Patents

Literature

624 results about "Magnalium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnalium is an aluminium alloy with 5% magnesium and 95% aluminum.

Corrosion-resistant magnesium aluminum alloy chromium-free passivation solution

InactiveCN104561970AHigh hardnessImprove stain resistanceMetallic material coating processesWater basedChromium free

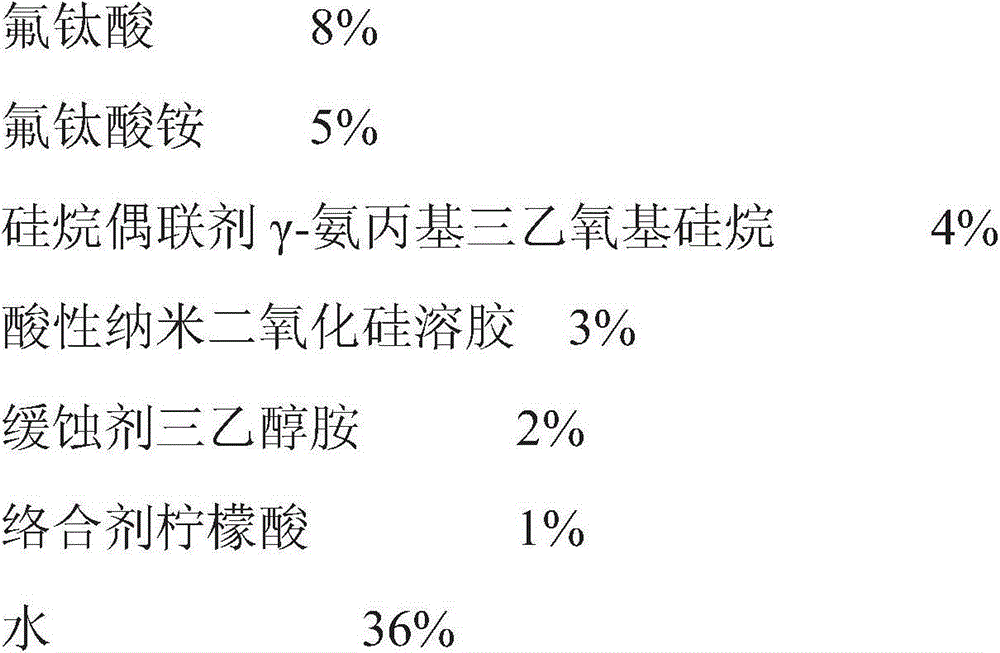

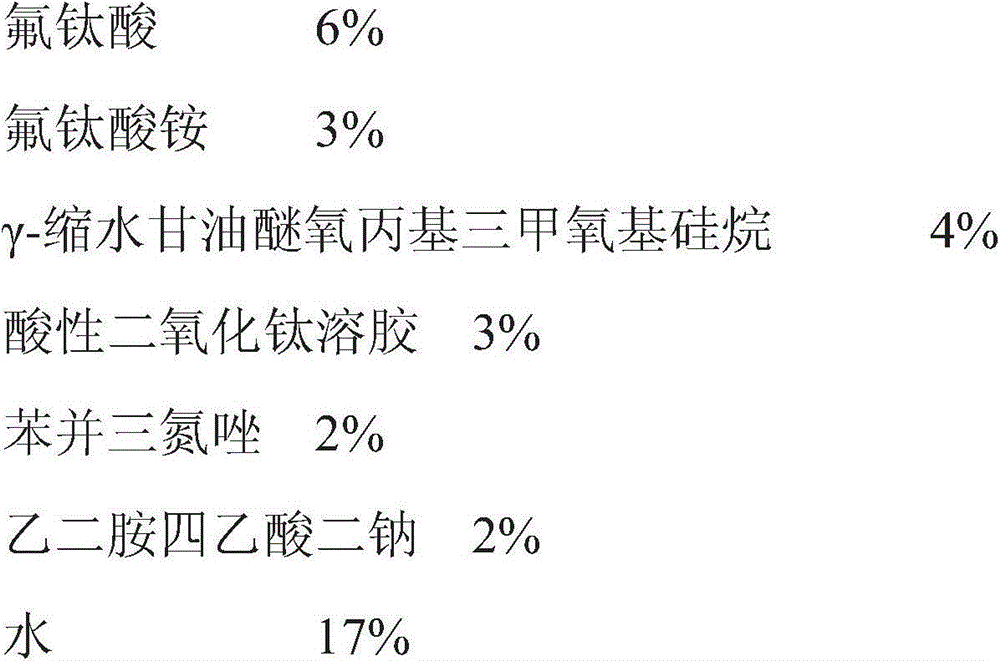

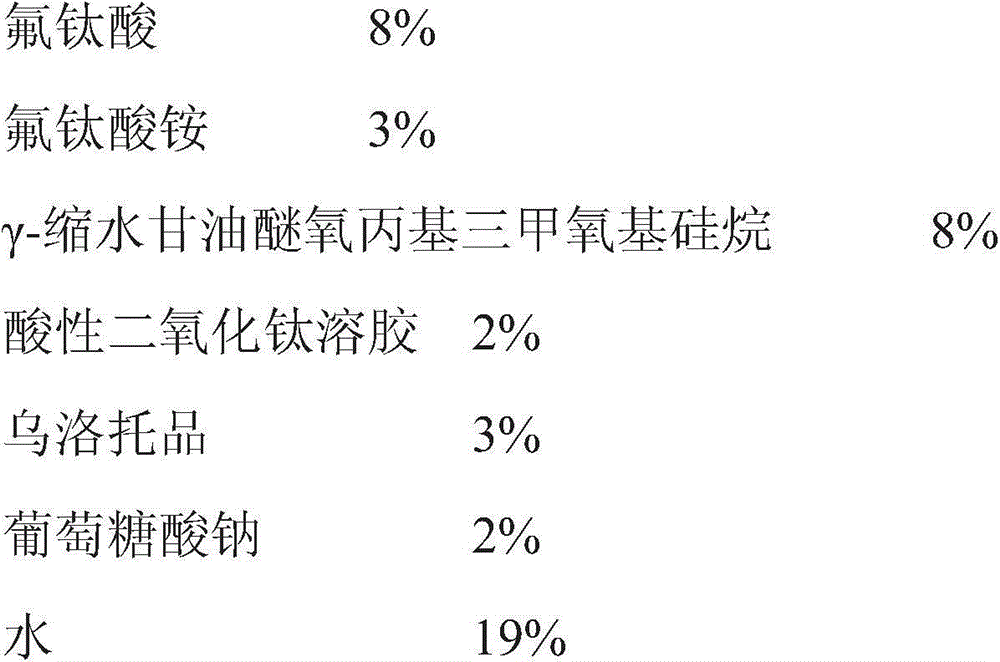

The invention discloses a corrosion-resistant magnesium aluminum alloy chromium-free passivation solution, which comprises the following components: 10-40 parts of water-base resin, 1-10 parts of nanoparticle sol, 1-10 parts of fluoric-containing acid, 1-5 parts of fluoric acid-containing salt, 1-5 parts of a rare earth catalyst, 1-10 parts of a silane coupling agent, 1-5 parts of a corrosion inhibitor, 1-2 parts of a complexing agent and 40-70% of water. The corrosion-resistant magnesium aluminum alloy chromium-free passivation solution does not contain chromium and other toxic and harmful substances, meets the ROHS environmental protection law of the European Union, and meanwhile, can form an organic and inorganic composite passivation film and a thin film on the surface of a magnesium aluminum layer, and the formed composite passivation film has an excellent physical property and corrosion resistance, and has higher corrosion resistance and long salt fog time, so that the corrosion resistance of a magnesium aluminum alloy plate is better improved.

Owner:苏州禾川化学技术服务有限公司

Magnesium alloy non cyanogen plating copper chemical plating nickle and its plating process

InactiveCN1598059AImprove bindingUniform coating thicknessSuperimposed coating processCopper platingChemical plating

The invention discloses a method of plating Nickel with magnalium alloy without cyanogen and the plating technique. The direction for the plating solution is: 20 to 80g.dm-3 of copper charred phosphate; one or several of the 60 to 320g.dm-3 of sodium charred phosphate or Potassium charred phosphate or 60 to 250g.dm-3 of sodium citric acid, 5 to 20g.dm-3 of Potassium sodium tartaric acid, 60 to 250g.dm-3 of HEDP and 60 to 250g.dm-3 of amine ethylene; one or several of the 5 to 20g.dm-3 of hydrogen amine di-fluorin or 5 to20 g.dm-3 sodium fluoride or 5 to 20g.dm-3 of Potassium fluoride or 5 to 20g.dm-3 of lithium fluoride. The plating solution chooses the nickel sulfate or alkali type nickel carbonate or nickel acetic acid as the main salt and adds the reducing agent, combination agent and stabilization agent. The plating technique adopts the acid plating copper-plating three nickel-plating chromium. The invention has little pollution to the environment, high binding power and erosion-proof property.

Owner:GCI SCI & TECH +1

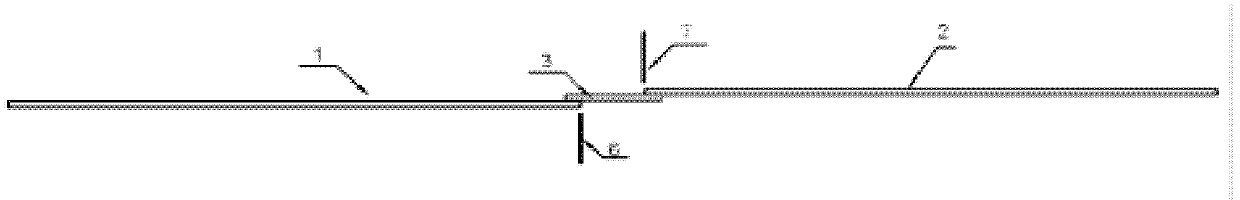

Microbeam tungsten argon arc welding method for magnesium alloy thin-walled tube

InactiveCN102554418AIncrease the difficultyLow yieldArc welding apparatusWelding/cutting media/materialsArc stabilityManganese

The invention relates to a microbeam tungsten argon arc welding method for a magnesium alloy thin-walled tube. A low-magnesium aluminum alloy welding wire is used as a filling material, and the thin-walled tube is welded by a microbeam tungsten argon arc welding process under inert gas shielding. The low-magnesium aluminum alloy welding wire comprise 9.5%-11.6% of Al (aluminum), 0.6%-1.75% of Zn (zinc), 0.15%-0.35% of Mn (manganese), 0.01%-0.05% of Cu (copper), 0.02%-0.05% of Si (silicon) and the balance Mg (magnesium) in mass percent. The microbeam tungsten argon arc welding method for the magnesium alloy thin-walled tube is high in welding efficiency and convenient and flexible in application, and can be used for obtaining a crack-free welding joint without magnesium-aluminum brittle compounds. Compared with a conventional tungsten argon arc welding method, the microbeam tungsten argon arc welding method has the advantages that arc stability of microbeam argon arc welding for the magnesium alloy thin-walled tube is obviously improved, the tensile strength of the welding joint is 30% higher than that of a conventional tungsten argon arc welding joint, the elongation of the welding joint is increased by 10%, and the use requirements of industrial production on magnesium alloy thin-walled tube welding component can be met.

Owner:SHANDONG UNIV

Magnalium composite board and method for producing the same

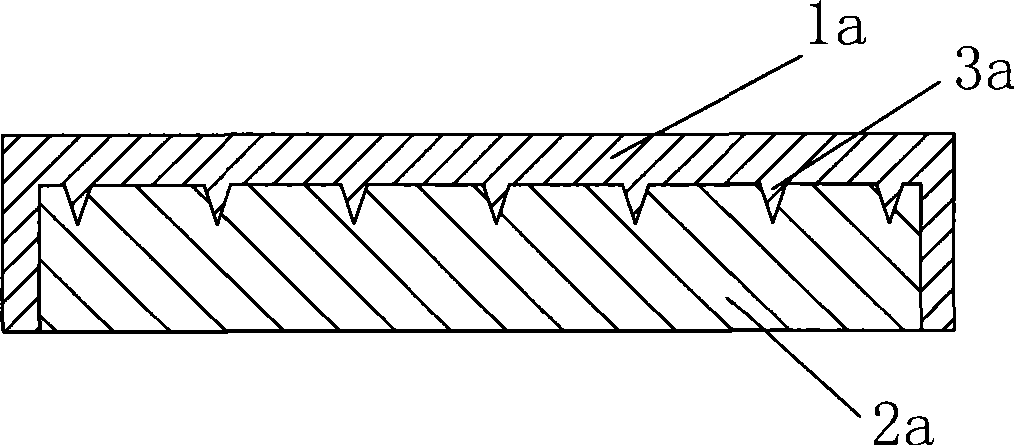

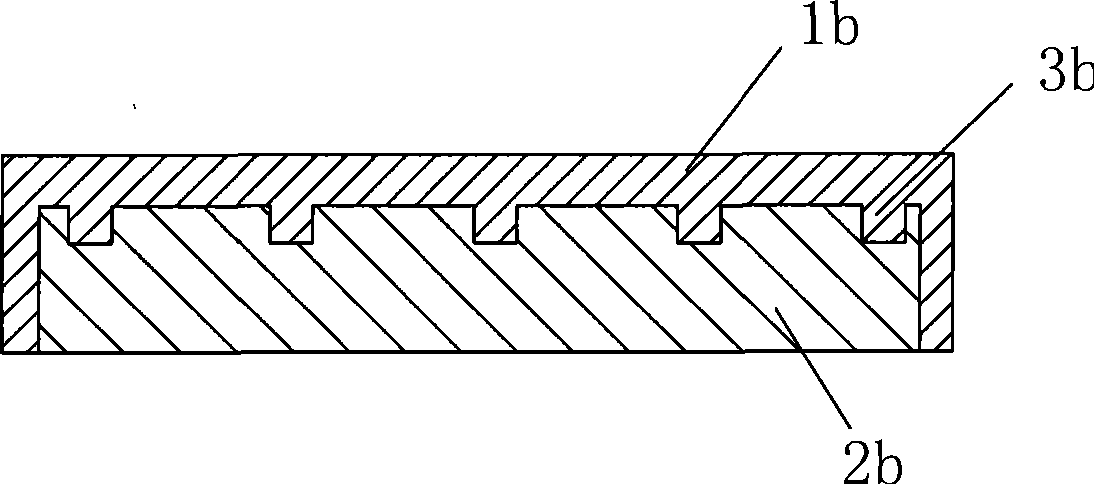

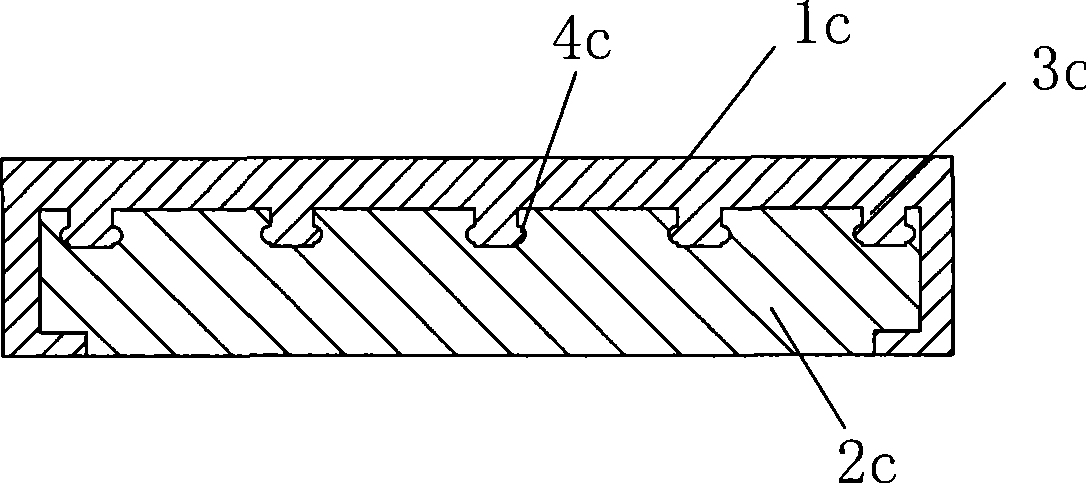

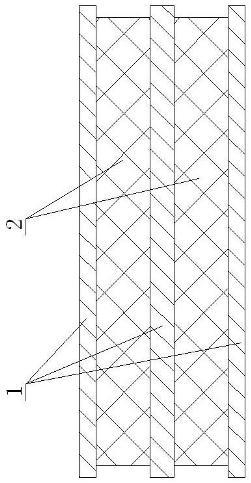

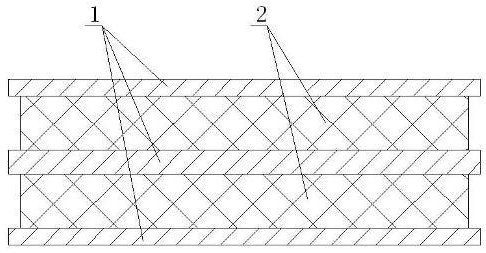

The invention discloses a magnesium-aluminum composite board and a method for manufacturing the same. The magnesium-aluminum composite board comprises at least one layer of magnesium or magnesium alloy plate and at least one layer of aluminum or aluminum alloy plate which are cast together by vacuum die-casting, and at least one two-layer joint surface which is provided with a mutually occlusive zigzag structure, namely the magnesium-aluminum composite board consists of a magnesium plate and an aluminum plate, or the magnesium alloy plate and the aluminum plate, or the magnesium plate and the aluminum alloy plate, or the magnesium alloy plate and the aluminum alloy plate by vacuum die-casting, and can be a structure with two layers, three layers or more than three layers. The method for manufacturing the composite board comprises the following steps: preheating a manufactured aluminum or aluminum alloy plate finished product as an insert of a die to certain temperature, and then putting the insert into a magnesium or magnesium alloy vacuumized die; matching the die in a vacuum pressure casting machine; pouring the molten magnesium or magnesium alloy molten; performing vacuumizing injection; and finally forming the magnesium-aluminum composite board. The joint surface of the composite board is provided with the mutually occlusive zigzag structure so that the layers are closely connected with each other sequentially and the combined strength is higher.

Owner:青岛地恩地材料科技有限公司

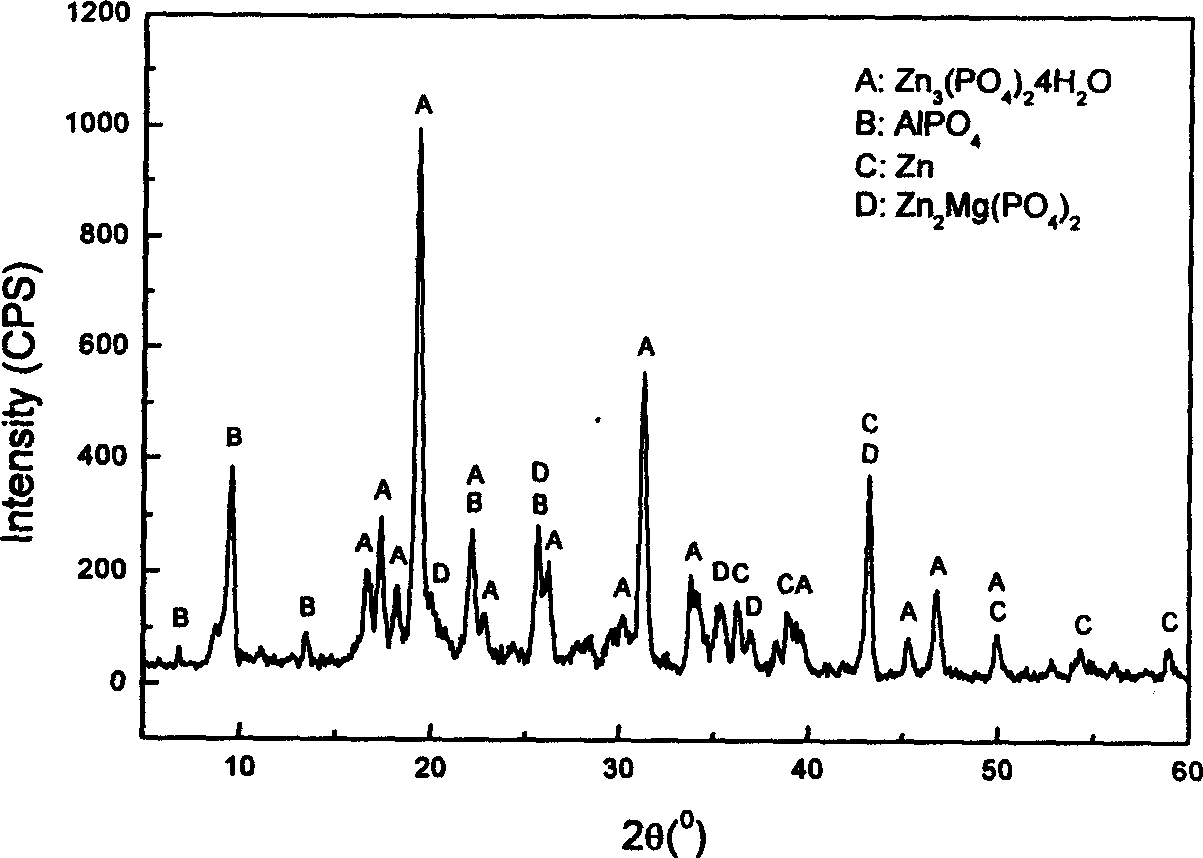

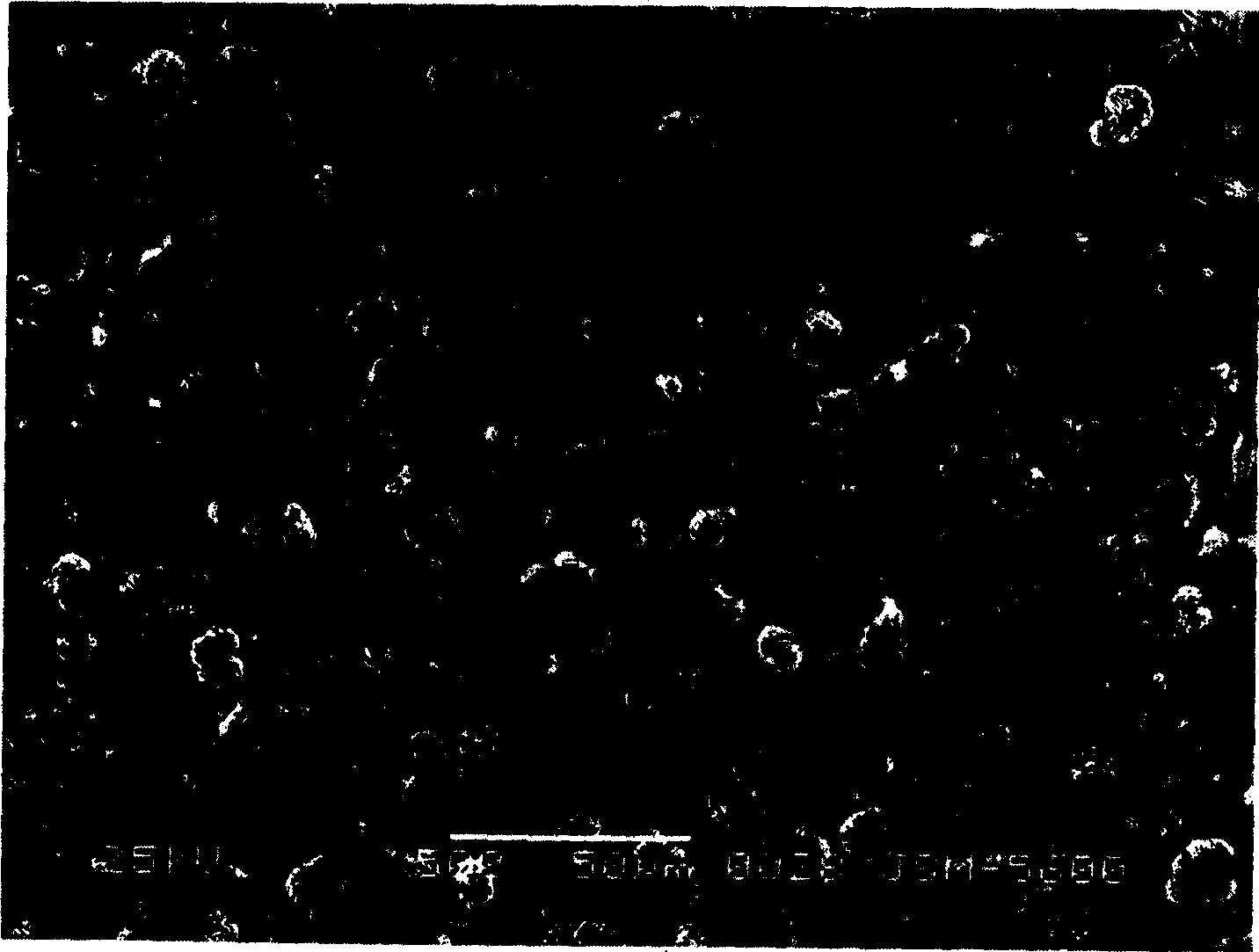

Magnesium alloy phosphorization solution and its phosphorized technology

InactiveCN1598055AProcess stabilityThe process is simple and easy to controlMetallic material coating processesPhosphatePhosphoric acid

Owner:JILIN UNIV

Magnesium borate whisker hydrothermal synthesis preparation method

InactiveCN1936104AStable structureSmall particle sizePolycrystalline material growthFrom normal temperature solutionsMagnesium saltWhiskers

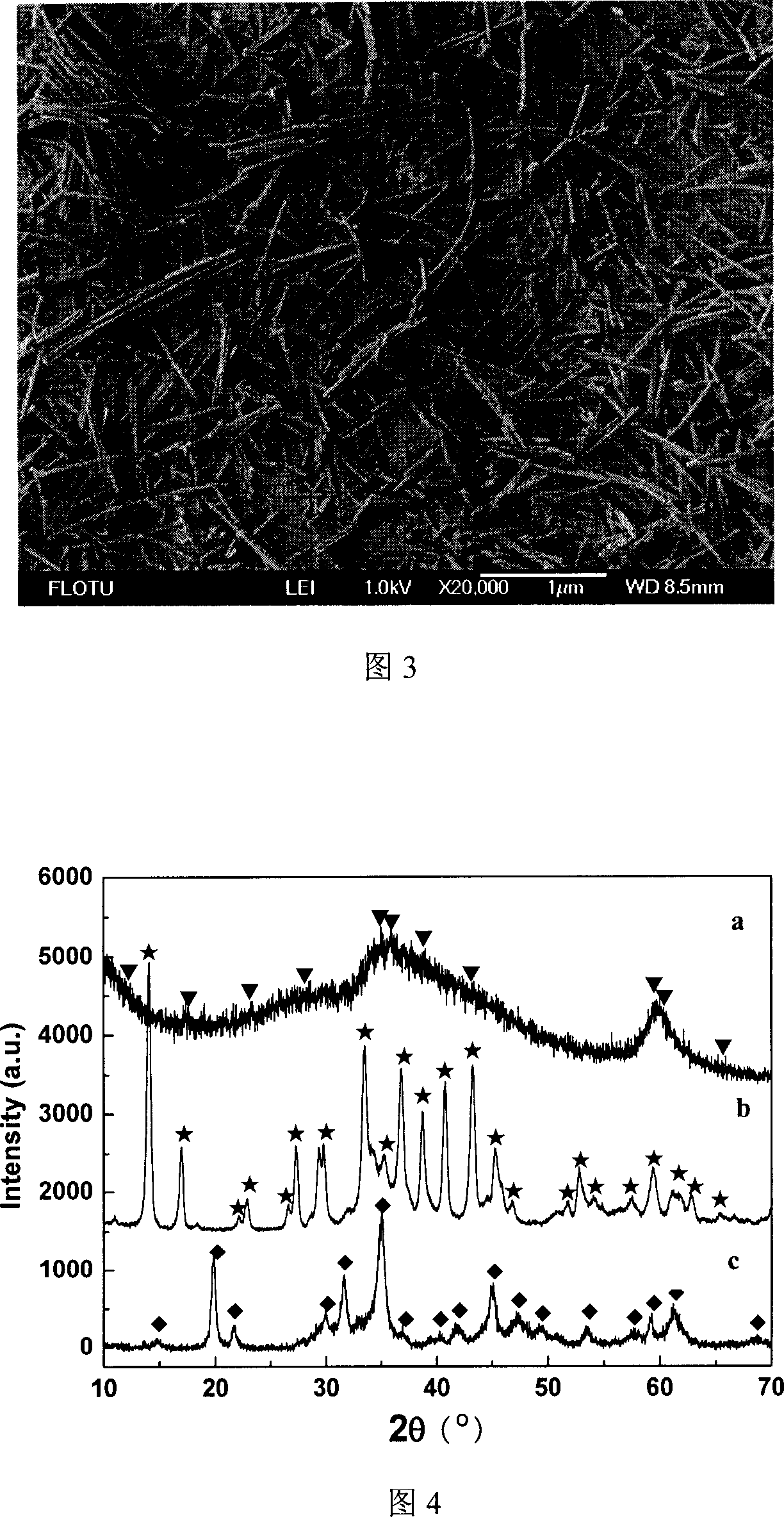

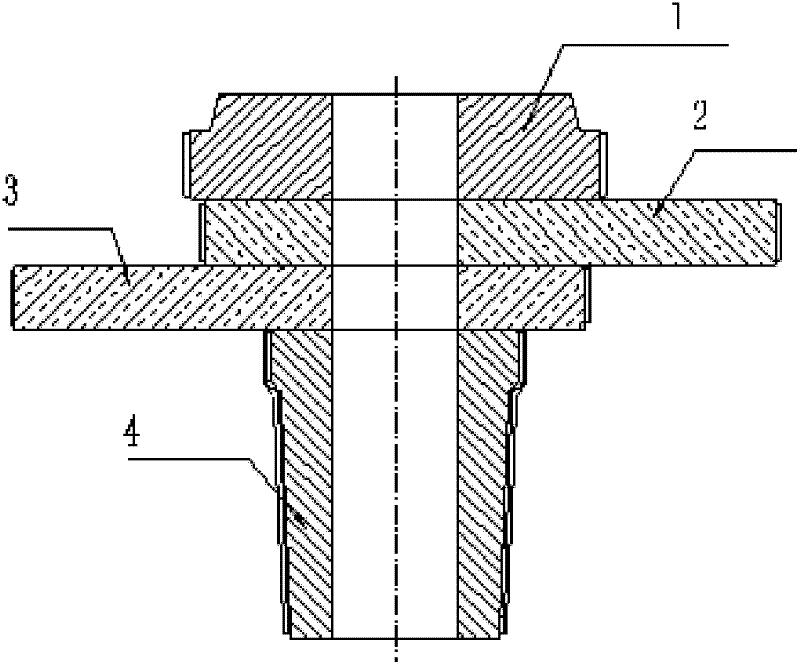

The invention relates to a hydrothermal synthesis manufacturing method for magnesium borate crystal whisker that adopts inorganic magnesium salt, magnesium borate and inorganic alkali as main raw material, adding inorganic alkali into mixture solution of magnesium salt and borate at 10-90 degree centigrade, taking hydrothermal treatment to normal temperature product at 100-300 degree centigrade, realizing directional growth through controlling hydrothermal rocks constituents and technology condition to gain one dimension appearance feather alkali magnesium borate crystal whisker, washing, drying the hydrothermal product, and baking under the existence of crystallographic form transforming agent at 600-800 degree centigrade to realize structure reconstruction and phase converting to gain regular appearance and equal size magnesium borate crystal whisker. The invention has the advantages of simple technology, mild condition, cheap raw material, and easy to be manufactured.

Owner:TSINGHUA UNIV

Plating solution of magnesium alloy nickle sulfate main salt and technology of chemical plating thereof

InactiveCN1598053ALow priceReduce manufacturing costLiquid/solution decomposition chemical coatingChemical platingThiourea

The invention discloses a plating solution of magnalium alloy Nickel sulfate and its chemical plating technique. The plating solution is made up of: (1) 5 to 40g.dm-3 of Nickel sulfate, (2) 10 to 50g.dm-3 of reducing agent of hypo-phosphite sodium; (3) one or several of the 2.5 to 30g.dm-3of the citric acid or tri-sodium citric acid, 2.5 to 30g.dm-3of the lactic acid, 2.5 to 30g.dm-3of the acetic acid, 2.5 to 30g.dm-3of the malic acid, 2.5 to 30g.dm-3 of the third acid and 2.5 to 30g.dm-3of the buta-acid; (4) one or several of the 5 to 30g.dm-3of Potassium fluoride, 5 to 30g.dm-3of sodium fluoride, 5 to 30g.dm-3of lithium fluoride and 5 to 30g.dm-3of NH4HF2; (5) 0.1 to 3g.dm-3of sulphur carbamide. The plating steps include: washing with ultrasonic->washing with alkali->washing with acid->activation->dipping it in the zinc solution->getting rid of the activation solution->secondary dipping it in the zinc solution->chemical plating->passivation and sealing the holes. The invention is featured by little pollution to the environment, low cost, uniform film and simpel technique.

Owner:HUNAN UNIV

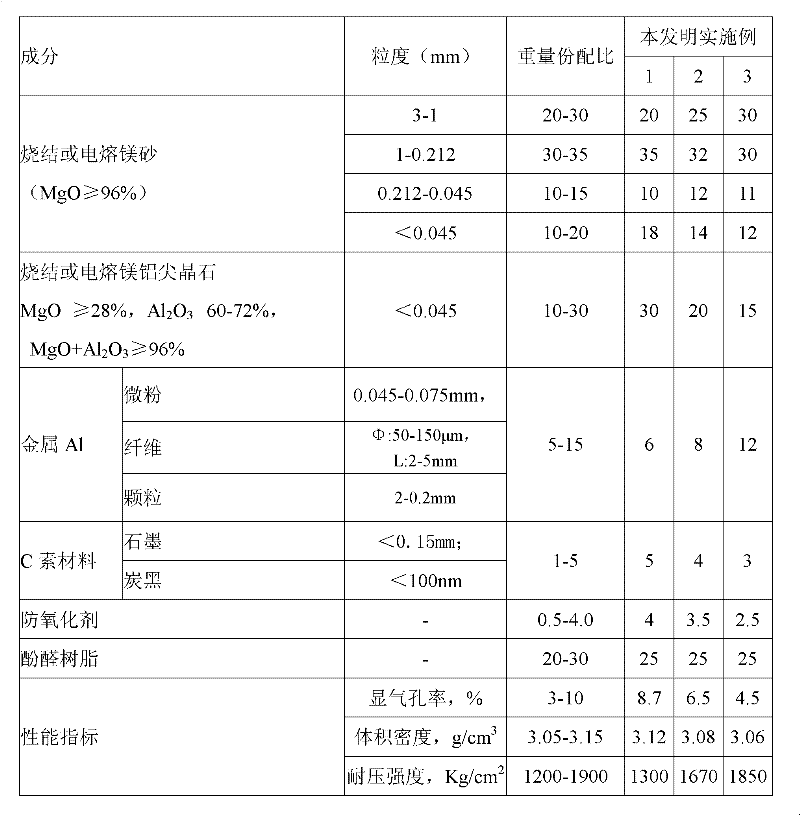

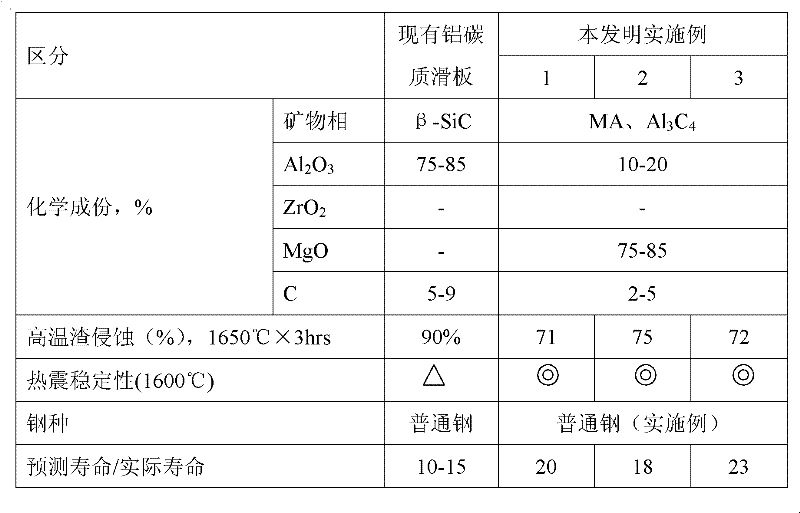

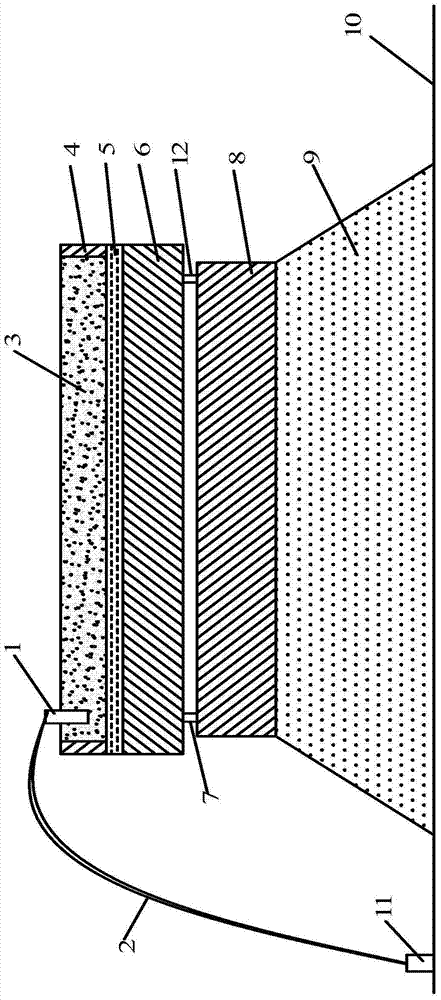

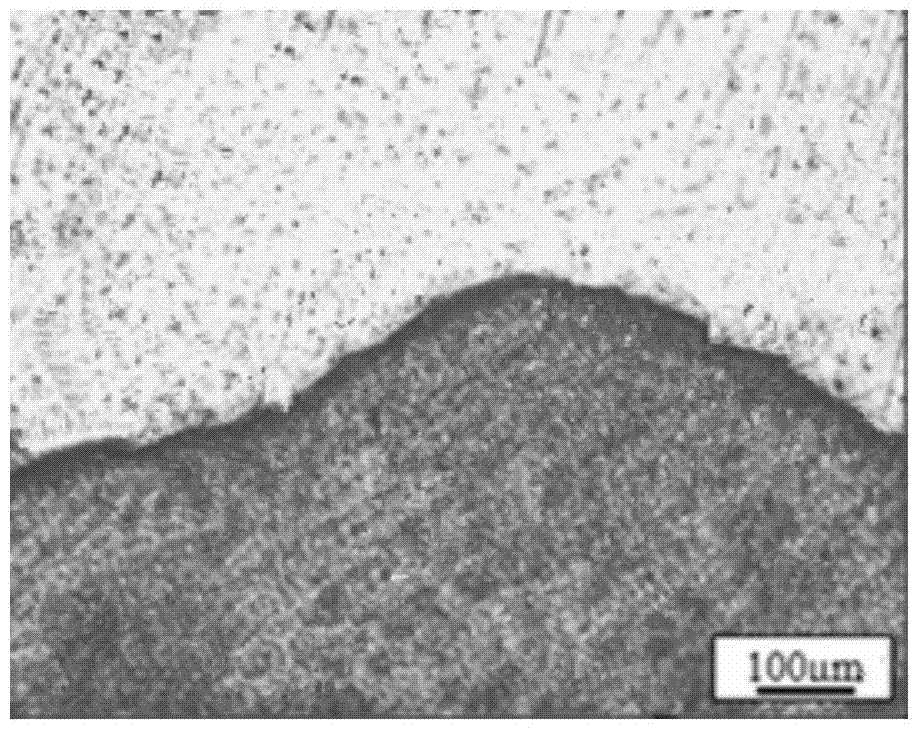

Aluminum magnesium carbon sliding plate brick for stopping slag at steel tapping hole of converter

Owner:ANSHAN CHOSUN REFRACTORIES

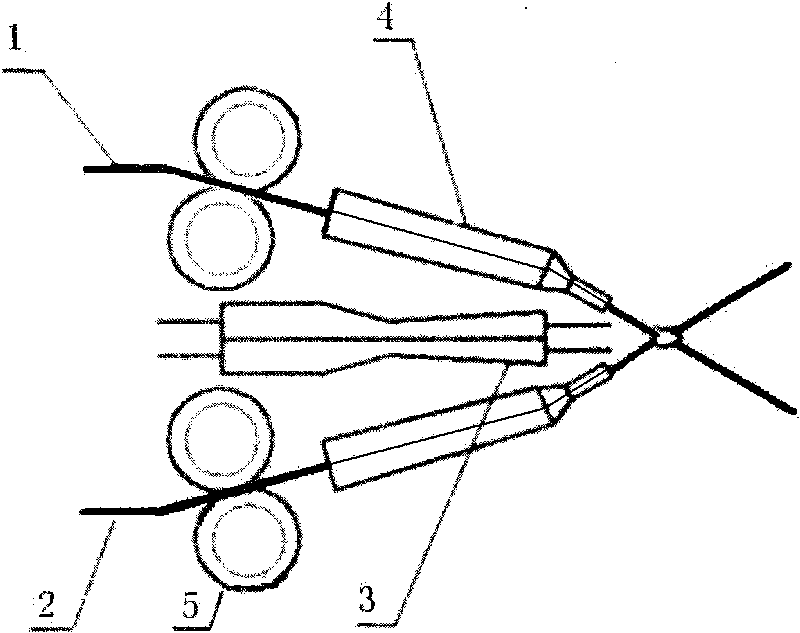

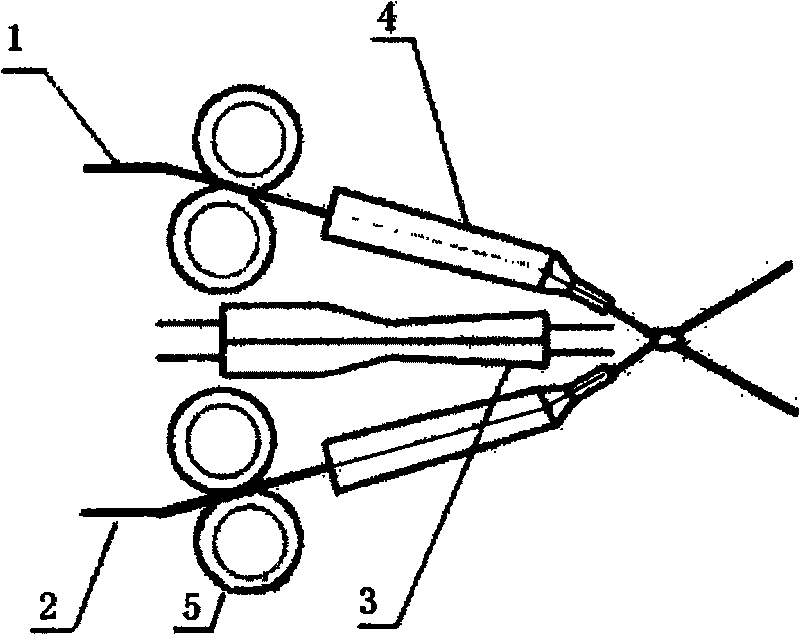

Explosive welding forming method of magnesium and aluminum alloy composite plates

InactiveCN103586574AImprove compactnessAdvancedMetal working apparatusNon-electric welding apparatusAlloy compositeFuel oil

The invention relates to an explosive welding forming method of magnesium and aluminum alloy composite plates. The explosive welding is performed according to the performance requirements of the magnesium and aluminum alloy composite plates, ammonium nitrate fuel oil mixture is adopted, and long-distance instantaneous explosive form is performed on a ground sand base. The welding method is high in forming speed, welding line is firm and is good in metallographic structure compactness, the combined rate is up to 99.5%, the interfacial shear strength is 120MPa, on the premise of strict operation, the welding process is safe and reliable, and the method is reliable and effective in magnesium and aluminum alloy composite plate production.

Owner:TAIYUAN UNIV OF TECH

A kind of sodium-free refining agent for aluminum and aluminum alloy and production method thereof

The invention discloses a sodium-free refining agent for aluminum and aluminum alloy, which consists of the following ingredients in percentage by weight: 15 to 25 percent of potassium aluminium fluoride, 5 to 15 percent of calcium fluoride, 10 to 25 percent of potassium carbonate, 10 to 25 percent of potassium sulfate, 5 to 15 percent of barium sulfate, 15 to 30 percent of potassium chloride and3 to 5 percent of anhydrous aluminium chloride. The invention also discloses a production method of the sodium-free refining agent. Because the sodium-free refining agent does not contain sodium salts, compared with sodium-containing refining agents, the sodium-free refining agent effectively solves the problem of antimony modification and phosphor modification influence caused by more or less sodium salt contained in the existing refining agent and overcomes the defects of alloy casting performance influence, melt flowability reduction and sodium brittleness possibly caused by the sodium element in aluminum-magnesium system alloy with the magnesium content being higher than 2 percent. A better use effect can be obtained in the antimony modification and phosphor modification alloys and high-magnesium-aluminum alloy. The invention belongs to the qualitative improvement on the prior art.

Owner:HEBEI SITONG NEW METAL MATERIAL CO LTD

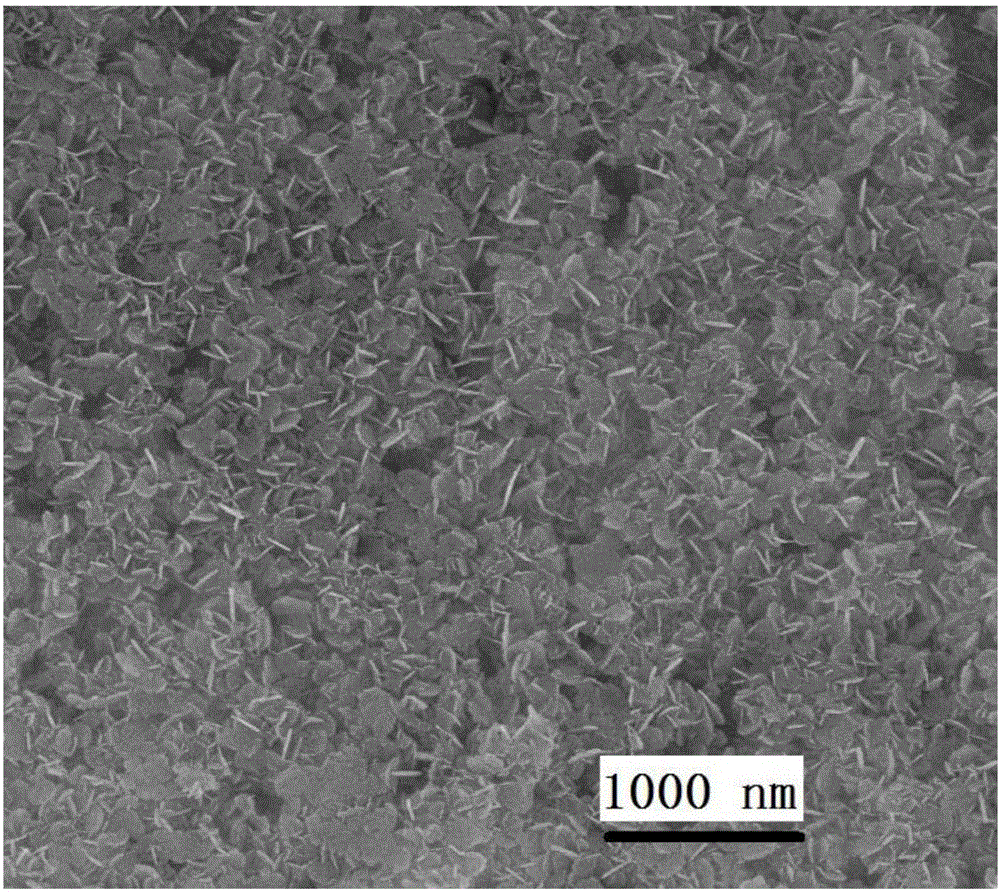

Metal super-hydrophobic surface and preparation method thereof

The invention relates to a metal super-hydrophobic surface and a preparation method thereof. The preparation method comprises following two steps: firstly, electroplating method is adopted, traditional Watts electroplate liquid is taken as a base electroplate liquid, conductive metal base materials such as stainless steel, copper, aluminium alloy, and magnesium aluminum alloy, are taken as a negative electrode, and copper sheets are taken as a positive electrode so as to prepare a nickel coating layer; and secondly, an obtained electroplated surface and an ethanol solution containing fluorosilane are delivered into a heating furnace for heat treatment, and an obtained sample is subjected to washing and blow drying so as to obtain the surface with super-hydrophobicity on metal workpieces. The preparation method of the metal super-hydrophobic surface is simple; cost is low; and the preparation method is convenient for industrialized application. Contact angle of the obtained metal super-hydrophobic surface is more than 155 DEG, and rolling angel is less than 10 DEG; the metal super-hydrophobic surface possesses excellent super hydrophobicity, self-cleaning performance, wear resistance, and corrosion resistance; the preparation method is suitable for obtaining the metal super-hydrophobic surfaces with super hydrophobicity, self-cleaning performance, wear resistance, and corrosion resistance on the surfaces of a plurality of metal base materials with complex shapes and large area.

Owner:SOUTH CHINA UNIV OF TECH

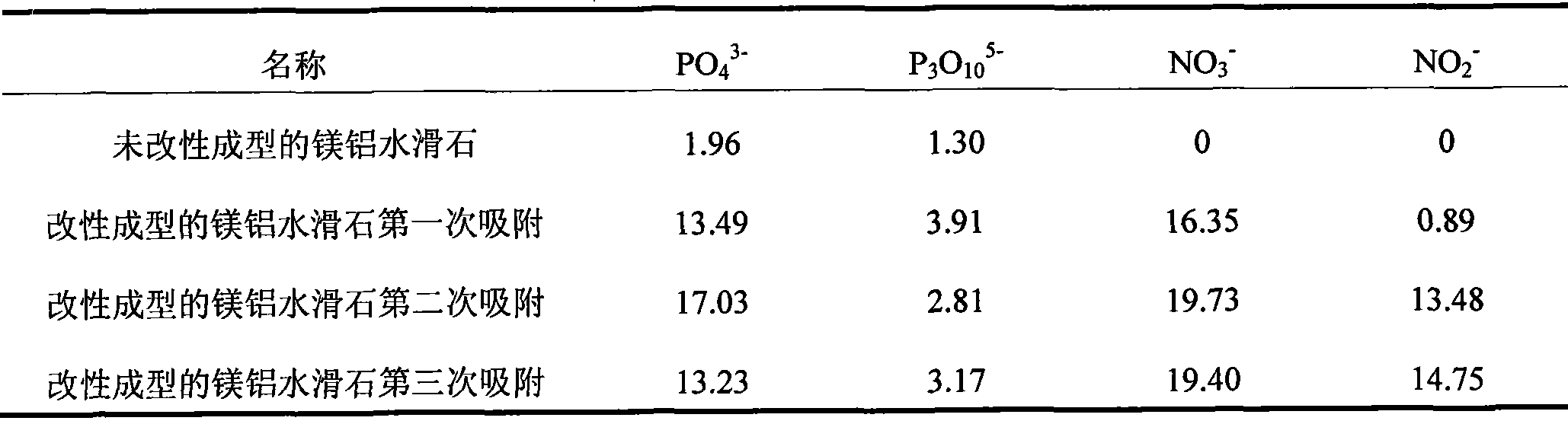

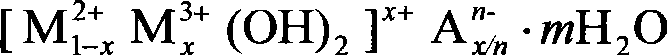

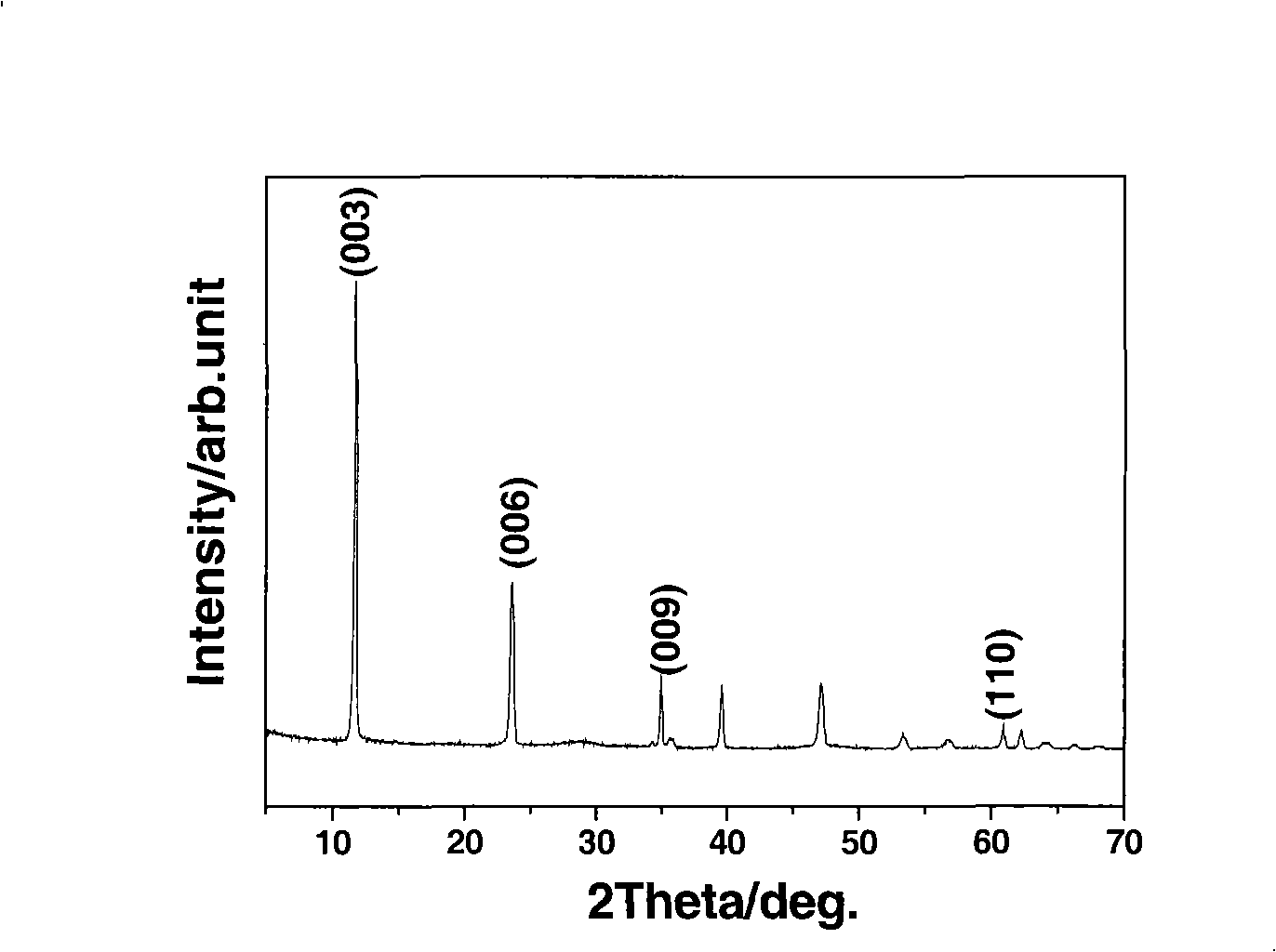

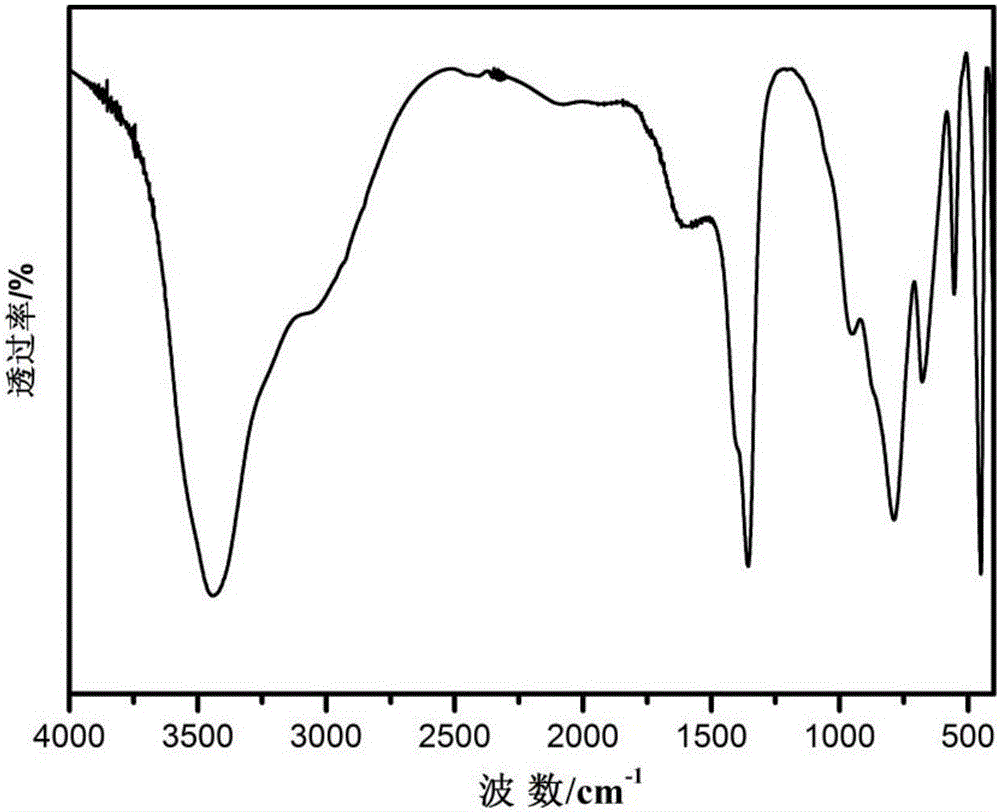

Method for preparing modification forming magnalium hydrotalcite and application

The invention discloses a preparation method of a modified and molded Mg-Al hydrotalcite and the application thereof. When in preparation, a mixed saline solution and a mixed aqueous alkali, containing Mg<2+> and Al<3+>, are respectively prepared and then mixed. Aging and crystallization are carried out after complete reaction, and the Mg-Al hydrotalcite is obtained after filtration, washing and drying; the Mg-Al hydrotalcite and a bonding agent are added into a magnesium saline solution and the pH value of the obtained paste is adjusted. After reaction, centrifugal separation, drying and extrusion molding are carried out, and then the paste is dried, roasted and cooled to the room temperature. When in adsorption and ion exchange, the product of the invention does not block a bed body and is easy for separation after reaction, suitable for the treatment of phosphorus and nitrogen anions in aqueous solution, water of a sewage disposal plant, seawater and breeding wastewater. A good treatment effect is available and an effluent standard can be met. Furthermore, after use, the product has better absorption effects after desorption and regeneration, thereby being beneficial to the realization of industrialized application.

Owner:OCEAN UNIV OF CHINA

Method for preparing polymeric ferric boron silicate aluminium magnesium flocculating agent

InactiveCN101117249AOvercome stabilityOvercome longevityWater/sewage treatment by flocculation/precipitationSilicic acidMagnesium salt

The invention discloses a fabrication method for a flocculant of polymerized silicic acid boron, magnalium, aluminium and ferro, and adopts sodium silicate, borax, aluminum salt, magnesium salt and iron saltferro-salt as main raw materials, and adopts water as a reacting solution; firstly the sodium silicate is added to a sulfuric acid solution, a pH value is adjusted to a certain degree, a quick mixing process is followed, a poly silicic acid is made out after reacting for a period of time; the aluminum salt, the borax, the magnesium salt and the ferro-salt are added to the poly silicic acid according to a certain chemical stoichiometric ratio and sequence requirement, the pH value is adjusted, and the quick mixing process is followed, after a period of time in the condensation polymerization process, the flocculant of polymerized silicic acid boron, magnalium, aluminium and ferro can be made out after static placement and aging process; the fabrication of the flocculant by the invention is easy and simple, the operation is easy, the medicament input quantity is small, the CODCr removing rate and the decoloring rate are high, the service life is long with a stability.

Owner:GUANGDONG UNIV OF TECH

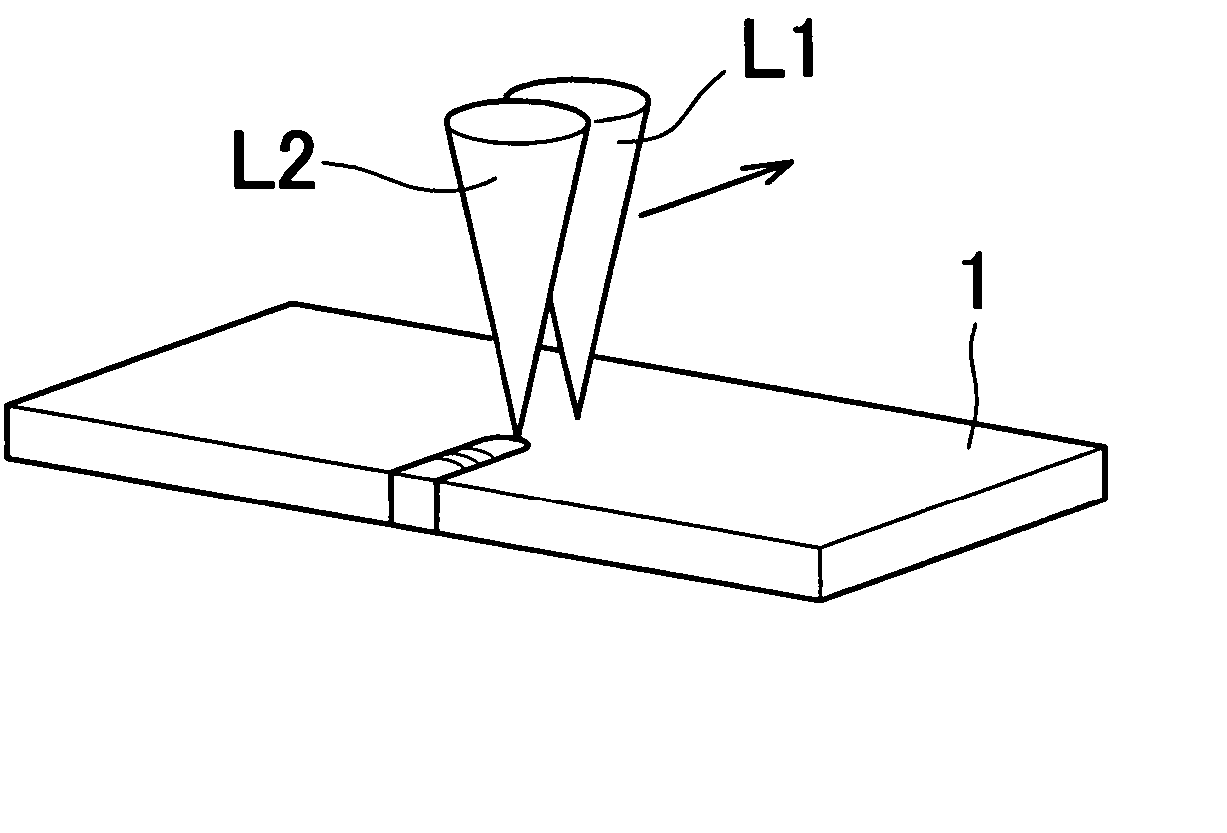

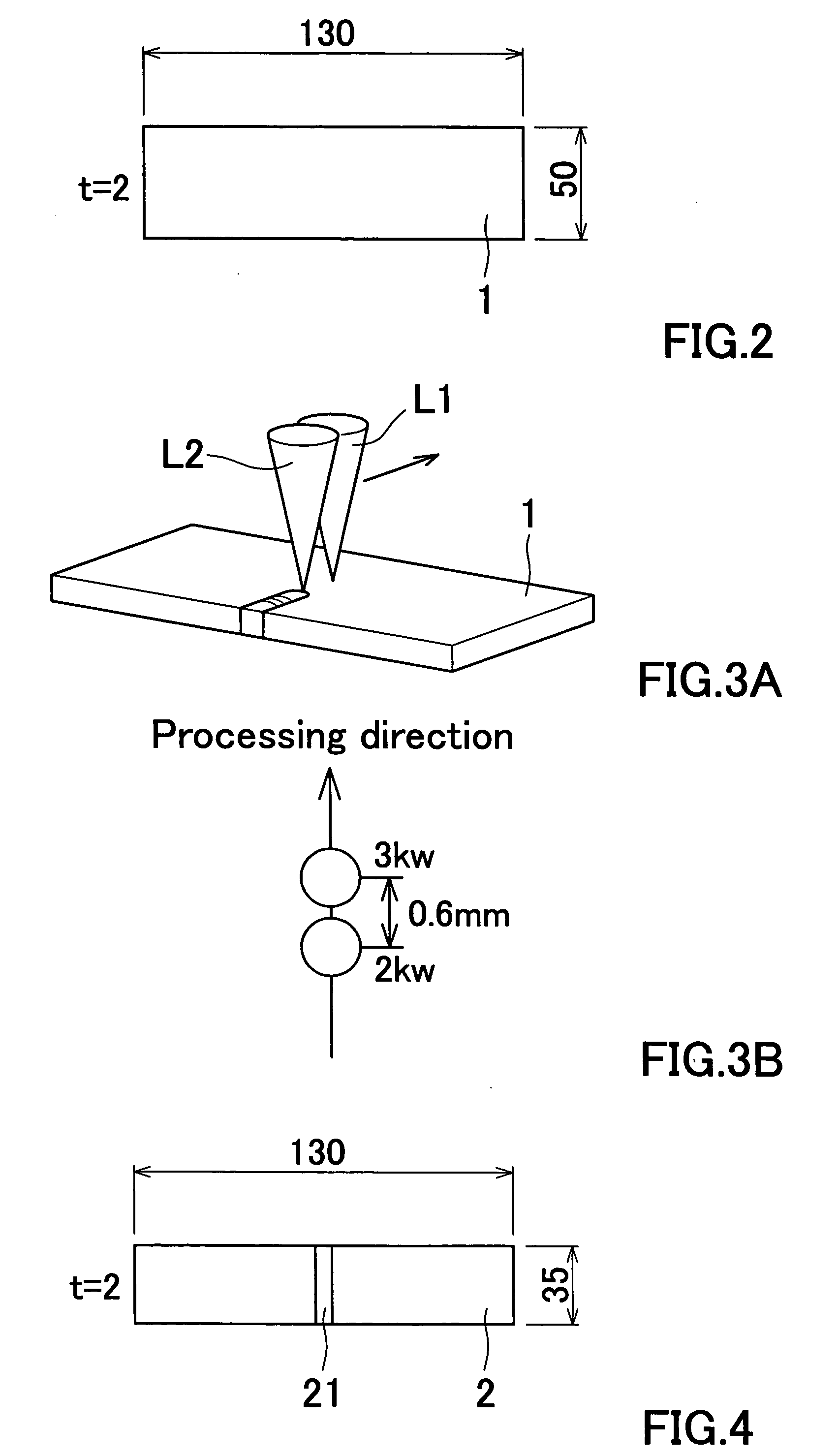

Filler material for use in welding of Mg-contained aluminum alloy die-cast members, welding method, and welded article

InactiveUS20050023258A1High strengthSuppress generationWelding/cutting media/materialsWelding/soldering/cutting articlesFilling materialsDie casting

An aluminum alloy filler material for use in welding of metal members including at least one aluminum die-cast member containing Mg includes an aluminum or an aluminum alloy as base material and Al—K—F series flux. The Al—K—F series flux is contained by 2 to 4 mass % with respect to the entire filler material.

Owner:NISSAN MOTOR CO LTD +1

Mixing fireworks and producing method thereof

A mixed 'firecracker-fireworks' having the effects of firecracker and fireworks and generating 5 colors is prepared from potassium perchlorate, Mg-Al alloy powder, strontium carbonate, phenolic resin, polyvinyl chloride, strontium nitrate, sulfur, glutinous rice flour, etc. Its advantages are simple preparing process, dual effect, multiple color and long perdurability.

Owner:黄远清 +1

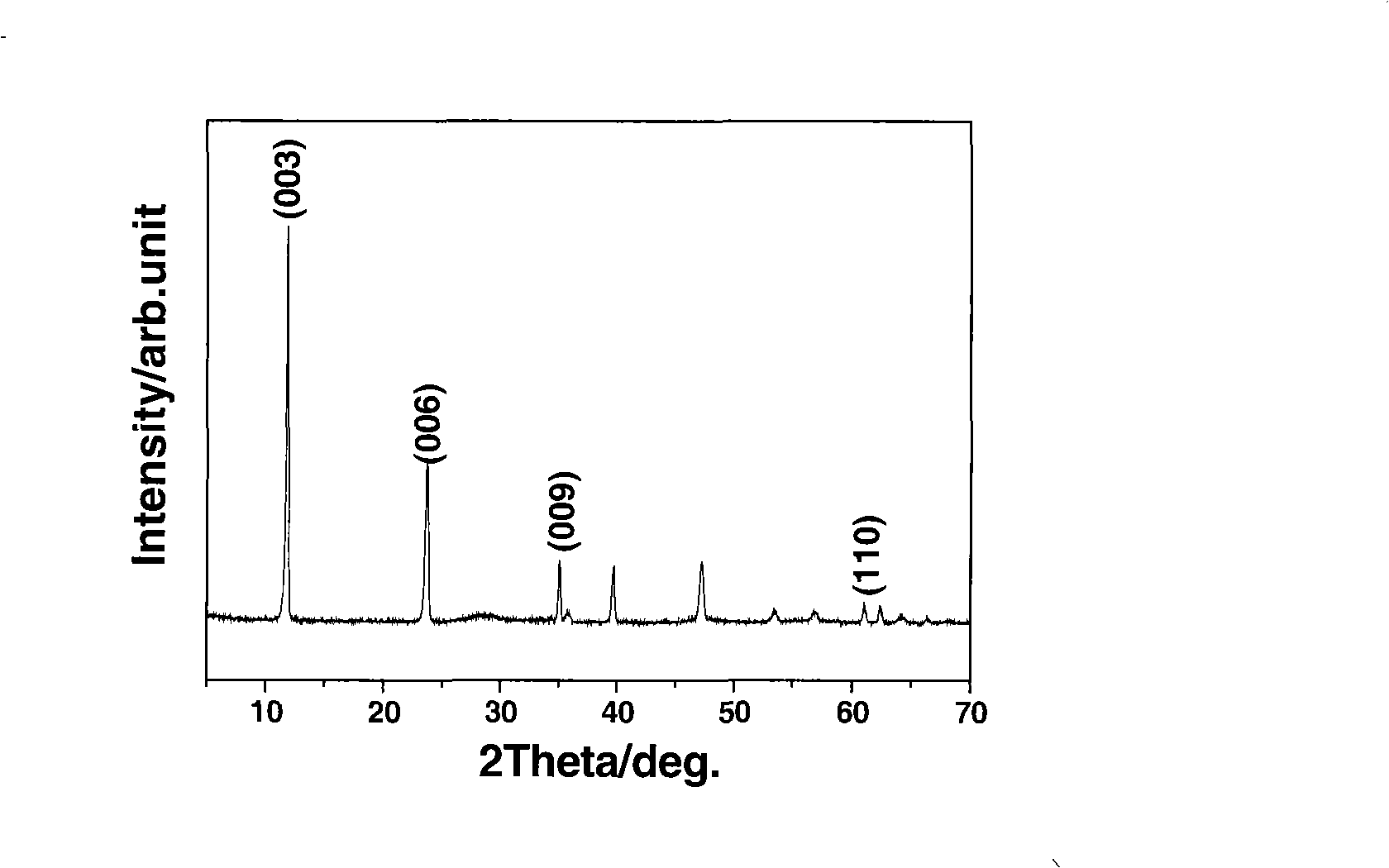

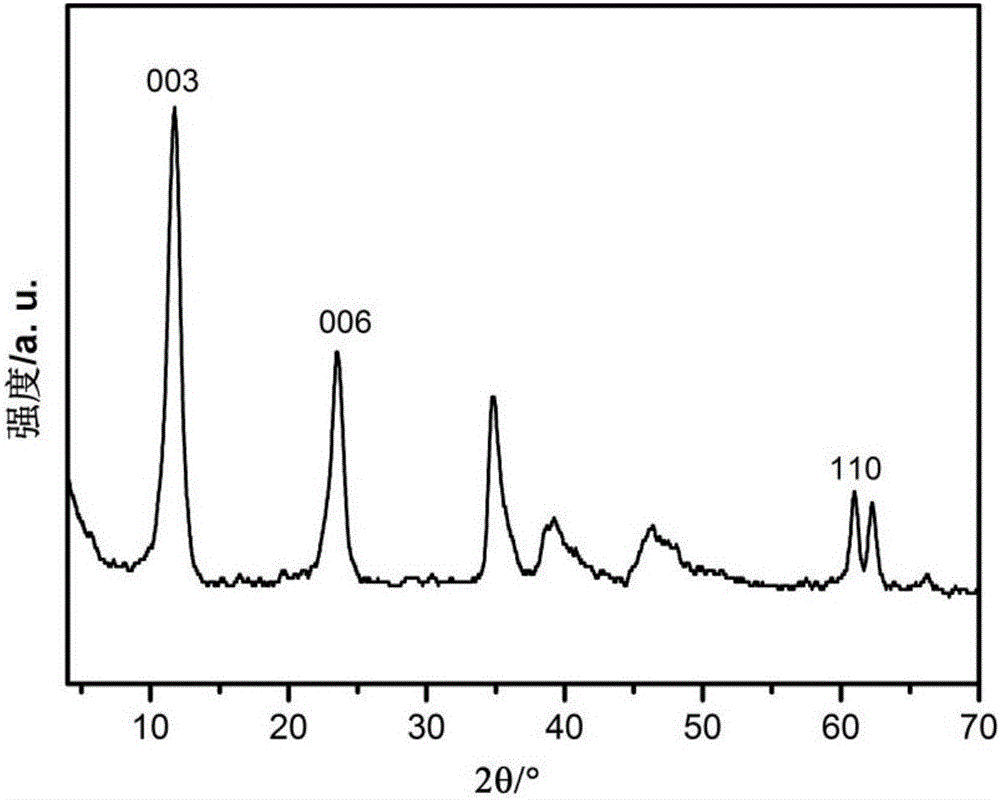

Method for preparing nano magnalium hydrotalcite and equipment thereof

The invention relates to a method for preparing nanometer magnalium hydrotalcite and equipment thereof. The method comprises the following reaction steps: a magnalium mixed salt solution is prepared; an ammonium hydrogen carbonate solution is prepared; two mixed solutions are simultaenosuly added into a static mixer and have chemical reaction to generate magnalium hydrotalcite microcrystal; and the magnalium hydrotalcite microcrystal grows through a curing reactor to obtain a nanometer magnalium hydrotalcite product. The method uses ammonium bicarbonate to replace the prior sodium hydroxide or urea as a precipitator, adopts the static mixer for liquid-liquid two-phase coprecipitation reaction and carries out the coprecipitation reaction of the magnalium salt solution and the ammonium hydrogen carbonate solution so as to separate the reaction and the ripening and control the generation and growth conditions of the microcrystal respectively. The method and the equipment overcome the disadvantages thatcrystal grains are too small and granules are uneven; and the whole dimension of the crystal grains and the dimension of the granules are difficult to control in the prior art, thereby preparing a magnalium hydrotalcite powder body with even distribution of nanometer dimension and granularity. The method can also reduce the production cost of the magnalium hydrotalcite and simultaneously simplify the production flow.

Owner:XIANGYANG CANGHAI TECH CO LTD

Aging resistance SBR (Styrenebutadiene rubber) modified road asphalt of magnalium base layer double hydroxide and preparation method of asphalt

ActiveCN102181162AImprove UV aging resistanceExtended service lifeBuilding insulationsAging resistanceUltraviolet

The invention relates to an aging resistance SBR modified road asphalt of magnalium base layer double hydroxide and a preparation method of the asphalt. The aging resistance SBR modified road asphalt of magnalium base layer double hydroxide is characterized by preparation from asphalt, SBR modifier, magnalium base layer double hydroxide and modified auxiliary. The mass percentage of all raw materials is as follows: 88.7-96.9% of asphalt, 2-5% of SBR modifier, 1-6% of magnalium base layer double hydroxide and 0.1-0.3% of modified auxiliary. By using the function of magnalium base layer double hydroxide in shielding and chemical absorption of multilayer physical scattering of ultraviolet rays, the invention can greatly promote the anti-ultraviolet ageing capacity of the SBR modified road asphalt and prolong the service life of asphalt road surfaces, with a wide application prospect.

Owner:WUHAN UNIV OF TECH

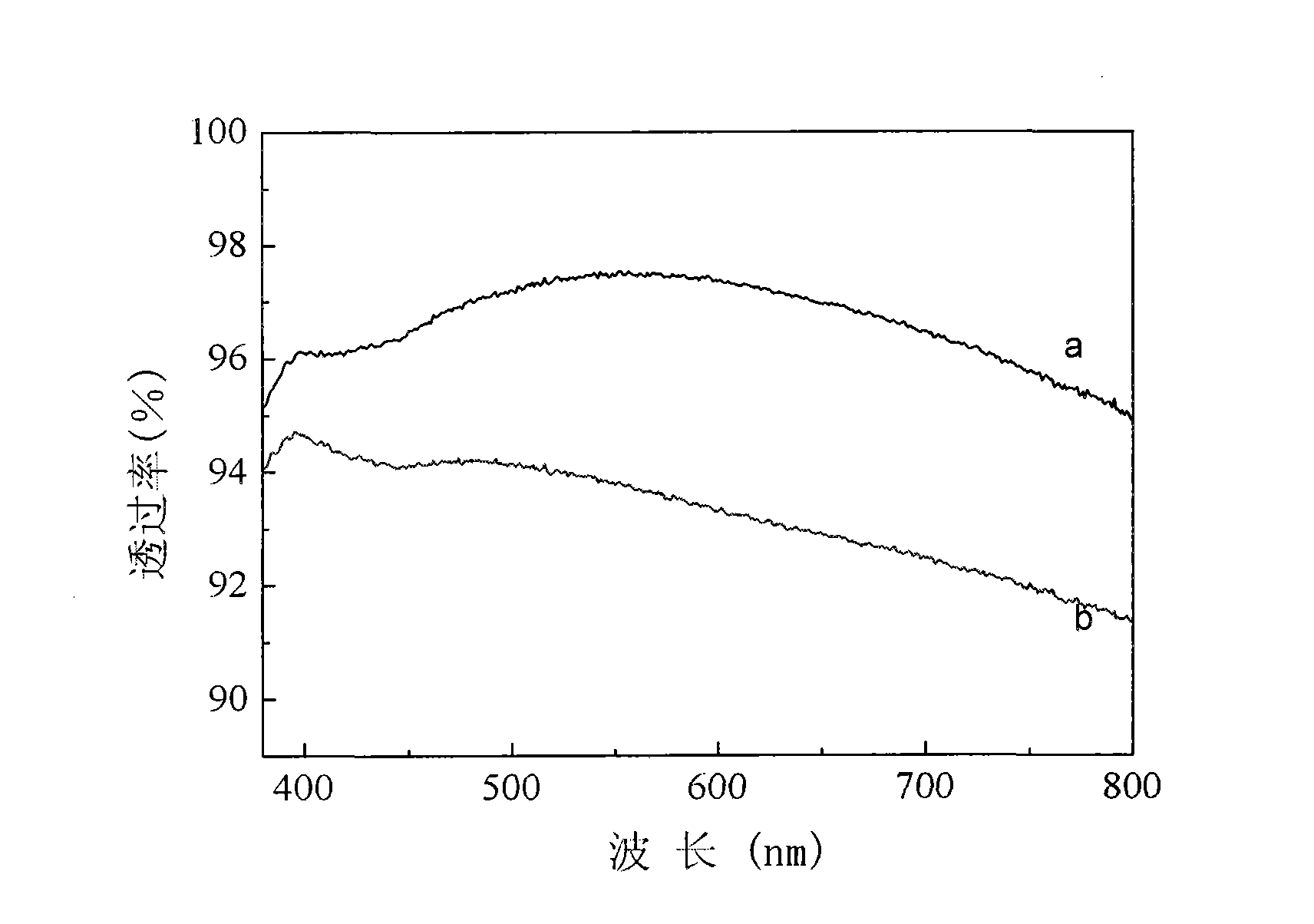

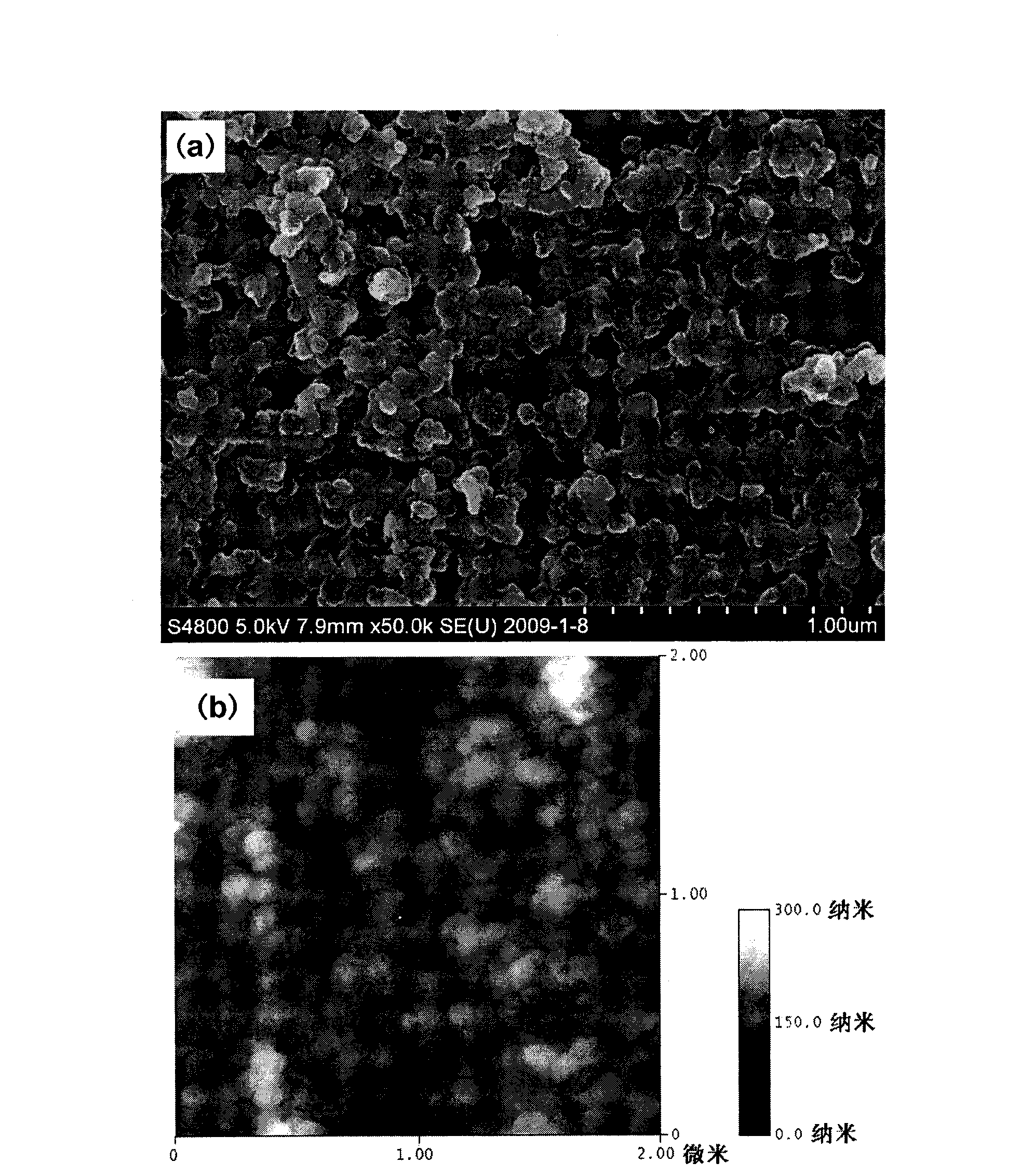

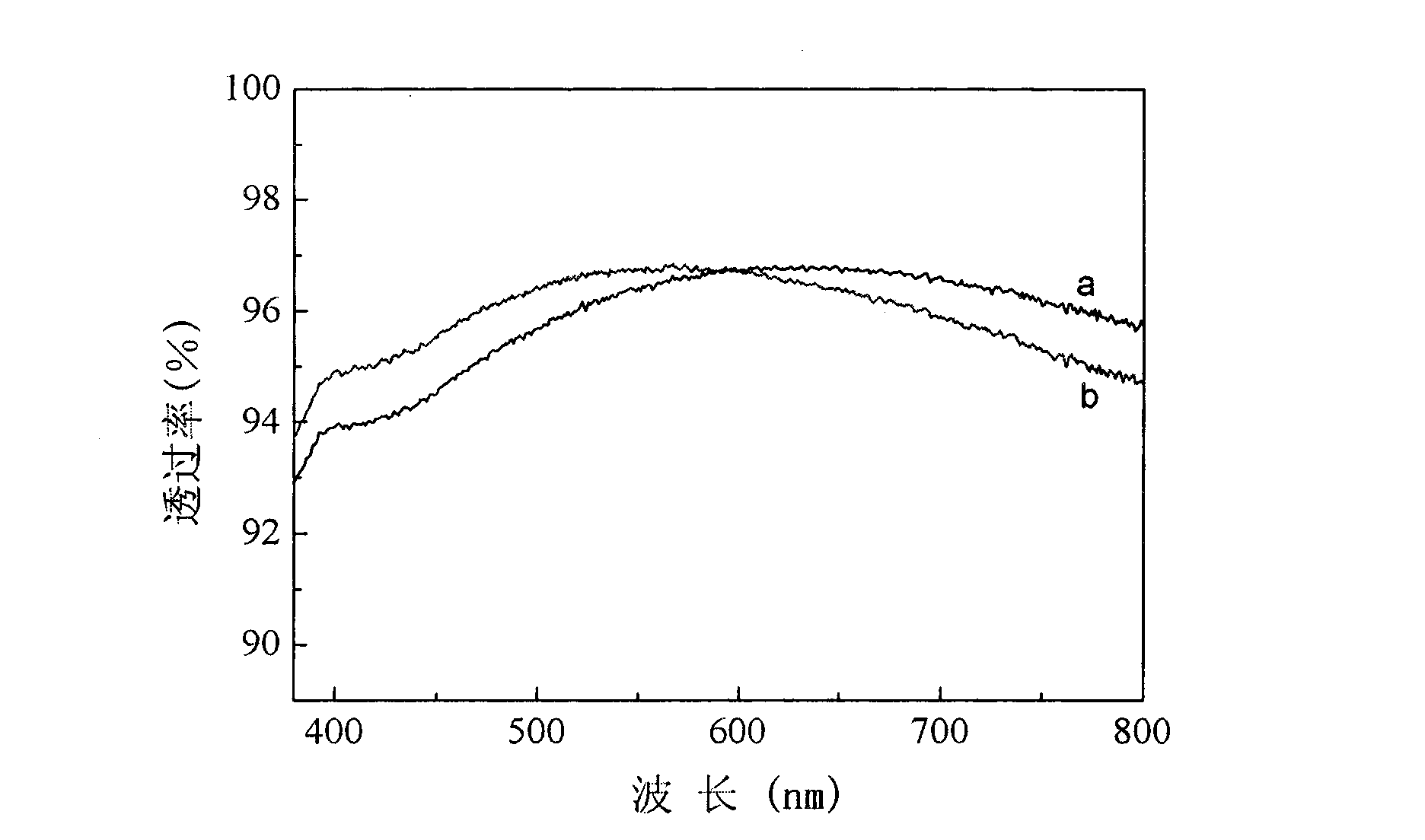

Method for preparing full nanometer granule visible light area antireflection film by layer upon layer self-assembly method

The invention relates to a method for preparing a full nanometer granule visible light area antireflection film by a layer upon layer self-assembly method, which comprises steps of: (1) scouring, alkali washing and drying a glass or quartzes substrate; (2) (a) soaking in colloid of magnalium layered double hydroxide for 3-20 minutes; (3) soaking in silicon dioxide sol or titanium dioxide sol for 3-20 minutes; (c) repeating the steps of (a) and (b) in sequence; (d) sintering for 0.5-4 hours in the temperature of 400-500 DEG C, thus obtaining the antireflection film. The method uses simple devices, has low cost and is suitable for industrialization production. The antireflection film has obvious effect in the visible light area; a multi-layer antireflection film formed on the surface of theglass can reach 97.4% of transmission rate at wave length of 550nm; and a multi-layer film containing titanium dioxide can reach no less than 93.7% of transmission rate at wave length of 550nm.

Owner:DONGHUA UNIV

Wood-plastic composite inflaming-retarding coating containing inorganic fire retardant

InactiveCN102220066AReduce pollutionSolve processabilityEpoxy resin coatingsEpoxyAluminium hydroxide

The invention relates to a wood-plastic composite inflaming-retarding coating containing inorganic fire retardant, comprising the following ingredients according to parts by weight: 100 parts of epoxide resin, 10-20 parts of ethanol, 0.9-1.5 parts of NDZ-201 titanate coupling agent, 0.45-0.75 part of KH570 silane coupling agent, 25-30 parts of curing agent, 60-100 parts of aluminium hydroxide, 30-50 parts of magnesium hydroxide, 10 parts of alumina, 5-15 parts of microcapsule red phosphorus, 10-20 parts of expanded graphite, and 4-12 parts of zinc borate. The wood-plastic composite inflaming-retarding coating has the advantages that pollution to environment is reduced owning to the usage of a low-smoke nontoxic halogen-free inflaming-retarding agent, and in the wood-plastic composite inflaming-retarding coating, the disadvantage that as the magnalium fire retardant has overhigh filler quantity, the processing property or physical property of the material can be reduced is overcome owning to the wood-plastic composite inflaming-retarding coating, and the inflaming-retarding coating has high surface hardness, so that the inflaming-retarding coating has good abrasive resistance, chemical resistance and aging resistance. The fineness of the inflaming-retarding coating is less than 90mum, the adhesive force is zero level, the surface drying time is less than 1.5h, and the hard drying time is less than 24h.

Owner:安徽海韵新材料科技有限公司

Process for preparing composite material of high magnesium aluminium alloy-expanding ore

A light and porous high-Mg Al-alloy-expanded ore composition is prepared from high-Mg Al-alloy and puffed vermiculite and pearlite through vacuum percolation casting method. Its density is less than 1.9 g / cu*cm. Its advantages are ease control of foam pore, and high compression strength and thermal insulating effect.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Bright green cold firework composition and production method thereof

The invention discloses a bright green cold firework composition and a preparation method thereof. The composition comprises the following ingredients by weight percentage: 25-40% of boron powder, 5-15% of magnalium powder, 6-12% of titanium powder, 8-15% of barium nitrate, 6-10% of 52# chlorinated paraffin, 15-20% of nitrocotton and 15-20% of ammonium perchlorate. The preparation method of the composition comprises the steps of fuel mixing, fuel granulation, fuel grain drying and composition mixing. A cold firework produced by the composition can emit bright green light, the color variety of the cold firework is enriched, and the enjoyment effect of the cold firework is improved.

Owner:NANJING UNIV OF SCI & TECH

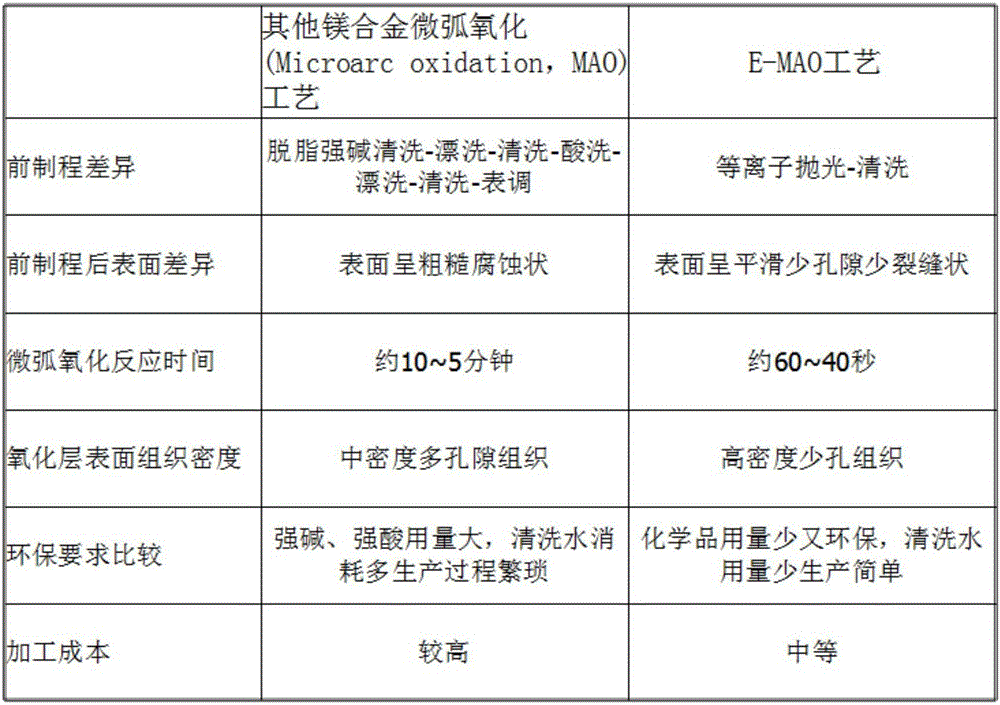

Micro-arc oxidation method for magnesium aluminum alloy and electrolyte

The invention discloses a micro-arc oxidation method for a magnesium aluminum alloy. The micro-arc oxidation method comprises the steps of S1, plasma polishing; S2, primary cleaning; S3, micro-arc oxidation; S4, secondary cleaning; S5, blow-drying; S6, hole sealing; S7, drying, and S8, coating. According to the magnesium aluminum alloy prepared in the method, the surface is smooth, clearances and cracks are less, burrs of which the thickness is 0.4 mm or below can be removed, thin cracks of a magnesium alloy object can be removed, computer numerical control (CNC) knife lines can be removed, and the magnesium alloy object does not need fine polishing and can be repaired after slight shrinkage; the micro-arc oxidation reaction time can be shortened from original 5 to 10 min to 40 to 60 s, 8 to 9 manufacture procedures are reduced, and 2 to 3 times of spraying can be reduced in later manufacture procedures; and the qualification rate is up to 95% or above, and the magnesium aluminum alloy can pass alcohol tests, rubber tests, adhesion cross-cut tests and surface abrasion resistance (RCA) tests.

Owner:苏州菲尔德精密制造有限公司

Preparation method of high-corrosion-resistance and easy-to-process magnesium aluminum alloy composite plate strip materials

ActiveCN102632076AImprove cold rolling plastic deformationImprove corrosion resistanceLaminationLamination apparatusAlloy compositeComposite plate

The invention discloses a preparation method of high-corrosion-resistance and easy-to-process magnesium aluminum alloy composite plate strip materials. The preparation method comprises the following steps of: a) flattening; b) cleaning; c) roughening; d) pre-compound treatment; e) warm rolling welding; and f) annealing heat treatment, so that the high-corrosion-resistance and easy-to-process magnesium aluminum alloy composite plate strip materials are obtained. The preparation method has the advantages that aluminum or aluminum alloy is covered between magnesium and magnesium alloy base materials and on the outer surfaces of the magnesium and magnesium alloy base materials, and good corrosion resistance performance and excellent plastic deformation of the aluminum and aluminum alloy are utilized for improving the magnesium cold rolling plastic deformation and improving the corrosion resistance performance.

Owner:CHONGQING MATERIALS RES INST

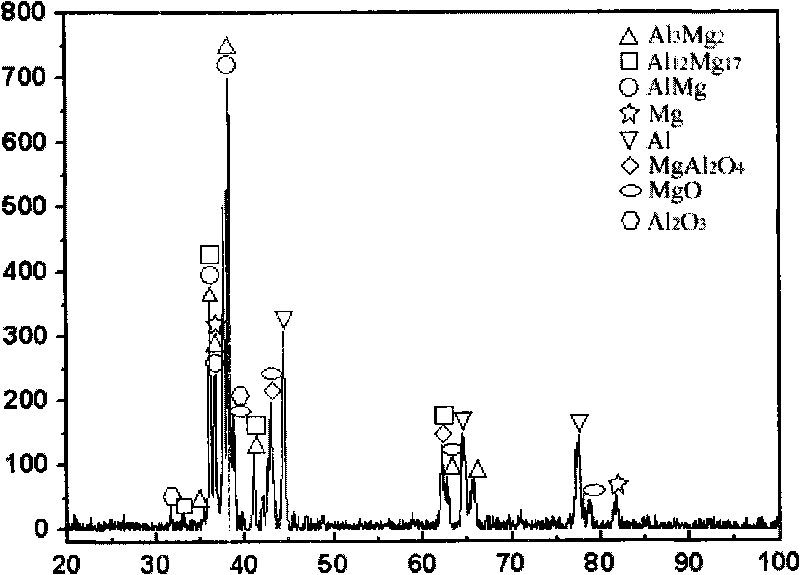

Magnalium special metal coating and preparation method thereof

InactiveCN101709448AImprove corrosion resistanceHigh hardnessMolten spray coatingElectrode potentialMetal coating

The invention belongs to the technical field of hot spraying, and relates to a preparation method of a special metal coating. The preparation method comprises the following steps: adopting electric arc spraying, plasma spraying or ultrasonic flame spraying; and performing electric arc spraying on magnesium wire or aluminum wire serving as two electrodes in the diameter ratio of 1:1-1:3, or performing plasma spraying or ultrasonic flame spraying on a mixture of magnesium powder with the particle size between 0.2 and 100mu m and aluminum powder serving as raw materials in a ratio of 1:1-1:9 to obtain the coating, wherein the coating comprises the following components by weight: 5.5 to 40.0 percent of Mg, 55.0 to 93.0 percent of Al and less than or equal to 10 percent of other components. The special coating has the advantages of having good cathode protection effect on steel and metals with lower electrode potential such as aluminum, zinc and the like. After being subjected to heat treatment at the temperature of between 200 and 470 DEG C for 30 to 150 minutes, the coating is rich in Al12Mg17 phase and Al3Mg2 phase, thereby further improving the rigidity and corrosion resistance of the coating.

Owner:DALIAN UNIV OF TECH

Formula of flux for middle temperature brazing magnesium-containing aluminum alloy

ActiveCN101407003AReduced active temperature rangeNon-hygroscopicWelding/cutting media/materialsSoldering mediaMoisture absorptionChloride

The invention relates to a formula for the braze welding of magnesium containing aluminum alloy, in particular to an intermediate temperature brazing flux formula which is applied to the braze welding of the magnesium containing aluminum alloy and of which the brazing temperature range is between 530 and 570 DEG C, and belongs to the welding technical field. Compared with the conventional chloride formula, the formula produces after-welding brazing flux residue which has the characteristics of no moisture absorption and no corrosivity; the formula better utilizes the characteristics of the phase diagram of a multicomponent compound, reduces the active temperature range of the brazing flux so as to be applied to the aluminum alloy with high strength level and low melting point, thereby widening the application range, lowering cost and improving the efficiency.

Owner:CHINA ELECTRONICS TECH GRP CORP NO 14 RES INST

Magnesium, aluminum and rare earth three-element hydrotalcite, preparation and use thereof

InactiveCN101302031AHigh crystallinityRegular shapeRare earth metal compoundsRare-earth elementHydrotalcite

The invention discloses a magnalium rare-earth three-metaclass hydrotalcite which is synthesized by a hydro-thermal method, comprising the following structure formula of [Mg8 Al 2-X Rex (OH)20 CO3. gamma H2O, wherein the x is more than or equal to 0.1 and less than or equal to 0.33, the gamma is the number of crystallization water, and the Re is a rare-earth element. The rare-earth elements comprise La, Ce, Pr, Nd, Pm, Sm, Eu, etc. The magnalium rare-earth three-metaclass hydrotalcite is synthesized by taking nitrate, sulphate, chloride of rare-earth metal and salts of other soluble rare-earth metal as a rare-earth metal source, and the doped amount of the rare-earth metal in the magnalium rare-earth three-metaclass hydrotalcite is adjusted and controlled to a certain degree according to the adjustable and synthesized condition. The product has the characteristics of high crystallinity and regular shape. Compared with the prior layered double hydrotalcite, a layer plate of the magnalium rare-earth three-metaclass hydrotalcite consists of hydroxide formed by a bivalent and trivalent main group or transition metallic cations and hydroxide containing the rare-earth metal elements.

Owner:广东炜林纳新材料科技股份有限公司

Clean preparation method of magnalium based laminated composite hydroxide

ActiveCN105836769ARich sourcesIncrease spawn rateAluminium compoundsZinc compoundsEnvironmental resistanceReaction temperature

The invention provides a clean preparation method of a magnalium based laminated composite hydroxide. The method uses magnesium hydroxide, magnesium oxide, pseudo boehmite, inorganic acid and a material containing functional anions as raw materials, uses magnesium chloride or magnesium nitrate as a circulation medium, and uses the property of peptization under acidic condition of boehmite to improve the reaction activity of pseudoboehmite; the concentration of magnesium ions in solution is increased by using magnesium chloride or magnesium nitrate. The method accelerates the formation rate of laminated composite hydroxide, promotes the dissolution of magnesium hydroxide and magnesium oxide, shortens the reaction time, overcomes the defects of high reaction temperature and long time consumption in hydrothermal method for synthesis of laminated composite hydroxide, and can rapidly prepare magnalium based laminated composite hydroxide under mild conditions. Magnesium chloride and magnesium nitrate can be recycled; and the preparation process has no waste discharge, and is green and environment-friendly. The method has the advantages of abundant raw materials, low cost, simple preparation process, mild reaction conditions, and easiness to industrial production.

Owner:BEIJING UNIV OF CHEM TECH

Composite spinel-zirconium refractory material for smelting colored heavy metal

The invention discloses a composite spinel-zirconium refractory material for smelting colored heavy metal. The technical scheme is as follows: the material comprises 30-45 parts of 5mm-0mm emery, 10-30 parts of 5mm-0mm magnesia chromite clinker,15-25 parts of 3mm-1mm magnalium spinel clinker, 7-20 parts of 3mm-0mm magnesite clinker, 1-5 parts of chrome green less than or equal to 0.045mm and 2-8 parts of zirconium dioxide less than or equal to 0.045mm by weight part and a bonding agent is aluminium dihydrogen phosphate liquid the adding amount of which is 3-15% of the total weight of the emery, the magnesia chromite clinker, the magnalium spinel clinker, the magnesite clinker, the chrome green and the zirconium dioxide. A hydraulic press is adopted for molding and the composite spinel-zirconium refractory material is sintered by a hyperthermia tunnel kiln. The content of Cr2O3 of the composite spinel-zirconium refractory material is less than 10%, so that the composite spinel-zirconium refractory material not only is environment-friendly, but also has better slag erosion resistance, high-temperature melt washing resistance, metal melt permeation resistance and thermal shock stability performance.

Owner:辽宁青花耐火材料股份有限公司

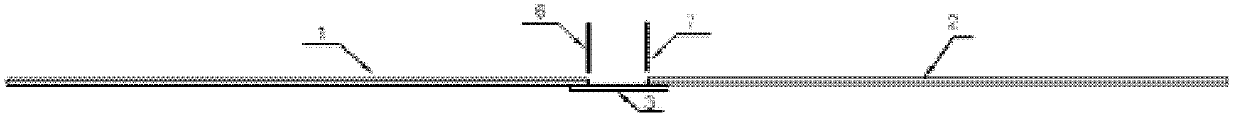

Cold metal transition melting-brazing welding connection method for dissimilar magnesium metal and aluminum metal

InactiveCN103372710AContinuous moldingUniform shapeArc welding apparatusWelding/cutting media/materialsShielding gasAluminum metal

Disclosed is a cold metal transition melting-brazing welding connection method for dissimilar magnesium metal and aluminum metal. Cold metal transition welding is adopted, argon is adopted as protecting gas, transition metal is a galvanized steel sheet, two types of welding wires are adopted, an aluminum-silicon welding wire is adopted on the aluminum side, and a magnalium zinc welding wire is adopted on the magnesium side. A welding gun is utilized to align to an aluminum edge and a magnesium edge, high-melting-point transition metal is clamped between magnesium and aluminum to stop mutual contact of liquid magnesium and liquid aluminum, so that melting-brazing welding connections between a magnesium melting welding joint and the transition metal (the galvanized steel sheet) as well as between an aluminum melting welding joint and the transition metal (the galvanized steel sheet) are realized, and connection of dissimilar metal between an aluminum alloy sheet and a magnesium alloy sheet is realized finally.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY +1

Magnesium-aluminum alloy and manufacturing method thereof

The invention provides a magnesium-aluminium alloy having an excellent synthetic mechanical performance and a method for preparing the same, wherein, the magnesium-aluminium alloy comprises the following components by weight: Al of 7-10%, Zn of 0.5-2%, Sn of 0.5-3%, Pb of 0.05-3.5% and Mg of the rest.The method for preparing the magnesium-aluminium alloy comprises steps of proportioning according to the mass percent of components that Al of 7-10%, Zn of 0.5-2%, Sn of 0.5-3%, Pb of 0.05-3.5% and Mg of the rest, mixing the proportioned pure Al ingots, Mg ingots, pure Sn bars, pure Pb blocks, Zn ingots in a protective atmosphere of N2 / CO2 / SF6, heating and melting them, volume ratio of N2 / CO2 / SF6 in the protective atmosphere being 8:16:76, and when the temperature increasing to 700-725DEG C, keeping the temperature for 4-8minutes, then cooling them to obtain the magnesium-aluminium alloy with high strength.The manufacture of the magnesium aluminium alloy only use common elements of stannum, plumbi, zincium and the like, avoid using large numbers of rare elements. The technique of preparing the magnesium aluminium alloy is simple and the cost of the alloy is low.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com