Patents

Literature

383results about How to "Increase ROP" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

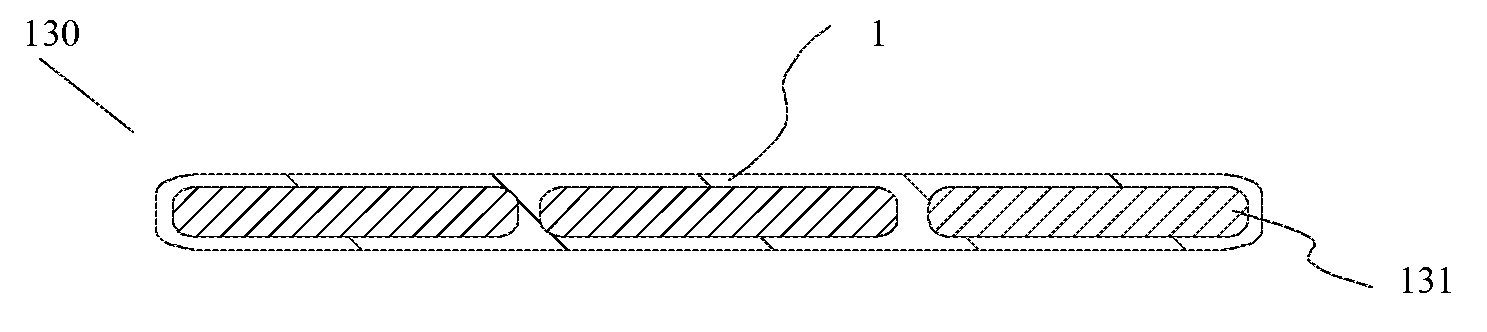

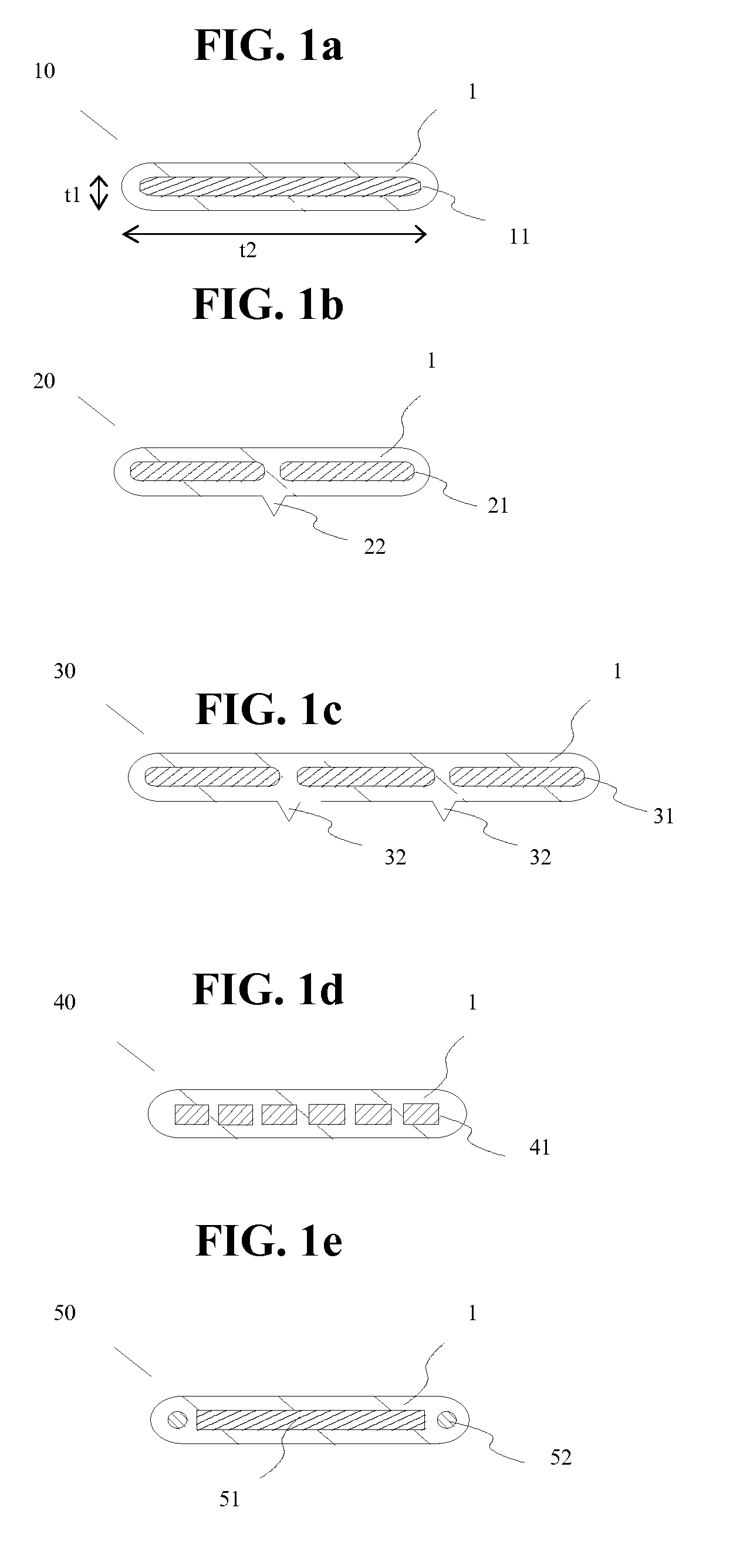

Rope for a hoisting device, elevator and use

ActiveUS20110000746A1Increase ROPDrawback can be obviatedWarp knittingCeramic layered productsGlass fiberFiber

A hoisting device rope has a width larger than a thickness thereof in a transverse direction of the rope. The rope includes a load-bearing part made of a composite material, said composite material comprising non-metallic reinforcing fibers, which include carbon fiber or glass fiber, in a polymer matrix. An elevator includes a drive sheave, an elevator car and a rope system for moving the elevator car by means of the drive sheave. The rope system includes at least one rope that has a width that is larger than a thickness thereof in a transverse direction of the rope. The rope includes a load-bearing part made of a composite material. The composite material includes reinforcing fibers in a polymer matrix.

Owner:KONE CORP

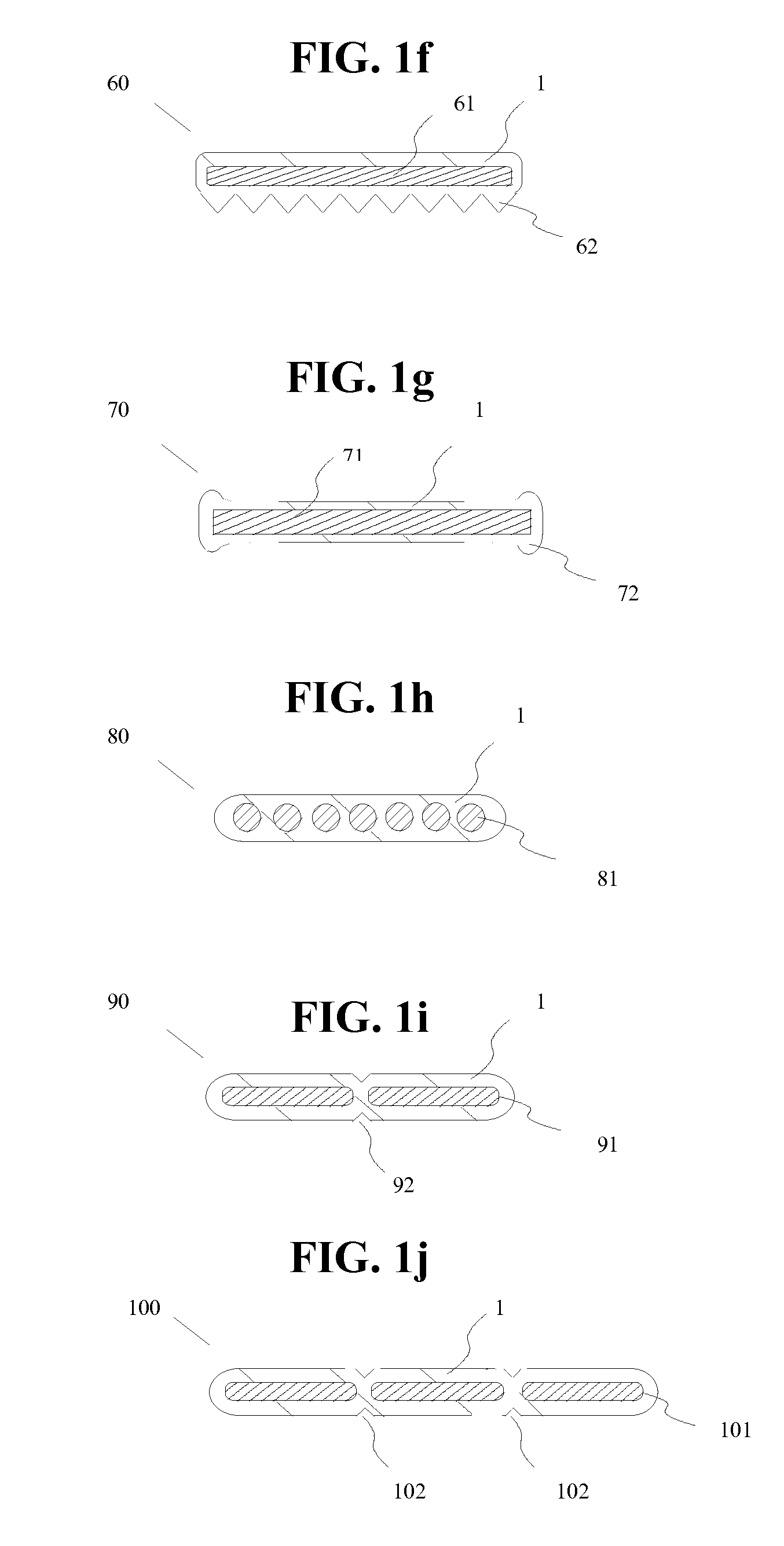

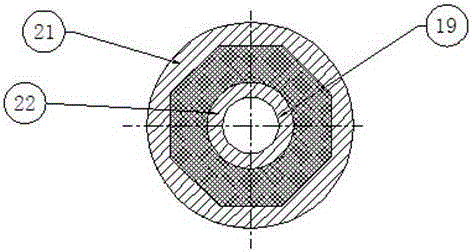

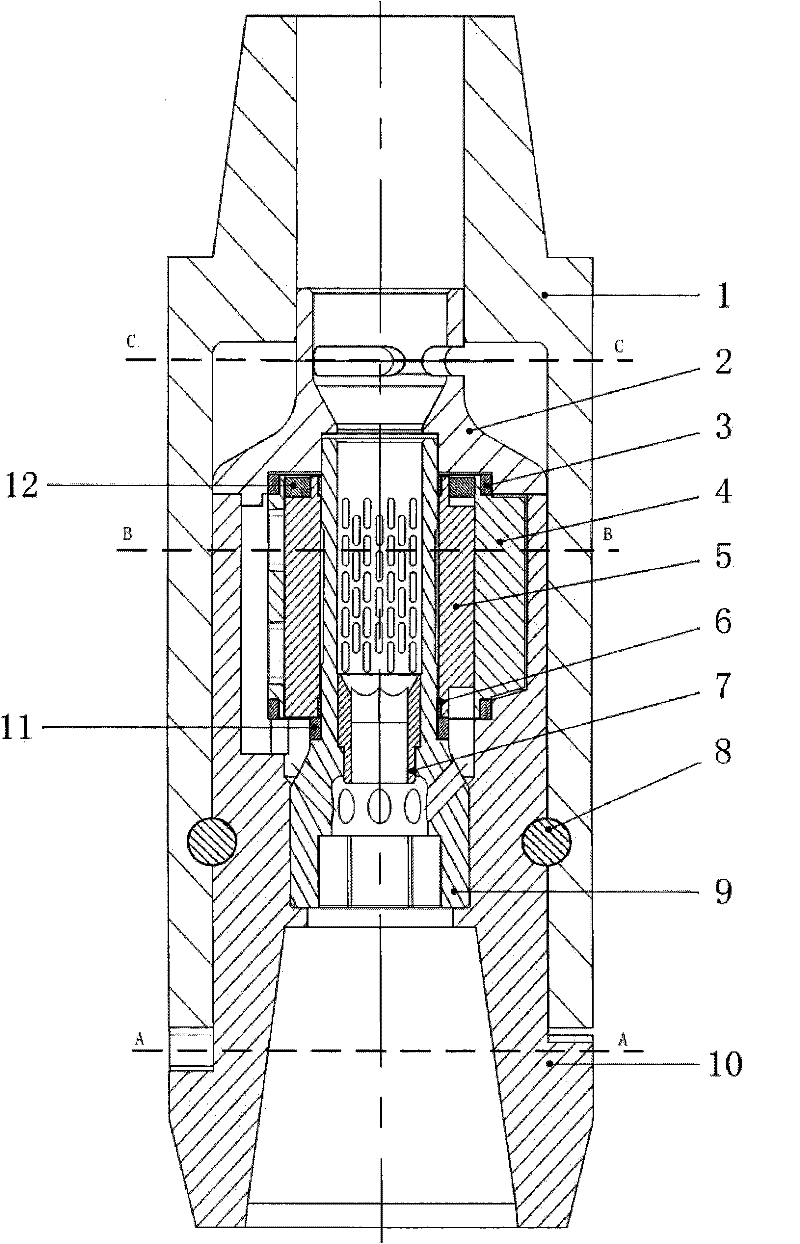

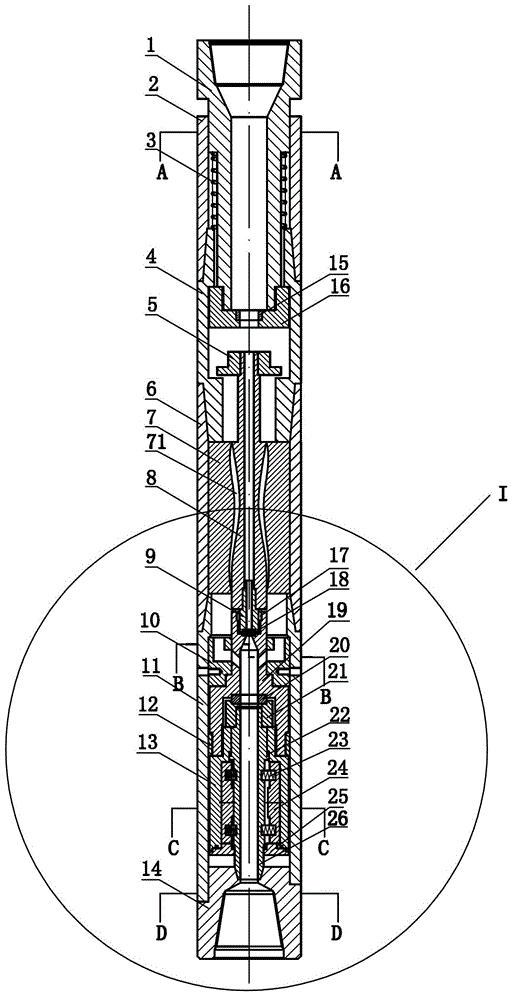

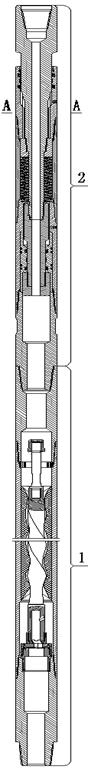

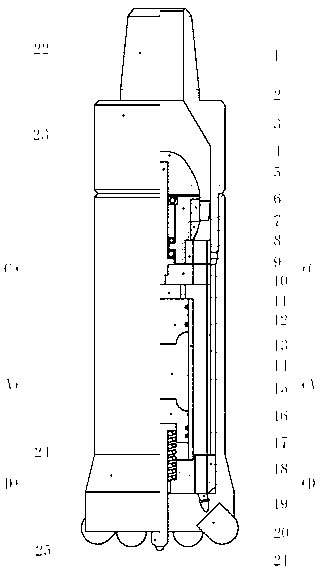

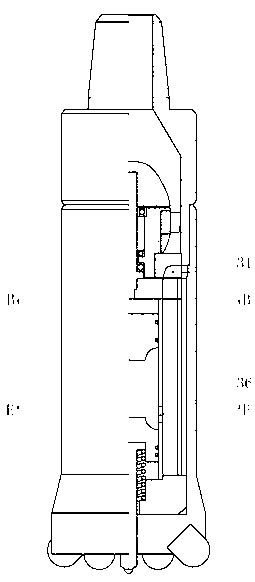

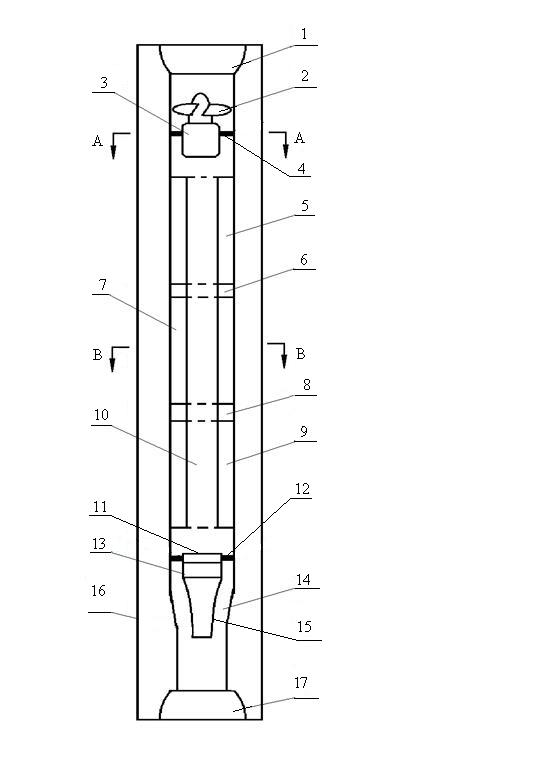

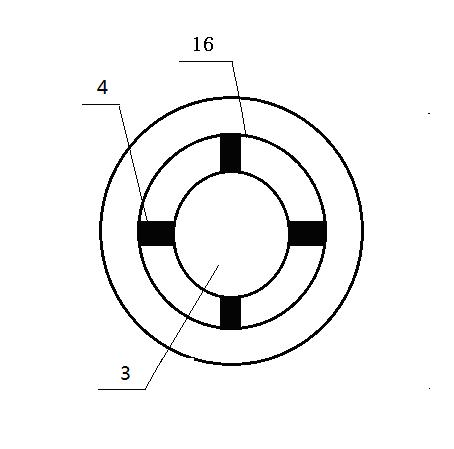

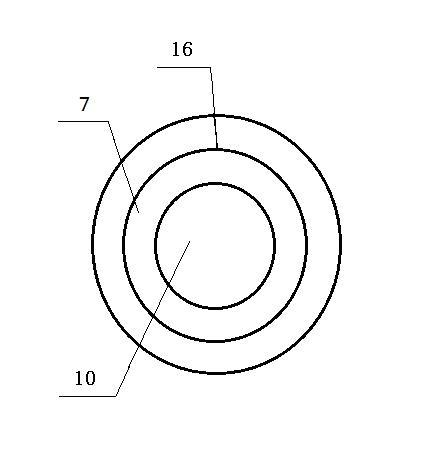

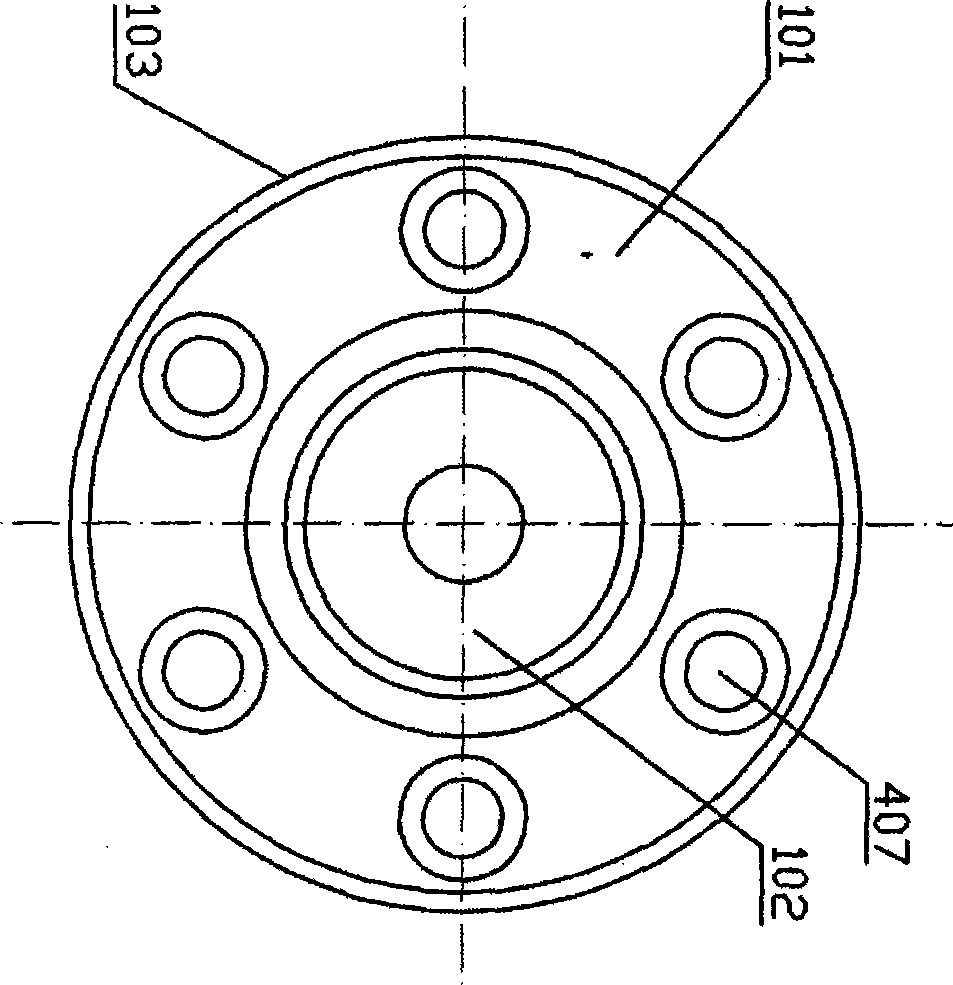

Torsional impact drilling tool

ActiveCN101463709AReduce stick-slipReduce the possibility of failureVibration drillingRate of penetrationDrive shaft

The invention relates to a torsional impact drilling tool used for applying low amplitude high frequency torsional impact to a drill bit during a drilling process, which can increase the drilling efficiency and the service life of the drill bit and lesson the tripping operation and the drilling cost. The technical scheme of the torsional impact drilling tool is as follows: a housing is connected with a short section of a drilling column led into the drill bit by a spline, and is positioned by a shaft shoulder; a screw motor rotor and a screw motor stator form a screw motor, the screw motor rotor is eccentrically connected to a transmission shaft by a universal shaft and two bearings, and four diversion holes are arranged on the transmission shaft; the lower end of the transmission shaft is connected with a carrier with a cavity; a sliding impactor is arranged in the cavity and is fixed by pins, and an impact hammer is arranged in the sliding impactor; a falling prevention ring is connected with the housing by screw threads; and the damping shaft shoulder on the short section of the drilling column led into the drill bit is matched with the impact hammer of the sliding impactor to form a ratchet wheel structure. The torsional impact drilling tool has simple structure, and can be used in hard strata of a deep well; and as being short, the tool is also applicable to the deflecting operation and can be used in crooked well holes, thereby reducing the phenomenon of stick-slip of the drill bit and improving the rate of penetration.

Owner:SOUTHWEST PETROLEUM UNIV

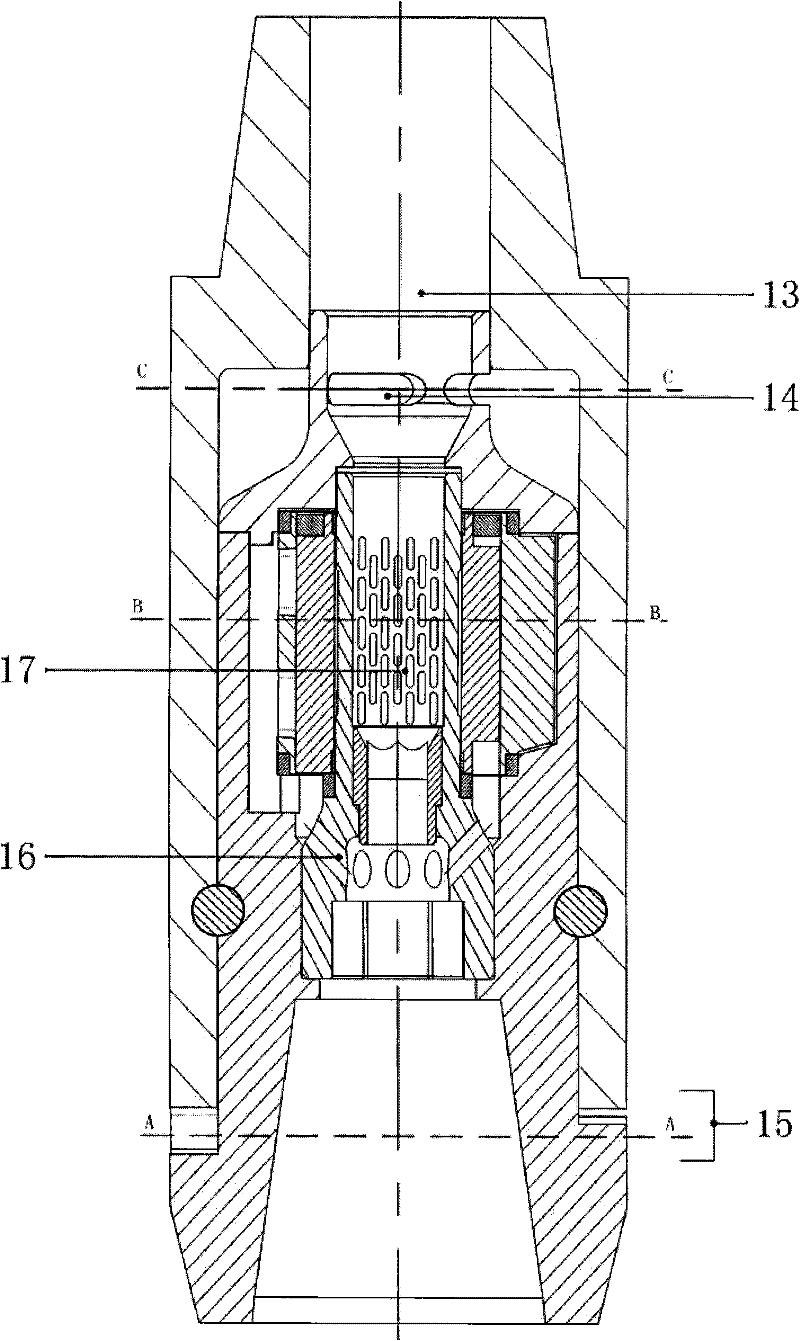

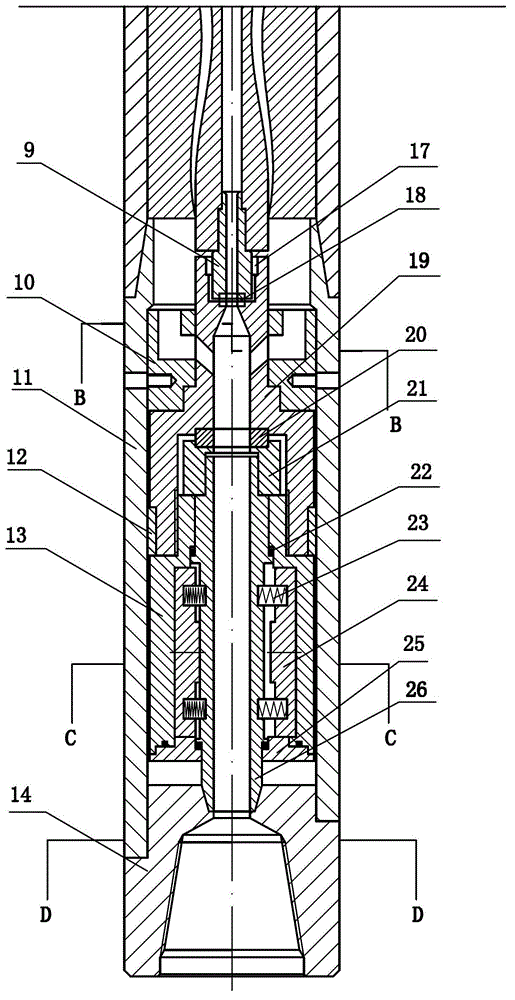

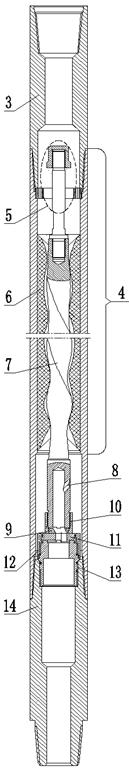

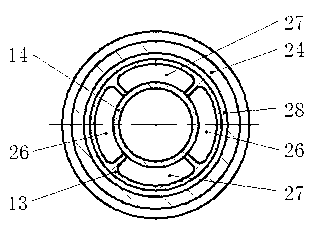

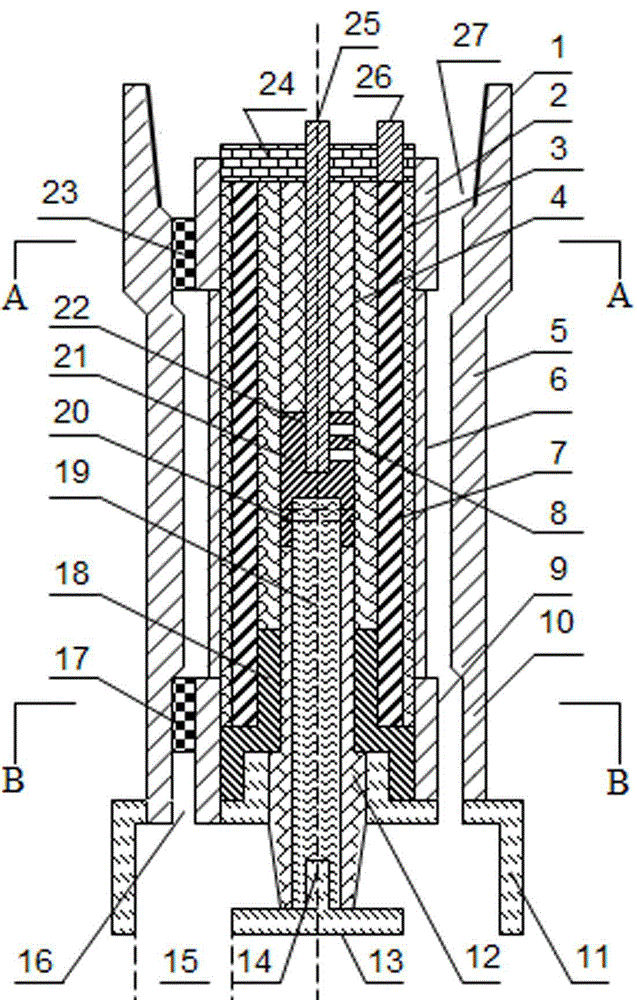

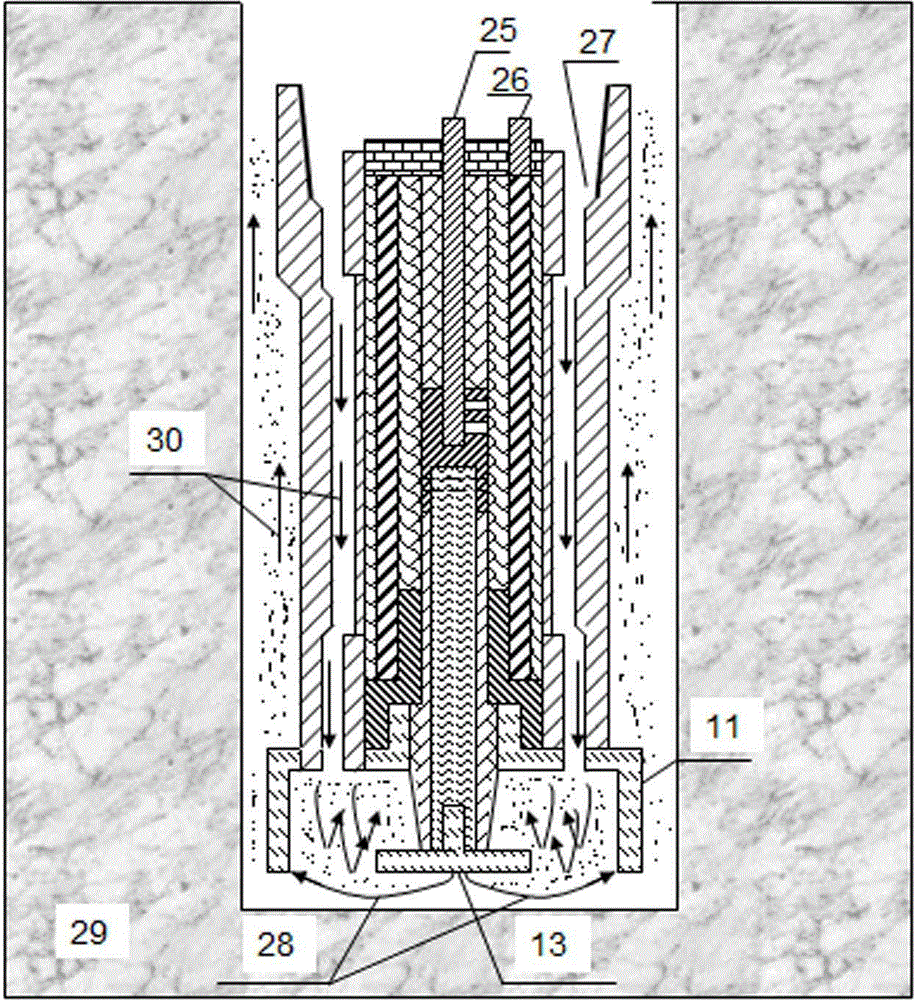

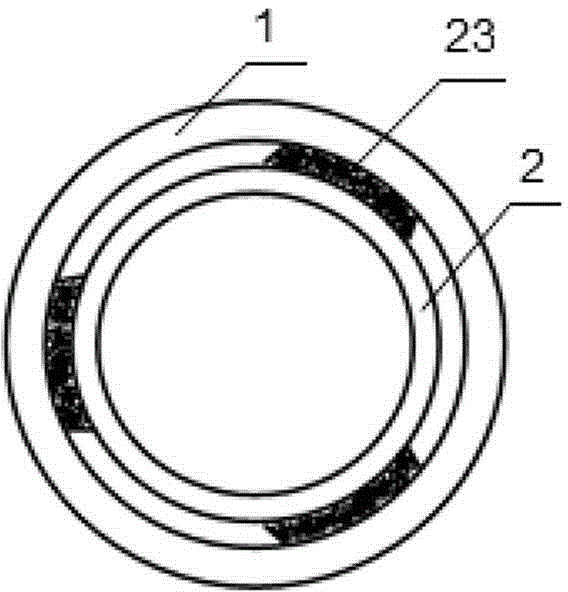

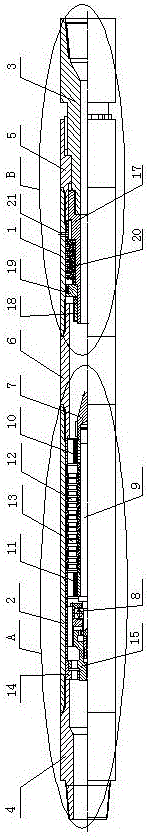

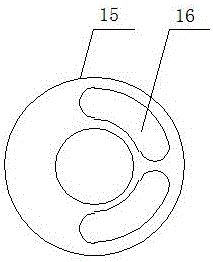

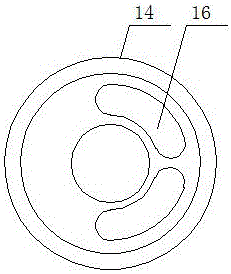

Downhole tool for achieving efficient rock breaking through spin vibration

InactiveCN105239929AQuality improvementImprove high temperature resistanceBorehole drivesVibration drillingDrive shaftSpins

The invention relates to a downhole tool for achieving efficient rock breaking through spin vibration, and belongs to the technical fields of petroleum and natural gas exploitation and drilling tools. According to the technical scheme, drilling fluid drives a turbine to rotate, a turbine rotor drives a transmission shaft to rotate to drive a disc valve set to periodically rotate, the open area changes, a periodic pressure pulse is generated to act on a vibration nipple to generate reciprocating vibration, the friction resistance between a drilling column and the well wall is effectively improved, and mechanical drilling speed is increased; the lower end of a tooth-shaped impact hammer head is provided with a tooth-shaped curved surface which is meshed with a tooth-shaped curved surface of a lower-end transmission connector, and the lower-end transmission connector is driven by a transmission shaft to generate rotating motion, so that the tooth-shaped impact hammer head is driven to rotate to generate axial reciprocating impact on the lower-end transmission connector under the joint action of the tooth-shaped impact hammer head and a force accumulating spring. According to the downhole tool, the structure is simple, the friction resistance is small, effective bit pressure and effective vibration are increased, the mechanical rotating speed is increased, and the cost is reduced.

Owner:SOUTHWEST PETROLEUM UNIV

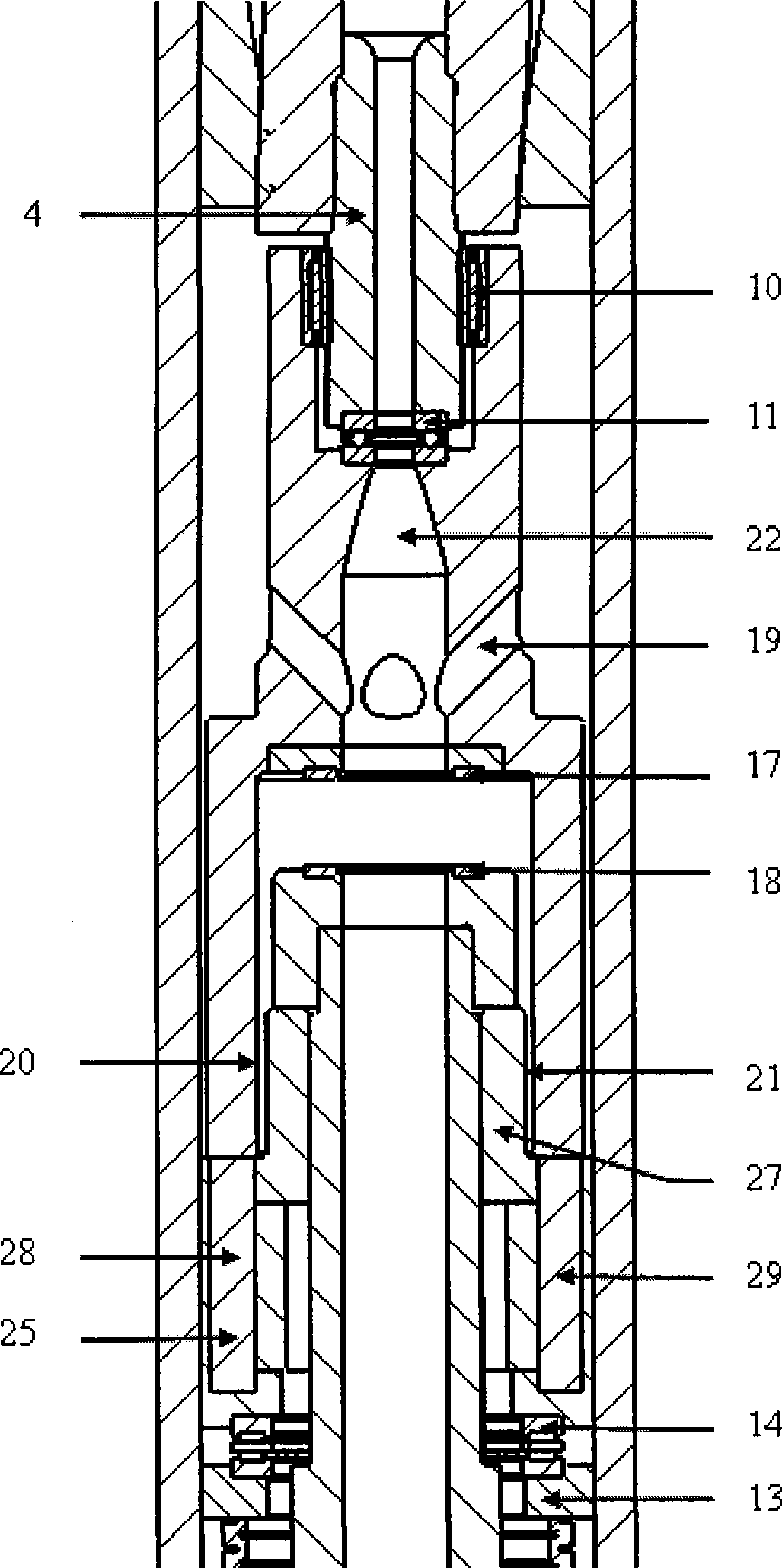

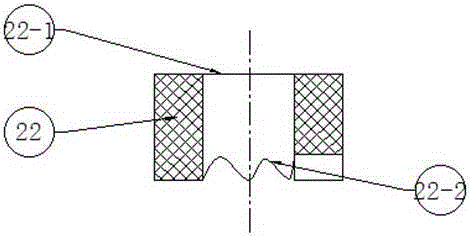

Torsional impact drilling tool

ActiveCN102454364ATorque stability and balanceReduce torsional oscillationsVibration drillingImpact hammerPetroleum engineering

The invention discloses a torsional impact drilling tool which can apply high-frequency torsion impact to a drilling bit in the drilling engineering. The technical scheme of the torsional impact drilling tool is as follows: the torsional impact drilling tool mainly comprises a short section of a drill collar, a torsional impact generator and a connecting body, wherein the short section of the drill collar and the torsional impact generator are in clearance connection through the connecting body and are located by splines; a diversion cover is fixed on a hammer seat; a cavity is formed inside the diversion cover; a closure nozzle, a sieve tube, a locating sleeve and an impact hammer are sequentially arranged in the cavity from inside to outside; the sieve tube is fixed with the hammer seat; the impact hammer, the locating sleeve, the sieve tube and the hammer seat are provided with through holes in the circumferential direction; and an impact hammer head and a starting hammer head are processed on the impact hammer. The torsional impact drilling tool is arranged between the drill collar and the drilling bit; and the drilling bit receives the high-frequency torsional impact generated by the impact hammer under the driving of fluids while receiving the rotational torsion of a drill column. Compared with other drilling tools, the torsional impact drilling tool disclosed by the invention has the advantages that the high-frequency torsional impact can be generated, the sticking-sliding phenomenon of the drilling bit is eliminated, the mechanical drilling rate of harder or abrasive formation is increased, the service life of matched components, such as the drilling bit and the like of the drill column is prolonged, the drilling efficiency is improved and the drilling cost is reduced.

Owner:CHINA PETROCHEMICAL CORP +3

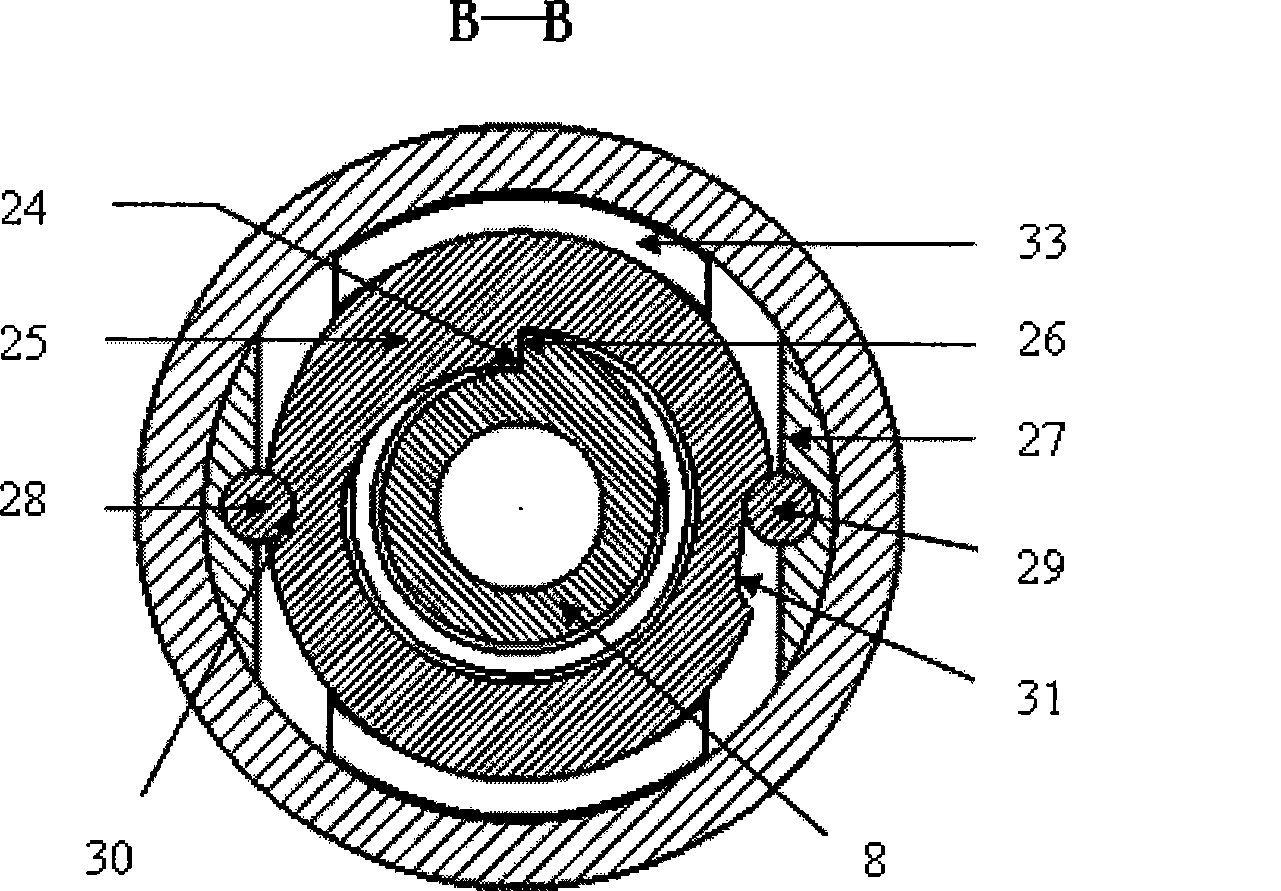

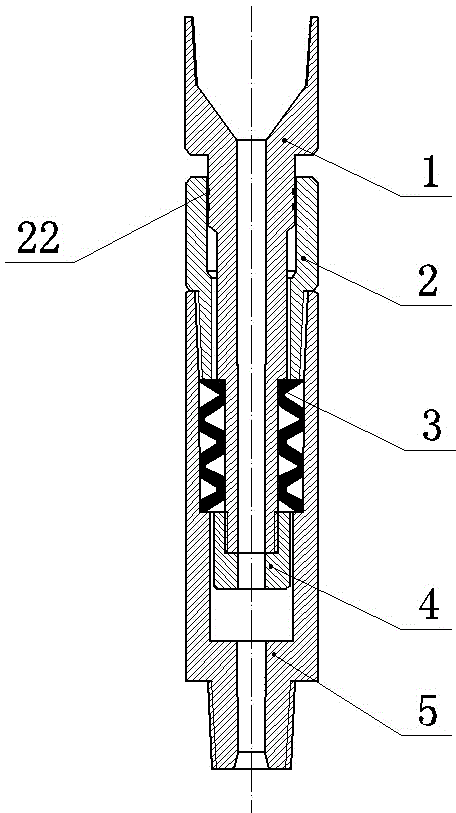

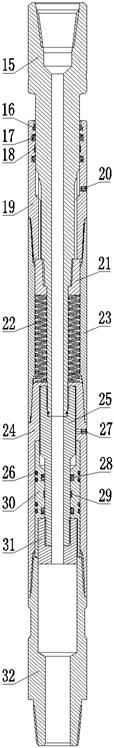

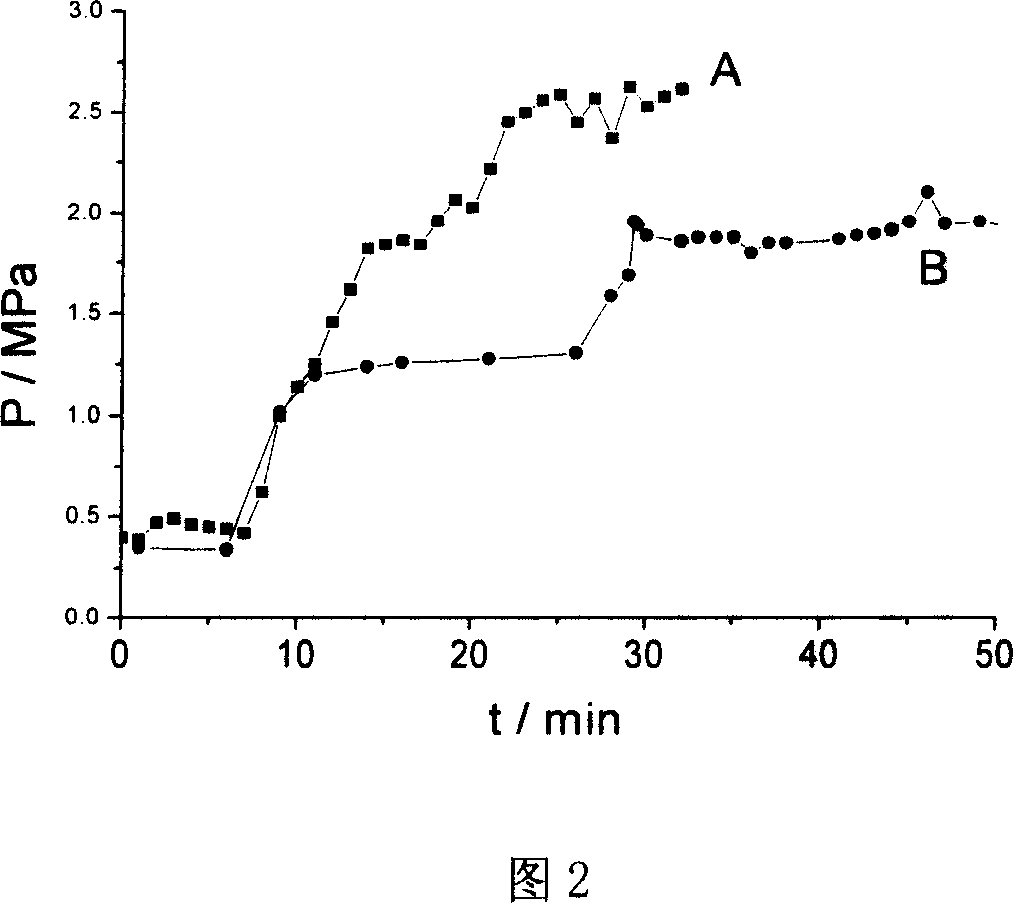

Dual-pulse hydraulic oscillator for well drilling

InactiveCN104405287AReduce frictional resistanceExtended service lifeVibration drillingWell drillingThrust bearing

The invention relates to a dual-pulse hydraulic oscillator for well drilling, and belongs to the technical fields of petroleum and natural gas exploration and well drilling tools. The dual-pulse hydraulic oscillator consists of an oscillation short section assembly and a power short section assembly, and is characterized in that the oscillation short section assembly consists of a spline mandrel, a connection sleeve, a pressure converter, an oscillation shell and the like; the power short section assembly comprises a pressing sleeve and a turbine shaft; a sealing piece is mounted between the spline mandrel and the connection sleeve; the connection sleeve is connected with the oscillation shell; the lower end of the turbine shaft is connected with the power short section assembly; the pressing sleeve at the upper end of the power short section assembly is connected with the oscillation shell; the lower end of the pressing sleeve is connected with a power shell; the turbine shaft is mounted at the center of the power shell; a straightening bearing, a turbine stator, a turbine rotor, two groups of movable valves and fixed valves, a sleeve, a flow division ring, a flow division sleeve and a thrust bearing are mounted on the turbine shaft in sequence from top to bottom. Radial swinging is avoided; under low flow, higher axial vibration with higher frequency can be realized; the friction resistance is low, so that effective drilling pressure is increased, and the mechanical drilling speed is increased.

Owner:YANGTZE UNIVERSITY

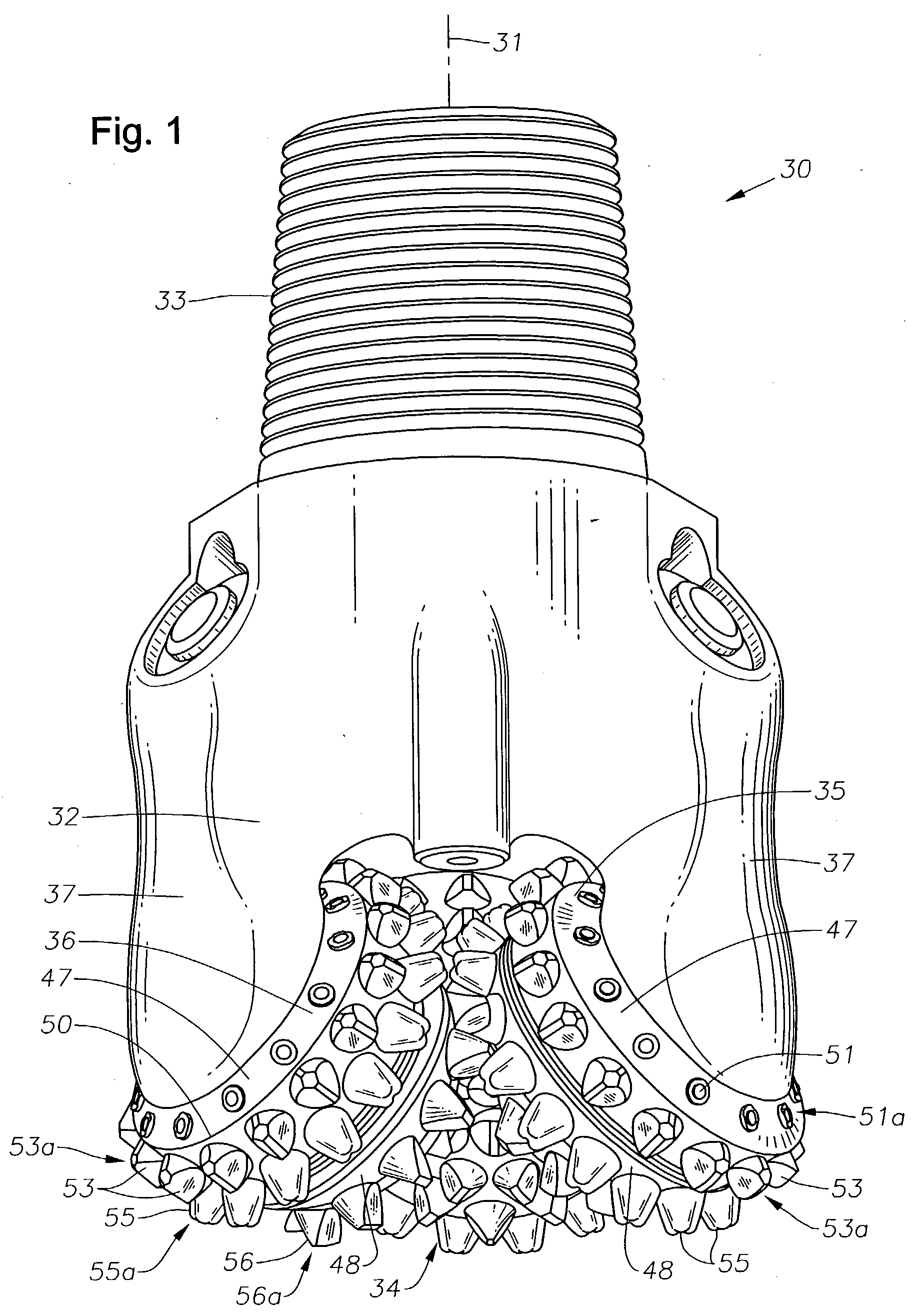

Drill bit cutter element having multiple cusps

InactiveUS20040163851A1Enhancing brittle rock formationIncrease ROPDrill bitsConstructionsEngineeringMechanical engineering

Cutter elements for use in rolling cones rock bits are disclosed having a crown that includes multiple, spaced-apart cusps for enhancing formation removal by creating overlapping Hertzian contact zones. The cusps may be partially dome-shaped, berm shaped or otherwise. The cutter elements provide multiple cutting edges for engaging the formation and may have differing radii and extension length as suitable for particular applications.

Owner:SMITH INT INC

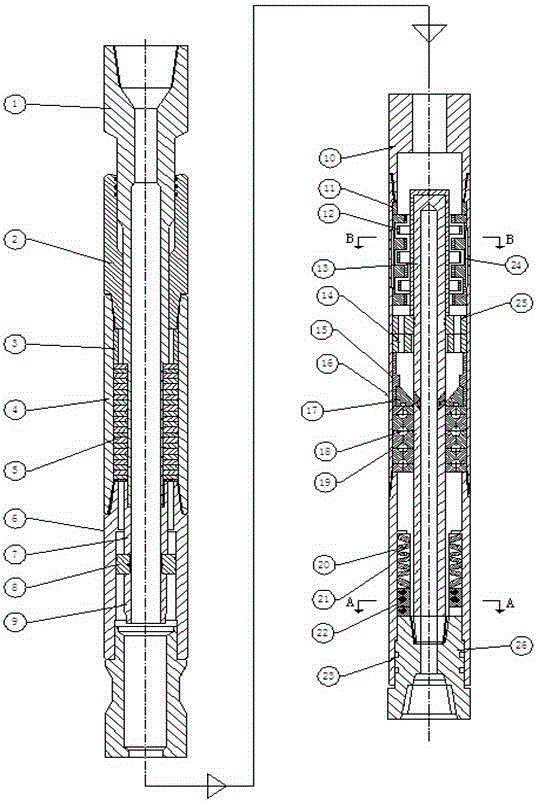

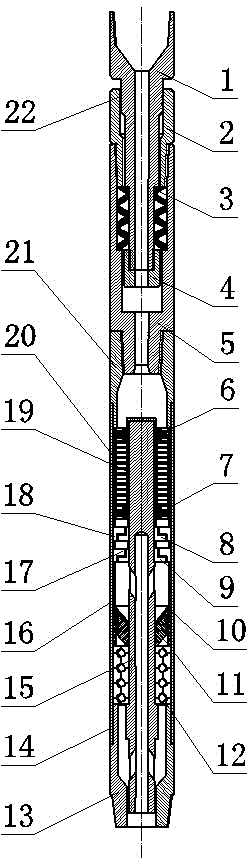

Compound vibrating well-drilling tool

ActiveCN102747958AEliminate \"drag\"Eliminates \"stick-slip\" phenomenonVibration drillingHydraulic cylinderWell drilling

The invention discloses a compound vibrating well-drilling tool which comprises a sleeve, a vibrating short joint, a vibrating short joint chuck, a screw motor, a conversion short joint connected with the lower end of the screw motor, an annular disc sleeved at the upper end of the conversion short joint, a hydraulic cylinder installed at the lower end of the conversion short joint, an impact short joint arranged in an inner cavity of the hydraulic cylinder and a torque transmitting short joint, wherein the vibrating short joint, the vibrating short joint chuck, the screw motor, the conversion short joint, the annular disc, the hydraulic cylinder, the impact short joint and the torque transmitting short joint are arranged in sequence from top to bottom. The well-drilling tool can be installed at different positions in a well-drilling column, the drilling column generate axial and circumferential high frequency compound vibration through the tool, and phenomena including 'pulling press' and 'stick slip' in the large-inclination well drilling process are eliminated, thereby remarkably improving mechanical drilling speed, prolonging the service life of a drill bit and reducing well-drilling cost.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Polyamine strong inhibitor for drilling fluid, and preparation method thereof

InactiveCN103087691AEnhanced inhibitory effectReduced tendency to absorb waterFlushingDrilling compositionSodium BentoniteInstability

The invention relates to a polyamine strong inhibitor for a drilling fluid. The polyamine strong inhibitor is prepared through the following step that: an amine compound and an epoxy compound are subjected to a reaction at a temperature of 90-110 DEG C in the presence of an alkali metal catalyst to synthesize the polyamine strong inhibitor for the drilling fluid, wherein the amine compound is polyether amine, alkyl amine, ether amine, tetraethylenepentamine, pentaethylenehexamine or polyethylene polyamine, and the epoxy compound is propylene oxide or ethylene oxide. According to the present invention, based on high temperature strong water sensitivity easy-instability stratum, special molecular structure design is adopted, such that the inhibitor has strong inhibition, and mud making of clay and hydration expansion of shale can be inhibited; and the inhibitor provides a stabilization effect for dynamic cutting force when the Xuanhua bentonite addition amount is up to 30%, wherein a debris rolling recovery rate can be more than 90%, a 8 h shale linear expansion rate is less than or equal to 10%, a temperature resistance performance is more than or equal to 180 DEG C, biological toxicity is low, and a LC50 value is more than 38010 mg / L.

Owner:CHINA PETROLEUM & CHEM CORP +1

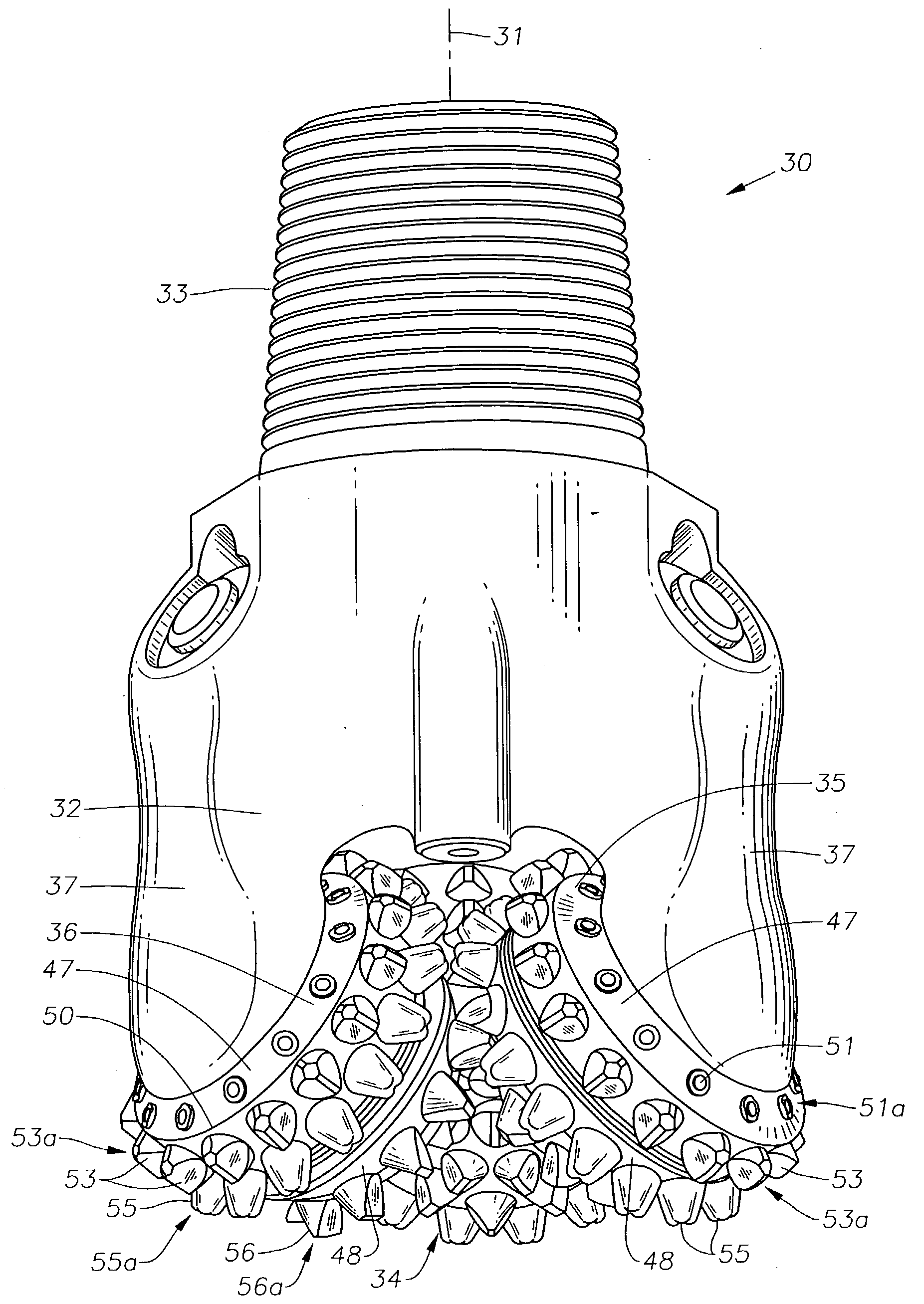

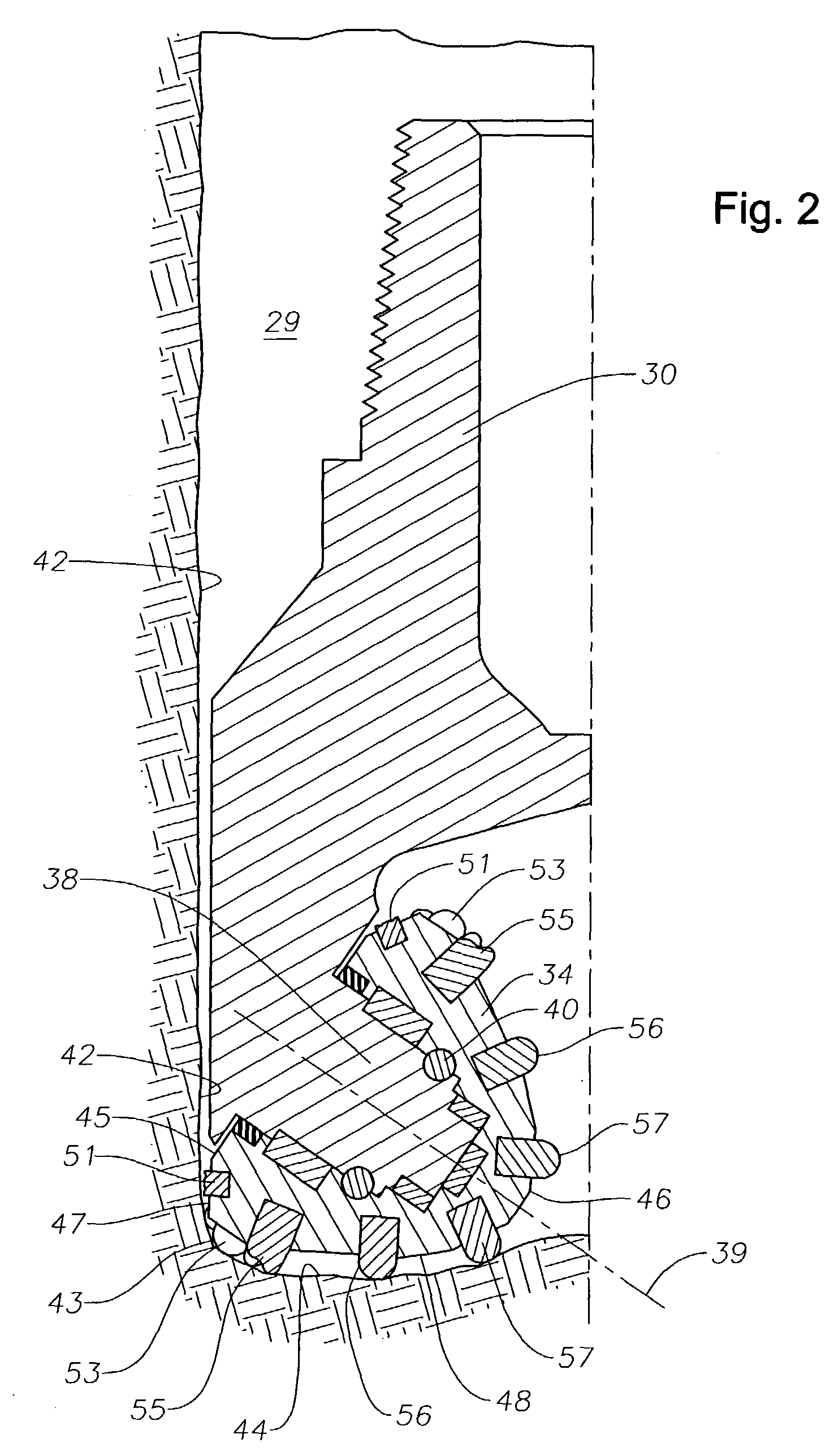

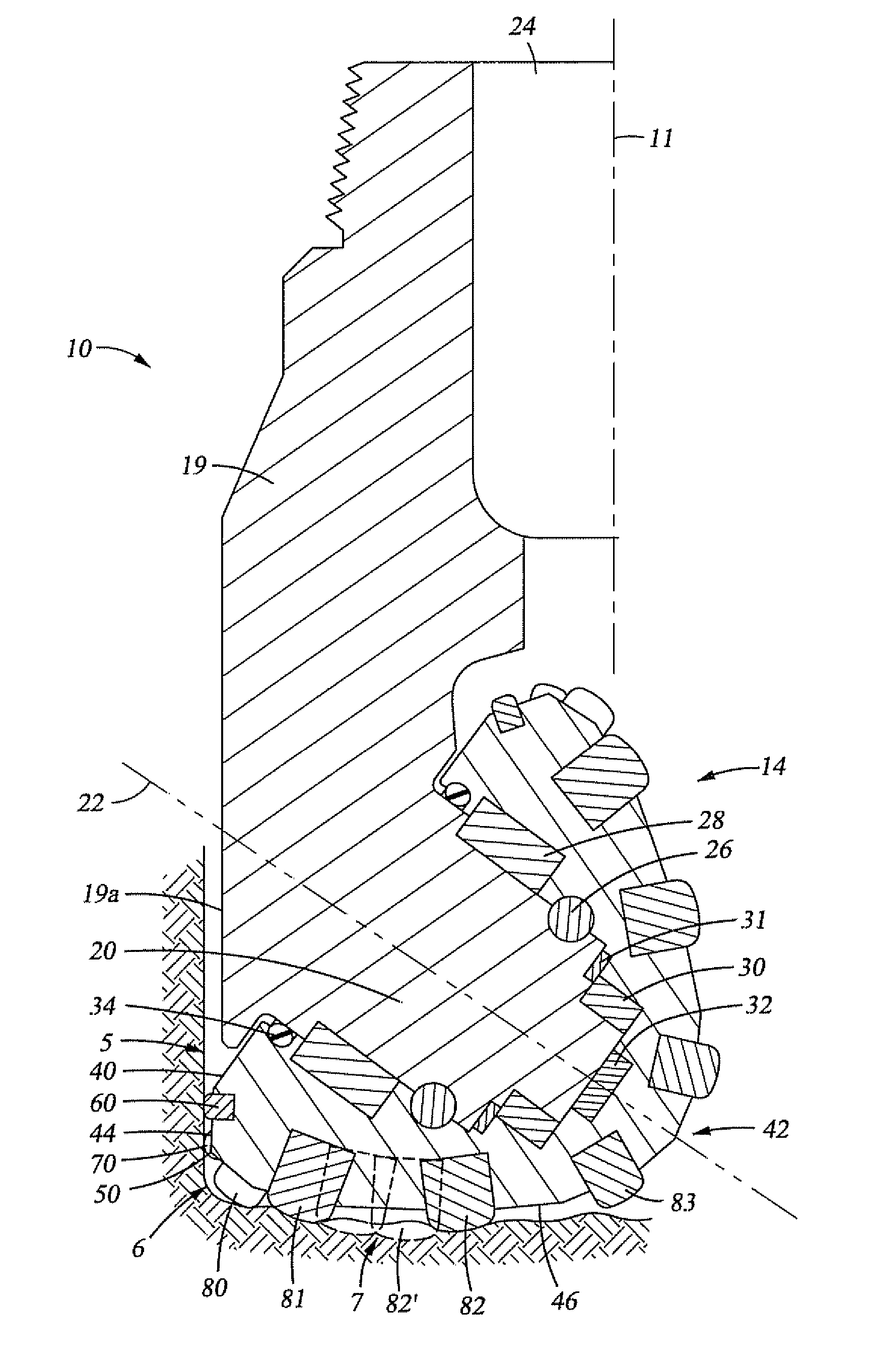

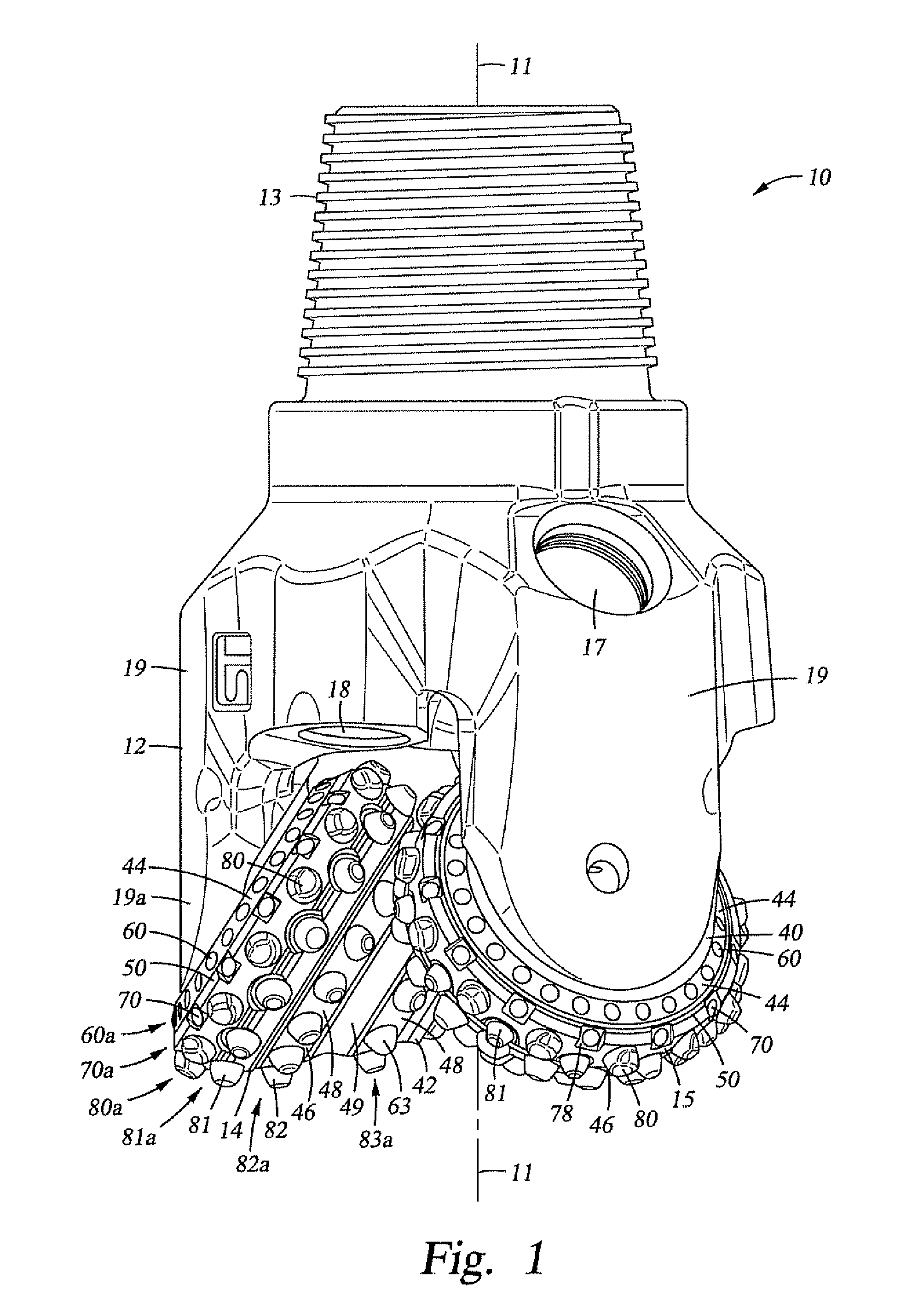

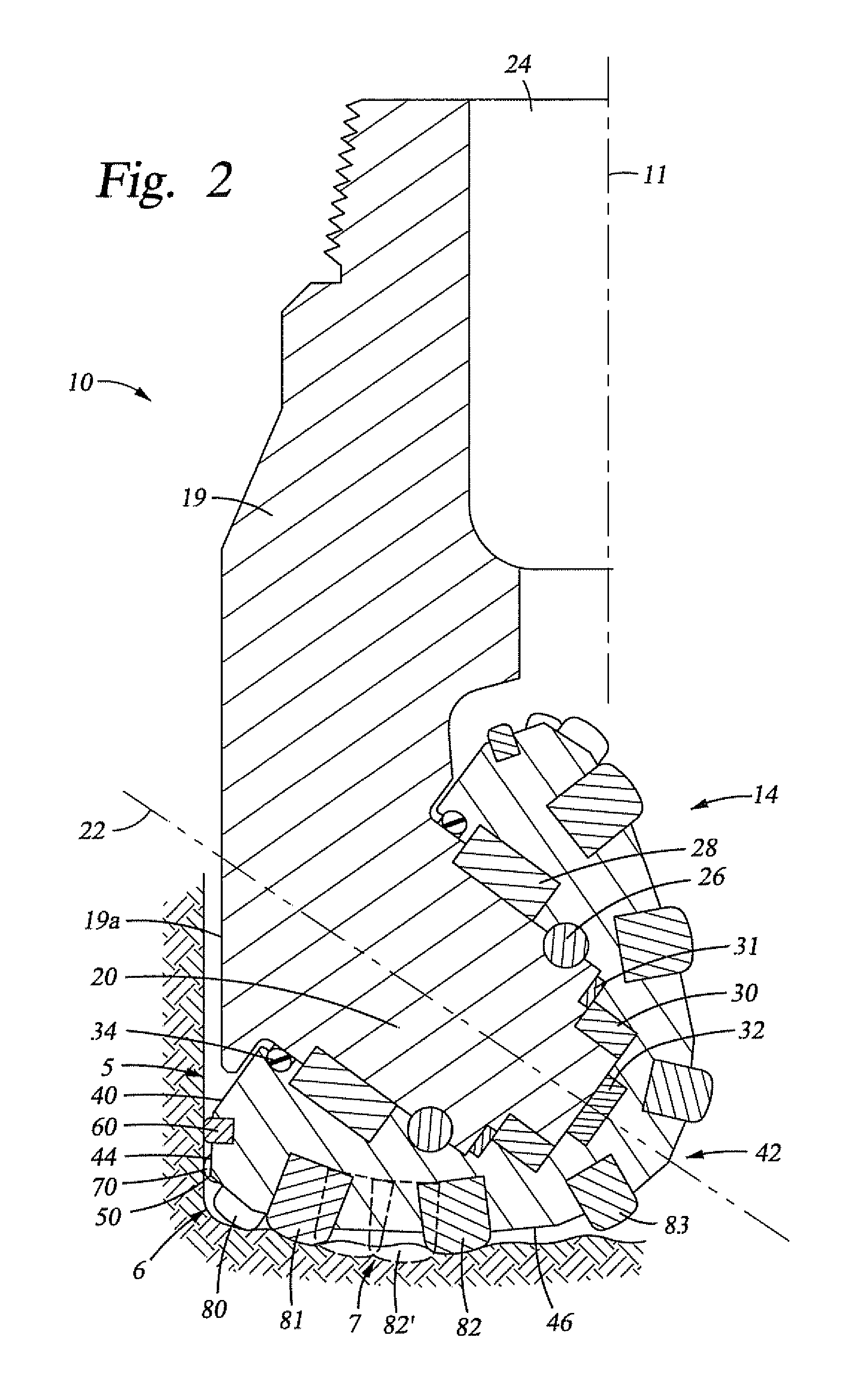

Drill Bit and Cutting Inserts For Hard/Abrasive Formations

ActiveUS20060260846A1Increase ROPIncreased durabilityDrill bitsMetal-working drilling toolsCircular coneEngineering

A rolling cone drill bit comprises a plurality of bottomhole cutter elements positioned in a first circumferential row, wherein at least one of the cutter elements comprises a cutting portion extending from a base portion to a point furthermost from the base portion, defining an extension height. The ratio of the cross-sectional area of the cutter element at a point equal to ninety-four percent of the extension height to the cross-sectional area of the cutter element base is greater than 0.2. Moreover, the ratio of the extension height to the base diameter is not greater than 0.75.

Owner:SMITH INT INC

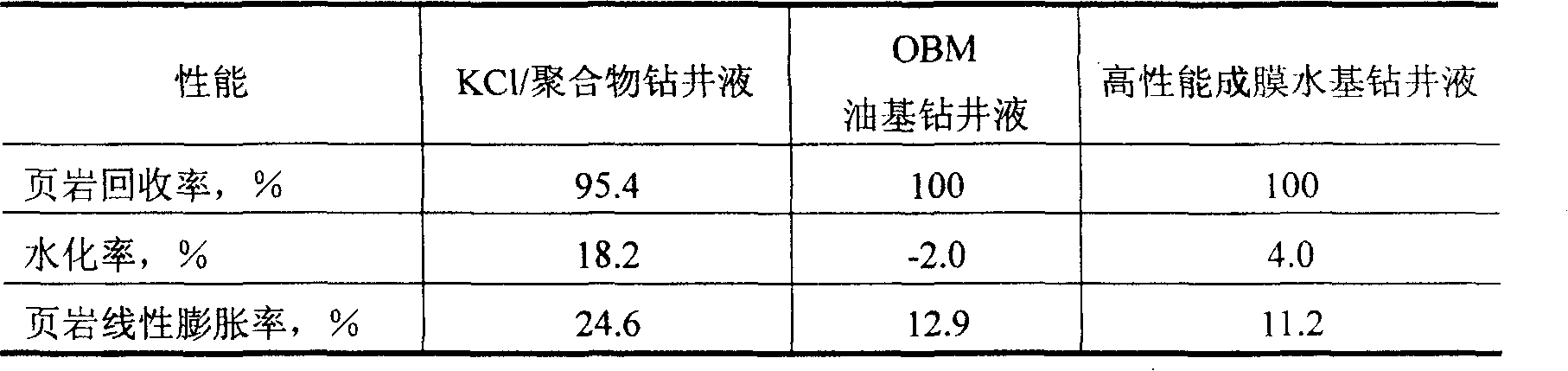

Method for preparing high-performance filming water-base drilling fluid

InactiveCN101200631AImprove the lubrication effectReduce frictionDrilling compositionWater basedFilm-forming agent

The present invention relates to a preparation method of a high-performance film-forming water-based drilling fluid system, which is characterized in that brine is used for confecting THE typical prescription of the high-performance film-forming water-based drilling fluid system, which is 10 percent of saturant NaCl solution, 1 percent to 3 percent of fluid loss additive, 0.3 percent to 0.5 percent of polymer viscosity increaser, 0.5 percent to 1 percent of coating agent, 2.5 percent to 5 percent of amine shale inhibitor, 3 percent to 4 percent of lubricant and 7 percent to 8 percent of film-forming agent. The drilling fluid system has the good performances of good film-forming character and strong inhibiting capability and is a novel drilling fluid system which can satisfy the requirement of the environmental protection and can replace oil-based drilling fluid (OBM).

Owner:张金波 +1

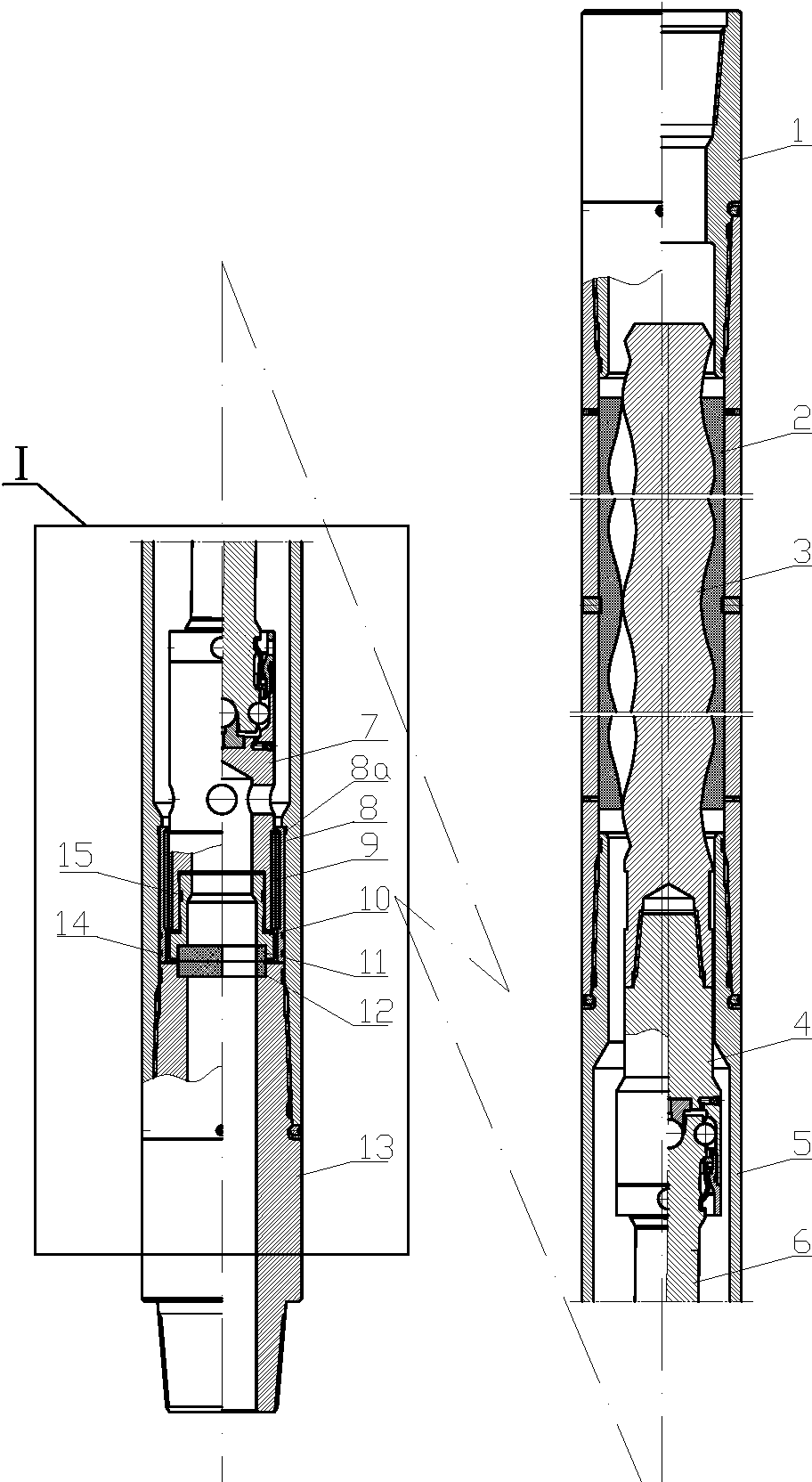

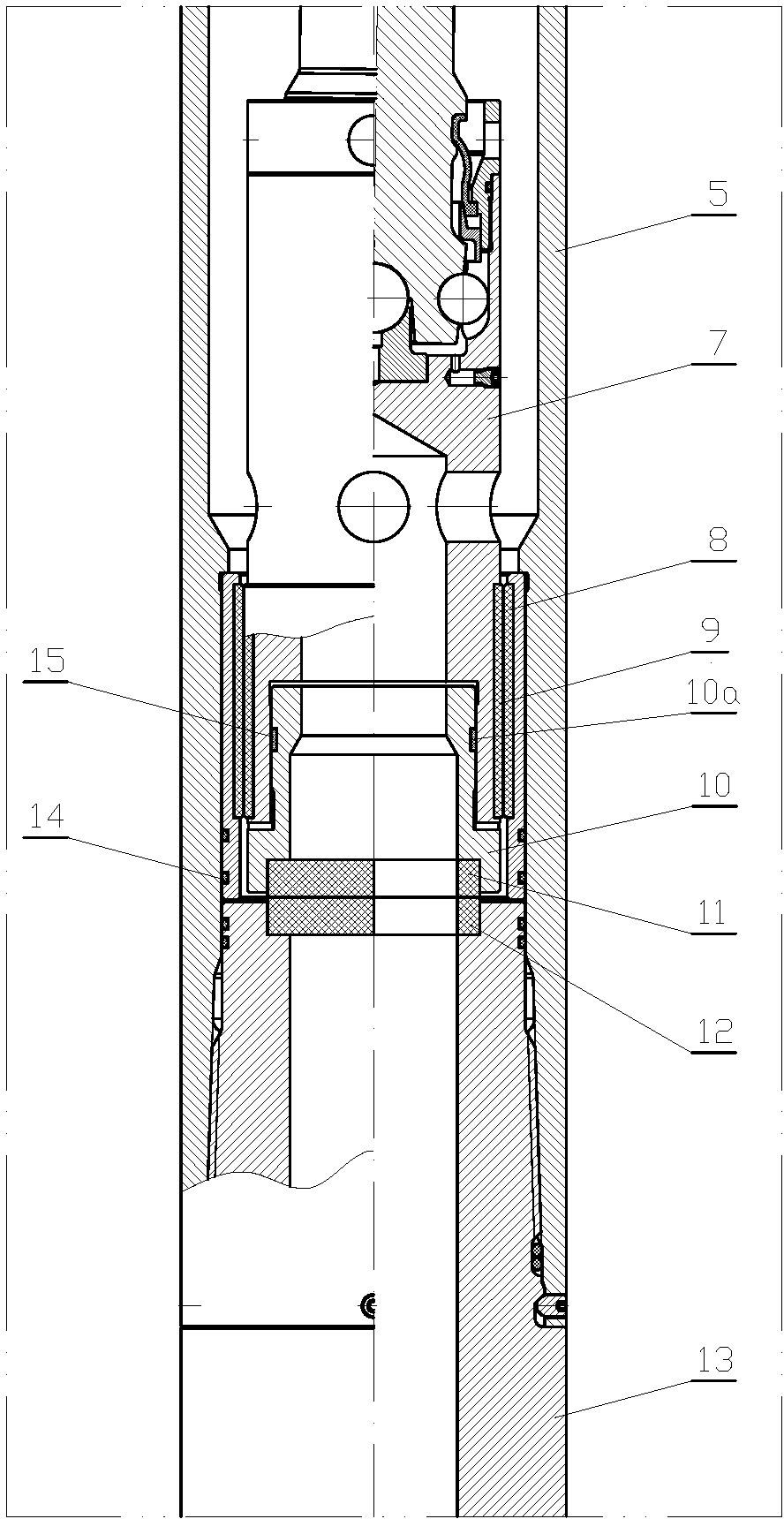

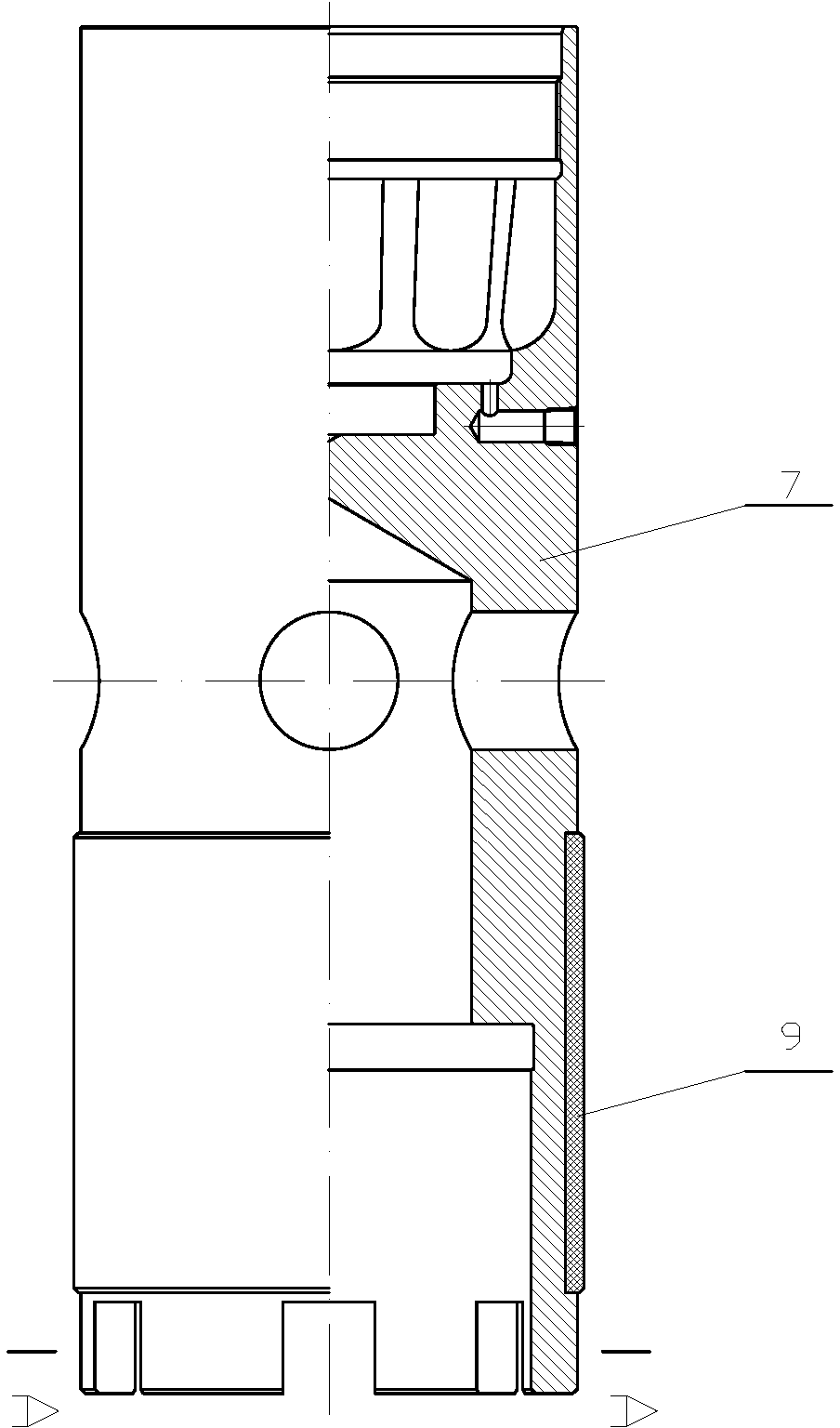

Pressure resistant tool for reducing frictional resistance of horizontal well section

ActiveCN102587832AStrong axial vibration capabilityEffective destructionDirectional drillingBorehole drivesUpper jointDrive shaft

The invention relates to a pressure resistant tool for reducing frictional resistance of a horizontal well section, which is used for reducing the frictional resistance of the horizontal well section and improving horizontal section extending and drilling capacity. The technical scheme includes: the pressure resistant tool for reducing the frictional resistance of a whole well consists of a pulse part and a vibration part. The pulse part mainly comprises an upper joint, a power part, an upper abrasion-resistant block, an upper fixing sleeve, a lower abrasion-resistant block, a lower fixing sleeve, a lower valve and a lower joint. The vibration part mainly comprises a spline transmission shaft, a spline righting tube, a locking nut, a disk spring, a supporting shell, a piston rod, a piston bush, a piston nut and a pulse pup joint. The vibration part is in threaded connection with the upper end of the pulse part. The overall overflowing area of a valve part driven by a motor rotor is gradually reduced, and fluid energy is converted into a series of pulse pressure to be transmitted to the vibration part. The pressure resistant tool has the advantages of high axial vibration capacity and simple structure, the frictional resistance between a drill stem and the well wall can be reduced, and the horizontal well and large-displacement well horizontal section extending and drilling capacity is improved.

Owner:SOUTHWEST PETROLEUM UNIV

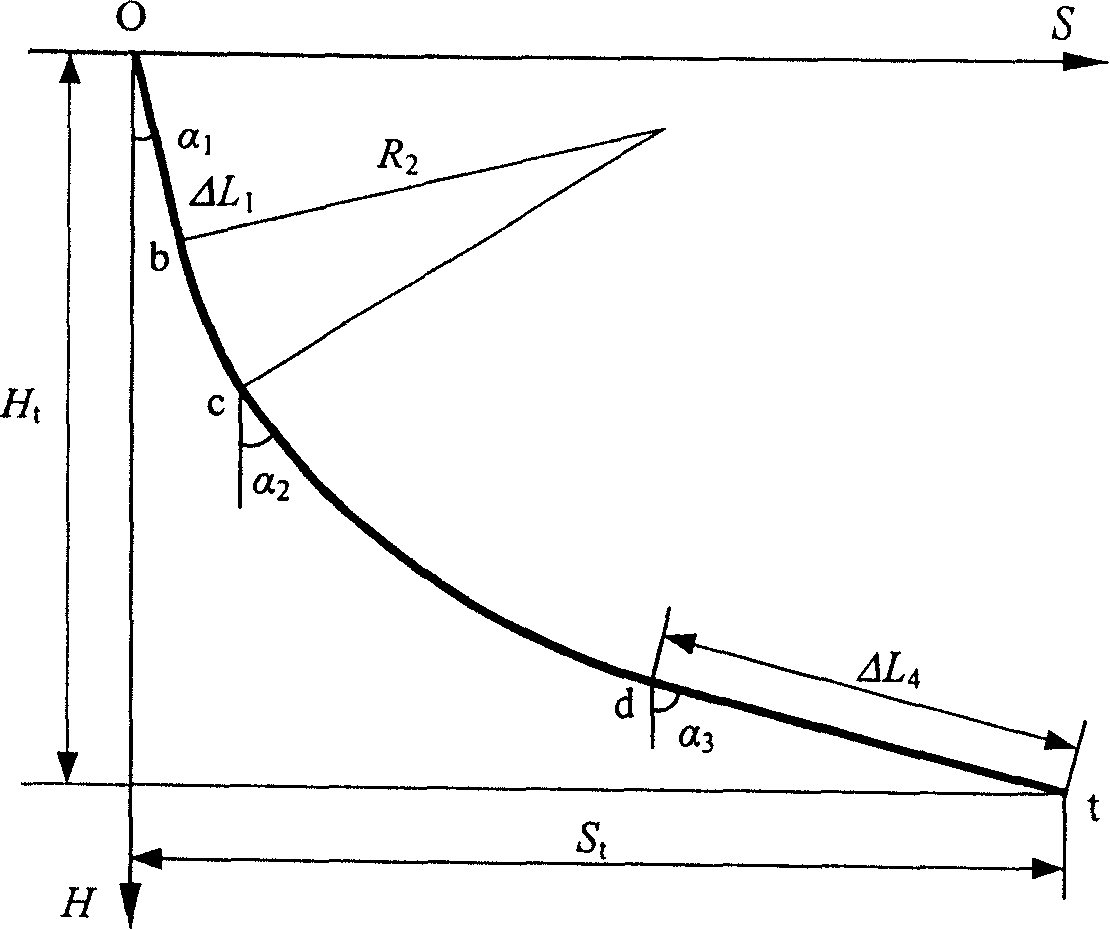

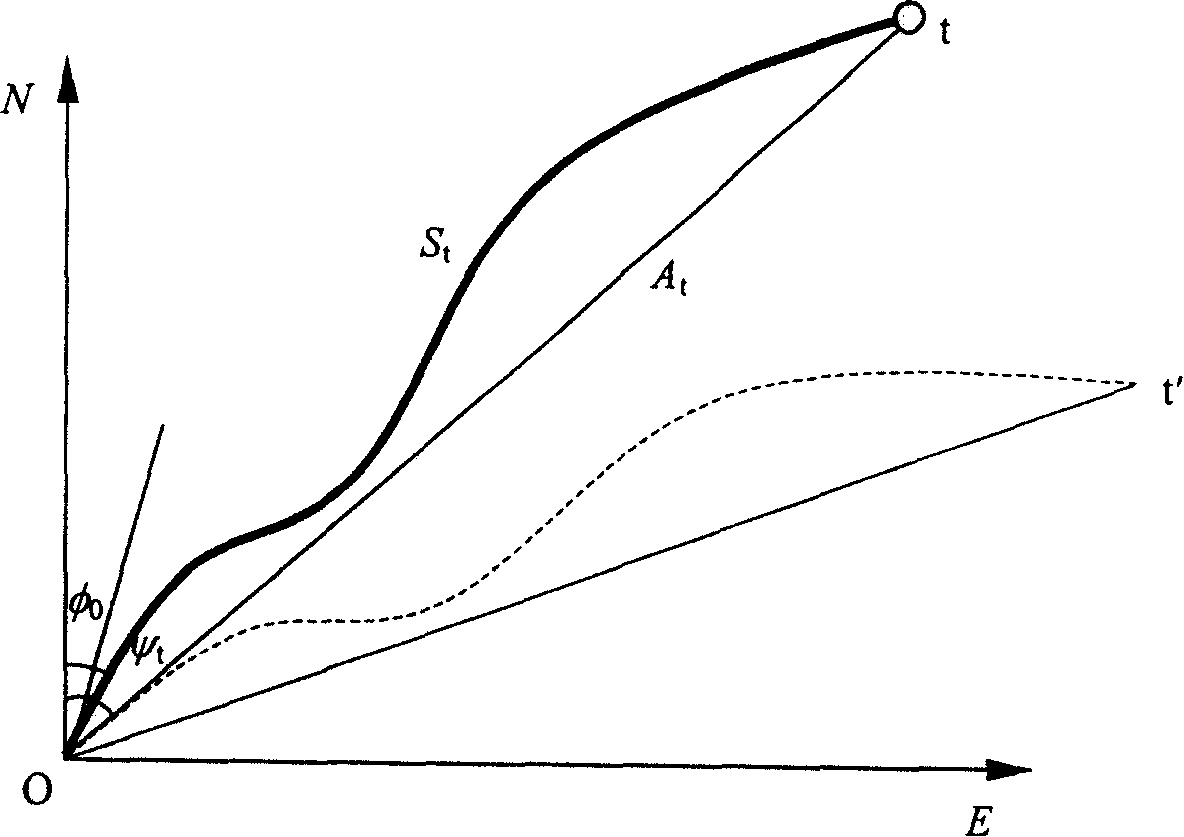

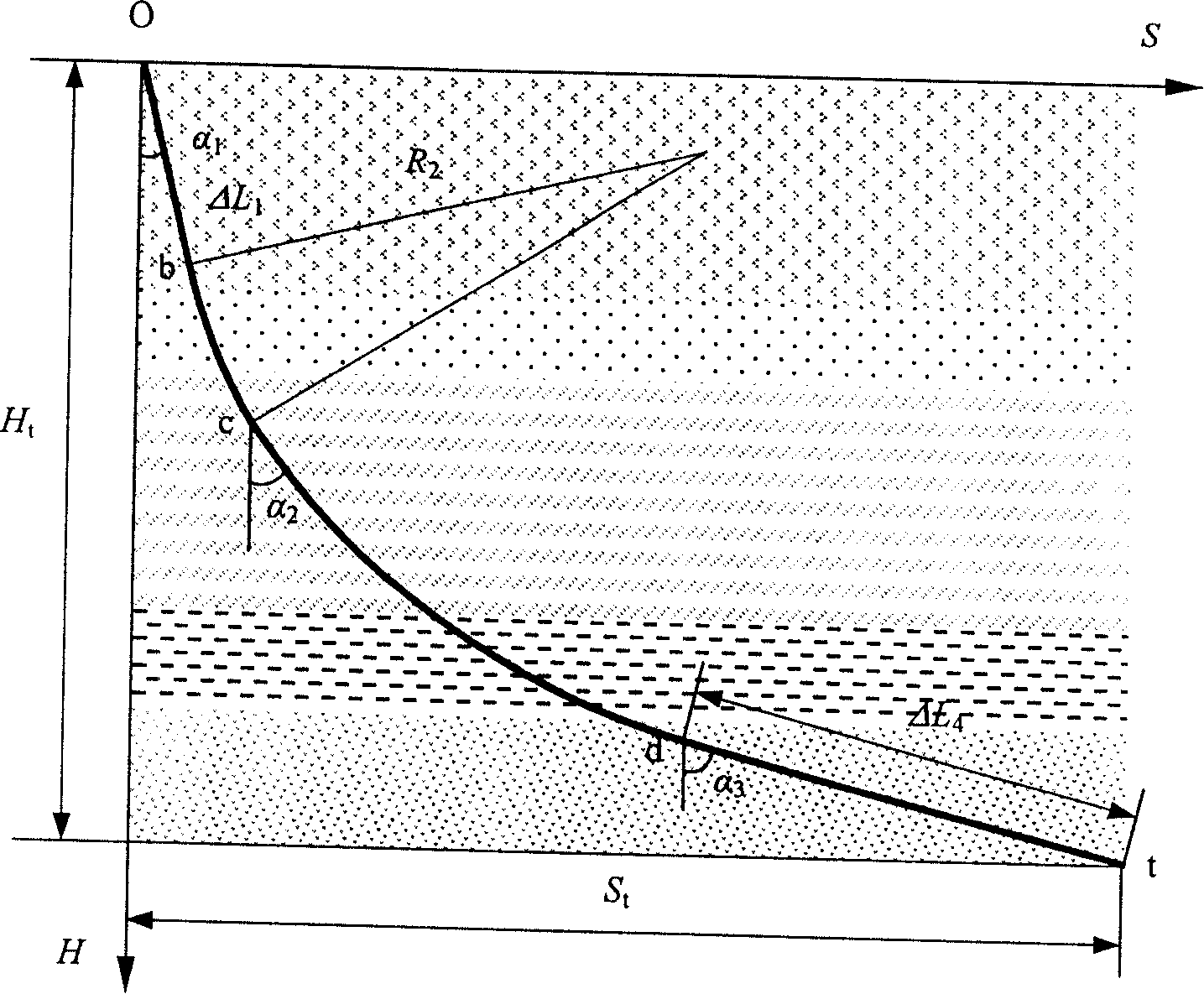

Funicular curve well drilling rail design method using stratum natural deflecting rule

ActiveCN101173598AIn line with formation conditionsRealize the designDirectional drillingSection planeThree stage

The invention relates to a drilling engineering design in the petroleum drilling engineering, in particular to wellbore trajectory optimized design and control in the highly-displacement well. For three-stage and four-stage catenary sections, the design of wellbore trajectory is finished through 12 steps. The invention puts forward a new method of two-dimensional catenary trajectory design. A plurality of units with different azimuth wander ratio is divided according to natural deviating rule of formation, which is combined to the formation condition that conforms to the actual situations of drilling engineering. On the basis of maintaining the characteristics and advantages of catenary trajectory and regarding to the influence of natural deviating rule of formation, a method of three-dimensional catenary trajectory design is put forward, which can not only scientifically work out the azimuth lead angle and initial azimuth, but also work out the trajectory parameters of every point inthe wellbore trajectory. The realization of three-dimensional wander trajectory design of catenary section has real meaning of guidance for the drilling design and construction of the highly-displacement well. The invention is used in the field of petroleum and geological exploration.

Owner:CHINA PETROLEUM & CHEM CORP +1

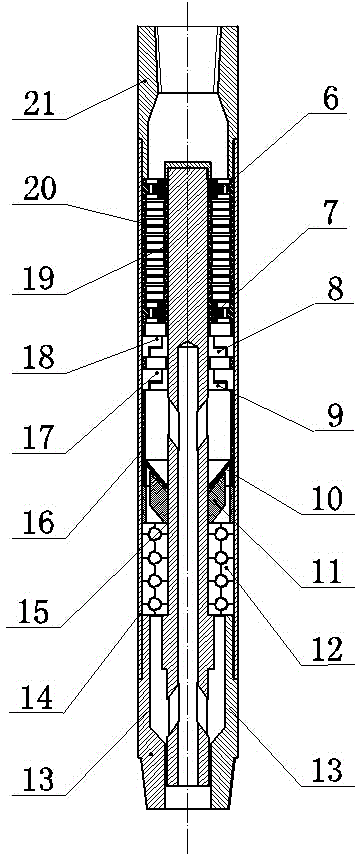

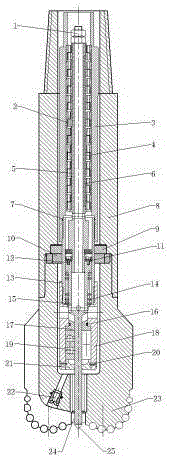

Hydraulic hammer rod type impact drilling tool

ActiveCN103244052AIncrease ROPTo achieve the requirements of different impact frequenciesBorehole drivesBall bearingThrust bearing

The invention provides a hydraulic hammer rod type impact drilling tool and belongs to the field of geological exploration engineering and oil drilling. The technical scheme of the hydraulic hammer rod type impact drilling tool includes that the hydraulic hammer rod type impact drilling tool is composed of a turbine driving device, a rotary valve flow distribution mechanism, a impact device, an end cap, a punch hammer, an outer cylinder, an inner cylinder, sealing rings, a flow diversion disk, a casing and drill bit. The turbine driving device comprises a fixed shaft, an upper deep groove ball bearing, a turbine disk, turbine blades, a pressing disk, a lower deep groove ball bearing and a thrust bearing, the rotary valve flow distribution mechanism comprises an upper valve plate and a lower valve plate, and the impact device comprises an impact base, a spring and a hammer rod. When the hydraulic hammer rod type impact drilling tool is operated, the turbine driving device drives the upper valve plate to rotate, an input hole is communicated with a first overflowing hole and a second overflowing hole of the lower valve plate alternately so as to enable the punch hammer to reciprocate in the inner cylinder to achieve circulation impact on an impact base, and impact energy is transmitted to the hammer rod for rock breaking. The hydraulic hammer rod type impact drilling tool can form high frequency axial impact force for assisting rock breaking, facilitates prolonging of service life of the drill bit, improves mechanical drilling speed, and is particularly suitable for hard formation drilling.

Owner:SOUTHWEST PETROLEUM UNIV

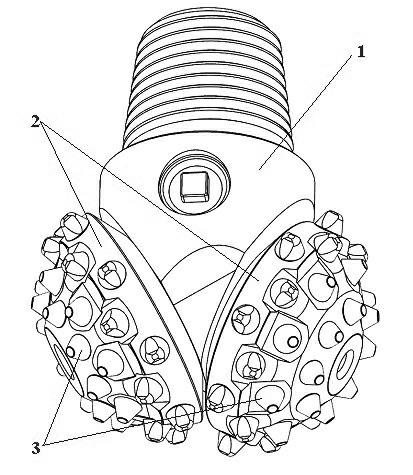

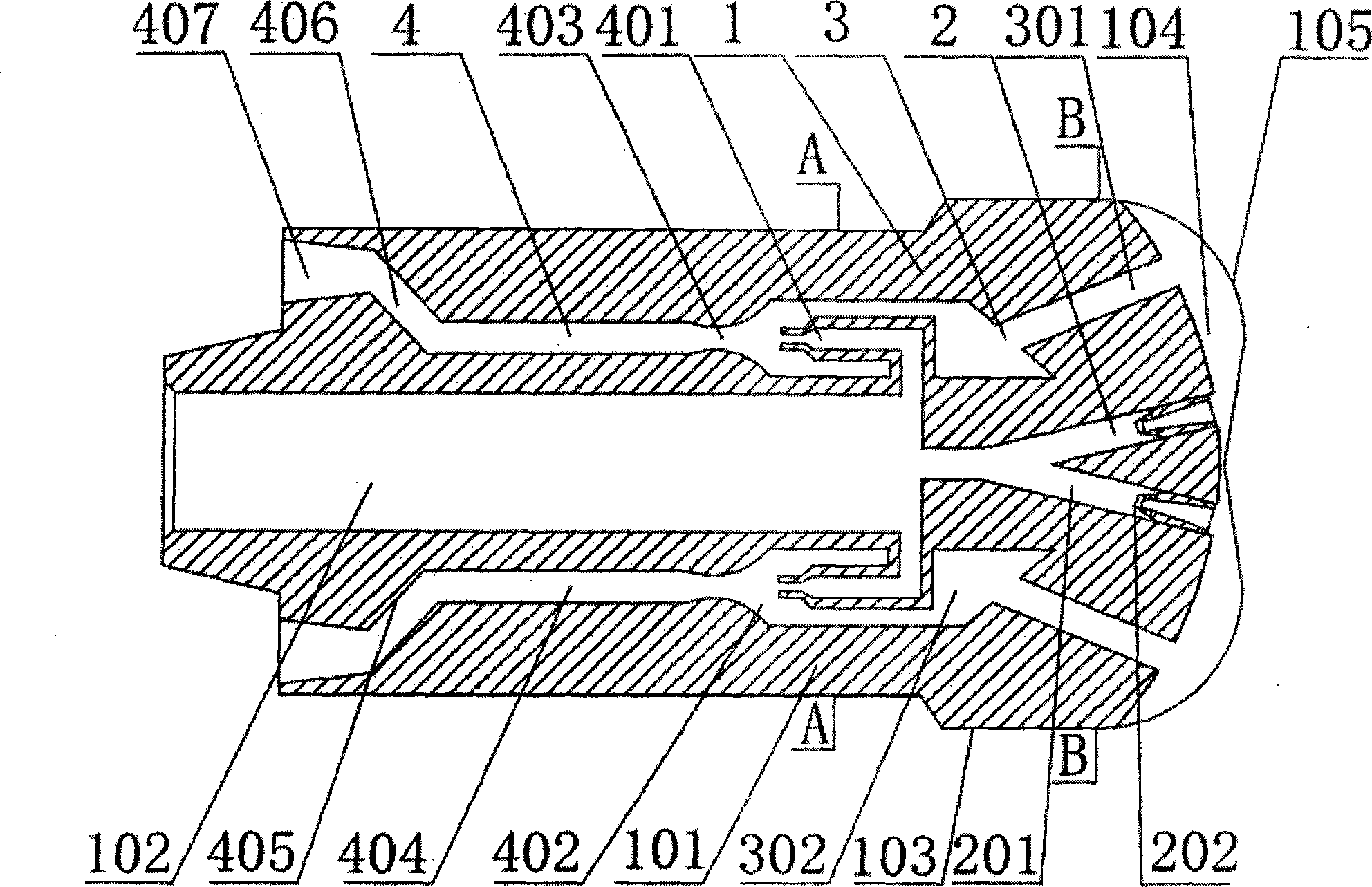

Novel PDC drill bit utilizing impact effect for improving heart rock breaking efficiency

The invention belongs to the field of technical equipment used in oil and natural gas drilling engineering, mine exploiting, geological drilling, constructional engineering, tunnel engineering, shielding and non-excavation, and relates to a novel PDC drill bit utilizing the impact effect for improving heart rock breaking efficiency. The PDC drill bit solves the problems that in the drilling process, a center rock column left in the center part influences drilling efficiency, and the position deviating from the center of a well hole shakes left and right. According to the technical scheme, the upper end of a turbine is fixed through a nut, the lower end of the turbine is fixed through a boss on a turbine shaft, an upper cam is connected to the turbine shaft through threads, a lower cam is fixed to a punch hammer through a sunk screw, the upper section of the punch hammer is hollow, a pore passage enabling drilling fluid to flow out is formed in the upper end of a shell on the lower portion, a pressing head with the top end provided with a tip-shaped PDC tooth is added to the tail end of a connecting cavity, as a main impact part, the lower end of the punch hammer becomes thin, and a bi-directional thrust ball bearing is placed at the lower end. The equipment enables the heart to generate longitudinal impact, improves the rock breaking efficiency and reduces drilling cost.

Owner:SOUTHWEST PETROLEUM UNIV

High-frequency pulsed jet flow resonance well drilling device and well drilling method thereof

InactiveCN102493768AIncrease compactionBuried deepLiquid/gas jet drillingMachines/enginesSteel jacketUltrasonic sensor

The invention relates to a high-frequency pulsed jet flow resonance well drilling device and a well drilling method thereof. The high-frequency pulsed jet flow resonance well drilling device comprises an outer steel jacket, wherein one end of the outer steel jacket is connected with an upper adapter; the other end of the outer steel jacket is connected with a lower adapter; the upper adapter is connected with a drill collar by a thread; the lower adapter is connected with a drill by the thread; a small hydrogenerator, a density logger, an acoustic logger, a controller and an ultrasonic transducer are successively installed from top to bottom in the outer steel jacket; the small hydrogenerator is composed of a blade and a generator; the blade is installed above the generator; the ultrasonic transducer comprises a fixed end, a transducer and an amplitude transformer; the position on the outer steel jacket, which corresponds to the amplitude transformer, is provided with a necking section; the density logger, the acoustic logger and the controller are mutually separated by cushion blocks; and after the density logger, the acoustic logger and the controller are connected, the inner cavities of the density logger, the acoustic logger and the controller are communicated to form a well drilling fluid path. According to the high-frequency pulsed jet flow resonance well drilling device, the mechanical drilling speed is drastically improved, the improvement amplitude is 1-2 times, and the well drilling cost is effectively lowered.

Owner:NORTHEAST GASOLINEEUM UNIV

Plasma drilling bit

ActiveCN104563882AAvoid severe wear and tearImprove efficiencyDrill bitsRate of penetrationWell drilling

The invention relates to a plasma drilling bit in the field of drilling bit tools. The technical scheme adopted by the invention is that a fluid passageway and an electrode through hole which respectively and axially communicated are preformed in a bit body; a high-voltage positive electrode and insulators are fixedly connected with the interior of the electrode through hole; the bottom part of the bit body is fixedly connected with an annular ground electrode; the bottom part of the high-voltage positive electrode is provided with a high-voltage panel mounting electrode; an annular interelectrode gap is reserved between the high-voltage panel mounting electrode and the annular ground electrode. The bit penetrates a plasma channel formed in front of to-be-drilled rock under the high-voltage pulse liquid phase microdischarge action to crush the rock, and does not need to be contacted with the surface of the rock, and mechanical lapping is not needed. The plasma drilling bit disclosed by the invention has the advantages that the abrasion of the bit can be reduced, the rate of penetration is increased, and the required energy is low; compared with the conventional mechanical rotary bit, the plasma drilling bit is low in cost and high in efficiency, and can also be applied to industry of mining and the like.

Owner:CHINA PETROCHEMICAL CORP +1

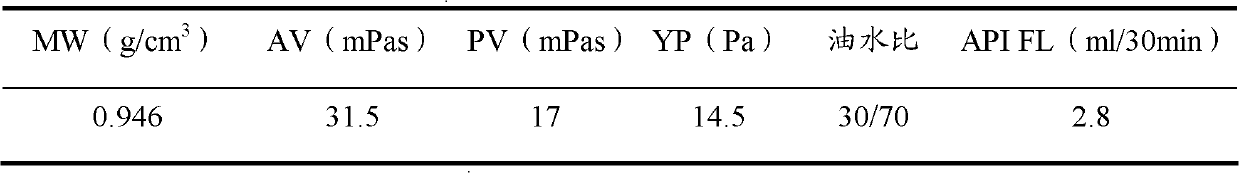

Oil-in-water drilling fluid suitable for different kinds of furnish preparation water and oils

ActiveCN102140334AImprove breadth and operabilityPrevent formation lossDrilling compositionGramSeawater

The invention discloses an oil-in-water drilling fluid suitable for different kinds of furnish preparation water and oils. The formula of the drilling fluid comprises the following components in parts by weight: 30-90 parts of seawater or fresh water, 70-10 parts of oil, 2.0-4.0 parts of main emulsifier, 0.2-0.5 part of auxiliary emulsifier, 0.5-1.5 parts of fluid loss additive, 0.5-1 part of tackifier, 0-233 parts of weighting material. By adopting the drilling fluid, the preparation requirement on different external phases (seawater and fresh water) and different internal phases (white oil and gas oil) can be met at the same time, and the application universality and operability of an oil-in-water drilling fluid system are enhanced; and the ratio of water to oil is variable between 9:1 and 3:7, the density can be lowered to 0.87 gram / cm<3>, the stratum leakage loss of a low-pressure depleted hydrocarbon reservoir and the increase in the mechanical drilling rate can be effectively prevented, the release of the hydrocarbon reservoir is facilitated, and the yield of an oil gas well is increased.

Owner:CHINA OILFIELD SERVICES +1

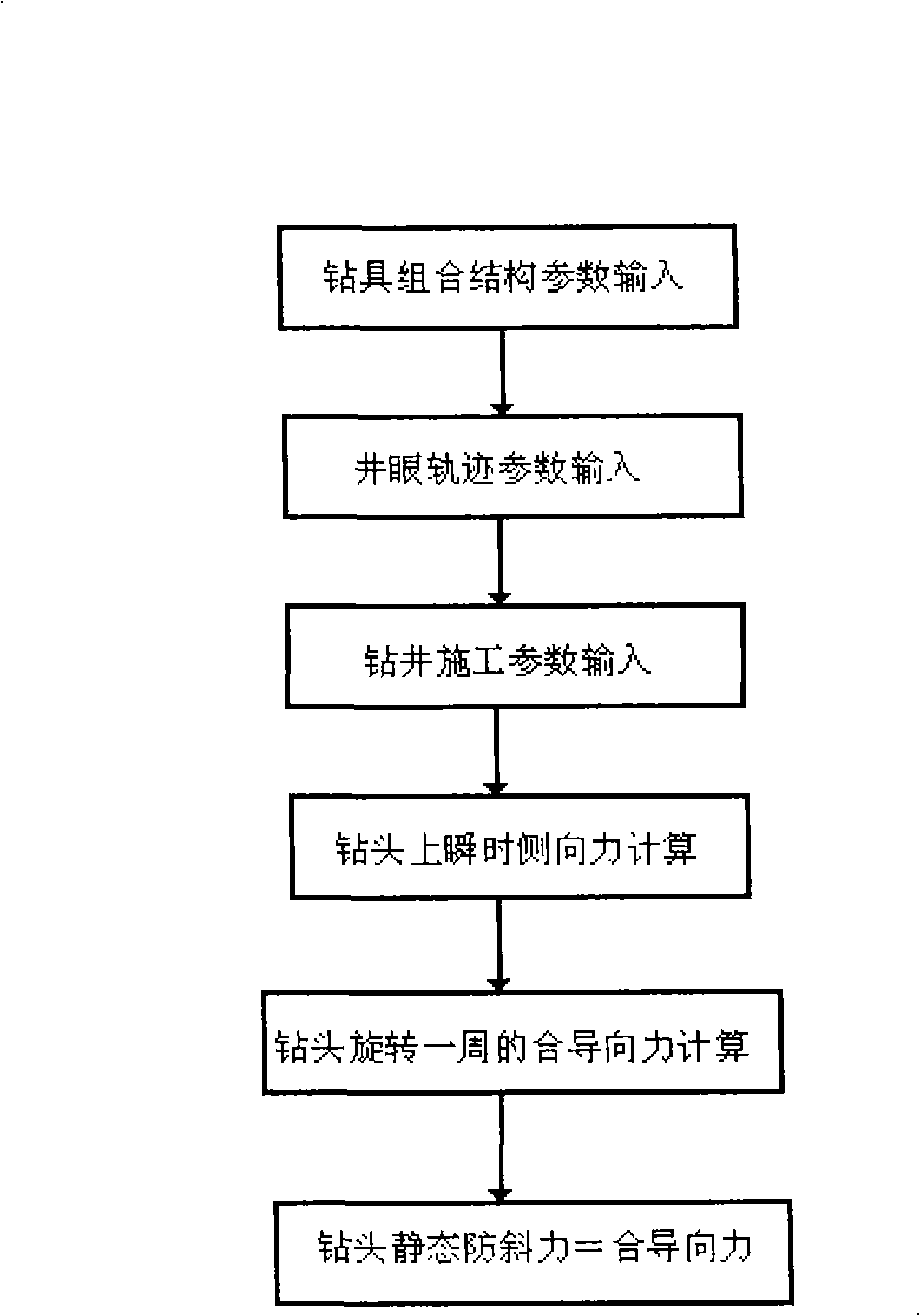

Prebending kinetics deviation control and fast drilling method

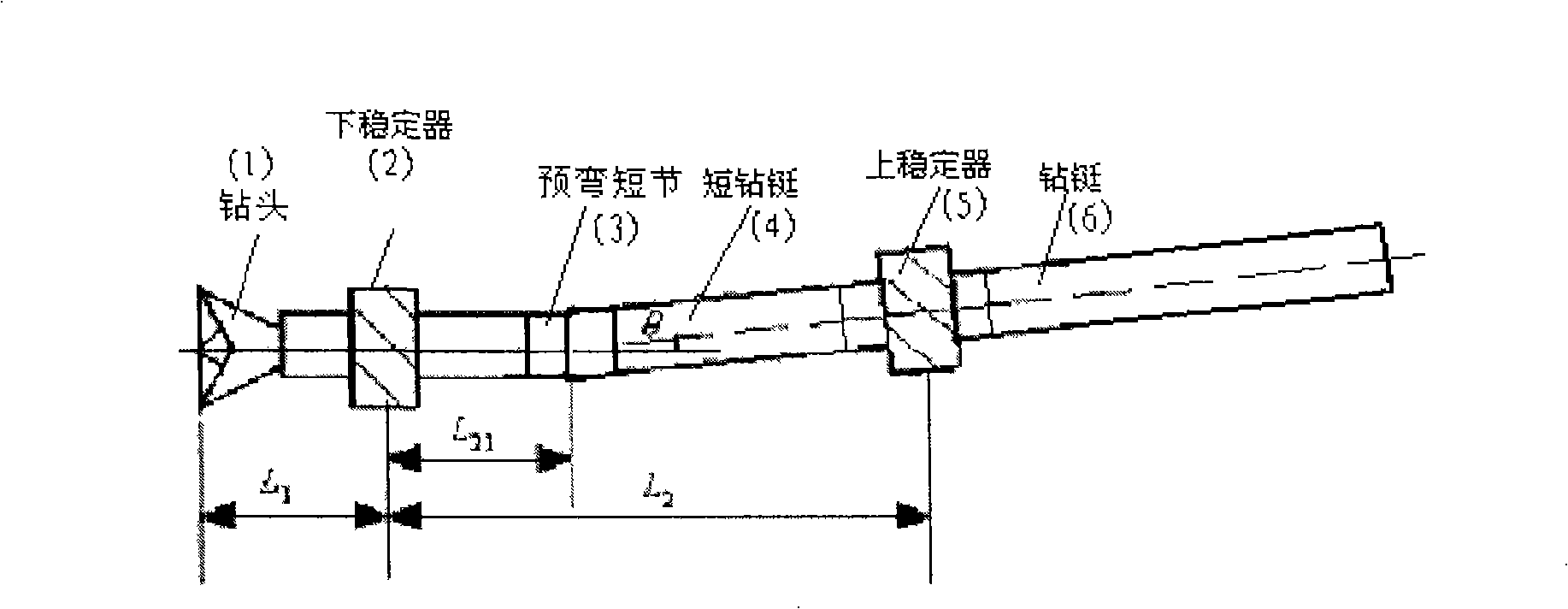

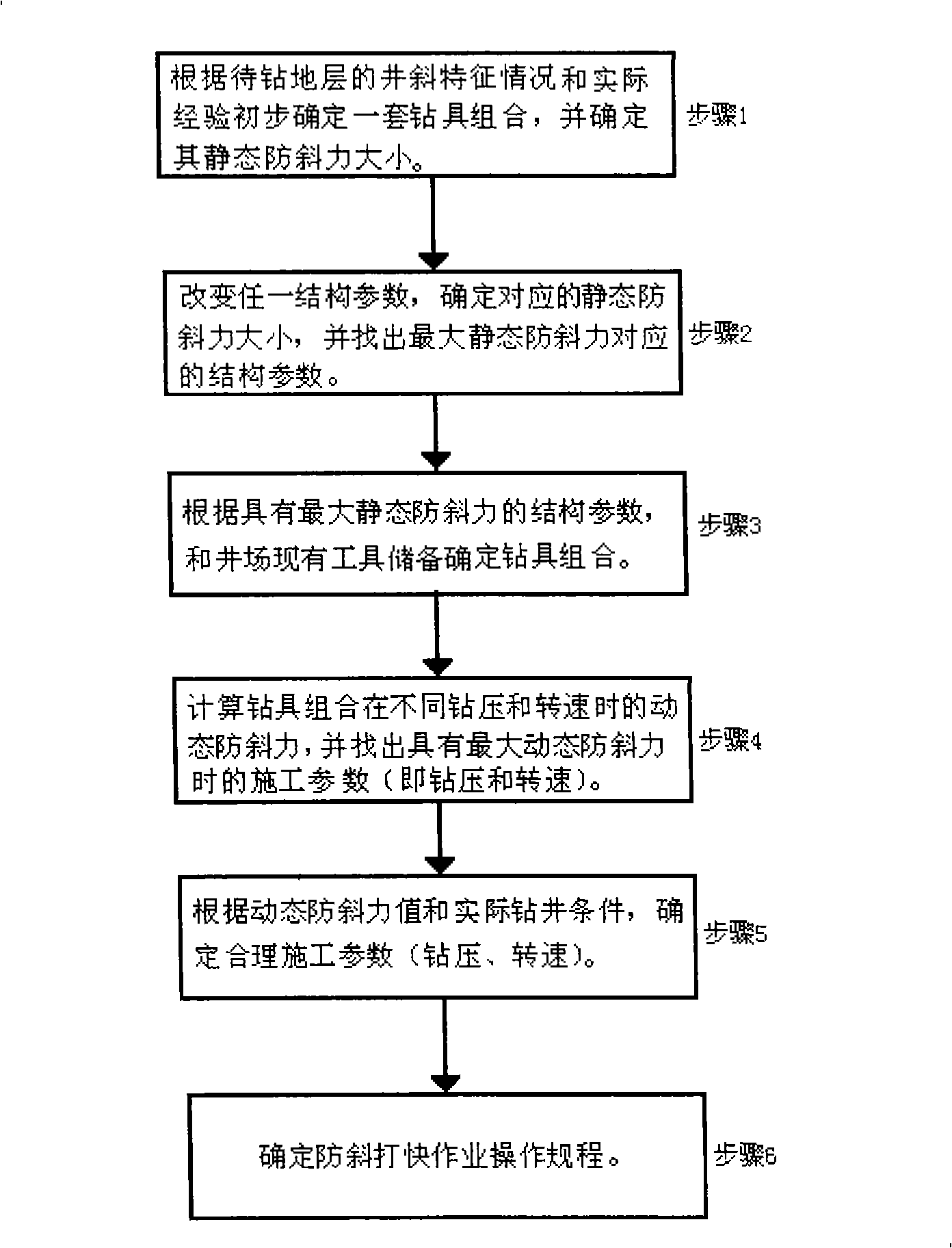

The invention relates to a prebuckling dynamics against sided strike rapid drilling method. The method adopts a drill assembly with a prebuckling structure and the ground driving way, begins with the analysis of the against sided force of an aiguille and the law for changing, determines the drill assembly, the technological operation regulations, the safety analysis and the detection and realizesthe against sided strike rapid drilling. The against sided strike rapid drilling method is used in the practical operation; the bit pressure is increased by more than 50 percent compared with a pendulum limit bit pressure, the mechanical drilling speed is greatly increased and is up to 700 percent.

Owner:SHANGHAI UNIV

Micro-nano blocking lubricant for drilling fluid and preparation method thereof

ActiveCN108239522AHigh fat contentImprove temperature resistanceDrilling compositionMicro nanoSolid particle

The invention relates to a micro-nano blocking lubricant for a drilling fluid and a preparation method thereof and belongs to the field of oil and gas field drilling and oilfield chemical auxiliary agents. The micro-nano blocking lubricant for the drilling fluid is prepared from the following components in parts by weight: 100-200 parts of a nano emulsion and 100 parts of composite graphite micropowder. The micro-nano blocking lubricant for the drilling fluid also contains a dispersant. The nanoemulsion is prepared from components including paraffin, white oil, a composite emulsifier, a co-emulsifier and water by a phase inversion emulsification method. The micro-nano blocking lubricant for the drilling fluid can resistant the temperature of 150 DEG C, does not have adverse effects to viscosity of the drilling fluid, can reduce the filter loss of the drilling fluid remarkably, improve the quality of mud cakes remarkably, reduce the frictional resistance of a drilling tool and improve the mechanical drilling speed, and can bridge and block micro-cracks of shale quickly by means of a small size effect to prevent solid particles and a filtrate from invading the stratum to achieve a good blocking effect, so that the micro-nano blocking lubricant for the drilling fluid is particularly suitable for blocking fine throats which are 0.05-50[mu]m.

Owner:CHINA PETROLEUM & CHEM CORP +1

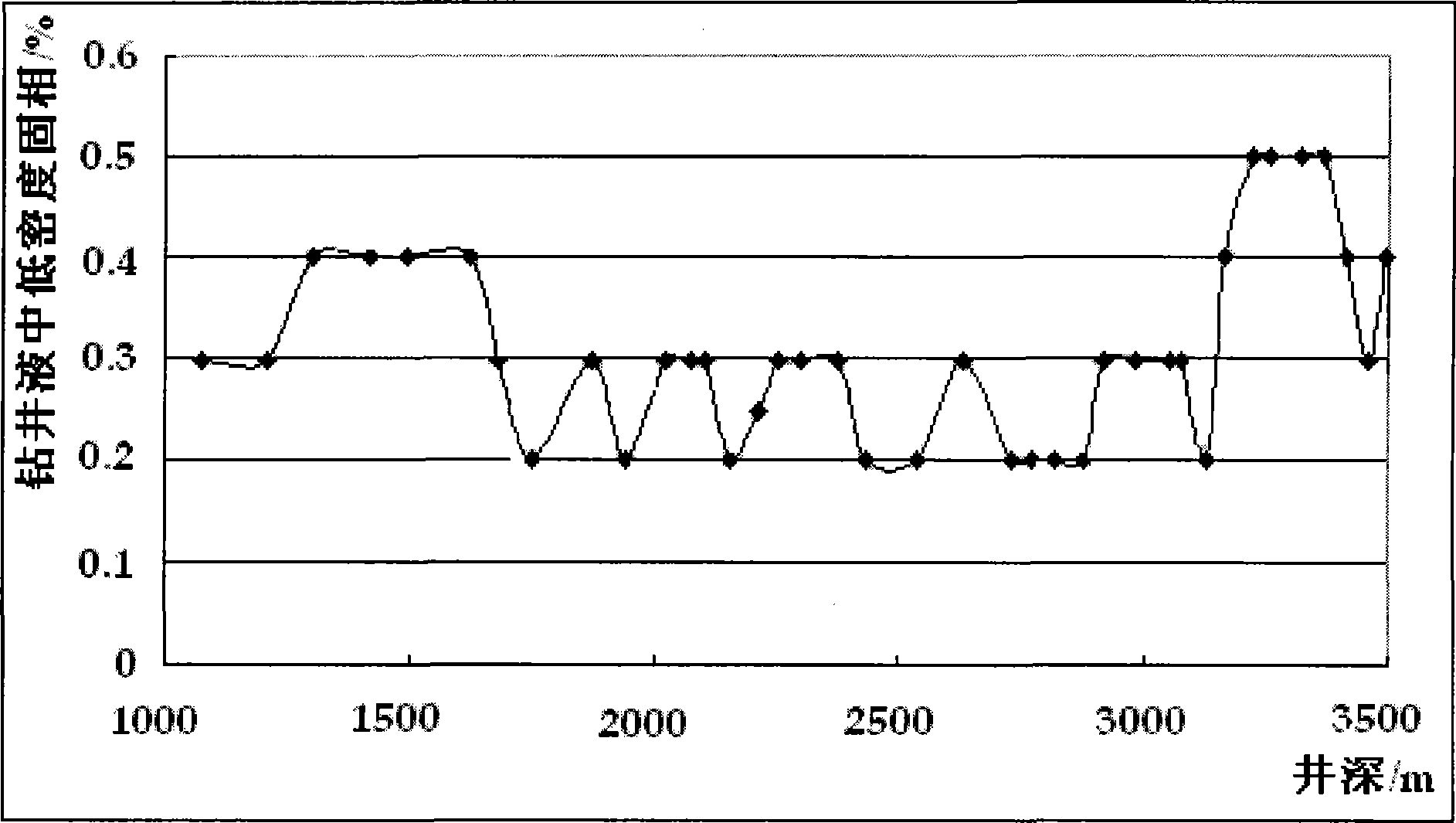

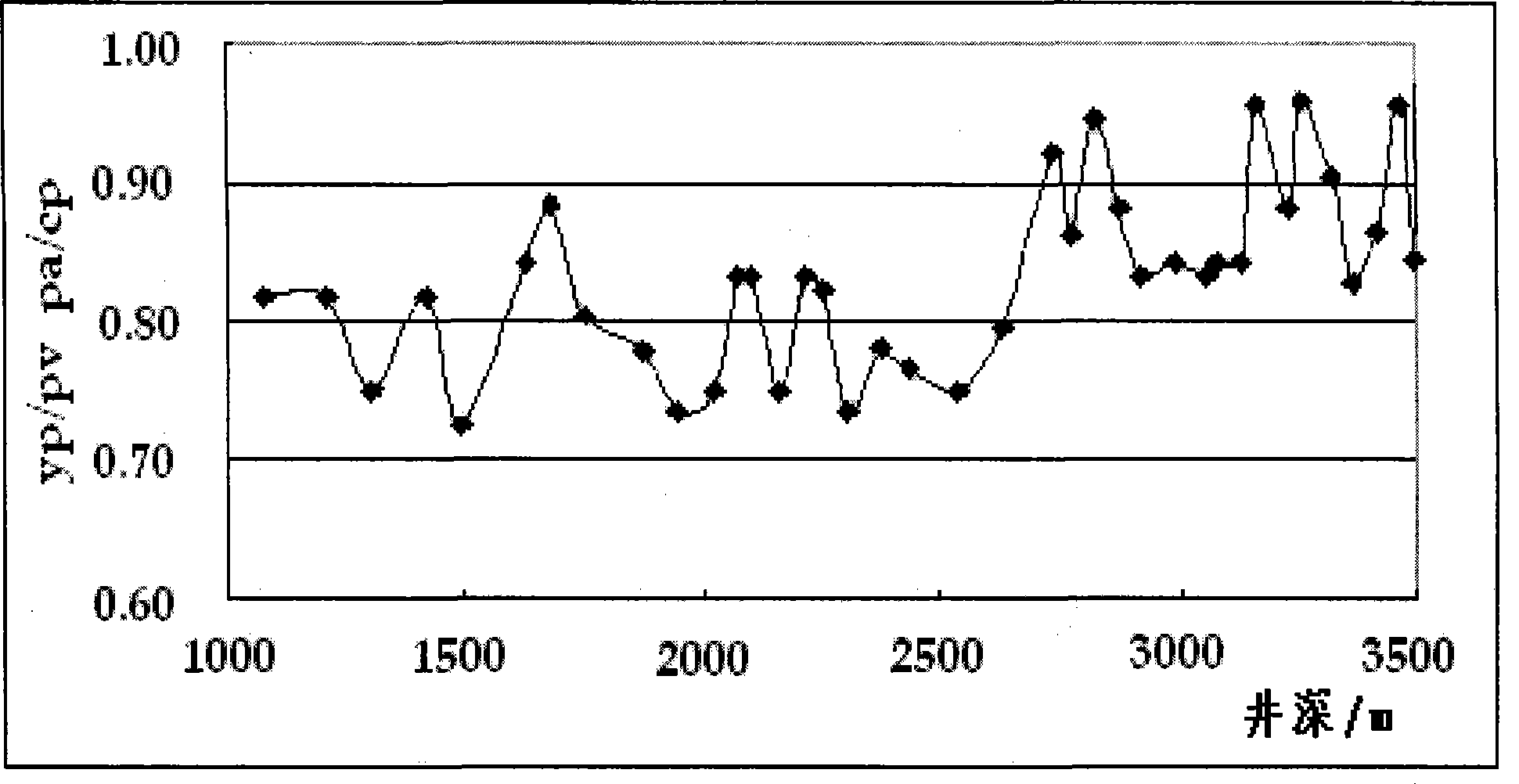

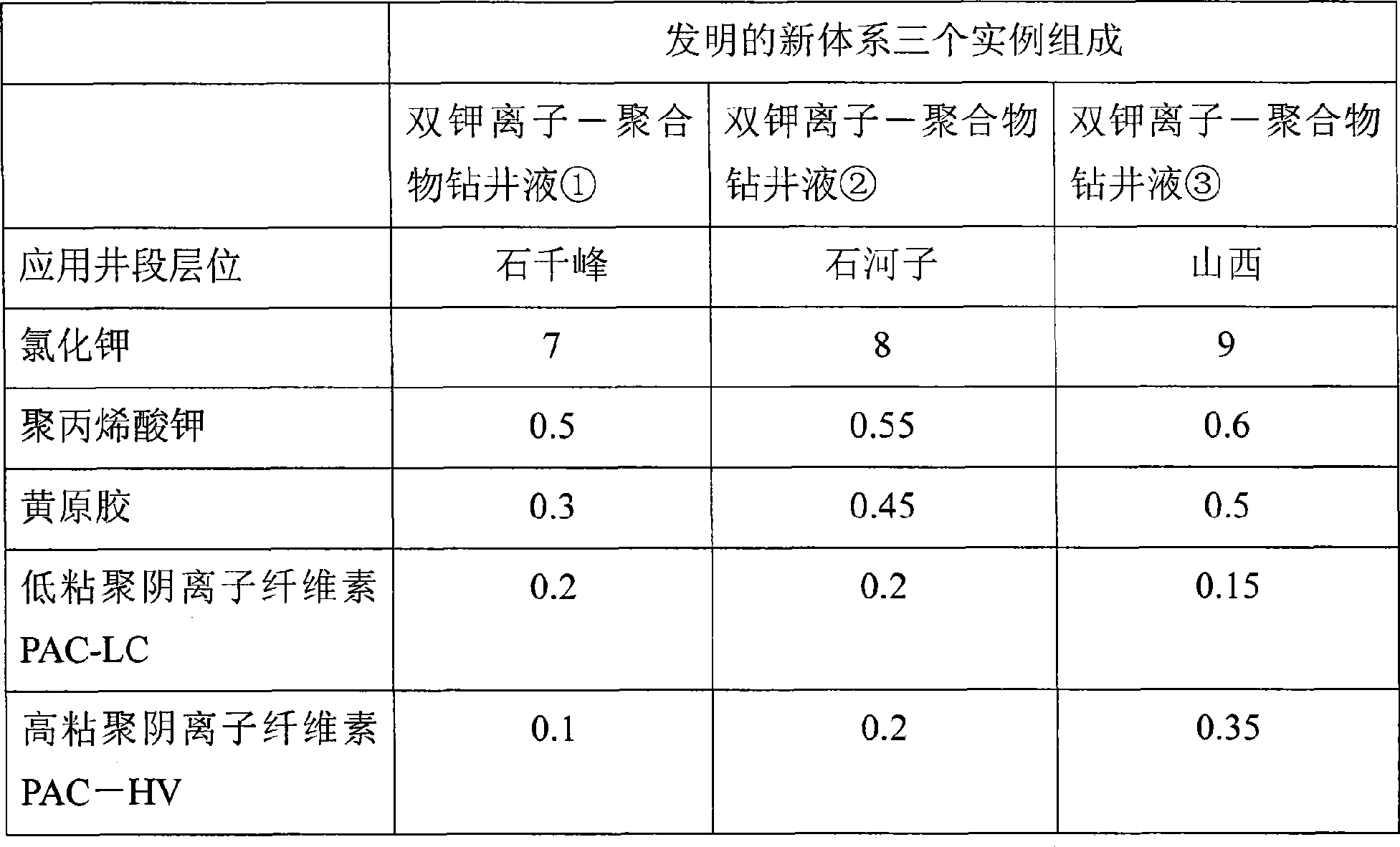

Di-kalium ion-polymer drilling fluid with strong rejection capability

InactiveCN101429424AImprove the lubrication effectTripping smoothlyDrilling compositionAlkalinityClay minerals

The invention relates to a strong inhibition double-kalium ion, namely polymer drilling fluid, which is characterized in that the strong inhibition double-kalium ion, namely polymer drilling fluid comprises the following materials in weight percentage: A. 7 to 9 percent of inorganic kali salt used as an inorganic inhibitor; B. 0.5 to 0.6 percent of organic kali salt used as an organic inhibitor; C. 0.3 to 0.5 percent of viscidity improving agent; D. 0.3 to 0.5 percent of filter loss reducing agent; E. 0.3 to 0.5 percent of alkalinity controlling agent; F. 0.03 to 0.1 percent of preservative agent; G. 0.1 to 0.2 percent of antifoaming agent; H. 1 to 8 percent of weight additive; and the balance being water. The drilling fluid has stronger functions of inhibiting hydration, expansion and dispersion of clay mineral, and also has better rheological property, so that the drilling fluid is low filter loss non-solid phase polymer drilling fluid.

Owner:CNPC SICHUAN GASOLINEEUM GEOPHYSICAL PROSPECTING ENG TECH RES INST

High temperature stratum self-generating foam composition and application thereof in viscous oil exploitation

InactiveCN1927993AImprove the spread factorEnhanced heavy oil recoveryDrilling compositionChemistryChemical substance

The present invention is foam-generating composition for high temperature stratum and its application in exploiting thick oil, and belongs to the field of surfactant technology. Chemicals capable of producing N2, CO2 and other gas are adopted to produce gases through the reaction of A+B+C-->N2+NH3+CO2+C, where A is reductant, B oxidant and C foaming agent. The reaction is controlled by temperature, and the foam-generating composition contains also surfactant with high heat resistance, high salt tolerance, high oil / water interface activity and high foam stability. After the chemicals are injected into the stratum at normal temperature, steam is injected to initiate reaction producing stable foam in the stratum, and the foam can plug to avoid steam fleeing, raise high temperature steam sweep efficiency, raise blotter efficiency, promote crude oil to disperse and raise the thick oil exploiting rate greatly.

Owner:SHANDONG UNIV

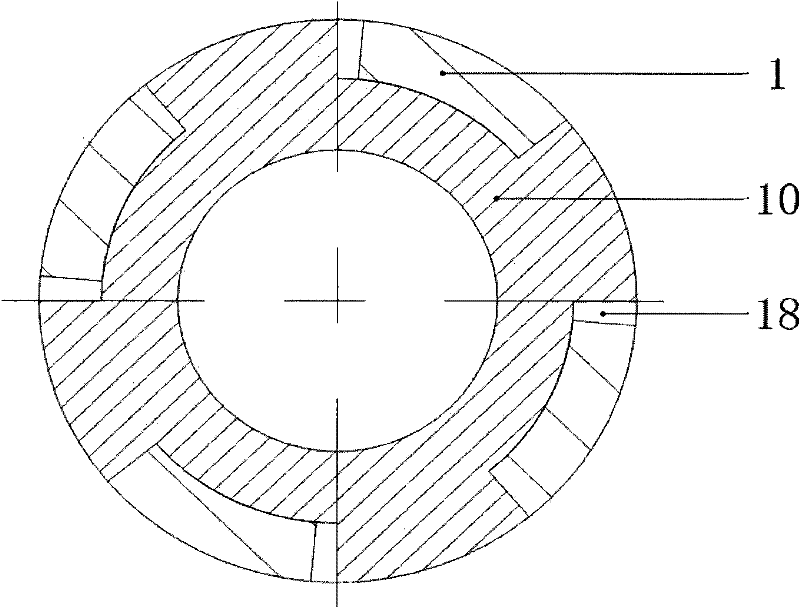

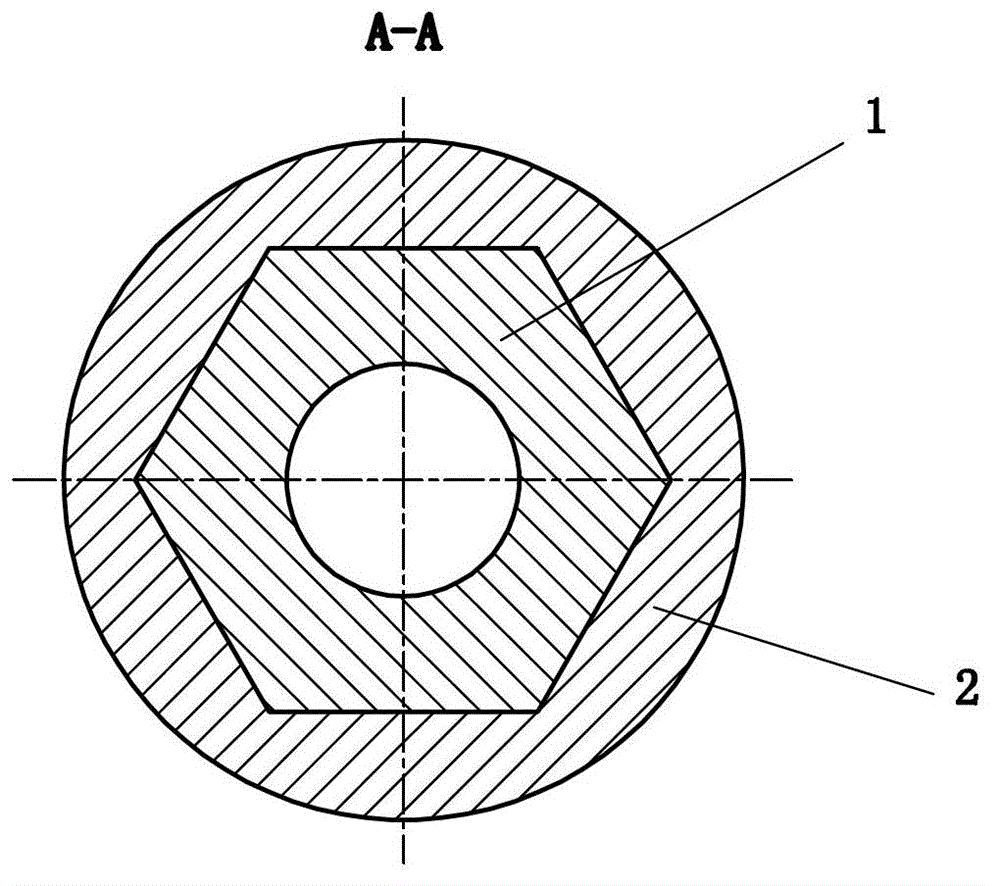

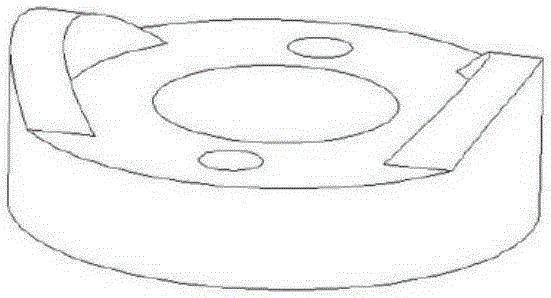

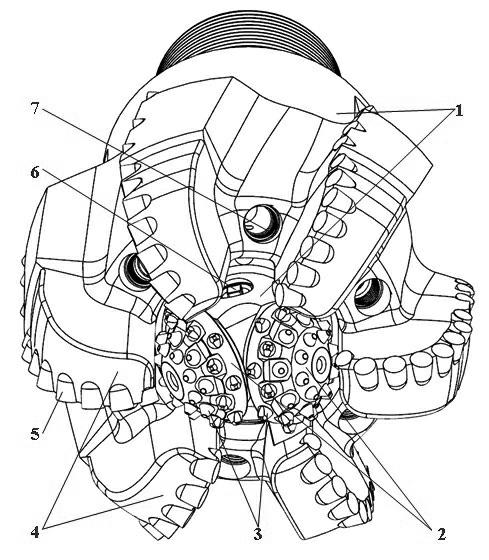

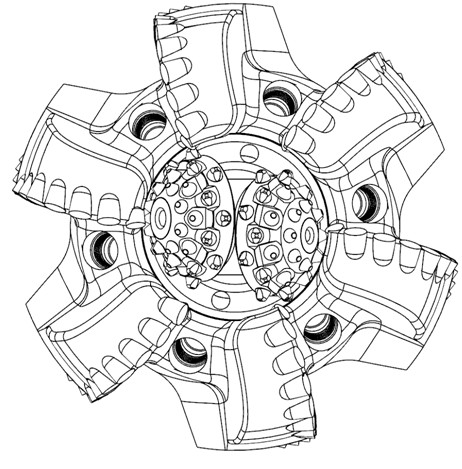

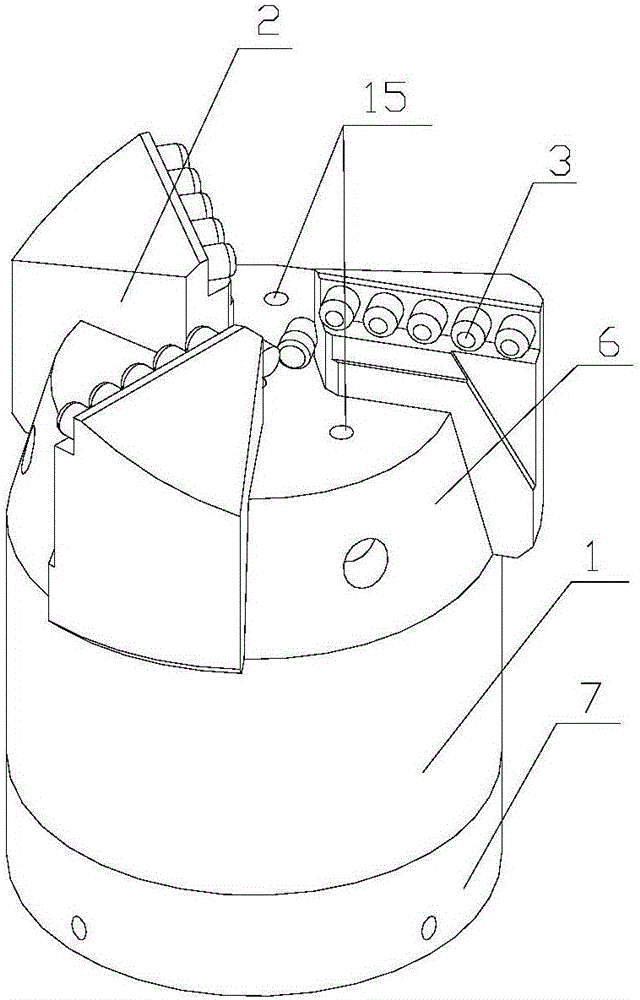

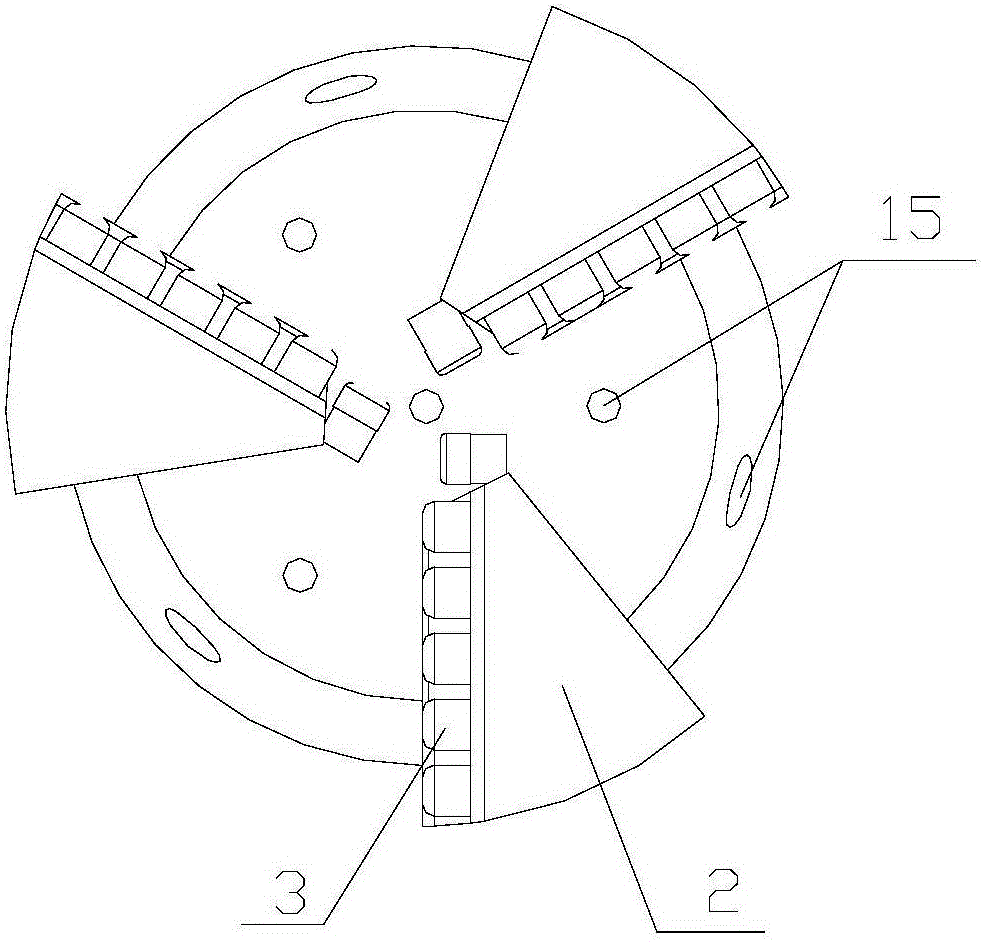

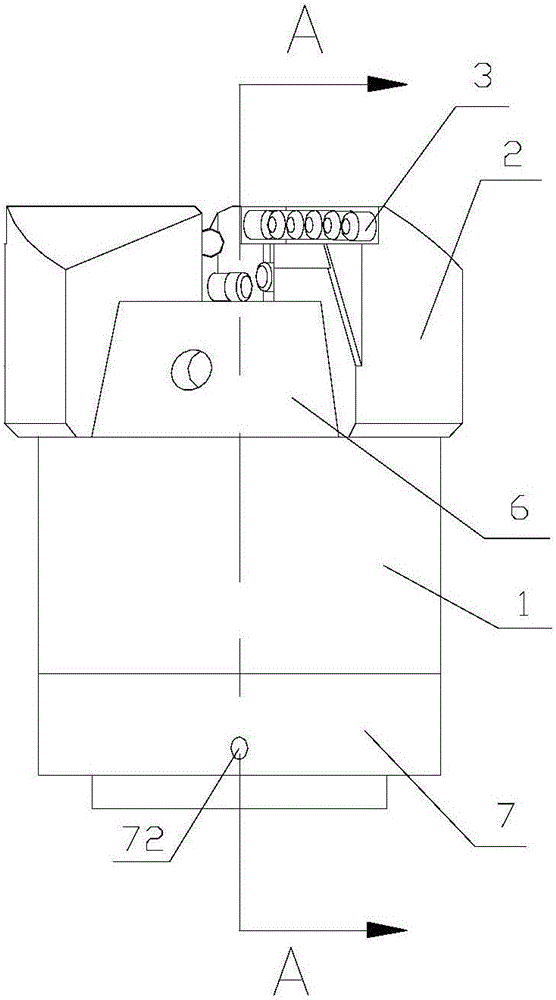

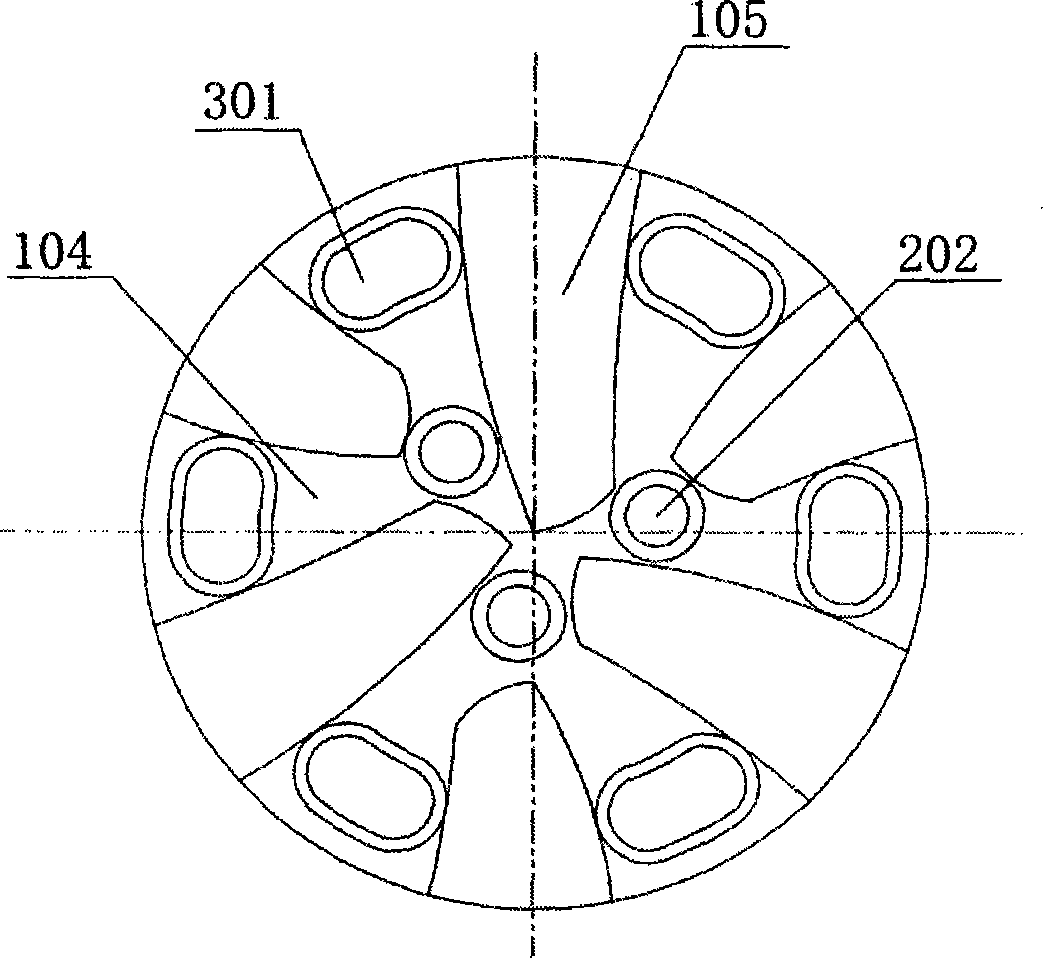

Composite bit with rotary cut rock-breaking function

ActiveCN102434105AExtended service lifeGood gauge effectDrill bitsConstructionsAgricultural engineeringPolycrystalline diamond

The invention discloses a composite bit with a rotary cut rock-breaking function, which comprises the composition of a rotary cut bit, a polycrystalline diamond compact (PDC) bit and a roller cone bit. The composite bit with the rotary cut rock-breaking function comprises a main body (1), a rotary cut bit roller cone (2), rotary cut bit cutting teeth (3), a PDC bit knife wing (4), PDC cutting teeth (5), an oil storage capsule (6) and a spray nozzle (7). The bit main body (1) comprises a roller cone shaft neck, a wiper block, a high-pressure mud channel and connecting screw threads. The composite bit with the rotary cut rock-breaking function has the advantages that the rotary cut bit cutting teeth in the composite bit impact, crush and cut rocks in rotary cut mode, central rock breaking efficiency is high, mechanical drilling speed is high, the composite bit has better dynamics performance, and the abrasion is even. Simultaneously, a bit bearing structure is improved, service life of the bit is prolonged while improvement of the rock-breaking efficiency is guaranteed, and the gauge protection effect is good. Different composite structures in the composite bit can achieve the effects of high central rock breaking efficiency, high mechanical drilling speed and good gauge protection effect.

Owner:SICHUAN DEEP & FAST OIL DRILLING TOOLS CO LTD

Waterpower oscillator

InactiveCN103410444AReal weight on bitEffectively exert pressure on bitVibration drillingWell drillingEngineering

The invention relates to a waterpower oscillator through which effective pressure can be exerted on a drill bit and well drilling efficiency can be improved in the technical field of oil exploitation. The waterpower oscillator comprises an upper connector, a stator, an outer shell and a lower connector all of which are sequentially connected in a sealed mode. A rotor is eccentrically arranged inside the stator, and the lower end of the rotor is sequentially connected with a cardan shaft upper connector, a cardan shaft and a cardan shaft transmission rod. The lower end of the cardan shaft transmission rod is connected with the outer shell in a sealed mode, the lower end of the outer shell is in threaded connection with the lower connector in a sealed mode, the lower end of the cardan shaft transmission rod is provided with a vibration valve in a matched and sleeved mode, and the vibration valve can do reciprocating sliding motion along the matched surface relative to the cardan shaft transmission rod. The lower end of the vibration valve is provided with a movable valve plate in a sealed and sleeved mode, wherein the movable valve plate and the vibration valve can do the synchronous movement, the upper end of the lower connector is correspondingly provided with a fixed valve plate attached to the movable valve plate, the movable valve plate and the fixed valve plate are respectively provided with a sector channel with the area larger than that of a half circle. An annular hollow part through which liquid can flow is formed among the rotor, the cardan shaft upper connector, the cardan shaft, the stator and the outer shell, the cardan shaft transmission rod is provided with a channel communicated with the annular hollow part, and the channel is communicated with a vibration valve cavity and the sector channels.

Owner:YANGZHOU TIANYE GASOLINEEUM MACHINERY

Ultralow-density oil-base drilling fluid and preparation method thereof

The invention relates to an ultralow-density oil-base drilling fluid. The invention is characterized in that the ultralow-density oil-base drilling fluid is prepared from the following raw materials: base oil, a density reducer, a suspension stabilizer, an emulsifier, a tackifier, a fluid loss additive, a flow pattern regulator, an alkalinity regulator and a calcium chloride water solution. The base mixed oil is prepared by the following steps: mixing 3# white oil, 5# white oil and natural gas prepared oil, adding a flash point enhancer while stirring, and standing for 0.5-1 hour; and stirring at low speed at the temperature of 30-40 DEG C, and slowly adding oil-soluble nano fumed silica while stirring, wherein the addition process is controlled at 2-3 hours. The ultralow-density oil-base drilling fluid has the advantages of favorable emulsifying stability, favorable rheological properties, high inhibition property for mud shale, high emulsion-breaking voltage, low filter loss, low density (0.75-0.90 g / cm<3>), and high sand carrying and pressure bearing capacities, is beneficial to cleaning the borehole and enhancing the mechanical drilling speed, solves the problem of severe lost circulation in the low-pressure formation and long-section shatter zone formation, and is especially suitable for low-pressure oil gas pools and depletion water-sensitive formations.

Owner:成都西油华巍科技有限公司 +1

Borehole wall stabilization method applicable to underbalanced drilling and experimental device

InactiveCN104563927APrevent intrusionImprove stabilitySemi-permeable membranesFlushingWell drillingWater activity

The invention relates to a borehole wall stabilization method applicable to underbalanced drilling and an experimental device. The method comprises the following steps: (1) determining stratum water activity of mud shale; (2) determining the pore pressure of a stratum to be drilled; (3) calculating the temperature of the stratum; (4) measuring the membrane efficiency of the stratum by using a membrane efficiency test experiment device; (5) determining the density of drilling fluid according to the liquid column pressure of the drilling fluid and borehole depth; (6) determining a difference value as an underbalanced value between the liquid column pressure of the drilling fluid and the pressure of the stratum if the density of the drilling fluid is determined, obtaining chemical potential difference by using the underbalanced value according to the principle that the total potential energy is balanced, and determining the activity of the drilling fluid according to the chemical potential difference and the stratum water activity; (7) adjusting the density or activity of the drilling fluid according to determined results so as to keep a borehole wall stable. The method has the beneficial effects that the action of chemical potential is taken into full consideration, the density of the drilling fluid at the time when the total potential energy of the stratum is kept balanced is given accurately, a drilling fluid filtrate is effectively prevented from invading the stratum, the stability of the borehole wall is improved, and the application and popularization of an underbalanced drilling technology are enhanced.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Turbo-type underground hydraulic oscillator

ActiveCN106639944AReduce frictionIncrease ROPVibration devicesVibration drillingPetroleumHigh frequency

The invention relates to a turbo-type underground hydraulic oscillator, and belongs to the technical field of petroleum underground equipment. The turbo-type underground hydraulic oscillator comprises an upper shell, a lower shell, an upper joint, a lower joint, a spline housing and a middle joint, wherein the upper shell is connected with the lower shell by screw thread by the middle joint, the lower joint is mounted by screw threads at the end of the lower shell, and the upper joint is mounted by screw threads at the end of the upper shell via the spline housing; a turbine shaft is mounted in the lower shell by an end cap of the turbine shaft and a thrust bearing. The hydraulic oscillator is driven by a turbine and does not have transverse oscillation caused by eccentric motion, so that the hydraulic oscillator does not have an effect on signal acquisition work of tools such as an LWD (Logging-While-Drilling) tool, an MWD (Measurement-While-Drilling) tool and the like; through own axial periodic high-frequency creeping, the friction condition between a drilling string and a borehole wall is changed, and the increasing speed of the coefficient of instantaneous sliding friction when a drill bit is elastically fed by the drilling string is lowered, thereby reducing friction resistance and improving mechanical drilling speed.

Owner:YANGTZE UNIVERSITY

Process for preparing drilling fluid for preventing polycrystalline diamond compact (PDC) bit balling

InactiveCN101892036AImprove anti-slump performanceImprove integrityDrilling compositionCelluloseWater dispersible

The invention relates to a process for preparing drilling fluid, in particular to a process for preparing the drilling fluid for preventing polycrystalline diamond compact (PDC) bit balling. The process comprises a construction process and a dosage formula of treating agents and is characterized in that: according to the dosage formula, the treating agents are prepared by mixing clear water polymer original slurry, poly anionic cellulose (PAC), calcium carbonate (QS-4), carboxymethyl starch (CMS), sulfonated phenolic resin(SMP-2), water dispersible cation emulsified asphalt powder (SFT-1), sodium chloride(NaCL) and sodium formate (WT-1) in a mass ratio of 1,000:2-3:30-40:20-30:2-3:1.5-2:50-100:20; and the construction process comprises the following steps of: according to a circulation circle, uniformly mixing a coating agent PAC, a filtrate reducer CMS, a salt and high-temperature resistant filtrate reducer SMP-2 and an anti-sloughing lubricant SFT-1 for 12h at first; adding QA-4, NaCL, WT-1 into the mixture and uniformly mixing the mixture; and regulating the mixture to have a density Rho of 1.06 to 1.10g / cm<3>, a funnel viscosity T of 38 to 45s and an API water loss FL of 4 to 6ml. The process has the advantages of effectively preventing the balling of a sticking bit and a PDC bit at a lower curved section, reducing a frictional resistance and a torque, eliminating a sticking phenomenon, improving a mechanical drilling rate and ensuring downhole safety.

Owner:中国石油集团川庆钻探工程有限公司长庆钻井总公司

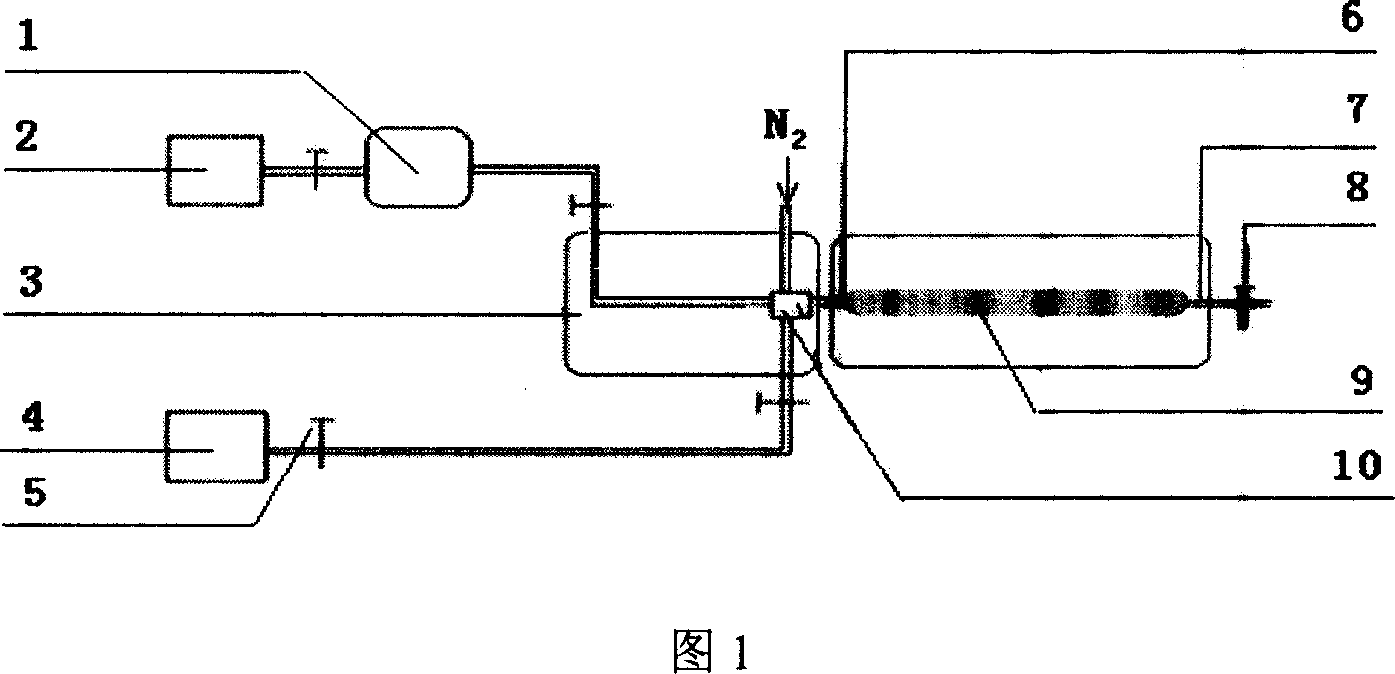

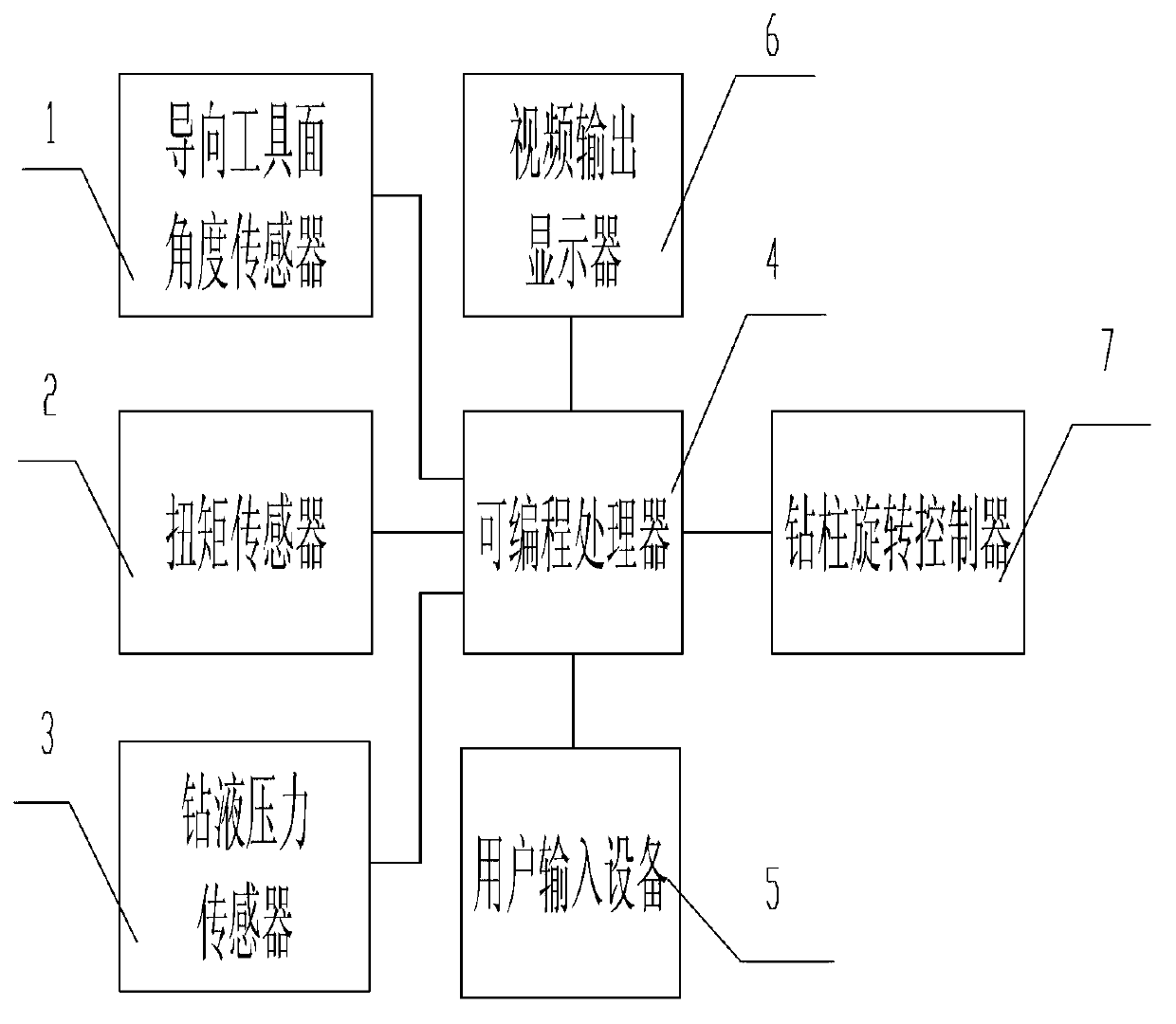

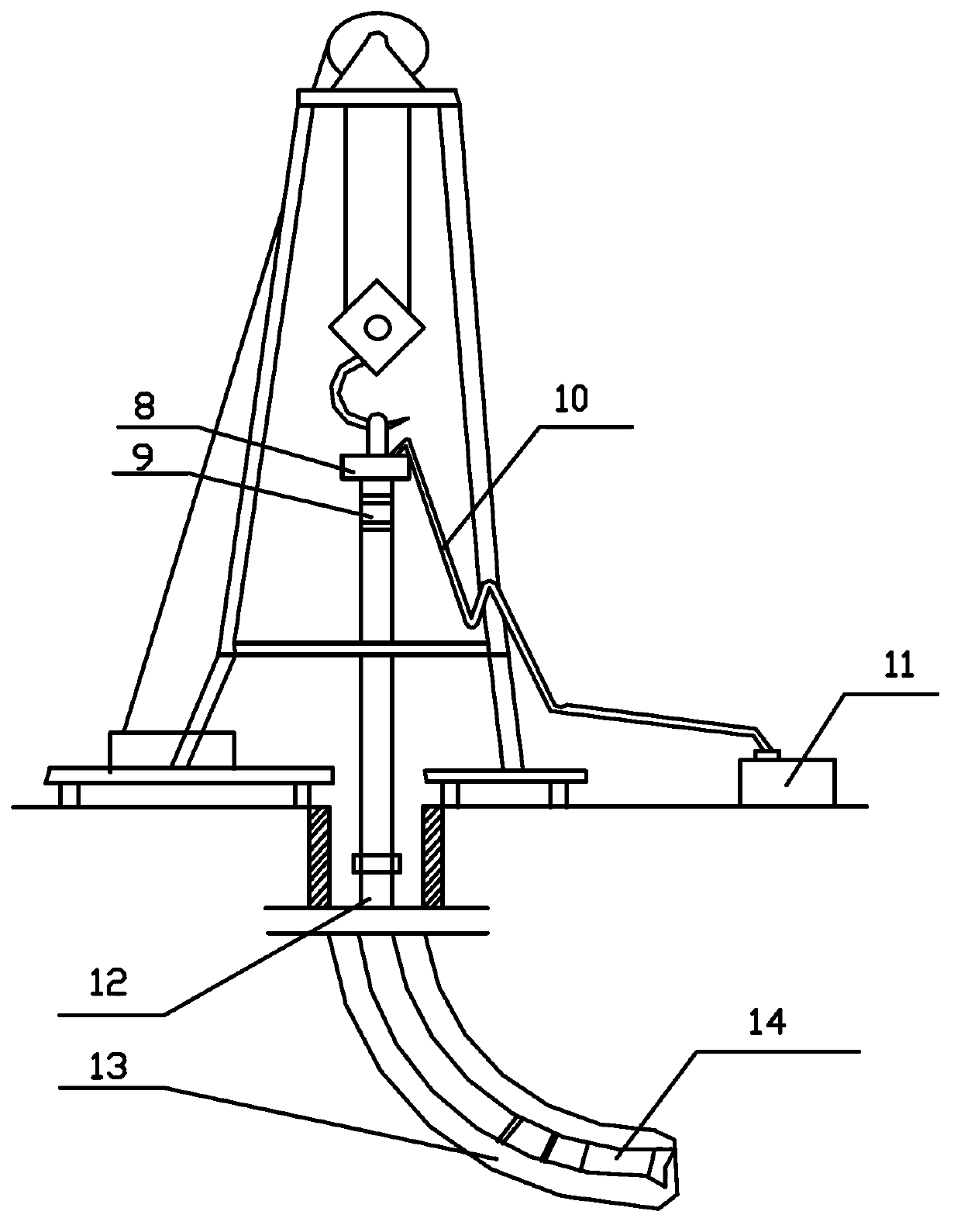

Automatic sliding well drilling control device

InactiveCN103277048AReduce work pressureImprove track qualityDirectional drillingAutomatic control for drillingWell drillingUser input

The invention relates to an automatic sliding well drilling control device, and belongs to the technical field of oil drilling tool design. The automatic sliding well drilling control device is characterized by being composed of a guiding tool face angle sensor (1), a toque sensor (2), a drilling fluid pressure sensor (3), a programmable processor (4), a user input device (5), a video output displayer (6) and a drill column rotating controller (7). The programmable processor (4) is used for receiving output signals form the guiding tool face angle sensor (1), the toque sensor (2) and the drilling fluid pressure sensor (3), the output signals is processed by the programmable processor (4) and the received information and a processing result are displayed on the video output displayer (6). After the programmable processor (4) processes the received information, the programmable processor (4) outputs a control instruction to the drill column rotating controller (7) and controls the drill column rotating controller (7). According to the automatic sliding well drilling control device, a tool face can be modified and oriented fast and accurately, the conversion between the sliding and the rotating drilling is fast, the drilling ability in a horizontal section is enhanced, and the automatic sliding well drilling control device has the advantages that mechanical drilling speed is increased, well track quality is improved, and the service life of a motor under a well is prolonged.

Owner:YANGTZE UNIVERSITY

Rotary jet flow PDC drill bit

InactiveCN105927160AIncrease ROPReduce the possibilityDrill bitsDrilling rodsFoundation engineeringHourglass

The invention relates to drill bits for drilling in the fields of oil-natural gas, mine engineering, building foundation engineering construction, geology and hydrology, in particular to a rotary jet flow PDC drill bit which comprises a drill bit body, knife wings and PDC cutting teeth. The knife wings are positioned at the crown of the drill bit body, the PDC cutting teeth are positioned on the knife wings, a cavity with the lower end open is arranged in the drill bit body, a diversion plate, a compression cavity and a storage cavity are sequentially arranged in the cavity from top to bottom, the compression cavity is communicated with a dendritic runner penetrating the diversion plate, a main body of the dendritic runner is of a hourglass-shaped structure with two ends wide and middle narrow, and a rotating element is arranged in the storage cavity and composed of a rotating element body and rotating blades spirally arranged on the periphery of the rotating element body. The rotary jet flow PDC drill bit is simple in structure and high in impact capability and mechanical drilling speed, secondary abrasion of the drill bit caused by rock debris is avoided, and service life is prolonged; a reverse nozzle joint structure is adopted, so that energy consumption of well drilling is lowered.

Owner:YICHANG SHENDA PETROMACHINE +1

Tangential injection type whirl flow jet flow grinding drill bit for horizontal well

The invention discloses a tangential injection type whirl flow jet flow grinding drill bit for a horizontal well. The grinding drill bit mainly comprises a PDC drill bit body and is characterized in that a debris discharging groove in the gauge protection portion of the PDC drill bit body is omitted, and the PDC drill bit body is internally and additionally provided with a tangential injection type rotating jet flow sand washing device, a high-concentration turbulence sand pumping device and a jet flow smashing device. According to the tangential injection type rotating jet flow sand washing device, high-speed rotation jet flow is generated through tangential injection type rotating jet flow spray nozzles, a well bottom whirl flow field beneficial to rock debris cleaning is formed, the stress condition of well bottom rock debris is improved, and the well bottom rock debris cleaning efficiency is improved. The high-concentration turbulence sand pumping device pumps and sucks the well bottom fluid based on the principle of a sand pumping pump, the well bottom pressure difference is reduced, unbalance is achieved, and the mechanical drilling speed is increased. The jet flow smashing device effectively smashes the rock debris based on the principle of a jet mill, the rock debris carrying efficiency is improved, the rock debris bed in the horizontal well is eliminated radically, and safe and efficient drilling of the horizontal well is finally achieved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com