Thin-wall annular gear processing method

A processing method and the technology of the inner ring gear are applied in the direction of metal processing equipment, metal processing machinery parts, gear teeth, etc., which can solve the problems of broken teeth, large deformation of the inner ring gear, high cost, etc., and achieve small deformation, high precision, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

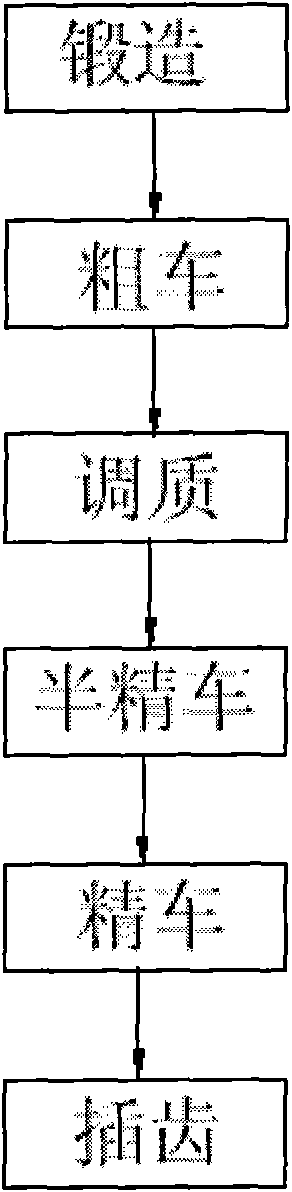

[0015] Example 1: see Figure 1 ~ Figure 3 : The processing method of the thin-walled inner ring gear shown includes the following steps: (1) forging, (2) rough turning, (3) quenching and tempering, (4) semi-finishing turning, (5) finishing turning and (6) inserting teeth, of which:

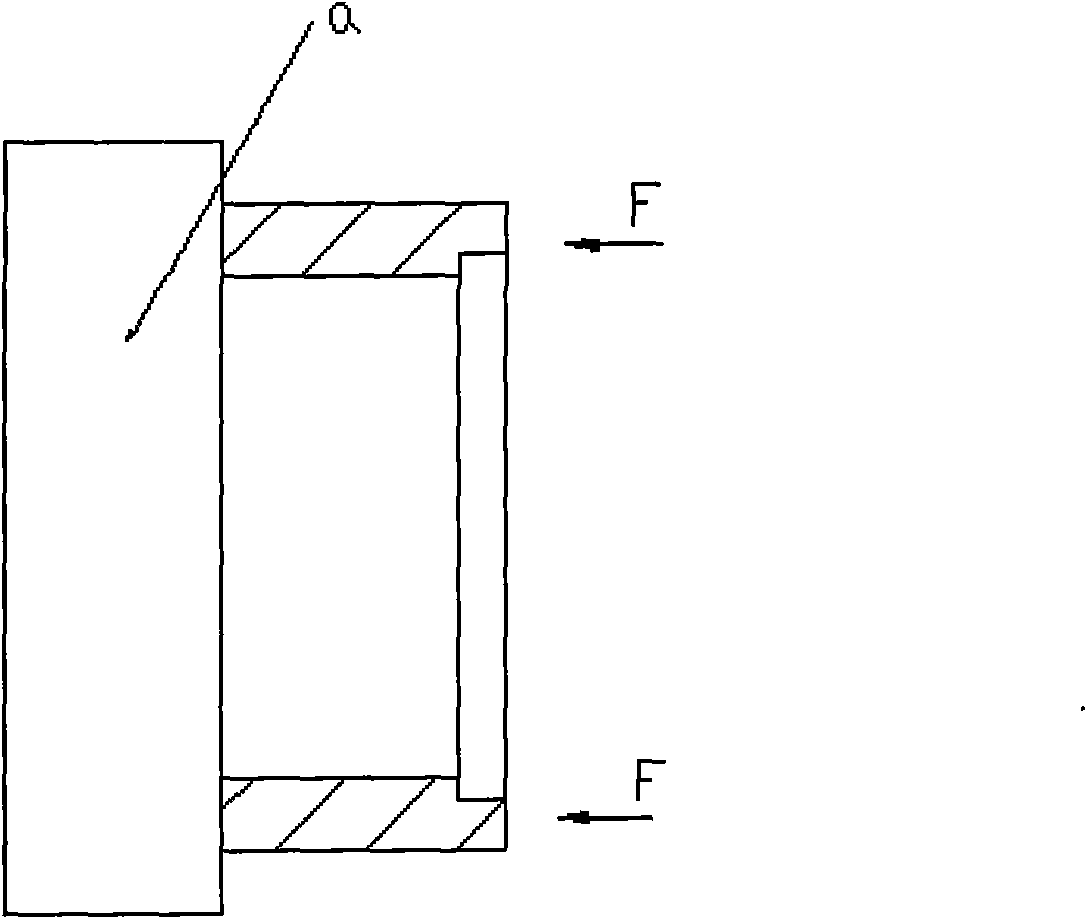

[0016] The step (5) finish turning is: take the end face of the thin-walled inner ring gear after the semi-finishing step (4) as the force-bearing surface, and act axial force to fix the thin-wall inner ring gear on the horizontal lathe for working On platform a, then the inner wall and outer wall of the thin-walled ring gear are turned;

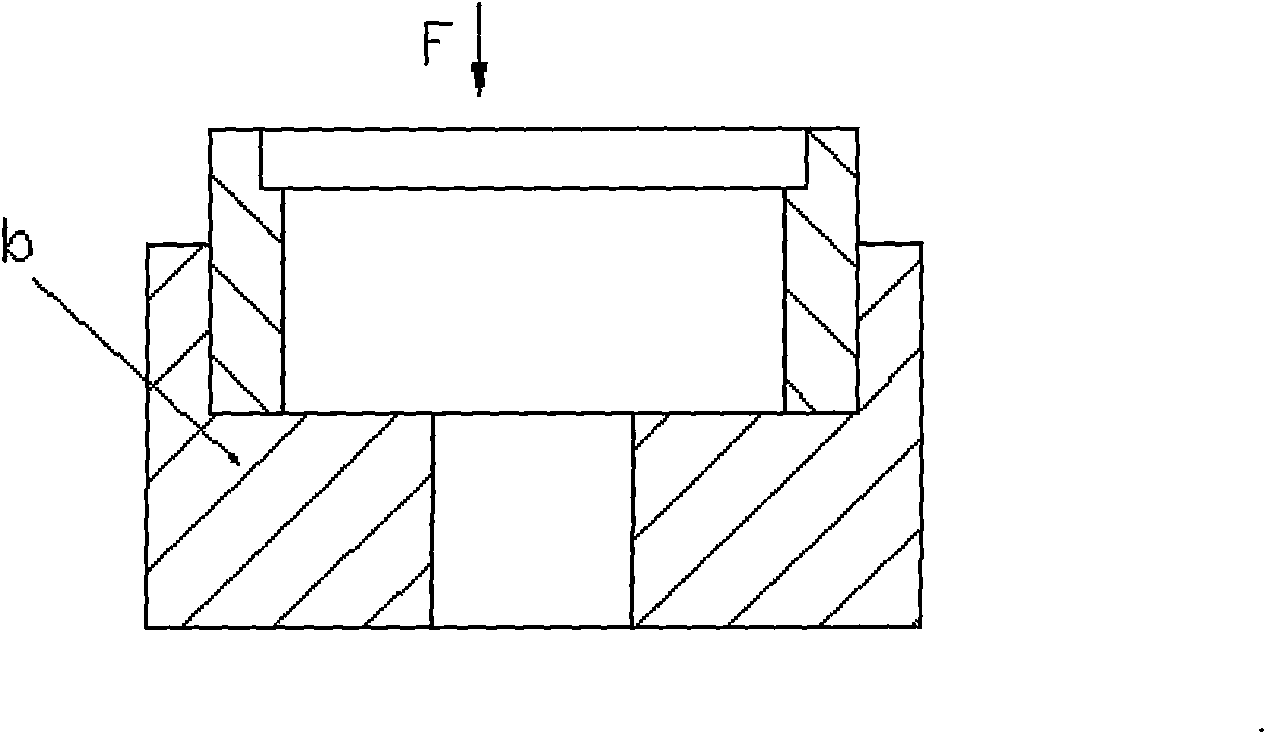

[0017] The step (6) of gear shaping is: using a fixture to simultaneously position the end face and outer wall of the thin-walled inner ring gear after finishing turning in step (5), and then perform gear shaping on the inner wall of the thin-walled inner ring gear.

[0018] In the step (5) in the finish turning process, the bottom surface and the outer circl...

Embodiment 2

[0019] Example 2: see Figure 1 ~ Figure 3 : The processing method of the thin-walled inner ring gear shown includes the following steps: (1) forging, (2) rough turning, (3) quenching and tempering, (4) semi-finishing turning, (5) finishing turning and (6) inserting teeth, of which:

[0020] The step (5) finish turning is: take the end face of the thin-walled inner ring gear after the semi-finishing step (4) as the force-bearing surface, and act axial force to fix the thin-wall inner ring gear on the horizontal lathe for working On platform a, then the inner wall and outer wall of the thin-walled ring gear are turned;

[0021] The step (6) of gear shaping is: using a fixture to simultaneously position the end face and outer wall of the thin-walled inner ring gear after finishing turning in step (5), and then perform gear shaping on the inner wall of the thin-walled inner ring gear.

[0022] See Figure 4 : the clamp adopted in the step (6) gear shaping process is a ring cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com