Valve element sealing lubricating agent composition

A lubricant composition and a technology for the composition are applied in the directions of lubricating compositions, petroleum industry, etc., to achieve the effects of excellent high temperature resistance, suitable for large-scale batch production, and simple and easy production and preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

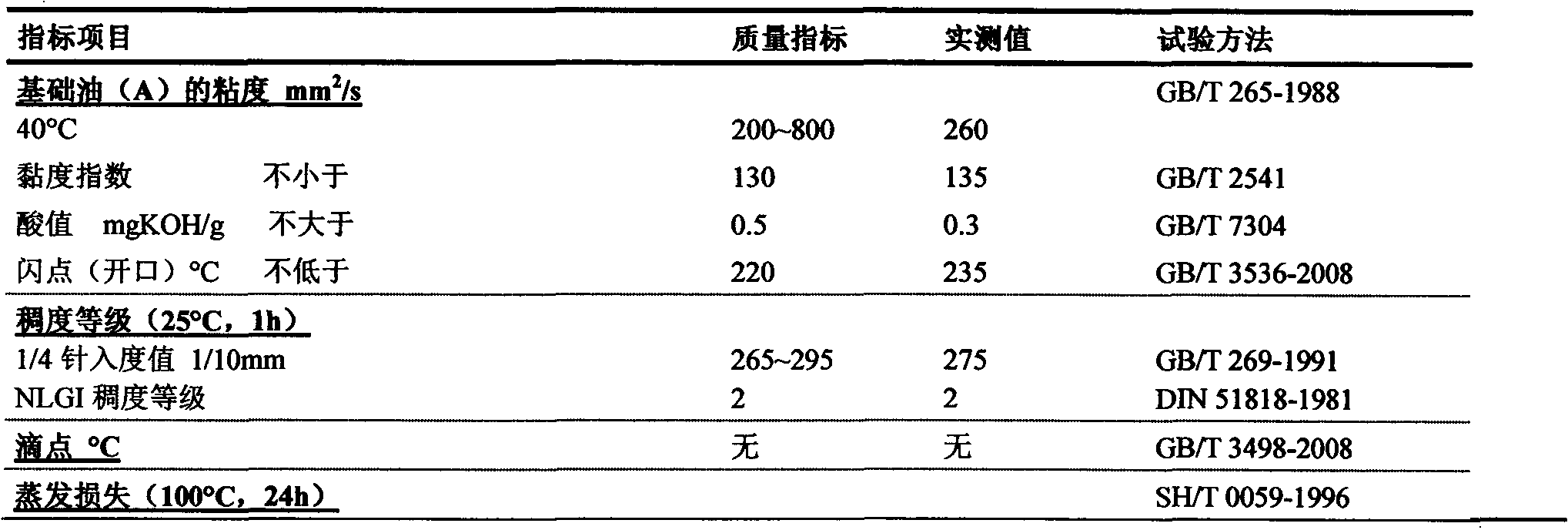

[0030] 1. Material composition and proportioning formula: see Table 1.

[0031] Table 1

[0032] Material composition

Specific material composition

Measuring formula

(A)

PAO synthetic oil

100.0

(B)

Nano Titanium Dioxide

20.0

(C)

Molybdenum disulfide

35.0

(D)

0.5

(E)

Alkylated diphenylamine

0.8

(F)

Zinc dialkyldithiocarbamate

1.5

(G)

0.5

(H)

sodium benzoate

0.9

[0033] 2. Process steps for making finished lubricants:

[0034] (1) Making base grease: Feed according to the formula, stir evenly and let it stand for 30 minutes; then grind, including 1 time of colloid mill and 2 times of three rollers; then set aside;

[0035] (2) Solid lubricant for surface modification treatment: Feed according to the formula, stir evenly and let stand for 10 minutes; then heat for ...

Embodiment 2

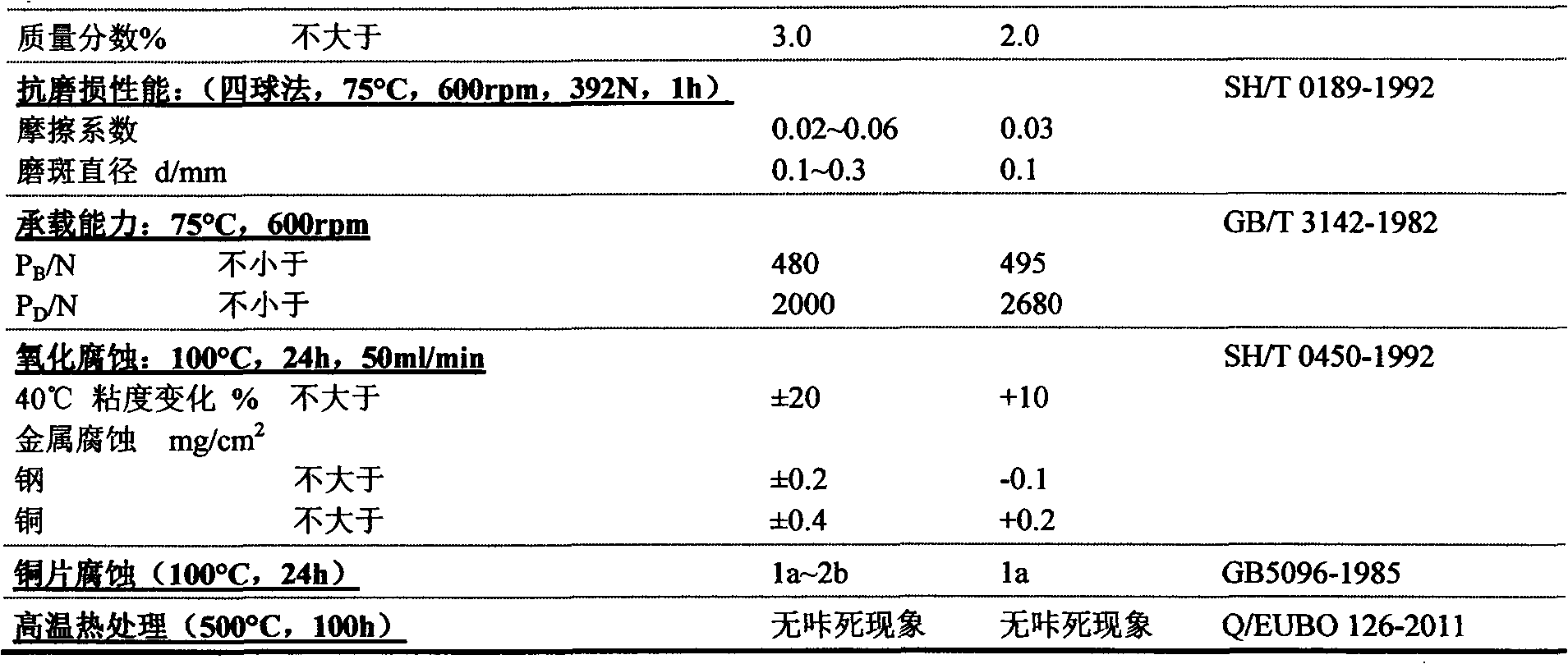

[0044] 1. Material composition and ratio measurement formula: see Table 3.

[0045] table 3

[0046] Material composition

Specific material composition

Measuring formula

(A)

Ester oil

100.0

(B)

Nano silica

25.0

(C)

Tungsten disulfide

15.0

(D)

1.0

(E)

Octylated diphenylamine

0.5

(F)

Zinc dipentyl dithiocarbamate

2.5

(G)

2,5-Dithiadiazole Disodium

1.0

(H)

Potassium sorbate

0.5

[0047] 2. Process steps for making finished lubricants:

[0048] (1) Making base grease: Feed according to the formula, stir evenly and let it stand for 20 minutes; then grind, including 1 time of colloid mill and 2 times of three rollers; then set aside;

[0049] (2) Solid lubricant for surface modification treatment: Feed according to the formula, stir evenly and let stand for 15 minutes; heat for 10 minutes, heat throu...

Embodiment 3

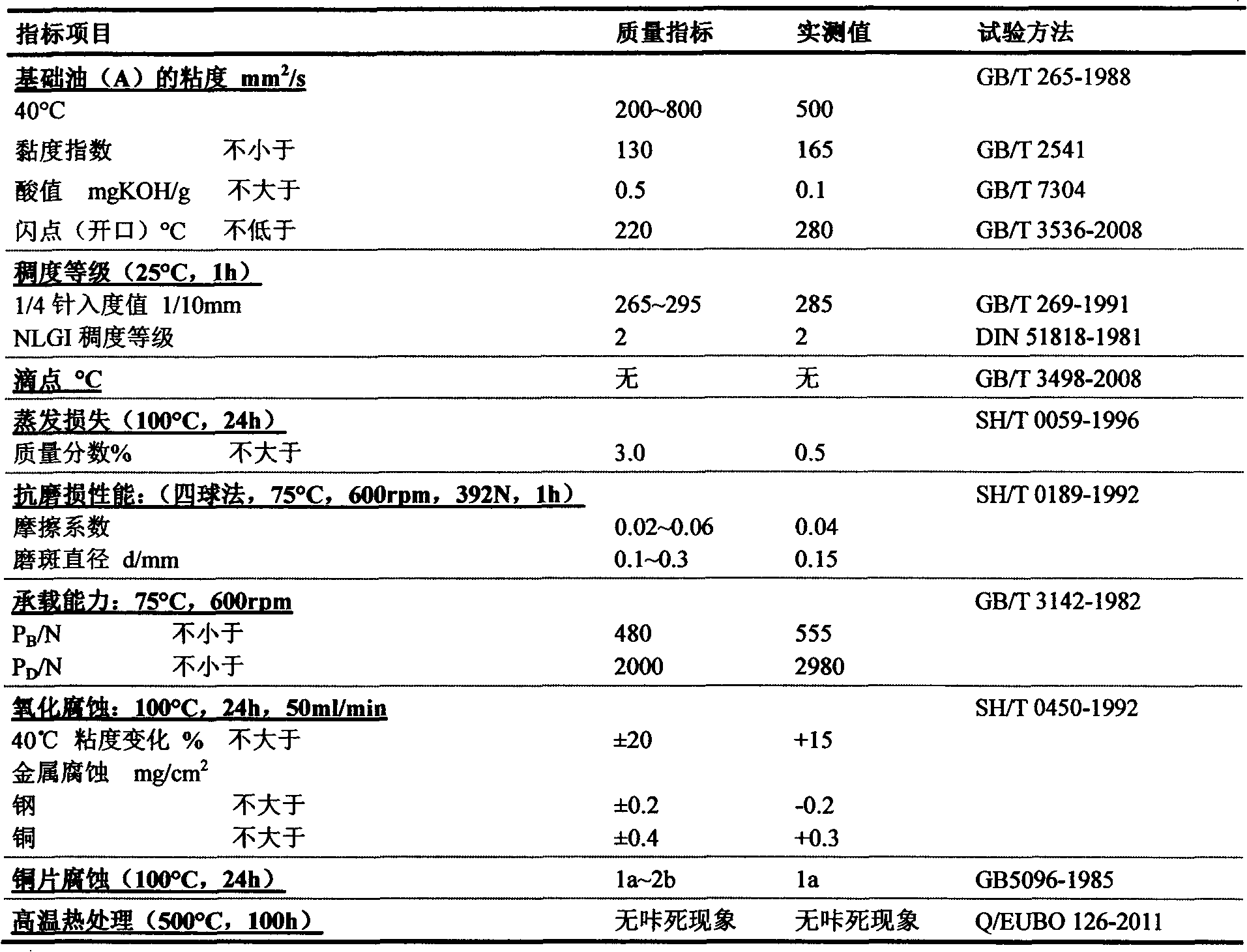

[0057] 1. Material composition and ratio measurement formula: see Table 5.

[0058] table 5

[0059] Material composition

Specific material composition

Measuring formula

(A)

silicone oil

100.0

(B)

Nano silica

15.0

(C)

50.0

(D)

polysiloxane

1.5

(E)

2,6-di-tert-butyl-p-cresol

1.0

(F)

Molybdenum dithiophosphate

1.0

(G)

Dioctyldiphenylamine

1.0

(H)

Sodium diacetate

0.2

[0060] 2. Process steps for making finished lubricants:

[0061] (1) Making base grease: Feed according to the formula, stir evenly and let it stand for 20 minutes; then grind, including 1 time of colloid mill and 2 times of three rollers; then set aside;

[0062] (2) Solid lubricant for surface modification treatment: Feed according to the formula, stir evenly and let stand for 15 minutes; heat for 10 minutes, heat through a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com