Patents

Literature

4560results about "Weighing by removing component" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

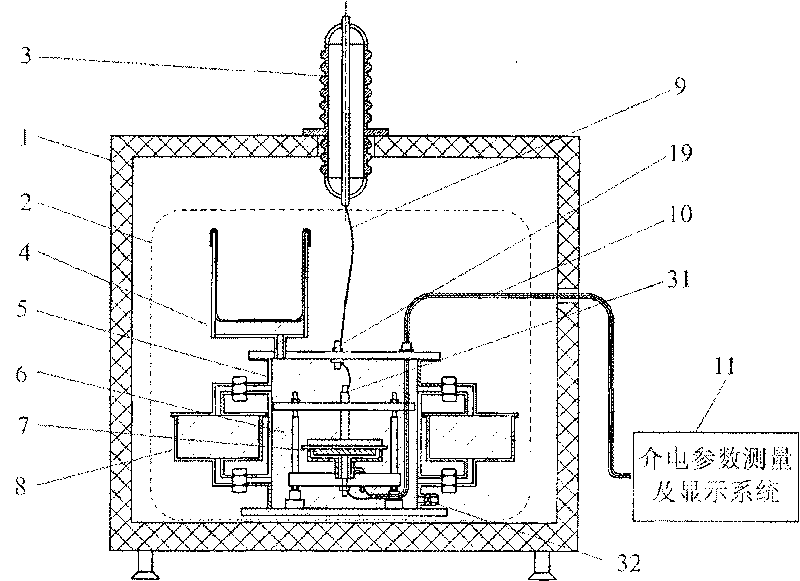

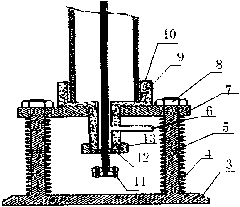

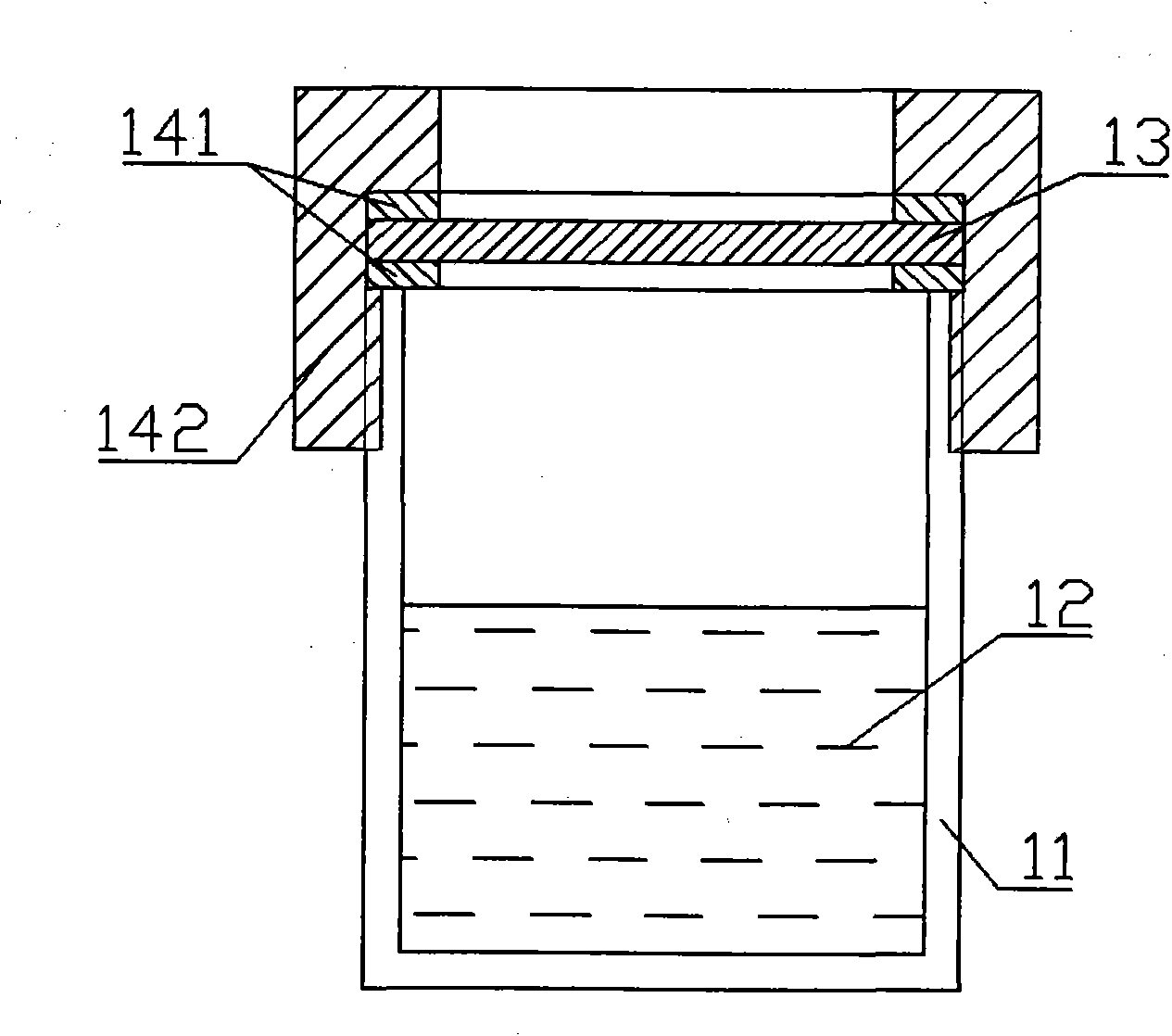

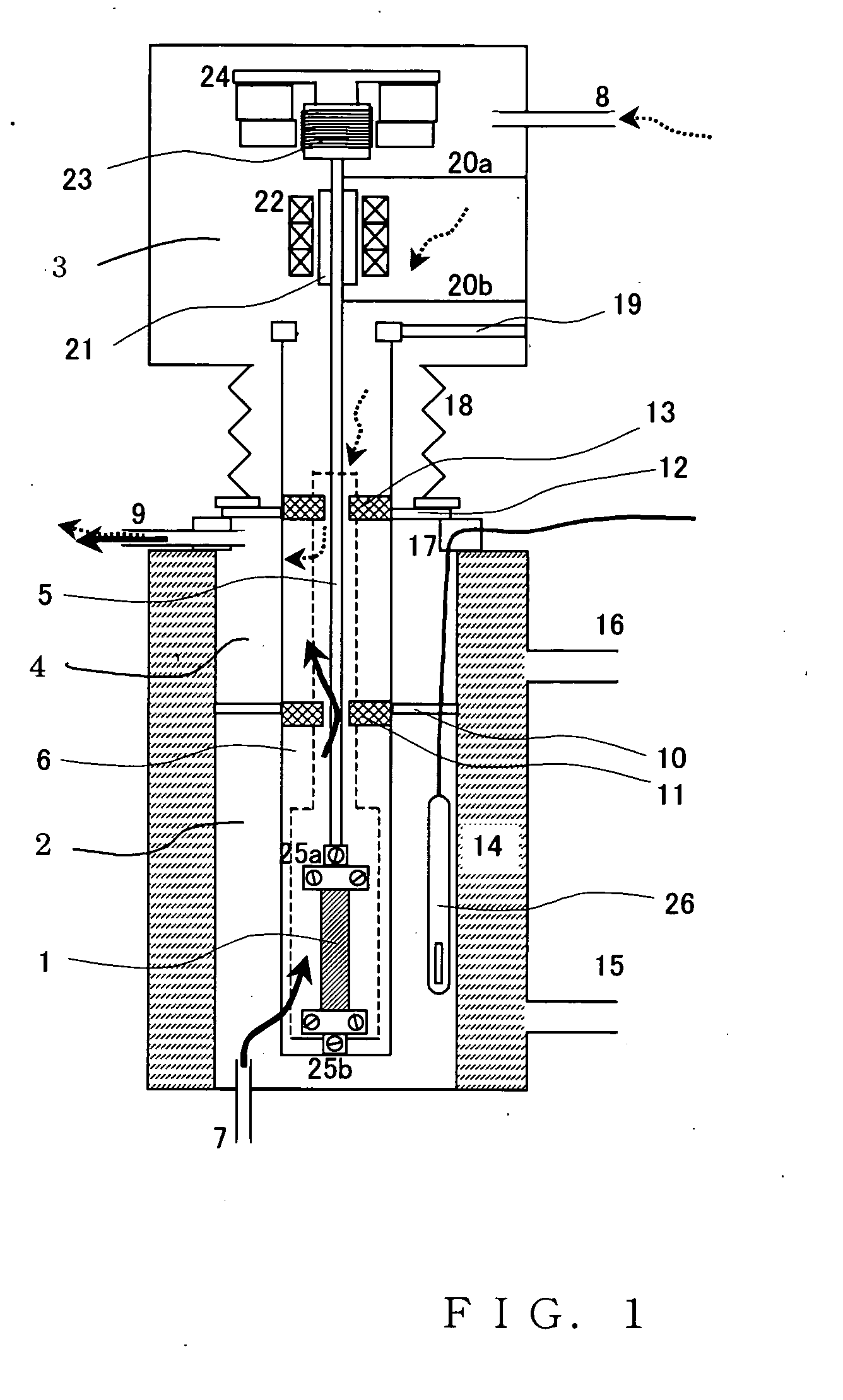

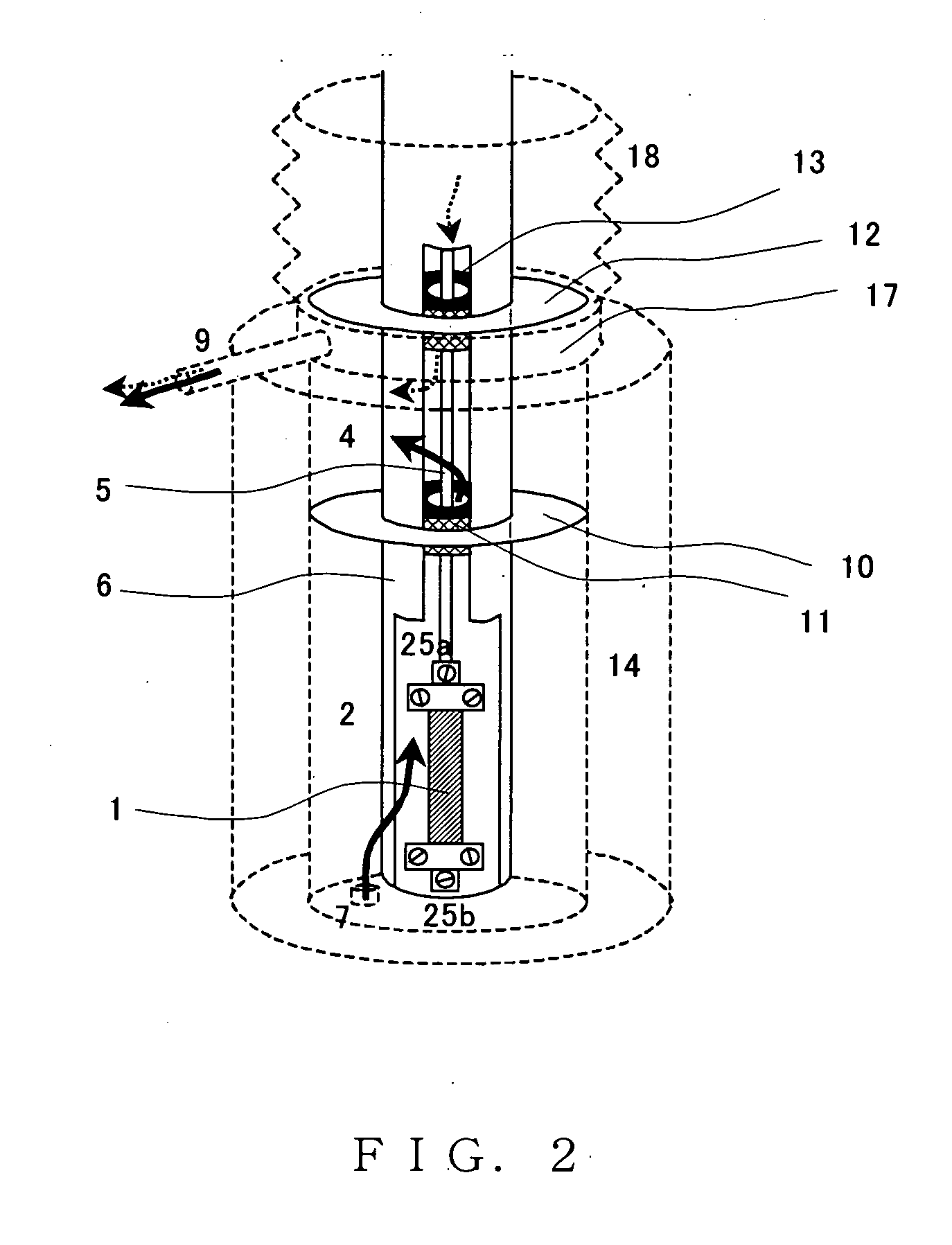

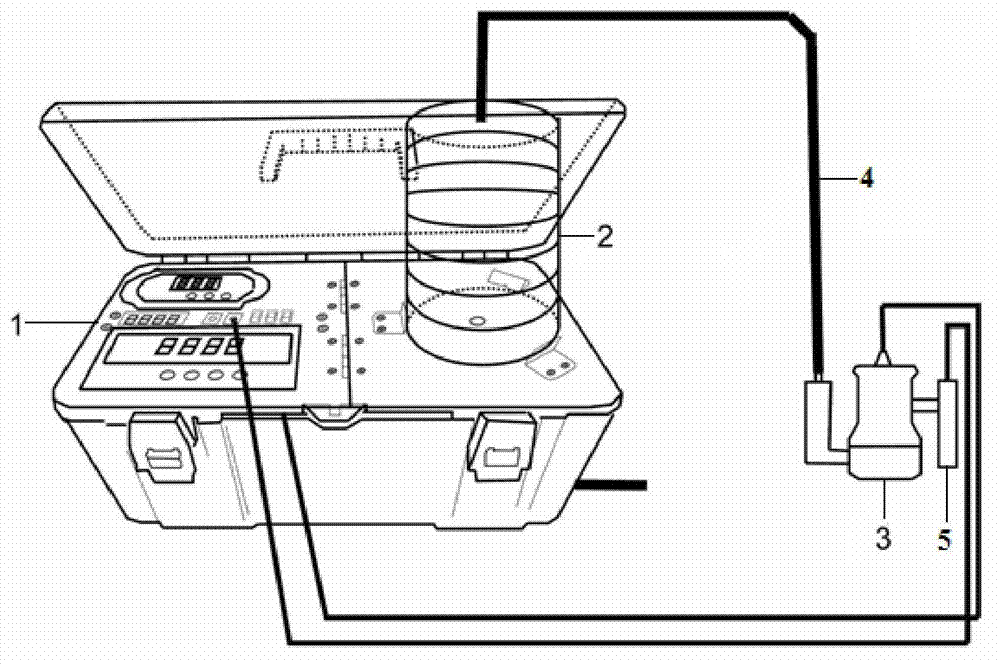

Experimental device and experimental method for transformer oilpaper insulating thermal ageing

InactiveCN101713721AWeighing by removing componentWeather/light/corrosion resistanceThermal ageingElectricity

Owner:XI AN JIAOTONG UNIV

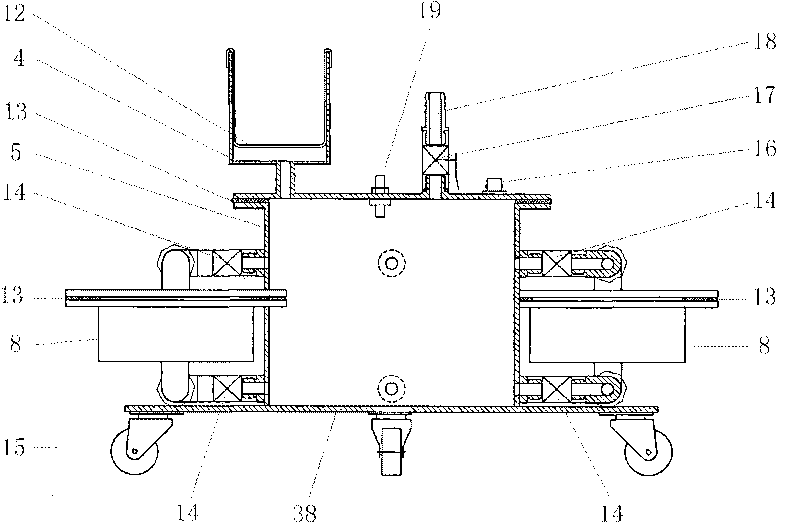

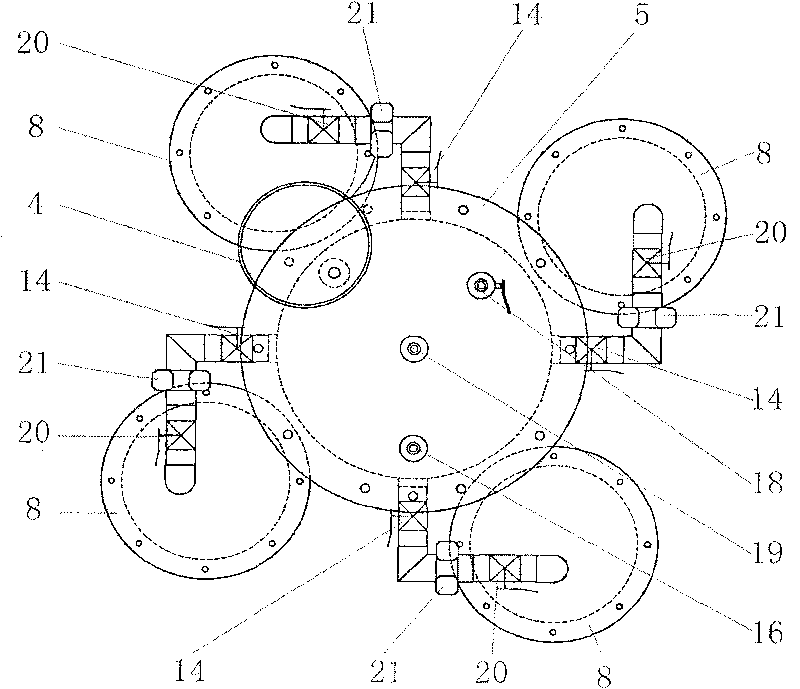

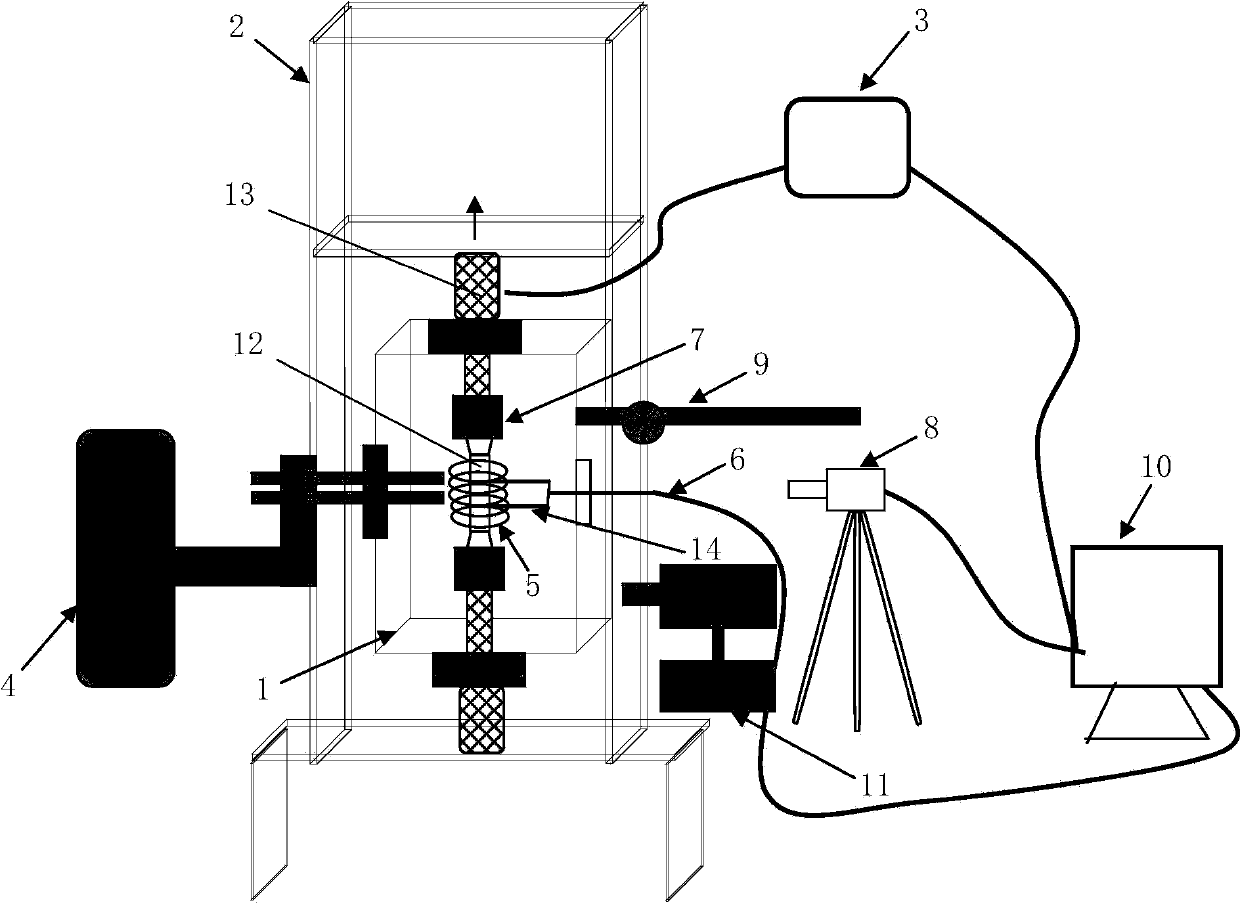

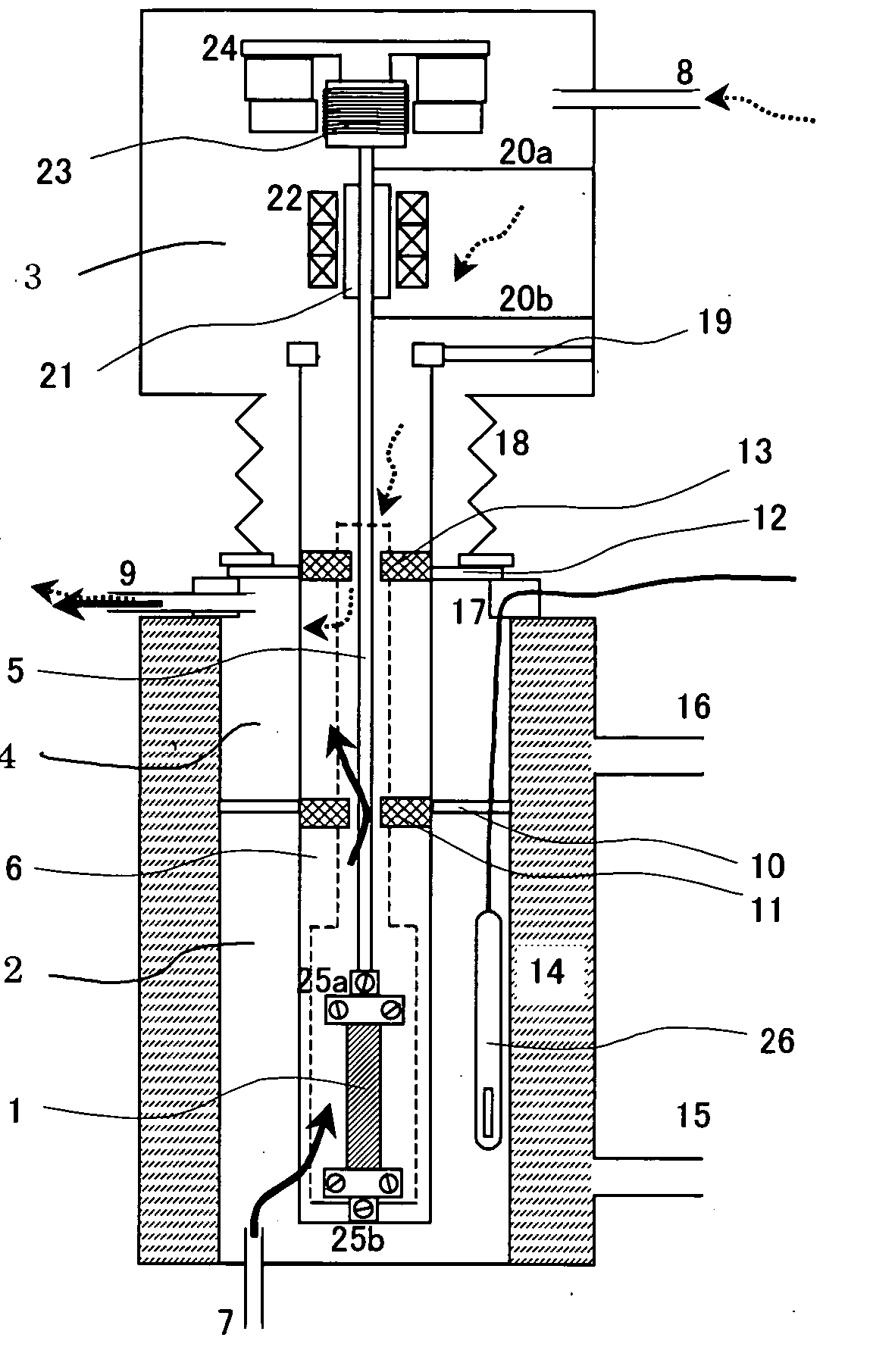

Thermo-mechanical-environmental coupling effect testing device and application from room temperature to ultrahigh temperature

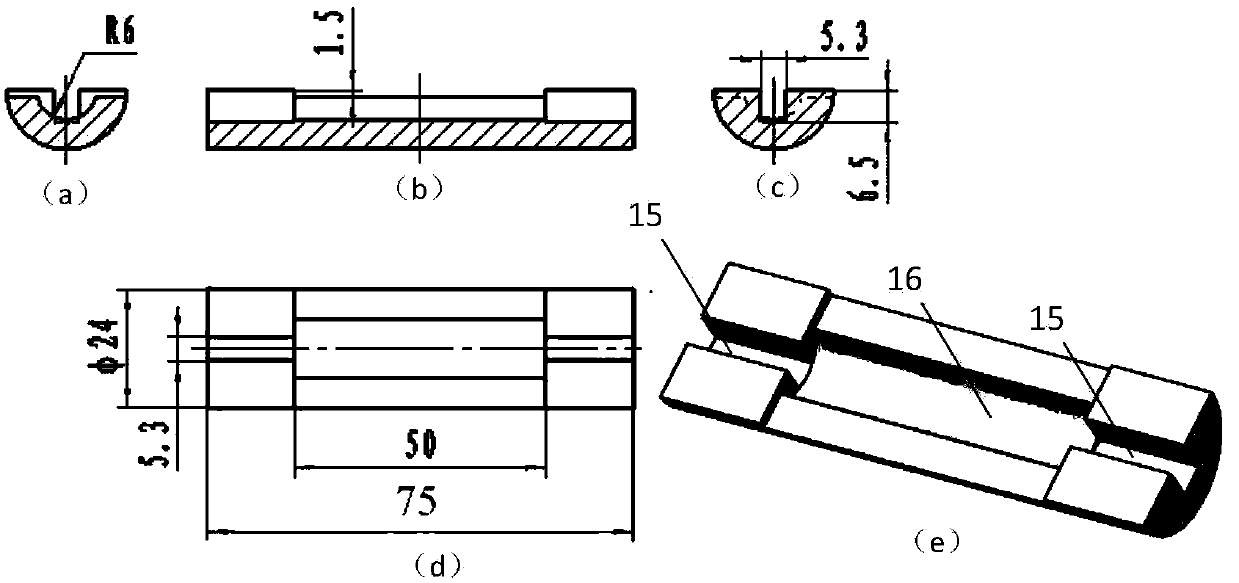

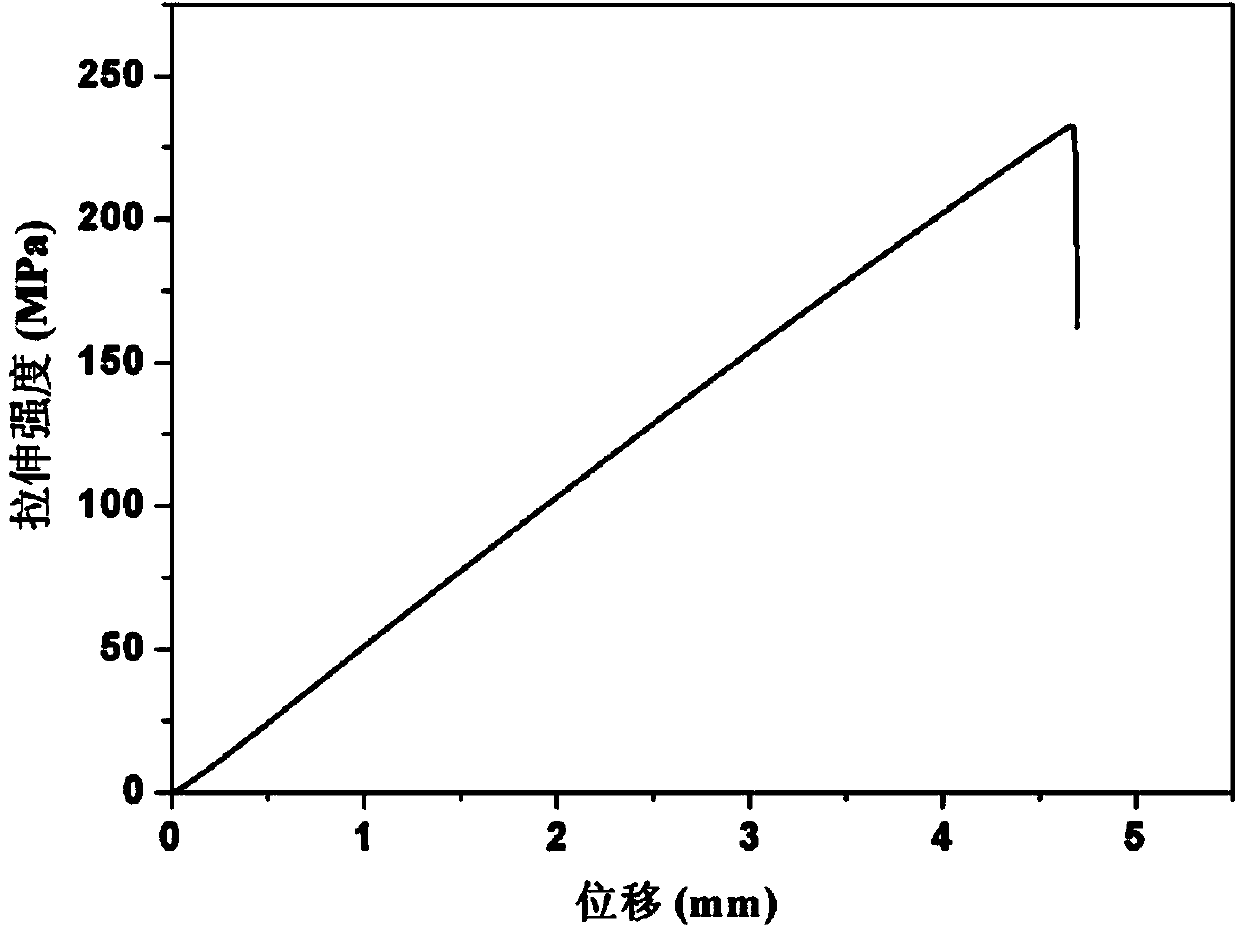

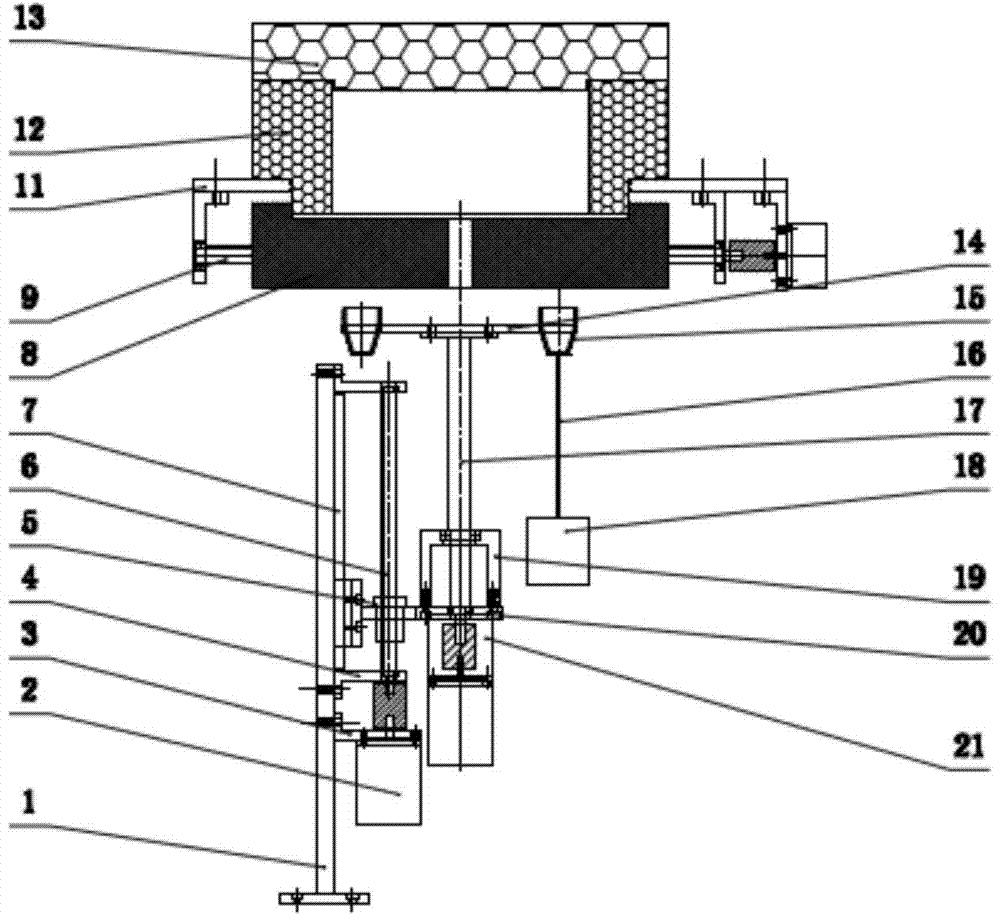

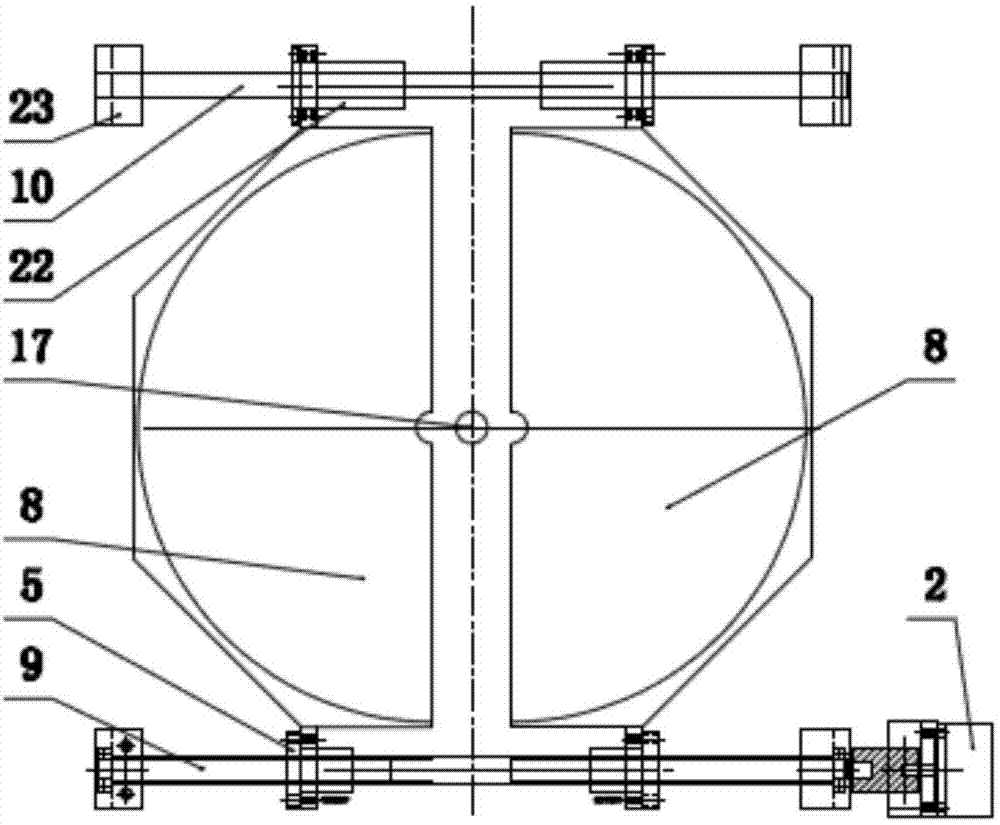

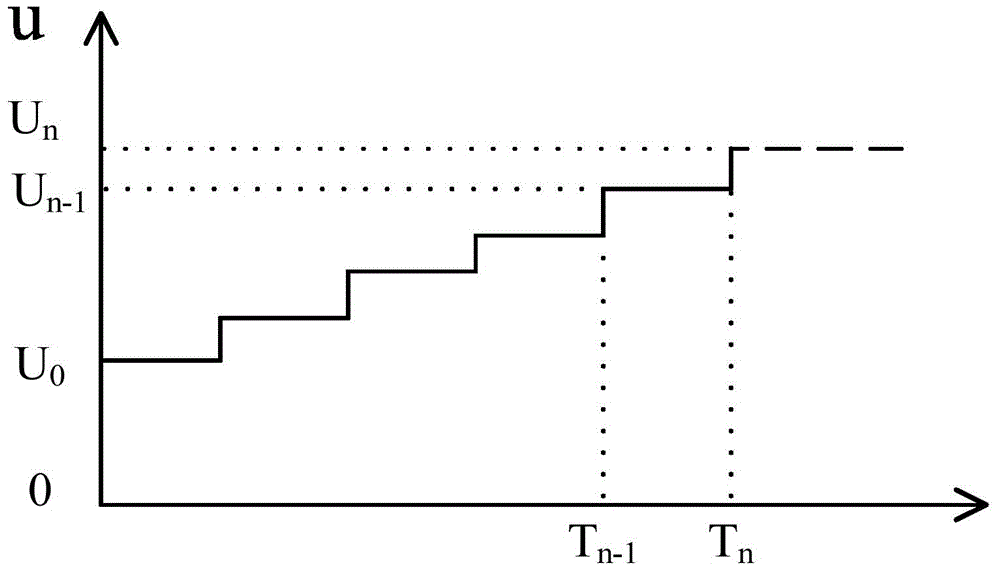

ActiveCN104215521APrecise temperature controlTestable tensile strengthWeighing by removing componentMaterial strength using tensile/compressive forcesPower control systemTest fixture

The invention relates to the field of test of mechanical properties of materials and in particular relates to a thermo-mechanical-environmental coupling effect testing device and application from room temperature to ultrahigh temperature. The device comprises an electronic universal testing machine, a loading control system, a power supply control system, an induction heater, a strain measurement system, a sample clamp, a temperature measuring system, a pressure control system, a display and analysis system and a vacuum system, wherein a vacuum cavity in the electronic universal testing machine is in a fully water-cooled design, and various functional windows, such as a sensor connector of the clamp and the electronic universal testing machine, an infrared or thermocouple temperature measuring opening of the temperature measuring system, a pressure control opening of the pressure control system, an induction power supply introduction opening of the power supply control system, an extensometer introduction opening of the strain measurement system and a connector of the vacuum system and the vacuum cavity, are reserved in different parts of the vacuum cavity. The device disclosed by the invention can quantitatively research the thermo-mechanical-environmental coupling effect and has the advantages of diversified tested mechanical property parameters, high sample heating and cooling speed and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

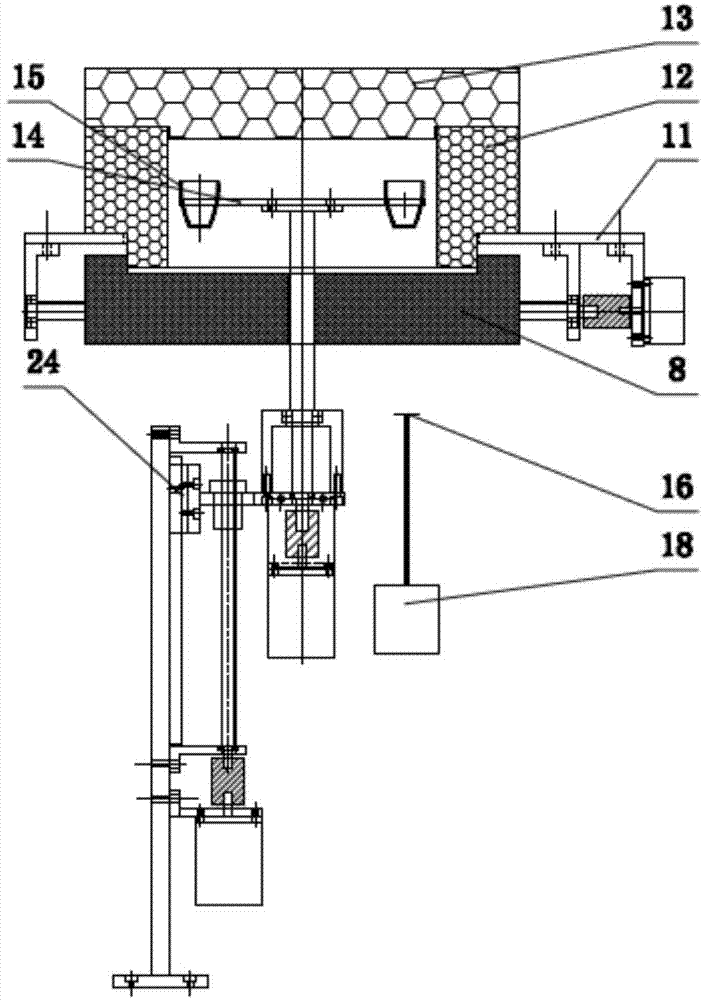

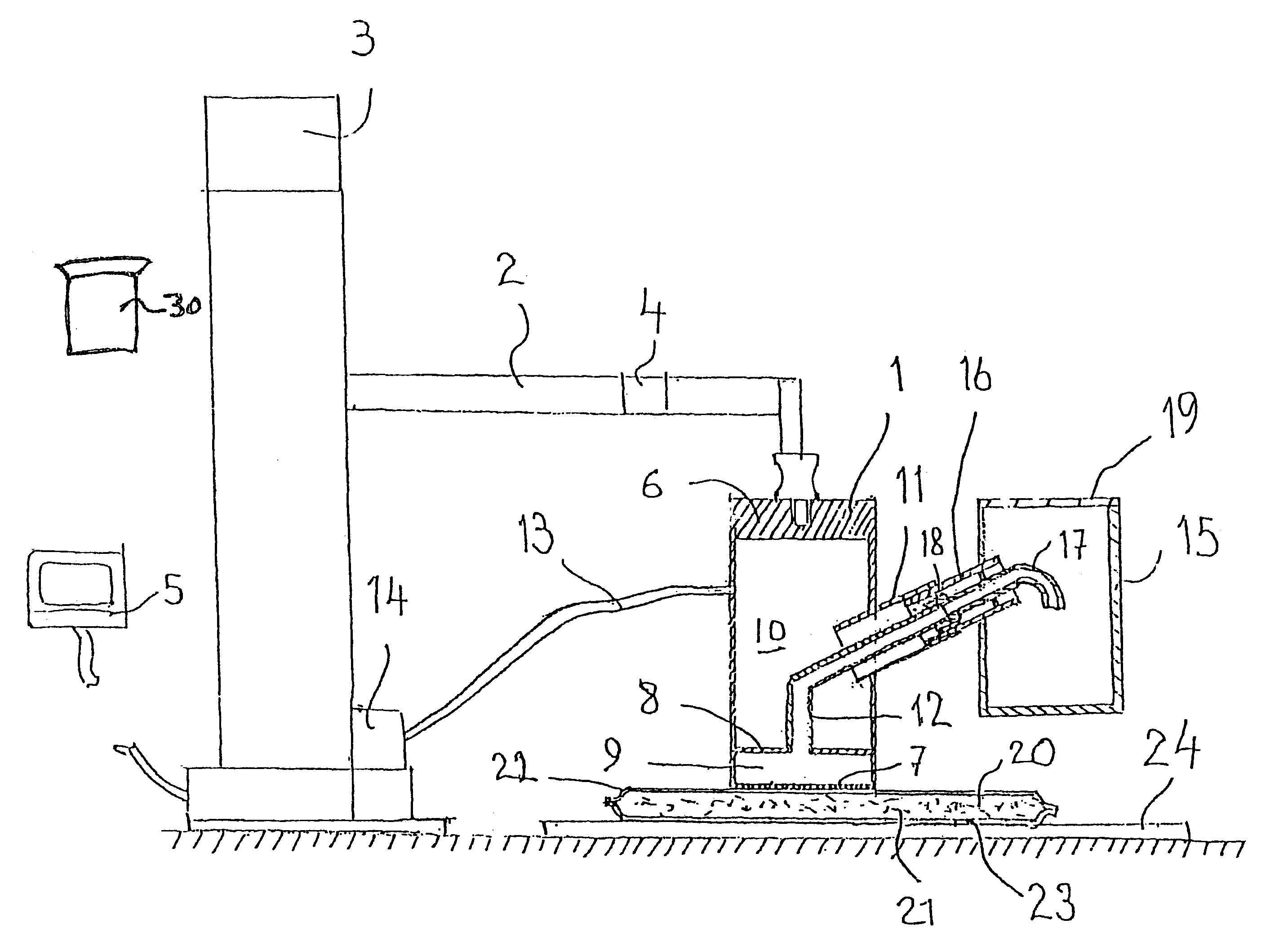

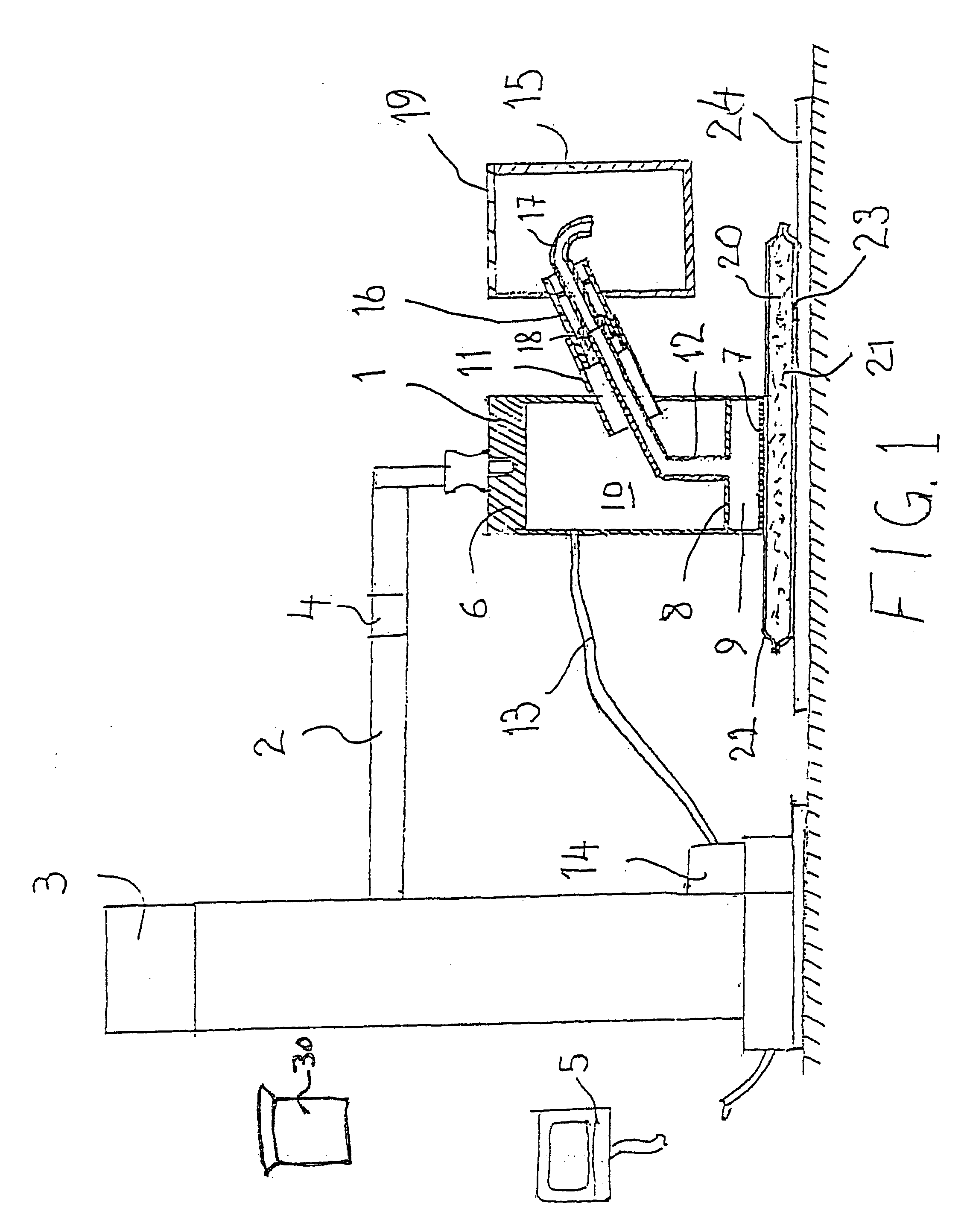

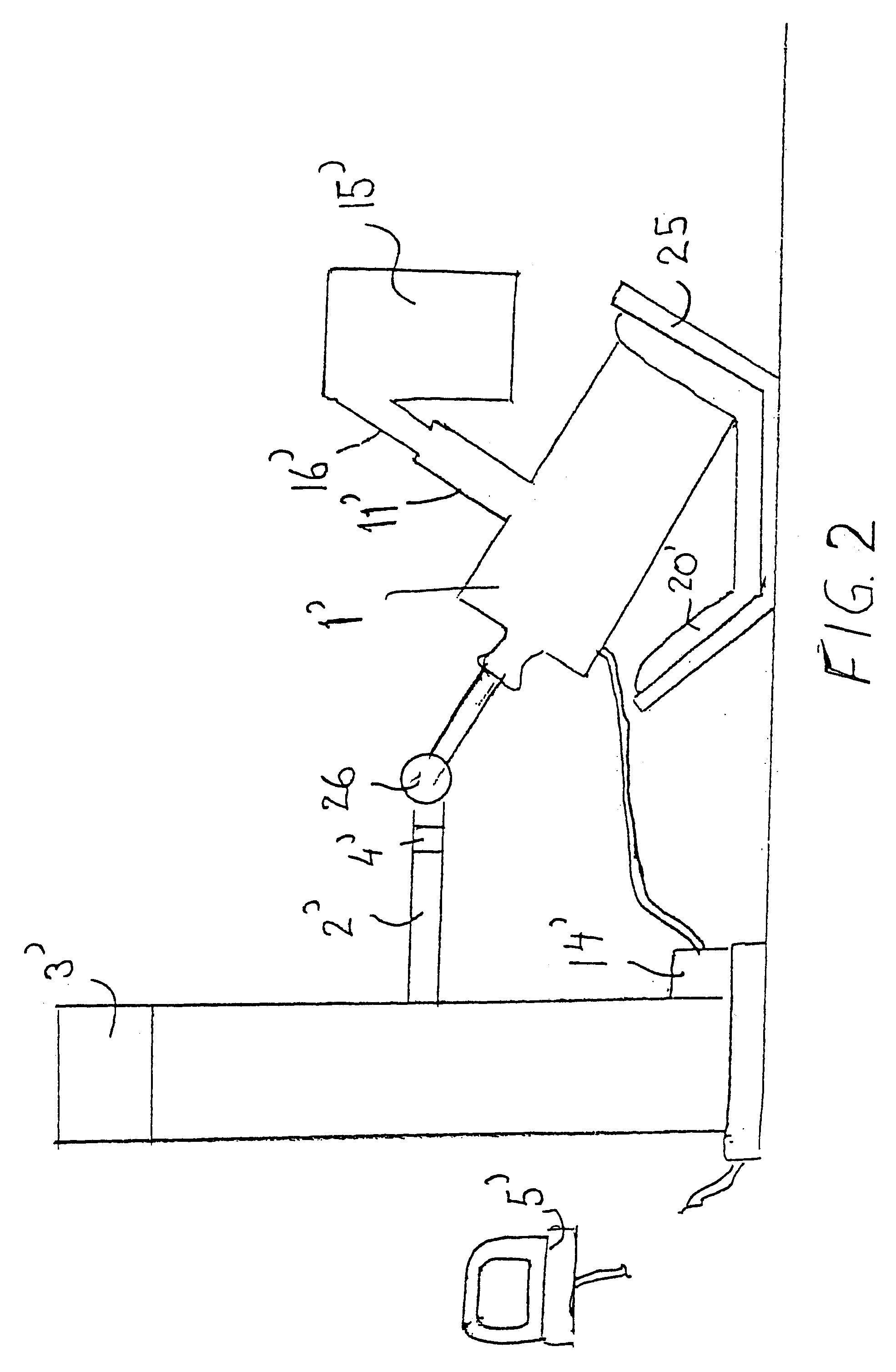

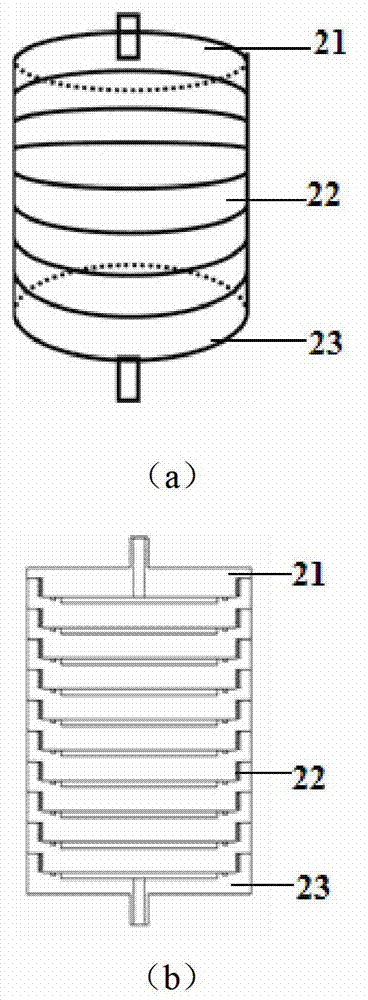

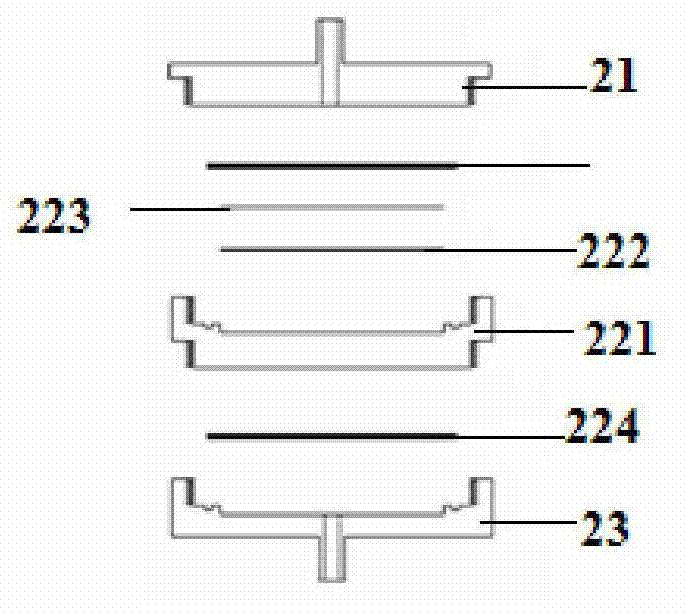

Automatic test equipment for volatiles of bituminous coal

InactiveCN104749066AImprove scienceIncrease authenticityWeighing by removing componentAutomatic test equipmentCrucible

The invention discloses automatic test equipment for the volatiles of bituminous coal. The automatic test equipment comprises a bituminous coal heating module and a bituminous coal weighing module, wherein the bituminous coal heating module has the function of automatically opening / closing a furnace door, and the bituminous coal weighing module is capable of automatically weighing the masses of each crucible containing bituminous coal before and after an experiment; experimenters only need to place the crucibles on a crucible tray and do not need to participate in the later experiment process. The invention discloses automatic test equipment which is simple and compact in structure, convenient to operate, capable of automatically weighing the masses of each crucible before and after the experiment, and capable of carrying out a volatile experiment on 20 crucibles simultaneously.

Owner:CHANGZHOU UNIV

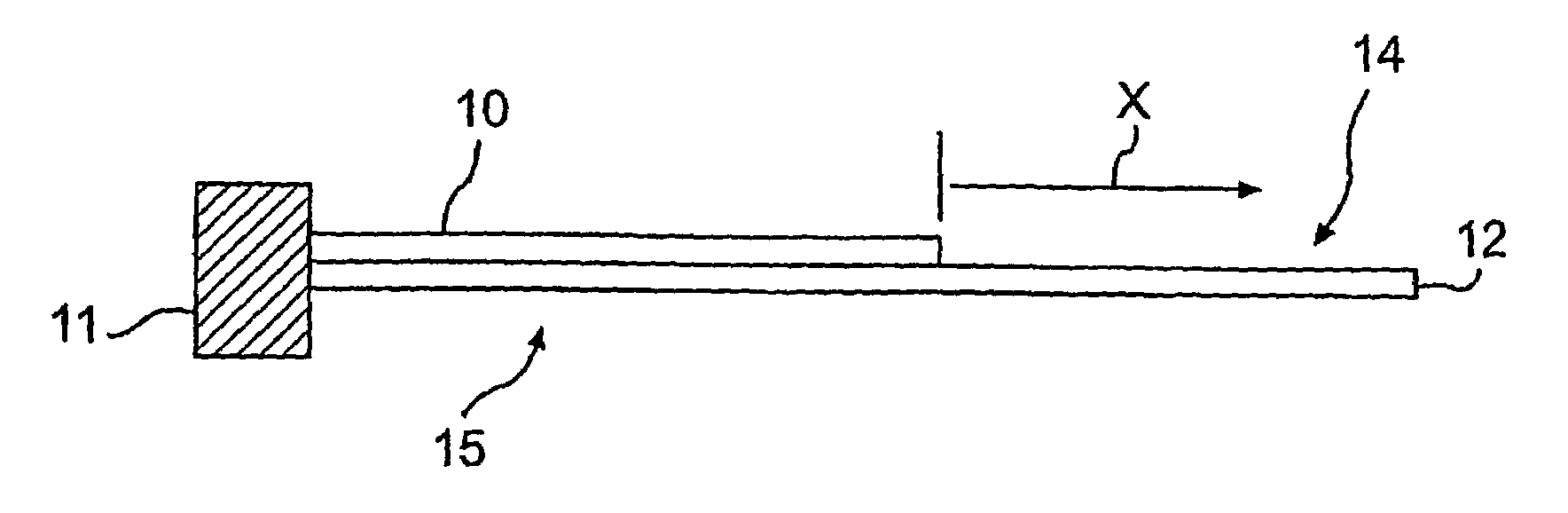

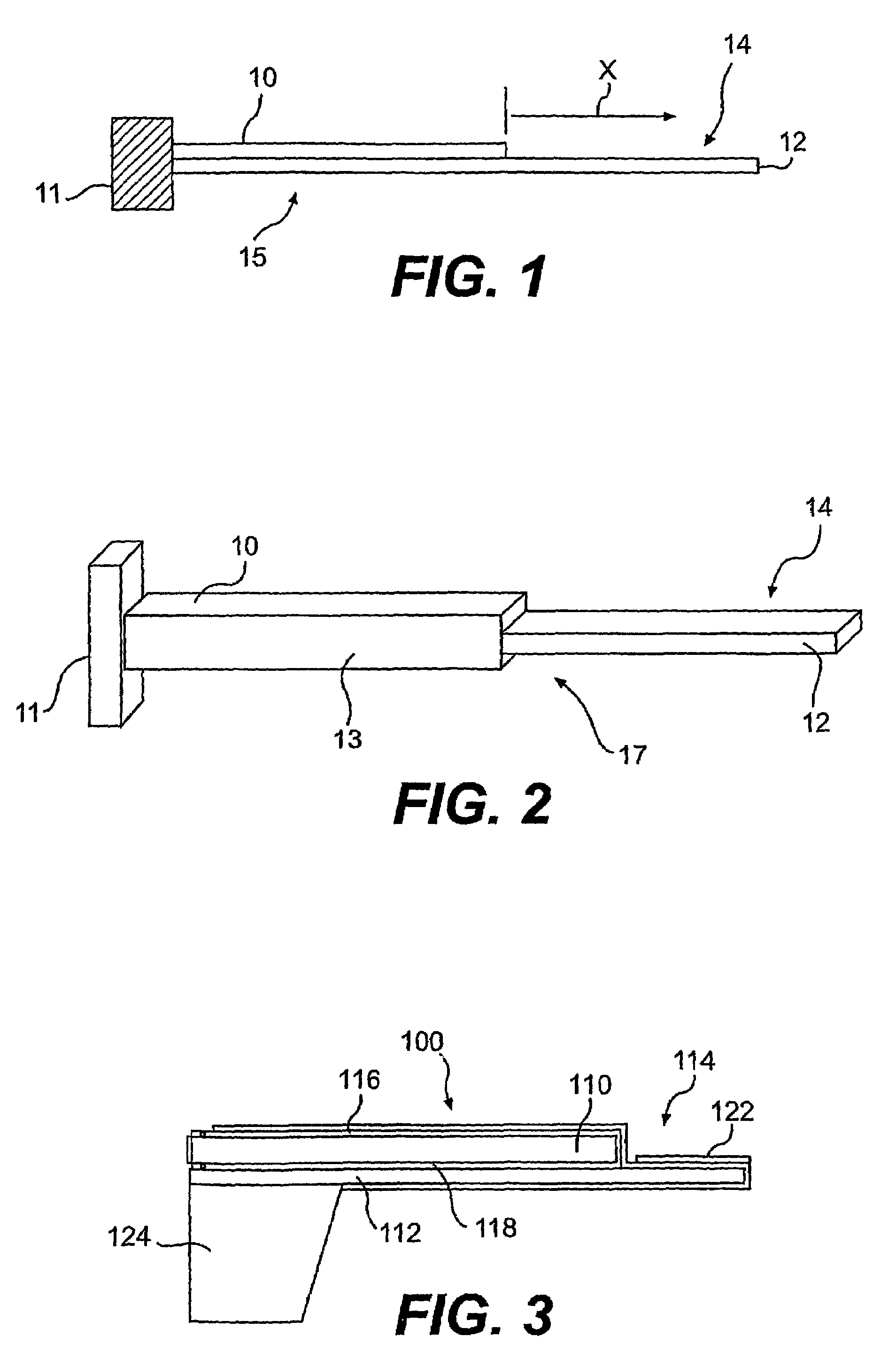

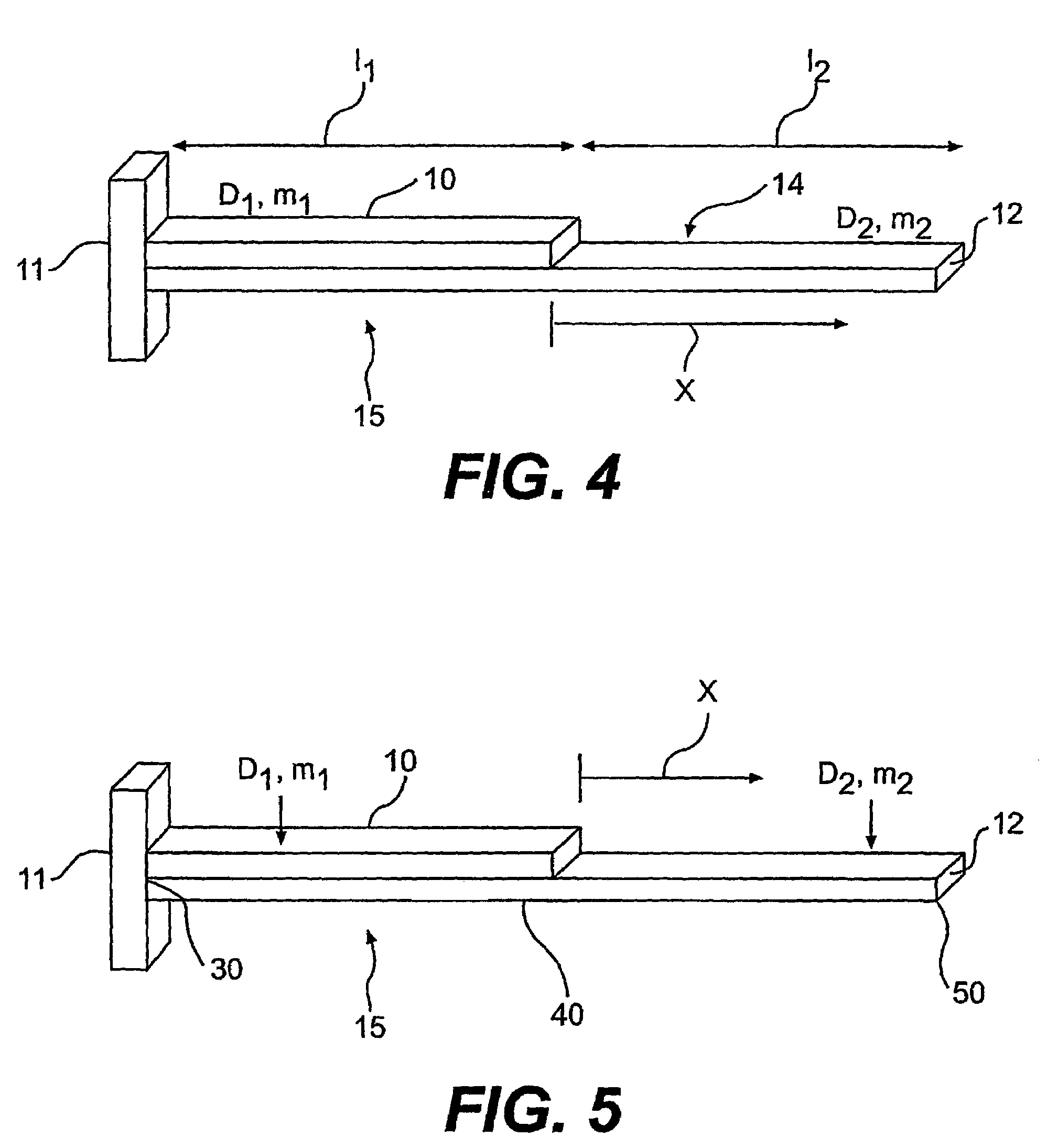

Piezoelectric cantilever sensors

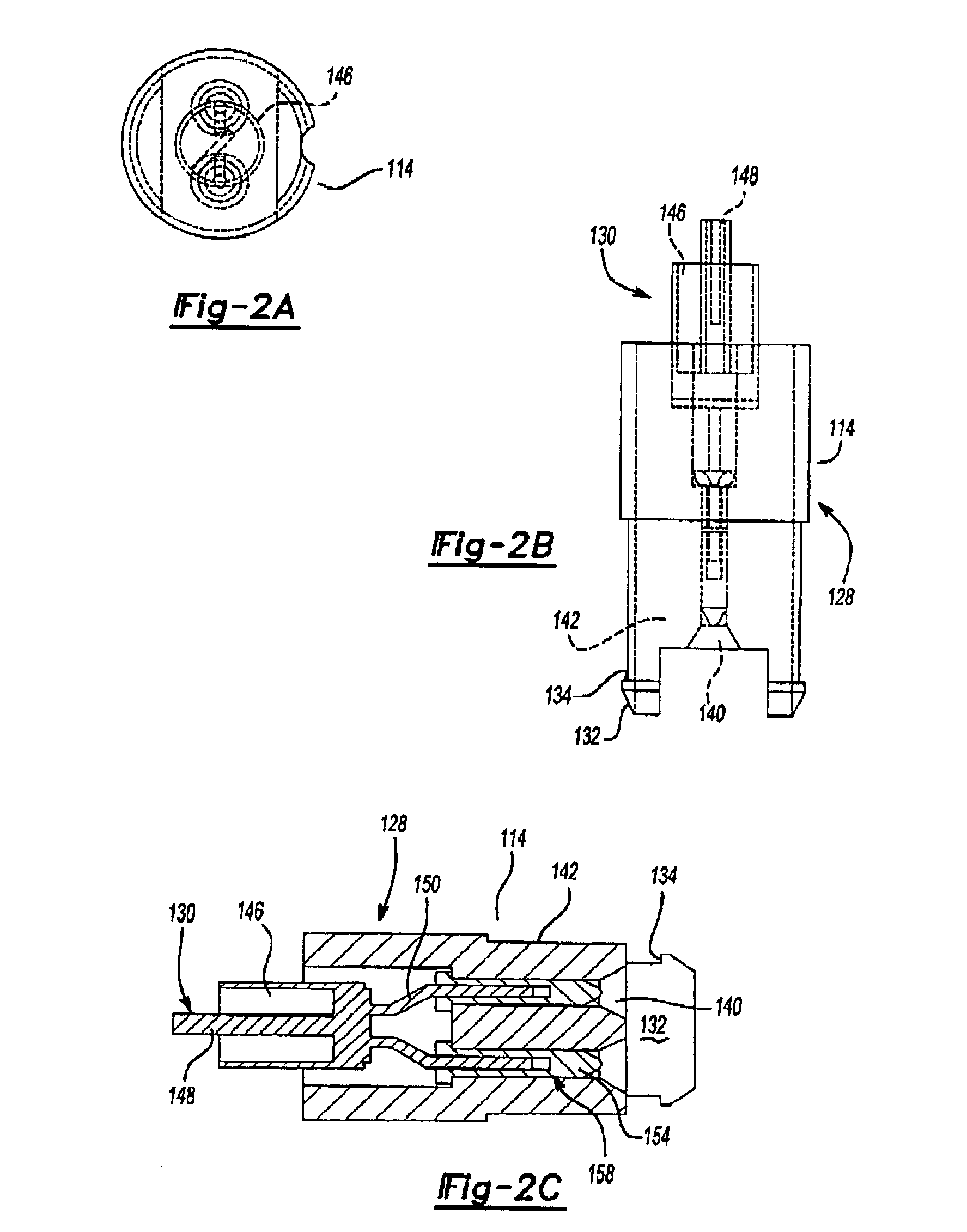

ActiveUS7458265B2Less lengthVibration measurement in solidsWeighing by removing componentViscous liquidAnalyte

A piezoelectric cantilever with a non-piezoelectric, or piezoelectric tip useful as mass and viscosity sensors. The change in the cantilever mass can be accurately quantified by monitoring a resonance frequency shift of the cantilever. For bio-detection, antibodies or other specific receptors of target antigens may be immobilized on the cantilever surface, preferably on the non-piezoelectric tip. For chemical detection, high surface-area selective absorbent materials are coated on the cantilever tip. Binding of the target antigens or analytes to the cantilever surface increases the cantilever mass. Detection of target antigens or analytes is achieved by monitoring the cantilever's resonance frequency and determining the resonance frequency shift that is due to the mass of the adsorbed target antigens on the cantilever surface. The use of a piezoelectric unimorph cantilever allows both electrical actuation and electrical sensing. Incorporating a non-piezoelectric tip (14) enhances the sensitivity of the sensor. In addition, the piezoelectric cantilever can withstand damping in highly viscous liquids and can be used as a viscosity sensor in wide viscosity range.

Owner:DREXEL UNIV

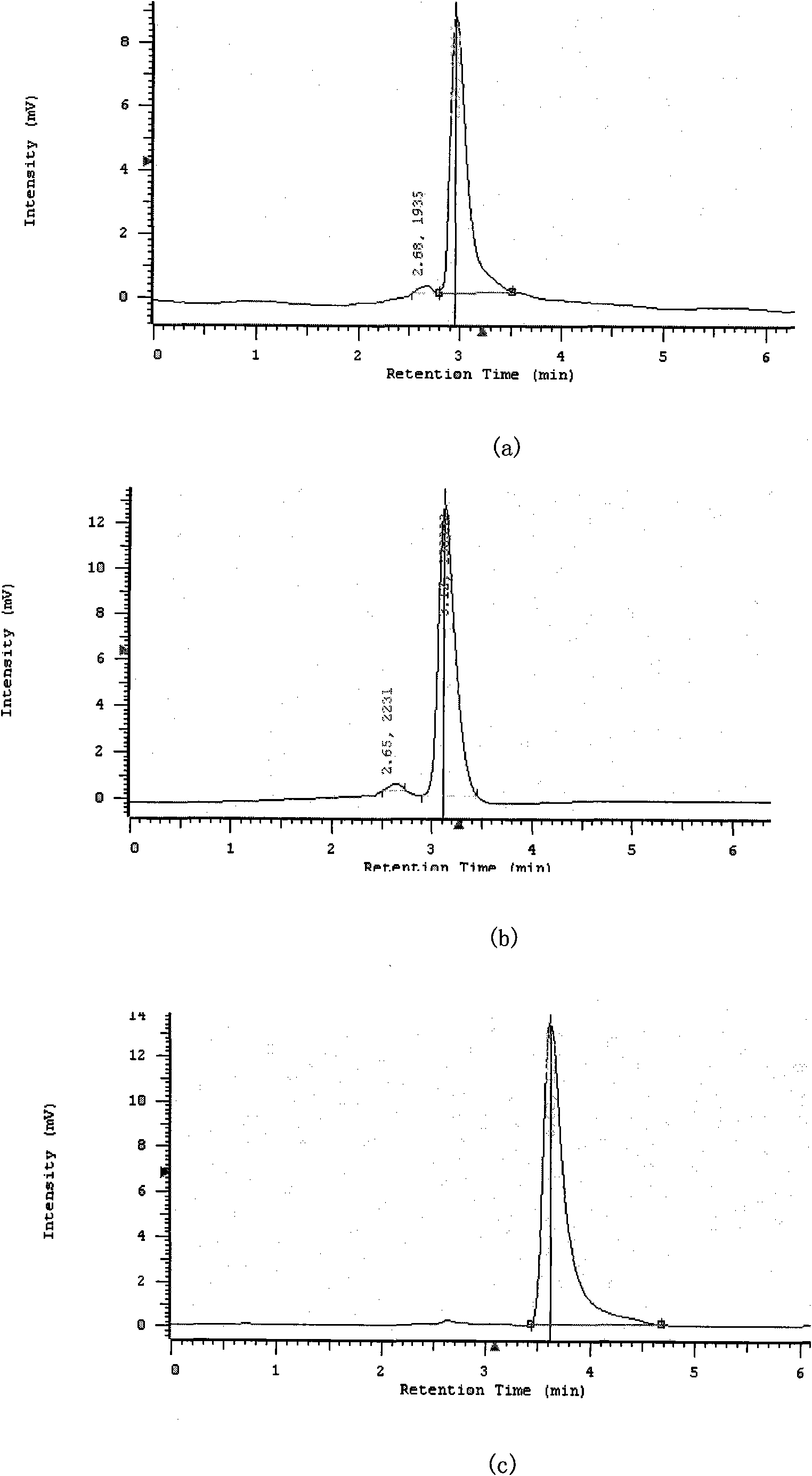

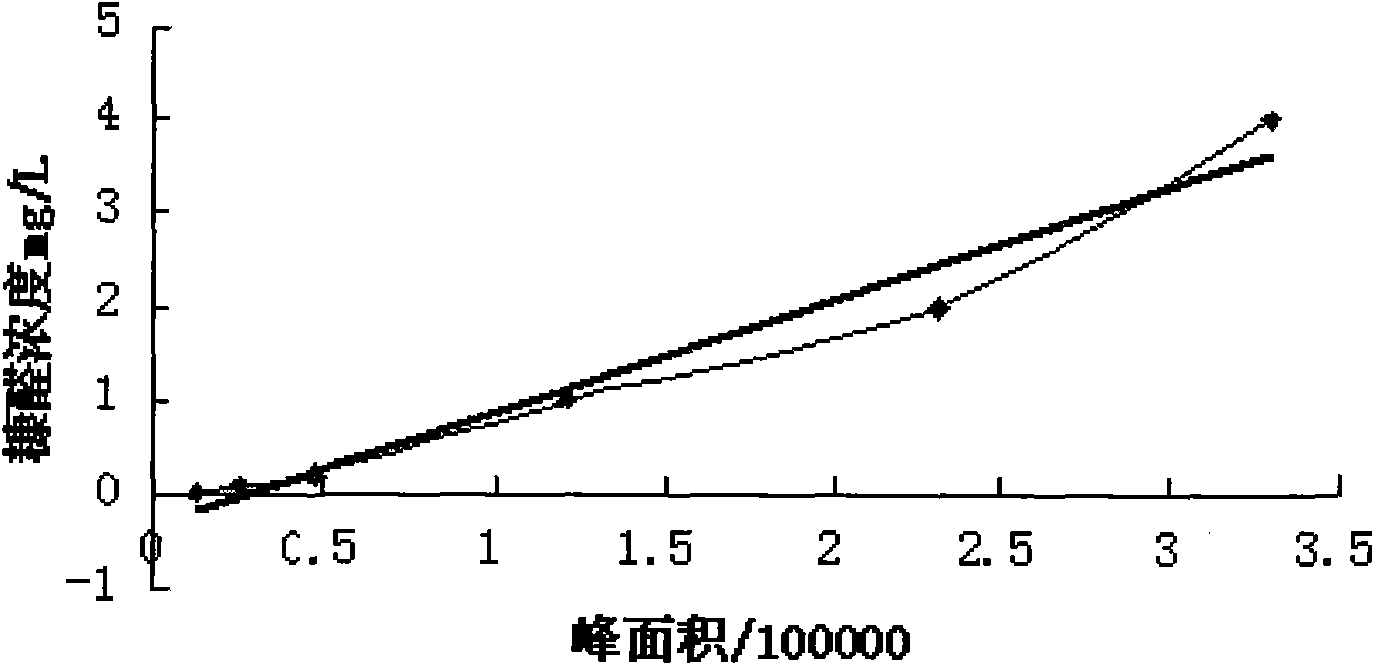

Judging method of solid insulating and aging degrees of transformer

InactiveCN101887094AEasy to operateNo power outageWeighing by removing componentComponent separationTransformerElectric network

The invention relates to a judging method of the solid insulating and aging degrees of a transformer, which sequentially comprises the following steps of: 1. preparing a gradient concentration standard solution of a furfural solution, carrying out liquid chromatographic detection, and making a standard curve I; 2. taking insulating paper samples in an actual electric network transformer, carrying out the liquid chromatographic detection, and obtaining the furfural concentration in each sample according to the standard curve I; 3. respectively measuring the water content H thereof by adopting the insulating paper samples in the step 2, computing the dry paper concentration C, additionally sampling, measuring the specific viscosity thereof, and computing the polymerization degree of the insulating paper samples according to a Martin empirical formula; 4. making a standard curve II by using the polymerization degree of insulating paper as an abscissa and using the logarithm of the furfural concentration as an ordinate; and 5. measuring the furfural concentration for an unknown sample, obtaining the polymerization degree of the insulating paper according to the standard curve II in the step 4, and judging the solid insulating and aging degrees of the transformer according to an IEC60450 standard. The method only needs to extract proper oil samples, has simple operation, does not need power failure, and is a quite practical method.

Owner:JIYUAN POWER SUPPLY COMPANY OF STATE GRID HENAN ELECTRIC POWER

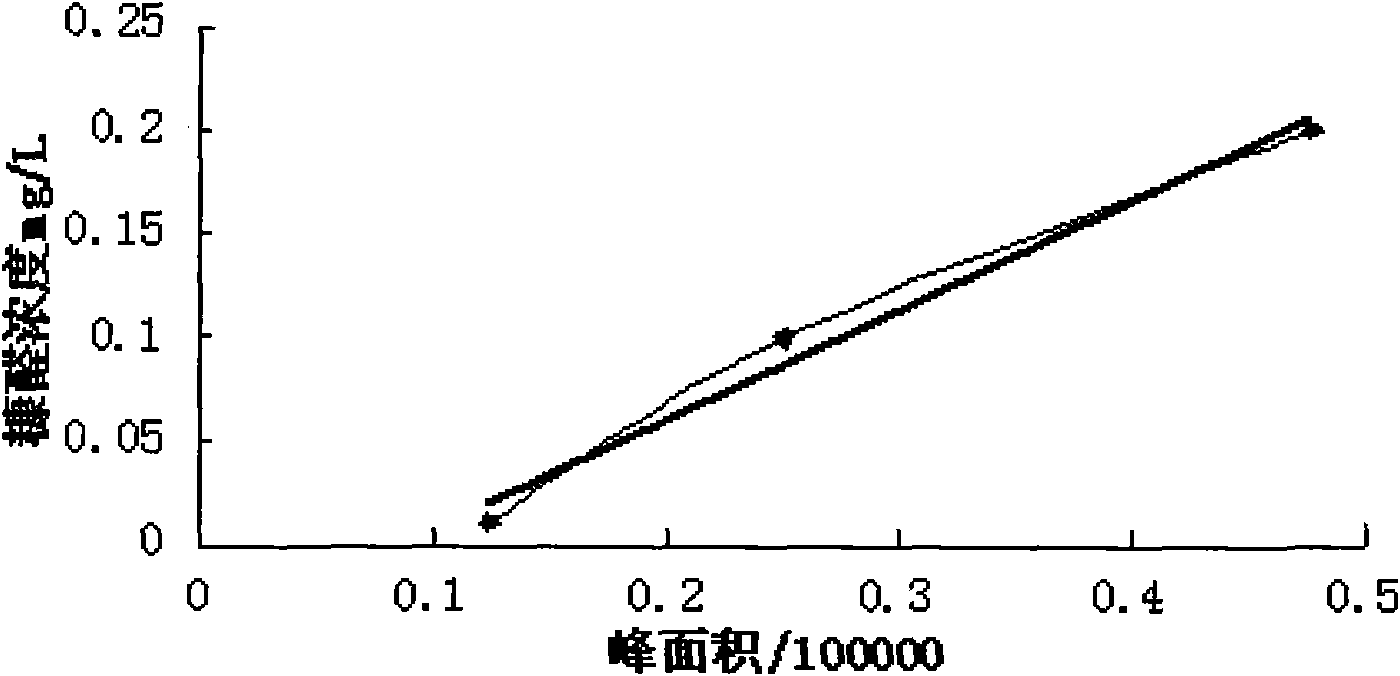

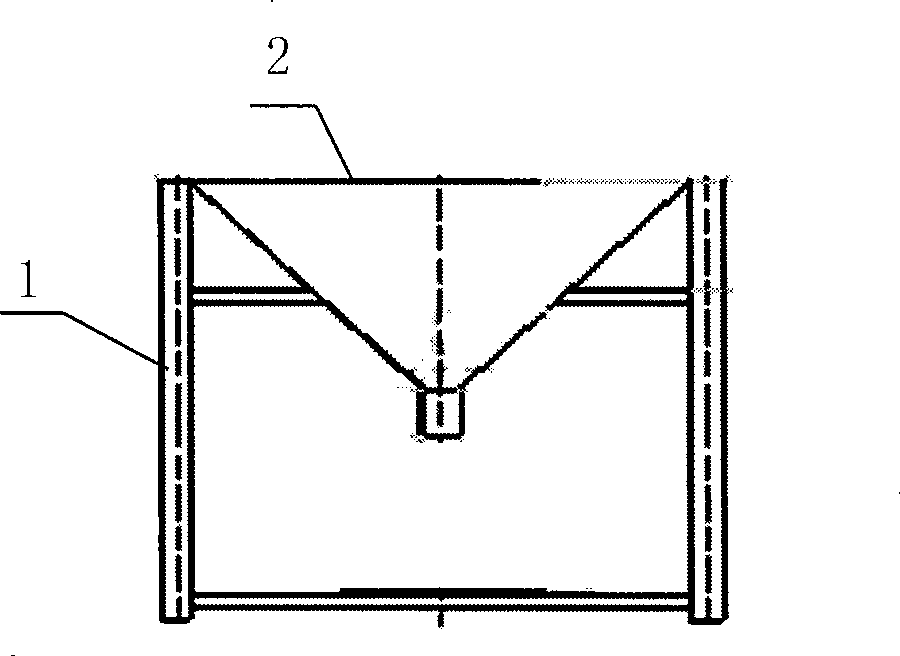

Detection method and device of coke reactivity and post-reaction heat-treatability

ActiveCN101825548AAppear thermal characterizationWeighing by removing componentThermometers using electric/magnetic elementsHearthEngineering

The invention discloses a detection method and device of the reactivity and post-reaction heat-treatability of coke and the method and device are used to detect the gasifying starting temperature, reactivity and post-reaction heat-treatability of coke. The detection method adopts an electric furnace as a heating furnace and uses an electronic balance for to weight. The reactivity detection method is performed on the condition of first heating and second keeping temperature constant, the electronic balance is used to measure the mass loss of a coke sample; and when the coke weight-loss ratio equals a specified value, the measurement weight-loss ratio (time) minus one is used as the reactivity index; the detection method of the post-reaction heat-treatability of coke is that when the coke weight-loss ratio equals the specified value, coke is continuously heated under the protection of inert gas, and the coke weight-loss ratio is used as the post-reaction heat-treatability index during the detection period of heat treatment. The detection device comprises the electronic balance, a reaction tube support, a reaction tube, the heating furnace and a heating furnace elevating mechanism. The method and device of the invention can provide 1500-1600 DEG C of detection temperature and the coke thermal characterization in the bosh (before an air port) and the hearth can be displayed.

Owner:山西今日太工煤焦技术研究有限公司

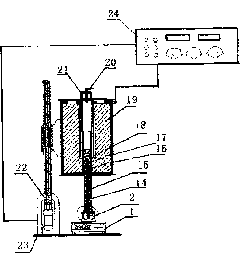

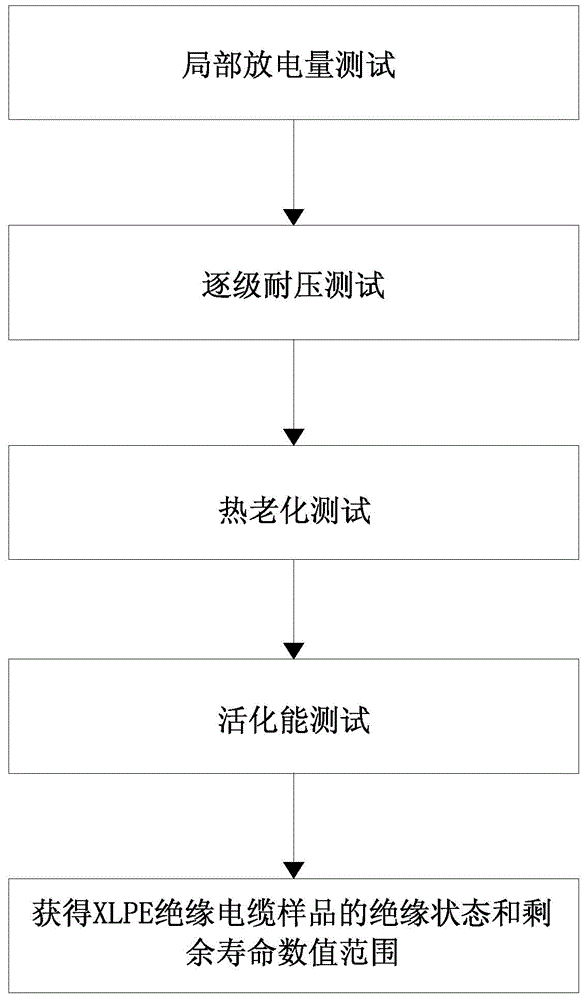

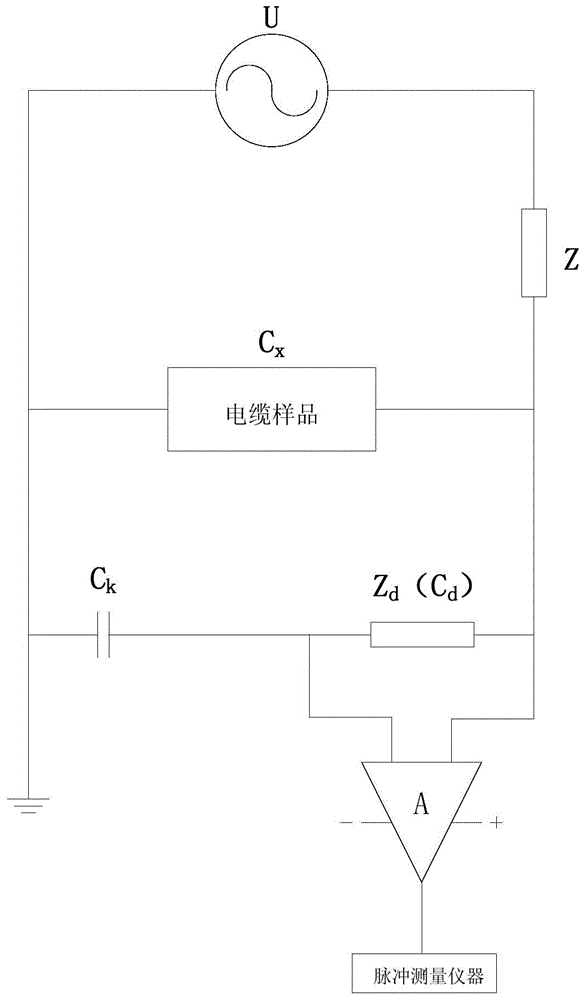

Insulating cable residual service life comprehensive evaluation method based on physical, chemical and electric properties

The invention discloses an insulating cable residual service life comprehensive evaluation method based on physical, chemical and electric properties. An insulating cable is an XLPE (Cross Linked Polyethylene) insulating cable. The method comprises a partial discharging amount test, a gradual layer voltage-resisting test, a thermal aging test and an activating energy test; an insulating state of an XLPE insulating cable sample is obtained according to a partial discharging amount calculated by he partial discharging amount test; a residual service life numerical value range of the XLPE insulating cable sample is obtained according to testing results of the gradual layer voltage-resisting test, the thermal aging test and the activating energy test. The method can integrate a plurality of indexes of cable aging evaluation, and combines macroscopic and microscopic change conditions, so that the residual service life data of the cable is completely analyzed in the three aspects of physical performances, chemical performances and electric performances, and the method has important guiding meanings on line modification and power grid planning.

Owner:SOUTH CHINA UNIV OF TECH

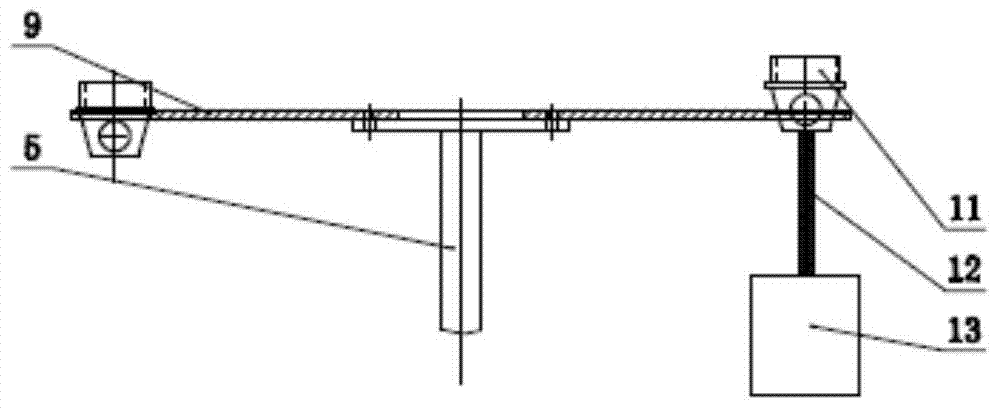

Equipment capable of automatically testing moisture of bituminous coal

The invention discloses equipment capable of automatically testing moisture of bituminous coal. The equipment comprises two main brackets, a bottom plate, a lower fiber plate, a hearth, an upper fiber plate, a turn plate, a rotating shaft, a secondary bracket, an elevating rack, a U-shaped rack, a motor rack, a rotating motor, two bearing brackets, a ball screw, a balance, a weighing lever, a guide block and a slide block, wherein the lower fiber plate is assembled on the bottom plate; the weighing lever is assembled on the balance. The equipment capable of automatically testing moisture of bituminous coal is high in automatic degree, high in work efficiency and convenient to operate.

Owner:CHANGZHOU UNIV

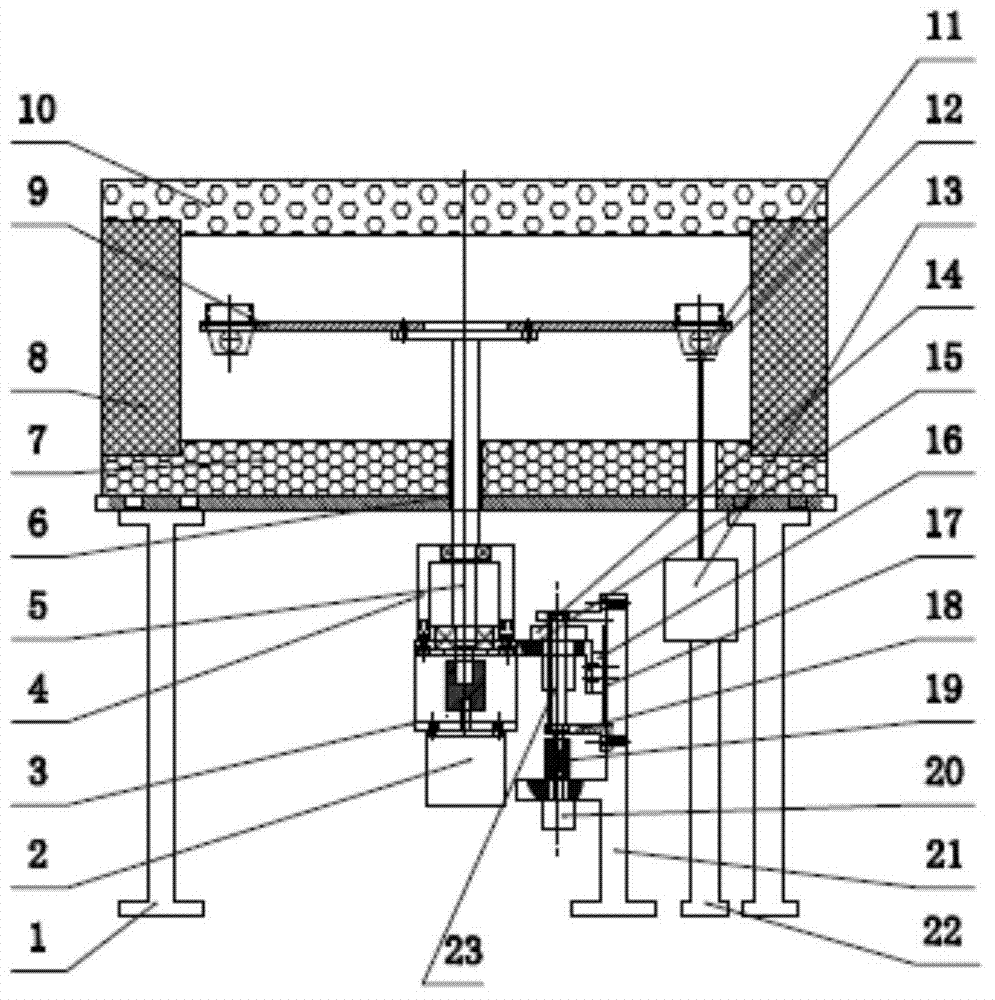

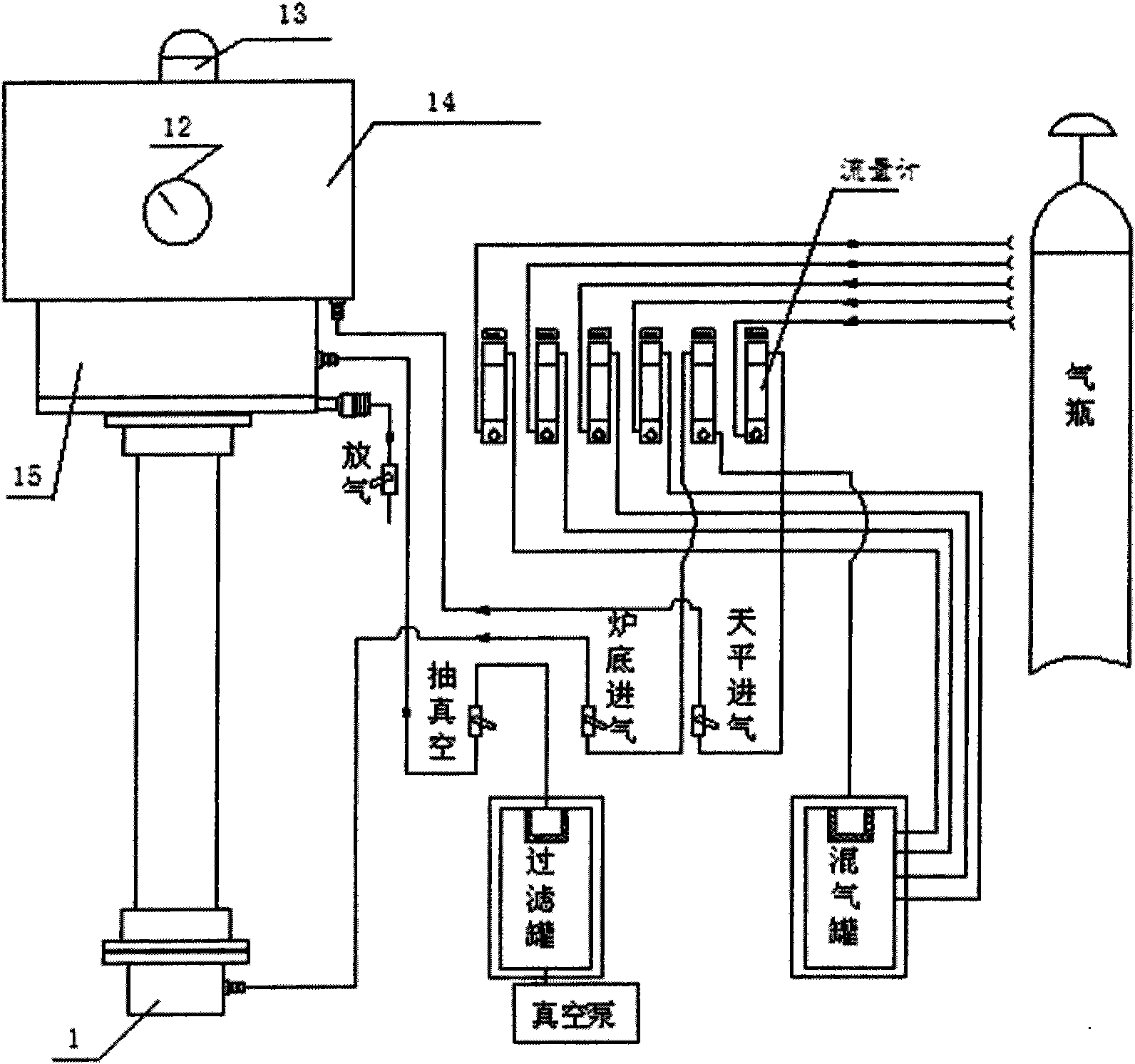

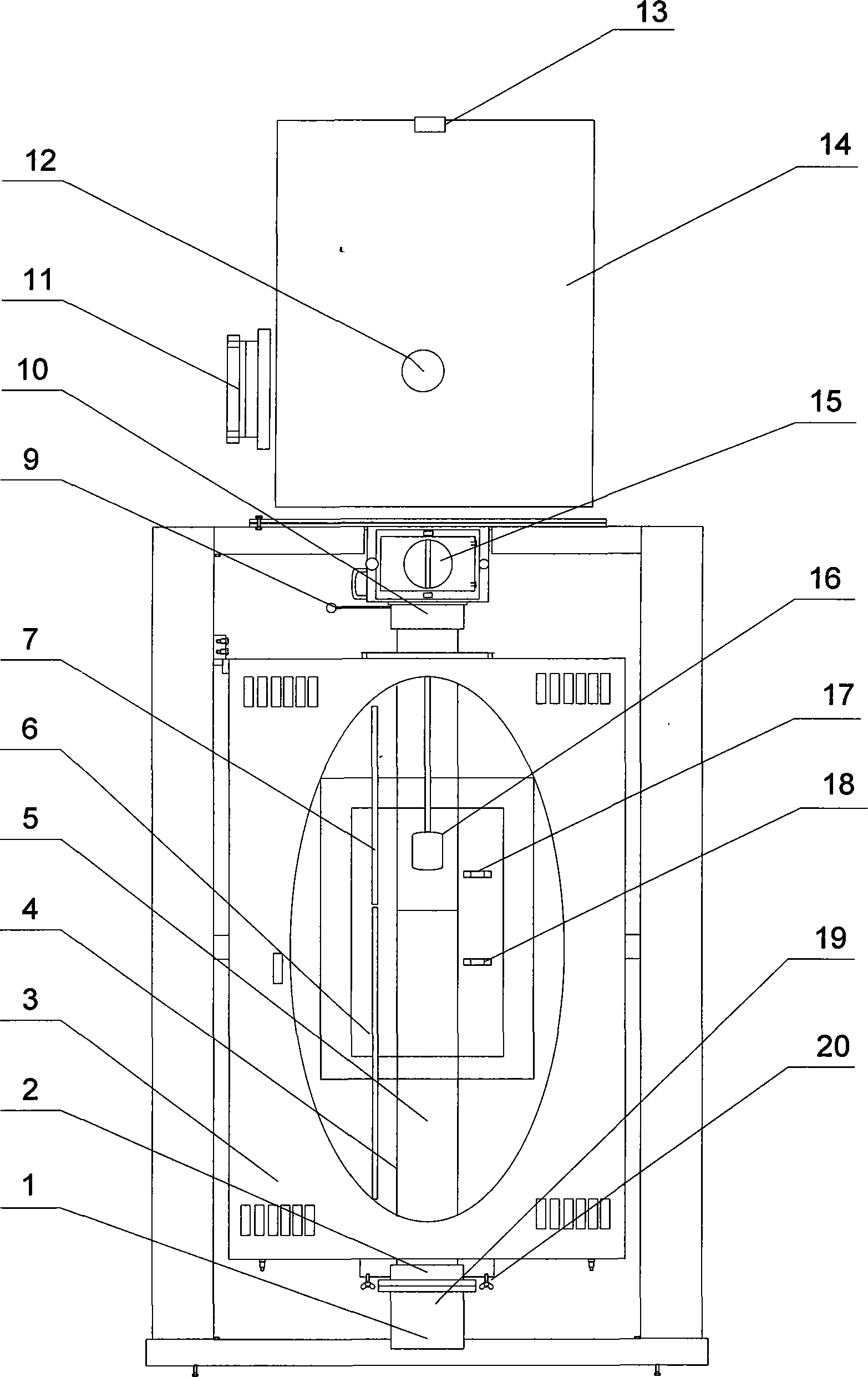

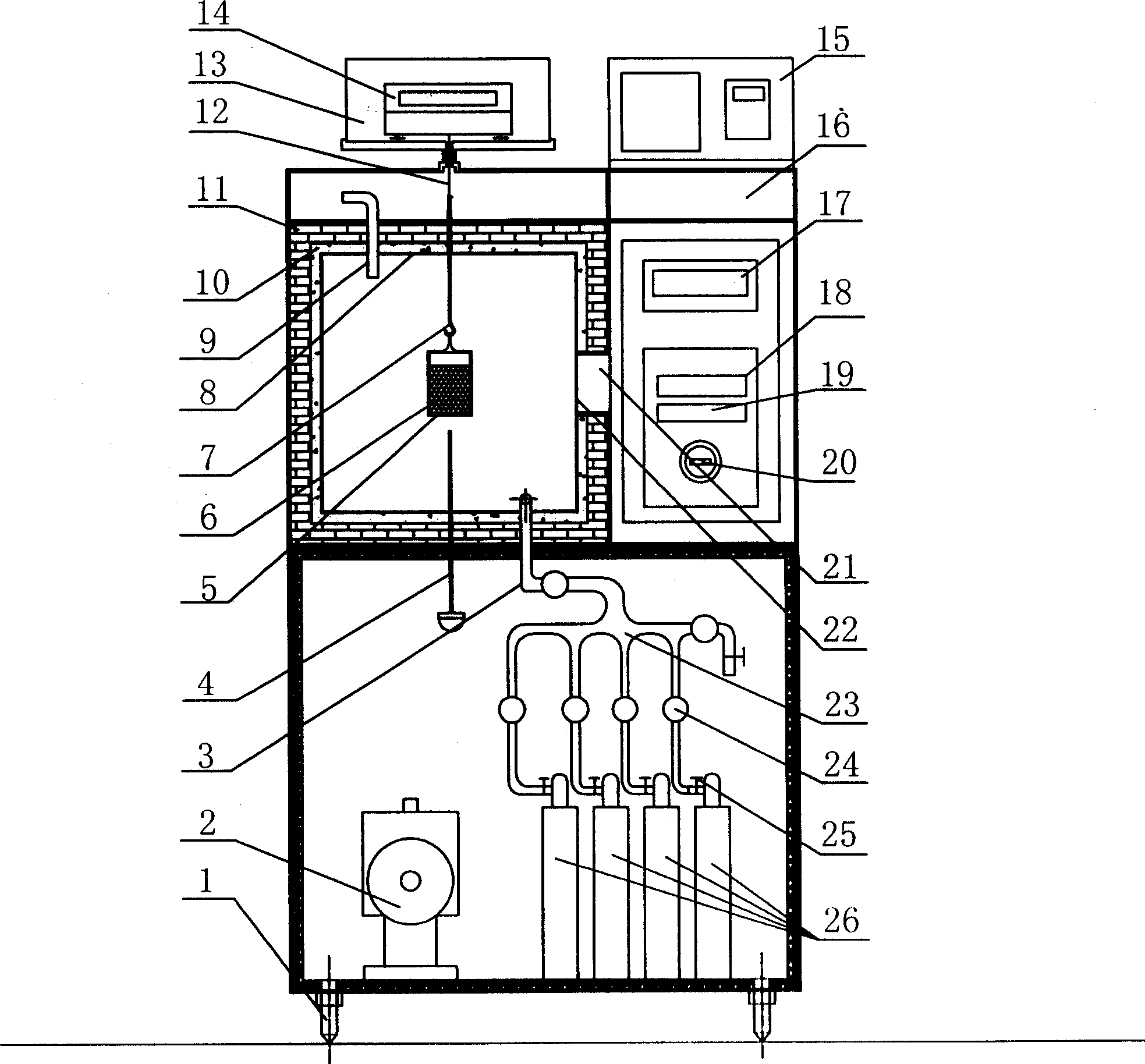

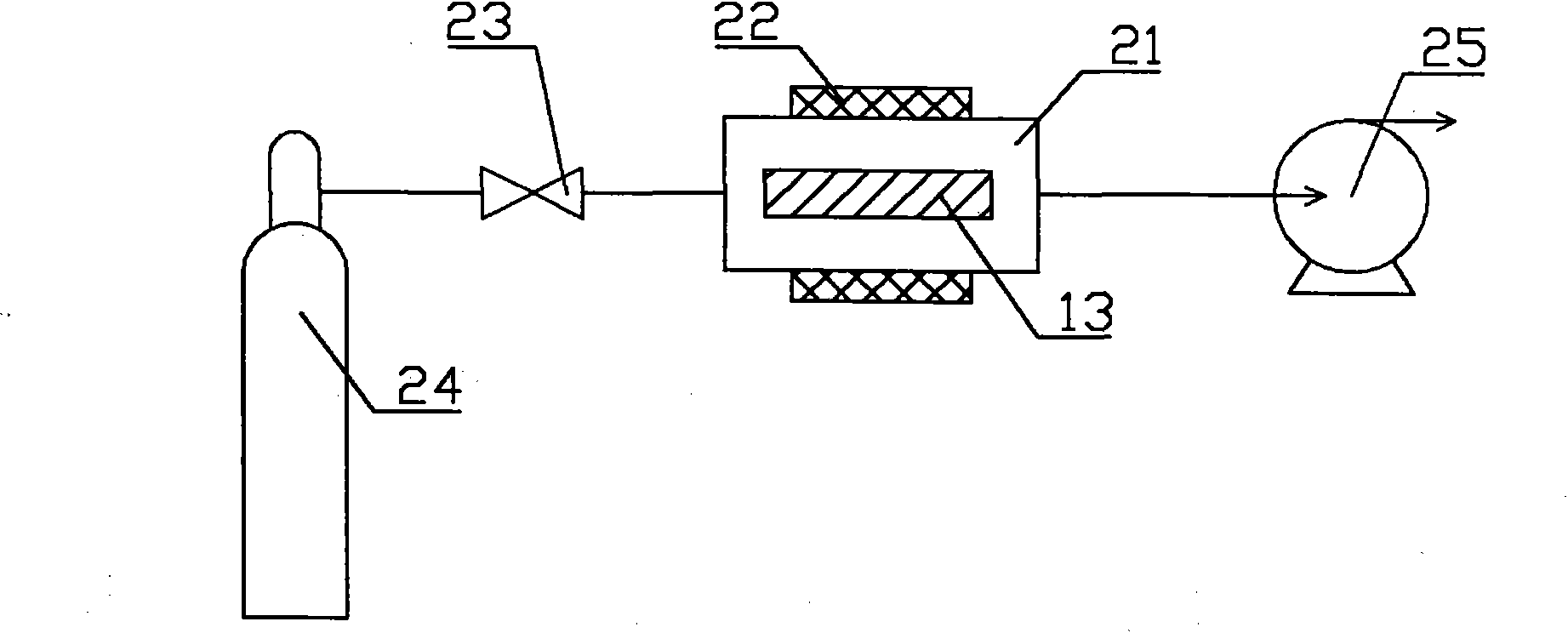

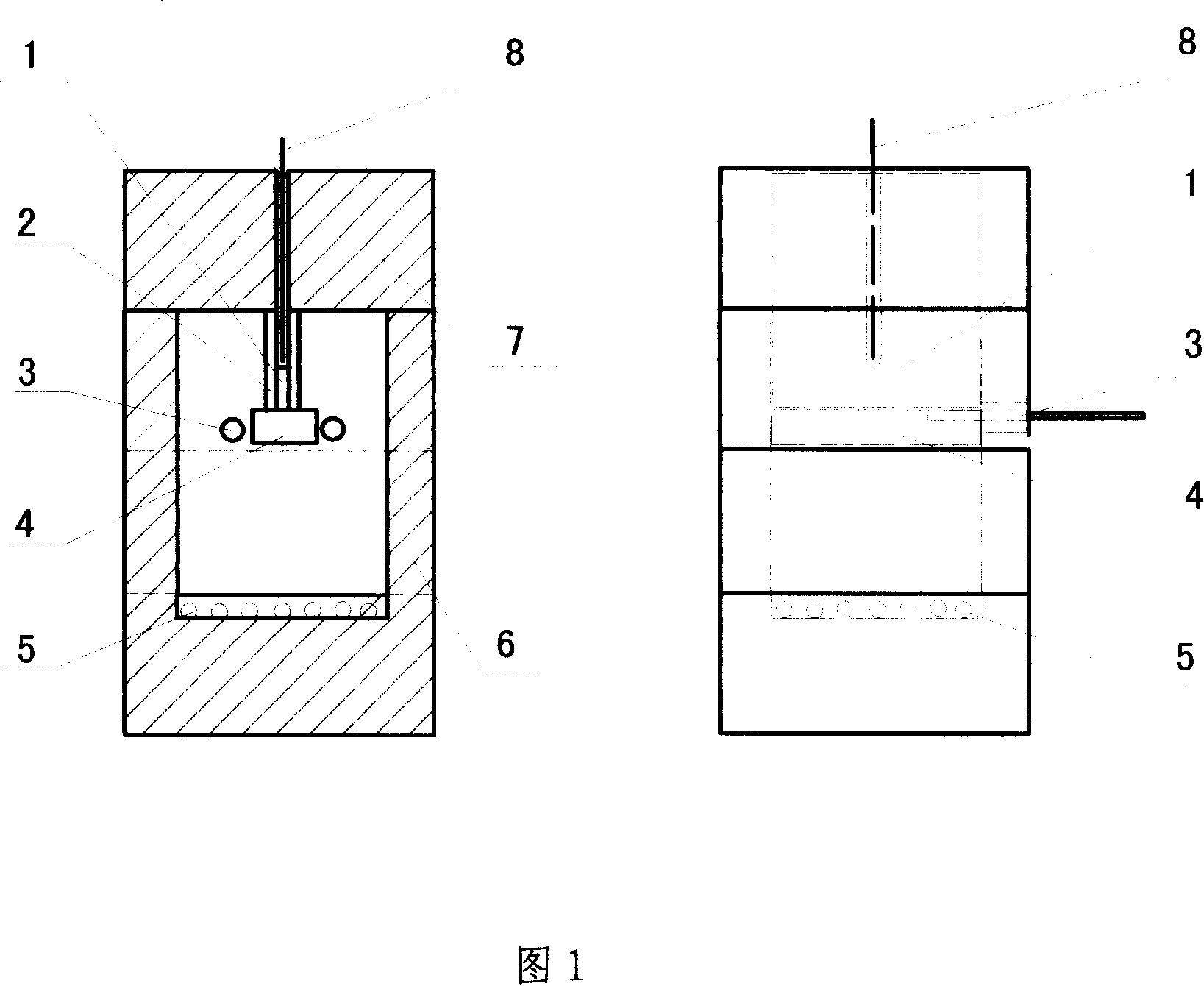

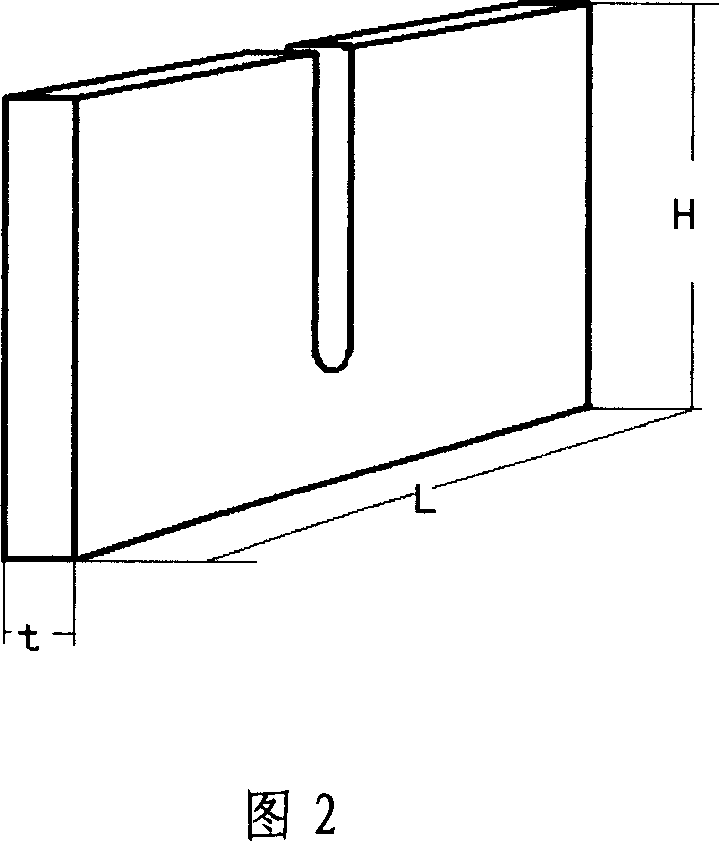

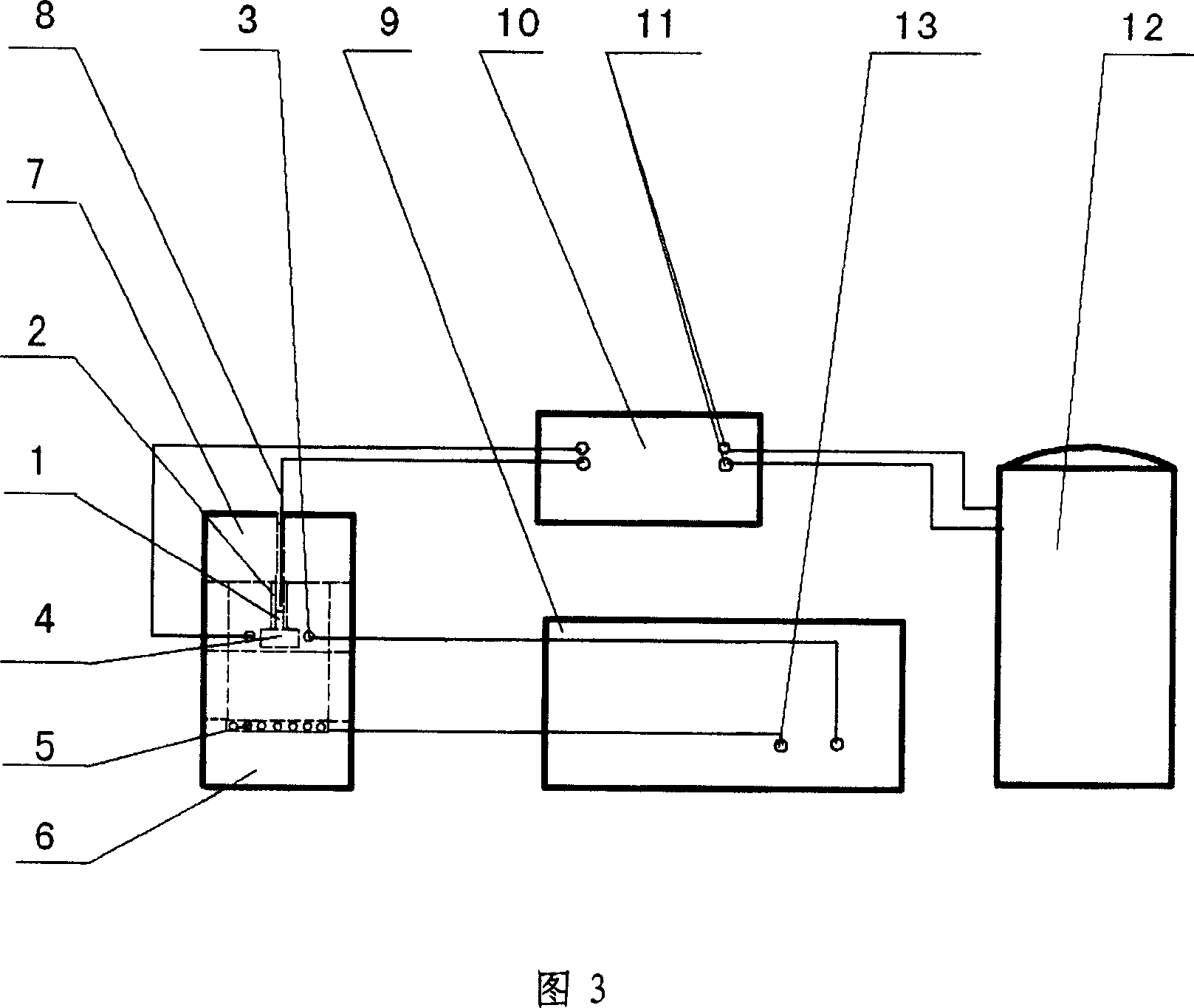

Controllable fast-heating up thermobalance reacting furnace

ActiveCN101799242ALarge controllable rangeEasy to manufactureWeighing by removing componentFurnace typesAir atmosphereTest sample

The invention discloses a controllable fast-heating up thermobalance reacting furnace, comprising a high temperature furnace reaction unit, a balance weighting device, an air control device and an electronic control unit, wherein the high temperature furnace reaction unit uses two-section heating, the temperature of the furnace body is set, collected and transmitted by the electronic control device; and when in an experiment, the air control device adjusts the air atmosphere in the high temperature furnace reaction unit, a sample is rapidly placed in a constant temperature zone of the high temperature furnace reaction unit to realize rapid heating up by a balance lifting mechanism in the balance weighting device, and mass change of the sample is converted into electronic signals in real time to be transmitted to the electronic control device for continuous monitoring and storing. The invention has the characteristics of large controllable range of heating rate, large range of test sample amount and controllable reaction atmosphere, thus meeting the requirement of the thermobalance test research under various reaction conditions with different sample amounts and heating rate; and common measurement equipment can perform on-line air component analysis, thus being favor of disclosing the action mechanism and control strategy in the reaction process.

Owner:HUAZHONG UNIV OF SCI & TECH

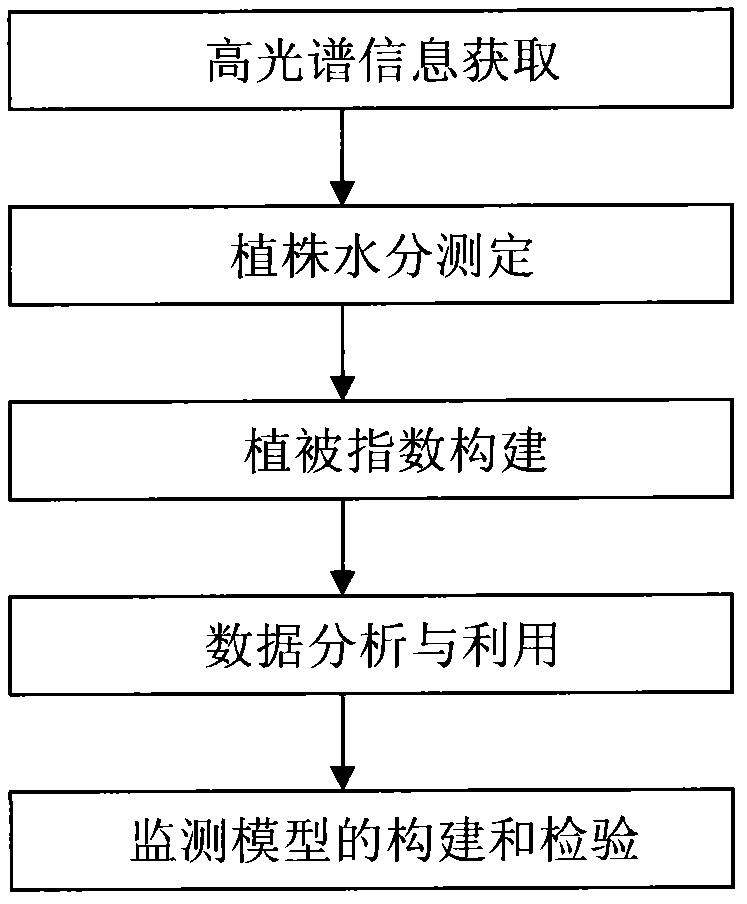

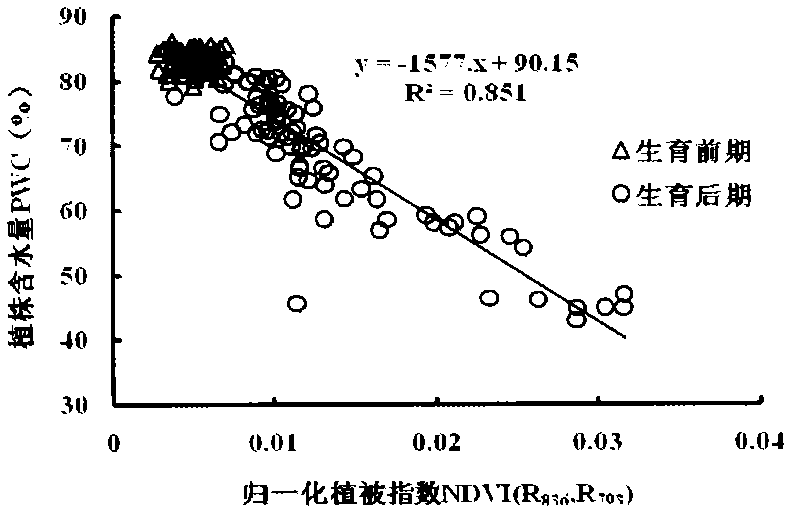

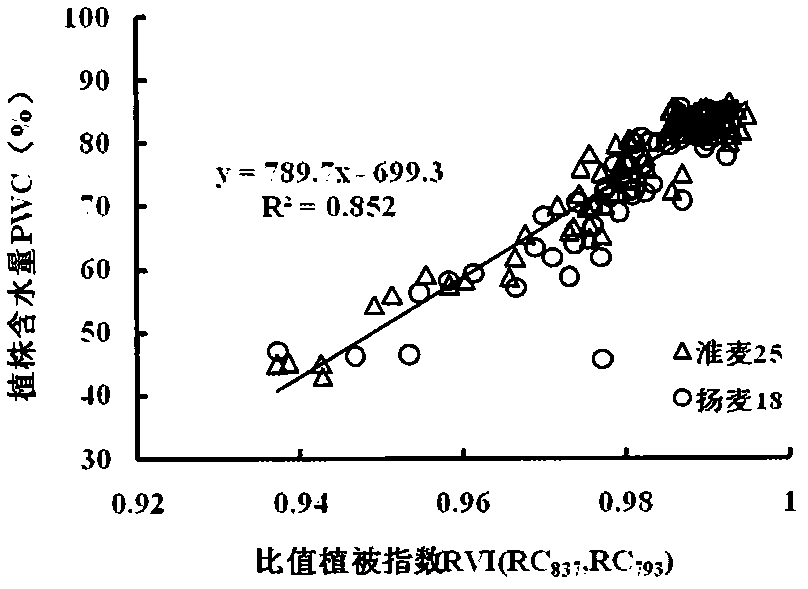

Wheat plant moisture monitoring method based on canopy high spectral index

ActiveCN102426153AImprove accuracyImprove stabilityWeighing by removing componentPhotogrammetry/videogrammetryWater contentWave band

The invention relates to a wheat plant moisture monitoring method based on a canopy high spectral index, which uses two-year wheat pool-planted test data of two-year 2 varieties under 4 different moisture treatments, adopts a decrement fine sampling method, and analyzes the quantitative relationship between a high spectral index combined by any two wave bands of an original spectrum and a reciprocal spectrum within the waveband range of 350-2500 nm and the wheat plant moisture content and the leaf layer moisture content; results show that the wheat plant moisture content can be monitored based on spectra of NDVI (R836, R793) and RVI (RC837, RC793), and the wheat leaf layer moisture content moisture content can be monitored based on original spectra of NDVI (R1100, R770) and RVI (R893, R805). The research conclusions of the invention provide new wave band combination and theoretical basis for the rapid lossless monitoring of wheat moisture conditions by using high spectral data.

Owner:NANJING AGRICULTURAL UNIVERSITY

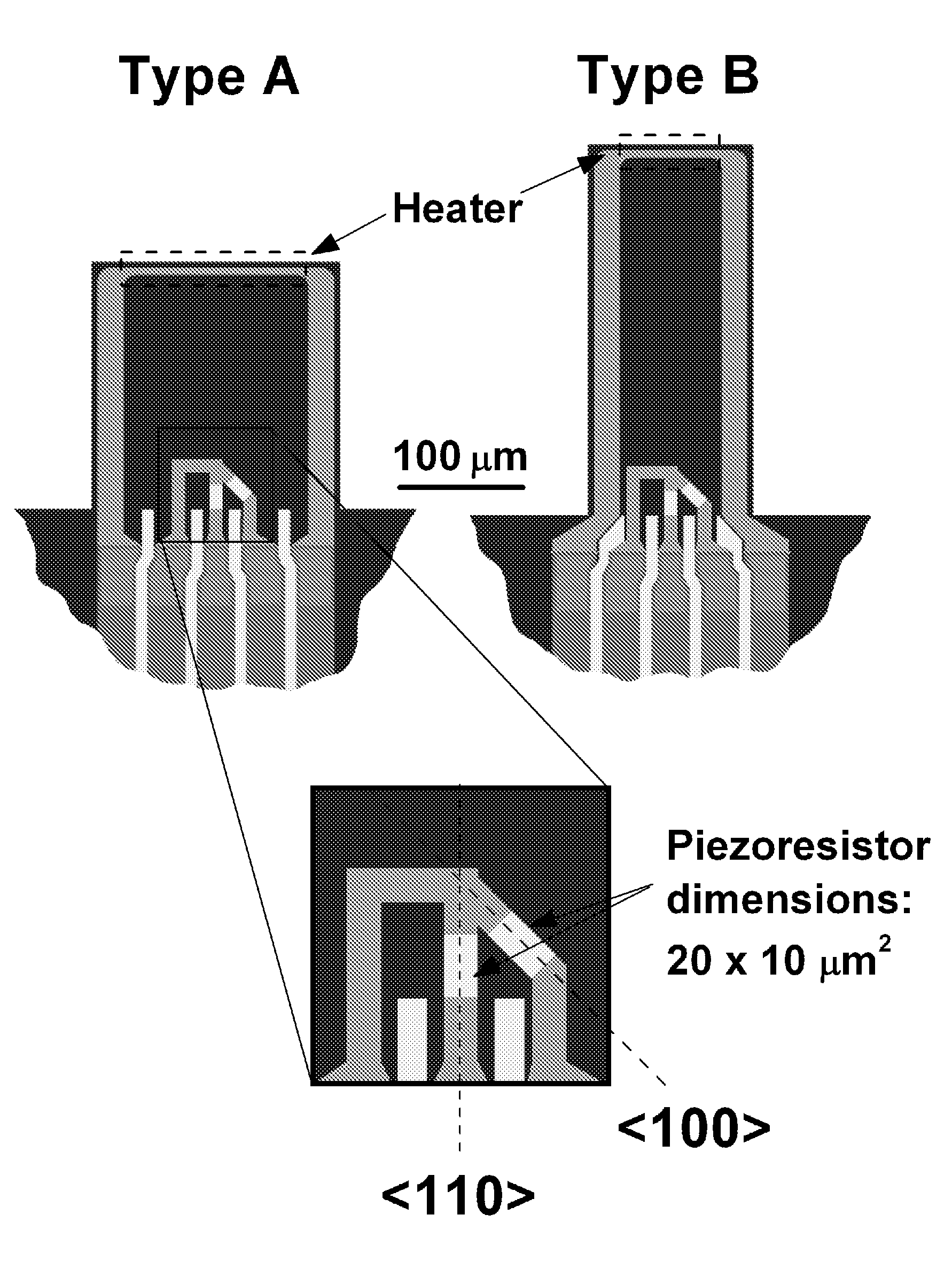

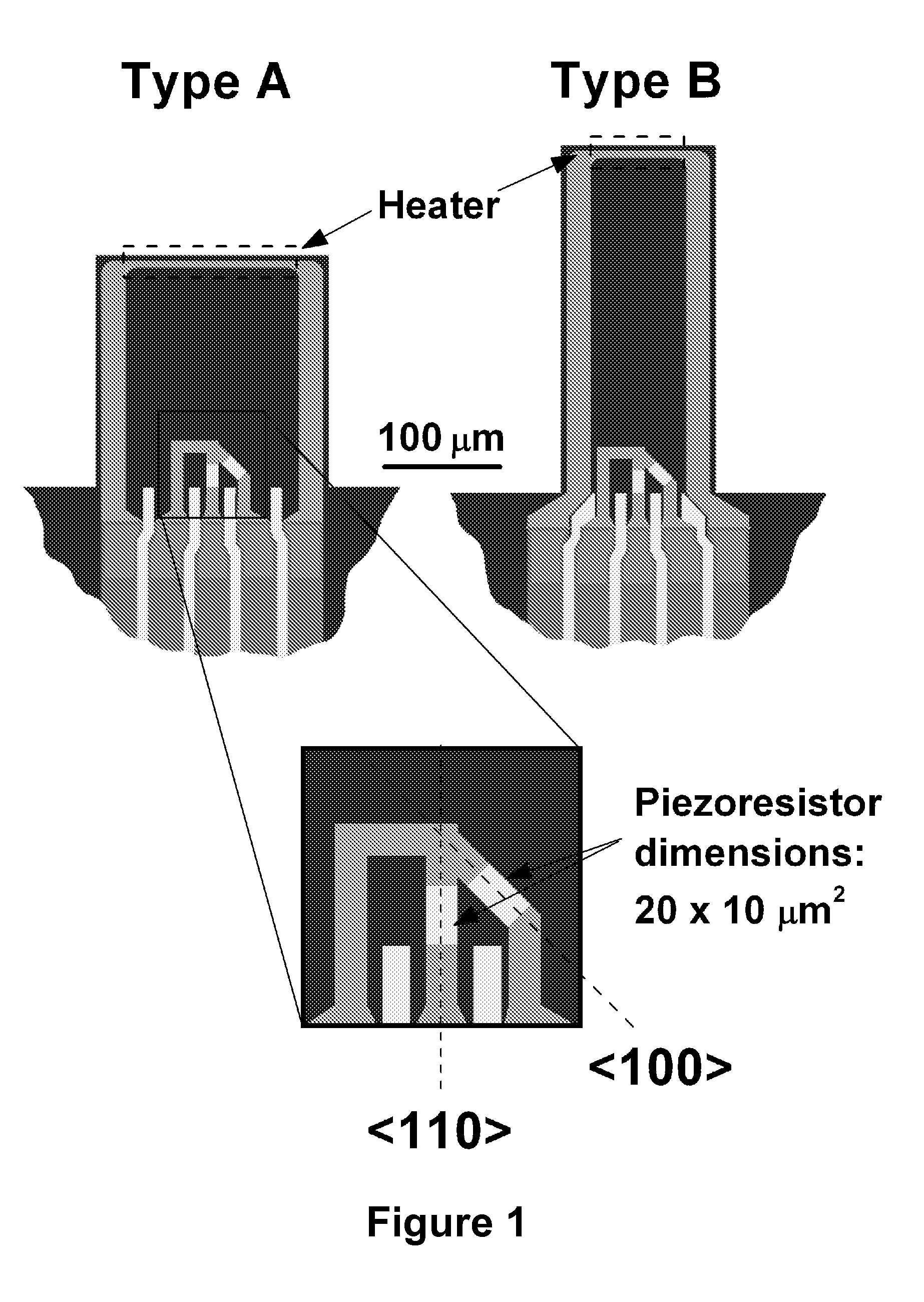

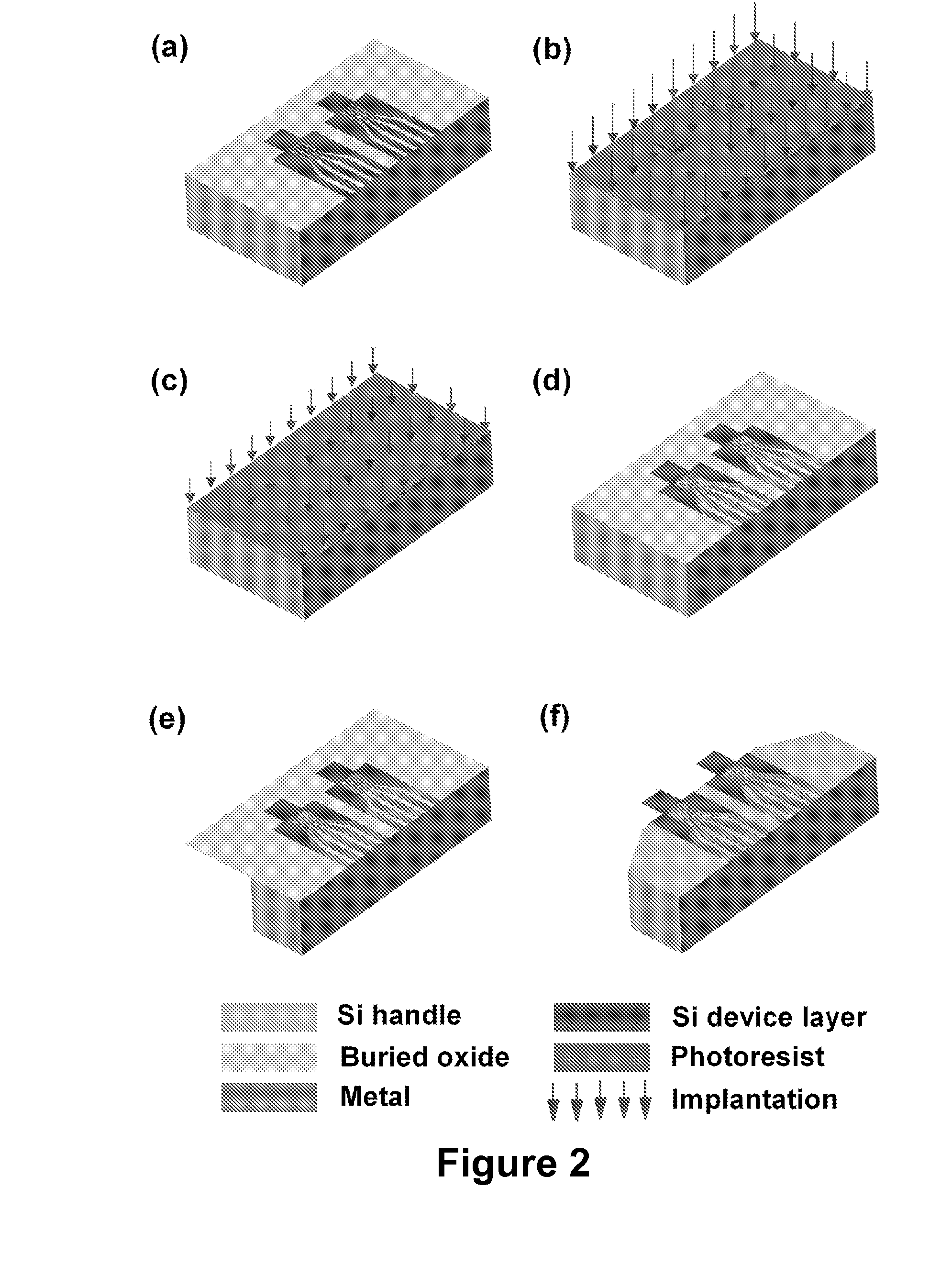

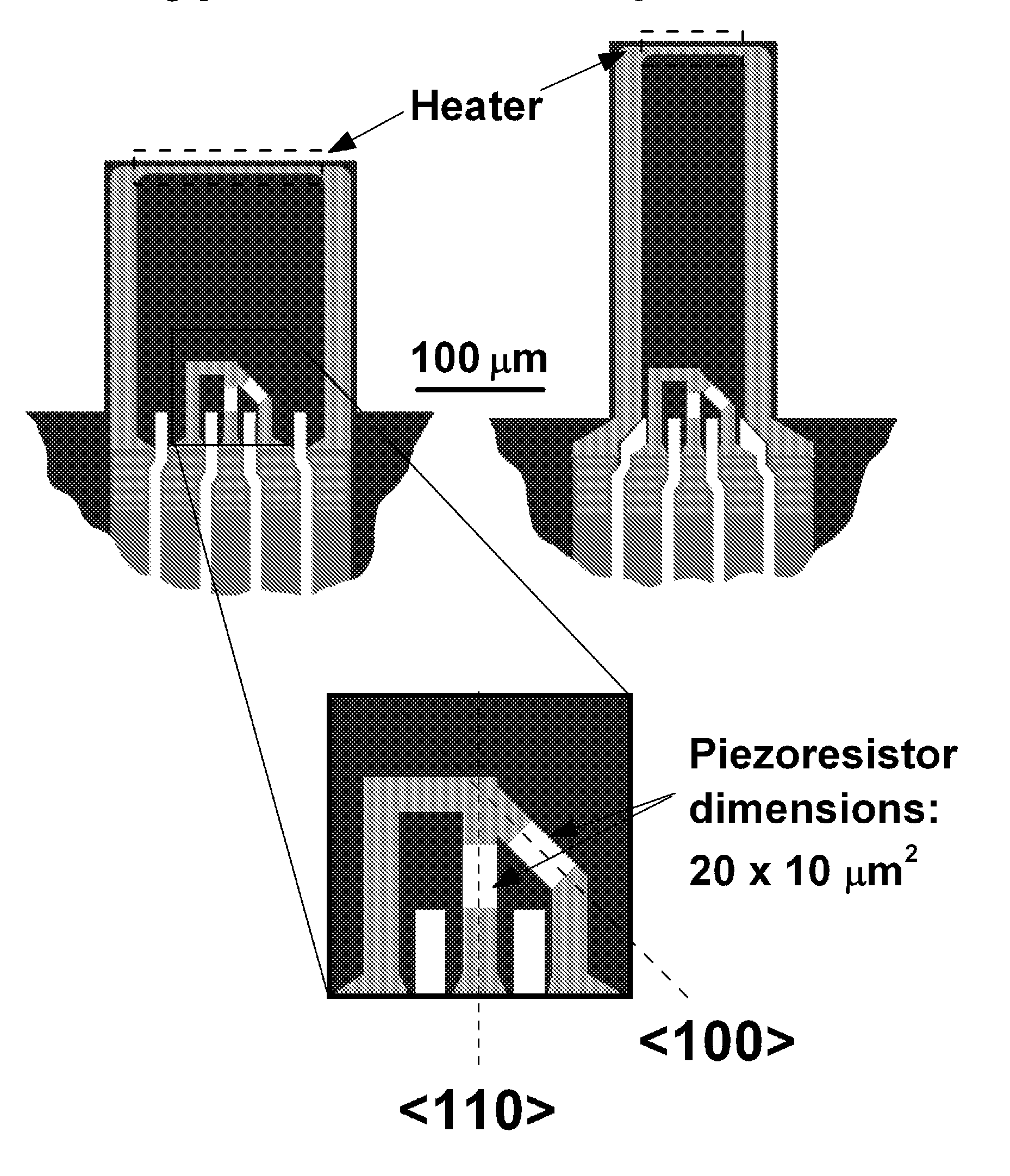

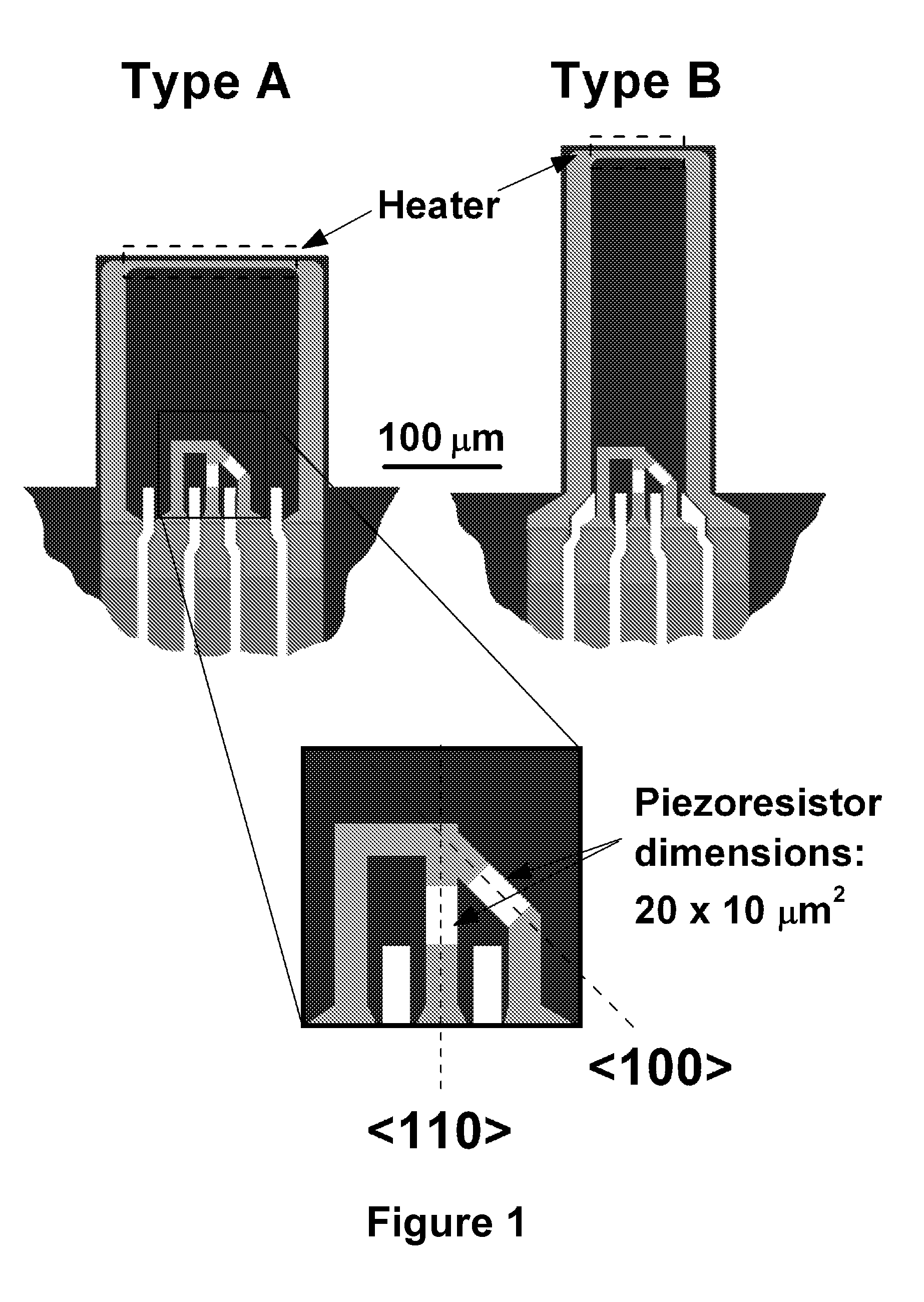

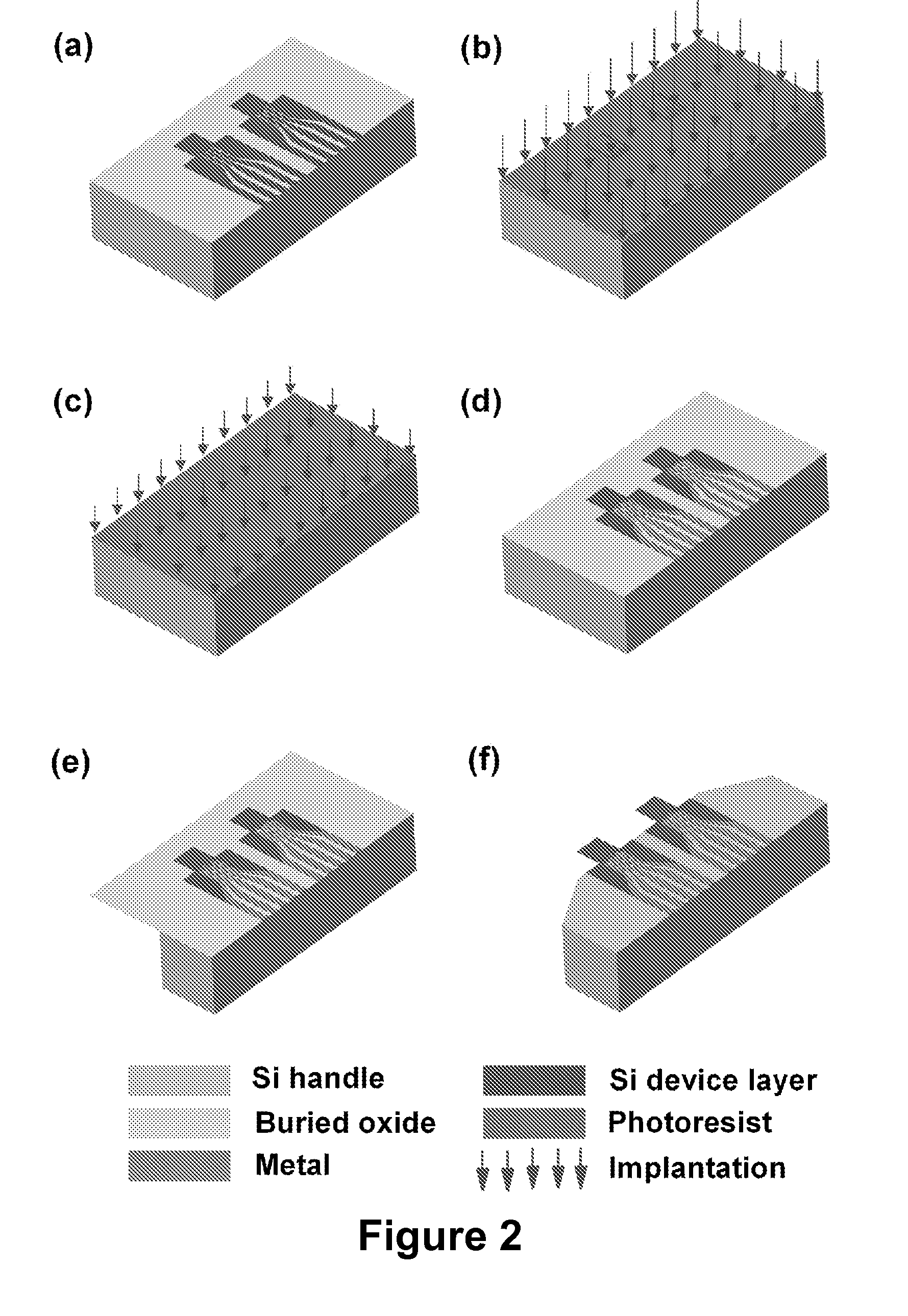

Microcantilever Heater-Thermometer With Integrated Temperature-Compensated Strain Sensor

InactiveUS20090139340A1Change resistanceWeighing by removing componentForce measurementSurface stressElectrical resistance and conductance

The present invention provides microcantilever hotplate devices which incorporate temperature compensating strain sensors. The microcantilever hotplate devices of the present invention comprise microcantilevers having temperature compensating strain sensors and resistive heaters. The present invention also provides methods for using a microcantilever hotplate for temperature compensated surface stress measurements, chemical / biochemical sensing, measuring various properties of compounds adhered to the microcantilever hotplate surface, or for temperature compensated deflection measurements.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

High throughput microbalance and methods of using same

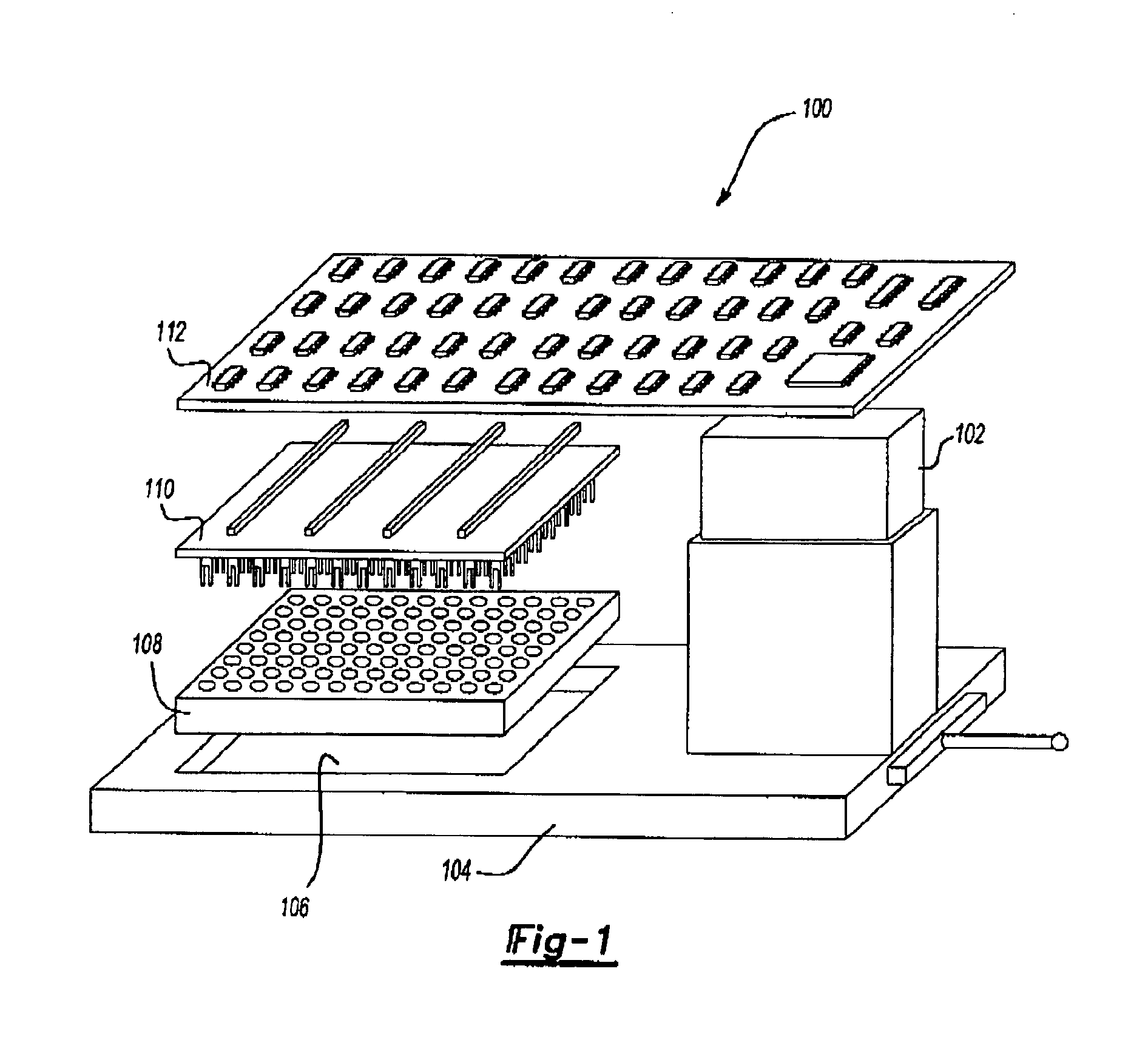

InactiveUS6928877B2Accurate measurementVibration measurement in solidsWeighing by removing componentSmall sampleHigh flux

A method and apparatus for measurement of mass of small sample sizes. The method and apparatus is particularly adapted for providing microbalance measurement of solid materials as part of a combinatorial research program. The method and apparatus contemplate monitoring the response of a resonator holding a sample and correlating the response with mass change in the samples.

Owner:MEAS FRANCE

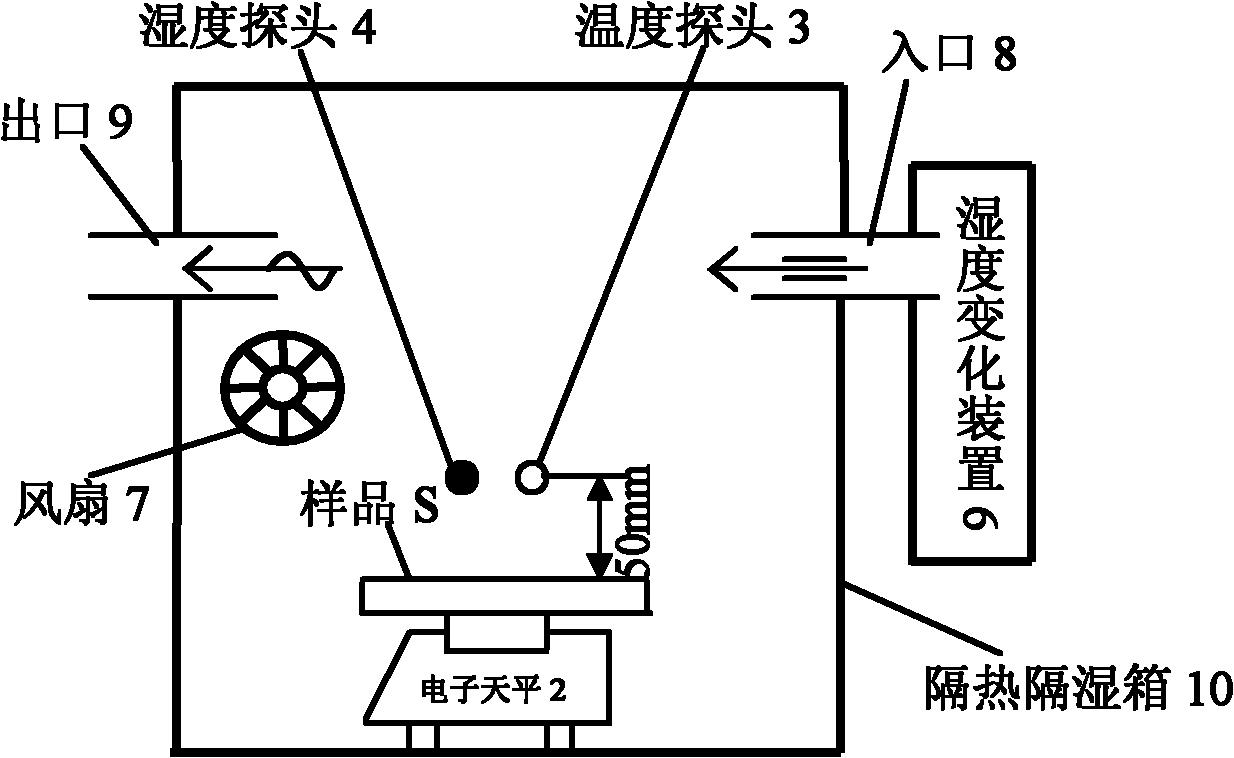

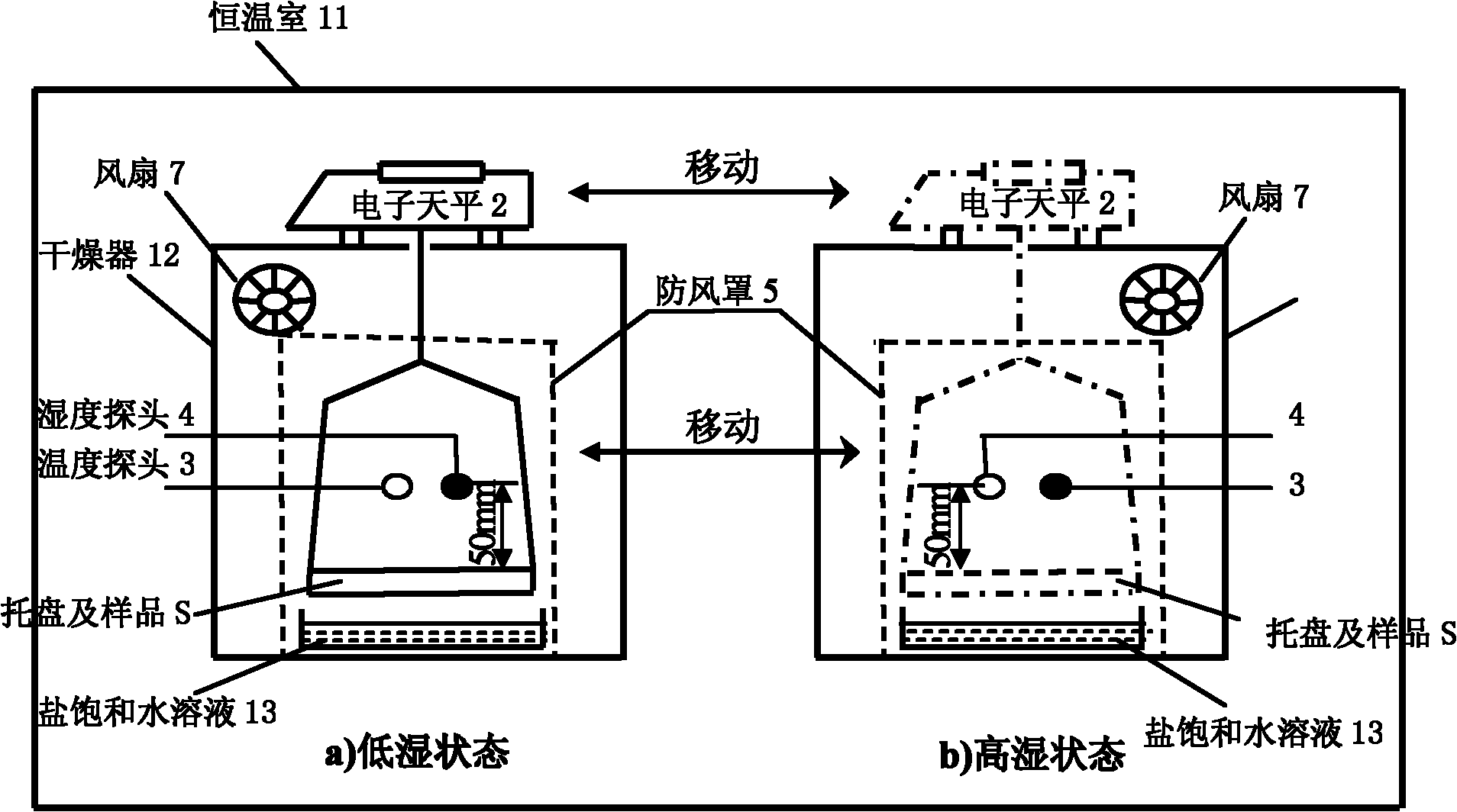

Performance testing equipment for humidifying function material and testing method

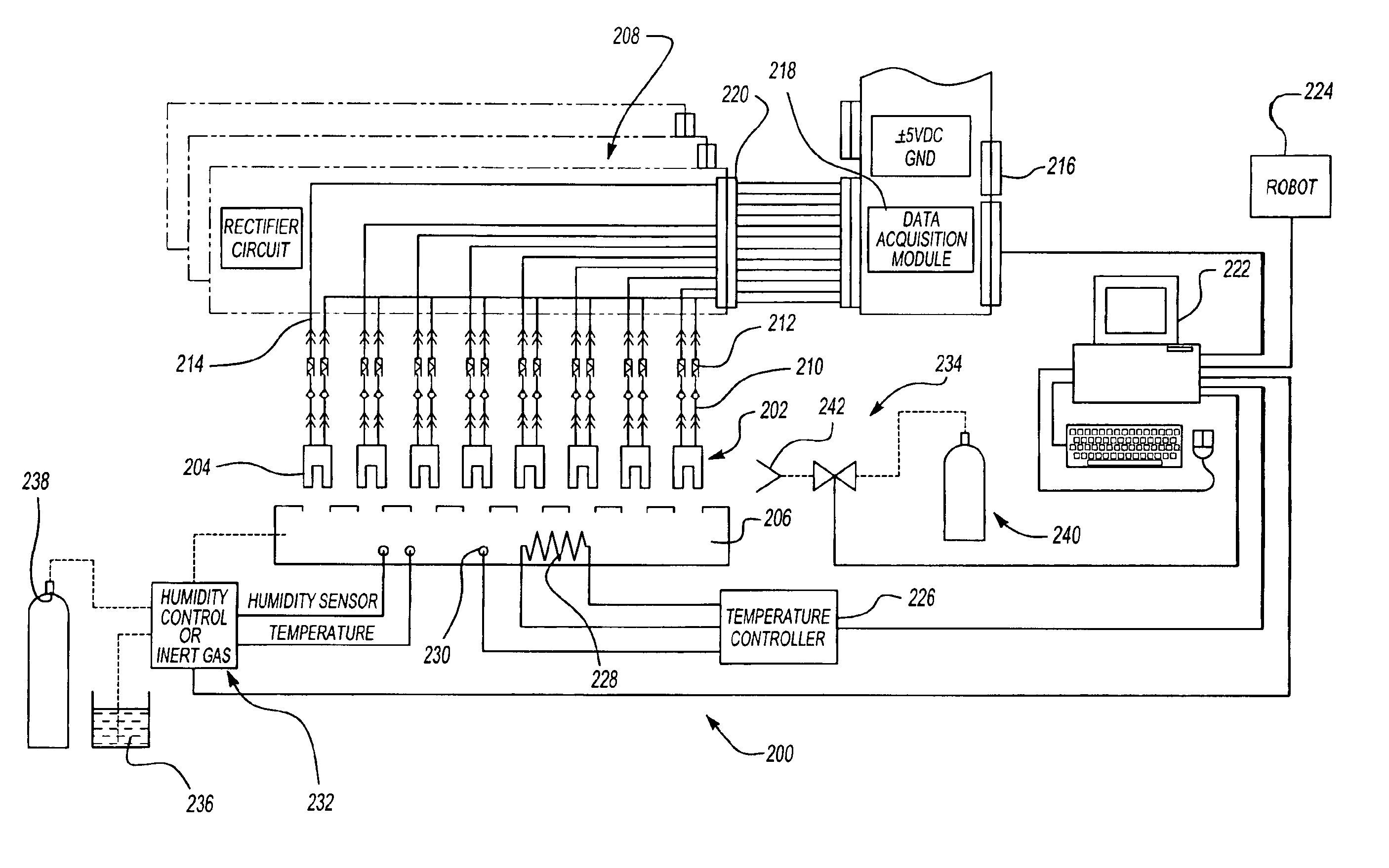

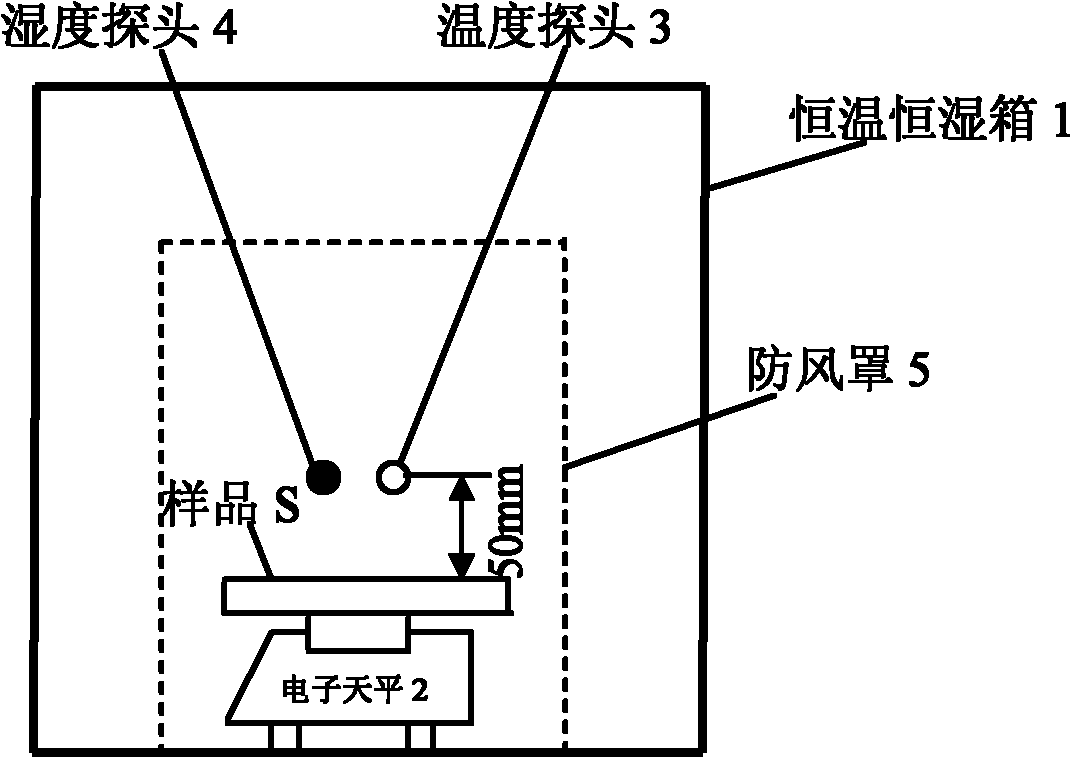

ActiveCN102252932AAccurate humidity controlImprove stabilityWeighing by removing componentWeighing by absorbing componentSaline waterEngineering

The invention discloses performance testing equipment for a humidifying function material and a testing method. The equipment disclosed by the invention comprises a relative humidity control part, a weighing part and a temperature and humidity monitoring part, wherein the relative humidity control part is a mechanical constant temperature cabinet system, a humidity change equipment system or a saturated saline water solution system and is provided with a closed space with adjustable temperature and humidity; a temperature probe and a humidity probe of the weighing part and the temperature andhumidity monitoring part are arranged in the closed space; the weighing part is an electronic balance; and the electronic balance, the temperature probe and the humidity probe are connected with a computer which is arranged outside the closed space. By means of different temperature and humidity control modes, the humidity absorption and release performances of the material are detected through ahumidity reaction method; the computer records the data of a detection sample which is weighed by the electronic balance in real time; and the humidity absorption and release capabilities of the sample are obtained by computing. The invention can accurately detect the humidifying performance of the material, and a testing result has good stability.

Owner:CHINA BUILDING MATERIALS ACAD

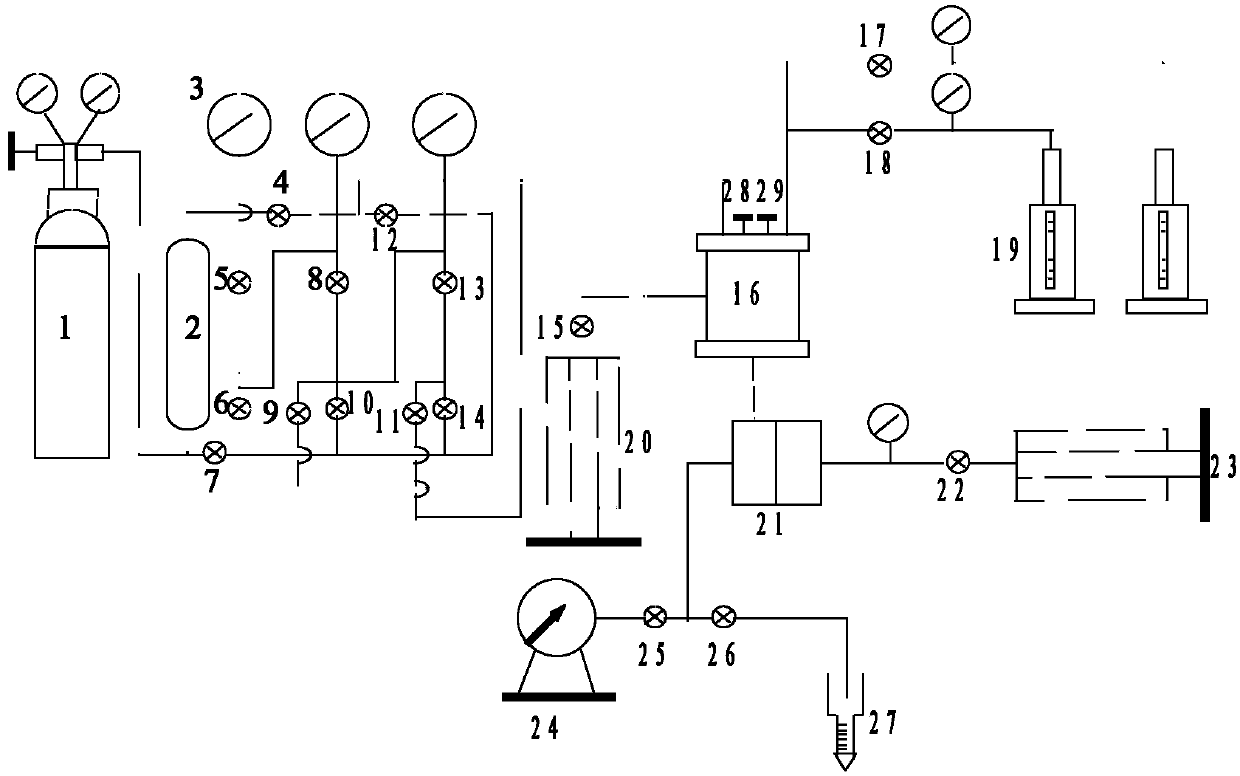

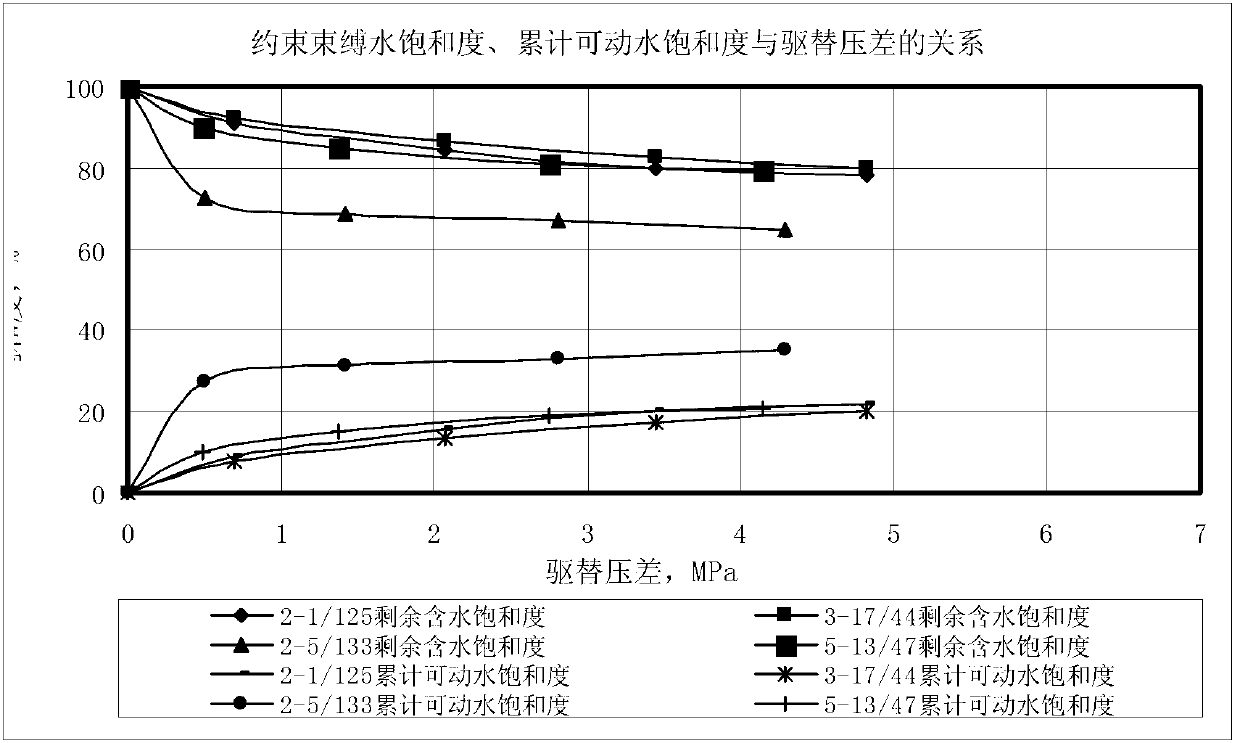

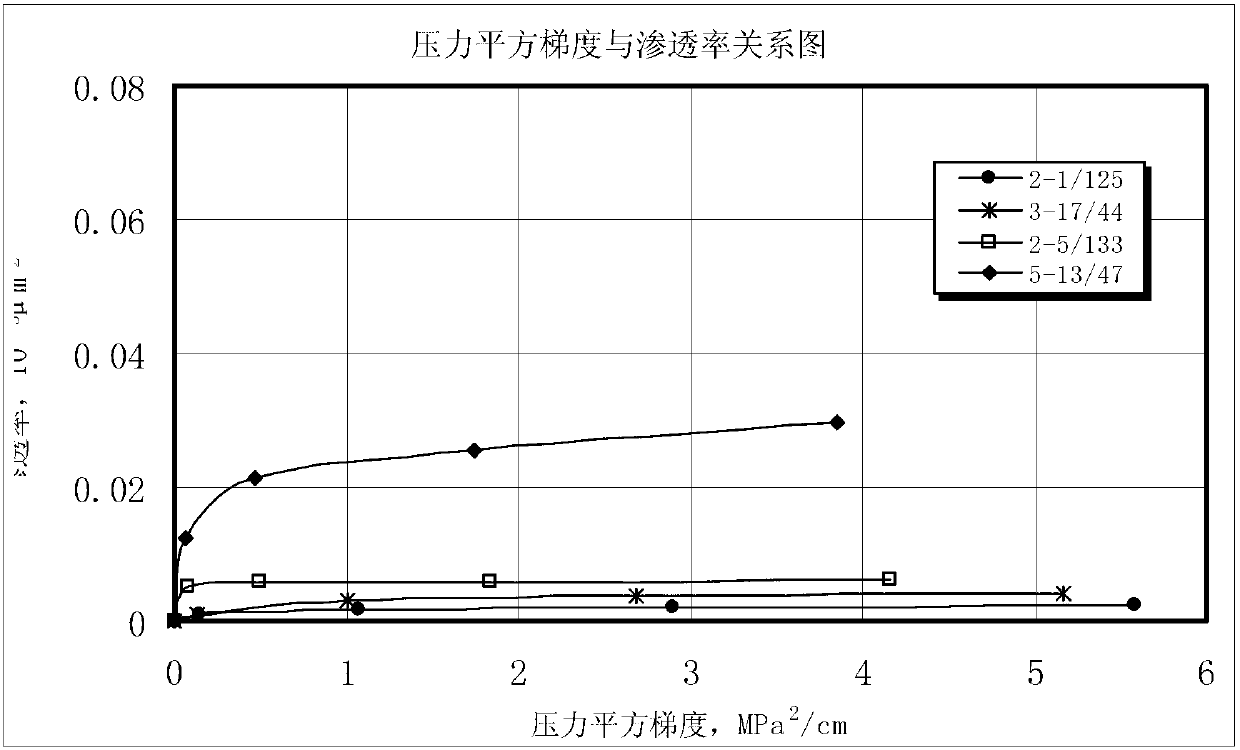

Determination device and method of constraint irreducible water saturation in reservoir rock core

InactiveCN103278418AReliable principleReasonable structureWeighing by removing componentRock coreDisplacement control

The invention discloses a determination device and method of constraint irreducible water saturation in a reservoir rock core. The device mainly comprises a high-pressure nitrogen source, a humidifier, a rock core holding device, an oil-water displacement pump, a loop pressure pump, a return pressure control pump, a gas metering instrument and a liquid metering instrument, wherein the rock core clamping device is arranged in a constant-temperature box; the high-pressure nitrogen source is connected with the inlet end of the rock core clamping device through the humidifier; the oil-water displacement pump is also connected with the inlet end of the rock core clamping device through an oil-water displacement control valve; the loop pressure pump is connectd with the rock core clamping device through a loop pressure control valve, and applies confining pressure to the rock core; and the outlet end of the rock core clamping device is connected with the return pressure control pump, and is also connected with the gas metering instrument and the liquid metering instrument respectively. The device is reliable in principle, is reasonable in structure, and is simple and convenient to operate, is utilized for determining the constraint irreducible water saturation in the reservoir rock core, can achieve the highest pressure of 70Mpa and the highest temperature of 150 DEG C, and remedies the defects of an existing gas reservoir log analysis and gas well production dynamic analysis method as well as the technique application.

Owner:SOUTHWEST PETROLEUM UNIV +1

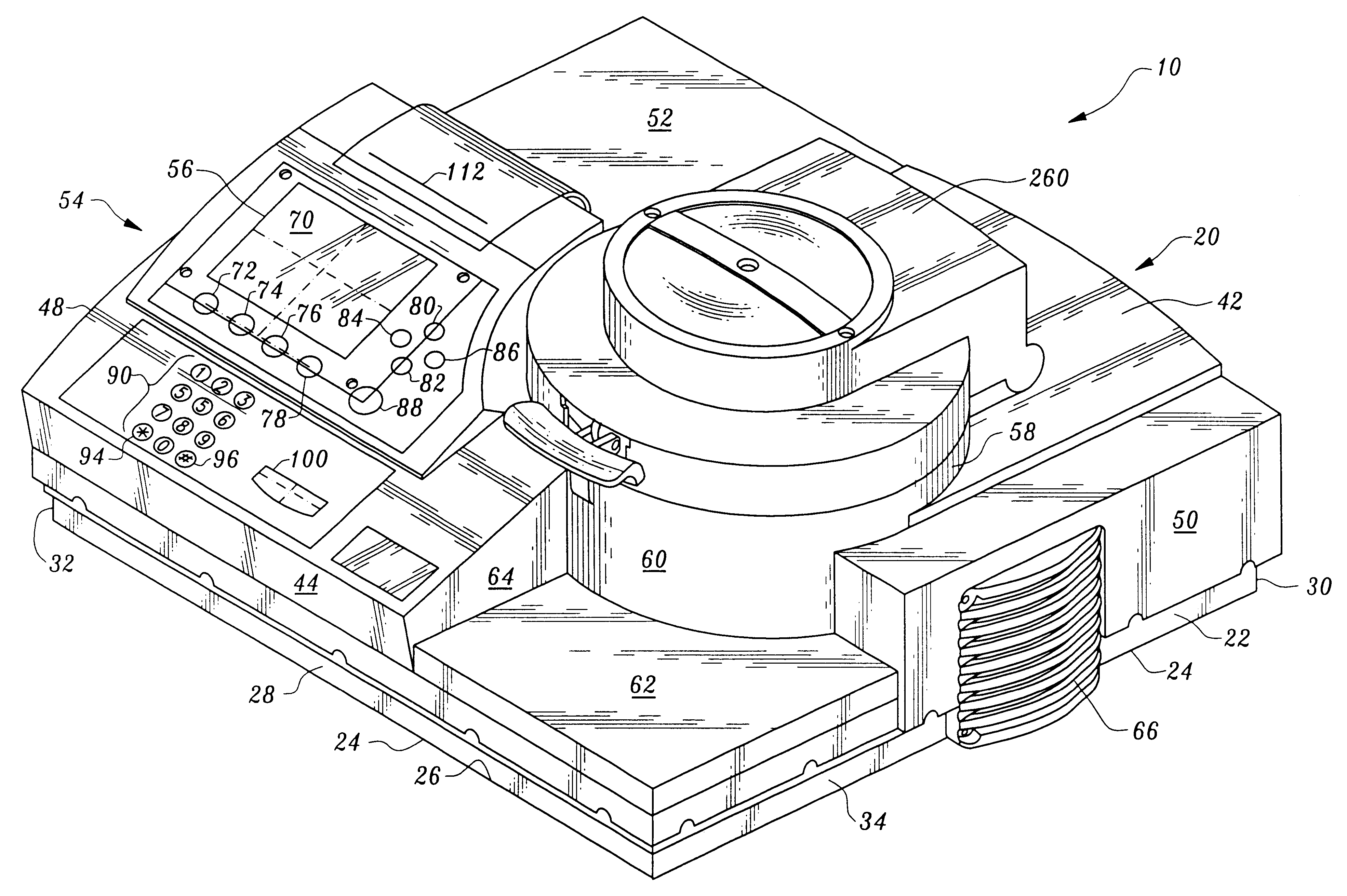

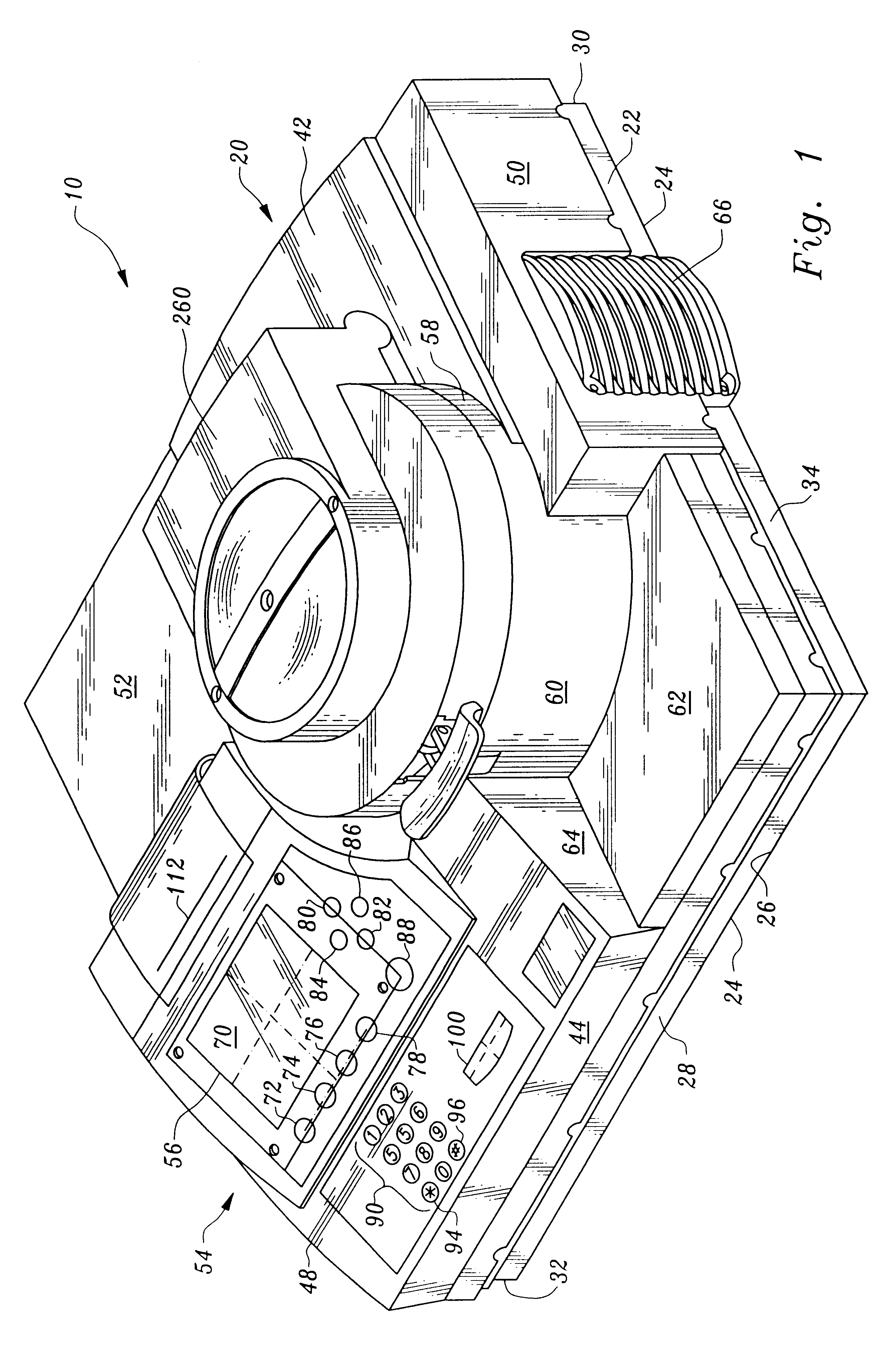

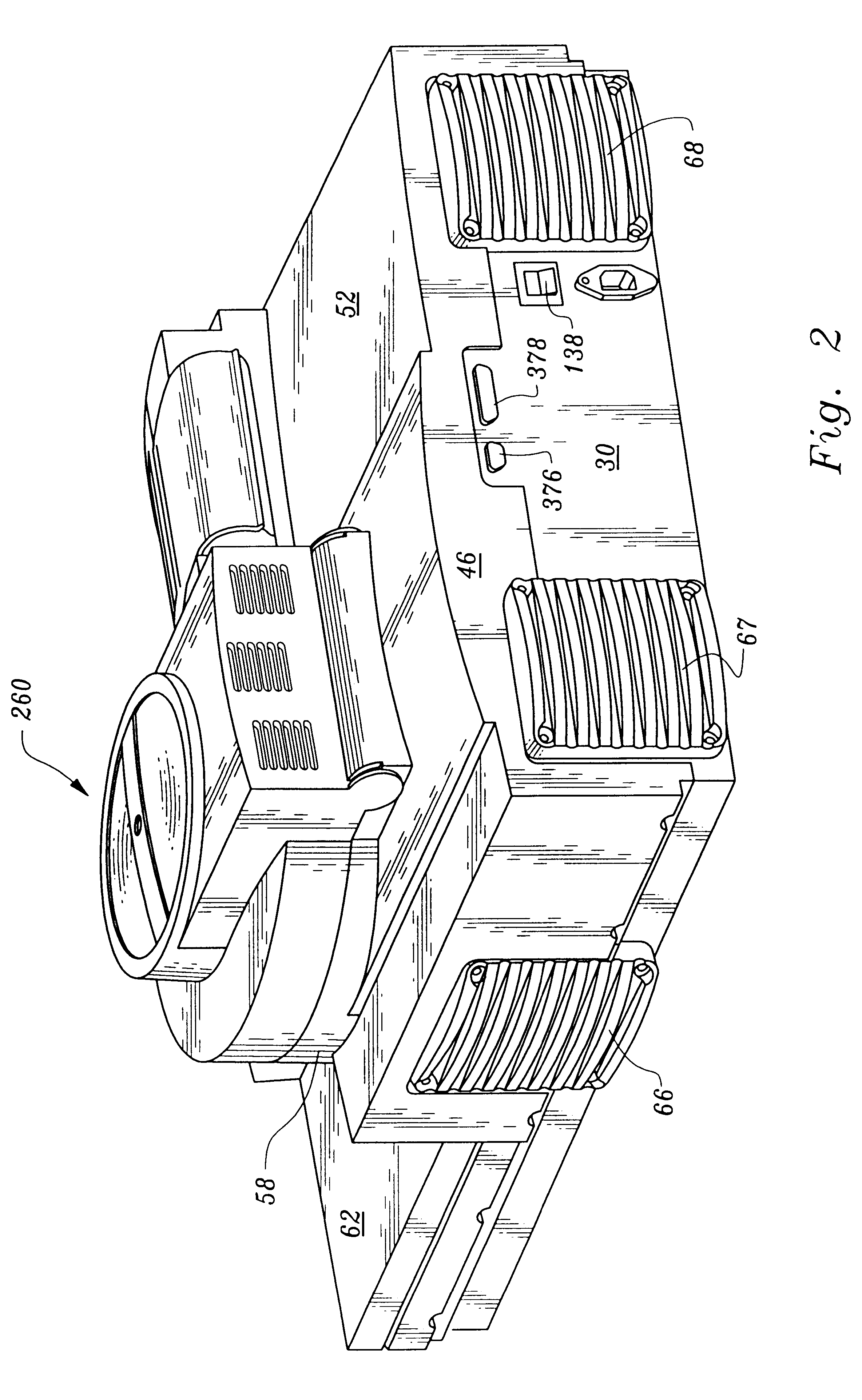

Microwave moisture analyzer: apparatus and method

InactiveUS6247246B1Reduce power consumptionWeighing by removing componentDrying solid materials with heatMicrowaveElectrical field strength

A toploading weighing instrumentality which determines loss on drying by a cylindrical microwave. The cylindrical cavity of the microwave includes a power supply, a magnetron, a power module operatively coupled between said power supply and said magnetron for driving said magnetron, a wave guide communicating with the magnetron and with a microwave containment chamber for delivering energy thereto, at least one microwave energy sensor for sensing microwave energy or magnetic and / or electric field strength within the chamber for controlling, inter alia, the loss on drying process of the sample being assayed and determining when the drying process is complete. A precision electronic balance is operatively disposed within the microwave chamber for allowing a specimen being assayed to be weighed. In addition, a ventilation chamber is provided for venting moisture from the microwave chamber. A processing unit and associated memory allows means for data acquisition, processing and storage of data from the power module driving the magnetron, the microwave energy sensor(s) for sensing magnetic and / or electric fields and the electronic balance for weighing the initial and final weights of the specimen for loss on drying moisture analysis. Both signaling the removal of microwave energy in the chamber.

Owner:DENVER INSTR

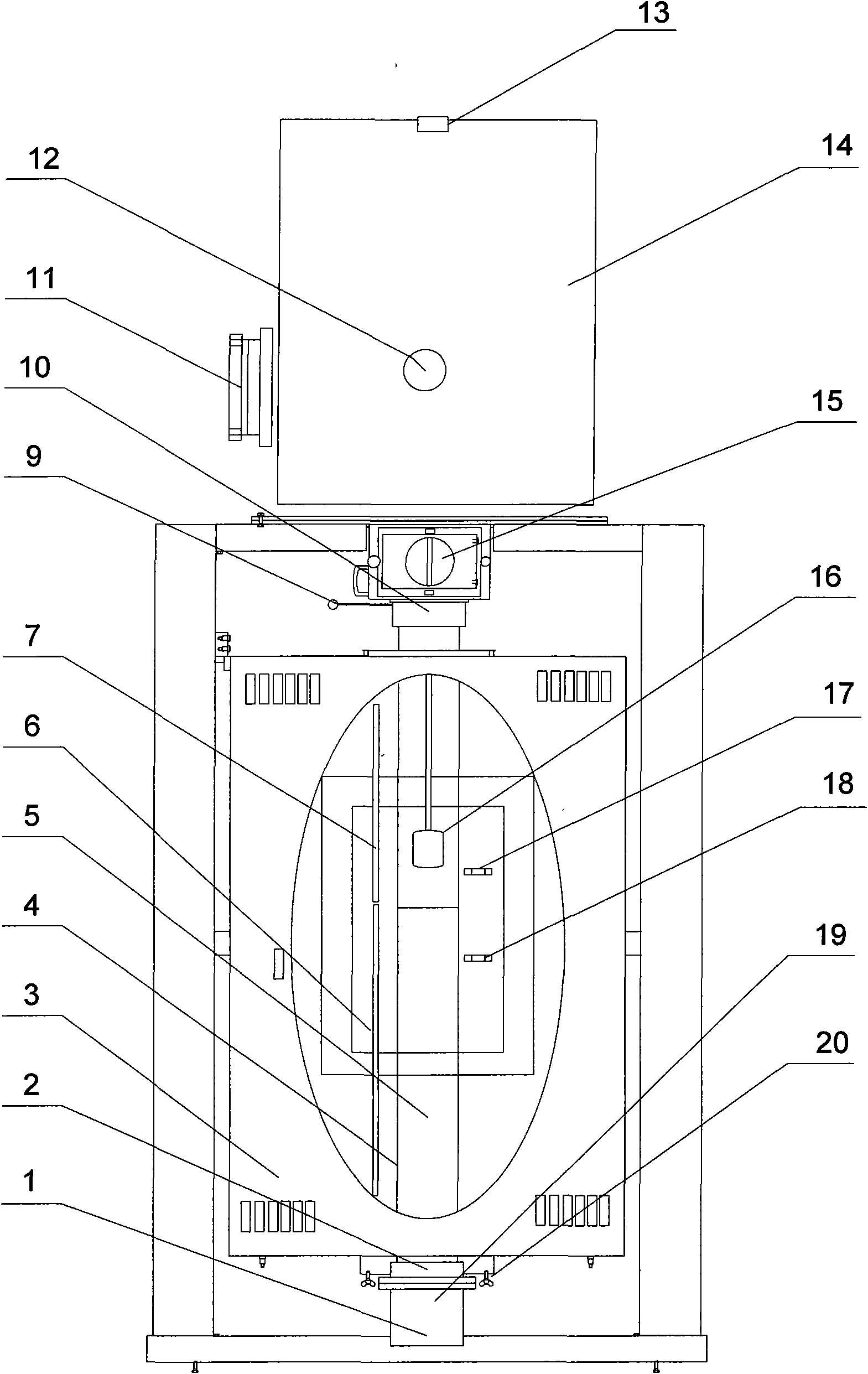

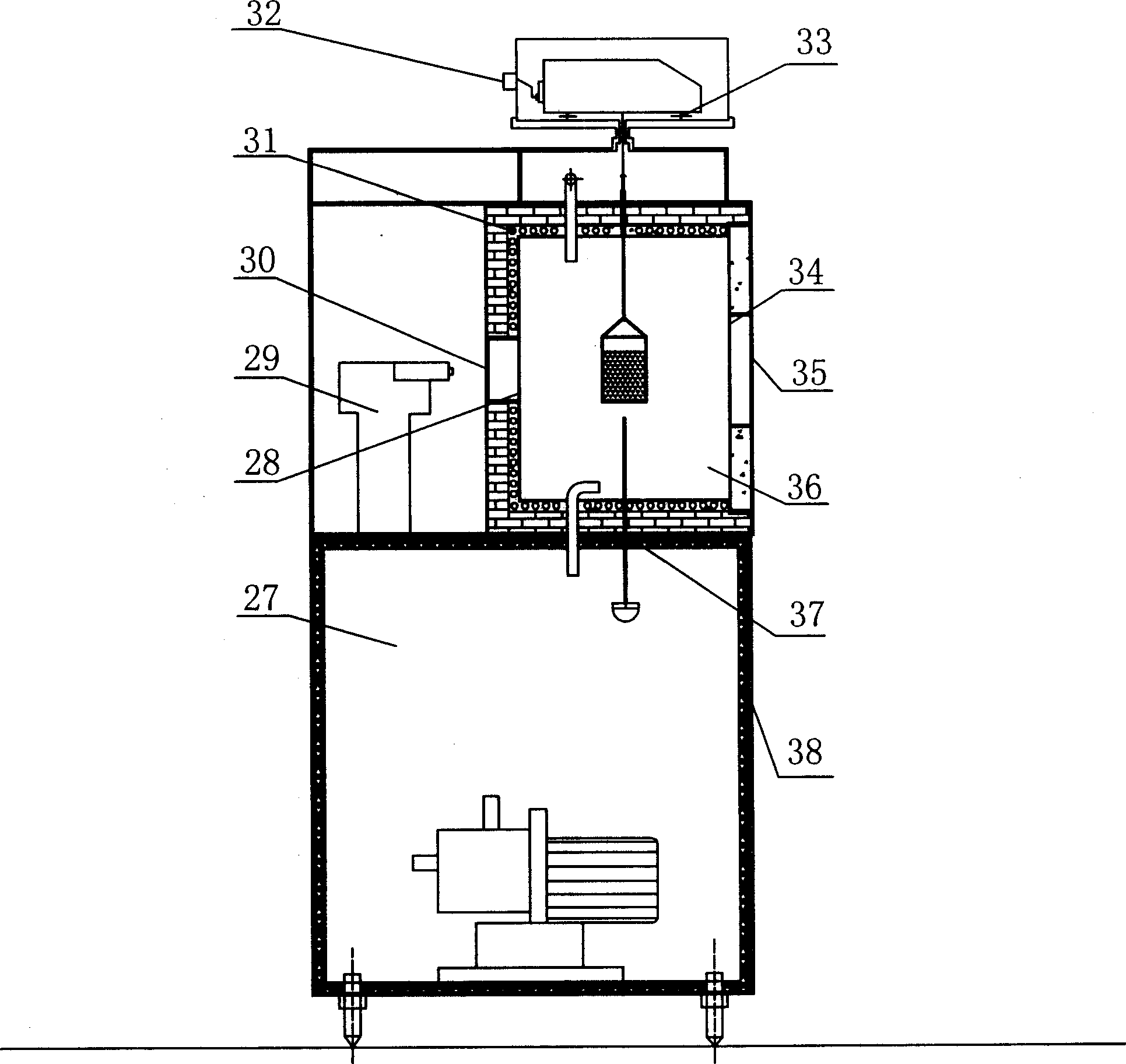

Gravitational thermal analysis method and device for heating sample by microwave

InactiveCN101382478AEnables microwave thermogravimetric analysisRealize dynamic measurementWeighing by removing componentPreparing sample for investigationAir atmosphereHearth

The invention discloses a microwave thermogravimetric analysis (TGA) method and a device, wherein, the device comprises four parts, namely, a microwave oven, a mass measurement system, a temperature measurement system and an atmosphere adjustment system. The microwave input power can be set to a fixed value and also can set to be linked with the temperature measurement system. The mass measurement system monitors the mass variation of a test sample in real time; the temperature measurement system utilizes an infrared thermometer and a thermocouple to monitor the temperature of the test sample and the hearth in real time. The atmosphere heating can be achieved by the atmosphere adjustment system and the heating atmosphere can be air atmosphere, inert atmosphere, oxidizing atmosphere or reducing atmosphere. The device provided by the invention has the advantages of simple structure, high degree of automation and convenient operation, the invention can obtain the relation among mass, time / mass, and temperature of multiple test samples under different atmospheres in the process of microwave heating, and realizes microwave thermogravimetric analysis of the test samples with larger mass or volume.

Owner:SHANDONG UNIV

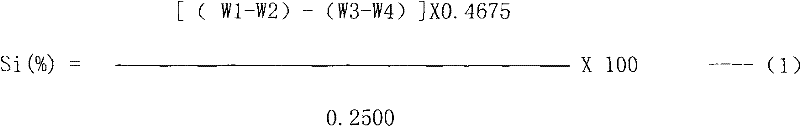

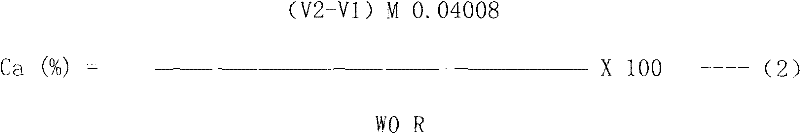

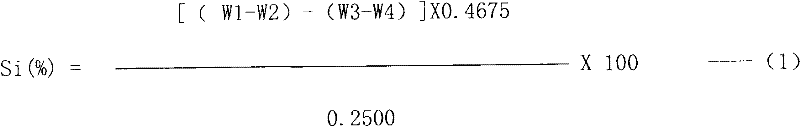

Method for measuring contents of silicon-calcium elements in silicon-calcium alloy

ActiveCN102213704AHighlight substantiveImprove work efficiencyWeighing by removing componentChemical analysis using titrationIonContinuous measurement

The invention relates to a method for measuring the contents of silicon-calcium elements in a silicon-calcium alloy. After a sample is grinded and passes through an analysis sieve with 180-200 meshes, the method provided by the invention is characterized in that the sample is fused at high temperature by adopting an alkali fusion method; the fusion course comprises the steps of: weighing and adding the sample and sodium hydroxide solid to a nickel crucible; after adding the mixture to a high temperature furnace to be heated, taking out and cooling; washing the fused analysis sample to an evaporation dish by utilizing deionized water and hydrochloric acid; drying and adding the hydrochloric acid to be acidized; adding warm water to be stirred until soluble salts are completely dissolved; instantly filtering by utilizing quantitative filter paper; enabling the filtrate to be constant volume in a volumetric flask to prepare a sample analysis solution; and maintaining the precipitations to be analysis components. The method for respectively measuring the contents of silicon and calcium provided by the invention comprises the following steps: measuring the content of the silicon with precipitation and filter paper by utilizing a weight analysis method after ashing, firing, cooling and weighing; and measuring the content of the calcium with the sample analysis solution by utilizing a volumetric method. The method provided by the invention has the advantages of once sample weighing, multi-element continuous measurement, time and labor saving, energy conservation, consumption reduction and the like and can reduce the damage of hydrofluoric acid to human bodies and environments.

Owner:TAIYUAN HEAVY IND

Microcantilever heater-thermometer with integrated temperature-compensated strain sensor

InactiveUS7928343B2Change resistanceWeighing by removing componentForce measurementSurface stressEngineering

The present invention provides microcantilever hotplate devices which incorporate temperature compensating strain sensors. The microcantilever hotplate devices of the present invention comprise microcantilevers having temperature compensating strain sensors and resistive heaters. The present invention also provides methods for using a microcantilever hotplate for temperature compensated surface stress measurements, chemical / biochemical sensing, measuring various properties of compounds adhered to the microcantilever hotplate surface, or for temperature compensated deflection measurements.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

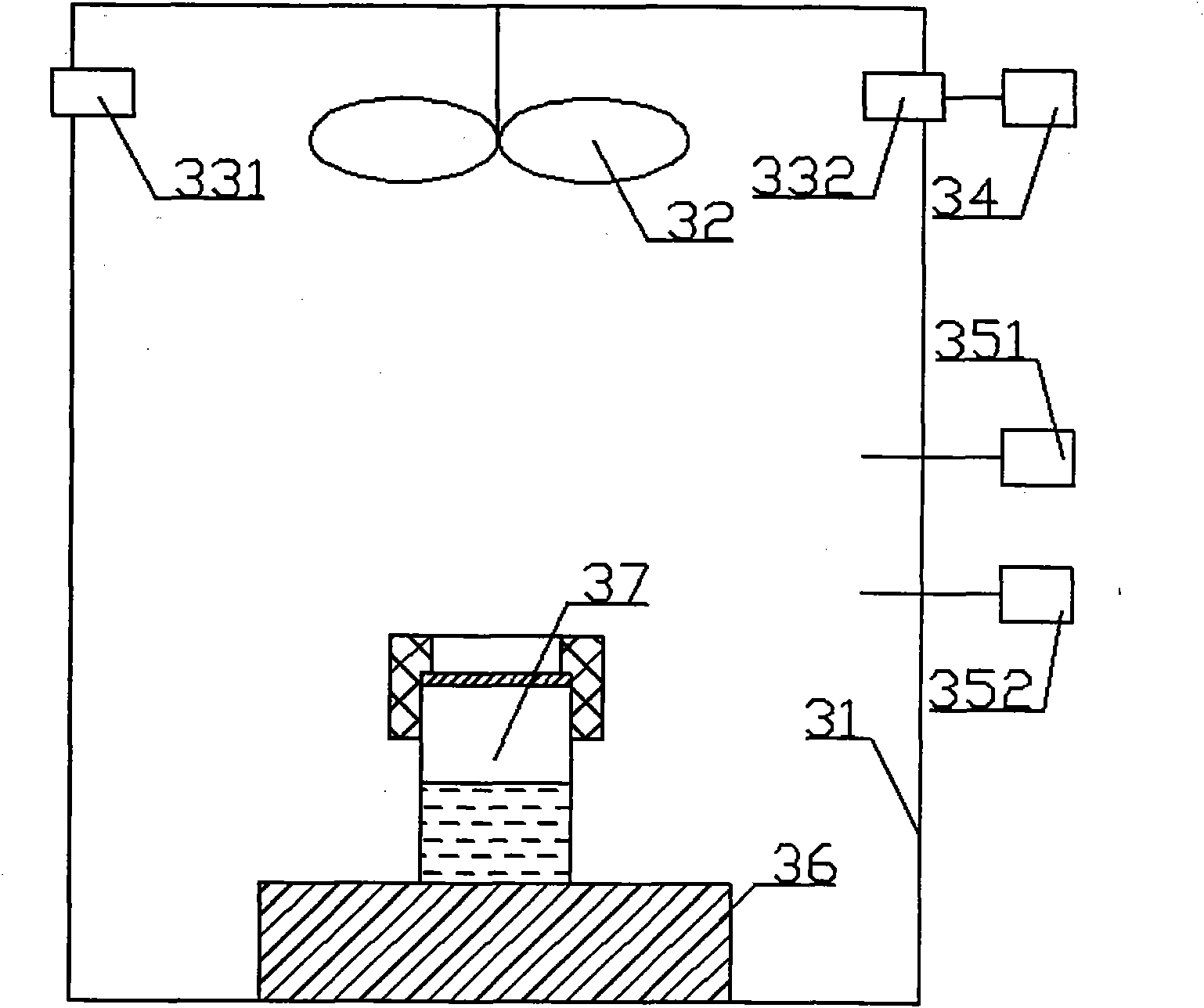

Standard distribution sample for detecting comprehensive performance of environmental chamber and detection method thereof

ActiveCN101881688ASimple methodEasy to operateWeighing by removing componentDetection of fluid at leakage pointEngineeringEnvironmental chamber

The invention relates to a standard distribution sample for detecting comprehensive performance of an environmental chamber and a detection method thereof and belongs to the field of indoor environment detection. The sample comprises a polytetrafluoroethylene cylindrical container of which the upper end is opened, organic volatile matter VOC liquid accommodated in the container, a barrier layer arranged on the upper end face of the cylindrical container and a sealing device fixing the barrier layer. The method comprises the following steps of: establishing a model; measuring the ventilation rate of the environmental chamber to be detected; placing the sample in the environmental chamber to be detected, placing the sample on an electronic balance, and recording the mass change of the standard distribution sample in real time; when the environmental chamber is in a sealed state, distributing the VOC liquid in the cylindrical container, calculating a distribution rate with the model according to the mass change, and calculating VOC concentration in the environmental chamber; acquiring the VOC concentration at an outlet of the environmental chamber in real time; and comparing the measured value and the calculated value of the VOC concentration to evaluate the comprehensive performance of the environmental chamber. The standard distribution sample and the detection method for the standard distribution sample have the advantages of simpleness and convenience, easy operation and relatively high precision and reliability.

Owner:TSINGHUA UNIV

Thermal analyzer with gas mixing chamber

ActiveUS20050123020A1Accurate measurementWeighing by removing componentMaterial thermal coefficient of expansionAtmospheric sciencesMoisture

In a thermomechanical measuring device and a thermogravimetry device, partition walls are provided in two sections such that two kinds of atmospheric gasses, which have passed a sample chamber and a detector chamber, respectively, do not flow back, and a thermally insulated gas mixing chamber is manufactured anew in the middle of the sample chamber and the detector chamber to make it possible to dilute a reactive gas and a water vapor gas having a high partial pressure. Consequently, it is possible to prevent moisture concentration to reduce an influence of water drops even in a high temperature and high humidity state at the time of humidity control and measurement.

Owner:HITACHI HIGH TECH SCI CORP

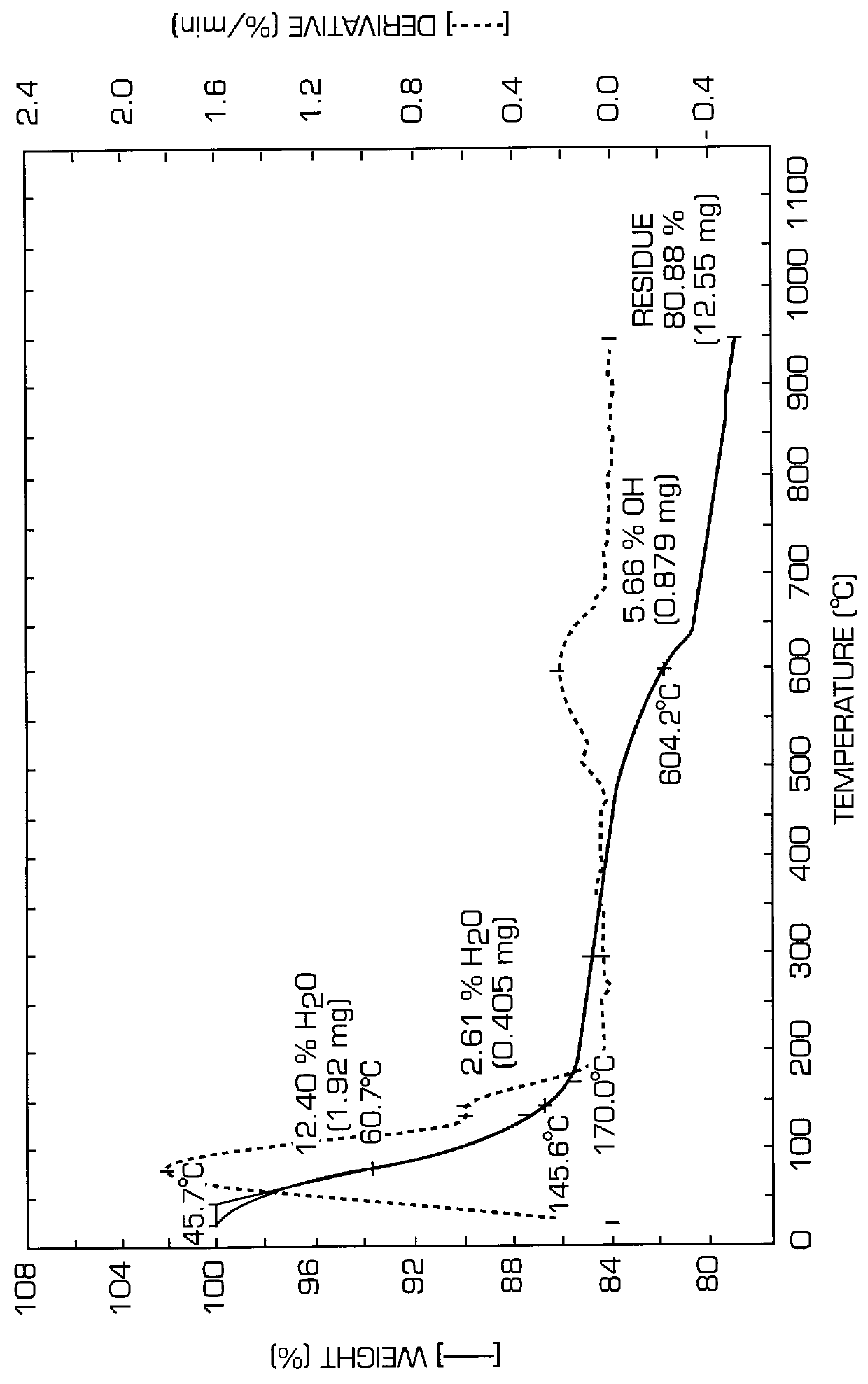

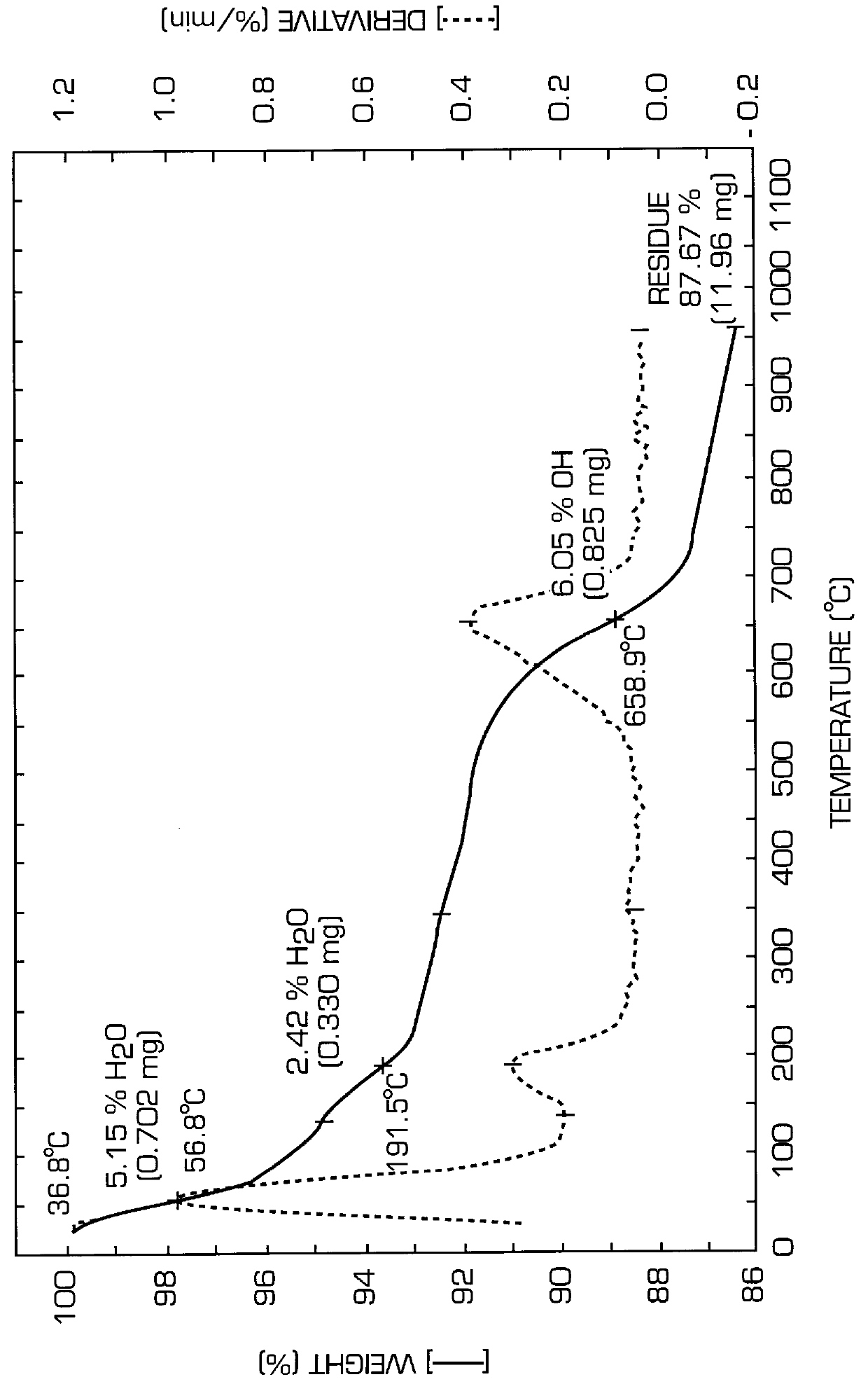

Method for evaluating drilling fluids

InactiveUS6009747AEffectively minimize borehole stability problemsWeighing by removing componentFlow propertiesWell drillingDrilling fluid

A method for evaluating drilling fluids to be used with clay-rich rocks such as shales which comprises collecting shales so as to preserve the downhole hydration condition and then submitting such preserved shale to Thermo-Gravimetric Analysis, so as to obtain the derivative curve of mass with respect to temperature, then immersing a sample of the same piece of rock in the drilling fluid of which the interaction with the clay-rich rock is to be ascertained and obtaining TGA analysis at successive periods of time of immersion of the sample, so as to determine the modifications undergone by the sample immersed in the drillling fluid. From the modifications undergone by the sample it is possible to evaluate the adequacy of the drilling fluid to be contacted with the clay-rich rock.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

Test method of sulphate content of desulfurization gypsum

InactiveCN101625300ASimple methodFast analysisWeighing by removing componentCooking & bakingWater content

The invention provides a test method of the sulphate content of desulfurization gypsum, comprising the following steps: 3-5 grams of gypsum samples are taken to be heated and dried for 30-60 minutes in a baking oven with the temperature of 42-48 DEG C and then placed into a drier to be cooled to room temperature and weighed by a 1 / 10000 level balance, the gypsum samples are repeatedly heated and weighed till the gypsum samples have constant weight, and the weight W (g) of the gypsum samples is recorded; the gypsum samples are placed back to the baking oven to be heated and dried for 30-60 minutes under the temperature of 350-370 DEG C and then placed into the drier to be cooled to the room temperature and weighed by the 1 / 10000 level balance, the gypsum samples are repeatedly heated and weighed till the gypsum samples have constant weight, and the weight W1 (g) of the gypsum samples is recorded; the computation of the crystallization water content of the gypsum samples is as follows: the crystallization water content X(%)=(W-W1)*100 / W, and the computation of the sulphate content of the gypsum samples is as follows: the sulphate content is indicated by calcium sulphate dehydrate content, CaSO4.2H2O(%)=X*100 / 20.9275. The method is simple, convenient and fast; and in addition, compared with the prior art, the invention greatly enhances the analysis speed, simplifies the analysis steps and decreases the experimental apparatus.

Owner:HEBEI ELECTRIC POWER RES INST

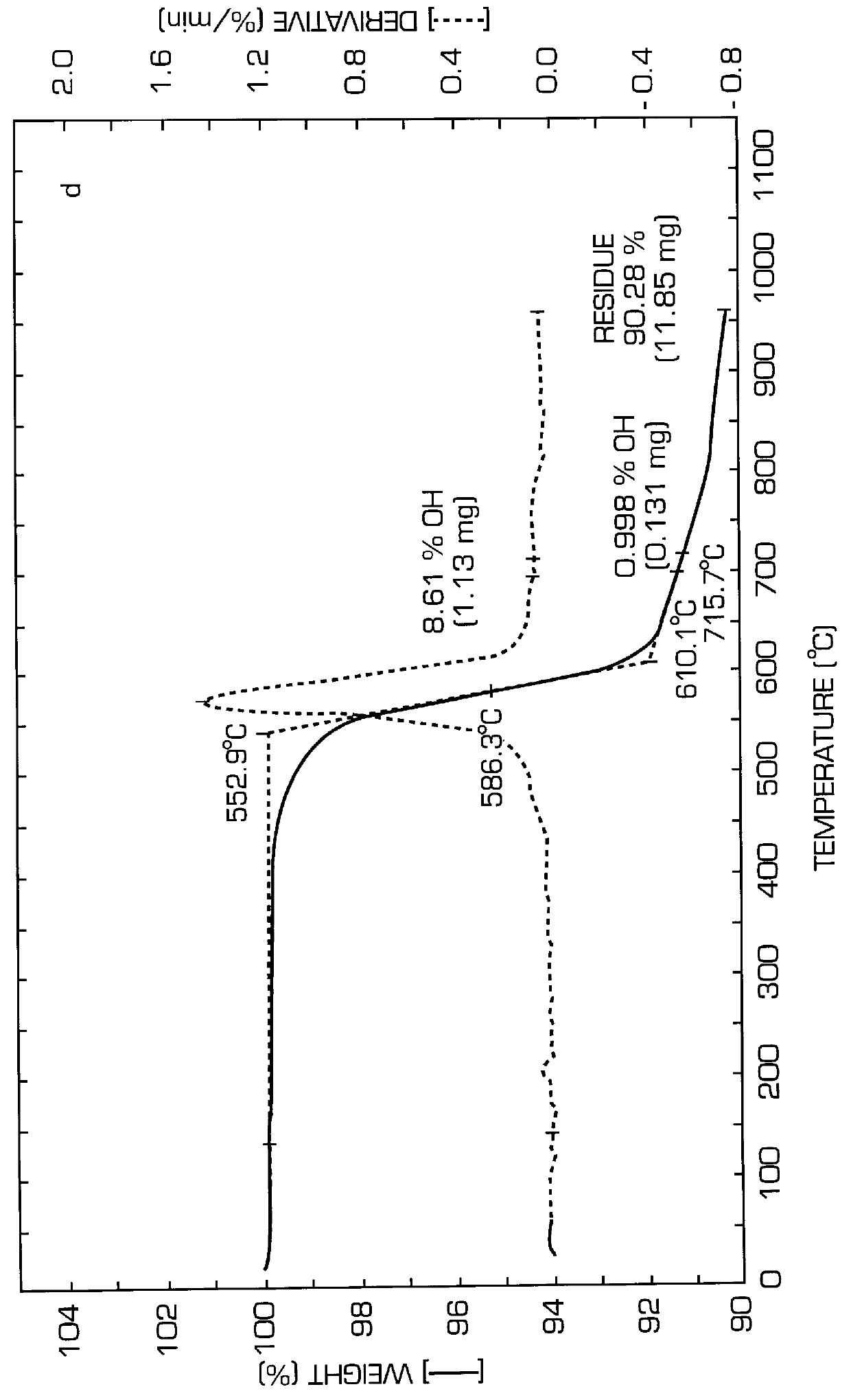

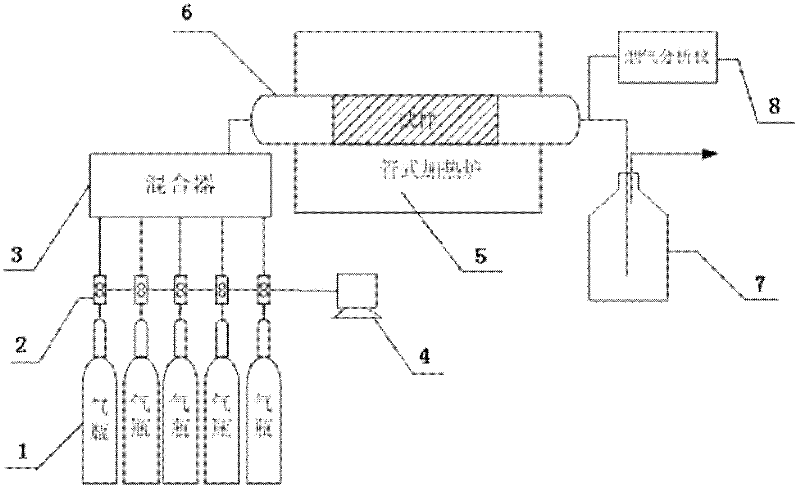

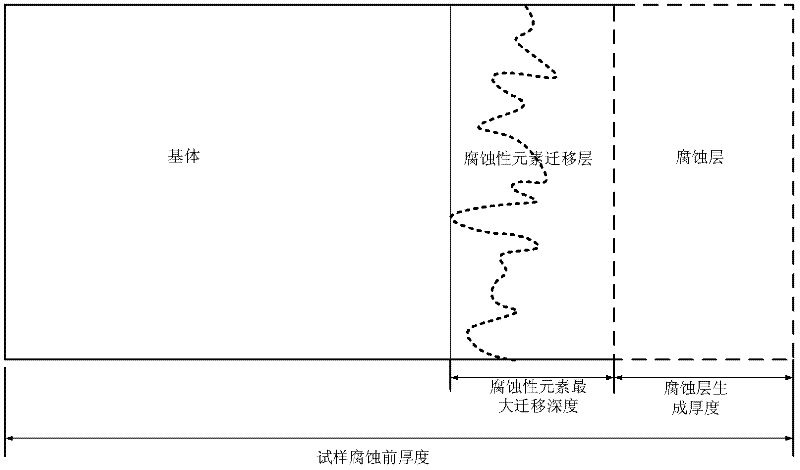

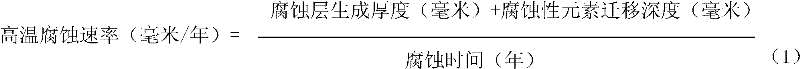

Experimental device and representation method of multiphase medium high-temperature corrosion rate

ActiveCN102539272AAchieve oxidationAchieving resilienceWeighing by removing componentWeather/light/corrosion resistanceGas phaseEngineering

The invention discloses an experimental device and a representation method of multiphase medium high-temperature corrosion rate. The experimental device comprises an air distribution device, a heating device and a tail gas treatment device which are communicated sequentially, wherein the air distribution device comprises a mixing device and a plurality of air bottles which are communicated with the mixing device; a quality flow meter connected with a computer is arranged among the mixing device and the air bottles; and the heating device comprises a heating furnace and a quartz tube reactor in the heating furnace. The representation method comprises the following steps: carrying out a gas phase or gas-liquid phase high-temperature corrosion experiment on a test sample according to the experiment requirement, thereby obtaining the decrement of the weights of the test sample before and after being corroded, and then converting the decrement into the thickness of the corroded test sample as the generation thickness of the corrosion layer during the test period of the test sample; and carrying out line energy spectrum line scanning experiment on the corroded test sample, thereby obtaining the maximal migration depth of a corrosive element in the thickness of the test sample, and finally calculating the high-temperature corrosion rate. By adopting the experiment device and the representation method provided by the invention, the high-temperature corrosion rate and the corrosion degree of a corrosive factor on the test sample are truly reflected from the macroscopic and microcosmic views.

Owner:XI AN JIAOTONG UNIV

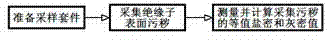

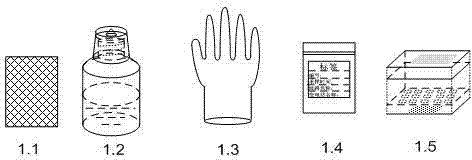

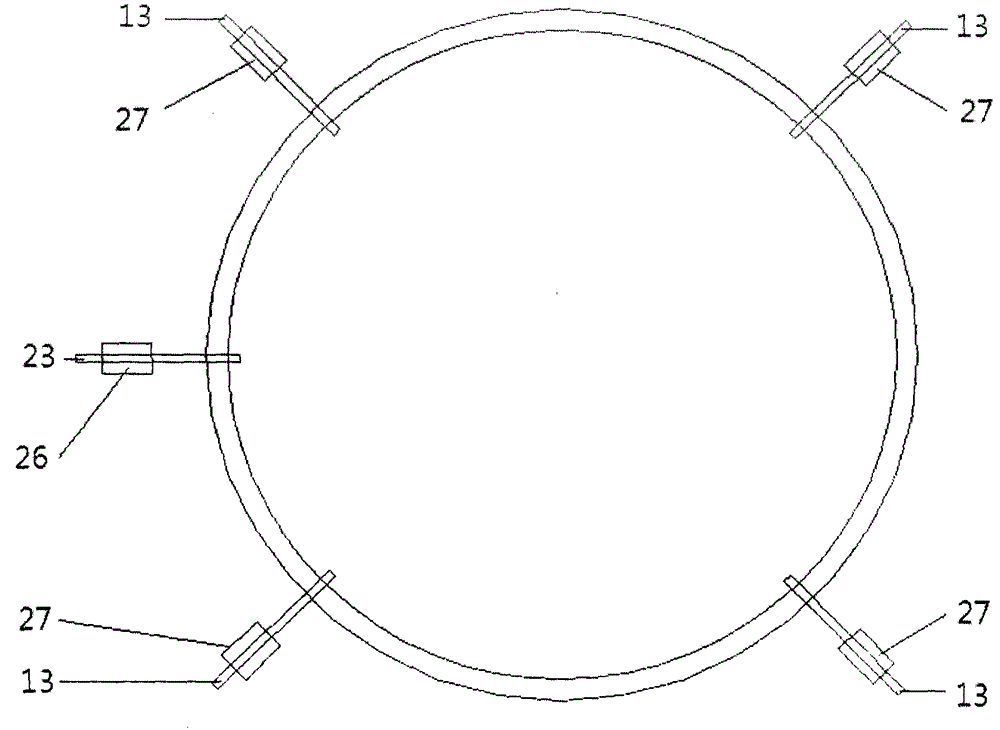

A method for on-site sampling and pollution degree measurement of insulator pollution

InactiveCN102288515ALess heavy workAvoid contamination lossWeighing by removing componentWithdrawing sample devicesEngineeringInsulator contamination

The invention discloses a method for on-site sampling and pollution degree measurement of insulator pollution. The method adopts a sampling cloth to directly wipe the pollution on the surface of the insulator to be tested without taking off the insulator, and completes the collection of pollution on the surface of the insulator to be tested. According to GB / T16434 or Q / GDW152-2006 measure the salt density and ash density value of the dirt on the sampling cloth, that is to get the salt density and ash density value of the surface of the insulator to be tested. The method of the invention does not need to take off the insulator, and has the advantages of convenient on-site measurement, small sampling workload, accurate measurement data and the like.

Owner:WUHAN UNIV +1

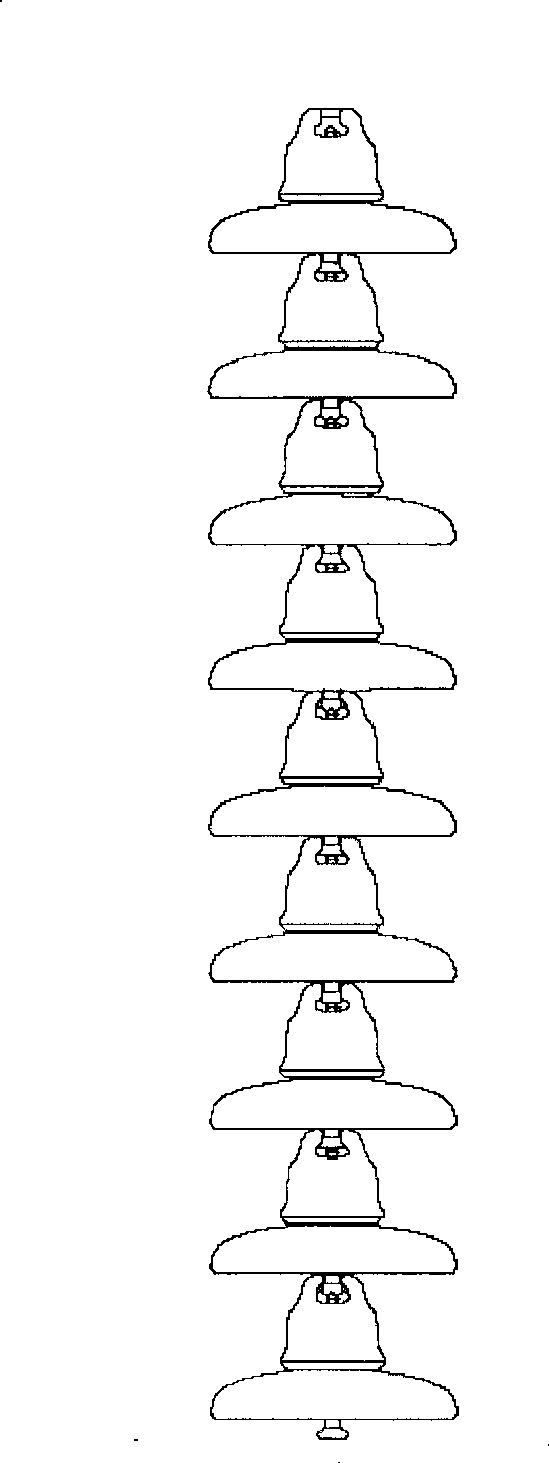

Insulator dirty degree sampling and measurement method and special funnel device

ActiveCN101393152ASolve incomplete problemsEasy to carryWeighing by removing componentPreparing sample for investigationWater bottleComputer science

Owner:STATE GRID CHONGQING ELECTRIC POWER CO ELECTRIC POWER RES INST

Electric furnace for expansive fireproof coating field detection and detecting method

ActiveCN1975371AReduced professional experience requirementsWeighing by removing componentMaterial thermal coefficient of expansionElectric arc furnaceBrick

This invention disclosed an improvement technique and testing method used for industrial electric cooker. The improved cooker consists of the main body, cap, heater and thermocouple. There was a fire resisting brick and a radiating chip in the hearth; the sample was stuck below the chip and above the brick; the upper side of the chip extends to the two cove boards. This invention meets the national standard and works precisely and efficiently so that it is not far from practical application.

Owner:BEIJING AVIATION MATERIAL INST NO 1 GRP CORP CHINA AVIATION IND

Method and a device for determining the liquid retention of absorbent articles

InactiveUS6557398B2Weighing by removing componentMaterial moisture contentEngineeringMechanical engineering

A method of measuring the liquid retention of absorbent articles (20) of the kind that includes an absorbent body having a top side which lies proximal to the wearer's skin when the article is worn, and a bottom side which is covered by a liquid-impermeable backing sheet, wherein the method comprises the steps of applying a determined amount of liquid to a region on the top side of the article, urging a pressure body (1) against a region of the top side of the article with a given force, and collecting and measuring the amount of liquid pressed out from the top side of the article. The force with which the pressure body (1) is pressed against the top side of the article, is set selectively on a device (2-4) for pressing the pressure body against the top side of the article (20), and the liquid pressed from the top side of the article is transported to a measuring vessel (15) with the aid of sub-pressure.

Owner:SCA HYGIENE PROD AB

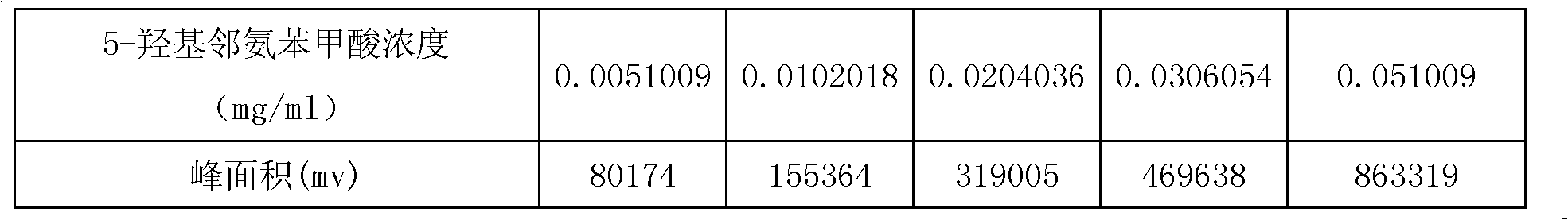

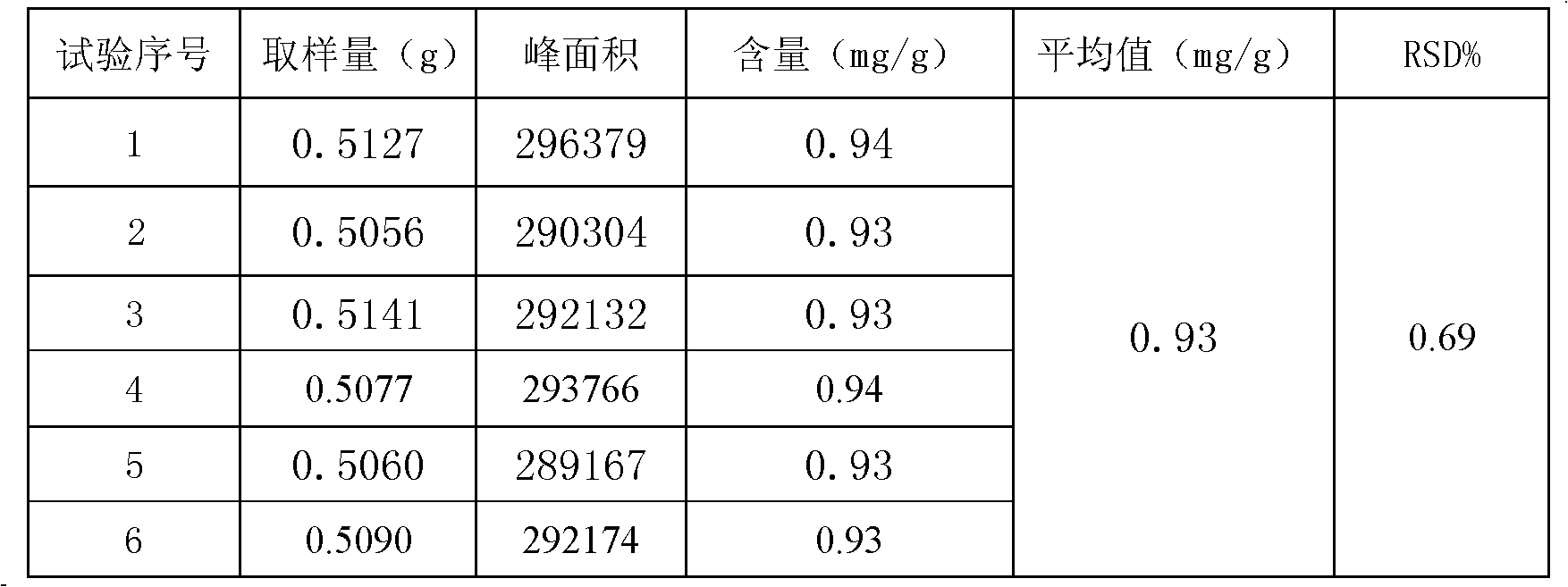

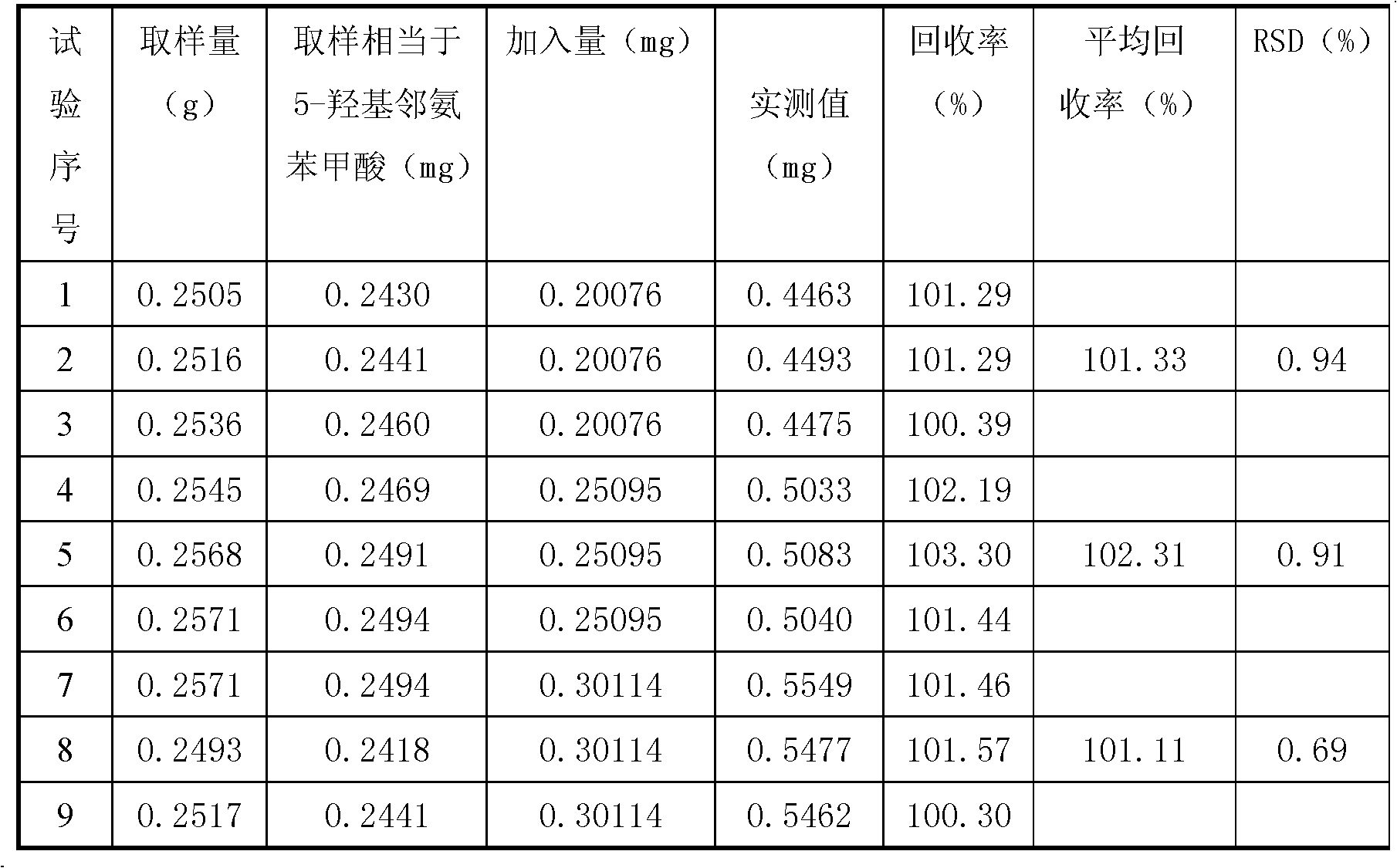

Method for detecting quality of compound capsule prepared from 8 kinds of amino acids and 11 kinds of vitamins

ActiveCN102072846AQuality improvementGuaranteed clinical efficacyWeighing by removing componentComponent separationVitamin b6Vitamin C

The invention discloses a method for detecting the quality of a compound capsule prepared from 8 kinds of amino acids and 11 kinds of vitamins, mainly comprising the steps of detecting whether the inclusion of the capsule is yellow or tangerine powder or particles, differentiating, checking the loss on drying and measuring the contents of amino acids, vitamin C, niacinamide, vitamin B1, vitamin B6, vitamin B2, calcium pantothenate, folic acid, vitamin A, vitamin D2, vitamin E and 5-hydroxy o-aminobenzoic acid in the capsule by adopting the high-performance liquid chromatography. The method for detecting the quality of the compound capsule prepared from 8 kinds of amino acids and 11 kinds of vitamins is scientific and reasonable, has high degree of accuracy, good repeatability, can comprehensively and effectively control the quality of the compound capsule prepared from 8 kinds of amino acids and 11 kinds of vitamins, and can ensure the clinical efficacy of the preparation.

Owner:GUIZHOU MAQIKA PHARMA

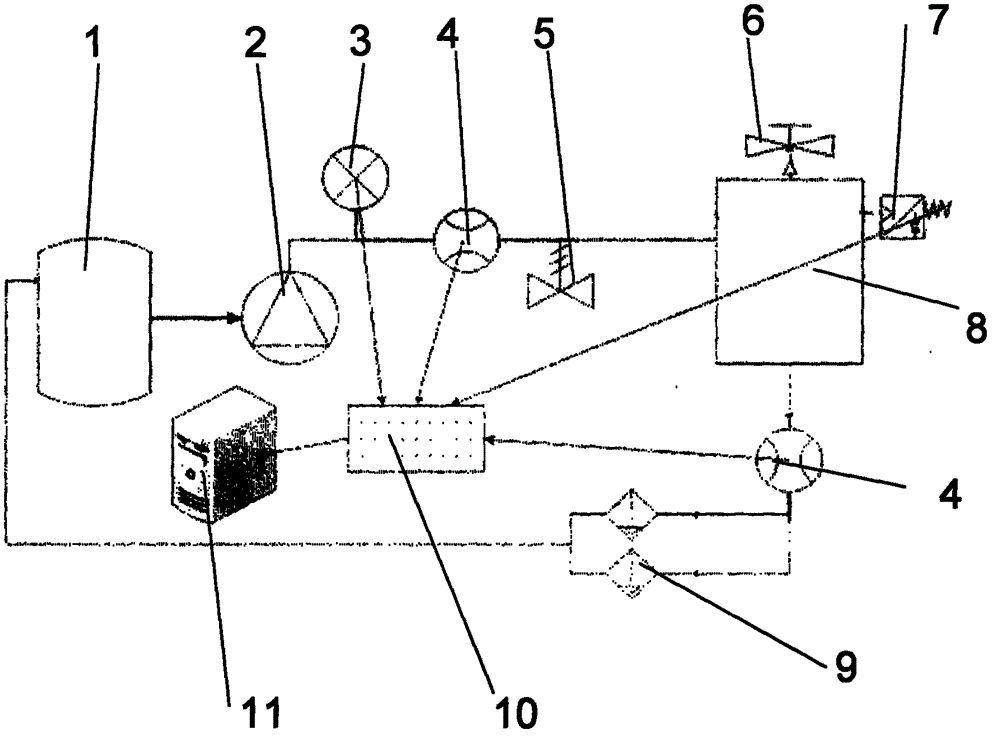

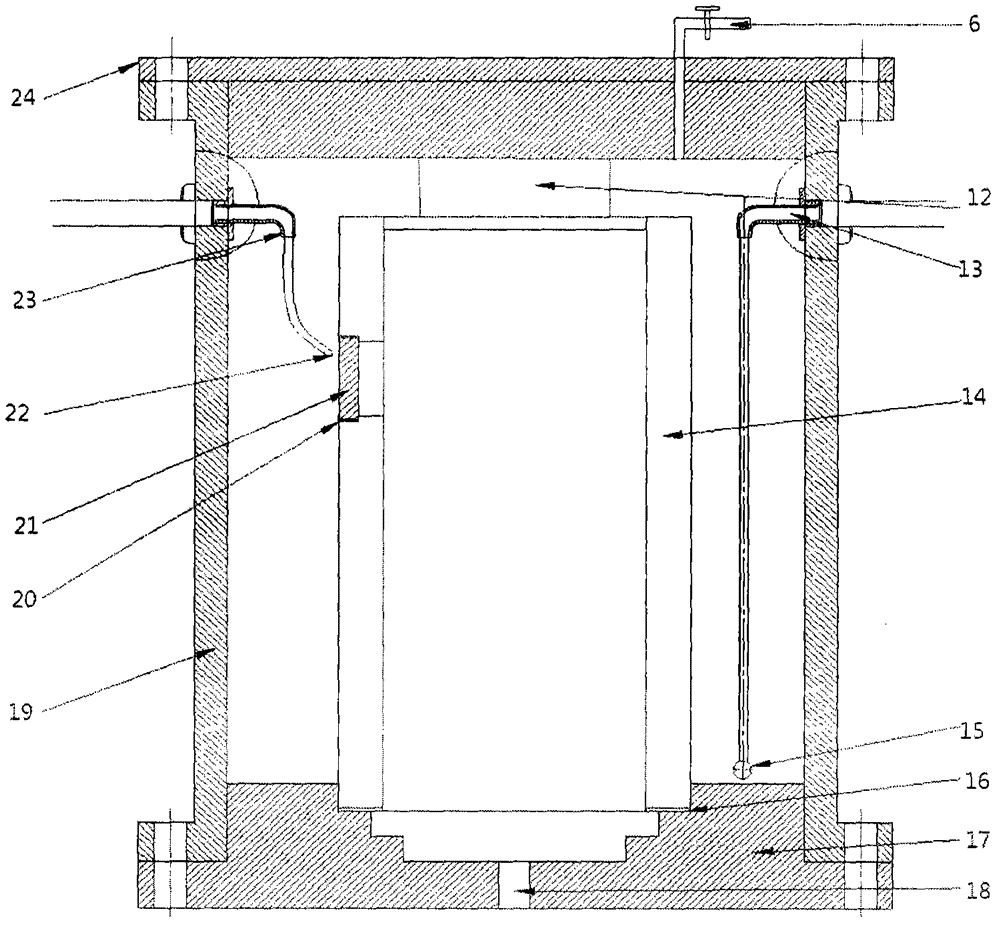

Method for evaluating erosion rate of sand control pipe and its special-purpose apparatus

InactiveCN104897510AWeighing by removing componentMaterial analysis using radiation diffractionExhaust valveErosion rate

The invention relates to a method for evaluating erosion rate of a sand control pipe and its special-purpose apparatus, which is characterized in that the on-site screen casings are used for processing to screen casing sheets for experiments. According to the invention, change of sand control pipe precision can be evaluated by a laser granularity analysis on sand from different periods of experiment process, erosion rate of the screen casing under specific reservoir condition and production condition can be evaluated according to the mass change of the screen casing sheet before and after the experiment, and finally the erosion rate and the usage life of the screen casing can be predicted. For solving the problems, a technical scheme is characterized in that the special-purpose apparatus is a whole set of fluid circulation apparatus, which comprises a circulation solution storage pot 1, a high pressure pump 2, a pressure gage 3, a flow monitor device 4, a safety exhaust valve 6, a pressure transducer 7, an enclosed autoclave body 8, an oil-sand separator 9, and a data acquisition system 10. According to the special-purpose apparatus, an erosion stand 14, a cleaning nozzle 22 and a sand washing nozzle 15 are arranged in the enclosed autoclave body 8.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

Hierarchical collection device of suspended matters of natural water body, and collection method of hierarchical collection device

InactiveCN102928257AGuaranteed original conditionPrevent coagulationWeighing by removing componentWithdrawing sample devicesEnvironmental engineeringSuspended matter

The invention discloses a hierarchical collection device of suspended matters of a natural water body, and a collection method of the hierarchical collection device. The collection device comprises a filtering combination suite, a control box, a submersible pump and a water pipe, wherein the filtering combination suite further comprises a water inlet element, filtering elements and a water outlet element, and a plurality of filtering elements are overlapped together and are arranged between the water inlet element and the water outlet element. According to the hierarchical collection device, the plurality of filtering elements are overlapped together, the apertures of the filtering elements are gradually reduced from top to bottom, the suspended matters in different particle sizes are separated in a layer-by-layer manner, and the suspended matters in different particle sizes can be separated at one time, so that the operation is simple and quick, and precision is improved. The collection device is easy to use during field sampling, depth and flow instruments can be used for quantitative sampling of the natural water bodies in different depths, the suspended matters are separated in place, and the original state of the suspended matters is ensured; and the difficulty in separation of bio-particles in a sedimentation method is overcome; and the collection device has the advantages of large flux, time saving and very low cost.

Owner:PEKING UNIV

Popular searches

Resistance/reactance/impedence Material strength using steady bending forces Analysing fluids using sonic/ultrasonic/infrasonic waves Analysing solids using sonic/ultrasonic/infrasonic waves Sampling Resonant frequency Material analysis by optical means Weighing apparatus for continuous material flow Particle suspension analysis Material analysis by using resonance

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com