Patents

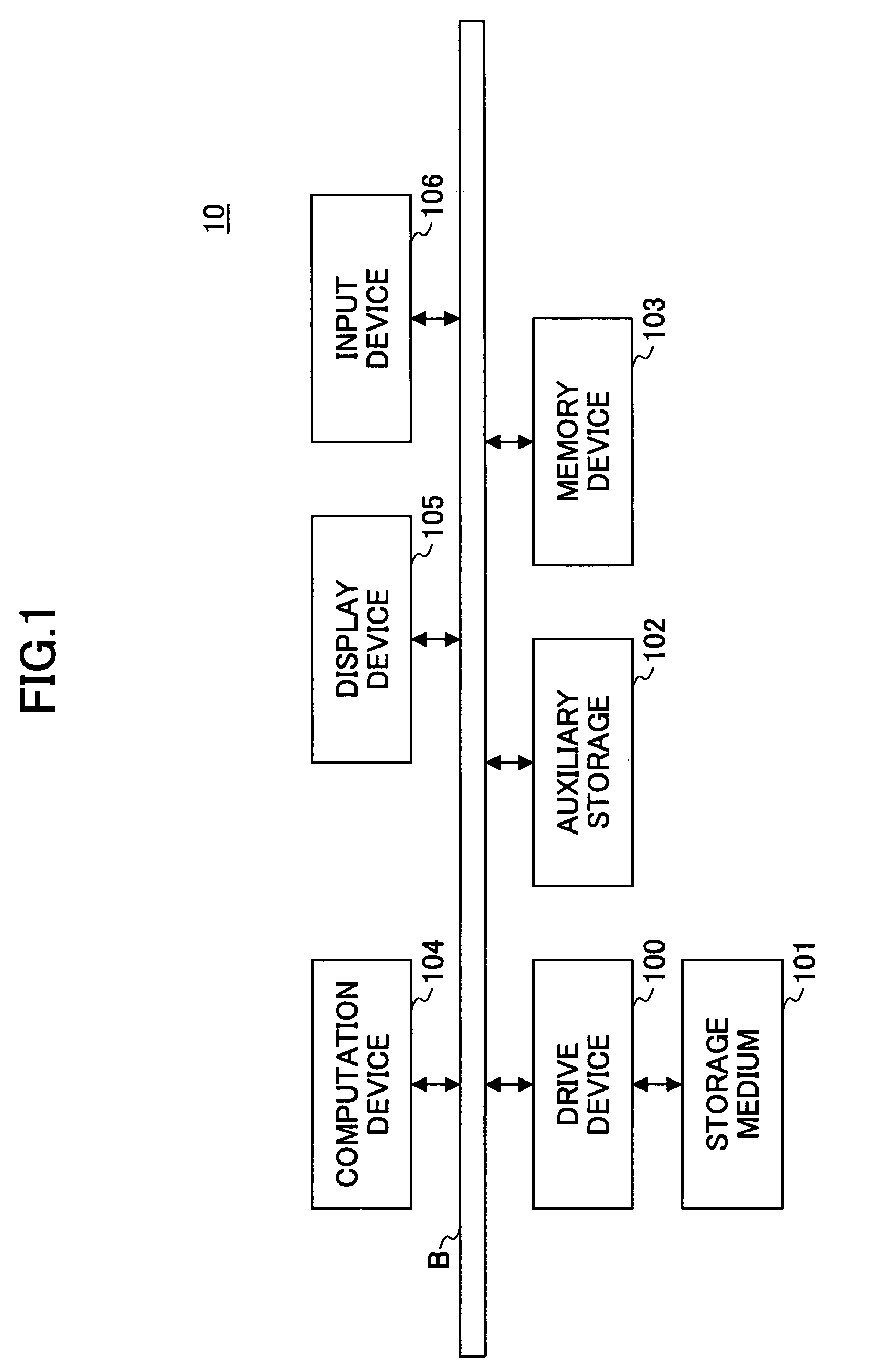

Literature

3263results about "Gear-cutting machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

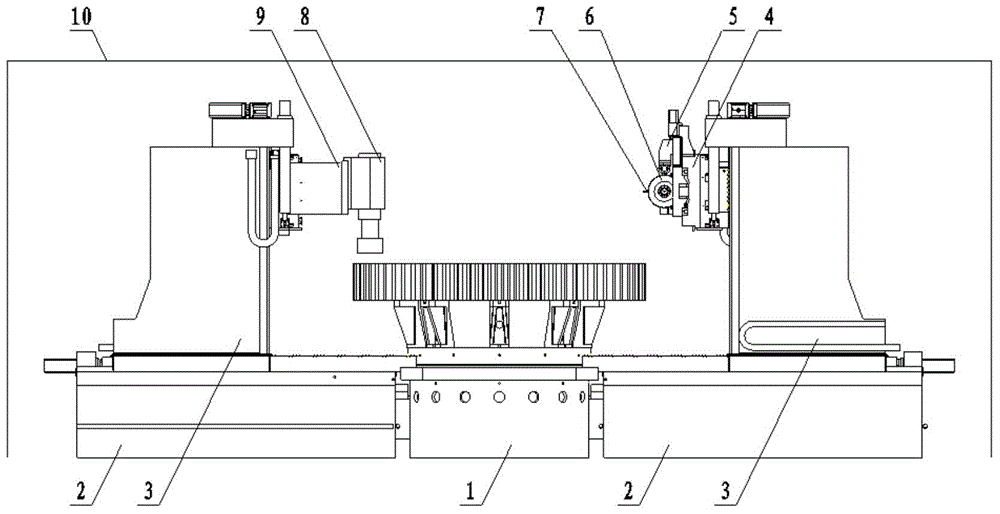

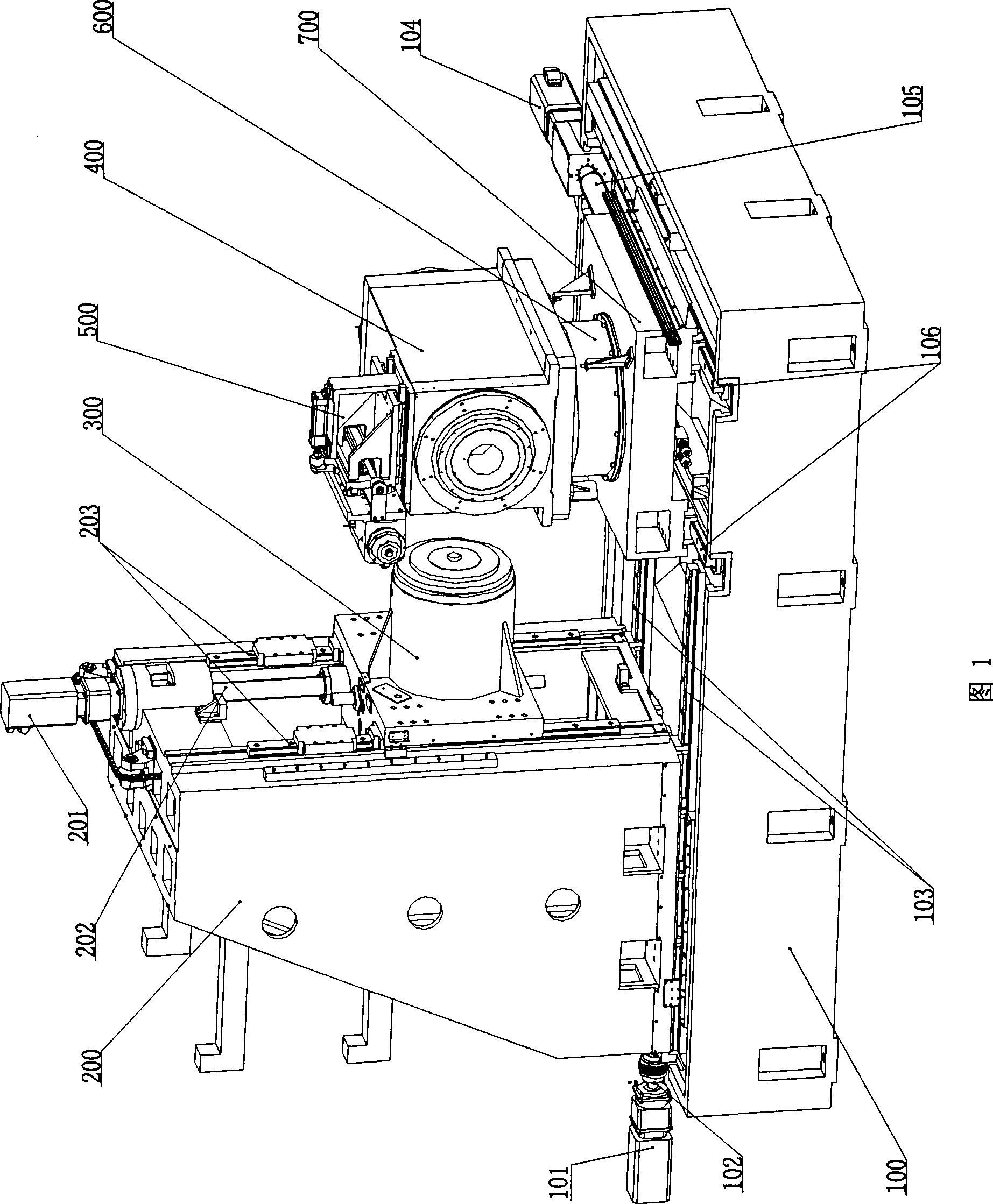

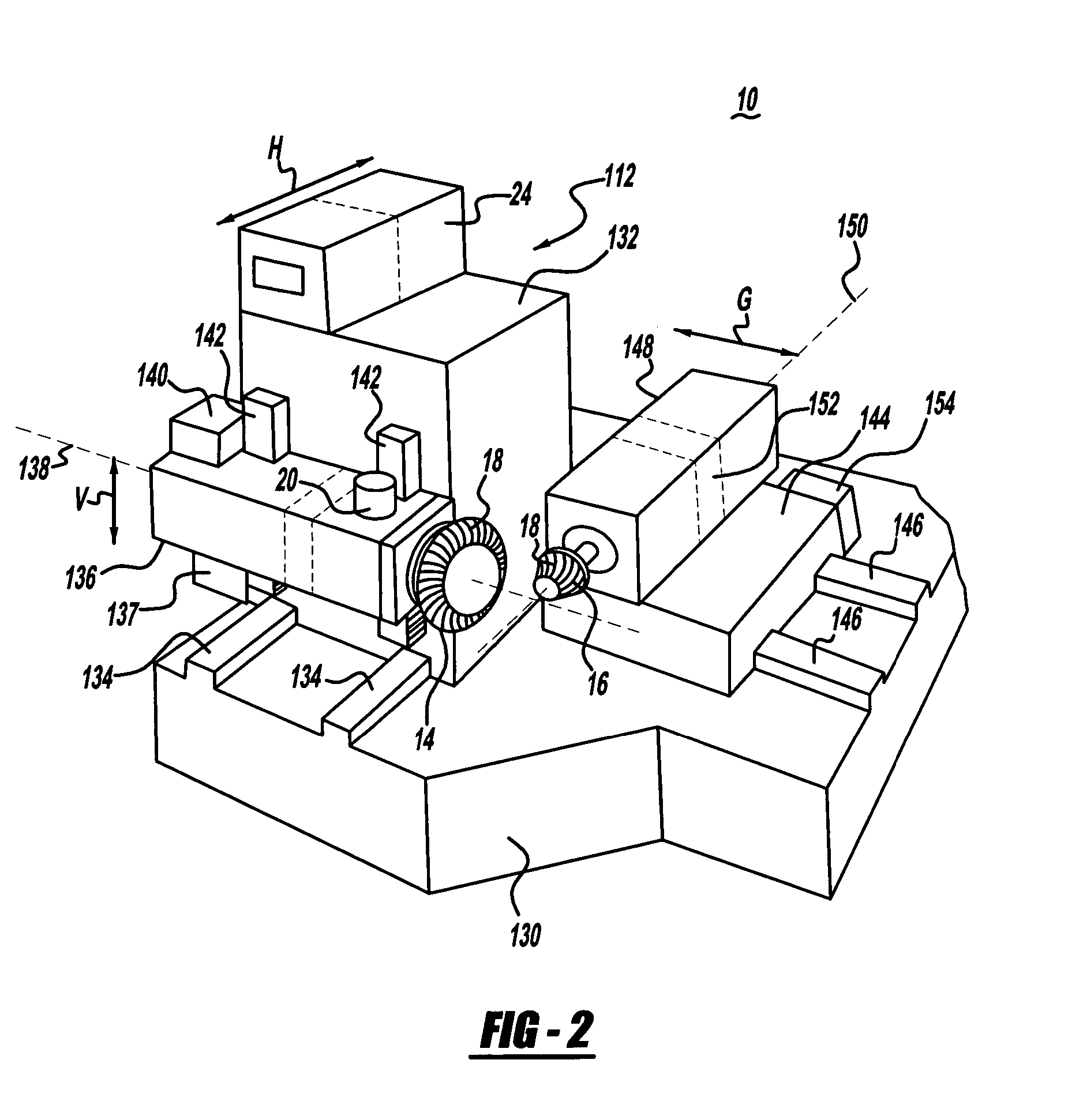

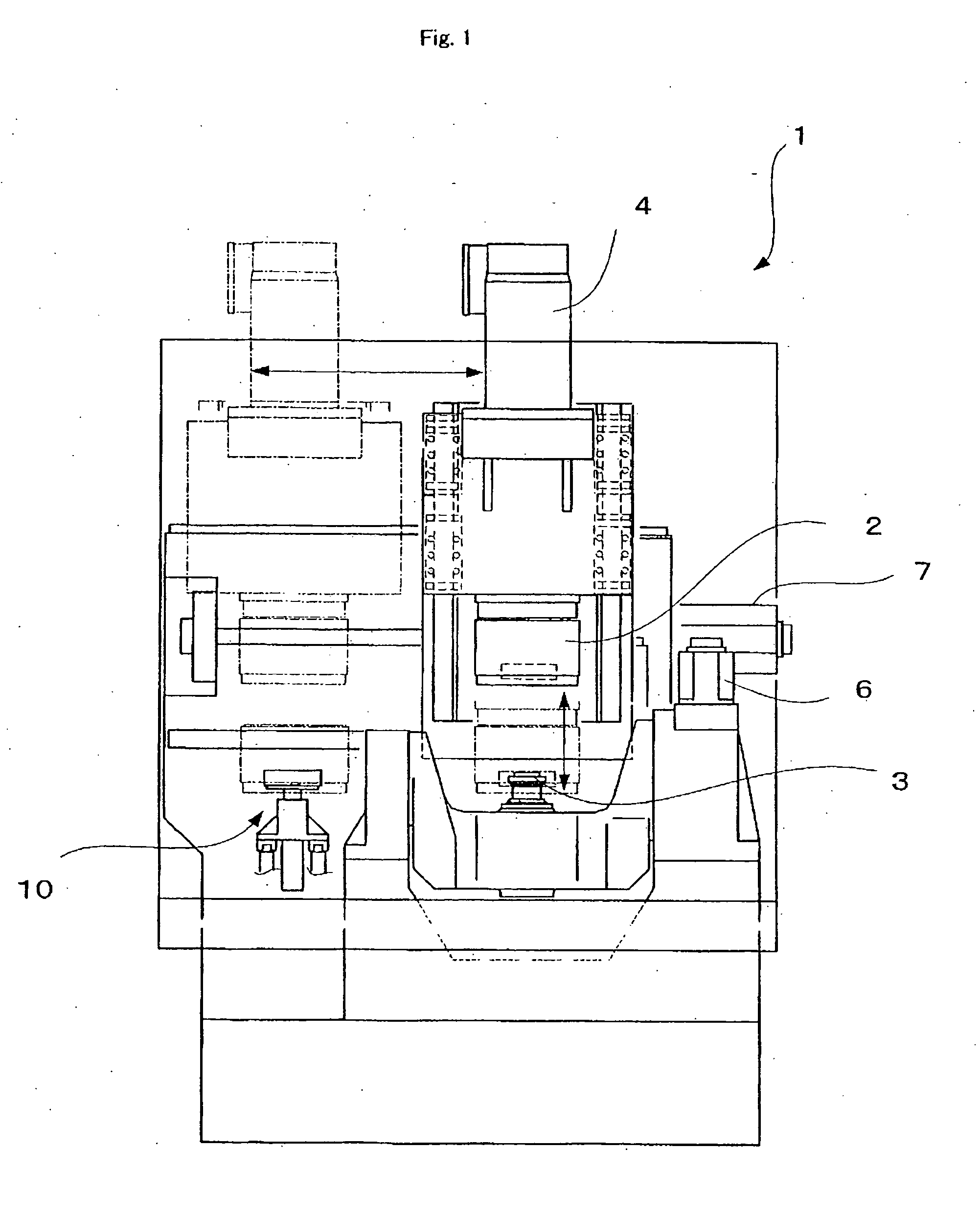

Large gantry polar-coordinate digital-control milling, hobbing and grinding gear combined machine

ActiveCN101700620AImprove machining accuracyImprove processing efficiencyOther manufacturing equipments/toolsLarge fixed membersHobbingGear wheel

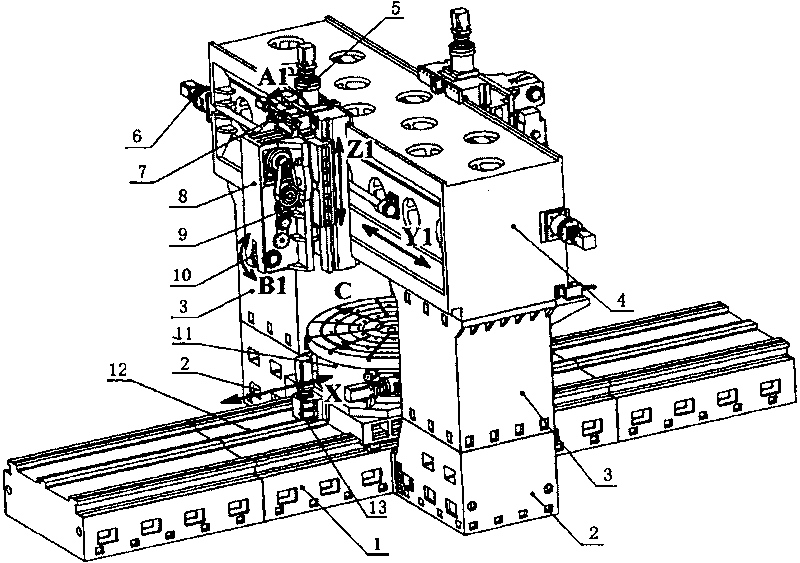

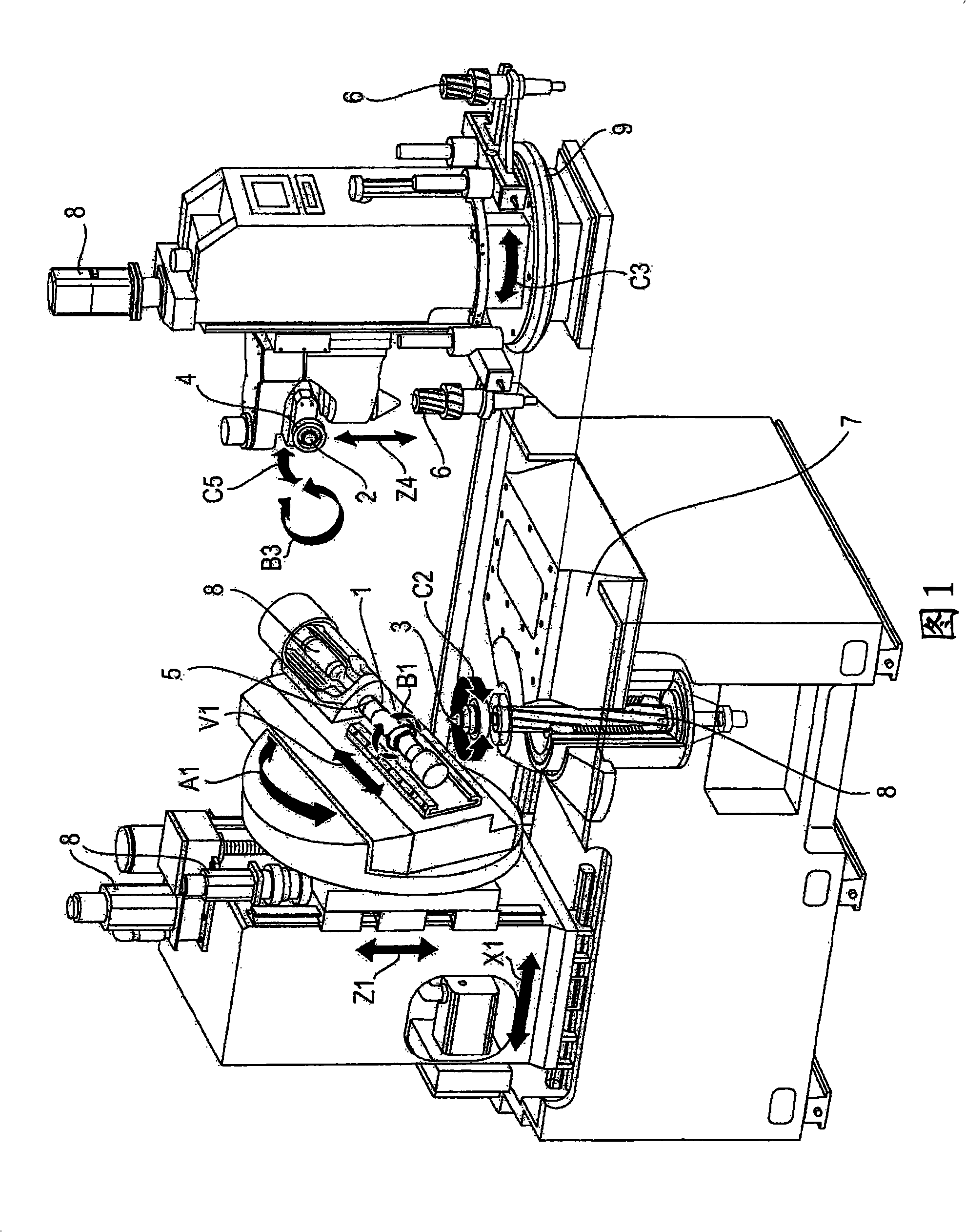

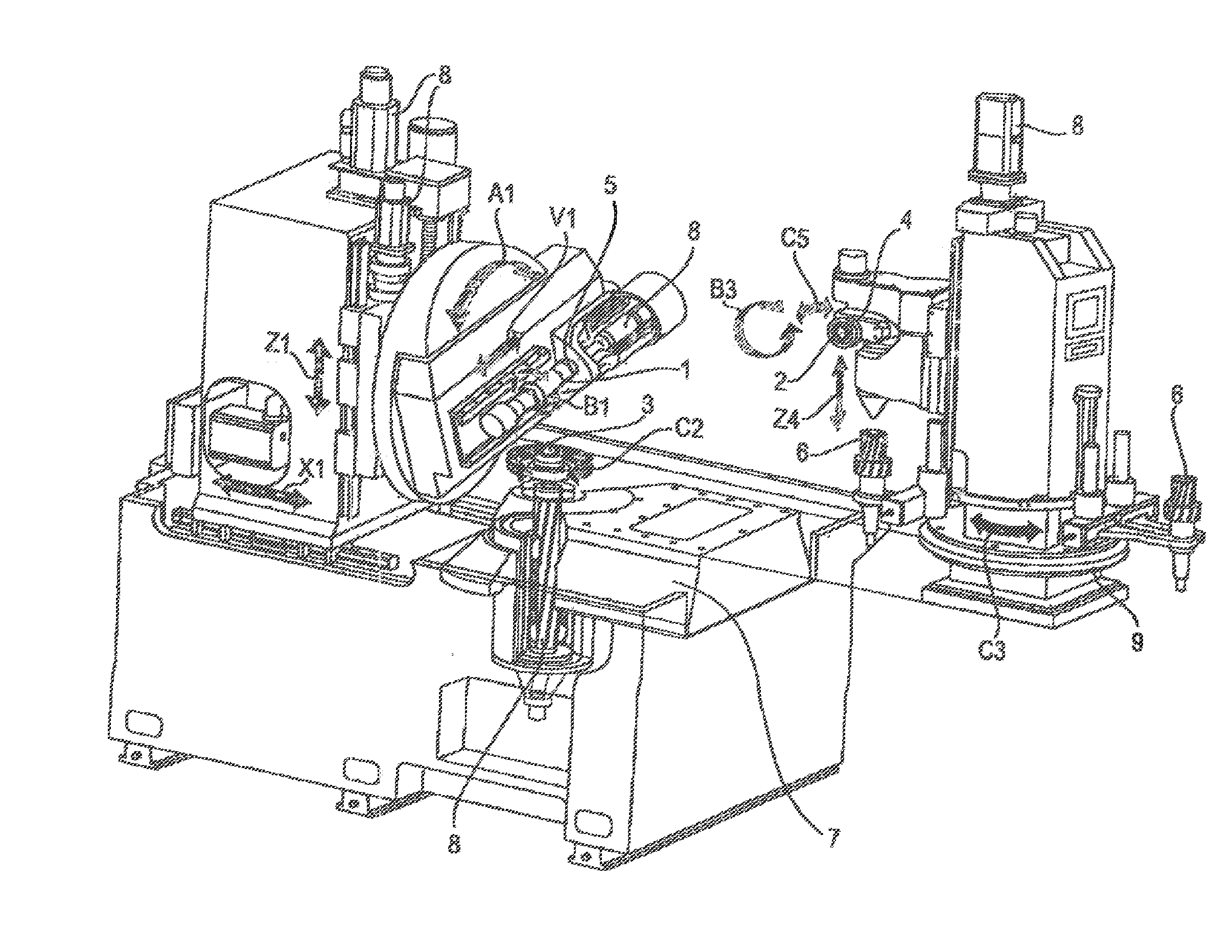

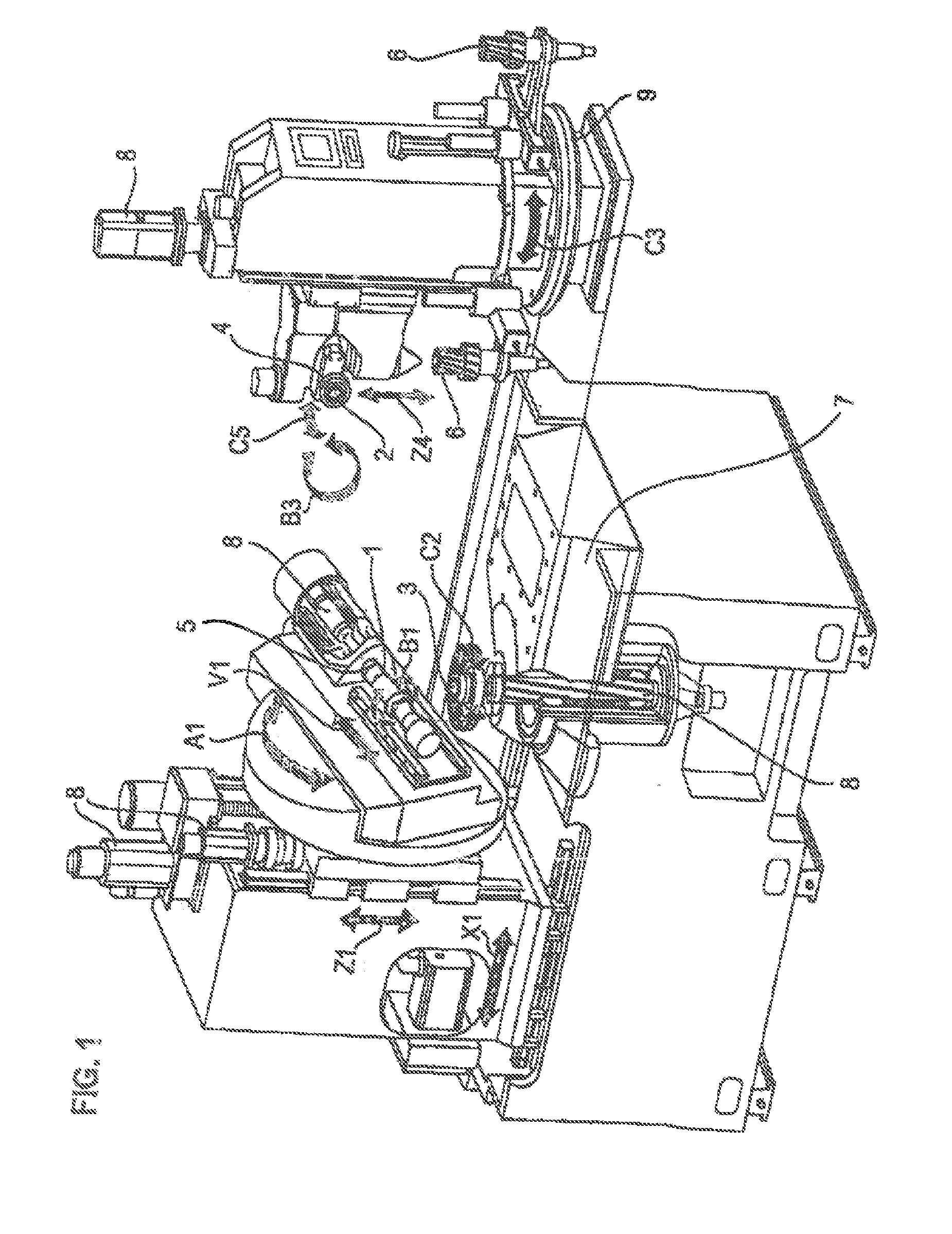

The invention relates to a large gantry polar-coordinate digital-control milling, hobbing and grinding gear combined machine adopting a beam both-side bearing structure by respectively hanging a milling gear headstock and a hobbing and grinding gear headstock at the left side and the right side of a beam. Compared with the prior art, the invention adopts the design concepts of polar coordinates and modularization and enables the connection sizes of lathes, bases, and the like as well as Y-direction and Z-direction feeding systems of a milling gear and a hobbing and grinding gear to have interchangeability, thereby decreasing the manufacture cost, lowering the assembly difficulty and improving the machining precision and the machining efficiency of large-module large-diameter gears. The invention integrates the machining characteristics for roughly and finely machining a milling gear, precisely spreading into a hobbing gear and molding a grinding gear with respective optimal process velocities and reasonably arranges a milling, hobbing and grinding gear headstock transmission chain capable of satisfying the requirements for molding the milling gear, spreading into the hobbing gear and molding the grinding gear.

Owner:NANJING UNIV OF TECH

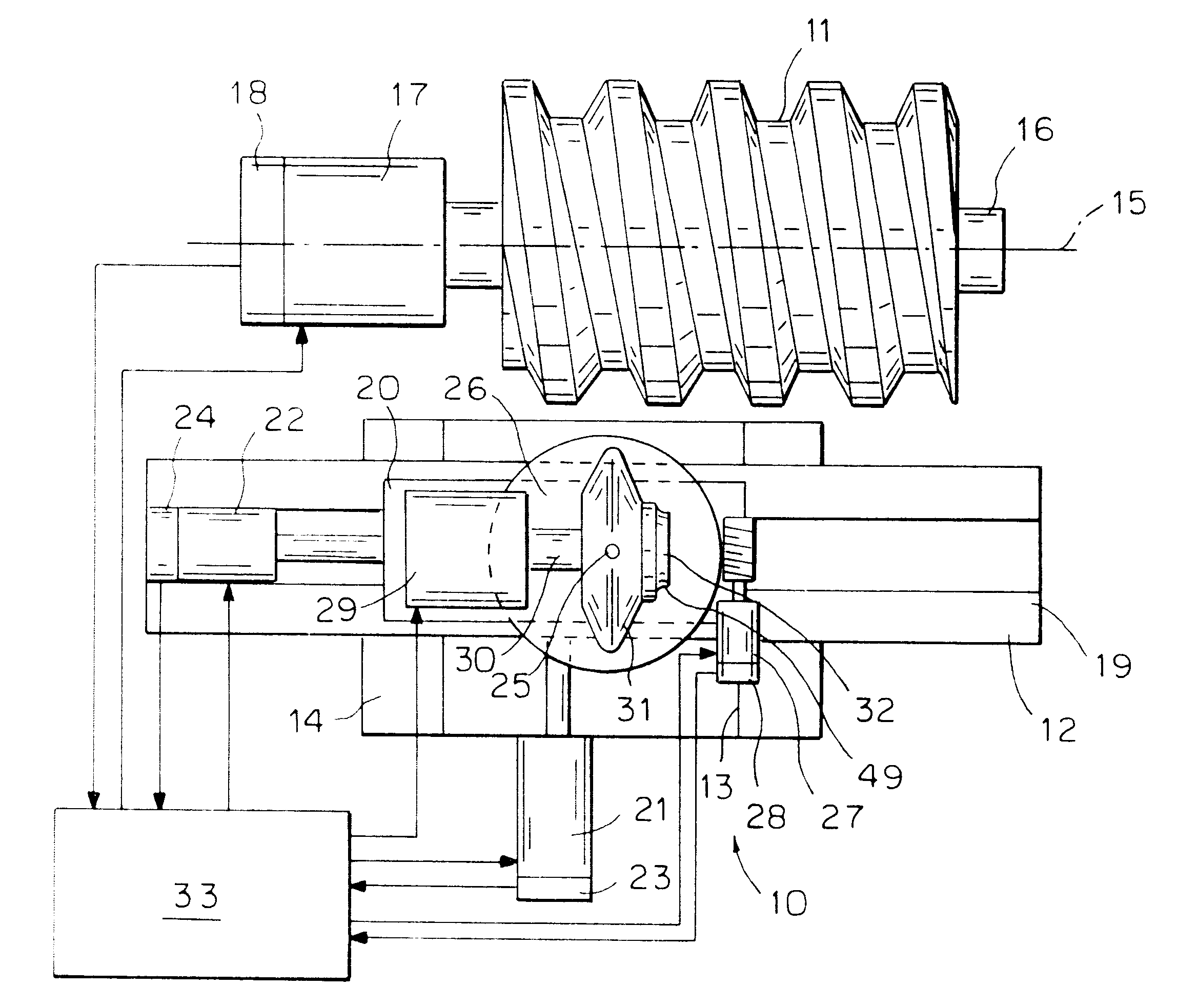

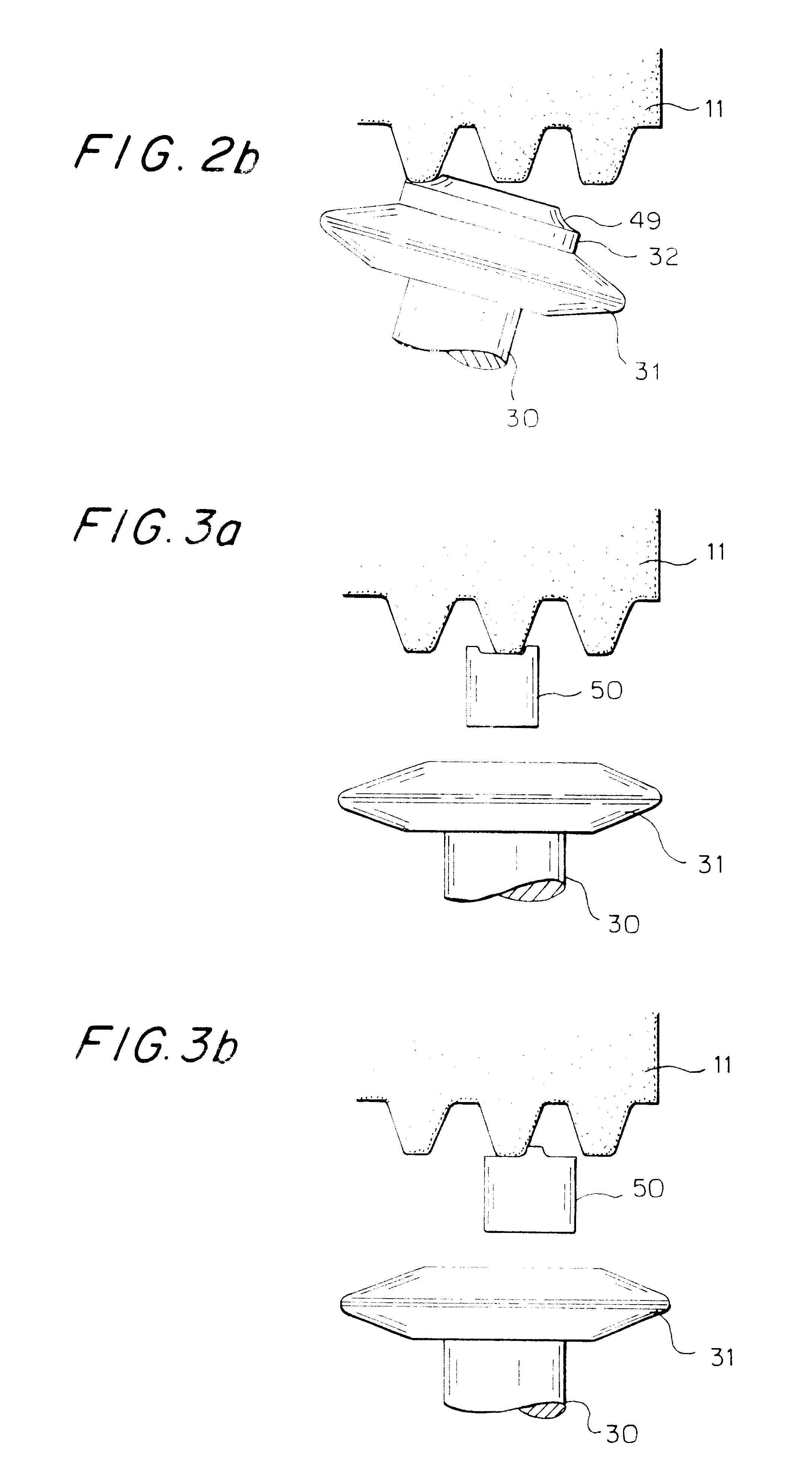

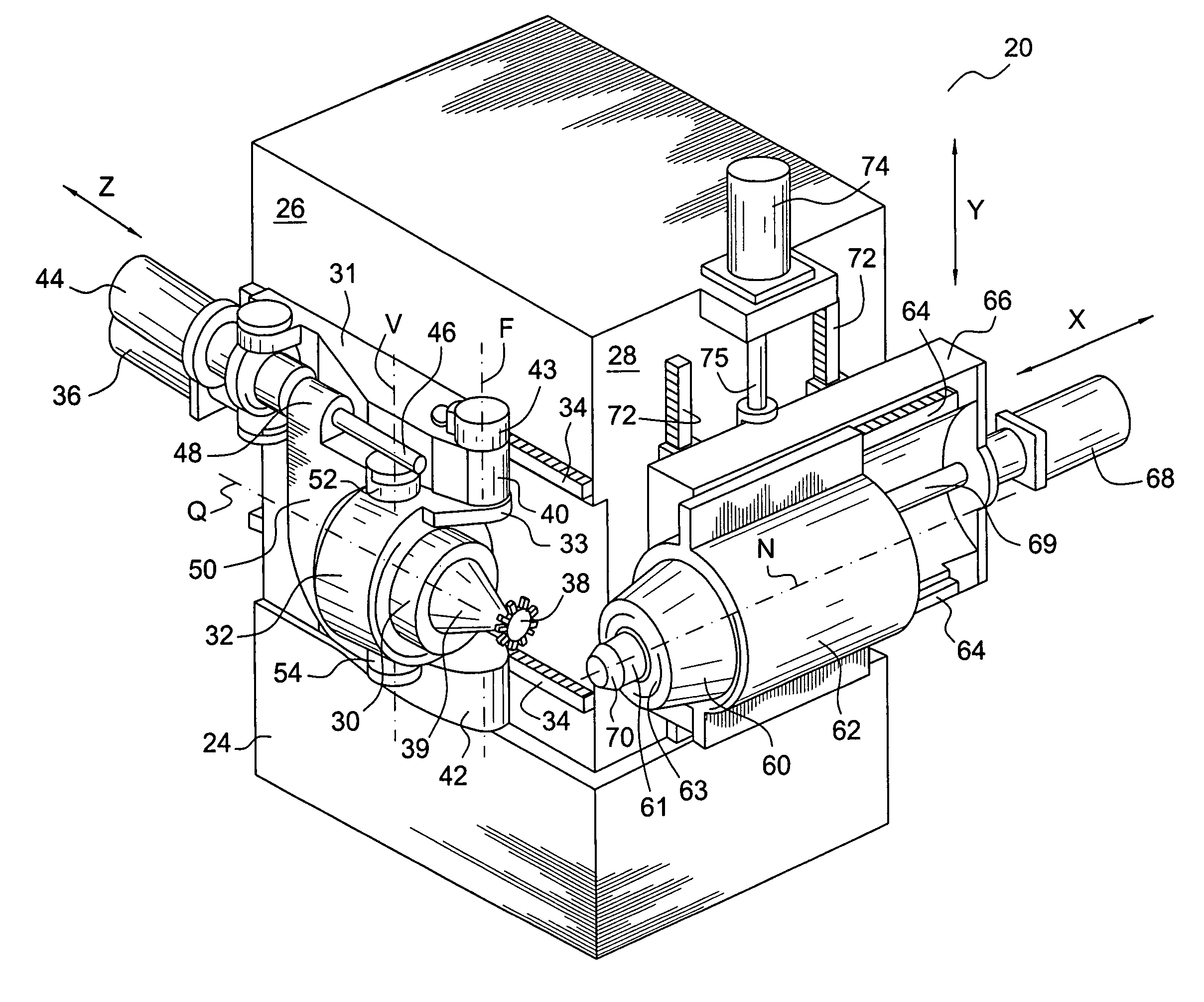

Device and method for profiling grinding worms

InactiveUS6234880B1Short dressing timeLittle effortGrinding drivesBelt grinding machinesEngineeringMechanical engineering

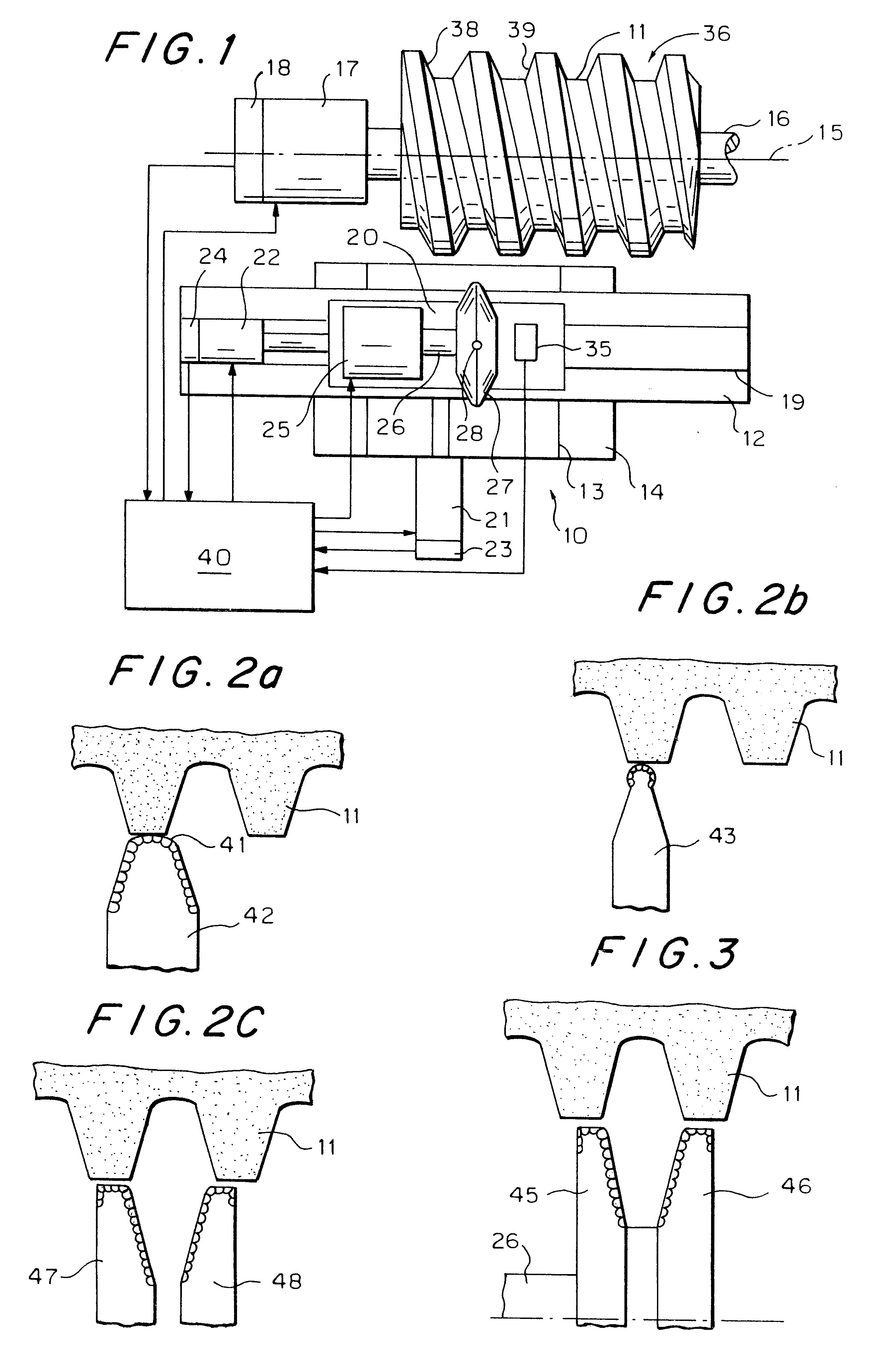

A radius-forming dressing roll (32) having a frustoconical working region (48) and an adjoining concave-toroidal working region (49) is mounted on the dressing spindle (30) coaxially to a dressing disc (31). In a first step, the flanks (42, 43) of the grinding-worm thread are profiled with the disc (31). After the dressing spindle (30) has been pivoted, the two tip radii (46, 47) and the cylindrical outer circumference (45) are profiled with the dressing roll (32). With little resetting effort and high flexibility, the method permits profiling with short dressing times.

Owner:REISHAUER

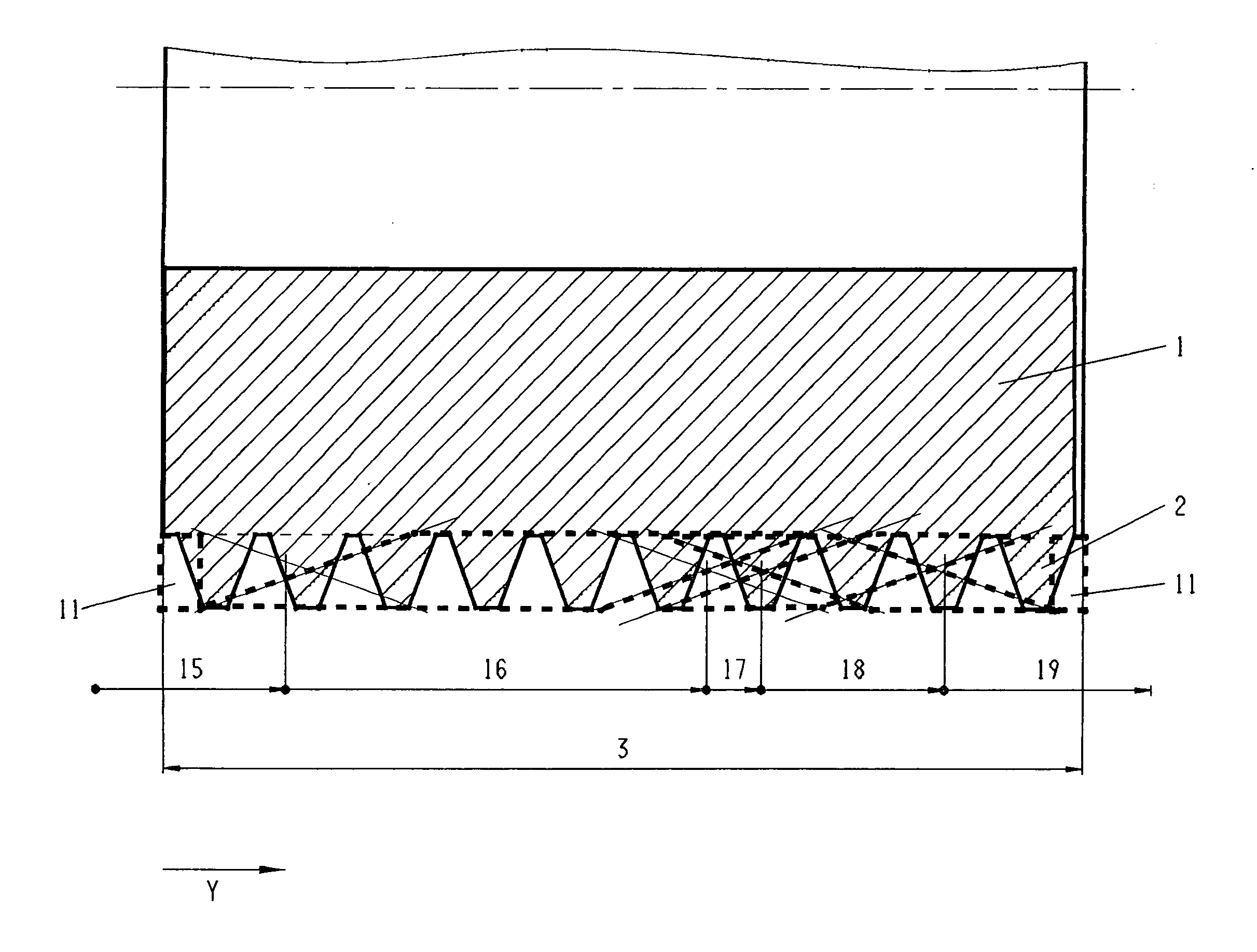

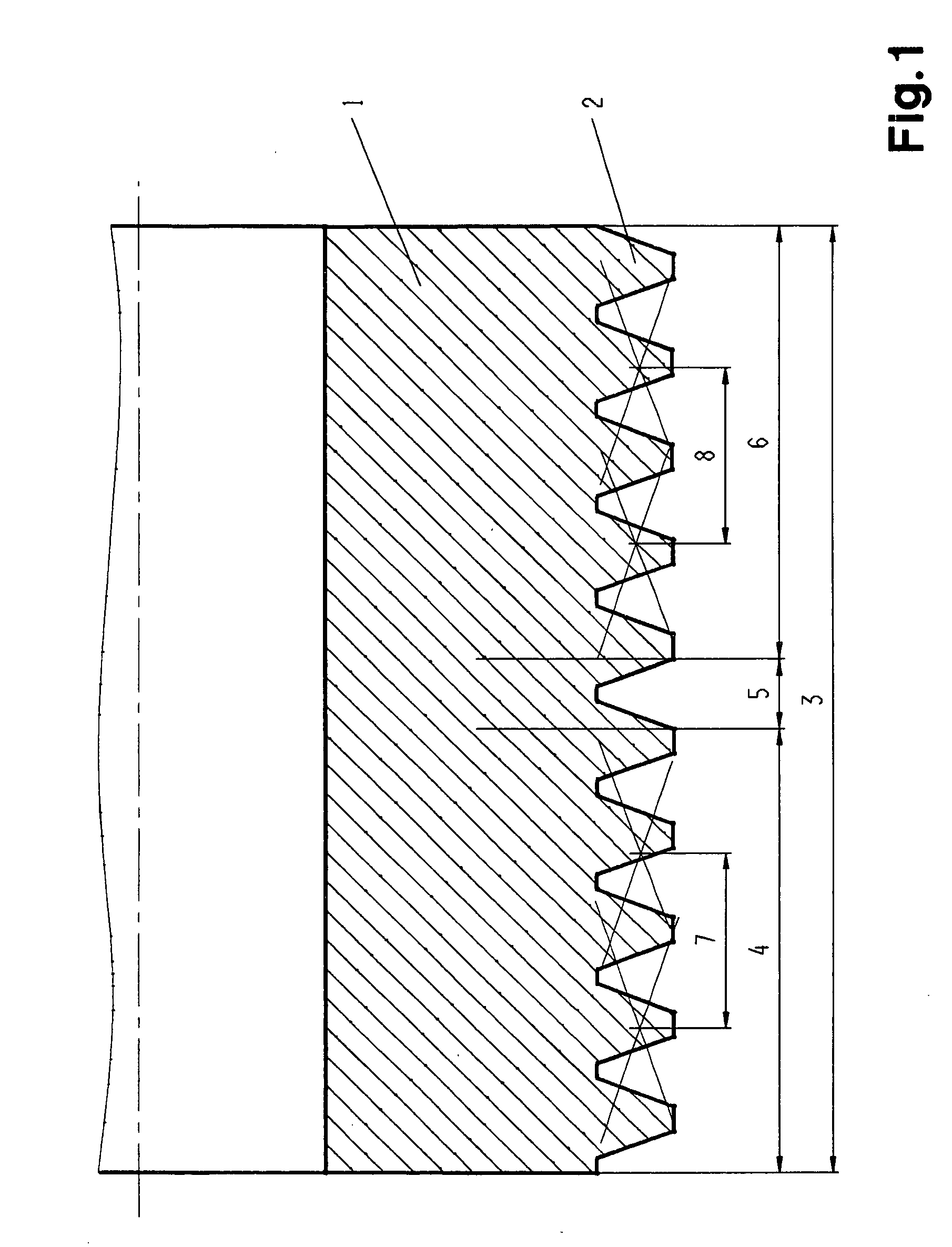

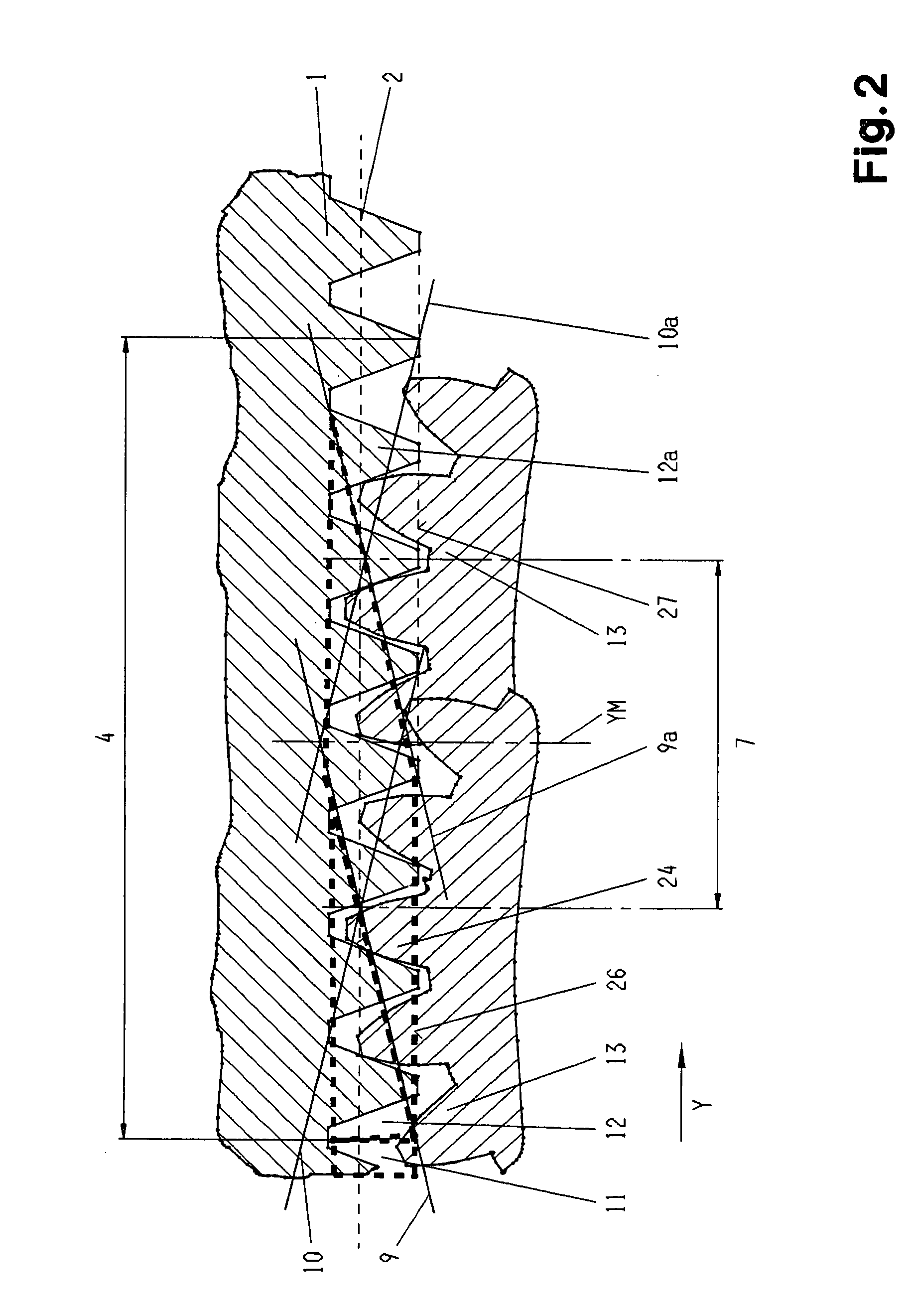

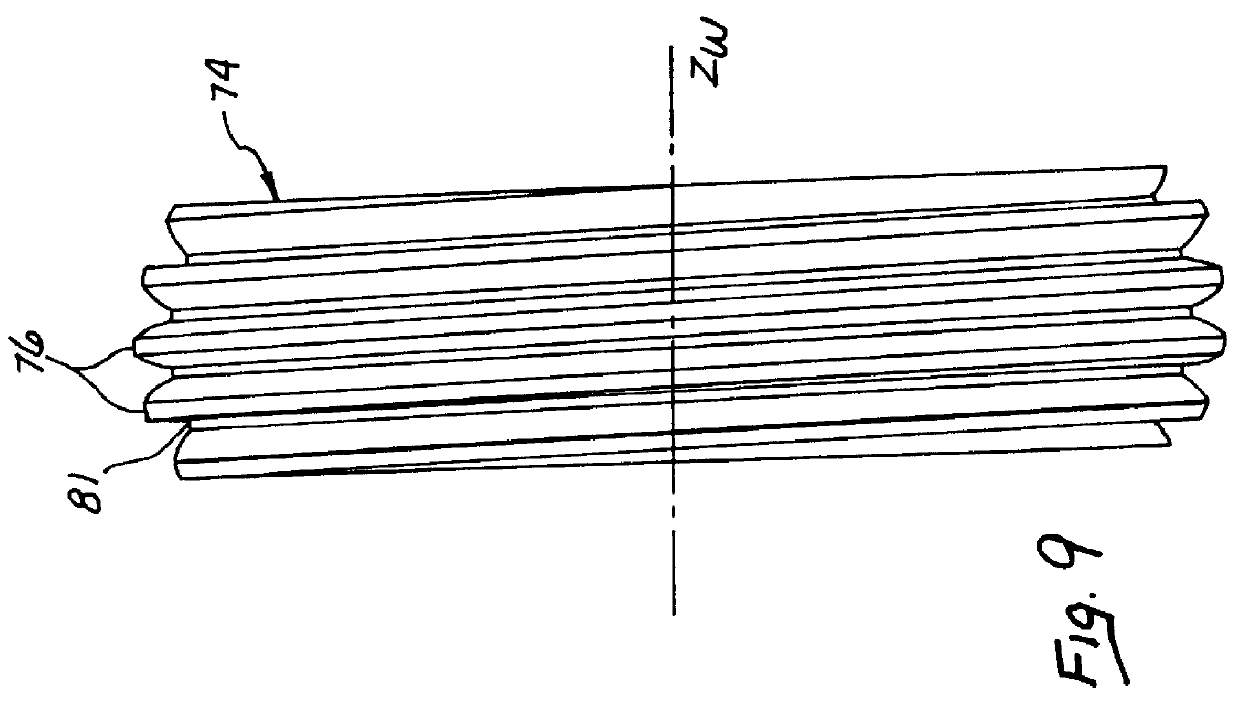

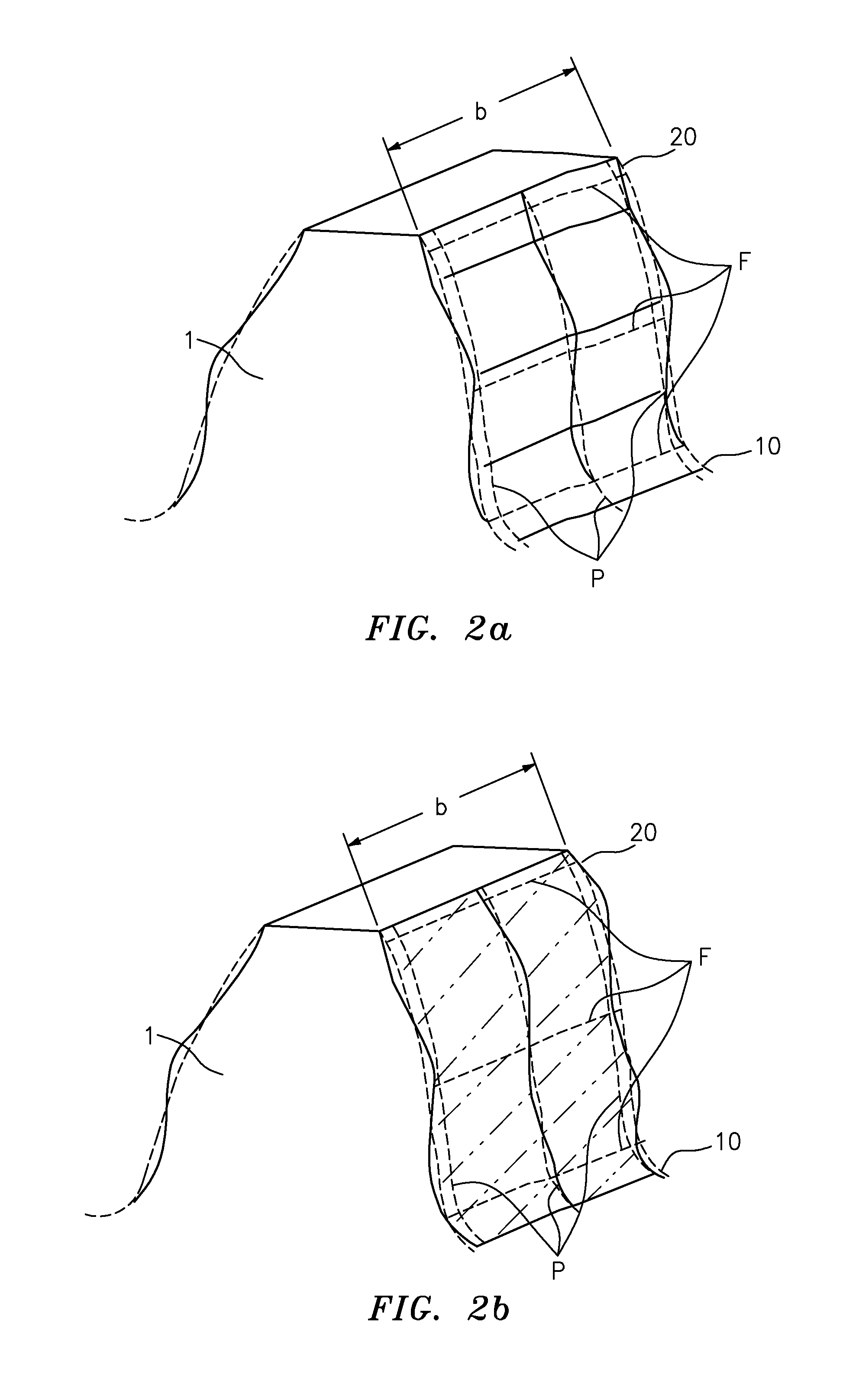

Grinding worm, profiling gear and process for the profiling of the grinding worm

ActiveUS20050239385A1Increased exploitationShort timeGrinding drivesBonded abrasive wheelsControl lineEngineering

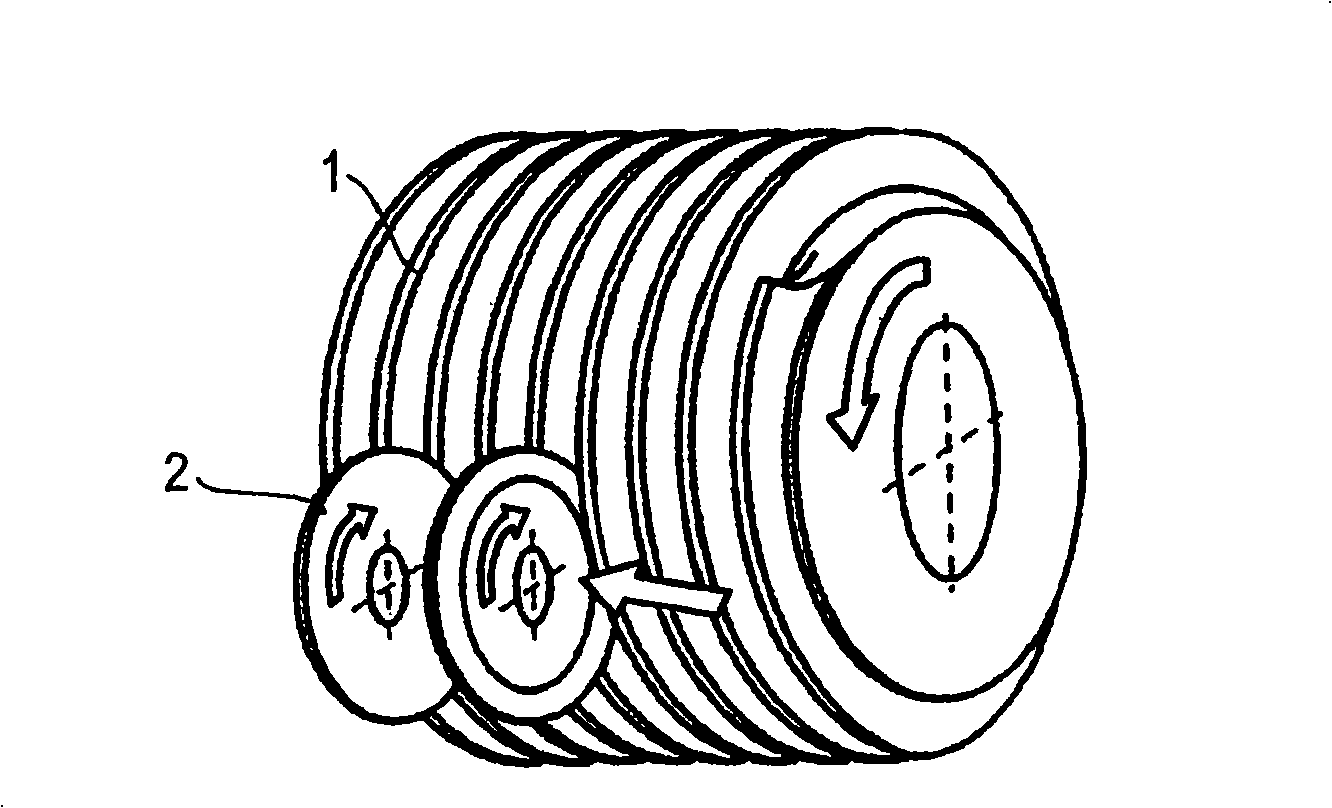

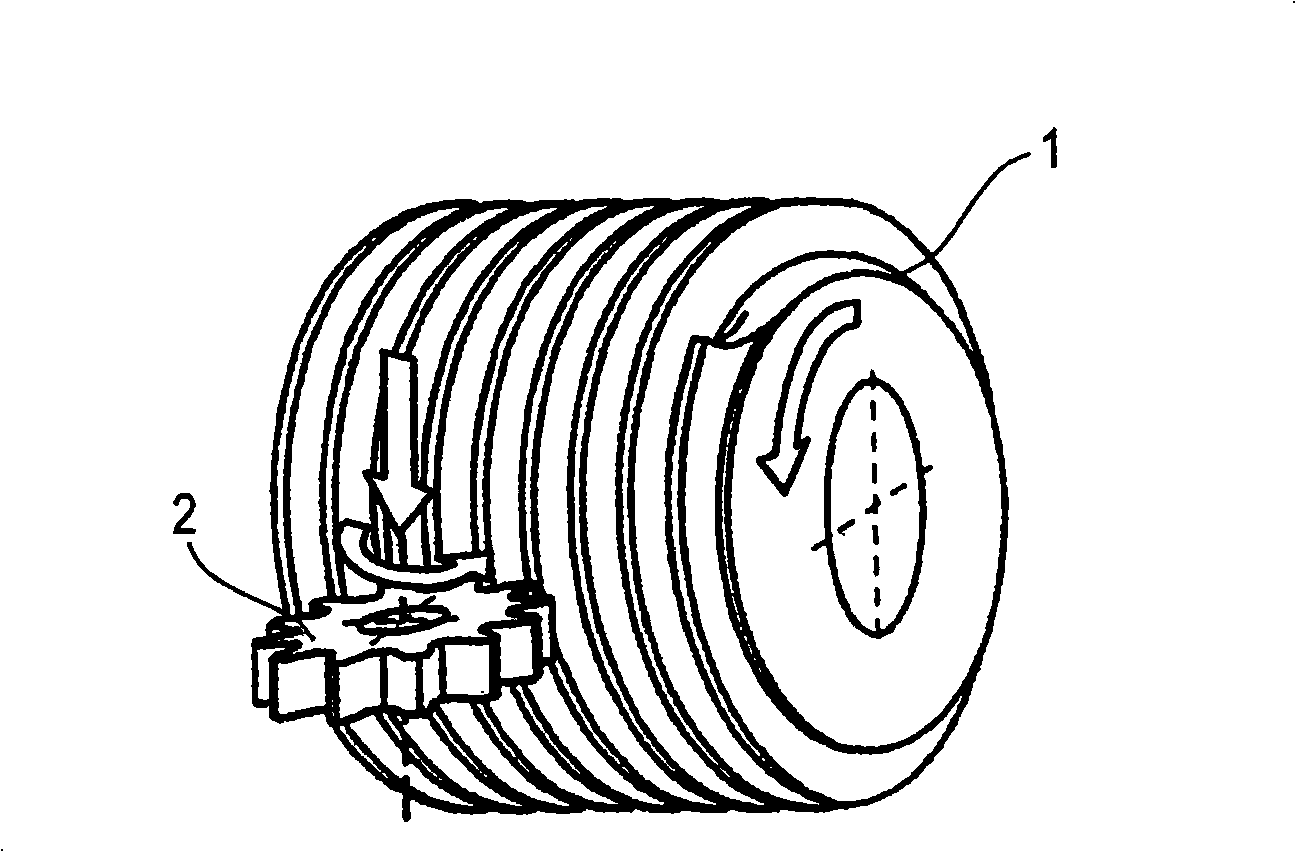

In a process for the profiling of a grinding worm (1) with at least two grinding width zones (4, 6) with differently modified thread profile for the grinding of spur and helical gears with three-dimensionally modified flank profile, the grinding width zones (4, 6) are arranged overlapping in order to gain optimum exploitation of the grinding worm width (3). In one variant, profiling of the grinding worm (1) is performed with an abrasive coated profiling gear (25) with a tooth flank geometry and facewidth differing from that of the workpiece to be ground. By suitable selection of the diagonal ratio and the allocation of the width zones (28, 29) of the profiling gear (25) to the grinding width zones (4, 6) of the grinding worm (1), it is possible to adapt the modifications of the grinding worm flanks to the requirements of the workpiece without having to alter the flank geometry of the profiling gear (25). In another variant the grinding worm (1) is profiled in a first stage across its entire width (3) with the desired profile form of the roughing zone, and in a second stage the finish grinding zone (36, 37) and the adjacent transition zones (34, 35) of the right and left flanks of the grinding worm (1) are finish profiled by means of NC controlled line by line profiling with a form dressing roll (40).

Owner:REISHAUER

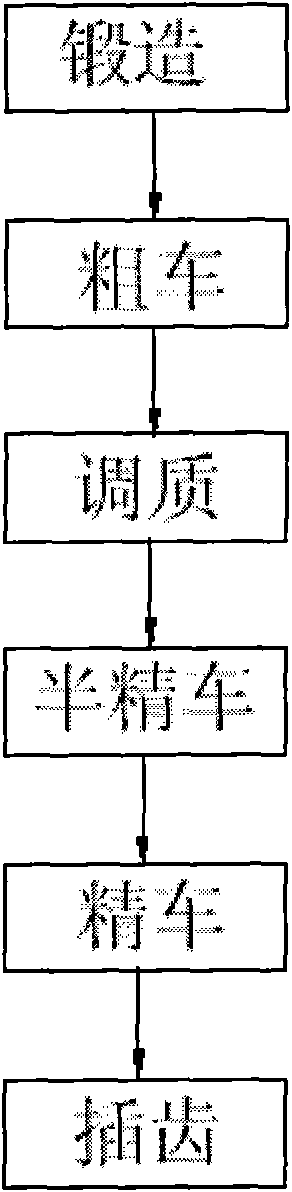

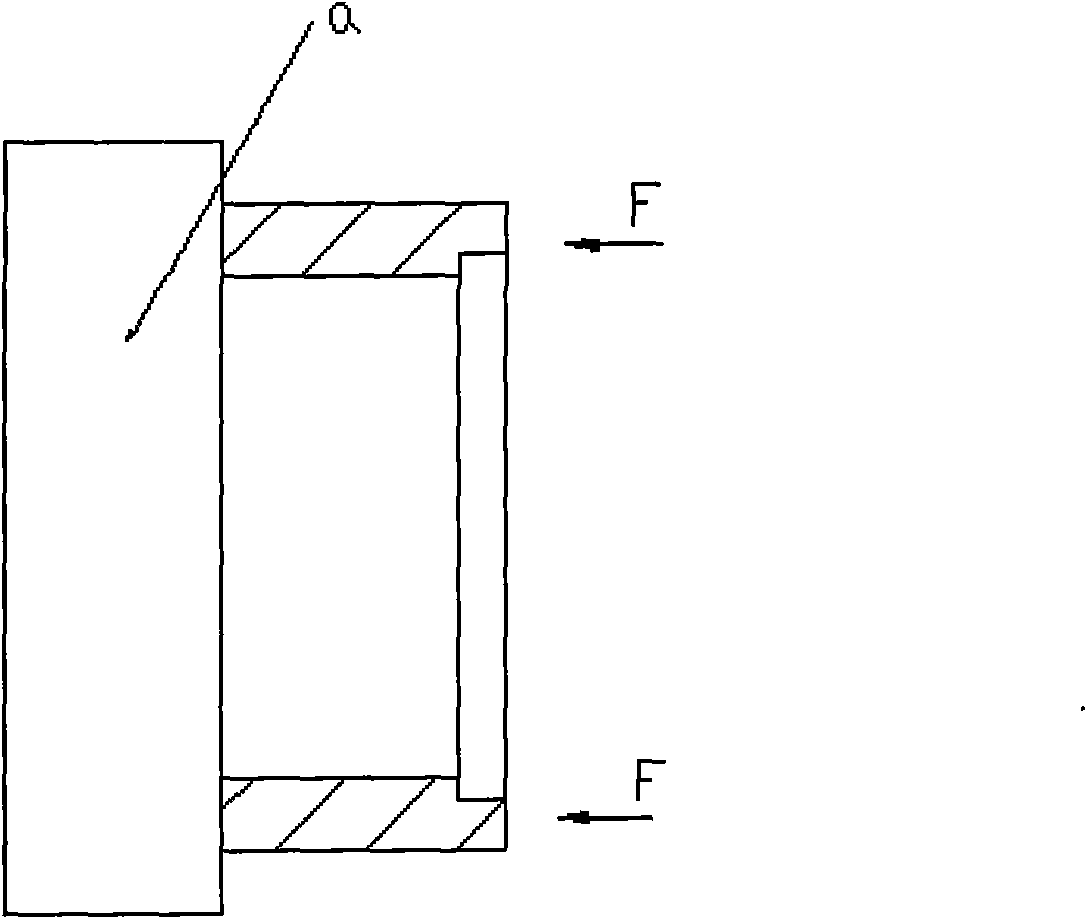

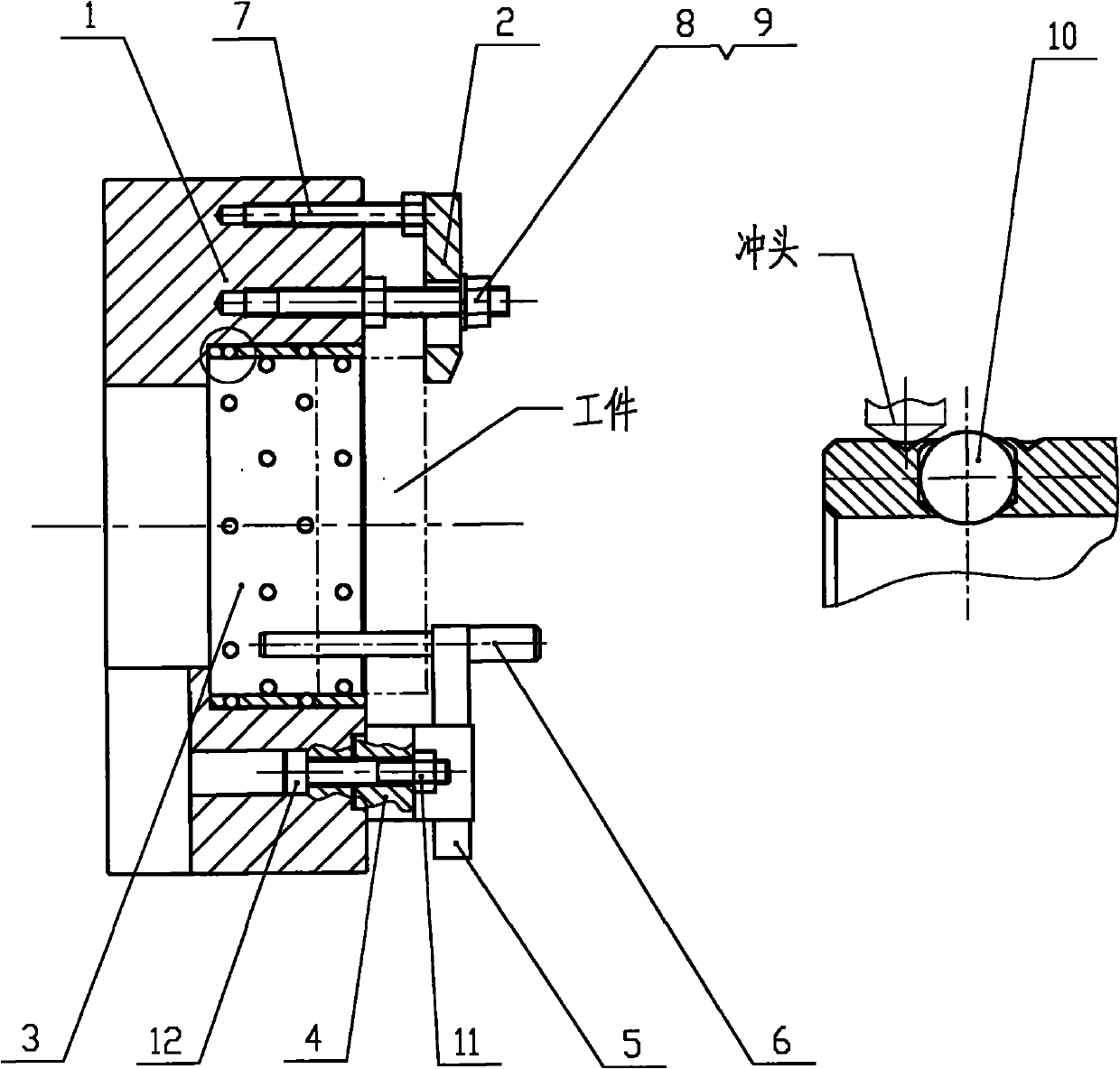

Thin-wall annular gear processing method

InactiveCN101659002AReduce distortionHigh precisionTurning machinesPositioning apparatusEngineeringAxial force

The invention discloses a thin-wall annular gear processing method which comprises the steps of forging, rough turning, tempering, half finished turning, finish turning and gear shaping, wherein the finish turning process comprises the steps of: taking the end surface of the thin-wall annular gear after half finished turning as a thrust surface, acting the axial force to fix the thin-wall annulargear on a horizontal lathe work bench, and then turning the inner wall and the outer wall of the thin-wall annular gear; and the gear shaping process comprises the steps of: using a fixture to simlutaneously fix the end surface and the outer wall of the thin-wall annular gear after finish turning, and then conducting gear shaping to the inner wall of the thin-wall annular gear. The thin-wall annular gear processing method can lead the thin-wall annular gear after processing to have small deformation, has high precision and high efficiency.

Owner:CHONGQING QINGPING MACHINERY

Method for operating a dovetail grinding machine

InactiveCN101513684AGear teeth manufacturing toolsGear-cutting machinesGear grindingMechanical engineering

The present invention relates to a method for operating a gear grinding machine, with the following operating phases of the gear grinding machine: machining a workpiece on the gear grinding machine by means of a grinding disk and / or grinding worm and dressing a profiling tool for profiling a grinding disk and / or grinding worm on the gear grinding machine.

Owner:LIEBHERR VERZAHNTECHNIK GMBH

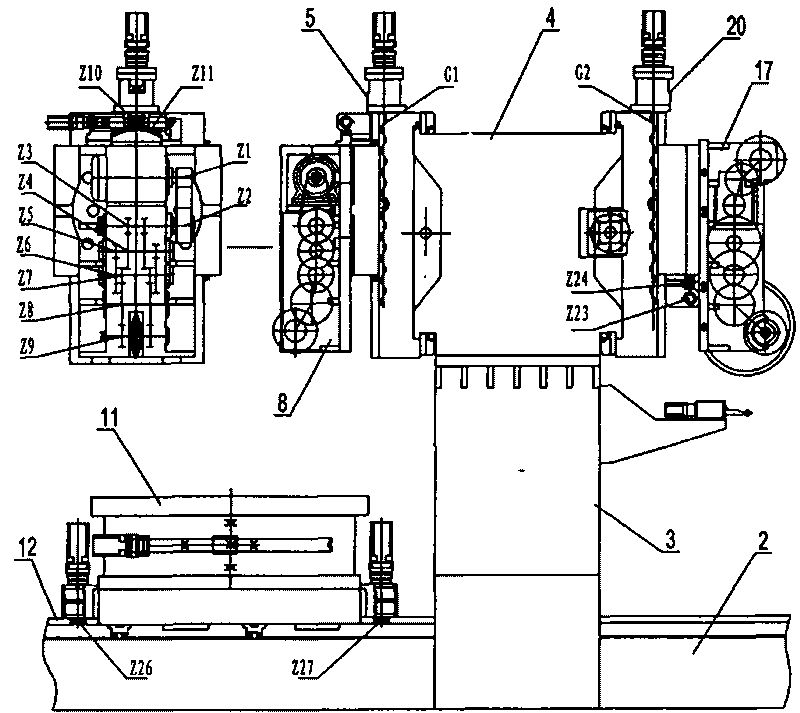

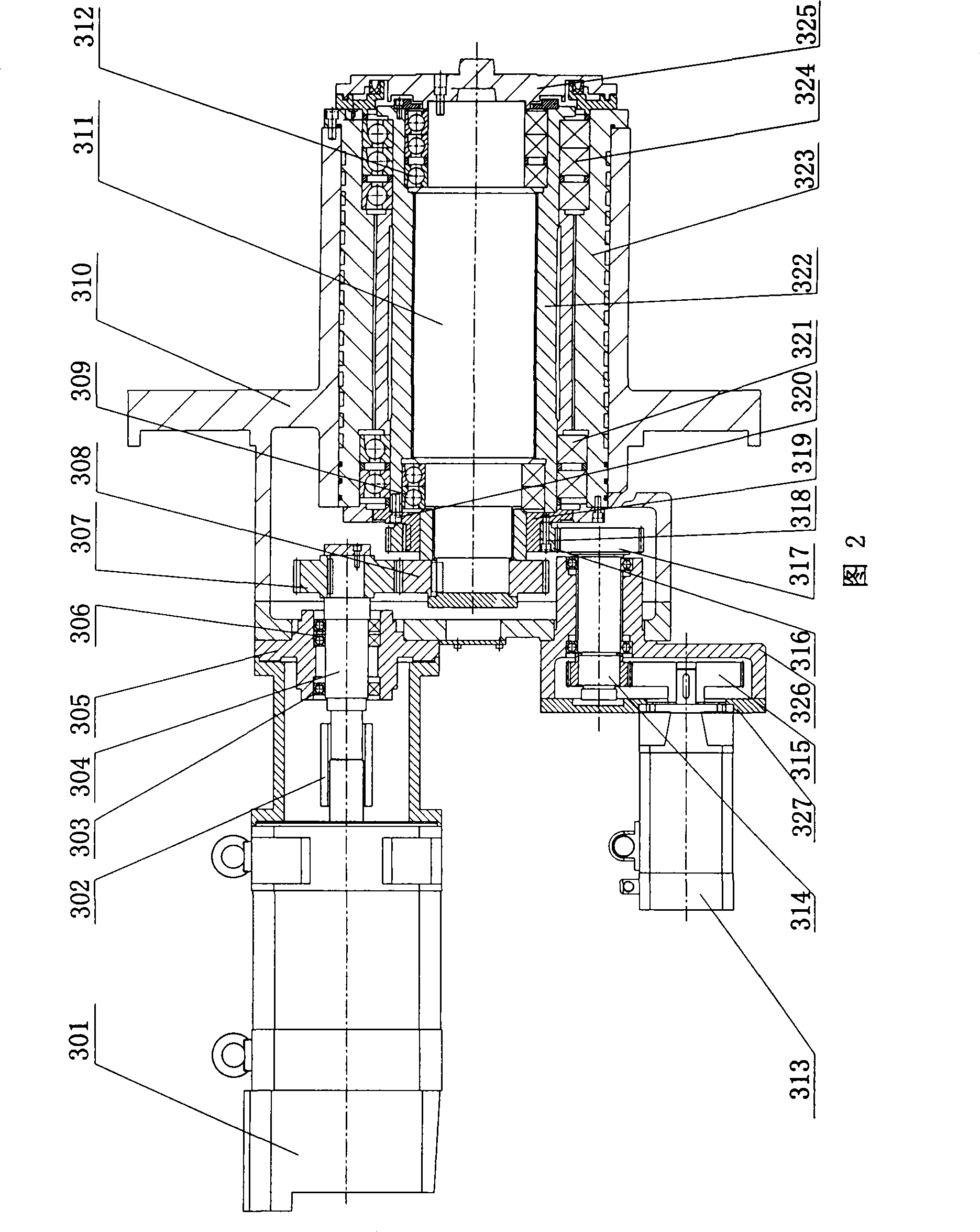

Main shaft device for numerical controlled gear hobbing machine

ActiveCN102059408AHigh precisionImprove work efficiencyGear-cutting machinesGear teethNumerical controlHobbing

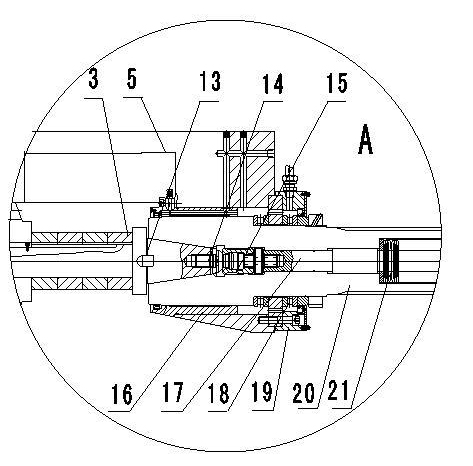

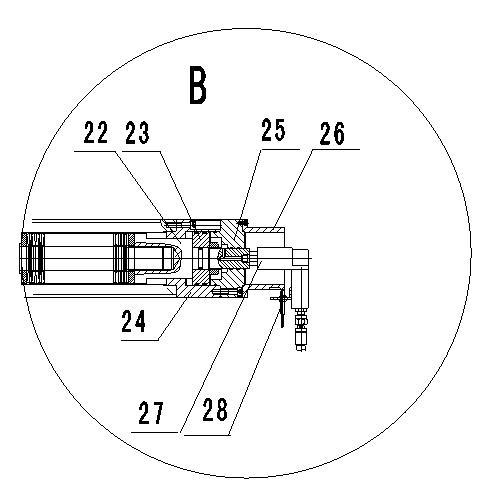

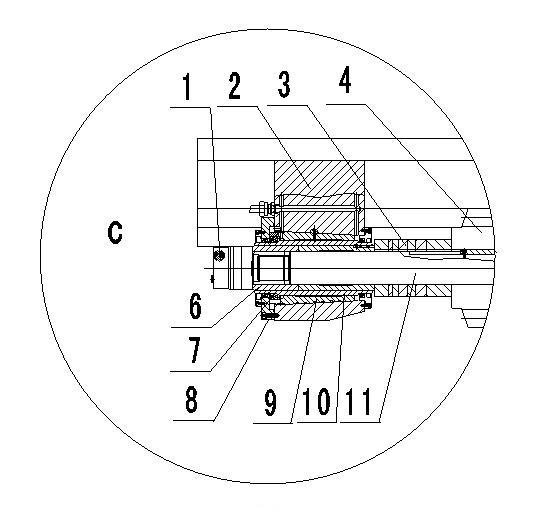

The invention discloses a main shaft device for a numerical controlled gear hobbing machine. The main shaft device comprises a cutter bar assembly, a cutter bar assembly clamping mechanism and a cutter changing mechanism, wherein the cutter bar assembly comprises a cutter bar, a hobbing cutter, a cutter regulating pad, an axle sleeve, a locking nut and a cutter bar blind rivet; the cutter bar assembly clamping mechanism consists of a square key and a claw assembly; and the cutter changing mechanism consists of a pull rod, a piston rod, a disc-shaped spring, a hydro-cylinder body, a flange plate, a bracket, a rotary joint and a spacing switch. The main shaft device has the advantages that: a hydrostatic bearing is arranged in the main shaft structure of the high-accuracy numerical controlled gear hobbing machine, so the main shaft device can constantly work under a heavy-load cutting condition; a main shaft has high accuracy and good accuracy retaining ability; and the cutter bar assembly with the hobbing cutter is arranged and set outside a machine in a cutter workshop; the cutter bar assembly is subjected to whole cutter changing on the gear hobbing machine; and the setting assisting time of the hobbing cutter does not occupy the total part machining time of a machine tool, so the whole machine tool has high working efficiency.

Owner:齐重数控装备股份有限公司

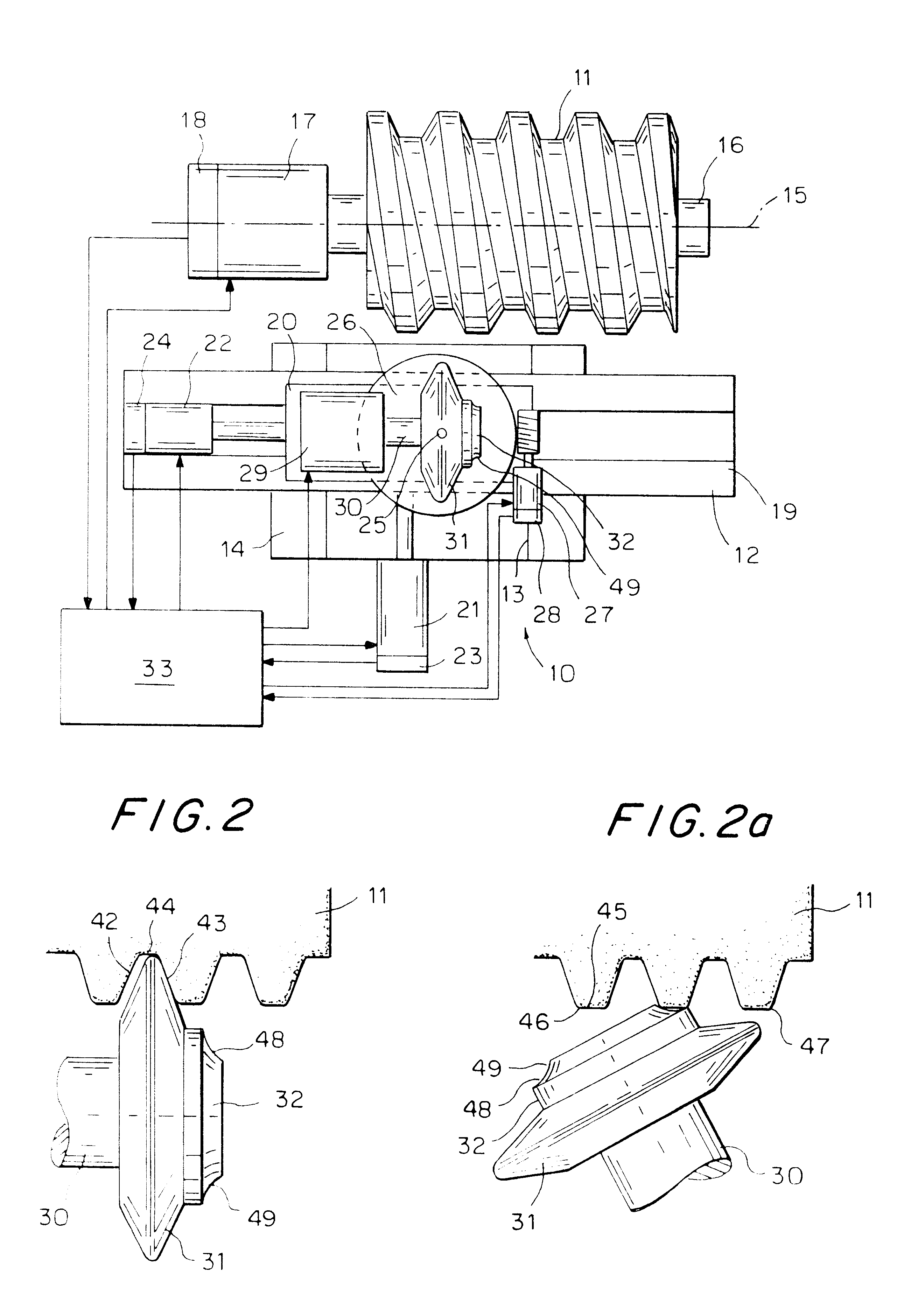

Method and device for centering a dressing tool in the thread of a grinding worm

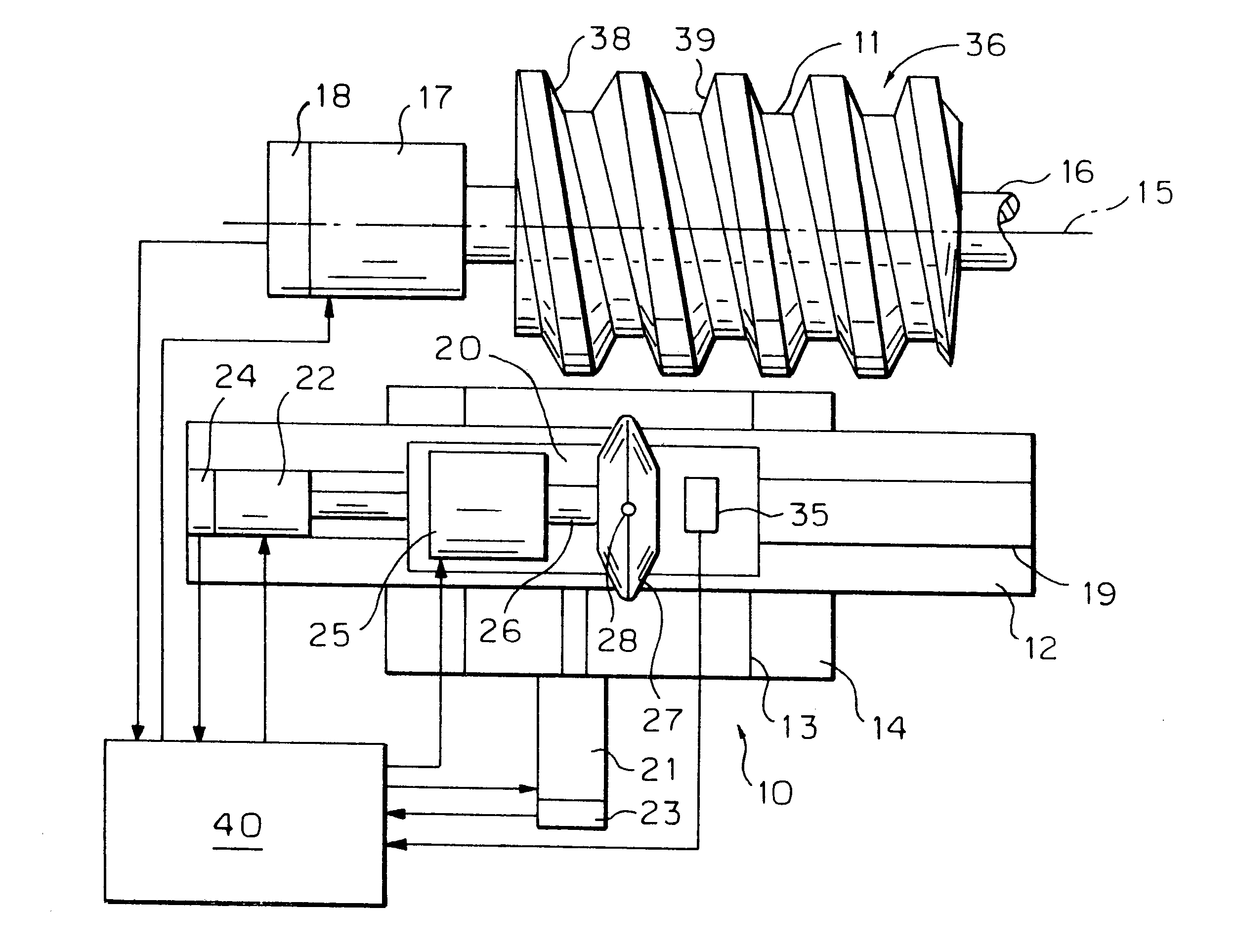

In a first step for the purpose of precentering, the dressing too; (27), without axial movement, is brought into contact with the circumference of the rotating grinding worm (11), and those rotary-angle positions of the grinding worm (11) at which the overrunning of the thread gap (36) starts of ends are determined by means of an acoustic-sensor signal and the shaft-angle encoder (18) of the grinding spindle (16). In a second step for the purpose of precision centering, the dressing tool (27) fed into the thread gap (36) is brought into contact with the left-hand and right-hand tooth flanks (38, 39) by axial displacement. In this case, the axial infeed is stopped by means of the acoustic-sensor signal, and the exact grinding-worm thread center is calculated from the contact positions of the dressing tool (27) achieved.

Owner:REISHAUER

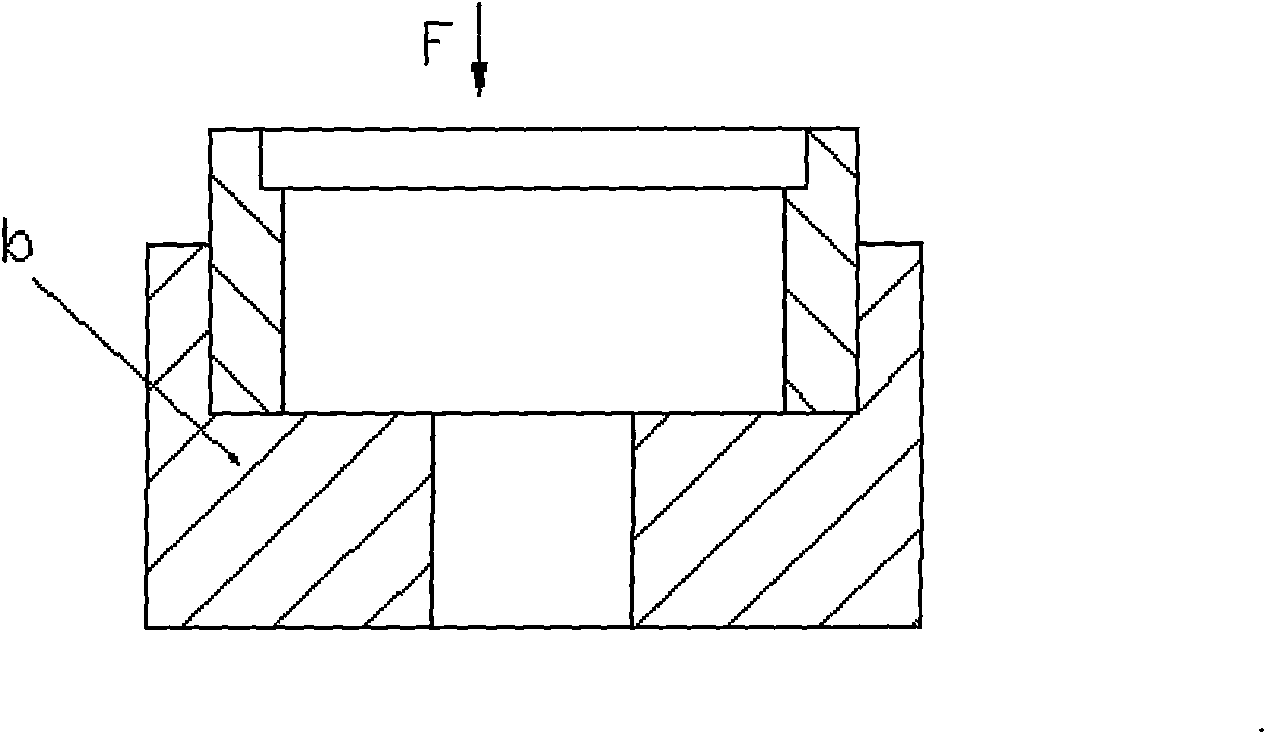

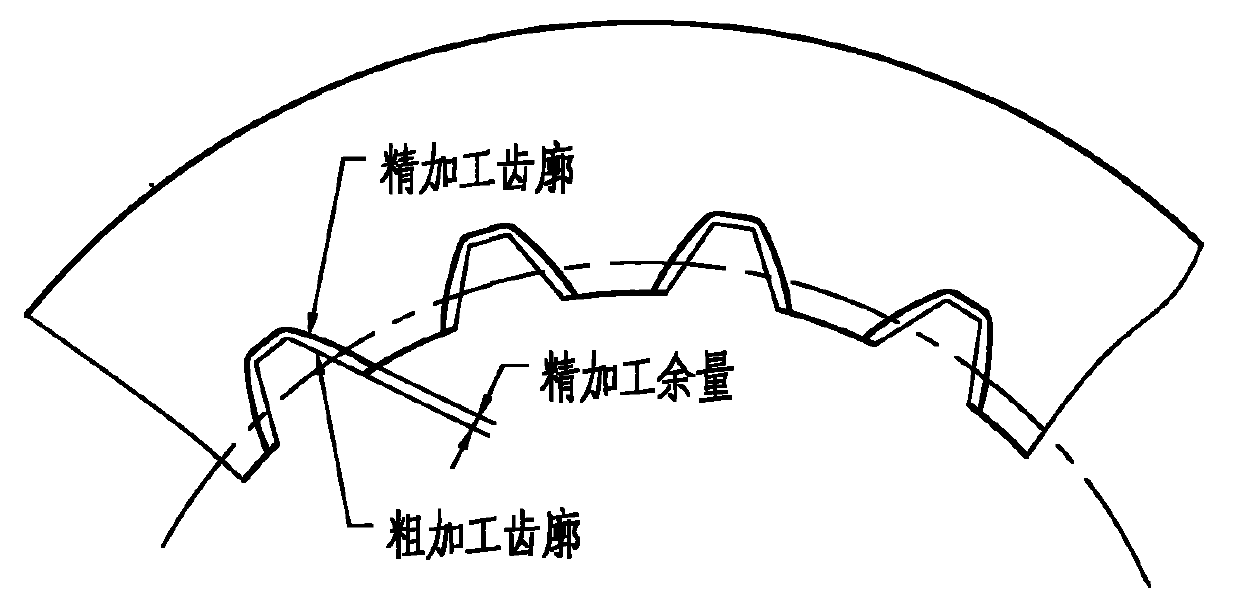

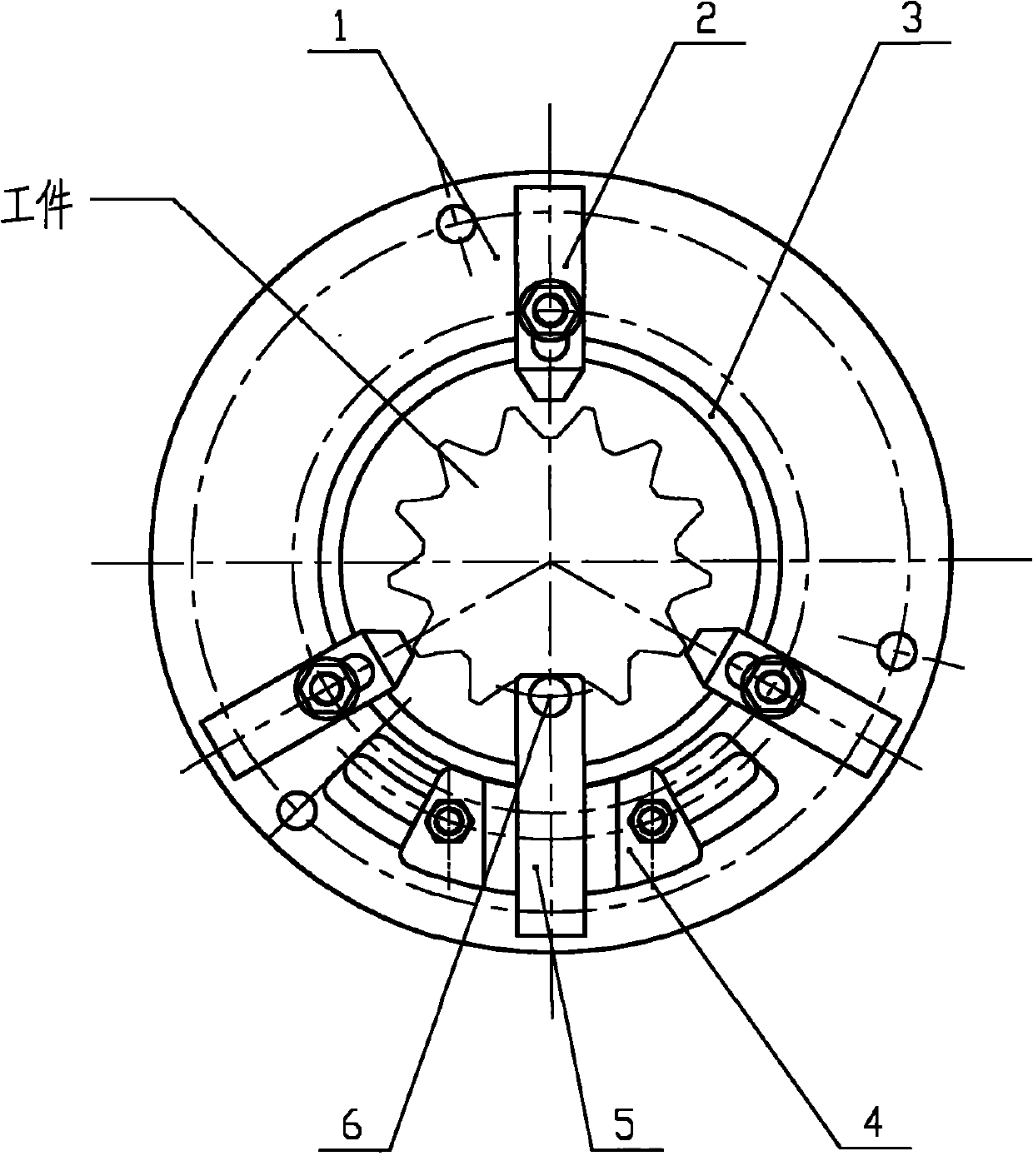

Inner gear machining method and special gear shaping clamp

The invention provides an inner gear machining method and a special gear shaping clamp. The processing method comprises the following steps: firstly carrying out rough machining on wheel teeth by virtue of the common shaping machine, adopting an indexing mechanism and a shaping tool with a trapezoidal cutting edge to machine gear grooves in a one-by-one manner, obtaining a trapezoidal middle tooth profile which is very close to the final tooth profile of an inner gear, and remaining a small amount of fine-machined allowance; and then adopting the shaping tool with a conjugate tooth profile on the gear shaping machine to carry out fine machining on the wheel teeth. The special gear shaping clamp comprises a base, pressing plates, an adjusting screw, a screw, a pressing nut, a steel ball, a retaining frame, a sliding block, sliding block bolts, sliding block nuts, a positioning rod and a positioning pin, and the special gear shaping clamp has the main functions of aligning the peripheral positions of the inner gear and the gear shaping tool and clamping a workpiece. In the inner gear machined by adopting the method, the gear shaping efficiency can be effectively improved, the wear of the gear shaping tool can be reduced and the machining accuracy of the wheel tooth can be improved.

Owner:上海航发机械有限公司

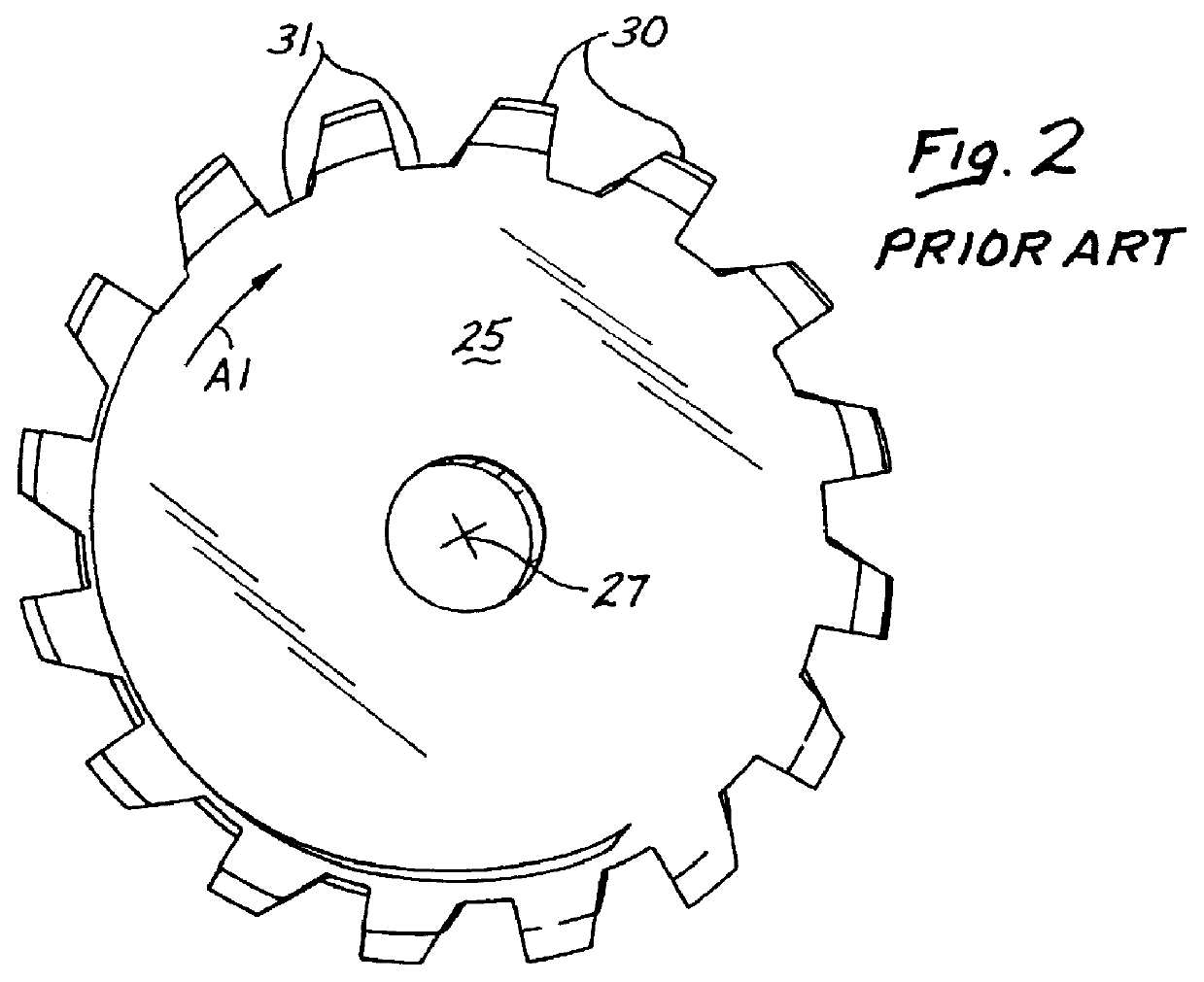

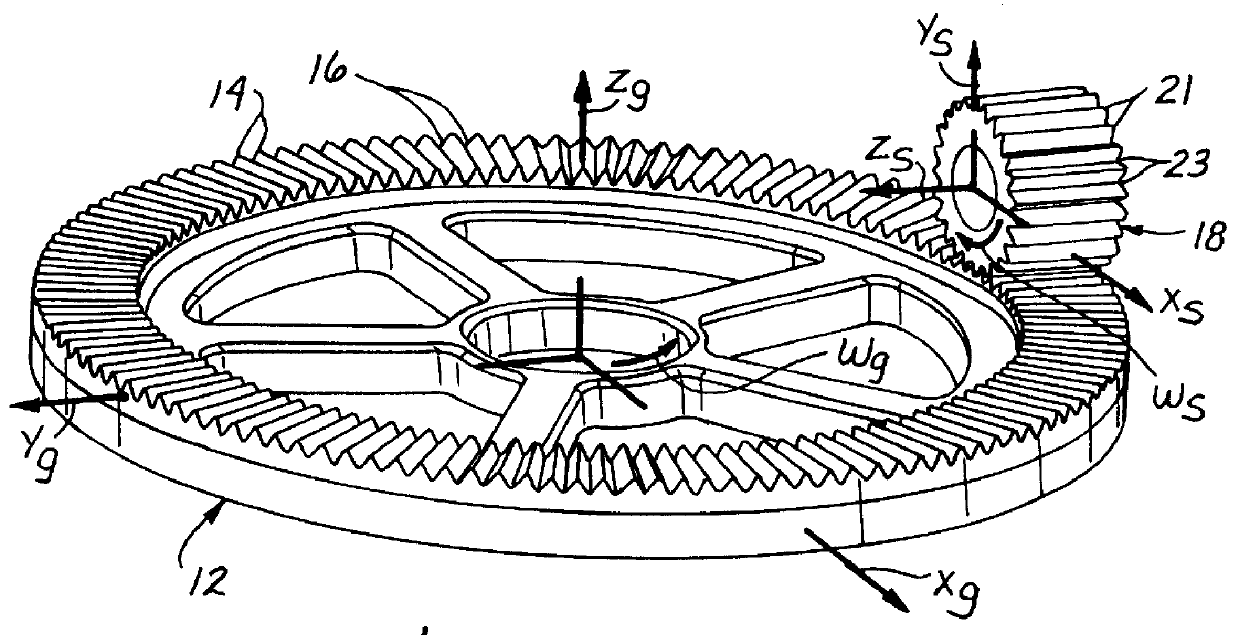

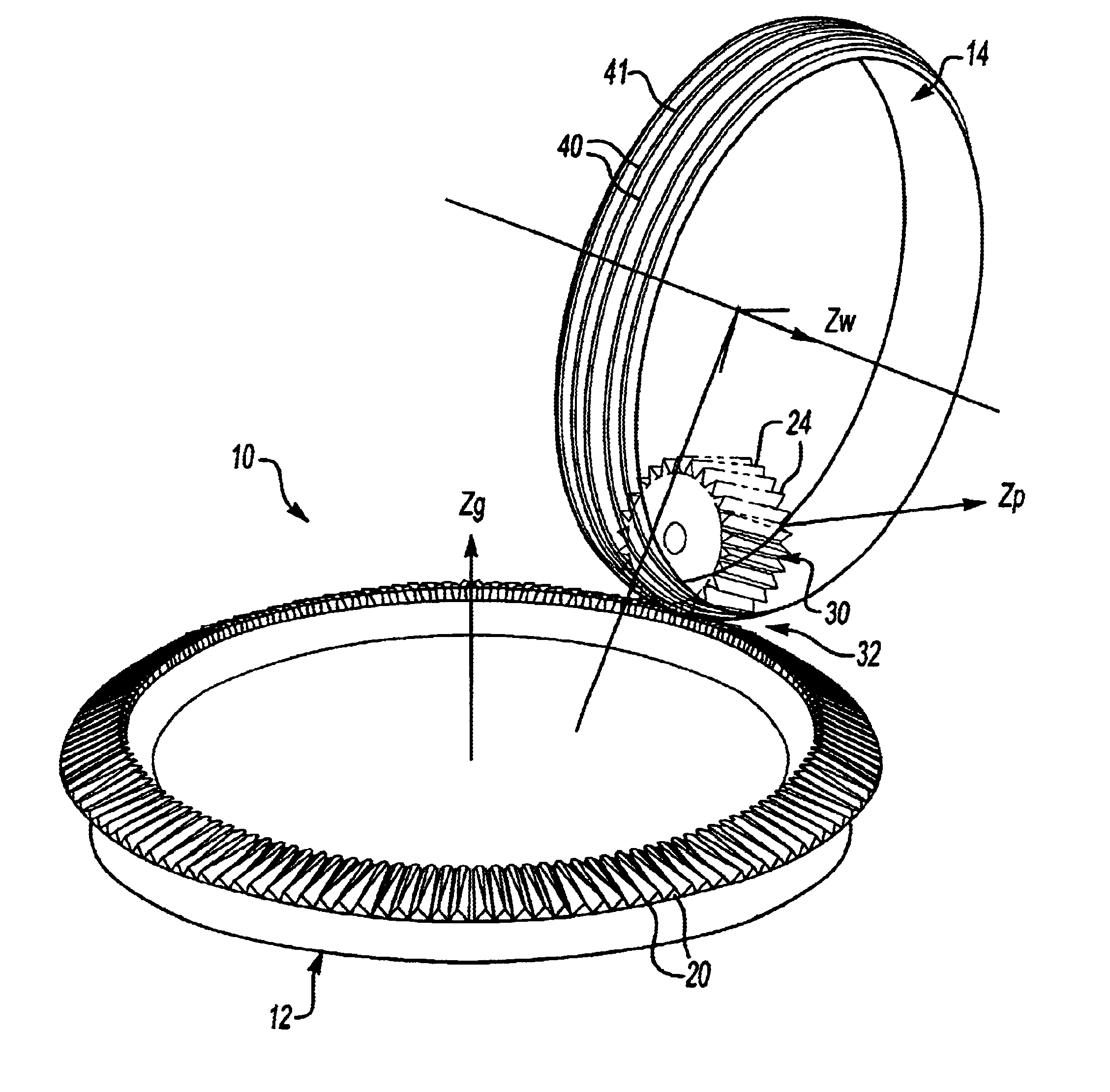

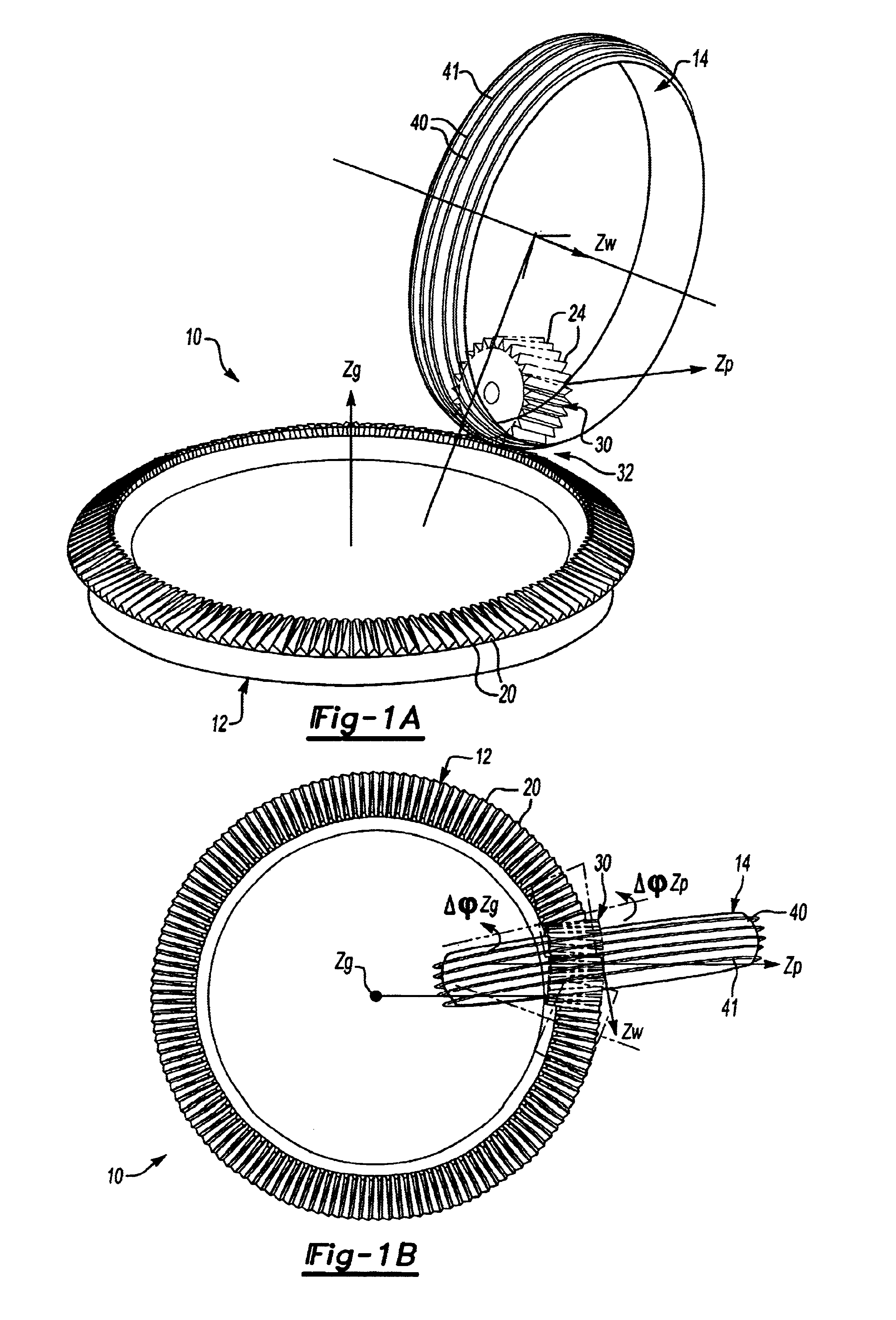

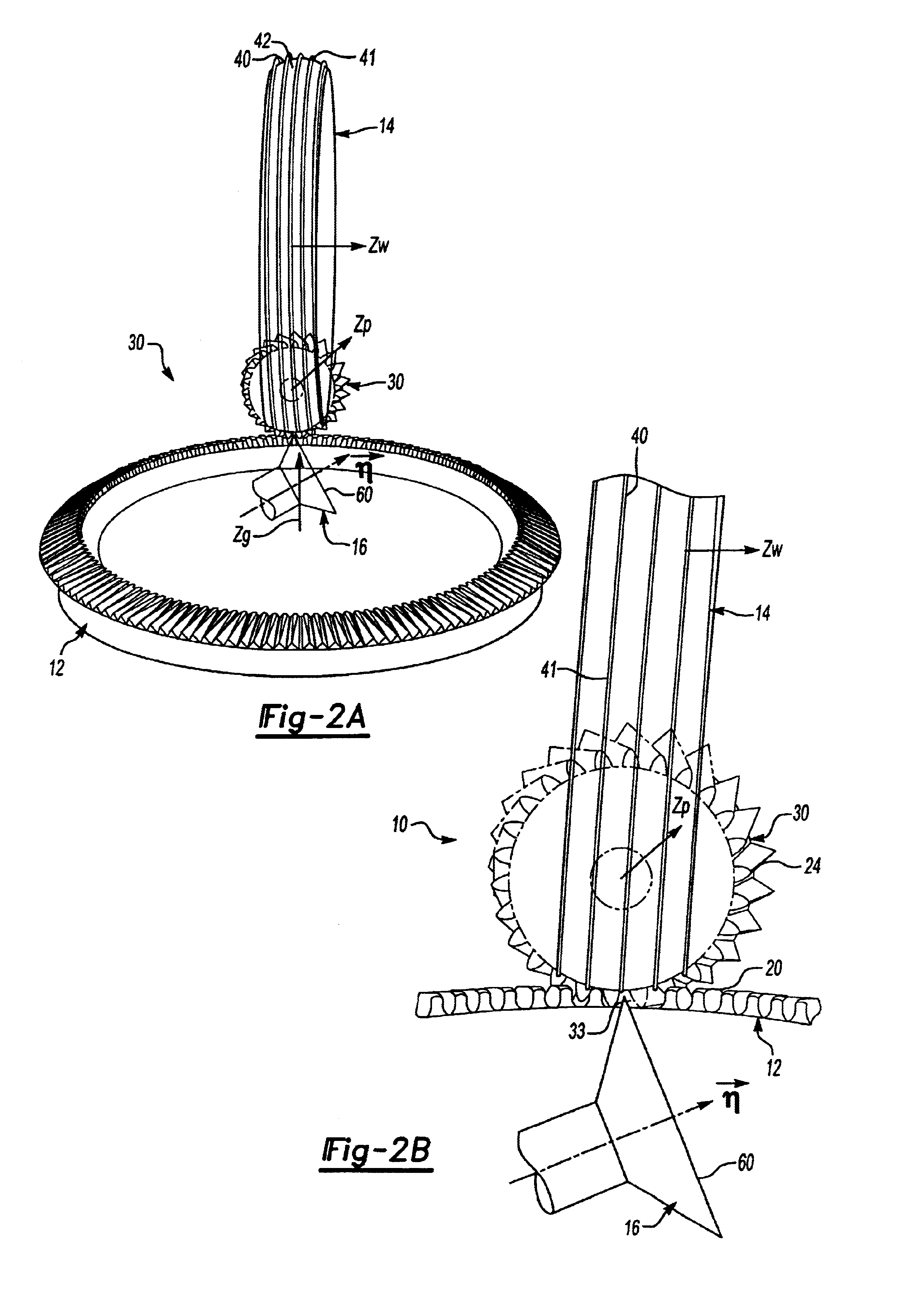

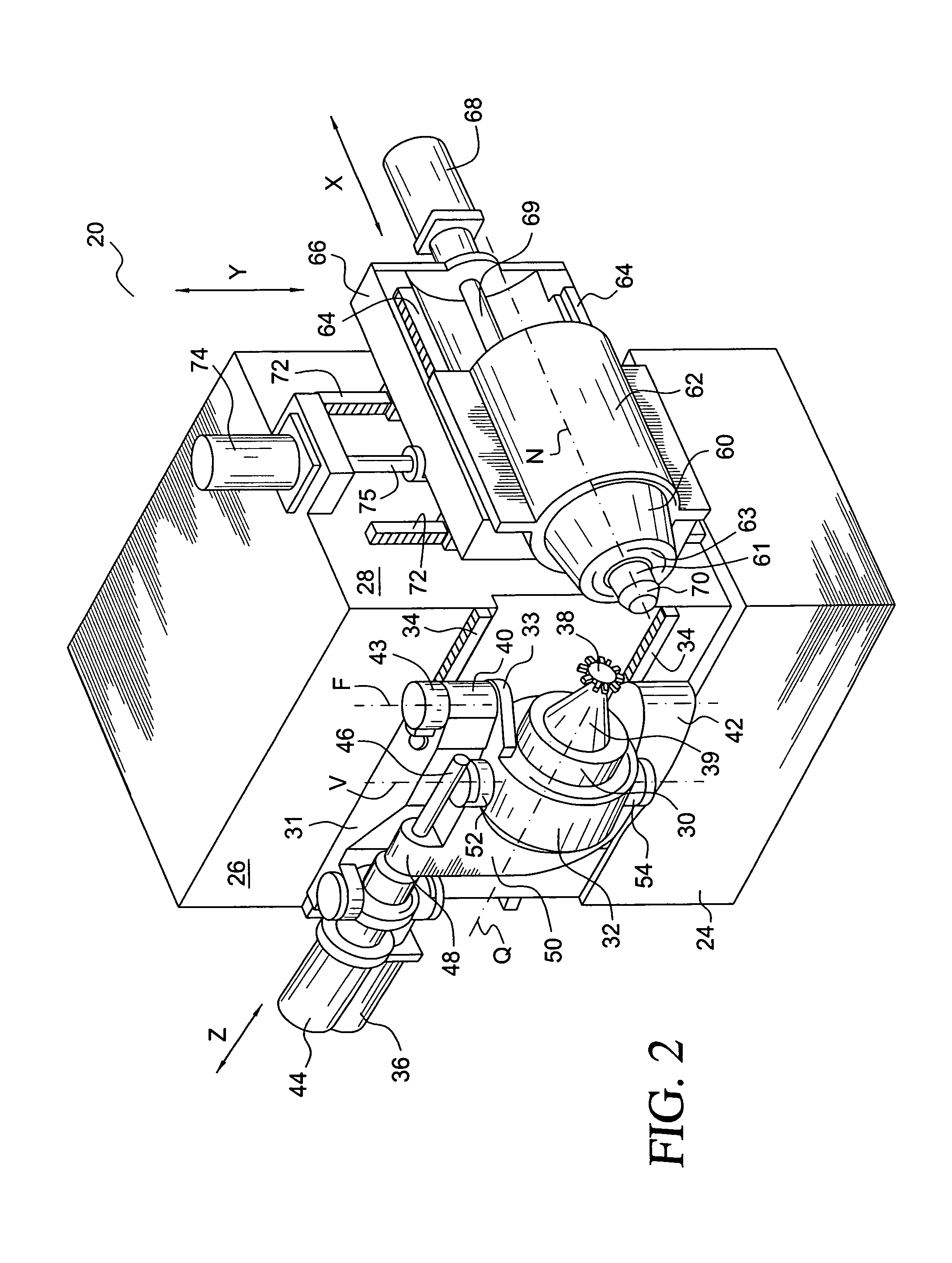

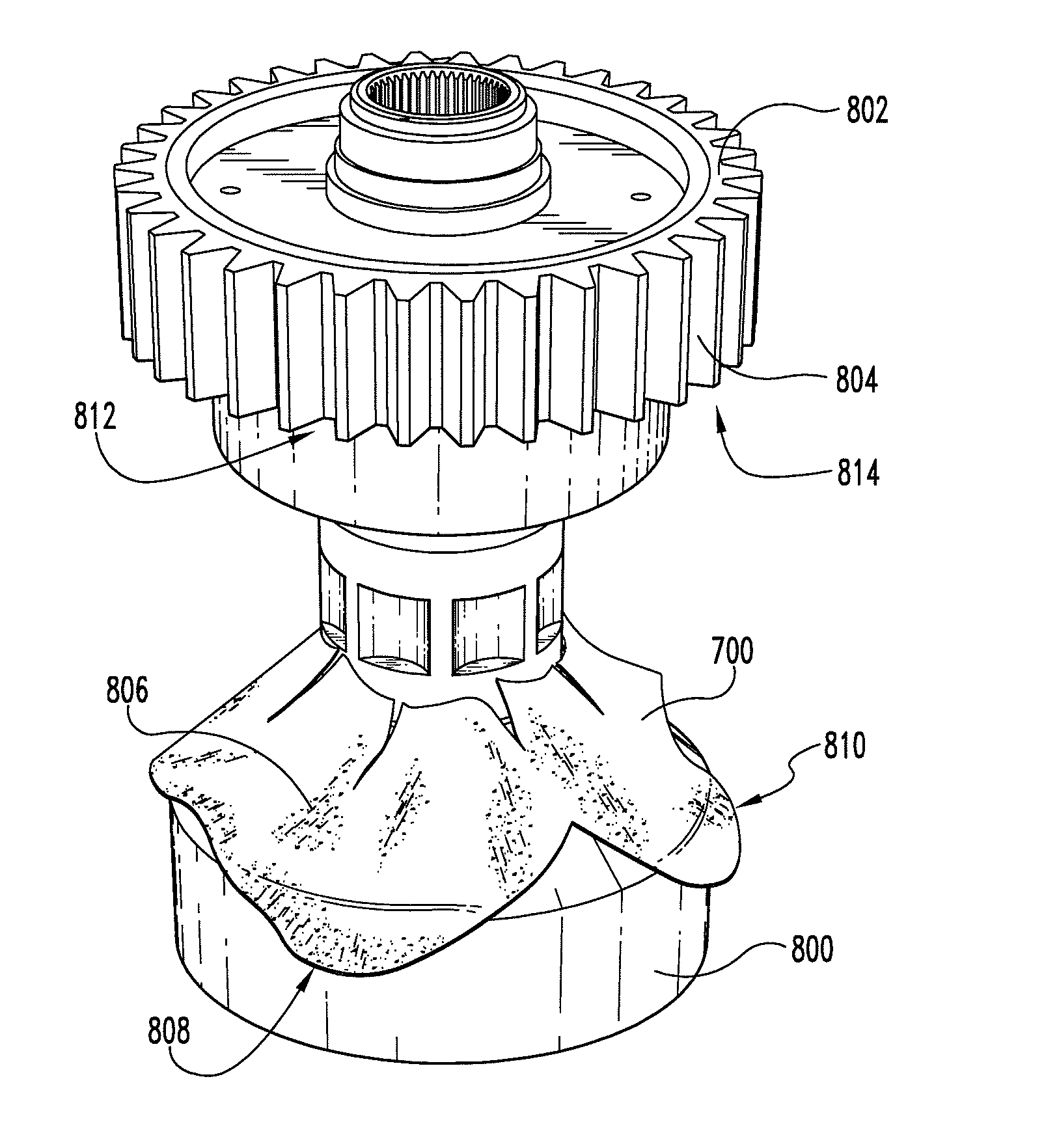

Apparatus and method for precision grinding face gear

InactiveUS6146253AAbrasive surface conditioning devicesGear-cutting machinesGear wheelCase hardening

A precision grinding apparatus includes a grinding worm for precision grinding a case-hardened face gear. A shaper is first placed into contact with a face gear, to thereby shape a surface of the face gear into a plurality of face gear teeth. The shaper is then removed, and the face gear is case hardened. The grinding worm is disposed in a normal orientation to the case-hardened face gear and includes a spiral tooth extending along a perimeter of the grinding worm. The spiral tooth of the grinding worm is adapted to contact and precision grind the case-hardened gear. A dressing tool includes a protrusion for contacting the spiral tooth of the grinding worm, as the spiral tooth contacts and precision grinds the case-hardened face gear. The dressing tool thus maintains the shape of the grinding worm to within a desired tolerance range.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

Method and apparatus for hard finishing modified gears

The present disclosure relates to a method for the manufacture of a workpiece having a corrected gear geometry and / or a modified surface structure, in particular by a hard finishing process, in particular generation grinding or honing. Provision is made in this respect that it is achieved by a direct generation of a wobble movement and / or of an eccentricity of the tool that a modification, in particular a profile modification or profile waviness, and / or a defined periodic flank waviness is generated on the active surface of the workpiece machined therewith.

Owner:LIEBHERR VERZAHNTECHNIK GMBH

Method for forming a grinding worm for forming a conical face gear that meshes with a conical involute pinion

A method for dressing a grinding worm that is to be used in forming a conical face gear that meshingly engages a conical involute pinion. The method employs true conjugate action between a theoretical conical involute pinion and a conical face gear to accurately position a dressing tool relative to a grinding worm.

Owner:THE BOEING CO

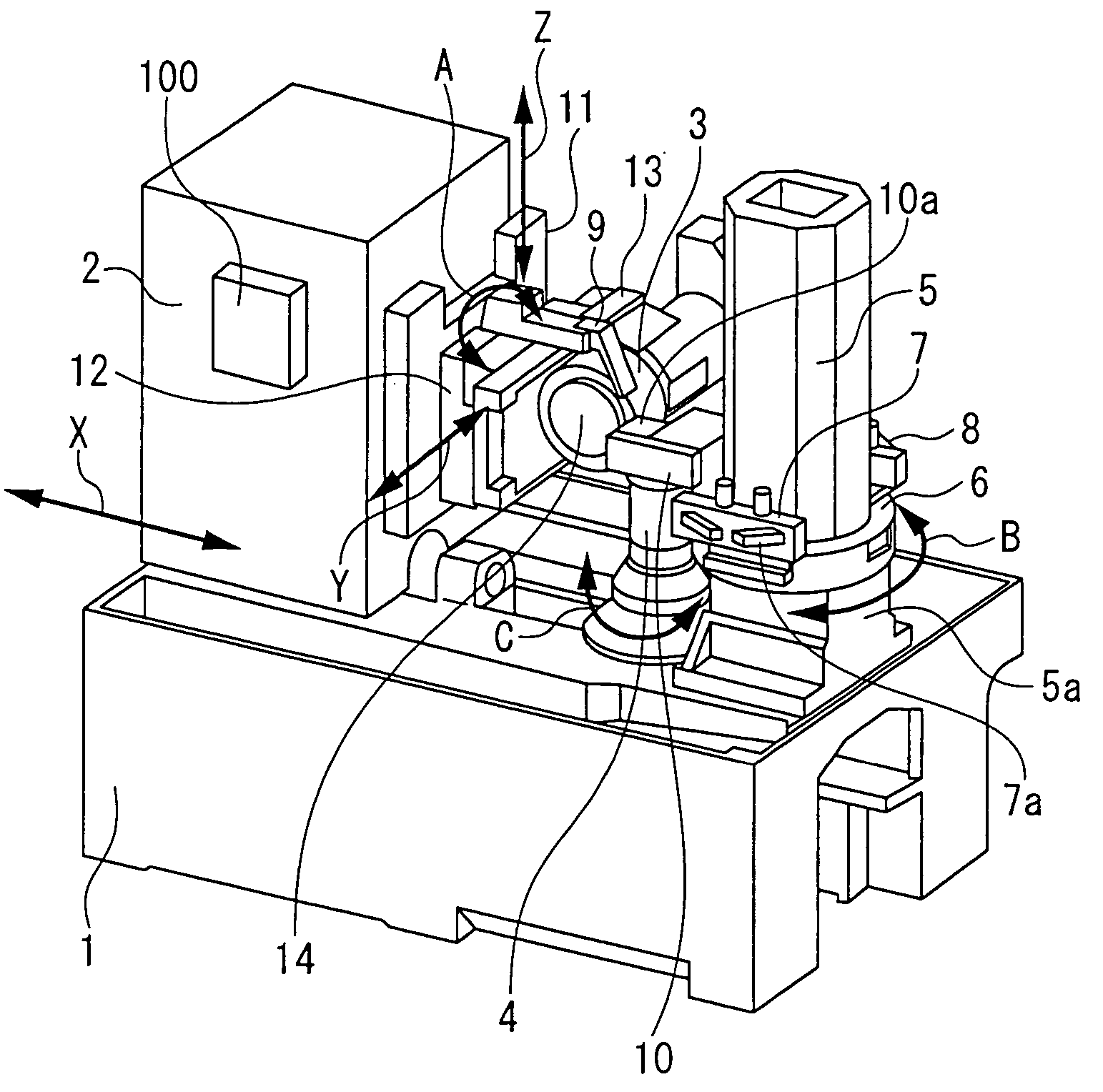

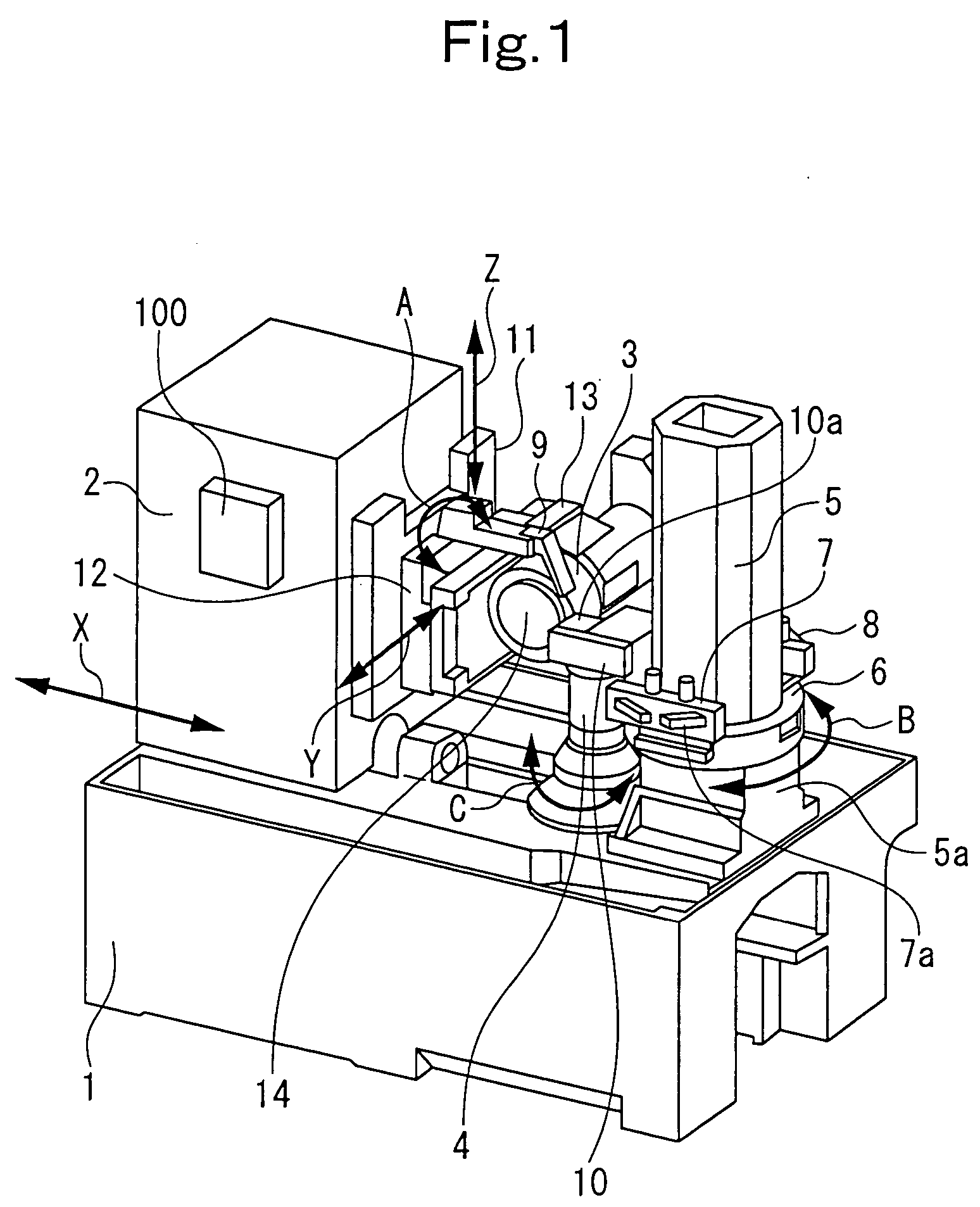

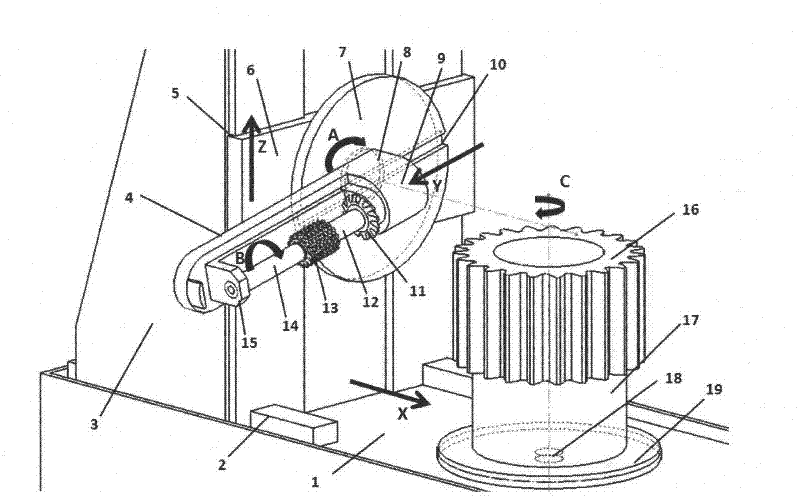

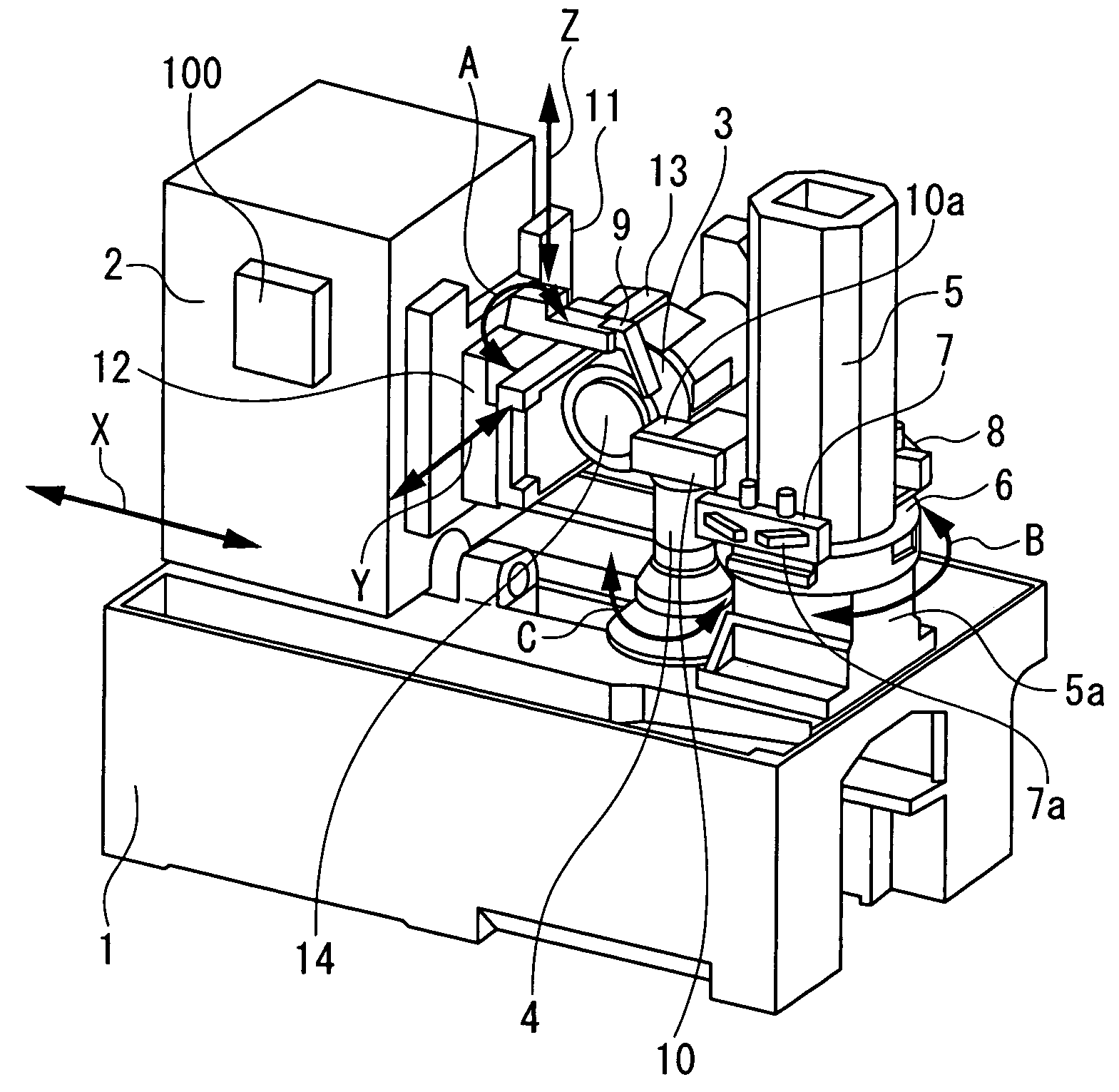

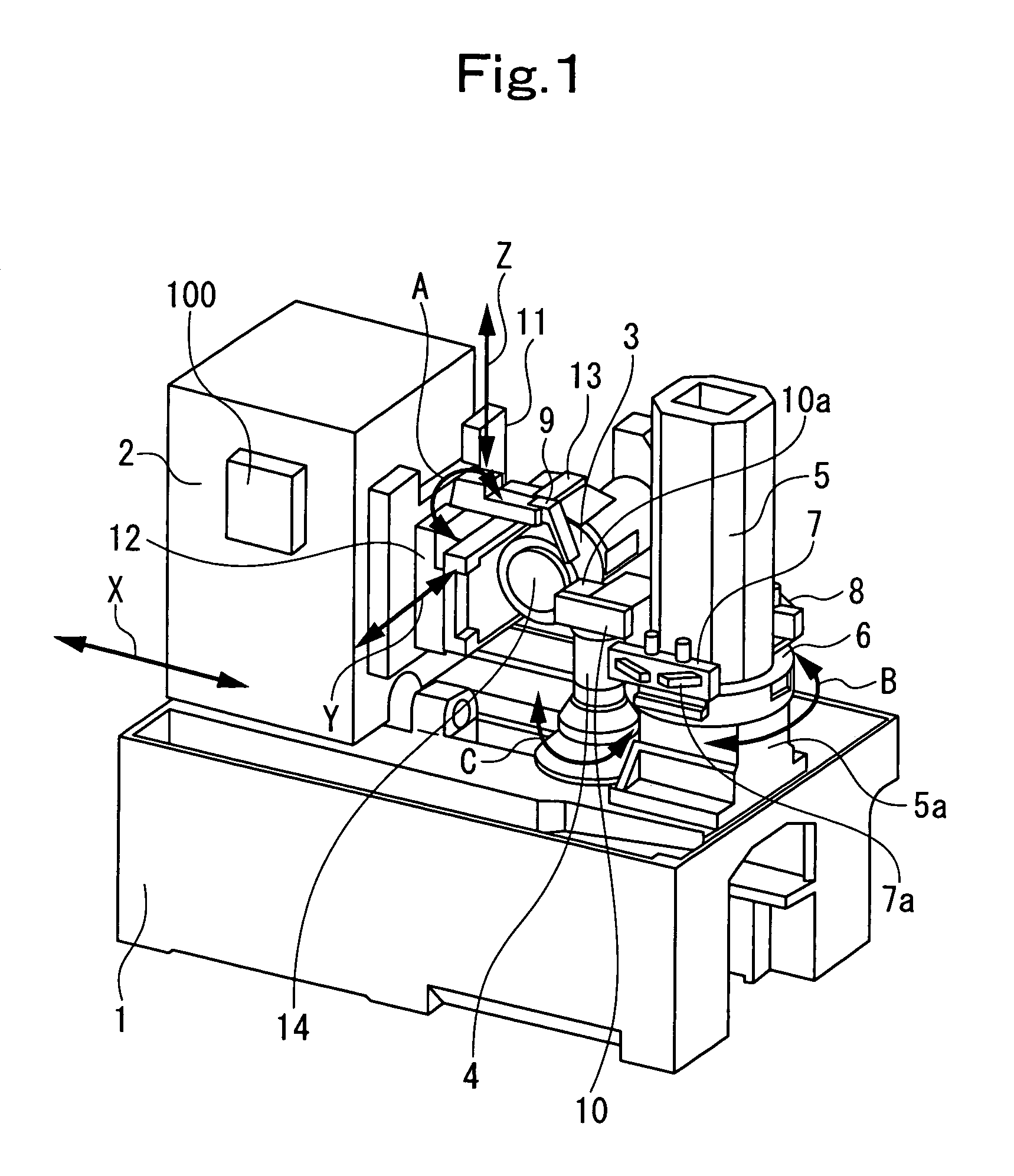

Gear grinding machine, method for dressing threaded grinding wheel and method for grinding work

ActiveUS20070202774A1Easy to retouchGrinding drivesAbrasive surface conditioning devicesGear grindingVertical plane

A gear grinding machine, a method for dressing a threaded grinding wheel, and a method for grinding a work are disclosed. A dressing tool is rotated in a vertical plane, with its position being fixed. The position of a threaded grinding wheel is NC-controlled, whereby the dressing tool is brought into contact with the starting point of the thread of the threaded grinding wheel at a somewhat lower surface of the circumferential surface of the threaded grinding wheel and, in accordance with the rotation of the threaded grinding wheel, the position of contact of the dressing tool with the threaded grinding wheel is moved along the circumferential surface of the threaded grinding wheel.

Owner:MITSUBISHI HEAVY IND MACHINE TOOL CO LTD

Process for machining rail traffic driven gear

The invention provides a process for machining a rail traffic driven gear, which improves a forging process of a blank, so as to establish a good foundation for follow-up machining. According to a hobbing procedure, two gear blanks are hobbed simultaneously, and the large end surfaces are directly pressed by using a clamp. Therefore, the strength is good; the grinding transformation is effectively avoided; the hobbing efficiency is improved; the grinding rigidity is enhanced; and the grinding precision is ensured.

Owner:重庆方禾机电设备有限公司

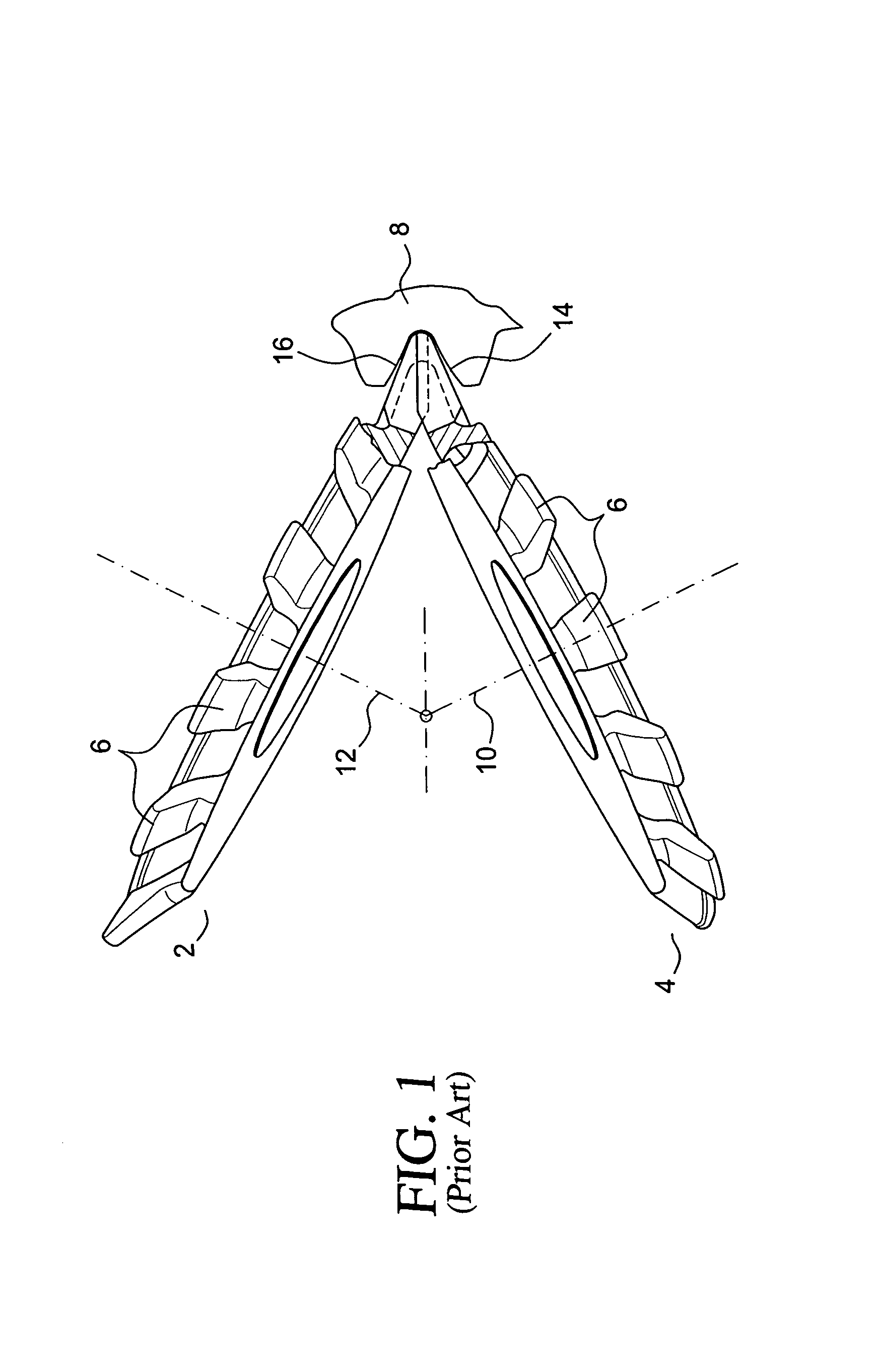

Manufacturing straight bevel gears

Owner:GLEASON WORKS

Gear grinding machine

To correct the tooth profile error of a ground gear, the wheel angle of a threaded grinding wheel is modified by dressing the threaded grinding wheel by a dressing device. To correct the helix form deviation of a ground gear, namely, to modify the helix angle of the gear, synchronization between the moving motion in the Z-direction of the threaded grinding wheel and the rotary motion of a table for installation of the gear is adjusted. When the helix form deviation is corrected by adjustment of the synchronization, a tooth profile change inevitably occurs. In consideration of the tooth profile change, correction of the tooth profile error by dressing is made.

Owner:MITSUBISHI HEAVY IND MACHINE TOOL CO LTD

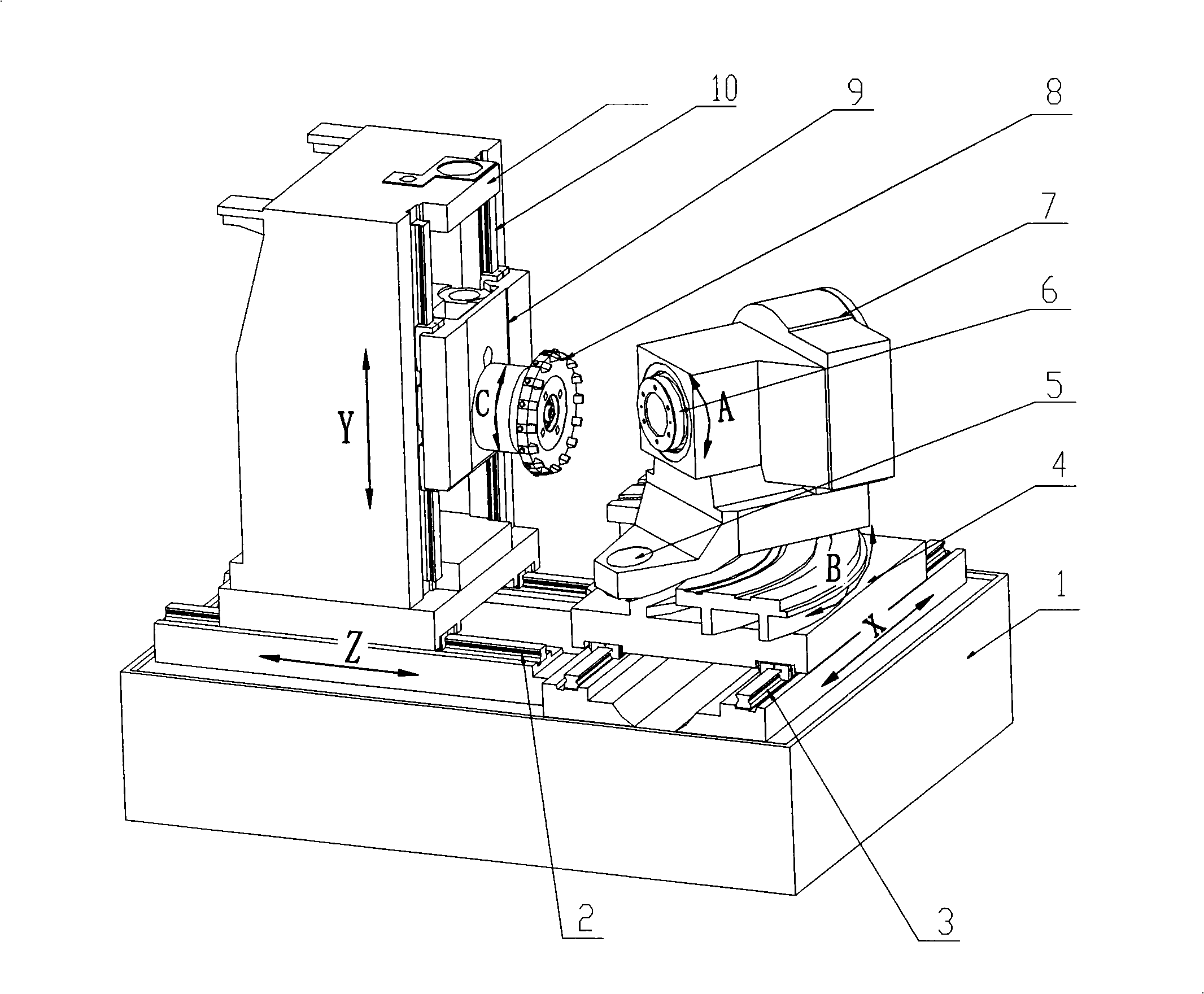

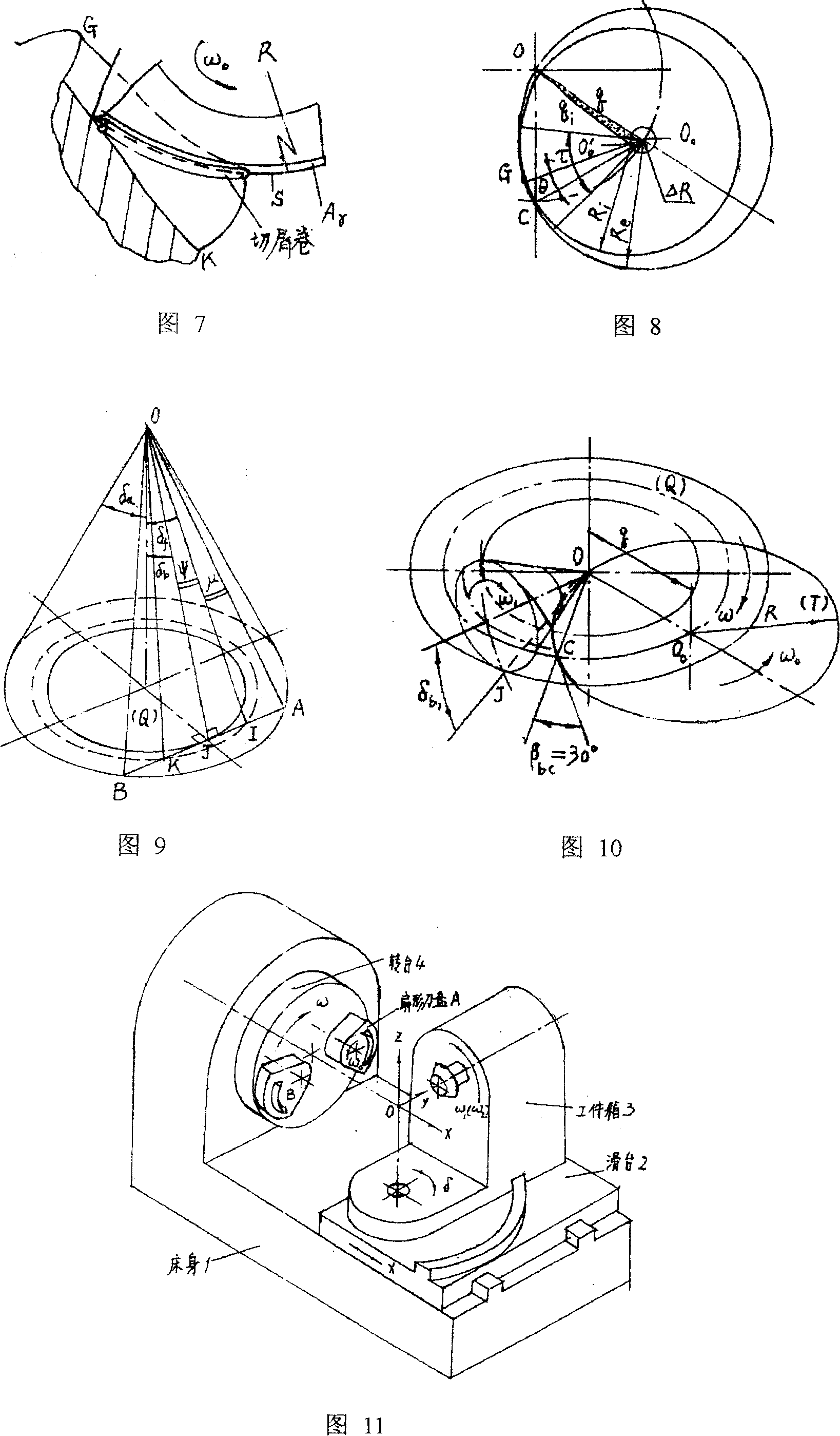

Four-shaft four-linkage numerical control spiral bevel gear milling machine arrangement

InactiveCN101342617AEasy loading and unloadingGood effectLarge fixed membersGear-cutting machinesNumerical controlReciprocating motion

The invention relates to a four-axis and four-linkage numerical control generating machine of arc bevel gear and belongs to the field of the gear generating machine technology. The invention comprises a machine body, a workpiece box and a cutting tool box. The machine body is fixedly provided with a straight guide rail of Z-axis and a straight guide rail of X-axis. The straight guide rail of X-axis drives a saddle to do the straight line motion via a servo motor. The saddle is provided with a workpiece box and rotates around a rotary shaft to do the rotary motion of B-axis for adjusting the required cone angle of gear root. The workpiece box is provided with a workpiece spindle which is driven by the servo motor to do the rotary motion of A-axis. The straight guide rail of Z-axis drives a vertical column to do the straight motion of Z-axis via the servo motor. The vertical column is fixedly provided with a straight guide rail of Y-axis which drives the cutting tool box to do the straight and reciprocating motion in the vertical direction of Y-axis via the servo motor. The main motor on the cutting tool box drives the cutting tool disk which is provided with the cutting tool to rotate for doing the rotary motion of C-axis of gear cutting. The four-axis and four-linkage numerical control generating machine of arc bevel gear has the advantages of simple structure, humanized layout, convenient loading and unloading of the workpiece, good dynamic rigidity and dynamic balancing, and small occupied area.

Owner:天津精诚机床股份有限公司

Machining Method for Hard-Fine Machining of Noise-Optimized Gears on a Gear-Cutting Machine

ActiveUS20140256223A1Improve uniformityAvoid and at least minimize vibration excitationAutomatic control devicesGrinding feed controlRotational errorEngineering

The present invention relates to a method for hard-fine machining of tooth flanks with corrections and / or modifications on a gear-cutting machine, wherein respective toothed wheel pairings which mesh with one another within a transmission or a test device are machined while taking account of the respective mating flanks, and wherein the tooth flanks of the relevant workpieces are provided with periodic waviness corrections or waviness modifications. In accordance with the invention, the rotational error extent is determined by means of rotational distance error measurement of the toothed wheel pairs in a gear measuring device and / or transmission. This measurement result serves as an input value for defining the amplitude, frequency and phase position for the periodic flank waviness corrections on the tooth flanks of the toothed wheel pairings for production in the gear-cutting machine.

Owner:LIEBHERR VERZAHNTECHNIK GMBH

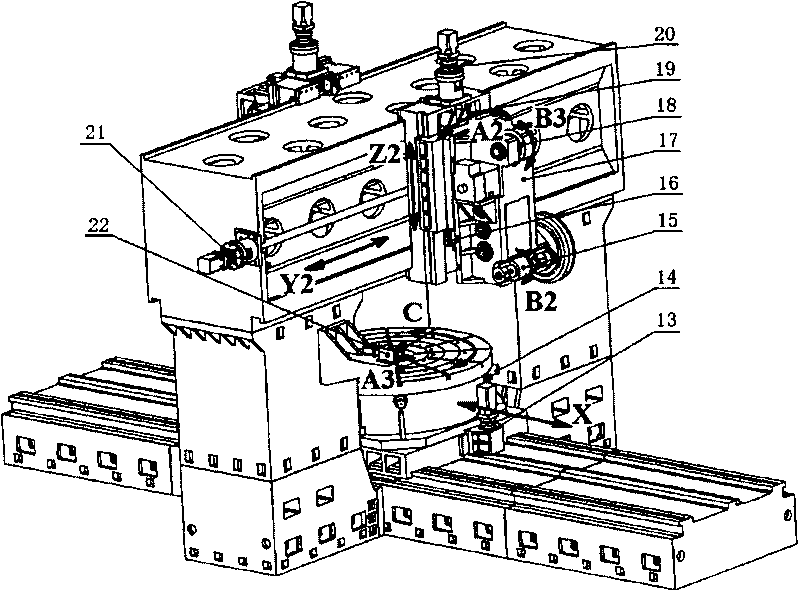

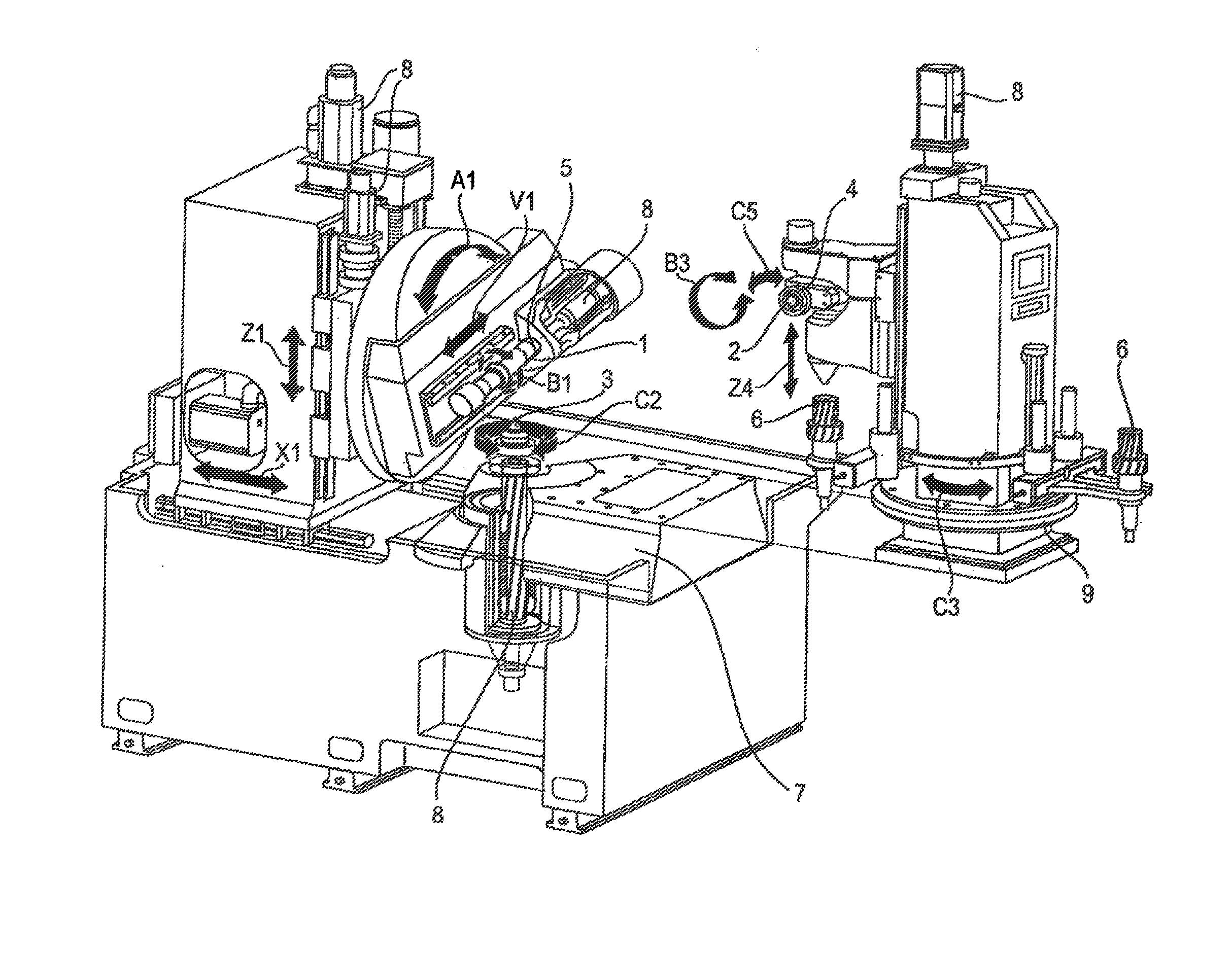

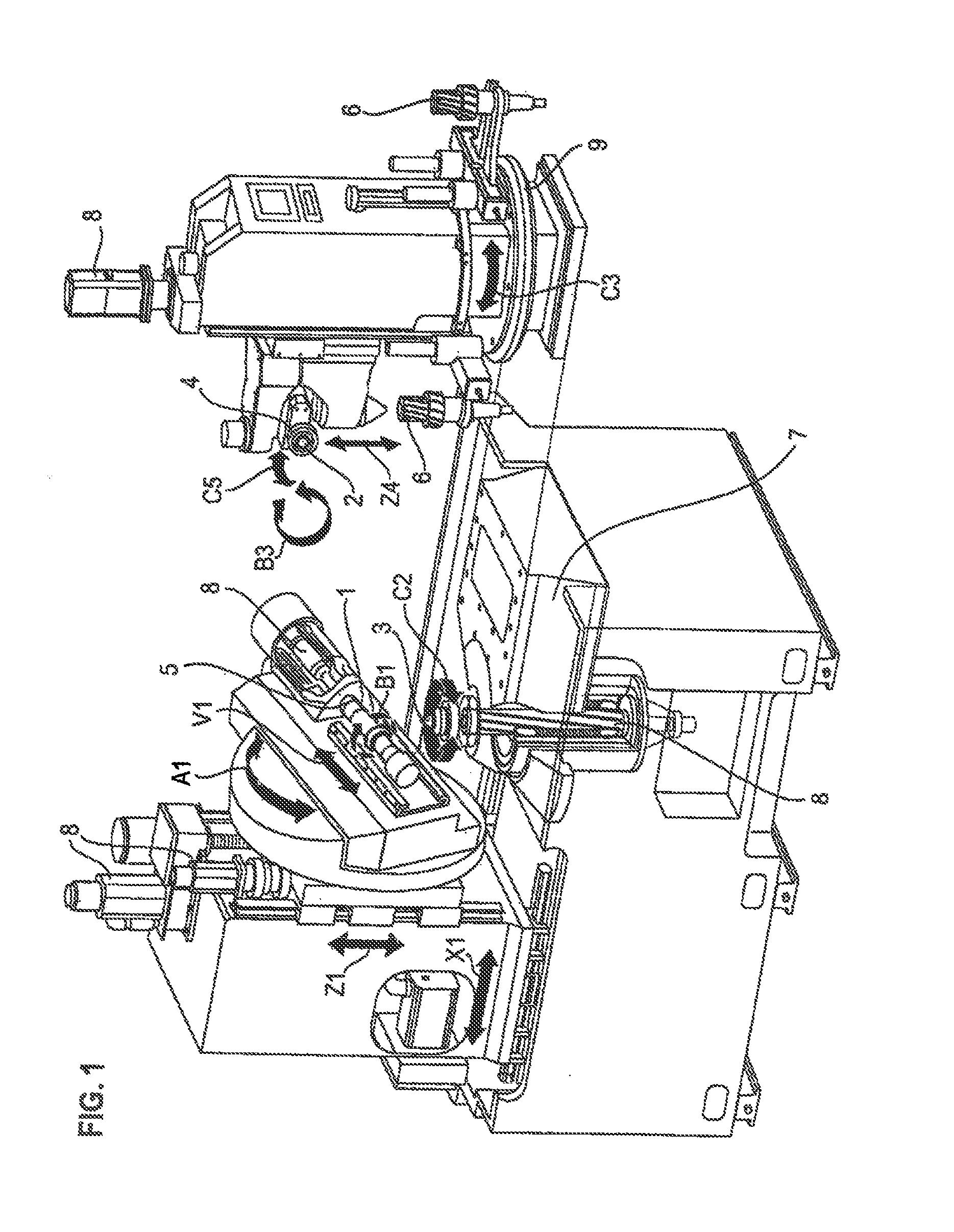

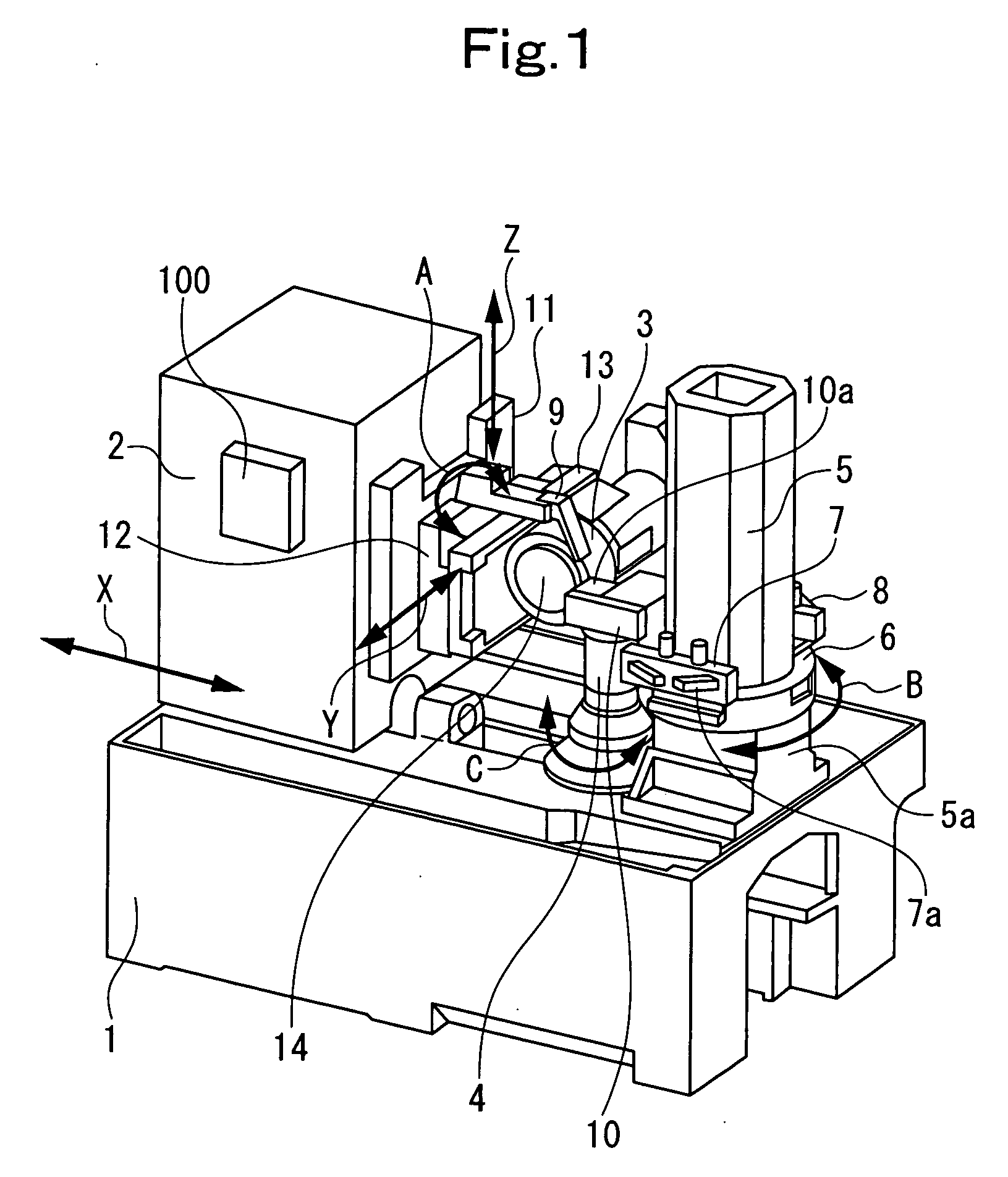

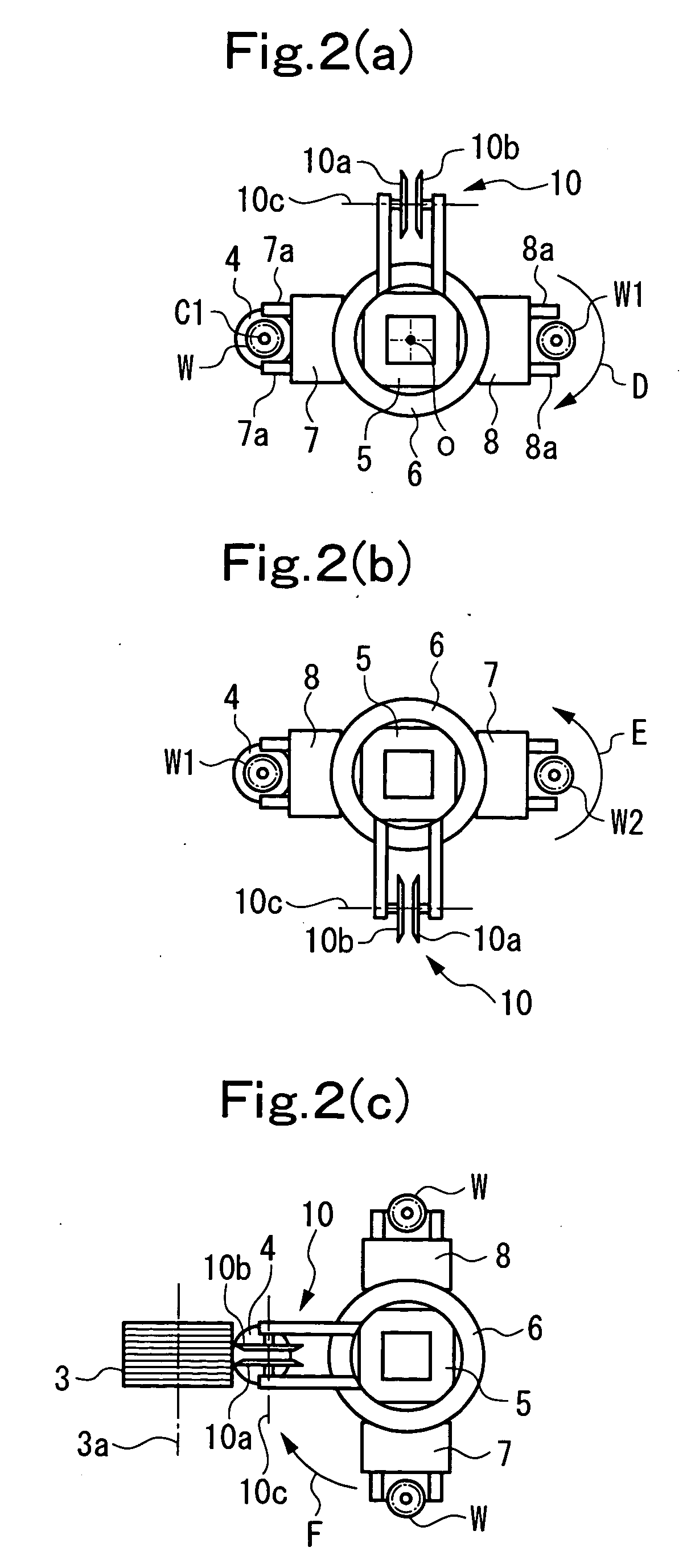

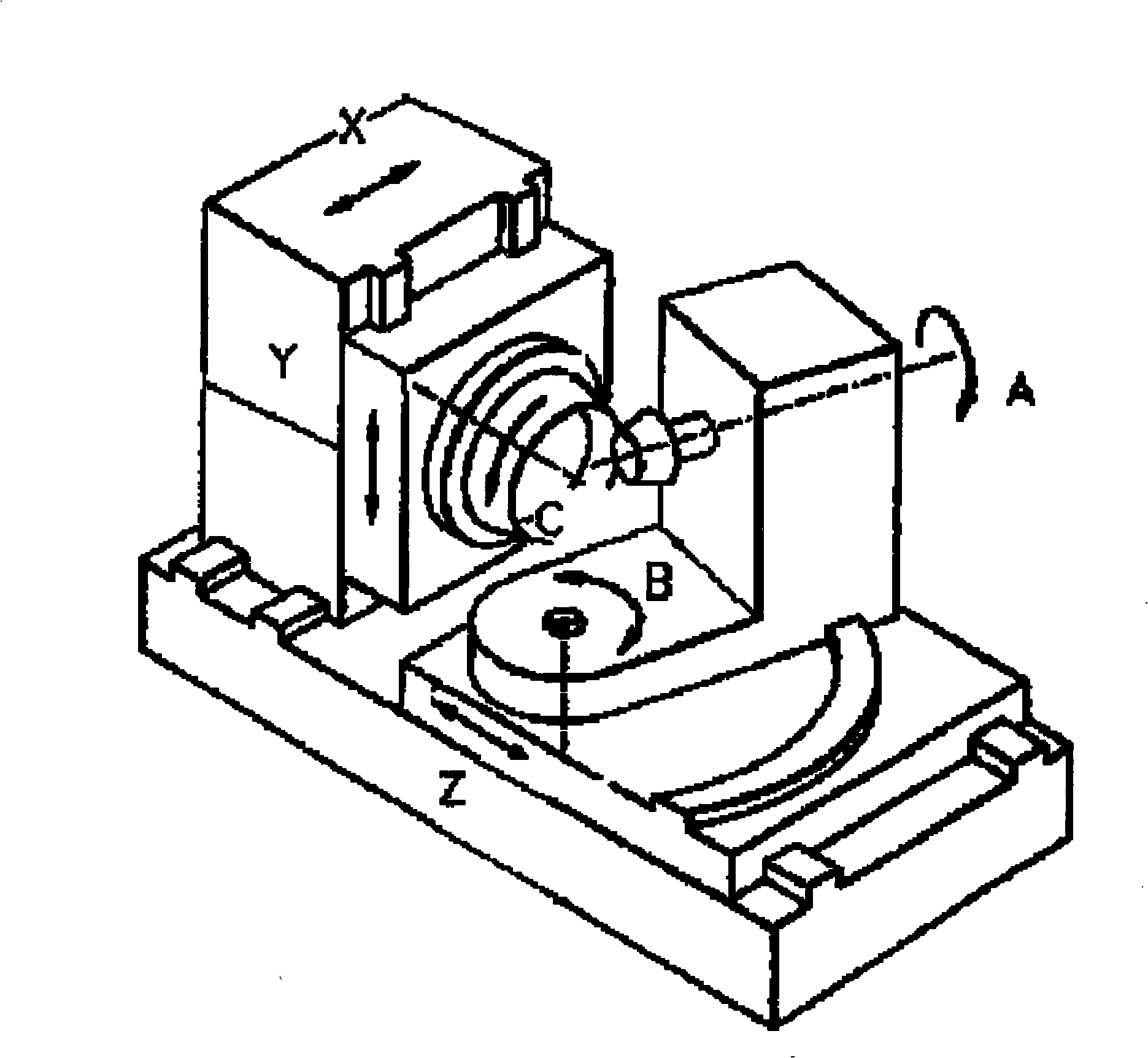

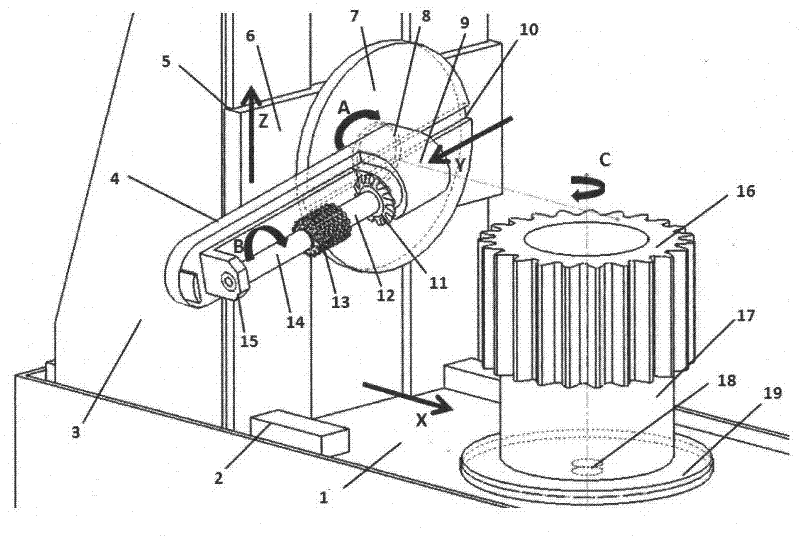

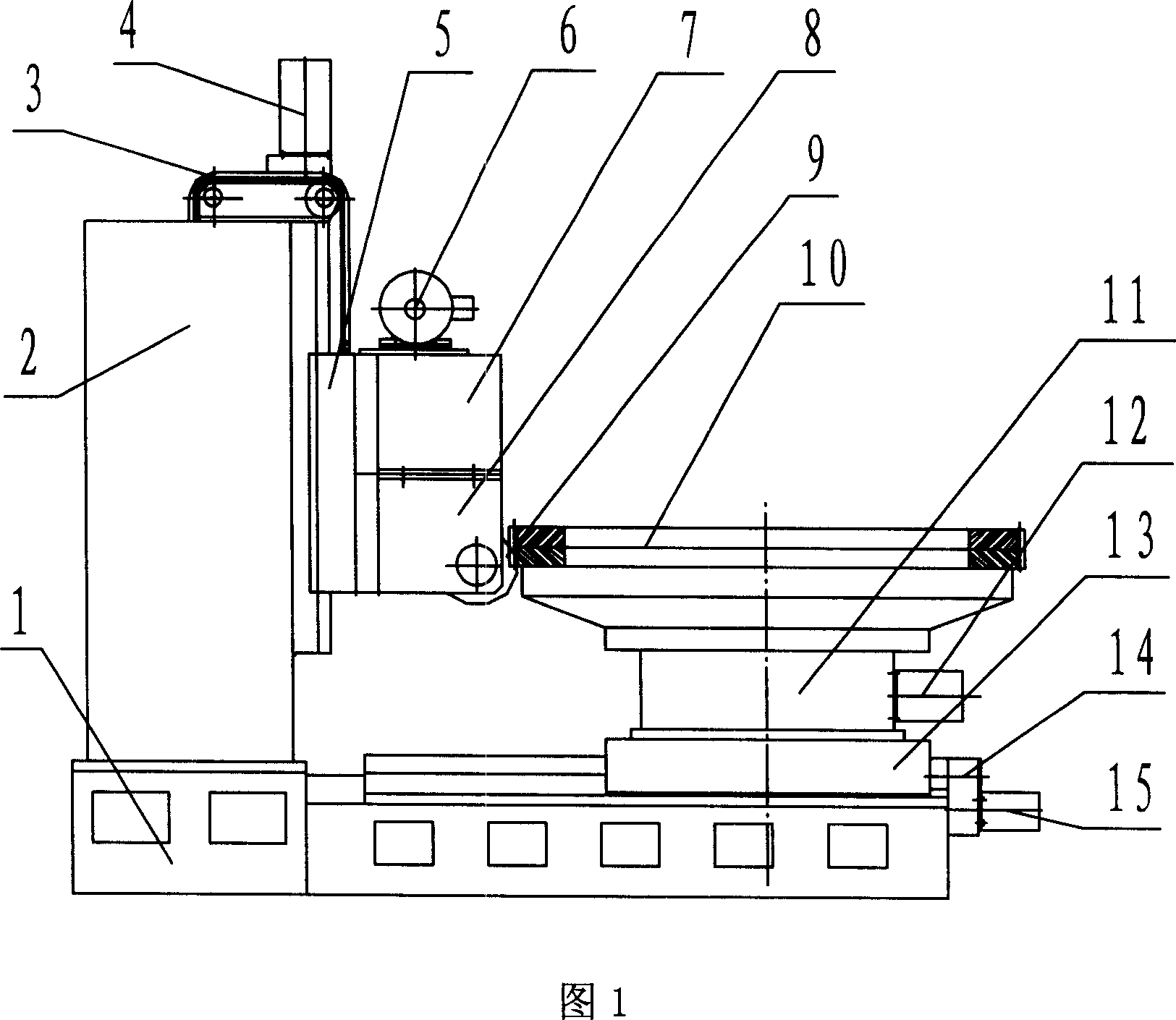

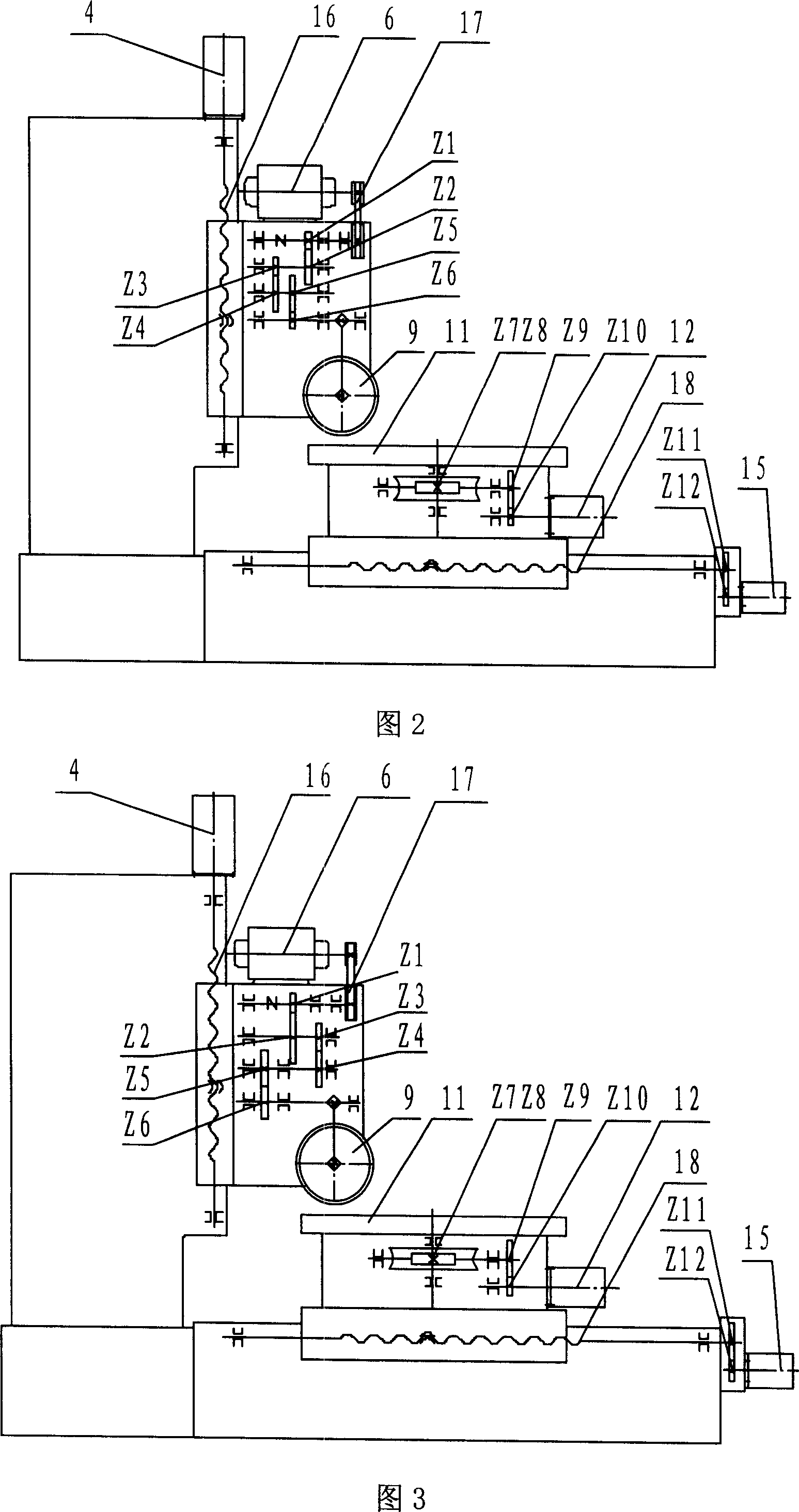

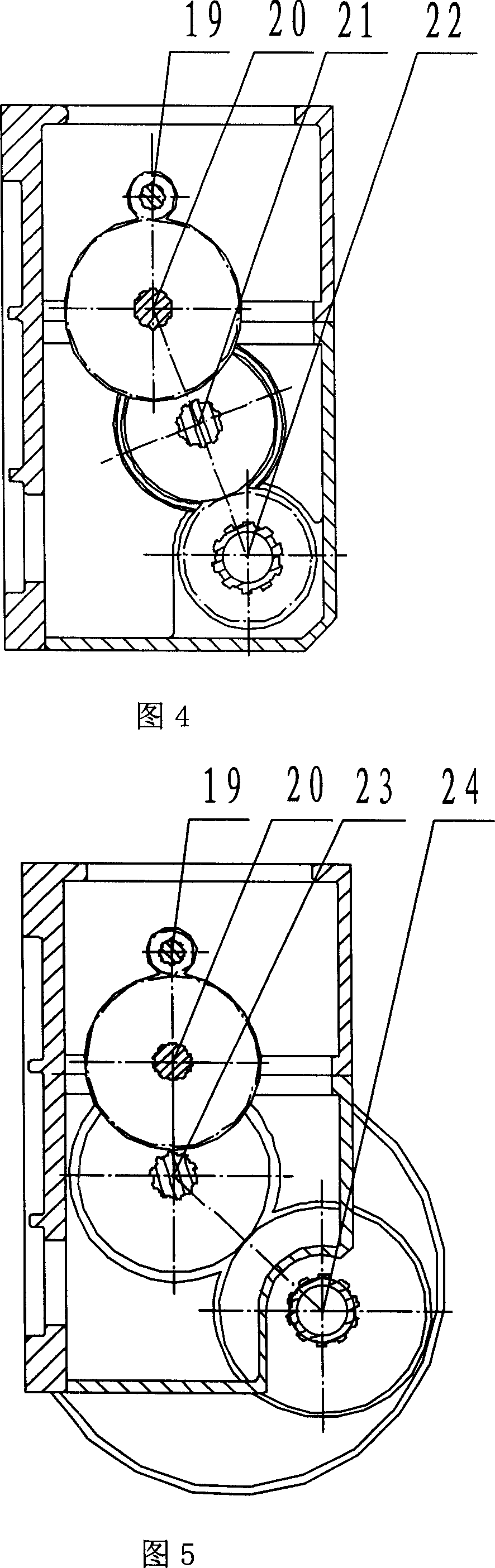

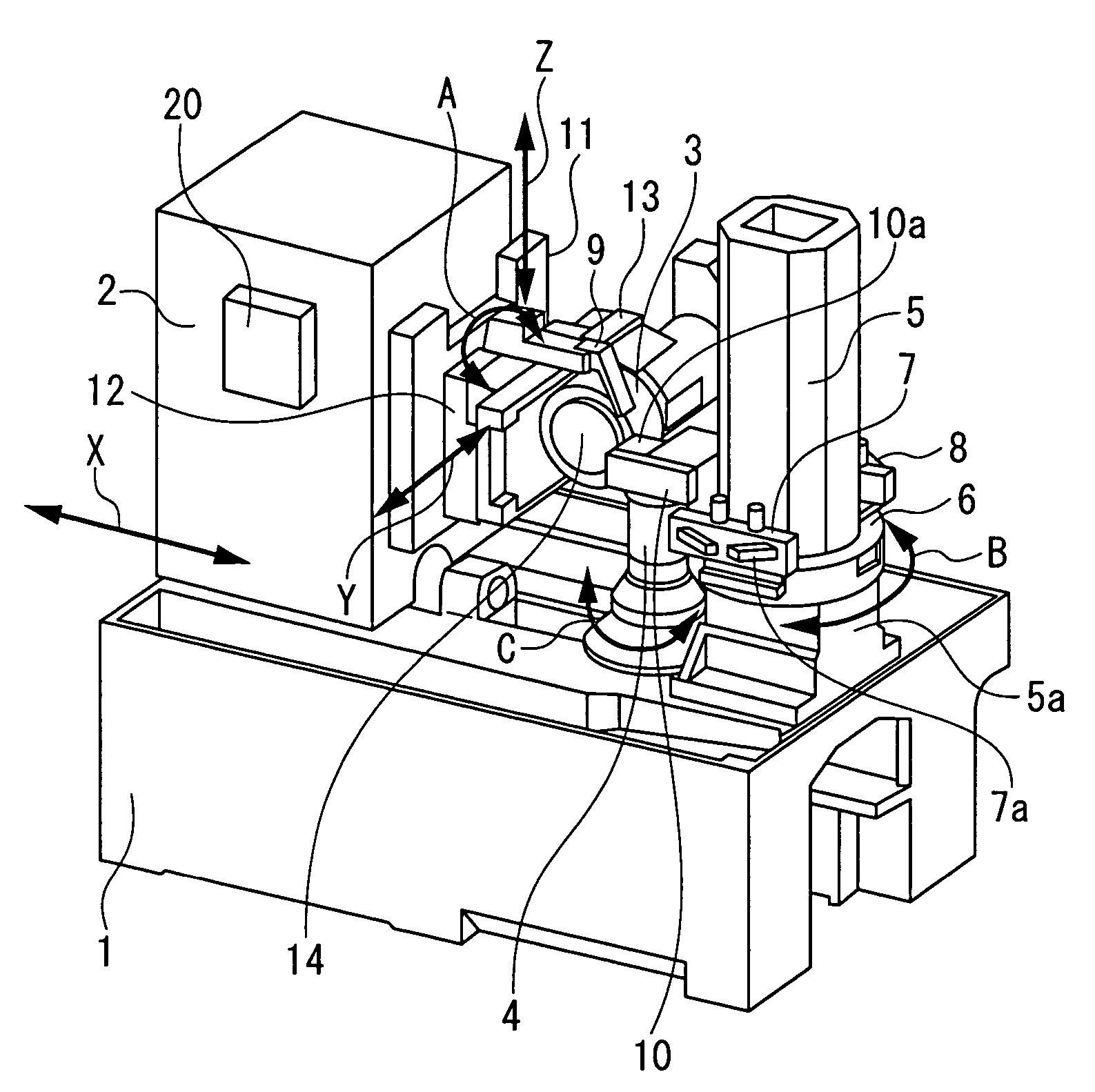

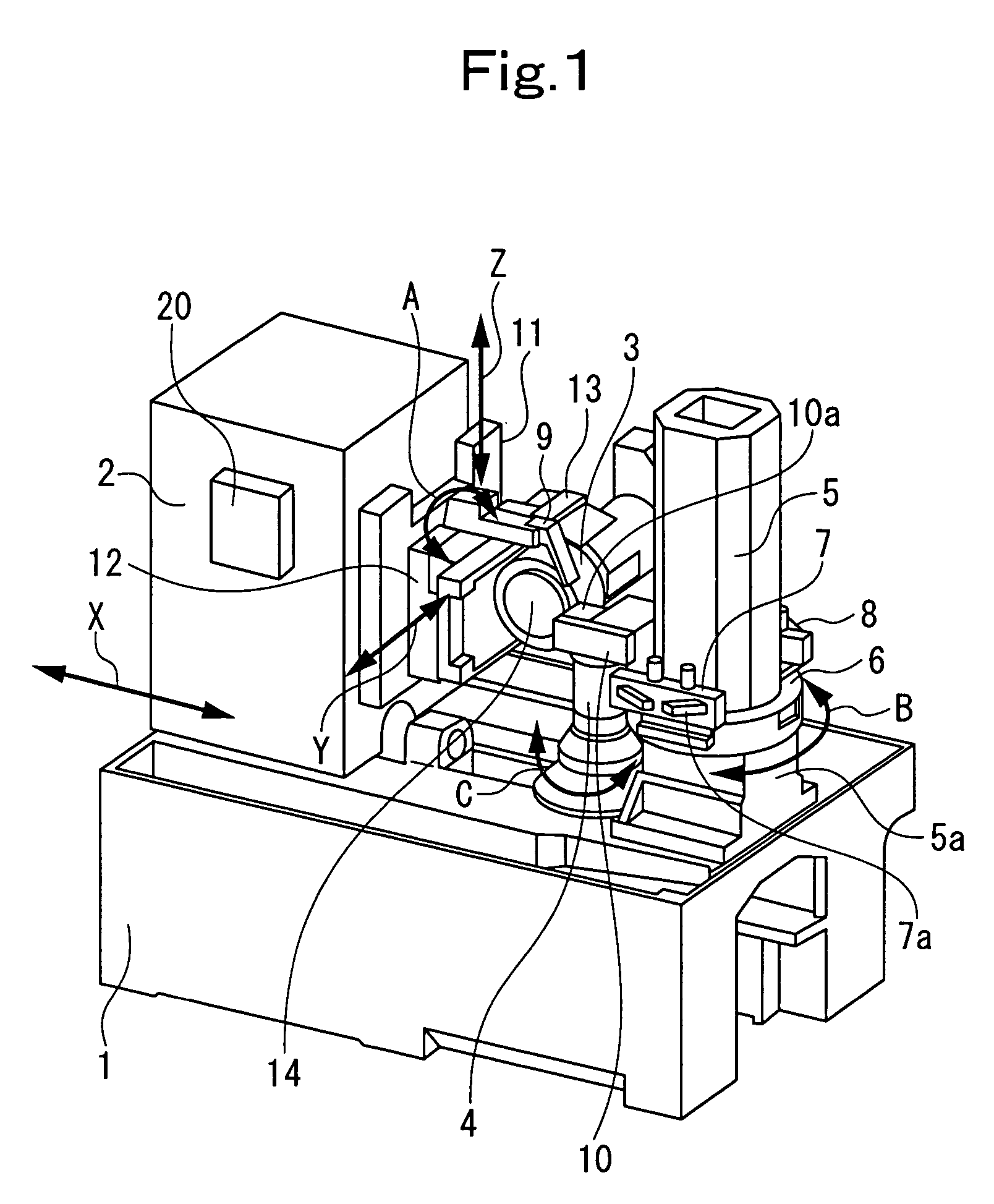

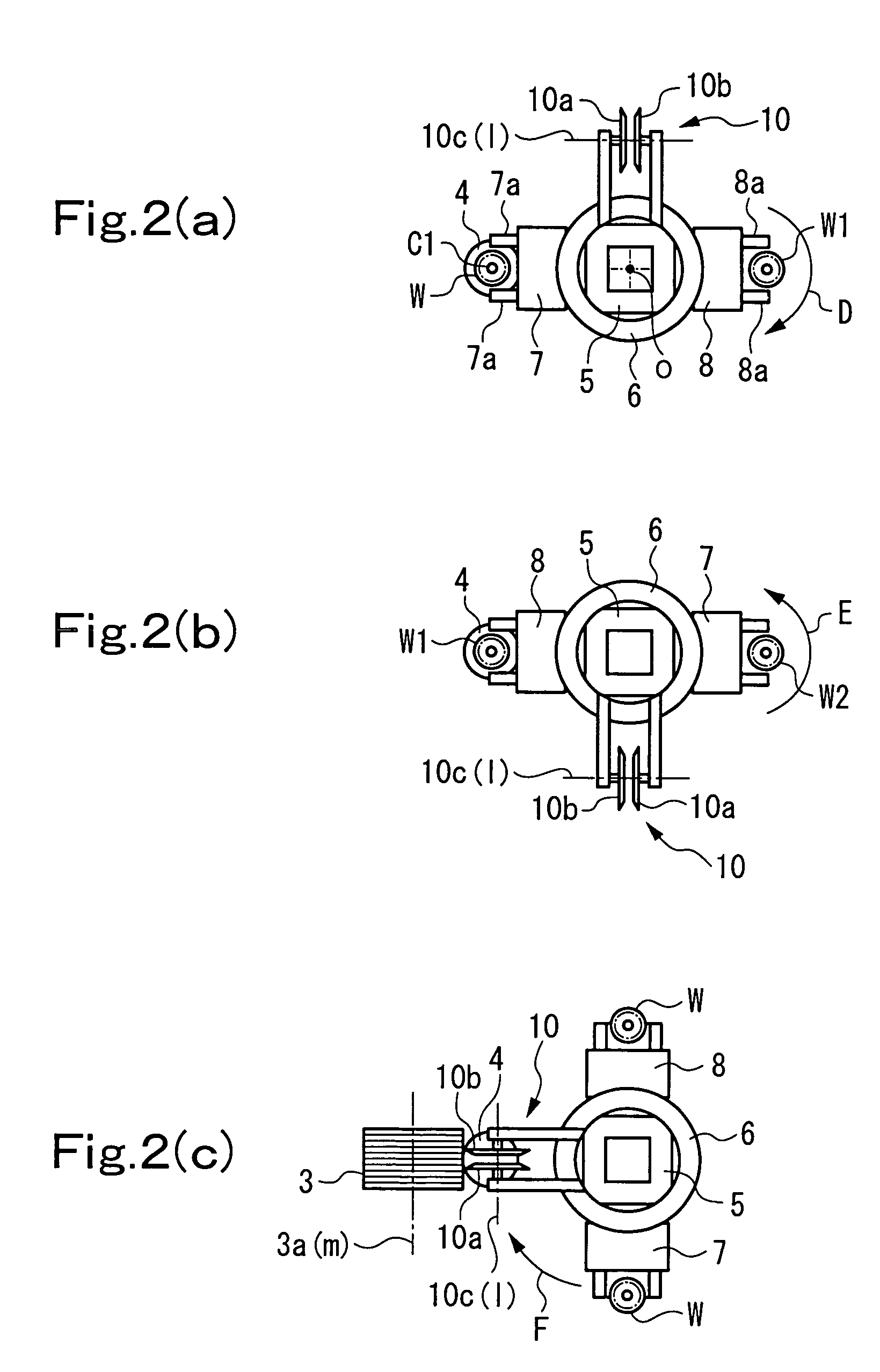

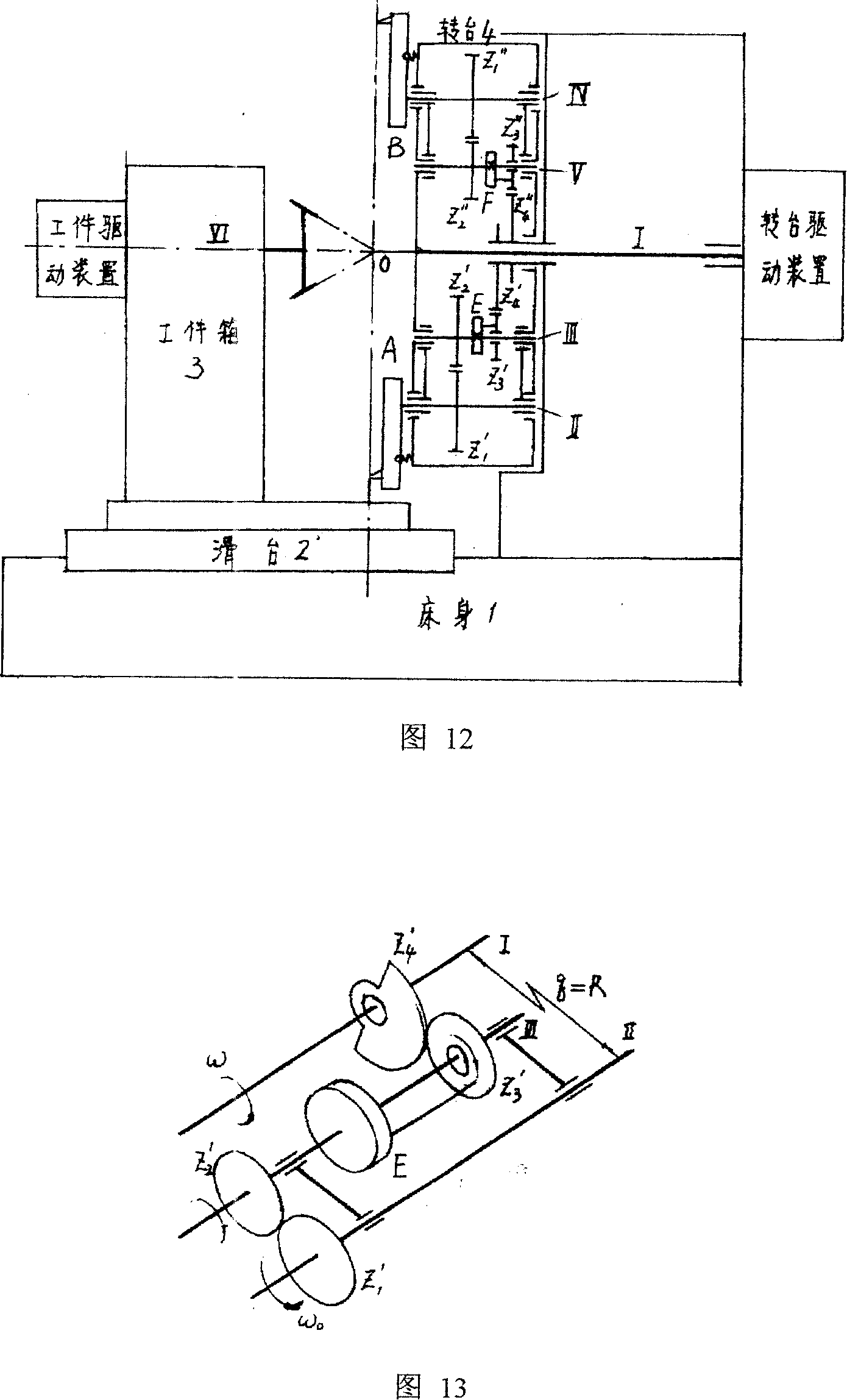

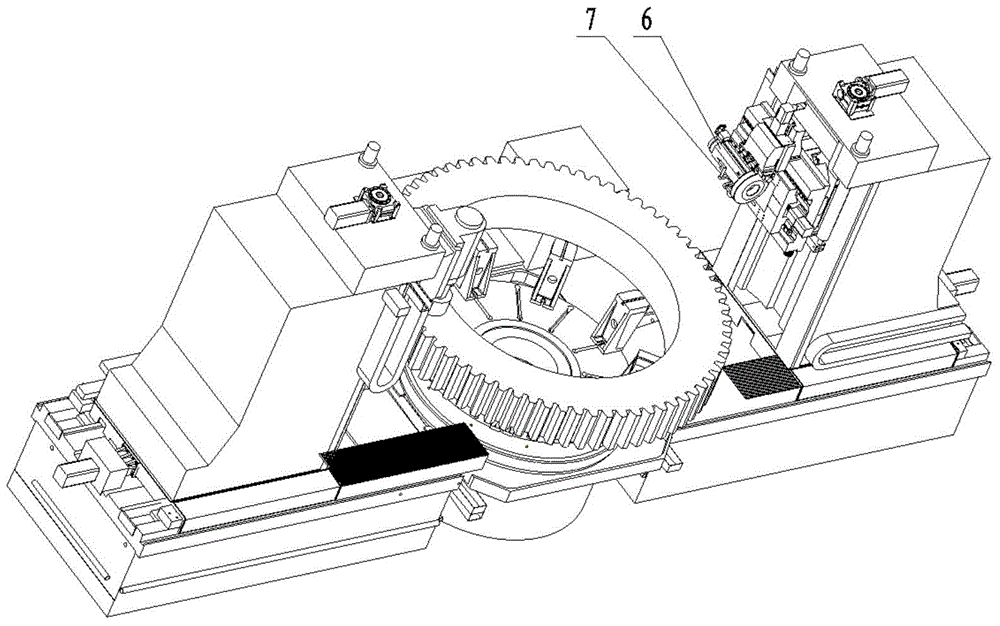

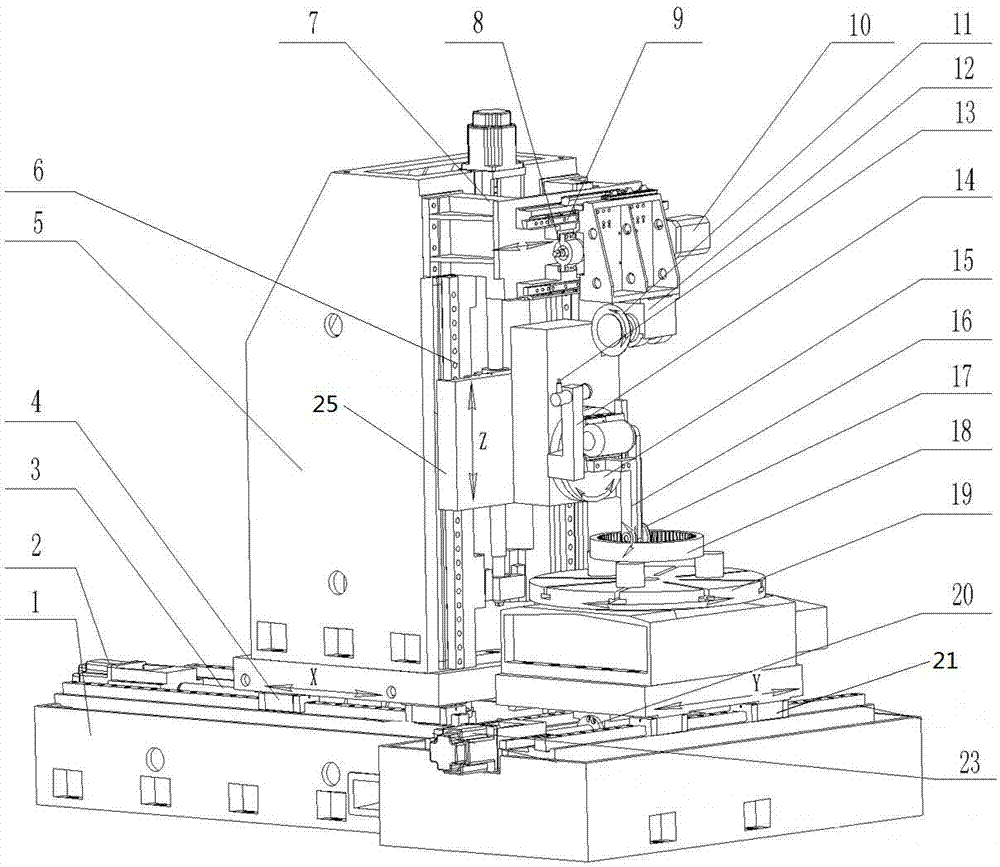

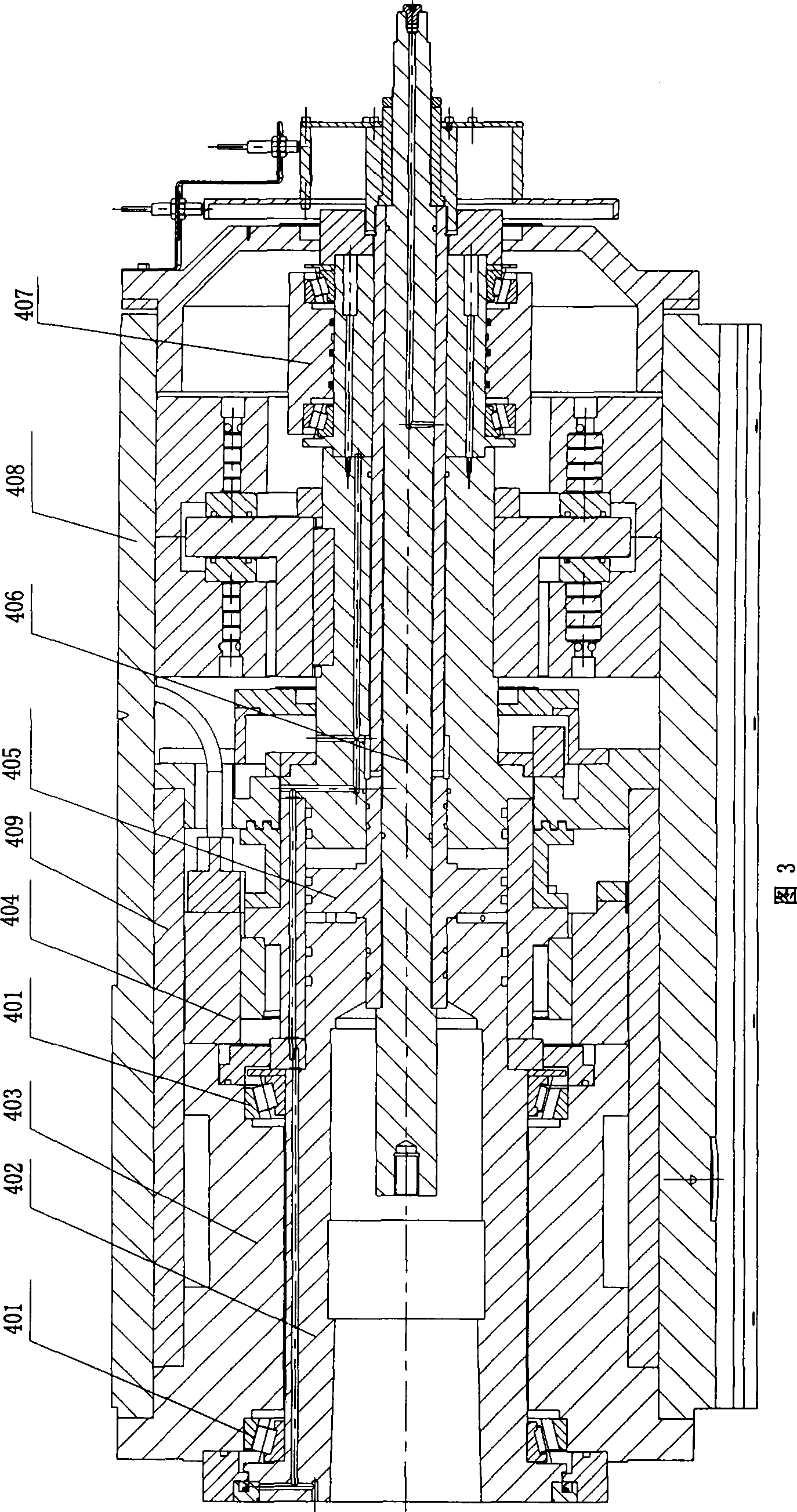

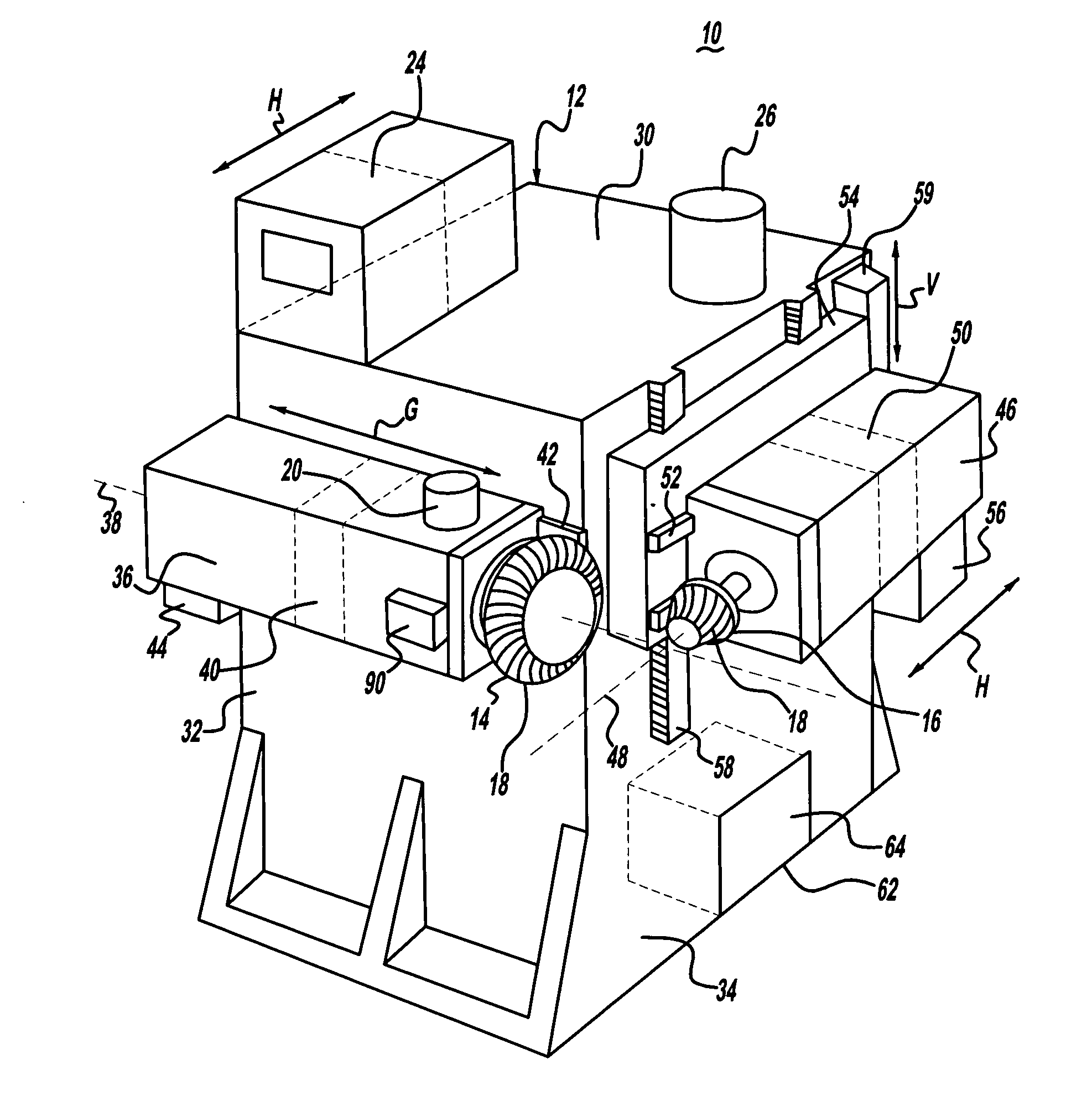

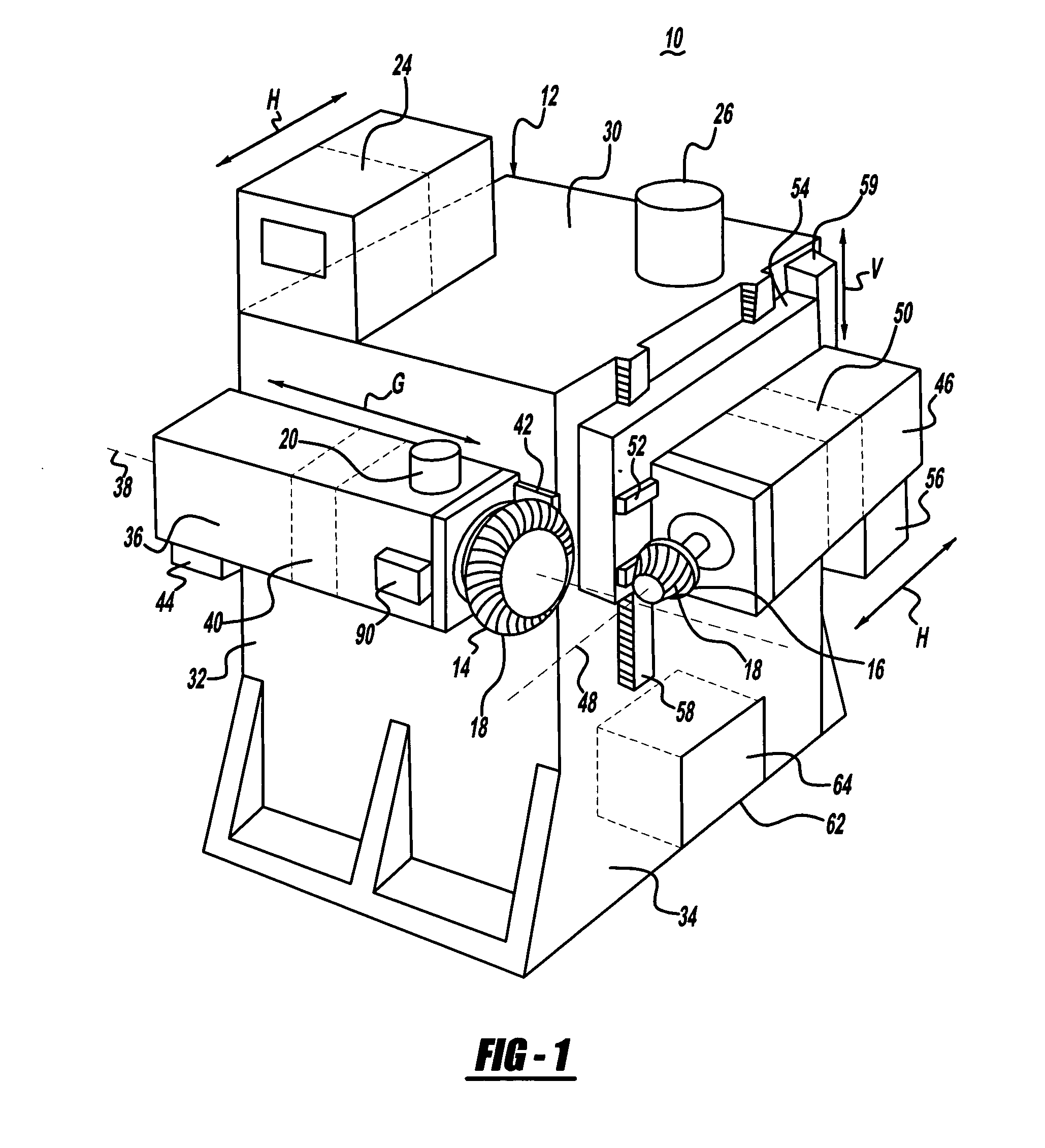

Numerical-control combined gear milling and hobbing machine for machining large-modulus gear and application thereof

ActiveCN102248226AGuaranteed accuracyLow costFeeding apparatusDriving apparatusNumerical controlHobbing

The invention relates to a numerical-control combined gear milling and hobbing machine for machining a large-modulus gear and application thereof. The machine comprises a numerical control computer and is characterized in that a disc milling cutter and a hobbing cutter are fixedly arranged on a cutter bar, and a cutter bar gasket group is arranged between the hobbing cutter and the disc milling cutter; one face of an angular sliding plate is abutted with a cutter holder through a Y-shaped guide track and a guide groove, the other face of the angular sliding plate is supported on a vertical sliding plate through an A-direction bearing and a bearing, and the other face of the vertical sliding plate is abutted with an upright column through a Z-direction guide track and a guide groove; the upright column is abutted with a bed body through a guide track which is arranged horizontally in an X direction and a guide groove; a gear blank workbench is supported on a bottom surface through a C-direction shaft and a bearing which are engaged with each other; and clamps are arranged on the gear blank workbench. Under the control of the numerical control computer, the machine can perform the milling operation and hobbing operation on a gear with the modulus more than or equal to 15 mm in one step, so as to greatly increase the work efficiency.

Owner:NANJING HIGH SPEED GEAR MFG

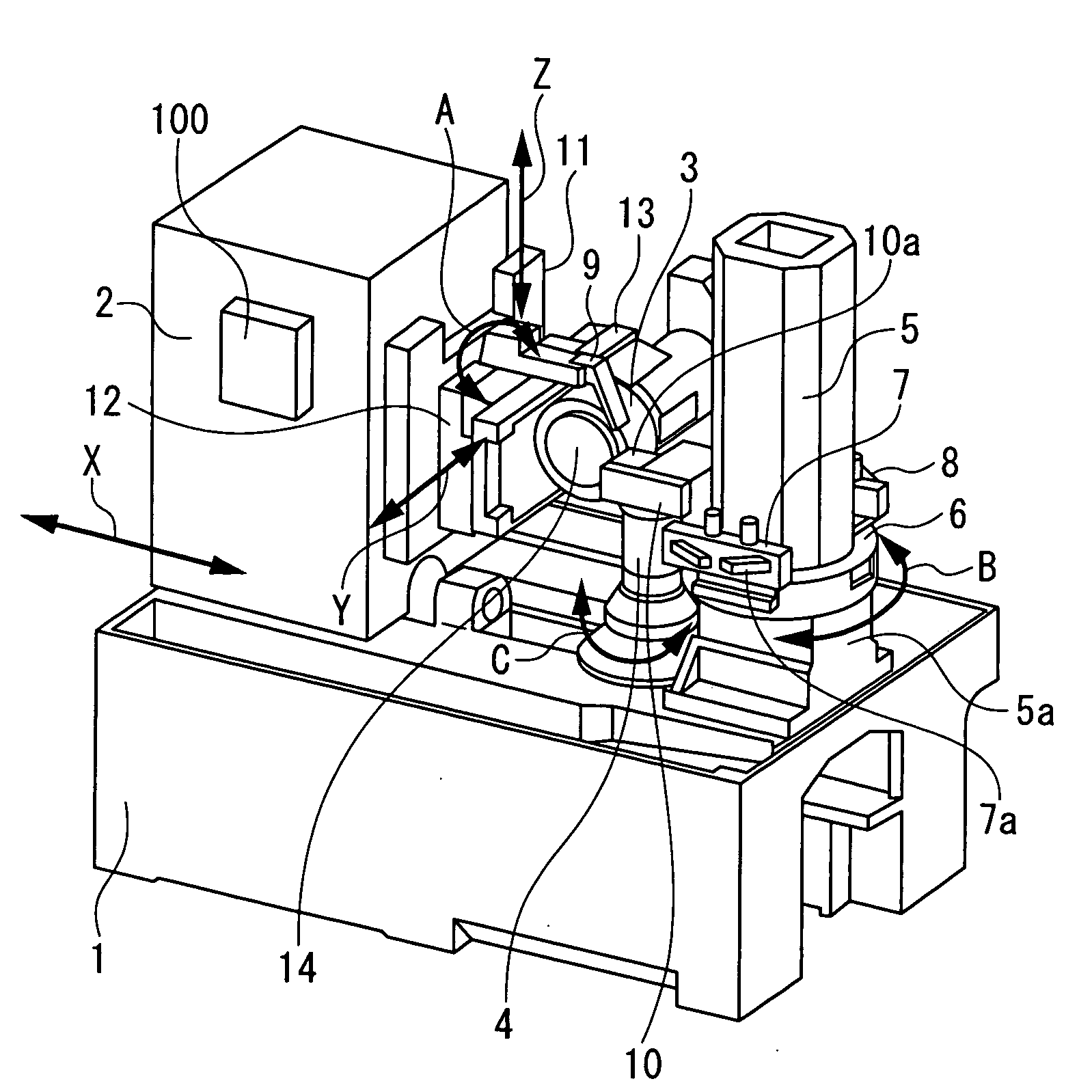

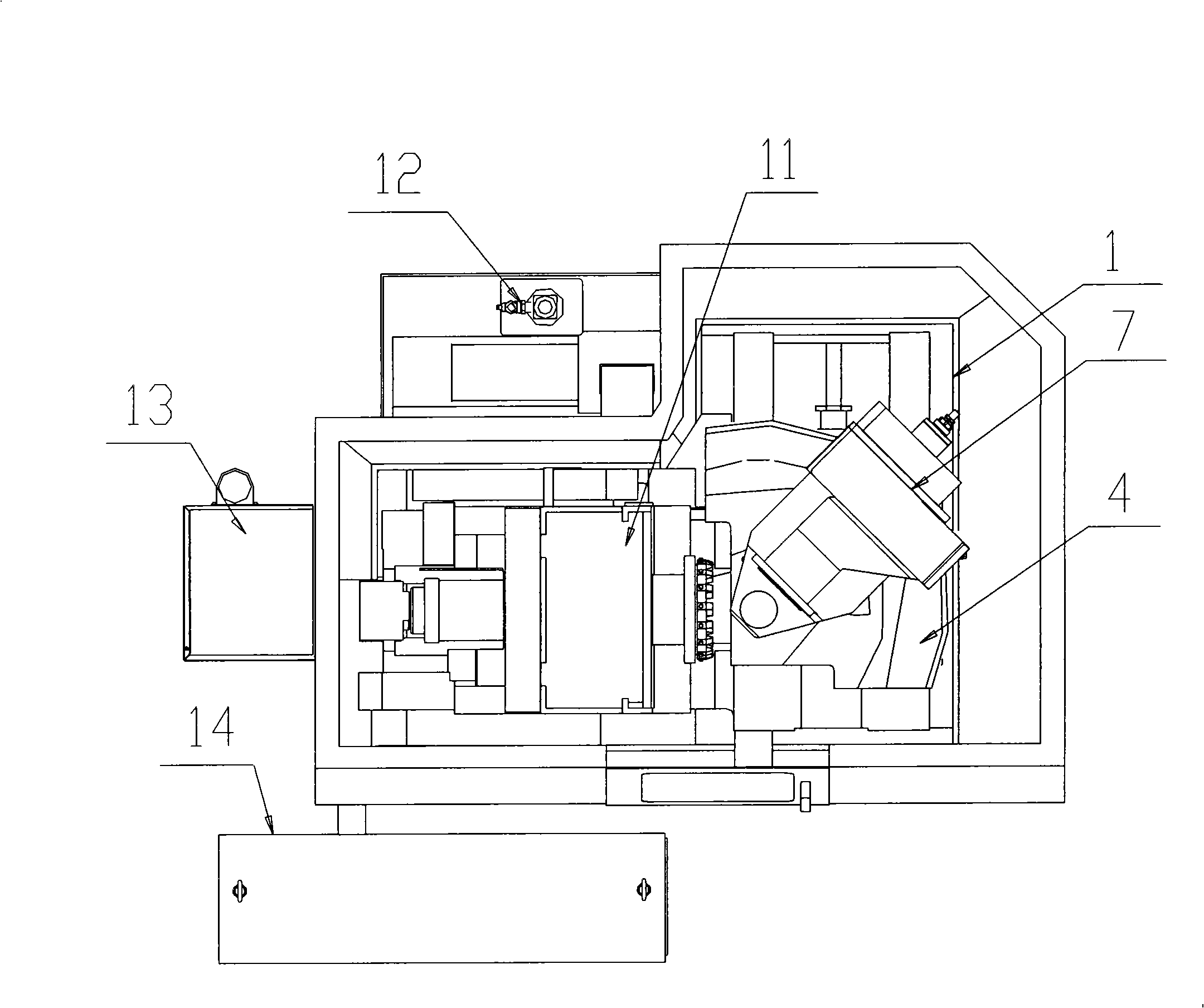

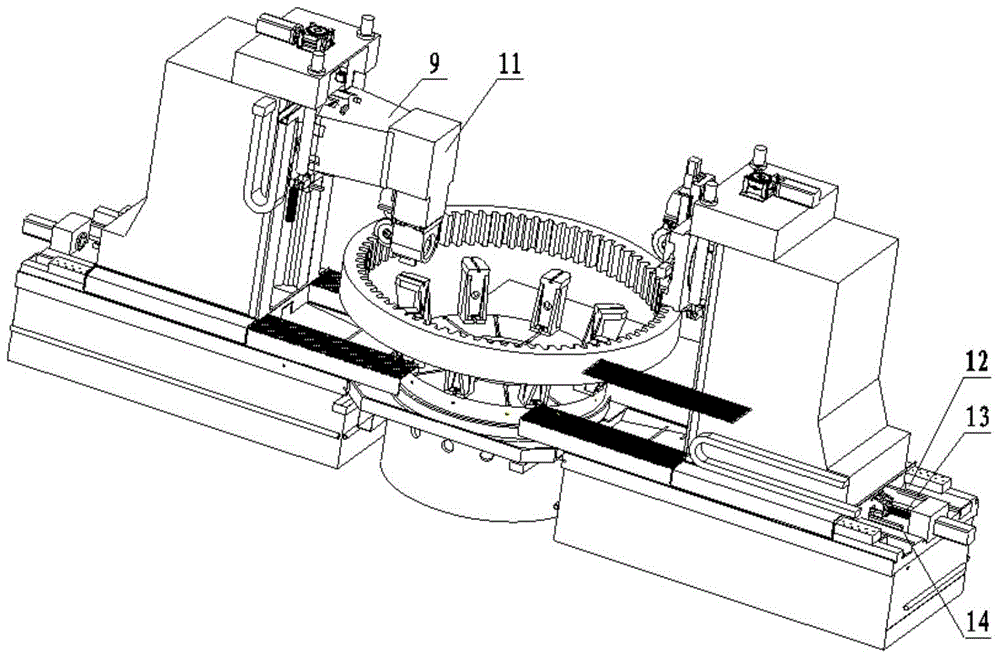

Polar coordinates numerical control highly effective milling and gear hobbing composition machine tool

ActiveCN101011762AReduce manufacturing costImprove processing efficiencyDriving apparatusPositioning apparatusNumerical controlHobbing

A radial coordinates digital control highly effective milling machine, hobbing composite machine, can improve machining efficiency 3-5 times, saving 50% budget, reducing land occupation 30%, with it composed of body, vertical post, horizontal feeding carriage, rotary working bench, highly effective milling and hobbing main shaft box module, with the vertical post on the body, rotary working bench fixed on the horizontal feeding carriage, highly effective milling and hobbing main shaft box module vertical to the feeding carriage. Through digital control interpolation and electronic gear box software, it realizes digital control machining.

Owner:NANJING GONGDA CNC TECH

Gear grinding machine

A gear grinding machine comprises: a moving mechanism rotatably mounted with a threaded grinding wheel, and arranged to move the threaded grinding wheel along directions of X, Z, and Y, and to turn the threaded grinding wheel in a Y-Z plane; an NC device for controlling the position of the threaded grinding wheel; and a rotary dressing device having a dressing tool which contacts the flanks of the threads of the threaded grinding wheel, while rotationally driven, to perform dressing. The NC device numerically controls the moving mechanism so as to adjust the positions in the directions of X and Z, and the turning position in the Y-Z plane of the threaded grinding wheel, while keeping contact of the dressing tool with the flanks of the threads of the threaded grinding wheel, in order to modify the wheel pressure angle of the threaded grinding wheel.

Owner:MITSUBISHI HEAVY IND MACHINE TOOL CO LTD

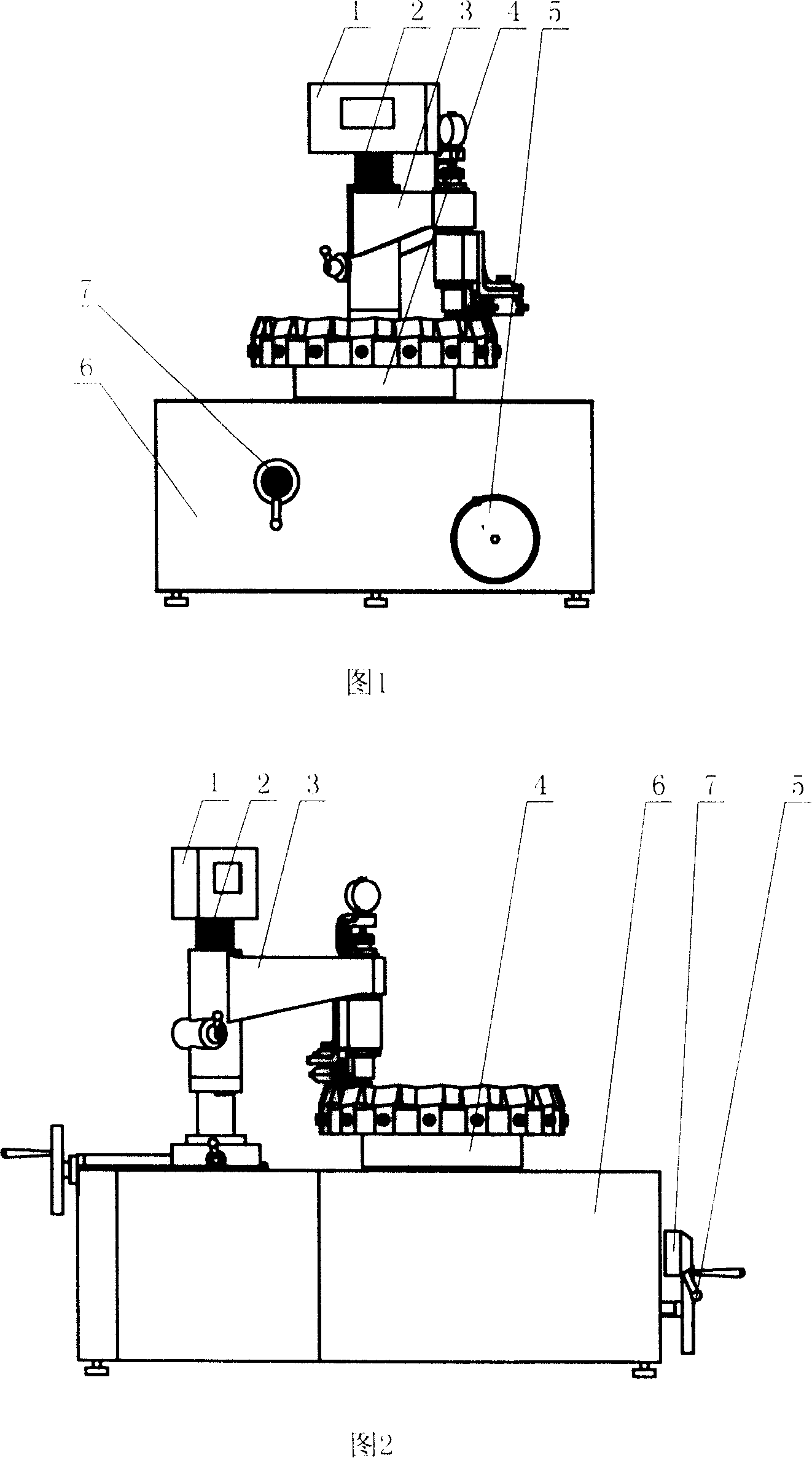

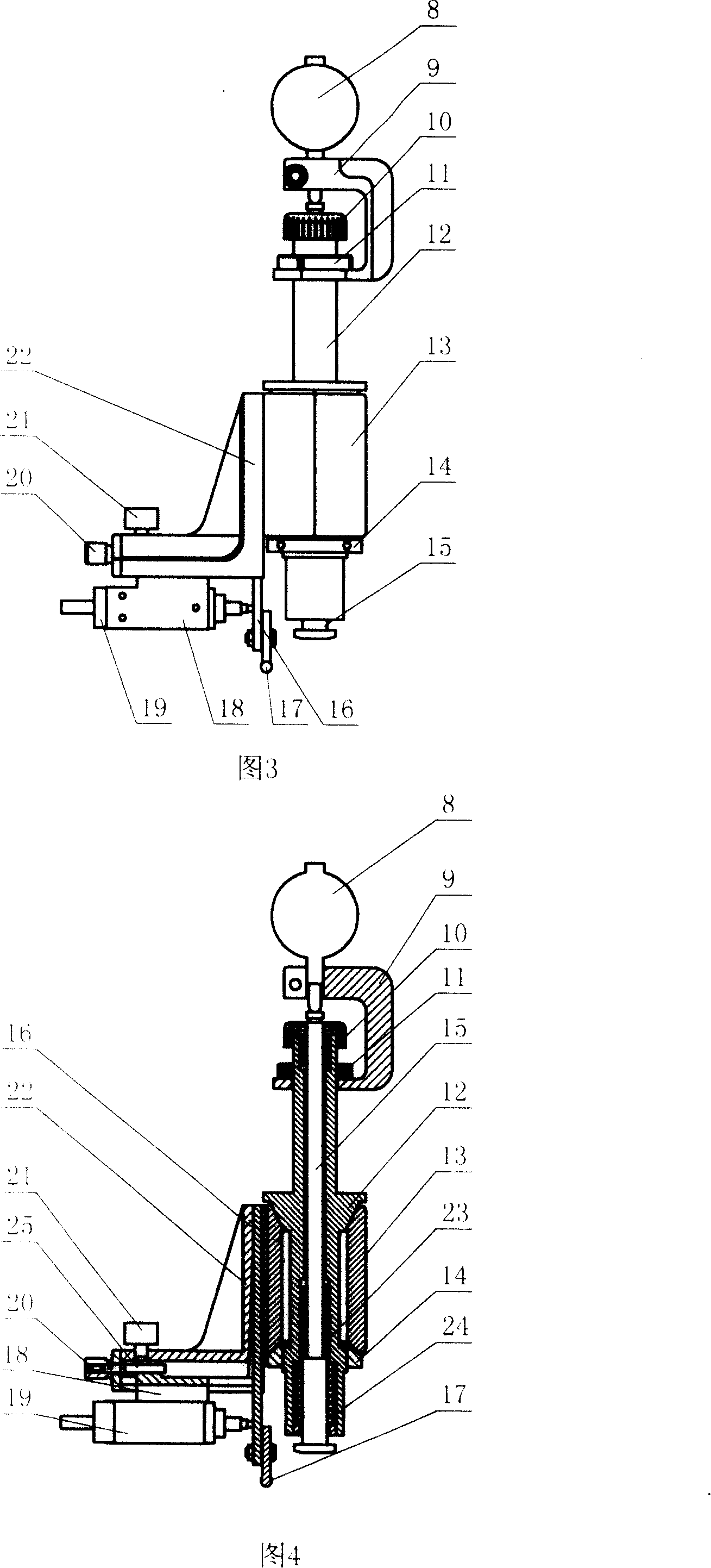

Intelligent spiral bevel gear assembled milling cutter disc measuring and regulating instrument

InactiveCN101147990ASignificant advantagesSignificant beneficial effectAutomatic control devicesMeasurement/indication equipmentsGear wheelMilling cutter

The present invention relates to one kind of intelligent measuring and regulating instrument for assembled milling cutter machining spiral bevel gear. Technologically, the intelligent measuring and regulating instrument includes one height measuring head with one digital dial gauge mounted in the end of the horizontal oscillation arm, and one radial measuring head with one digital dial gauge coaxially with the height measuring head. The measured data is stored, analyzed and processed in a computer and the processed result is shown in a display screen. The present invention can raise the milling cutter measuring and regulating precision and efficiency, and has simple structure and low manufacture cost.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

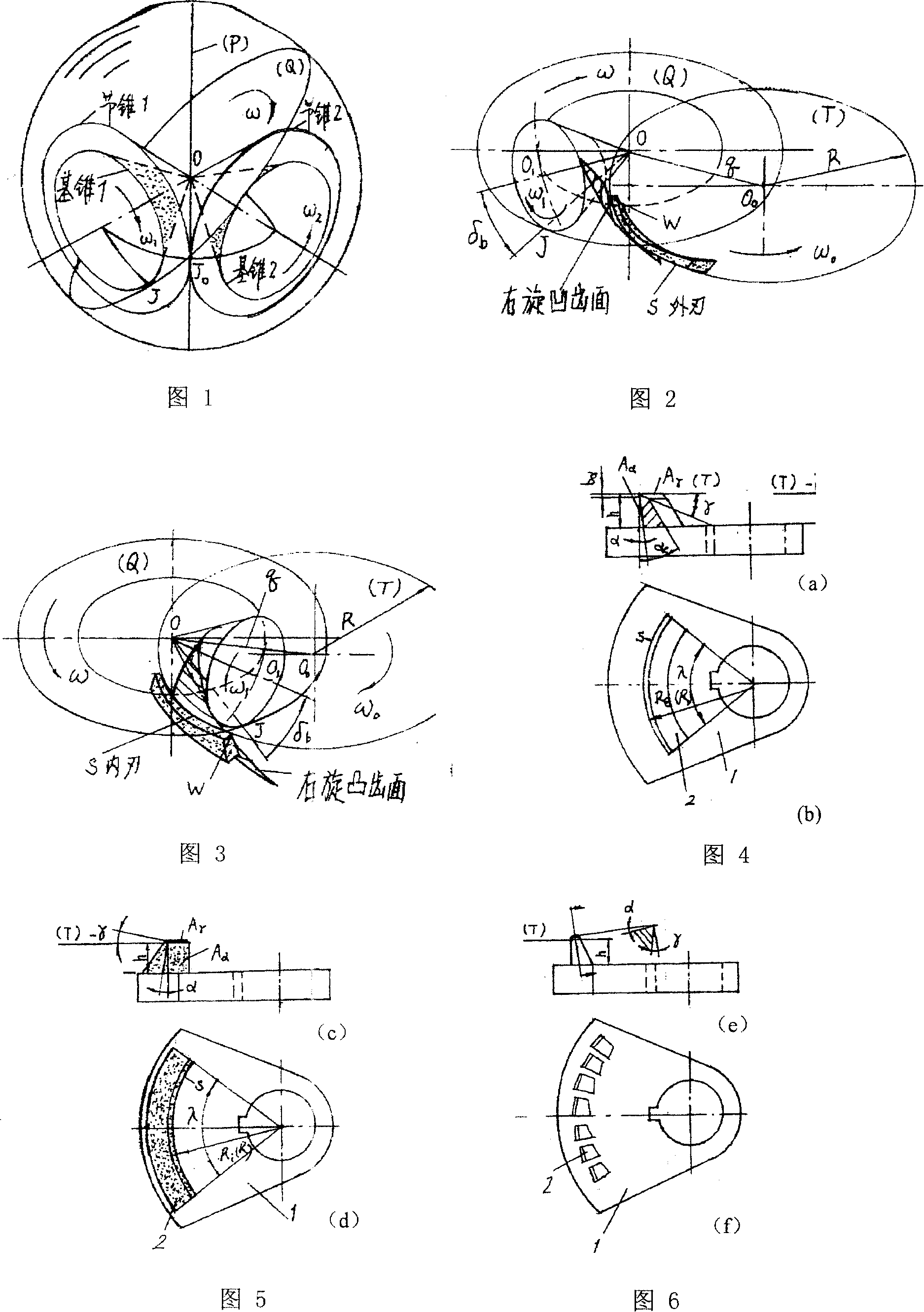

Method for producing cutter teeth of spiral bevel gear with spherical involute profile of tooth tapered tooth

InactiveCN101152677AImprove mesh qualitySimple configurationMilling equipment detailsGear teeth manufacturing toolsGear wheelEngineering

The invention relates to a gear cutting method for manufacture of spiral bevel gear with spherical involute tooth profile shrinkage tooth which is the gear cutting method that an arc-shaped cutting edge skiving cutterhead with turning radius of R on an end surface (T) is adopted for turning of spherical involute tooth profile and the shrinkage tooth is adopted to manufacture the tooth surface of the spiral bevel gear. When in cutting, a tooth casting is tangental to spherical large round plane (Q) represented by machine tool shaking station turning plane and maintains pure rolling according to base cone, rotating speed of every shaft of the machine tool is set up according to following speed ratio relations: when rotating speed of the shaking station is omega, rotating speed of the tooth casting is (1) type, wherein, ZQ is hypothetical tooth number of the shaking station, rotating speed of a cutterheadshaft is (2) type, and omega is opposite to the direction of omega 0; skiving cutterhead knife edge S is tangental to processed tooth surface and tooth surface fine turning process without generation of undercut is finished in the state of large bevel turning. Engaging quality of the cutting gear manufactured with the method is improved, with transient speed ratio constancy and insensitivity of influence of contacting area by transmission included angle alteration, moreover, the gear processed with the method can be exchanged and the invention simplifies the design of the gear and machine tool.

Owner:彭福华

Large high-accuracy gear composite grinding center

ActiveCN104889863AReduce in quantityReduce auxiliary timeGrinding carriagesGrinding feed controlGear wheelMeasuring instrument

Owner:秦川机床工具集团股份公司

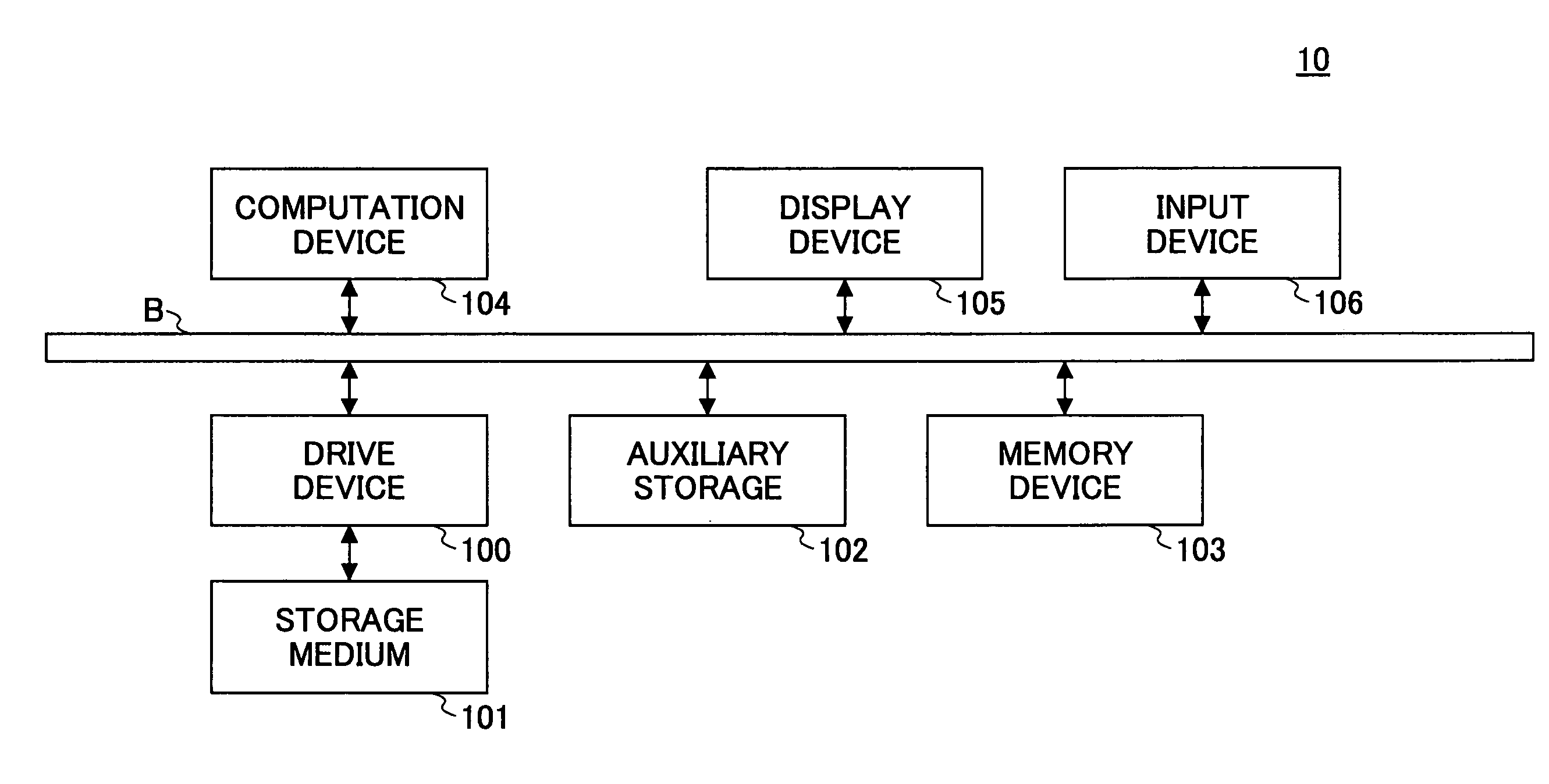

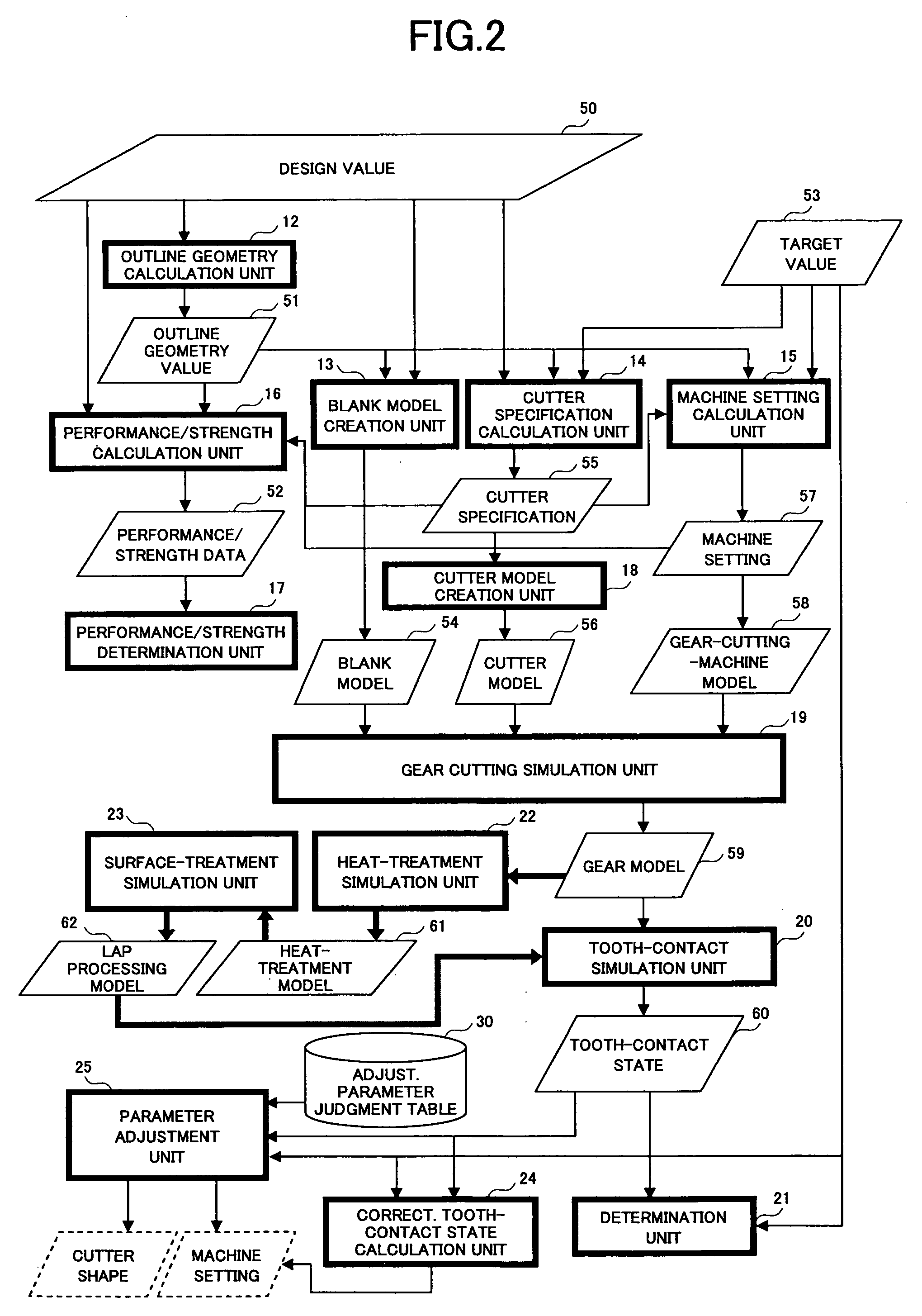

Gear cutting simulation method, gear cutting simulation program, and gear cutting simulation device

InactiveUS20050159938A1Eliminate the problemSure easyComputer controlSimulator controlEngineeringGear cutting

In a gear cutting simulation method and device, a gear-cutting-machine model which specifies relative positions between a blank model and a cutter model is created. A gear model is created as a result of simulation of gear cutting which is performed with the blank model and the cutter model arranged in the gear-cutting-machine model.

Owner:SUMITOMO HEAVY IND LTD

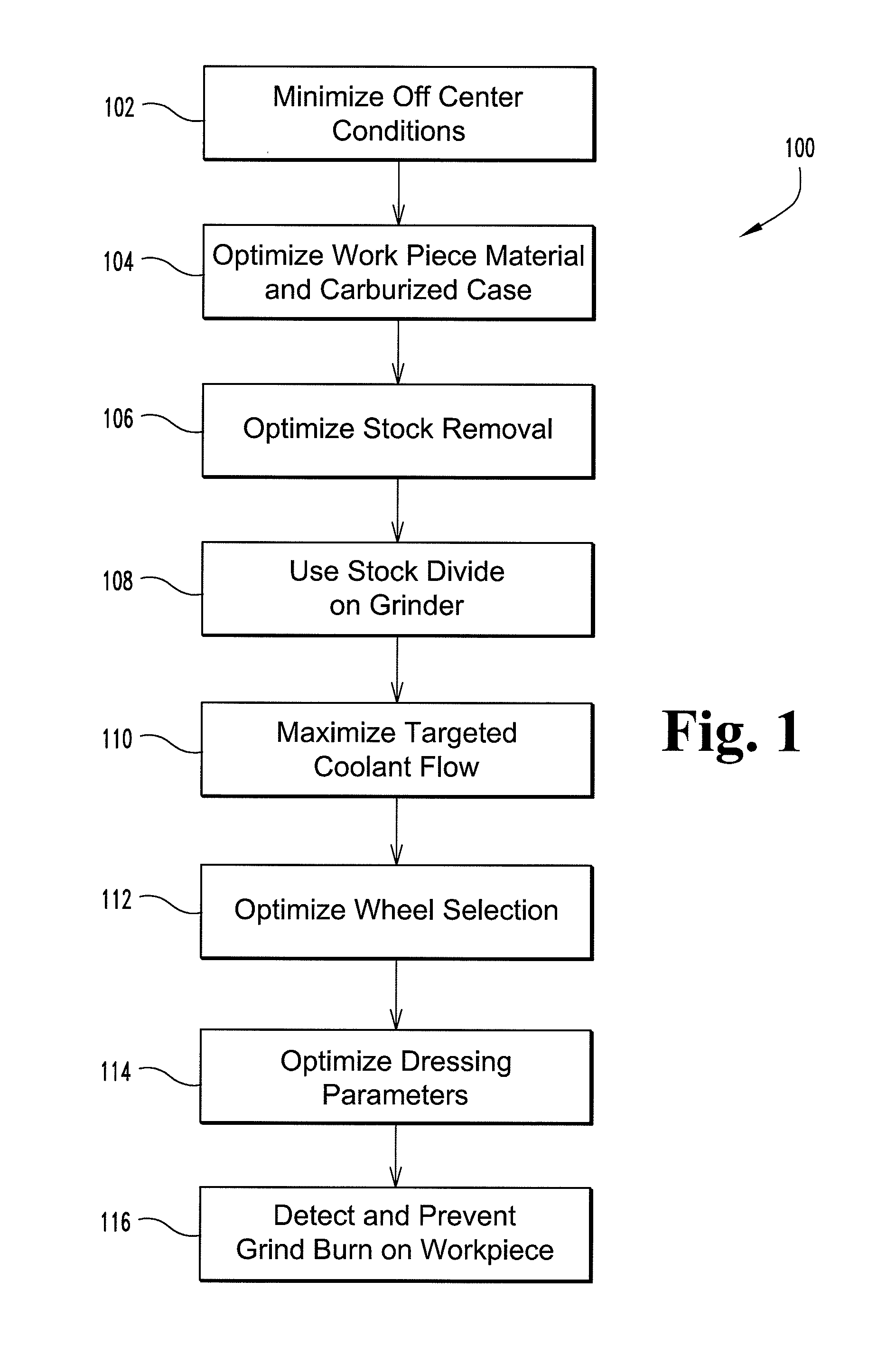

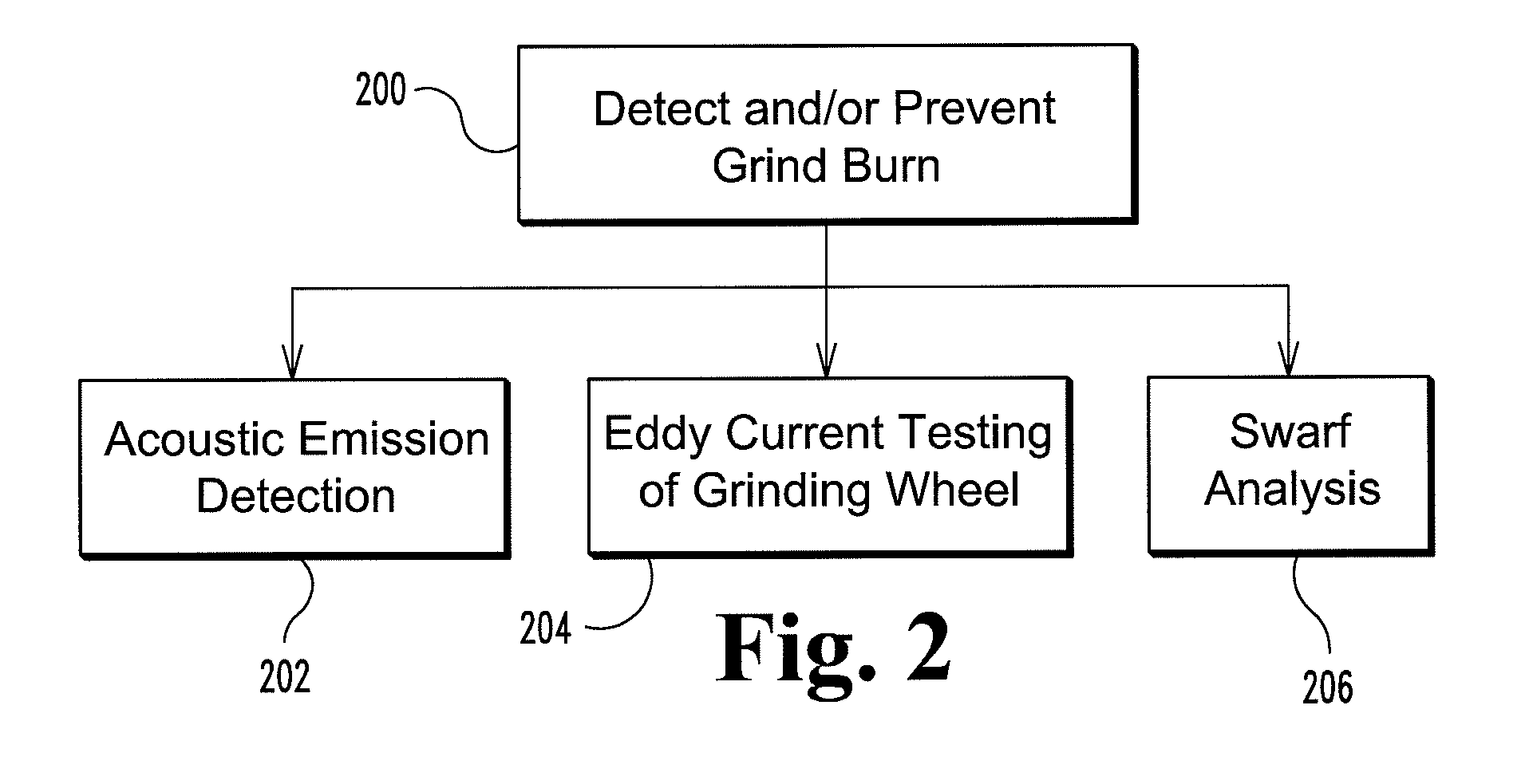

Method for detecting and/or preventing grind burn

ActiveUS20110136408A1Low costThe test result is moreGrinding feed controlAbrasive surface conditioning devicesAcoustic emissionEngineering

The present invention provides a method of detecting and preventing grind burn from developing on a gear. The method includes performing acoustic emission testing while the gear is being ground during a grinding operation. The grinding wheel is evaluated during an eddy current test to detect material buildup on the grinding wheel which could cause grind burn. In addition, the method includes collecting swarf from the gear during the grinding operation and inspecting the swarf for an indication of grind burn.

Owner:ALLISON TRANSMISSION INC

Gear grinding machine with numerical control forming grinding wheel

ActiveCN102814553AHigh precisionImprove processing efficiencyAbrasive surface conditioning devicesGear-cutting machinesGear grindingNumerical control

The invention discloses a gear grinding machine with a numerical control forming grinding wheel; the grinding wheel comprises a stand which is provided with a horizontal sliding guide rail and a longitudinal sliding guide rail; a work piece rotary part is slidably assembled on the longitudinal sliding guide rail in a guiding way; a vertical column is slidably assembled on the horizontal sliding guide rail in a guiding way; and a grinding mechanism which is used for grinding a processed gear is slidably assembled on the vertical column in a guiding way along a vertical direction. The gear grinding machine with the numerical control forming grinding wheel also comprises a grinding wheel forming and finishing device which finishes a grinding wheel; the grinding wheel forming and finishing device comprises a finishing device base which is independently assembled on the vertical column above the grinding mechanism and a finishing wheel with the axis extending along a longitudinal direction; and the finishing wheel is slidably assembled on the sliding guide rail of a longitudinal finishing device of the finishing device base through a finishing wheel frame which extends outwards in a guiding way. According to the gear grinding machine with the numerical control forming grinding wheel, the problems of the prior art that the processing surface of the grinding wheel cannot be finished to be consistent with the shape of the gear slot of the processed gear, and the precise of the processing gear and the processing efficiency of the gear with a large specification are affected are solved.

Owner:洛阳科大越格数控机床有限公司

Gear grinding machine, method for dressing threaded grinding wheel and method for grinding work

ActiveUS7341501B2Easy to retouchGrinding drivesAbrasive surface conditioning devicesGear grindingVertical plane

Owner:MITSUBISHI HEAVY IND MACHINE TOOL CO LTD

Numerical control tooth grinder for spiral bevel gear

InactiveCN101433983AGuaranteed stabilityCutting stabilityGear-cutting machinesGear teethGrinding wheelMachine tool

The invention relates to a numerical control curve-tooth bevel gear grinder, which comprises a lathe bed, and is characterized by also comprising an upright post, a grinding wheel main shaft box, a workpiece main shaft box, an electric turntable, a grinding wheel correcting mechanism and a numerical control system. The lathe bed in the horizontal direction is provided with linear guide rails vertical to each other, the upright post and a bed saddle are arranged on the linear guide rails respectively, and an upright post automatic moving mechanism is arranged between the bottom of the upright post and the lathe bed; one lateral surface of the upright post is provided with the linear guide rail and the grinding wheel main shaft box, and the same side of the upright posts close to the top is provided with a moving mechanism for driving the grinding wheel main shaft box to move; and the bed saddle is provided with the electric turntable which is provided with the workpiece main shaft box on which the grinding wheel correcting mechanism is arranged. The numerical control curve-tooth bevel gear grinder has the advantages that the grinder simplifies the prior mechanical transmission, shortens adjusting time of a machine tool, has compact and reasonable structure, accurate processing with high accuracy, high automation degree to remarkably improve processing efficiency, and has low manufacturing cost to relieve economic burden of enterprises.

Owner:TIANJIN NO 1 MACHINE TOOL WORKS

Method and apparatus for lapping gears

InactiveUS20060111018A1Revolution surface grinding machinesGrinding feed controlVibration controlGear wheel

A method for lapping the gears of a gear set as well as a gear lapping system. The gear set generally includes a first gear in meshed engagement with a second gear, each of the first and second gears having a plurality of gear teeth each with drive and coast flank surfaces. The method includes the steps of lapping the gear set by rotating the first gear in a first direction while the first gear is in mesh with the second gear. The method further includes sensing the vibrations occurring in the gear mesh during rotation and controlling the step of lapping based on the sensed vibrations. The gear lapping system includes an automated lapping machine that is adapted to lap the gear set including a ring gear and a pinion gear. The automated lapping machine is adapted to lap the gear set by rotating at least one of the ring and pinion gears while in mesh, in the presence of a lapping compound, and while translating the gear mesh back and forth across the gear flank surfaces for a plurality of cycles. A vibration sensor is operably coupled to the automated lapping machine and senses the amplitude of vibration and energy occurring in the gear mesh during each of the plurality of cycles. This sensor produces a vibration output signal that is proportional to the amplitude of the vibration energy. An automated controller is adapted to receive the vibration output signal as well as to calculate and transmit a control command signal to the automated lapping machine based on the amplitude of the vibration energy.

Owner:FORD GLOBAL TECH LLC

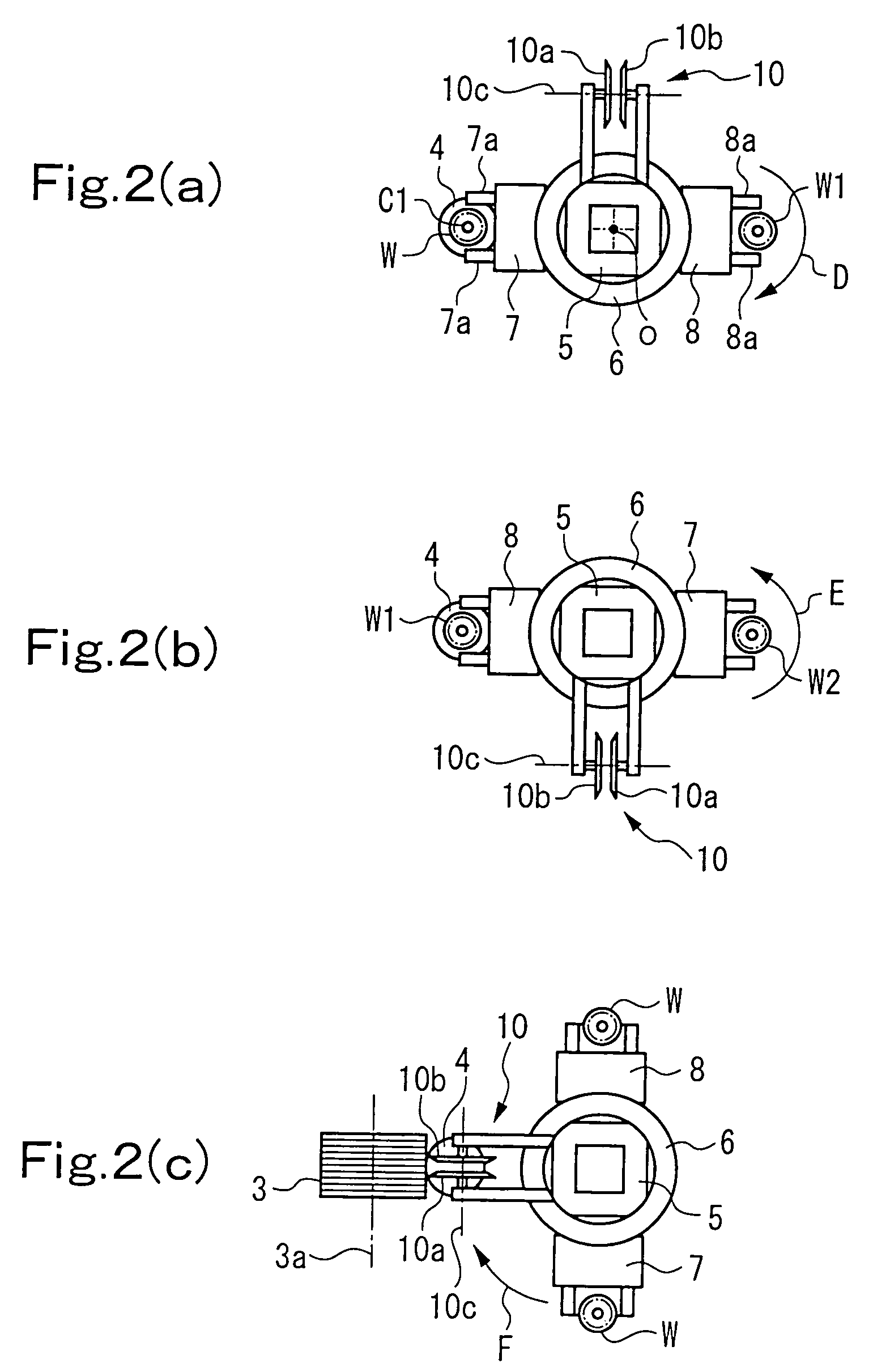

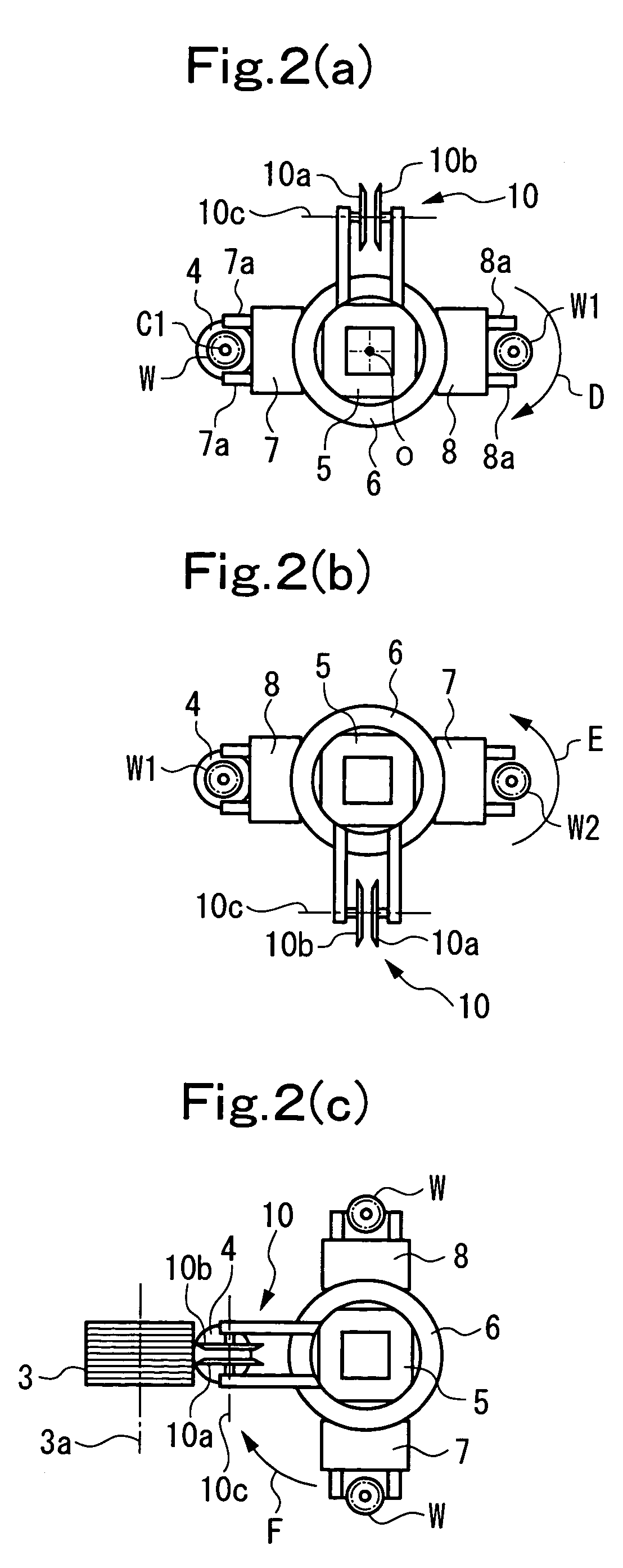

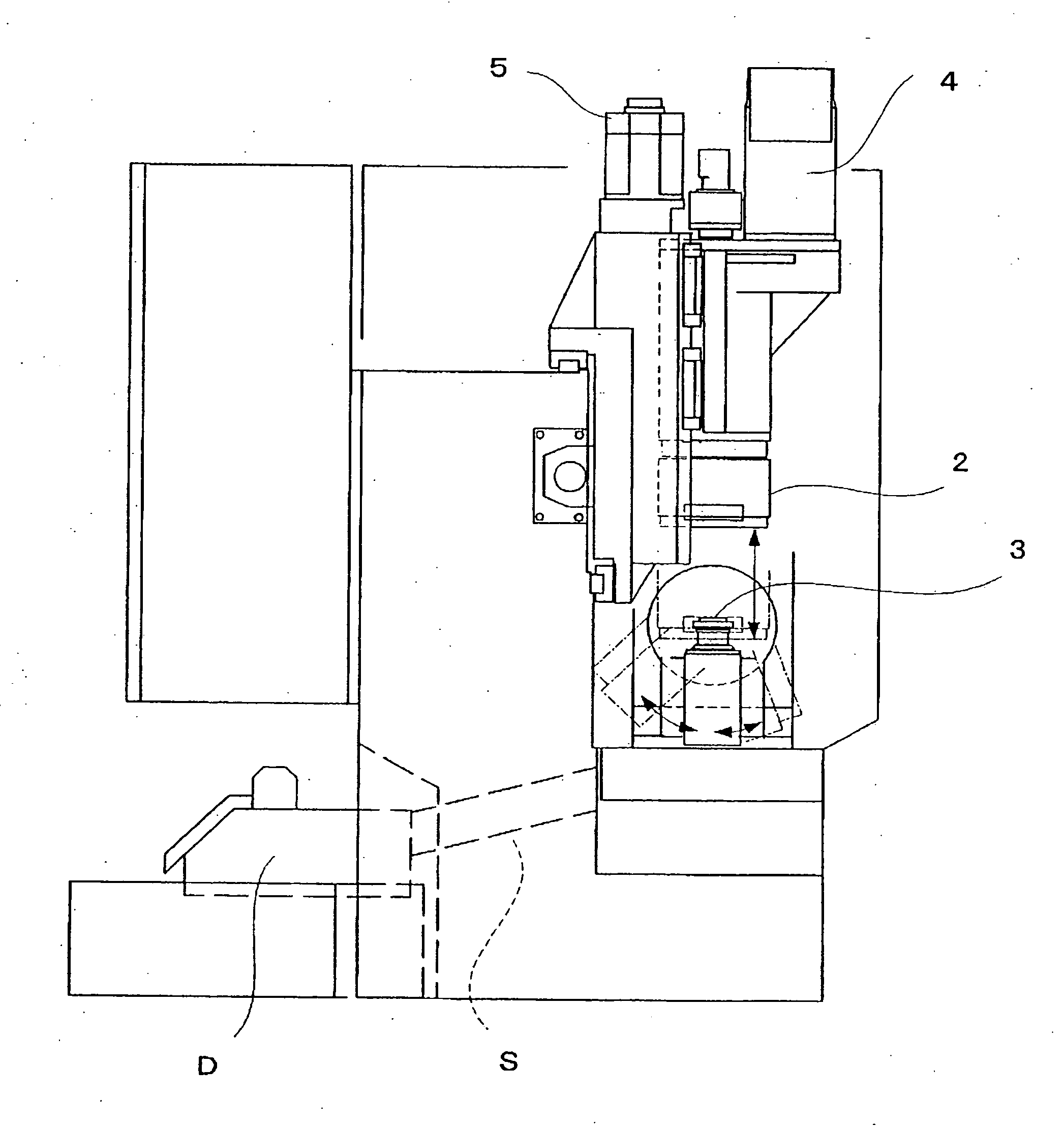

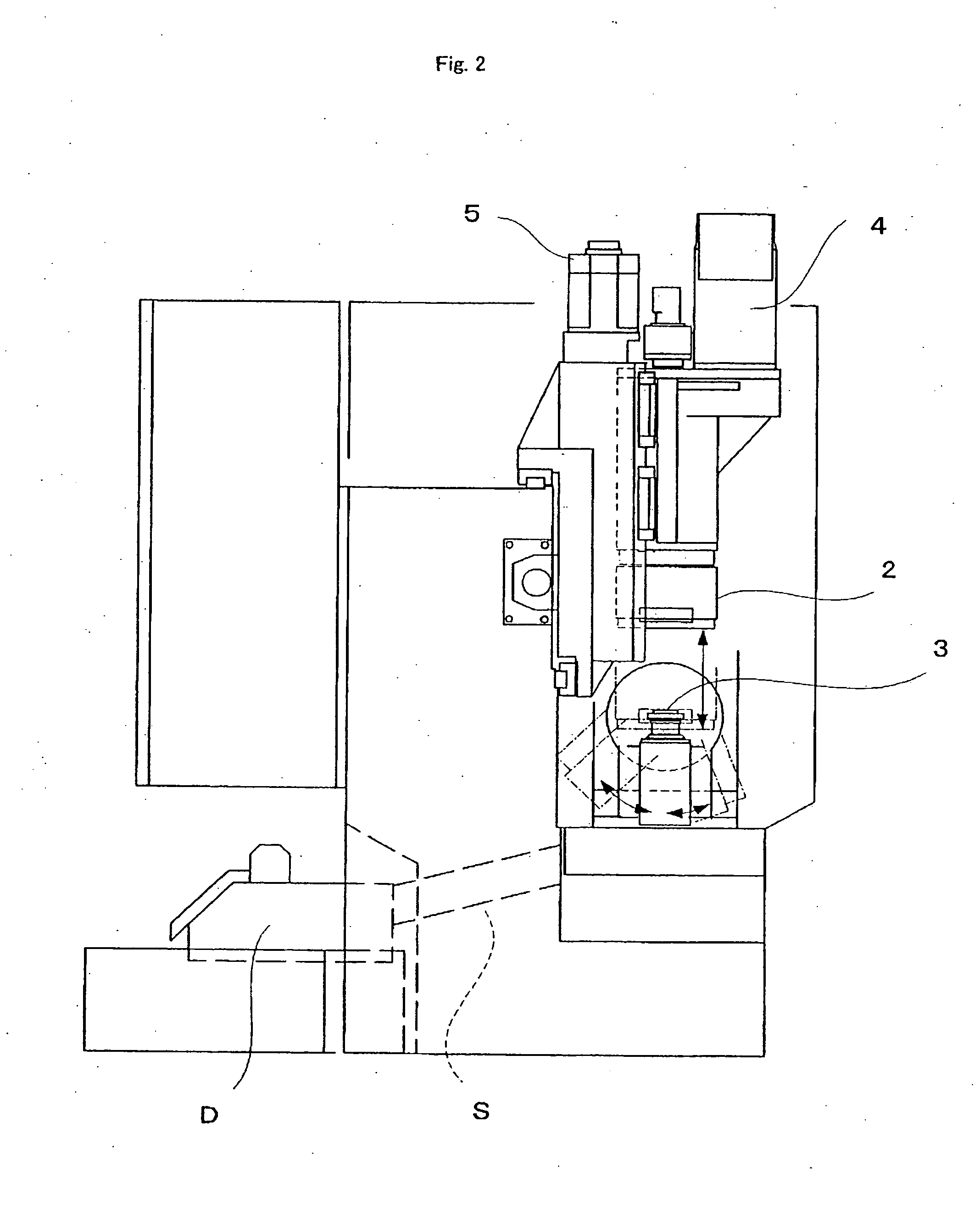

Internal gear shaving machine

An internal gear shaving machine 1 which brings a shaving cutter 3 and an internal gear held by a workpiece chuck 2 into engagement with a crossed axes angle, and subjects the tooth flanks of the internal gear to final machining while it rotationally drives at least one of the shaving cutter 3 and the workpiece chuck 2. The workpiece chuck 2 and shaving cutter 3 are supported movably toward and away from each other in a vertical direction with the workpiece chuck 2 higher and supported movably in the horizontal direction relative to each other. The workpiece chuck 3 is constituted to hold the outer circumferential surface of the internal gear with the axis of rotation of the internal gear oriented in a up-down direction so that shavings produced during processing by the shaving cutter can fall downwardly from the internal gear.

Owner:KANZAKI KOKYUKOKI MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com