Patents

Literature

63results about How to "Increase flow pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

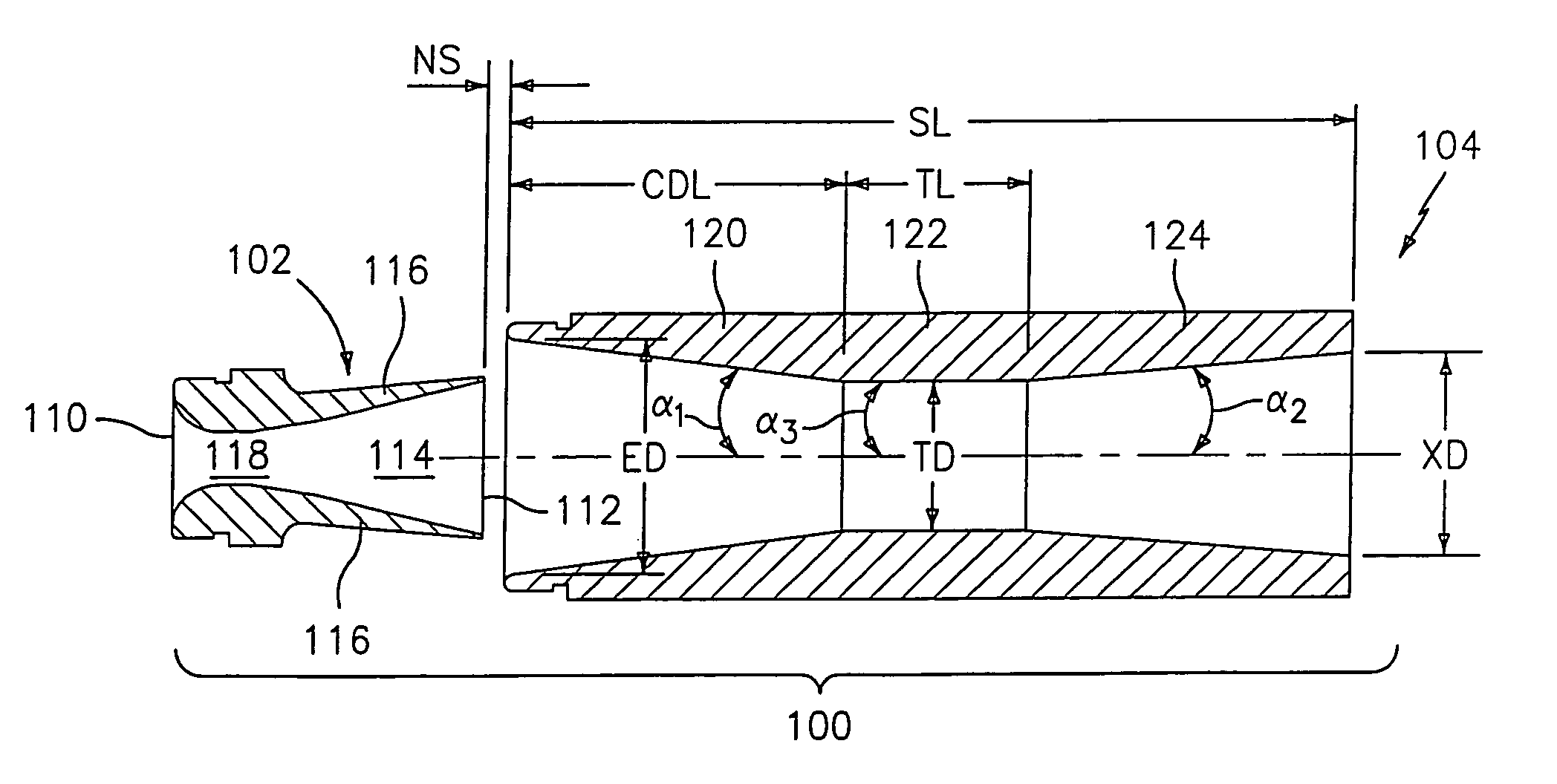

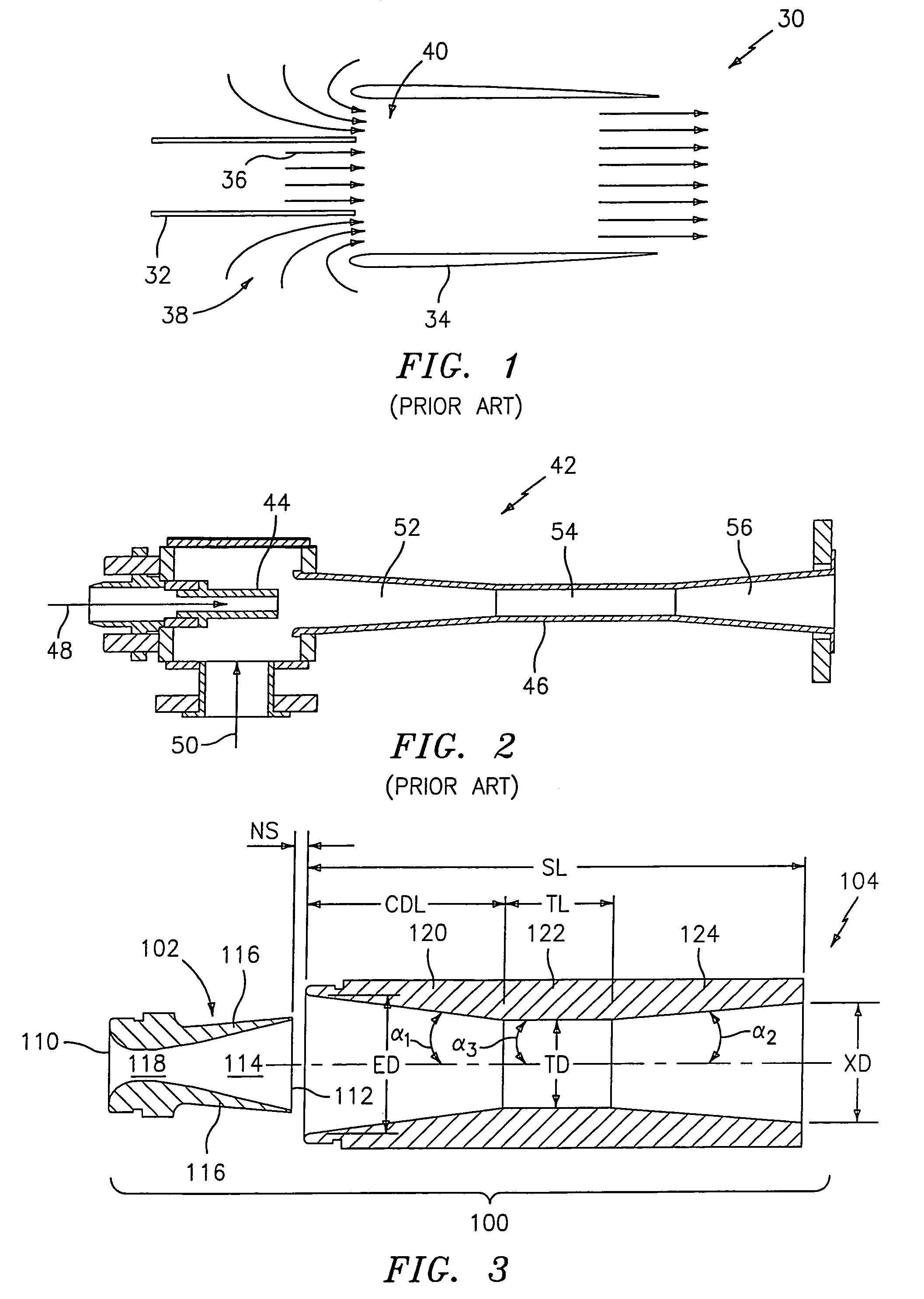

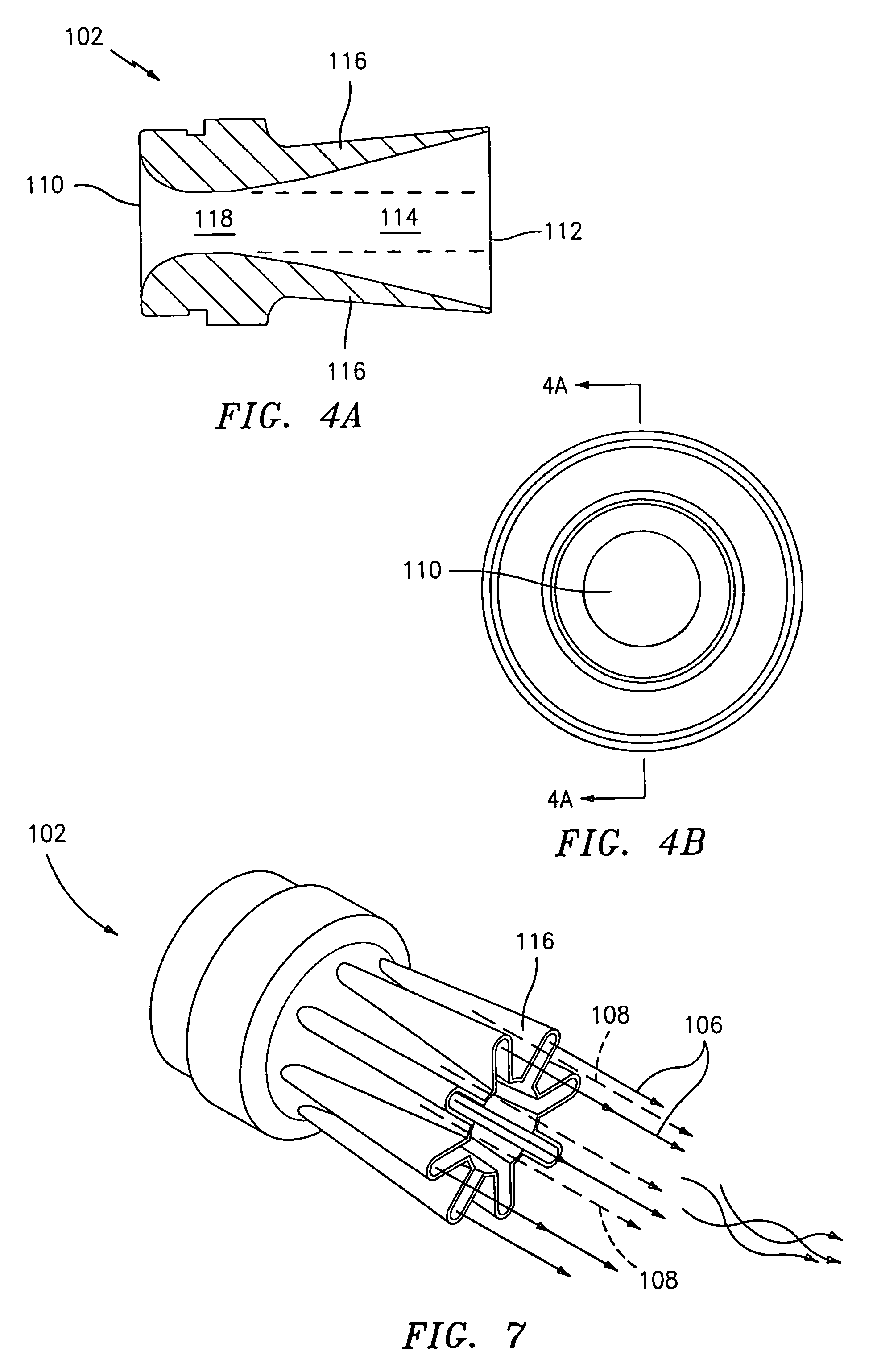

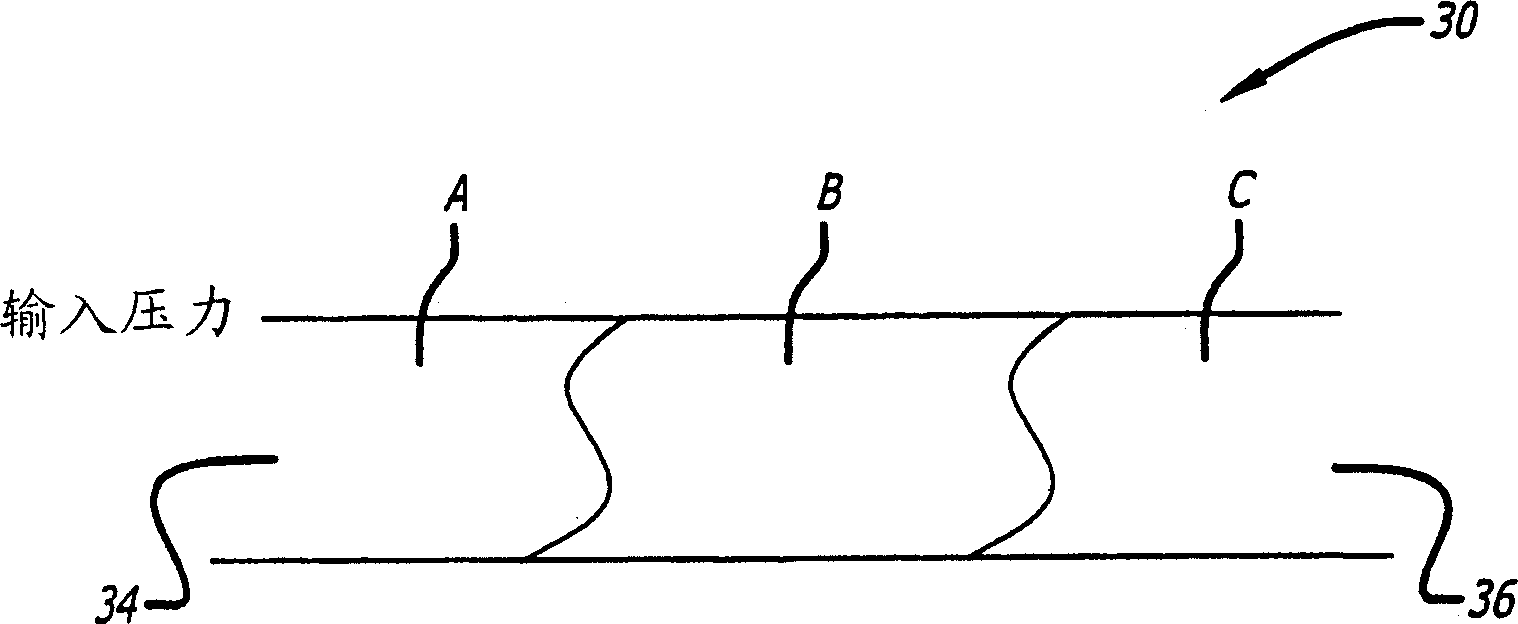

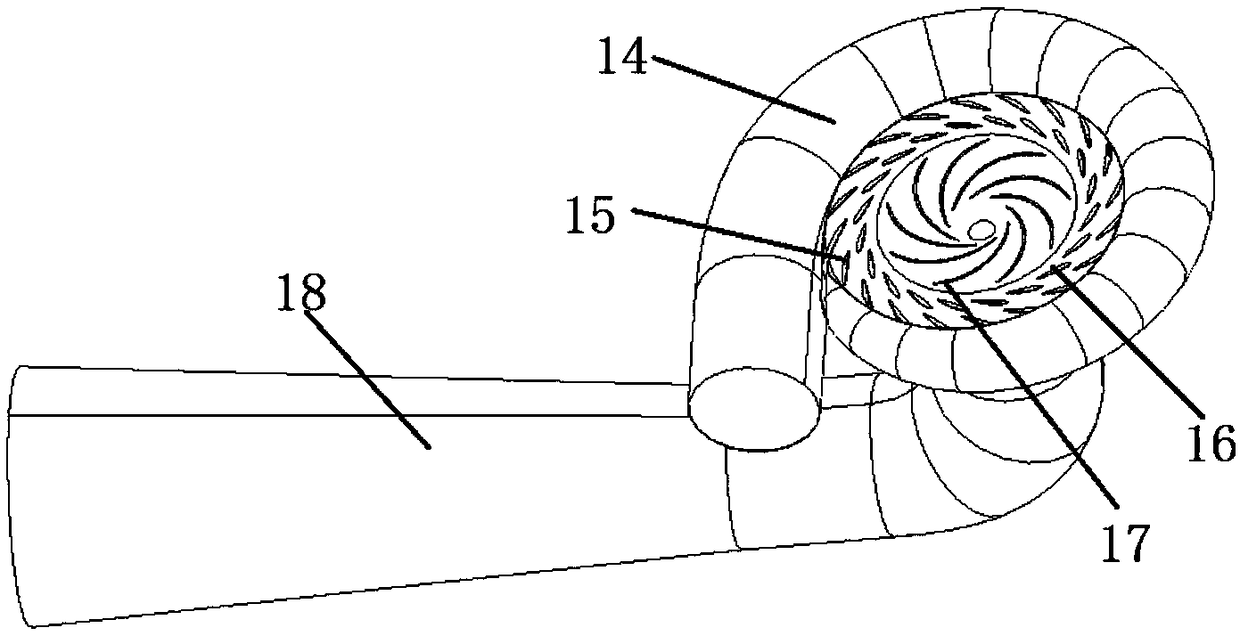

Lobed convergent/divergent supersonic nozzle ejector system

InactiveUS6877960B1Smaller length-to-entrance-diameter ratioIncrease flow pressureJet pumpsMachines/enginesDiameter ratioHigh pressure

An ejector system comprises a lobed, supersonic primary nozzle and a convergent / divergent ejector shroud. The lobed nozzle is just upstream from the ejector shroud, such that there is an annular space between the nozzle and shroud for admitting a secondary flow. In operation, a primary flow of high-pressure steam or air is directed through the primary nozzle, where it is accelerated to supersonic speed. The primary flow then exits the primary nozzle, where it entrains and is mixed with the secondary flow, creating a low pressure region or vacuum. The ejector shroud subsequently decelerates the combined flow while increasing the flow pressure, which increases suction performance and reduces energy loss. Because the primary nozzle mixes the two flows, the ejector shroud is able to have a length-to-entrance-diameter ratio significantly smaller than typical shrouds / diffusers, which decreases the system's size and increases performance.

Owner:FLODESIGN WIND TURBINE

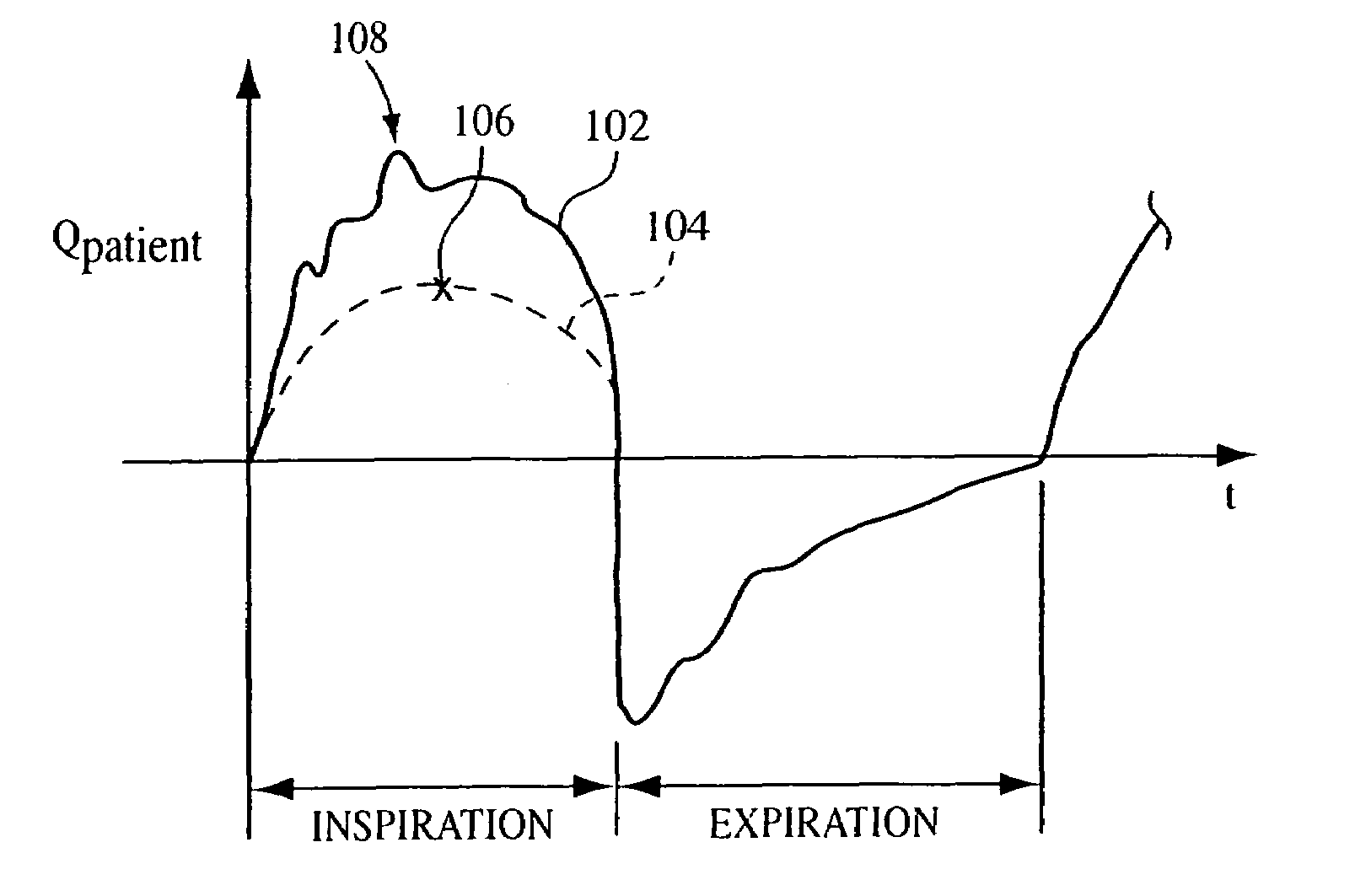

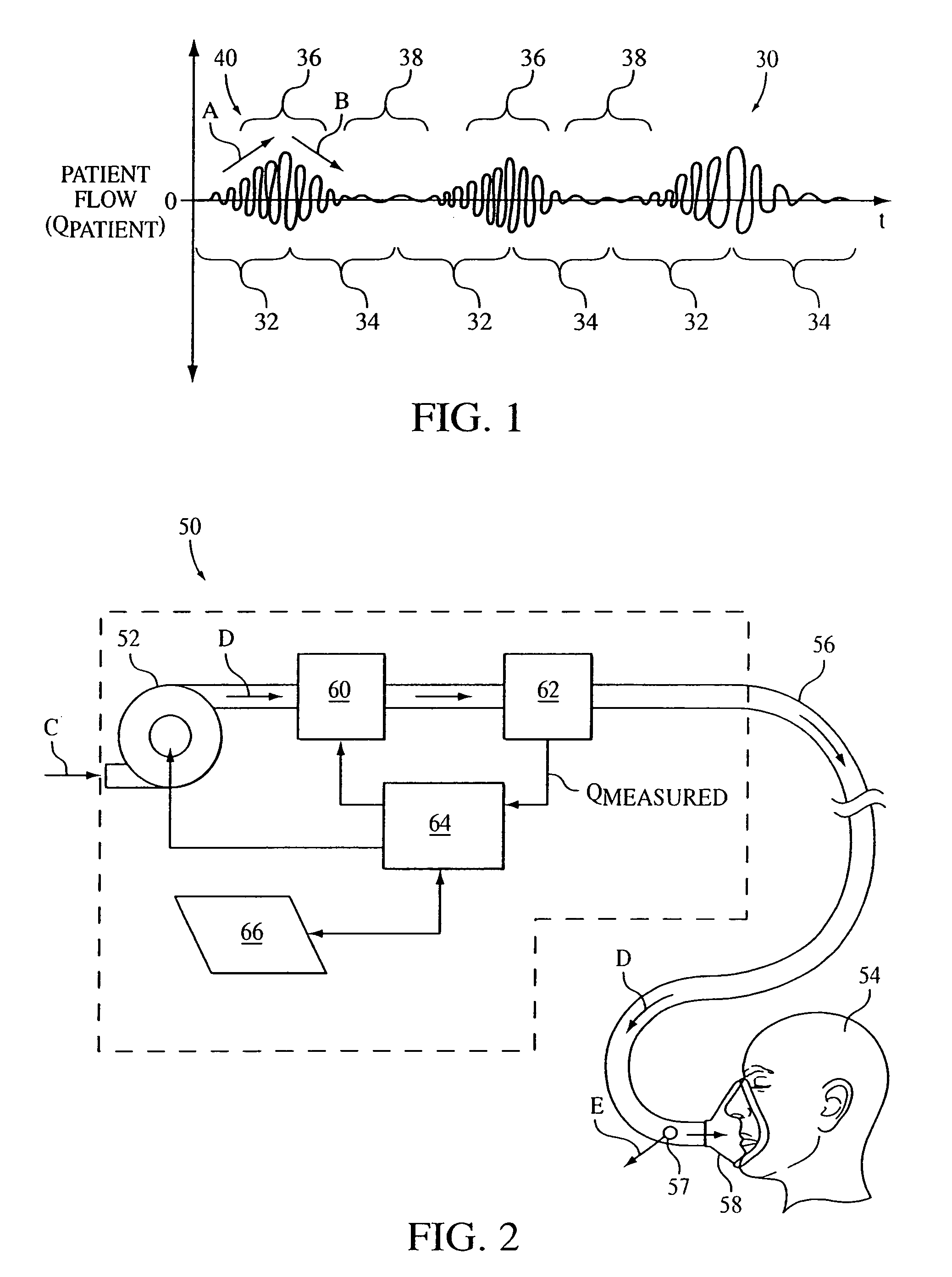

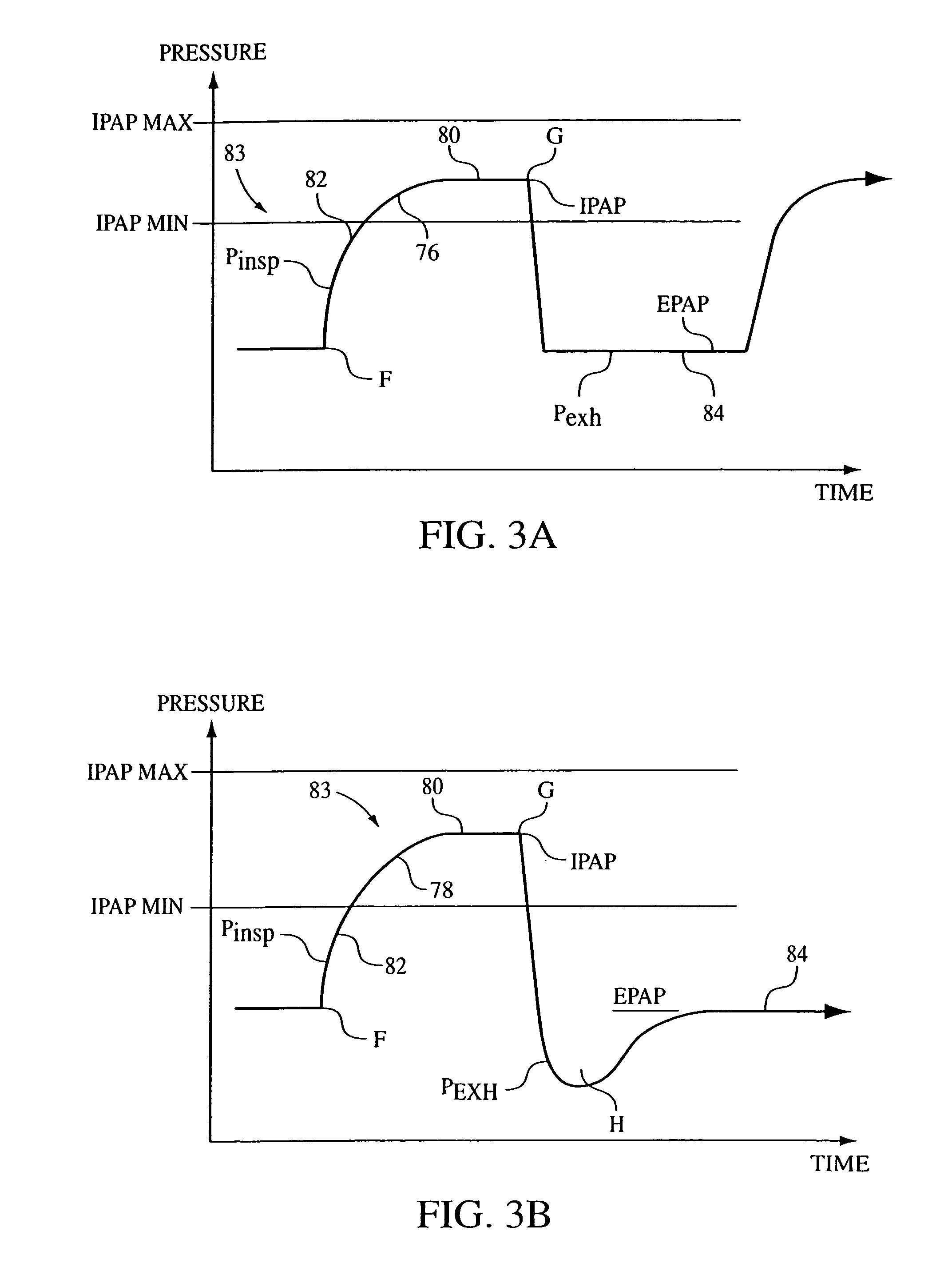

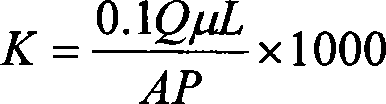

Method and apparatus for treating Cheyne-Stokes respiration

ActiveUS7717110B2Increase flow pressureReduce pressureRespiratorsOperating means/releasing devices for valvesPhysical medicine and rehabilitationSleep disordered breathing

A system and method for delivering a flow of breathing gas to an airway of a patient. A characteristic that varies based on variations of the flow of the breathing gas is monitored and used to determine a Target Flow for the gas delivered to the patient. The Target Flow is set to a level sufficient to treat Cheyne-Stokes respiration or a sleep disordered breathing event. The Target Flow is altered if the patient experiences a sleep disordered breathing event. In a further embodiment, the system determines an apnea detection time (Tapnea) as Tinsp plus a constant, and delivers a machine triggered breath if an amount since the start of inspiration reaches Tapnea. Yet another embodiment monitors the characteristic during an inspiratory phase of a respiratory cycle, and controls the flow of gas during the inspiratory phase of the respiratory cycle based on a result of this comparison.

Owner:PHILIPS RS NORTH AMERICA LLC

Three-segment type block releasing technique for oil layer

InactiveCN101196109ARestore or increase permeabilityReduce energy consumptionFluid removalDrilling compositionChemistryMaterial Perforation

The invention relates to an oil layer three-section block removing technology with excellent block removing effect. A block removing agent will be injected at three sections; then, clear water will be injected after the reaction of 4 to 24 hours at each section; the quantity of clear water will be 1 to 2 times of the sum between the volume of an oil pipe and the volume of the circular space from the bottom of the oil pipe to the top of a perforation interval. Because the composition and function of the block removing agents different from each other, the invention can be applied in a broad scope to adopt to the needs in various stratum, realize excellent block removing effect with the removing rate of over 75 percent, thus satisfying the industrial needs.

Owner:DAQING GASOLINEEUM INST +1

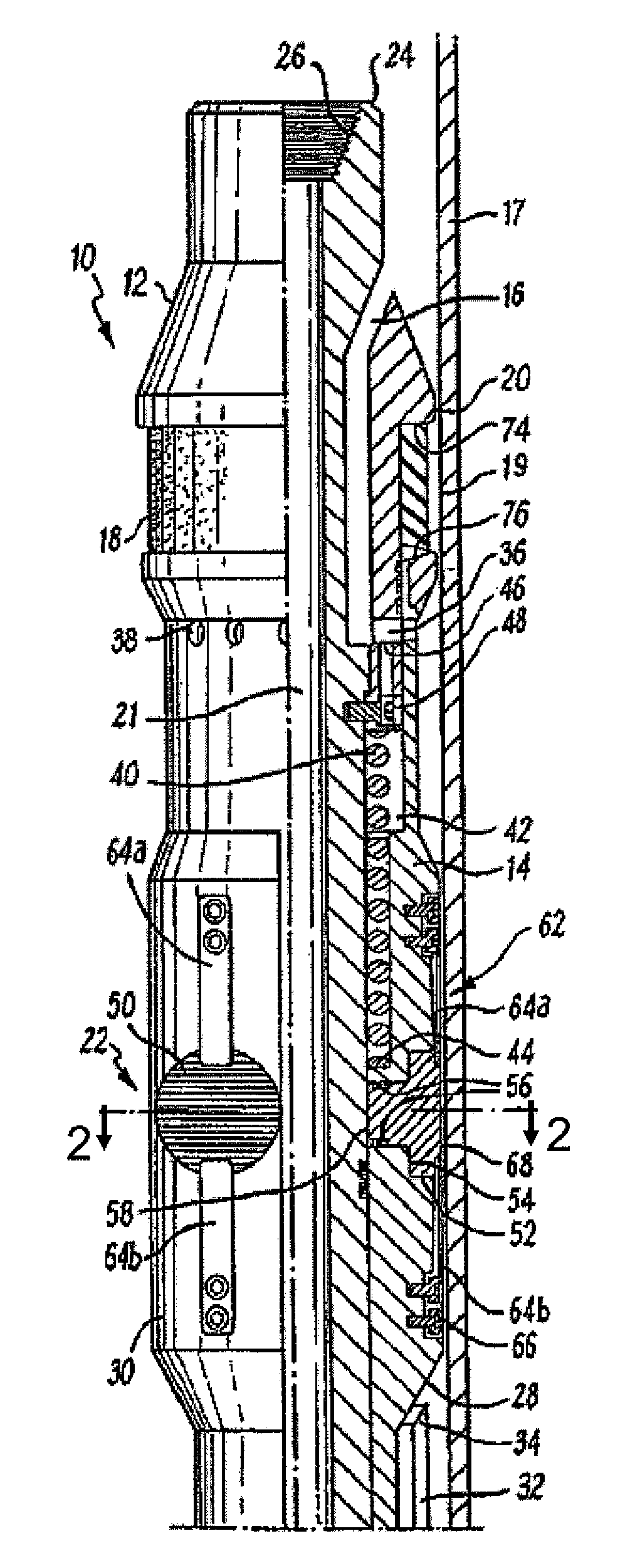

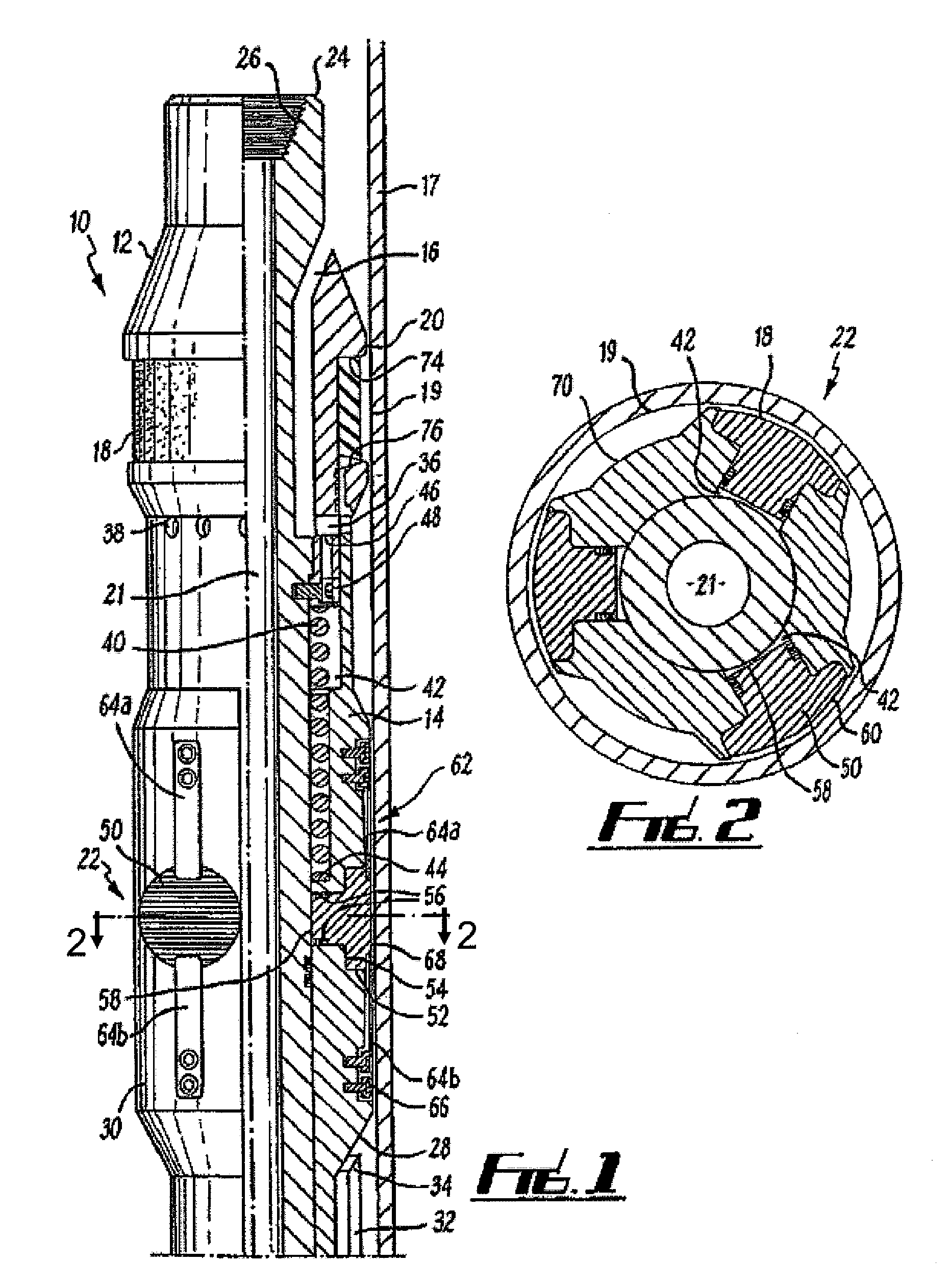

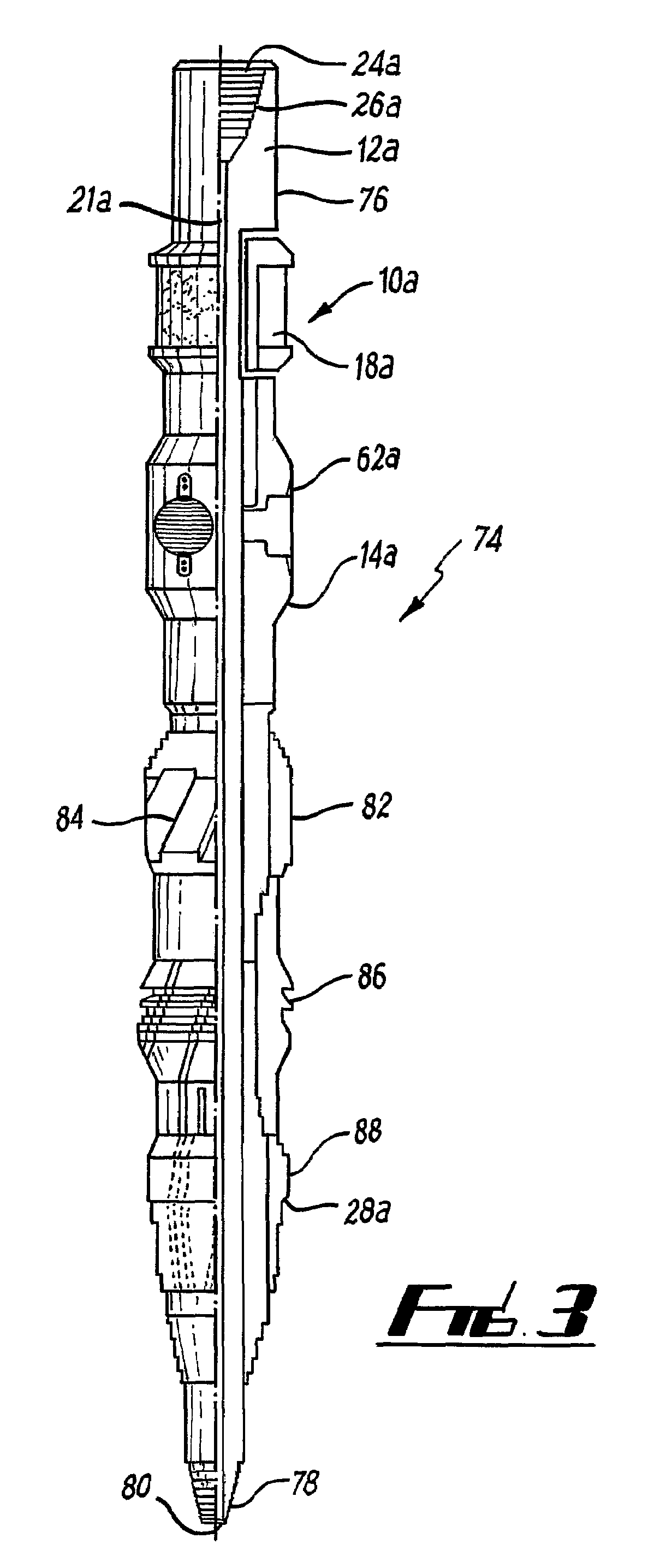

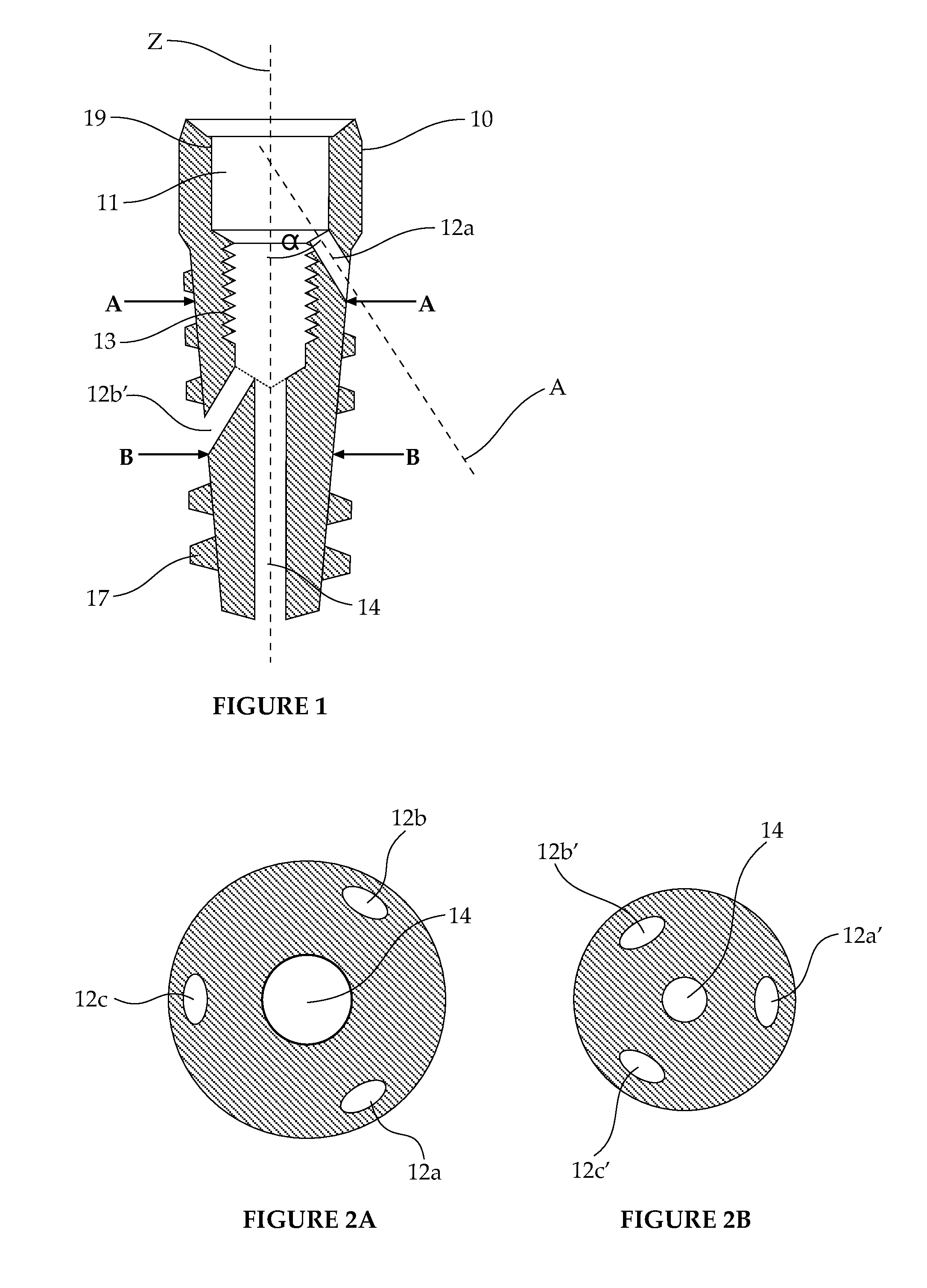

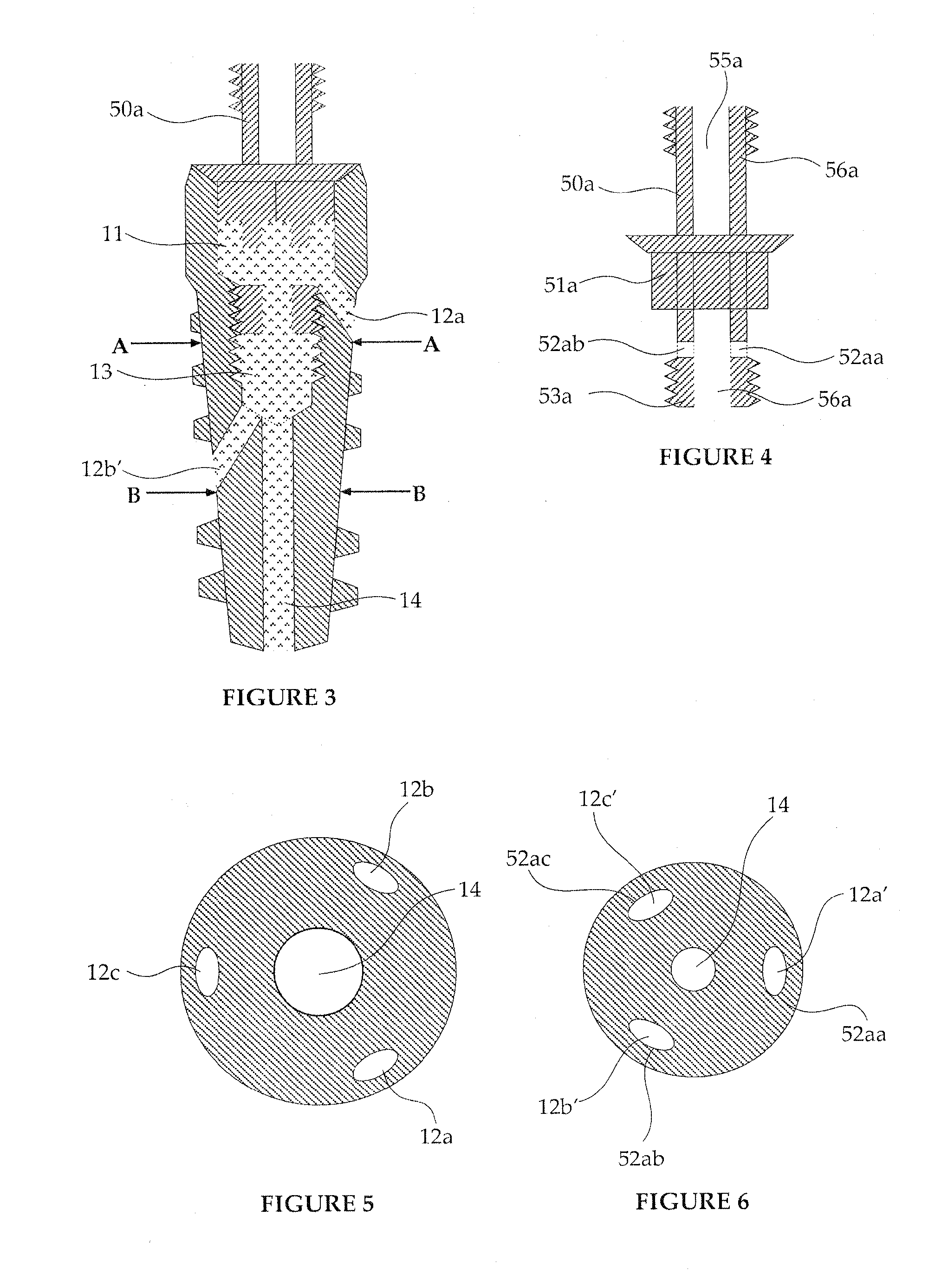

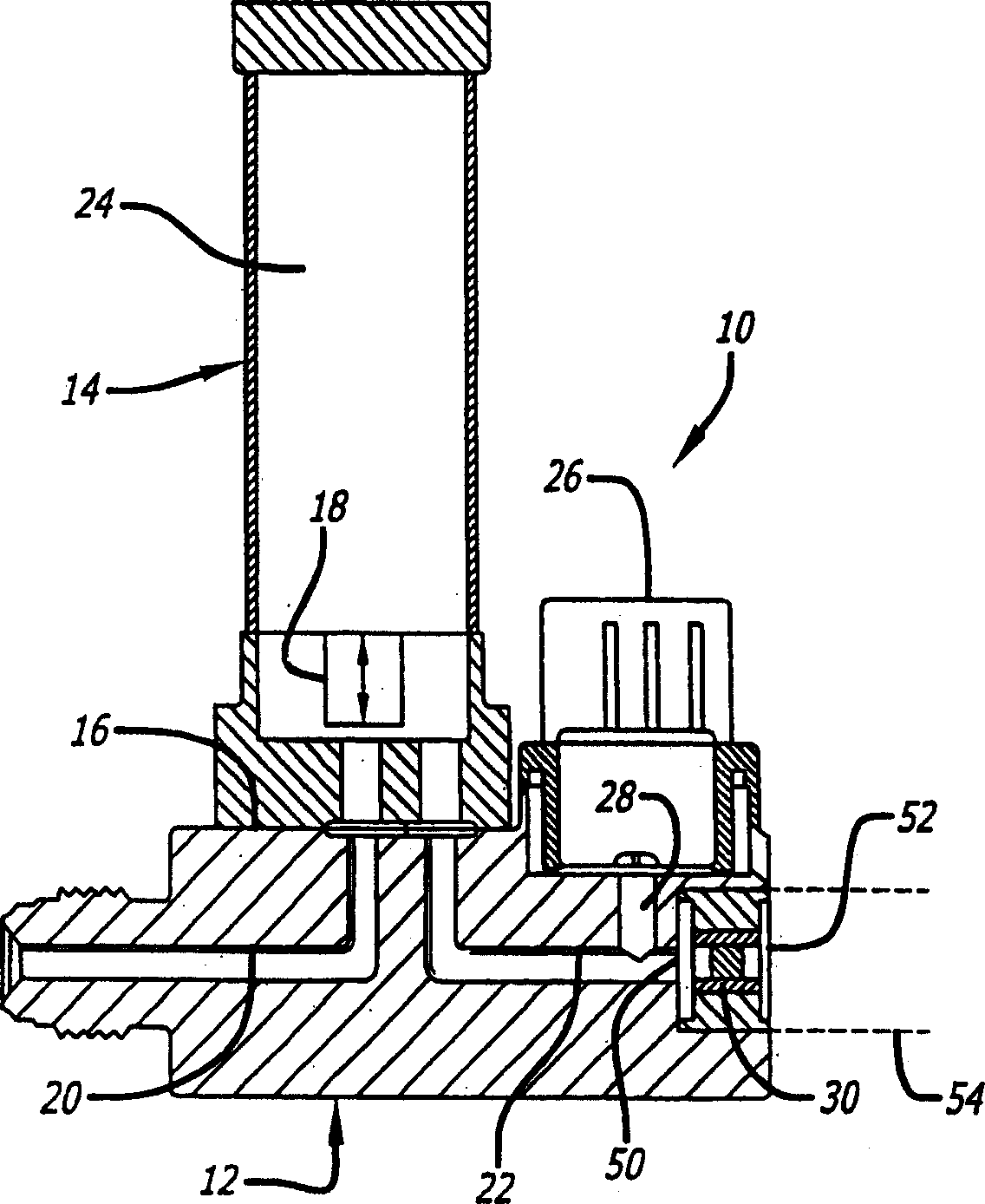

Packer

There is disclosed a downhole packer for use in a well bore, and in particular, a packer which can be used for downhole testing. In an embodiment of the invention, a packer tool (10) for mounting on a work string to provide a seal against a tubular (32) is disclosed, the packer tool comprising a body (12) with one or more packer elements (18) and a sleeve (14), the packer tool being set by movement of the sleeve relative to the tool body compressing the one or more packer elements, wherein the tool has a plurality of bypass channels (16) to provide a fluid path past the packer elements, the sleeve including at least owe anchoring member (22, 50), the at least one anchoring member being actuate to contact the tubular by fluid pressure from the bypass channels when the packer is set.

Owner:SPECIALISED GASOLINEEUM SERVICES GROUP

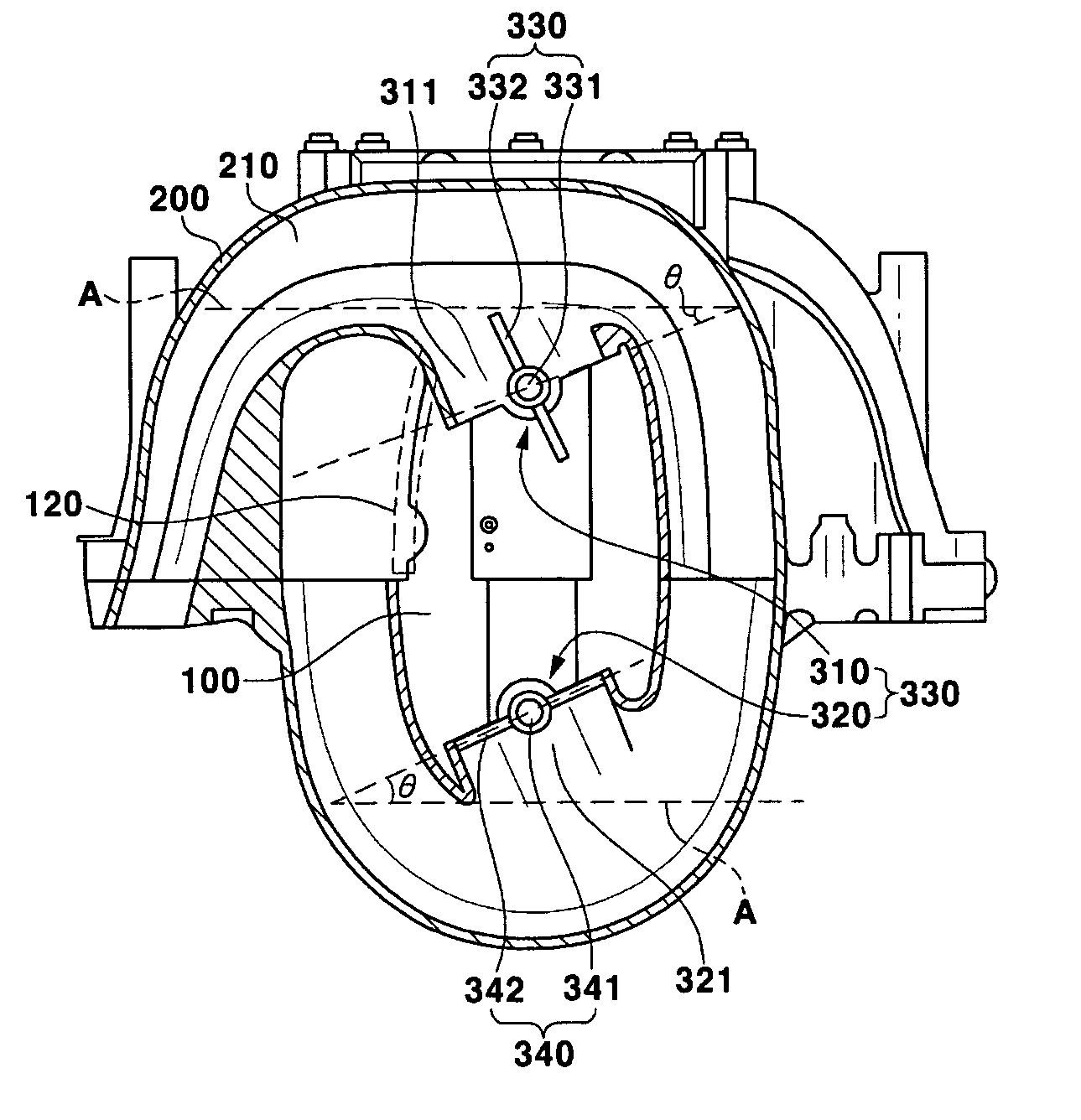

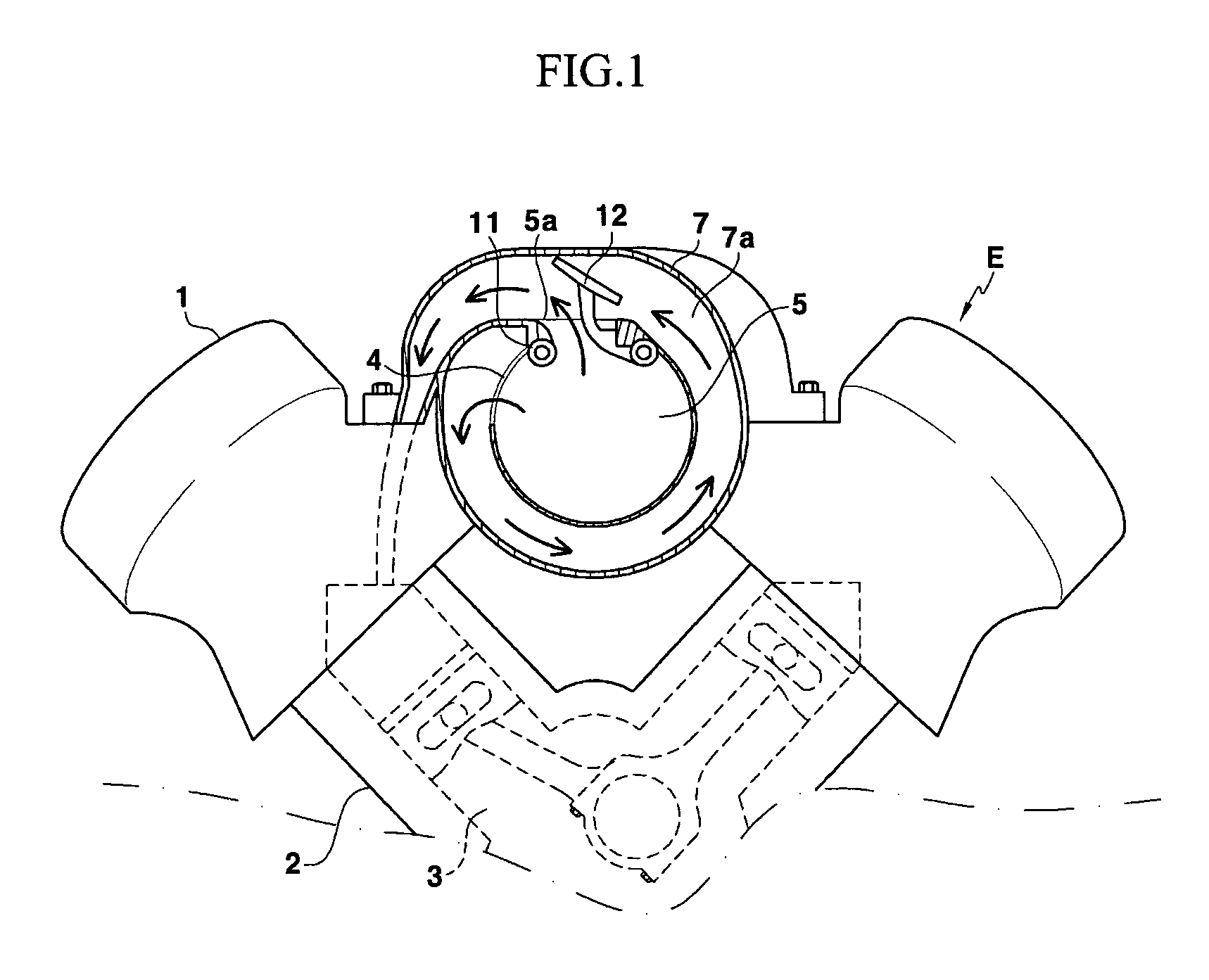

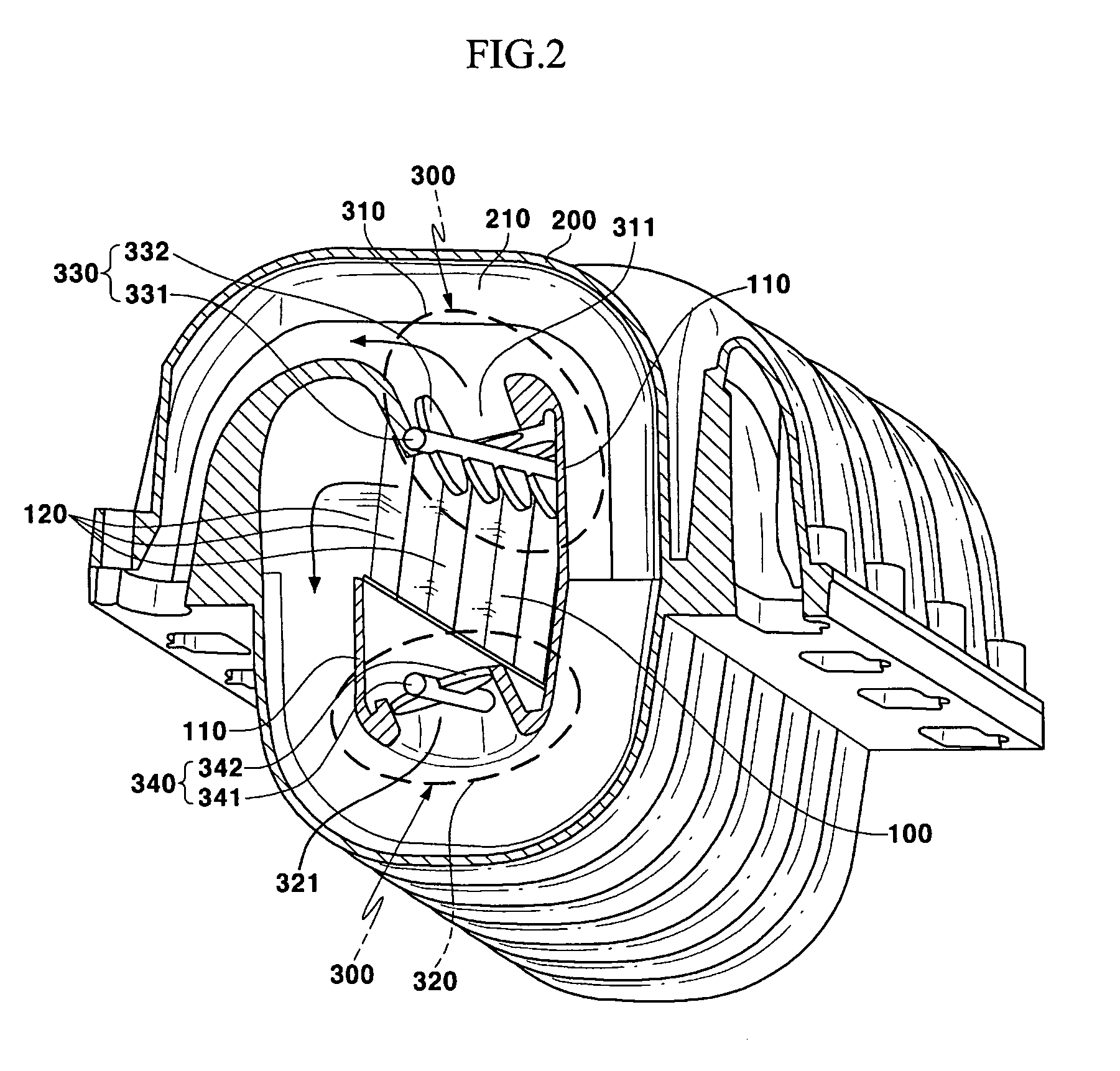

Variable intake system of a vehicle

InactiveUS20050279312A1Increase flow pressureVelocity increasesInternal combustion piston enginesEngine controllersEngineeringVehicle driving

A variable intake system of a vehicle includes a plenum into which an external air is flowed, an intake manifold comprising a plurality of runners connected with the plenum and respectively guiding the air of the plenum into a plurality of cylinders, and a varying unit controlling a length of the runners according to a vehicle driving condition.

Owner:HYUNDAI MOTOR CO LTD +1

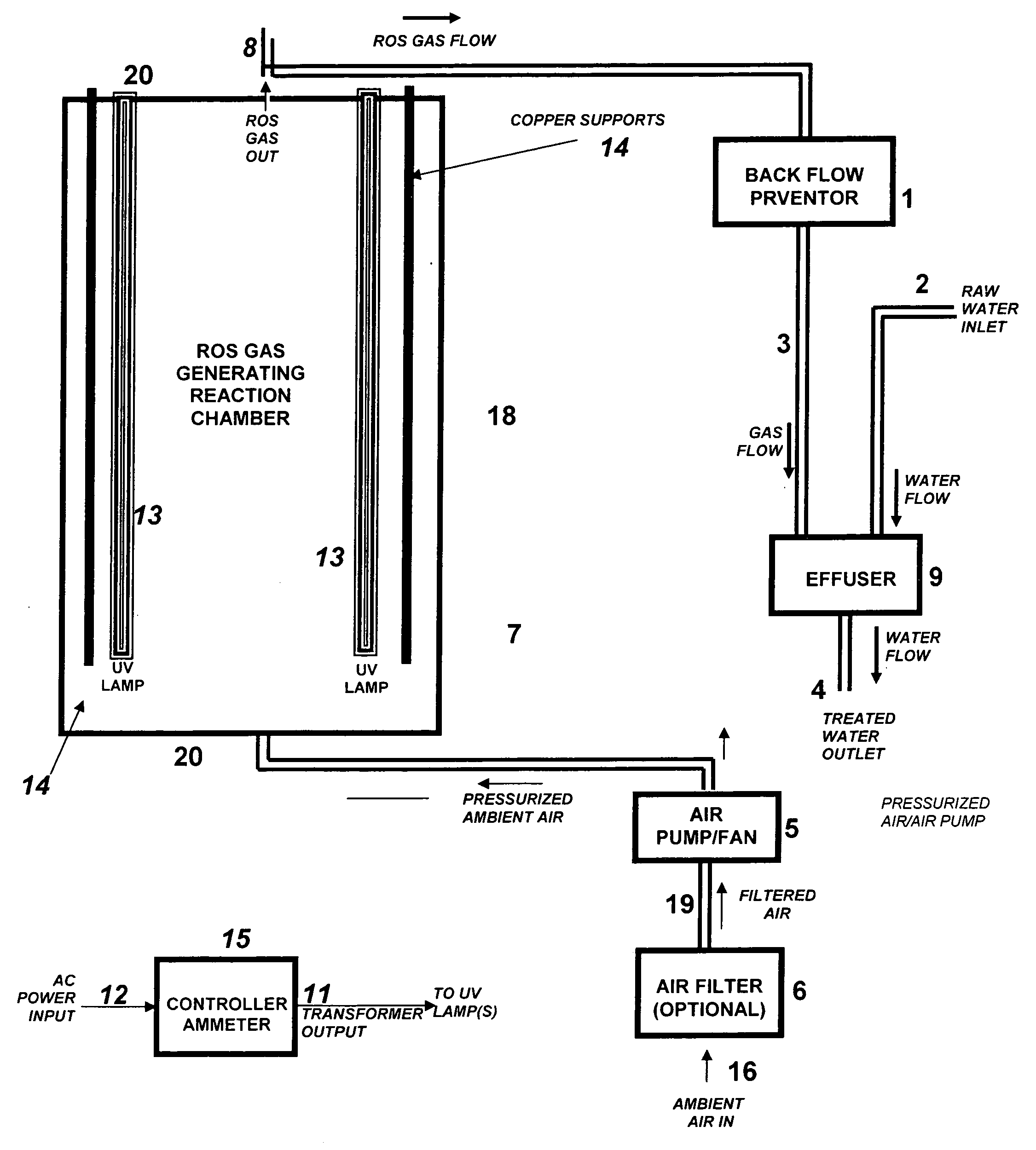

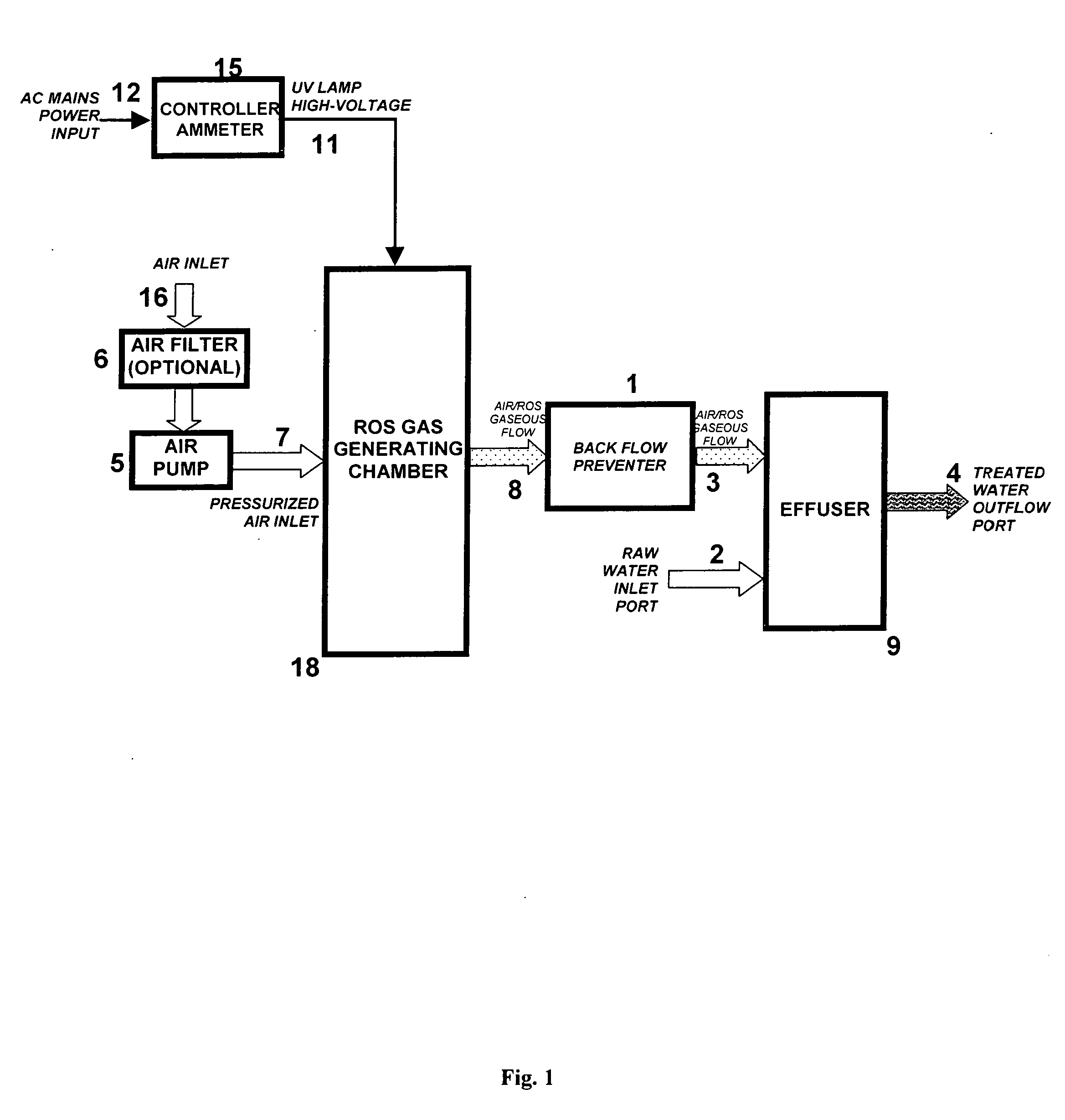

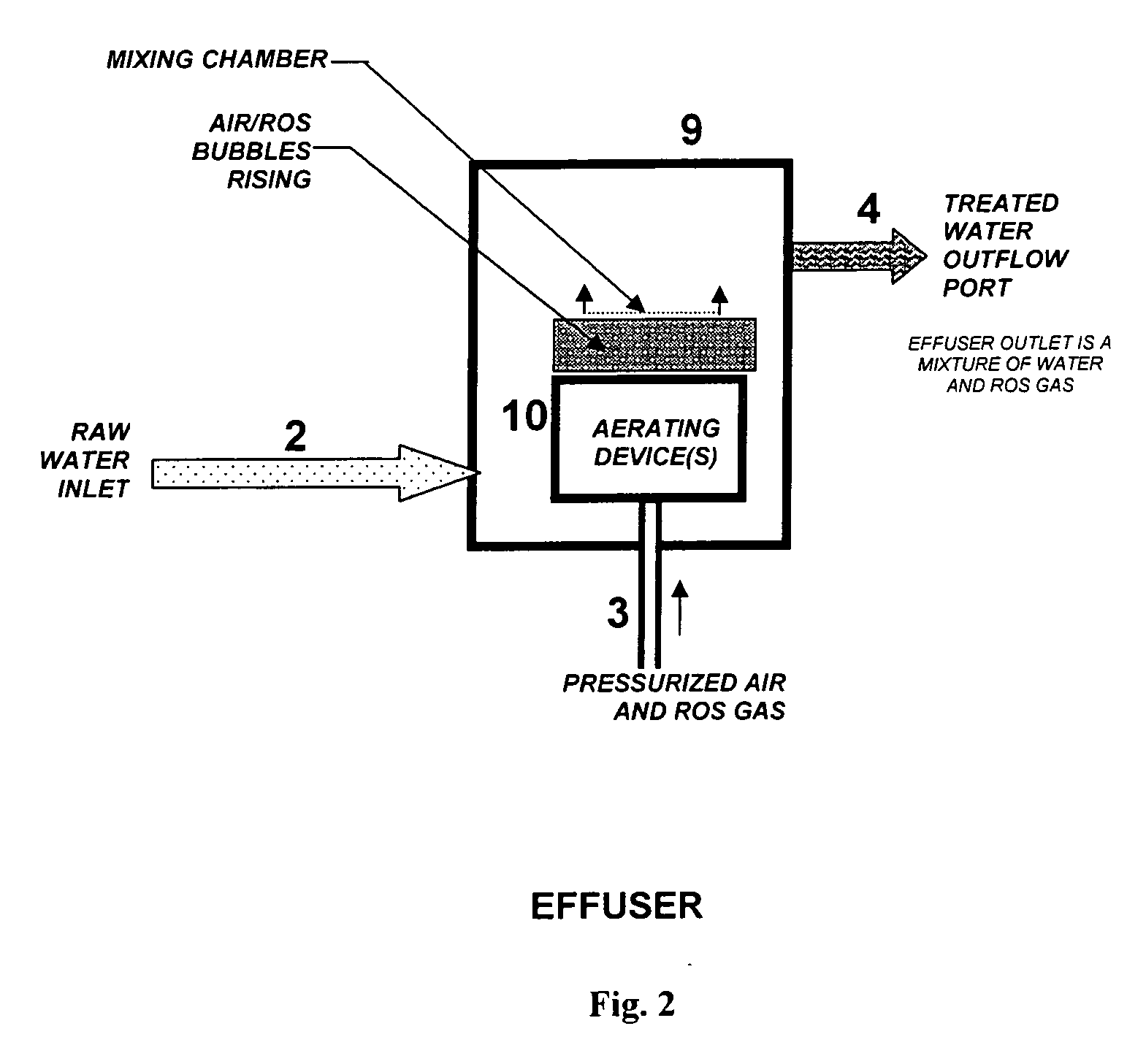

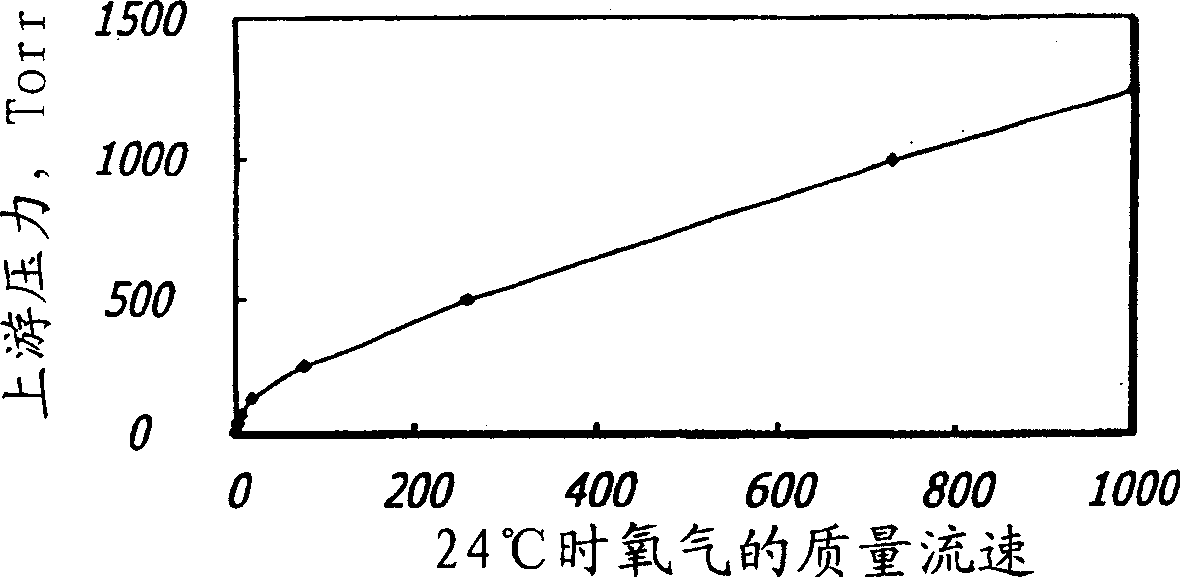

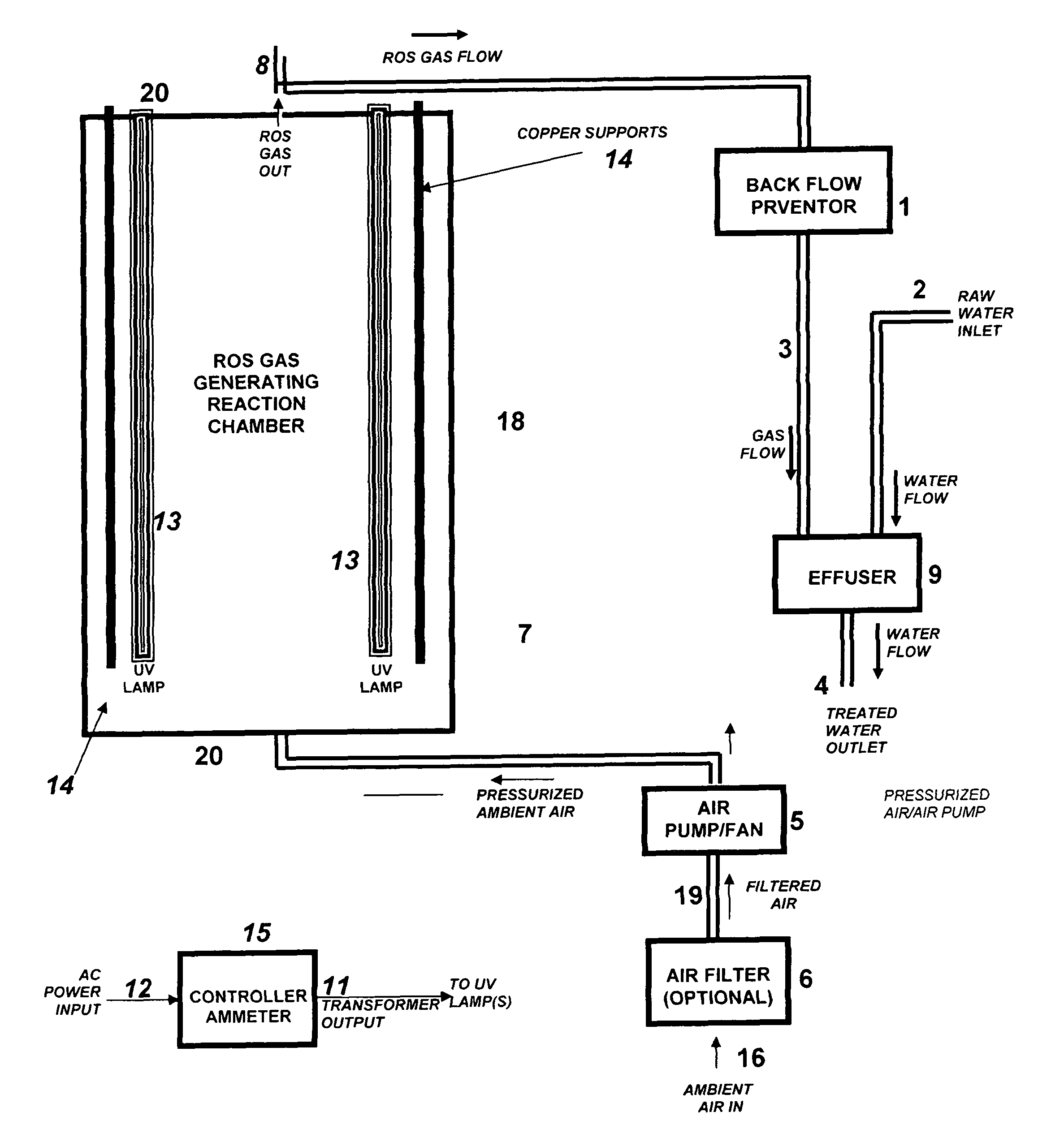

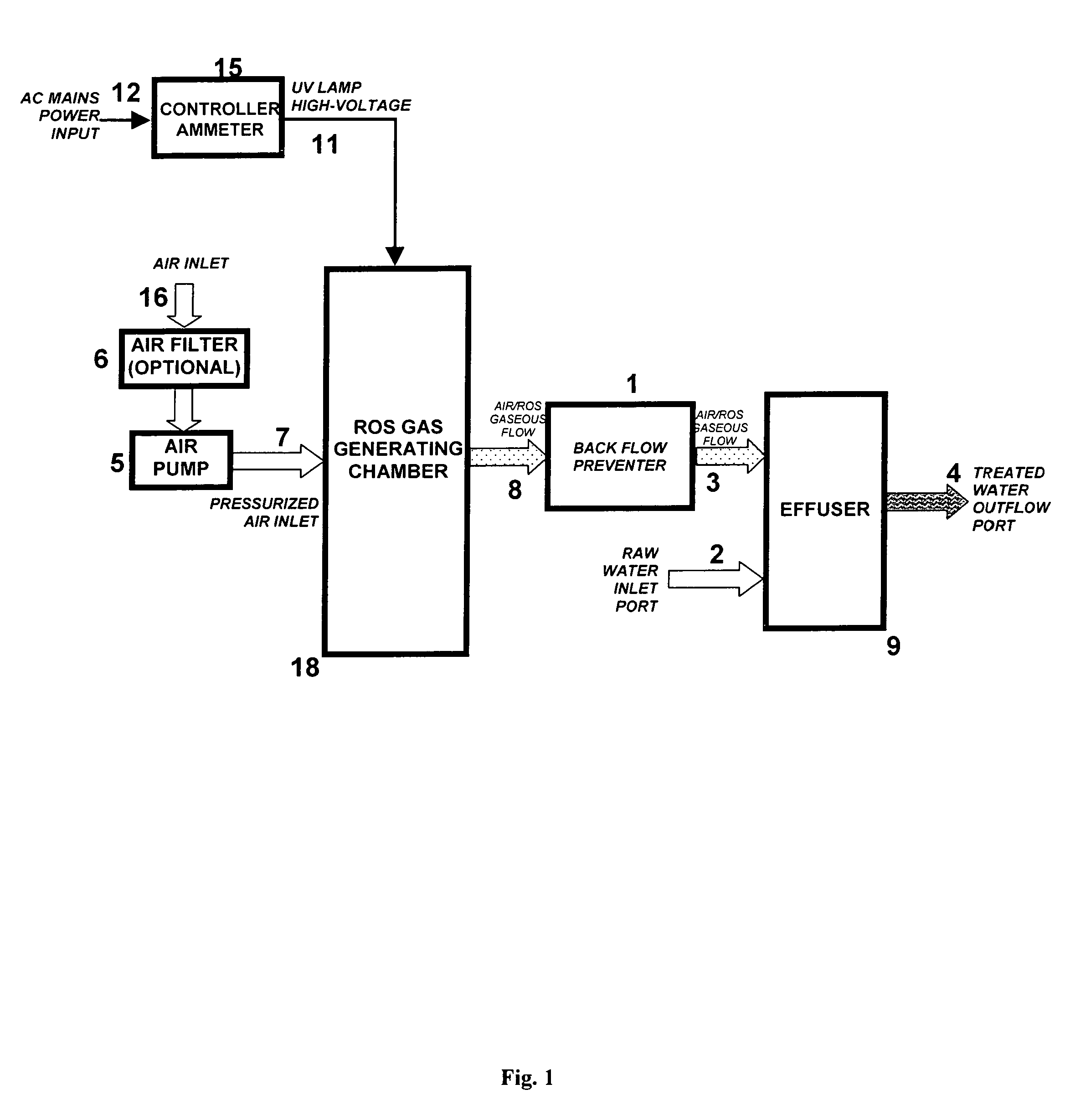

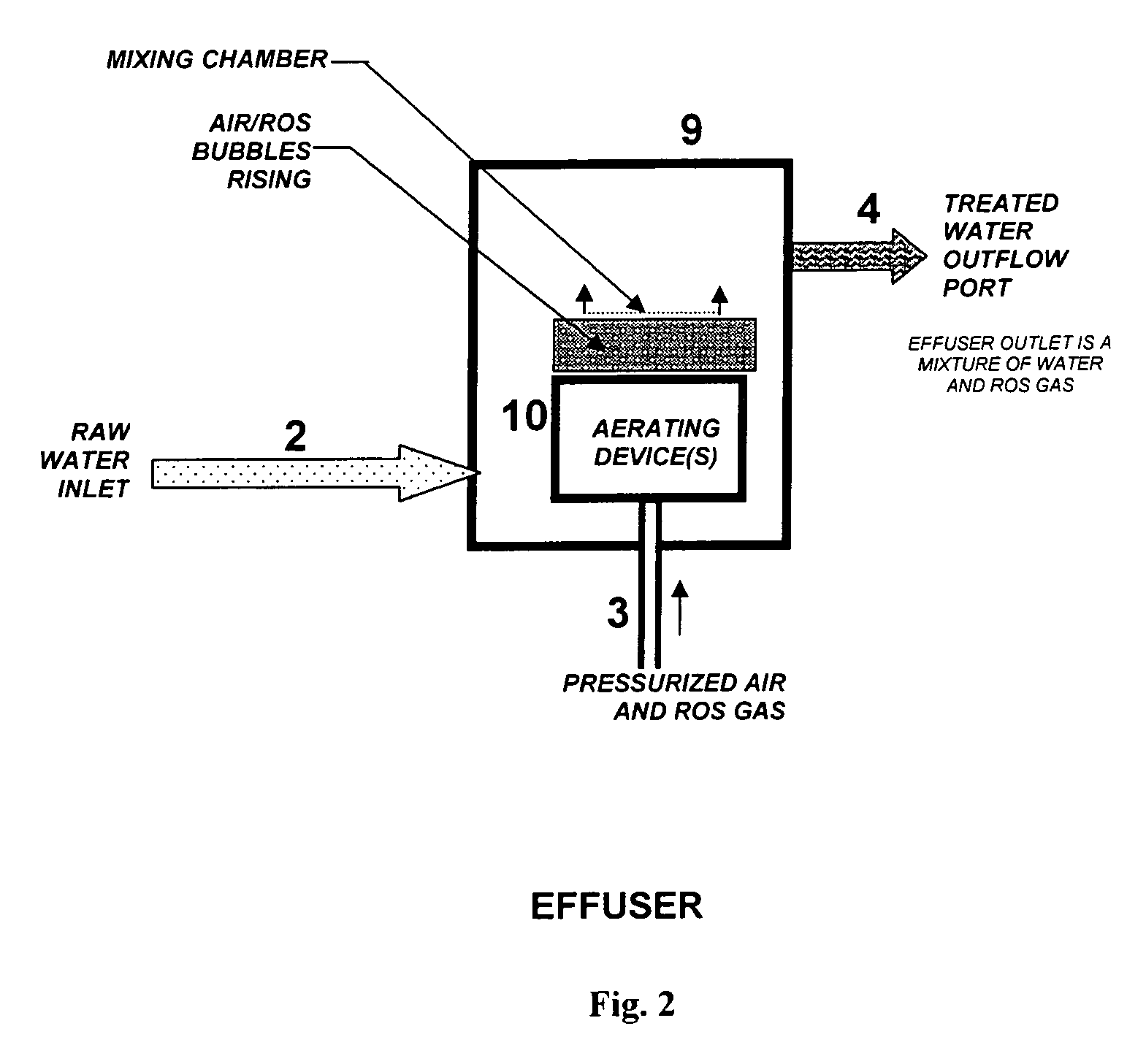

Water treatment apparatus and process to reduce pipe scale and biomass using positive pressure ultraviolet oxygenation

ActiveUS20120272676A1Reduce formationReduce scaleWater treatment compoundsWater softeningPositive pressureSuperoxide

A method of treating water in order to minimize scaling and biomass buildup in water conduits or containers in which the treated water is used includes pressurizing and optionally filtering ambient air, processing the pressurized ambient air in a chamber including at least one ultraviolet light source operated to generate an output flow mixture of pressurized air and reactive oxygen species (ROS) gas, mixing the pressurized ROS / gas output mixture to realize a flow of water / pressurized ROS gas / air mixture and outputting the flow of water / pressurized ROS gas / air mixture as the treated water process product. The process includes generating reactive oxygen species (ROS) gas in the pressurized ROS / gas output mixture including at least one of Super Oxide (O2−), Peroxide (—O2—), Hydro peroxide (HO2−), Hydroxyl Radicals (OH·), Ozone (O3−) and Molecular Oxygen (O2). The ultraviolet light source, the flow rate of the pressurized air, the water, the water / pressurized ROS gas / air mixture and the output volume are controlled to optimize scaling and biomass reduction.

Owner:ECOLAB USA INC

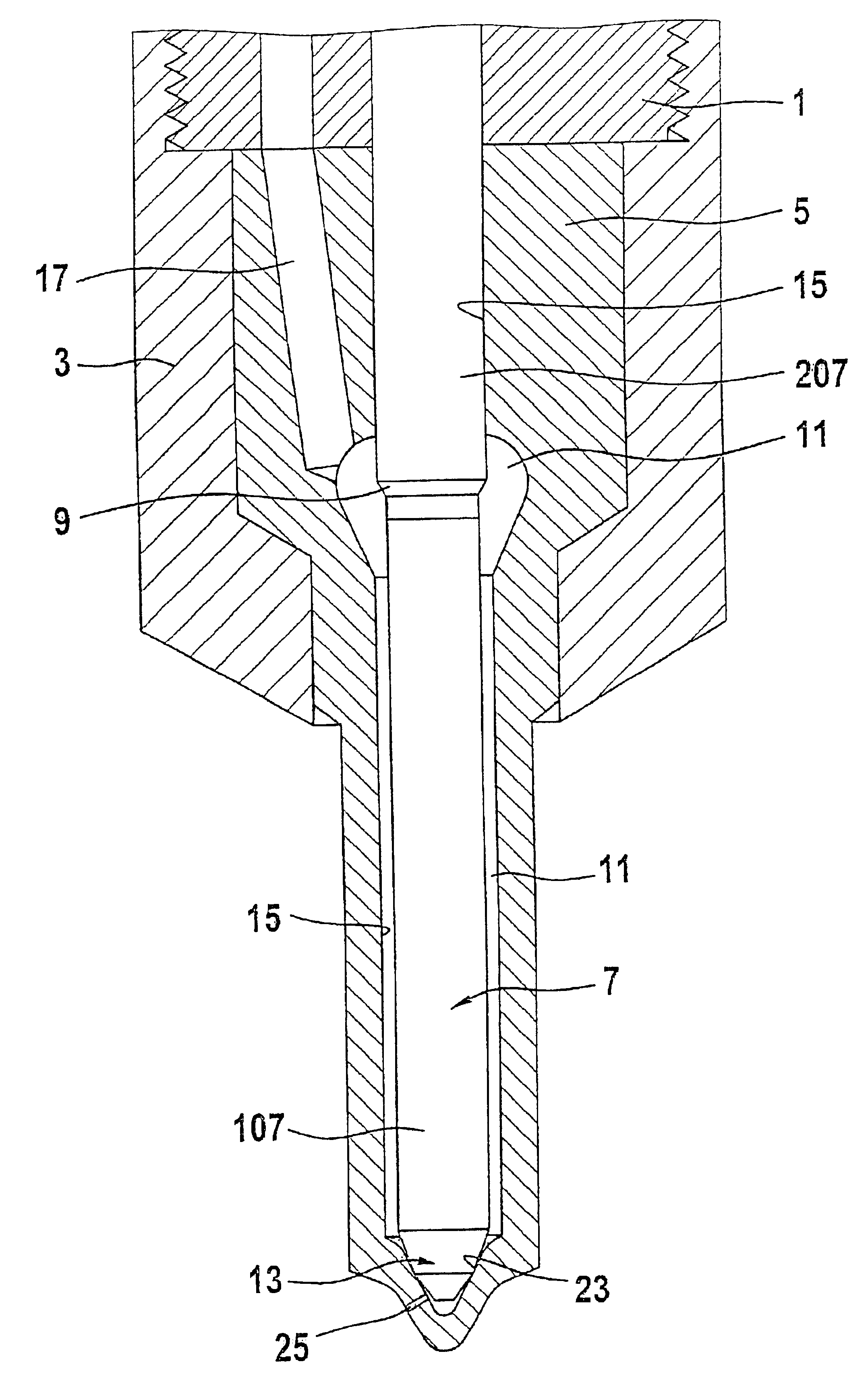

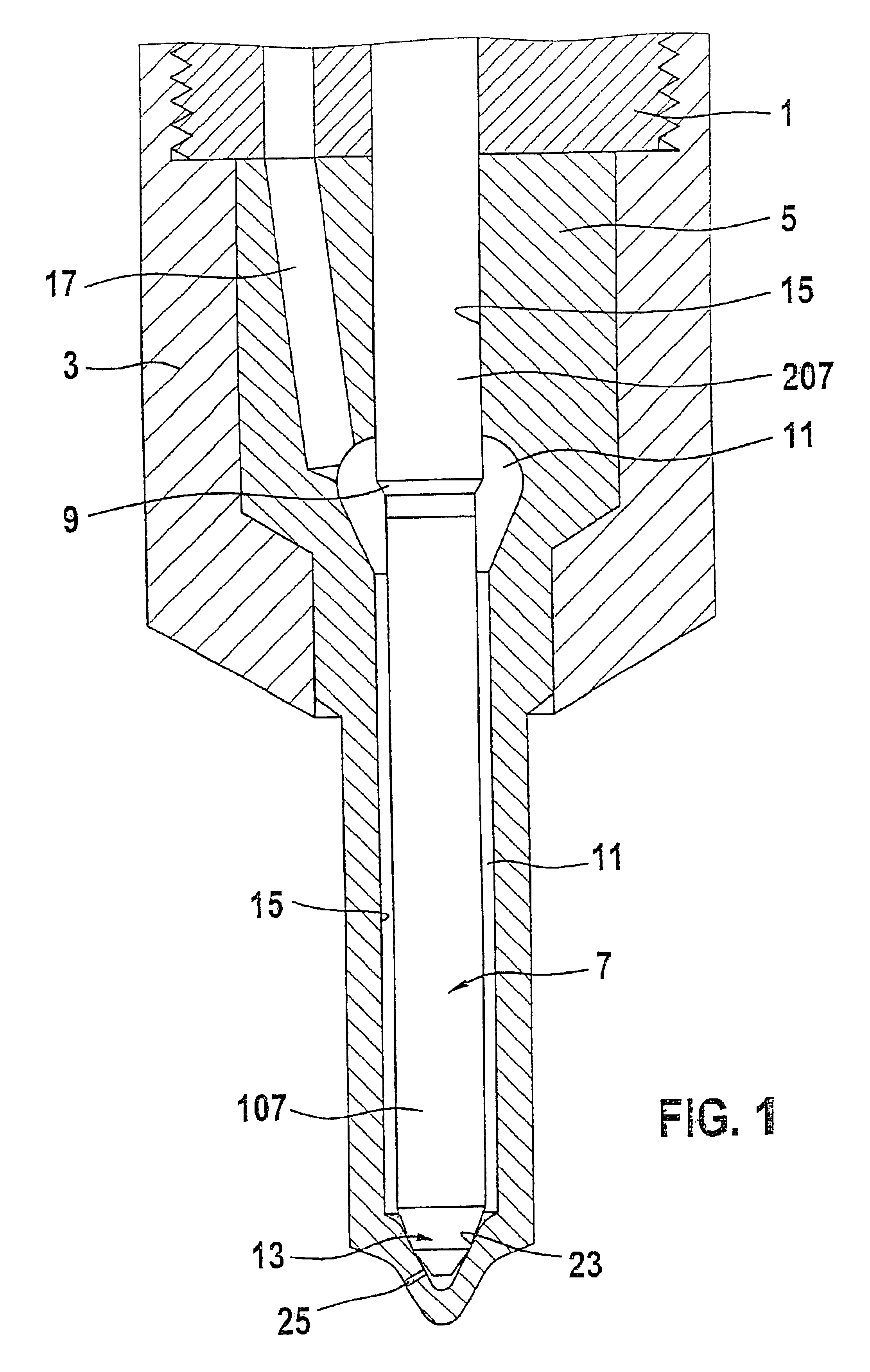

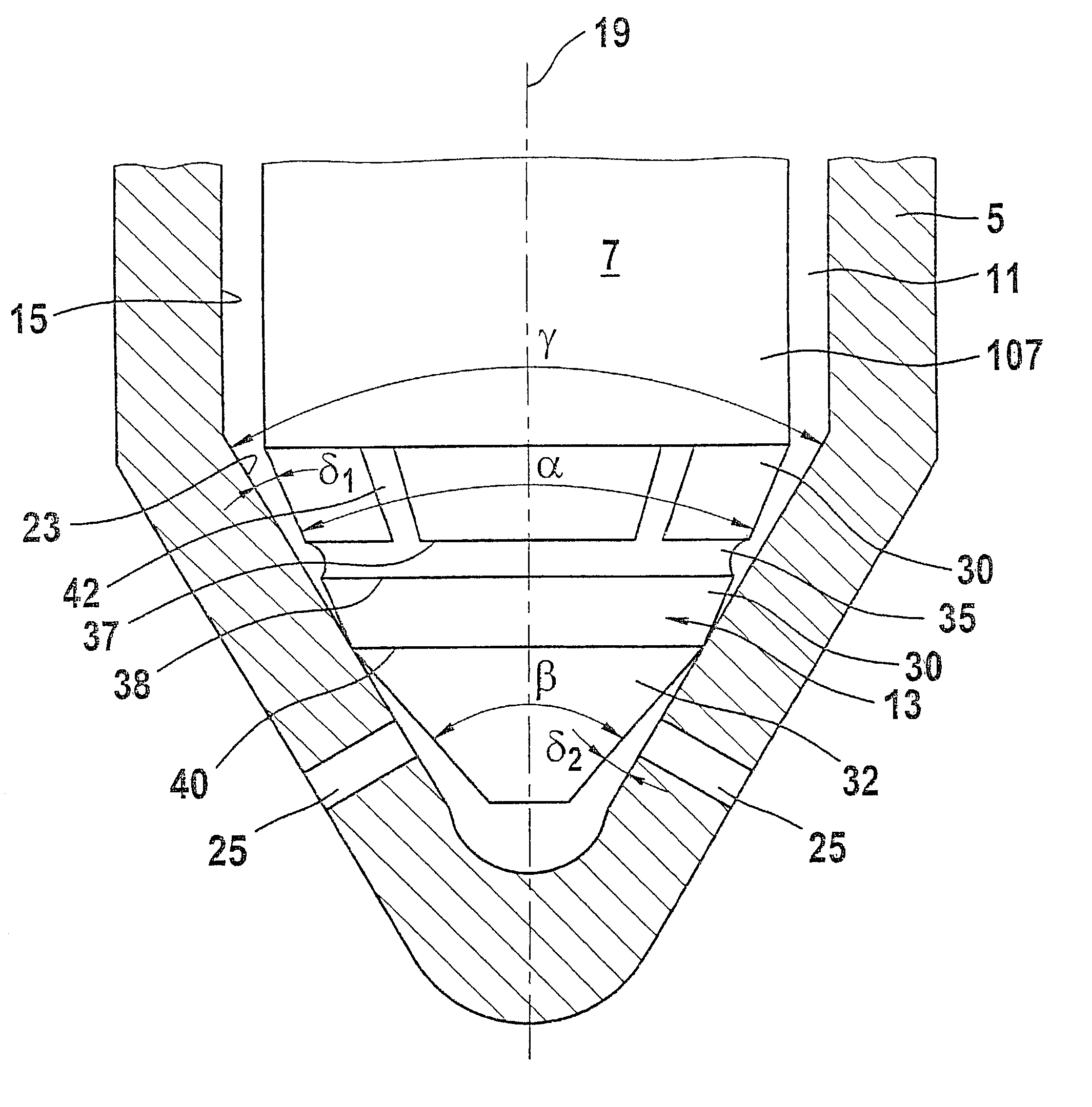

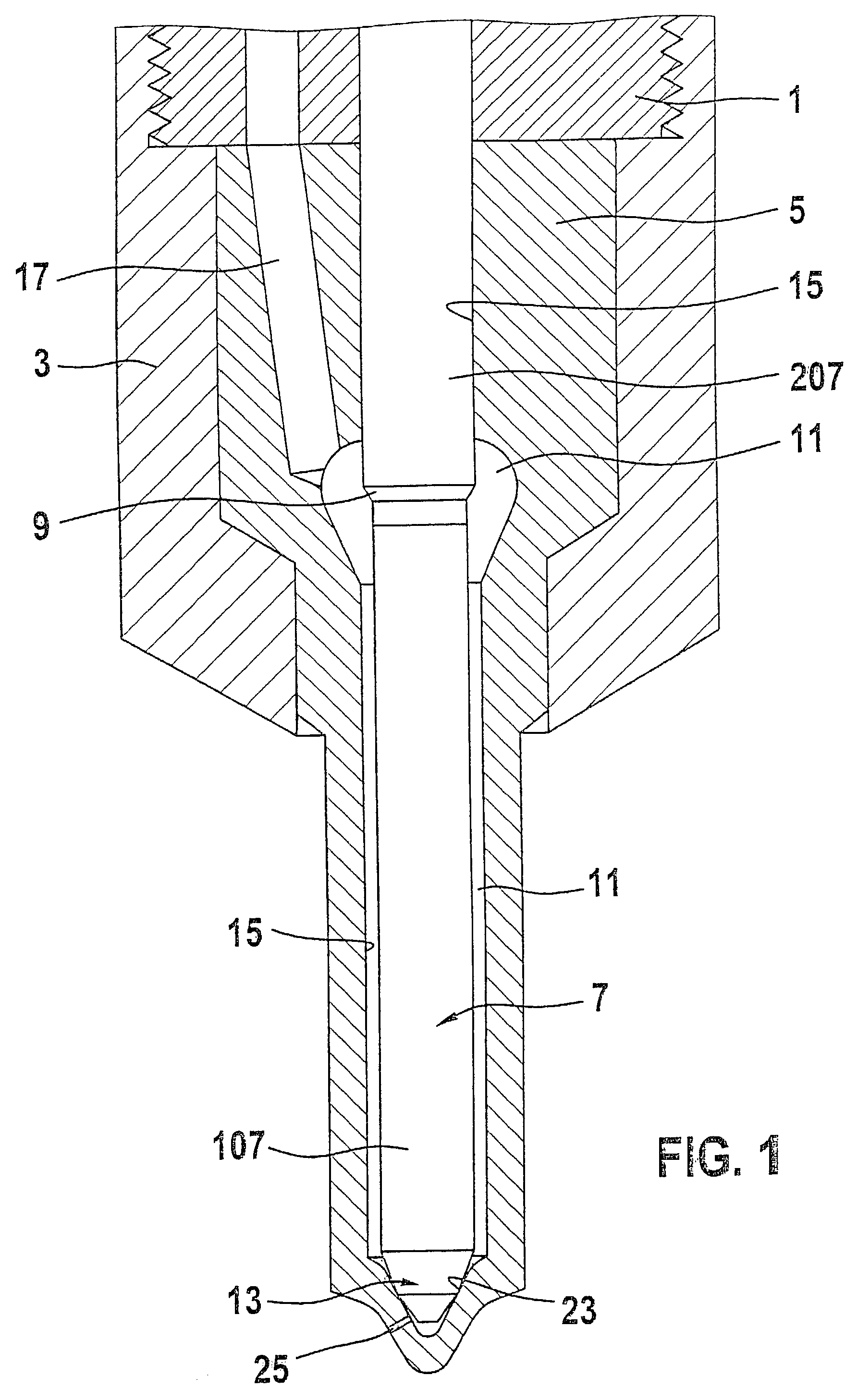

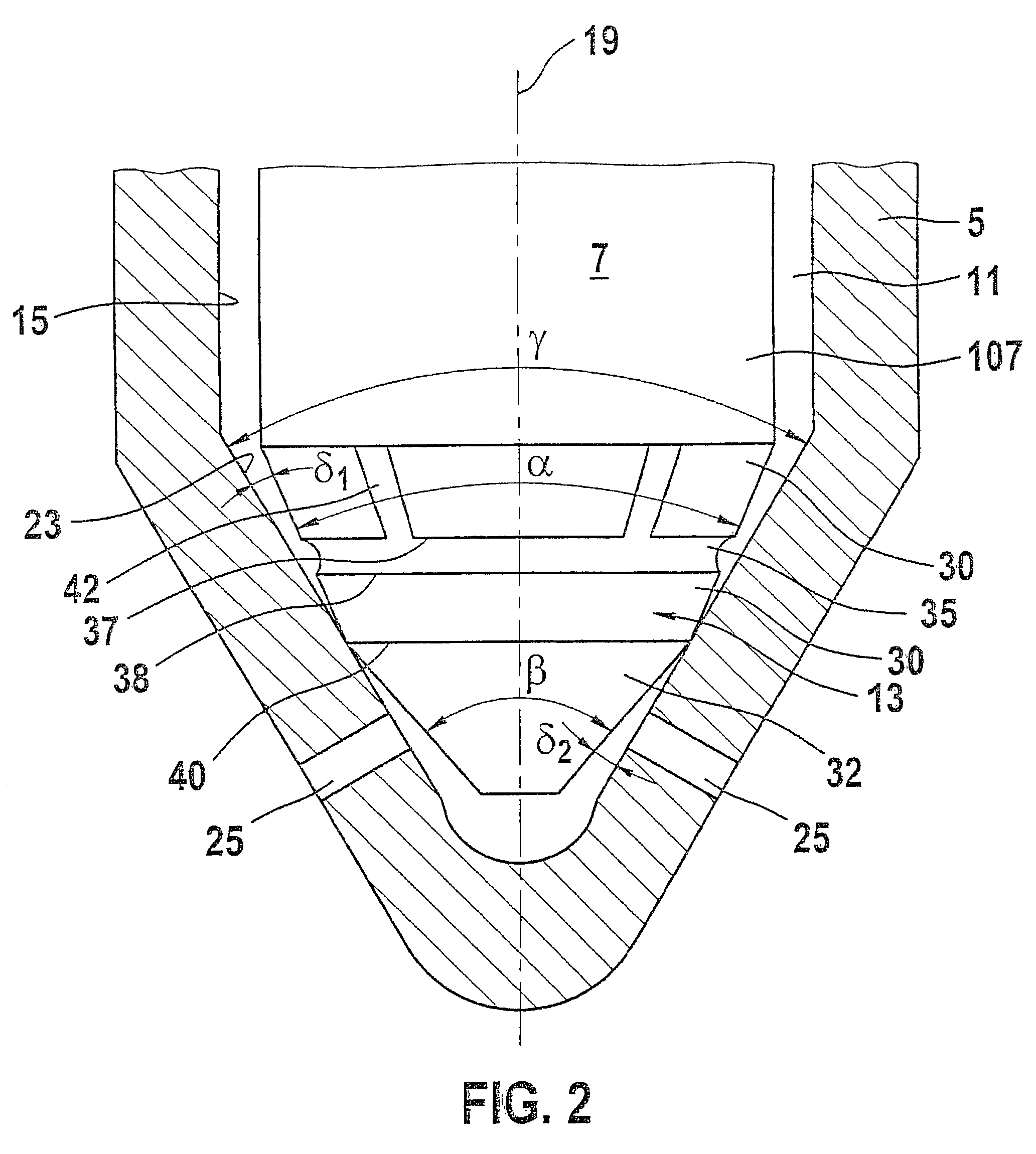

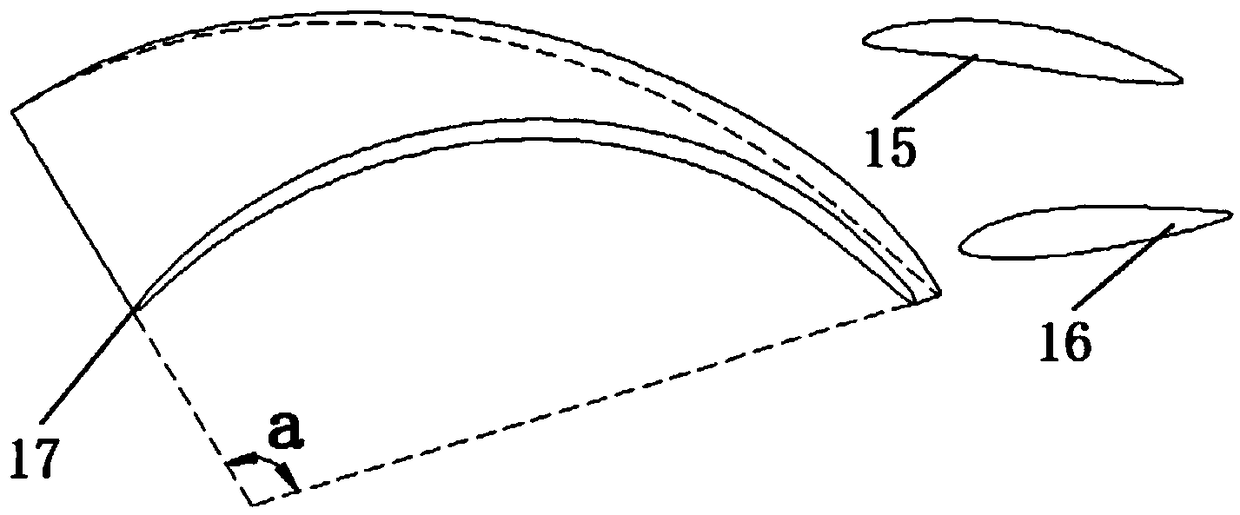

Fuel injection valve for internal combustion engines

InactiveUS6827297B2Increase flow pressureHigh trafficSpray nozzlesMachines/enginesInjection portCombustion chamber

Owner:ROBERT BOSCH GMBH

Method for Pretreatment of Wastewater and Recreational water with Nanocomposites

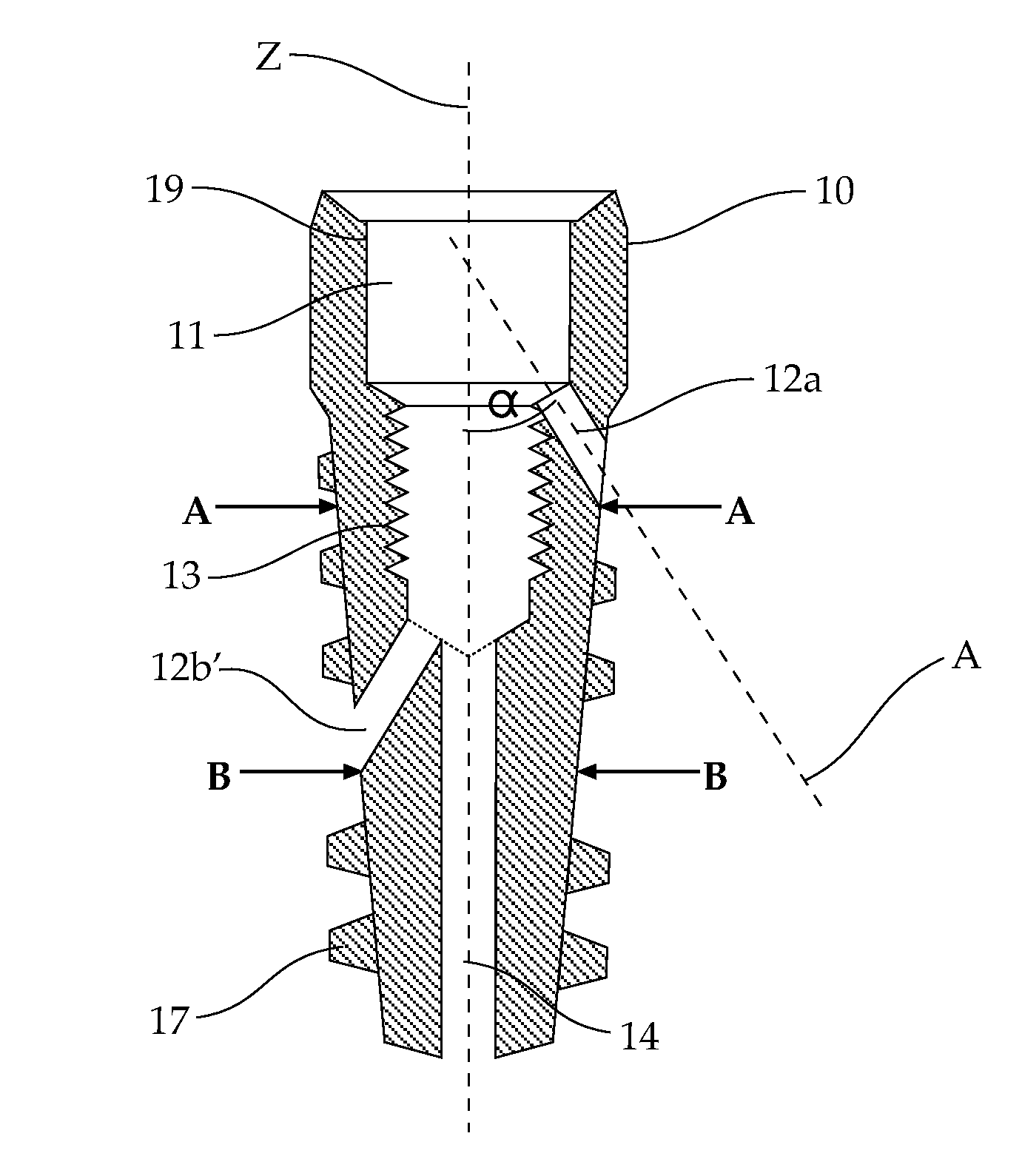

InactiveUS20150056569A1Increase flow pressureEnhancing implant gripDental implantsCoffinsWastewaterDentistry

A method and a dental implant system for accessing selected intra-cavity locations there-through that includes: (a) a dental implant having a plurality of openings configured for being implanted in an intra-cavity area of a patient, wherein each one of the plurality of openings allows access from an external area of the dental implant to a space in the intra-cavity area between the implant and a jawbone of the patient, when the dental implant is installed in the intra cavity; and (b) one or more directing element that is removably securable to the dental implant, wherein the directing element includes openings and is configured to allow access to one or more specific locations at this space through a selected at least one of the plurality of openings of the dental implant, when secured thereto.

Owner:REGEV DAVID +4

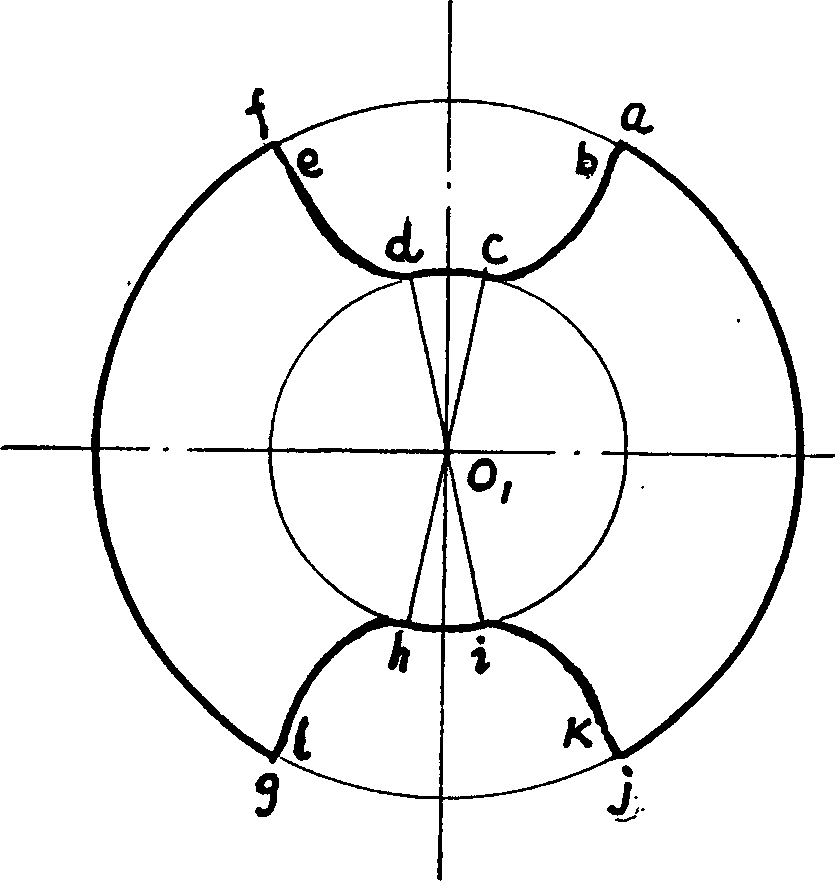

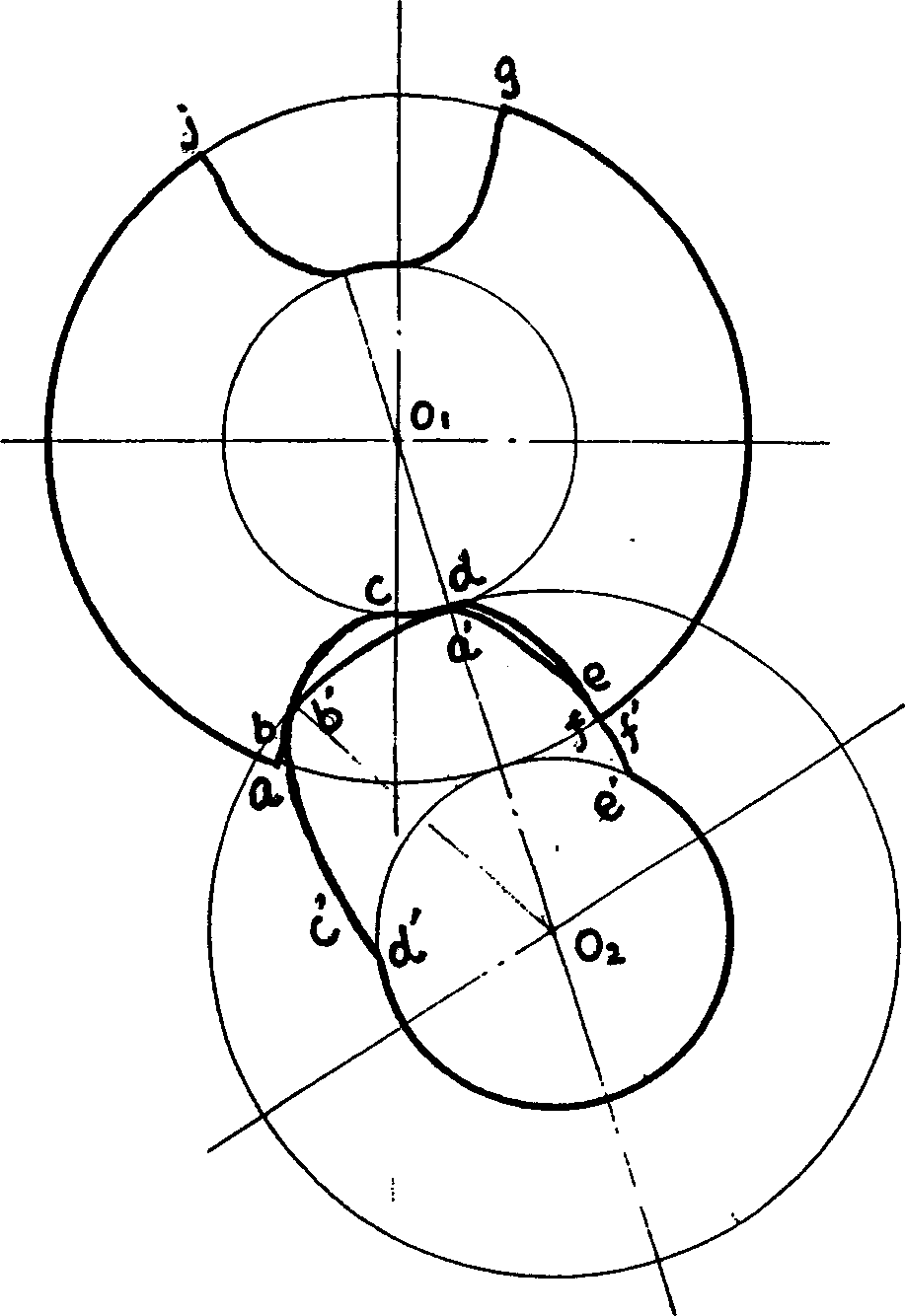

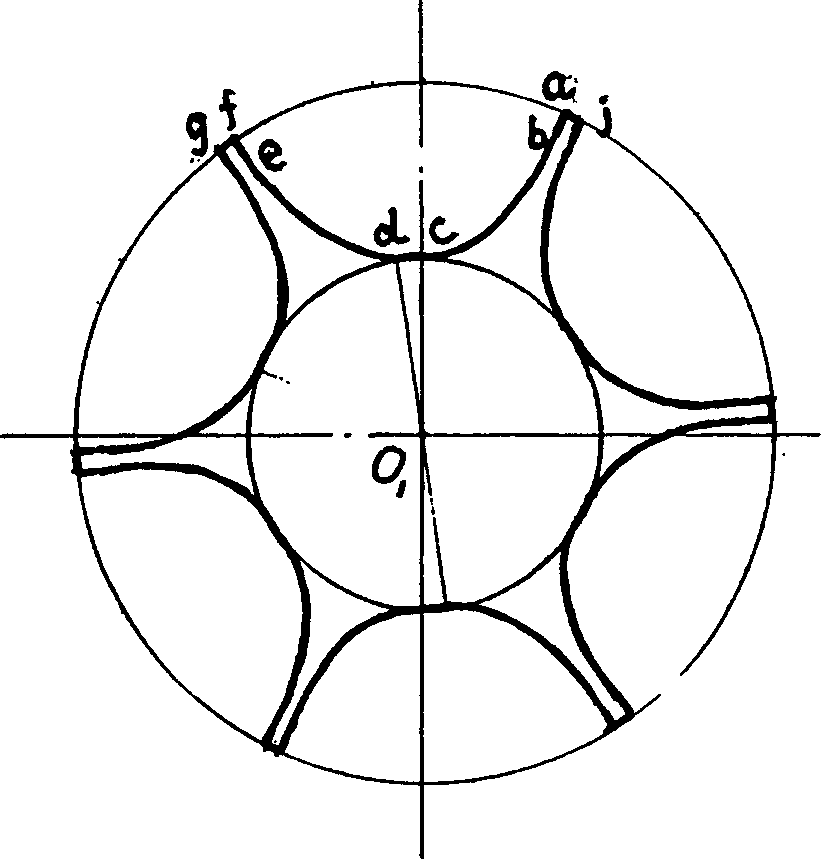

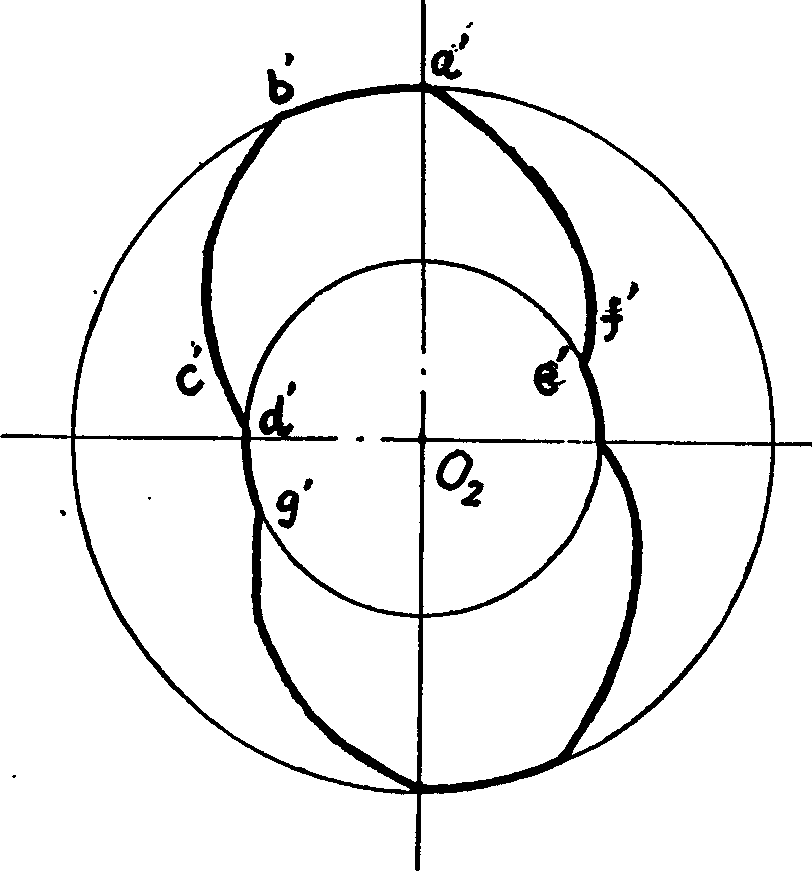

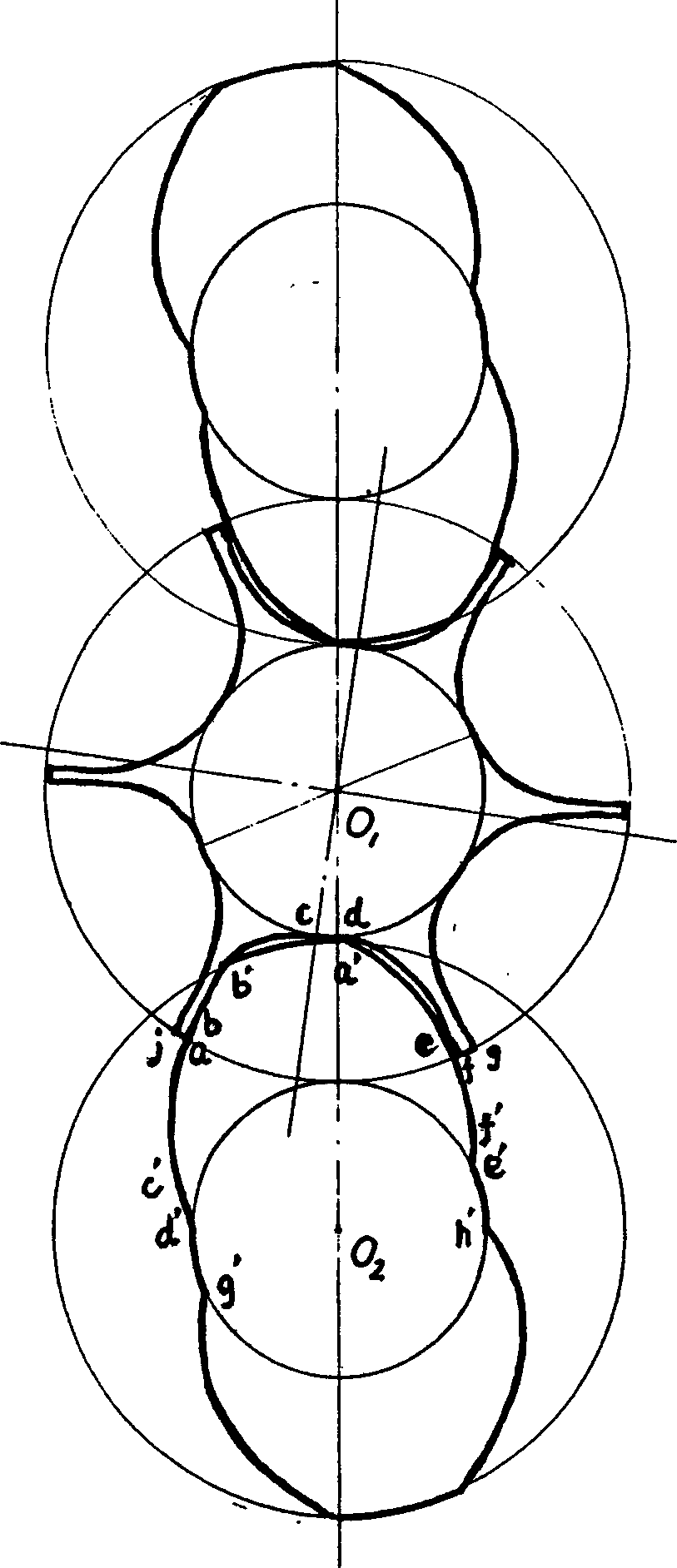

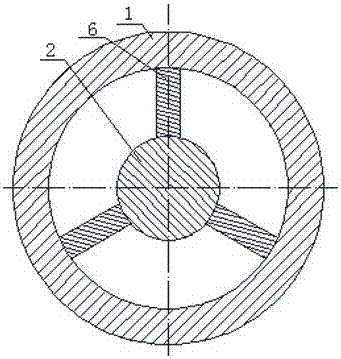

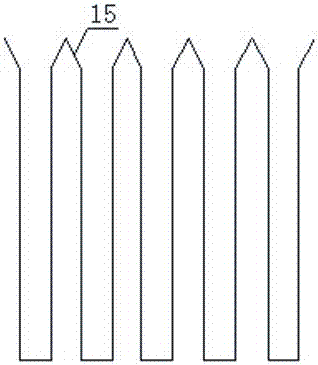

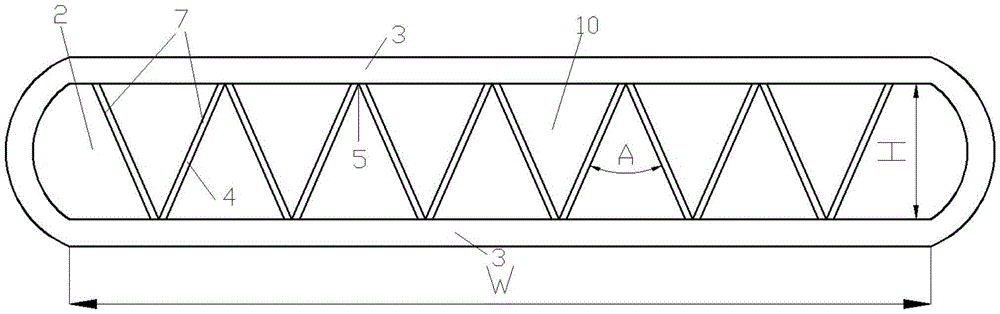

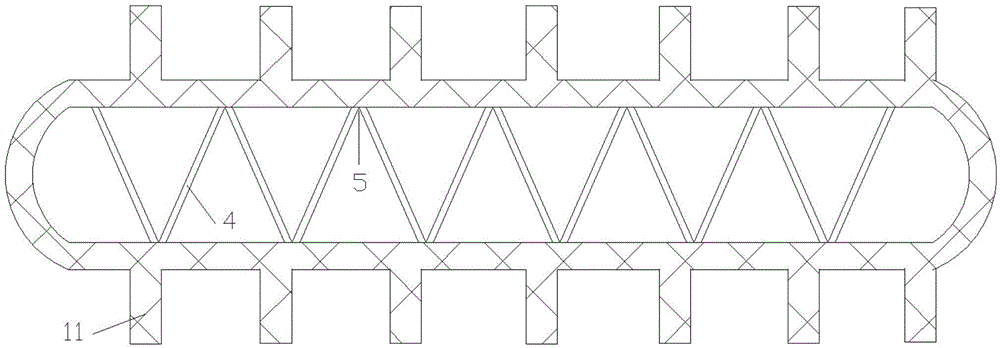

Screw profile for high flow high-pressure dual-screw pump

InactiveCN1743678AImprove sealingIncrease flow pressureRotary piston pumpsRotary piston liquid enginesEngineeringHigh pressure

This invention discloses screw tooth shape for high flow high pressure triangle screw pump, which contains single-thread screw and double-thread screw. Said invention has shorter seal line, fine seal property, multiple increased output flow and pressure.

Owner:ZHEJIANG UNIV

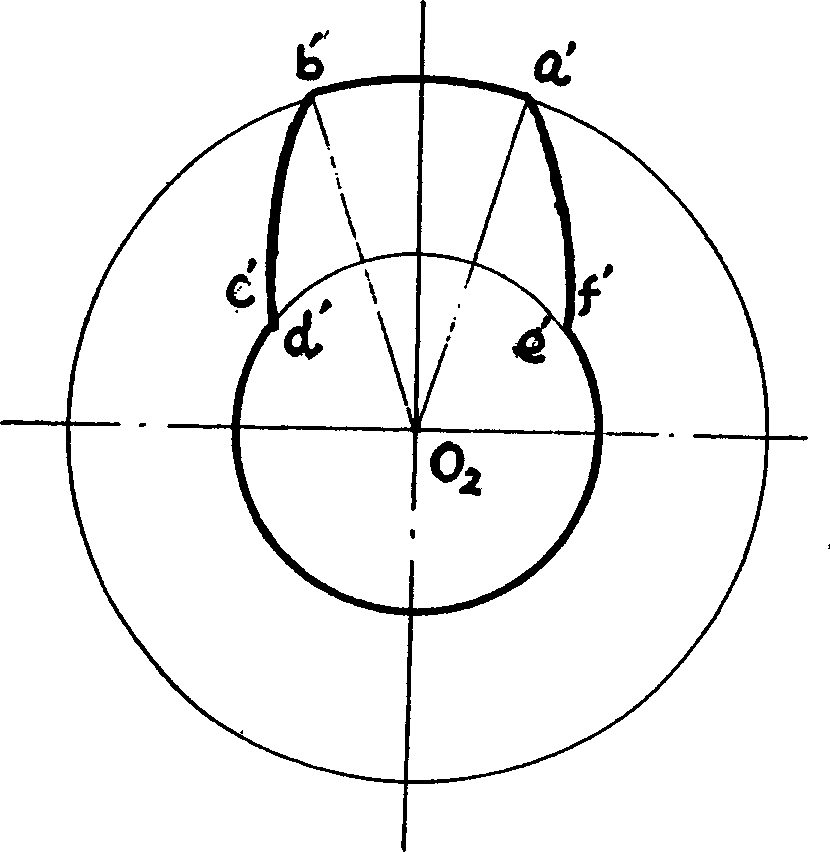

Unequal-tooth-number screw profile for high-flow high-pressure three-screw pump

InactiveCN1743675AShort sealing lineGood sealing performanceRotary piston pumpsRotary piston liquid enginesEngineeringHigh pressure

This invention discloses screw tooth shape with unequal tooth number for high flow high pressure triangle screw pump, which contains double-thread male screw slave screw and six-thread female screw active screw. Said invention has shorter seal line, fine seal property, multiple increased output flow and pressure.

Owner:陈行 +1

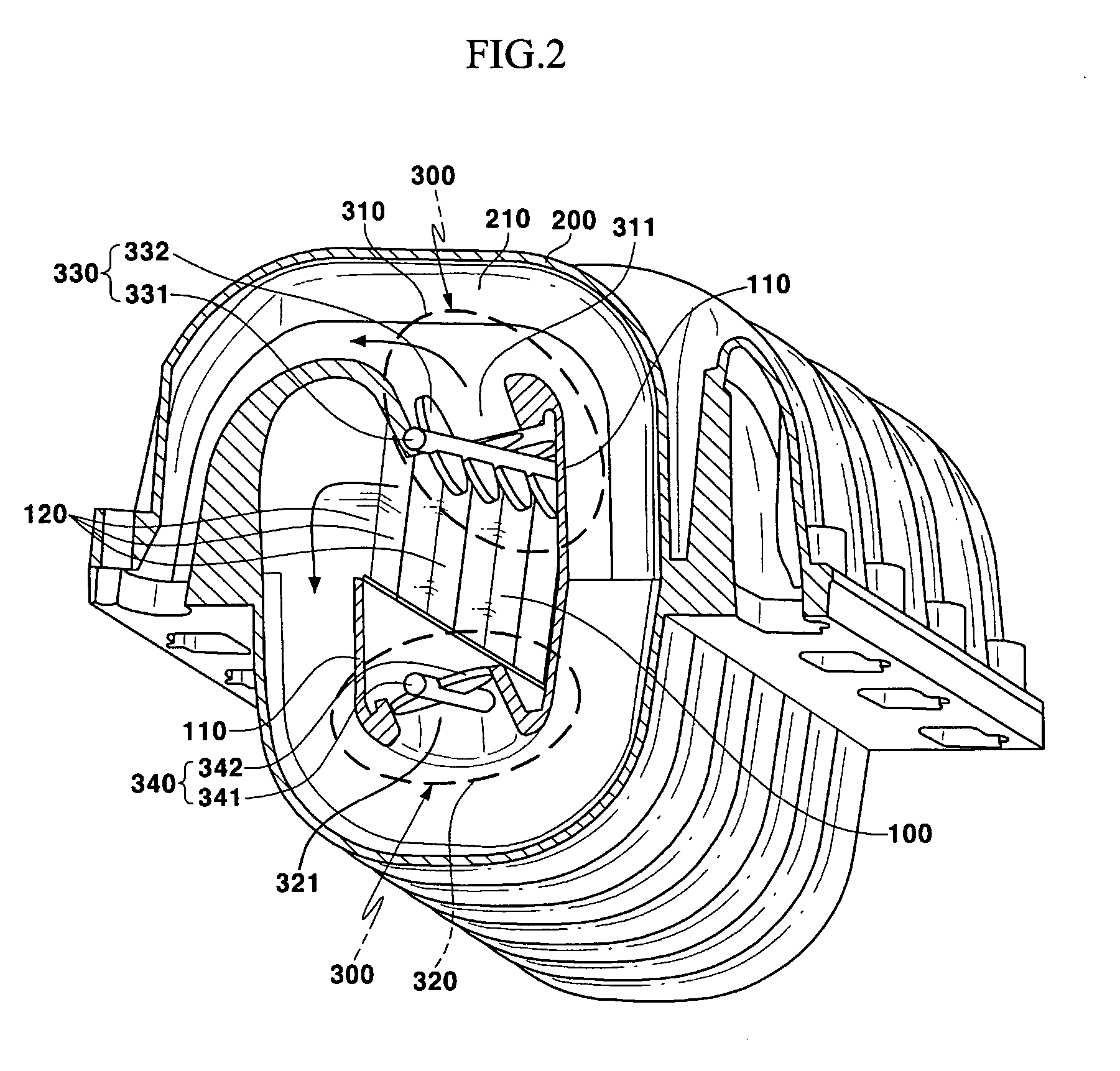

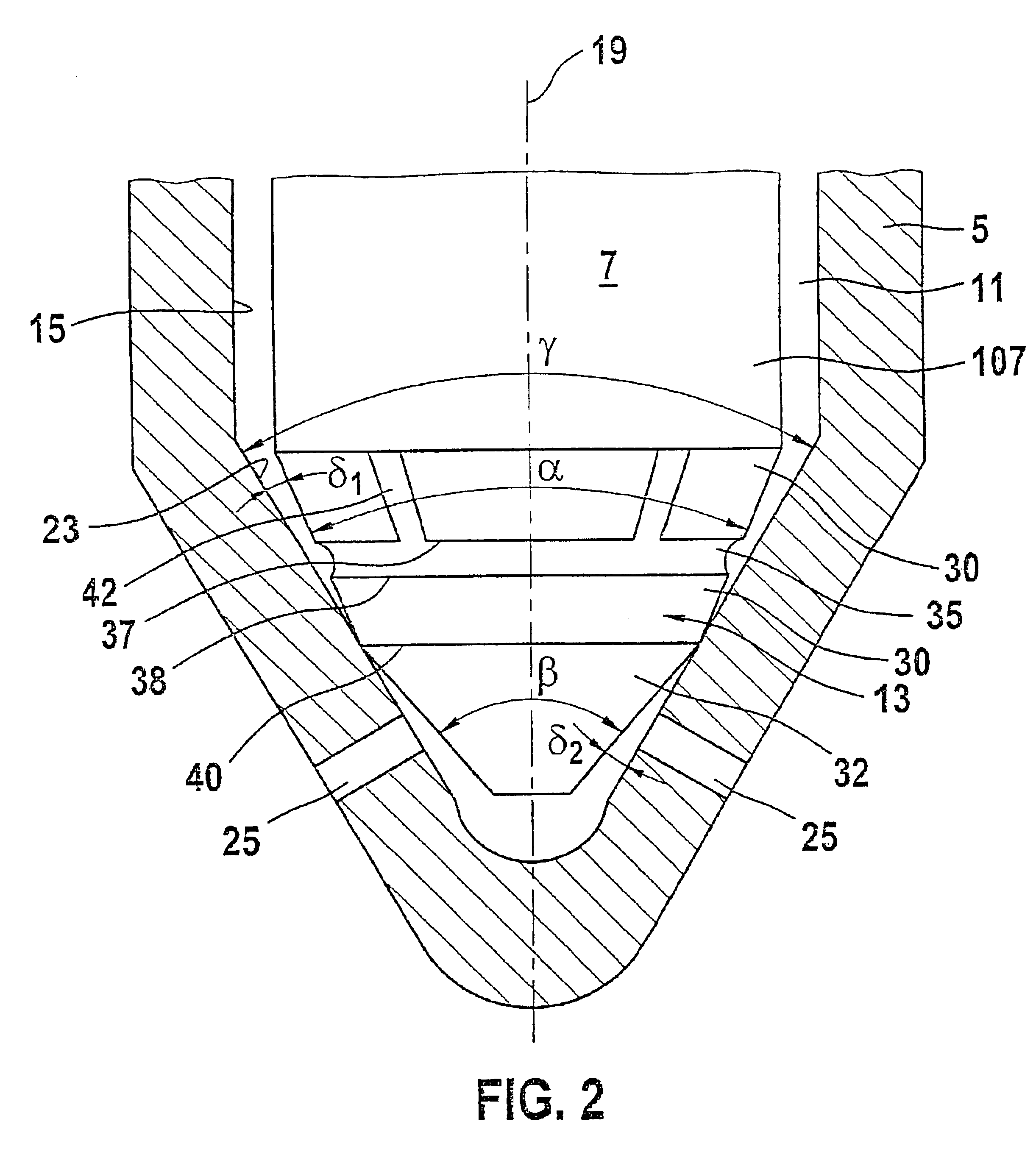

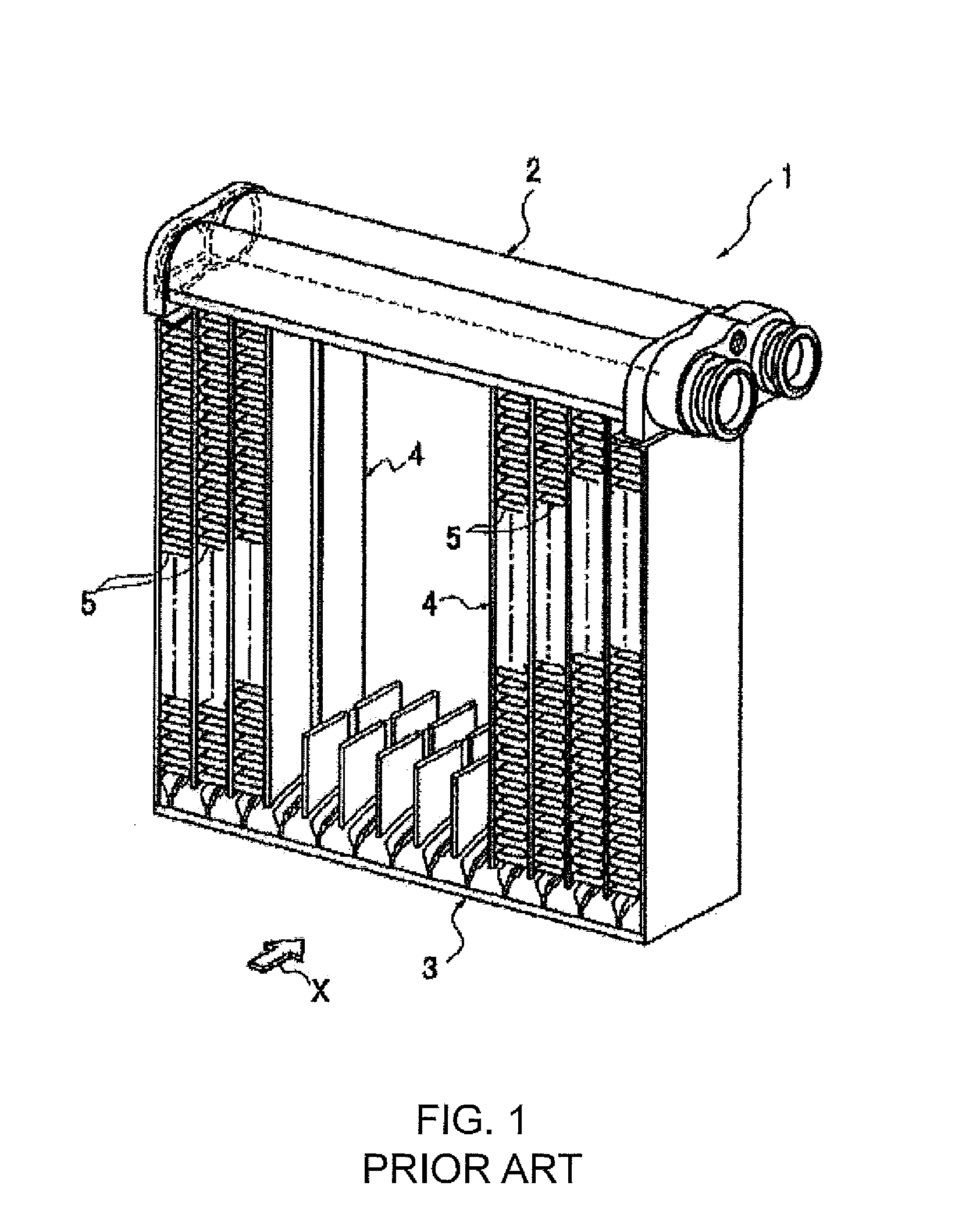

Fuel injection valve for internal combustion engines

InactiveUS20020162906A1Increase is limitedIncrease flow pressureSpray nozzlesMachines/enginesInjection portCombustion chamber

A fuel injection valve having a valve body (5), in which a pistonlike valve member (7) is guided longitudinally displaceably in a bore (15) embodied as a blind bore. A conical valve seat (23) and at least one injection port (25) are embodied on the bottom face of the bore (15), and the injection port connects a pressure chamber (11), formed between the portion (107) of the valve member (7) toward the combustion chamber and the bore (15), with the combustion chamber. On the end toward the combustion chamber of the valve member (7), there is a valve member tip (13), on which a first conical face (30), adjacent to the valve member (7), and a second conical face (32), disposed on the combustion chamber side of the first conical face, are embodied. The cone angle (alpha) of the first conical face (30) is less, and the cone angle (beta) of the second conical face (32) is greater, than the cone angle (gamma) of the valve seat (23), so that a sealing edge (40) is formed at the transition of the two conical faces (30, 32). Embodied on the first conical face (30) is an encompassing annular groove (35), which limits an increase in the hydraulically effective seat diameter caused by the plastic deformation of the sealing edge (40) and the valve seat (23) to a precisely defined extent (FIG. 2).

Owner:ROBERT BOSCH GMBH

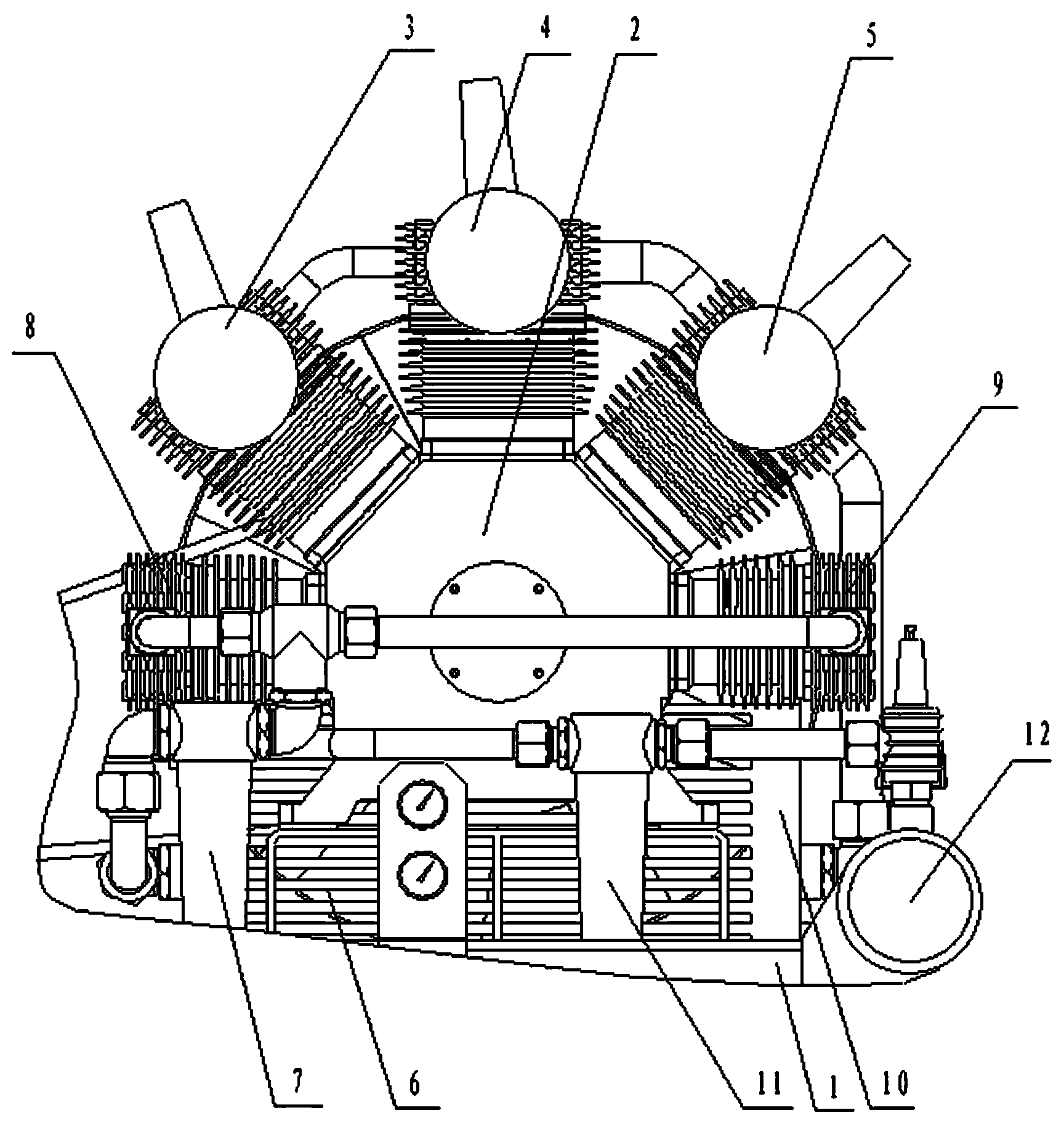

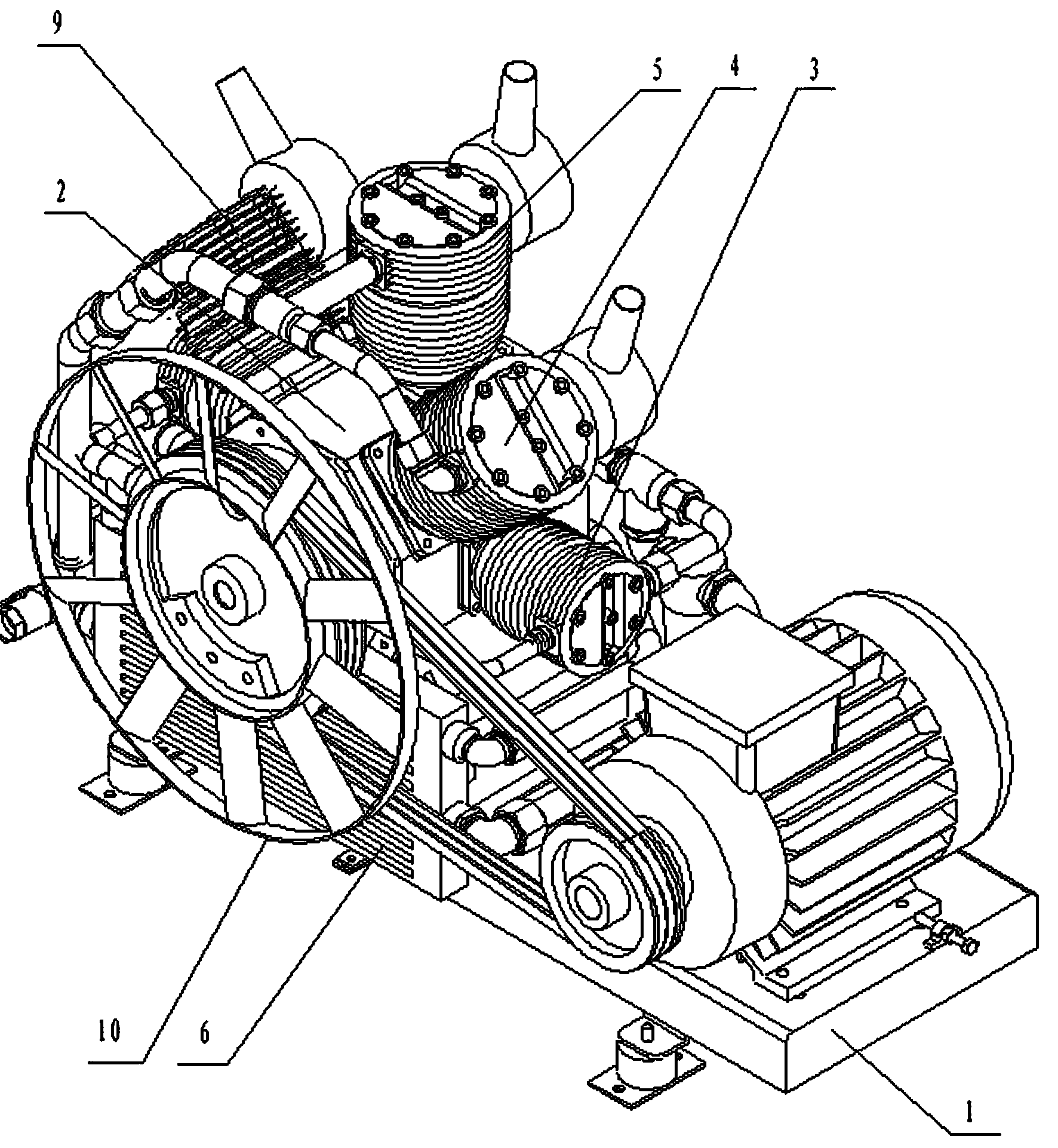

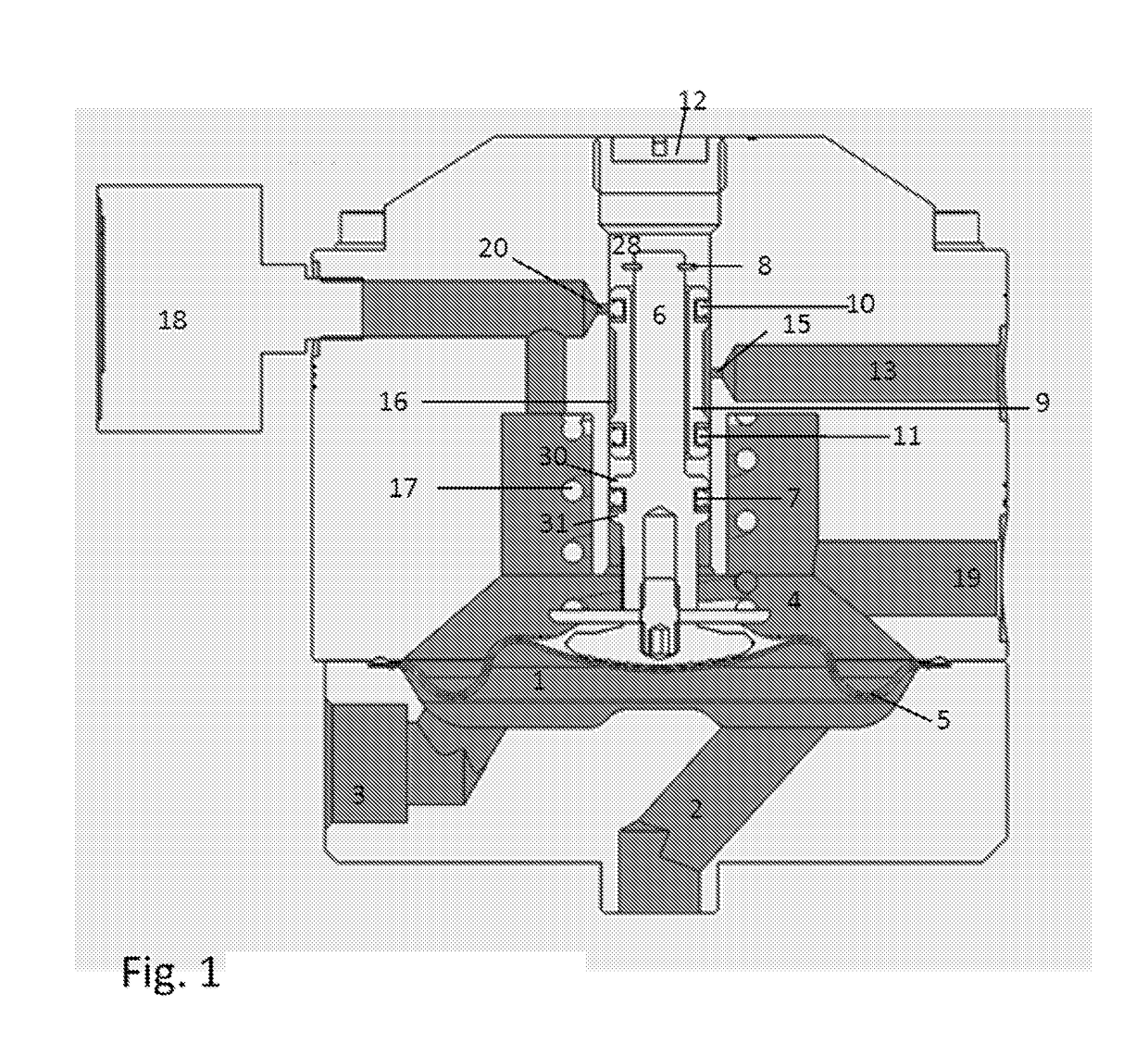

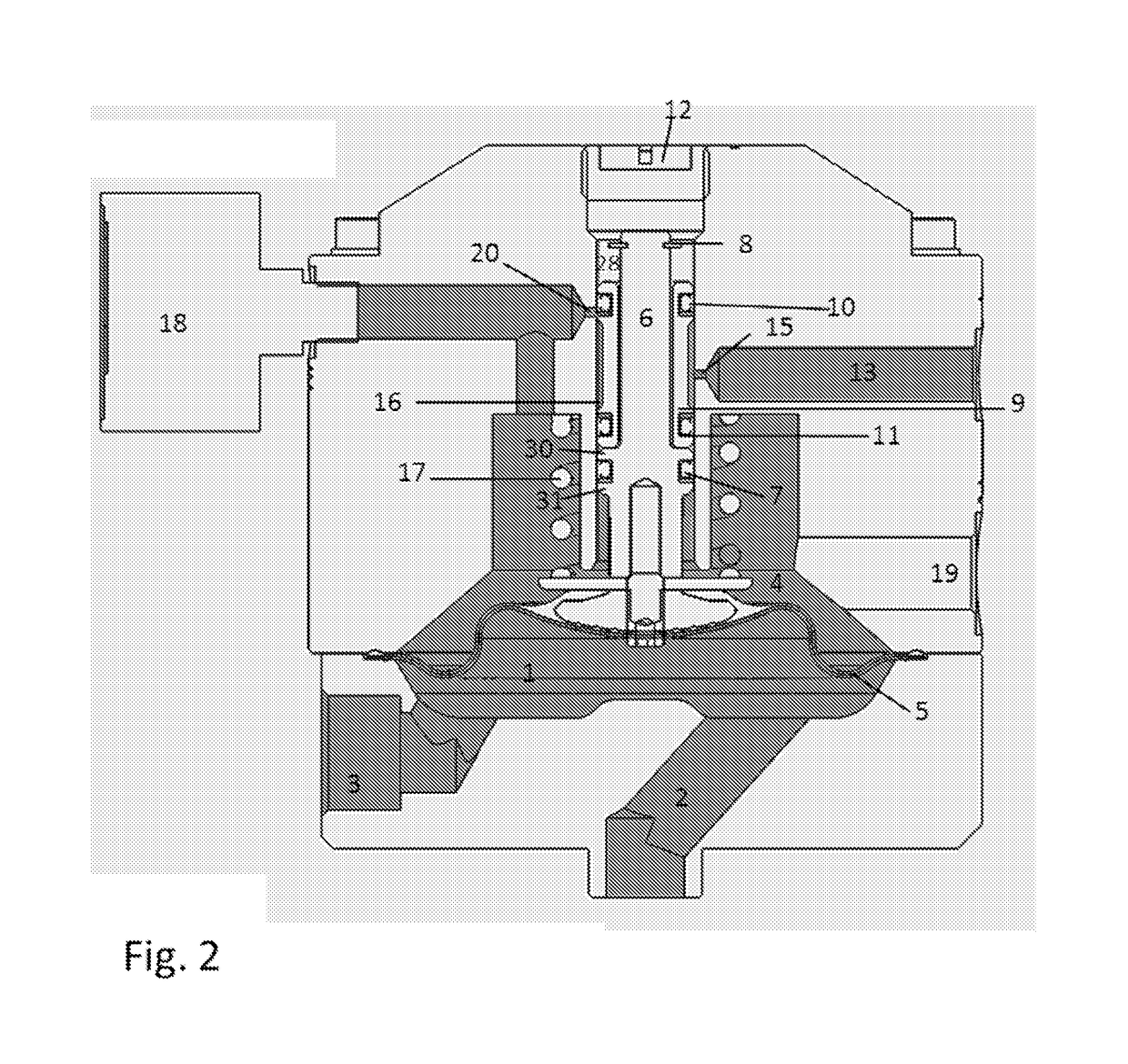

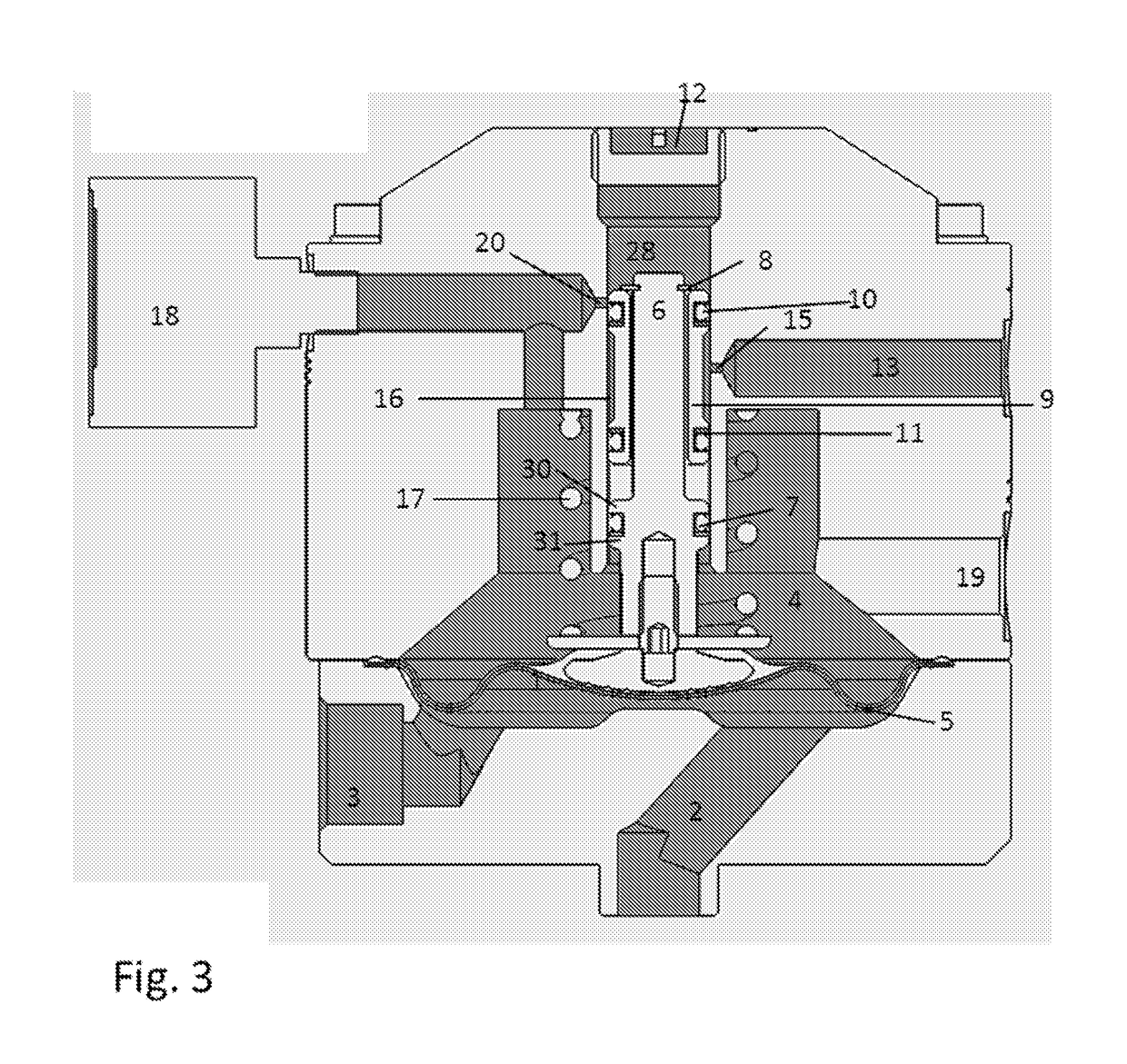

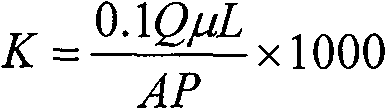

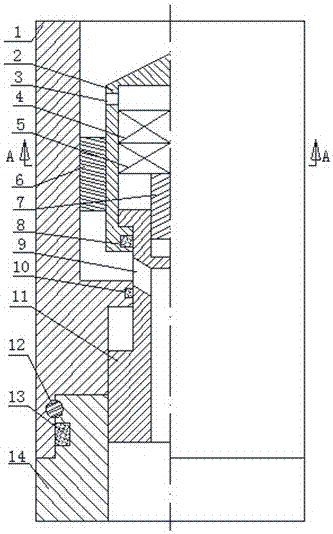

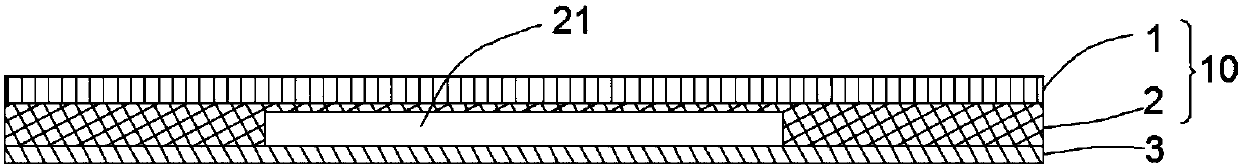

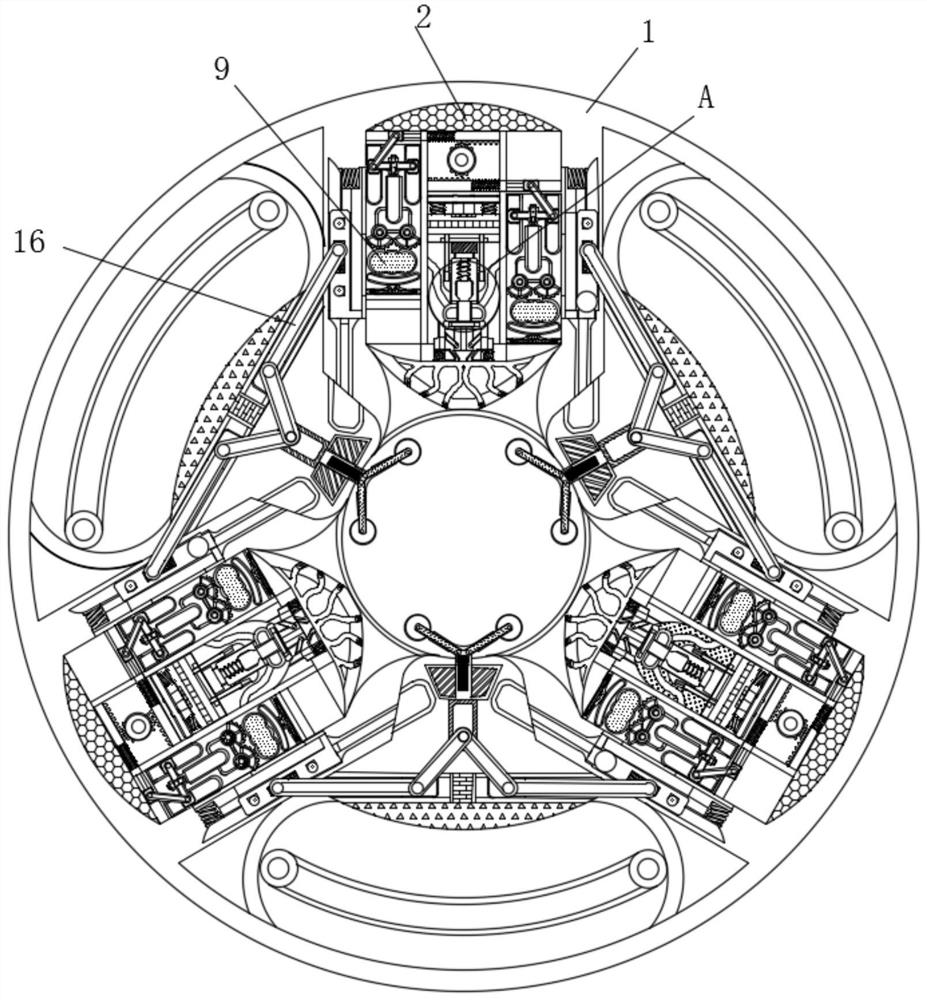

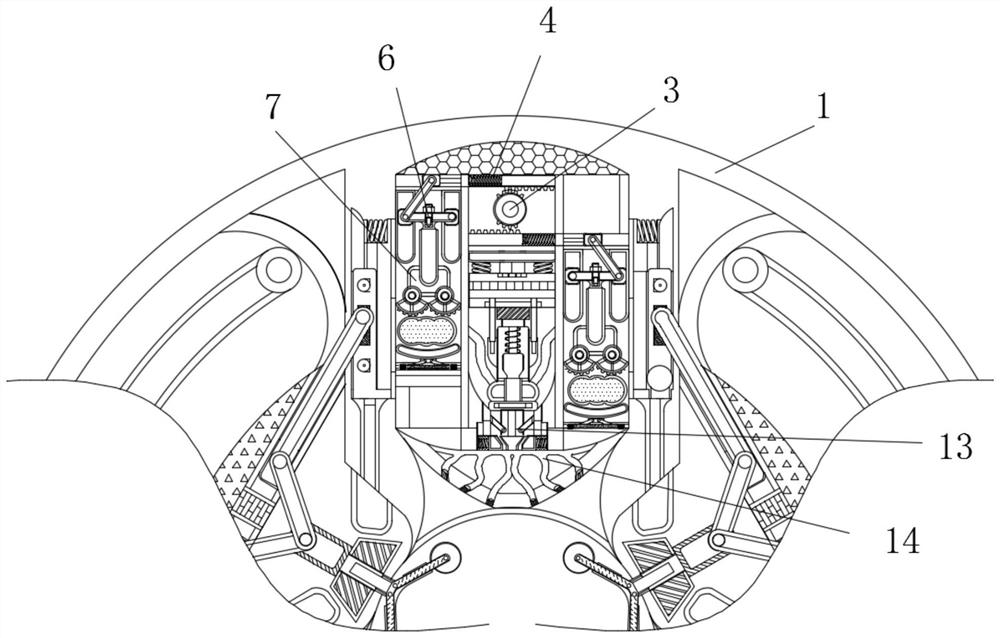

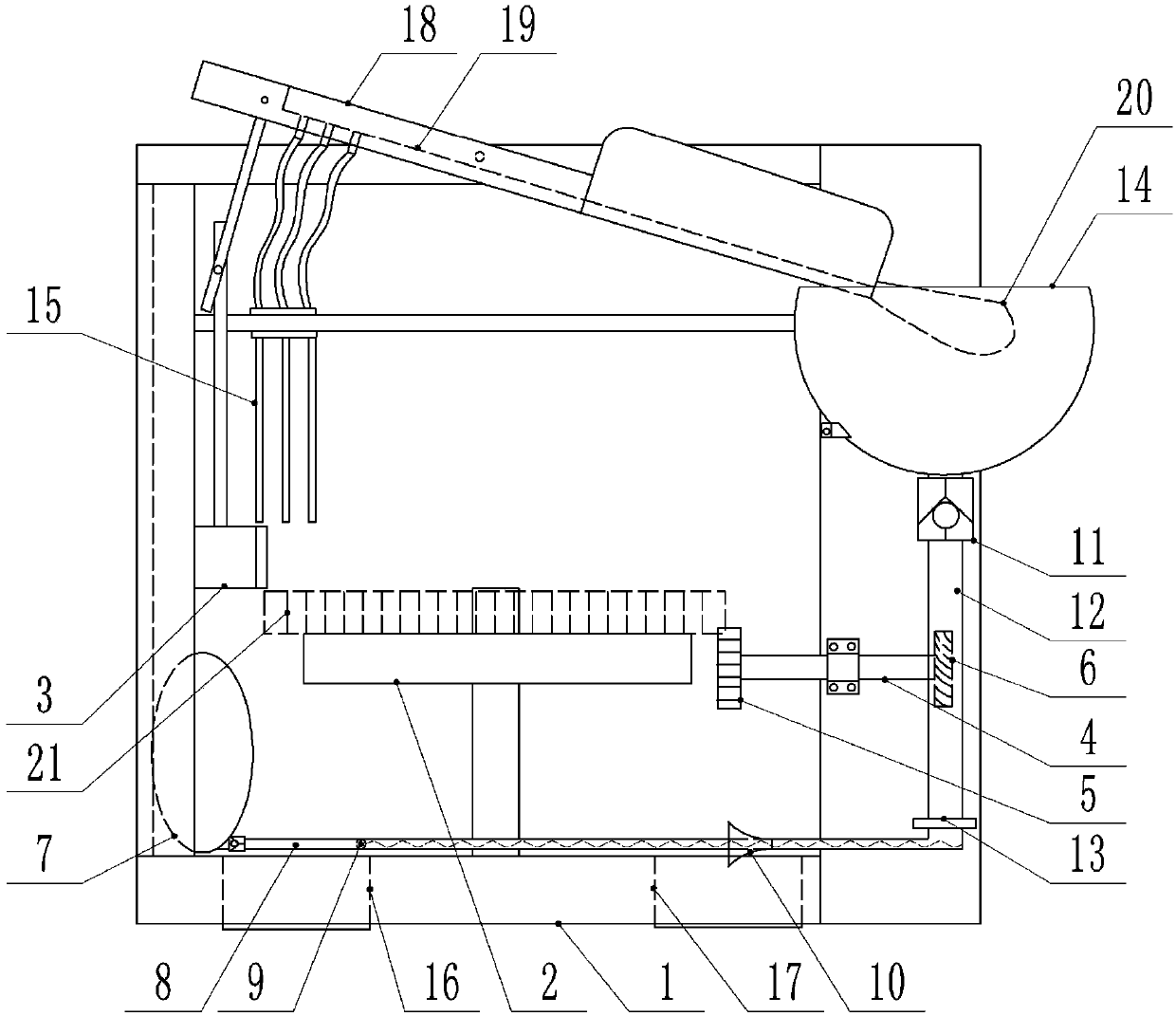

Piston type oil-less air compressor

ActiveCN103410697AIncrease flow pressureIncrease exhaust pressurePositive displacement pump componentsMulti-stage pumpsLinear compressorCrankcase

The invention discloses a piston type oil-less air compressor. The piston type oil-less air compressor comprises a machine base, a crank case fixed on the machine base, a primary cylinder I, a primary cylinder II, a primary cylinder III, an intermediate cooler, a primary air-water separator, a secondary cylinder I, a secondary cylinder II, an after-cooler, a secondary air-water separator and an air storage tank fixed on the machine base. The primary cylinder I, the primary cylinder II and the primary cylinder III are fixed on the crank case respectively and distributed in a fan-shaped mode, an included angle between the primary cylinder I and the primary cylinder II and between the primary cylinder III and the primary cylinder II are 40-55 degrees, and the secondary cylinder I and the secondary cylinder II are arranged on the left side and the right side of the crank case respectively. By adopting the technical scheme, the piston type oil-less air compressor is compact in structure, a space occupied by the air compressor is saved, the installing area of a valve is increased, cooling is facilitated, the effective volume flow and exhaust pressure of the piston type oil-less air compressor are improved, an application range is expanded, the service life and the air quality are prolonged and improved, and the working reliability is improved.

Owner:ANHUI HUAJING MACHINERY

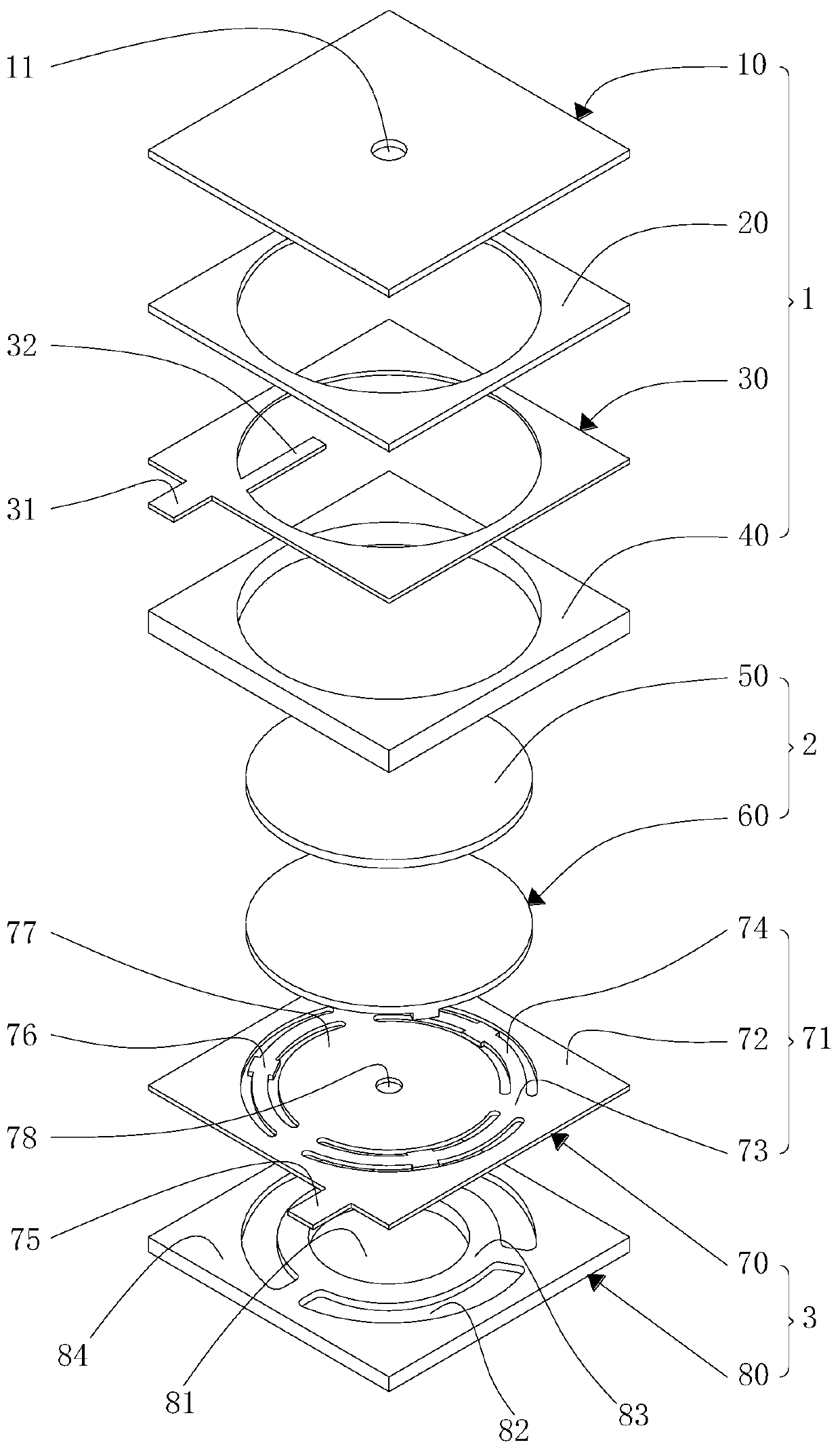

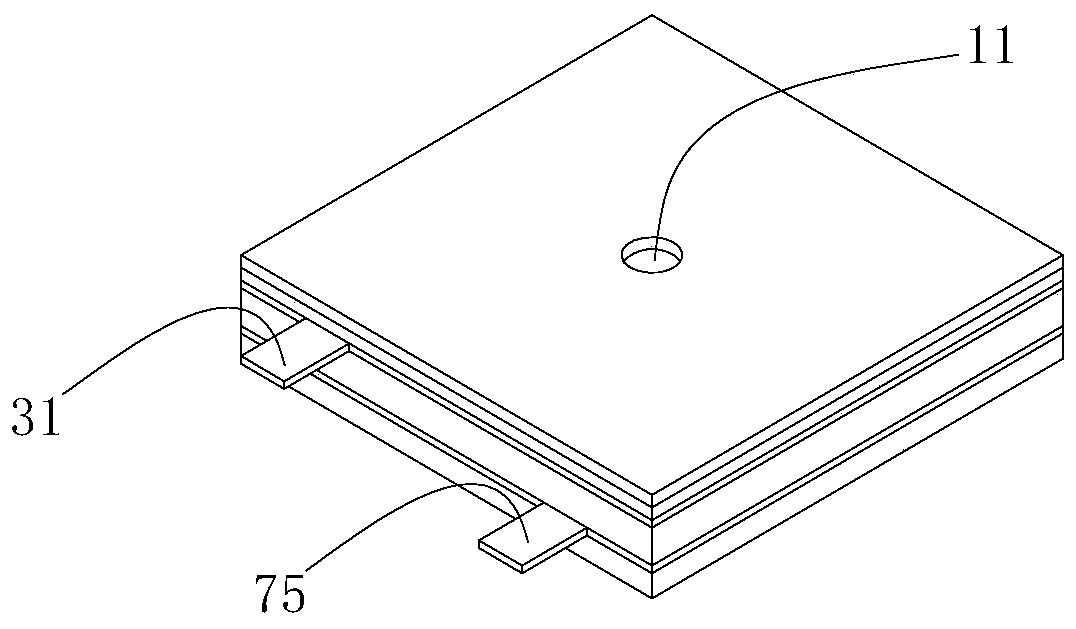

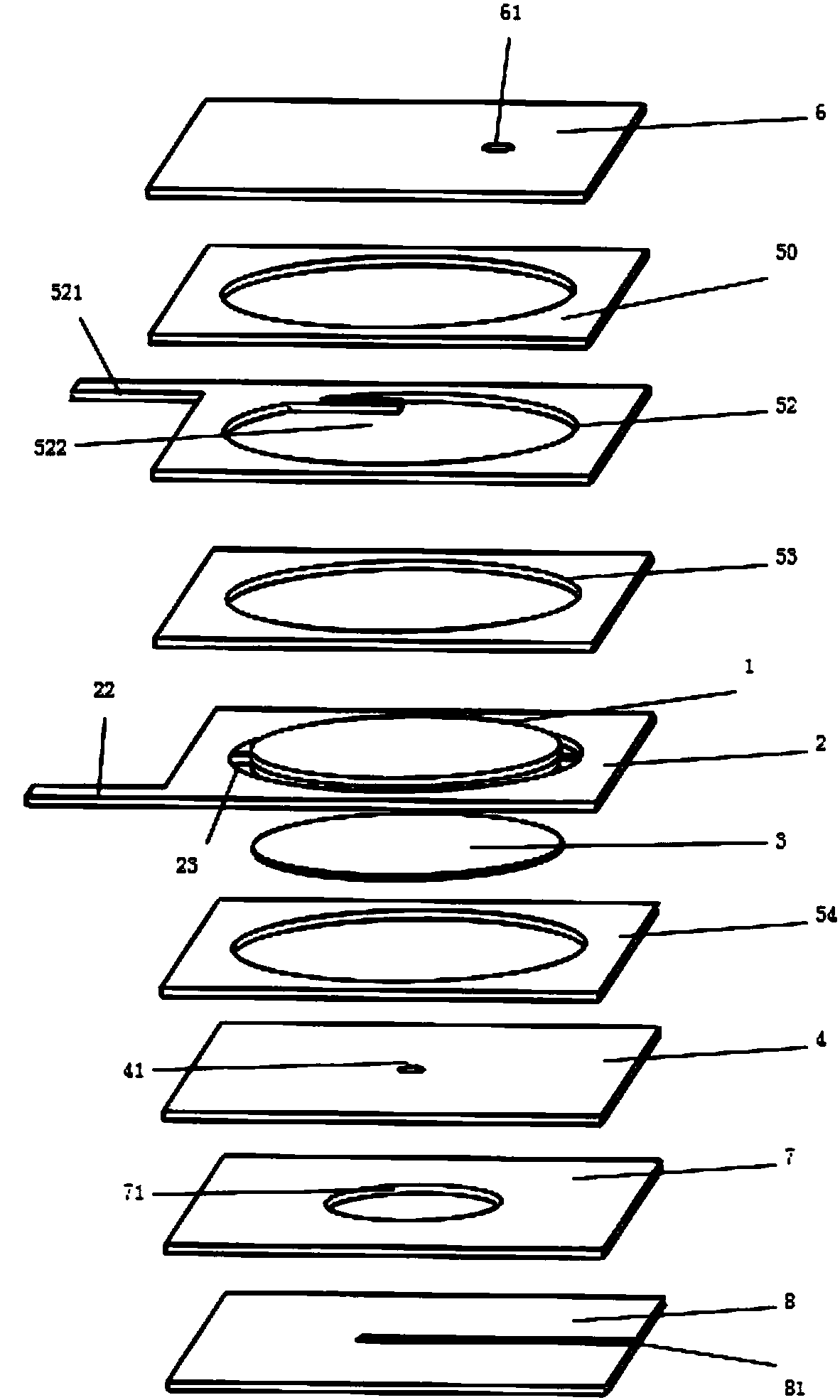

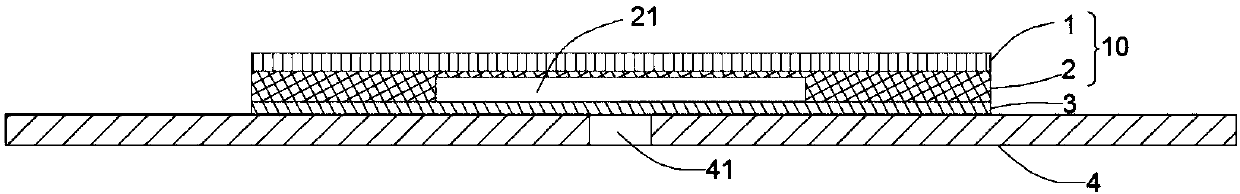

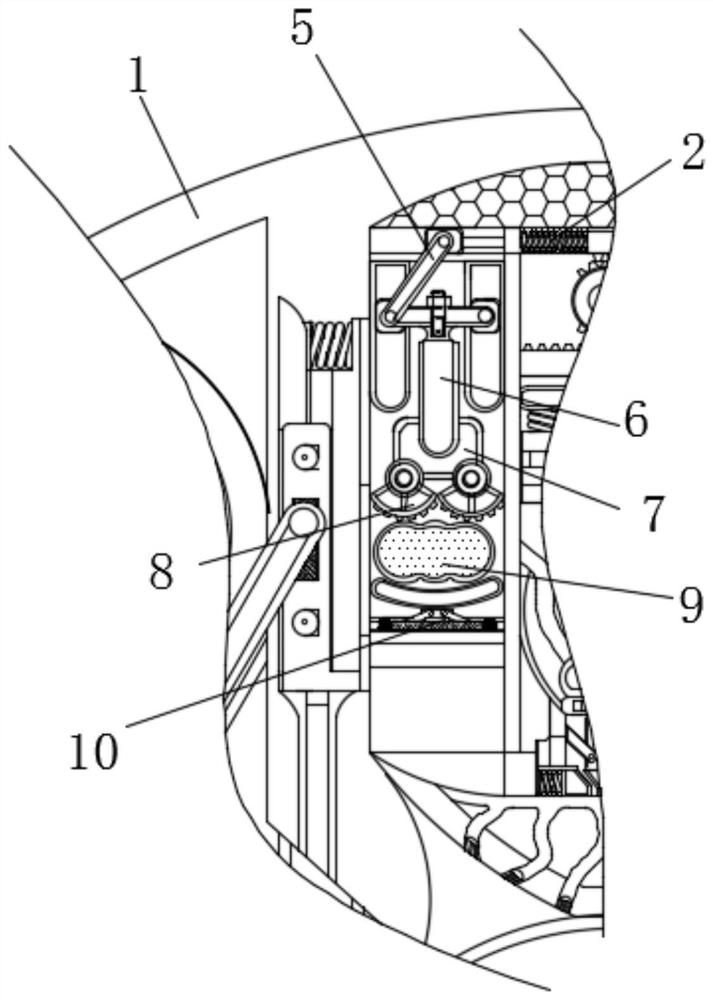

Vertically-supported micro-piezoelectric pump

PendingCN109869302AReduce volumeSmall sizeFlexible member pumpsPositive-displacement liquid enginesElectricityEngineering

The invention belongs to the technical field of fluid conveying, and relates to a vertically-supported micro-piezoelectric pump. The vertically-supported micro-piezoelectric pump comprises a pump body, a supporting structure, an actuator and one or more air holes, wherein a pump cavity is formed by the supporting structure and the pump body, the actuator is arranged in the pump cavity and connected with the supporting structure, and the air holes communicating with the pump cavity are formed in the pump body and the supporting structure; the actuator comprises a vibration base plate and one ormore piezoelectric elements arranged on the vibration base plate, and a plurality of avoidance parts are arranged on the side, close to the supporting structure, of the vibration base plate; and thesupporting structure includes a bottom plate, a flexible plate is arranged on the side, close to the vibration base plate, of the bottom plate, beam parts corresponding to the positions of the avoidance parts are arranged on the flexible plate, and avoidance grooves corresponding to the positions of the beam parts are formed in the bottom plate. According to the vertically-supported micro-piezoelectric pump, the volume and the peripheral size of the micro-piezoelectric pump can be reduced under the premises that the output capacity (output pressure and output flow) is not changed or increasedand the driving voltage is low, the efficiency is high, the market value is great, and the popularization is worthy.

Owner:常州威图流体科技有限公司

Active surge chamber

ActiveUS20190050004A1Reduce fluid pressureEffecting disconnectionFlexible member pumpsFluid pressure control without auxillary powerEngineeringFluid supply

An active surge chamber for use in a paint supply system comprising a paint channel, a fluid chamber connected to a pressurised fluid supply, a diaphragm, a spring, and means responsive to movement of the diaphragm for effecting connection and disconnection of the pressurised fluid supply to the fluid chamber and for relieving pressure of fluid in the chamber. The paint channel is sealingly separated from the fluid chamber by the diaphragm. The spring has a spring rate such that the force exerted on the diaphragm by the spring restricts movement of the diaphragm over a selected range of pump outlet pressures in order to attenuate the movement of the diaphragm and reduce the susceptibility of the system to unwanted oscillation. Pressure fluctuations in a paint flow induced by usage of a reciprocating pump upstream of the active surge chamber are minimised.

Owner:CARLISLE FLUID TECH INC

Higher accuracy pressure based flow controller

InactiveCN1688839AIncrease flow pressureOperating means/releasing devices for valvesVolume/mass flow by thermal effectsTransducerNonlinear flow

Owner:霍里巴斯特克公司

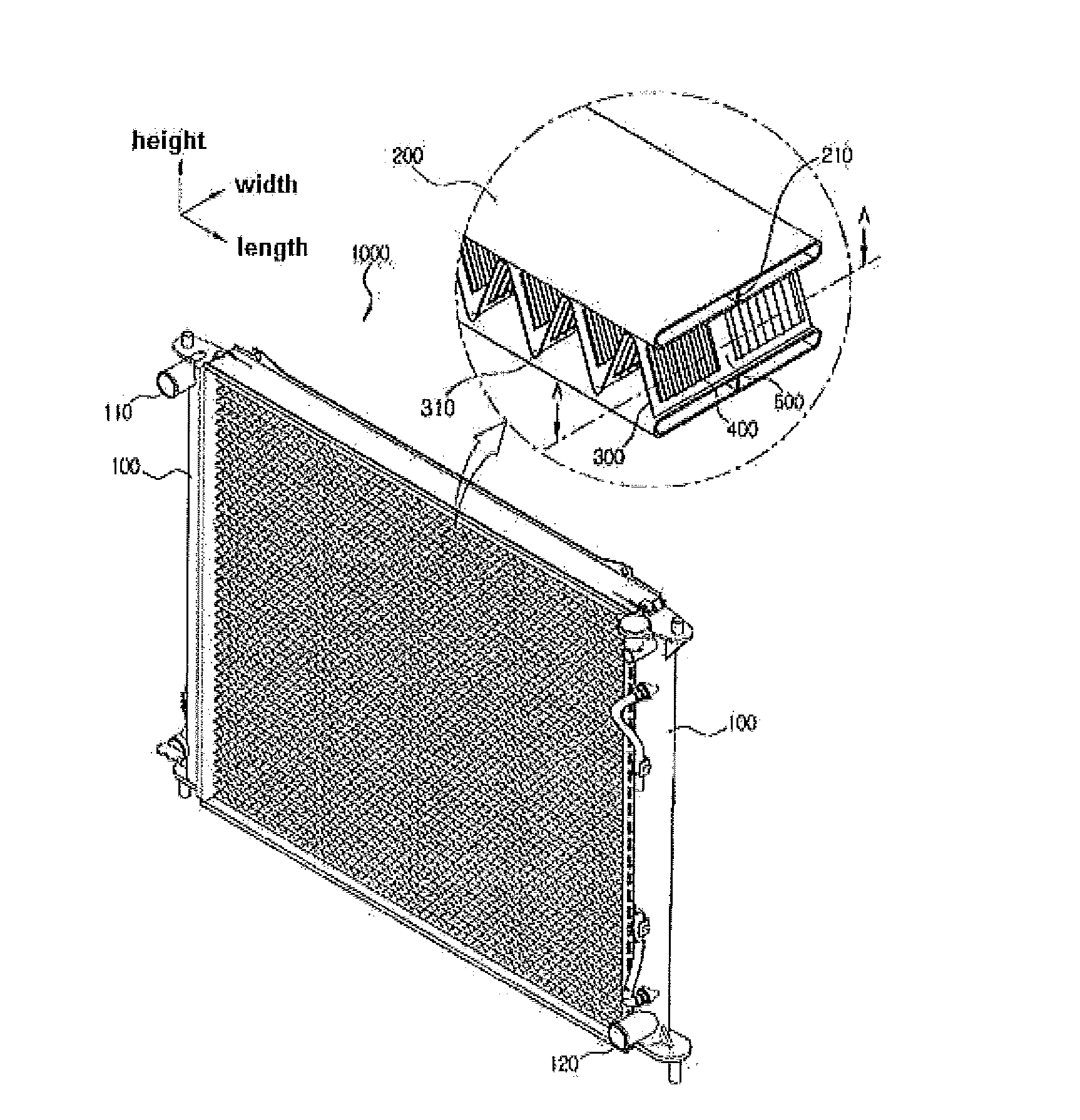

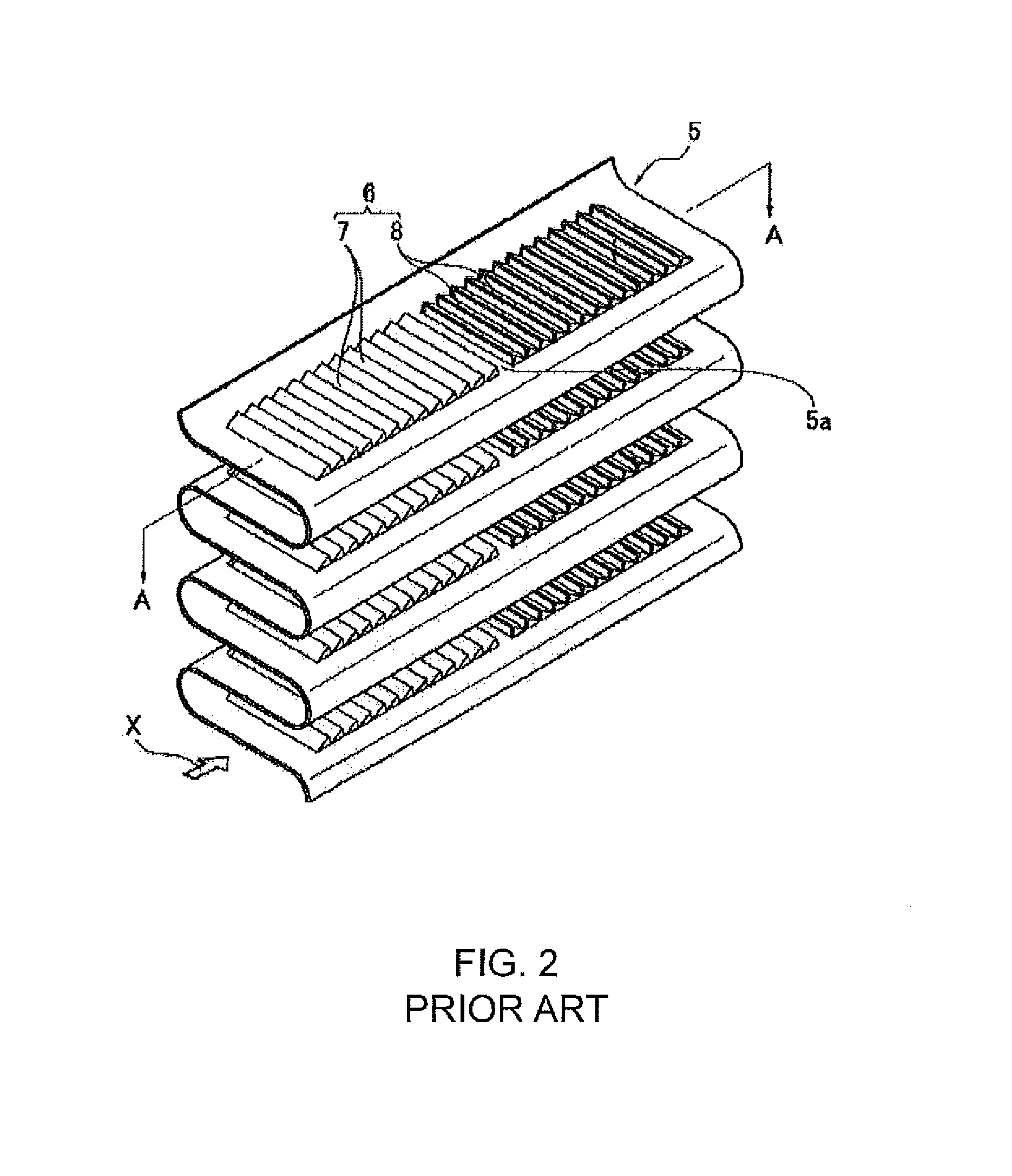

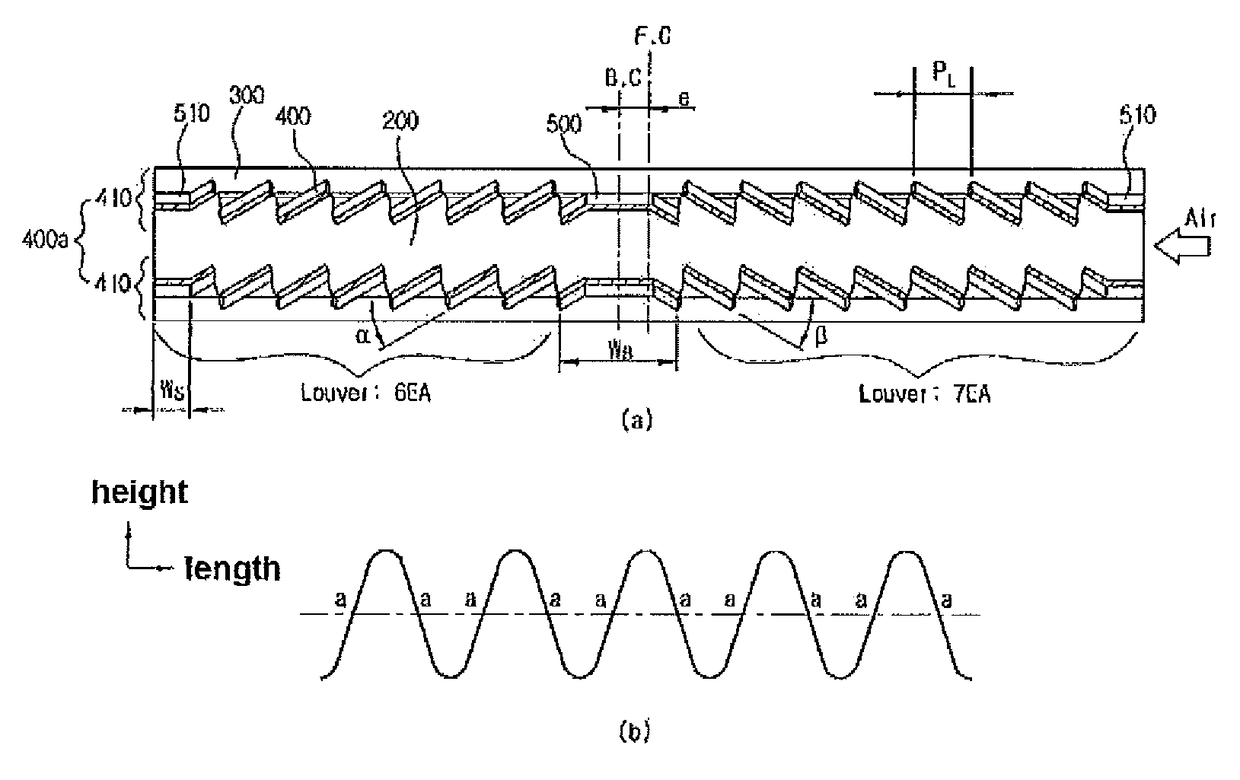

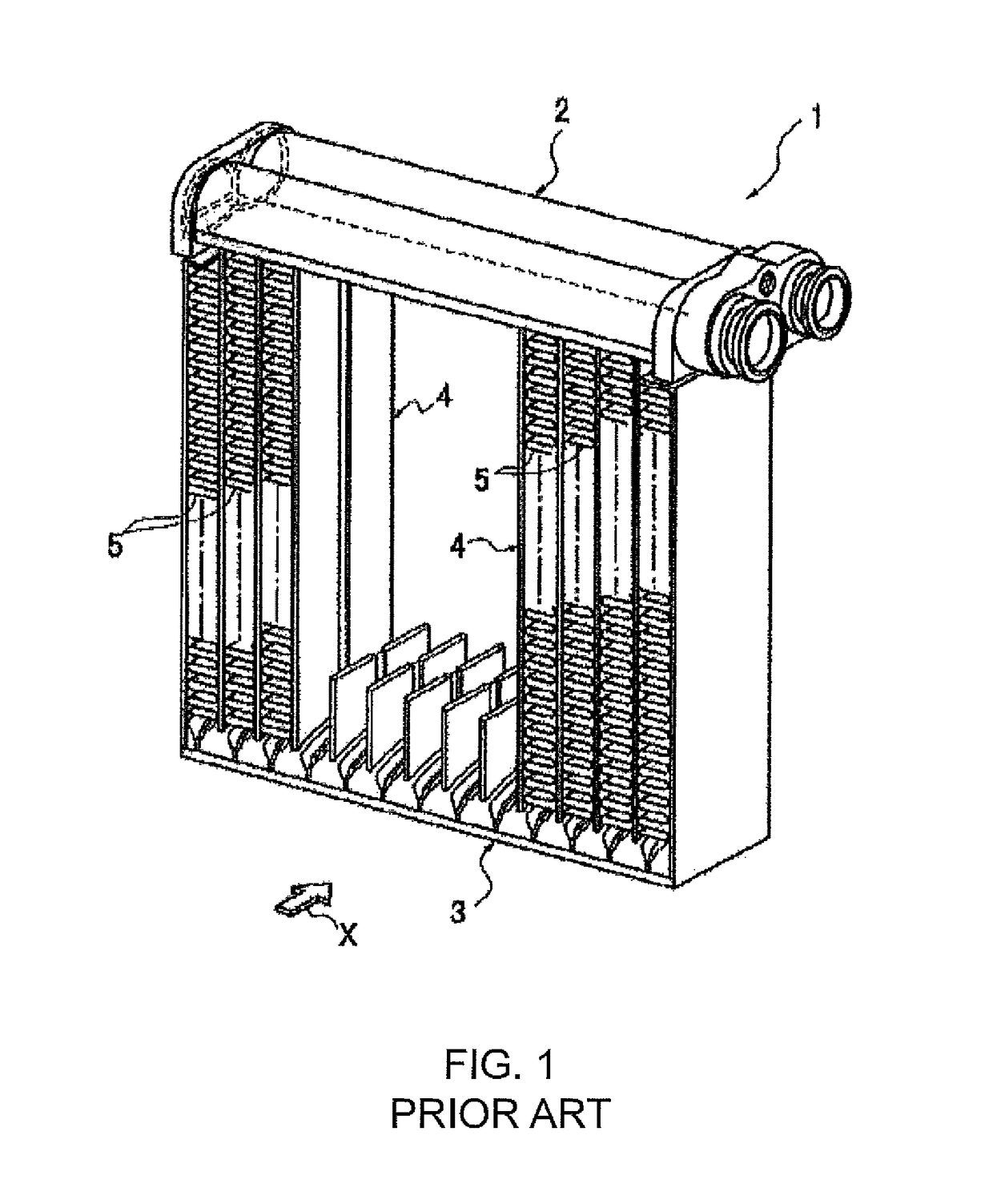

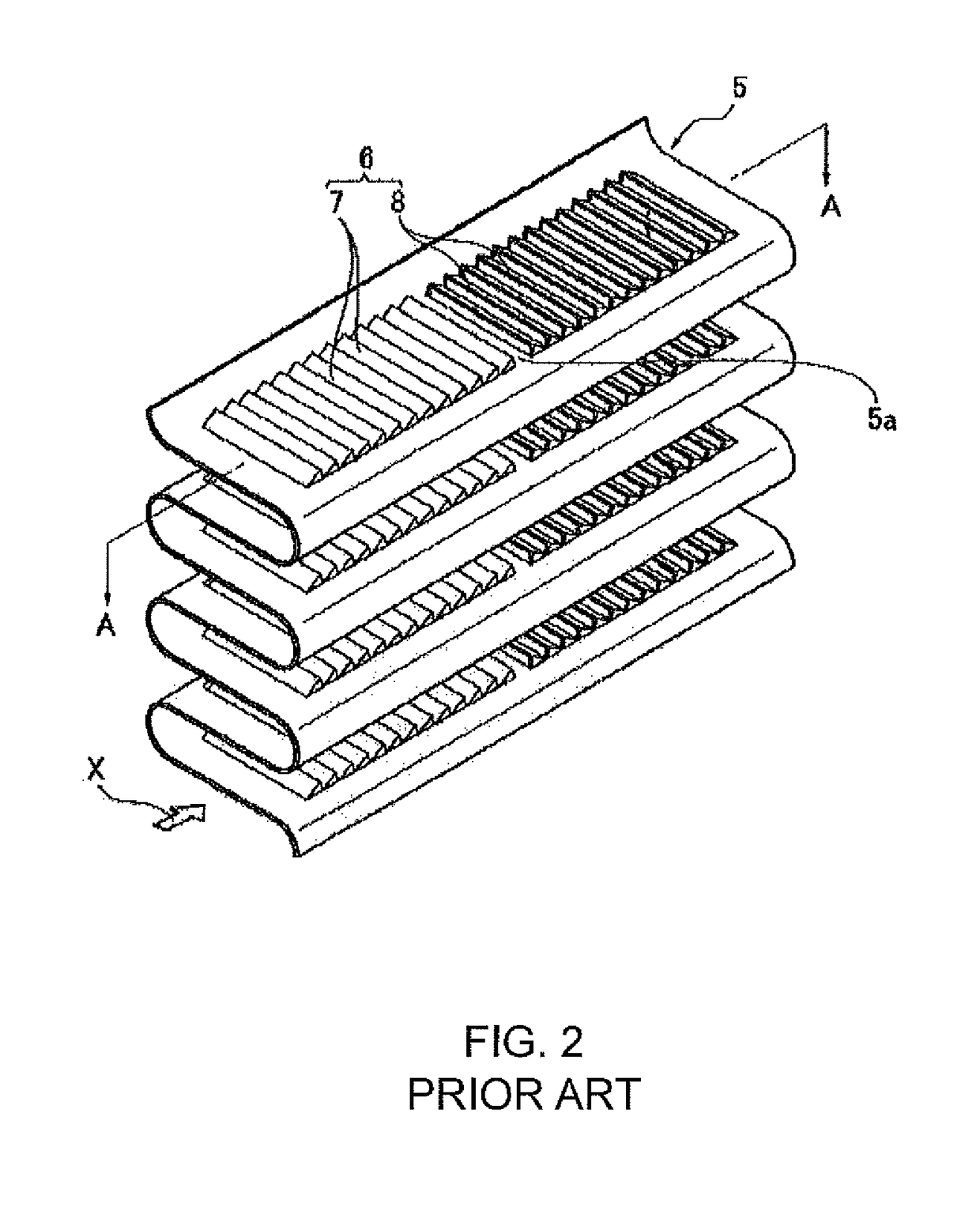

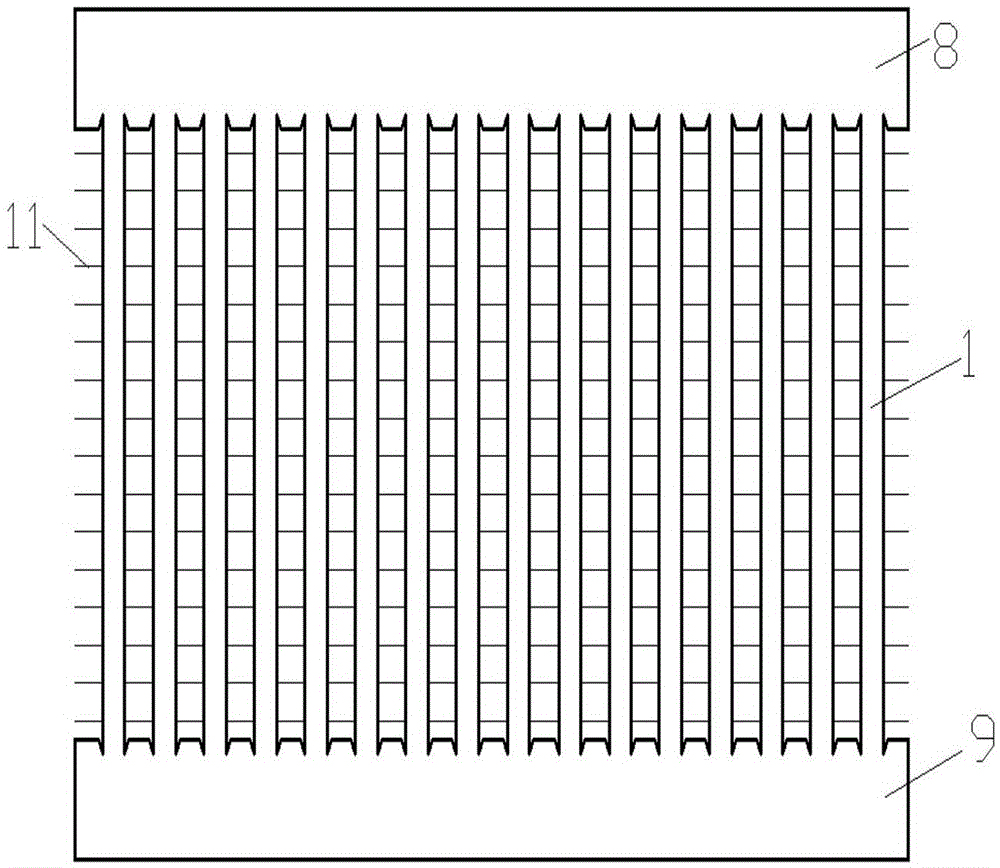

Heat exchange system

ActiveUS20150377558A1Improve cooling effectIncrease cooling air flowStationary conduit assembliesHeat exchanger casingsEngineeringLouver

Provided is a heat exchanger, and more particularly, a heat exchanger including a pair of header tanks formed in parallel, spaced apart from each other by a predetermined distance, a plurality of tubes having both ends fixed to the pair of header tanks to form a channel for a heat exchange medium; a plurality of fins fixed to abut between the tubes, and a plurality of louvers formed at the fins to contact air passing through the circumference of the fins, in which the louvers are formed to be asymmetrical to each other based on a center in a width direction of the fin or louver columns formed at one side or the other side of the fin in an asymmetrical form are alternately formed in a length direction of the fins to improve a flow of cooling air, thereby improving a heat radiation performance.

Owner:HANON SYST

Three-segment type block releasing technique for oil layer

InactiveCN101196109BDecontaminationEliminate secondary pollutionFluid removalDrilling compositionMaterial PerforationChemistry

The invention relates to an oil layer three-section block removing technology with excellent block removing effect. A block removing agent will be injected at three sections; then, clear water will be injected after the reaction of 4 to 24 hours at each section; the quantity of clear water will be 1 to 2 times of the sum between the volume of an oil pipe and the volume of the circular space from the bottom of the oil pipe to the top of a perforation interval. Because the composition and function of the block removing agents different from each other, the invention can be applied in a broad scope to adopt to the needs in various stratum, realize excellent block removing effect with the removing rate of over 75 percent, thus satisfying the industrial needs.

Owner:DAQING GASOLINEEUM INST +1

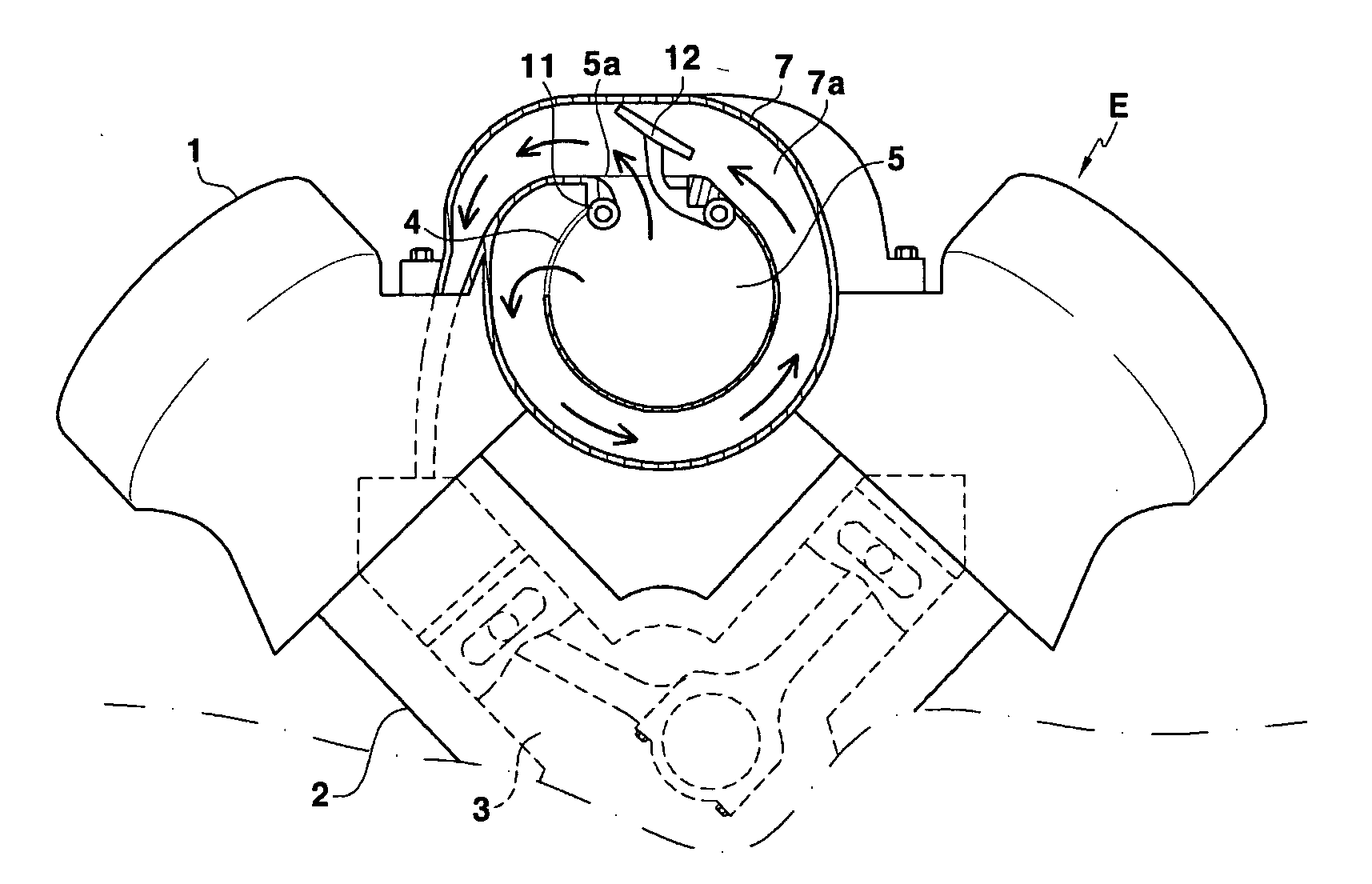

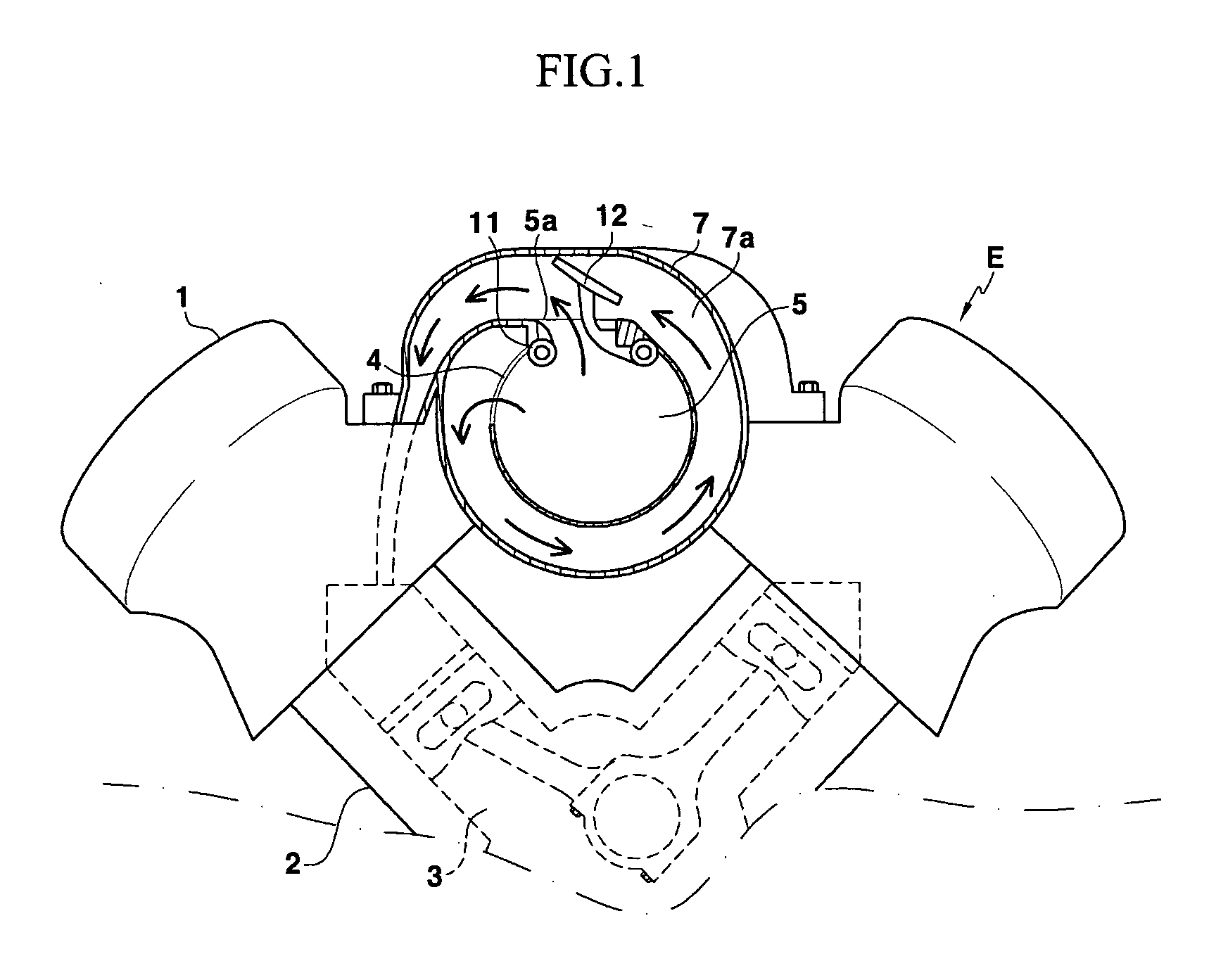

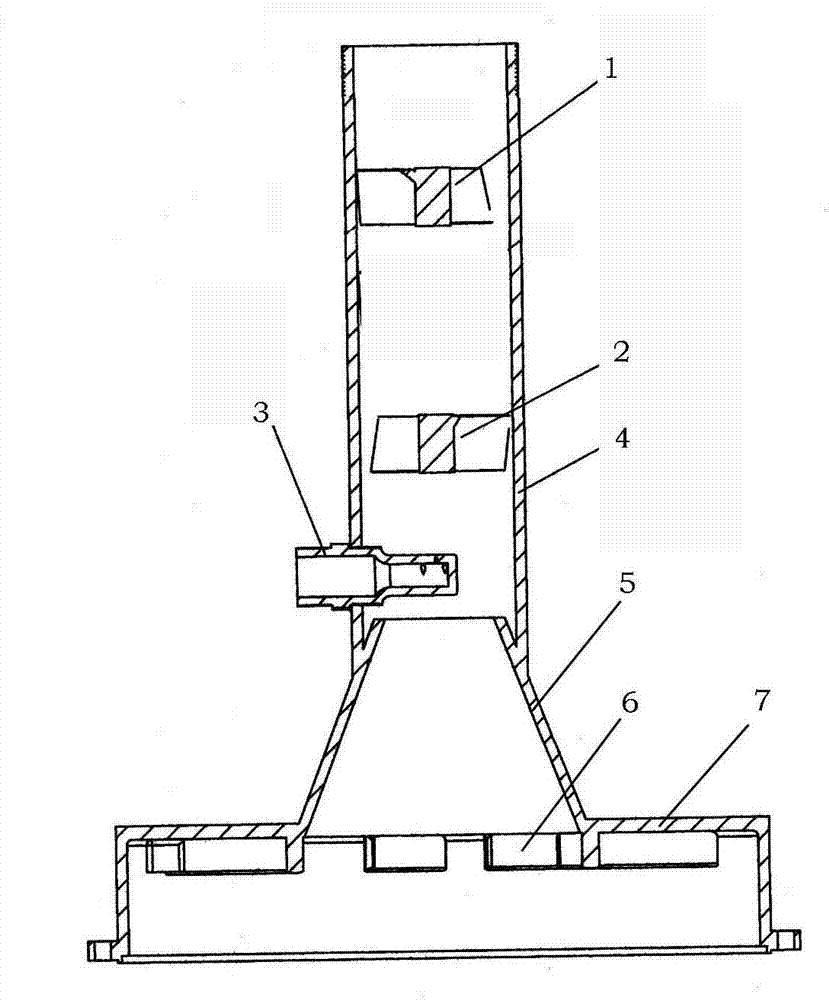

Tertiary premix energy-saving gas distribution chamber for stove

The invention discloses a stove and particularly relates to a tertiary premix energy-saving gas distribution chamber for the stove. According to the tertiary premix energy-saving gas distribution chamber, a first air fan (1) and a second air fan (2) are arranged in a fan pipeline (4), fan blades of the first air fan (1) and the second air fan (2) are opposite in direction, the lower end of the fan pipeline (4) is connected with a conical barrel (5), and the diameter of the upper end of the conical barrel (5) is smaller than that of the lower end of the conical barrel (5). Primary premix is formed at the positions of fan impellers of the first air fan in the fan pipeline, secondary premix is formed at the positions of fan impellers of the second air fan, and tertiary premix is formed from the fan impellers of the second air fan to the bottom of a stove end. By means of the tertiary gas premix, the gas is sufficiently burned, the sufficient burning of the gas can reach 95%, the calorific value of the gas is high, plenty of energy is saved, waste is reduced greatly, flowing pressure of air is large, safety is good, and pollution to air is reduced.

Owner:SHENYANG LUBO KITCHEN IND

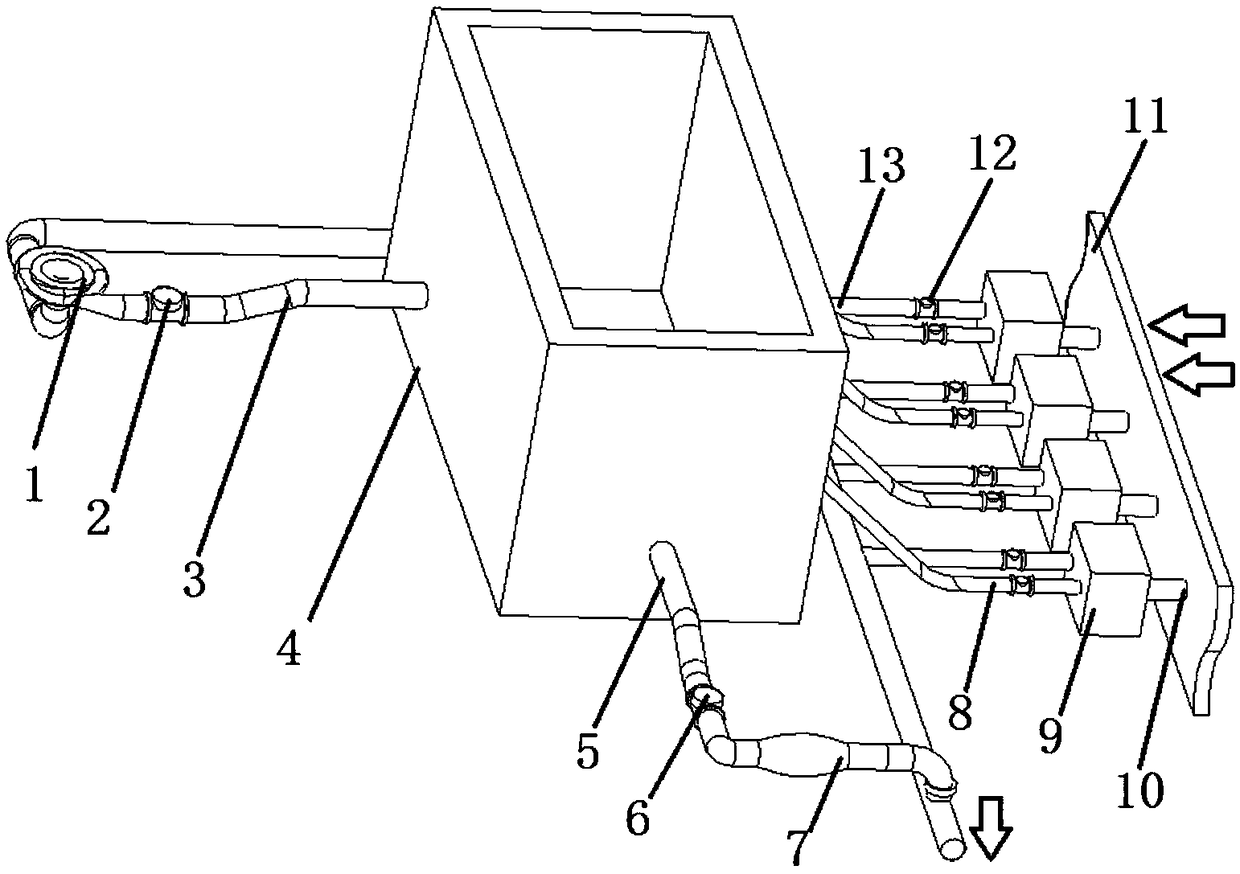

Power generation device capable of applying wave energy

ActiveCN108953041AImprove stabilityMeet additional requirementsHydro energy generationMachines/enginesWater turbineNew energy

The invention discloses a power generation device capable of applying wave energy. The device comprises an integration water level system, a generator set and an adjusting unit; the integration waterlevel system comprises a wave energy acting plate, a water flow pressurizer, a check valve, a flow inlet pipeline, a flow outlet pipeline and an impounding reservoir; the generator set comprises a flow outlet pipeline, a check valve and a bulb-type water-turbine generator set, and the adjusting unit is an extremely-low-head mixed flow reversible pump turbine. During work, unstable wave energy canpush the acting plate, the water flow passes through a fluid pressurizer, then flows to the impounding reservoir and serves as a water source of the generator set and the adjusting unit to be used foracting, and finally, the water flow is converted into electric energy. Traditional power generation and new energy power generation are combined, the device is a green and environment-friendly powergeneration device and has stability, the device has the wide application prospect and popularization value, and the device is of great significance in new energy development of the China.

Owner:NORTHWEST A & F UNIV

Heat exchange system

ActiveUS9927179B2Improve cooling effectSpeed up the flowStationary conduit assembliesTubular elementsEngineeringLouver

Provided is a heat exchanger, and more particularly, a heat exchanger including a pair of header tanks formed in parallel, spaced apart from each other by a predetermined distance, a plurality of tubes having both ends fixed to the pair of header tanks to form a channel for a heat exchange medium; a plurality of fins fixed to abut between the tubes, and a plurality of louvers formed at the fins to contact air passing through the circumference of the fins, in which the louvers are formed to be asymmetrical to each other based on a center in a width direction of the fin or louver columns formed at one side or the other side of the fin in an asymmetrical form are alternately formed in a length direction of the fins to improve a flow of cooling air, thereby improving a heat radiation performance.

Owner:HANON SYST

Variable intake system of a vehicle

InactiveUS7080618B2Increase flow pressureVelocity increasesInternal combustion piston enginesEngine controllersEngineeringVehicle driving

A variable intake system of a vehicle includes a plenum into which an external air is flowed, an intake manifold comprising a plurality of runners connected with the plenum and respectively guiding the air of the plenum into a plurality of cylinders, and a varying unit controlling a length of the runners according to a vehicle driving condition.

Owner:HYUNDAI MOTOR CO LTD +1

Water treatment apparatus and process to reduce pipe scale and biomass using positive pressure ultraviolet oxygenation

ActiveUS8696915B2Reduce formationReduce scaleDomestic cooling apparatusLighting and heating apparatusPositive pressureUltraviolet lights

A method of treating water in order to minimize scaling and biomass buildup in water conduits or containers in which the treated water is used includes pressurizing and optionally filtering ambient air, processing the pressurized ambient air in a chamber including at least one ultraviolet light source operated to generate an output flow mixture of pressurized air and reactive oxygen species (ROS) gas, mixing the pressurized ROS / gas output mixture to realize a flow of water / pressurized ROS gas / air mixture and outputting the flow of water / pressurized ROS gas / air mixture as the treated water process product. The process includes generating reactive oxygen species (ROS) gas in the pressurized ROS / gas output mixture including at least one of Super Oxide (O2−), Peroxide (—O2—), Hydro peroxide (HO2−), Hydroxyl Radicals (OH.), Ozone (O3−) and Molecular Oxygen (O2). The ultraviolet light source, the flow rate of the pressurized air, the water, the water / pressurized ROS gas / air mixture and the output volume are controlled to optimize scaling and biomass reduction.

Owner:ECOLAB USA INC

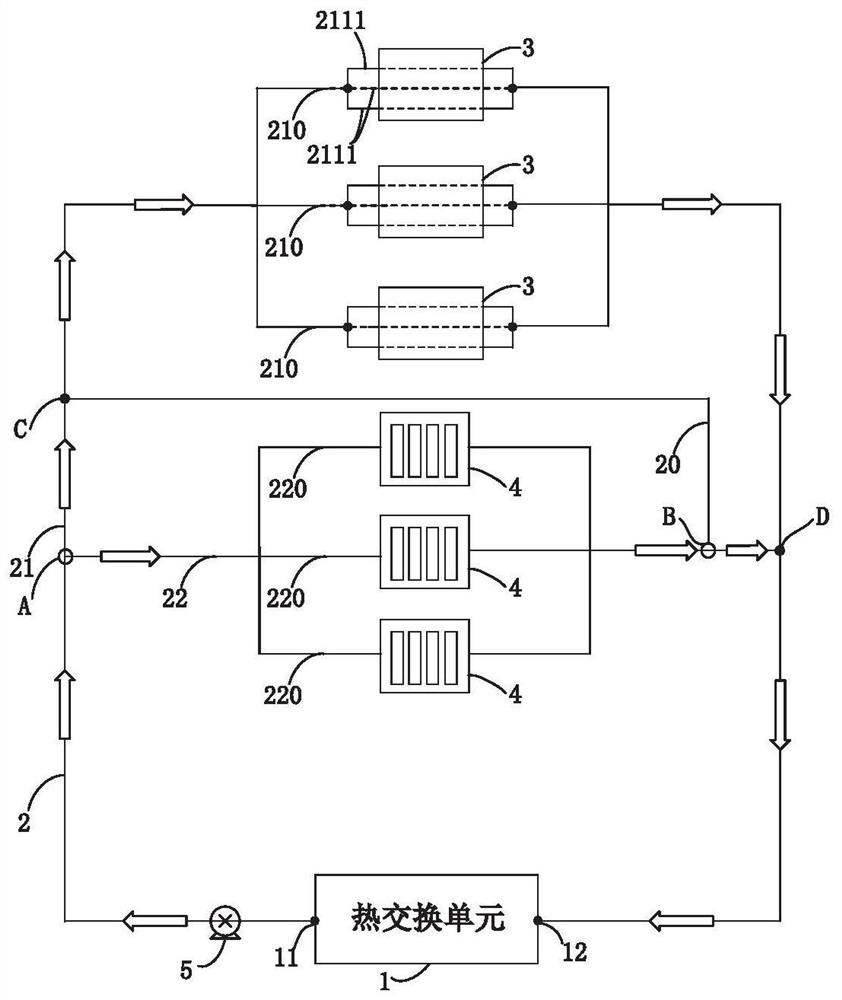

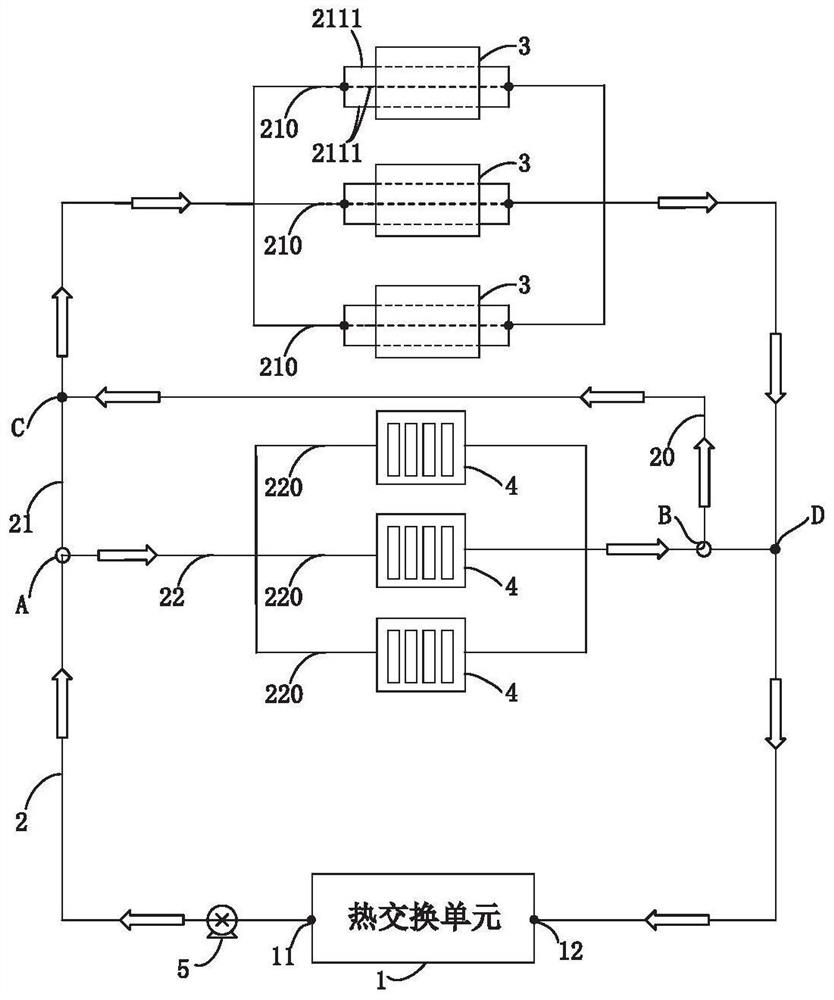

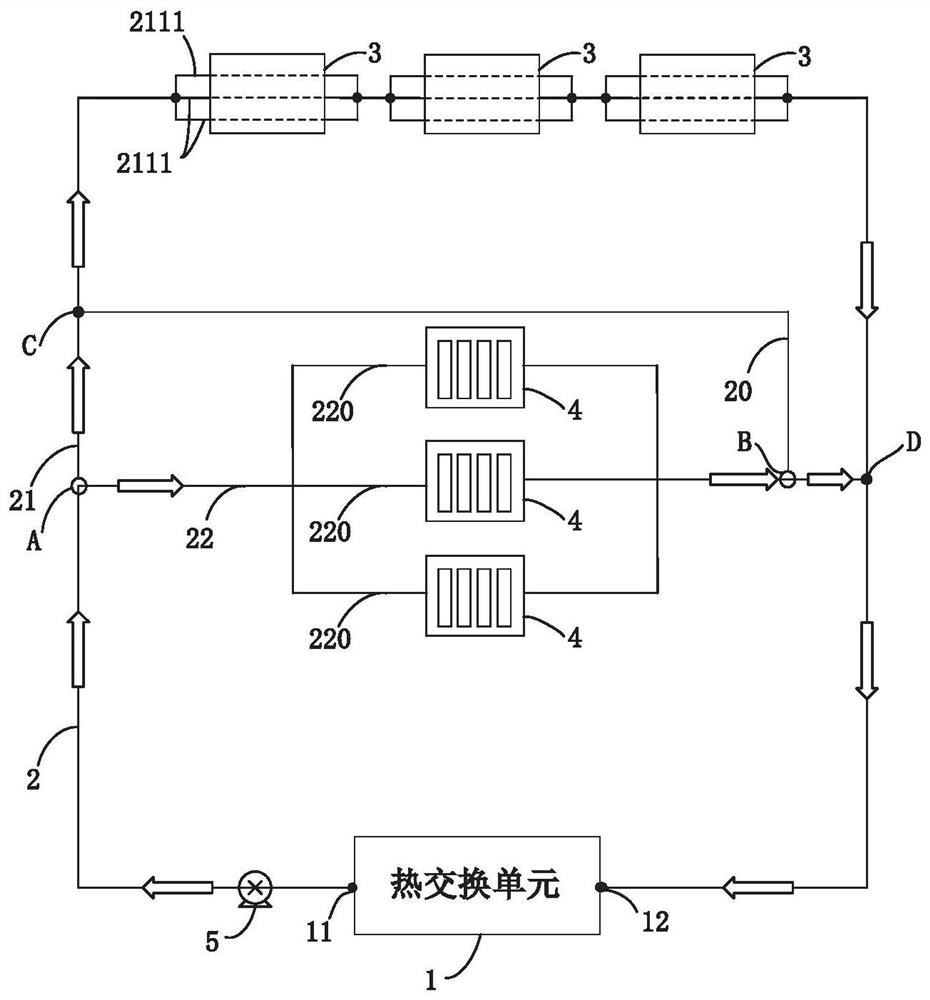

Vehicle temperature control system

ActiveCN112566443AReduce layoutOptimize layoutCell temperature controlElectric propulsion mountingTemperature controlFluid control

The embodiment of the invention provides a vehicle temperature control system which comprises a vehicle-mounted control unit temperature control flow path for controlling the temperature of a vehicle-mounted control unit by passing two or more temperature control branches, wherein at least one temperature control branch passes through the interior of the vehicle-mounted control unit; a battery temperature control flow path which is used for carrying out temperature control on the plurality of battery units, and is shunted to a plurality of parallel branches to respectively carry out temperature control on the plurality of battery units, wherein each parallel branch corresponds to one battery unit; a heat exchange unit which comprises an output port and a backflow port and is used for providing temperature control fluid for the vehicle-mounted control unit temperature control flow path and the battery temperature control flow path; and a control valve unit which is used for controllingthe vehicle-mounted control unit temperature control flow path and the battery temperature control flow path to be connected in parallel or in series. Through the vehicle temperature control system, layout of the temperature control flow path can be optimized, and the temperature control efficiency of the vehicle-mounted control unit and the battery is improved.

Owner:HUAWEI TECH CO LTD

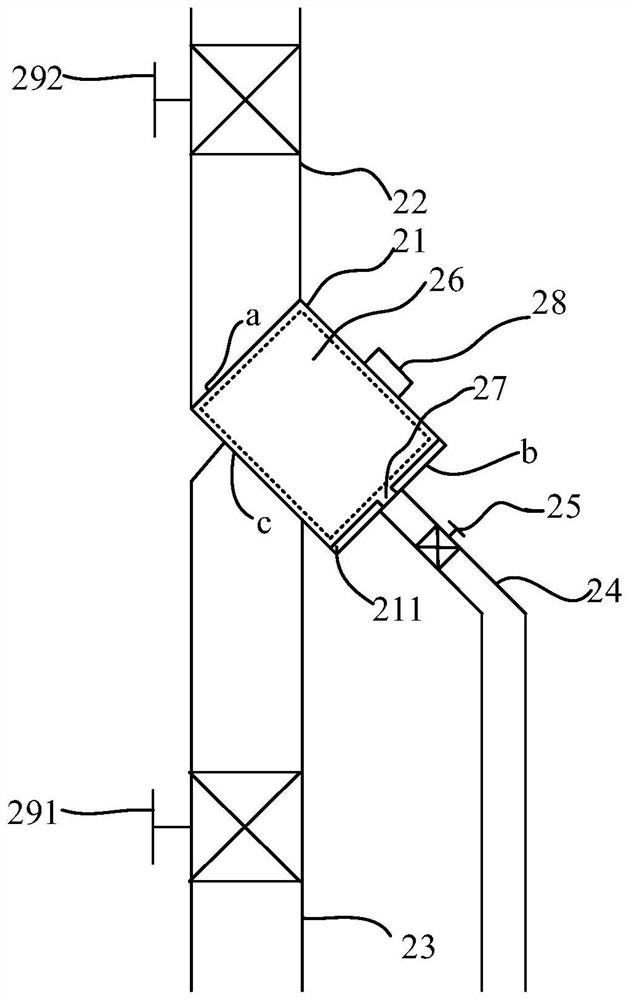

Semi-automatic torque coupling device

PendingCN107269724AIncrease flow pressureReduce frictional resistanceYielding couplingDirectional drillingHorizontal wellsRemote control

The invention relates to a semi-automatic torque coupling device in the field of a petroleum and gas well drilling device. The device is mainly composed of an upper shell, a protection device, a pressure transfer hole, a pressure sensing device, a stepping motor, a fixed rib plate, a transmission shaft, a seal device, a bypass hole, a spline shaft, a bearing, a lower shell and a spline leading-in body. In the drilling process, torque generated by a ground device is transmitted to a well bottom drill bit along a drill combination, the semi-automatic torque coupling device is mounted in the drill combination according to drill well design, an operator uses opening and closing of a motor in a drilling fluid remote control part so as to control the spline shaft to stretch out of or retract and be locked, torque connection and disconnection are achieved, the semi-automatic torque coupling device can effectively solve the pressure dragging problem commonly existing in the drilling process of complex structure wells of long horizontal segment horizontal wells, large displacement wells and the like, and the device has the important significance in further reducing sliding friction resistance between the drill combination and the well wall, improving the well hole smoothness and improving the drilling efficiency of the complex structure wells.

Owner:中石化石油工程技术服务有限公司 +2

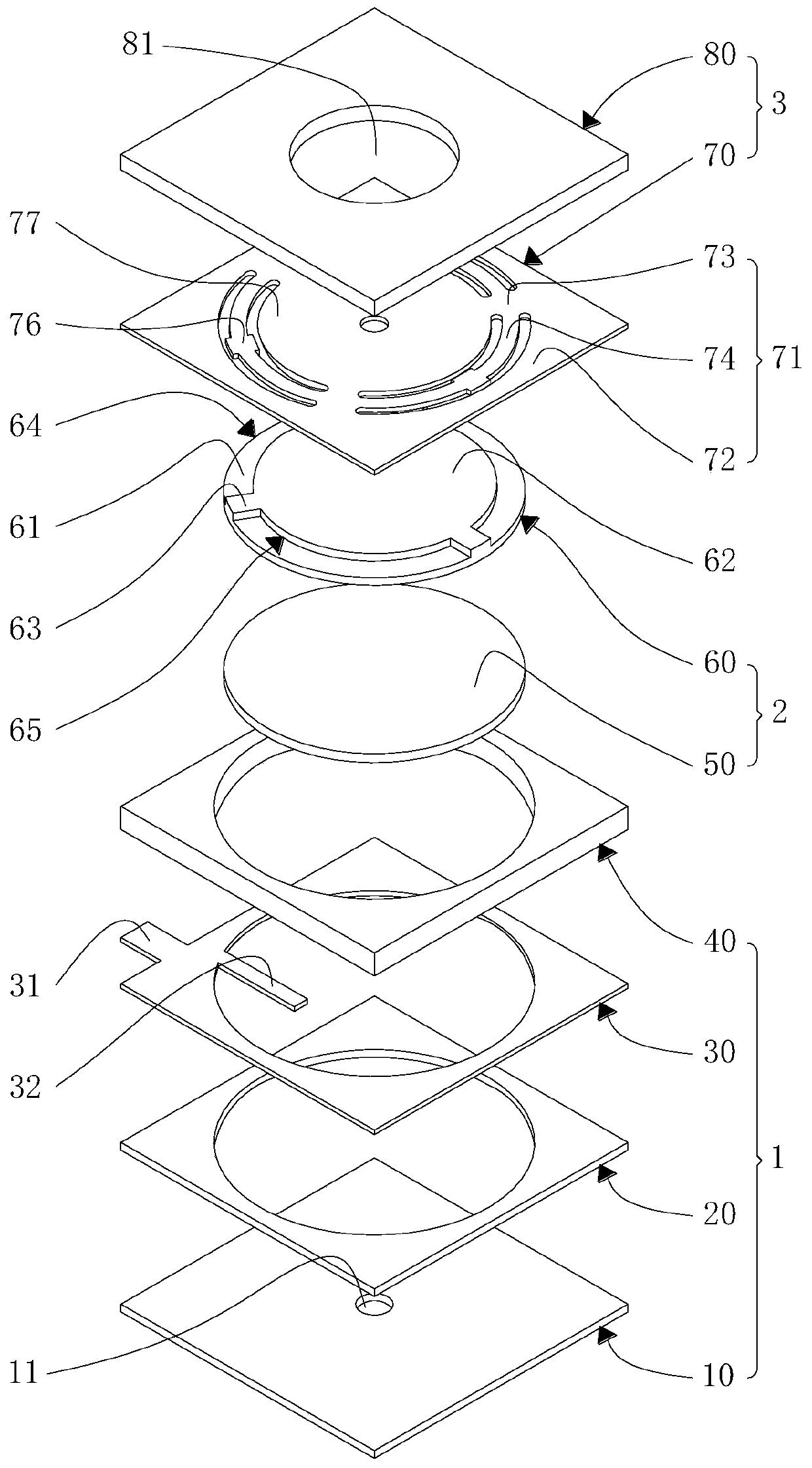

Fluid pump and excitation element

PendingCN109695562AIncrease flow pressureHigh output pressurePositive displacement pump componentsFlexible member pumpsElectricityResonance

The invention belongs to the technical field of fluid delivery, and relates to a fluid pump and an excitation element. The fluid pump comprises a piezoelectric vibrator, a vibration diaphragm and a planar part, wherein the piezoelectric vibrator comprises a vibration substrate and a piezoelectric element which is arranged on one side of the vibration substrate; the vibration diaphragm is arrangedon one side of the vibration substrate; the vibration diaphragm is arranged on the other side of the vibration substrate, and one side, close to the vibration diaphragm, of the vibration substrate isprovided with a sunk cavity; and the planar part is arranged on one side, far away from the vibration substrate, of the vibration diaphragm in a manner of being close to and opposite to the vibrationdiaphragm, and at least one vent hole is formed in the area, opposite to the sunk cavity, of the plane part; and a certain frequency of alternating voltage is applied to the piezoelectric element, thevibration substrate is bent and deformed to enable the vibration diaphragm to generate resonance, the vibration diaphragm is bent and deformed along with the vibration substrate in the same direction, and then the fluid pump sucks the fluid from the vent hole and is discharged from the circumferential direction of the vent hole. According to the fluid pump and the excitation element, higher output pressure and output flow can be obtained, great market value is achieved, and the fluid pump and the excitation element is worthy of popularization.

Owner:常州威图流体科技有限公司

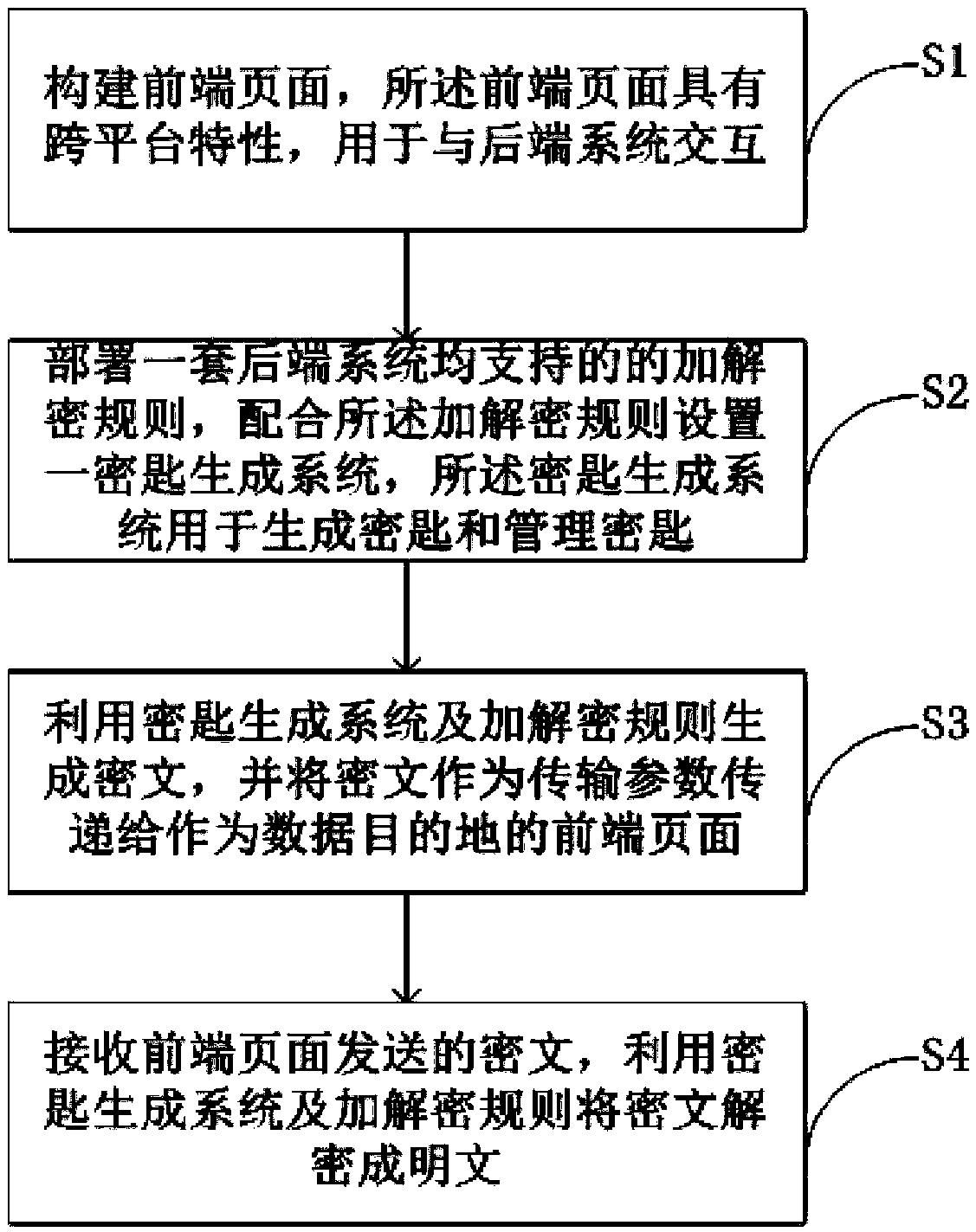

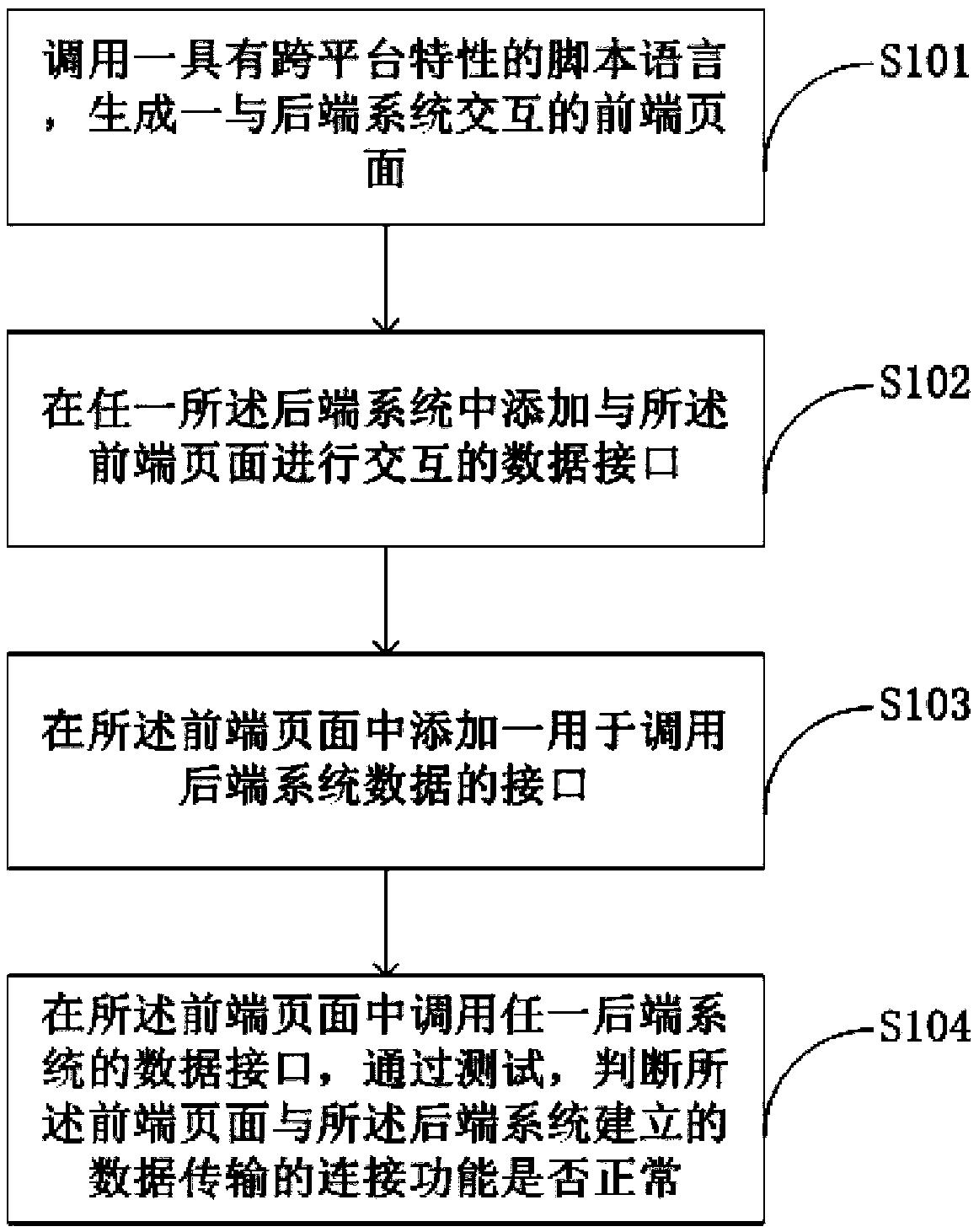

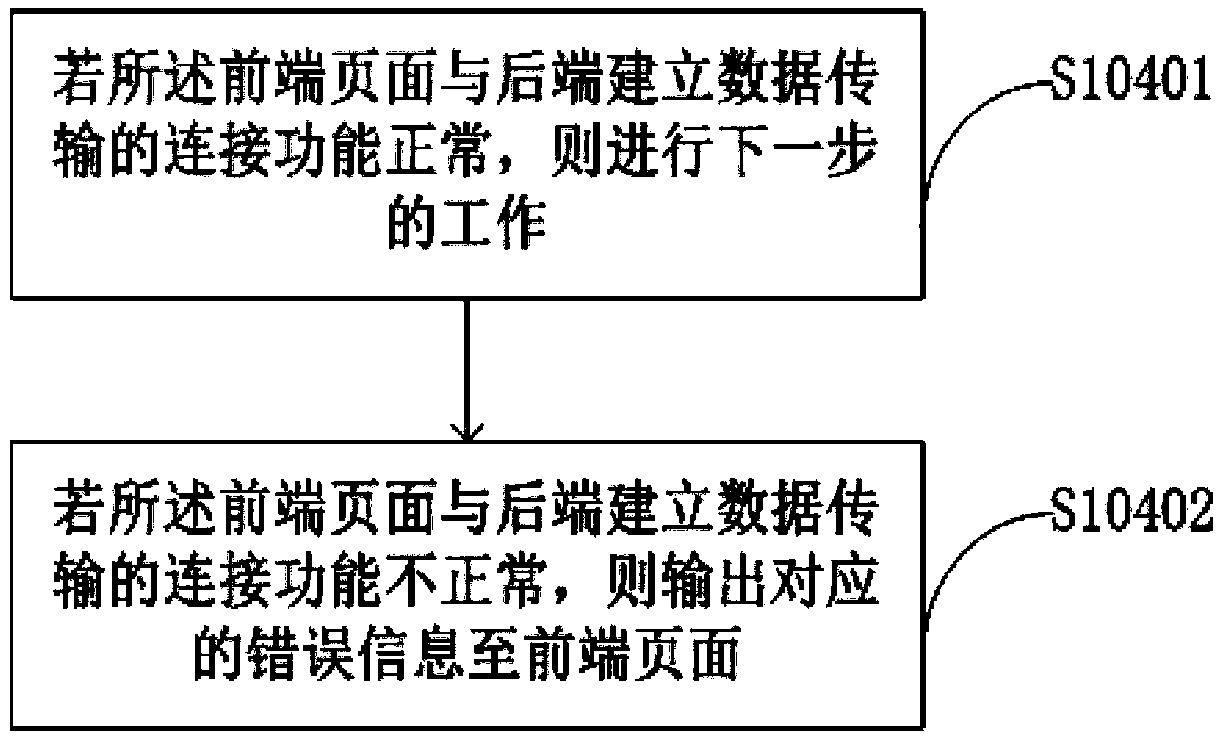

Data transmission method and device, mobile terminal and storage medium

ActiveCN108777620AIncrease flow pressureHigh maintenance costKey distribution for secure communicationHigh level techniquesData transmissionTraffic volume

The present invention relates to the field of internet data transmission, especially to a data transmission method and device, a mobile terminal and a storage medium. The method comprises the steps of: constructing a front-end page having a cross-platform feature and configured to perform interaction with rear-end systems; deploying a set of encryption and decryption rules supported by the rear-end systems, and cooperating with the encryption and decryption rules to set a key generation system configured to generate keys and management keys; employing the key generation system and the encryption and decryption rules to generate ciphertext, and taking the ciphertext as transmission parameters and transmitting the ciphertext to the front-end page as a data destination; and receiving the ciphertext sent by the front-end page, and employing the key generation system and the encryption and decryption rules to decode the ciphertext to plaintext. The data transmission method and device, the mobile terminal and the storage medium achieve decoupling of data interaction between the rear-end systems, avoid occupation of transmission channel resources and relieve the flow pressure and improvethe safety of the data transmission, and the data are not easy to be broken by brute force.

Owner:ONE CONNECT SMART TECH CO LTD SHENZHEN

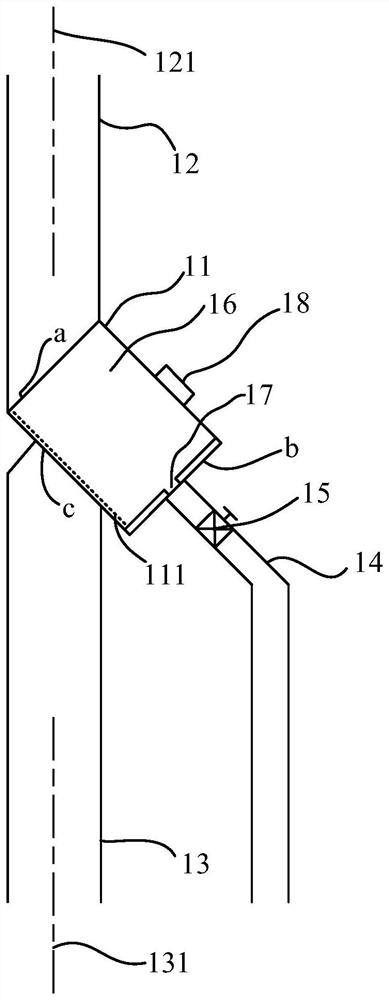

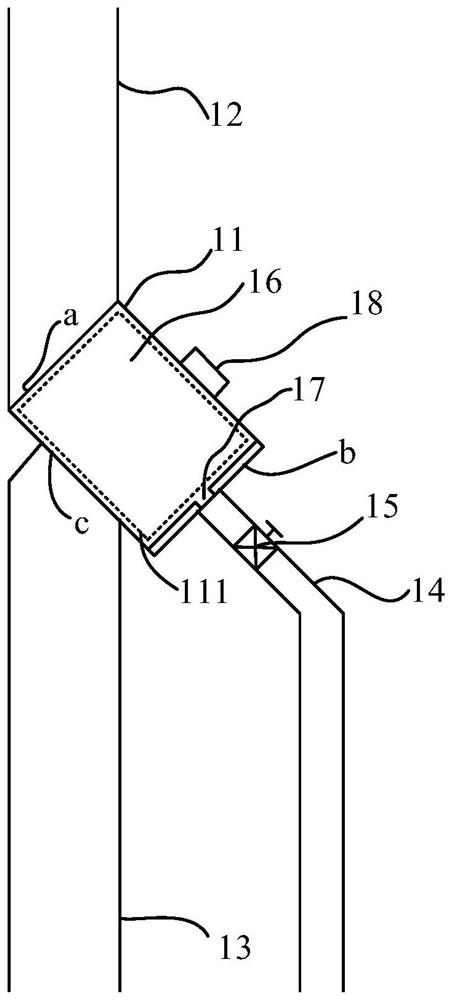

Fat heat exchange pipe with communicated inner fins

ActiveCN105605960AReduce flow pressureSolve the problem of uneven internal pressureHeat exhanger finsTubular elementsInternal pressureEngineering

The invention provides a flat heat exchange pipe with communicated inner fins. The flat heat exchange pipe comprises a flat pipe body and the fins. The flat pipe body comprises parallel pipe walls, a fluid channel is formed between the parallel pipe walls, and the fins are arranged between the pipe walls. Each fin comprises an inclined part inclined to the pipe walls, the inclined parts are connected with the parallel pipe walls, the fluid channel is separated by the inclined parts into a plurality of small channels, the adjacent inclined parts are connected on the pipe walls, and triangles are formed by the adjacent inclined parts and the pipe walls. Communicating holes are formed in the inclined parts, and therefore the adjacent small channels are communicated. According to the flat heat exchange pipe, it is guaranteed that the adjacent small channels are communicated, the problem that the internal pressure of the flat pipe body is uneven under the condition of heat exchange is solved, the heat exchange efficiency is improved, and the service life is prolonged.

Owner:SHANDONG UNIV

Filtering device and water cooling system

PendingCN112755631AImprove cleaning efficiencyReduce physical exertionStationary filtering element filtersEngineeringMechanics

The embodiment of the invention provides a filtering device and a water cooling system, the filtering device comprises a filter body, wherein the filter body defines a cavity, the cavity is internally provided with a filtering structure, a liquid inlet pipeline and a liquid outlet pipeline, the liquid inlet pipeline and the liquid outlet pipeline are communicated with the cavity, and the filtering structure is located at the joint of the liquid outlet pipeline and the filter body; a liquid discharging hole which is formed in one end of the filter body and communicated with the cavity, wherein a liquid flowing path between the liquid inlet pipeline and the liquid discharging hole is different from a liquid flowing path between the liquid inlet pipeline and the liquid outlet pipeline; a liquid discharging pipe which is connected with the liquid discharging hole; and a first valve which is mounted on the liquid discharging pipe to control the liquid discharging pipe to be opened or closed. According to the embodiment of the invention, the filter structure can be cleaned without manually disassembling the filter body, the cleaning process is simple, and the physical output of cleaning personnel is small, so that the consumed time is short, the labor cost is low, and the cleaning efficiency is high.

Owner:SHANGHAI TELECOMM ENG

Device for uniformly spraying paint to various wooden toy parts based on photoresistors

InactiveCN112705375AIncrease flow pressureEvenly paintedLiquid spraying apparatusSpray nozzleStructural engineering

The invention relates to the technical field of wooden toy manufacture, and discloses a device for uniformly spraying paint on various wooden toy parts based on photoresistors. The device comprises a shell, a protective box body is movably connected to the interior of the shell, a half gear is movably connected to the interior of the protective box body, the upper end of the half gear is meshed with a rack, the left end of the rack is rotationally connected with a transmission rod, the lower end of the transmission rod is rotationally connected with a T-shaped rod, the lower end of the T-shaped rod is fixedly connected with a connecting block, the lower end of the connecting block is fixedly connected with a half-moon pressing block, and the lower end of the half-moon pressing block is movably connected with an air bag. The internal pressure intensity of a spraying nozzle is increased, so that sprayed paint is emitted in a mist shape, paint spraying is more uniform, meanwhile, due to the fact that teeth distributed on half gear are not complete, the rack reciprocates left and right, airflow in the air bag is continuously conveyed into a paint feeding mechanism, and therefore the effect of automatic and uniform paint spraying is achieved.

Owner:云和县木制玩具科创研究所

Driving gear fixing and machining device

ActiveCN109551061AIncrease flow pressureGood effectGear-cutting machinesGear teethAirflowEngineering

The invention relates to the field of gear grinding machining processing equipment, and discloses a driving gear fixing and machining device. The device comprises a base and a rotating table rotationally connected to the base, wherein a sliding block is arranged on the base in a sliding mode, a grinding part is arranged on the sliding block, a driving rod is further rotationally connected to the position, on the outer side of the rotating table, of the base, a driving gear which can mesh with a gear to be machined is fixedly connected to one end of the driving rod, an air bag capable of abutting against the sliding block is further arranged on the base, the air bag is connected with an air inflation pipe and an air suction pipe, a one-way pressure valve which only allows airflow to enter the air bag is arranged on the air suction pipe, a one-way pressure valve allowing the airflow to be discharged out of the air bag is arranged on the air inflation pipe, the end, far away from the airbag, of the air inflation pipe is connected with an air inlet pipe, a turbine is rotationally arranged in the air inlet pipe, and the end, away from the driving gear, of the driving rod penetrates into the air inlet pipe and is fixedly connected with the turbine. According to the device, the problem that an existing gear grinding device is tedious to operate due to the fact that a rotating table is required to be rotated by hands, and the machining efficiency is influenced is solved.

Owner:CHONGQING RUNYUE MACHINERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com