Patents

Literature

180 results about "Erosion rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

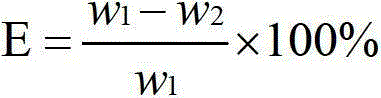

The erosion rate measures the amount of soil mass lost over a specified time period. If 30,000 kilograms of soil was lost over four years, then: Erosion rate equals 30,000 divided by 4, or 7,500 kilograms per year.

Method and apparatus which reduce the erosion rate of surfaces exposed to halogen-containing plasmas

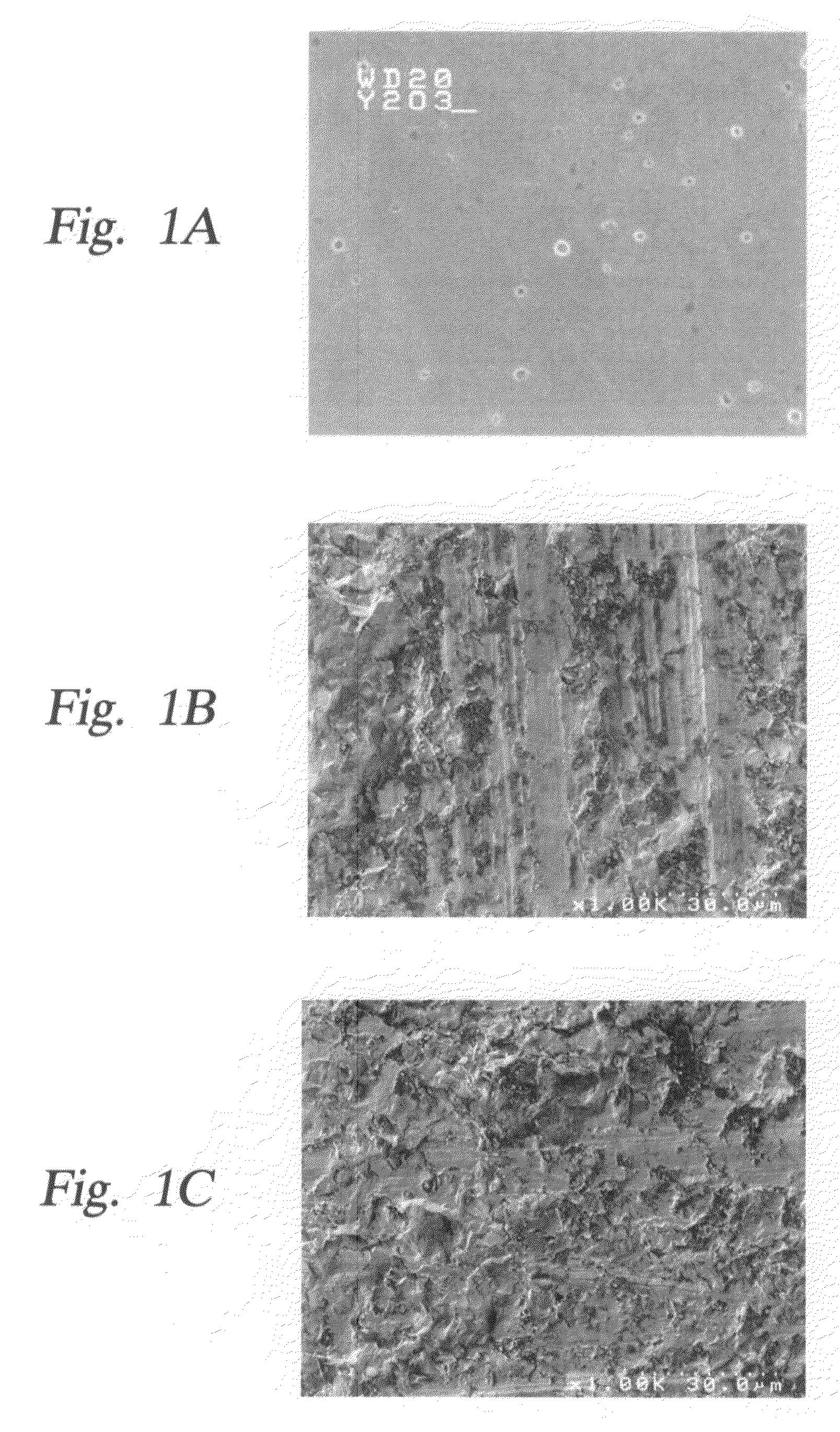

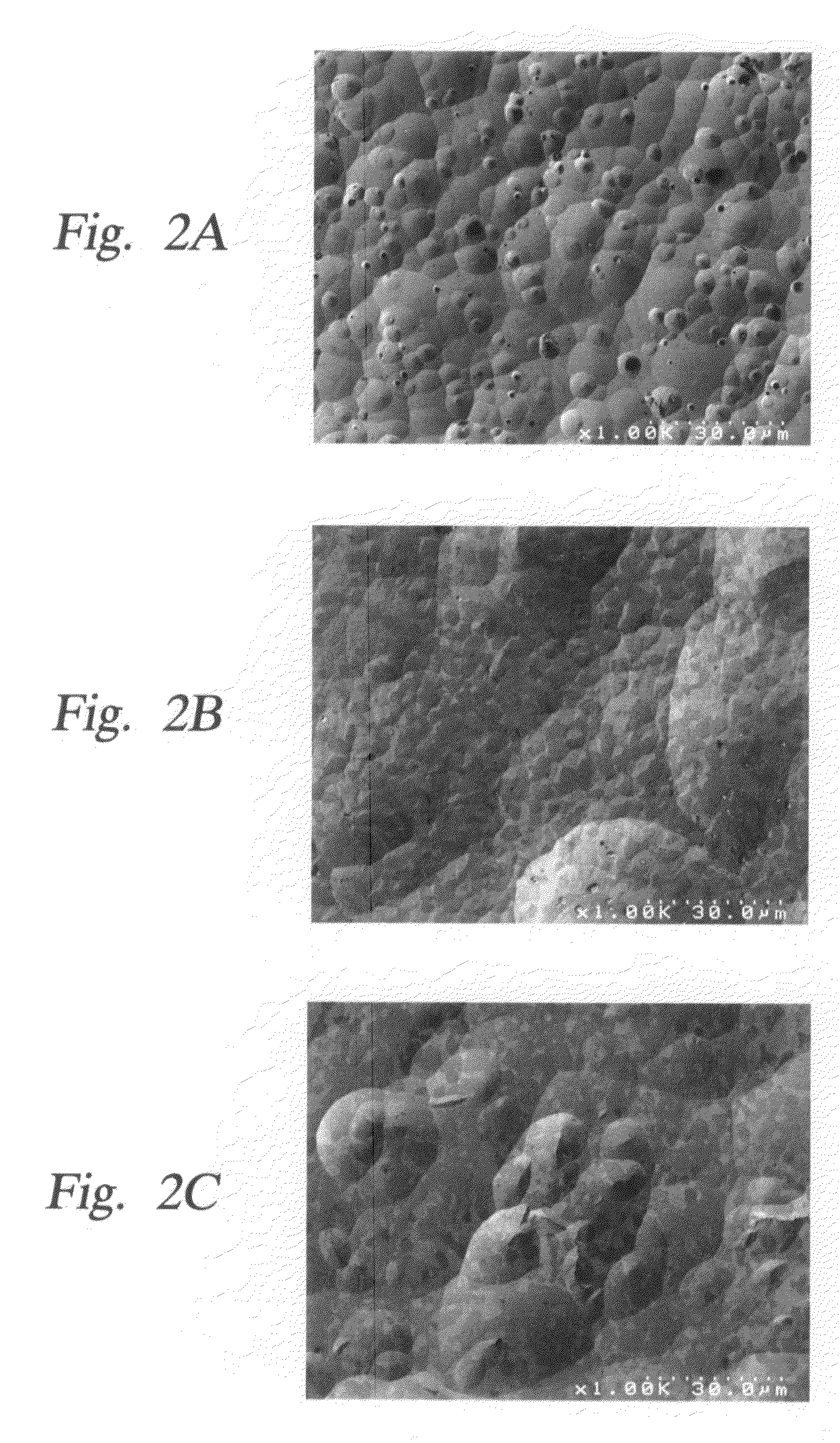

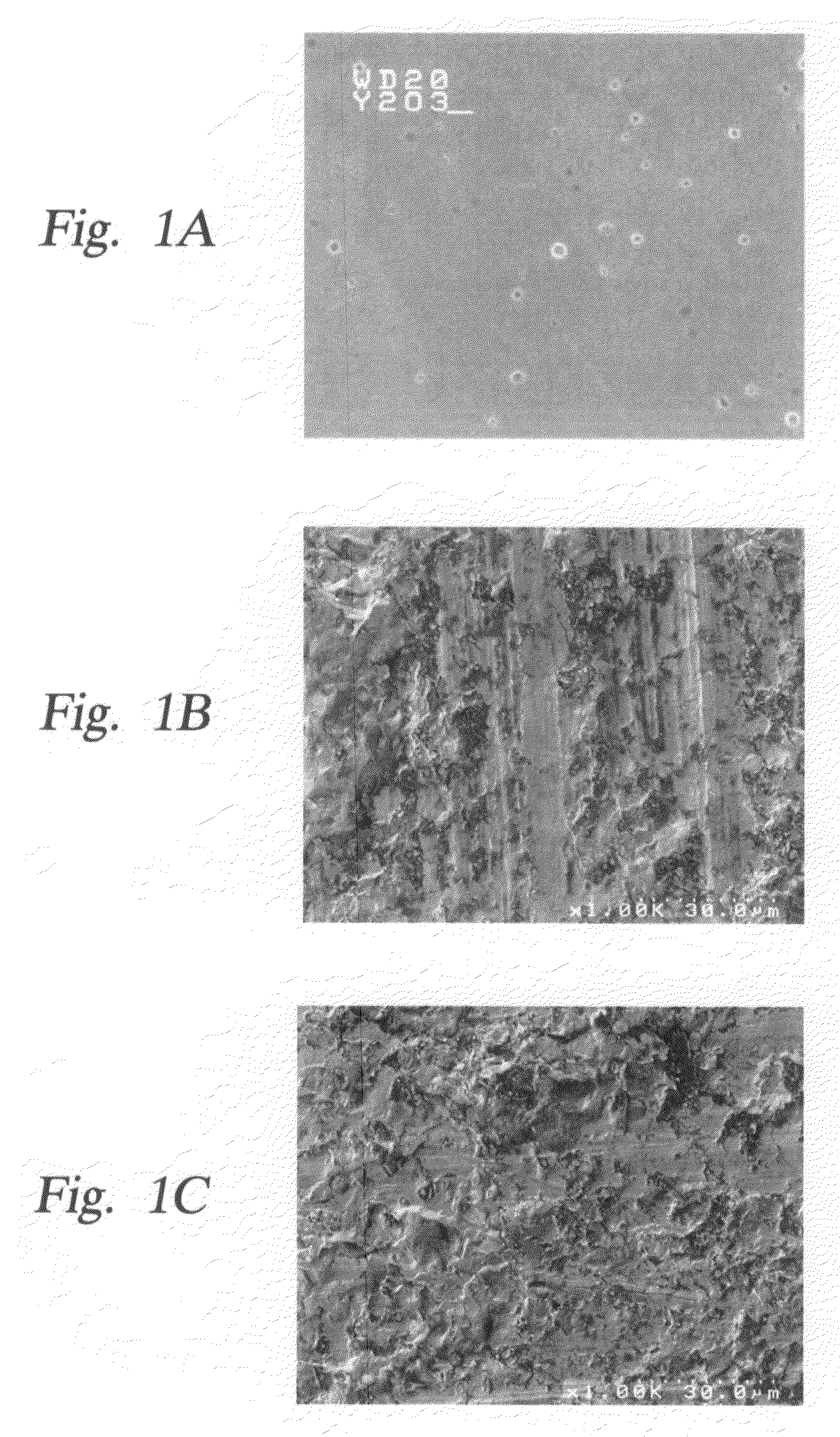

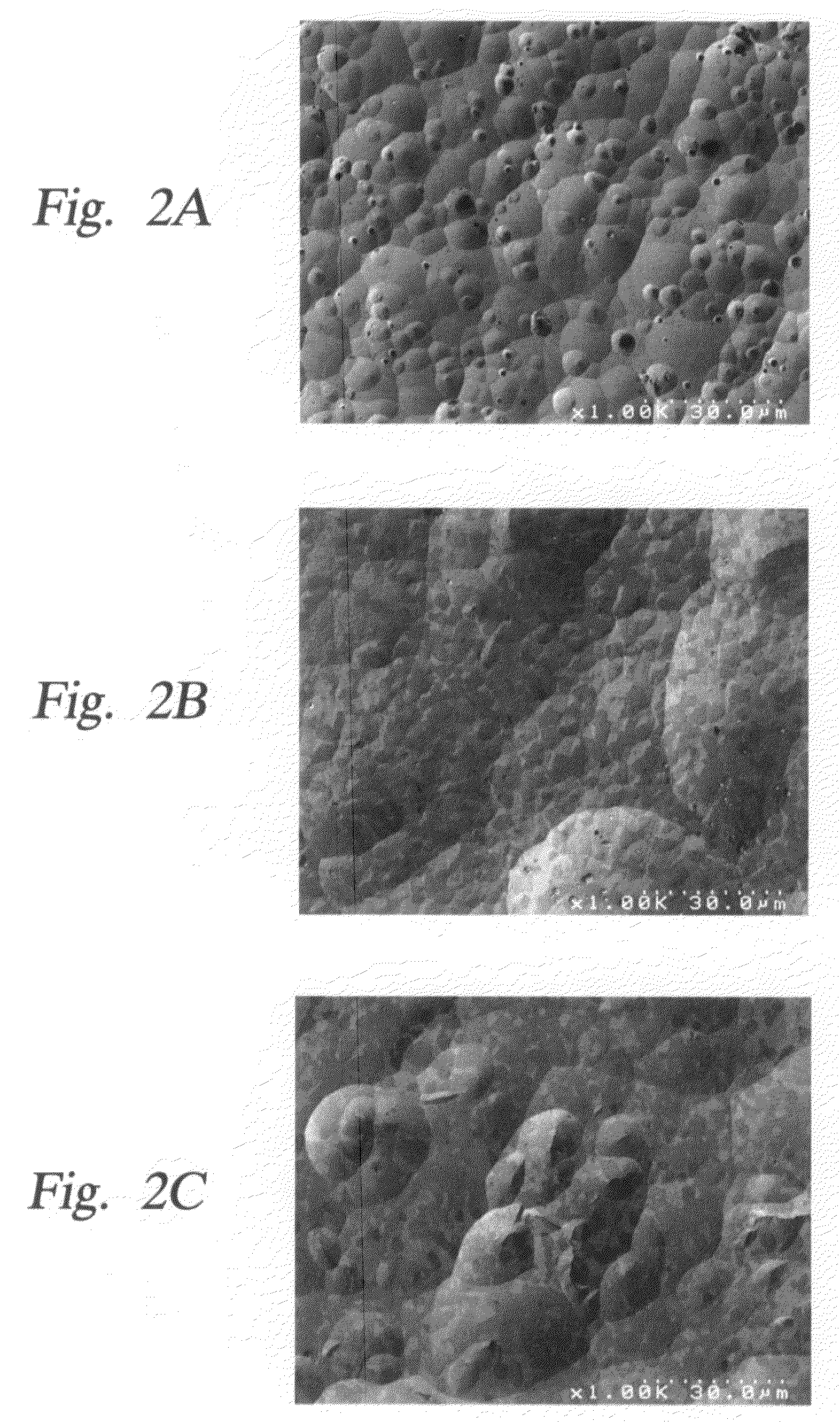

ActiveUS20080264565A1Improve plasma resistanceImprove corrosion resistanceElectric discharge tubesSemiconductor/solid-state device manufacturingYTTERBIUM OXIDEErosion rate

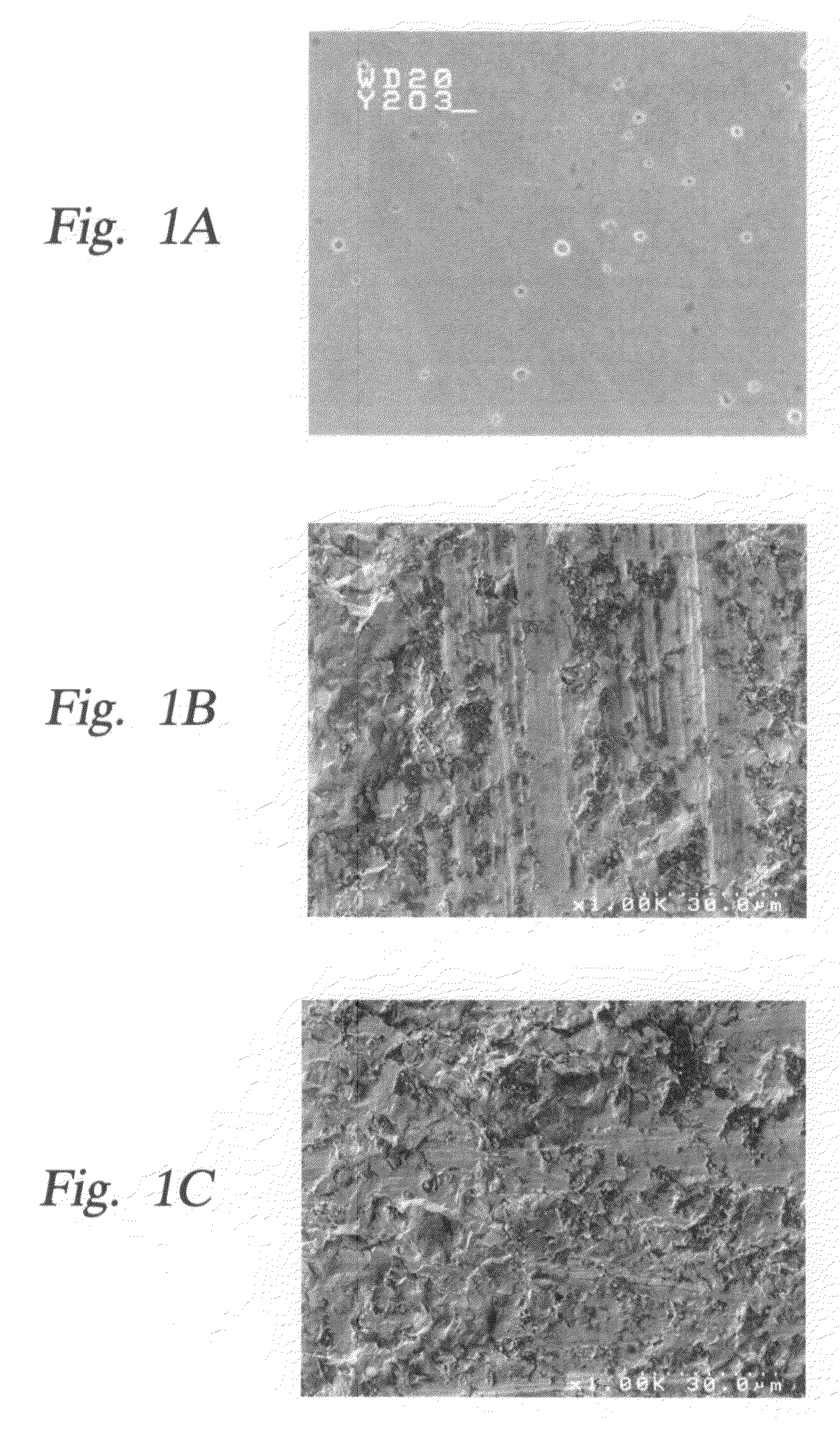

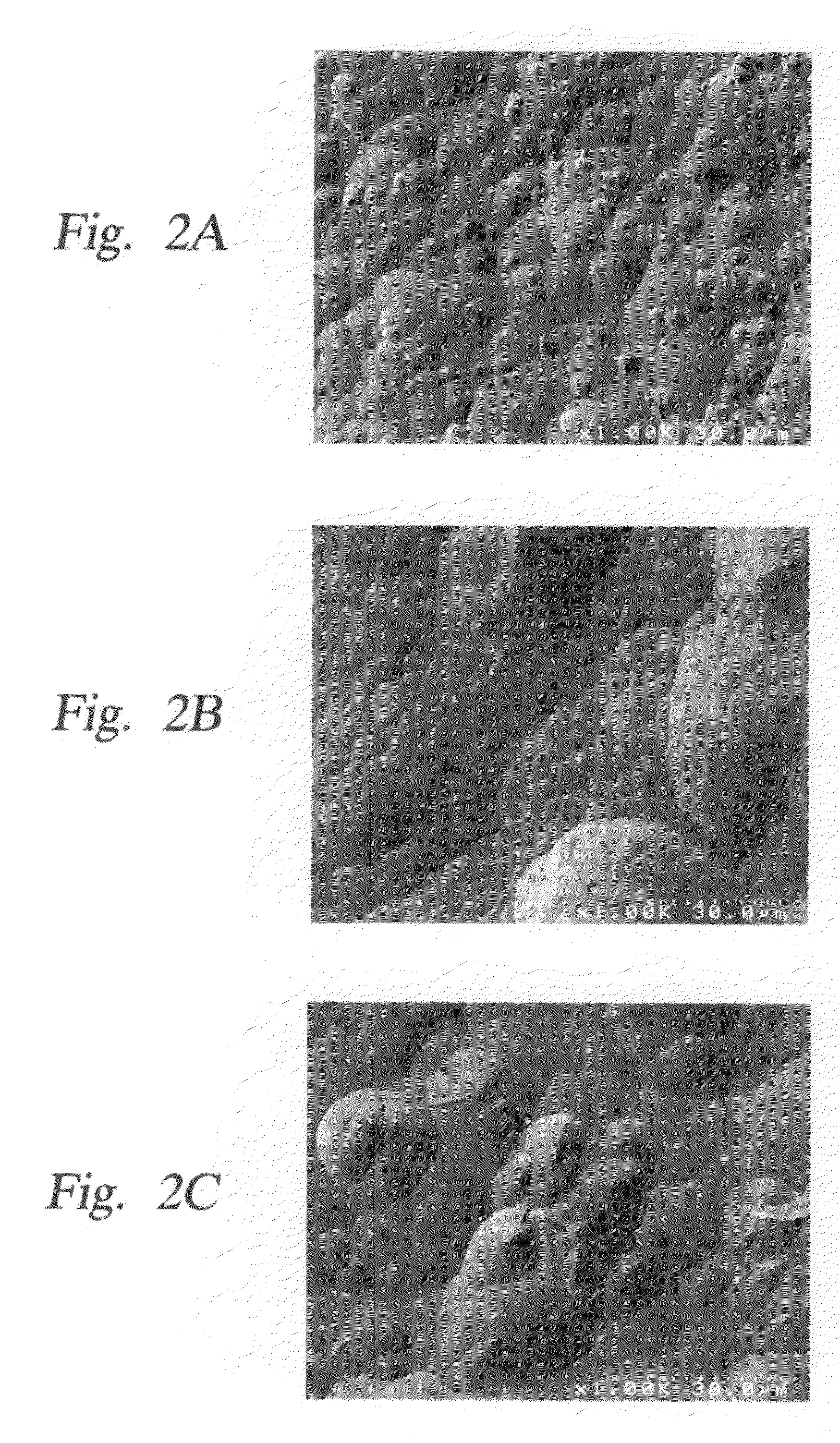

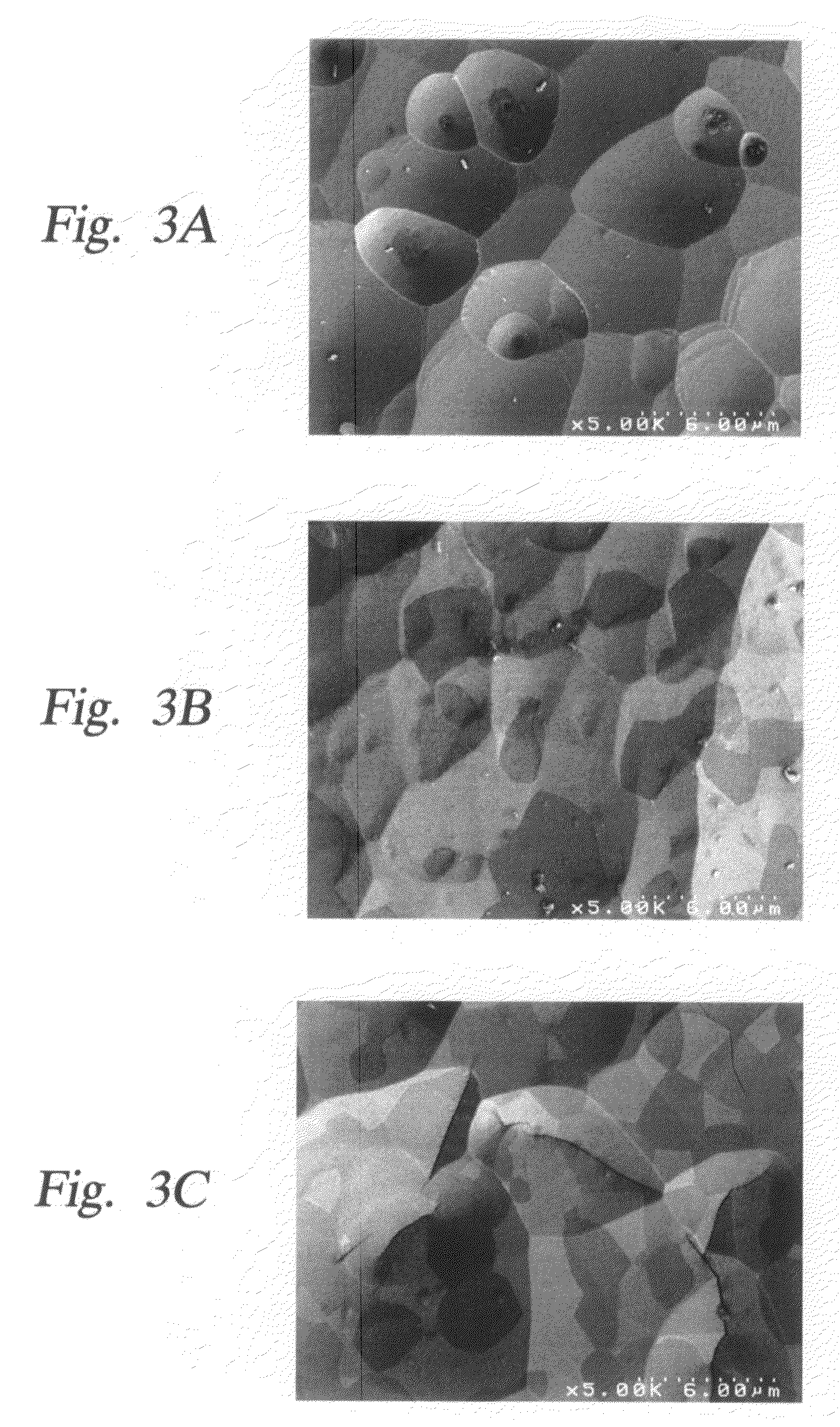

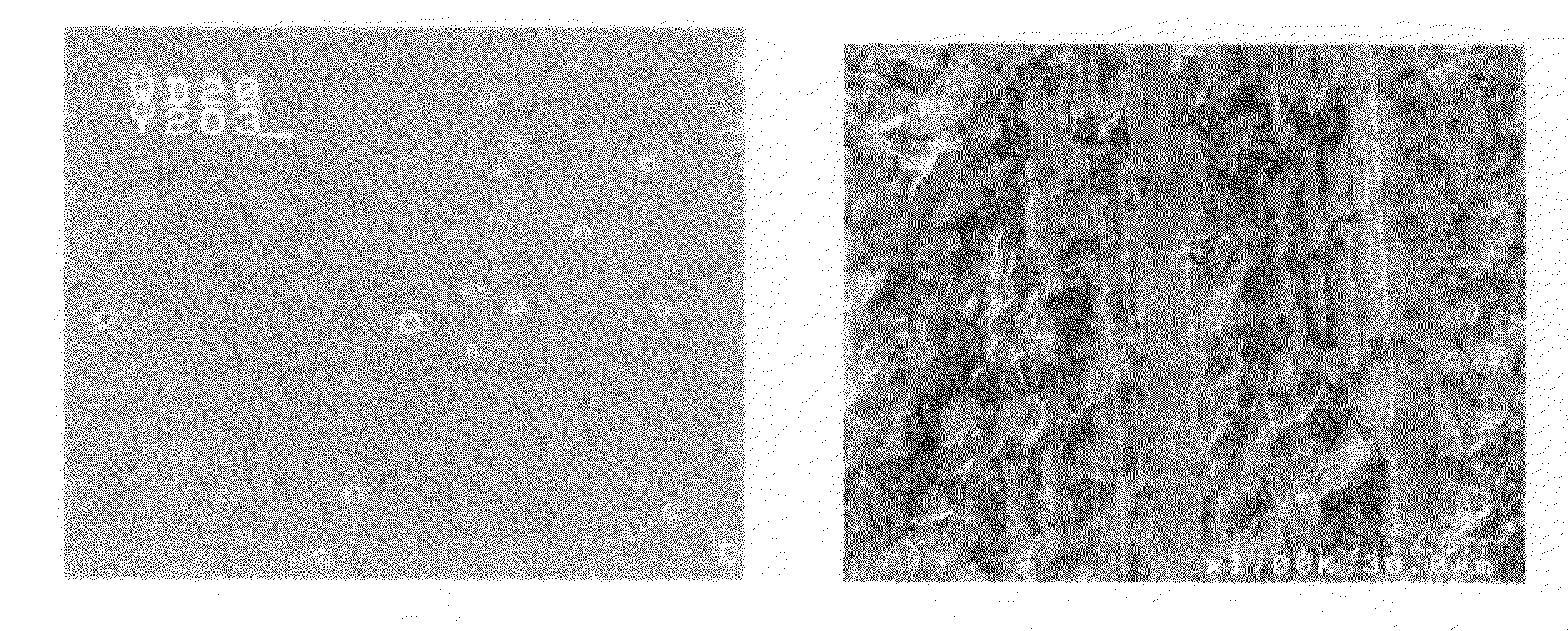

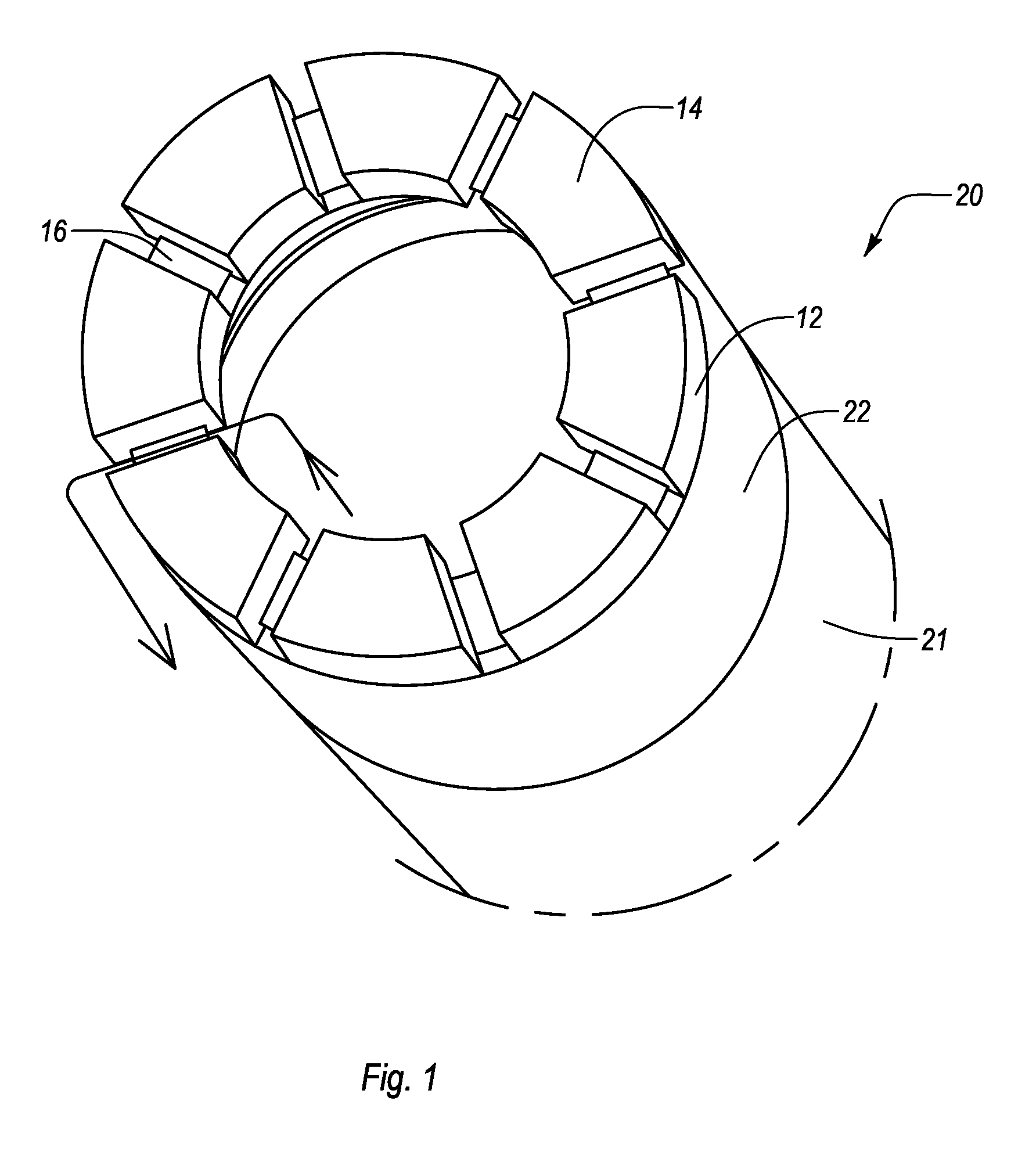

A ceramic article which is resistant to erosion by halogen-containing plasmas used in semiconductor processing. The ceramic article includes ceramic which is multi-phased, typically including two phase to three phases. The ceramic is formed from yttrium oxide at a molar concentration ranging from about 50 mole % to about 75 mole %; zirconium oxide at a molar concentration ranging from about 10 mole % to about 30 mole %; and at least one other component, selected from the group consisting of aluminum oxide, hafnium oxide, scandium oxide, neodymium oxide, niobium oxide, samarium oxide, ytterbium oxide, erbium oxide, cerium oxide, and combinations thereof, at a molar concentration ranging from about 10 mole % to about 30 mole %.

Owner:APPLIED MATERIALS INC

Method and apparatus which reduce the erosion rate of surfaces exposed to halogen-containing plasmas

ActiveUS7696117B2Reduce erosion rateImprove mechanical propertiesElectric discharge tubesSemiconductor/solid-state device manufacturingErosion rateYttrium

A ceramic article which is resistant to erosion by halogen-containing plasmas used in semiconductor processing. The ceramic article includes ceramic which is multi-phased, typically including two phase to three phases. The ceramic is formed from yttrium oxide at a molar concentration ranging from about 50 mole % to about 75 mole %; zirconium oxide at a molar concentration ranging from about 10 mole % to about 30 mole %; and at least one other component, selected from the group consisting of aluminum oxide, hafnium oxide, scandium oxide, neodymium oxide, niobium oxide, samarium oxide, ytterbium oxide, erbium oxide, cerium oxide, and combinations thereof, at a molar concentration ranging from about 10 mole % to about 30 mole %.

Owner:APPLIED MATERIALS INC

Method of reducing the erosion rate of semiconductor processing apparatus exposed to halogen-containing plasmas

InactiveUS20080264564A1Improve plasma resistanceImprove corrosion resistanceElectric discharge tubesSemiconductor/solid-state device manufacturingErosion rateYttrium

A ceramic article useful in semiconductor processing, which is resistant to erosion by halogen-containing plasmas. The ceramic article is formed from a combination of yttrium oxide and zirconium oxide. In a first embodiment, the ceramic article includes ceramic which is formed from yttrium oxide at a molar concentration ranging from about 90 mole % to about 70 mole %, and zirconium oxide at a molar concentration ranging from about 10 mole % to about 30 mole %. In a second embodiment, the ceramic article includes ceramic which is formed from zirconium oxide at a molar concentration ranging from about 96 mole % to about 94 mole %, and yttrium oxide at a molar concentration ranging from about 4 mole % to about 6 mole %.

Owner:APPLIED MATERIALS INC

Mixtures of various triblock polyester polyethylene glycol copolymers having improved gel properties

InactiveUS7018645B1Good curative effectMinimize side effectsPowder deliveryPeptide/protein ingredientsPolymer scienceErosion rate

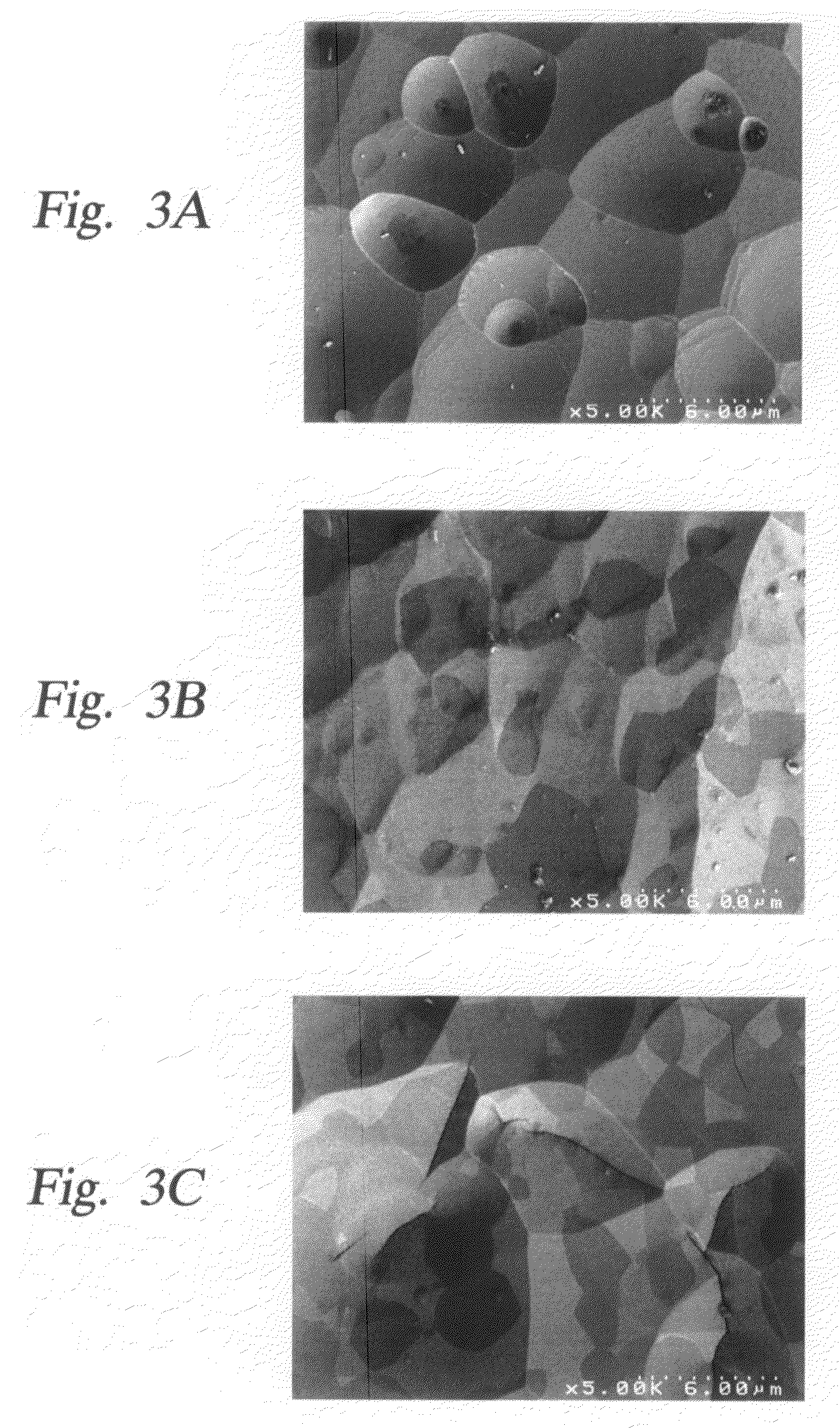

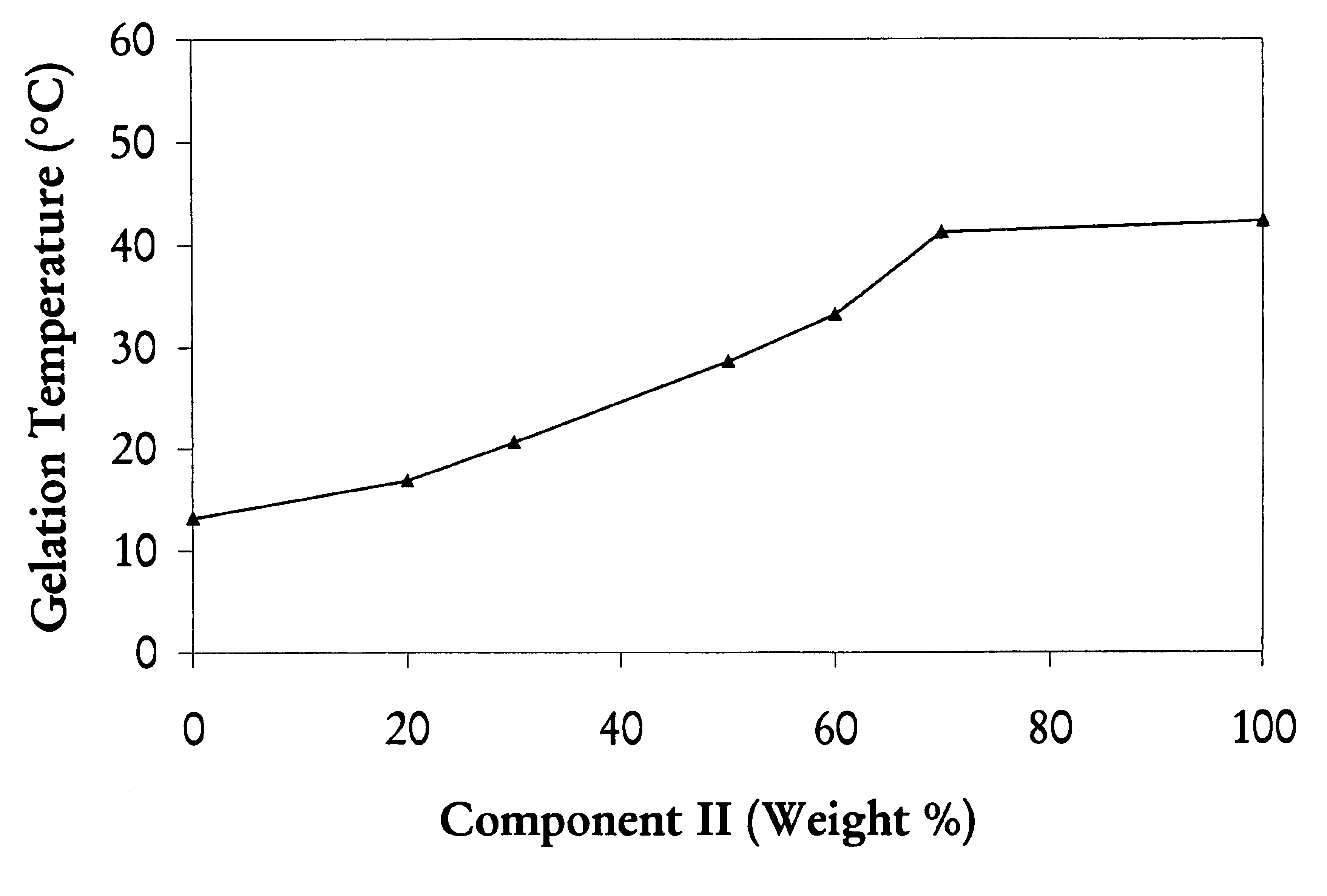

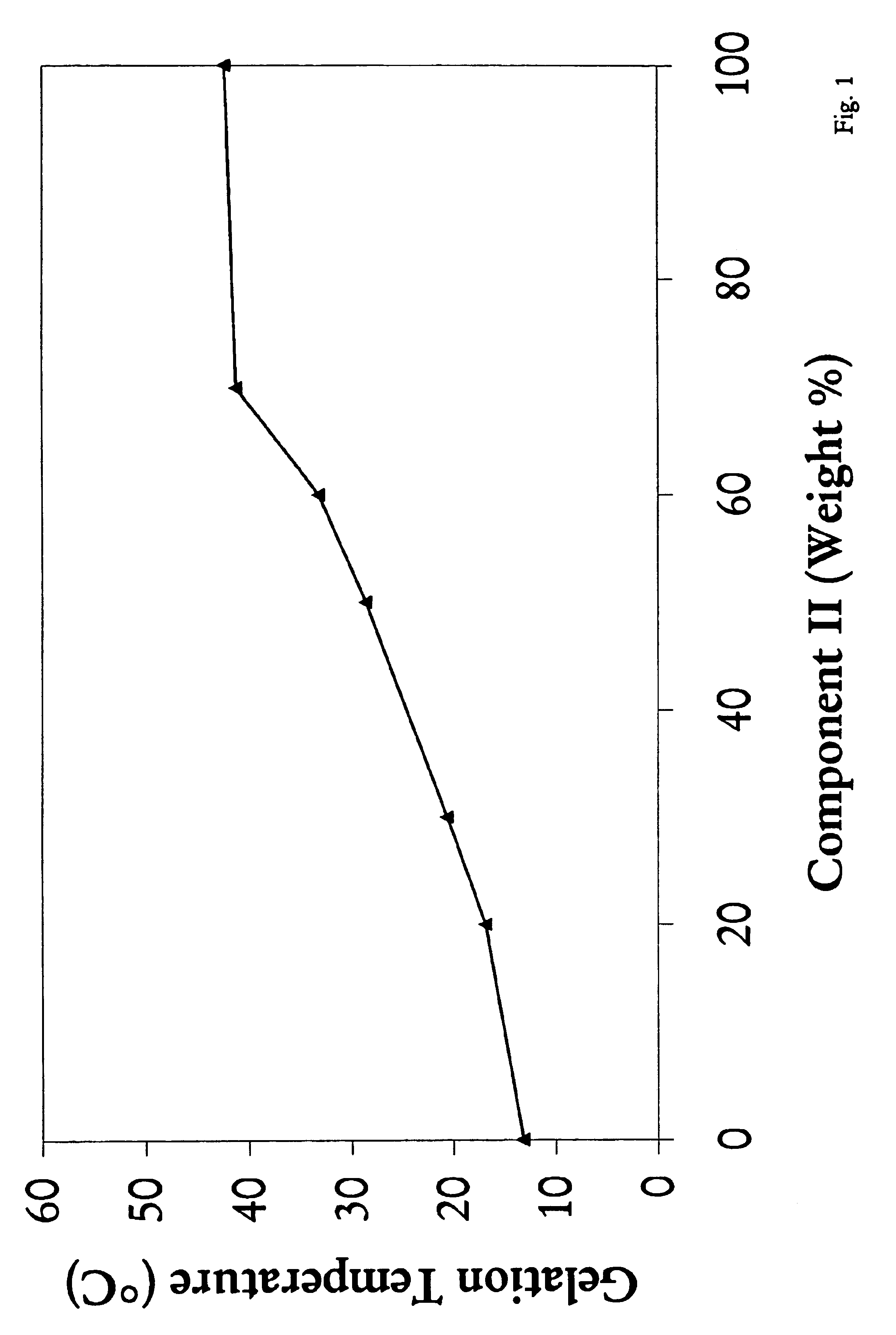

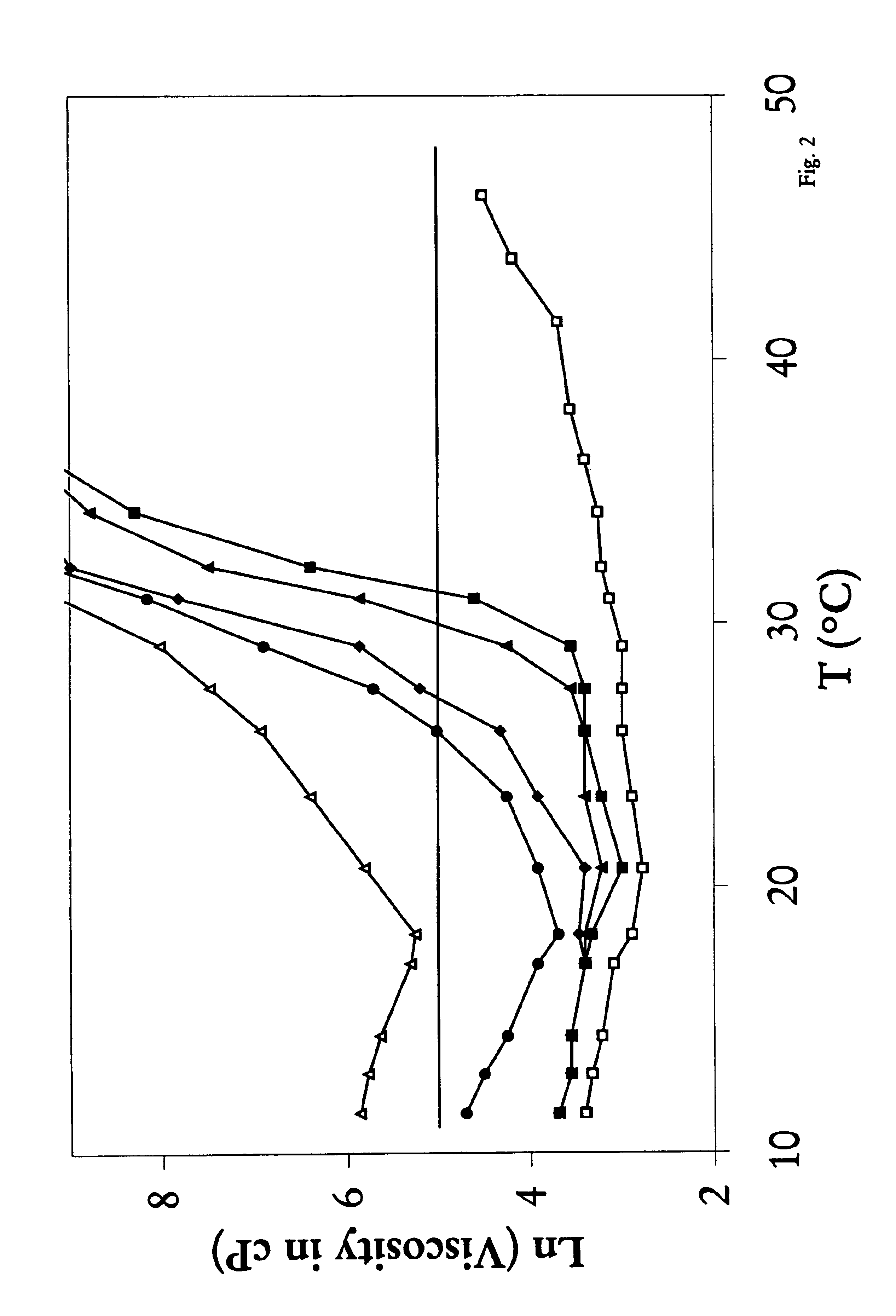

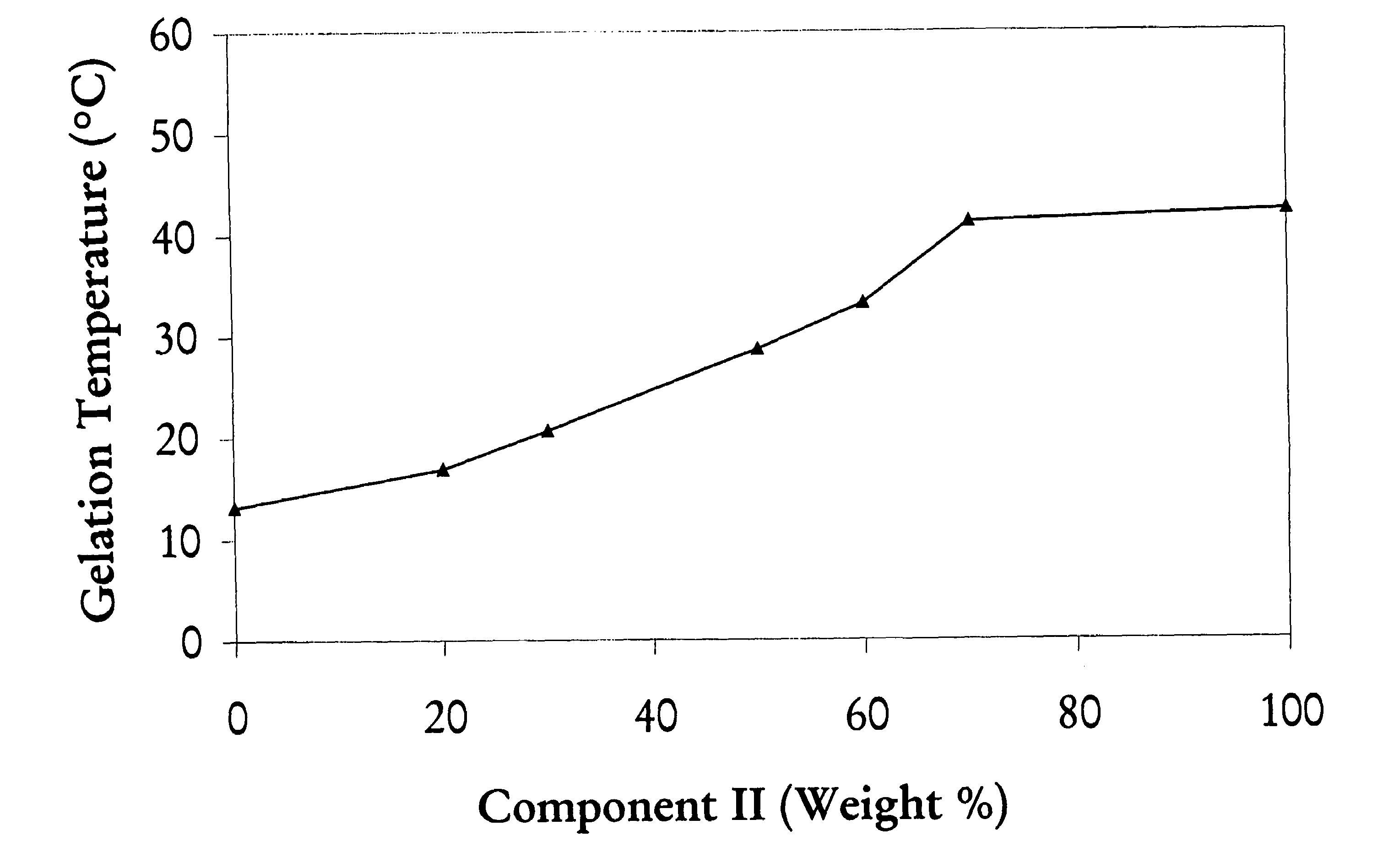

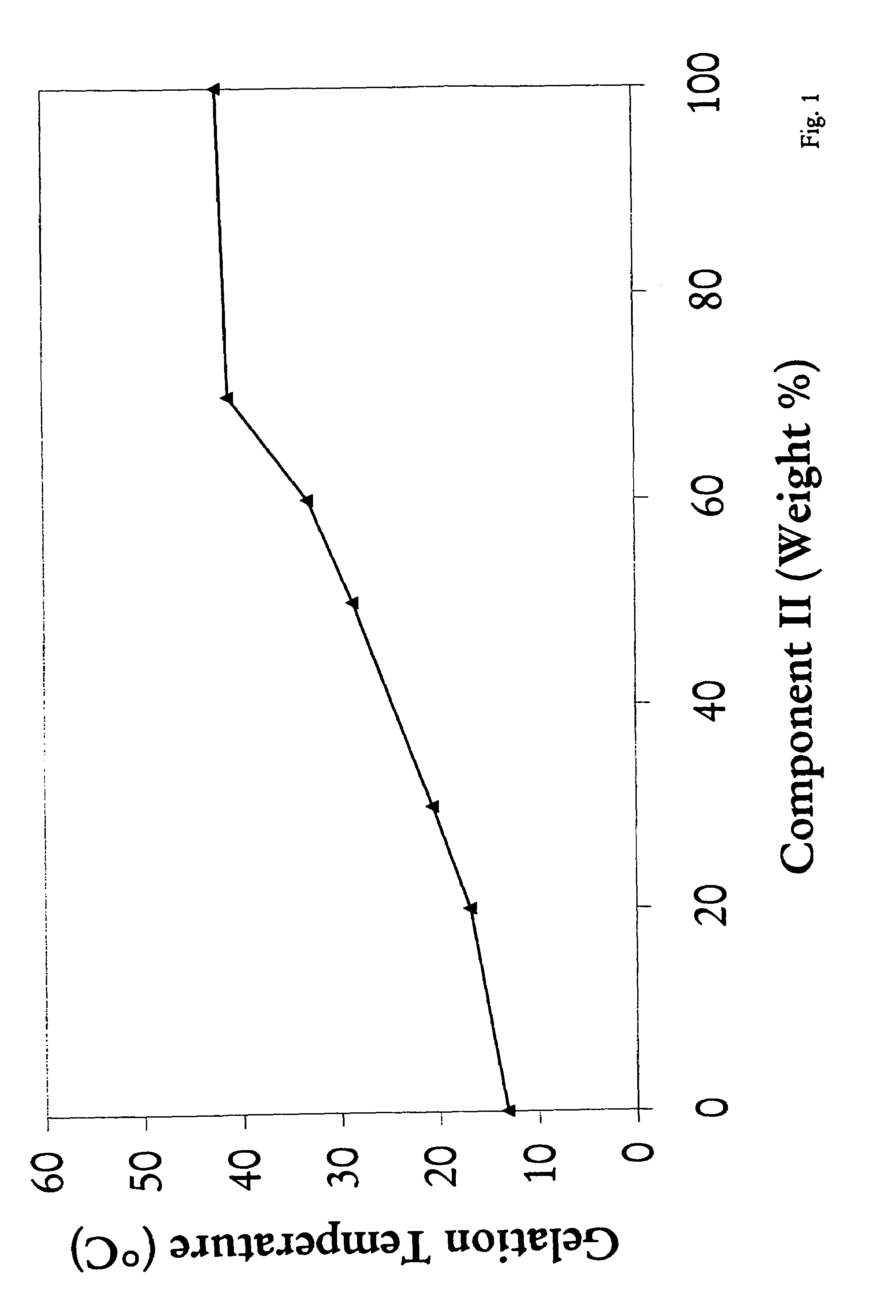

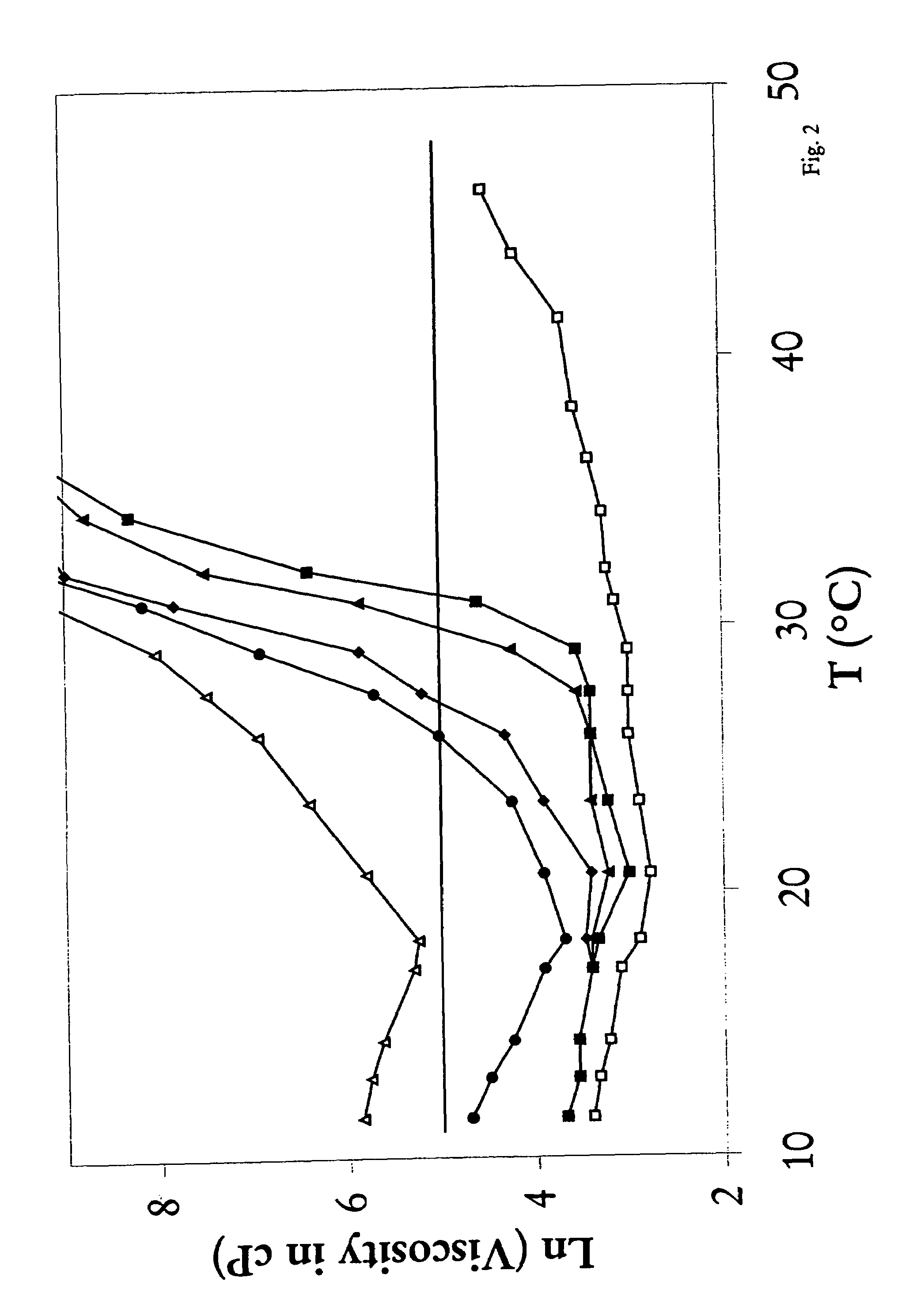

A water soluble, biodegradable reverse thermal gelation system comprising a mixture of at least two types of tri-block copolymer components is disclosed. The tri-block copolymer components are made of a hydrophobic biodegradable polyester A-polymer block and a hydrophilic polyethylene glycol B-polymer block. The drug release and gel matrix erosion rates of the biodegradable reverse thermal gelation system may be modulated by various parameters such as the hydrophobic / hydrophilic component contents, polymer block concentrations, molecular weights and gelation temperatures, and weight ratios of the tri-block copolymer components in the mixture.

Owner:BTG INT LTD

Mixtures of various triblock polyester polyethylene glycol copolymers having improved gel properties

InactiveUS7135190B2Improve gelationGood drug release propertiesPowder deliveryGogglesPolymer scienceErosion rate

A water soluble, biodegradable reverse thermal gelation system comprising a mixture of at least two types of tri-block copolymer components is disclosed. The tri-block copolymer components are made of a hydrophobic biodegradable polyester A-polymer block and a hydrophilic polyethylene glycol B-polymer block. The drug release and gel matrix erosion rates of the biodegradable reverse thermal gelation system may be modulated by various parameters such as the hydrophobic / hydrophilic component contents, polymer block concentrations, molecular weights and gelation temperatures, and weight ratios of the tri-block copolymer components in the mixture.

Owner:BTG INT LTD

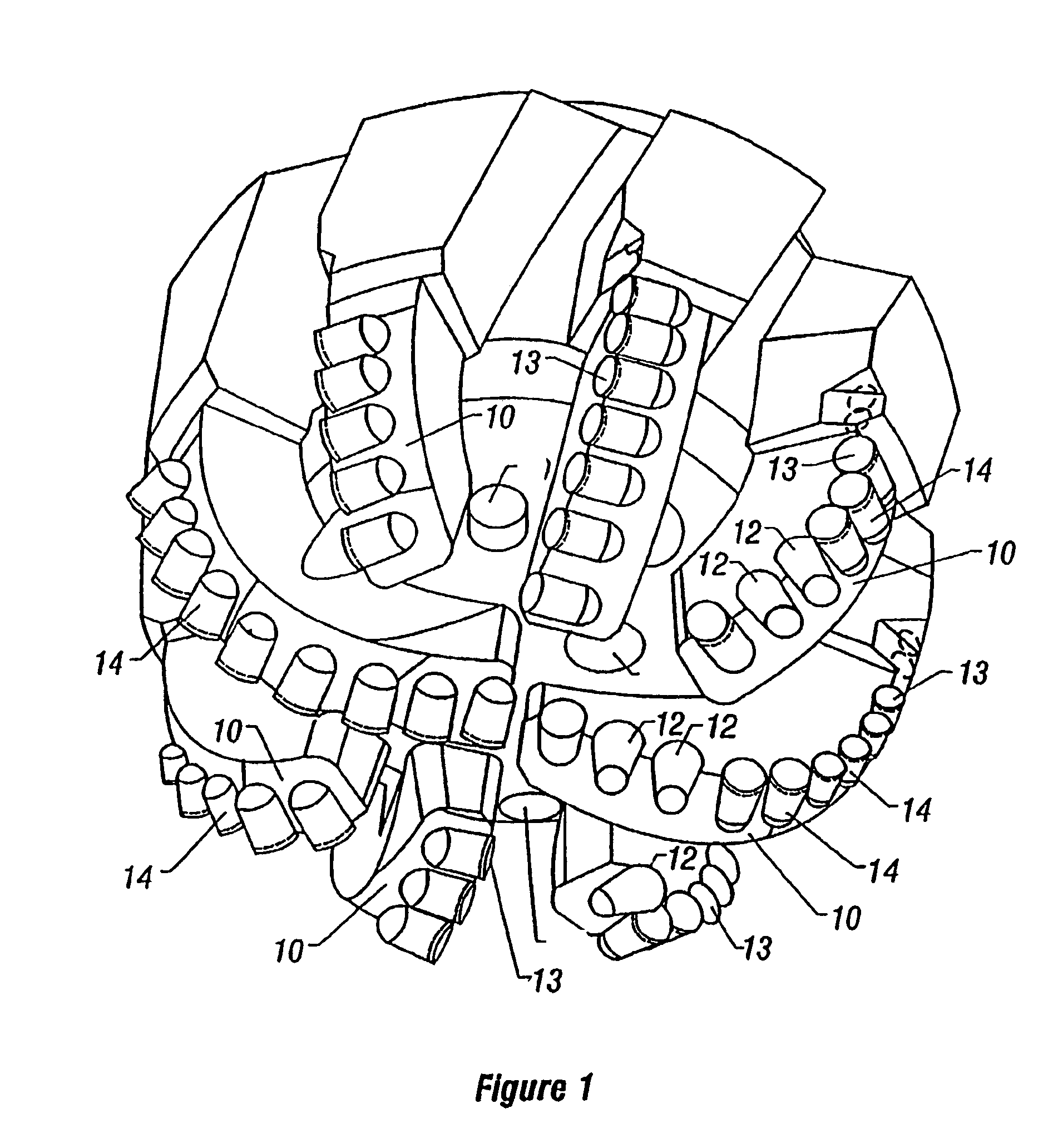

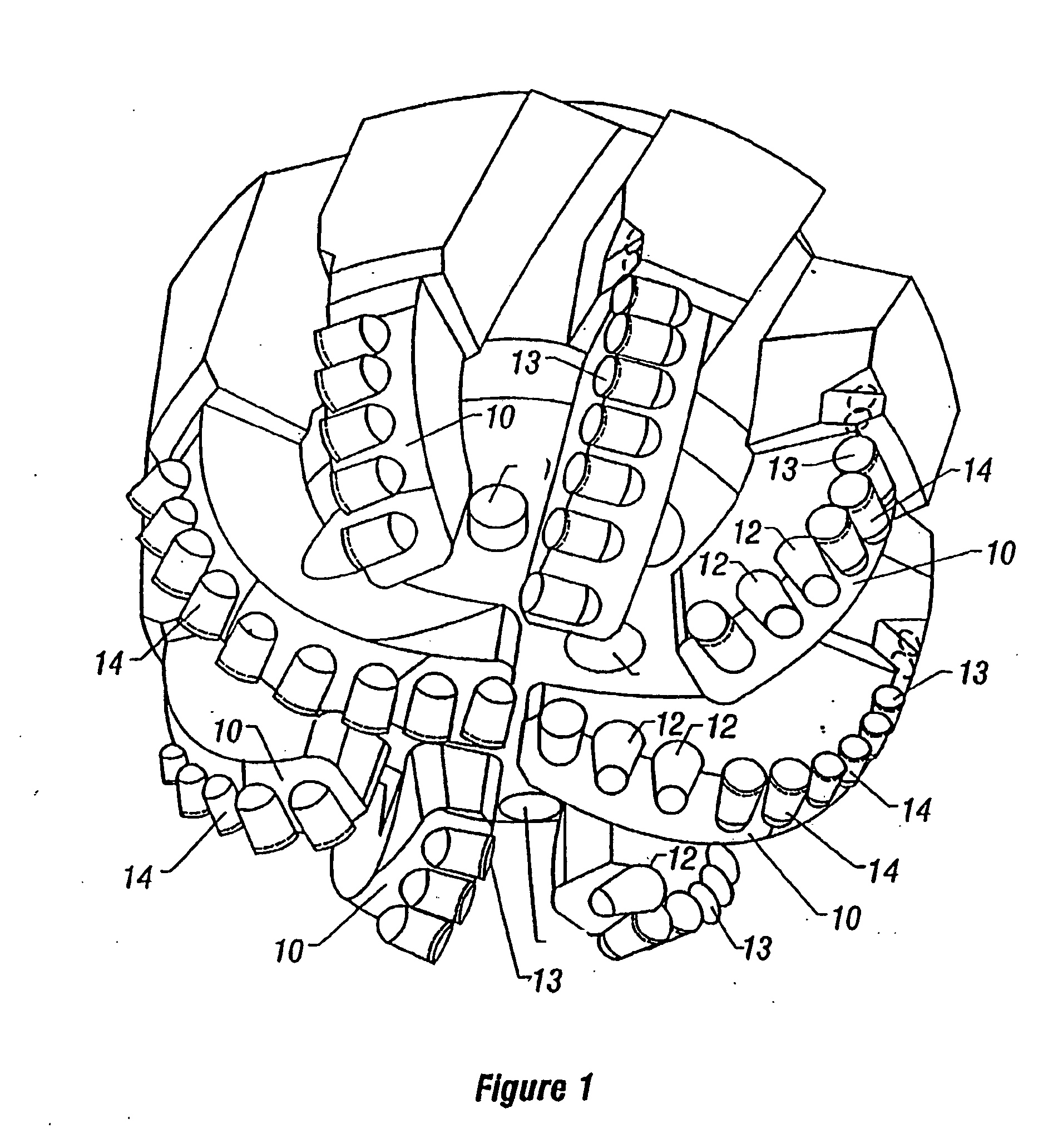

High-strength, high-toughness matrix bit bodies

Owner:SMITH INT INC

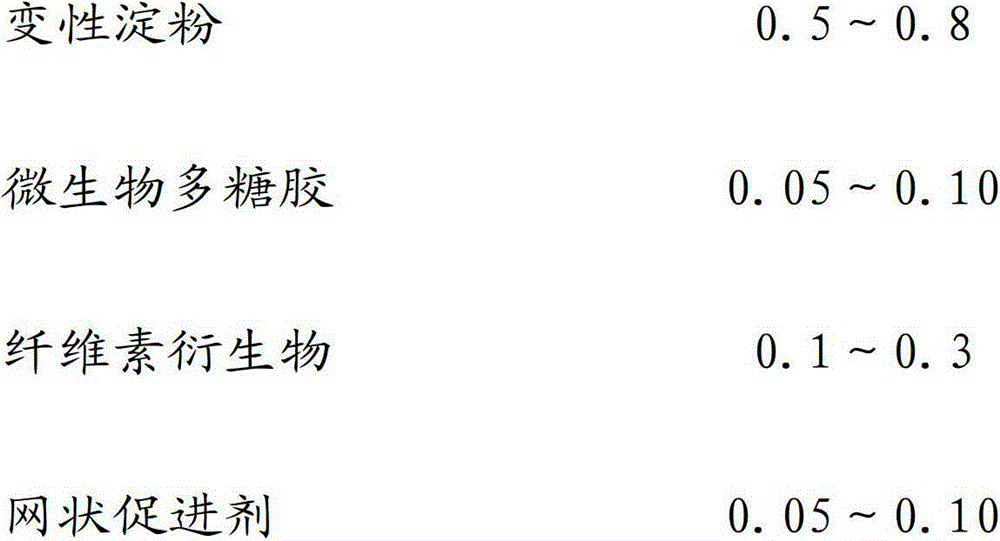

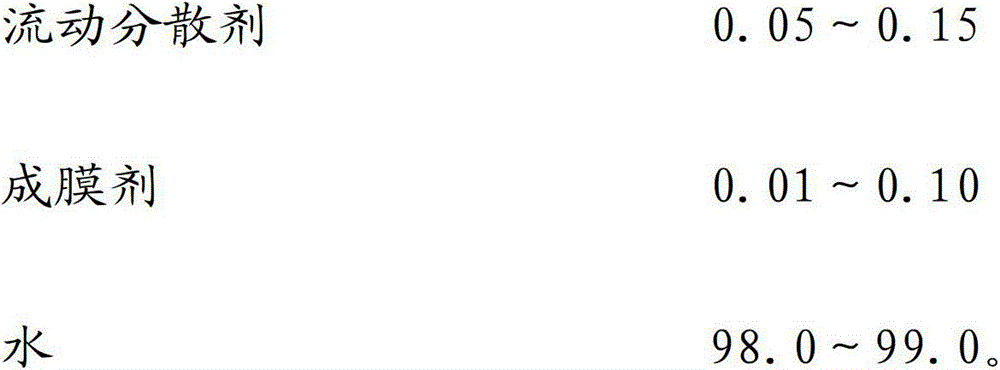

Ecological environment-friendly dust inhibitor

InactiveCN103184034AViscosity quick releaseIncrease viscosityOther chemical processesEcological environmentErosion rate

The invention provides an ecological environment-friendly dust inhibitor which comprises the following components by weight percent: 0.5-0.8% of modified starch, 0.05-0.10% of microbial polysaccharide, 0.1-0.3% of cellulose derivative, 0.05-0.10% of netty accelerant, 0.05-0.15% of flow dispersant, 0.01-0.10% of film forming agent and 98.0-99.0% of water. The dust inhibitor can enable coal or mineral powder to form a layer of curing film on the surface, is high in viscosity and low in wind erosion rate, can avoid the flowing dust pollution and the flowing dust loss of the coal or the mineral powder to the way side in the railway transportation process, and has a huge economic benefit and a social benefit of environmental protection for railway transportation and coal or mineral powder customers; and the components and a solution of the dust inhibitor do not have any toxic side effect and corrosive effect, the dust inhibitor does not cause any secondary pollution as the dust inhibitor can be quickly and biochemically degraded in the nature after the dust inhibition action period, and the soil can be properly improved.

Owner:BEIJING SUNSHINE COLORFUL TECH

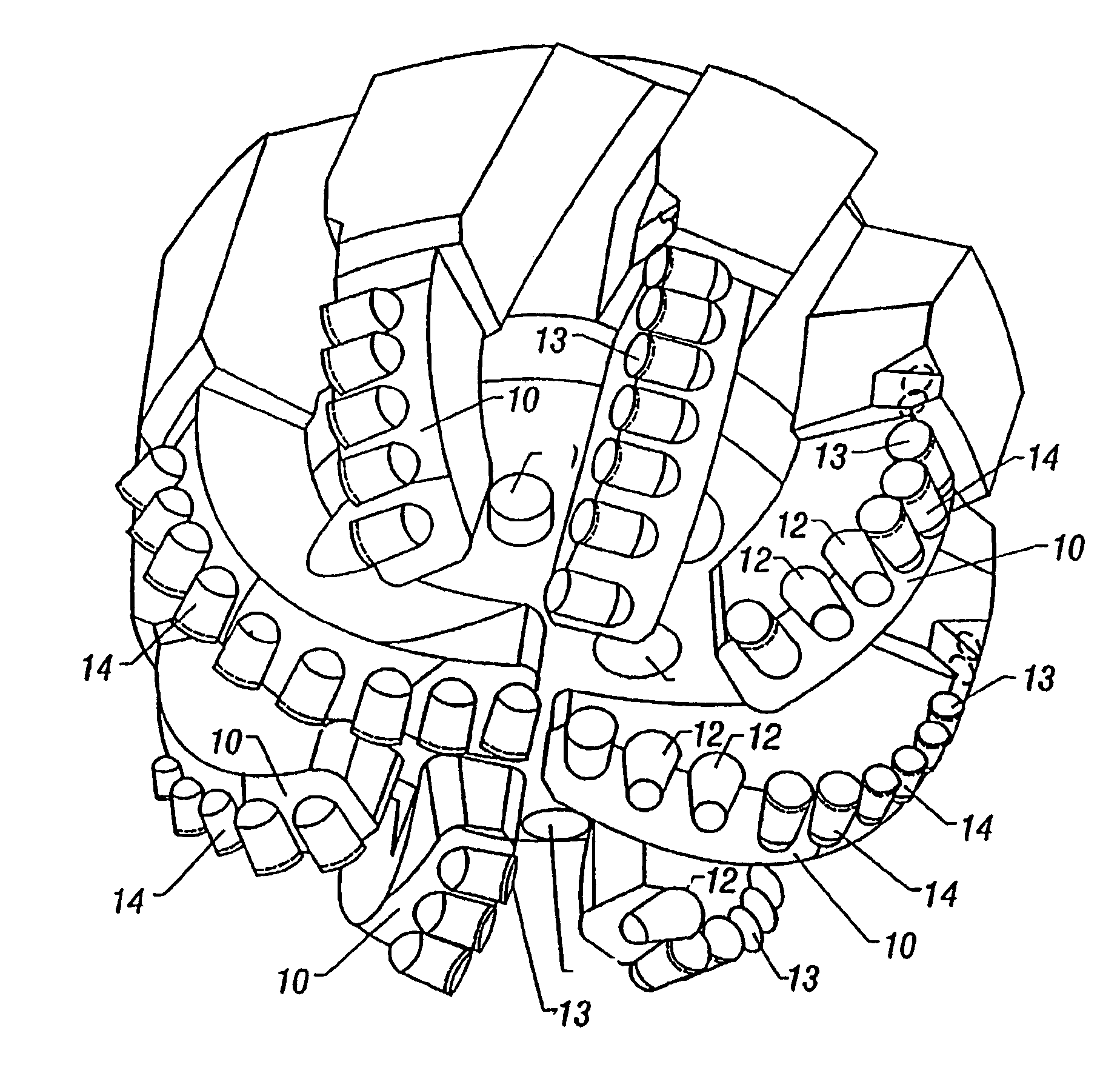

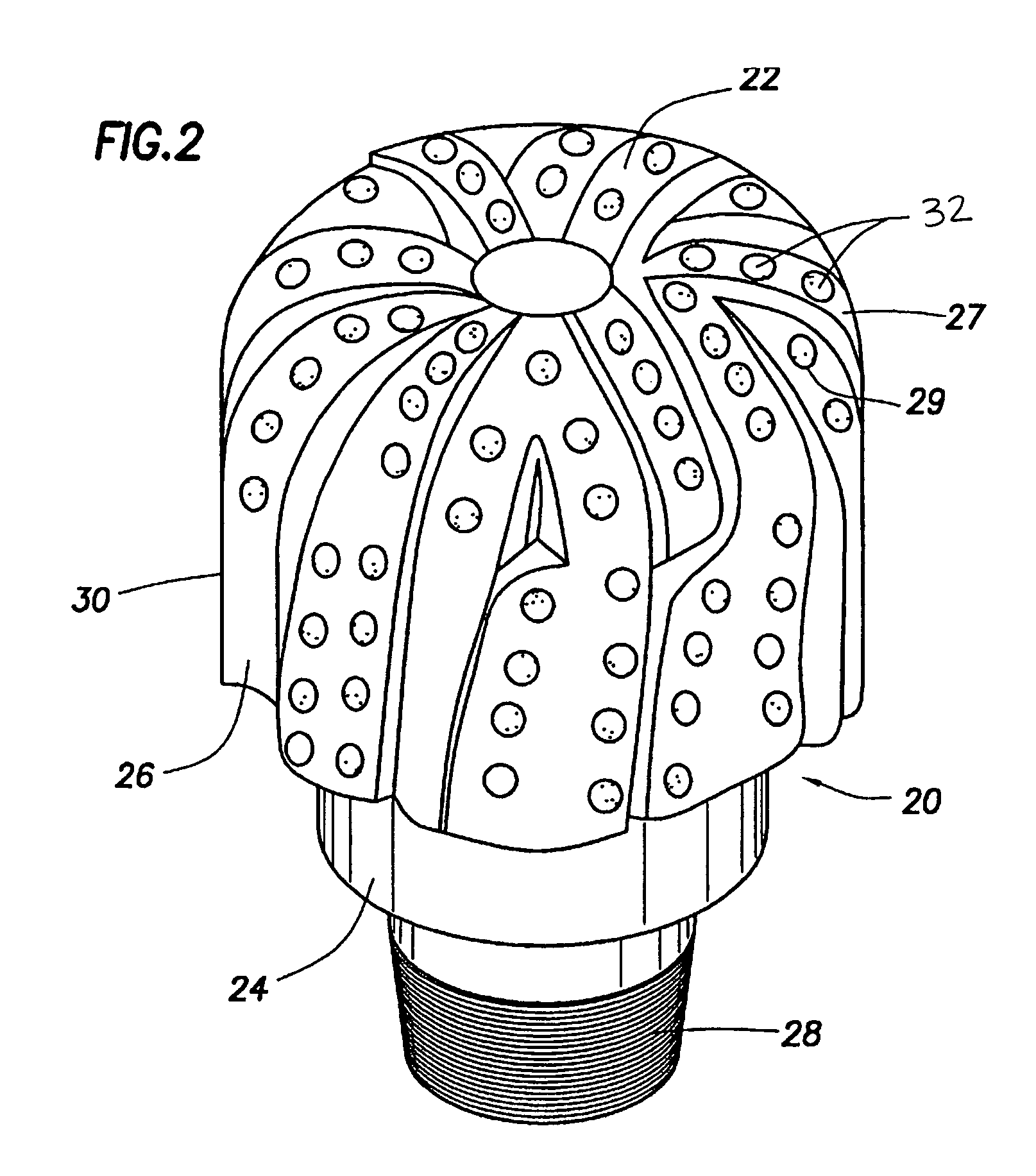

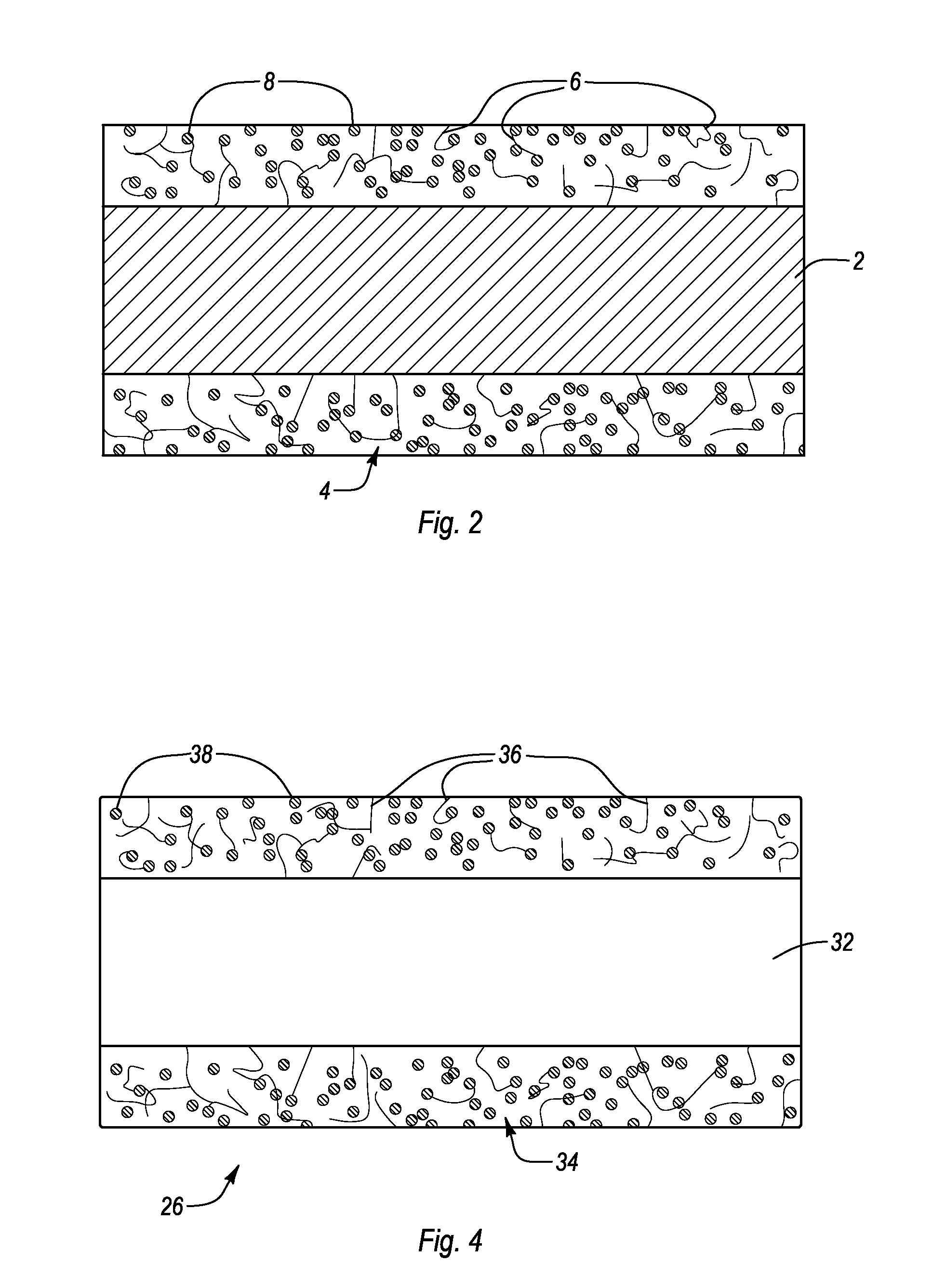

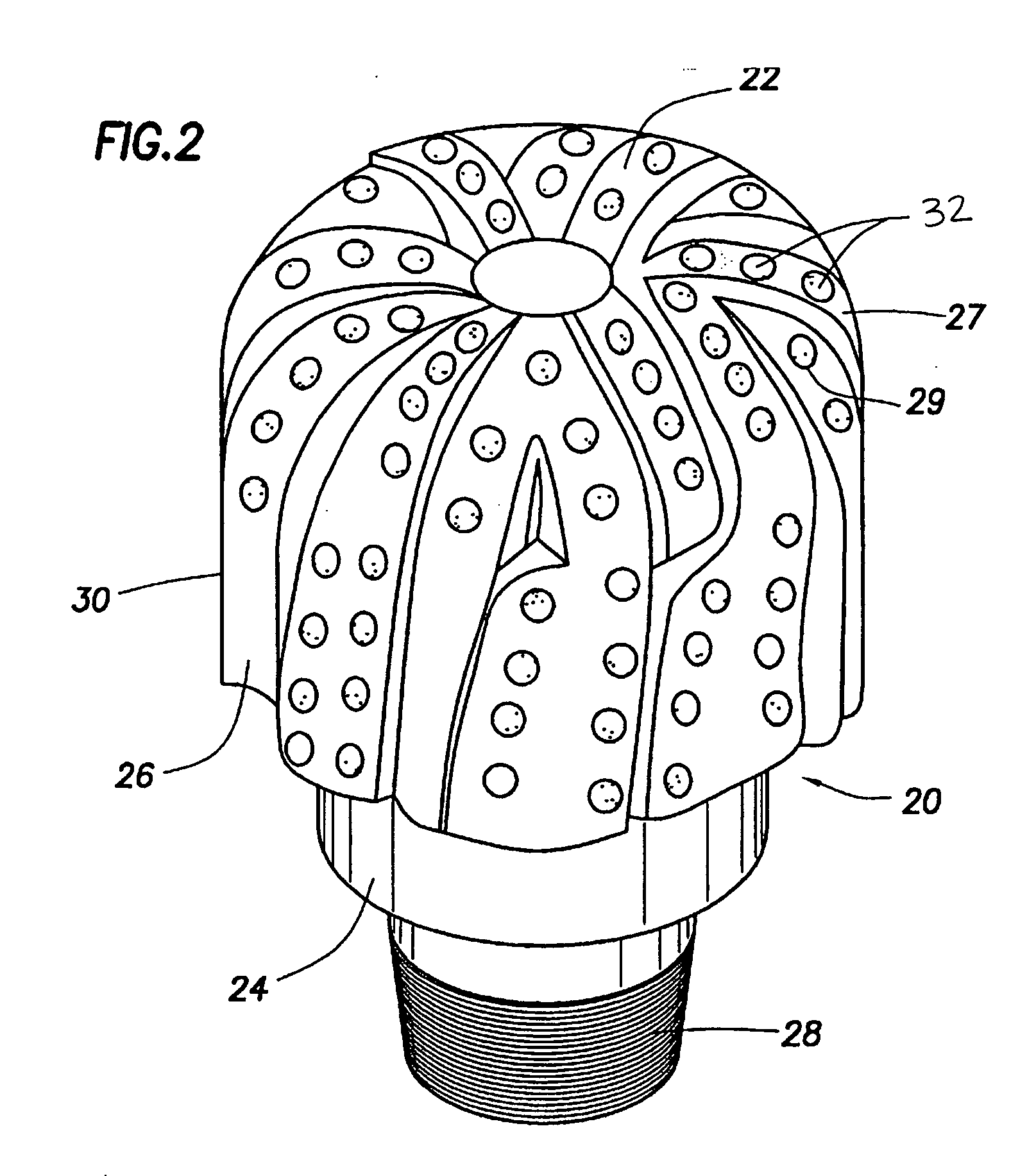

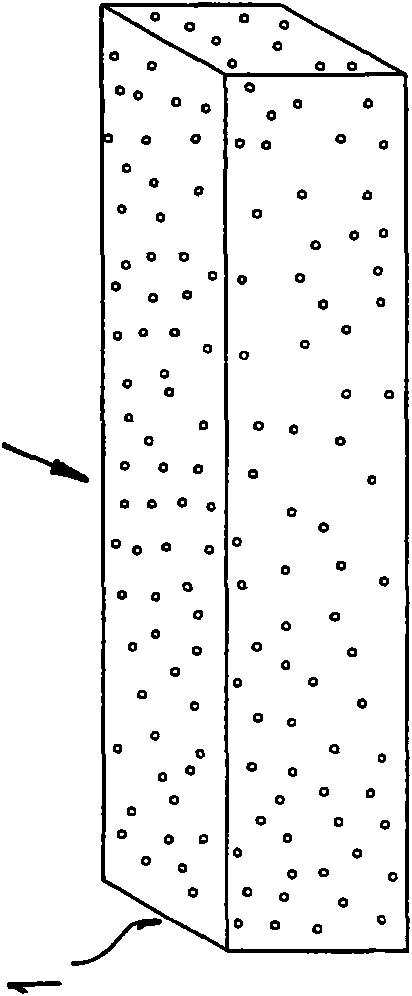

Methods of forming and using fiber-containing diamond-impregnated cutting tools

ActiveUS20090078469A1Improve cutting performanceLean structureDrill bitsConstructionsFiberErosion rate

Fibers for diamond-impregnated cutting tools and their associated methods for manufacture and use are described. A matrix is formed that contains fibers made from carbon, glass, ceramic, polymer, and the like. The matrix is then sintered to form a cutting portion of a drill bit. The type and concentration of the fibers can be modified to control the tensile strength and the erosion rate of the matrix to optimize the cutting performance of the tools. Additionally, the fibers may be added to the cutting section to weaken the structure and allow higher modulus binders to be used for the cutting tools at a lower cost, allowing the amount of fibers to be tailored to retain the diamonds in the cutting portion for the desired amount. As the cutting portion erodes, the fibers may also increase the lubricity at the face of the cutting portion.

Owner:BOART LONGYEAR

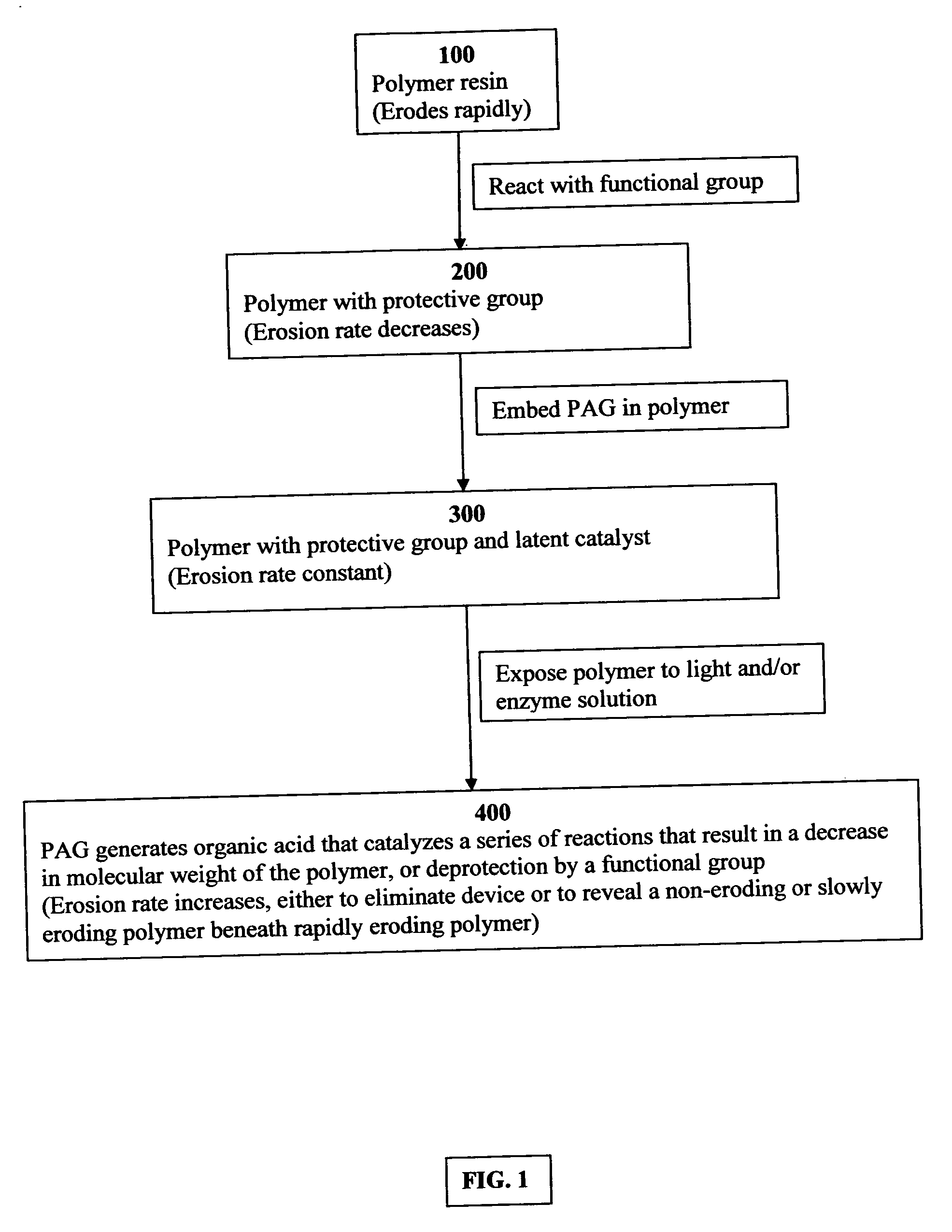

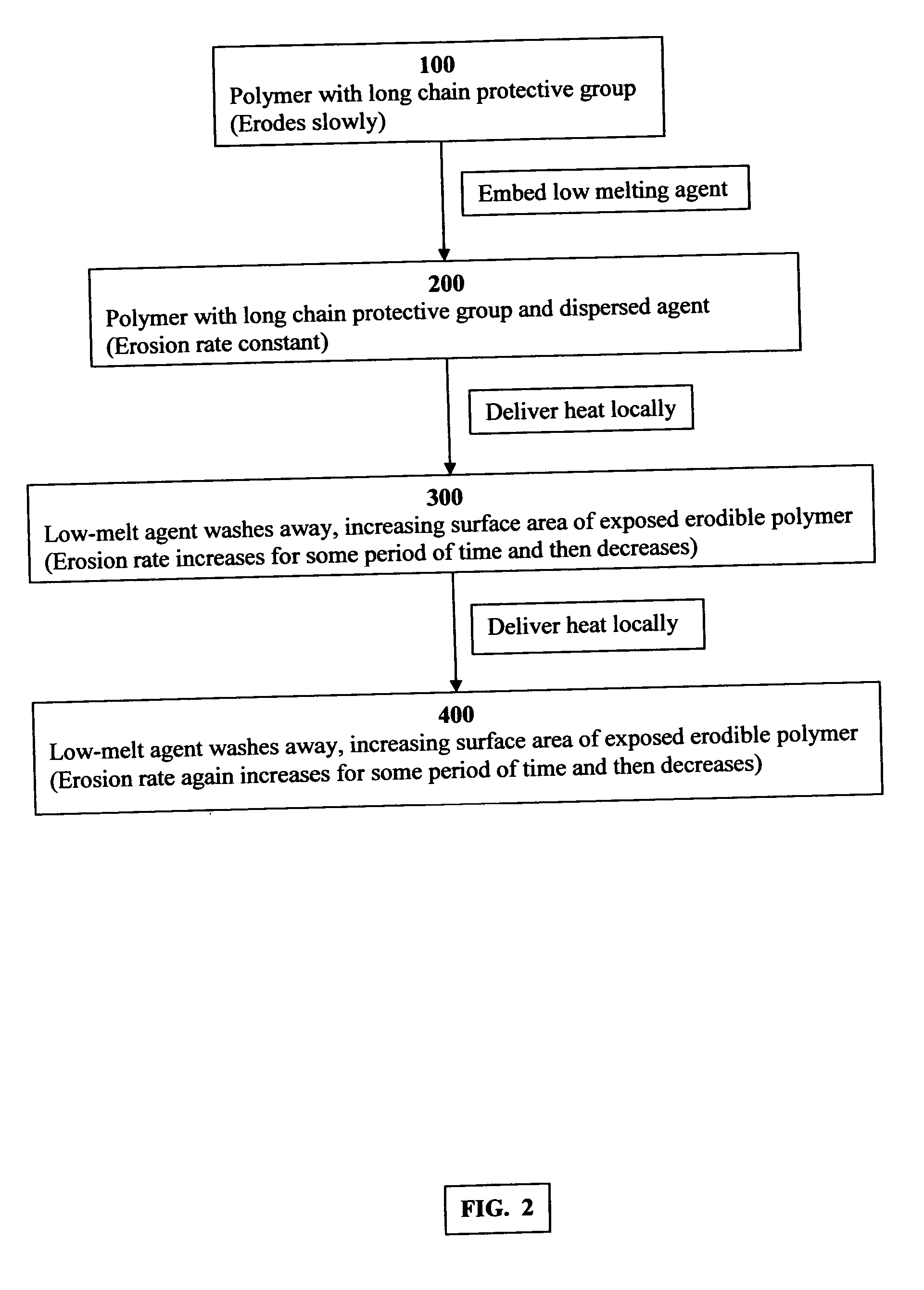

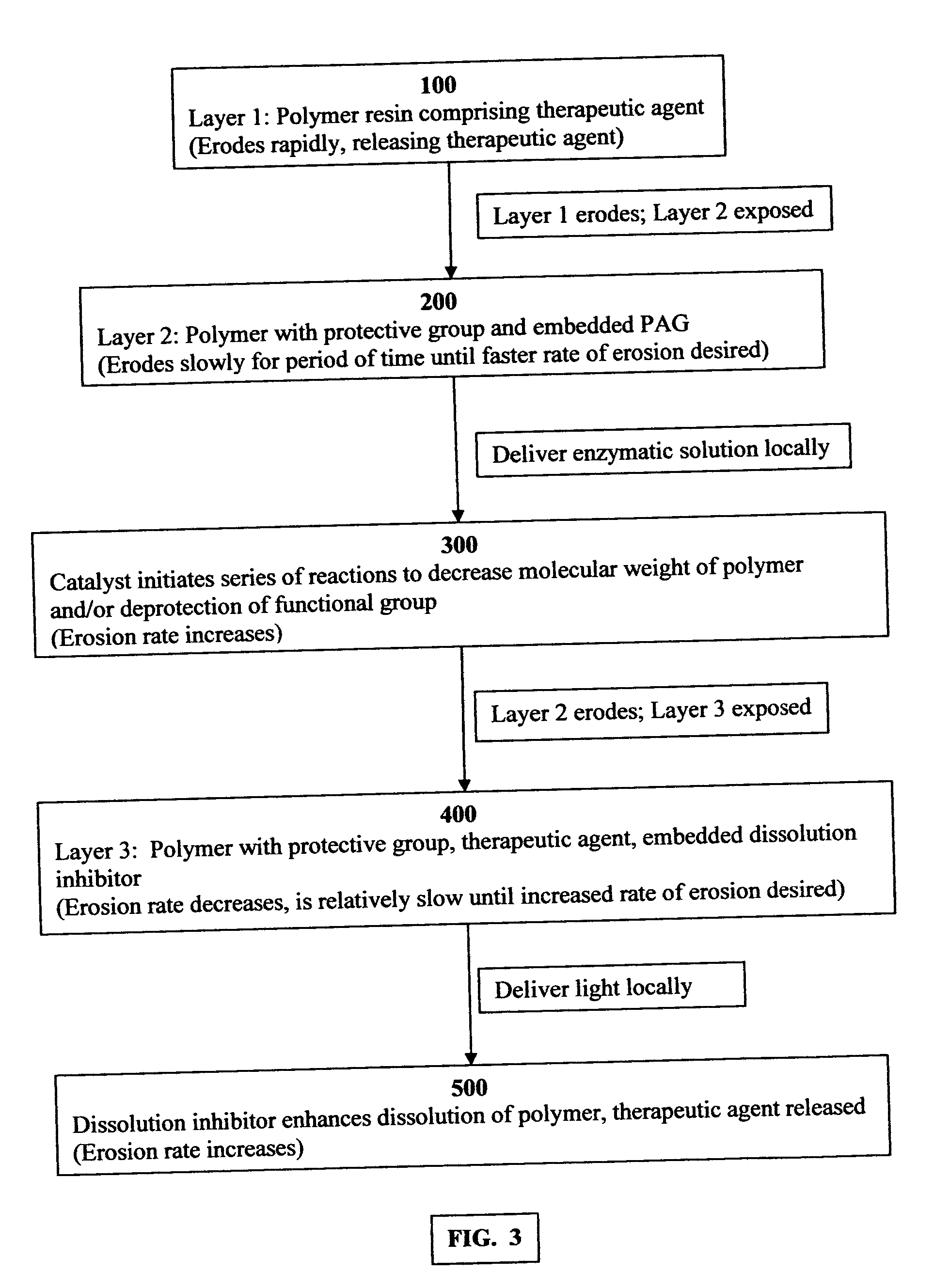

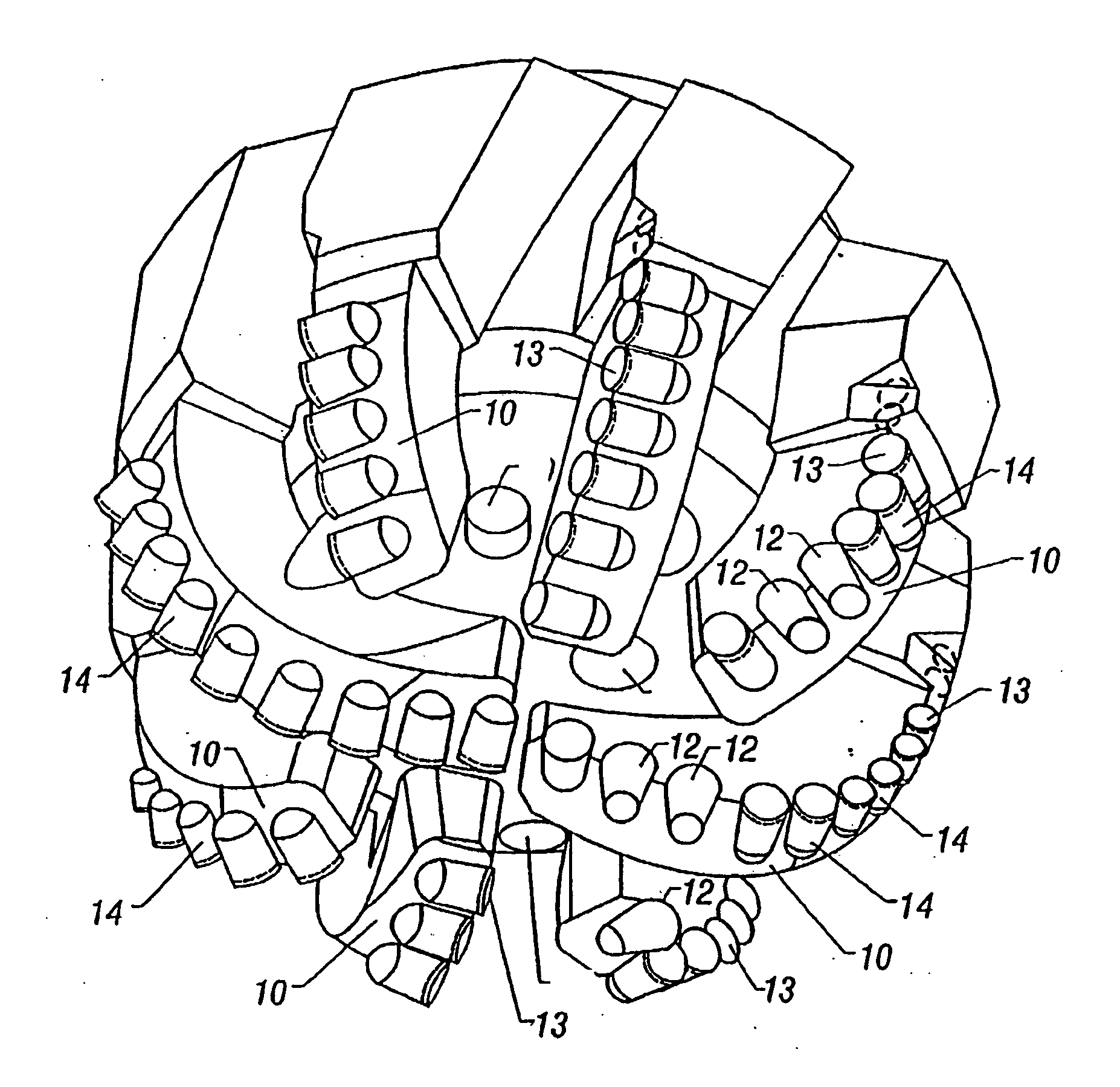

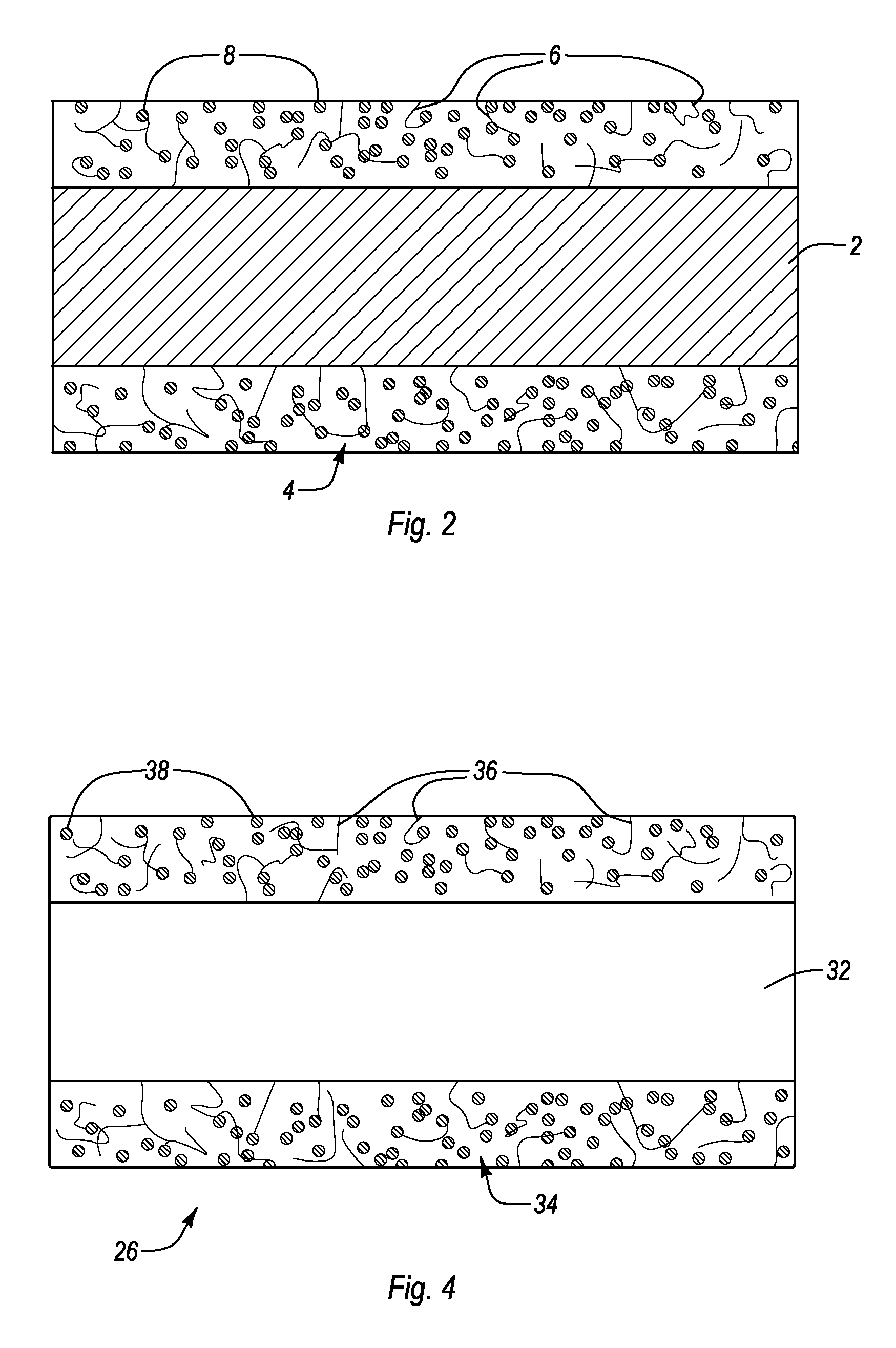

Polymeric endoprostheses with modified erosion rates and methods of manufacture

InactiveUS20060121087A1Reduce erosion rateIncreasing and decreasing rate of erosionSenses disorderMetabolism disorderErosion rateProsthesis

An erodible prosthesis comprising alternate rates of erosion is disclosed, wherein said alternate rates of erosion can be selectively initiated. Some embodiments according to the invention may comprise an agent for initiating an alternative rate of erosion, such as, for example, a sensitizer, dissolution inhibitor, photo-acid generator, biochemically active additive, thermally activated catalyst, light activated catalyst, electromagnetic radiation activated catalyst, hydration activated catalyst, pH activated catalyst, low melting agent, and / or enzyme activated catalyst. One or more of the foregoing agents may be dispersed within one or more layers.

Owner:WILLIAMS MICHAEL S +1

High-strength, high-toughness matrix bit bodies

A drill bit that includes a bit body formed from a matrix powder and at least one cutting element for engaging a formation, wherein the matrix powder included (a) stoichiometric tungsten carbide particles, (b) cemented tungsten carbide particles, and (c) cast tungsten carbide particles, and wherein after formation with the matrix powder, the bit has an erosion rate of less than 0.001 in / hr, a toughness of greater than 20 ksi(in0.5), and a transverse rupture strength of greater than 140 ksi is disclosed.

Owner:SMITH INT INC

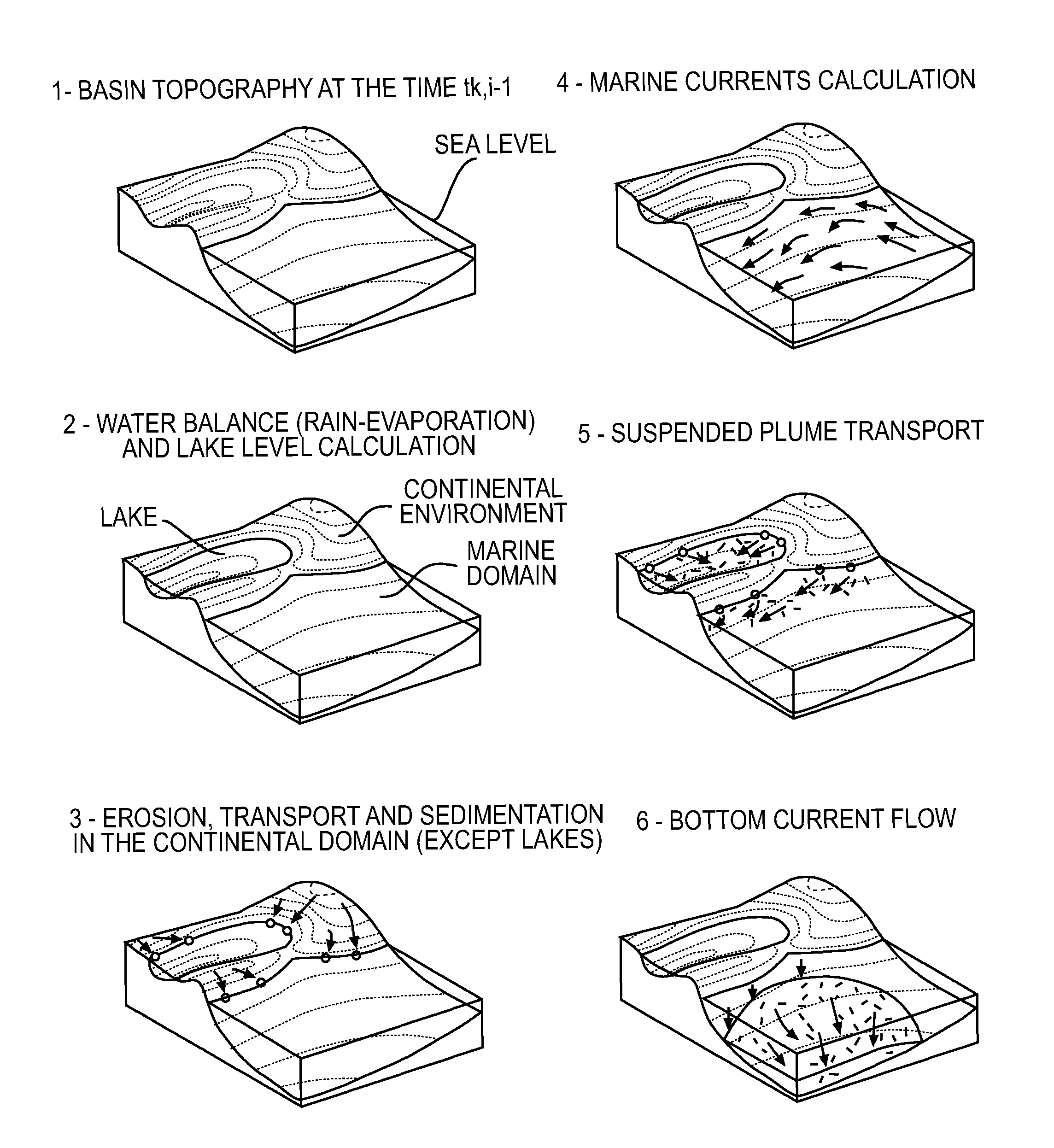

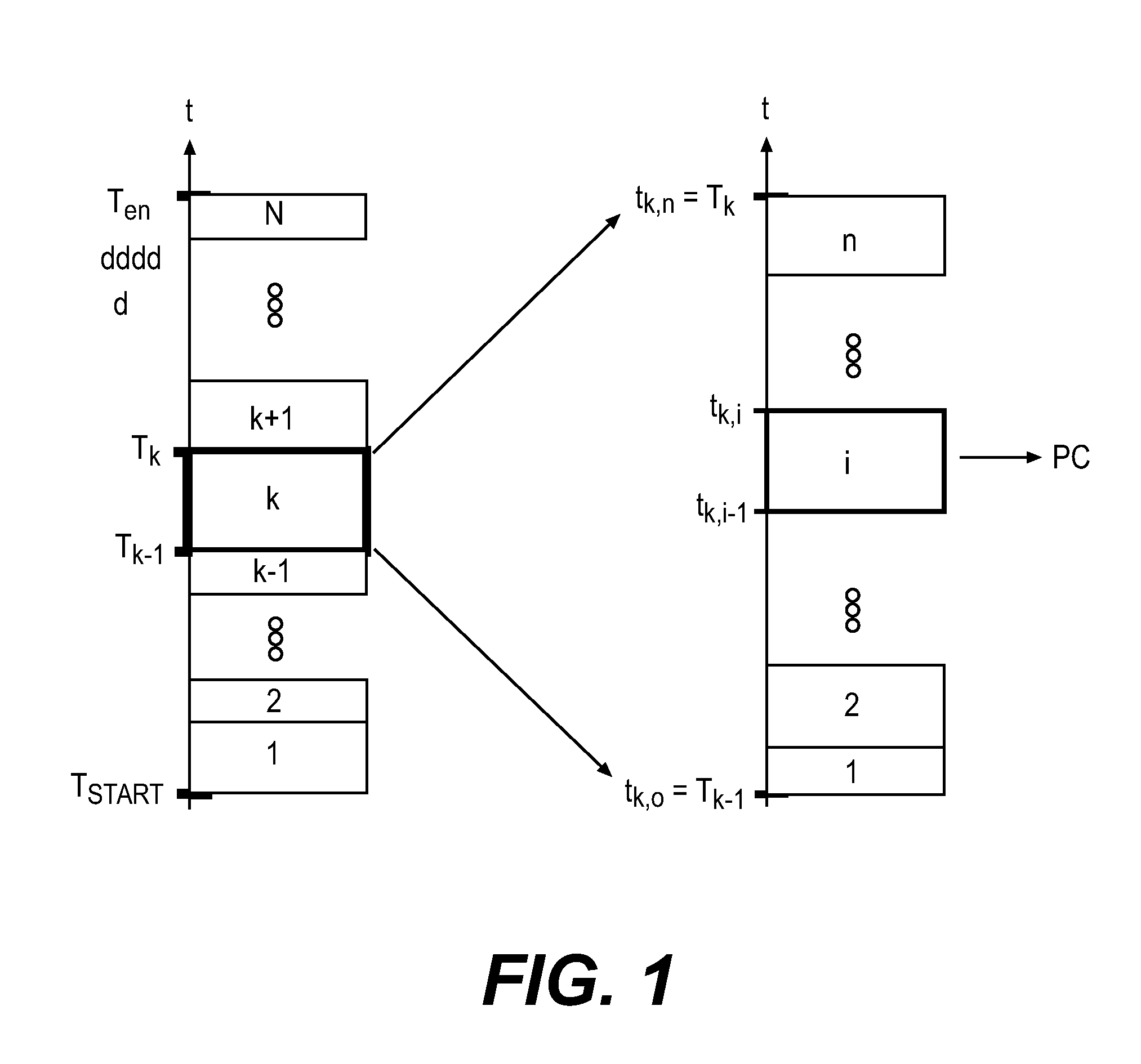

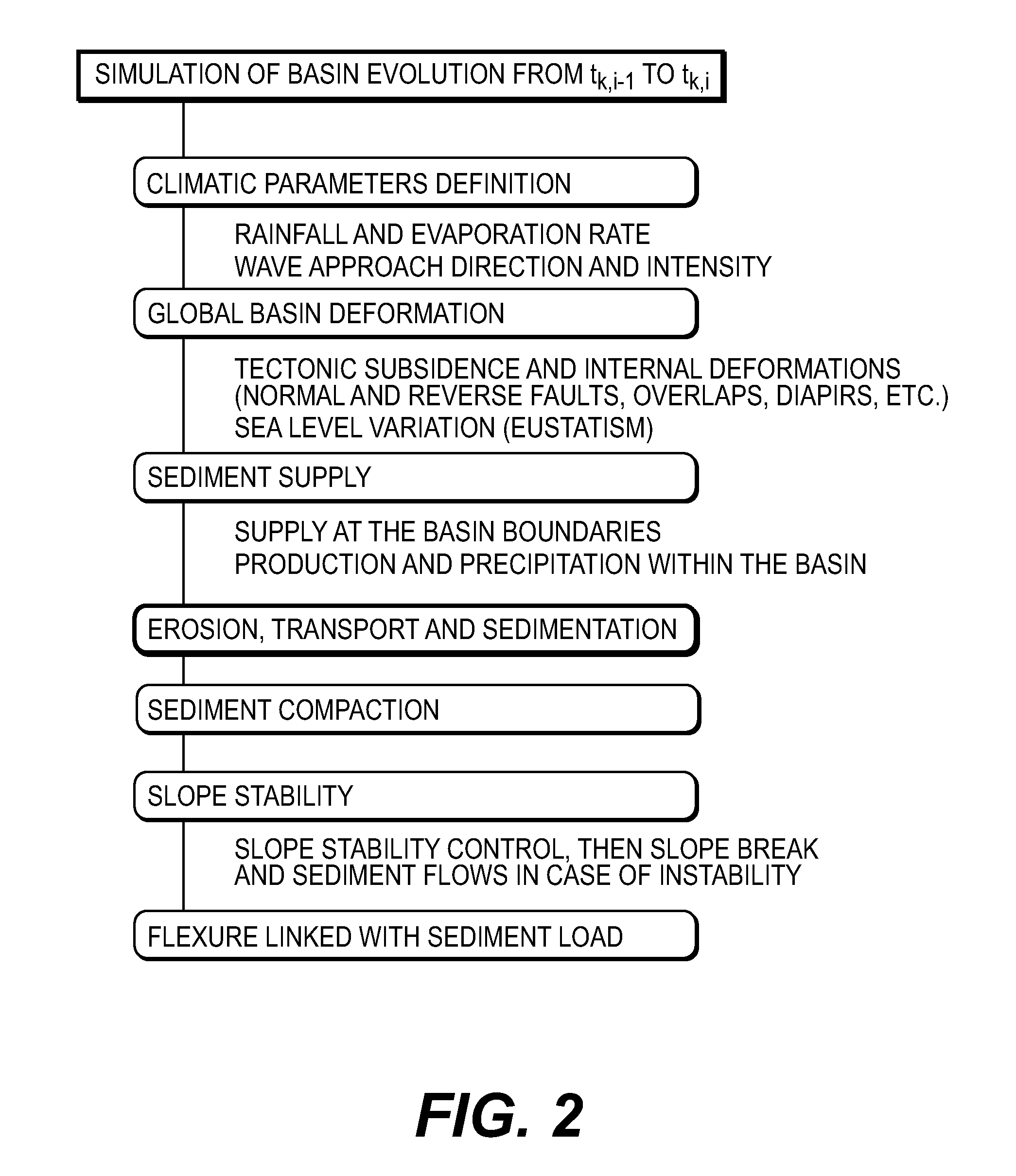

Method of developing a sedimentary basin from a stratigraphic simulation of multilithologic filling taking account of fine sediment transport

The invention is a method of developing a sedimentary basin from a stratigraphic simulation of multilithologic filling accounting for fine sediment transport. The sedimentary basin is broken up into geologic layers with each geologic layer being subdivided into a series of climatic layers. Each climatic layer is associated with at least one constant climatic parameter. A stratigraphic simulation is performed within each climatic layer using a stratigraphic model. The sediment transport in the continental domain and sediment bottom layer transport in the marine and lacustrine domains are modelled using nonlinear diffusion equations under maximum erosion rate constraint. Suspended sediment transport in the marine and lacustrine domain is modeled using an advection-diffusion equation accounting for a particle fall rate and of a marine and lacustrine current velocity. The climatic layers belonging to a single geologic layer are then homogenized and the basin is developed according to the stratigraphic simulation results.

Owner:INST FR DU PETROLE

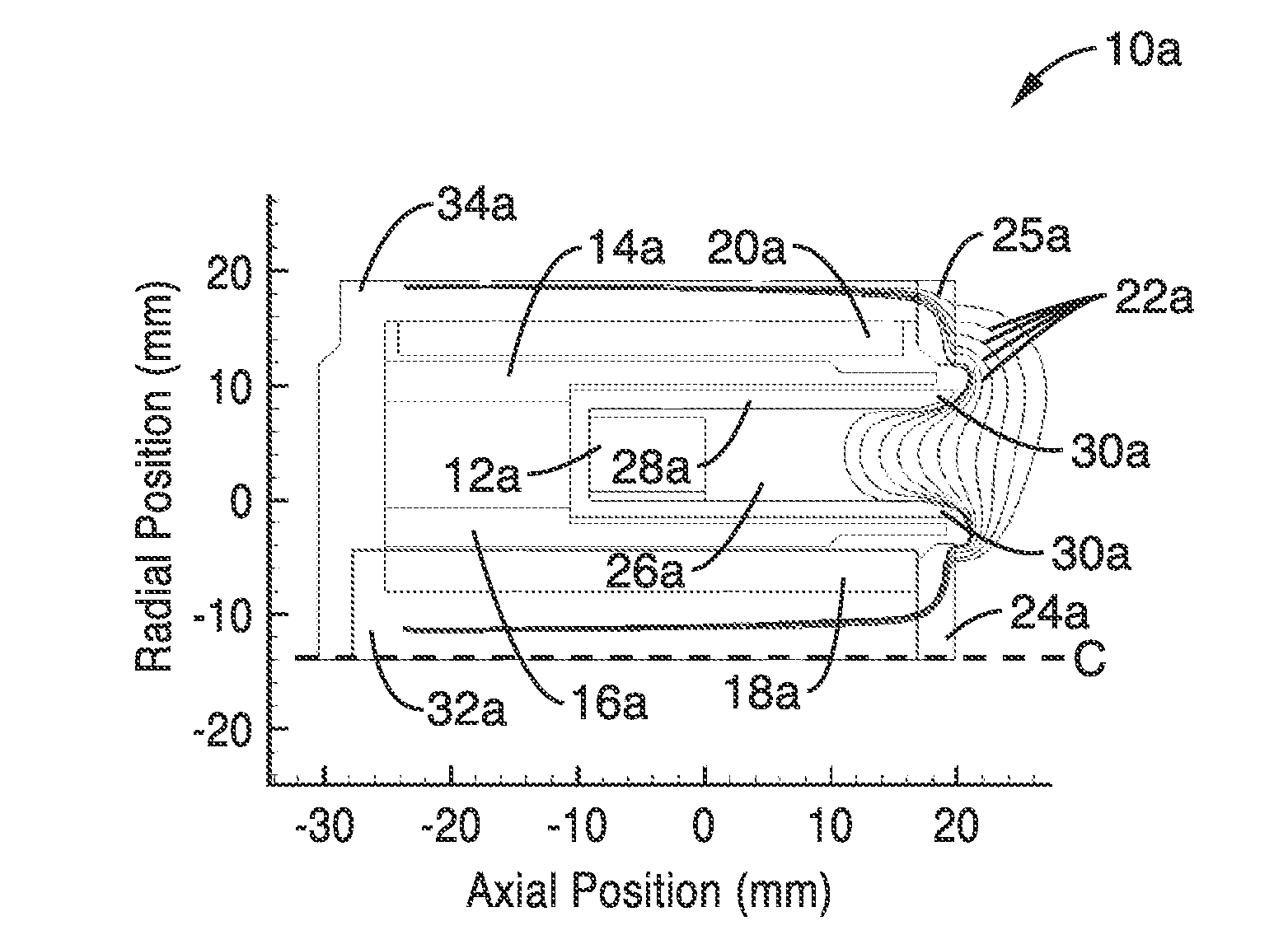

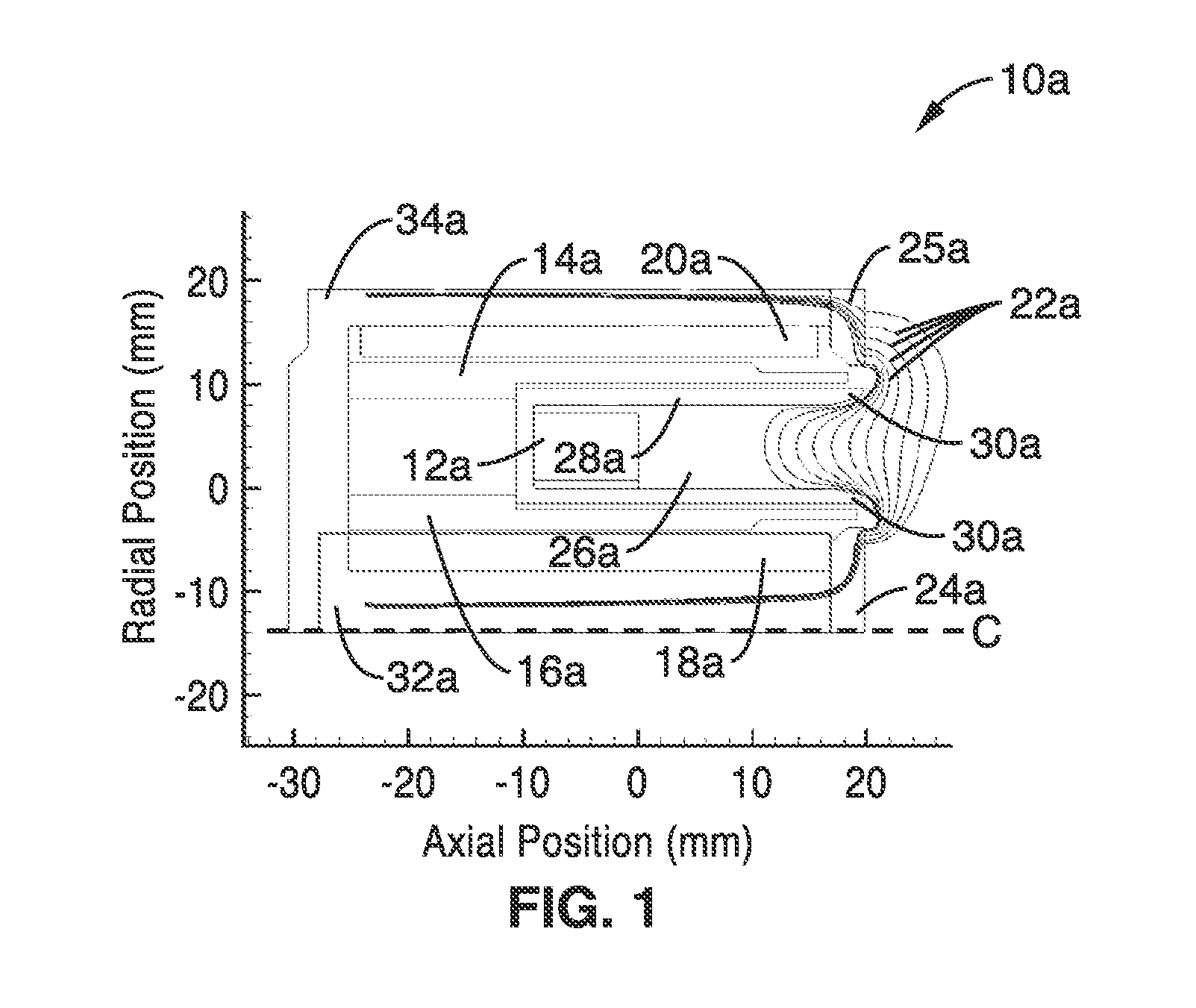

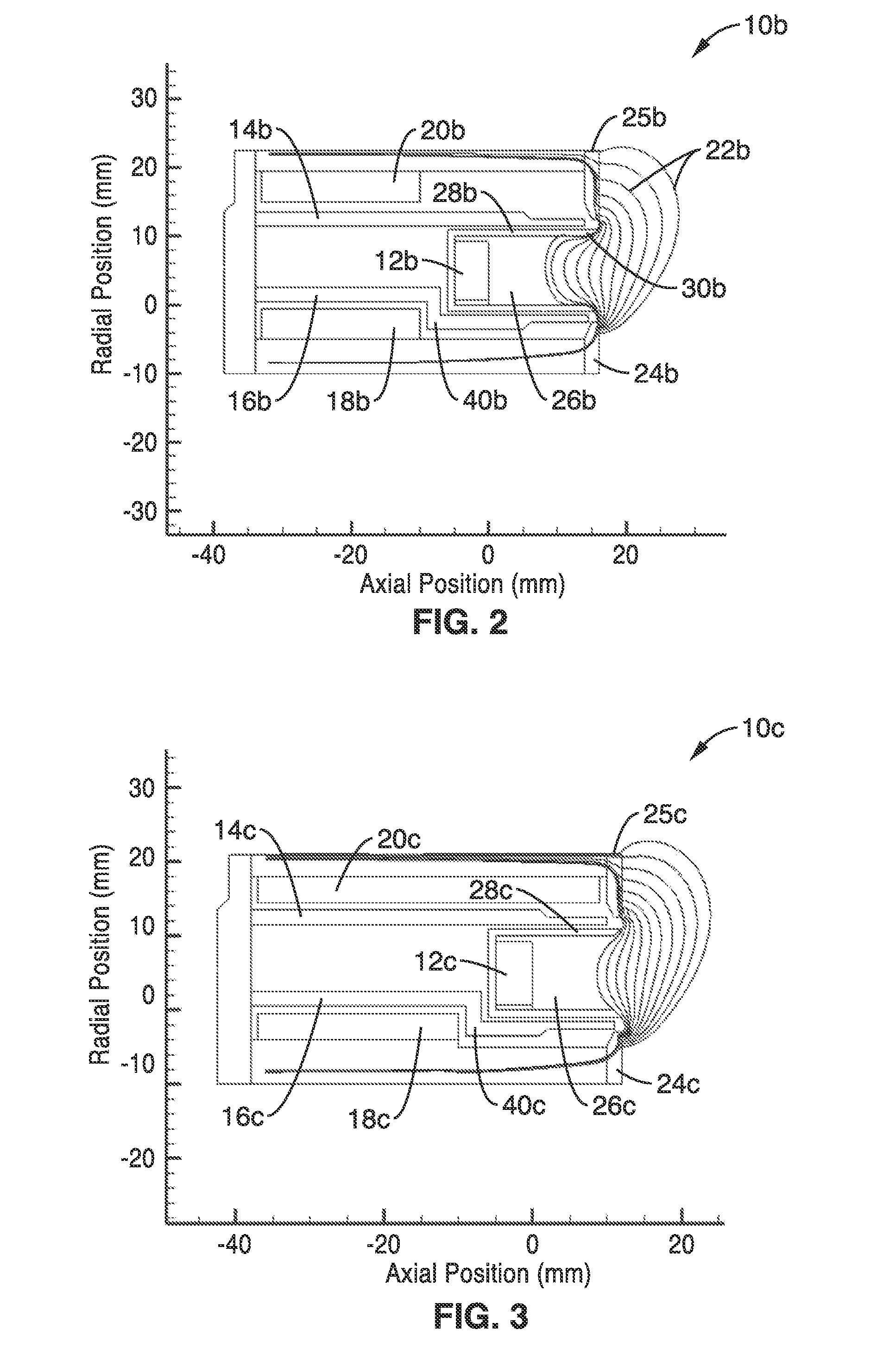

Magnetically shielded miniature hall thruster

InactiveUS20150128560A1Eliminates effect of ion bombardment erosionLonger thruster lifetimeMachines/enginesUsing plasmaElectron temperatureErosion rate

Magnetically shielded miniature Hall thrusters are disclosed that use a unique magnetic field topology that prevents the magnetic field lines from intersecting the discharge channel walls in the acceleration region of the thruster. Instead, the lines of force originating from both the inner and outer pole pieces curve around the downstream edges of the discharge channel and follow the channel walls towards the anode. This unique field topology results in low electron temperature at the discharge channel walls while eliminating strong electric field components that would otherwise lead to high erosion rates and power deposition from ion acceleration into the channel walls.

Owner:RGT UNIV OF CALIFORNIA

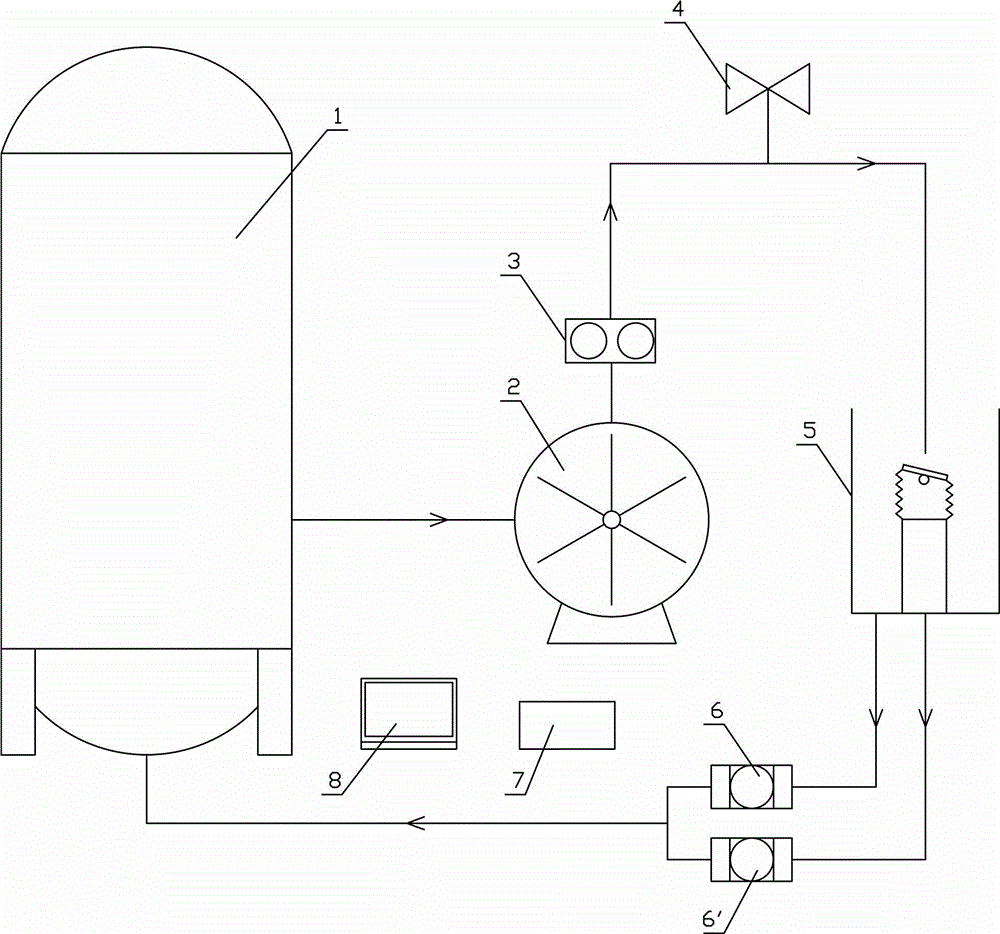

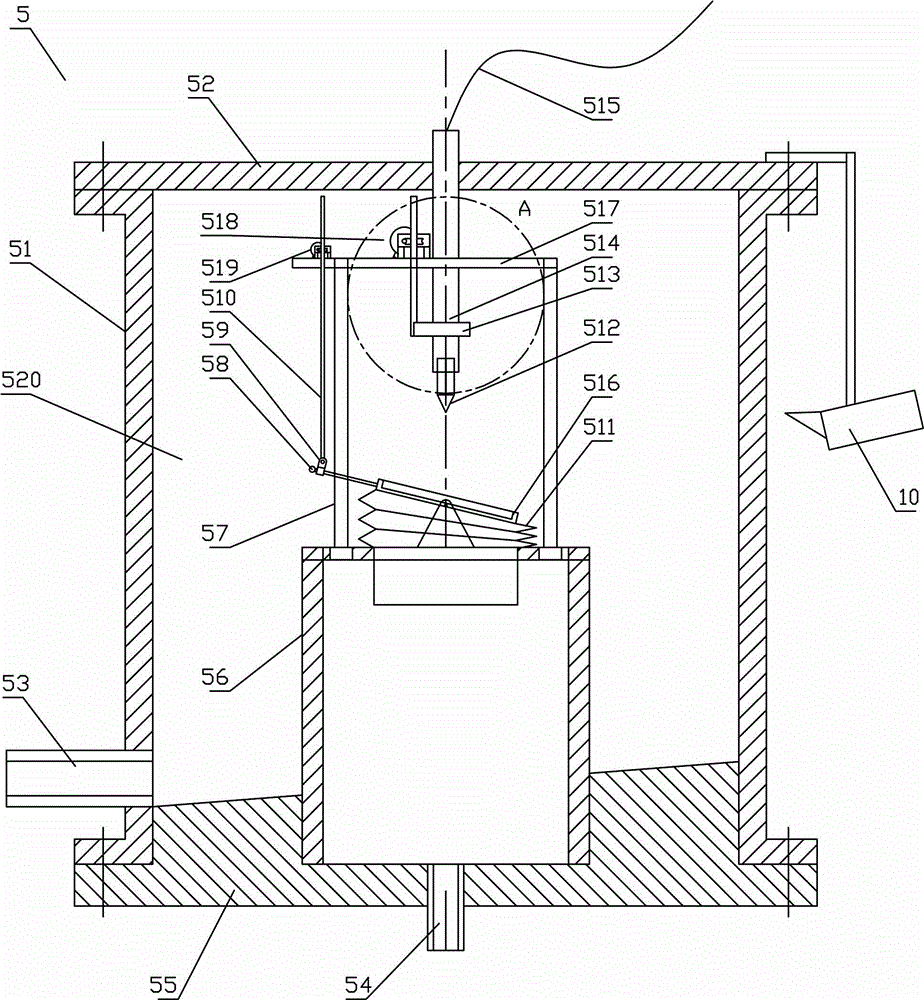

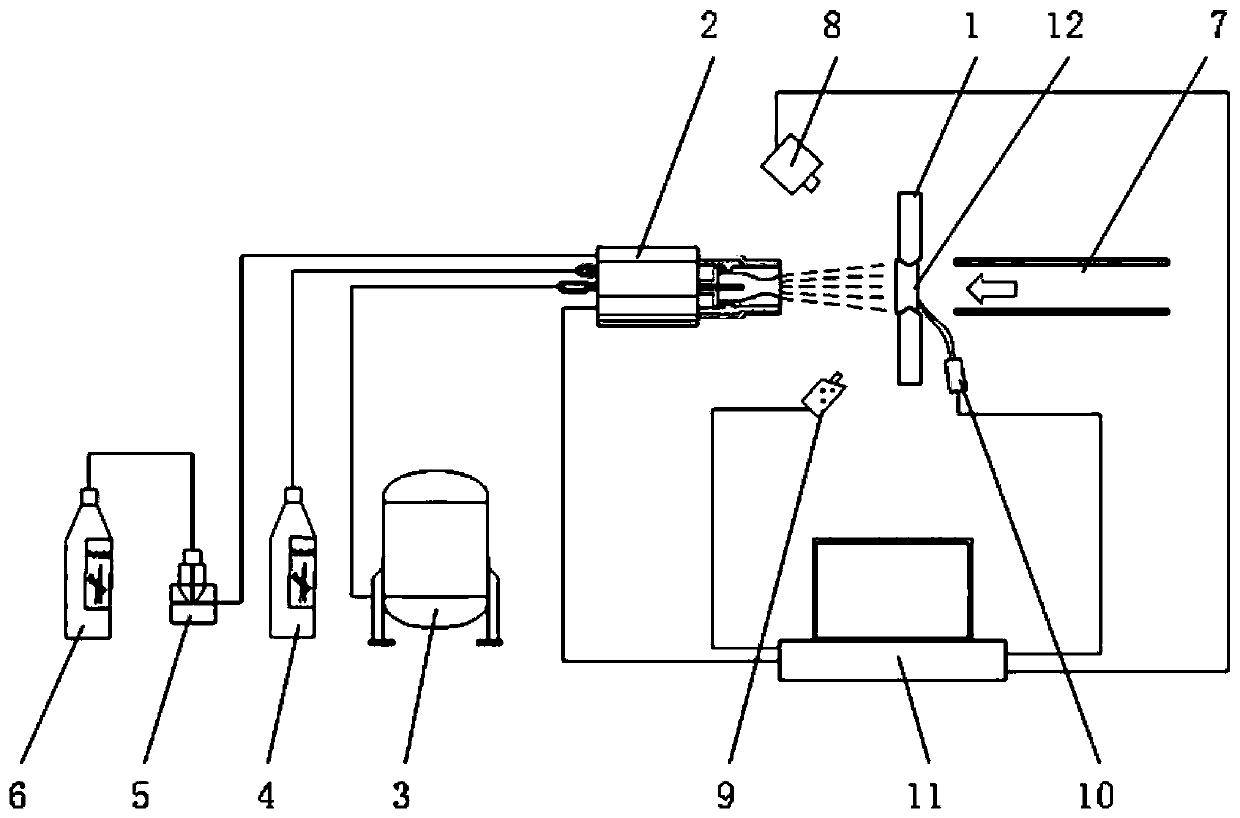

Method for evaluating erosion rate of sand control pipe and its special-purpose apparatus

InactiveCN104897510AWeighing by removing componentMaterial analysis using radiation diffractionExhaust valveErosion rate

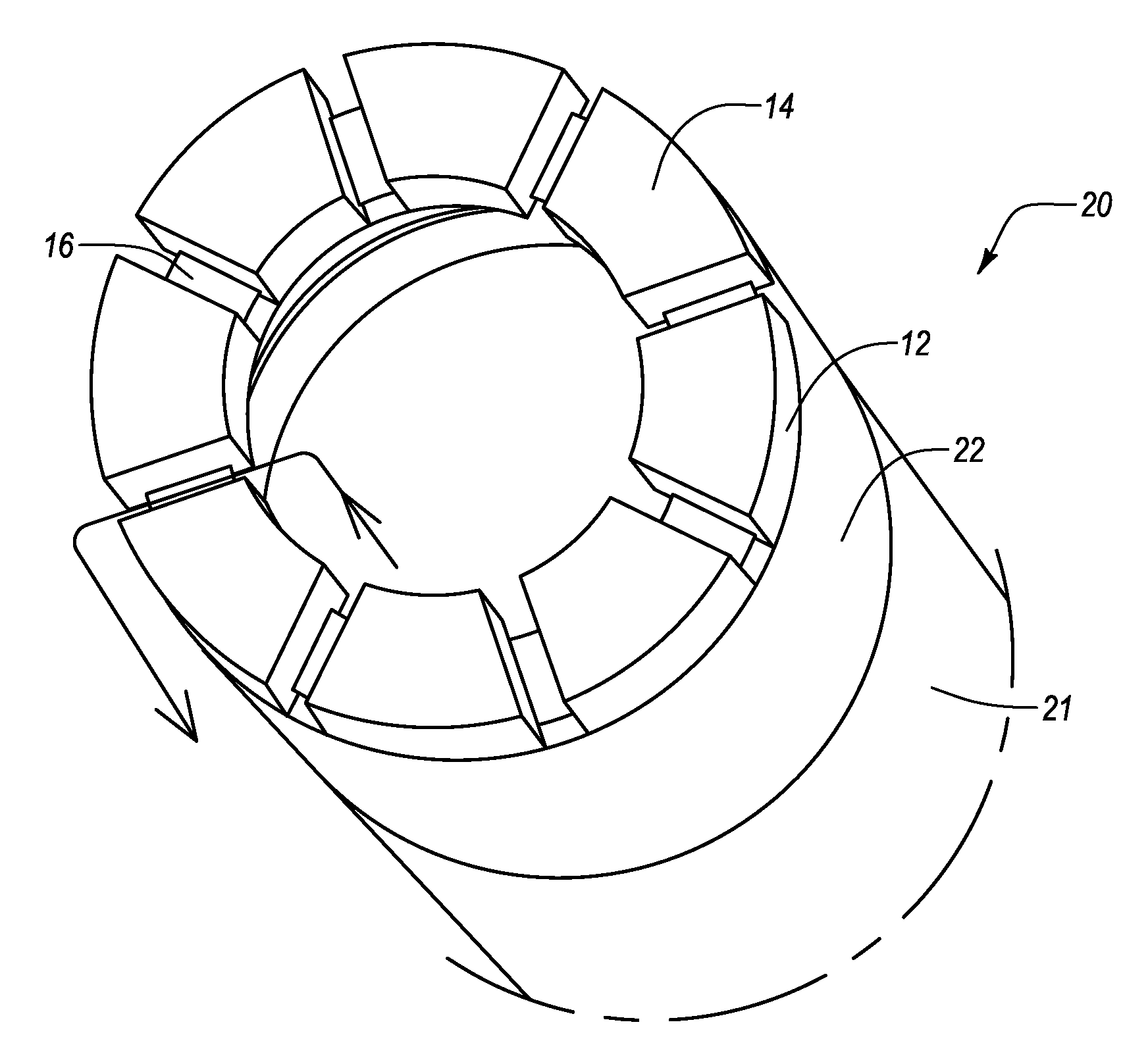

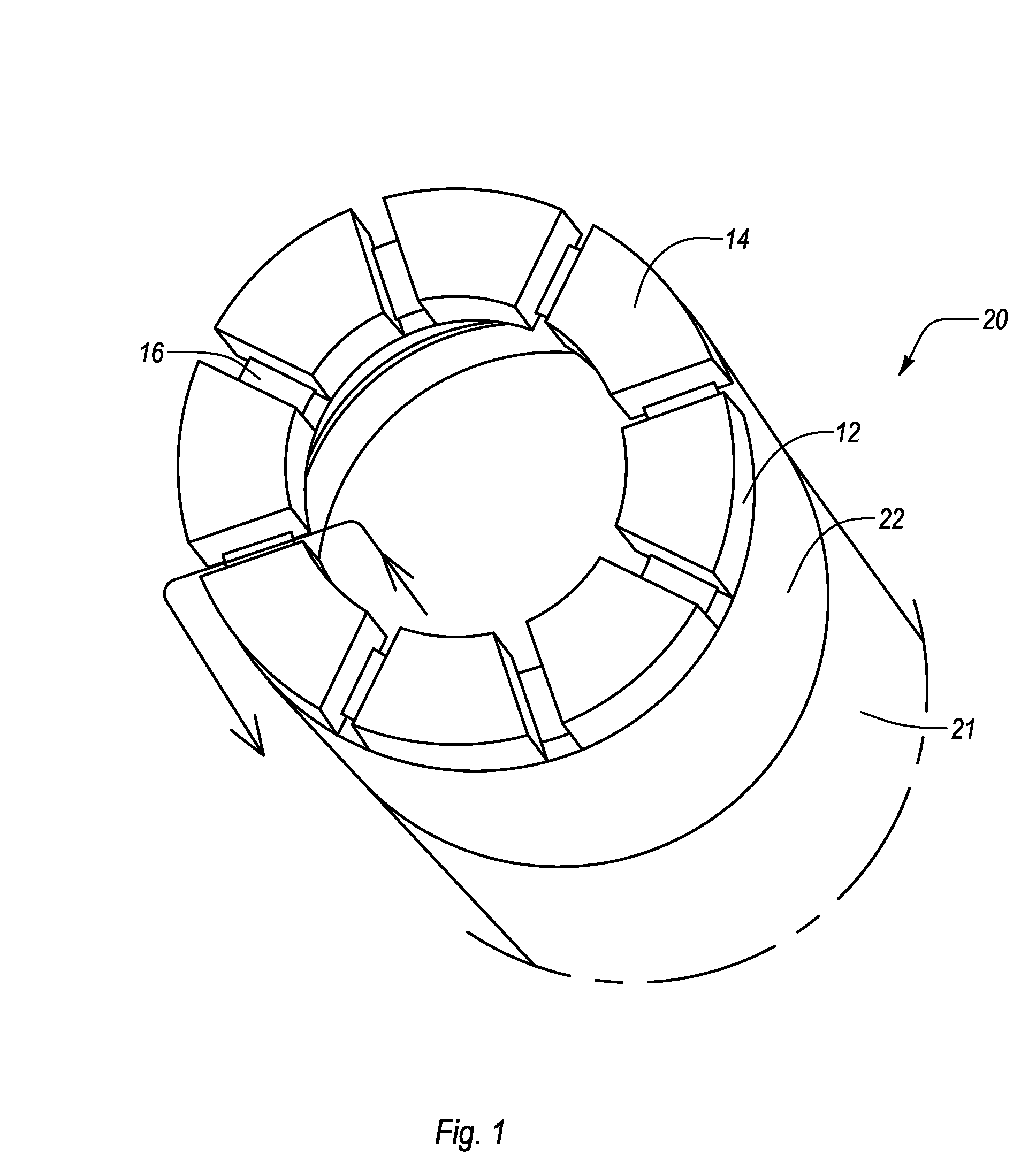

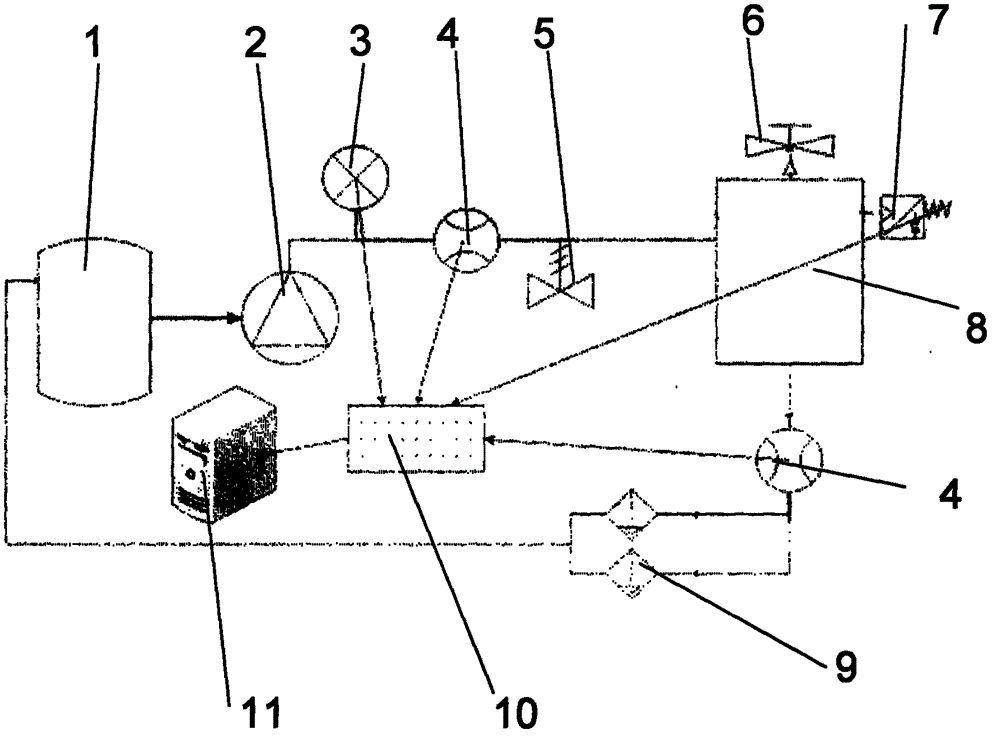

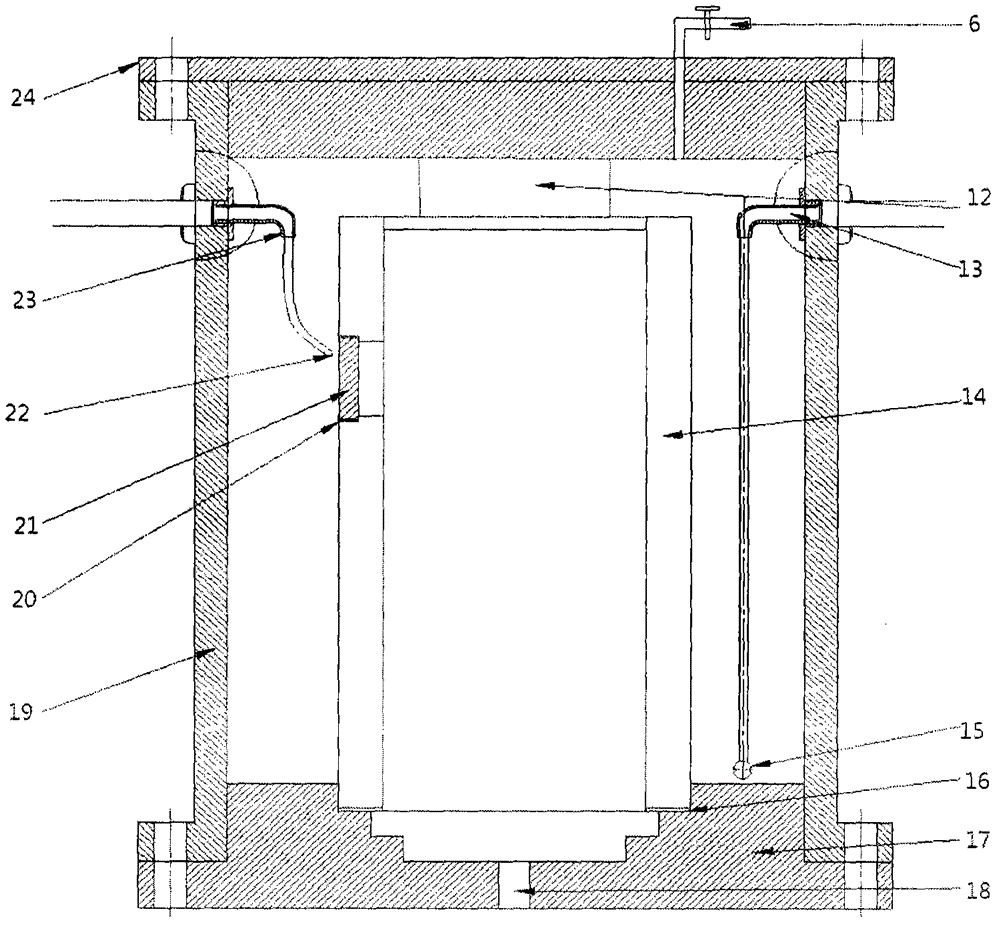

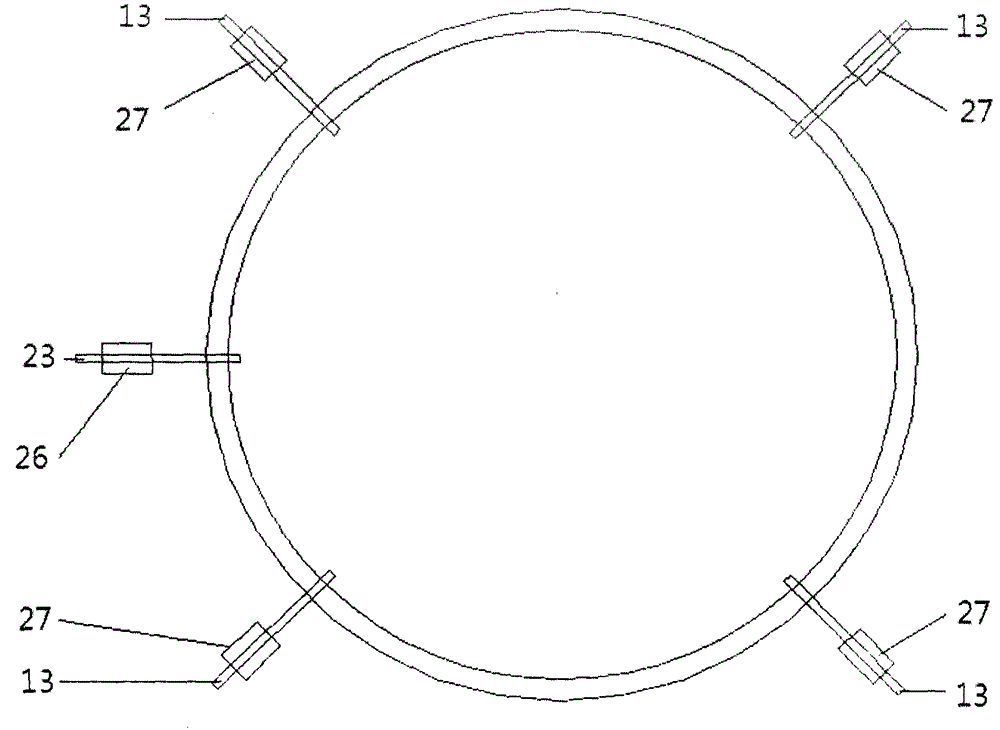

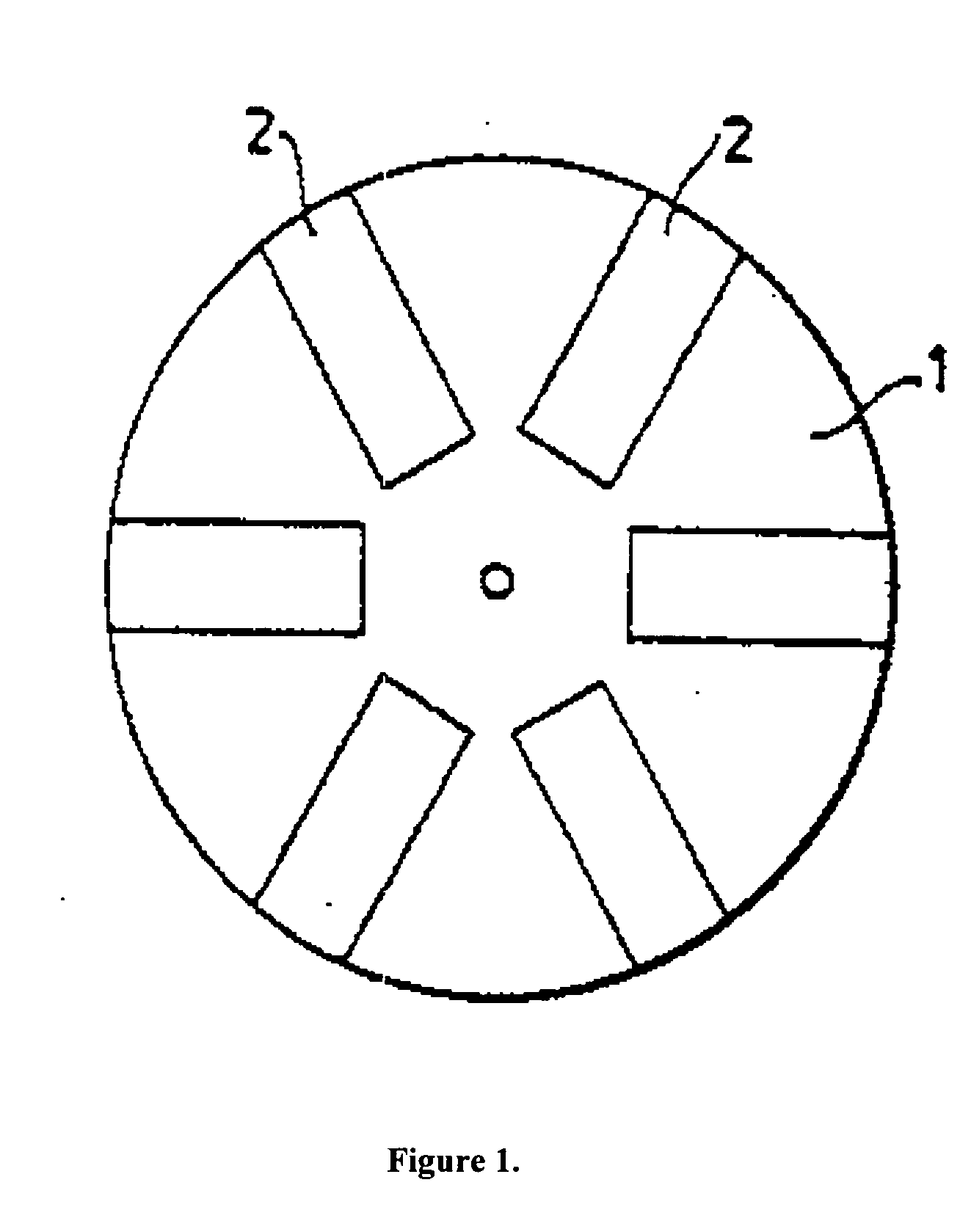

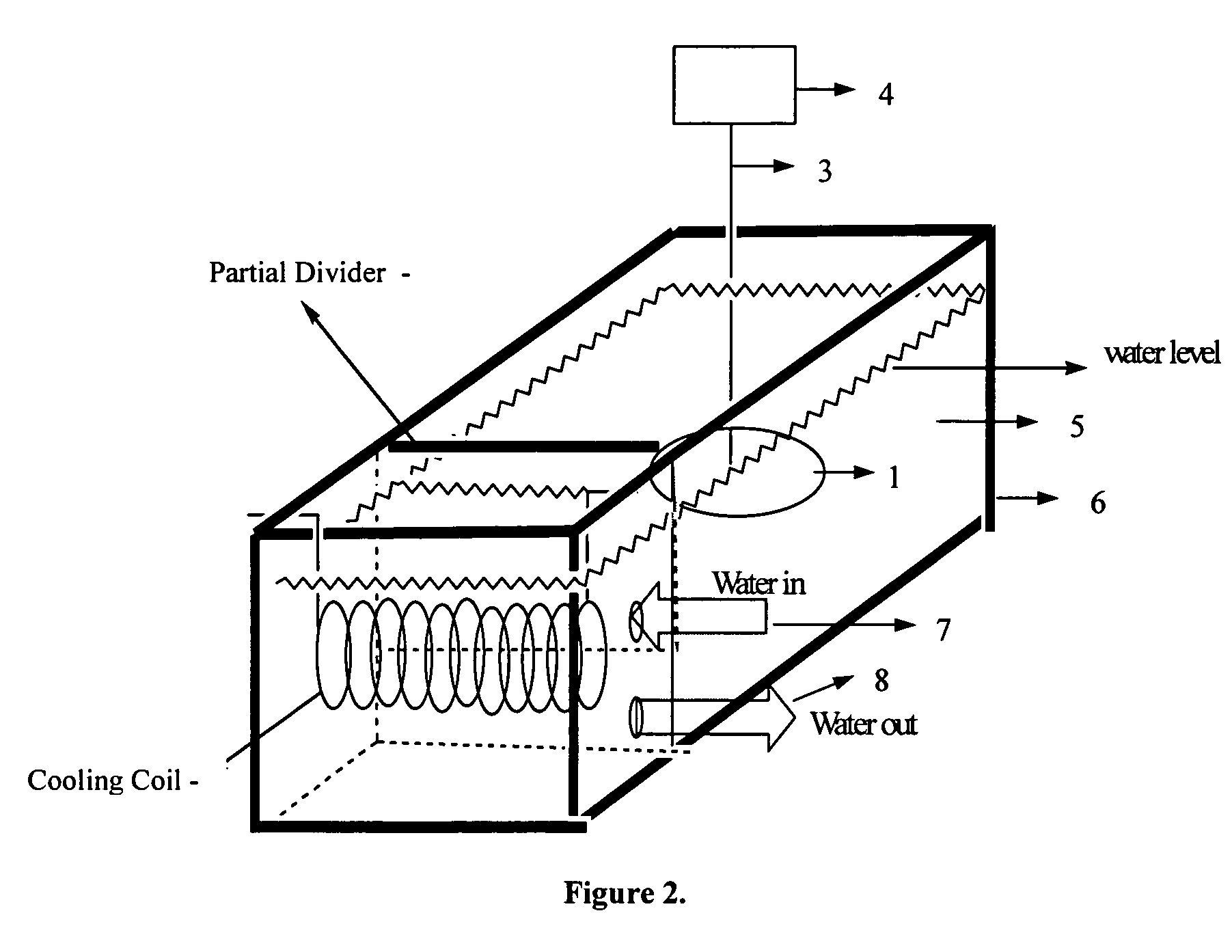

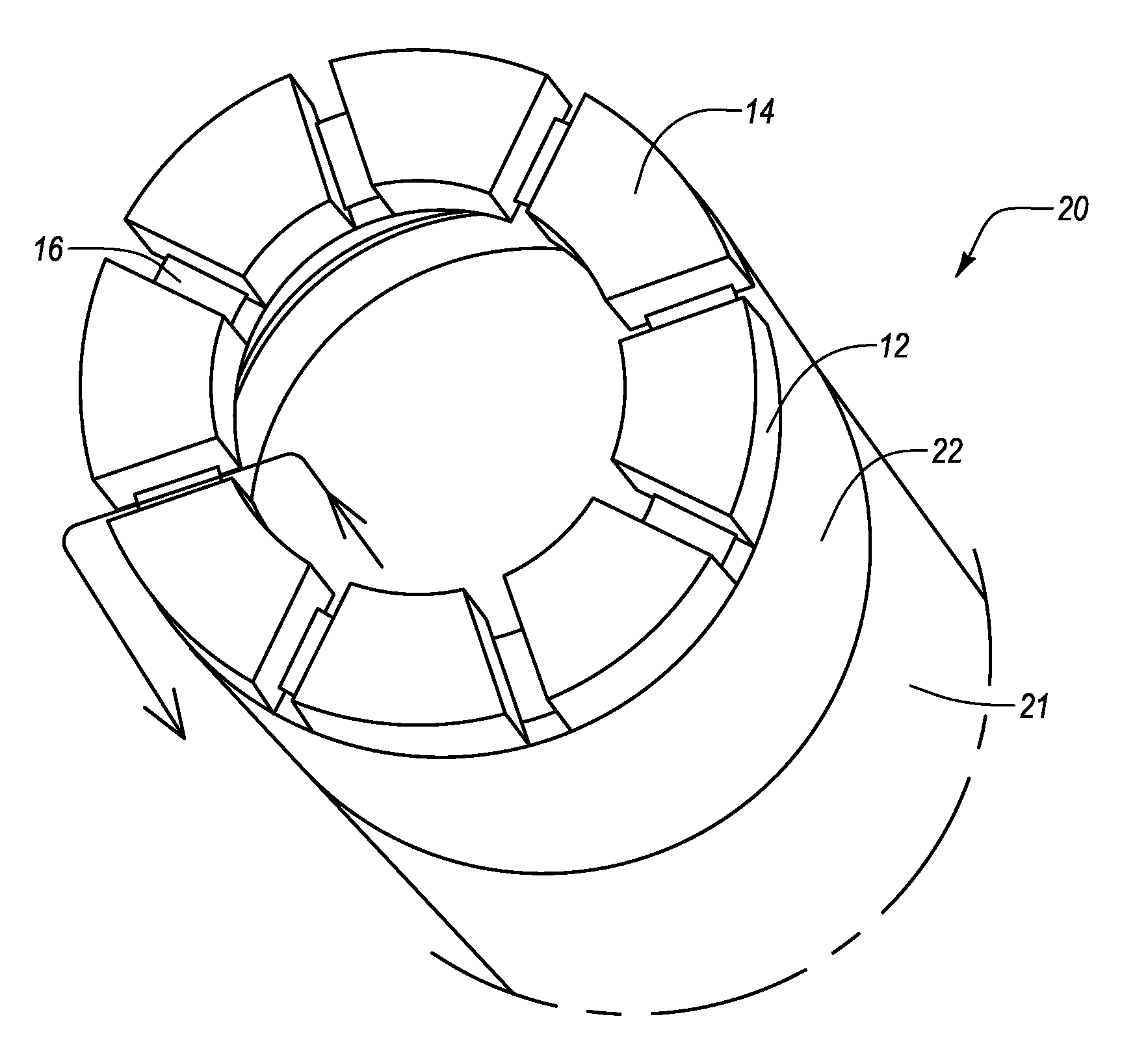

The invention relates to a method for evaluating erosion rate of a sand control pipe and its special-purpose apparatus, which is characterized in that the on-site screen casings are used for processing to screen casing sheets for experiments. According to the invention, change of sand control pipe precision can be evaluated by a laser granularity analysis on sand from different periods of experiment process, erosion rate of the screen casing under specific reservoir condition and production condition can be evaluated according to the mass change of the screen casing sheet before and after the experiment, and finally the erosion rate and the usage life of the screen casing can be predicted. For solving the problems, a technical scheme is characterized in that the special-purpose apparatus is a whole set of fluid circulation apparatus, which comprises a circulation solution storage pot 1, a high pressure pump 2, a pressure gage 3, a flow monitor device 4, a safety exhaust valve 6, a pressure transducer 7, an enclosed autoclave body 8, an oil-sand separator 9, and a data acquisition system 10. According to the special-purpose apparatus, an erosion stand 14, a cleaning nozzle 22 and a sand washing nozzle 15 are arranged in the enclosed autoclave body 8.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

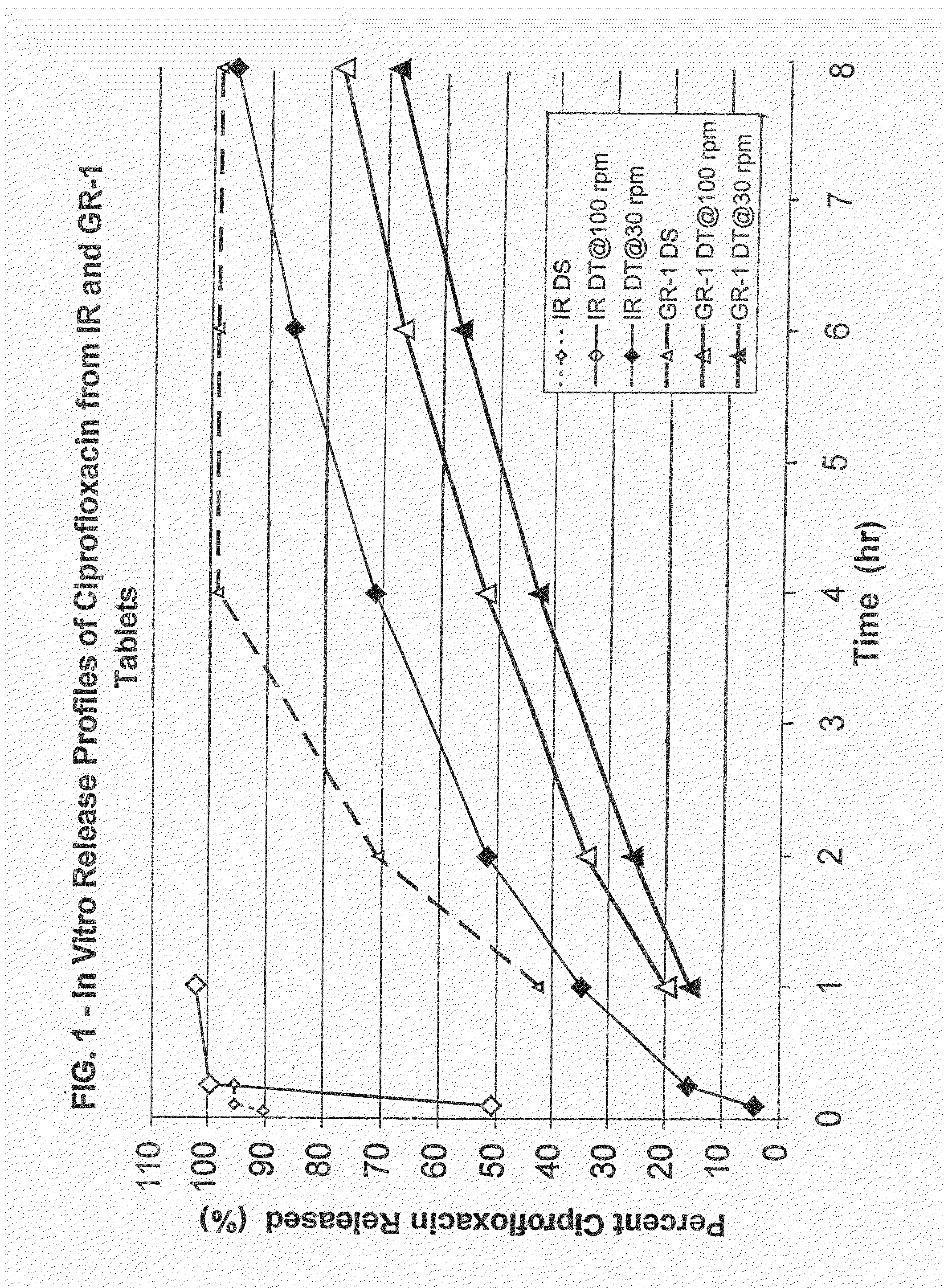

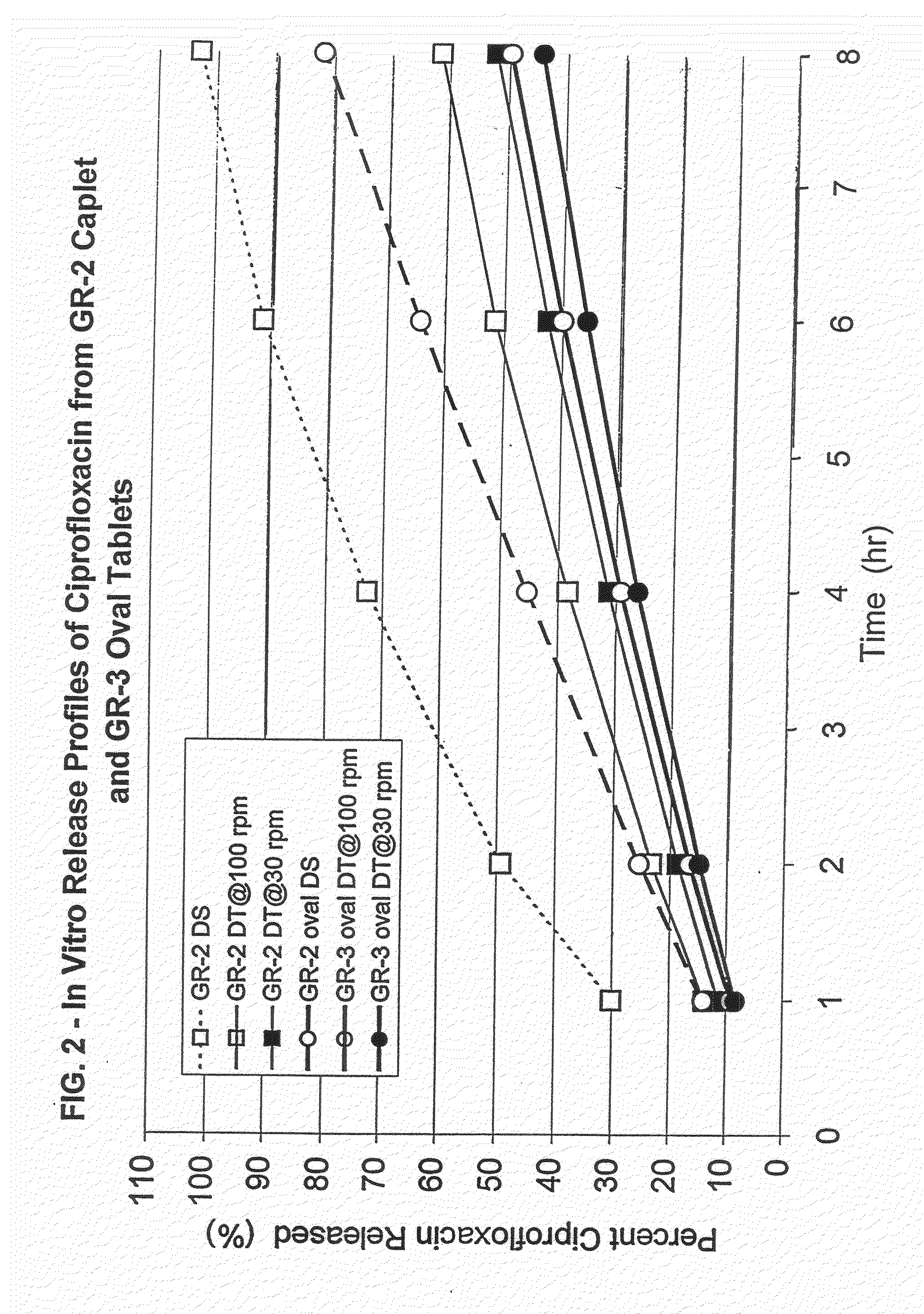

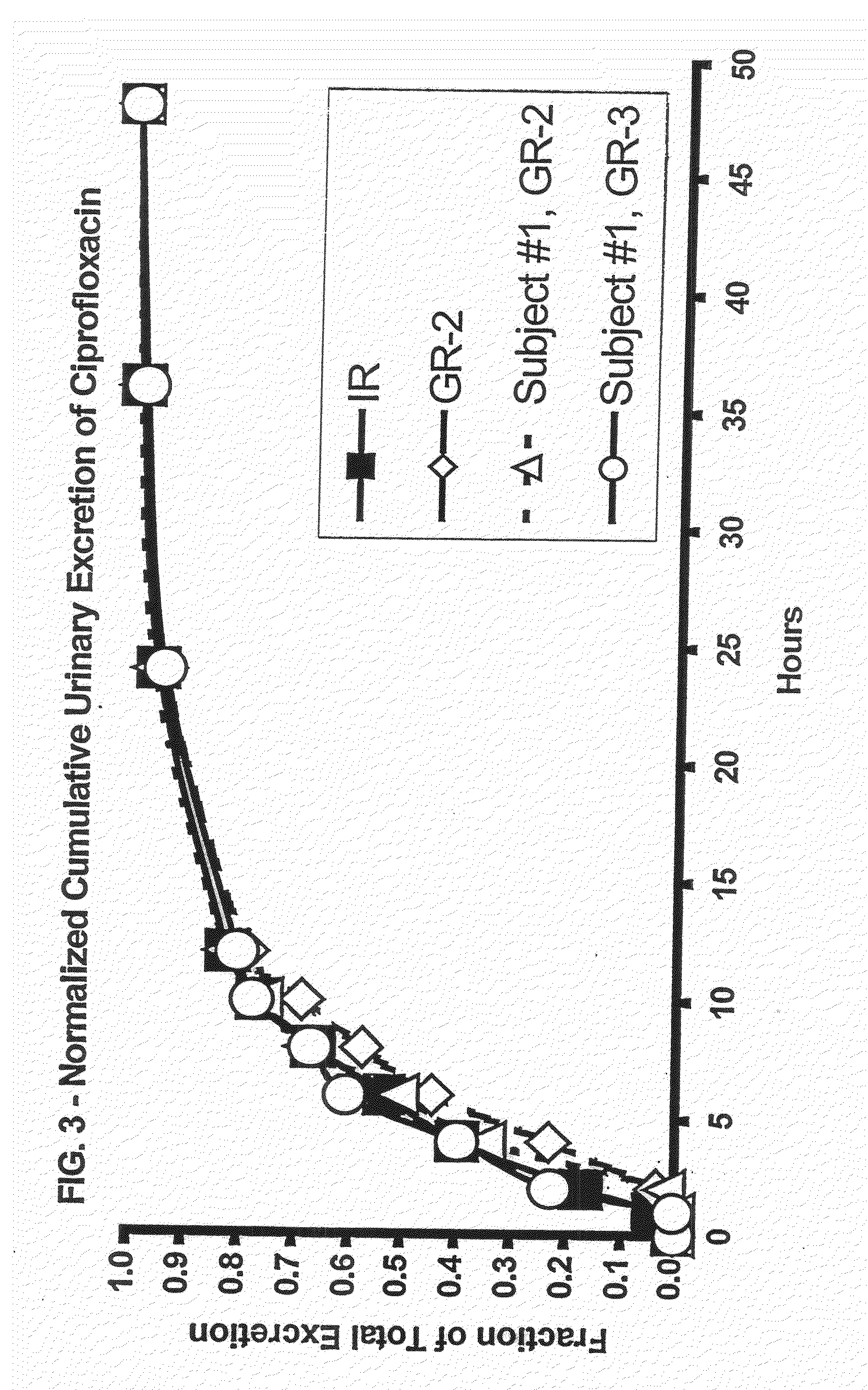

Gastric retentive oral dosage form with restricted drug release in the lower gastrointestinal tract

InactiveUS20110301129A1Minimizes variabilityIncreasing and decreasing drug loadingAntibacterial agentsBiocideDrug release rateErosion rate

Owner:DEPOMED SYST INC

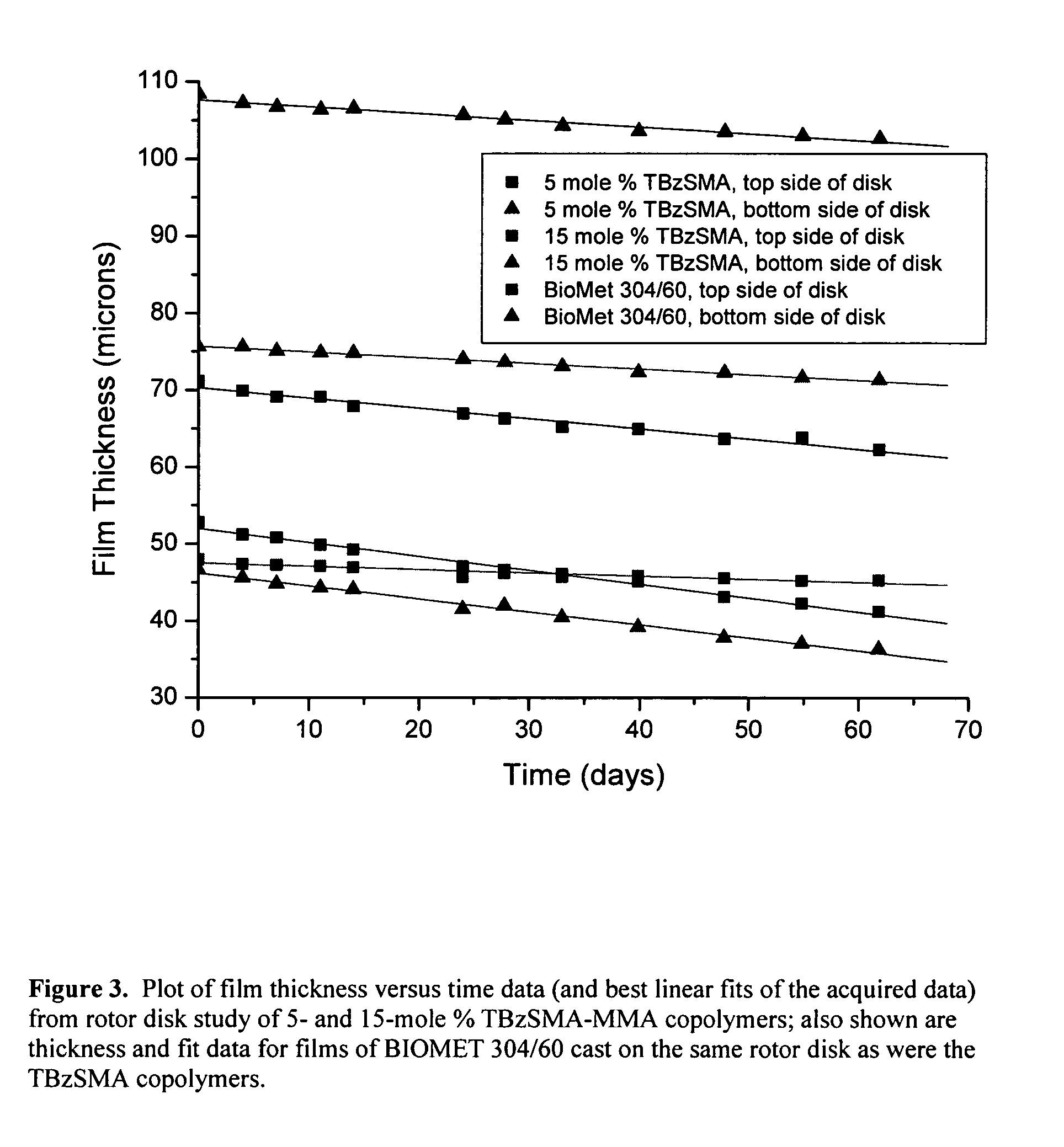

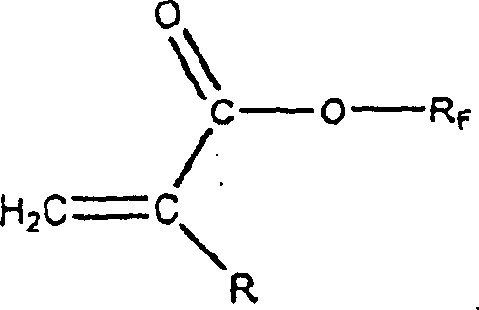

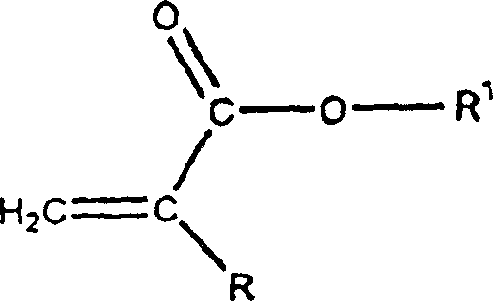

Benzylsilyl(meth)acryloyl-containing polymers for marine coating compositions

InactiveUS20060189708A1Control erosionAntifouling/underwater paintsPaints with biocidesMeth-Erosion rate

This invention relates to polymers for self-polishing marine antifouling coatings. More particularly, the invention relates to polymer binders, which provide an erosion rate in seawater that is suitable for use in marine antifouling coatings. These polymer binders contain pendant benzylsilylacrylate groups. Additionally it was found that marine antifouling coatings could be formed with lower silyl acrylate levels using the monomers of the invention, and still achieve a suitable erosion rate in seawater.

Owner:ARKEMA INC

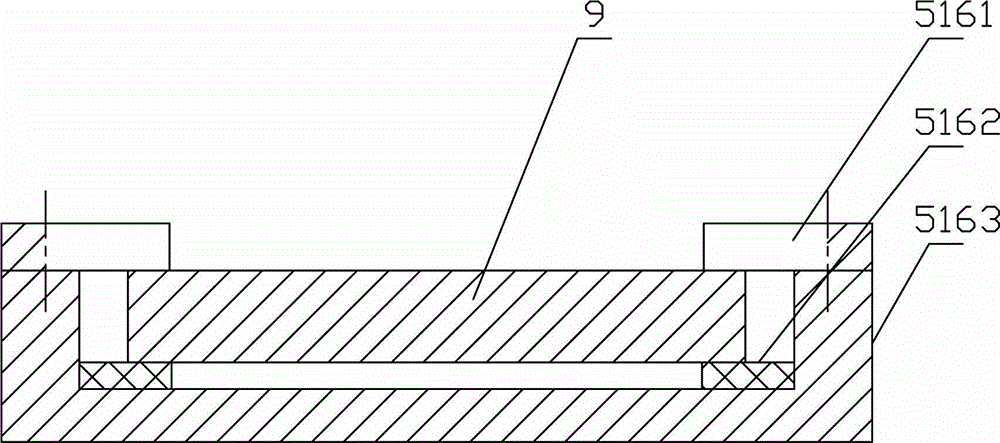

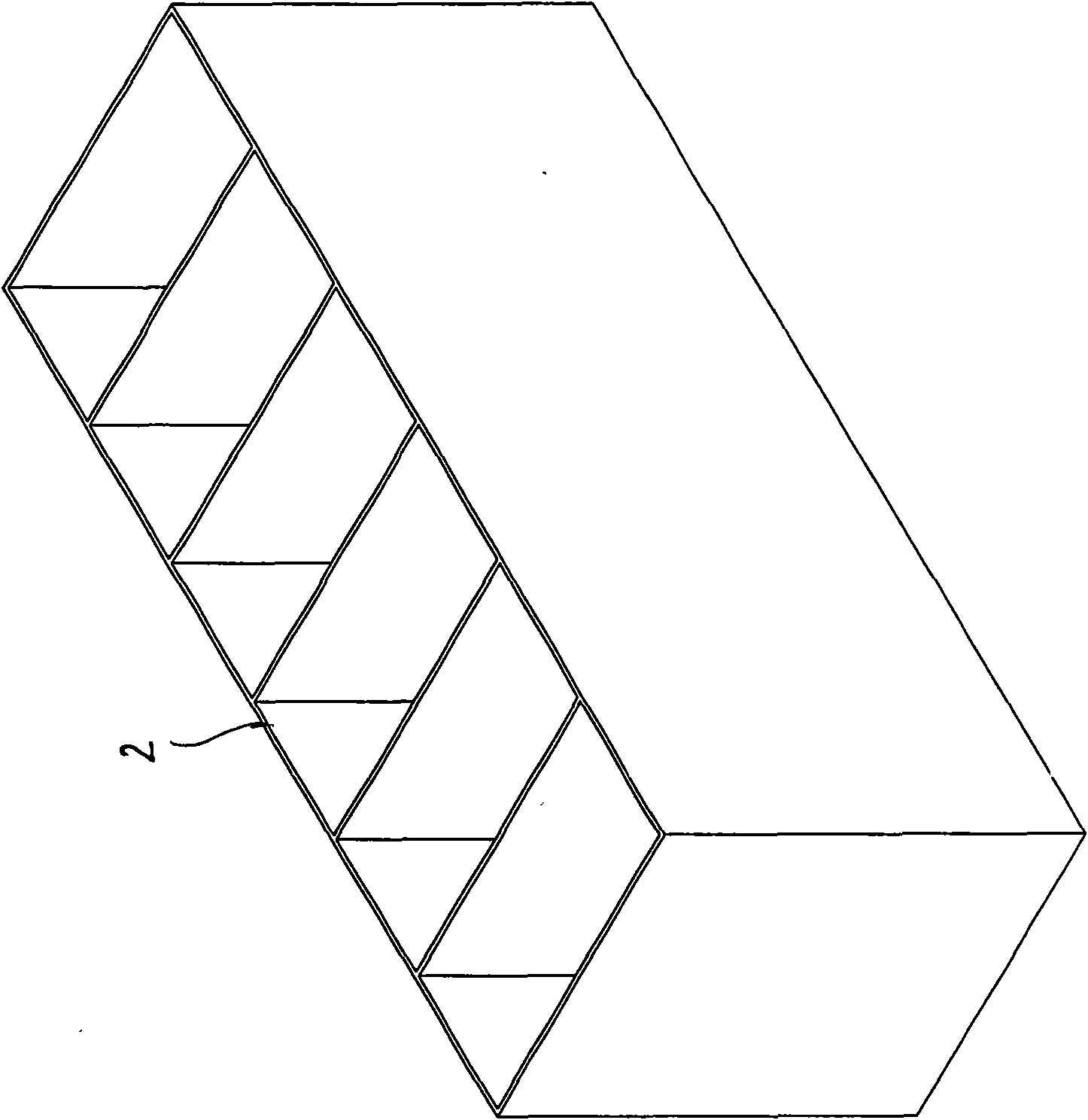

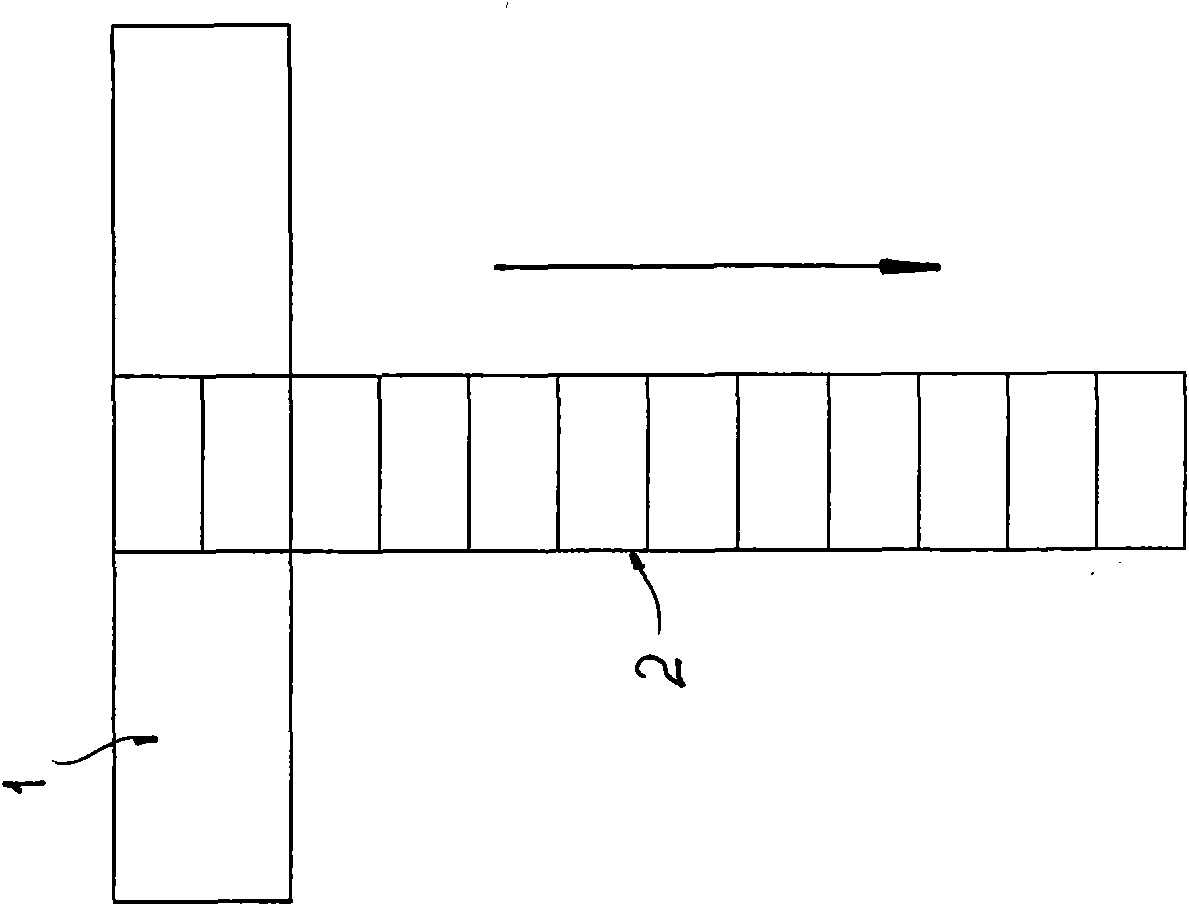

Sand control pipe erosion rate experiment device

InactiveCN105067464AAccurate assessmentReduce labor intensityWeather/light/corrosion resistanceInvestigating abrasion/wear resistanceAutomatic controlErosion rate

A sand control pipe erosion rate experiment device is disclosed. A storage tank is connected to a pump through a pipeline. The pump is connected to an erosion device through a pipeline. The erosion device is connected to an oil-sand separation device through a pipeline. The oil-sand separation device is connected to the storage tank. In the erosion device, a liftable nozzle is arranged above a sample seat with an adjustable inclined angle and is connected to the pump. Through the structure mentioned above, the samples collected by an oil-field common screen pipe can be used to carry out experiments, the different production conditions can be simulated, the simulated production conditions are closed to the real working conditions, such as the physical characteristics of different stratums, production requirements including pressure requirement and flow requirement, and the like; the experiment parameters can be adjusted in time, the erosion on a sand control pipe can be simulated, and thus the sand control pipe erosion rate can be evaluated more precisely. Furthermore, automatic control is adopted during the experiment process, the data is collected automatically, and the labor intensity is reduced.

Owner:YANGTZE UNIVERSITY

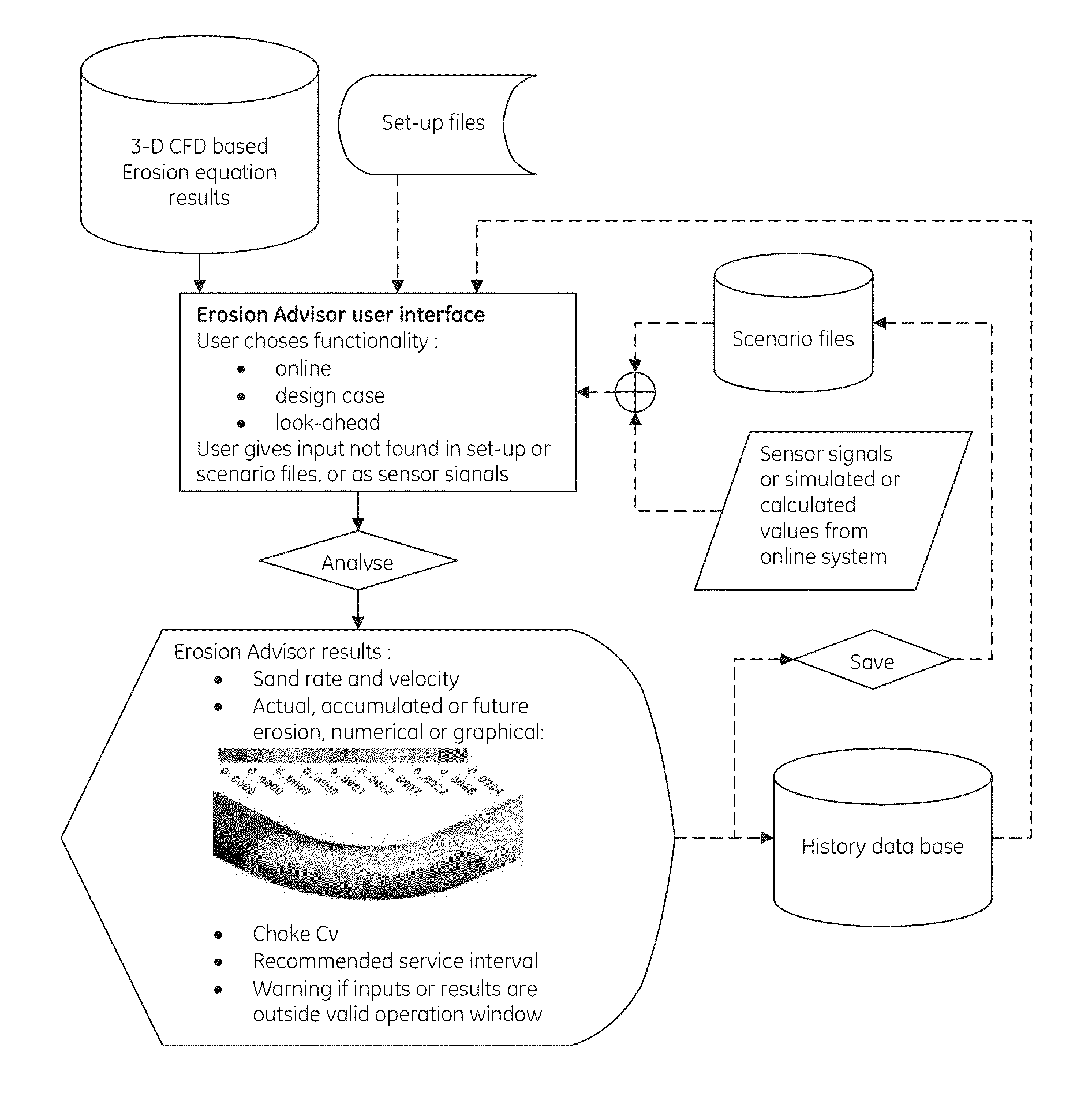

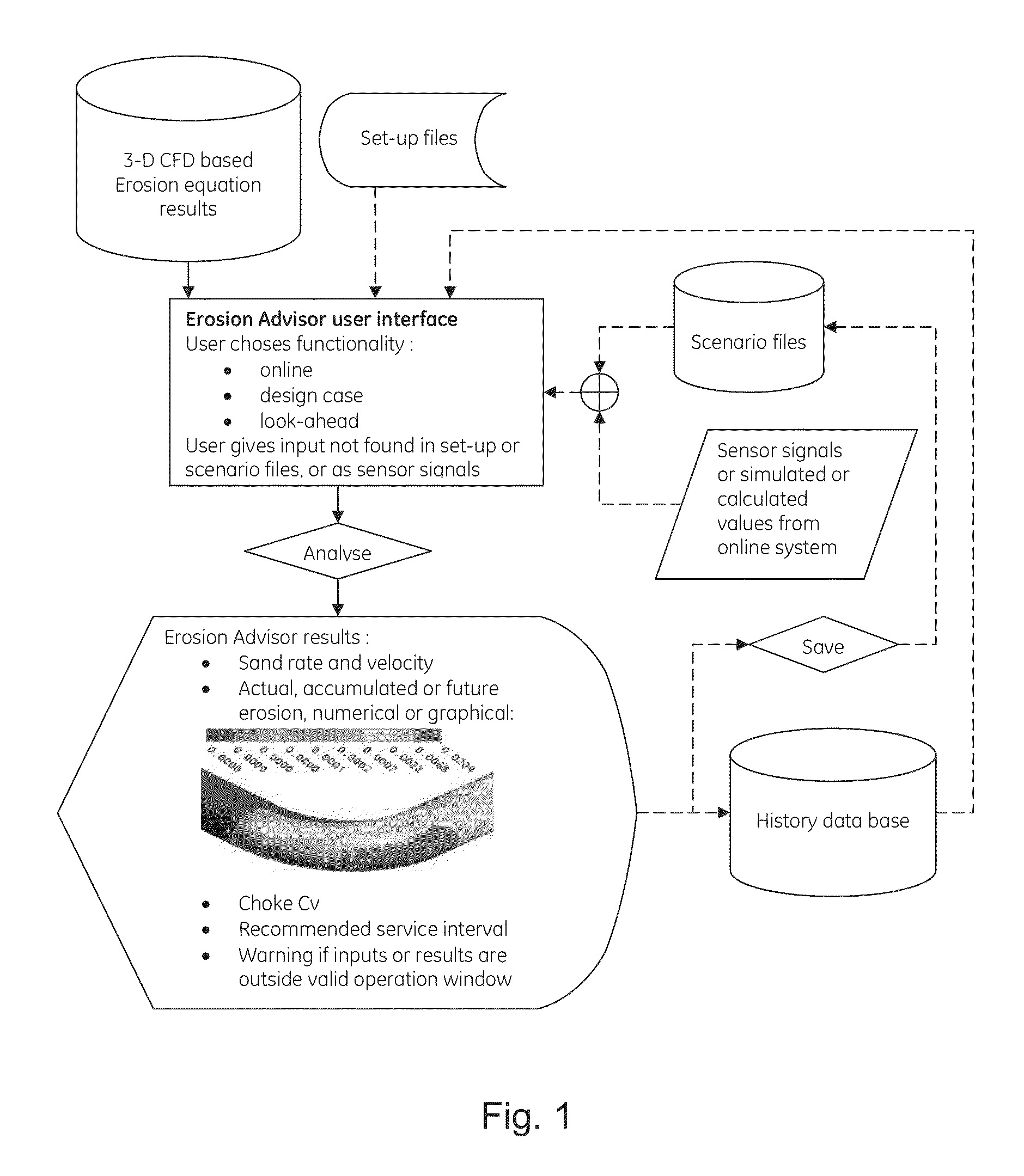

Method and module for determination of erosion in systems

InactiveUS20130008649A1Accurately erosionAccurately in gas productionSurveyInvestigating abrasion/wear resistanceErosion rateComputer program

A method of providing information regarding erosion in an oil and / or a gas production system, which system includes at least one equipment / piping, the method including the steps of obtaining CFD results regarding hot spots in the equipment / piping from a CFD analysis of the equipment / piping for a range of pressures, flow rates and sand rates; and to, during production, obtaining data regarding erosion rates in a particular location in the system; and combining the data regarding erosion rates and CFD results to estimate and monitor sand erosion rates in the hot spots of the system. Further disclosed is a module performing the method steps as well as a computer program.

Owner:VETCO GRAY SCANDINAVIA

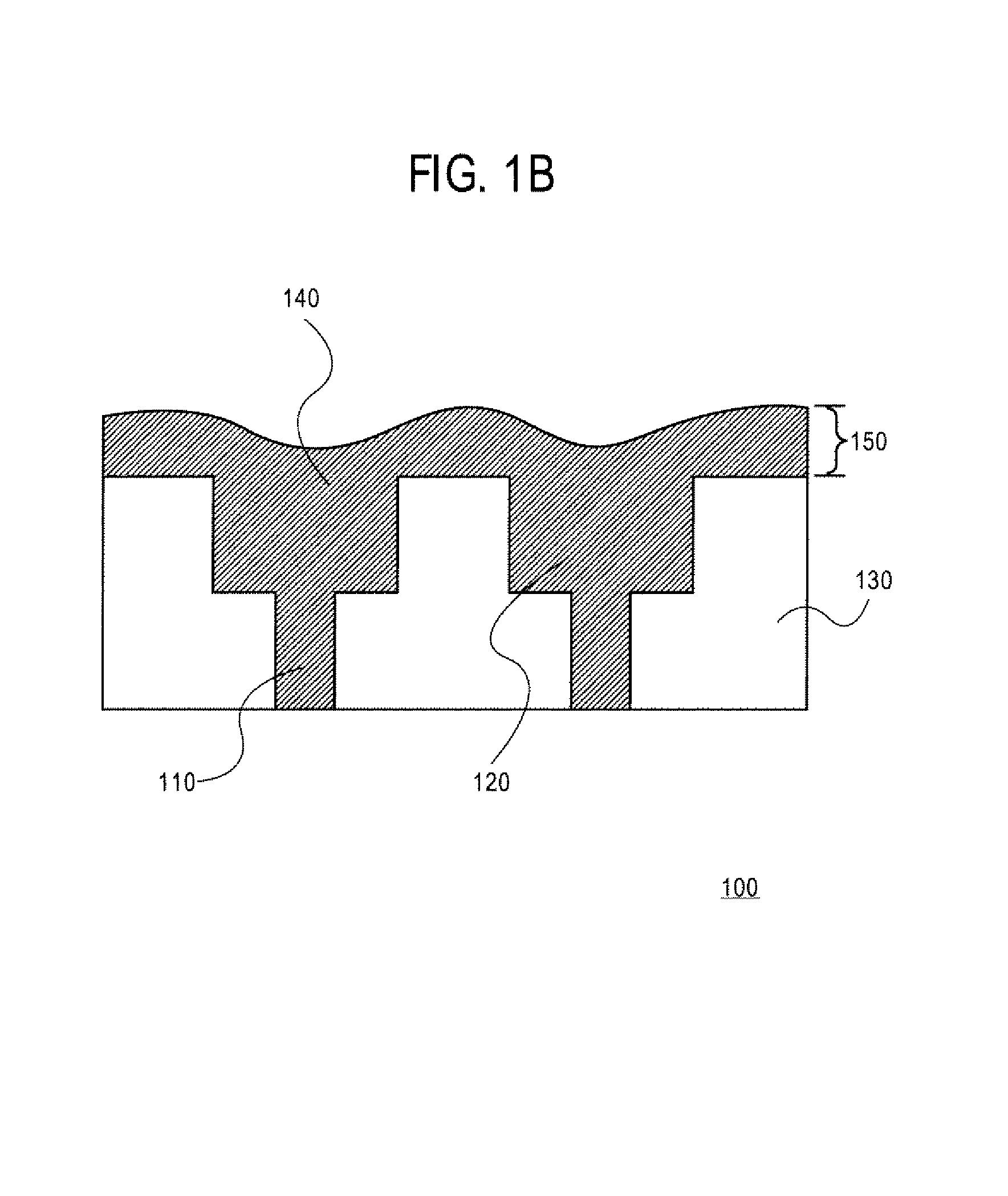

Surfactant slurry additives to improve erosion, dishing, and defects during chemical mechanical polishing of copper damascene with low k dielectrics

Slurries and methods for the chemical mechanical polishing of high density copper interconnects in a low k ILD are presented. In a particular embodiment of the present invention, a slurry for polishing copper is formed by combining a surfactant comprising an alkyl ethoxy organic acid such as glycolic acid ethoxylate lauryl ether (GAELE), an abrasive such as silica, an oxidizing agent such as hydrogen peroxide, and a chelating buffer system such as citric acid and potassium citrate dissolved in the mixture. This slurry provides a very low incidence of bent line defects, a low erosion rate, and a low dishing rate on a substrate comprising high density copper interconnects in a low k ILD. Embodiments of methods of the present invention use the disclosed slurries.

Owner:INTEL CORP

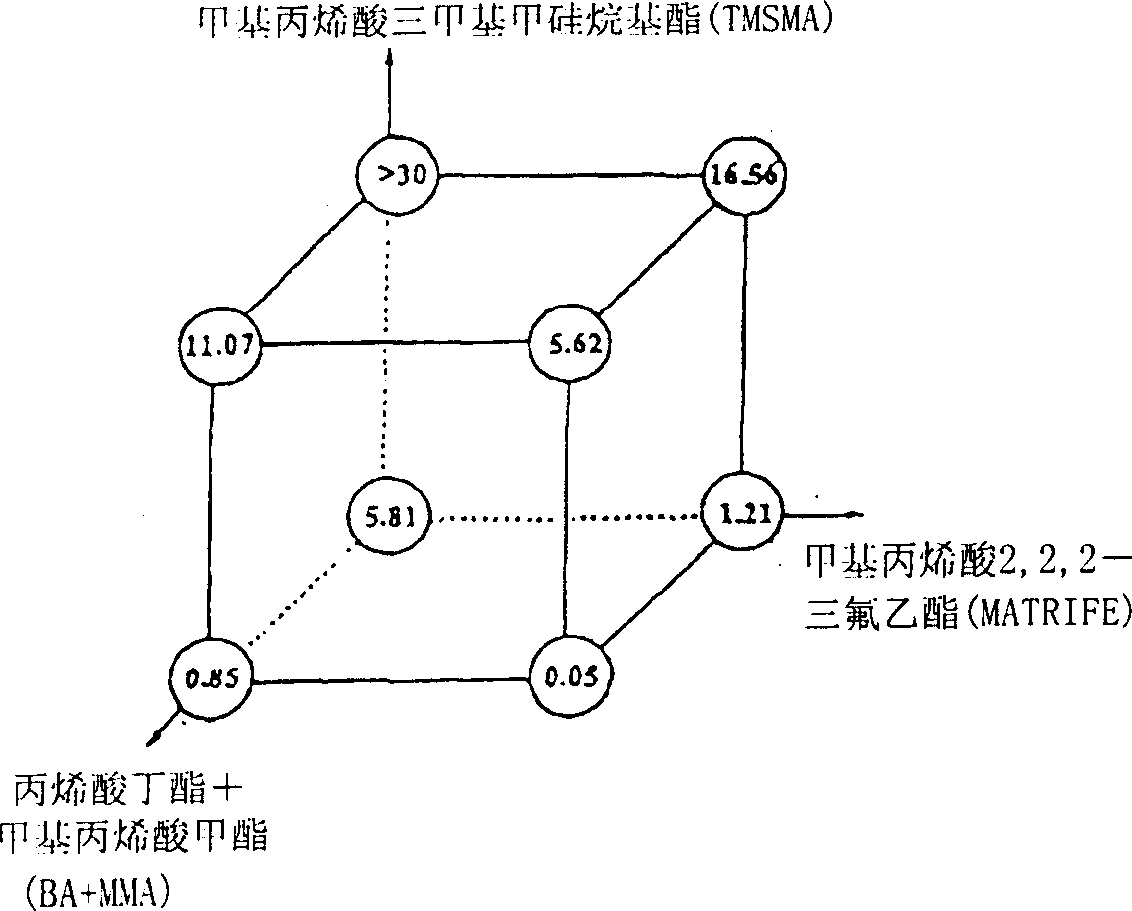

Copolymers containing fluorine and silyl and their use in anti-pollution composition of ship

Copolymers of at least three monomer units selected from the group consisting of fluorinated acrylic (methacrylic) monomers, triorganosilylacrylic (e.g. trimethylsilyl methacrylate) monomers and acrylic monomers not containing an organosilyl moiety, (e.g. methyl methacrylate) and optionally containing from 0-5 weight percent of a cross-linking agent are novel compositions useful as polymeric binders in long life marine antifoulant coatings. The erosion rate and resistance to cracking of the copolymer of the present invention when used as a binder in a marine antifoulant paint is controlled by adjusting the proportions of each monomer and the amount of crosslinking agent in the copolymer of the present invention.

Owner:ARKEMA FRANCE SA

Drilling systems including fiber-containing diamond-impregnated cutting tools

InactiveUS20090071724A1Improve cutting performanceLean structureDrill bitsConstructionsFiberErosion rate

Diamond-impregnated cutting tools including fibers and drilling systems incorporating such tools are described. The cutting tools contain a diamond-impregnated cutting portion that contains fibers made from carbon, glass, ceramic, polymer, and the like. The fibers may be used to both control the tensile strength and the erosion rate of the matrix to optimize the cutting performance of the tools. Additionally, the fibers may also weaken the structure and allow higher modulus binders to be used for the cutting tools at a lower cost, allowing the amount of fibers to be tailored to retain the diamonds in the cutting portion for the desired amount. As the cutting portion erodes, the fibers may also increase the lubricity at the face of the cutting portion. Using the fibers allows the cutting tools to last longer and make them safer and more economical because they need to be replaced less often.

Owner:LONGYEAR TM

Tillage erosion measurement magnetism tracer method

InactiveCN101603946AHigh measurement accuracyRapid determinationUsing electrical meansMaterial magnetic variablesSoil scienceErosion rate

Owner:INST OF MOUNTAIN HAZARDS & ENVIRONMENT CHINESE ACADEMY OF SCI

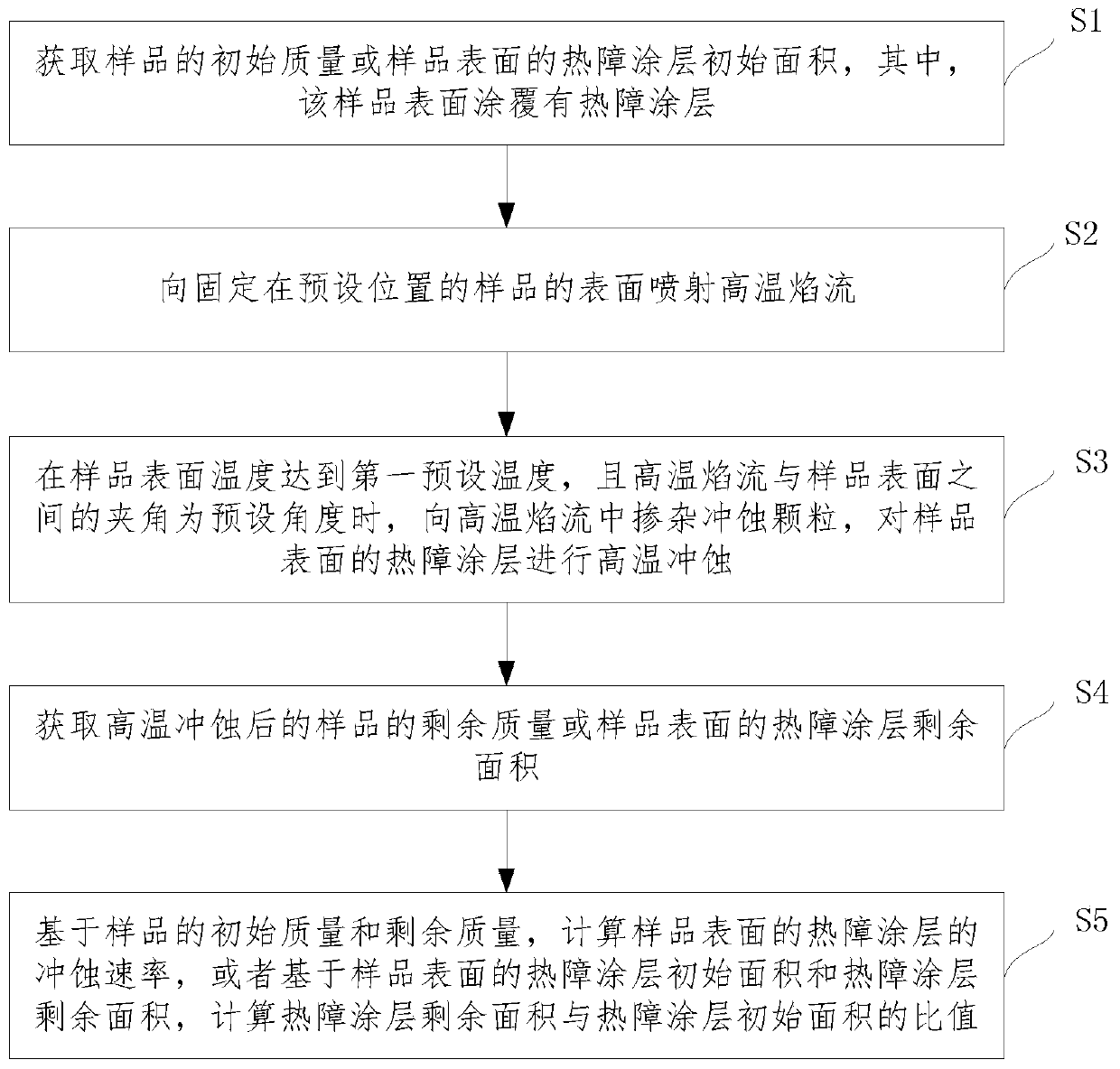

Thermal barrier coating high temperature erosion detection method

ActiveCN109900577AThe erosion rate is scientific and reasonableImprove detection efficiencyInvestigating abrasion/wear resistanceErosion rateThermal barrier coating

A thermal barrier coating high temperature erosion detection method is disclosed. The method comprises the following steps of acquiring initial mass of a sample or an initial area of a thermal barriercoating on a sample surface; spraying a high temperature flame flow to the sample surface fixed at a preset position; when a sample surface temperature and the direction of the high temperature flameflow satisfy certain conditions, doping erosion particles into the high temperature flame flow, and carrying out high temperature erosion on the thermal barrier coating on the sample surface; obtaining residual mass of the sample after high temperature erosion or the remaining area of the thermal barrier coating of the sample surface; and calculating an erosion rate of the thermal barrier coatingof the sample surface based on the initial mass and the residual mass of the sample, or calculating a ratio of the remaining area of the thermal barrier coating and the initial area of the thermal barrier coating based on the initial area of the thermal barrier coating on the sample surface and the remaining area of the thermal barrier coating. Through simulating a high temperature erosion environment under a working condition of an aero-engine, high temperature erosion detection is performed on the thermal barrier coating, a reliable basis is provided for the research of a thermal barrier coating material and detection efficiency of the thermal barrier coating is improved.

Owner:XIANGTAN UNIV

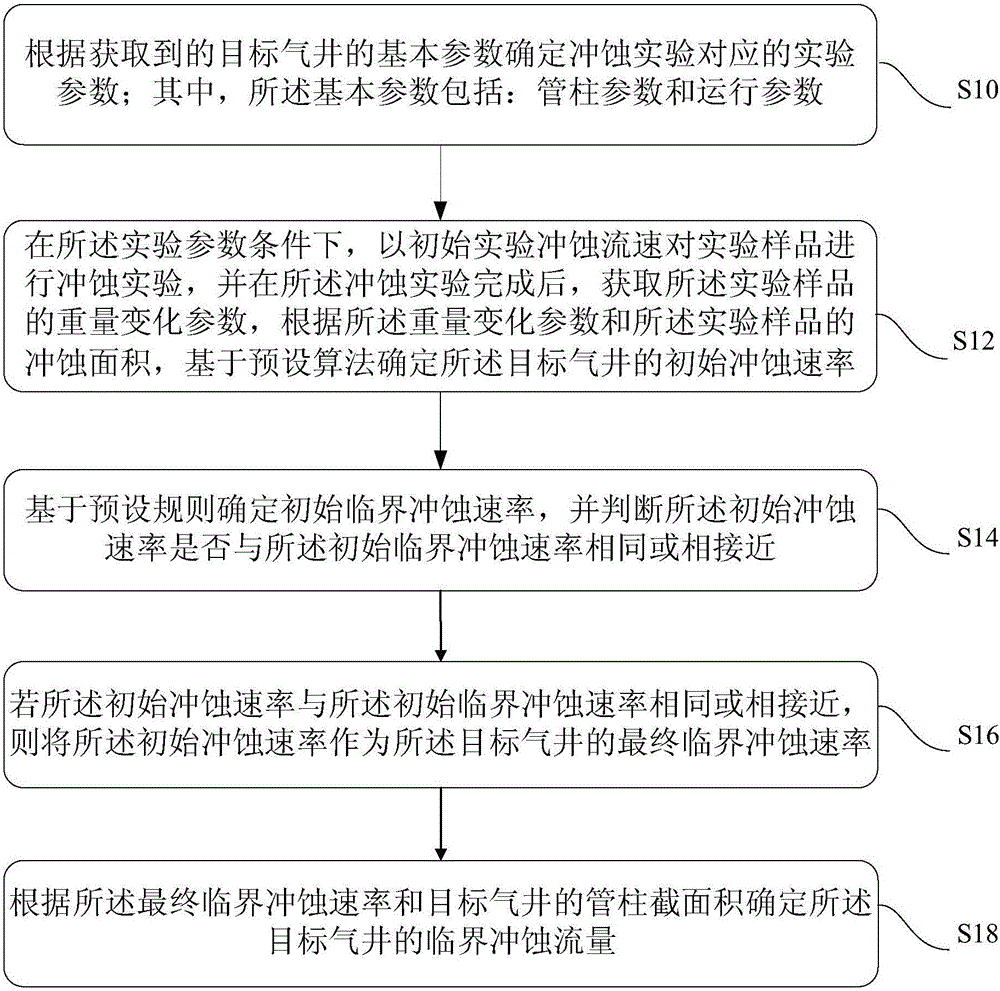

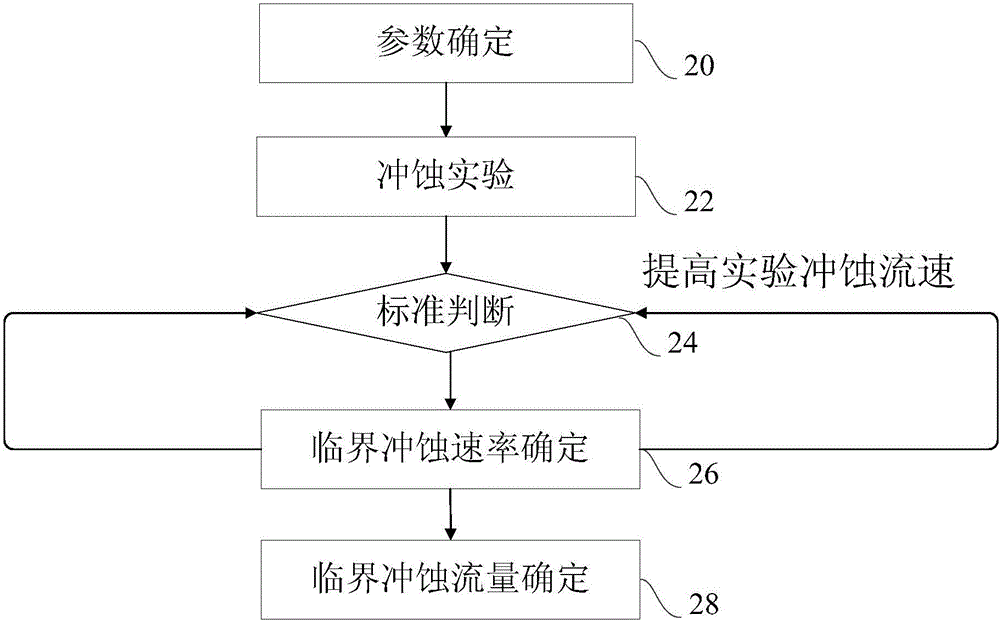

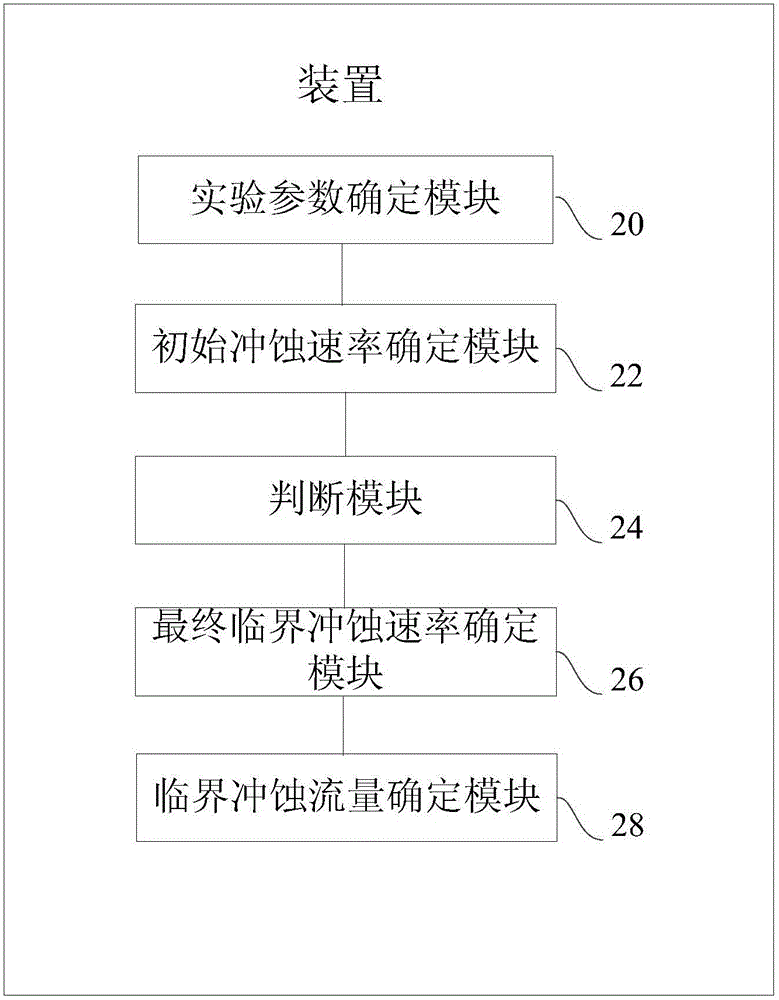

Method and device for determining critical erosion rate and flow rate of gas well

InactiveCN106124349ADetermining the critical erosion rateImprove operational efficiencyInvestigating abrasion/wear resistanceWeight changeErosion rate

The invention discloses a method and device for determining the critical erosion rate and flow rate of a gas well. The method includes: determining the experimental parameters corresponding to the erosion experiment according to the obtained basic parameters of the target gas well; under the conditions of the experimental parameters, Perform an erosion experiment on the experimental sample at the initial experimental erosion flow rate, and obtain the weight change parameter of the experimental sample, and determine the target gas well based on a preset algorithm according to the weight change parameter and the erosion area of the experimental sample The initial erosion rate; determine the initial critical erosion rate based on preset rules, and judge whether the initial erosion rate is the same or close to the initial critical erosion rate; if the same or close, the initial The erosion rate is taken as the final critical erosion rate of the target gas well. The purpose of the present invention is to provide a method for determining the critical erosion rate and flow rate of a gas well, which can determine a reasonable critical erosion rate and flow rate of a gas well.

Owner:PETROCHINA CO LTD

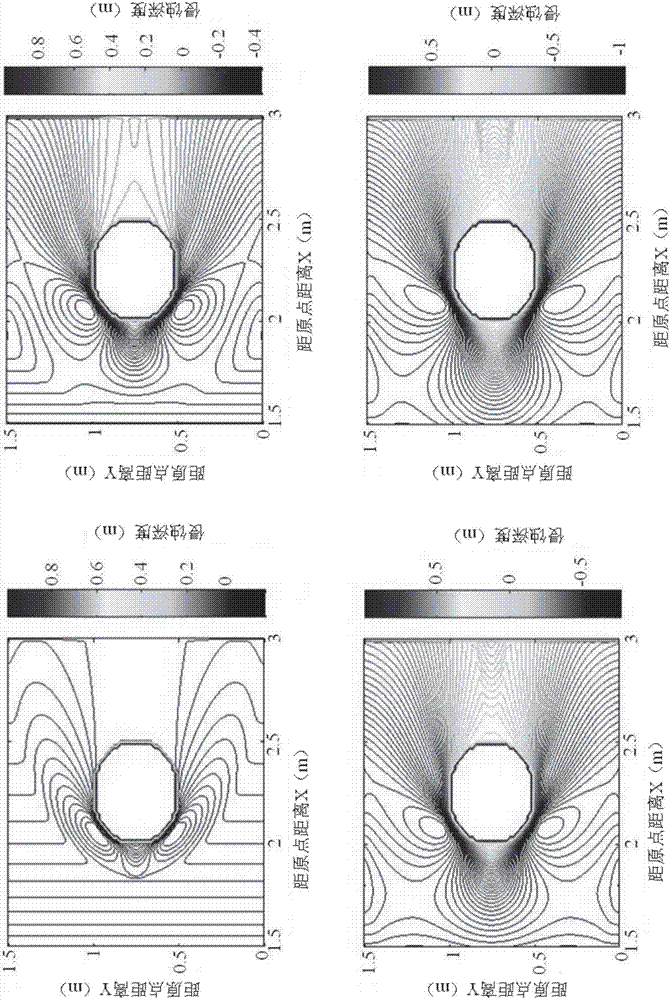

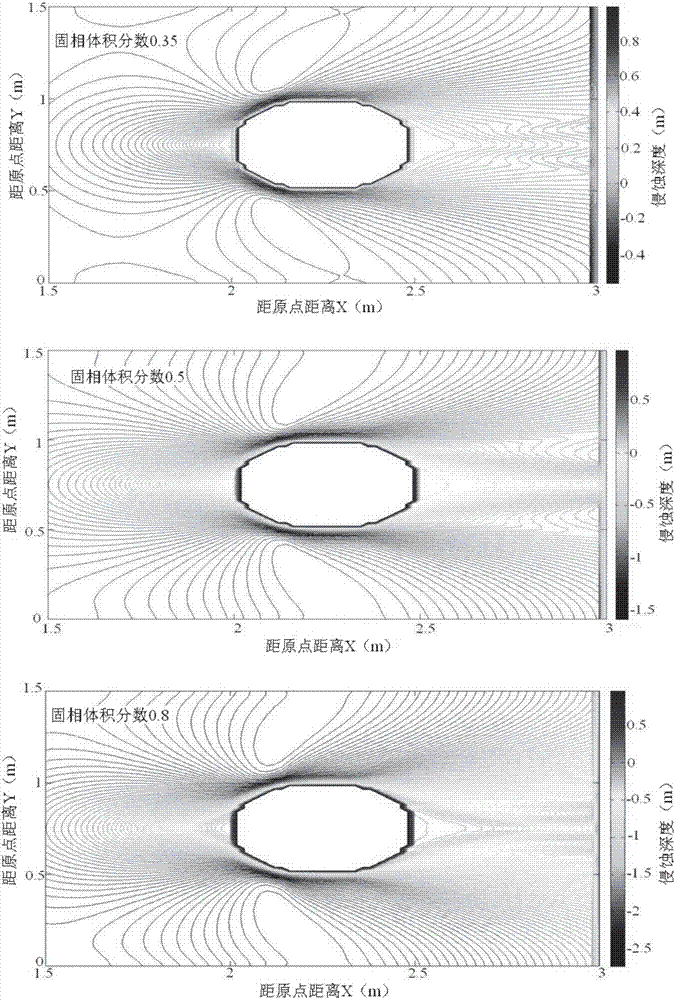

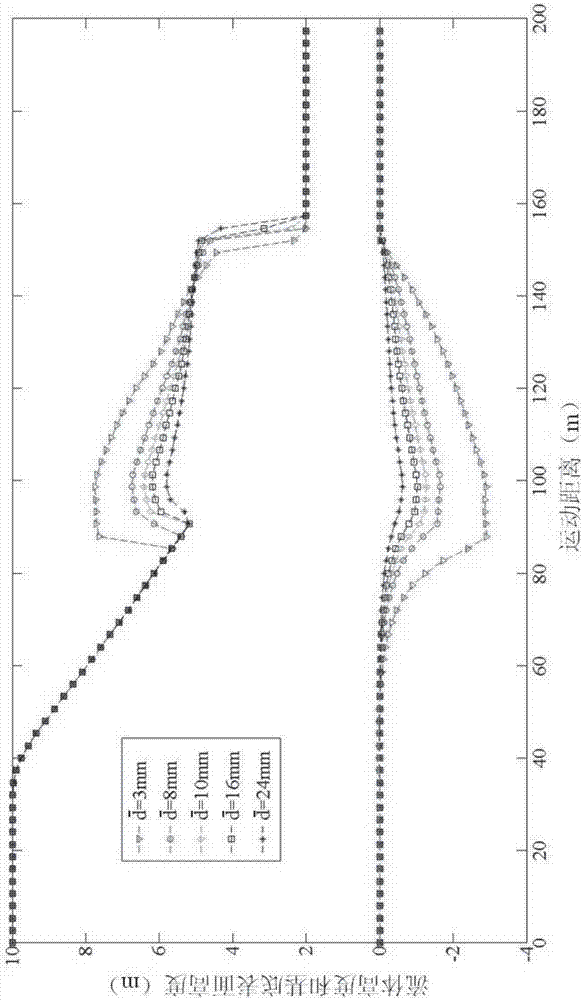

Calculation method of scouring bridge pier by debris flow

ActiveCN108009363ADetermine the degree of washoutComputational ConsiderationsGeometric CADDesign optimisation/simulationImaging processingErosion rate

The invention discloses a calculation method of scouring a bridge pier by debris flow. The method includes: establishing an erosion rate formula of scouring a bridge by the debris flow, wherein it isassumed that the debris flow is homogeneous mixture and is in an incompressible state in a motion process, an empirical parameter xi is introduced, and the revised erosion rate formula is obtained; completing numerical calculation according to working condition physical-parameters determined by scouring the bridge by the debris flow, wherein the revised erosion rate calculation formula is transformed into a vector form, dispersion on time and space is carried out, the physical parameters of the debris flow are determined, assignment is carried out, a finite volume method is adopted for solvingof the flux Riemann problem, solving is respectively carried out in x and y directions according to the above-mentioned dispersion equations and calculation formats, scouring condition judgement is carried out according to the revised erosion rate formula, and thus a calculation cycle is completed; and carrying out visualization processing to obtain scouring information results, wherein computergraphics and image processing technology are utilized to convert calculation data into graphs or images for output, and conclusions of scouring the bridge pier by the debris flow are obtained.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

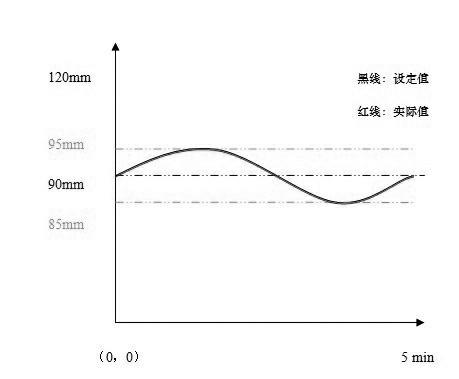

Automatic liquid level control method for crystallizer of large square bland continuous-casting machine

ActiveCN102328044AReduce erosion rateExtended service lifeAutomatic controlProportion integration differentiation

The invention relates to an automatic liquid level control method for a crystallizer of a large square bland continuous-casting machine, and belongs to the metallurgical steel-making technical field. According to the technical scheme, the automatic liquid level control method comprises the following steps: firstly setting a liquid level output value to be a sinusoidal variation curve; secondly controlling the actual liquid level value to change according to the set liquid level output value by a PID (proportion integration differentiation) control module in a liquid level control program of acomputer so as to finally realize sinusoidal liquid level control of the crystallizer. The automatic liquid level control method has the beneficial effects that by programming and setting the controlmodule, the actual liquid level value of the crystallizer is changed according to the set liquid level value as well as the change cycle and amplitude so as to realize sinusoidal liquid level controlon the crystallizer, thereby effectively reducing the erosion rate of a submersed nozzle of a large square bland, prolonging the continuous casting time and improving the surface quality of casting blank. Statistical data shows that the automatic liquid level control method has obvious effect of prolonging the service life of the nozzle and the continuous casting time; and meanwhile as the liquidlevel of the crystallizer is active and casting powder has good slagging effect, the repair rate of the (casting) blank and (steel) products caused by surface defects is lowered.

Owner:石钢京诚装备技术有限公司

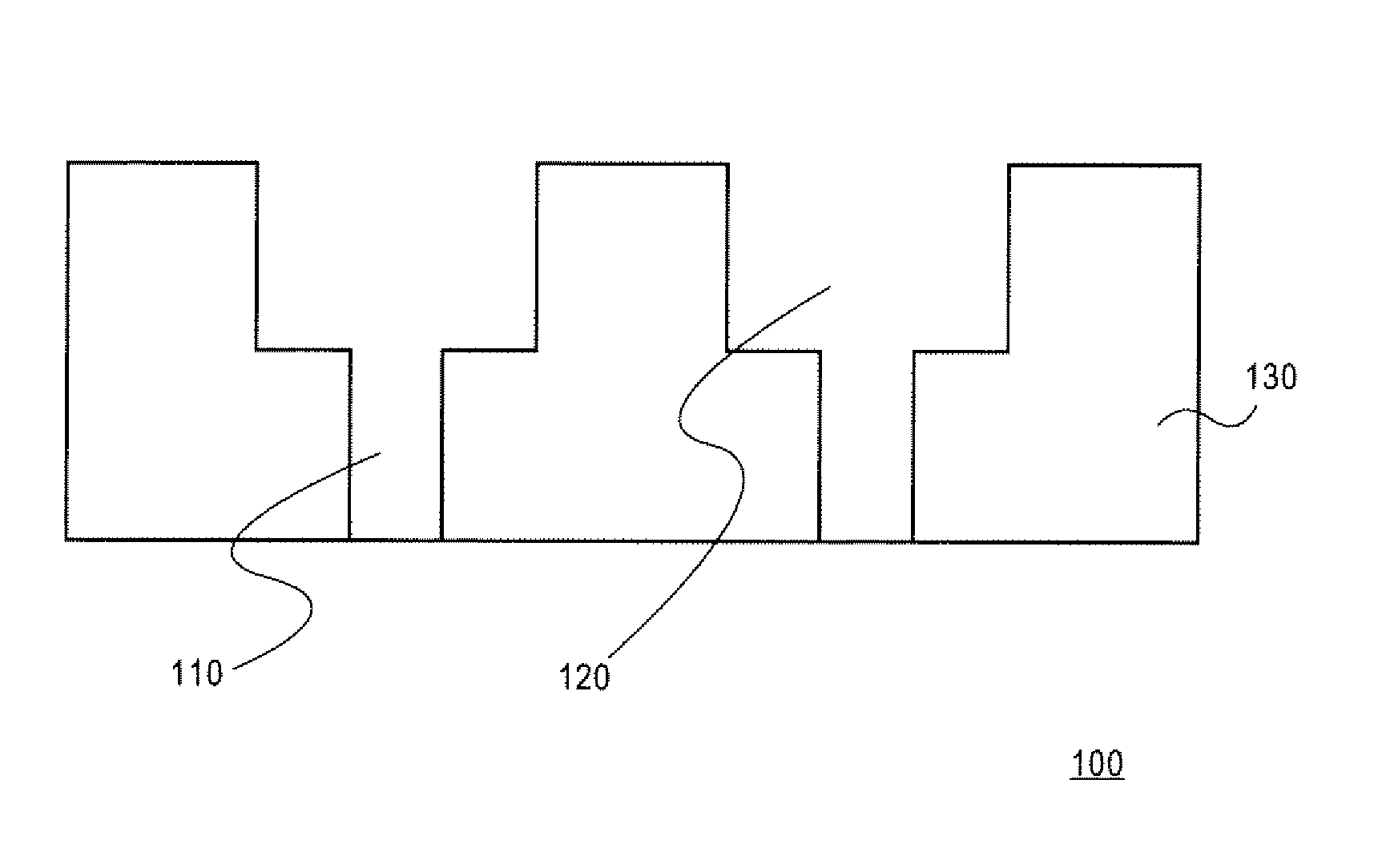

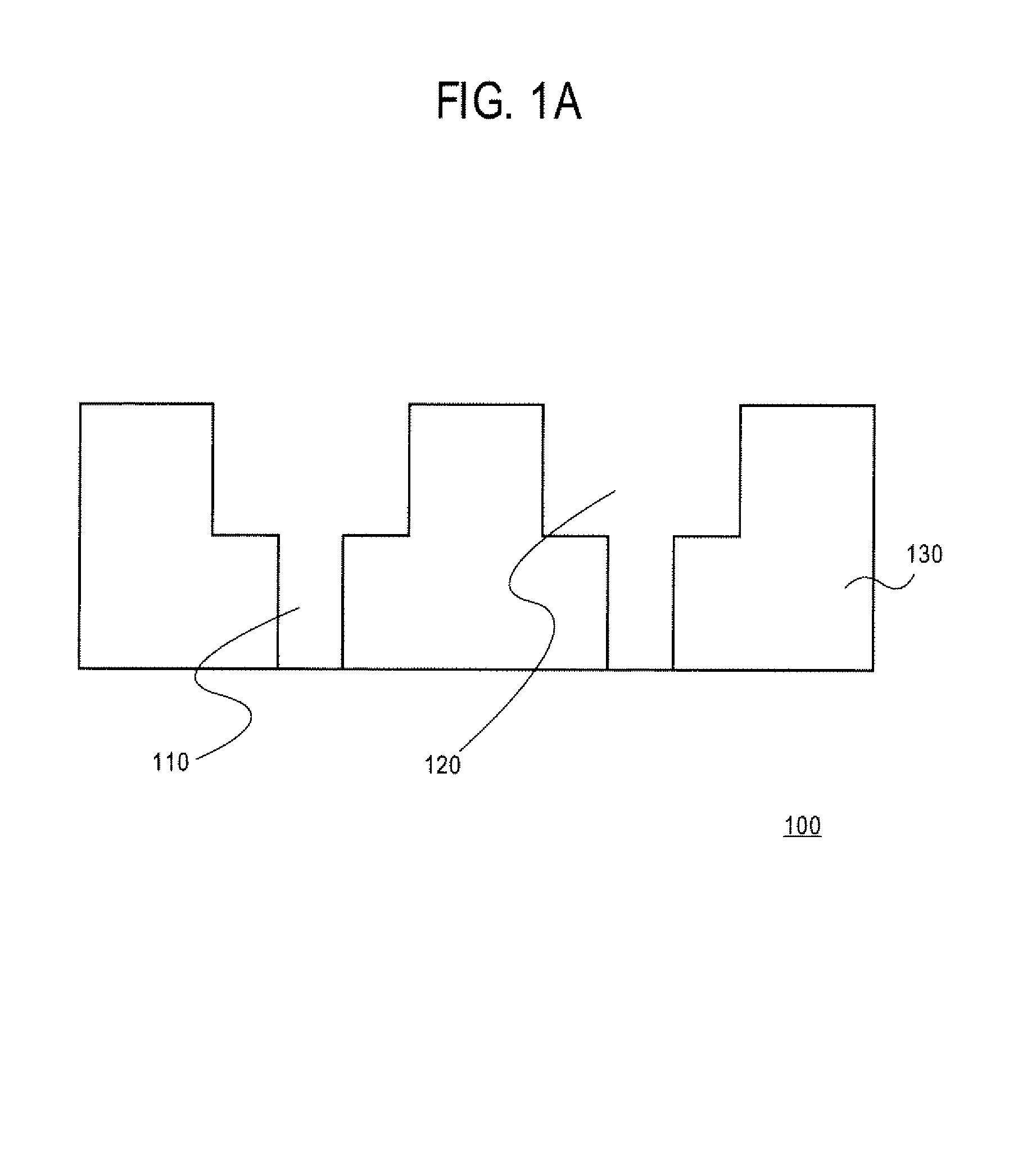

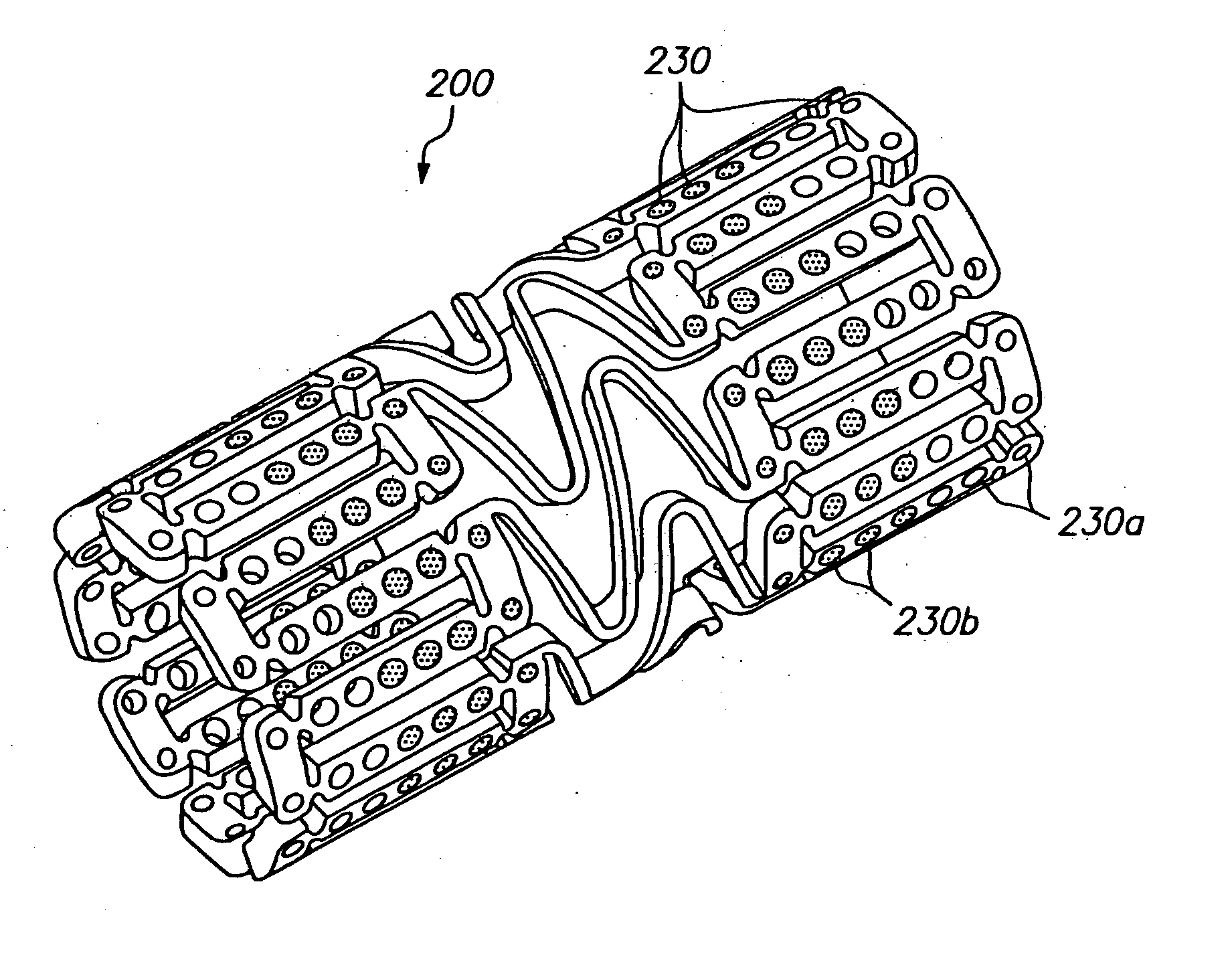

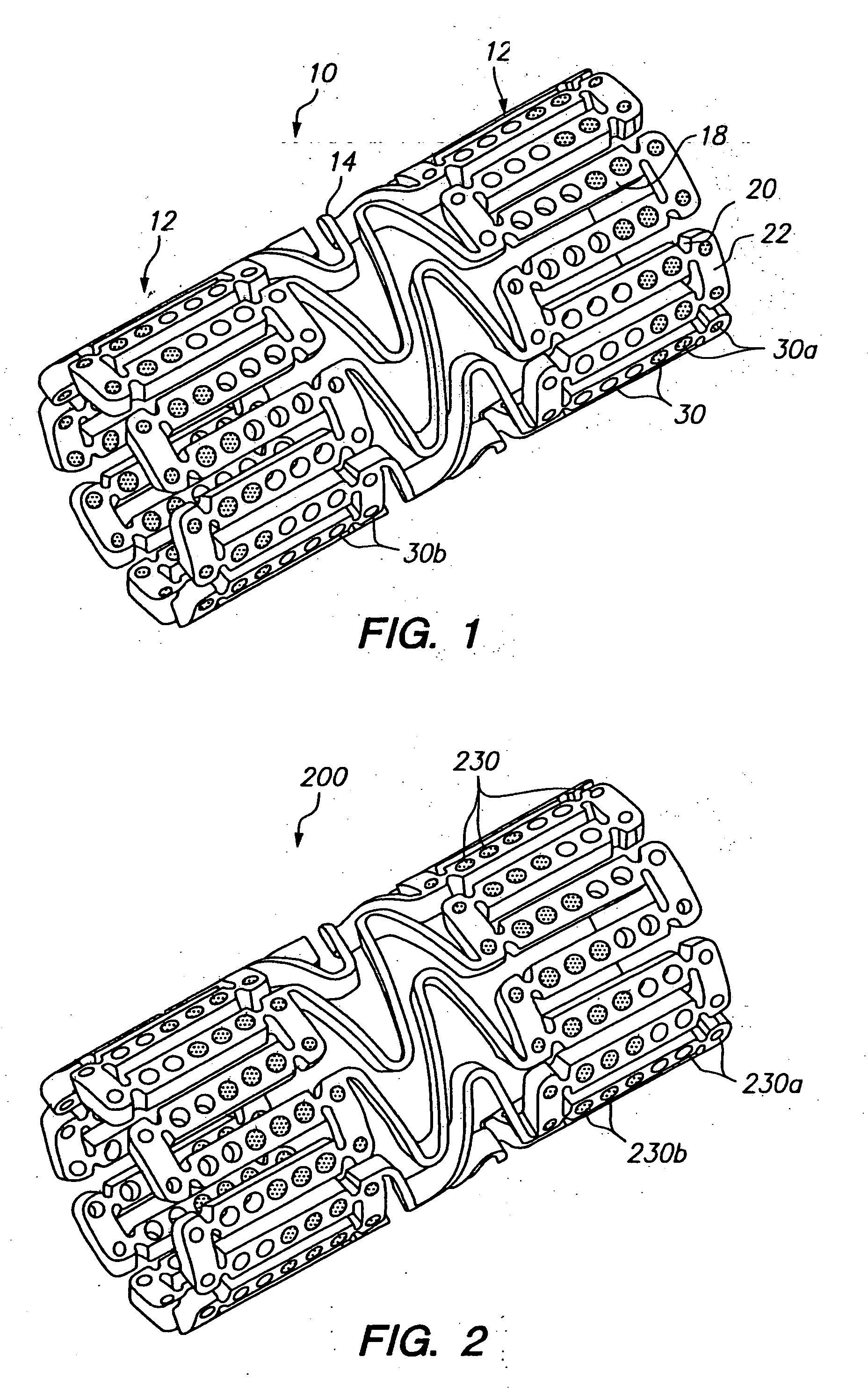

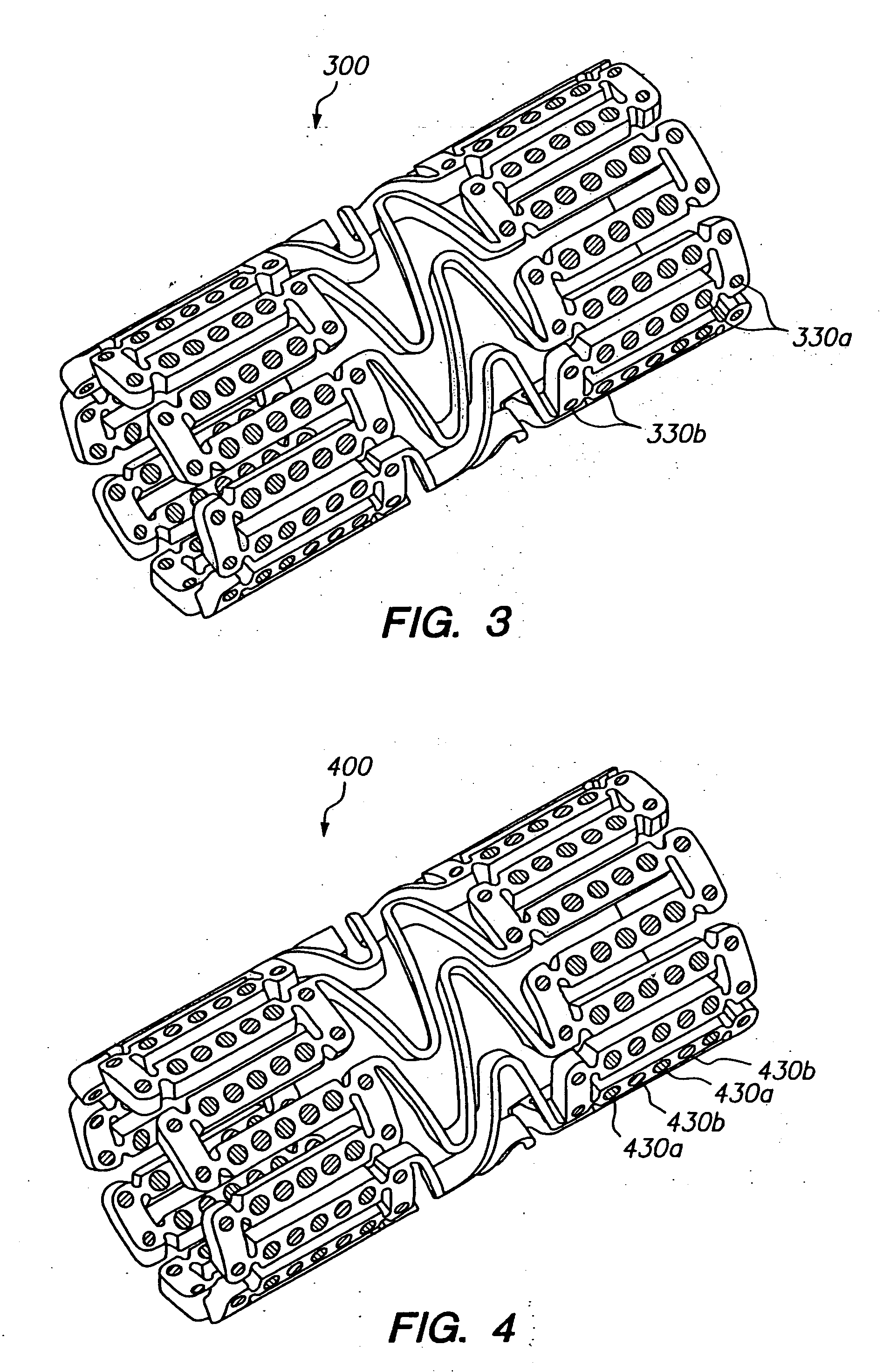

Expandable medical device with openings for delivery of multiple beneficial agents

InactiveUS20050234544A1Increasing effective wall thicknessAdversely impactingStentsSurgeryEdge effectsErosion rate

An expandable medical device includes a plurality of elongated struts, forming a substantially cylindrical device which is expandable from a cylinder having a first diameter to a cylinder having a second diameter. A plurality of different beneficial agents can be loaded into different openings within the struts for delivery to the tissue. For treatment of specified conditions such as edge effect restenosis or for improved spacial distribution of the delivered beneficial agent, different beneficial agents are loaded into different openings in the device in a predefined pattern. The different beneficial agents may include one or more different drugs, the same drugs in different concentrations or with different erosion rates, or different forms of the same drug.

Owner:INNOVATIONAL HLDG LLC

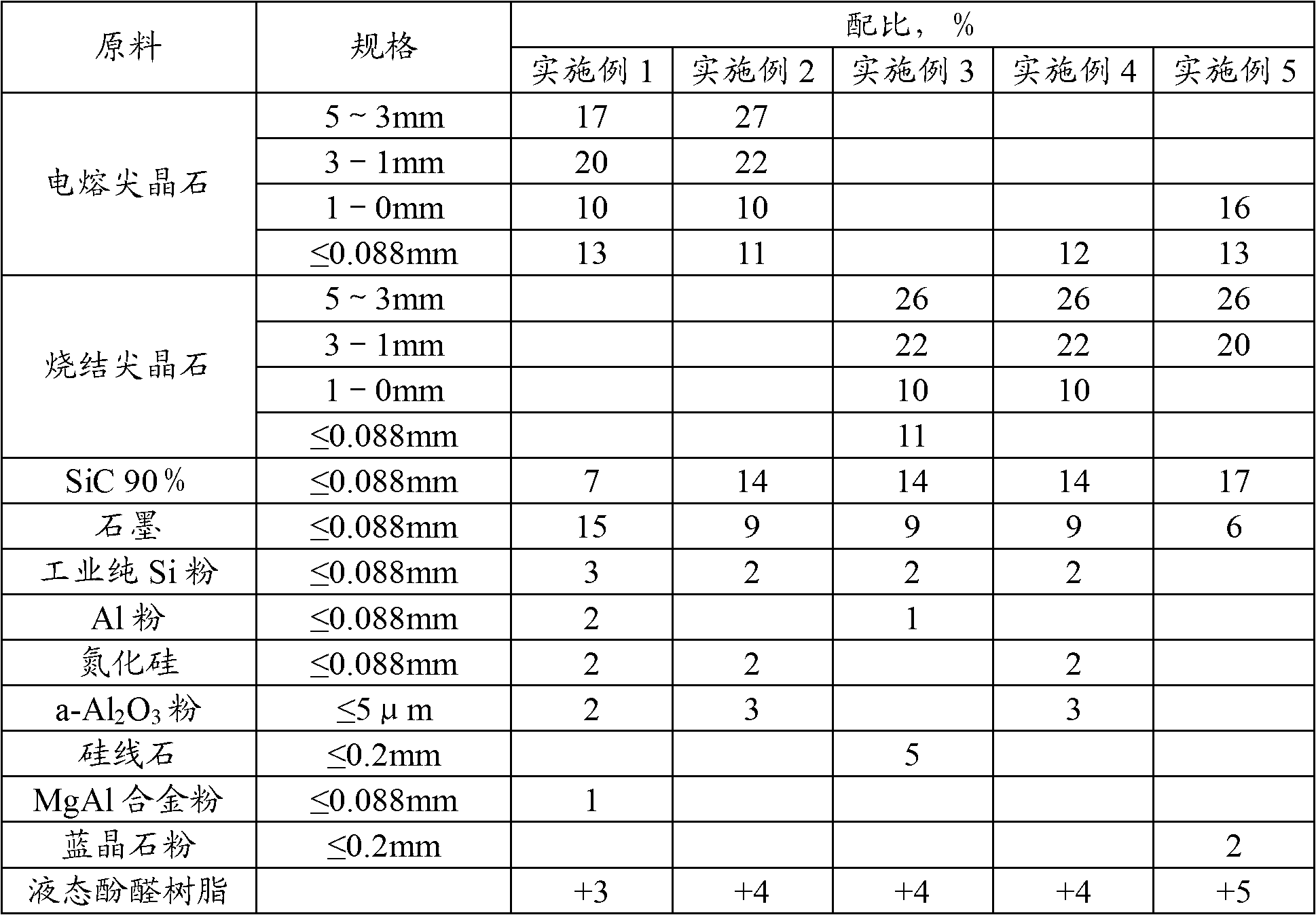

Composite fireproof material and preparation method thereof

The invention discloses a composite fireproof material, and belongs to the technical field of fireproof material. The composite fireproof material includes the following components in percentage by mass: 60 to 75% of electric-molten and / or sintering magnalium spinel, 5 to 17% of carborundum, 5 to 15% of graphite, 1 to 10% of additive, and 3 to 5% of resin binder which is 3 to 5% of the total mass of all the mentioned components above. The invention further discloses a preparation method of the composite fireproof material. The magnalium spinel is introduced as the main component of the composite fireproof material, thus forming a magnalium spinel-carborundum-carbon fireproof material; compared with alumina, the magnalium spinel reduces the reactivity of CaO in the desulfurizined slag, therefore, the slag resistance of the material is improved, the erosion rate is reduced, and the benefit is brought for prolonging the service life of the pre-desulfurizing hot metal ladle. The composite fireproof material can be applied to a ferrous metallurgy high-temperature container, and particularly serves as the lining of the hot metal ladle for iron-making; and the requirement on smelting the pre-processing hot metal ladle can be met.

Owner:SHOUGANG CORPORATION

Long-lasting grounding anti-corrosion resistance reduction agent (modified type)

InactiveCN1866409AExcellent corrosion protectionStable chemical propertiesNon-metal conductorsChemical inhibitorsElectricityErosion rate

The invention discloses a long-acting ground antiseptic resistance-reducing agent (modified), which is characterized by the following: consisting of sodium base alta-mud and graphite; making each item of parameter satisfy all index; keeping resistance property stable under multitime industrial frequency and punching electricity action; protecting ground metal; reducing erosion rate from 0.0245 mm per year to 0.0064 mm per year.

Owner:肖竹升

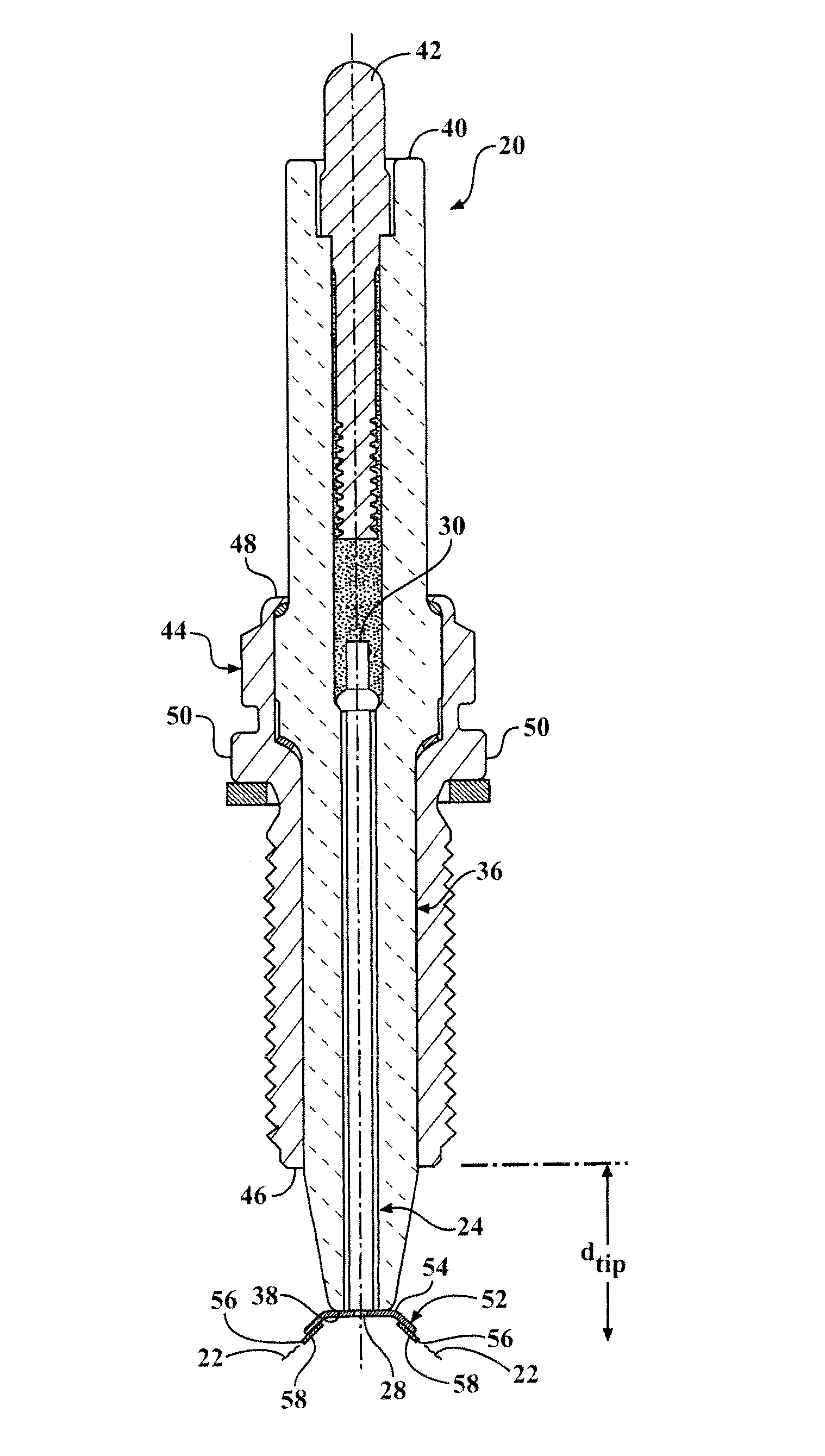

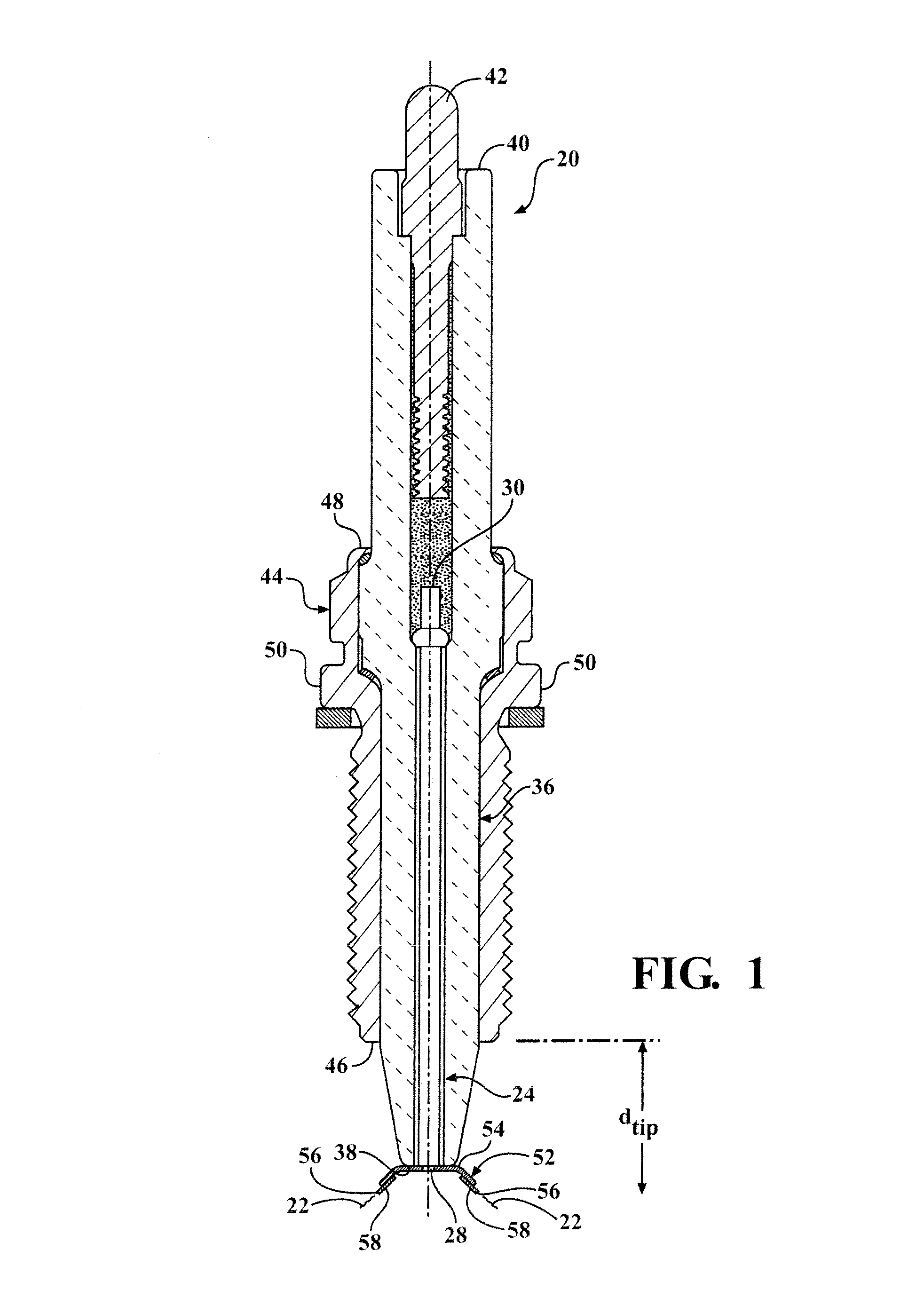

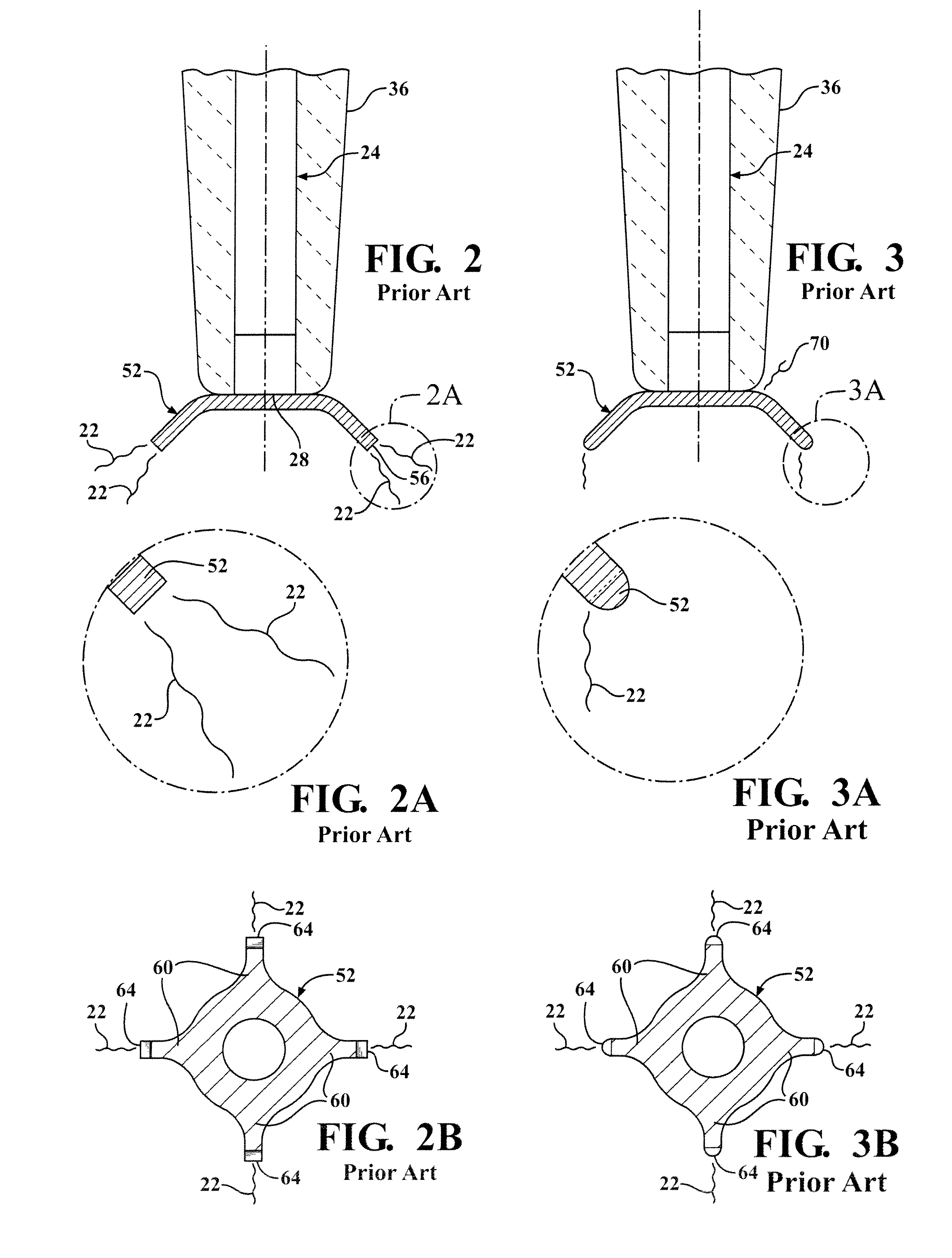

Igniter including a corona enhancing electrode tip

ActiveUS8776751B2Reduce erosion rateStrong electrical fieldWave amplification devicesAnti-theft devicesElectrical field strengthErosion rate

An igniter (20) emitting an electrical field including a plurality of streamers forming a corona includes a corona enhancing tip (52) at an electrode firing end (28). The corona enhancing tip (52) includes an emitting member (58) such as a wire, layer, or sintered mass, formed of a precious metal and disposed on a base member (54). The base member (54) is formed of a nickel alloy. The emitting member (58) has a lower electrical erosion rate and chemical corrosion rate than the base member (54). The emitting member (58) presents the smallest spherical radius of the corona enhancing tip (52) at the outermost radial point (56) to concentrate the electrical field emissions and provide a consistently strong electrical field strength over time.

Owner:FEDERAL MOGUL IGNITION

Quick monitoring method for soil erosion rate

ActiveCN102565301AAvoid human disturbanceHigh precisionEarth material testingSample plotErosion rate

The invention discloses a quick monitoring method for soil erosion rate, which comprises the following steps: 1) in a preselected monitoring region, laying out erosion scales in rows and columns, wherein the erosion scales are perpendicular to the monitoring sample plot surface, a zero graduation line and a gas cylinder on the surface of earth, and numbering orderly; 2) according to a predetermined monitoring system, taking photos of each erosion scale by a high-definition digital camera, and ensuring clear imaging of the erosion scales; 3) according to the number sequence, reading buried or exposed height of each erosion scale orderly by using an instant browsing function and an image amplifying tool of a camera, or by means of a computer; and 4) calculating the soil erosion amount. According to the method of the invention, a large amount of building projects of a runoff plot are abandoned, the monitoring precision on par with the runoff plot is achieved, the artificial disturbance of the traditional measuring method to the monitoring sample plot surface is avoided, the precision of the soil erosion rate measuring method with erosion needle can be increased, moreover, the labor intensity of the measuring workers is greatly reduced, and the working efficiency is increased.

Owner:芷兰生态环境建设有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com