Patents

Literature

3016 results about "Diameter ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Diameter ratio. The ratio between the distance an aircraft moves from one revolution of the propeller(s), under specified conditions, and the propeller diameter. Also known as an advance ratio.

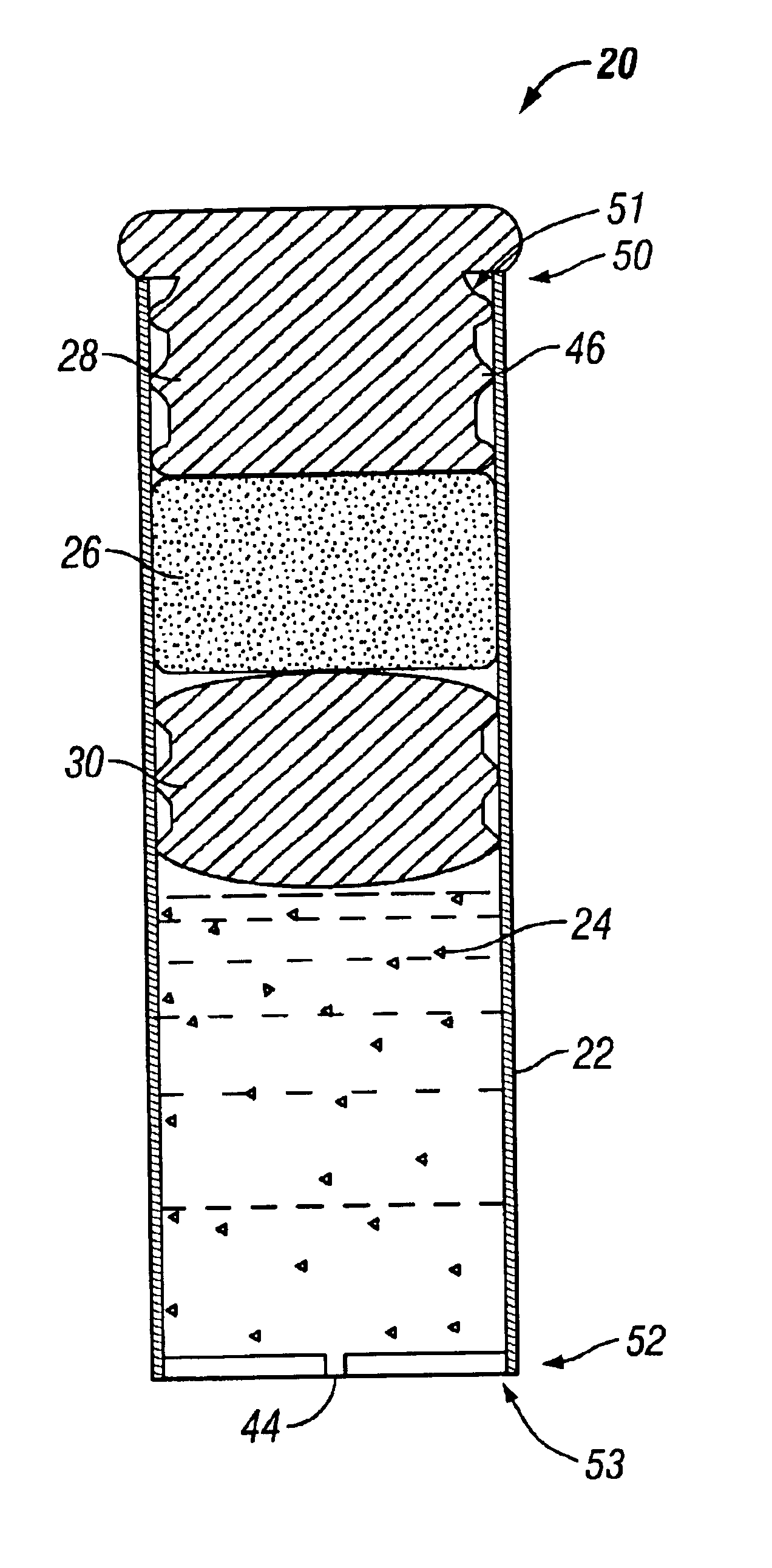

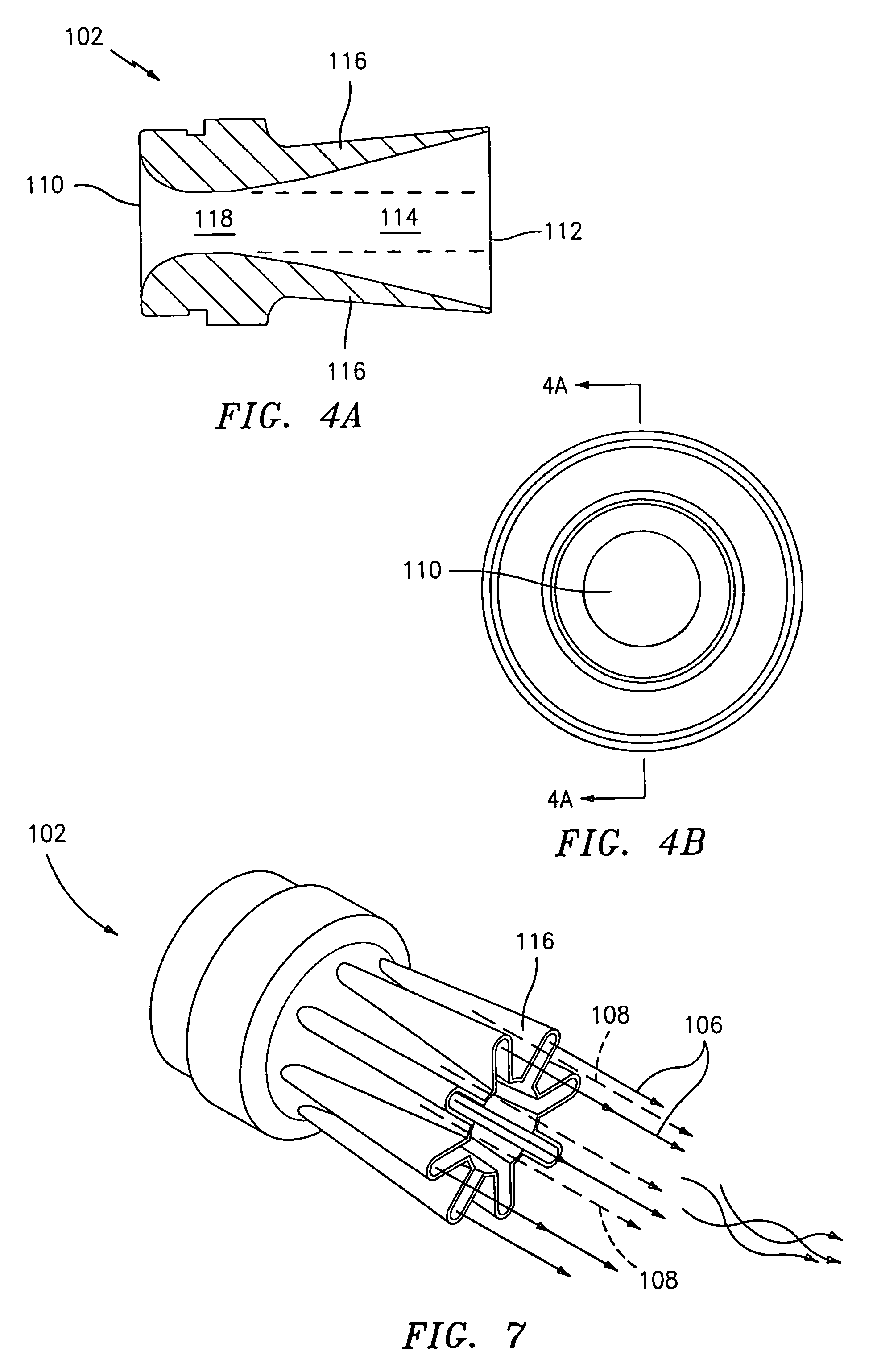

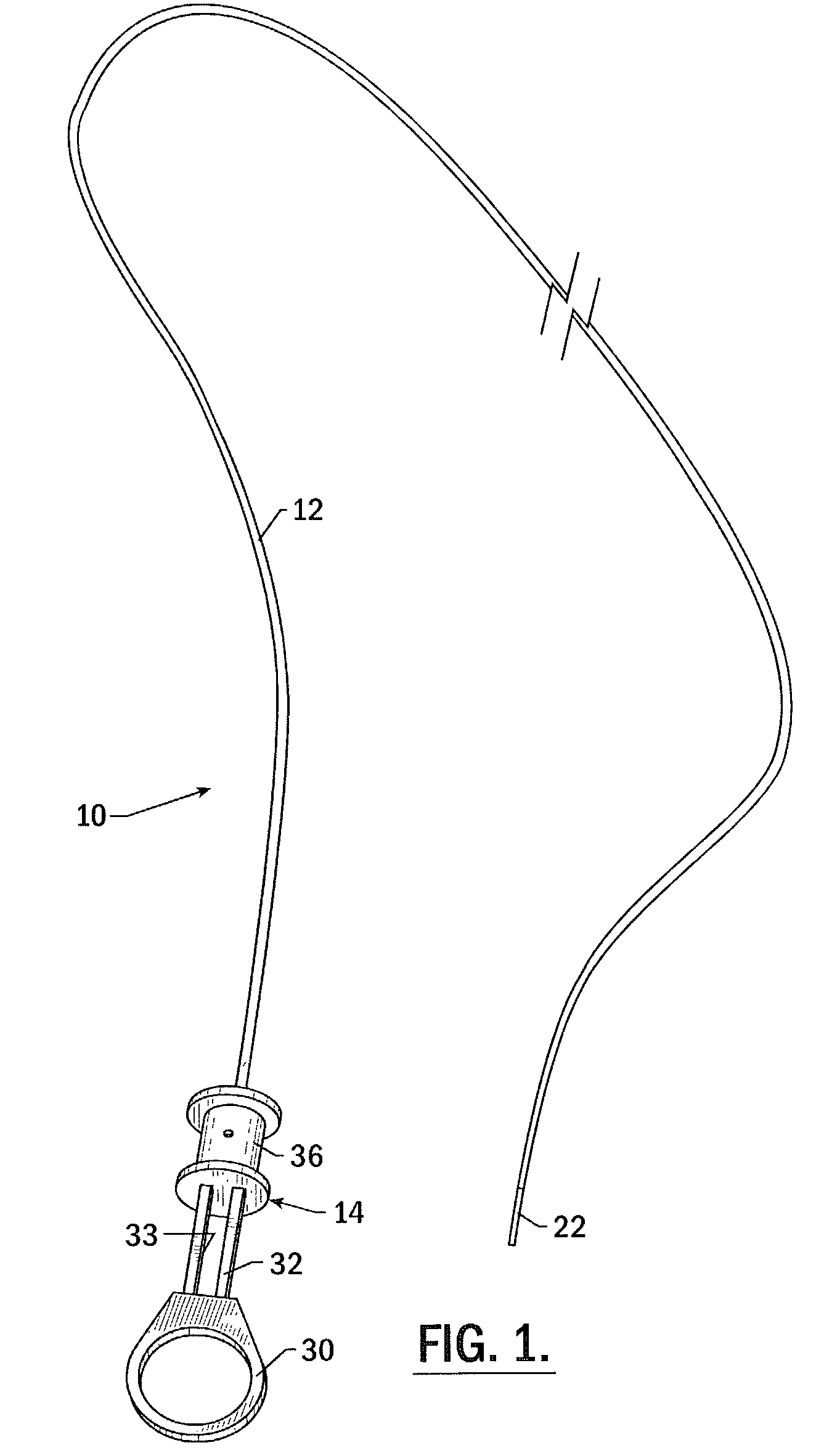

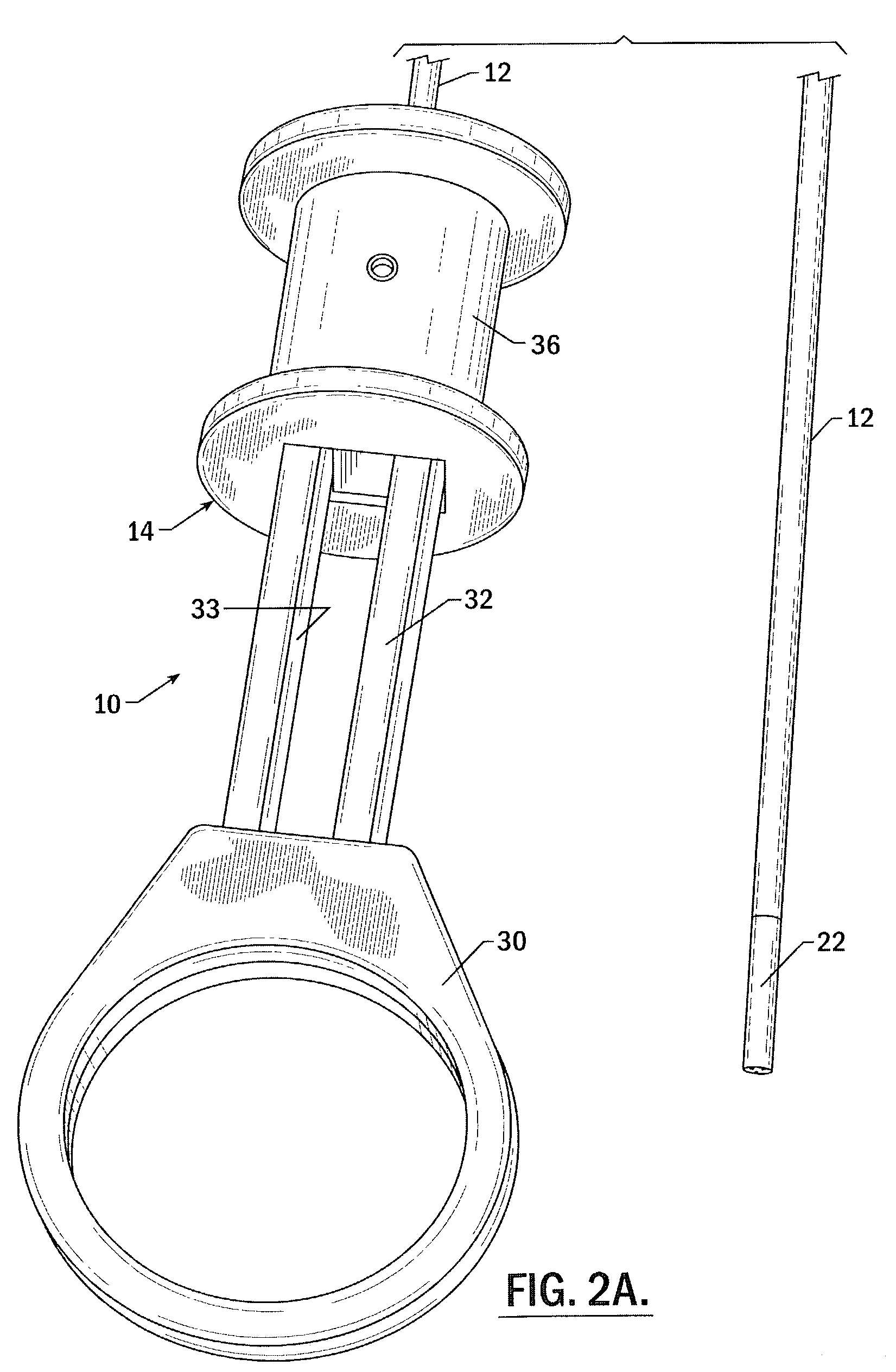

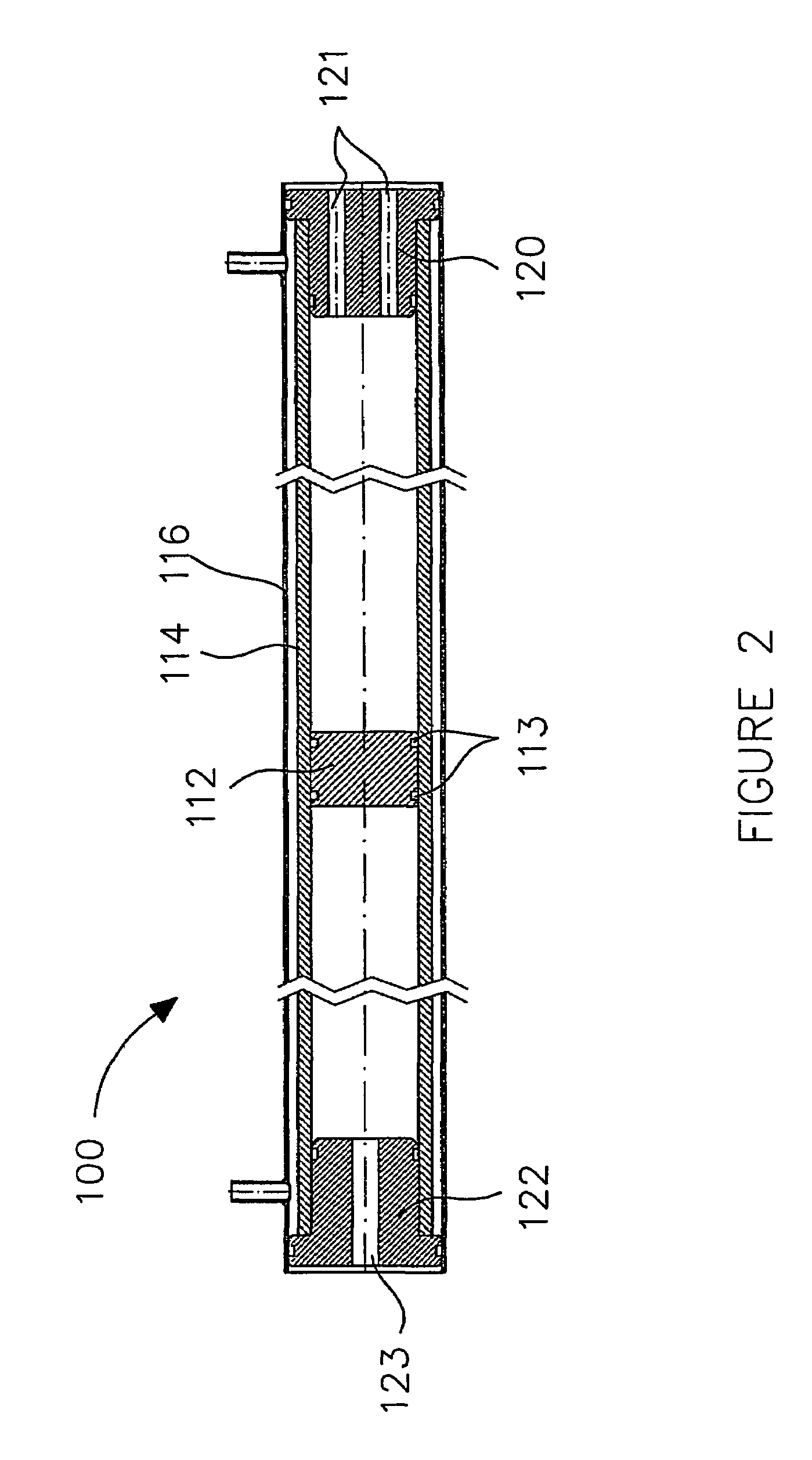

Minimally compliant, volume efficient piston for osmotic drug delivery systems

ActiveUS6939556B2Improve space efficiencyIncrease in sizeMedical devicesPressure infusionDiameter ratioOsmotic pump

An osmotic pump having a minimally compliant, volume-efficient piston positioned within a capsule is provided. The capsule has an interior surface, a beneficial agent, and an osmotic agent. The piston is movable with respect to an interior surface of the capsule, and defines a movable seal with the interior surface of the capsule. The movable seal separates the osmotic agent from the beneficial agent. The piston has a length-to-total-diameter ratio of about 1.1:1 and a core-diameter-to-total-diameter ratio of about 0.9:1. The piston enables greater beneficial agent and / or osmotic agent payload without increasing the size of the capsule. The osmotic agent imbibes liquid from a surrounding environment through a semipermeable body to cause the piston to move and, in turn, cause delivery of the beneficial agent from the capsule.

Owner:INTARCIA THERAPEUTICS INC

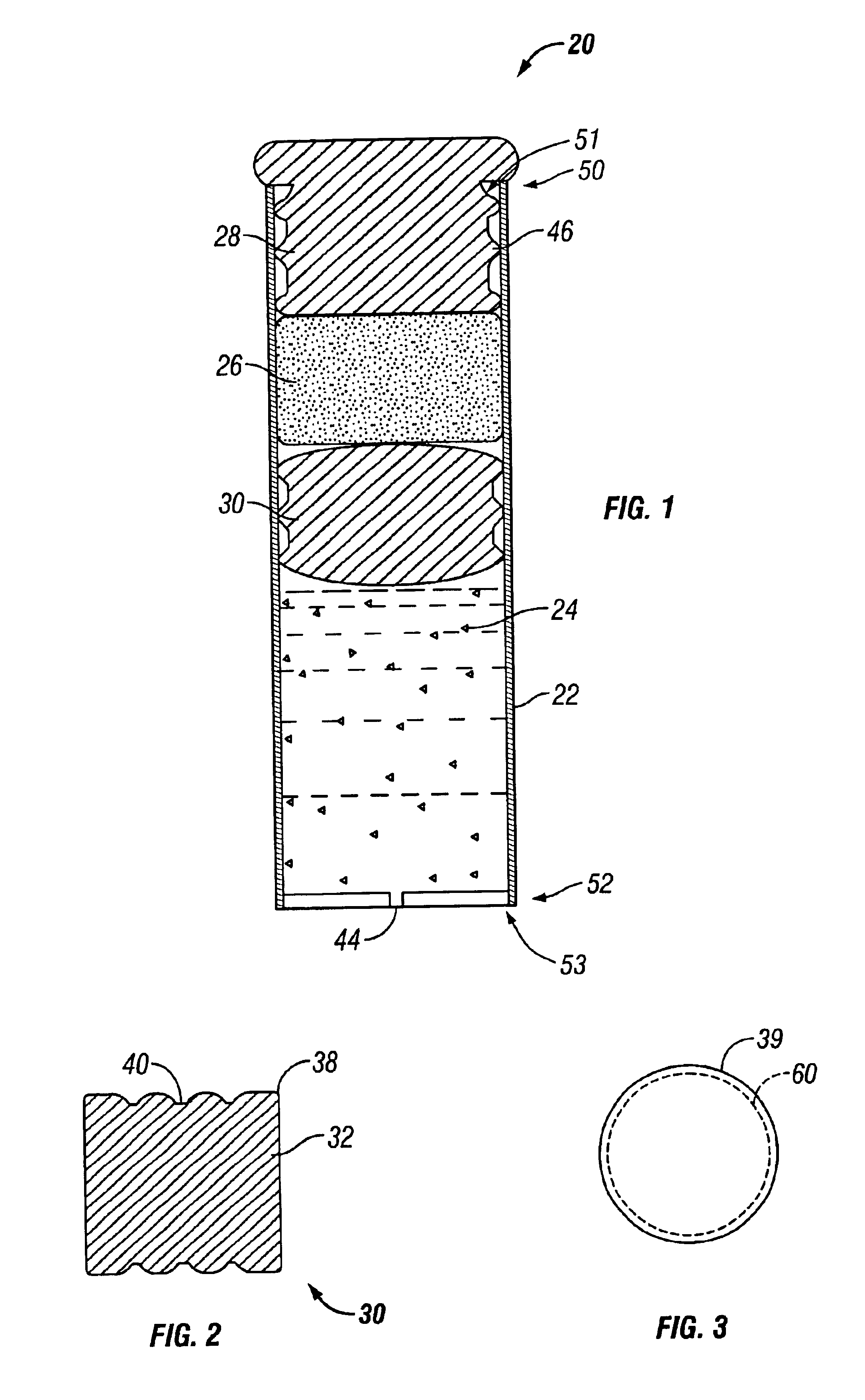

Method for gas-solid contacting in a bubbling fluidized bed reactor

InactiveUS6894183B2Eliminate and drastically reduce bypassEffective contactThermal non-catalytic crackingCatalytic crackingForming gasSolid particle

Owner:COUNCIL OF SCI & IND RES

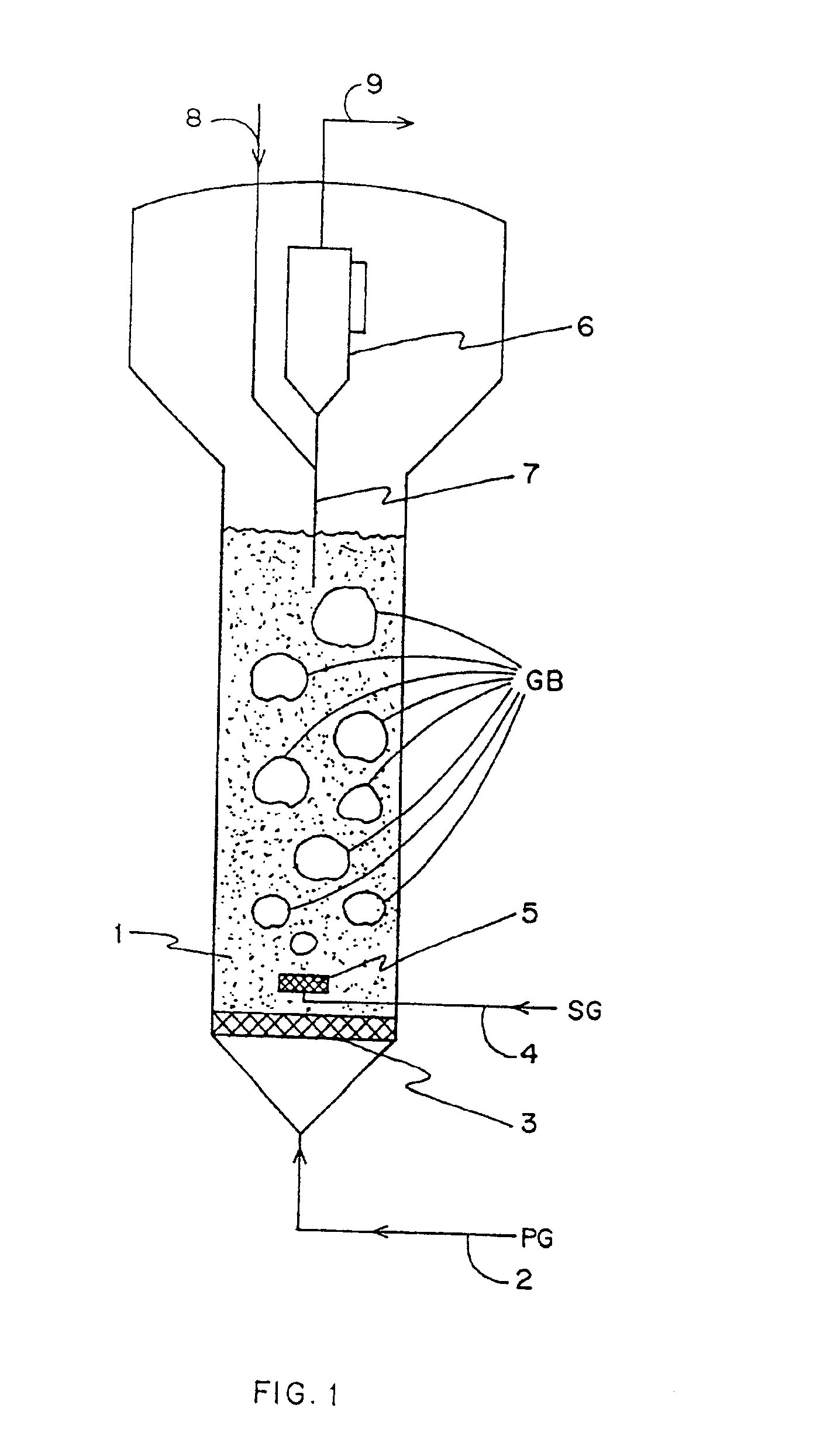

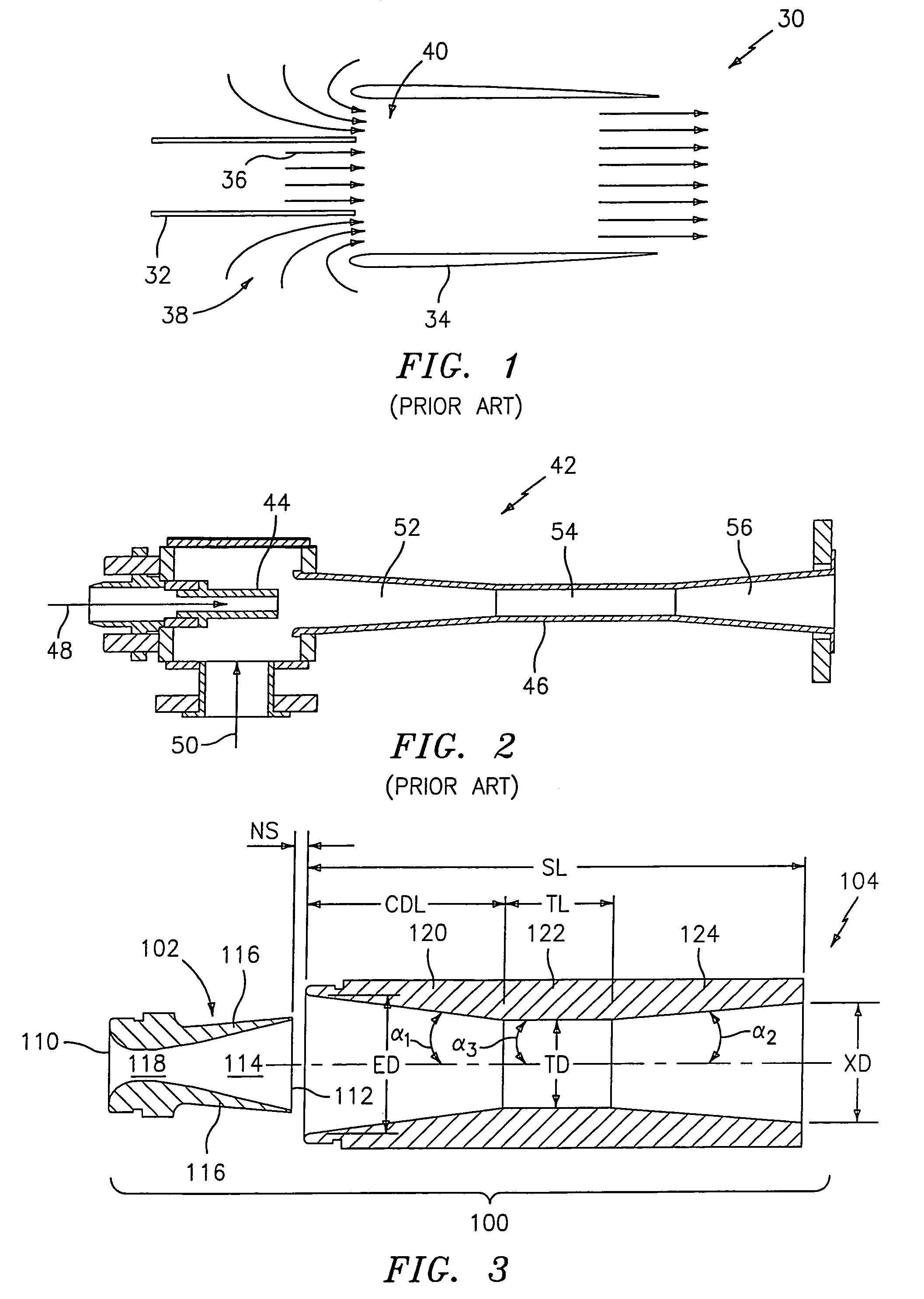

Lobed convergent/divergent supersonic nozzle ejector system

InactiveUS6877960B1Smaller length-to-entrance-diameter ratioIncrease flow pressureJet pumpsMachines/enginesDiameter ratioHigh pressure

An ejector system comprises a lobed, supersonic primary nozzle and a convergent / divergent ejector shroud. The lobed nozzle is just upstream from the ejector shroud, such that there is an annular space between the nozzle and shroud for admitting a secondary flow. In operation, a primary flow of high-pressure steam or air is directed through the primary nozzle, where it is accelerated to supersonic speed. The primary flow then exits the primary nozzle, where it entrains and is mixed with the secondary flow, creating a low pressure region or vacuum. The ejector shroud subsequently decelerates the combined flow while increasing the flow pressure, which increases suction performance and reduces energy loss. Because the primary nozzle mixes the two flows, the ejector shroud is able to have a length-to-entrance-diameter ratio significantly smaller than typical shrouds / diffusers, which decreases the system's size and increases performance.

Owner:FLODESIGN WIND TURBINE

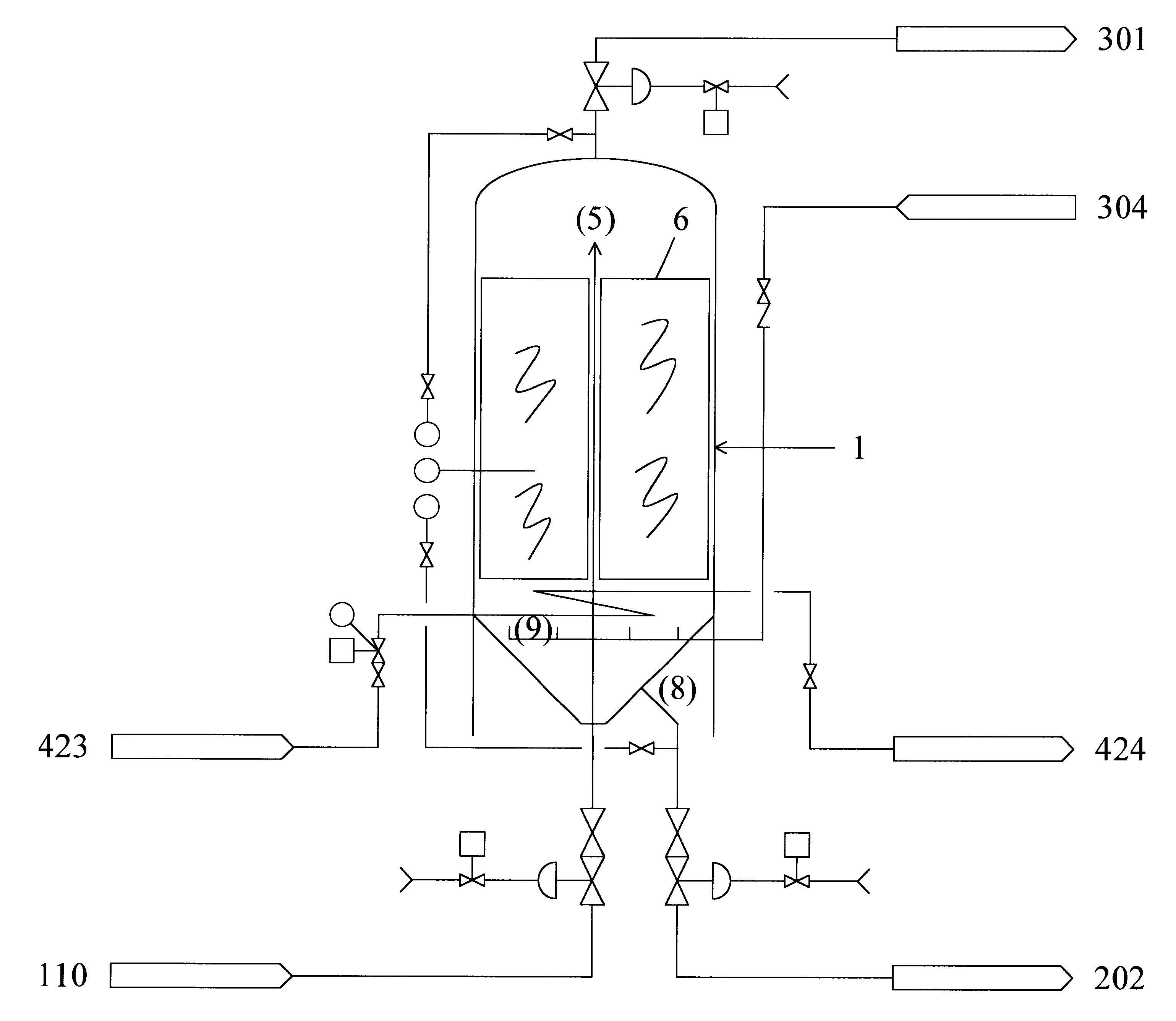

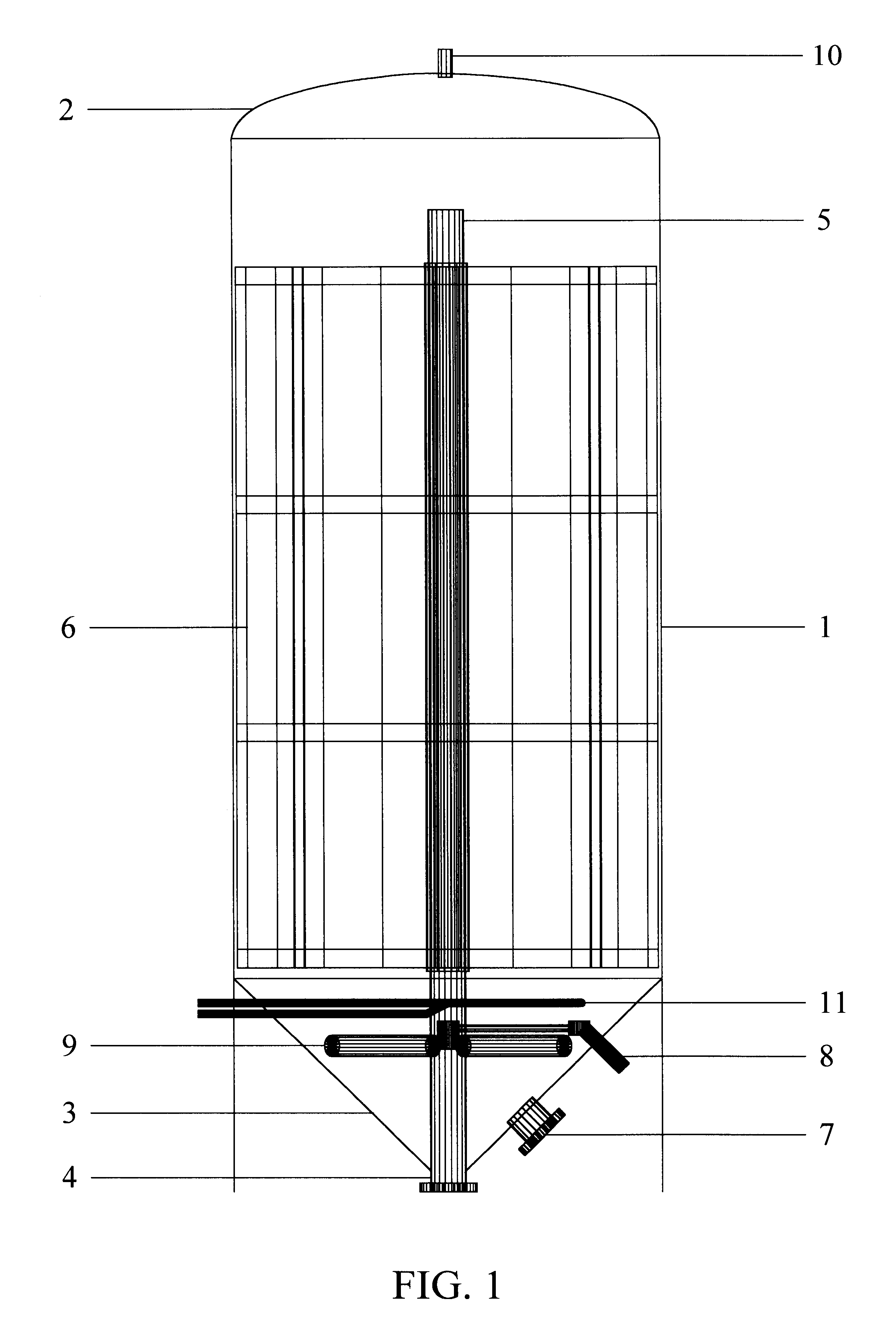

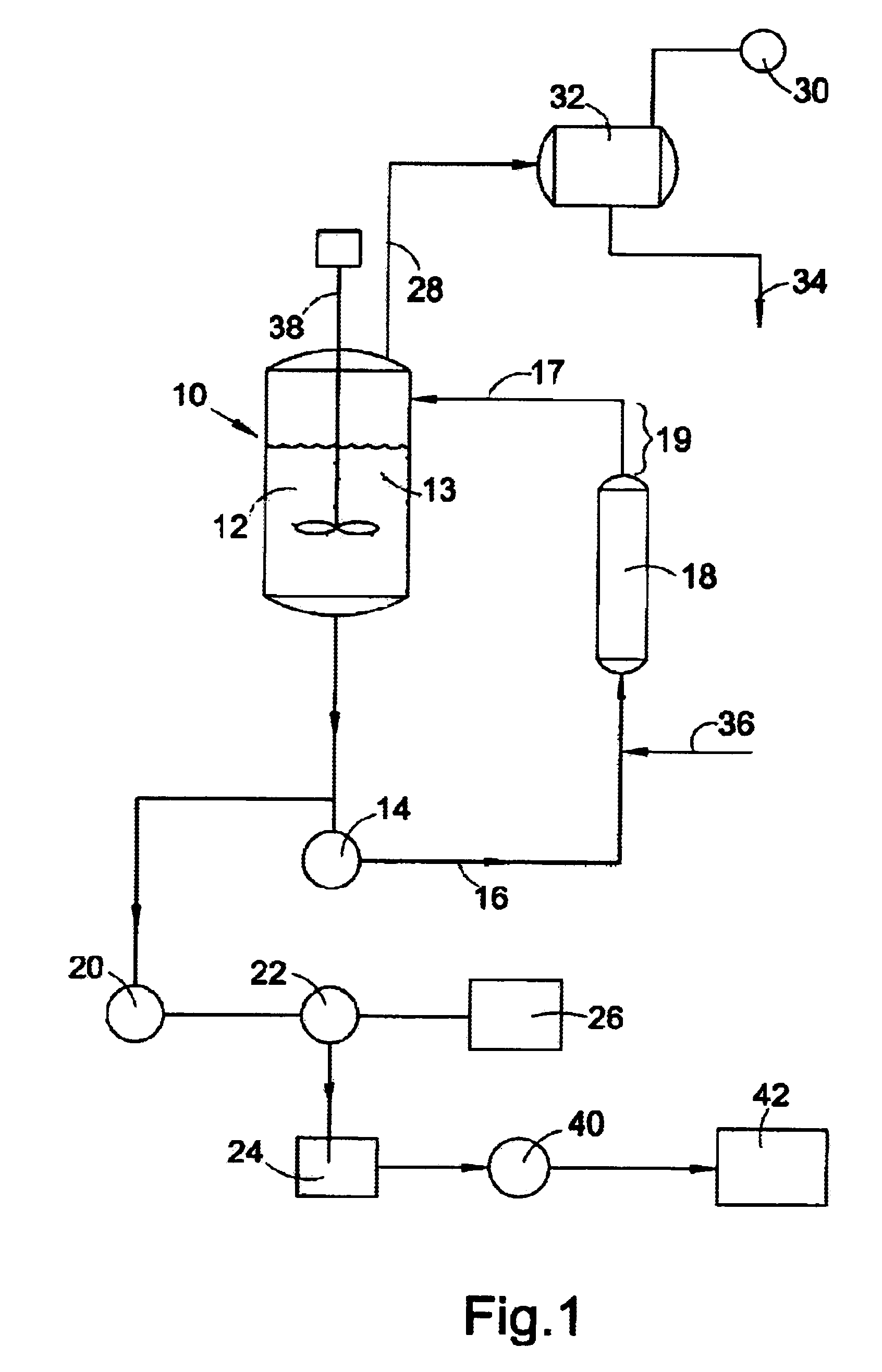

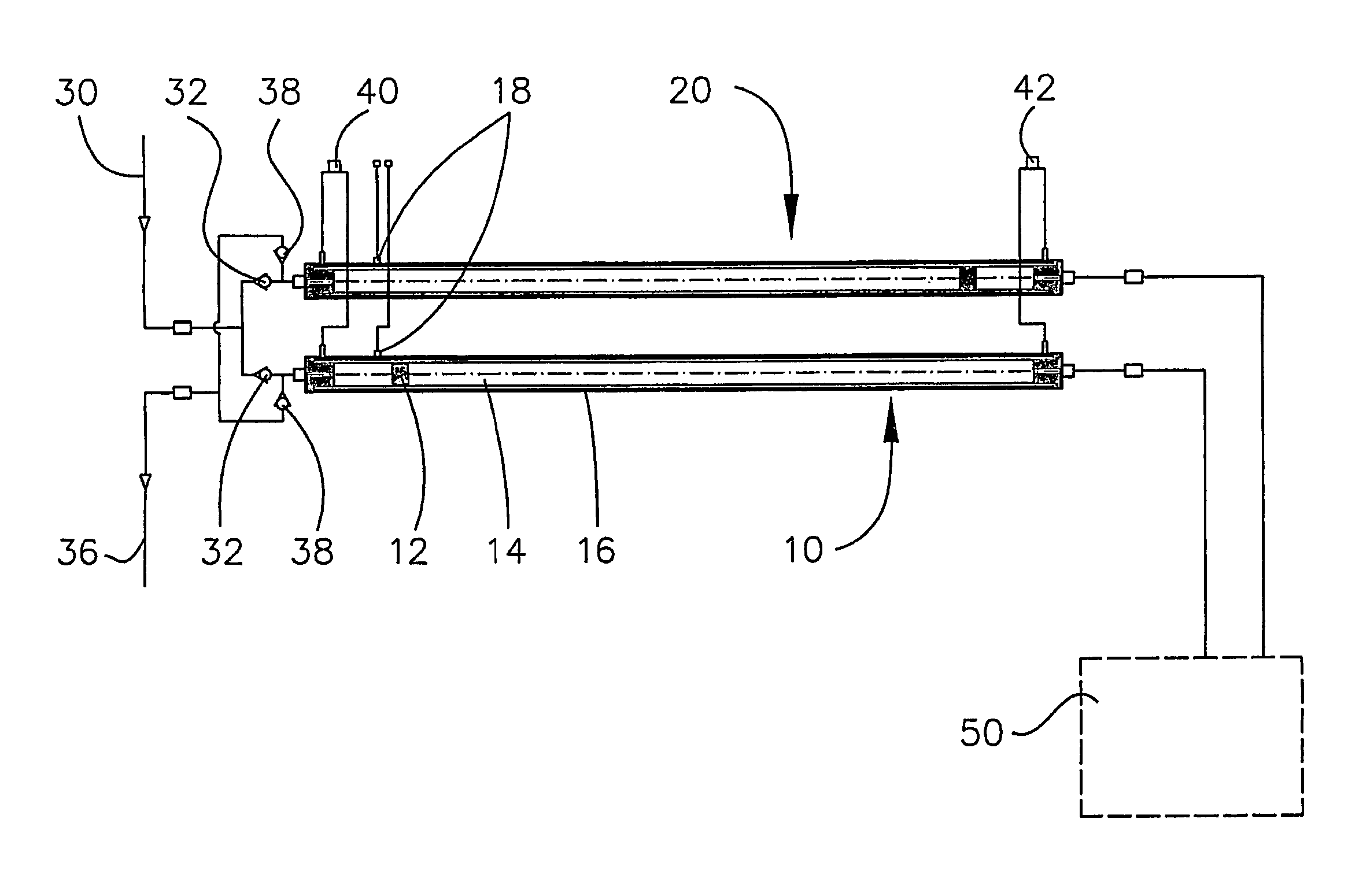

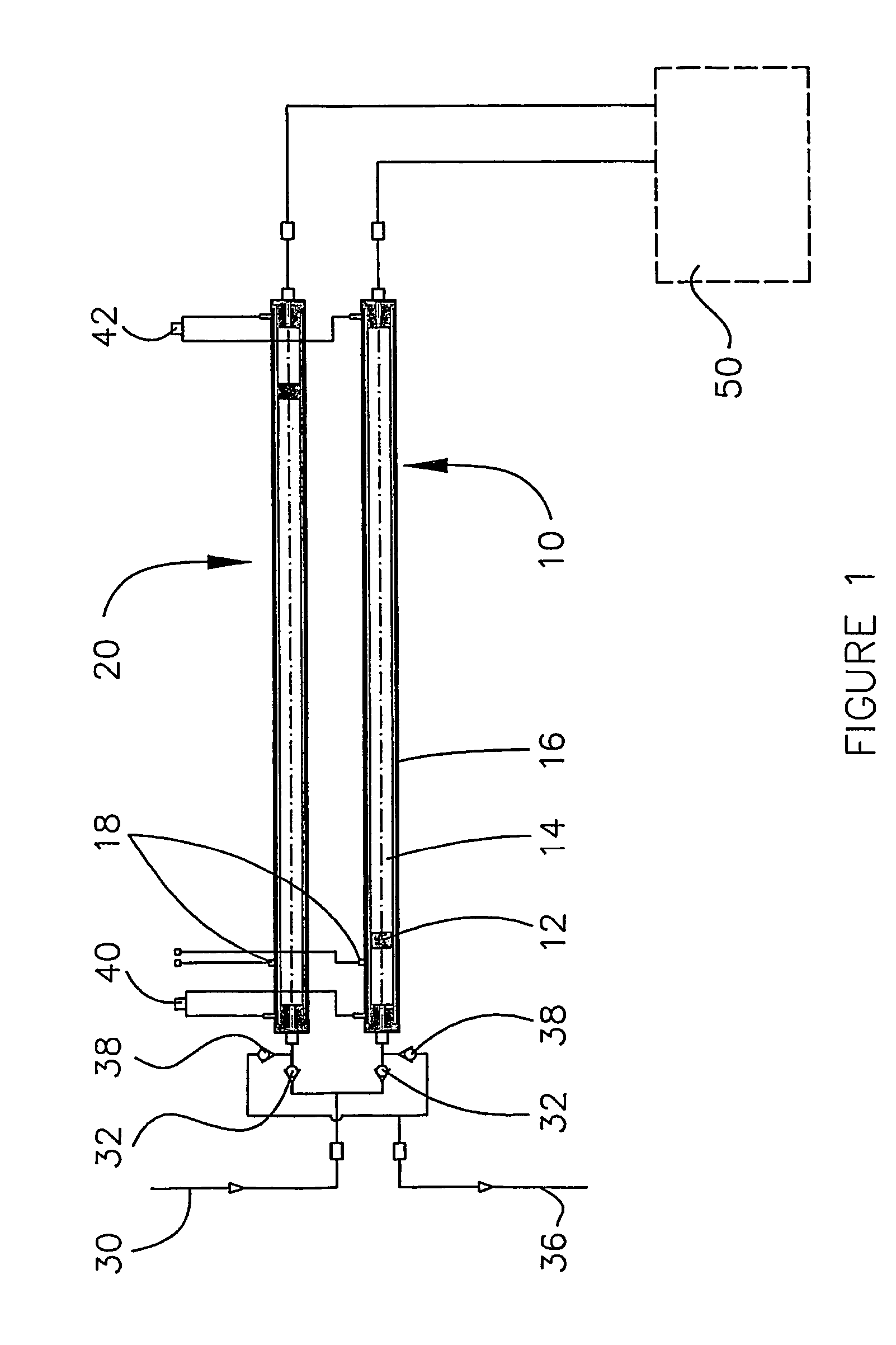

Anaerobic digester system and method

InactiveUS6254775B1High densityIncrease alkalinityGas production bioreactorsTreatment with aerobic and anaerobic processesSlurryMethane gas

An anaerobic digester system has a vertically upright vessel, a matrix arranged in the vessel supporting a microorganism biomass thereon, an input for supplying an input slurry of liquid and suspended solids at an upper portion of the vessel above the matrix, a gas output at the top of the vessel for withdrawing gas generated by anaerobic digestion of solids, and an effluent output at the bottom of the vessel for withdrawing liquid and remaining solids. The vessel has a preferred liquid height to diameter ratio of 2 to 1, and is constructed of inert fiberglass-reinforced plastic coated with a translucent blue gel pigment layer for filtering light at wavelengths that promote biomass cultivation. The matrix is formed as an array of panels mounted to a spindle with wheels fixed at spaced intervals along its vertical height, and the panel are made of a polyethylene grass matting providing a high surface area to volume ratio of at least 20 to 1. Gas from the top of the vessel is recycled to the bottom to generate bubbles for mixing the feedstock. The related method of anaerobic digestion includes comminuting input wastes with a slurry grinder into a pumpable slurry 8-10 % by weight solids, and providing as the biomass hydrolytic bacteria, and fermentative bacteria including acetogenic and methanogenic bacteria to produce a methane gas product. Other products include an organic soil additive, bacterial solids plant food, and a filtrate used as plant tonic.

Owner:RENERGY

Heat conductive insulation material and preparation method thereof

InactiveCN101899209AExcellent formabilityImprove insulation performanceLiquid crystal compositionsPlastic/resin/waxes insulatorsFiberMetallurgy

The invention discloses a heat conductive insulation material and a preparation method thereof. The heat conductive insulation material comprises the following components in percentage by weight: 15 to 50 percent of plastic substrate, 15 to 45 percent of heat conductive insulation filler A, 5 to 15 percent of heat conductive filler B, 10 to 30 percent of mineral fiber C, 0 to 2 percent of coupling agent and 0 to 2 percent of lubricant. The heat conductive insulation material has the advantages of perfect forming processing performance, high heat conductivity, higher uniformity and a small amount of gas content during processing; heat conductive fillers with different length-diameter ratios are combined, fillers with a large length-diameter ratio are arranged in melt flowing direction, and fillers with a small length-diameter ratio fill gaps left when the fillers with the large length-diameter ratio are arranged, so that the number of interfaces among filler components is greatly reduced, a conduction network is formed more easily, and heat conductivity is remarkably increased; moreover, the mineral fiber is added during the second machining process, so that the loss of material performance can be compensated due to the addition of high-powder fillers, and performance is better.

Owner:KINGFA SCI & TECH CO LTD +1

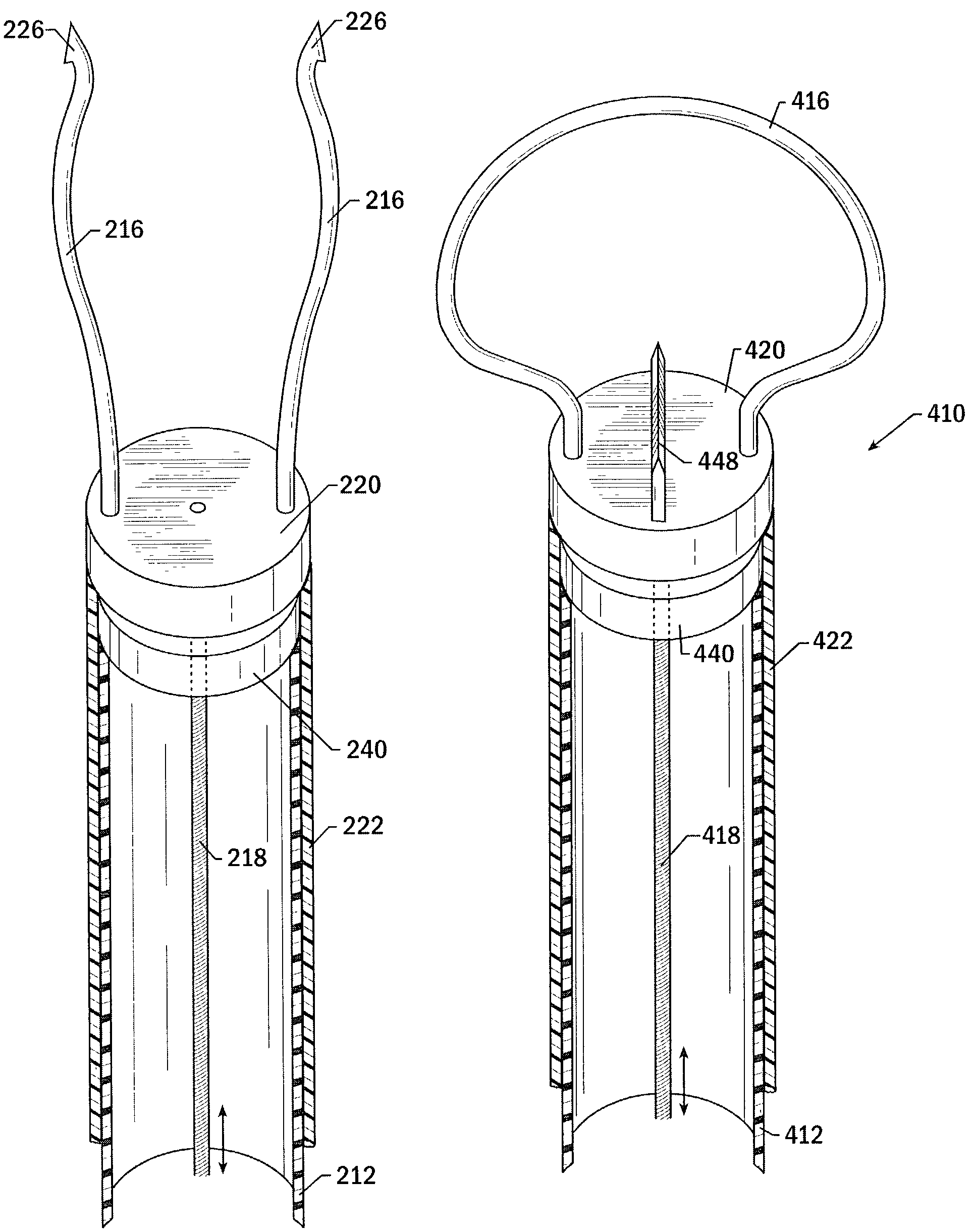

Controlled - motion endoscopic grasping instrument

InactiveUS7294139B1Complicating abilityComplicating to maneuverDiagnosticsSurgical needlesDiameter ratioEndoscopic Procedure

An improved controlled-motion instrument is provided for grasping, holding or otherwise manipulating an object in operations such as endoscopic procedures. The instrument opens and closes jaws or other manipulation members by way of a longitudinally movable cam member, but maintains the longitudinal position of the manipulation members constant relative to the instrument's body regardless of opening and closing motion. The manipulation members thus have increased length-to-diameter ratio and column strength, and the cam provides positive lateral jaw support and stability during opening and closing. The movable cam member can also include other manipulation members thereon that work in conjunction with the longitudinally fixed manipulation members.

Owner:C M WRIGHT INC

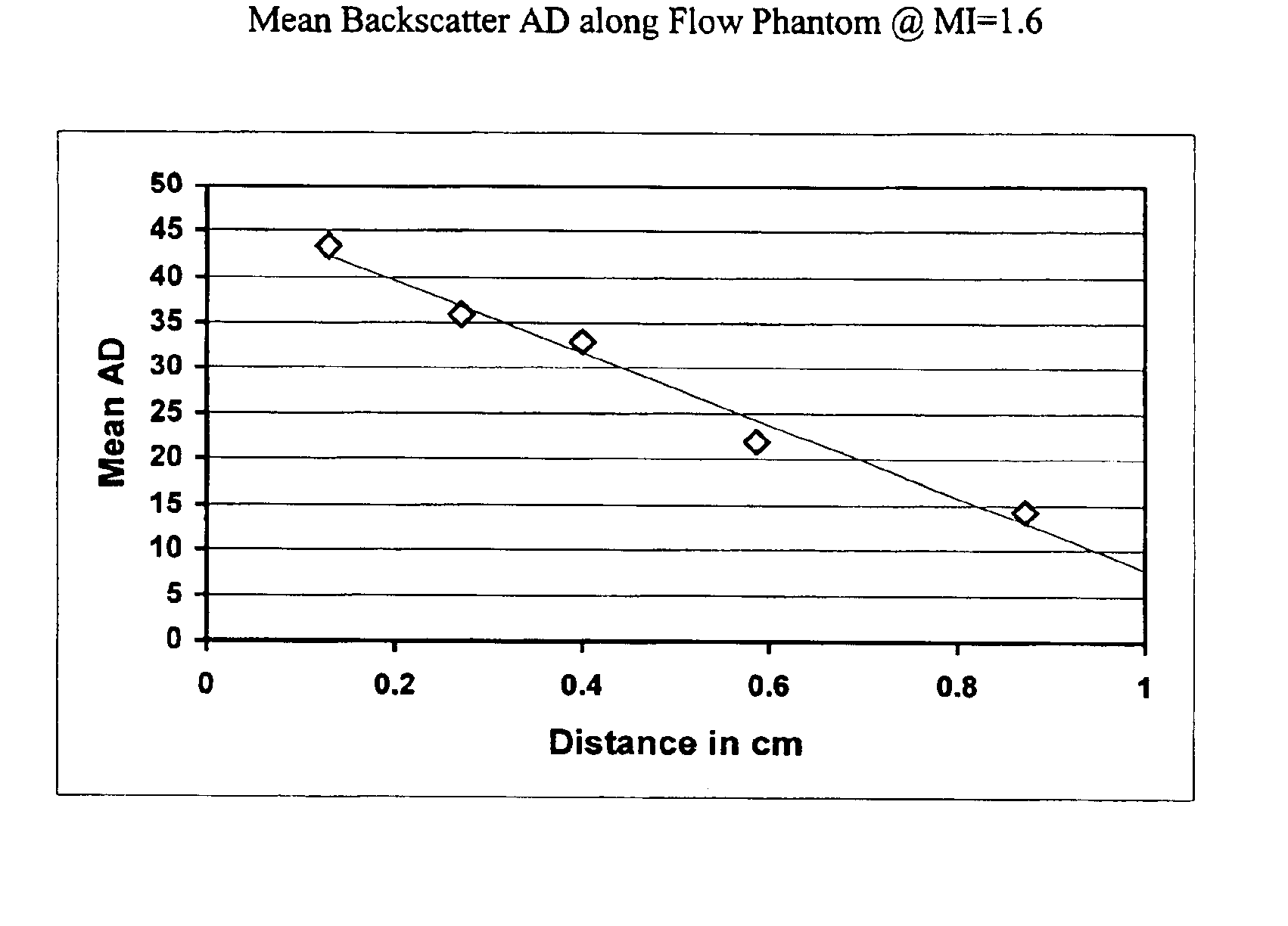

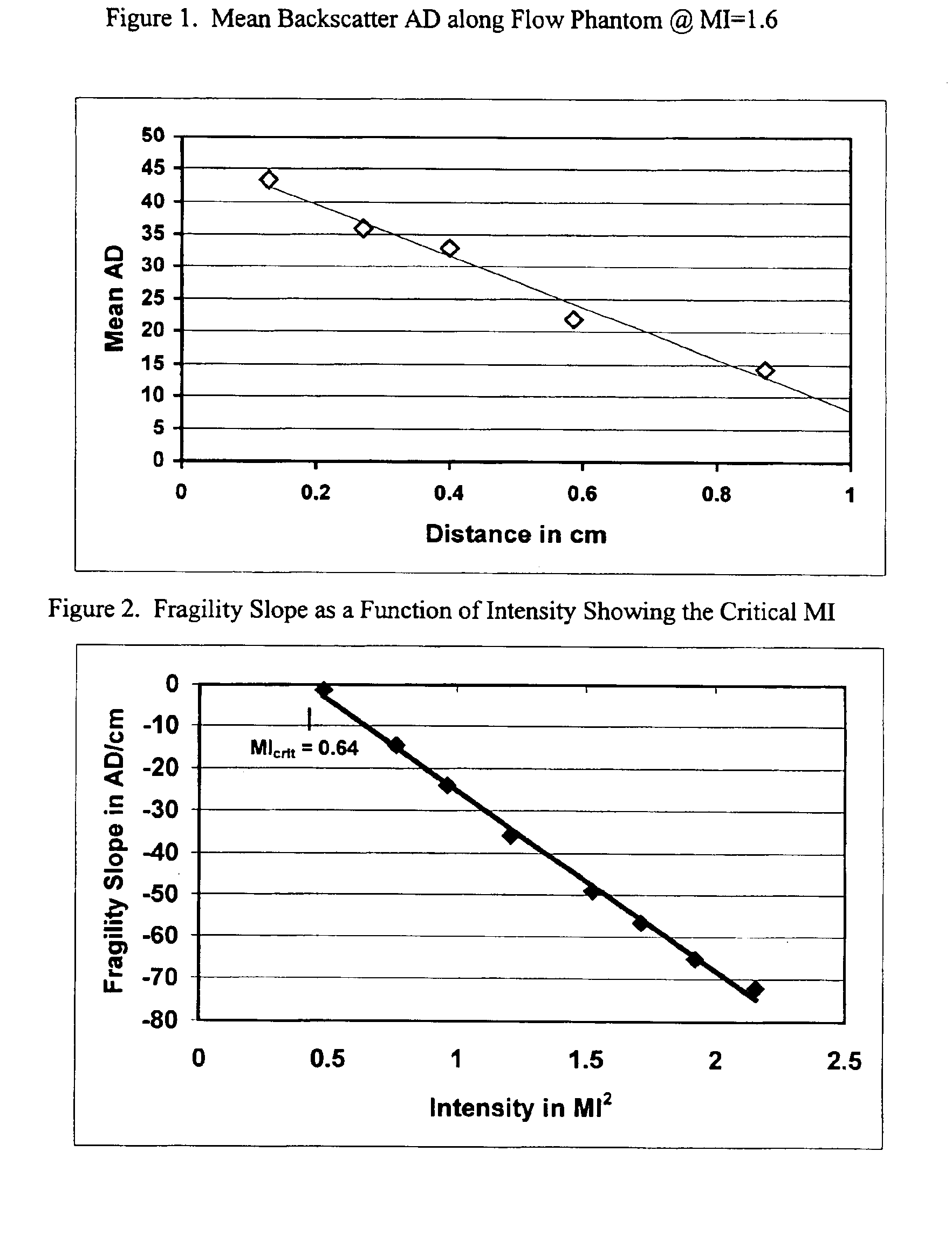

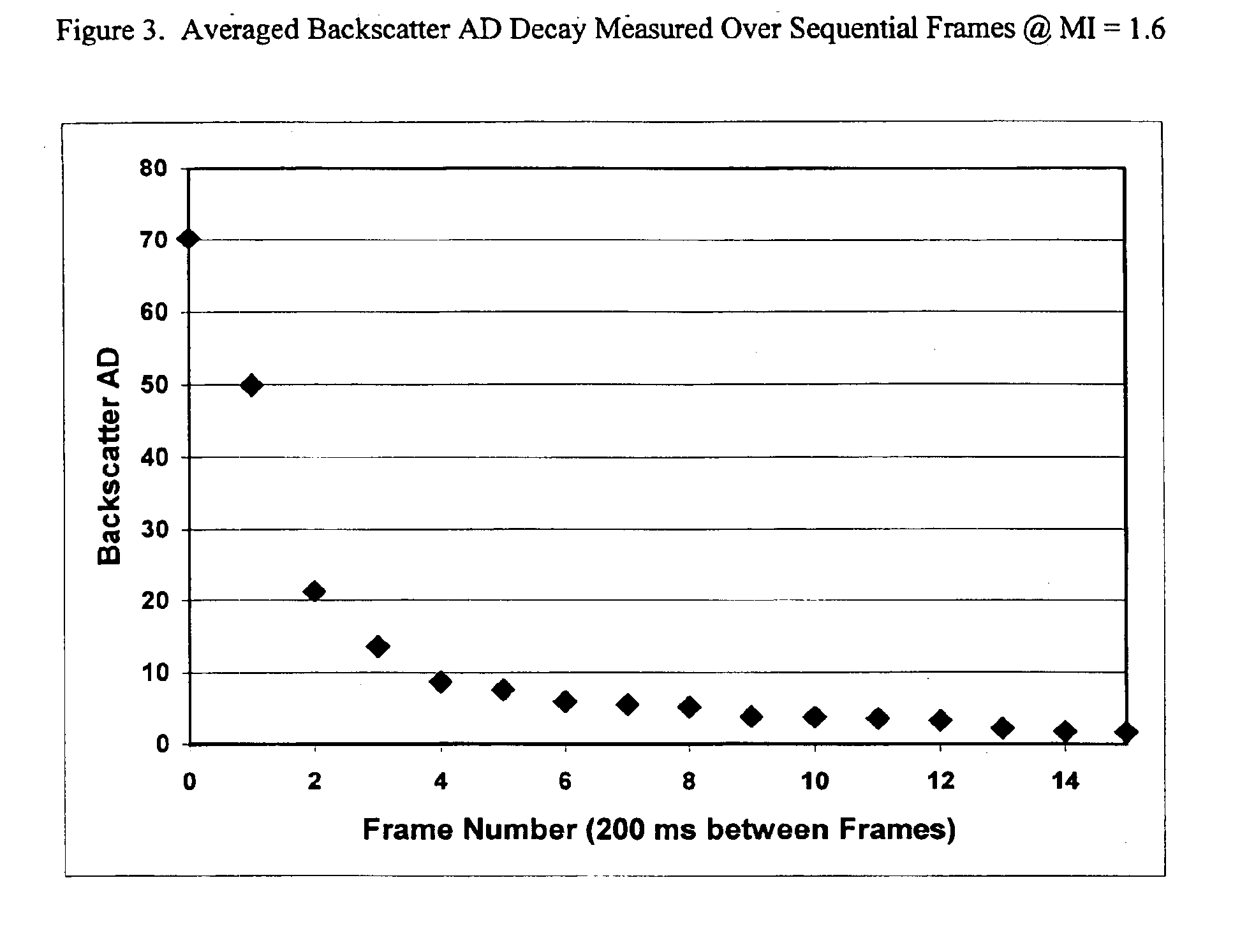

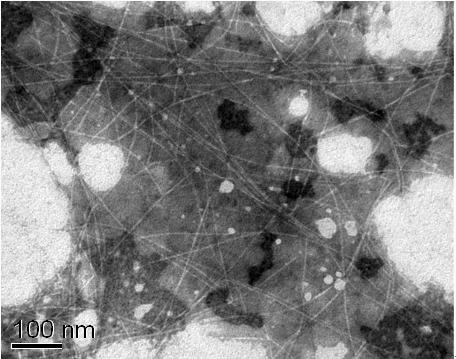

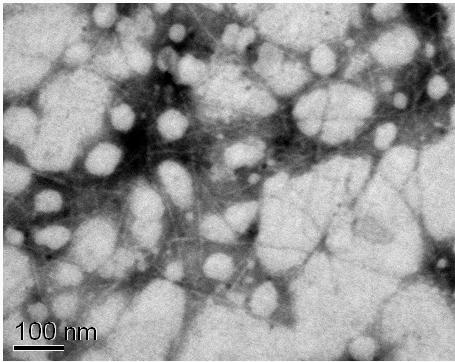

Method for ultrasound triggered drug delivery using hollow microbubbles with controlled fragility

InactiveUS6896659B2Ultrasonic/sonic/infrasonic diagnosticsChiropractic devicesMicrobubblesDiagnostic agent

Owner:UNIVERSITY OF PITTSBURGH

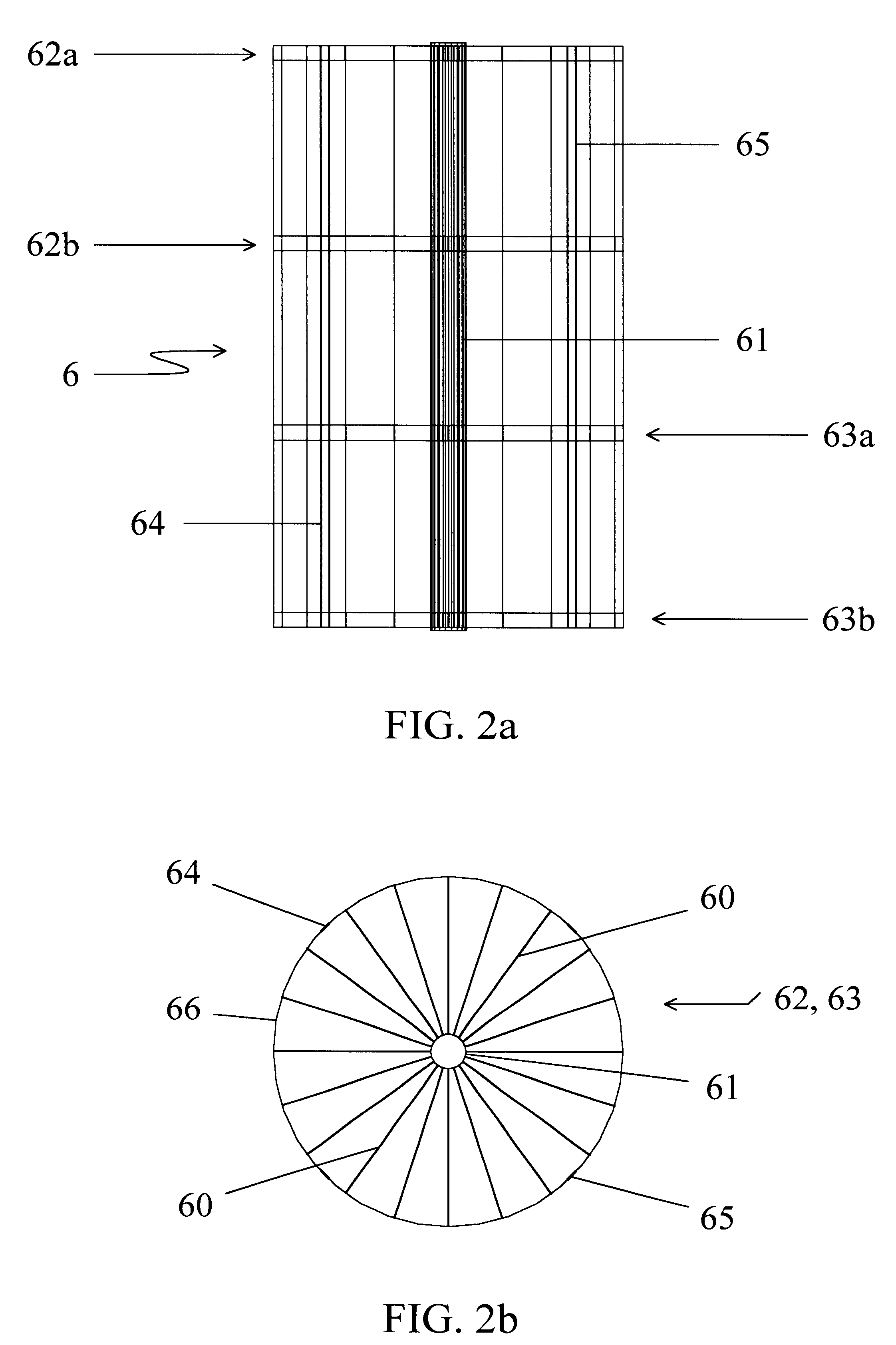

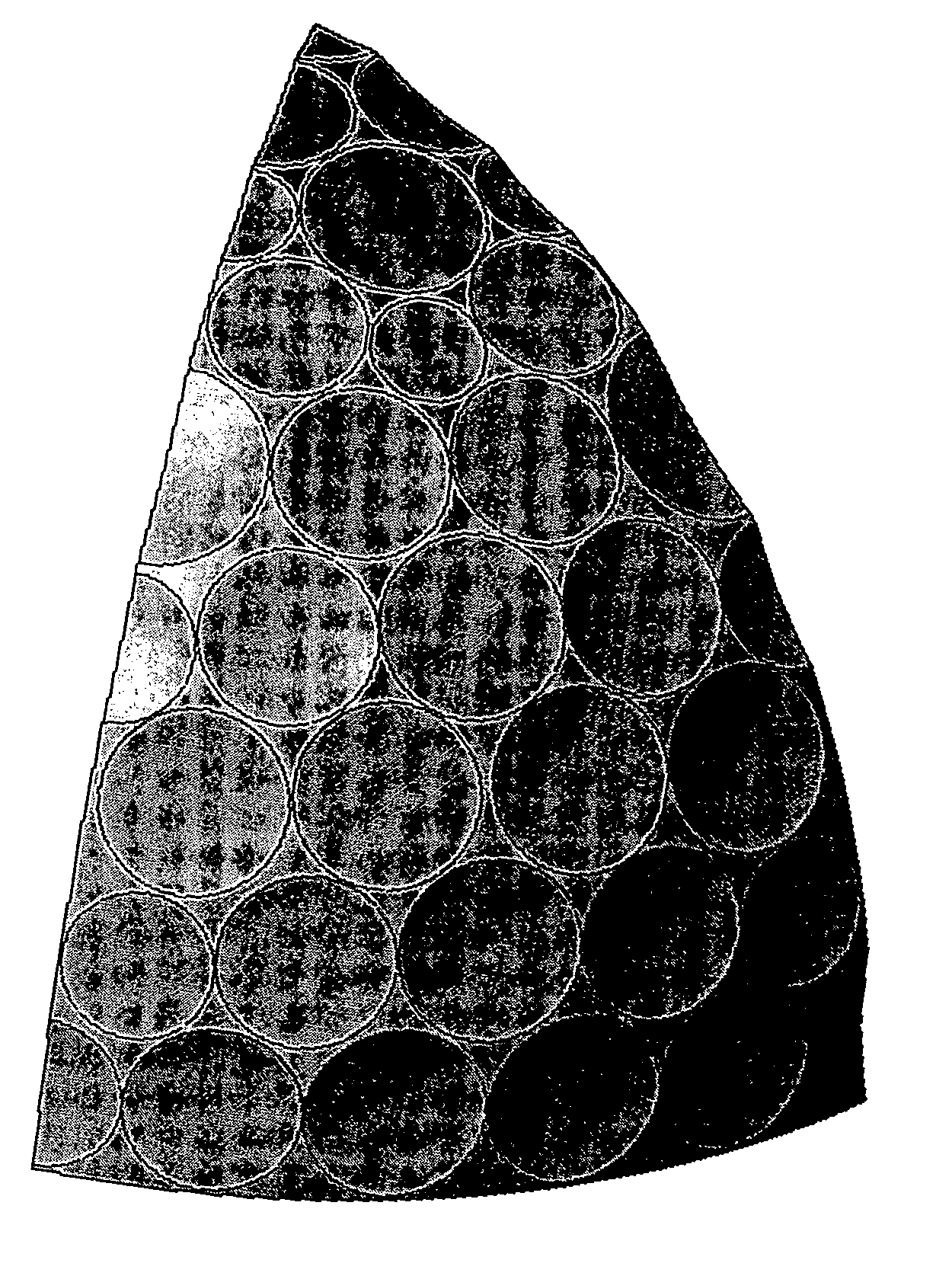

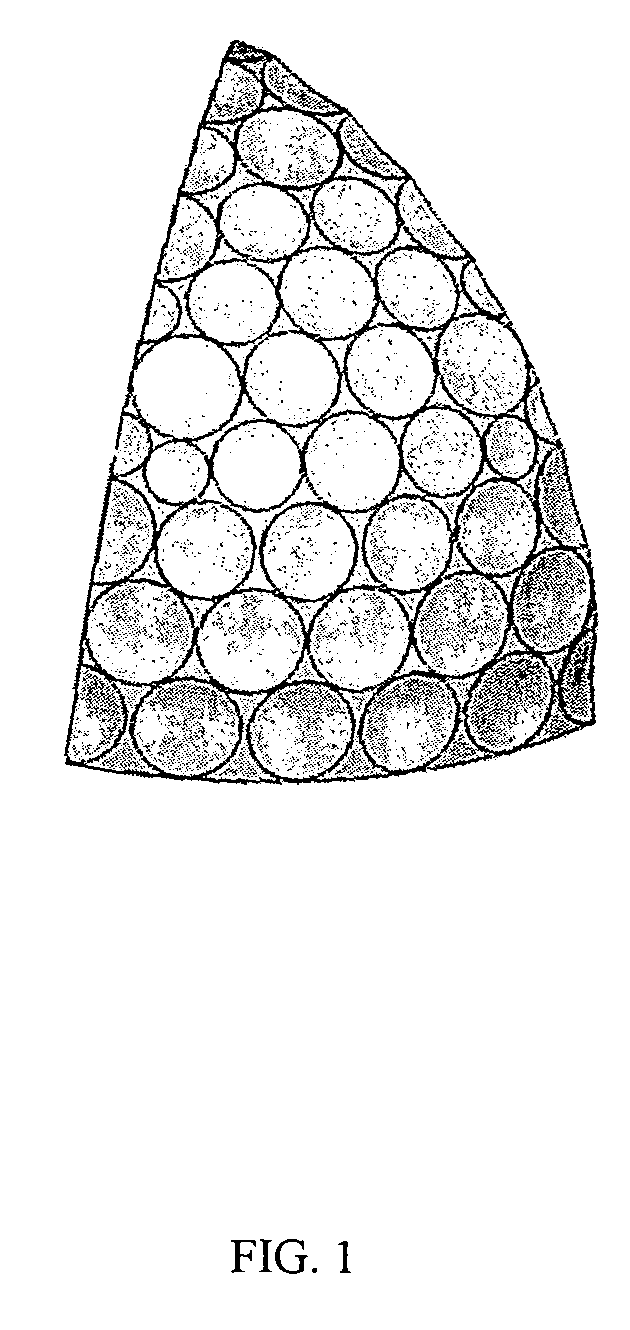

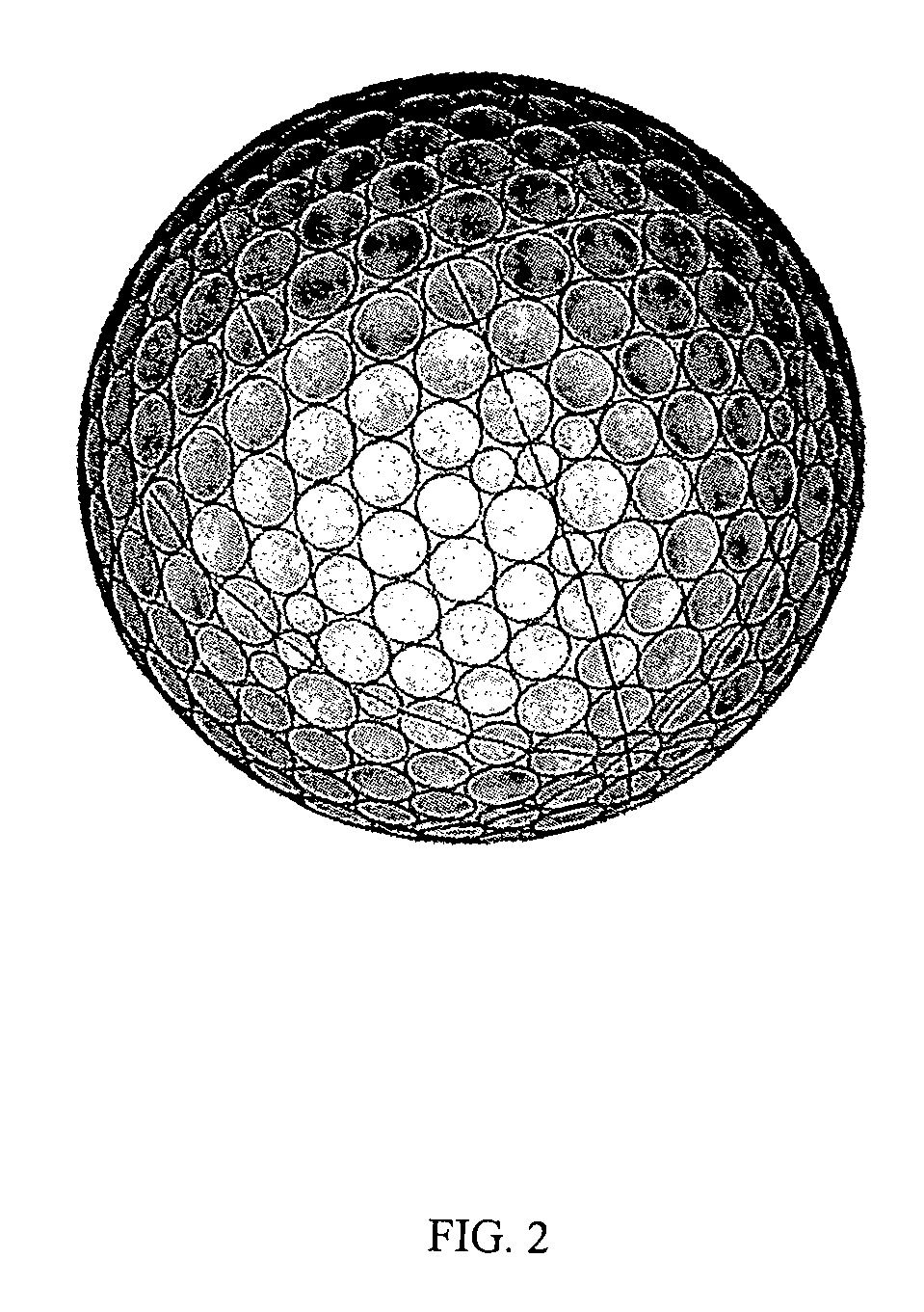

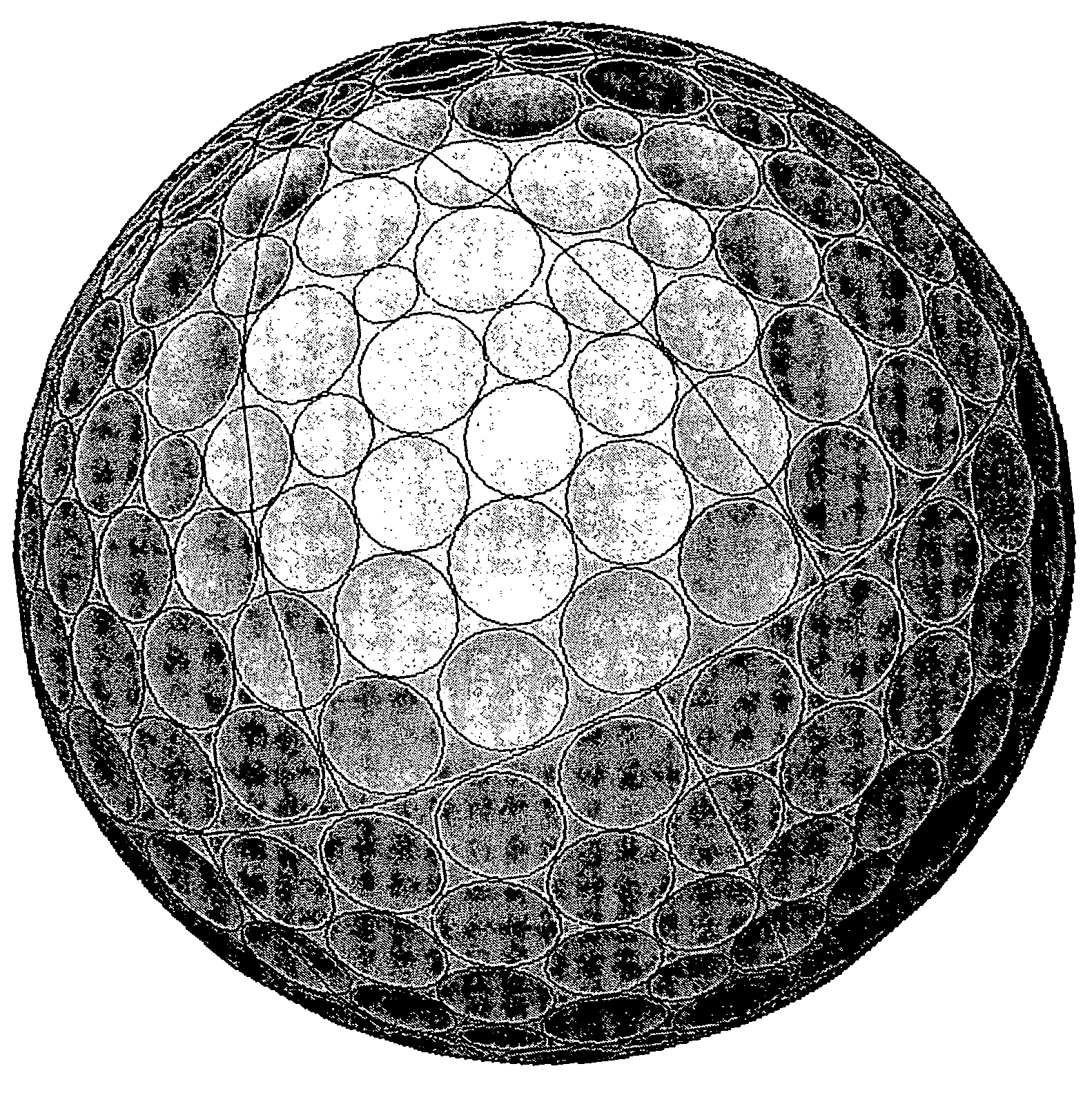

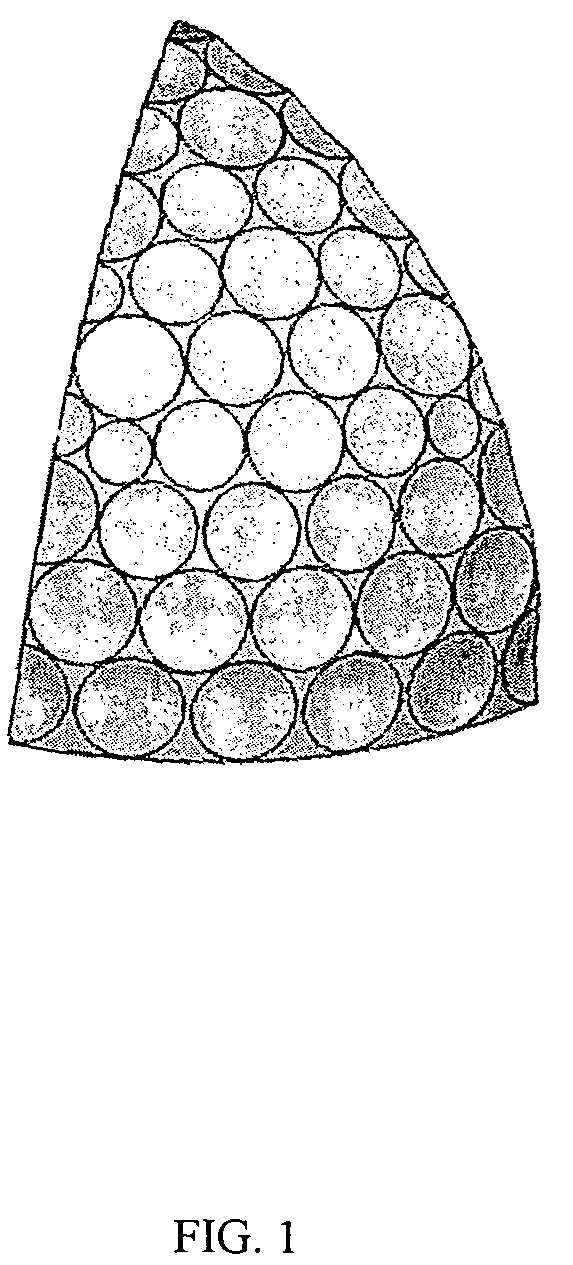

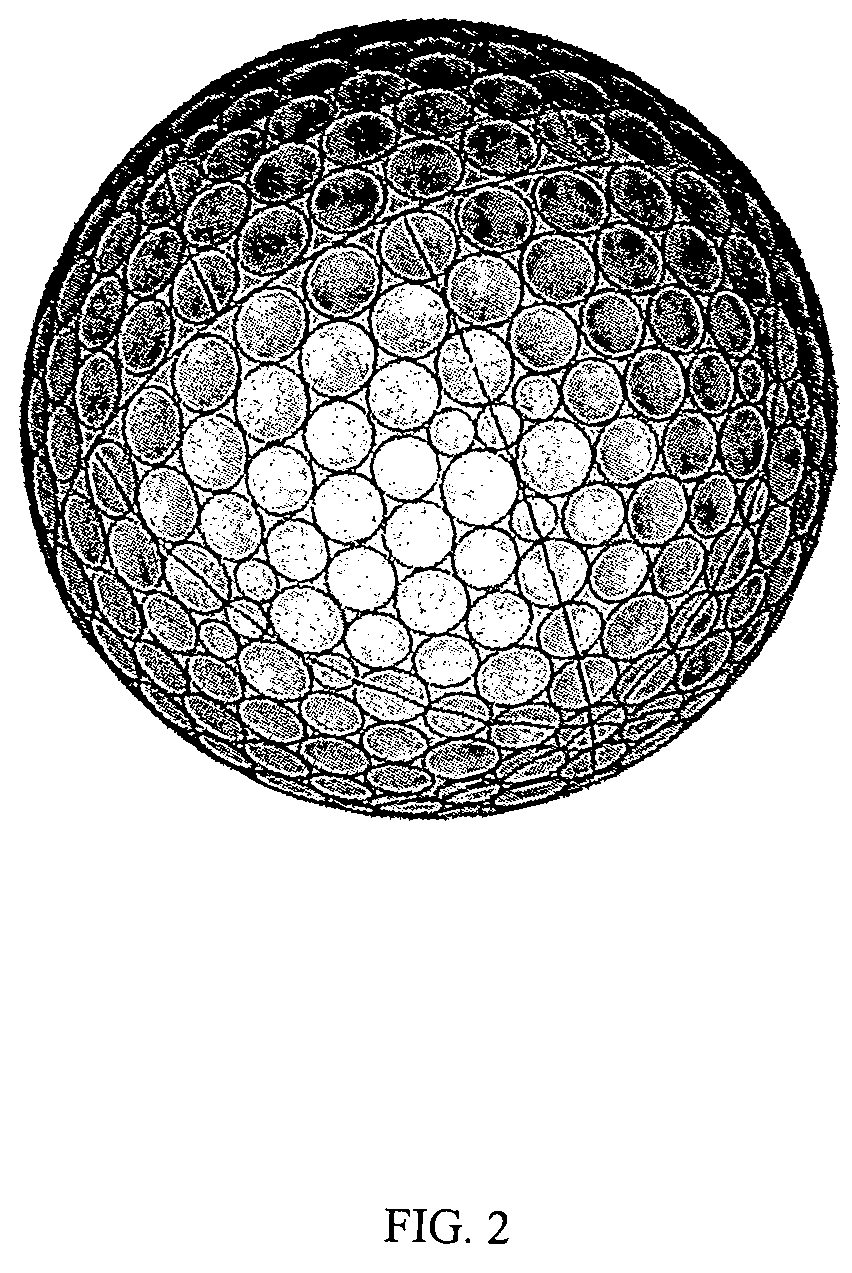

Dimple patterns for golf balls

A golf ball dimple pattern based on a hexagonal dipyramid polyhedron is disclosed. Preferably, the dimple pattern disclosed by the present invention includes dimples that are arranged such that at least a portion of neighboring dimples have one or more predetermined diameter ratios. The dimples are arranged based on six substantially similar mating dimple sections on each hemisphere. Each of the six substantially similar mating dimple sections on each hemisphere share a dimple positioned at the pole of that hemisphere. The dimple pattern is capable of achieving a surface coverage of about 82% or greater.

Owner:ACUSHNET CO

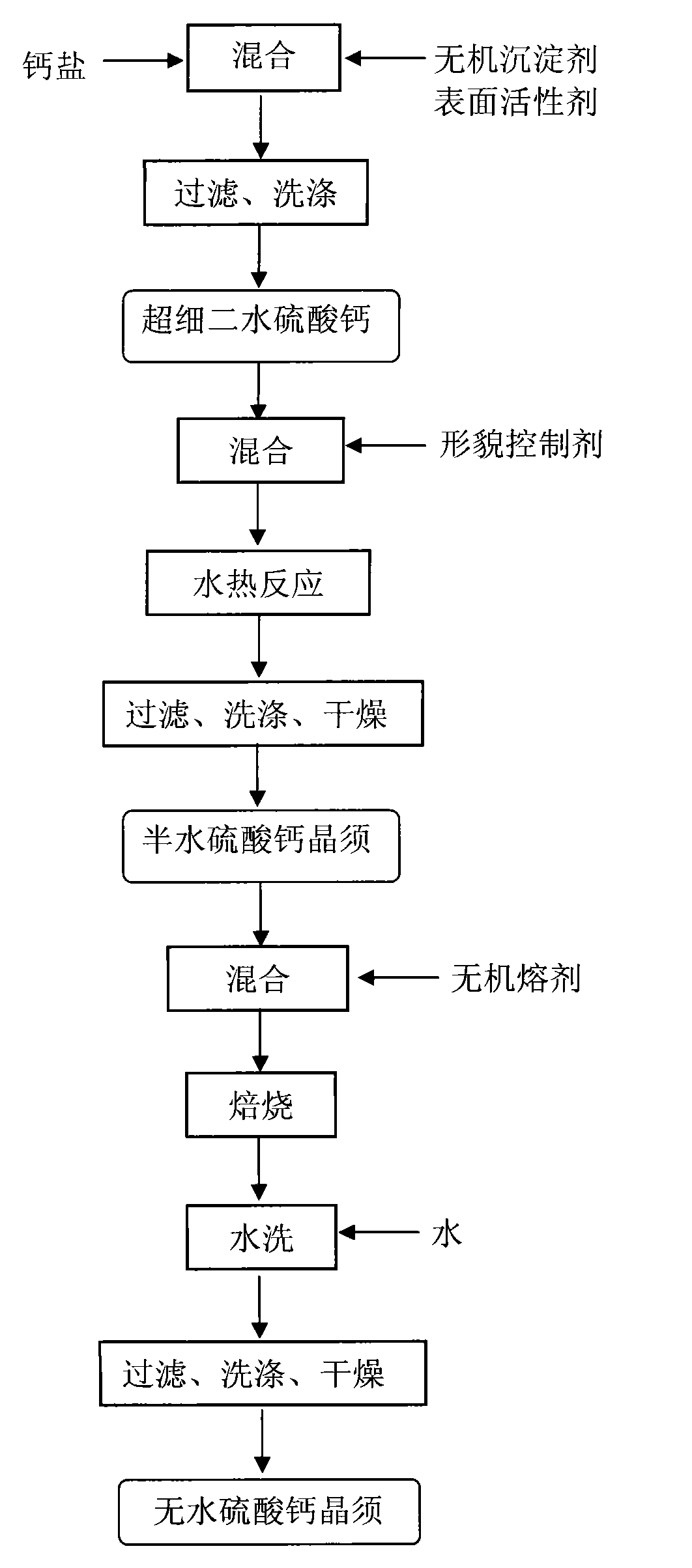

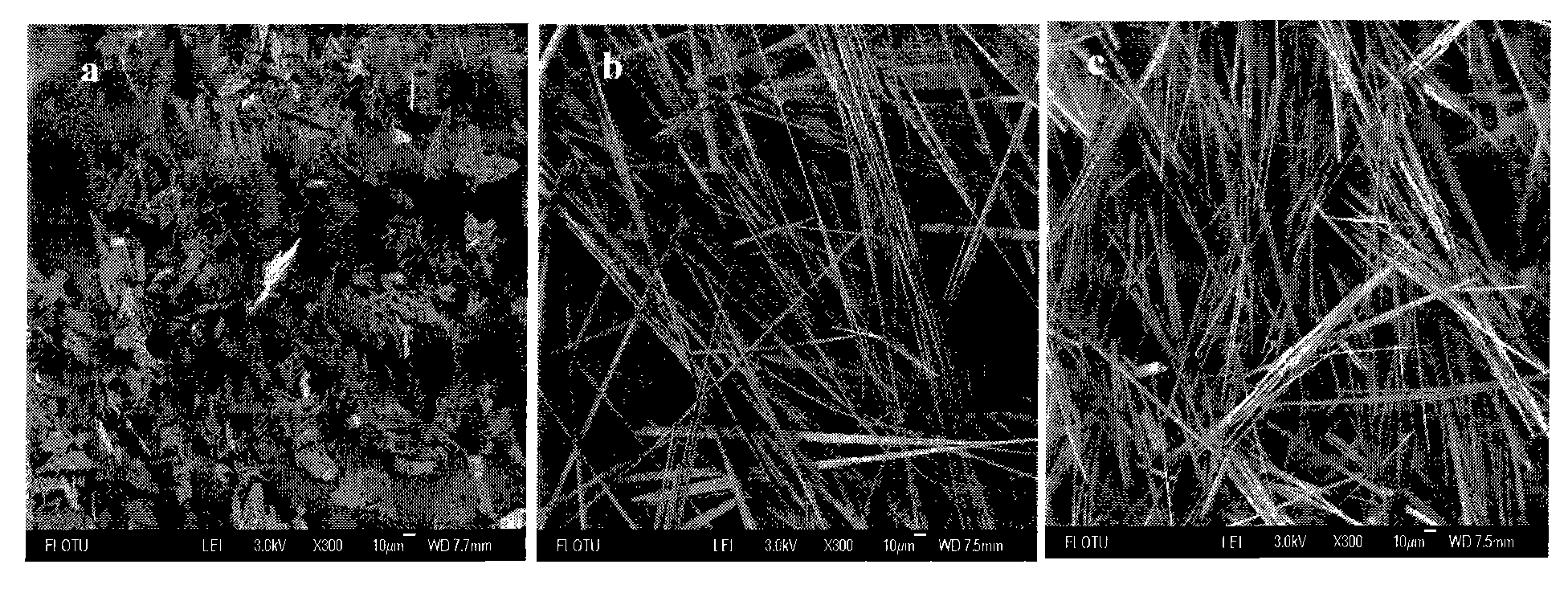

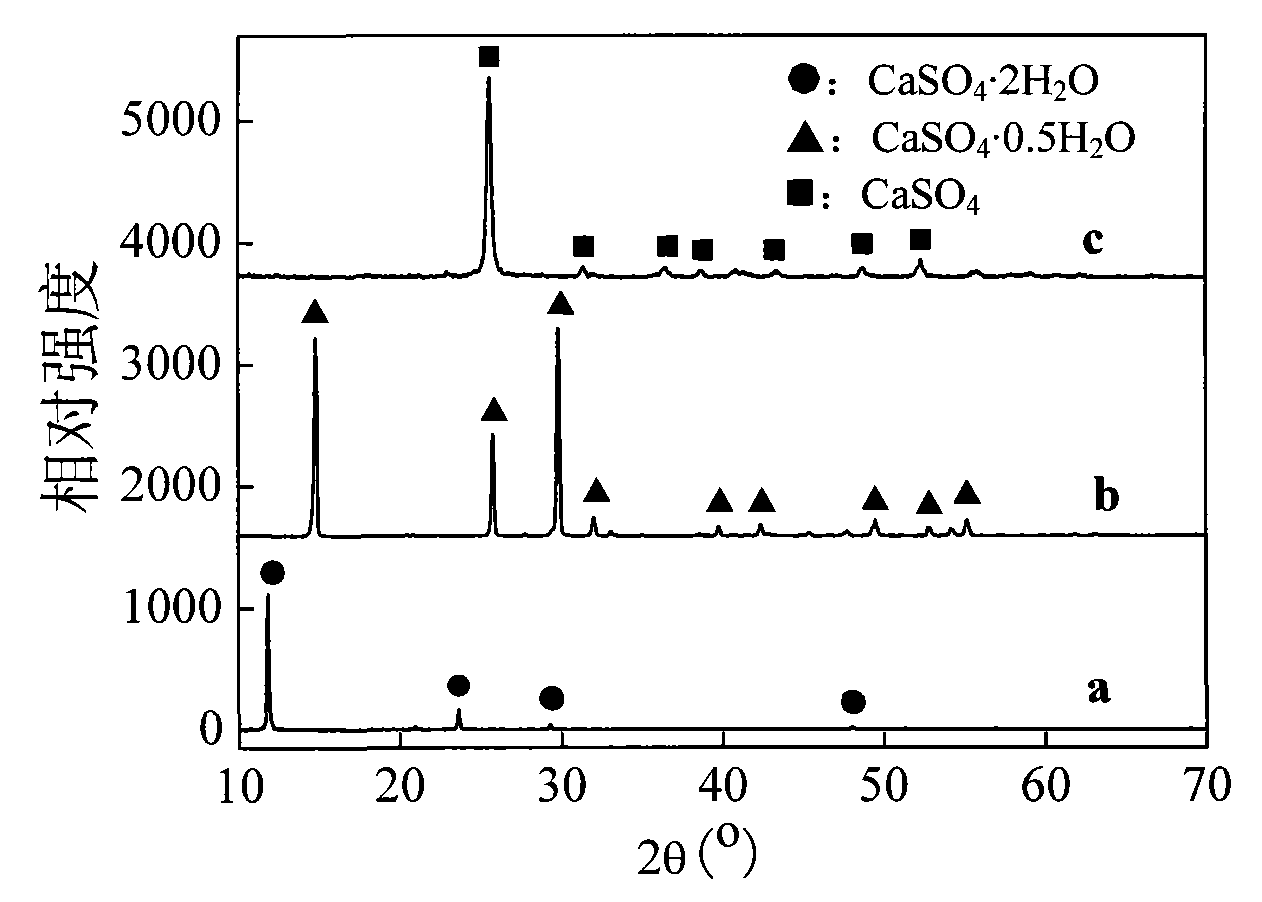

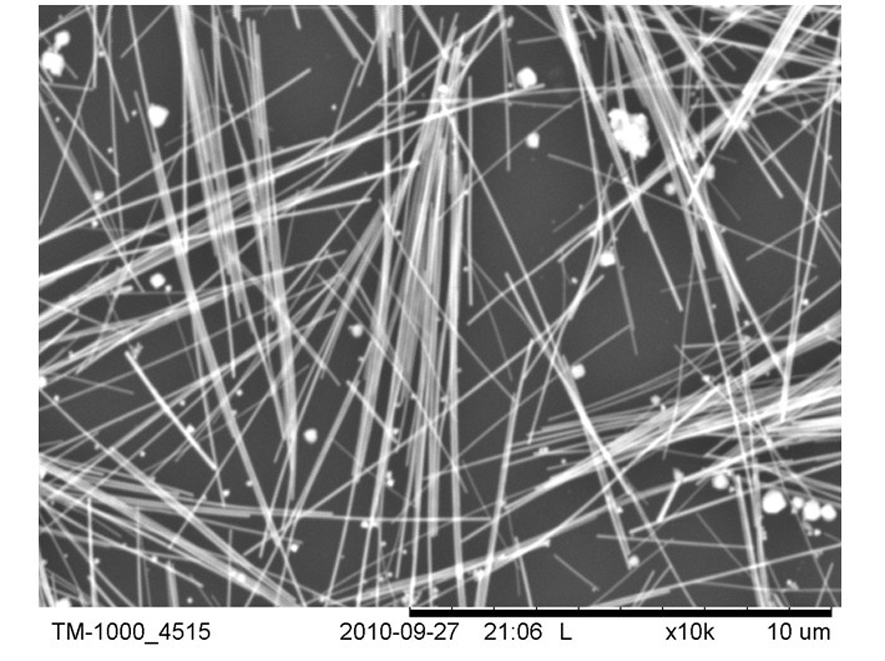

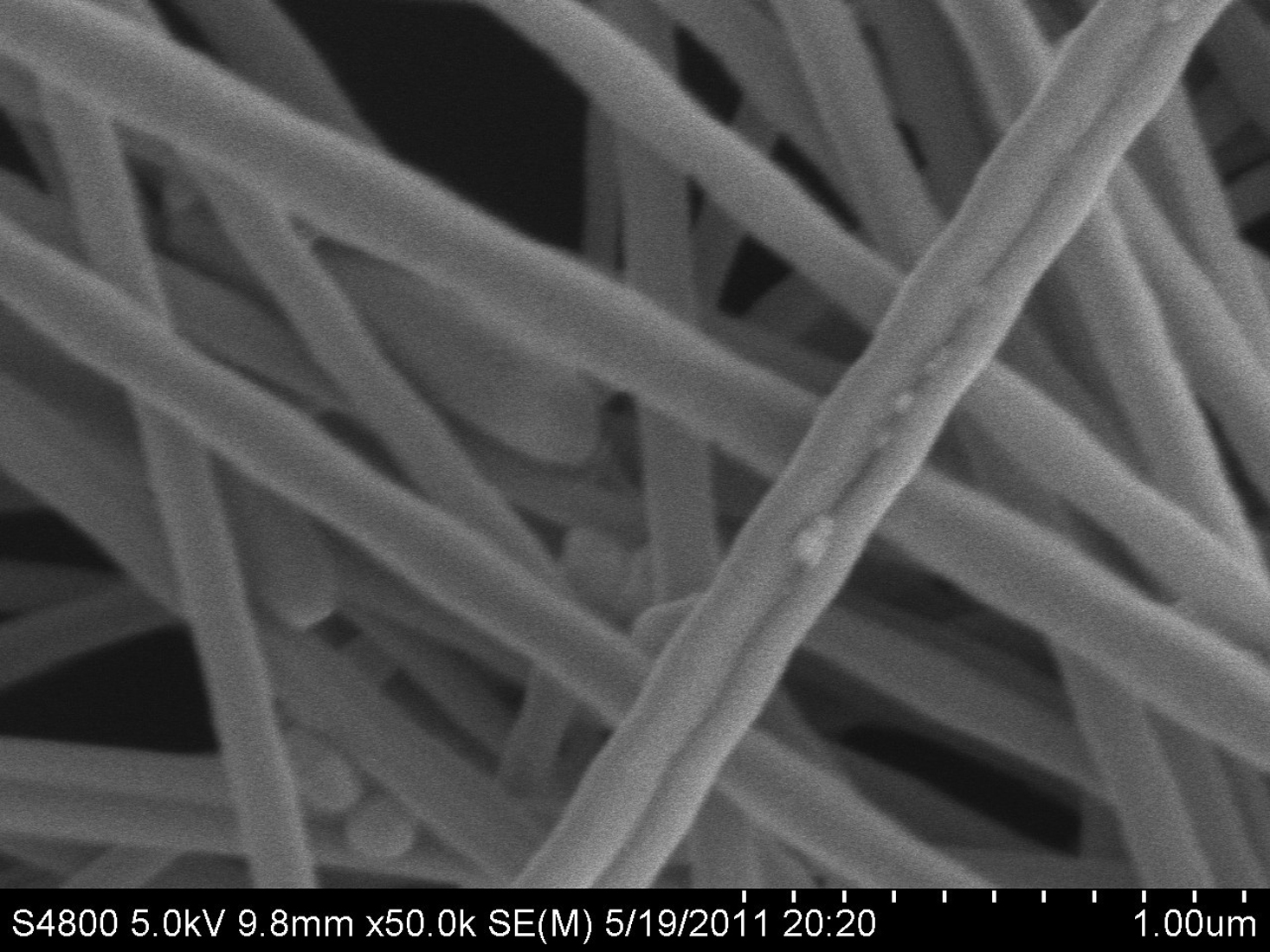

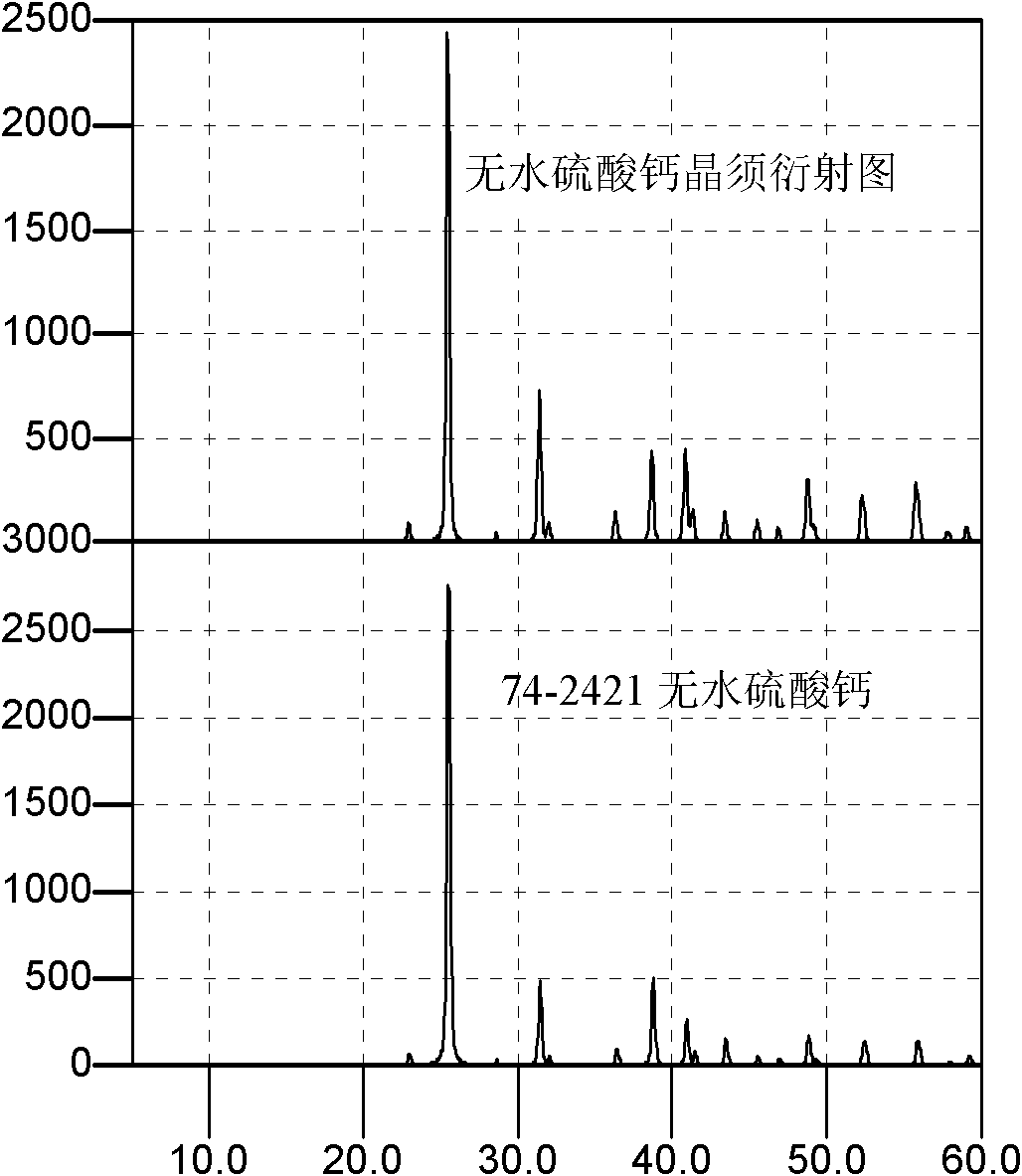

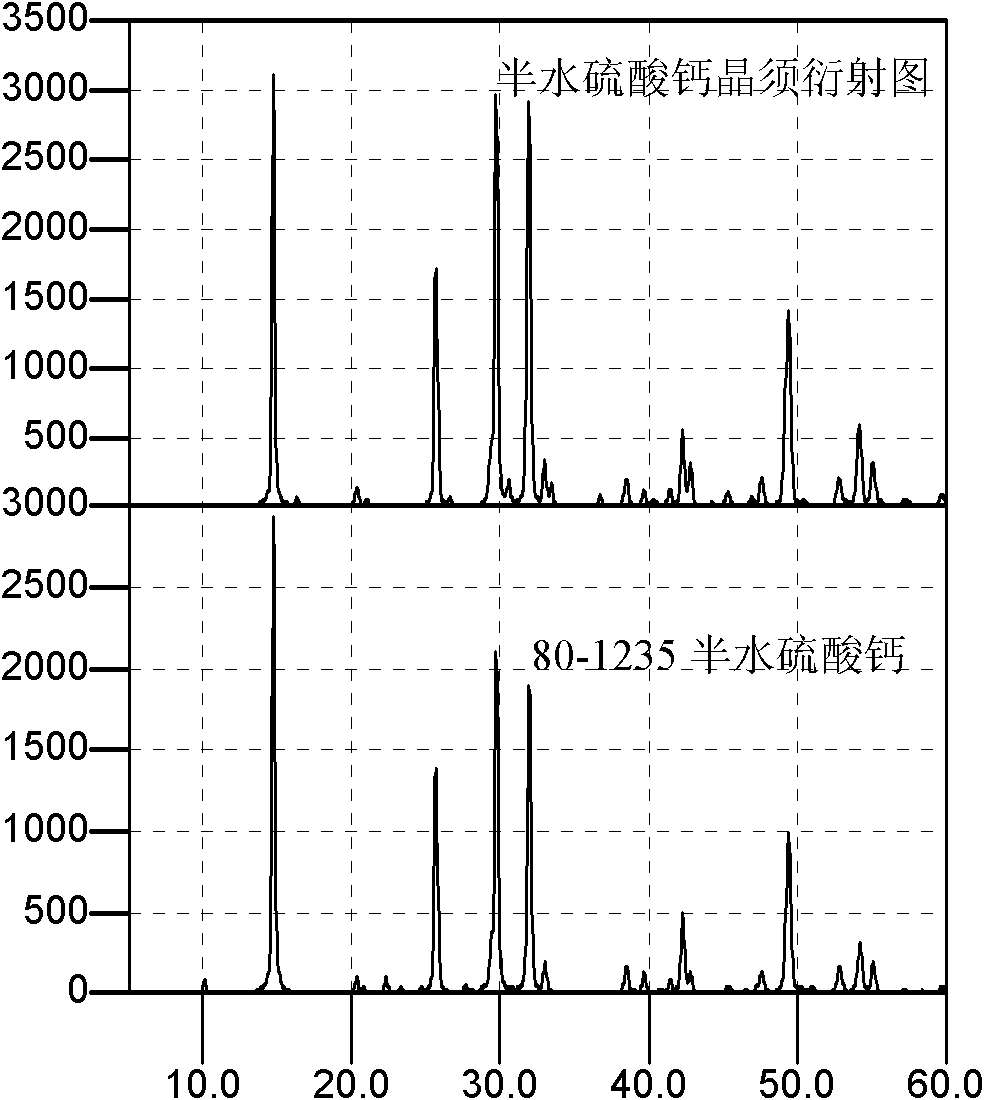

Preparation method of high length-diameter ratio anhydrous calcium sulfate whisker

ActiveCN101671848AHigh crystallinityMorphological rulesPolycrystalline material growthFrom normal temperature solutionsAnhydrous Calcium SulfatePapermaking

A preparation method of high length-diameter ratio anhydrous calcium sulfate whisker belongs to the technical field of inorganic chemical material preparation. The method takes inorganic calcium saltand inorganic precipitant as raw materials and surfactant as dispersant, and includes the following steps: first preparing superfine calcium sulphate dihydrate precursor with good dispersion at the temperature of 10-90 DEG C; then adding the precursor into water solution containing shape control agent to conduct hydrothermal reaction for 0.5-10h at the temperature of 100-250 DEG C, and obtaining calcium sulfate hemihydrate whisker; mixing the calcium sulfate hemihydrate whisker with inorganic solvent; and roasting the mixture for 0.5-6h at the temperature 200-800 DEG C to obtain anhydrous calcium sulfate whisker with the length of 20-2000mum, the diameter of 0.5-20mum, the length-diameter ratio of 40-1000 and the main content greater than 95wt% after washing and drying. The technology is simple, the cost is low and the added value of the product is high. The prepared calcium sulfate whisker has large length-diameter ratio and regular shape and can be used as reinforcing material to beapplied in industries such as plastics, rubber, ceramics, cement, papermaking and the like.

Owner:TSINGHUA UNIV

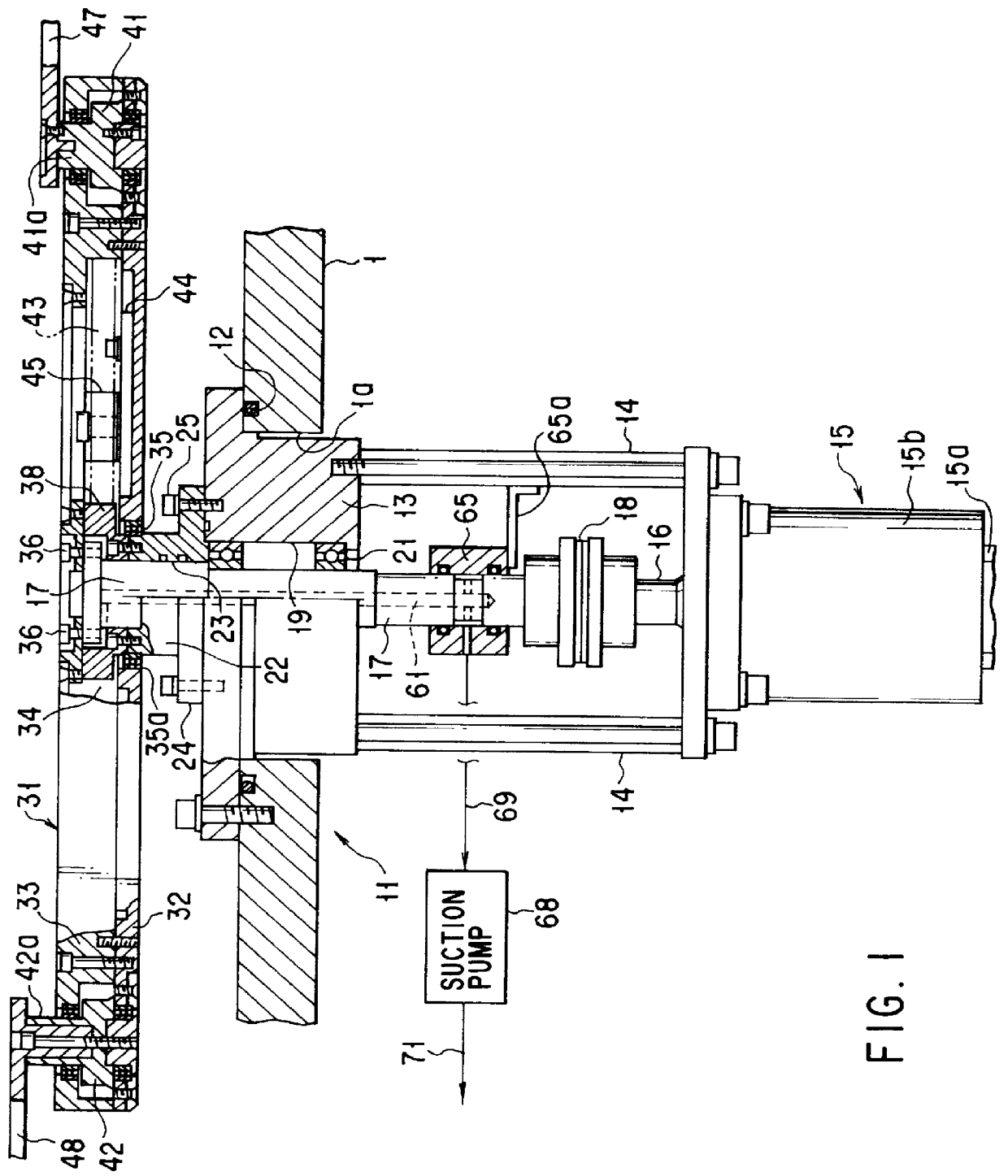

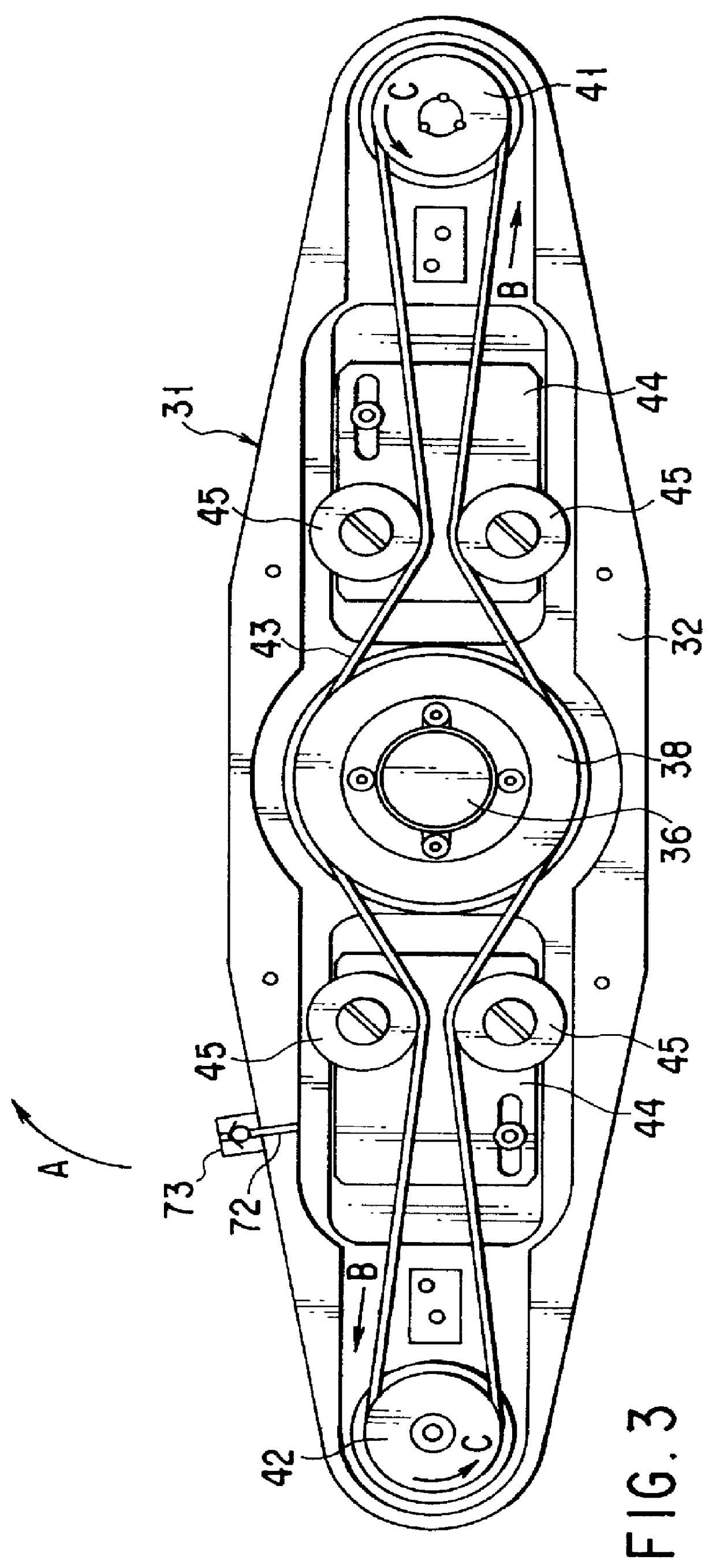

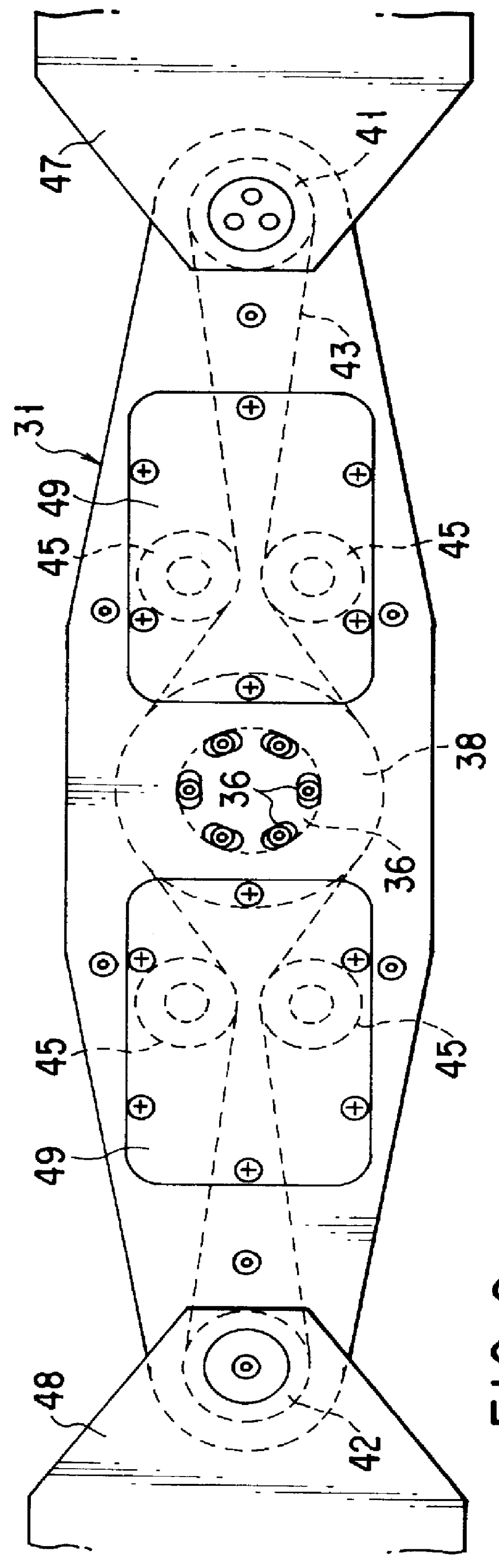

Robot apparatus and treating apparatus

InactiveUS6045315AShort working hoursIncrease in costProgramme-controlled manipulatorJointsDiameter ratioEngineering

A robot apparatus has a rotatable arm member. A stationary pulley is arranged in the center of the arm member, while a pair of rotatable pulleys are arranged at the respective ends of the arm member. A pair of fingers, used for conveying a work, are attached to the respective rotatable pulleys. A driving force transmission member is engaged with the stationary pulley and the rotatable pulleys. When the arm member is rotated, the driving force transmitting means rotates the rotatable pulleys in accordance with the outer diameter ratio of the stationary pulley to the rotatable pulleys.

Owner:SHIBAURA MECHATRONICS CORP +1

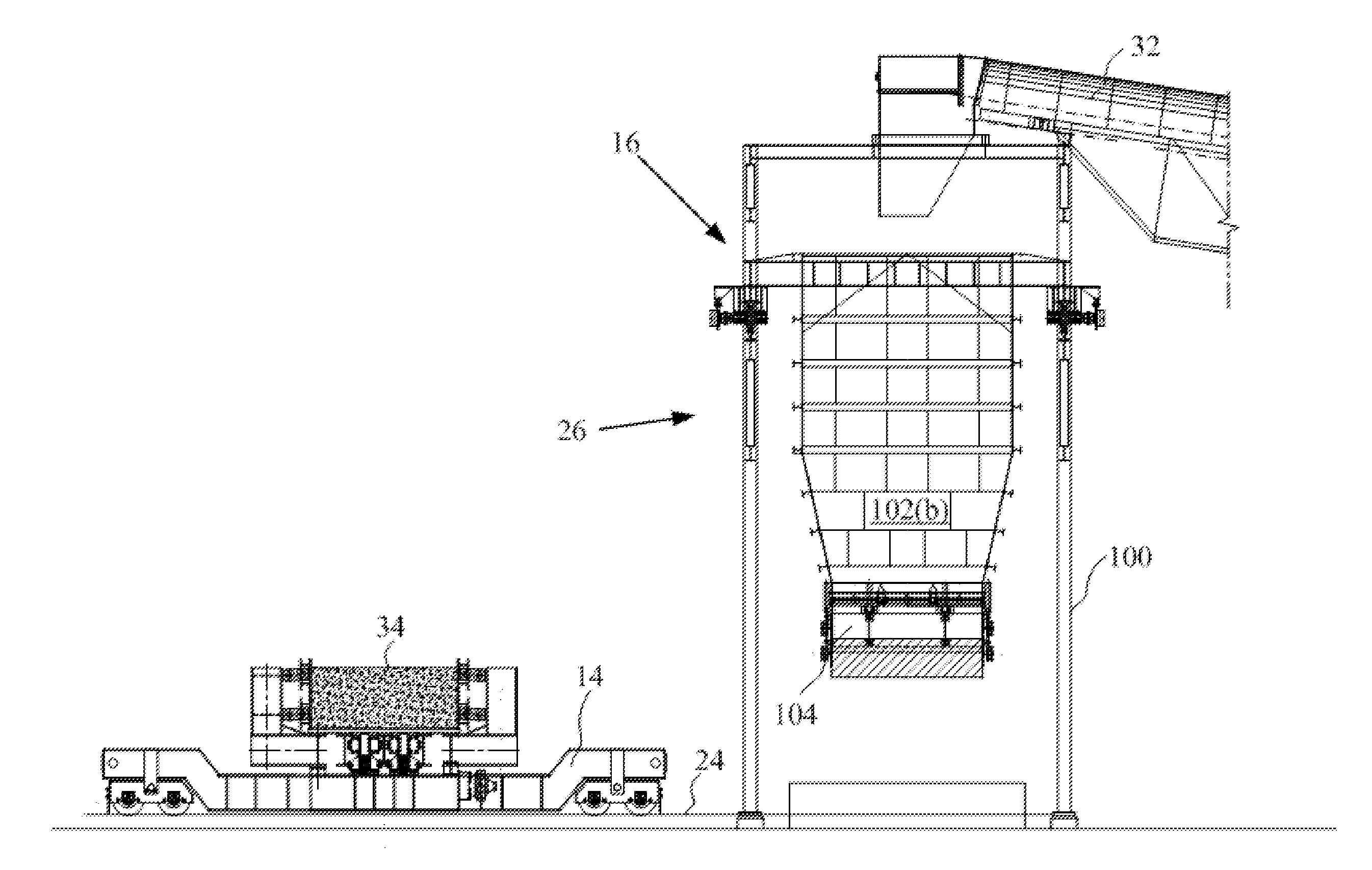

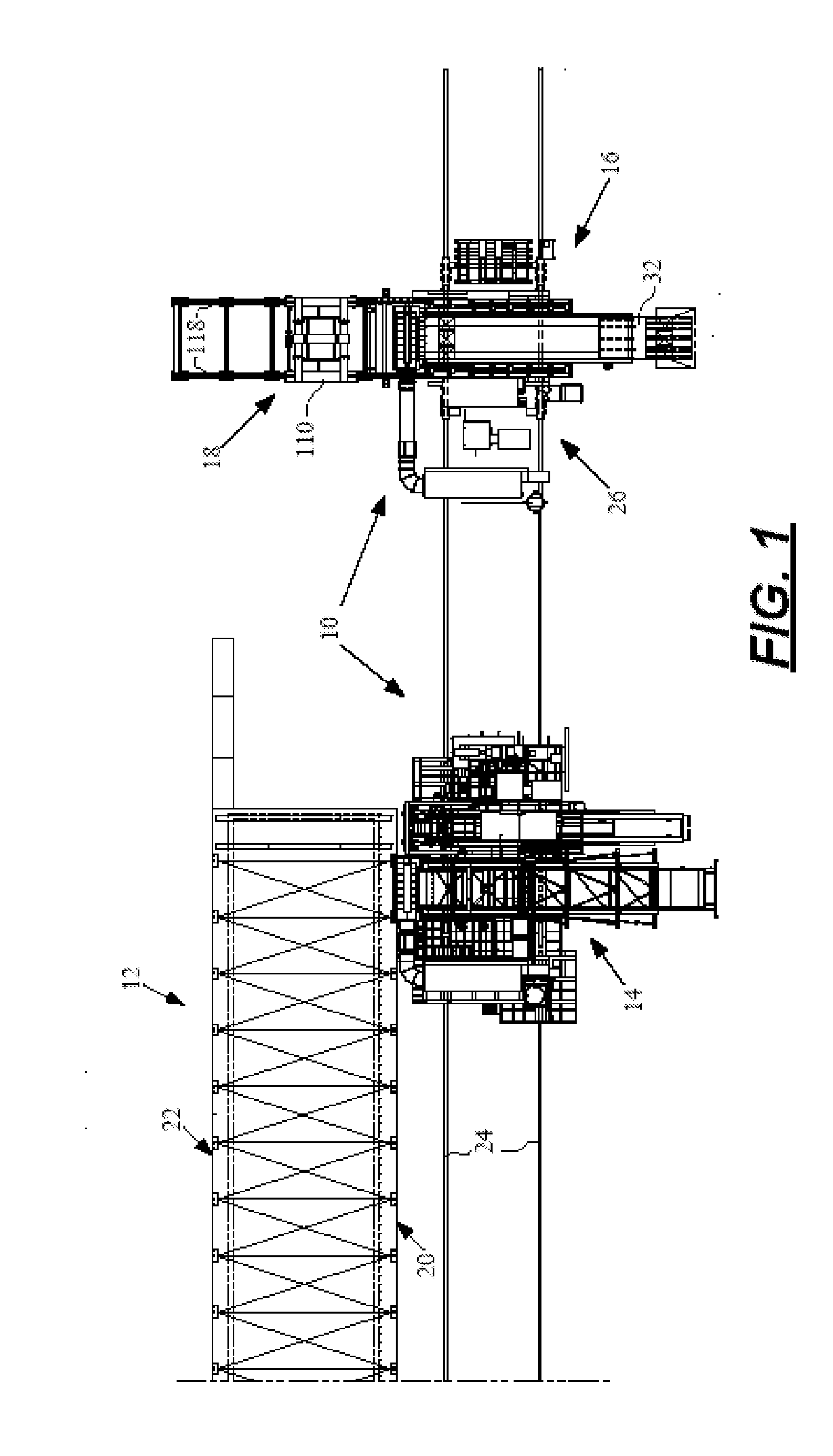

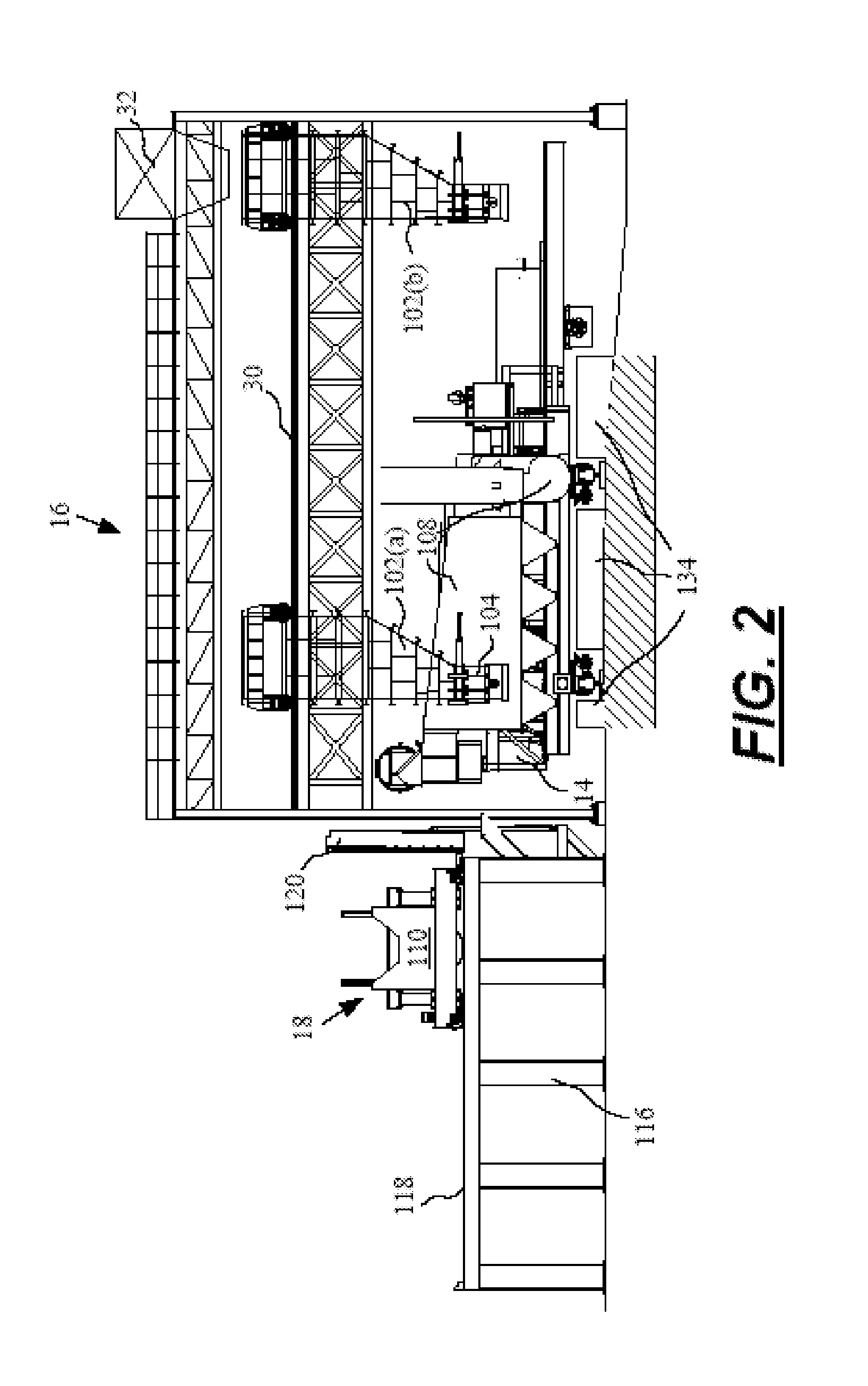

Method and apparatus for compacting coal for a coal coking process

ActiveUS20120030998A1High bulk densityShort timeCharging-discharging device combinationsSolid fuelsDiameter ratioEngineering

Relatively high speed methods for increasing the bulk density of coal particles without impacting the coal particles and an apparatus for compacting coal for making metallurgical coke. The method includes depositing coal particles onto a charging plate external to a coking oven. The charging plate has side walls, and at least one movable end wall to provide an elongate bed of dry, uncompacted coal having an upper surface on the charging plate. The uncompacted coal is compacted by passing a vibratory cylindrical compactor along a length of the uncompacted coal for a number of passes sufficient to decrease a thickness of the bed of coal to less than about 80 percent of an original thickness of the uncompacted coal. The vibratory cylindrical compactor has a length to diameter ratio ranging from about 1.4:1 to about 2:1.

Owner:SUNCOKE TECH & DEV LLC

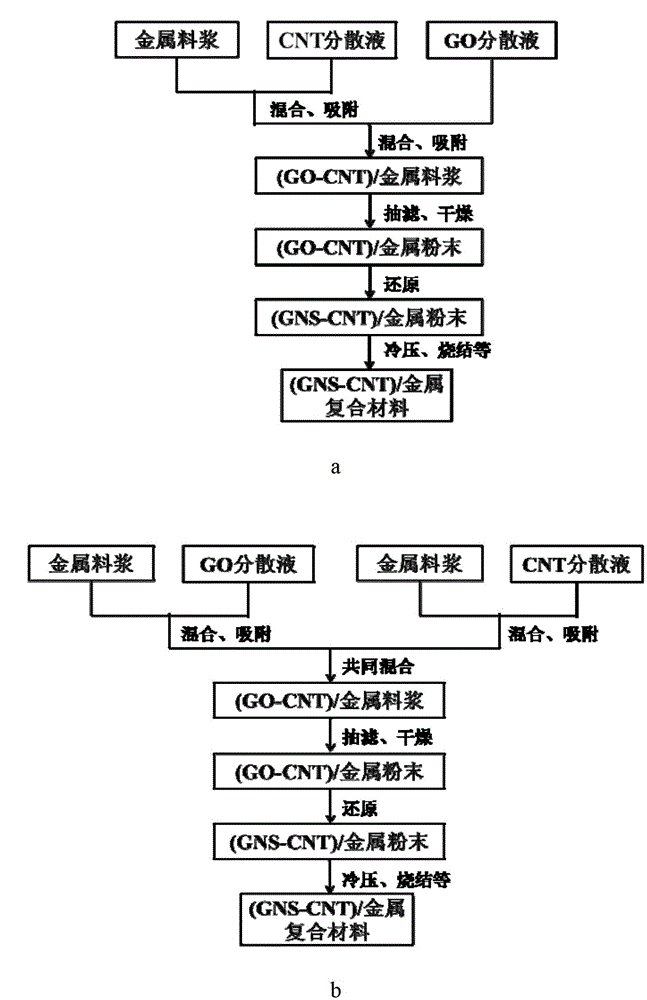

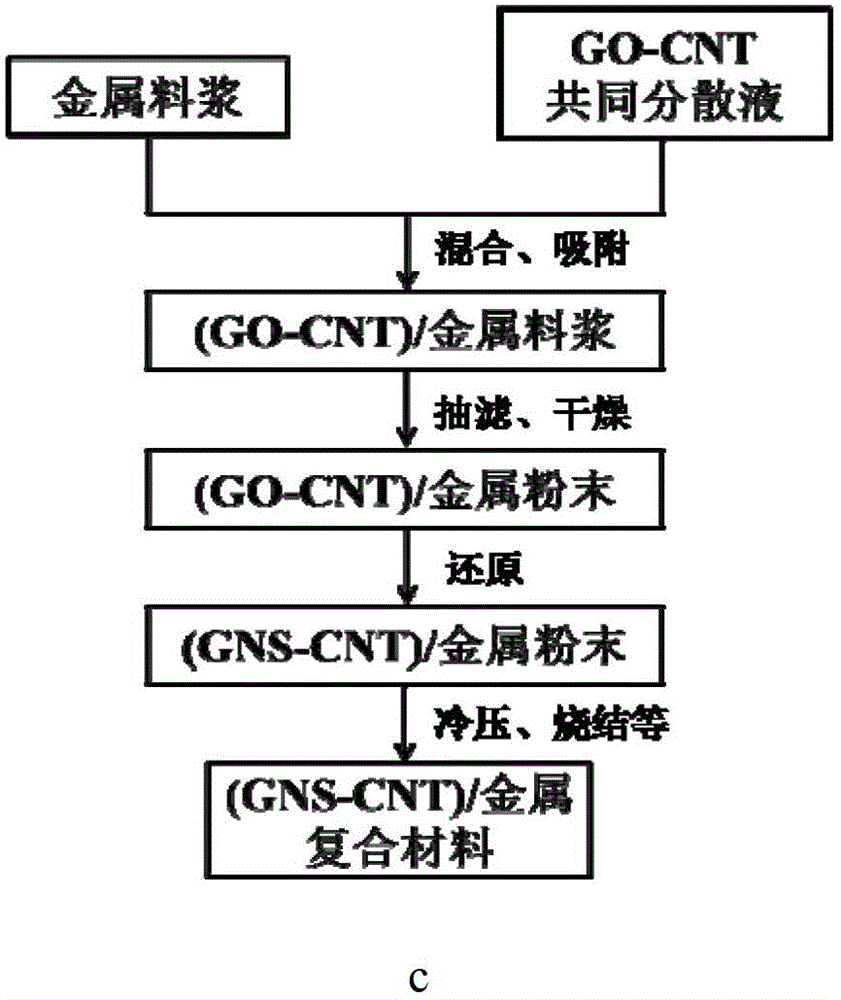

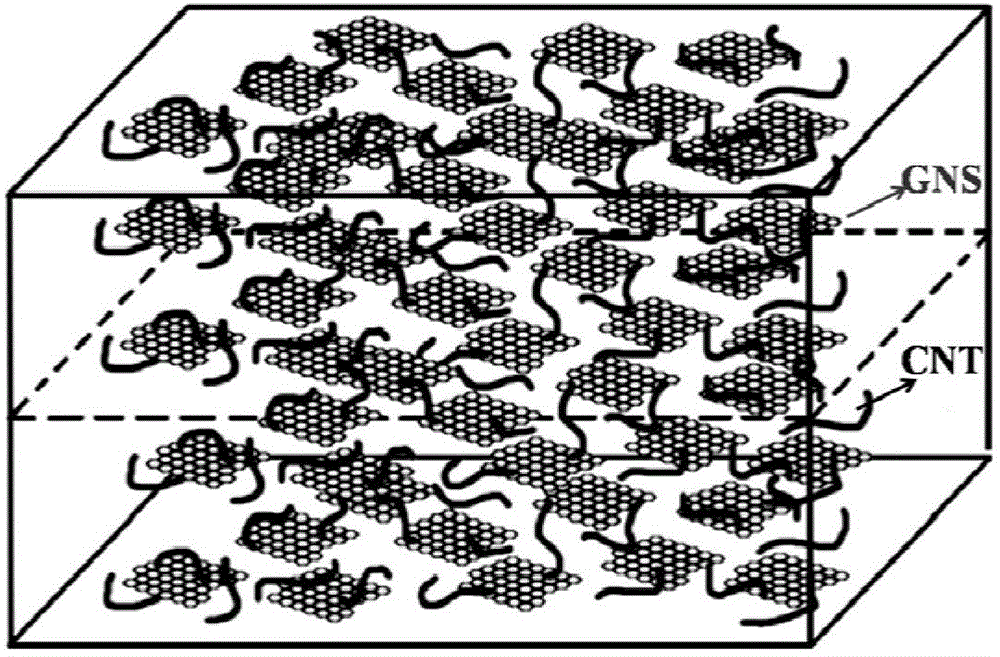

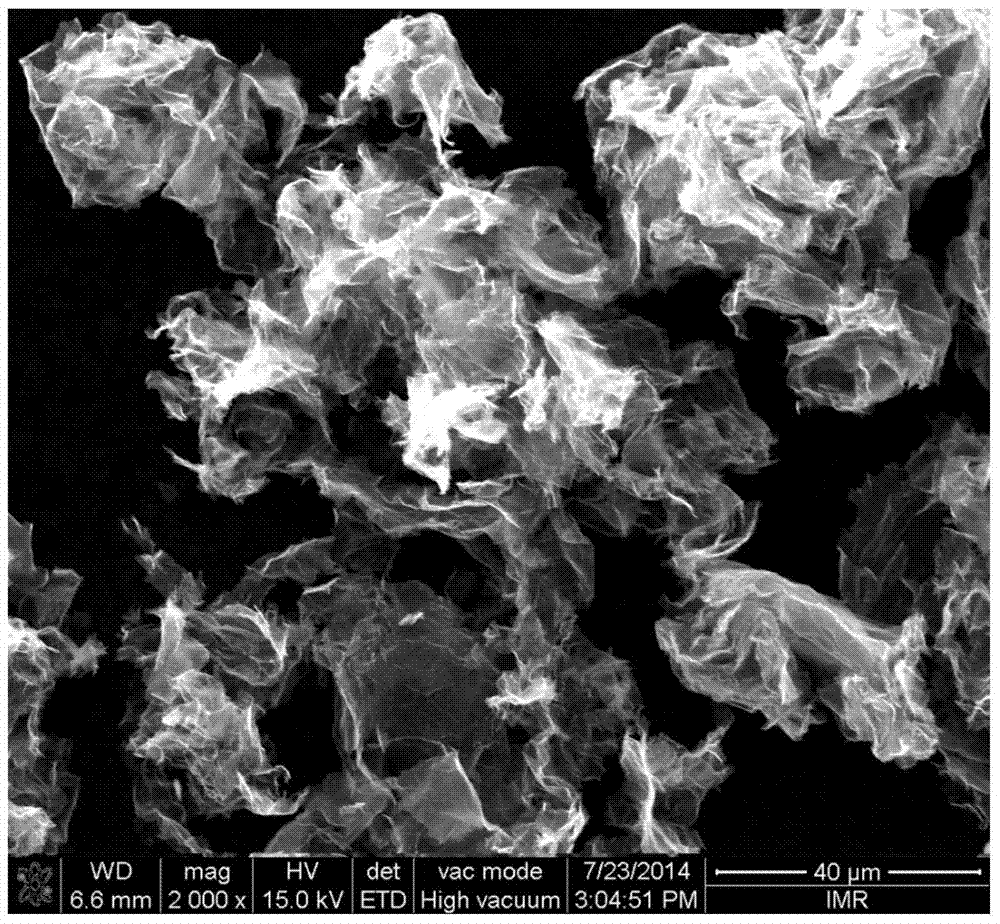

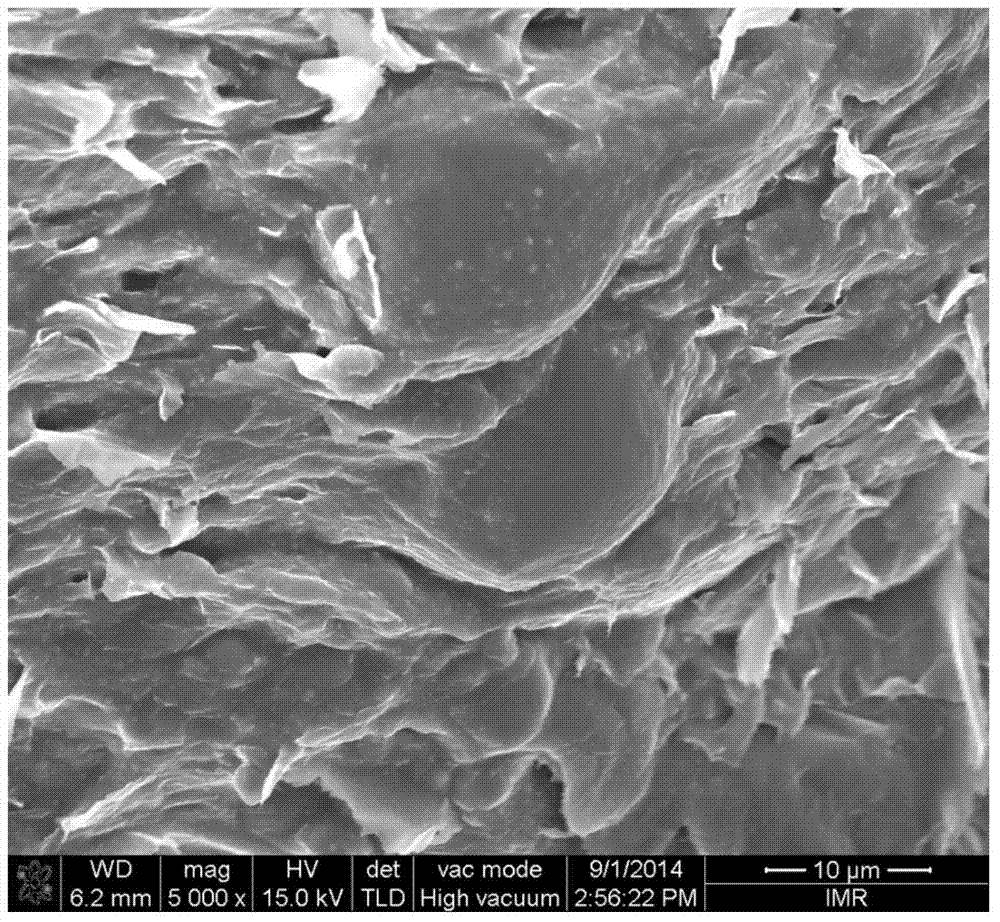

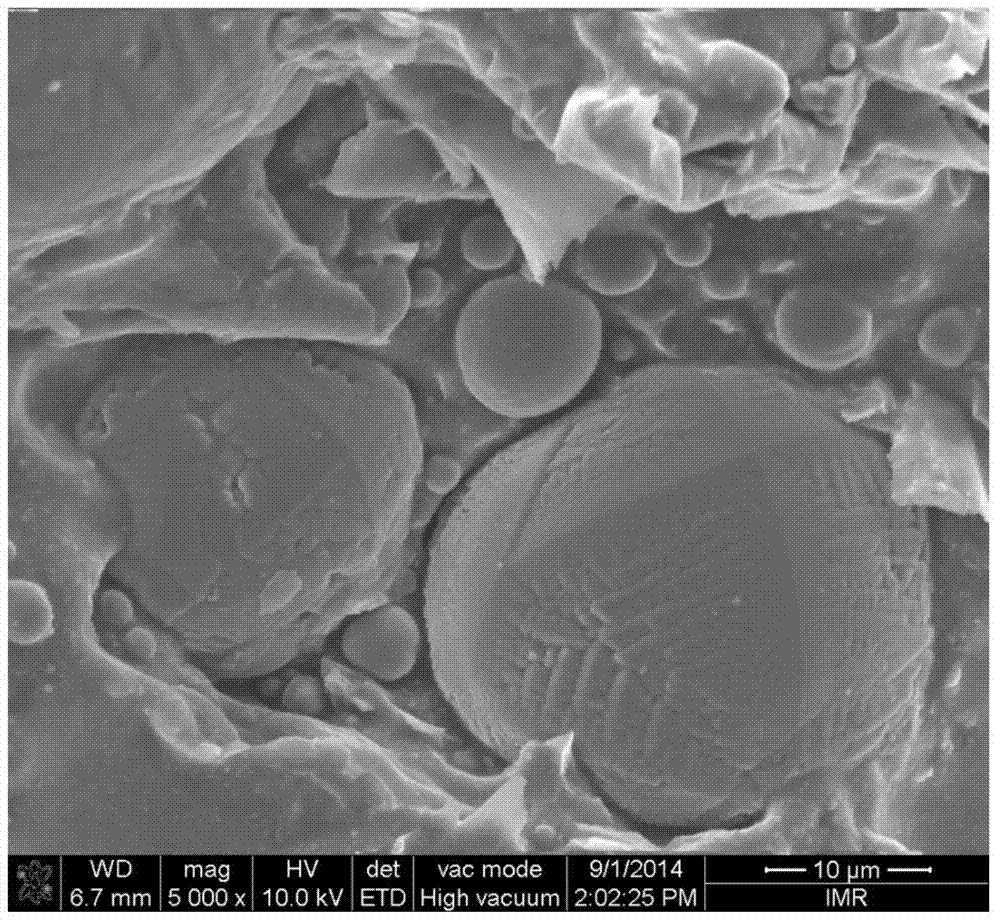

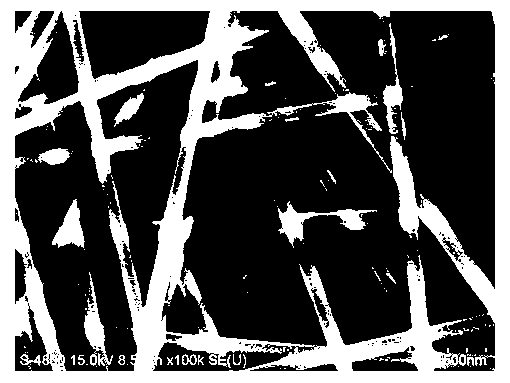

Graphene and carbon nanotube mixed enhanced metal-matrix composite material and preparation method thereof

The invention discloses a graphene and carbon nanotube mixed enhanced metal-matrix composite material and a preparation method thereof. The graphene and carbon nanotube mixed enhanced metal-matrix composite material is characterized in that graphene and a carbon nanotube are mutually connected to constitute an enhanced network in a metal matrix, wherein the graphene is few-layer graphene with 10 layers or less, the radius-thickness ratio of the graphene is larger than 200, and the volume fraction of the graphene is 0.1-1%; and the carbon nanotube is a single-wall, double-wall or multi-wall carbon nanotube, the length-diameter ratio of the carbon nanotube is larger than 20, and the volume fraction of the carbon nanotube is 0.5-5%. Compared with the composite material enhanced only by the carbon nanotube, the graphene and carbon nanotube mixed enhanced metal-matrix composite material disclosed by the invention not only has greatly improved mechanical properties, but also has more excellent electric conduction and heat conduction properties, and is a multi-purpose structure and function integrated material. In addition, the preparation method provided by the invention based on slurry blending and graphene oxide reduction is simple and efficient and is easy for large-scale production.

Owner:SHANGHAI JIAO TONG UNIV

Dimple patterns for golf balls

A golf ball dimple pattern based on a hexagonal dipyramid polyhedron is disclosed. Preferably, the dimple pattern disclosed by the present invention includes dimples that are arranged such that at least a portion of neighboring dimples have one or more predetermined diameter ratios. The dimples are arranged based on six substantially similar mating dimple sections on each hemisphere. Each of the six substantially similar mating dimple sections on each hemisphere share a dimple positioned at the pole of that hemisphere. The dimple pattern is capable of achieving a surface coverage of about 82% or greater.

Owner:ACUSHNET CO

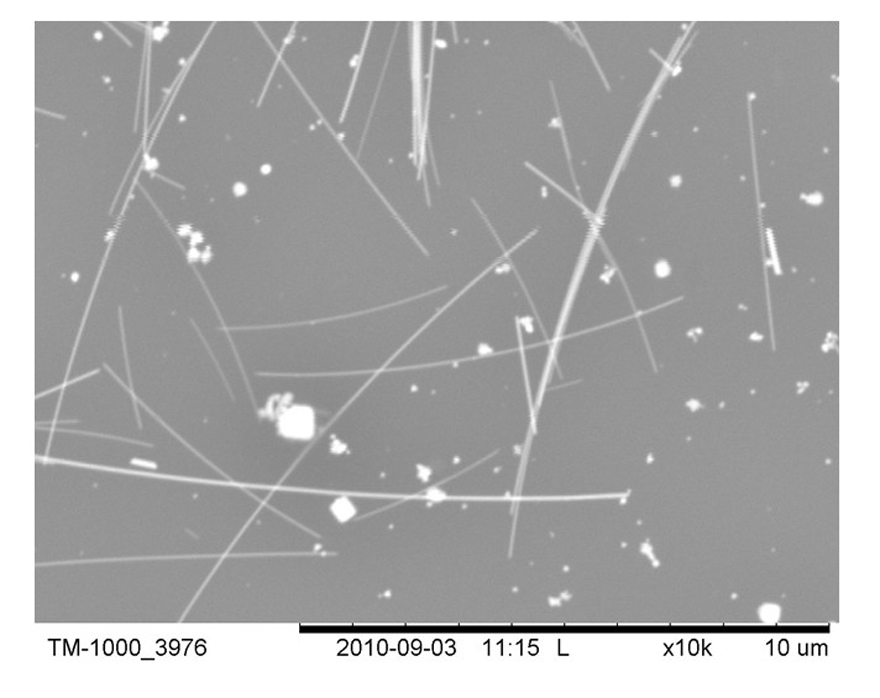

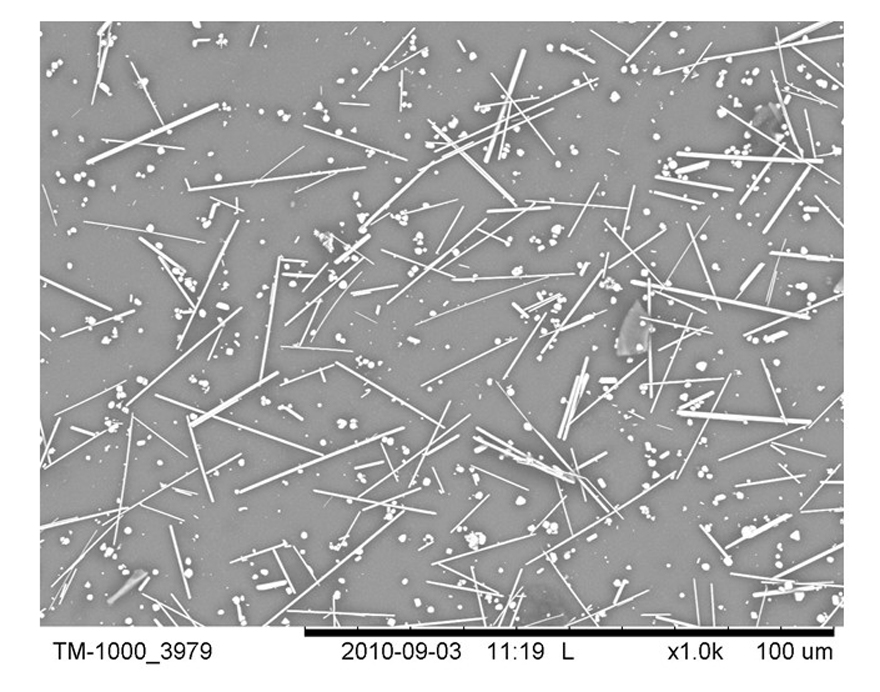

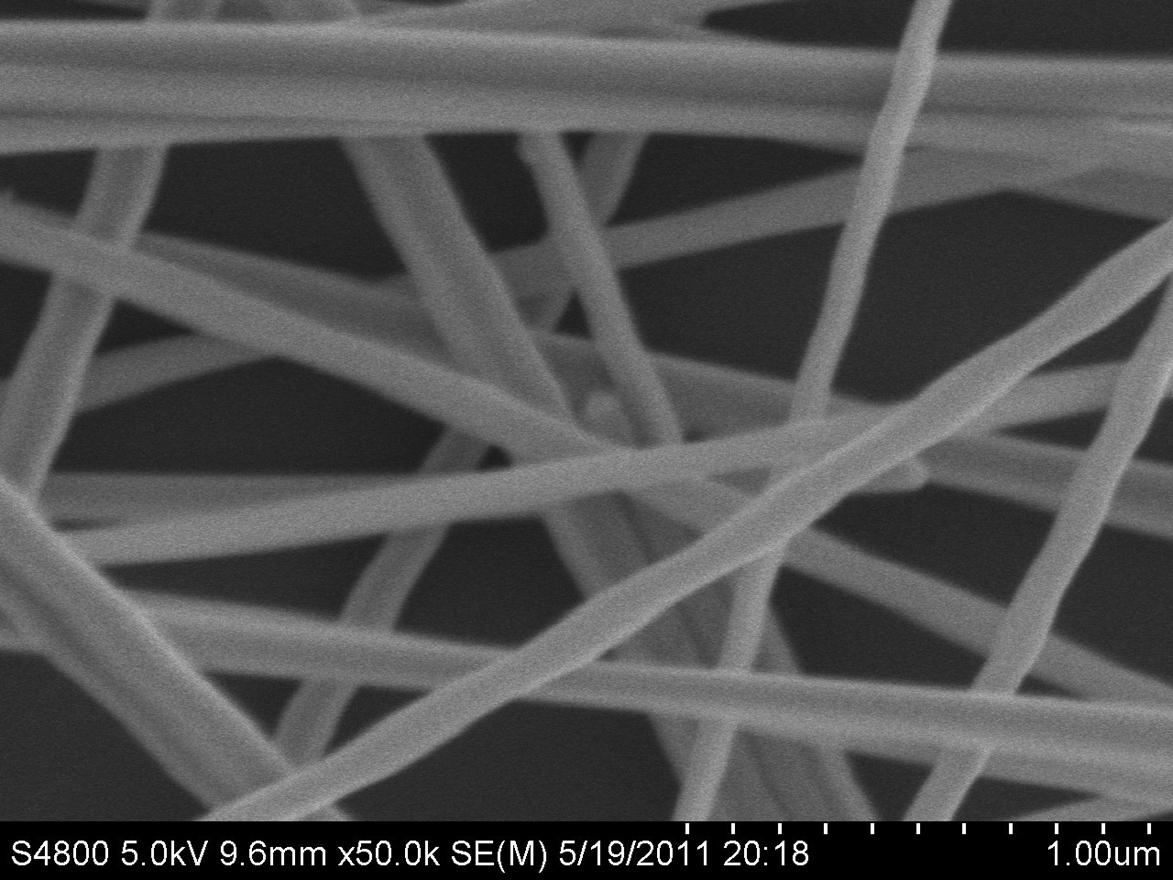

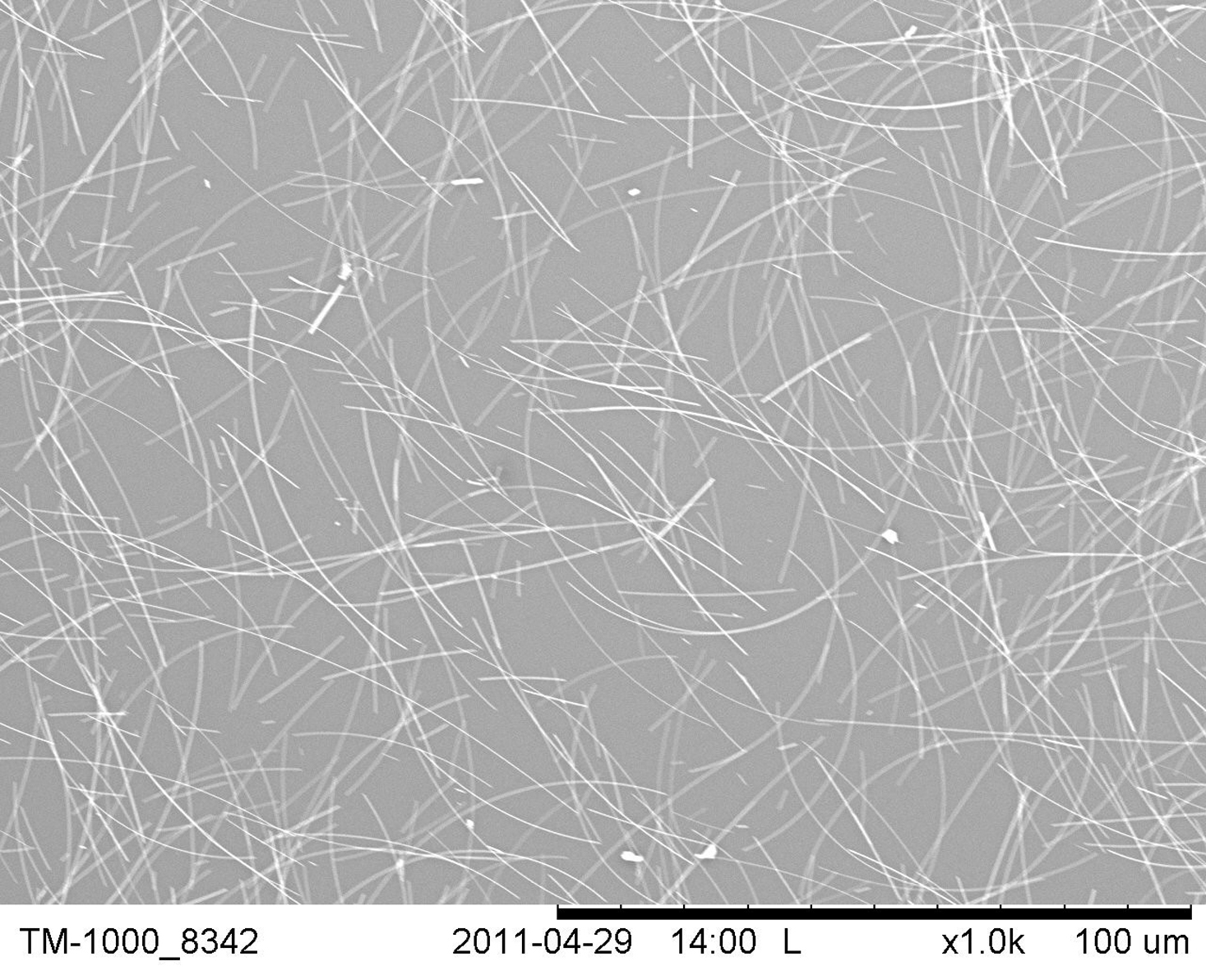

Method for preparing silver nanometer wire with controllable wire diameter by cation control microwave method

ActiveCN102029400APolycrystalline material growthSingle crystal growth detailsMicrowave methodDiameter ratio

The invention provides a method for preparing silver nanometer wire with controllable wire diameter by a cation control microwave method, aiming at solving the problems of rough wire diameter, low diameter ratio and the like during preparation of the silver nanometer wire by the traditional microwave method. The method comprises the following steps of: (1) adding a mixture of silver nitrate powder and a dispersing agent into ethylene glycol and preparing a solution reaction system containing silver ions; (2) adding a cation control agent in the solution reaction system containing silver ions and evenly stirring to obtain a reaction precursor; and (3) irradiating the reaction precursor under microwave, centrifuging, ultrasonically washing and drying the solution prepared through microwave irradiation to obtain the silver nanometer wire powder with controllable wire diameter. The invention has the advantages of simple preparation method, high efficiency and low cost and ensures that the high-quality silver nanometer wire can be prepared repeatedly within wide range of reaction condition. By using a soft template method, the size of the wire diameter is controlled by using the cation control agent without introducing any impurity.

Owner:JIANGSU NANOWELL ADVANCED MATERIALS SCI&TECH

Preparation method of homogenized fine nano-cellulose fiber

InactiveCN101851295ALow degree of mutual aggregationEvenly dispersedArtificial filaments from cellulose solutionsStrong acidsCatalytic oxidation

The invention relates to a preparation method of a homogenized fine nano-cellulose fiber. The preparation method can solve the problems of uniform diameter distributor of biomass nano-cellulose prepared by the existing strong acid hydrolysis method and the high-strength mechanical shearing method, easy gathering among the nano-fiber and a narrow range of applications of the TEMPO catalytic oxidation method. The preparation method comprises the following steps: 1) extracting biomass fiber with benzyl alcohol solution; 2) carrying out treatment by using acidified sodium chlorite; 3) carrying out gradient treatment with alkaline liquor; 4) using TEMPO, sodium bromide and sodium hypochlorite for catalytic oxidation treatment; 5) using sodium chlorite for treatment; and 6) carrying out nano-scale processing by using the long-term stirring method, the ultrasonic method or the high-pressure homogenization method, drying, and then obtaining the homogenized fine nano-cellulose fiber. The fiber has the uniform diameter distribution, the diameter is 3-5nm, the length-diameter ratio is not less than 500, the fiber is mutually interwoven into a mesh snarling structure, and the method is applicable to preparing the nano-cellulose fiber by using wood pulp, paper-making pulp, wood, bamboo and crop straw.

Owner:NORTHEAST FORESTRY UNIVERSITY

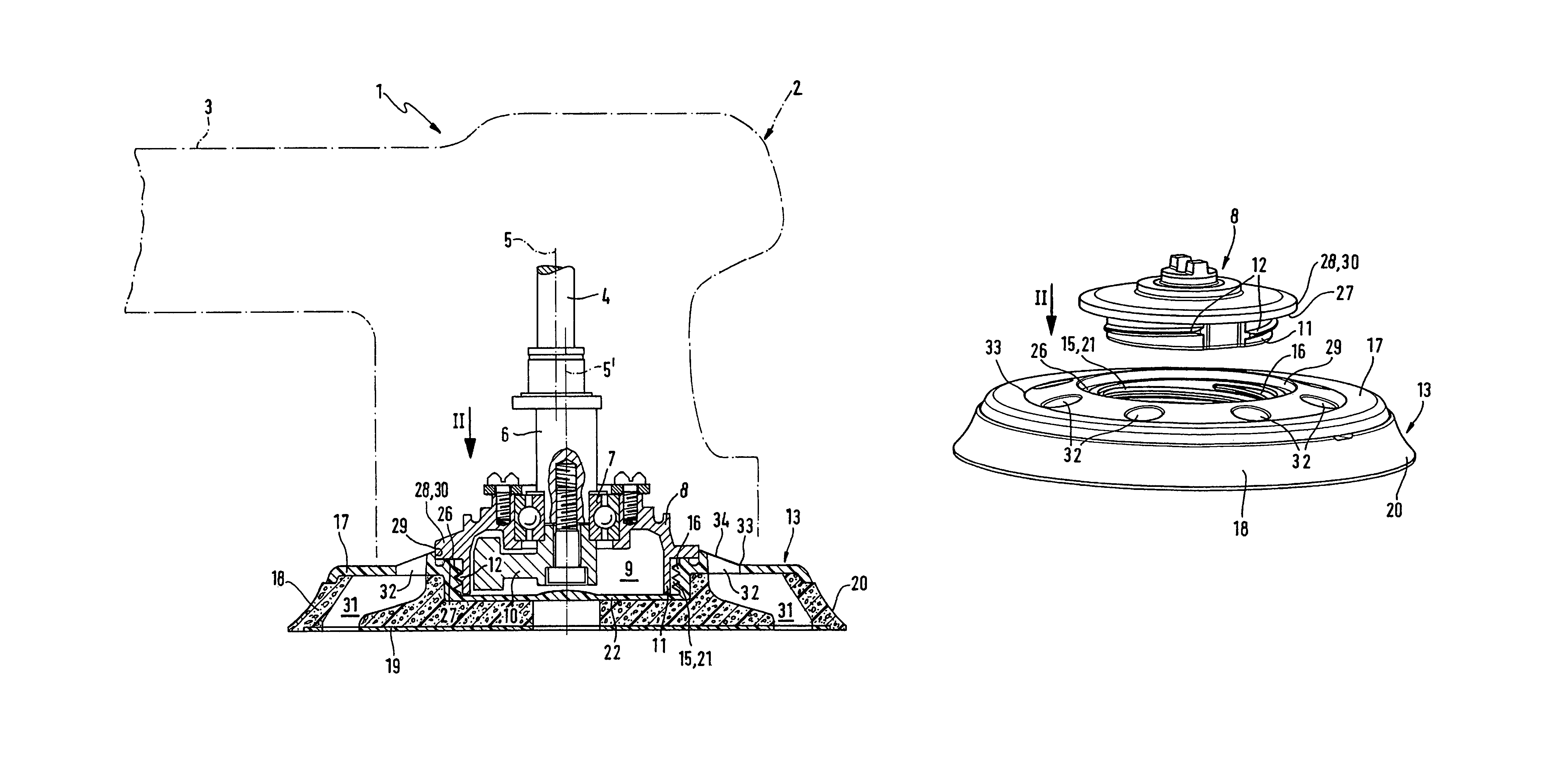

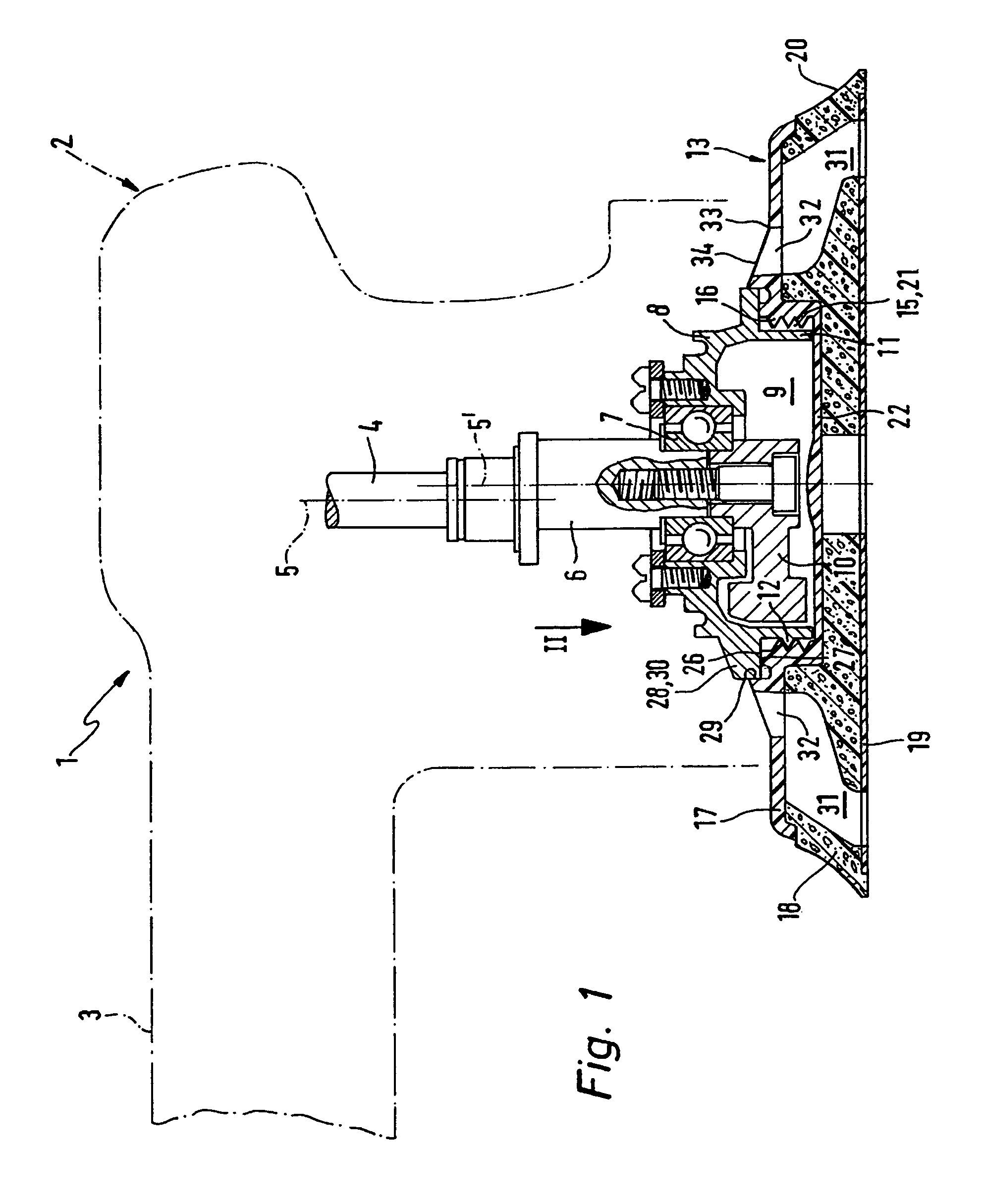

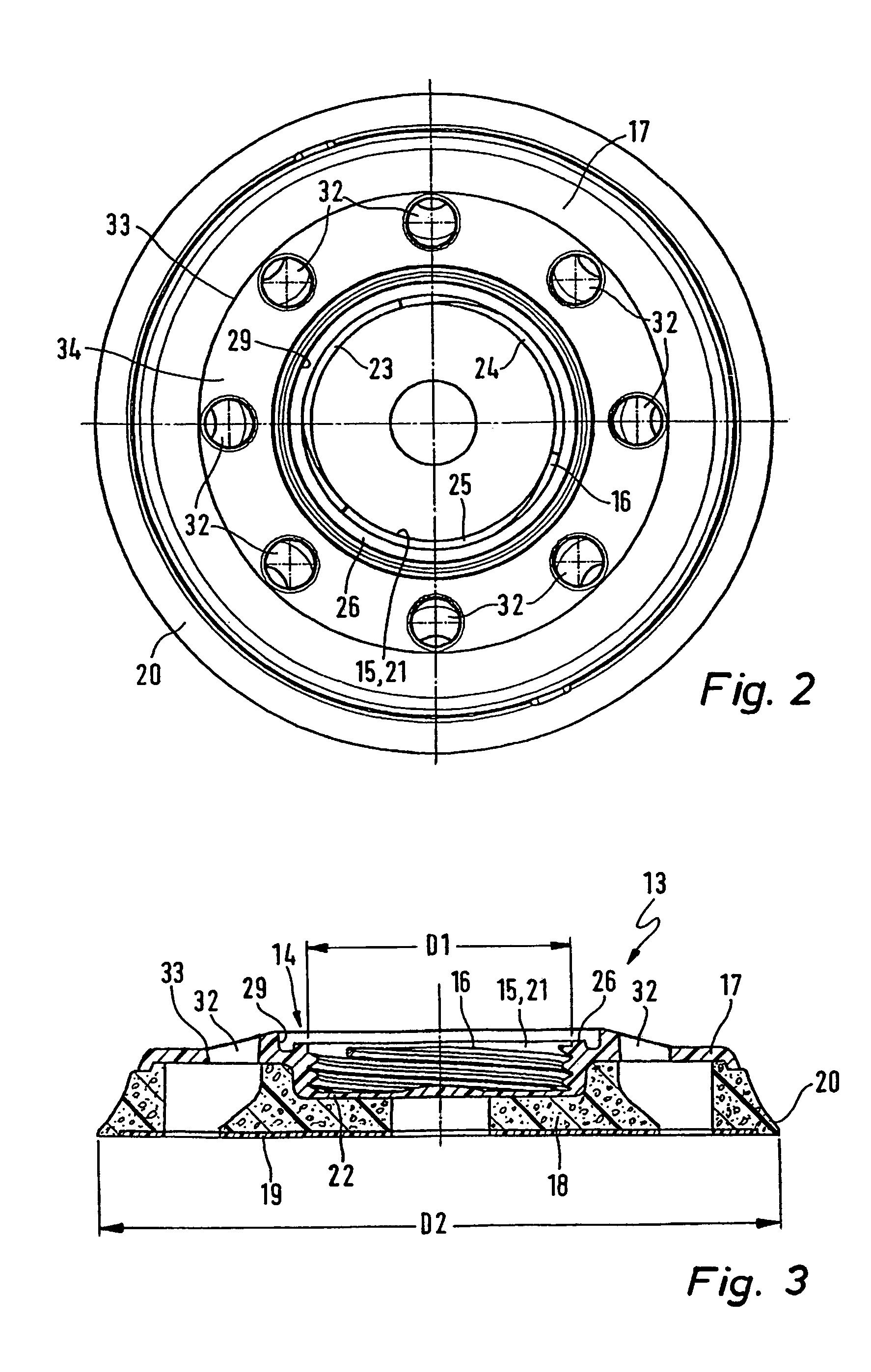

Grinding disk

ActiveUS7029384B2High torqueFine pitchGrinding wheel securing apparatusRevolution surface grinding machinesDiameter ratioEngineering

A grinding disk (13) for manually held, motor-driven grinders (1) has a centrally arranged fastening recess (15) open at the grinding disk upper side with an internal thread arrangement (16), with which the grinding disk (13) can be screwed onto a connecting part (8), which is arranged on the side of the grinder and is driven for the grinding motion during operation, and which connecting part has a thread section (11) with an external thread arrangement (12), which is associated with the internal thread arrangement (16) of the grinding disk (13). The internal thread arrangement (16) is formed by a multiple thread with at least two thread courses, which are arranged angularly offset to one another. The diameter ratio between the diameter of the internal thread arrangement (16) and the outside diameter of the grinding disk (13) is at least approximately 0.25.

Owner:FESTOOL GMBH

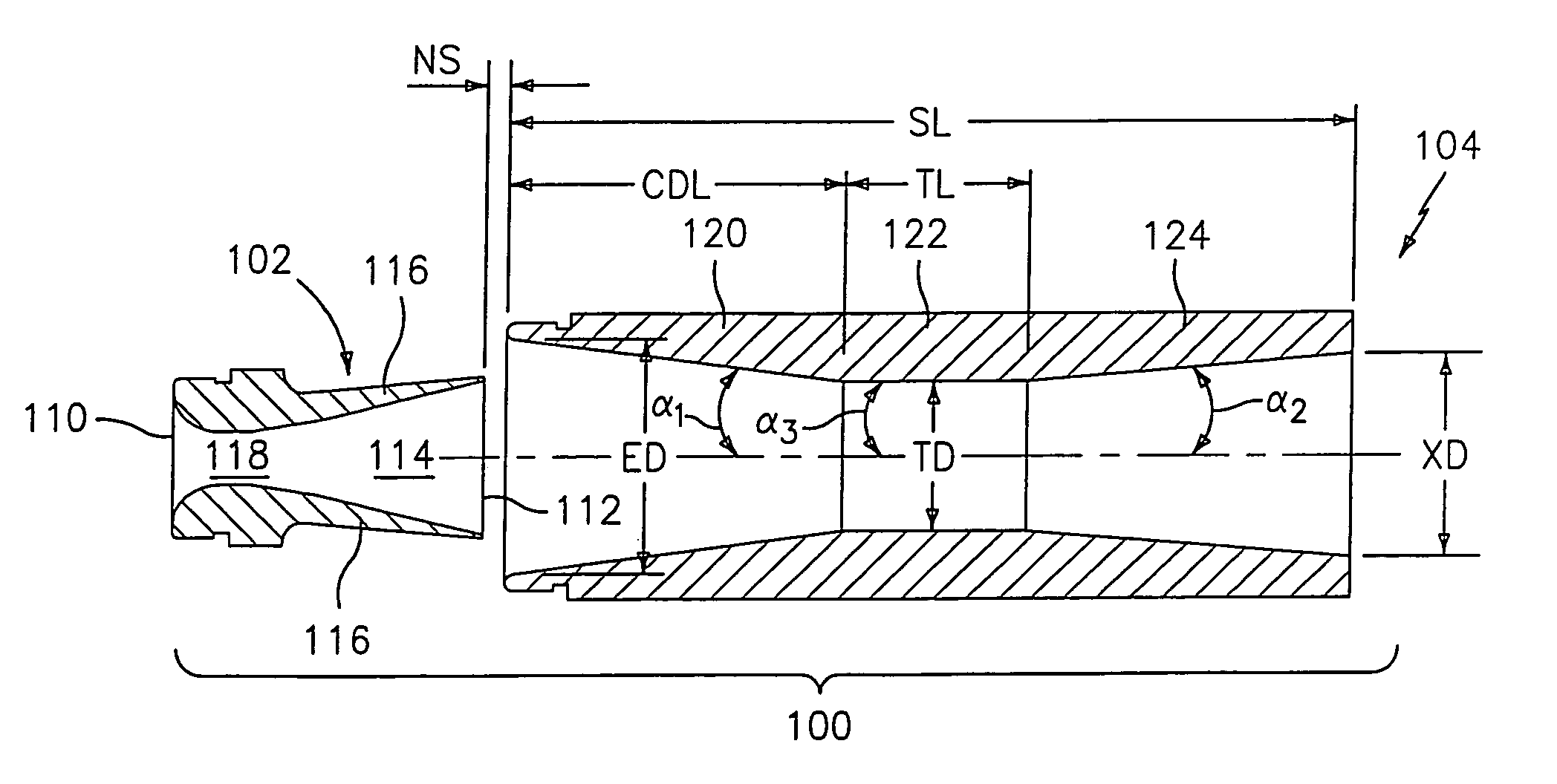

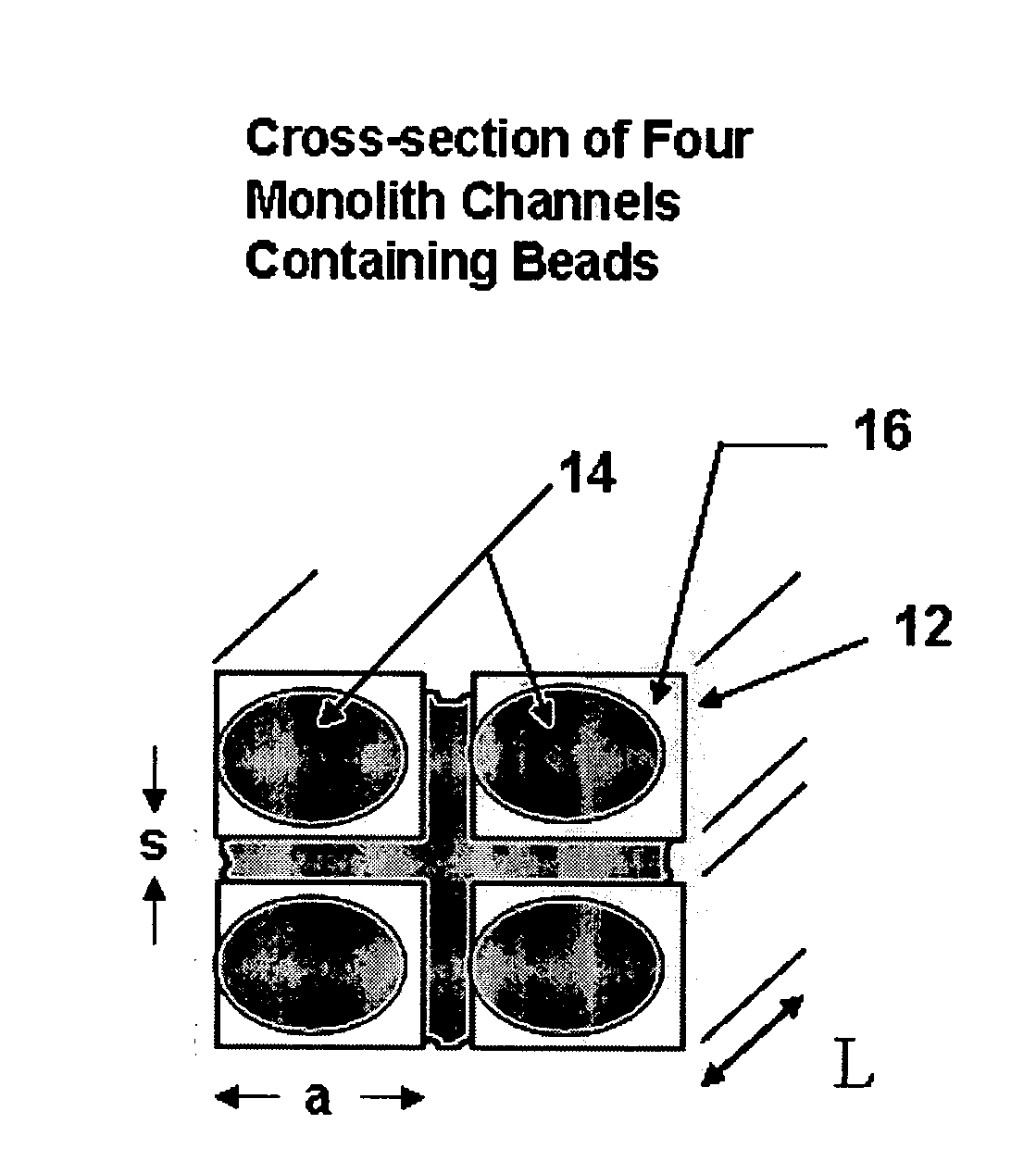

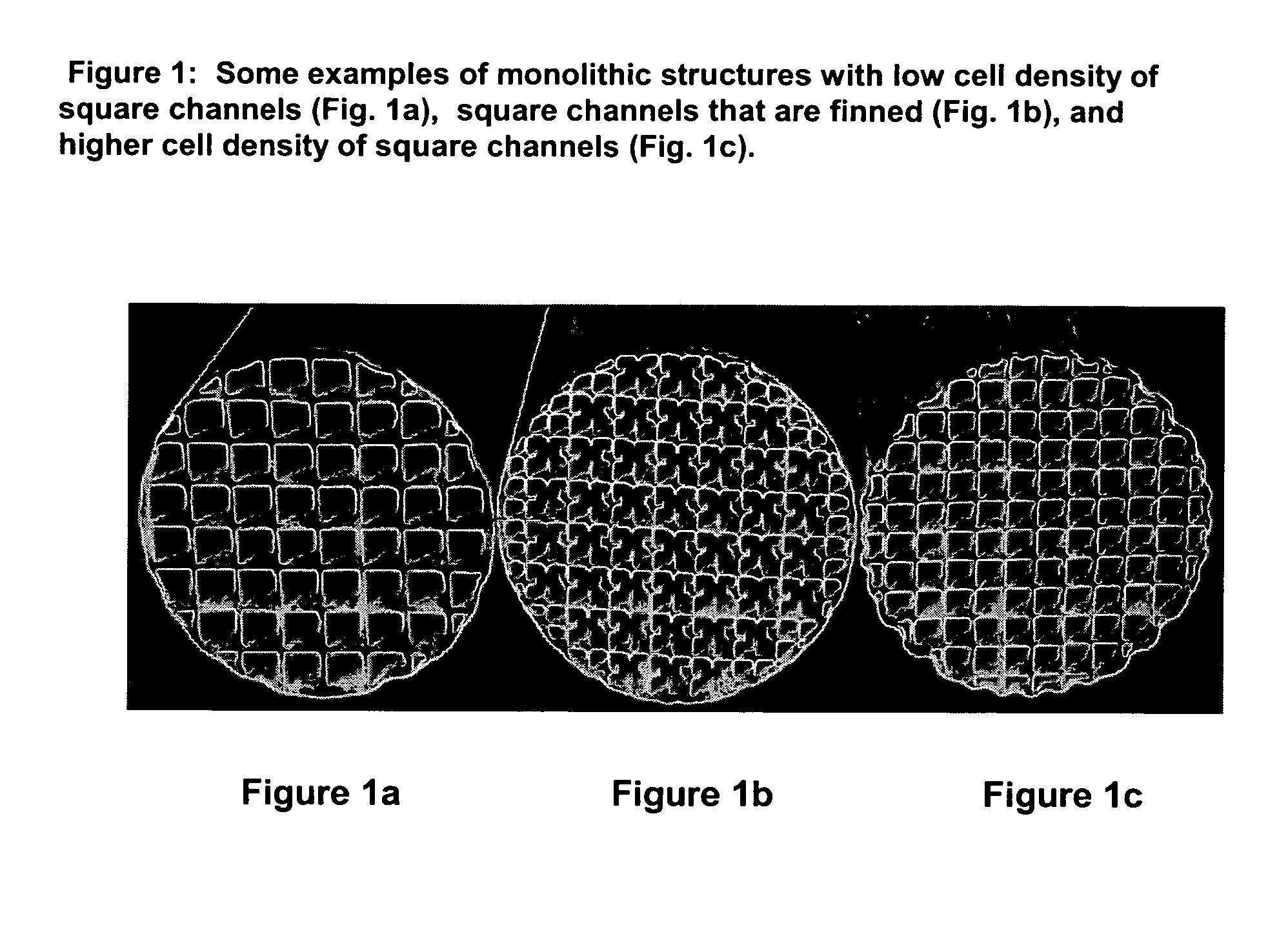

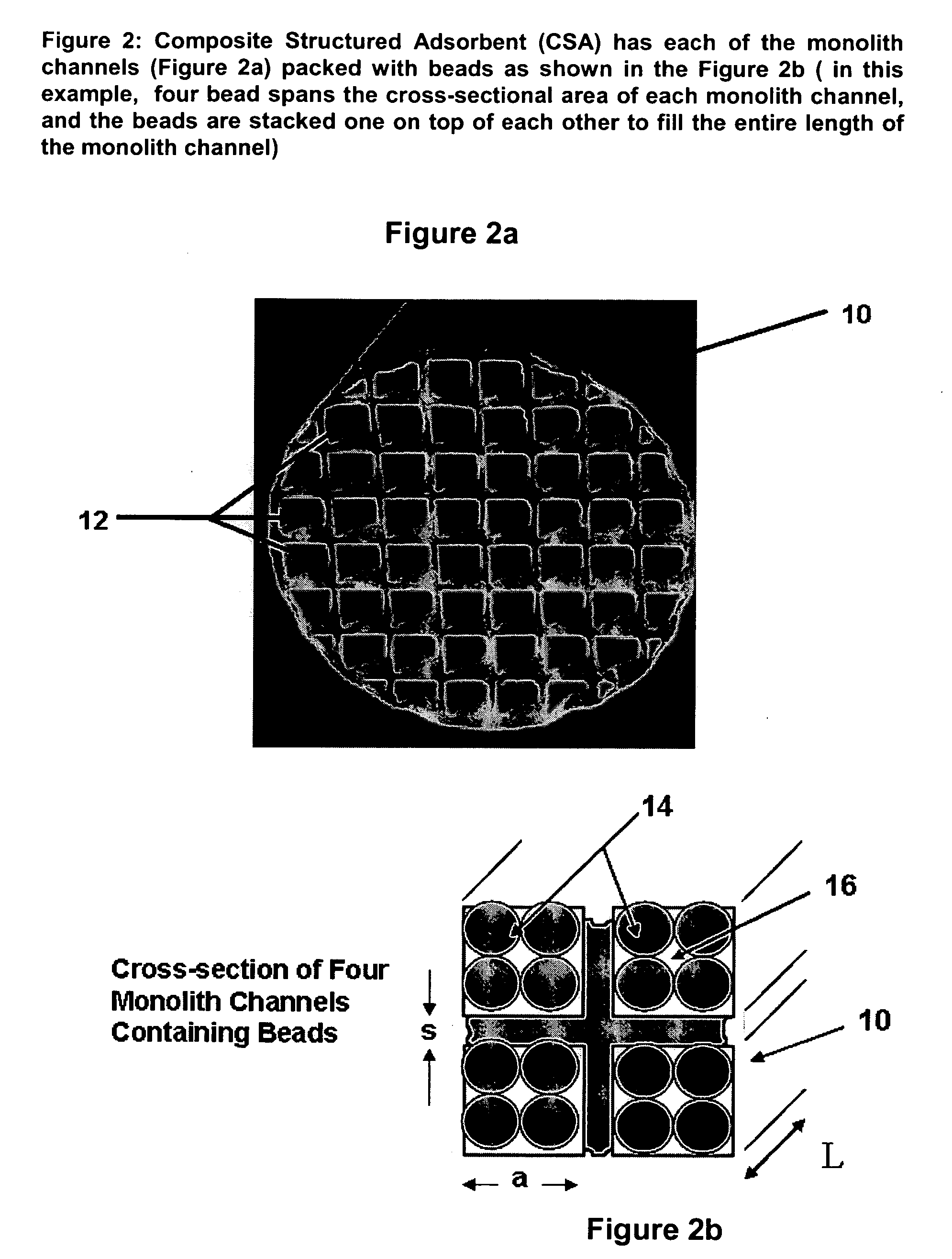

Composite structured adsorbents

InactiveUS20080148936A1Lower overall pressure dropReduce power consumptionGas treatmentIsotope separationVacuum pressureSorbent

The present invention relates to composite structured adsorbents and methods of use therefor. The invention more particularly relates to composite structured adsorbents that can include a multi-channel framework (e.g., monoliths), the channels of the multi-channel framework containing adsorbent beads particles therein, with a channel-to-particle diameter ratio in the range of 1 to 10, more preferably 1 to 7 and even more preferably 1 to 5. In the case of non-spherical particles, the hydraulic diameter is used in the calculation of the channel-to-particle diameter. The composite structured adsorbents of the present invention can be used in various industrial applications, for example in pressure swing adsorption (PSA) or vacuum pressure swing adsorption (VPSA) processes to produce O2 from air.

Owner:PRAXAIR TECH INC

Graphene-containing silicon rubber heat-conducting composite material and preparation method thereof

The invention relates to the field of heat-conducting high-polymer composite materials, particularly a graphene-containing silicon rubber heat-conducting composite material and a preparation method thereof. The heat-conducting composite material is mainly composed of graphene, an inorganic heat-conducting filler and a silicon rubber matrix, wherein the graphene accounts for 0.1-10 wt% of the silicon rubber heat-conducting composite material, and the graphene constitutes a heat-conducting network in the heat-conducting composite material. The method comprises the following steps: uniformly compounding the inorganic heat-conducting filler, graphene, crosslinking agent and other assistants and silicon rubber on a double-roll open mill to obtain a heat-conducting silicon rubber prepolymer; and carrying out primary vulcanization on the prepolymer on a flat vulcanizing machine, and carrying out secondary vulcanization in a drying oven to finally obtain the composite heat-conducting silicon rubber. Since the two-dimensional graphene has large thickness-diameter ratio and can easily constitute an effective heat-conducting network in the silicon rubber, a small amount of two-dimensional graphene can obviously enhance the heat-conducting property of the silicon rubber (the heat conductivity coefficient at 40 DEG C is 4.98 W / m.K). The silicon rubber composite heat-conducting material can be widely used in the field of heat dissipation of electronic products.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

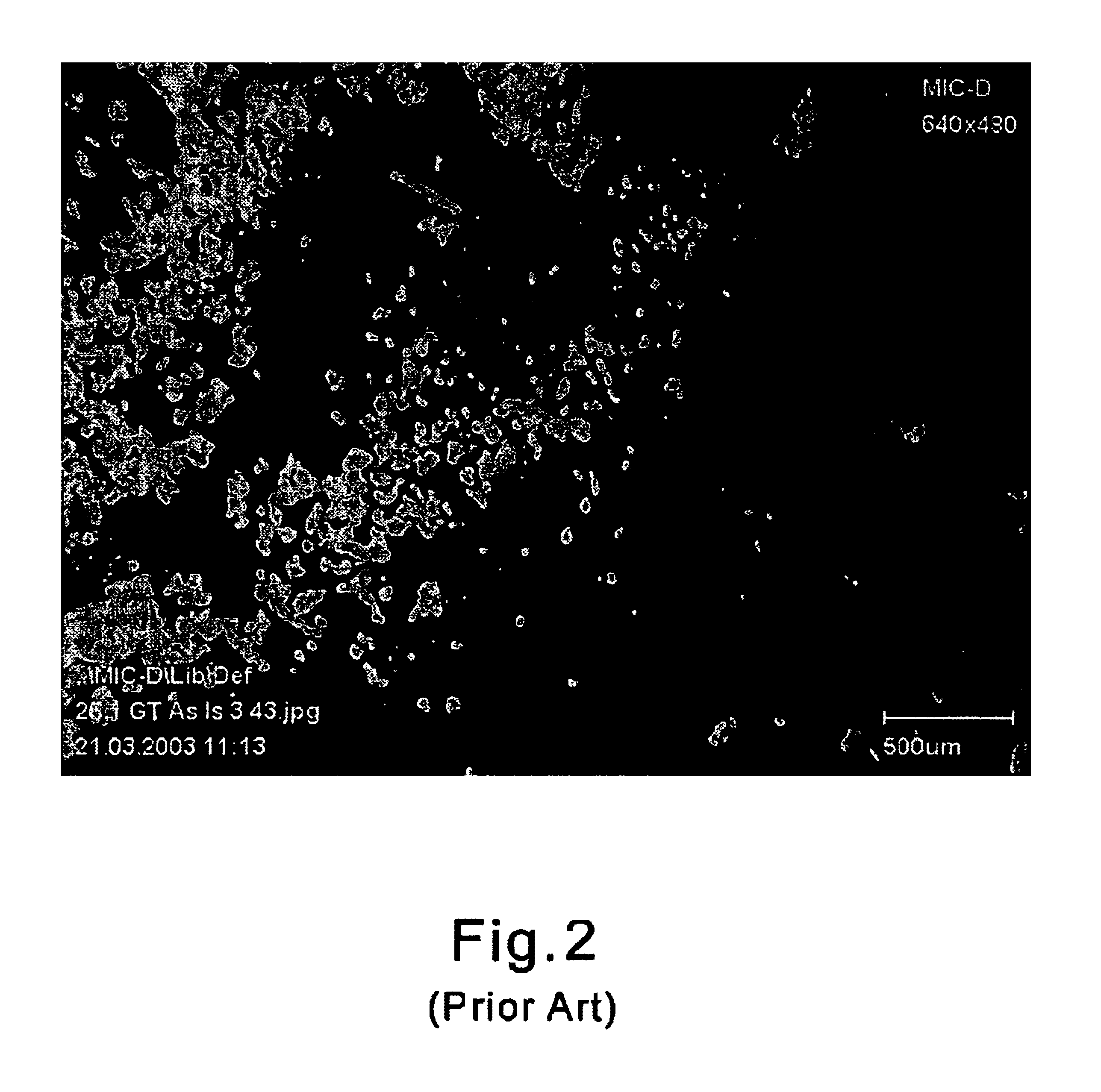

Crystalline form of sucralose, and method for producing it

A crystalline form of sucralose, and a method of making it. The method involves continuously crystallizing sucralose from an aqueous solution by a process providing continuous removal and recirculation of the vessel contents, and providing a long residence time for sucralose in the system. The crystals thus formed are of a relatively low length / diameter ratio, have an unsymmetrical shape, and exhibit good stability. The larger crystals in particular are tapered as compared to the rod-like larger crystals in prior art product.

Owner:TATE & LYLE TECH LTD

Method for preparing length-diameter-ratio nano-silver wire by pH-value regulation solvothermal method

The invention relates to a method for preparing a length-diameter-ratio nano-silver wire by a pH-value regulation solvothermal method. The method comprises the following steps of: preparing the following ethylene glycol solution, namely an ethylene glycol solution A of silver nitrate or silver acetate, an ethylene glycol solution B of polyvinyl pyrrolidone (PVP), an ethylene glycol solution C of water-soluble chloride and concentrated acid D; mixing the components according to a certain amount and fully stirring to form a final mixed solution; moving the final mixed solution into a reaction kettle; placing in an oven for reaction for a certain time; taking the reaction kettle out and cooling to room temperature to obtain mother liquid of the nano-silver wire; adding alcohol into the mother liquid for diluting, and removing supernatant liquor to obtain a precipitate; and repeatedly performing centrifugal separation, and thus obtaining nano-silver wire dispersion liquid uniformly dispersed in the alcohol. The method is simple, high in efficiency and low in cost, and can prepare high-quality nano-silver wires within a wider range of reaction condition; and prepared products are high in length-diameter ratio, good in length uniformity and low in impurity content.

Owner:JIANGSU NANOWELL ADVANCED MATERIALS SCI&TECH

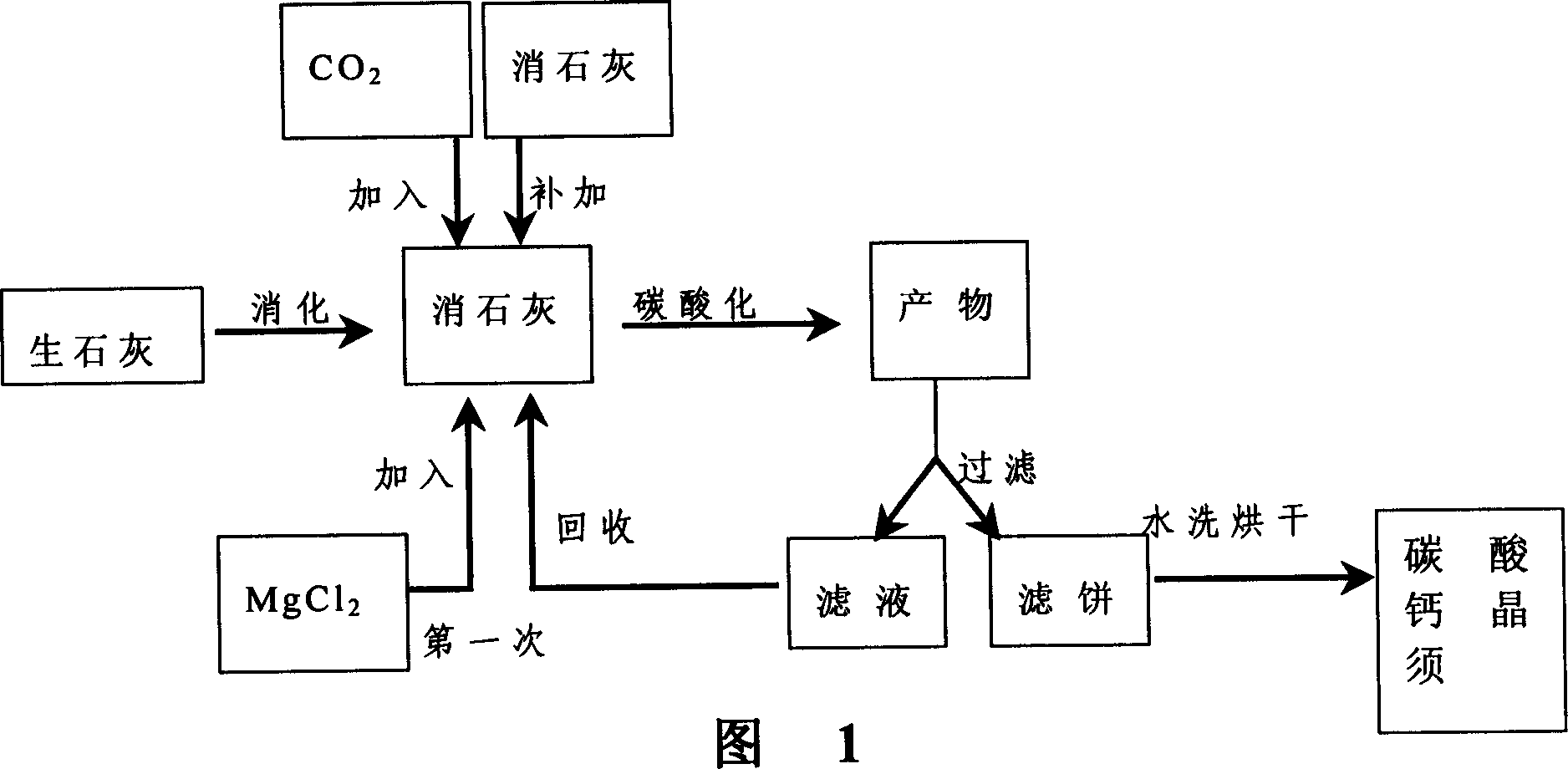

Method for preparing aragonite type calcium carbonate whisker

InactiveCN1641077AReduce manufacturing costReduce qualityCalcium/strontium/barium carbonatesPolycrystalline material growthMagnesium saltDiameter ratio

The present invention relates to the preparation process of high purity aragonite type calcium carbonate whisker. The present invention prepares aragonite type calcium carbonate whisker with lime or slaked lime as main material and magnesium salt as crystal salt controlling agent and through a CO2 carbonating process. The process features the repeated use of the magnesium salt solution and the homogeneous replenishment of lime slurry during carbonating reaction. The process has low production cost, less environmental pollution and high calcium carbonate whisker yield, and the prepared calcium carbonate whisker has high purity and high length / diameter ratio. The process is suitable for industrial production of calcium carbonate whisker.

Owner:NAT UNIV OF DEFENSE TECH

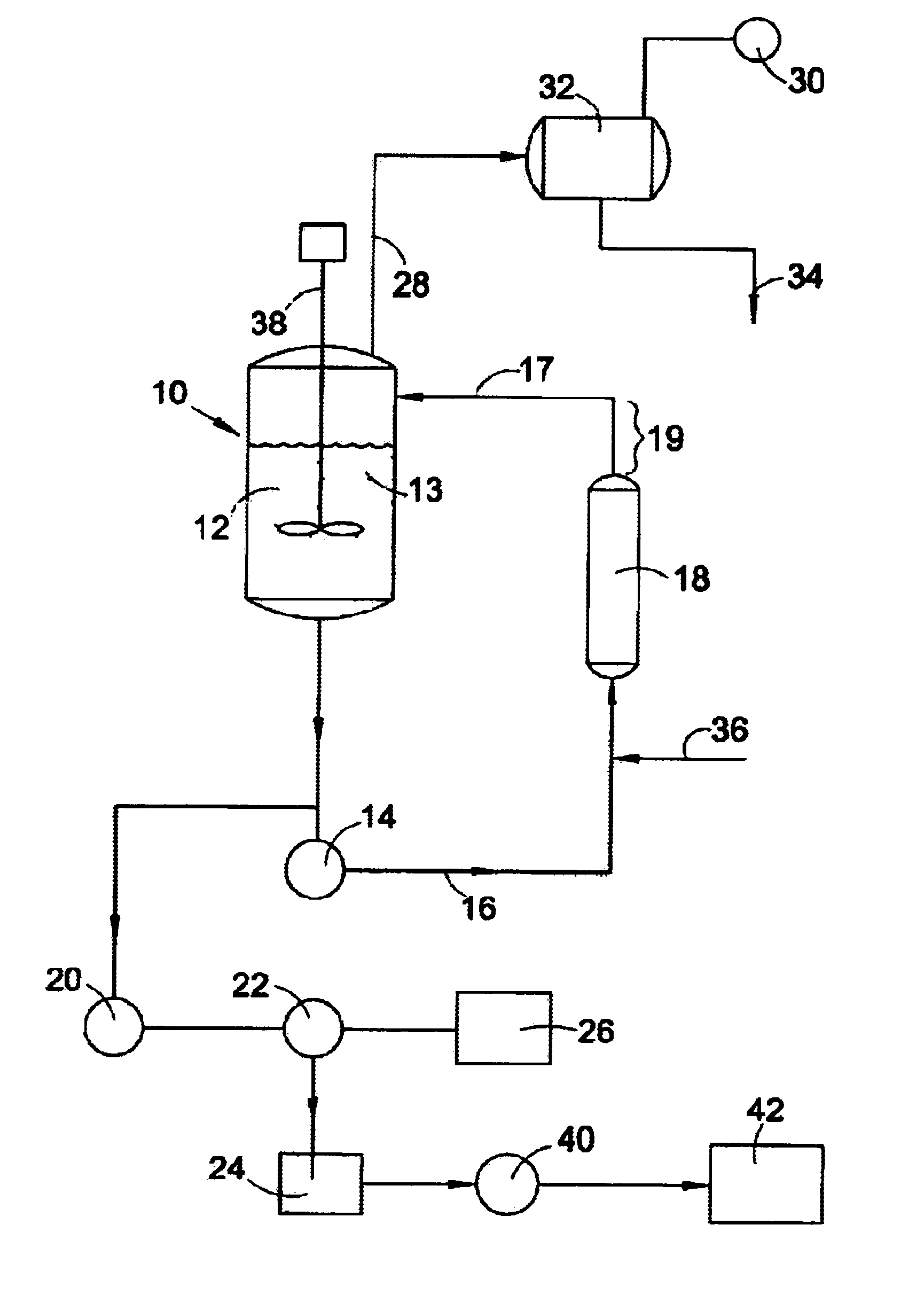

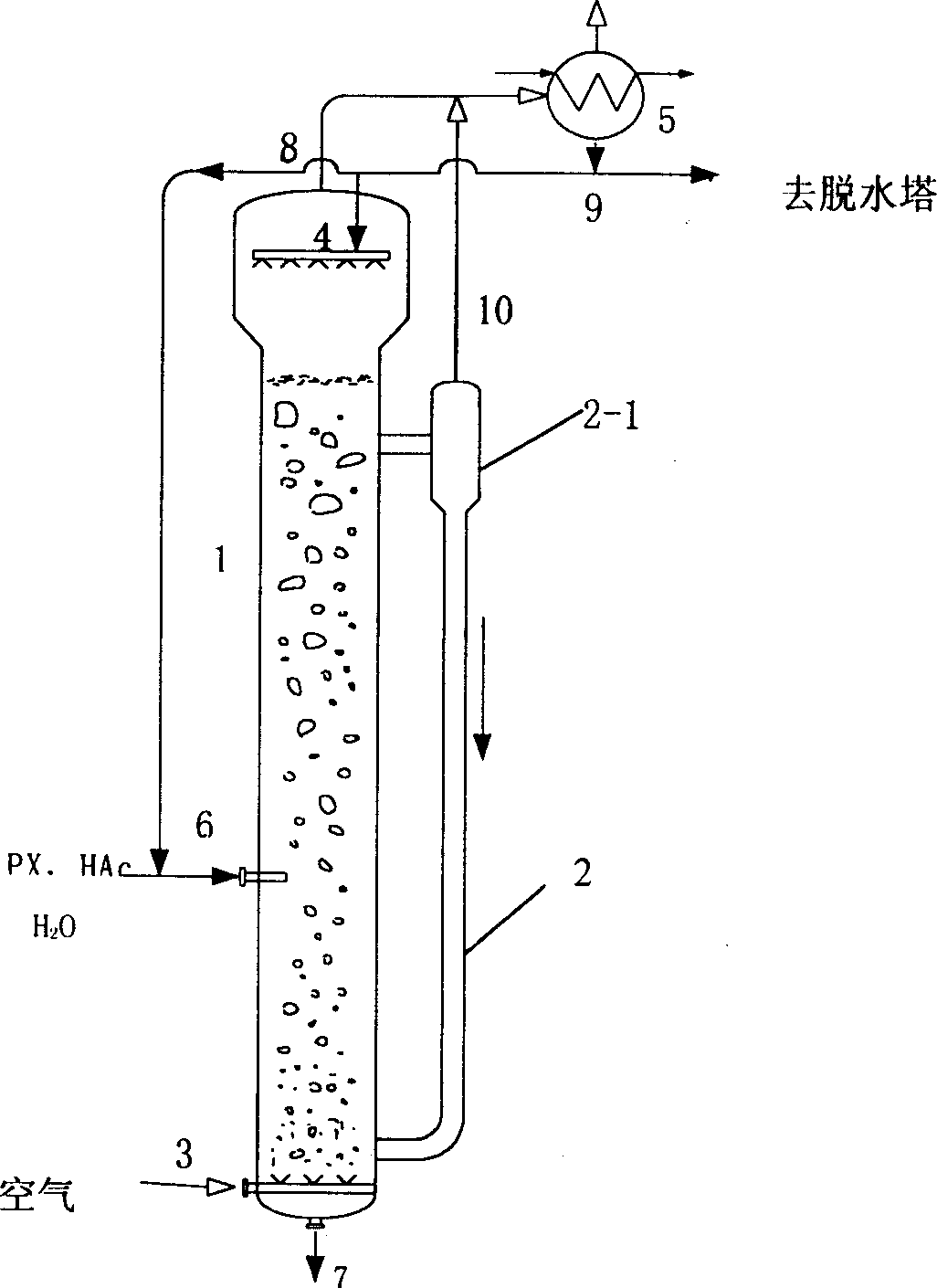

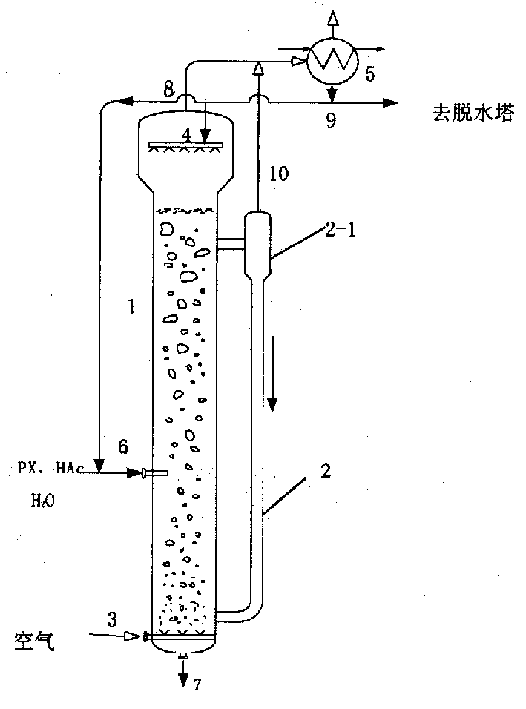

Air lift externally circulating bubble fower oxidation unit for producing terephthalic acid

InactiveCN1486968ASimple structureLow costOrganic compound preparationCarboxylic compound preparationCatalytic oxidationEngineering

The air lift externally circulation bubble tower oxidation apparatus includes cylinder bubble tower with top expanded section, outer circulating pipe, gas distributor, reflux liquid distributor and condensator. The outer circulating pipe has its upper end and lower end communicated with the upper part and the lower part of the bubble tower reaction section separately and is used to lead slurry from the upper part of the tower to the lower part via air lift effect so as to form the fluid circulation in the whole tower and complete the liquid phase catalytic oxidation of xylene. The bubble tower has relatively high height / diameter ratio and thus reinforced gas-liquid mass transfer and the air lift outer circulation pipe improves the temperature distribution and concentraion distribution inside the tower. The tower has no moving part, simple structure and low cost and is suitable for oxidizing xylene to prepare terephthalic acid via different technological processes.

Owner:CHINA TEXTILE IND ENG INST +2

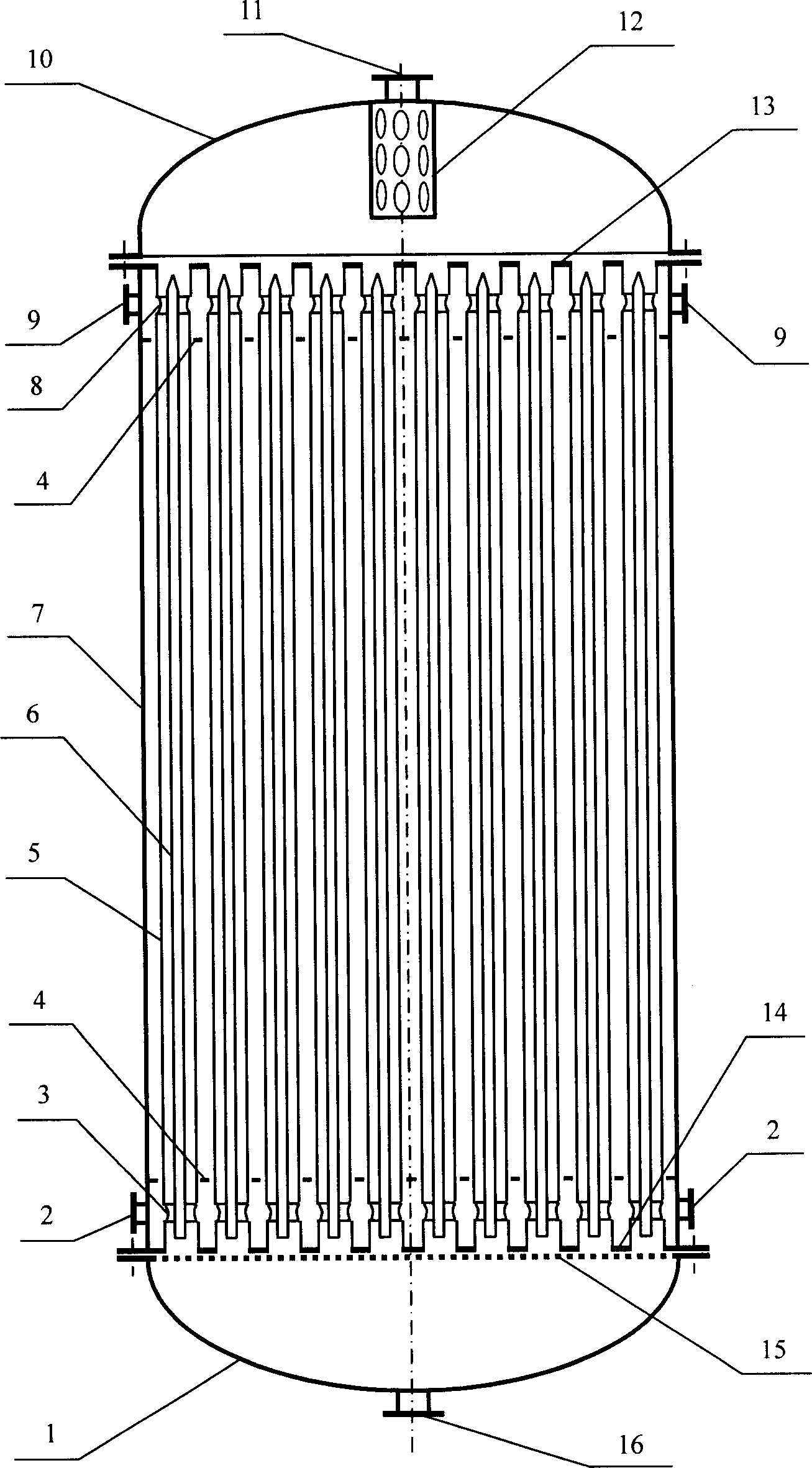

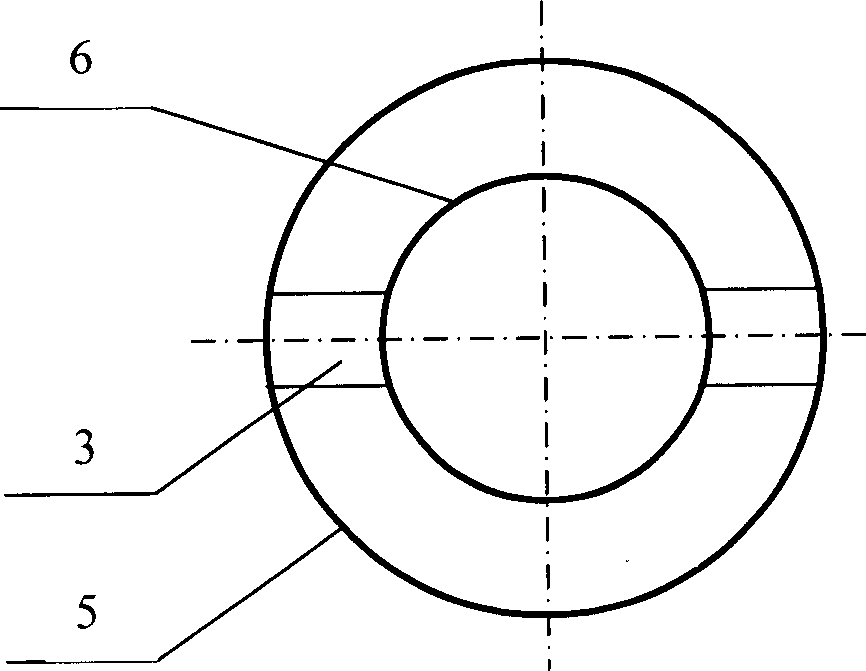

Non-hot spot calandria type fixed bed reactors

InactiveCN1736574AIncrease the heat exchange areaIncrease heat transfer areaChemical/physical processesReaction rateDiameter ratio

Disclosed is a non- thermal point tubular fixed bed reactor, which is technically characterized in that: every tube of the reactor adopts annular tube structure, the inner tubes being closed, the inner tube and outer tube being linked to the shell side of the reactor by canal, the catalyst being filled into the space between tubes to form a catalyst bed layer, the bottom and top of the tubes being equipped with a cooling medium distributing plate. The diameter ratio of the inner tube to outer tube can be regulated according to the reaction rate and the operation temperature to make the reaction heat transfer to the double- side. Dimension of opening of the cooling medium distributing plate and dimension of the opening of the side- wall of double terminals of inner tube can be regulated to control the distribution of cooling medium between inner tube and the shell side of reactor. With the invention, in the condition of no increasing the number of tubes largely, it can increase the heat- exchange area of the tubular fixed bed reactor and decrease the heat- exchange route.

Owner:TSINGHUA UNIV

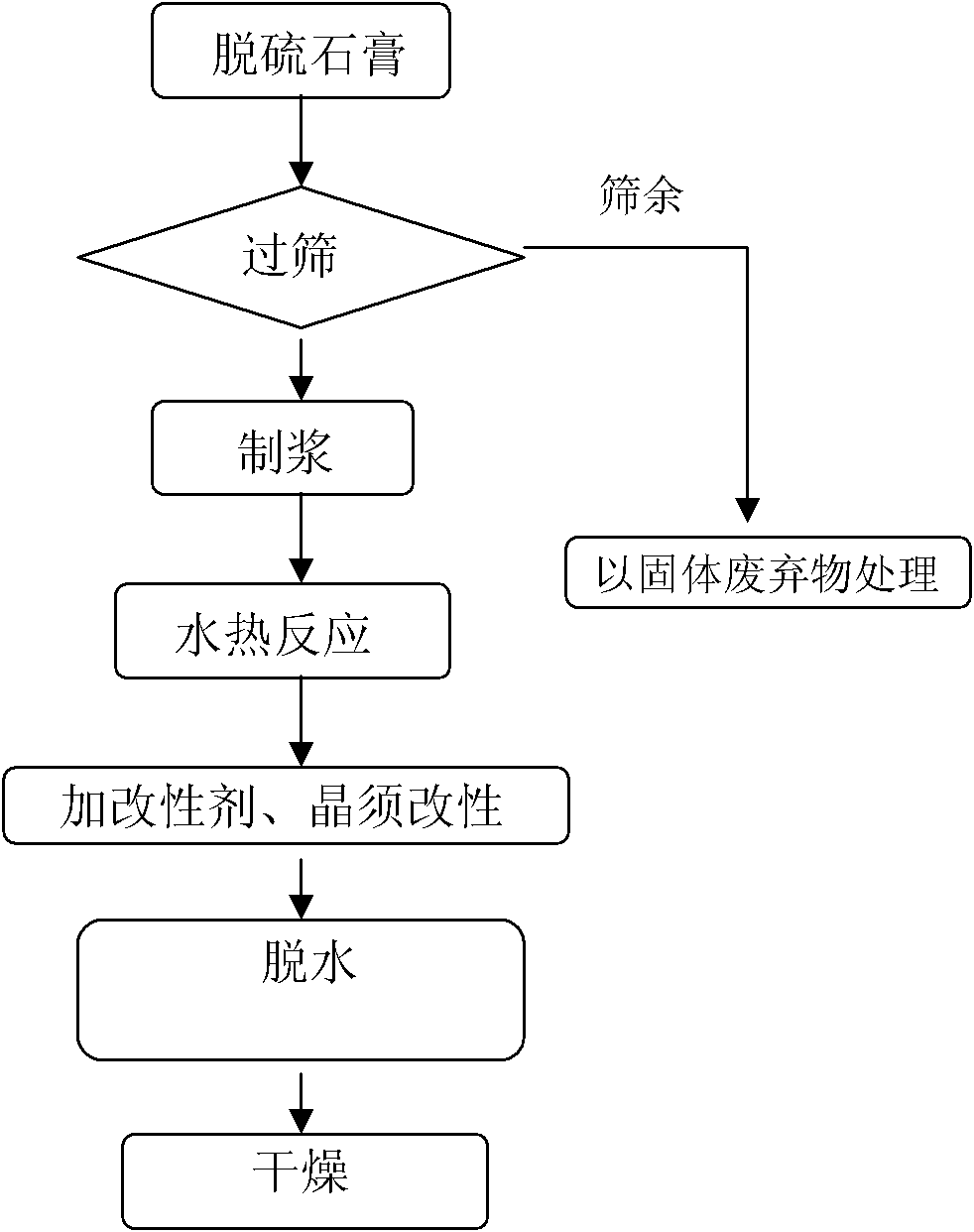

Method for preparing modified calcium sulfate whisker by using desulfurization gypsum

ActiveCN101994153AGood compatibilitySolve the problem of prone to hydration leading to whisker breakagePolycrystalline material growthFrom normal temperature solutionsSulfateMicrometer

The invention discloses a method for preparing a modified calcium sulfate whisker by using desulfurization gypsum, comprising the following steps of sieving, pulping, performing hydro-thermal reaction and whisker surface modification, dewatering and drying, wherein the reaction temperature ranges from 107 DEG C to 180 DEG C, the concentration of desulfurization gypsum and water is 5-33wt% and the drying temperature ranges from 100 DEG C to 300 DEG C, and a modifier which is 0.05-5% of the weight of desulfurization gypsum in the calcium sulfate whisker suspension formed in hydro-thermal reaction. The invention solves the problem that CaSO4.0.5H2O whisker is easy to hydrate in the drying process tocause fracture of the whisker and enhances the compatibility of the calcium sulfate whisker and the high polymer materials. The prepared modified calcium sulfate whisker has a diameter of 0.5-6 micrometers, a length of 30-300 micrometers and a diameter ratio of 15-115 and the contact angle of water on the surface of the modified calcium sulfate whisker ranges from 12 to 140 degrees. The invention has the advantages of good modified effect, simple process, low production cost, the use of the non-toxic modifier and environmental-friendly preparation process.

Owner:JIANGSU EFFUL SCIENCE AND TECHNOLOGY CO LTD

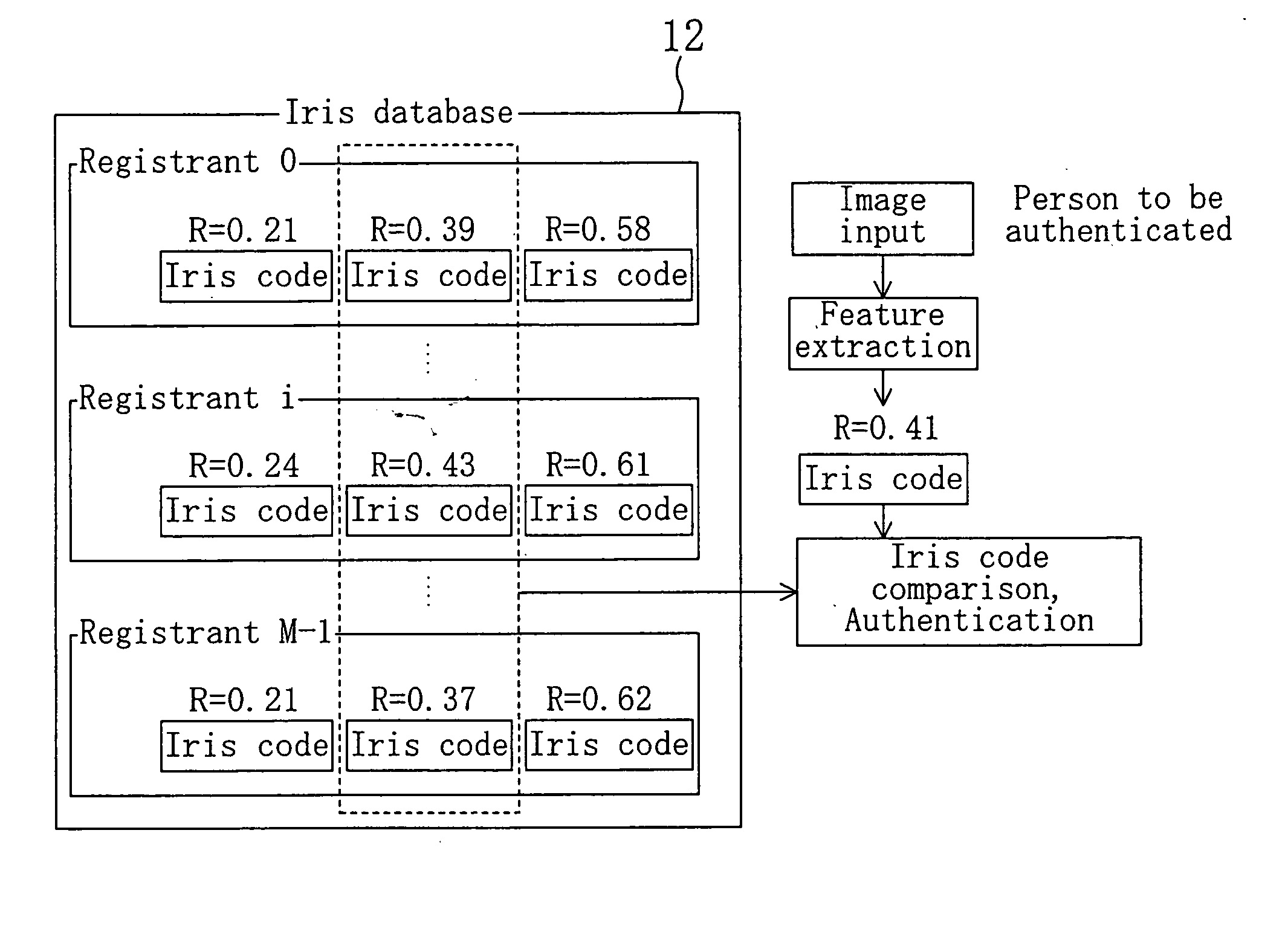

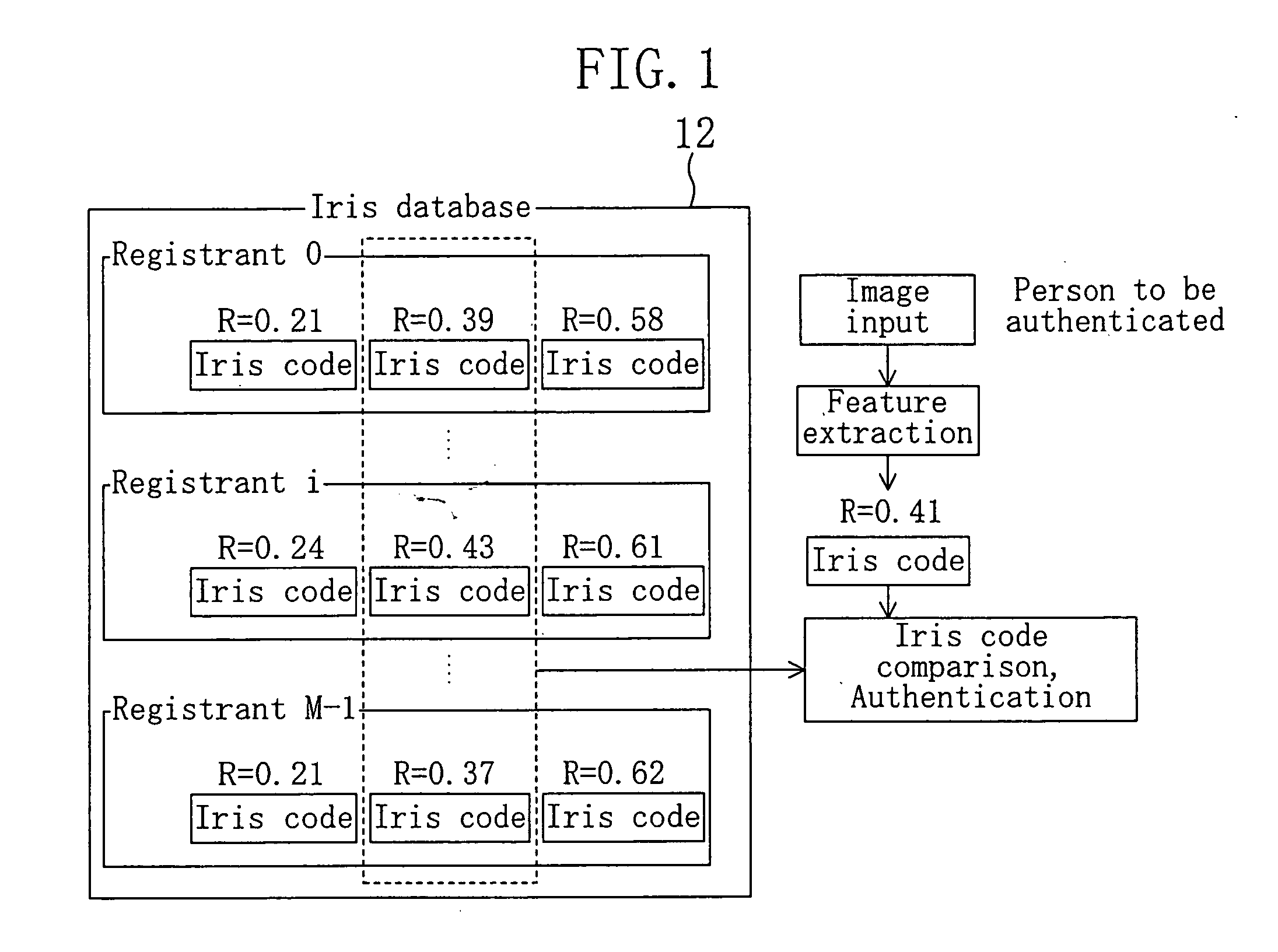

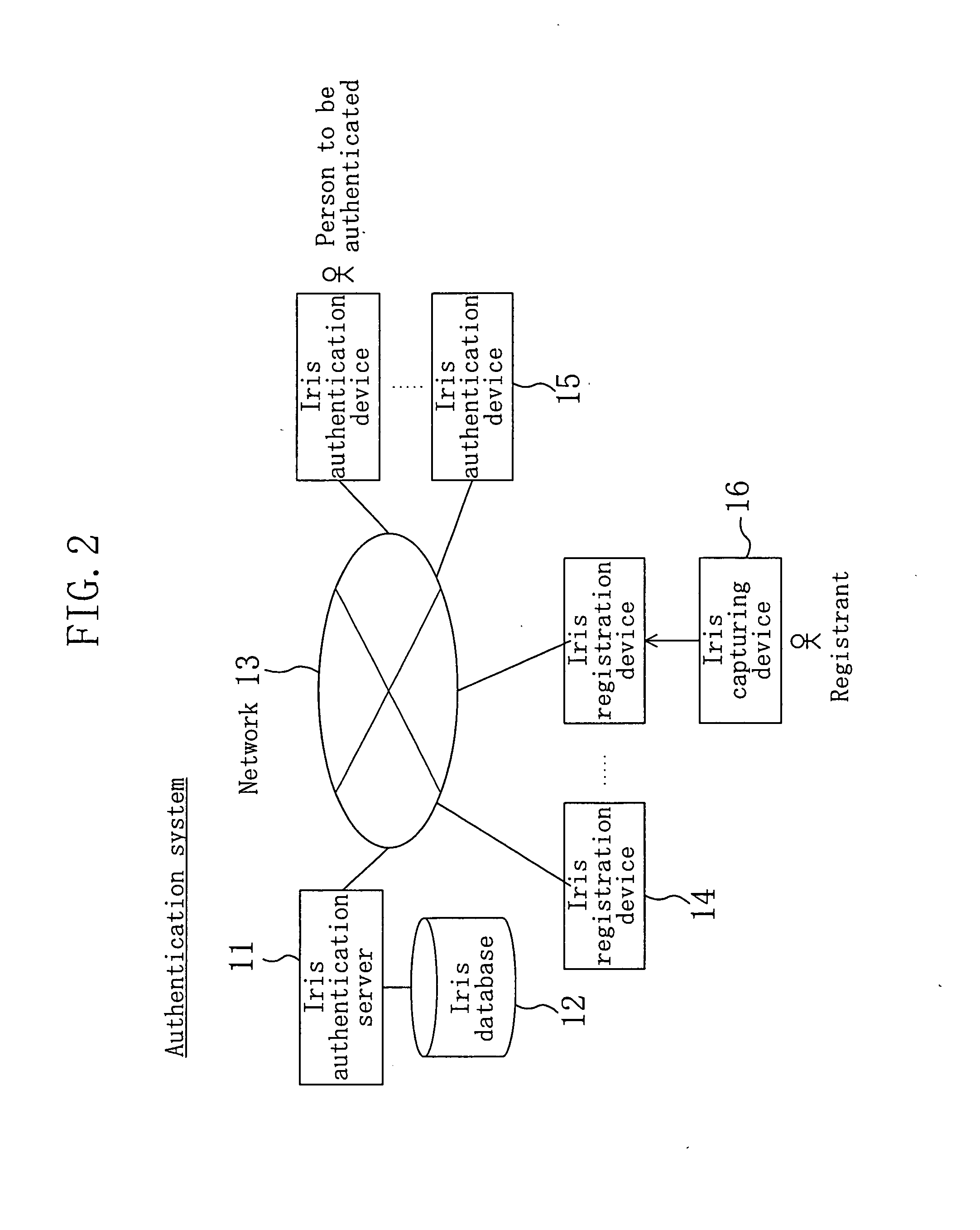

Method for cerficating individual iris registering device system for certificating iris and program for cerficating individual

ActiveUS20050152583A1Reduce false reject rateShort timeImage enhancementElectric signal transmission systemsPupil diameterFeature extraction

A plurality of iris codes are registered for each registrant in an iris database (12) together with pupil diameter-iris diameter ratio R. At the time of authentication, an iris code is obtained from a captured iris image by feature extraction while pupil diameter-iris diameter ratio R is obtained. Ratio R obtained at the time of registration and ratio R obtained at the time of authentication are compared to specify an appropriate iris code from the iris database (12) as an item to be collated before authentication.

Owner:PANASONIC CORP

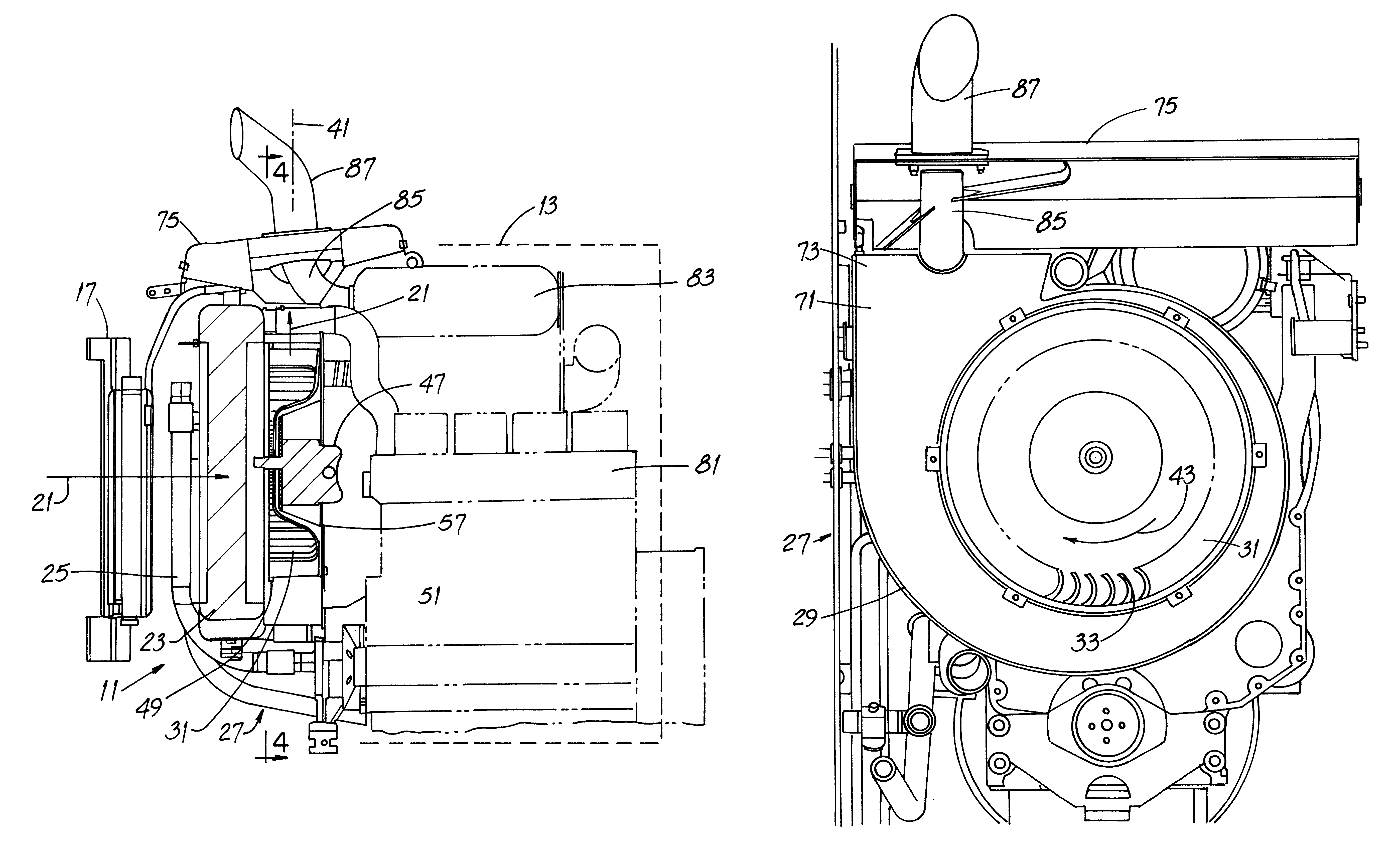

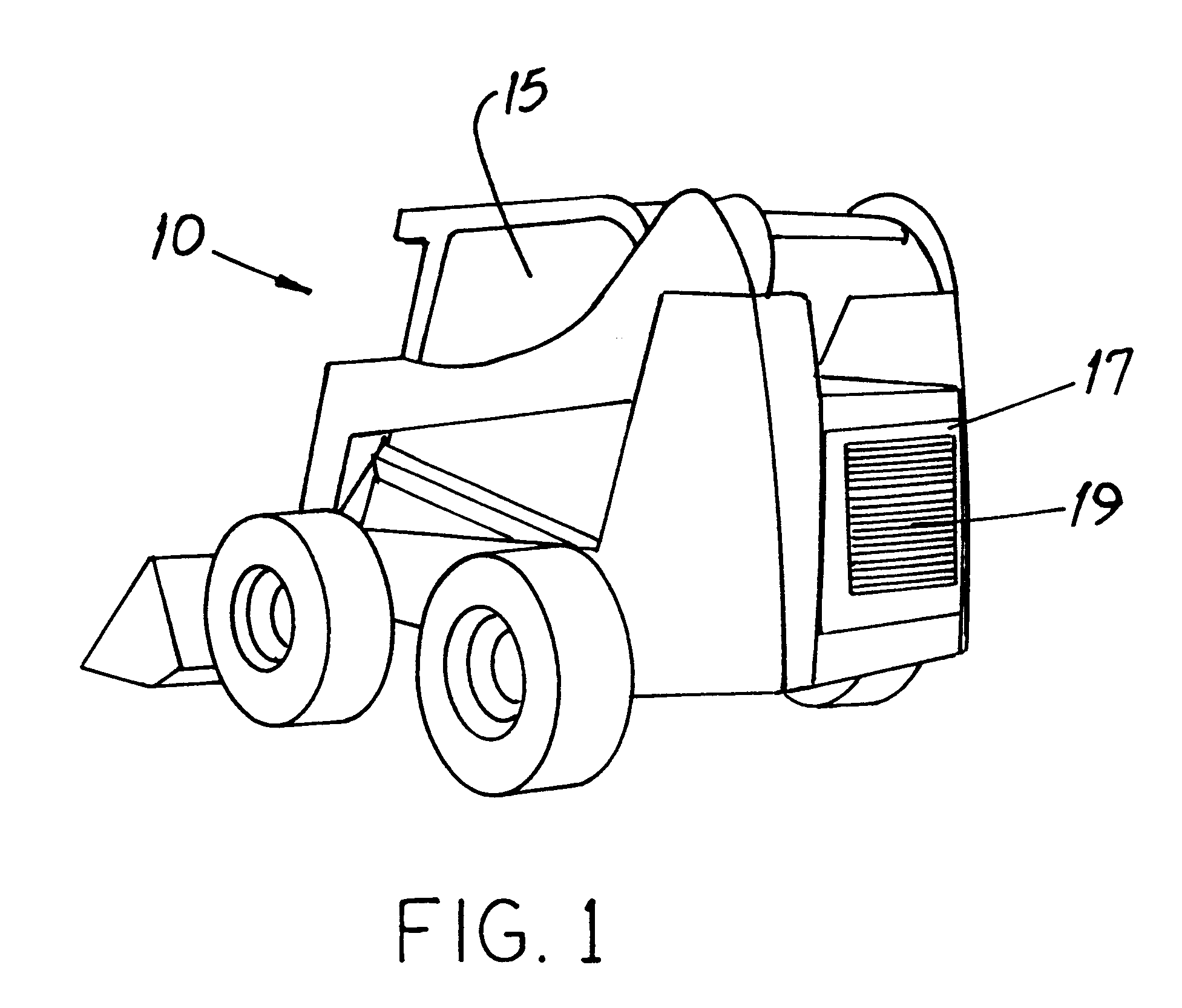

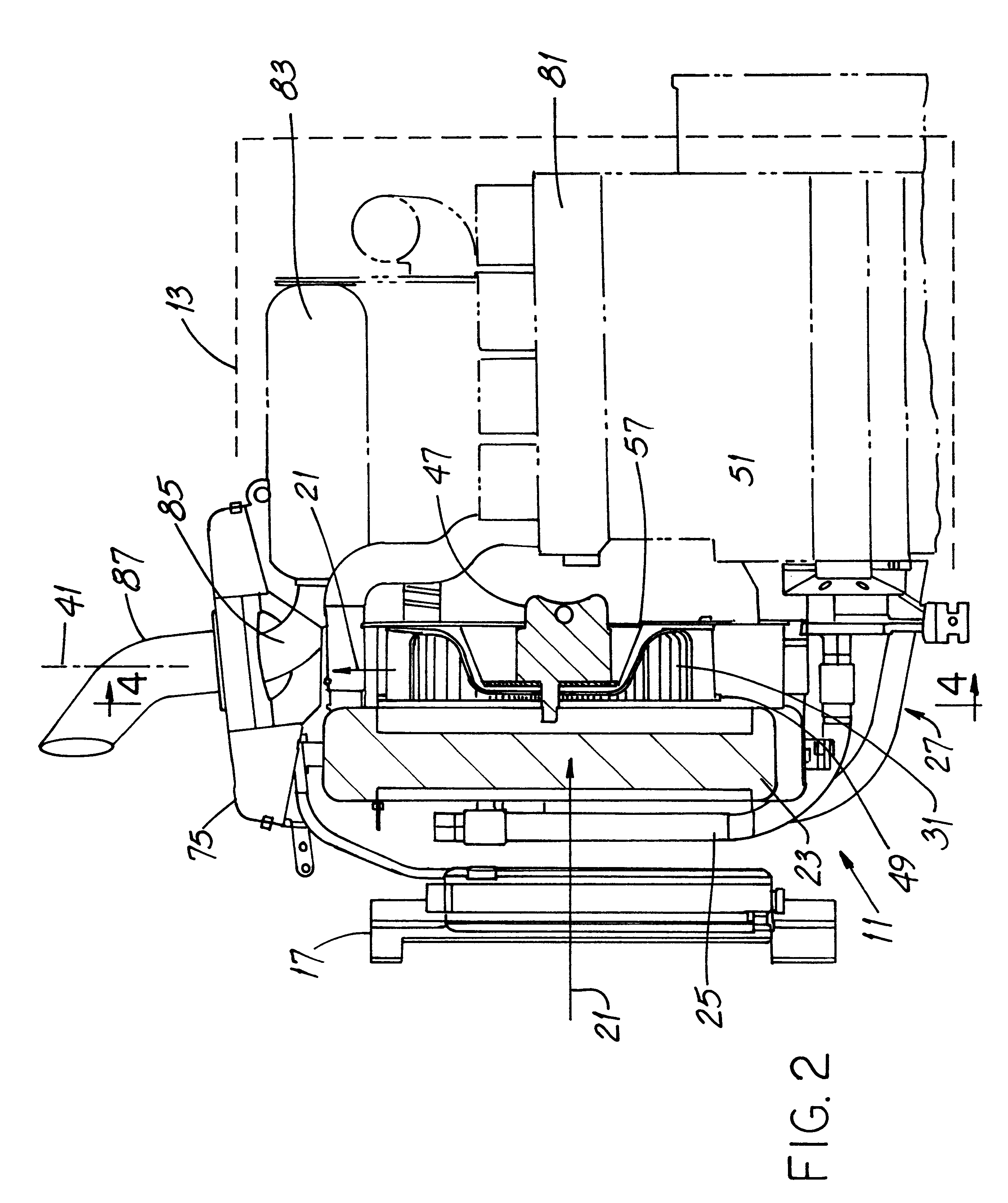

Cooling system for an off-highway vehicle

InactiveUS6216778B1Reduce system noiseReduce back pressurePump componentsExhaust apparatusDiameter ratioControl theory

A cooling system for an off-highway vehicle includes a heat exchanger (e.g., an engine coolant or hydraulic oil heat exchanger) and a fan mechanism for flowing air along a flow path through the heat exchanger. In the improvement, the fan mechanism is a centrifugal fan mechanism and is substantially the sole means for flowing air along the flow path. That is, there is substantially no ram-urged air. The mechanism includes a housing and a fan in the housing. The fan has forward curved blades, thereby to reduce system noise. A preferred fan has a depth-to-diameter ratio not in excess of about 0.4 and, most preferably, not in excess of about 0.25. An alternate embodiment includes what might be termed a split-discharge arrangement wherein air blown by the fan is discharged along two paths.

Owner:BLUE LEAF I P INC +1

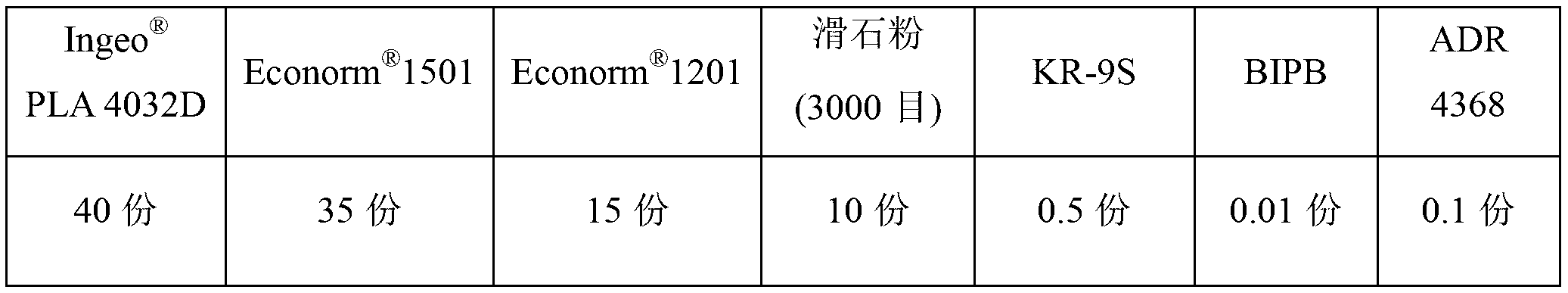

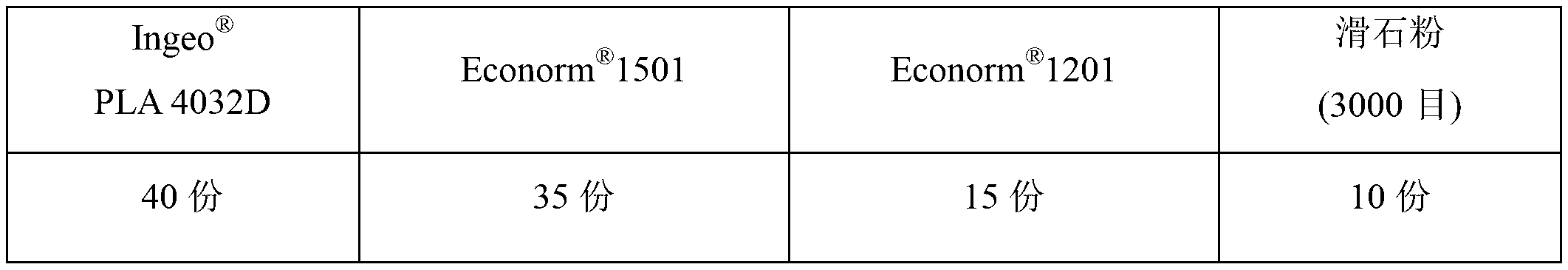

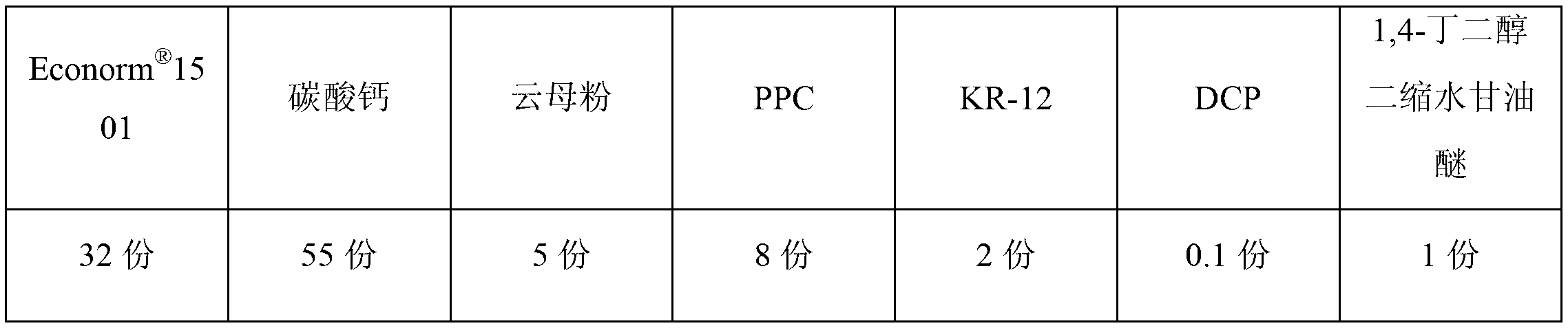

Method for increasing capacity of biodegradable polyester blend film

The invention relates to a biodegradable polyester blend film, and in particular relates to a method for increasing the capacity of a biodegradable polyester blend film. The method for increasing the capacity of the biodegradable polyester blend film comprises the steps of: adding a high-activity titanate coupling agent, a free radical cross-linking agent and a multi-epoxy group compound into a blending compound system of two or more than two biodegradable polyesters and an inorganic or organic filler; initiating and promoting transesterification, proper intermolecular cross-linking reaction and end-group chain extension in a double-screw extruder with the length-diameter ratio of more than or equal to 48 and the total kneading blocks of more than or equal to 16 under the action of high temperature and high shear strength, thus increasing the capacity of blending polyester. Through utilizing the double-screw extruder with the high length-diameter ratio and high shear strength and introducing the titanate coupling agent, the free radical cross-linking agent and the multi-epoxy group compound are introduced, on-line capacity increasing of a biodegradable polyester / filler blend compound system is carried out, so that the anisotropy of the mechanical property of the film is greatly improved.

Owner:山东悦泰生物新材料有限公司

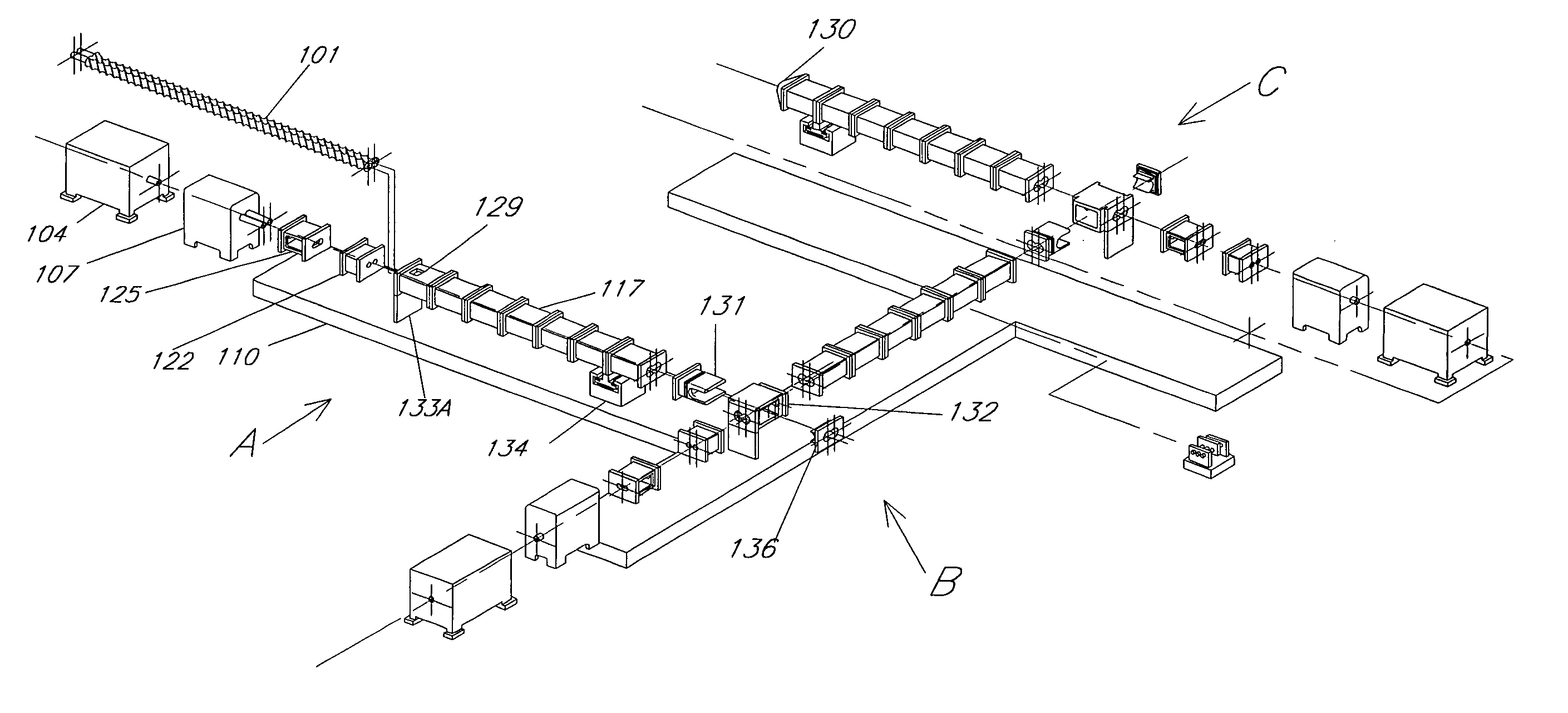

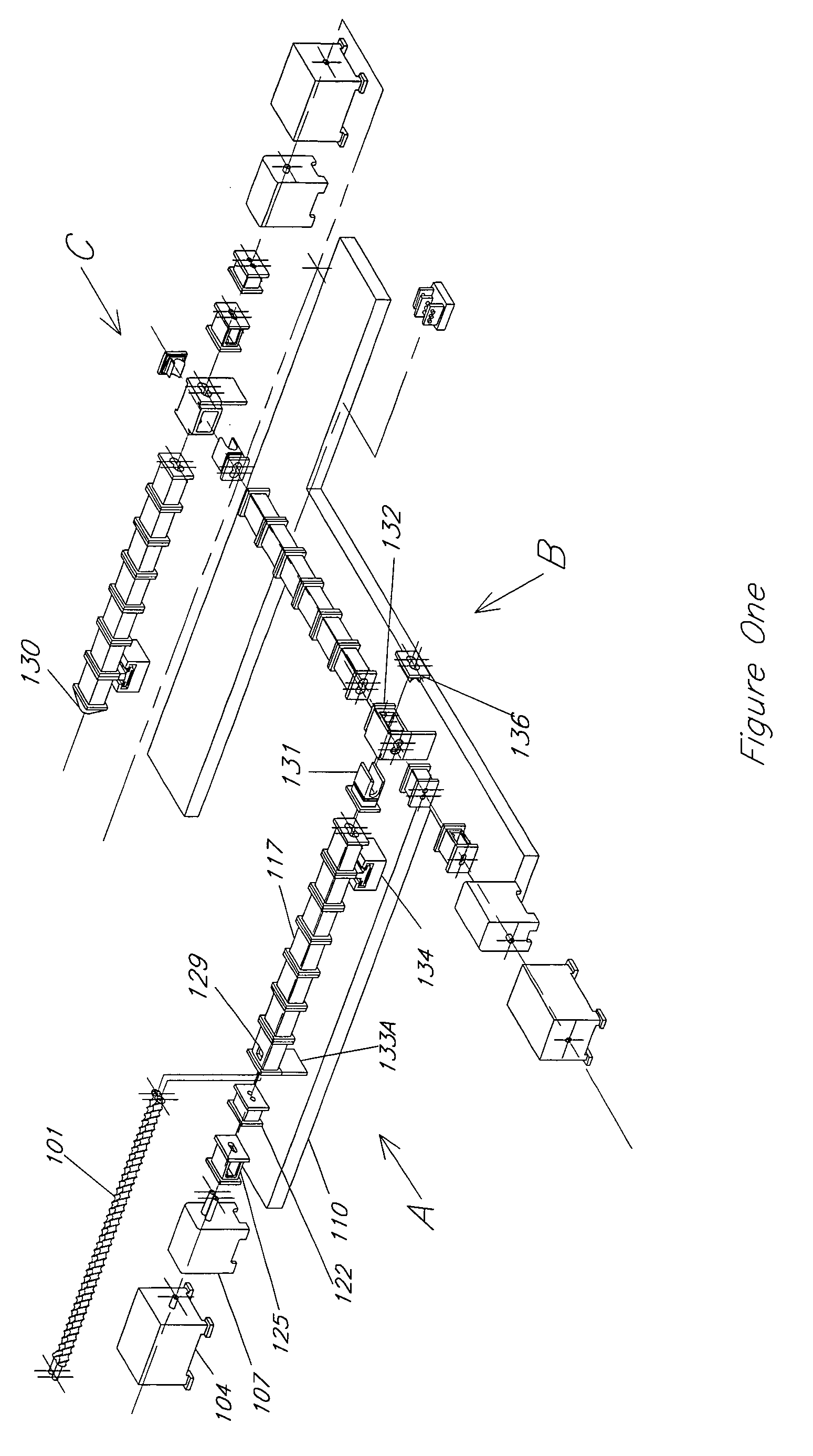

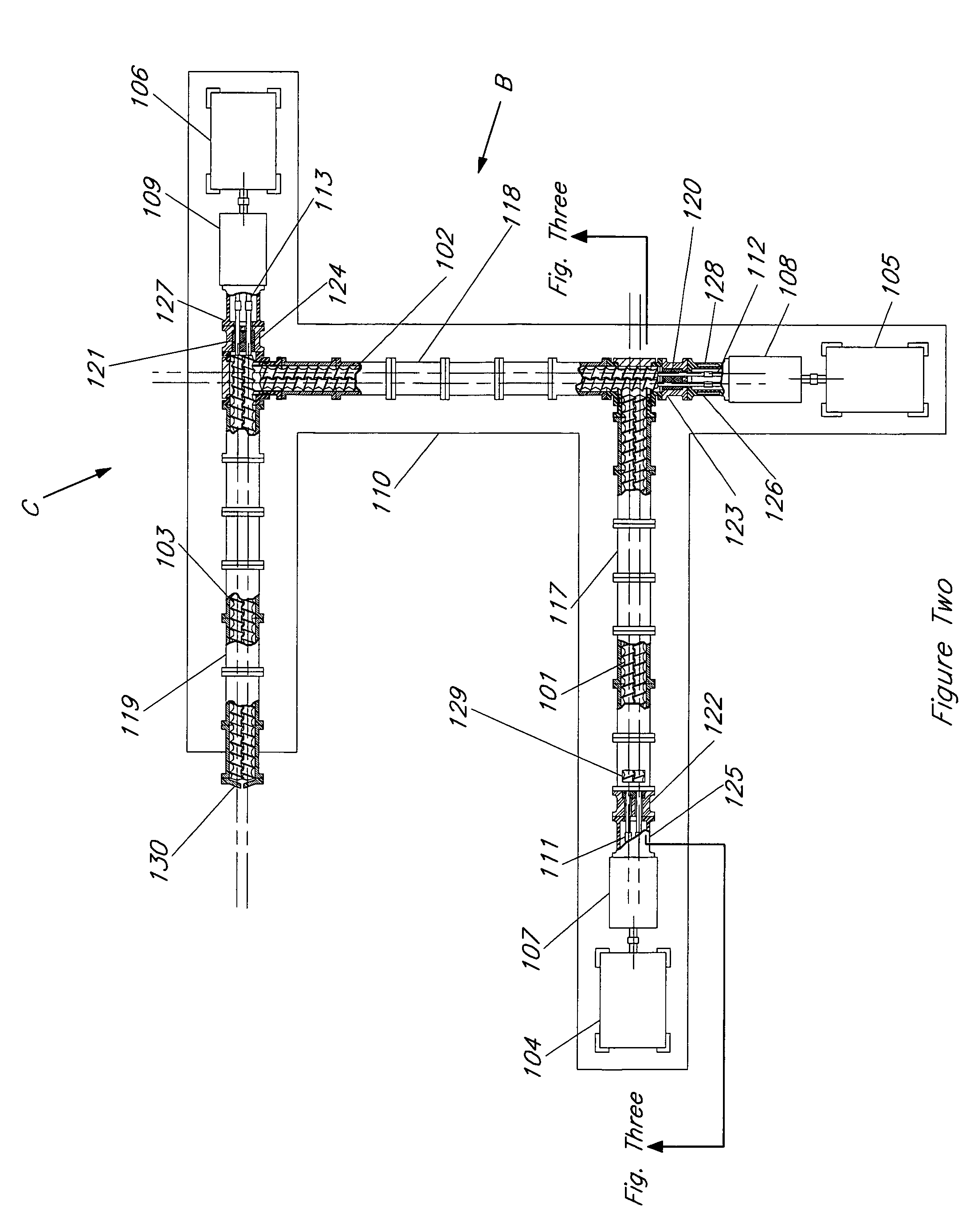

Multiple extruder assembly and process for continuous reactive extrusion

Methods are disclosed for a novel and useful single pass extrusion process for the reactive extrusion and compounding of polymers. Traditional extruders utilized in reactive processes are of length to diameter ratios ranging from 30 to 1 to as high as 56 to 1. The process disclosed uses a series of sequential, very closely-coupled, independently driven screw extruders having a total effective length to diameter ratio much greater than 70 to 1 and as high as 132 to 1 or greater, and providing greatly extended reaction times, separate and multiple introductions of reactive and non-reactive agents and mechanical connections allowing for convenient screw changes and differential thermal expansion. The assembly is employed to economically produce grafted polyolefins, produce ionomers without employing the use of strong caustic agents, remove large volumes of unwanted polymer processing solvents and produce other reacted polymer species in one continuous pass.

Owner:ORREX PLASTICS CO LLC

Method for manufacturing silver nanowire

The invention discloses a method for manfuacturing a silver nanowire, and the method comprises the following steps of: (a) providing a mixed solution, wherein the mixed solution at least contains a protective agent and an additive, and the additive is a halide or a compound capable of generating an insoluble salt with silver ions; (b) providing a silver precursor solution containing silver compounds, and adding the precursor solution in the mixed solution at least in twice; and (c) separating to obtain the silver nanowire. The method for manufacturing a silver nanowire has the beneficial effects that the protective agent is adopted at first, and then the silver precursor solution is added at least in twice rather than one time, the silver nanowire with high wire diameter ratio and suitability for production in a large scale can be obtained.

Owner:NUOVO FILM SUZHOU CHINA INC

Method and apparatus for compressing a gas to a high pressure

ActiveUS7527482B2Increase volumeReduce volumePositive displacement pump componentsFlexible member pumpsElectronic controllerFoot per second

A method is provided for compressing a gas in a single cycle and in a single cylinder to a pressure of at least 17.2 Mpa with a compression ratio of at least about five to one. The method further comprises dissipating heat from the cylinder during the compression stroke whereby the gas is discharged with a temperature significantly less than isentropic. The apparatus comprises a hollow cylinder and a reciprocable free-floating piston disposed therein. The piston divides the cylinder into: (a) a compression chamber within which a gas can be introduced, compressed, and discharged; and, (b) a drive chamber, into which a hydraulic fluid can be introduced and removed for actuating the piston. The apparatus further comprises a piston stroke length to piston diameter ratio of at least seven to one. For operating the apparatus with a compression ratio of at least five to one, an outlet pressure of at least 17.2 Mpa, and a gas discharge temperature significantly less than isentropic, the apparatus can further comprise a variable displacement hydraulic pump for controlling piston velocity, an electronic controller for maintaining an average piston velocity that is less than 0.5 feet per second, and a heat dissipator for dissipating heat from the cylinder.

Owner:WESTPORT FUEL SYST CANADA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com