Patents

Literature

1390 results about "Tunnel engineering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

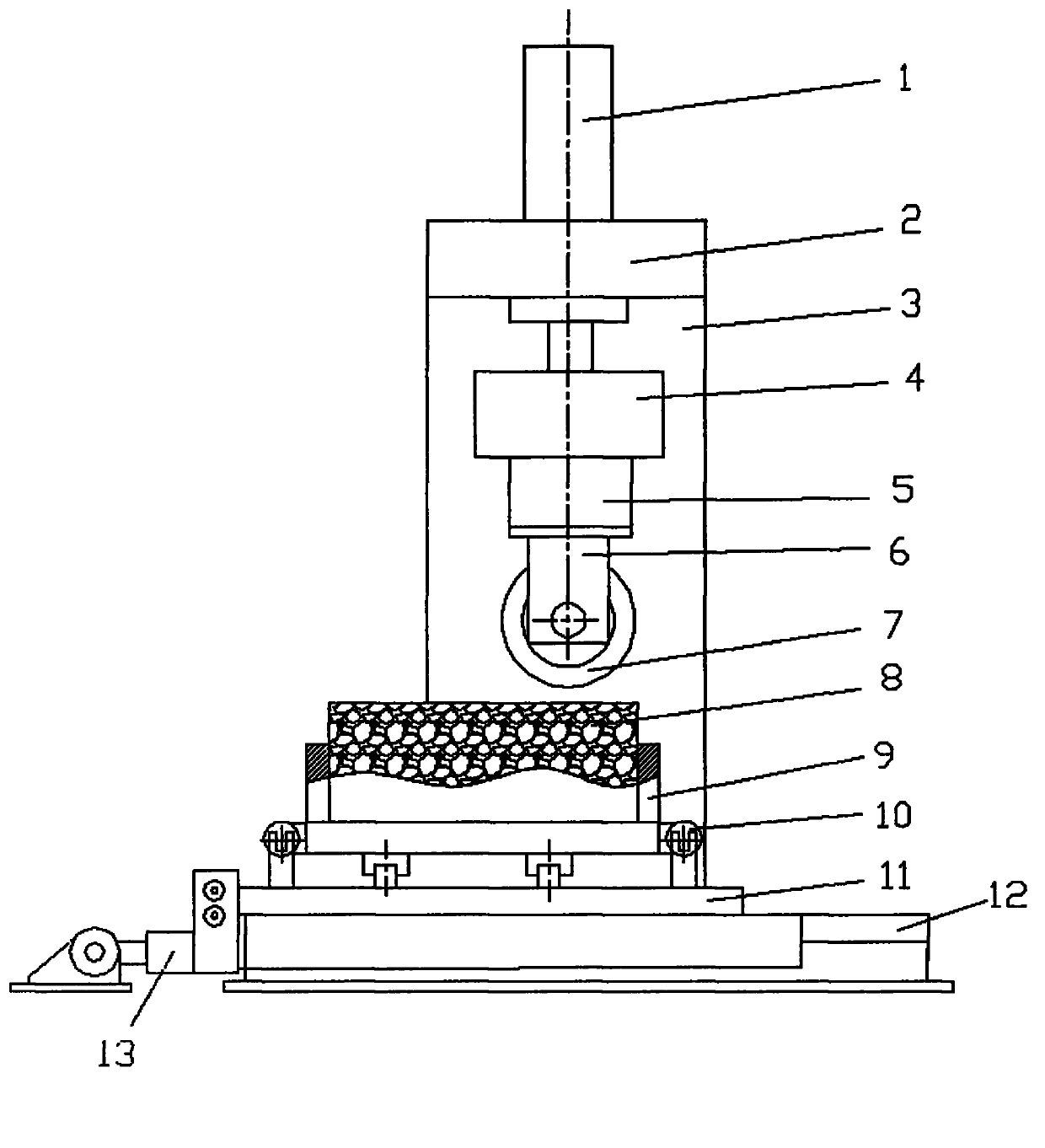

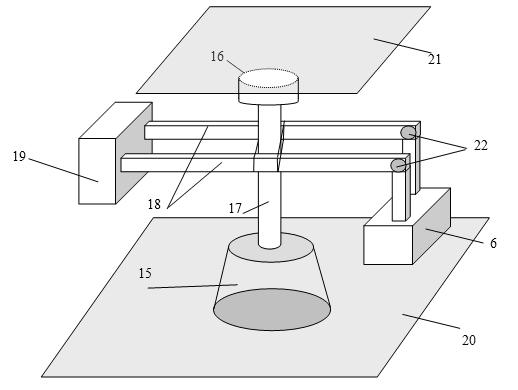

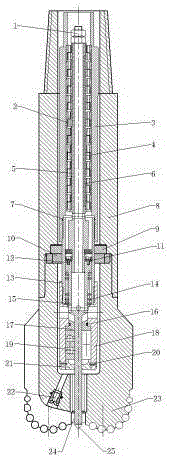

A hard rock hobbing cutter rock breaking characteristic testing device

InactiveCN103969141AObservable breakage featuresInvestigating abrasion/wear resistanceInvestigating machinabilityHobbingData acquisition

A hard rock hobbing cutter rock breaking characteristic testing device used in the field of tunnel engineering is provided. A rock silo supporting seat is positioned on a guide rail pair and realizes longitudinal motion by a longitudinal-moving hydraulic cylinder; a rock silo is positioned on the rock silo supporting seat and realizes lateral movement by lateral moving hydraulic cylindersfixed on the rock silo supporting seat; rock samples are positioned inside the rock silo. Two columns are vertically arranged at both sides of the rock silo, top ends of the columns are connected by a beam and thus a gantry structure is formed. A vertical hydraulic cylinder is fixed on the beam, and the lower part of the vertical hydraulic cylinder is connected with a walking beam. Under the walking beam, a hobbing cutter is installed to simulate the process of hobbing cutter rock breaking, or a similar hobbing cutter wearing module is installed to simulate the process of similar hobbing cutter wearing. An industrial computer, a data acquisition card, a three-axis force sensor, an acoustic emission device and a high-speed digital camera system are used to monitor the processes of hobbing cutter rock breaking and wearing. The device is capable of simulating the process of rolling-type rock breaking of the hobbing cutter, the process of rolling and impact-combined type rock breaking of the hobbing cutter and the process of similar hobbing cutter wearing.

Owner:CENT SOUTH UNIV

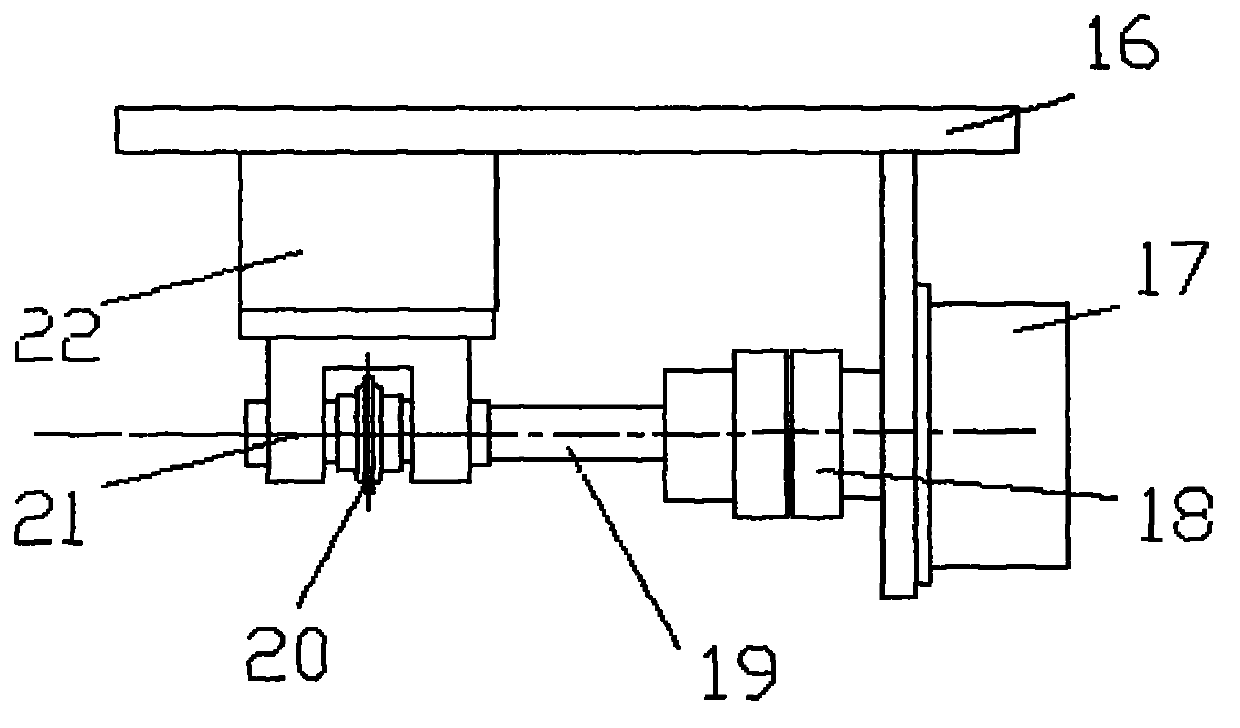

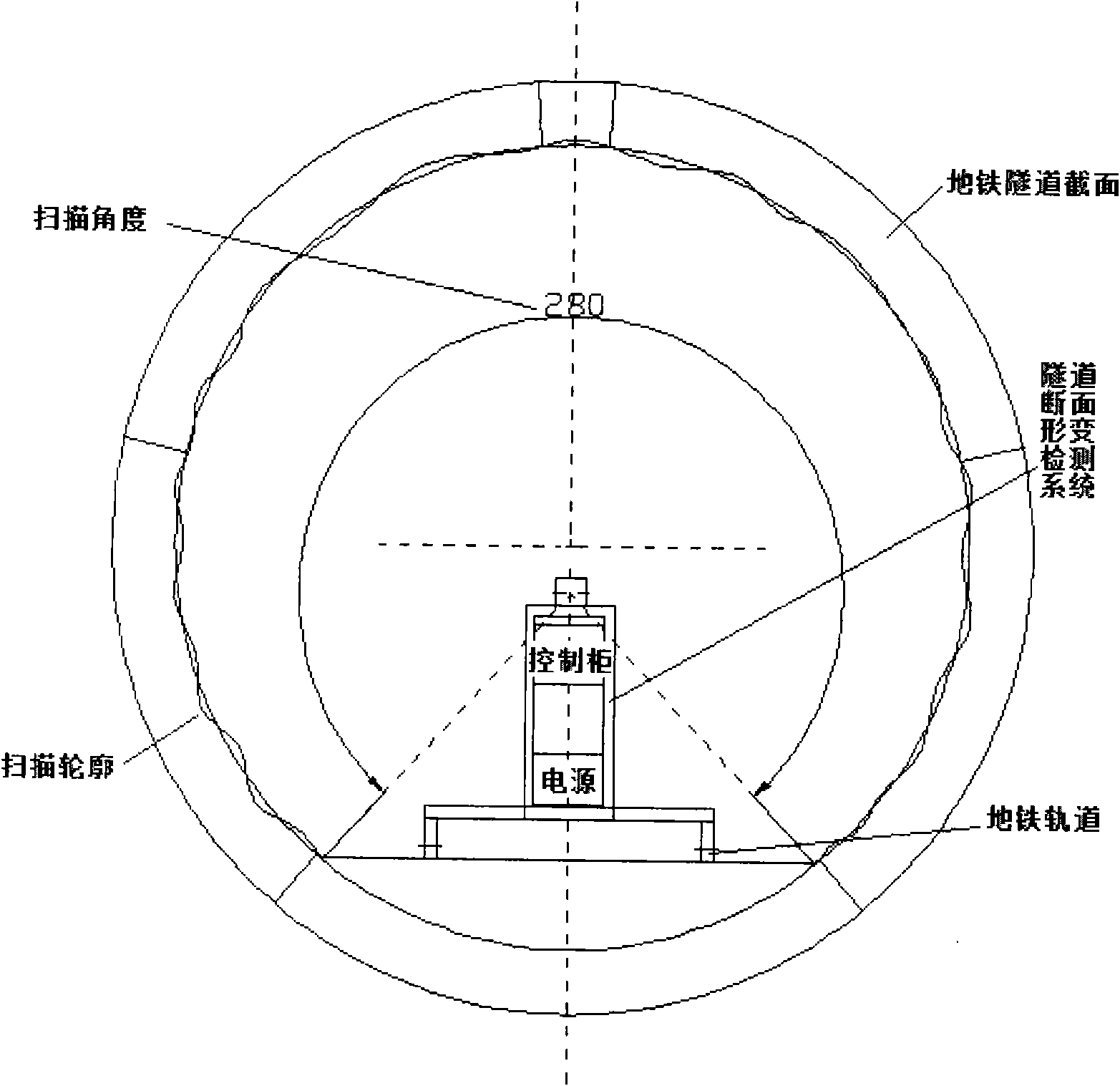

Metro tunnel fracture surface deformation detection system

ActiveCN101943577AWith long-term useWith automatic monitoringMeasurement devicesRailway auxillary equipmentData processing systemEngineering

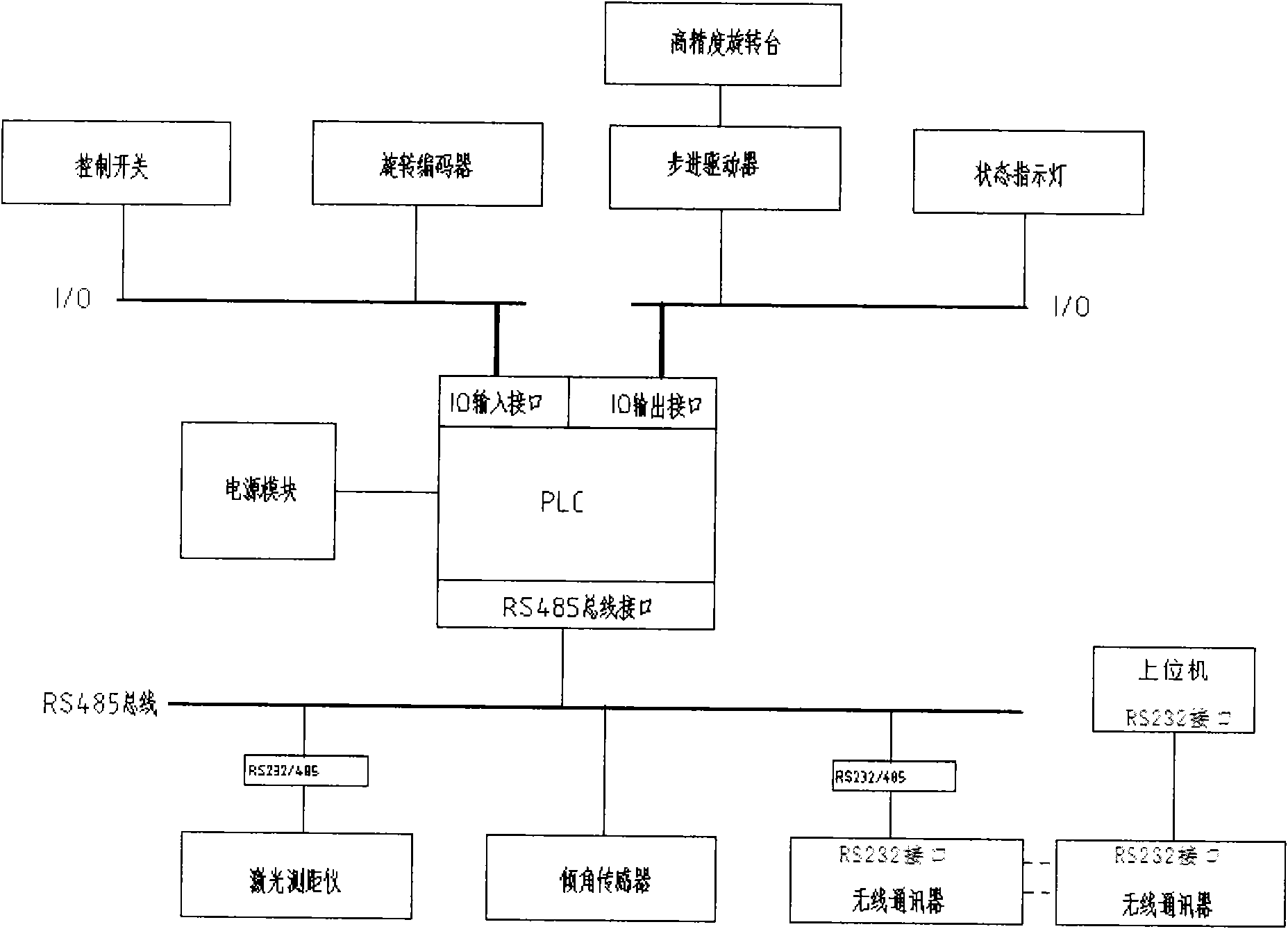

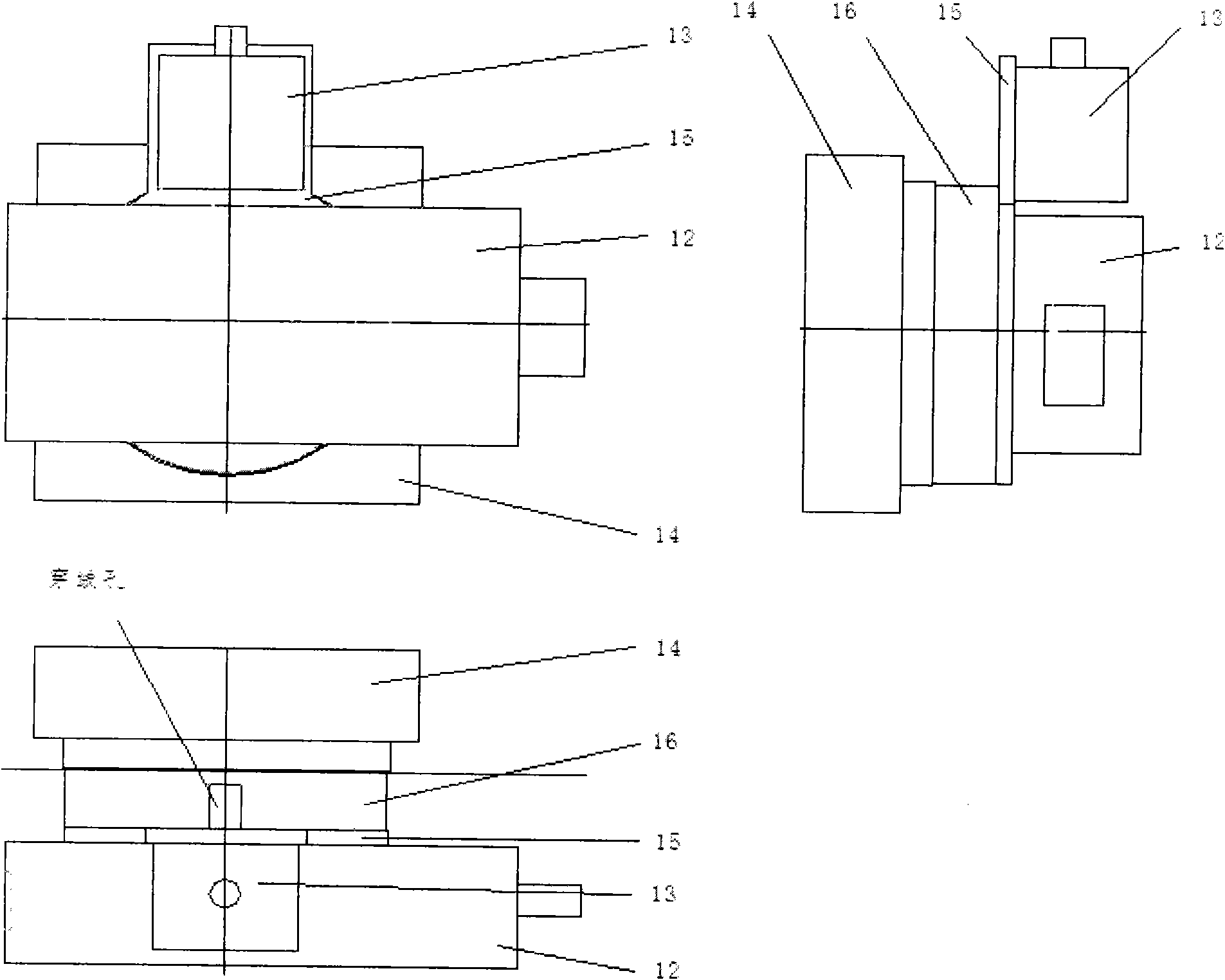

The invention discloses a metro tunnel fracture surface deformation detection system, belonging to the tunnel engineering monitoring technical field. The system comprises a fracture surface scanning device, a mileage positioning device, an electrical equipment control device, a power source, a track detection vehicle and a station data processing system, wherein, the fracture surface scanning device, the mileage positioning device and the electrical equipment control device are arranged on the track detection vehicle; the power source is respectively connected with the fracture surface scanning device, the mileage positioning device and the electrical equipment control device through a power source convertor to supply power for the fracture surface scanning device, the mileage positioning device and the electrical equipment control device; a PLC controller is arranged in the electrical equipment control device; a rotary coder in the mileage positioning device, a sensor in the fracture surface scanning device and a rotary table stepped driver are respectively connected with the PLC controller; the PLC controller is connected with a wireless communicator through a wireless communicator in the station data processing system. The whole detection system of the invention has high portable integration degree, automatic operation process, convenient operation, low specialty technical requirements, rapid operation speed, extremely-time section surface measuring and high measuring precision, and the system precision is less than 3mm.

Owner:上海地铁盾构设备工程有限公司

Method for monitoring and measuring full section of tunnel through three-dimensional laser

InactiveCN102564393AGuarantee authenticityAvoid human influenceProfile tracingPoint cloudMaterial resources

The invention relates to a method for monitoring and measuring a full section of a tunnel through three-dimensional laser, and belongs to the field of tunnel engineering construction monitoring. The method comprises the following steps of: arranging target points in a tunnel to be measured according to a requirement; determining whether to adopt one-station scan or multi-station scan according to the monitoring length of the tunnel; erecting an instrument at a proper position and scanning the full section of the tunnel; after the scan is finished, importing data into a computer; registering point cloud data acquired through the scan to generate a three-dimensional model by applying three-dimensional data processing software; and generating a comparison model by combining a previous three-dimensional model for the same tunnel at different time, and selecting a specific section and characteristic points to generate a variation analysis chart and a variation analysis sheet for a corresponding position. By the method, the full section of the tunnel is monitored in real time, the speed and accuracy of monitoring and measuring work are improved, manpower and material resources are saved, the speed and quality for monitoring and measuring the tunnel are improved, and reliable guarantee is provided for tunnel engineering construction.

Owner:BEIJING UNIV OF TECH +1

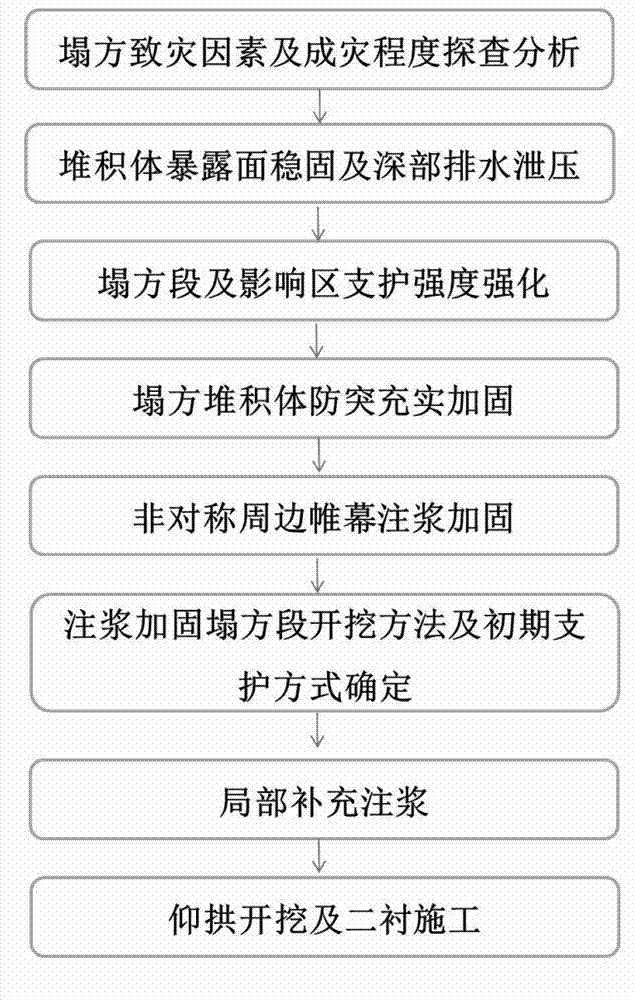

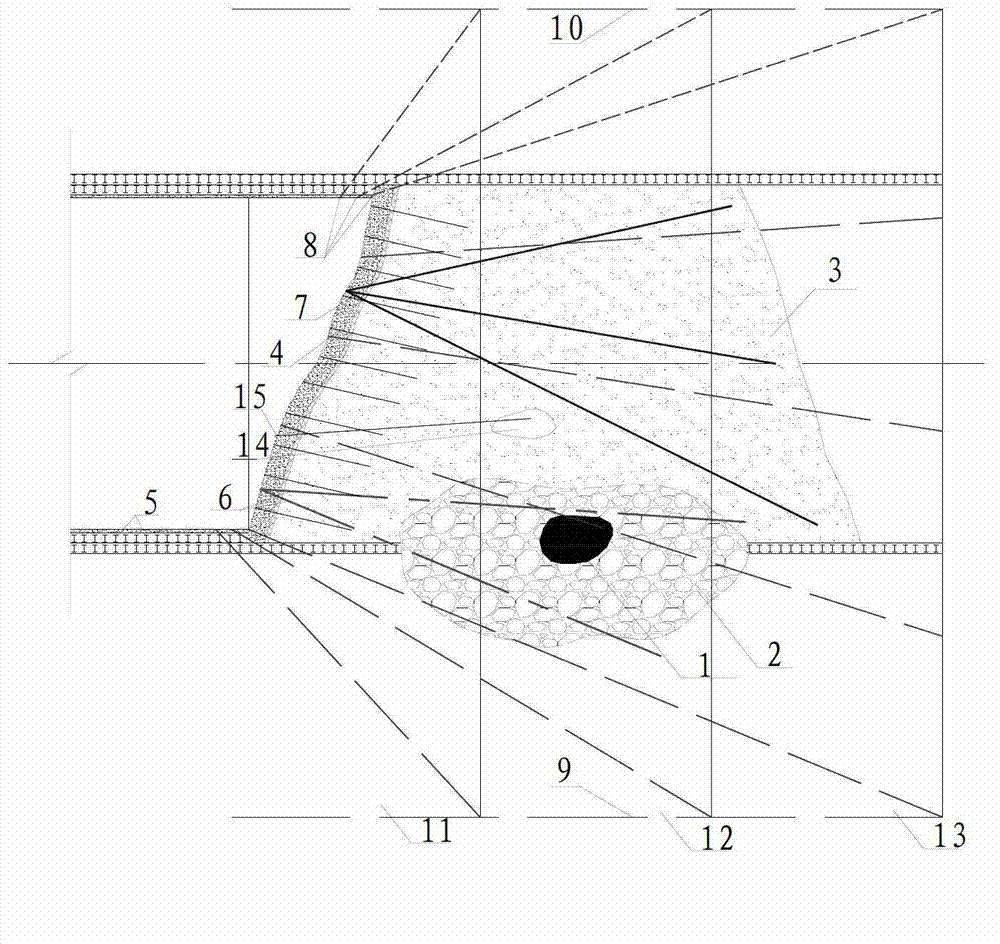

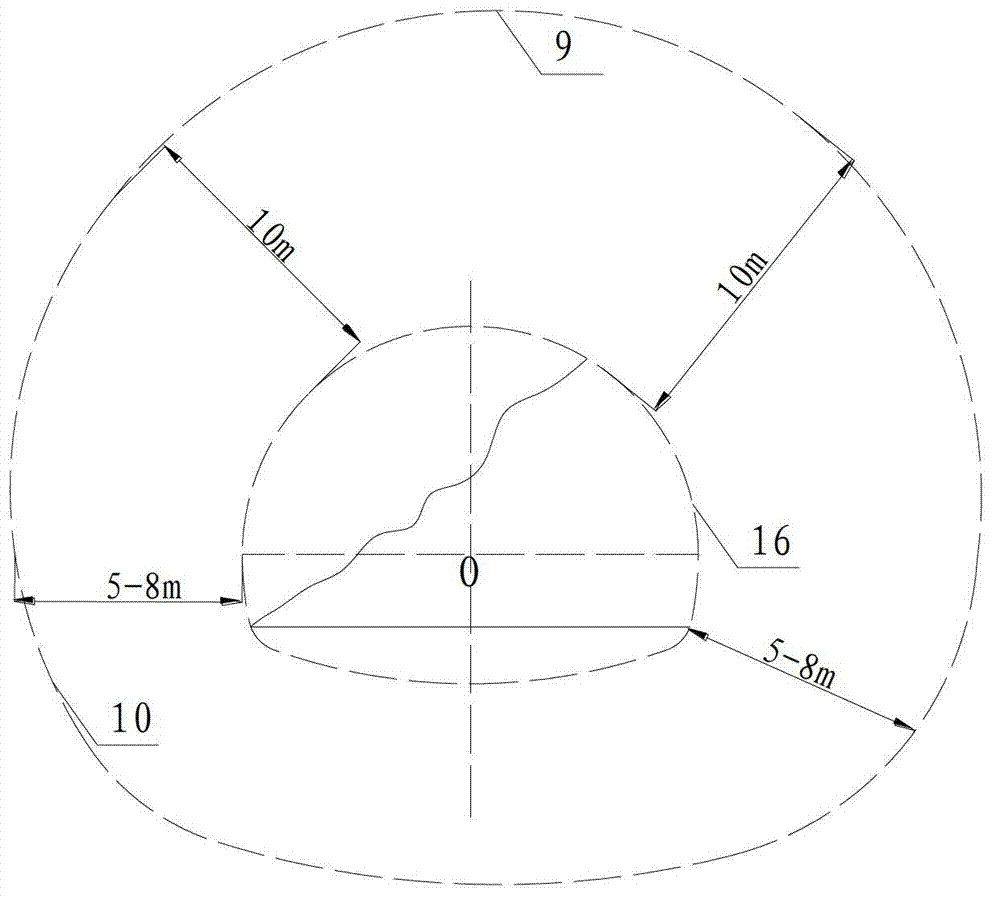

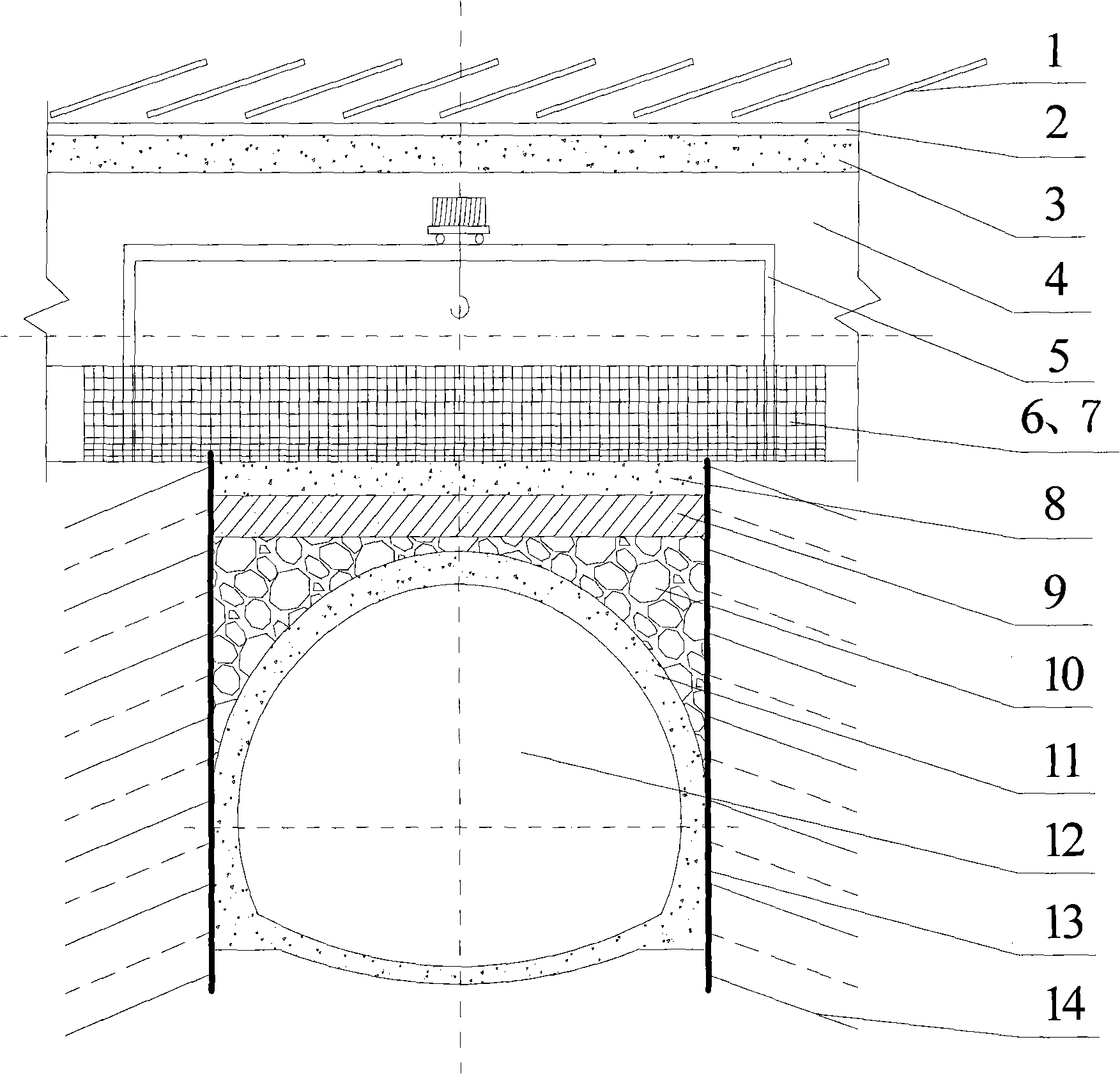

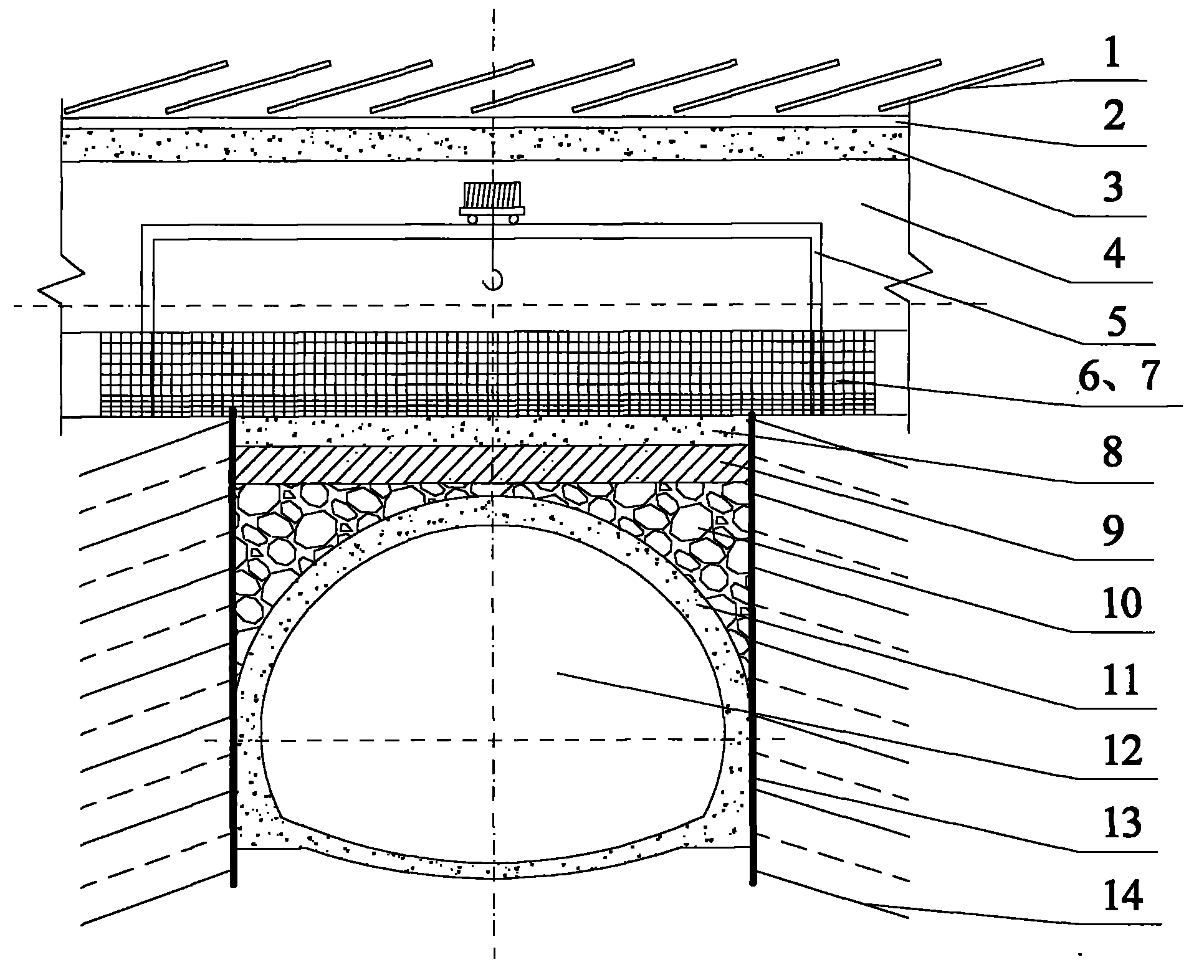

Control method of surrounding rocks in water-rich very-broken surrounding rock tunnel collapse sections

ActiveCN103089275AImprove stabilityEnsure stabilityUnderground chambersDrainageSocial benefitsRock tunnel

The invention relates to the field of tunnel engineering construction, in particular to a control method of surrounding rocks in water-rich very-broken surrounding rock tunnel collapse sections. According to the control method, problems in the existing methods that managing circle is long, reinforcing range and effect are bad, secondary geological disasters are triggered easily because of deformation and cracking of exceeding clearance limit of preliminary bracing and the like are solved. The method includes the following steps: searching and analyzing factors leading to collapse and disaster degree, stabilizing exposed face of an accumulation body and dewatering and decompressing deep parts, strengthening supporting intensity in the collapse sections and influencing areas, outburst prevention filling and strengthening the collapse accumulation body, grouting reinforcing asymmetrical peripheral curtains, confirming an excavating method in grouting reinforcing collapse sections and primary supporting patterns, replenishing grouting in parts, excavating inverted arches, and constructing second liners. The control method of surrounding rocks in water-rich very-broken surrounding rock tunnel collapse sections has the advantages that collapse disposing construction period of water-rich very-broken surrounding rock tunnels is shortened, reinforcing range and intensity of the surrounding rocks are guaranteed, grouting reinforcement is fully conducted on the surrounding rocks in direct collapse areas, deformation in the preliminary bracing is relieved, occurrence of the exceeding clearance limit and the secondary geological disasters is avoided, disposing quality of collapse accidents is improved effectively, and good social benefit and economical benefit are created.

Owner:SHANDONG UNIV

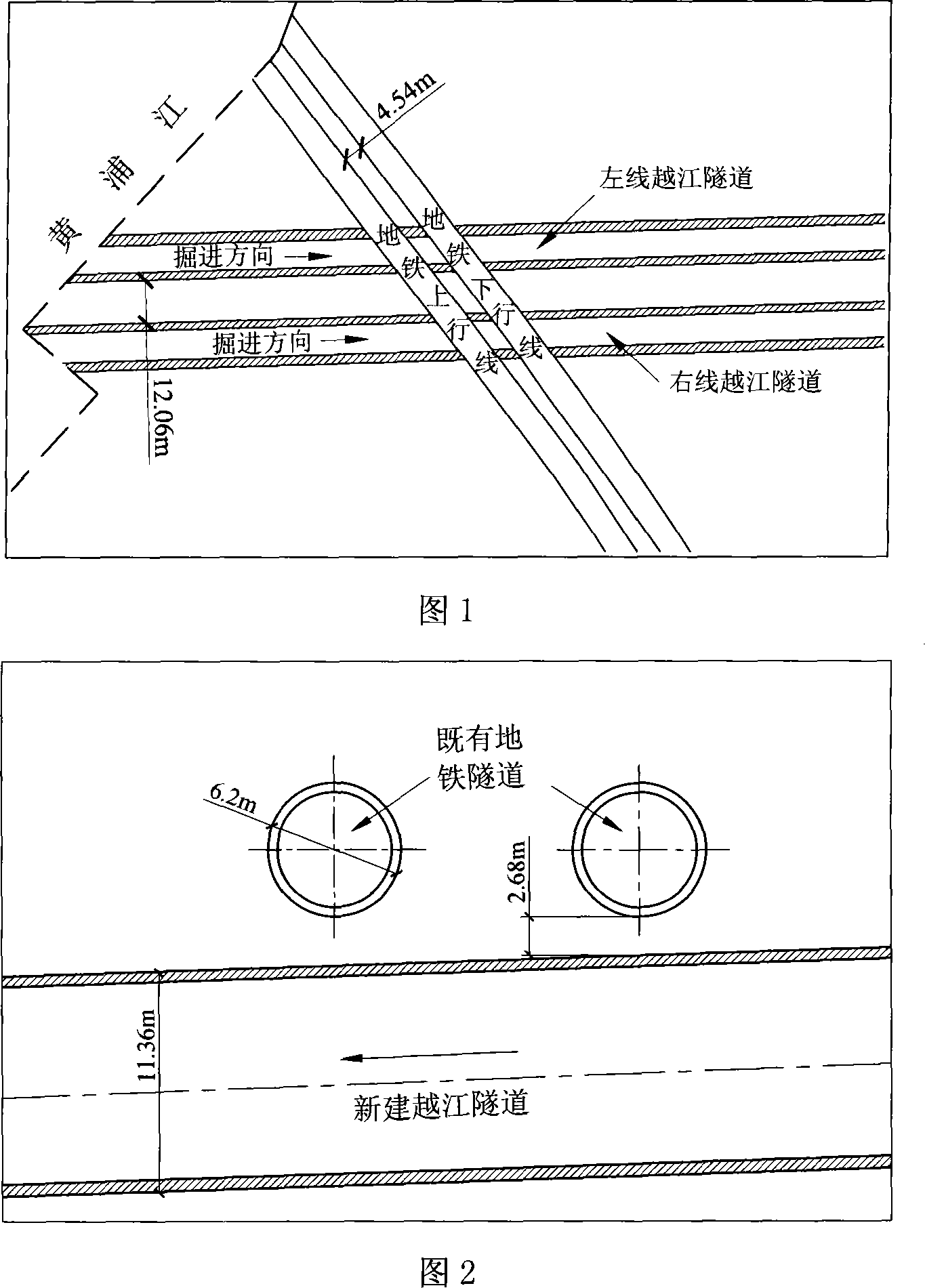

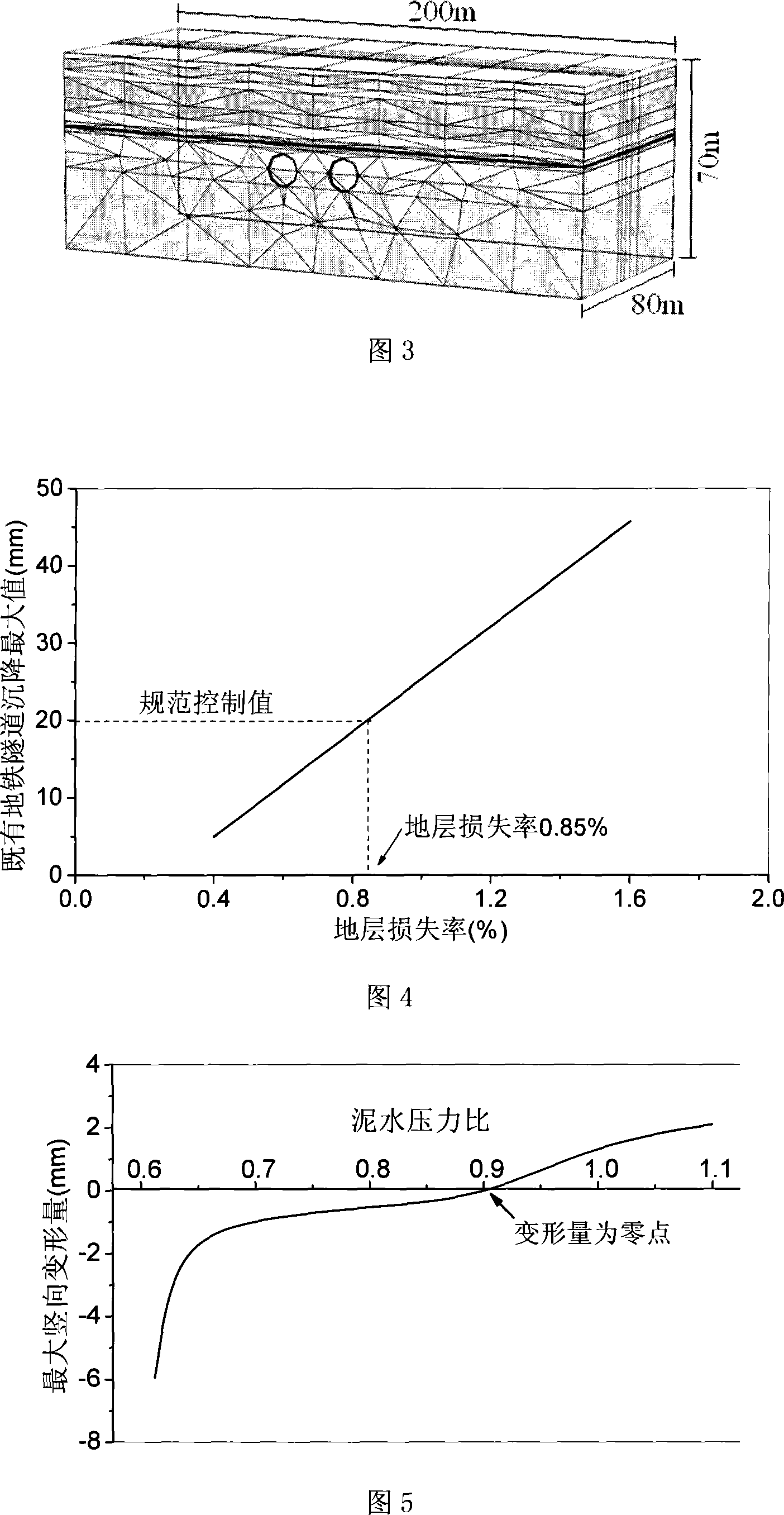

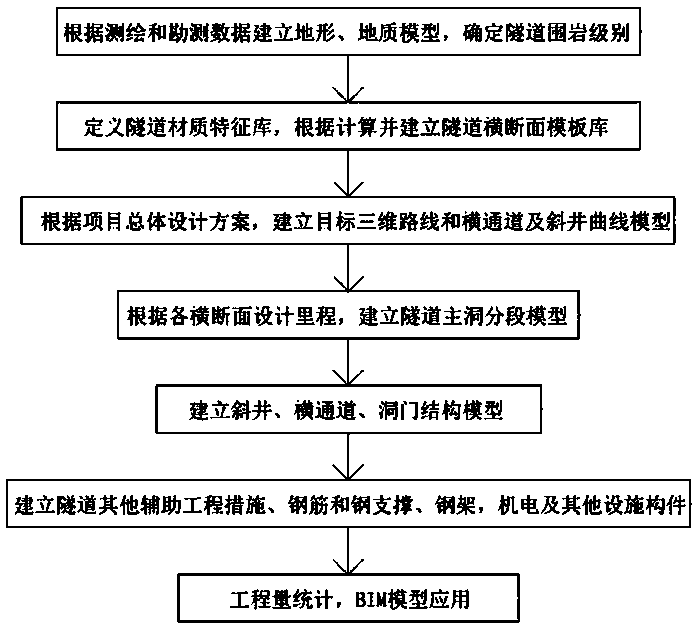

Large diameter tunneling close range down-traversing small diameter subway tunnel distortion control method

InactiveCN101215969AGuarantee smooth constructionEnsure safetyTunnelsUnderground tunnelFinite element method

The invention discloses a method for controlling distortion for deep large diameter shield tunnels to under-pass small diameter tunnels, which pertains to the technical field of tunnel engineering. According to the method, the control range of the stratum loss ratio of newly established tunnels and the optimum value of the support pressure of the shield cut surface are acquired by using the finite-element method; soil pressure in front of the shield cut surface is kept relatively balanced by setting the optimal value of the support pressure, and the support pressure fluctuation range of the cut surface is controlled to range from minus 10kPa to plus 10kPa; the stratum loss ratio of the newly established tunnels is controlled within the allowed range. According to the construction technique measures, a test propelling area is arranged before the shield reaches a cross position. In the area, construction is carried out according to the situation of the existing underground tunnels above; and construction parameters are controlled and regulated to adjust the support pressure, the propulsive velocity and the amount of the grout to be injected in time; the shield passes through the cross position in combination with the optimal values of the construction parameters of the test propelling area. The invention can not only ensure the construction of tunnels to be carried out safely and smoothly, but also minimize the influence of construction on ambient environment.

Owner:SHANGHAI JIAO TONG UNIV

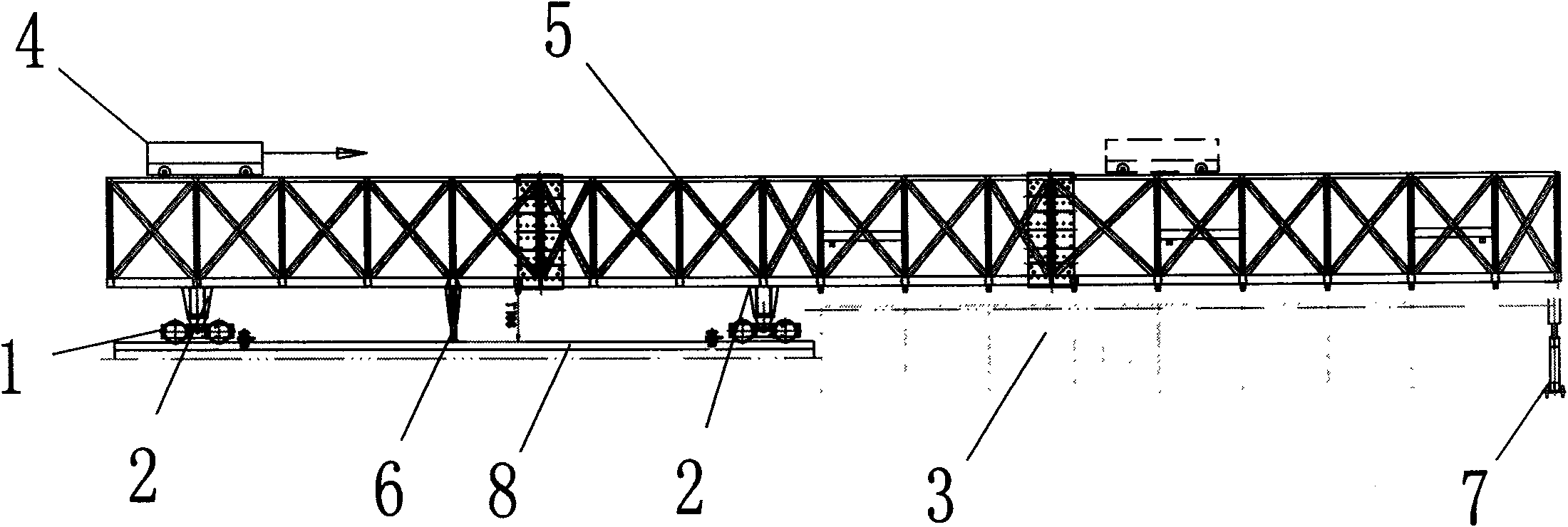

Highway tunnel designing method based on BIM

The invention discloses a highway tunnel designing method based on BIM. The highway tunnel designing method based on the BIM includes the steps that 1, according to mapping and reconnaissance data, aterrain model and a geologic model are built, and tunnel surrounding rock grades are determined; 2, a tunnel texture feature library is defined, and a tunnel cross section model library is establishedthrough calculation; 3, according to a project overall design scheme, a tunnel three-dimensional path and cross aisle and inclined shaft space curve model is built; 4, according to design kilometersof all tunnel cross sections, a tunnel main cave subsection model is built; 5, an inclined shaft model, a cross-aisle model and a tunnel portal structure model are built; 6, other tunnel auxiliary engineering measure components including reinforcing steel bars, steel shotcrete, steel frames and electromechanical parts are built; 7, tunneling work amount accounting is conducted, and a BIM model isapplied. According to the highway tunnel designing method based on the BIM, the terrain model and the geologic model are fused with a tunnel main body, three-dimensional paths can be modified in realtime, related drawings are automatically modified, therefore, the purpose is achieved that engineering design information is completely reflected in the BIM model, and model information transfer and application in the later period are facilitated.

Owner:HENAN PROVINCIAL COMM PLANNING & DESIGN INST CO LTD

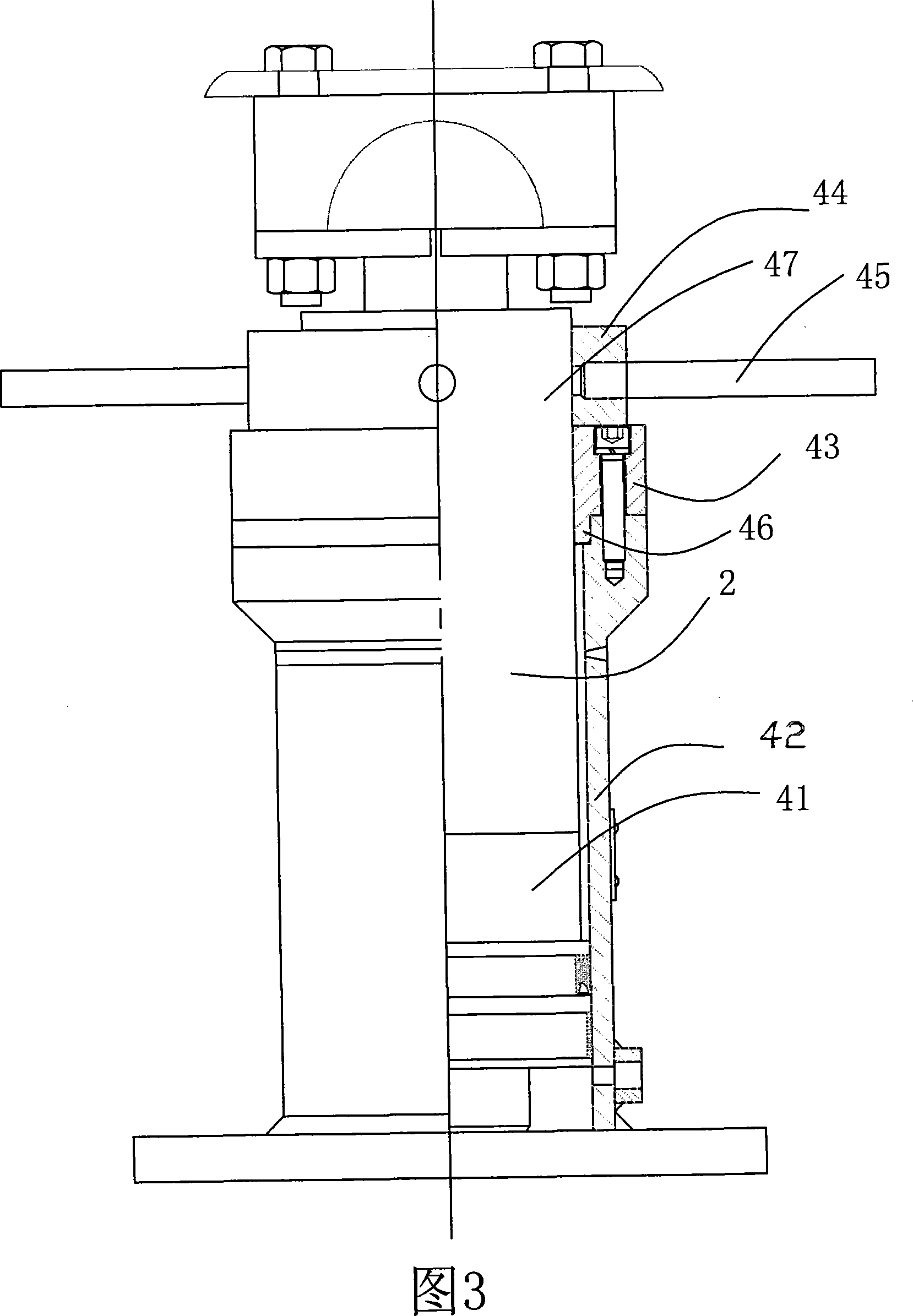

Self-propelled inverted arch template construction method

The invention discloses a self-propelled inverted arch template construction method for a tunnel, which comprises the following construction steps of: setting out a control line for an inverted arch digging section and a longitudinal construction joint according to the design requirement; performing smooth-wall blasting digging on an inverted arch of the tunnel; moving an inverted arch trestle in place; conveying inverted arch stone slag out of the tunnel by using an excavator and a conveying device and abandoning the stone slag in a slag field, and cleaning an inverted arch base; assembling an inverted arch end template; laying steel rails, and moving the inverted arch template to longitudinally move in place per se; starting a hydraulic device to lower the inverted arch template, and supporting the template firmly by using a screw jack; pouring inverted arch concrete; and curing the concrete with equal strength, folding the screw jack, withdrawing a hydraulic cylinder, and releasing a die. The construction method has low cost, is convenient to operate, and improves the construction efficiency; and the longitudinal construction joint is vibrated densely compared with common template construction, and has positive effect of improving the construction quality of tunnel engineering.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

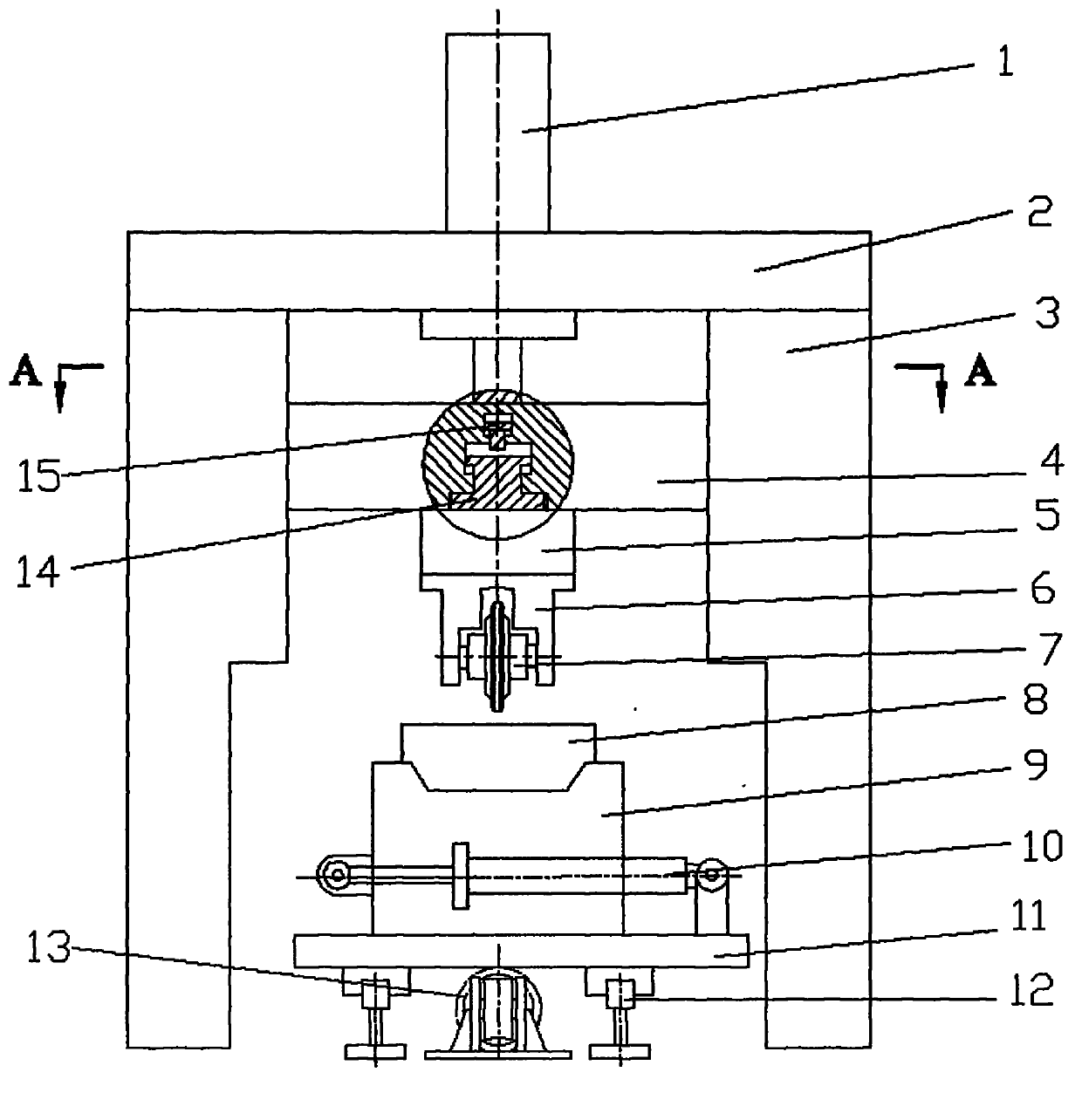

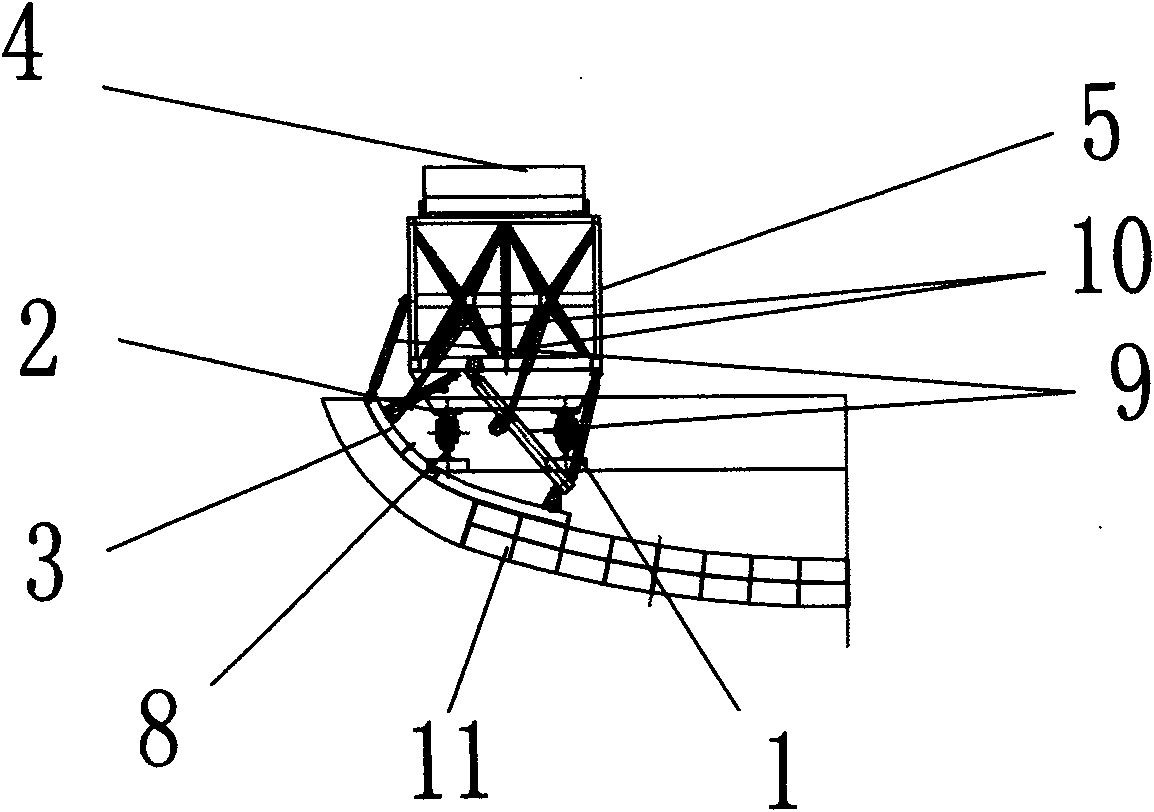

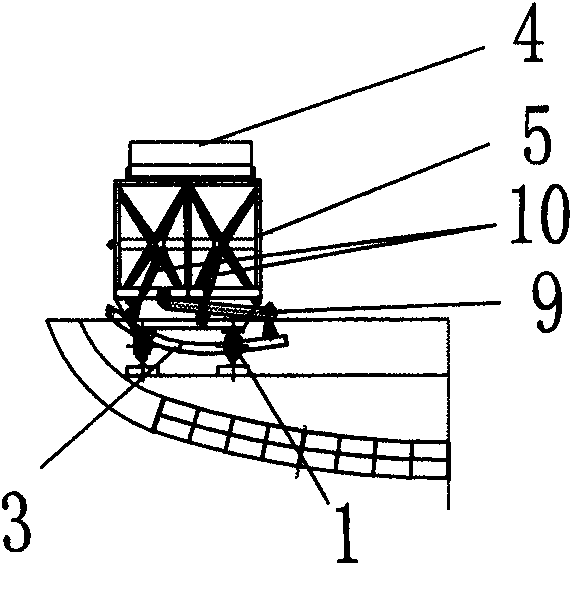

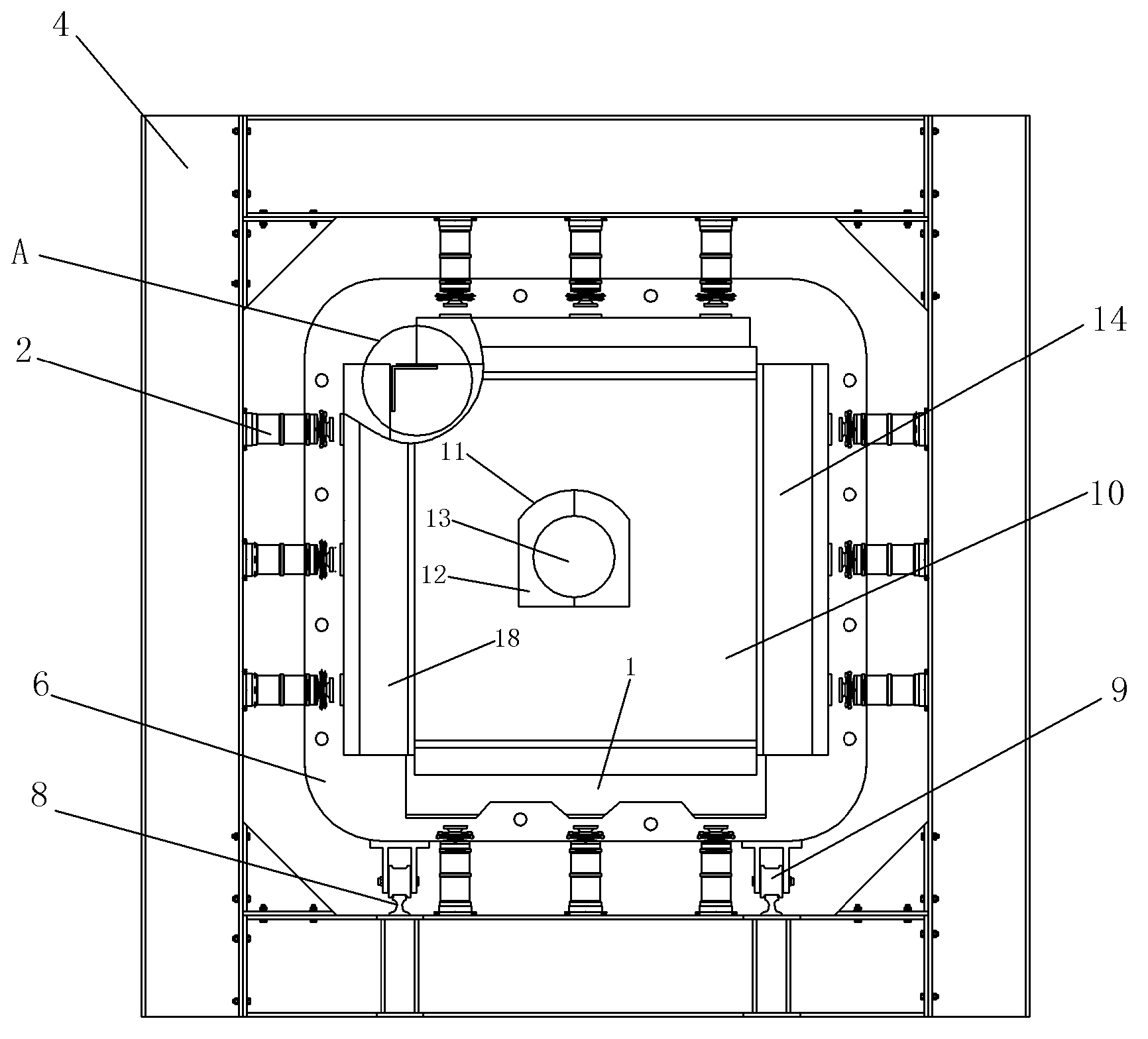

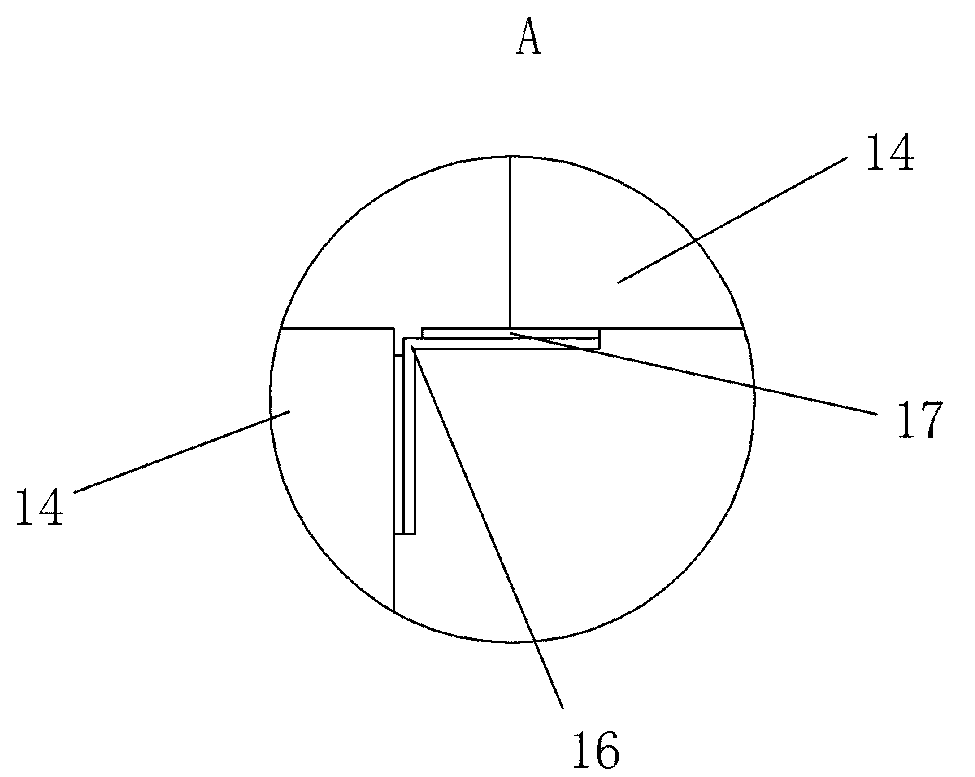

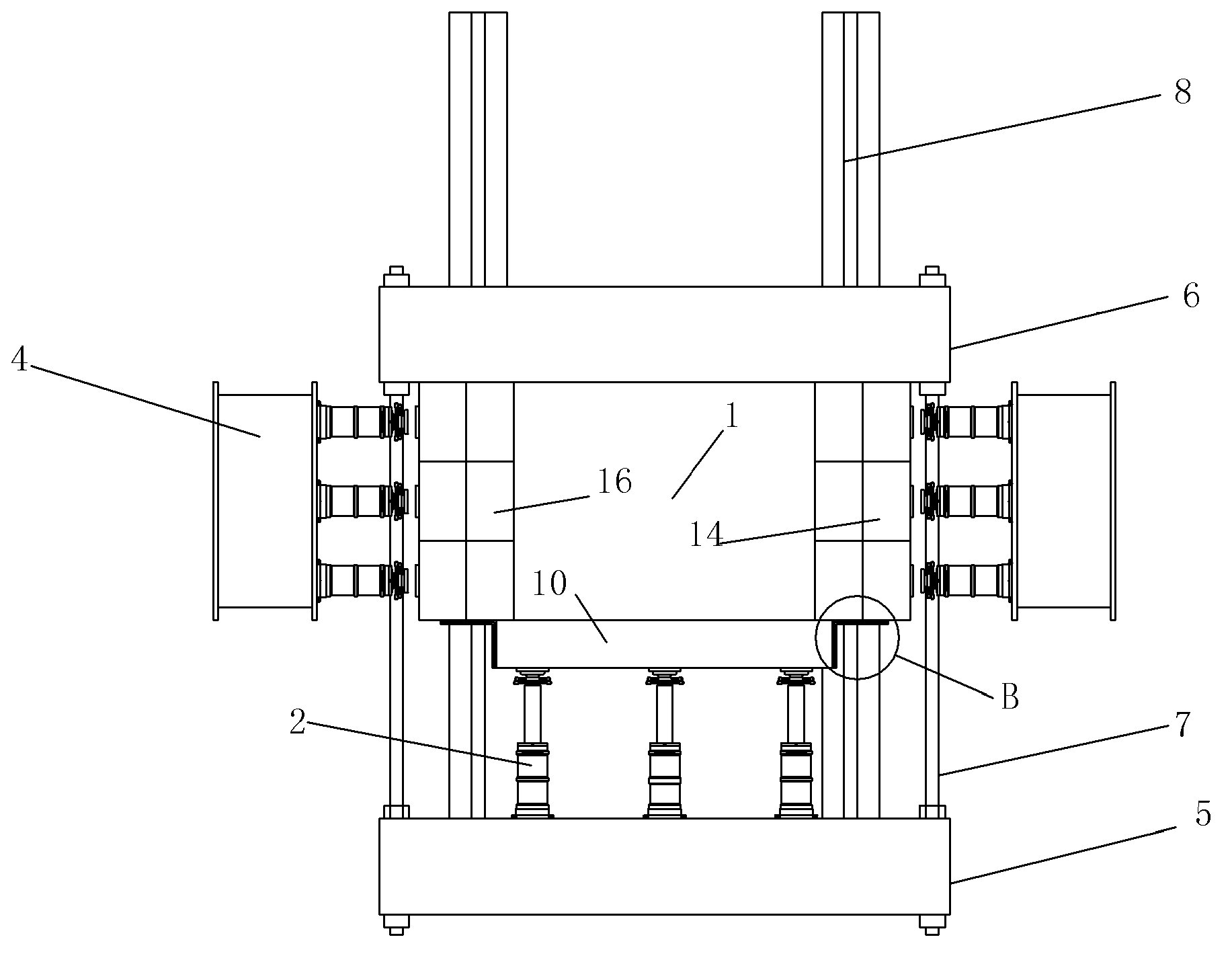

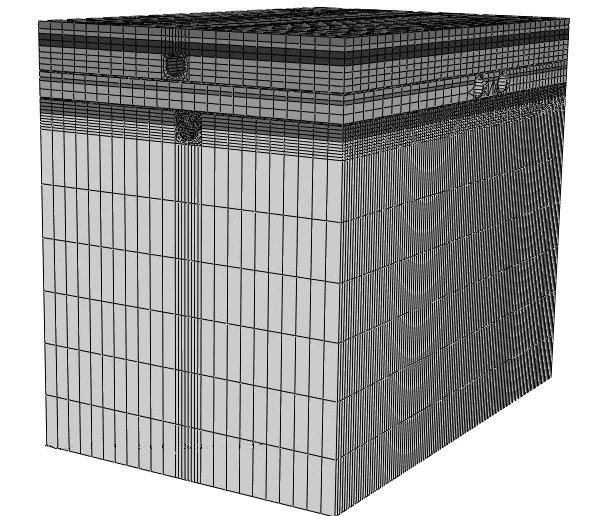

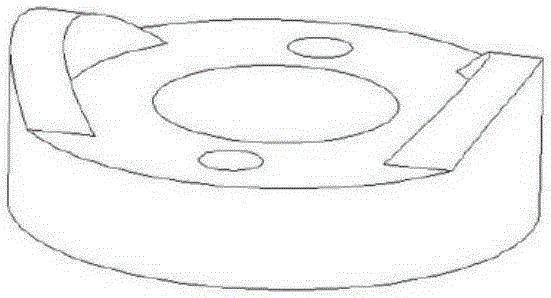

Tunnel three-dimensional stress field simulator

ActiveCN103076128AReliable acquisitionRich surrounding rock stress conditionsStructural/machines measurementApparatus for force/torque/work measurementFront loadingEngineering

The invention relates to a tunnel three-dimensional stress field simulator, which comprises a test box, lifting jacks and a hydraulic loading and control device, wherein the test box is arranged in a frame-shaped loading beam; a front loading plate is arranged in front of the test box; a rear loading plate is arranged on a rear wall of the test box; the peripheries of the front loading plate and the rear loading plate are connected through pull rods; the lifting jacks are respectively and fixedly arranged on an inner side of the loading beam and an inner surface of the front loading plate; two longitudinal support steel rails are arranged on a bottom part of the loading beam; and pulleys on bottom parts of the front loading plate and the rear loading plate are matched with the support steel rails. The device preferably simulates a three-dimensional surrounding rock stress field of a stratum where a shield tunnel and a mining method tunnel are located, and realizes construction simulation of excavation, support and the like of tunnel engineering under the condition of the three-dimensional stress field, so that the disturbance influence of construction on the surrounding rocks is researched, the stress performance of a tunnel structure under the condition of a complex stress field is analyzed, a more reliable test basis is provided for the design and the construction of the tunnel, and further the safety and the economy of the tunnel are ensured better.

Owner:SOUTHWEST JIAOTONG UNIV

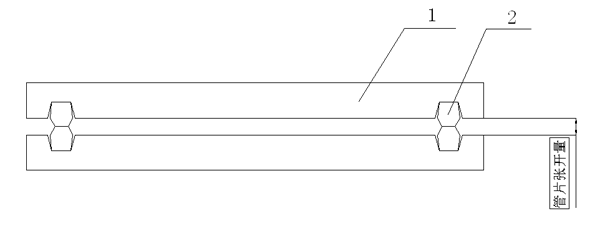

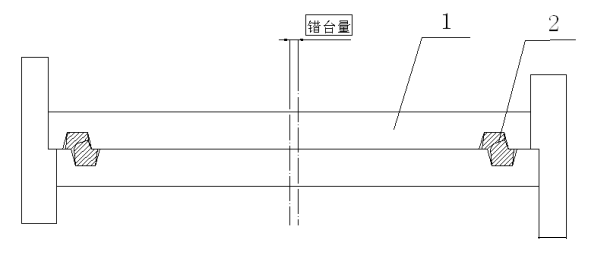

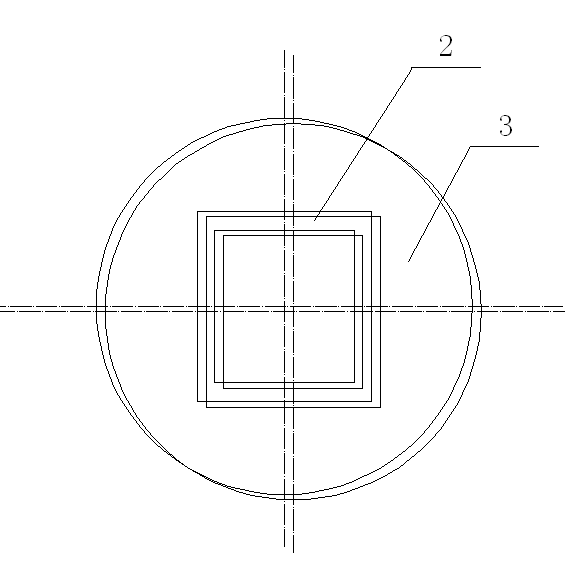

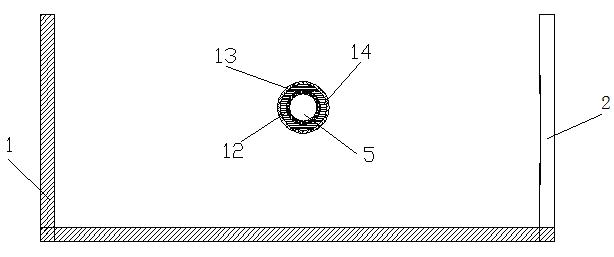

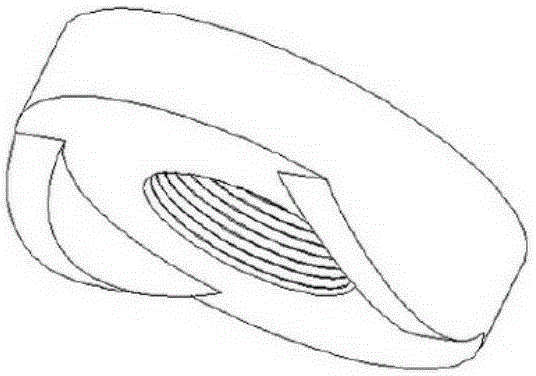

In-line water tightness testing device for elastic sealing gasket of shield tunnel

InactiveCN101929911AAccurately verify waterproof abilityAccurate evaluation systemMaterial strength using tensile/compressive forcesFluid-tightness measurement using fluid/vacuumEngineeringWater tightness

The invention belongs to the field of tunnel engineering, and in particular relates to an in-line water tightness testing device for an elastic sealing gasket of a shield tunnel, which simulates the waterproof capacity of a waterproof sealing gasket of segment joints of the shield tunnel in a straight joint erecting state. The device of the invention comprises two abutted rectangular cover plates, wherein an air outlet hole and a water inlet hole are arranged on the cover plates; corresponding rectangular grooves are arranged in the central positions of the abutted surfaces of the two cover plates; the two cover plates are fastened and abutted by bolts distributed on the peripheries of the cover plates; and a spacing plate is installed laterally on the cover plate. The invention has the advantages that the device of the invention can precisely verify the waterproof capacity of the elastic sealing gasket under the conditions of different opening value of segments and different dislocation, thus the evaluating system of the waterproof capacity is more precise.

Owner:TONGJI UNIV

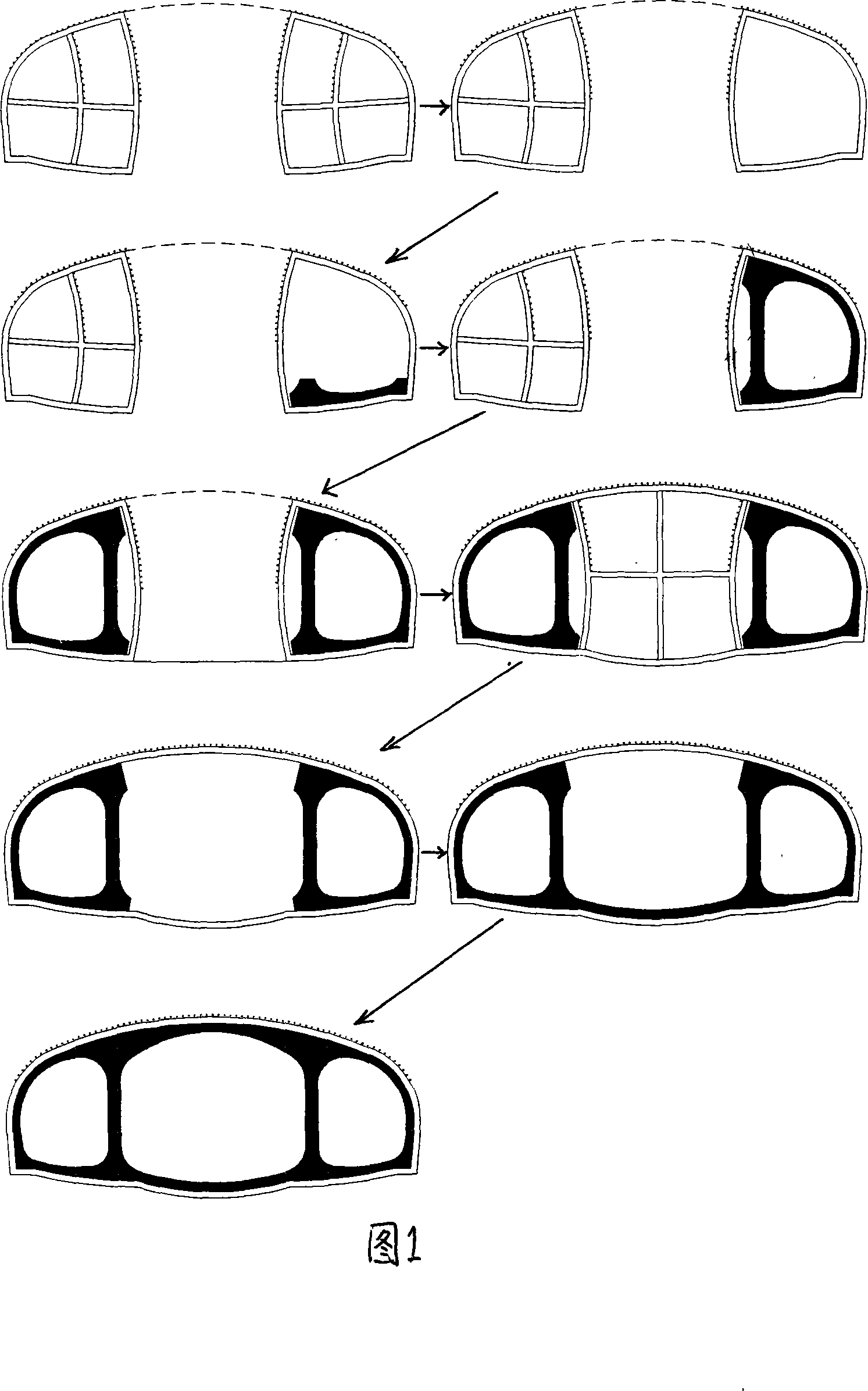

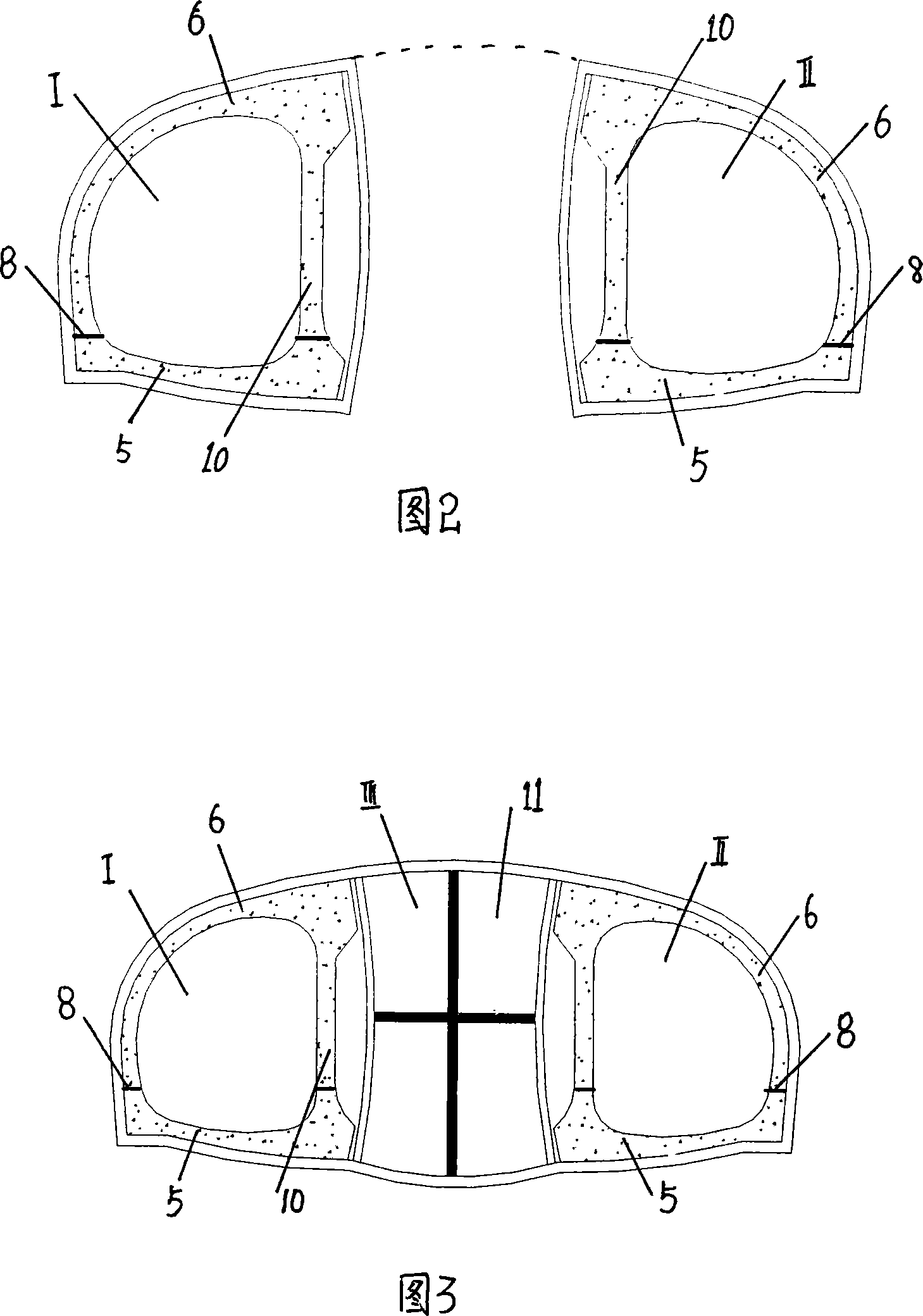

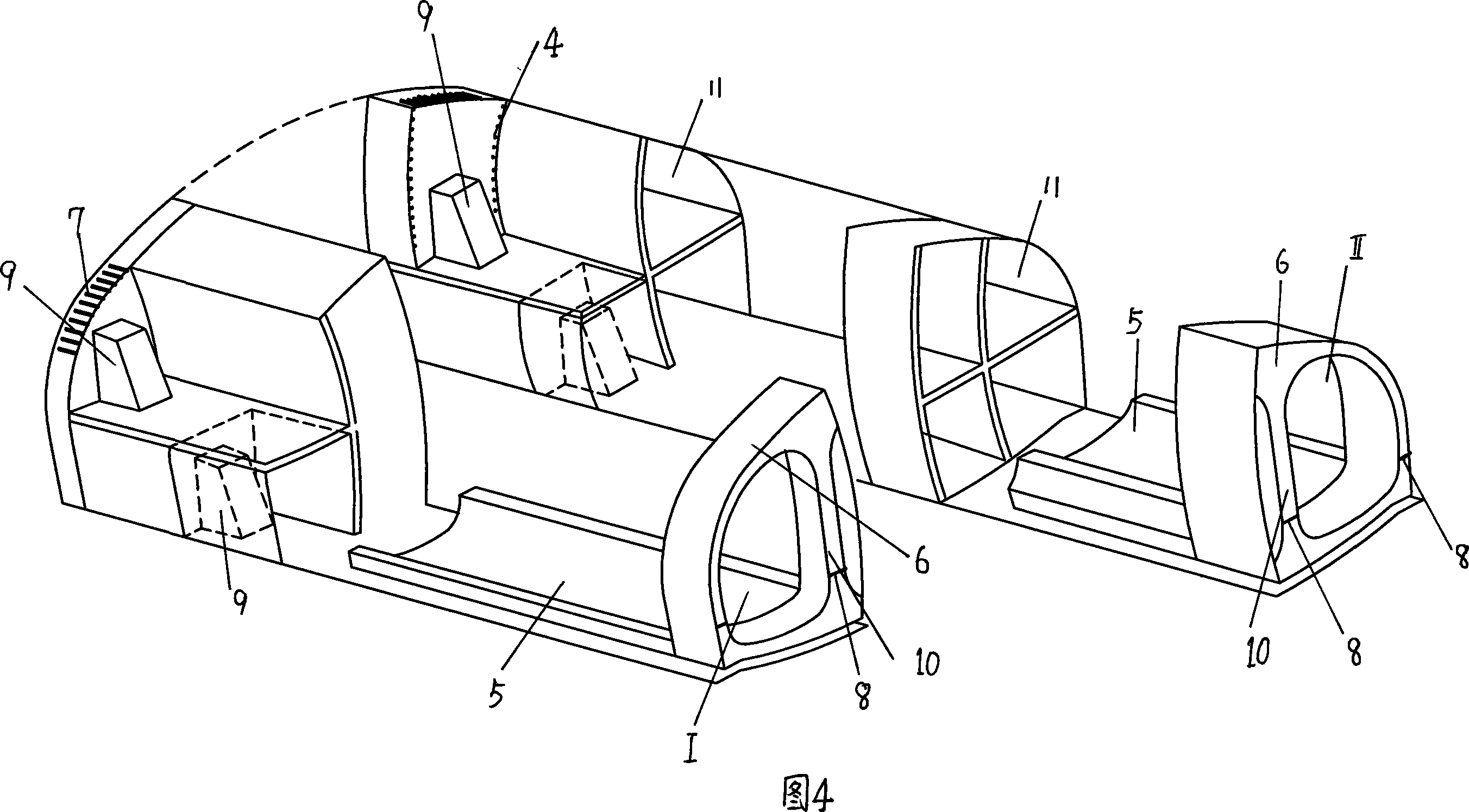

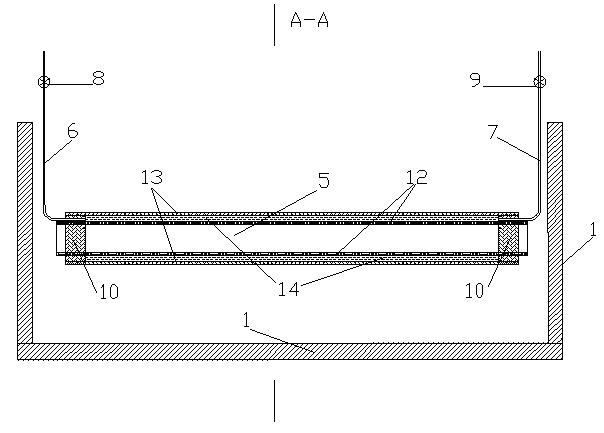

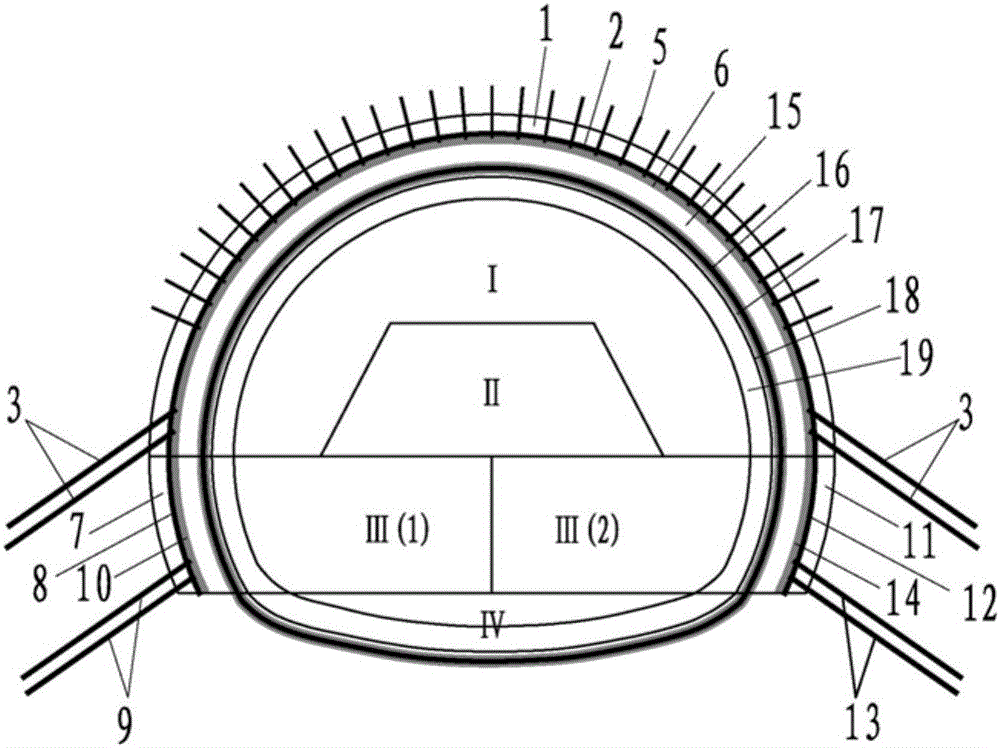

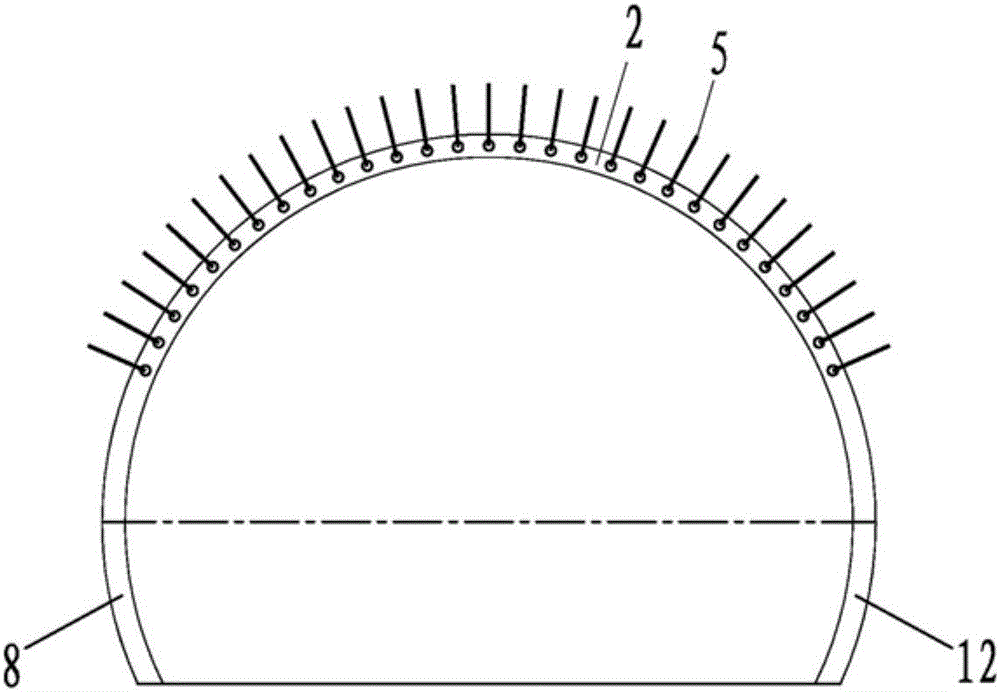

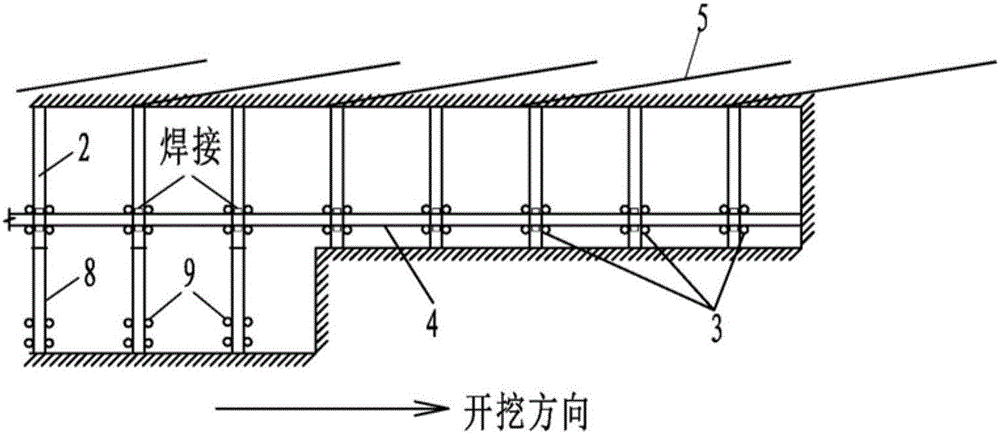

Three-connected-arch tunnel double-side cavity construction method for soft geological

InactiveCN101196116AReasonable division of single excavation areaSuitable for manual excavationUnderground chambersTunnel liningEnvironment effectWall rock

The invention relates to the technical field for the engineering of large-section tunnel, in particular to an engineering method for the double lateral tunnel of a three-arc tunnel on soft and weak geological condition, which resolves the problem of longer duration for the exposure of wall rock, easy deformation of tunnel and poor waterproof effect in existing tunnel engineering method. The invention comprises: (1) excavation of lateral tunnel; (2) lining of later tunnel: first of all, dismantle the primary support of the whole section, then pour the arc invert secondary lining and arc section secondary lining with the construction joint being configured at the lower section of the middle wall for the lateral tunnel; (3) after the circular lining a left lateral tunnel I and a right lateral tunnel II on a same section, excavate and line a middle tunnel III. This method realizes simple equipment and convenient engineering; with the construction sequence of building the lateral tunnel and then the middle tunnel, the invention gives full play to the supporting function of the secondary lining of the middle wall, so as to reduce the load borne by the primary support of the arc section of middle tunnel and elevate the safety coefficient; the invention reduces the settlement and impact on peripheral environment, so as to ensure the stability and safety of the excavation working face; small number of construction joint and high working efficiency.

Owner:CHINA RAILWAY 12TH BUREAU GRP

No-shrinkage grouting filler with adjustable performance

The present invention belongs to the field of building material, and is especially one kind of no-shrinkage grouting filler with adjustable performance. The no-shrinkage grouting filler is hydraulic mixture comprising Portland cement and fly ash or silica fume as cementing material, quartzite, water reducing agent, expanding agent, water loss reducing agent, early settling preventing agent and early contract preventing agent. It has high flowability, no settling, no weeping, micro plastic expansion, no shrinkage, no cracking, adjustable performance, and no plastic settling and other excellent performance, and may be applied widely in installing large precise equipment, large area leveling, emergency repair engineering, etc.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Centrifugal experimental simulation testing device for surface subsidence induced by city shield tunnel construction

InactiveCN102071943AAccurate measurementPlay a shockproof roleHeight/levelling measurementTunnelsLinear variable differential transformerEngineering

The invention belongs to the field of tunneling in geotechnical engineering and underground engineering, and particularly relates to a centrifugal experimental simulation testing device for surface subsidence induced by city shield tunnel construction. The testing device mainly comprises a model box, a small displacement meter bracket, a big displacement meter bracket, a tunnel excavation device, a linear variable differential transformer (LVDT) displacement meter and the like, wherein the model box is a hollow cuboid; the small displacement meter bracket and the big displacement meter bracket adjust the LVDT displacement meter along the horizontal direction and the vertical direction, so that the surface subsidence and the soil layer deformation can be measured; and the tunnel excavation device can simulate the soil body deformation caused by stratum loss by discharging a certain volume of water. Through the device, the deformation influence of the city shield tunnel construction on surrounding soil layer can be more conveniently, really and effectively simulated, so more real and accurate experimental data can be provided for tunnel design and construction, and high efficiency and safety of the city shield tunnel construction are guaranteed.

Owner:SHANGHAI UNIV

Construction process for large-section soft rock large-deformation tunnel

ActiveCN106761769AReduce stressImprove bearing capacityUnderground chambersTunnel liningShotcreteSteel frame

The invention relates to the field of tunnel engineering, in particular to a construction process for a large-section soft rock large-deformation tunnel. The adopted construction process comprises the steps that (1) an upper step is constructed; (2) a middle step is constructed; (3) a lower step is constructed; (4) reserve core soil is excavated; (5) an inverted arch is excavated, specifically, every time cycle excavation is conducted for 3 m, primary spraying is conducted immediately after the inverted arch part is excavated; (6) an inner layer steel frame is erected in time, HW200*200 profile steel is adopted, after closing ring formation, an inner layer is made, and concrete is sprayed to the designed thickness; (7) a concrete inner surface is sprayed on the inner layer, and a waterproof board is laid; (8) after tunnel deformation reaches designed reserved deformation, secondary lining is made; and (9) under supporting of advanced grouting small duct, the next cycle of construction is conducted till the tunnel is made through. The construction process meets the requirement of soft rock large deformation, limit intrusion is avoided, meanwhile, stress of a support structure can be reduced, and safety of the support structure is ensured.

Owner:CHANGAN UNIV

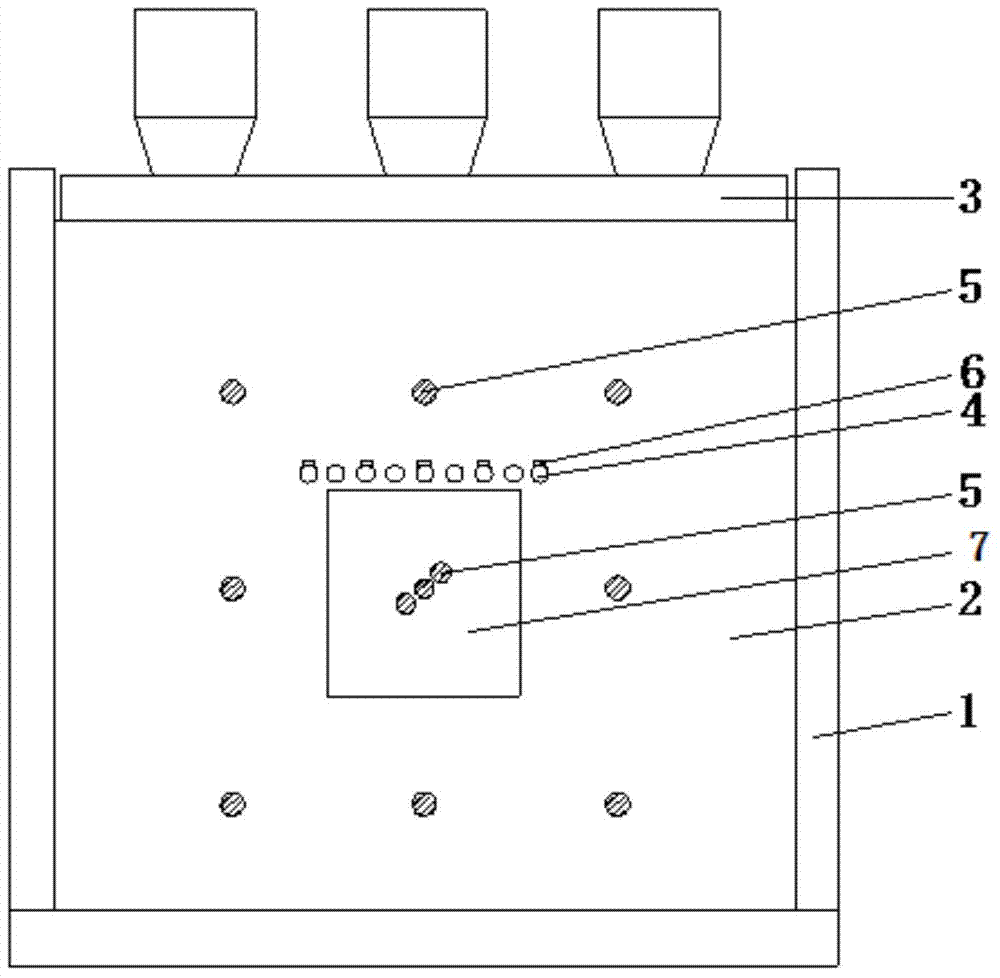

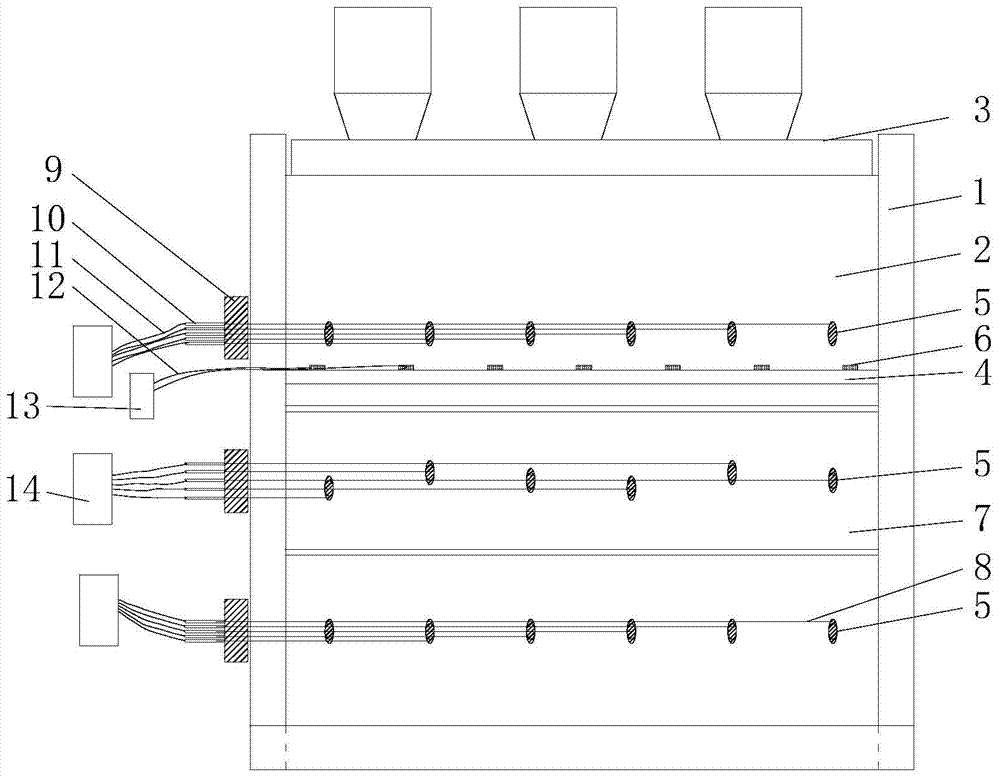

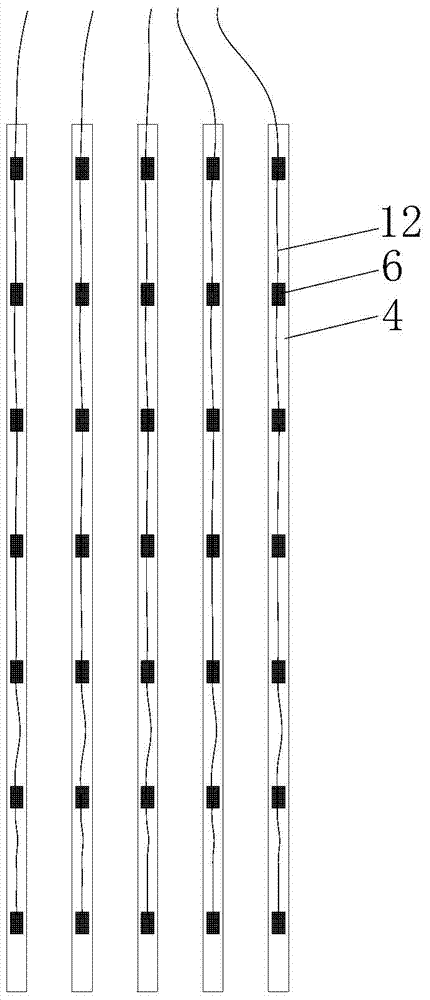

Indoor model experience device with existing tunnel affected by double subway construction

InactiveCN103115788AImprove scalabilitySimulation is accurateUsing electrical meansStructural/machines measurementRubber membraneFull bridge

The invention belongs to the field of tunnel engineering, and particularly relates to an indoor model experience device with an existing tunnel affected by double subway construction. The experience device mainly comprises a subway excavation simulating device, a tunnel model, a strainometer, a displacement support frame, a displacement meter, and the like. A hollow aluminum pipe is arranged in the middle of the tunnel excavation simulating device, a rubber membrane filled with water is arranged on the periphery of the tunnel excavation simulating device, and soil deformation which is caused by the tunnel excavation is simulated by drainage of water with a certain size. The tunnel model is simulated by aluminum alloy pipes, and the outer wall of the tunnel model is pasted with the strainometer in a full-bridge mode to achieve strain measurement on the existing tunnel. The displacement meter is fixed on the displacement support frame, and measurement on longitudinal settlement of the existing tunnel can be achieved. The indoor model experience device with the existing tunnel affected by the double subway construction can conveniently and effectively simulate the existing tunnel deformation caused by the double subway construction of a city, and has important reference value for establishing a tunnel construction security traversing technology standard and an adjacent structure security protective measurement.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Shield tunnel intelligent construction auxiliary system based on big data technology and application method

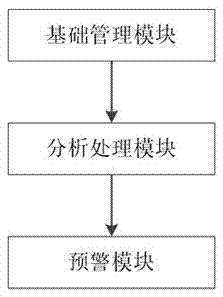

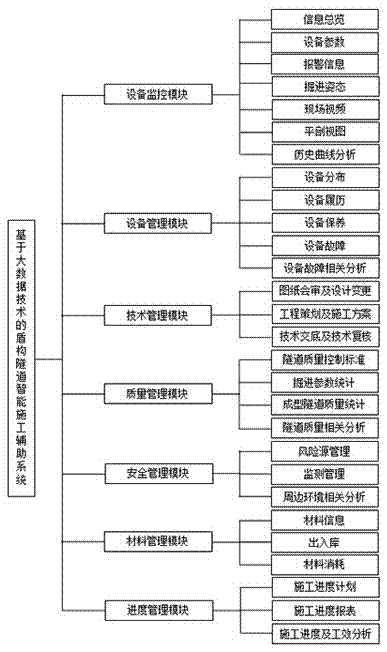

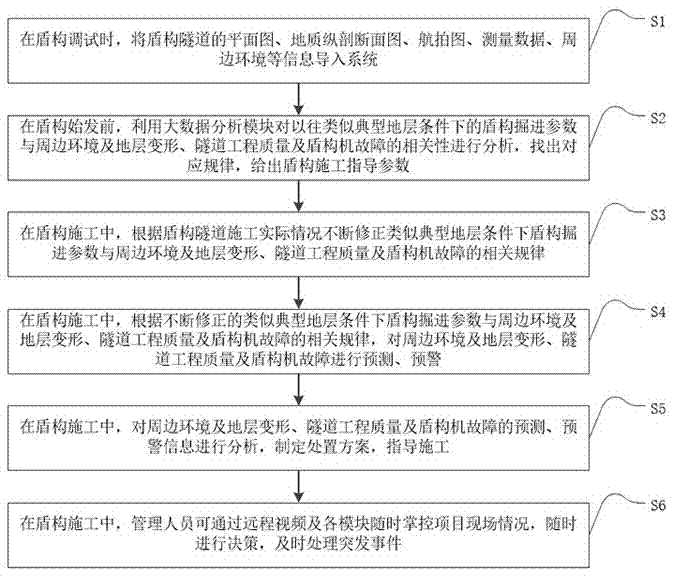

ActiveCN107503757ATimely processingReduce unsafe behaviorTunnelsWireless networkEquipment monitoring

The invention discloses a shield tunnel intelligent construction auxiliary system based on the big data technology and an application method. The intelligent construction auxiliary system comprises a basic management module, an analyzing and processing module and a pre-warning module, wherein the basic management module is connected with the analyzing and processing module through a wireless network, and the analyzing and processing module is provided with a database, compares on-site basic management data with the database, performs analysis and outputs corresponding parameter control or performs pre-warning through the pre-warning module; the basic management module comprises an equipment monitoring module, an equipment management module, a technology management module, a quality management module, a safety management module, a material management module and a progress management module. The intelligent construction auxiliary system has the advantages that ambient environment and ground deformation, tunnel project quality and shield tunneling machine faults are predicted and pre-warned, unsafe behaviors during construction are reduced, the operation efficiency of shield tunneling equipment, the safety of tunnel construction and tunnel engineering quality are increased, and the construction cost of tunnel engineering is lowered.

Owner:CHINA CONSTR COMM ENG GRP UNITED

Shield method tunnel synchronous grouting slurry applied to compound stratum with upper soft part and lower hard part

ActiveCN101654356AImprove consistencyNot easy to segregateSolid waste managementUnderground chambersSlurryEarth surface

The invention discloses shield method tunnel synchronous grouting slurry which belongs to the technical field of shield tunnel engineering. The shield method tunnel synchronous grouting slurry consists of mortar and water glass, wherein the weight ratio of the mortar to the water glass is 1:4, and the weigh ratio of various raw materials in the mortar of cement to sand to fly ash to swell soil towater is 1:4.8-5.71:2.93-3.31:0.25-0.27:3.13-3.30. The shield method tunnel synchronous grouting slurry has good consistency and insusceptible separation, can effectively prevent the phenomena of slurry separation and grouting pipe blockage, can timely and effectively fill a building gap between a digging surface and the periphery of a pipe piece and control the ground surface settlement within 5to 7mm.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD

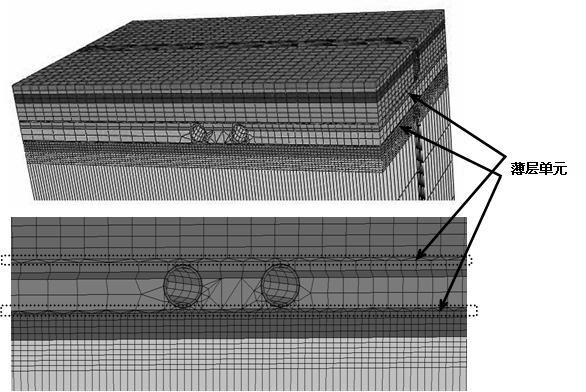

Method for simulating construction course and tunnel deformation influence value of multiline overlapping tunnel

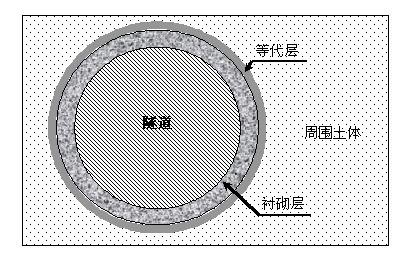

ActiveCN102306225AConvenient guidanceConvenient consultationSpecial data processing applicationsClassical mechanicsSlurry

The invention belongs to the field of tunnel engineering and particularly relates to a method for simulating the construction course and a tunnel deformation influence value of a multiline overlapping tunnel. The method provided by the invention comprises the following operation steps: (1) determining a soil constitutive model; (2) simulating an initial dead-weight stress field; (3) simulating anequivalent layer structure; (4) simulating a tunnel duct piece structure; (5) simulating a slurry hardening course; and (6) simulating the influence course of shield propelling on subway tunnel operation. In the method provided by the invention, the complicated working conditions of multiline overlapping tunnel construction are considered in detail; a rigidness migration method is used for simulating a shield propelling course, wherein a life and death unit is preset in a lining and soil disturbance zone; and the dynamic course of shield construction is reflected by a method for activating the life and death unit to change the mechanics characteristics of the unit material in different construction steps. In the simulation method provided by the invention, a thin film unit is used for simulating the oblique crossing construction working conditions of the multiline overlapping tunnel at any angle; and the defect that a conventional finite element method is difficult to converge when the construction working conditions are simulated can be avoided.

Owner:SHANGHAI UNIV +1

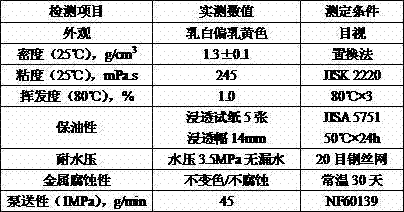

Preparation method and application of environment-friendly type shield tail sealing grease

The invention discloses a preparation method and an application of environment-friendly type shield tail sealing grease. The shield tail sealing grease mainly comprises the following components: 14-30% of lubricating oil, 7-22% of oil plasticizer, 3-15% of thickening agent, 3-12% of lubricating grease, 3-8% of natural degradable fiber, 35-60% of filling granular material, 1-3% of coloring agent and 0.1-2% of preservative. The environment-friendly type shield tail sealing grease prepared by using the method is used for sealing a shield tail of a shield tunneling machine in tunnel engineering, and has the advantages of good water pressure sealing performance, excellent pumping performance, high adhesivity, good lubrication, stable properties, no corrosion, antioxidation, wide raw material resources, environment-friendliness and simple preparation process.

Owner:东莞市明洁隧道建设材料有限公司

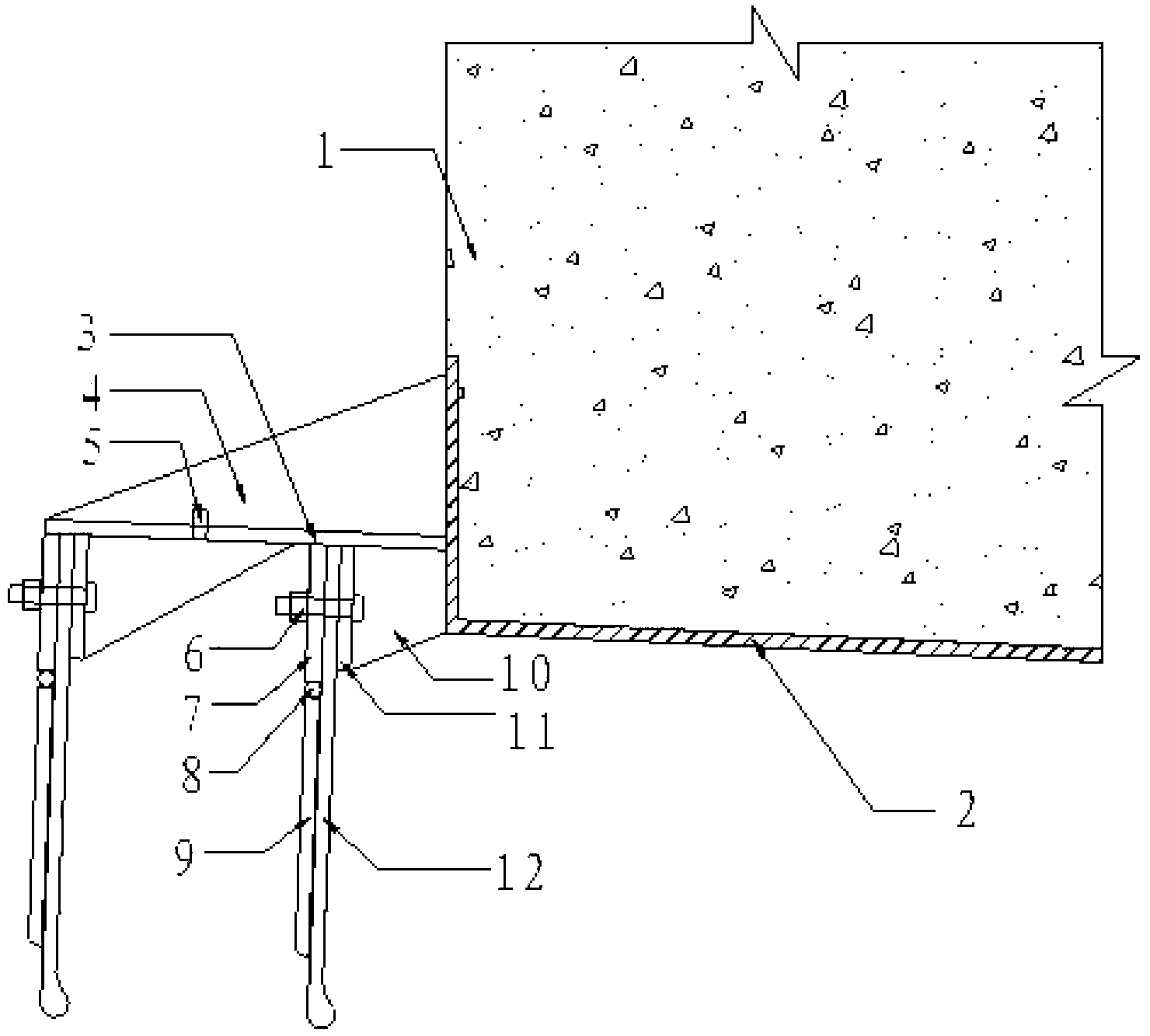

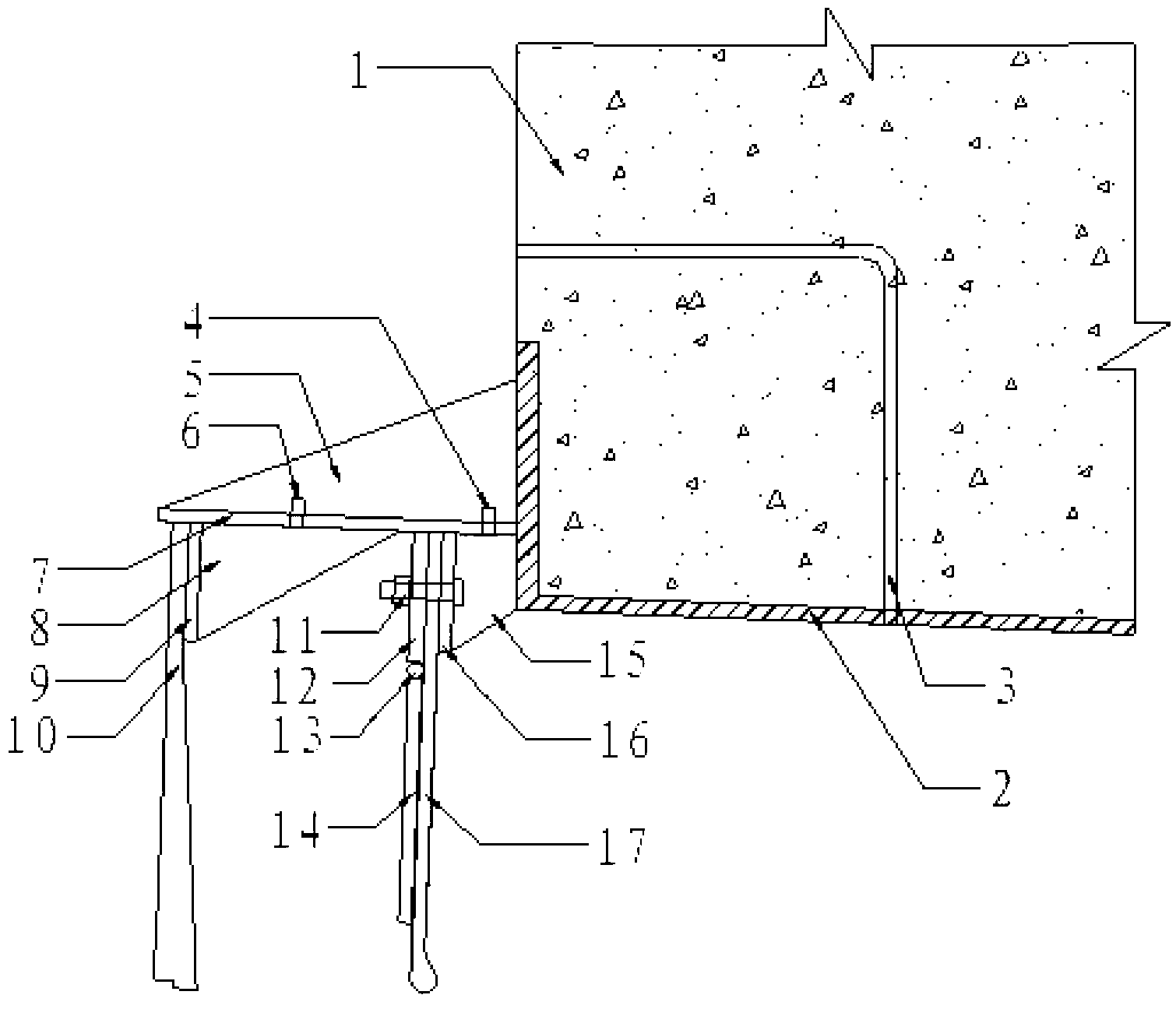

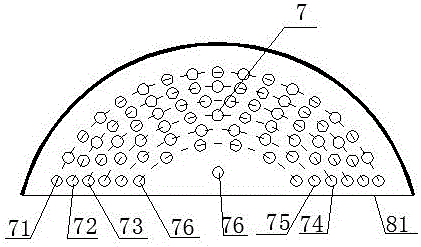

Shield tunnel portal sealing device and shield tunnel portal sealing method

InactiveCN103266898APrevent gushingPrevent water seepageUnderground chambersTunnel liningEngineeringShield tunneling

The invention belongs to the technical field of shield tunnel engineering and particularly relates to a shield tunnel portal sealing device and a shield tunnel portal sealing method. The shield tunnel portal sealing device comprises a lined wall, an embedded steel ring is arranged on the lined wall, a sealing box is arranged on the embedded steel ring and comprises a sealing steel ring, a fixing plate, a fold type support plate and two waterproof structures, a plurality of grease injecting holes are evenly circumferentially reserved in the sealing steel ring between the two waterproof structures, each waterproof structure comprises a steel wire brush and a cord fabric rubber plate, the cord fabric rubber plates are arranged on one side close to the embedded steel ring, and grouting holes are reserved in the lined wall and in the sealing steel ring on the inner sides of the cord fabric rubber plates. The shield tunnel portal sealing device has the advantages that the cord fabric rubber plates are primarily used for sealing to prevent a major part of water and soil from pouring out, so that 'pouring prevention' is achieved; water penetration is prevented as the steel wire brushes secondarily achieve seamless contact with a shield tunneling machine shell or duct pieces; and the grouting holes reserved in the lined wall and the sealing steel ring can achieve grouting sealing timely in emergencies.

Owner:CCCC SECOND HARBOR ENG

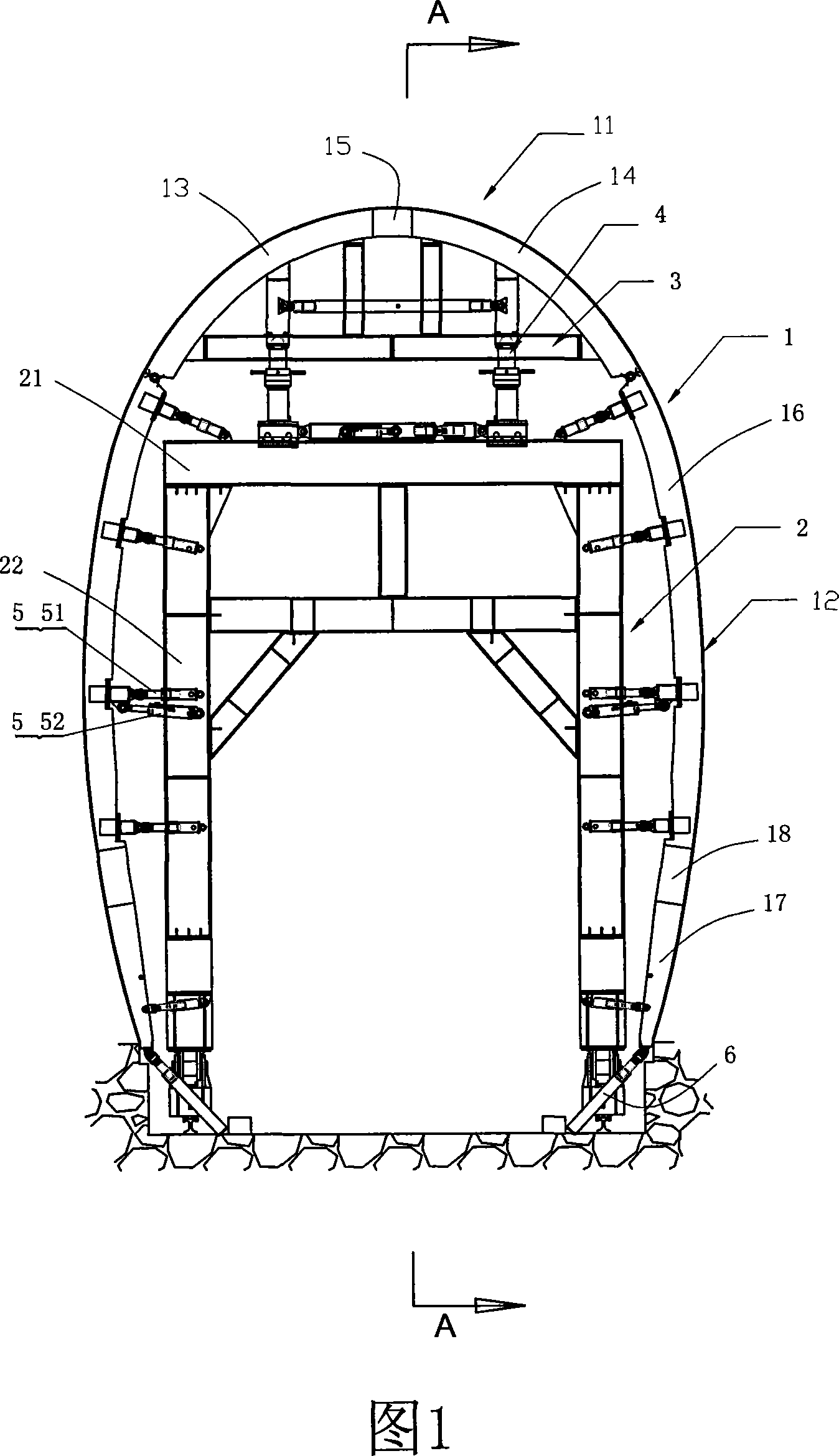

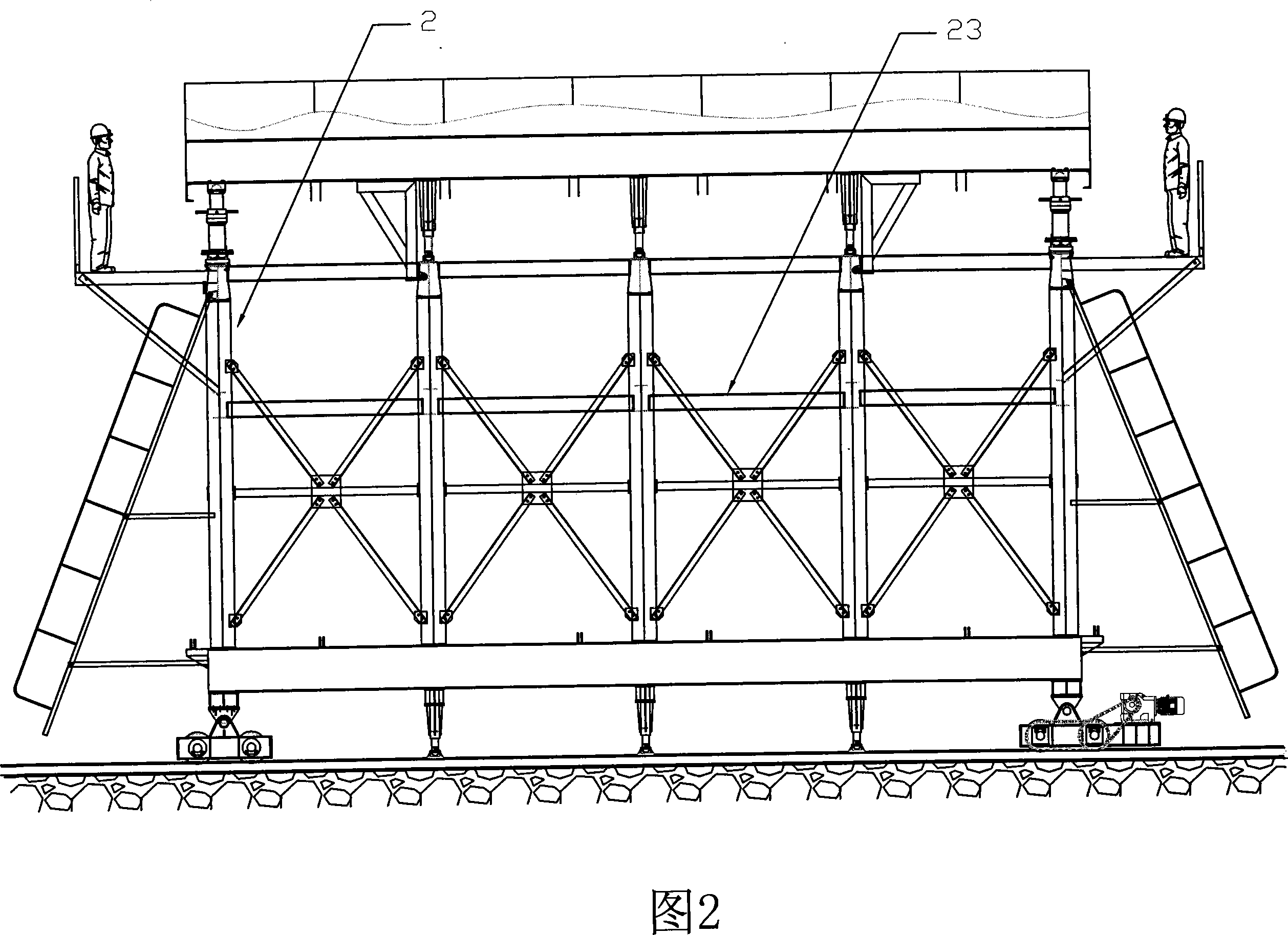

Single-track railway tunnel lining trolley

InactiveCN101082280AReduce construction costsReduce labor intensityUnderground chambersTunnel liningRailway tunnelBilateral symmetry

The invention discloses a lining platform car of the single-thread railway tunnel, which contains the arched mould including the roof and side follow boards, the bracket with a lifting cylinder, the gantry and the supporting component of the arched mould. It is characterized in that: the roof follow board contains the left and right roof follow boards in bilateral symmetry. There is an adjusting roof follow board for changing the sectional width between them. The side follow board contains the detachable upper and lower side follow boards. A side adjusting follow board for changing the sectional height and radius can be added between them. With the adjusting roof follow board and the side adjusting follow board, the sectional size of the arched mould can be adjusted in certain range to adapt the tunnel engineering with different sections. It can reduce the engineering cost, lighten the working strength and improve the working efficiency.

Owner:湖南五新智能科技股份有限公司

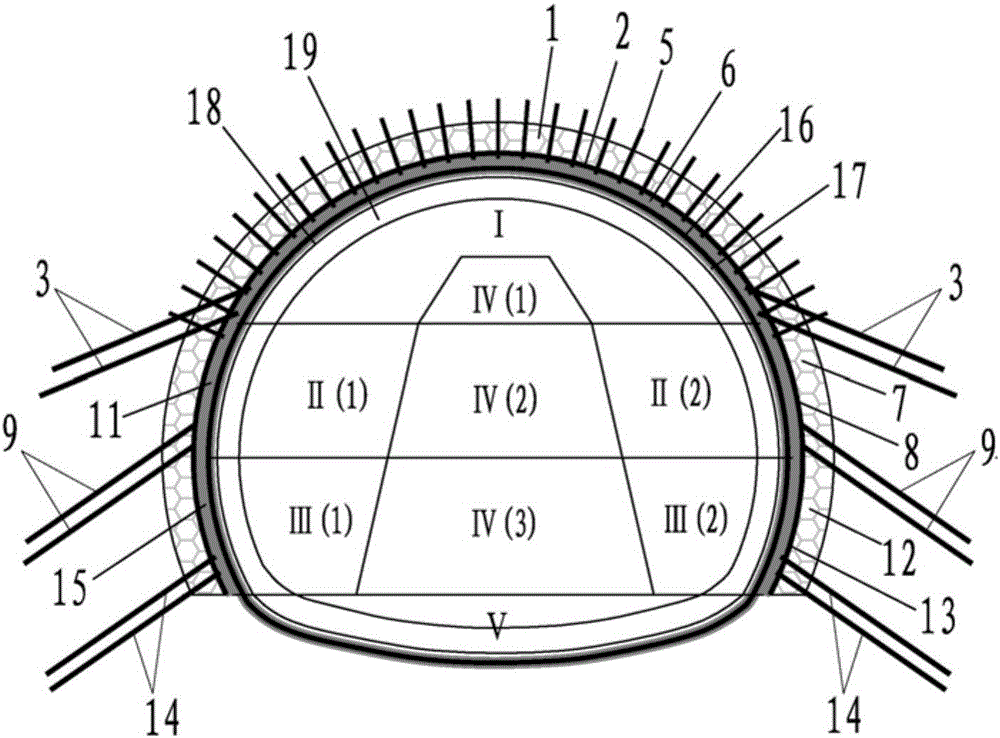

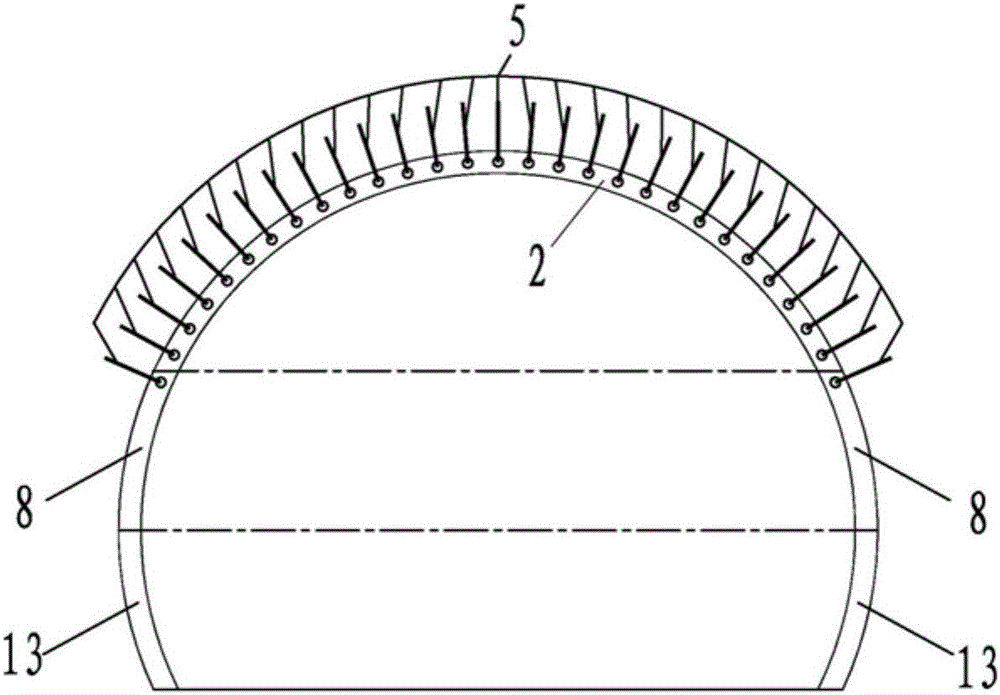

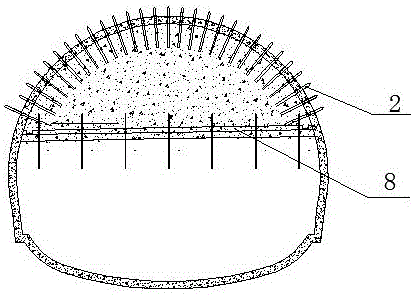

Soft rock large-deformation tunnel support structure system and construction method thereof

ActiveCN106761810APrevent intrusionReduce surrounding rock pressureUnderground chambersTunnel liningShotcreteStructure of the Earth

The invention relates to the field of tunnel engineering, in particular to a soft rock large-deformation tunnel support structure system and a construction method thereof. According to the soft rock large-deformation tunnel support structure system and the construction method thereof, double layers of elastic foam boards are arranged between surrounding rock and primary supports, thus enough surrounding rock deformation space is reserved so as to adapt to the requirement of soft rock tunnel large deformation, the problem of limit intrusion caused by too large surrounding rock deformation can be avoided, and surrounding rock pressure acting on a support structure can also be reduced effectively. The primary supports are reinforced, sprayed concrete spalling chipping, steel frame warp dislocation breakage, secondary lining cracking and other phenomena caused by too large stress on the support structure can be avoided by adopting the double-layer primary supports, and finally safety and reliability of the soft rock large-deformation tunnel support structure are ensured. Aiming at the characteristics that a soft rock large-deformation tunnel system is not obvious in anchor rod effect and waste time and labor, application of a system anchor rod in a soft rock large-deformation tunnel is canceled, the measures of reinforcement of a locking anchor pipe and steel frame longitudinal connection are provided, corresponding reasonable support parameters are given, and thus tunnel subsidence can be controlled better.

Owner:CHANGAN UNIV

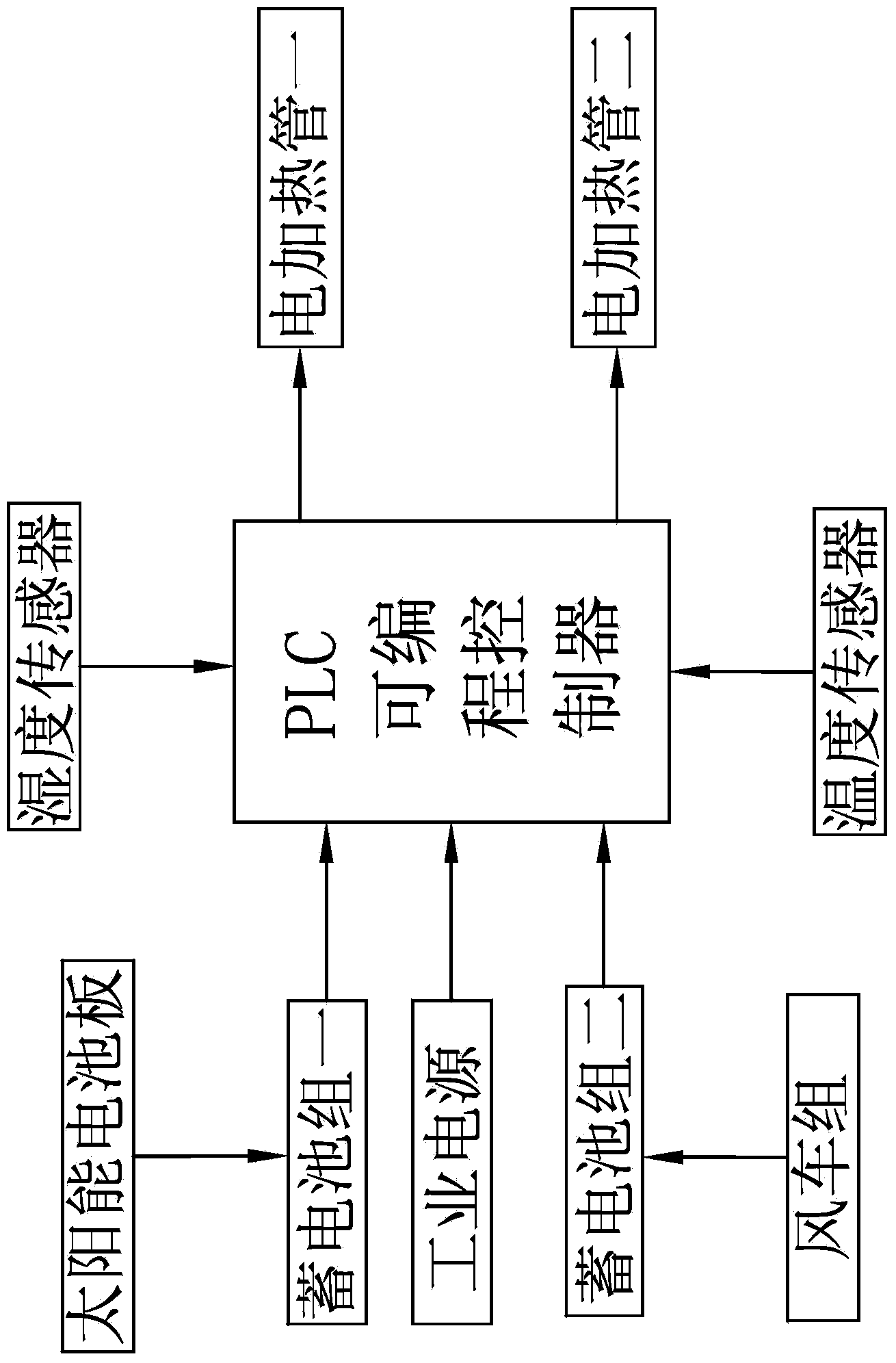

Tunnel anti-freezing dehumidification system

InactiveCN103437799APrevent frostbiteFreezing damage will not occurUnderground chambersTunnel/mines ventillationElectricityAnti freezing

The invention provides a tunnel anti-freezing dehumidification system, and belongs to the technical field of tunnel engineering. The tunnel anti-freezing dehumidification system solves the problems that an existing tunnel is low in temperature and high in humidity. The tunnel anti-freezing dehumidification system comprises a plurality of solar heat collection pipelines and a plurality of electric heating pipes I, wherein the solar heat collection pipelines are arranged at a tunnel portal, the electric heating pipes I are arranged inside a tunnel, one end of each solar heat collection pipeline is a closed end, and the other end of each solar heat collection pipeline is connected with a heating pipeline; electric heating pipes II are further arranged in the solar heat collection pipelines and connected with a storage battery pack II; the electric heating pipes I are evenly arranged on the two side walls inside the tunnel and connected with a storage battery pack I; a solar cell panel and a windmill set are also arranged at the tunnel portal, wherein the solar cell panel is connected with the storage battery pack I, and the windmill set is connected with the storage battery pack II. The tunnel anti-freezing dehumidification system can heat the tunnel so as to prevent rails from freeze injury and can dehumidify the tunnel so as to prevent the rails from rotting at the same time.

Owner:ZHEJIANG OCEAN UNIV

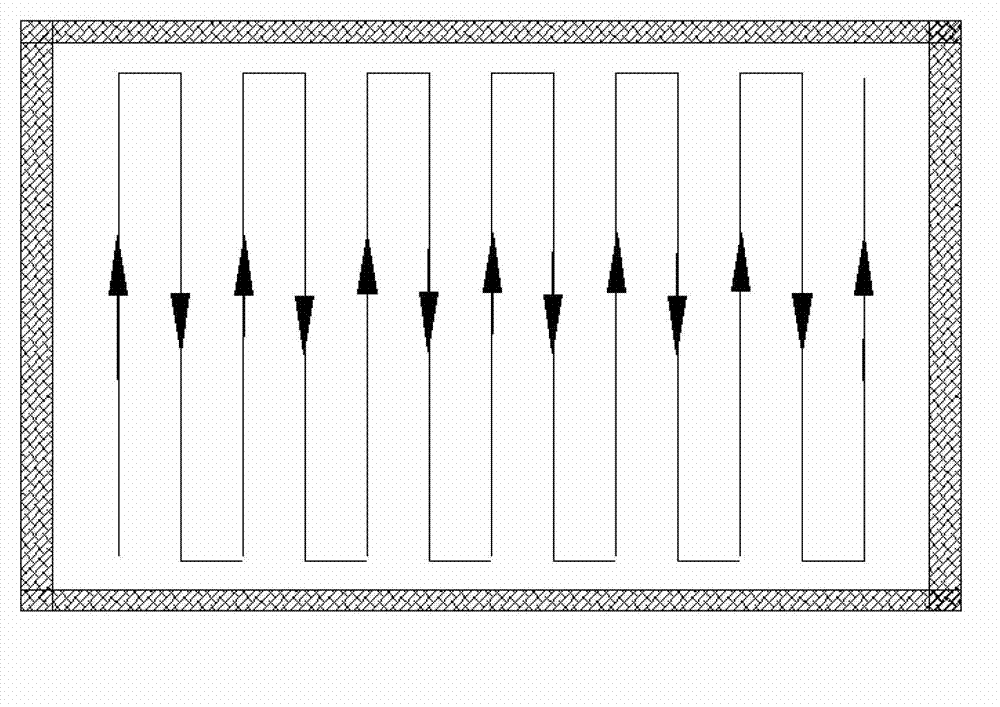

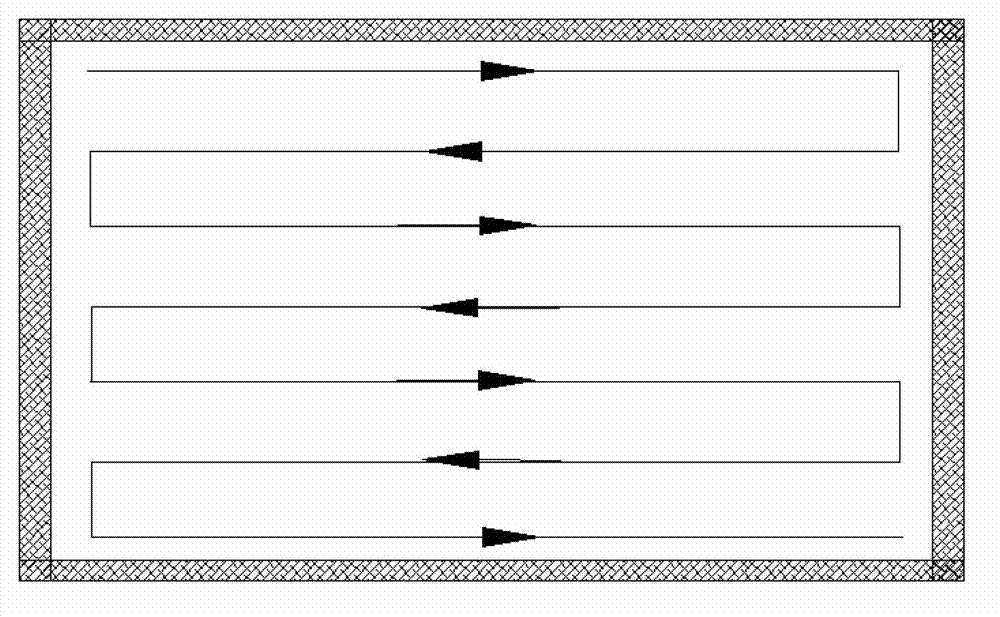

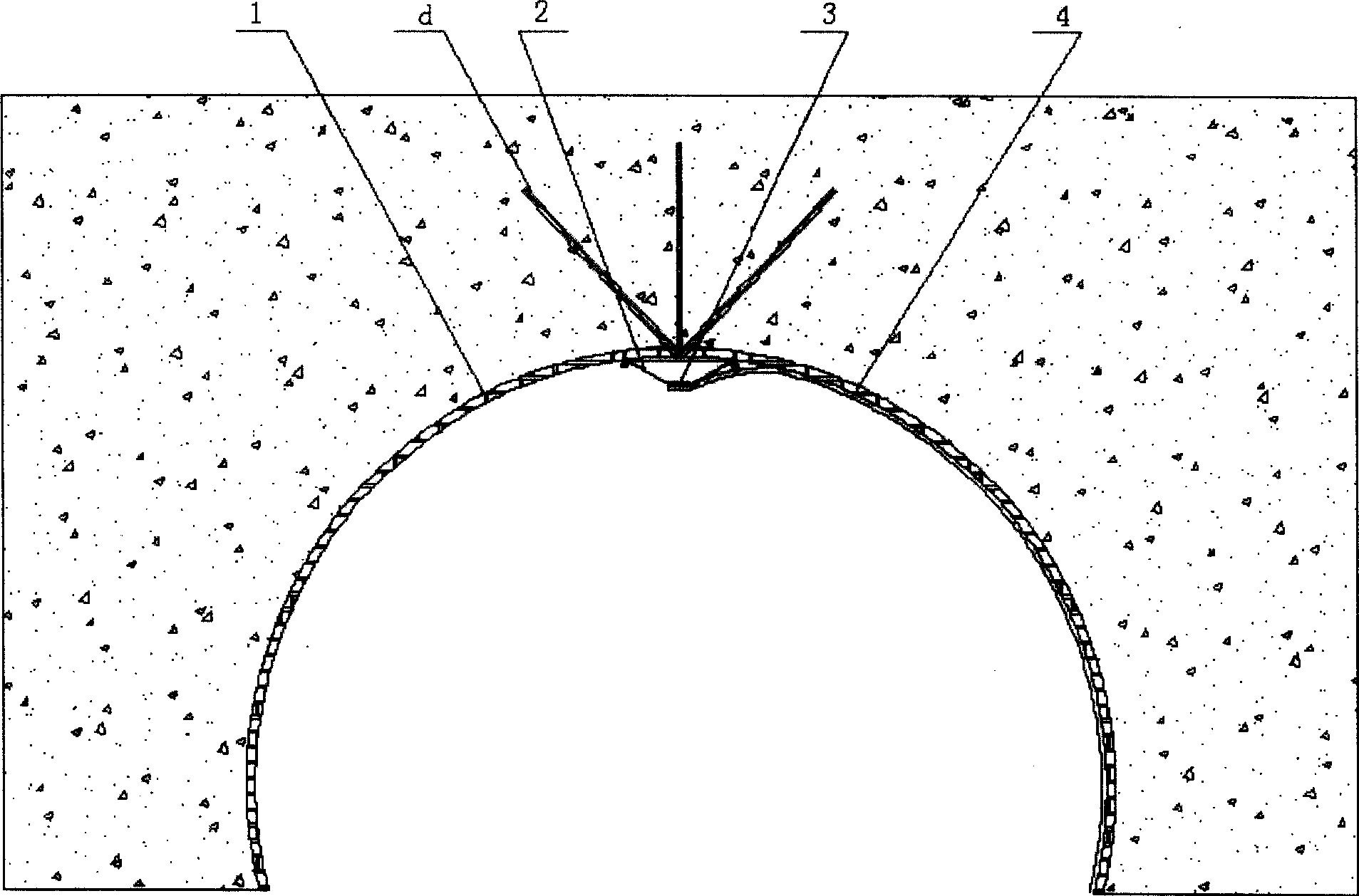

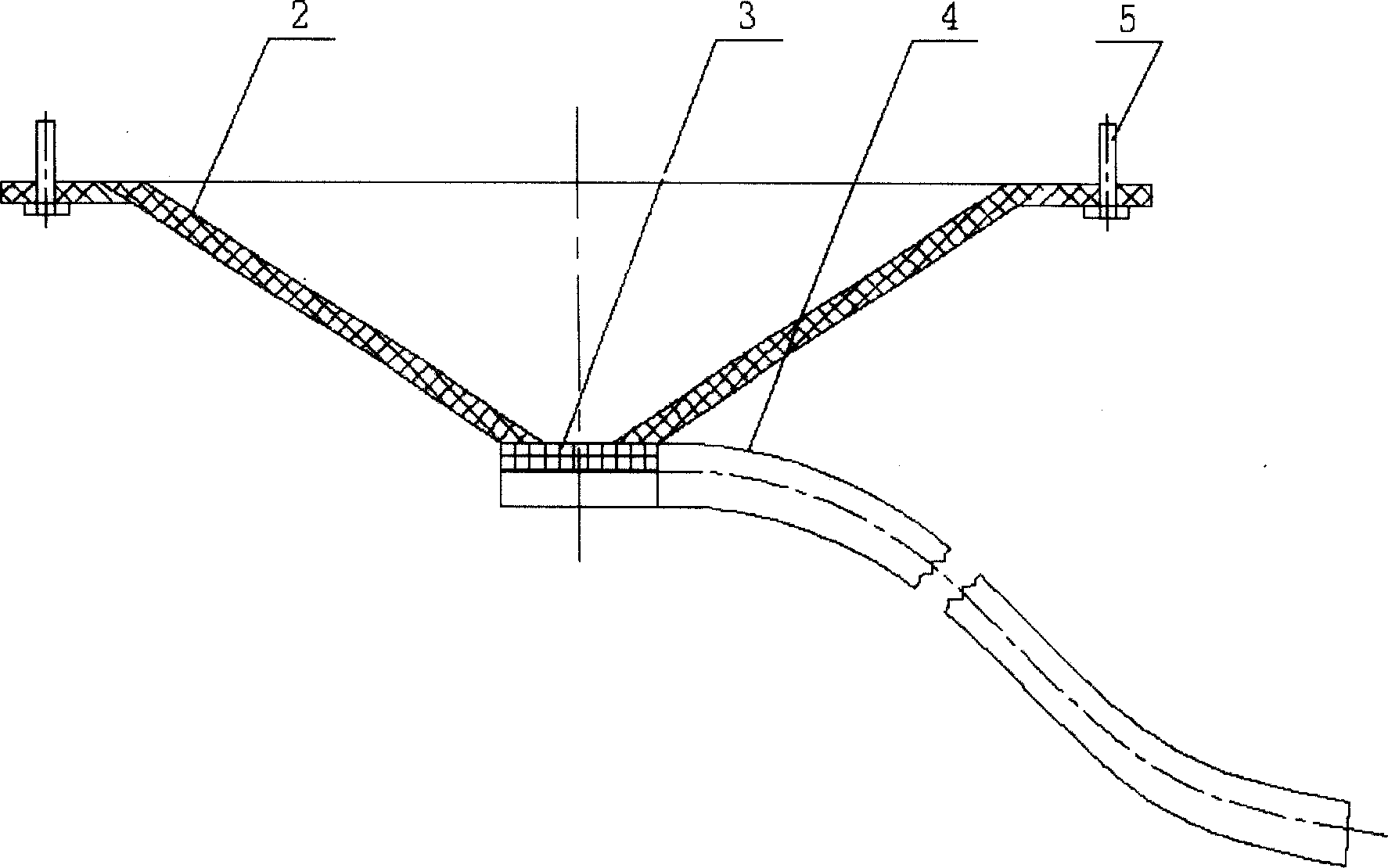

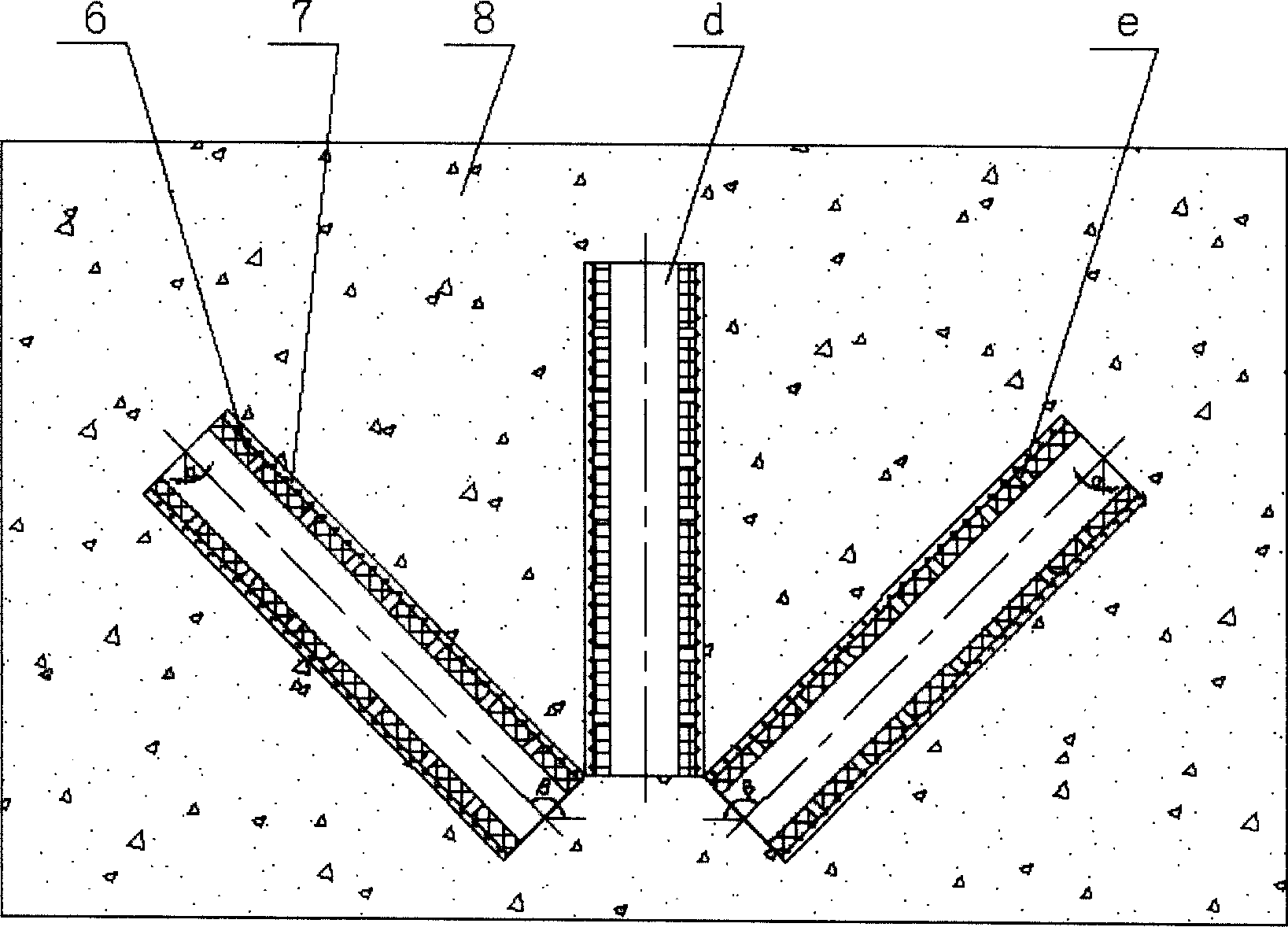

Centralized water discharge apparatus and method for tunnelling

The invention discloses a concentrated drainage device and method of tunnel engineering, which comprises the following parts: water diversion pipe, filter layer on the outside of water diversion pipe, funnel under the initial support water diversion pipe, screen under the funnel and drainage pipe under the screen, wherein the water diversion pipe is set in the water diversion hole d of tunnel adjacent bed creepage centralization part. The method comprises the following steps: drilling the water diversion hole d in the tunnel initial support and tunnel adjacent bed creepage centralization part; leveling the initial support surface; setting the concentrated drainage device in the tunnel engineering.

Owner:CHANGAN UNIV

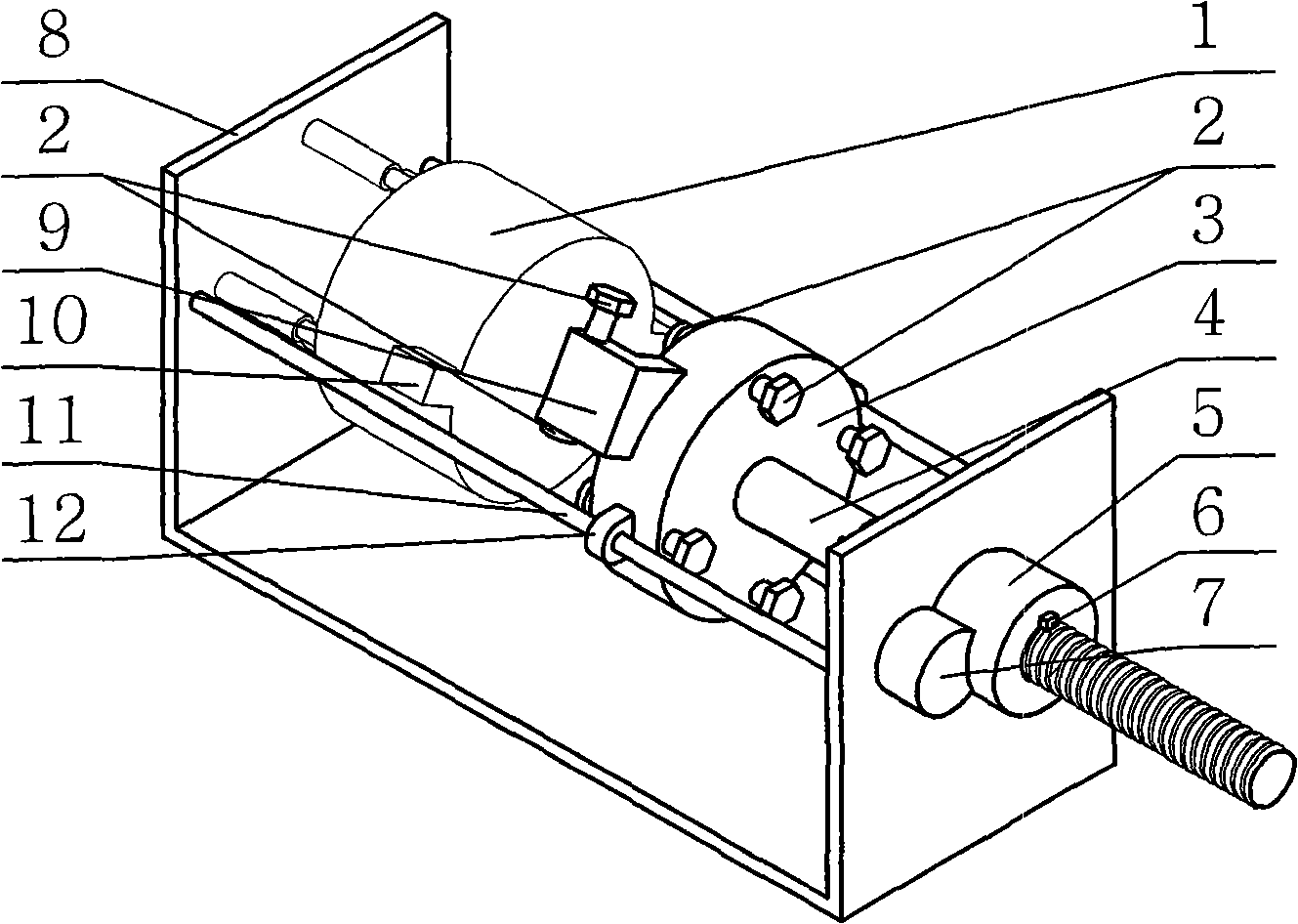

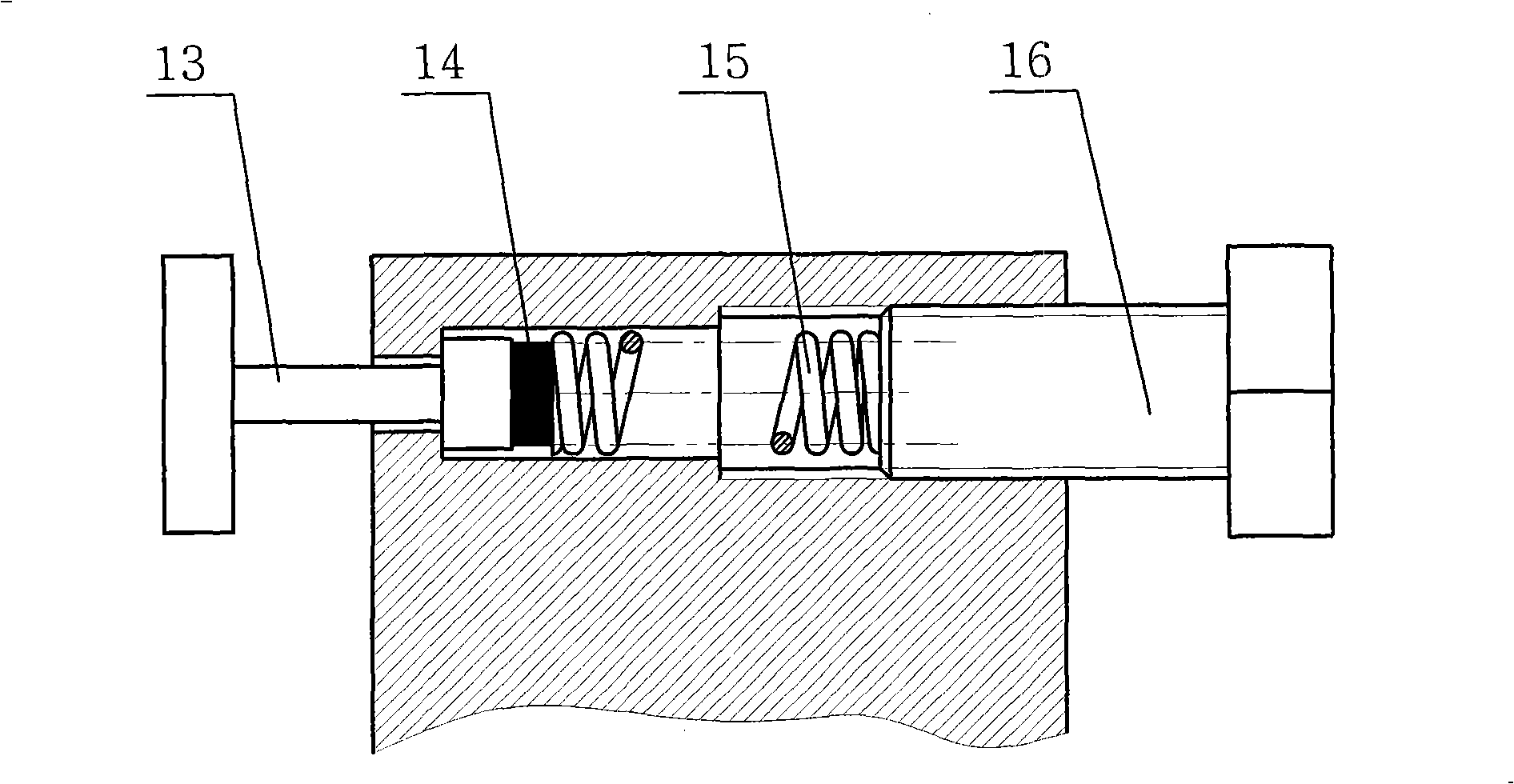

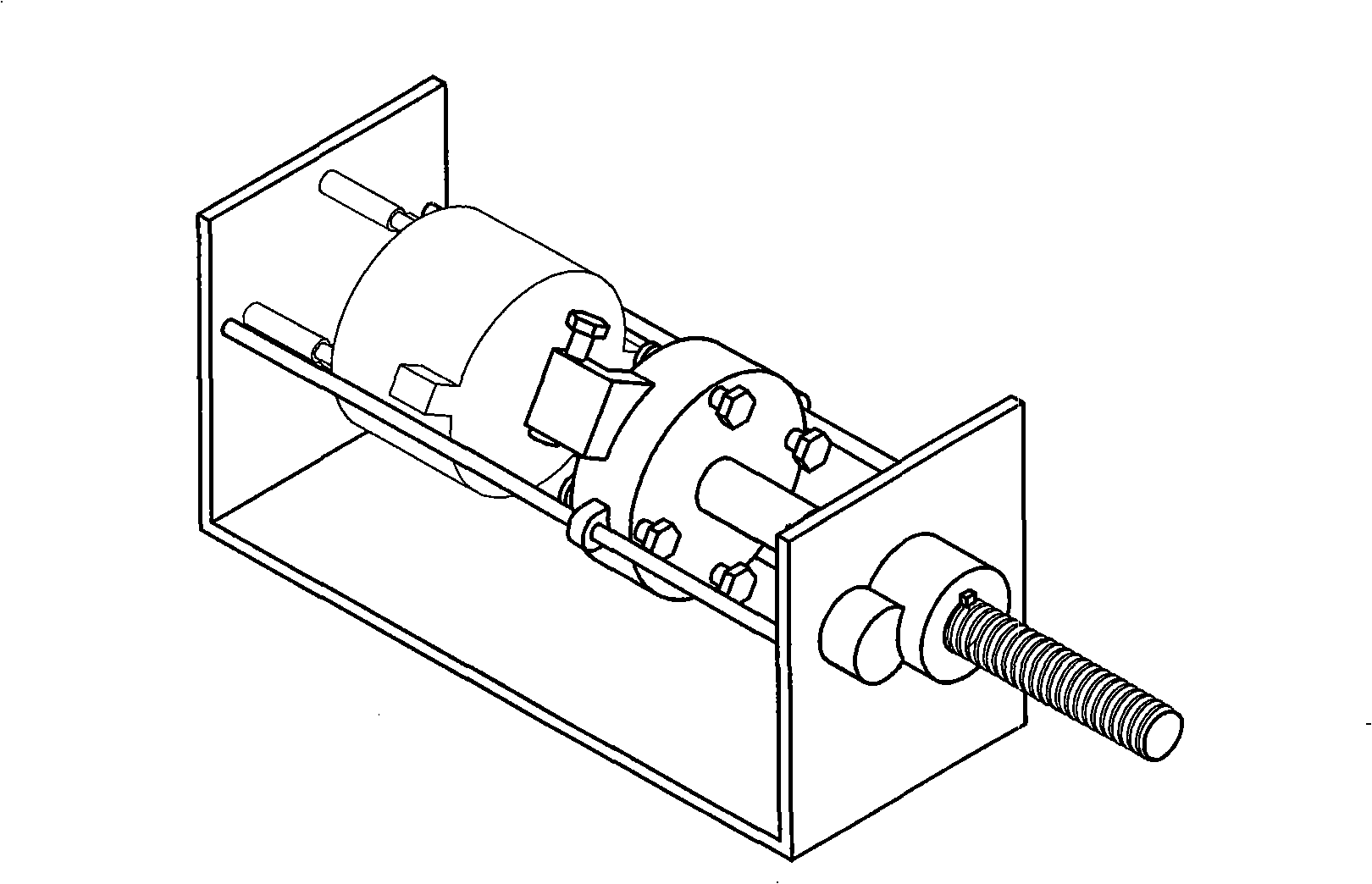

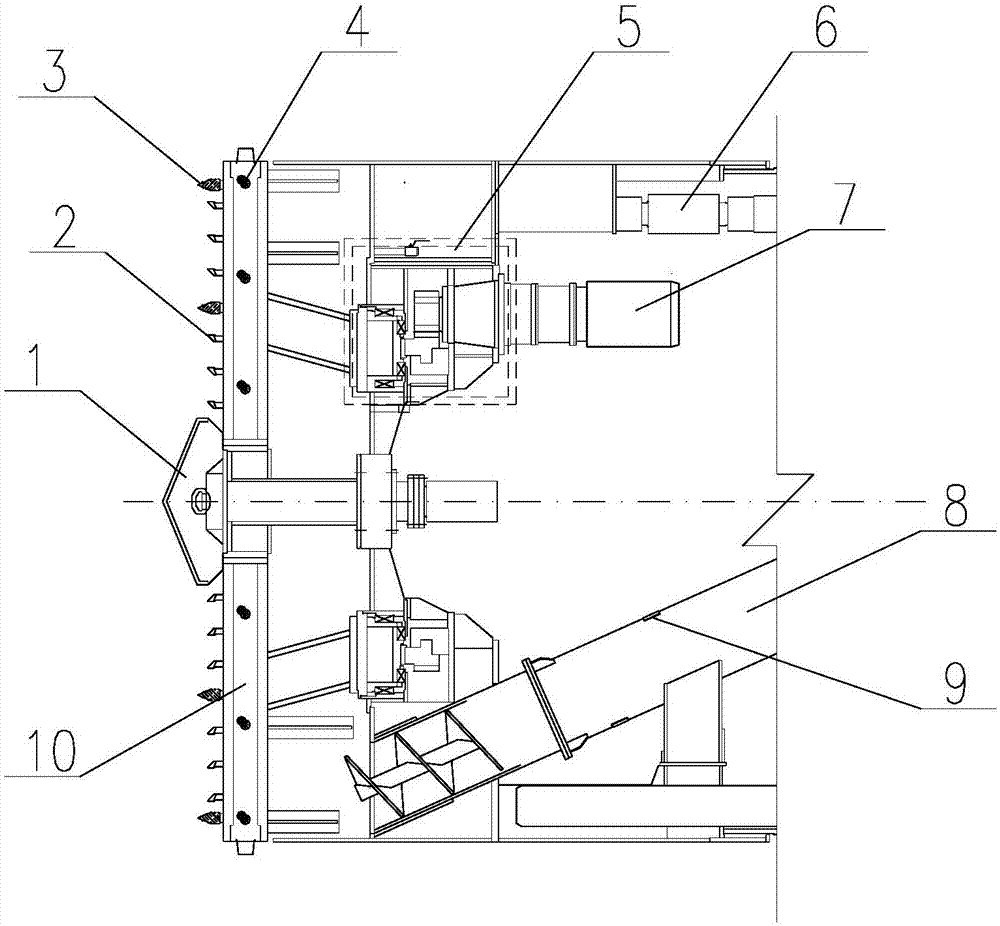

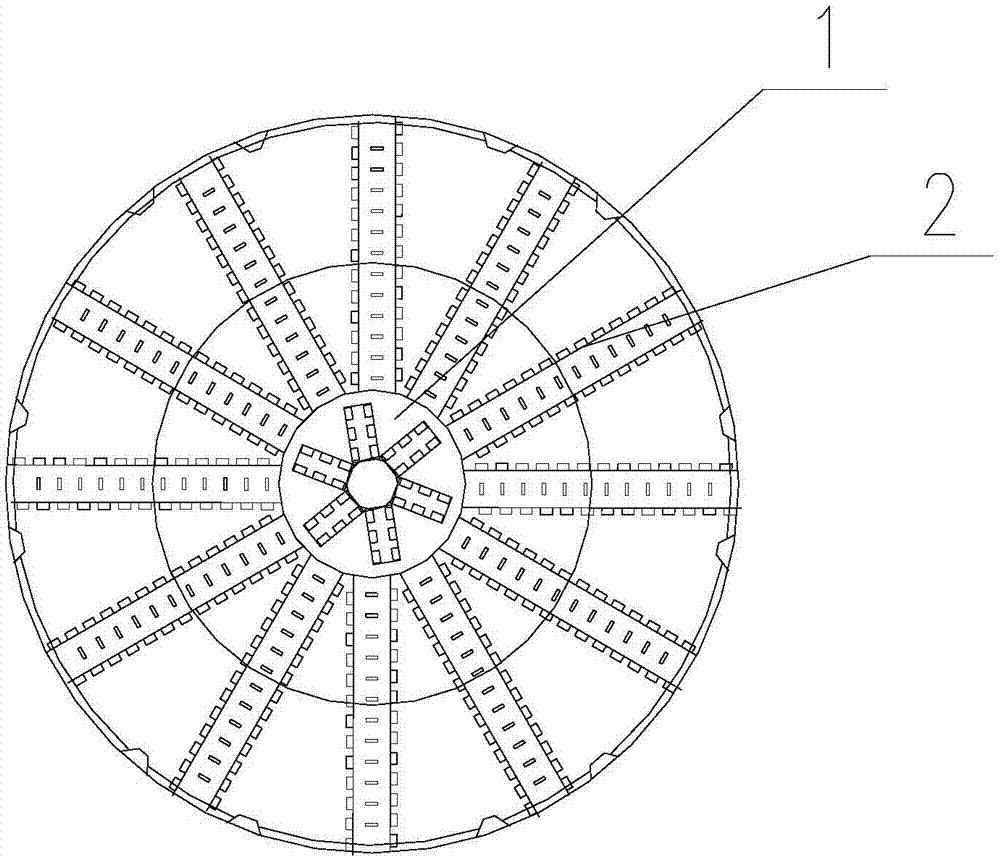

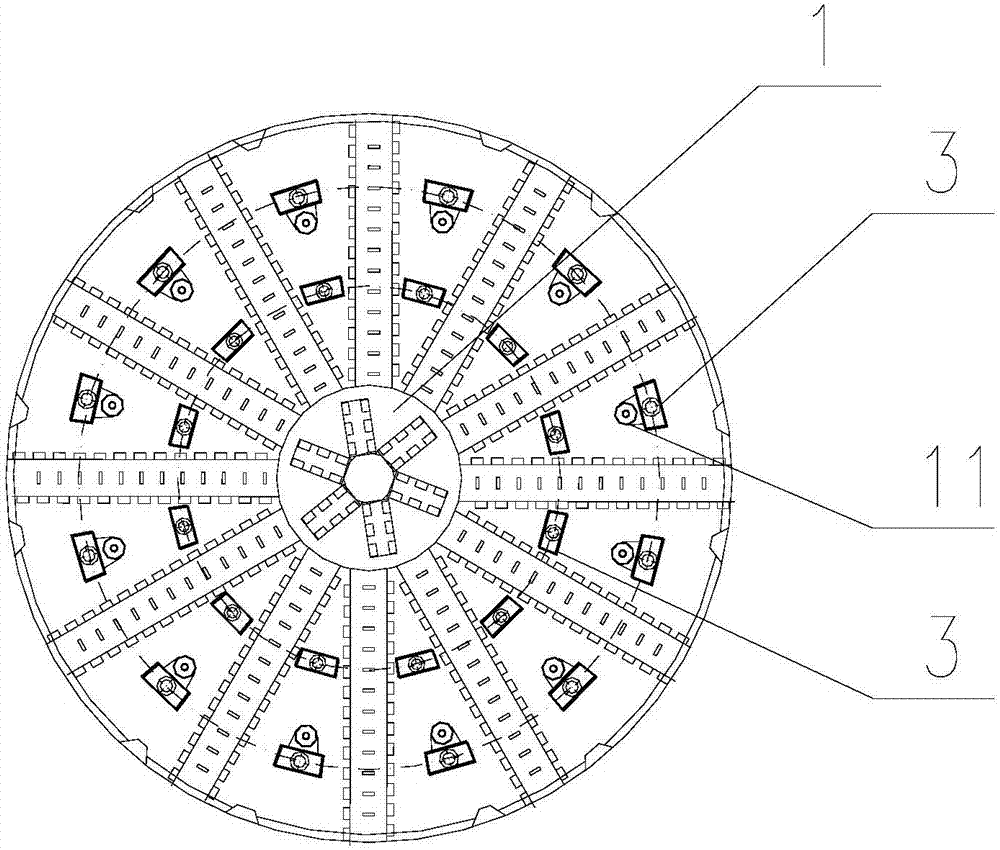

Torsional moment and force loading unit for shield excavation simulation

InactiveCN101285386ASimple and fast operationSimple structureStructural/machines measurementTunnelsEngineeringShield tunneling

The invention discloses a torque and force loading device for shield tunneling simulation, belonging to the tunnel engineering technical field. The device comprises a frame, a simulation shield head, a loading disc and a slide rail fixed on the frame. The simulation shield head is arranged on the left end of the frame. A force bearing projection is arranged on a cylinder-shaped lateral surface at the right end of the simulation shield head. The loading disc is arranged on the right end of the frame and is slidably connected with the slide rail. The right end of the loading disc is fixedly connected with a lead screw which passes through the frame to be connected with a reduction device and an electric motor in sequence. A loading projection is fixed on the cylinder-shaped lateral surface at the left end of the loading disc. A force loading unit which passes through the loading projection is arranged on the loading projection. When the simulation shield head is contacted with the loading disc, an end surface of the force loading unit is contacted with the force bearing projection on the simulation shield head. Force loading units which pass through the loading disc along the axial direction are uniformly arranged on the loading disc along the circumferential direction. The device realizes tunneling simulation of the shield under different working conditions by adjusting the force loading units on a force loading system and a torque loading system.

Owner:TSINGHUA UNIV

Novel PDC drill bit utilizing impact effect for improving heart rock breaking efficiency

The invention belongs to the field of technical equipment used in oil and natural gas drilling engineering, mine exploiting, geological drilling, constructional engineering, tunnel engineering, shielding and non-excavation, and relates to a novel PDC drill bit utilizing the impact effect for improving heart rock breaking efficiency. The PDC drill bit solves the problems that in the drilling process, a center rock column left in the center part influences drilling efficiency, and the position deviating from the center of a well hole shakes left and right. According to the technical scheme, the upper end of a turbine is fixed through a nut, the lower end of the turbine is fixed through a boss on a turbine shaft, an upper cam is connected to the turbine shaft through threads, a lower cam is fixed to a punch hammer through a sunk screw, the upper section of the punch hammer is hollow, a pore passage enabling drilling fluid to flow out is formed in the upper end of a shell on the lower portion, a pressing head with the top end provided with a tip-shaped PDC tooth is added to the tail end of a connecting cavity, as a main impact part, the lower end of the punch hammer becomes thin, and a bi-directional thrust ball bearing is placed at the lower end. The equipment enables the heart to generate longitudinal impact, improves the rock breaking efficiency and reduces drilling cost.

Owner:SOUTHWEST PETROLEUM UNIV

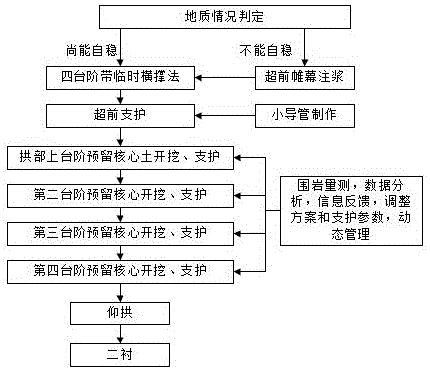

Construction method for tunnel trunk penetrating through loess interface water-rich strata

InactiveCN106121661APrevent sinking deformation damageSuppress vertical displacementUnderground chambersTunnel liningTruckCross bracing

The invention relates to the technical field of tunnel construction, in particular to a construction method for a tunnel trunk penetrating through loess interface water-rich strata. The construction method comprises the following steps that (1) the geological condition of the strata where the tunnel truck passes is surveyed and analyzed, and the geological condition in front of a tunnel face is analyzed at the same time; (2) whether advance longhole curtain grouting is adopted or not is determined according to the stability situation of the tunnel face; (3) advance supporting is conducted, and excavation and supporting are conducted by means of a four-step and temporary cross bracing method; and (4) excavation, supporting and lining building are conducted on an inverted arch of a tunnel. According to the construction method for the tunnel trunk penetrating through the loess interface water-rich strata, the geologic structure of a loess interface is analyzed, and advance grouting and the four-step and temporary cross bracing method are adopted for the interface water-rich strata, so that mud bursting of the tunnel face in the water-rich interface strata is effectively suppressed, and conditions are created for excavation; and the four-step and temporary cross bracing method effectively prevents overlarge overall sinking and deformation damage of the tunnel trunk when the tunnel truck penetrates through the loess interface water-rich strata, and the construction method has very important guiding significance for design and construction of tunneling in loess-like strata.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

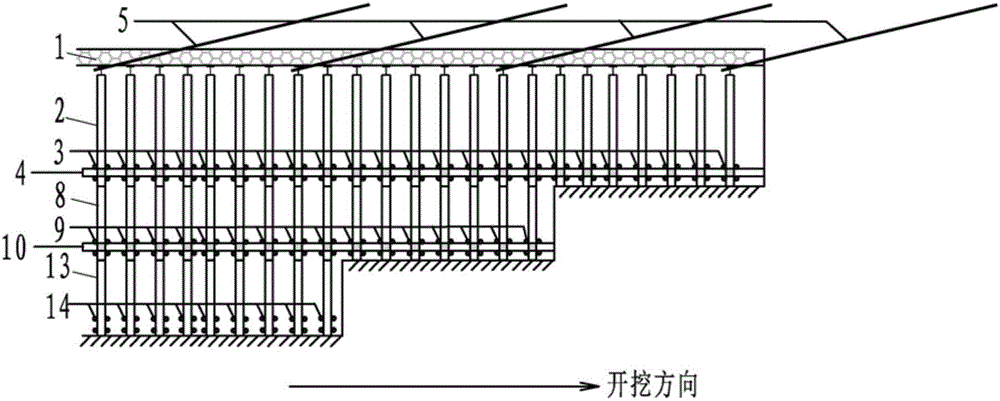

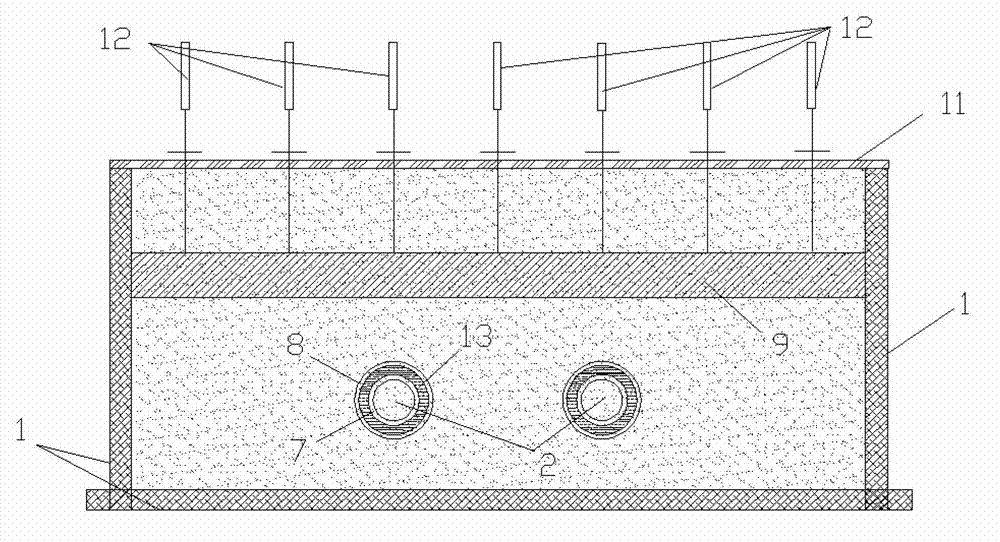

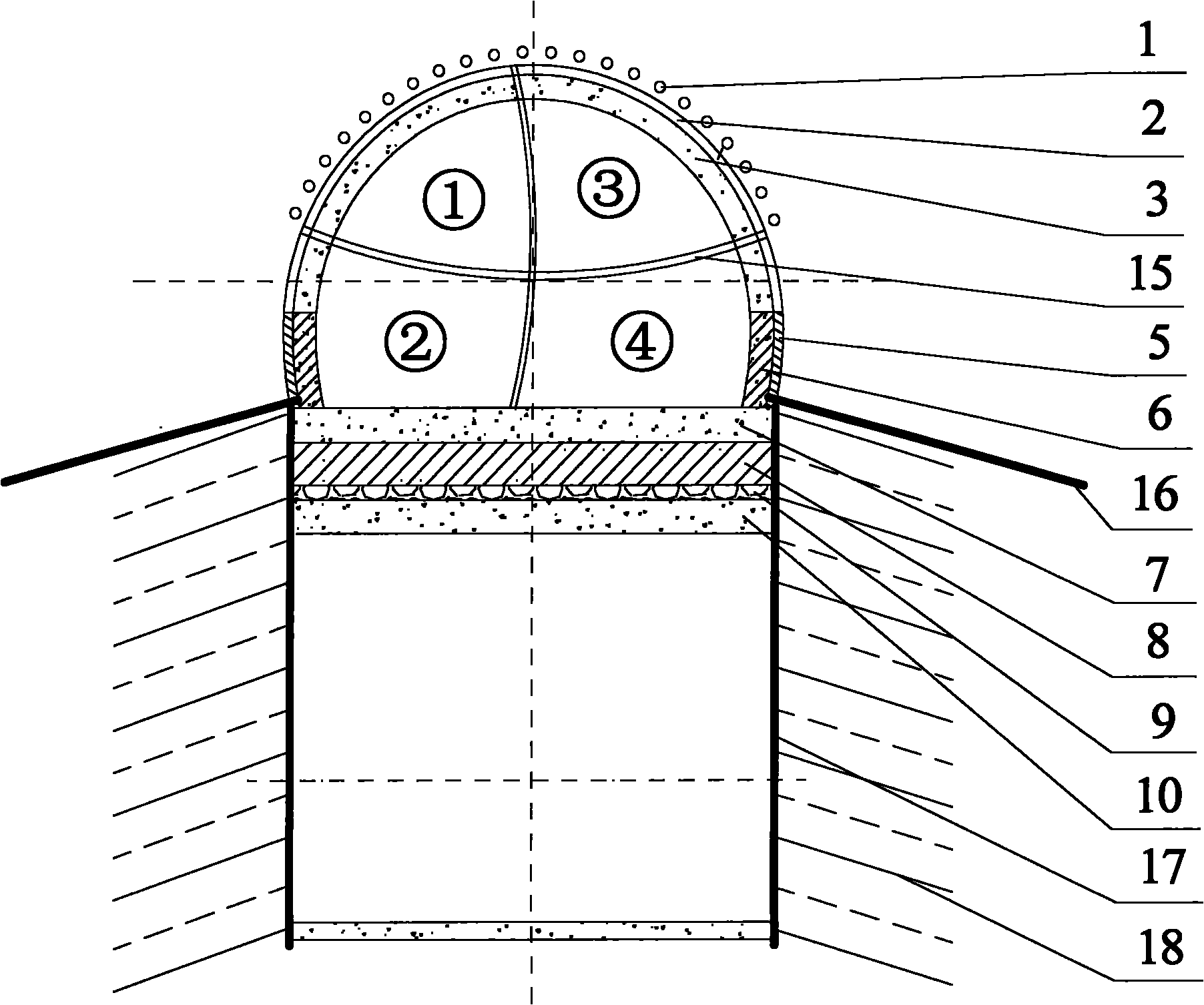

Zero spacing construction method for overlapping part of upper main tunnel and lower main tunnel of underground overpass

InactiveCN101775987AAvoid influenceAvoid secondary perturbationUnderground chambersMaterial fill-upReinforced concreteRebar

The invention discloses a zero spacing construction technical method for an intersecting and overlapping part of an upper main tunnel and a lower main tunnel of an underground overpass, which belongs to construction technologies of tunnel engineering. The method comprises four procedure steps of: (1) excavating and supporting an upper-layer tunnel CRD (cross diaphragm) and strengthening the construction of reinforced concrete edge beams; (2) excavating and supporting a base pit of a lower-layer tunnel; (3) carrying out secondary lining construction outside the lower-layer tunnel; and (4) refilling the upper part of the secondary lining outside the lower-layer tunnel. The invention realizes the technical method which does not retain soil mass at the intersecting and overlapping part of the upper-layer main tunnel and the lower-layer main tunnel of the underground overpass and finishes the construction of the excavation and the support structure of the upper main tunnel and the lower main tunnel of an intersecting section in one step and solves the problems of structure influence to early built tunnel by the late built tunnel and the secondary disturbance to the ambient soil mass which are caused by the upper penetration or lower penetration due to the early and late construction of the upper main tunnel and the lower main tunnel.

Owner:BEIJING JIAOTONG UNIV

Laser-assisted tunnel boring machine and rock breaking method thereof

ActiveCN106884662AReduce wearImprove rock breaking efficiencyTunnelsIntelligent control systemTunnel engineering

The invention belongs to the technical field of tunnel engineering and discloses a laser-assisted tunnel boring machine and a rock-breaking method thereof. The machine is characterized by two rock breaking modes, a laser-hob rock breaking mode and a hob rock breaking mode. Identification and conversion of the two rock breaking modes can be achieved by an intelligent control system. The laser-hob rock breaking mode is used in hard rock sections for the improvement of rock breaking efficiency, while the hob rock breaking mode is used in soft rock sections. The main breaking mode of the laser-assisted rock breaking is hot-break, wherein a laser is used with a laser head installed on a cutter of the tunnel boring machine, supplemented by a water spray system, so that the goal of hot crack by laser irradiation with rapid cooling for assisting rock breaking by water spray and further excavation by mechanical rock breaking is achieved. With the reasonable selection of the rock breaking modes, the adaptation of the tunnel boring machine to complex geological conditions alternated with soft and hard rocks is improved, thereby the rock breaking efficiency is enhanced and the construction cost is saved.

Owner:DALIAN UNIV OF TECH

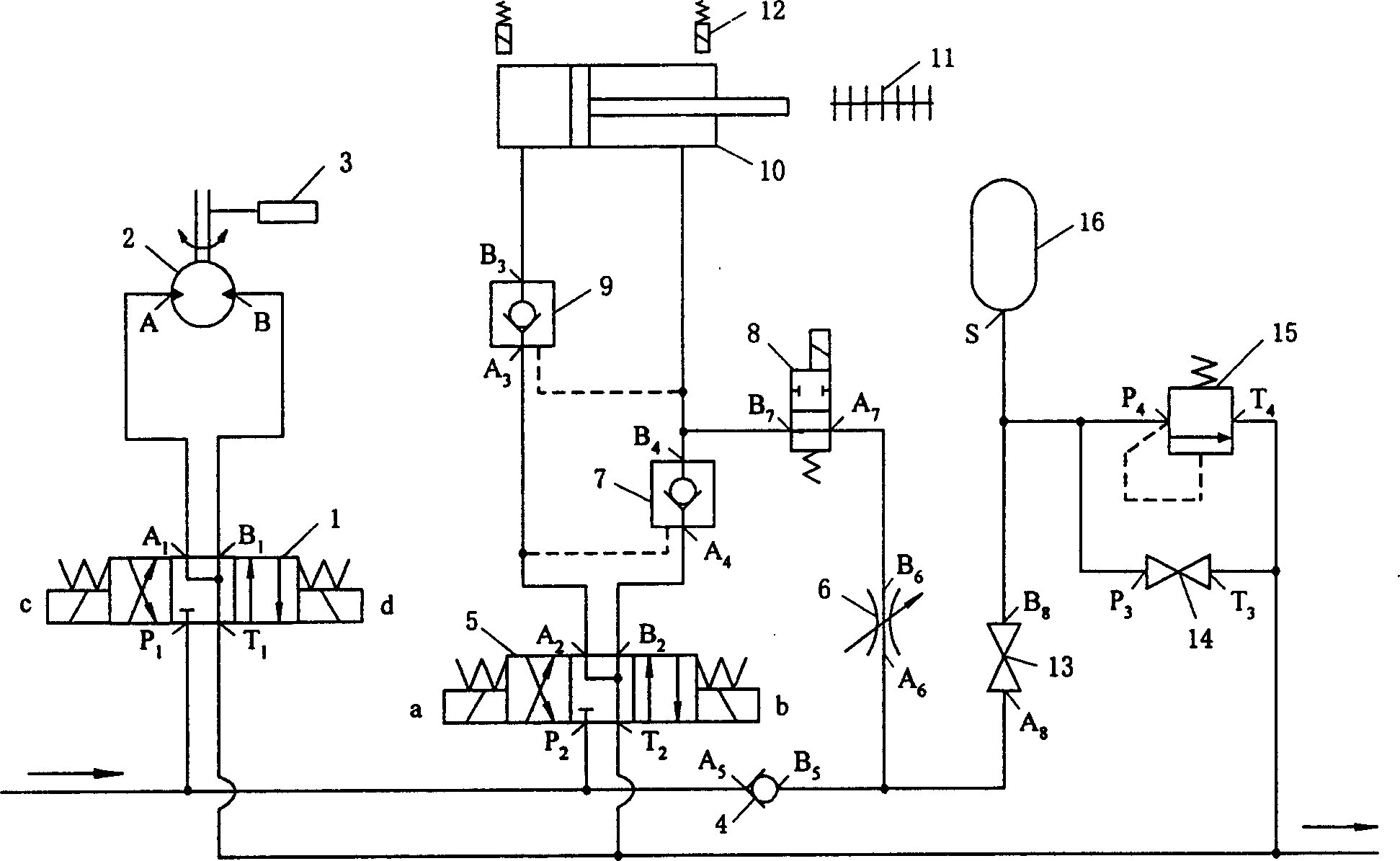

Shielding spiral conveyor hydraulic system with proportional feedback control and accumulator oil supplementary

InactiveCN1584346AControl disturbanceAdjustable speedFluid-pressure actuator safetyServomotorsEarth surfaceShuttle valve

A hydraulic system of shield spiral conveying machine with ratio feedback control and energy storing device for oil supplement consists of a three-position and four-way solenoid change valve, a motor, a rotation sensor, a one-way valve, a liquid-controlled one-way valve, a throttle valve, a two-position and two-way solenoid reversal valve, a shift sensor, a hydraulic cylinder, a range switch, a stop ball valve, a unloading valve, an overflow valve and an energy storing device. The machine has a sensor to monitor rotation and makes variable pump controlled according soil cabin pressure so as to control soil discharge volume and to achieve a hydraulic control system of a continuous real time controllable spiral-conveying machine. The energy-storing device is used oil supplement to close exhaust outlet reliably when accident occurs to guarantee safety for tunnel engineering. The electric feedback and ratio feedback are used to control turbulence to soil body when shield tunneling and reduce settlement of earth surface. The machine can be adaptable for various strata reliably.

Owner:ZHEJIANG UNIV

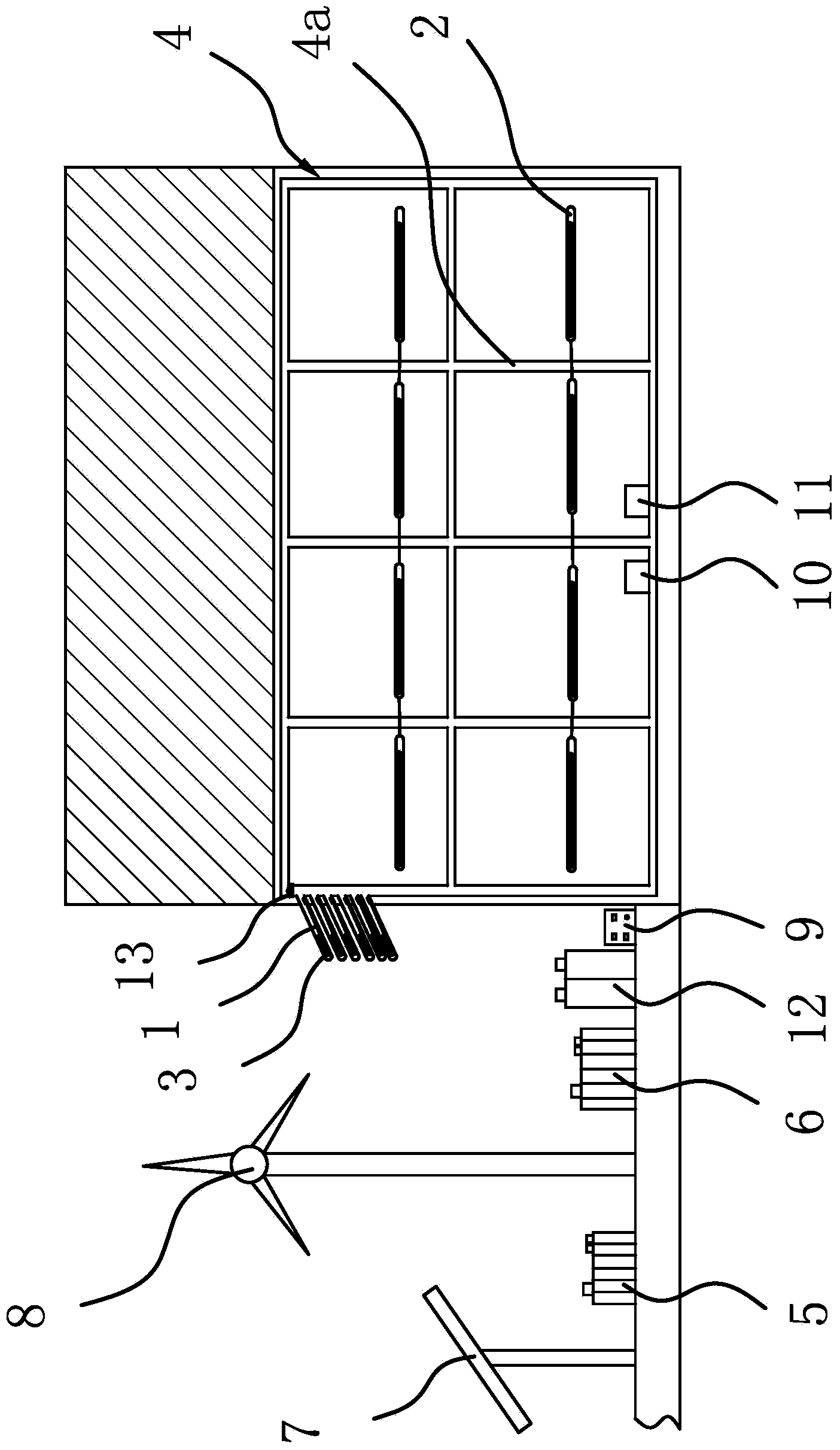

Monitoring system and method for simulating excavation device through tunnel pipe roof construction method

InactiveCN103940394ASimple structureEasy to operateElectrical/magnetic solid deformation measurementTest frameData acquisition

The invention provides a monitoring system and method for simulating an excavation device through a tunnel pipe roof construction method and belongs to data collection methods of geotechnical engineering model tests. The monitoring system comprises a three-dimensional test frame, a loading device, a geotechnical body model, a pipe roof supporting structure, a displacement sensor, a strain gauge, a strain data collection system and a displacement data collection system; the geotechnical body model is arranged in the three-dimensional test frame; the upper end of the geotechnical body model is provided with the loading device; a simulation excavation tunnel penetrates the geometrical center of the geotechnical body model; a plurality of displacement sensor measuring heads are connected with the inside and the periphery of the simulation excavation tunnel; the upper end of the simulation excavation tunnel is provided with the pipe roof supporting structure; the strain gauge is pasted on the pipe roof supporting structure; the strain gauge is connected with the strain data collection system through a strain gauge lead; the displacement sensor is connected with the displacement data collection system through a lead. According to the monitoring system and method for simulating the excavation device through the tunnel pipe roof construction method, the dynamic construction process of tunnel engineering under the pipe roof supporting structure is approximately simulated through an indoor test and accordingly strain parameters of the tunnel and a stratum in the excavation process can be accurately obtained and support can be provided for actual construction.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com