Patents

Literature

41961 results about "Cellulose" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

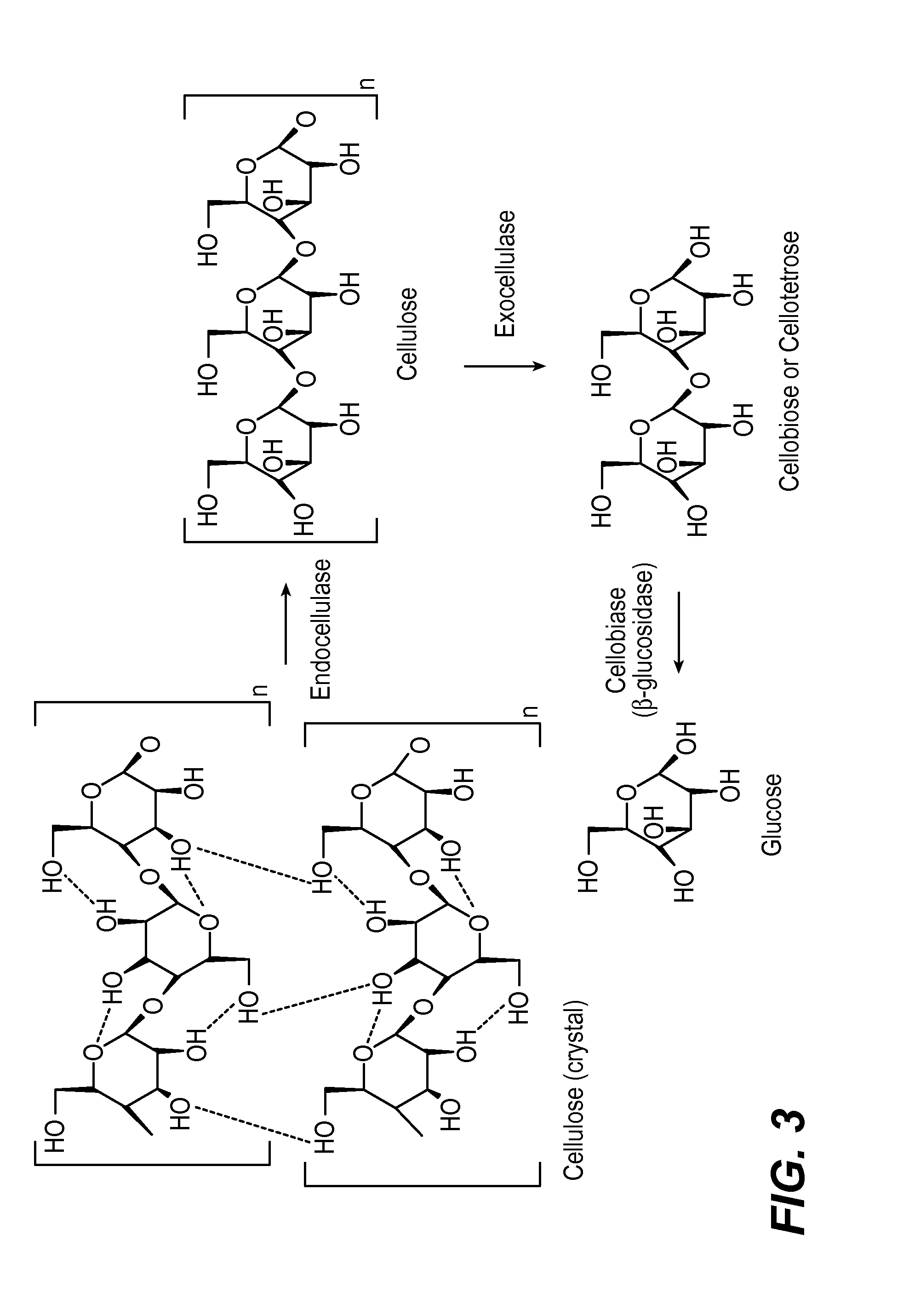

Cellulose is an organic compound with the formula (C₆H₁₀O₅)ₙ, a polysaccharide consisting of a linear chain of several hundred to many thousands of β(1→4) linked D-glucose units. Cellulose is an important structural component of the primary cell wall of green plants, many forms of algae and the oomycetes. Some species of bacteria secrete it to form biofilms. Cellulose is the most abundant organic polymer on Earth. The cellulose content of cotton fiber is 90%, that of wood is 40–50%, and that of dried hemp is approximately 57%.

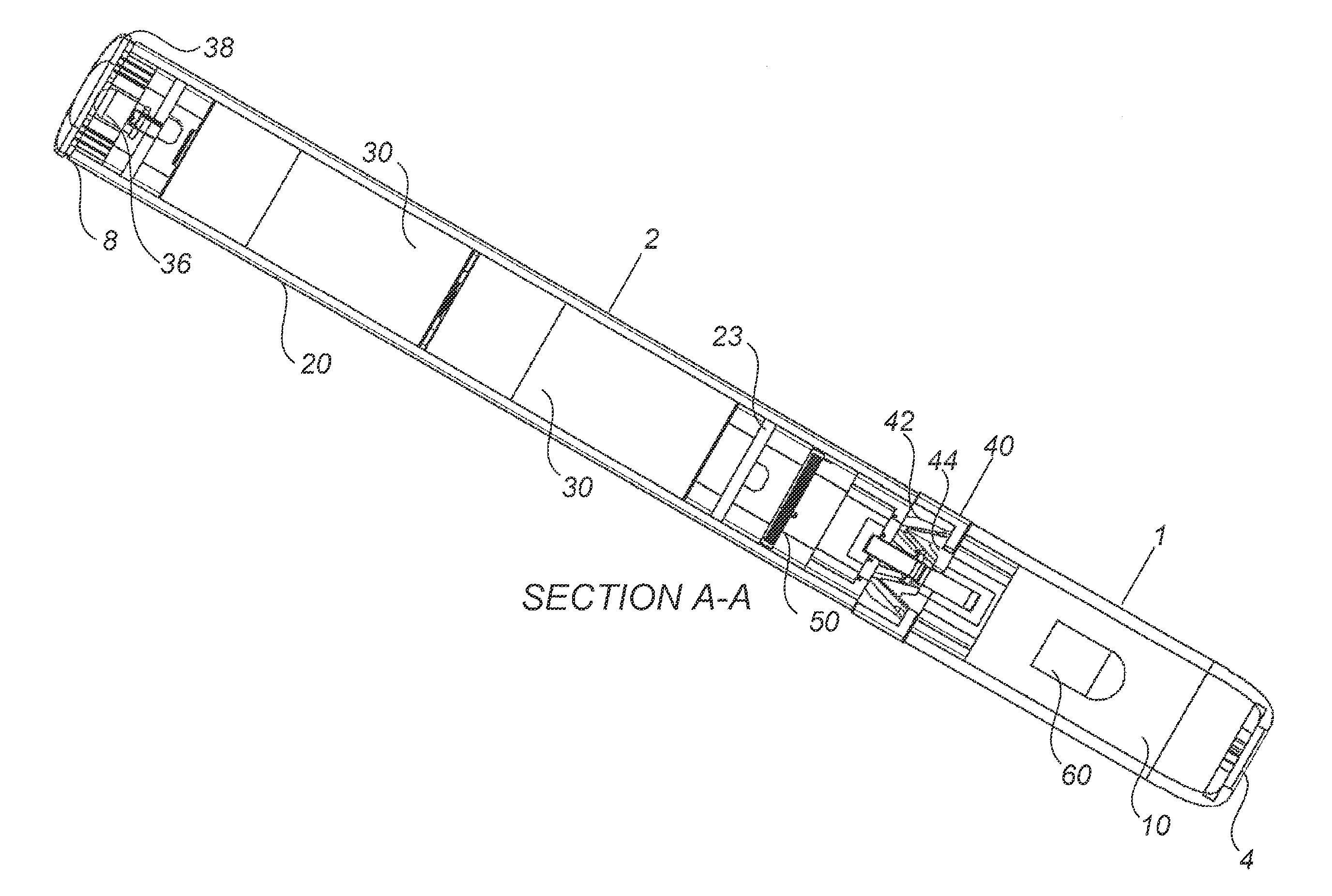

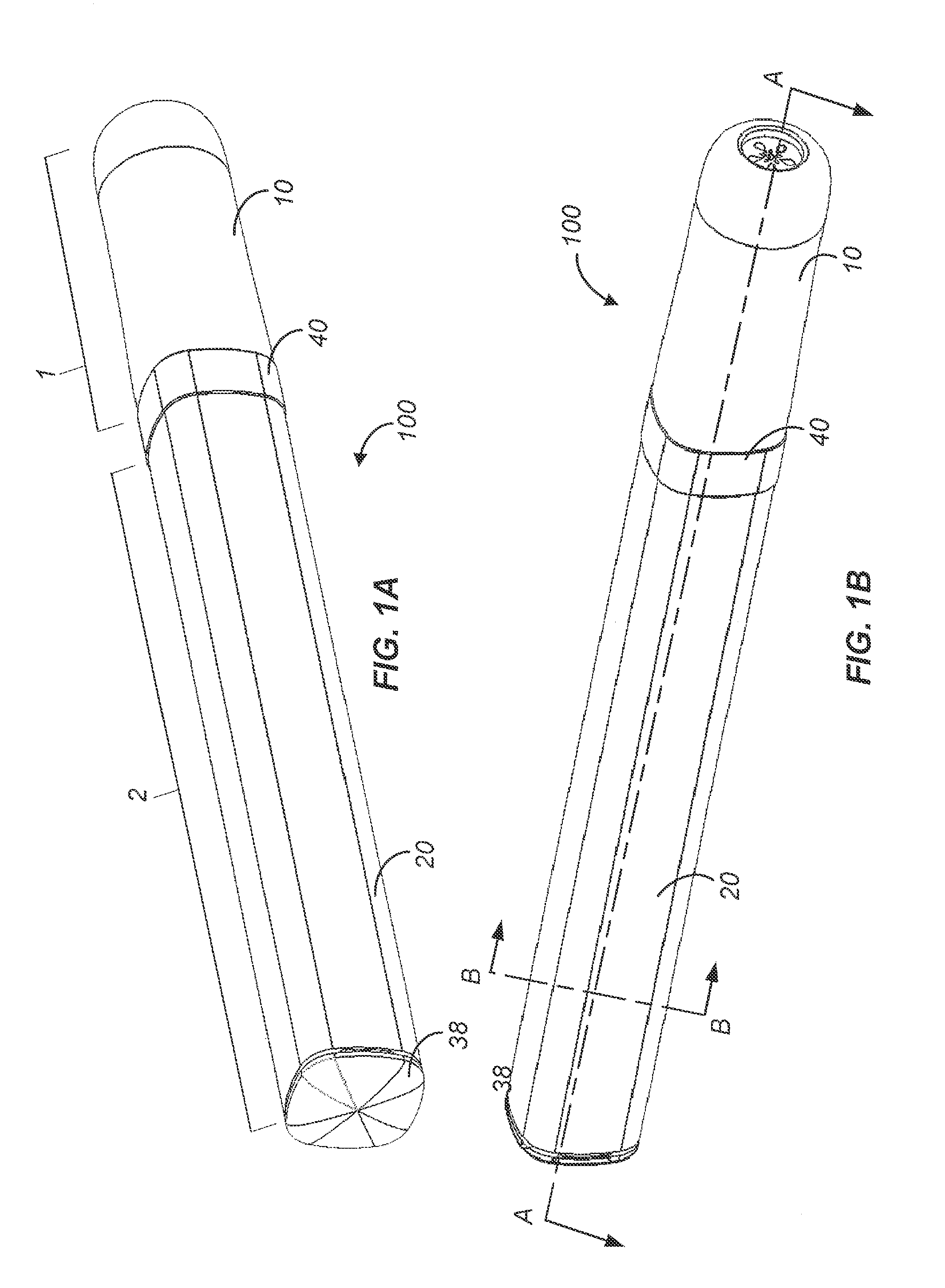

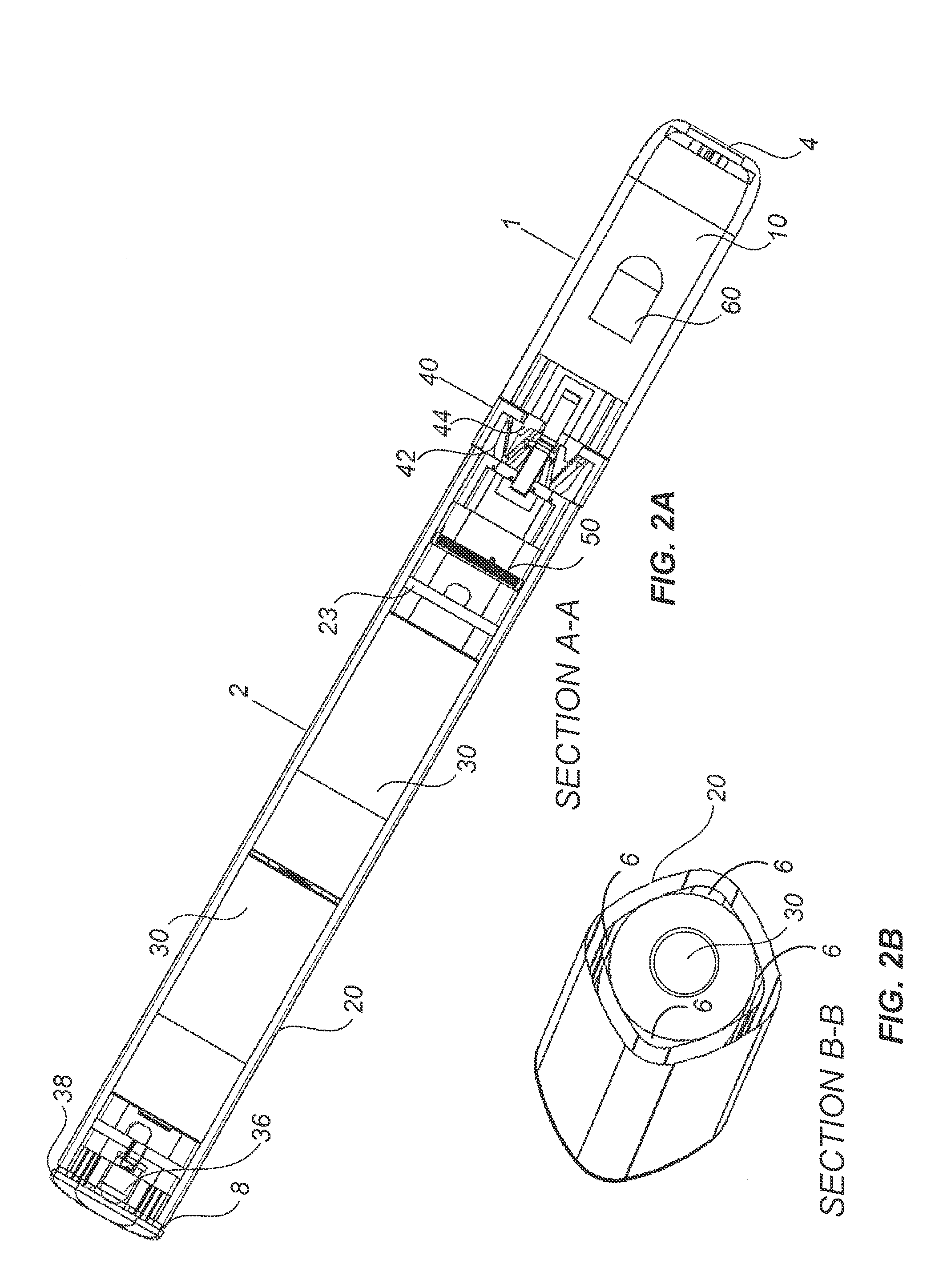

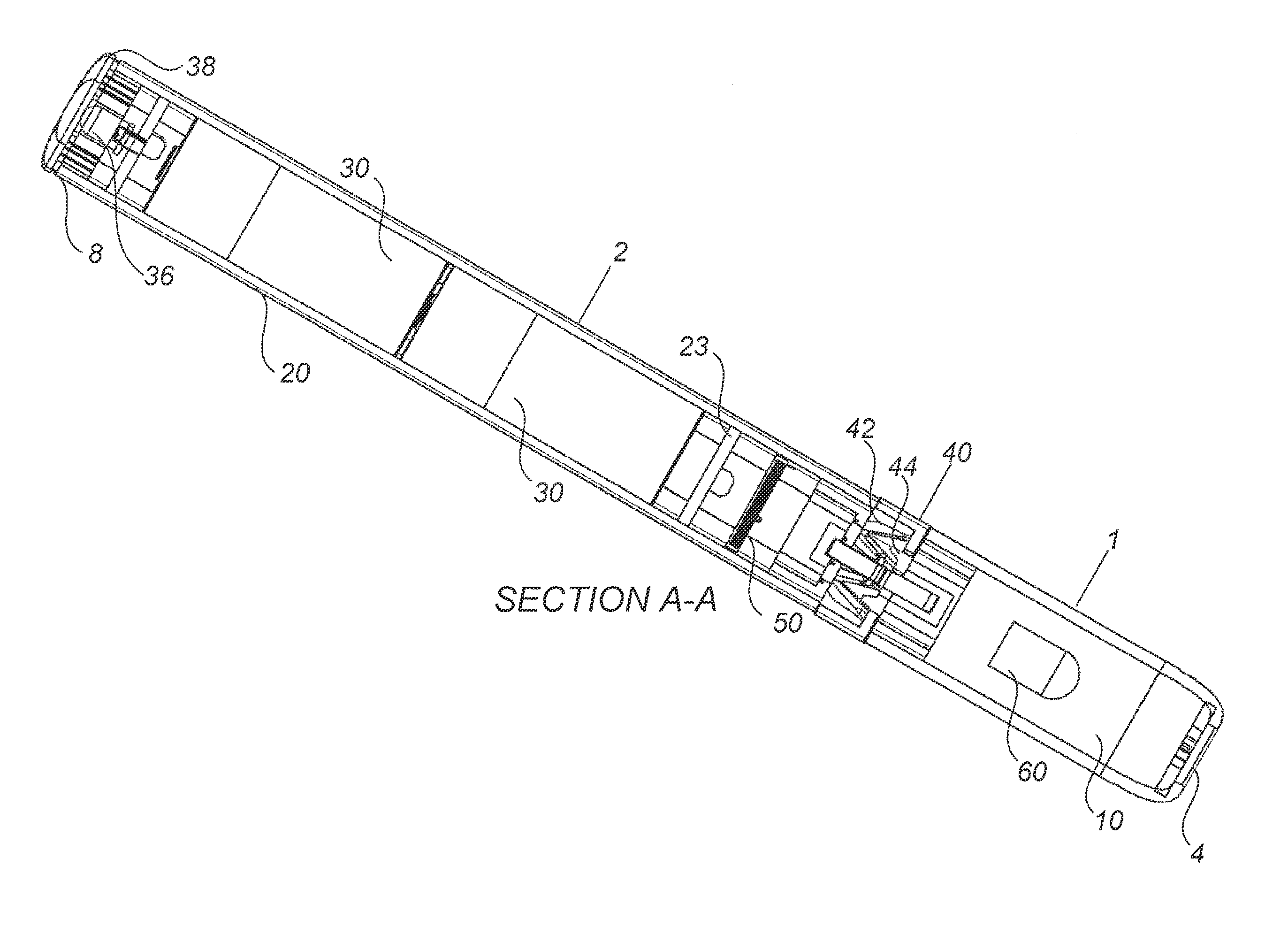

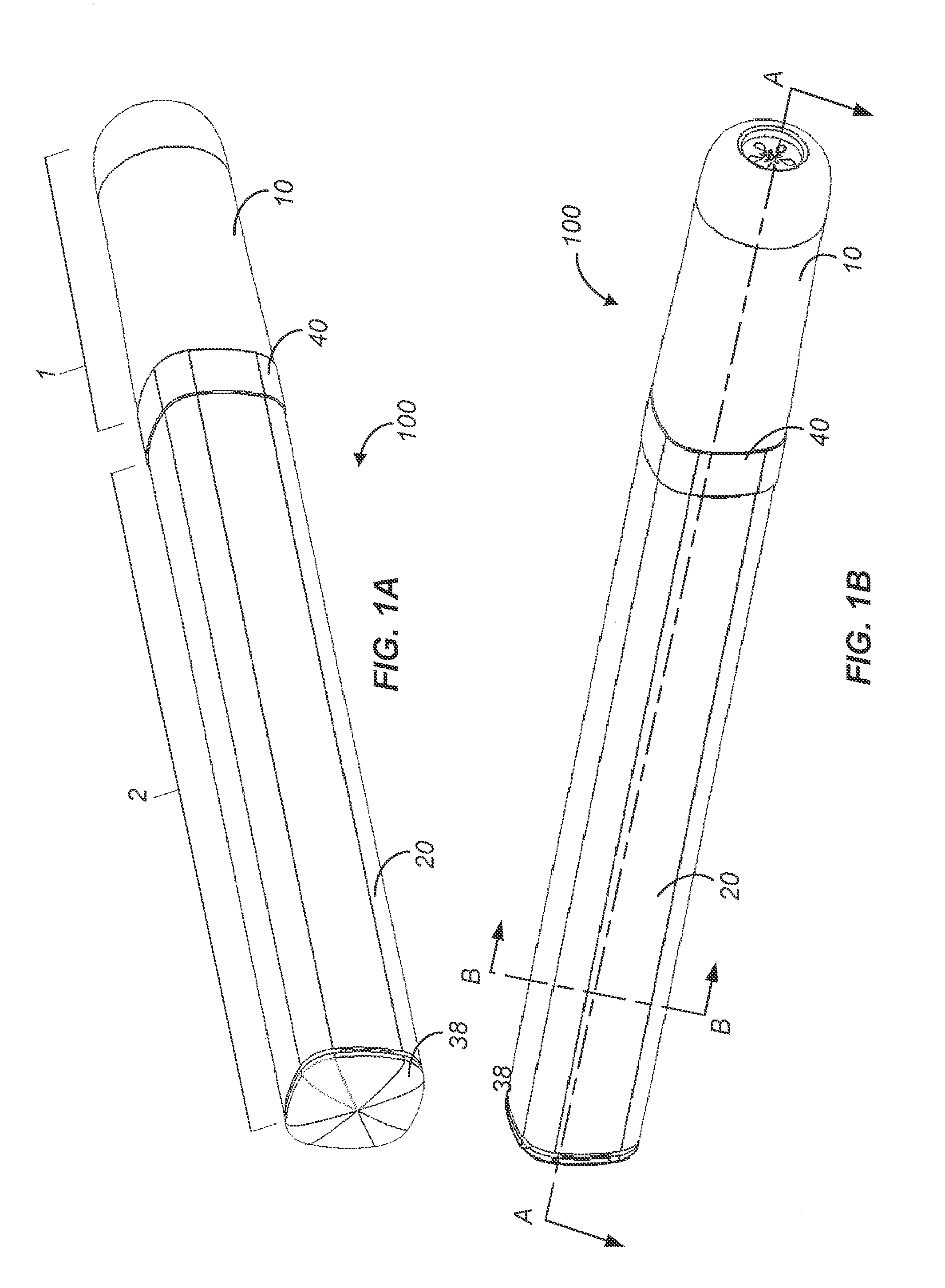

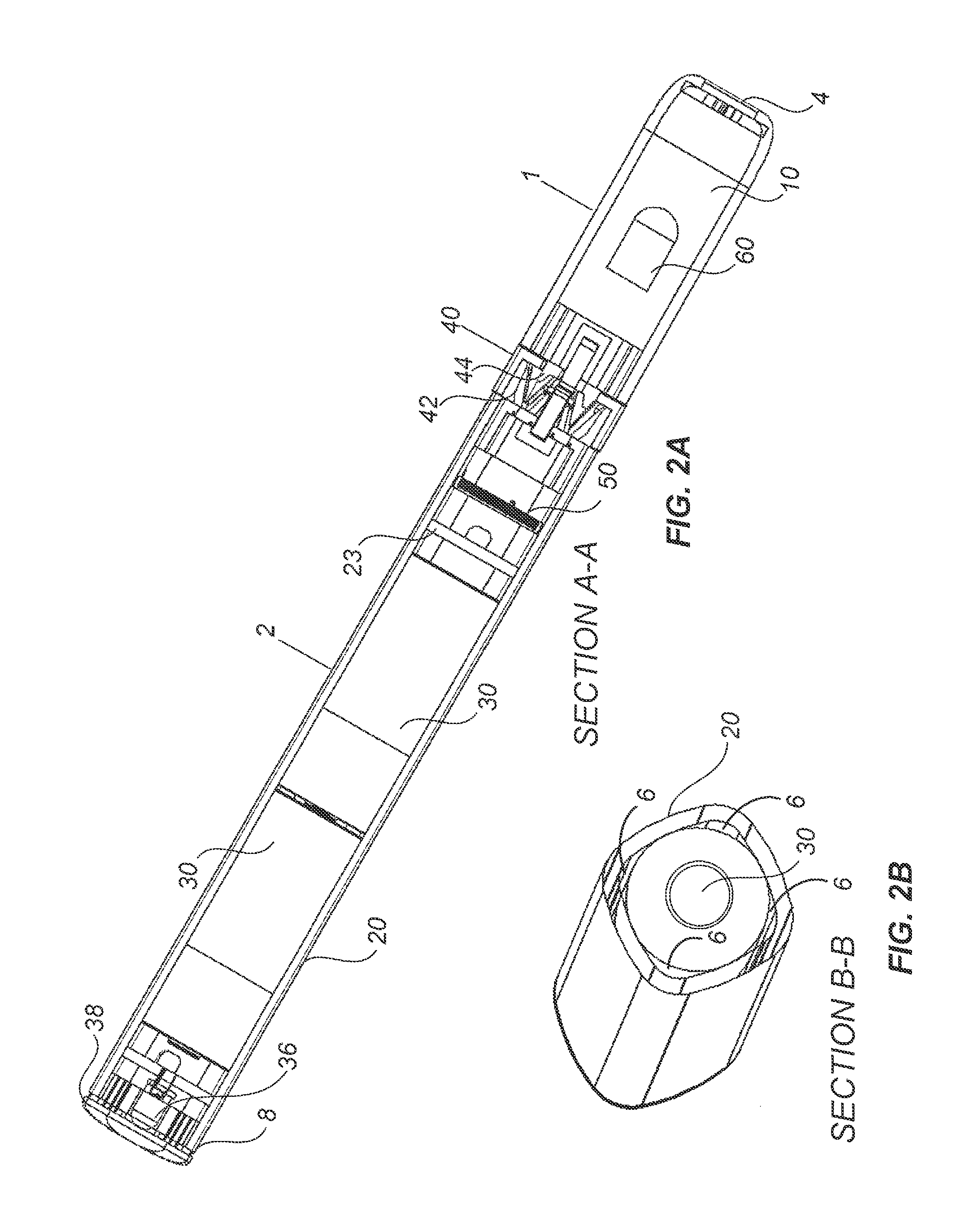

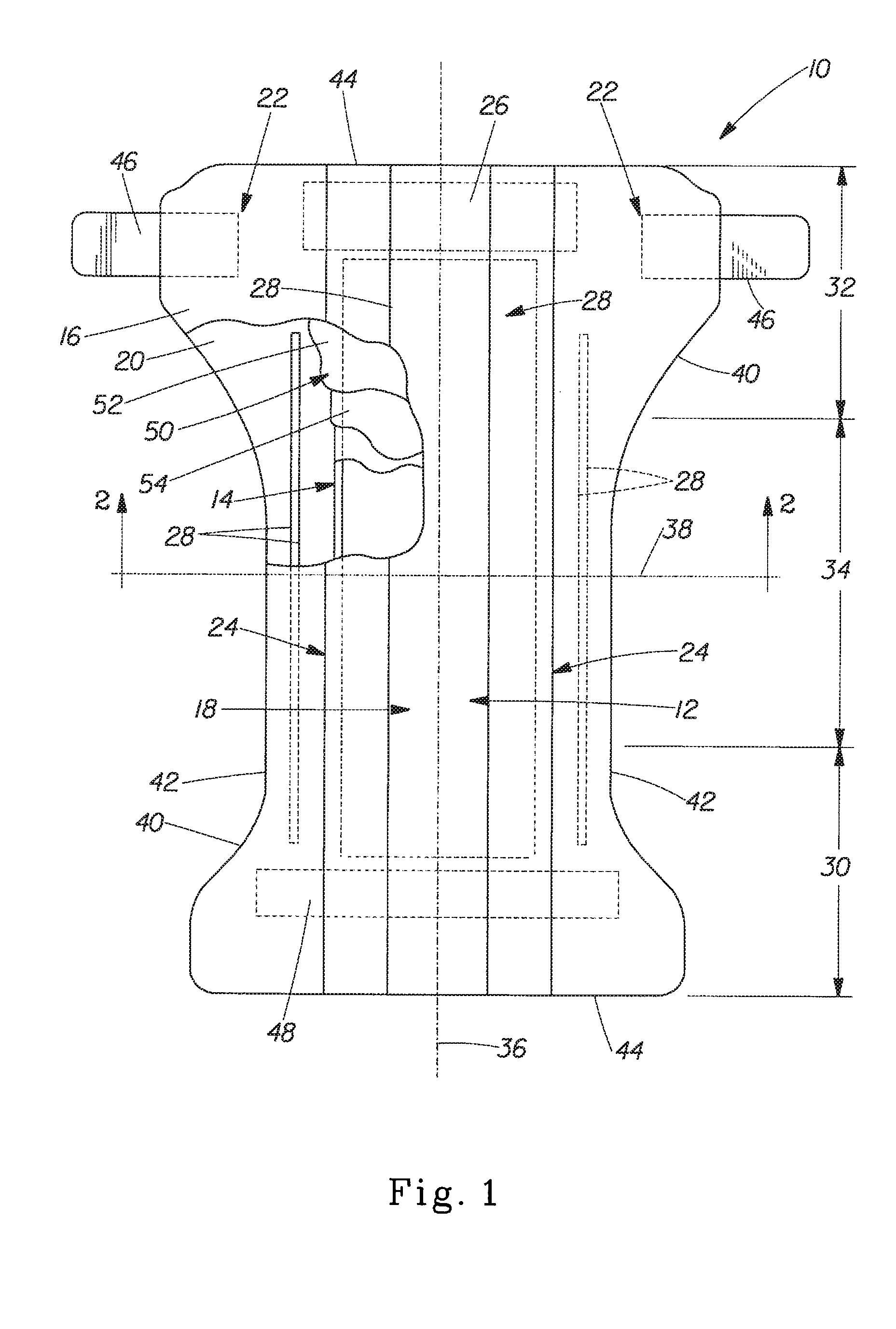

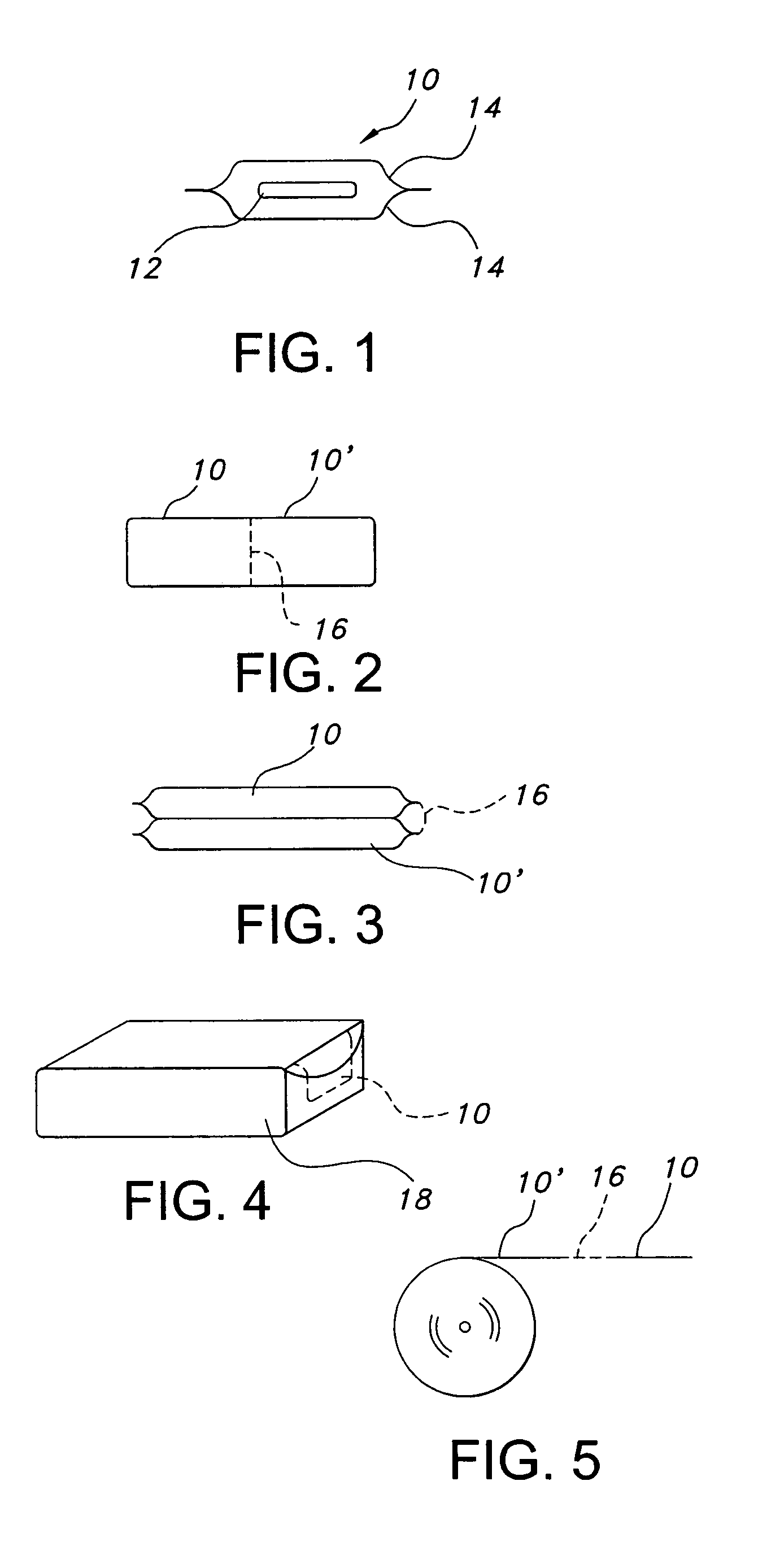

Electronic vaporizing device and methods for use

InactiveUS20130298905A1Increase heatImproved vaporizing capabilityTobacco devicesInhalatorsCelluloseBrick

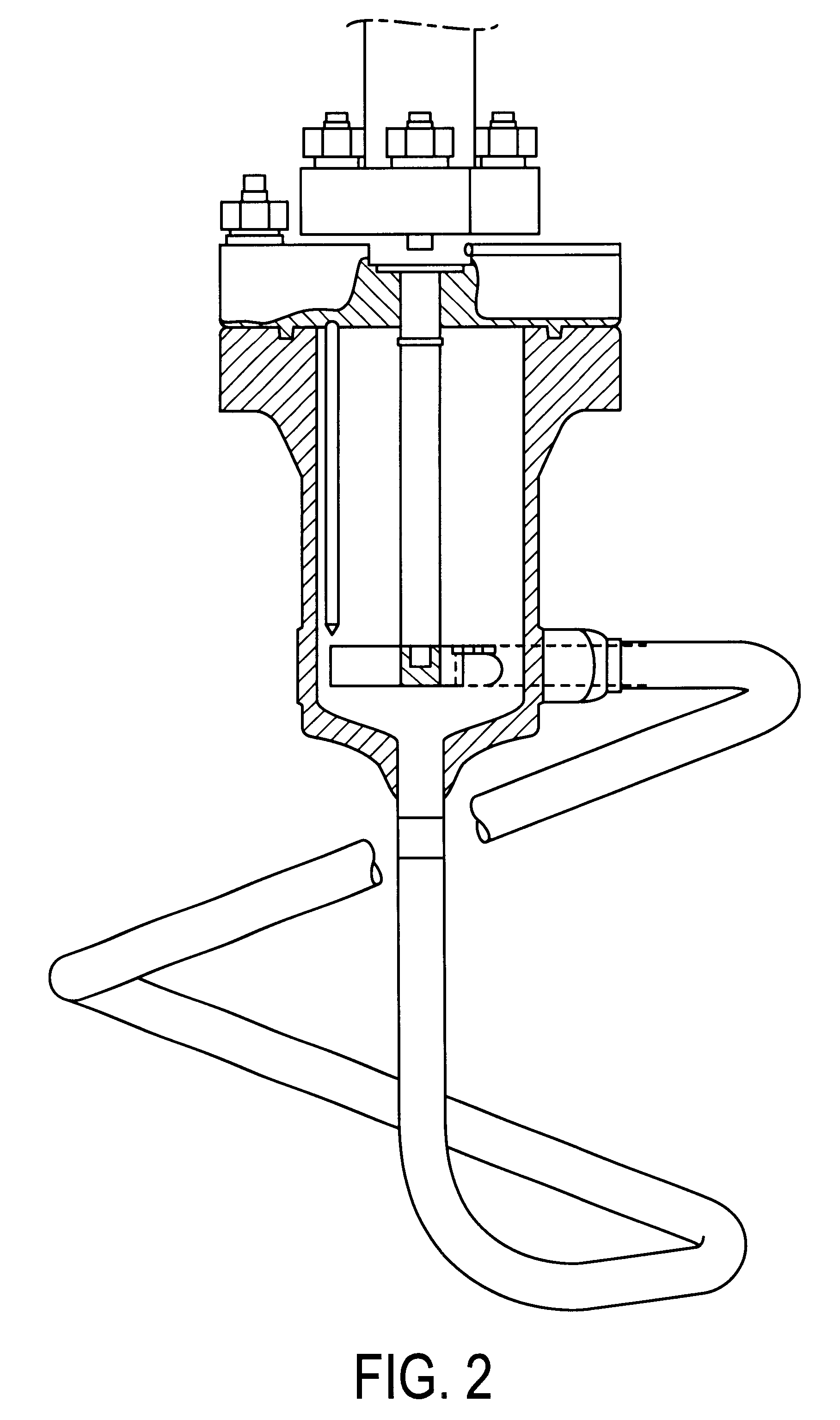

Devices and methods for vaporizing active ingredients of a selected substance for inhalation using a portable vaporization device are provided herein. In certain aspects, the device includes a portable power source, a heating portion, an inhalation sensor, a temperature sensor, a distal light source, and a grinding portion. In response to an inhalation by a user, the power source energizes a heating element of the heating portion so as to heat air flow to a desired vaporization temperature within a few seconds of detecting inhalation, using convection and radiative heating. The device may include a receptacle for receiving a cartridge containing a pre-prepared substance, such as a liquid, gel, powder, or solid brick, and a grinding portion to allow a user to grind intact portions of cellulose-based material into smaller pieces to facilitate vaporization by manually rotating portions of the device relative to each other.

Owner:UPTOKE

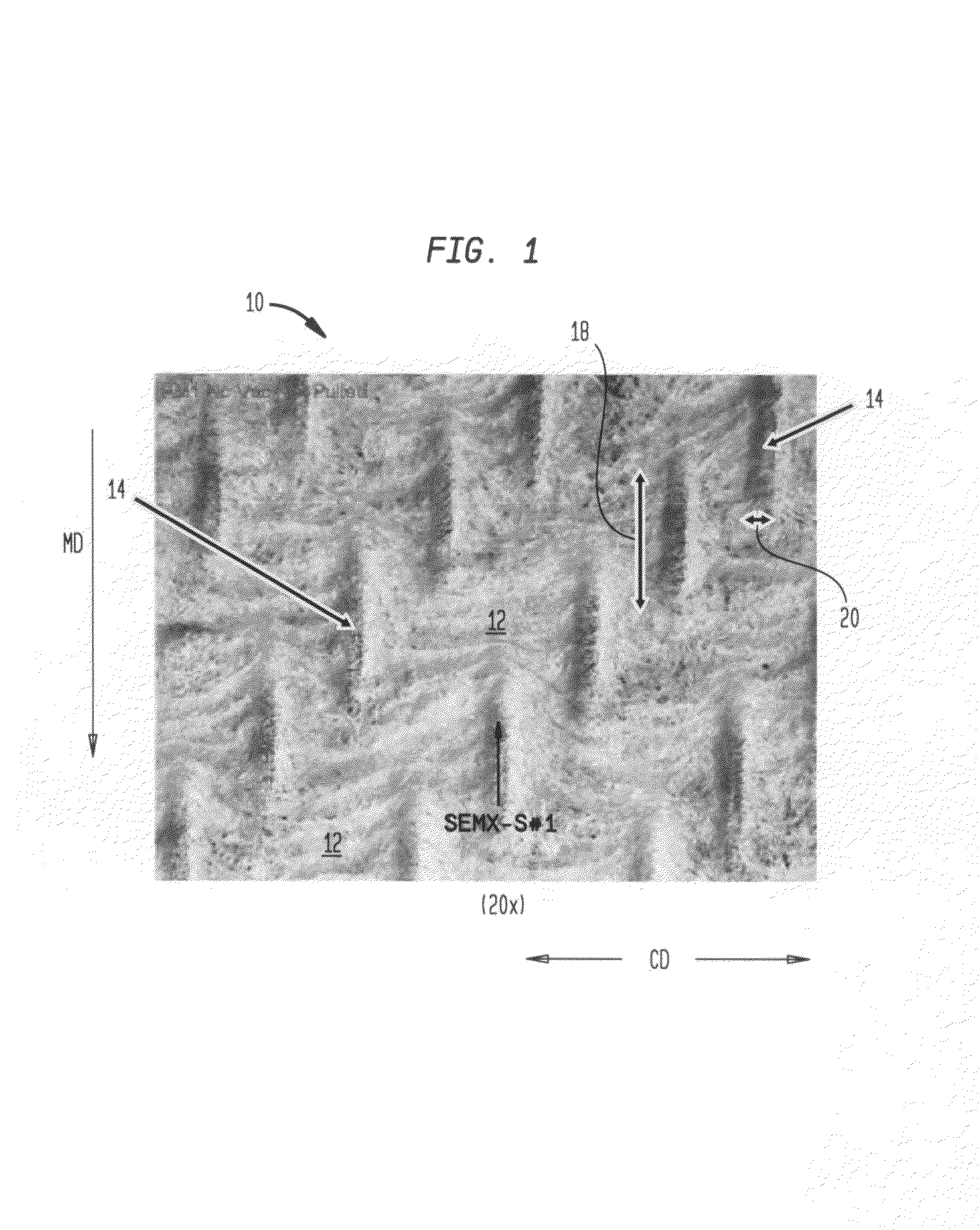

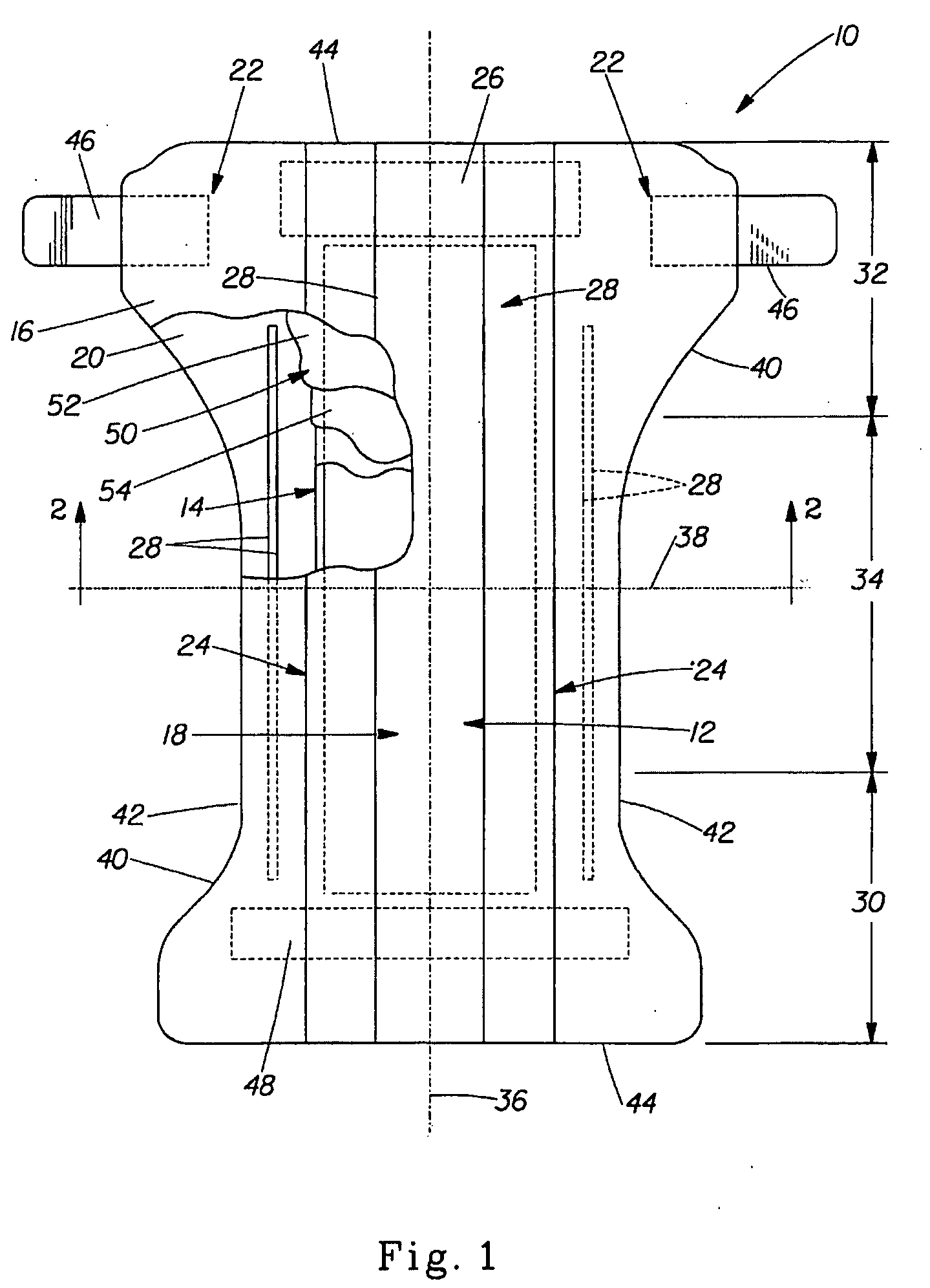

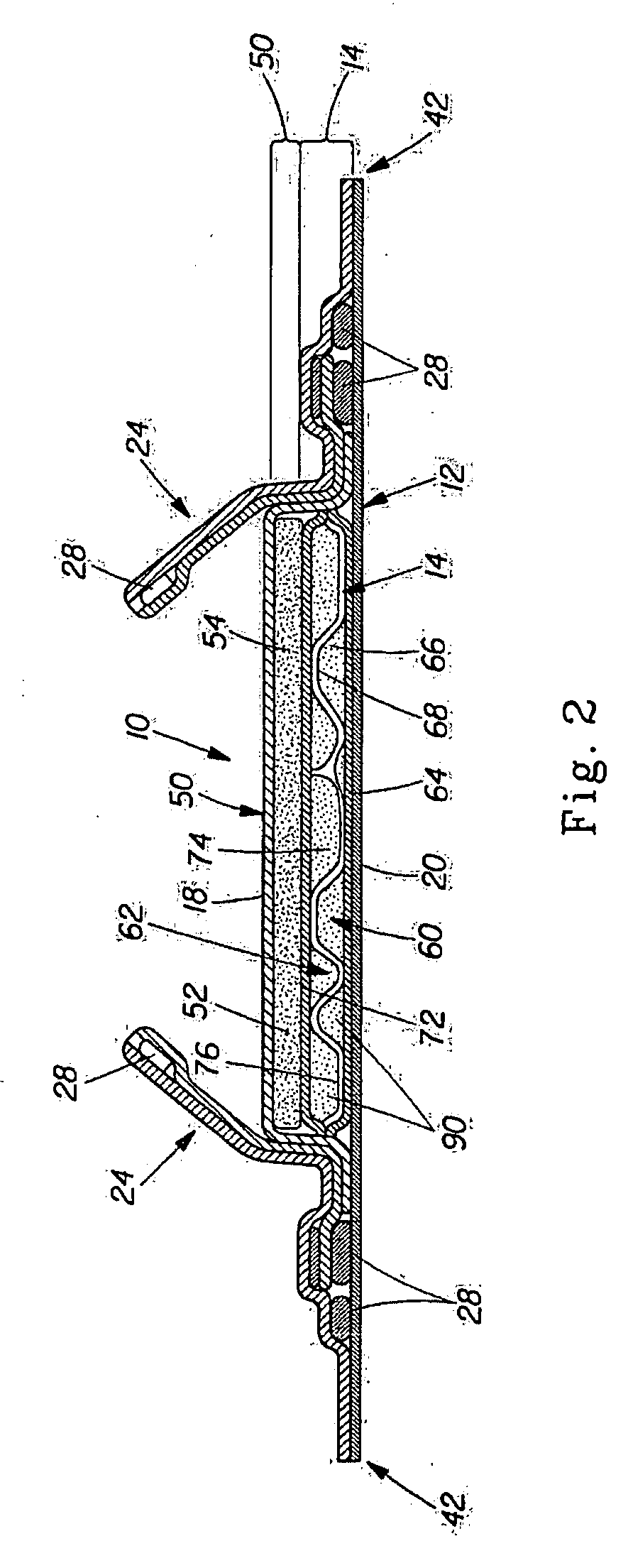

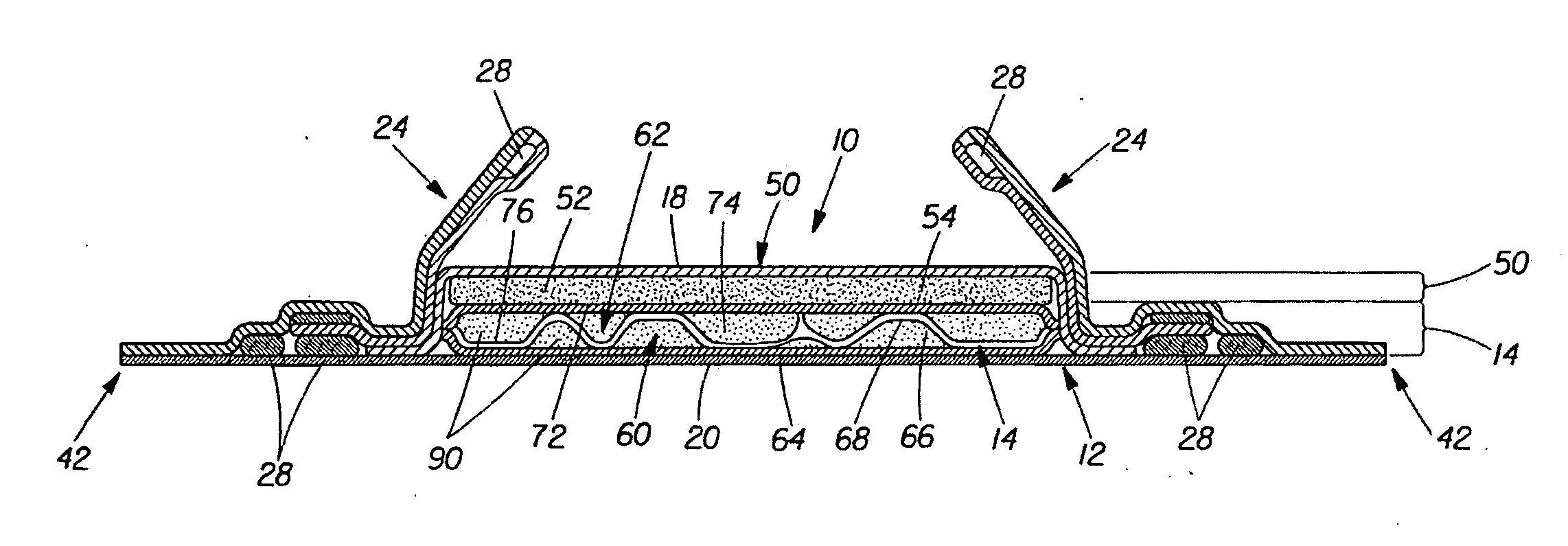

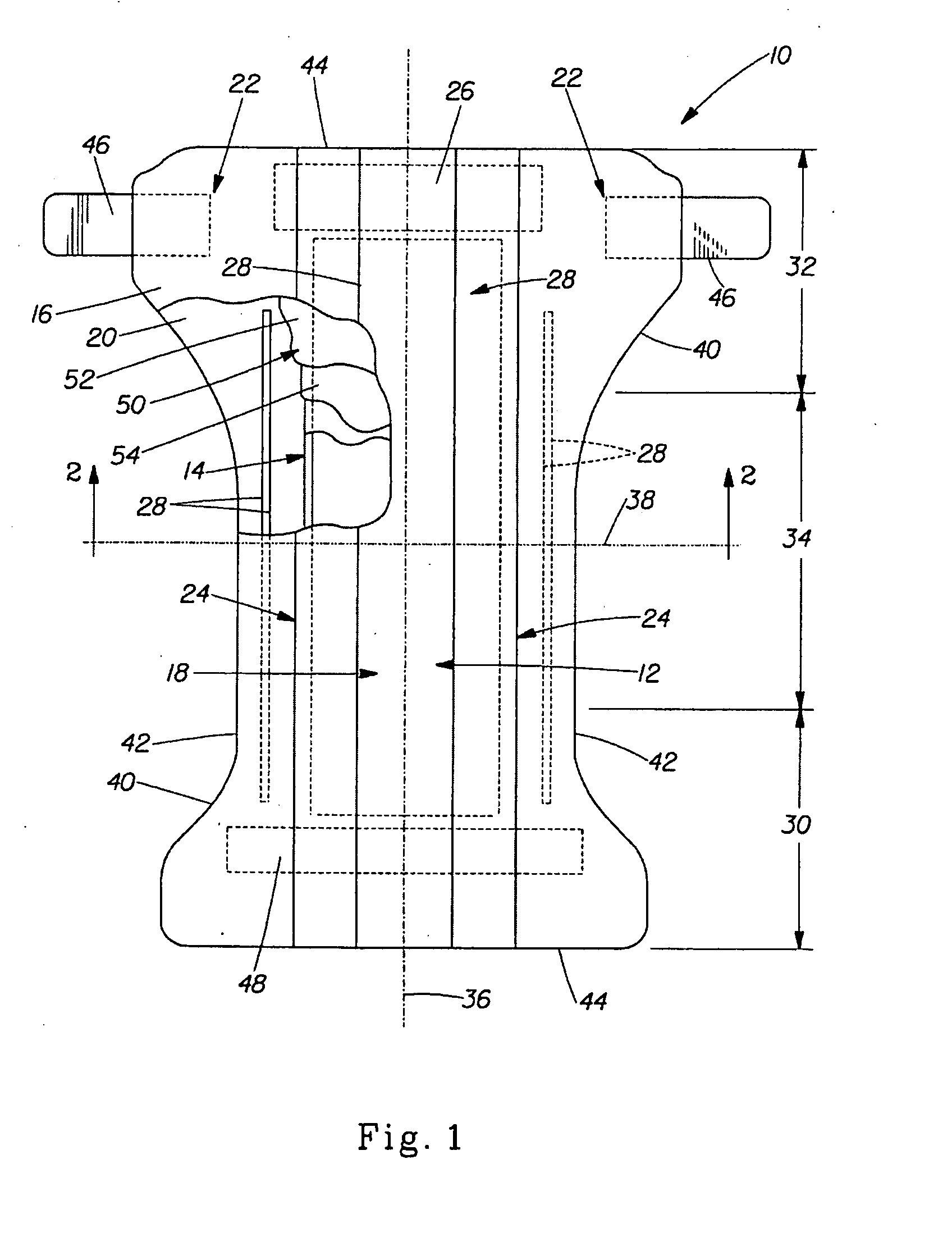

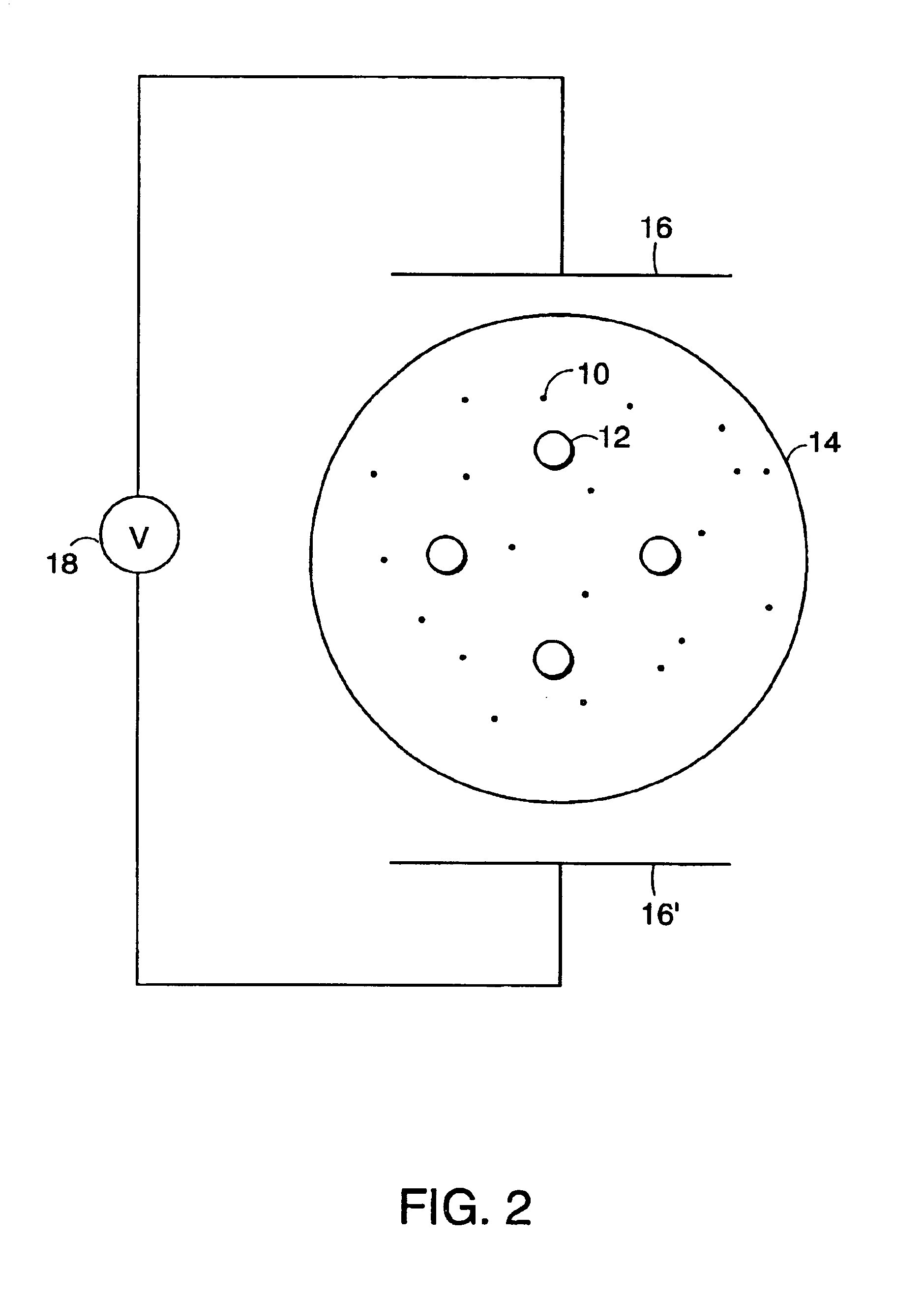

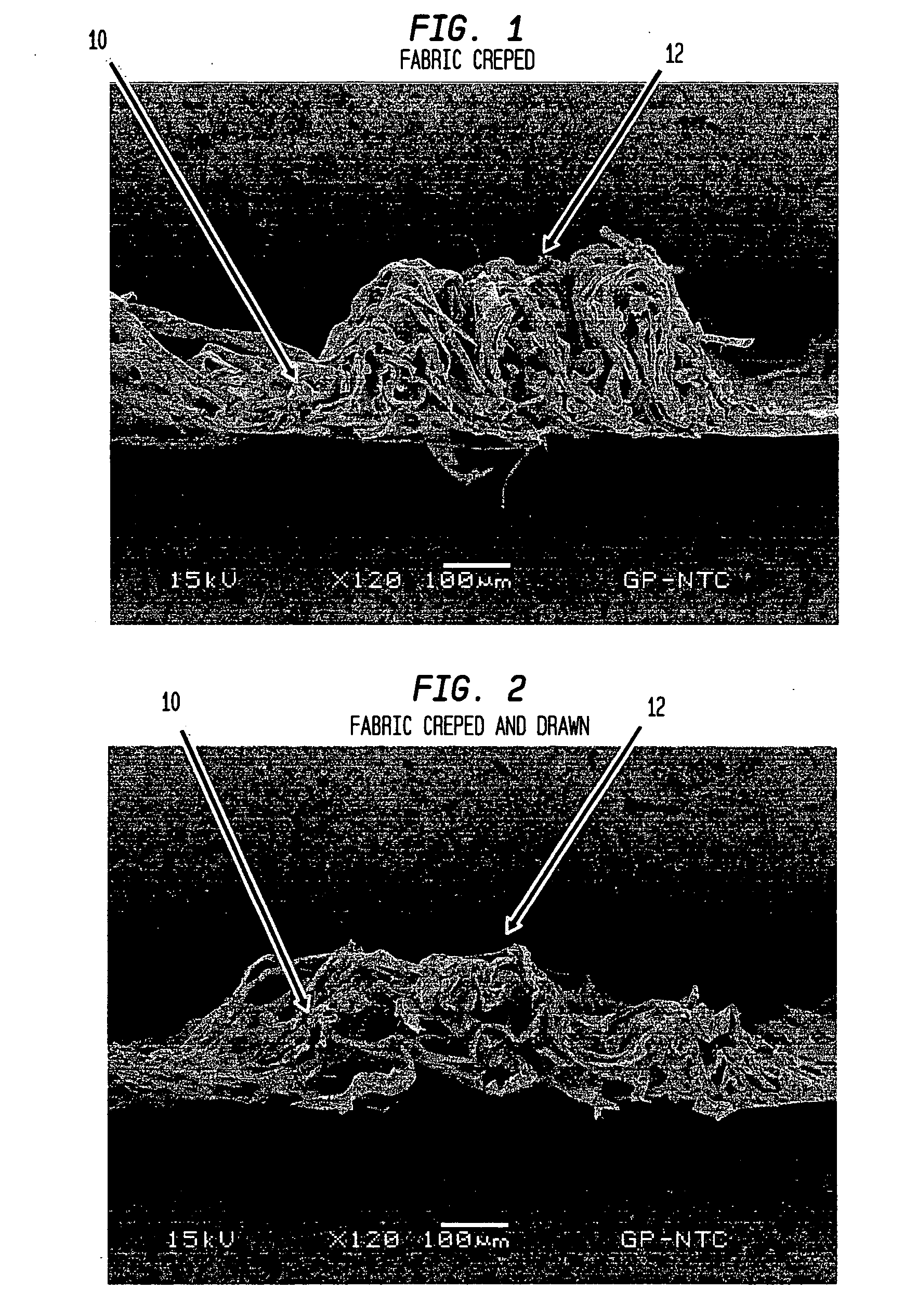

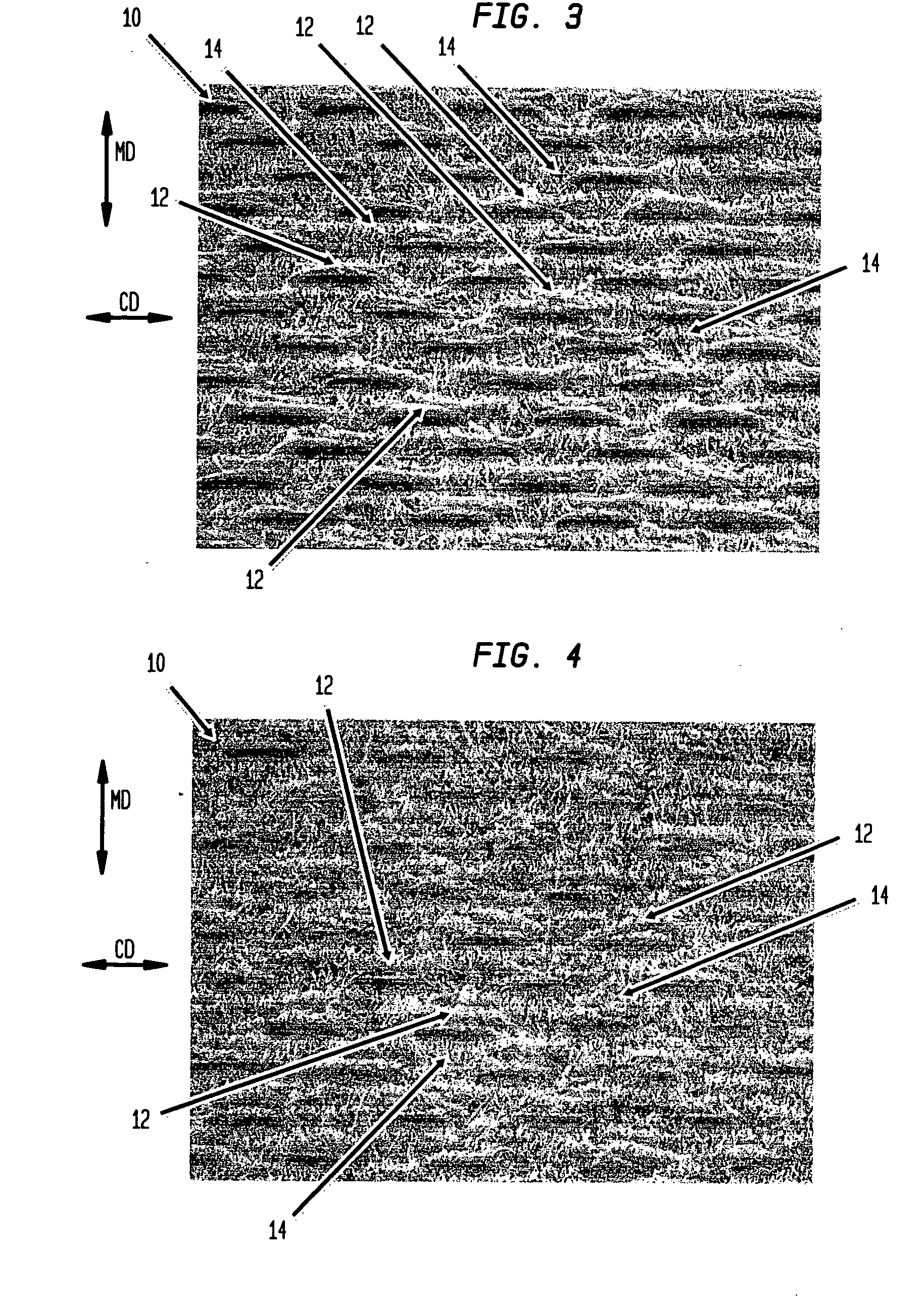

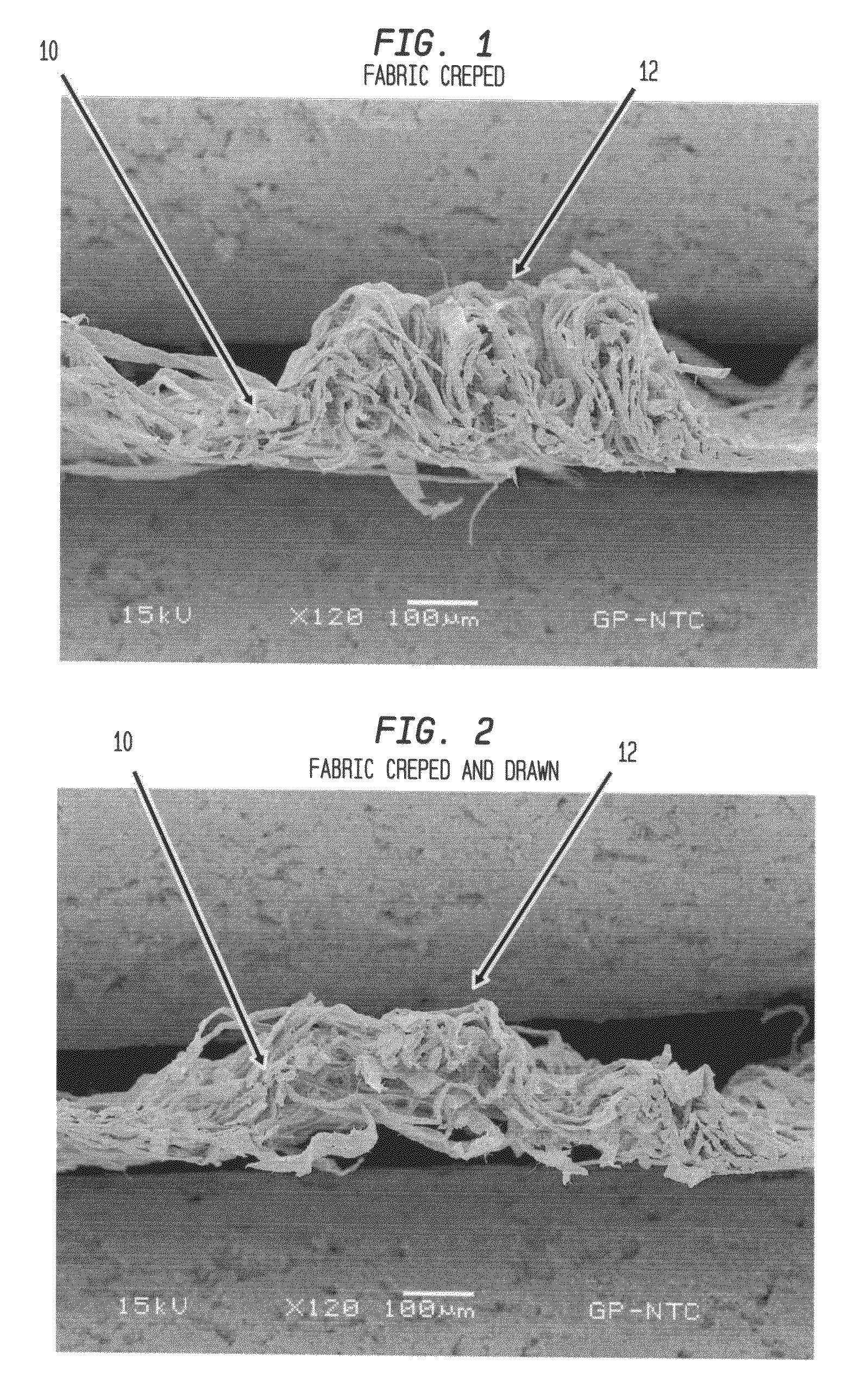

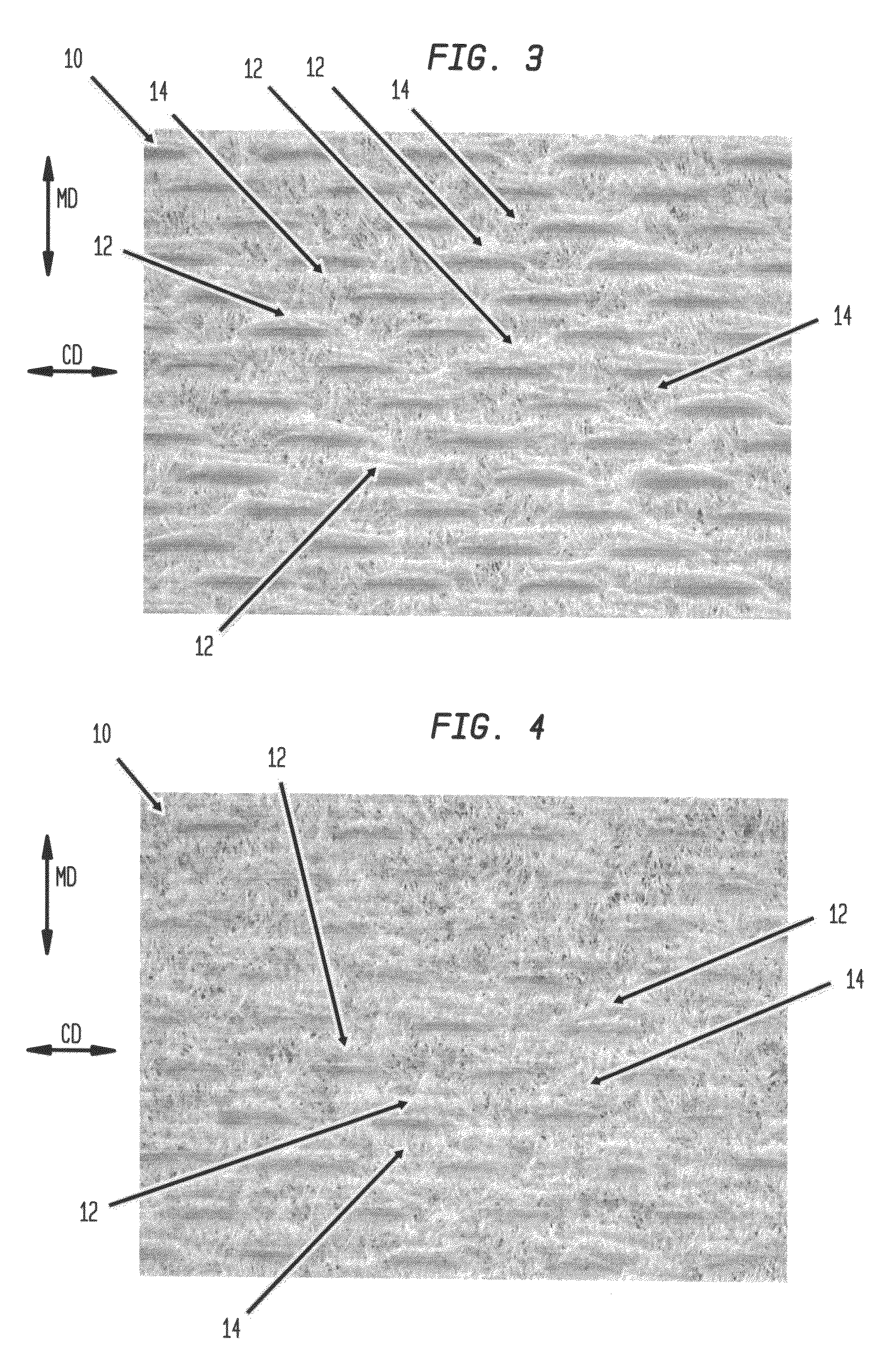

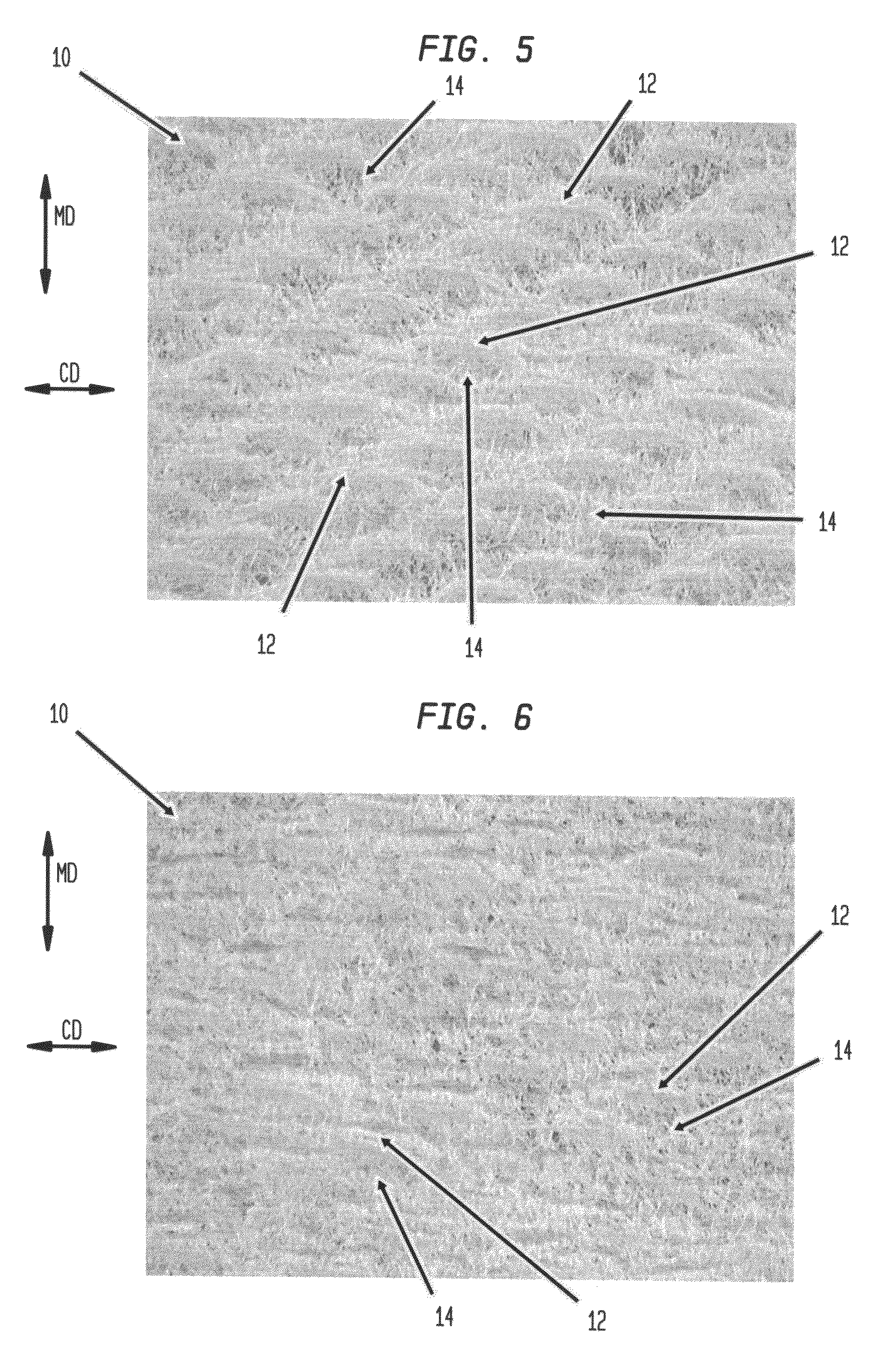

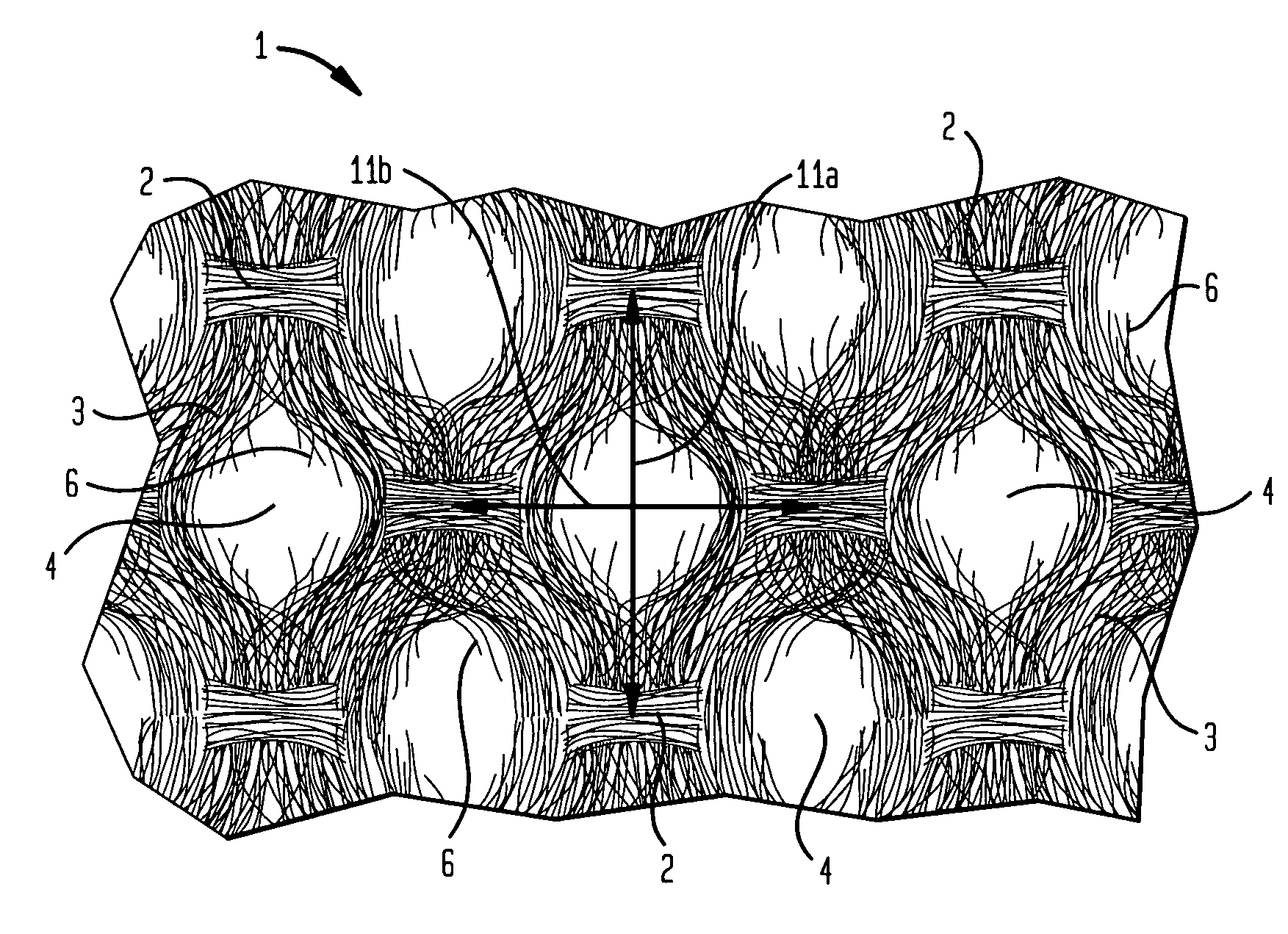

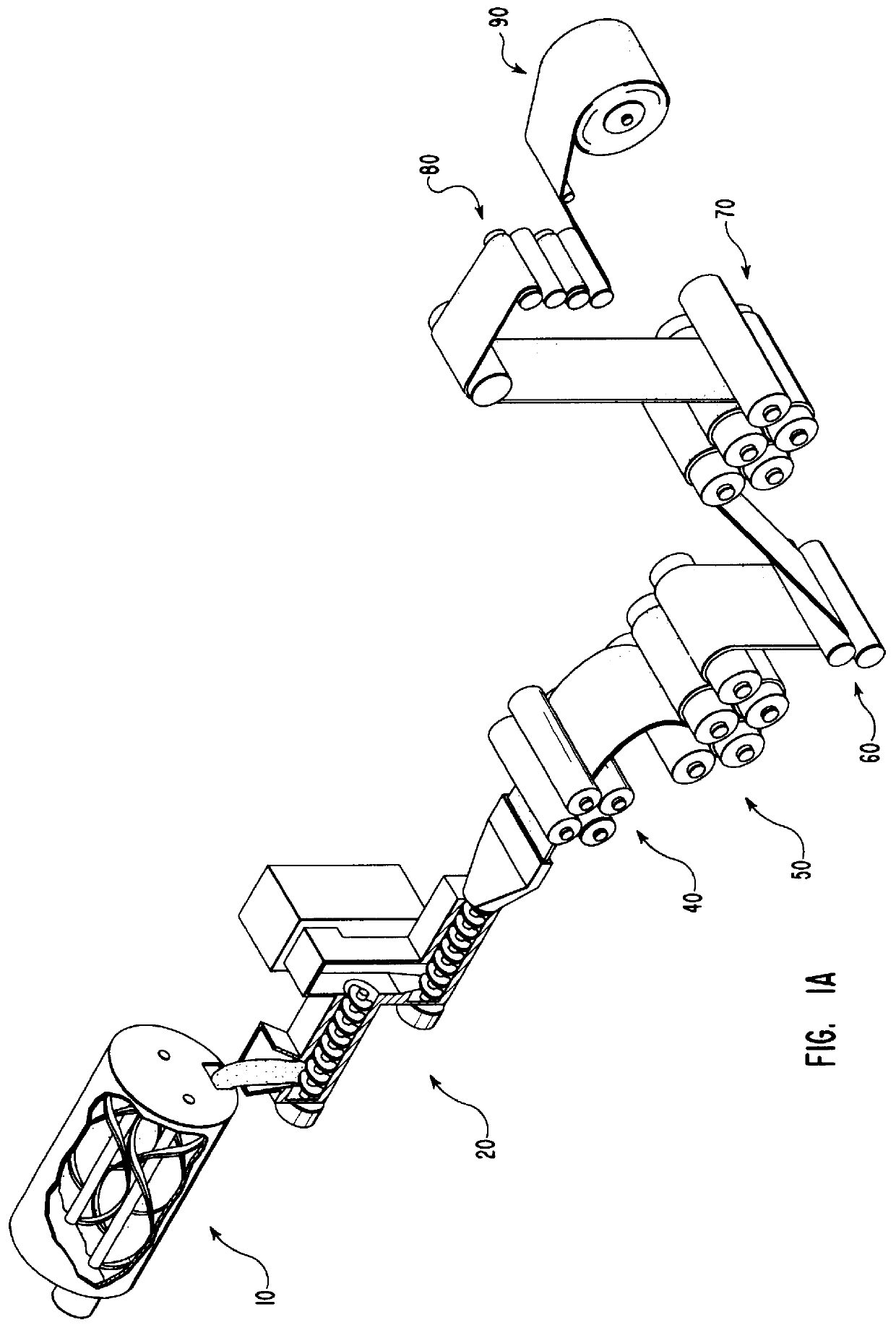

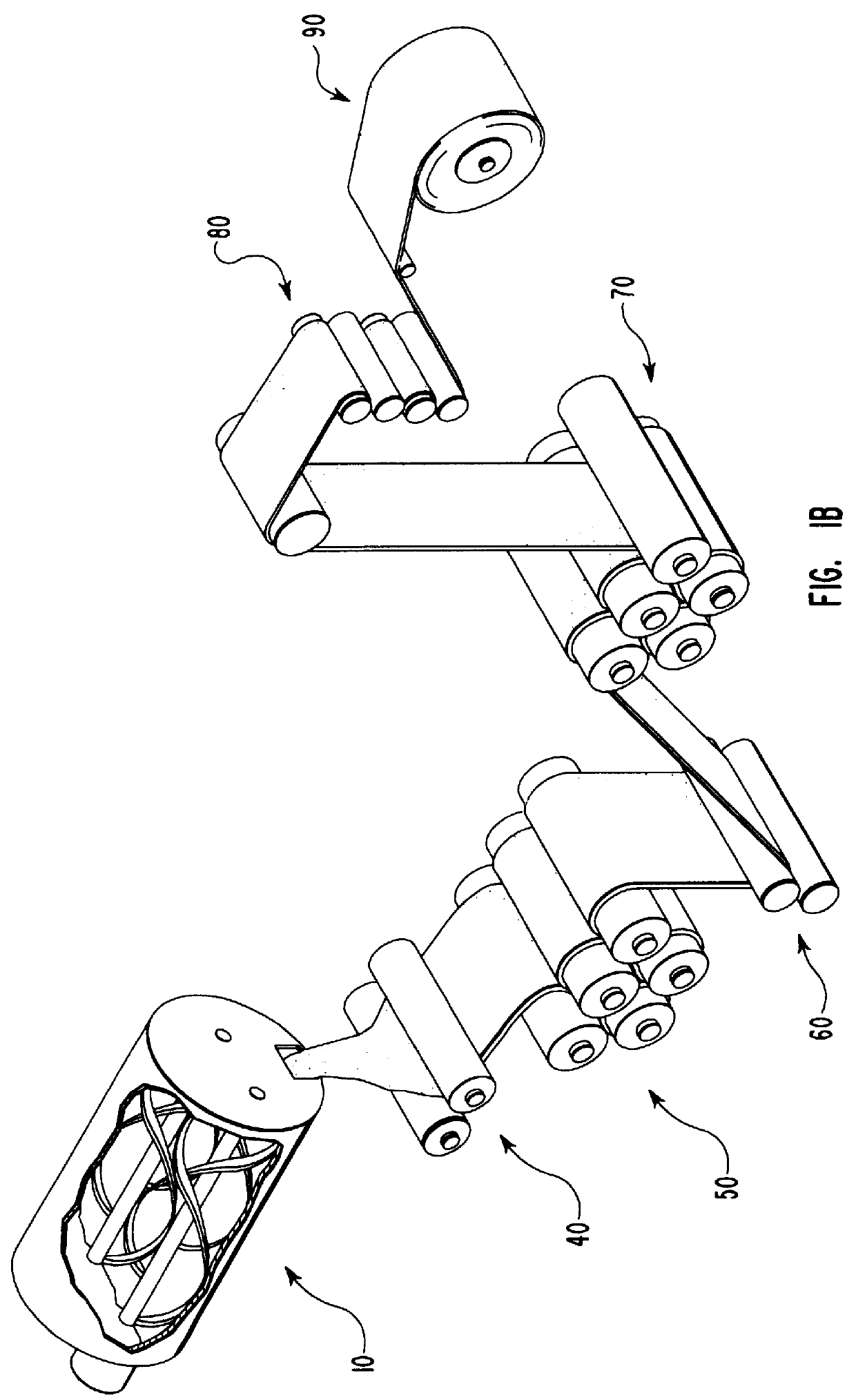

Fabric creped absorbent sheet with variable local basis weight

InactiveUS7494563B2Improve water absorptionSurprising softnessNatural cellulose pulp/paperMechanical working/deformationFiberPapermaking

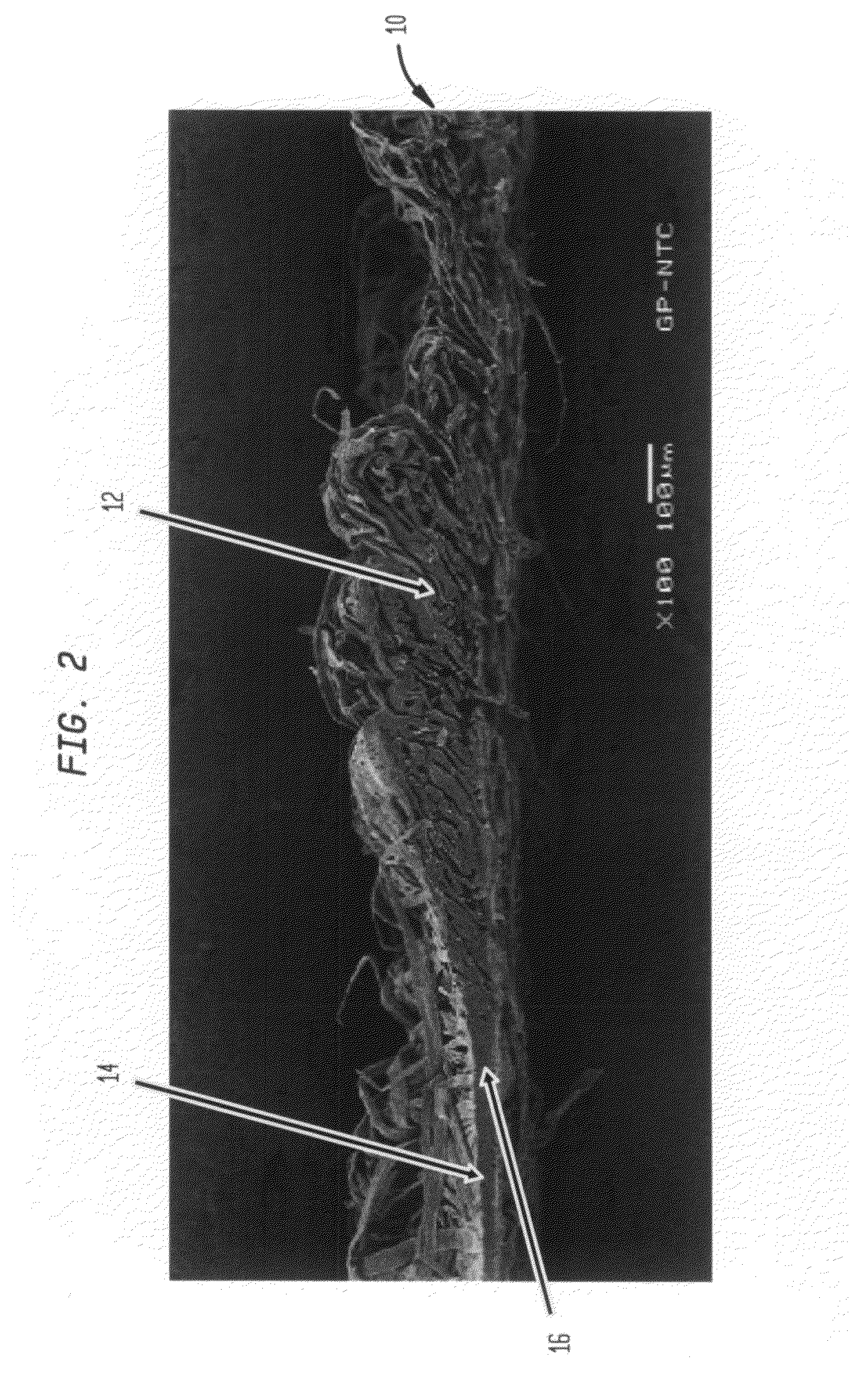

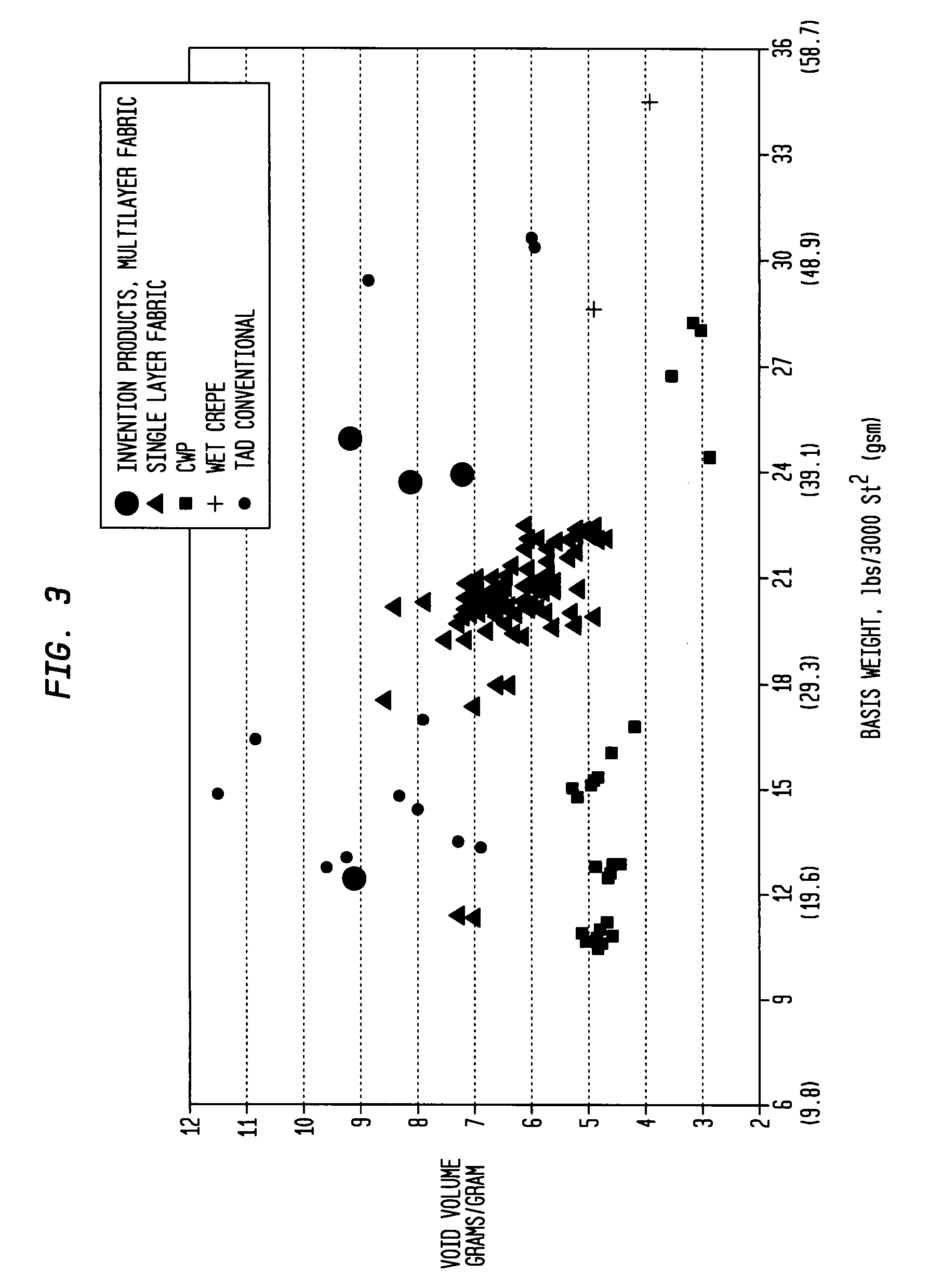

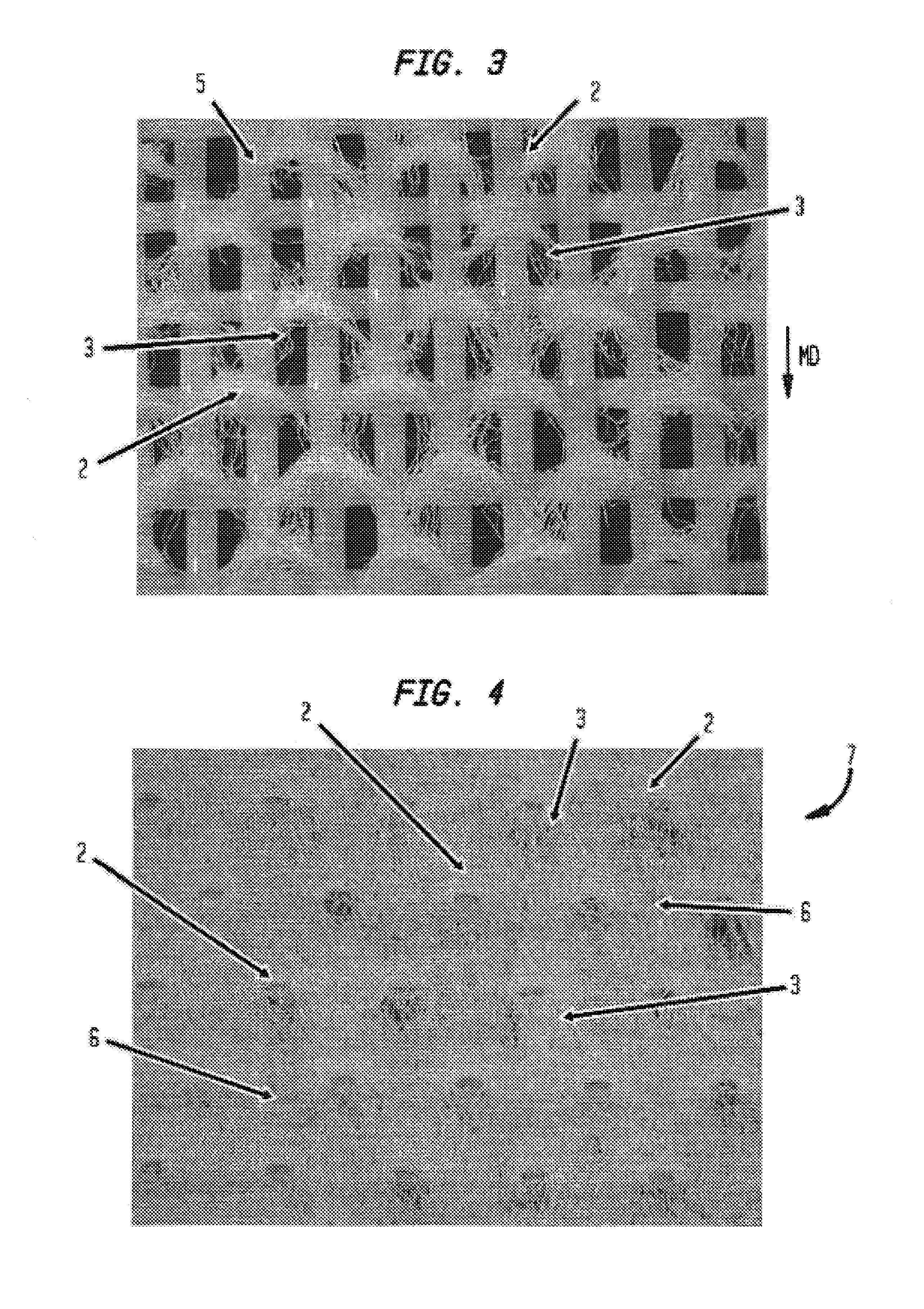

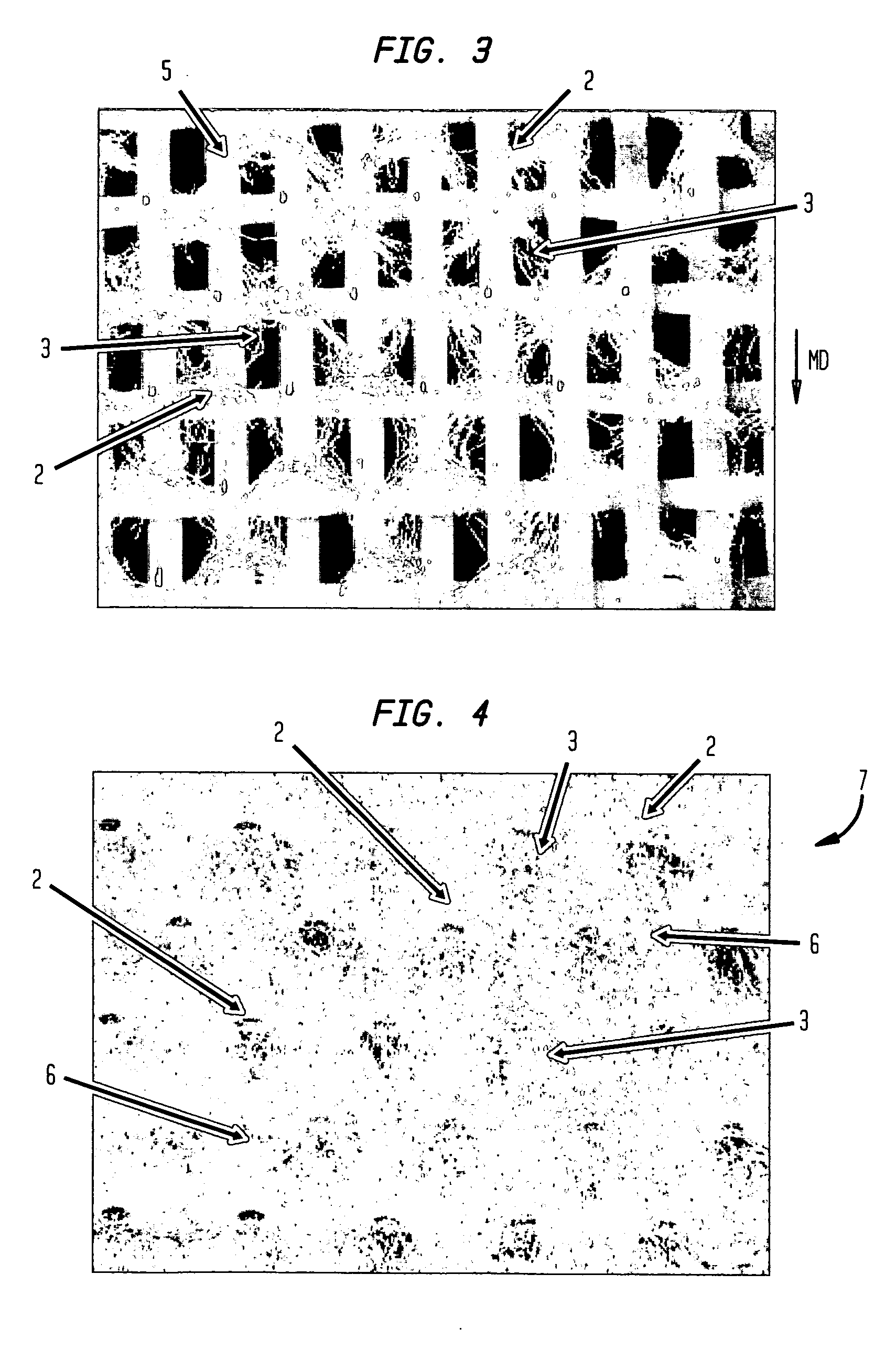

An absorbent cellulosic sheet having variable local basis weight includes a papermaking-fiber reticulum provided with (i) a plurality of cross-machine direction (CD) extending, fiber-enriched pileated regions of relatively high local basis weight interconnected by (ii) a plurality of elongated densified regions of compressed papermaking fibers. The elongated densified regions have relatively low local basis weight and are generally oriented along the machine direction (MD) of the sheet and have an MD / CD aspect ratio of at least 1.5. The products are most preferably prepared by way of a compactive dewatering / wet crepe process.

Owner:GPCP IP HLDG LLC

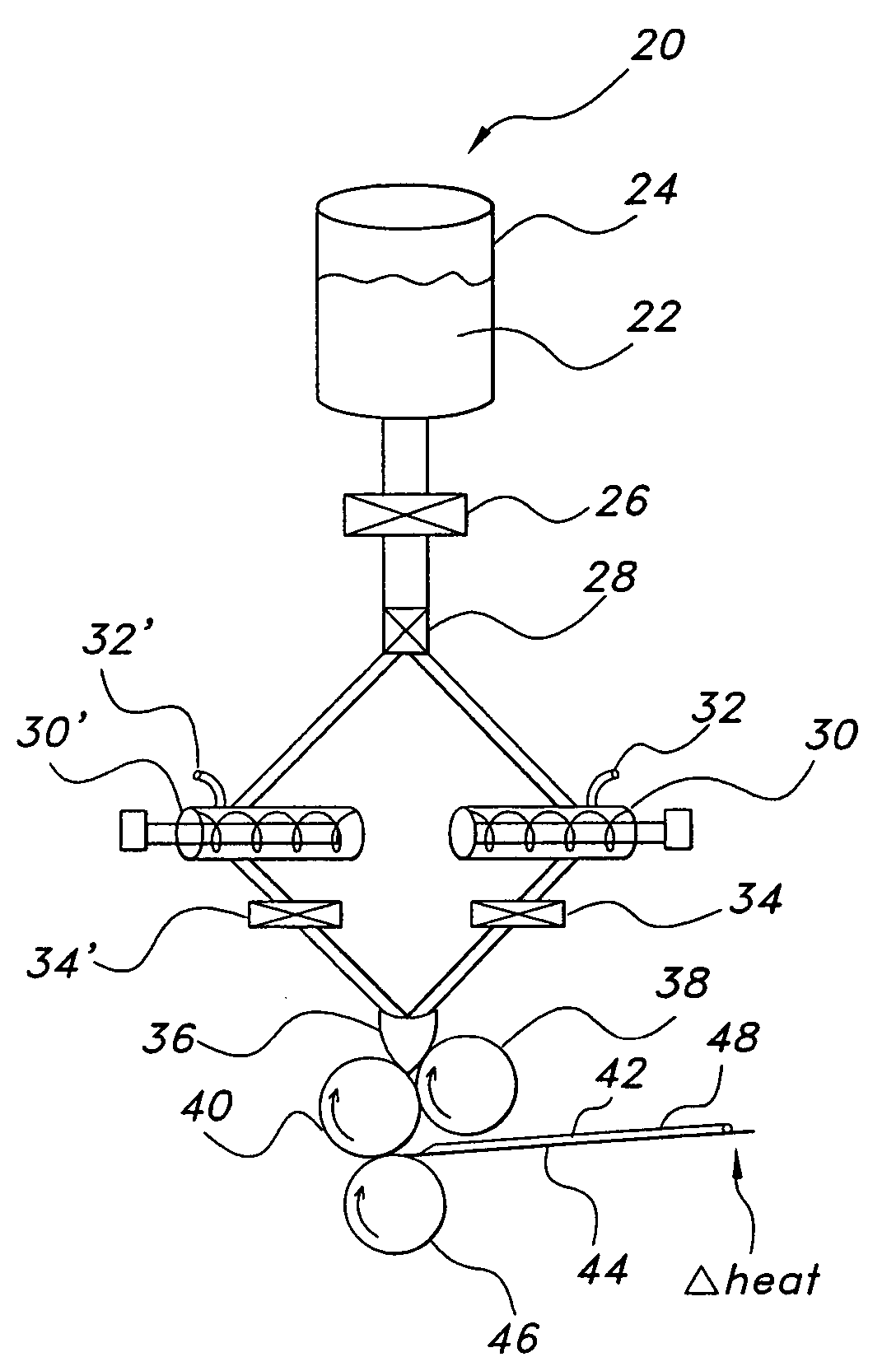

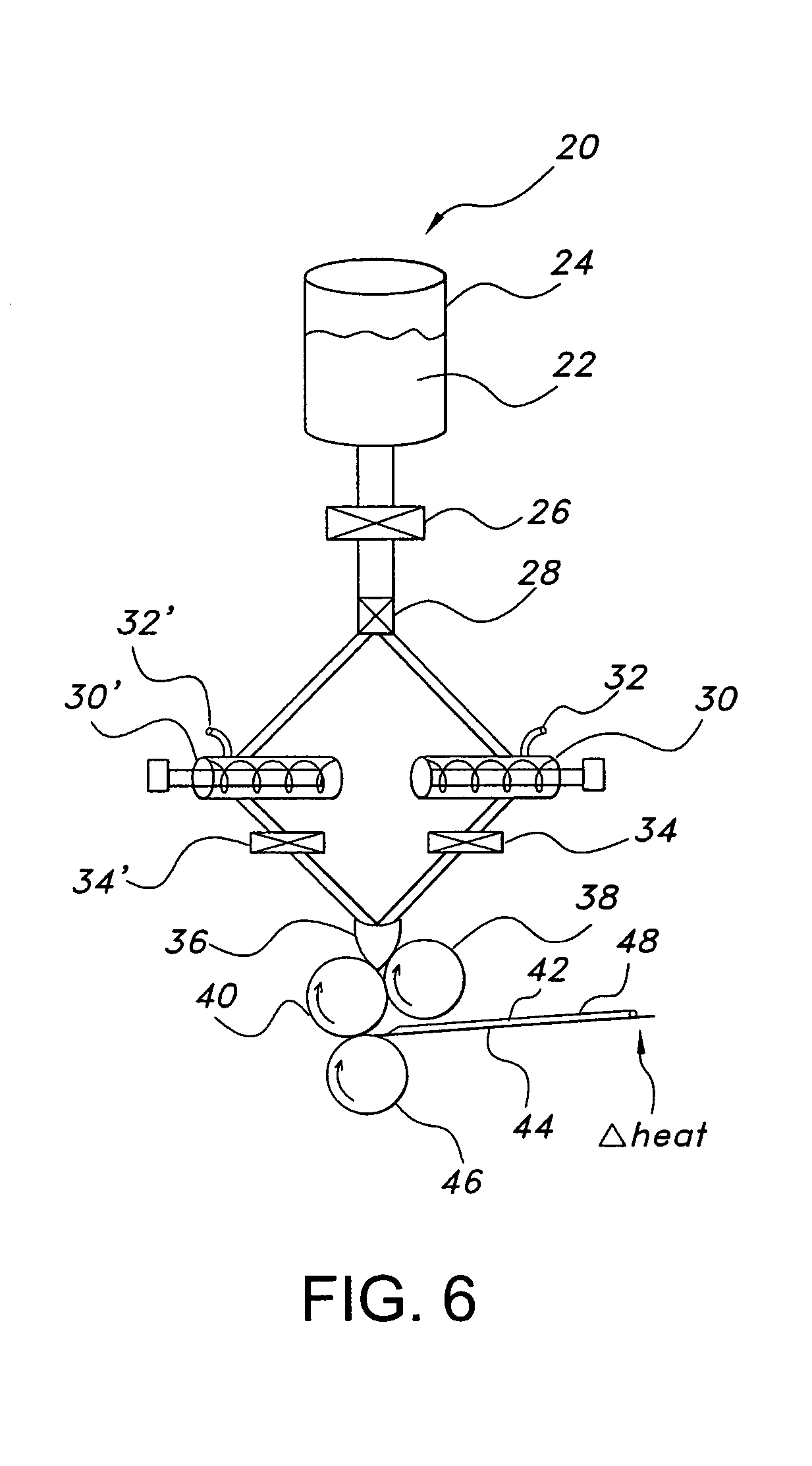

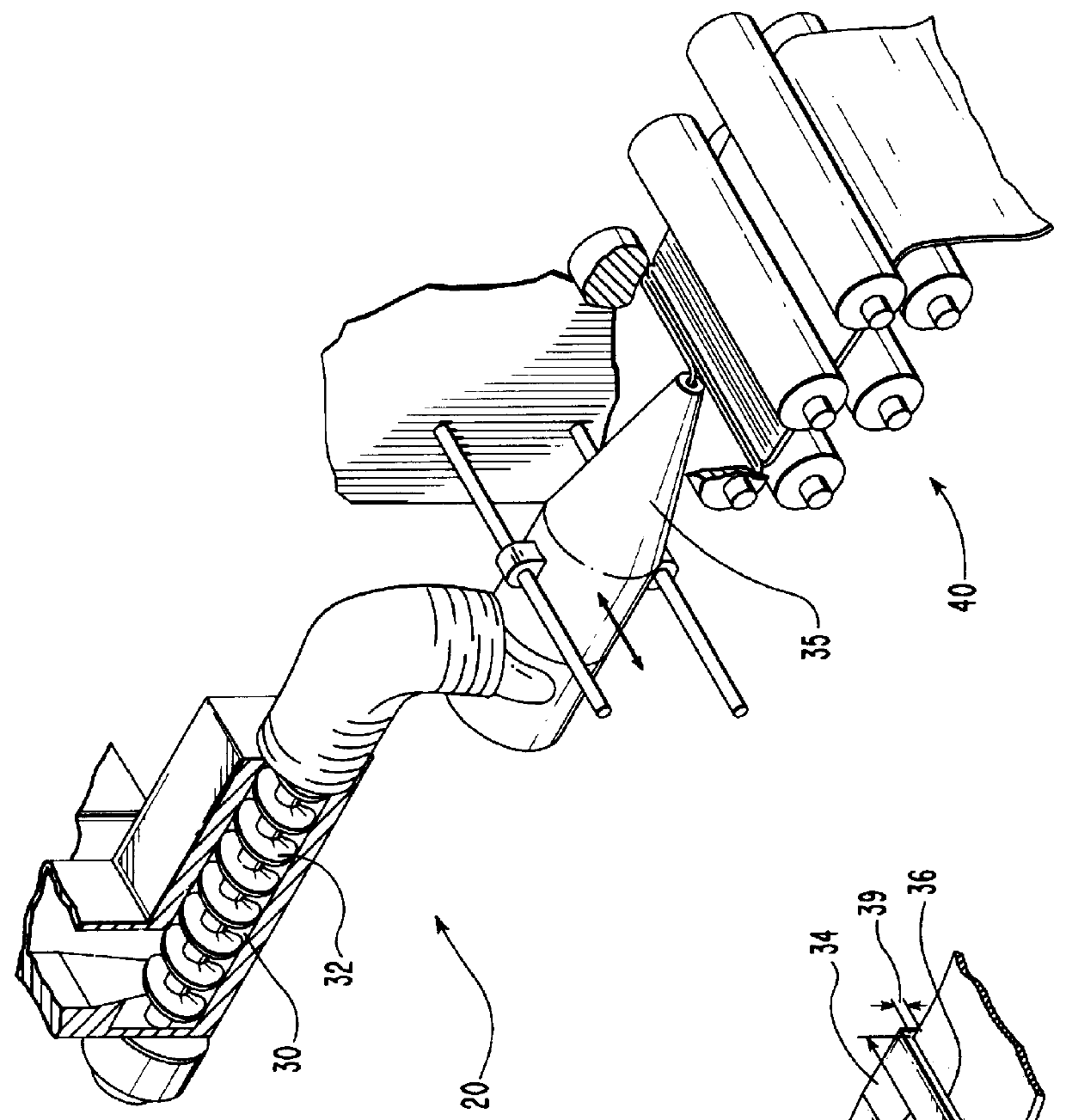

Fabric crepe process for making absorbent sheet

ActiveUS7399378B2High speed transmissionGuaranteed high speed operationNatural cellulose pulp/paperMechanical working/deformationFiberAdhesive

A process for making absorbent cellulosic paper products such as sheet for towel, tissue and the like, includes compactively dewatering a nascent web followed by wet belt creping the web at an intermediate consistency of anywhere from about 30 to about 60 percent under conditions operative to redistribute the fiber on the belt, which is preferably a fabric. In preferred embodiments, the web is thereafter adhesively applied to a Yankee dryer using a creping adhesive operative to enable high speed transfer of the web of intermediate consistency such as a poly(vinyl alcohol) / polyamide adhesive. An absorbent sheet so prepared from a papermaking furnish exhibits an absorbency of at least about 5 g / g, a CD stretch of at least about 4 percent, and an MD / CD tensile ratio of less than about 1.1, and also exhibits a maximum CD modulus at a CD strain of less than 1 percent and sustains a CD modulus of at least 50 percent of its maximum CD modulus to a CD strain of at least about 4 percent. Products of the invention may also exhibit an MD modulus at break 1.5 to 2 times their initial MD modulus.

Owner:GPCP IP HLDG LLC

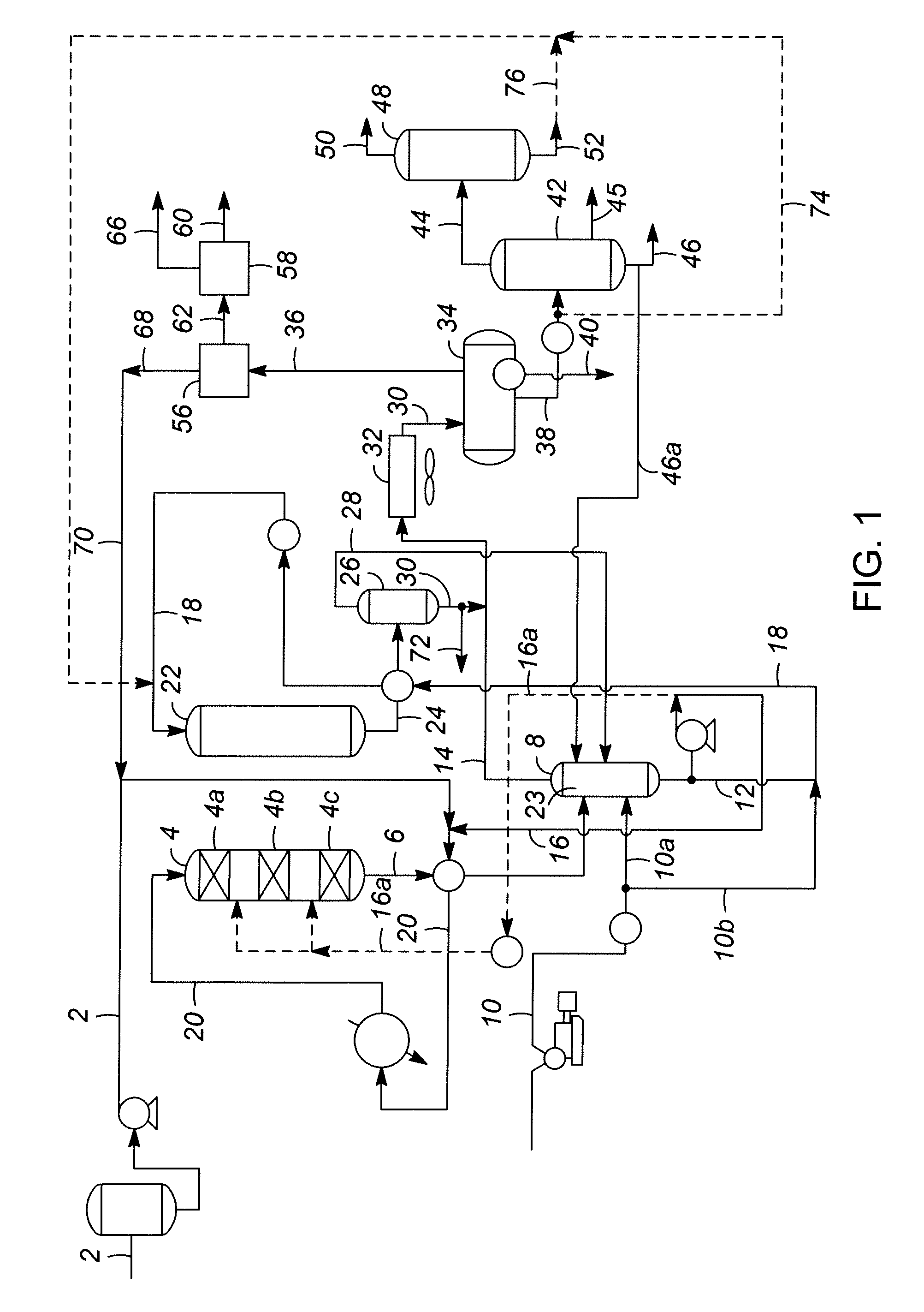

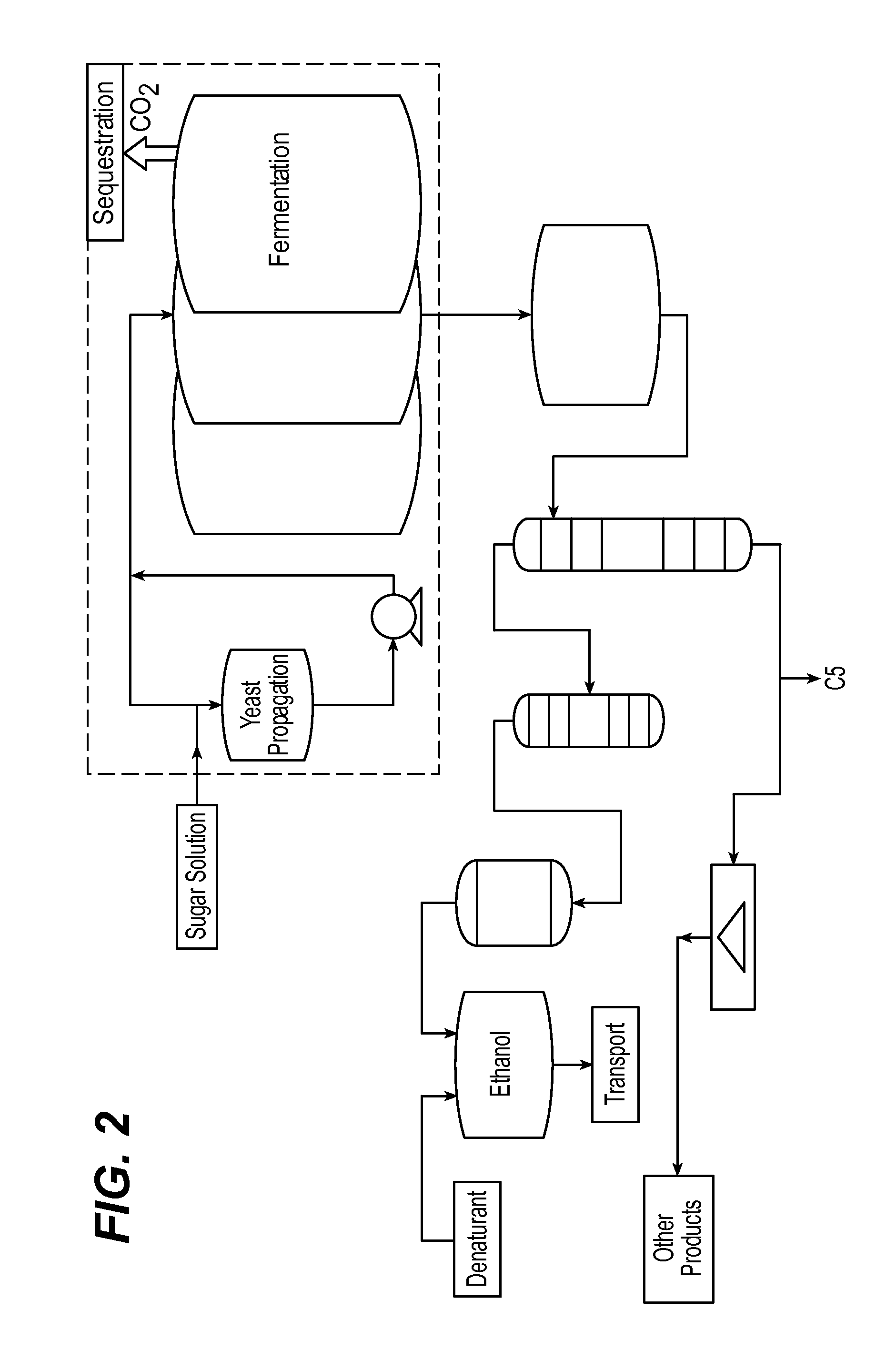

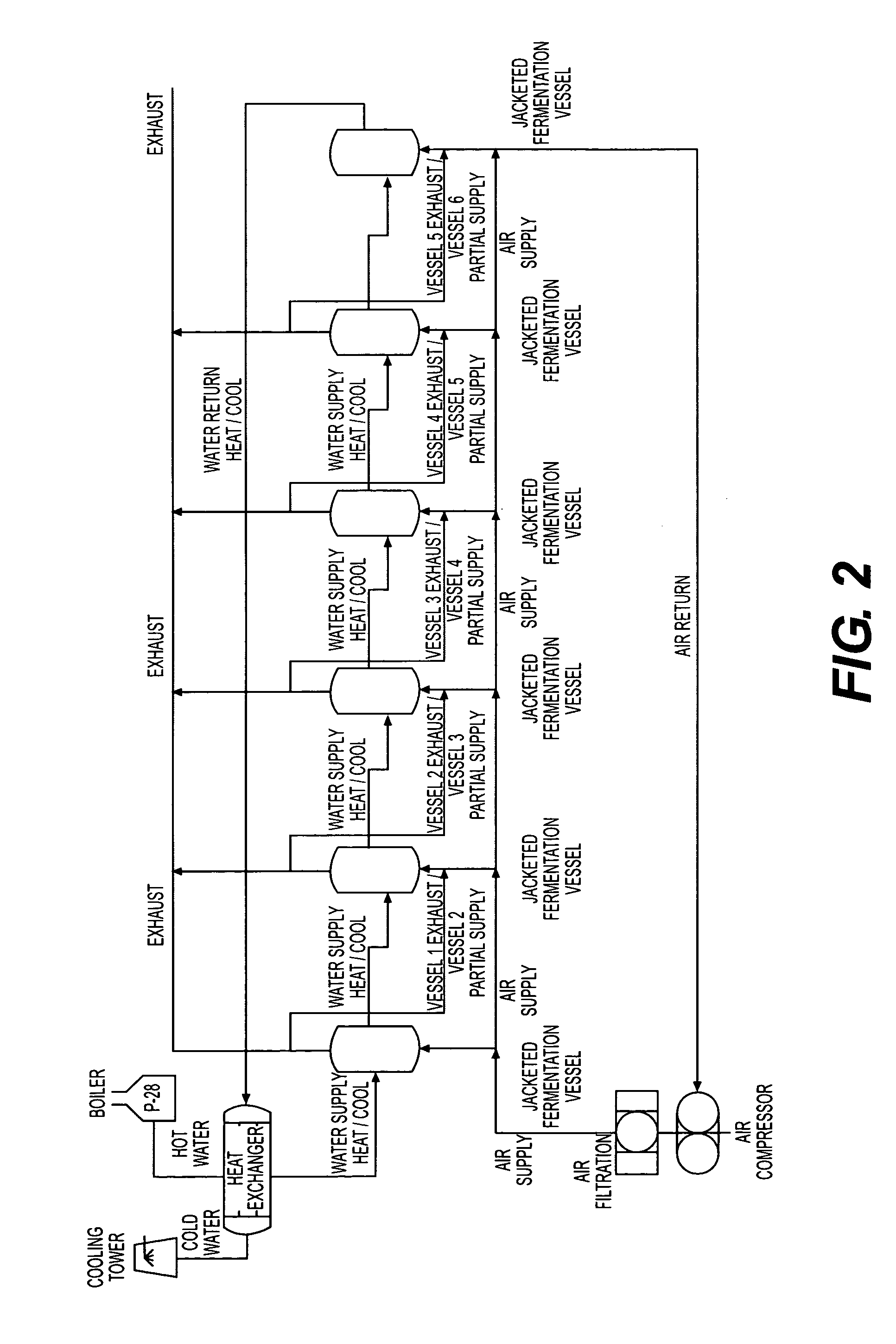

Method for processing lignocellulosic material

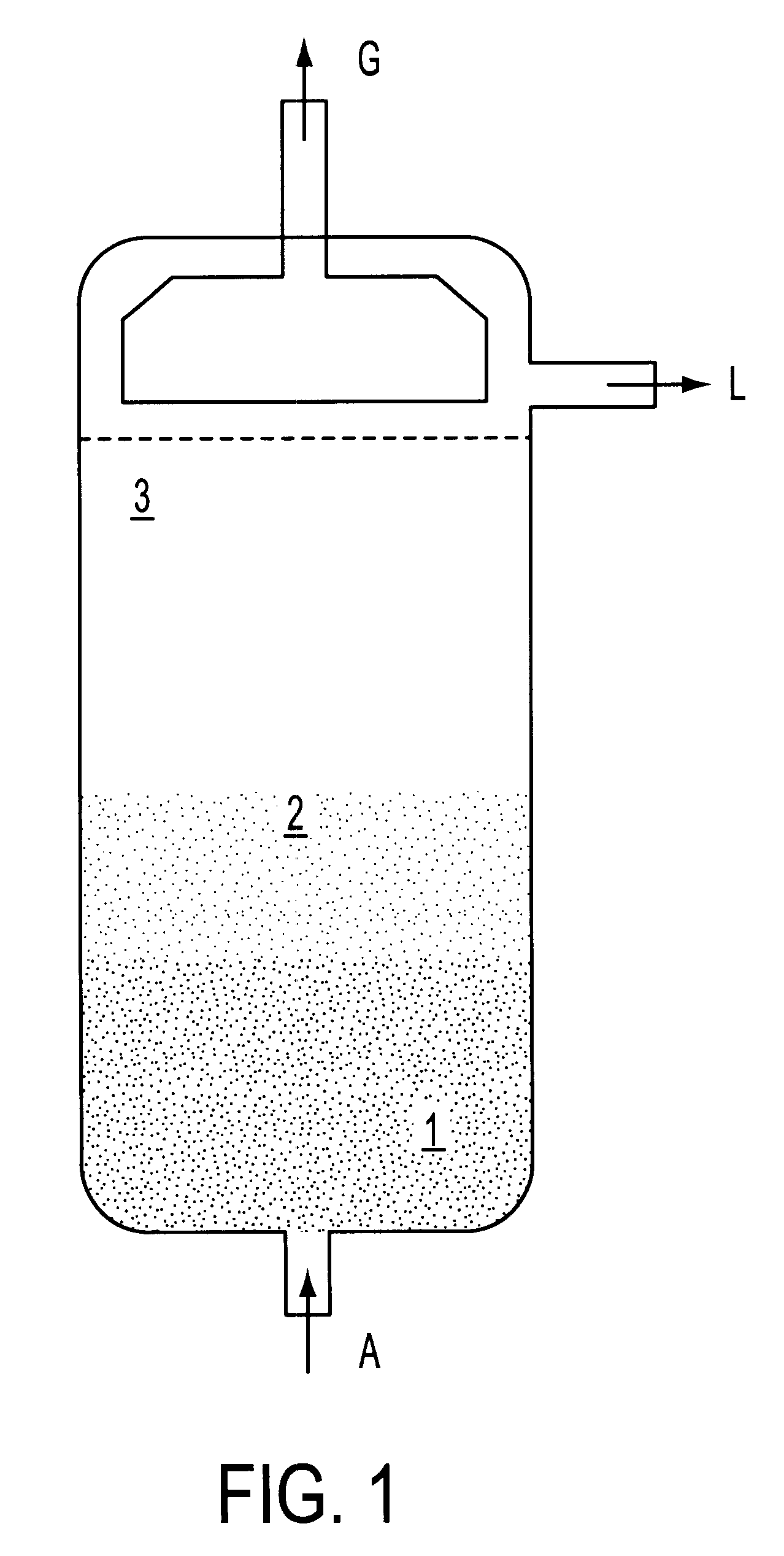

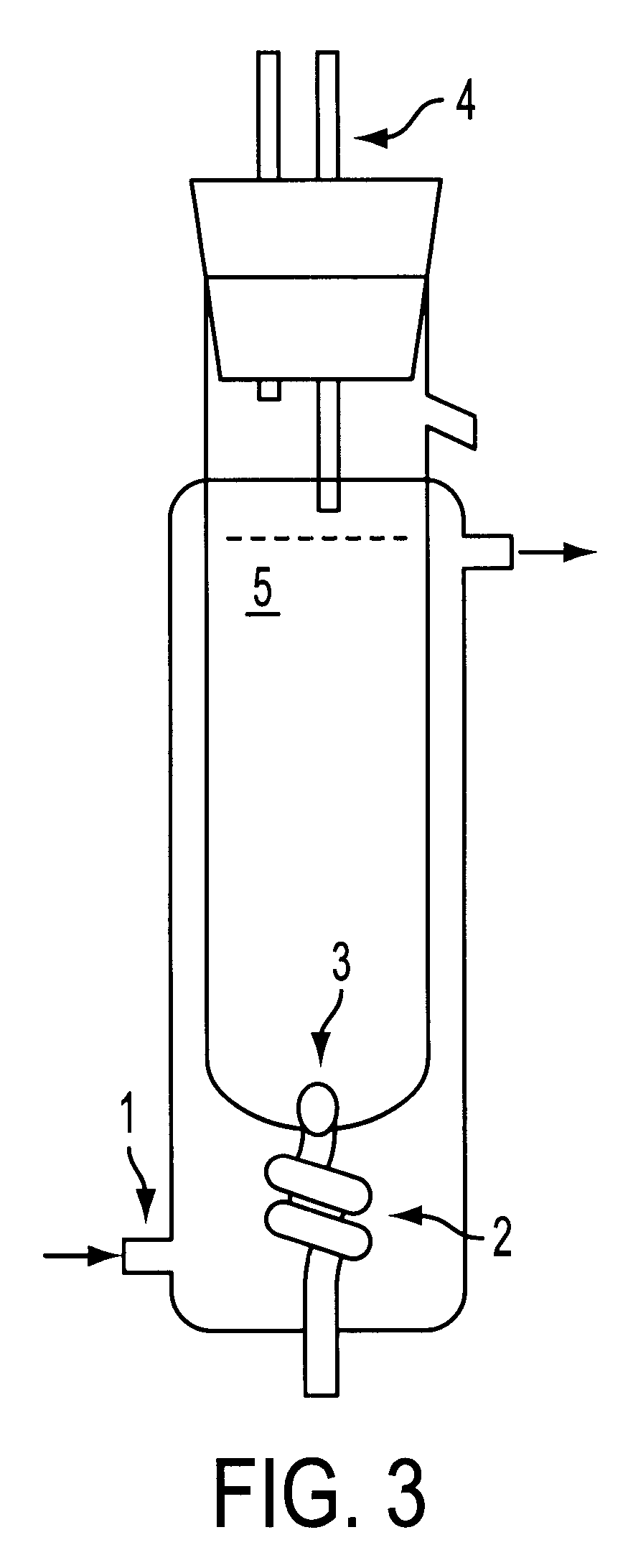

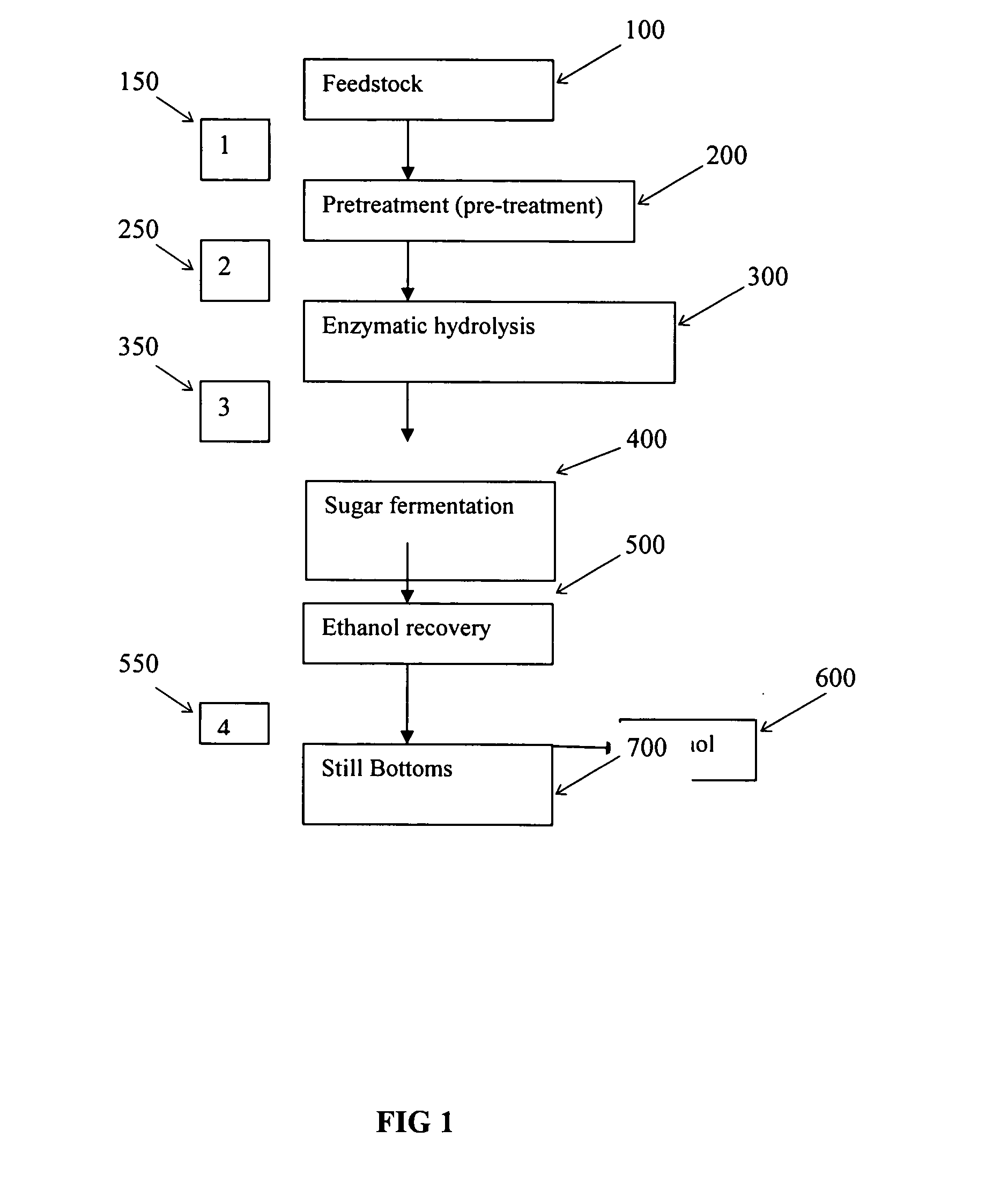

InactiveUS6555350B2High degreeReduce water consumptionSludge treatment by oxidationBiofuelsCelluloseWater flow

A method wherein lignocellulosic biomass materials are converted into combustible fuel products. In particular, the method is a continuous process, involving wet oxidation or steam explosion, for fermentatively converting such biomass materials into ethanol using a process design that permits all or part of the process water from the ethanol fermentation process to be recycled to reduce the consumption of process water. The effluent from the ethanol fermentation step may be subjected to an anaerobic fermentation step generating methane and a water effluent in which the amount of potentially inhibitory substances is at a sub-inhibitory level, which in turn permits all or part of the effluent water from the anaerobic fermentation step to be recycled into the process.

Owner:POET RES INC

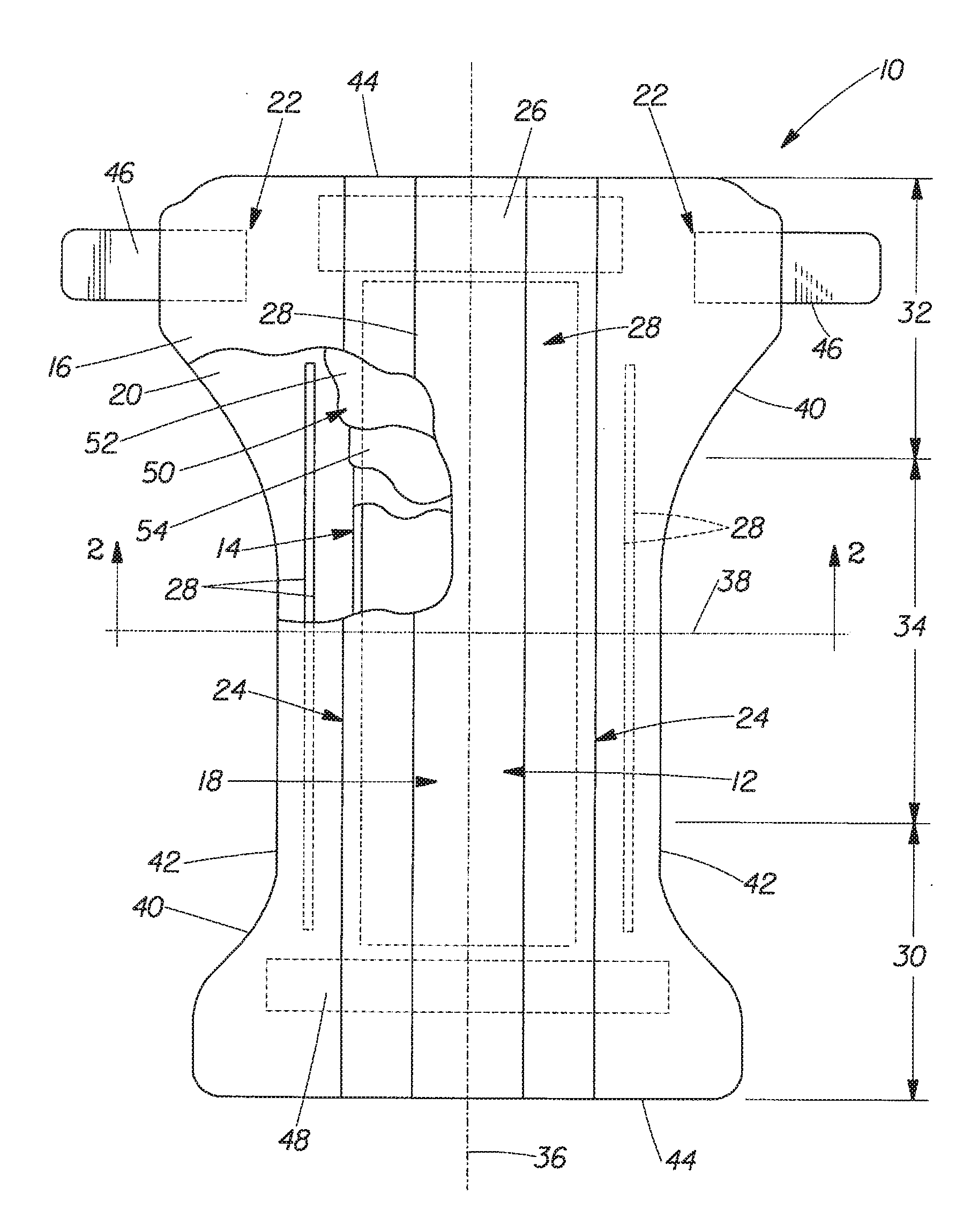

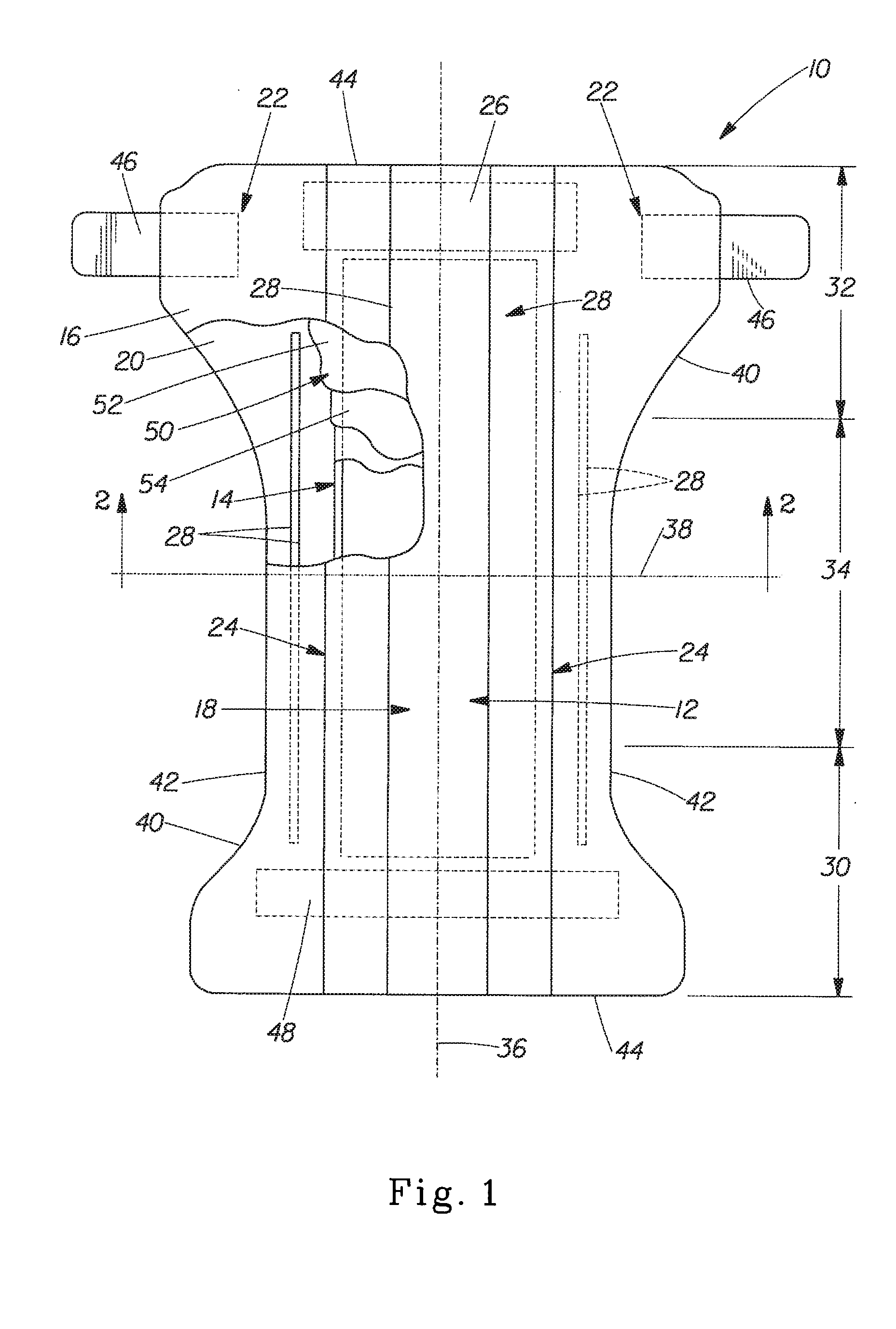

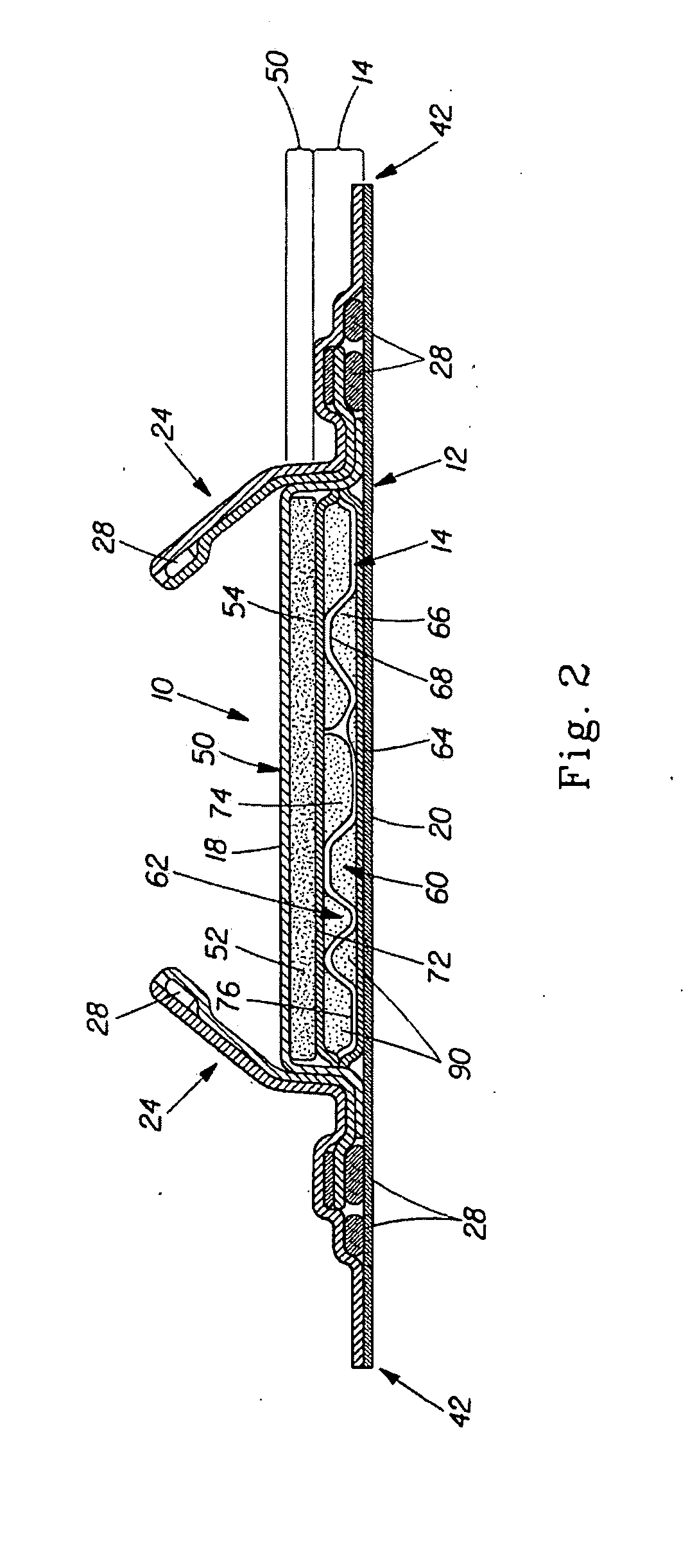

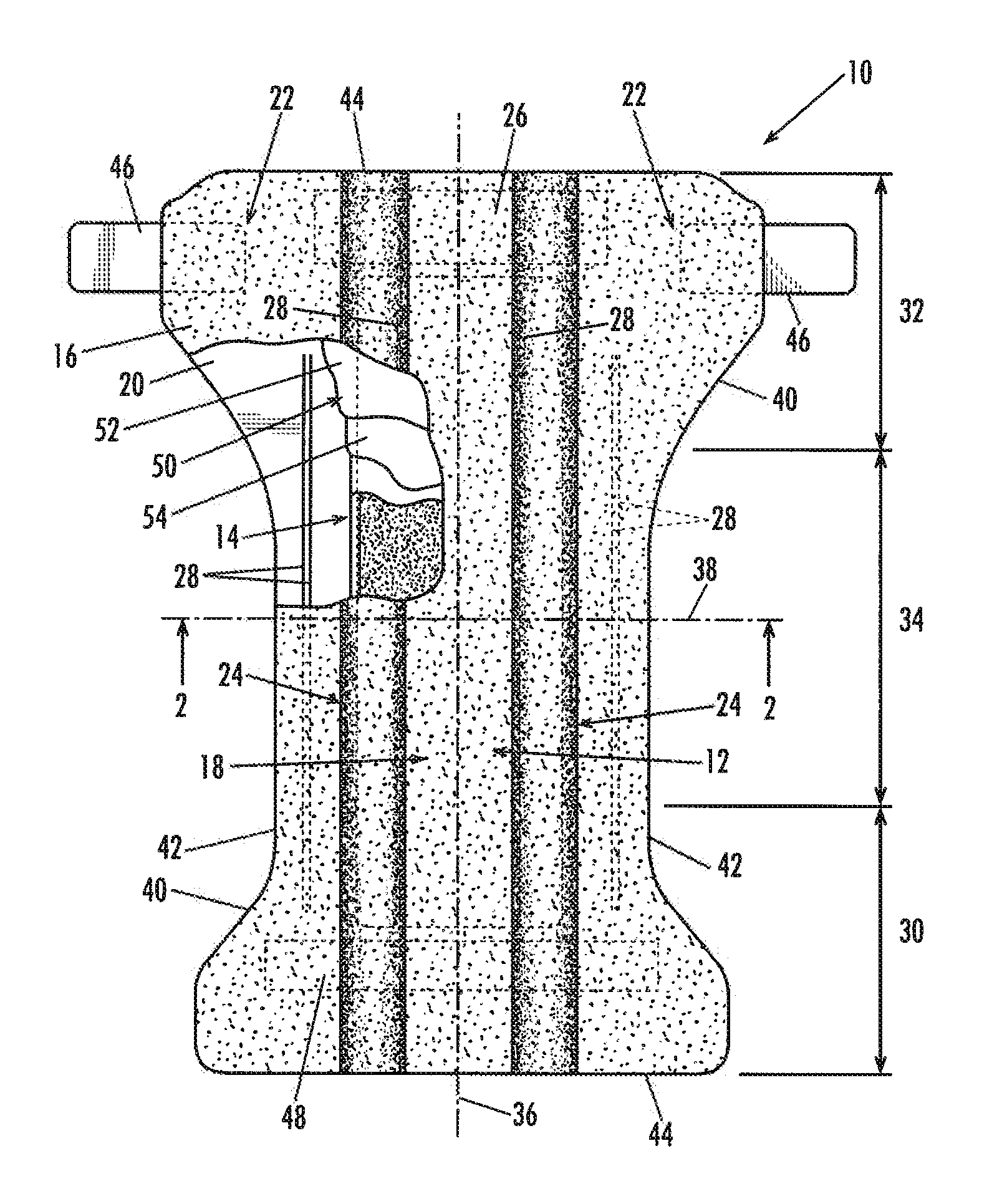

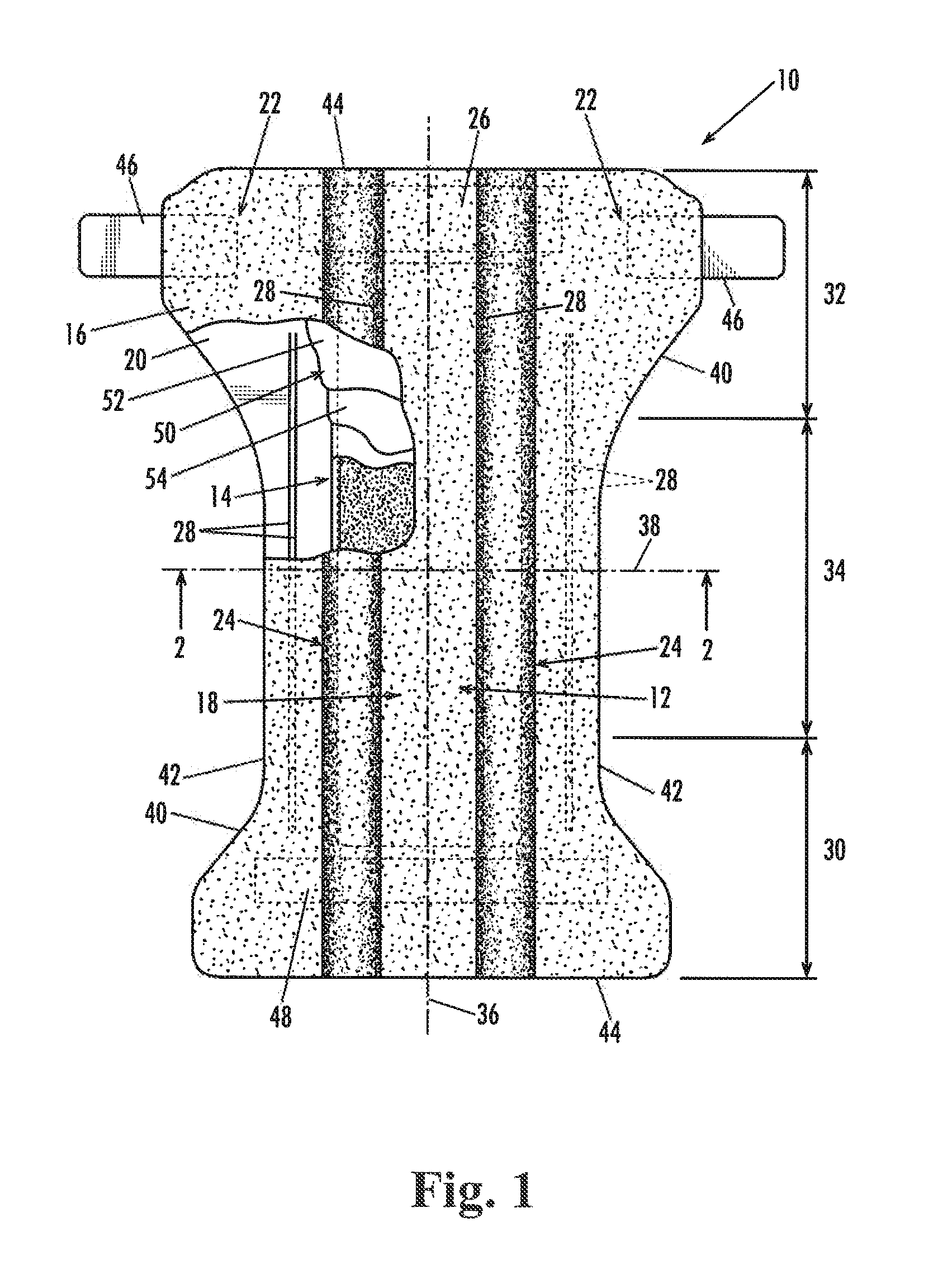

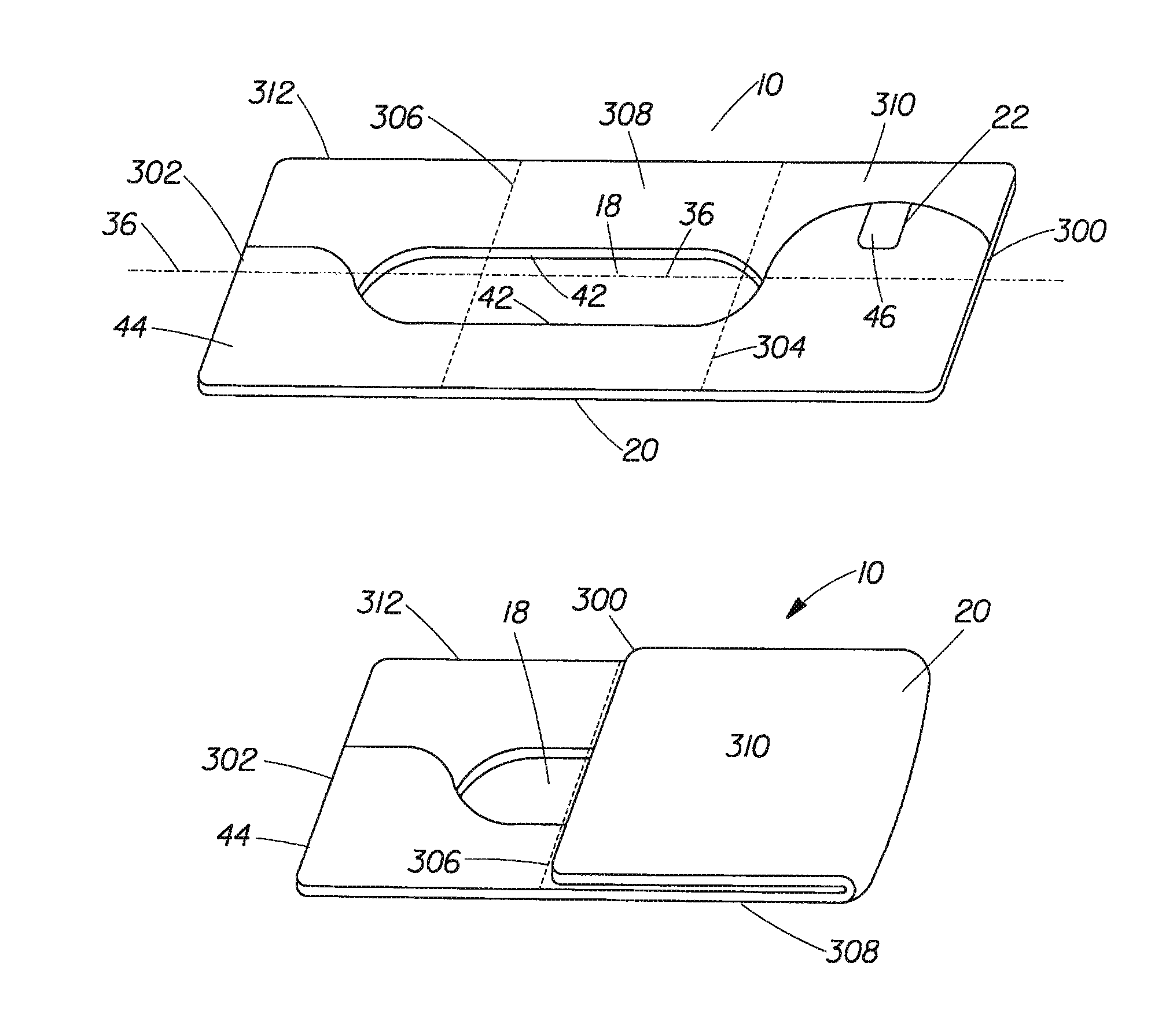

Tri-Folded Disposable Absorbent Article, Packaged Absorbent Article, And Array of Packaged Absorbent Articles With Substantially Continuously Distributed Absorbent Particulate Polymer Material

A tri-folded disposable absorbent article comprising a substantially cellulose free absorbent core located in a chassis between a topsheet and a backsheet and comprising absorbent particulate polymer material. An array of absorbent article packages comprising disposable absorbent articles comprising a substantially cellulose free absorbent core is also disclosed.

Owner:THE PROCTER & GAMBLE COMPANY

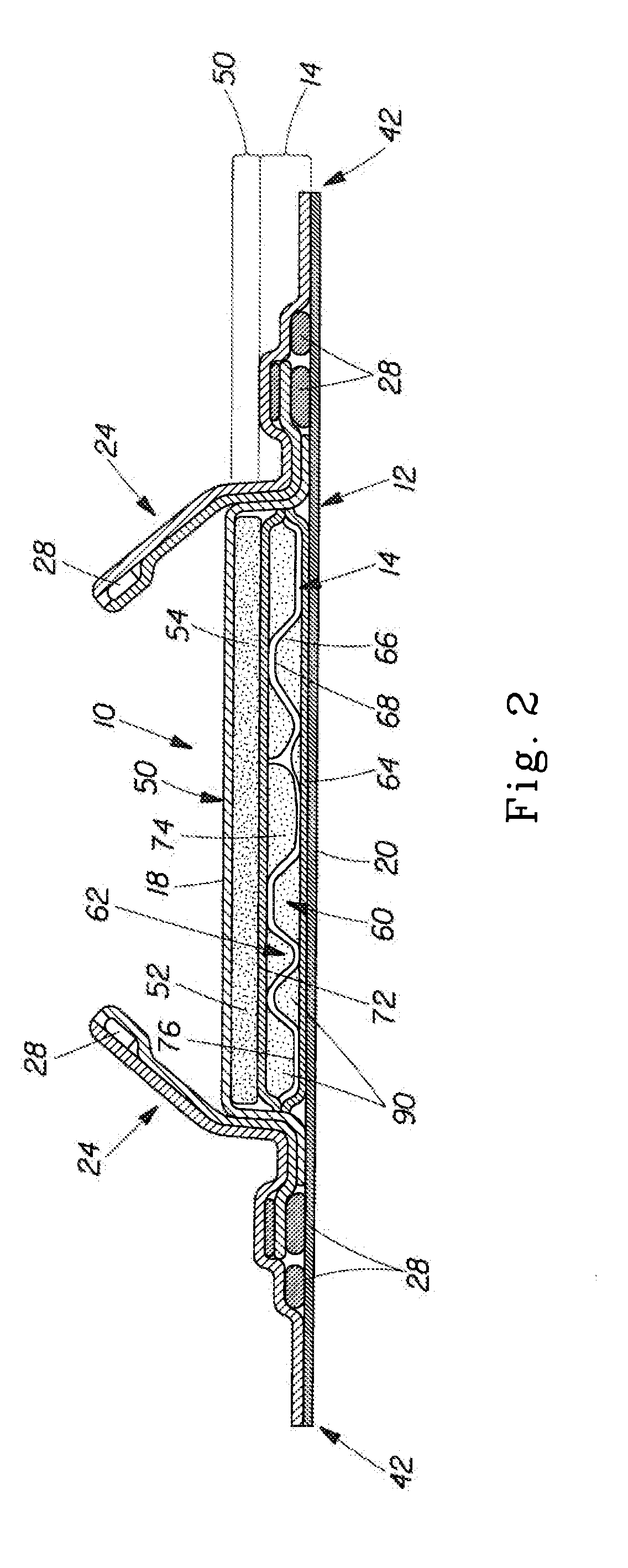

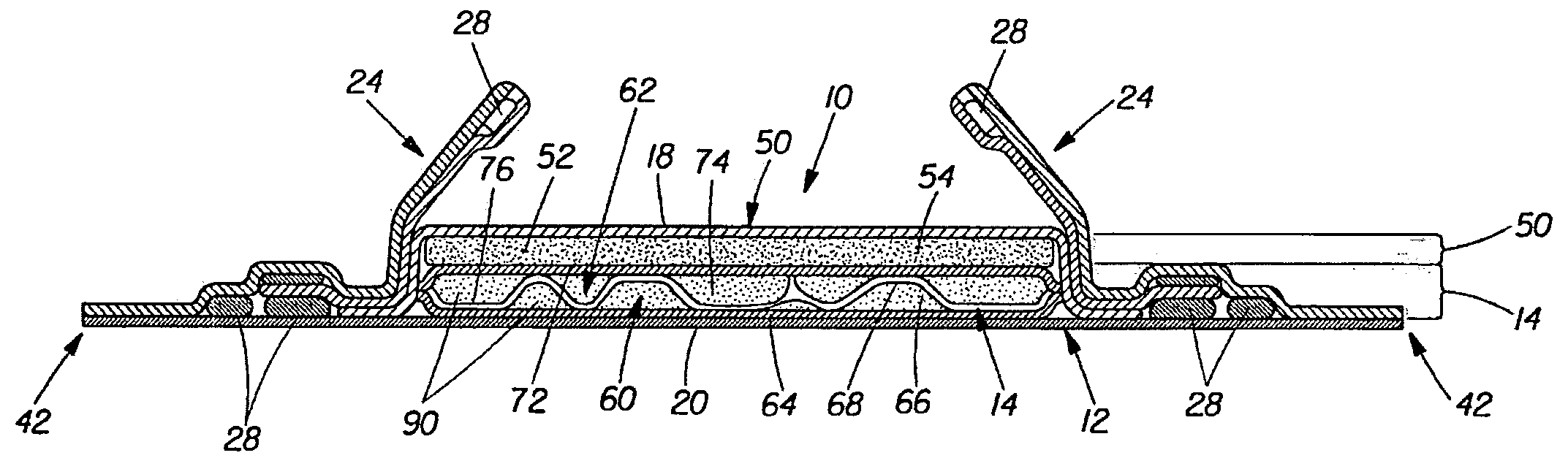

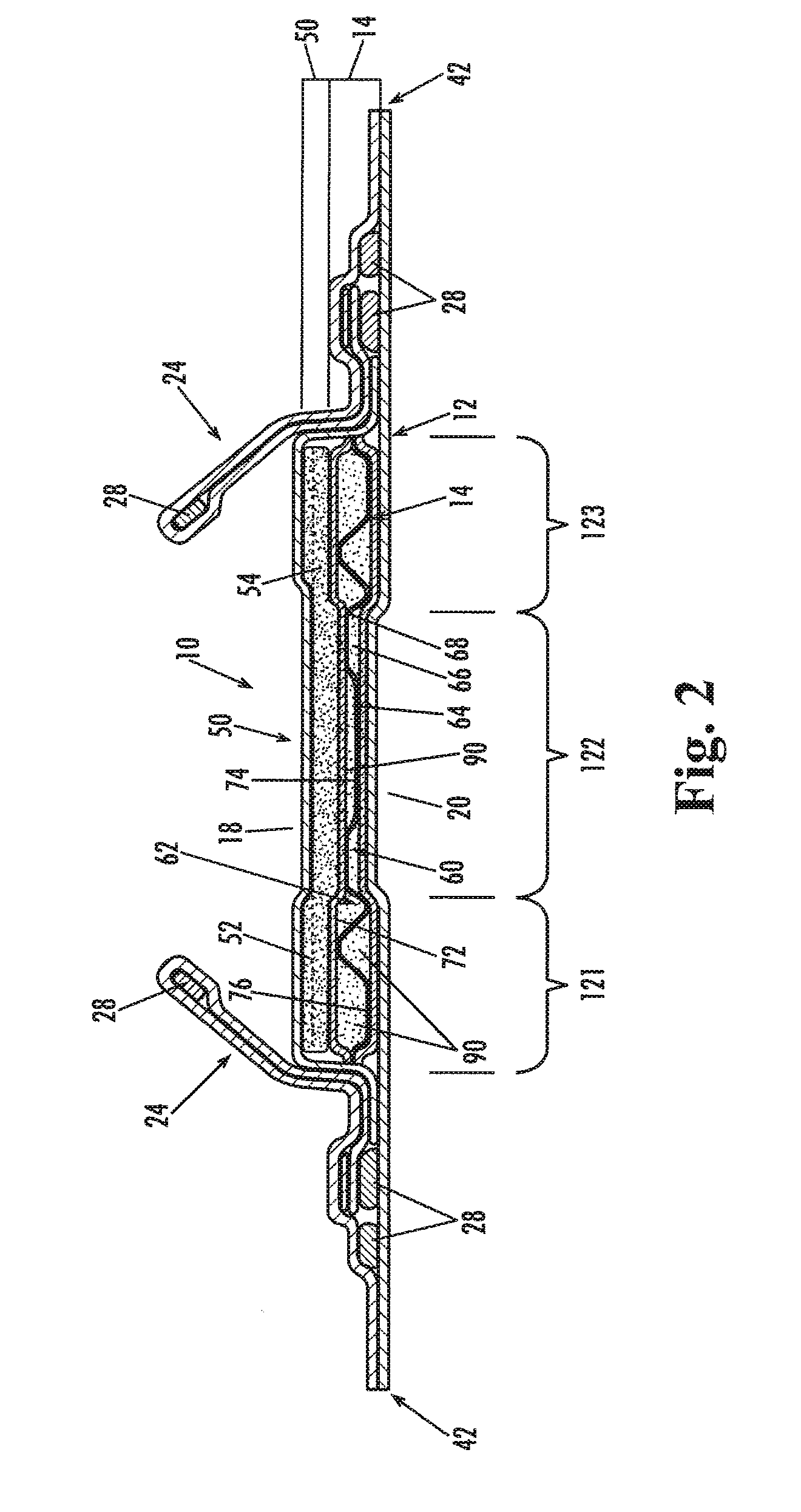

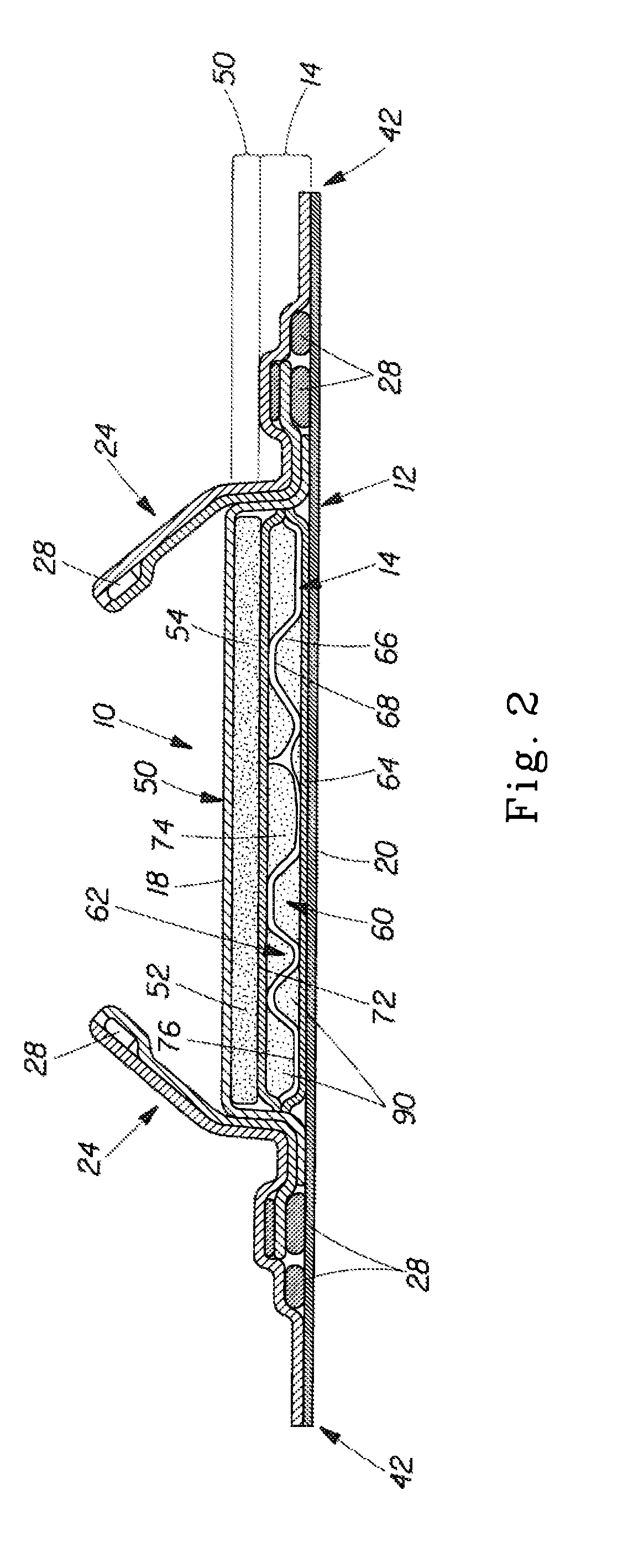

Disposable Absorbent Article With Sealed Absorbent Core With Absorbent Particulate Polymer Material

A disposable absorbent article includes a chassis and an absorbent core which is substantially cellulose free. The chassis may contain a topsheet and a backsheet. The absorbent core may be located between the topsheet and the backsheet and may include (i) a storage layer which comprises an absorbent particulate polymer material and has a wearer facing side and an opposed garment facing side, (ii) a first core wrap sheet covering the wearer facing side of the storage layer, and (iii) a second core wrap sheet covering the garment facing side of the storage layer, the first core wrap sheet being joined to the second core wrap sheet along at least one traverse sealing zone.

Owner:THE PROCTER & GAMBLE COMPANY

Disposable Absorbent Article With Sealed Absorbent Core With Substantially Continuously Distributed Absorbent Particulate Polymer Material

A disposable absorbent article includes a chassis and an absorbent core which is substantially cellulose free. The chassis may contain a topsheet and a backsheet. The absorbent core may be located between the topsheet and the backsheet and may include (i) a storage layer which comprises an absorbent particulate polymer material and has a wearer facing side and an opposed garment facing side, (ii) a first core wrap sheet covering the wearer facing side of the storage layer, and (iii) a second core wrap sheet covering the garment facing side of the storage layer, the first core wrap sheet being joined to the second core wrap sheet along at least one traverse sealing zone.

Owner:THE PROCTER & GAMBLE COMPANY

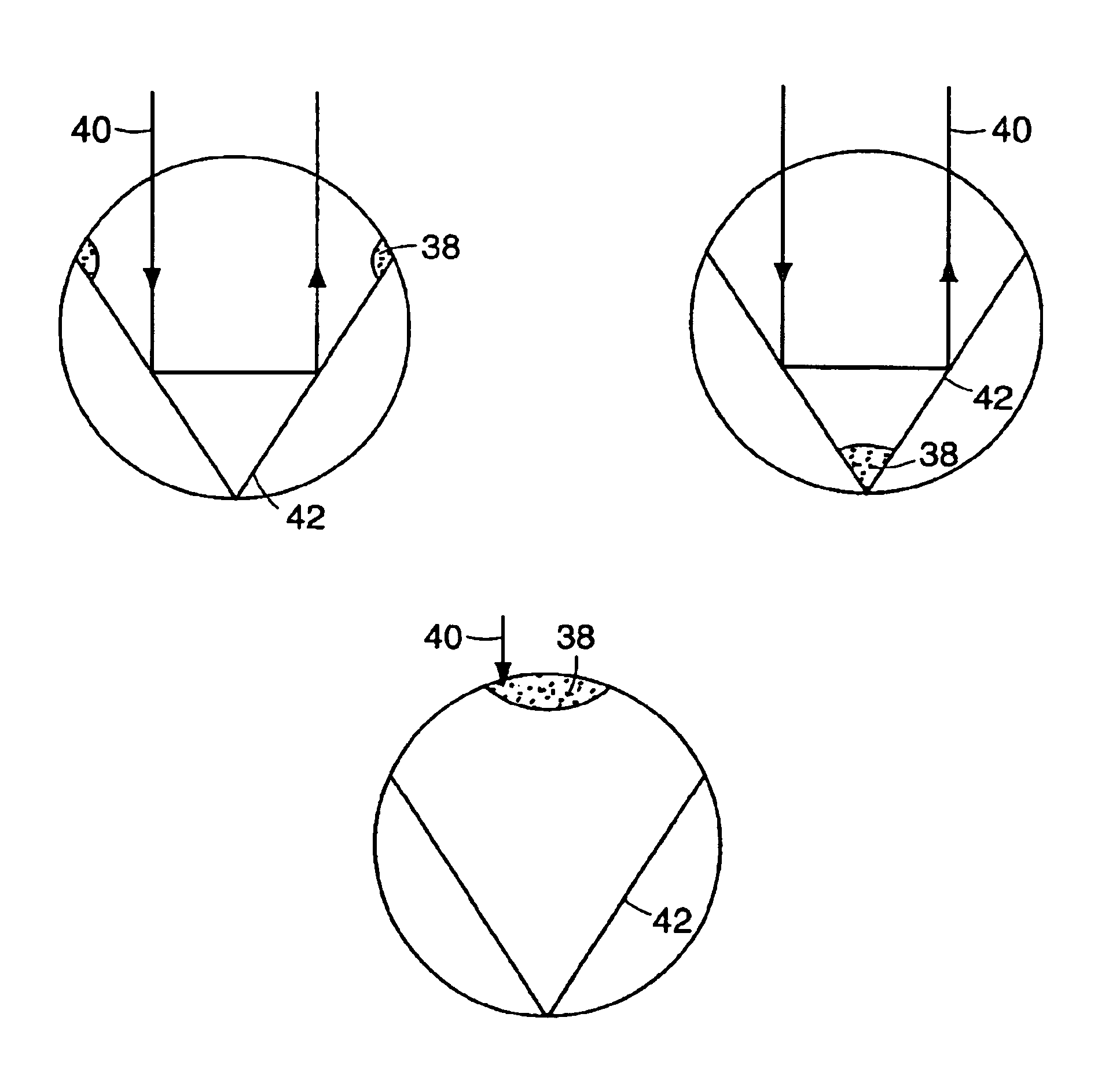

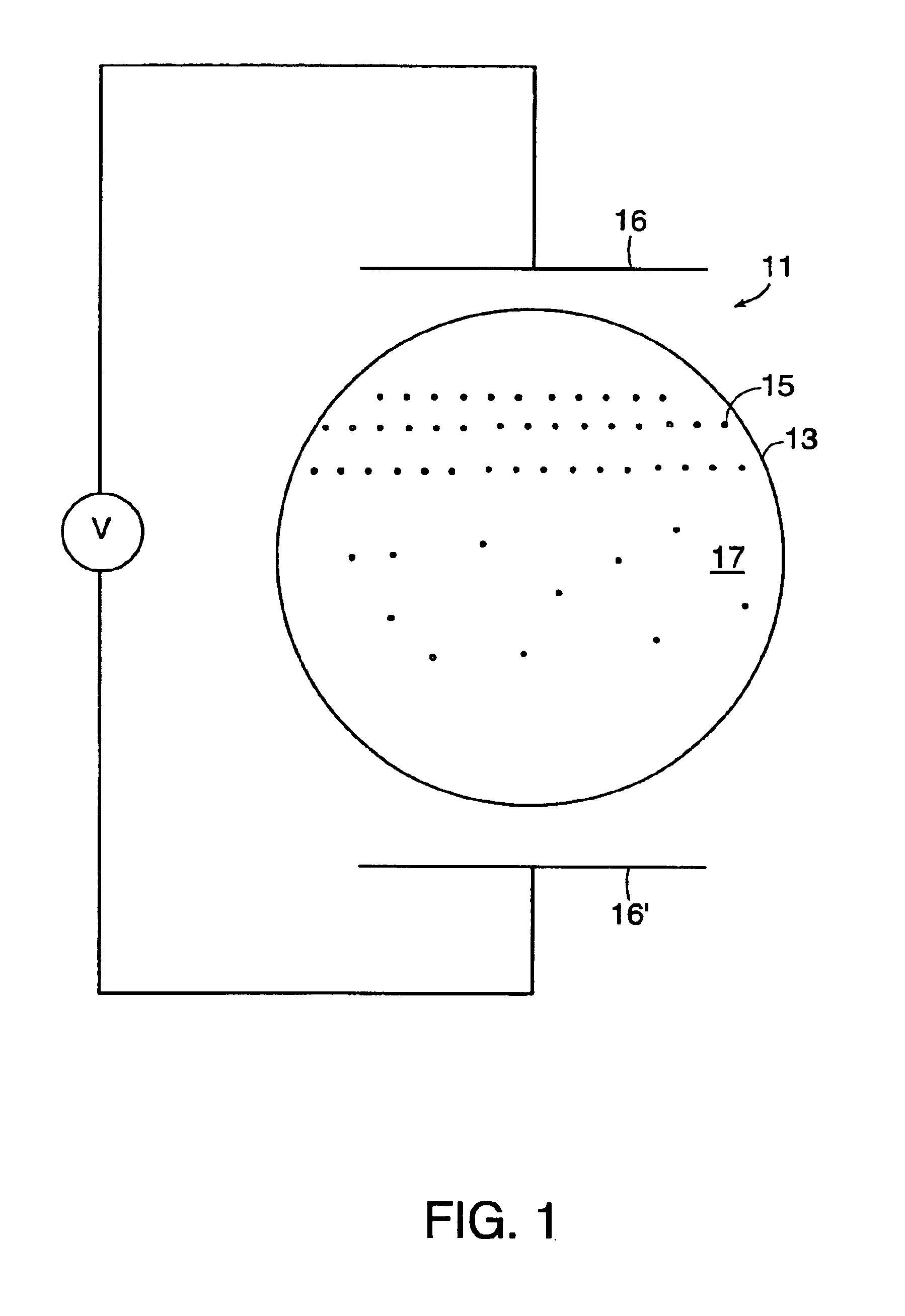

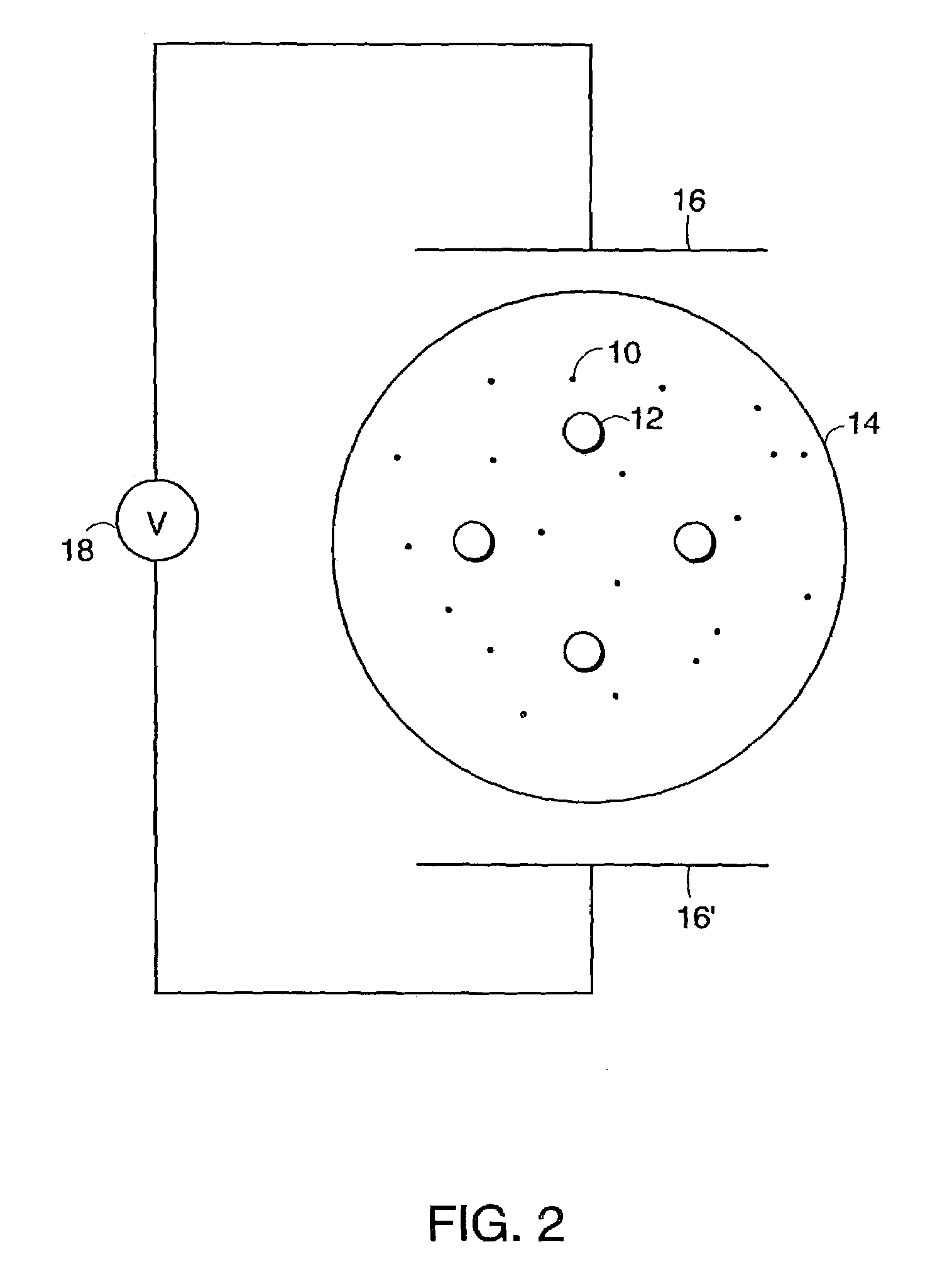

Retroreflective electrophoretic displays and materials for making the same

InactiveUS7071913B2High level controlDisorientingMechanical clocksStatic indicating devicesCelluloseOptical property

Disclosed herein are novel electrophoretic displays and materials useful in fabricating such displays. In particular, novel encapsulated displays are disclosed. Particles encapsulated therein are dispersed within a suspending, or electrophoretic, fluid. This fluid may be a mixture of two or more fluids or may be a single fluid. The displays may further comprise particles dispersed in a suspending fluid, wherein the particles contain a liquid. In either case, the suspending fluid may have a density or refractive index substantially matched to that of the particles dispersed therein. Finally, also disclosed herein are electro-osmotic displays. These displays comprise at least one capsule containing either a cellulosic or gel-like internal phase and a liquid phase, or containing two or more immiscible fluids. Application of electric fields to any of the electrophoretic displays described herein affects an optical property of the display.

Owner:E INK CORPORATION

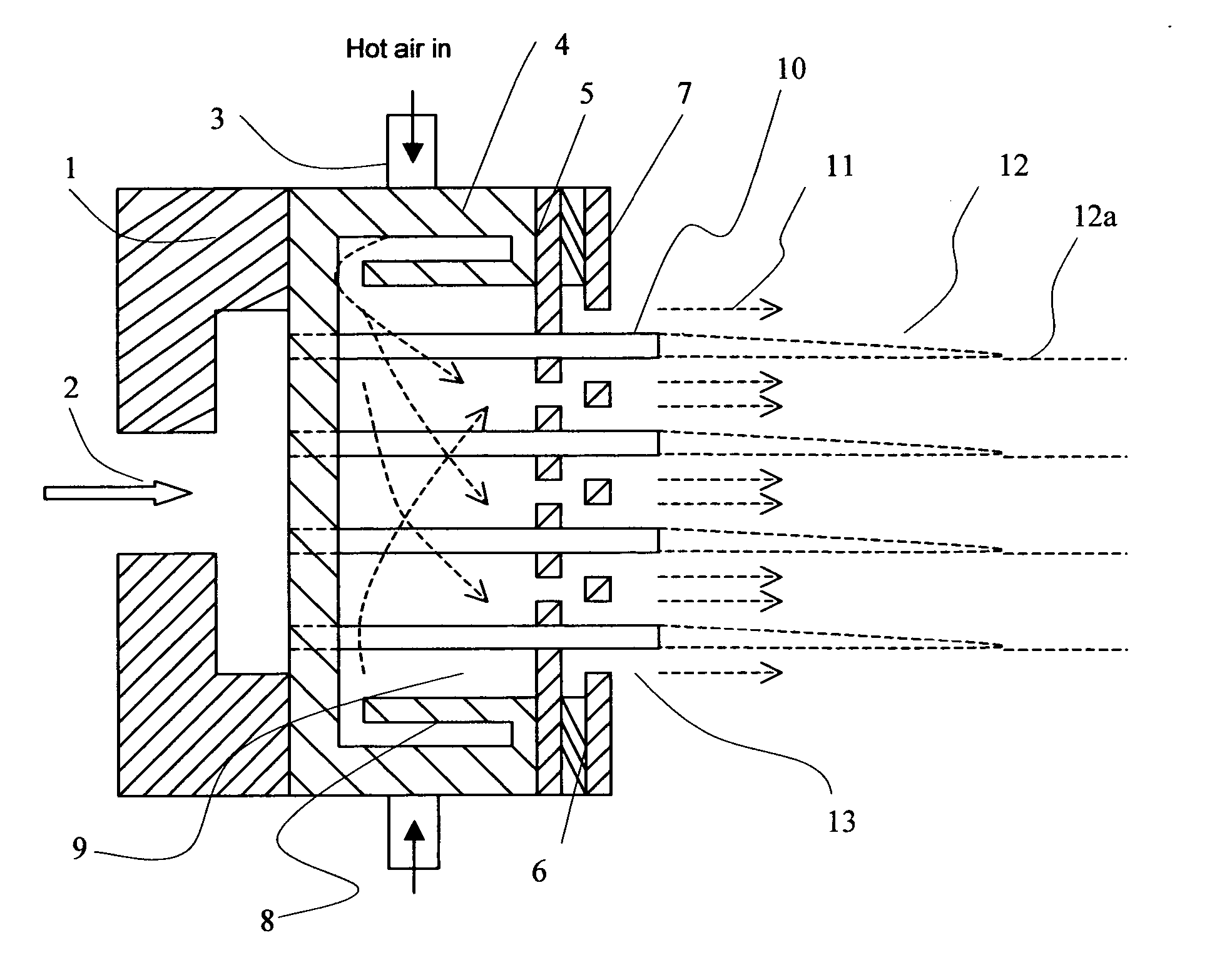

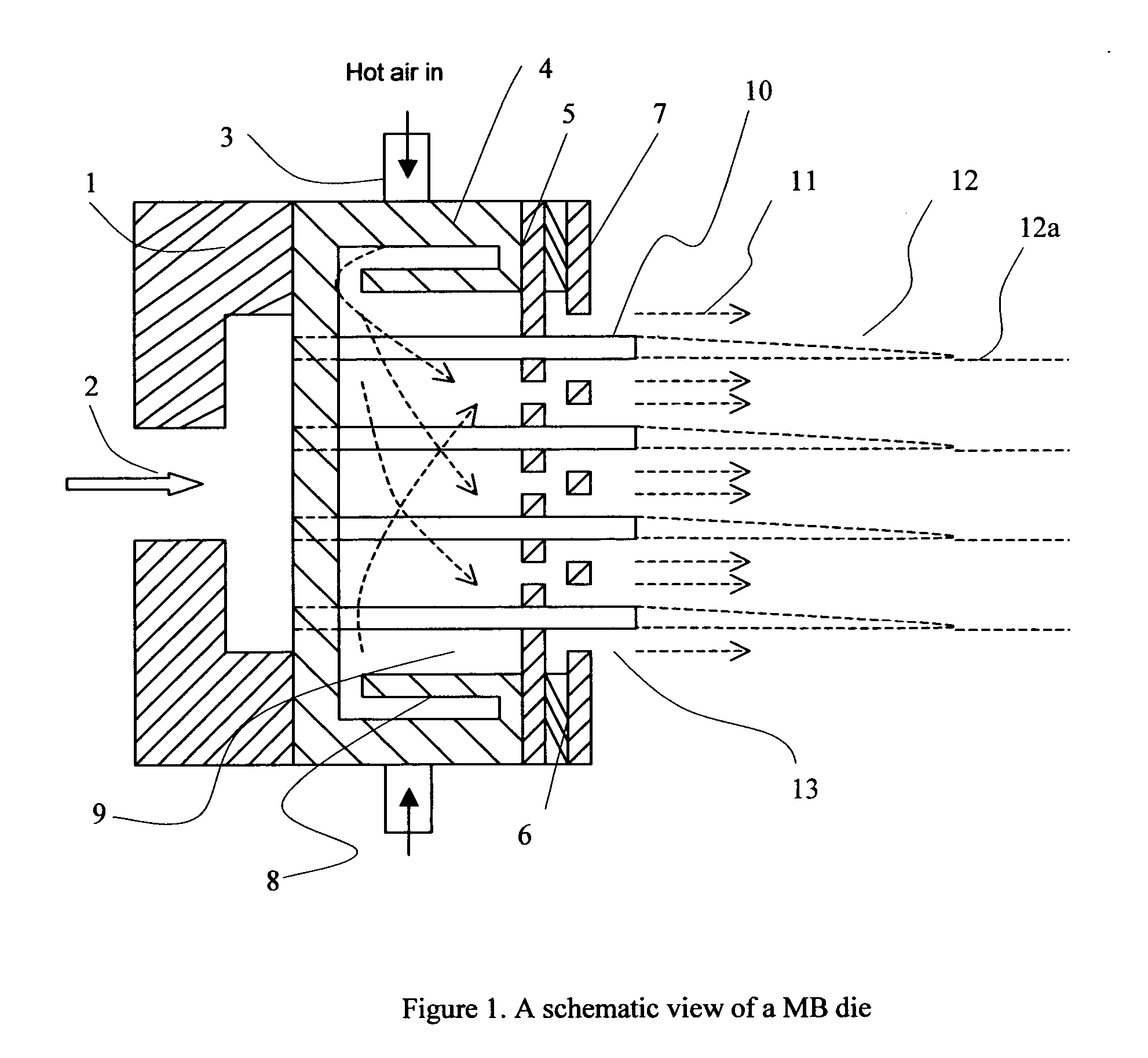

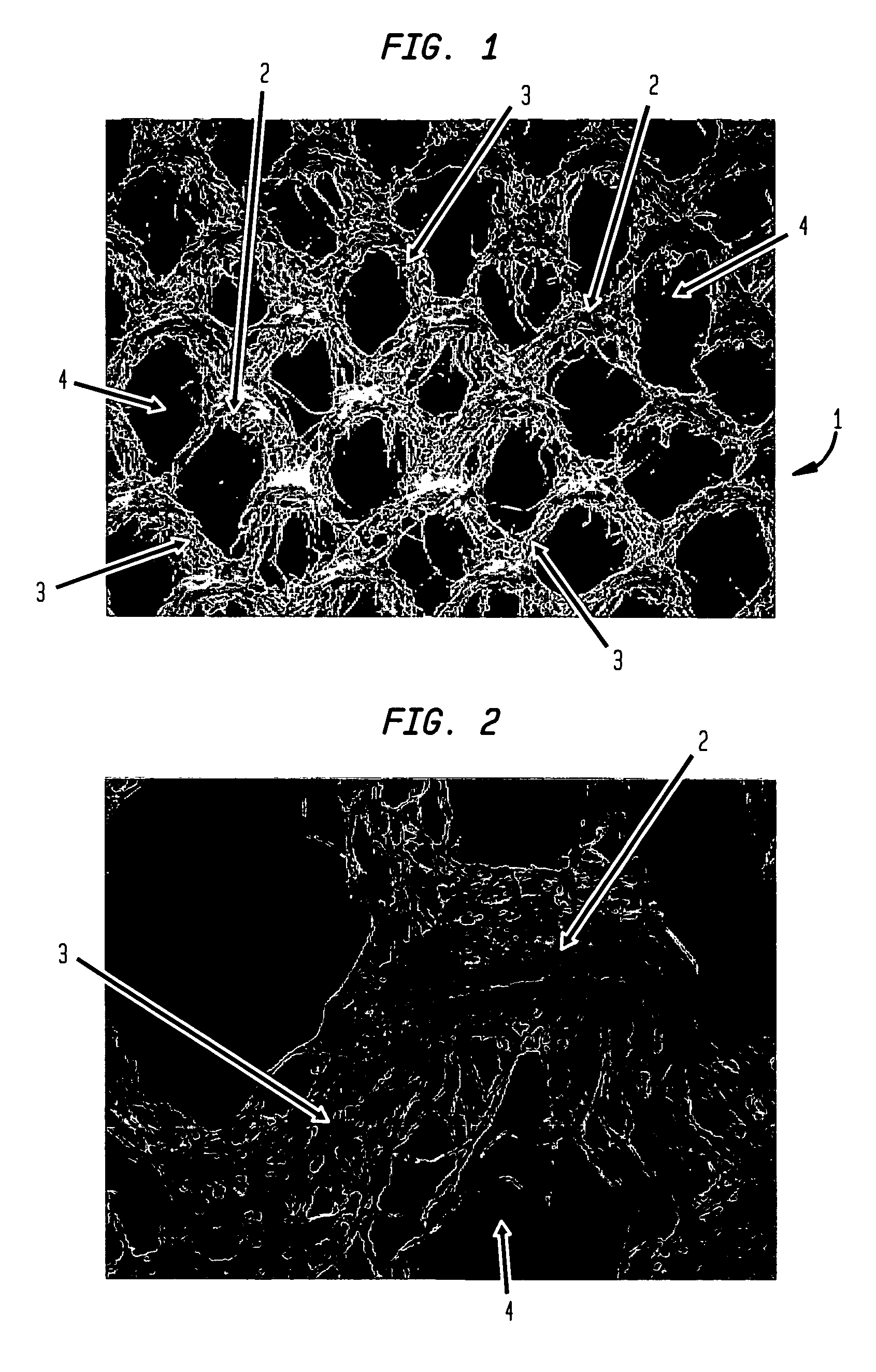

Process for forming micro-fiber cellulosic nonwoven webs from a cellulose solution by melt blown technology and the products made thereby

InactiveUS20050056956A1Artificial filament washing/dryingLoose filtering material filtersNon solventEngineering

This invention relates to a process of melt blowing a cellulose solution through a concentric melt blown die with multiple rows of spinning nozzles to form cellulosic microfiber webs with different web structures. The process comprises the steps of (a) extruding a cellulose solution (dope) through a melt blown spinneret with multiple rows of spinning nozzles; (b) drawing each individual extrudate filament to fine fiber diameter by its own air jet; (c) coagulating and entangling the fine fibers with a series of pressured hydro needling jets of recycling solution of the mixture of cellulose solvent and non-solvent in the spin-line; (d) collecting the stream of microfibers, air and needling jets on a moving collecting surface to form cellulosic fiber web; (e) hydro-entangling the said pre-bonded web downstream with at least one set of hydro needling jets of recycling solvent / non-solvent solution for forming well bonded nonwoven web; (f) regenerating the fine fibers in at least one bath for at least 5 seconds; (g) further regenerating and washing the fine fibers in another bath for at least 5 seconds; (h) pinching the well bonded melt blown cellulosic nonwoven with pressure rollers to remove major portions of the non-solvent; (i) drying the nonwoven web by heat, or vacuum or both, and (j) winding the nonwoven web into rolls.

Owner:BIAX FIBERFILM CORP

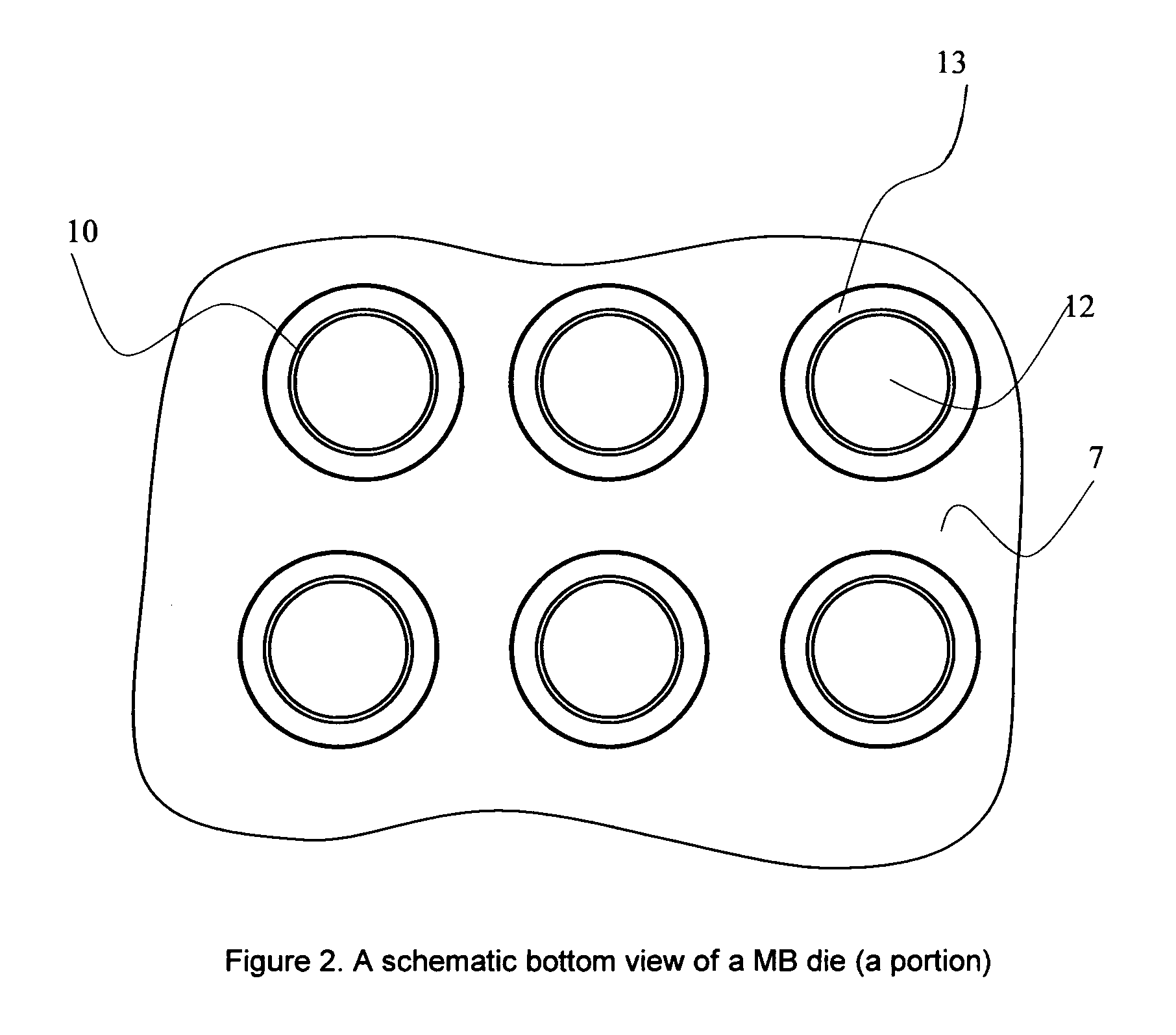

Use of Cellulosic Materials for Cultivation of Microorganisms

Owner:CORBION BIOTECH INC

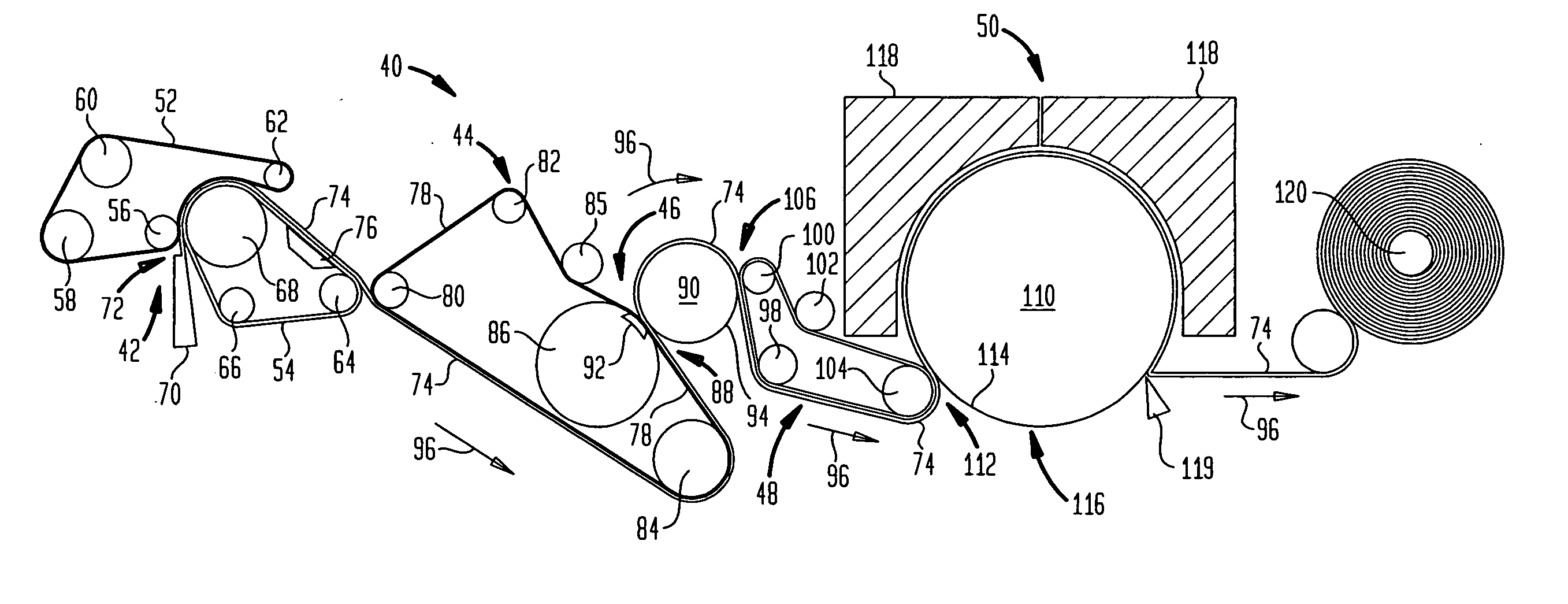

Fabric crepe/draw process for producing absorbent sheet

ActiveUS20050217814A1Increase in sizeDecrease sidednessMechanical working/deformationPaper coatingFiberPapermaking

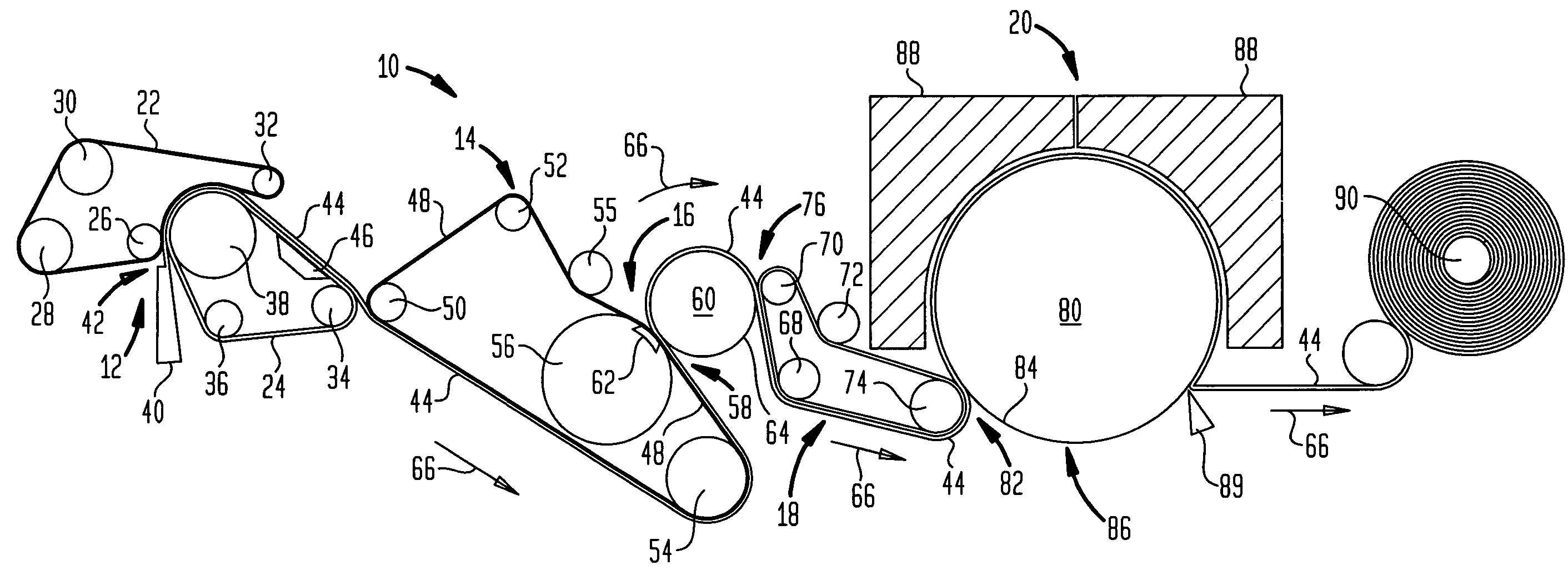

A method of making a fabric-creped absorbent cellulosic sheet comprising: a) compactively dewatering a papermaking furnish to form a nascent web having an apparently random distribution of papermaking fiber; b) applying the dewatered web having the apparently random fiber distribution to a translating transfer surface moving at a first speed; c) fabric-creping the web from the transfer surface at a consistency of from about 30 to about 60 percent utilizing a patterned creping fabric, the creping step occurring under pressure in a fabric creping nip defined between the transfer surface and the creping fabric wherein the fabric is traveling at a second speed slower than the speed of said transfer surface, the fabric pattern, nip parameters, velocity delta and web consistency being selected such that the web is creped from the transfer surface and redistributed on the creping fabric to form a web with a drawable reticulum.

Owner:GPCP IP HLDG LLC

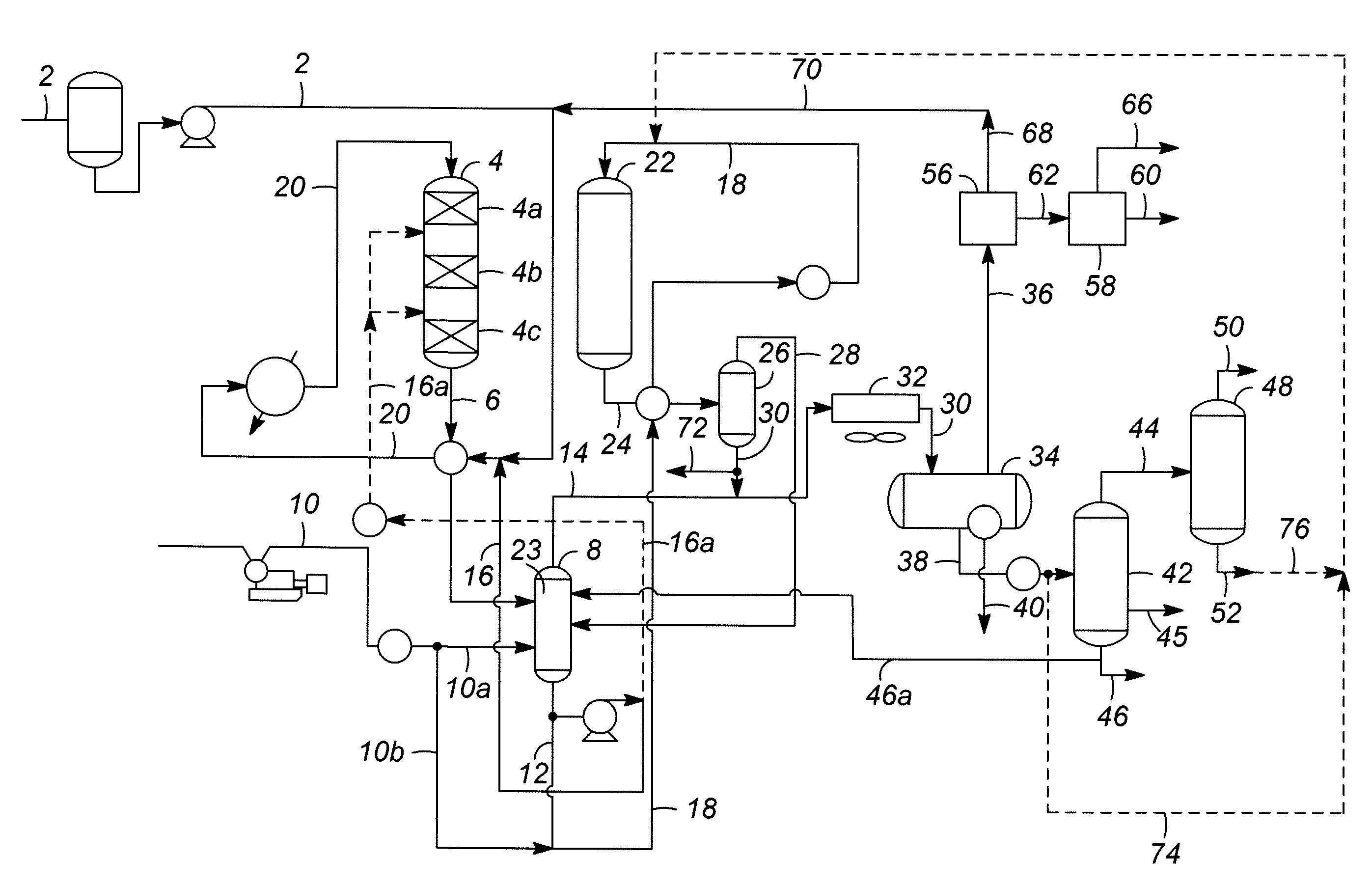

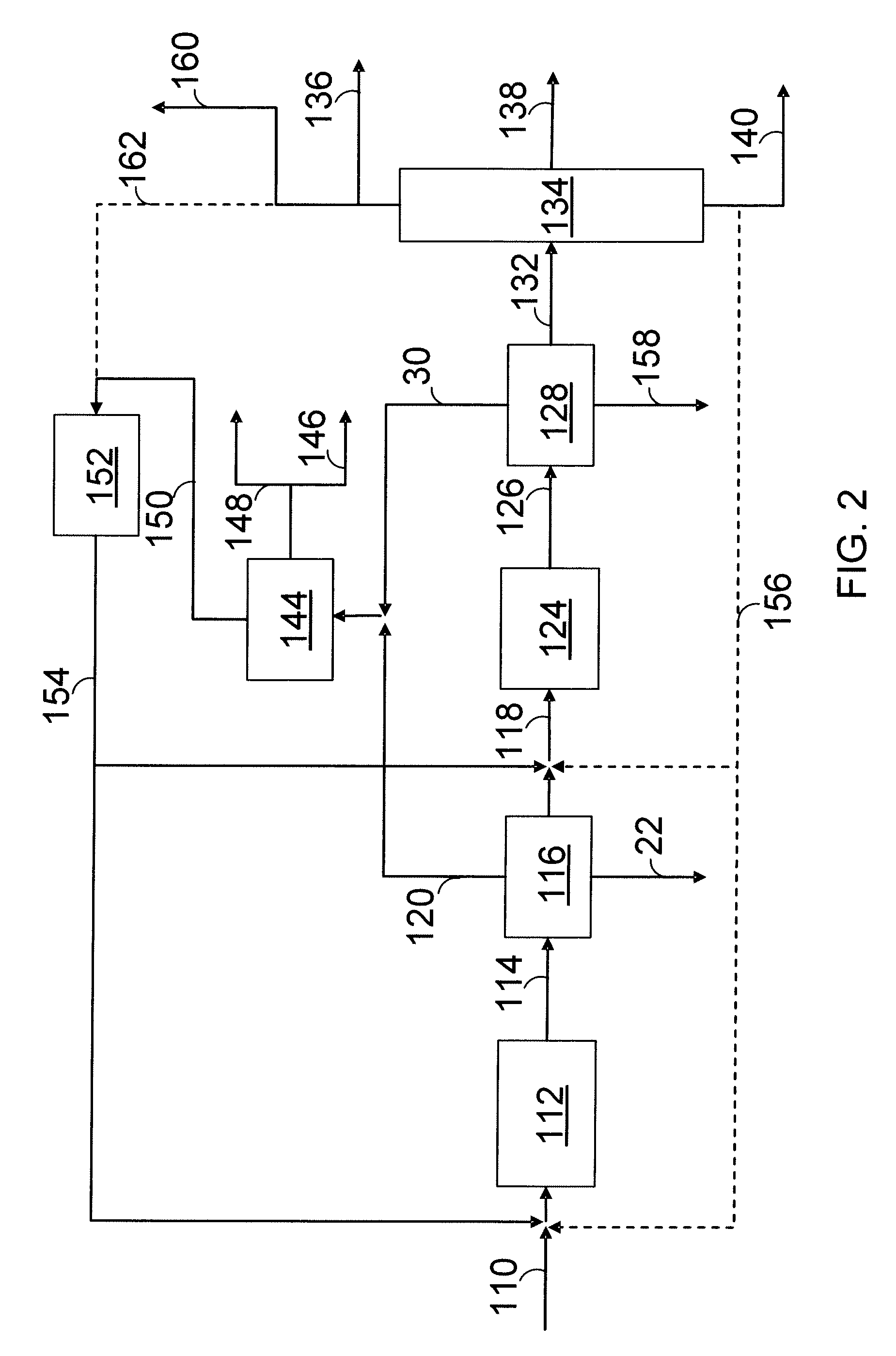

Production of Blended Fuel from Renewable Feedstocks

A process for producing a blended fuel from a paraffin rich component and a cyclic rich component, where each of the components are generated from a renewable feedstock, is presented. The paraffin rich component is generated from a first renewable feedstock comprising at least one component selected from the group consisting of glycerides, free fatty acids, biomass, lignocellulose, free sugars, and combinations thereof. The cyclic rich component is generated from a second renewable feedstock comprising at least one component selected from the group consisting of glycerides, free fatty acids, free fatty alkyl esters, biomass, lignocellulose, free sugars, and combinations thereof. The blended fuel may a gasoline boiling point range blended fuel, a diesel boiling point range blended fuel, an aviation boiling point range blended fuel, any combination thereof, or any mixture thereof.

Owner:UOP LLC

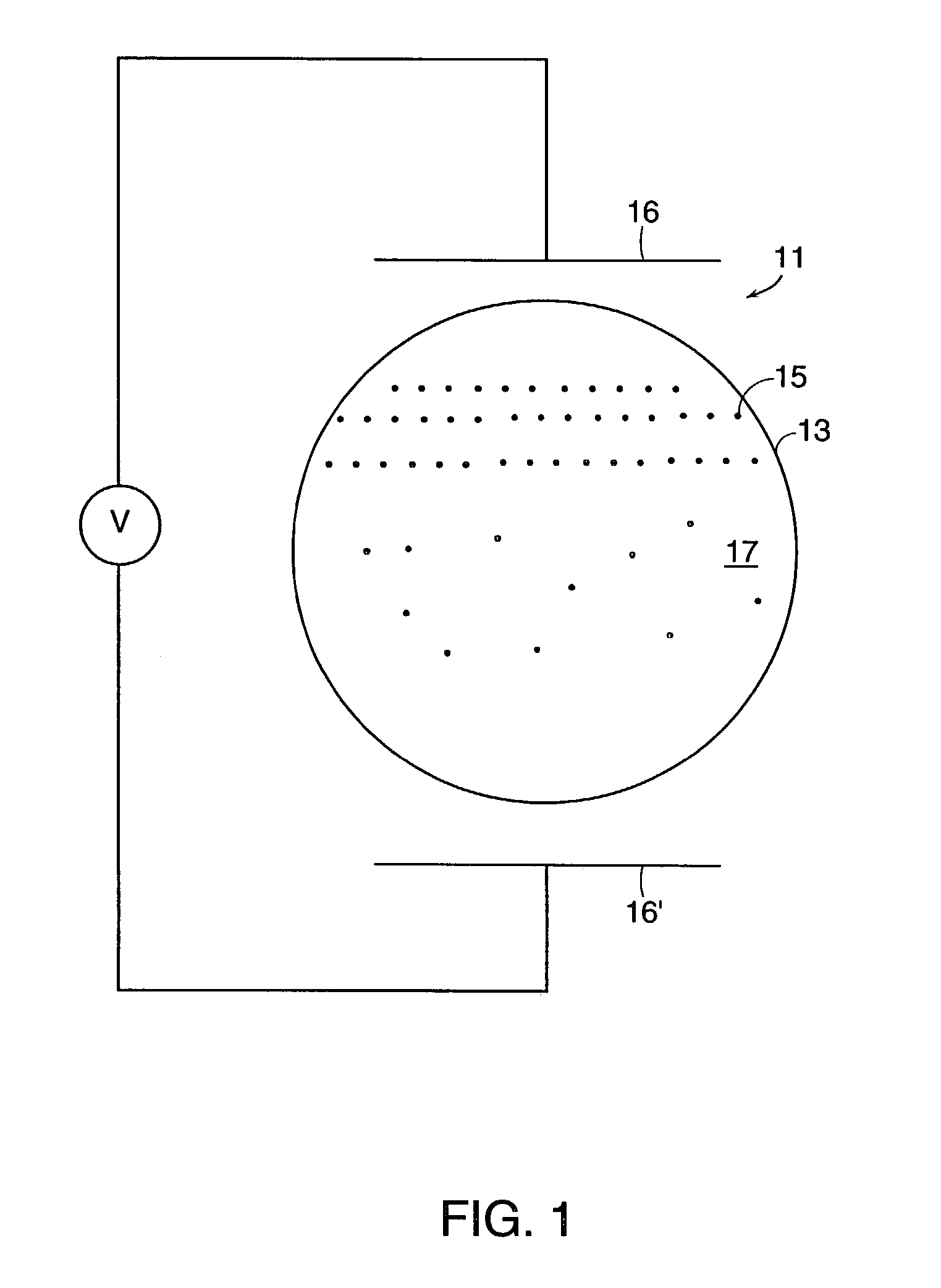

Non-spherical cavity electrophoretic displays and methods and materials for making the same

InactiveUS7109968B2High level controlEasy to chargeStatic indicating devicesNanoinformaticsCelluloseOptical property

Disclosed herein are novel electrophoretic displays and materials useful in fabricating such displays. In particular, novel encapsulated displays are disclosed. Particles encapsulated therein are dispersed within a suspending, or electrophoretic, fluid. This fluid may be a mixture of two or more fluids or may be a single fluid. The displays may further comprise particles dispersed in a suspending fluid, wherein the particles contain a liquid. In either case, the suspending fluid may have a density or refractive index substantially matched to that of the particles dispersed therein. Finally, also disclosed herein are electro-osmotic displays. These displays comprise at least one capsule containing either a cellulosic or gel-like internal phase and a liquid phase, or containing two or more immiscible fluids. Application of electric fields to any of the electrophoretic displays described herein affects an optical property of the display.

Owner:E INK CORPORATION

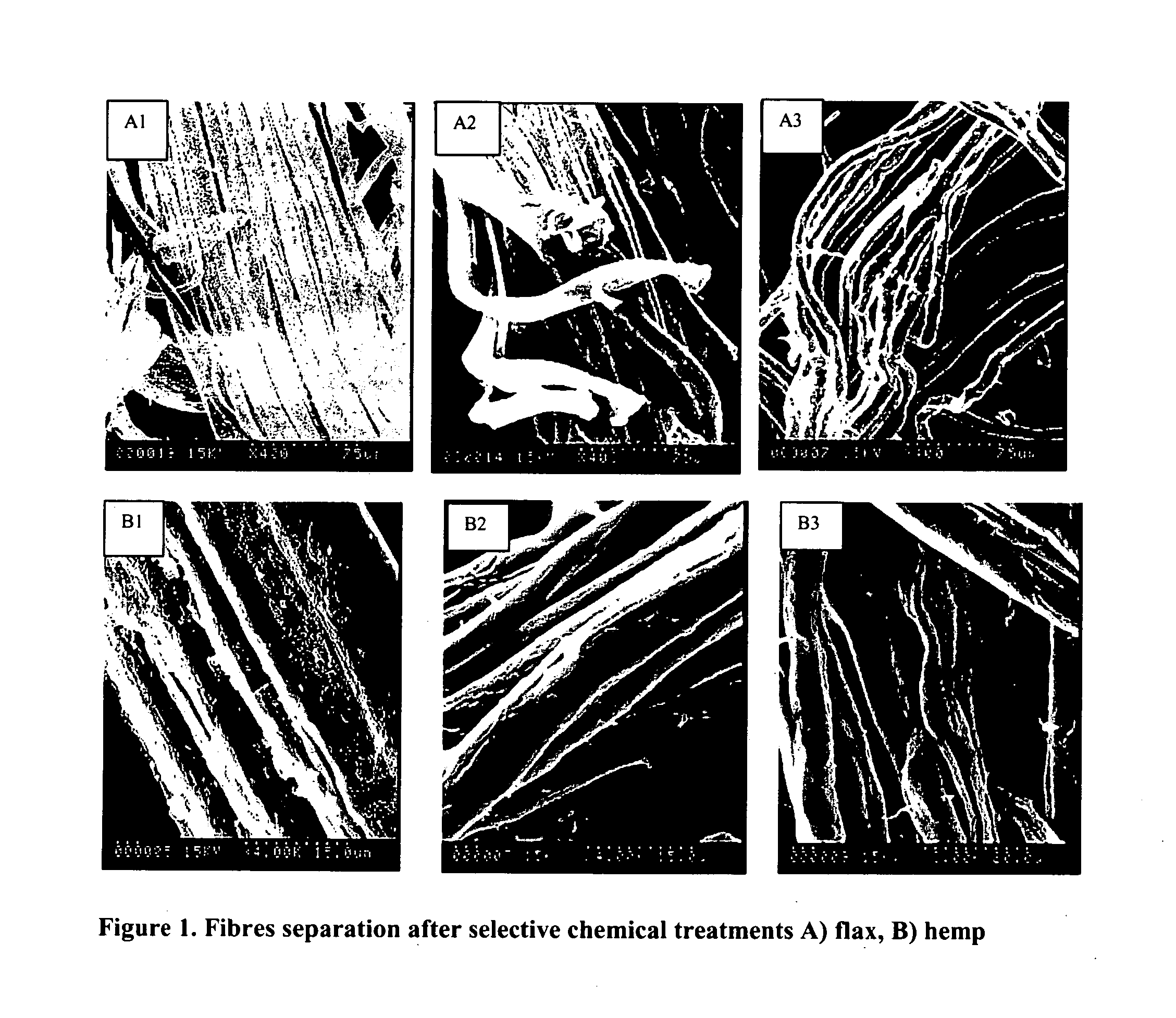

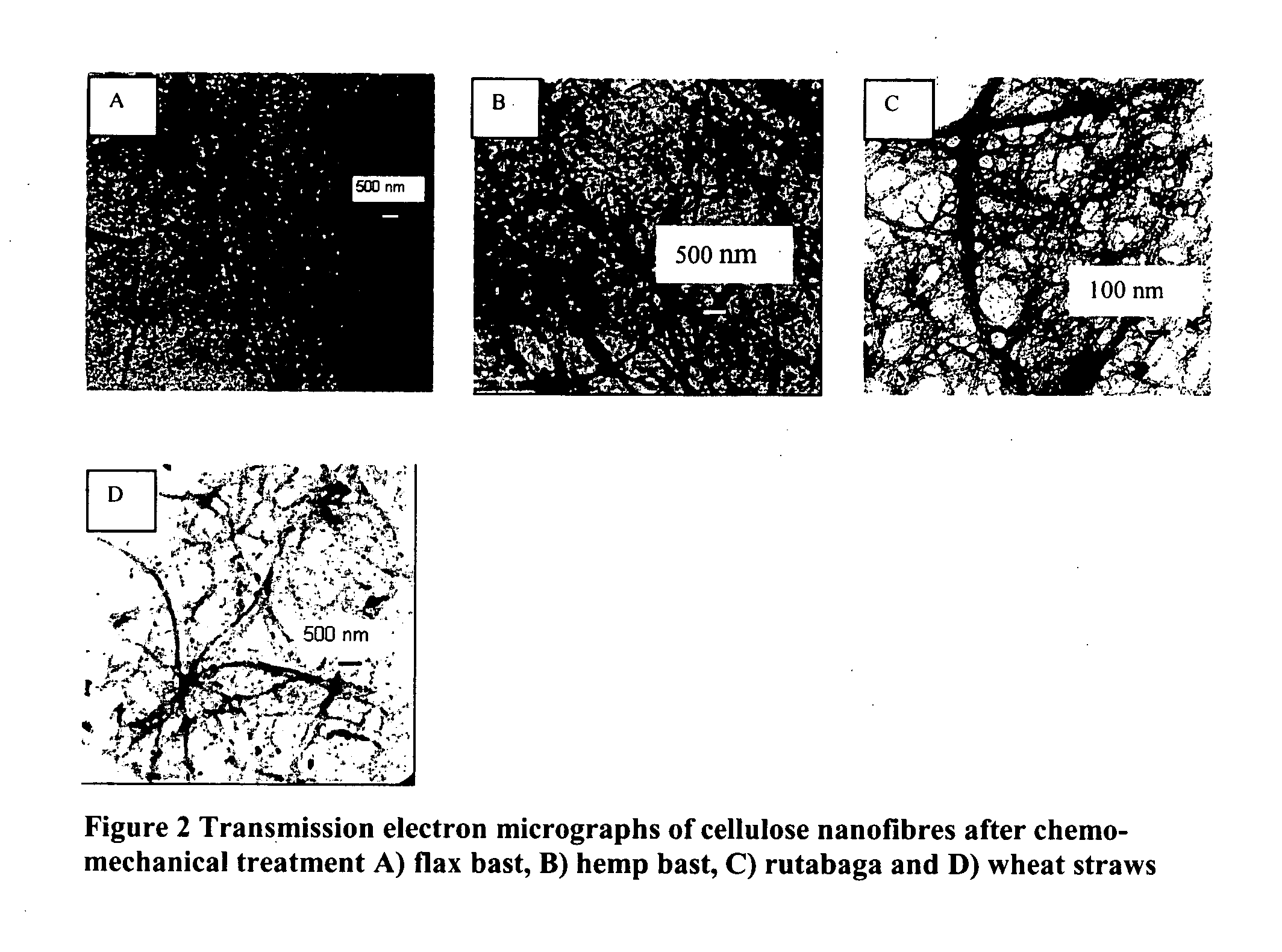

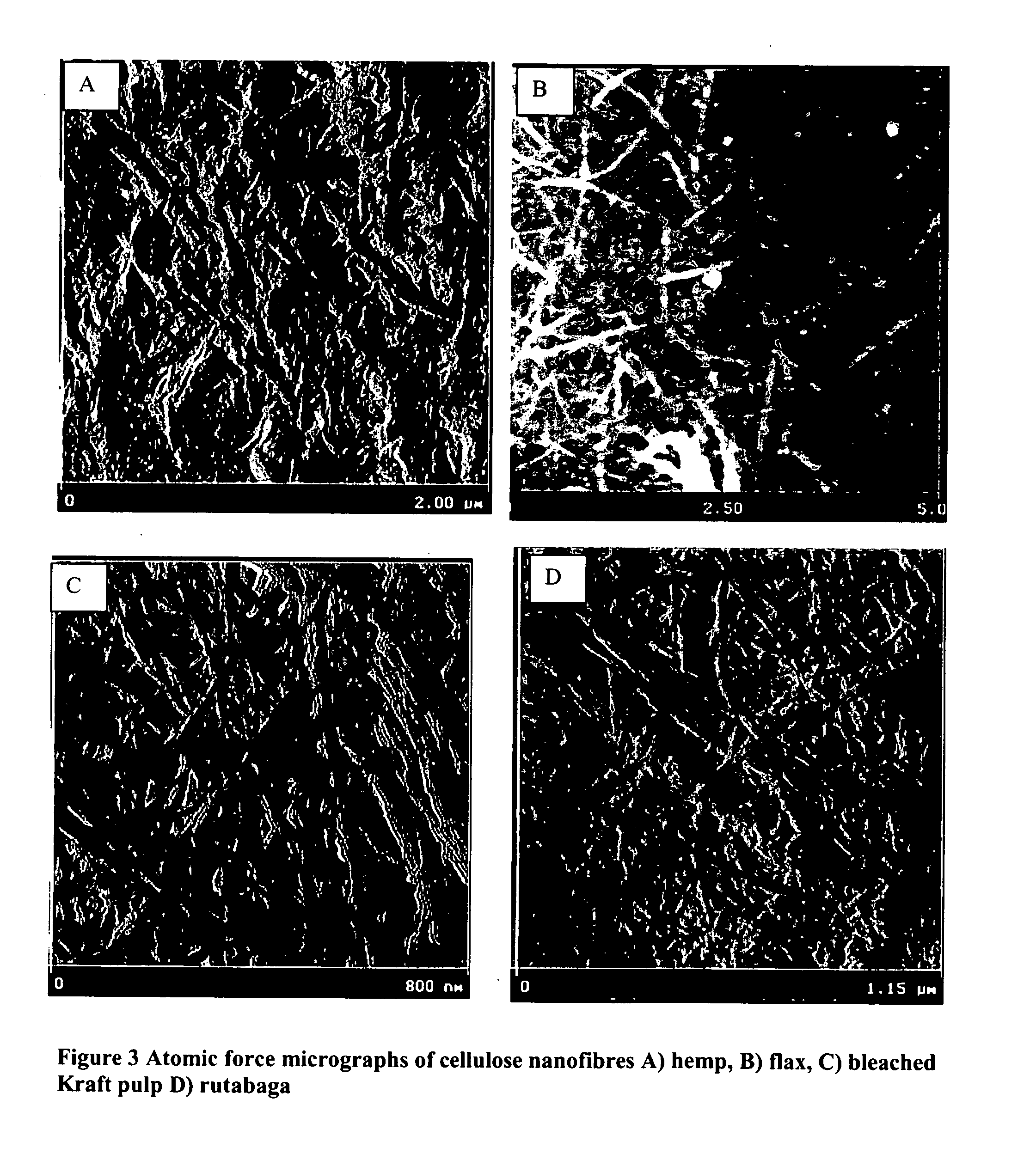

Manufacturing process of cellulose nanofibers from renewable feed stocks

InactiveUS20080146701A1High aspect ratioRaise the potentialMaterial nanotechnologyFats/resins/pitch/waxes removal in pulpCelluloseNatural fiber

Cellulose nanofibers have been processed from renewable feedstock in particularly from natural fibers, root crops and agro fibers, wherein the pulp was hydrolysed at a moderate temperature of 50 to 90 degree C., one extraction was performed using dilute acid and one extraction using alkali of concentration less than 10%; and residue was cryocrushed using liquid nitrogen, followed by individualization of the cellulose nanofibers using mechanical shear force. The nanofibers manufactured with this technique have diameters in the range of 20-60 nm and much higher aspect ratios than long fibers. Due to its lightweight and high strength its potential applications will be in aerospace industry and due to their biodegradable potential with tremendous stiffness and strength, they find application in the medical field such as blood bags, cardiac devices, valves as a reinforcing biomaterial.

Owner:SAIN MOHINI M +1

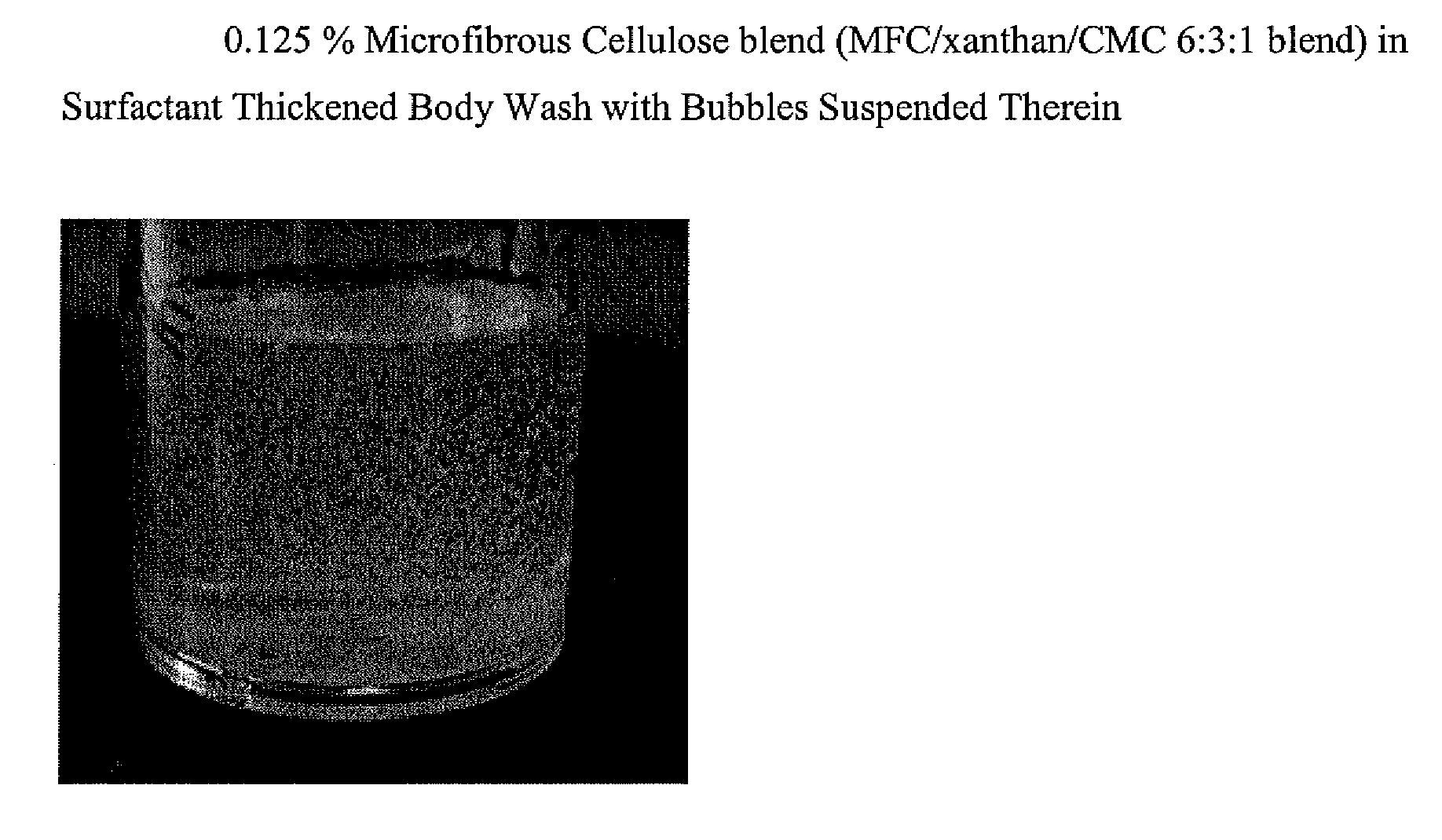

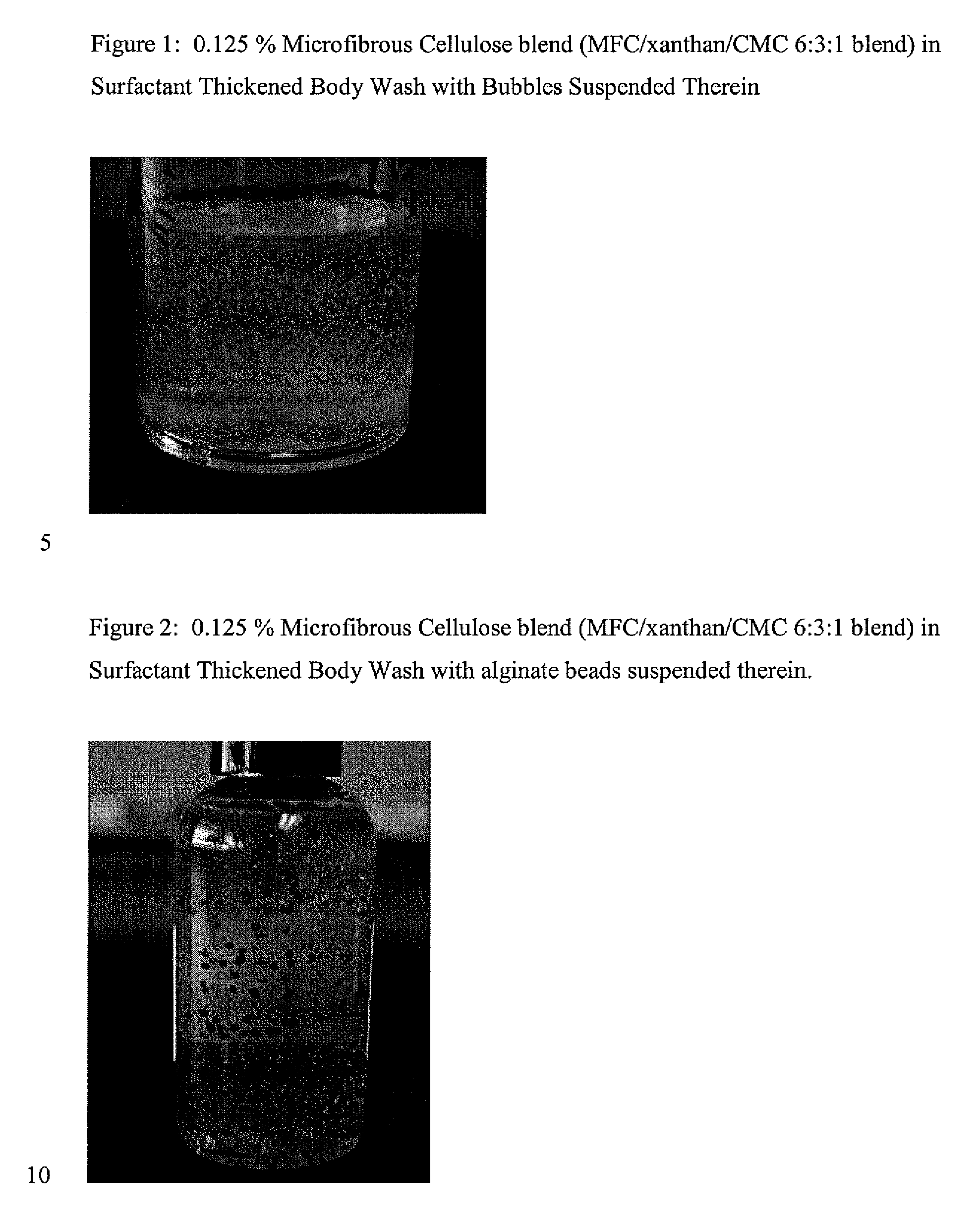

Surfactant Thickened Systems Comprising Microfibrous Cellulose and Methods of Making Same

Surfactant systems, using microfibrous cellulose to suspend particulates therein, are described. Methods of making these systems are also described.

Owner:CP KELCO U S INC

Fabric crepe/draw process for producing absorbent sheet

ActiveUS7789995B2Increase in sizeDecrease sidednessMechanical working/deformationPaper coatingCelluloseFiber

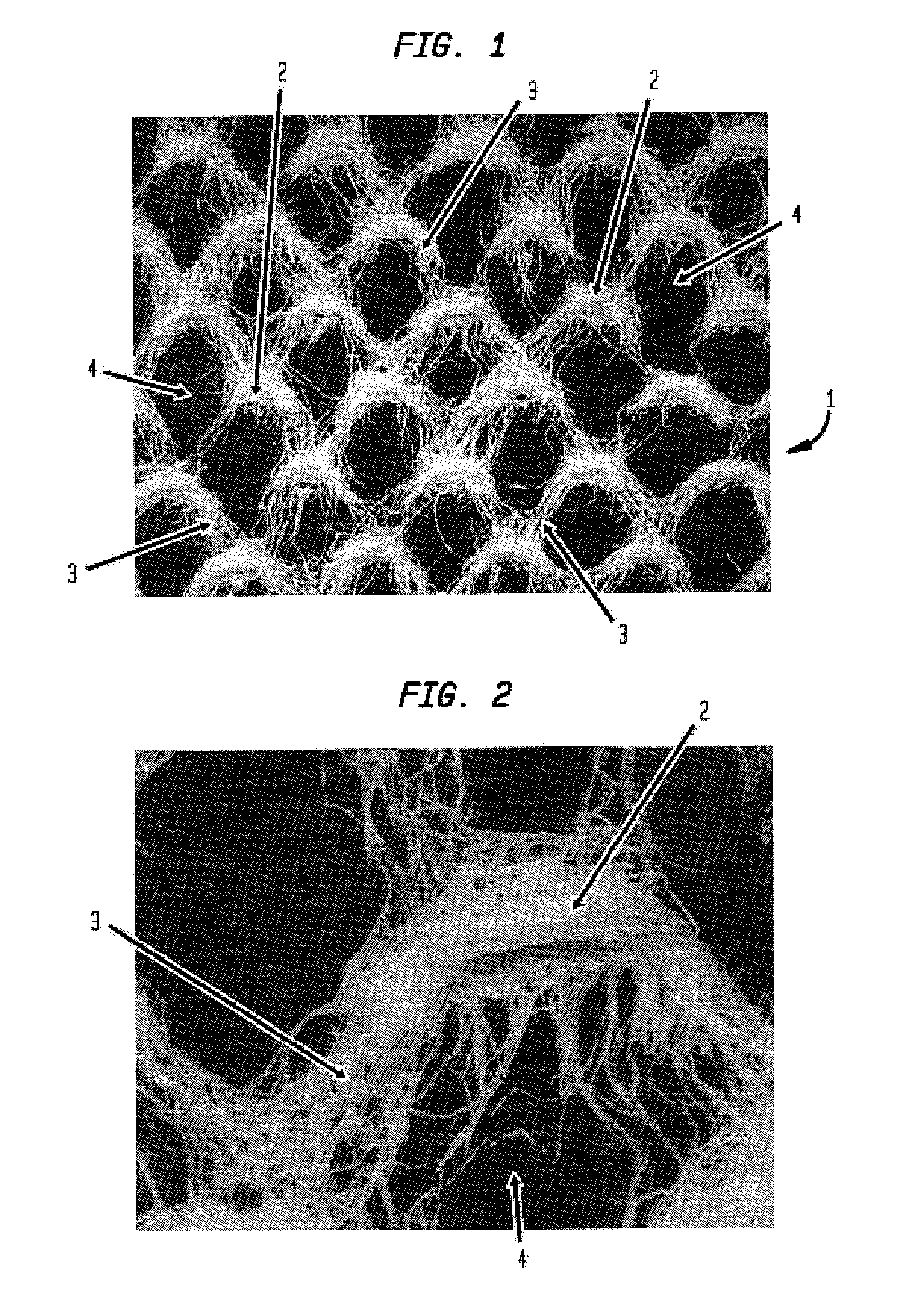

A method of making a fabric-creped absorbent cellulosic sheet comprising: a) compactively dewatering a papermaking furnish to form a nascent web having an apparently random distribution of papermaking fiber; b) applying the dewatered web having the apparently random fiber distribution to a translating transfer surface moving at a first speed; c) fabric-creping the web from the transfer surface at a consistency of from about 30 to about 60 percent utilizing a patterned creping fabric, the creping step occurring under pressure in a fabric creping nip defined between the transfer surface and the creping fabric wherein the fabric is traveling at a second speed slower than the speed of said transfer surface, the fabric pattern, nip parameters, velocity delta and web consistency being selected such that the web is creped from the transfer surface and redistributed on the creping fabric to form a web with a drawable reticulum.

Owner:GPCP IP HLDG LLC

Masonry cement having higher strength and water retention

InactiveCN101182139AHigh strengthSolve the difficult problem of preparing high-strength grade building mortarSolid waste managementCelluloseLower grade

The invention discloses a masonry cement with high strength and water retention. According to the weight percentage, the masonry cement consists of 21-98.99 percent of porland cement clinker, 0-50 percent of blending materials, 1-12 percent of gypsum, 0.01-2 percent of cellulose ether and 0-15 percent of other additives. With the cellulose ether of high water retention material added, the water retention of the masonry cement is greatly improved. At the same time, through breaking through the limitation that the using amount of the blending materials in the original masonry cement is not less than 50 percent, the using amount of the blending materials is lowered to be 50 percent below to improve the strength of novel masonry cement. The strength of the prepared masonry cement is high, and the masonry cement with the strength grades of 12.5, 22.5, 52.5R, 62.5, 62.5R, etc. can be made. The hard problems of using low-grade blending materials to produce masonry cement with high water retention and using low- grade strength masonry cement of 12.5 and 22.5 to produce high-grade strength building mortar are solved.

Owner:SOUTH CHINA UNIV OF TECH

Electronic vaporizing device and methods for use

Devices and methods for vaporizing active ingredients of a selected substance for inhalation using a portable vaporization device are provided herein. In certain aspects, the device includes a portable power source, a heating portion, an inhalation sensor, a temperature sensor, a distal light source, and a grinding portion. In response to an inhalation by a user, the power source energizes a heating element of the heating portion so as to heat air flow to a desired vaporization temperature within a few seconds of detecting inhalation, using convection and radiative heating. The device may include a receptacle for receiving a cartridge containing a pre-prepared substance, such as a liquid, gel, powder, or solid brick, and a grinding portion to allow a user to grind intact portions of cellulose-based material into smaller pieces to facilitate vaporization by manually rotating portions of the device relative to each other.

Owner:UPTOKE LLC

Disposable Absorbent Article With Absorbent Particulate Polymer Material Distributed For Improved Isolation Of Body Exudates

A disposable absorbent article is provided having an absorbent core located in a chassis and including absorbent particulate polymer material defining at least one cavity for improved isolation of fecal matter or other body exudates. The absorbent core may be substantially cellulose free. Methods for making such an absorbent core and corresponding disposable absorbent article are also disclosed.

Owner:THE PROCTER & GAMBLE COMPANY

Premixing mortar with high moisture retention and production method thereof

The invention discloses pre-stirring mortar with high moisture retention and a production method thereof. The premixing mortar comprises the following components by weight ratio: 100 parts of cement with the high moisture retention, 1 to 900 parts of fine aggregate and 30 to 200 parts of water, wherein the cement with the high moisture retention contains a cellulose ether component and has the moisture retention above 90 percent; and the fine aggregate is natural sand or artificial sand obtain through screen sizing or removing harmful components, and has the maximum grain diameter of 1.18 mm to 2.36 mm. The production method comprises the following steps: arranging a mortar stirring machine on a construction site or nearby; adopting the cement with the high moisture retention and the fine aggregate to automatically meter and stir, enable mortar to be usable while stirring, and the like to ensure the mortar quality; and adopting a closed stirring mode, a dust-collecting mode and the like to reduce dust raise. The pre-stirring mortar can effectively improve and ensure the qualities of the mortar buildings, obviously improves the construction environment, greatly decreases the production cost of the pre-stirring mortar and solves the difficult problems that the prior pre-stirring mortar has over-high cost and are difficult to popularize and apply.

Owner:SOUTH CHINA UNIV OF TECH

Multi-ply paper towel with absorbent core

ActiveUS7662257B2VariationImprove performanceNon-fibrous pulp additionNatural cellulose pulp/paperCellulosePaper towel

A multi-ply absorbent sheet of cellulosic fiber with continuous outer surfaces is provided an absorbent core between the outer surfaces. The absorbent core includes a non-woven fiber network having: (i) a plurality of pileated fiber enriched of relatively high local basis weight interconnected by way of (ii) a plurality of lower local basis weight linking whose fiber orientation is biased along the direction between pileated interconnected thereby, and (iii) a plurality of fiber-deprived cellules between the fiber enriched and linking regions, also being characterized by a local basis weight lower than the fiber enriched regions. The cellules provide a sponge-like internal structure of low fiber density regions.

Owner:GPCP IP HLDG LLC

Inorganic salt recovery during processing of lignocellulosic feedstocks

InactiveUS20080102502A1Reduce inhibitionOvercome disadvantagesBiofuelsFermentationInorganic saltsCellulose

A method for recovering inorganic salt during processing of a lignocellulosic feedstock is provided. The method comprises pretreating the lignocellulosic feedstock by adding an acid or a base to the feedstock to produce a pretreated lignocellulosic feedstock. A soluble base or acid is then added to the pretreated lignocellulosic feedstock to adjust the pH and produce a neutralized feedstock. The neutralized feedstock is then hydrolyzed to produce an hydrolyzed feedstock and a sugar stream. Inorganic salt is recovered from a wash stream obtained from the pretreated lignocellulosic feedstock, a stream obtained from the neutralized feedstock, a stream obtained from the sugar stream, or a combination of these streams. The inorganic salt may be concentrated, clarified, recovered and purified by crystallization, electrodialysis, drying, or agglomeration and granulation, and then used as desired, for example, as a fertilizer.

Owner:IOGEN ENERGY CORP

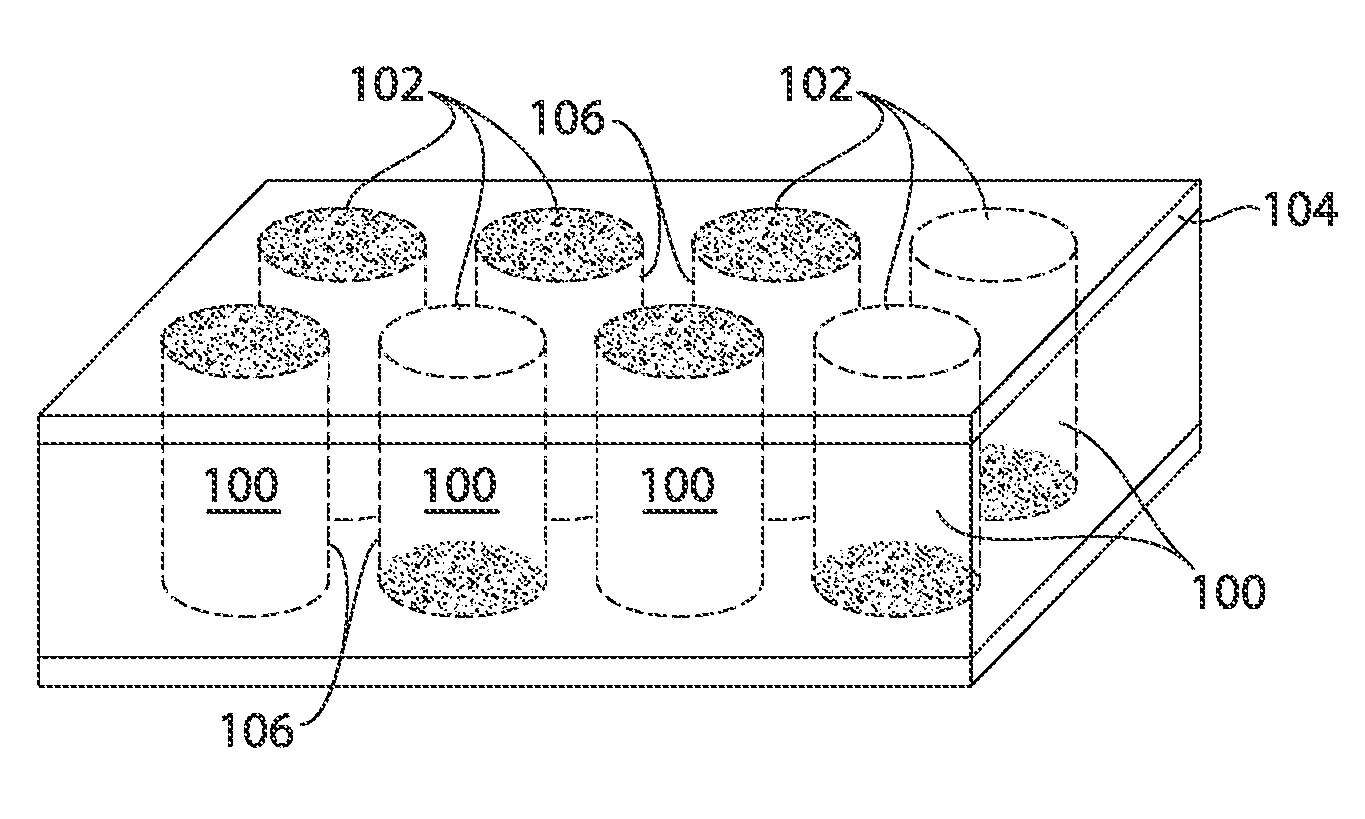

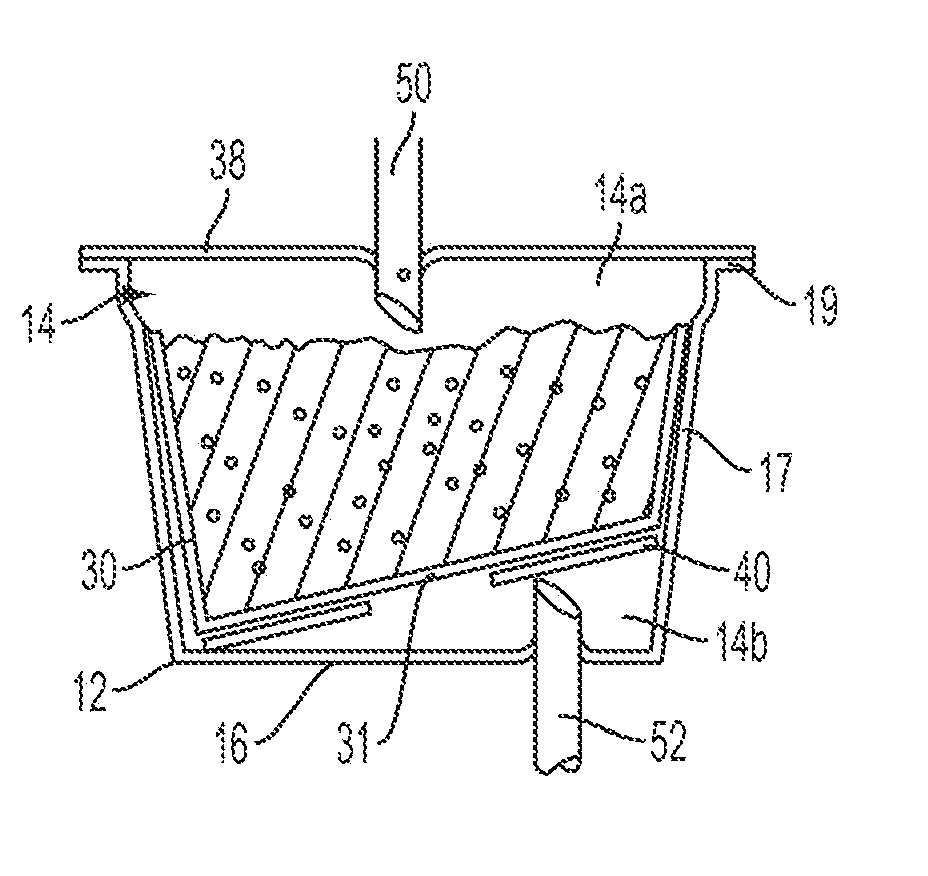

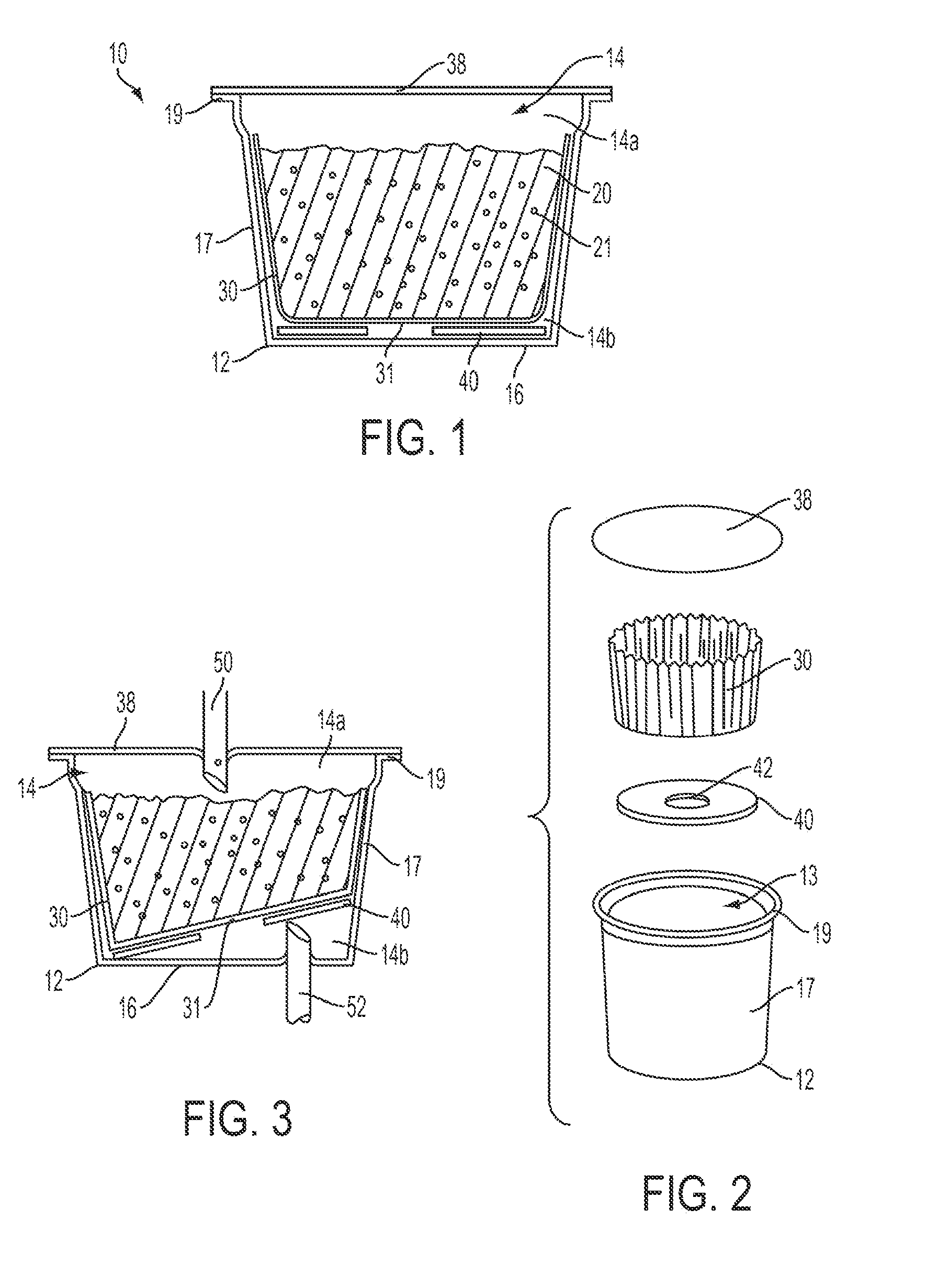

Beverage cartridge and method for beverage formation using filter aid

InactiveUS20110076361A1Speed up circulationReduce cloggingTea extractionBeverage vesselsParticulatesCellulose

A method and apparatus for forming a beverage involves the use of a filter aid, e.g., that is provided in a beverage cartridge with a beverage medium in a dry state. In one embodiment, a cartridge including a dried fruit material may also include a filter aid, such as perlite, diatomaceous earth or cellulose, that is mixed together with the fruit material. The filter aid may assist in flow through the beverage medium or through a filter, e.g., by helping prevent the clogging of pores of a filter used to remove particulate from a beverage formed by interaction of the beverage medium with water introduced into the cartridge. Thus, the filter aid may permit the use of some beverage media that would otherwise clog a filter and / or prevent proper dissolution of materials in the beverage media without the filter aid.

Owner:GREEN MOUNTAIN COFFEE ROASTERS INC

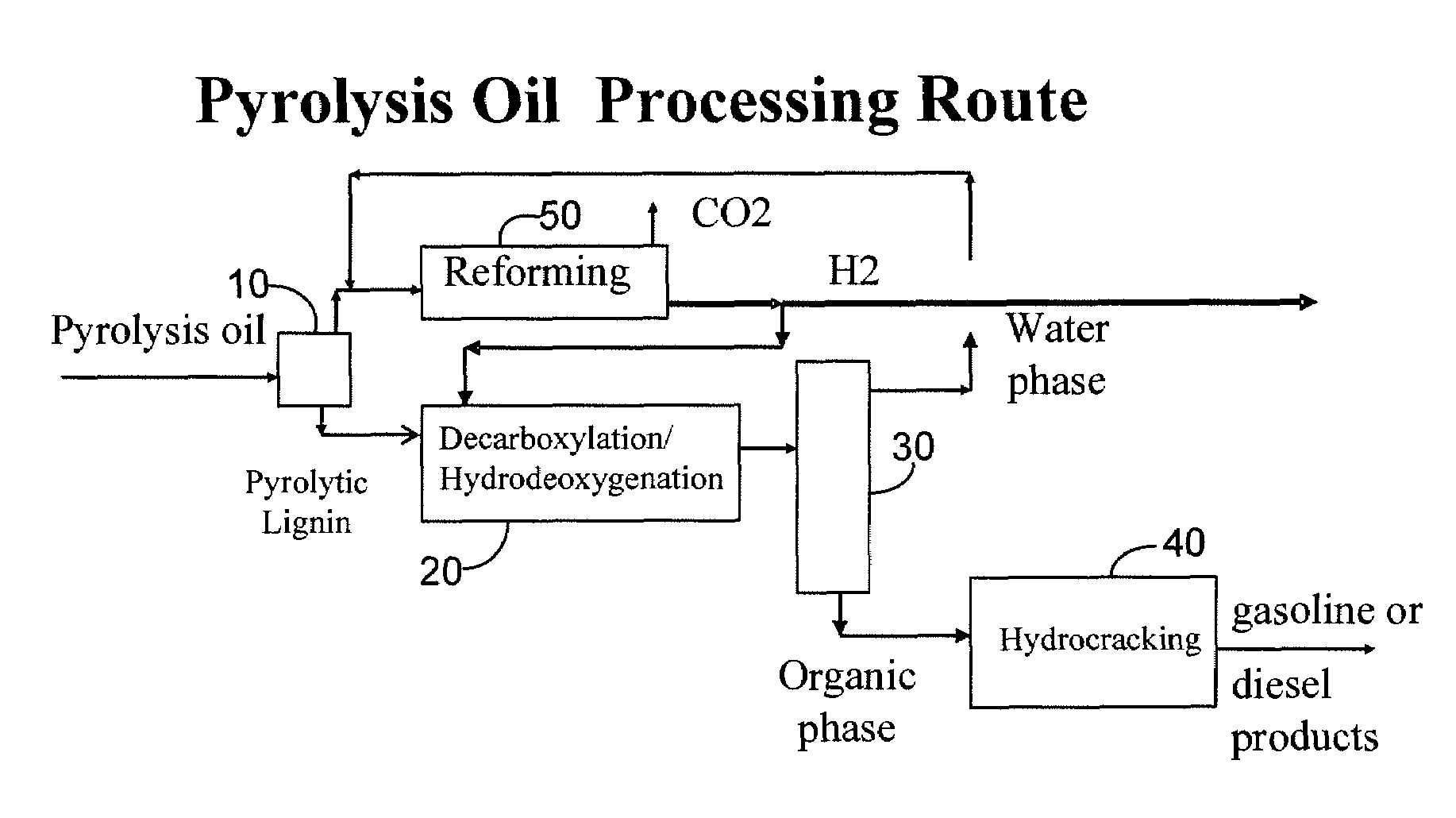

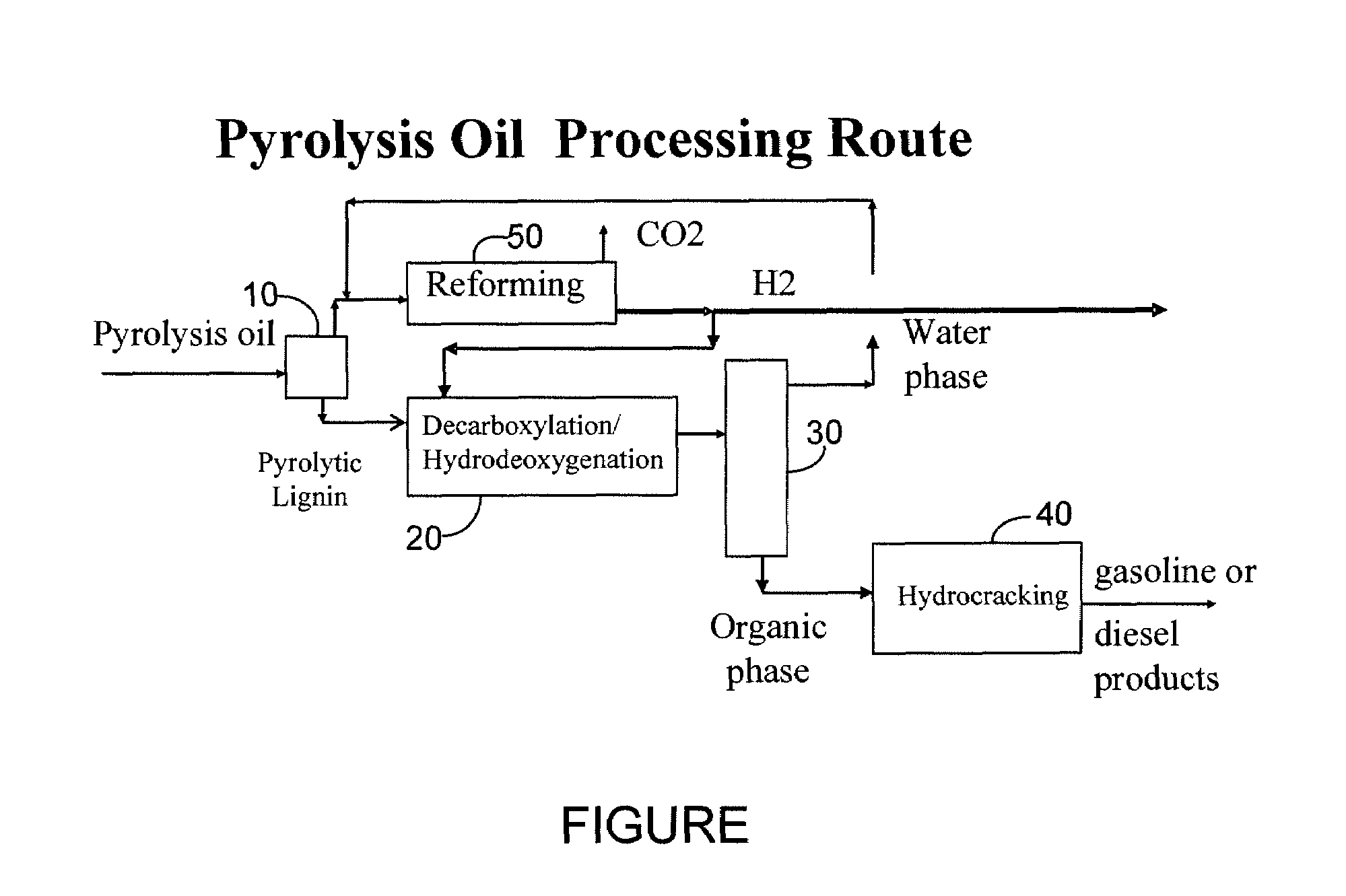

Gasoline and diesel production from pyrolytic lignin produced from pyrolysis of cellulosic waste

InactiveUS7578927B2Treatment with plural serial cracking stages onlyTreatment with plural serial stages onlyCelluloseNaphtha

A process for the conversion of biomass to a liquid fuel is presented. The process includes the production of diesel and naphtha boiling point range fuels by hydrocracking of pyrolysis lignin extracted from biomass.

Owner:UOP LLC

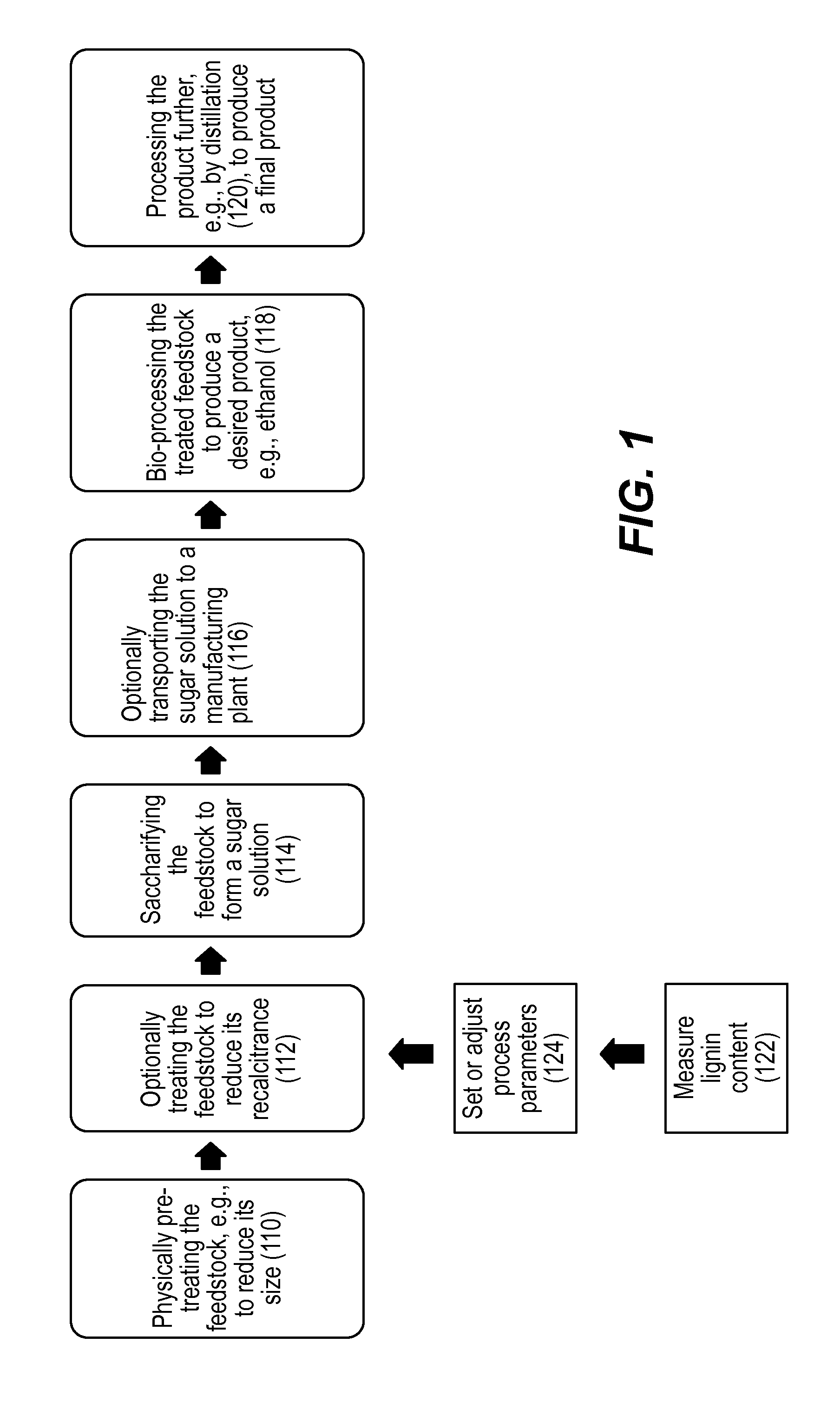

Processing biomass

Biomass (e.g., plant biomass, animal biomass, and municipal waste biomass) is processed to produce useful intermediates and products, such as energy, fuels, foods or materials. For example, methods are described that can use feedstock materials, such as cellulosic and / or lignocellulosic materials, to produce an intermediate or product, e.g., by fermentation.

Owner:XYLECO INC

Tri-folded disposable absorbent article, packaged absorbent article, and array of packaged absorbent articles with substantially continuously distributed absorbent particulate polymer material

A tri-folded disposable absorbent article comprising a substantially cellulose free absorbent core located in a chassis between a topsheet and a backsheet and comprising absorbent particulate polymer material. An array of absorbent article packages comprising disposable absorbent articles comprising a substantially cellulose free absorbent core is also disclosed.

Owner:THE PROCTER & GAMBLE COMPANY

Polyethylene oxide-based films and drug delivery systems made therefrom

The invention relates to the film products and methods of their preparation that demonstrate a non-self-aggregating uniform heterogeneity. Desirably, the films disintegrate in water and may be formed by a controlled drying process, or other process that maintains the required uniformity of the film. The films contain a polymer component, which includes polyethylene oxide optionally blended with hydrophilic cellulosic polymers. Desirably, the films also contain a pharmaceutical and / or cosmetic active agent with no more than a 10% variance of the active agent pharmaceutical and / or cosmetic active agent per unit area of the film.

Owner:AQUESTIVE THERAPEUTICS INC

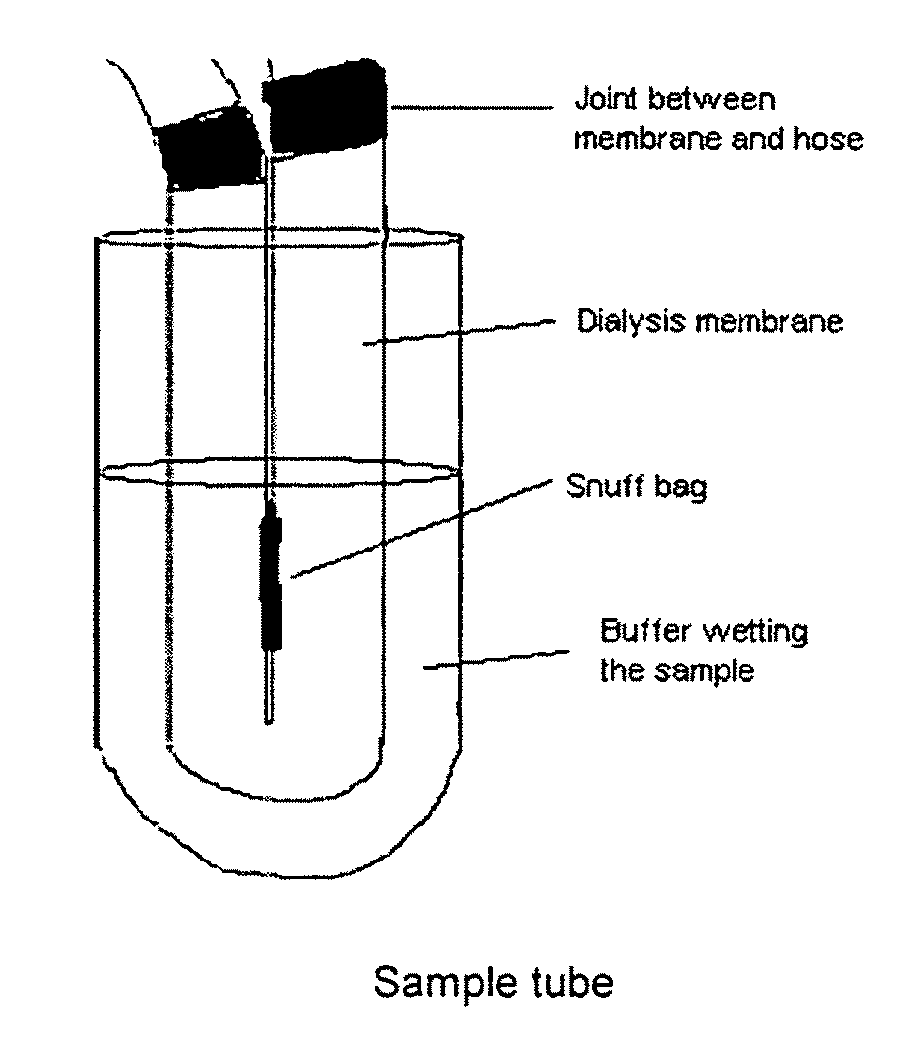

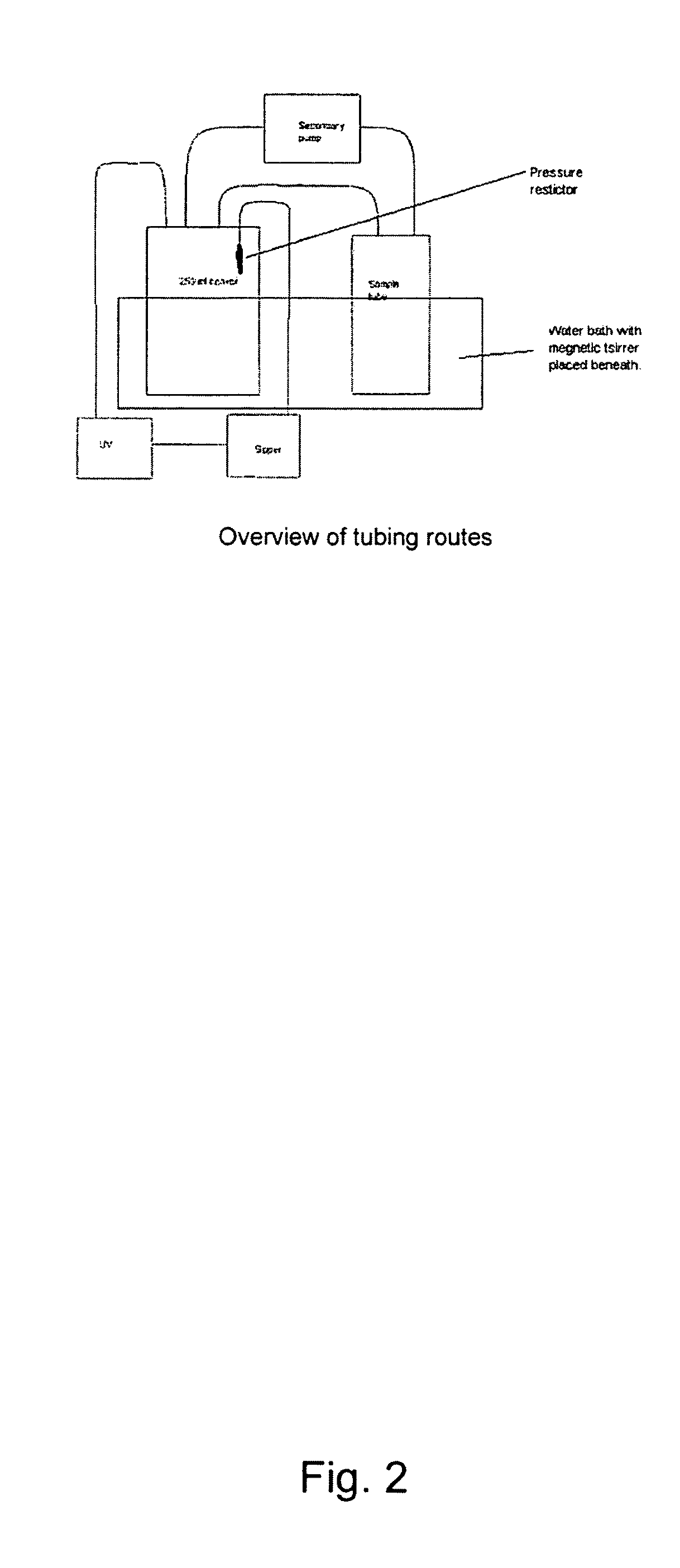

Snuff Composition

ActiveUS20090293895A1Quick effectRapid onsetPowder deliveryOrganic active ingredientsCellulosePharmacology

Use of a nicotine-cellulose combination for the preparation of a snuff composition for achievement of a fast onset of action of nicotine after application of the snuff composition to the oral cavity of a subject, wherein the composition has a high release rate so that when subjected to an in vitro dissolution test about 45% or more of the total content of nicotine is released within 30 minutes. Moreover, the invention relates to an improved snuff composition for application to the oral cavity.

Owner:MODORAL BRANDS INC

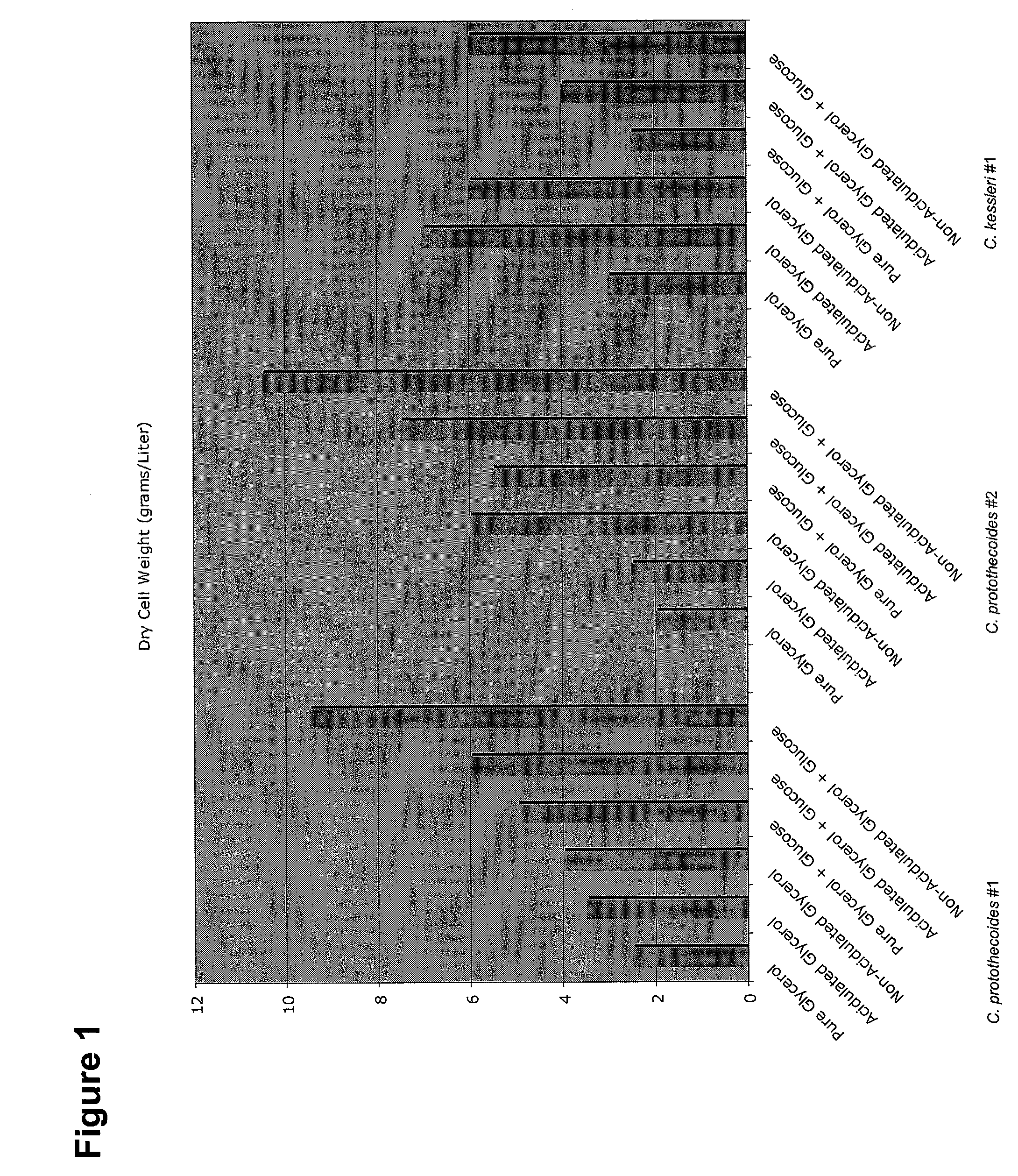

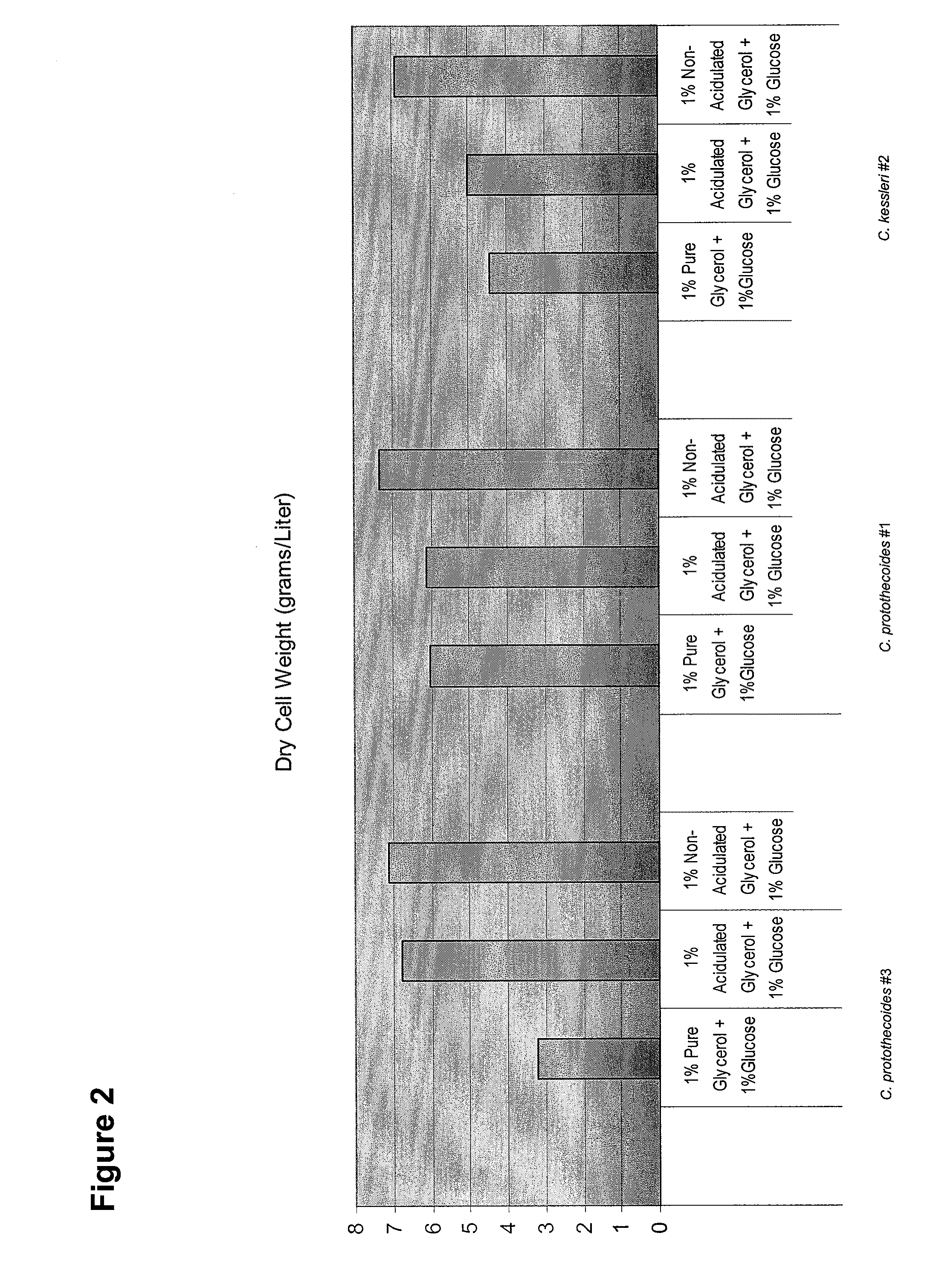

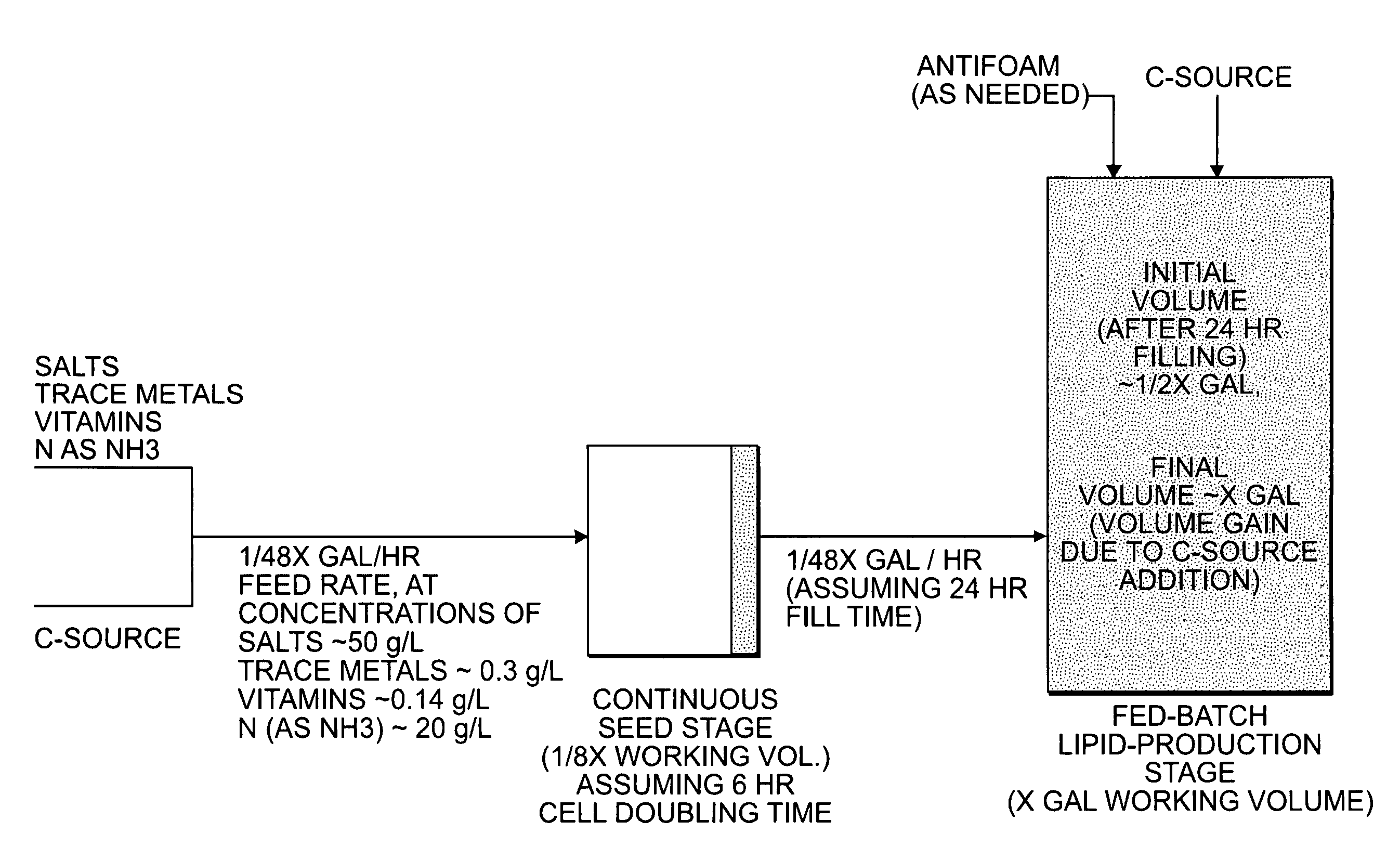

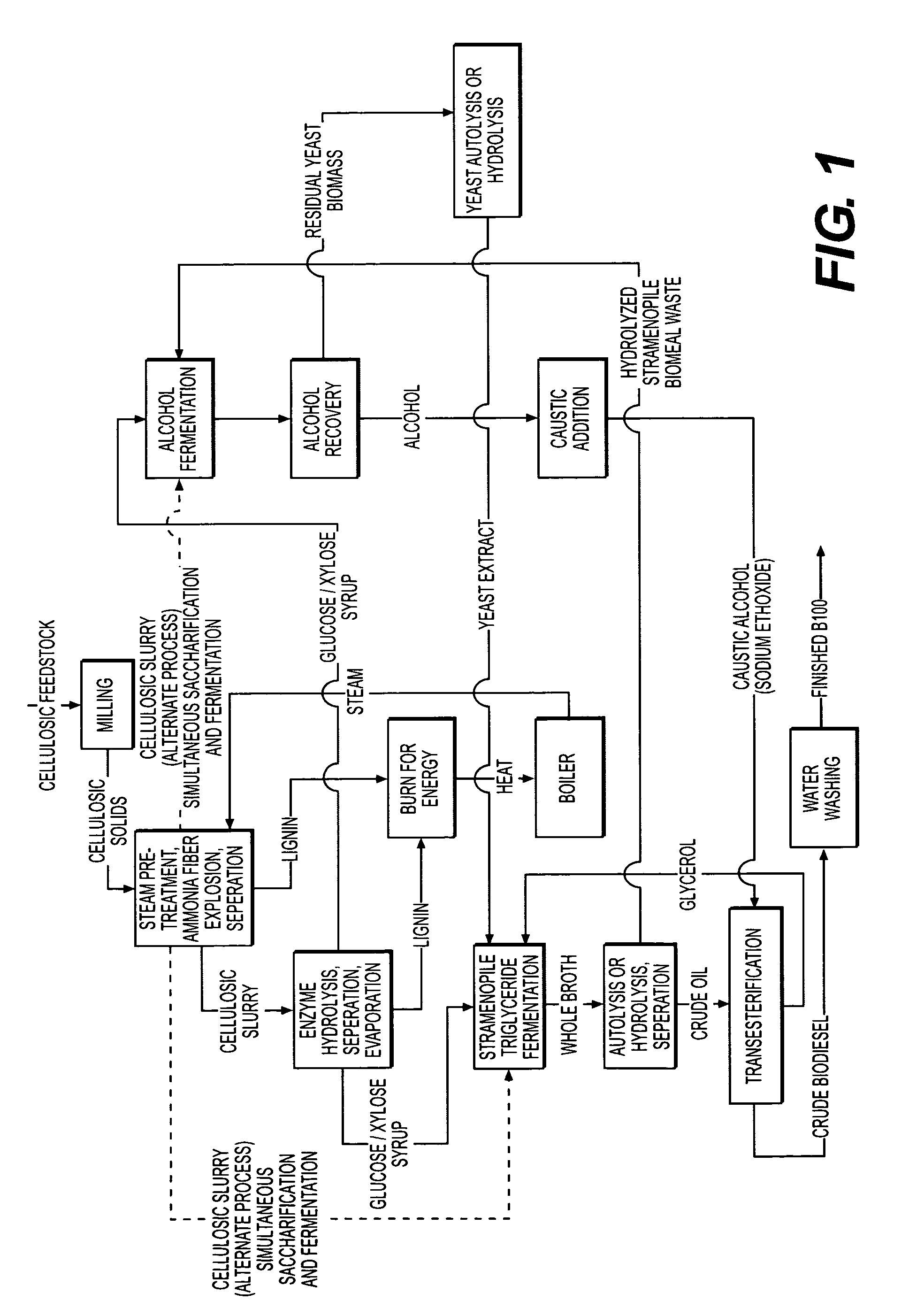

Biological oils and production and uses Thereof

The present invention provides biological oils and methods and uses thereof. The biological oils are preferably produced by heterotrophic fermentation of one or more microorganisms using cellulose-containing feedstock as a main source of carbon. The present invention also provides methods of producing lipid-based biofuels and food, nutritional, and pharmaceutical products using the biological oils.

Owner:MARTEK BIOSCIENCES CORP

Sheets having a starch-based binding matrix

Compositions and methods for manufacturing sheets having a starch-bound matrix, optionally reinforced with fibers and optionally including an inorganic mineral filler. Suitable mixtures for forming the sheets are prepared by mixing together water, unmodified and ungelatinized starch granules, a cellulosic ether, optionally fibers, and optionally an inorganic mineral filler in the correct proportions to form a sheet having desired properties. The mixtures are formed into sheets by passing them between one or more sets of heated rollers to form green sheets. The heated rollers cause the cellulosic ether to form a skin on the outer surfaces of the sheet that prevents the starch granules from causing the sheet to adhere to the rollers upon gelation of the starch. The green sheets are passed between heated rollers to gelatinize the starch granules, and then to dry the sheet by removing a substantial portion of the water by evaporation. The starch and cellulosic ether form the binding matrix of the sheets with the fibers and optional inorganic filler dispersed throughout the binding matrix. The starch-bound sheets can be cut, rolled, pressed, scored, perforated, folded, and glued to fashion articles from the sheets much like paper or paperboard. The sheets are particularly useful in the mass production of containers, such as food and beverage containers.

Owner:E KHASHOGGI INDS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com