Patents

Literature

1046 results about "Test frame" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

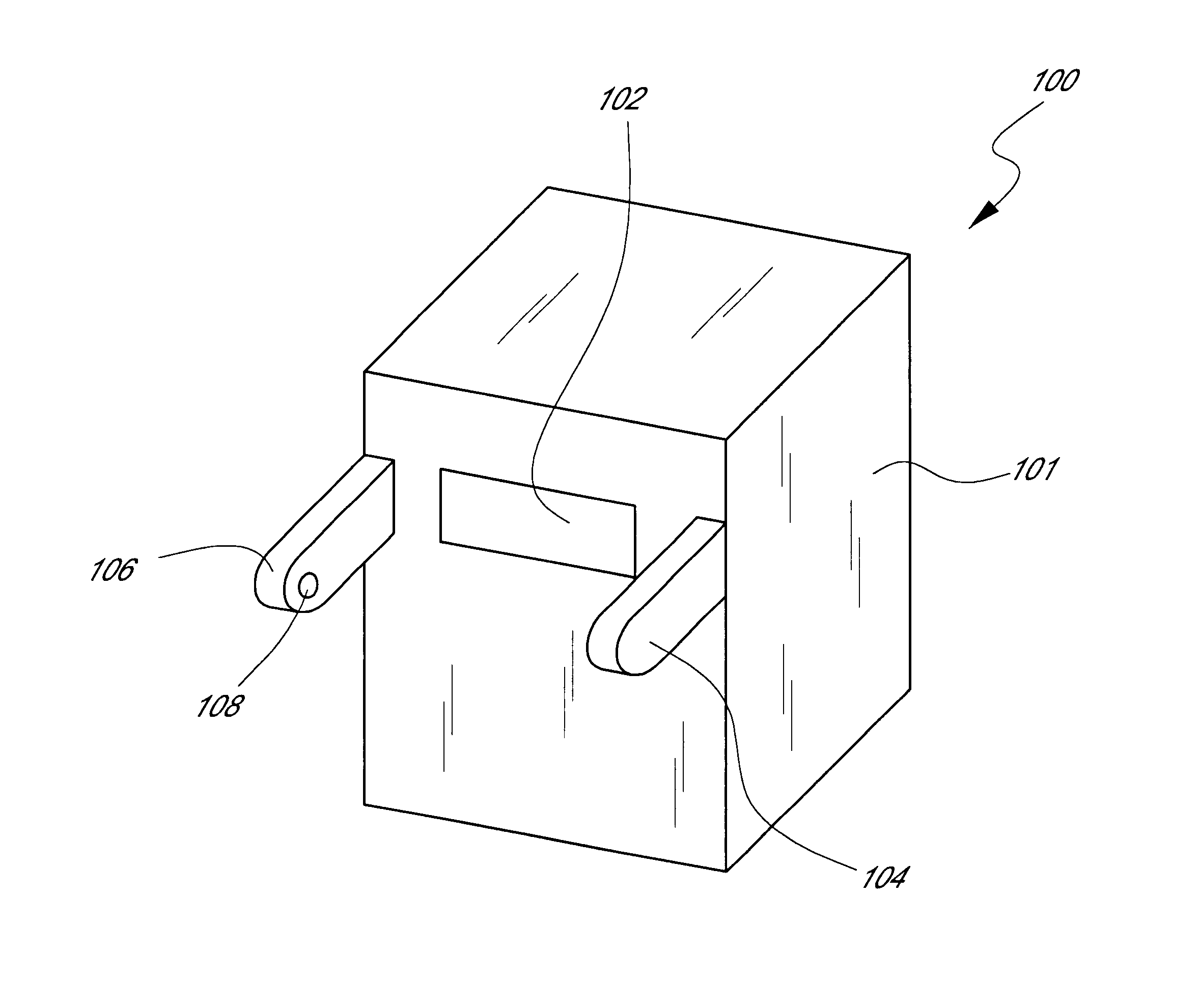

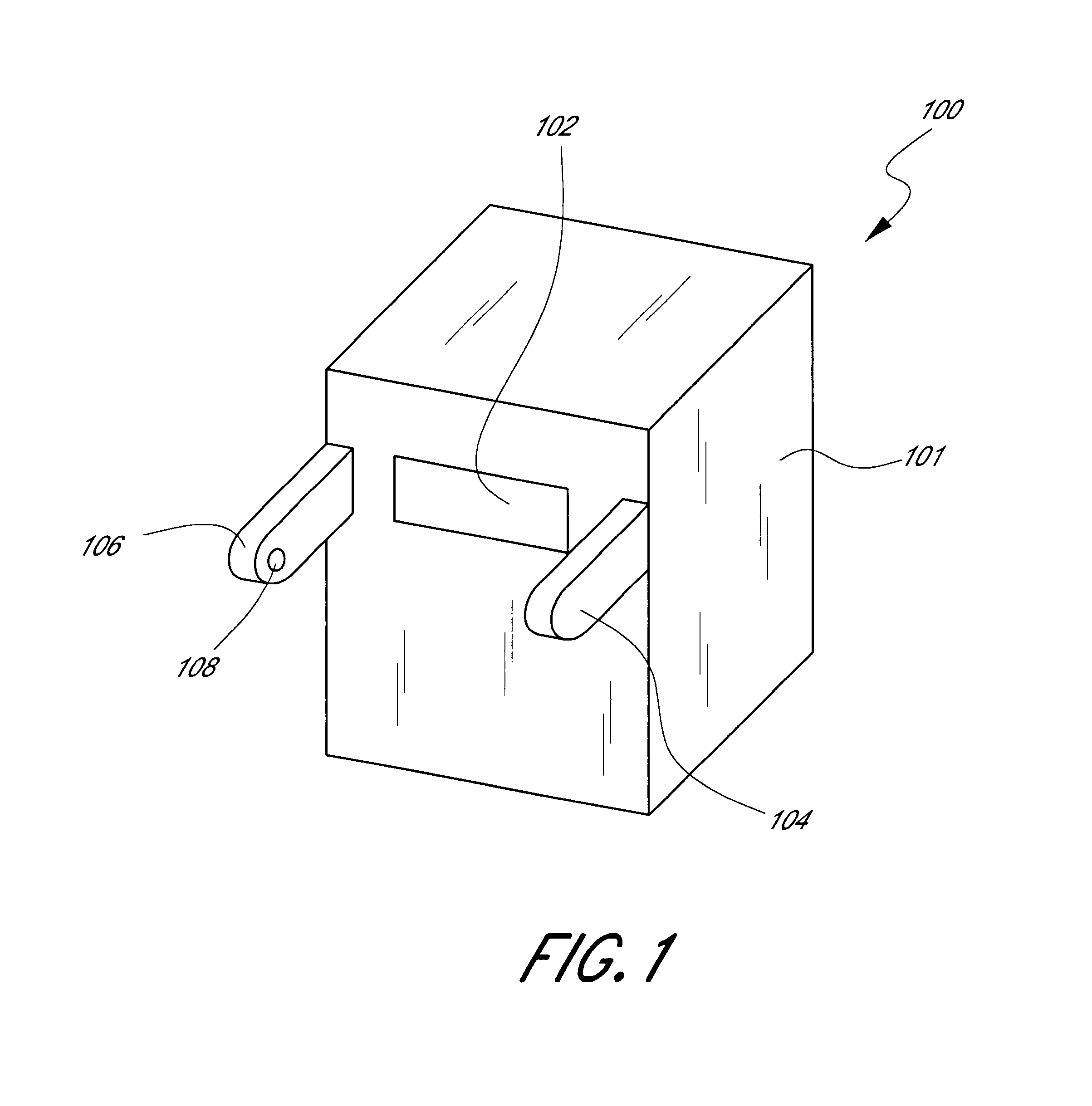

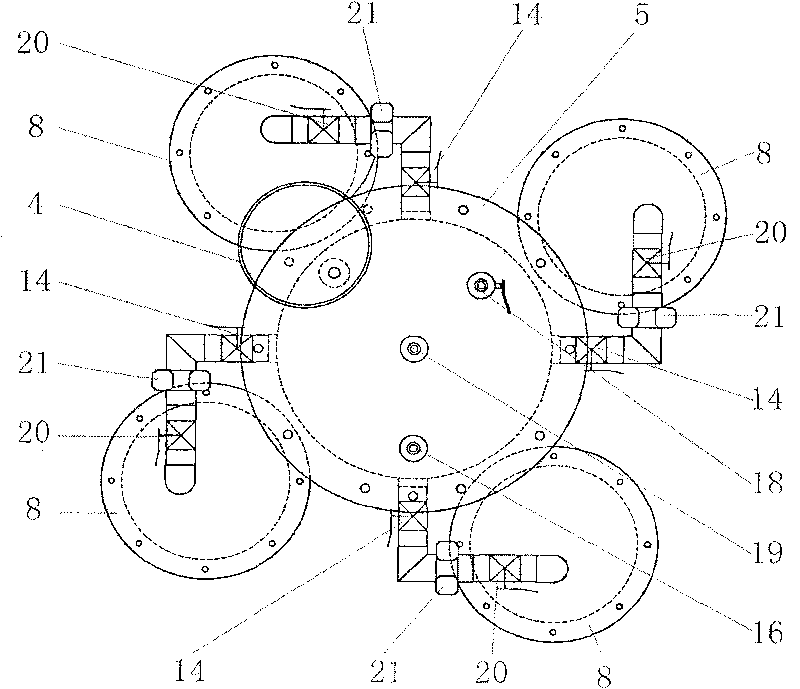

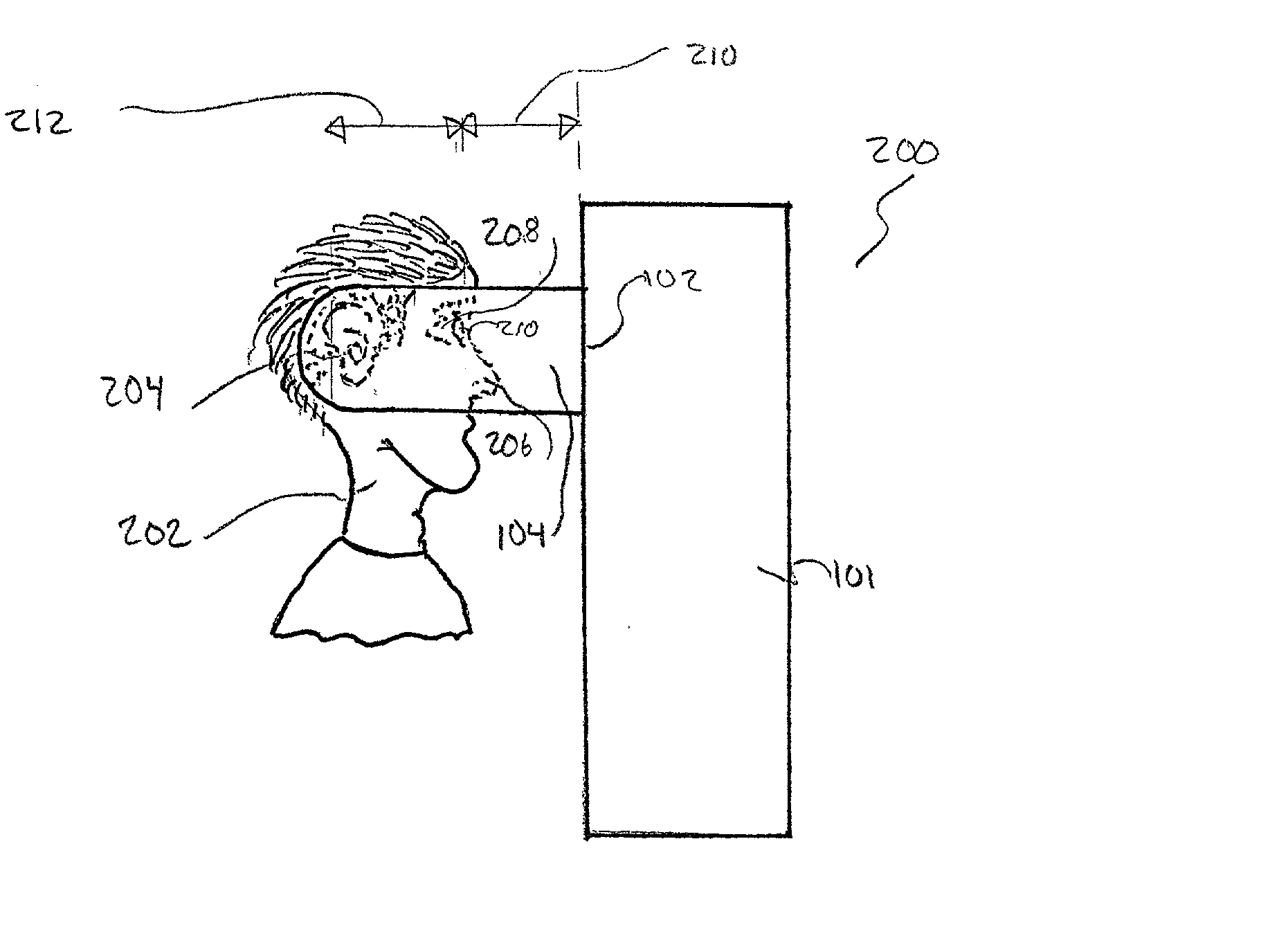

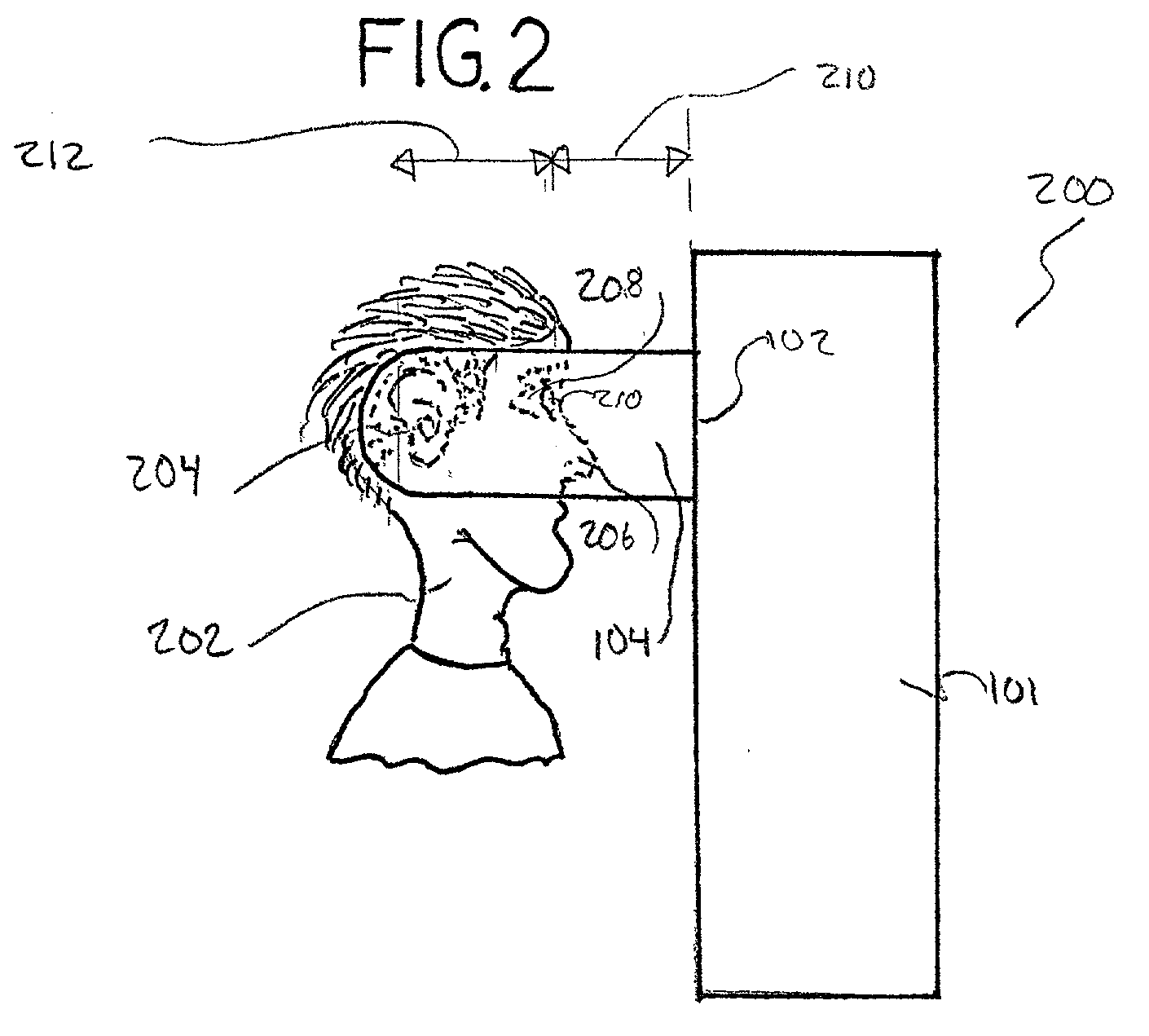

Custom eyeglass manufacturing method

A Custom Eyeglass Manufacturing Method includes a wavefront measuring device with a plurality of cameras directed at a patient's face. The resulting images are processed by a computer to determine the location of pupils, center of pupils, pupil distance, width of face, ear location, distance of corneal apex from the wavefront measuring device, distance from ear to corneal apex, and other desired parameters necessary to quantify a patient's face for custom eyeglass fittings. Moldings may be applied to patient's nose, temples, and ears in order to construct a pair of eyeglasses that fix perfectly on patient's head. Additionally, a test frame may be used in combination with the wavefront measuring device in order to allow computer to find some of the areas automatically. Lastly, registration markers may be applied to either the test frame, the moldings, or both in order to further aide the computer in locating desired parameters.

Owner:ESSILOR INT CIE GEN DOPTIQUE +1

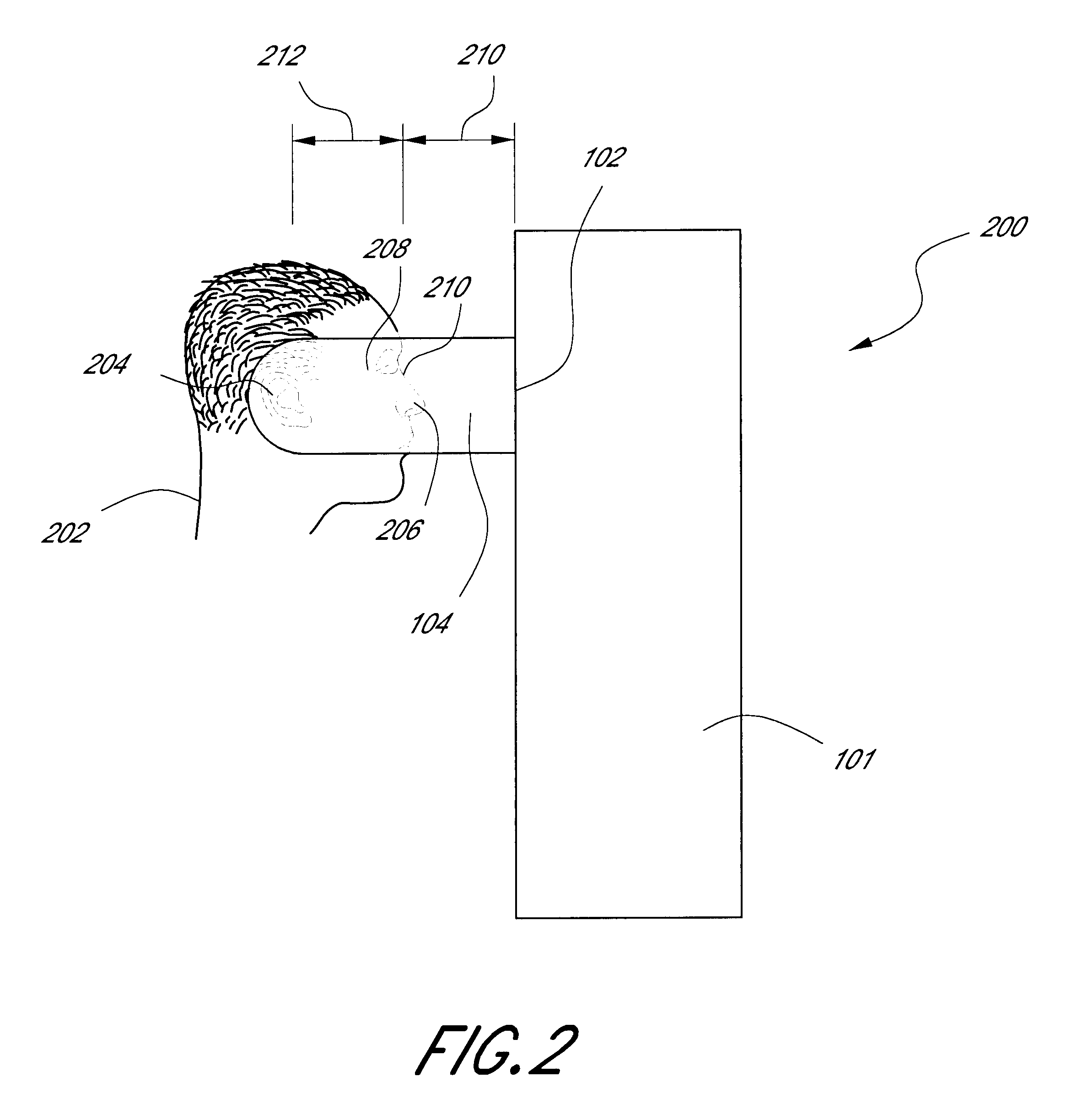

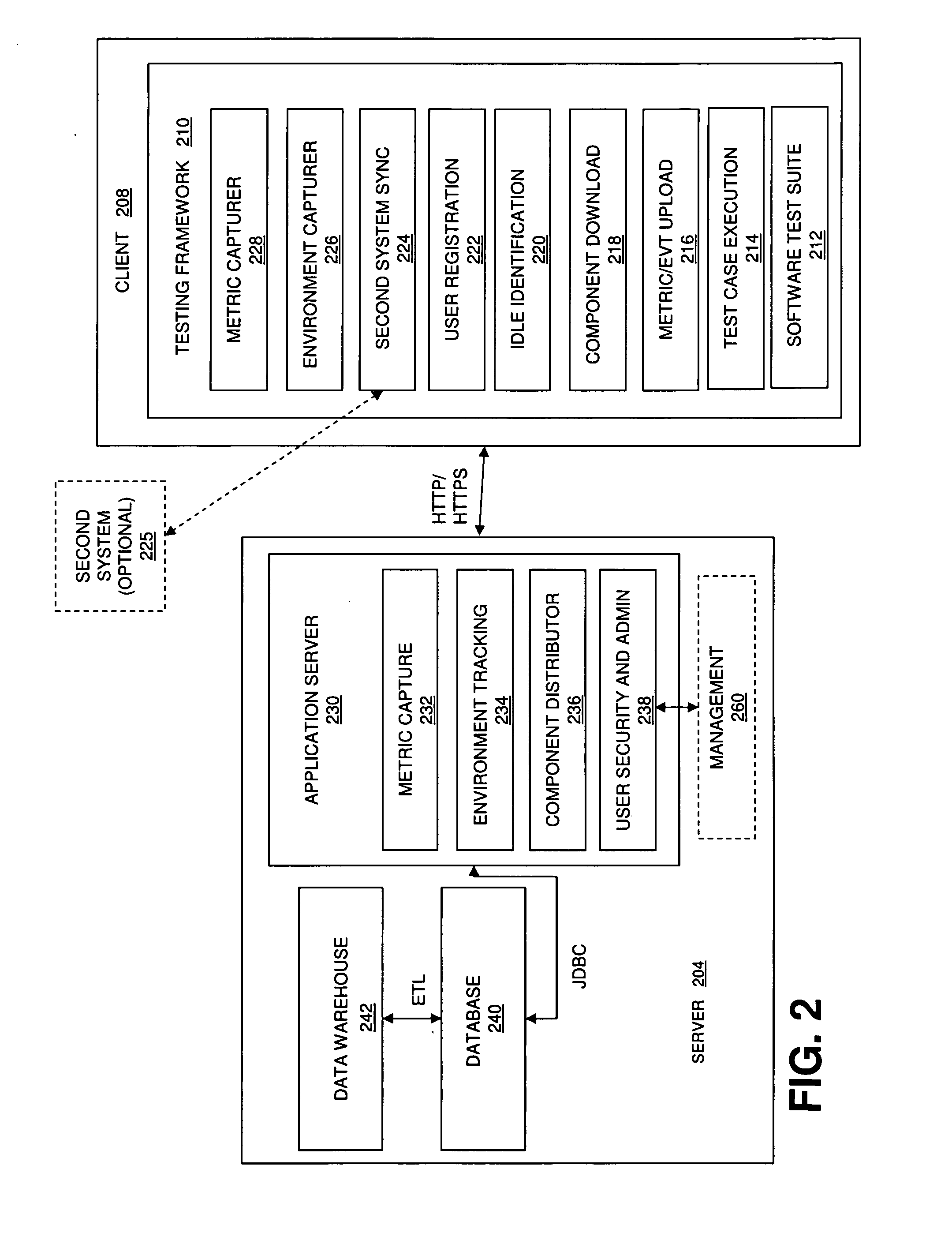

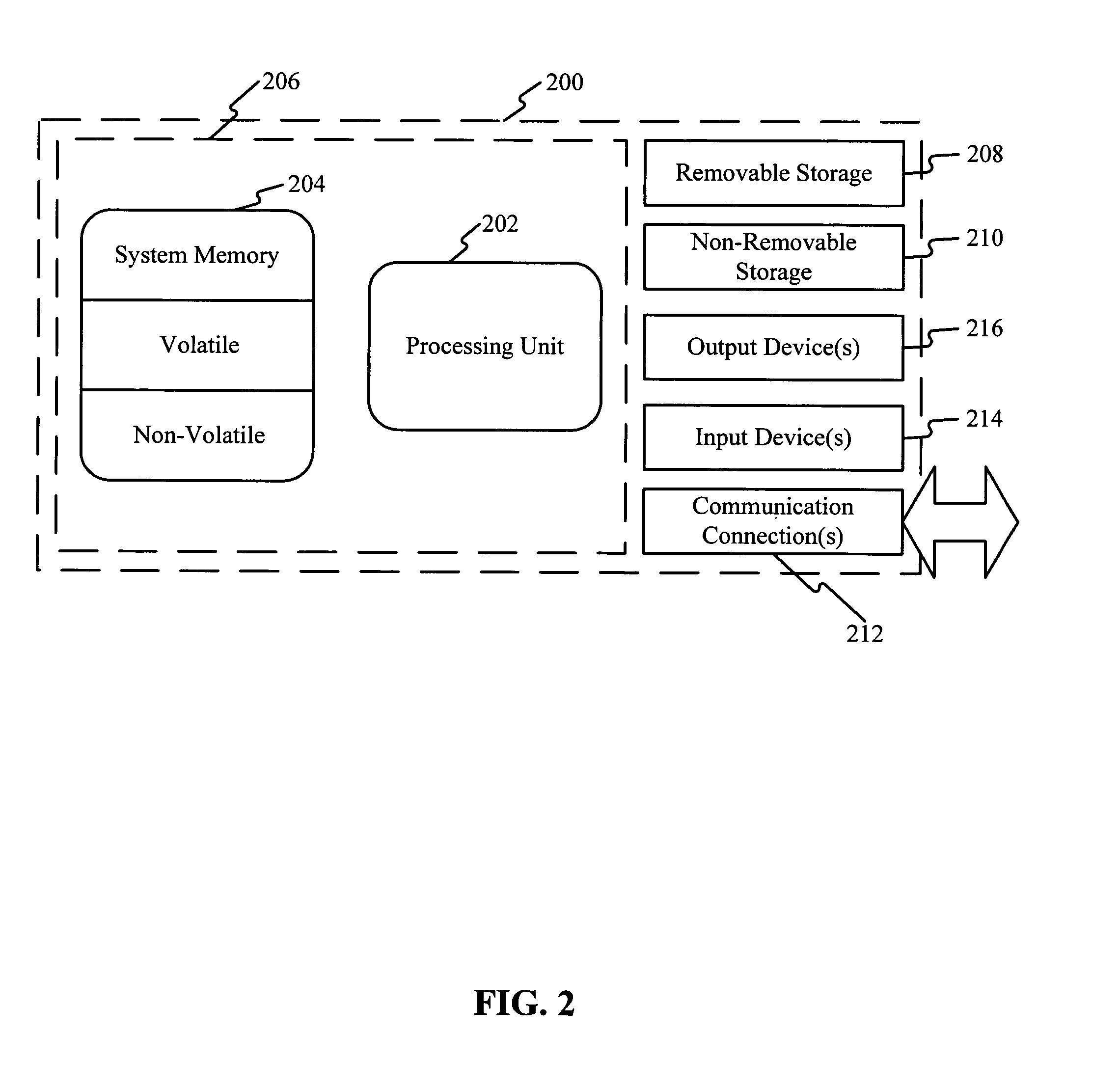

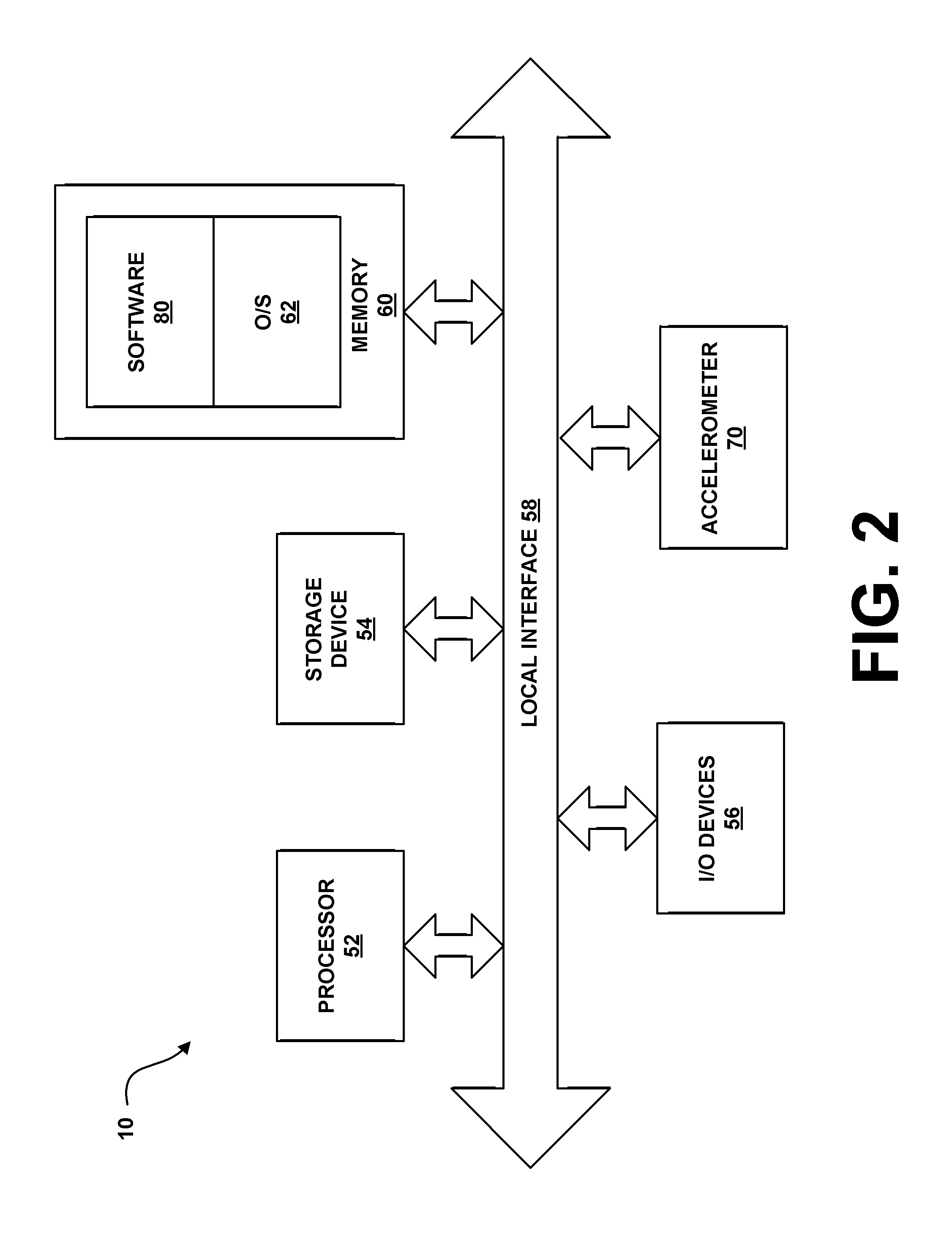

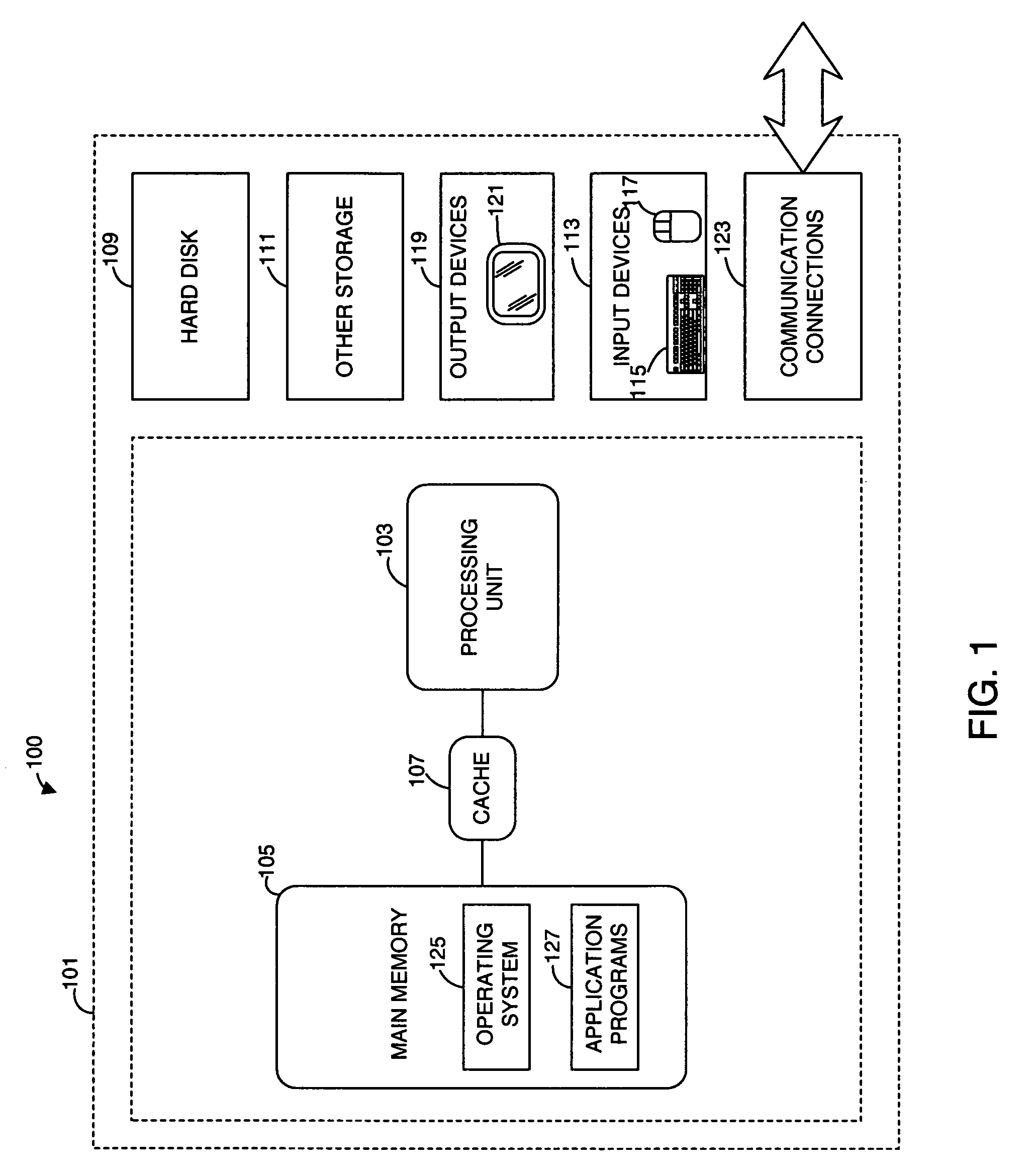

Automated software testing framework

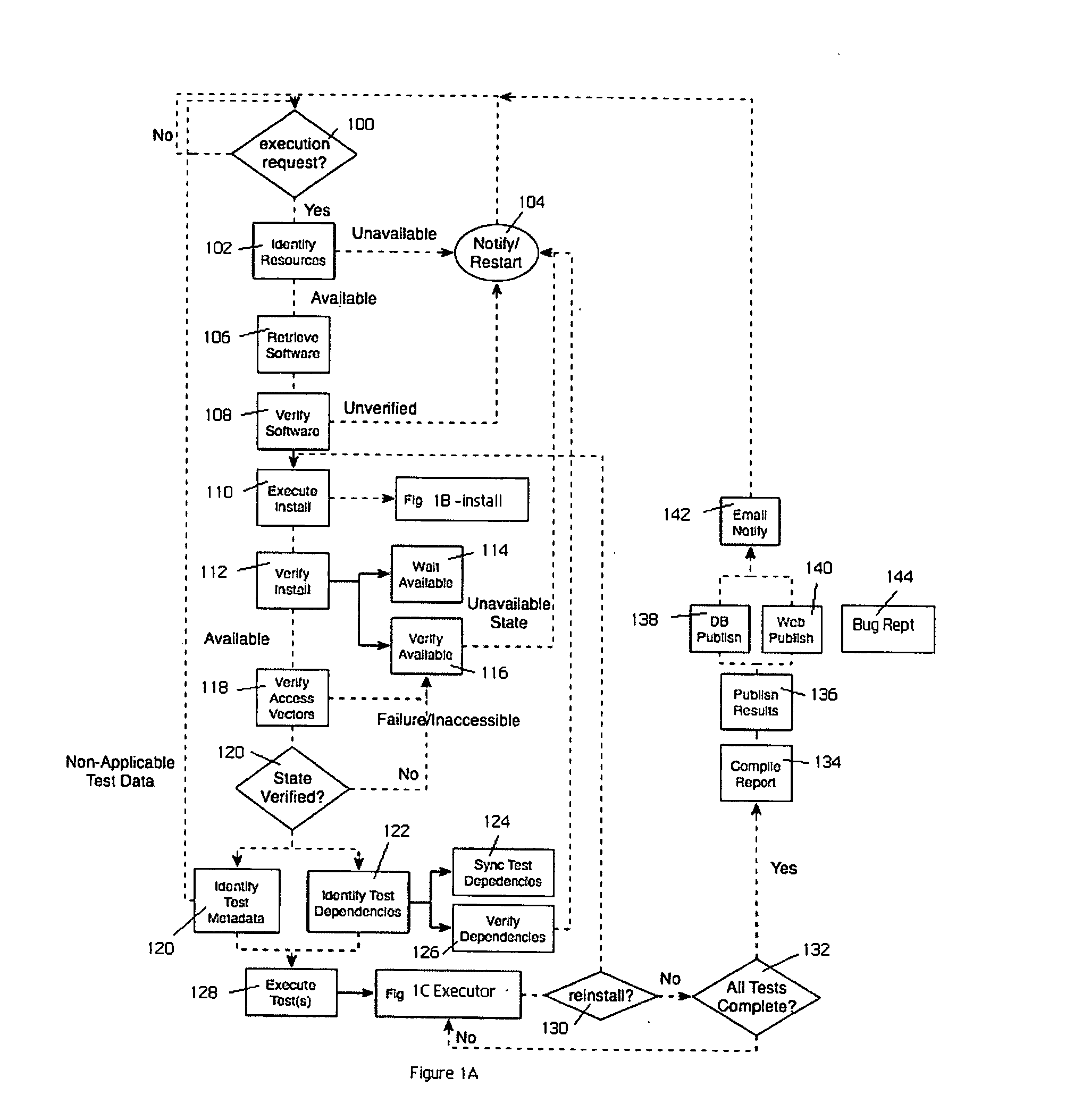

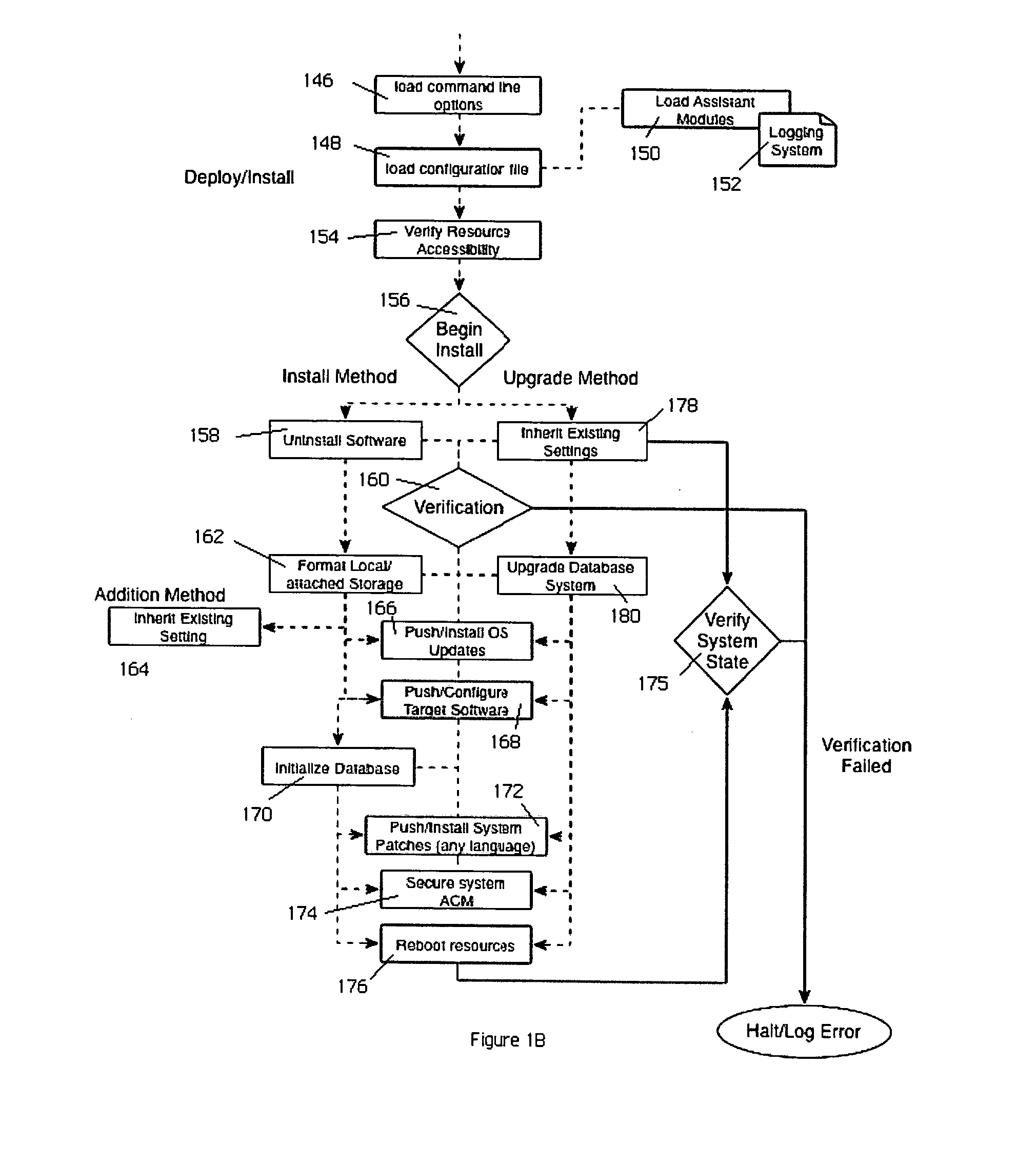

InactiveUS20070234293A1Improve scalabilitySimple and efficientError detection/correctionSpecific program execution arrangementsSpecific testWeb service

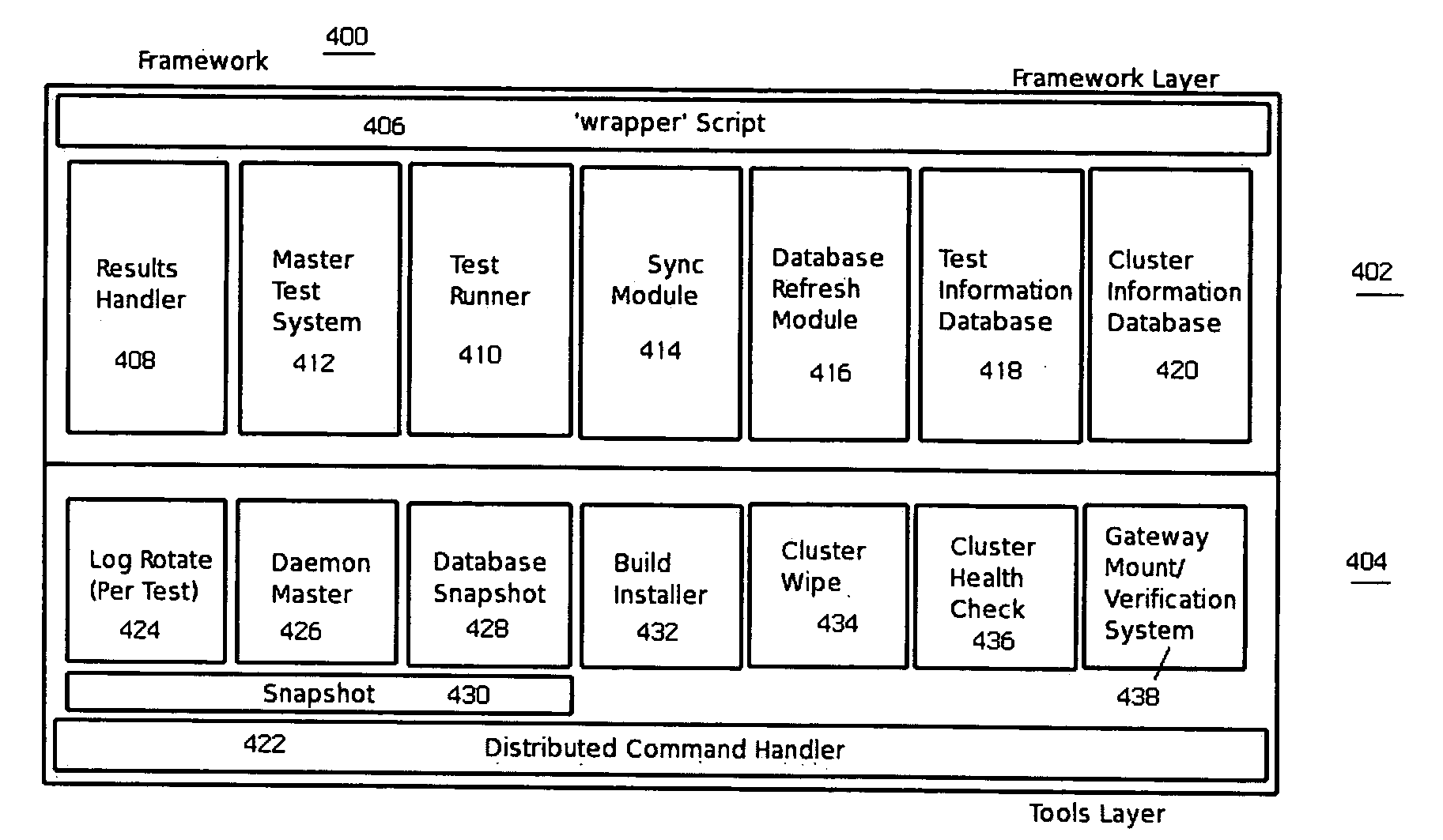

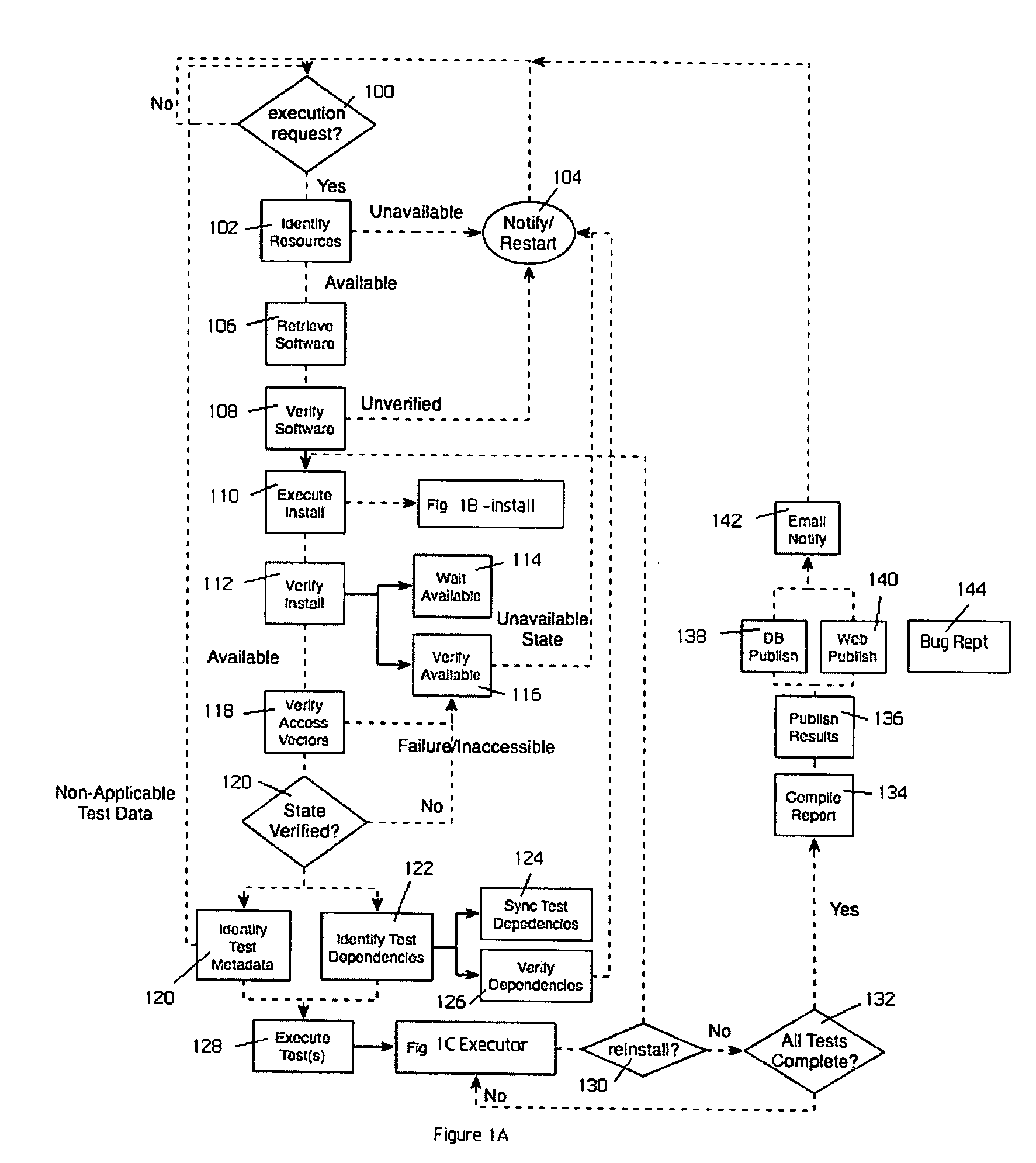

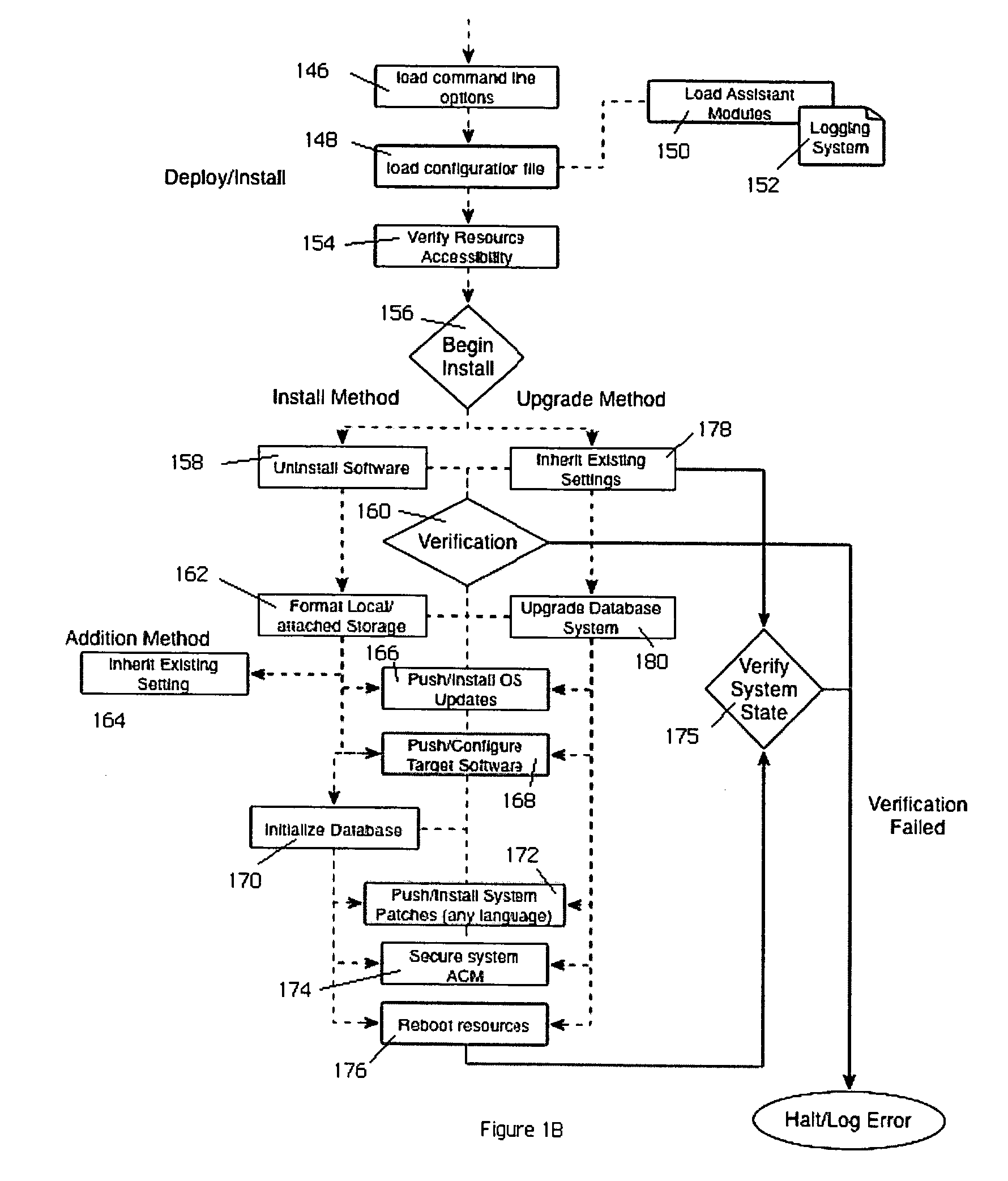

A generic testing framework to automatically allocate, install and verify a given version of a system under test, to exercise the system against a series of tests in a “hands-off” objective manner, and then to export information about the tests to one or more developer repositories (such as a query-able database, an email list, a developer web server, a source code version control system, a defect tracking system, or the like). The framework does not “care” or concern itself with the particular implementation language of the test as long as the test can issue directives via a command line or configuration file. During the automated testing of a given test suite having multiple tests, and after a particular test is run, the framework preferably generates an “image” of the system under test and makes that information available to developers, even while additional tests in the suite are being carried out. In this manner, the framework preserves the system “state” to facilitate concurrent or after-the-fact debugging. The framework also will re-install and verify a given version of the system between tests, which may be necessary in the event a given test is destructive or otherwise places the system in an unacceptable condition.

Owner:HITACHI DATA SYST CORP

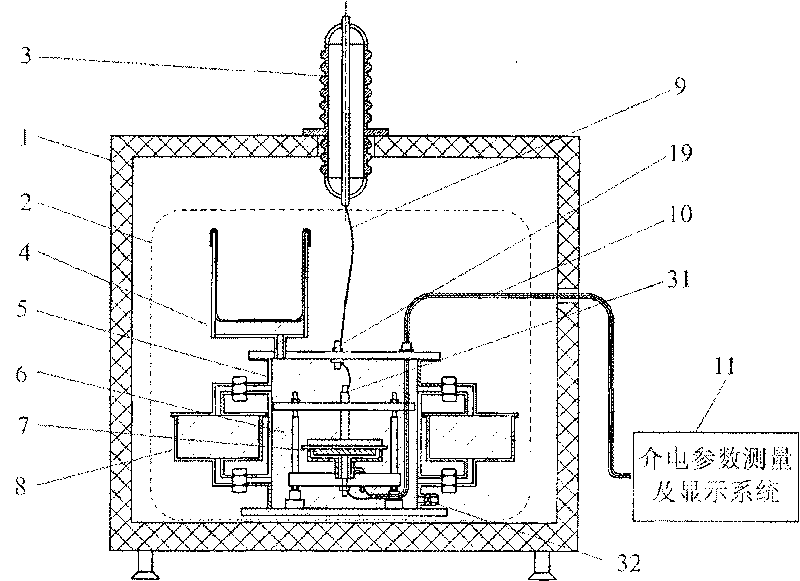

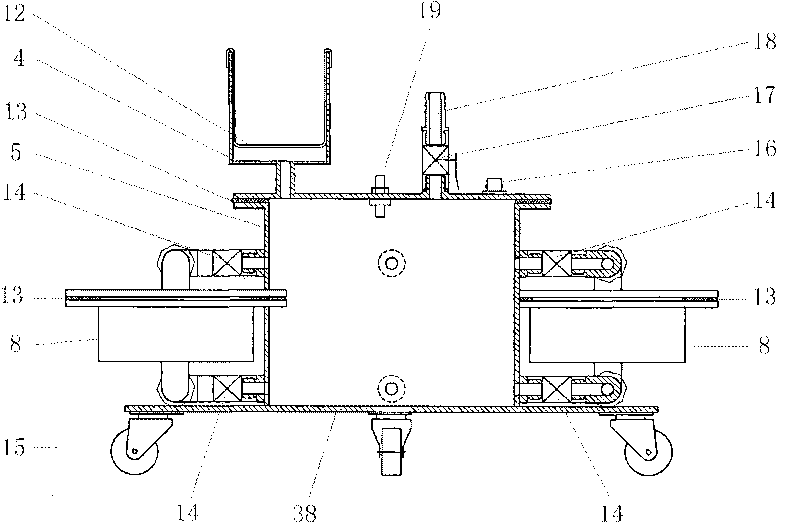

Experimental device and experimental method for transformer oilpaper insulating thermal ageing

InactiveCN101713721AWeighing by removing componentWeather/light/corrosion resistanceThermal ageingElectricity

Owner:XI AN JIAOTONG UNIV

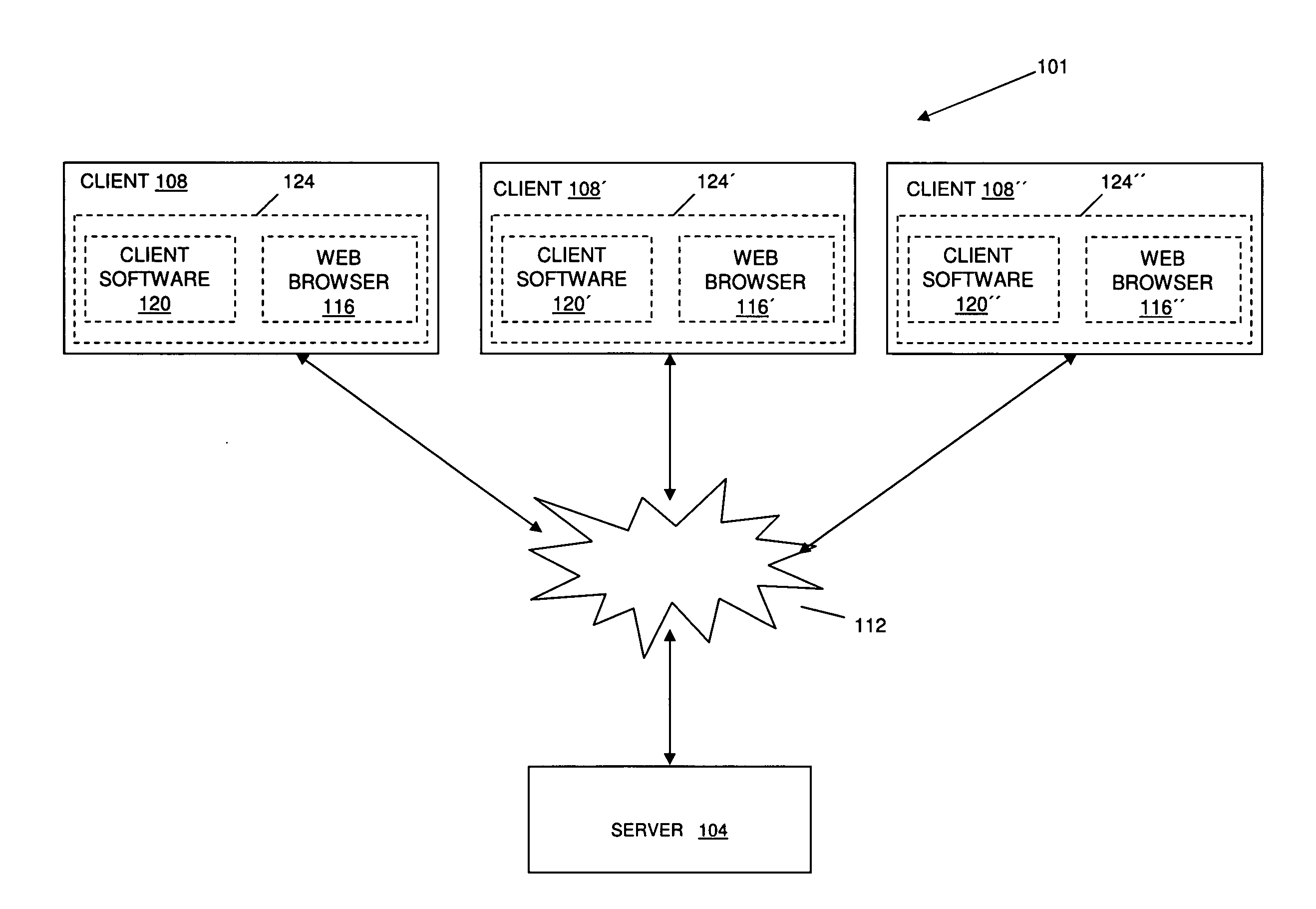

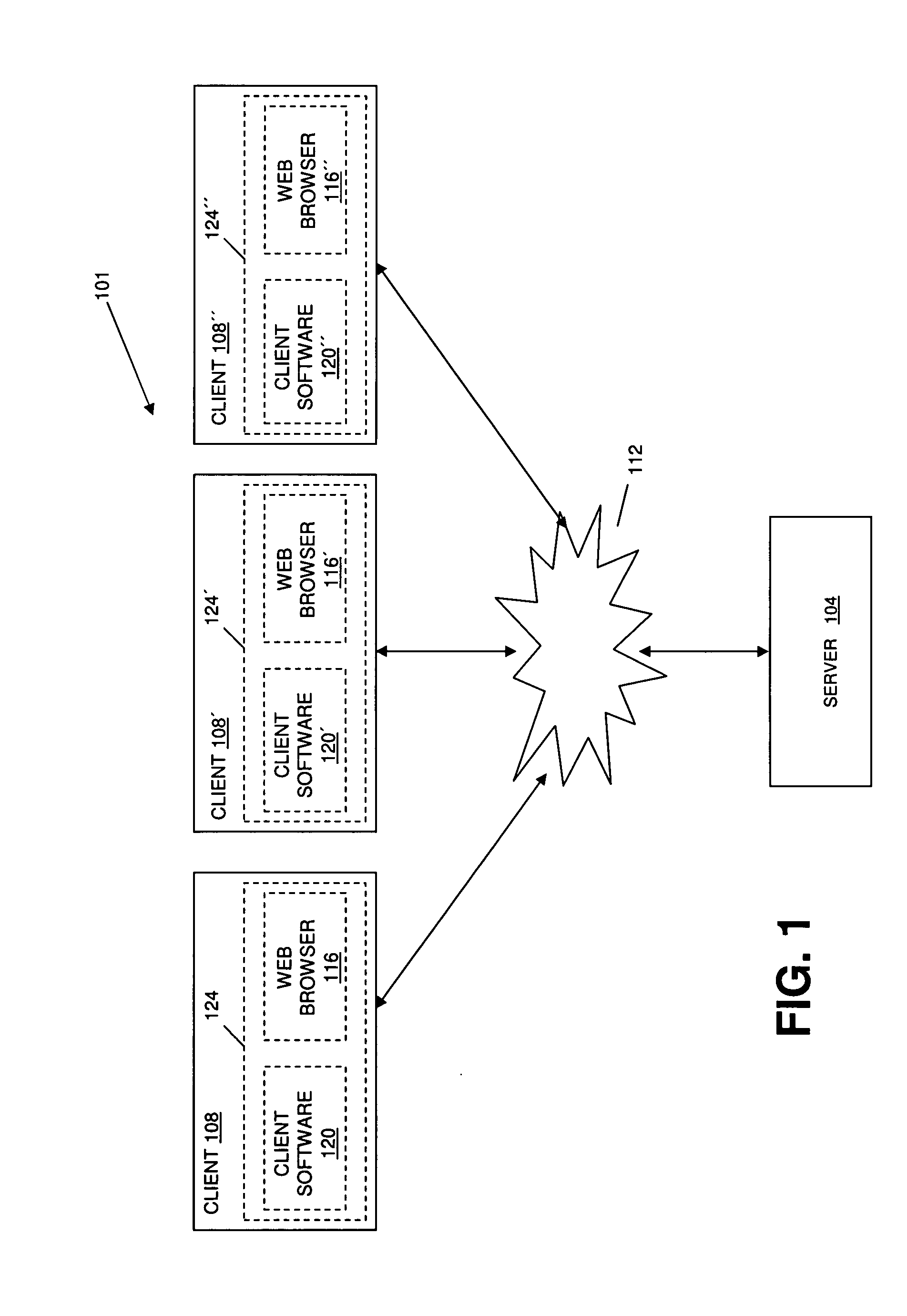

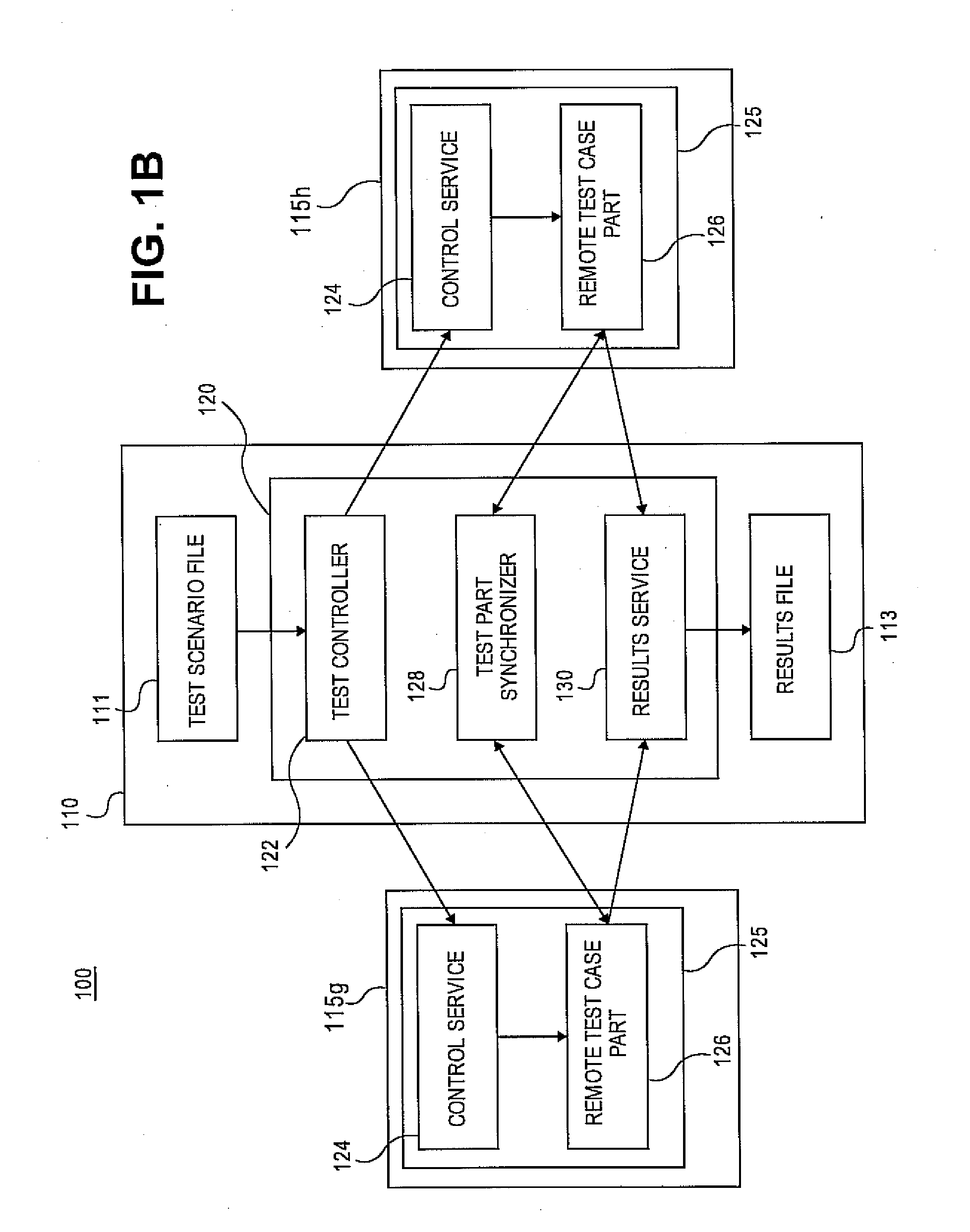

System and method for distributed software testing

ActiveUS20090007074A1Error detection/correctionSpecific program execution arrangementsComputer hardwareTest frame

In general, in one aspect, a method for distributed testing includes providing a testing framework for the distributed testing of software to a number of clients at least some of which have a different operating environment than other of the clients, transmitting to each testing framework a component for testing, receiving client environment data and testing results from each testing framework, storing the testing results and environment data in a database; and reporting the results of running the tests on the clients.

Owner:TOPCODER

Automated software testing framework

InactiveUS7694181B2Simple and efficientEasy to exportError detection/correctionSpecific program execution arrangementsWeb serviceSystem under test

A generic testing framework to automatically allocate, install and verify a given version of a system under test, to exercise the system against a series of tests in a “hands-off” objective manner, and then to export information about the tests to one or more developer repositories (such as a query-able database, an email list, a developer web server, a source code version control system, a defect tracking system, or the like). The framework does not “care” or concern itself with the particular implementation language of the test as long as the test can issue directives via a command line or configuration file. During the automated testing of a given test suite having multiple tests, and after a particular test is run, the framework preferably generates an “image” of the system under test and makes that information available to developers, even while additional tests in the suite are being carried out. In this manner, the framework preserves the system “state” to facilitate concurrent or after-the-fact debugging. The framework also will re-install and verify a given version of the system between tests, which may be necessary in the event a given test is destructive or otherwise places the system in an unacceptable condition.

Owner:HITACHI DATA SYST CORP

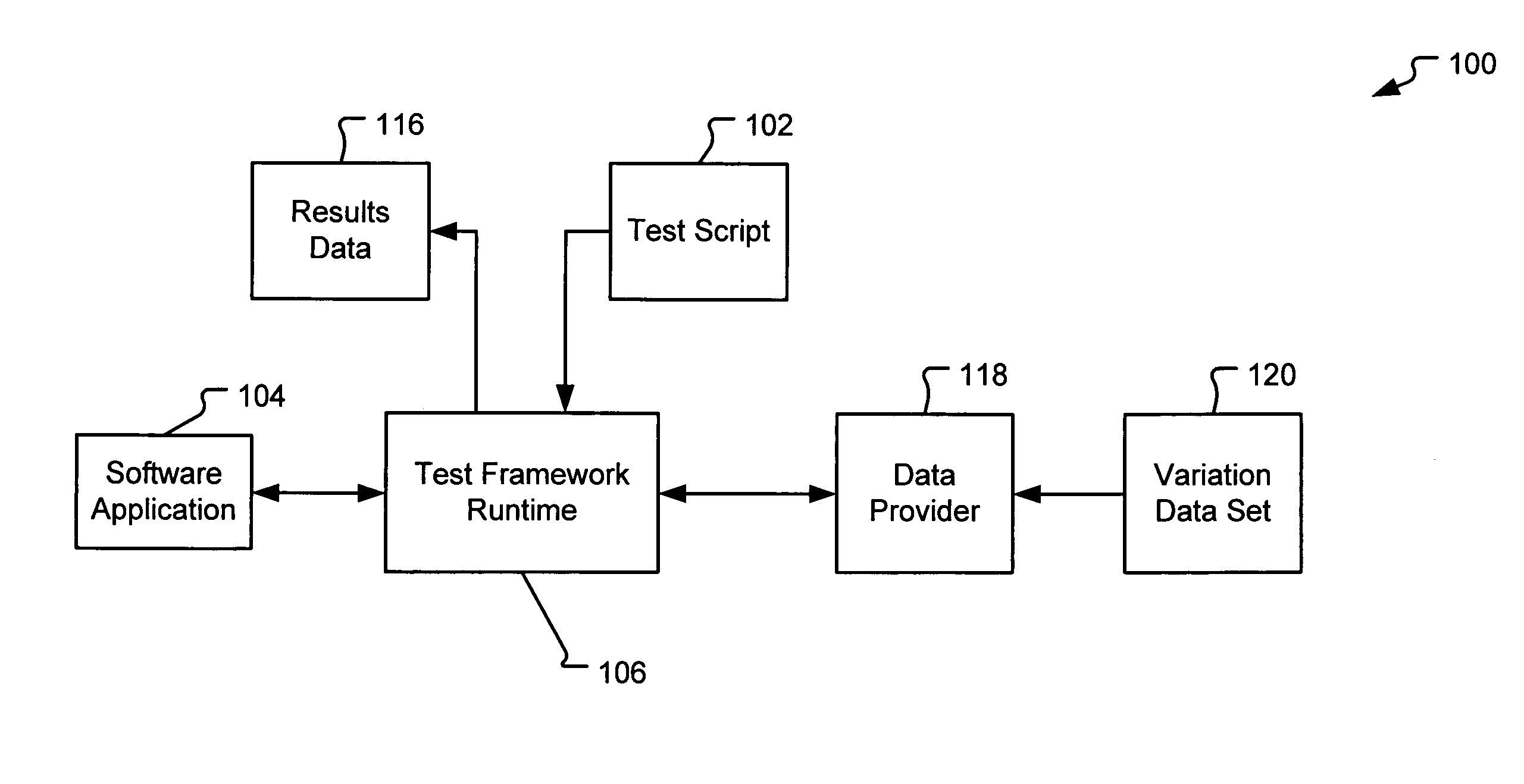

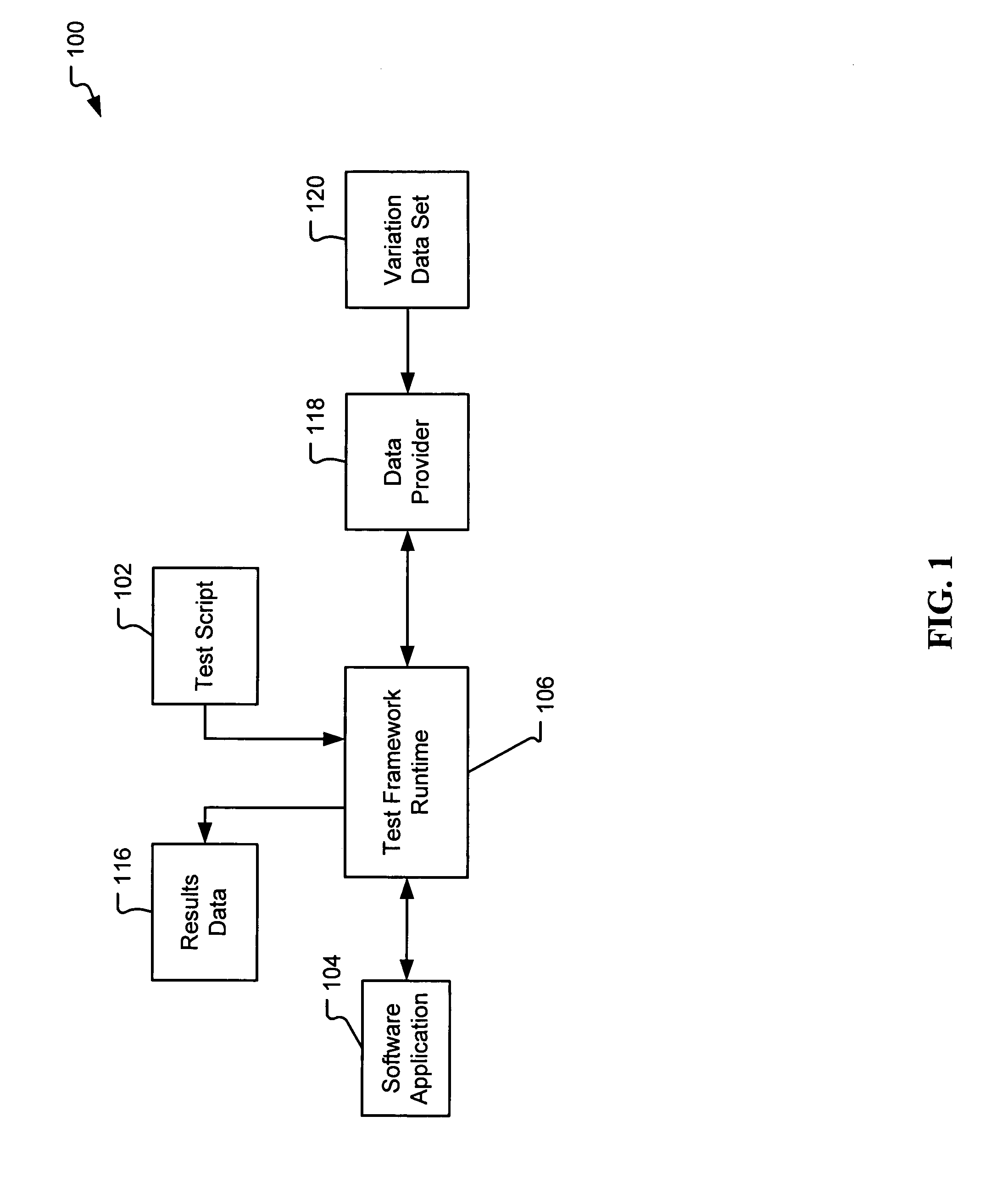

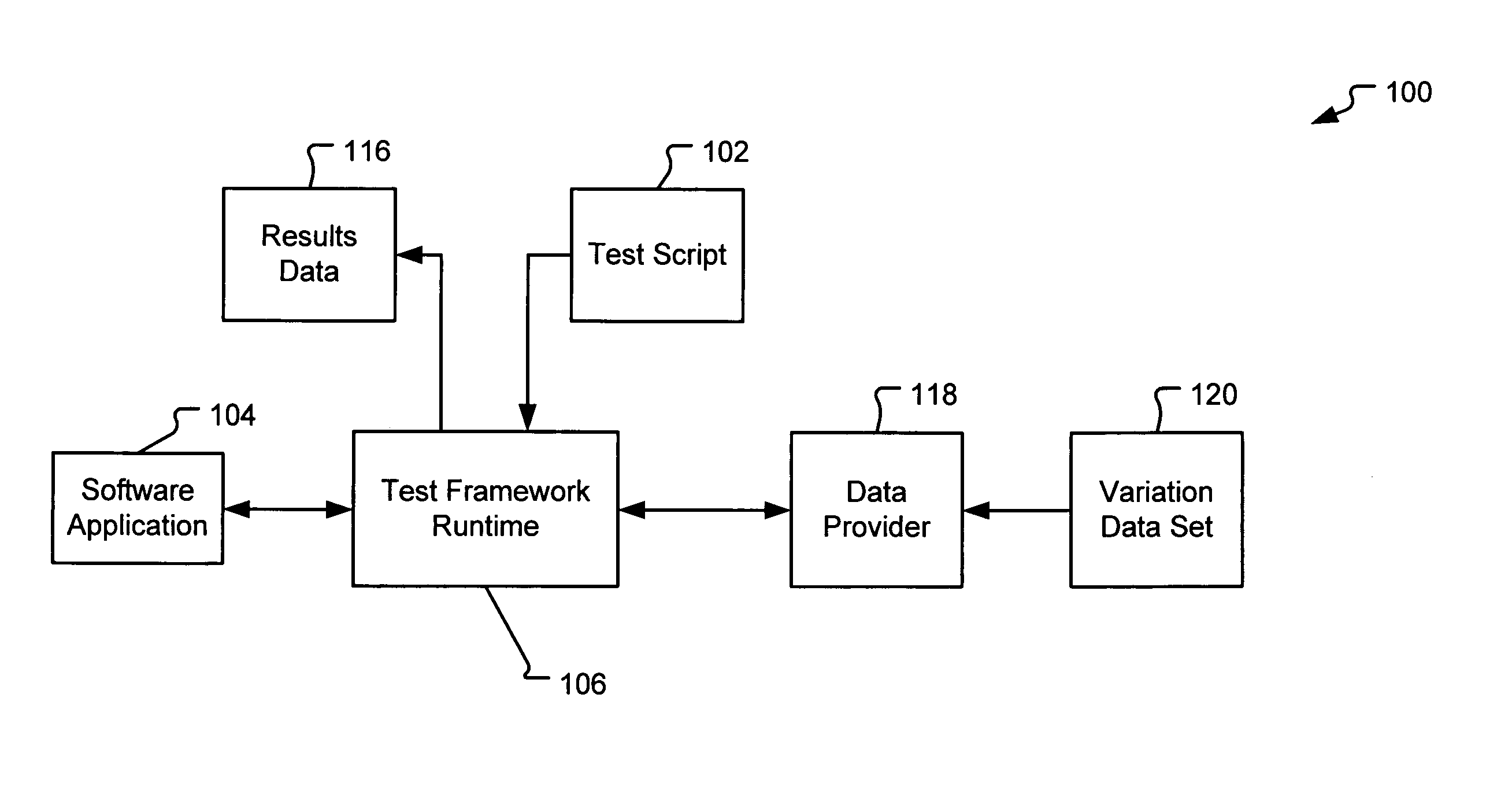

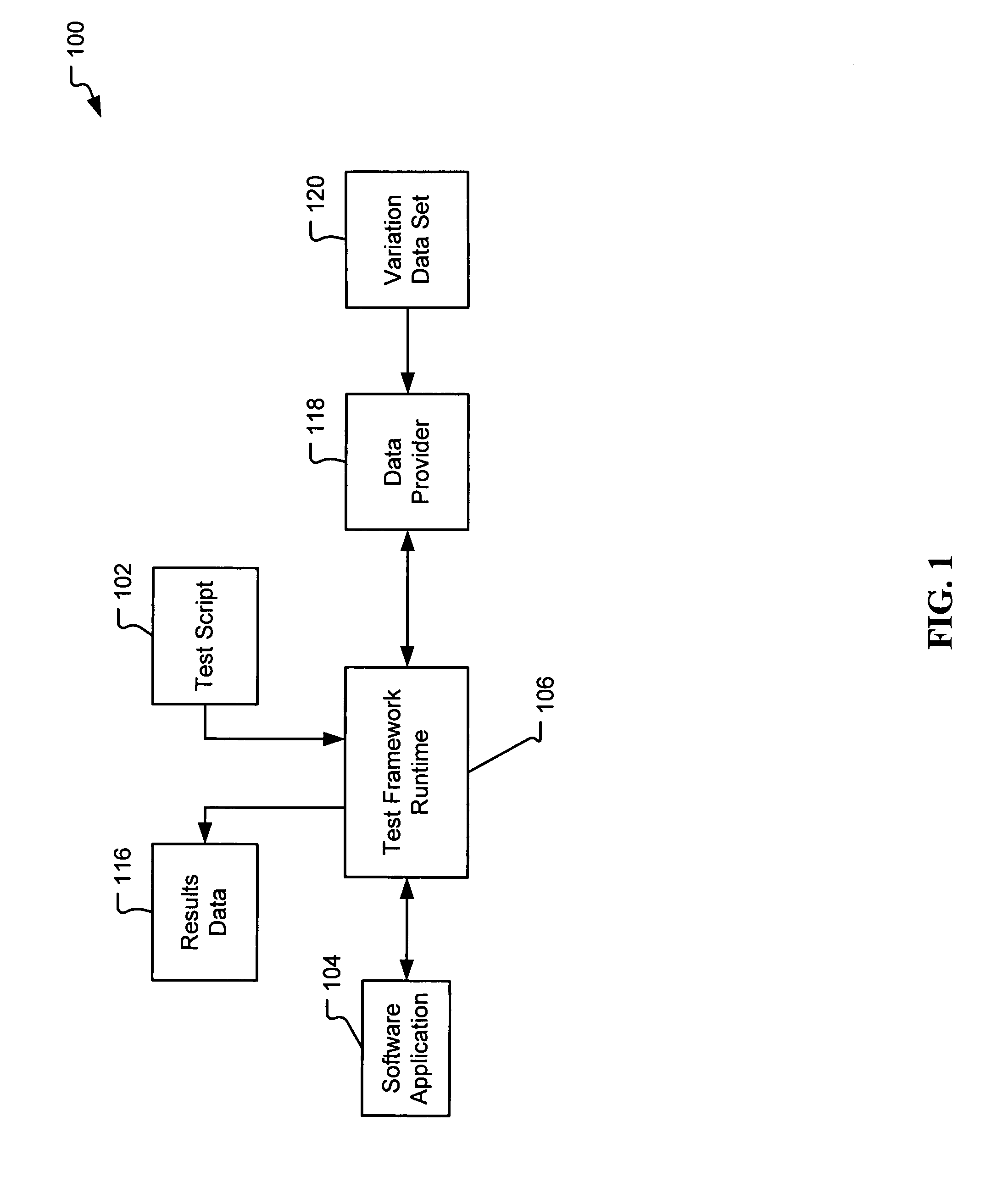

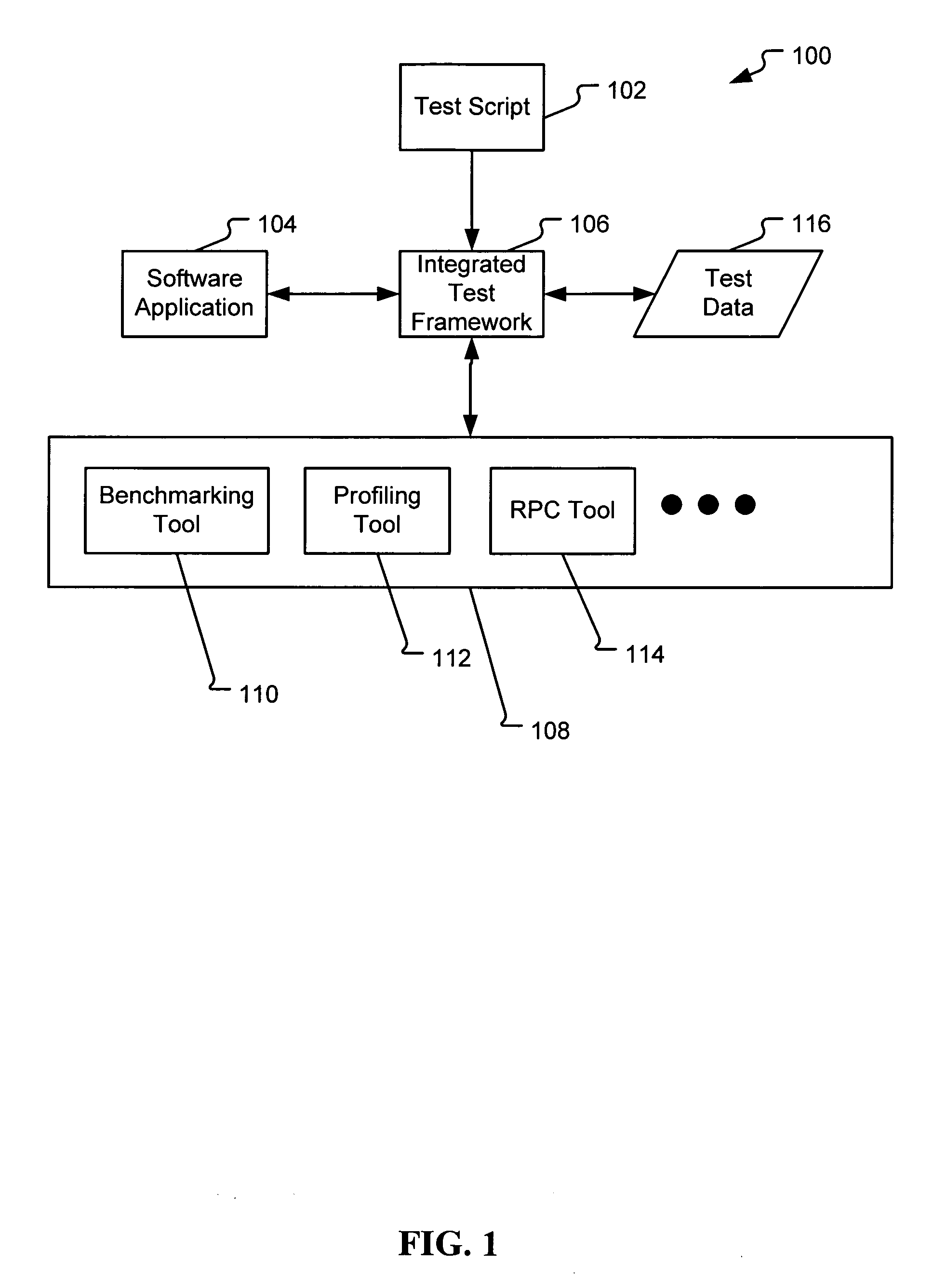

System and method for testing software using data-driven test variations

The integrated test framework of the present invention includes a test framework runtime that executes test scripts and that also allows a script to identify a variation tool called a “data provider” that is responsible for providing data to the test framework runtime and controlling the iteration of the runtime through the variations. The script also identifies the type of data set from which the data provider should obtain the data from which the variations are derived and the location of the data set. Multiple variation data providers may be used in conjunction with an adapter layer that coordinates the iteration of each variation data provider and creates an aggregated variation over multiple varying parameters of different scope.

Owner:MICROSOFT TECH LICENSING LLC

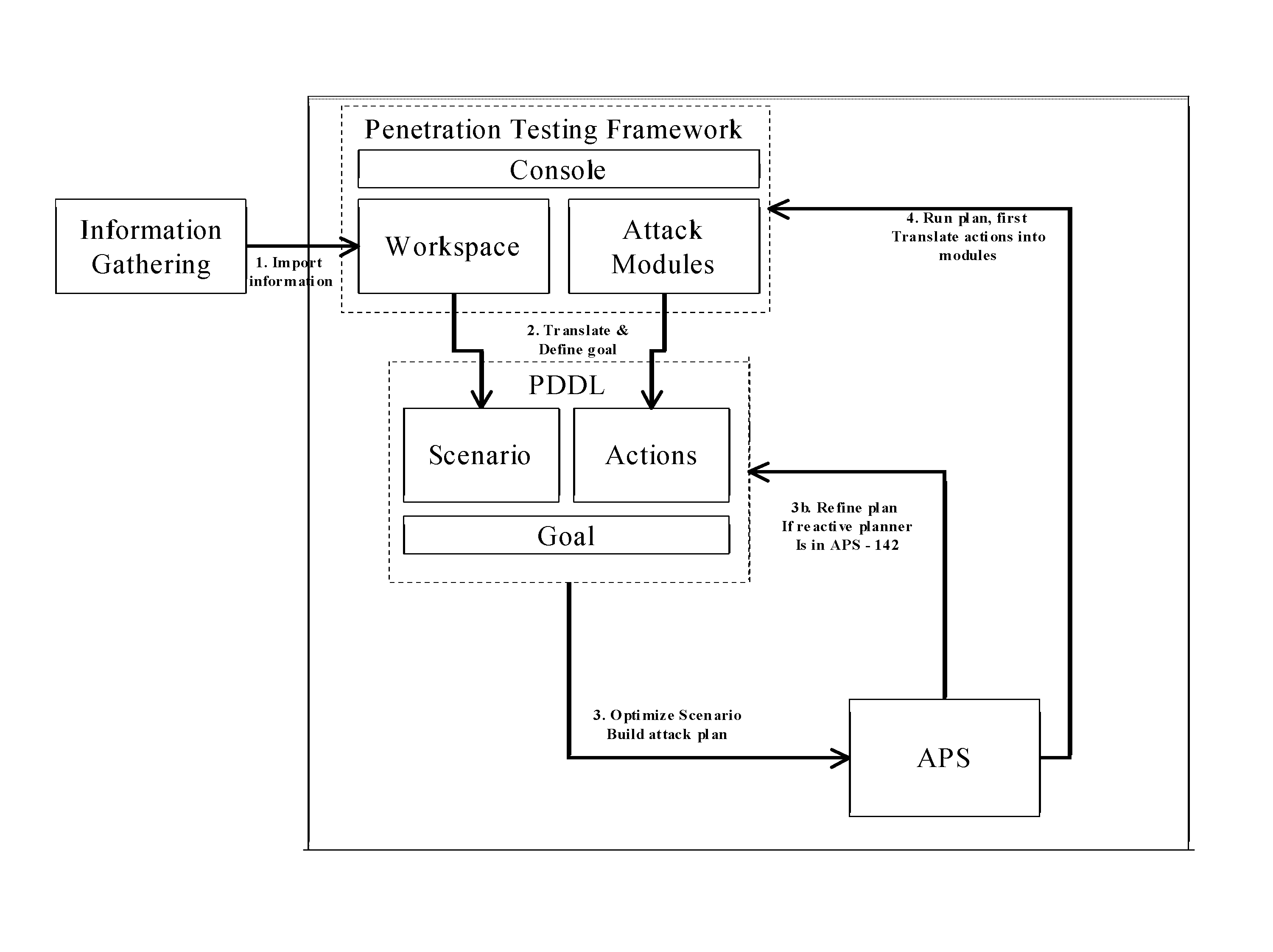

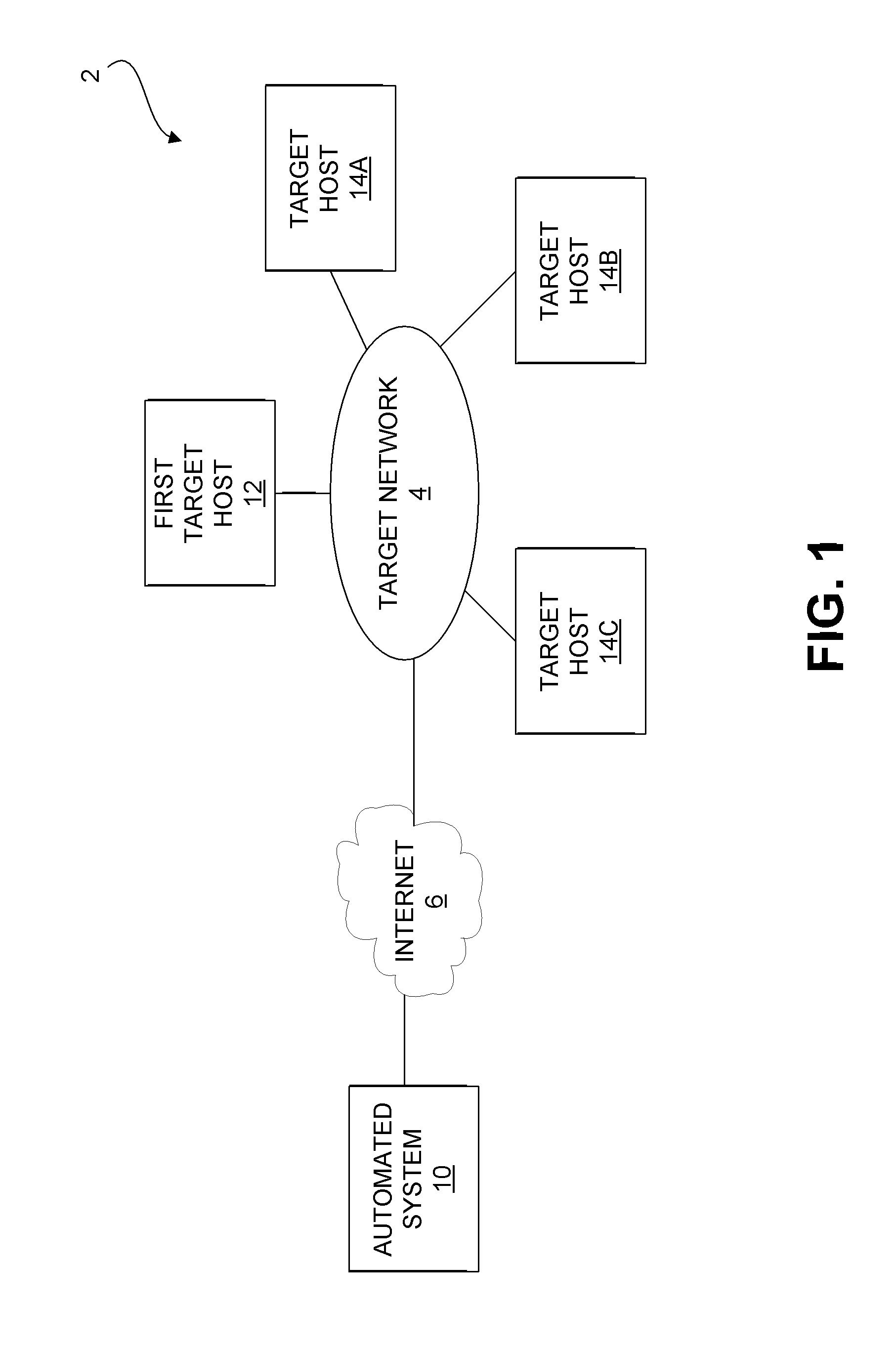

System and method for extending automated penetration testing to develop an intelligent and cost efficient security strategy

ActiveUS20110035803A1Memory loss protectionError detection/correctionProgram planningSecurity policy

A system and method for extending automated penetration testing of a target network is provided. The method comprises: computing a scenario, comprises the steps of: translating a workspace having at least one target computer in the target network, to a planning definition language, translating penetration modules available in a penetration testing framework to a planning definition language, and defining a goal in the target network and translating the goal into a planning definition language; building a knowledge database with information regarding the target network, properties of hosts in the network, parameters and running history of modules in the penetration testing framework; and running an attack plan solver module, comprising: running an attack planner using the scenario as input, to produce at least one attack plan that achieves the goal, and executing actions defined in the at least one attack plan against the target network from the penetration testing framework.

Owner:FORTRA LLC

System and method for testing software using data-driven test variations

The integrated test framework of the present invention includes a test framework runtime that executes test scripts and that also allows a script to identify a variation tool called a “data provider” that is responsible for providing data to the test framework runtime and controlling the iteration of the runtime through the variations. The script also identifies the type of data set from which the data provider should obtain the data from which the variations are derived and the location of the data set. Multiple variation data providers may be used in conjunction with an adapter layer that coordinates the iteration of each variation data provider and creates an aggregated variation over multiple varying parameters of different scope.

Owner:MICROSOFT TECH LICENSING LLC

Custom eyeglass manufacturing method

A Custom Eyeglass Manufacturing Method includes a wavefront measuring device with a plurality of cameras directed at a patient's face. The resulting images are processed by a computer to determine the location of pupils, center of pupils, pupil distance, width of face, ear location, distance of corneal apex from the wavefront measuring device, distance from ear to corneal apex, and other desired parameters necessary to quantify a patient's face for custom eyeglass fittings. Moldings may be applied to patient's nose, temples, and ears in order to construct a pair of eyeglasses that fix perfectly on patient's head. Additionally, a test frame may be used in combination with the wavefront measuring device in order to allow computer to find some of the areas automatically. Lastly, registration markers may be applied to either the test frame, the moldings, or both in order to further aide the computer in locating desired parameters.

Owner:ESSILOR INT CIE GEN DOPTIQUE +1

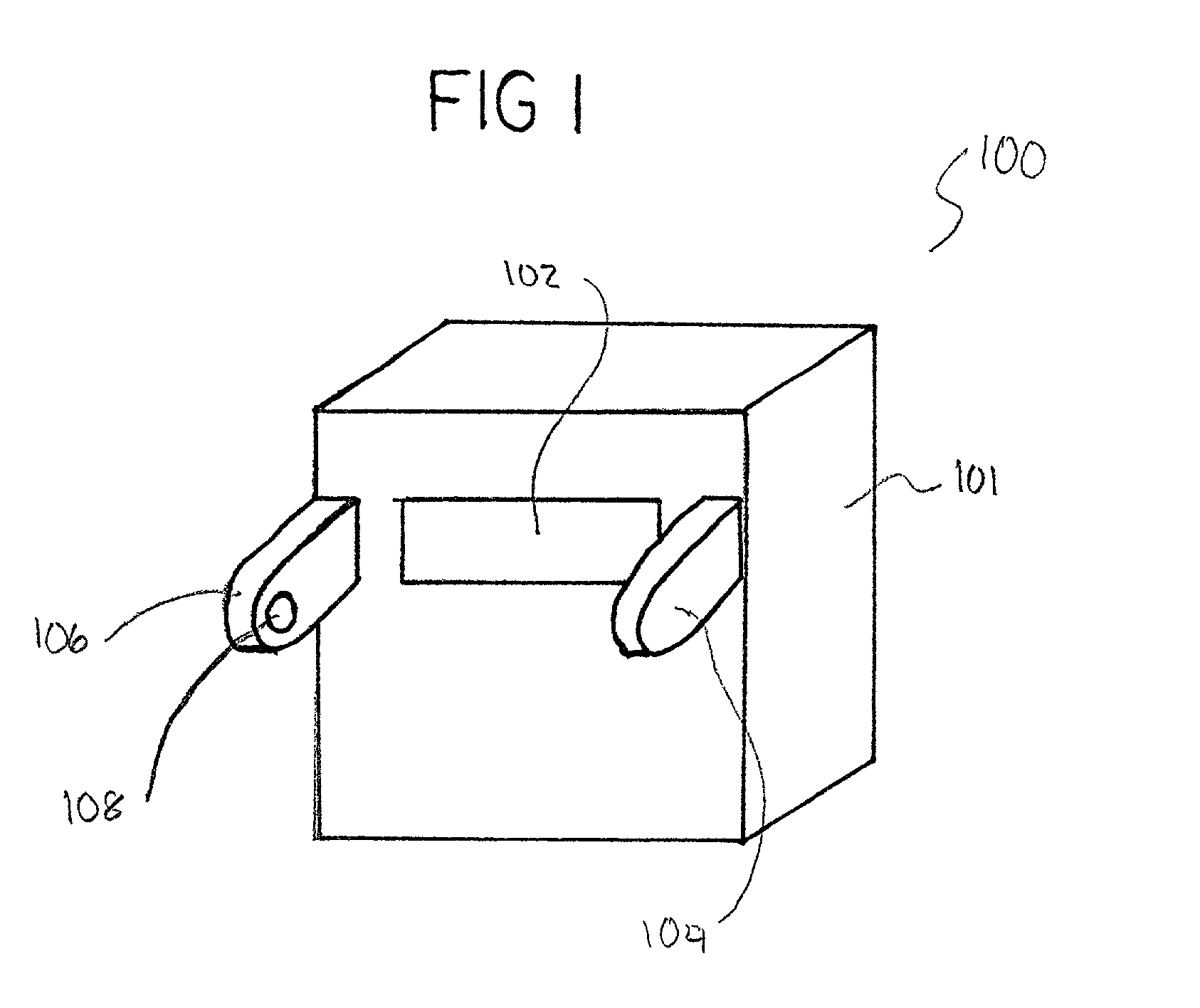

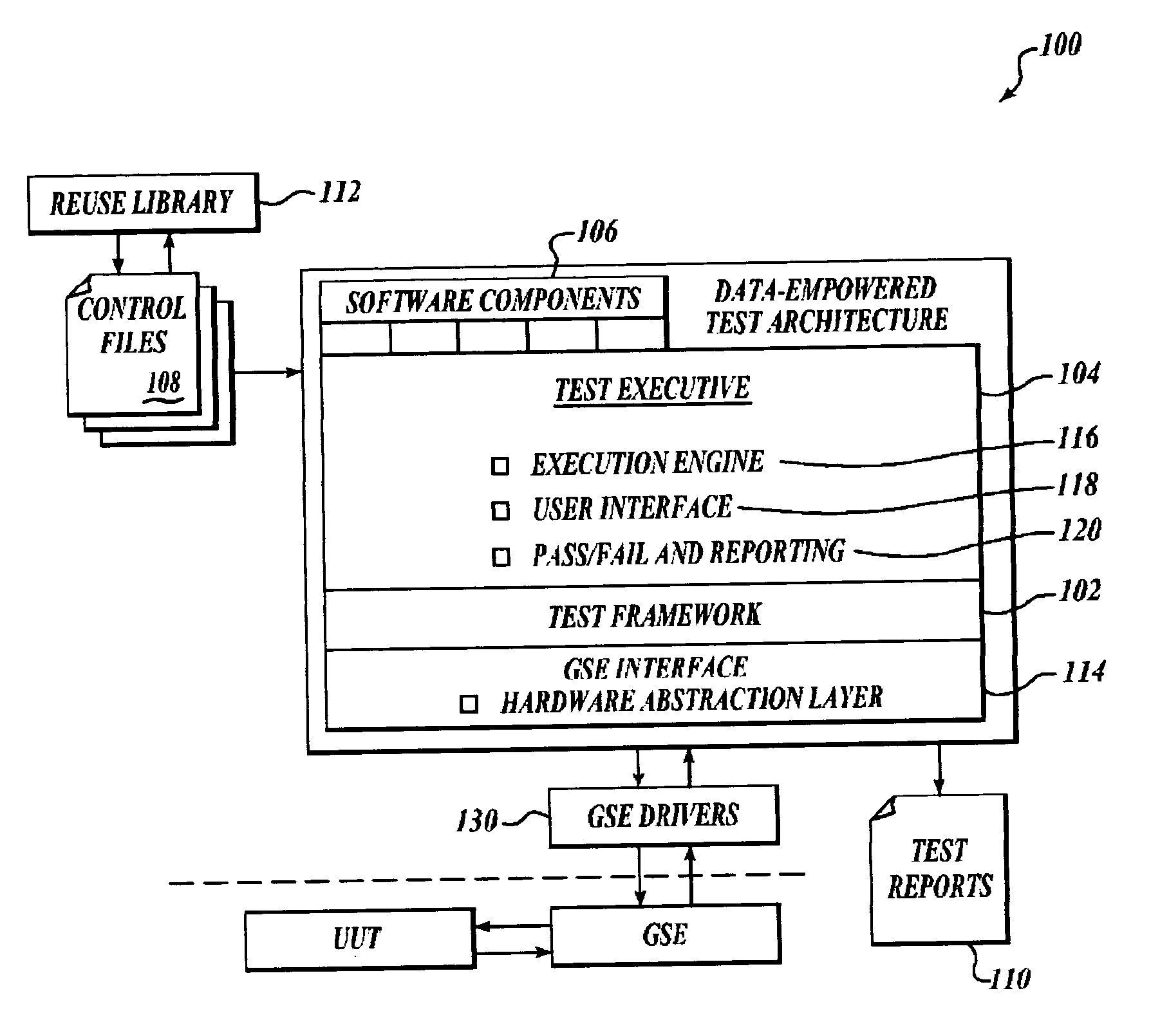

Data empowered laborsaving test architecture

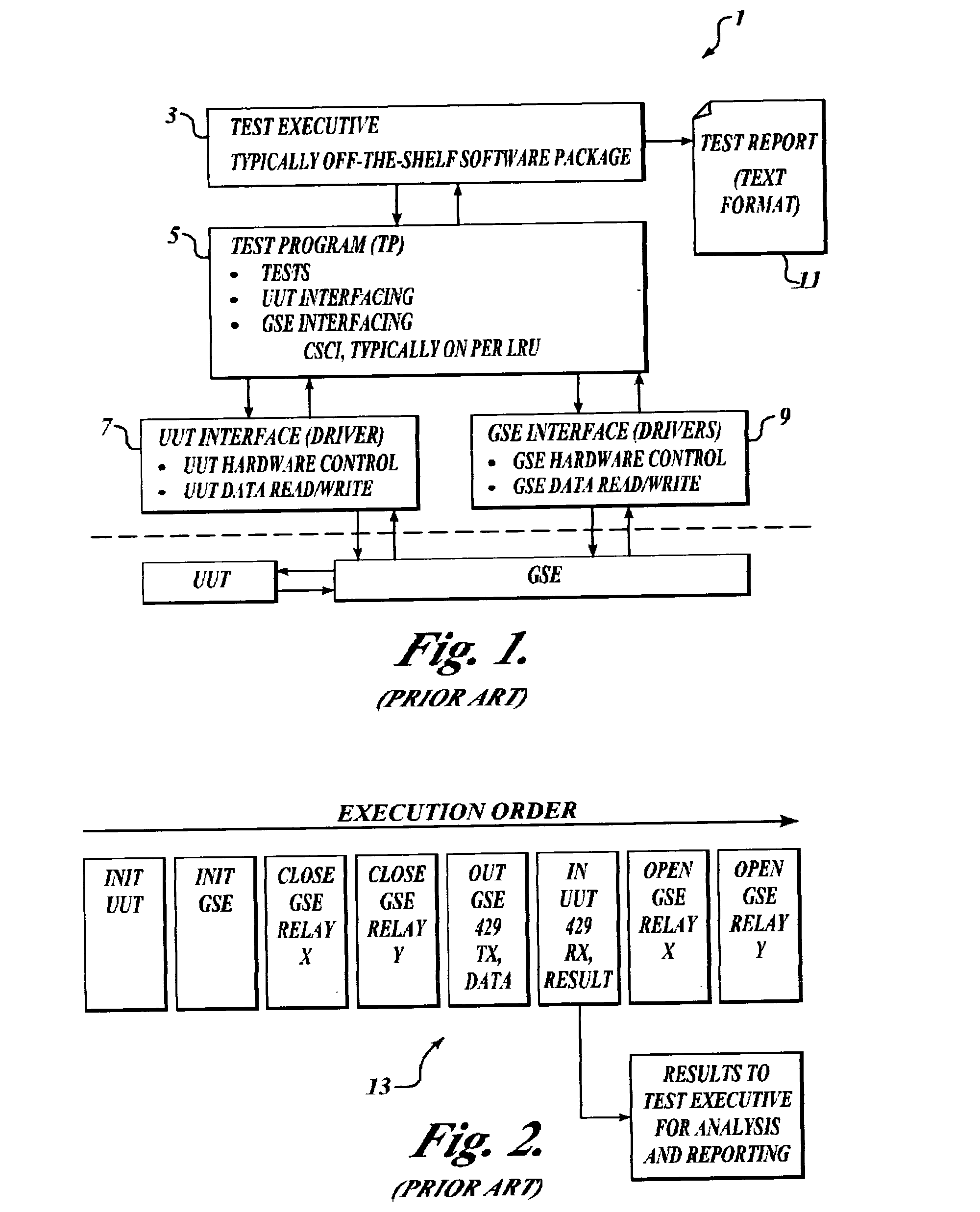

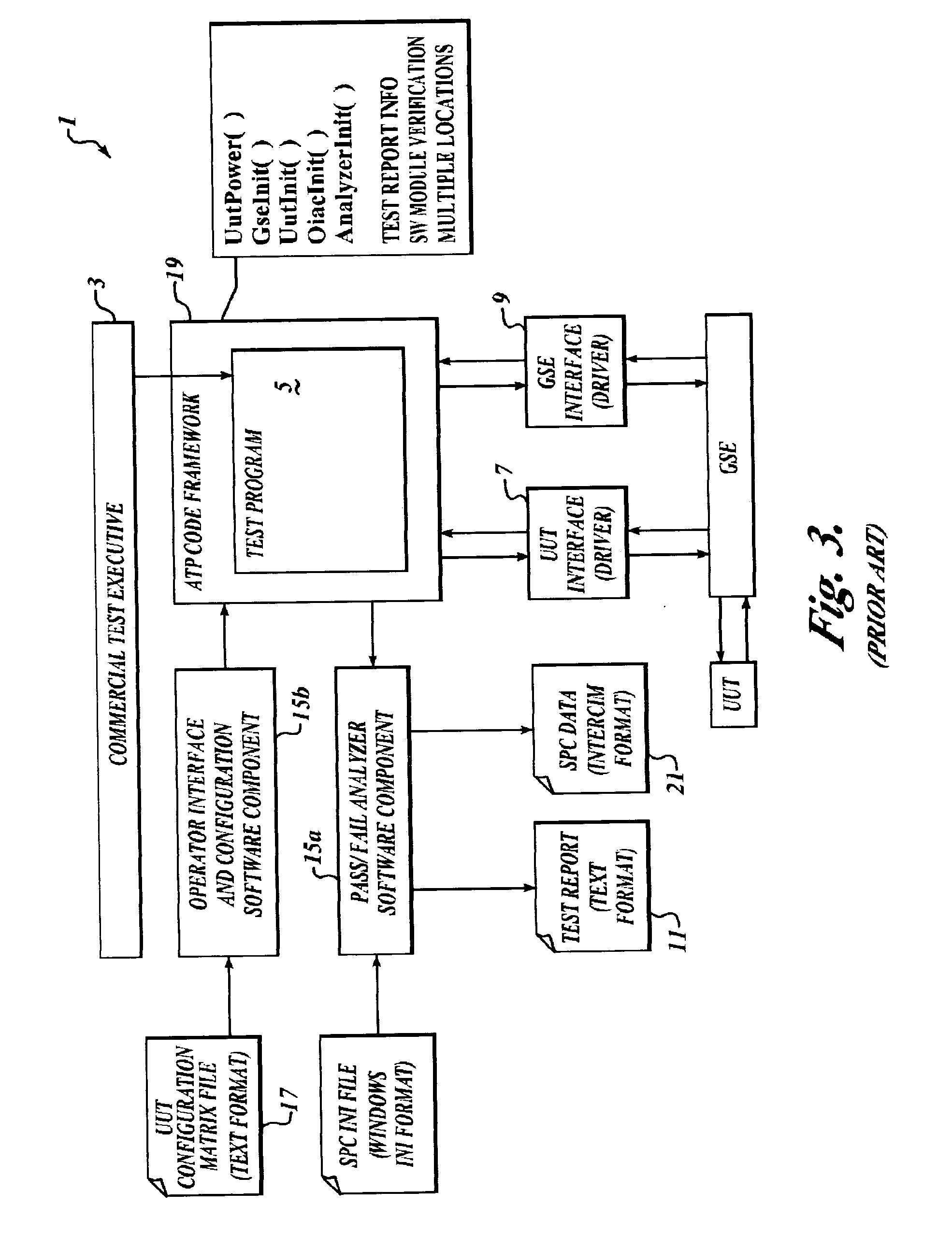

InactiveUS20050097515A1Easy to operateOvercome limitationsError detection/correctionSpecific program execution arrangementsComputer hardwareTest frame

A test program development method embodied in a data-empowered test program architecture including a test executive software module; a test framework software module having externally configurable generic software code and being coupled for interaction with the test executive software module; a plurality of software components in a software components module coupled for interaction with the test framework software module and structured for outputting one or more test reports; and one or more external control files coupled for configuring the generic software code of the test framework software module.

Owner:HONEYWELL INT INC

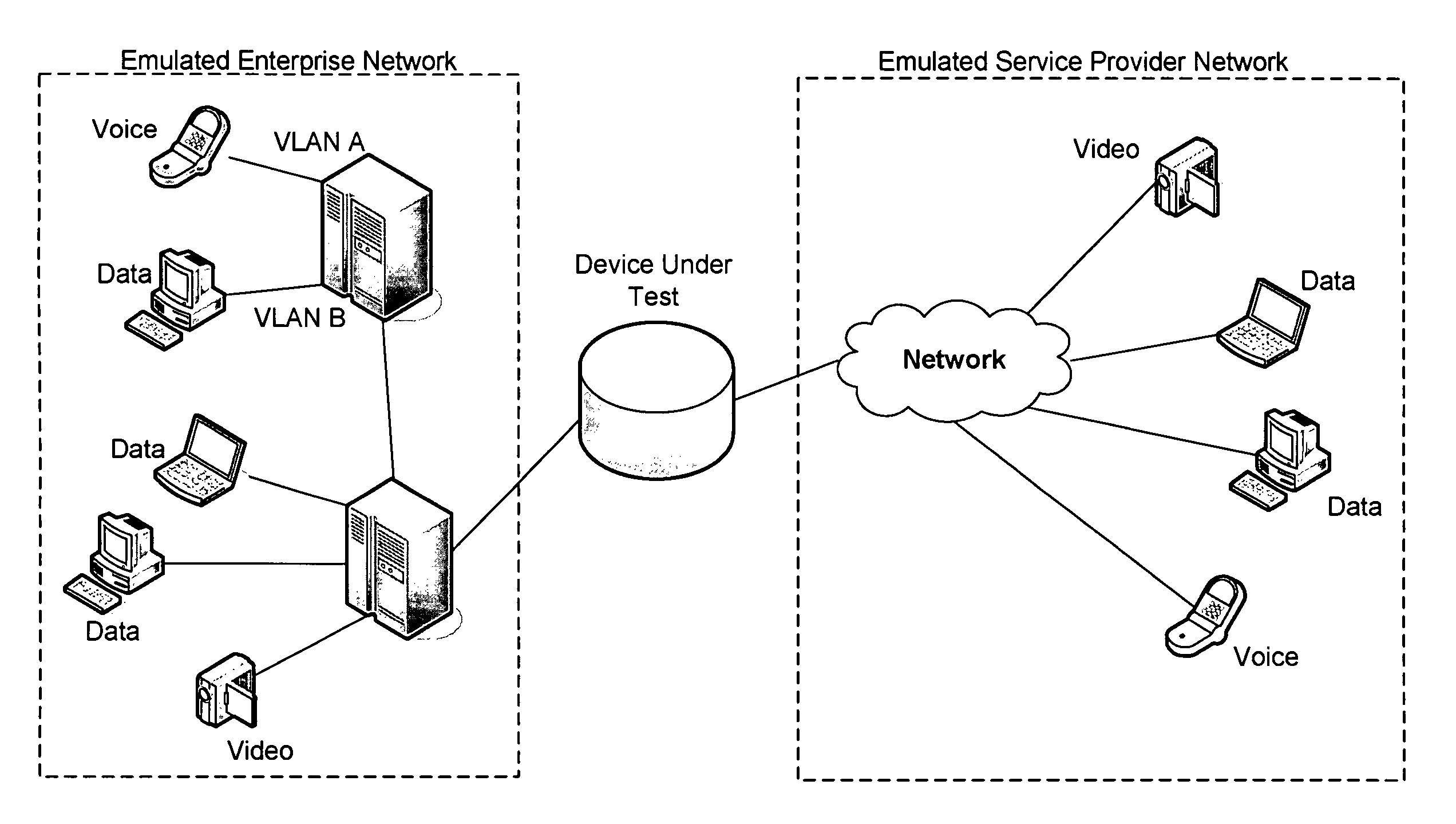

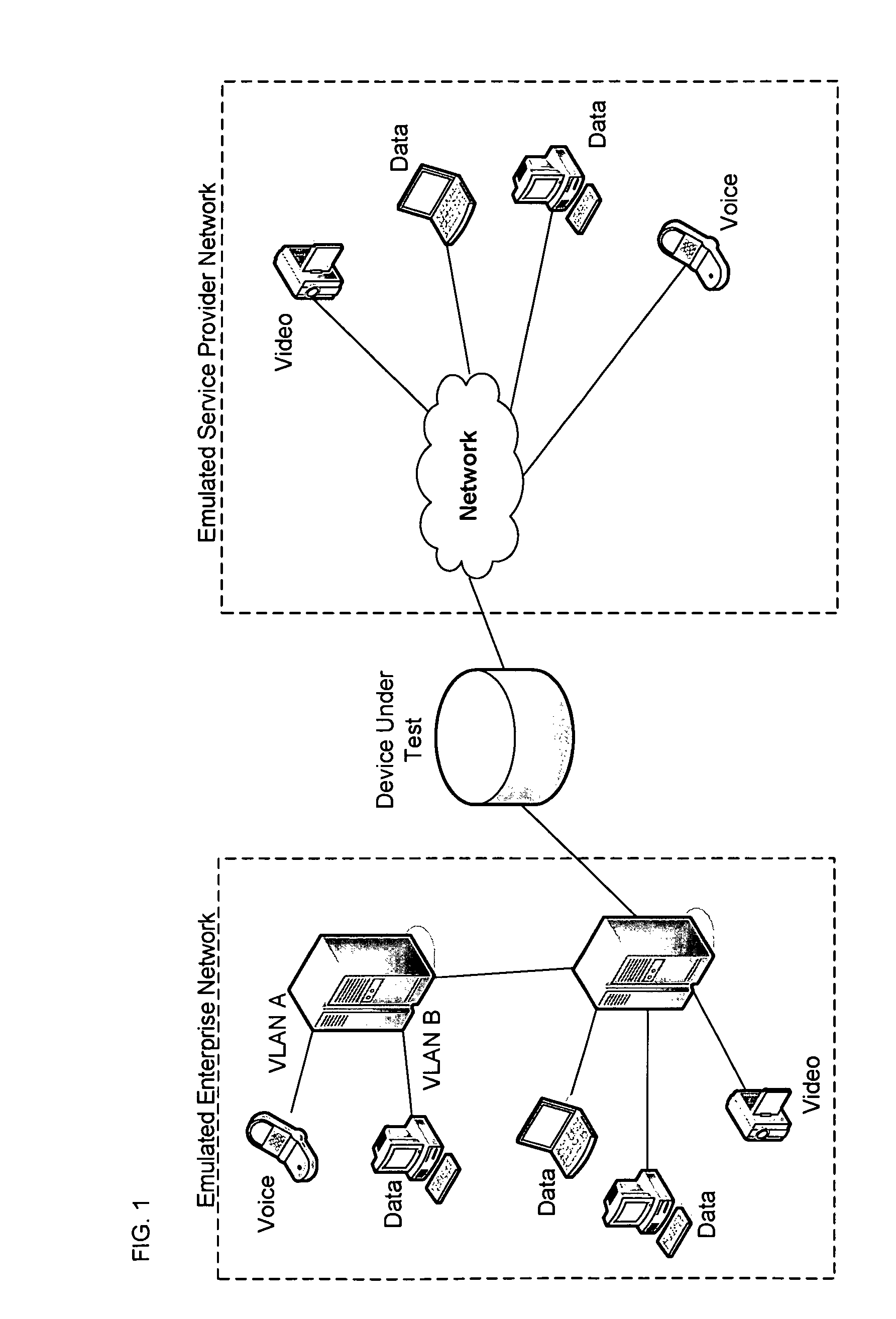

Method and device test data streams bound to emulated devices

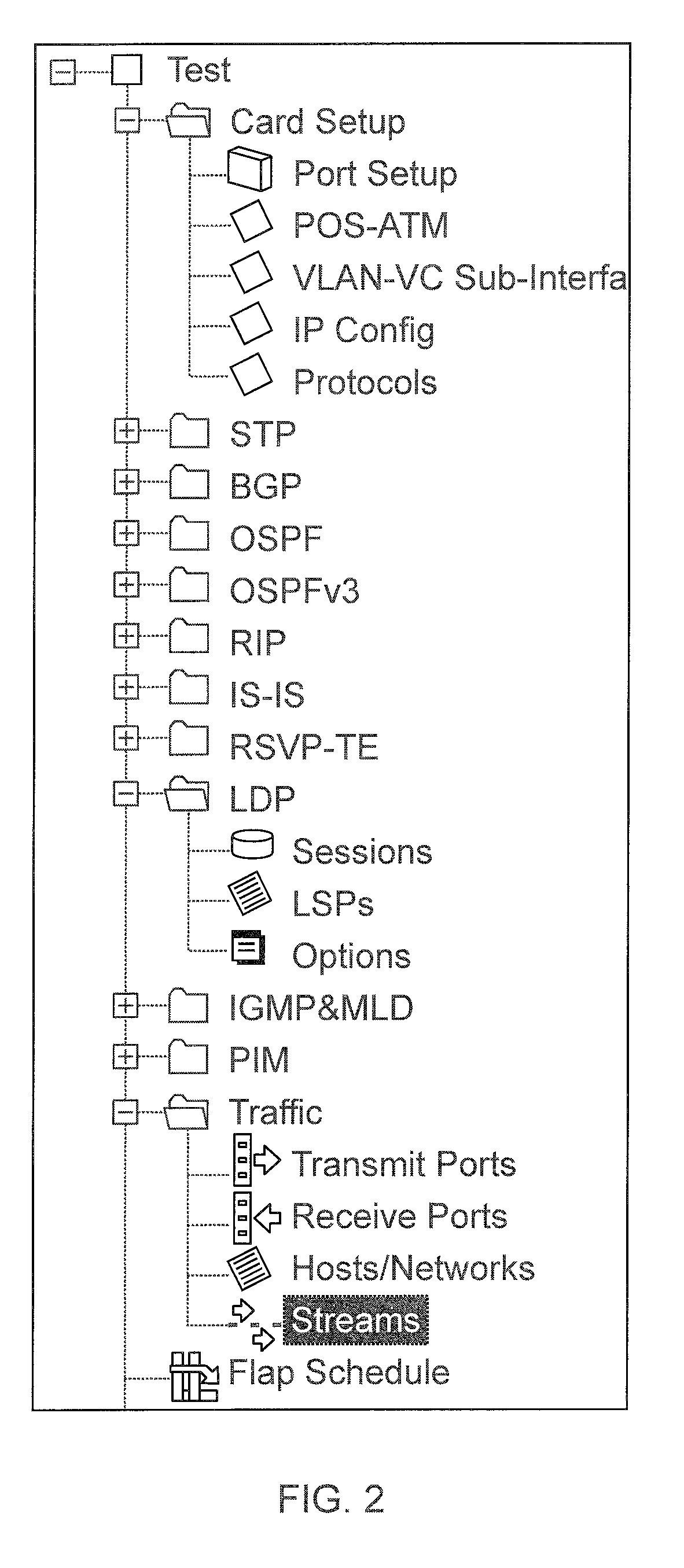

InactiveUS7826381B1Improve automationSimple designError preventionTransmission systemsData streamSoftware architecture

The technology disclosed includes a software architecture for methods and devices used to test routers, switches and the like, particularly high volume infrastructure devices. In particular, this architecture associates test data stream definitions with emulated devices that send test frames or packets to and receives them from a system or device under test (“DUT”). By relating the test data stream definitions to definitions of the emulated devices that are coupled to the DUT, automation of test frame and / or test packet design improves, especially where some of the information needed to generate test frames and / or packets is dynamically generated during a test.

Owner:SPIRENT COMM

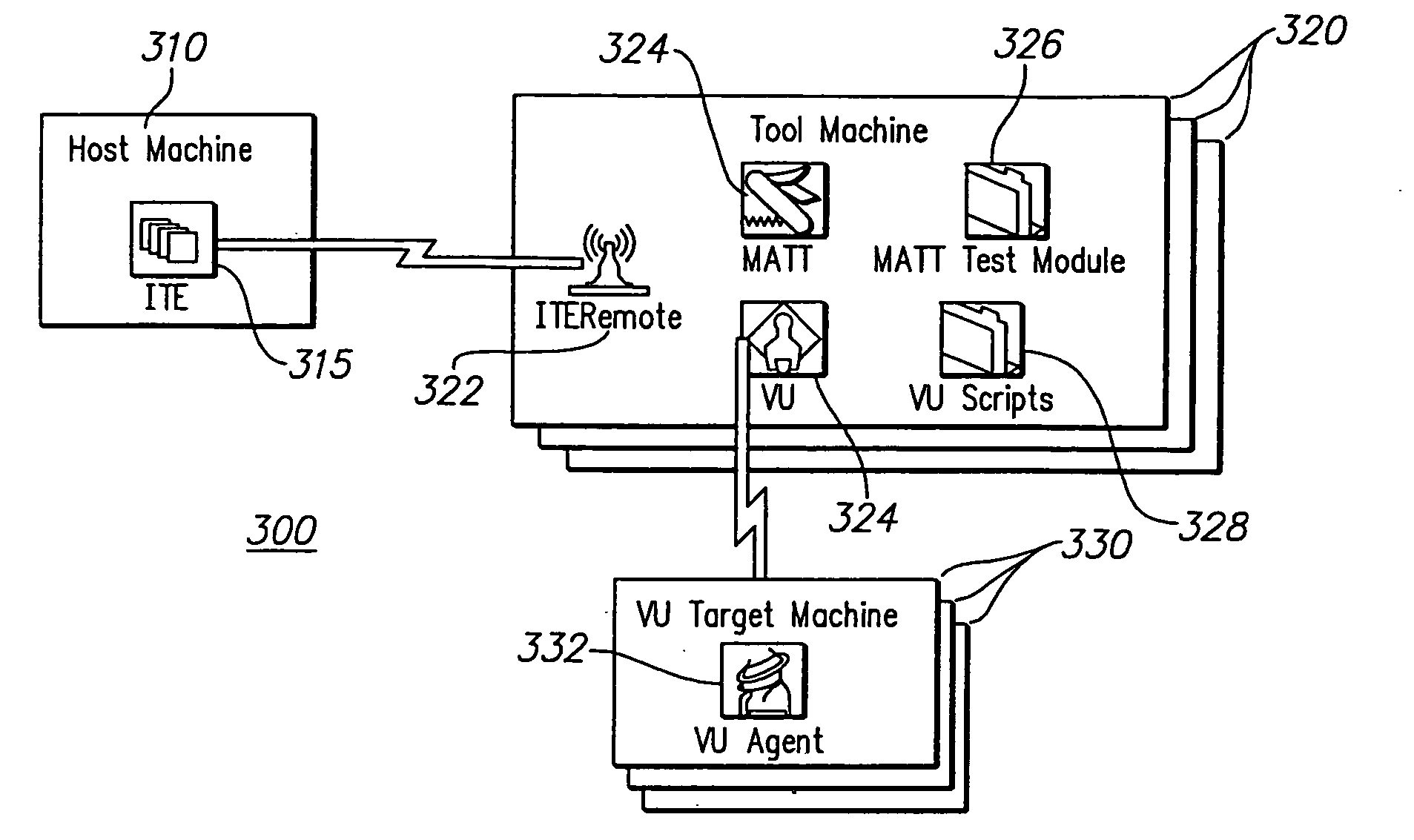

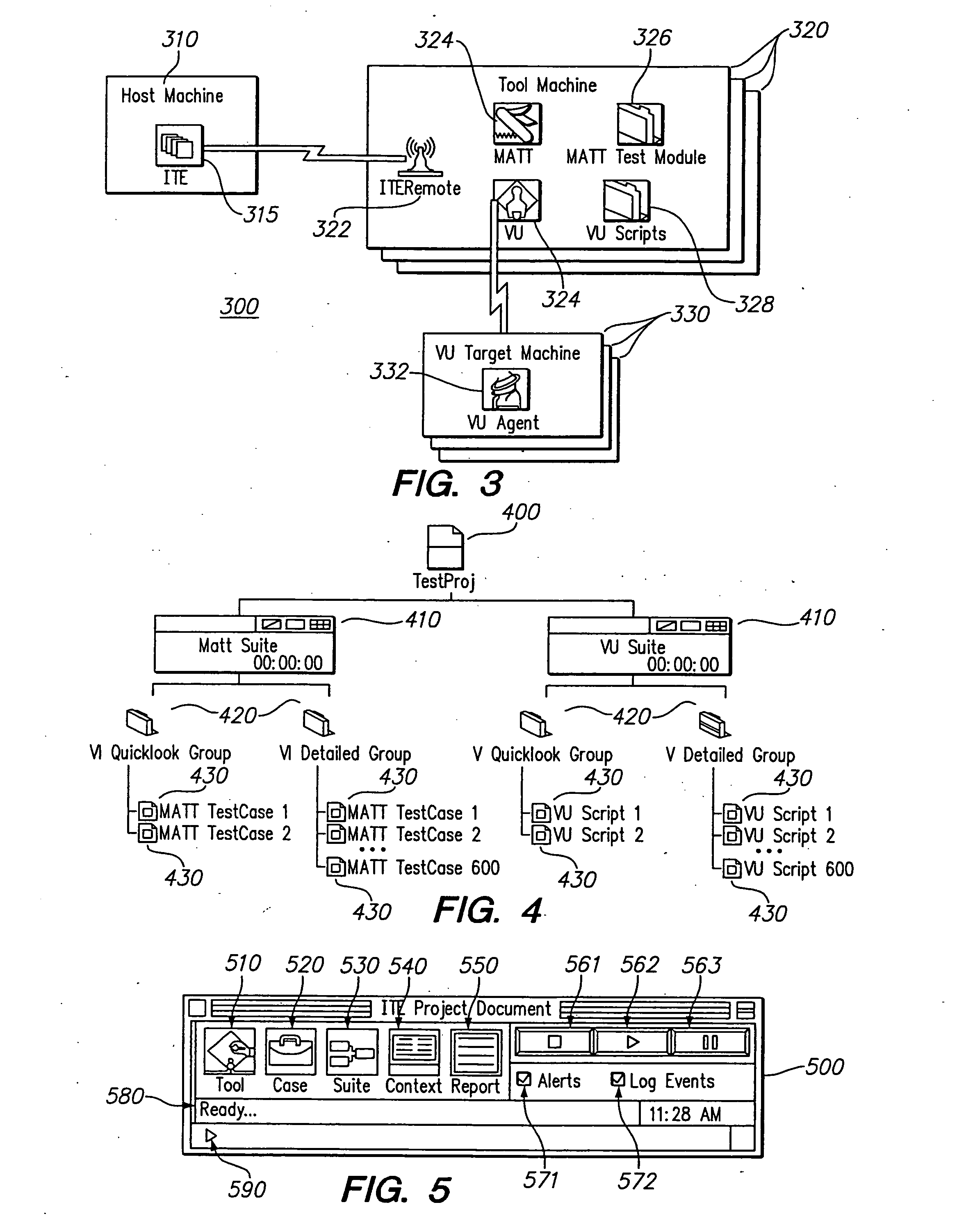

Integrated computer testing and task management systems

InactiveUS20060206870A1Easy to createImprove development efficiencyError detection/correctionSpecific program execution arrangementsCommunication interfaceComputer users

Methods and apparatus for constructing integrated computer testing and task management applications provide a computer user access to multiple testing and task management tools, all through a single, uniform interface. According to exemplary embodiments, an integrated testing application controls known test tools through a well defined communications interface, either locally on a single machine or in a distributed fashion across multiple networked machines. Advantageously, such an integrated testing application provides a scalable, tool independent testing framework and thereby enables an organization to readily create sophisticated testing solutions using a heterogeneous mix of available testing and task management tools. Using the methods and apparatus of the invention, organizations can combine, schedule, regress, and report tests and other tasks with a degree of flexibility not previously possible using conventional techniques.

Owner:APPLE INC

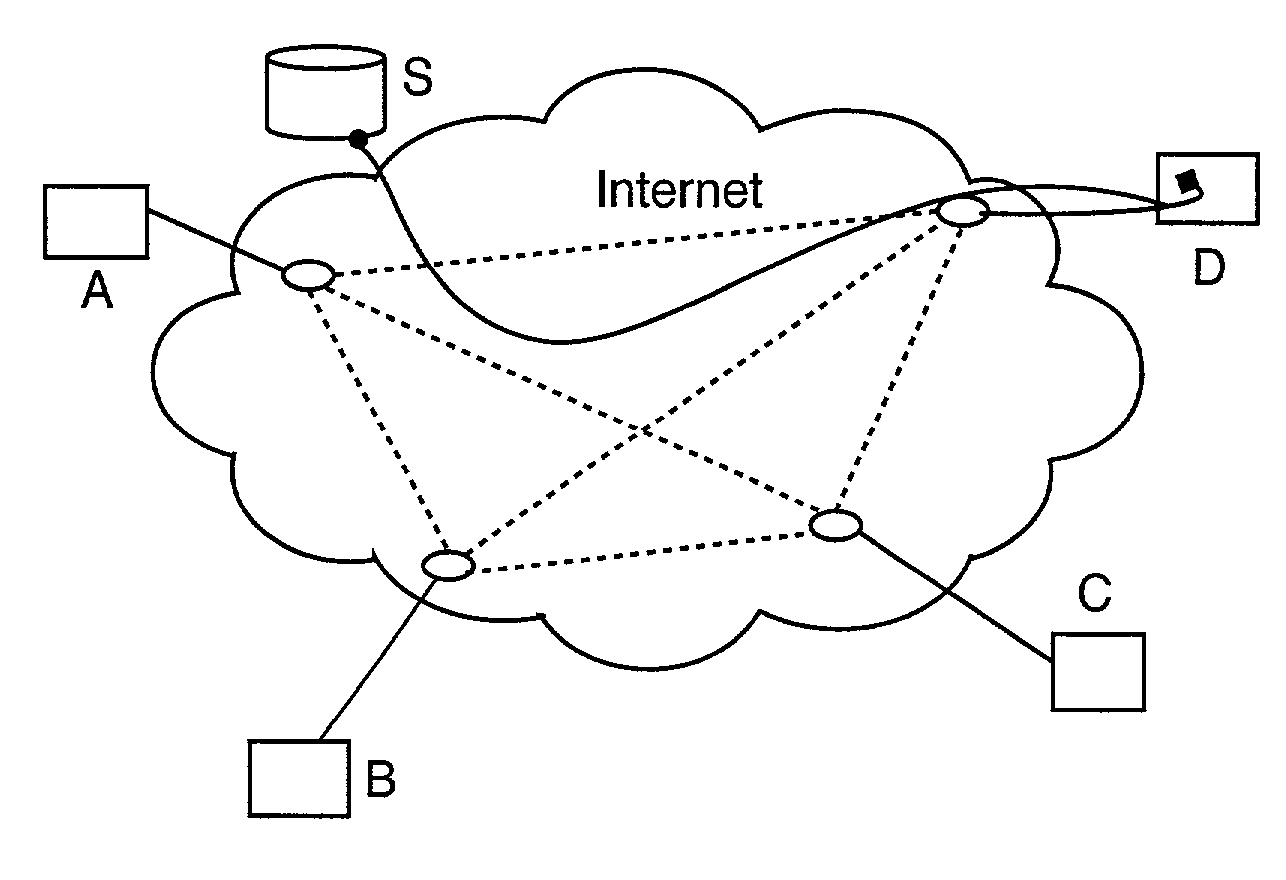

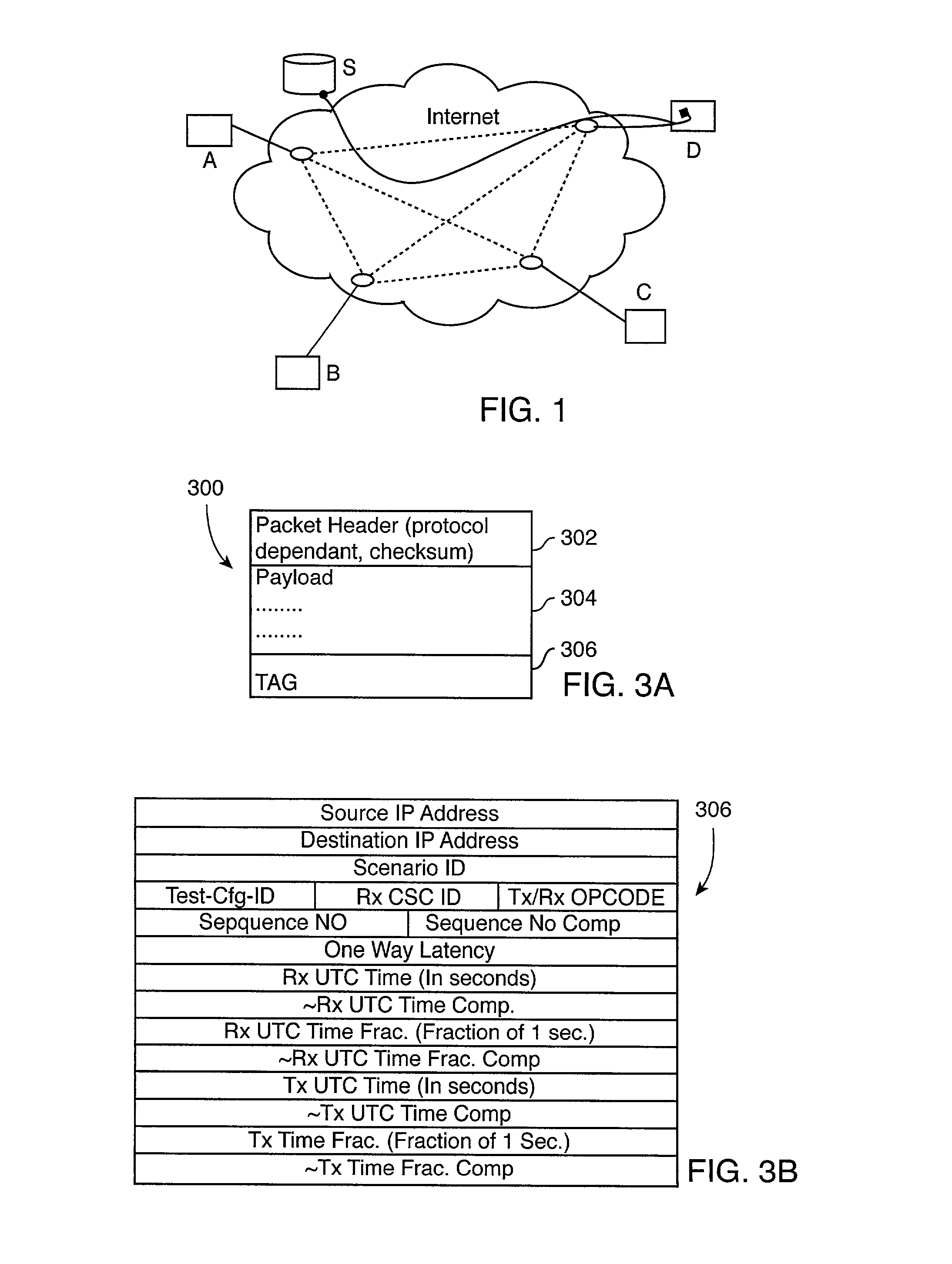

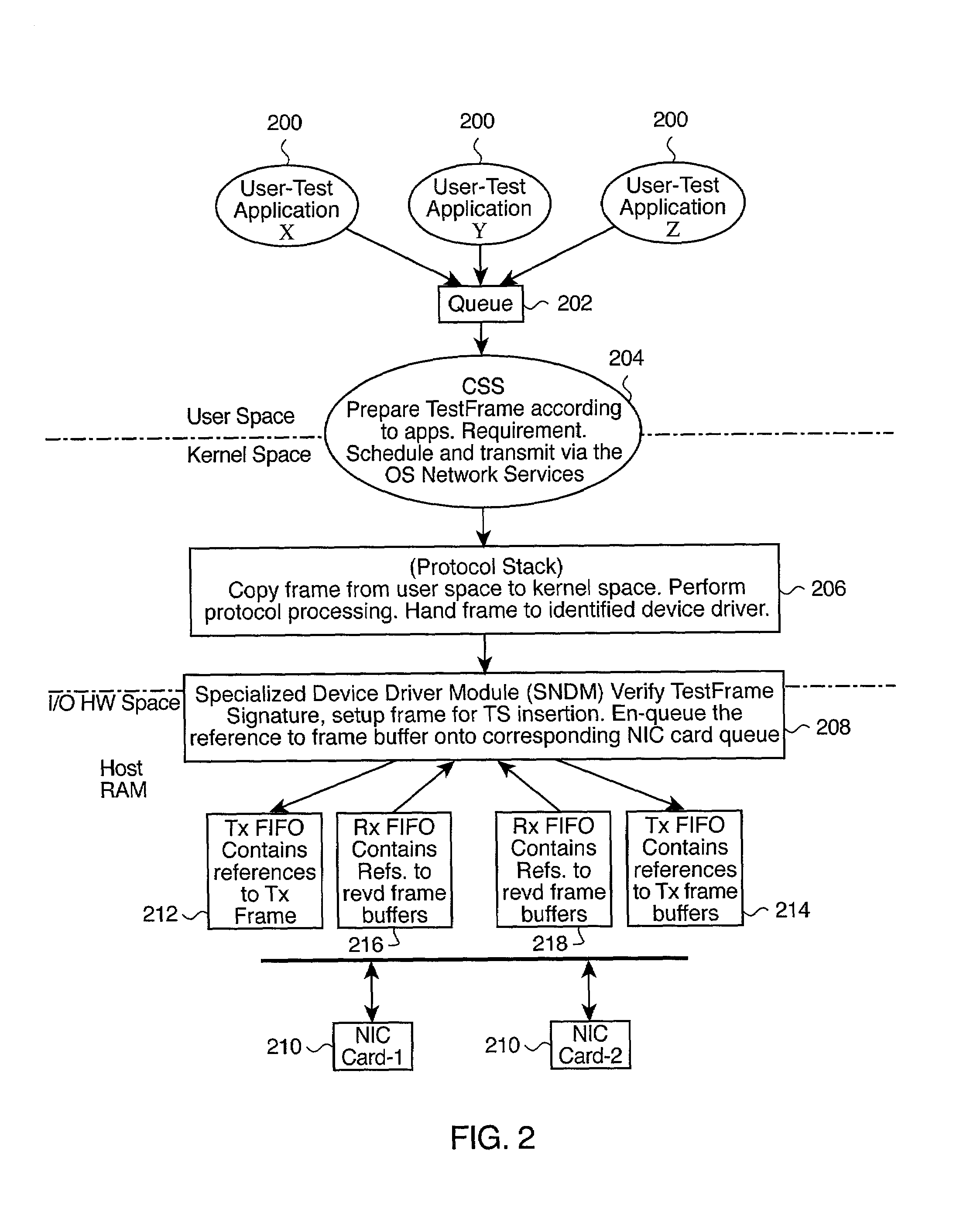

Method for creating accurate time-stamped frames sent between computers via a network

InactiveUS7080160B2Avoid delayTime-division multiplexData switching by path configurationReal-time computingTest frame

A method for creating time-stamped frames sent between computers includes receiving and generating a universal coordinated time reference signal using a global positioning system. Clocks independent of operating systems of the sending and receiving computer are synchronized with the reference signal. A test frame is created including a tag having reserved fields for transmit and receive time stamps. The transmit time stamp is inserted into the reserved transmit time stamp field, without intervention of the sending computers central processing unit, that corresponds to the time on the synchronized clock at the instant the test frame is sent. The test frame having the transmit time stamp is received by the receiving computer, and a receive time stamp is inserted into the reserved receive time stamp field corresponding to the time on the synchronized clock of the receiving computer when the test frame was received.

Owner:TIONESTA

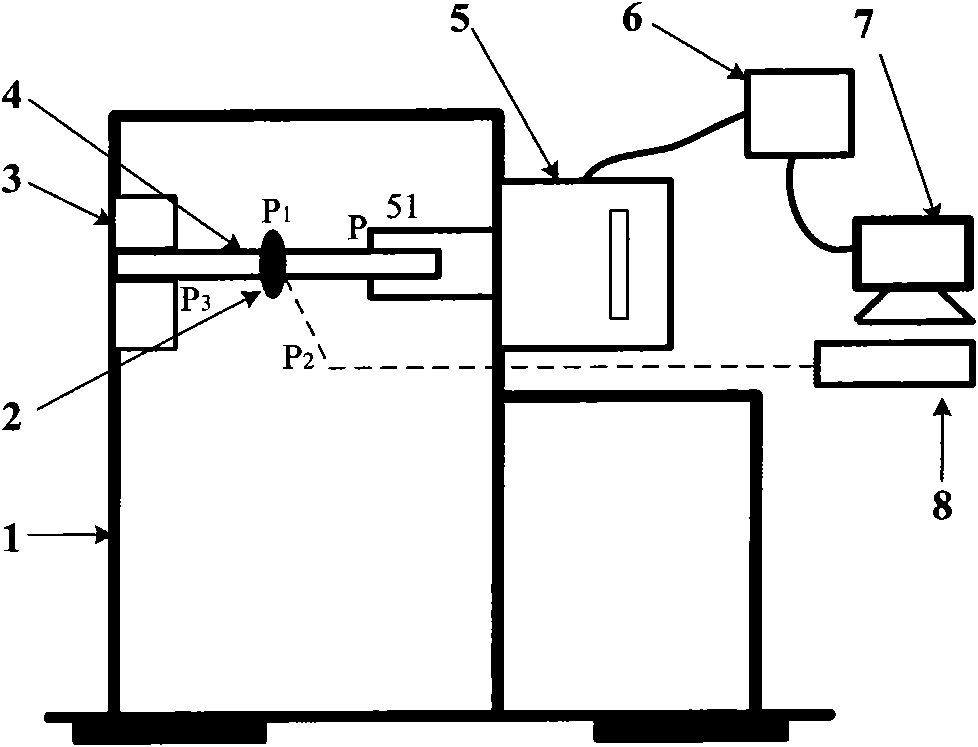

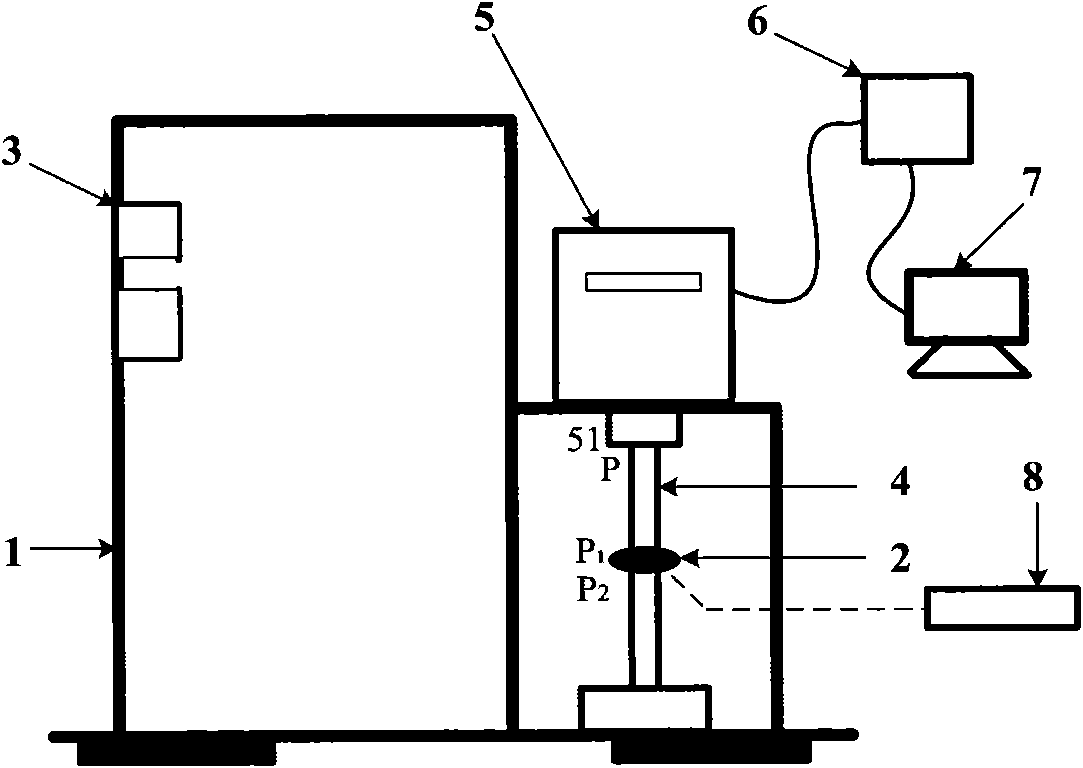

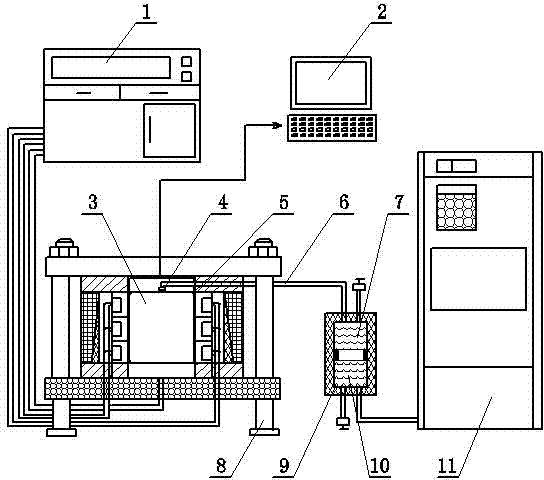

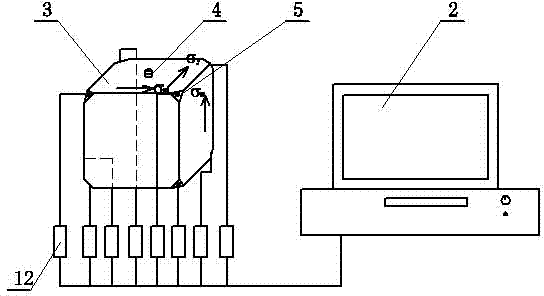

Method for detecting mechanical properties of local heating loading test material under high temperature oxidation environment and device thereof

ActiveCN101936854ASimple test operationSave test costMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesFlexural strengthMechanical property

The invention provides a test method capable of simply and conveniently testing mechanical properties of tensile strength, compressive strength, bending strength and fracture toughness of ceramic material and composite material thereof under superhigh temperature oxidation environment with the temperature of more than 1500 DEG C and a test device thereof. The test device is composed of a test frame, a fixed sample system, a loading system, a superhigh temperature flaming heating system, a record display system and a non-contact type infrared temperature measuring system. The method includes that acetylene or gasoline aeration flaming technology is adopted to locally and rapidly heat a sample, so that local temperature thereof reaches more than 1500 DEG C, a portable tester is utilized to apply bending, stretching or compressive load on the sample, and load value is recorded, thus obtaining mechanical properties of material. The invention has the advantages that operation is simple, the technology of local high temperature and synchronous loading on superhigh temperature sample is realized, superhigh temperature mechanical properties which can not be tested before such as strength and toughness of material can be conveniently measured under superhigh temperature oxidation environment by utilizing the test device of the invention.

Owner:CHINA TEST & CERTIFICATION INT GRP CO LTD

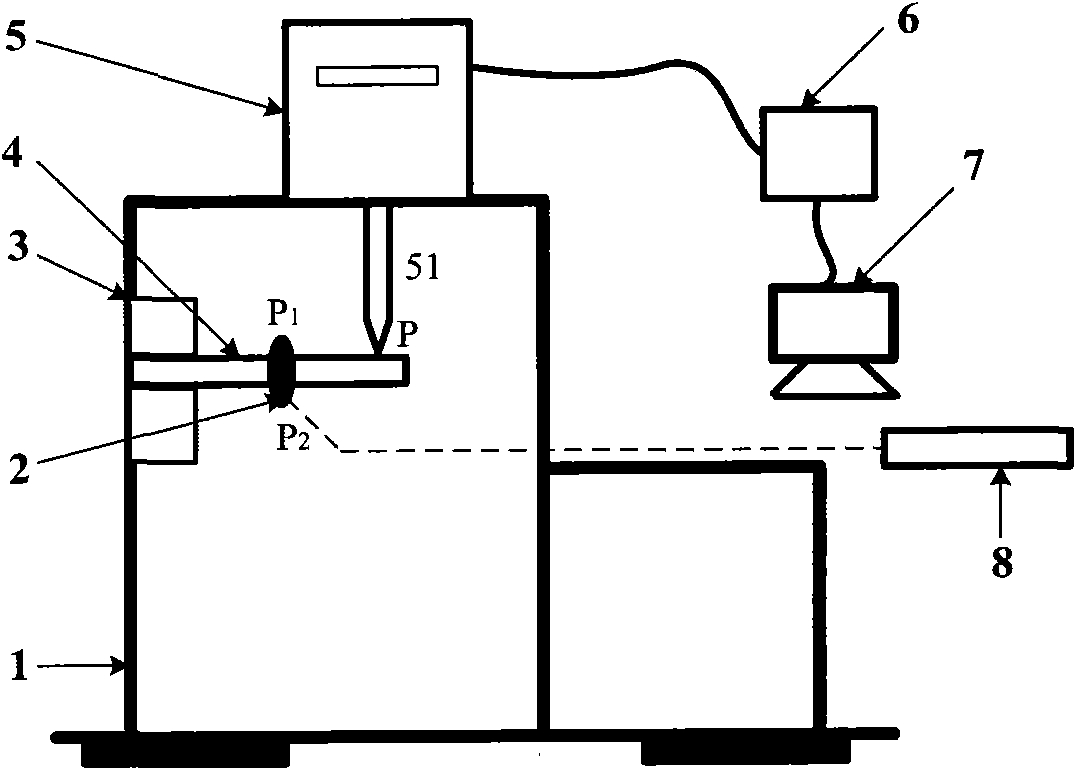

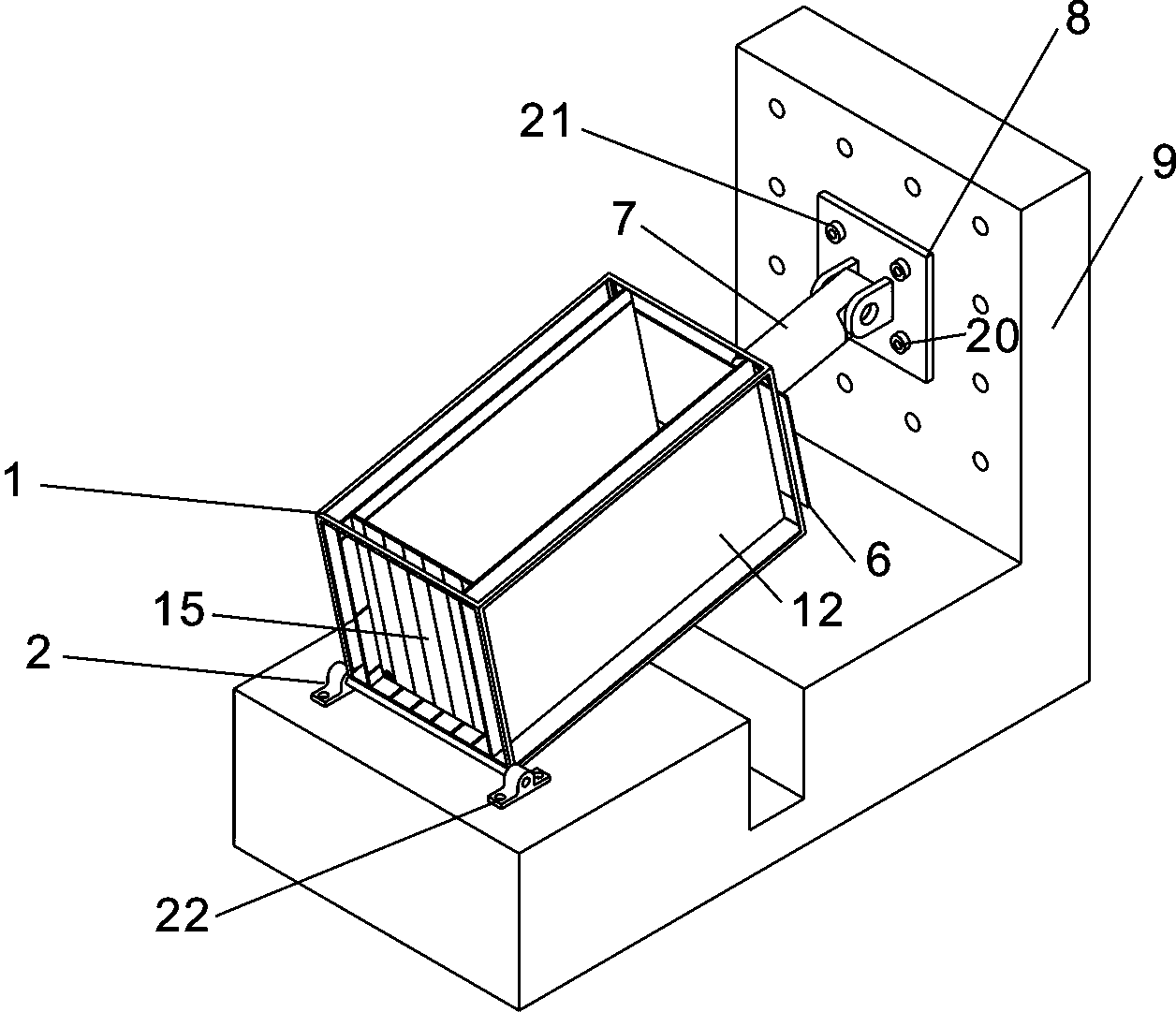

Large movable lateral uplifting composite lading slope physical model test apparatus

InactiveCN103353516AMeet the test requirementsAvoid sizeEarth material testingPhysical modelEngineering

A large movable lateral uplifting composite lading slope physical model test apparatus comprises a test framework, a bottom uplifting mechanism, a rear portion loading mechanism and a water level elevating simulation mechanism; the bottom of the front portion of the test frame is hinged to the test site ground surface, the test frame is formed by mutually splicing a front panel at the front portion, at least two vertically-arranged guard boards and a frame baseboard at the bottom portion, and the spacing between adjacent guard boards is adjustable; the bottom uplifting mechanism is arranged below the test frame and is used for driving the rotation of the test frame around the hinge pint at the front portion; and the rear portion loading mechanism comprises a loading steel board, an electro-hydraulic servo loading machine and a counterforce wall, the counterforce wall is arranged behind the test frame, the rear end of the electro-hydraulic servo loading machine is hinged to the counterforce wall, the front end of the electro-hydraulic servo loading machine is connected with the loading steel board, and the rear portion loading mechanism is used for applying action force to a slope physical model in the test frame from the rear end of the test frame. The apparatus is suitable for large-size slope physical models, and can realize the establishment of three-dimensional models better satisfying geometric similarity conditions than real slopes.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

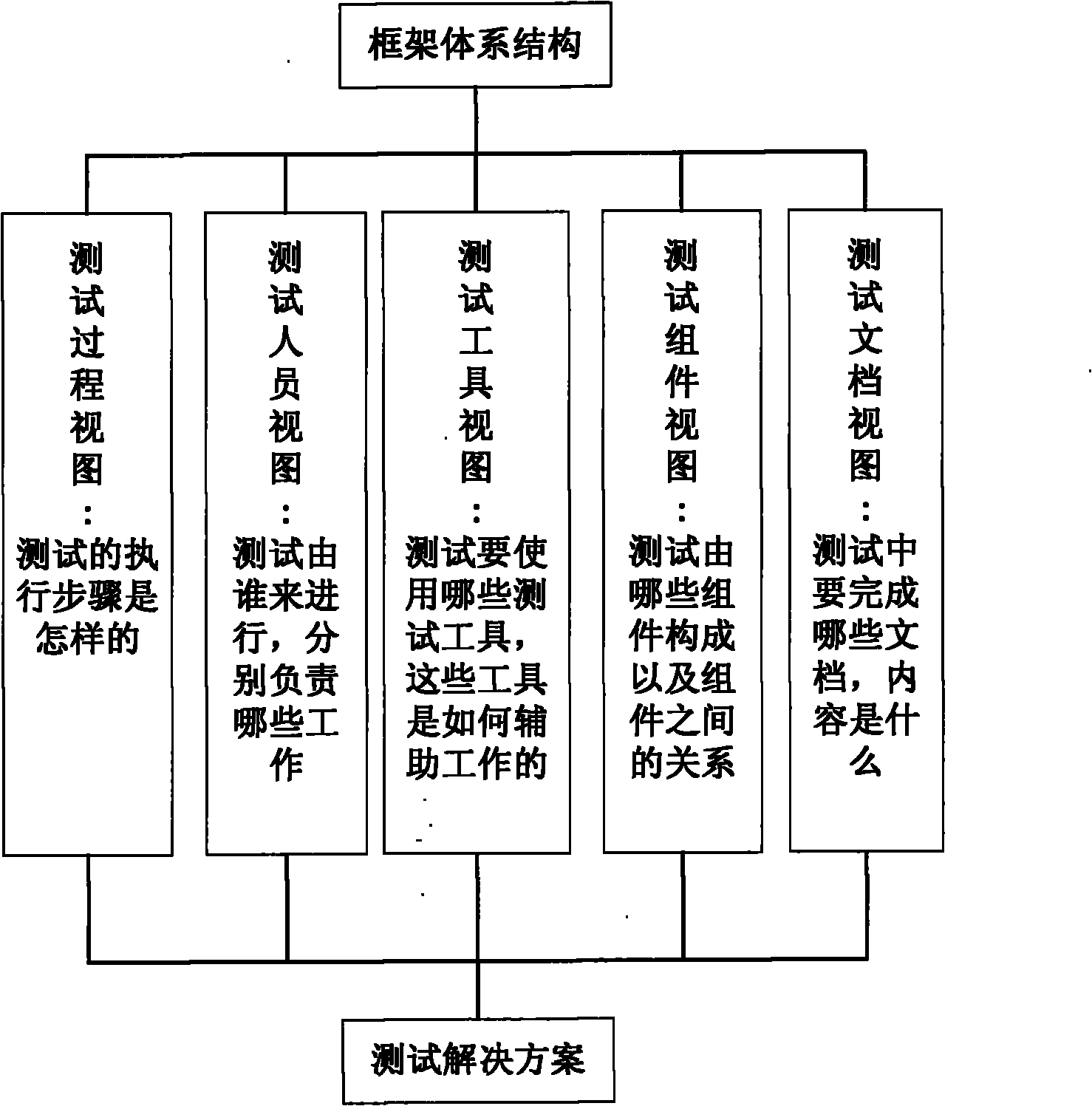

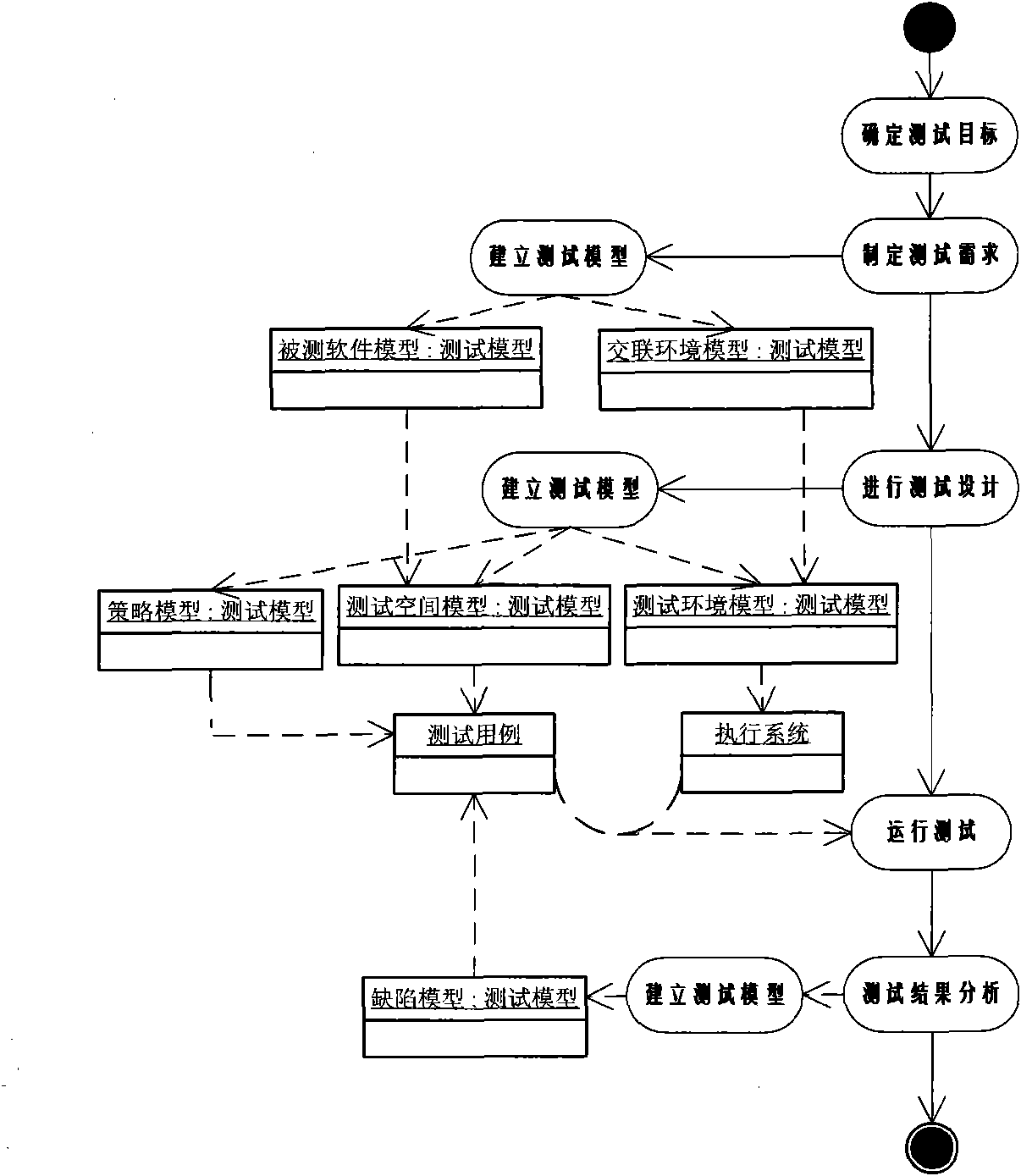

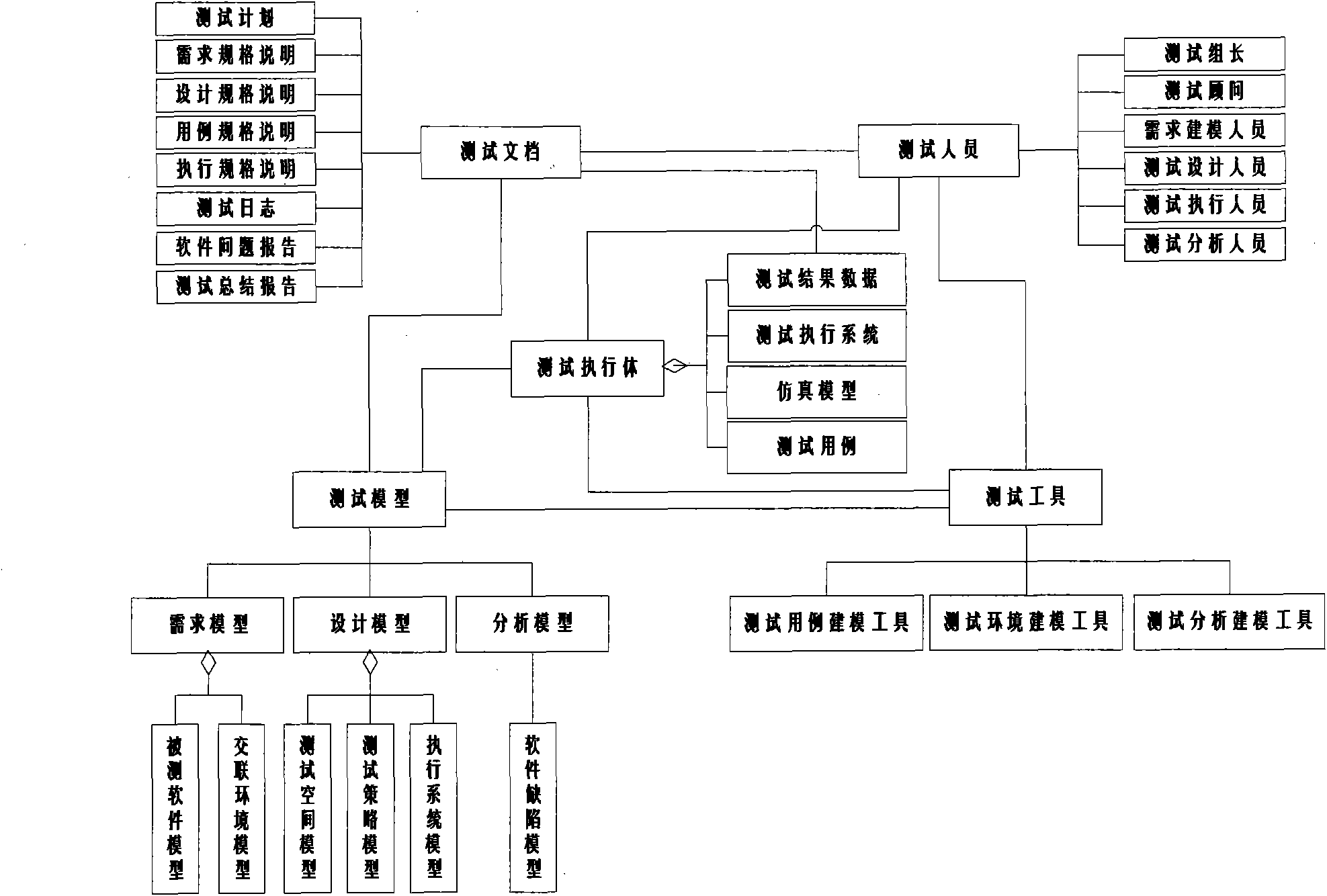

Method for testing software based on testing framework

The invention discloses a method for testing software based on a testing framework, which belongs to the field of software test. In the method, a basic testing framework is constructed for the same series of software to finish the test of the same series of software, and the problems existing in the field of software test that the testing quality is remarkably limited by sources, the testing efficiency is low and the testing quality can not be guaranteed are solved through the instantiation of the framework and the multiplexing of the framework during test. The basic testing framework is constructed from the following five aspects in cluding testing process, testing personnel, testing tool, testing component and testing document.

Owner:王轶辰

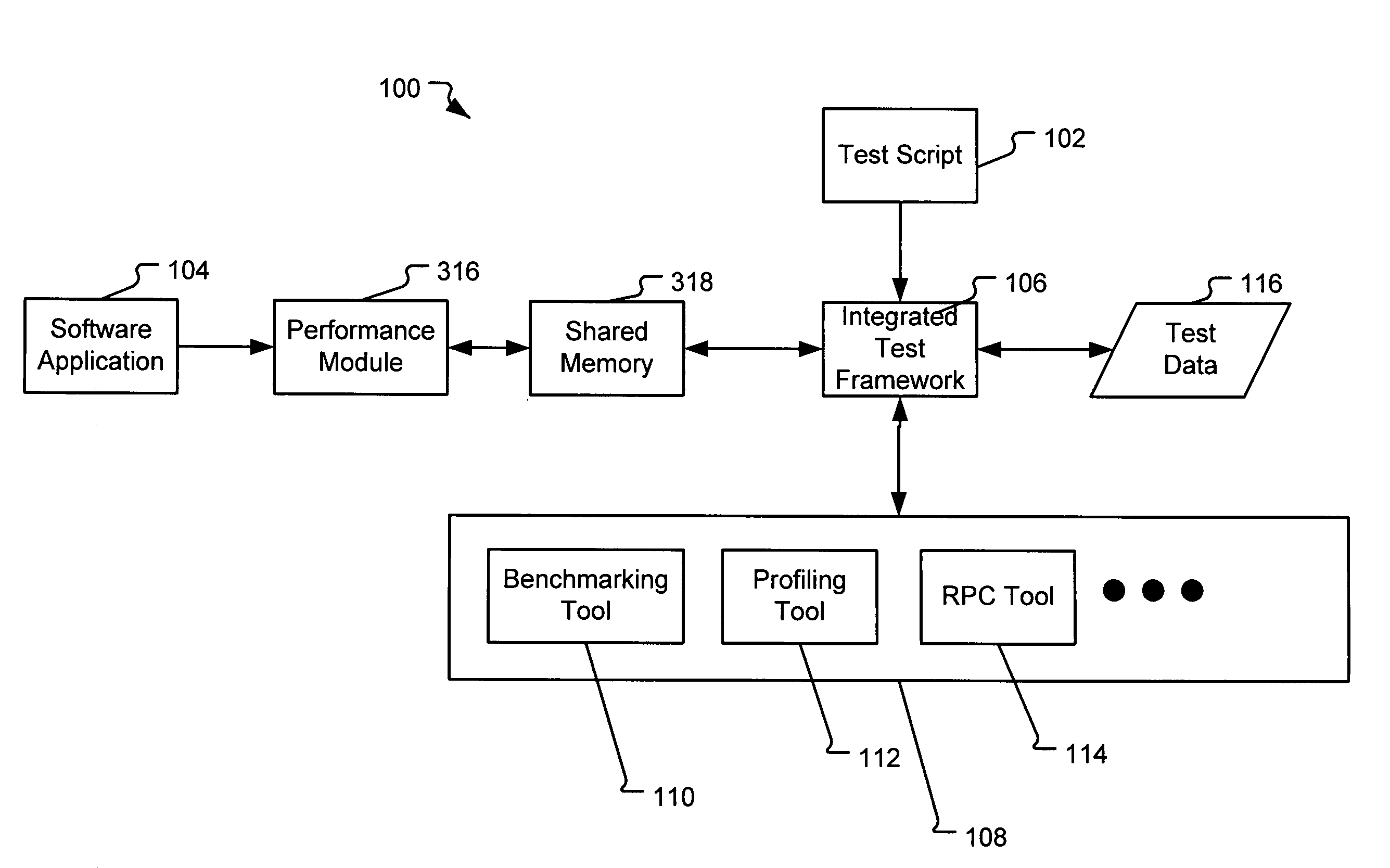

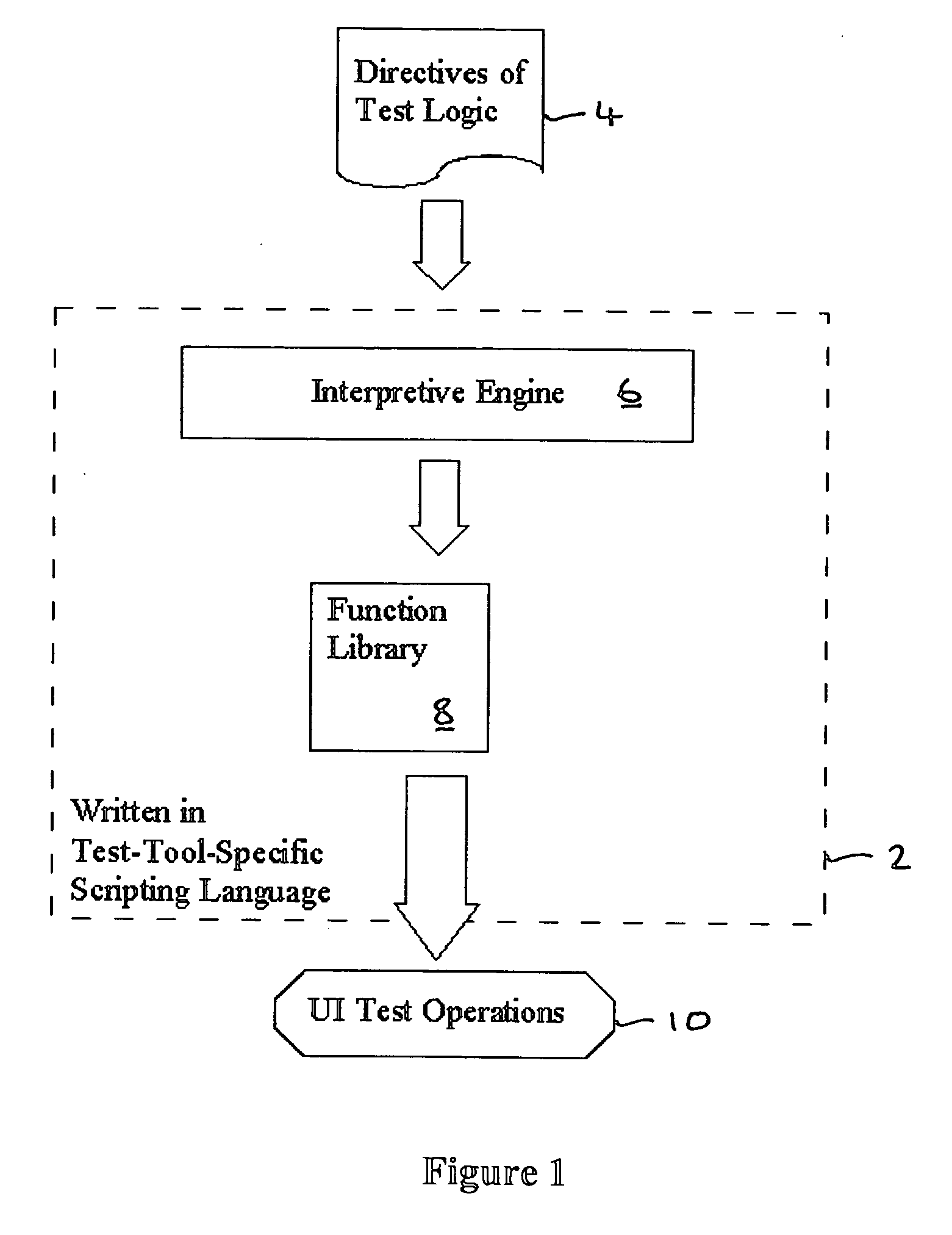

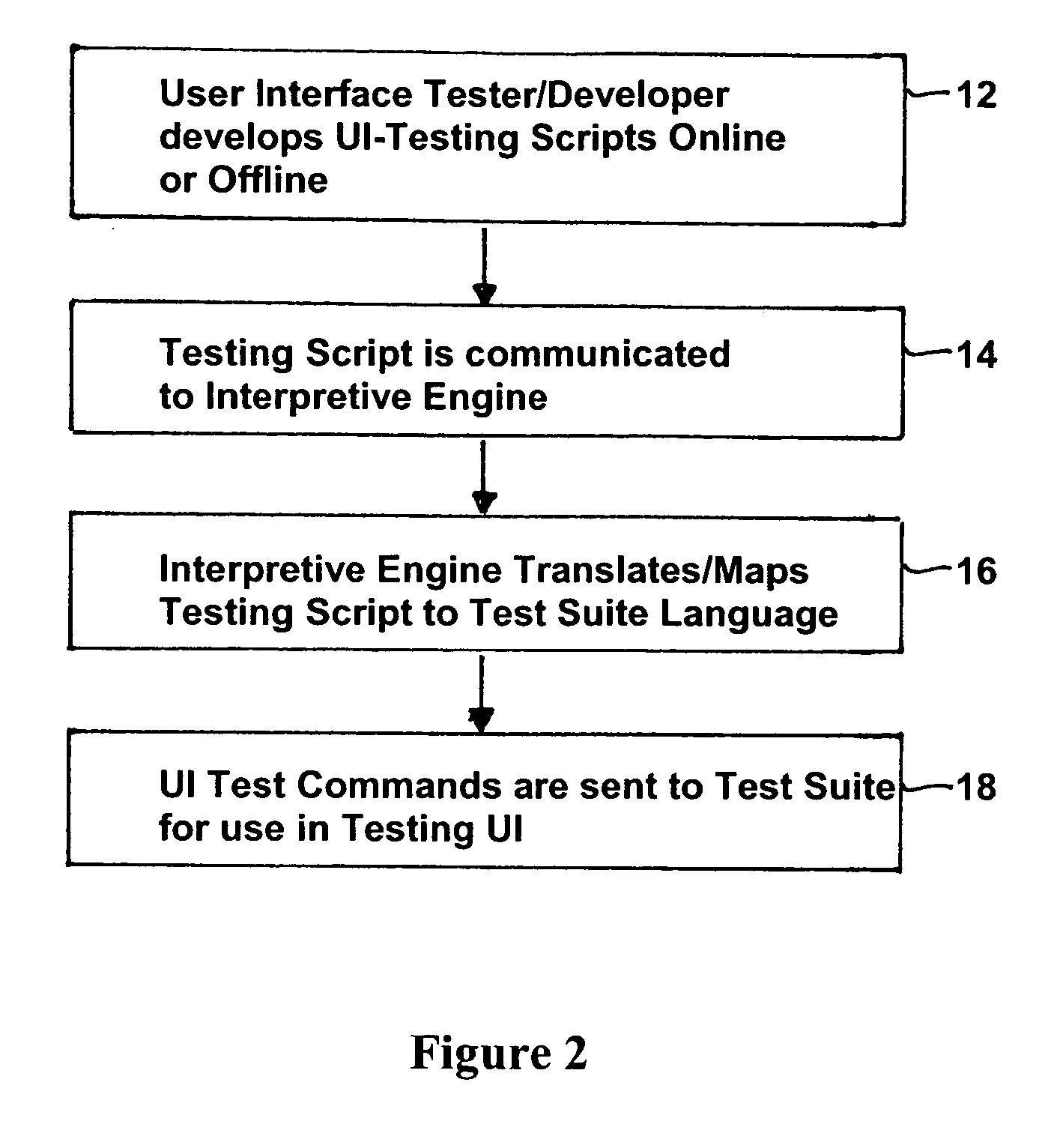

Integrated software test framework for performance testing of a software application

InactiveUS7415635B1Manage the operation of the softwareError detection/correctionSpecific program execution arrangementsTest scriptAuto-configuration

In accordance with the present invention, the above and other problems are solved by an integrated test framework that can receive measurement commands from a test script, automatically configure and execute any performance metrics required to effectuate the measurements and further manage the operation of the software to be tested. The integrated test framework can interpret script commands directed at any testing tool in a testing tool library accessible to the framework. Furthermore, the integrated test framework can identify and utilize code markers during the testing of software applications that utilize embedded code markers as well as identifying script markers. Thus, the integrated framework allows testing scenarios to be created incorporating both code markers and script markers to control performance testing of the executing software application.

Owner:MICROSOFT TECH LICENSING LLC

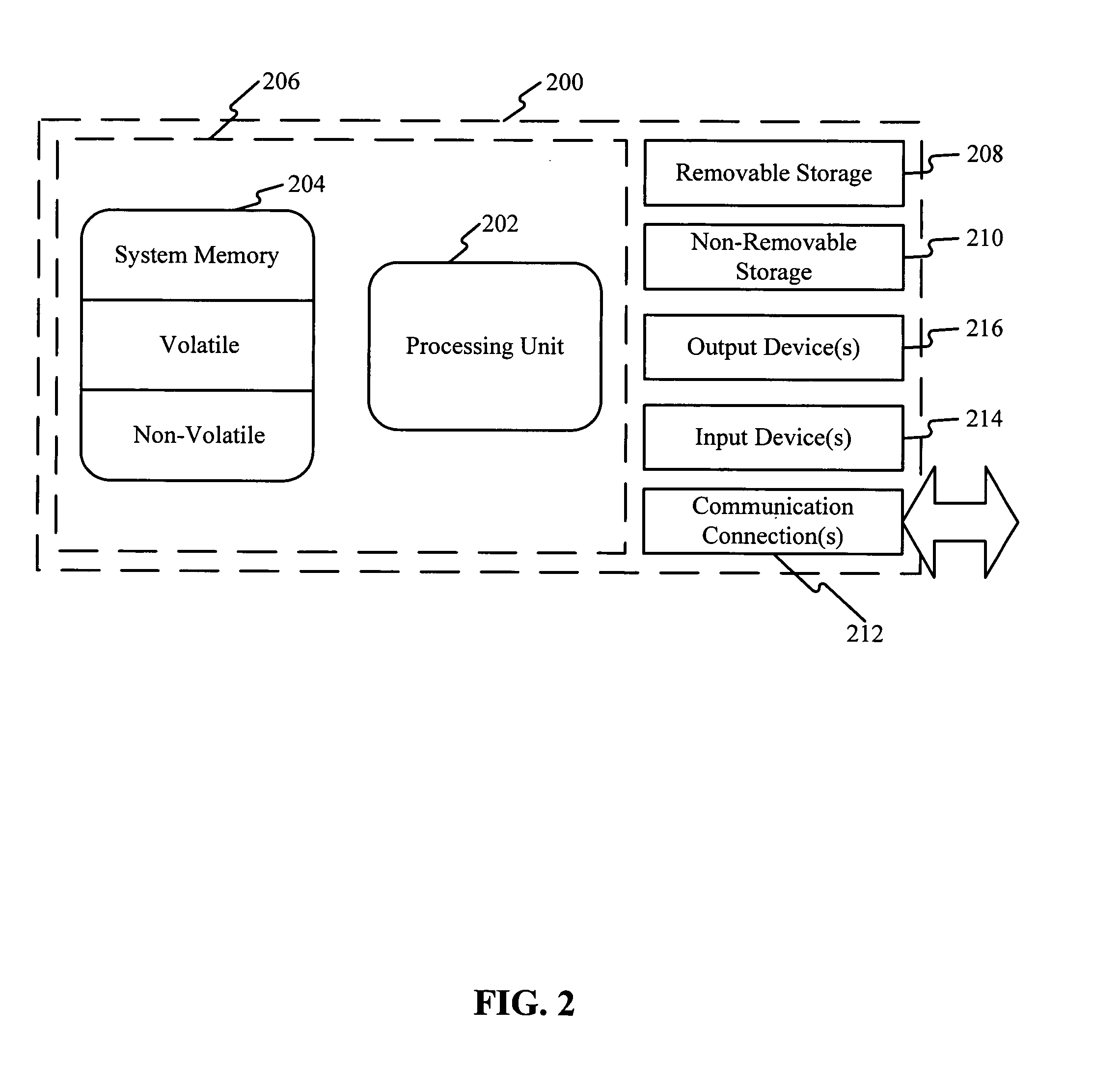

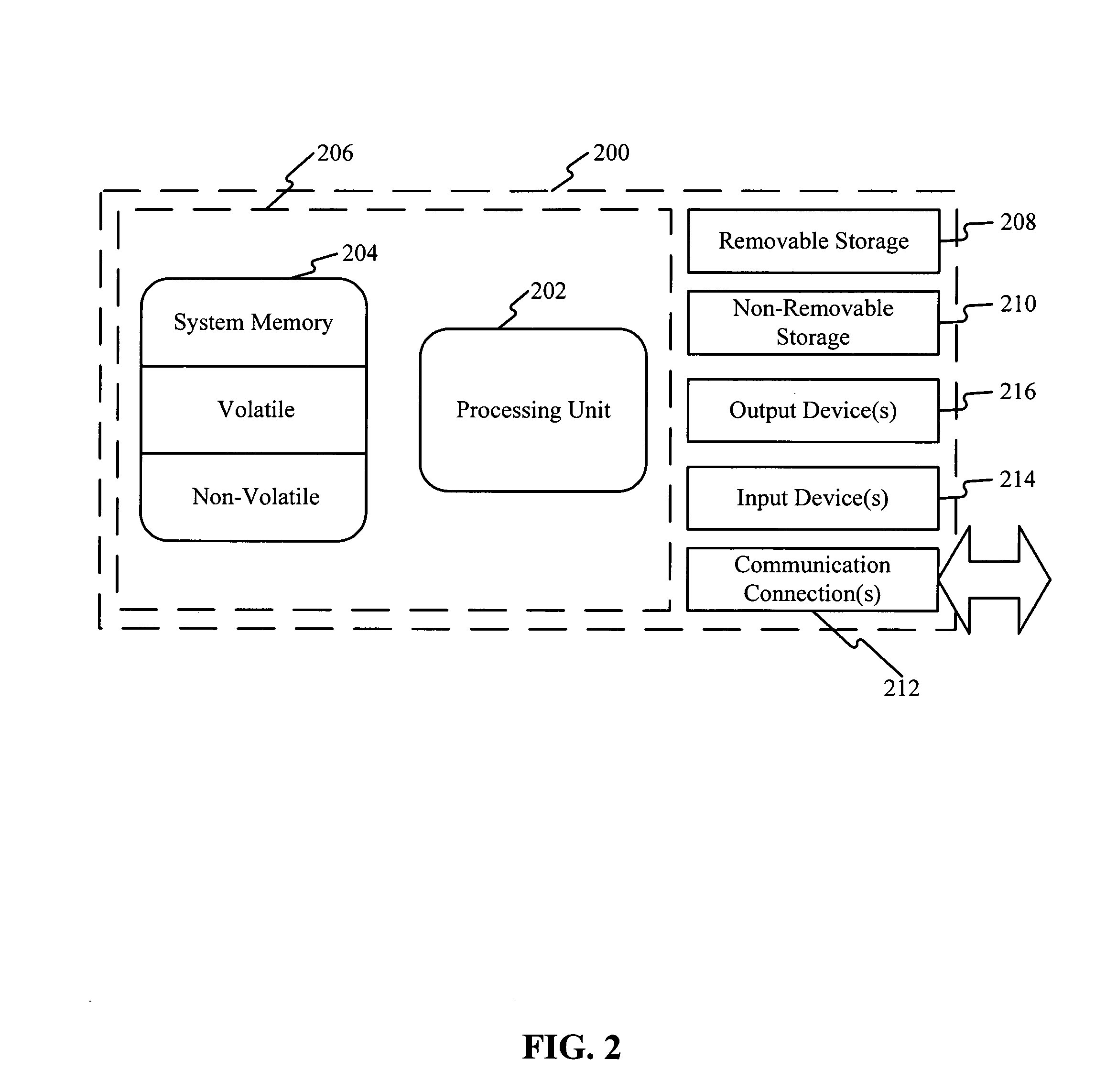

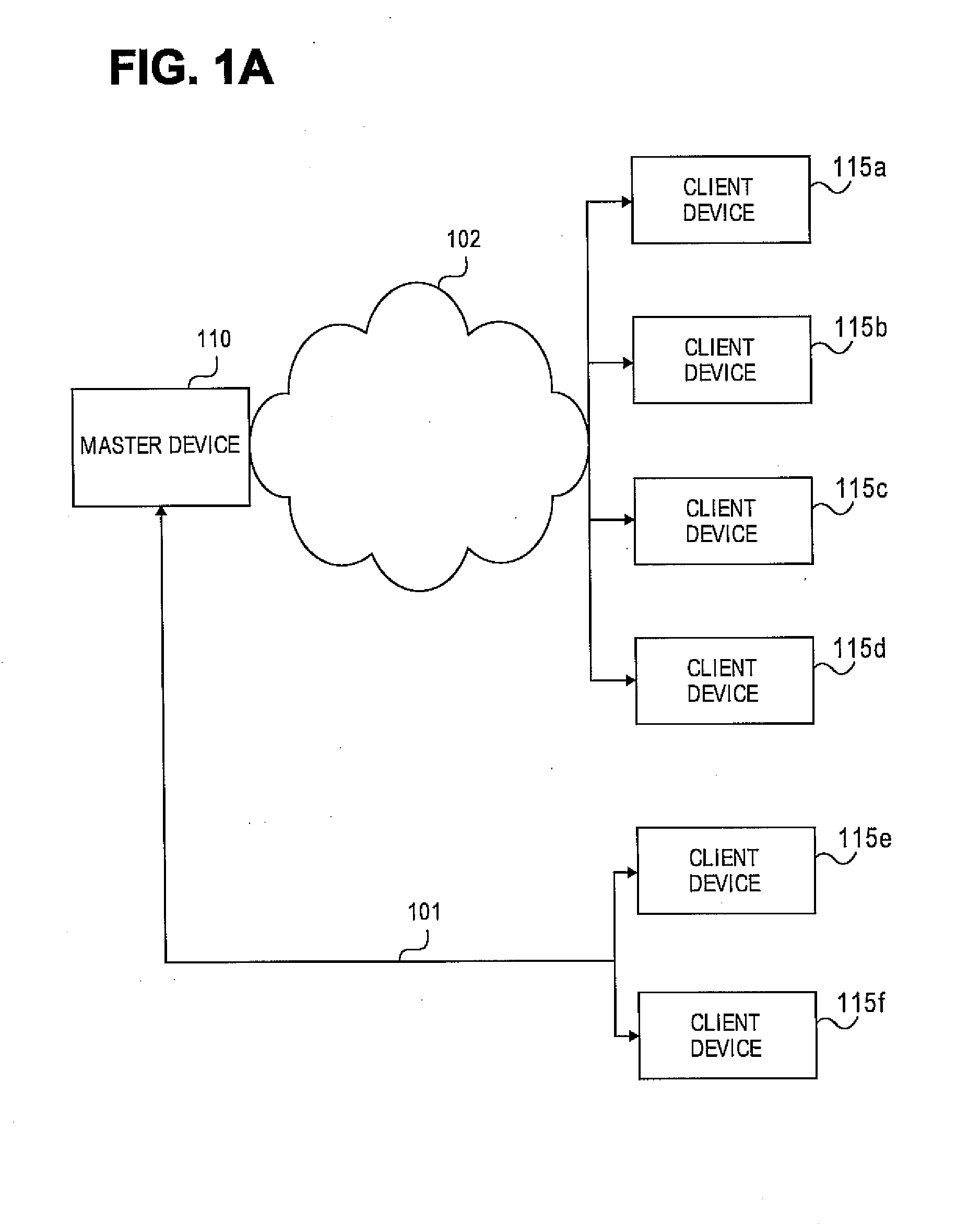

Test framework for testing an application

A device, method and / or computer-readable medium for testing an application within a test framework includes a framework controller associated with the test framework installed on a master device and a test driver associated with the test framework installed on one or more client devices. The master device is connected to the one or more client devices and a virtual machine (VM) module is installed on each of the one or more client devices. VMs can be created on the client devices and the application is installed on at least one of the VMs. The application is executed on the VMs according to a test scenario file. The framework controller collects data to generate an output result.

Owner:RED HAT

Physical simulation method of coal-bed gas well hydraulic fractures

The invention discloses a physical simulation method of coal-bed gas well hydraulic fractures. According to the method, a real three-shaft fracture simulating test frame is arranged, a fracture test piece with a wellbore hole simulator is placed in the real three-shaft fracture simulating test frame, and sound transmitting probes tightly adhere to the eight corners of the fracture test piece respectively through plastic cement and are connected with sound transmitting receivers through acoustic emission signal amplifiers; a hydraulic pressure stabilizer is connected to the exterior of the real three-shaft fracture simulating test frame; the top of the wellbore hole simulator is connected with an oil and water separator through a fracturing liquid pipeline, guar glue hydraulic fracturing liquid is added to the upper portion of the oil and water separator, and oil is added to the lower portion of the oil and water separator; a control panel is connected to the bottom of the oil and water separator. With the physical simulation method of coal-bed gas well hydraulic fractures, generation and development of fractures in the test piece can be detected in real time in the hydraulic fracturing physical simulation process in a laboratory, the three-dimensional characteristic analysis of the fractures is paid attention to, the method is not confined to observation on the extension of the fractures on the surface of the fracture test piece, and the extension process of the fractures can be better reflected.

Owner:CHINA UNIV OF MINING & TECH

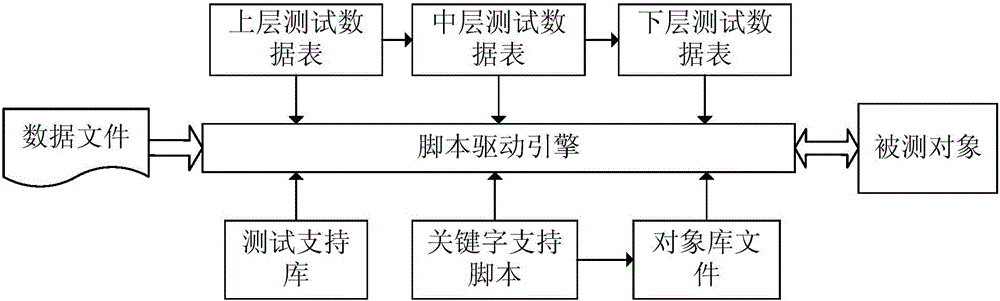

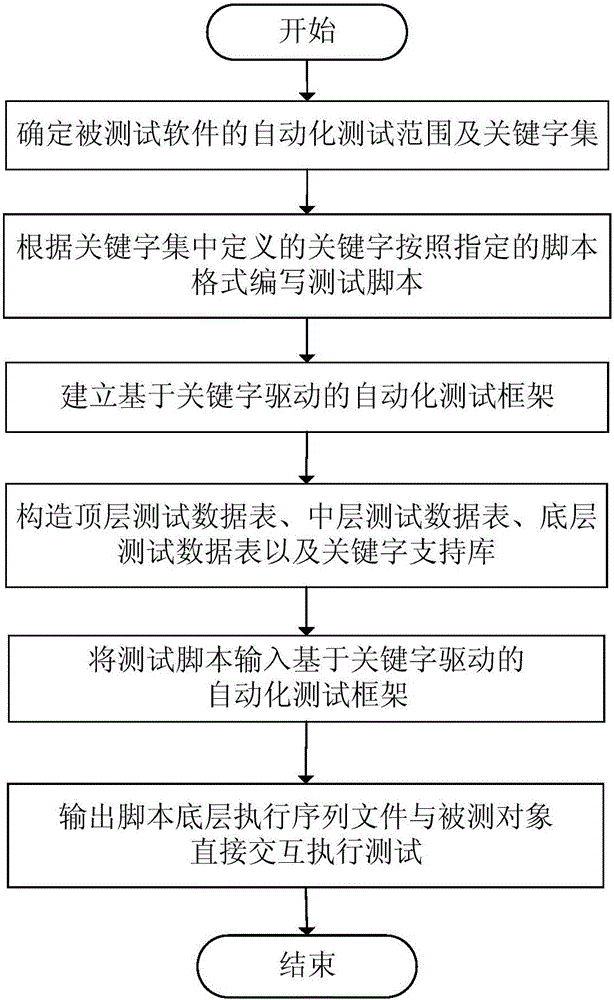

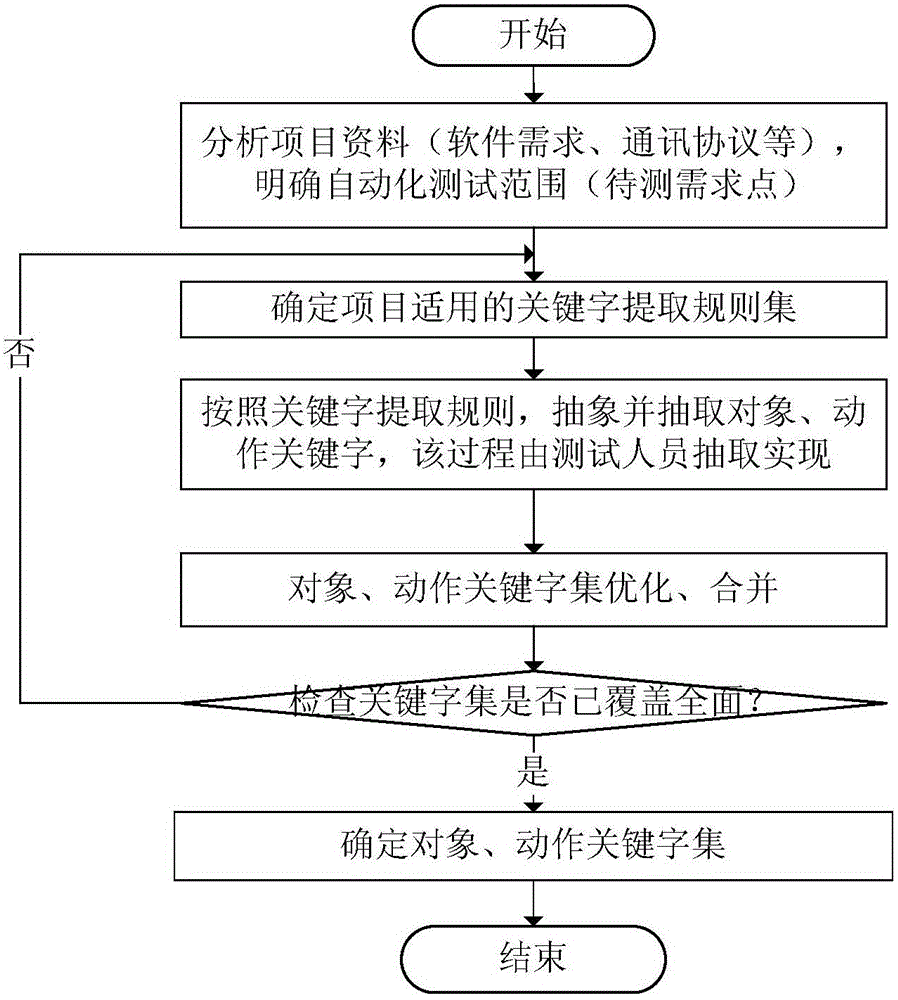

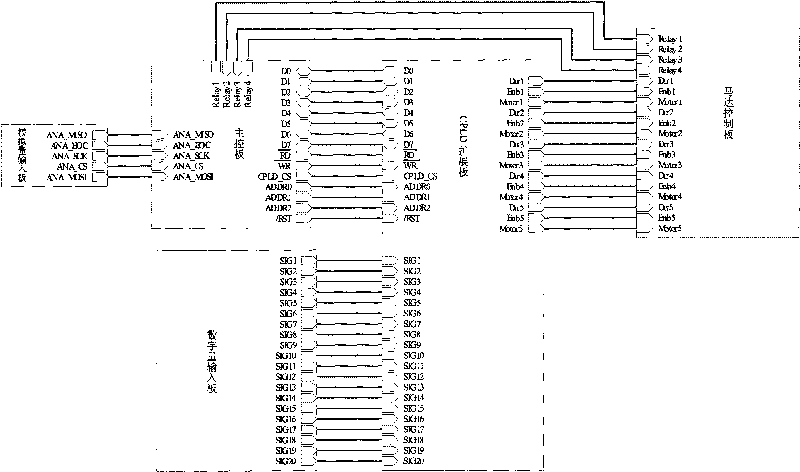

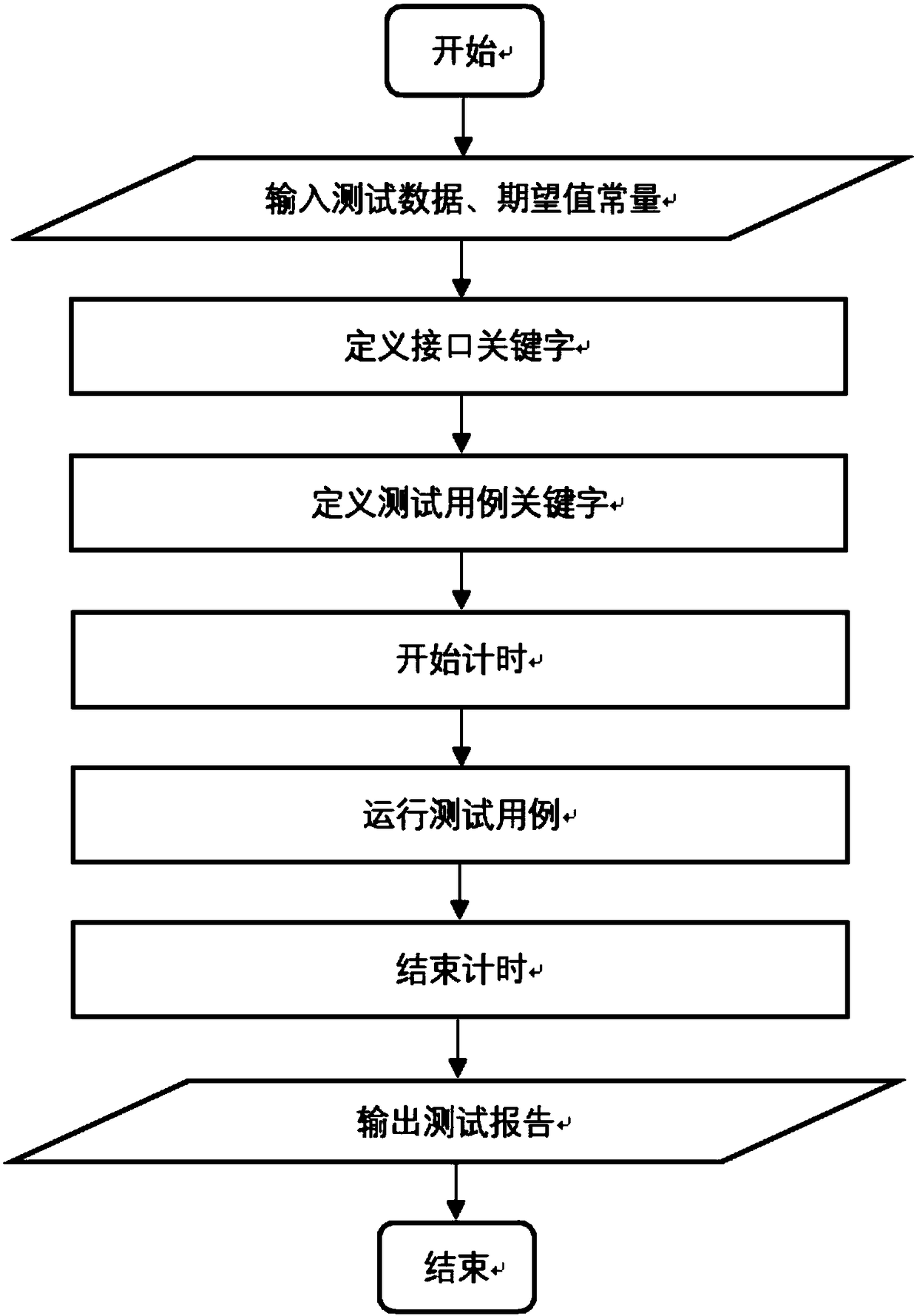

Keyword drive-based automatic test method of urban rail drive control units

InactiveCN105068927AImprove reusabilityImprove maintainabilitySoftware testing/debuggingTest scriptAutomatic test equipment

The invention discloses a keyword drive-based automatic test method of urban rail drive control units. The method comprises the following steps: determining a keyword set of a tested object; compiling a test script according to the keyword set; establishing a keyword drive-based automatic test frame and constructing a top layer test data table, a middle layer test data table, a bottom layer test data table and a keyword support library for the automatic test frame; inputting the test script into the automatic test frame, successively calling drives of the layers to inquire the contents in the test data tables on the basis of a test drive engine of the automatic test frame in allusion to each objective keyword in the test script; and calling bottom layer functions of the keyword support library to output a script bottom layer execution sequence file and directly and interactively carrying out test with the tested object. The keyword drive-based automatic test method of urban rail drive control units has the advantages of reducing the skill requirement for the test personnel, being high in test script reusability and good in maintainability and portability, shortening the test script development and maintenance time and reducing the test script development and maintenance cost.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

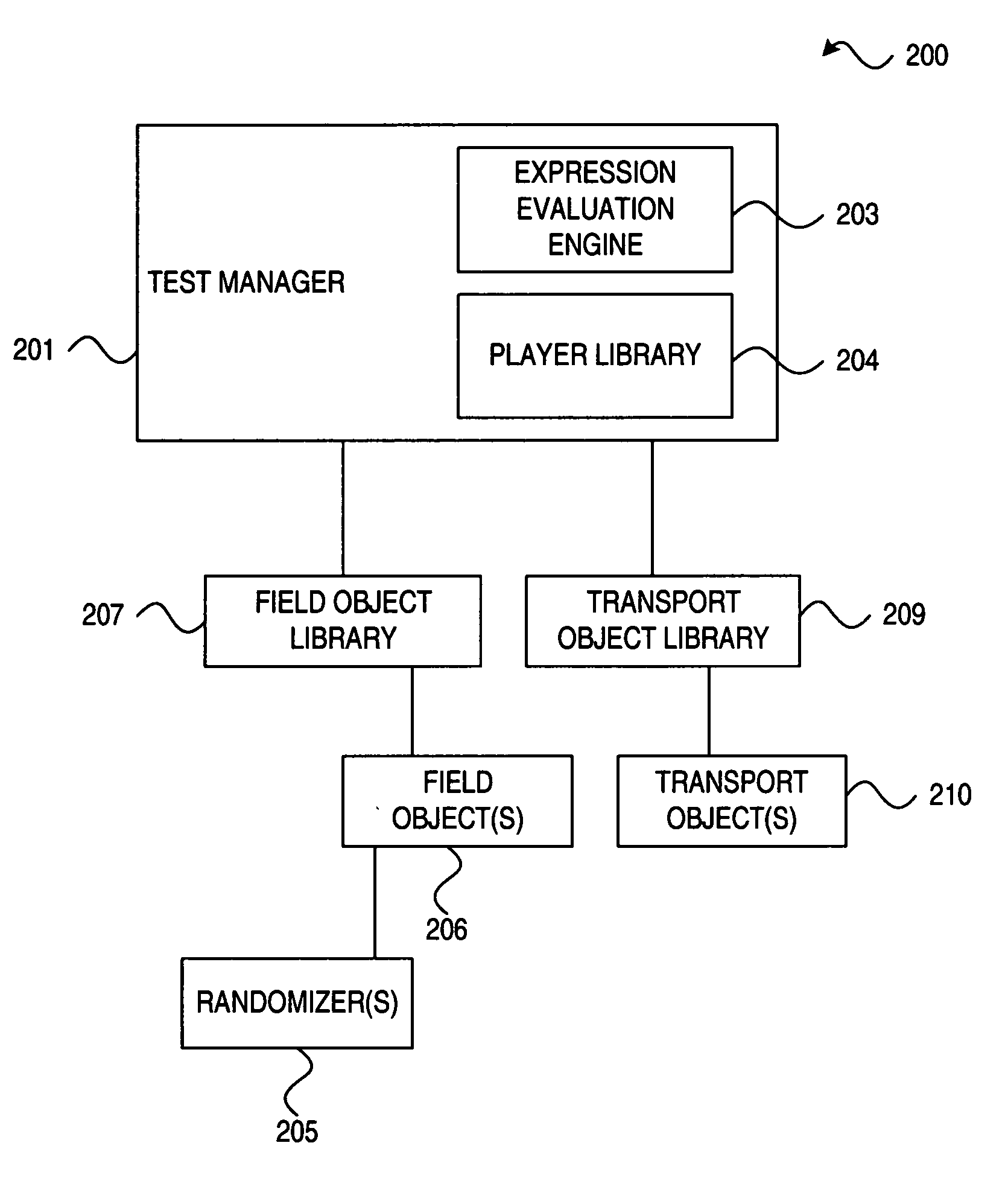

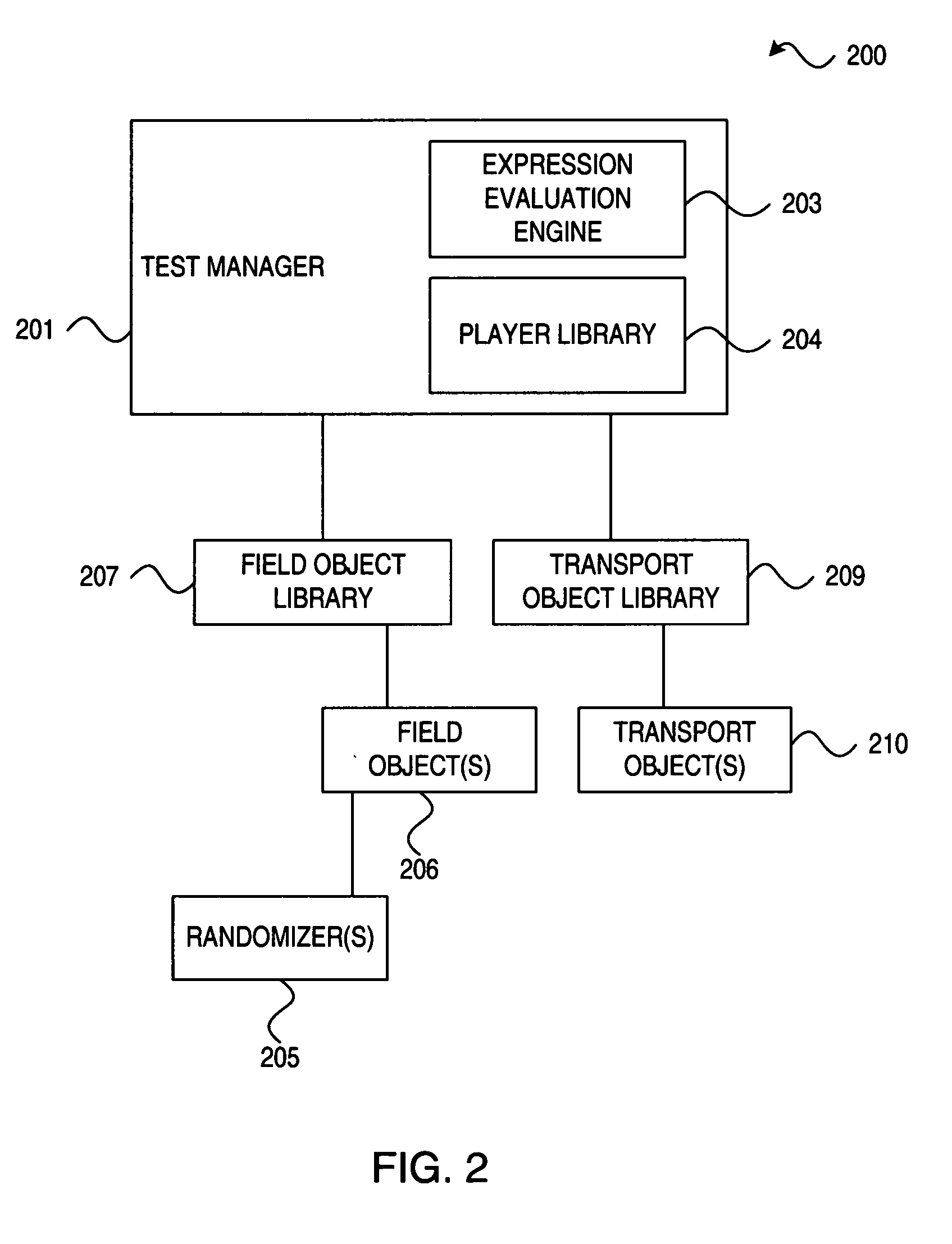

Extensible testing framework

InactiveUS20070006153A1Error detection/correctionInterprogram communicationCommand-line interfaceTest frame

Methods and systems for providing an extensible testing framework are provided. An extensible testing framework may use field objects to represent test data values of various data types, including char, int, string, and the like. The framework is extensible in that new field objects may be added as new data types are needed during testing. The extensible testing framework may use transport objects to communicate test values to and from the target software being tested, e.g., using TCP Client, TCP Server, UCP Client, and the like. The framework is extensible in that new transport objects can be added as new transport protocols are needed, e.g., for a command line interface. Each test executes under the control of a test manager, as defined by configuration information provided in a configuration file or via an external executable control application.

Owner:MICROSOFT TECH LICENSING LLC

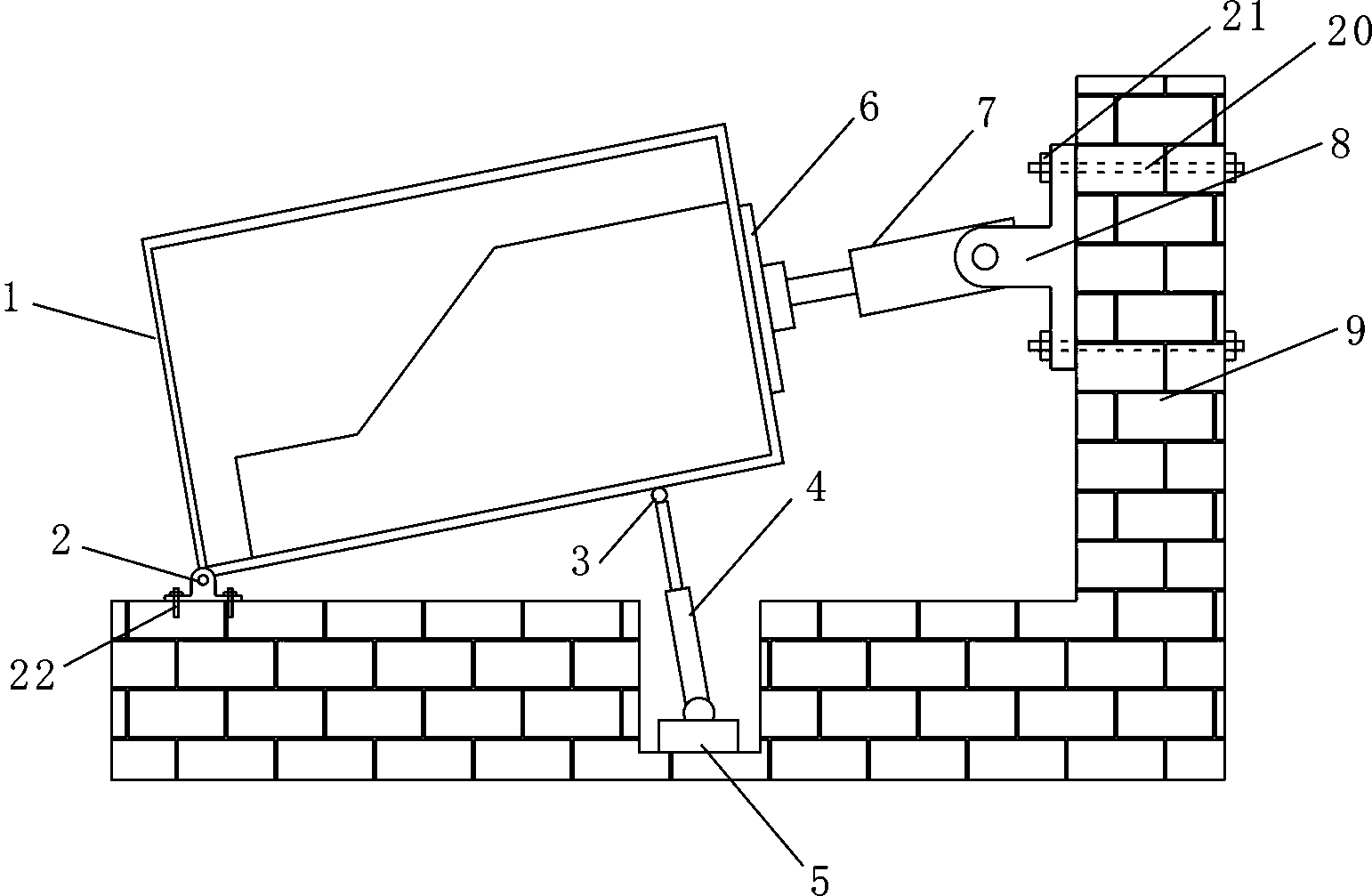

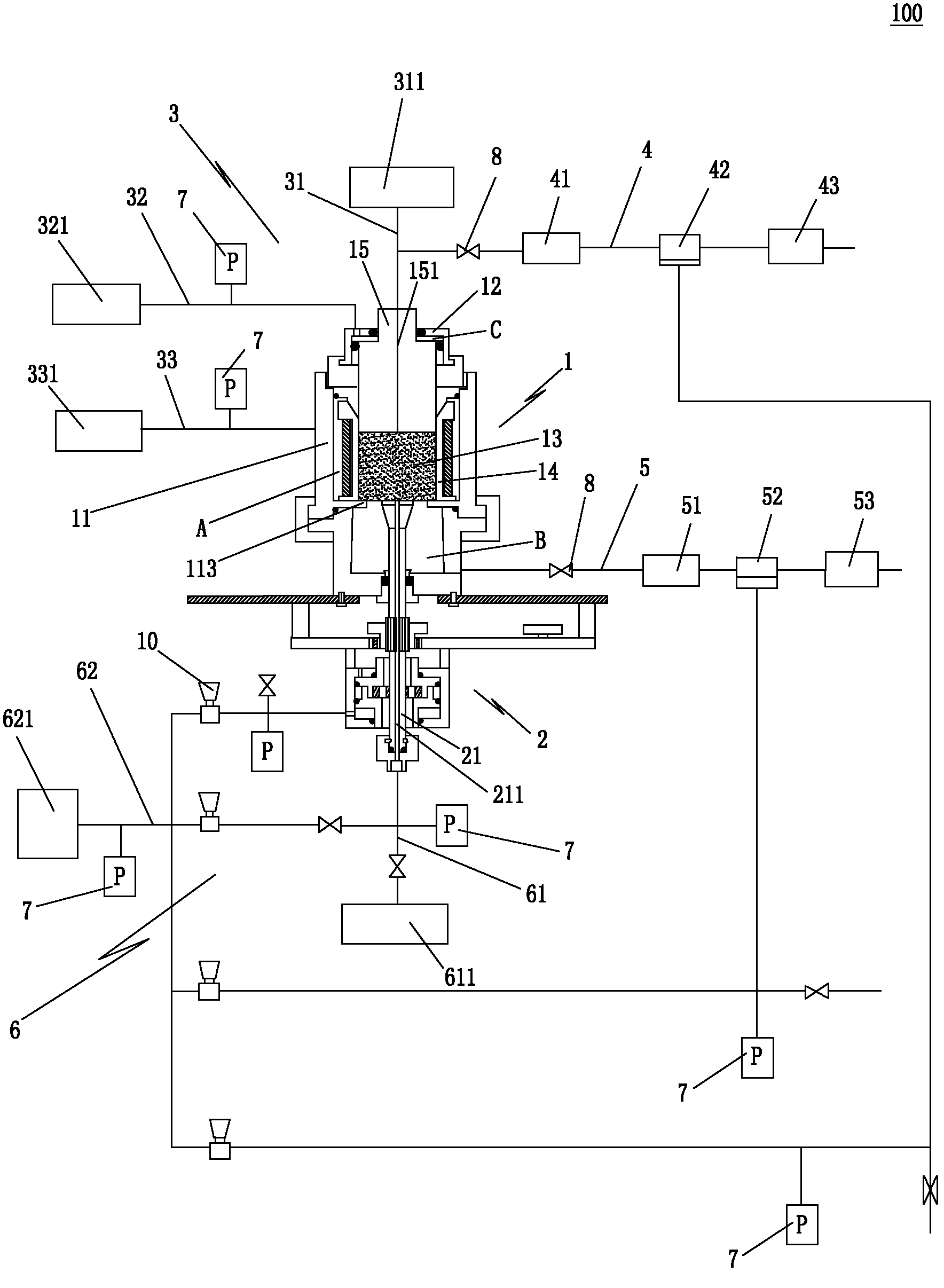

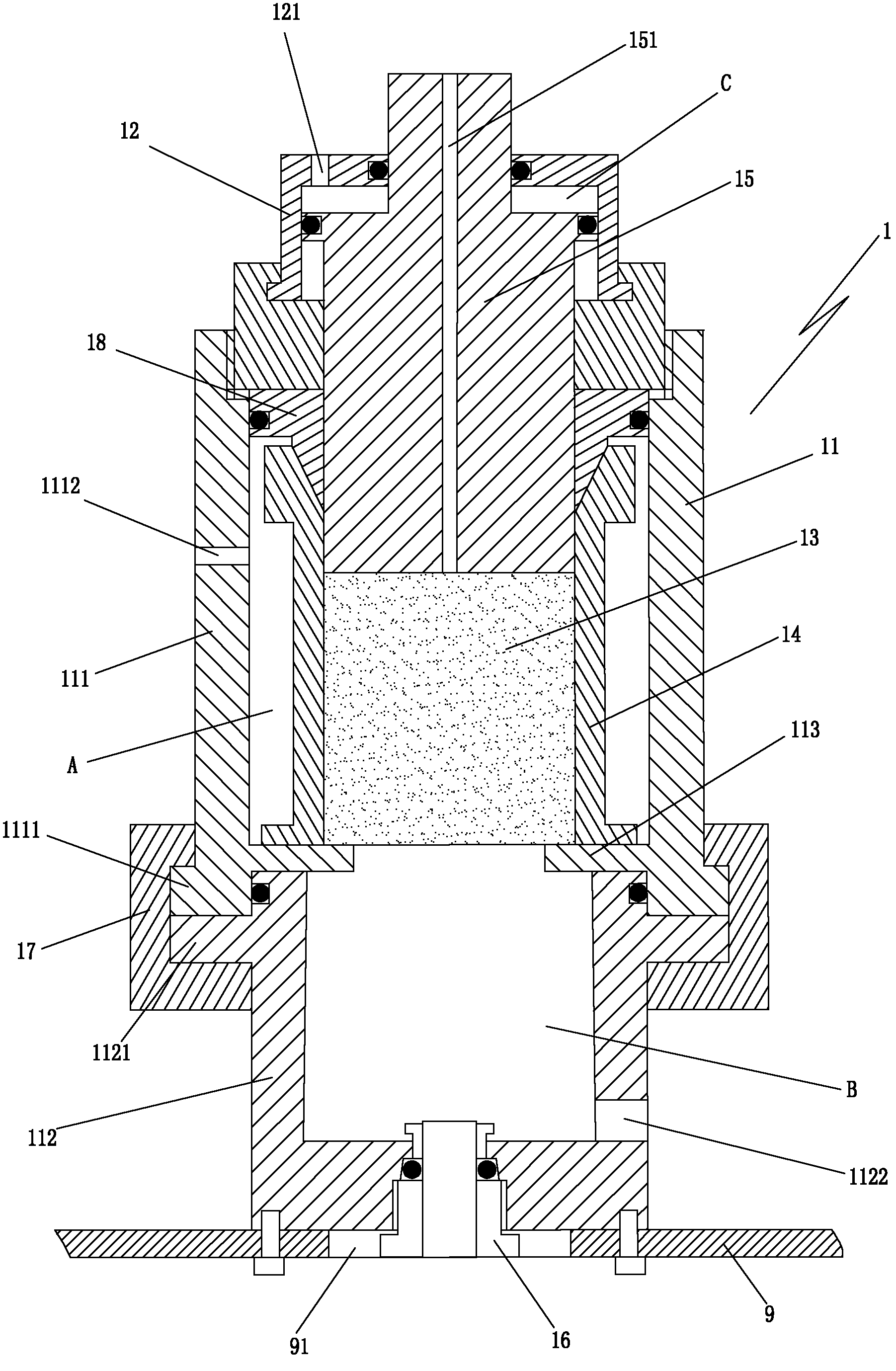

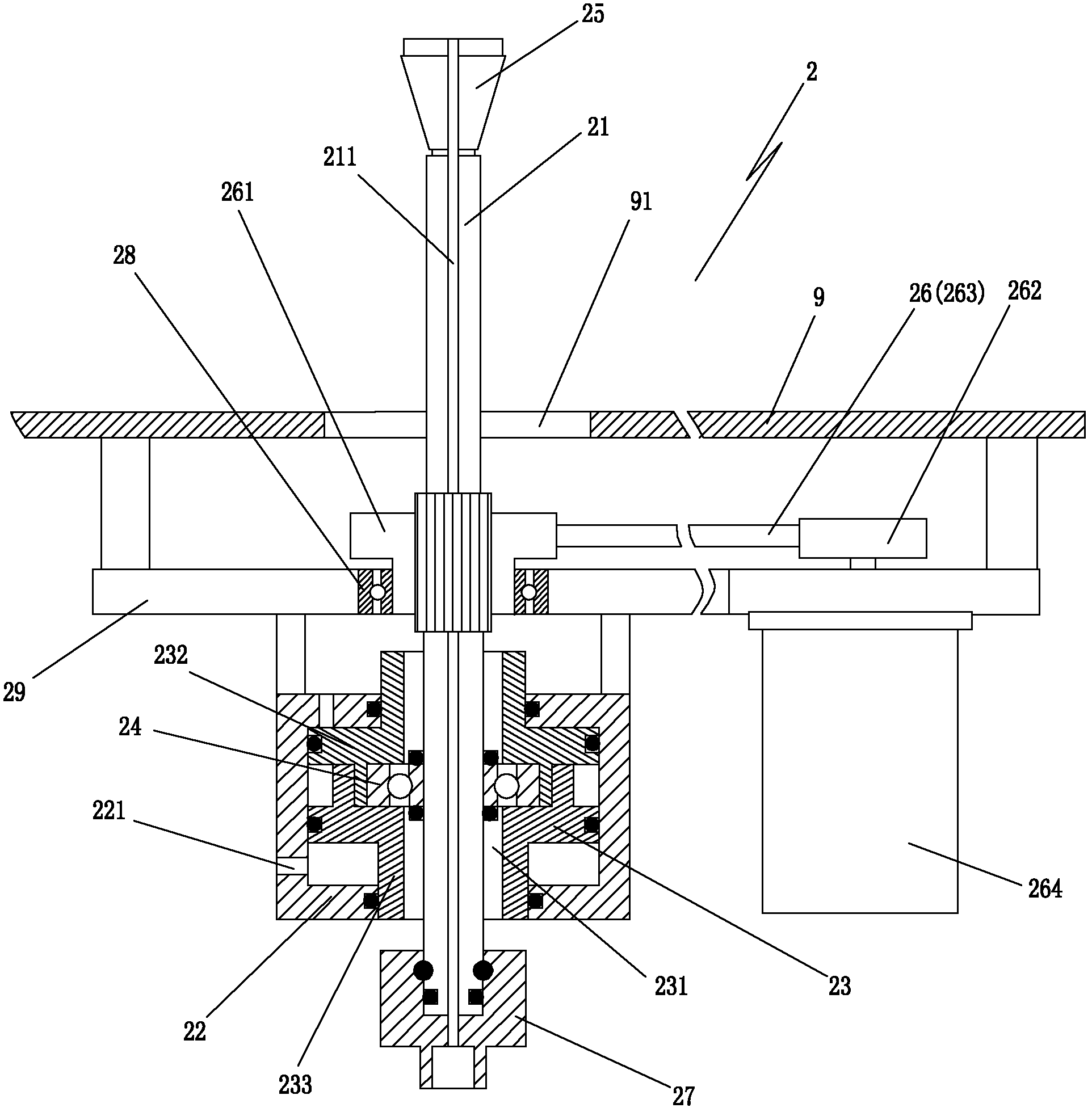

Drilling simulation experiment device

InactiveCN102288742AIncrease drilling speedImprove drilling qualityEarth material testingRock coreWell drilling

The invention relates to a well drilling simulation test device. The well drilling simulation test device comprises a rock core clamping mechanism, a drilling mechanism, a pressing mechanism and a pressing control pipeline, wherein the rock core clamping mechanism and the drilling mechanism are concentrically arranged above and below a test frame; constant pressure liquid which is applied to the upper end of the rock core by a constant pressure pump of the pressing mechanism and constant pressure liquid or high pressure gas which is pressed on the rock core by a constant pressure pump of the drilling mechanism or a high pressure gas source are converged in a simulated cavity at the bottom of the well, and are controlled to flow out by the pressing control pipeline consisting of a filter, a back pressure device and a flowmeter; the back pressure device is connected with the high pressure gas source of the drilling mechanism and controls the pressure of the simulated cavity at the bottom of the well by controlling the gas supply pressure of the high pressure gas source; the pressing mechanism, a pressure sensor of the back pressure device and the flowmeter transmit signals to a computer; and change of related parameters is controlled by the computer program, so that various drilling schemes are simulated and tested, and indoor test data is provided for increasing drilling speed,improving drilling quality and reducing drilling cost.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

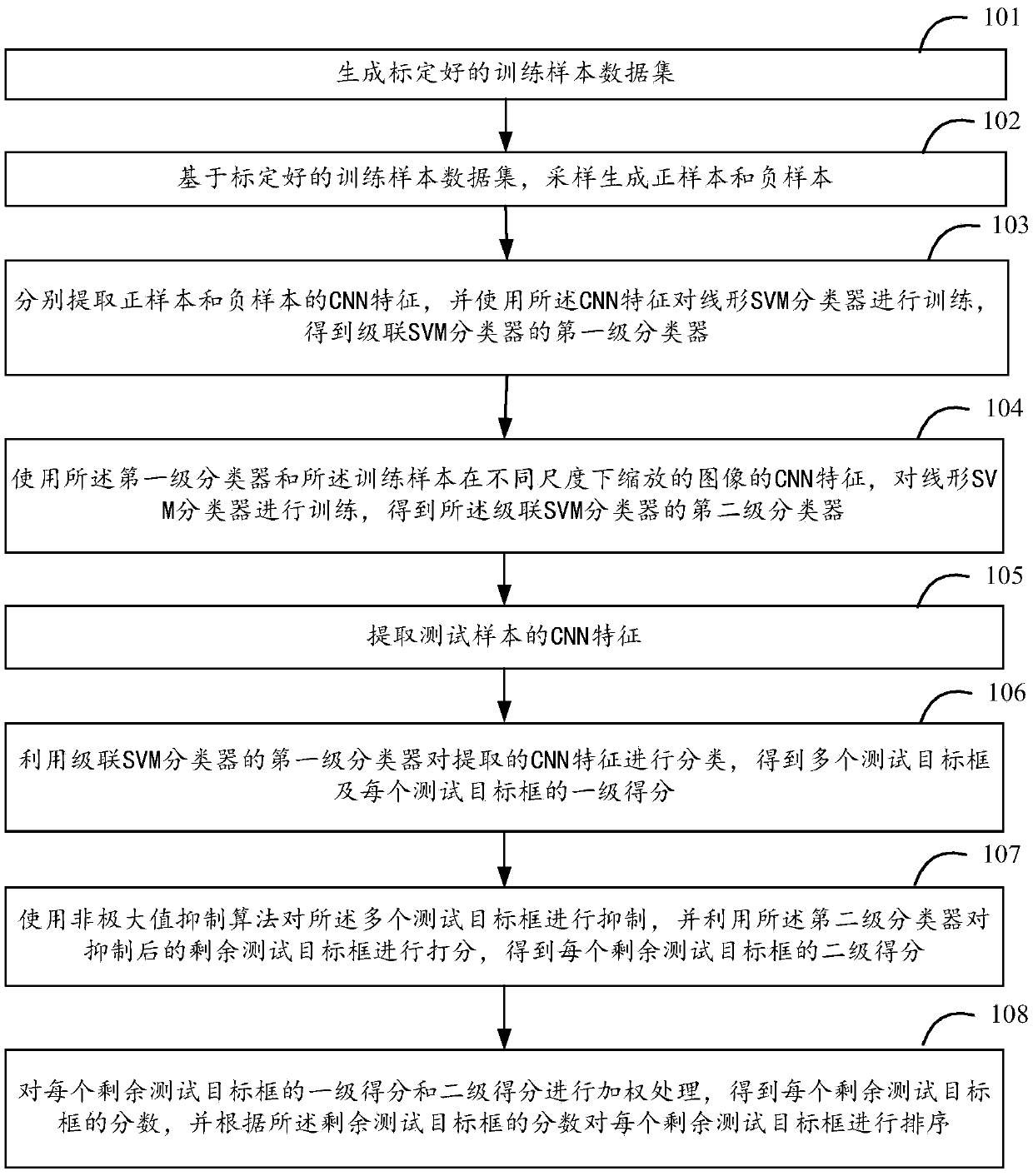

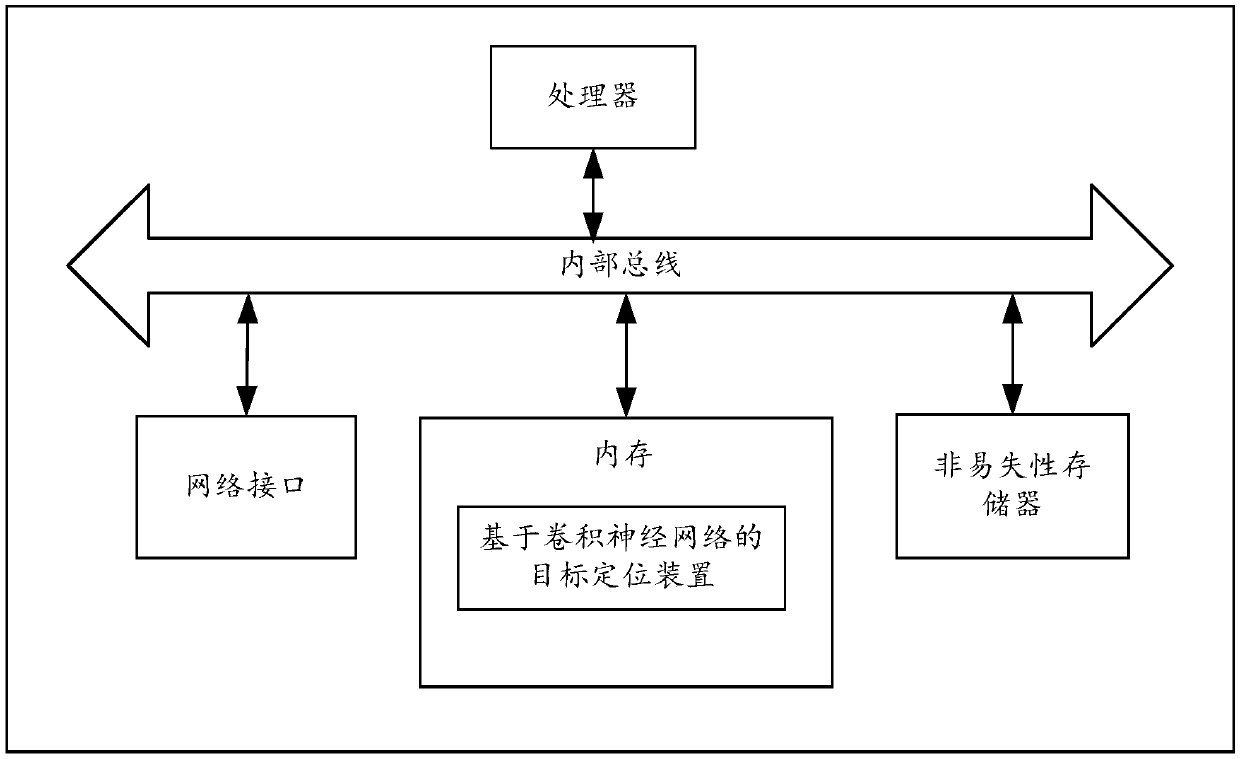

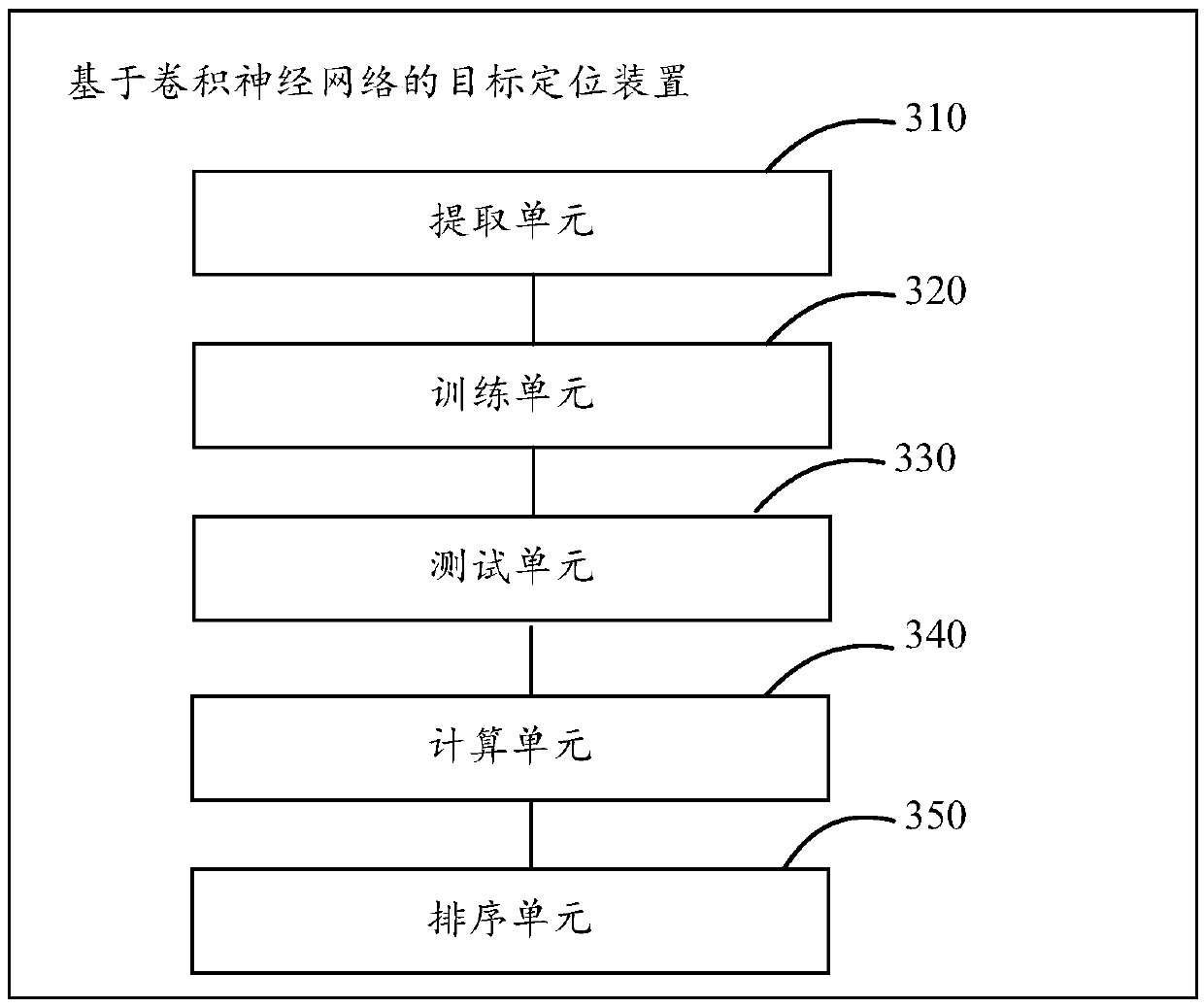

Target positioning method and device based on convolution neural network

ActiveCN105512683AImprove accuracyUniversalCharacter and pattern recognitionPhysical realisationTest frameSvm classifier

The present invention provides a target positioning method and device based on a convolution neural network. The method comprises a step of extracting the CNN feature of a training sample, a step of using the CNN feature to train an SVM classifier to obtain a first-class classifier, a step of training the SVM classifier by using the first-class classifier and the CNN features of the image zoomed in different scales by the training sample to obtain a second-class classifier, a step of extracting the CNN feature of the training sample, carrying out detection by using the first-class classifier, and obtaining multiple test target frames and corresponding first-class scores, a step of using the second-class classifier to grade remaining target testing frames with maxima suppression, and obtaining the second-class score of each remaining target test frame, and a step of carrying out weighted processing on the first-class score and the second-class score of each remaining target test frame, and sorting each remaining target test frame. The application of the target positioning method to carry out target positioning is not limited by a scene, and the accuracy of the target positioning is high.

Owner:ZHEJIANG UNIVIEW TECH CO LTD

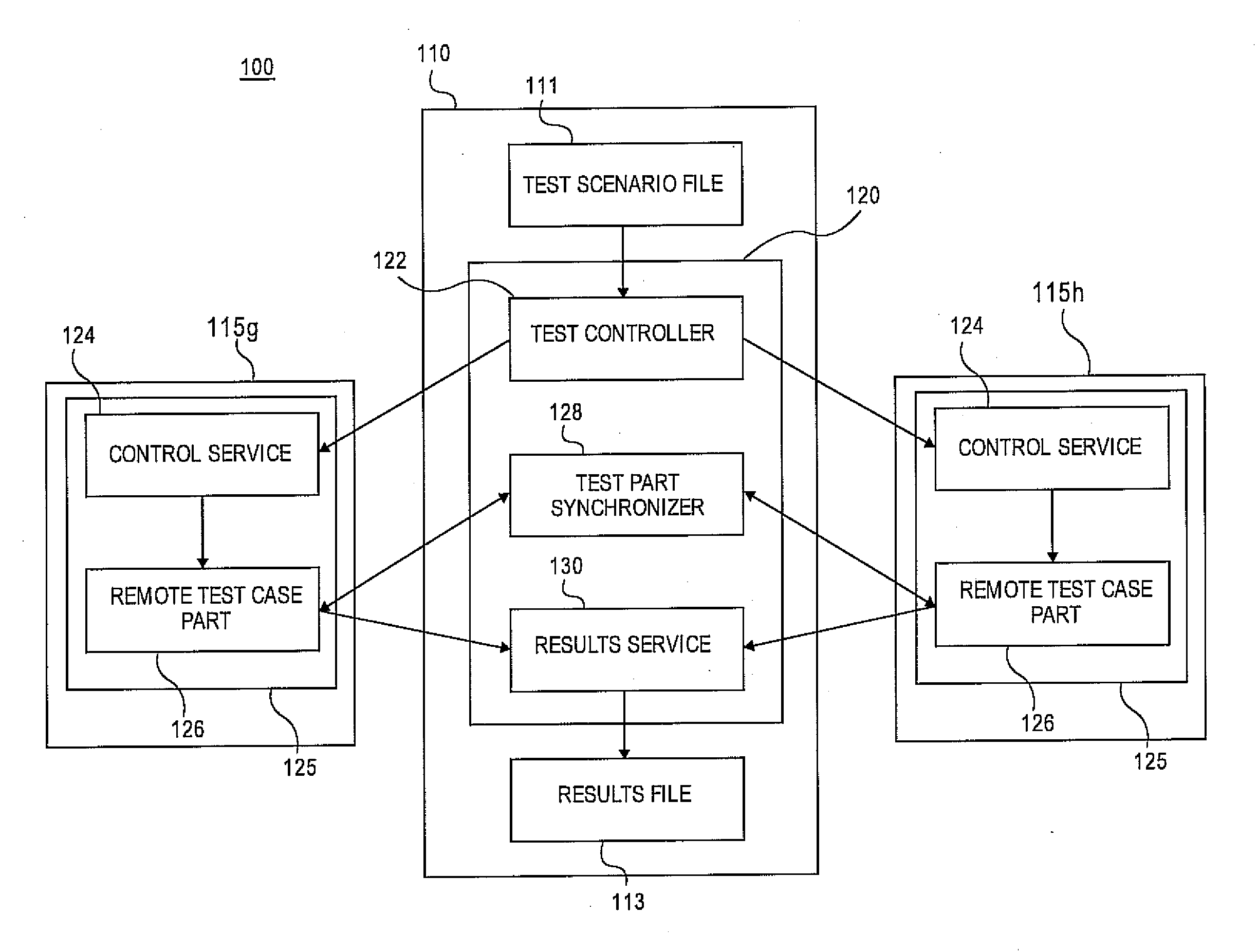

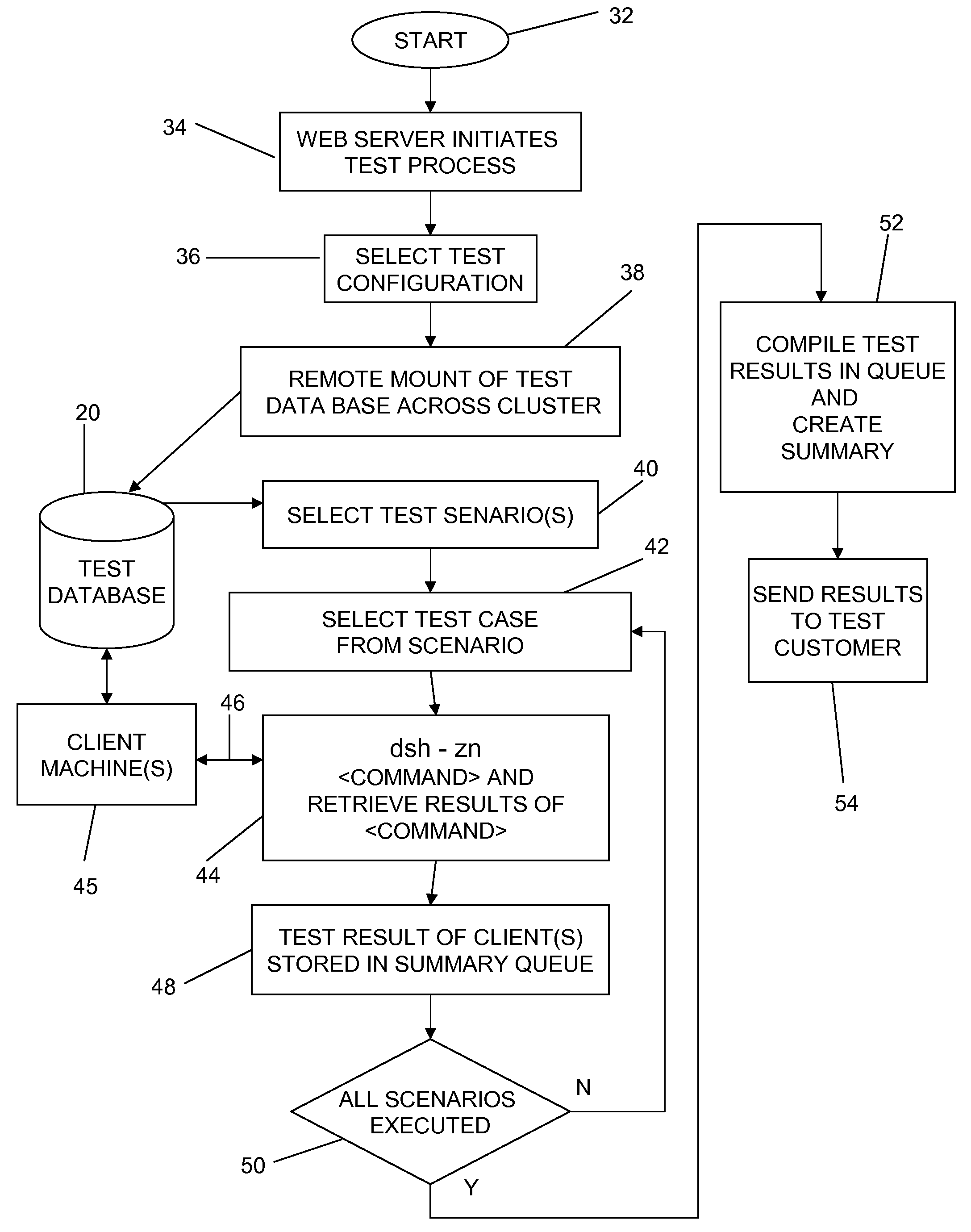

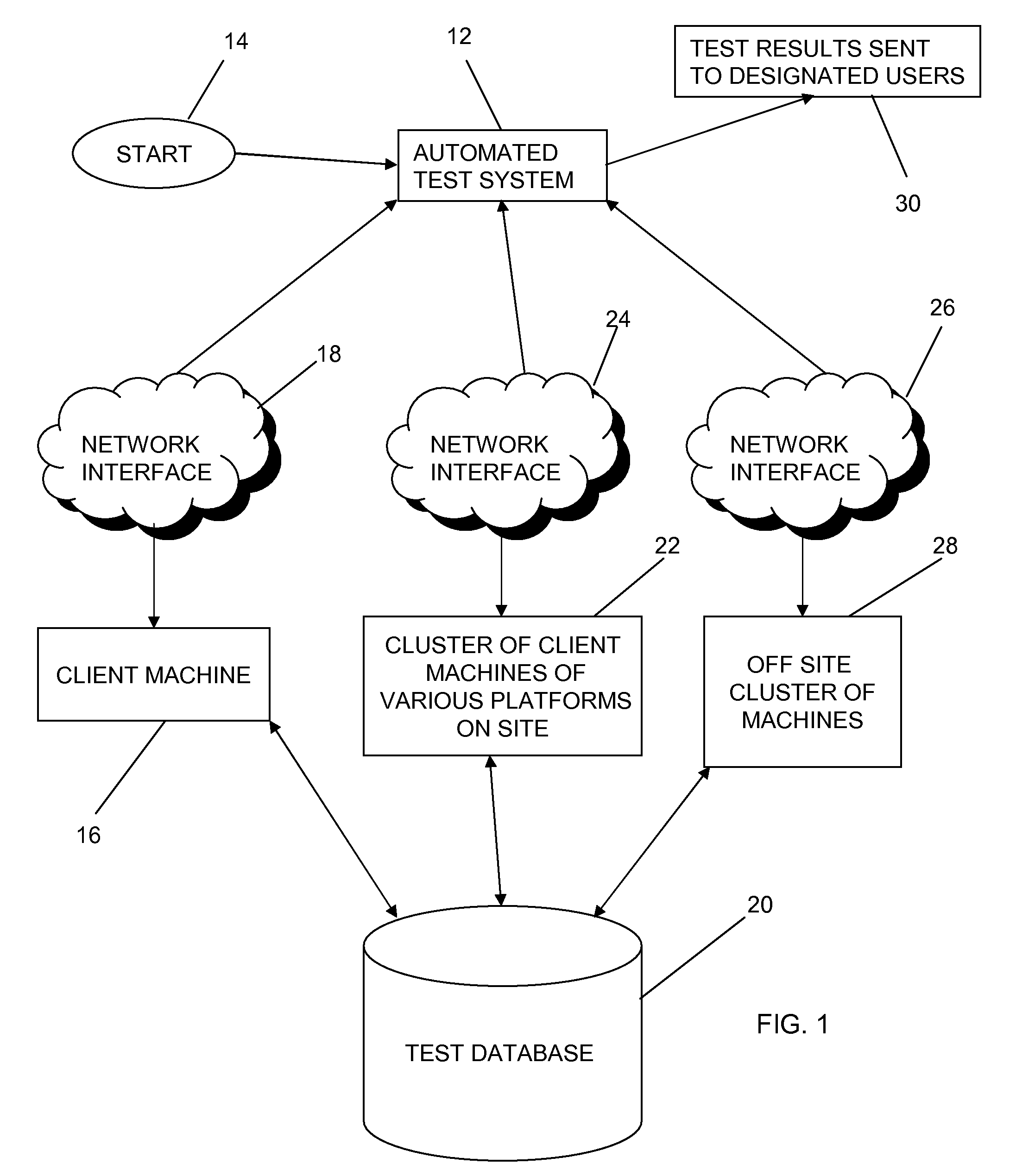

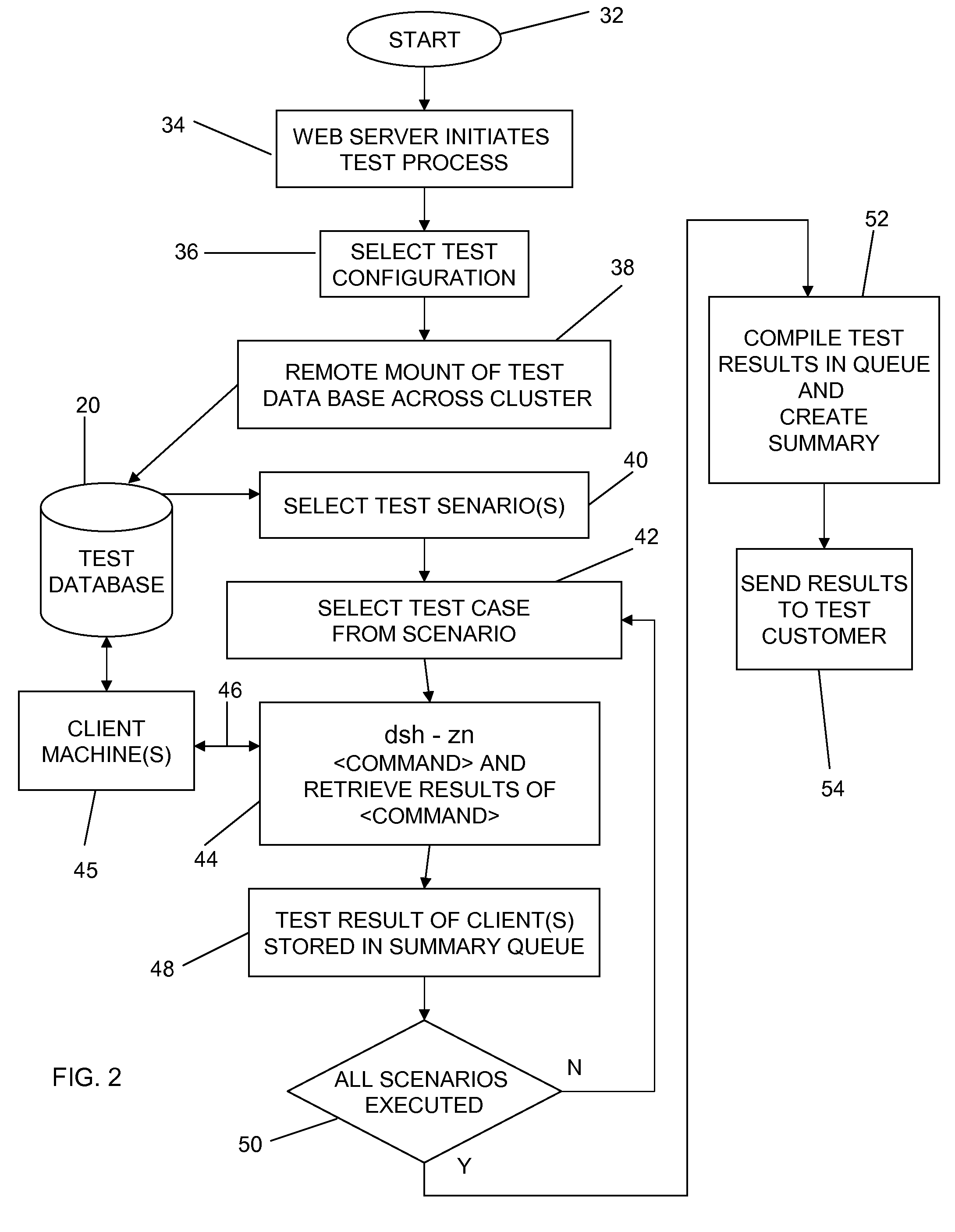

Method, apparatus and program product for creating a test framework for testing operating system components in a cluster system

InactiveUS20080320071A1Reduce test bucket design timeEliminating time spent in creating documentError detection/correctionMultiple digital computer combinationsOperational systemTest frame

A method, apparatus and program product include an Automatic Testing System for creating a test framework for testing operating system components. The Automatic Testing System resides on a server and includes a master driver which assists in creating test cases and scenarios. The Automatic Testing System issues commands to distribute execution to one or more remote client machines in a cluster through, for instance, an external remote shell program. Results of the command are retrieved, as though it was invoked on the machine directly. The logic and parameters needed to run the test scenarios are stored in a database accessible on the web, and test results are compiled and stored in the database to be sent to any designated test customer.

Owner:IBM CORP

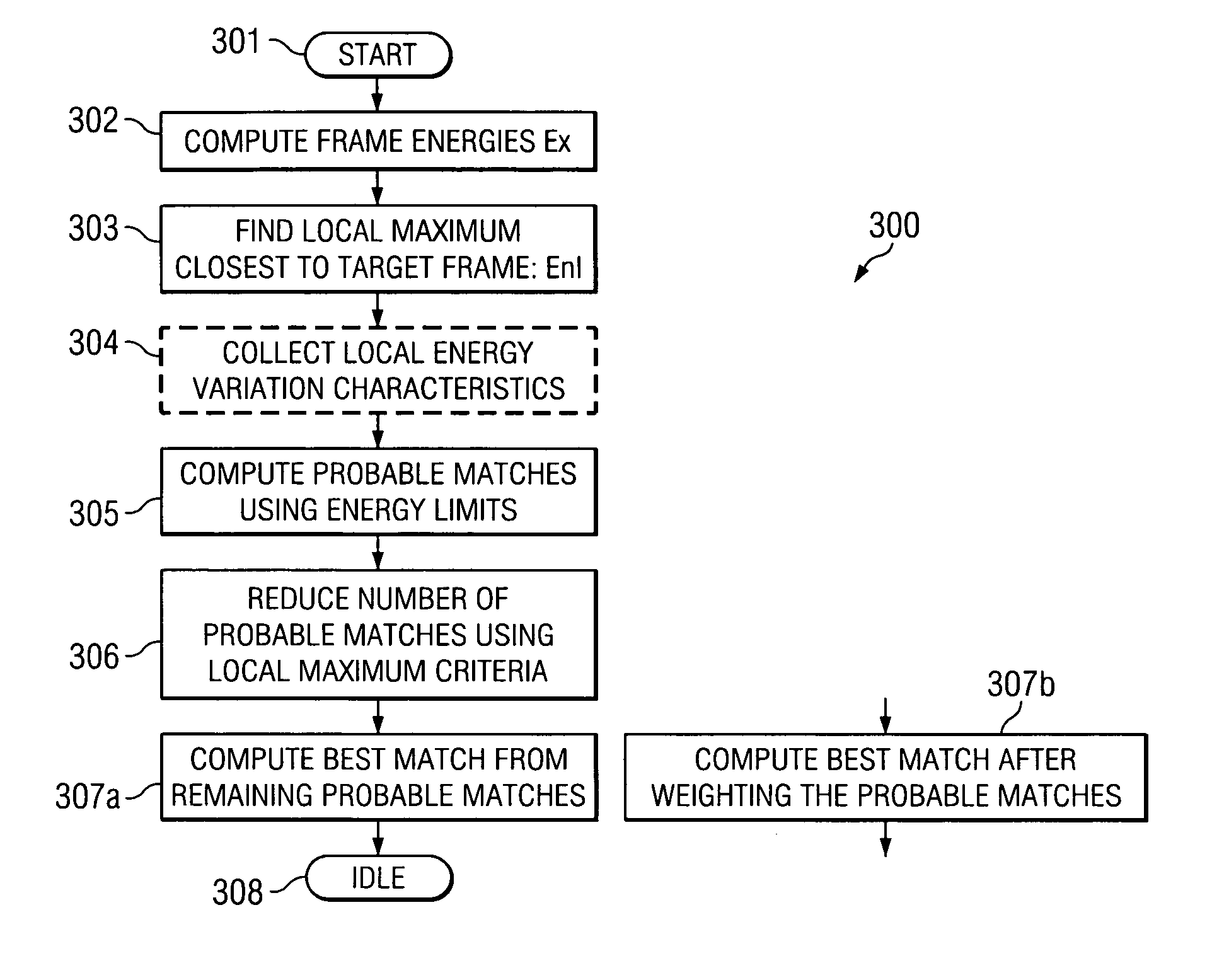

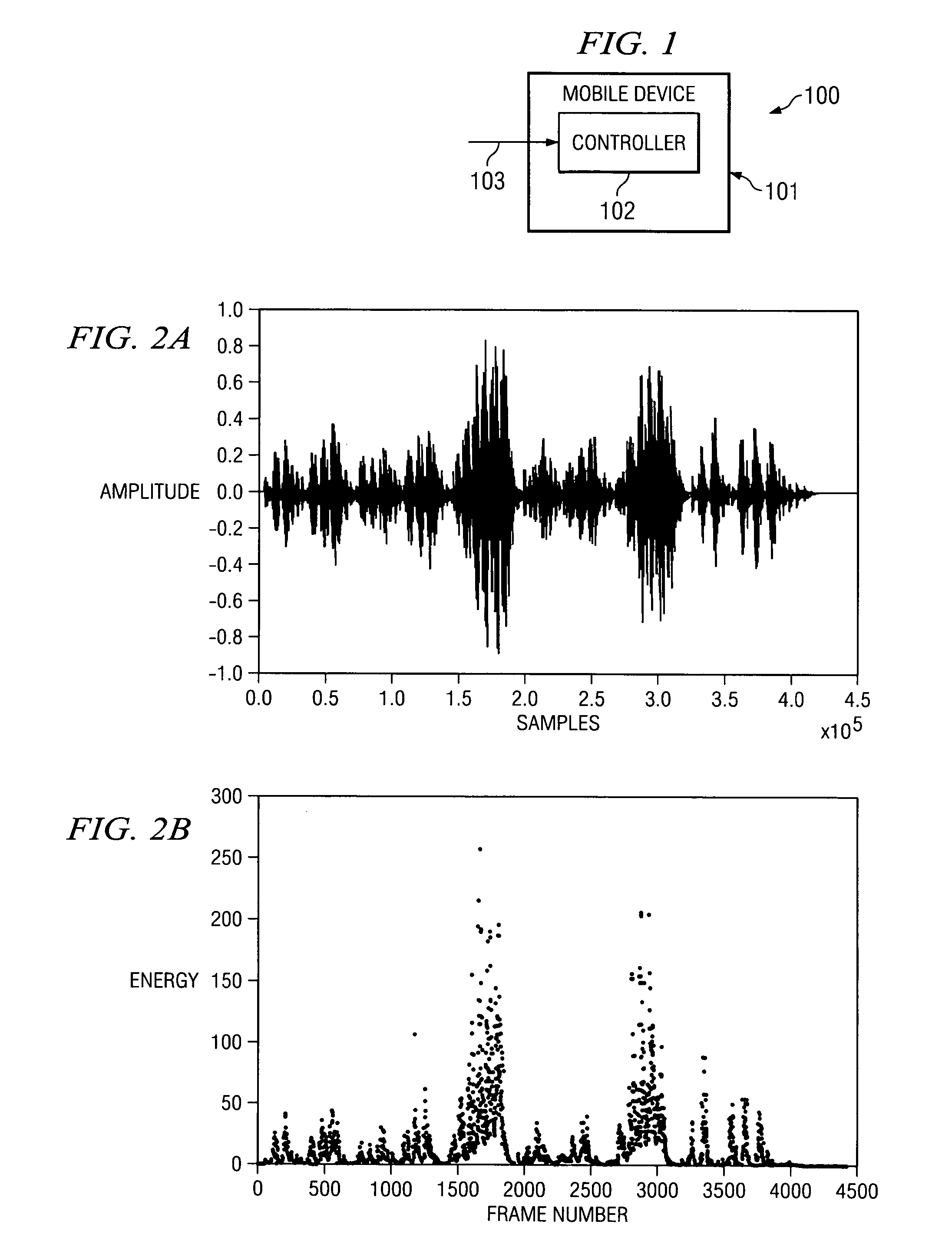

Energy-based audio pattern recognition

ActiveUS20050273326A1Electrophonic musical instrumentsSpeech recognitionPattern recognitionPattern matching

An energy-based pattern recognition algorithm receives the input frames of an audio signal and a test frame sequence and returns a best match in the audio signal to the given test frame sequence. The energy of each input frame is computed, and input frames for which the energy is within a predetermined degree of closeness to the local maximum energy within the test frame sequence are identified as probable matches. Probable matches are then eliminated if the respective probable match does not correspond to a local maximum within a respective neighborhood of adjacent frames. The difference between overall energy for frames neighboring the remaining probable matches and the test frame sequence is computed as a percentage, with the minimum percent deviation in energy from the test frame sequence being returned as the best pattern match. Local signal characteristic matching may be employed to refine matching.

Owner:STMICROELECTRONICS ASIA PACIFIC PTE

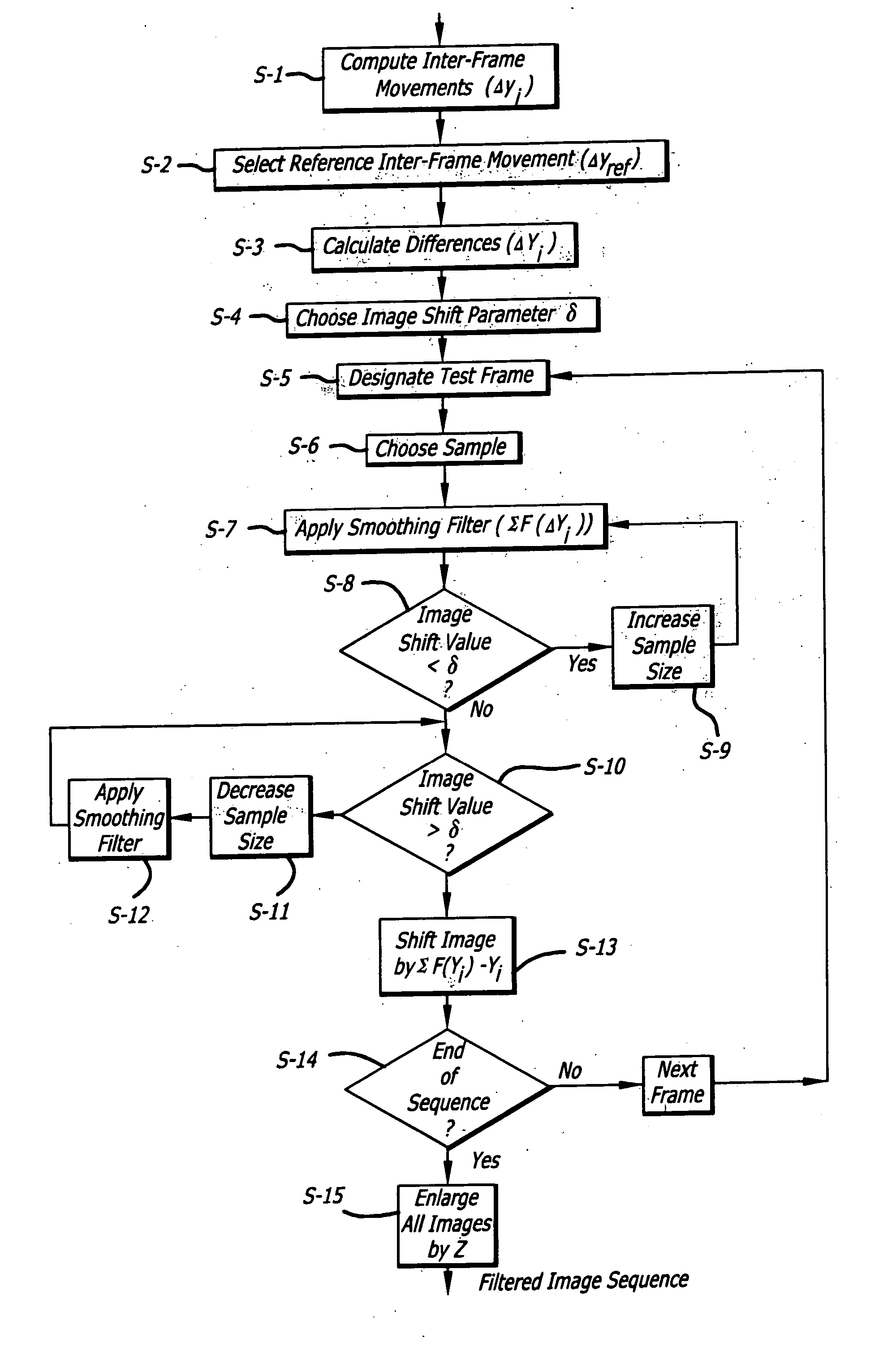

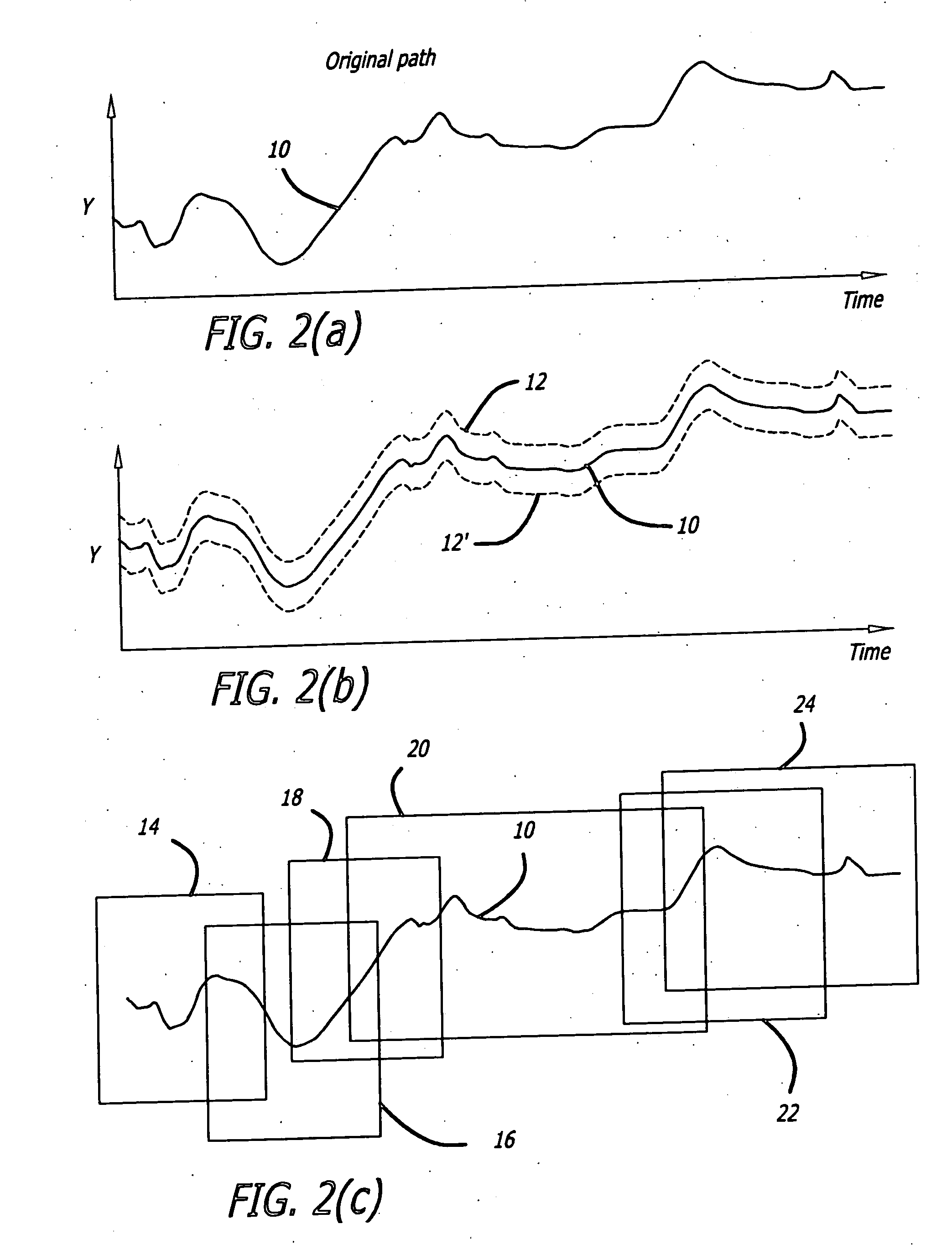

Method for image stabilization by adaptive filtering

ActiveUS20050213840A1Television system detailsCharacter and pattern recognitionTest frameImage stabilization

A method for removing undesired motion from a sequential plurality of related images utilizes adaptive filtering of image motion to determine image shifts. Differences between sequential image motions are taken with respect to a reference frame and a smoothing filter is applied to such differences of a sample of images adjacent a test image. Image shift values are calculated by subtracting the difference associated with a test frame from a filtered sample that includes the test frame. The image shift values are compared to an image shift parameter and sample sizes adjusted and image shift values calculated in accordance with the adjusted sample sizes so that image stability is obtained without boundary flicker.

Owner:HTC CORP

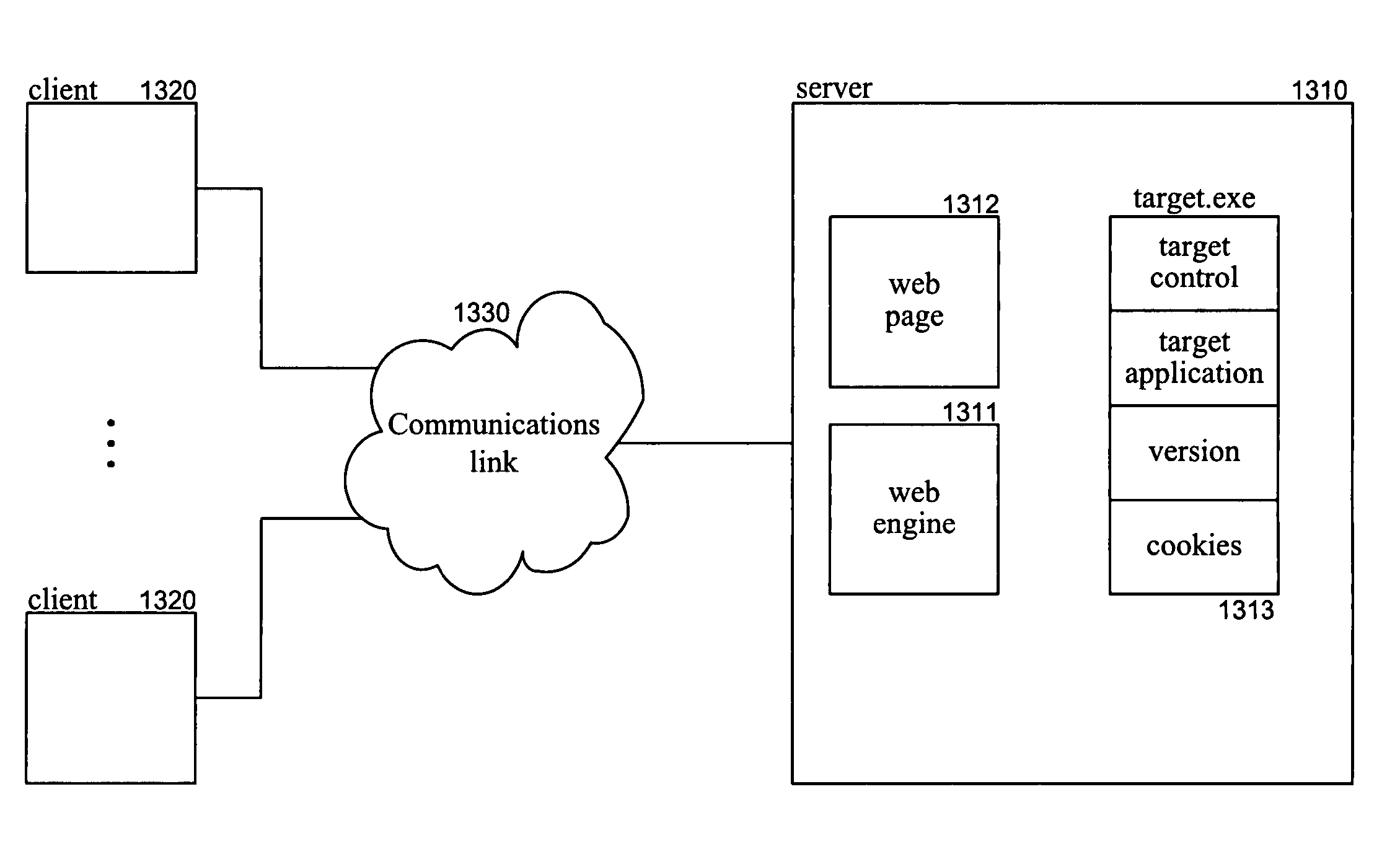

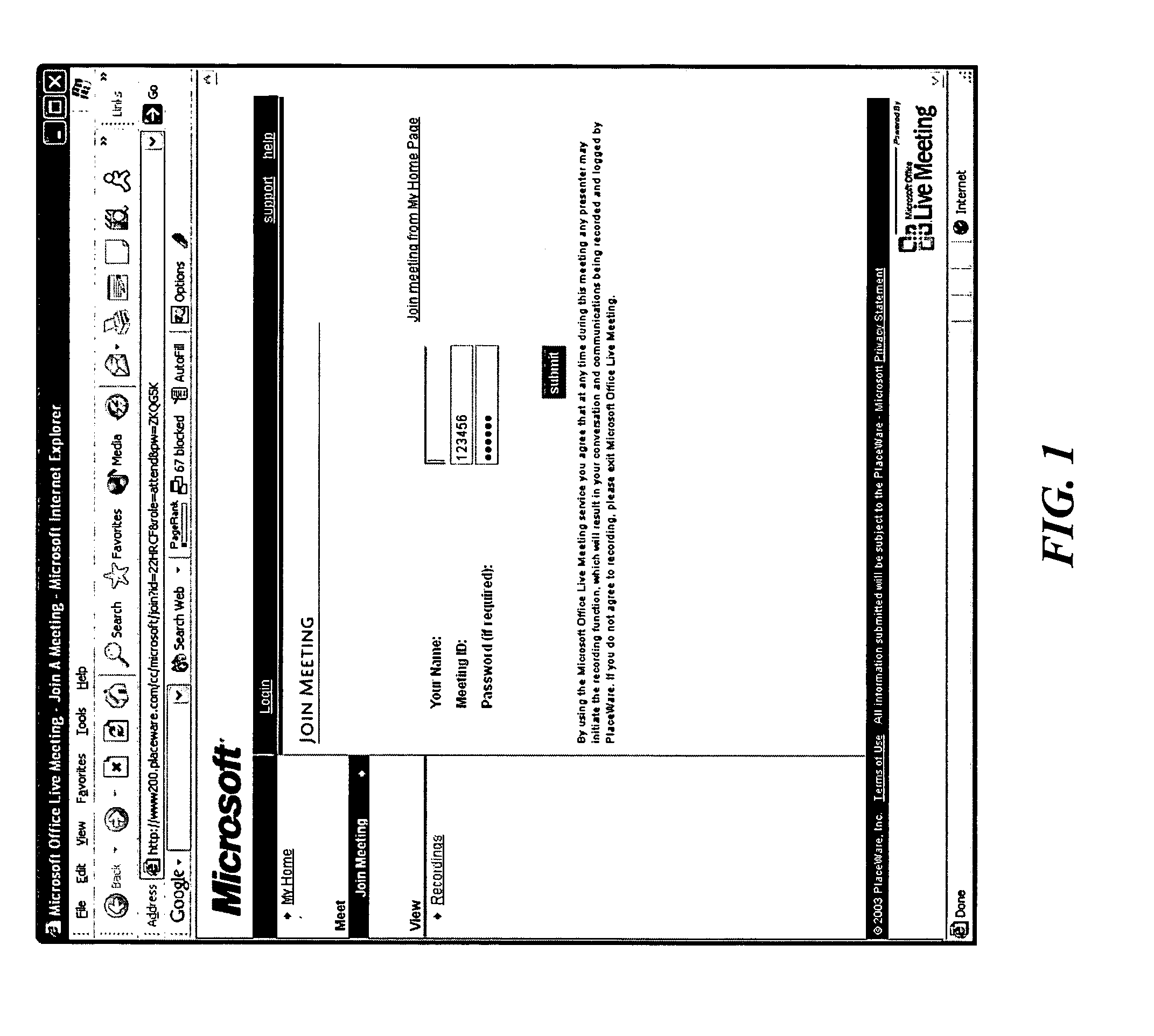

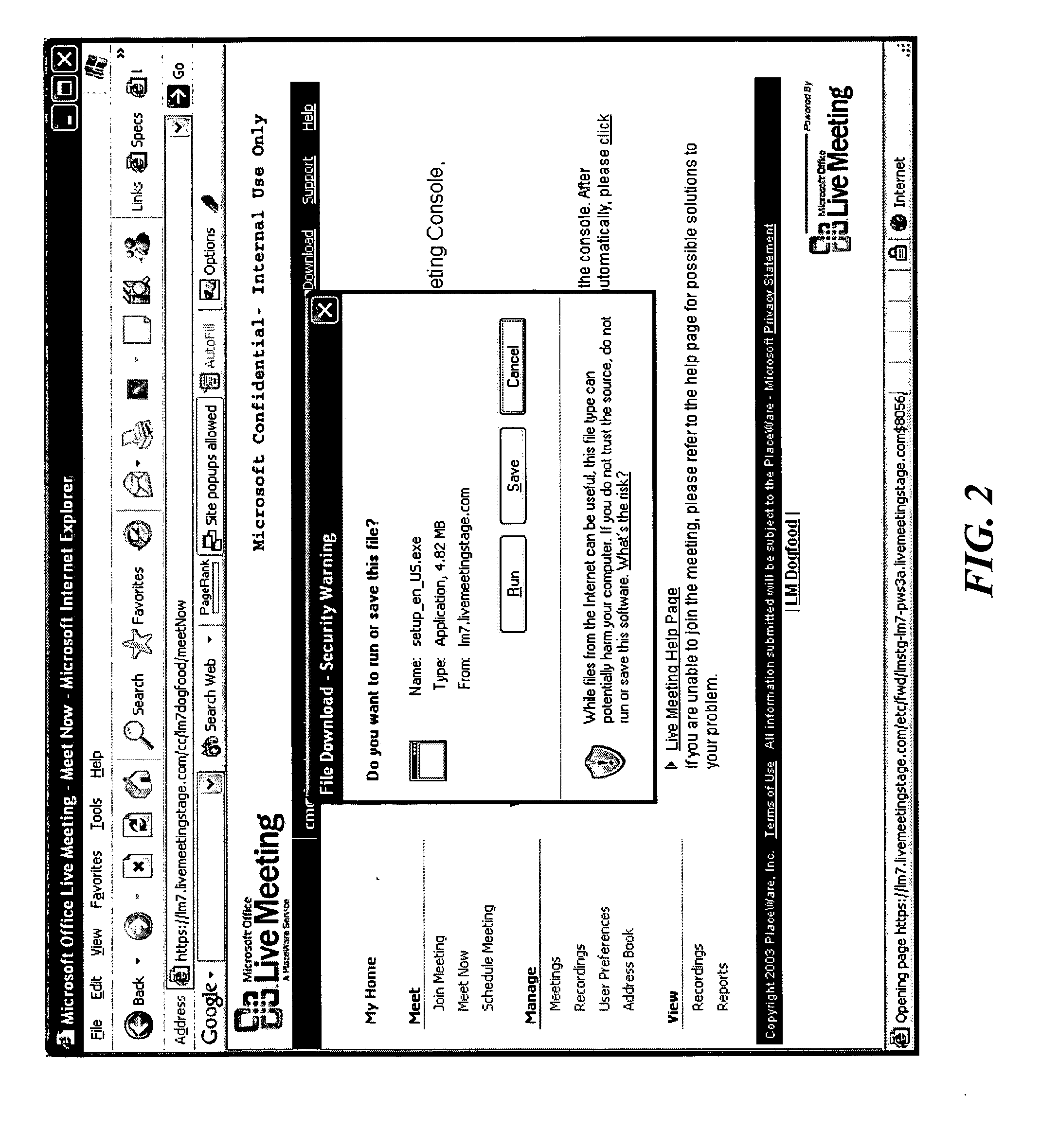

Method and system for installing applications via a display page

InactiveUS20060212548A1Multiple digital computer combinationsProgram loading/initiatingTarget controlTest frame

A method and system for downloading via a browser a target application using a target control is provided. An installation system provides a web page that is downloaded from a web server to a computer system on which the target application is to be installed. The web page includes a setup frame, a test frame, and an execution frame. The test frame determines whether the target application is installed at the computer system and, if not, effects the invocation of a download / installation component to download and install the target application and an associated target control. The test frame is periodically reloaded and checks to see if the target control is installed. If the target control is installed, then the test frame notifies the execution frame. The execution frame then invokes the target control to effect the launching of the target application.

Owner:MICROSOFT TECH LICENSING LLC

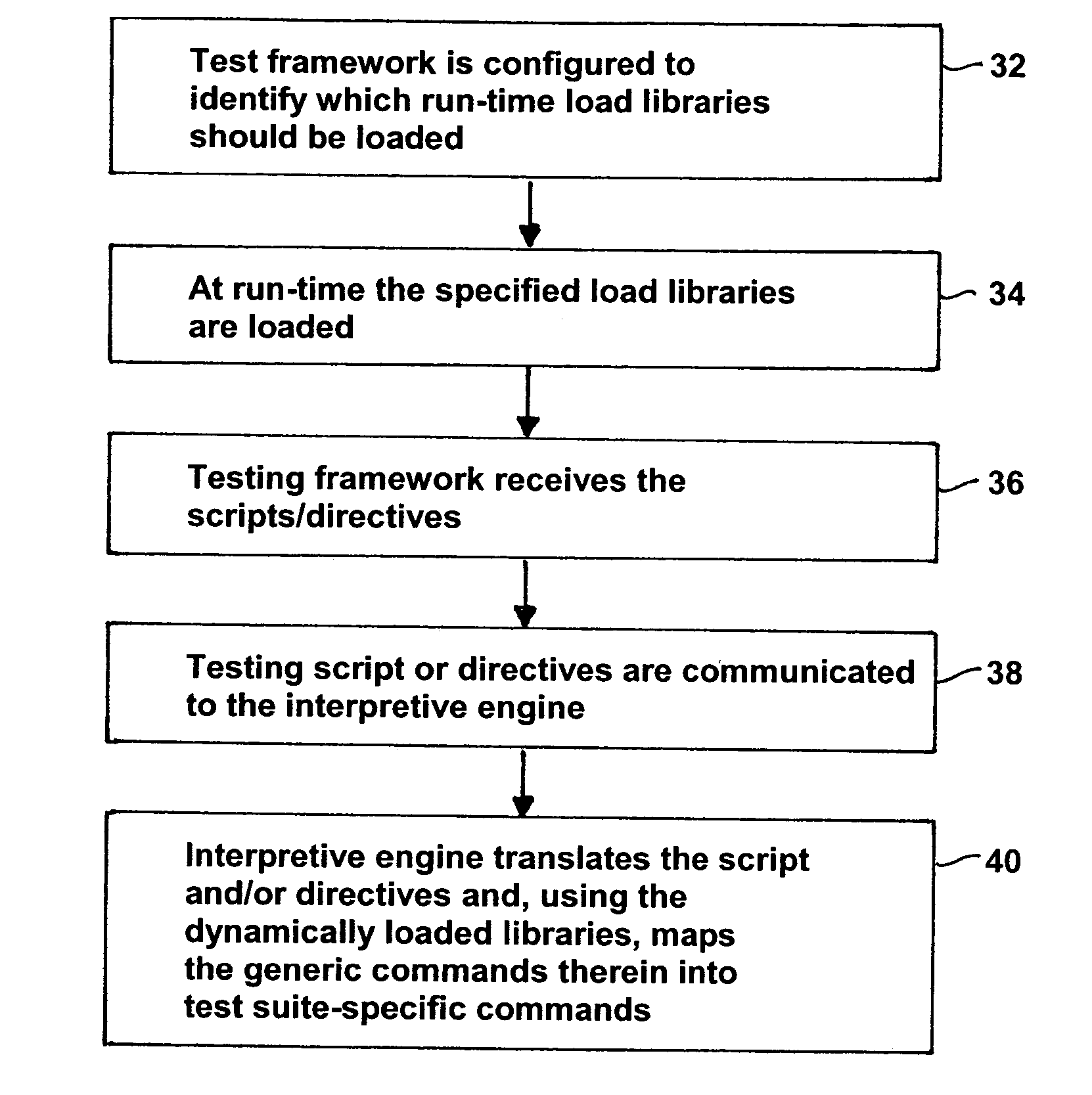

Generic user interface testing framework with load-time libraries

InactiveUS20050229161A1Increase flexibilityImprove efficiencyError detection/correctionSoftware engineeringComputer hardwareLoad time

A system and method for providing a generic user interface testing framework, together with a mechanism such that libraries which are applicable to the desired application(s) can be qualified, and the test framework will load those libraries at execution time. With the ability to dynamically load only the desired libraries one is able to plug in new testing modules as needed, thus being able to accommodate new product qualification efforts with greater flexibility and efficiency.

Owner:BEA SYST INC

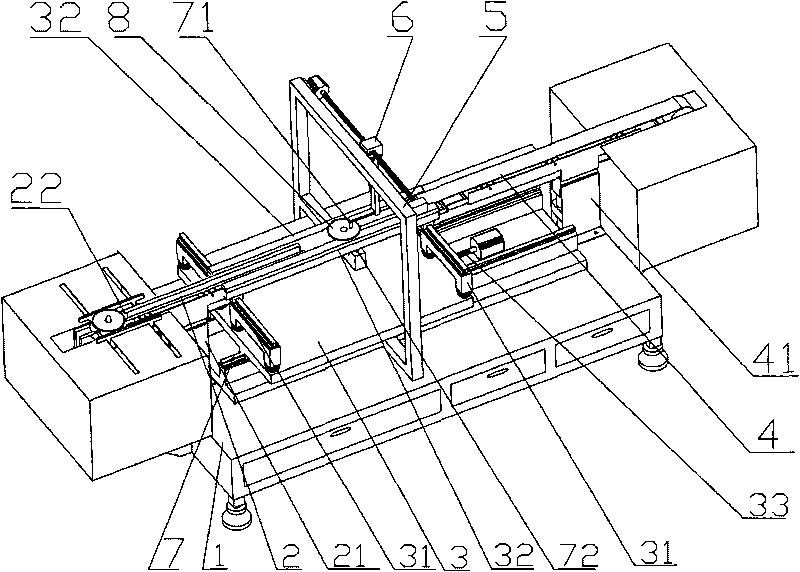

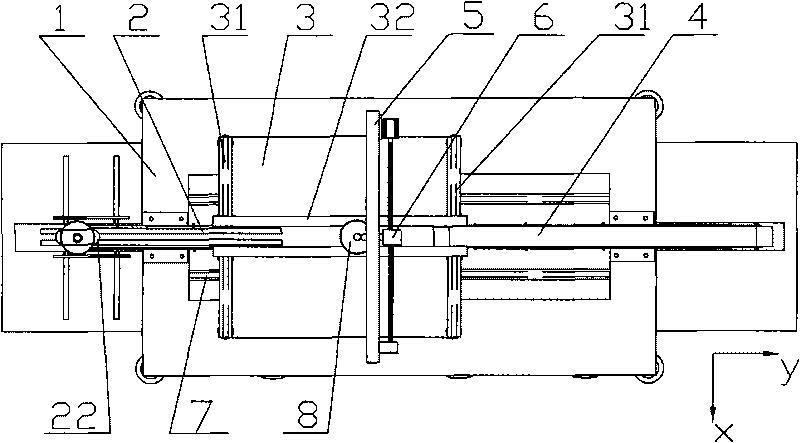

Automatic test device of flatness and thickness of metal sheet

InactiveCN101726243AGuaranteed correctnessRealize coordinated and continuous operationElectric/magnetic roughness/irregularity measurementsElectrical/magnetic thickness measurementsTest efficiencyAutomatic test equipment

The invention relates to an automatic test device of the flatness and thickness of a metal sheet, which comprises a machine frame, a feeding mechanism, a test platform and a discharging mechanism. The machine frame and the test platform are connected through a Y-directional track. The test platform comprises a test frame, guide rails, a test cross beam, a cantilever fixing frame, a cantilever, an upper test probe, a lower test probe, a Y-directional ball screw mechanism and a measuring circuit. The automatic test device has the following beneficial effects that: the test is accurate; the test efficiency and the test precision are improved because the probes always cover the effective test range of a saw blade; mechanical and electrical integration technology is fully used, the structure is simple, the operation and maintenance are convenient, and the application in the field of the test of the flatness and thickness of other metals can be realized with a little improvement, and the promotion and use are easy; and an eddy induction principle is used to realize the test of the flatness and the thickness of the metal sheet, the interference of water and other non-metal impurities on the saw blade is eliminated effectively, precise positioning of the saw blade is not required in test, the price is low, and the operation is simple.

Owner:WUHAN TEXTILE UNIV

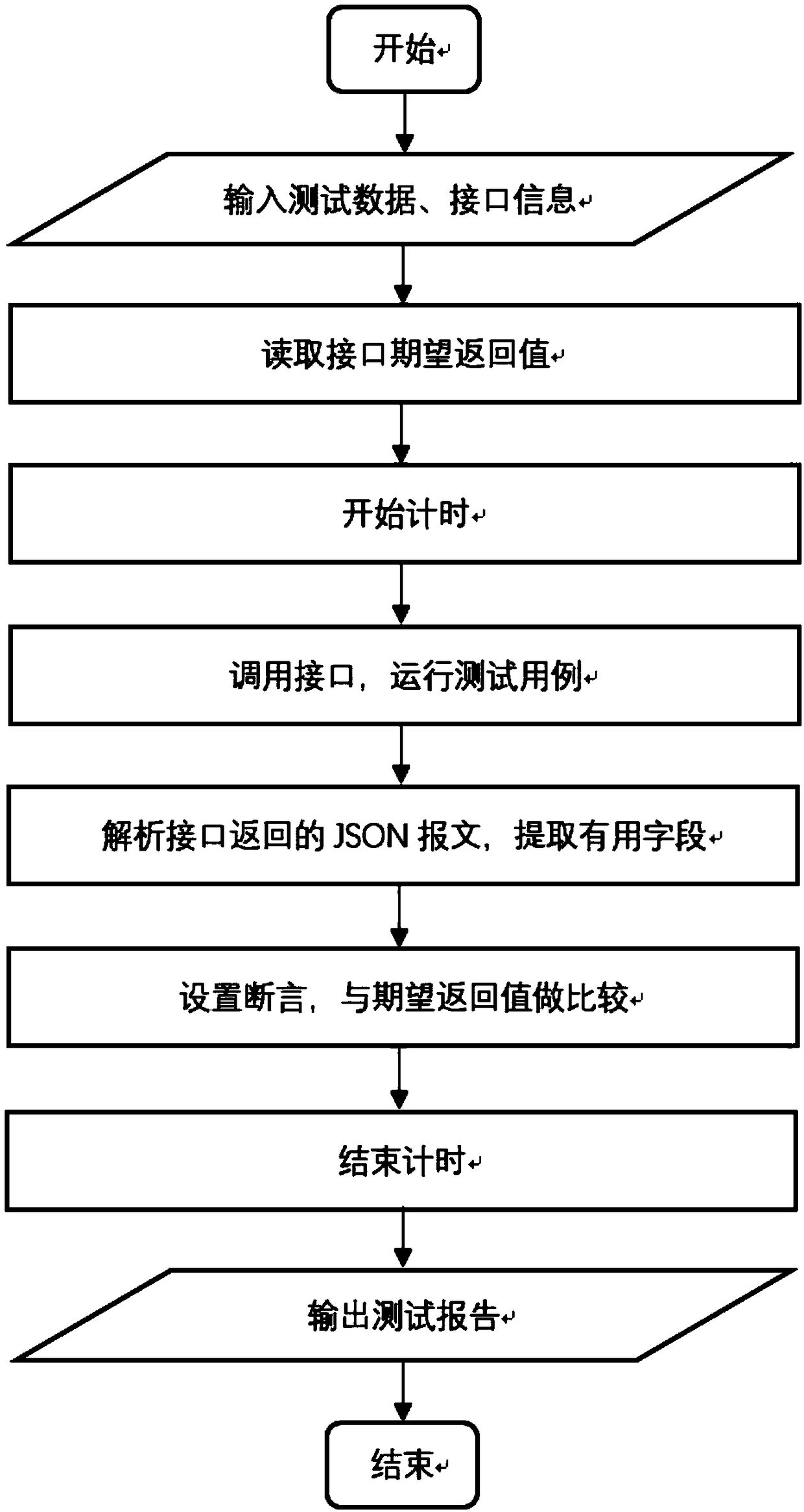

Python-based interface automation test method

ActiveCN109189684AReduced execution timeImprove efficiency in locating defectsSoftware testing/debuggingTest scriptTest frame

The invention discloses a Python-based interface automation test method, comprising the steps of defining an interface template and a test case template, reading the test case, calling the interface to send a request, analyzing the interface return message and outputting a test report. The Python-based interface automation test method of the invention follows the basic principle of the test framework, separates the business logic from the test script, separates the test script from the test data, can be changed at any time according to requirements, and can greatly reduce the requirement on the coding level of the tester.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com