Magnalium special metal coating and preparation method thereof

A technology for dissimilar metals and coatings, which is applied in the field of preparation of dissimilar metal coatings, can solve the problem of not proposing a method for magnesium-aluminum intermetallic compounds, etc., and achieve the effects of improving hardness and corrosion resistance, low cost, and improved corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1 Preparation of magnesium-aluminum dissimilar metal coating by arc spraying on the surface of aluminum alloy

[0025] The aluminum-silicon casting alloy ZL102 is selected as the substrate to be protected, and the surface is sandblasted with 30 mesh alumina particles to remove surface oxides and dirt to achieve a cleanliness and roughness suitable for spraying.

[0026] The spraying electrode adopts high-purity magnesium wire with a magnesium content of more than 99.7% and a high-purity aluminum wire with an aluminum content of more than 99.7%, both of which have a diameter of 2.0mm.

[0027] Use the DPT302 high-speed arc spraying machine, the arc spraying process parameters are: spraying voltage 28V, current 150A, spraying distance 150mm, air pressure 0.6MPa.

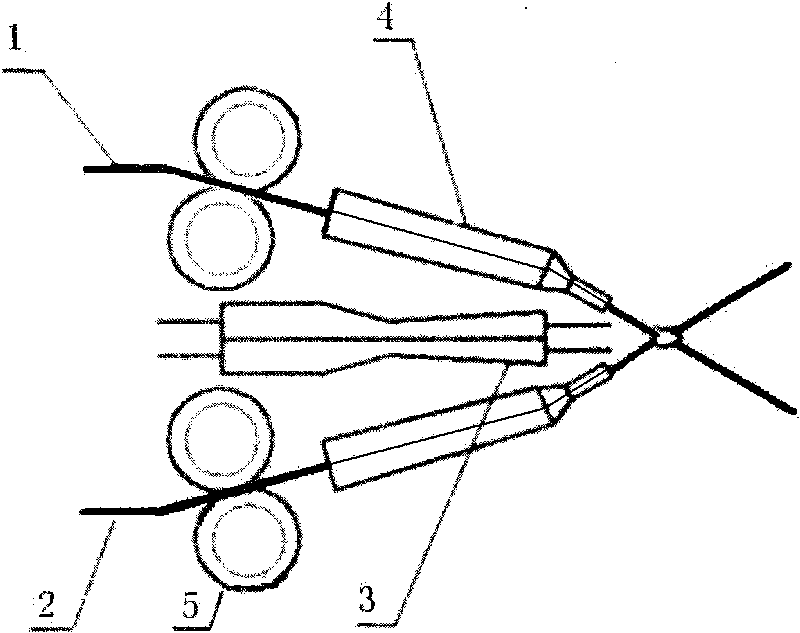

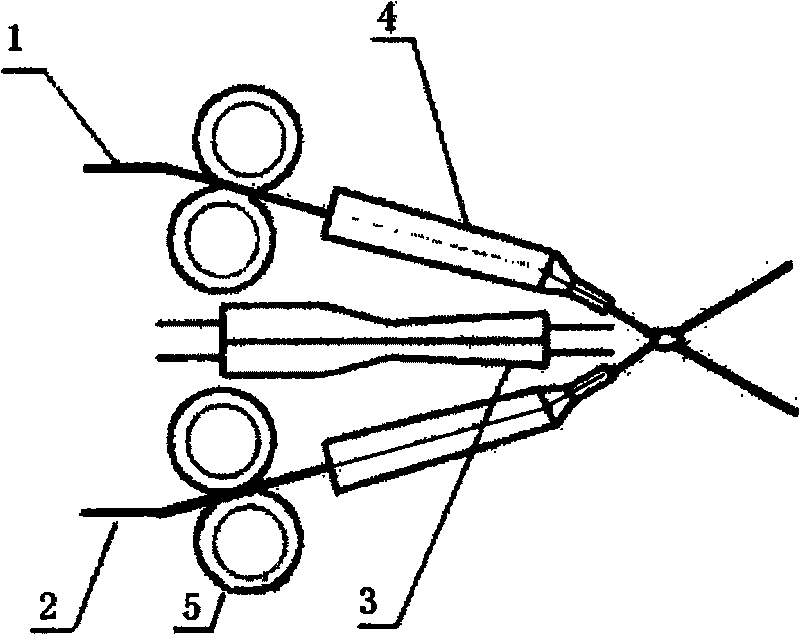

[0028] Such as figure 1 As shown, the magnesium wire 1 and the aluminum wire 2 are used as two electrodes, which are controlled by the wire feed wheel 5 to enter the contact tip 4 respectively. After th...

Embodiment 2

[0031]Example 2 Preparation of magnesium-aluminum dissimilar metal coatings by arc-spraying magnesium on the surface of aluminum alloy

[0032] The selection of the substrate to be protected and the surface treatment before spraying are the same as in Example 1.

[0033] The spraying electrode adopts magnesium alloy wire (96.8%Mg+3%Al+0.2% impurity) with a diameter of 1.6mm, and aluminum wire (99.7%Al+0.3% impurity) with a diameter of 2.0mm.

[0034] Use the DPT302 high-speed arc spraying machine, the arc spraying process parameters are: spraying voltage 29V, current 160A, spraying distance 160mm, air pressure 0.7MPa.

[0035] The spraying process is the same as in Example 1, and the obtained coating composition and its weight ratio are: Mg22-25%, Al74-77%, other 2-10% (mainly oxygen).

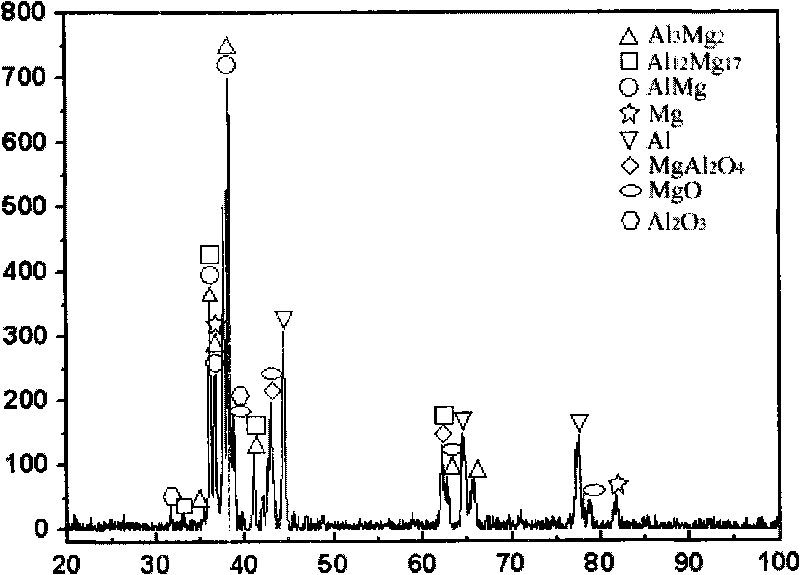

[0036] The coating is heat-treated at 420°C for 50 minutes in an argon-filled heat treatment furnace. According to XRD detection, the coating structure is rich in Al 12 Mg 17 Phase and Al ...

Embodiment 3

[0038] Example 3 Preparation of Magnesium-Al Alloy Dissimilar Metal Coating by Plasma Spraying on Aluminum Alloy Surface

[0039] The selection of the substrate to be protected and the surface treatment before spraying are the same as in Example 1.

[0040] The raw materials for spraying are magnesium powder and aluminum powder with a purity higher than 99.9% and a particle size of 10 μm, and the volume ratio is 1:6.

[0041] Using ZB-80 plasma spraying machine, the process parameters are spraying current 500A, voltage 50V, Ar flow rate 60L / min, H 2 The flow rate is 6L / min, the powder feeding rate is 3.0Kg / h, and the spraying distance is 150mm.

[0042] The magnesium-aluminum mixed powder is sent into the flame flow part through the powder feeding system to generate a plasma flame flow, and an aluminum-magnesium metal coating with high bonding strength and dense coating structure is prepared on the surface of the aluminum alloy substrate. The composition and weight ratio of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com