Ultramicro ginger powder and method for producing the same

A technology of micro-ginger and ginger powder is applied in directions such as powder conveying, pharmaceutical formulations, plant raw materials, etc., which can solve the problems of easy sticking on the wall of a pulverizer, loss of active ingredients of ginger, and large particle size of ginger powder, and saves ginger resources. , suitable for large-scale industrial production, the effect of simple production methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

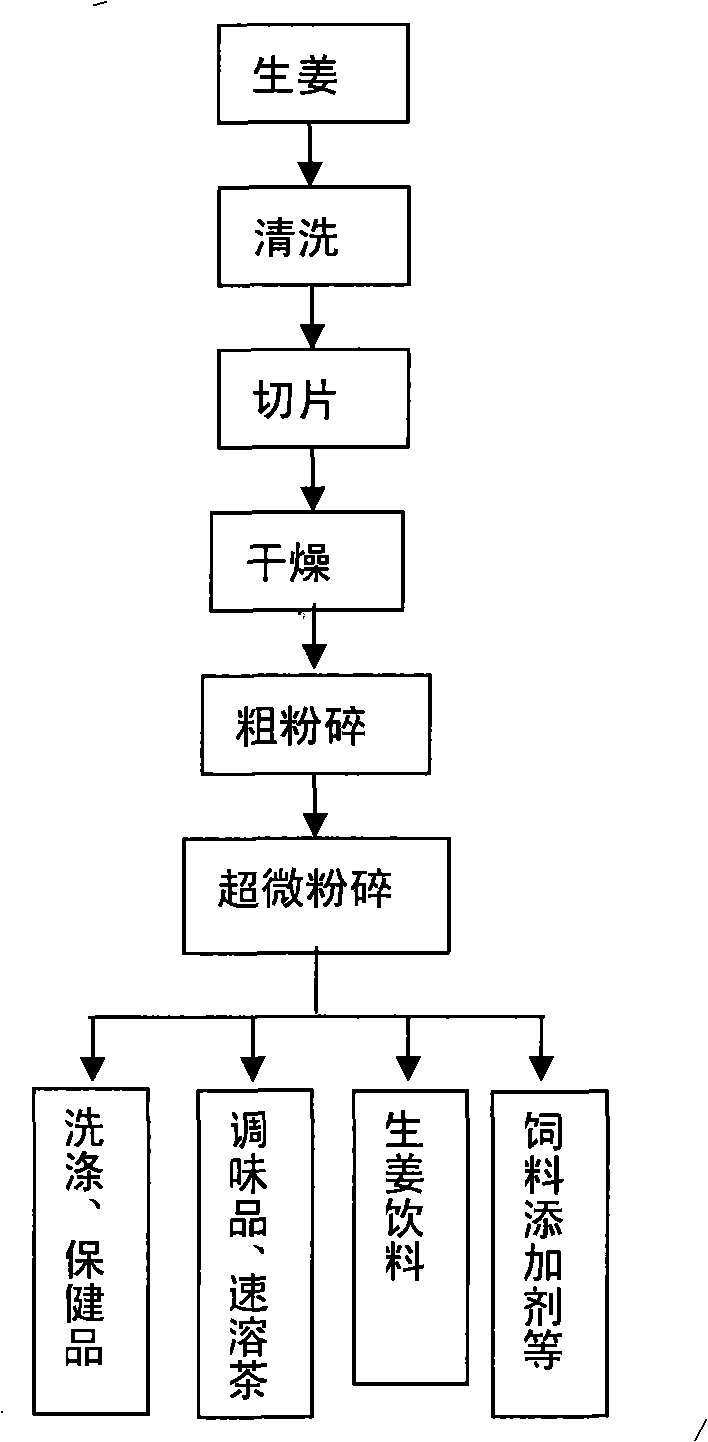

[0033] The preparation of embodiment 1 superfine ginger powder

[0034] Include the following steps:

[0035] (1) fresh ginger 60kg cleaned with water is cut into thick ginger slices of 3mm, for preventing ginger from browning, blast drying at 40°C to moisture content is 6% immediately after sectioning, obtains 3kg dried ginger slices;

[0036] (2) Coarse grinding: Grinding the dried ginger slices into 120 mesh ginger coarse particles with a particle size of 20 DEG C with an RT silent grinding grinder (Beijing Tianyuan Huanya Machinery Grinding Co., Ltd.);

[0037] (3) Ultrafine pulverization: 220g of ginger coarse particles and the air after cooling and drying are jointly injected into the ultrafine pulverizer, and 200g of particle size is made of 1600 mesh ultrafine ginger powder by adopting high-speed airflow pulverization, and the process parameters are after freeze-drying The pressure of air injected into the ultrafine pulverizer is 1.0MPa, the working pressure of the su...

Embodiment 2

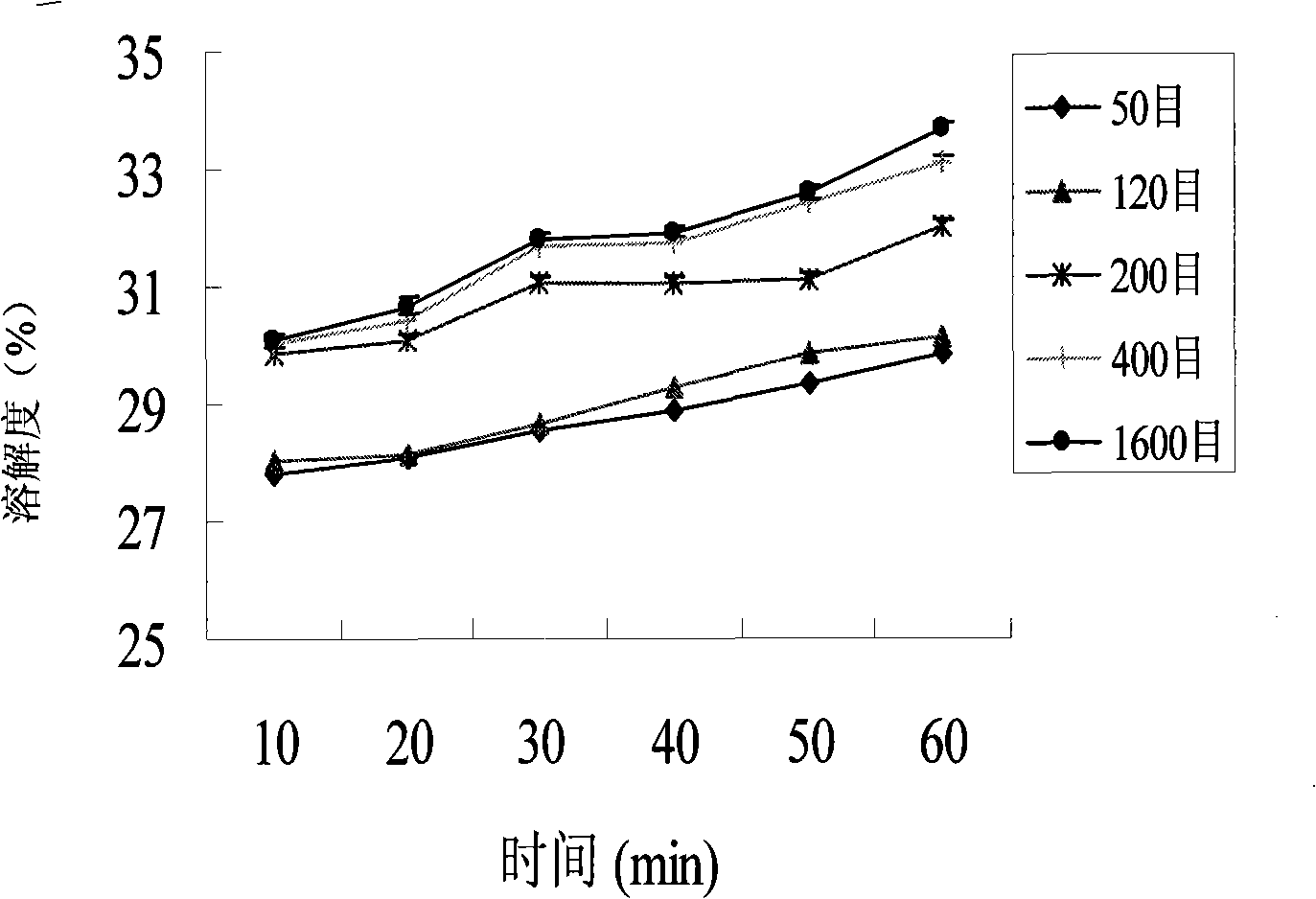

[0040] Embodiment 2 ginger powder solubility test

[0041] Test materials: Weigh dried ginger, and then use FDV liquid nitrogen cooling pulverizer (produced by Beijing Tianyuan Huanya Machinery Pulverization Equipment Co., Ltd.) to prepare ginger powder with a particle size of 50, 120, 200 and 400 mesh. The 1600 purpose superfine ginger powder of embodiment 1 gained.

[0042] Experimental method: Accurately weigh 5g each of ginger powder with a particle size of 50, 120, 200, 400 mesh and the 1600 mesh ultrafine ginger powder obtained in Example 1, then place in 100ml water to prepare ginger powder milk, and take 20ml of 5% ginger powder The powdered milk was stirred and heated at 80°C, and the solubility was measured under the conditions of 10, 20, 30, 40, 50, and 60 min, respectively. Calculate its solubility according to the following formula:

[0043]

[0044] A - Amount of Ginger Powder Dissolved

[0045] W - weight of ginger sample

[0046] Results (such as figur...

Embodiment 3

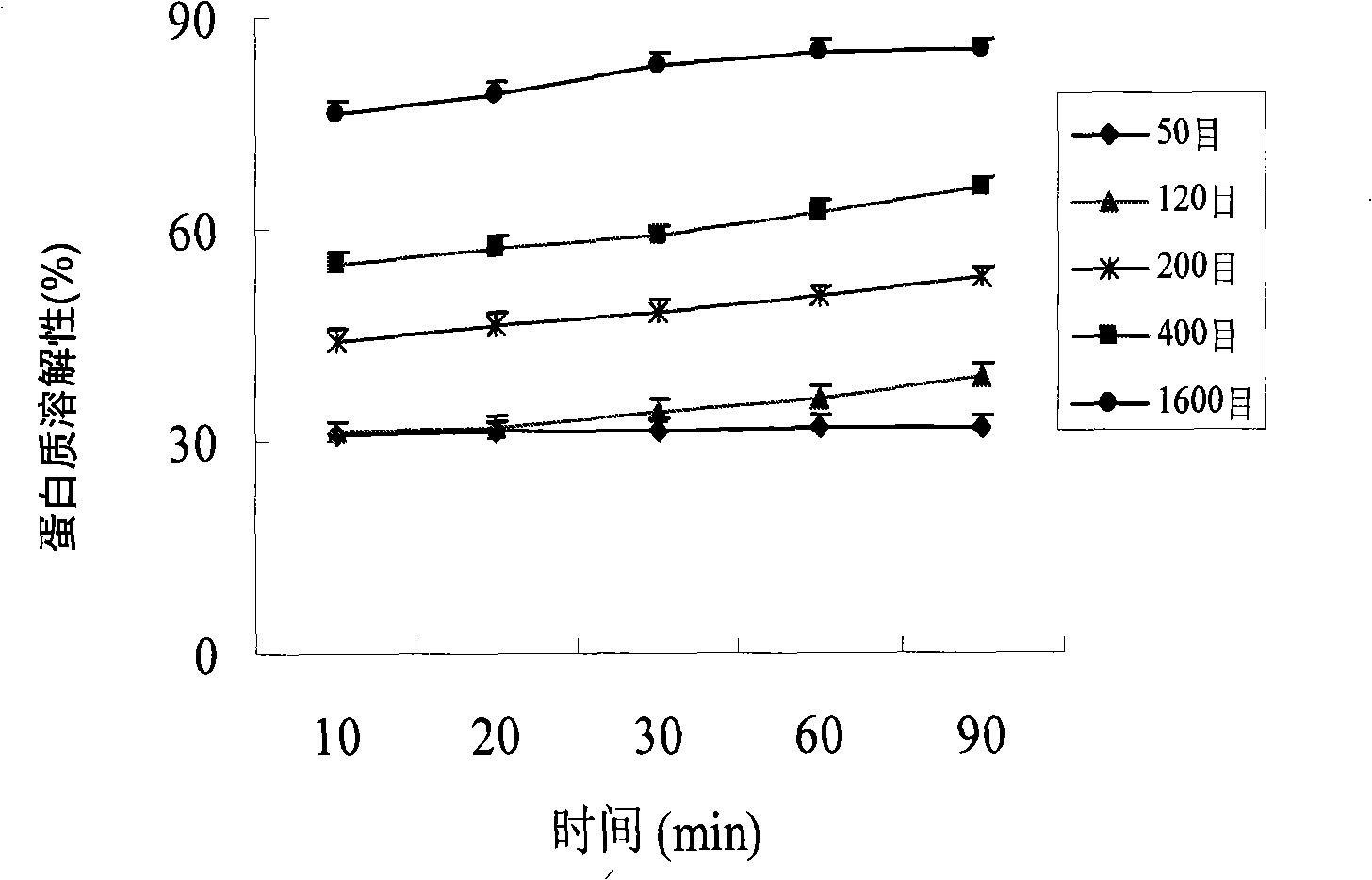

[0047] Embodiment 3 Ginger powder protein solubility comparative test

[0048] According to the principle of combining Coomassie brilliant blue G250 with protein established by Bradford in 1976, a method for rapid and sensitive quantitative determination of protein was established. Weigh each 10g of the 50, 120, 200, 400, 1600 mesh ginger powder obtained in Examples 1 and 2, place them in 40ml water, shake and extract at 45°C, and measure the conditions of 10, 20, 30, 60, 90min at different times lower solubility.

[0049]

[0050] S-Ginger Powder Dissolved Protein Content

[0051] C-Protein content in raw materials of ginger powder

[0052] Results (such as image 3 ) shown. The protein solubility of ultrafine ginger powder is higher than that of ordinary ginger powder, which shows that the ultrafine grinding of ginger is beneficial to improve the dissolution rate of protein.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com