Patents

Literature

18055 results about "Thickening agent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A thickening agent or thickener is a substance which can increase the viscosity of a liquid without substantially changing its other properties. Edible thickeners are commonly used to thicken sauces, soups, and puddings without altering their taste; thickeners are also used in paints, inks, explosives, and cosmetics.

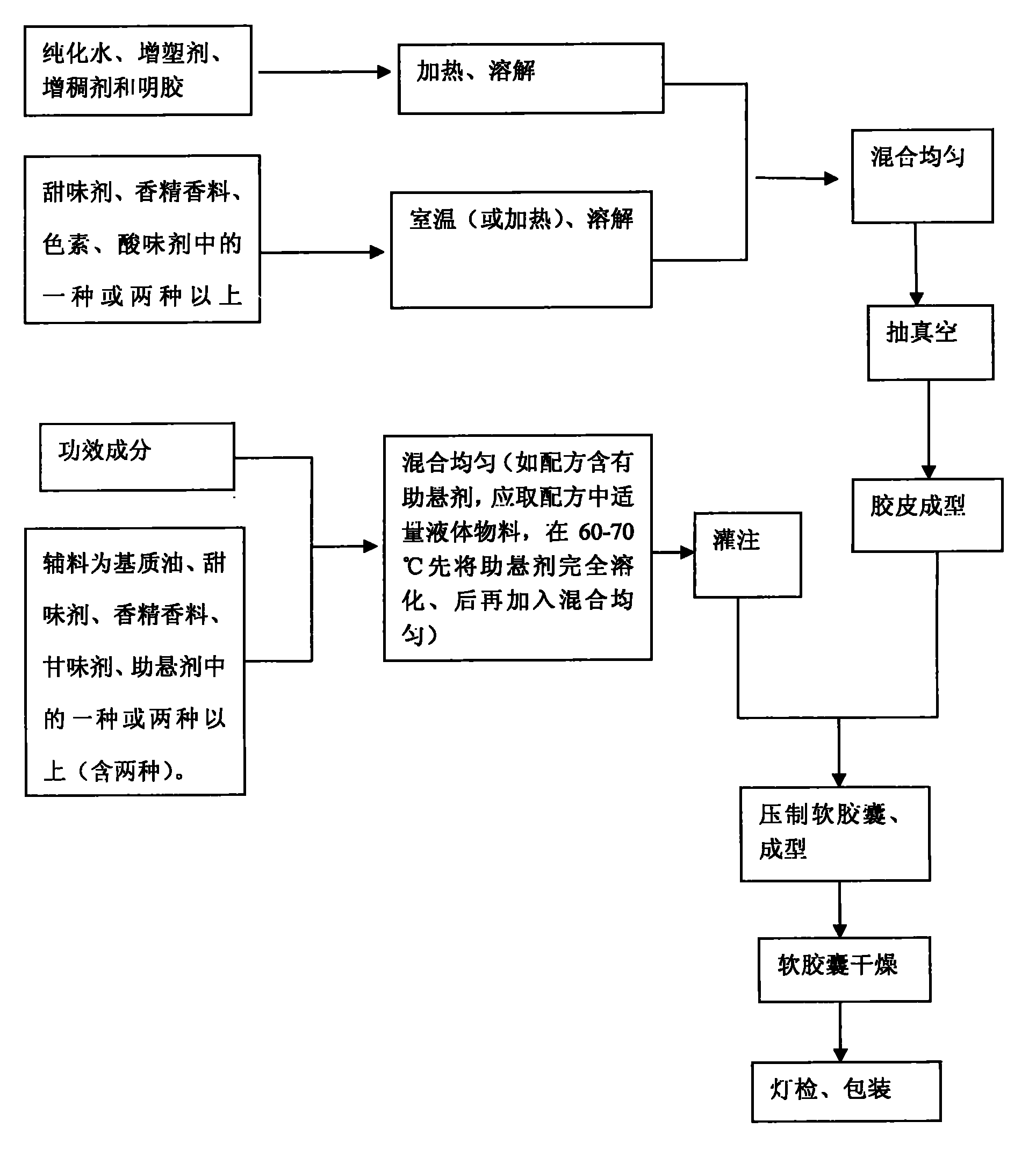

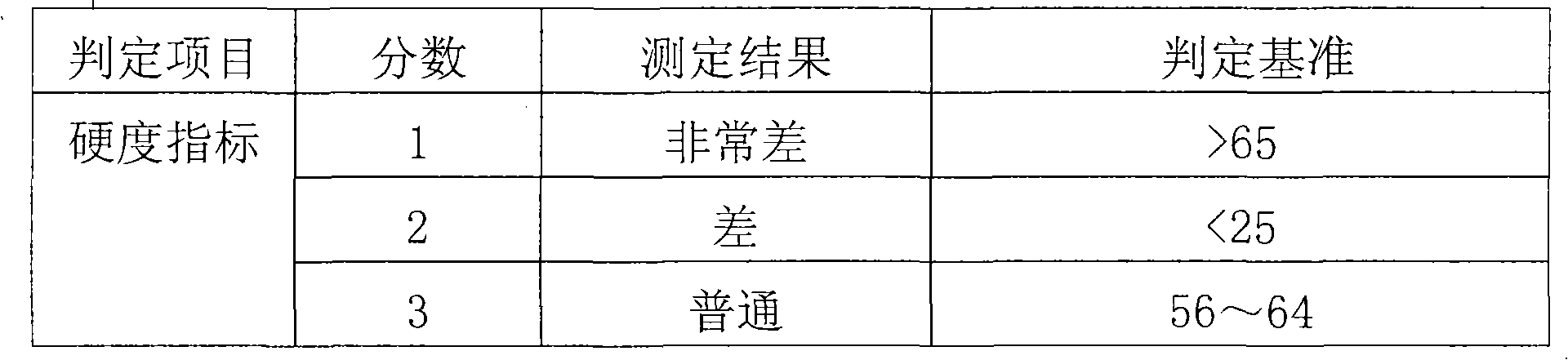

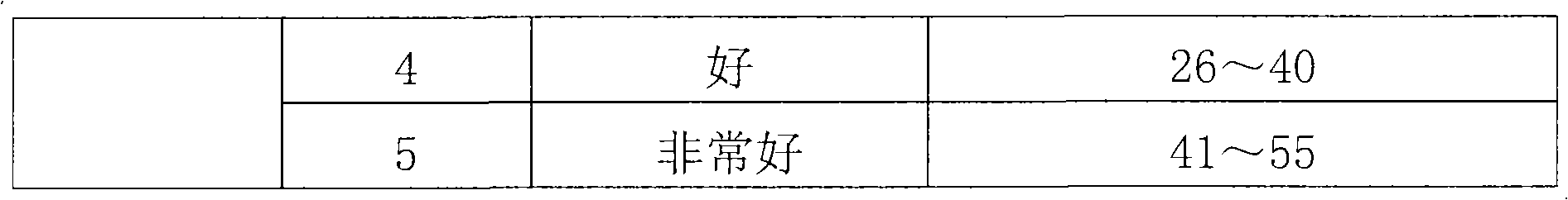

Chewable soft capsules and method for preparing same

ActiveCN101810336ADissolution stabilityRapid dissolutionFood shapingFood preparationFlavorPlasticizer

The invention discloses chewable soft capsules, which comprise capsule shells and contents sealed in the capsule shells. The chewable soft capsules are characterized by comprising the following raw materials in part by weight: 25 to 65 parts of glutin, 1 to 25 percent of thickening agent, 18 to 65 parts of plasticizer, 4 to 16 parts of water and a mixture containing one or more of 0.005 to 20 parts of sweetening agent, 0.005 to 2 parts of essence, 0.0001 to 10 parts of pigment and 0.0001 to 5 parts of acid additive. The invention also discloses a method for preparing the novel chewable soft capsules. The chewable soft capsules have the advantages of reasonable blending ratio, proper hardness, good temperature resistance, no adhesion, no deformation, stable storage, quick dissolution of effectively components and high chewiness; and when the chewing soft capsules are chewed, tastes of the capsule shells and the contents easily and uniformly spread in the mouth so as to cover up bad taste of raw materials.

Owner:SIRIO PHARMA CO LTD

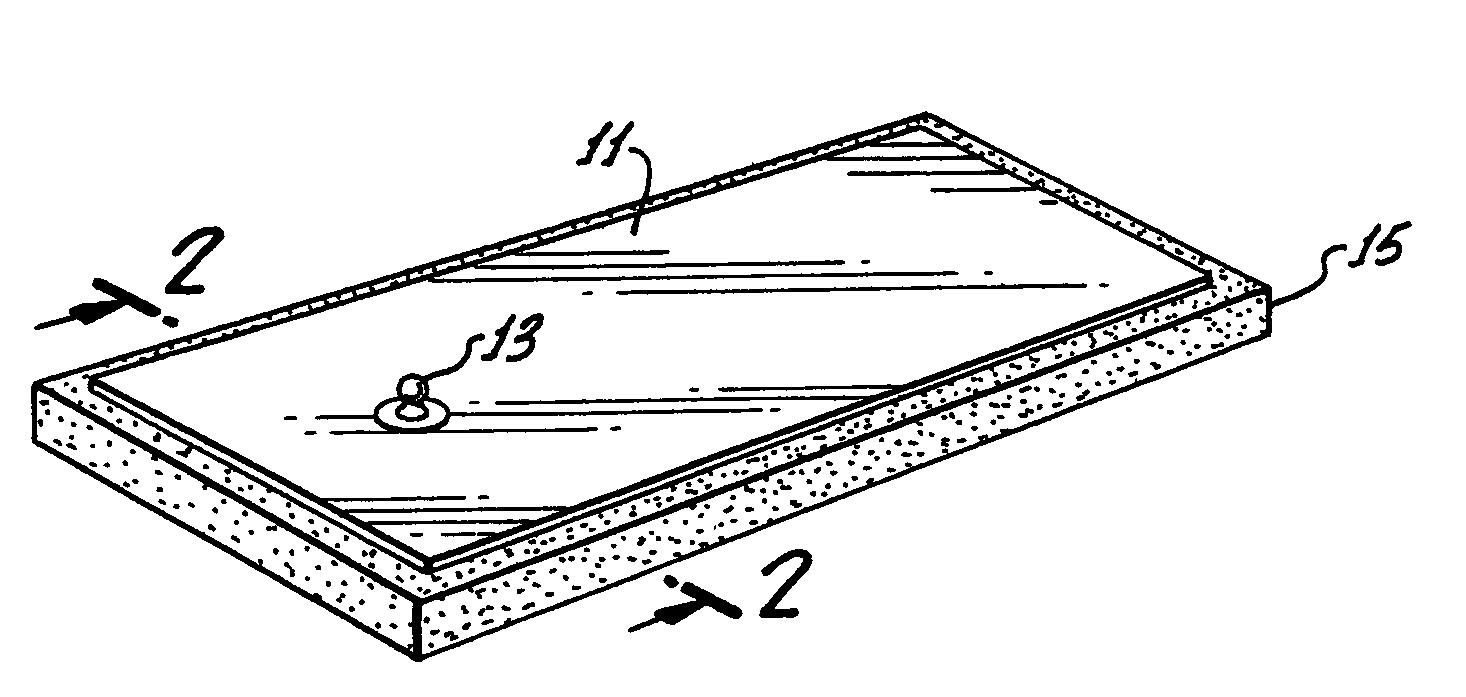

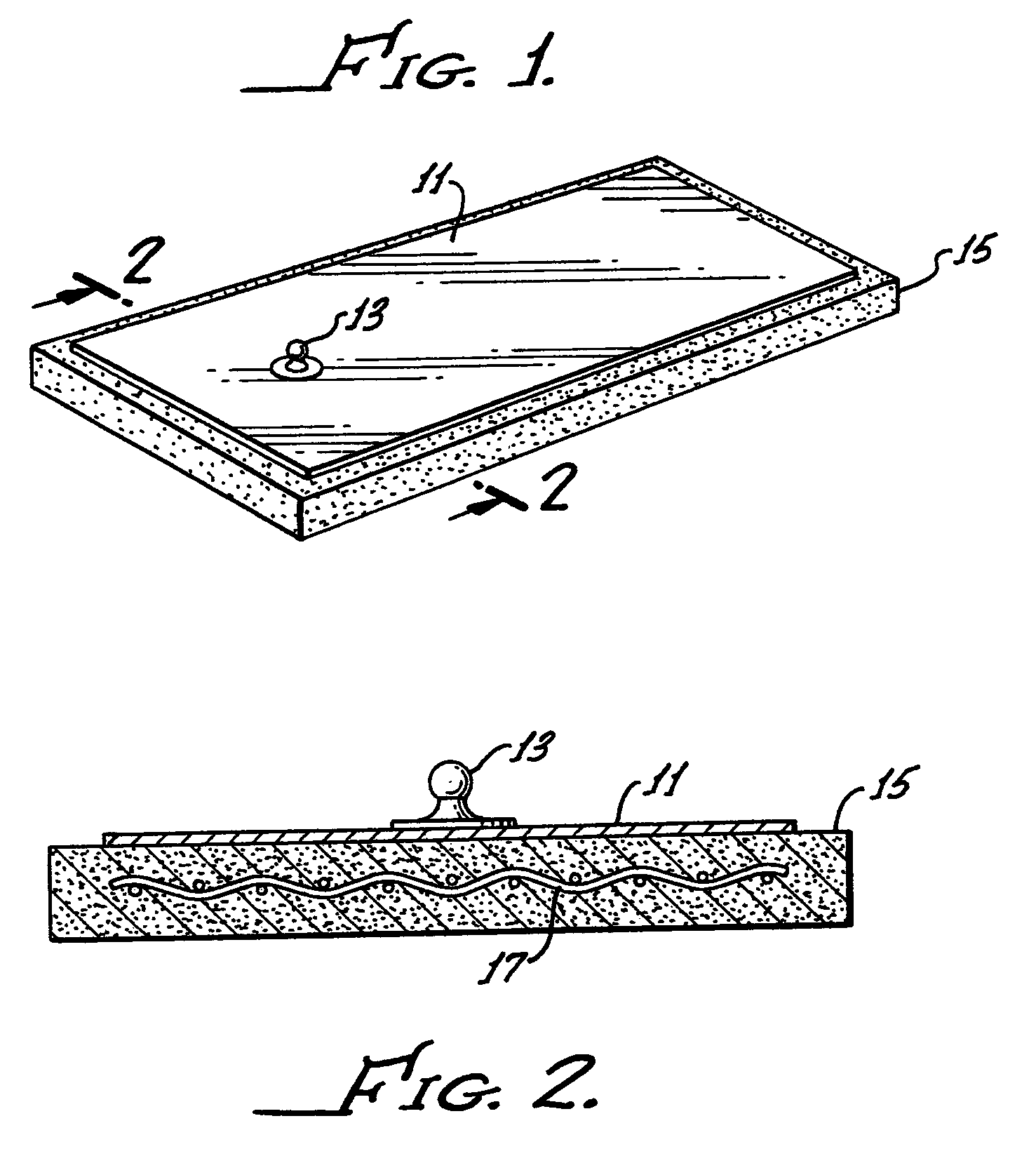

Medical electrode

An electrode providing electrical contact with a patient's skin includes a conductive member adapted for connection to an external electrical apparatus and a non-liquid film for electrically interfacing to said patient's skin, the liquid film being electrically and mechanically connected to said conductive member. The non-liquid film includes an electrically conductive organic polymer plasticized with a polyhydric alcohol with said organic polymer being derived from a monomeric mixture comprising from about 15 to 30 pph acrylic acid, 0.5 to 30 pph N-vinylpyrrolidone and 0.01 to 2 pph of a crosslinking agent. The monomeric mixture may further comprise from about 0.5 to 8 pph of a thickening agent selected from the group consisting of N-vinylpyrrolidone / acrylic acid copolymers, N-vinylpyrrolidone / vinylacetate copolymers, and N-vinylpyrrolidone / vinylimidazole copolymers.

Owner:AXELGAARD MANUFACTURING COMPANY INC

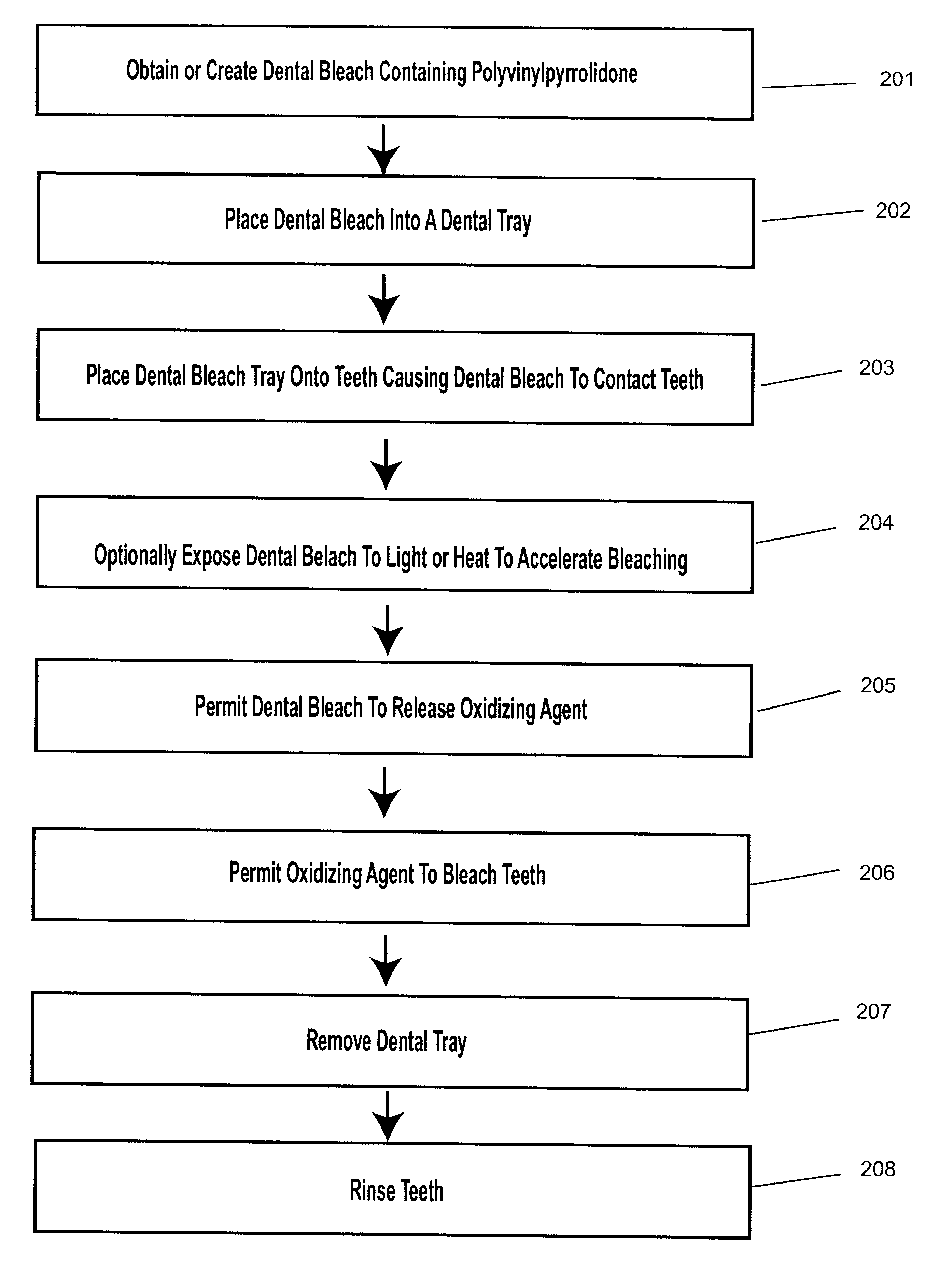

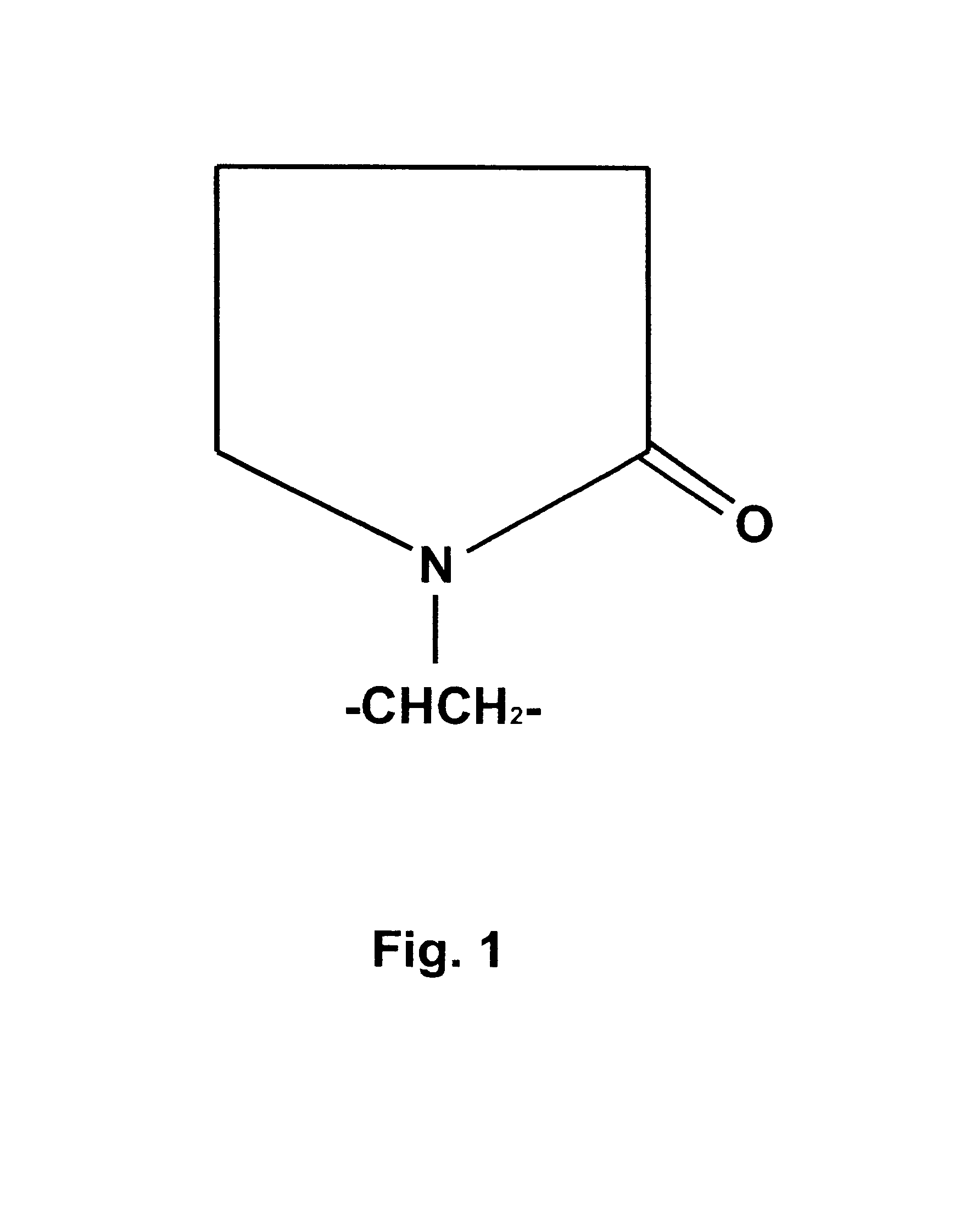

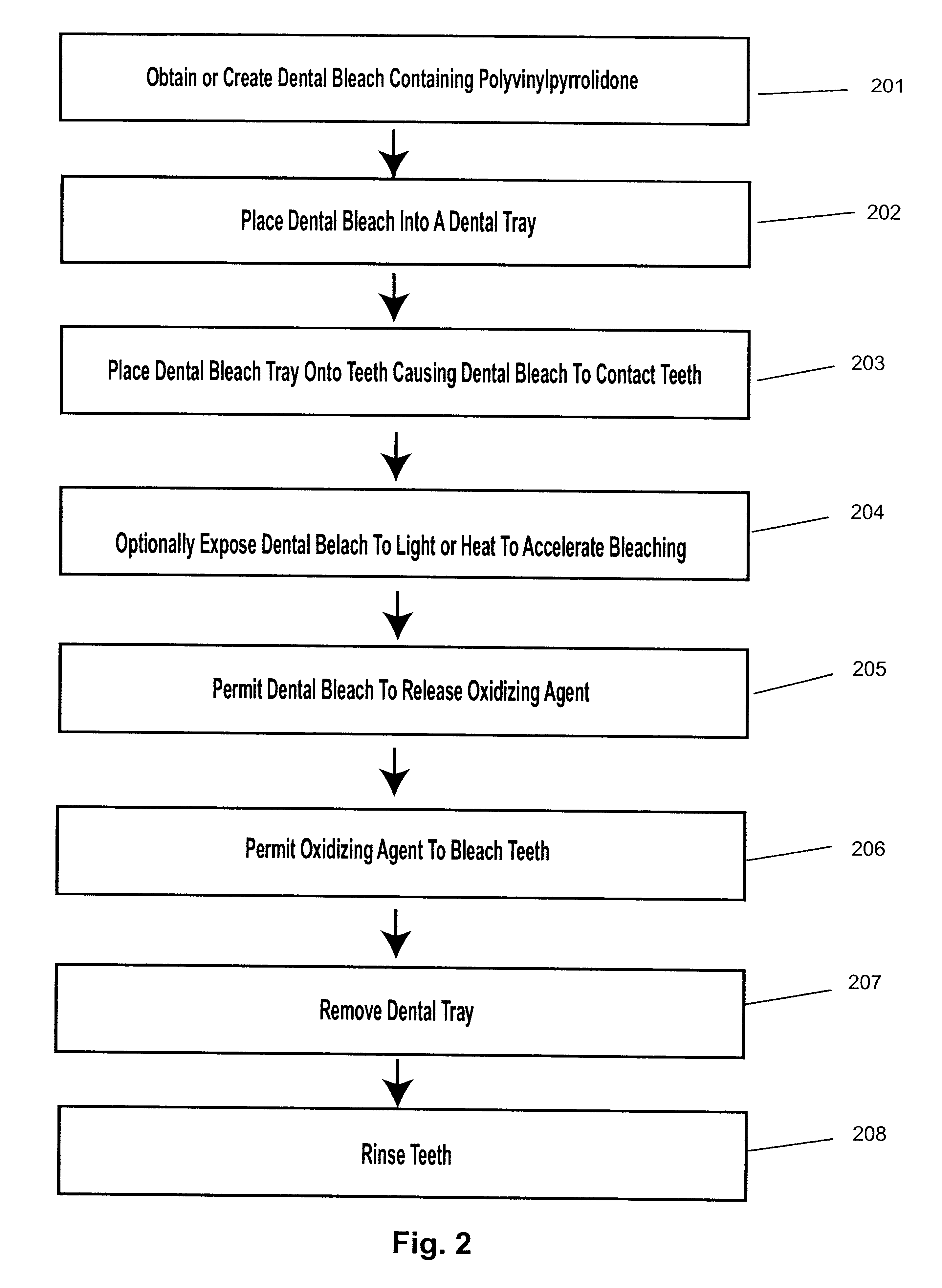

Enamel-safe tooth bleach and method for use

InactiveUS6500408B2High viscositySignificant interferenceBiocideCosmetic preparationsBleachTeeth Bleaching

A dental bleach that includes a bleaching agent and a thickening agent. The bleaching agent is typically a peroxide and the thickening agent is polyvinylpyrrolidone. A viscous or sticky dental bleach results. Optionally, a basic agent, light or heat may be added to accelerate bleaching. Bleaching may take place with the use of a dental tray. Bleach may be placed into the dental tray from a single barrel, double barrel or multi-barrel syringe containing the components of the bleach. Bleach may be placed against a flexible strip which is placed onto teeth to be bleached.

Owner:ULTRADENT PROD INC

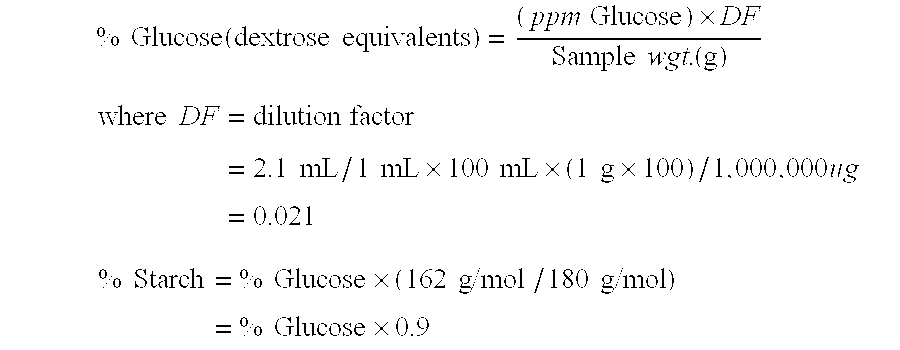

Methods for dispersing fibers within aqueous compositions

InactiveUS6379446B1Quantity maximizationMinimize interstitial spaceNon-fibrous pulp additionProtein adhesivesFiberSolid component

Compositions and methods in which dry-committed fibers are substantially homogeneously dispersed throughout a fibrous composition. The fibrous composition is characterized as having sufficient yield stress and viscosity such that the shearing forces from the mixing apparatus are effectively transferred down to the fiber level. This is accomplished by means of an appropriate thickening agent, e.g, gelatinized starch. The dry-committed fibers are exemplified by flash dry fibers or fibrous sheets that have been cut or torn into fragments less than 2 cm across. Providing fibers that have been dry-committed greatly reduces the time that it takes to obtain substantially homogeneous dispersion of the fibers throughout the fibrous composition. This, in turn, reduces the risk of mixture spoilage and mechanical or chemical damage to the solid components within the fibrous composition.

Owner:E KHASHOGGI INDS

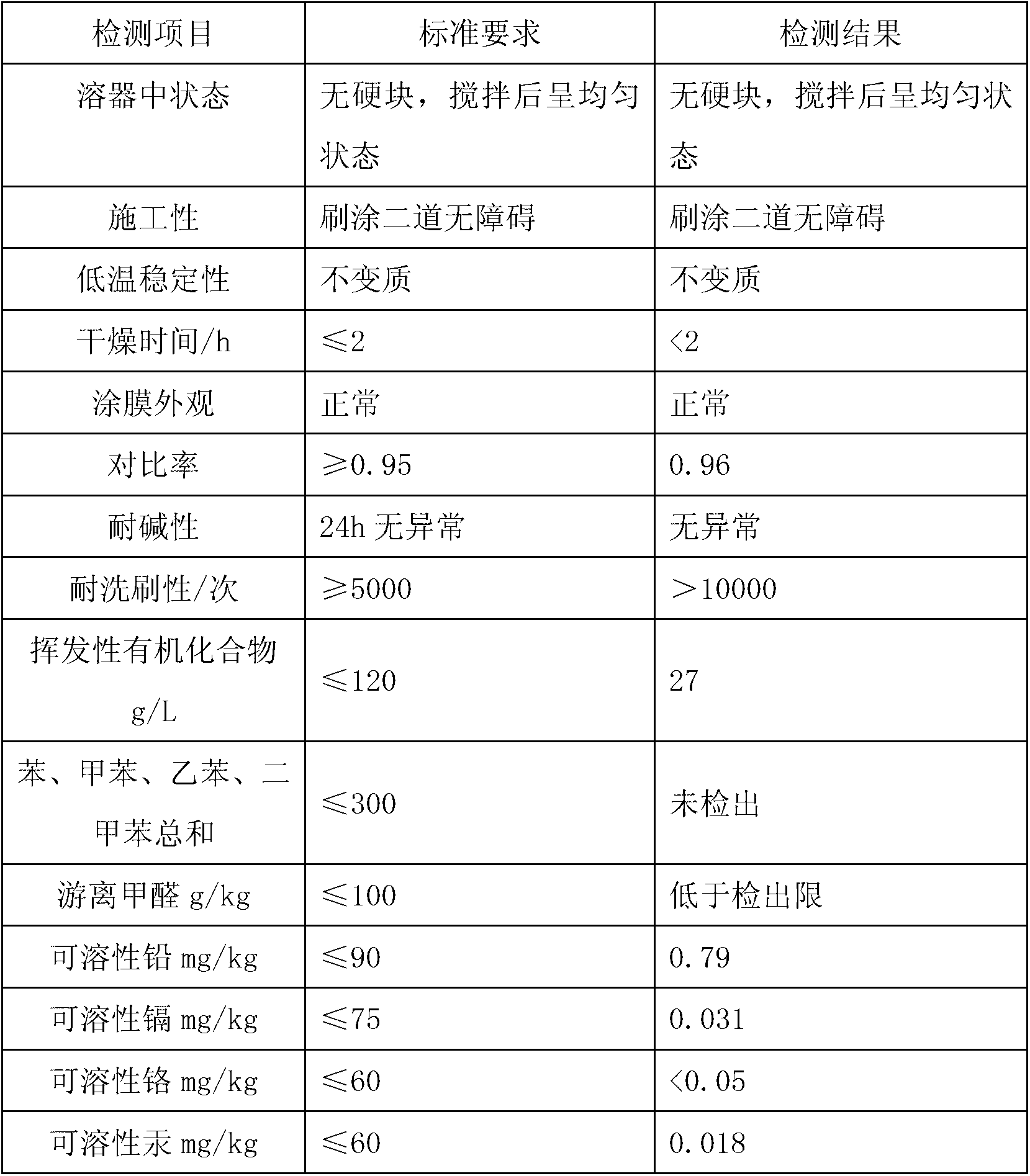

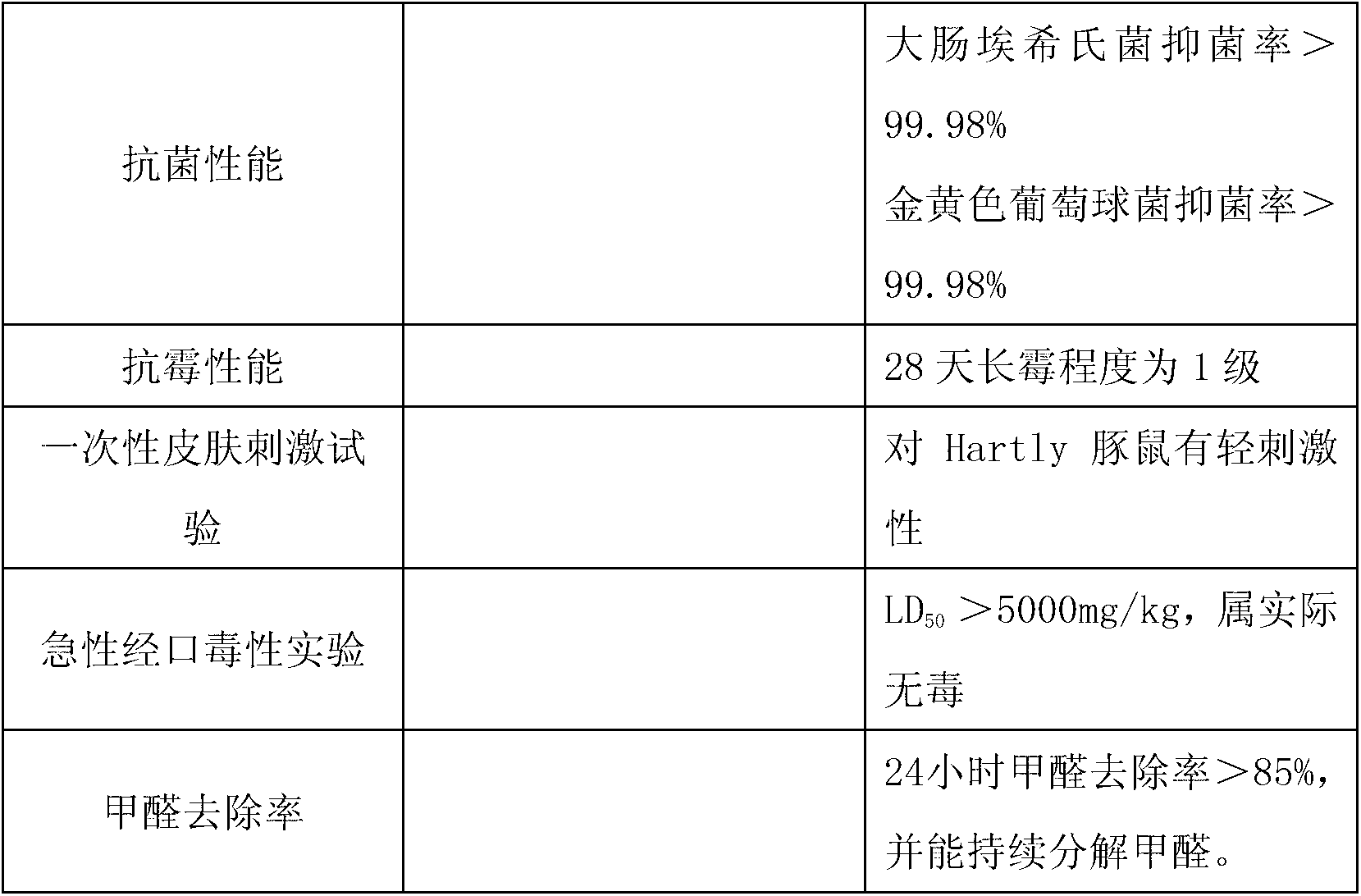

Odorless anti-formaldehyde environment-friendly internal wall latex paint and preparation method thereof

ActiveCN103059679AStrong absorption capacityStrong sustainable degradation abilityEmulsion paintsEmulsionSlurry

The invention discloses an odorless anti-formaldehyde environment-friendly internal wall latex paint and a preparation method thereof. The odorless anti-formaldehyde environment-friendly internal wall latex paint is prepared from the following components in percentage by weight: 1-15% of visible light induced nano titanium dioxide photocatalyst slurry, 15-35% of odorless emulsion, 1-15% of formaldehyde absorbent, 0.5-2% of dispersing agent, 0.2-3% of thickening agent, 0.2-1% of wetting agent, 0.1-1% of defoaming agent, 0.5-5% of film-forming assistant, 0.2-3% of anti-freeze agent, 20-40% of pigment and filler, 0.1-1% of pH regulator, 0.01-0.1% of anticorrosive bactericide and 15-40% of deionized water. The invention adopts an IPS+odorless technique, and the visible light induced nano titanium dioxide photocatalyst and the formaldehyde absorbent are added, thereby achieving the optimal effect of removing formaldehyde and other harmful substances through physical adsorption and chemical decomposition. The invention can be widely used for decorative spraying of various internal walls and other constructions.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN) +1

Light or heat activated dental bleaching compositions

InactiveUS6387353B1Solve the lack of lifePromote decompositionCosmetic preparationsImpression capsBleachBiological activation

Dental bleaching compositions are made with a bleaching agent and a stable radiant-energy absorbing compound that acts as a bleaching agent activator. The dental bleaching compositions of the present invention can be one-part, pre-mixed compositions that do not require mixing at the time of treating a patient's teeth but which remain stable over time. The bleaching agent may consist of hydrogen peroxide, either in aqueous form or complexed with urea (carbamide peroxide) or sodium perborate. The bleaching agent activator includes hydrocarbons that are stable in the presence of the bleaching agent, which do not prematurely accelerate liberation of the bleaching agent, but which allow for selective activation of the bleaching agent by irradiation of the bleaching composition with radiant energy. The bleaching composition may optionally include a neutralizing agent to adjust the pH, a carrier to help provide proper consistency and potency, and a stabilizing agent to maintain maximum potency of the bleaching agent over time. The bleaching composition may also include a thickening agent to achieve a selected viscosity. The dental bleaching compositions may be adapted to be loaded into and delivered from a syringe.

Owner:ULTRADENT PROD INC

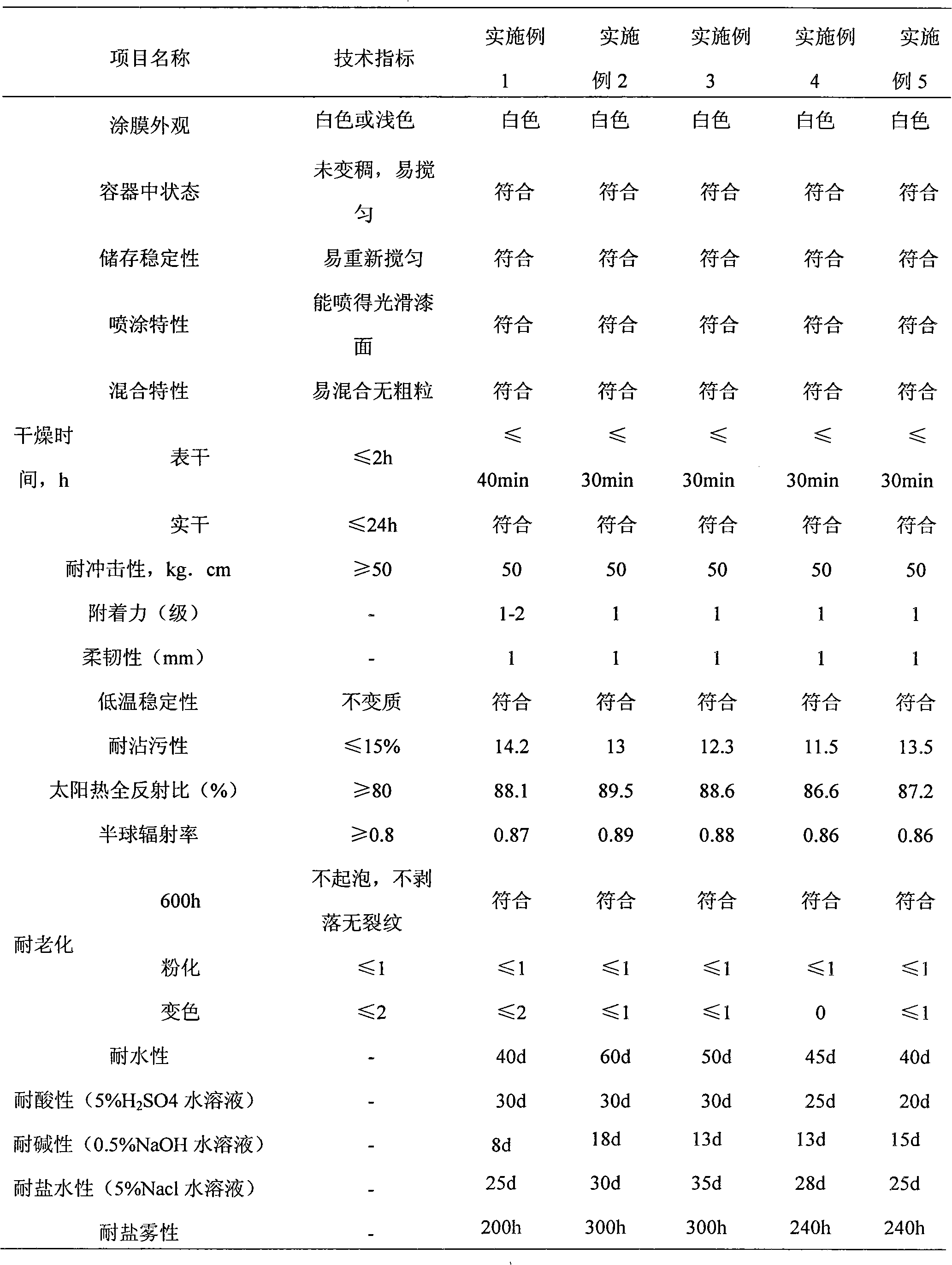

Nanometer compound water-based heat insulation anticorrosion paint used for metal and preparation method thereof

ActiveCN101665645AGood heat insulationImprove corrosion resistanceAnti-corrosive paintsReflecting/signal paintsWater basedAcrylic resin

The invention discloses a nanometer compound water-based heat insulation anticorrosion paint used for metal and a preparation method thereof. The raw materials of the paint consists of the following components: tap water, watercraft acrylic resin, rustproofing pigment, reflection pigment and filler, hollow micro-beads, watercraft nanometer size, anti-settling agent, wetting and dispersing agent A,wetting and dispersing agent B, film-forming assistant, defoaming agent, flatting agent, anti-flash rustproofing agent and thickening agent. Watercraft polyacrylic emulsion is styrene-crylic acid copolymerization emulsion, pure crylic acid polymerization emulsion or organic silicon-crylic acid copolymerization emulsion. The wetting and dispersing agent A is block macromolecule copolymer, multivalence carboxylate polymer and / or synthetic macromolecule copolymer, and the wetting and dispersing agent B is anion wetting agent and / or nonionic wetting agnet. The product contains no organic solvent,heavy metal and other harmful substances, is extremely excellent in environmental conservation, integrates the functions of anticorrosion and heat insulation as a whole and is simple and convenient for construction, safe in storage and stable in performance.

Owner:GUANGZHOU JOINTAS CHEM

Dilute fabric care compositions comprising thickners and fabric care compositions for use in the presence of anionic carry-over

InactiveUS20060252668A1Save user effortLow costCationic surface-active compoundsOrganic detergent compounding agentsPolymer scienceActive agent

Owner:THE PROCTER & GAMBLE COMPANY

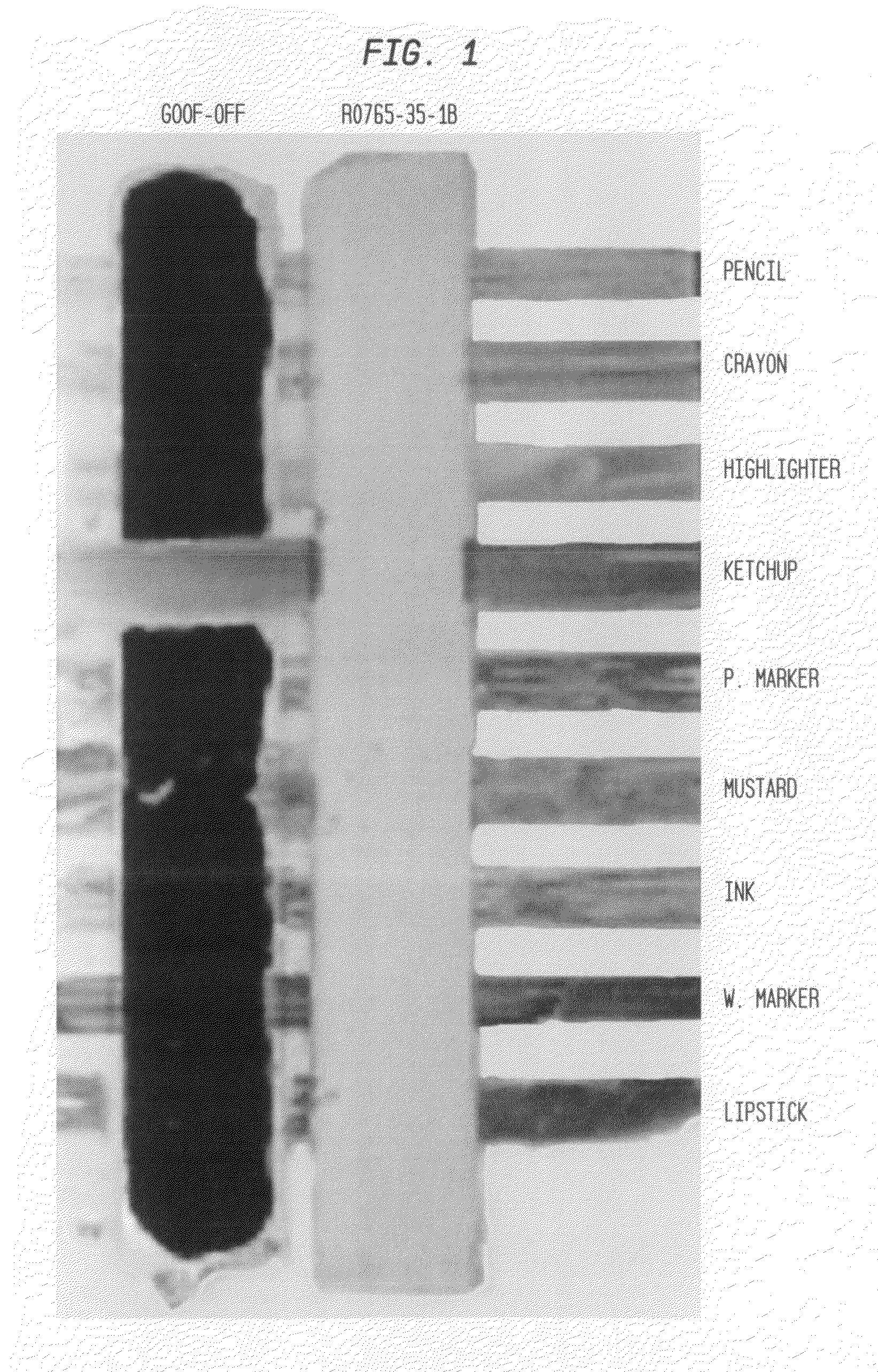

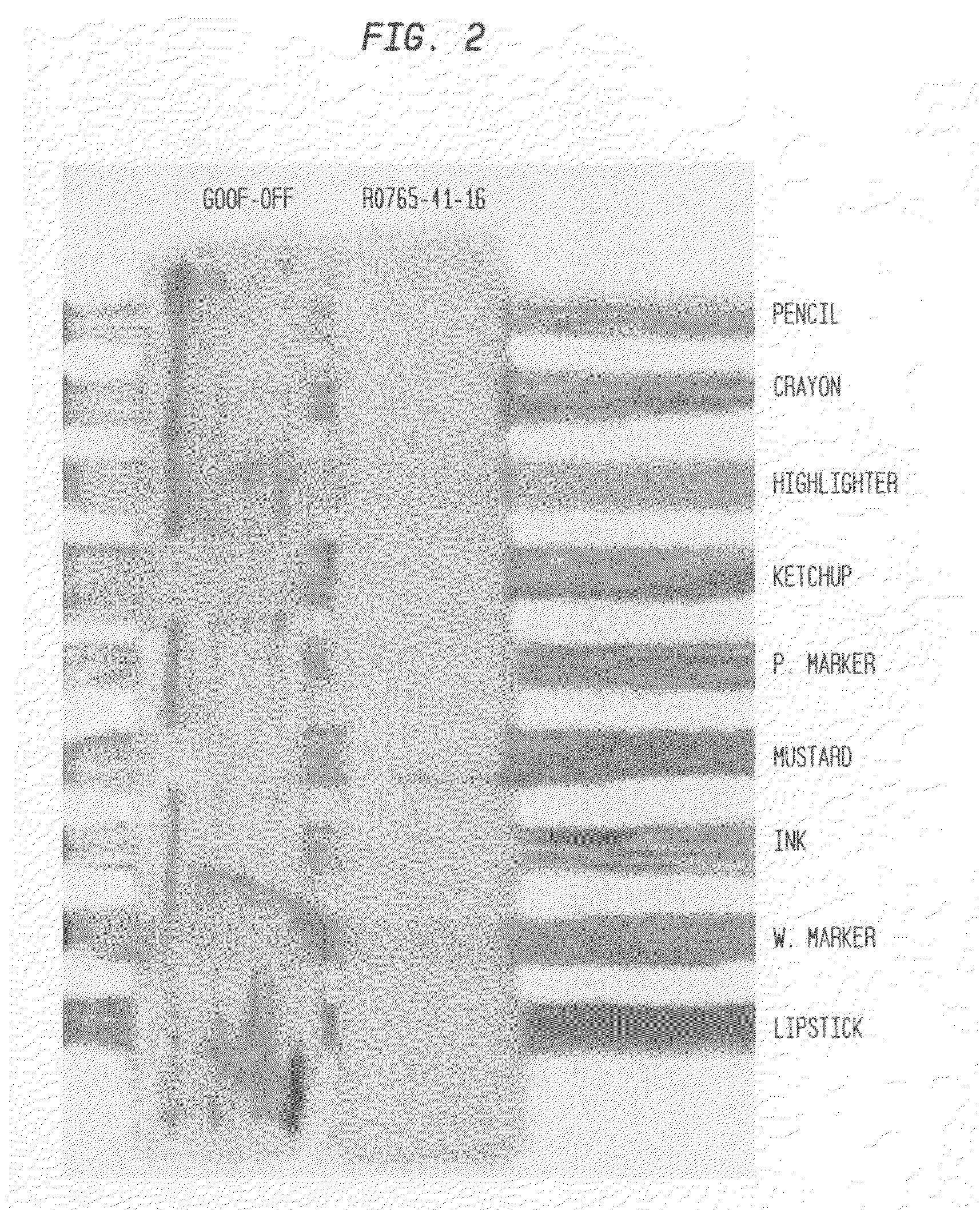

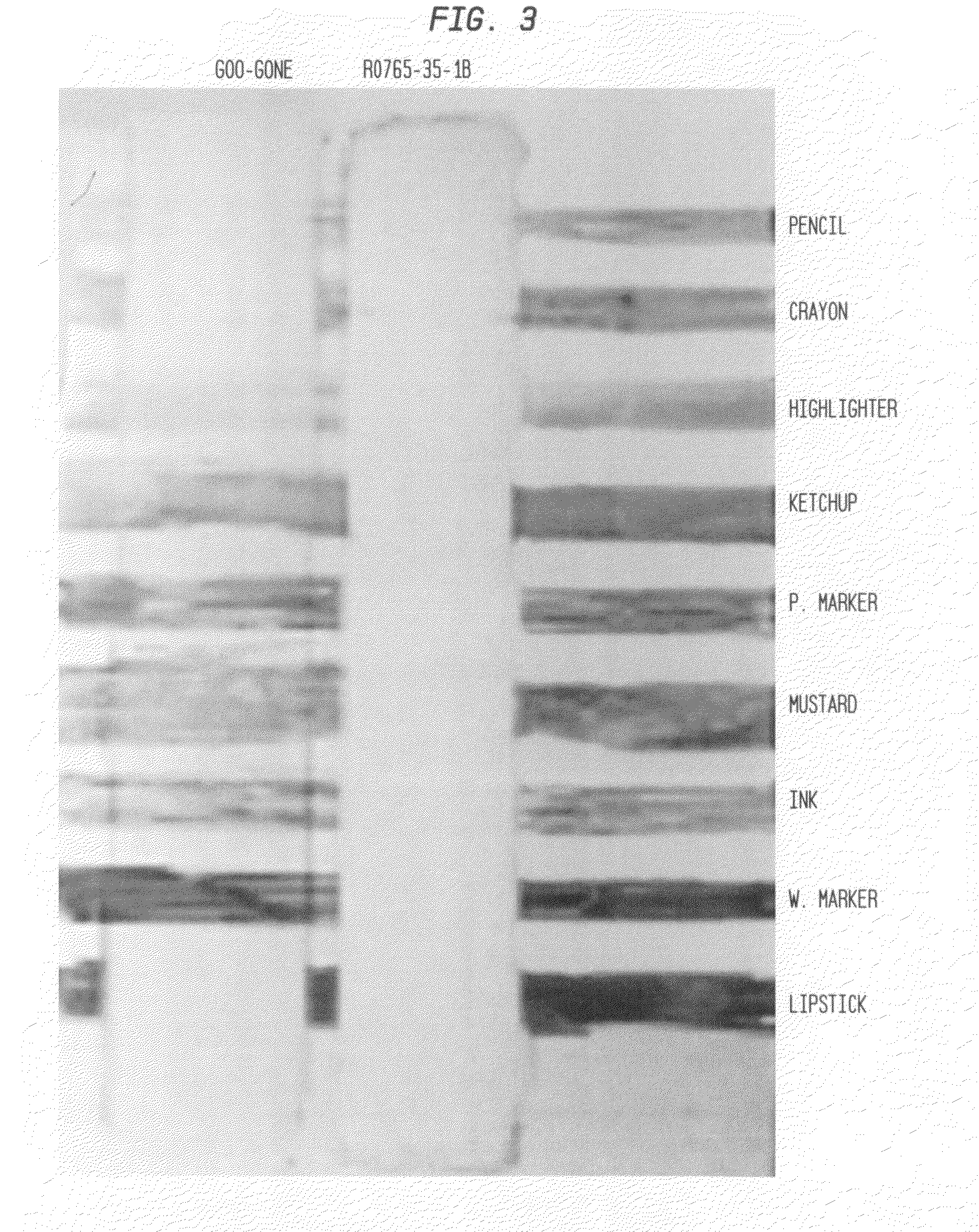

Cleaning compositions incorporating green solvents and methods for use

ActiveUS20090281012A1High flash pointLow vapor pressureOrganic detergent compounding agentsDetergent mixture composition preparationGlutaric acidActive agent

An environmentally-friendly cleaning composition for industrial and consumer applications comprising (a) a blend of dibasic esters, (b) one or more surfactants (c) and, optionally, (d) water or a solvent. The dibasic esters are be derived from a blend of adipic, glutaric, and succinic diacids, and, in one particular embodiment, the blend comprises dialkyl adipate, dialkyl methylglutarate and dialkyl ethylsuccinate, wherein the alkyl groups individually comprise a C1-C12 hydrocarbon group. The one or more surfactants are typically chosen from alcohol alkoxylate, an alkyl phenol ethoxylate, a terpene, a terpene alkoxylate or any derivates thereof. Optionally, additional components or additives including delaminates such as pinene and d-limonene, fragrances, whiteners, stabilizers, thickeners and the like can be added to the composition. The industrial or consumer application selected from the group consisting of a graffiti cleaner, a painted-substrate cleaner, an ink cleaner, a metal substrate cleaner, a plastic substrate cleaner, an environmentally friendly cleaner, a stain-spot cleaner, an industrial hand cleaner, a resin cleaner, a tar resin cleaner, a textile cleaner, a paint stripper and any combination thereof.

Owner:RHODIA OPERATIONS SAS

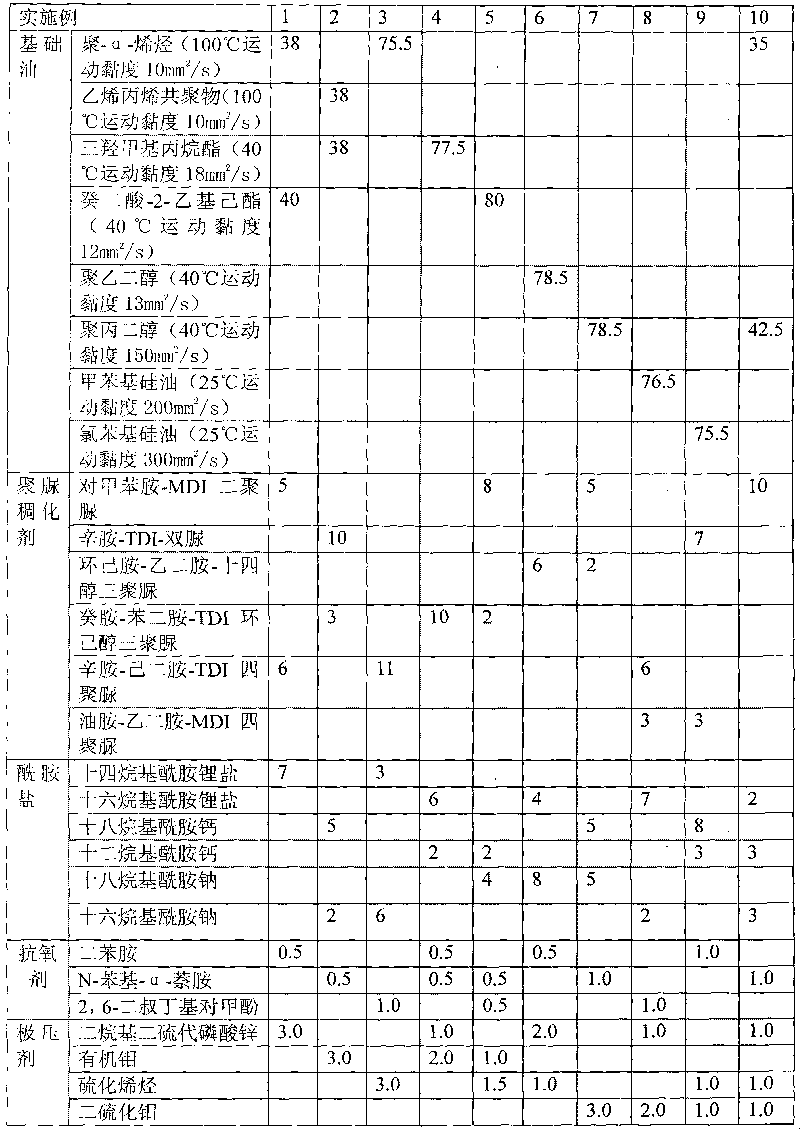

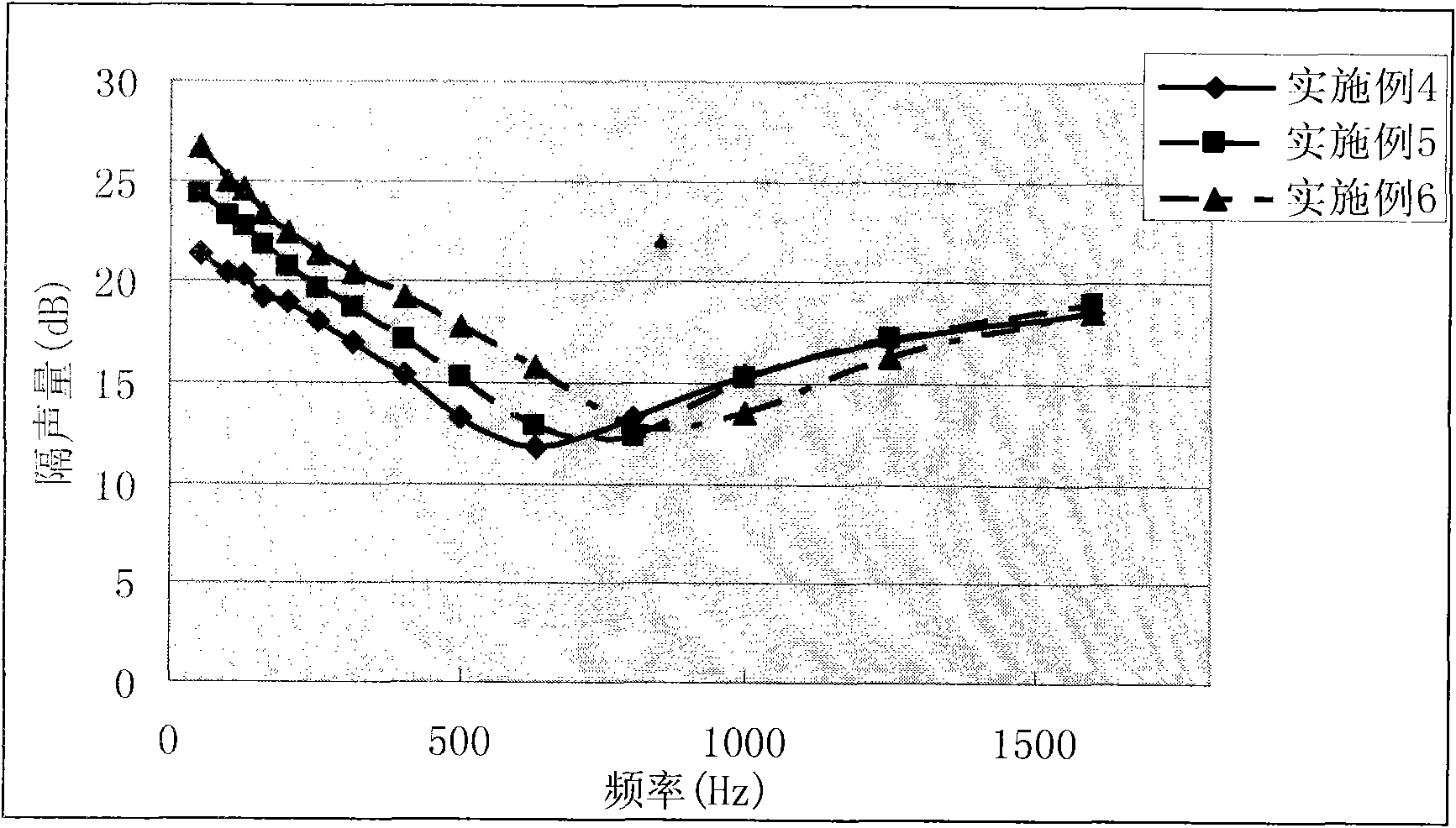

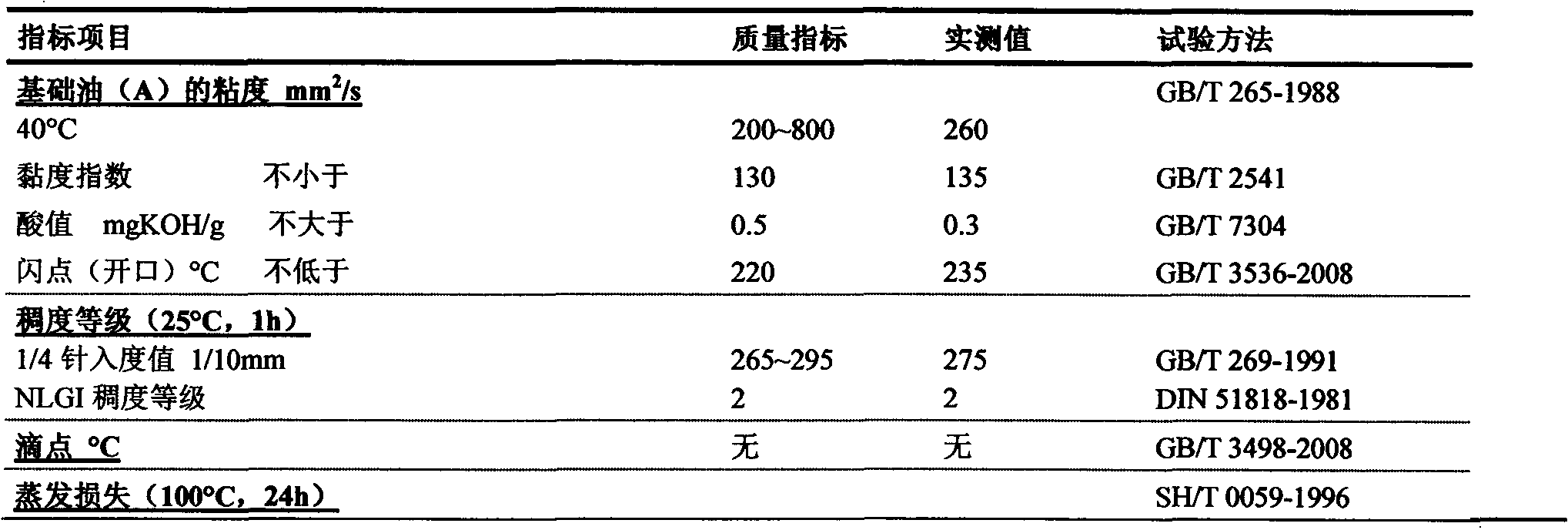

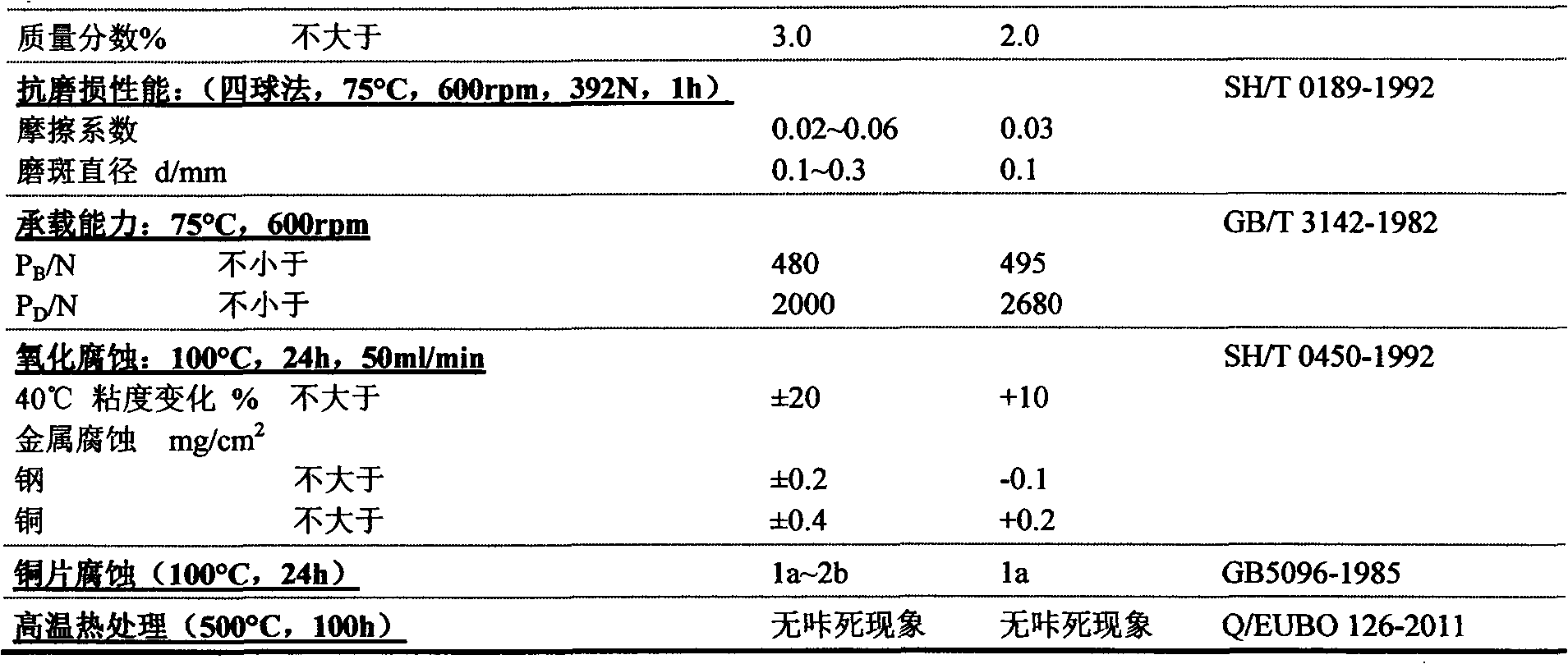

Polyurea grease composite

ActiveCN1657599AImprove extreme pressure and anti-wear performanceGood extreme pressure and anti-wear propertiesThickenersComposition BBase oil

Two lubricating polyurea-ester compositions with high stability and extreme-pressure antiwear performance contain proportionally basic oil, urea-based thickening agent, Ca-based thickening agent and extreme-pressure agent for composition A, or the composition A plus inorganic Ca salt for composition B.

Owner:CHINA PETROLEUM & CHEM CORP +1

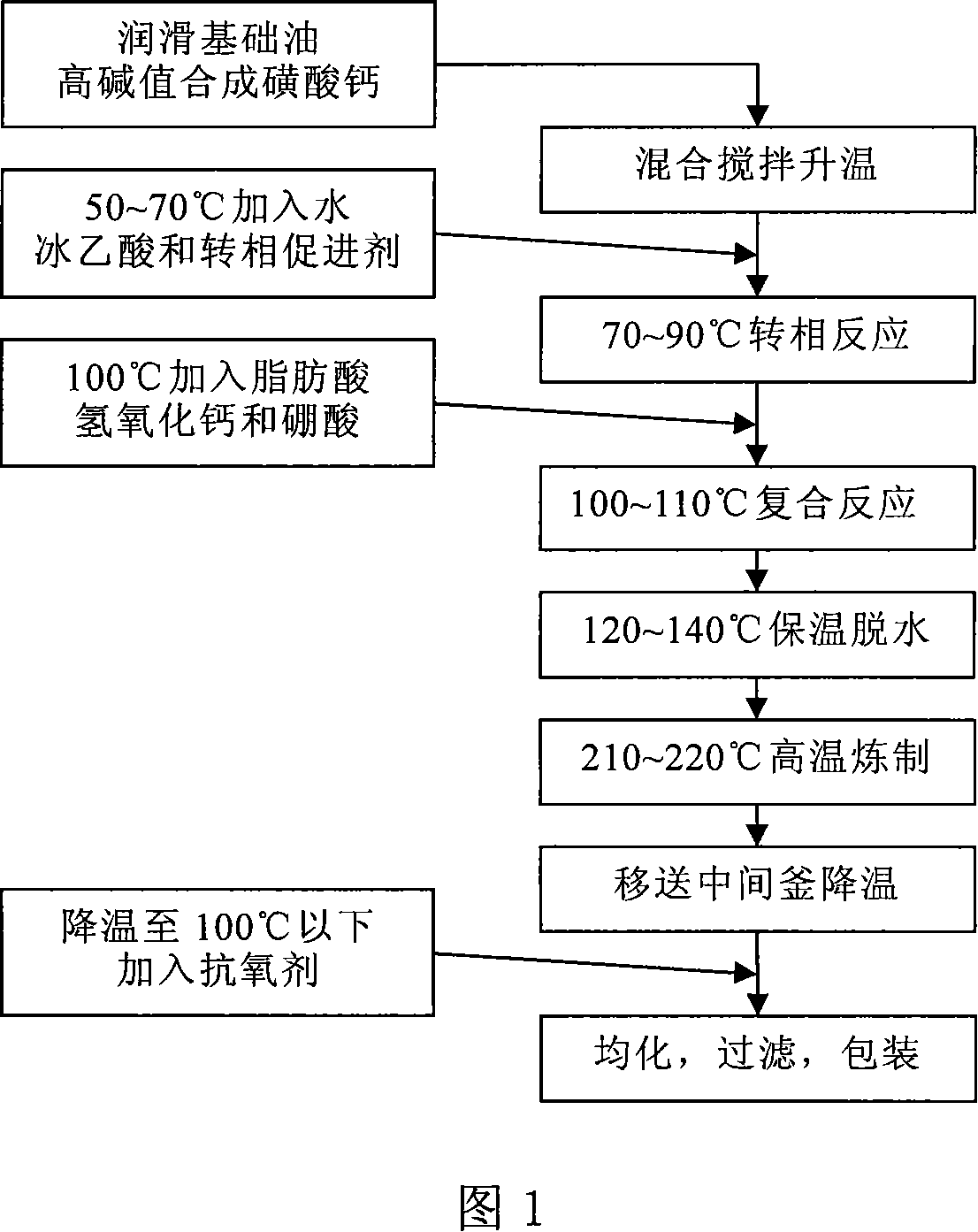

Compound sulphonic acid albany grease and method for producing the same

ActiveCN101153239AImprove performanceImprove water resistanceLubricant compositionAntioxidantManufacturing enterprises

The invention relates to calcium sulfonate complex grease and a manufacture method thereof, in particular to grease producing the thickening agent by synthetic reaction with super-high base value. At first, the lubricating base oil and the calcium sulfonate are added into an opening reaction kettle to be stirred, the phase inversion promoter, the glacial acetic acid and the water are added into the kettle to boost the temperature to make the insulating reaction until the materials are thickened, then the calcium hydroxide, the aliphatic acid and the boric acid are added into make an insulating reaction, a temperature rise, an insulating dehydration and a refining in turn, then the materials are moved into an intermediate kettle, the antioxidant is added to disperse and homogenize, and the finished product is produced after the filtering. The invention has excellent anti-spray performance, excellent high temperature performance, good extreme pressure anti-abrasion performance, prominent anti-shear performance, good pumping performance, anti-rust performance and water adding shear stability; has apparent phase inversion effect and good product performance, decreases the grease exchange times under the same working condition and increases the service life of the equipment, which is proved by the trial applications of a plurality of appliance manufacture enterprises, steel works, paper mills and so on.

Owner:无锡中石油润滑脂有限责任公司

Anti-regurgitation infant formula

Infant formula containing certain thickening agents useful for treating regurgitation. The thickening agent can be waxy corn starch, waxy rice starch, or a mixture thereof.

Owner:BRISTOL MYERS SQUIBB CO

Chia seed beverage and related method

InactiveUS20090181114A1Enhancing heart healthImprove regularityBiocideDigestive systemFruit juiceFlavored water

A beverage is disclosed that is effective for enhancing gastrointestinal regularity and heart health. It is formed by a liquid comprising fruit derived juices, water or naturally or artificially flavored water. A composition of matter is mixed within the liquid in a shelf stable pasteurized beverage form and formed from sterilized whole seed extracted from Salvia hispanica L. The resulting beverage exhibits a pH dependent viscosity requiring no additional thickening agents and suitable as a beverage for human consumption.

Owner:US NUTRACEUTICALS LLC

Stabilization of cosmetic compositions

A composition of matter is used as an ingredient in cosmetics comprising at least 0.5% by weight and preferably 1-30% by weight of highly refined cellulose fiber in a cosmetic composition. Additionally present in the composition are other conventional cosmetic ingredients as known in the art. This composition may include at least colorants (dyes and pigments), lipophilic materials, aqueous materials (water and aqueous solutions), waxes, binding agents (polymers, thickening agents), emollients, emulsifiers, thickening agents, antioxidants, natural and synthetic oils and extracts, clays, ultraviolet radiation absorbers, and the like.

Owner:FIBERSTAR BIO INGREDIENT TECH

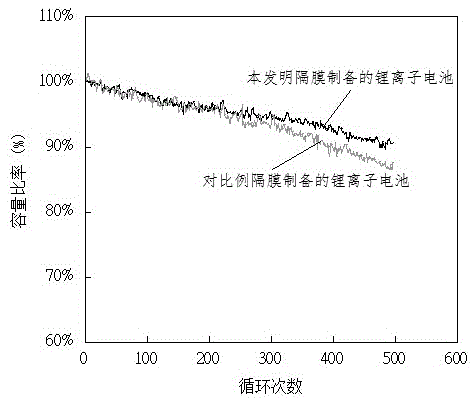

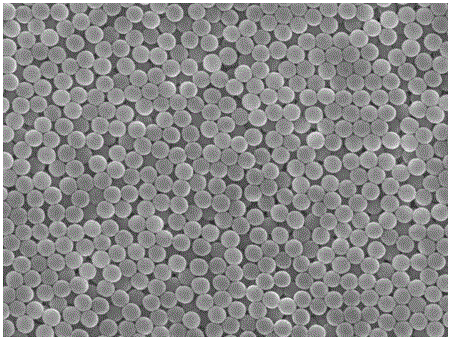

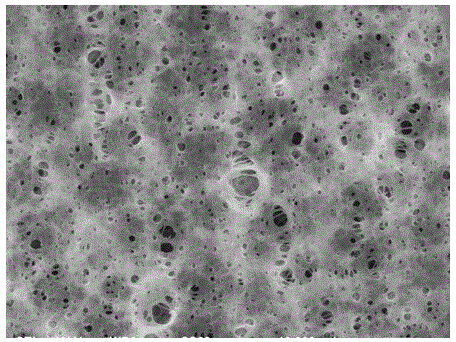

PVDF-coated lithium-ion battery separator and preparation method thereof

The invention provides a PVDF-coated lithium-ion battery separator and a preparation method thereof. The PVDF-coated lithium-ion battery separator comprises a base film and a coating, wherein the coating coats a single side or double sides of the base film; the coating is obtained by coating and drying slurry; and the coating is 0.1-0.5 micron in thickness and contains evenly arranged PVDF spherical particles. According to the PVDF-coated lithium-ion battery separator, a traditional technology that an existing PVDF-coated lithium-ion battery separator takes oil substances of acetone and the like as solvents is abandoned. Water is adopted as the solvent of a PVDF material; and no a thickening agent is added, so that the low-viscosity water-based PVDF coating slurry is obtained; an ultra-thin coating of which the PVDF particles are regularly arranged and which is relatively loose is obtained after the slurry is coated; the ultra-thin coating improves the hardness of a pole piece and the effective utilization space of the battery when effectively bonded to the lithium-ion battery separator and the pole piece; and the ventilation loss caused by the thickness of the coating is reduced.

Owner:CANGZHOU MINGZHU SEPARATOR TECH CO LTD

High SPF transparent or translucent, cytoprotective, biodegradable, UV radiation resistant compositions

ActiveUS20080233060A1Protect the skinEliminating possible endocrine disruption responseCosmetic preparationsToilet preparationsCarrageenanPhospholipid

A composition comprising purified water using ozonation, ionization, or distillation or any combination thereof wherein alcohol may be substituted for, or combined with water at least one emollient including but not limited to chitosan, and aloe vera gel, individually or in any combination; an oil component with spf boosting agents including but not limited to; ethyl macadamiate, non-toxic silicone oil and essential oils, butter milk, waxes impregnated with inorganic sun-block or sunscreen agent and organic / inorganic micronized particles, wood powder and bentonite clay, keratin, either individually or in any combination; at least one inorganic sun-block or sunscreen agent including any metal oxide, glass microsphere, silica and silica compound, and optionally metal oxide pigments with particles that are micronized, submicronized, nanoparticle sized, or otherwise individually or in any combination that can be homogenized in either a water phase, a water-aloe phase, an oil phase or any phase of said composition; at least one emulsifier wherein said emulsifier includes but is not limited to a phospholipid and / or liposome or an aloe vera gel or an ester of coconut oil individually or in any combination, for emulsifying the water, water-aloe, or oil phase in combination with an homogenizer; where any of components are preferably mixed with an homogenizer and where an appropriate thickening agent including but not limited to xanthan gum, carageenan, either individually or in any combination is added as required.

Owner:GRUNE GUERRY L

Antimicrobial skin treatment composition and methods for producing and using an antimicrobial skin treatment composition

The invention relates to an antimicrobial skin treatment composition and methods for producing and using an antimicrobial skin treatment composition. The antimicrobial skin treatment composition includes an antimicrobial package that can provide extended protection against germs and bacteria. The antimicrobial package can include any of the following: a quaternium ammonium antimicrobial agent, a protease enzyme, a preservative, a natural antimicrobial agent, or a lower alcohol. The composition can also include, among other ingredients, a thickening agent, a skin healing ingredient, a humectant, an emollient, a skin moisturizer, or water.

Owner:WHHC HAND SANITIZER

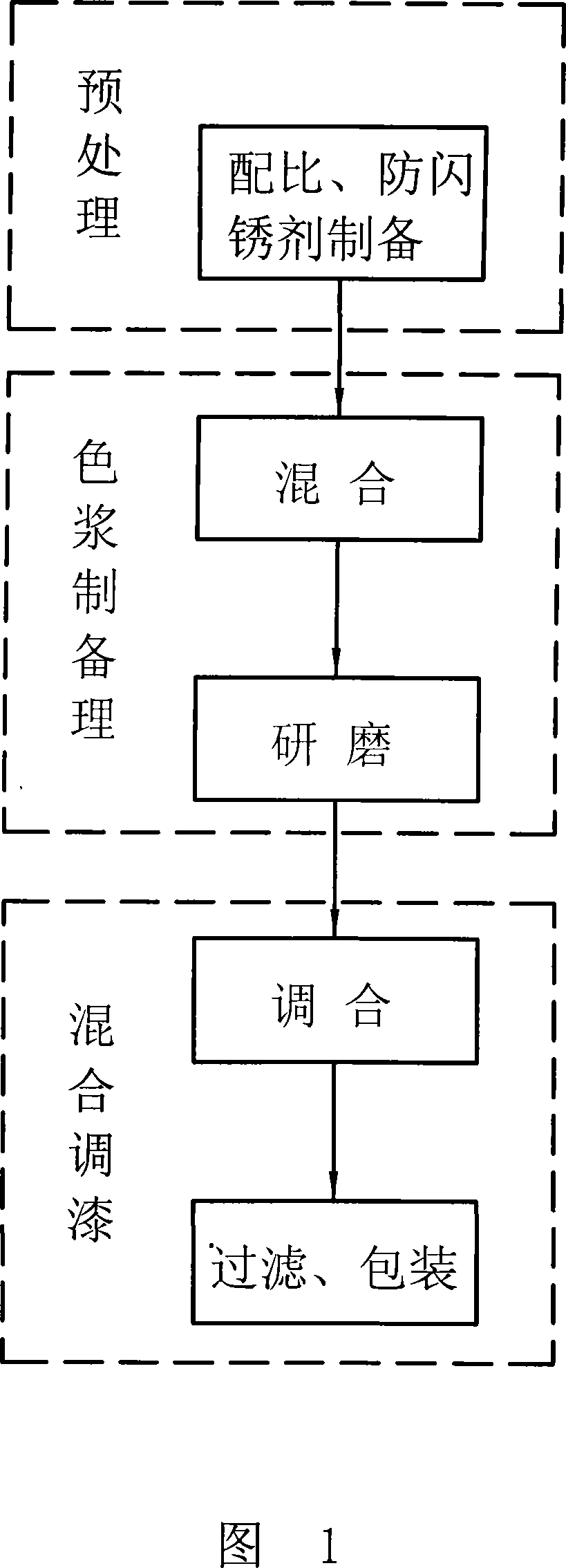

Water industrial antirust paint and preparation method thereof

InactiveCN101045843AHigh hardnessStrong adhesionAnti-corrosive paintsEmulsion paintsEpoxyALUMINUM PHOSPHATE

This invention relates to a aquosity industry anti-rust paint and its preparation method. According to weight it includes 8 to 11% aquosity acroleic acid modified epoxy, 33 to 40% acroleic acid latices, 0.1 to 0.3% defoamer, 0.05 to 0.15% wetting agent, 0.3 to 0.5% dispersant, 0.3 to 0.5% rust-resistant agent, 7.5 to 9% iron oxide red, 6 to 8% French chalk, 5 to 10% modified zinc phosphate, 2.5 to 10% trimerization aluminum phosphate, 3 to 3.5% precipitated baryte , 0.5 to 1% zinc oxide, 3 to 5% mica ferric oxide, alcohol ester twelve 1 to 2%, triethanolamine 1 to 2%, thickening agent 0.3 to 0.6%, preservative 0.05 to 0.1%, 5 to 20% de-ionized water, through pretreatment, color paste preparation and blending and adjusting to gain product.

Owner:邹磊

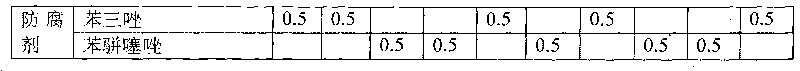

Synthetic high-temperature lubricating grease and production method thereof

InactiveCN101693851AGood colloidal stabilityGood shear stabilityThickenersAdditivesAntioxidantColloid

The invention discloses a synthetic high-temperature lubricating grease and a production method thereof. The synthetic high-temperature lubricating grease is produced by taking synthetic oil as base oil and mixing the base oil with thickening agents, an extreme-pressure additive, an antioxidant and an anticorrosive agent, wherein the weight ratios of all ingredients are as follows: 47-94% of base oil, 2-20% of polyurea thickening agent, 2-20% of acylamide thickening agent, 0.5-5.0% of antioxidant, 1.0-5.0% of extreme-pressure additive and 0.5-3.0% of anticorrosive agent. In the invention, the synthetic base oil, the polyurea thickening agent and the acylamide thickening agent all have excellent high-temperature performance, and the organic combination thereof leads the lubricating grease to obtain excellent high-temperature performance; the polyurea thickening agent endows the lubricating grease with good colloid stability, and the acylamide thickening agent endows the lubricating grease with excellent anti-shear stability, therefore, the organic combination of colloid stability and anti-shear stability leads the lubricating grease to have excellent high-temperature performance and good losing resistance, does not change to thin and avoids losing at high temperature. The extreme-pressure anti-wear additive endows the lubricating grease with excellent extreme-pressure anti-wear performance, and the bearing capacity is high.

Owner:CHINA PETROLEUM & CHEM CORP

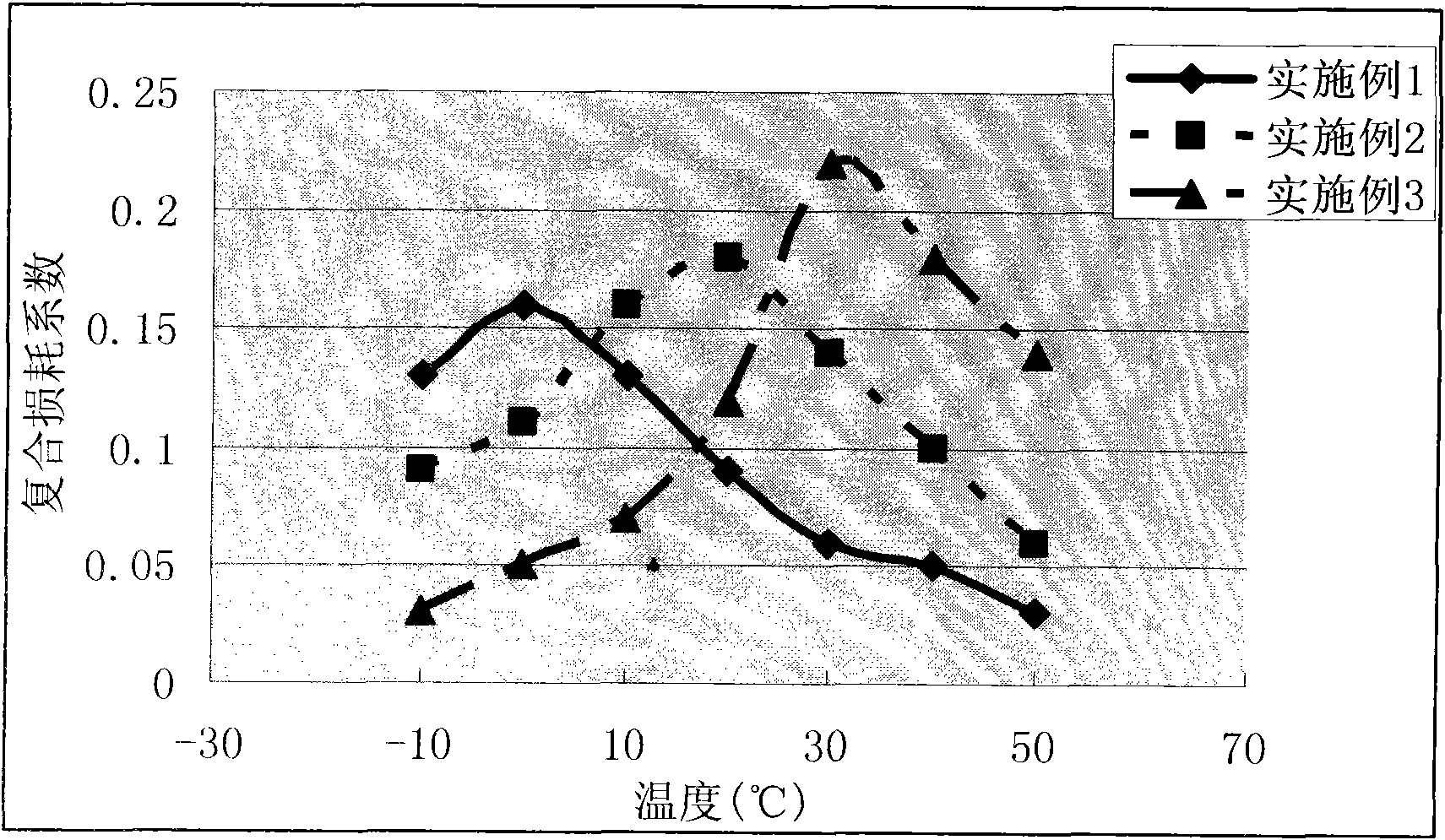

Water-based sound-proof damping coating and preparation method thereof

ActiveCN101891990AImprove performanceGood damping of vibrationPolyurea/polyurethane coatingsFiberWater based

The invention discloses a water-based sound-proof damping coating and a preparation method thereof. The water-based sound-proof damping coating comprises the following raw materials in part by weight: 15 to 35 parts of polymer emulsion, 35 to 55 parts of inorganic filler, 10 to 20 parts of powdery flame retardant, 2 to 5 parts of auxiliary agent, and 10 to 20 parts of deionized water. The preparation method comprises the following steps of: uniformly mixing the deionized water and a wetting and dispersing agent, and adding part of inorganic filler with stirring at a high speed to prepare inorganic filler water dispersible slurry; and adding the polymer emulsion into the inorganic filler water dispersible slurry with stirring at the high speed, sequentially adding the powdery flame retardant, the rest part of inorganic filler, reinforcing fibers, a mould inhibitor and an antifoaming agent, and finally adding a thickening agent to adjust consistency. The coating of the invention has excellent vibration and noise reduction effect, is mainly used for internal coating of carriage floors, side walls and roofs of vehicles, and can play a good role in inhibiting vibration and reducing noise.

Owner:BOGE RUBBER&PLASTICS ZHUZHOU CO LTD

Composite emulsified asphalt waterproof coating and preparation method thereof

InactiveCN104449381AGood dispersionHigh viscosityConjugated diene hydrocarbon coatingsNatural rubber coatingsBituminous waterproofingEmulsion

The invention relates to a composite emulsified asphalt waterproof coating and a preparation method thereof. The composite emulsified asphalt waterproof coating is prepared from the following raw materials in parts by weight: 150-220 parts of emulsified asphalt, 50-105 parts of a polymeric emulsion, 70-130 parts of inorganic powder, 0.5-2 parts of a stabilizer, 6-10 parts of a dispersant, 2-5 parts of a wetting agent, 1-3 parts of a thickener I, 1-3 parts of a thickener II, 2-7 parts of a defoaming agent and 15-40 parts of water. The invention further relates to a preparation method of the composite emulsified asphalt waterproof coating. The viscosity, strength, application property, solid content and storage stability of the emulsified asphalt waterproof coating are remarkably improved, and the cost is lowered to a great extent.

Owner:JINZHOU DONGFANG YUHONG BUILDING MATERIALS

Reaction bonding type node sealant and preparation method thereof

ActiveCN102911638AImprove stabilityImprove bindingNon-macromolecular adhesive additivesOther chemical processesChemical LinkagePolyvinyl chloride

The invention provides a reaction bonding type node sealant and a preparation method thereof. The sealant comprises asphalt, modifiers, an emulsifier, a crosslinking agent, thickeners, a reinforcing agent and water. In the formula system, more appropriate modifiers are adopted compared with the prior art, so that a rubber asphalt mixture can achieve good emulsification effect, elasticity and strength of a sealing layer after drying are greatly improved, and the sealing effect can be good and lasting; the chemical linkage effect with concrete is formed by using the crosslinking agent, and bonding force with the concrete is improved; and a lot of thickeners are used for adjusting the stickness of the sealant system, so that the reaction bonding type node sealant can better adhere to the surface of a pentatricopeptide repeats (PPR) or polyvinyl chloride (PVC) pipe, and good sealing at positions where PPR or PVC water supply and drainage pipes are connected with base surfaces of concrete.

Owner:XI NIU PI WATERPROOFING TECH CO LTD

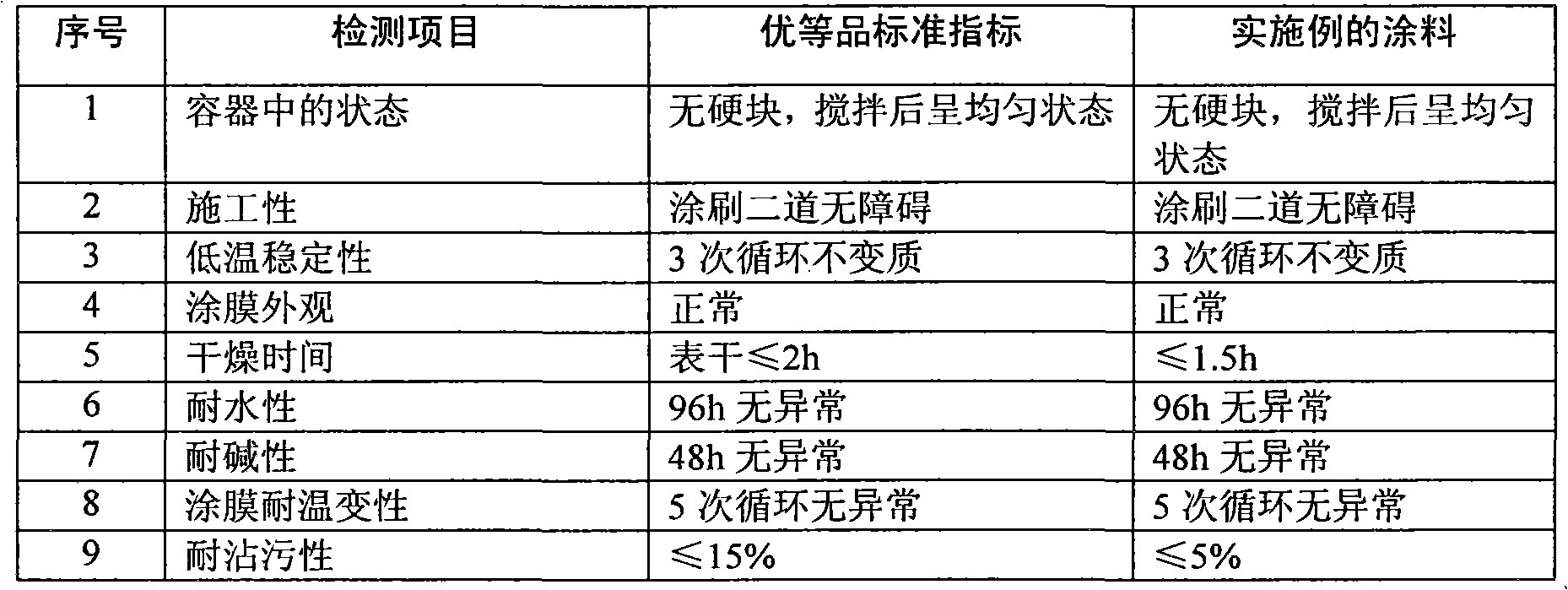

Exterior wall coating and preparation method thereof

InactiveCN101974273ASimple preparation processLow equipment requirementsAnti-corrosive paintsPolymer scienceDefoaming Agents

The invention discloses a multifunctional exterior wall coating with strong weather resistance, brushing resistance and high adhesion and a preparation method thereof. The exterior wall coating is prepared from the following raw materials in percentage by weight: 10-30% of silicone acrylic emulsion with a interpenetrating network structure, 10-40% of acrylic ester emulsion, 1-15% of hydrophobically modified inorganic nanoparticles, 10-40% of pigment and filler, 0.3-1% of a dispersing agent, 0.1-0.2% of a defoaming agent, 0.1-0.3% of a preservative, 0.3-0.6% of a flatting agent, 1-2% of a thickening agent, and the balance deionized water. The exterior wall coating of the invention has the advantages of strong weather resistance, brushing resistance, strong adhesion, long service life, simple and convenient preparation process and low equipment requirement, thus being easy for large-scale popularization and application. The exterior wall coating overcomes the defects of poor brushing resistance, poor ageing resistance and the like of the existing exterior wall coating.

Owner:广州市枫源化工有限公司

Solution forms of cyclodextrins for nasal or throat delivery of essential oils

This invention further relates to a method for preventing or treating diseases or conditions of the oral cavity, throat or nose of warm-blooded animals including humans. More particularly, the invention pertains to a composition and method for spraying essential oils to the oral cavity, throat or nasal mucosa as cyclodextrin inclusion complexes. The spray composition includes a cyclodextrin in an amount of from about 0.1% w / v to about 20% w / v; at least one essential oil in an amount of from about 0.001% w / v to about 5.0% w / v; an effective amount of an antimicrobial preservative composition; and water. The composition may further comprise an alcohol co-solvent, a thickening agent, a sweetener, an antitussive, an anticholinergic, a decongestant, an antihistamine, an astringent, an anti-inflammatory steroid composition, a vitamin, a respiratory stimulant, a mucolytic agent, a bronchodilator, a beta-antagonist, an antidiarrheal agent, or combinations thereof.

Owner:QPHARMA

Multifunctional high-efficiency thermal insulation insulating mold paint

The invention relates to a multifunctional high-efficiency heat-preservation heat-insulation coating material. The compositions in percentage by weight of the coating material are: 10 to 20 percent of water, 0.1 to 0.2 percent of multifunctional auxiliary agent, 0.1 to 0.2 percent of wetting agent, 0.5 to 0.8 percent of dispersing agent, 0.3 to 0.5 percent of antifoam agent, 1.5 to 3.0 percent of propylene glycol, 16 to 20 percent of rutile-type titanium pigment, 3 to 5 percent of mica powder, 6 to 8 percent of hollow glass microballoon, 3 to 5 percent of infrared powder, 3 to 4 percent of fire retardant, 35 to 40 percent of elastic acrylic acid emulsion, 3 to 5 percent of opaque polymer, 0.5 to 0.8 percent of film-forming auxiliary agent, 0.2 to 0.3 percent of bactericide and preservative and 0.3 to 0.6 percent of thickening agent. The multifunctional high-efficiency heat-preservation heat-insulation coating material is of aqueous monocomponent and does no harm to human body and the environment so as to be an environment-friendly product; meanwhile, the coating material also has excellent waterproof and fire-retardation functions, convenient and quick construction, excellent adhesion strength, outstanding crack resistance, infrequent pollution and service life as long as 15 years; moreover, during practical use, the coating material can effectively reduce solar heat accumulated in a house by approximately 8 to 15 DEG C, and can greatly reduce energy consumption.

Owner:董善刚

Monocomponent high elastic aqueous polyurethane/acrylate waterproof paint and process for preparing same

InactiveCN1670096AImprove performanceIncrease elasticityPolyurea/polyurethane coatingsEmulsion paintsEmulsionPolymer science

The invention discloses a monocomponent high elastic aqueous polyurethane / acrylate waterproof paint which comprises (by weight ratio) polyurethane / acrylic ester composite emulsion 30-90 parts, filling pigment 5-45 parts, dispersing agent 0.2-1.1 parts, film forming adjuvant 0.6-1.5 parts, levelling agent 0.05-0.35 part, defoaming agent 0.08-0.32 part, plasticizer 0.6-12 parts, thickening agent 0.01-1.0 part, pH stabilizing agent 0.01-5.0 parts, ultraviolet absorbent 0.5-1.0 part, water 1-15 parts. The preparation process is also disclosed.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD

Lubricating grease and preparation method thereof

ActiveCN103060070ADrop point highGood colloidal stabilityLubricant compositionBall bearingBoiling point

The invention relates to lubricating grease, comprising 40-95 wt% of lubricating base oil, 1-59 wt% of a compound zirconium-based thickening agent and 1-59 wt% of a tetrapolyurea, wherein the compound zirconium-based thickening agent is a compound zirconium sceps formed by reacting a higher aliphatic acid, an aromatic acid and water with zirconium alkoxide. The invention also relates to a preparation method of the lubricating grease. The method comprises the steps of performing a first contact reaction on the zirconium alkoxide, the higher aliphatic acid and the aromatic acid in the lubricating base oil at a temperature of 60-120 DEG C; then performing a second reaction on the obtained mixture from the first contact reaction with water at a temperature of 85-100 DEG C; and heating the obtained product from the second reaction for dehydration; and then introducing the tetrapolyurea in the obtained reaction product. The lubricating grease has relatively high boiling point, presents excellent colloid stability and has good extreme pressure antiwear property and ball bearing lubrication life.

Owner:CHINA PETROLEUM & CHEM CORP +1

Stable foamed compositions

Stable foamed compositions are described. These compositions contain water and at least one alkoxylated silicone compound, selected from one or more of the following compound classes: bis-alkoxylated silicone compounds, alkoxylated silicone waxes, water-insoluble alkoxylated silicone compounds and esters of fatty acids and alkoxylated silicone compounds. The solid foamed compositions preferably contain additional consistency-imparting agents, which are waxy substances that are solid at 25° C. and / or thickeners. The mixture of ingredients, from which the stable foamed composition is made, is foamed with air and / or an inert gas and has a stable density of less than or equal to 0.8 g / cm2.

Owner:WELLA AG

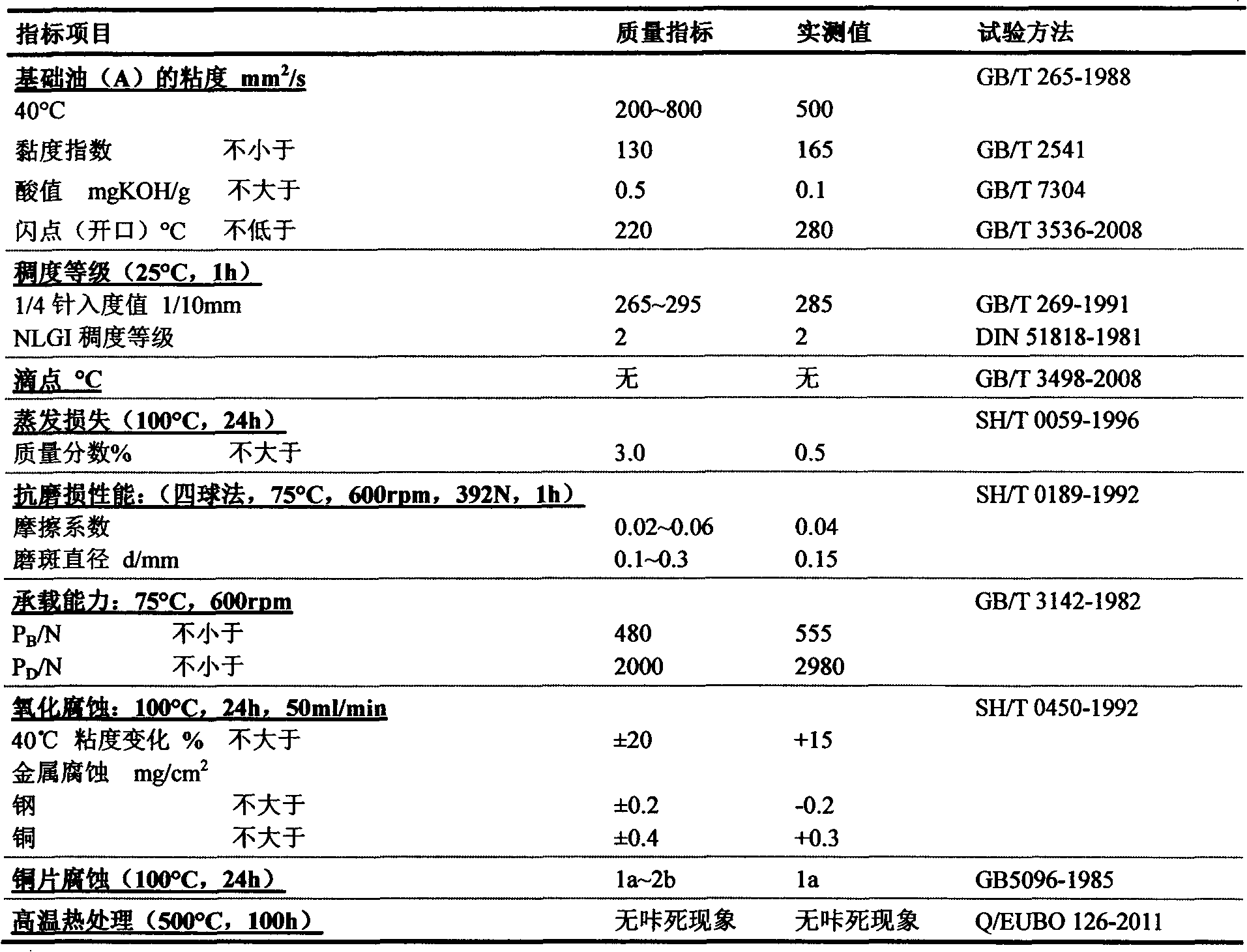

Valve element sealing lubricating agent composition

InactiveCN102433204ASimple production methodImprove high temperature resistanceLubricant compositionBase oilWear resistance

The invention relates to the field of lubricating materials, in particular to a valve core sealing lubricating agent composition, which comprises: (A) 100.0 weight parts of base oil; (B) 5.0 to 35.0 weight parts of thickening agent; (C) 3.0 to 55.0 weight parts of solid lubricating agent; (D) 0.1 to 3.0 weight parts of surfactant; (E) 0.1 to 2.5 weight parts of antioxygen; (F) 0.1 to 4.0 weight parts of extreme pressure antiwear agent; (G) 0.1 to 2.0 weight parts of metal passivating agent; and (H) 0.1 to 1.5 weight parts of antimicrobial agent. The finished lubricating agent prepared according to the mixing ratio has high high-temperature resistance, high antiwear and wear-resistance performance and high dead-locking-preventing performance. Meanwhile, the production and preparation method of the lubricating agent are simple, convenient and easy to implement and is suitable for large-scale batch production.

Owner:SHENZHEN EUBO NEW MATERIAL TECH

Two-part dental bleaching systems having improved gel stability and methods for bleaching teeth using such systems

InactiveUS6503485B1Maintain bleaching potencyHigh concentrationCosmetic preparationsGum massageParticulatesAlkaline earth metal

Dental bleaching systems that include a bleaching component and a neutralizing component which, when mixed together, yield a mixed composition having a desired bleaching activity and viscosity. The bleaching composition includes a suitable bleaching agent, such as aqueous hydrogen peroxide, in a concentration of about 3% to about 95% by weight of the bleaching composition component. The neutralizing component includes a particulate base dispersed within a stable gel that includes at least one polymeric thickening agent. The neutralizing component is substantially water-free to prevent destruction of the gelling capability of the thickening agent by the base. The particulate base may include oxides, hydroxides or carbonates of alkali metals or alkaline earth metals. Maintaining the bleaching agent and neutralizing agent in separate components provides increased stability during storage and transport.

Owner:ULTRADENT PROD INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com