Patents

Literature

619results about "Treatment with plural serial cracking stages only" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for Co-Producing Jet Fuel and LPG from Renewable Sources

ActiveUS20080244962A1Improve cold flowHydrocarbon by hydrogenationLiquid hydrocarbon mixture productionEngineeringRenewable resource

The present invention generally relates to a method for producing an isoparaffinic product useful as jet fuel from a renewable feedstock. The method may also include co-producing a jet fuel and a liquefied petroleum gas (LPG) fraction from a renewable feedstock. The method includes hydrotreating the renewable feedstock to produce a hydrotreating unit heavy fraction that includes n-paraffins and hydroisomerizing the hydrotreating unit heavy fraction to produce a hydroizomerizing unit heavy fraction that includes isoparaffins. The method also includes recycling the hydroisomerizing unit heavy fraction through the hydroisomerization unit to produce an isoparaffinic product that may be fractionated into a jet fuel and an LPG fraction. The present invention also relates to a jet fuel produced from a renewable feedstock having improved cold flow properties.

Owner:REG SYNTHETIC FUELS LLC

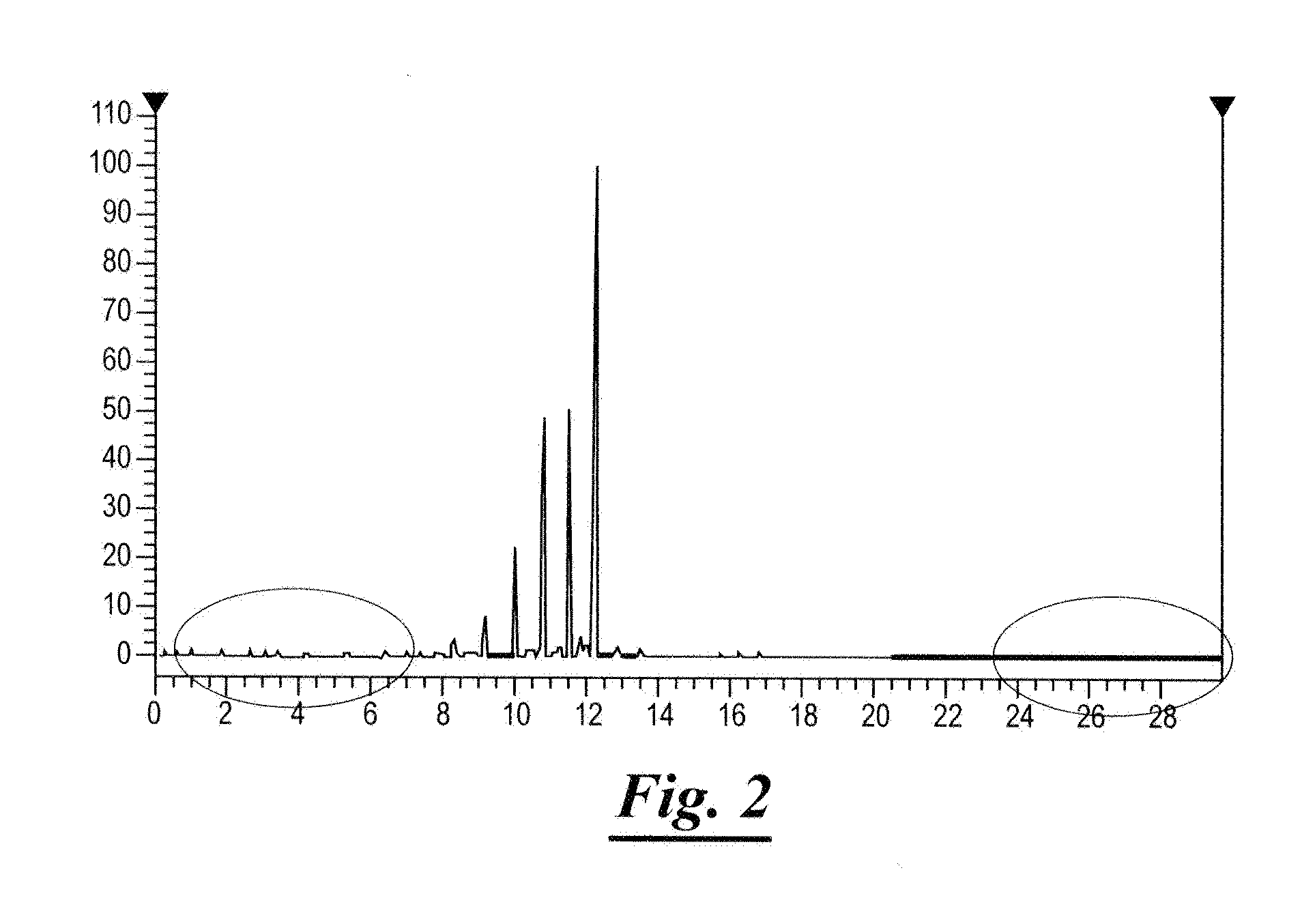

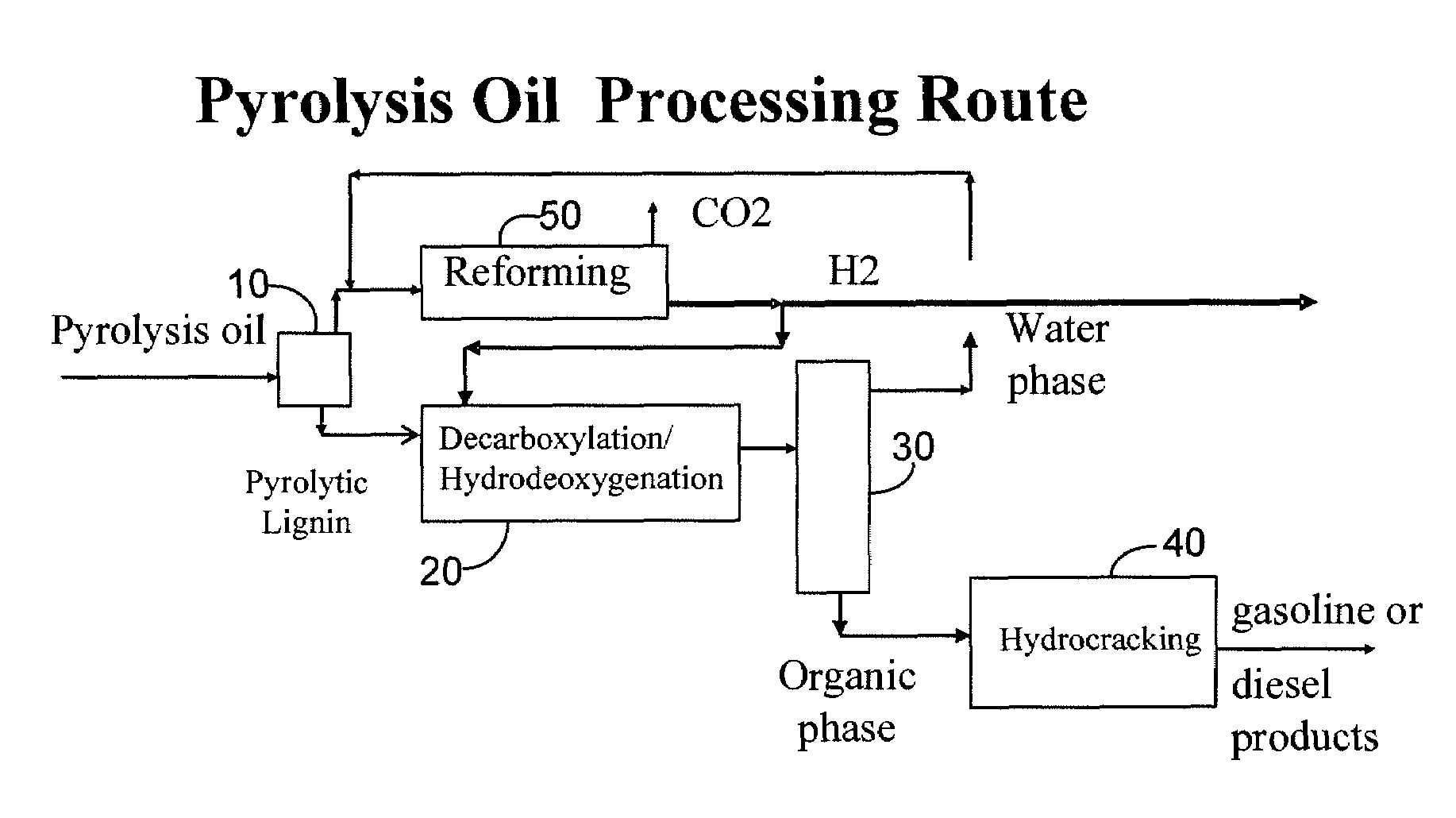

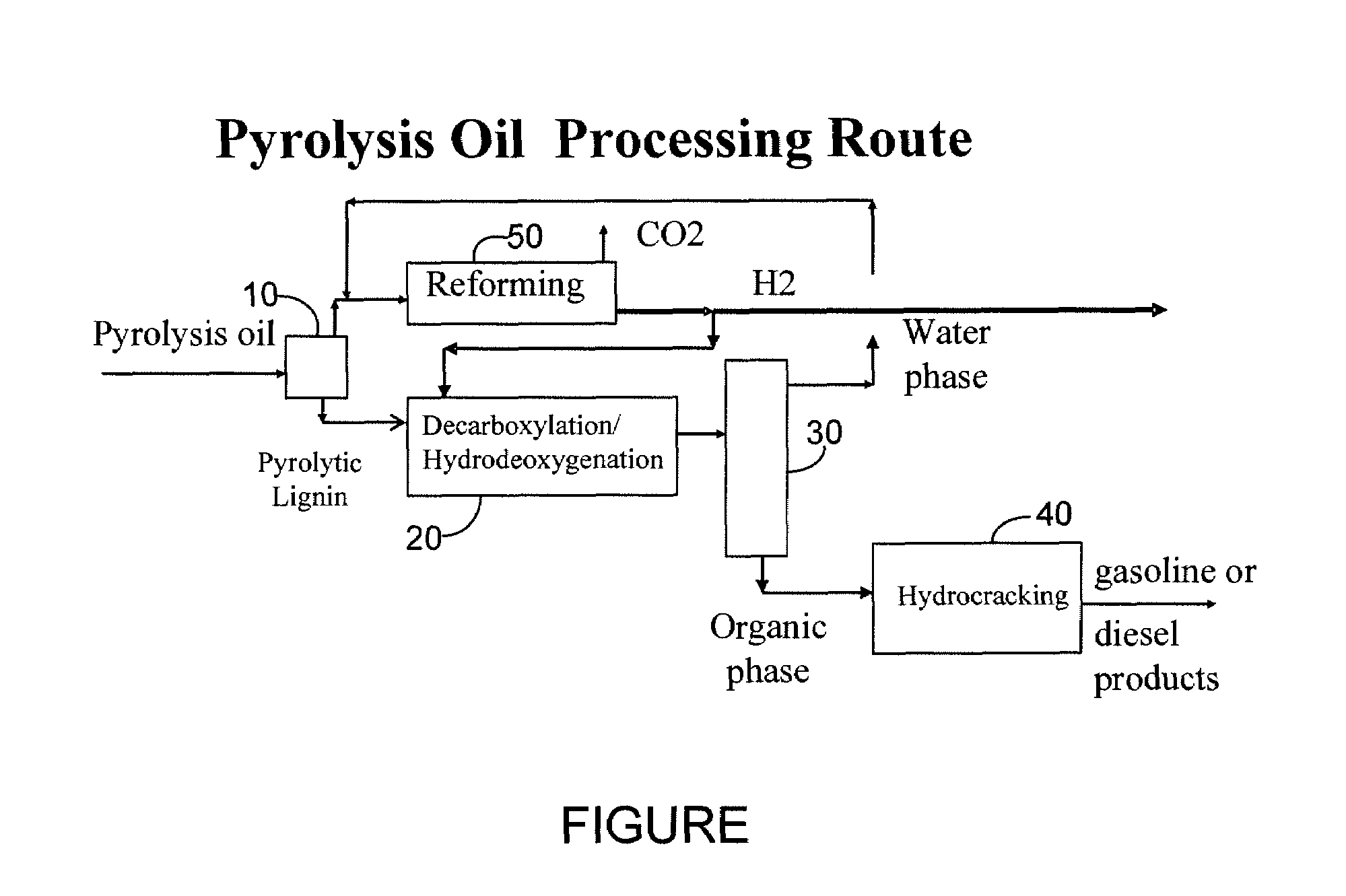

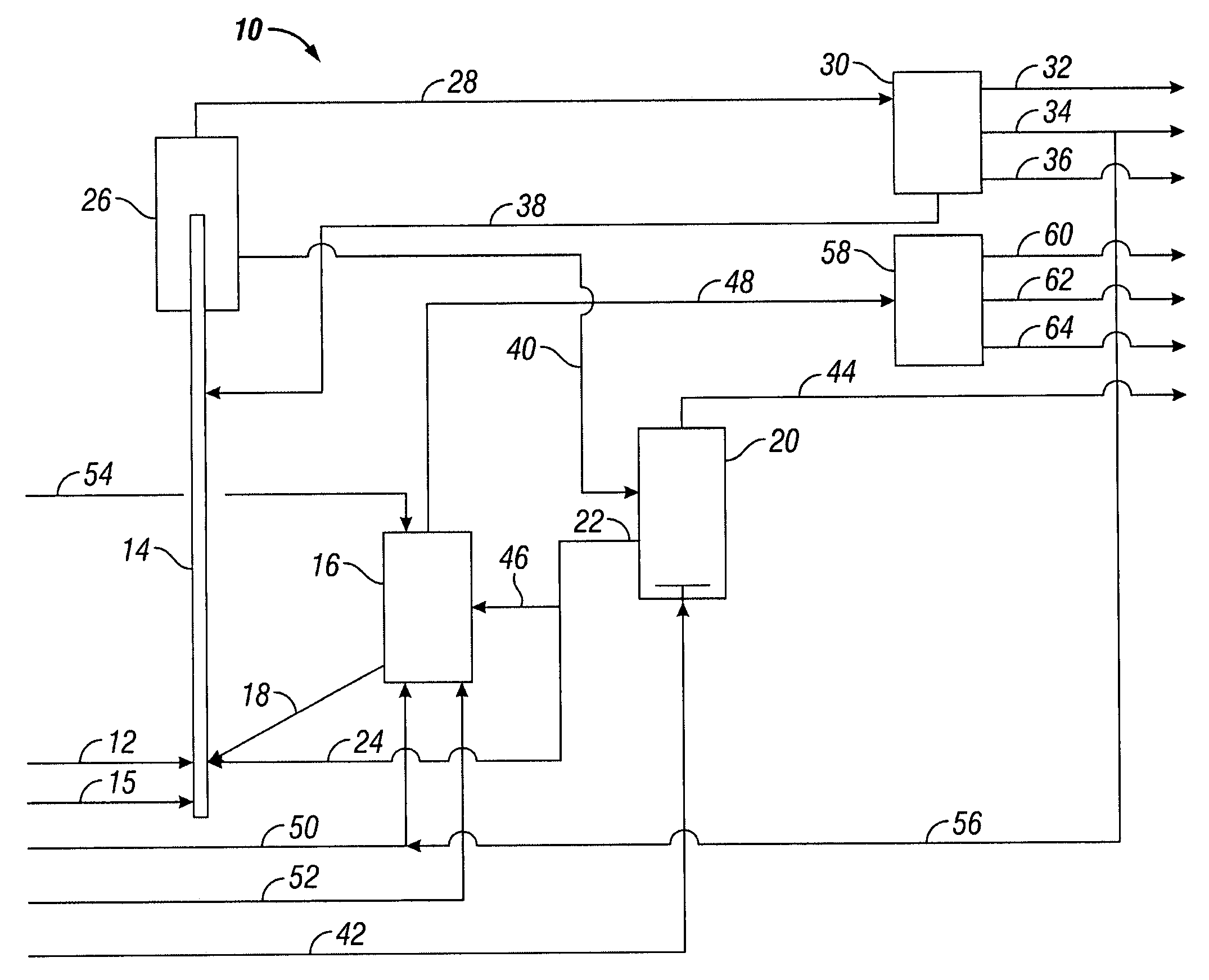

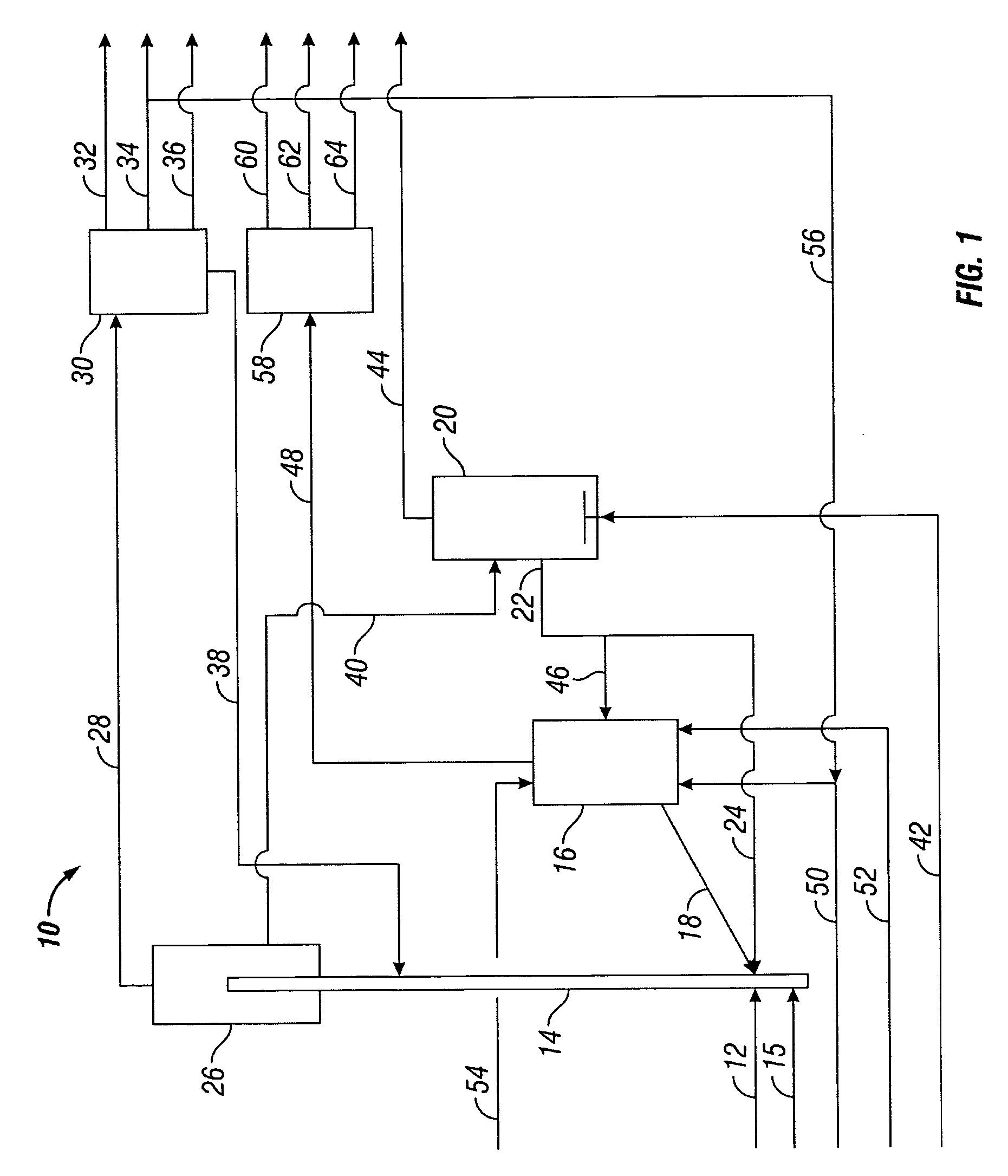

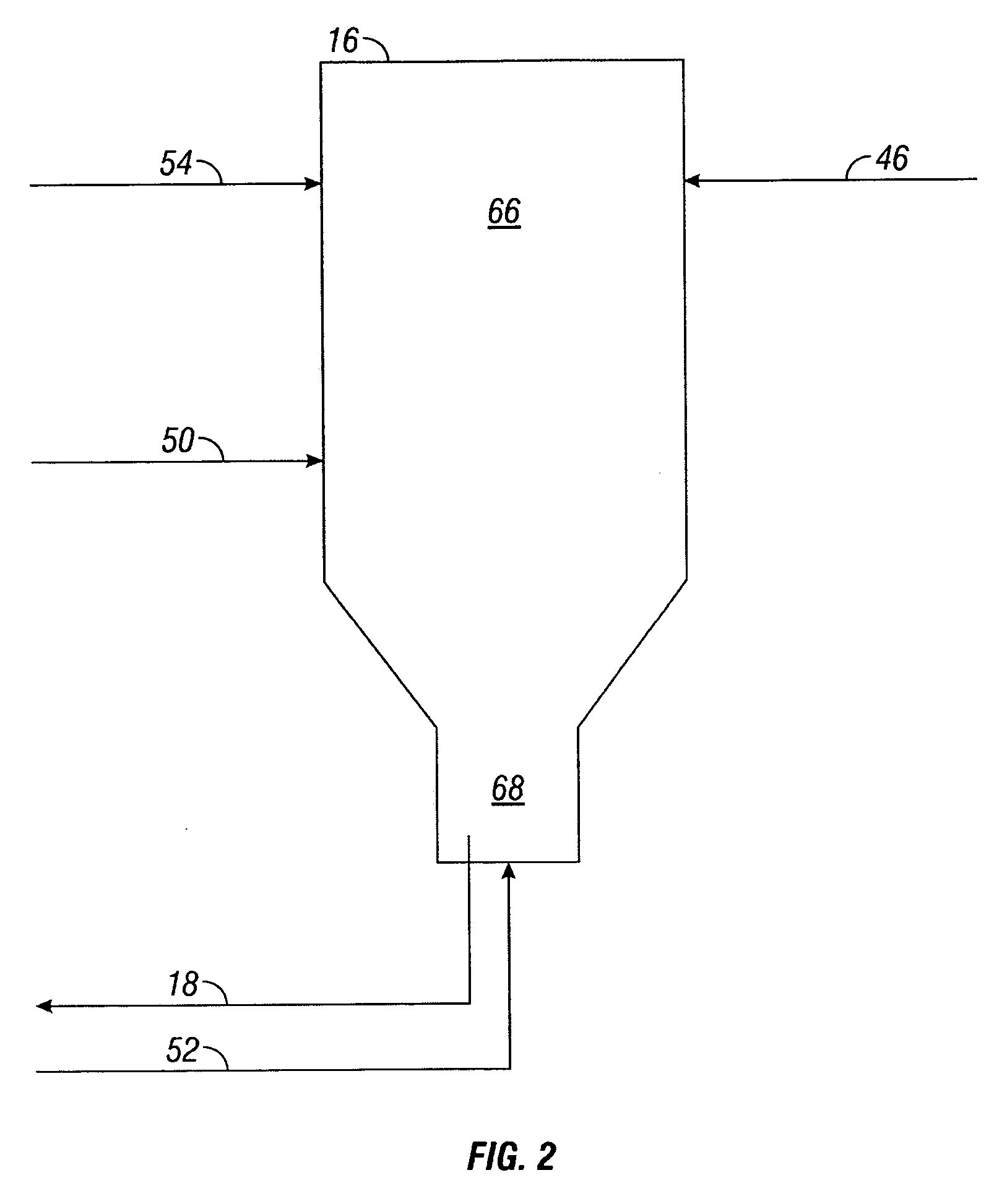

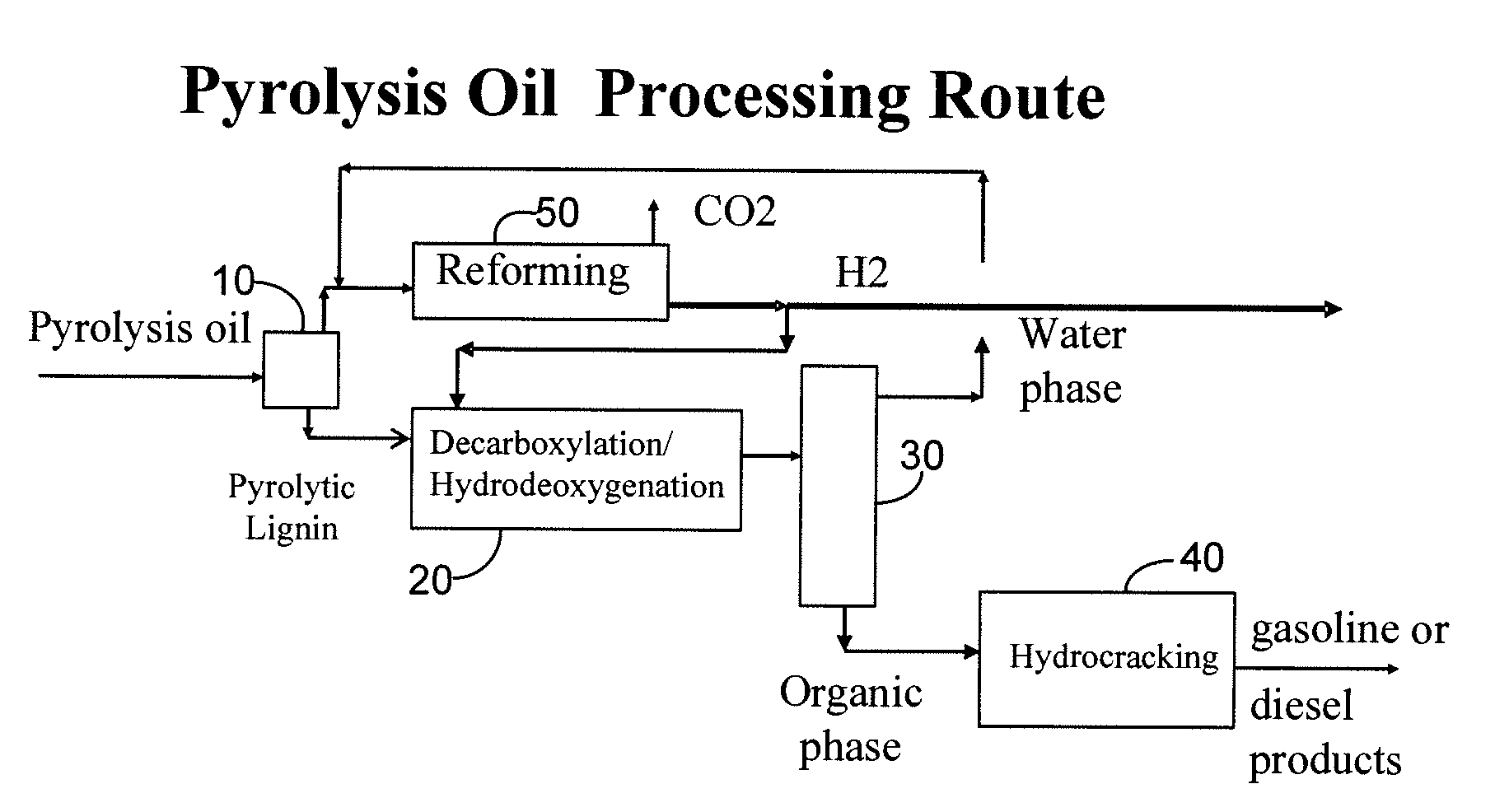

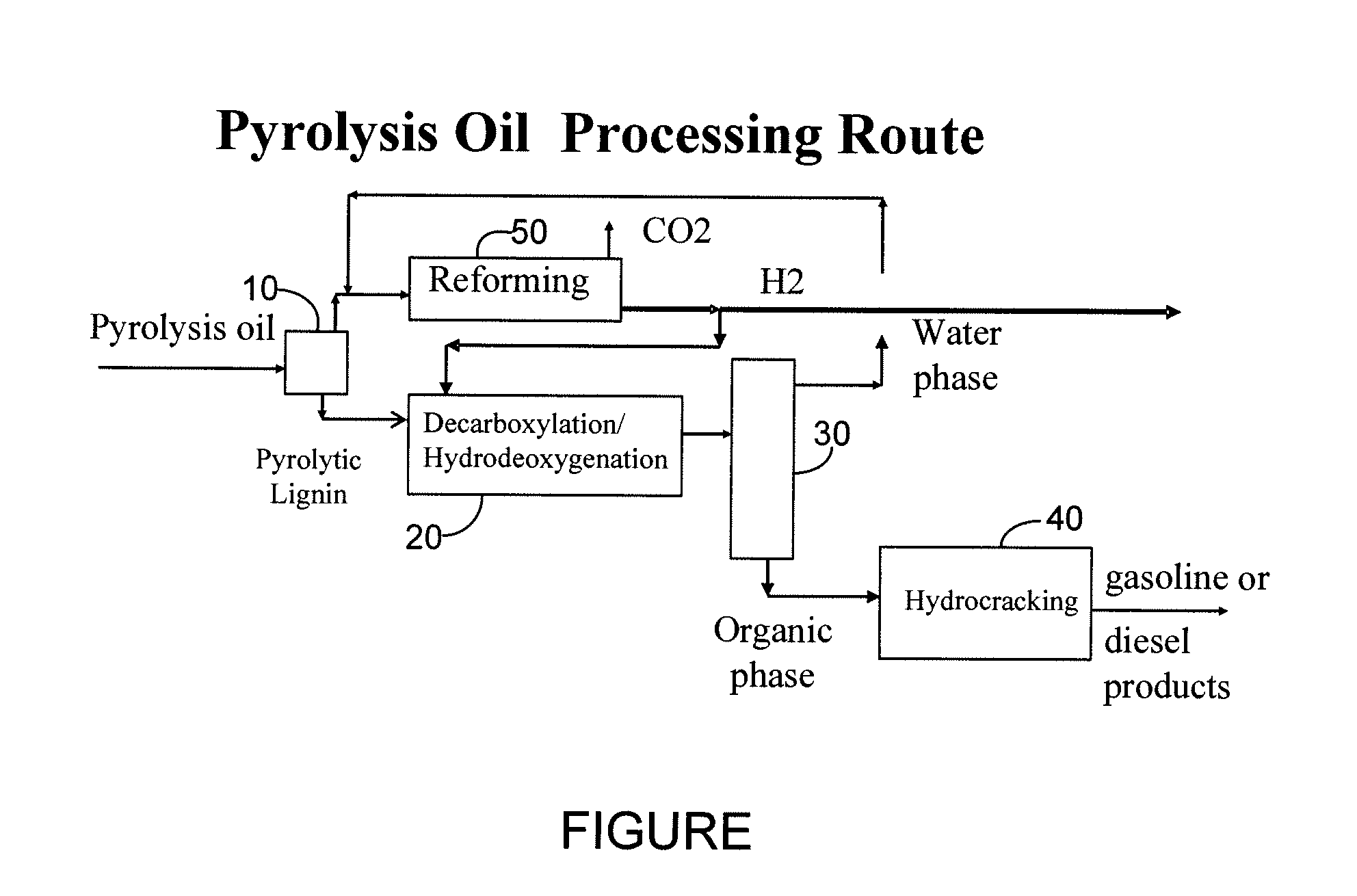

Gasoline and diesel production from pyrolytic lignin produced from pyrolysis of cellulosic waste

InactiveUS7578927B2Treatment with plural serial cracking stages onlyTreatment with plural serial stages onlyCelluloseNaphtha

A process for the conversion of biomass to a liquid fuel is presented. The process includes the production of diesel and naphtha boiling point range fuels by hydrocracking of pyrolysis lignin extracted from biomass.

Owner:UOP LLC

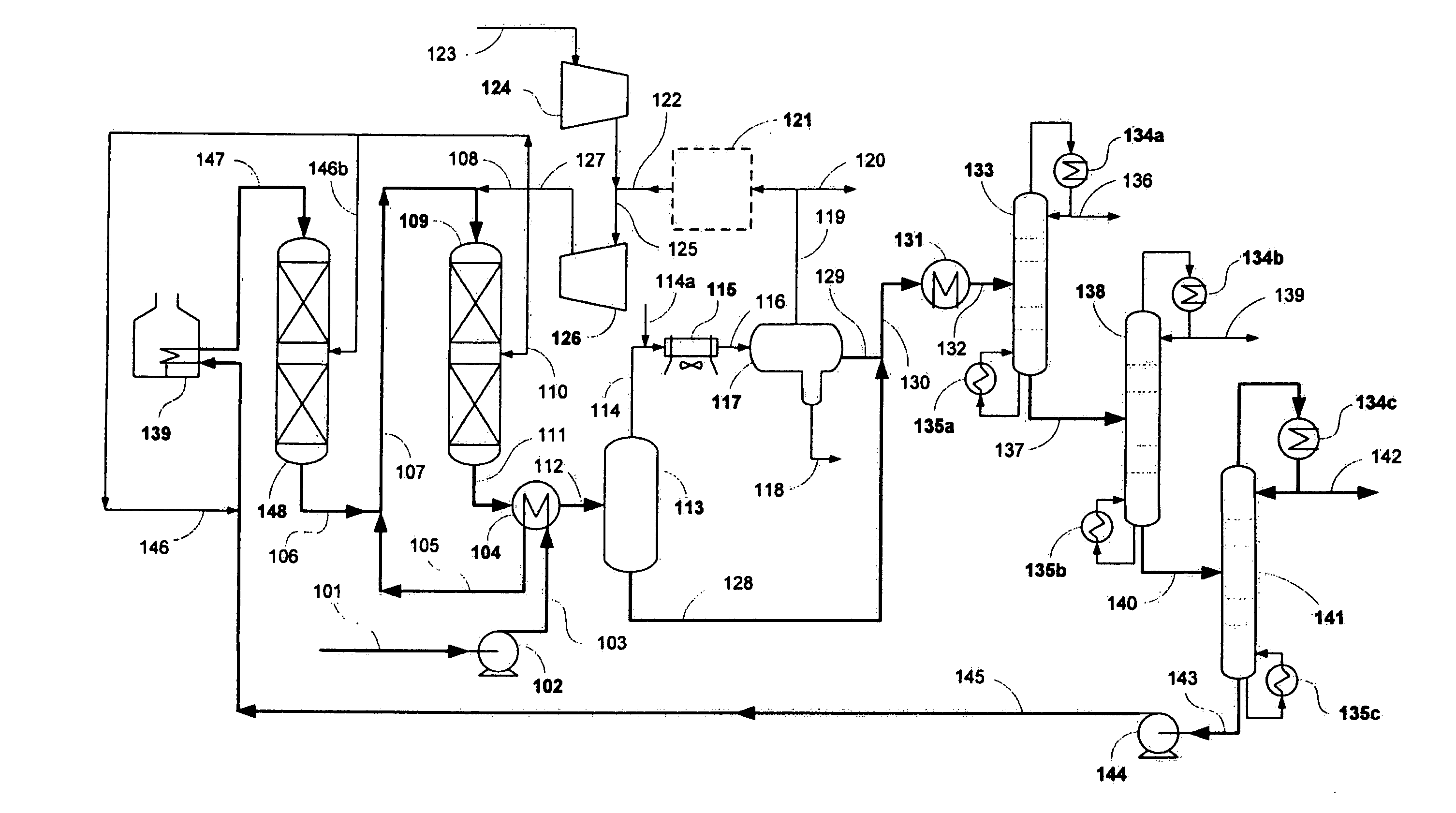

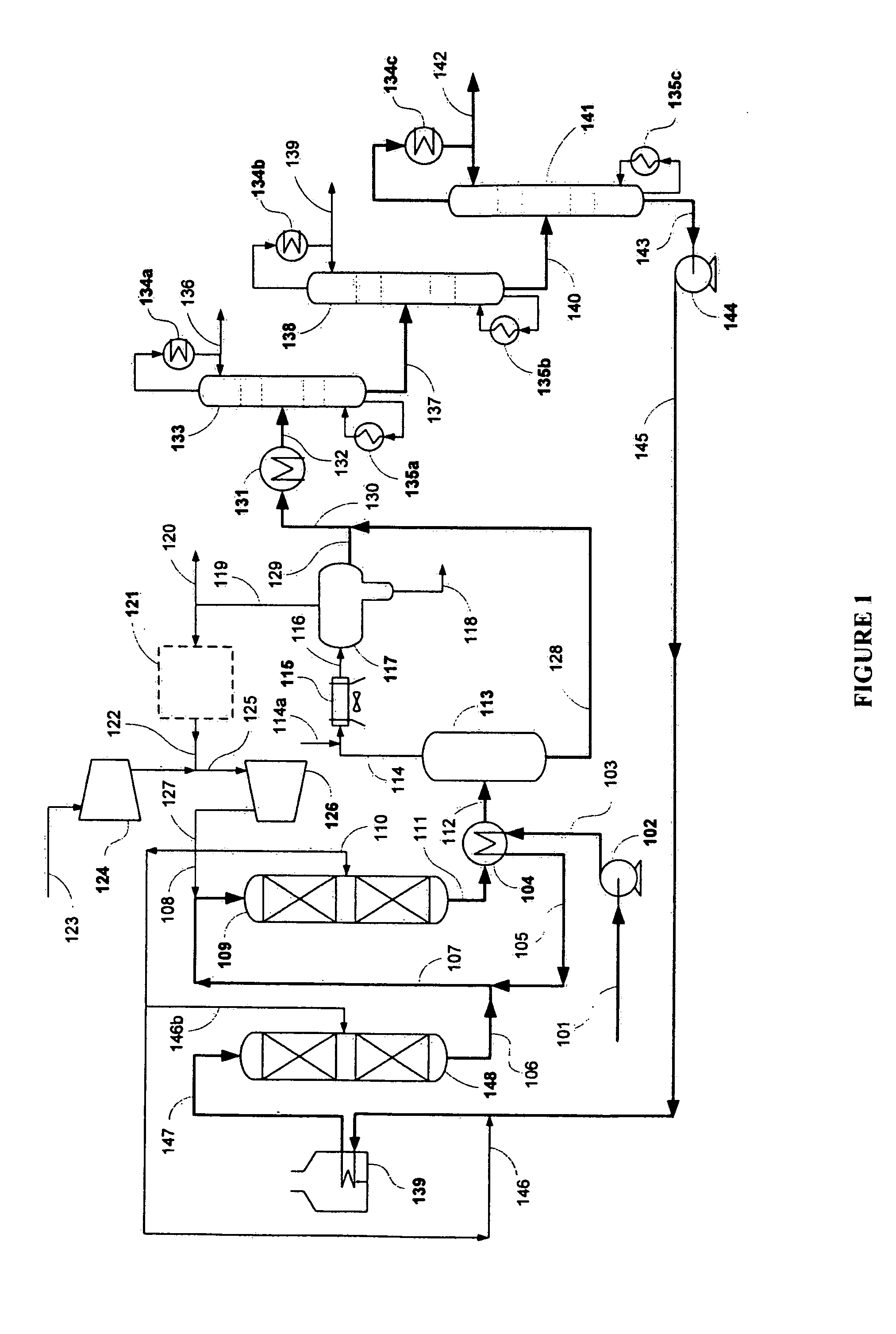

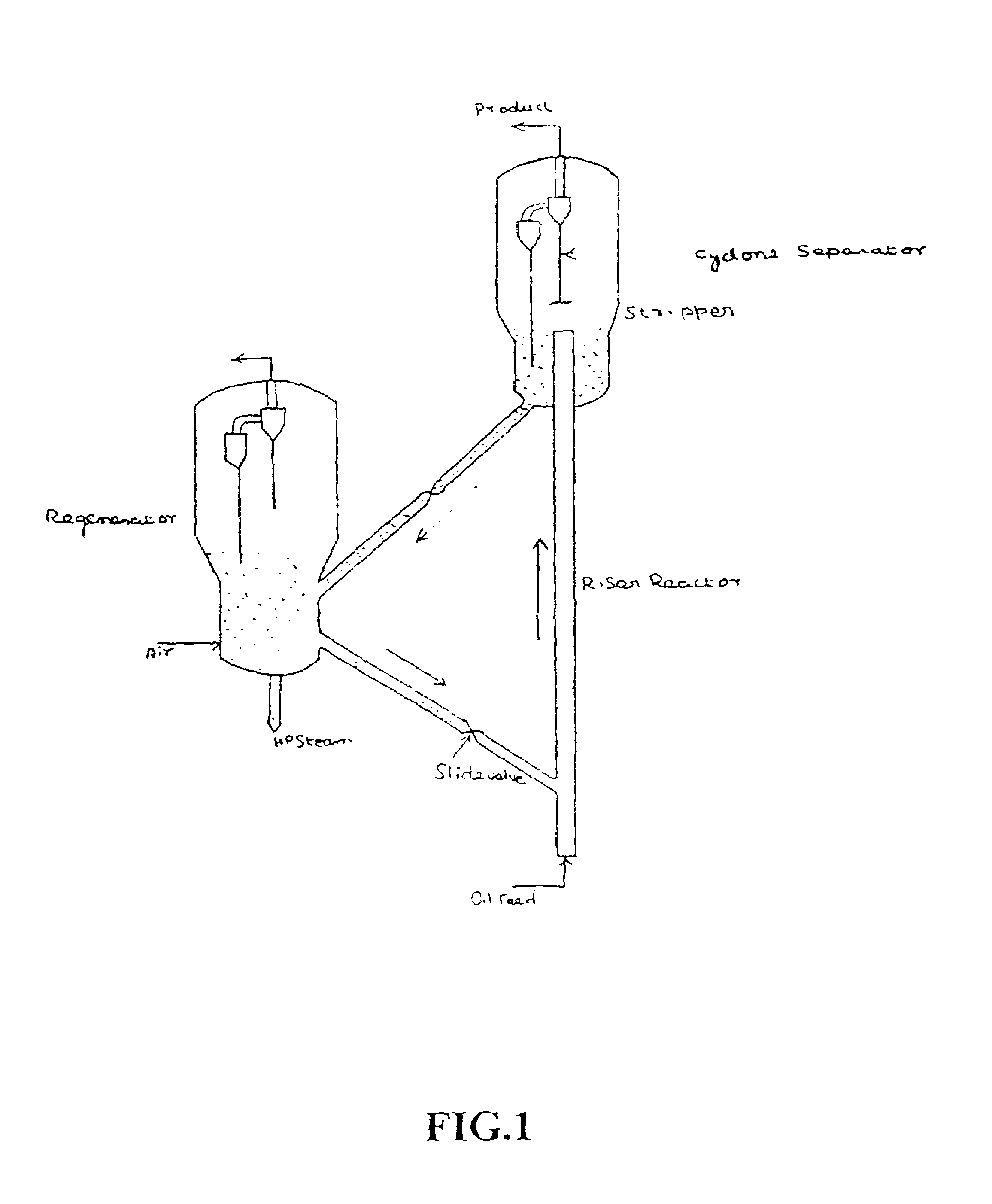

Method and apparatus for making a middle distillate product and lower olefins from a hydrocarbon feedstock

ActiveUS20060178546A1Yield maximizationCatalytic crackingCatalytic naphtha reformingPetroleum productGasoline

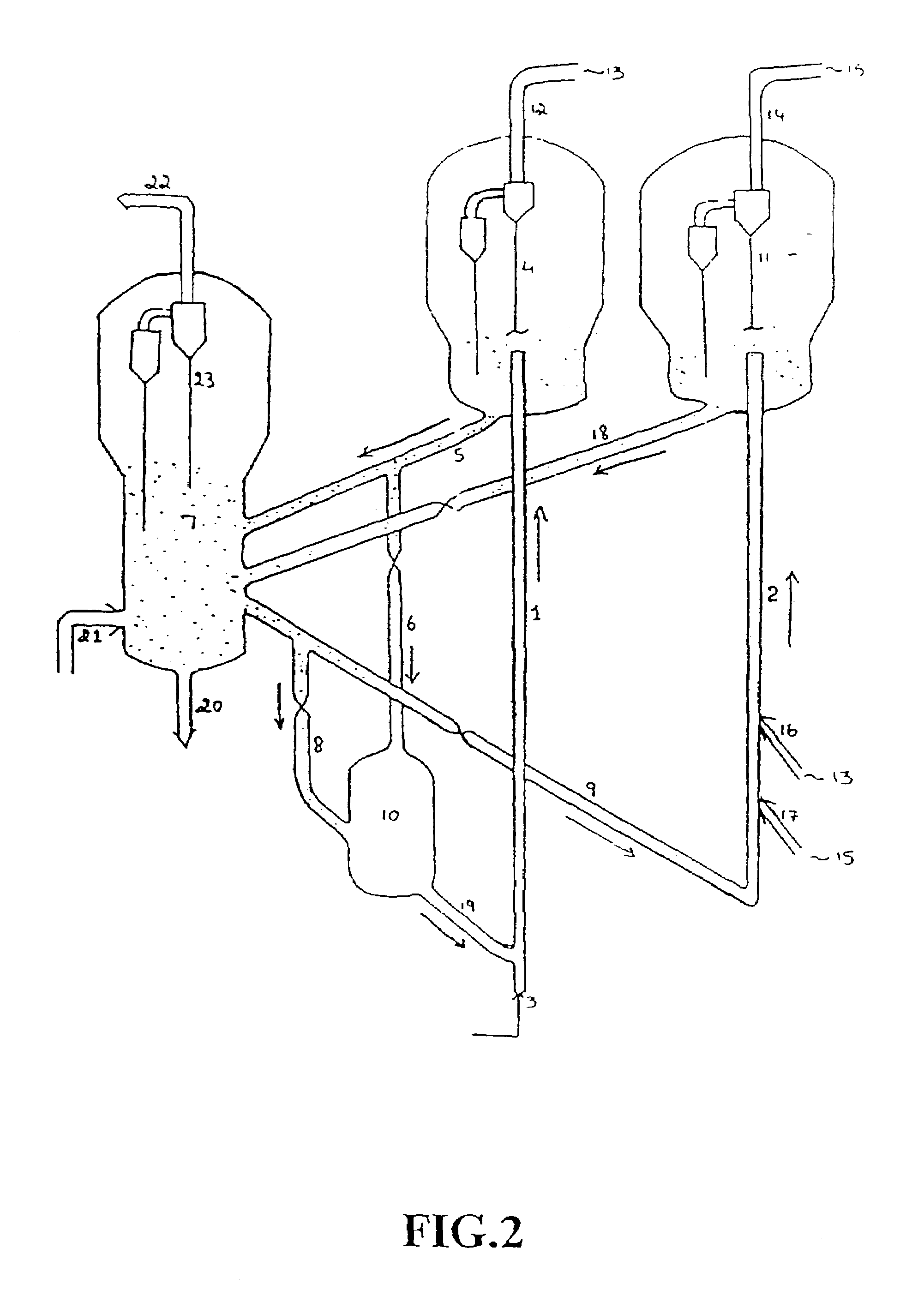

Disclosed is a process for making middle distillate and lower olefins. The process includes catalytically cracking a gas oil feedstock within a riser reactor zone by contacting under suitable catalytic cracking conditions within the riser reactor zone the gas oil feedstock with a middle distillate selective cracking catalyst that comprises amorphous silica alumina and a zeolite to yield a cracked gas oil product and a spent cracking catalyst. The spent cracking catalyst is regenerated to yield a regenerated cracking catalyst. Within an intermediate cracking reactor such as a dense bed reactor zone and under suitable high severity cracking conditions a gasoline feedstock is contacted with the regenerated cracking catalyst to yield a cracked gasoline product and a used regenerated cracking catalyst. The used regenerated cracking catalyst is utilized as the middle distillate selective catalyst.

Owner:SHELL USA INC

Production of Aviation Fuel from Renewable Feedstocks

ActiveUS20090283442A1Improve solubilityMinimize severityTreatment with plural serial cracking stages onlyRefining to change hydrocarbon structural skeletonIsomerizationBoiling point

A hydrocarbon product stream having hydrocarbons with boiling points in the aviation fuel range is produced from renewable feedstocks such as plant and animal oils. The process involves treating a renewable feedstock by hydrogenating, deoxygenating, isomerization, and selectively hydrocracking the feedstock to produce paraffinic hydrocarbons having from about 9 to about 16 carbon atoms and a high iso / normal ratio in a single reaction zone containing a multifunctional catalyst, or set of catalysts, having hydrogenation, deoxygenation, isomerization and selective hydrocracking functions.

Owner:UOP LLC

Fluid cat cracking with high olefins prouduction

InactiveUS20020003103A1Increase productionMaximize lightThermal non-catalytic crackingTreatment with plural serial cracking stages onlyNaphthaOrganic chemistry

The propylene production of a fluid catalytic cracking unit employing a large pore zeolite cracking catalyst, produces more propylene by adding a naphtha cracking riser and a medium pore zeolite catalytic component to the unit, and recycling at least a portion of the naphtha crackate to the naphtha riser. The large pore size zeolite preferably comprises a USY zeolite and the medium pore size is preferably ZSM-5. Propylene production per unit of naphtha feed to the naphtha riser is maximized, by using the 60-300.degree. F. naphtha crackate as the feed.

Owner:EXXON RES & ENG CO

Premium synthetic lubricant base stock (Law734) having at least 95% noncyclic isoparaffins

A premium synthetic lubricating oil base stock having a high VI and low pour point is made by hydroisomerizing a Fischer-Tropsch synthesized waxy, paraffinic feed wax and then dewaxing the hydroisomerate to form a 650-750° F.+ dewaxate. The waxy feed has an initial boiling point in the range of about 650-750° F., from which it continuously boils up to at least 1050° F. and has a T90-T10 temperature difference of at least 350° F. The feed is preferably hydroisomerized without any pretreatment, other than optional fractionation. The 650-750° F.+ dewaxate is fractionated into two or more base stocks of different viscosity.

Owner:EXXON RES & ENG CO

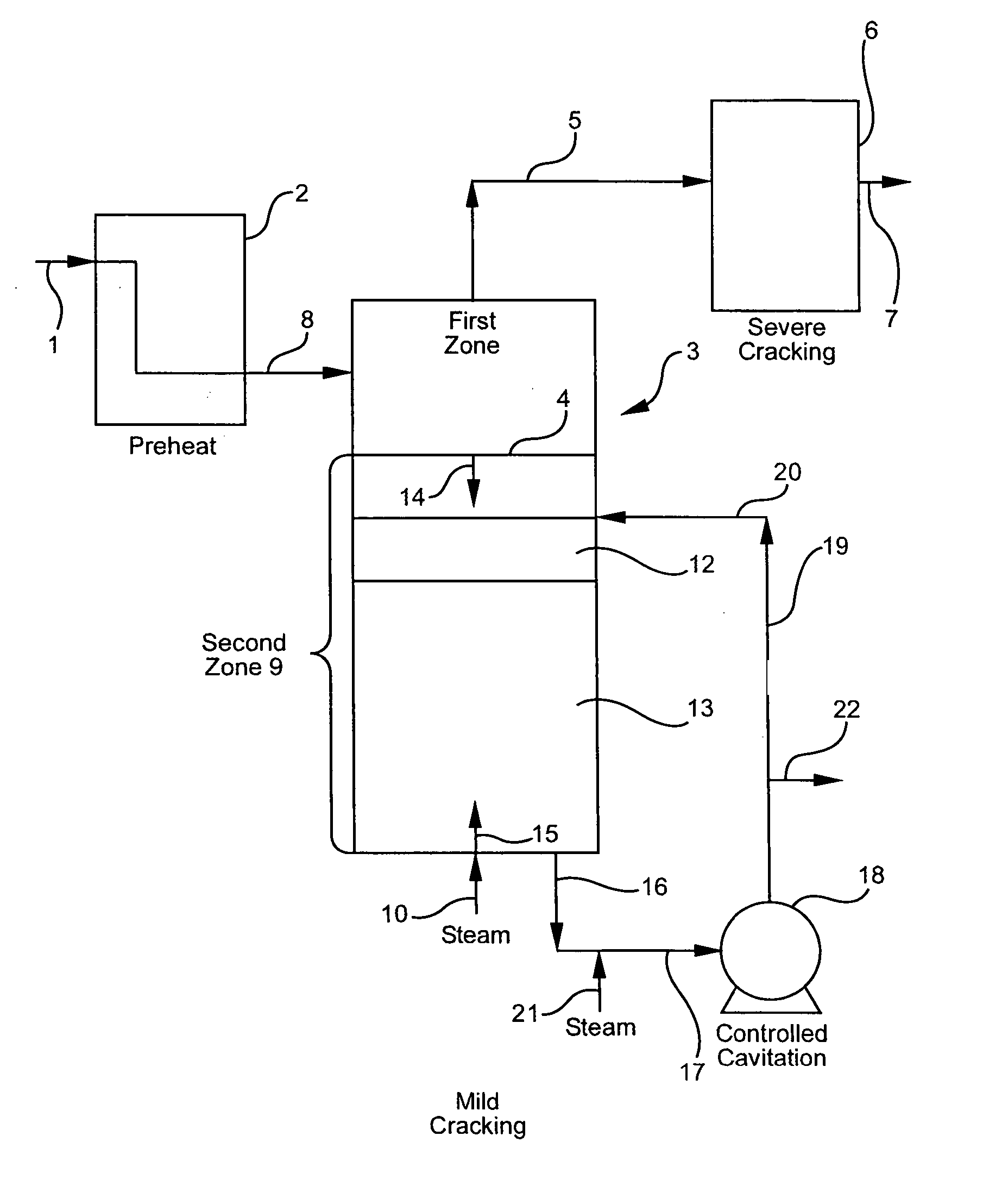

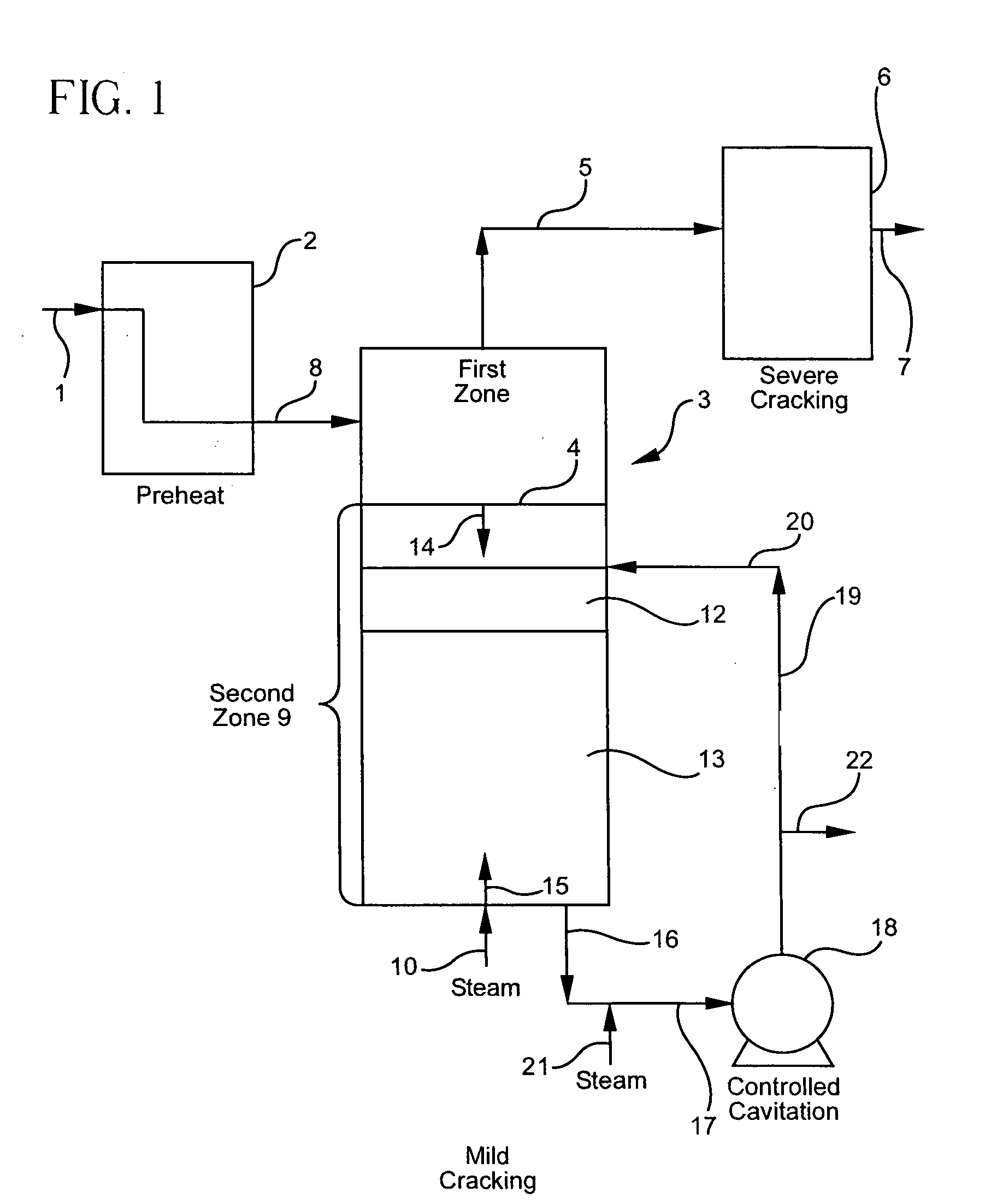

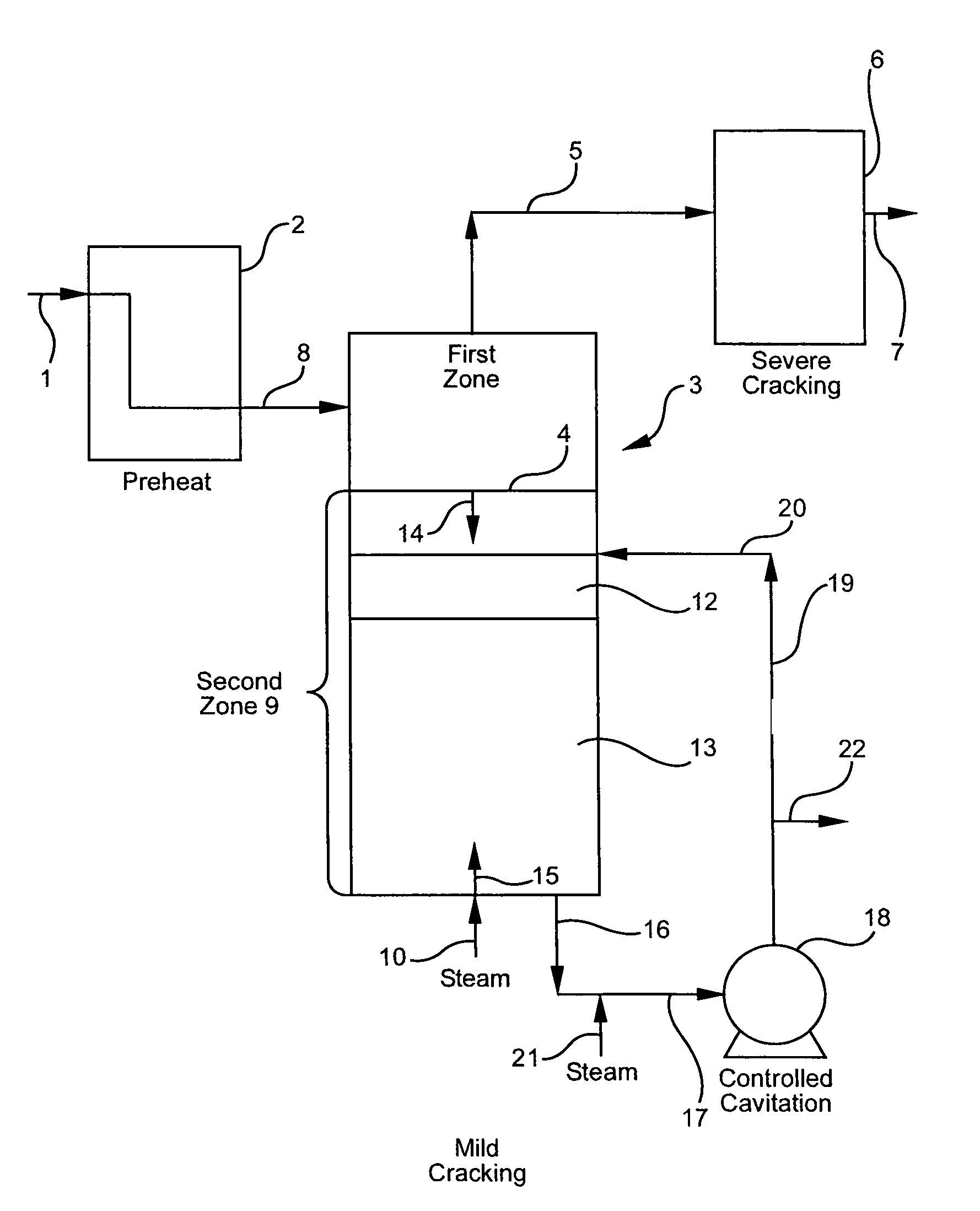

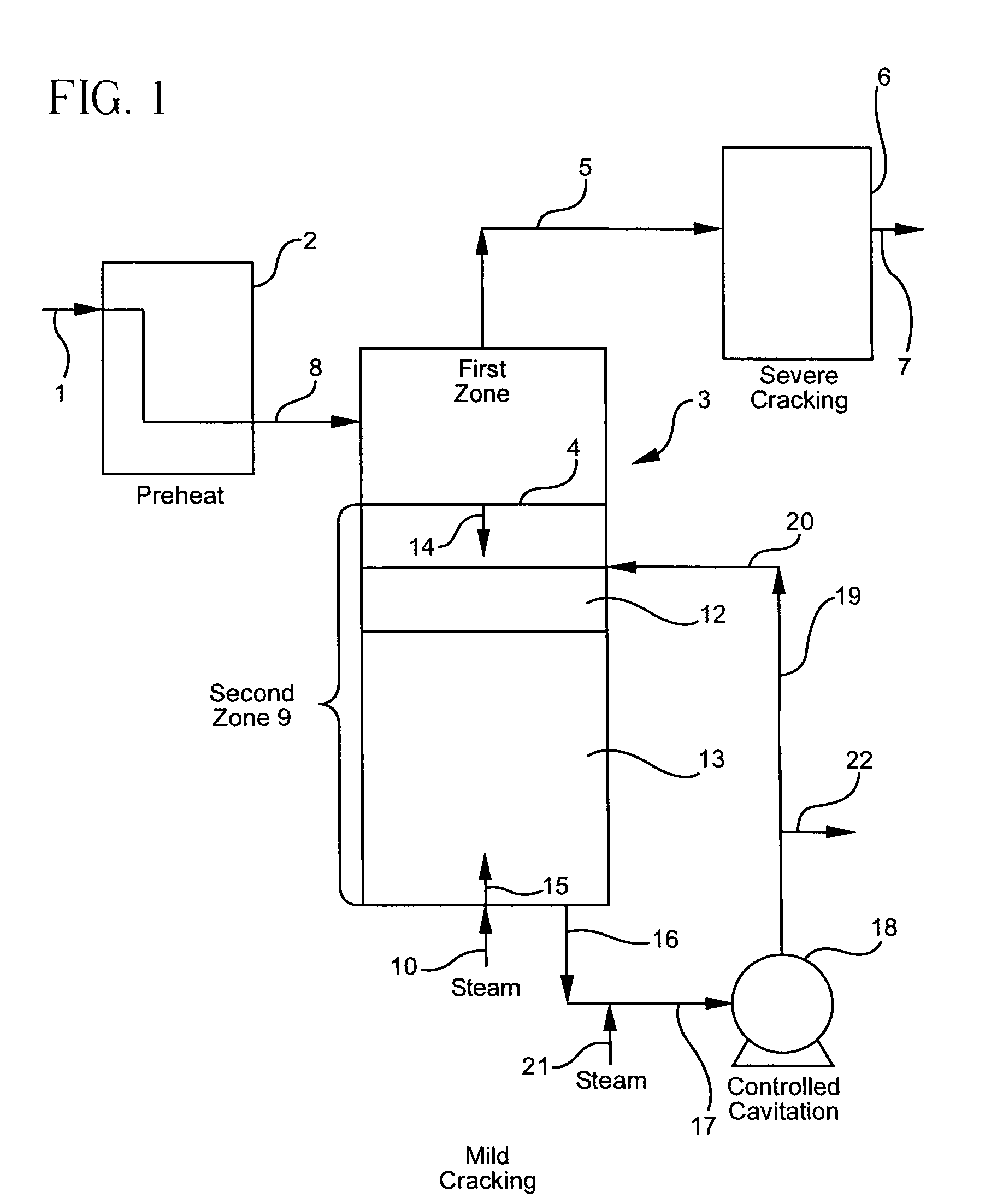

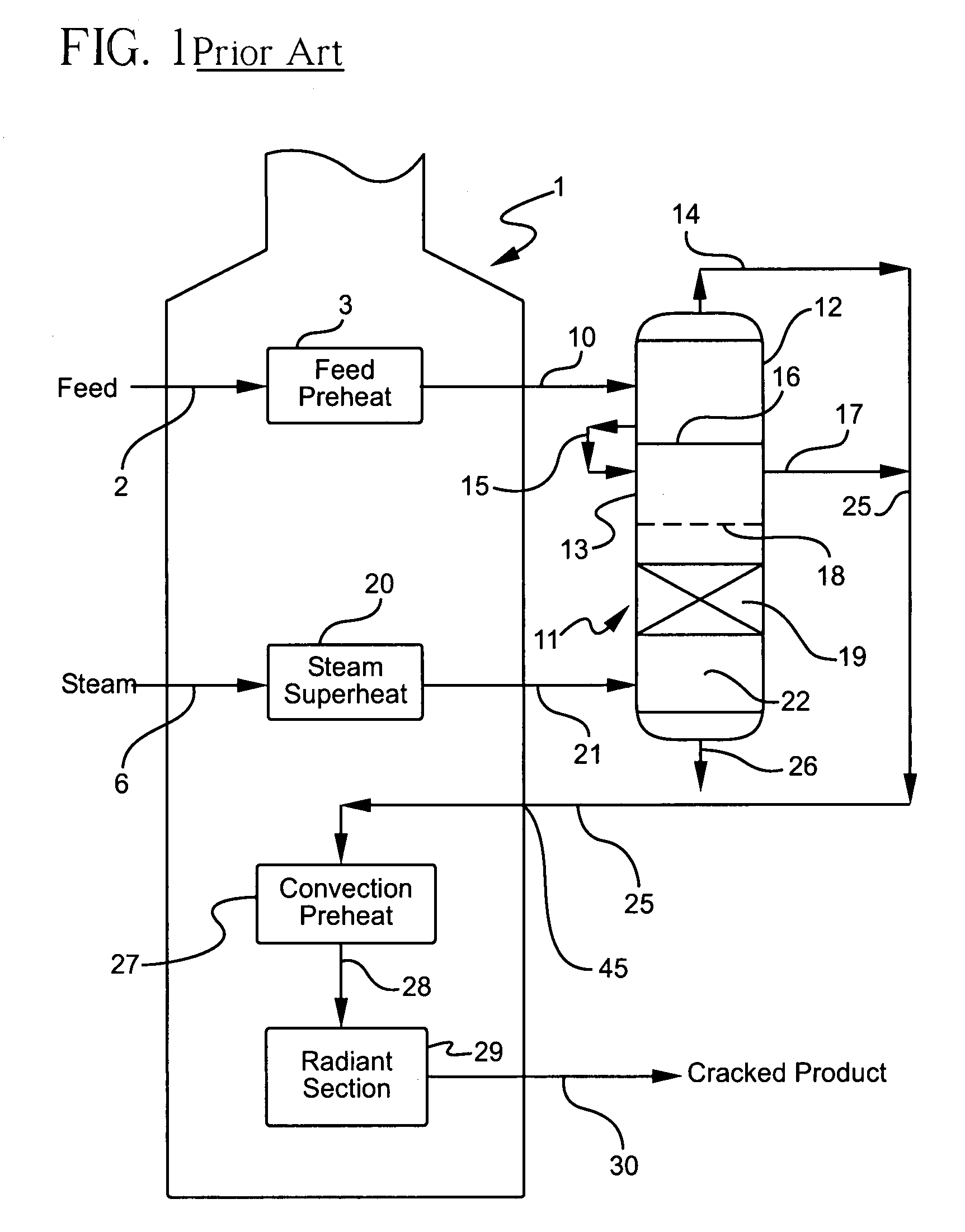

Olefin production utilizing whole crude oil and mild controlled cavitation assisted cracking

InactiveUS20050010075A1Thermal non-catalytic crackingTreatment with plural serial cracking stages onlyCavitationAlkene

A method for utilizing whole crude oil as a feedstock for the pyrolysis furnace of an olefin production plant wherein the feedstock after preheating is subjected to mild thermal cracking assisted with controlled cavitation conditions until substantially vaporized, the vapors being subjected to severe cracking in the radiant section of the furnace.

Owner:EQUSR CHEM LP

Upgrading of tar using POX/coker

ActiveUS8083931B2Reduce and eliminate needThermal non-catalytic crackingTreatment with plural serial cracking stages onlyNaphthaPartial oxidation

The invention is directed to a process wherein a feedstock or stream comprising steam cracker tar is passed to a vacuum pipestill. A deasphalted cut of tar is obtained as an overhead (or sidestream) and a heavy tar asphaltenic product is obtained as bottoms. In preferred embodiments, at least a portion of the bottoms product is sent to a partial oxidation unit (POX) wherein syn gas may be obtained as a product, and / or at least a portion of the bottoms product is used to produce a light product stream in a coker unit, such as coker naphtha and / or or coker gas oil. In another preferred embodiment at least a portion of the overheads product is added to refinery fuel oil pools and in yet another preferred embodiment at least a portion of the overheads product is mixed with locally combusted materials to lower soot make. Two or more of the aforementioned preferred embodiments may be combined.

Owner:EXXONMOBIL CHEM PAT INC

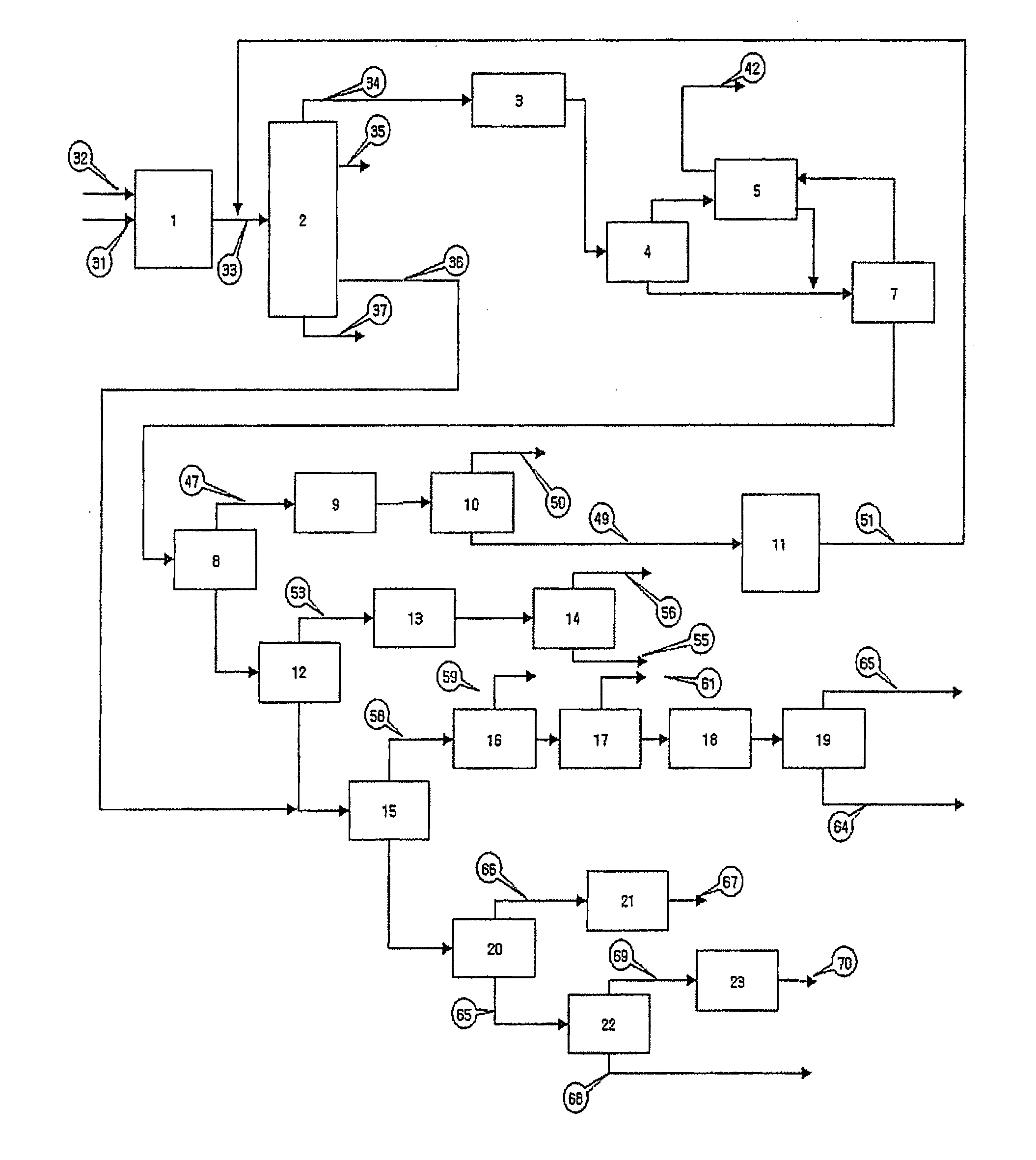

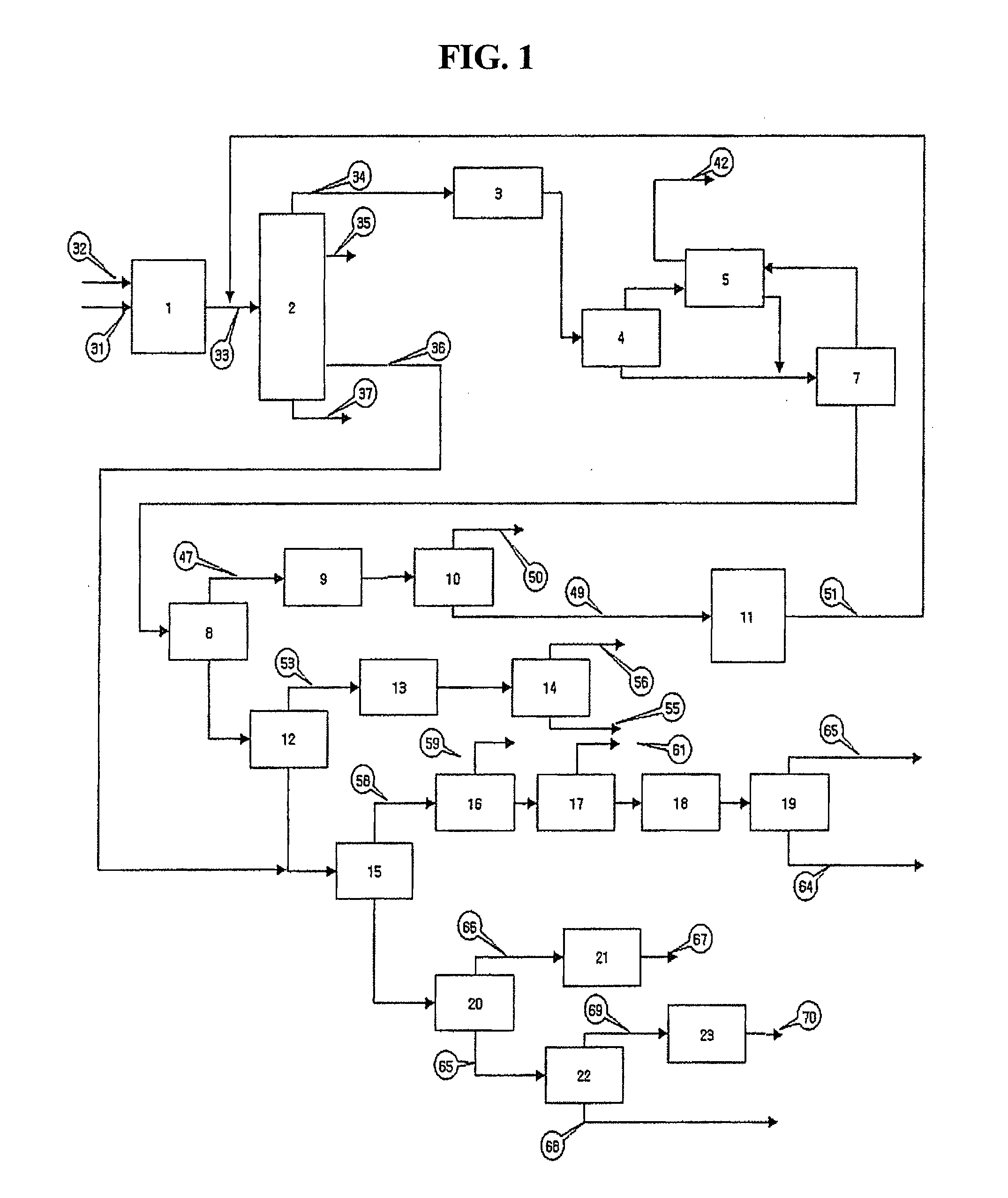

Process for increasing production of light olefins from hydrocarbon feedstock in catalytic cracking

ActiveUS20070083071A1Increase productionEconomical efficiencyTreatment with plural serial cracking stages onlyCatalytic crackingProduction ratePhotochemistry

Disclosed is a process for increasing production of light olefinic hydrocarbons from hydrocarbon feedstock by catalytic cracking. In the process, an effective separation process structure and recycle method of light olefins are used not only to increase the productivity and efficiency of an overall process, thus effectively increasing the production of light olefins, but also to simplify the overall process.

Owner:SK INNOVATION CO LTD

Modified thermal processing of heavy hydrocarbon feedstocks

InactiveUS7572362B2Quick upgradeReducing H2S contentThermal non-catalytic crackingTreatment with plural serial cracking stages onlyLiquid productParticulates

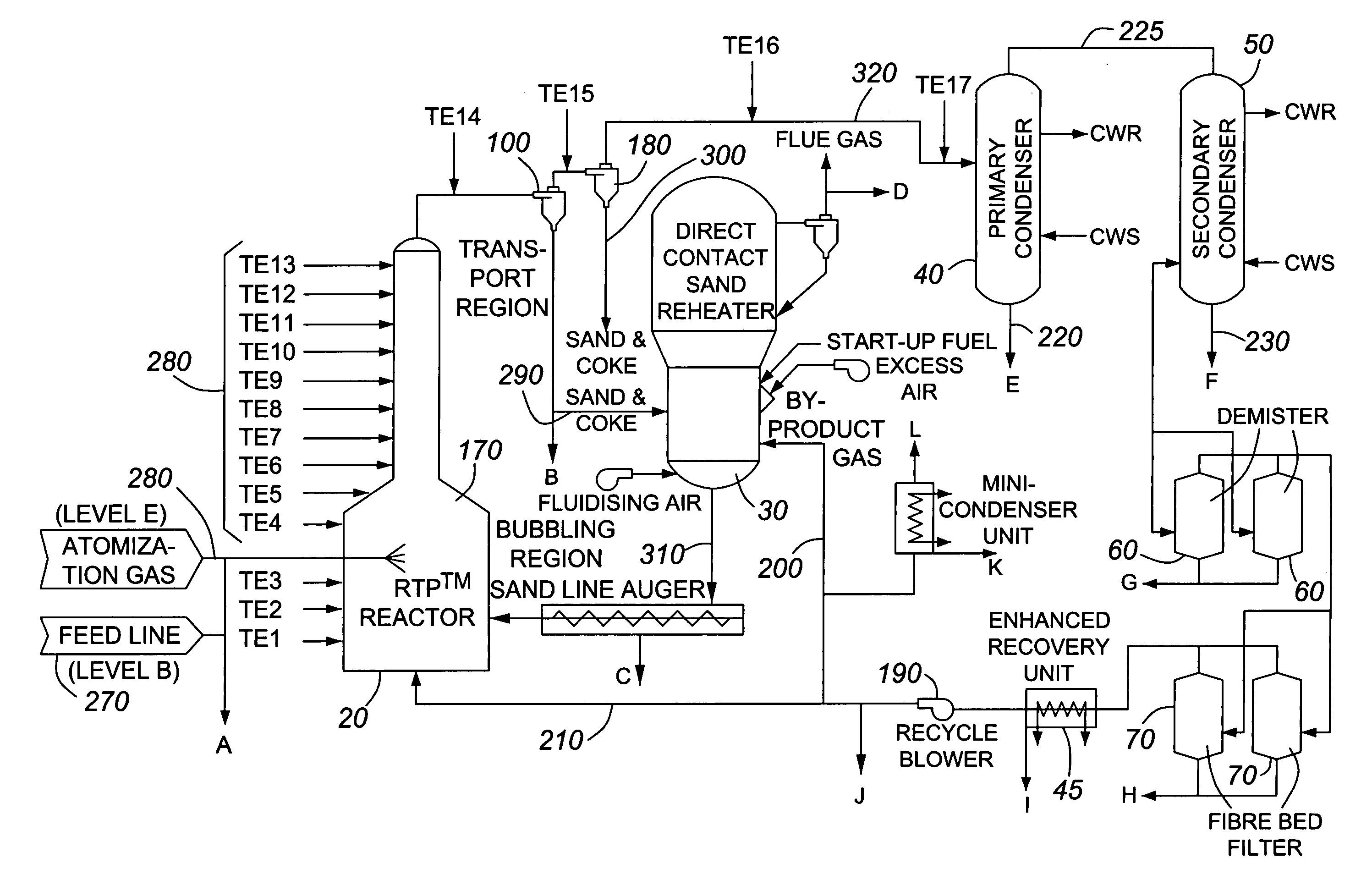

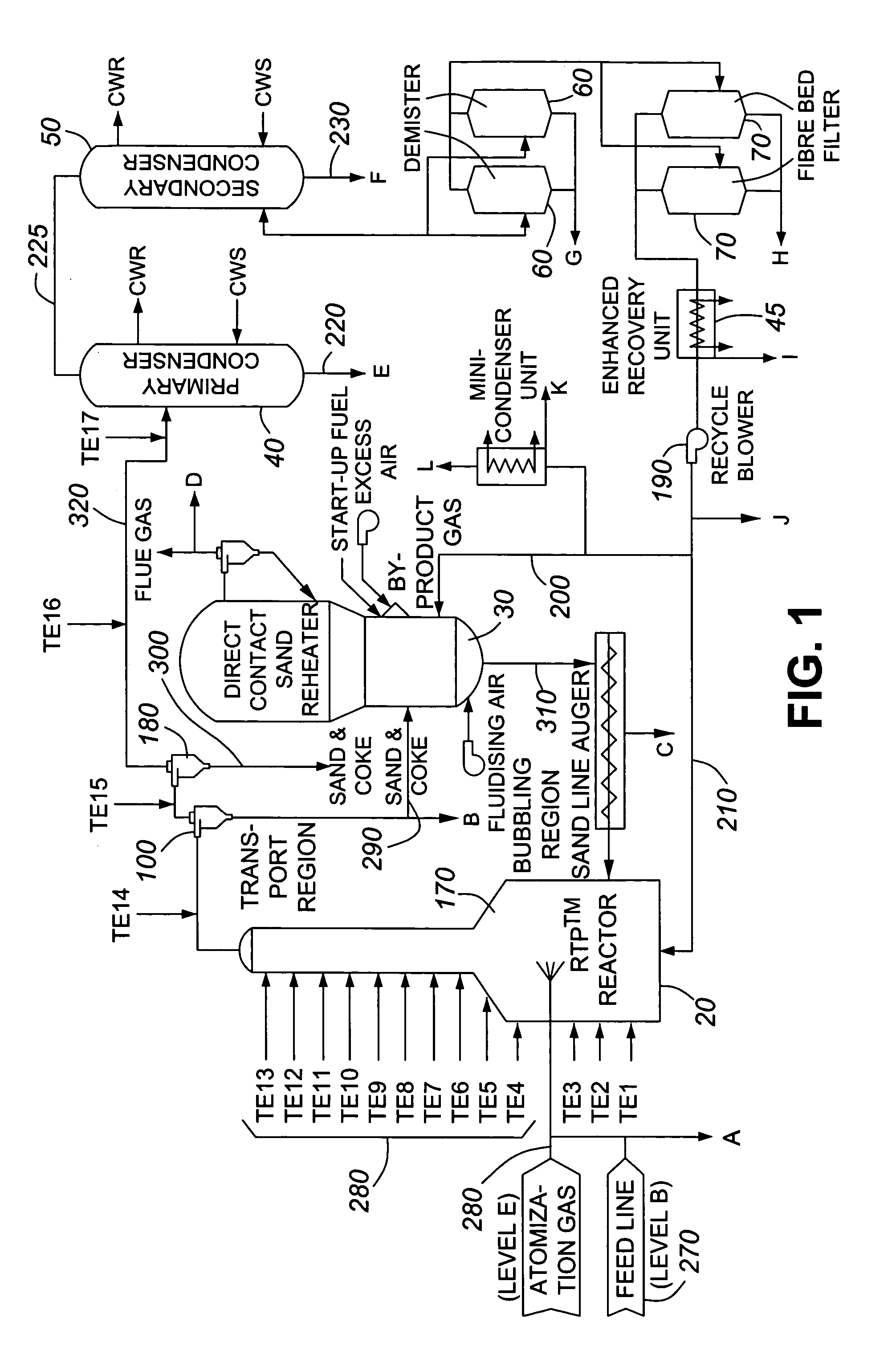

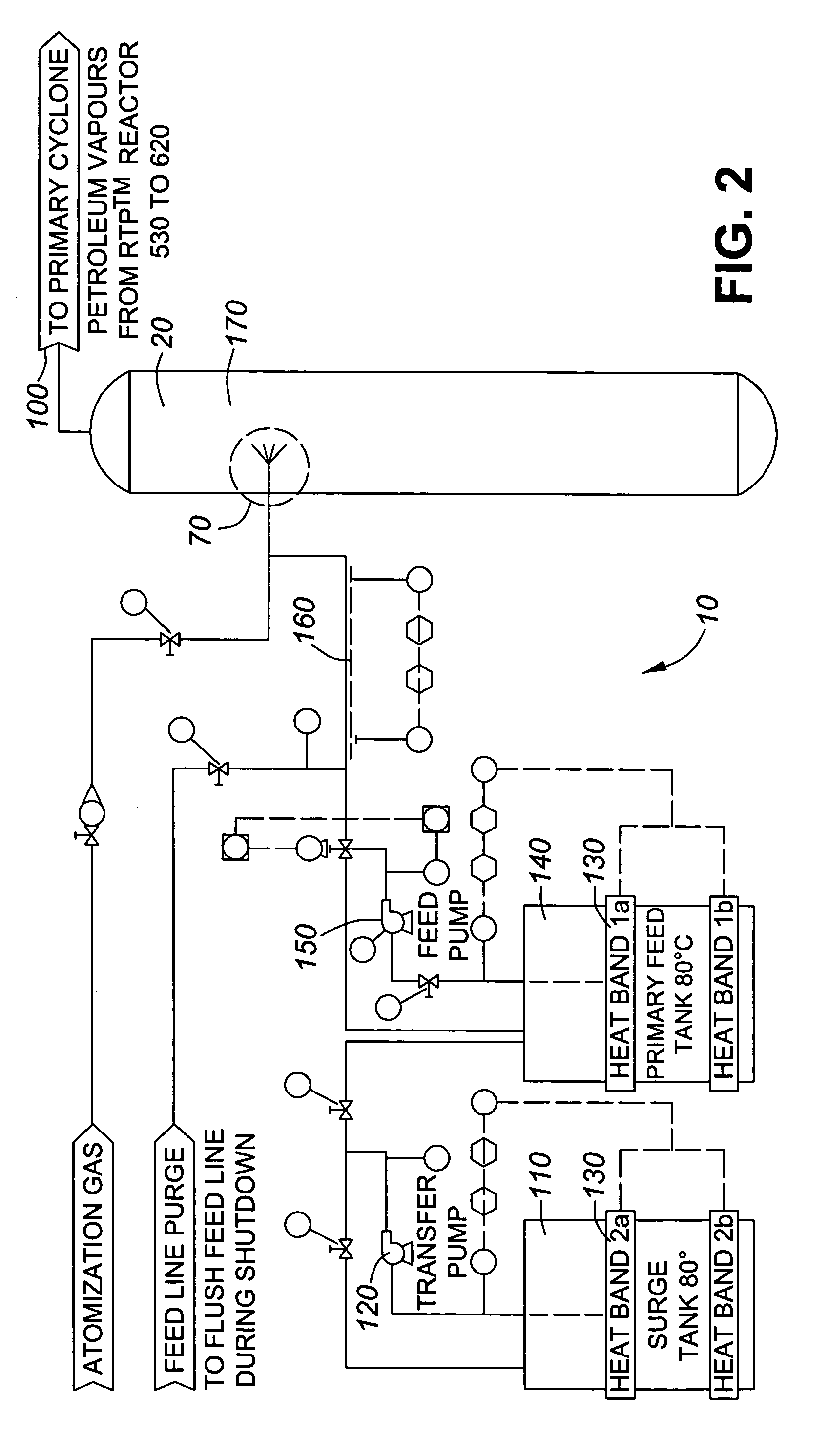

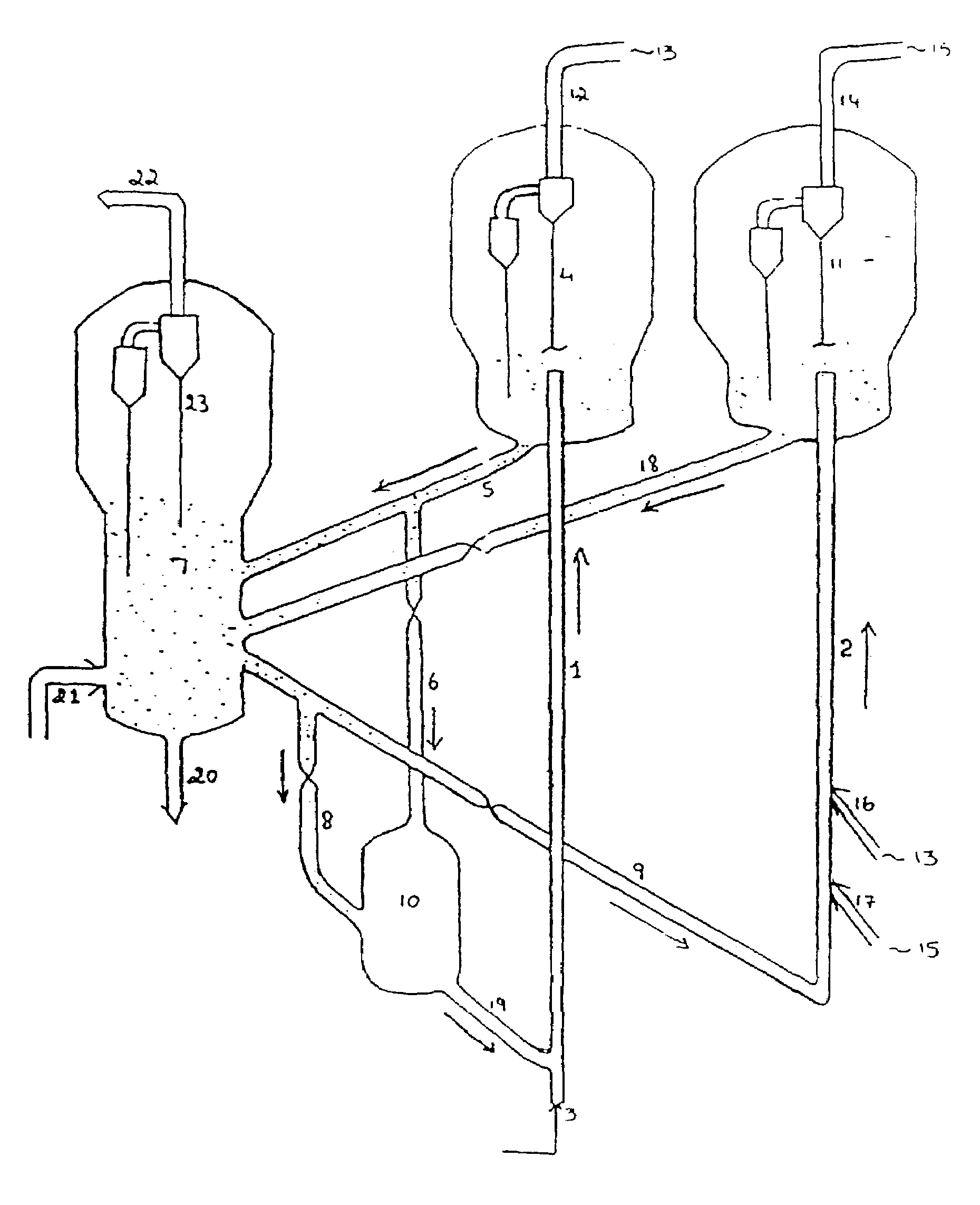

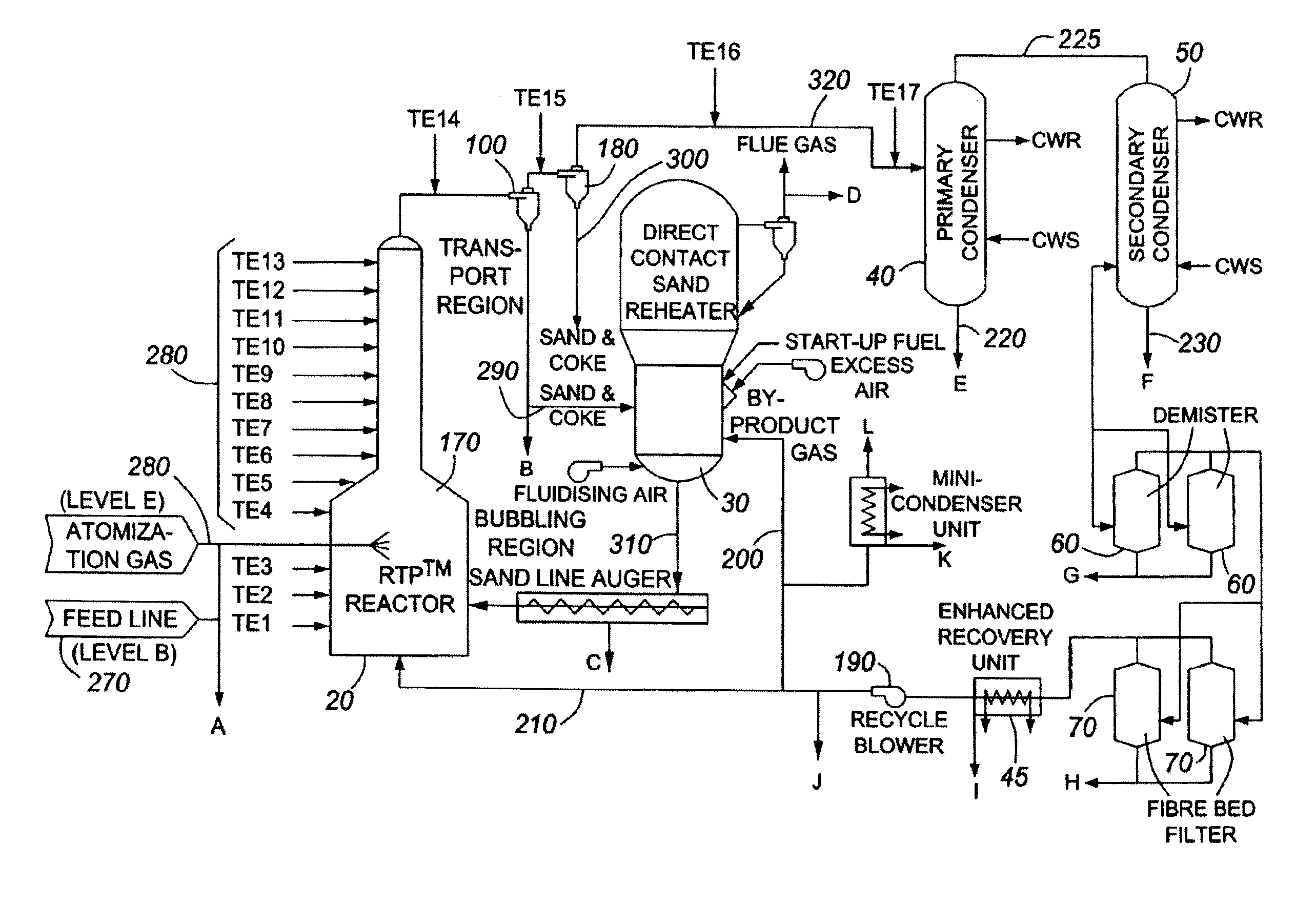

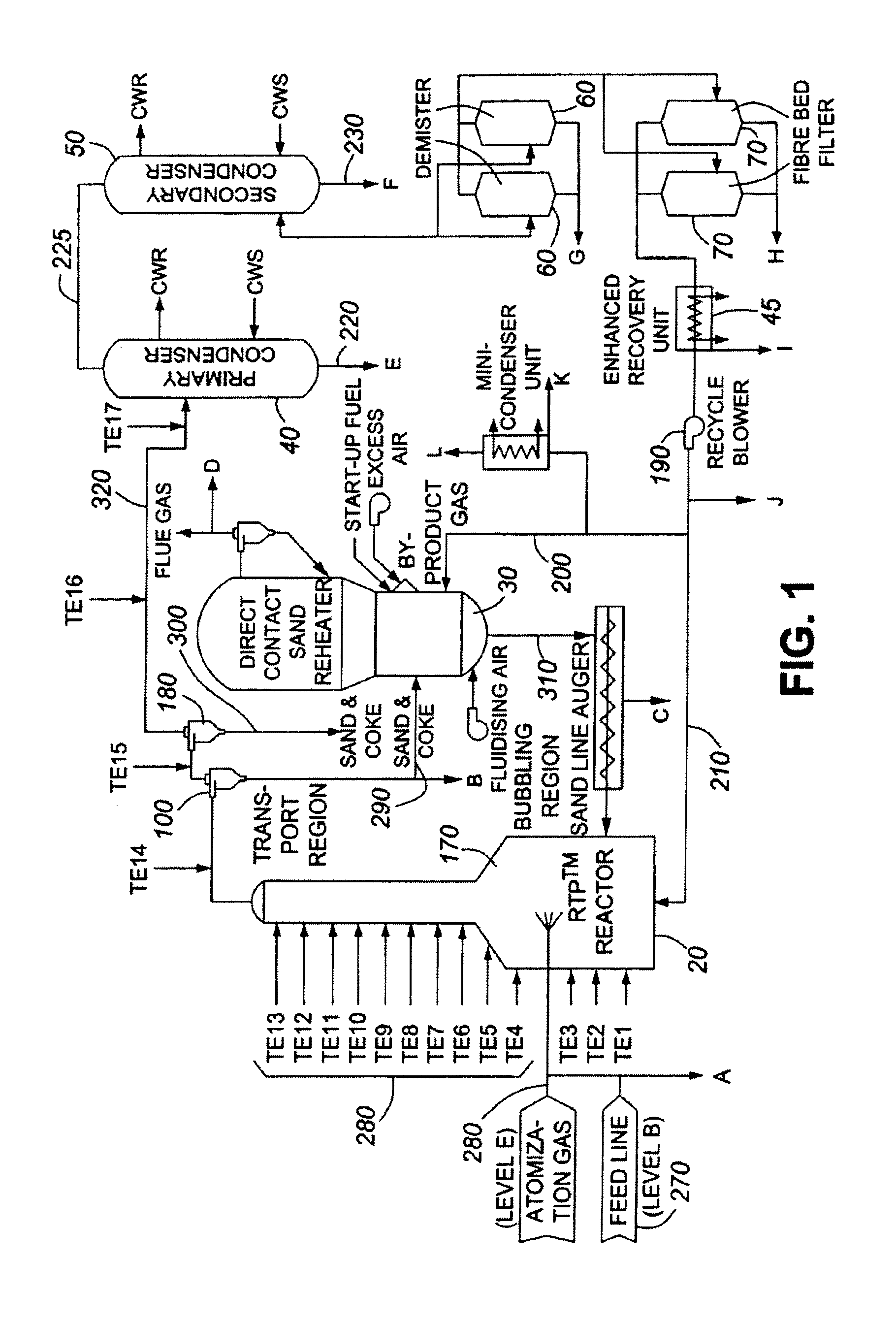

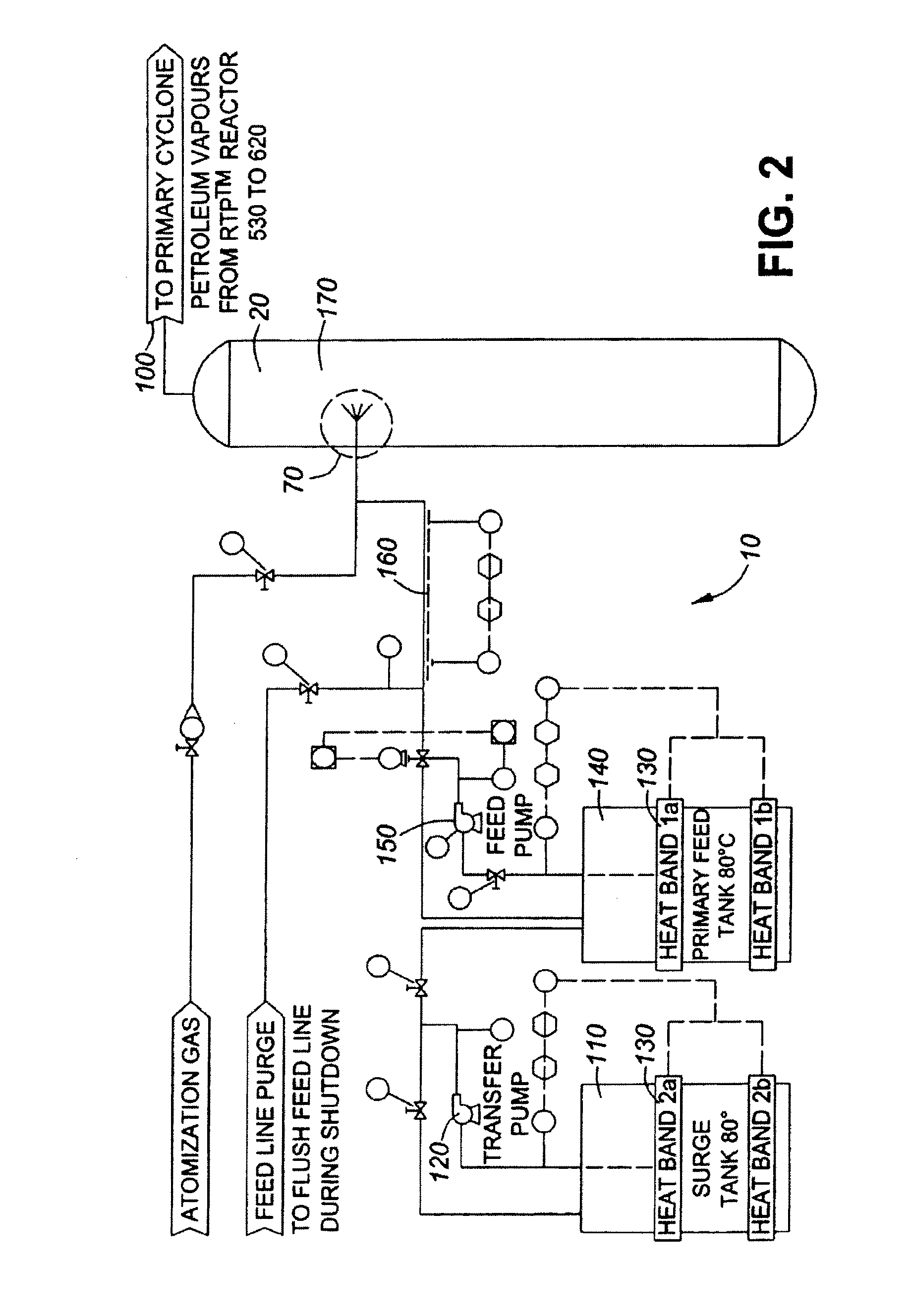

The present invention is directed to the upgrading of heavy petroleum oils of high viscosity and low API gravity that are typically not suitable for pipelining without the use of diluents. It utilizes a short residence-time pyrolytic reactor operating under conditions that result in a rapid pyrolytic distillation with coke formation. Both physical and chemical changes taking place lead to an overall molecular weight reduction in the liquid product and rejection of certain components with the byproduct coke. The liquid product is upgraded primarily because of its substantially reduced viscosity, increased API gravity, and the content of middle and light distillate fractions. While maximizing the overall liquid yield, the improvements in viscosity and API gravity can render the liquid product suitable for pipelining without the use of diluents. This invention particularly relates to reducing sulfur emissions during the combustion of byproduct coke (or coke and gas), to reducing the total acid number (TAN) of the liquid product, and to reducing the hydrogen sulfide content of one, or more than one component of the product stream. The method comprises introducing a particulate heat carrier into an up-flow reactor, introducing the feedstock at a location above the entry of the particulate heat carrier, allowing the heavy hydrocarbon feedstock to interact with the heat carrier for a short time, separating the vapors of the product stream from the particulate heat carrier and liquid and byproduct solid matter, regenerating the particulate heat carrier in the presence of the calcium compound, and collecting a gaseous and liquid product from the product stream.

Owner:IVANHOE HTL GASOLINEEUM

Gasoline and diesel production from pyrolytic lignin produced from pyrolysis of cellulosic waste

InactiveUS20080053870A1High yieldTreatment with plural serial cracking stages onlyTreatment with plural serial stages onlyCelluloseNaphtha

Owner:UOP LLC

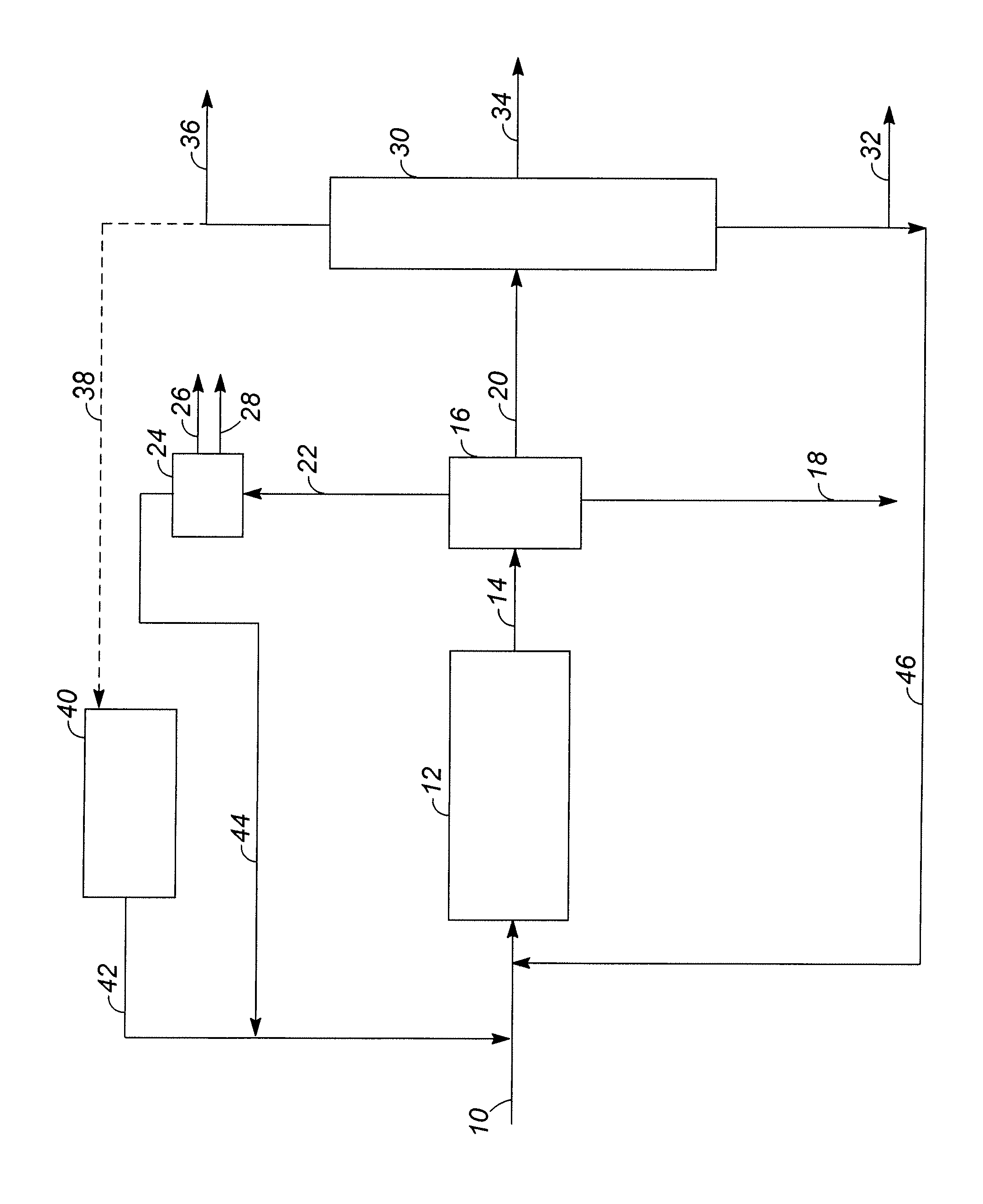

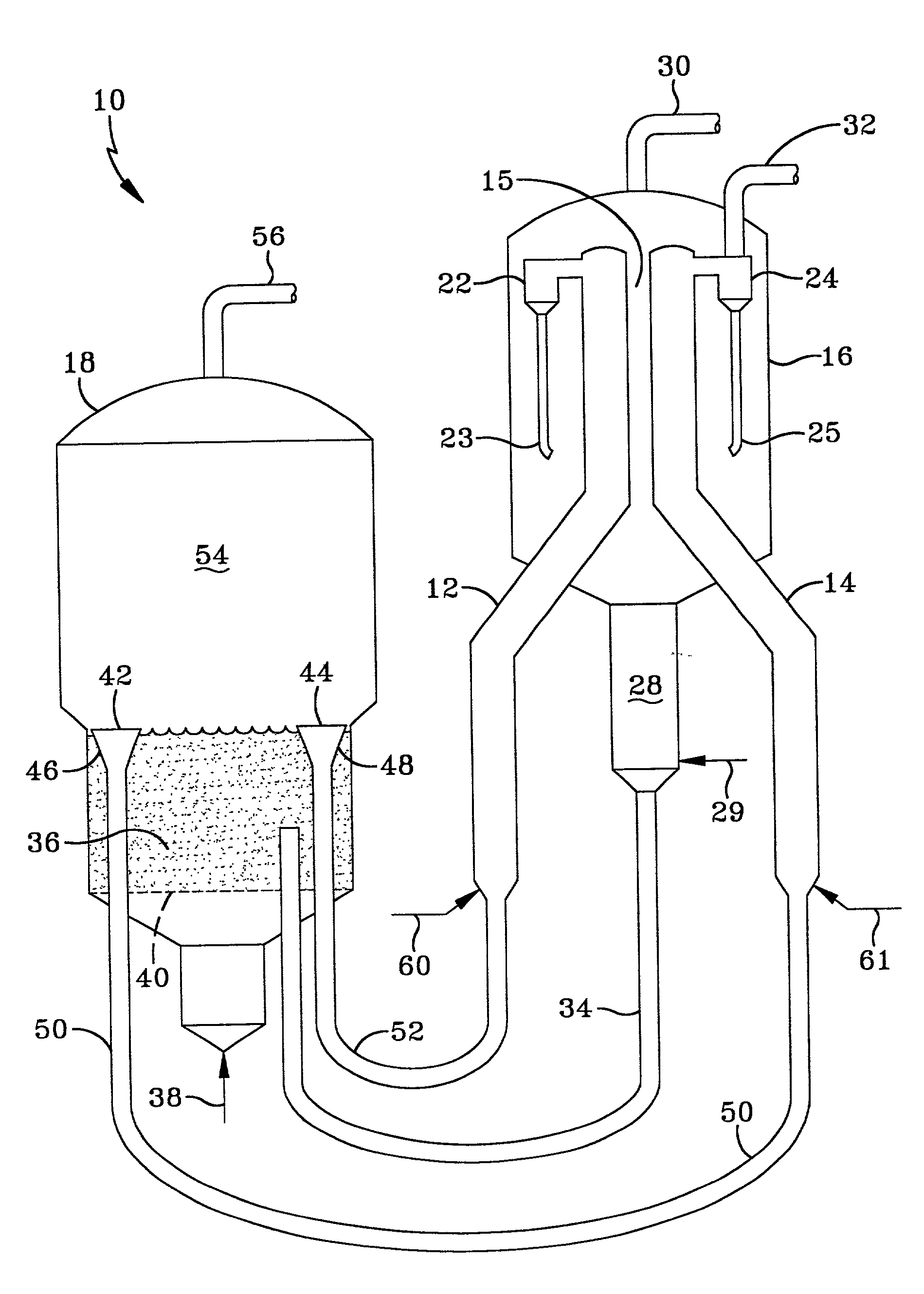

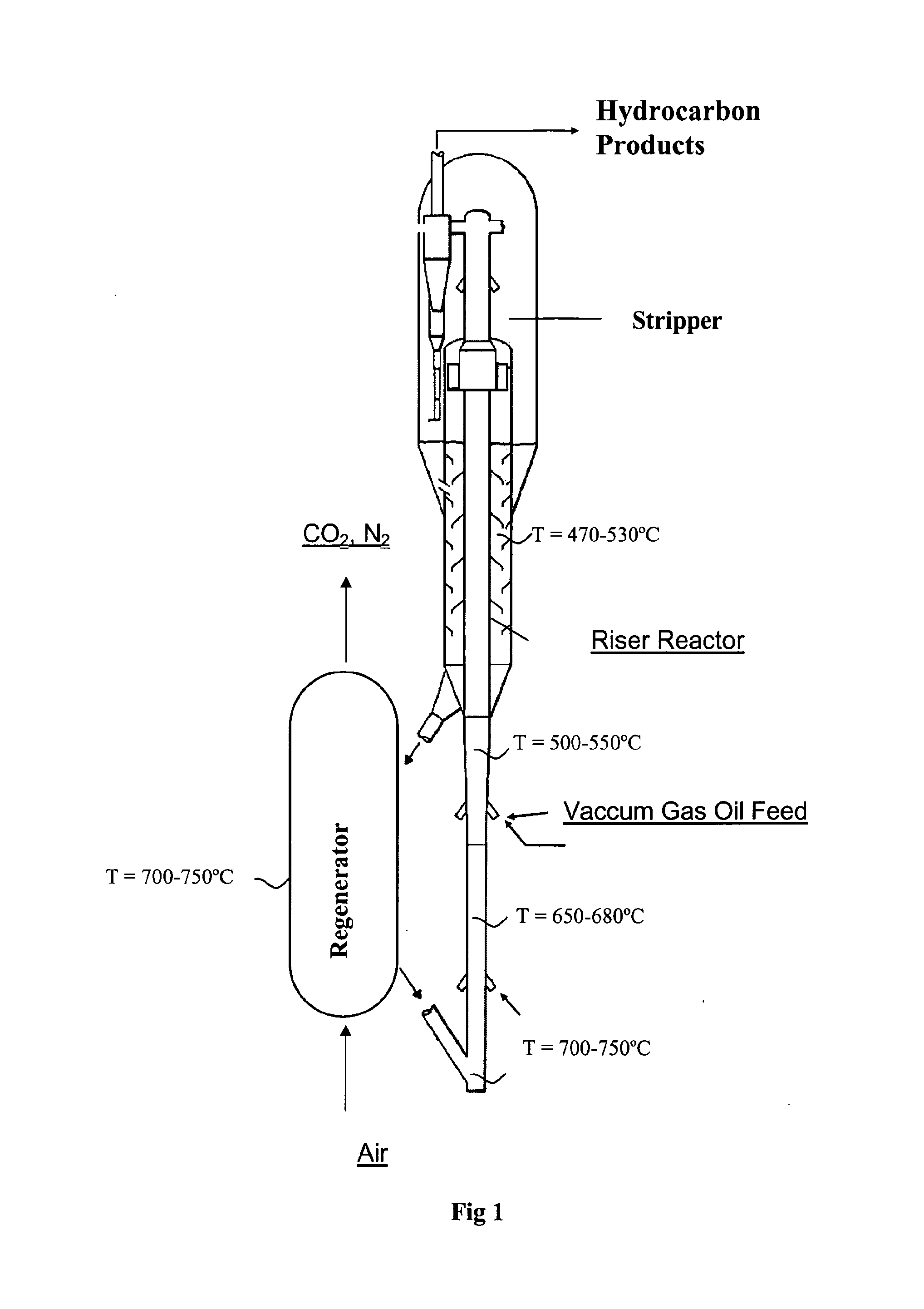

Multi stage selective catalytic cracking process and a system for producing high yield of middle distillate products from heavy hydrocarbon feedstocks

InactiveUS7029571B1MinimizeImproving cetane qualityTreatment with plural serial cracking stages onlyCatalytic crackingFluidized bedPetroleum

According to this invention, there is provided a process and apparatus for catalytic cracking of various petroleum based heavy feed stocks in the presence of solid zeolite catalyst and high pore size acidic components for selective bottom cracking and mixtures thereof, in multiple riser type continuously circulating fluidized bed reactors operated at different severities to produce high yield of middle distillates, in the range of 50–65 wt % of fresh feed.

Owner:INDIAN OIL CORPORATION

Method for making a heavy wax composition

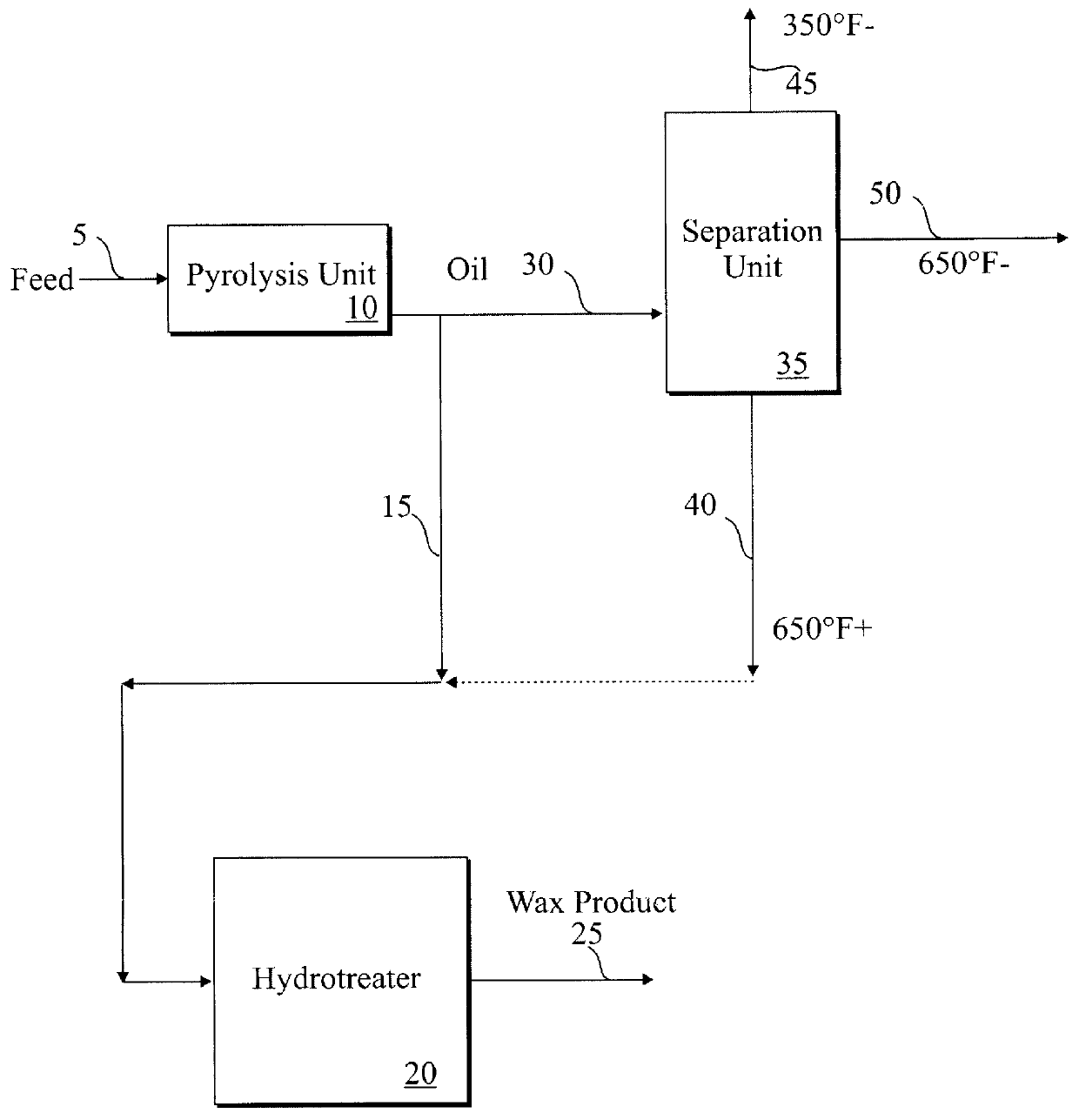

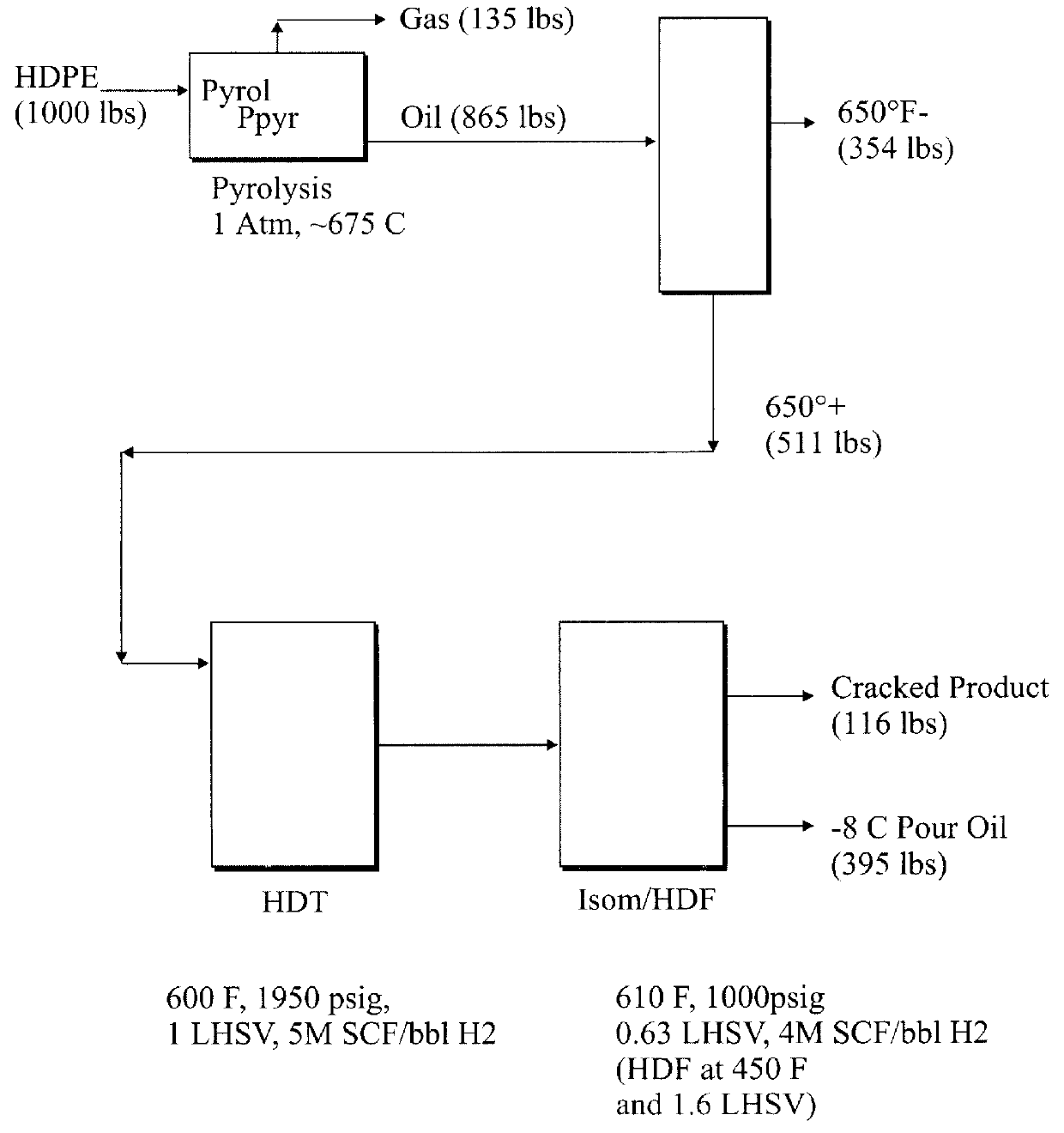

InactiveUS6143940ATreatment with plural serial cracking stages onlyTreatment with plural serial stages onlyWaxAlkane

The invention includes a process of making a wax composition including: a process for making a heavy wax composition including the steps of (1) contacting a waste plastics feed containing primarily polyethylene in a pyrolysis zone at sub-atmospheric pressure, whereby at least a portion of the waste plastics feed is cracked, thereby forming a pyrolysis zone effluent including 1-olefins and n-paraffins; and (2) passing the pyrolysis zone effluent to a hydrotreating zone, for contacting with a hydrotreating catalyst at catalytic conditions.

Owner:UNIV OF KENTUCKY RES FOUND

Olefin production utilizing whole crude oil and mild controlled cavitation assisted cracking

InactiveUS6979757B2Thermal non-catalytic crackingTreatment with plural serial cracking stages onlyCavitationAlkene

A method for utilizing whole crude oil as a feedstock for the pyrolysis furnace of an olefin production plant wherein the feedstock after preheating is subjected to mild thermal cracking assisted with controlled cavitation conditions until substantially vaporized, the vapors being subjected to severe cracking in the radiant section of the furnace.

Owner:EQUSR CHEM LP

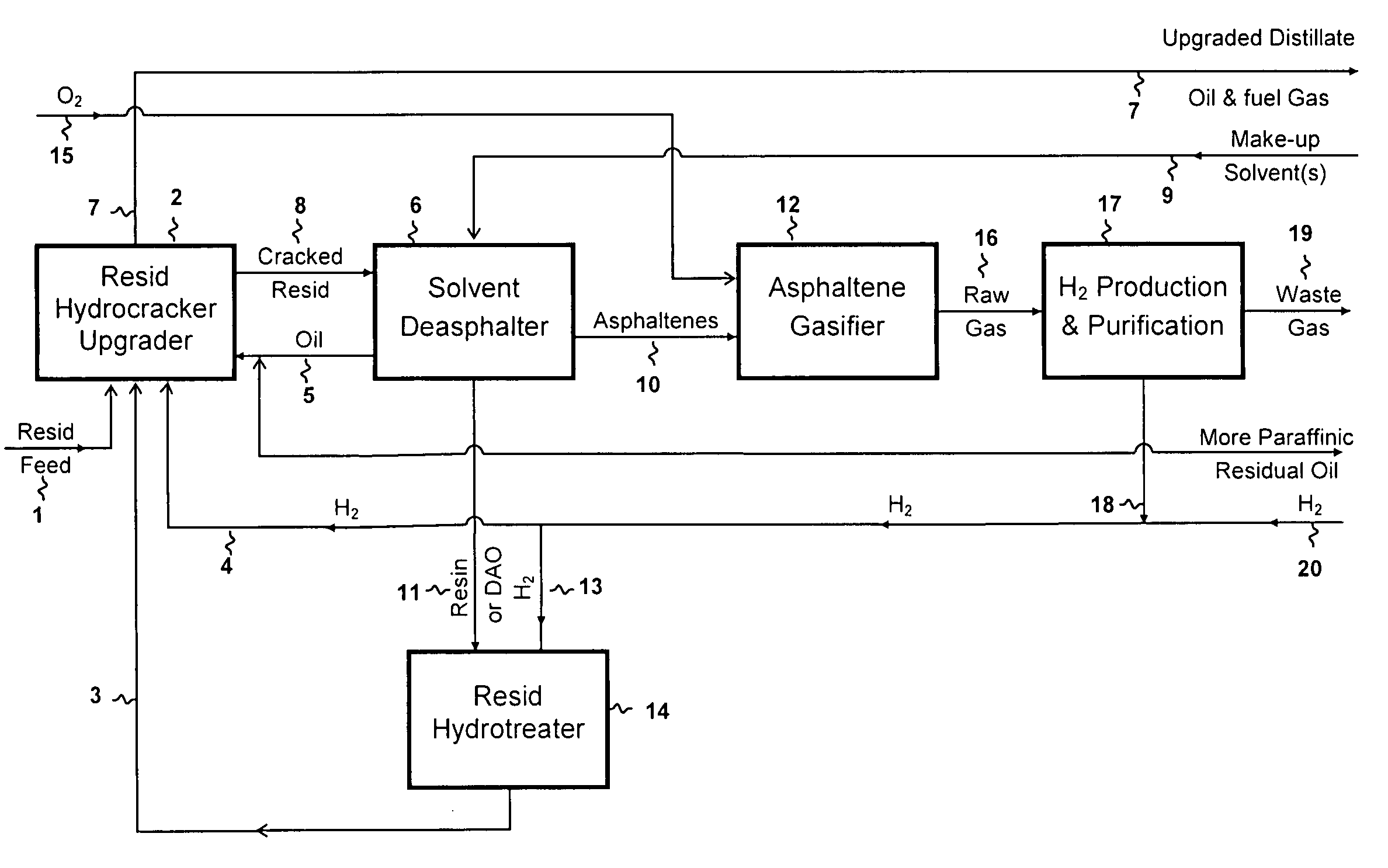

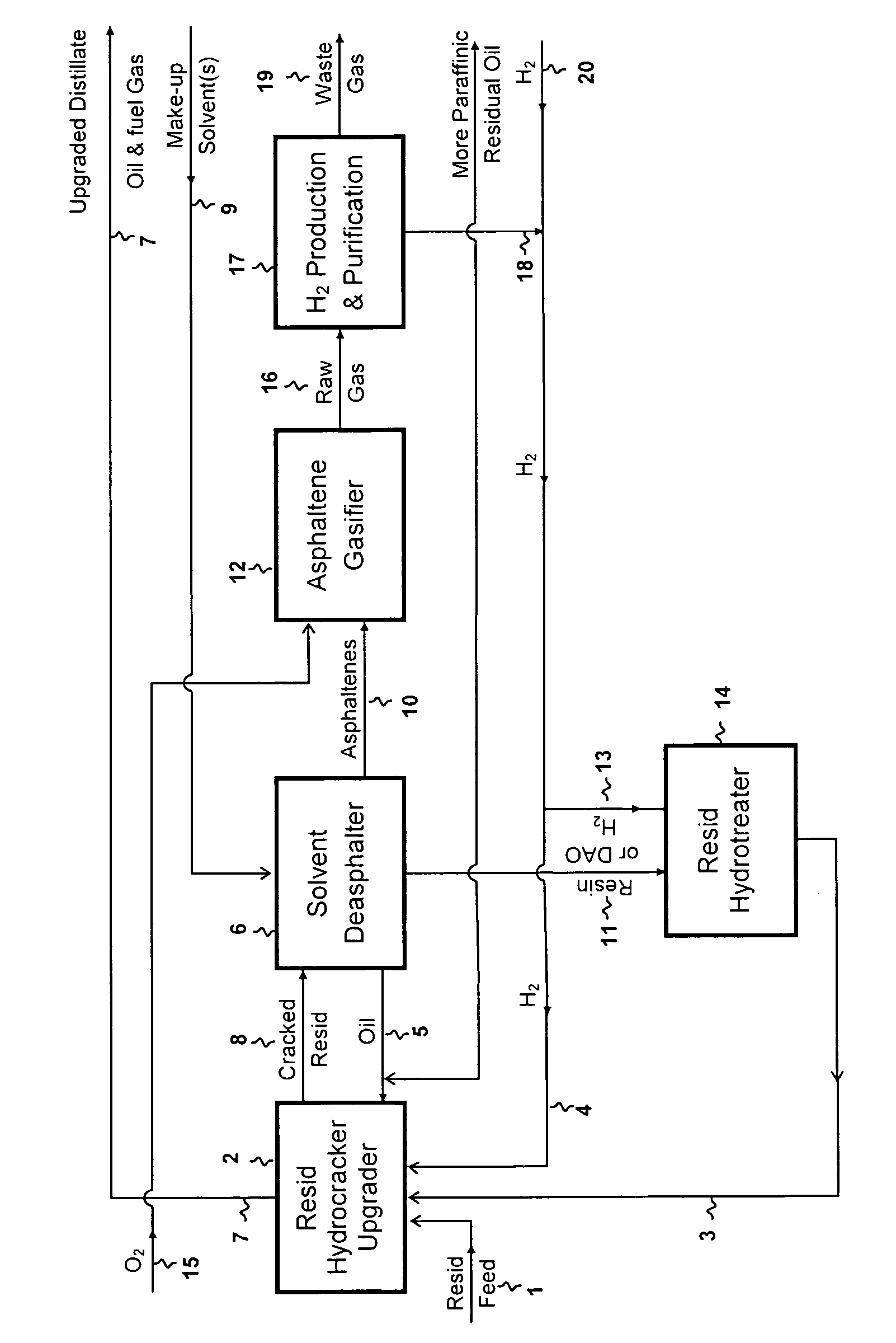

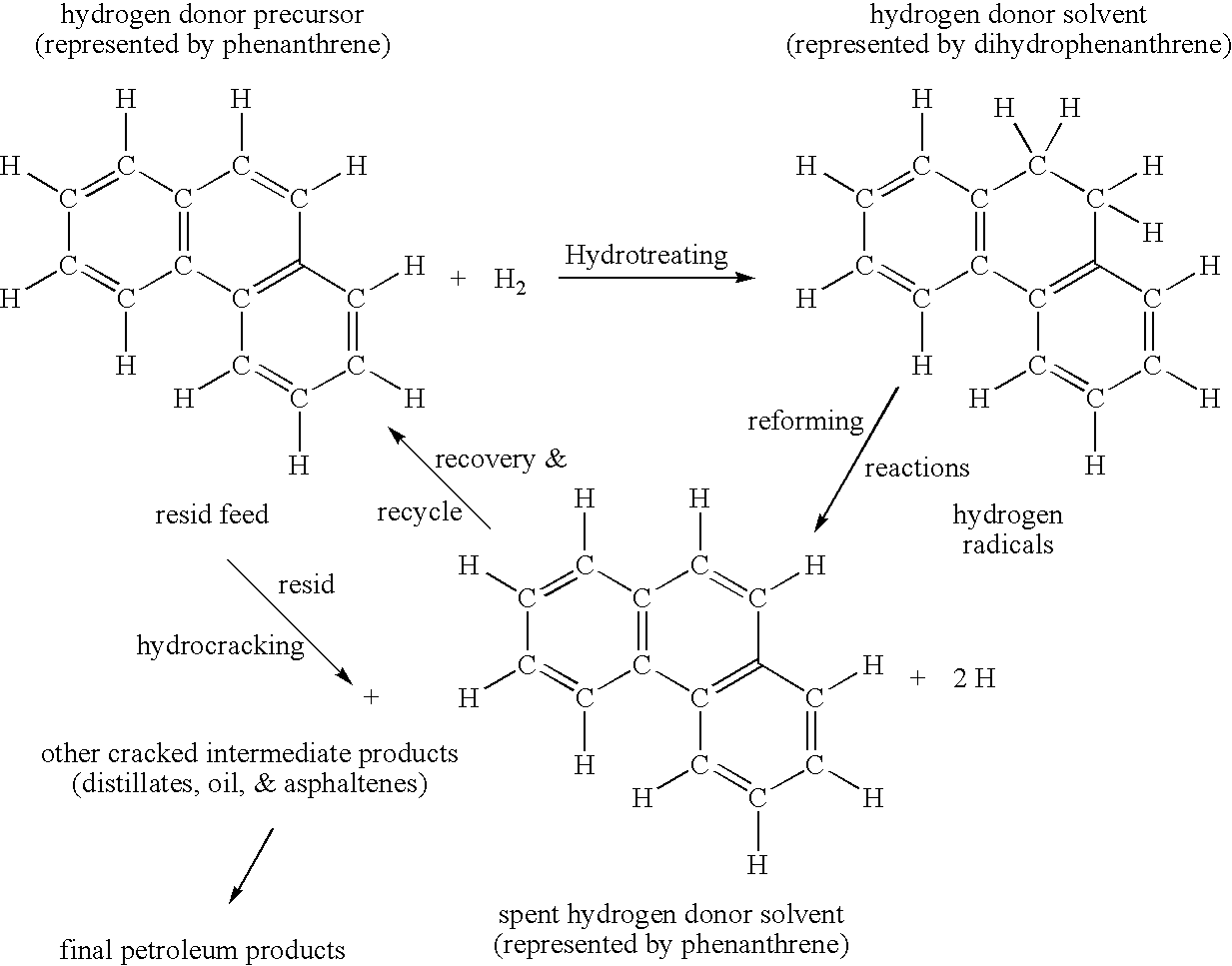

Hydrogen donor solvent production and use in resid hydrocracking processes

InactiveUS20070108100A1Treatment with plural serial cracking stages onlyCoke ovensHydrogenBoiling point

A process derived hydrogen donor solvent is used to increase the maximum resid conversion and conversion rate in an ebullated bed resid hydrocracker. The hydrogen donor solvent precursor is produced by hydroreforming reactions within the resid hydrocracker, recovered as the resin fraction from a solvent deasphalting unit, regenerated in a separate hydrotreater reactor, and recycled to the ebullated bed resid hydrocracker. The major advantage of this invention relative to earlier processes is that hydrogen is more efficiently transferred to the resin residual oil in the separate hydrotreater and the hydrogen donor solvent effectively retards the formation of coke precursors at higher ebullated bed resid hydrocracker operating temperatures and resid cracking rates.

Owner:BOC GRP INC

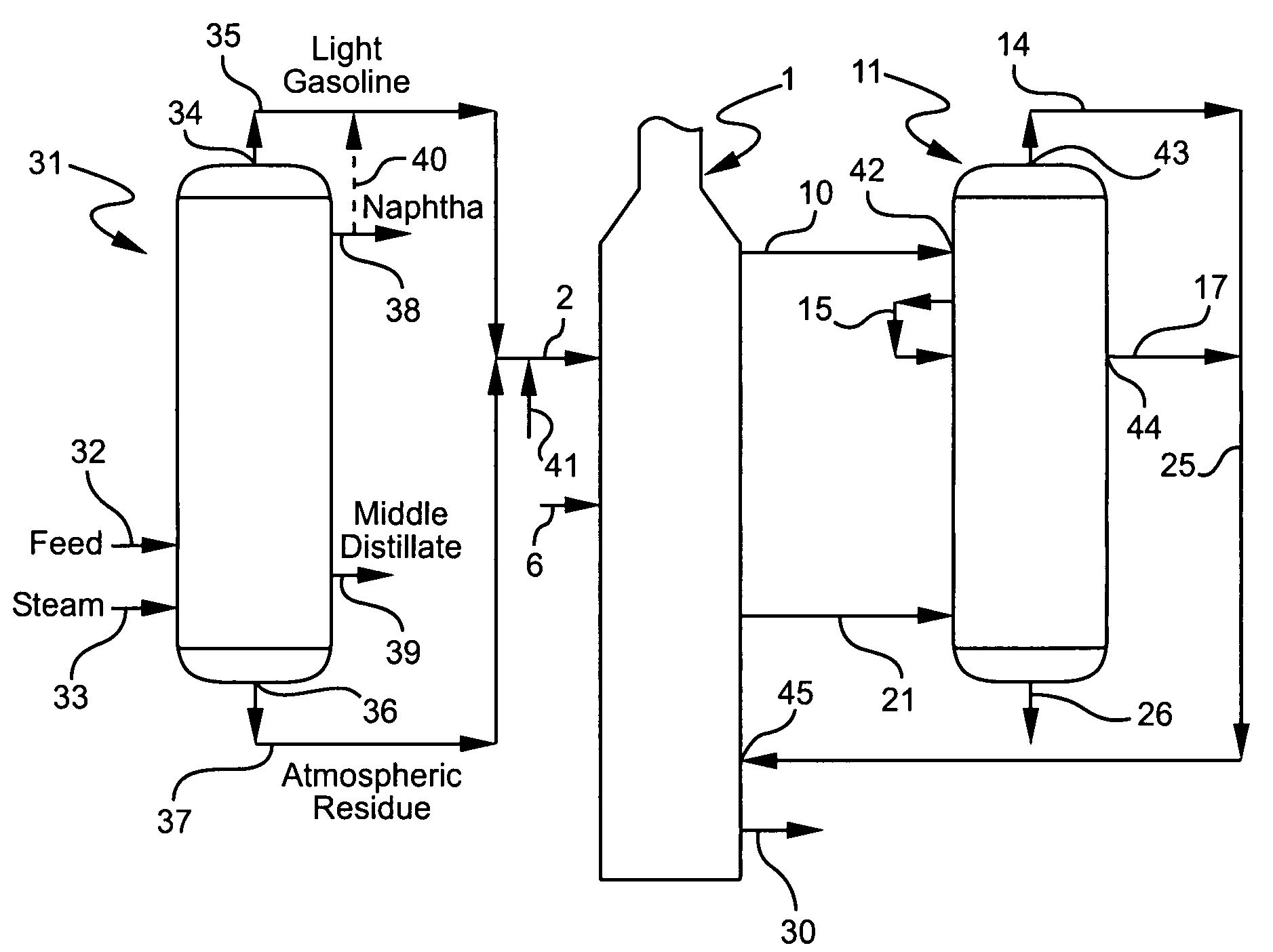

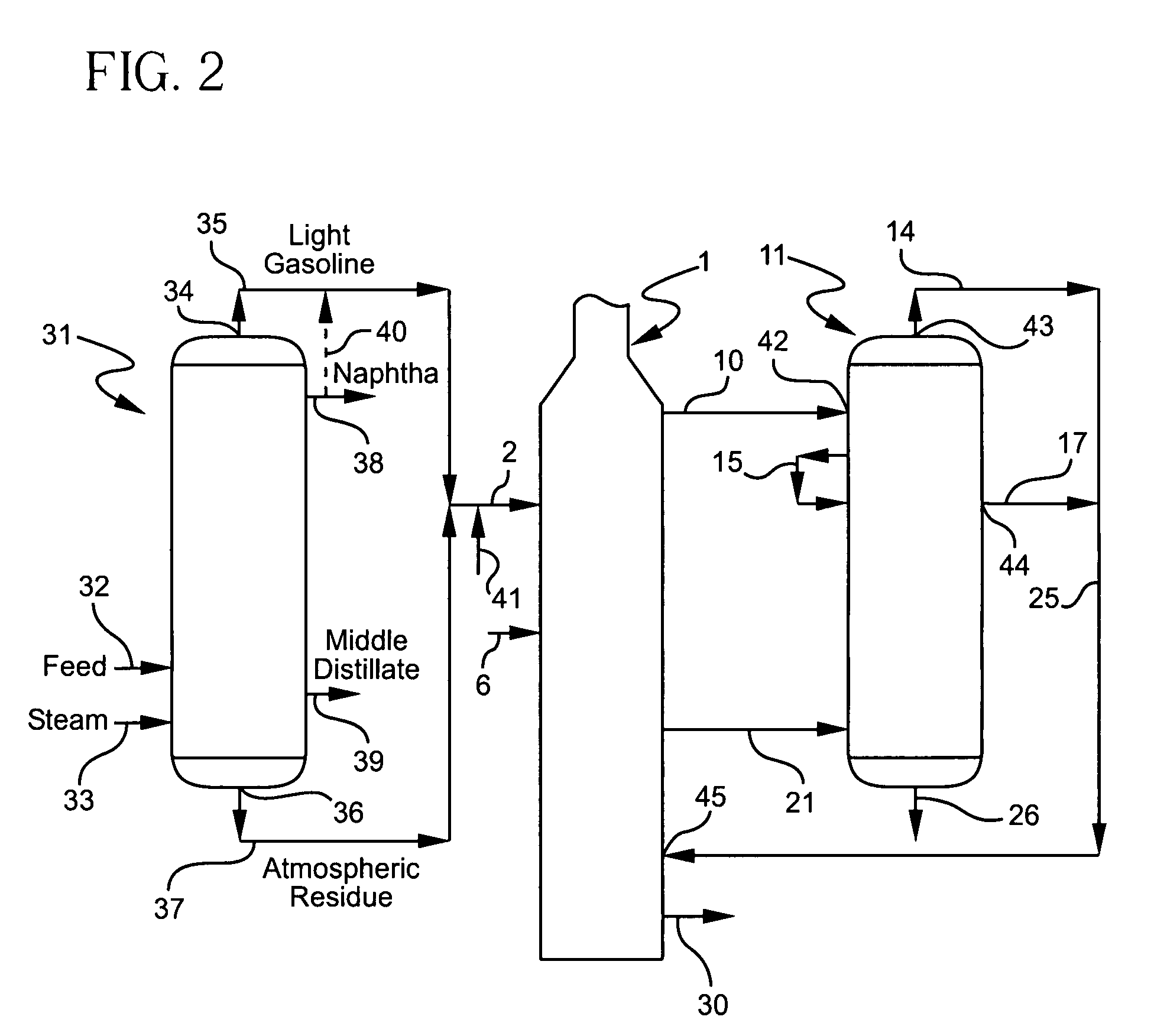

Hydrocarbon thermal cracking using atmospheric distillation

ActiveUS7404889B1Thermal non-catalytic crackingTreatment with plural serial cracking stages onlyDistillationGasoline

A method for thermally cracking a hydrocarbonaceous feed wherein the feed is first processed in an atmospheric thermal distillation step to form a light gasoline and atmospheric residuum mixture. The light gasoline / residuum combination is gasified at least in part in a vaporization step, and the gasified product of the vaporization step is thermally cracked.

Owner:EQUSR CHEM LP

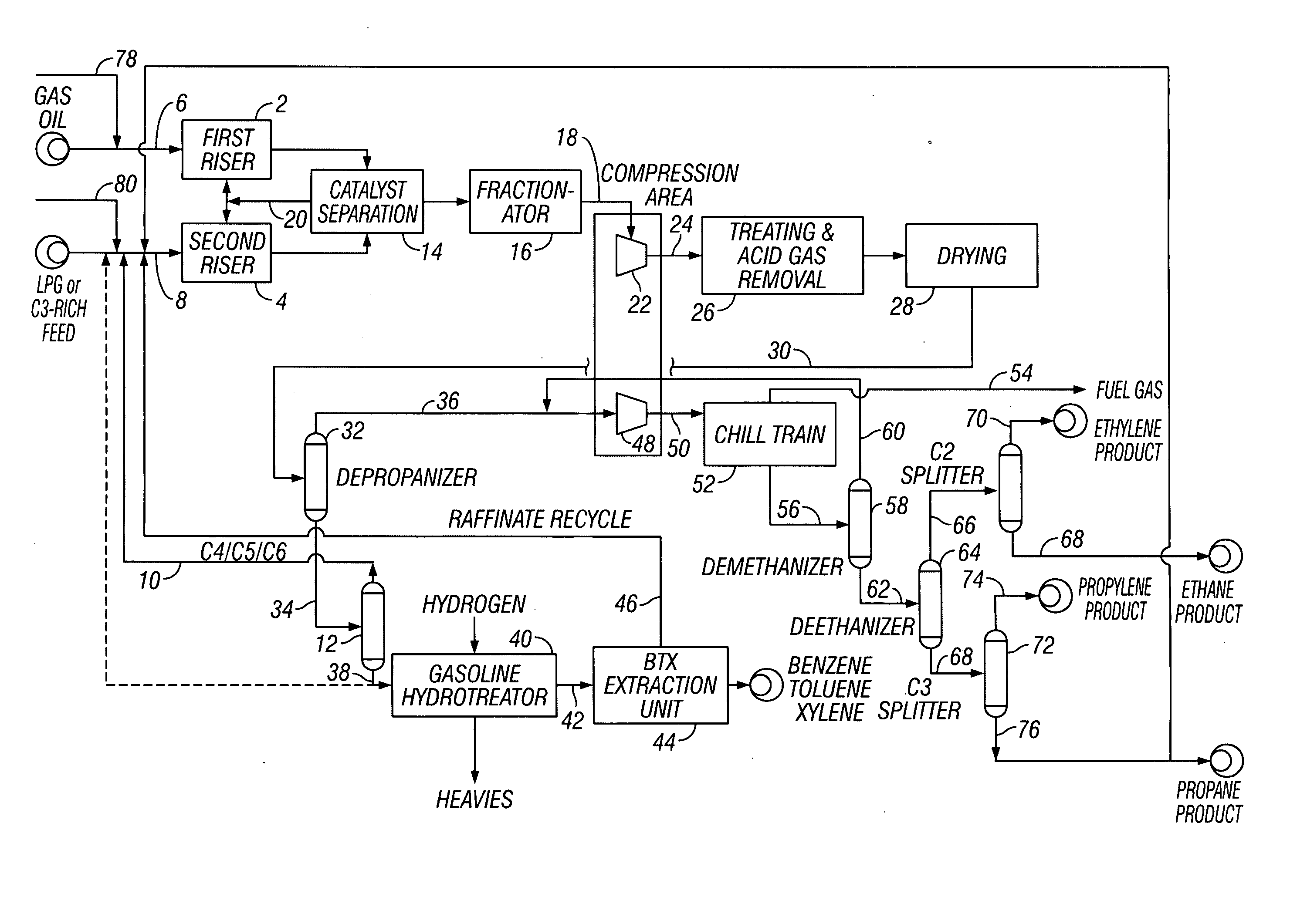

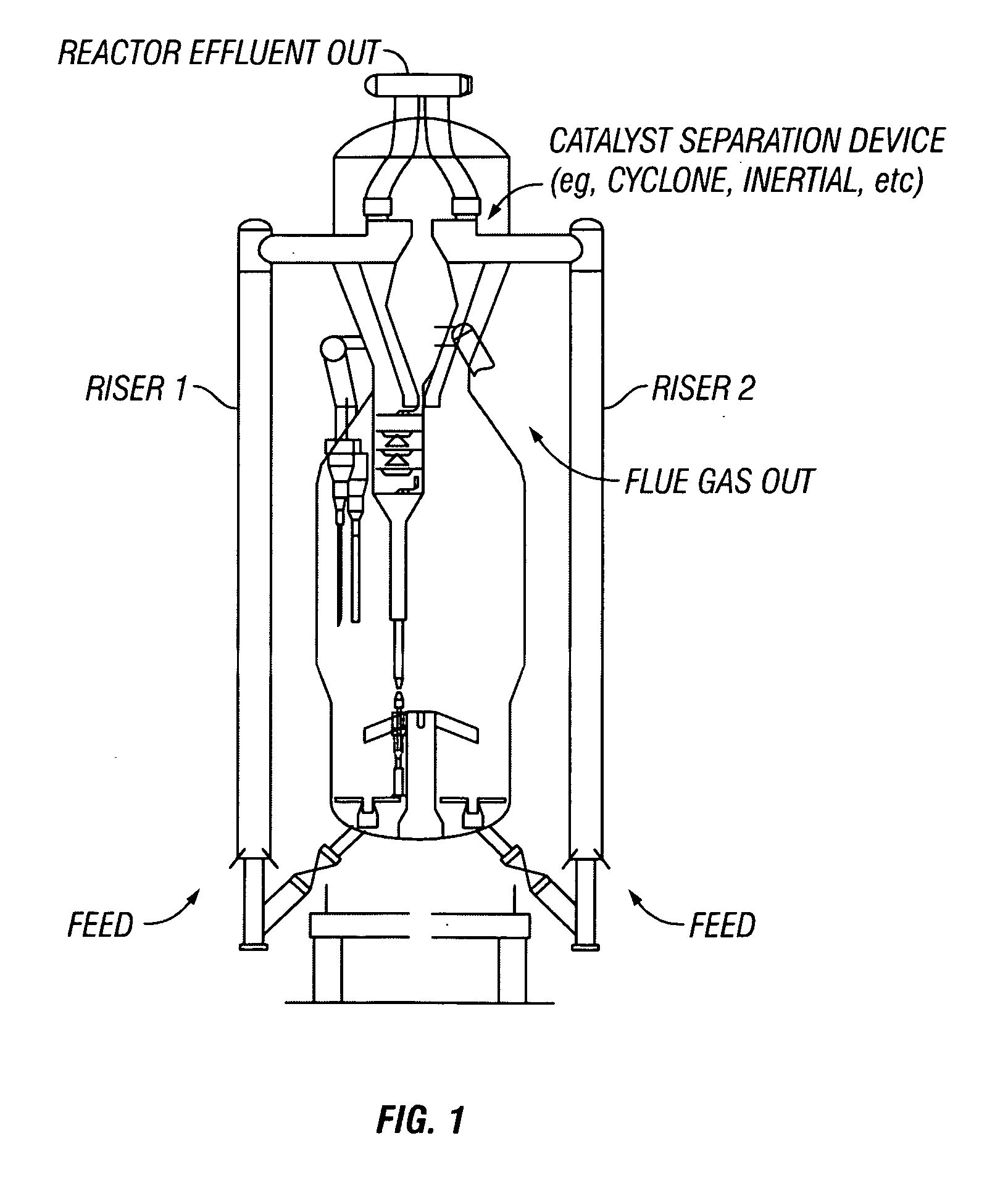

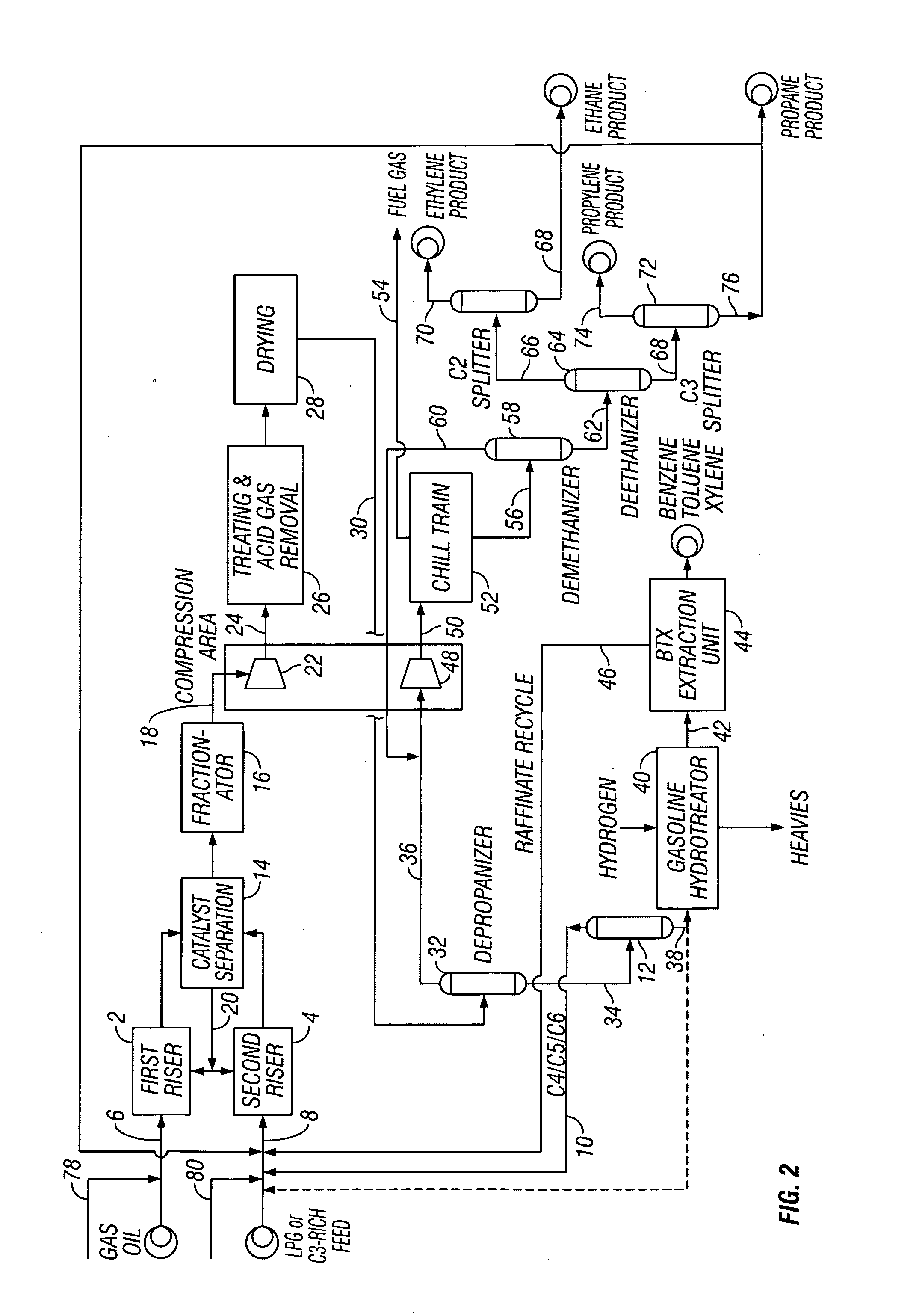

FCC process for converting C3/C4 feeds to olefins and aromatics

ActiveUS20080156696A1Treatment with plural serial cracking stages onlyCatalytic crackingEngineeringAlkene

A dual riser FCC process for converting C3 / C4-containing feedstocks to aromatics. First and second hydrocarbon feeds (5, 6) are supplied to the respective first and second risers (2, 4) in a dual-riser FCC unit with a gallium enriched catalyst to make an effluent rich in ethylene, propylene and aromatics. The first riser (2) is operated at less severe conditions than the second riser (4) and can receive a relatively heavy feed such as gas oil. The feed to the second riser (4) includes propane, for example LPG, propane recycle from the C3 splitter (72), etc. The FCC catalyst can include gallium to promote aromatics formation.

Owner:KELLOGG BROWN & ROOT LLC

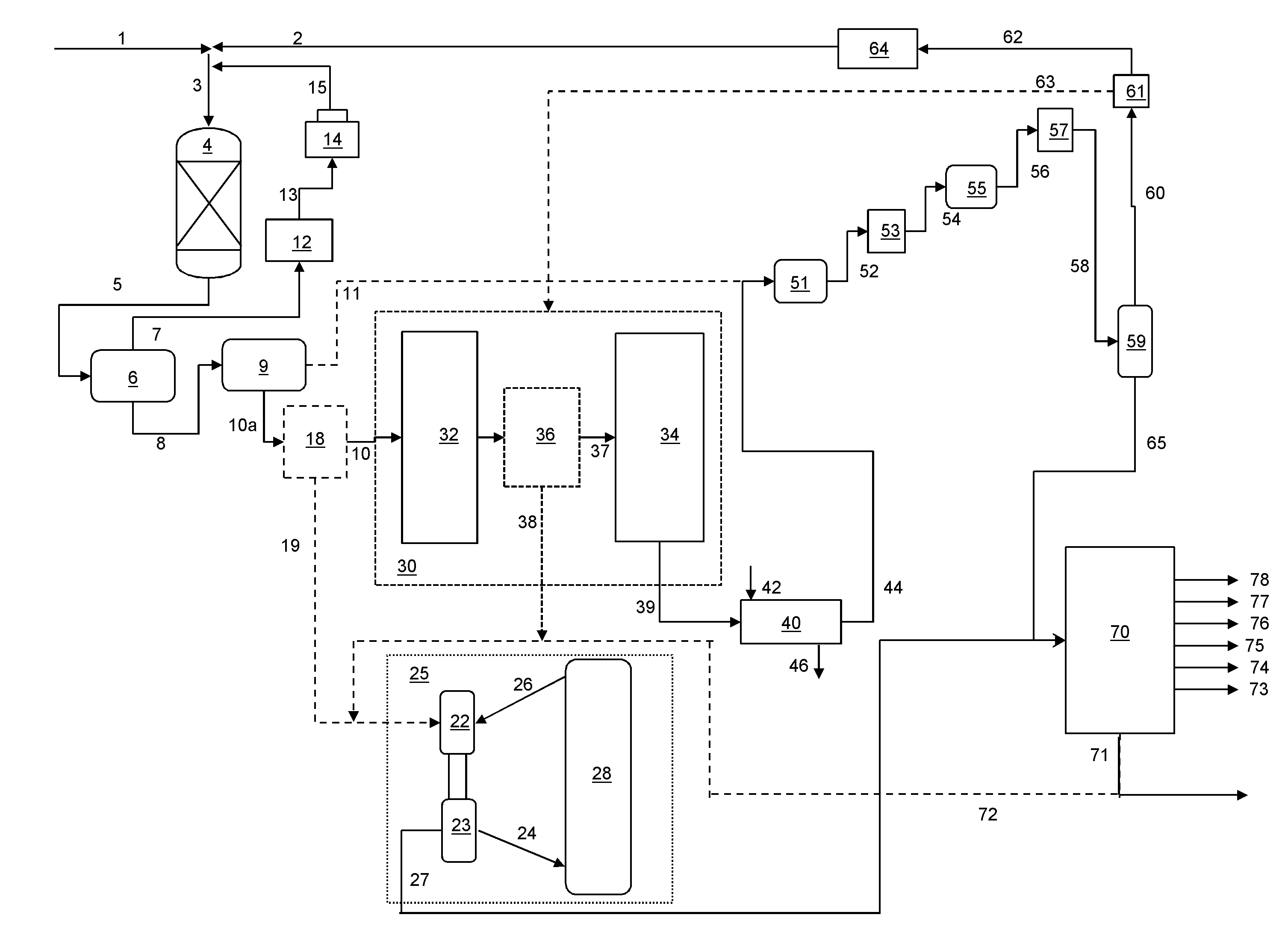

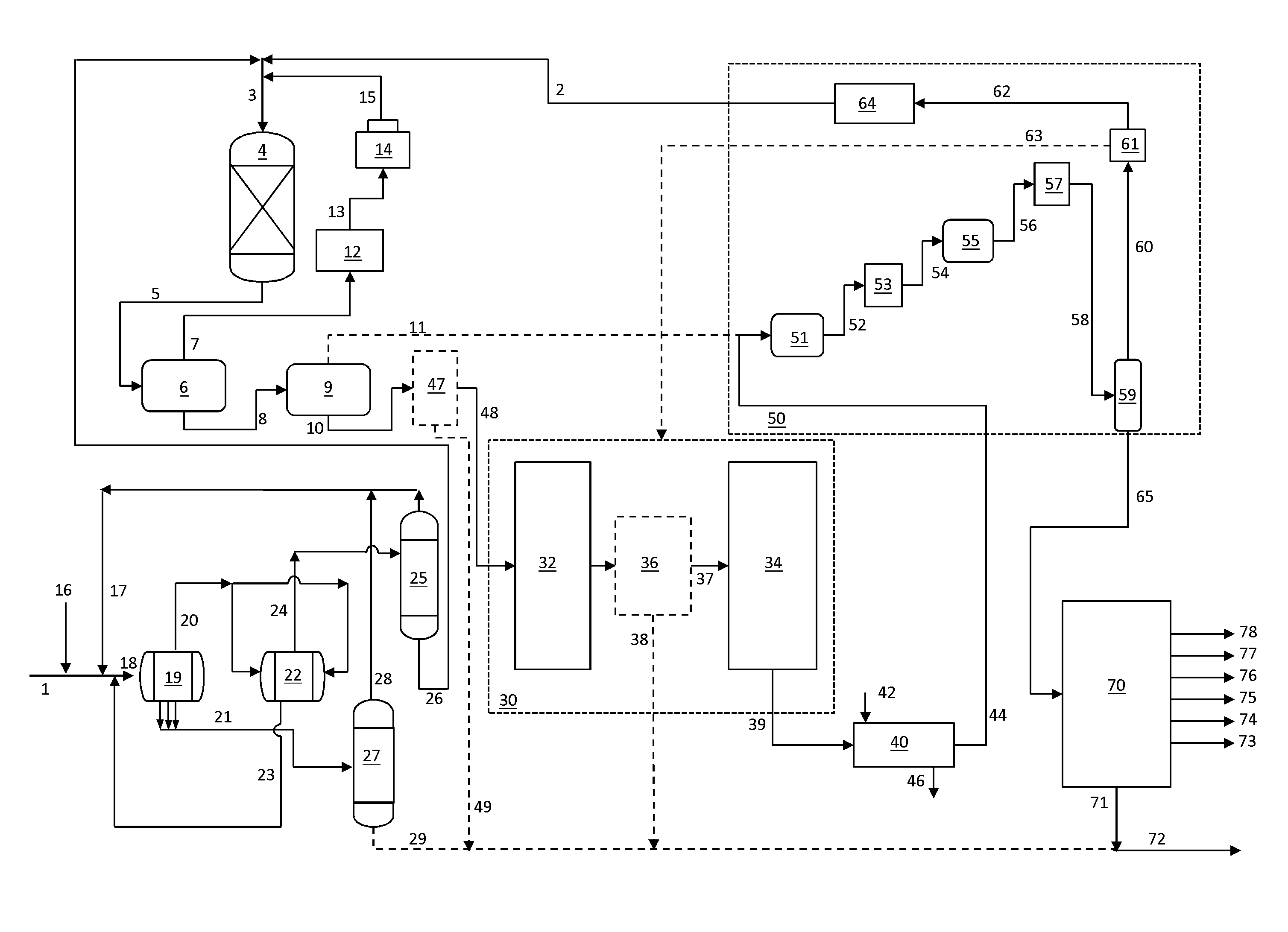

Integrated hydroprocessing, steam pyrolysis and catalytic cracking process to produce petrochemicals from crude oil

ActiveUS20130248419A1Reduce pollutant contentIncreased paraffincityThermal non-catalytic crackingTreatment with plural serial cracking stages onlySteam pyrolysisChemistry

An integrated hydrotreating, steam pyrolysis and catalytic cracking process for the production of olefins and aromatic petrochemicals from a crude oil feedstock is provided. Crude oil and hydrogen are charged to a hydroprocessing zone under conditions effective to produce a hydroprocessed effluent, which is thermally cracked in the presence of steam in a steam pyrolysis zone to produce a mixed product stream. Heavy components are catalytically cracked, which are derived from one or more of the hydroprocessed effluent, a heated stream within the steam pyrolysis zone, or the mixed product stream catalytically cracking. Catalytically cracked products are produced, which are combined with the mixed product stream and the combined stream is separated, and olefins and aromatics are recovered as product streams.

Owner:SAUDI ARABIAN OIL CO

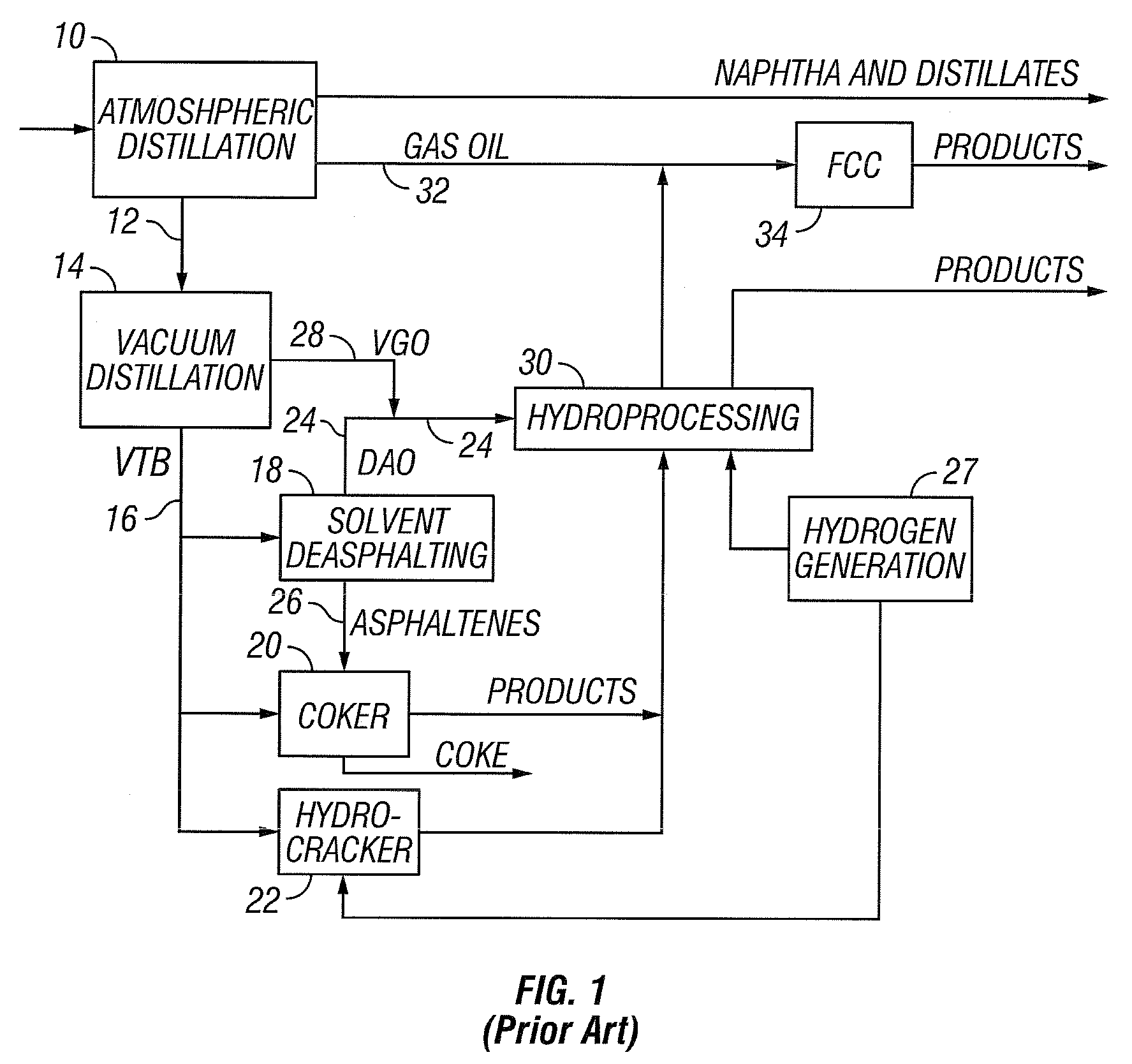

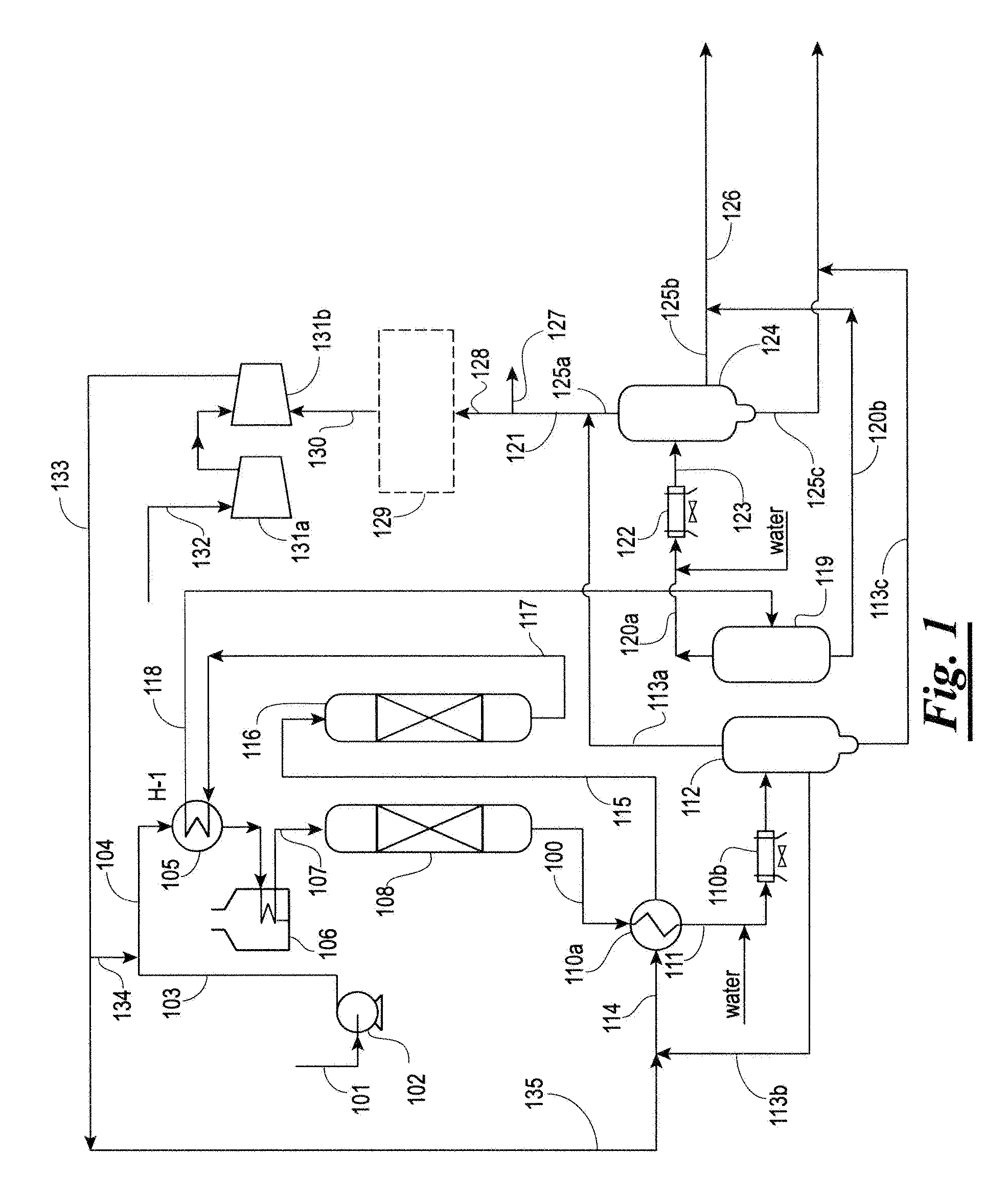

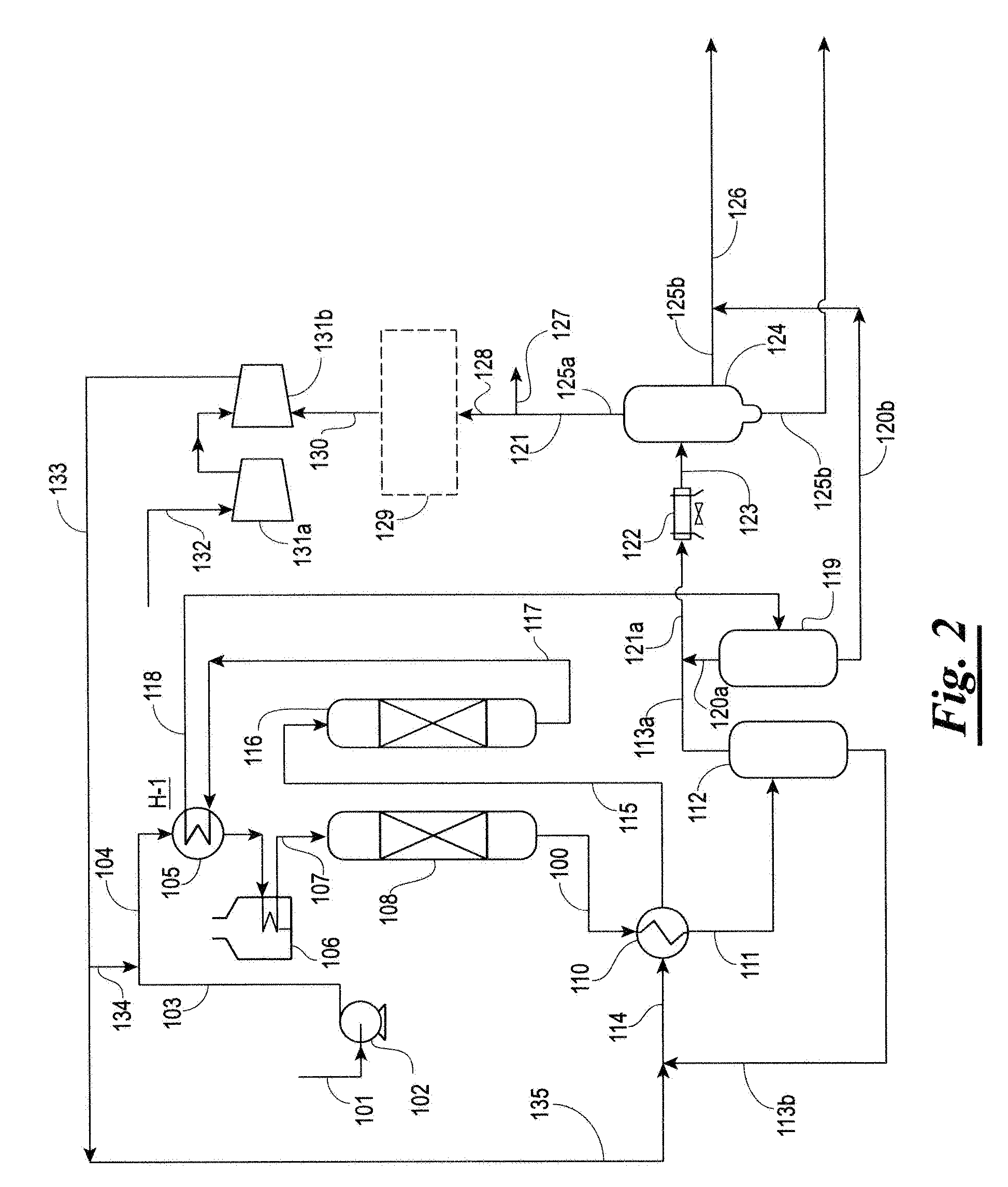

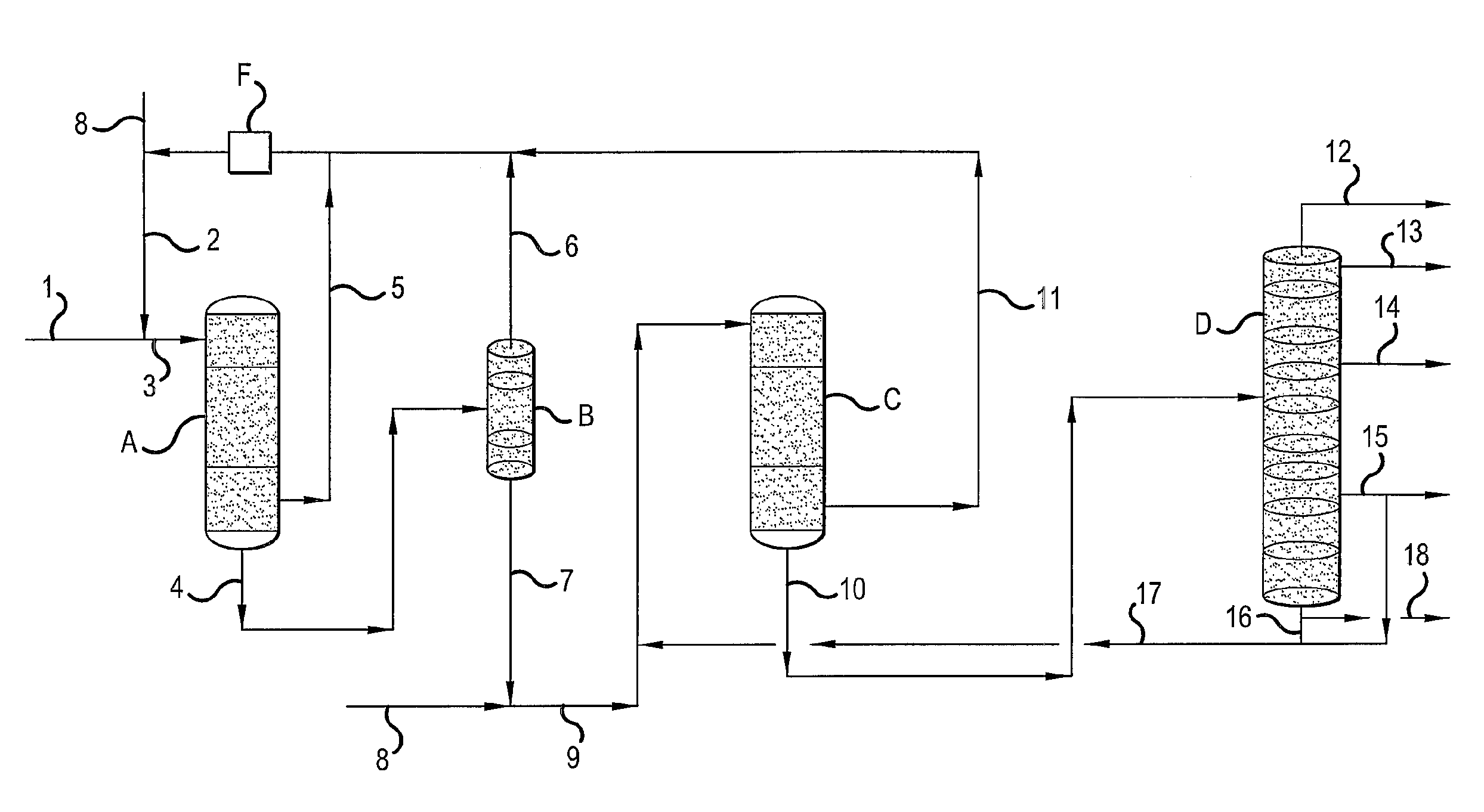

Process for multistage residue hydroconversion integrated with straight-run and conversion gasoils hydroconversion steps

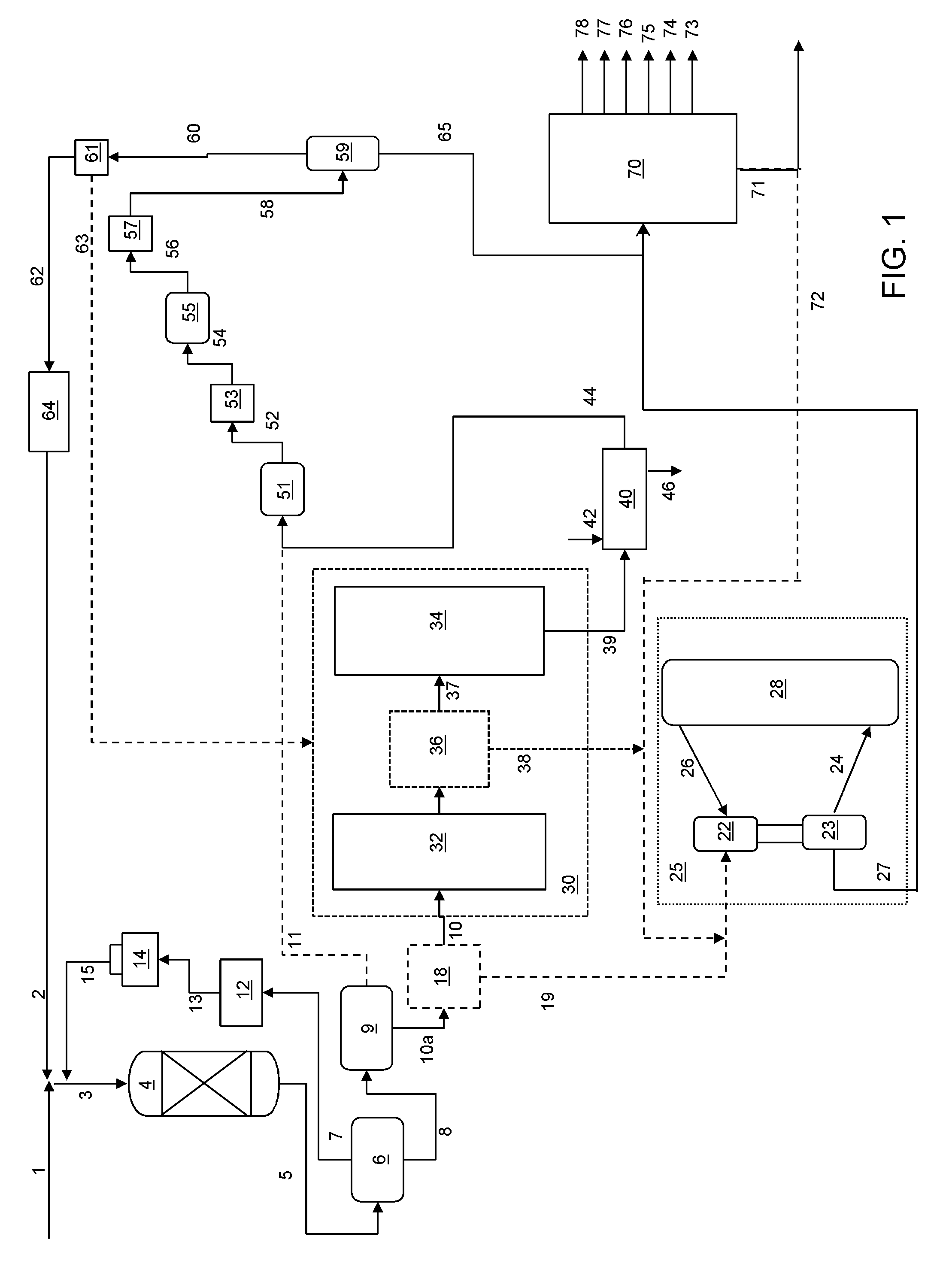

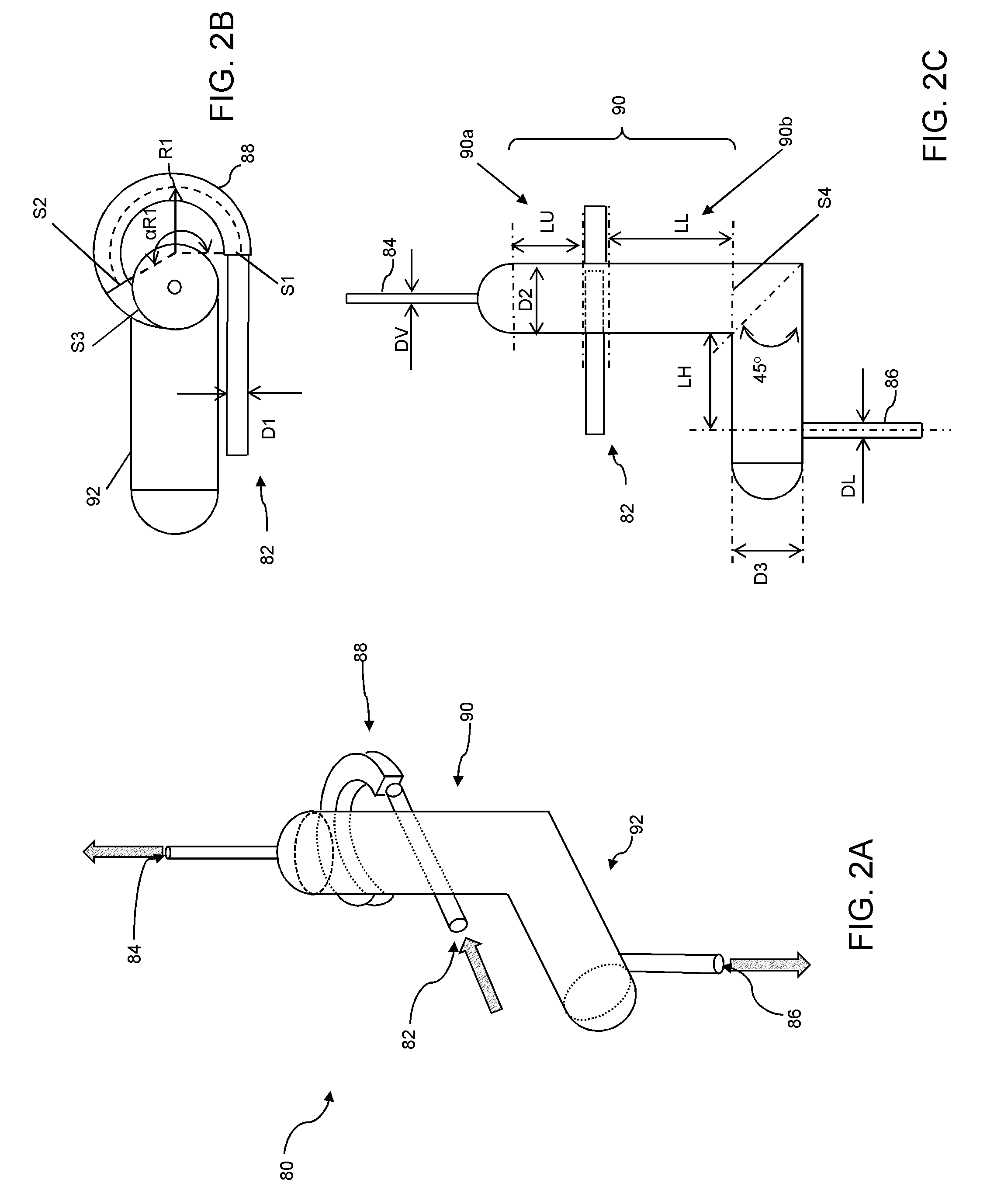

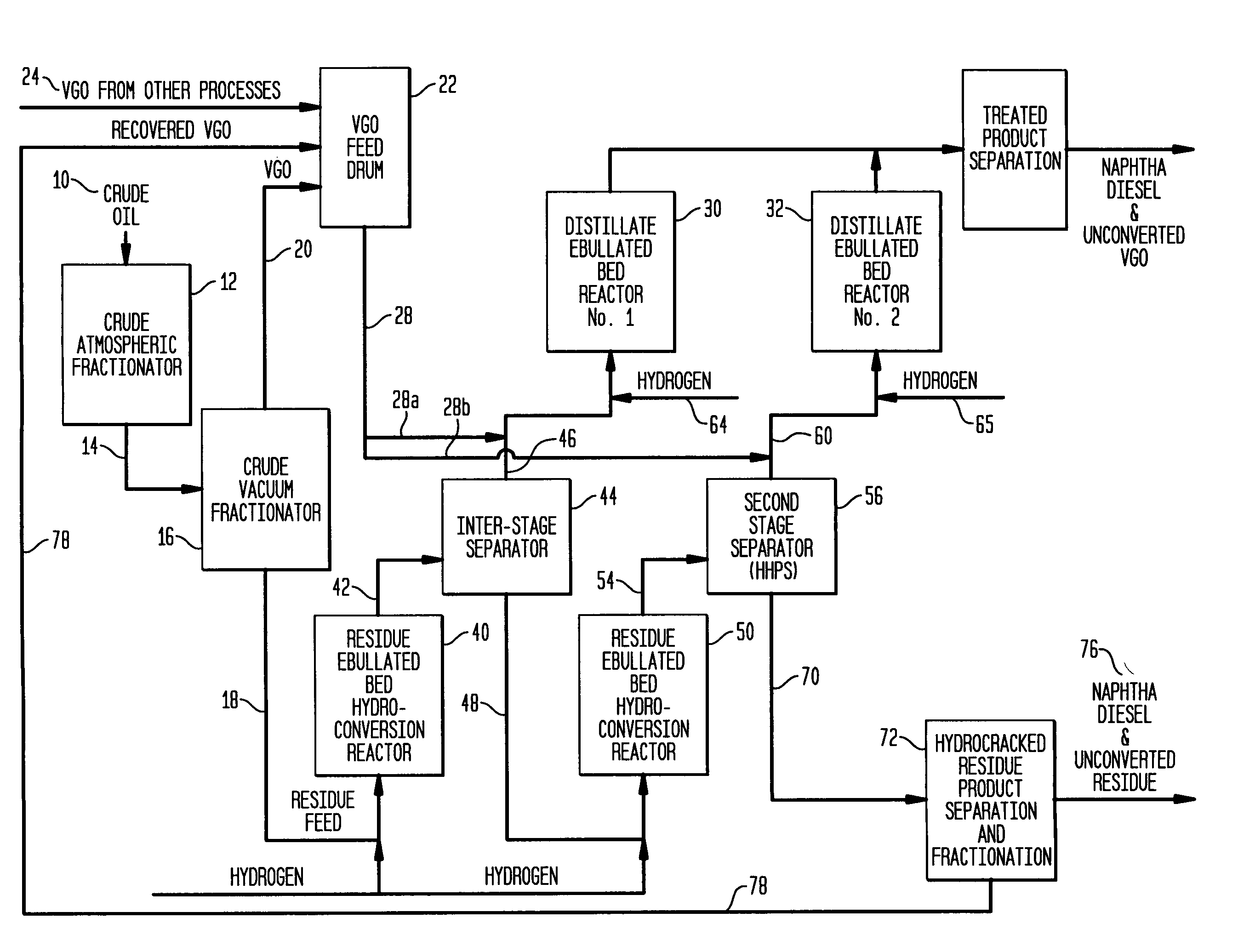

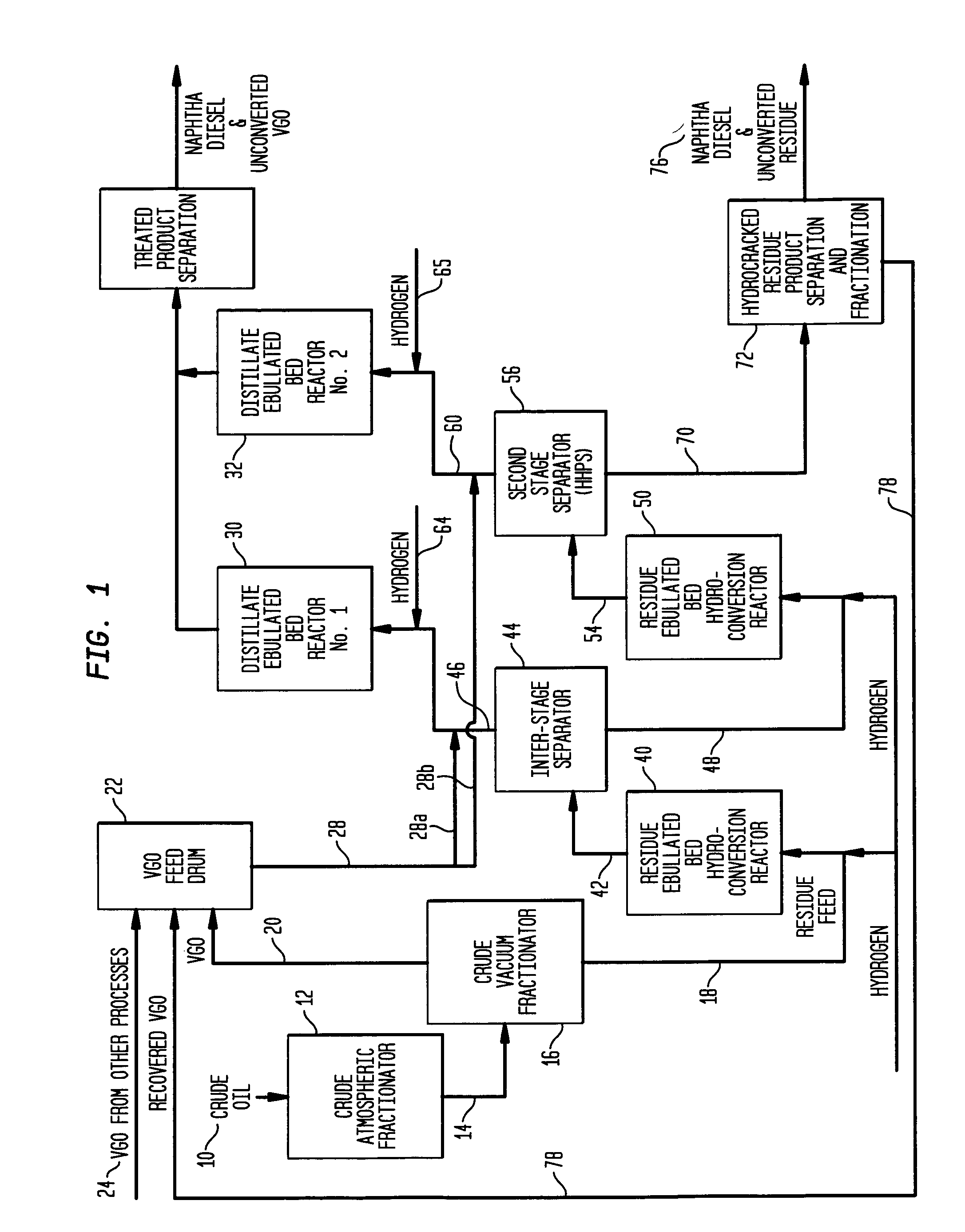

InactiveUS7938952B2Improve throughputMitigate issueTreatment with plural serial cracking stages onlyMolecular sieve catalystsVapor liquidLiquid product

This invention relates to a novel integrated hydroconversion process for converting heavy atmospheric or vacuum residue feeds and also converting and reducing impurities in the vacuum gas oil liquid product. This is accomplished by utilizing two residue hydroconversion reaction stages, two vapor-liquid separators, and at least two additional distillate ebullated-bed hydrocracking / hydrotreating reaction stages to provide a high conversion rate of the residue feedstocks.

Owner:INST FR DU PETROLE

Supercritical hydrocarbon conversion process

ActiveUS7144498B2Thermal non-catalytic crackingTreatment with plural serial cracking stages onlyReaction temperatureUnit operation

Supercritical conversion of hydrocarbons boiling above 538° C. (1000° F.) with a solvating hydrocarbon at a weight ratio of solvating hydrocarbon to high-boiling hydrocarbons of at least 2:1 and at conditions above the critical temperature and pressure of the high-boiling hydrocarbons-solvent mixture, in the presence of hot fluidized solids. The hydrocarbons are supplied to a reaction zone at a temperature below that of the hot solids supplied thereto, whereby the resulting hydrocarbons-solids suspension has a thermal equilibrium temperature corresponding to the reaction temperature. The conversion has high rates of sulfur, nitrogen and metals removal, nearly complete conversion to lower molecular weight products, high naphtha and distillate selectivity, and low coke formation. The supercritical conversion can replace crude distillation, vacuum distillation, solvent deasphalting, coking, hydrocracking, hydrotreating, and / or fluid catalytic cracking, and / or used in parallel with such unit operations for debottle-necking or increasing capacity.

Owner:KELLOGG BROWN & ROOT LLC

Hydrodeoxygenation process

A process for producing a hydrocarbon from biomass. A feed stream having free fatty acids, fatty acid esters or combinations thereof is provided. The feed stream is heated in the presence of a first catalyst to produce a partially hydrodeoxygenated stream. The partially hydrodeoxygenated stream is heated in the presence of a second catalyst to produce an effluent stream containing the hydrocarbon.

Owner:REG SYNTHETIC FUELS LLC

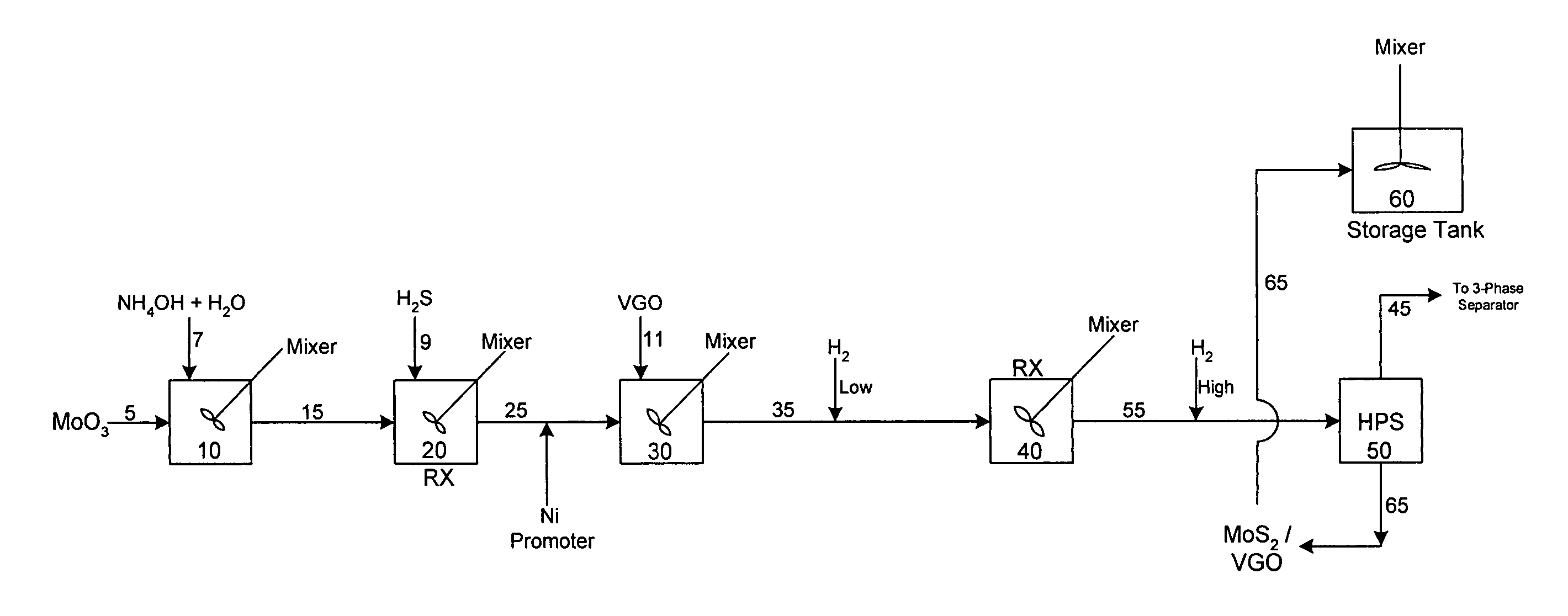

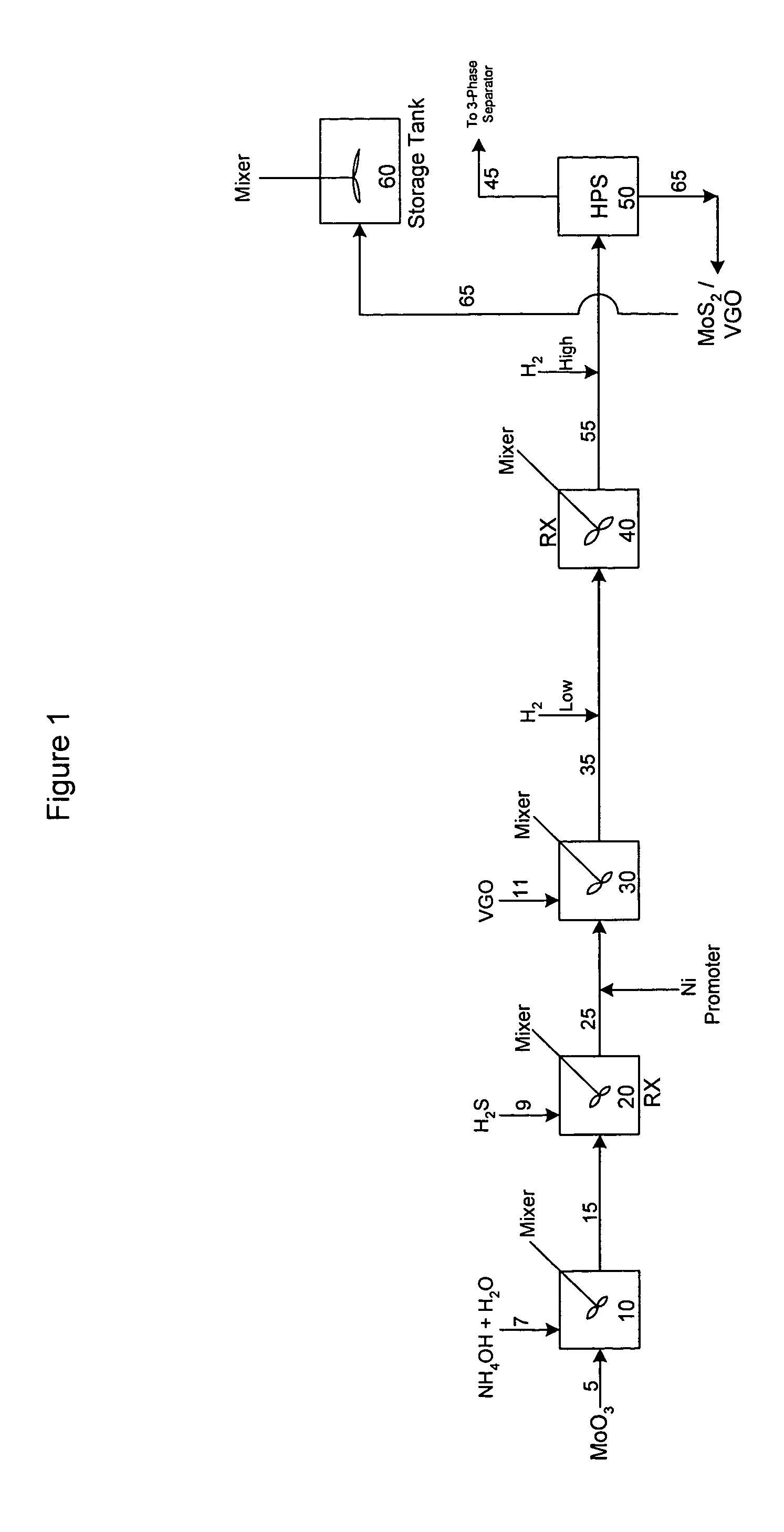

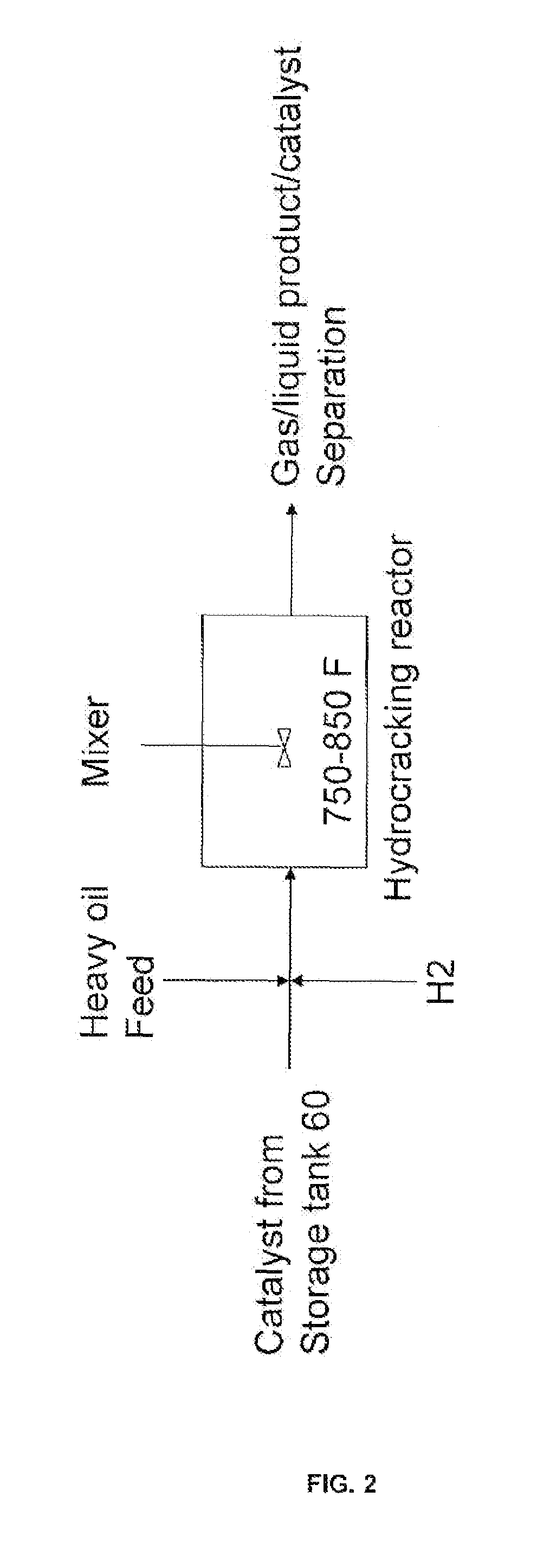

Process for upgrading heavy oil using a highly active slurry catalyst composition

ActiveUS7214309B2High viscosityTreatment with plural serial cracking stages onlyTreatment with plural serial stages onlyHydrogenSlurry

The instant invention is directed to a process for upgrading heavy oils using a slurry composition. The slurry composition is prepared in a series of steps, involving mixing a Group VIB metal oxide with aqueous ammonia to form an aqueous mixture and sulfiding the mixture to form a slurry. The slurry is then promoted with a Group VIII metal compound. Subsequent steps involve mixing the slurry with a hydrocarbon oil, and combining the resulting mixture with hydrogen gas (under conditions which maintain the water in a liquid phase) to produce the active slurry catalyst.

Owner:CHEVROU USA INC

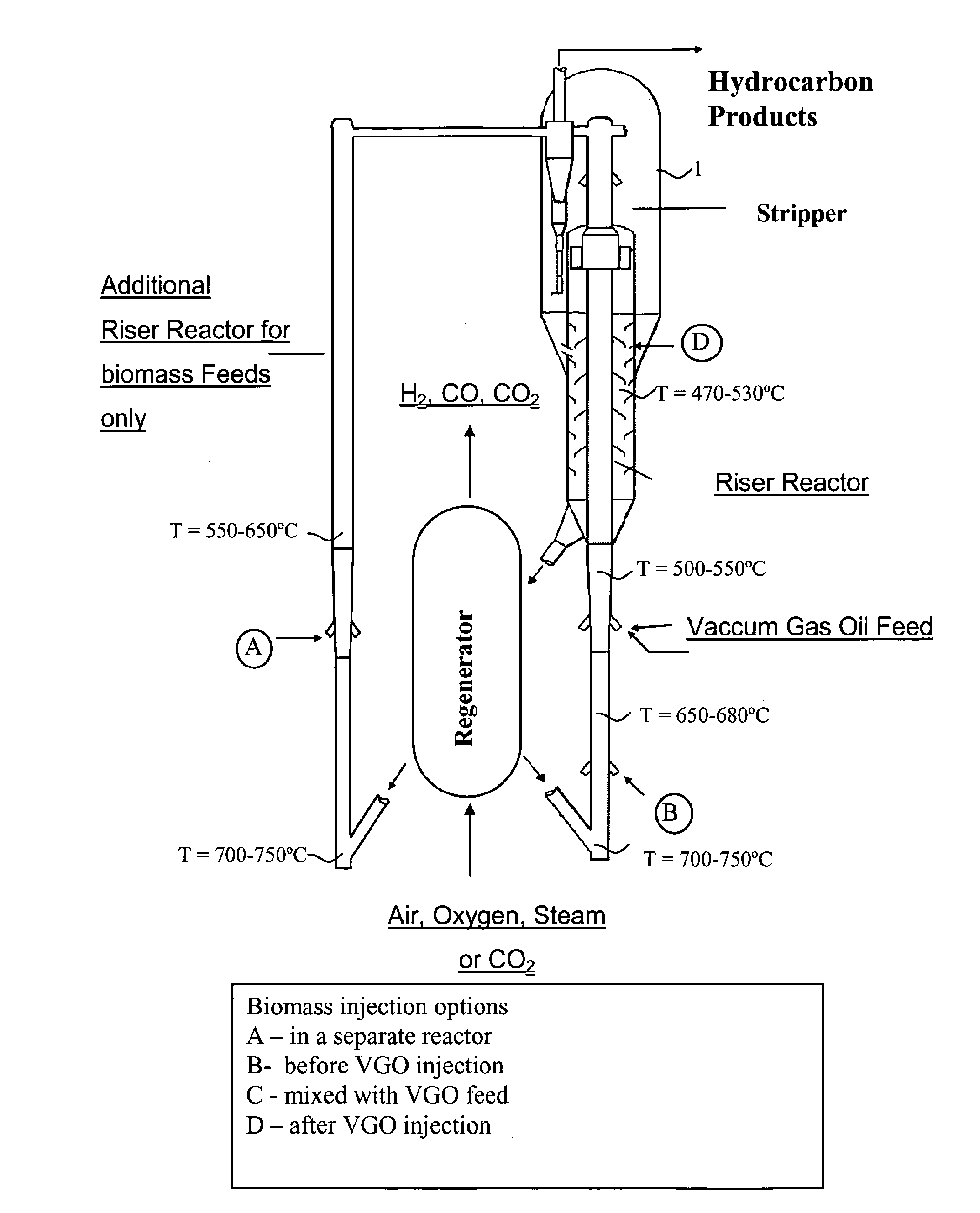

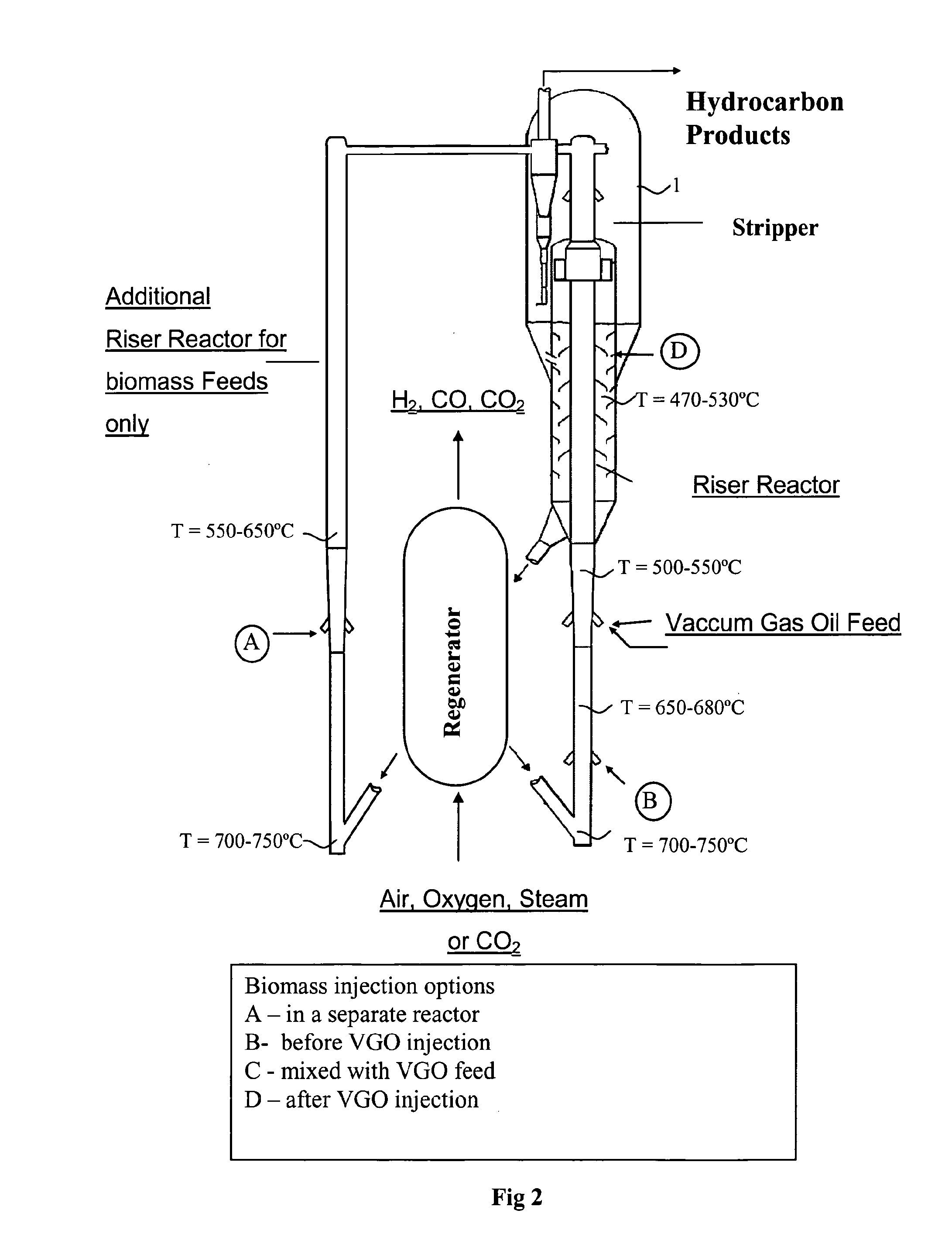

Fluid catalytic cracking of oxygenated compounds

ActiveUS20100222620A1Treatment with plural serial cracking stages onlyCatalytic crackingCompound aGlycerol

A process is disclosed for fluid catalytic cracking of oxygenated hydrocarbon compounds such as glycerol and bio-oil.In the process the oxygenated hydrocarbon compounds are contacted with a fluid cracking catalyst material for a period of less than 3 seconds.In a preferred process a crude-oil derived material, such as VGO, is also contacted with the catalyst.

Owner:MARD INC

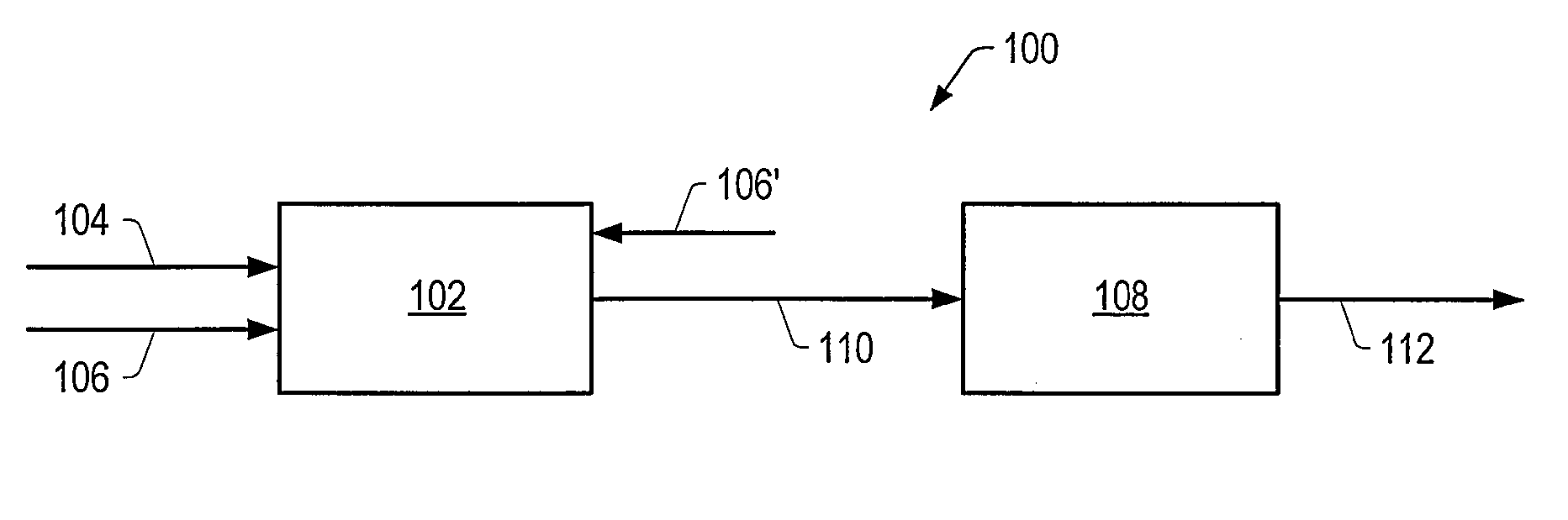

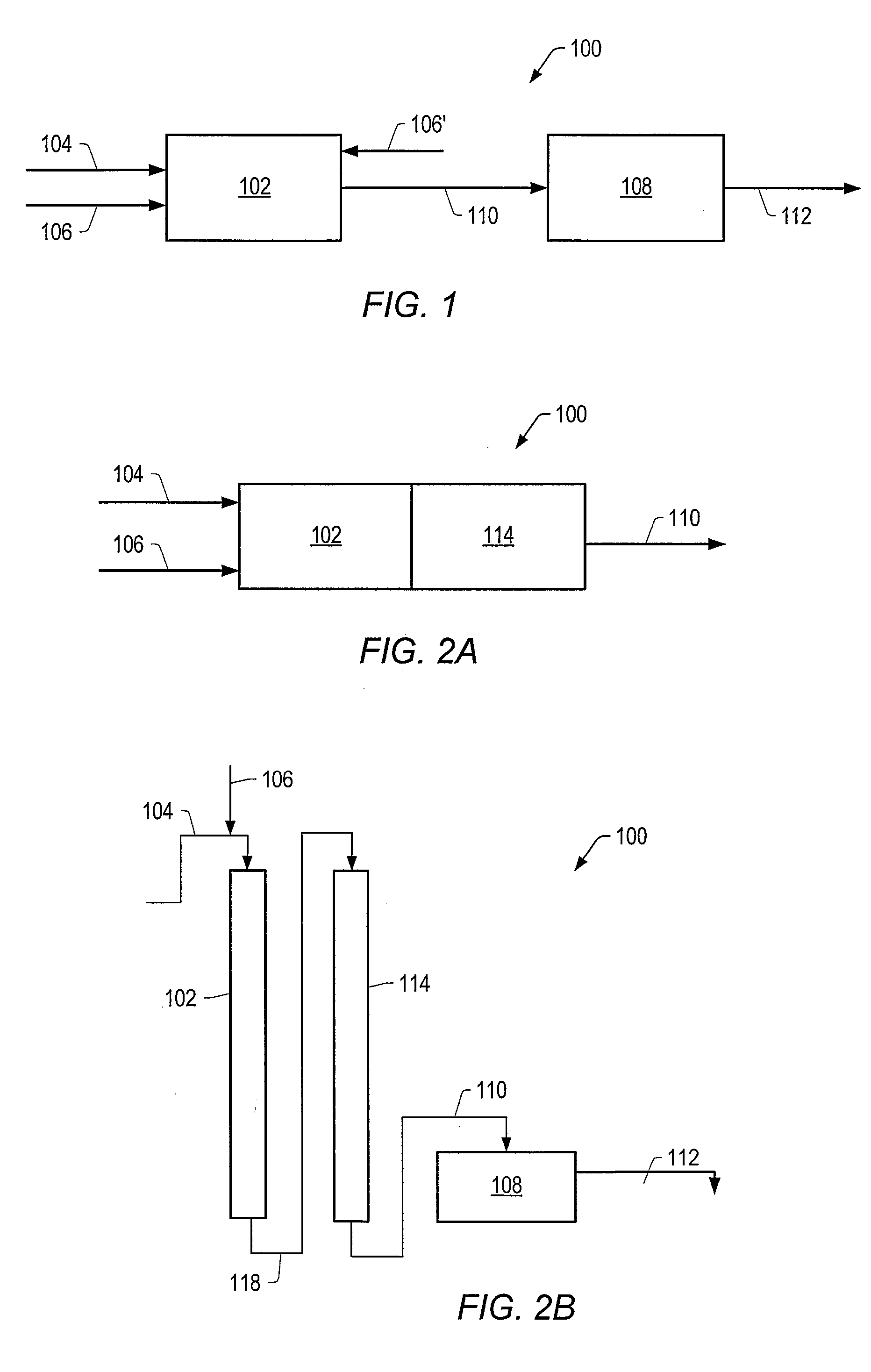

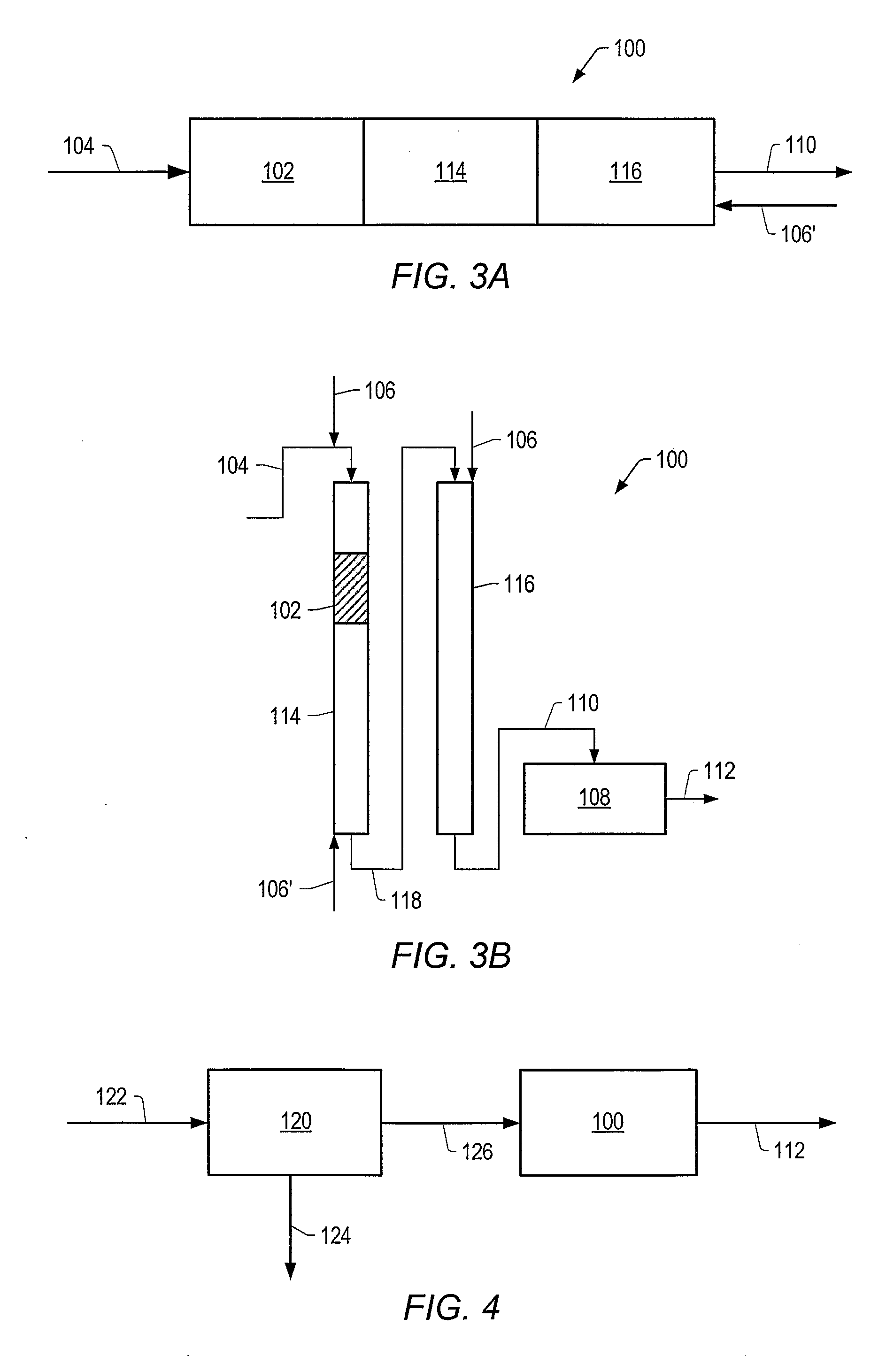

Systems and methods for producing a crude product and compositions thereof

InactiveUS20080087575A1Treatment with plural serial cracking stages onlyCatalyst activation/preparationContact zoneHydrocarbon

Systems and methods for producing a crude product are described herein. Systems include an upstream contacting zone and a downstream contacting zone coupled to the upstream contacting zone. The upstream contacting zone and the downstream contacting zone include one or more catalysts. Contact of a hydrocarbon feed with the one or more of the catalysts produces a hydrocarbon feed / total product mixture having a molybdenum content of at most 90% of the molybdenum of the hydrocarbon feed. Contact of the hydrocarbon feed / total product mixture in downstream with one or more downstream catalysts produces a crude product having a molybdenum content of at most 90% of the molybdenum content of the hydrocarbon feed and at most 90% of the residue content of the hydrocarbon feed. Methods of producing a crude product using said systems are described herein. Compositions of said crude product produced from said systems and methods are described herein.

Owner:SHELL OIL CO

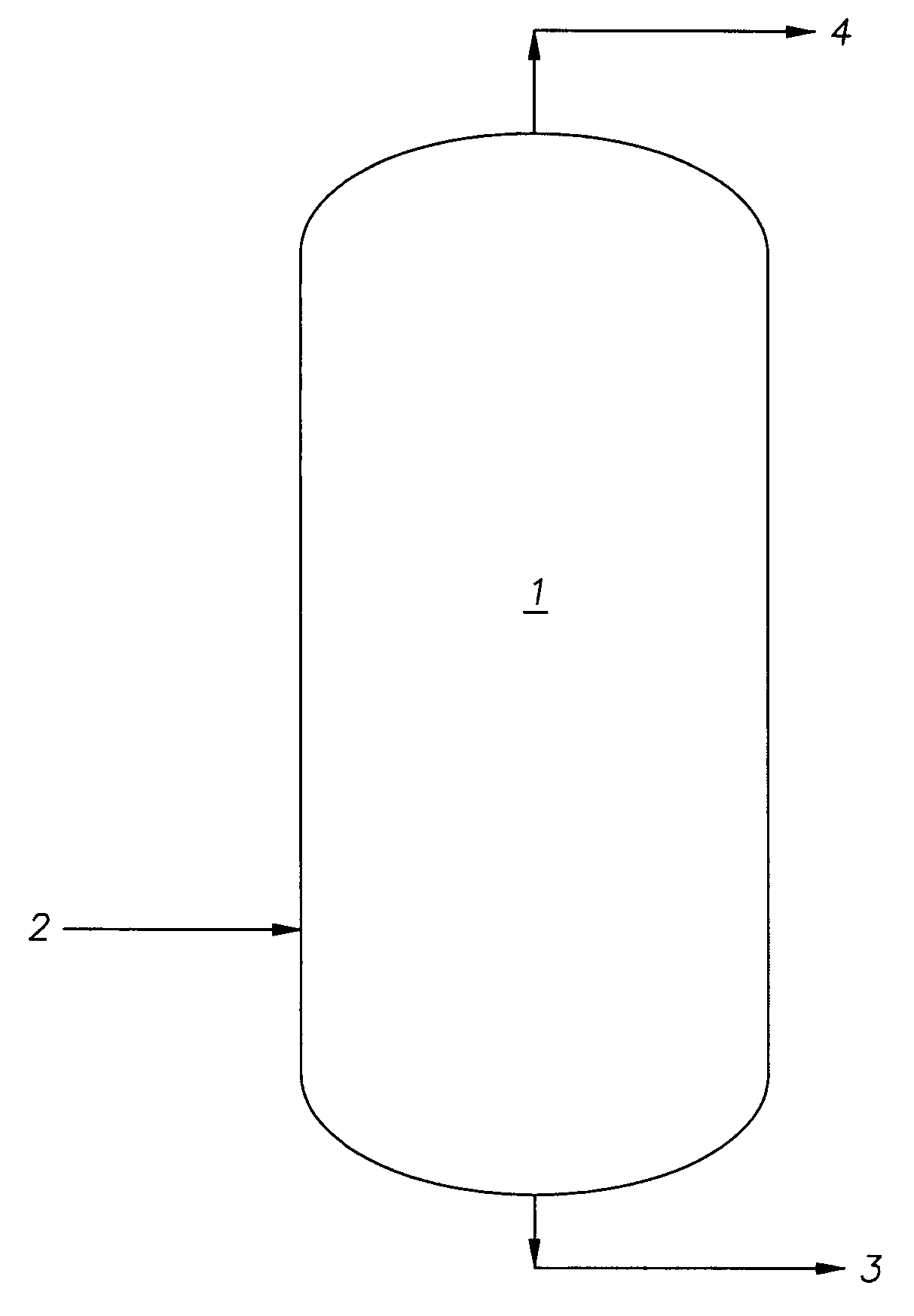

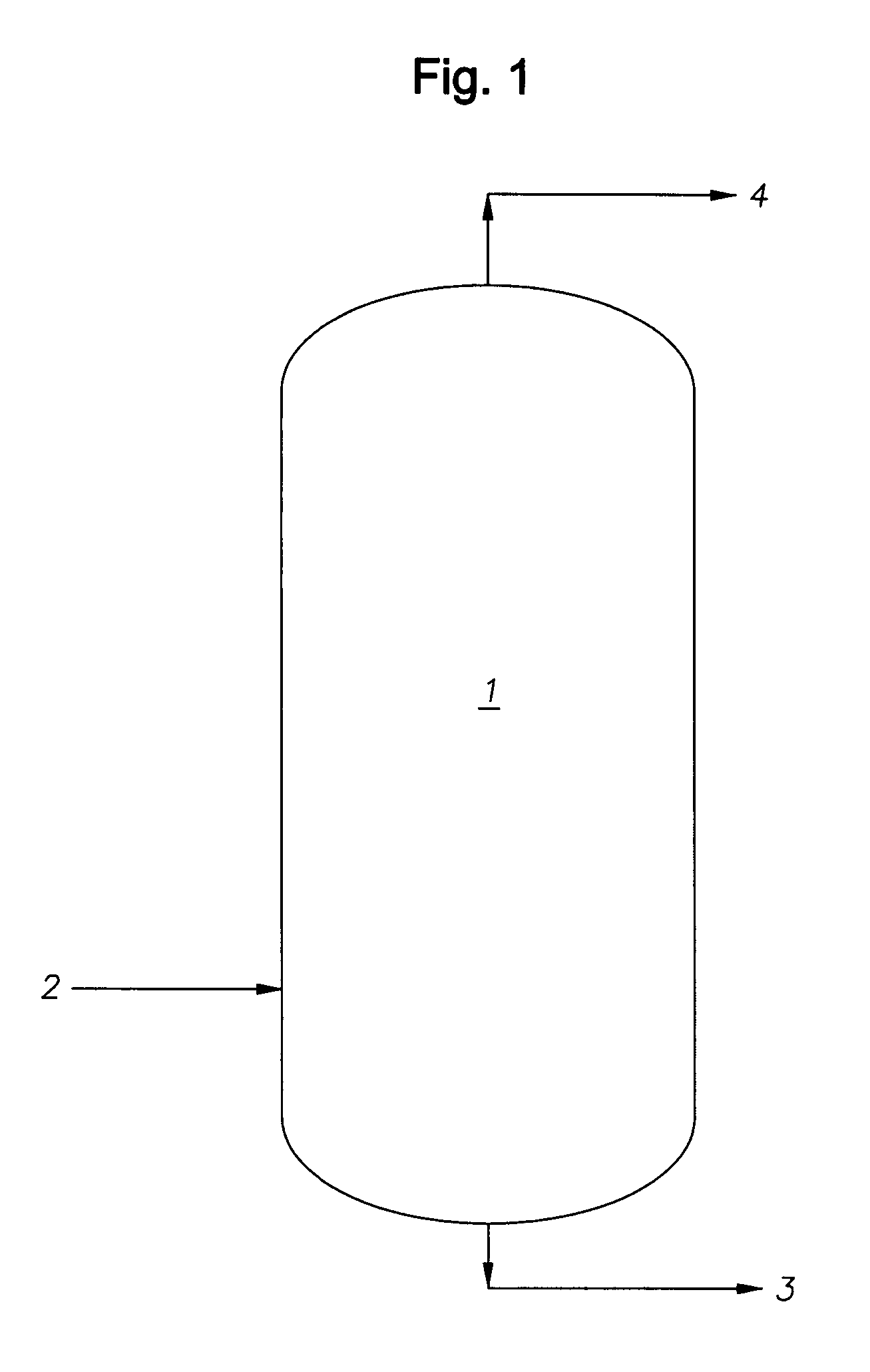

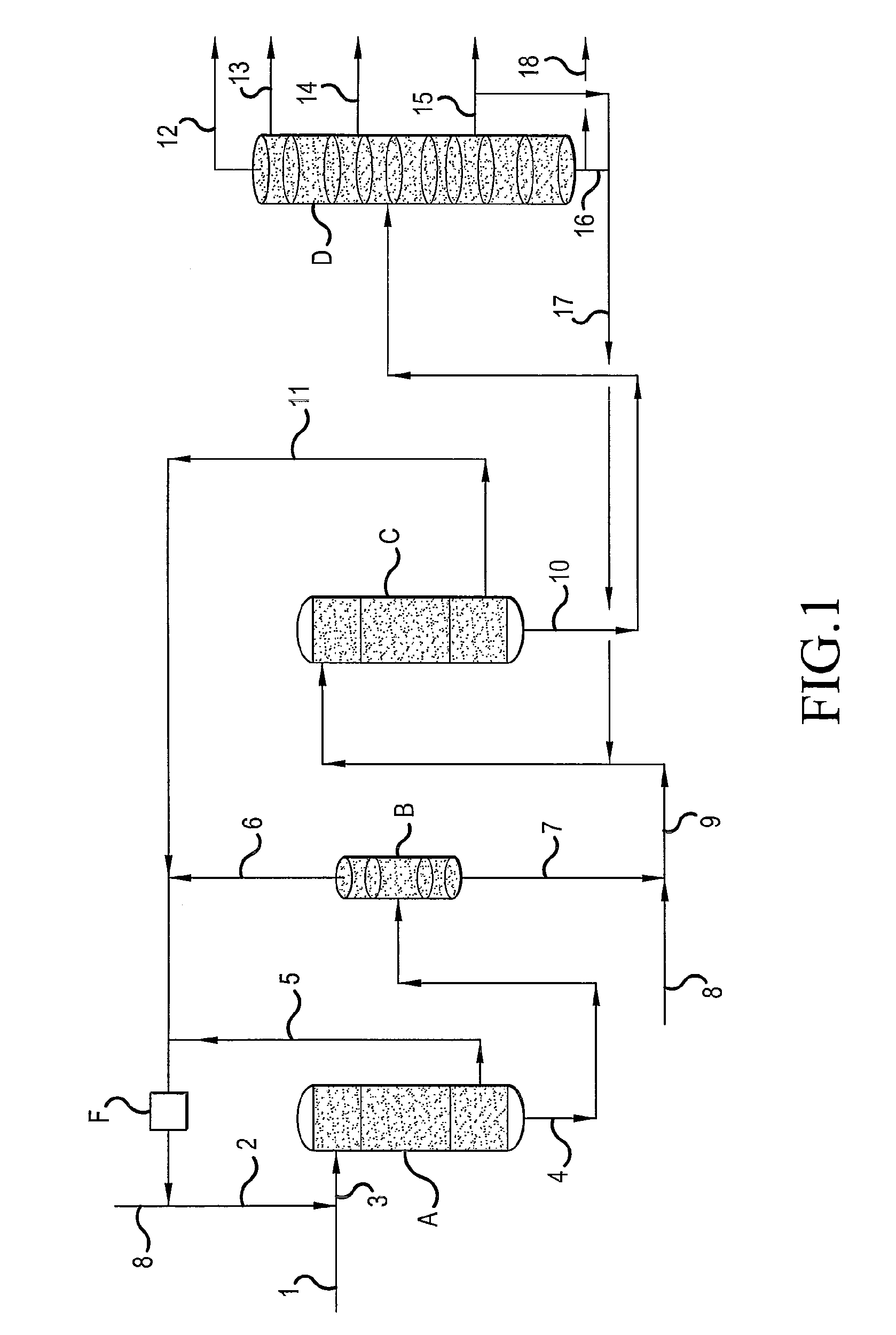

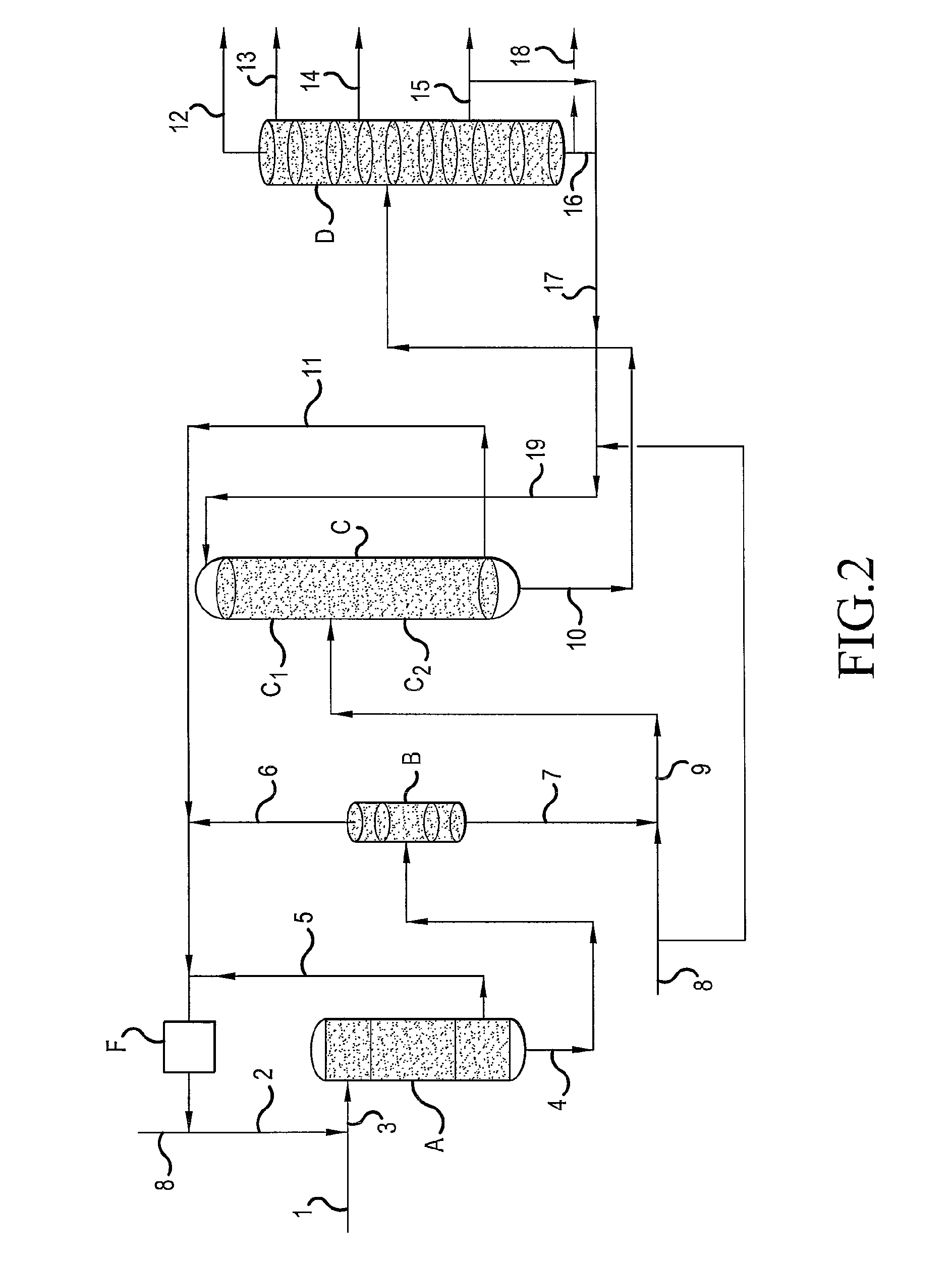

Process for the manufacture of hydrocarbon components

The present invention relates to hydrocarbons and particularly to the manufacture of hydrocarbon components suitable as aviation fuels or jet fuels and as blending stocks for aviation fuels. The process comprises the stages, wherein in the first stage an oil feed of biological origin and hydrogen gas are subjected to conditions sufficient to effect hydrodeoxygenation in the presence of a hydrodeoxygenation catalyst to yield n-paraffins;in the second stage the n-paraffins and hydrogen gas are subjected to conditions sufficient to effect isomerisation in the presence of an isomerisation catalyst to yield isoparaffins and separating fractions; andrecycling the fraction boiling at a temperature above 200° C. under atmospheric pressure obtained from the second stage to reisomerisation, where isomerisation is effected in the presence of an isomerisation catalyst.

Owner:NESTE OIL OY

Two stage fluid catalytic cracking process for selectively producing C2 to C4 olefins

InactiveUS7323099B2Treatment with plural serial cracking stages onlyCatalytic naphtha reformingPtru catalystNaphtha

A process for selectively producing C2 to C4 olefins from feedstock such as a gas oil or resid. The feedstock is reacted in a first stage comprising a fluid catalytic cracking unit wherein it is converted in the presence of a mixture of conventional large pore zeolitic catalyst and a medium pore zeolitic catalyst to reaction products, including a naphtha boiling range stream. The naphtha boiling range stream is introduced into a second stage where it is contacted with a catalyst containing from about 10 to about 50 wt. % of a crystalline zeolite having an average pore diameter less than about 0.7 nanometers at reaction conditions which include temperatures ranging from about 500 to about 650° C. and a hydrocarbon partial pressure from about 10 to about 40 psia (about 70 to about 280 kPa).

Owner:EXXONMOBIL CHEM PAT INC

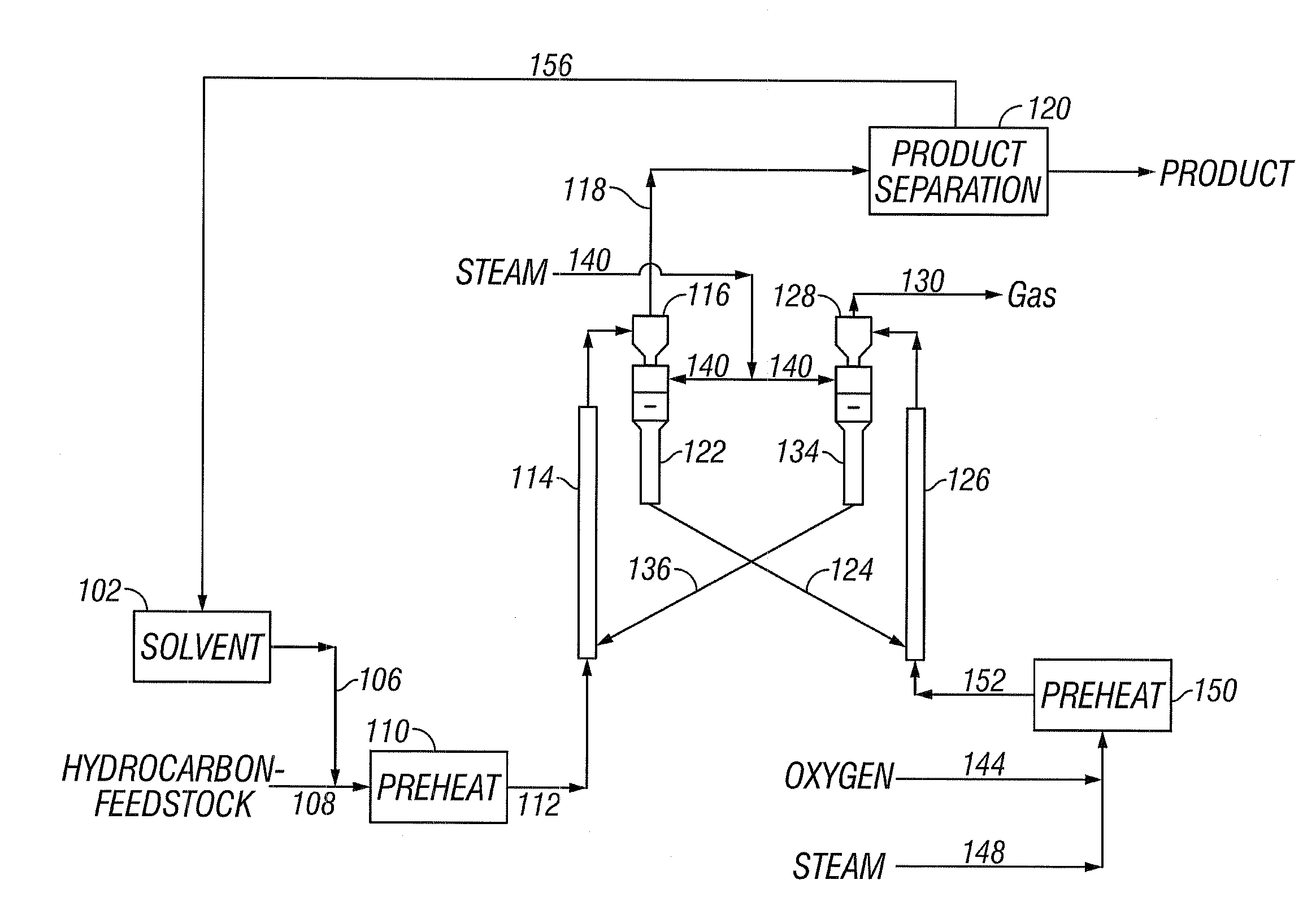

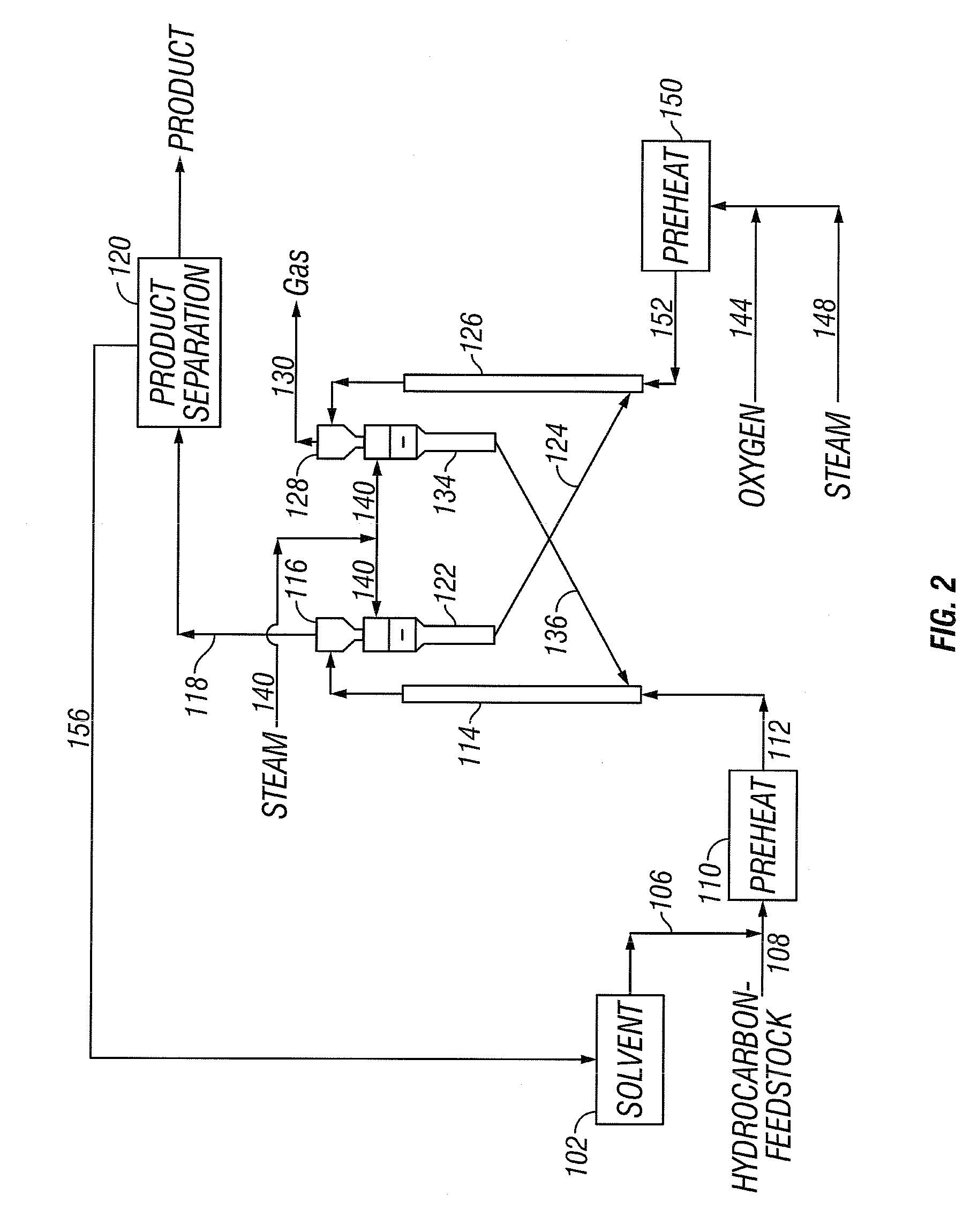

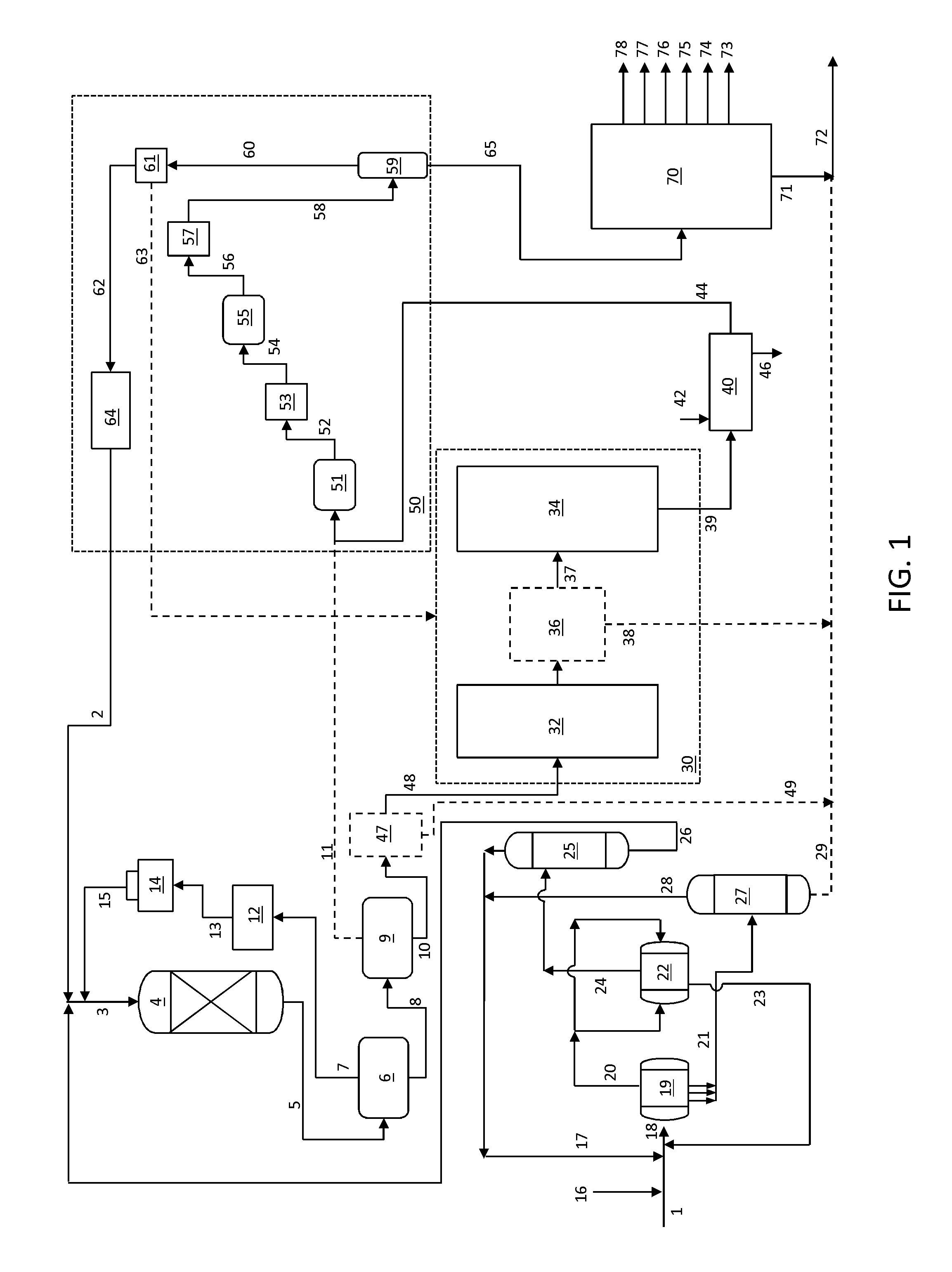

Integrated solvent deasphalting, hydrotreating and steam pyrolysis process for direct processing of a crude oil

ActiveUS9284502B2Thermal non-catalytic crackingTreatment with plural serial cracking stages onlySteam pyrolysisFuel oil

A process is provided that is directed to a steam pyrolysis zone integrated with a solvent deasphalting zone and a hydrotreating zone to permit direct processing of crude oil feedstocks to produce petrochemicals including olefins and aromatics. The integrated solvent deasphalting, hydrotreating and steam pyrolysis process for the direct processing of a crude oil to produce olefinic and aromatic petrochemicals comprises: charging the crude oil to a solvent deasphalting zone with an effective amount of solvent for producing a deasphalted and demetalized oil stream and a bottom asphalt phase; charging the deasphalted and demetalized oil stream and hydrogen to a hydroprocessing zone operating under conditions effective to produce a hydroprocessed effluent reduced having a reduced content of contaminants, an increased paraffinicity, reduced Bureau of Mines Correlation Index, and an increased American Petroleum Institute gravity; thermally cracking the hydroprocessed effluent in the presence of steam to produce a mixed product stream; separating the mixed product stream; purifying hydrogen recovered from the mixed product stream and recycling it to the hydroprocessing zone; recovering olefins and aromatics from the separated mixed product stream; and recovering pyrolysis fuel oil from the separated mixed product stream.

Owner:SAUDI ARABIAN OIL CO

Methods and Systems for Producing Reduced Resid and Bottomless Products from Heavy Hydrocarbon Feedstocks

InactiveUS20080230440A1Cost controlReduce operating costsThermal non-catalytic crackingTreatment with plural serial cracking stages onlyParticulatesLiquid product

The present invention is directed to the upgrading of heavy petroleum oils of high viscosity and low API gravity that are typically not suitable for pipelining without the use of diluents. The method comprises introducing a particulate heat carrier into an up-flow reactor, introducing the feedstock at a location above the entry of the particulate heat carrier, allowing the heavy hydrocarbon feedstock to interact with the heat carrier for a short time, separating the vapors of the product stream from the particulate heat carrier and liquid and byproduct solid matter, collecting a gaseous and liquid product mixture comprising a mixture of a light fraction and a heavy fraction from the product stream, and using a vacuum tower to separate the light fraction as a substantially bottomless product and the heavy fraction from the product mixture.

Owner:IVANHOE HTL GASOLINEEUM

Flow-through cavitation-assisted rapid modification of crude oil

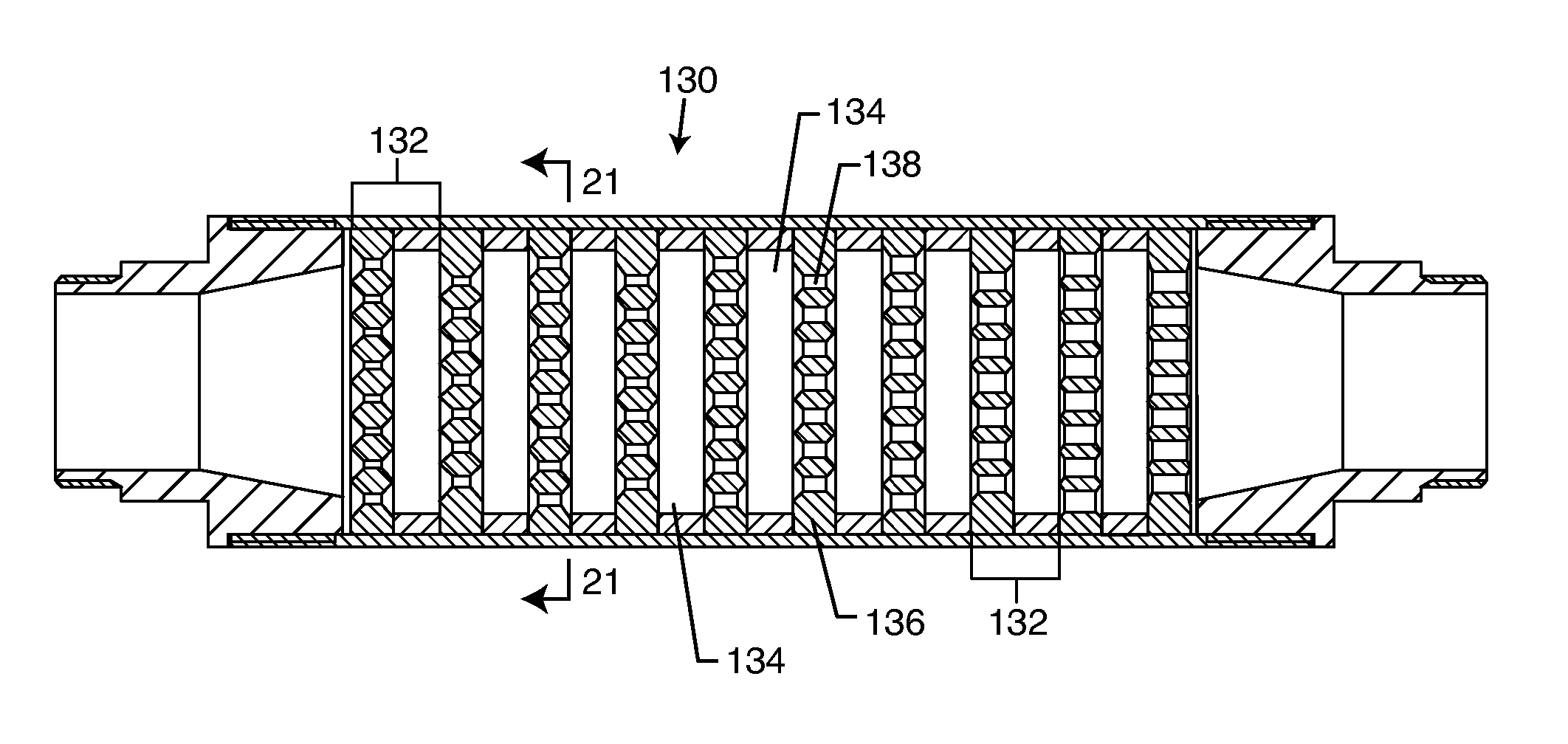

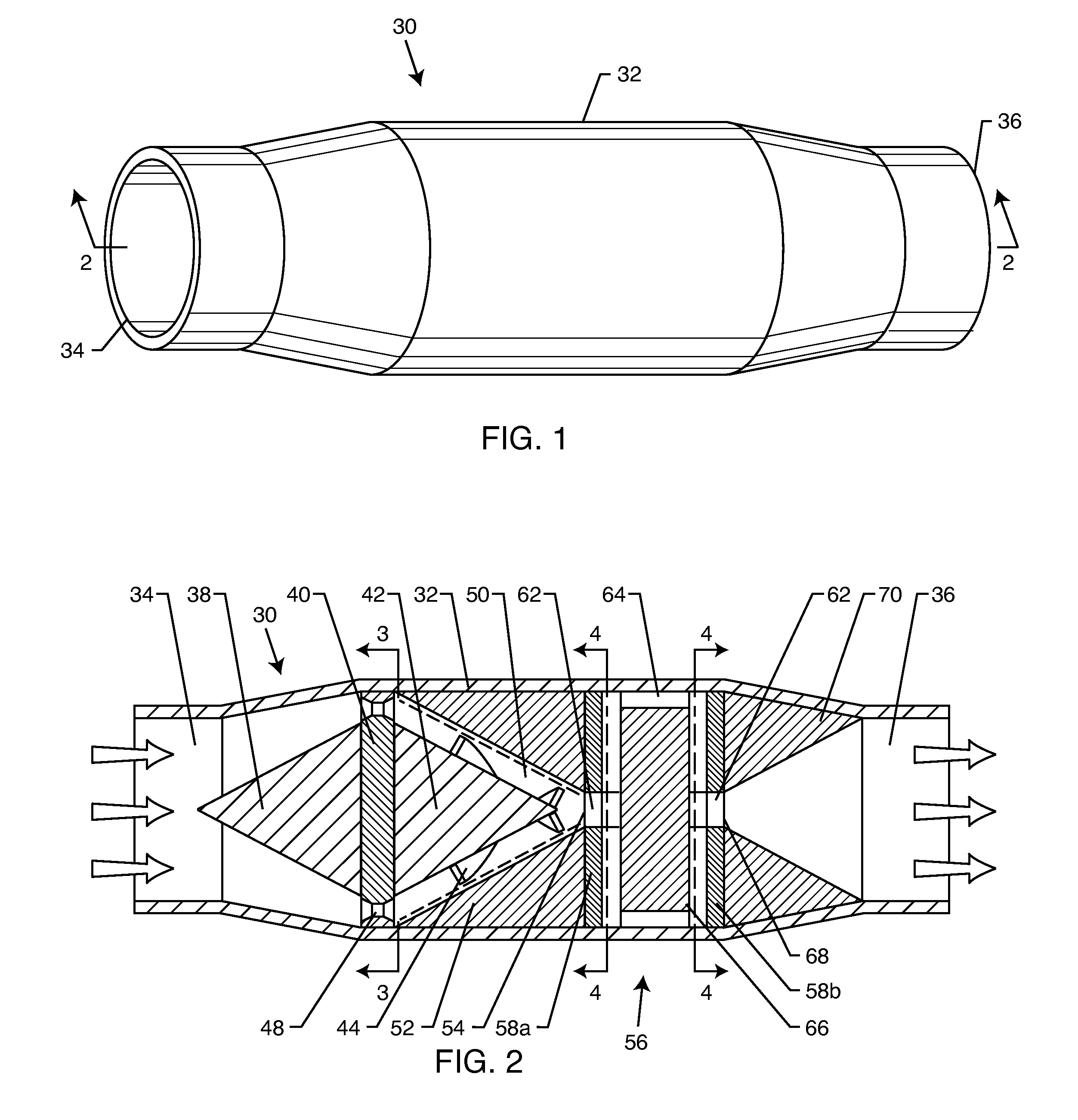

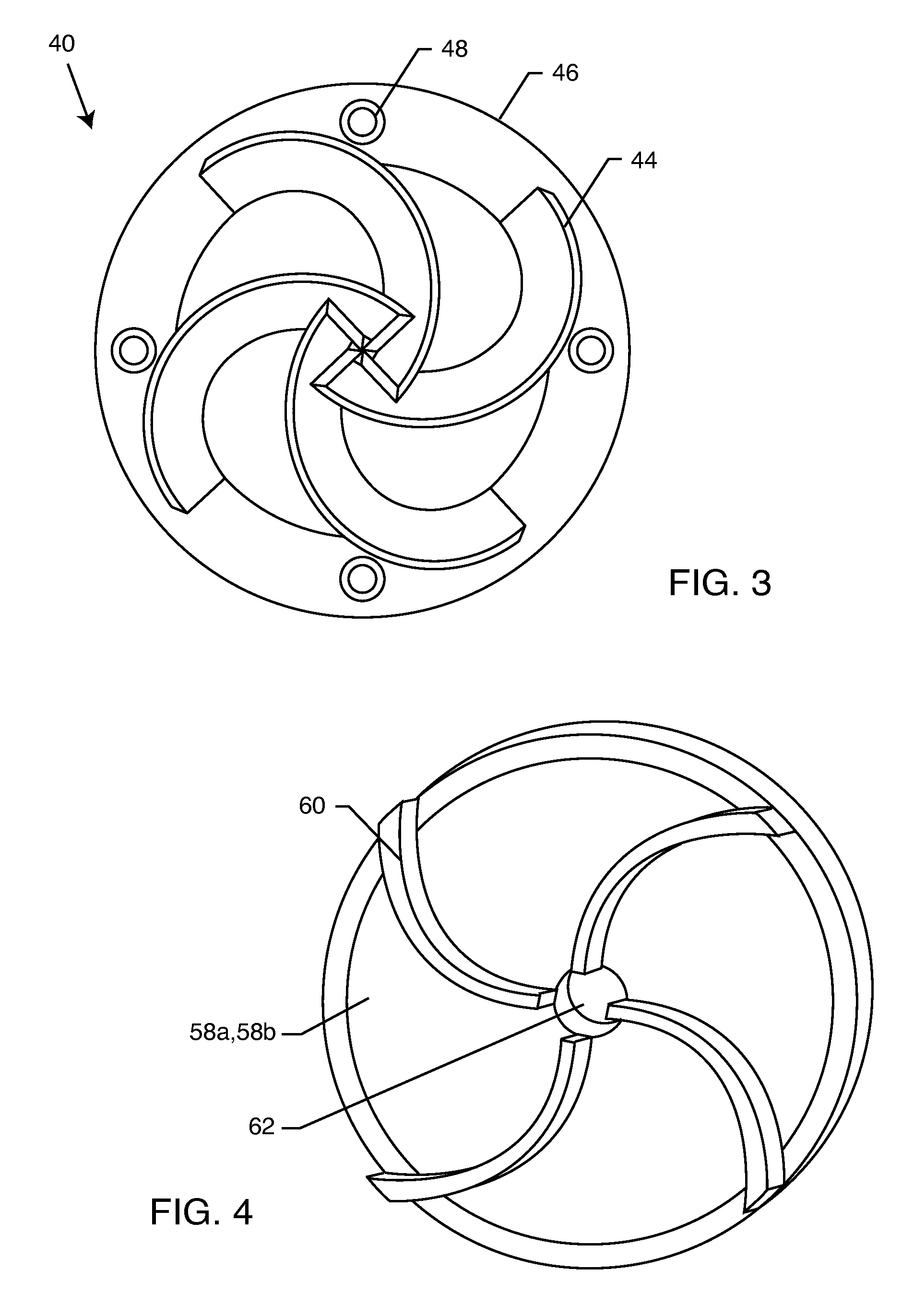

ActiveUS20100101978A1Improve effectivenessThermal non-catalytic crackingTreatment with plural serial cracking stages onlyCavitationChemical composition

A device and method are provided for manipulating petroleum, non-conventional oil and other viscous complex fluids made of hydrocarbons that comprise enforcement of fluid in a multi-stage flow-through hydrodynamic cavitational reactor, subjecting said fluids to a controlled cavitation and continuing the application of such cavitation for a period of time sufficient for obtaining desired changes in physical properties and / or chemical composition and generating the upgraded products. The method includes alteration of chemical bonds, induction of interactions of components, changes in composition, heterogeneity and rheological characteristics in order to facilitate handling, improve yields of distillate fuels and optimize other properties.

Owner:CAVITATION TECH

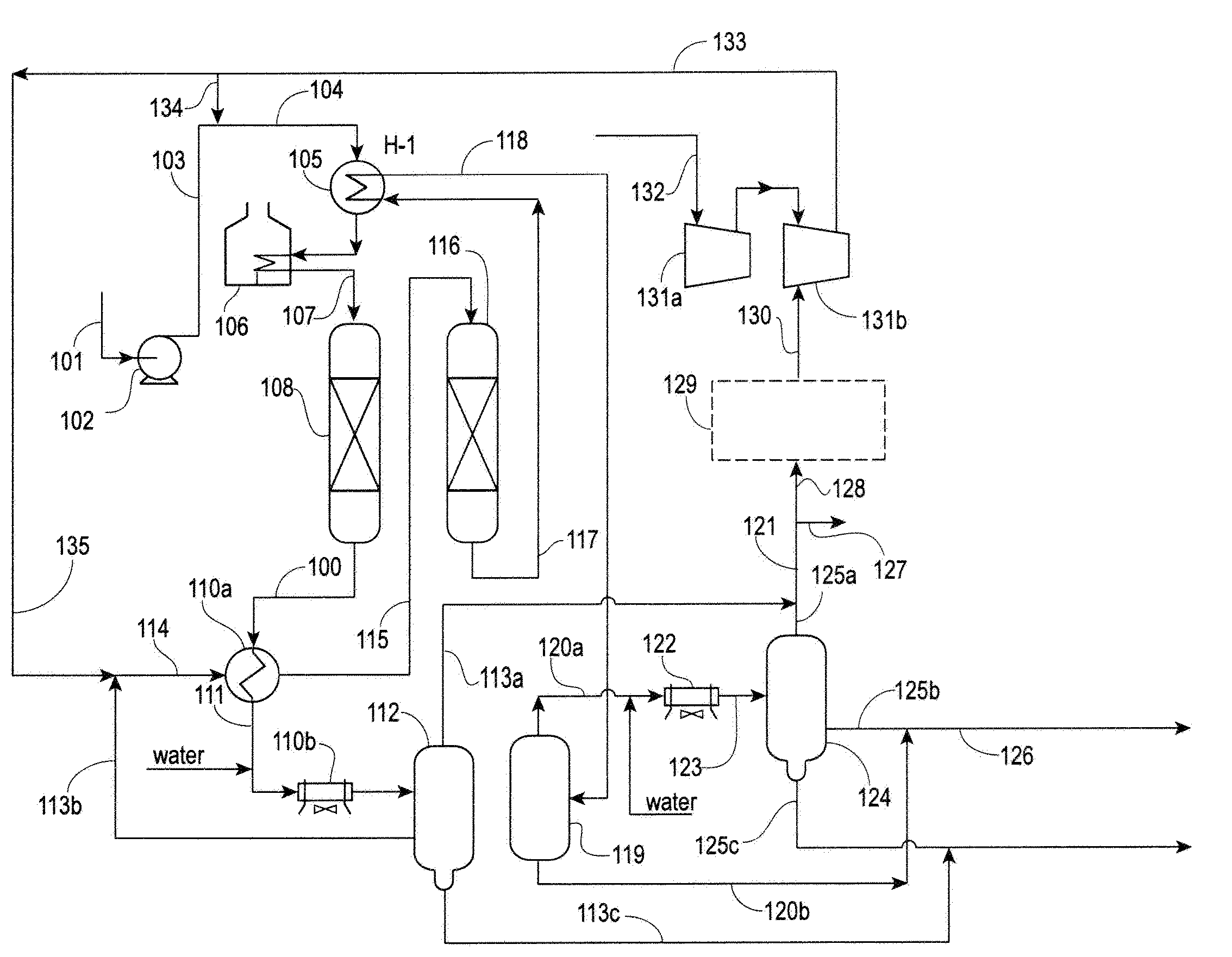

Integrated hydrotreating and steam pyrolysis process for direct processing of a crude oil

ActiveUS9255230B2Thermal non-catalytic crackingTreatment with plural serial cracking stages onlySteam pyrolysisCorrelation index

An integrated hydrotreating and steam pyrolysis process for the direct processing of a crude oil is provided to produce olefinic and aromatic petrochemicals. Crude oil and hydrogen are charged to a hydroprocessing zone operating under conditions effective to produce a hydroprocessed effluent reduced having a reduced content of contaminants, an increased paraffinicity, reduced Bureau of Mines Correlation Index, and an increased American Petroleum Institute gravity. Hydroprocessed effluent is thermally cracked in the presence of steam to produce a mixed product stream, which is separated. Hydrogen from the mixed product stream is purified and recycled to the hydroprocessing zone, and olefins and aromatics are recovered from the separated mixed product stream.

Owner:SAUDI ARABIAN OIL CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com