Patents

Literature

706 results about "Contact zone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Arts of the Contact Zone. In "Arts of the Contact Zone," Pratt describes a manuscript from 1613 penned by Andean man named Felipe Guaman Poma de Ayala.The manuscript was a letter written to King Phillip III of Spain and was titled The First New Chronicle and Good Government.The manuscript details Spanish conquest in South America.

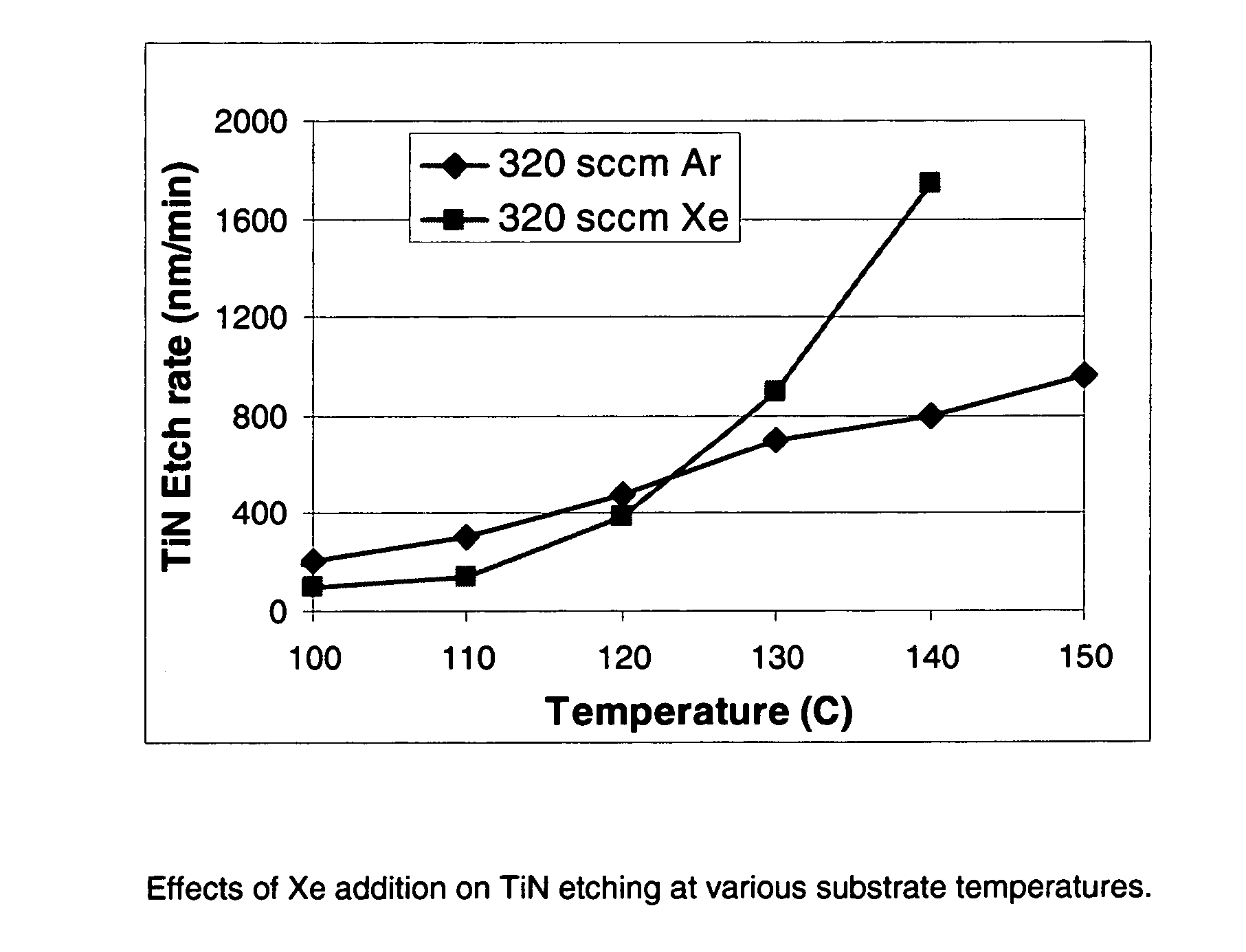

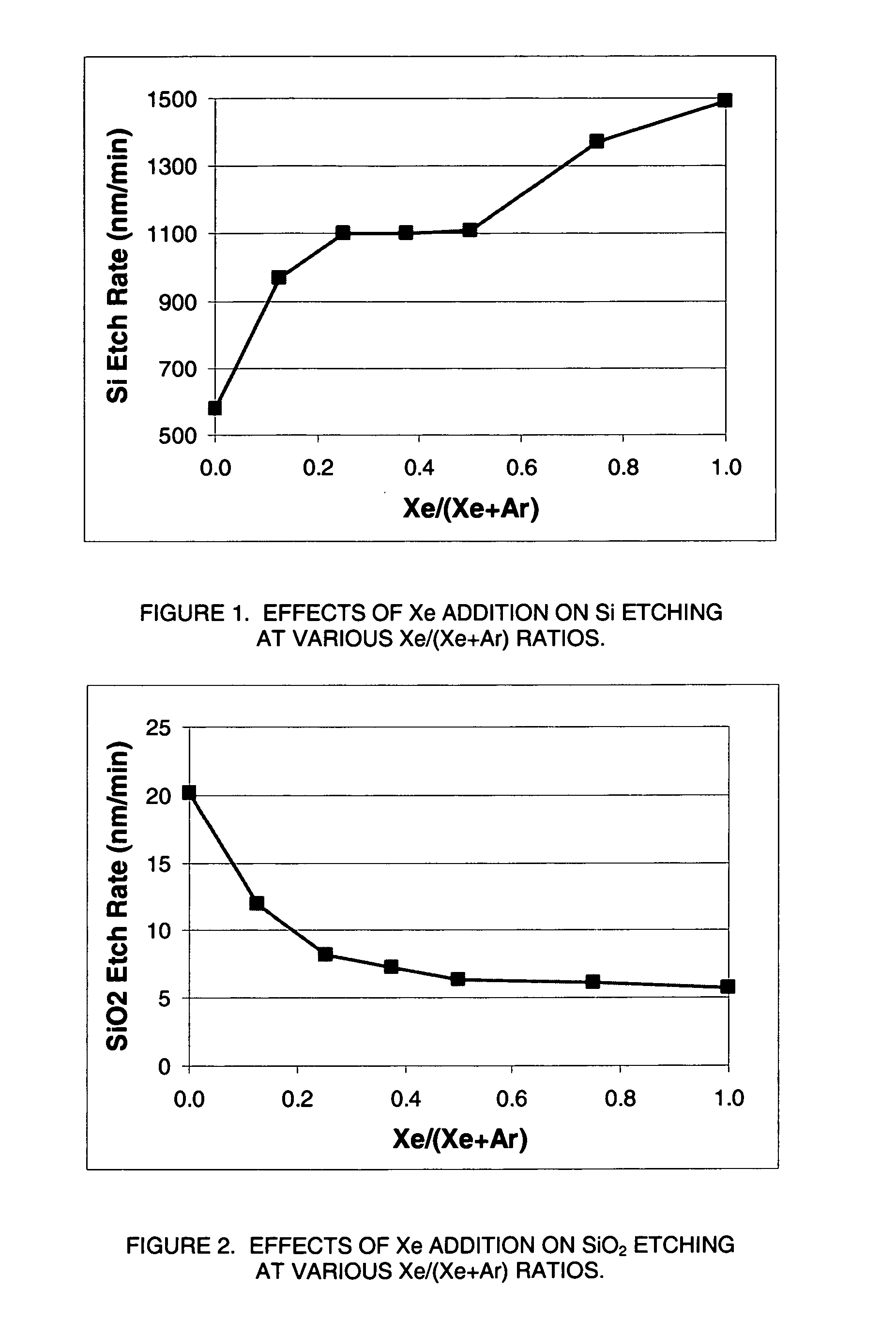

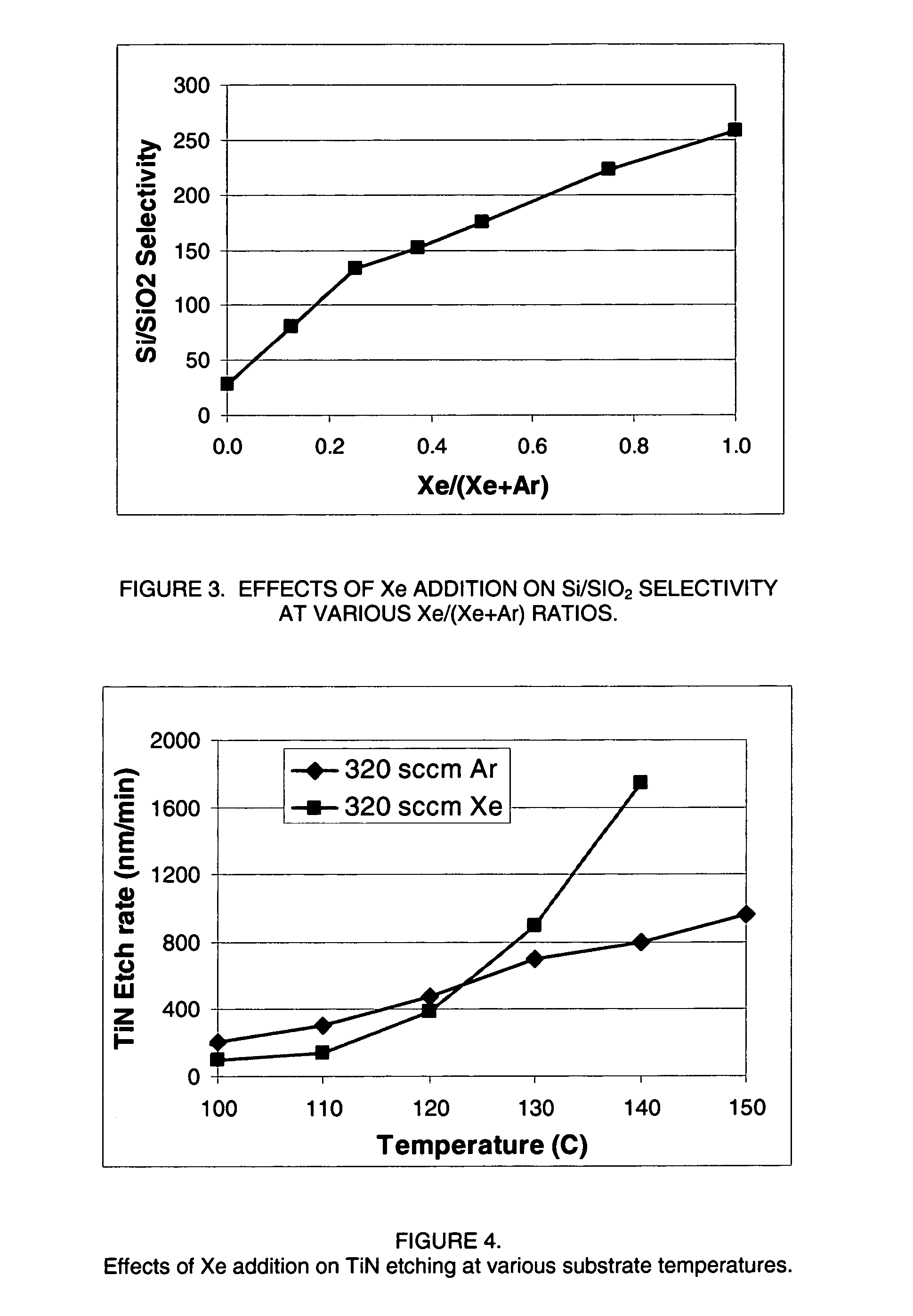

Selective etching of titanium nitride with xenon difluoride

InactiveUS20070117396A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingEtchingTitanium nitride

This invention relates to an improved process for the selective etching of TiN from silicon dioxide (quartz) and SiN surfaces commonly found in semiconductor deposition chambers equipment and tools. In the process, an SiO2 or SiN surface having TiN thereon is contacted with XeF2 in a contact zone to selectively convert the TiN to a volatile species and then the volatile species is removed from the contact zone. XeF2 can be preformed or formed in situ by reaction between Xe and a fluorine compound.

Owner:VERSUM MATERIALS US LLC

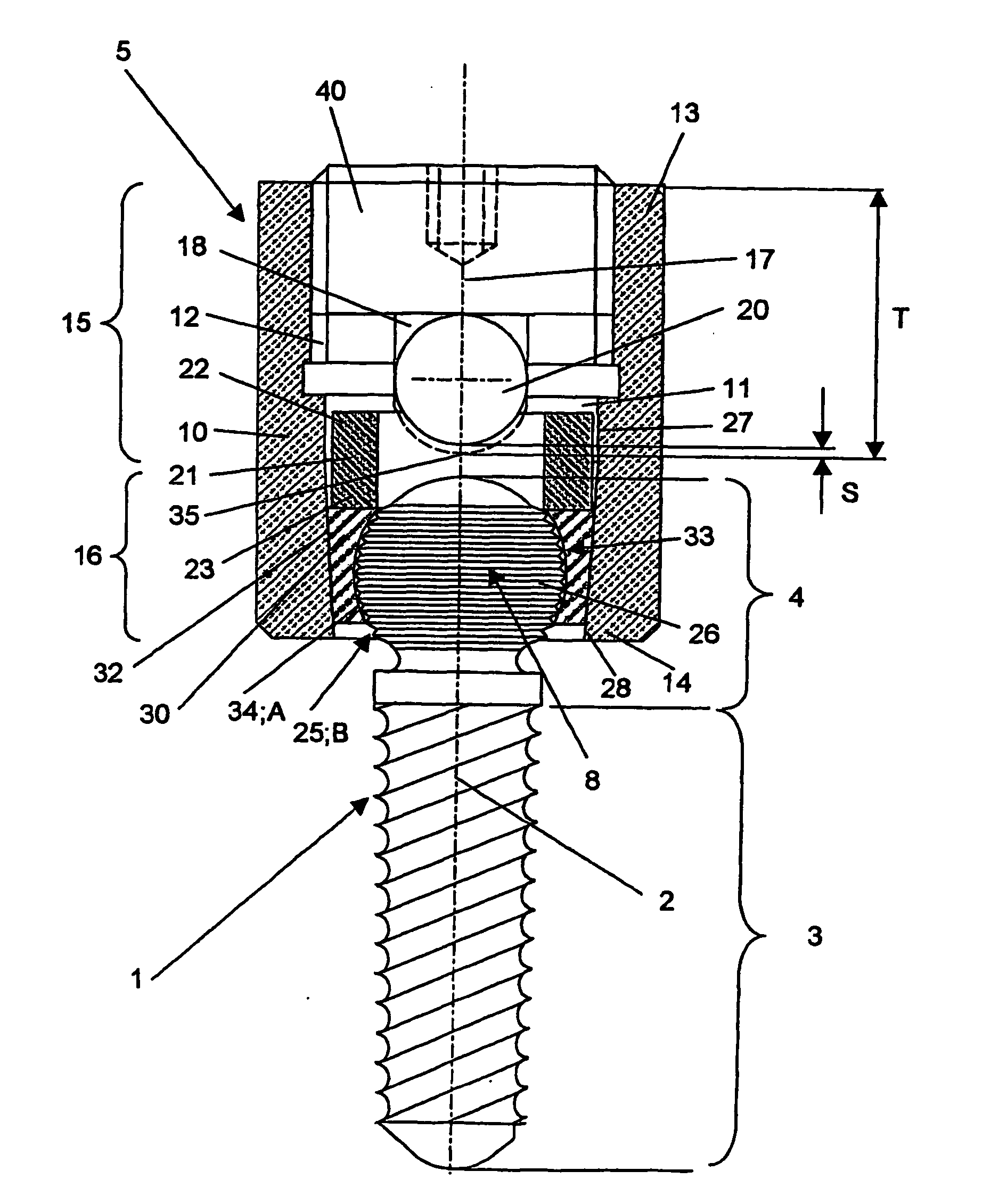

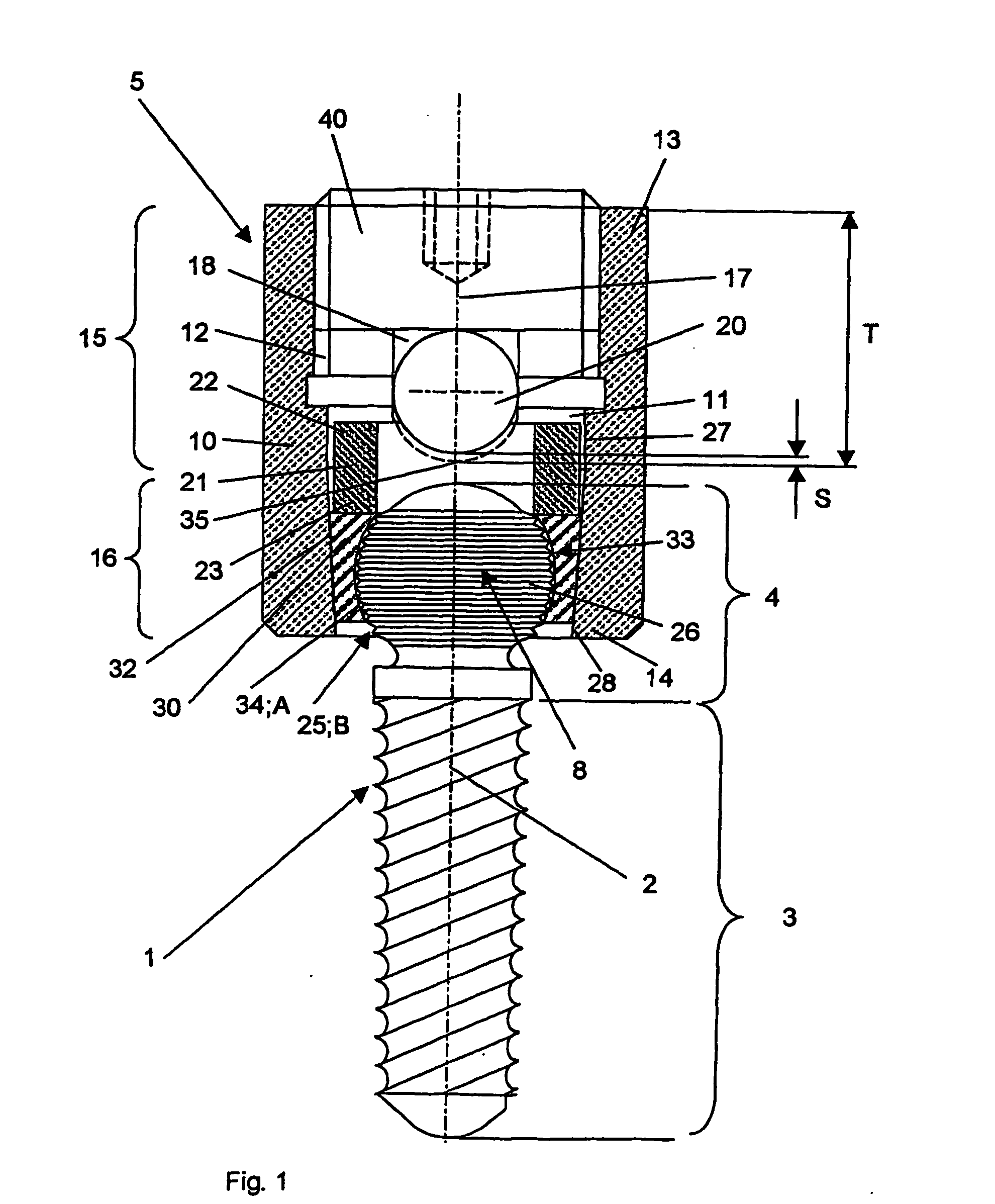

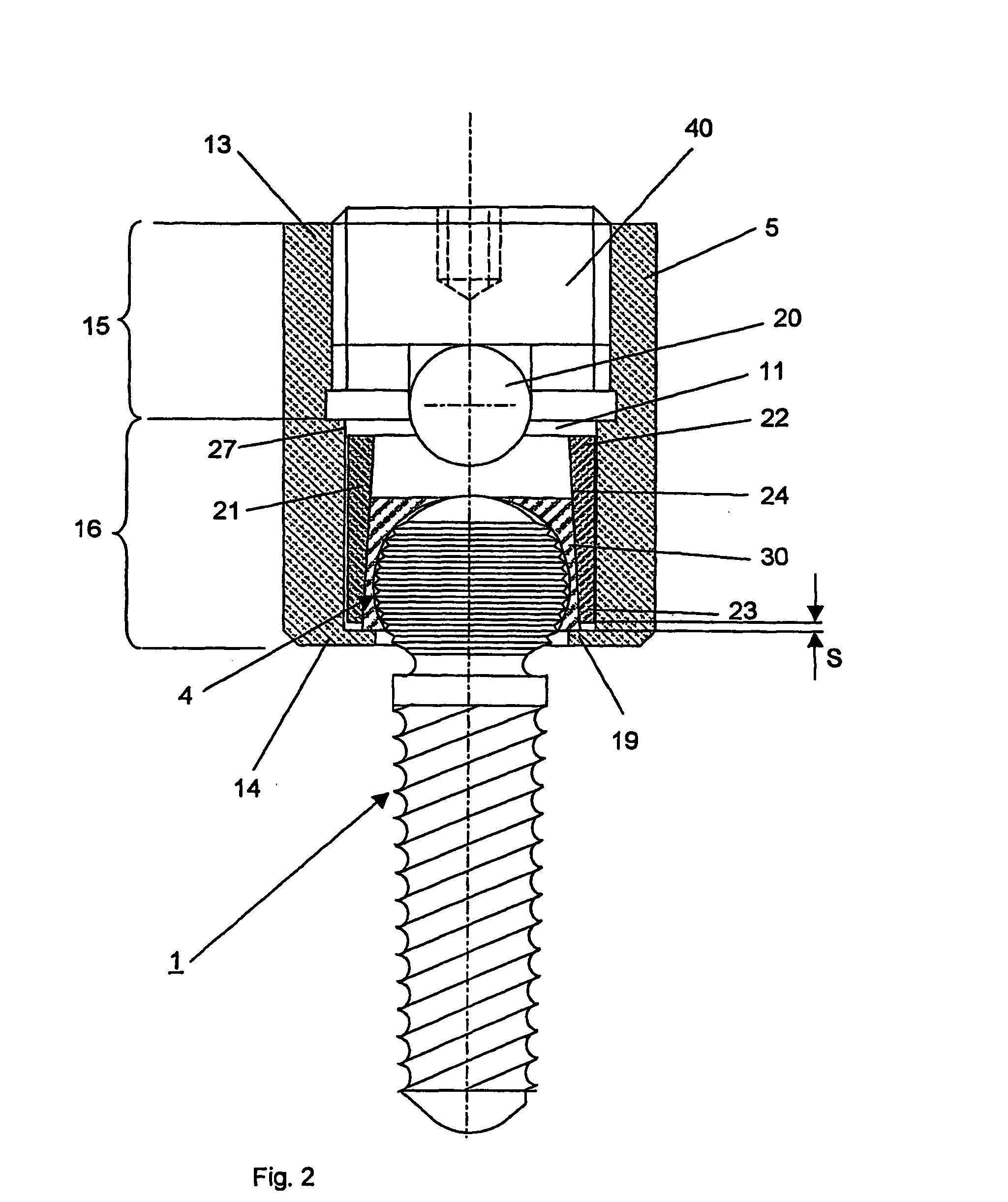

Device for the dynamic fixation of bones

InactiveUS20070233087A1Relieve pressureIncrease elasticitySuture equipmentsInternal osteosythesisDynamic fixationCoaxial cavity

An intermediate element for a detachable, lockable, ball joint-like connection in a device for the dynamic fixation of bones has a longitudinal axis, an outer wall concentric with the longitudinal axis, and an inner wall forming a coaxial cavity. Either the outer wall or the inner wall comprises one of two contact zones that form the ball joint-like connection. The intermediate element is at least partly made of a super-elastic or visco-elastic material.

Owner:SYNTHES USA

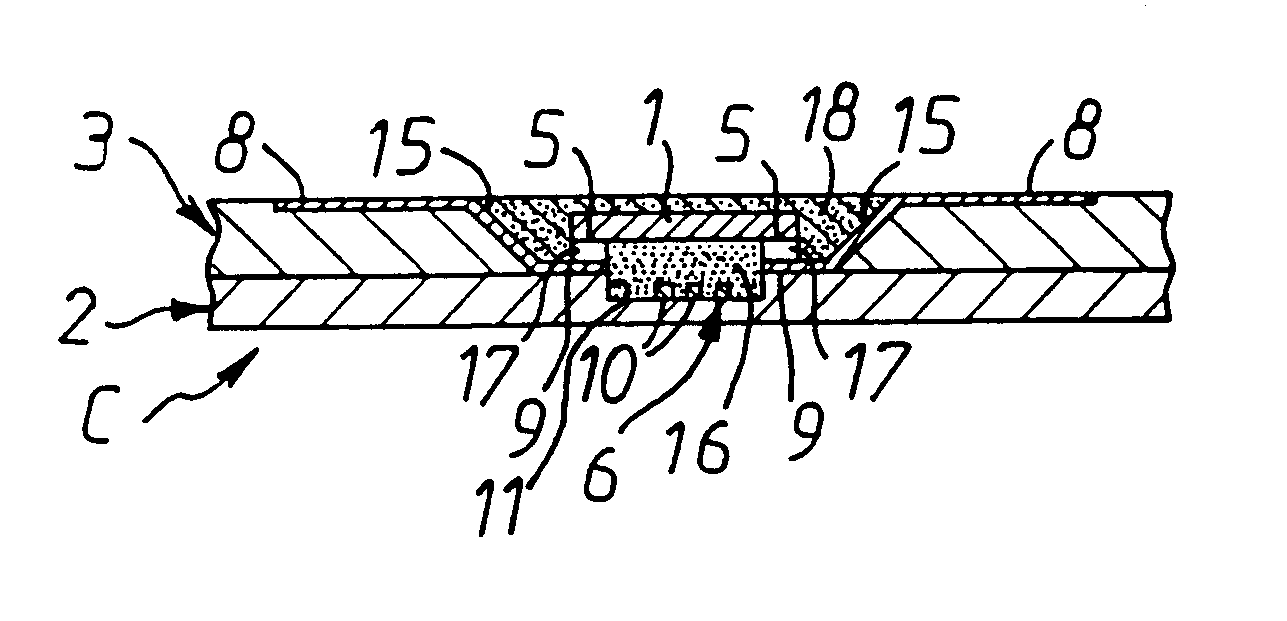

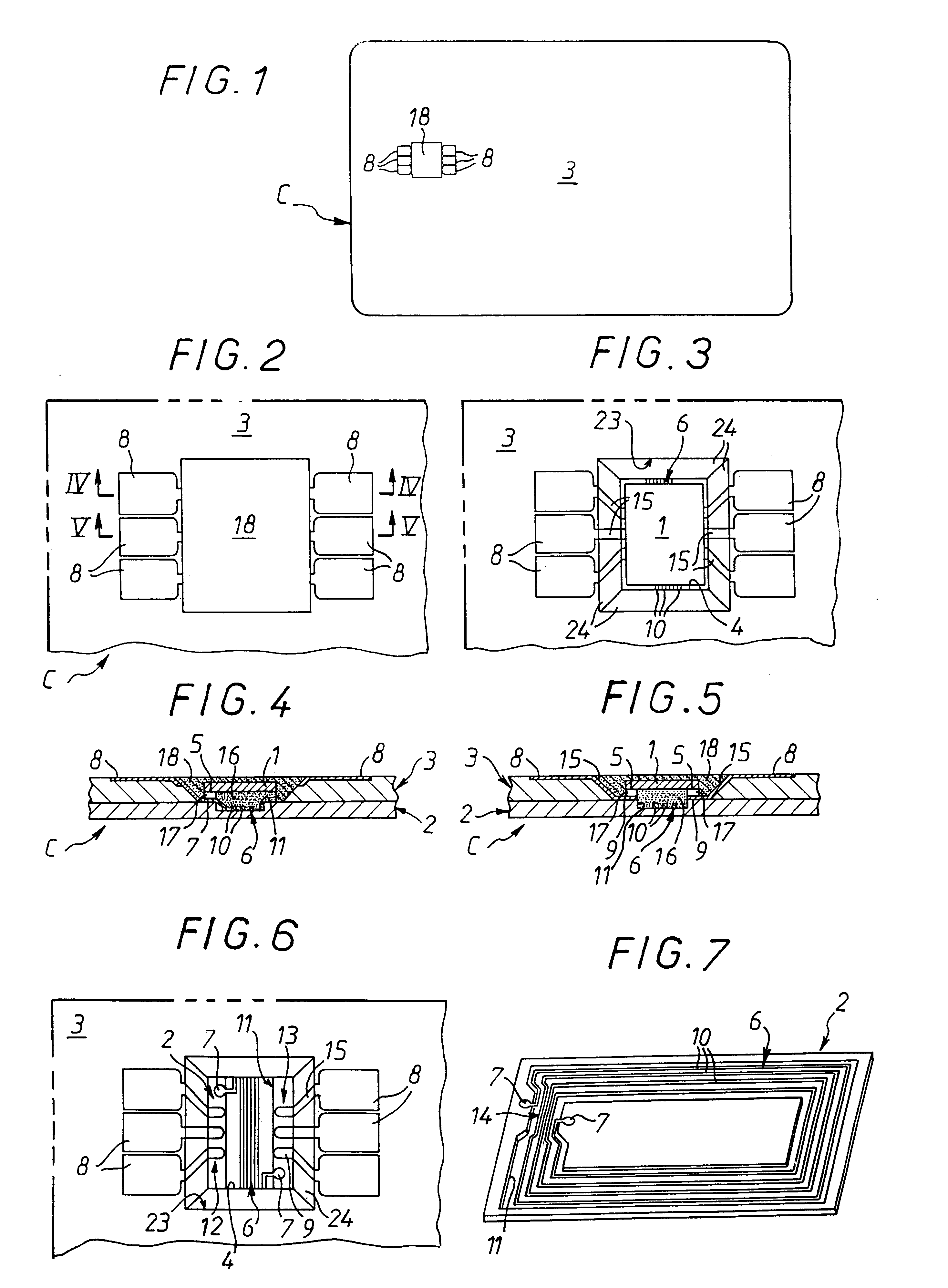

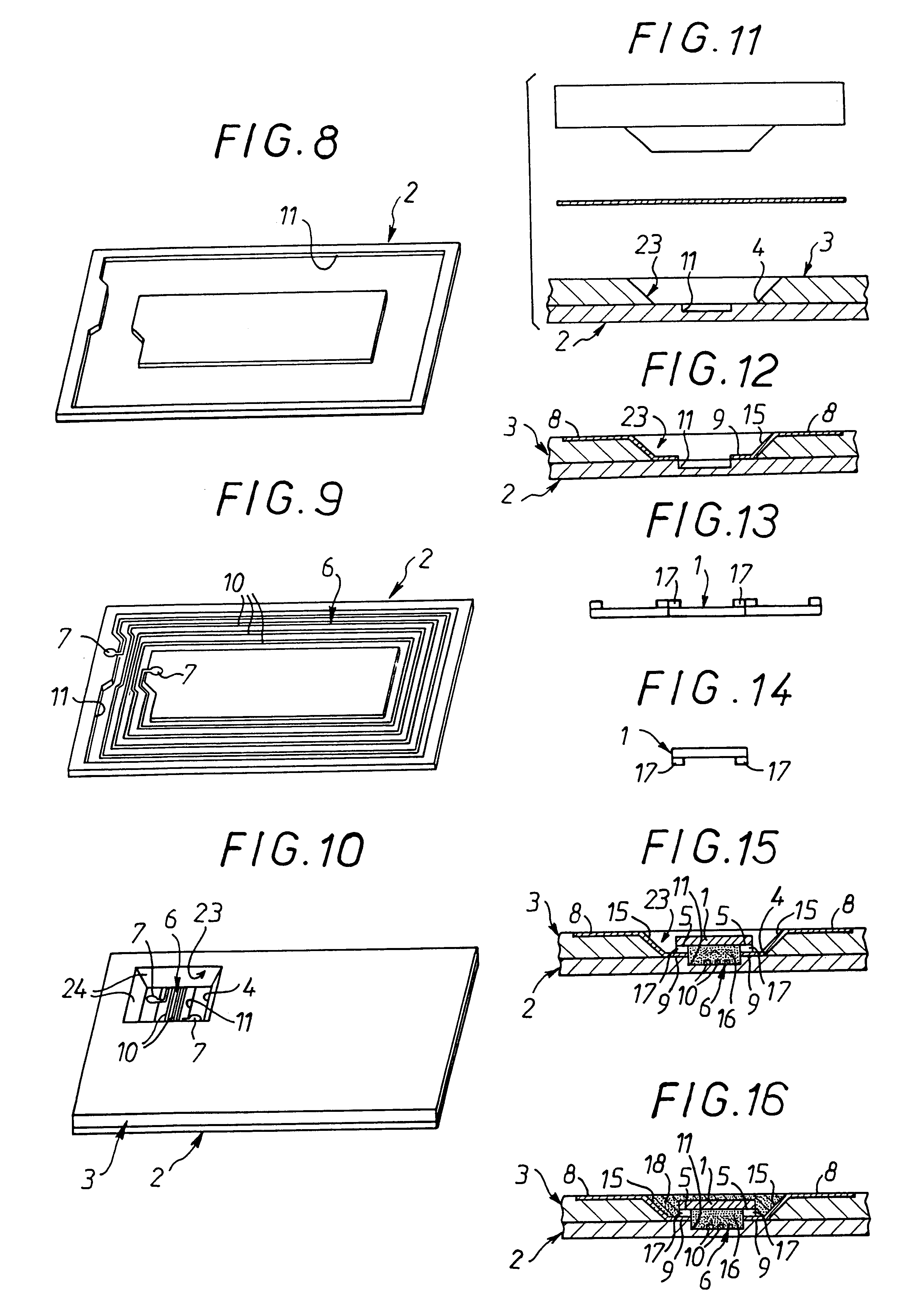

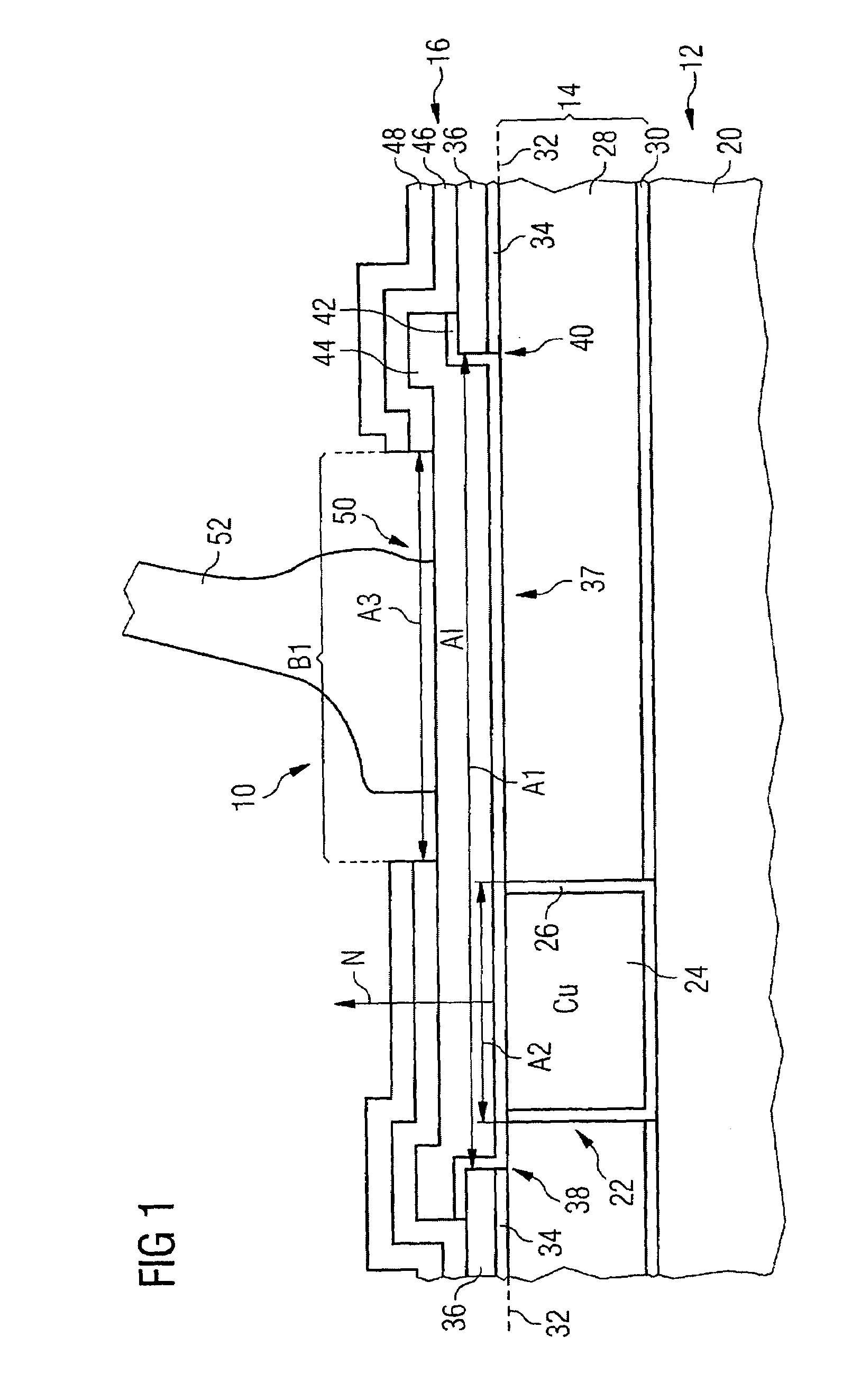

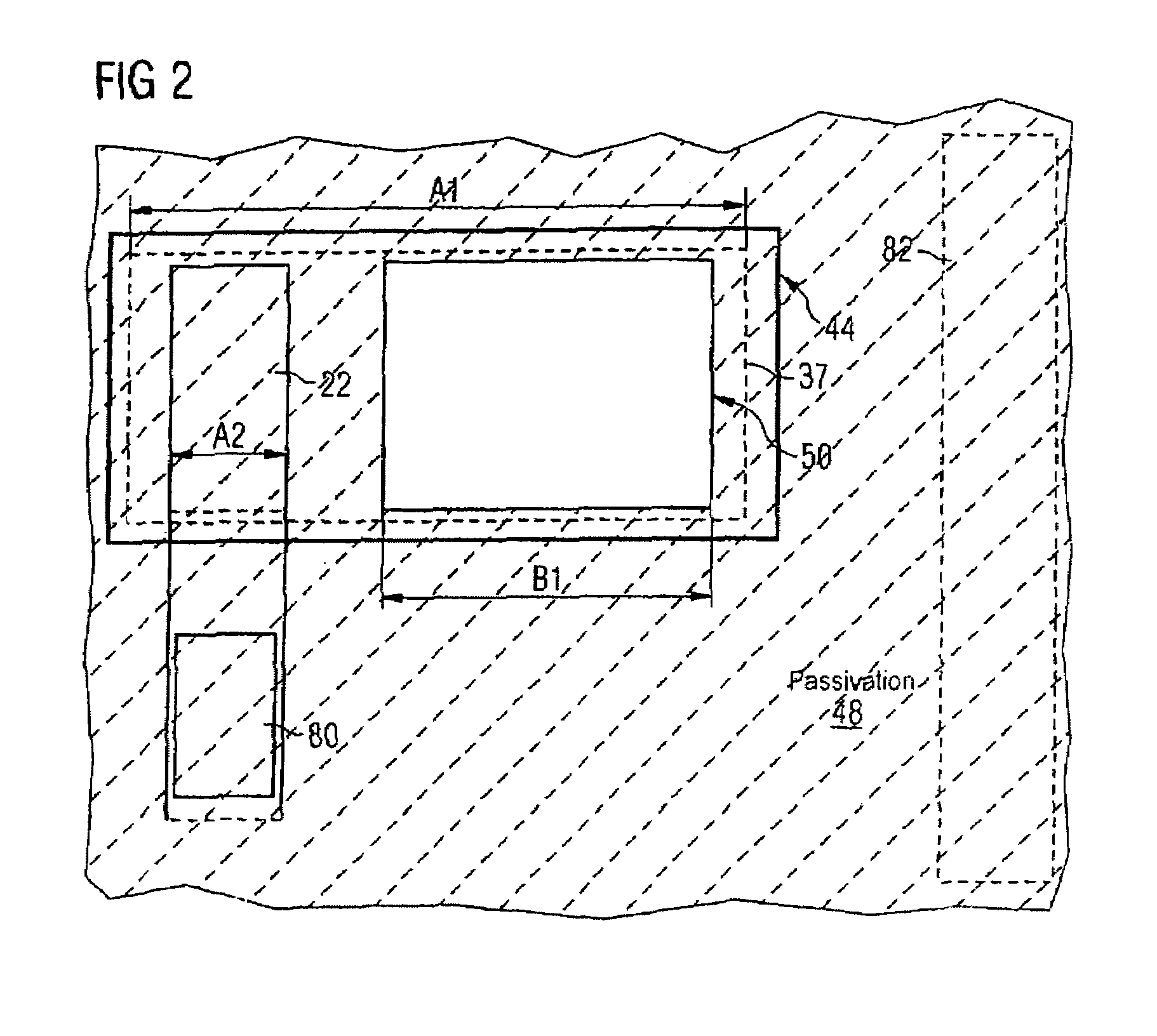

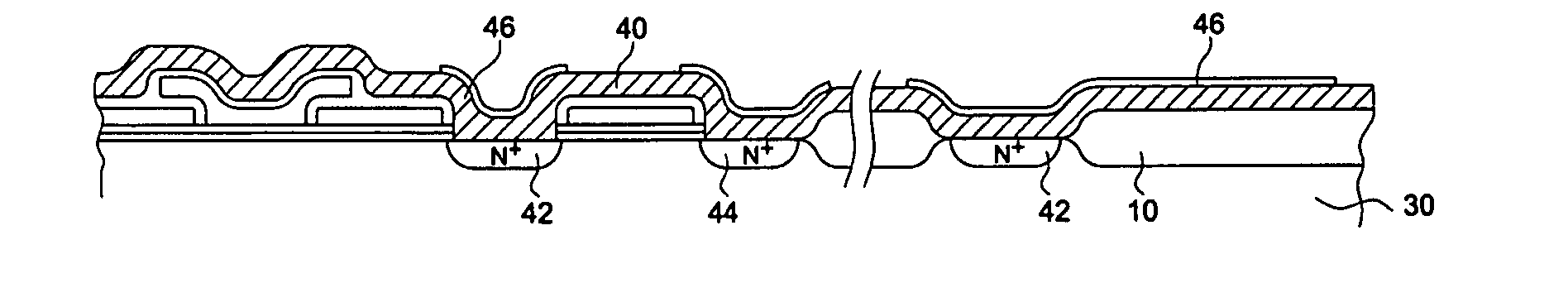

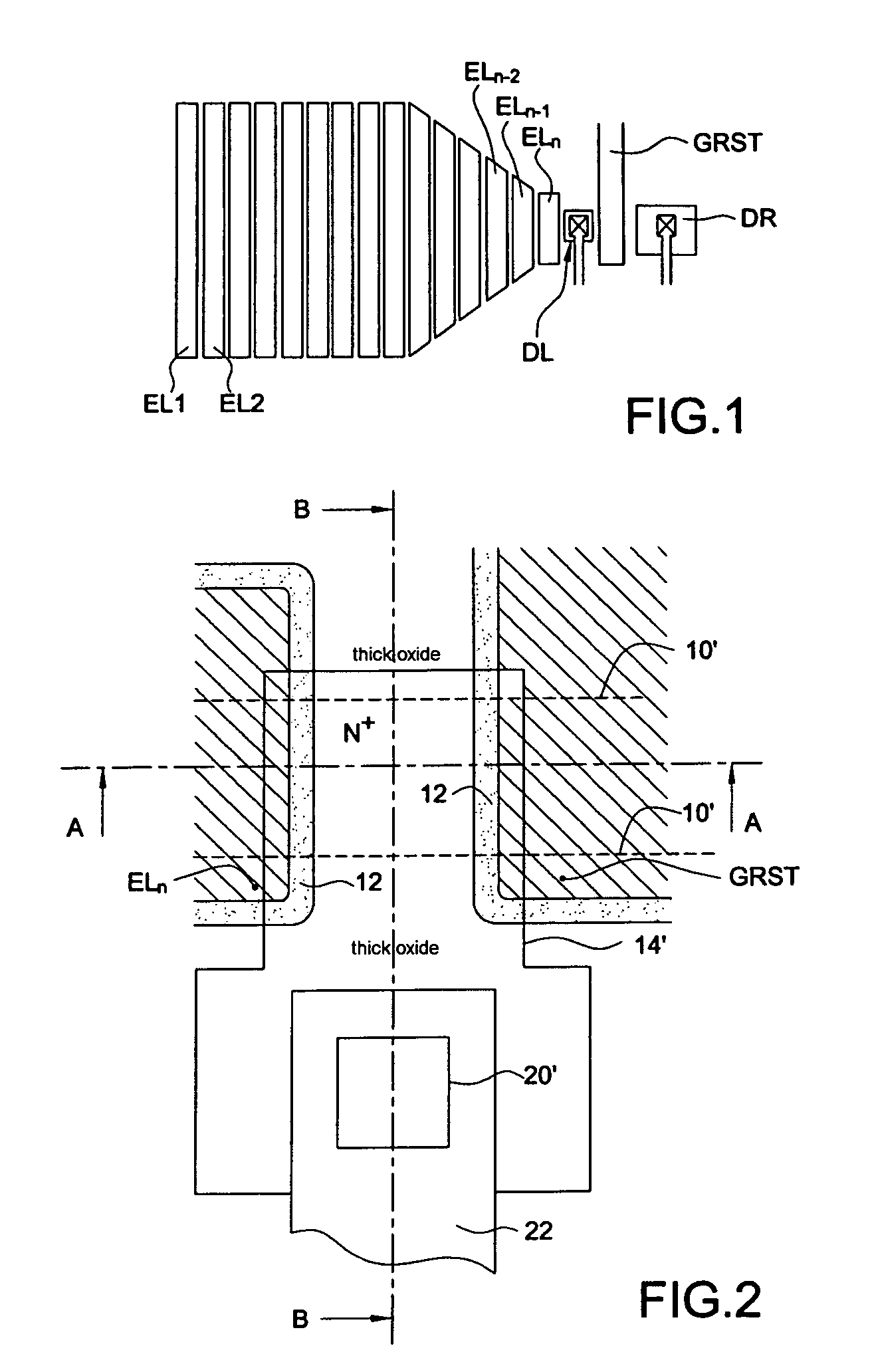

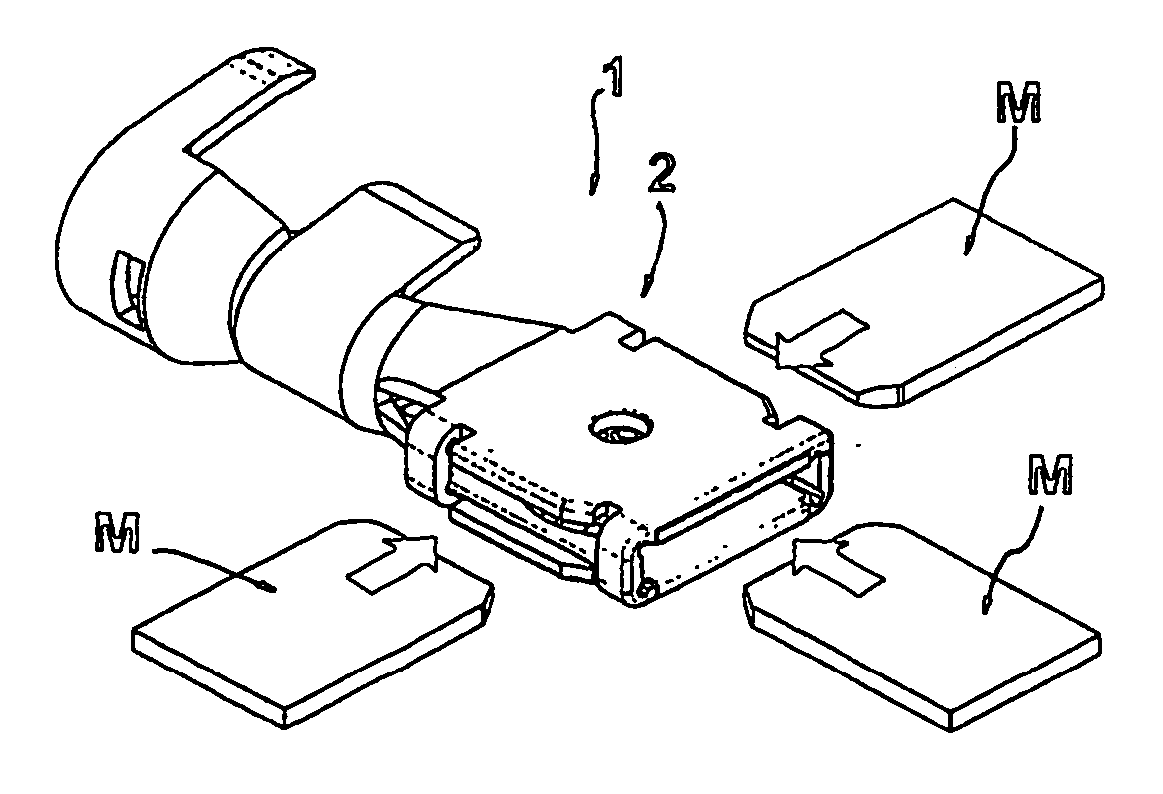

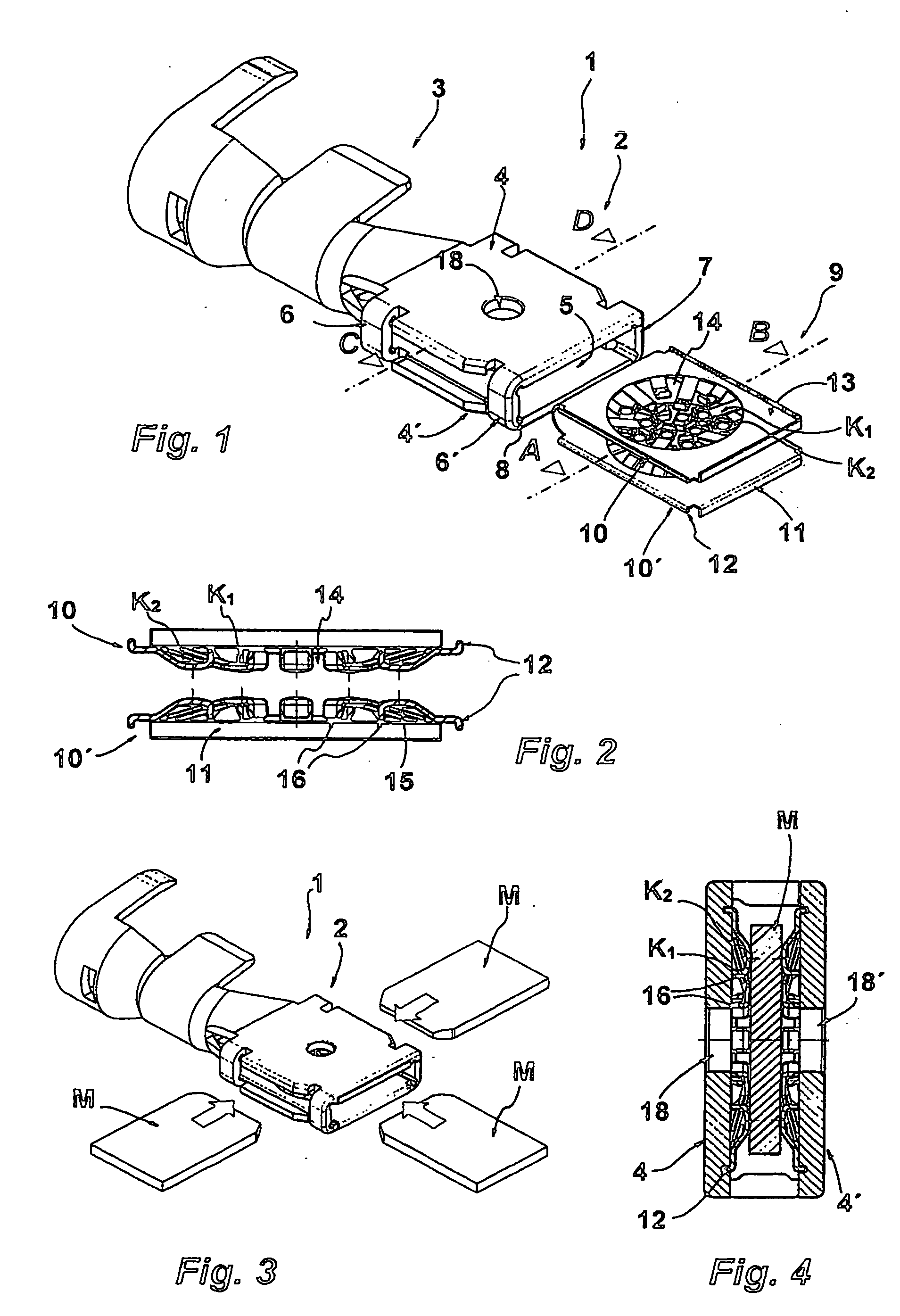

Integrated circuit board combining external contact zones and an antenna, and process for manufacturing such a board

InactiveUS6320753B1Printed circuit assemblingPrinted electric component incorporationIntegrated circuit layoutPrinted circuit board

Integrated circuit board combining external contact zones and an antenna to receive data transmitted by a terminal, and process for manufacturing such a board.The integrated circuit board in accordance with the invention comprises a single integrated circuit connected both to an antenna by connection terminals and to external contact zones by other connection terminals; the antenna is arranged between a support and a strip; the above-mentioned connection terminals are arranged opposite the corresponding connection ends of the integrated circuit and are respectively connected to them; the integrated circuit is arranged by a process know by the name "flip-chip" in a cavity in which the connection terminals of the antenna and those of the external contact zones are accessible.The board in accordance with the invention may by used both with a reader connected to the external contact zones or with a terminal transmitting data without contacts, by means of the antenna.

Owner:DE LA RUE CARTES & SYST

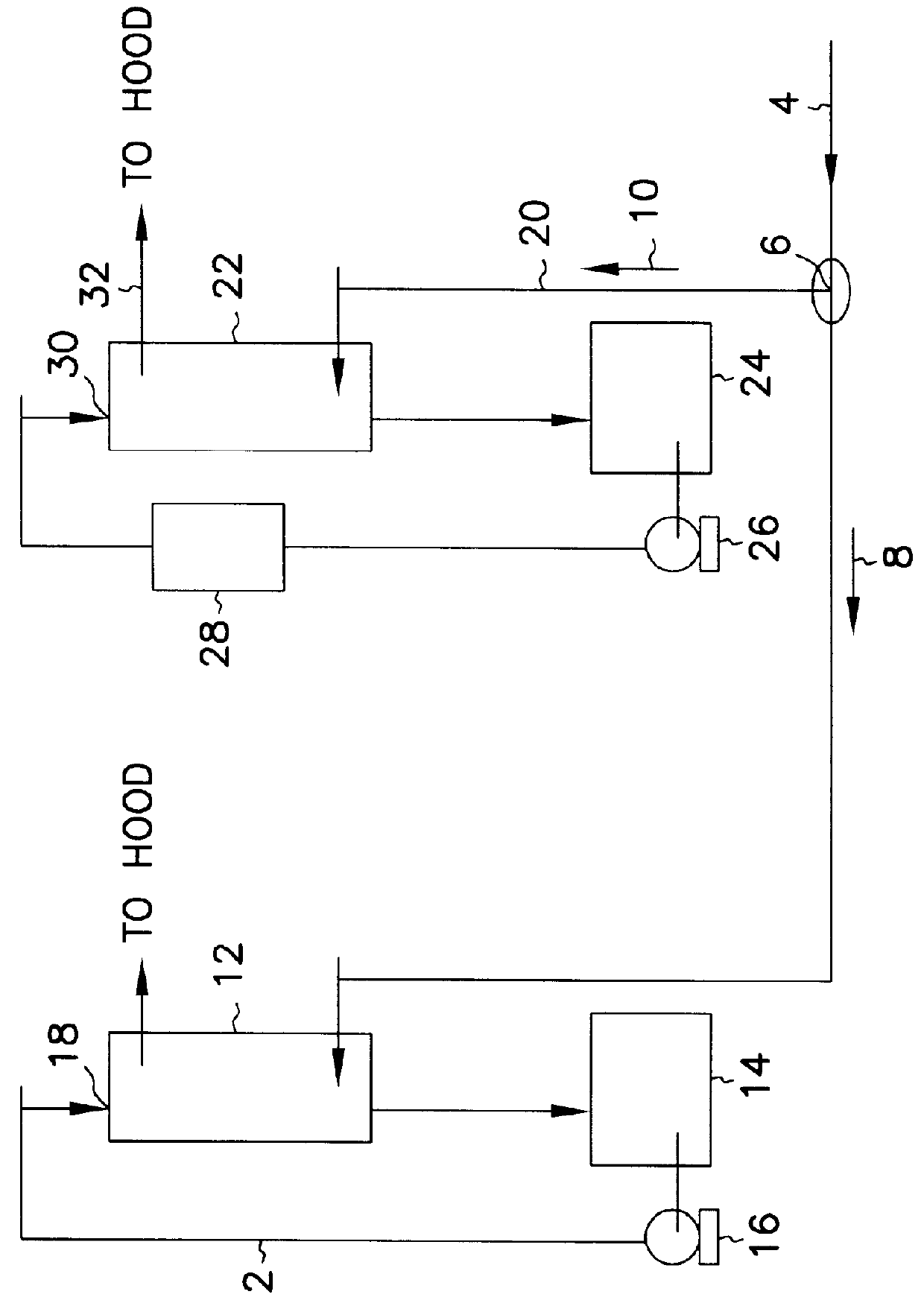

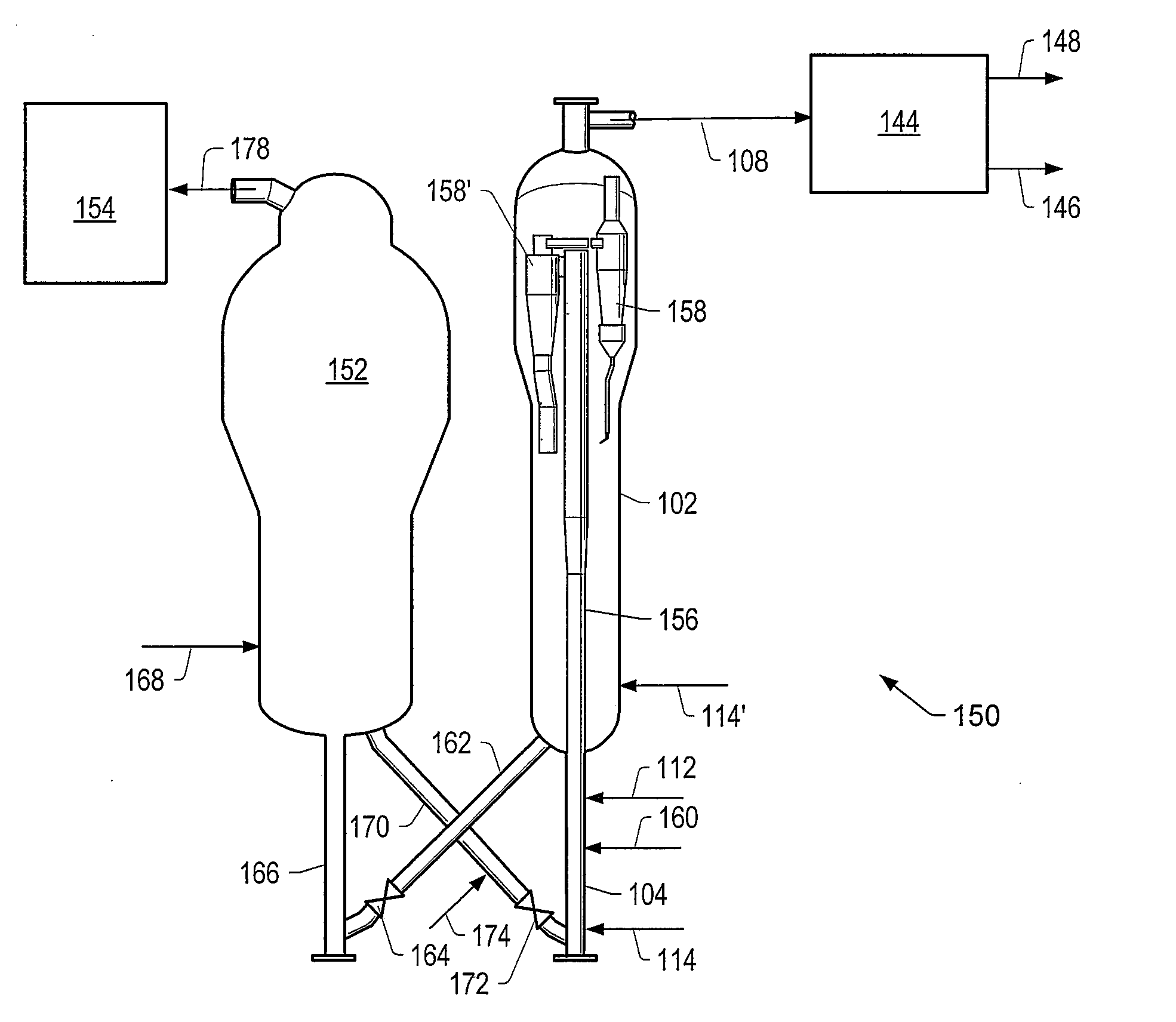

Process and equipment for nitrogen oxide waste conversion to fertilizer

The present invention describes a process for converting vapor streams from sources containing at least one nitrogen-containing oxidizing agent therein to a liquid fertilizer composition comprising the steps of: a) directing a vapor stream containing at least one nitrogen-containing oxidizing agent to a first contact zone, b) contacting said vapor stream with water to form nitrogen oxide(s) from said at least one nitrogen-containing oxidizing agent, c) directing said acid(s) as a second stream to a second contact zone, d) exposing said second stream to hydrogen peroxide which is present within said second contact zone in a relative amount of at least 0.1% by weight of said second stream within said second contact zone to convert at least some of any nitrogen oxide species or ions other than in the nitrate form present within said second stream to nitrate ion, e) sampling said stream within said second contact zone to determine the relative amount of hydrogen peroxide within said second contact zone, f) adding hydrogen peroxide to said second contact zone when a level of hydrogen peroxide less than 0.1 % by weight in said second stream is determined by said sampling, g) adding a solution comprising potassium hydroxide to said second stream to maintain a pH between 6.0 and 11.0 within said second stream within said second contact zone to form a solution of potassium nitrate, and h) removing said solution of potassium nitrate from said second contact zone.

Owner:NAT AERONAUTICS & SPACE ADMINISTATION U S GOVERNMENT AS REPRESENTED BY THE ADMINISTATOR

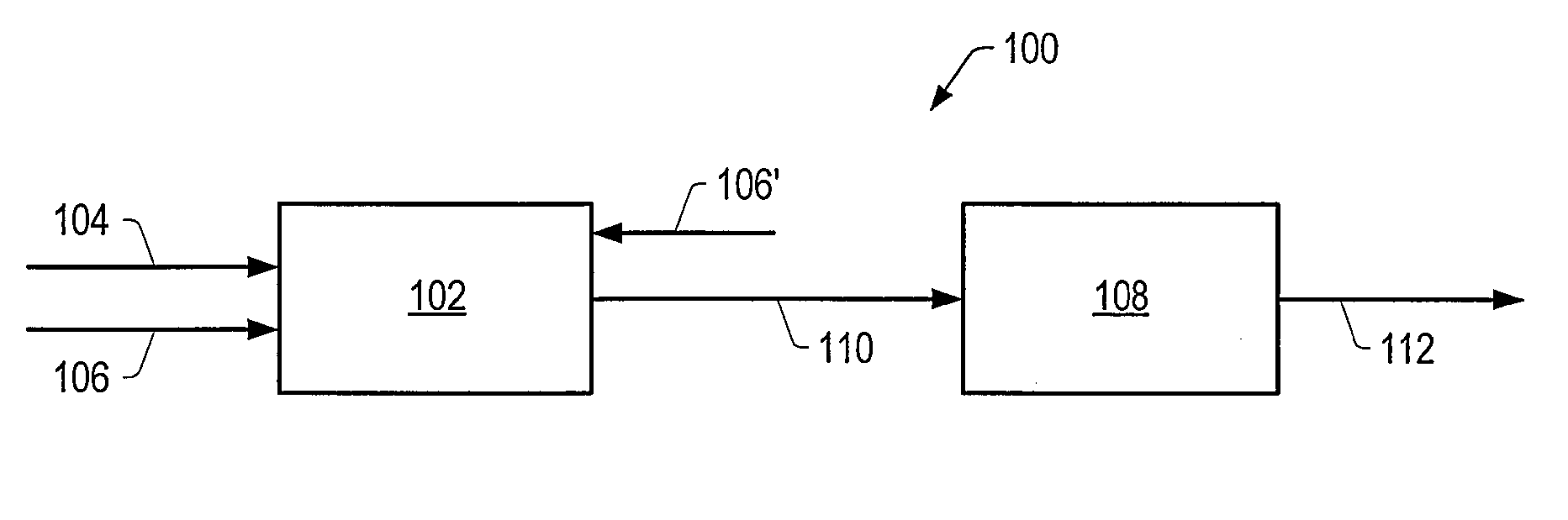

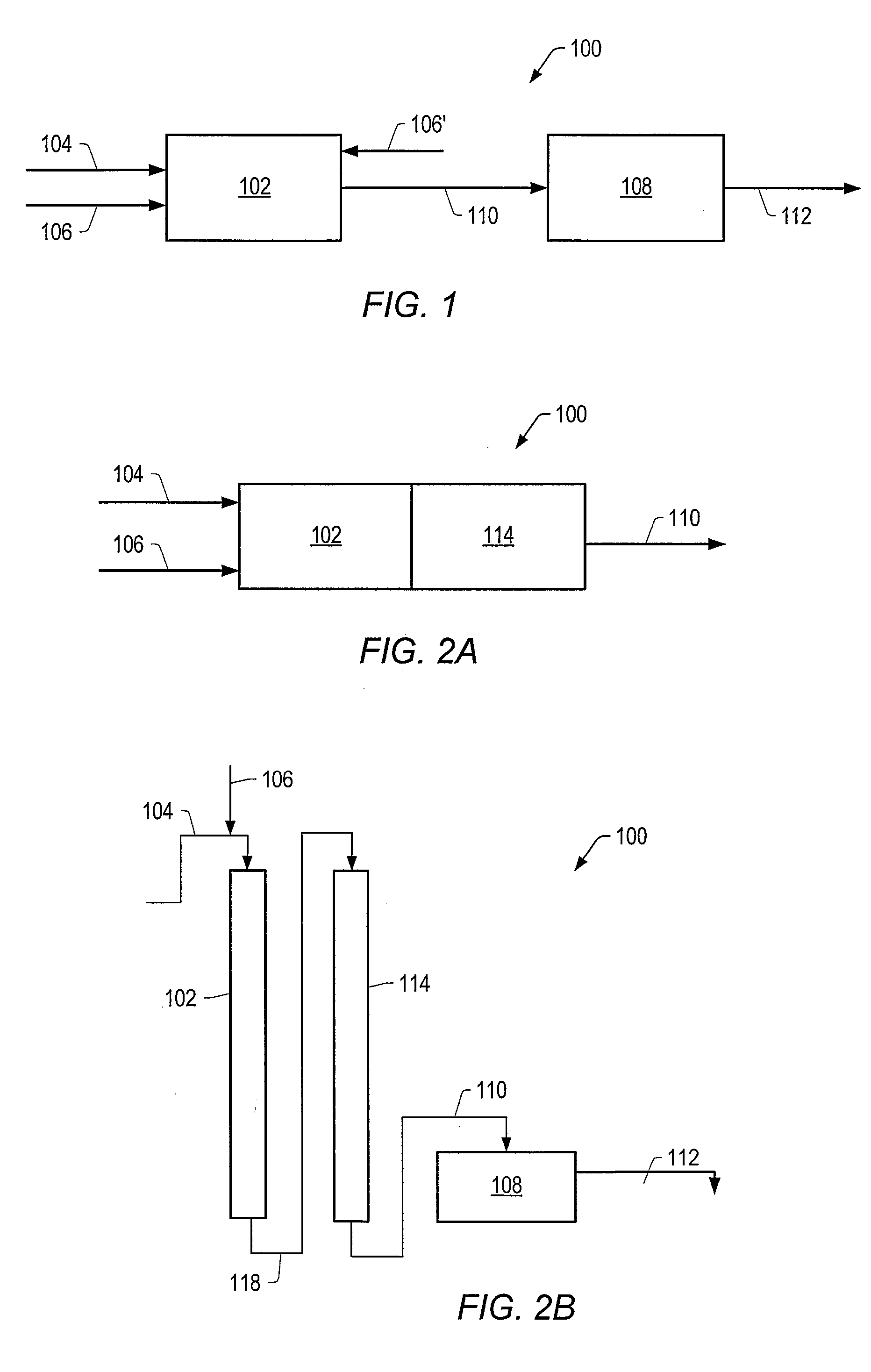

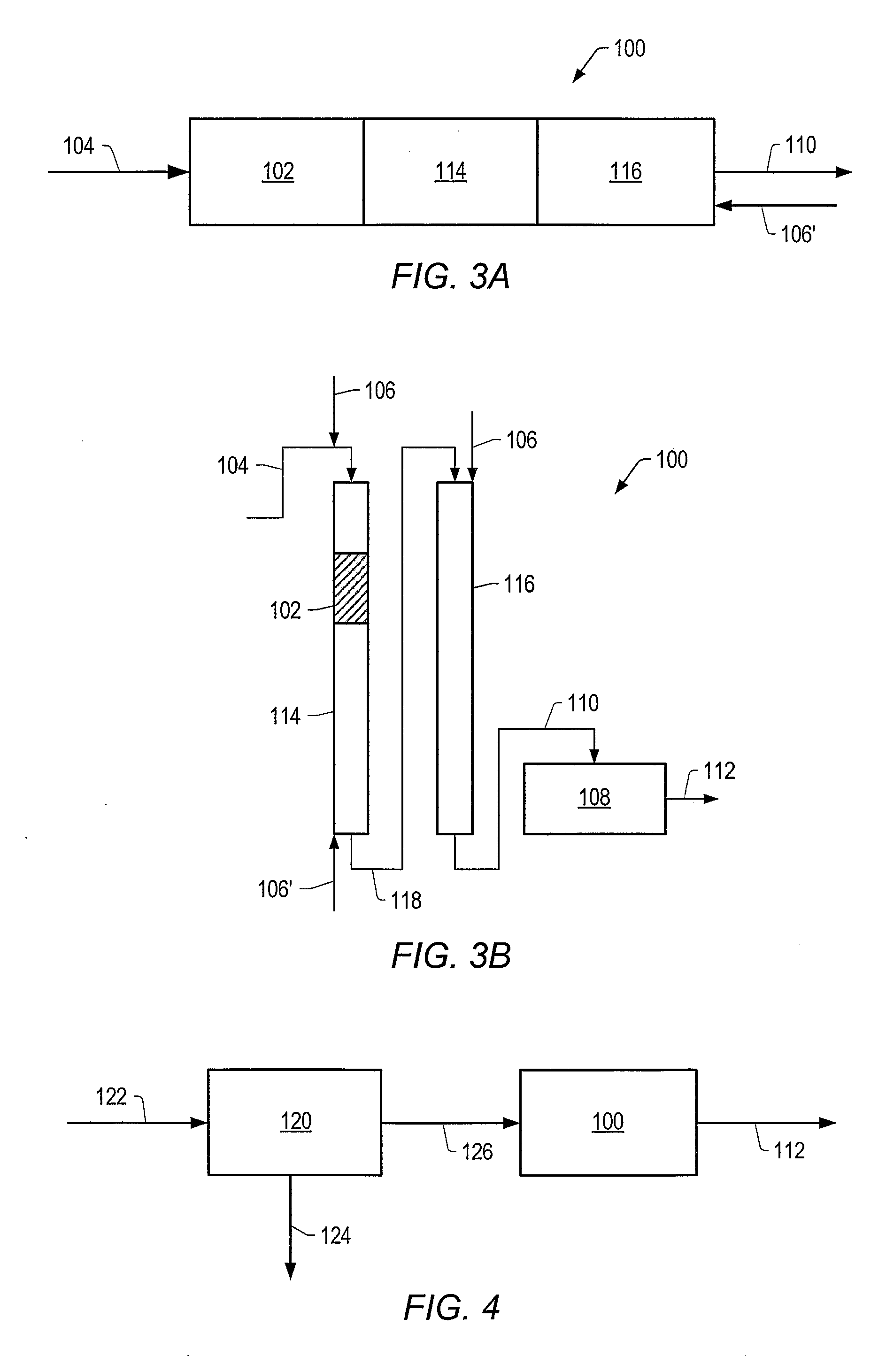

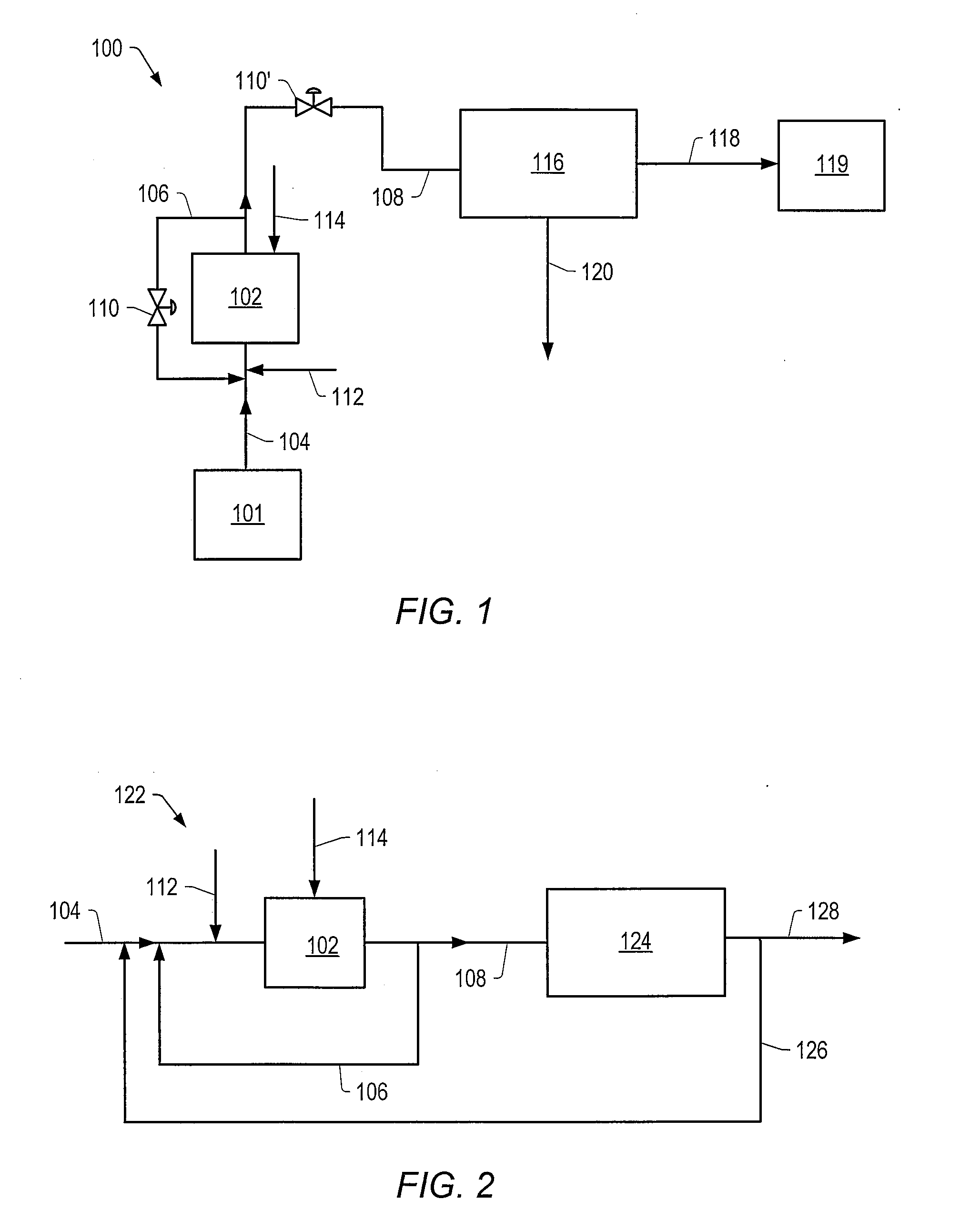

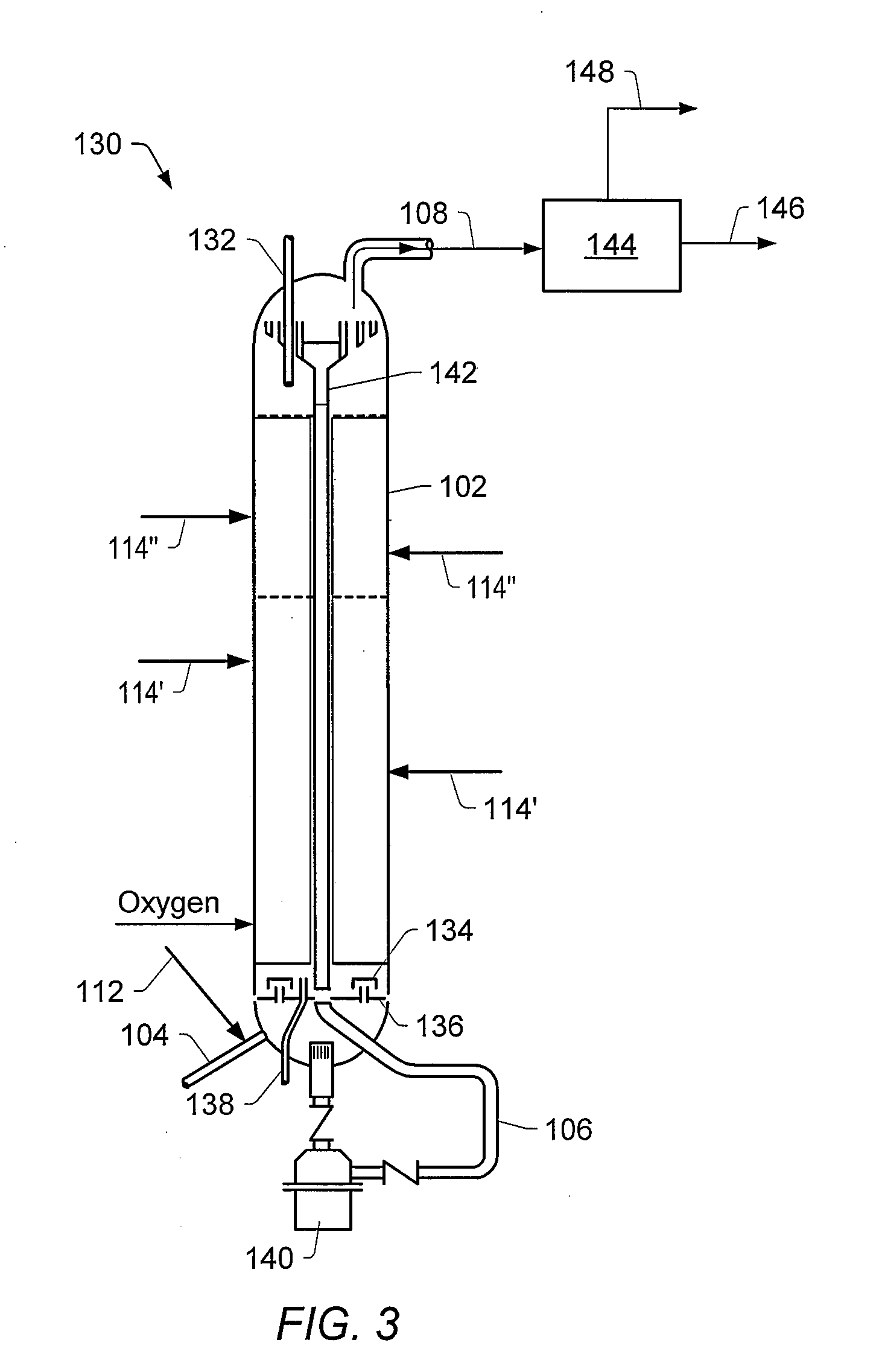

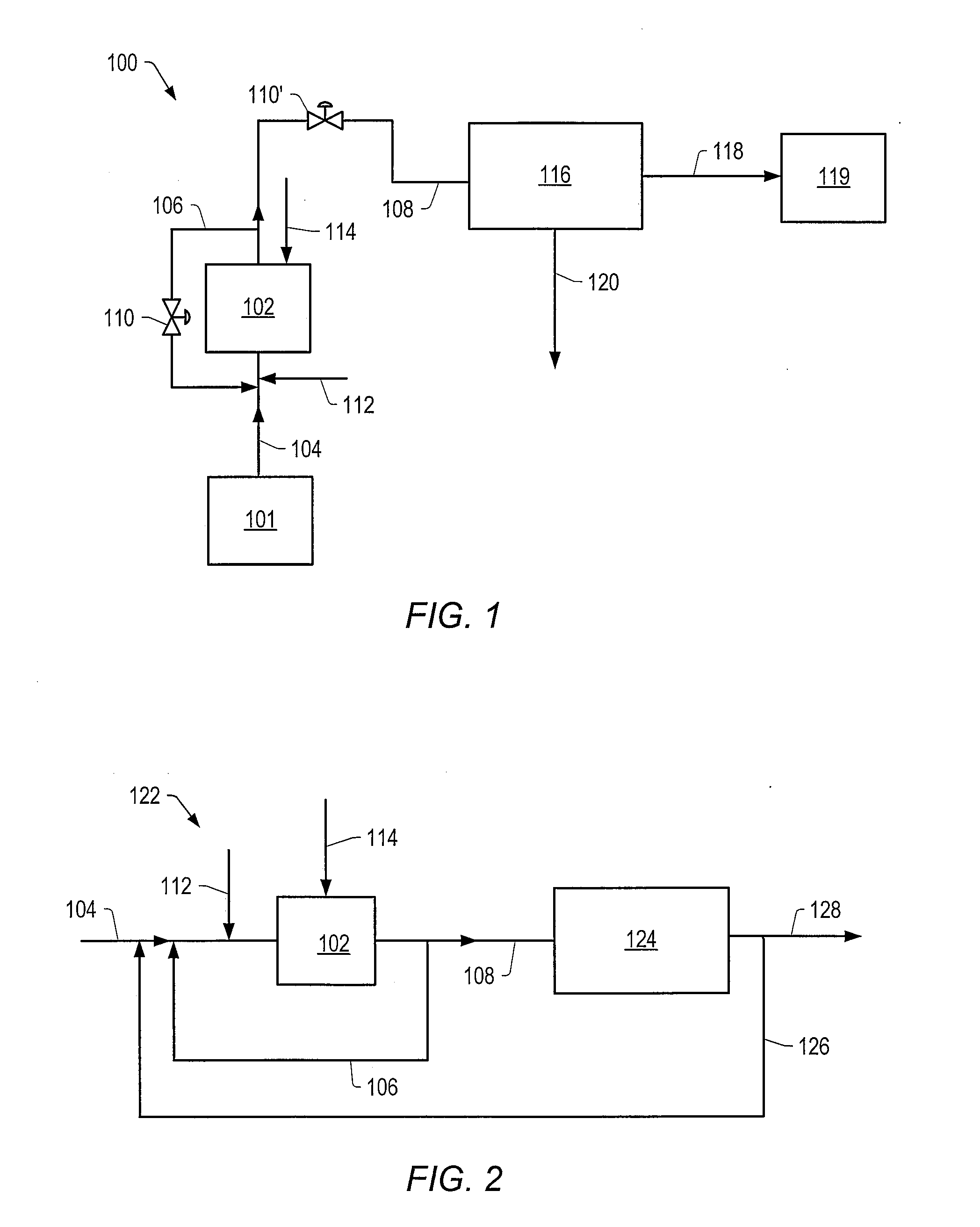

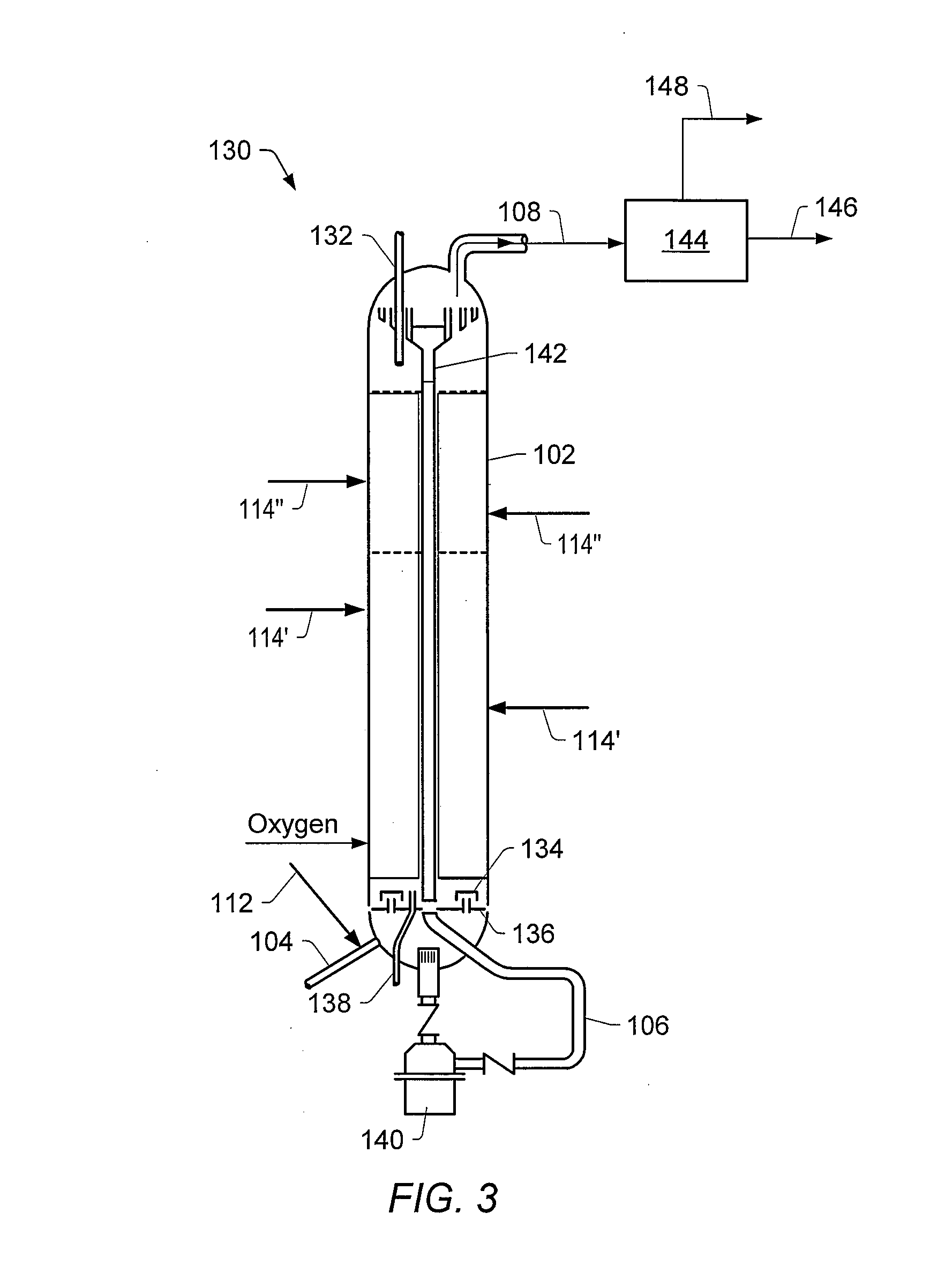

Systems and methods for producing a crude product and compositions thereof

InactiveUS20080087575A1Treatment with plural serial cracking stages onlyCatalyst activation/preparationContact zoneHydrocarbon

Systems and methods for producing a crude product are described herein. Systems include an upstream contacting zone and a downstream contacting zone coupled to the upstream contacting zone. The upstream contacting zone and the downstream contacting zone include one or more catalysts. Contact of a hydrocarbon feed with the one or more of the catalysts produces a hydrocarbon feed / total product mixture having a molybdenum content of at most 90% of the molybdenum of the hydrocarbon feed. Contact of the hydrocarbon feed / total product mixture in downstream with one or more downstream catalysts produces a crude product having a molybdenum content of at most 90% of the molybdenum content of the hydrocarbon feed and at most 90% of the residue content of the hydrocarbon feed. Methods of producing a crude product using said systems are described herein. Compositions of said crude product produced from said systems and methods are described herein.

Owner:SHELL OIL CO

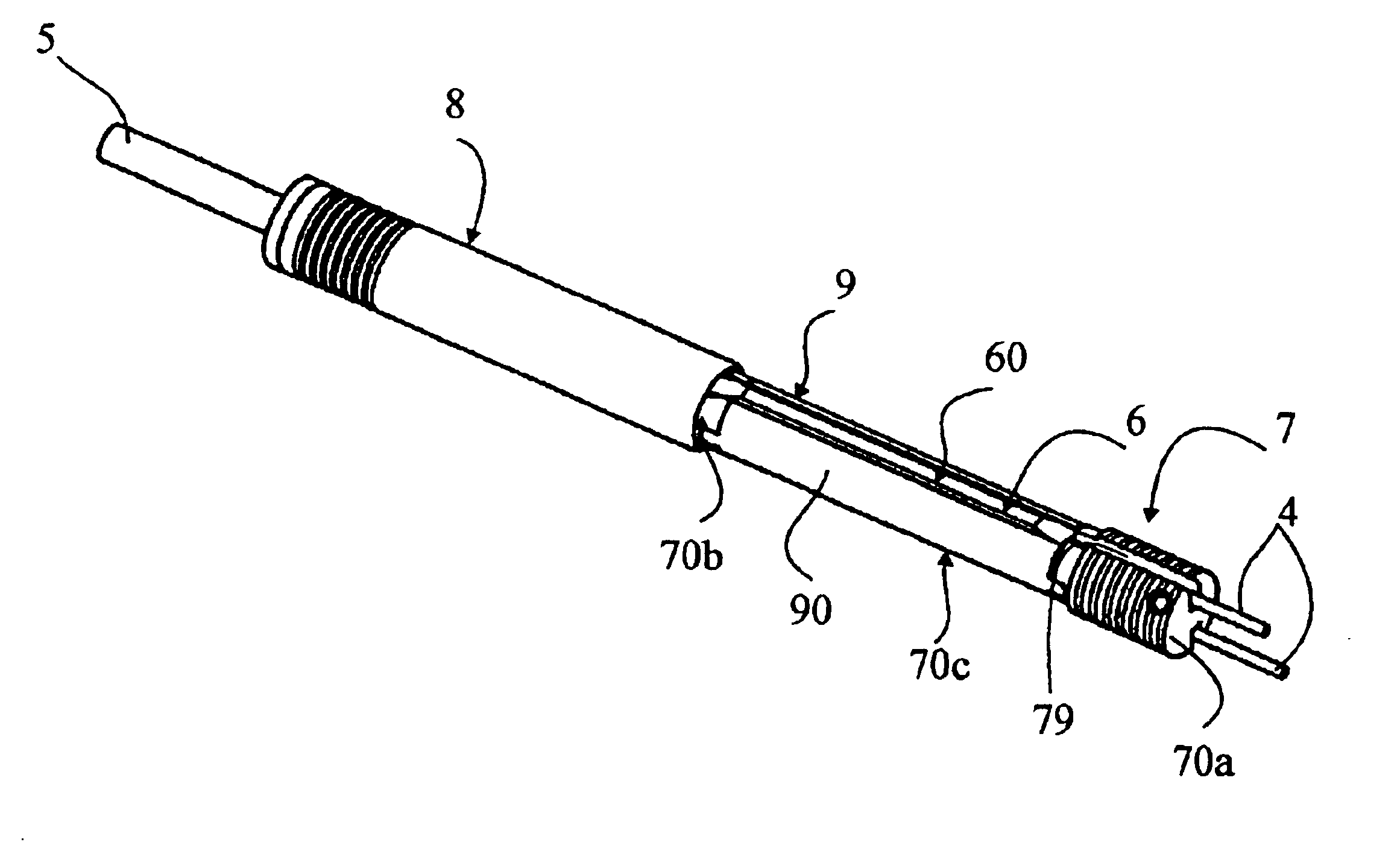

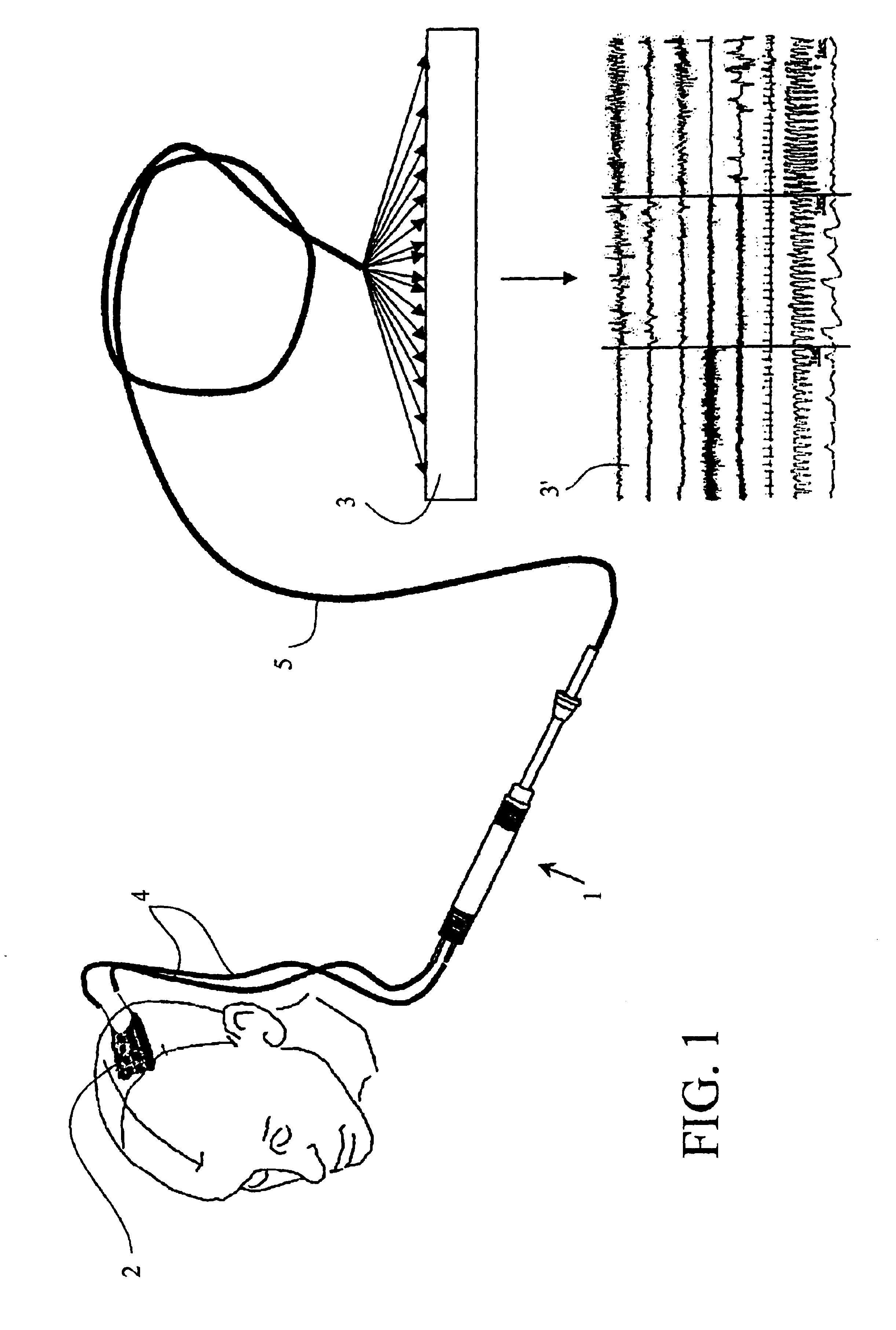

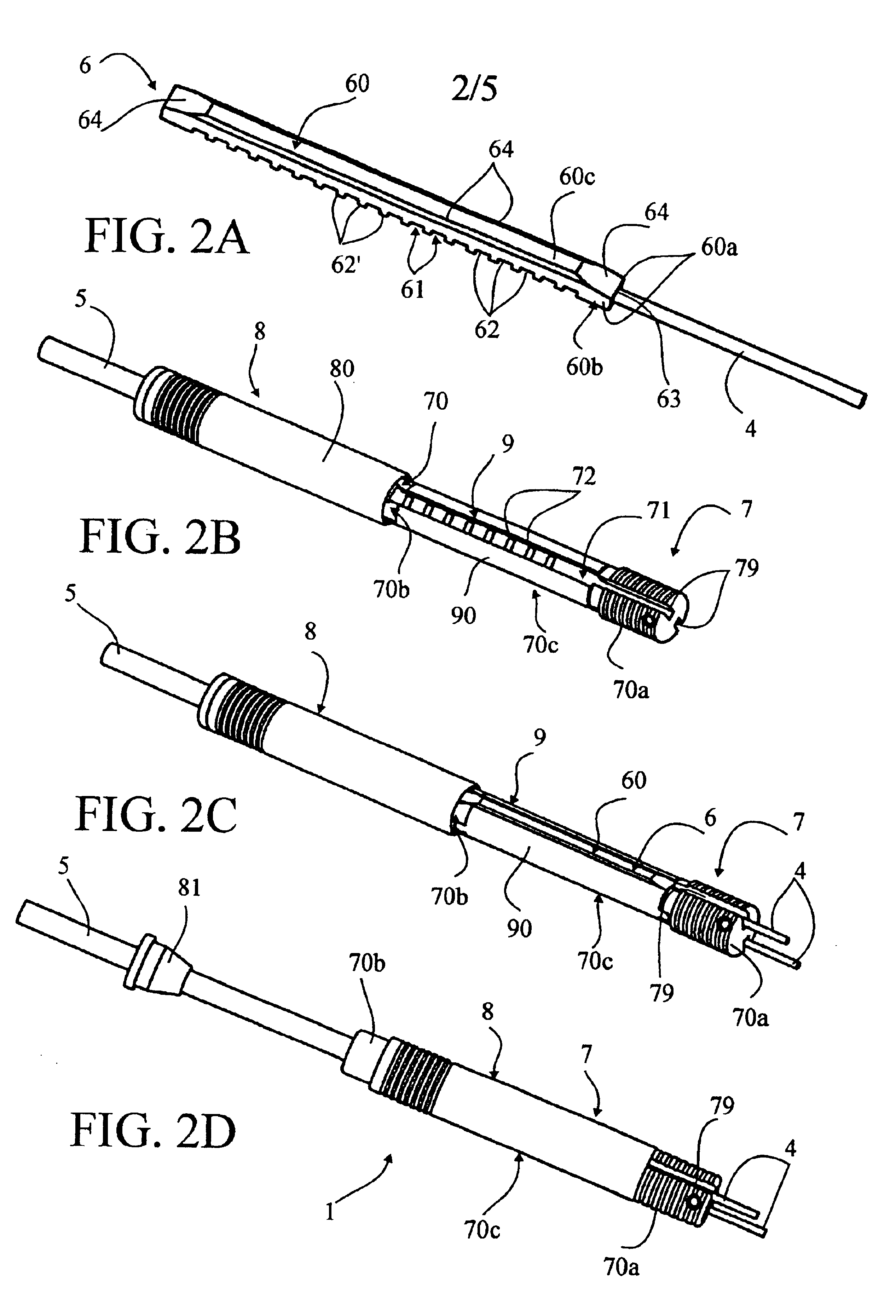

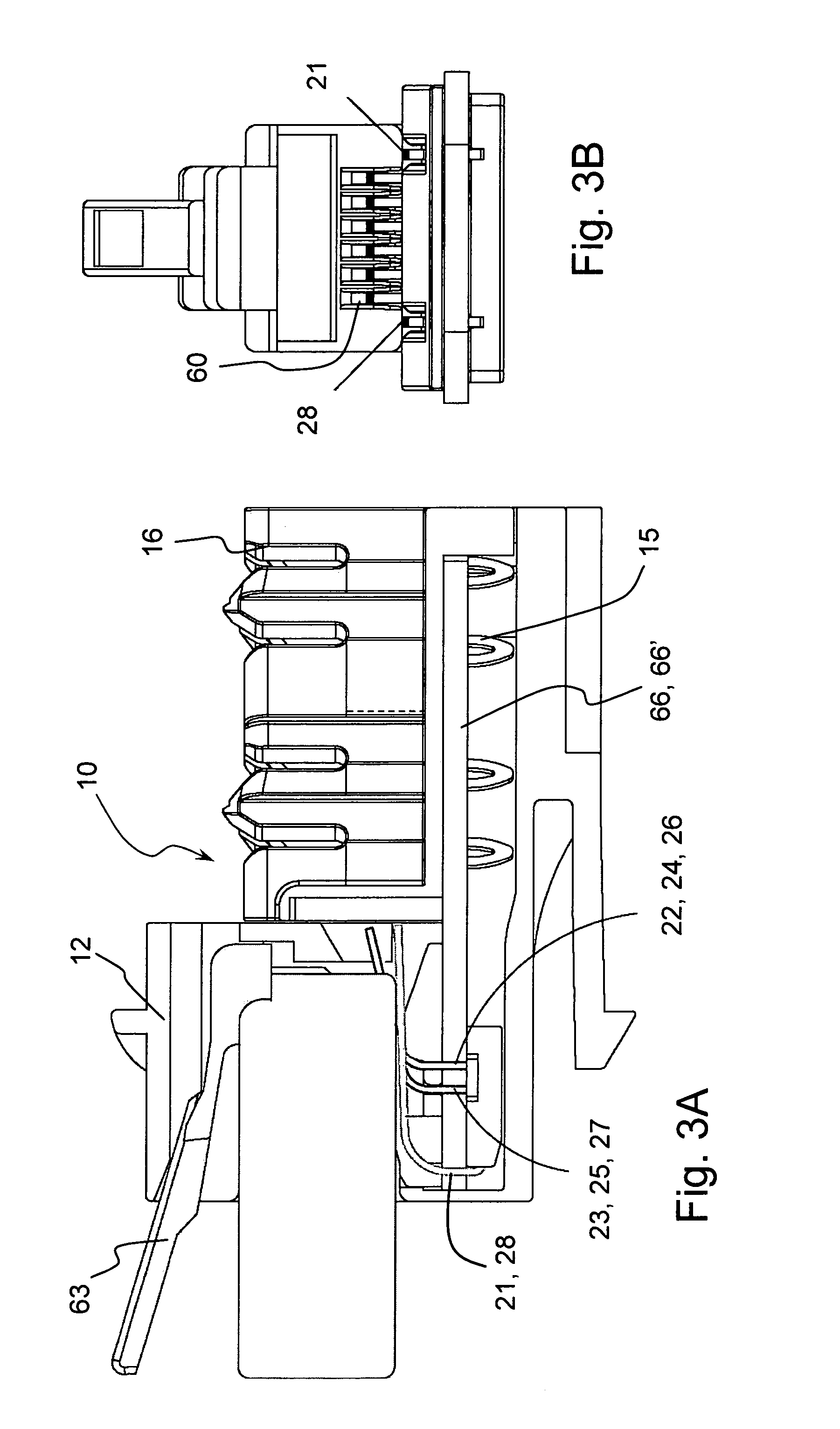

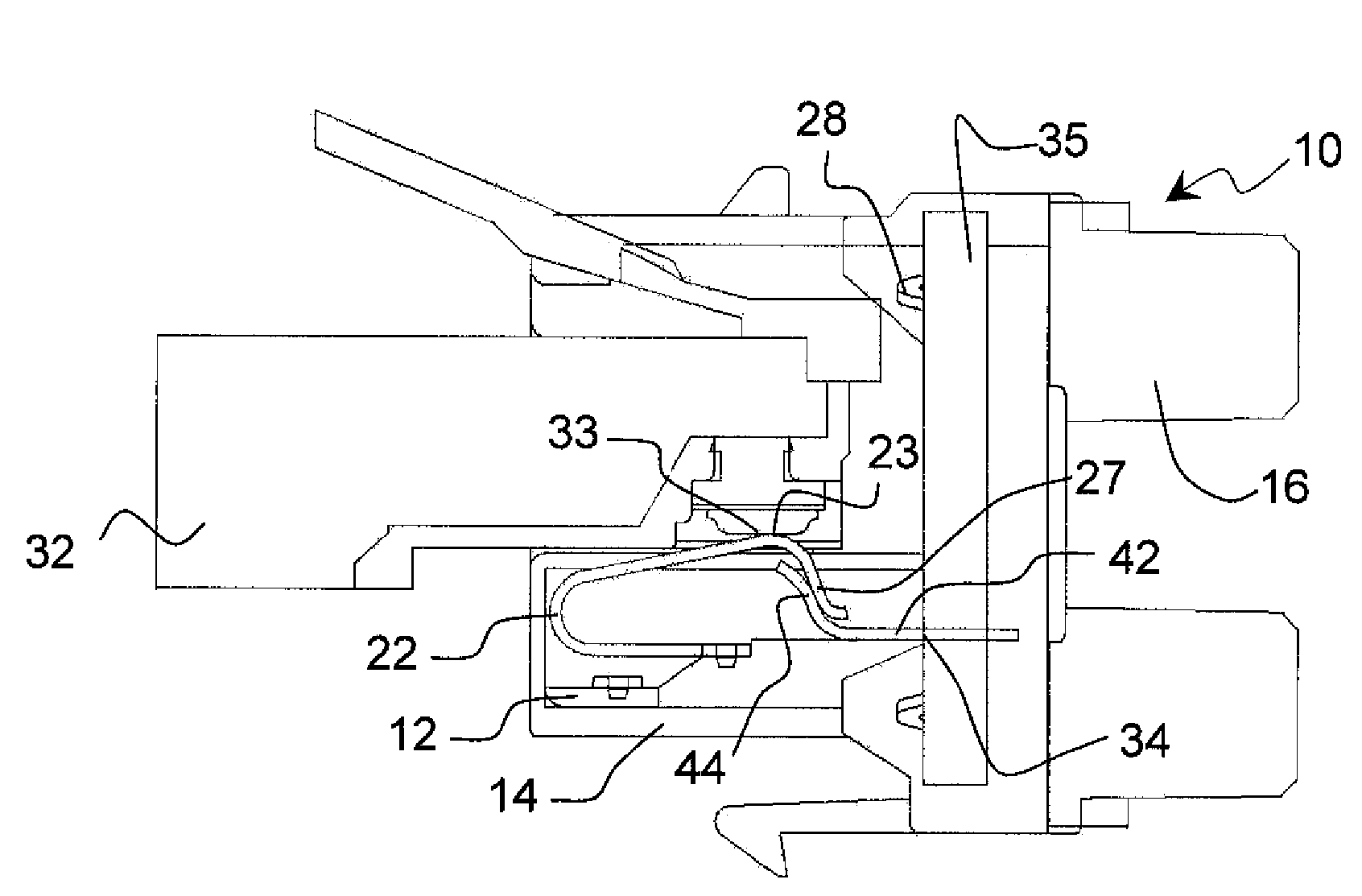

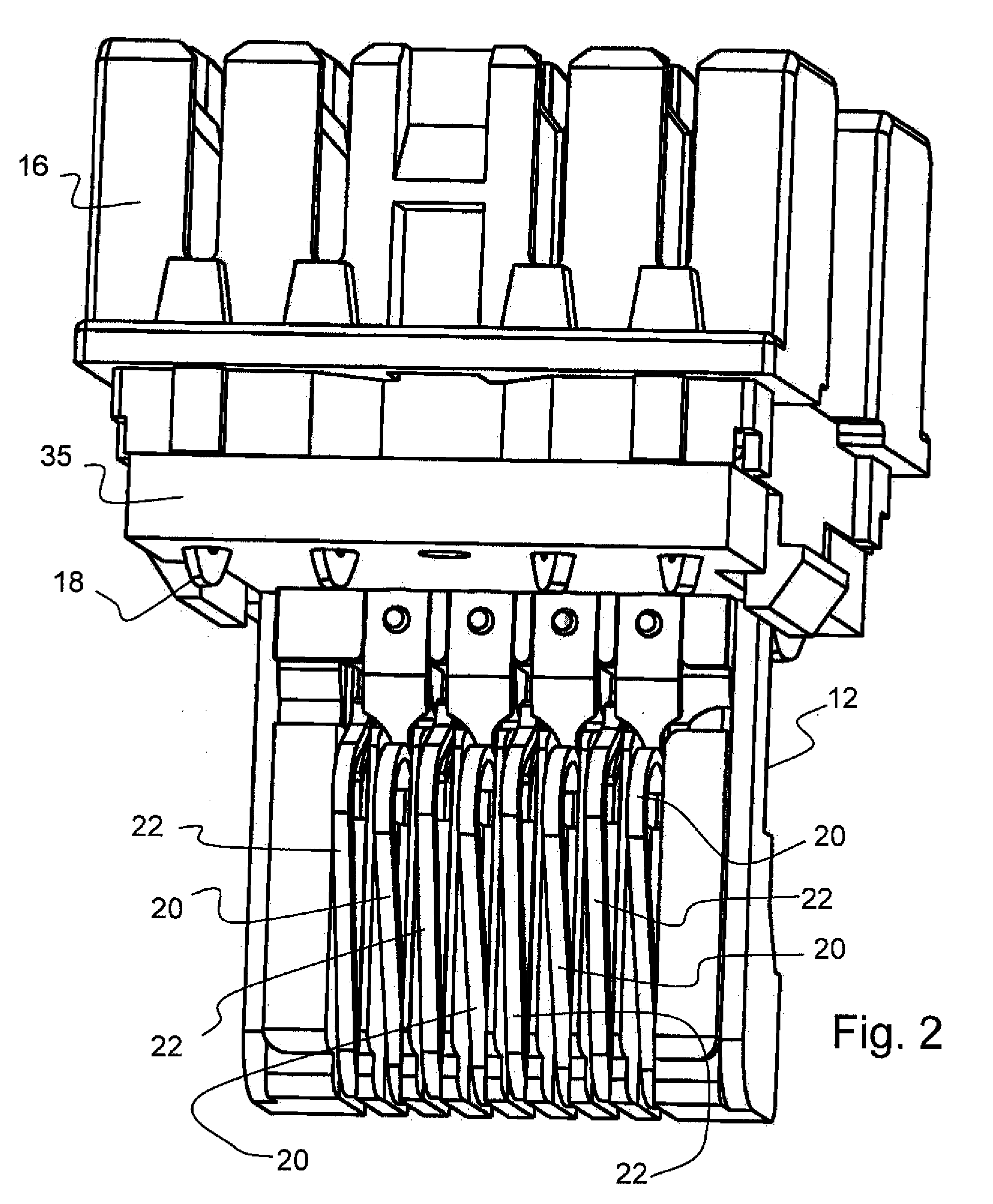

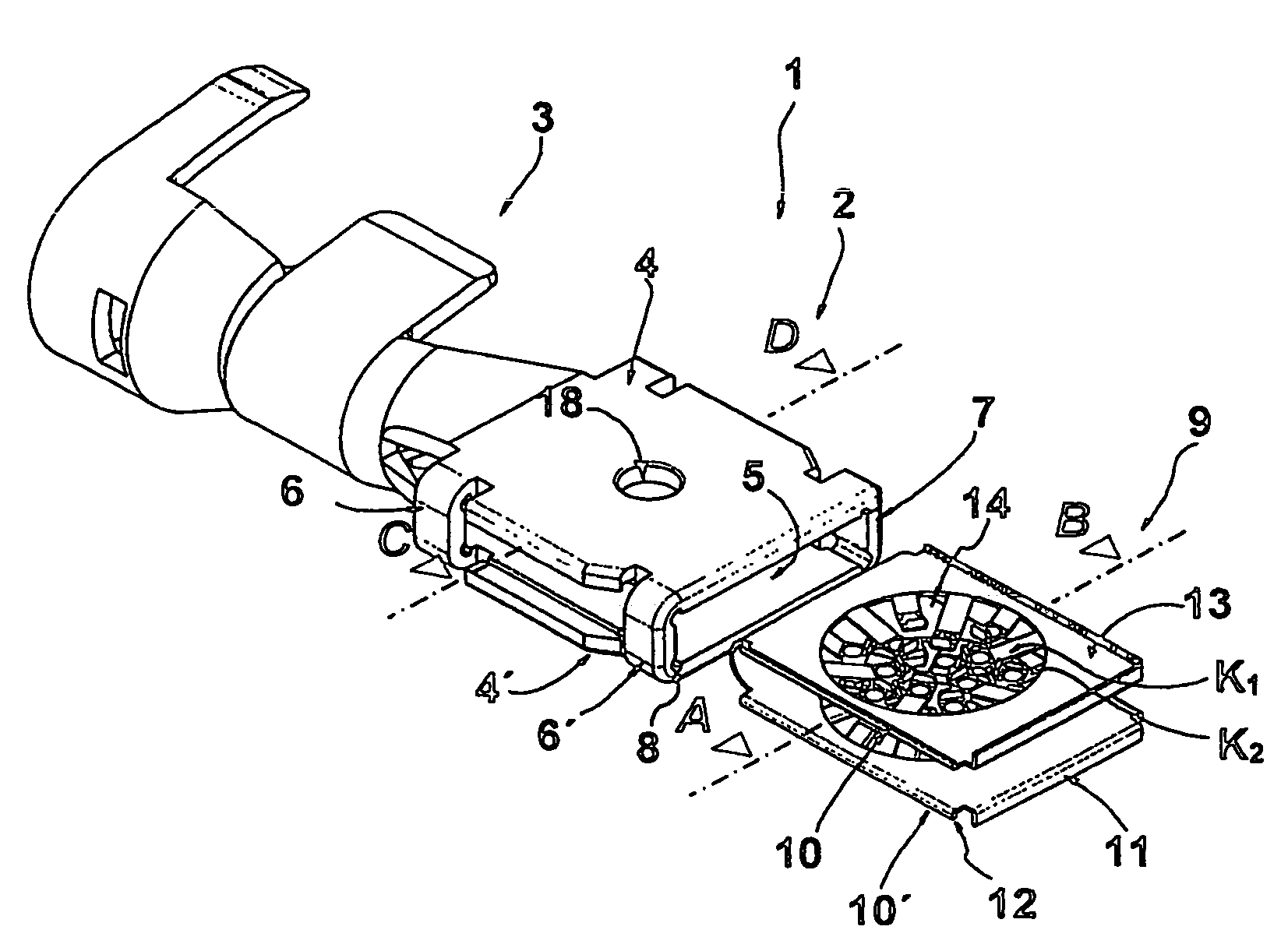

Multi-contact connector for electrode for example for medical use

InactiveUS6913478B2Reduce the space requiredReduce weightElectroencephalographyEngagement/disengagement of coupling partsElectrical connectionEngineering

Multiple contact connector for an electrode, for example, for medical use.The present invention relates to a multiple contact connector with reduced space requirement and weight regardless of the number of electrical contacts of the electrode, which can receive one or two electrodes, which guarantees a reliable and secured electrical connection with no risk of accidental disconnection and which is not a problem for a patient in whom the electrodes are implanted.This connector (1) consists of male plug (6) which has elongated support (60) provided on at least one of its sides with a number of contact zones (61) equal to the number of contacts of said electrode (2) and which are aligned parallel to the axis of first cable section (4), and female socket (7) having roughly cylindrical body (70) arranged in the extension of second cable section (5) and having at least one housing (71) provided with a number of contact elements (72) equivalent to the number of contact zones (61) of said male plug (6) and capable of receiving said support (60). This connector (1) is characterized in that it has tightening sleeve (8) arranged in order to maintain support (60) in housing (71) and to exert a radial pressure of contact zones (61) on contact elements (72) in such a way as to ensure the electrical connections.

Owner:DIXI MEDICAL

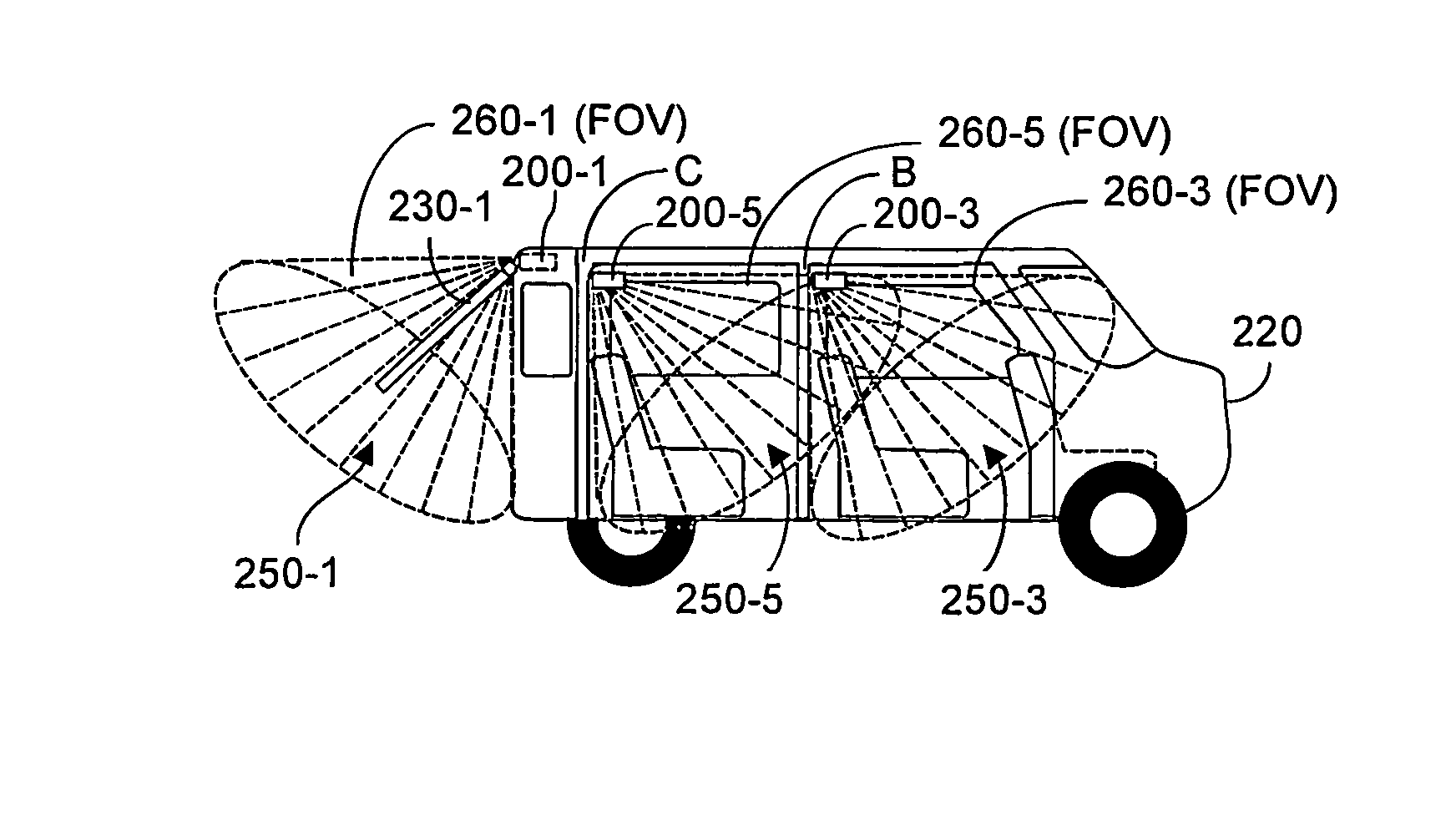

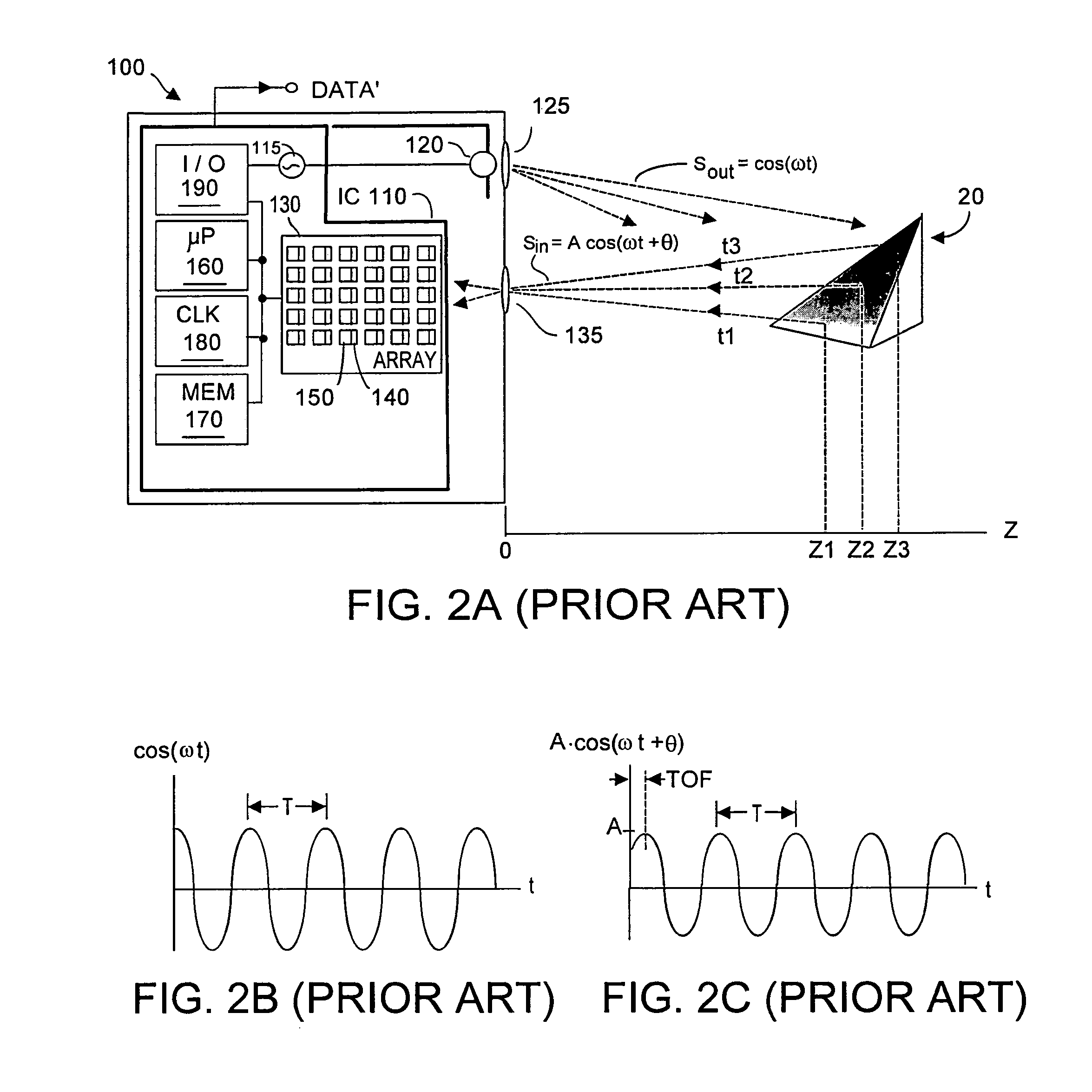

Contactless obstacle detection for power doors and the like

Time-of-flight (TOF) three-dimensional sensing systems are deployed on or in a motor vehicle to image contact zones associated with potential contact between an avoidable object and the vehicle or vehicle frame and / or remotely controllable motorized moving door or liftgate. An algorithm processes depth data acquired by each TOF system to determine whether an avoidable object is in the associated contact zone. If present, a control signal issues to halt or reverse the mechanism moving the door. A stored database preferably includes a depth image of the contact zone absent any object, an image of the door, and volume of the door. Database images are compared to newly acquired depth images to identify pixel sensors whose depth values are statistically unlikely to represent background or the door. Pixels within the contact zone so identified are an object, and the control signal is issued.

Owner:MICROSOFT TECH LICENSING LLC

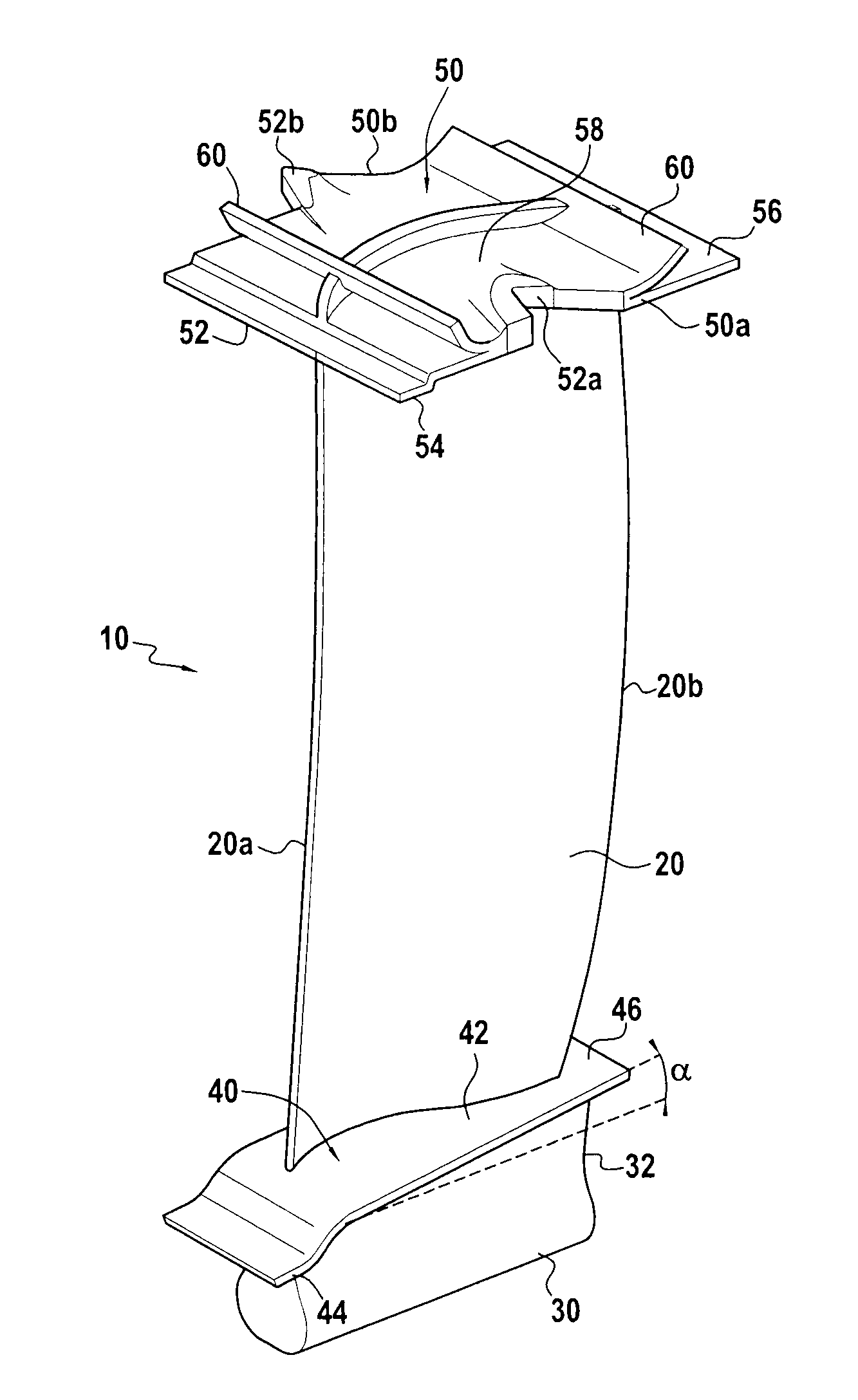

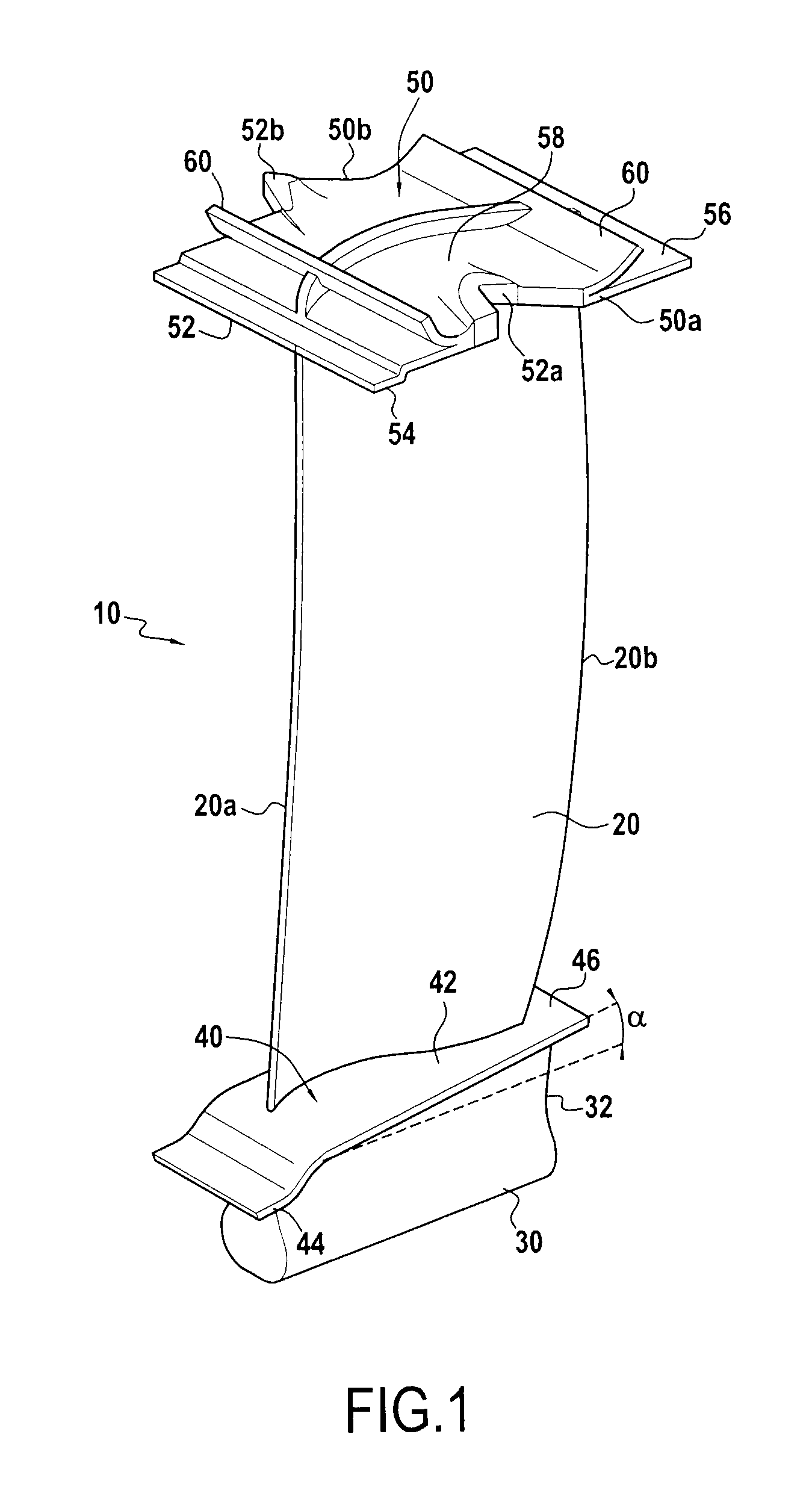

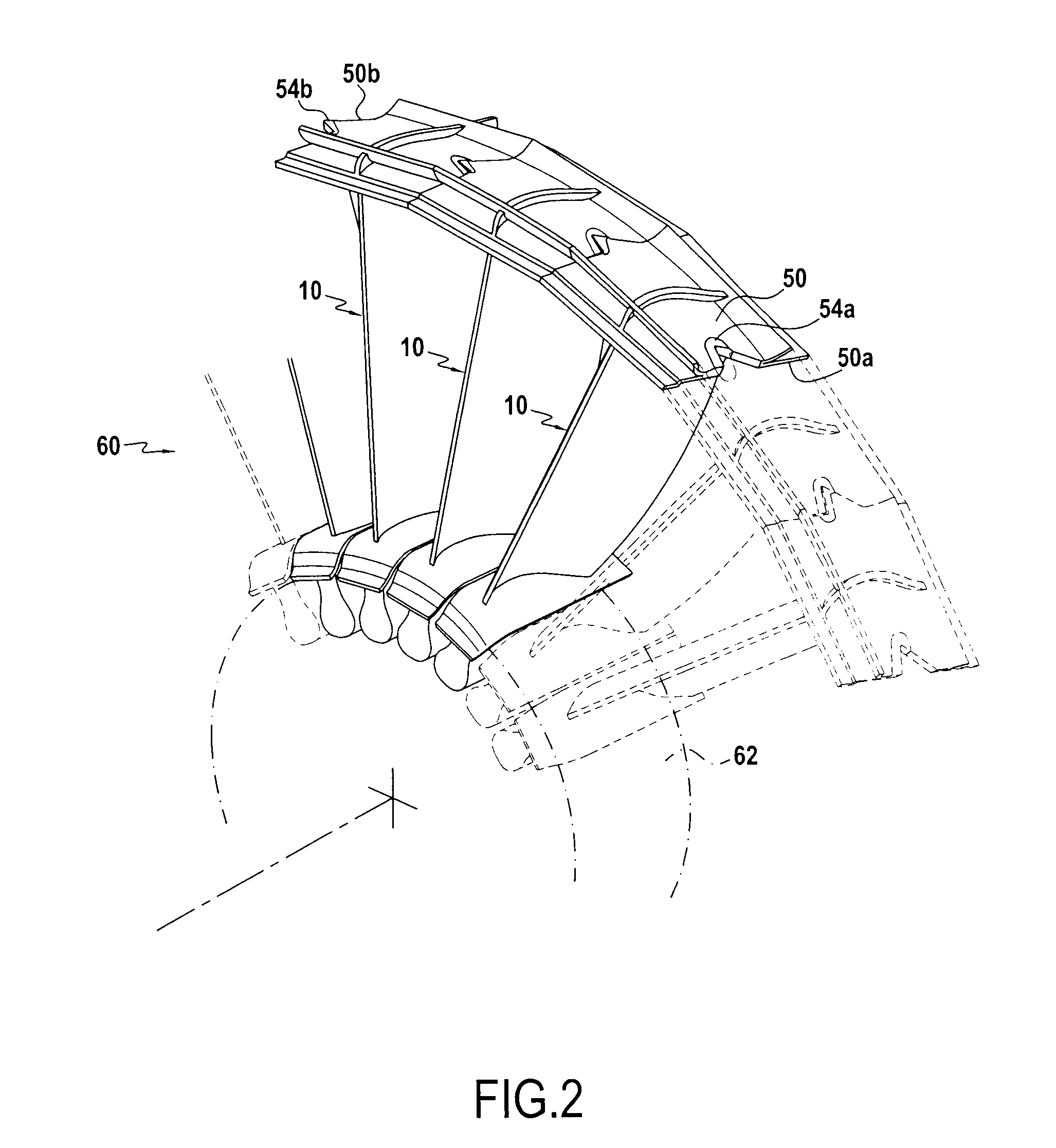

Cmc turbine engine blades and a rotor wheel for a turbine engine and a turbine engine integrating them

InactiveUS20120195766A1Improve wear resistanceImprove behaviorPropellersRotary propellersTurbineMutual engagement

A rotor wheel of a turbine engine includes a plurality of CMC blades each having a first portion constituting a blade airfoil and root and made as a single piece with a second portion forming an outer platform. The blades are held under twisting prestress by mutual engagement via contact zones between the outer platforms of adjacent blades, and the contact zones that are situated on opposite sides of the outer platform of a blade are defined by at least one insert that is integrated in the outer platform and that is, for example, made of a carbon-based material.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

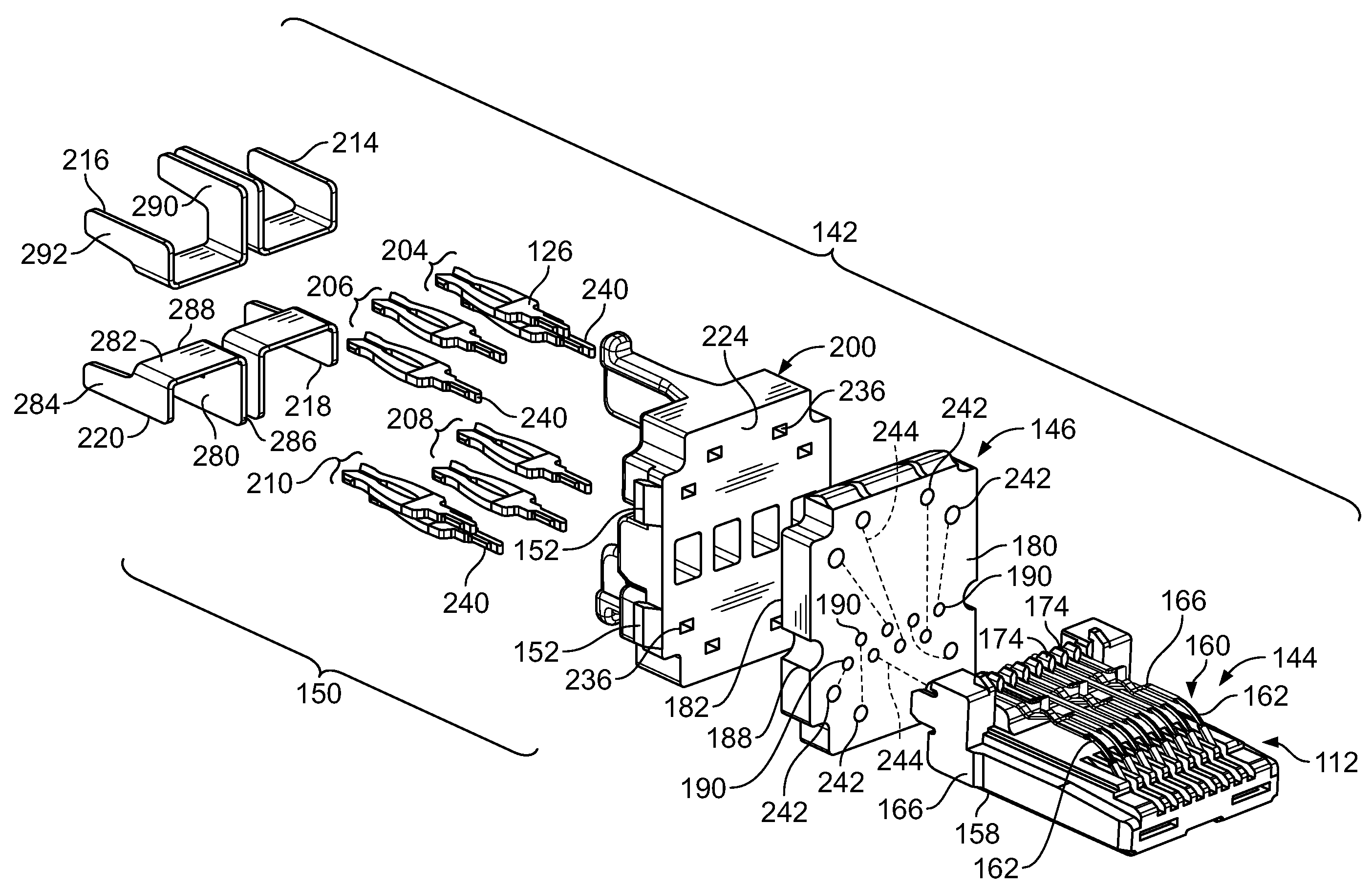

Electrical connector with enhanced back end design

ActiveUS7575482B1Securely holdElectrically conductive connectionsCoupling device detailsEngineeringElectrical connector

An electrical connector includes a back end sub-assembly including a back end housing extending along a longitudinal axis between a forward side and a rearward side. The back end housing defining a plurality of contact zones. At least one contact is held in each of the plurality of contact zones. A shield is provided within each of the plurality of contact zones with each shield at least partially surrounding at least one contact in the corresponding contact zone. Each shield is non-common with and does not electrically engage any other shield in the back end housing.

Owner:BISON PATENT LICENSING LLC

Integrated connection arrangements

ActiveUS7619309B2Reduce thicknessReduced current carrying capacitySemiconductor/solid-state device detailsSolid-state devicesInsulation layerContact zone

Owner:INFINEON TECH AG

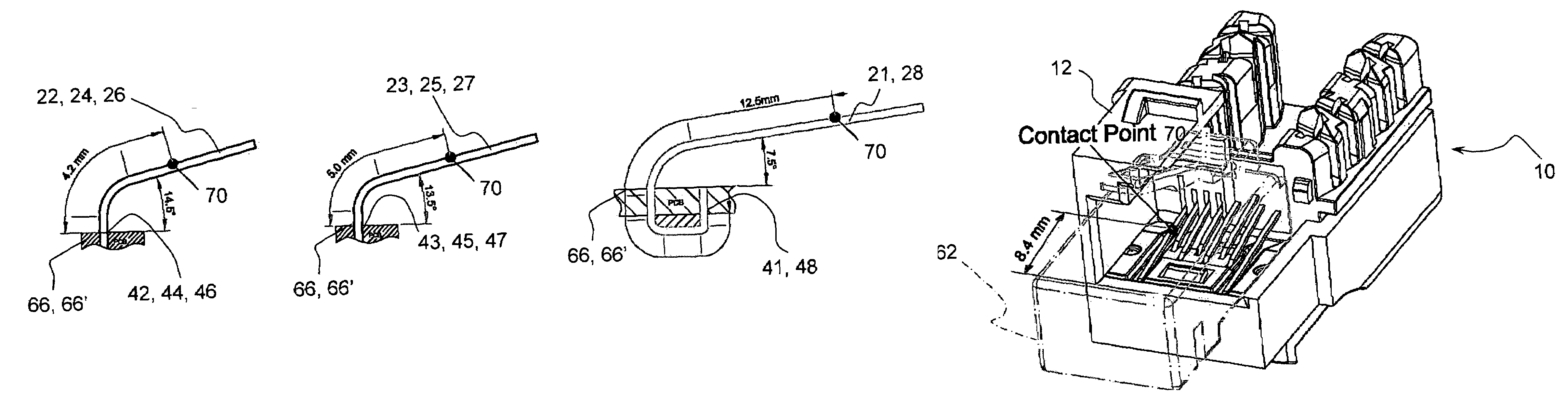

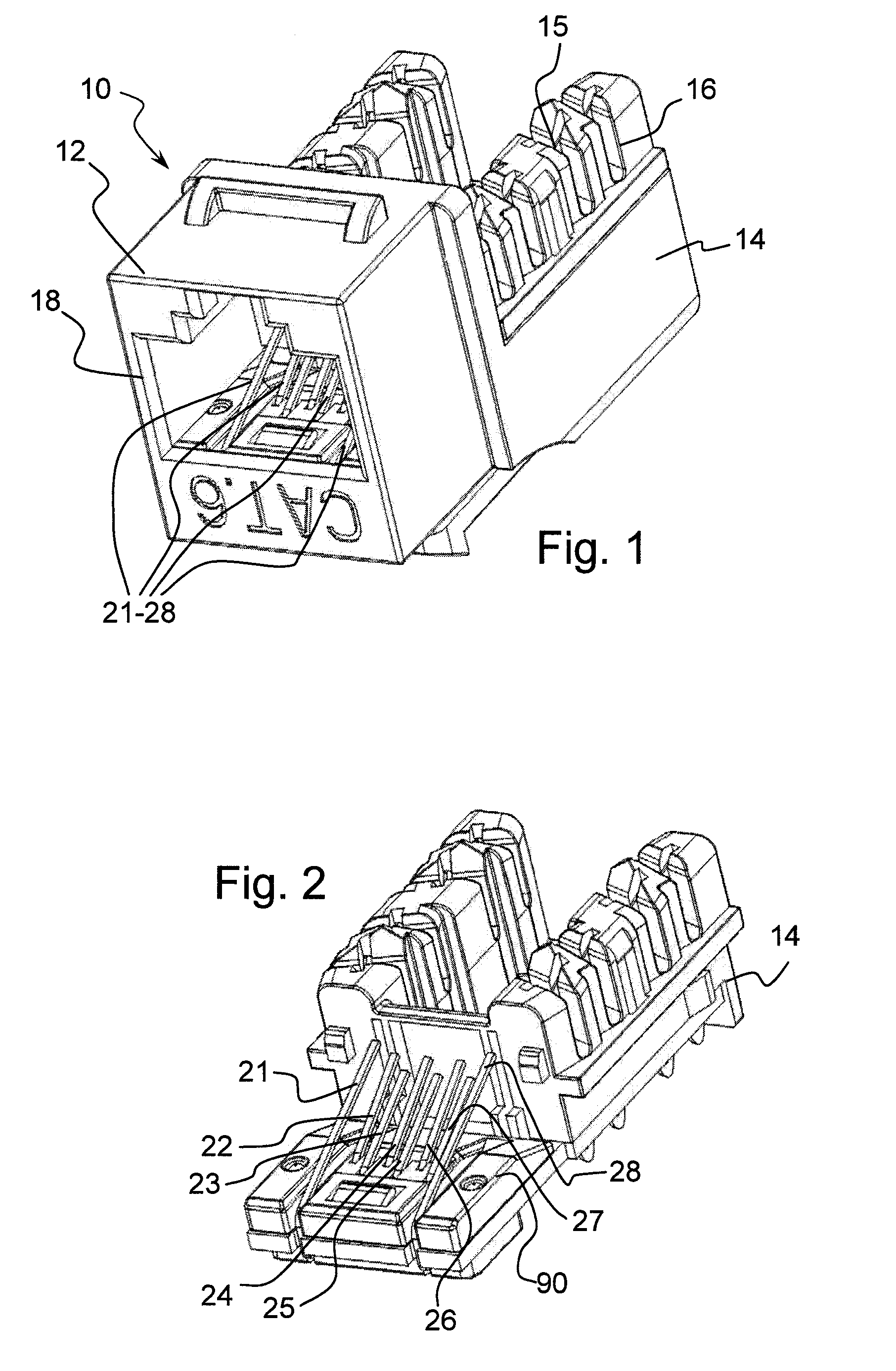

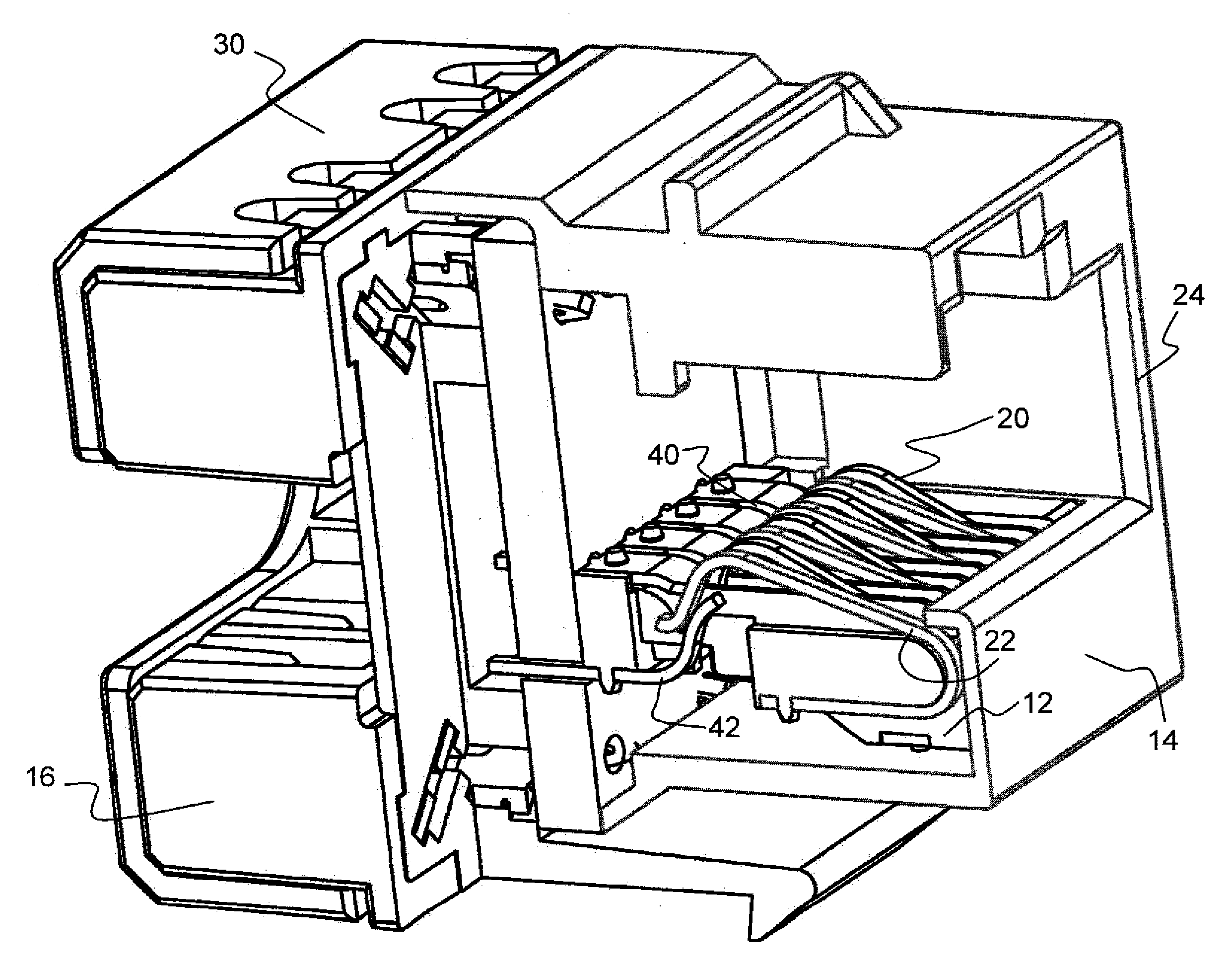

Electrical connector with shortened contact and crosstalk compensation

ActiveUS7367849B2Improve the level ofCoupling device detailsTwo-part coupling devicesElectrical conductorPath length

An electrical connector is provided with a circuit board with interconnecting conductors respectively extending between spring contact termination locations and other termination locations. Sets of spring contact conductors are provided terminating at respective spring contact termination locations. Each of the spring contact conductors of the set of spring contact conductors has a plug contact zone and defines a spring contact conductive path from an associated plug contact zone to a respective spring contact termination location. The sets of spring contact conductors provide different conductive path lengths from an associated plug contact zone to a respective spring contact termination location.

Owner:SURTEC INDS

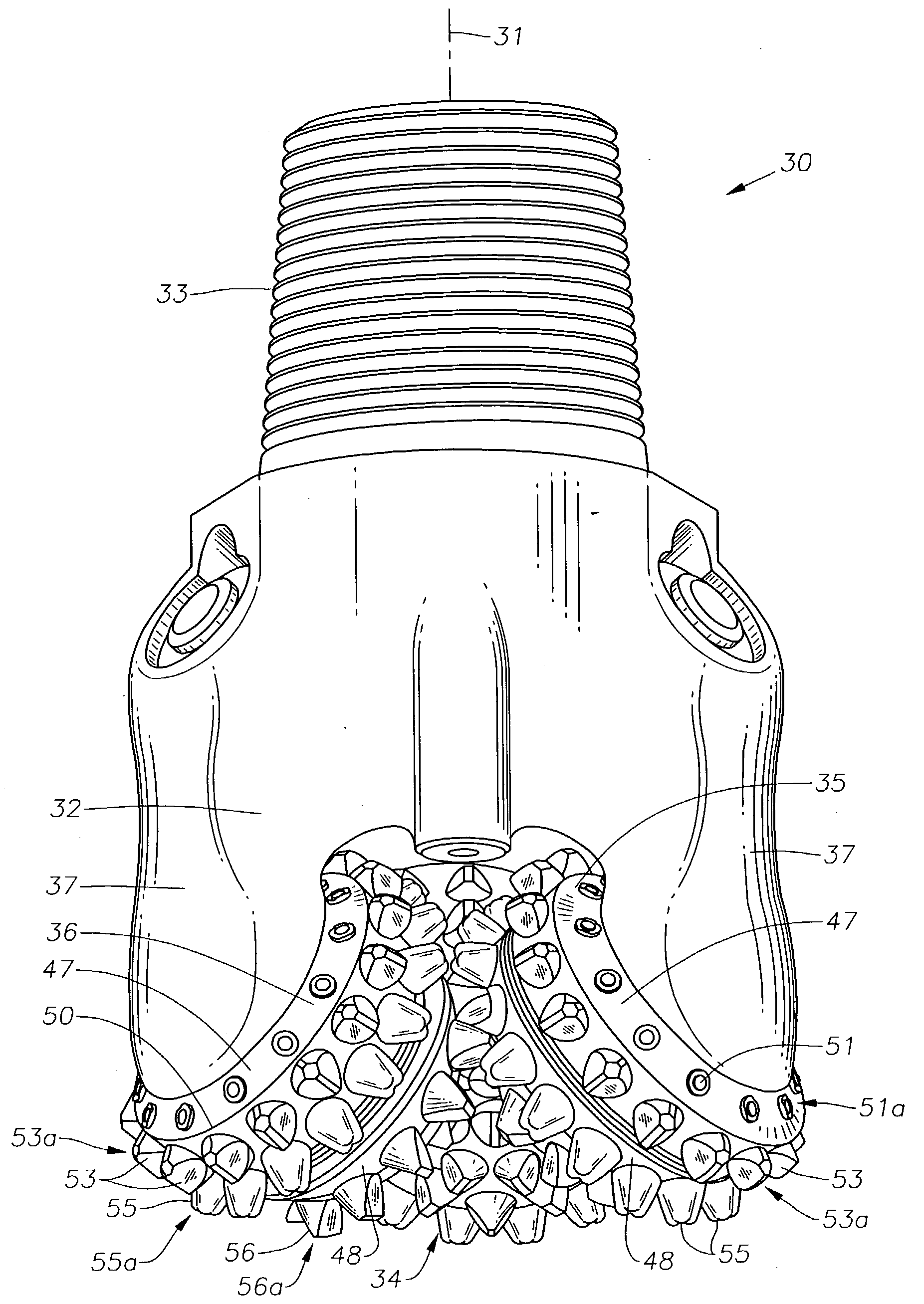

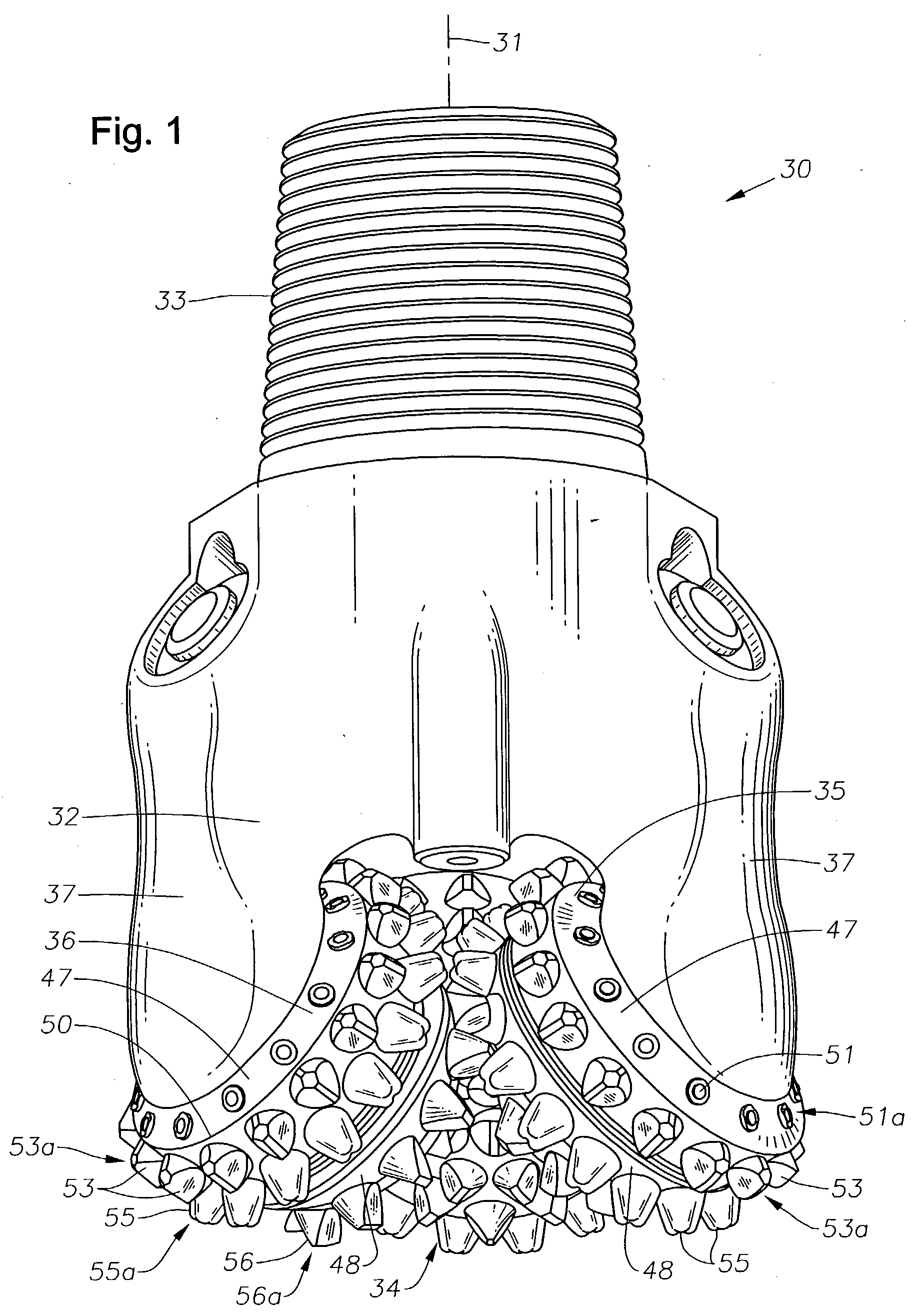

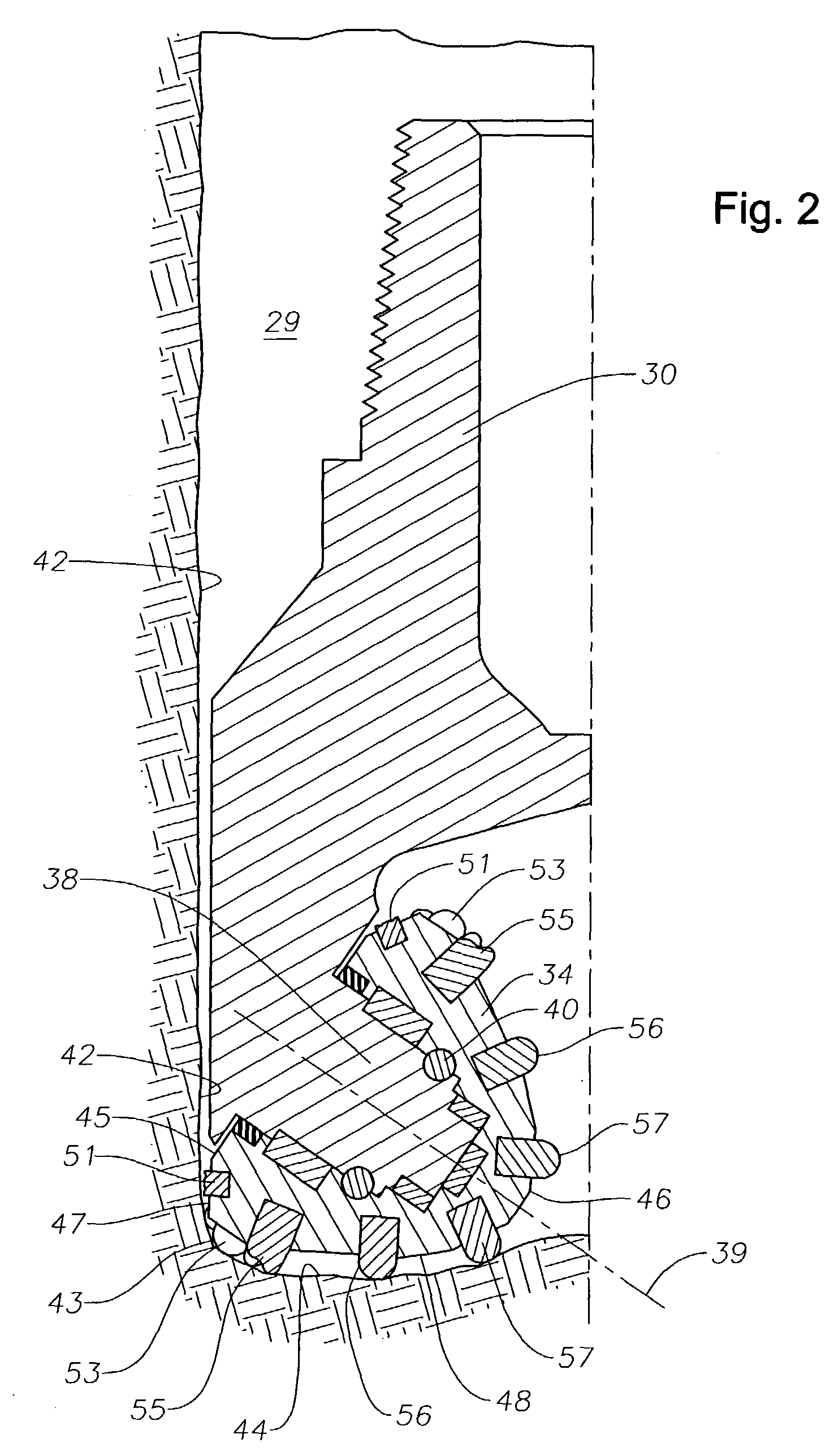

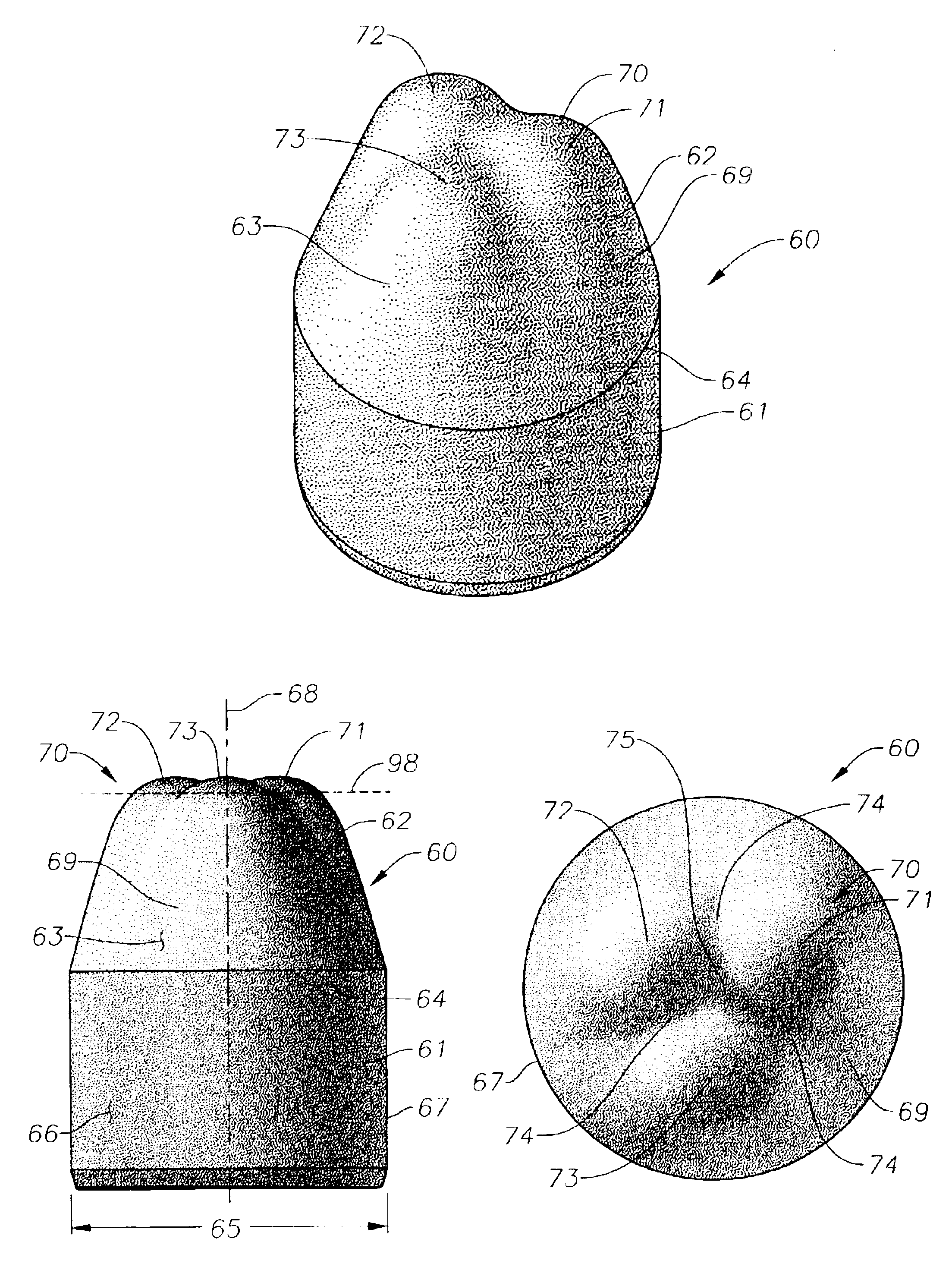

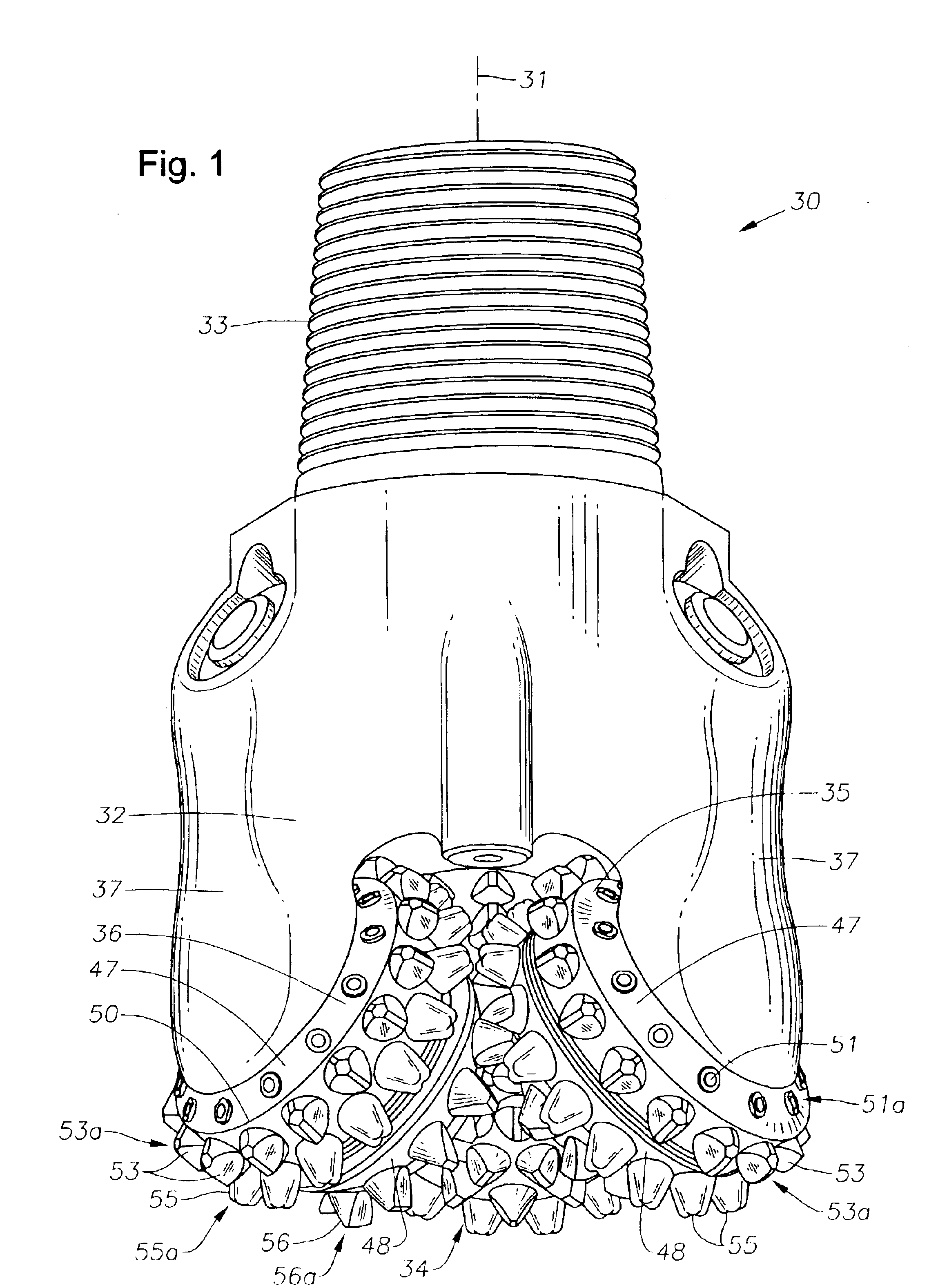

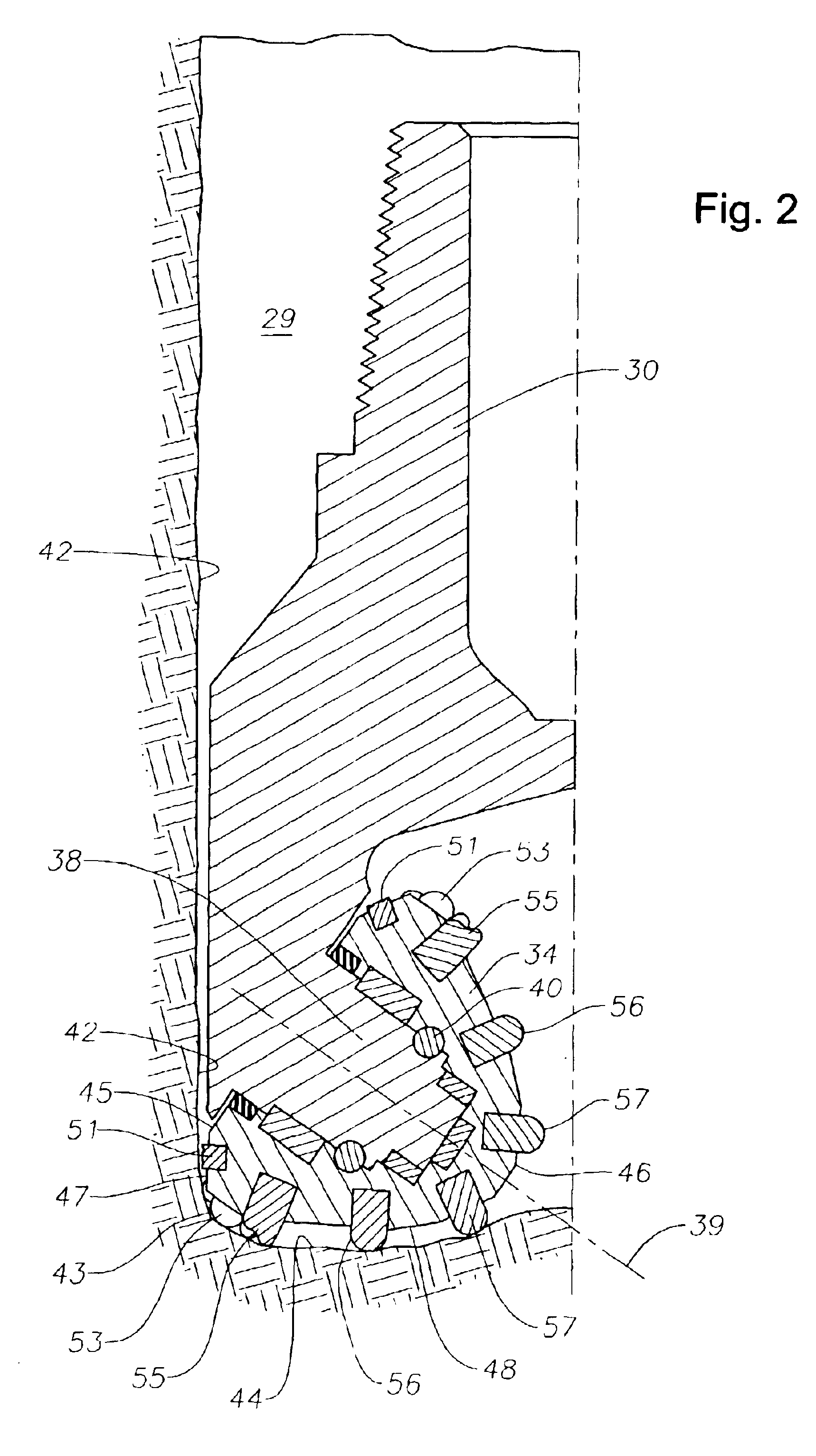

Drill bit cutter element having multiple cusps

InactiveUS20040163851A1Enhancing brittle rock formationIncrease ROPDrill bitsConstructionsEngineeringMechanical engineering

Cutter elements for use in rolling cones rock bits are disclosed having a crown that includes multiple, spaced-apart cusps for enhancing formation removal by creating overlapping Hertzian contact zones. The cusps may be partially dome-shaped, berm shaped or otherwise. The cutter elements provide multiple cutting edges for engaging the formation and may have differing radii and extension length as suitable for particular applications.

Owner:SMITH INT INC

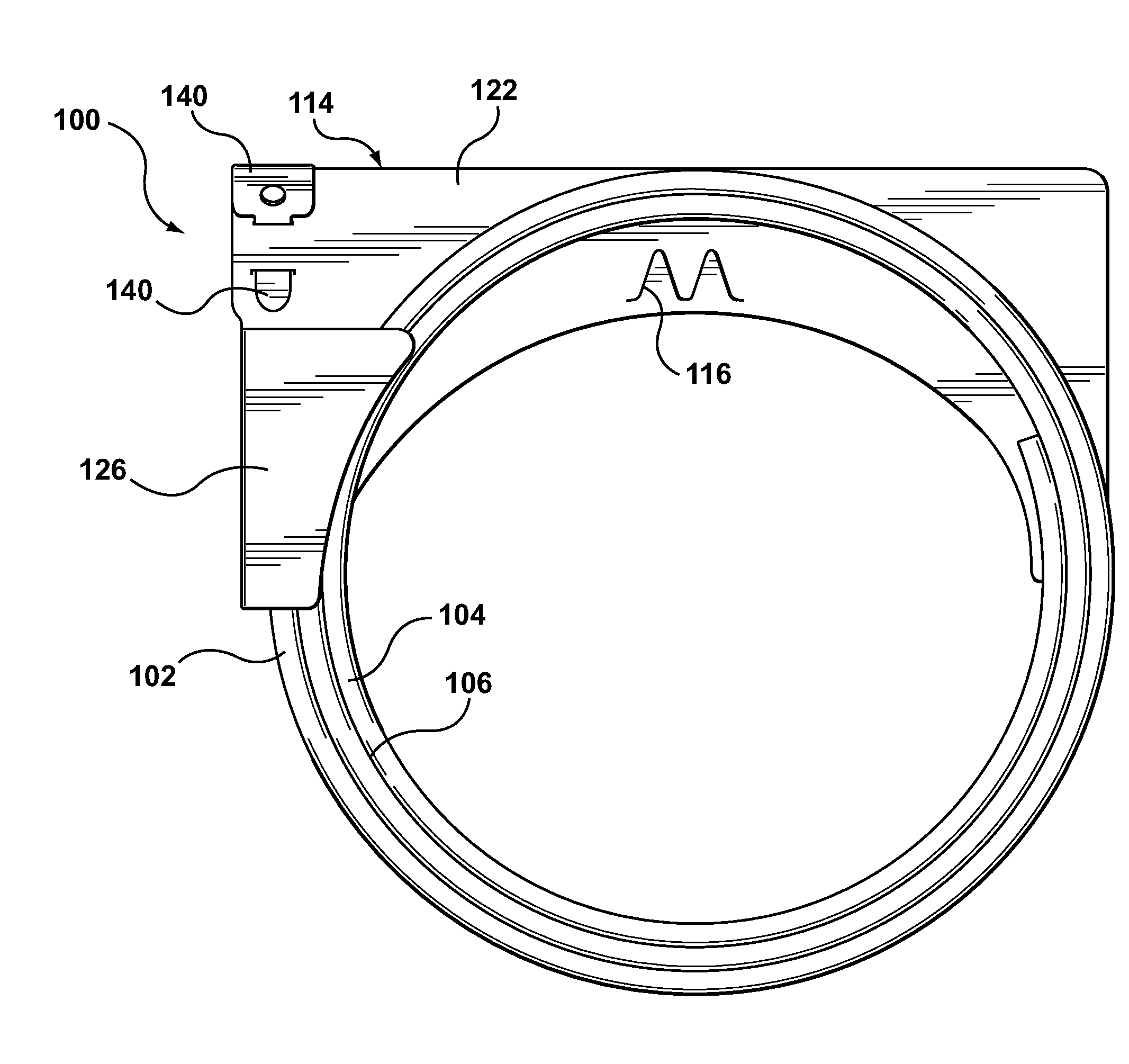

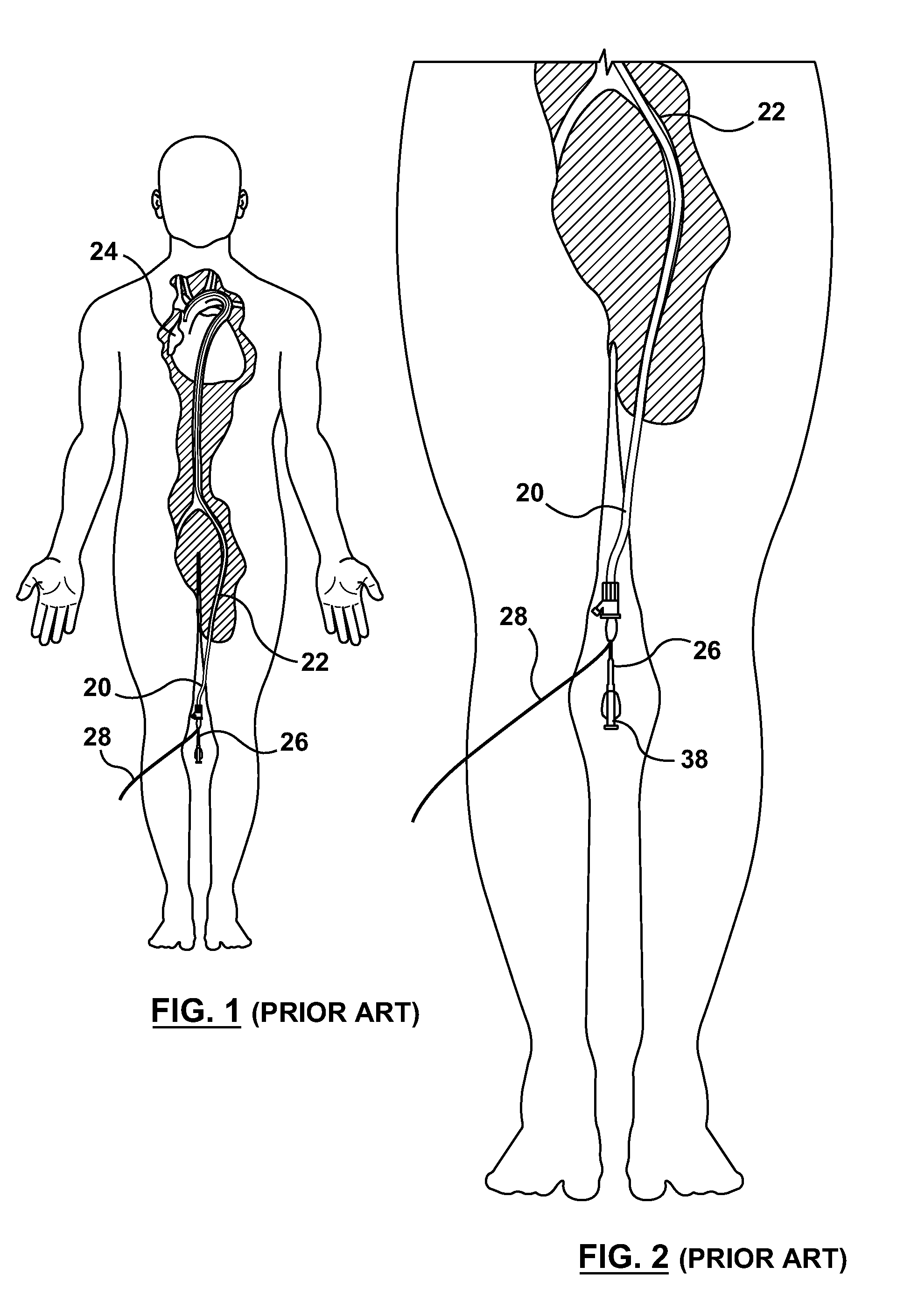

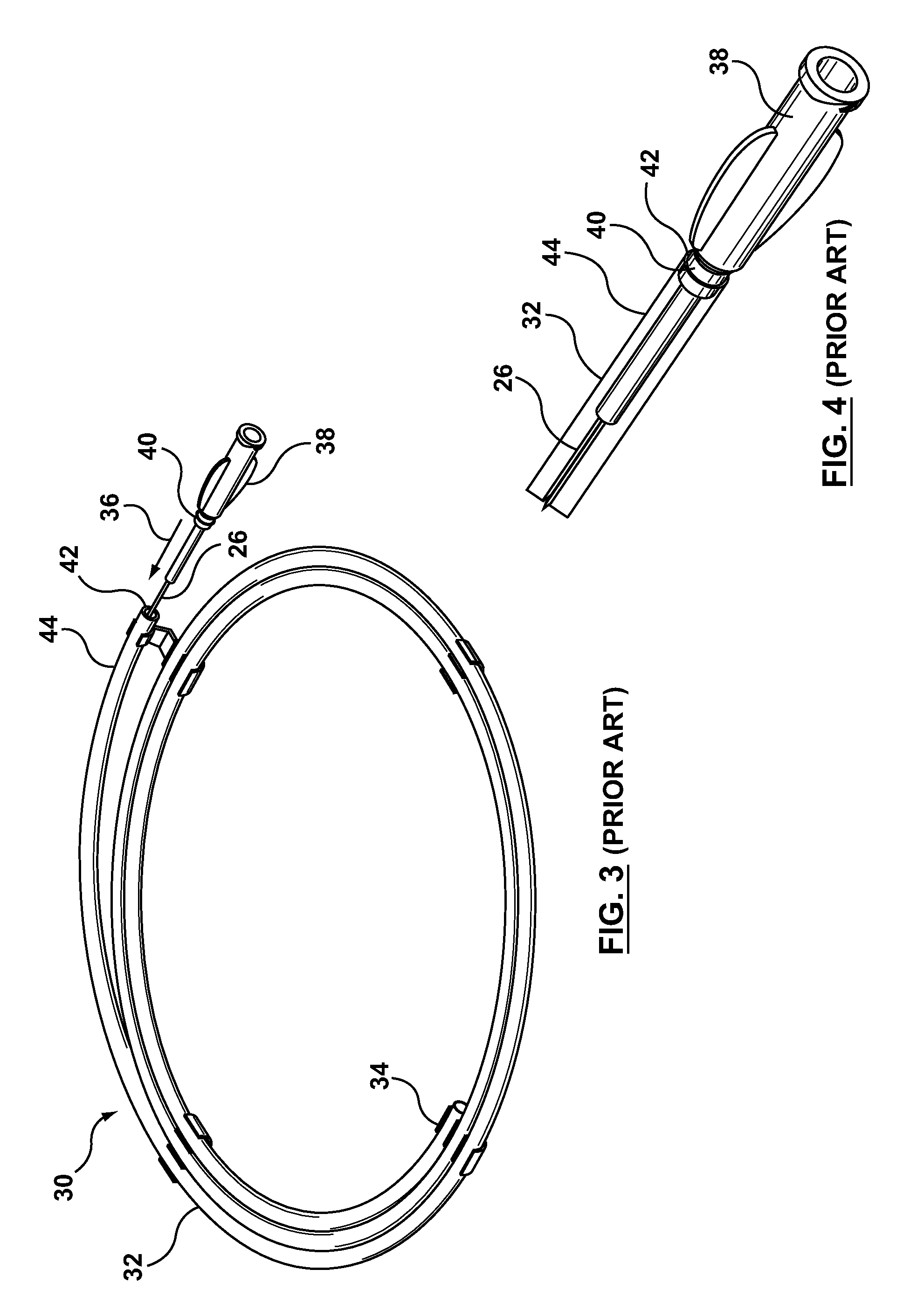

Packaging for a Catheter

ActiveUS20120261290A1Ease of insertionHigh removal rateDispensing apparatusDiagnosticsCatheter accessoriesInsertion stent

Packaging for a catheter includes coiled tubing for receiving the catheter and a mounting card coupled to the coiled tubing. The windings of the coiled tubing are welded together to maintain the coiled configuration. The mounting card includes an integral support flap for reducing the risk of damage during catheter insertion and removal, an integral luer retainer for securing a catheter luer, and one or more integral tabs for attaching catheter accessories to the packaging. The integral support flap creates a contact zone which discourages grasping the packaging at a location that can potentially damage an object passing through the packaging, such as a balloon and / or stent. The integral luer retainer is configured to selectively alternate between a configuration which secures the catheter luer and configuration which allows releases the luer for easy insertion and removal of the catheter.

Owner:MEDTRONIC VASCULAR INC

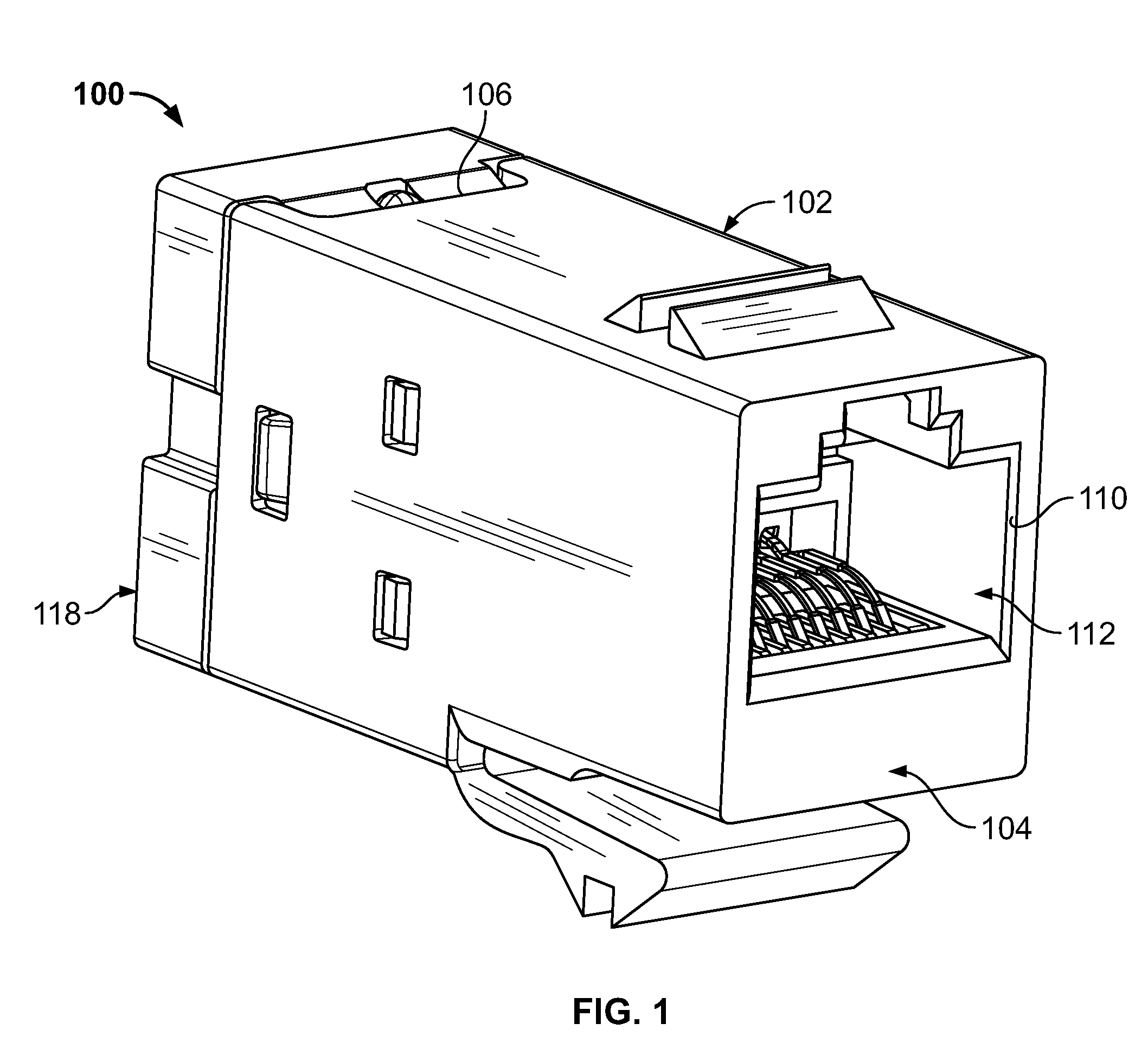

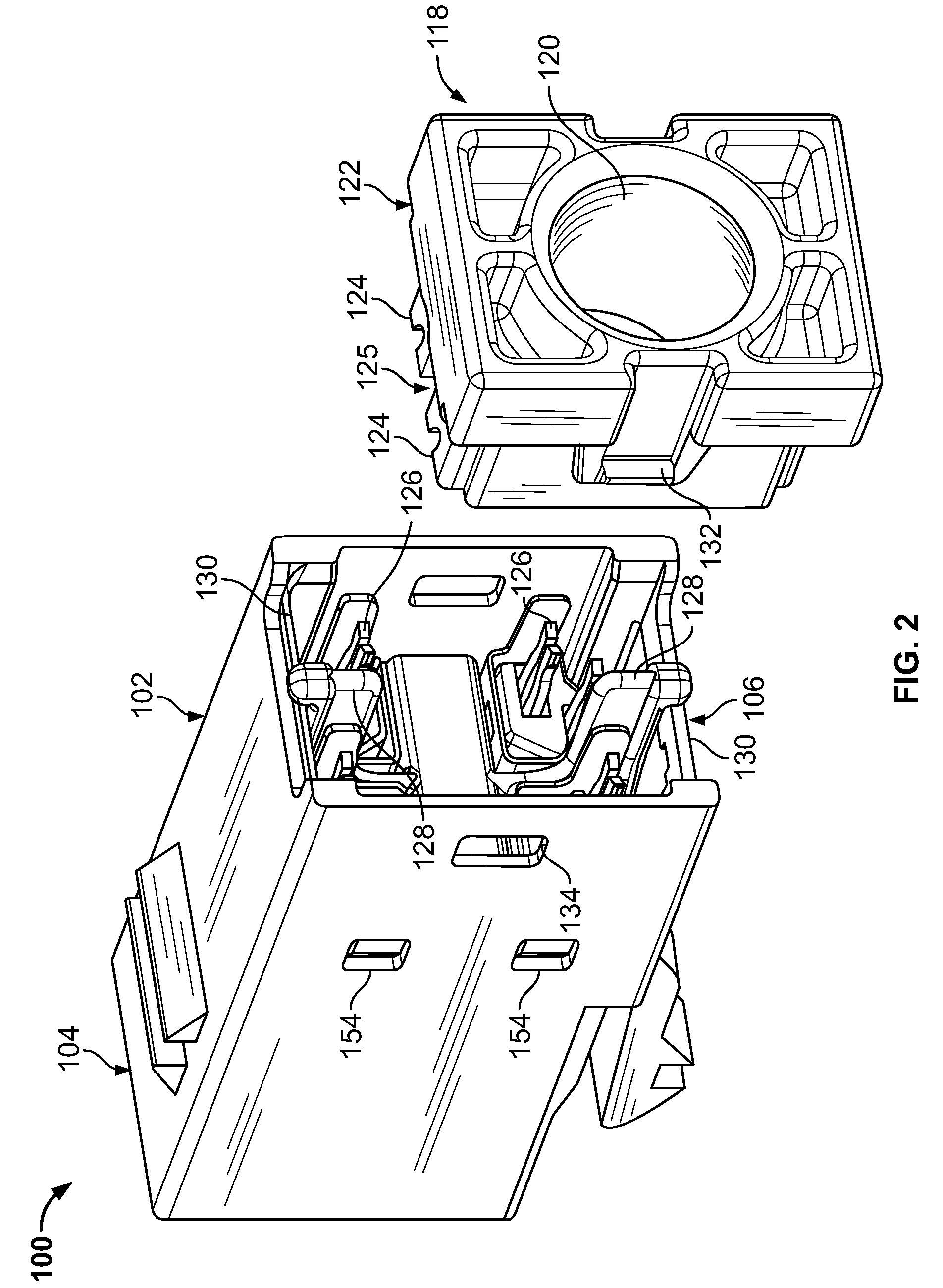

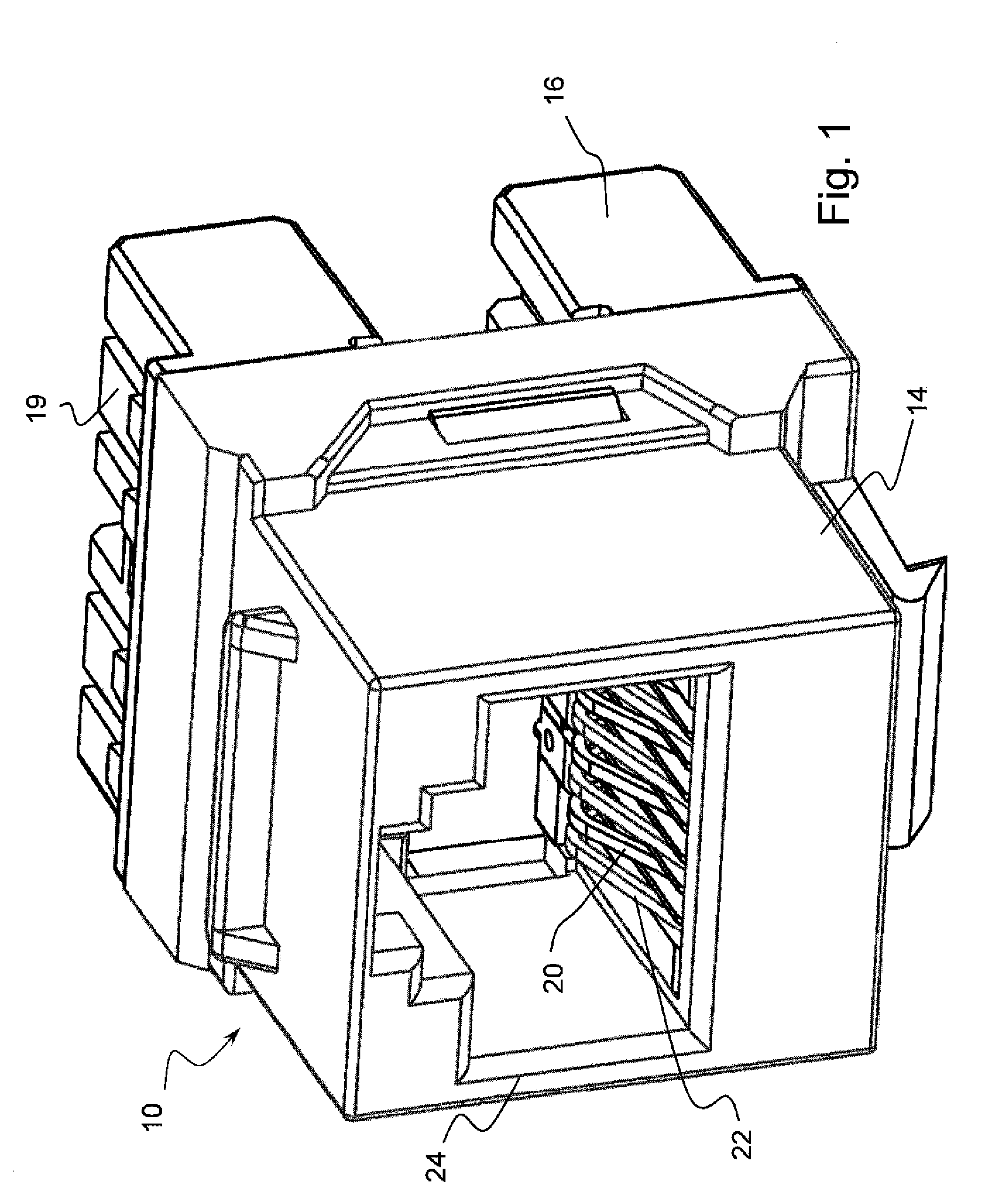

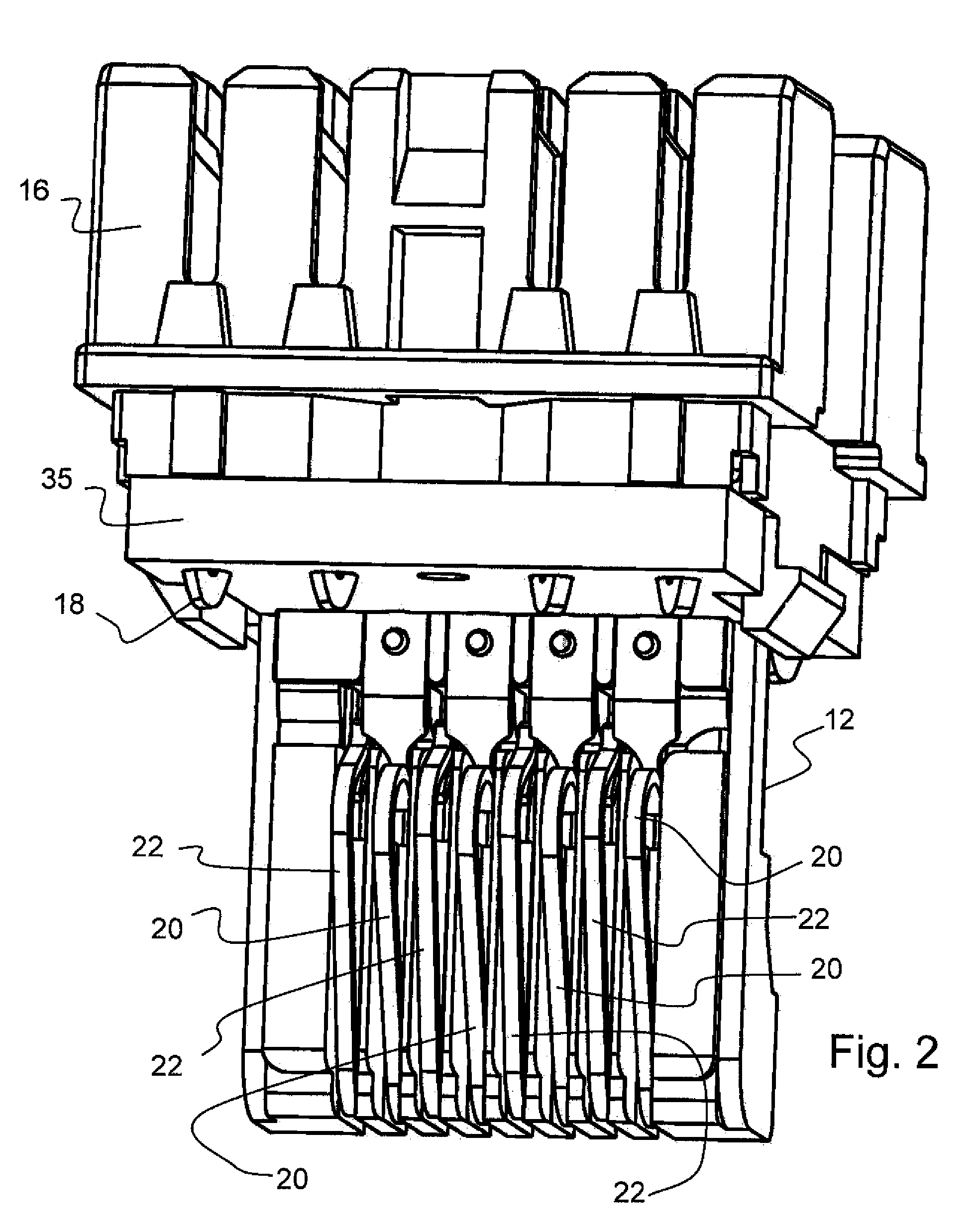

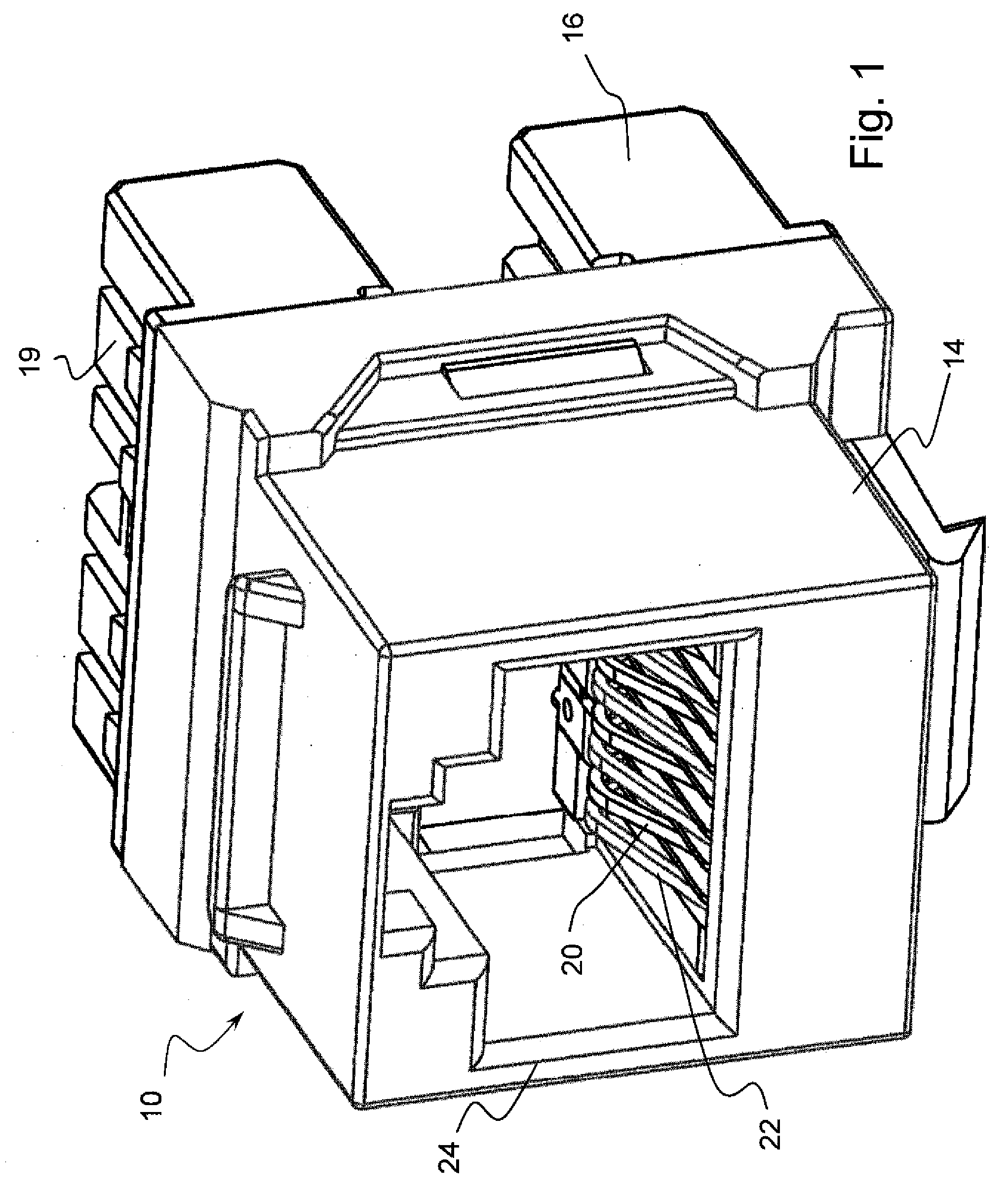

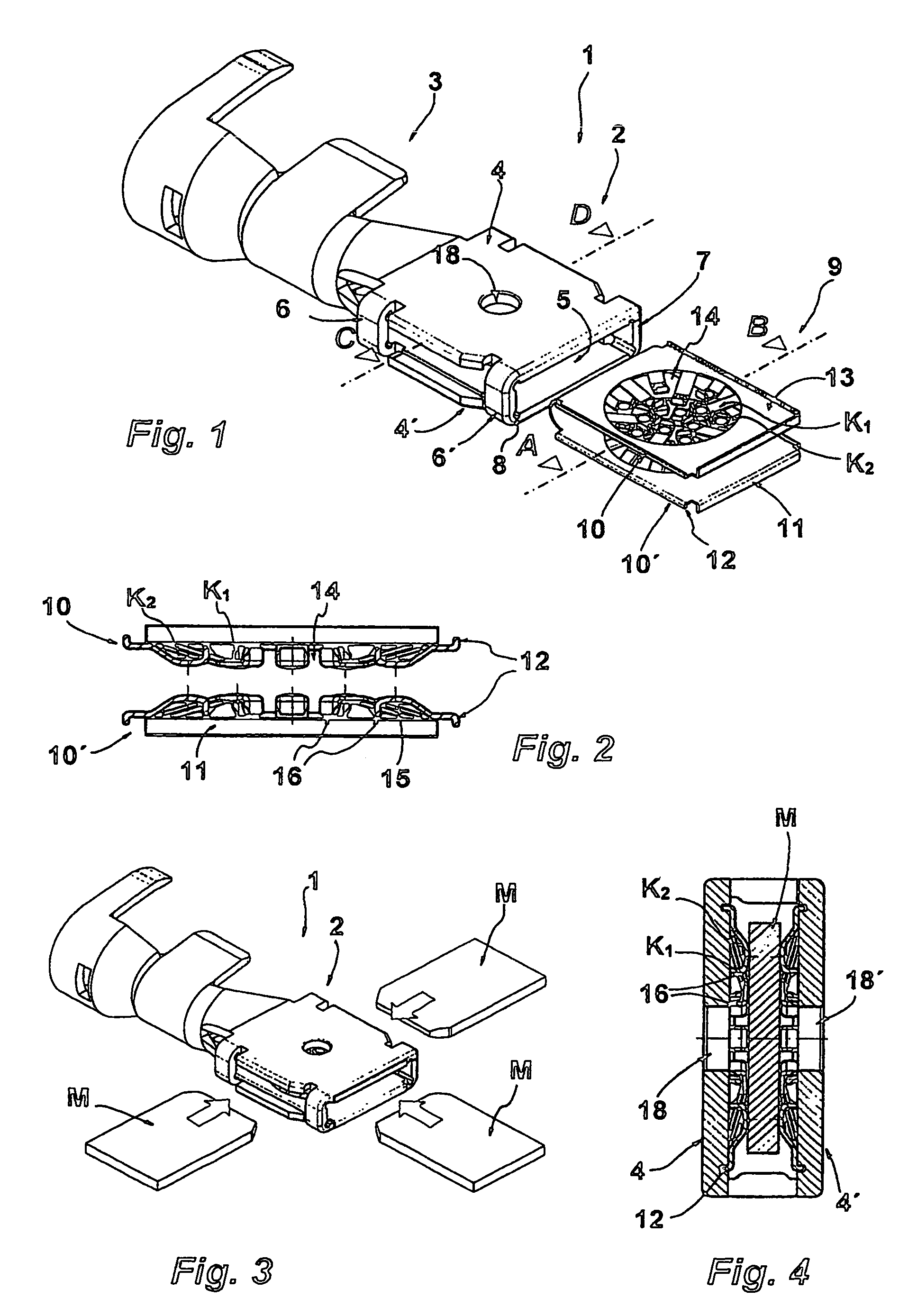

High performance jack

InactiveUS7294025B1High levelImprove performancePrinted circuit aspectsCoupling device detailsElectrical conductorEngineering

An electrical connector jack is provided including a body with a support portion and a plug receiving portion defining an opening. A circuit board is mounted to the support portion to position the circuit board relative to the plug receiving portion. The circuit board has interconnecting conductor circuit traces respectively extending from spring contact termination locations. A plurality of terminated spring contact conductors is provided with each terminating at a respective one of the spring contact termination locations, each of the terminated spring contact conductors having a contact zone. A plurality of supported spring contact conductors are supported by the body and extend therefrom. The supported spring contact conductors each have a plug contact zone and a terminated spring contact conductor zone. With contact of the plug contact zone with a plug, the supported spring contact conductors are respectively in contact with respective contact zones of the terminated spring contact conductors providing a transmission path from the plug to the circuit traces of the circuit board.

Owner:SURTEC INDS

High performance jack

InactiveUS20070259571A1Improve performanceHigh levelPrinted circuit aspectsCoupling device detailsElectrical conductorEngineering

An electrical connector jack is provided including a body with a support portion and a plug receiving portion defining an opening. A circuit board is mounted to the support portion to position the circuit board relative to the plug receiving portion. The circuit board has interconnecting conductor circuit traces respectively extending from spring contact termination locations. A plurality of terminated spring contact conductors is provided with each terminating at a respective one of the spring contact termination locations, each of the terminated spring contact conductors having a contact zone. A plurality of supported spring contact conductors are supported by the body and extend therefrom. The supported spring contact conductors each have a plug contact zone and a terminated spring contact conductor zone. With contact of the plug contact zone with a plug, the supported spring contact conductors are respectively in contact with respective contact zones of the terminated spring contact conductors providing a transmission path from the plug to the circuit traces of the circuit board.

Owner:SURTEC INDS

Methods for producing a total product at selected temperatures

Method of producing a total product are described. A method includes providing a feed and a supported inorganic salt catalyst to a contacting zone. Contact of the supported inorganic salt catalyst with the feed in the presence of a hydrogen source and steam in the contacting zone at a temperature of at most 1000° C. and a total operating pressure of at most 4 MPa produces the total product.

Owner:BROWNSCOMBE THOMAS FAIRCHILD +7

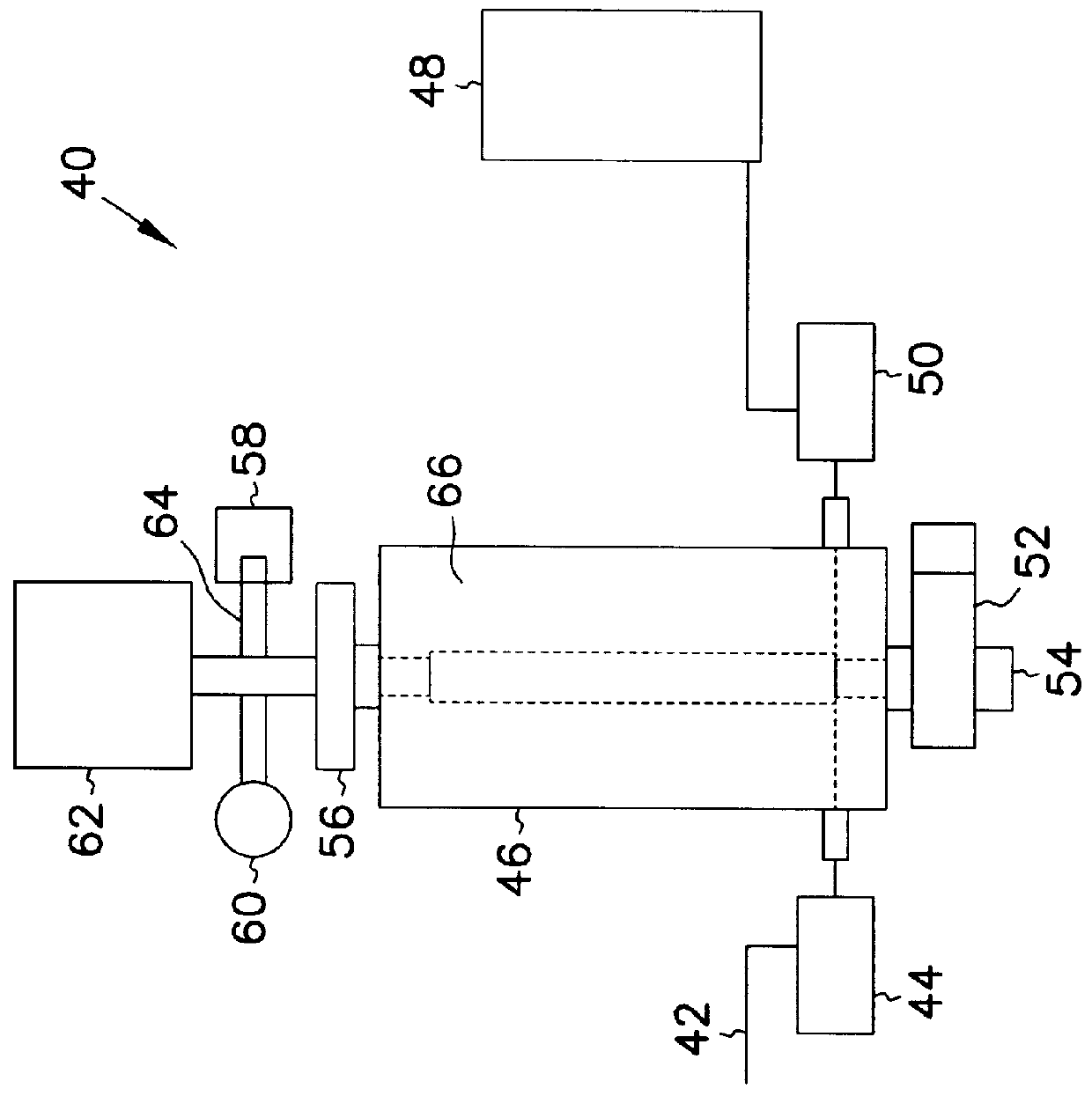

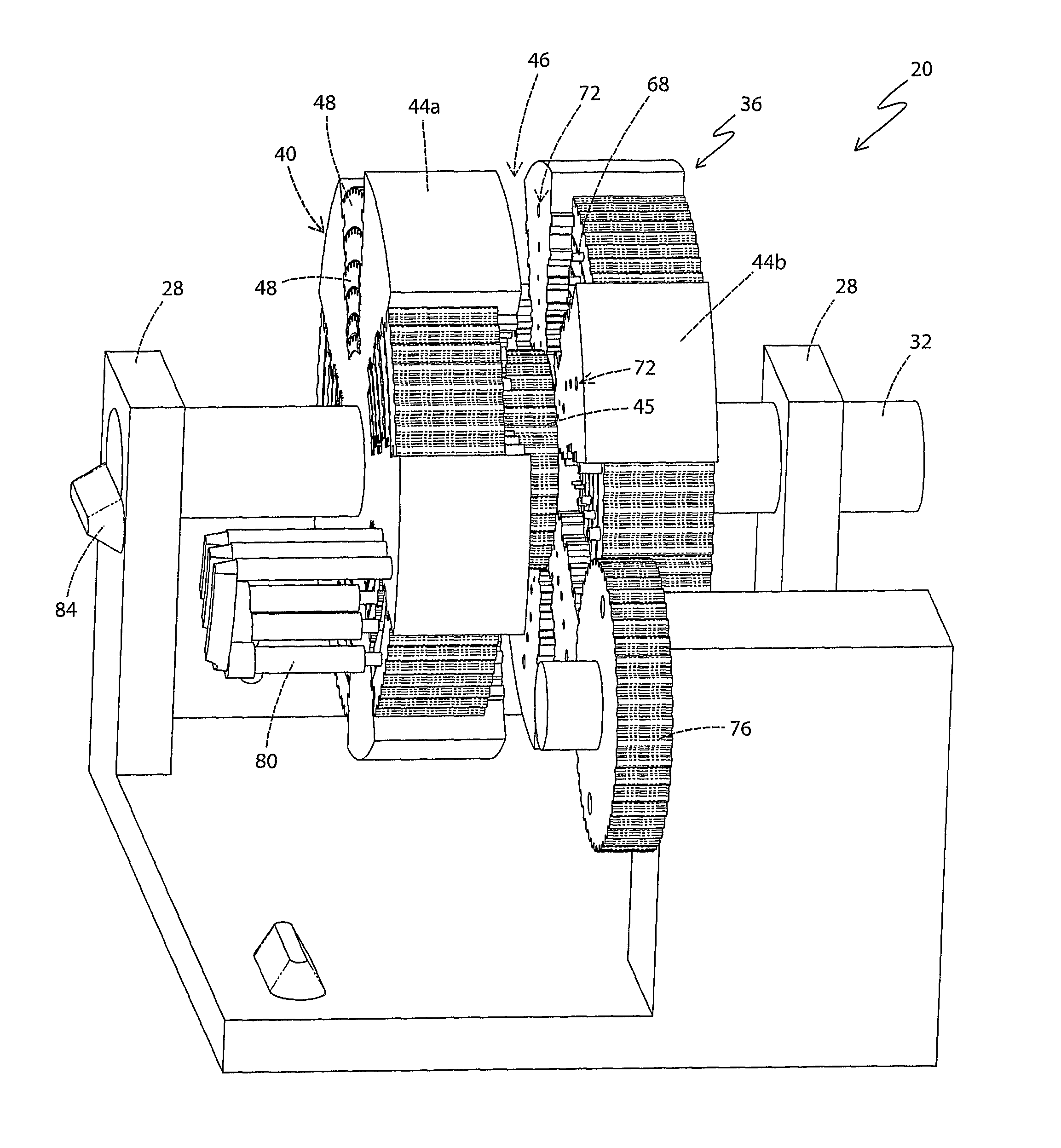

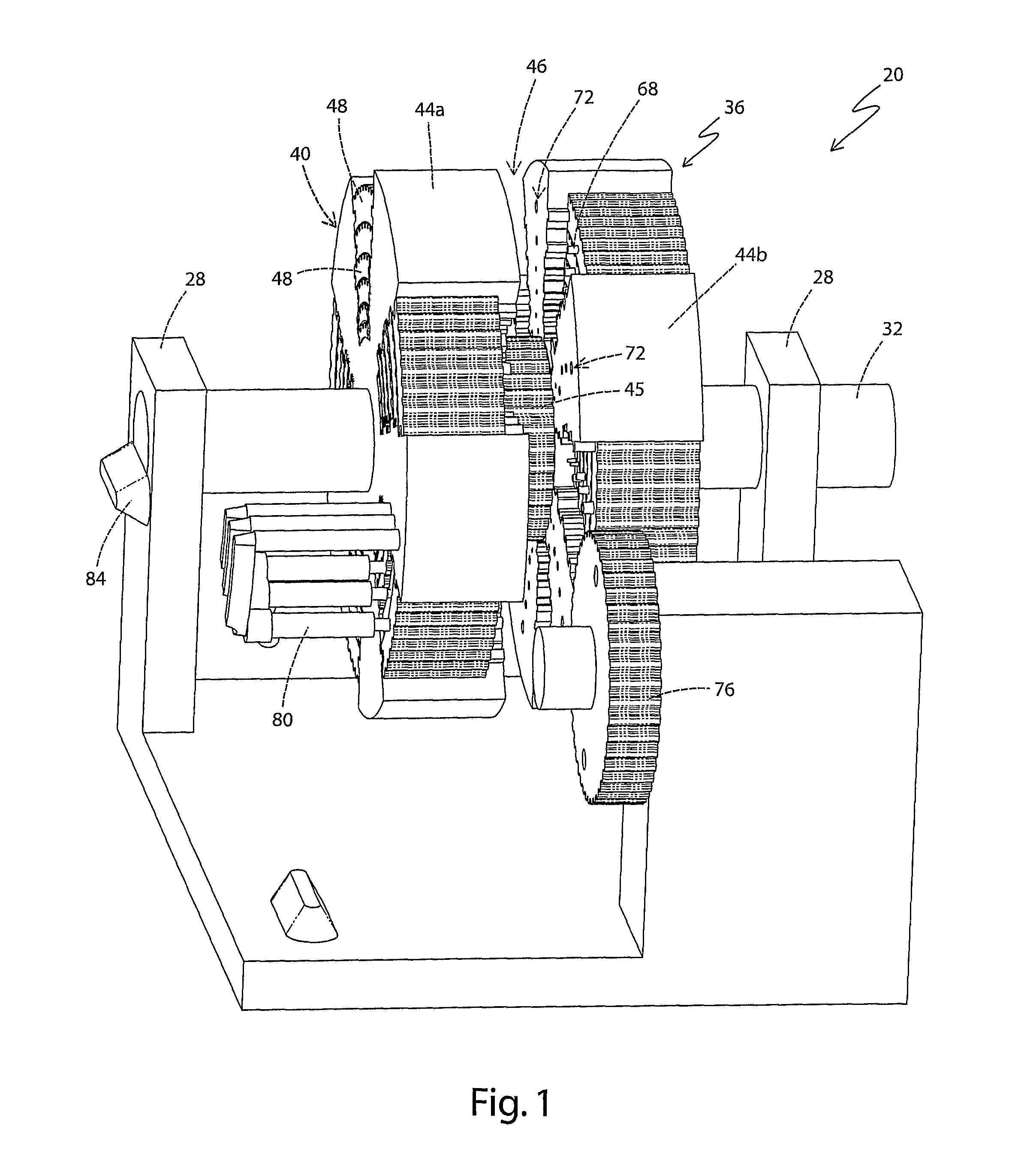

Synchronized segmentally interchanging pulley transmission system

A segmented pulley transmission [20] is provided. A pulley assembly [36] is rotationally mounted on an axle [32]. The pulley assembly [36] includes a core pulley [45] having a first set of mating features on a peripheral surface thereof. A pulley segment set comprises a number of pulley segments [48] slidably mounted in the pulley assembly and arranged in a ring concentric with the core pulley [45]. The pulley segments [48] are individually actuatable out of the pulley assembly into an engaging position and into the pulley assembly into a non-engaging position. The pulley segments [48] have a second set of mating features [52] on an peripheral surface matching the first set of mating features. An endless drive member [47] has corresponding mating features on an inside surface for engaging the first and second sets of mating features of the core pulley [45] and the pulley segments [48] in an engaging position. Contact between the endless drive member [47] and a core pulley defines a contact zone [CZ]. An actuator [80] actuates the pulley segments [48] between the engaging and non-engaging positions when the pulley segments [48] are outside of the contact zone [CZ]. One of the pulley segments [48] in the pulley segment set is a key pulley segment [48a] that is positioned relative to the care pulley [45] such that when the key pulley segment [48a] is actuated to the engaging position and rotated into the contact zone [CZ], the corresponding mating features of the endless drive member [47] engage the first set of mating features of the core pulley [45] and the second set of mating features [52] of the key pulley segment [48a] without the introduction of significant slack or tension.

Owner:1783590 ONTARIO

Spring based continuity alignment apparatus and method

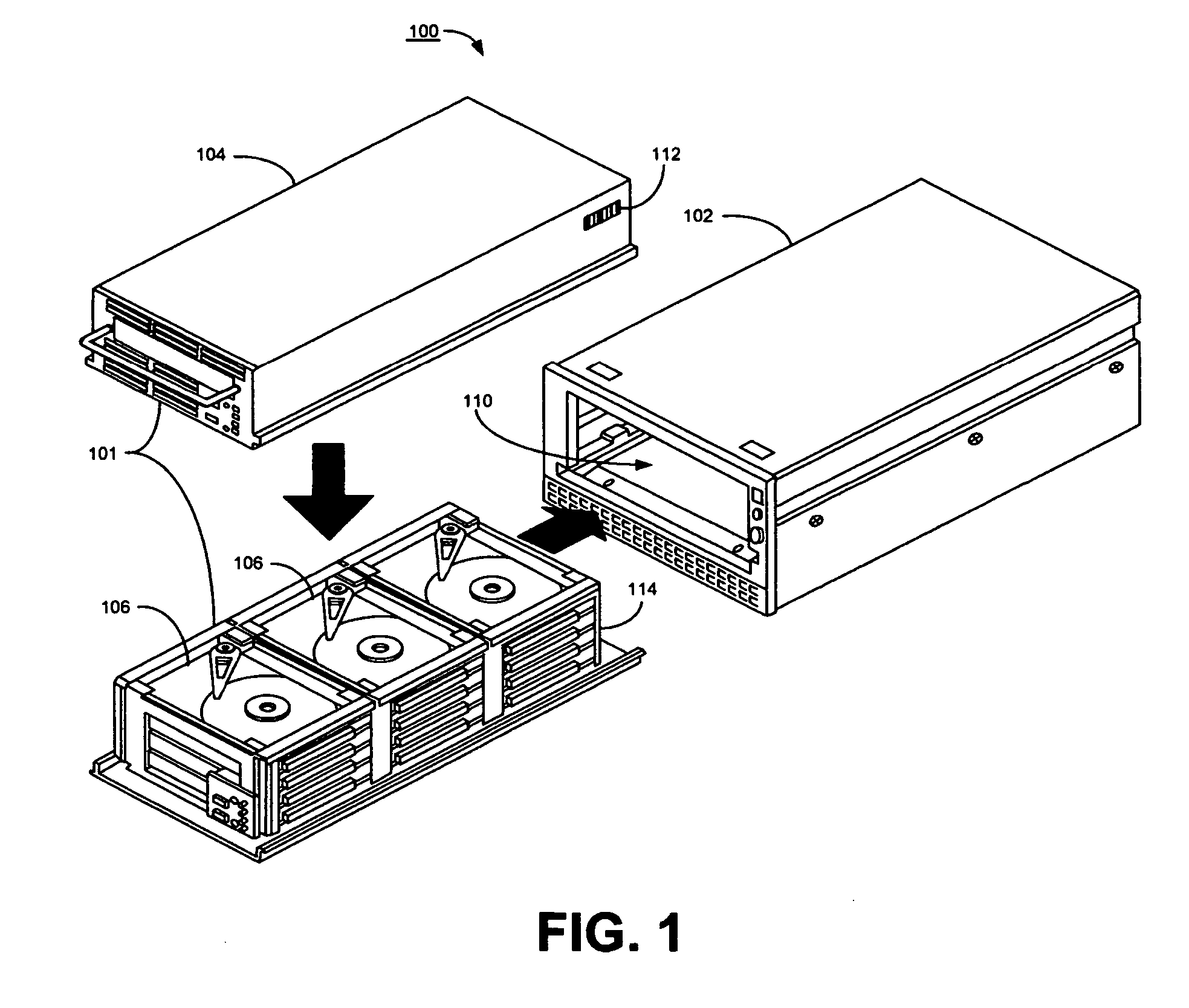

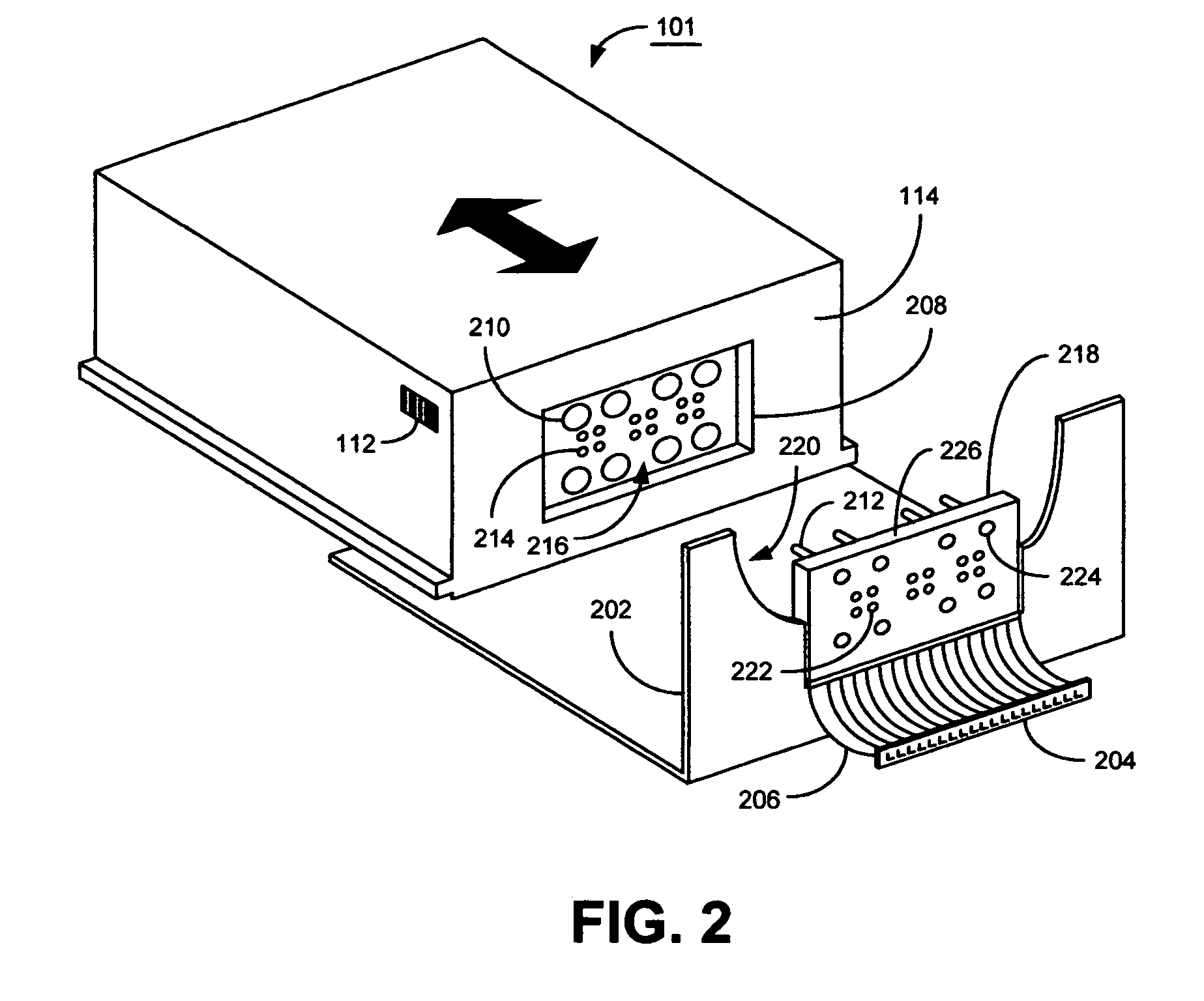

ActiveUS20060134997A1Increase the number ofCoupling contact membersRecord information storageContact zoneElectrical and Electronics engineering

Disclosed is a method and apparatus for an alignment system for use in a data storage system for enabling numerous contact cycles between two surfaces in a robust manner. The system includes a first and a second surface each having at least two contact zones. Each of the contact zones comprise either a conductive spring or a conductive pad. Each of the conductive springs is adapted to engage a corresponding conductive pad, wherein the engaging location on the pad is substantially flat, to form at least one closed circuit when the first and the second surfaces are aligned and are in contact. A continuity confirmation device can further be used to confirm the closed circuit.

Owner:SPECTRA LOGIC

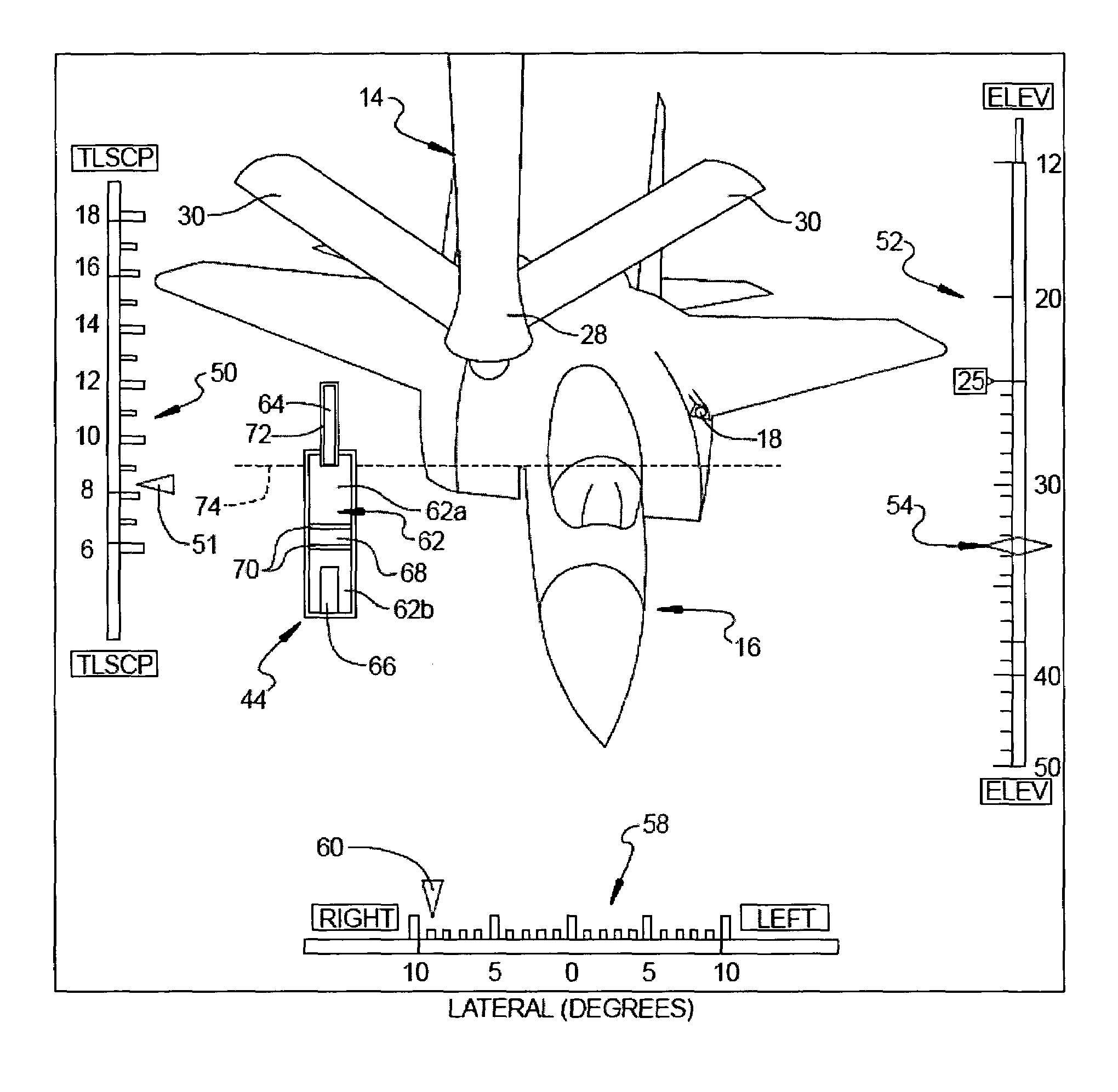

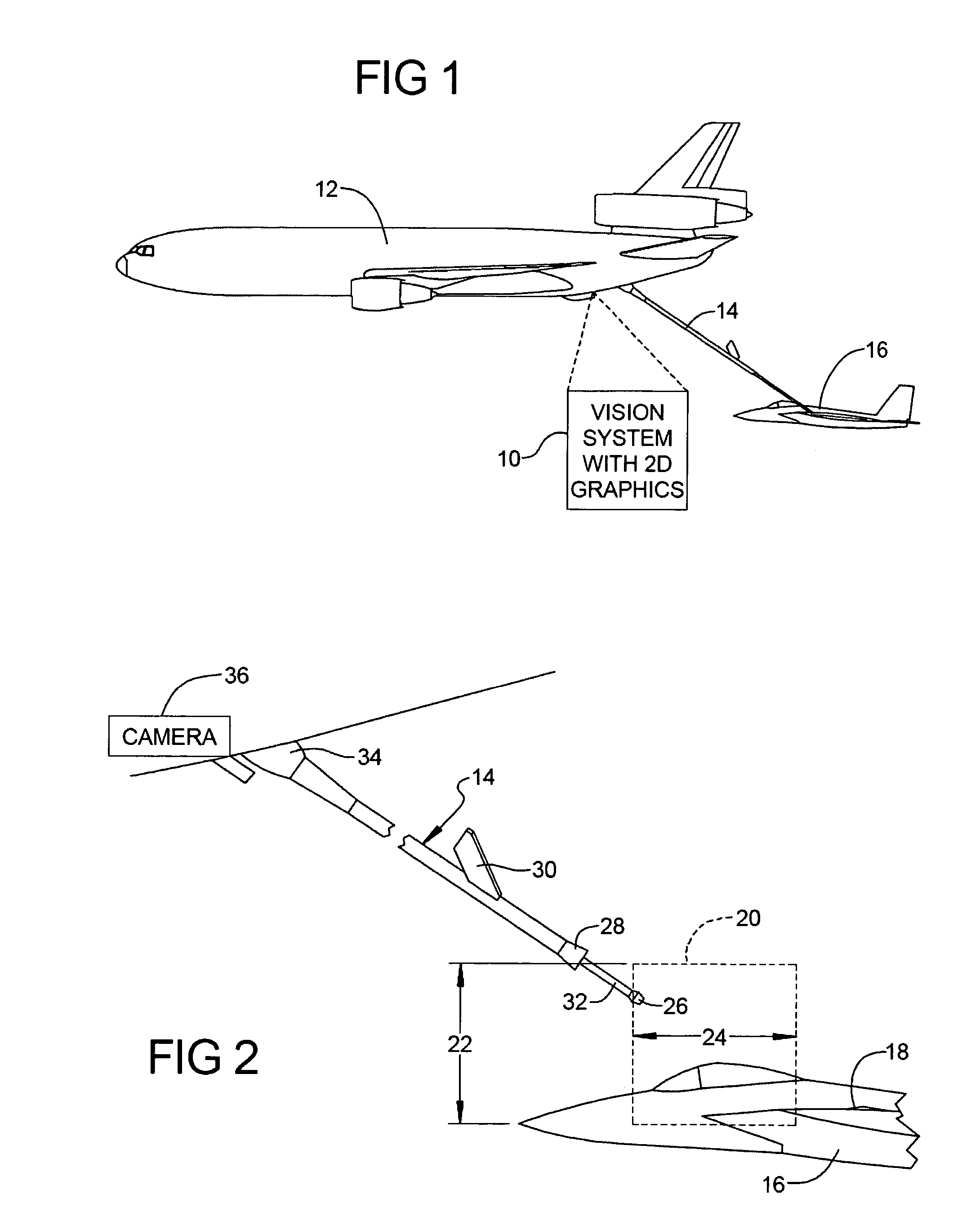

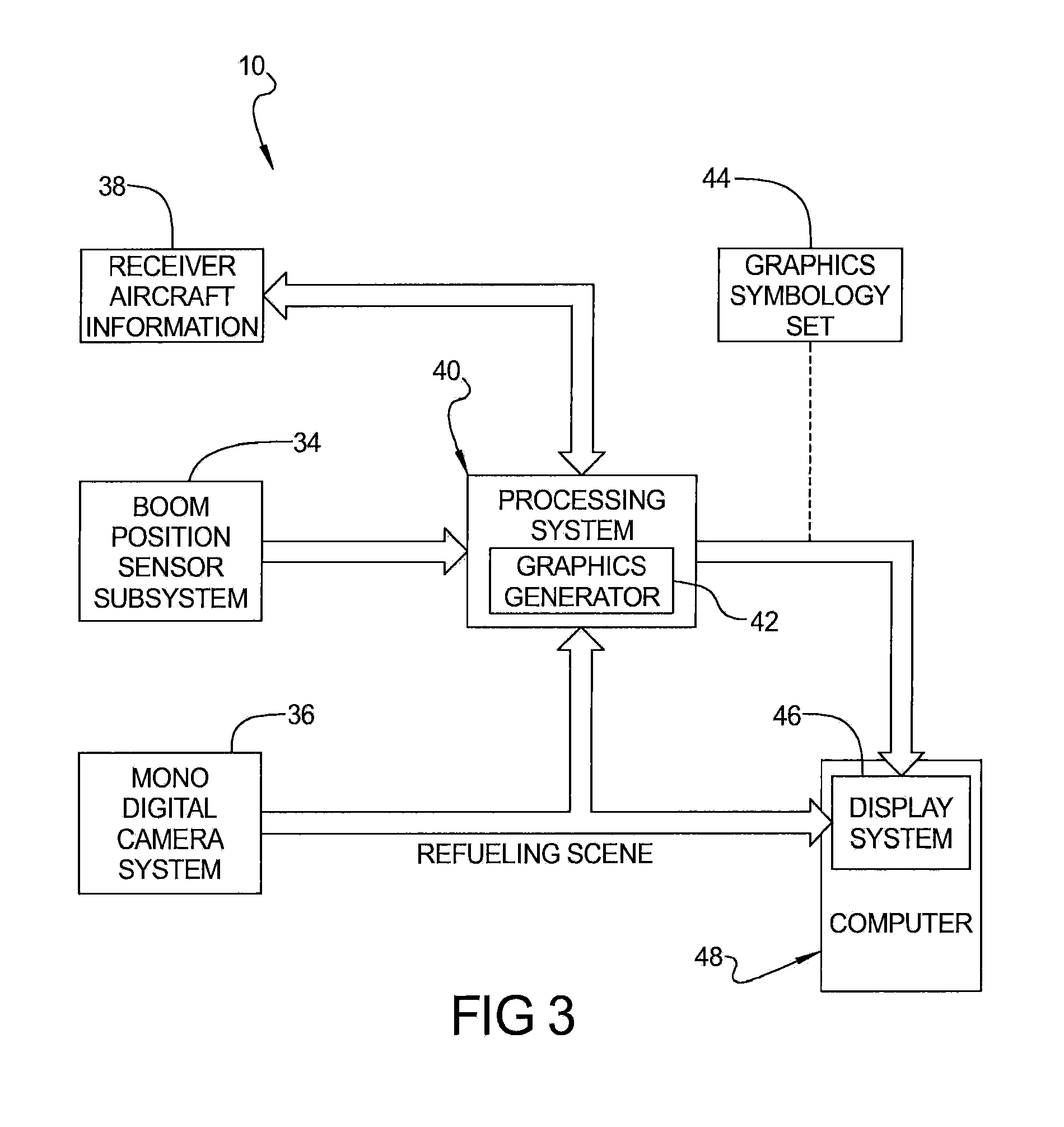

Vision system and method incorporating graphics symbology for use in a tanker refueling system

A vision system and method for use on a refueling tanker to assist a boom operator in performing an airborne refueling operation on a receiver aircraft. The system includes a digital camera system, a sensor subsystem and a processing system that receives information from the sensor system and the camera system. The processing system includes video processing capability and a graphics generator that generates a two dimensional graphics symbology set that is displayed on a display terminal along with a real time image of the boom and the receiver aircraft. The graphics symbology set includes a plurality of graphic symbols that indicate the position of the refueling boom and the position of the receiver aircraft relative to a desired contact zone within which physical contact between the boom tip and a refueling receptacle on the receiver aircraft can be made. The graphics symbology set also makes use of various colors to indicate warning conditions to the boom operator.

Owner:THE BOEING CO

Methods for producing a crude product from selected feed

Methods of producing a crude product are described. A method includes providing a feed and a supported inorganic salt catalyst to a contacting zone. The feed has at total content, per gram of feed, of at least 0.9 grams of hydrocarbons having a boiling range distribution between 343° C. and 538° C. Contact of the supported inorganic salt catalyst with the feed in the presence of a hydrogen source and steam is performed such that the supported inorganic salt catalyst becomes fluidized, and a total product that includes a crude product is produced. The crude product has a total content of at least 0.2 grams per gram of crude product of hydrocarbon have a boiling range distribution between 204° C. and 343° C.

Owner:SHELL OIL CO

Drill bit cutter element having multiple cusps

Cutter elements for use in rolling cones rock bits are disclosed having a crown that includes multiple, spaced-apart cusps for enhancing formation removal by creating overlapping Hertzian contact zones. The cusps may be partially dome-shaped, berm shaped or otherwise. The cutter elements provide multiple cutting edges for engaging the formation and may have differing radii and extension length as suitable for particular applications.

Owner:SMITH INT INC

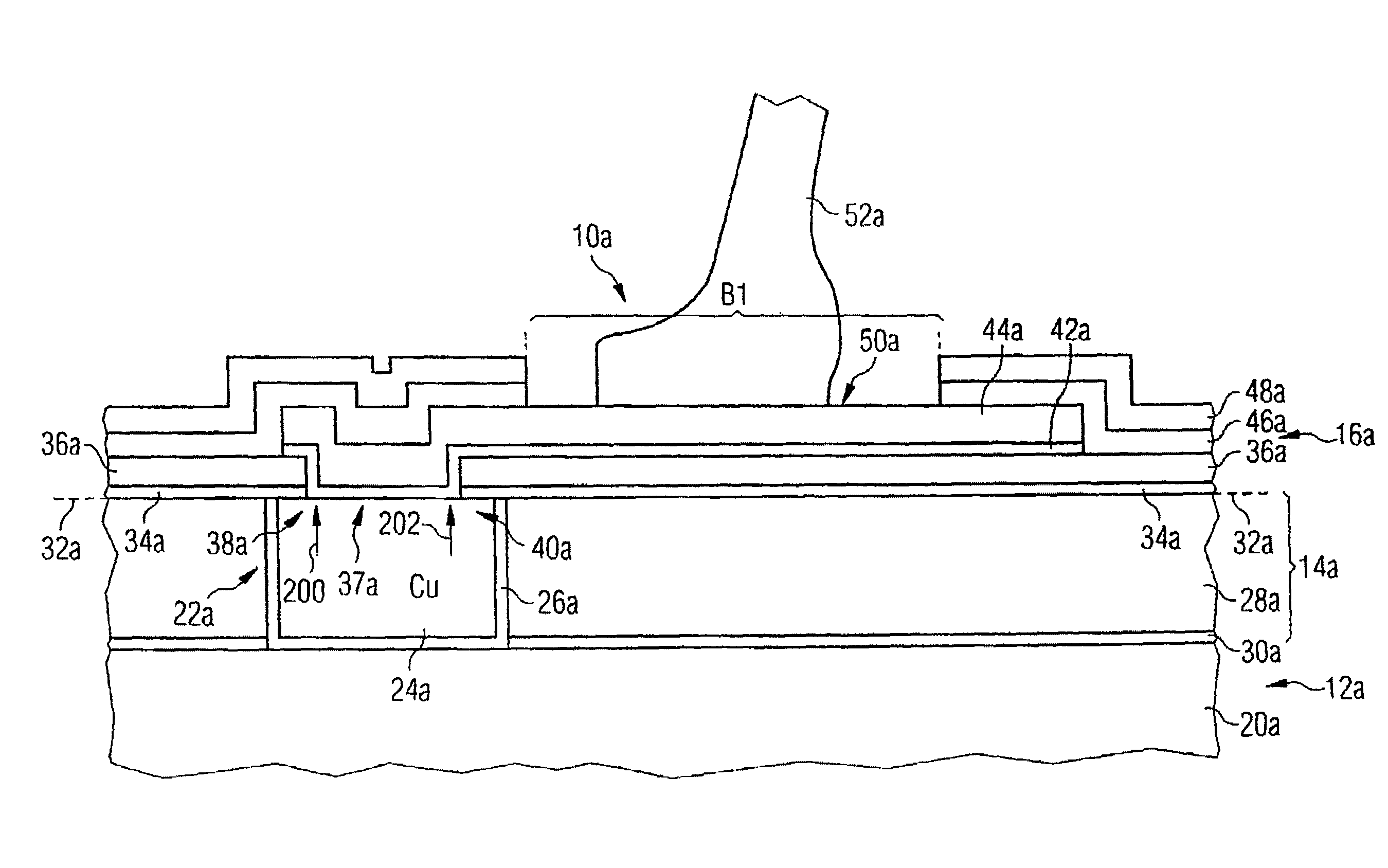

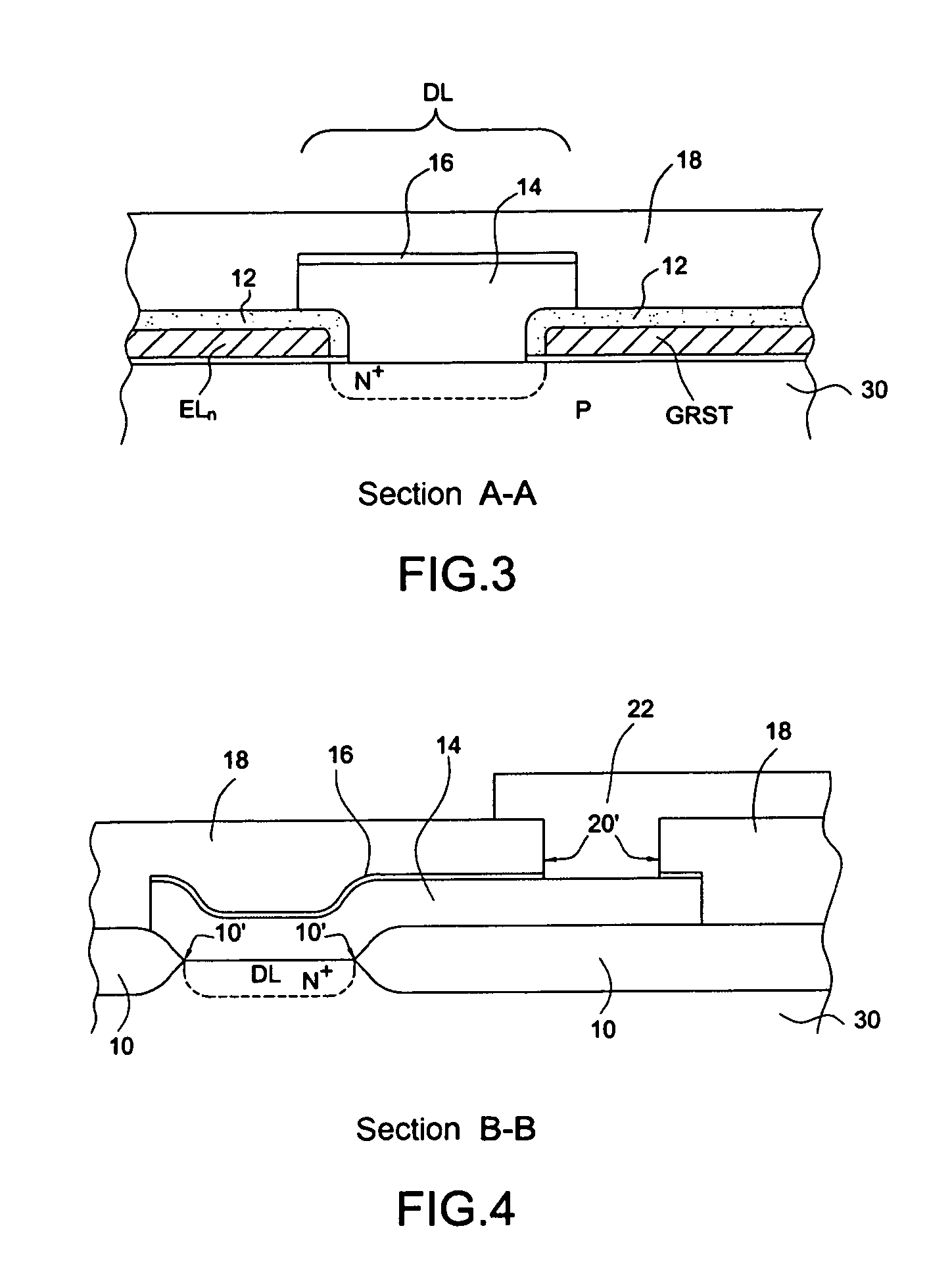

Integrated circuit with a very small-sized reading diode

InactiveUS20070184653A1Not possibleSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductorContact zone

The invention relates to integrated circuits comprising both conductive gates deposited above a semiconductor substrate and a diode is formed between two electrodes. In order to achieve a diode of very small dimensions, the following procedure is adopted: producing the electrodes (ELn, GRST, then thermally oxidizing the electrodes, then exposing the surface of the substrate between the electrodes, then the following operations: depositing doped polycrystalline silicon in order to form one pole (42) of the diode, the substrate forming the other pole, delimiting a desired silicon pattern covering the space left between the electrodes and also covering a region lying outside this space, depositing an insulating layer, locally etching an opening into this insulating layer above the polycrystalline silicon outside the space lying between the electrodes, in order to form an offset contact zone, depositing a metal layer and etching the metal layer.

Owner:ATMEL GRENOBLE

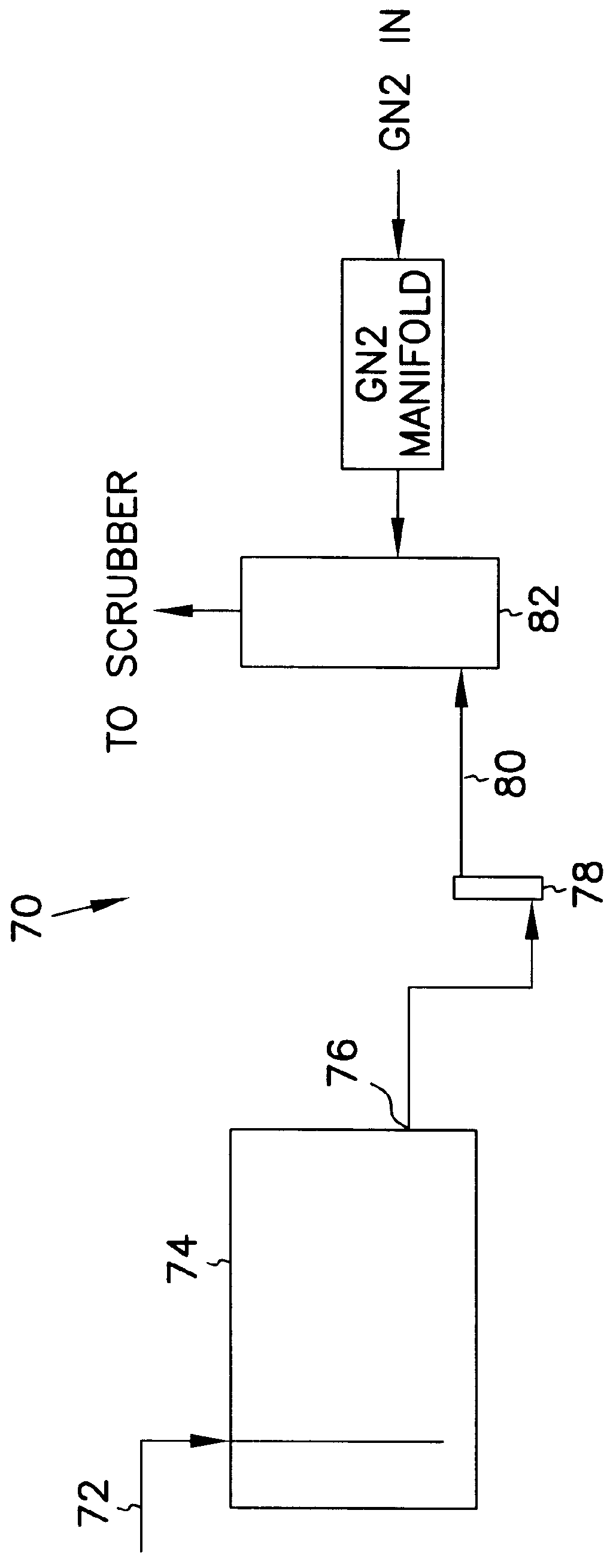

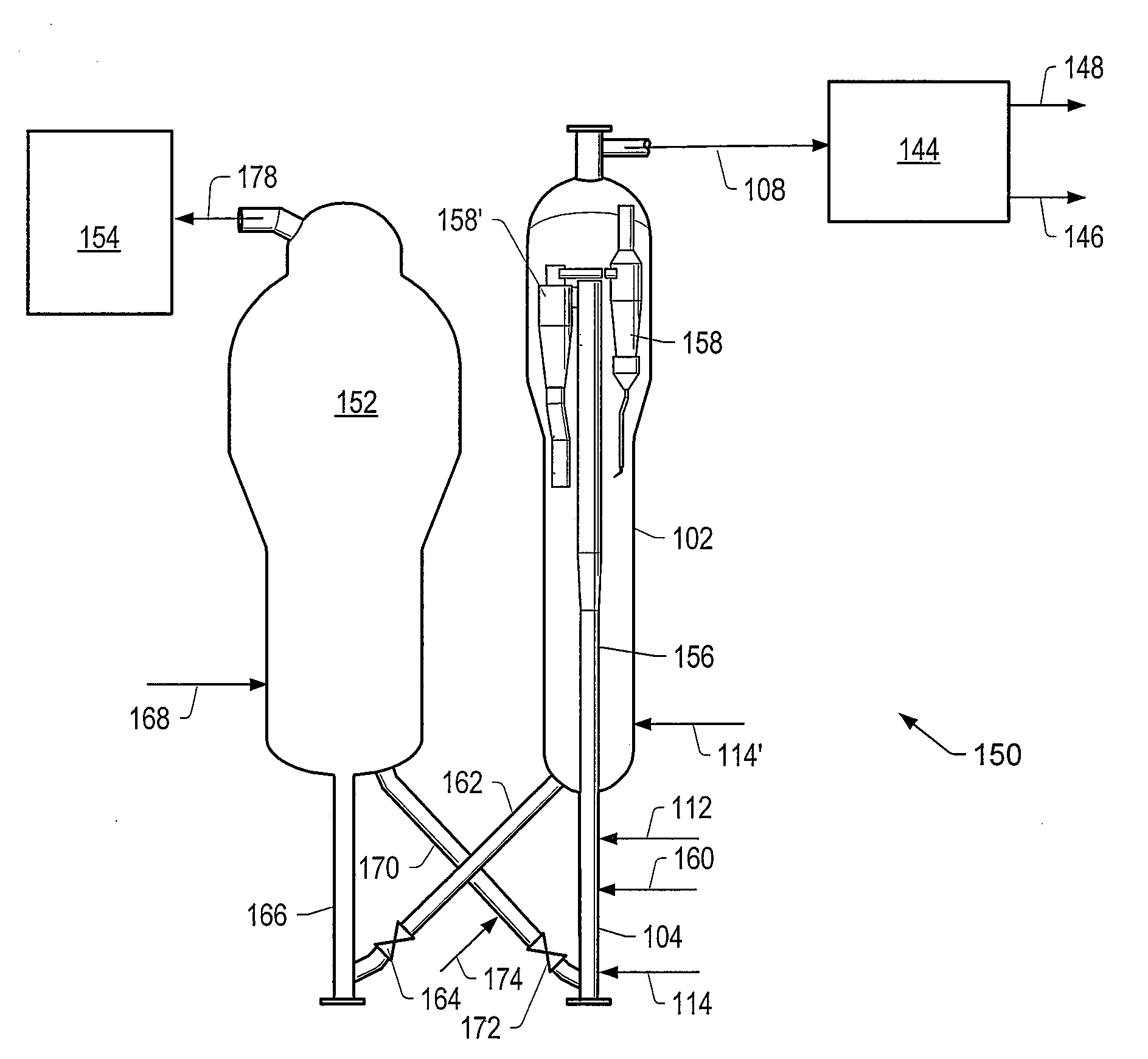

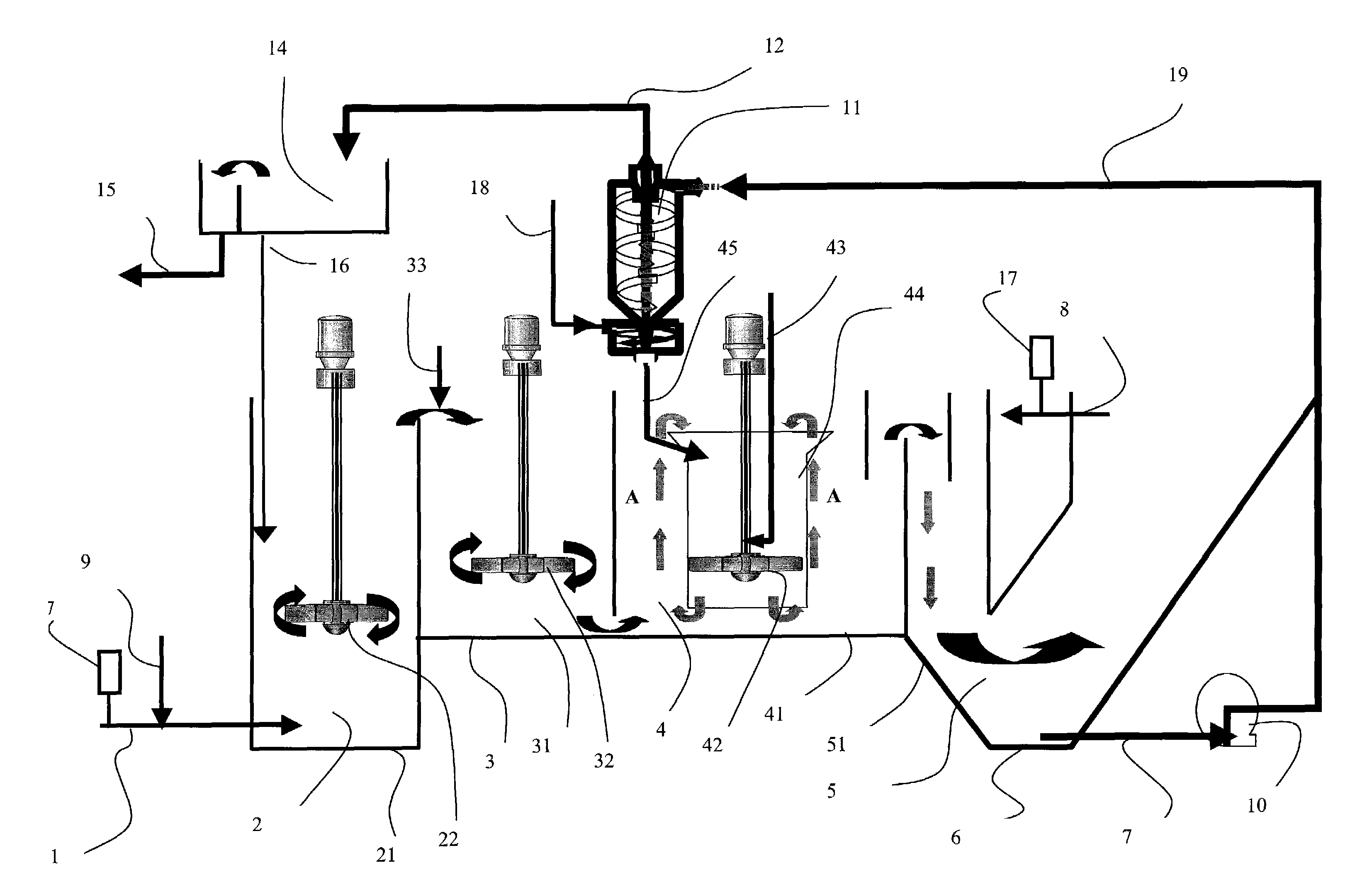

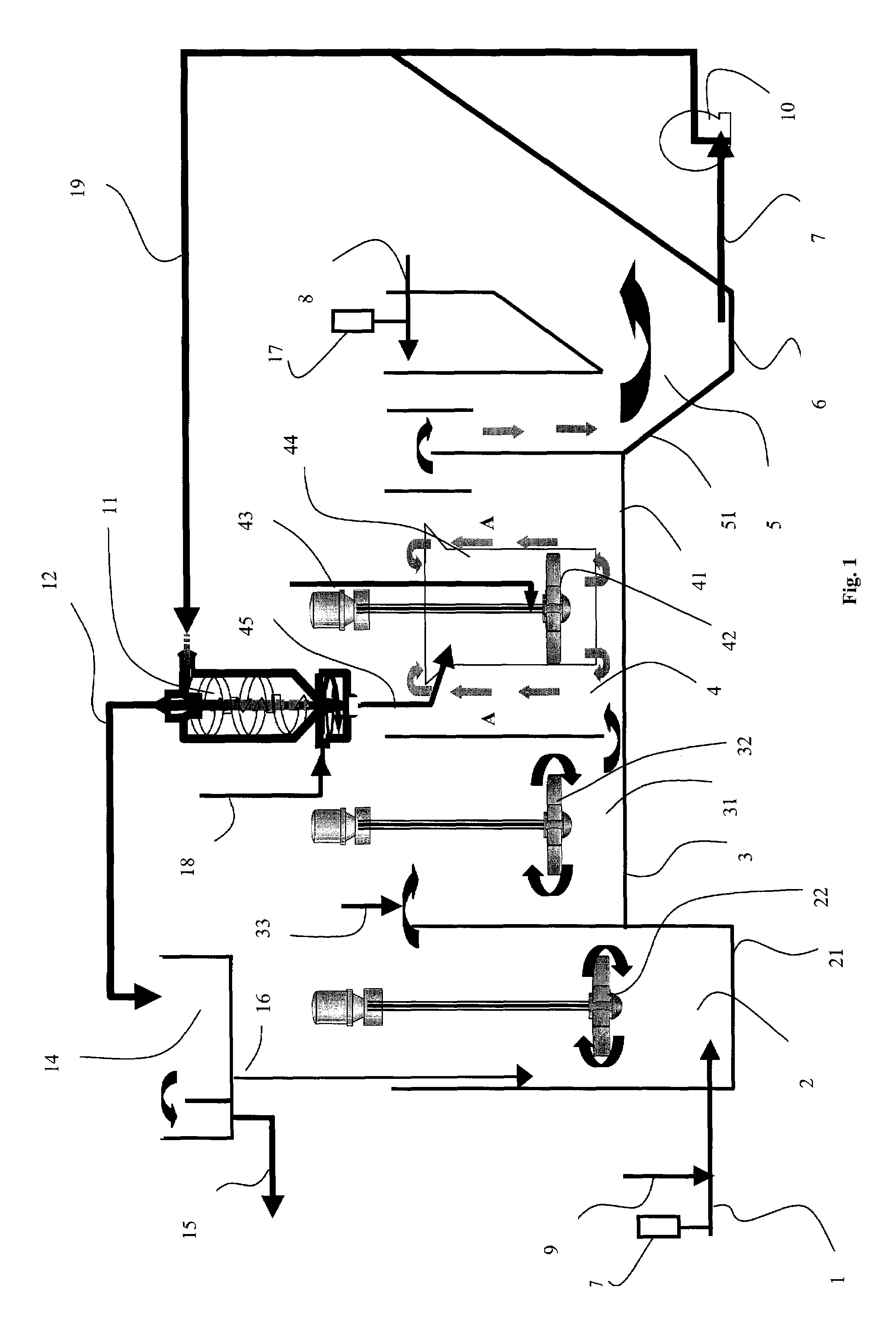

Water treatment method by ballasted flocculation, settling, and prior adsorbent contact

ActiveUS7648637B1Quality improvementLow costWater/sewage treatment by centrifugal separationWater treatment compoundsFlocculationSludge

The invention relates to a method for removing impurities from an aqueous stream. The method includes directing the aqueous stream into an adsorbent contact zone and contacting the aqueous stream with an adsorbent material in the adsorbent contact zone so that impurities in the aqueous stream are adsorbed onto the adsorbent material. The aqueous stream and the adsorbent material is then directed to a ballasted flocculation zone where the adsorbent material is mixed with ballast to form sludge. The aqueous stream is then separated from the sludge to produce treated water and the sludge is settled in a settling zone. The ballast is then separated from the sludge and directed to the ballasted flocculation zone while the sludge and the adsorbent material are directed to a transition zone. In addition, the method requires measuring the concentration of the adsorbent material in the adsorbent contact zone and adding adsorbent material to the aqueous stream if the value of the measured concentration of the adsorbent material in the absorbent contact zone is below a predetermined threshold value.

Owner:VEOLIA WATER SOLUTIONS & TECH SUPPORT

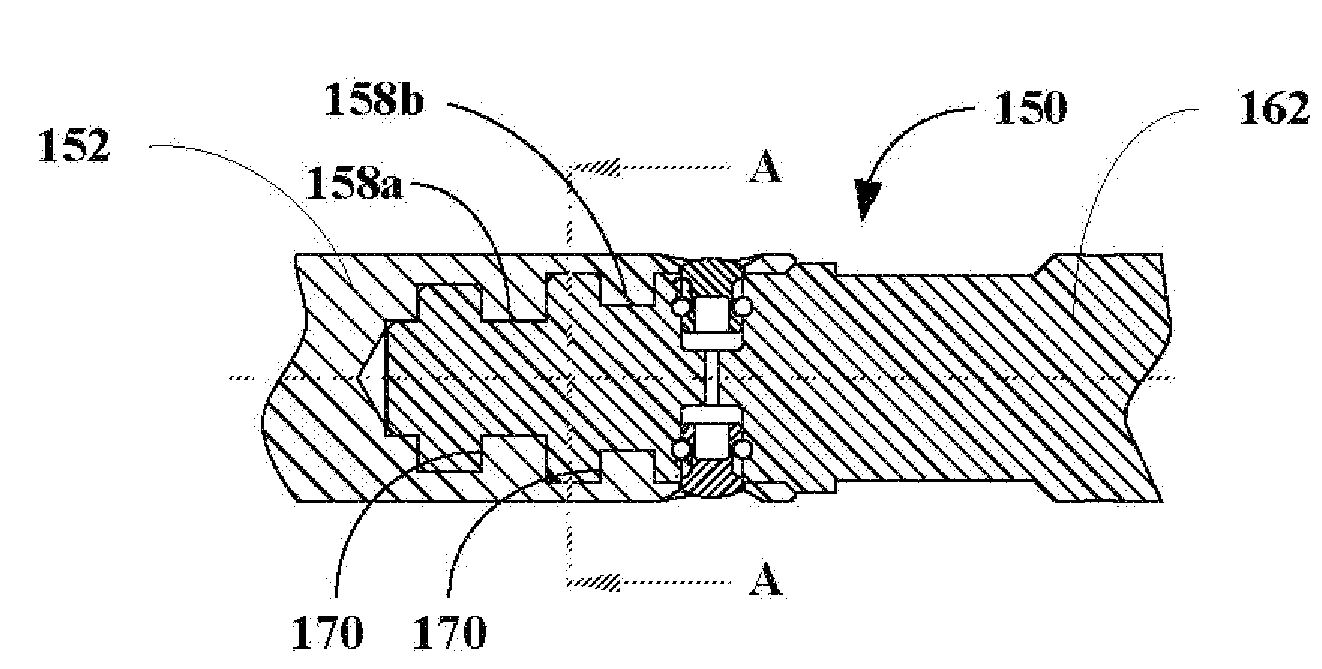

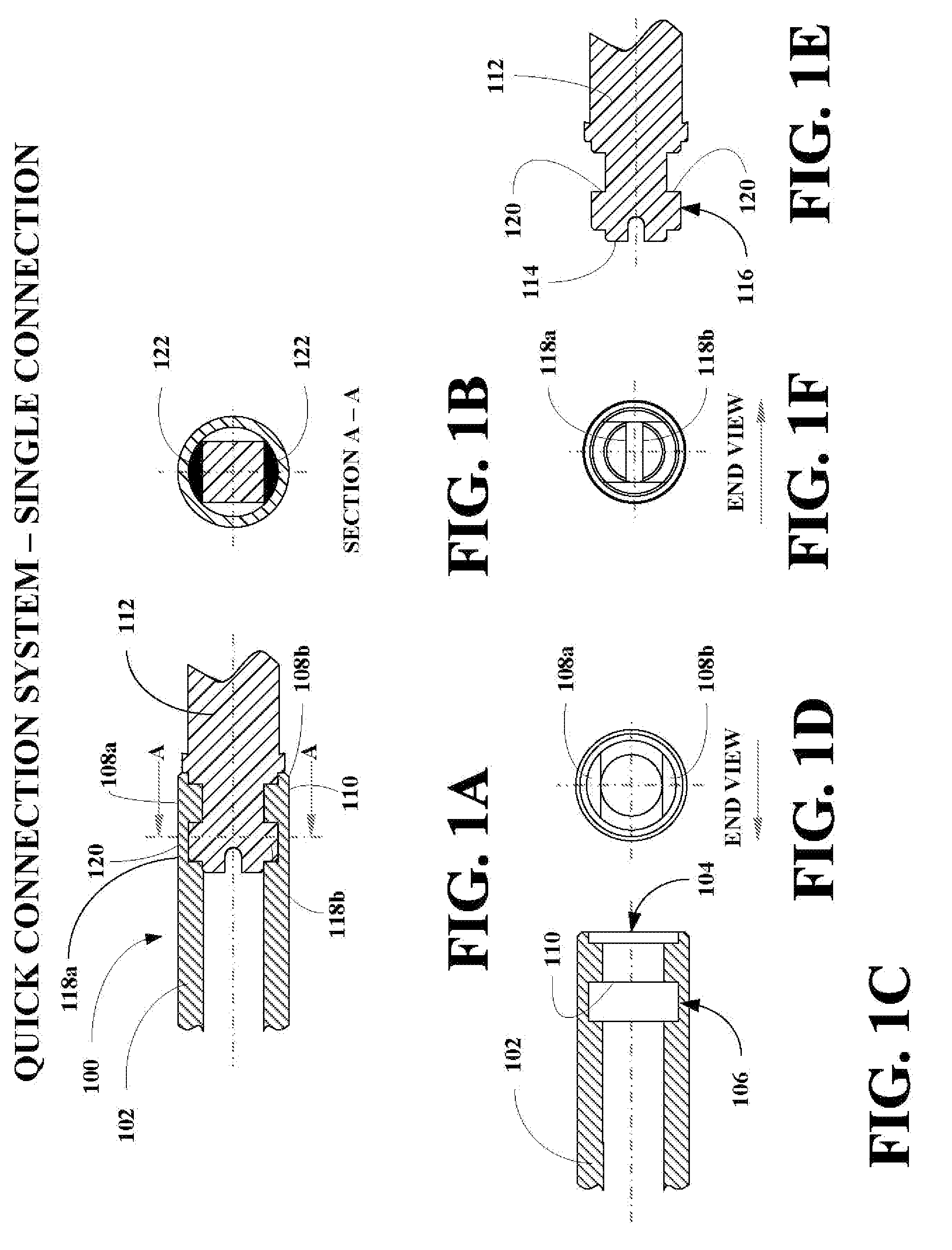

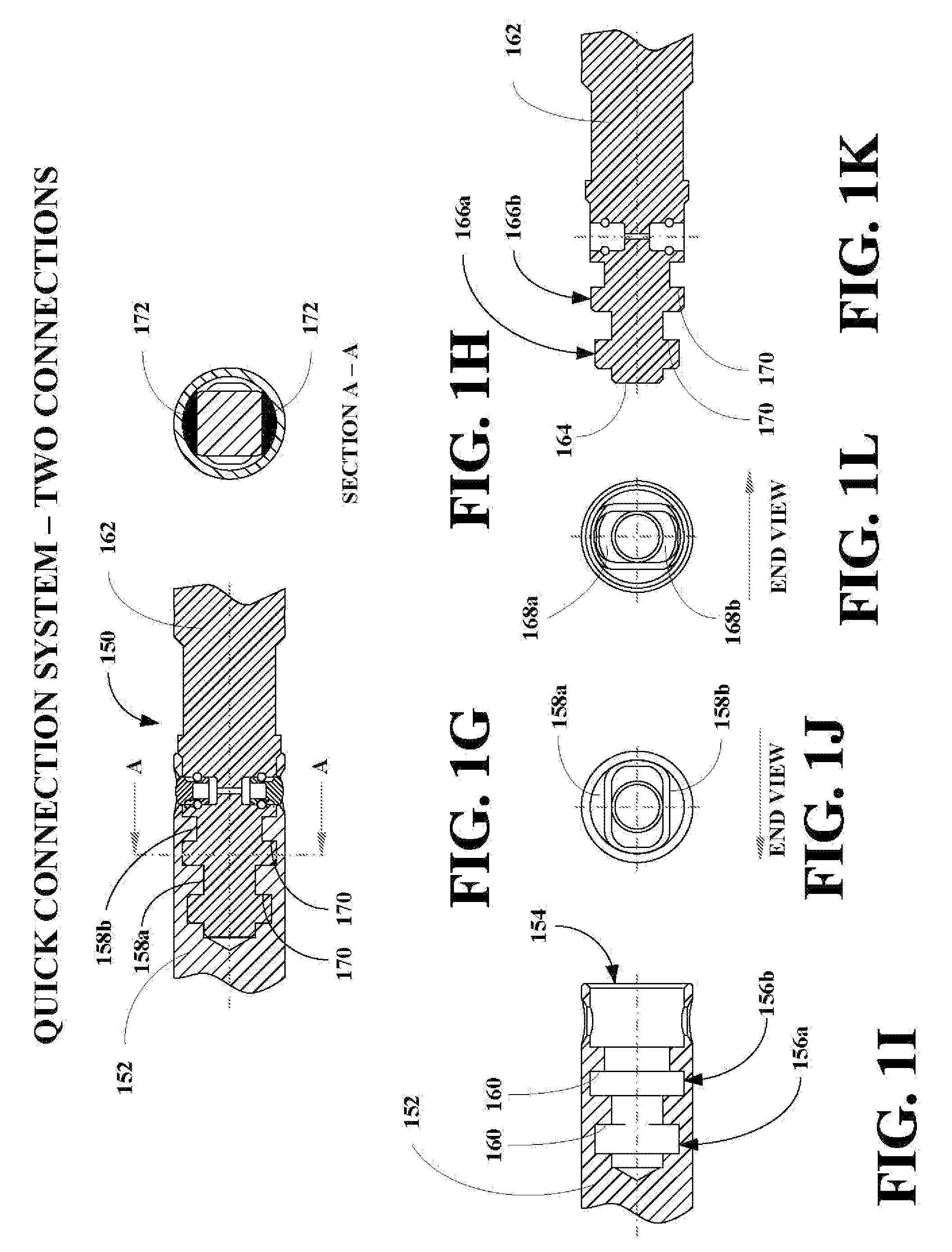

Quick lock wireline valve/blow-out preventor and methods for making and using same

A blow out preventor (BOP) apparatus is disclosed that includes a BOP body including a quick connection system including one female connector or a plurality of female connectors, disposed in each actuator receiving aperture, each female connector having a female engaging profile and one male connector or a plurality of male connectors, disposed on an outer surface of an actuator cylinder, one for each female connector, each male connector having a male engaging profile, where the male engaging profile is adapted to register with the female engaging profile upon insertion of an actuator into its corresponding receiving aperture and upon rotation of the actuator through a rotational angle, the male profile engages the female profile in at least one contacting zone, and where the rotational angle depends on the profiles.

Owner:WEATHERFORD TECH HLDG LLC

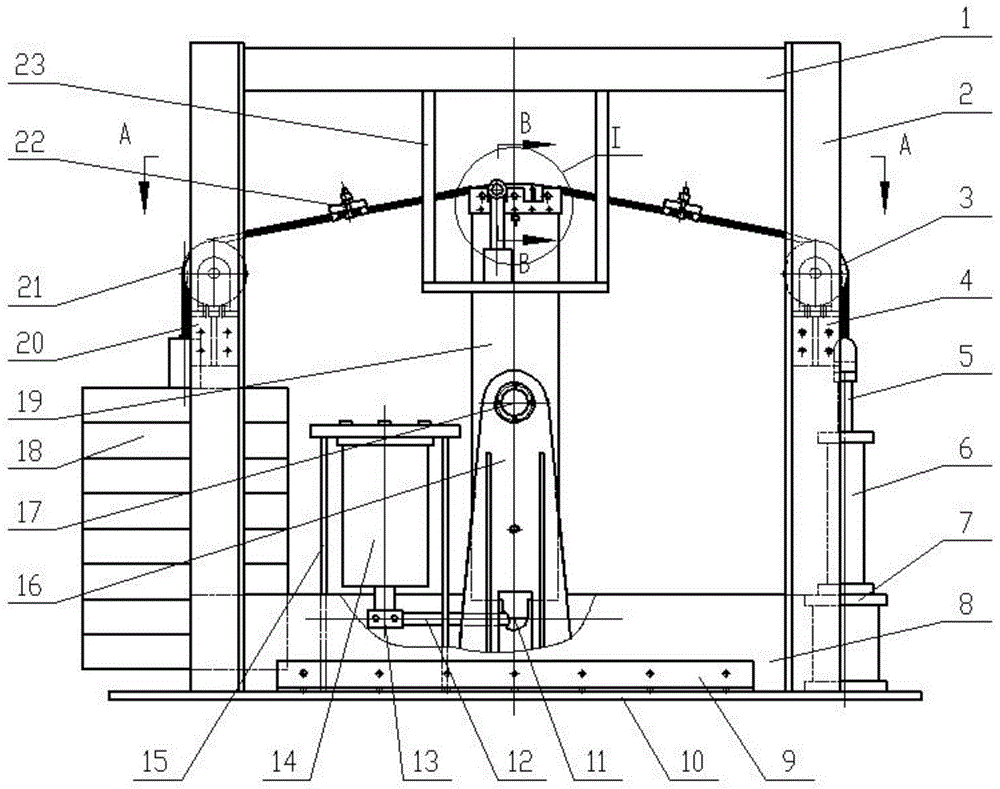

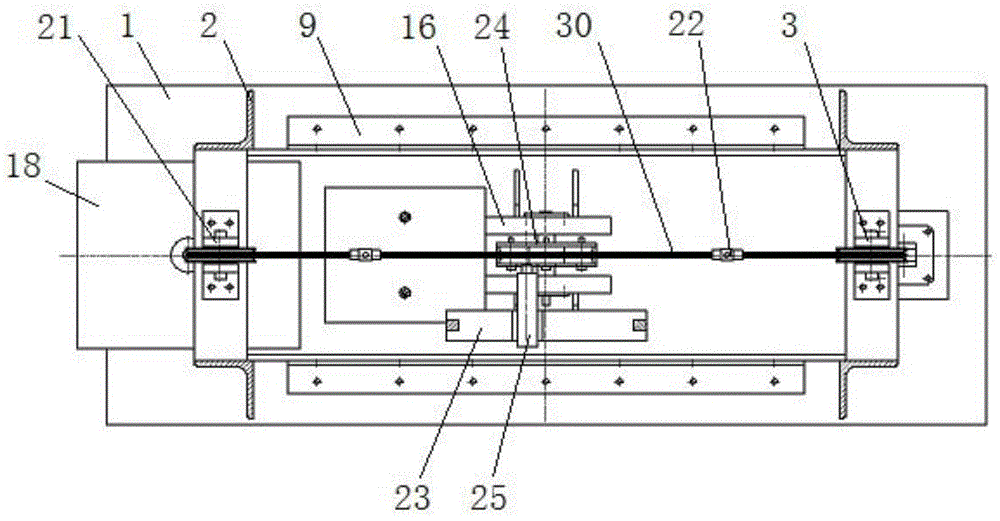

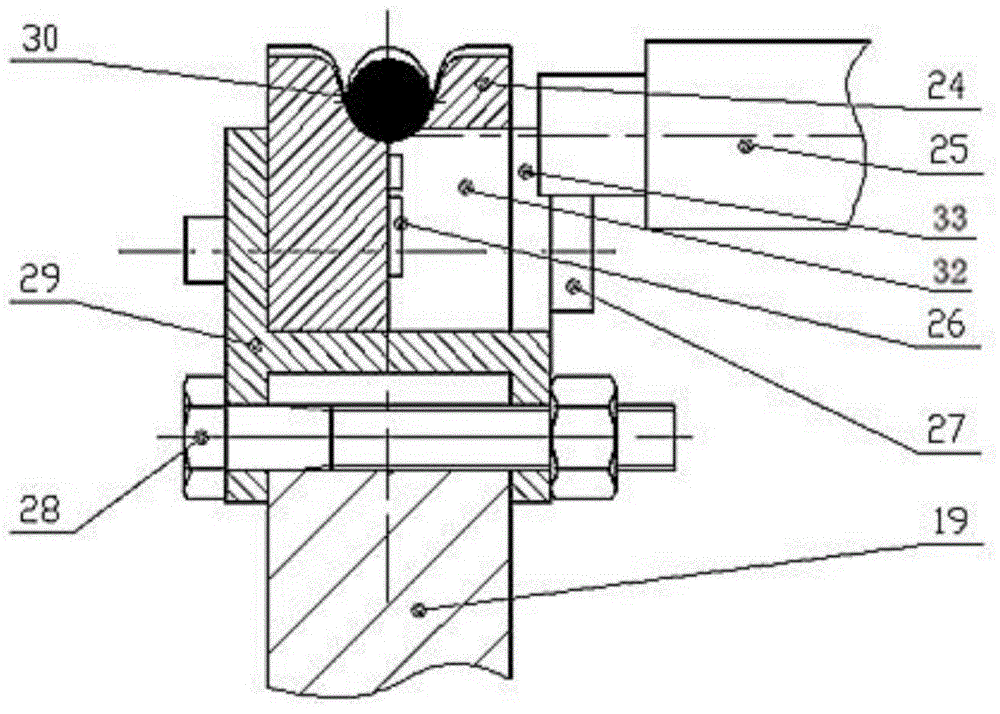

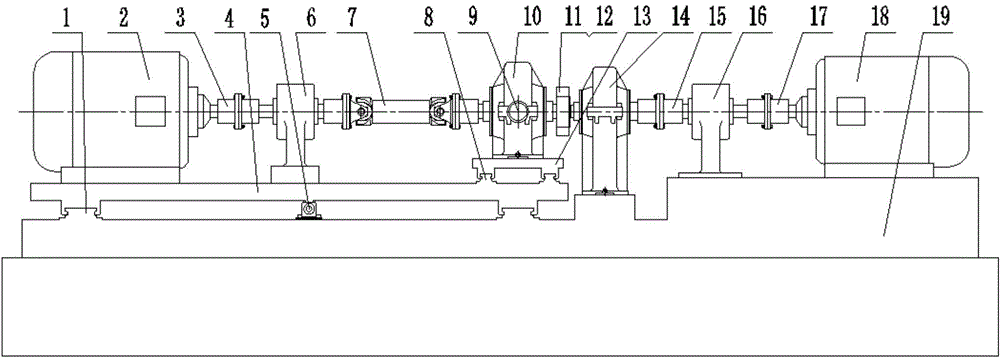

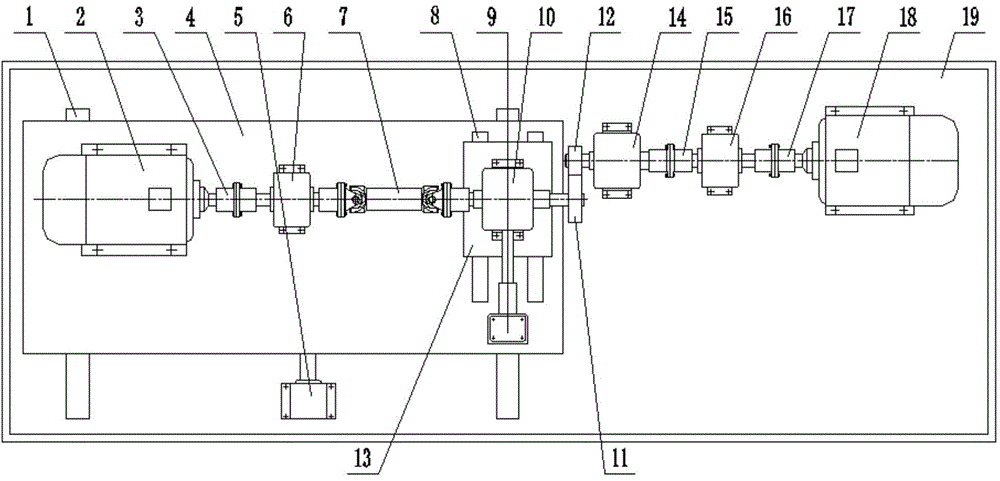

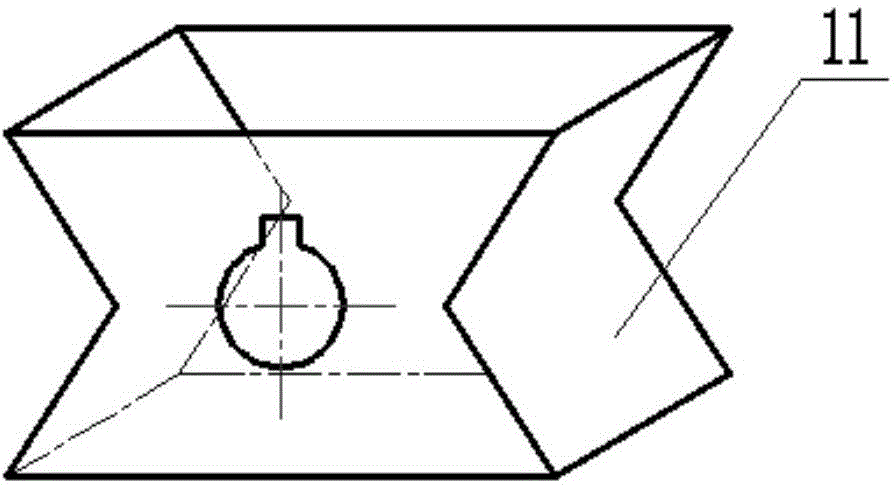

Testing device and method for monitoring steel wire rope-friction pad dynamic micro-friction state

ActiveCN103954553AReal-time measurement of dynamic tension evolutionSimple structureUsing mechanical meansMaterial analysisEngineeringDynamic Tension

The invention discloses a testing device and a testing method for monitoring steel wire rope-friction pad dynamic micro-friction state. The testing device comprises a base frame, a loading system, a micro-slip system and a state monitoring system, wherein the loading system comprises a weight loading system, a hydraulic loading system and a steel wire rope; the micro-slip system comprises a support system, a drive system and a friction transmission system; the state monitoring system comprises a dynamic tension monitoring system, a pad stress measuring system, a friction force measuring system and a micro-slip monitoring system. By utilizing the testing device and the testing method, dynamic alternating tension can be applied to the steel wire rope and dynamic micro-friction can be applied between the steel wire rope and a friction pad simultaneously, and dynamic tension evolution of the steel wire ropes at both sides of the friction pad, micro-slip amplitudes of different sections of a contact arc of the steel wire rope and the friction pad, stress change of the friction pad near the contact zone of the steel wire rope and the friction pad and dynamic friction force between the steep wire rope and the friction pad can be measured in real time.

Owner:CHINA UNIV OF MINING & TECH

Electrical socket contact for high current applications

ActiveUS20070066152A1Avoid cloggingImprove toleranceVehicle connectorsCoupling contact membersEngineeringMechanical engineering

An electrical socket contact for high-current applications includes a cage-like receptacle housing having two lateral plates on opposite sides. The lateral plates forming an interspace therebetween for holding a complementary plug contact. The socket contact further includes a contact plate insert arranged within the interspace of the lateral plates of the housing. The contact plate insert has a contact plate body extending parallel to the lateral plates of the housing. The contact plate body has a base and first and second contact plates. Each contact plate has first and second ends. The first ends of the contact plates are connected to the base of the contact plate body and the second ends of the contact plates each has a contact zone projecting away from the base of the contact plate body.

Owner:KOSTAL KONTAKT SYST

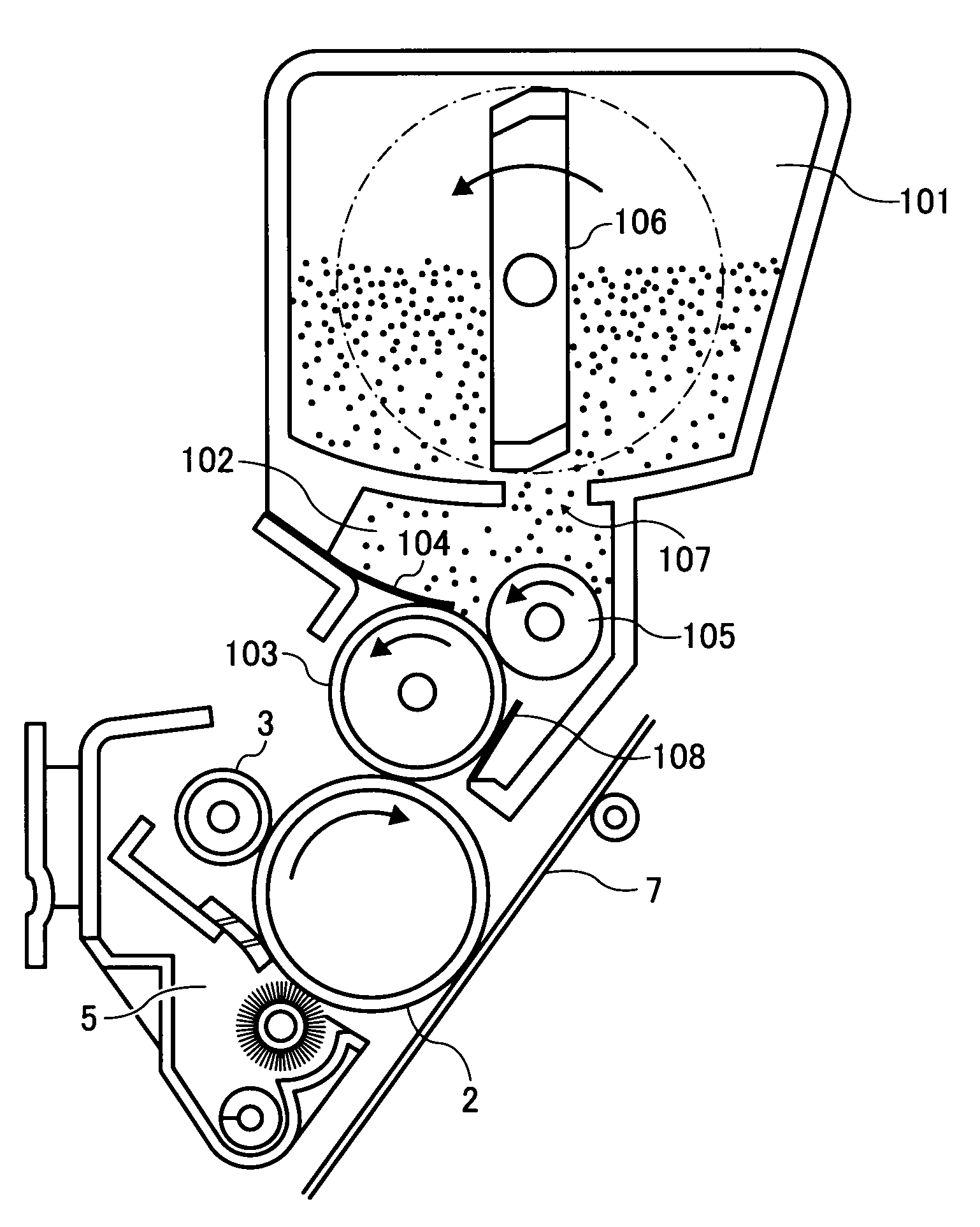

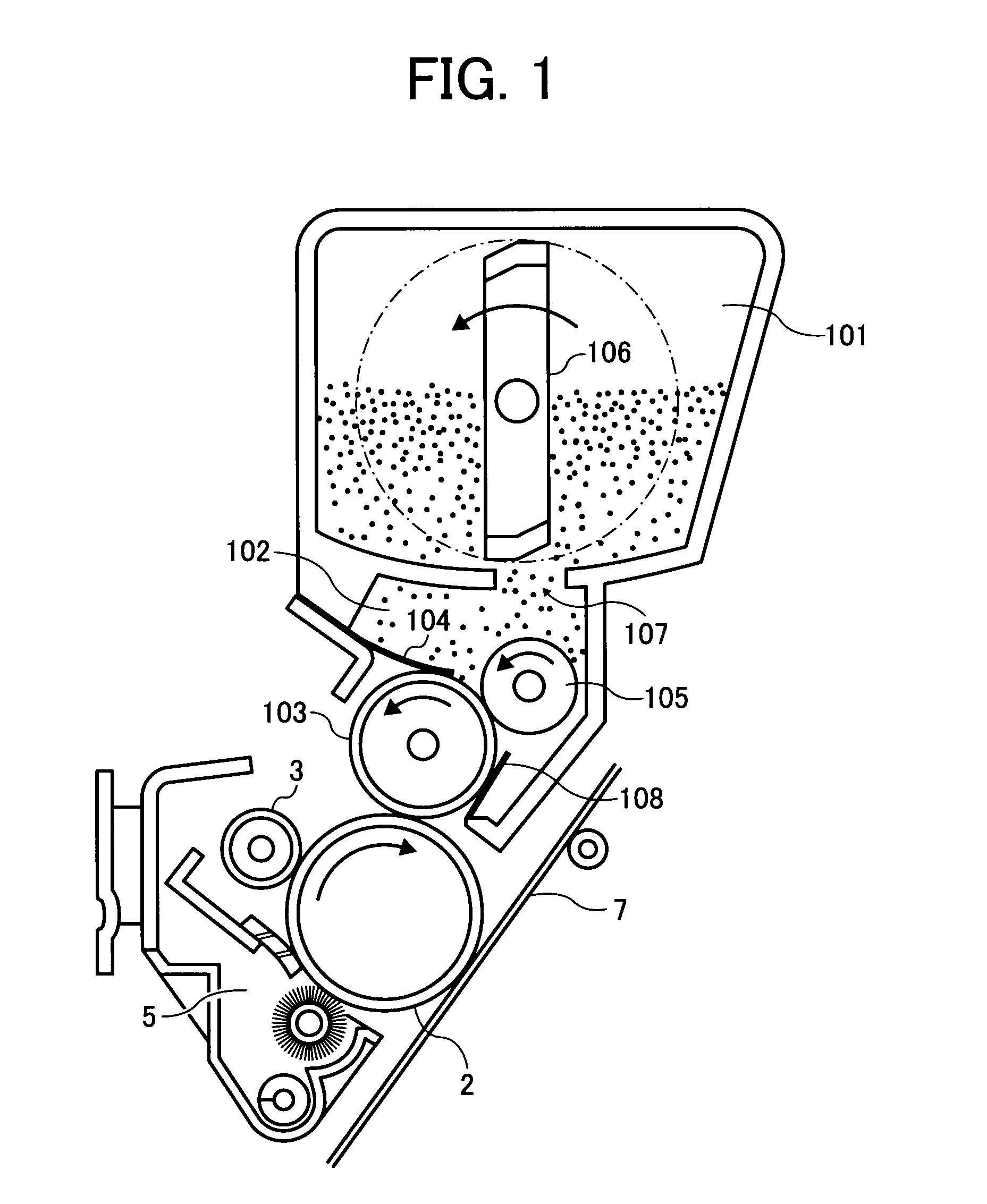

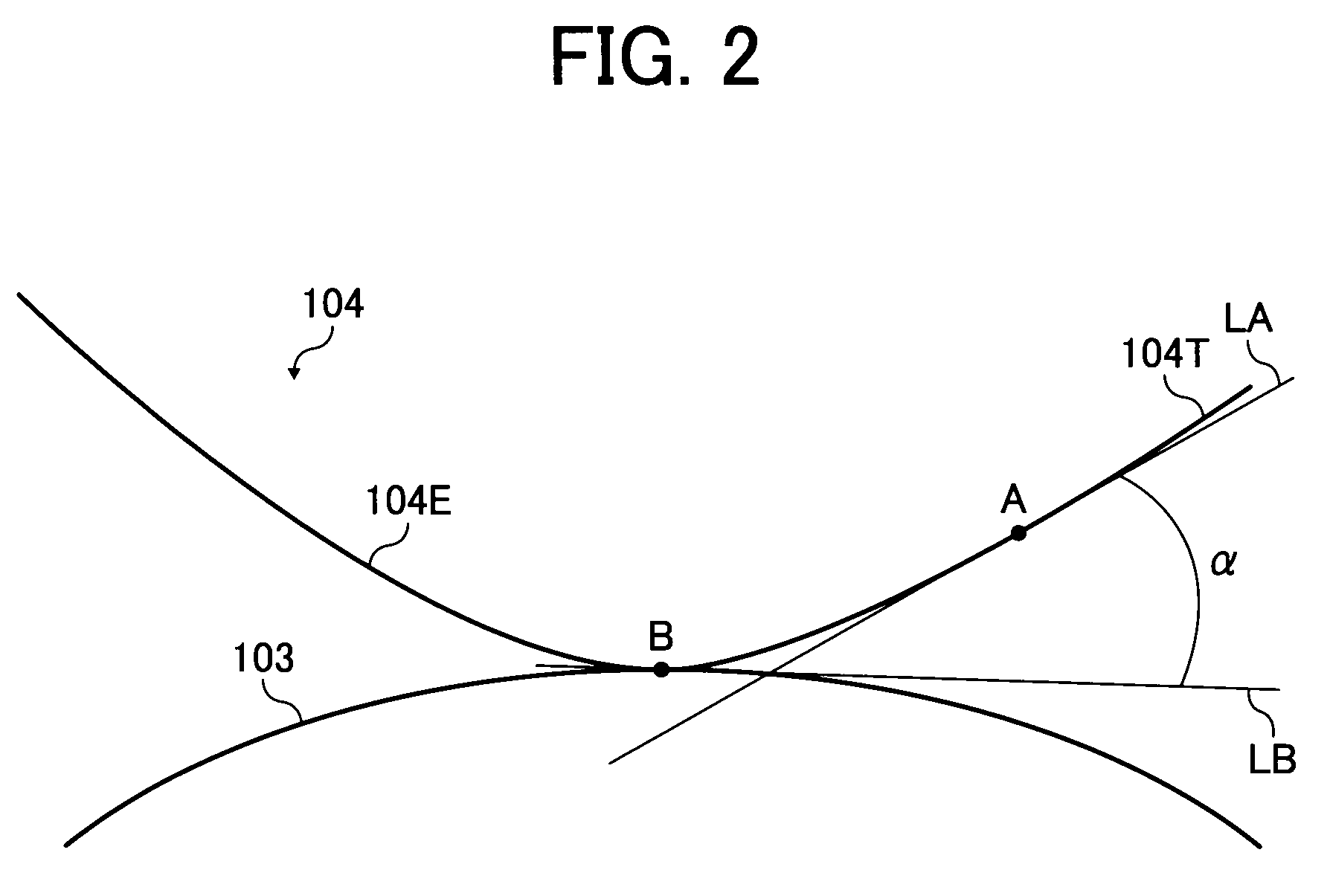

Developing device and image forming method using one component developer, and process cartridge using the developing device

InactiveUS20080227009A1Electrographic process apparatusElectrographic processes using charge patternWaxImage formation

A developing device including a developing roller and a developer layer forming member for forming a layer of a one component developer on the roller. The developing device satisfies the relationships (1) 20<X<65−14α, and (2) 12.7α−25>Q / M>13.1α−44.5, wherein X represents the ratio (% by weight) of the wax present on the surface of the developer to the total of the wax therein; α represents the angle formed by a tangent line to the member at a point B, which is the center of the contact zone of the member contacted with the roller, and another tangent line at a point A thereof 0.5 mm apart from the point B toward the tip of the member, wherein α is 0 to π / 2 radian; and Q / M represents the charge quantity (μC / g) of the toner per unit weight.

Owner:RICOH KK

Transmission and friction experiment table for multifunctional mechanical part

InactiveCN104155102ARealize online detectionWide range of test objectsMachine gearing/transmission testingInvestigating abrasion/wear resistanceResearch ObjectVibration acceleration

The invention relates to a transmission and friction experiment table for a multifunctional mechanical part. The transmission and friction experiment table comprises a first guiding rail, a second guiding rail, a first driving motor, a second driving motor, a first supporting plate, a second supporting plate, a first main shaft box, a second main shaft box, a first test-piece, a second test-piece,a first torque sensor, a second torque sensor, a first rigid coupler, a second rigid coupler, a third rigid coupler, a first supporting plate sliding driving motor, an universal coupler, a loading electric cylinder, a bedplate, an acceleration vibration sensor, a temperature sensor, a displacement sensor, a pressure sensor, a lubricating system, a cooling system and a general controlling computer. According to the invention, various low and high friction pairs in a contact zone can be tested online for frictional wear, energy consumption, vibration and material behaviors under the different loads, rotating speeds and lubrication conditions, and transmission parts and systems can be conducted with friction and transmission process experiments; when testing data is gathered, parts and systems to be tested can be analyzed for the following situations such as frictional wear, power consumption, stress and the service behaviors of transmission pairs, so that the behavior features, variation rules and failure mechanisms of research objects in the operating process can be obtained.

Owner:CHONGQING UNIV

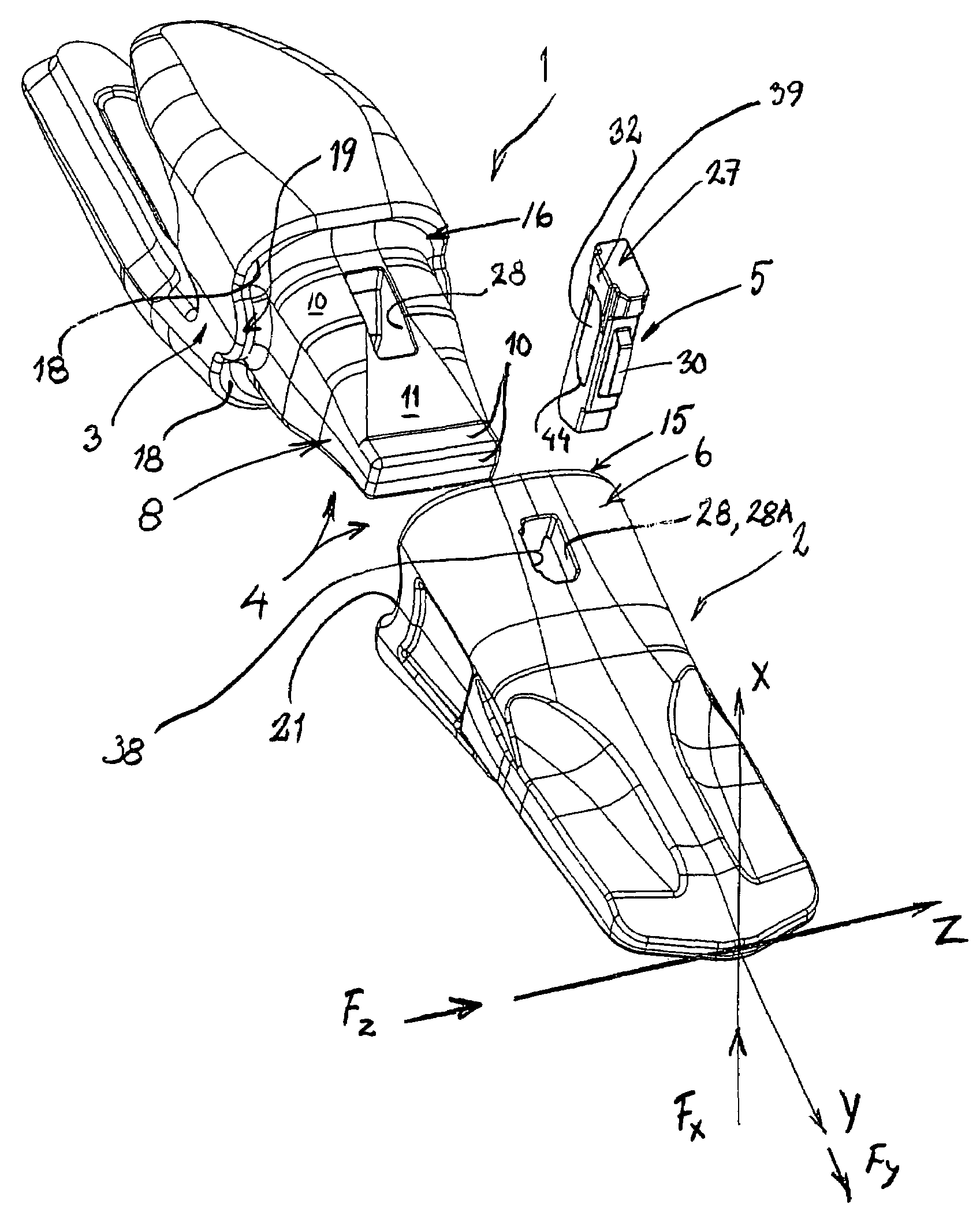

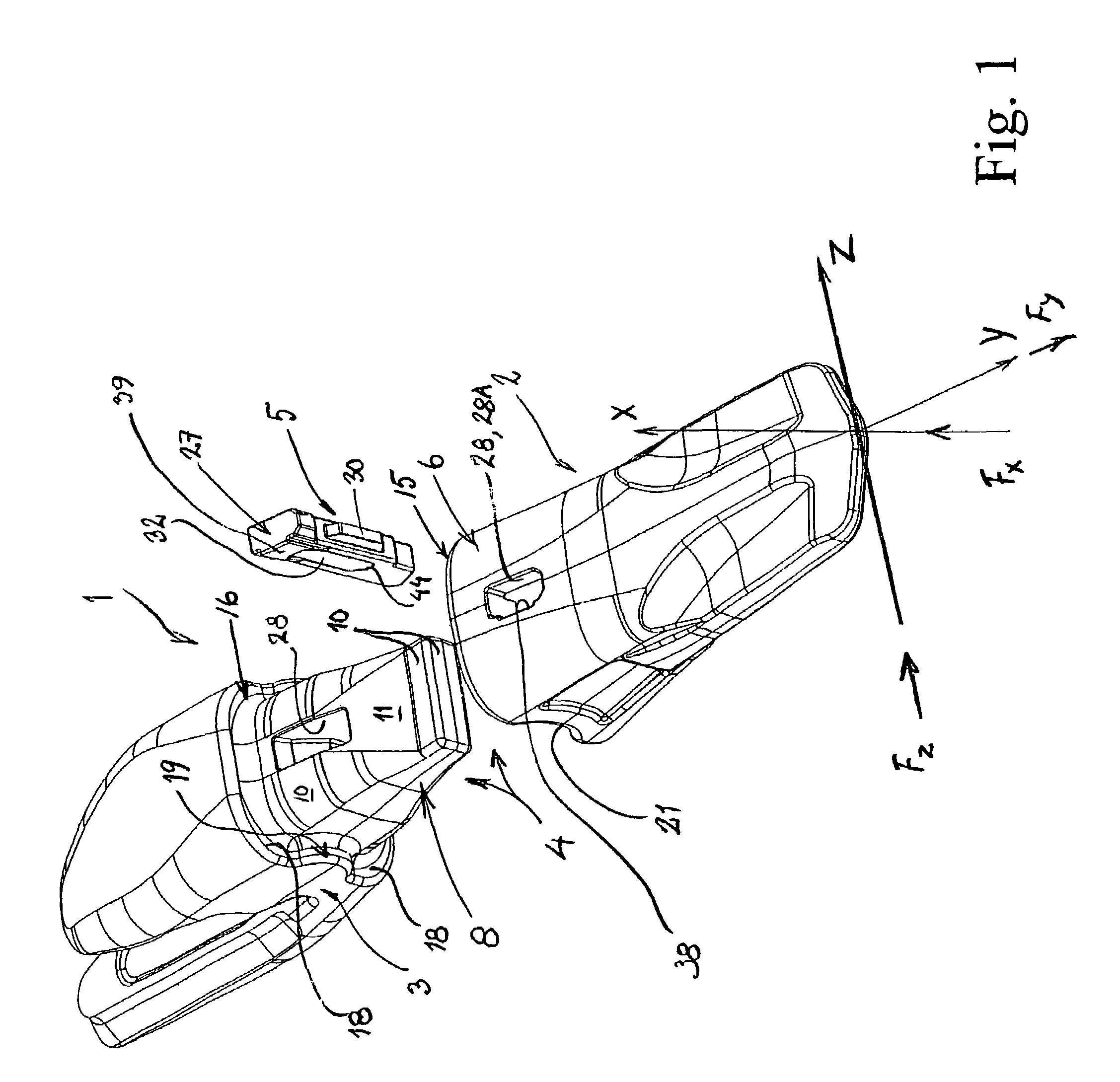

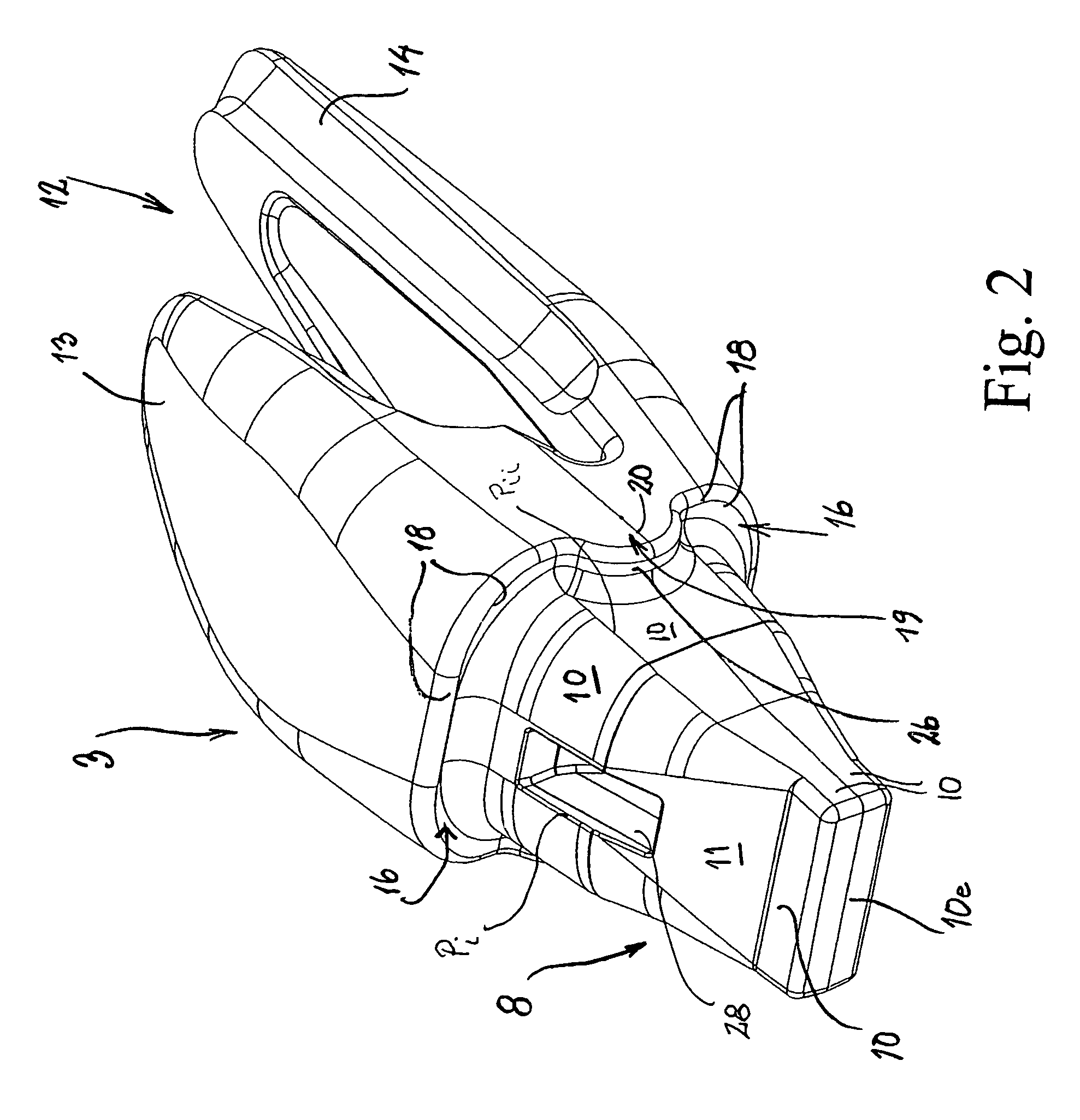

Wearing parts system for detachable fitting of wearing parts for the tool of a cultivating machine

ActiveUS7703224B2Effective strikeImprove stabilitySoil-shifting machines/dredgersEngineeringMechanical engineering

The invention relates to a wearing parts system (1) intended for the tool of a tilling machine of the type which comprises a holder part (3), having a front end part (8), and an exchangeable wearing and / or replacement part (2), arranged over this end part and comprising a hood-shaped (6) hollow (7) which, when the wearing part (2) is fitted in place, is designed to grip over the end part and is fixed thereto by means of at least one locking device (27) placed through interacting openings (28), the end part and the hollow having front, rear and collateral contact zones (9, 22, 23), each comprising contact faces (10, 25, 26), disposed one on the holder part and one on the wearing part, for the absorption of acting vertical, horizontal and collateral forces Fx, Fy and Fz. The contact faces (25, 26) are designed to interact so as, on the one hand, to limit the pushing-on of the wearing part over the holder part and, on the other hand, to ensure that the contact between the contact faces will be made, primarily, at the common centre M0, of the two radii (of a recess and a projection) essentially in the horizontal plane YZ and secondarily, as the wear has progressed, symmetrically about this mid contact point as an increasingly large contact zone (22′, 23′).

Owner:COMBI WEAR PARTS AB

High-current terminal blade type connector

ActiveUS7241189B2Easy to produceAvoid cloggingVehicle connectorsCoupling contact membersEngineeringMechanical engineering

An electrical socket contact for high-current applications includes a cage-like receptacle housing having two lateral plates on opposite sides. The lateral plates forming an interspace therebetween for holding a complementary plug contact. The socket contact further includes a contact plate insert arranged within the interspace of the lateral plates of the housing. The contact plate insert has a contact plate body extending parallel to the lateral plates of the housing. The contact plate body has a base and first and second contact plates. Each contact plate has first and second ends. The first ends of the contact plates are connected to the base of the contact plate body and the second ends of the contact plates each has a contact zone projecting away from the base of the contact plate body.

Owner:KOSTAL KONTAKT SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com