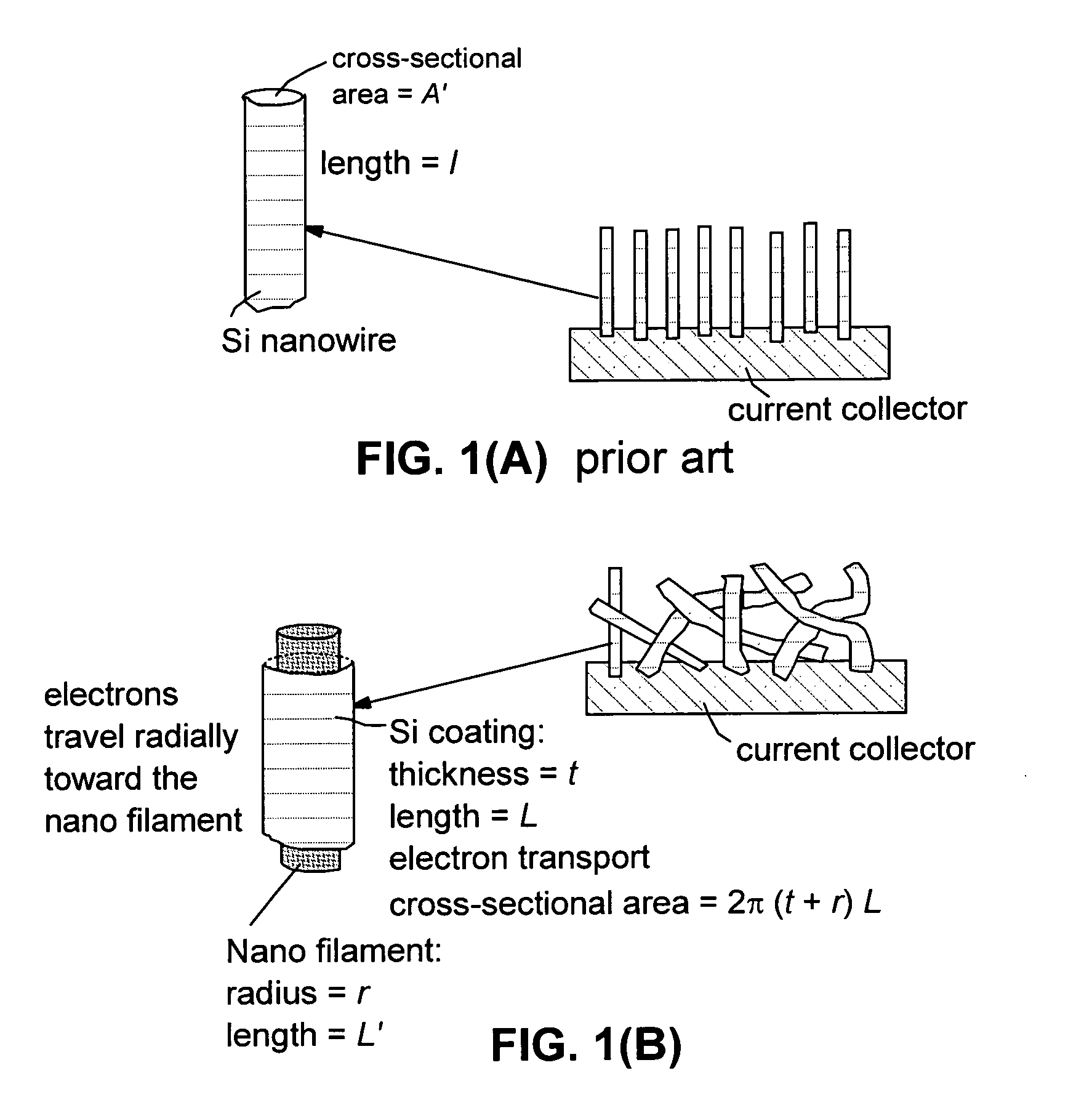

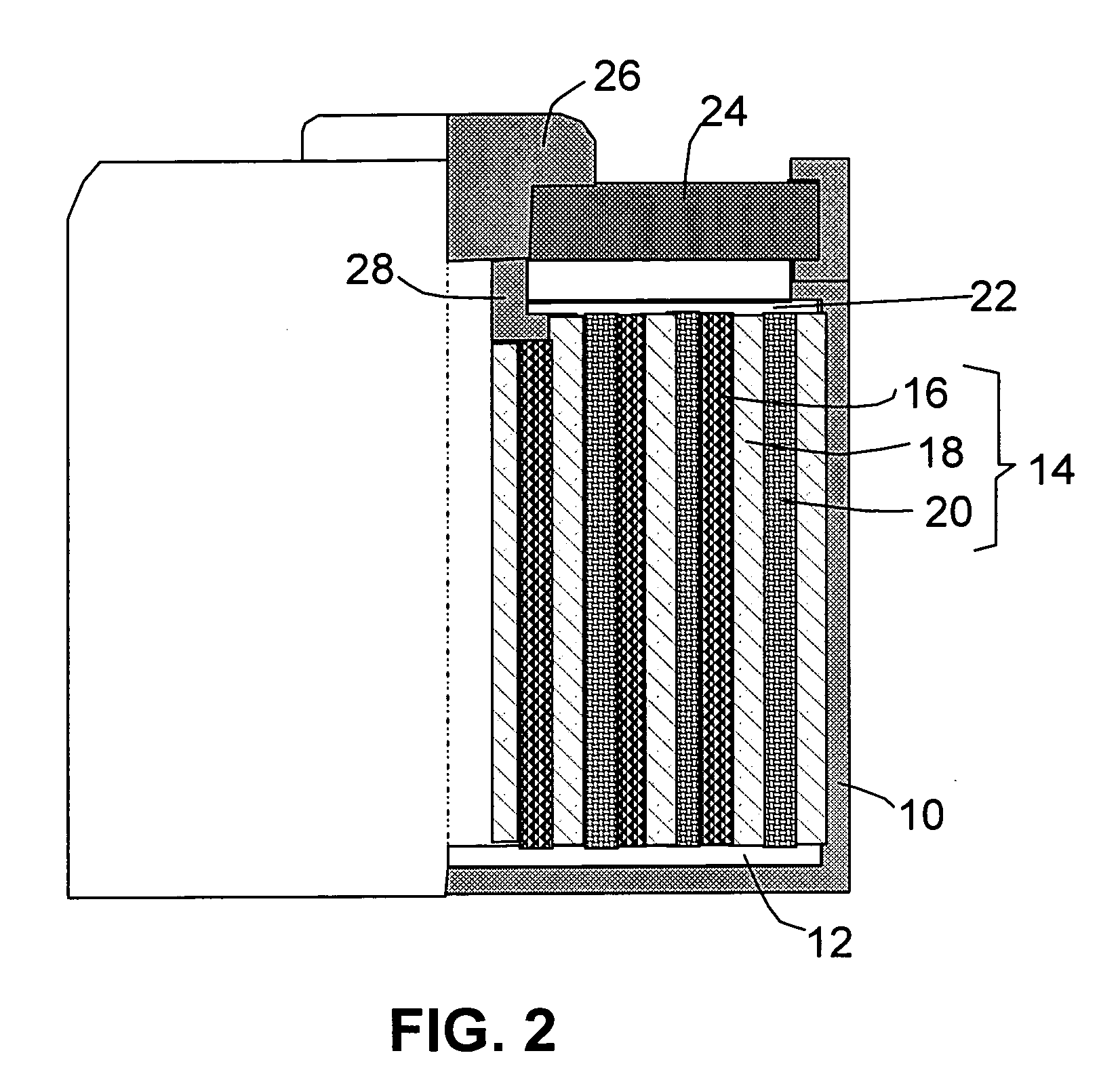

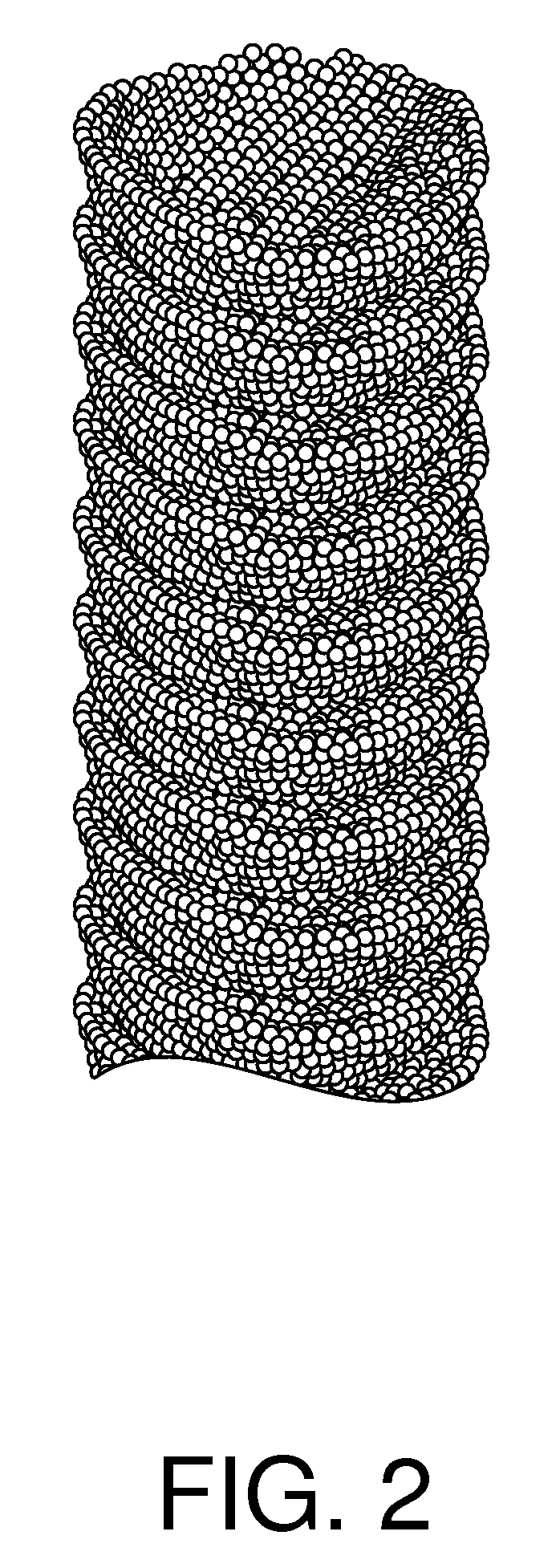

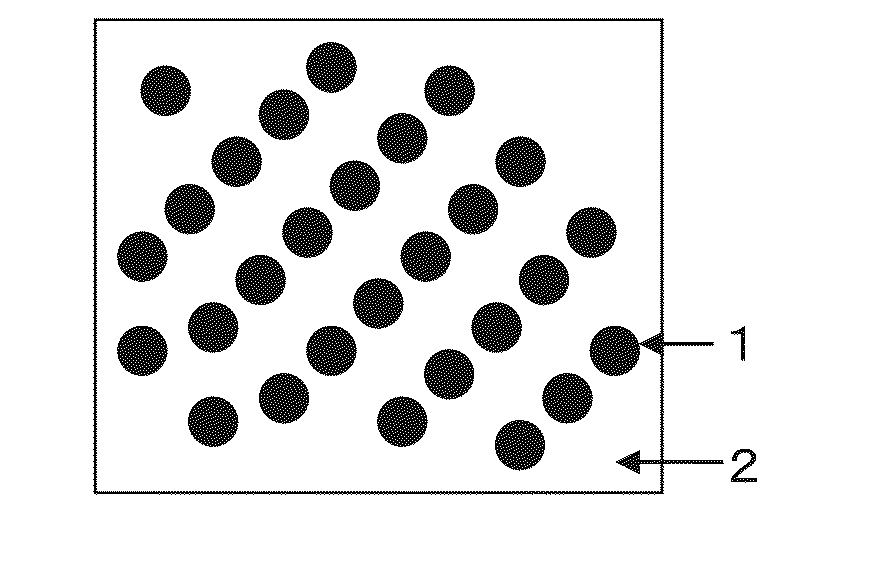

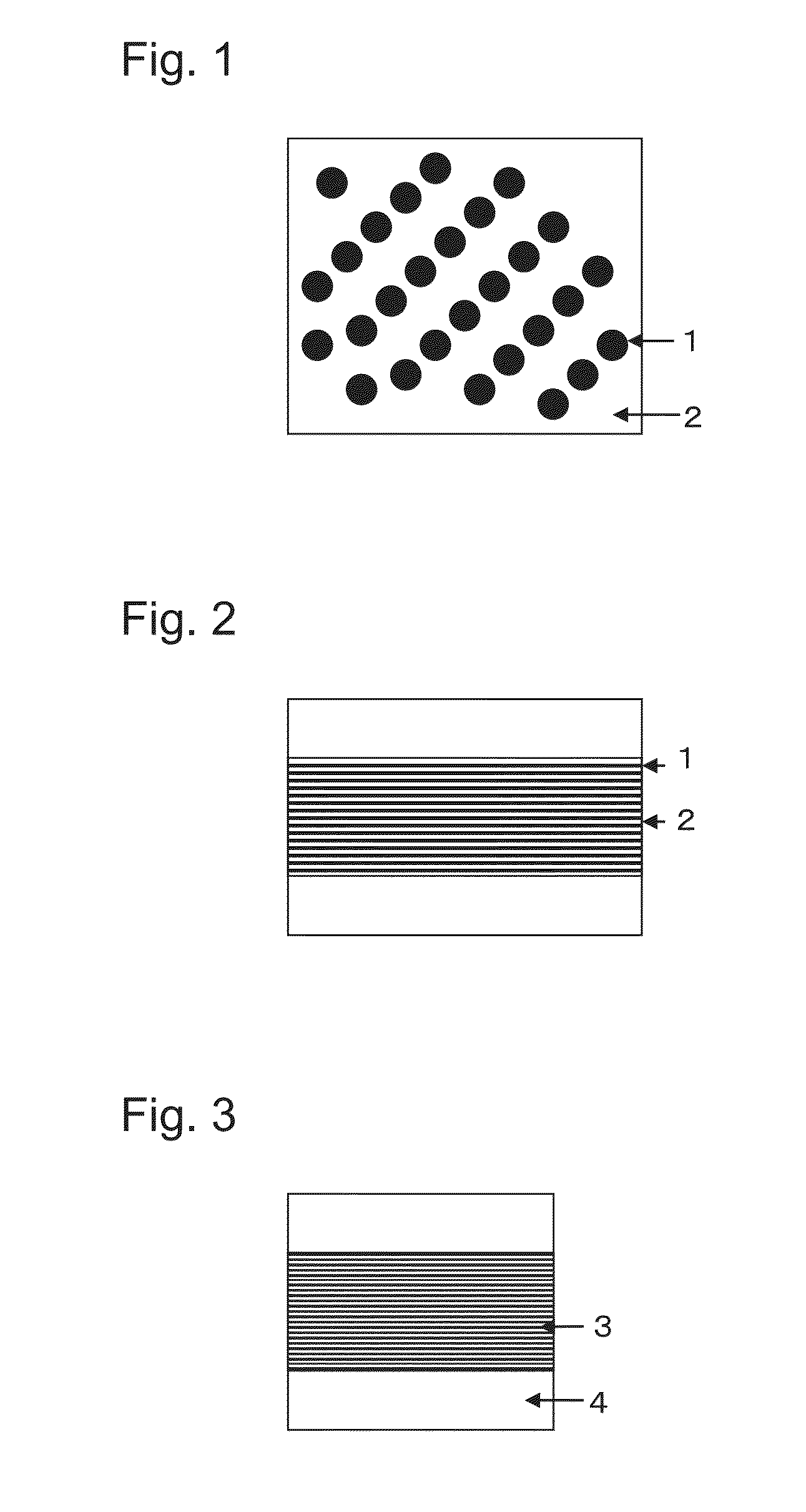

This invention provides a hybrid nano-filament composition for use as an electrochemical cell electrode. The composition comprises: (a) an aggregate of nanometer-scaled, electrically conductive filaments that are substantially interconnected, intersected, or percolated to form a porous, electrically conductive filament network comprising substantially interconnected pores, wherein the filaments have an elongate dimension and a first transverse dimension with the first transverse dimension being less than 500 nm (preferably less than 100 nm) and an aspect ratio of the elongate dimension to the first transverse dimension greater than 10; and (b) micron- or nanometer-scaled coating that is deposited on a surface of the filaments, wherein the coating comprises an anode active material capable of absorbing and desorbing lithium ions and the coating has a thickness less than 20 μm (preferably less than 1 μm). Also provided is a lithium ion battery comprising such an electrode as an anode. The battery exhibits an exceptionally high specific capacity, an excellent reversible capacity, and a long cycle life.

Owner:GLOBAL GRAPHENE GRP INC

Aerogel composite with fibrous batting

InactiveUS7078359B2Improve thermal efficiencyMinimized volumeShielding materialsCeilingsUltrasound attenuationPliability

Aerogel composite materials having a lofty fibrous batting reinforcement preferably in combination with one or both of individual short randomly oriented microfibers and conductive layers exhibit improved performance in one or all of flexibility, drape, durability, resistance to sintering, x-y thermal conductivity, x-y electrical conductivity, RFI-EMI attenuation, and / or burn-through resistance.

Owner:ASPEN AEROGELS INC

Aqueous carbon nanotube applicator liquids and methods for producing applicator liquids thereof

ActiveUS20060204427A1Low toxicityEasy to takeMaterial nanotechnologyCarbon fibresLiquid mediumVolumetric Mass Density

Certain applicator liquids and method of making the applicator liquids are described. The applicator liquids can be used to form nanotube films or fabrics of controlled properties. An applicator liquid for preparation of a nanotube film or fabric includes a controlled concentration of nanotubes dispersed in a liquid medium containing water. The controlled concentration is sufficient to form a nanotube fabric or film of preselected density and uniformity.

Owner:ZEON CORP

Method of producing hybrid nano-filament electrodes for lithium metal or lithium ion batteries

ActiveUS20090169725A1High reversible capacityLower internal resistanceElectrochemical processing of electrodesElectrode thermal treatmentChemical LinkageFiber

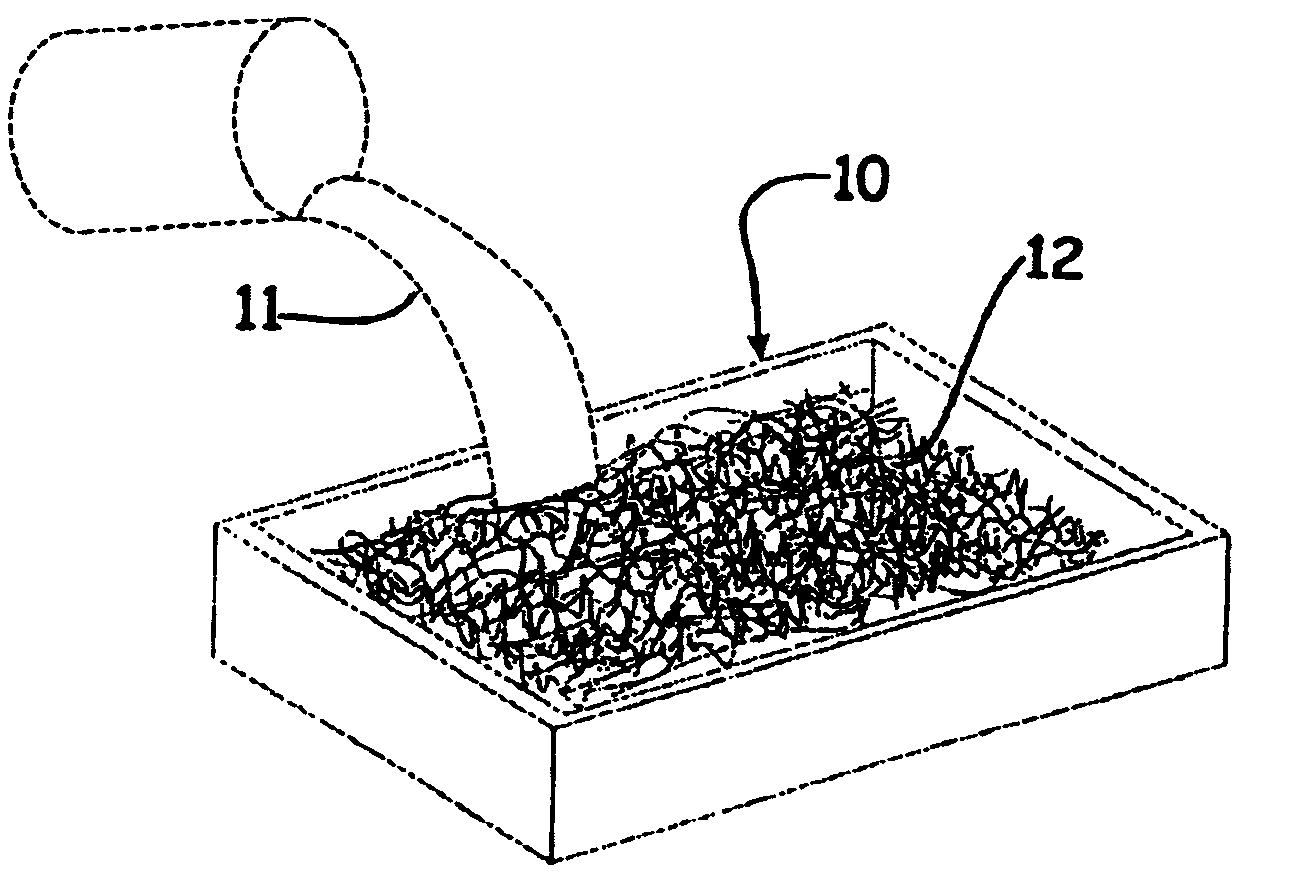

Disclosed is a method of producing a hybrid nano-filament composition for use in a lithium battery electrode. The method comprises: (a) providing an aggregate of nanometer-scaled, electrically conductive filaments that are substantially interconnected, intersected, physically contacted, or chemically bonded to form a porous network of electrically conductive filaments, wherein the filaments comprise electro-spun nano-fibers that have a diameter less than 500 nm (preferably less than 100 nm); and (b) depositing micron- or nanometer-scaled coating onto a surface of the electro-spun nano-fibers, wherein the coating comprises an electro-active material capable of absorbing and desorbing lithium ions and the coating has a thickness less than 10 μm (preferably less than 1 μm). The same method can be followed to produce an anode or a cathode. The battery featuring an anode or cathode made with this method exhibits an exceptionally high specific capacity, an excellent reversible capacity, and a long cycle life.

Owner:GLOBAL GRAPHENE GRP INC

Modification of reinforcing fiber tows used in composite materials by using nanoreinforcements

ActiveUS20090176112A1High strengthIncrease stiffnessMaterial nanotechnologyPump componentsFiberCarbon fibers

This invention is directed to nacelles and nacelle components for use in aircraft engines. The nacelles and components comprise composite material containing carbon fiber. The carbon fiber comprises from 0.1 to 20 percent by weight nanoreinforcement material.

Owner:THE BF GOODRICH CO +1

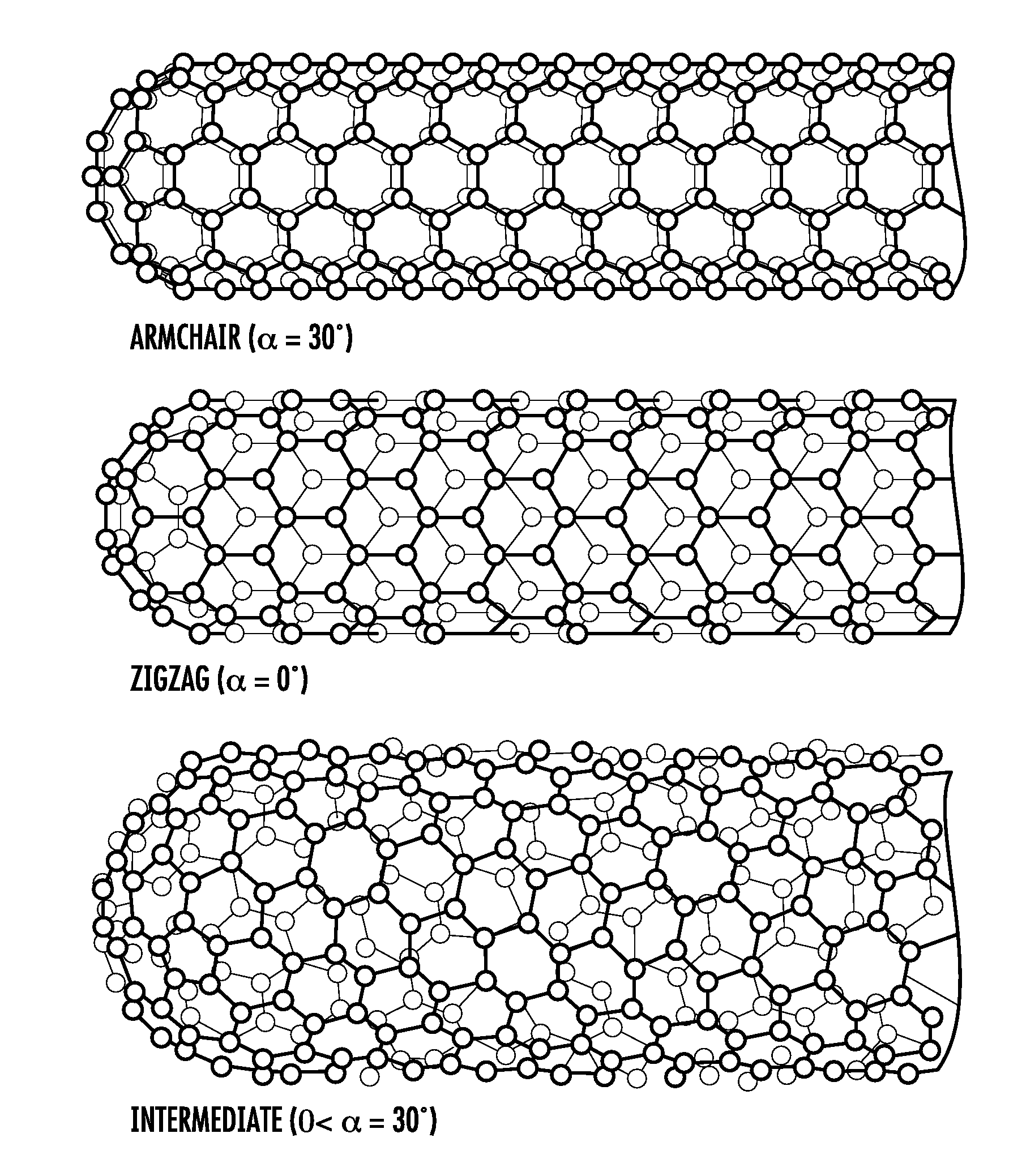

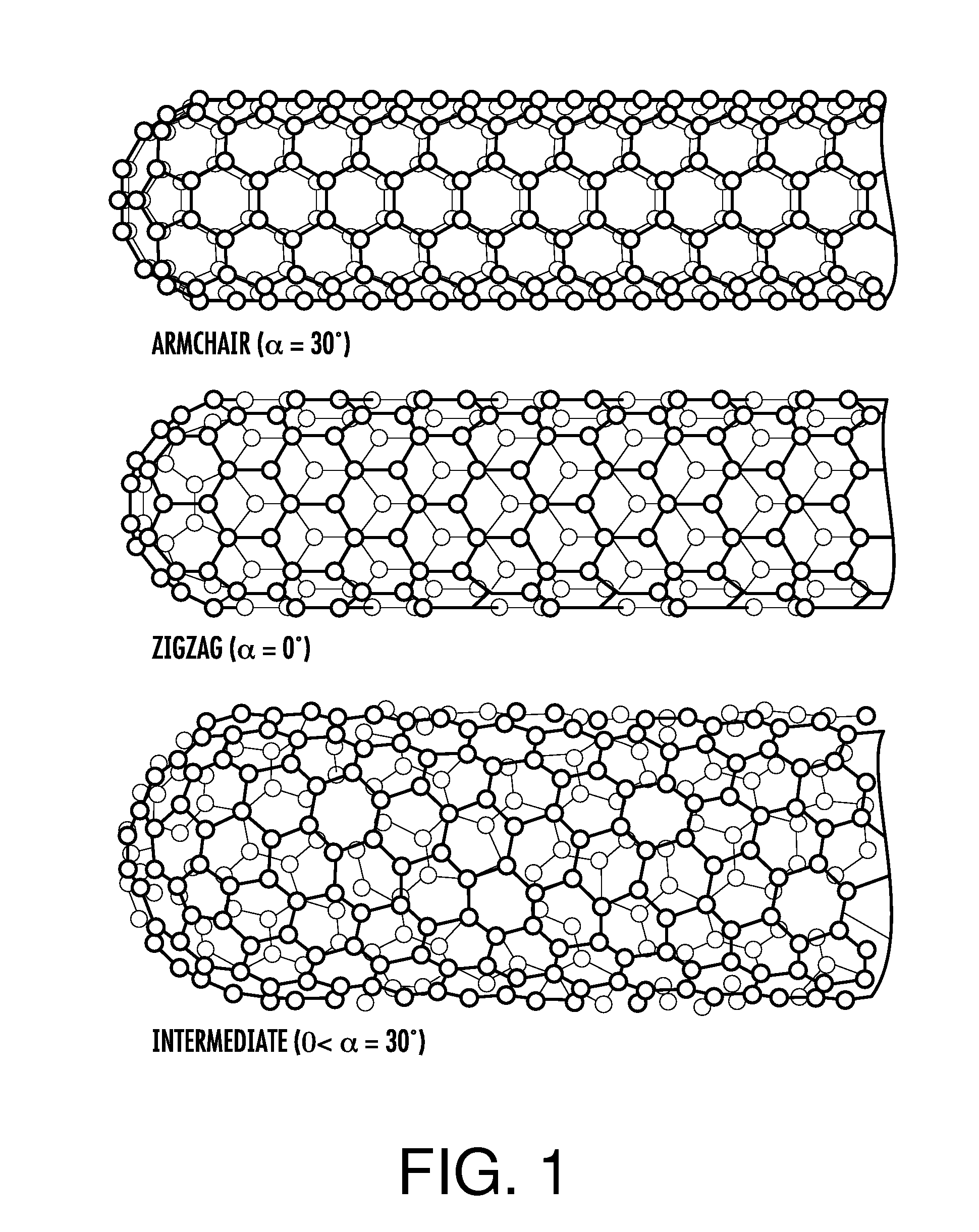

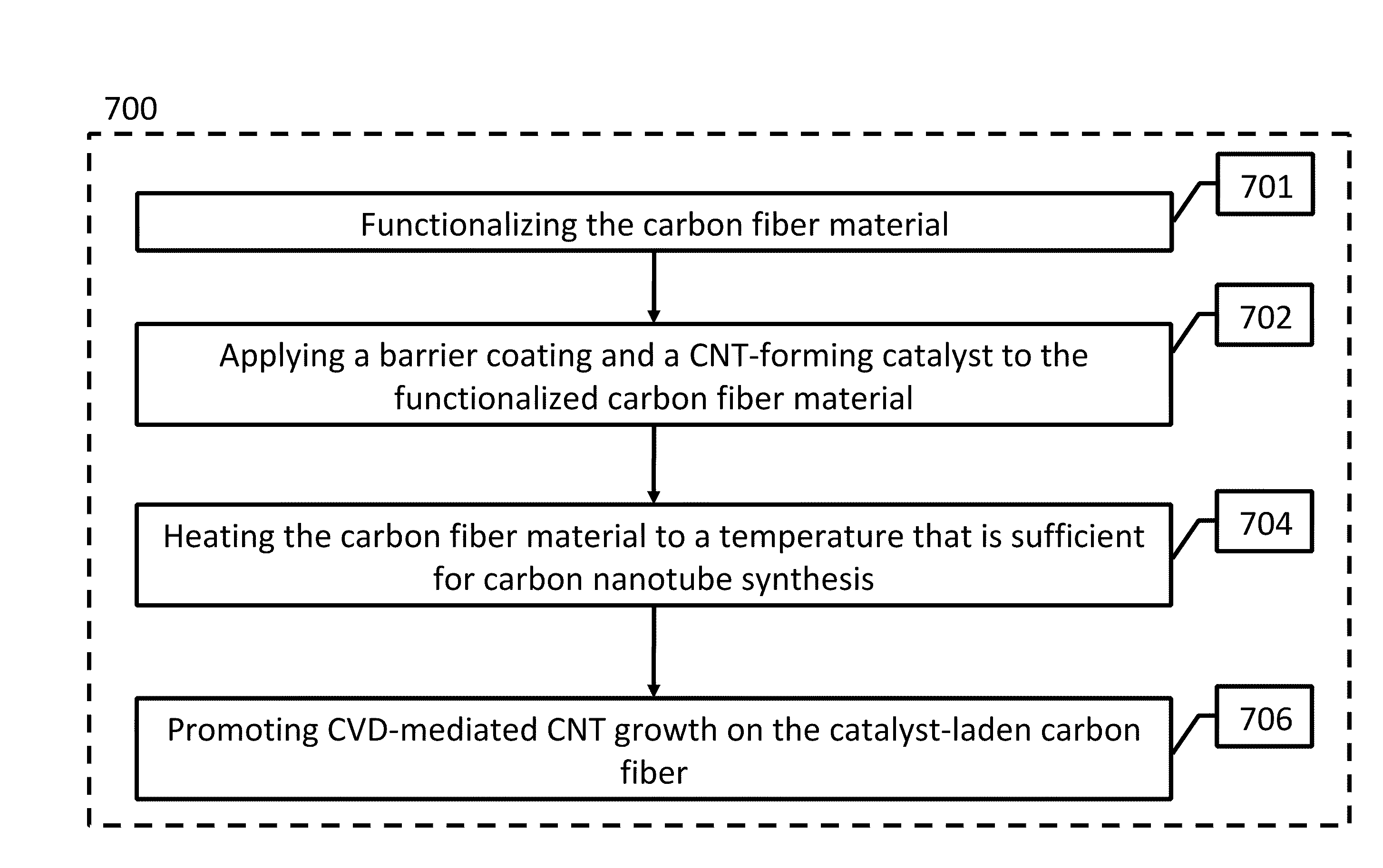

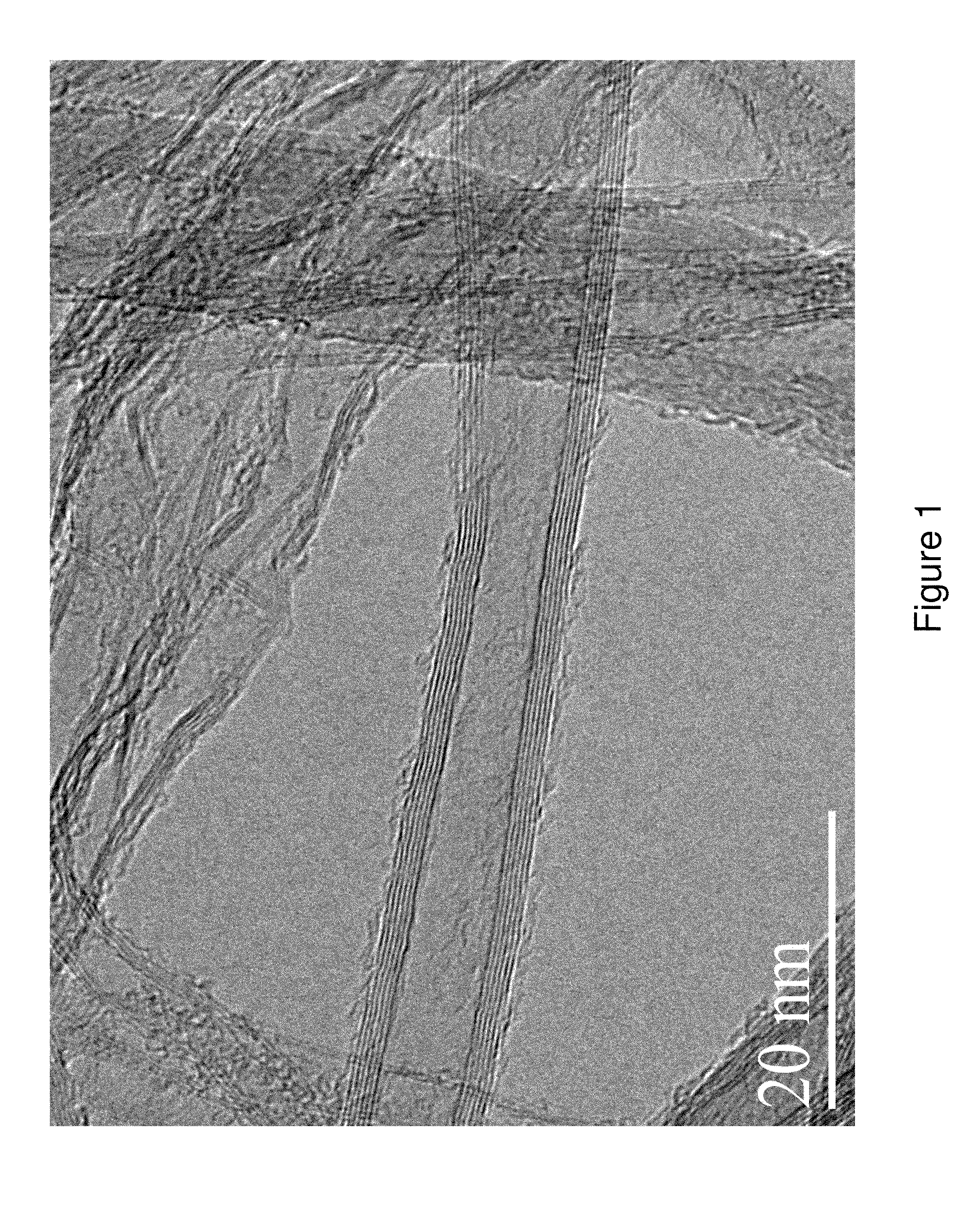

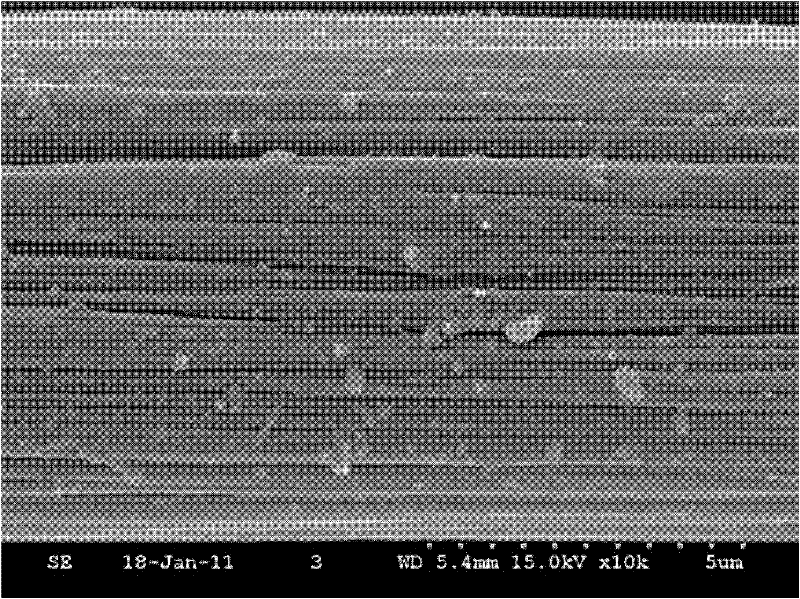

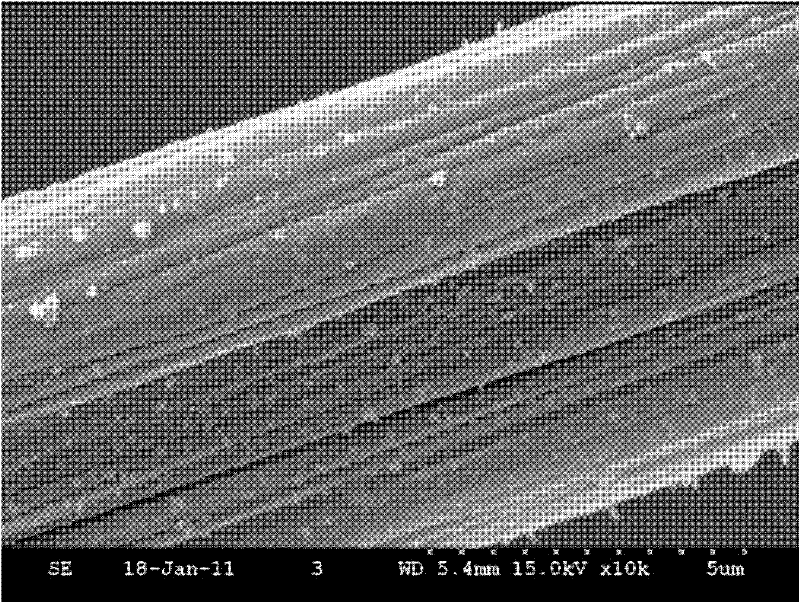

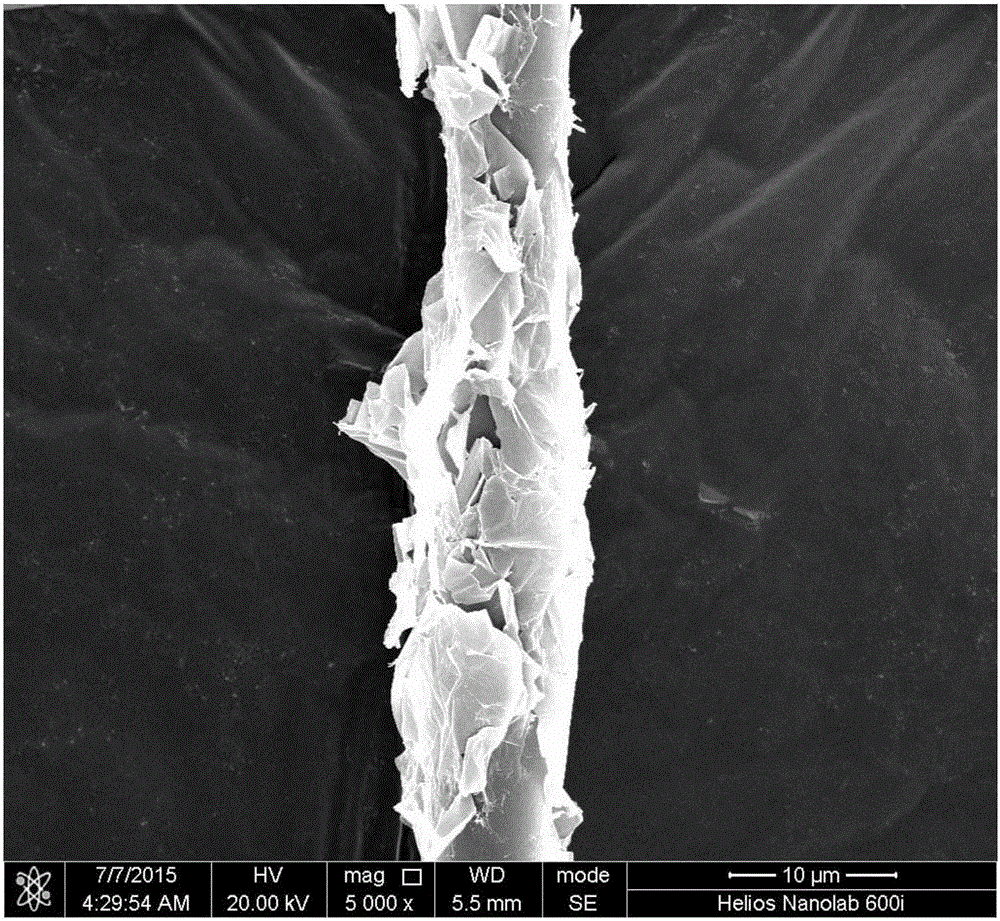

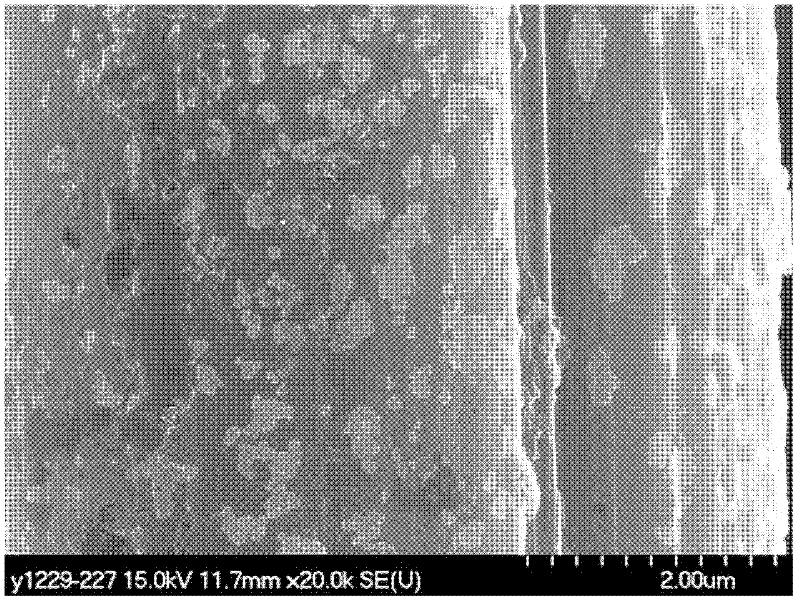

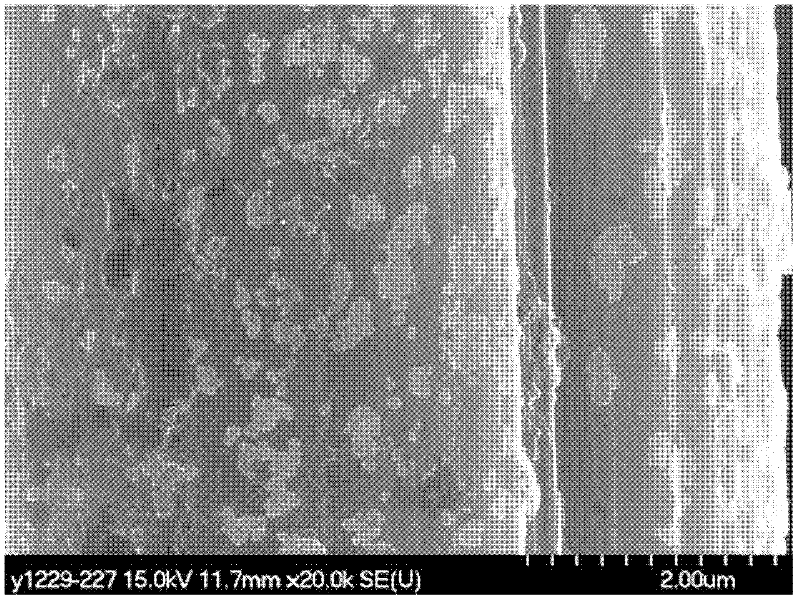

Cnt-infused carbon fiber materials and process therefor

A composition includes a carbon nanotube (CNT)-infused carbon fiber material that includes a carbon fiber material of spoolable dimensions and carbon nanotubes (CNTs) infused to the carbon fiber material. The infused CNTs are uniform in length and uniform in distribution. The CNT infused carbon fiber material also includes a barrier coating conformally disposed about the carbon fiber material, while the CNTs are substantially free of the barrier coating. A continuous CNT infusion process includes: (a) functionalizing a carbon fiber material; (b) disposing a barrier coating on the functionalized carbon fiber material (c) disposing a carbon nanotube (CNT)-forming catalyst on the functionalized carbon fiber material; and (d) synthesizing carbon nanotubes, thereby forming a carbon nanotube-infused carbon fiber material.

Owner:APPL NANOSTRUCTURED SOLUTIONS LLC

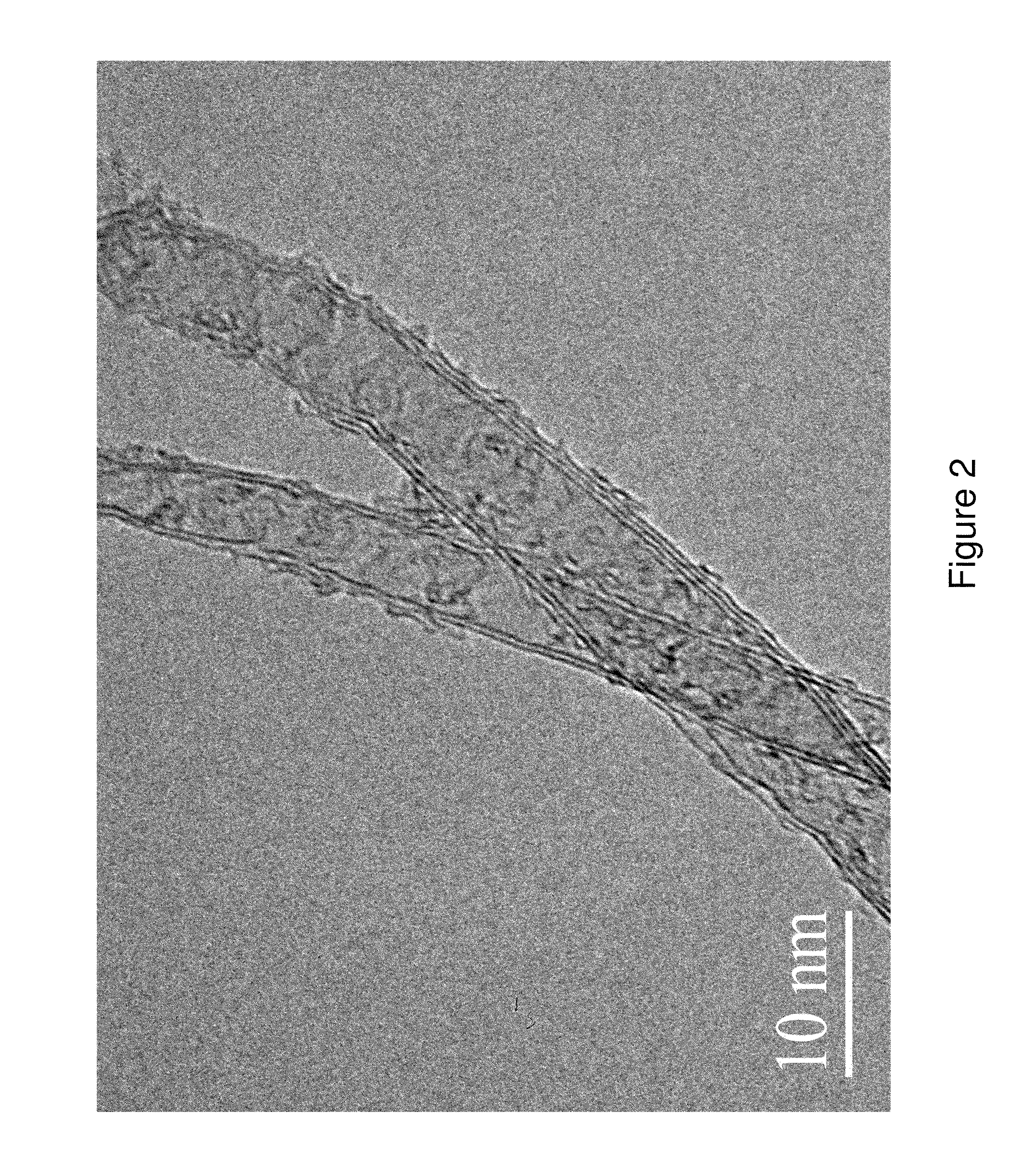

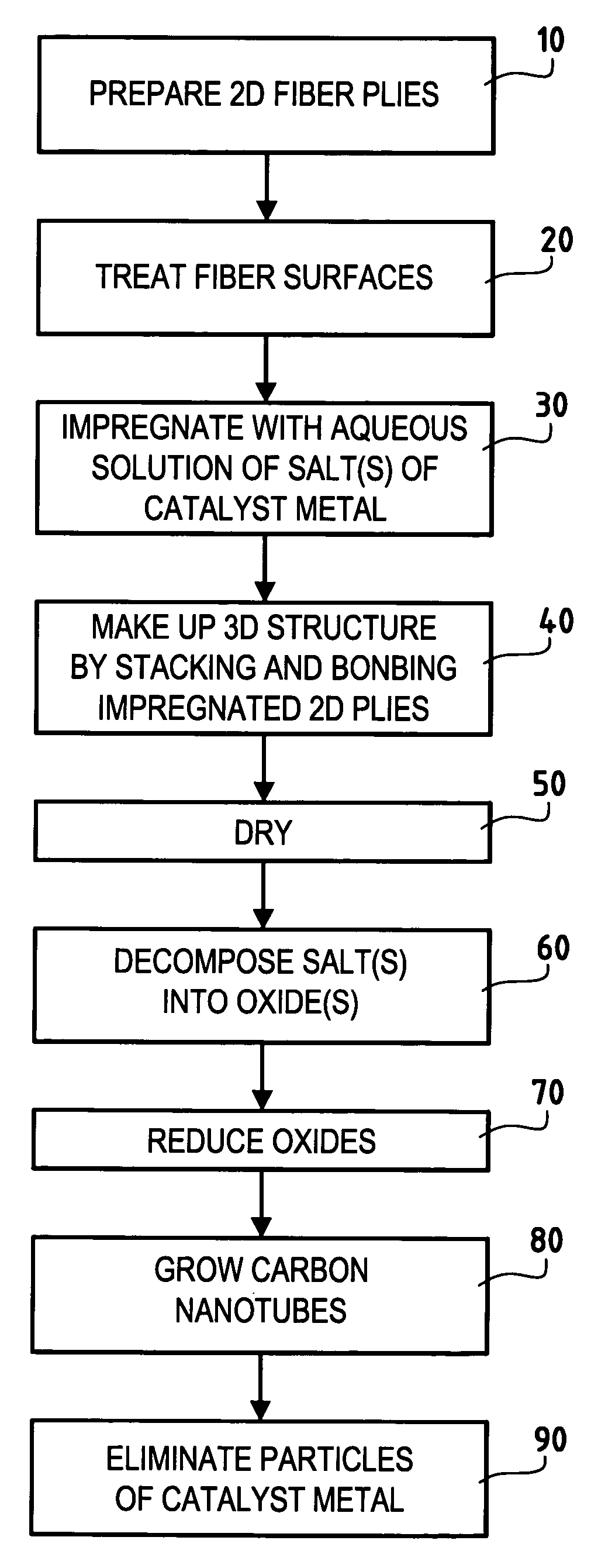

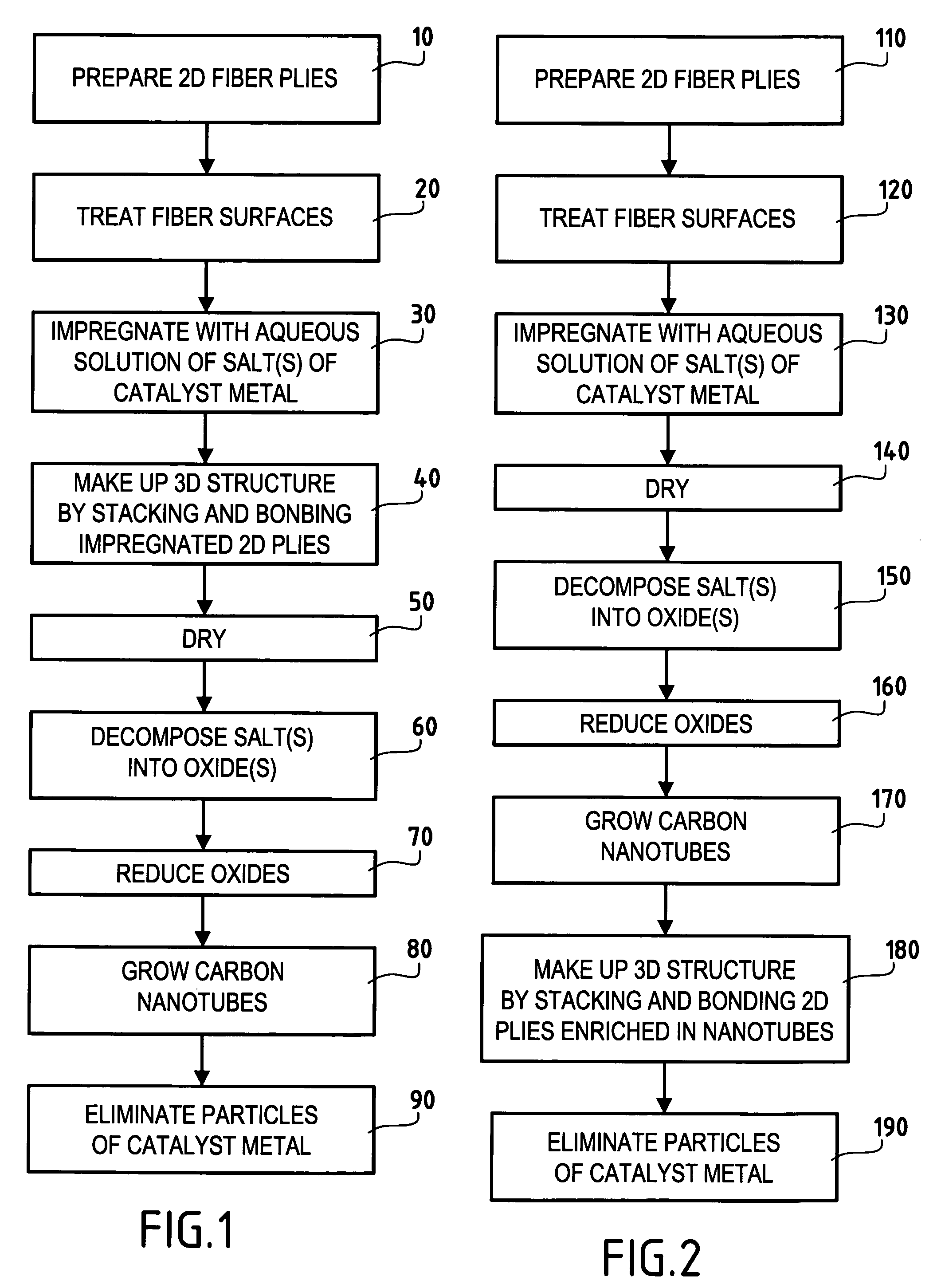

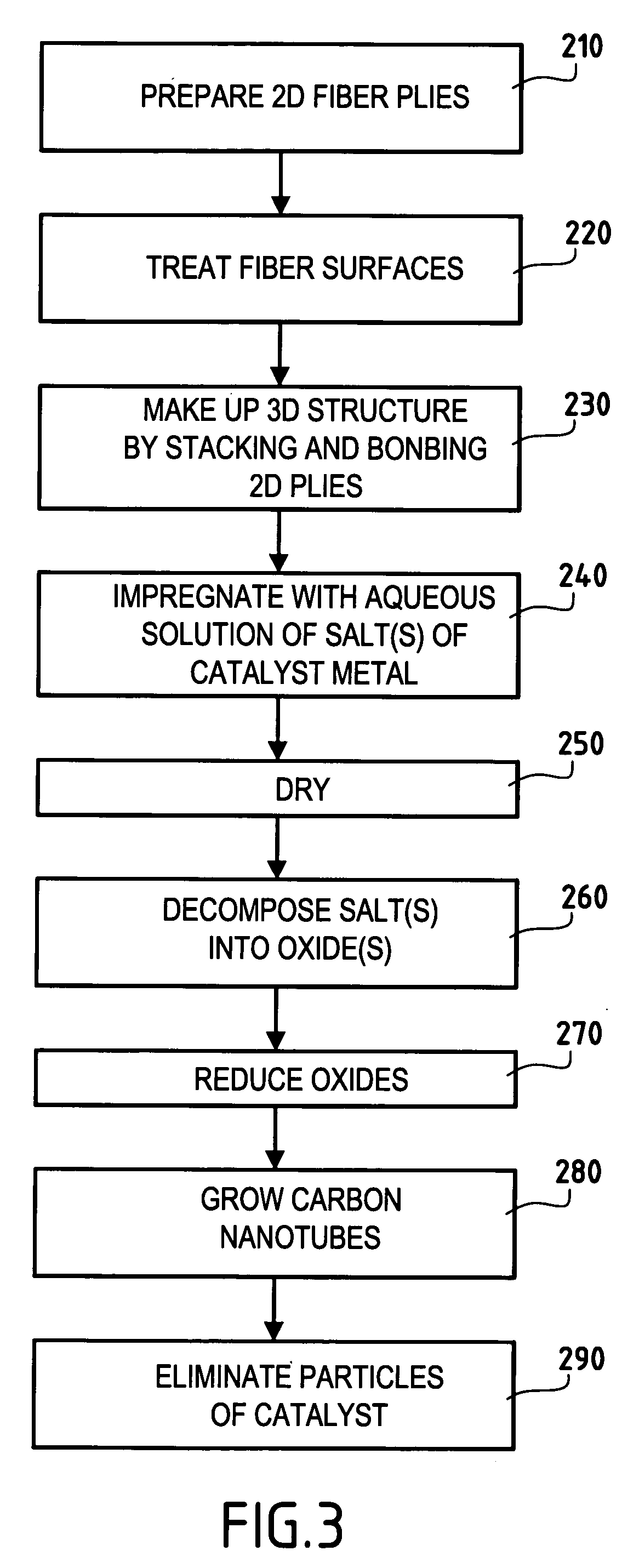

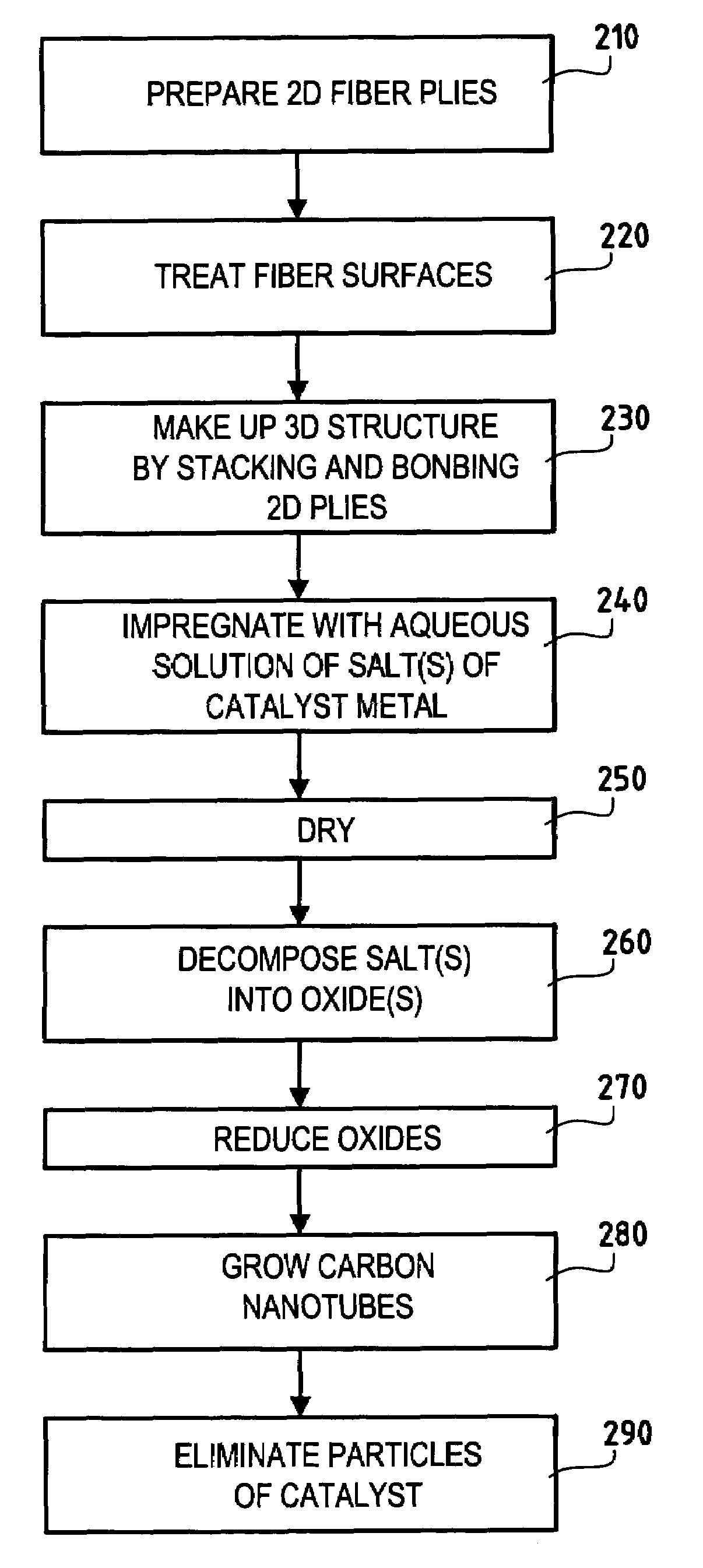

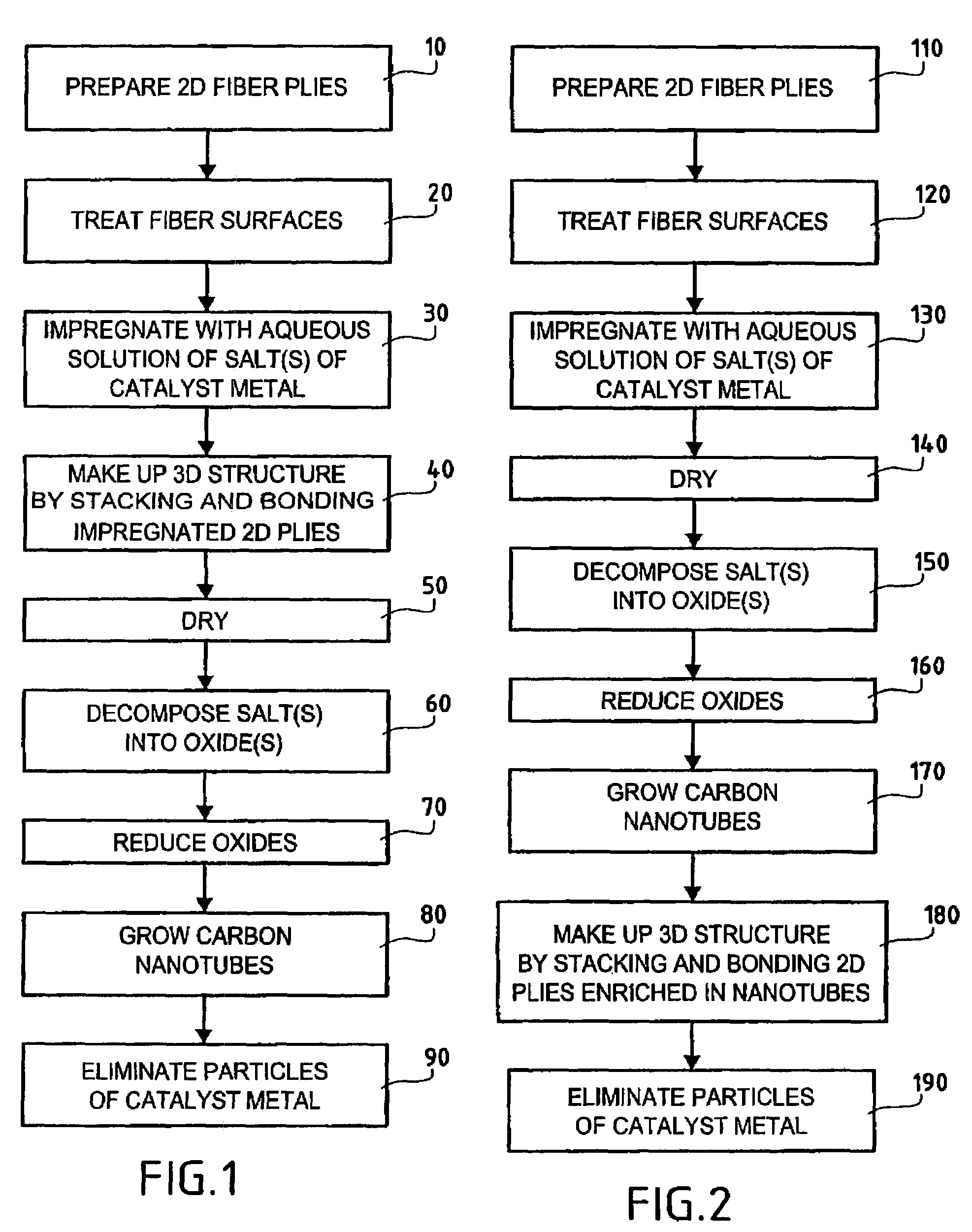

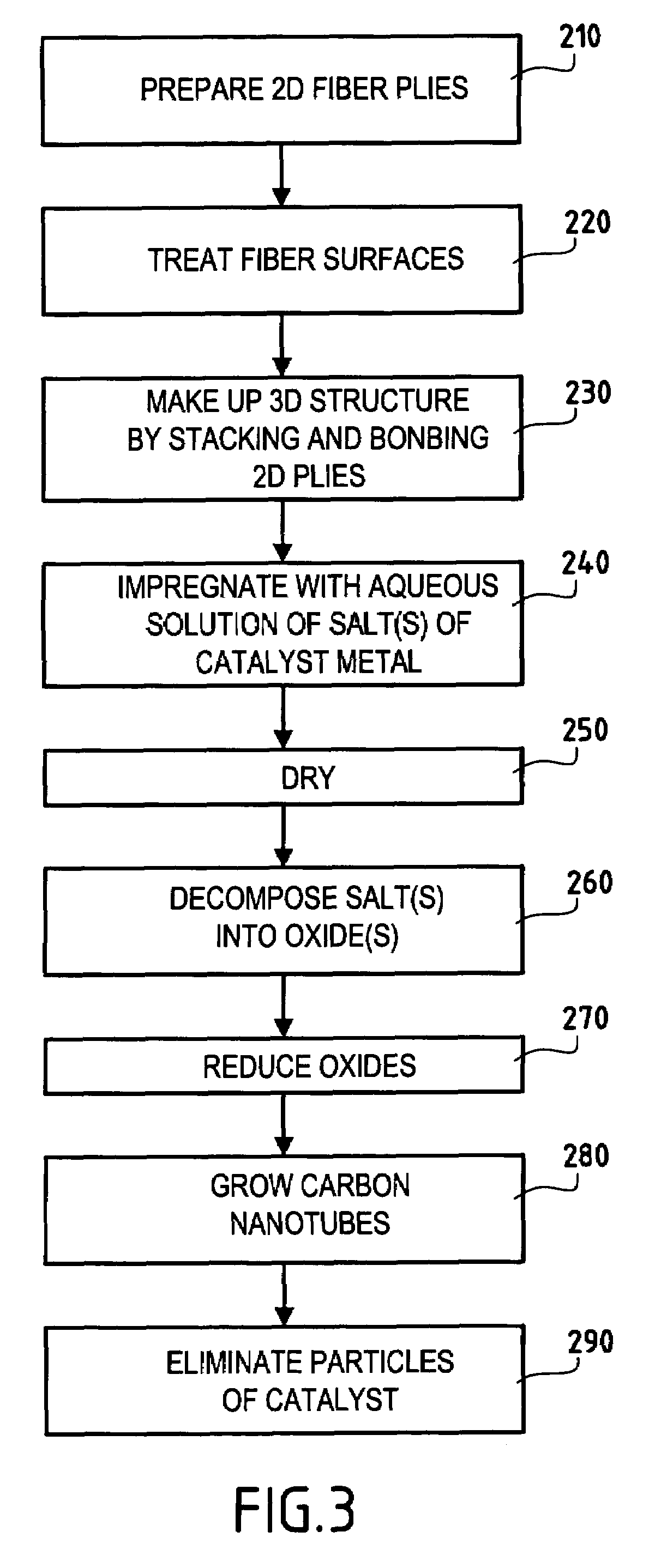

Three-dimensional fiber structure of refractory fibers, a method of making it, and thermostructural composite materials, in particular friction parts, made therefrom

ActiveUS20050176329A1Improve propertiesEasy to prepareMaterial nanotechnologyCarbon fibresMetallurgyCarbon nanotube

Carbon nanotubes are incorporated in the fiber structure by growing them on the refractory fibers of the substrate so as to obtain a three-dimensional substrate made of refractory fibers and enriched in carbon nanotubes. The substrate is densified with a matrix to form a part of composite material such as a friction part of C / C composite material.

Owner:CENT NAT DE LA RECHERCHE SCI

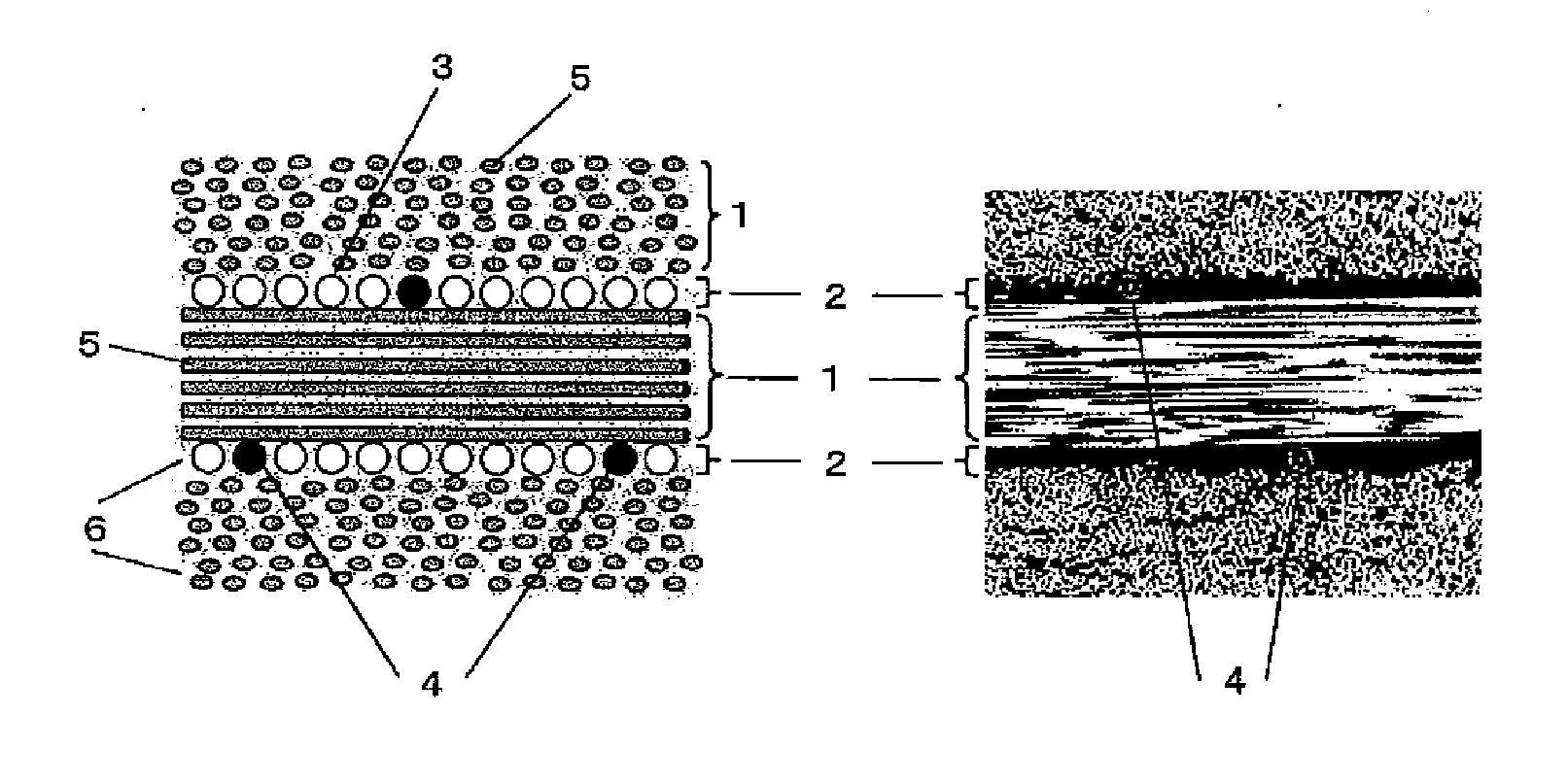

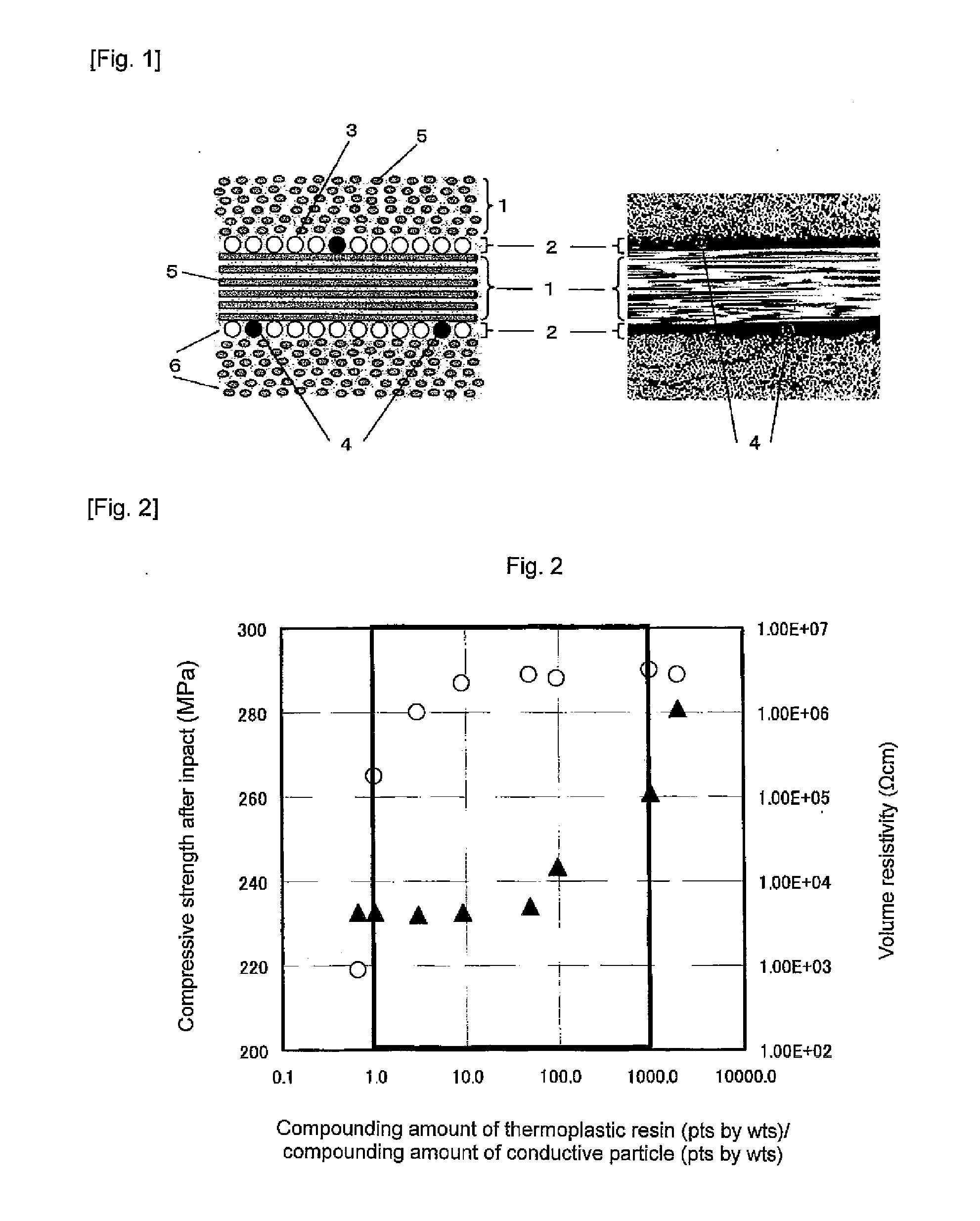

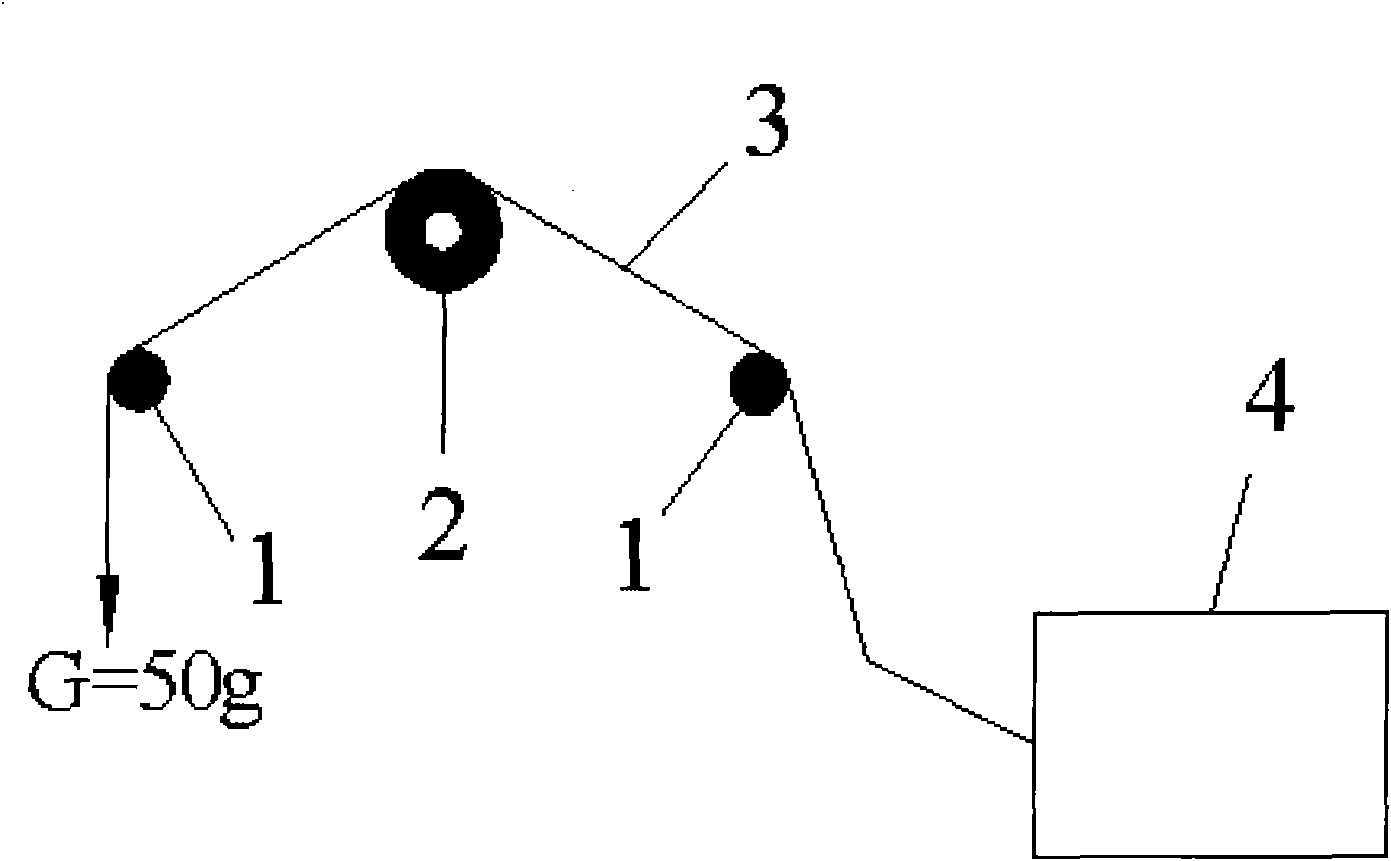

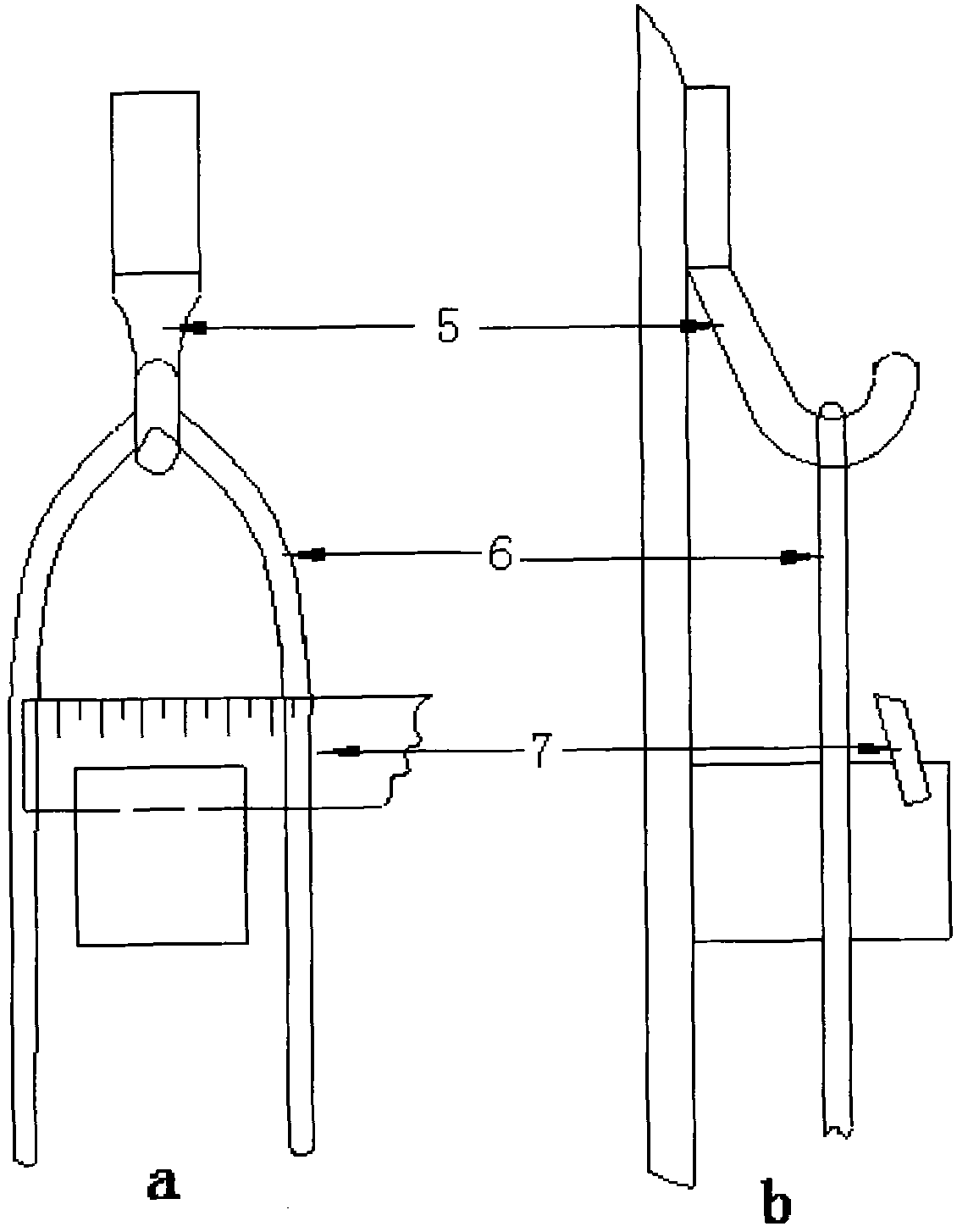

Prepreg and carbon fiber reinforced composite materials

ActiveUS20100178487A1Improve conductivityImprove impact resistanceNon-metal conductorsCarbon fibresCarbon fiber reinforced compositePre-preg

A prepreg containing a carbon fiber [A] and a thermosetting resin [B], and in addition, satisfying at least one of the following (1) and (2).(1) a thermoplastic resin particle or fiber [C] and a conductive particle or fiber [D] are contained, and weight ratio expressed by [compounding amount of [C] (parts by weight)] / [compounding amount of [D] (parts by weight)] is 1 to 1000.(2) a conductive particle or fiber of which thermoplastic resin nucleus or core is coated with a conductive substance [E] is contained.

Owner:TORAY IND INC

Nanotube polymer composite and methods of making same

The invention relates to derivatized, well-dispersed CNTs that have enhanced miscibility with organic agents. Composite materials may be made using such CNTs. The composite materials, in turn, may be used in optical and electronic applications.

Owner:RENESSELAER POLYTECHNIC INST

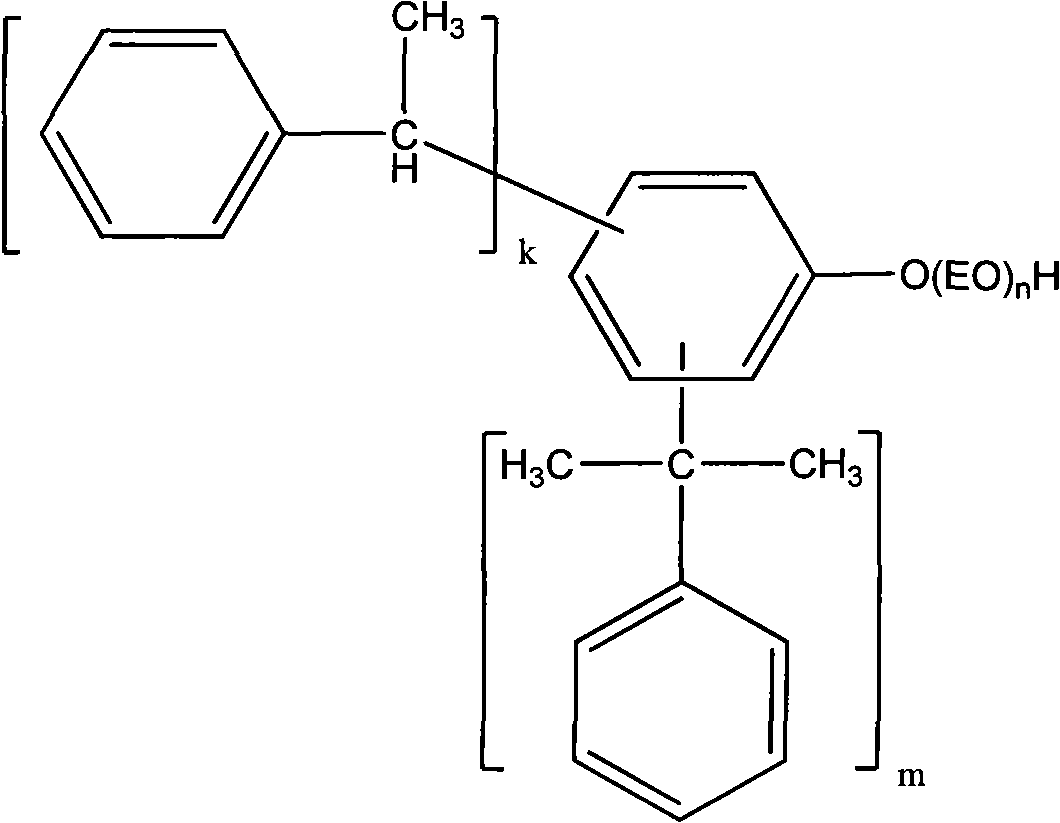

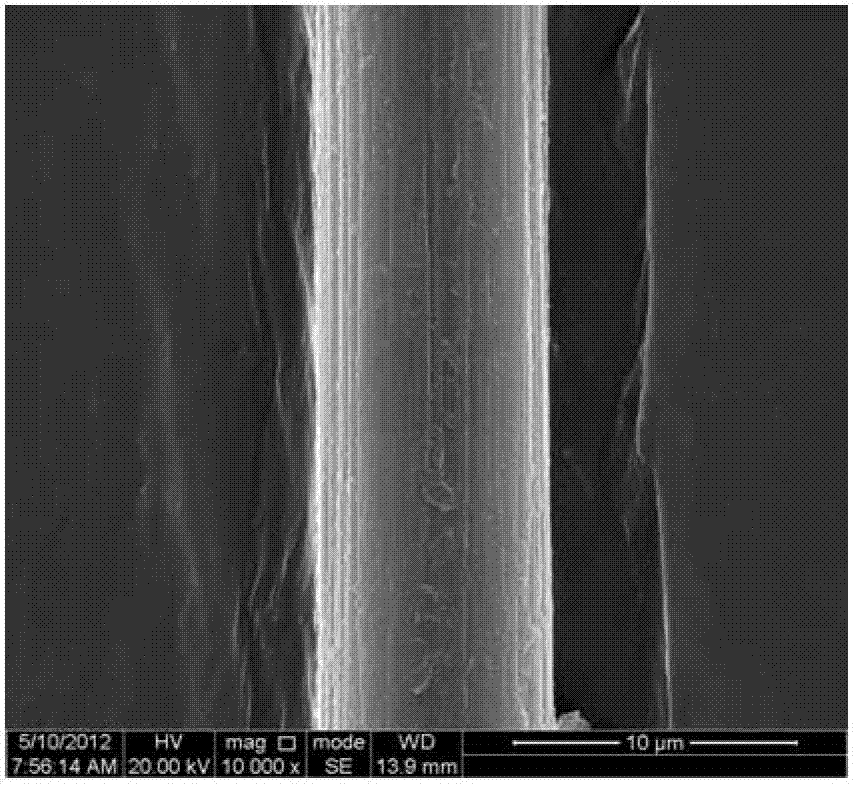

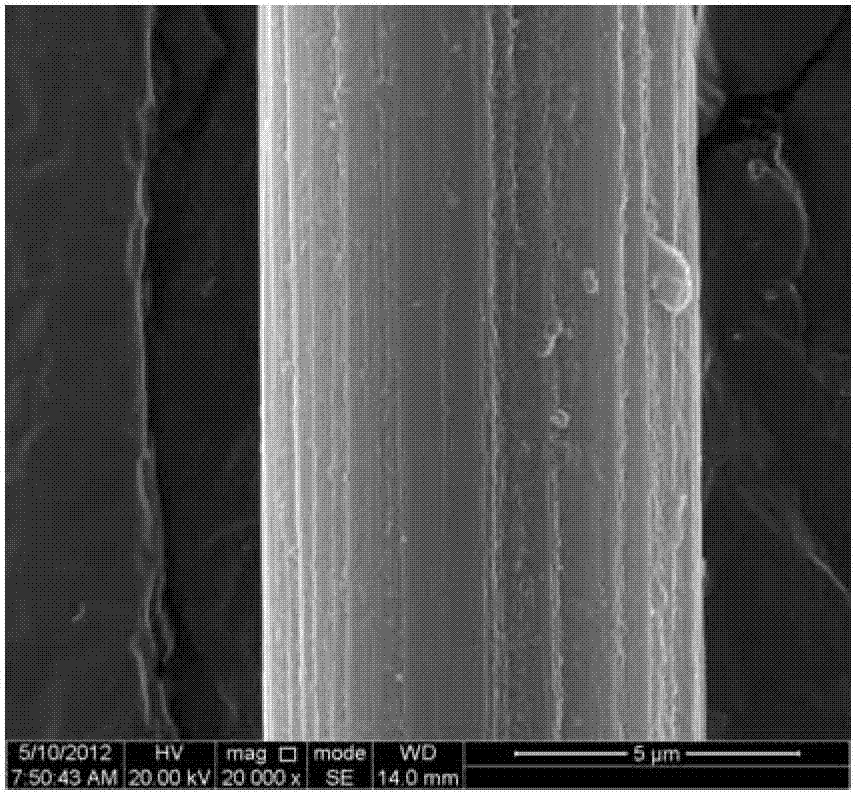

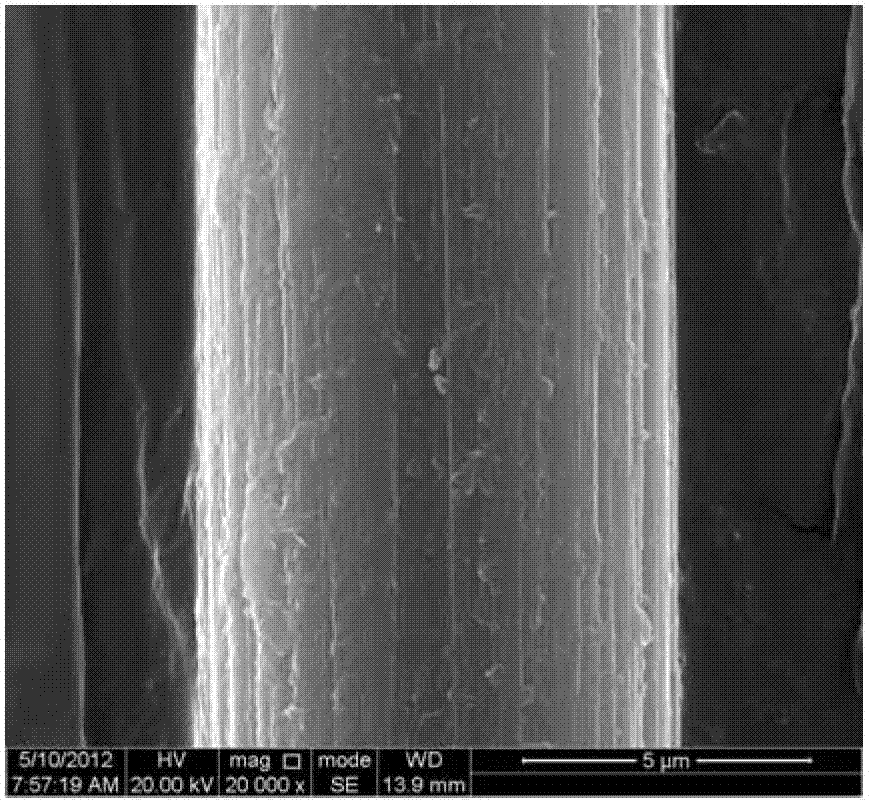

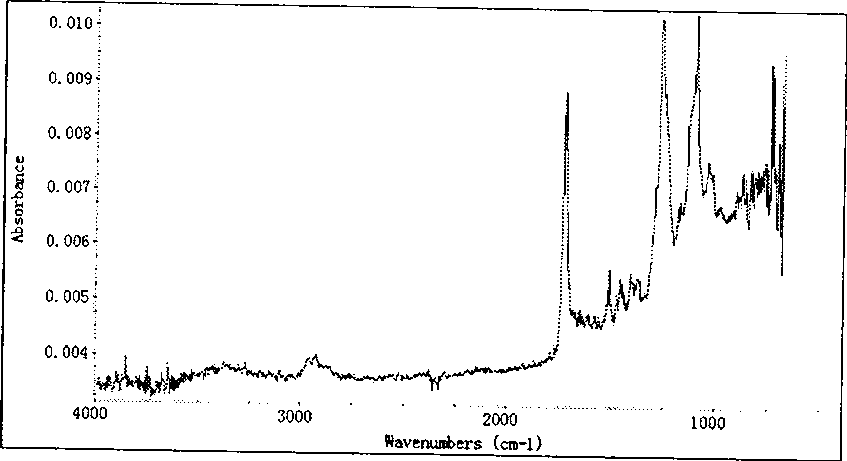

Emulsion type carbon fiber sizing agent and preparation method and application thereof

The invention discloses an emulsion type carbon fiber sizing agent, which comprises main size, an emulsifier, an aid and deionized water. The aid comprises a diluent and a penetrant, wherein the emulsifier is 5 to 15 mass percent of the main size, the diluent is 0 to 120 mass percent of the main size, the penetrant is 1 to 5 mass percent of the main size, and the mass ratio of the deionized water to the main size is 50-90:10-50. The invention also discloses a preparation method and application of the sizing agent. The sizing agent is suitable for unsaturated polyester resin and solves the problem of poor adhesion of the unsaturated polyester resin and the carbon fiber. After the sizing agent is used for sizing, the wear resistance of the carbon fiber is improved, and the broken filament amount is reduced, the post-processing performance of the fiber is improved, the interface adhesion of the carbon fiber and matrix resin is better, the shear strength between layers is improved, and the performance of composite materials is also improved.

Owner:UNIV OF JINAN

Graphene modified carbon fiber emulsion sizing agent and preparation method thereof

The invention relates to a graphene modified carbon fiber emulsion sizing agent and a preparation method thereof. The conventional solvent sizing agent is not environment-friendly. The sizing agent is a mixed system consisting of organic resin, an emulsifying agent, a lubricating agent, graphene, an organic solvent and deionized water, wherein the emulsifying agent, the lubricating agent, the graphene and the organic solvent are respectively 2 to 14 percent, 0.5 to 2 percent, 0.05 to 1 percent and 30 to 200 percent based on the mass of the organic resin; and the solid content of the mixed system is 0.1 to 5 percent. The preparation method of the sizing agent comprises the following steps of: dissolving the organic resin in the organic solvent to form organic resin solution, adding the emulsifying agent, the lubricating agent and the deionized water into the organic resin solution, and stirring until the mixed system is subjected to phase transfer; adding the deionized water until the solid content is 30 to 50 percent to obtain organic resin emulsion; and adding the graphene into the organic resin emulsion, and adding the deionized water to dilute the mixed system until the solid content is 0.1 to 5 percent so as to obtain the graphene modified sizing agent. The method is simple and reliable, and the prepared graphene modified sizing agent can well protect carbon fibers and effectively improve the interface property of the carbon fibers and matrix resin.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method for preparing graphene oxide grafting surface modification carbon fiber

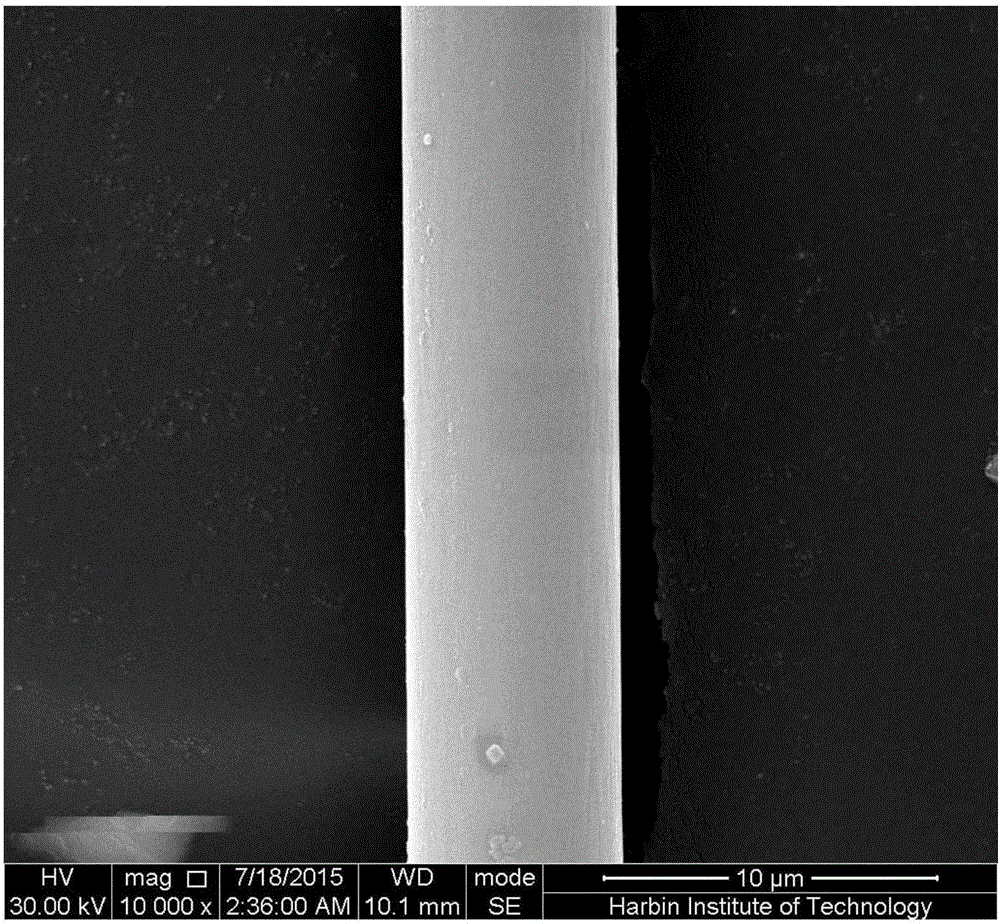

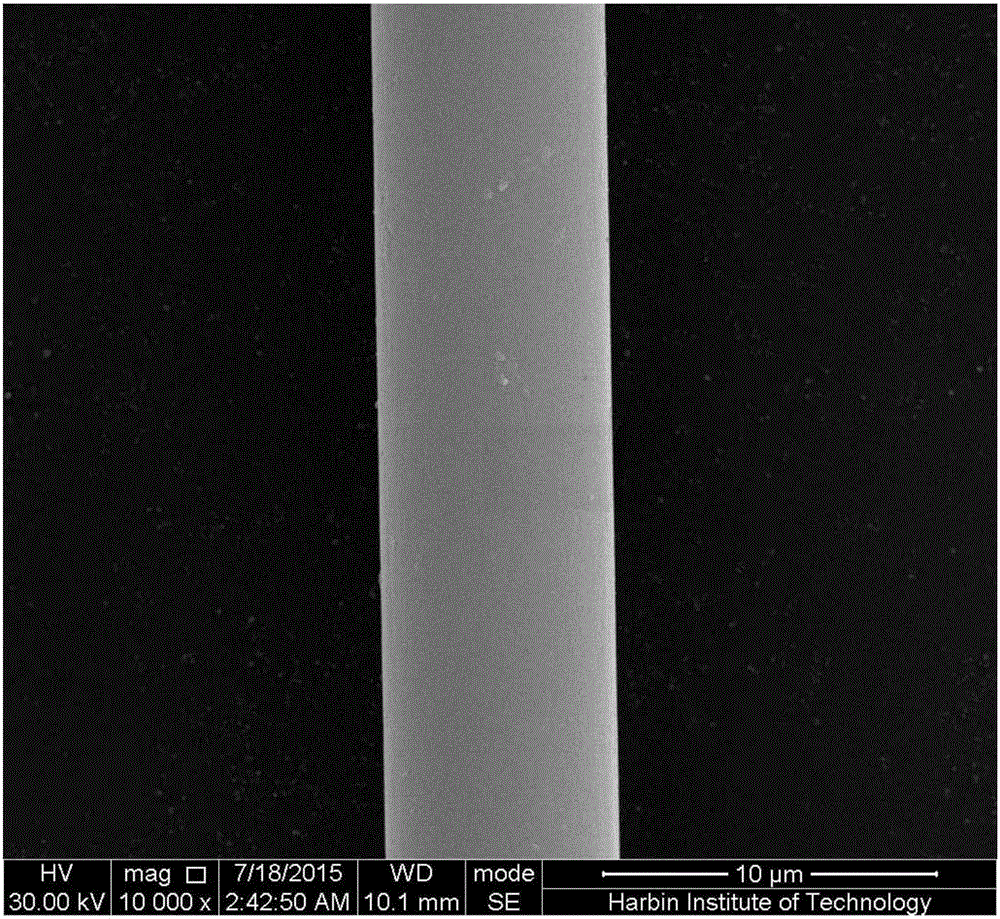

ActiveCN102787488AIncrease roughnessImprove interface performanceCarbon compoundsCarbon fibresCarbon compositesResin matrix

A method for preparing a graphene oxide grafting surface modification carbon fiber relates to a carbon fiber modification method, and is used for solving the technical problems that the existing carbon fiber has low surface activity, reduced surface tension and poor wettability with a resin matrix, and the interlaminar shear strength of a composite material is caused to reduce. The method comprises the steps as follows: 1, graphite oxidization; 2, separation of graphite oxide mother liquor; 3, functionalization of graphite oxide; 4, carbon fiber surface functionalization; and 5, carbon fiber surface graphite oxide treatment. The graphite oxide uniformly covers the carbon fiber surface, the roughness of the carbon fiber surface can be greatly improved, and accordingly, the interfacial properties of a carbon fiber reinforced composite material can be improved by an anchoring action. The interfacial shear strength of the surface grafting graphene oxide carbon fiber / carbon composite material which is prepared through graphene oxide grafting modification can be improved by 25% in comparison with that of the untreated surface grafting graphene oxide carbon fiber / carbon composite material.

Owner:HARBIN INST OF TECH

Preparation method of water-base epoxy resin sizing agent for carbon fiber

The invention discloses a preparation method of water-base epoxy resin sizing agent for carbon fiber, relating to a sizing agent preparation. The invention solves the problems that the cost of existing foreign latex sizing agent and that the performance of domestically researched emulsion sizing agent is not good. The method comprises: 1. preparing water-base epoxy resin; 2. preparing water-base epoxy resin curing agent; 3. diluting water-base epoxy resin with de-ionized water, and dispersing to obtain water-base epoxy resin emulsion; 4. mixing the water-base epoxy resin emulsion with the water-base epoxy resin curing agent to obtain a water-base epoxy resin emulsion system; and 5. mixing the water-base epoxy resin emulsion system with aid to obtain water-base epoxy resin sizing agent for carbon fiber. The water-base epoxy resin sizing agent for carbon fiber in the invention has good performance, good strengthening function to carbon fiber, better clustering property, smoothness and flexibility, and low cost, and the performance indexes such as overall loose degree of filaments of the fiber, fiber opening property and cross-linking degree among signal fibers.

Owner:HARBIN INST OF TECH

Carbon fiber emulsion sizing agent improved by carbon nano tube and preparation method of carbon fiber emulsion sizing agent

InactiveCN102212967APlay the role of stress transmissionIncreased interlaminar shear strengthCarbon fibresEmulsionCarbon fibers

The invention relates to a carbon fiber emulsion sizing agent improved by a carbon nano tube and a preparation method of the carbon fiber emulsion sizing agent. The carbon fiber emulsion sizing agent comprises a carbon fiber sizing agent, the carbon nano tube, a dispersing agent and a solvent. The preparation method comprises the following steps of: 1, preparing the carbon fiber sizing agent; and 2, adding the carbon fiber sizing agent into the solvent to prepare a sizing working solution, mixing the carbon nano tube and the sizing working solution, performing ultrasonic treatment for 1 to 4 hours at the power of 300 to 600w, adding the dispersing agent, and performing ultrasonic dispersion for 2 to 4 hours to obtain the carbon fiber emulsion sizing agent improved by the carbon nano tube. The carbon fiber emulsion sizing agent has favorable stability, the post processability of carbon fiber can be improved after being processed by the emulsion sizing agent, the interfacial bond strength between the carbon fiber and substrate resin can be enhanced, the shear strength among layers is enhanced, and the performance of a composite material is improved to a certain extent. Moreover, the preparation method is simple, low in cost and environment-friendly.

Owner:DONGHUA UNIV

Self-emulsifying polyurethanes epoxy sizing agent for carbon fibers and preparation method thereof

The invention relates to a self-emulsifying polyurethanes epoxy sizing agent for carbon fibers and a preparation method thereof. The sizing agent comprises the following components in part by weight: 10 to 15 parts of self-emulsifying polyurethanes epoxy emulsion, 0.2 to 0.3 part of aid, and 84.7 to 89.8 parts of deionized water. The method for preparing the sizing agent comprises the following steps of: (1) preparing hydrophilic polyurethane prepolymer of the self-emulsifying polyurethanes epoxy emulsion; (2) preparing a prepolymer of which the end group is an epoxy group; (3) adding 6 to 20 parts of neutralizer into the prepolymer of which the end group is an epoxy group for neutralization, pouring the neutralized solution into water for dispersing, and removing the solvent through reduced pressure distillation to obtain the self-emulsifying polyurethanes epoxy emulsion; and (4) adding the aid and the deionized water into the polyurethanes epoxy emulsion in the ratio, and uniformly mixing to obtain the self-emulsifying polyurethanes epoxy sizing agent for the carbon fibers. The self-emulsifying polyurethanes epoxy sizing agent for the carbon fibers and the preparation method thereof have reasonable design. The sizing agent can improve the mechanical property of carbon fiber composite materials, and has excellent dilution stability.

Owner:天津碧海蓝天水性高分子材料有限公司

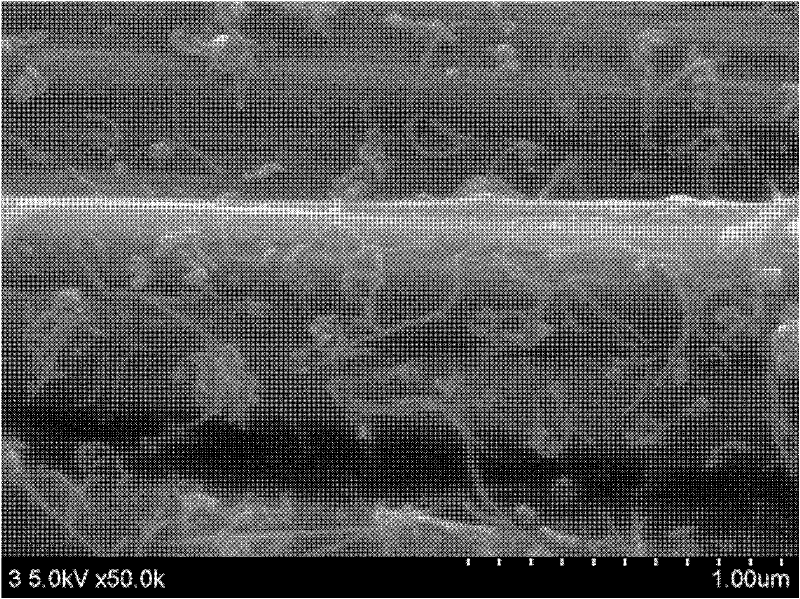

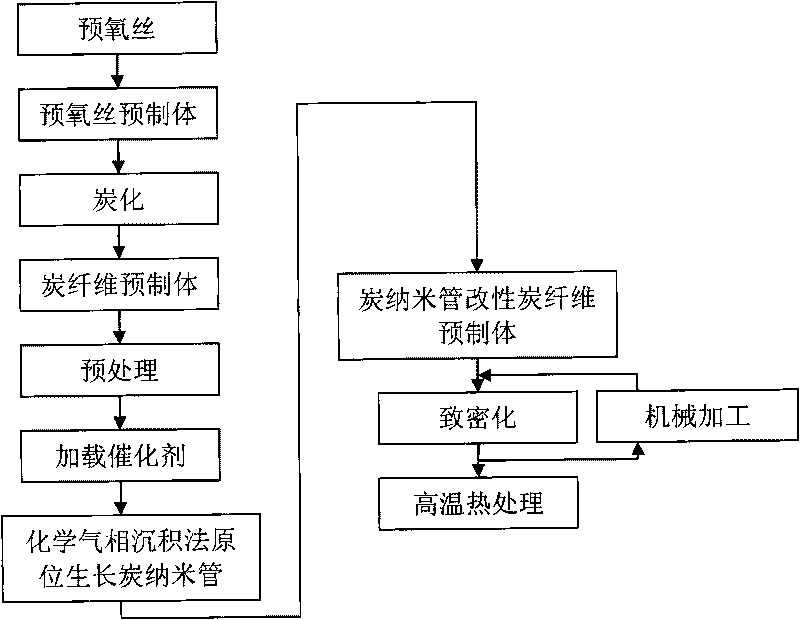

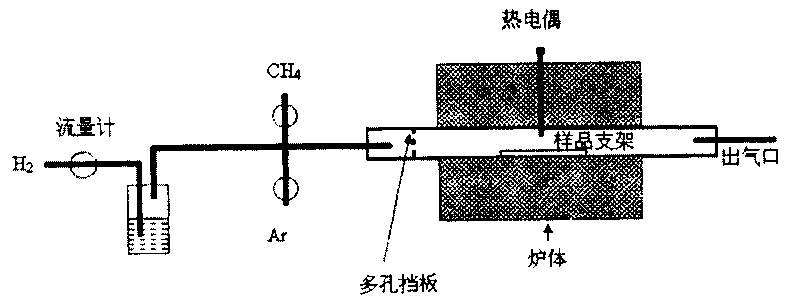

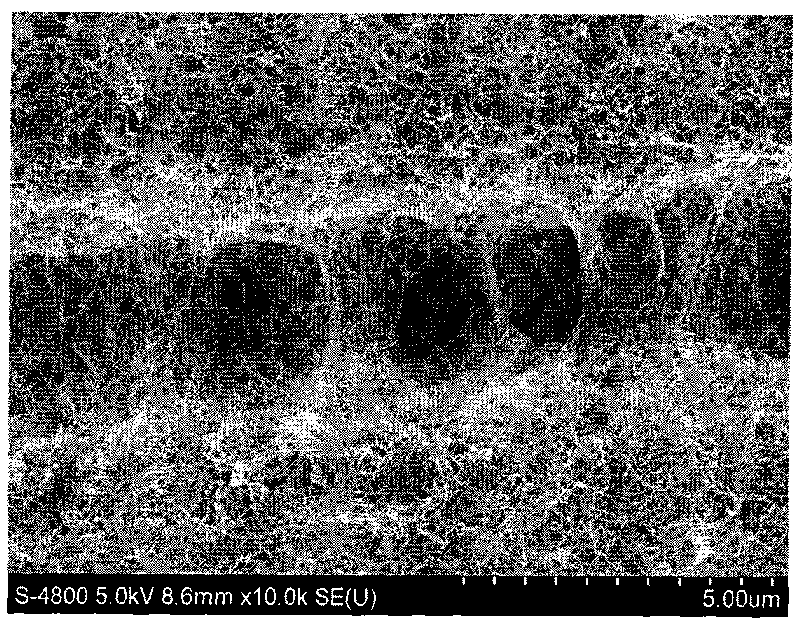

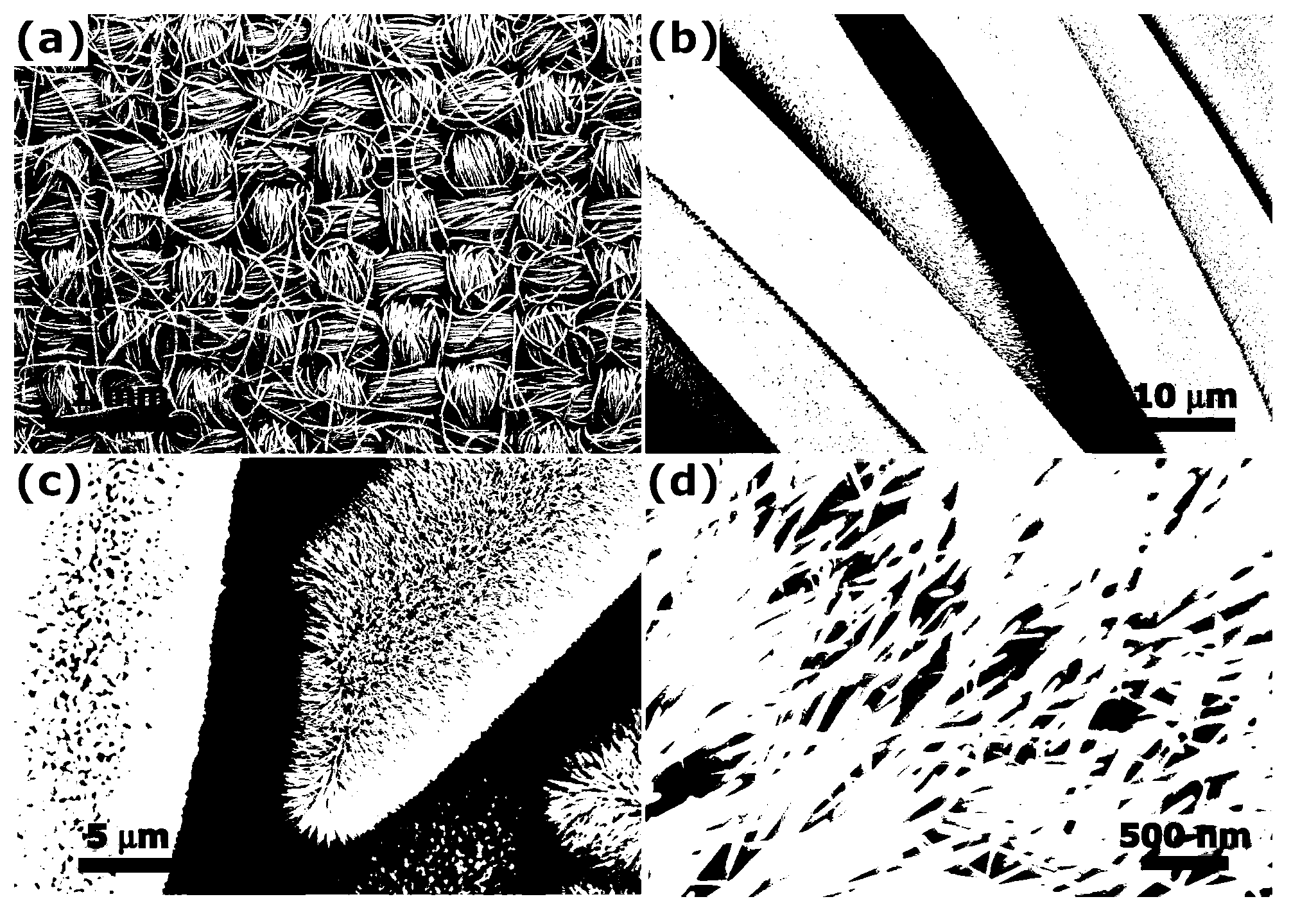

Method for modifying carbonized pre-oxidized fiber preform interface by carbon nanotube

The invention relates to a method for modifying a carbonized pre-oxidized fiber preform interface by a carbon nanotube. The method comprises the following steps: (1) performing carbonization at a set heating rate in a carbonizing furnace under the conditions of vacuum and six temperature sections (room temperature to 200 DEG C, 200 to 350 DEG C, 350 to 400 DEG C, 400 to 600 DEG C, 600 to 650 DEG C and 650 to 1,000 DEG C; (2) firstly removing colloid on the surface of carbon fiber at 600 to 800 DEG C, and then removing impurities on the surface of the fiber with the mixed acid of nitric acid and sulfuric acid; (3) firstly placing a processed carbon fiber punched preform into an organic solution of a catalyst precursor, and then growing the carbon nanotube in situ in a chemical vapor deposition furnace; (4) densifying the preform by a chemical vapor deposition process, and depositing the densified preform for 200 to 350 hours to ensure that the density of the preform reaches 1.70 to 1.75 g / cm3; and (5) placing materials in the vacuum carbonizing furnace, heating the materials until the temperature reaches 2,000 to 2,300 DEG C at the heating rate of 30-50 DEG C per hour under the protection of nitrogen, argon and the like, and keeping the temperature for 3 to 5 hours to obtain a finished product.

Owner:BEIHANG UNIV

Method of modifying polymeric material and use thereof

ActiveUS20040242794A1High strengthImprove adhesionOther chemical processesCarbon fibresPolyolefinFiber

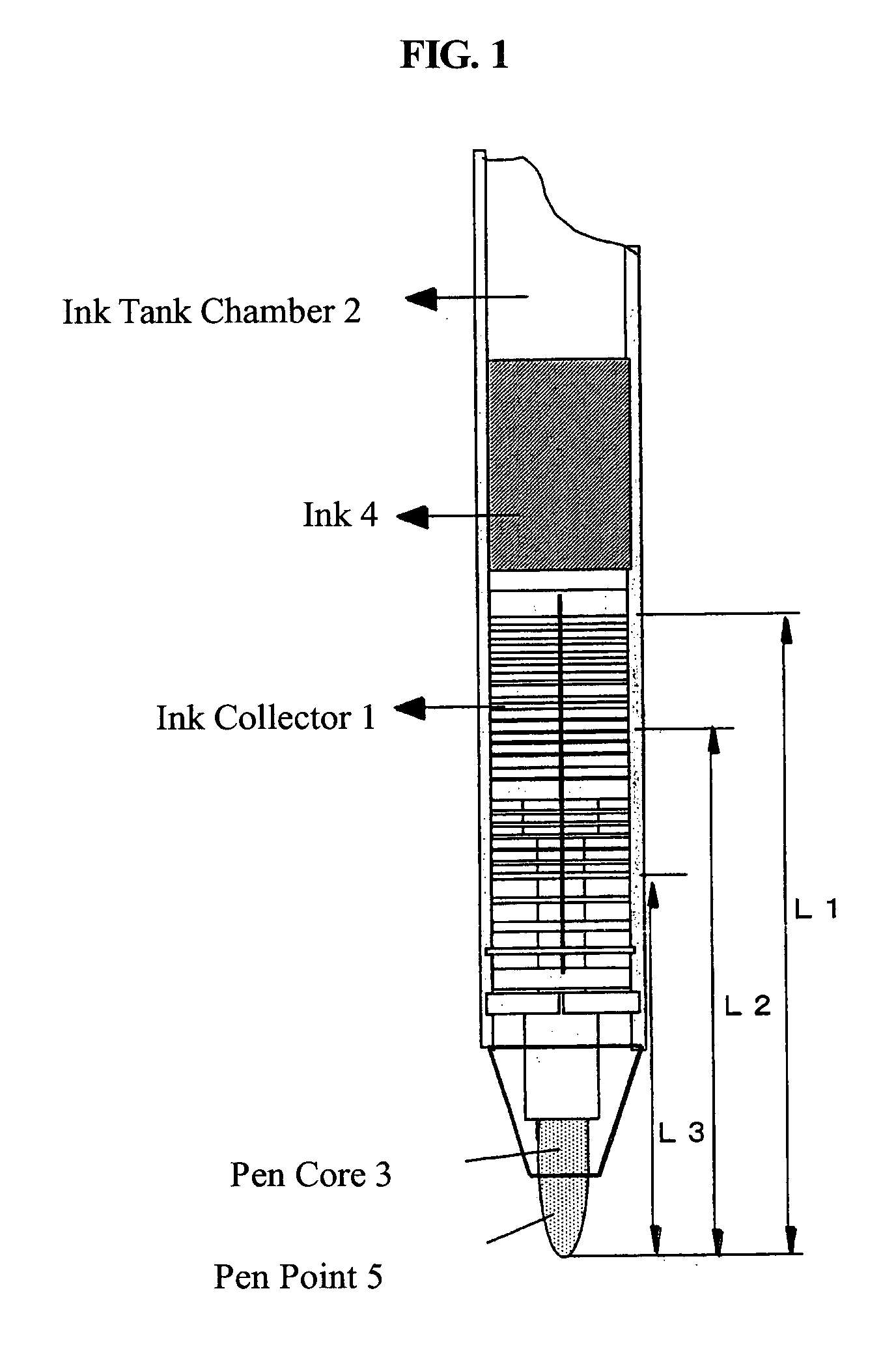

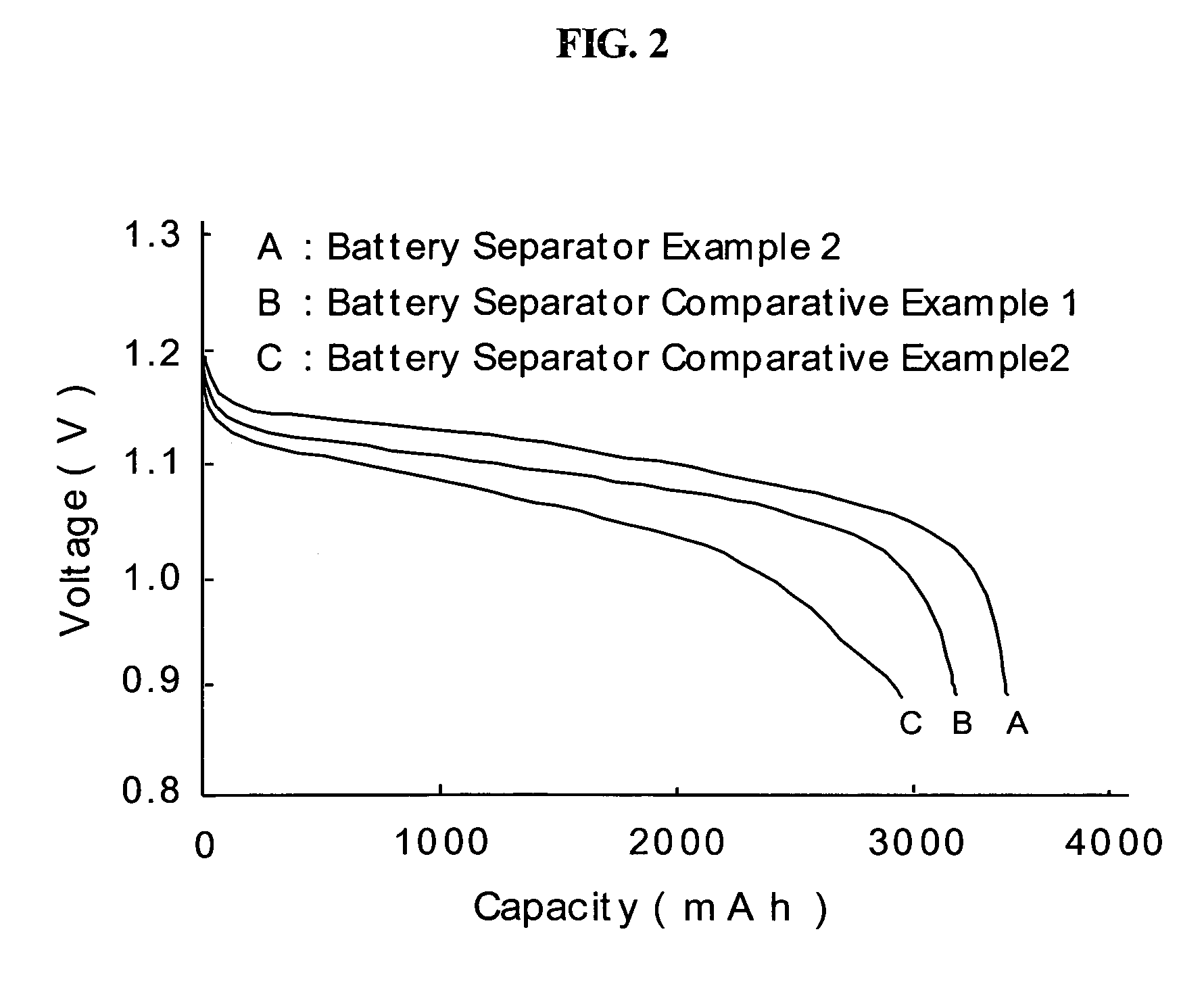

A method of modifying a polymeric material whereby the polymeric material is modified to give a highly durable surface without decreasing its strength. Namely, a polymeric material is modified by the method comprising a combination of an impregnation step, an activation step, a step of grafting a monomer and a step of a treatment with a hydrophilic polymer. Thus, the hydrophilic nature, adhesiveness, and so forth of polymeric materials such as polyolefins can be improved without causing any decrease in the practical strength. The thus obtained polymeric materials are usable in articles with a need for high water absorptivity and high adhesiveness, for example, water-absorbing materials and water-retaining materials for medical, sanitary, cosmetic articles or supplies, agricultural materials, synthetic papers, filters and fiber products for clothes, for improving adhesiveness of composite materials and the like. Among all, these materials are particularly usable in dentition orthodontic appliances, writing implements and battery separators.

Owner:FIBERMARK GRESSNER

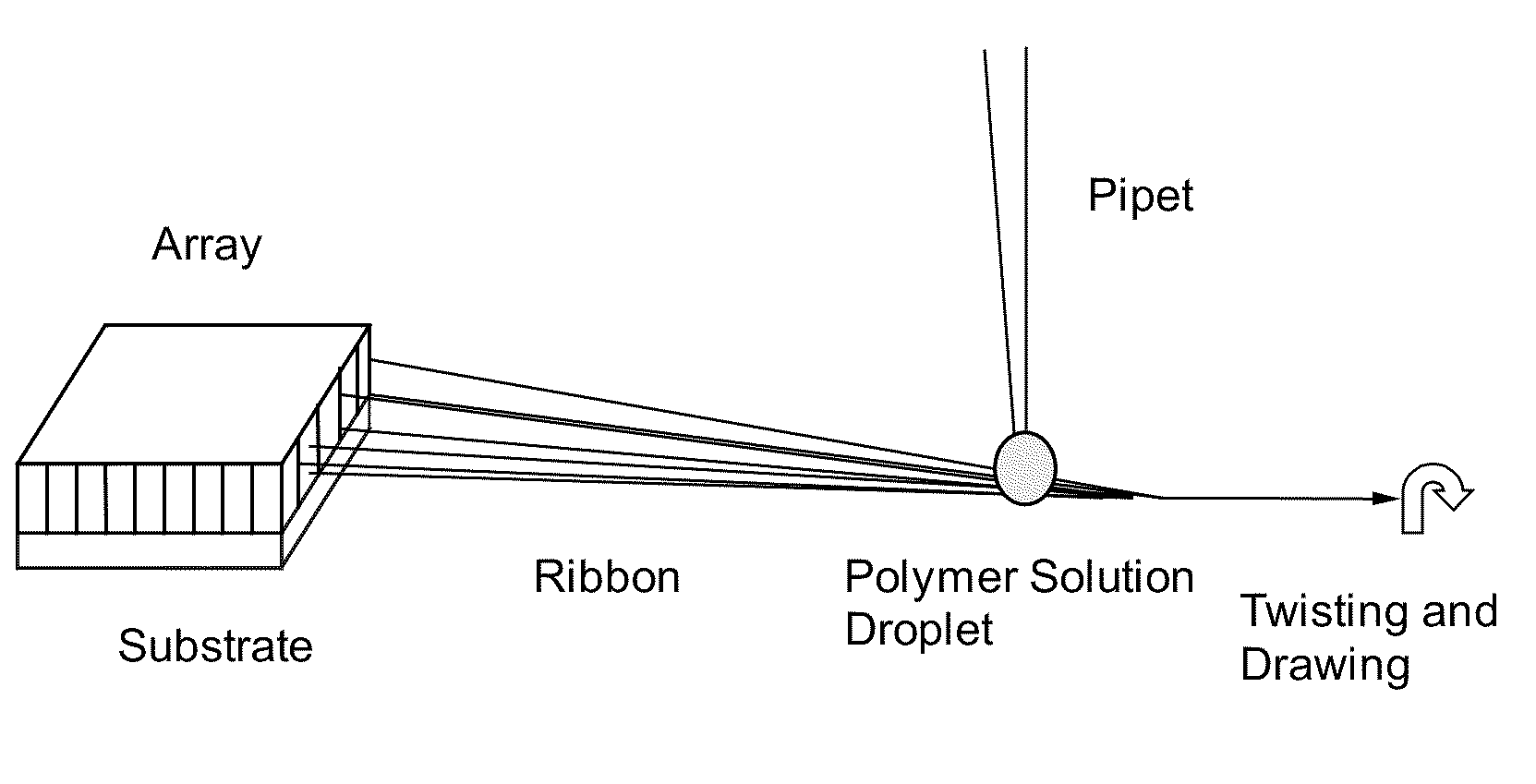

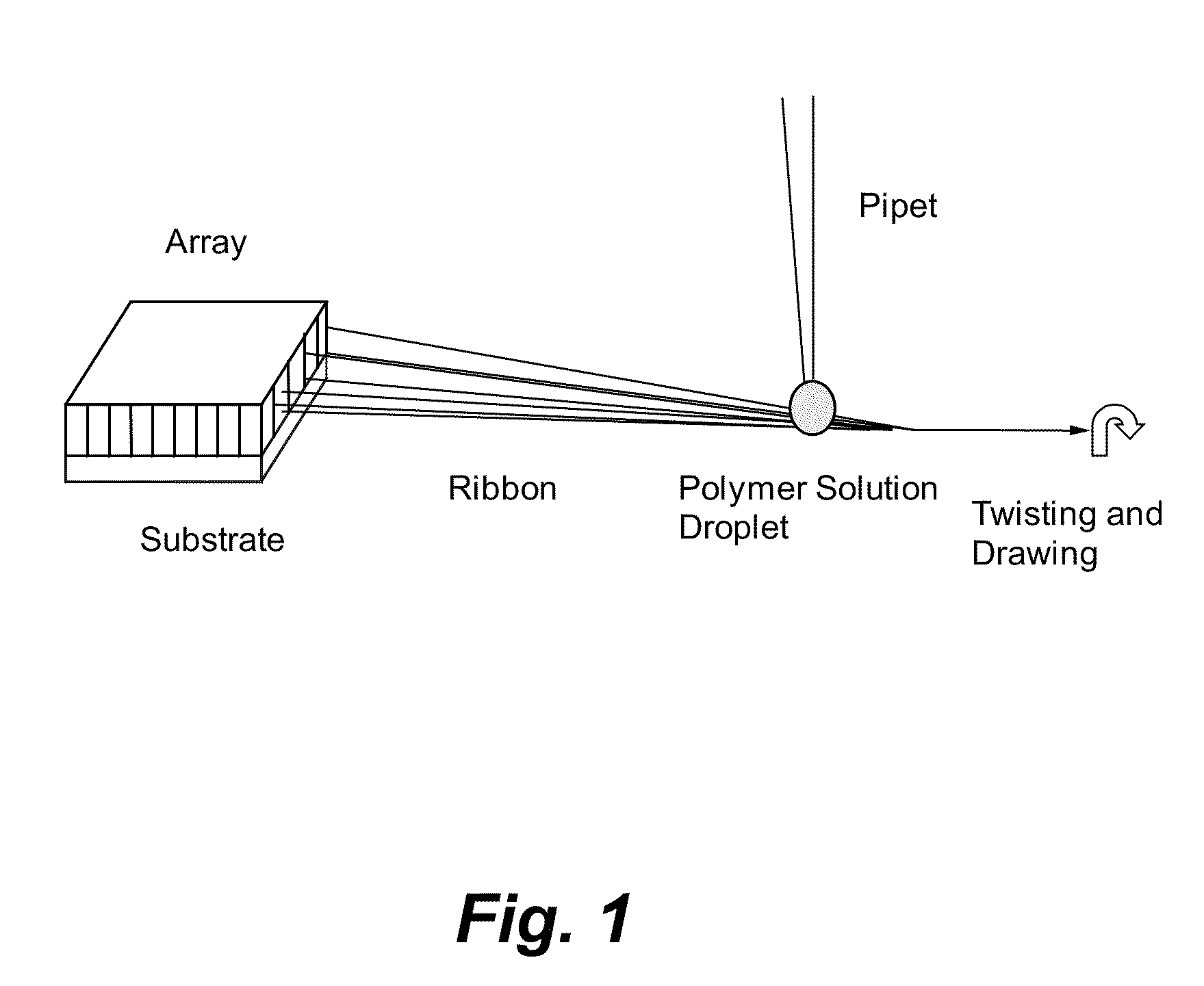

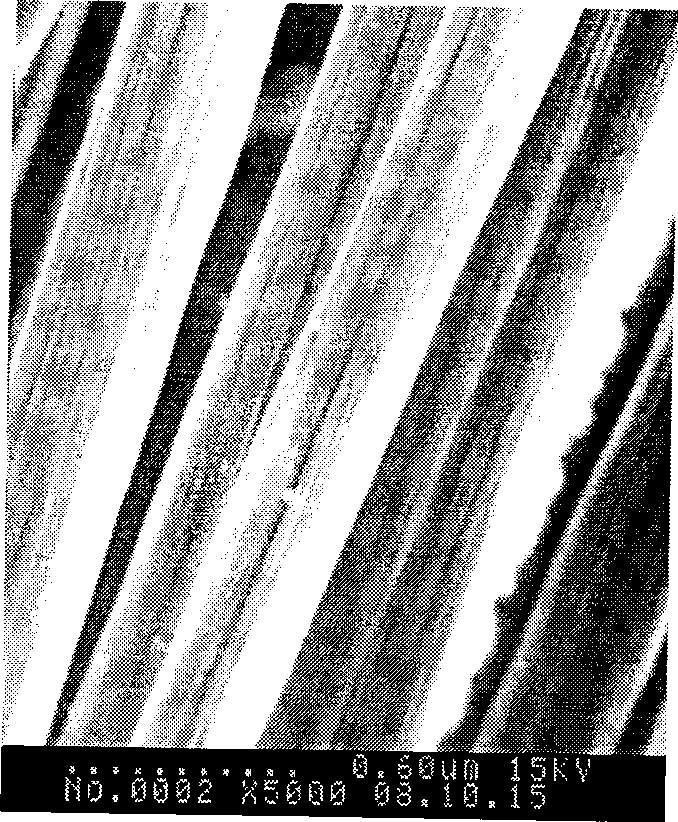

Carbon nanotube fiber spun from wetted ribbon

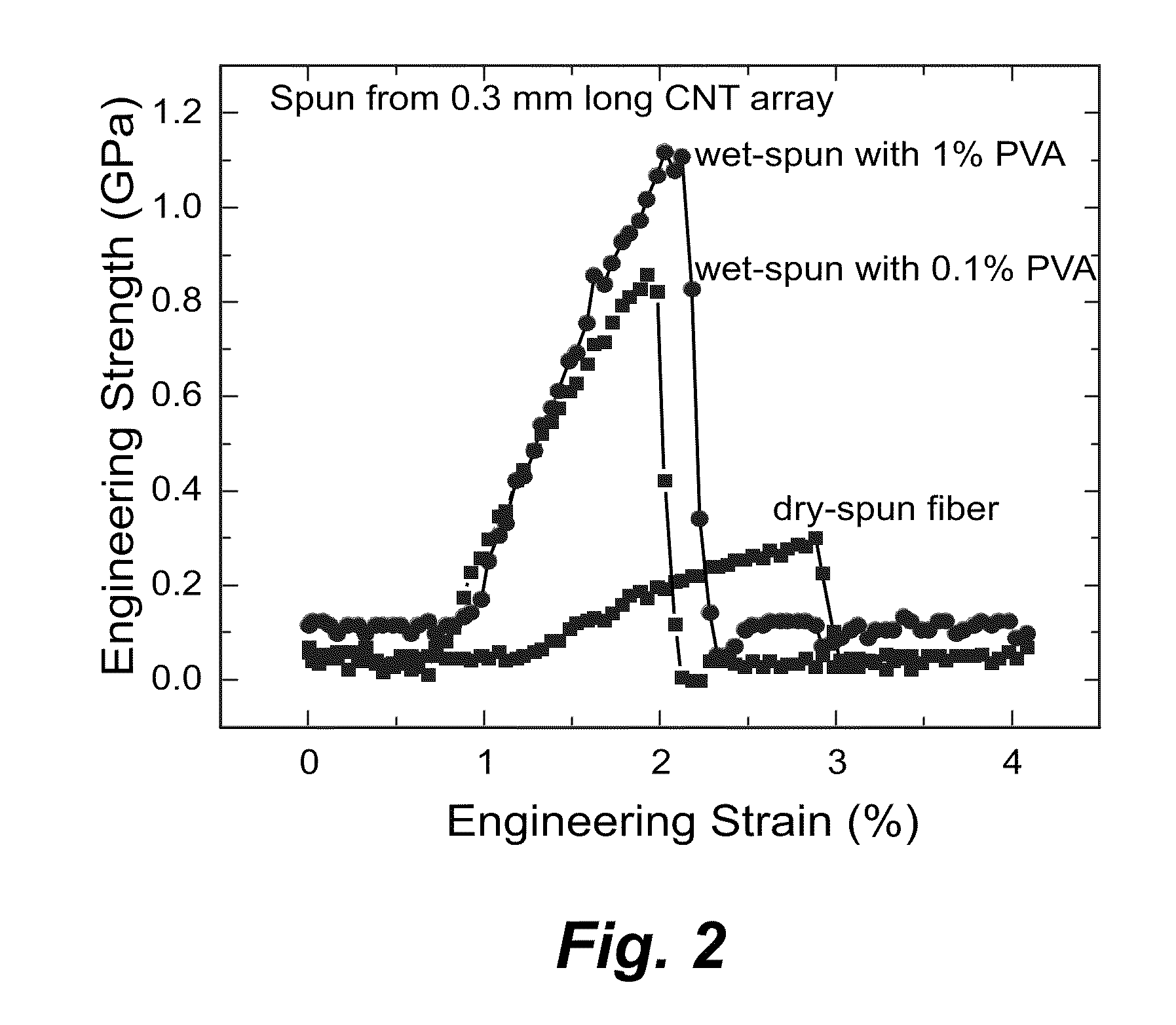

A fiber of carbon nanotubes was prepared by a wet-spinning method involving drawing carbon nanotubes away from a substantially aligned, supported array of carbon nanotubes to form a ribbon, wetting the ribbon with a liquid, and spinning a fiber from the wetted ribbon. The liquid can be a polymer solution and after forming the fiber, the polymer can be cured. The resulting fiber has a higher tensile strength and higher conductivity compared to dry-spun fibers and to wet-spun fibers prepared by other methods.

Owner:TRIAD NAT SECURITY LLC

Carbon Fiber Strand for Reinforcing Thermoplastic Resins and Method of Producing the Same

InactiveUS20090062426A1Superior in adhesivityHigh mechanical strengthCarbon fibresPretreated surfacesFiberButene

There are disclosed a carbon fiber strand for reinforcement of thermoplastic resin, wherein a sizing agent containing a resin composition obtained by mixing a component [A], i.e. an acid-modified polyolefin copolymer having a weight-average molecular weight of 15,000 to 150,000, which has, as the main chain, an ethylene-propylene copolymer, a propylene-butene copolymer or an ethylene-propylene-butene copolymer and in which the main chain has been modified with 0.1 to 20% by mass of an unsaturated carboxylic acid, and a component [B], i.e. an acid-modified polypropylene having a weight-average molecular weight of 3,000 to 150,000, which has, as the main chain, a polypropylene and in which the main chain has been modified with 0.1 to 20% by mass of an unsaturated carboxylic acid, at a mass ratio of 1:20 to 10:5, is adhered to 100 parts by mass of a carbon fiber in an amount of 0.1 to 8.0 parts by mass; a method for producing the above strand; and a carbon fiber-reinforced thermoplastic resin containing the above strand.

Owner:TEIJIN TECHNO PRODUCTS LTD

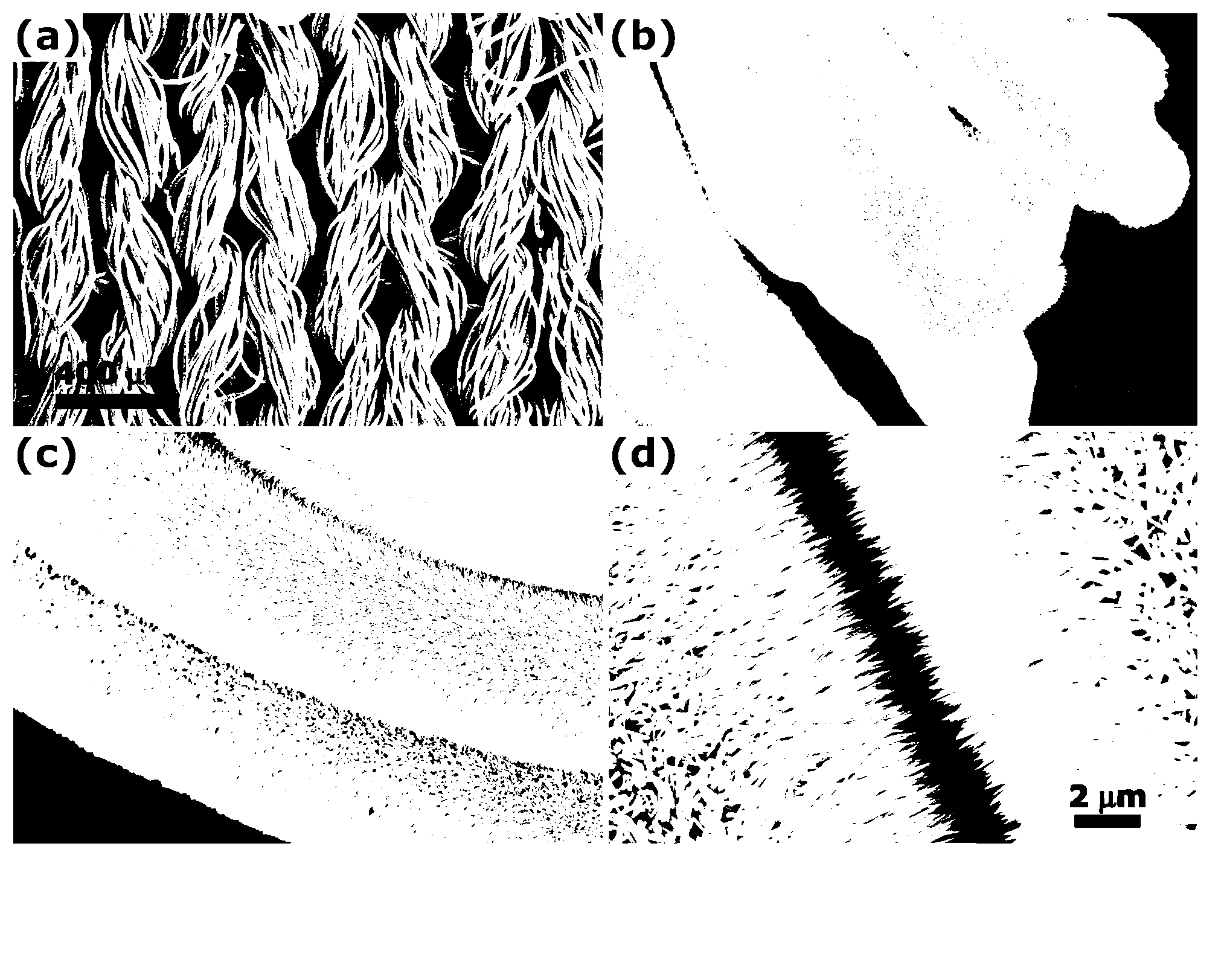

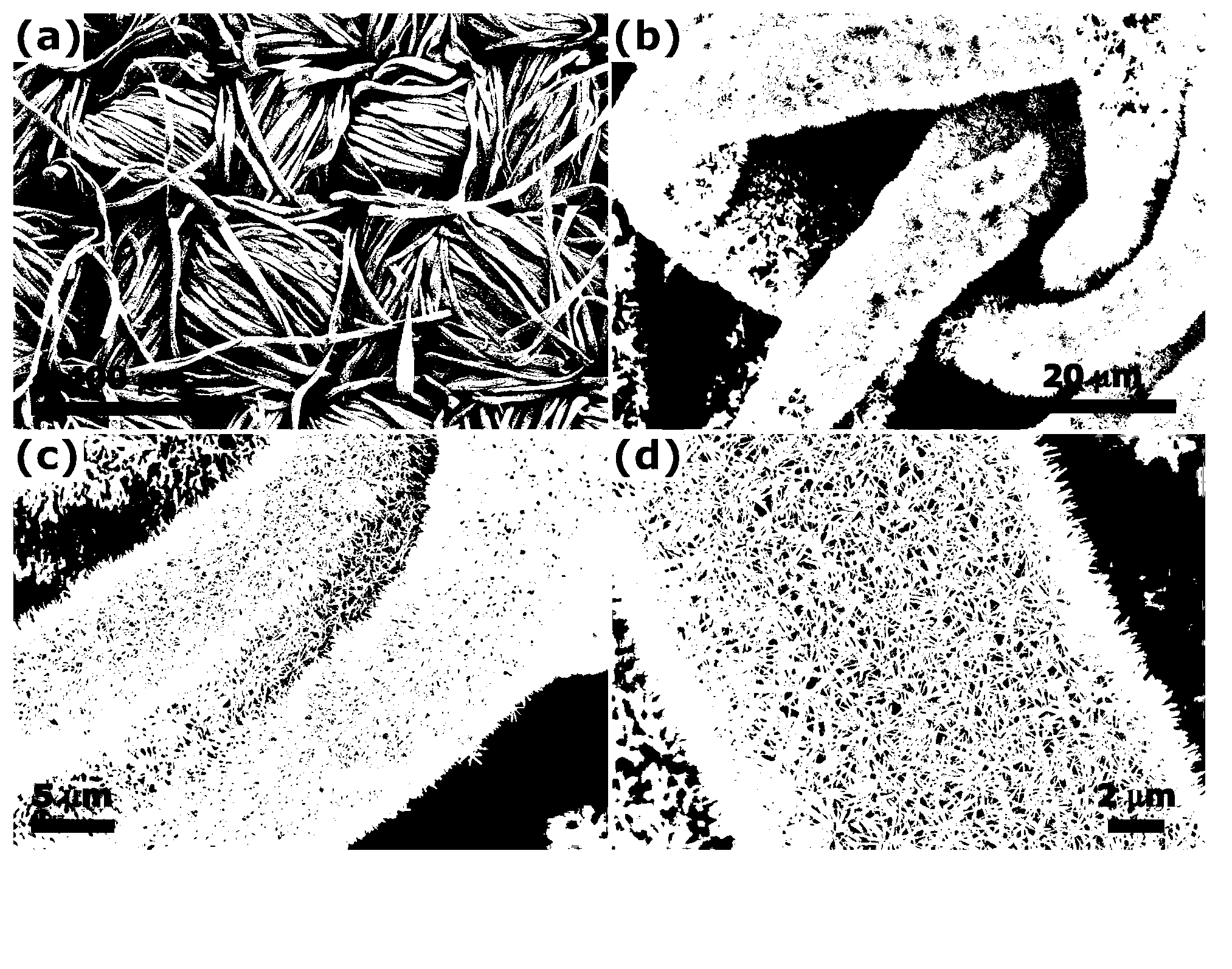

Nano-silver antibacterial fabric and preparation method thereof

InactiveCN103015166ASmall sizeImprove release efficiencyPhysical treatmentSynthetic fibresAir filtrationBio aerosol

The invention provides a nano-silver antibacterial fabric and a preparation method thereof. The nano-silver antibacterial fabric has the characteristics that a zinc oxide nano line grows on the fabric; and silver nano particles are deposited on the zinc oxide nano line. The zinc oxide nano line is synthesized by a solution chemical method; and the silver nano particles are deposited on the zinc oxide nano line by a simple 'immersion-illumination' method. The nano-silver antibacterial fabric prepared by the method has extremely obvious long-time antibacterial performance; the silver nano particles are small in size and cannot be accumulated; a synthesis process is environment-friendly; and the nano-silver antibacterial fabric can be recycled and reused. The nano-silver antibacterial fabric can be used for single-point water treatment to reduce microorganism content in water and can be suitable for medical surgical dressing and medical fabrics; and the nano-silver antibacterial fabric can be used as an antibacterial air filtration device for preventing bio-aerosol from being gathered on a ventilating, heating and air conditioning system.

Owner:BEIHANG UNIV

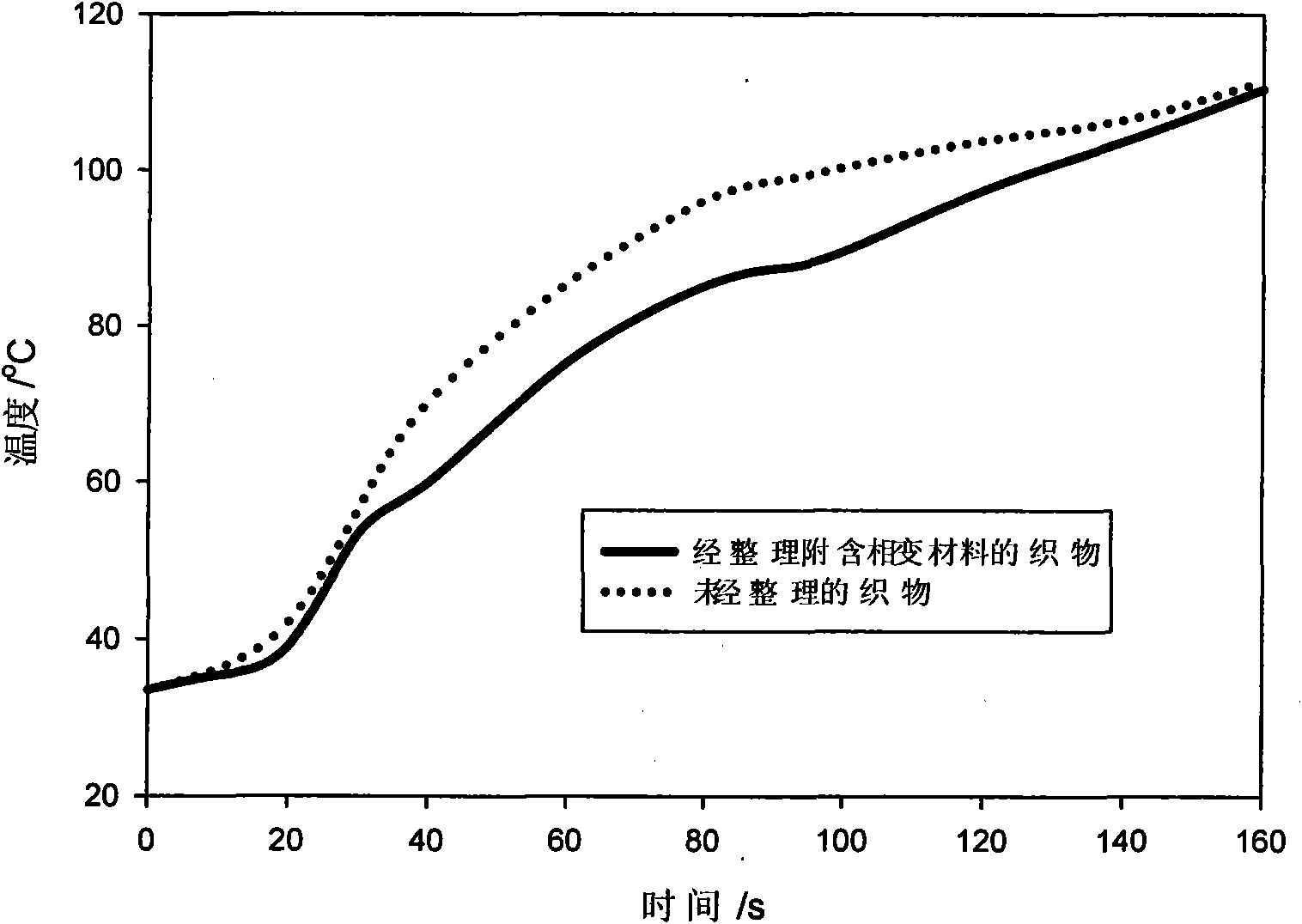

Preparation method of fire resistant phase transition thermal insulation layered fabric for firefighter clothing

InactiveCN102337673ANot burnImprove wearing comfortChemical protectionHeat protectionChemical industryCross-link

A preparation method of fire resistant phase transition thermal insulation layered fabric for firefighter clothing comprises the following steps of: immersing nonwoven felt prepared by combining 50-90% of aramid fiber 1313 fiber, 5-20% of carbon fiber and 0-30% of fire resistant viscose fiber into a prepared fire resistant phase transition microcapsule operating fluid, and carrying out two dipping and padding technology to obtain the fire resistant and temperature regulated phase transition thermal insulation layered fabric for firefighter clothing. A prepared phase transition finishing liquid contains 5-10% of an adhesive, 5-10% of a cross-linking fire retardant, 1-5% of a thickening agent and 1-5% of a fabric softener. The thermal insulation layered fabric which has undergone phase transition finishing is used to obviously raise thermal protective performance of firefighter clothing. The prepared fibrofelt fabric is applied in fire extinguishment and is also widely applied for individual protection equipment in different industries and fields such as metallurgy, petroleum, steel chemical industry, army war clothing and the like.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Nacelles and nacelle components containing nanoreinforced carbon fiber composite material

Owner:THE BF GOODRICH CO +1

Temp, resisting type carbon fibre emulsion sizing agent and its preparation process and application

The heat resisting emulsion sizing agent for carbon fiber consists of main sizing agent and assistant in 1-5 wt% of the main sizing agent. The main sizing agent is mixture of thermoplastic polyimide resin and glycidol ether type epoxy resin in the weight ratio of 50-90 to 10-50; and the assistant includes emulsifier, wetting agent and defoaming agent in the weight ratio of 10-80 to 10-80 to 10. The present invention has the advantages of low cost, stable performance, convenient use and no environmental pollution.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Method of chemically-grafting graphene oxide onto surface of carbon fiber

InactiveCN105239357AImprove surface roughnessImprove surface wettabilityCarbon fibresFiberCarbon fibers

A method of chemically-grafting graphene oxide onto surface of carbon fibers. The invention relates to a surface modification method of the carbon fibers and aims to solve the problems of high surface inertia, low surface energy and poor mechanical and thermal performances of the carbon fibers in the prior art. The method includes following steps: (1) preparing graphene oxide through improved Hummer's method; (2) oxidizing the carbon fibers; (3) performing surface modification amination treatment to the carbon fibers; and (4) chemically-grafting the graphene oxide onto the surface of the carbon fibers. The surface of the carbon fibers is improved significantly in wettability and adhesivity and is significantly improved in roughness after grafting, so that the strength and toughness of the carbon fiber are significantly improved, wherein the strength is increased by 20-25% than carbon fiber raw filament and the toughness is increased by 35-40% that the carbon fiber raw filament. The method is used for surface modification of the carbon fibers.

Owner:HARBIN INST OF TECH

Method of making a three-dimensional fiber structure of refractory fibers

ActiveUS7384663B2Improve propertiesEasy to prepareMaterial nanotechnologyCarbon fibresNanotubeFiber carbon

Owner:CENT NAT DE LA RECHERCHE SCI

Preparation method of carbon fiber reinforcement grafted by graphene oxide

A preparation method of a carbon fiber reinforcement grafted by graphene oxide relates to a preparation method of a carbon fiber reinforcement grafted by graphene oxide. The invention solves the problems of harsh process conditions, long process period, toxic process, and difficult industrial production for current carbon fiber surface modification methods. The invention adopts a 'grafting' method, and grafts graphene oxide on acidified carbon fiber surfaces through an acylation reaction by using polyamide-amine with a lot of amido active groups; the invention has low cost, is simple, practical, environment-friendly, and nontoxic, and can be completed within a short period. The method particularly comprises the following steps: mixing acidified carbon fibers and a polyamide-amine methanolsolution, reacting to prepare carbon fibers modified by polyamide-amine, adding the prepared carbon fibers in a graphene oxide acetone suspension, mixing, reacting, filtering, drying the precipitatestill the weight is constant. The obtained carbon fiber reinforcement has interfacial shear strength with epoxy resin of up to 79.77-105.50 MPa which is improved.

Owner:HARBIN INST OF TECH

Lightning strike protection

ActiveUS20110049292A1Carbon fibresWarp knittingElectrical resistance and conductanceLightning strike

An aircraft component having an external surface includes an improved lightning strike protection surface film disposed on or proximate to the external surface. The surface film includes a preform that includes a substrate having a first areal weight density and a plurality of spaced carbon nanotubes grown on the substrate, the nanotubes having a second areal weight density. The sum of the first areal weight density and the second areal weight density is less than about 500 grams per square meter, and the preform has a surface resistance less than about 1 ohm / square.

Owner:ROHR INC +1

Method for carbon fiber surface modification of plasma coated with nano colloidal sols by plasma treatment

InactiveCN101413209AImprove performanceImprove surface propertiesPhysical treatmentCarbon fibresFiberCarbon fibers

The invention relates to a method for modifying the surface of carbon fiber coated with nano sol through plasma treatment, which comprises the following steps: firstly, nano particles are prepared into an organic solvent, a sol solution of water or a sol solution prepared by hybridization reaction of a precursor solution of organic-inorganic nano particles by the ultrasonic vibrating technology; secondly, the sol solution is coated on the surface of the carbon fiber, treated by means of spray coating and padding, and dried; and thirdly, the dried carbon fiber is placed on a special transport unit for plasma processing equipment and a plasma is sprayed on the surface of the carbon fiber to make the carbon fiber move in the plasma atmosphere, so as to generate surface modification, wherein the treating power is between 10 and , watts, and the treatment time is between 0.5 and 300 seconds. The method can effectively improve the performance of the fiber, improves the molded manufacturability and the overall properties of composite materials of the fiber, has simple technology, quick processing speed, good treatment effect and low cost, is convenient to operate and difficult to cause environmental pollution, can reduce energy consumption, and is suitable for industrial production.

Owner:DONGHUA UNIV +1

Fiber-reinforced polypropylene resin composition, molding material and prepreg

ActiveUS20140356612A1Improve interface adhesionImprove featuresCarbon fibresSynthetic resin layered productsPolyolefinPolypropylene

A molded article excellent in dynamic characteristics and water degradation resistance can be obtained by using a fiber-reinforced polypropylene resin composition including a carbodiimide-modified polyolefin (a), a polypropylene resin (b) and reinforcing fibers (c), wherein the content of the carbodiimide group contained in a resin component in the fiber-reinforced polypropylene resin composition is 0.0005 to 140 mmol based on 100 g of a matrix resin component, and the reinforcing fibers (c) are sizing-treated with a polyfunctional compound (s); and a molding material using the fiber-reinforced polypropylene resin composition.

Owner:TORAY IND INC

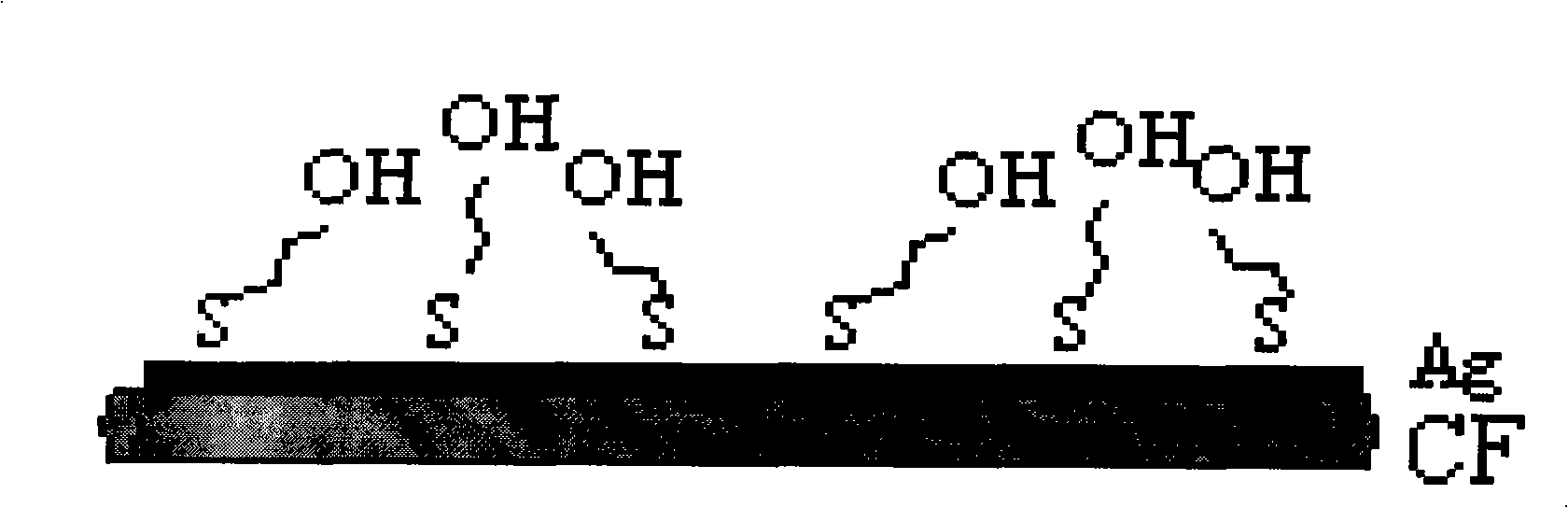

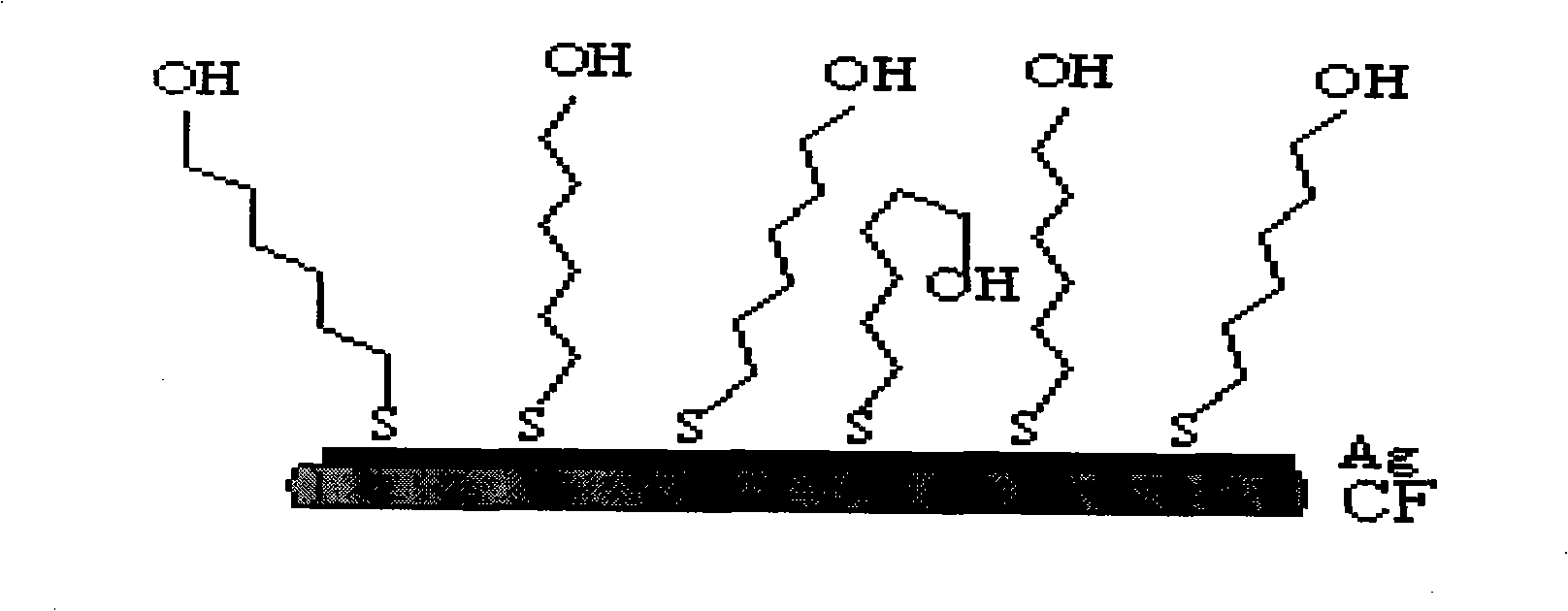

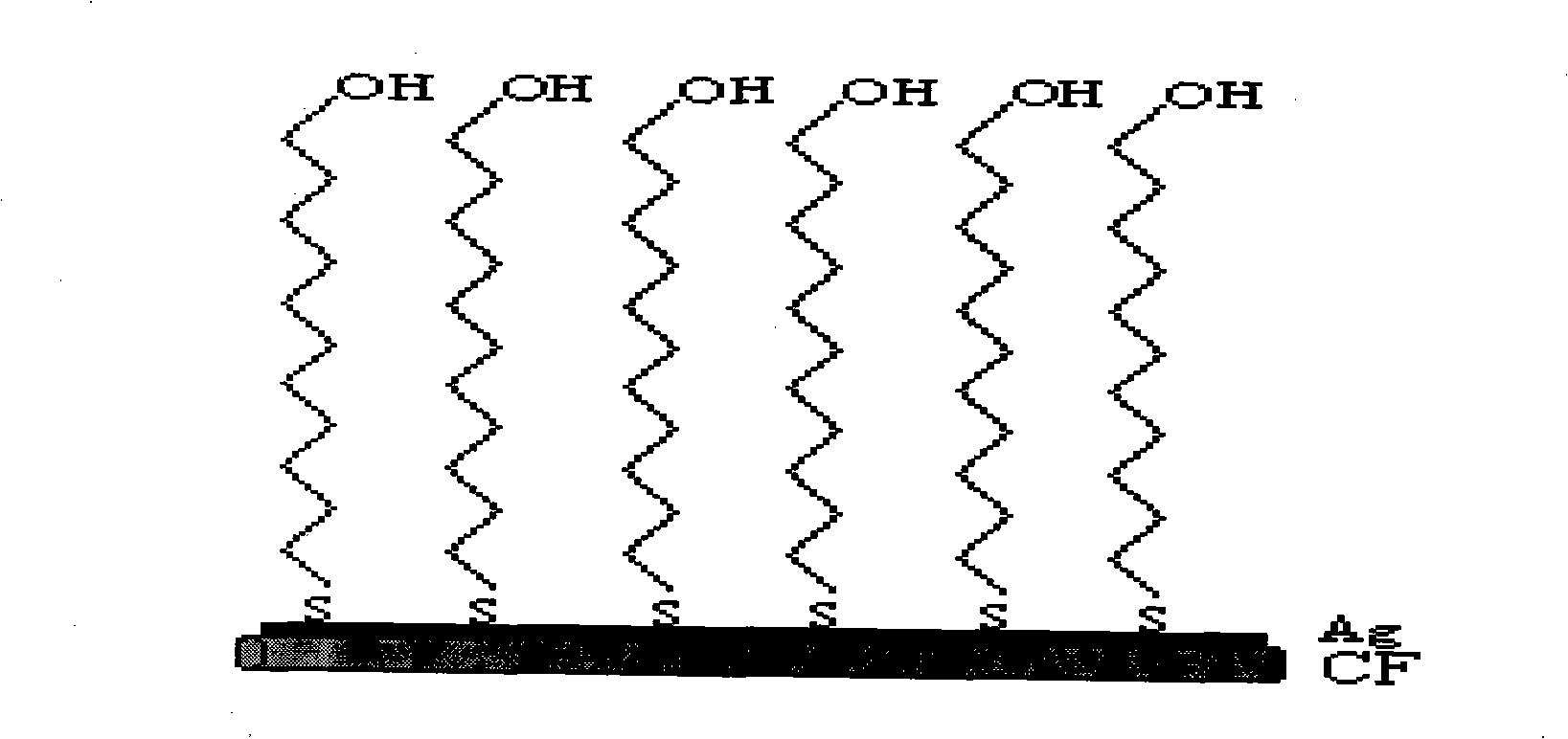

Carbon fiber surface modification method

The invention discloses a carbon fiber surface modification method, and relates to a carbon fiber modification method. The invention solves the problem of the uncontrollability of the distribution and arrangement of a carbon fiber surface functional group, which is not propitious to the study of the mechanism of a carbon fiber interface. The carbon fiber is plated with silver after surface pre-processing, then the carbon fiber with the silver-plated surface is infused in the dilute solution of thiol molecule containing sulfur element; depending on the coactions of the bonding reaction of sulfur atoms and metb and the force among self-assembly molecules, the thiol molecule has chemical absorption on the fiber surface and forms a closely arranged and ordered two-dimensional self-assembly single molecule membrane; two procedures are as follows: 1. the chemical plating of silver on the carbon fiber surface; and 2. the self assembly of molecules of organic sulfide on the silver-plating carbon fiber. The carbon fiber surface modification method has the advantages of realizing controllable, directional and ordered arrangement on the carbon fiber surface functional group from the molecule level, thus being beneficial to the study of the mechanism of the carbon fiber composite material interface.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com