Patents

Literature

3854results about How to "Reduce deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

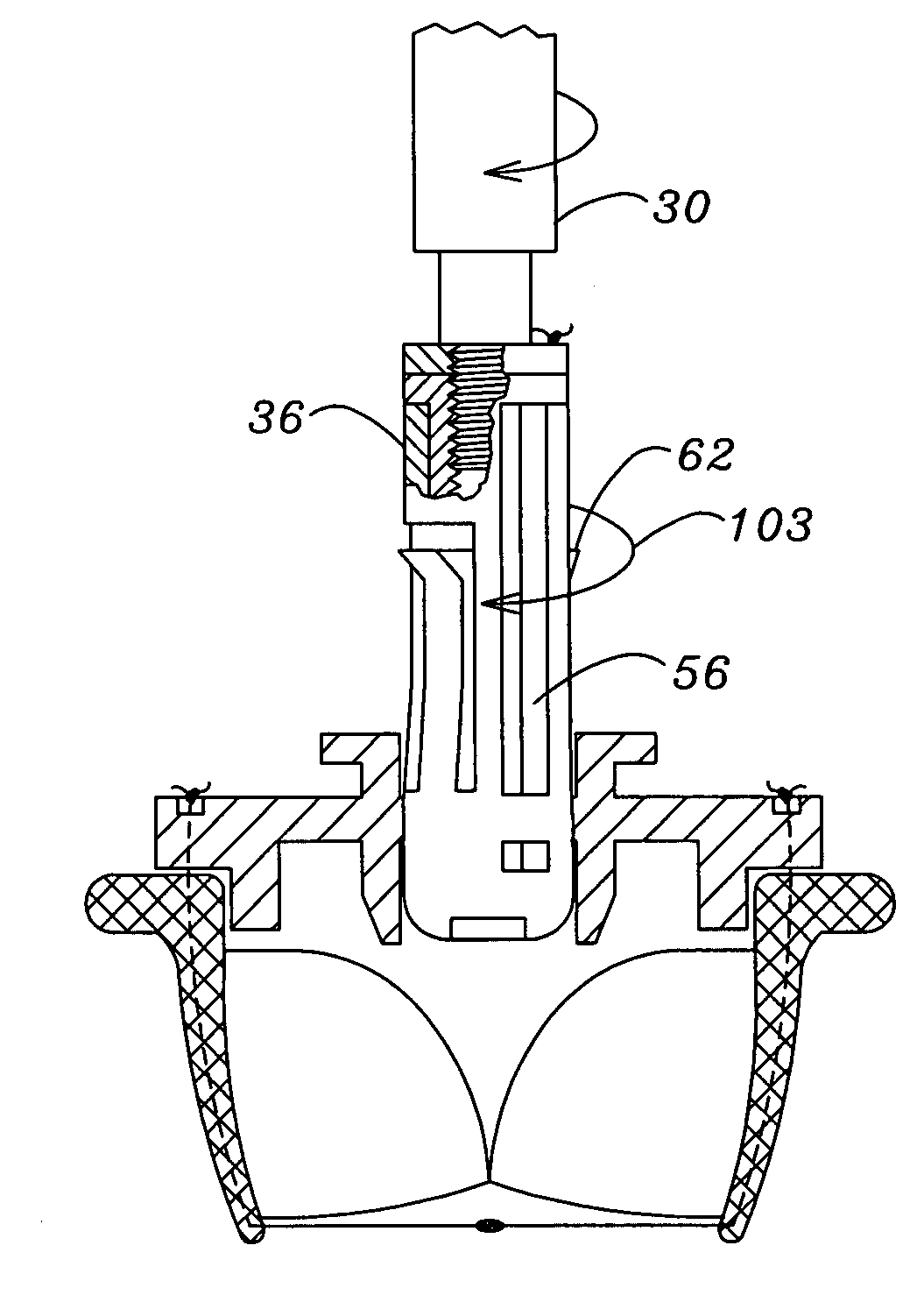

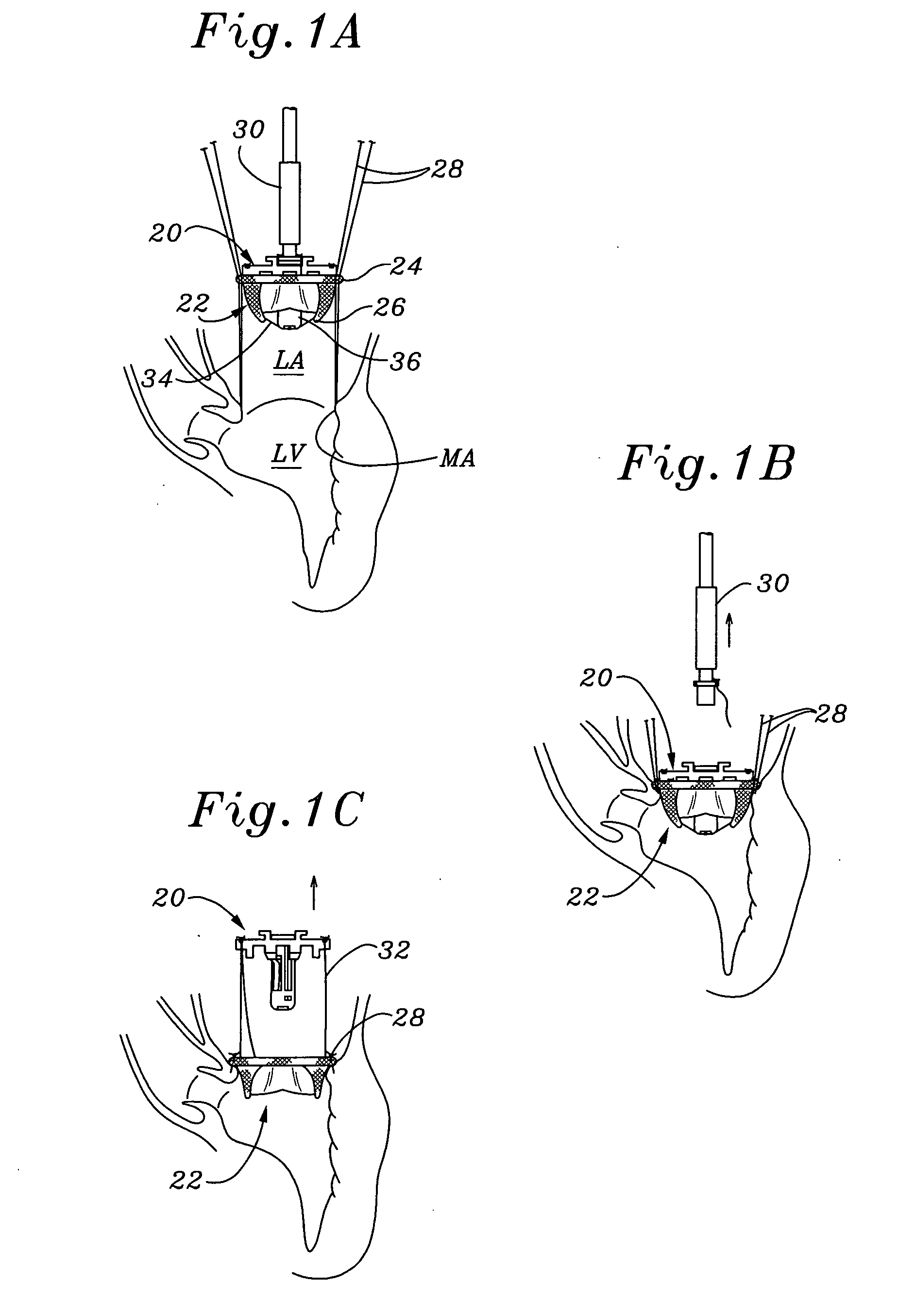

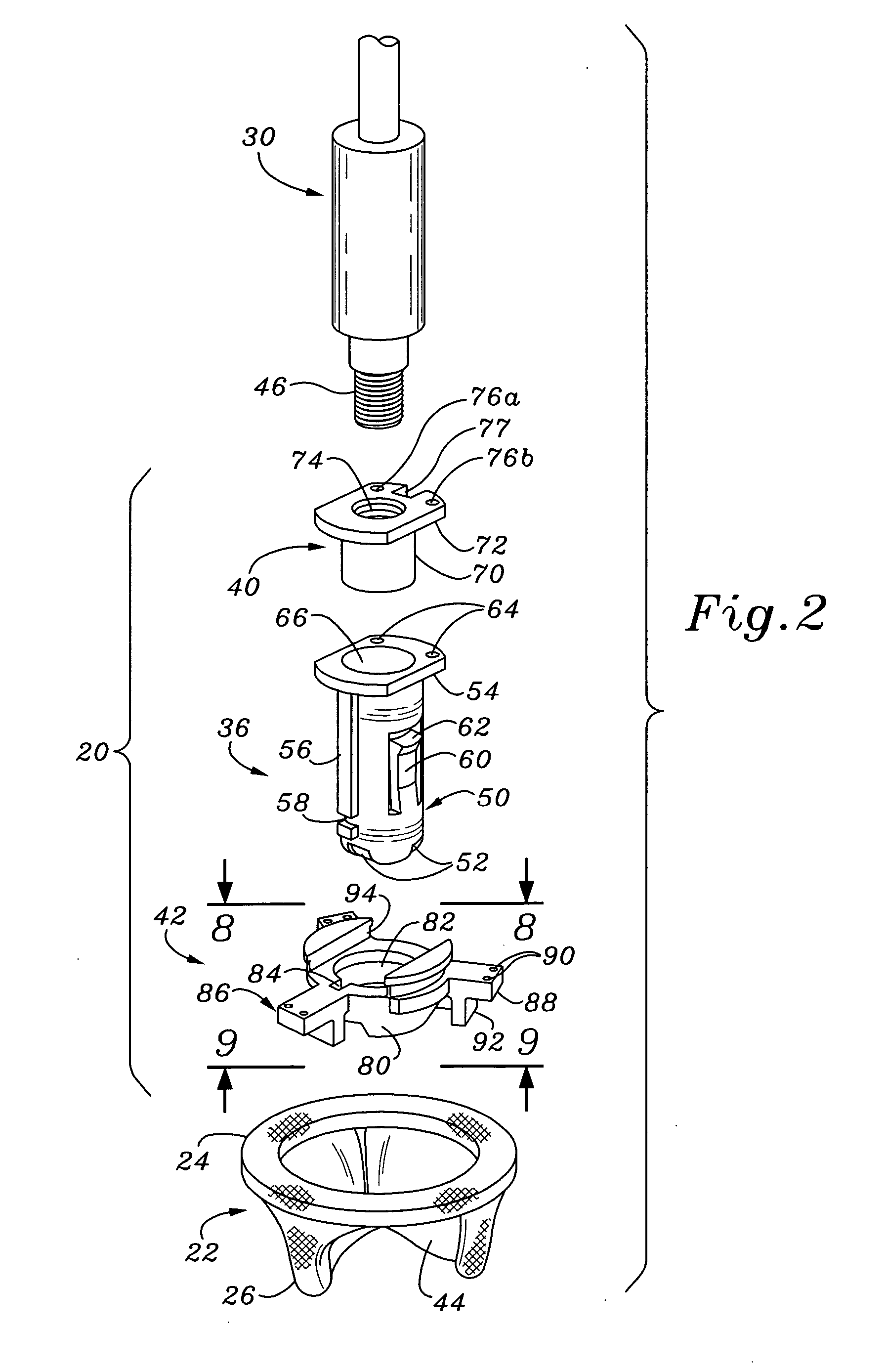

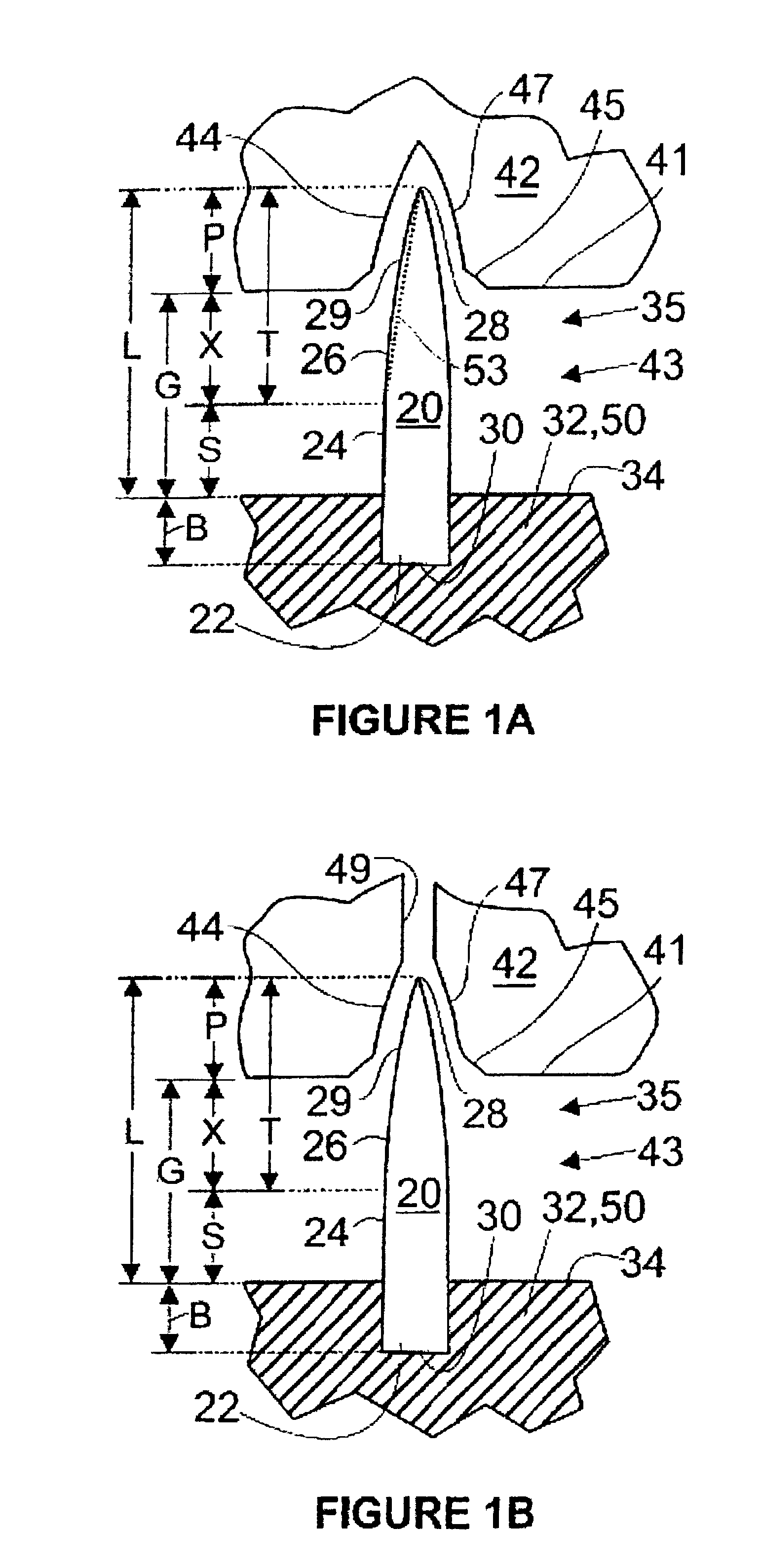

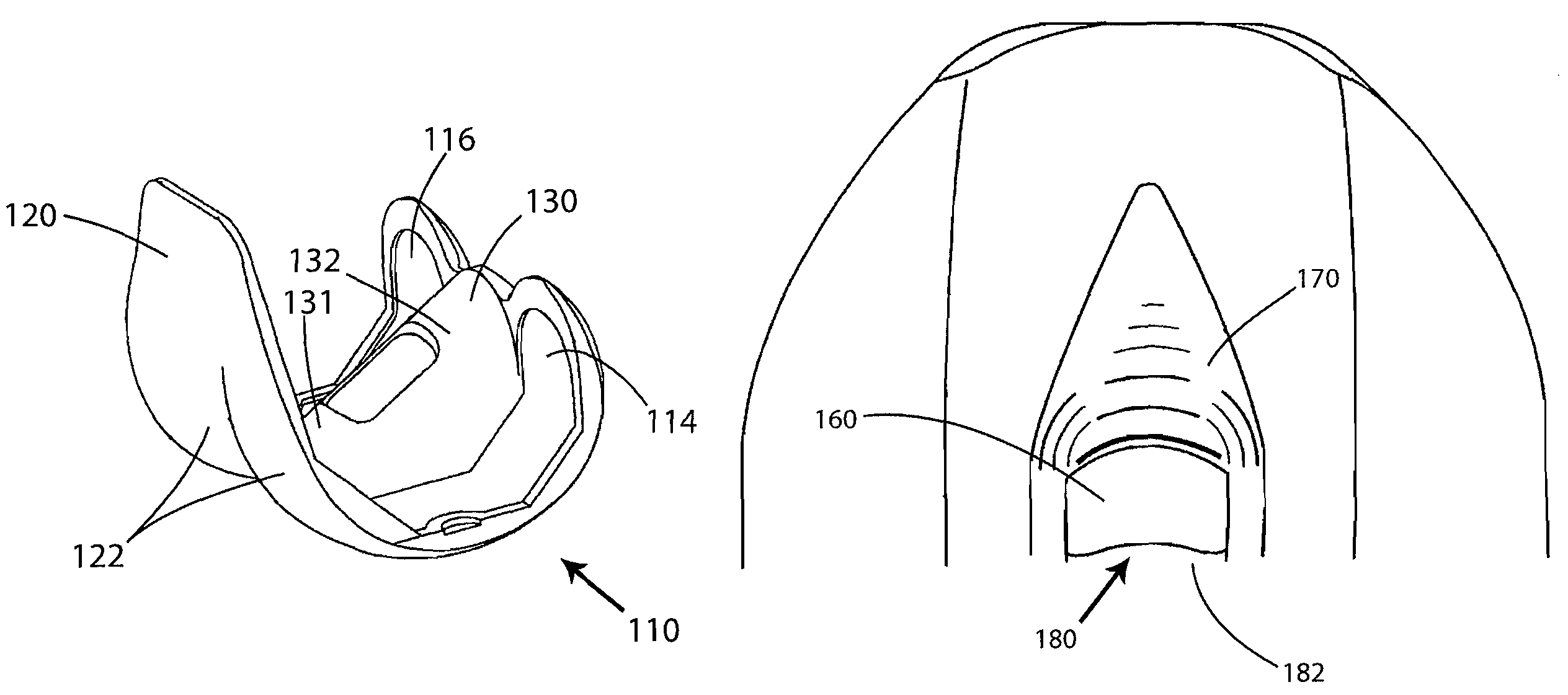

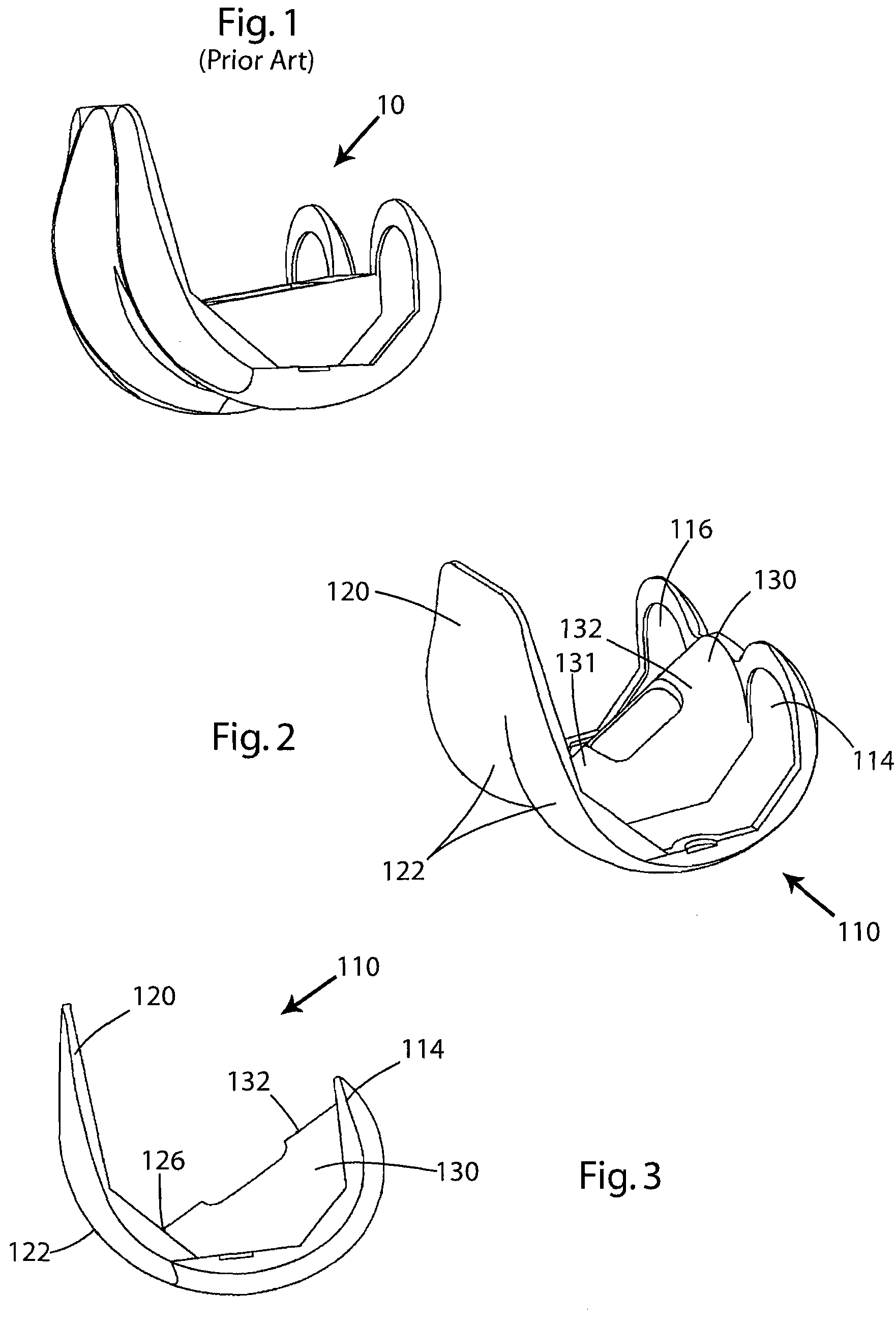

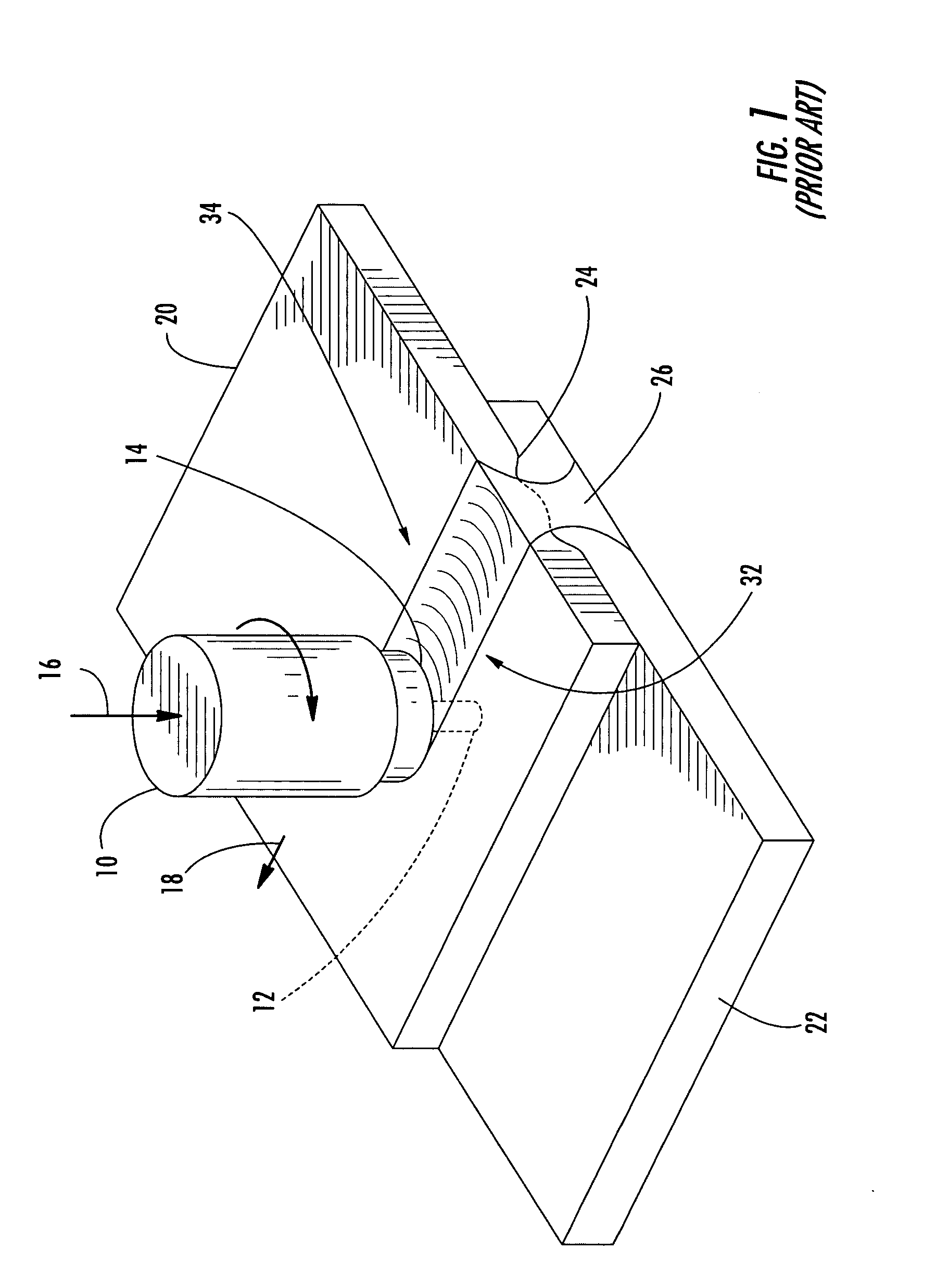

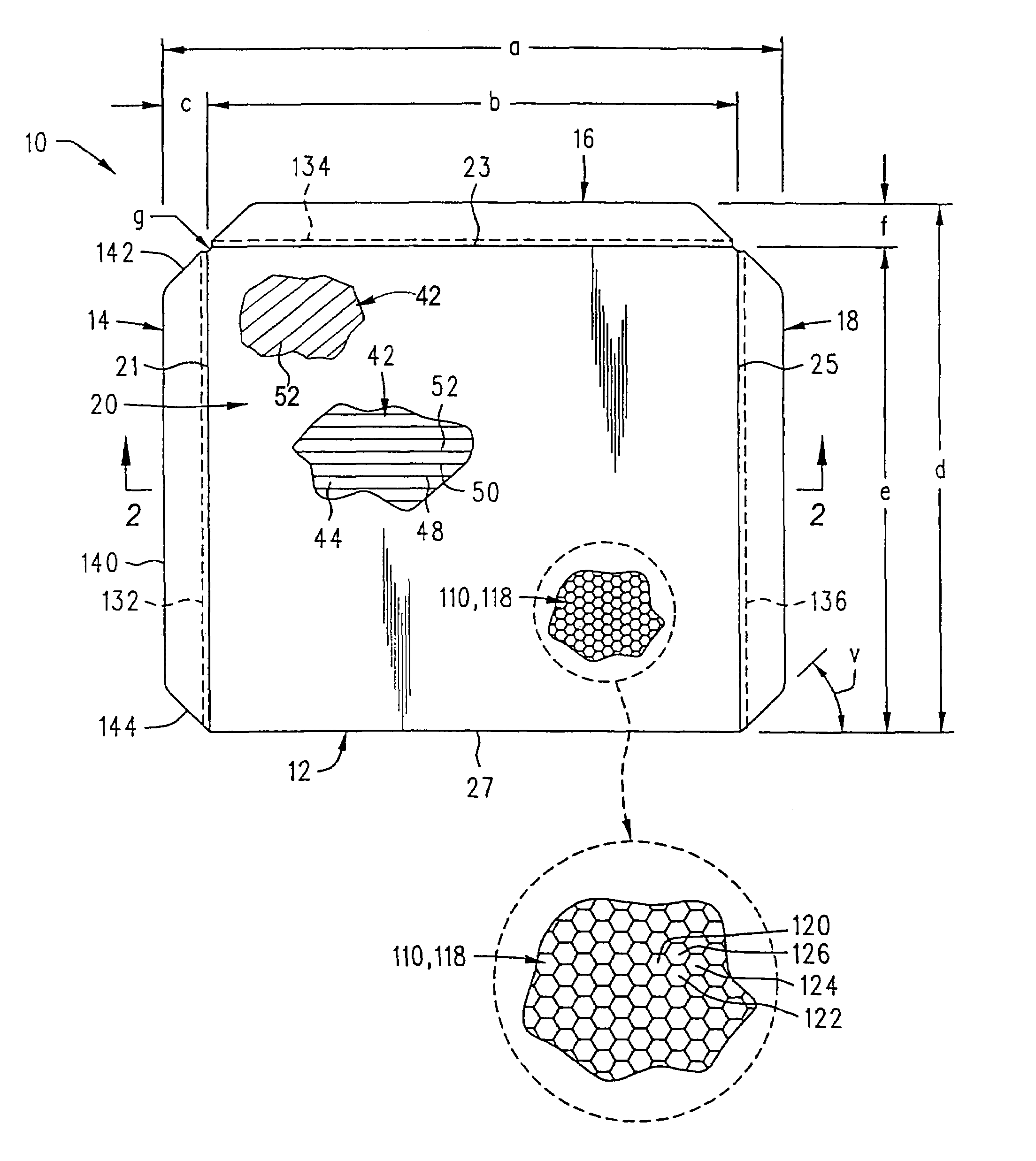

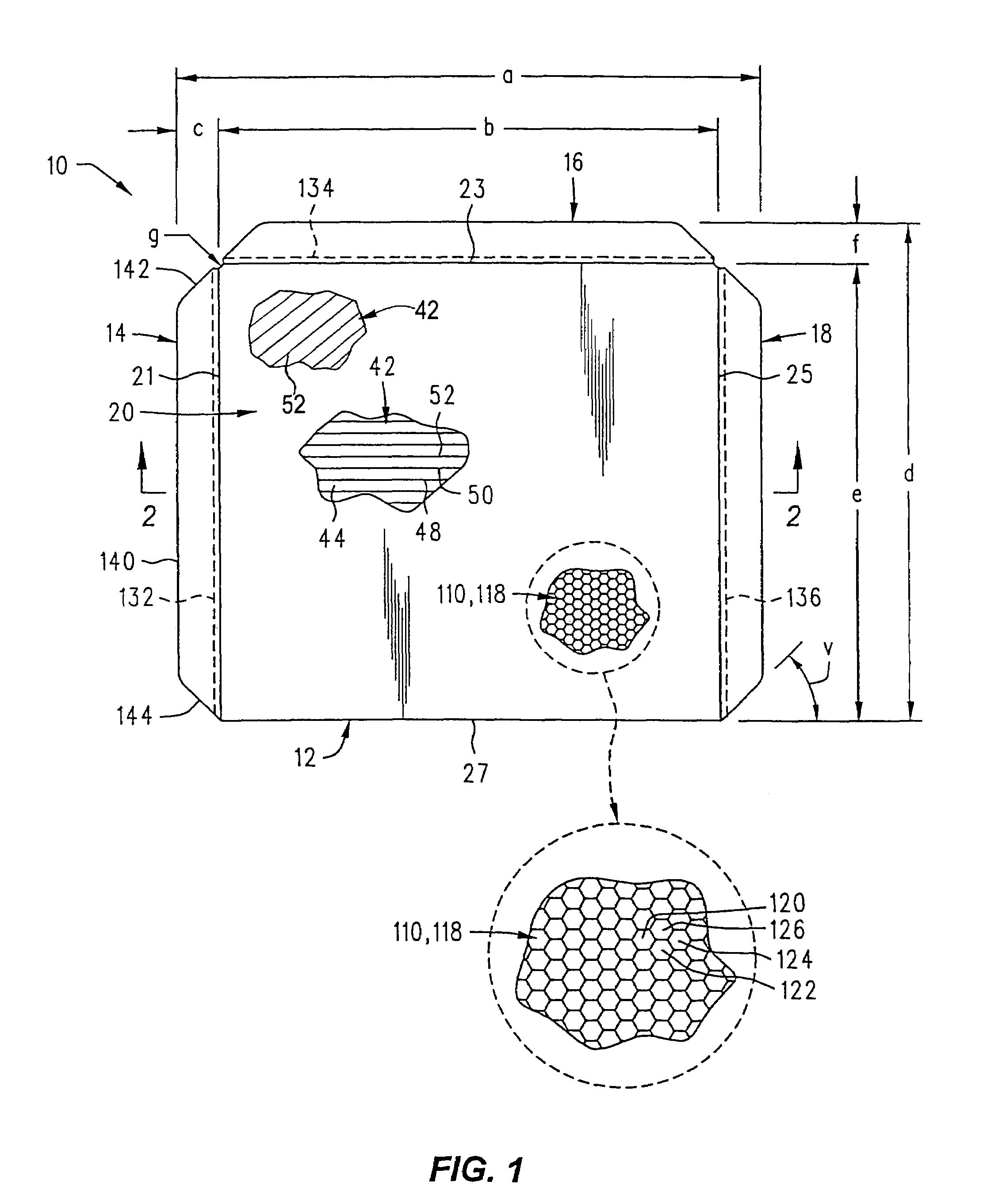

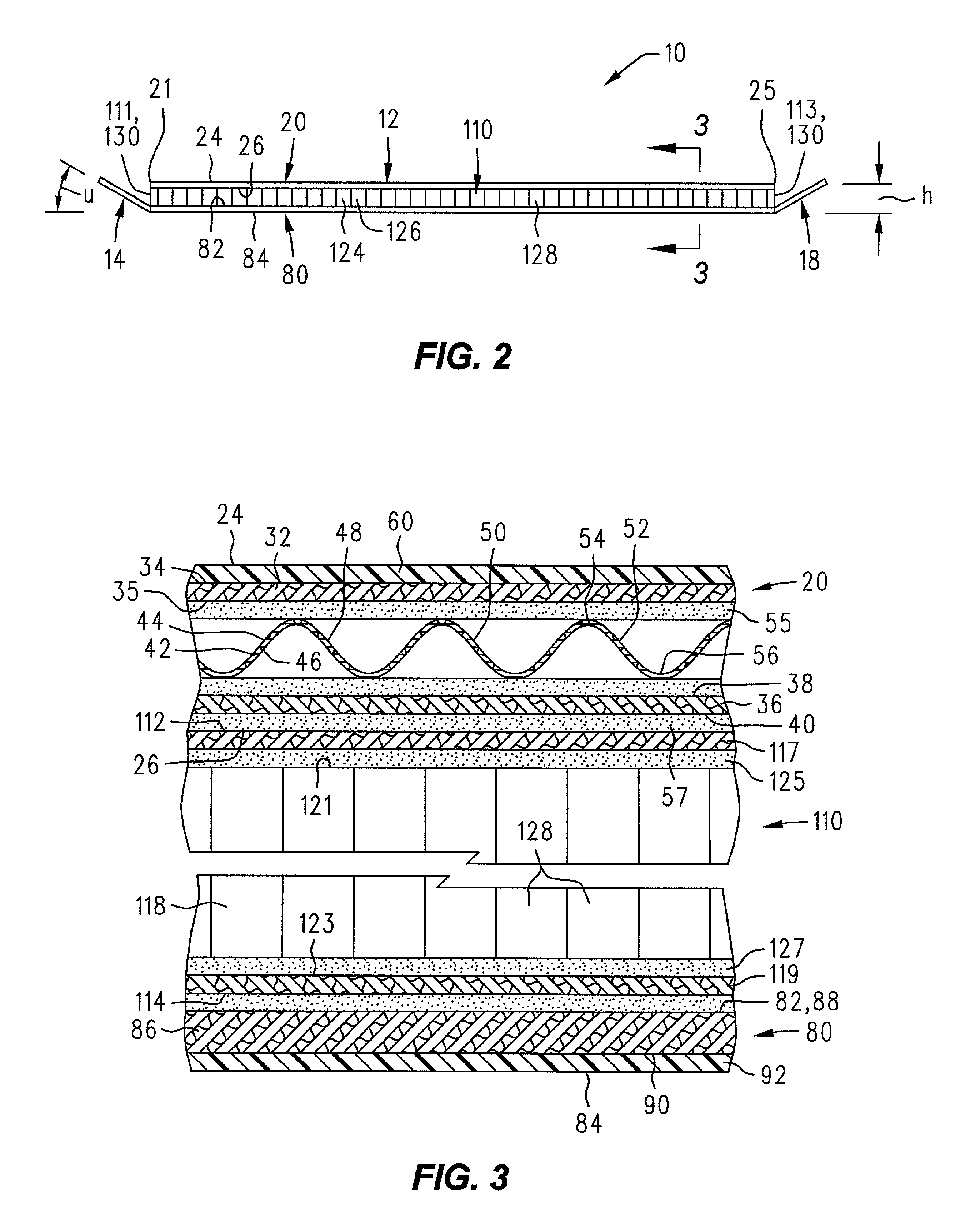

Heart valve holder and method for resisting suture looping

An improved holder and method for implanting a tissue-type prosthetic mitral heart valve that prevents suture looping and may also constrict the commissure posts of the valve. An upstanding or shaft member axially positioned on the holder causes the lengths of attachment sutures to extend axially beyond the commissure post tips to create a tent and prevent looping of any of an array of pre-implanted sutures around the tips during deployment of the valve. The shaft member may be axially movable such that it can be initially retracted and then actuated just prior to valve deployment. The shaft member may have notches on its distal tip for capturing the attachment sutures, which are crossed over along the valve axis to ensure engagement by the notches. The attachment sutures may be strands or filaments, or may be wider bands of flexible biocompatible material. If bands are used, they desirably cover the commissure post tips to further help prevent suture looping thereover. The flexible lengths of material extend directly between commissures of the valve, or may extending radially inward from each commissure to a central upstanding member.

Owner:EDWARDS LIFESCIENCES CORP

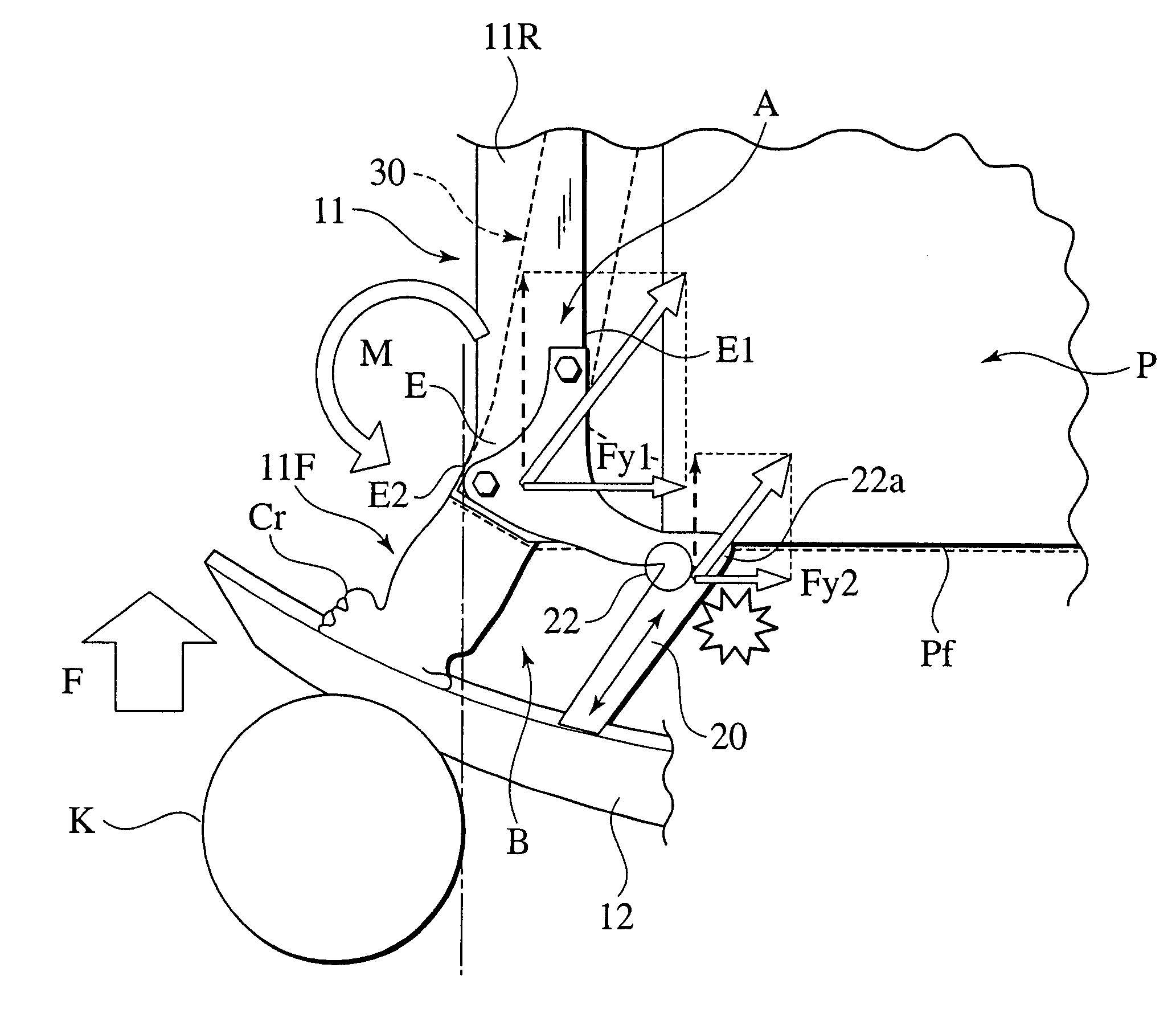

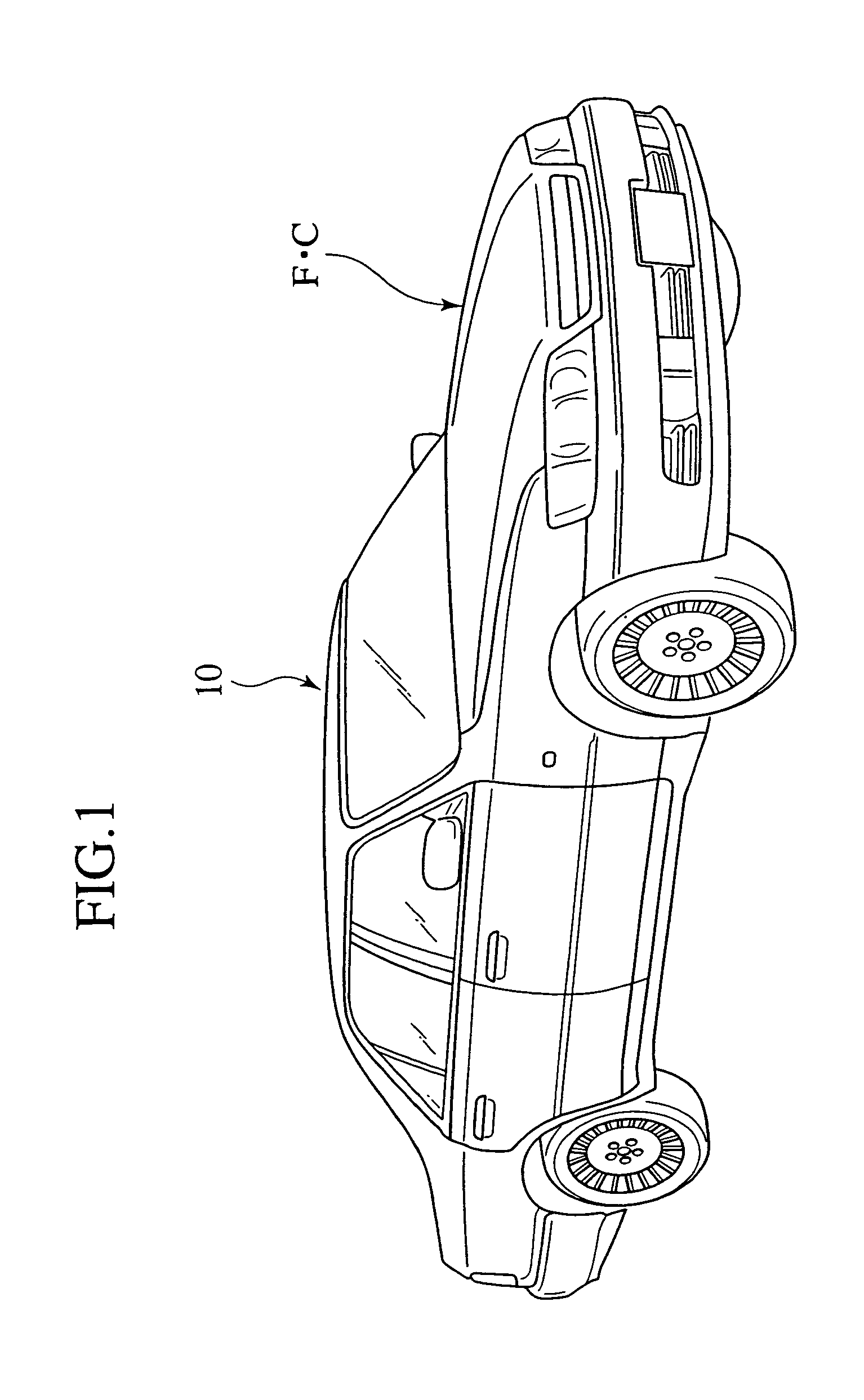

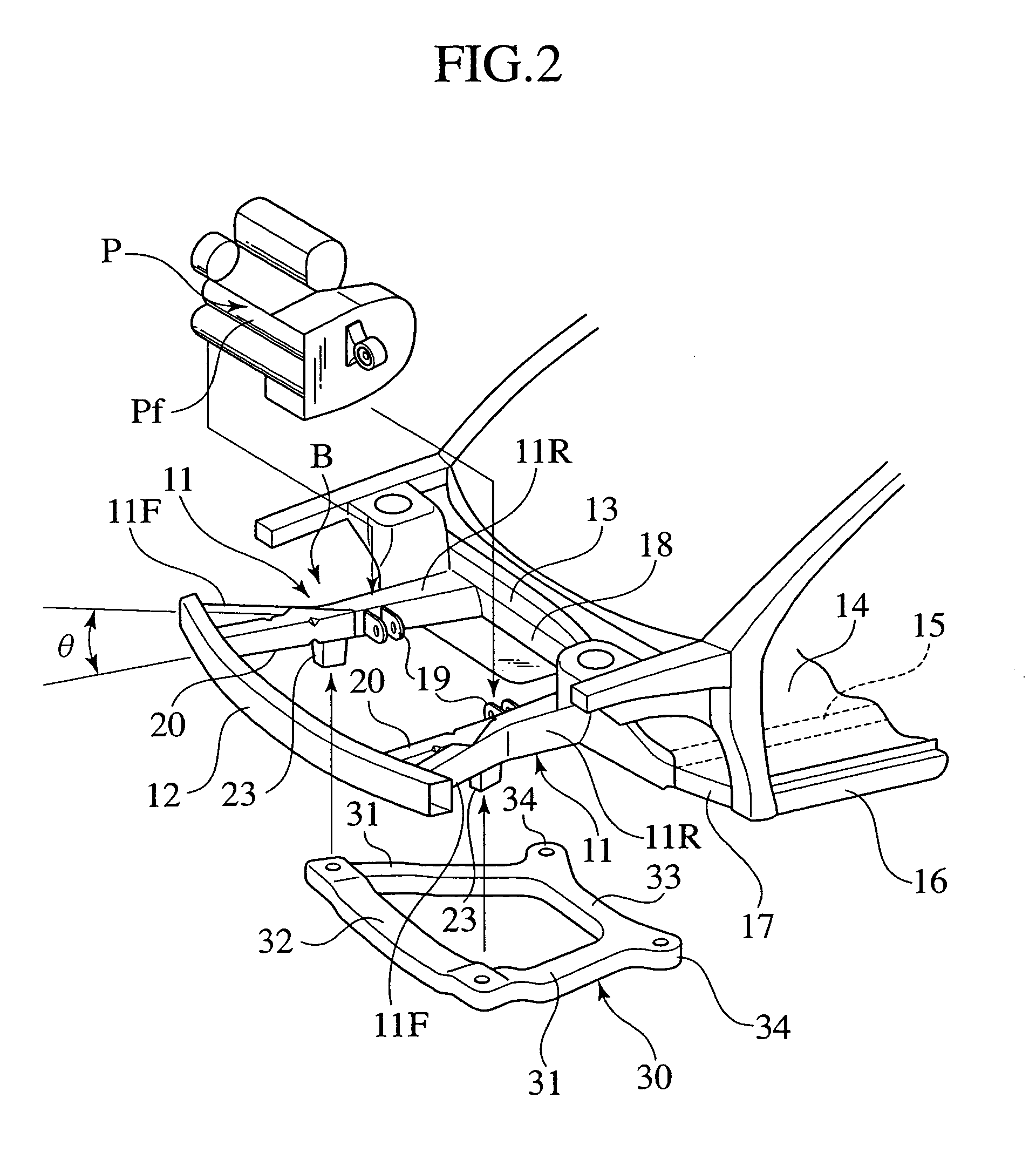

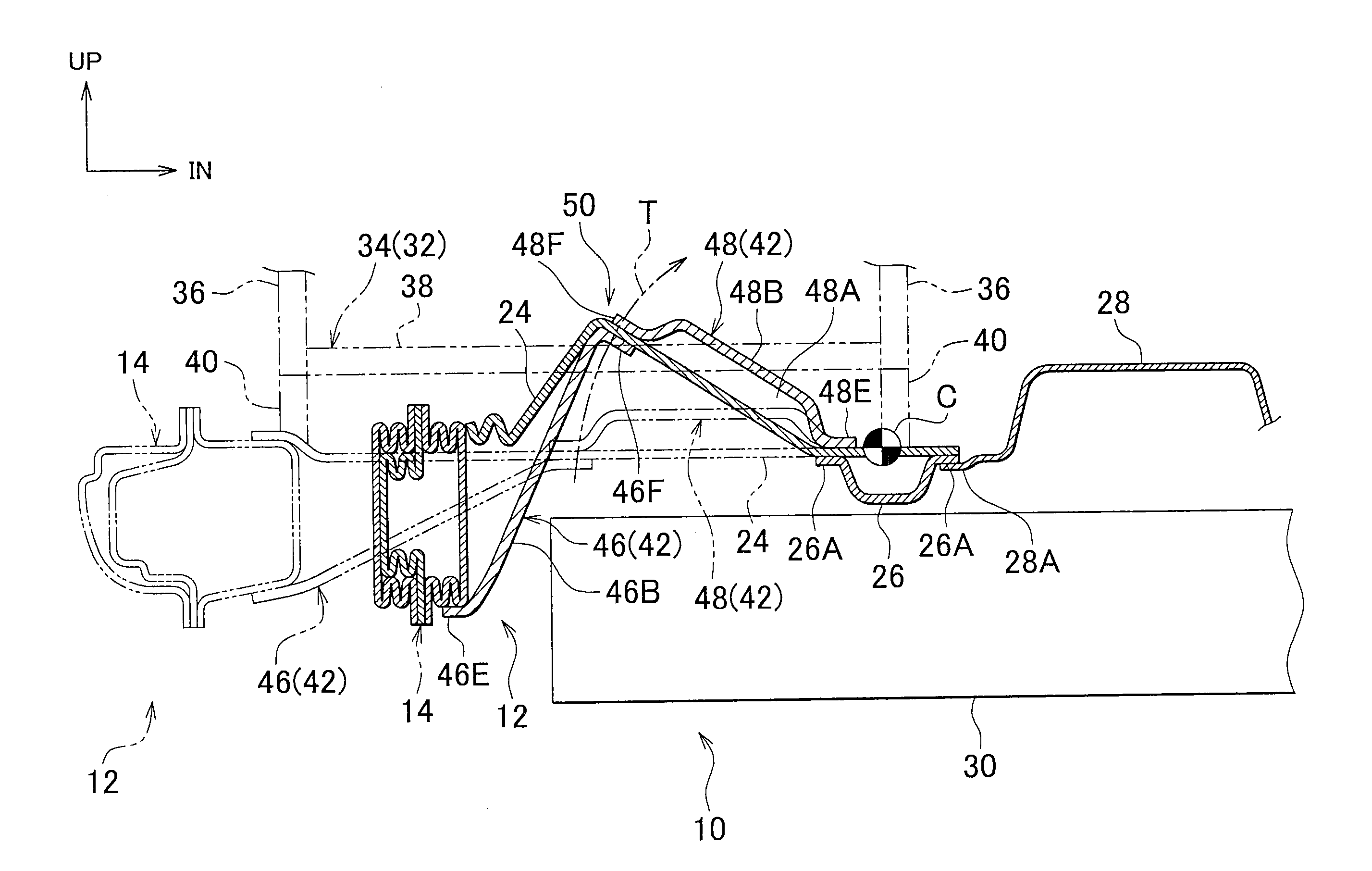

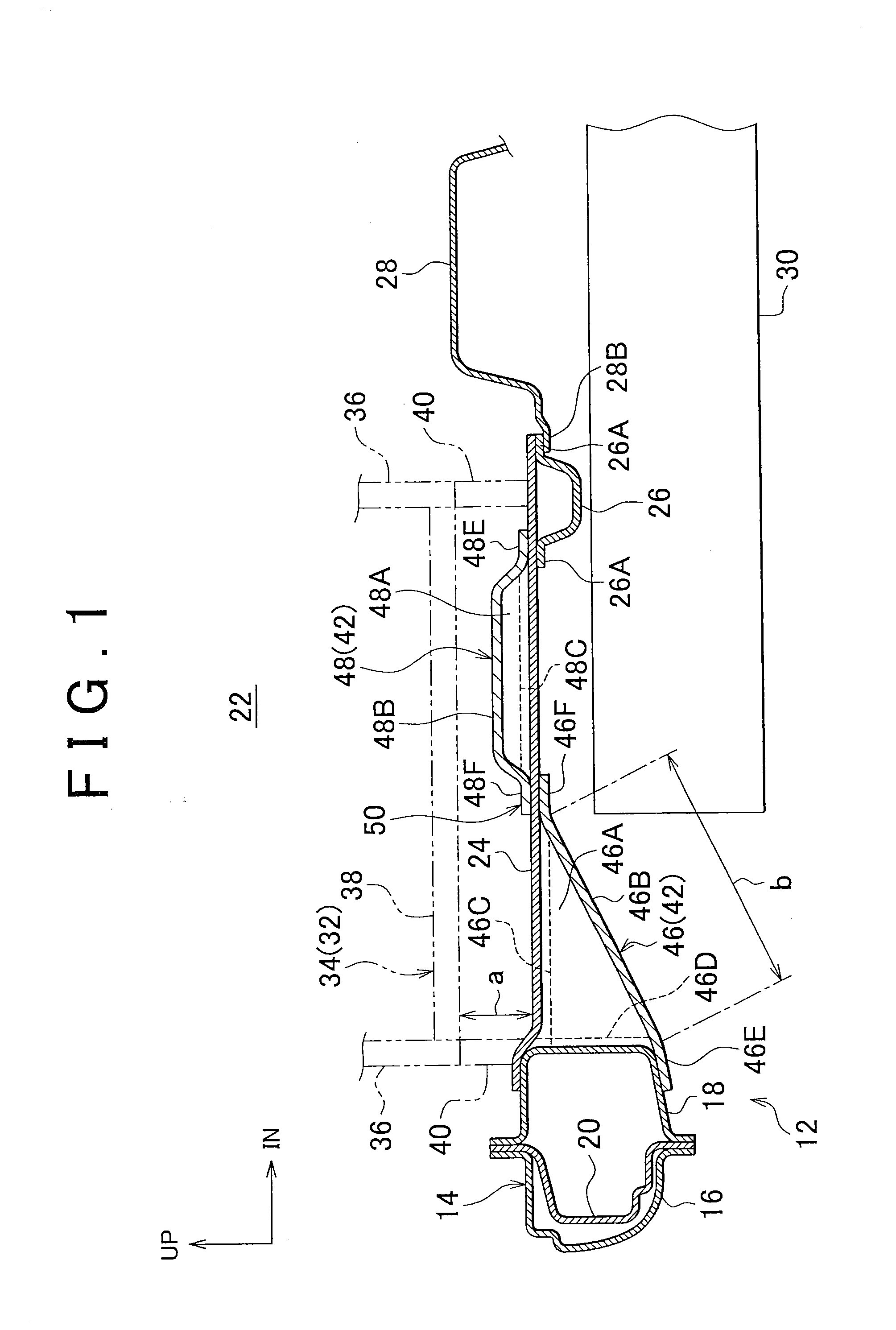

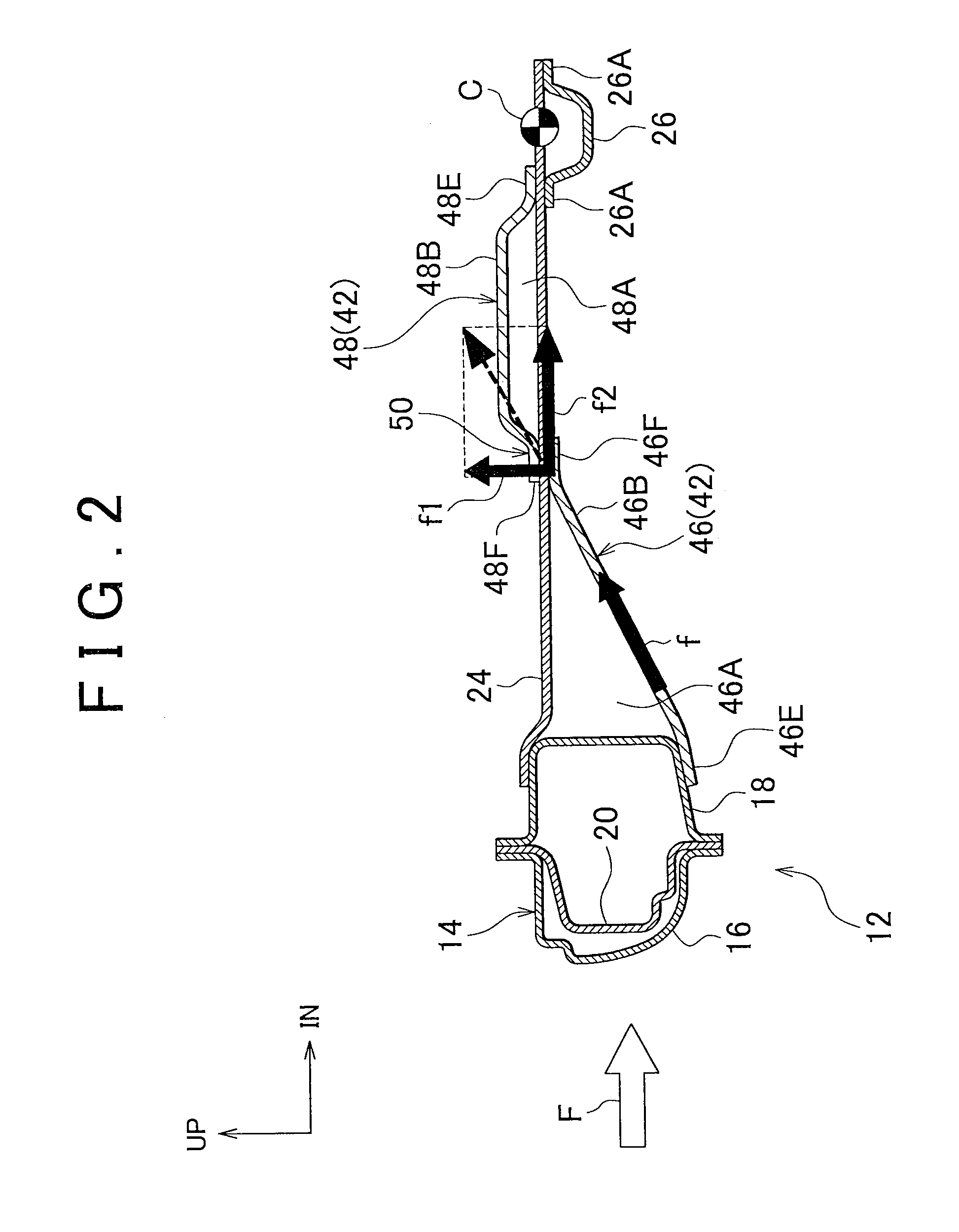

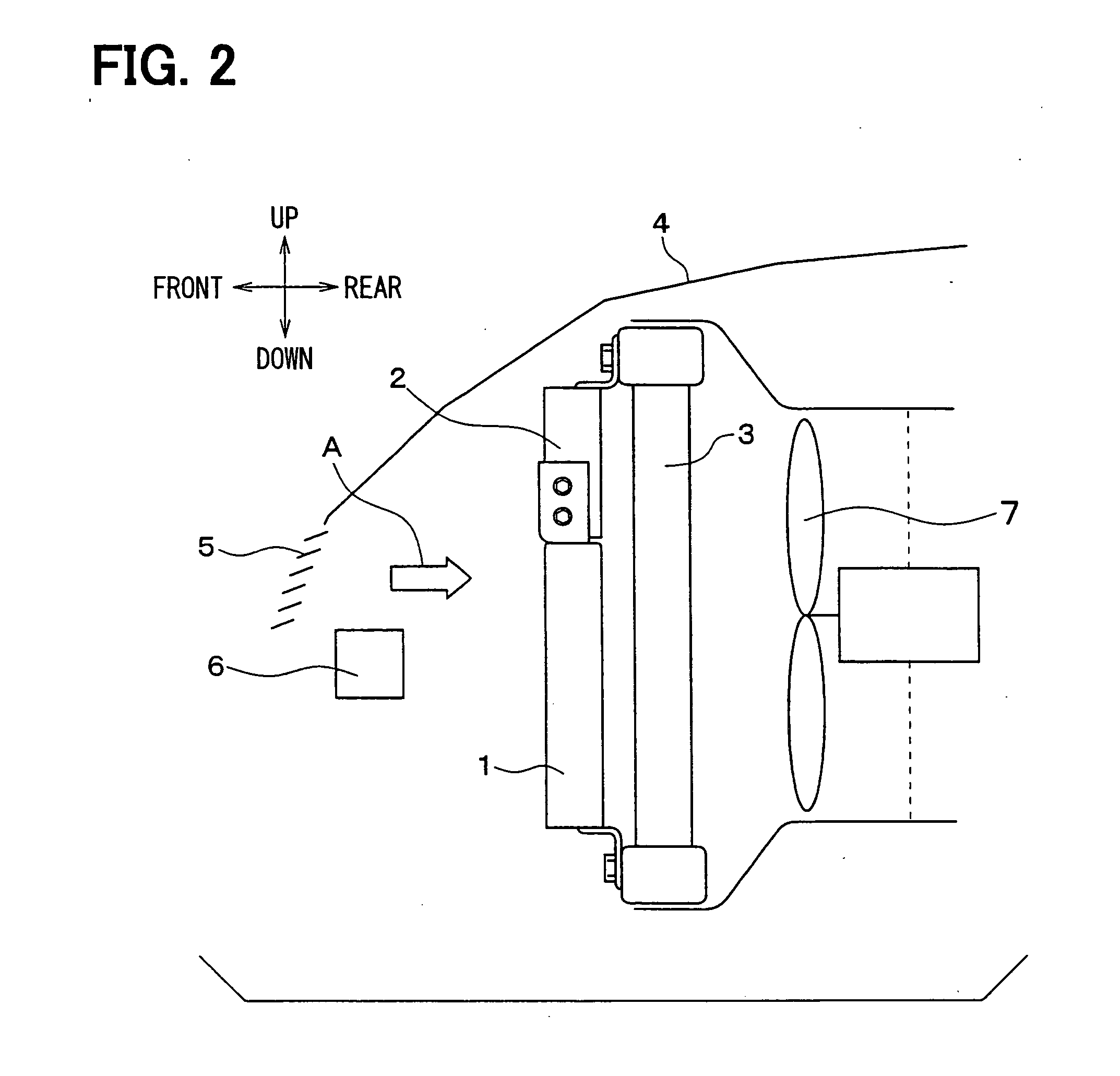

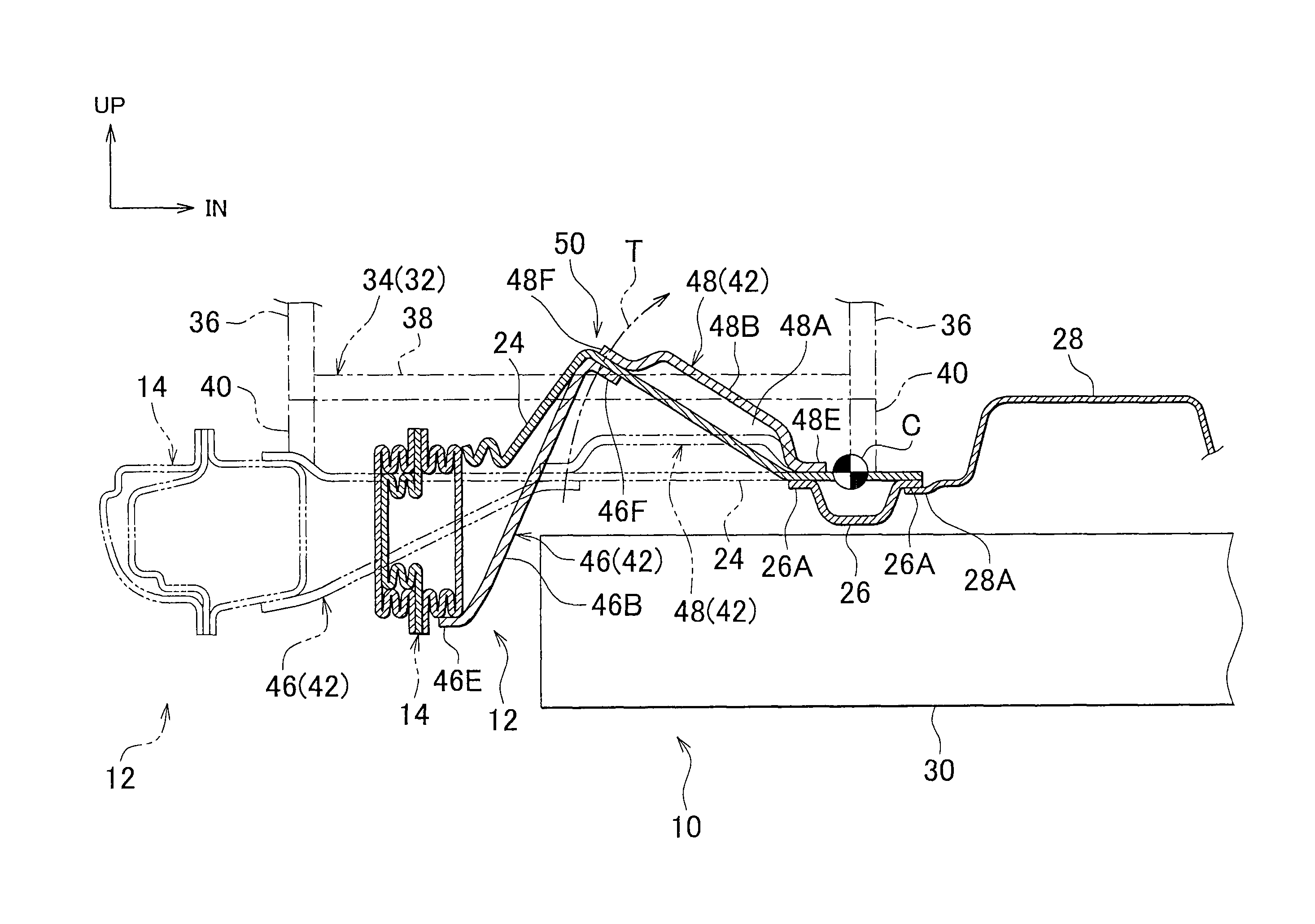

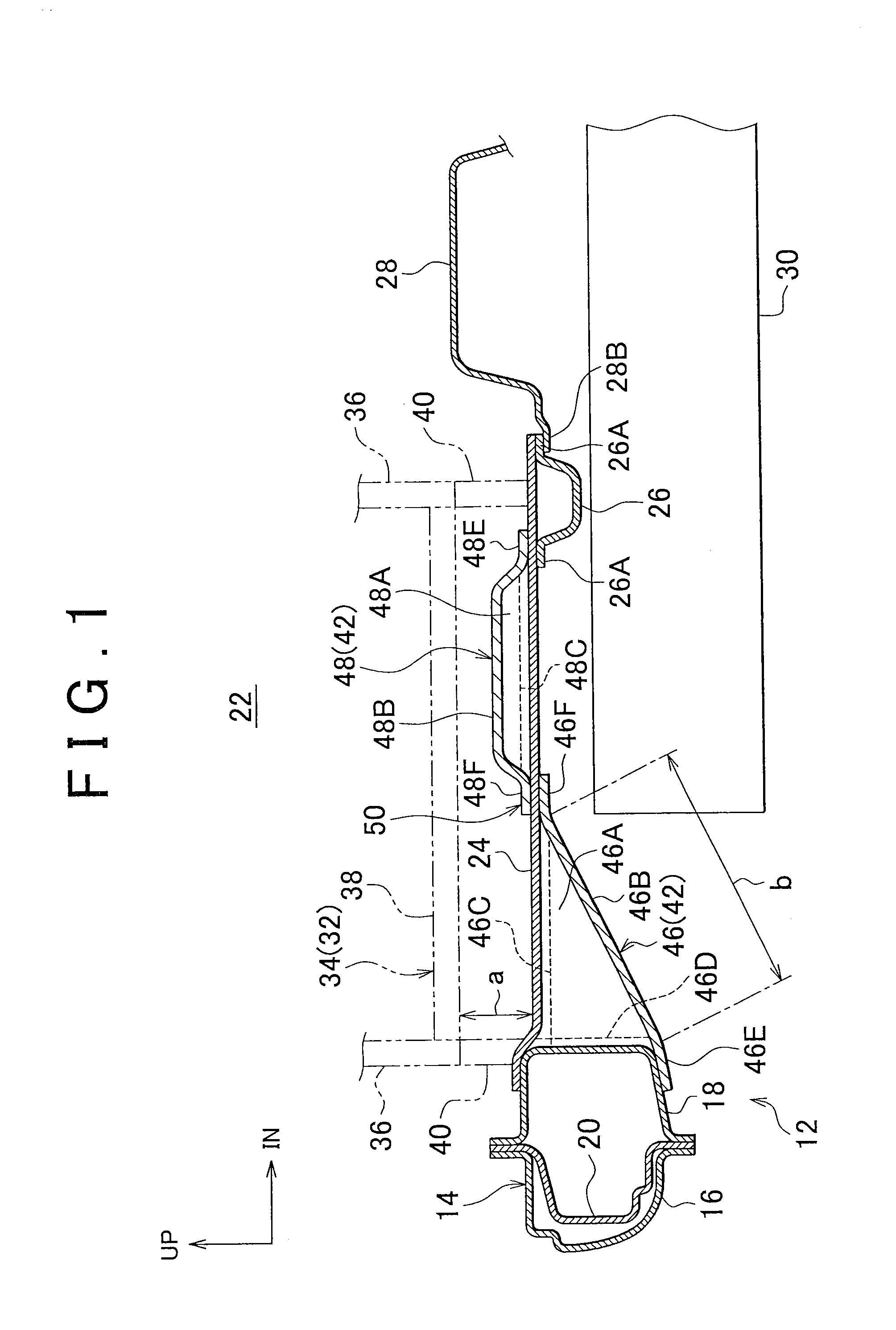

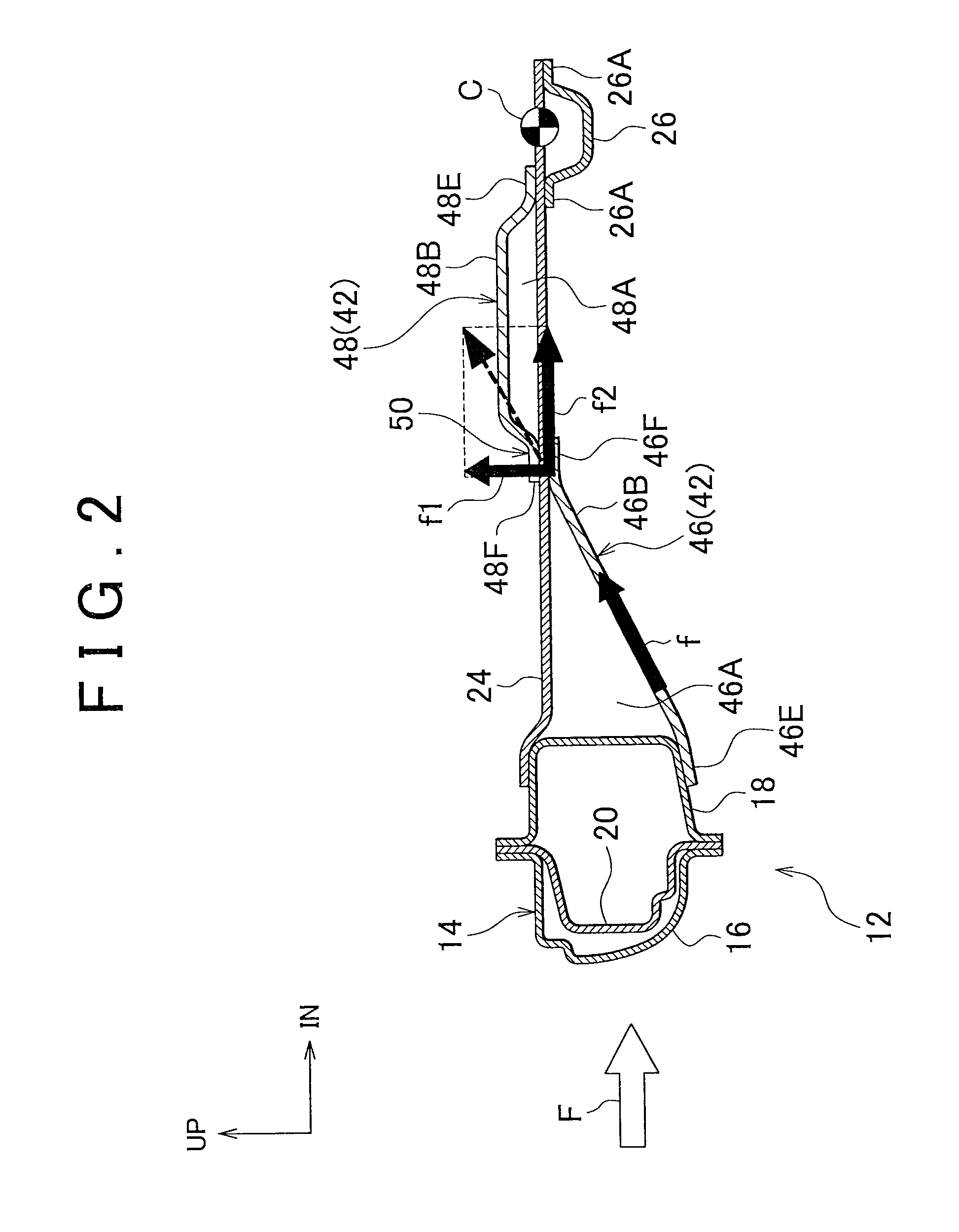

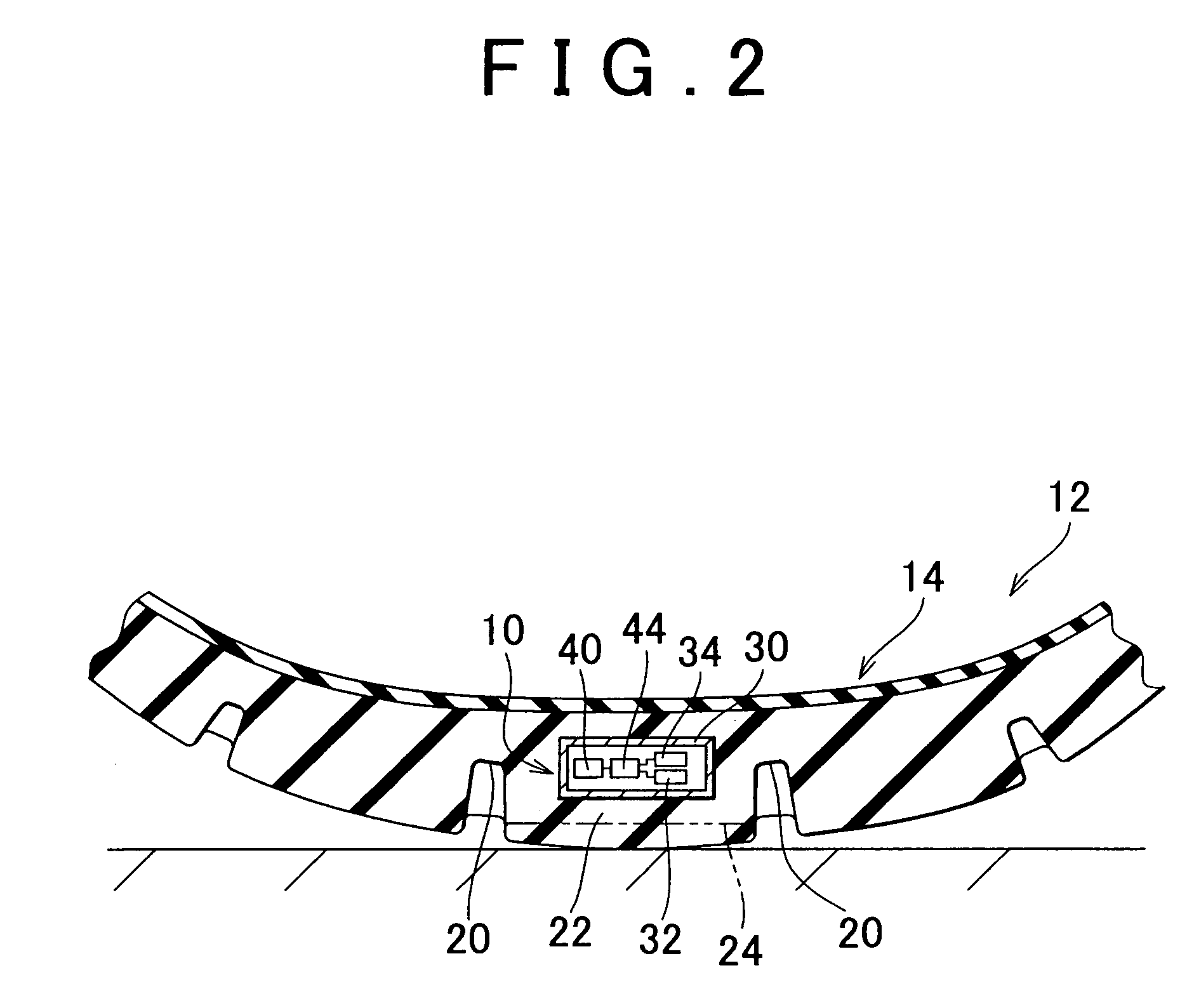

Front body structure for vehicle

ActiveUS6957846B2Reduce amount of deformationPromote lateral displacementVehicle seatsPedestrian/occupant safety arrangementTransfer mechanismPower unit

A vehicle front body structure includes a side-member front area 11F inclined outwardly in the width direction of a vehicle as directing ahead of the vehicle, a strength control mechanism C provided in the side-member front area 11F, a sub-side member 20 extending from the vicinity of a continuous base of the side-member front area 11F toward the front of the vehicle, substantially straight to an extension of a side-member rear area 11R. The front end of the sub-side member 20 is connected with the rear face of a bumper reinforcement 12. The sub-side member 20 is provided with a deformation-mode control mechanism D that allows the sub-side member 20 to be deformed inwardly in the width direction of the vehicle due to a collision input and interferes with a power unit P, forming an impact load transfer mechanism B.

Owner:NISSAN MOTOR CO LTD

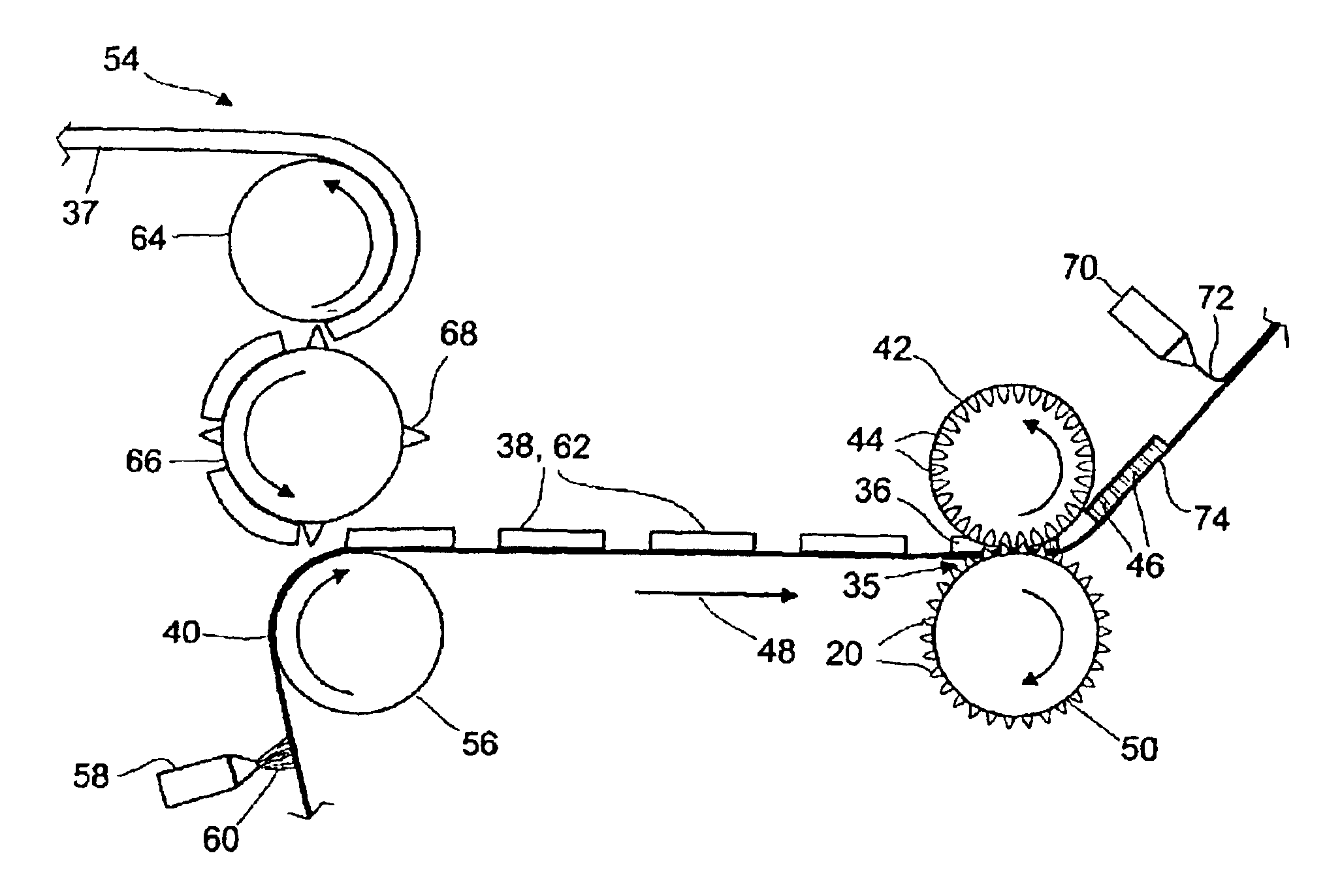

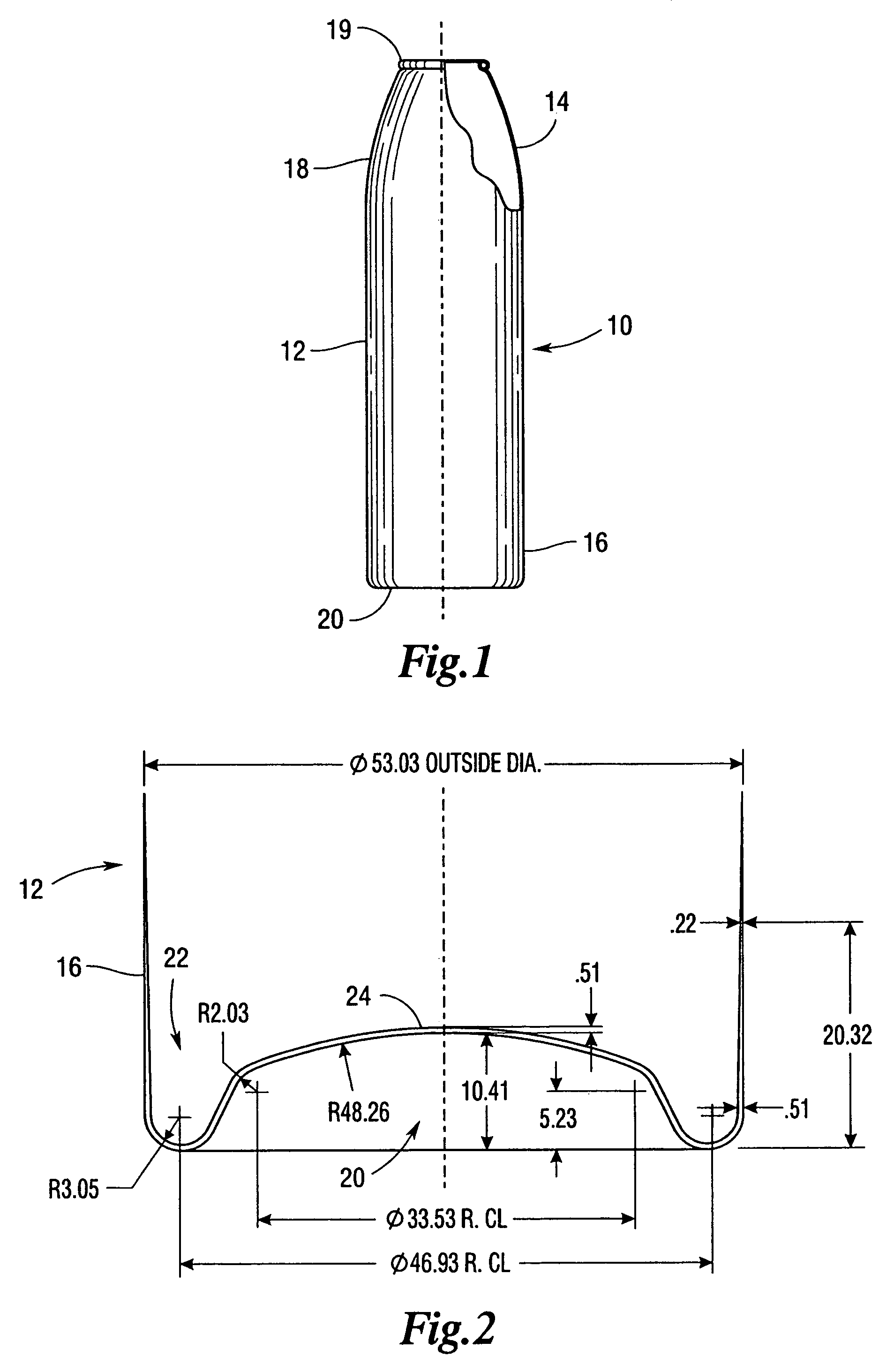

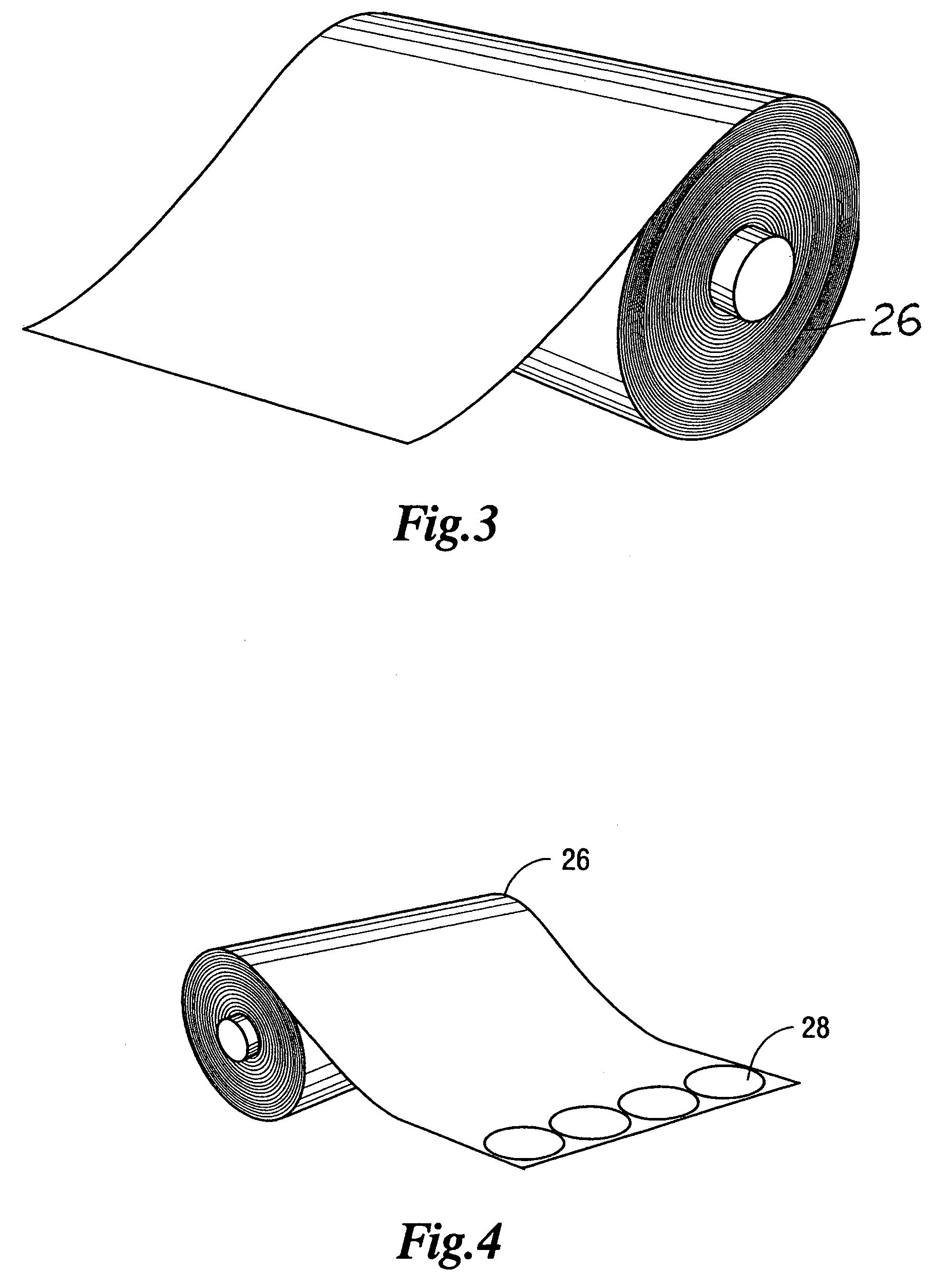

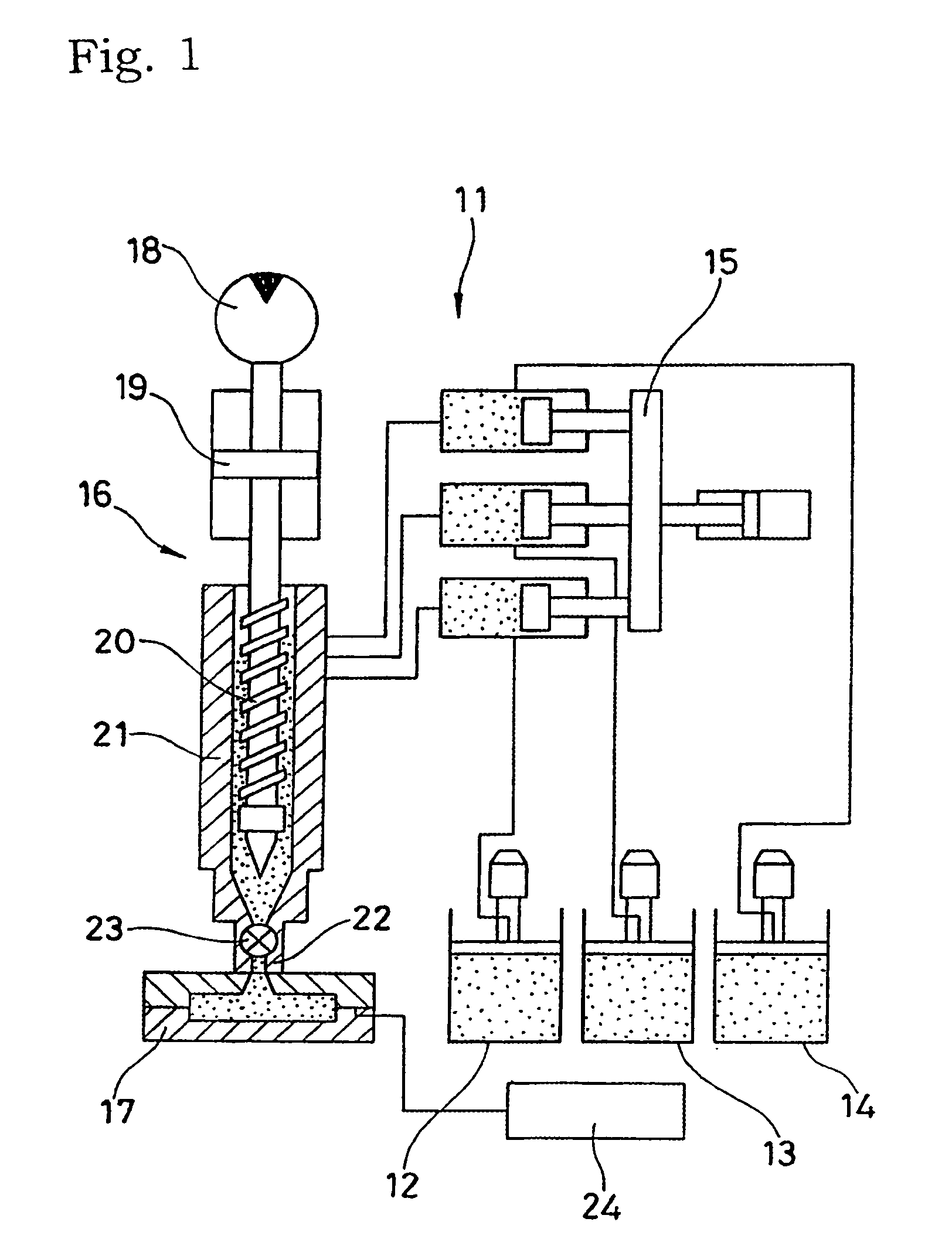

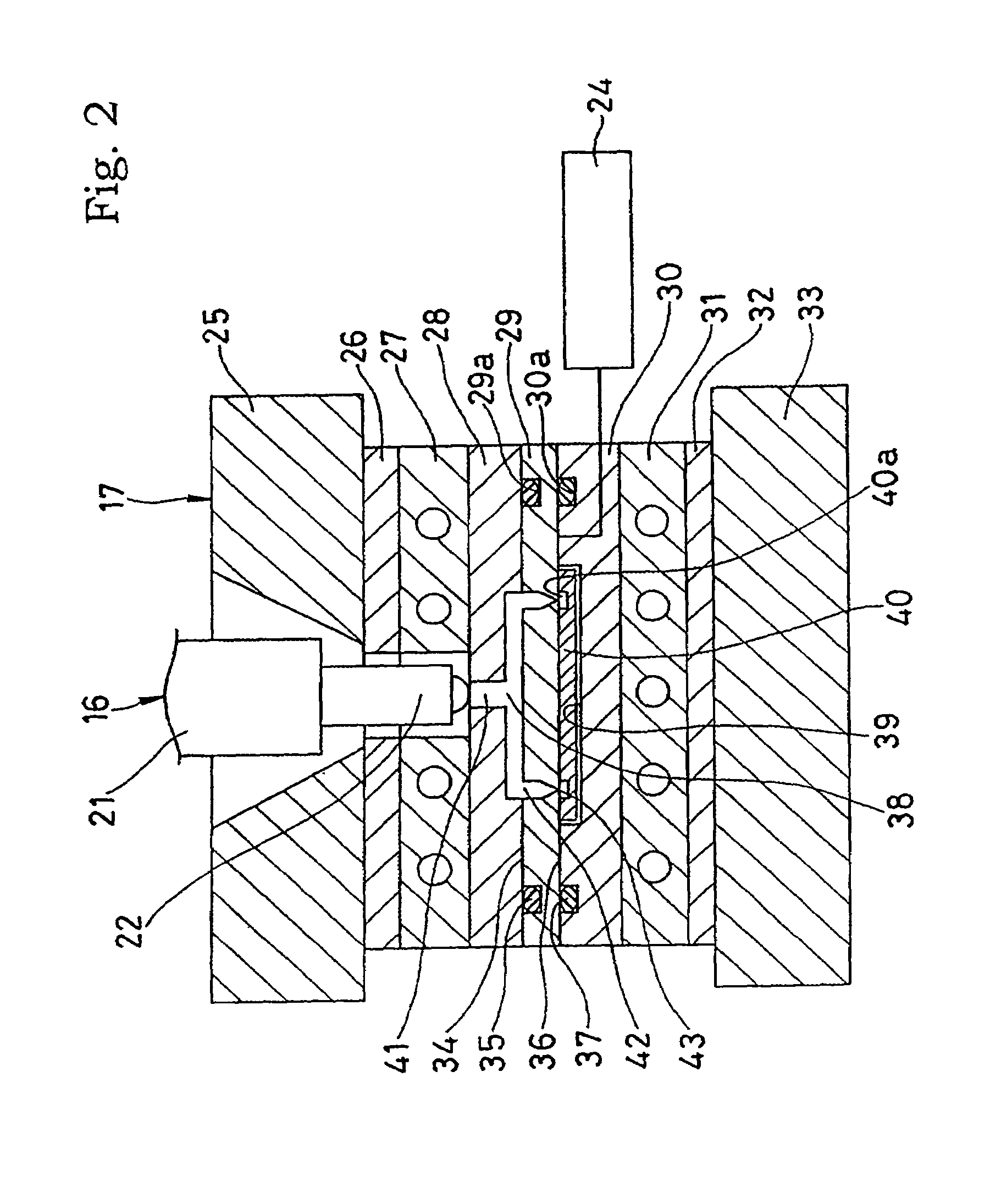

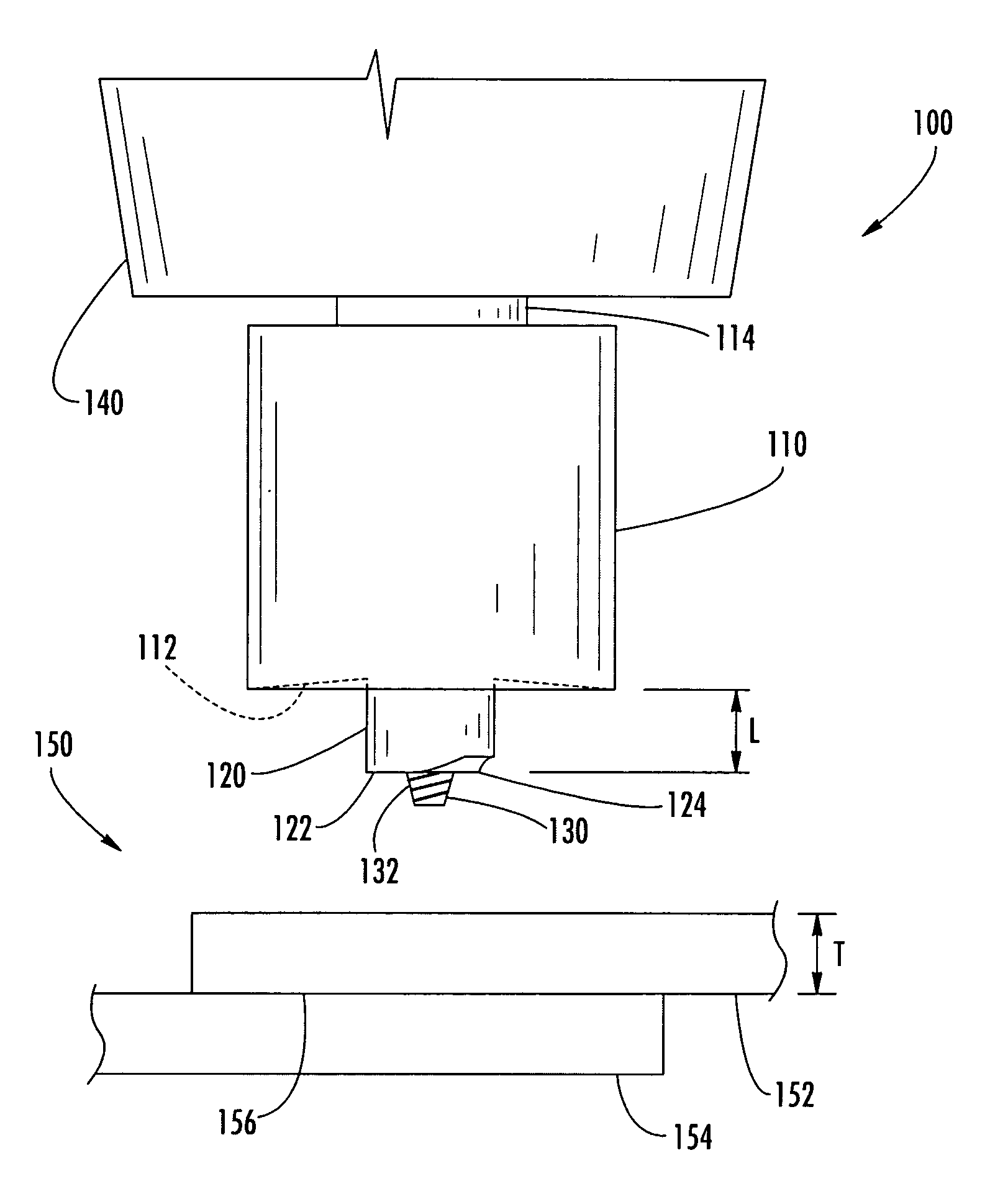

System for aperturing and coaperturing webs and web assemblies

InactiveUS6837956B2Reduce distortionReduce frictionLamination ancillary operationsLaminationEngineeringMechanical engineering

Improved aperturing of a web can be obtained by providing pins with an extended tapered section that is substantially convex in shape. When the tapered section is longer than the penetration depth of the pins into the receiving recesses of a female roll, frictional forces in the nip between layers are reduced. Pins with extended tapered sections can be used in devices for producing apertured composite web assemblies comprising sections of absorbent matter attached to a nonwoven web or other carrier layer.

Owner:KIMBERLY-CLARK WORLDWIDE INC

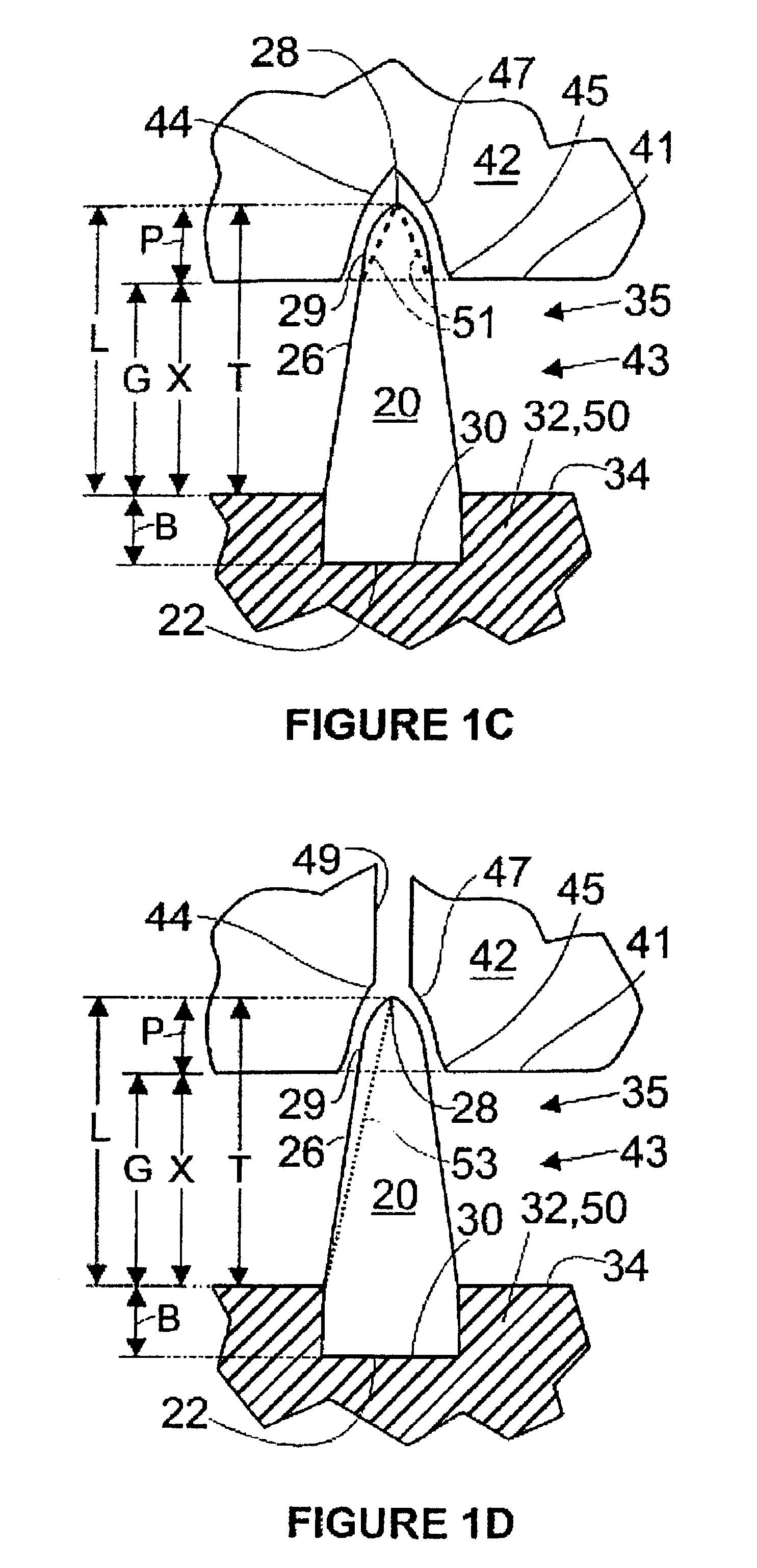

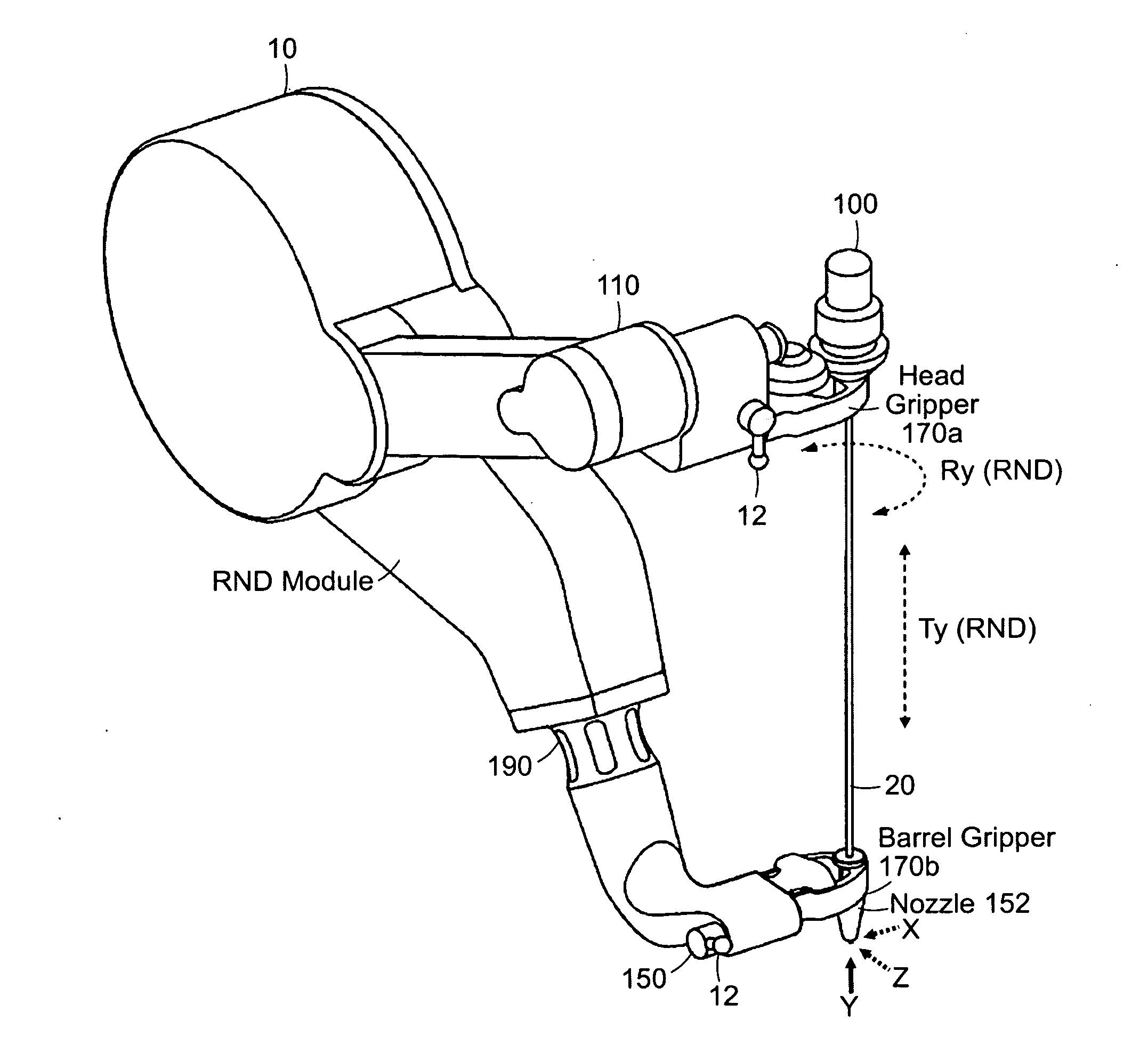

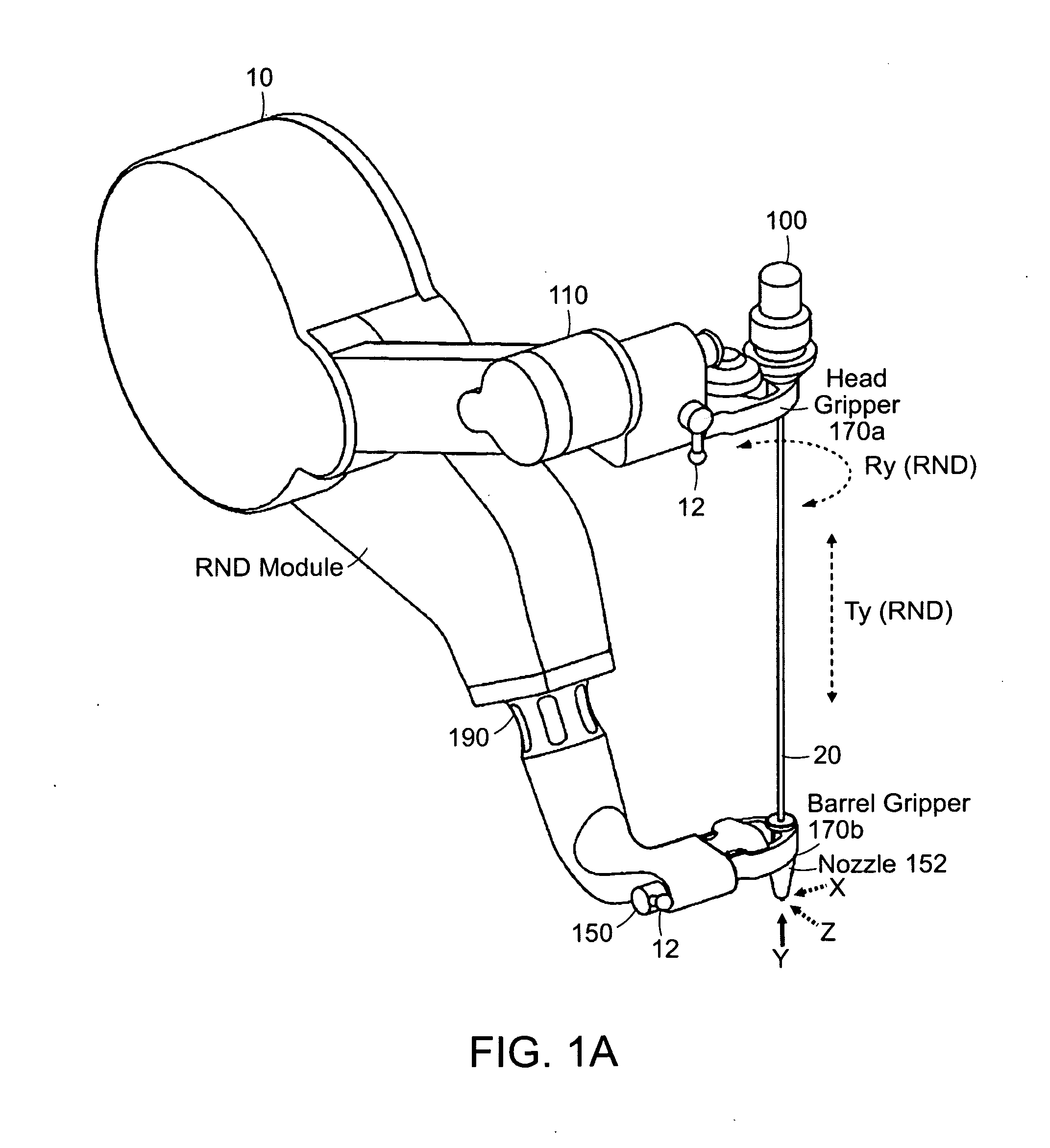

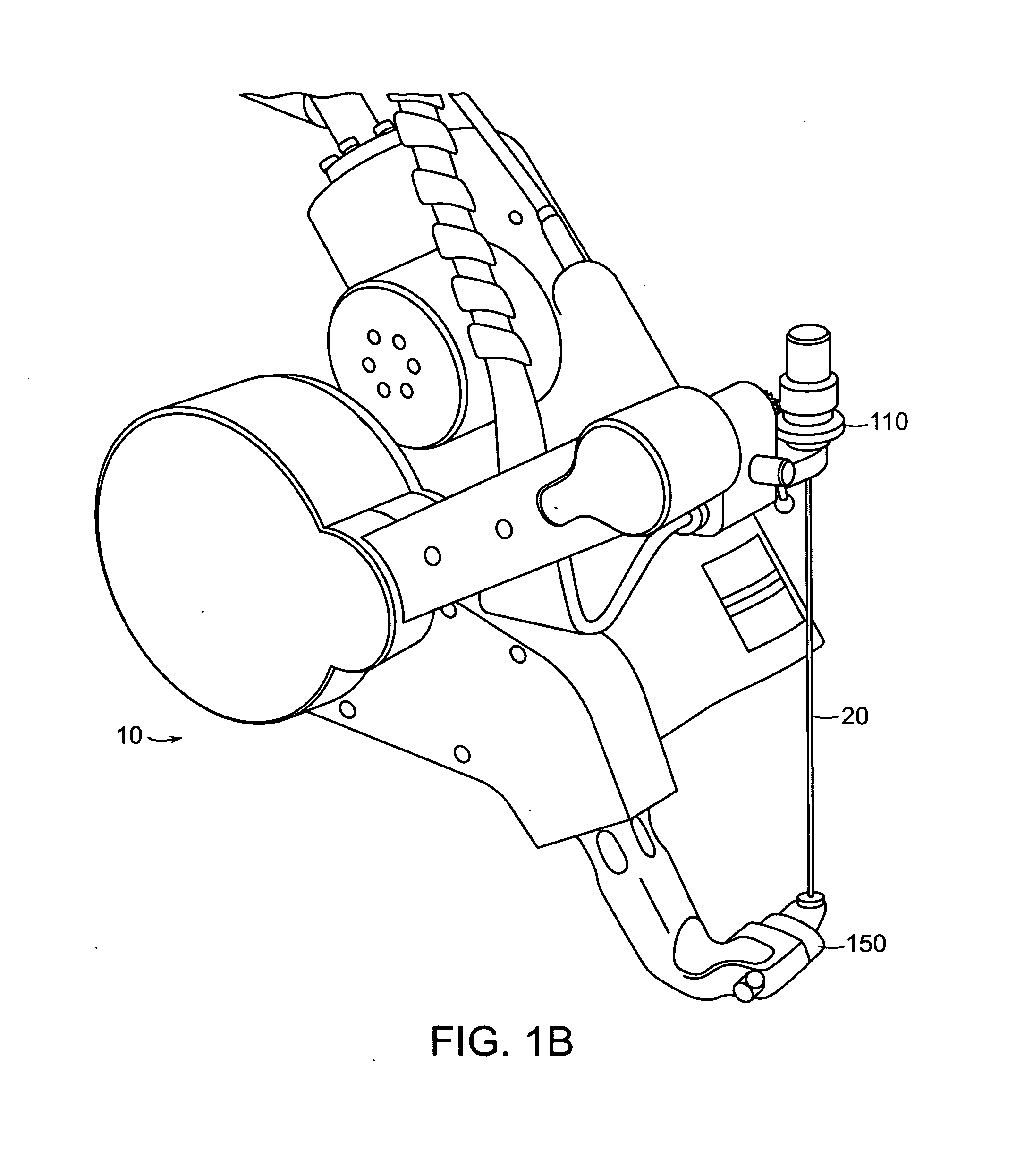

Rotating needle driver and apparatuses and methods related thereto

ActiveUS20100234856A1Reduce insertion forceReduce deformationVaccination/ovulation diagnosticsSurgical manipulatorsAbdominal trocarBiomedical engineering

Featured is a medical instrument driver, a robotic apparatus embodying such a medical instrument driver and methods related thereto for inserting a medical instrument into tissue of a mammal (e.g., human). Such medical instruments include medical needles, biopsy needles, trocars, cutters and introducers. Such a medical instrument driver according to the present invention is configured and arranged so that medical instrument is rotated as it is being moved longitudinally for insertion into the tissue such that the medical instrument is spiraling as it pierces and traverses the tissue to the target area.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

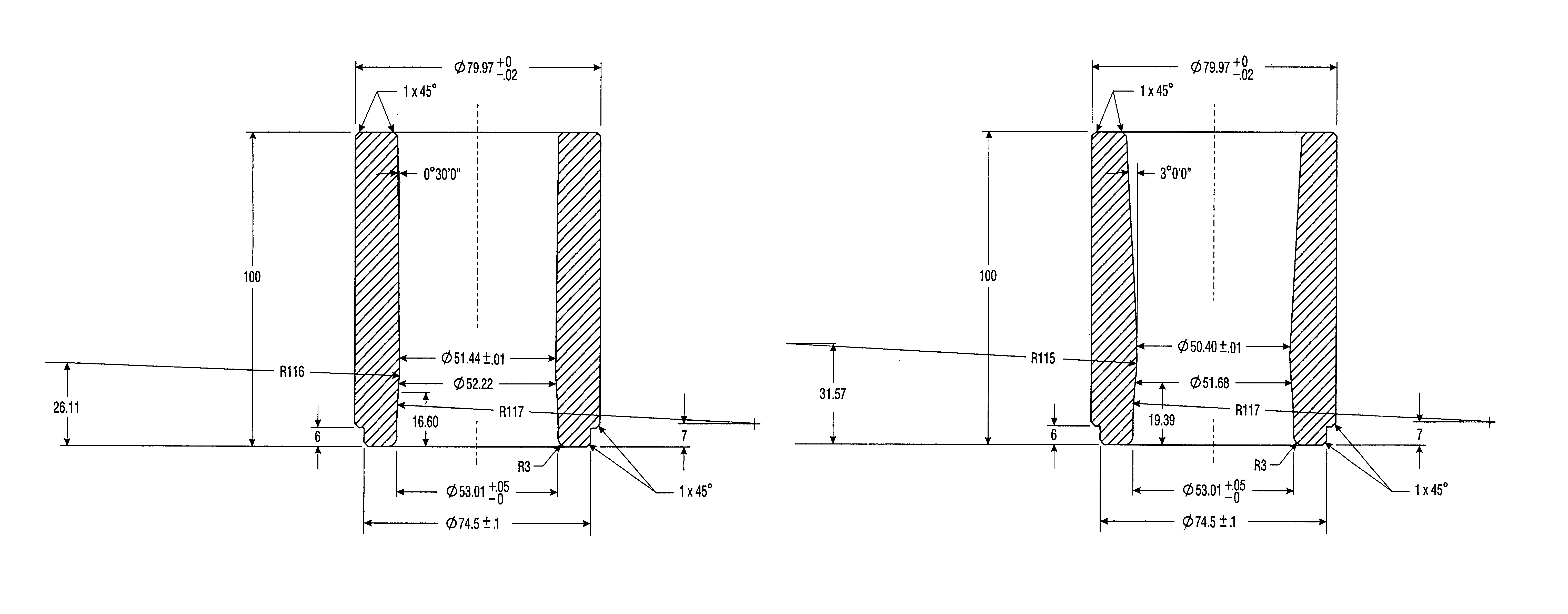

Method of producing aluminum container from coil feedstock

InactiveUS7140223B2Avoid stickingIncrease the number ofCans/barrels/drumsLiquid dispensingUltimate tensile strengthAerosol

Aerosol cans, more particularly, aluminum aerosol cans made from disks of aluminum coil feedstock, are provided. A method for necking aerosol cans of a series 3000 aluminum alloy is also provided. The method prevents the cans from sticking in the necking dies and produces a can with a uniquely shaped profile. The aluminum aerosol cans that are produced have the attributes of strength and quality, while being produced at a cost that is competitive with steel aerosol cans.

Owner:EXAL

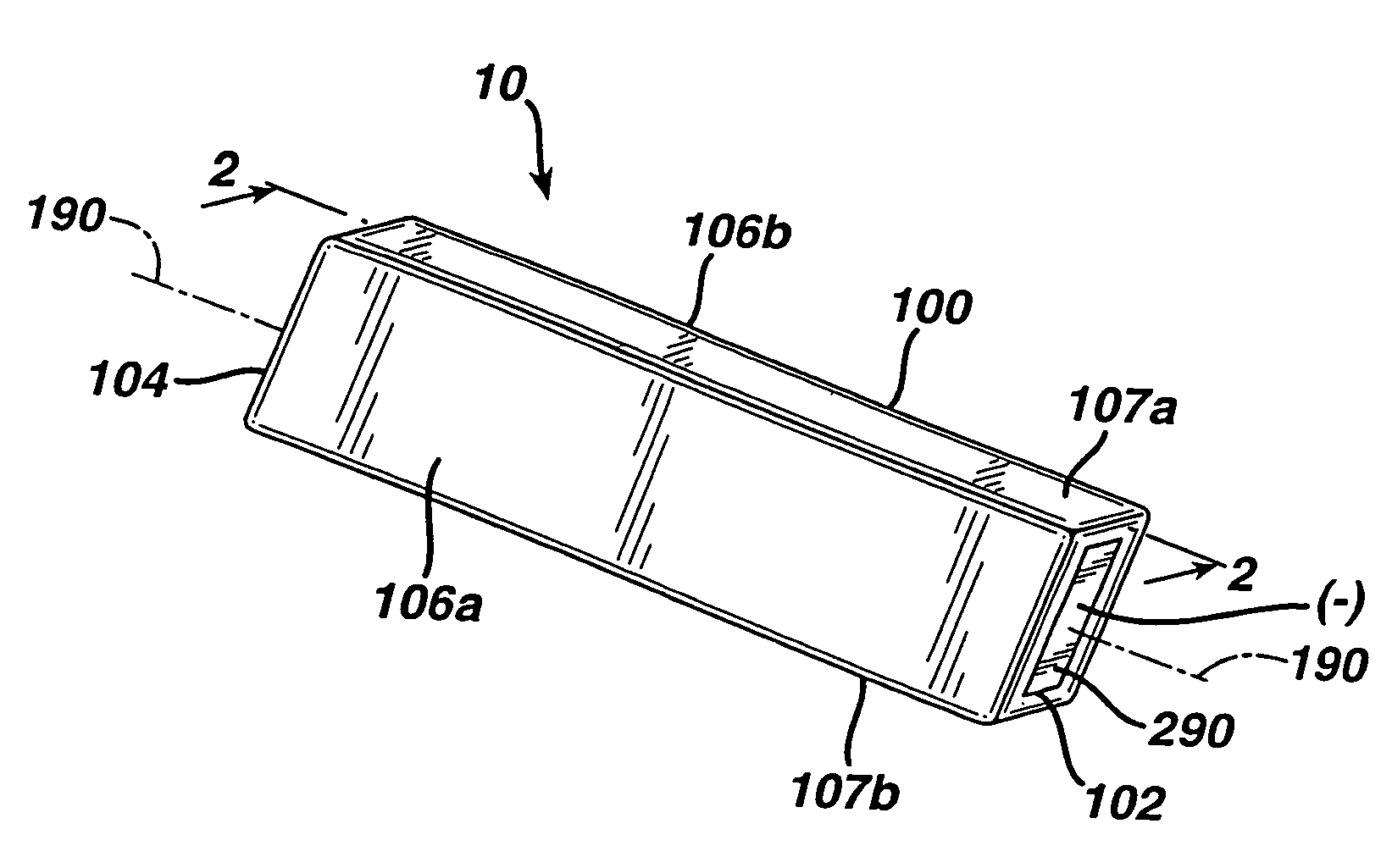

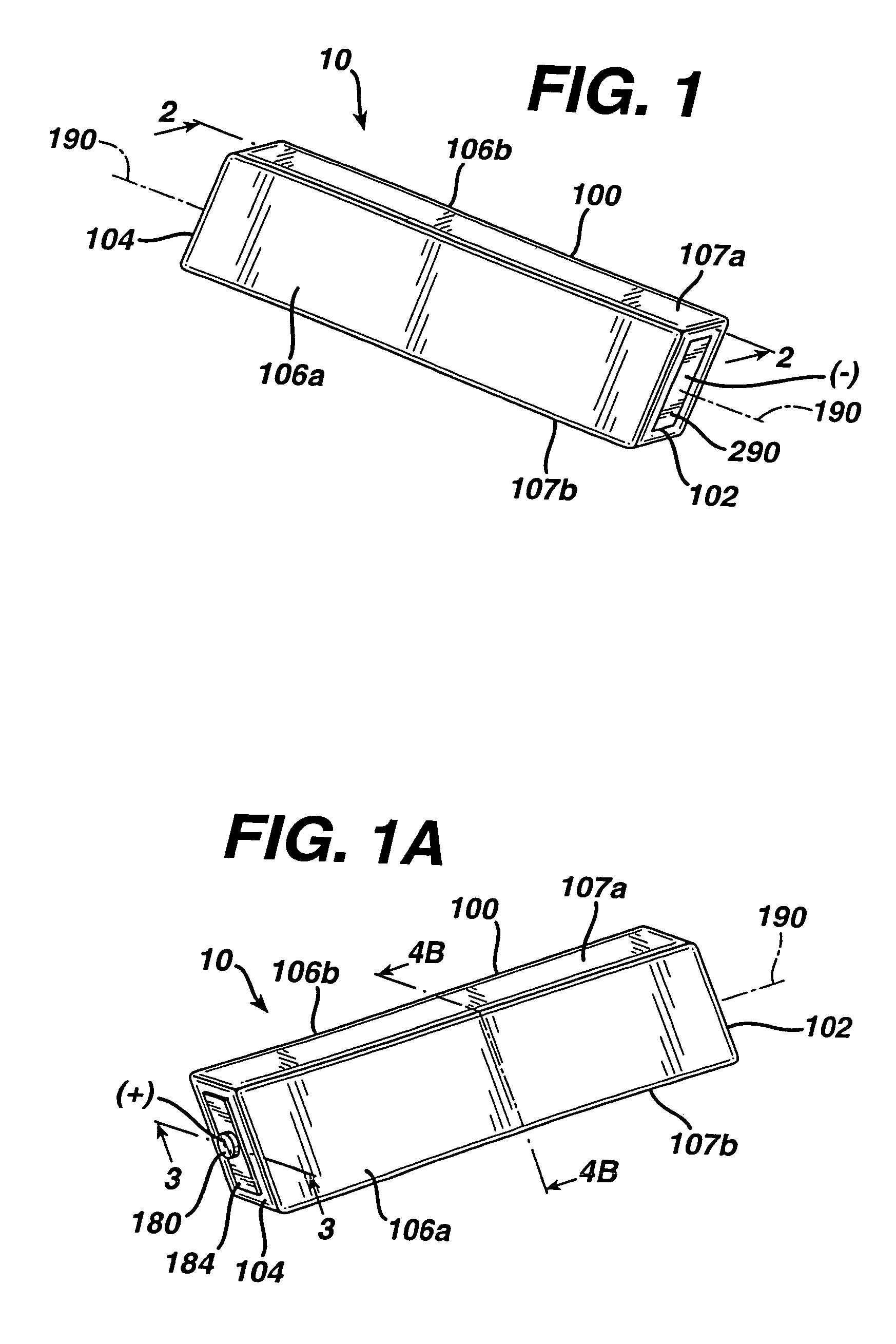

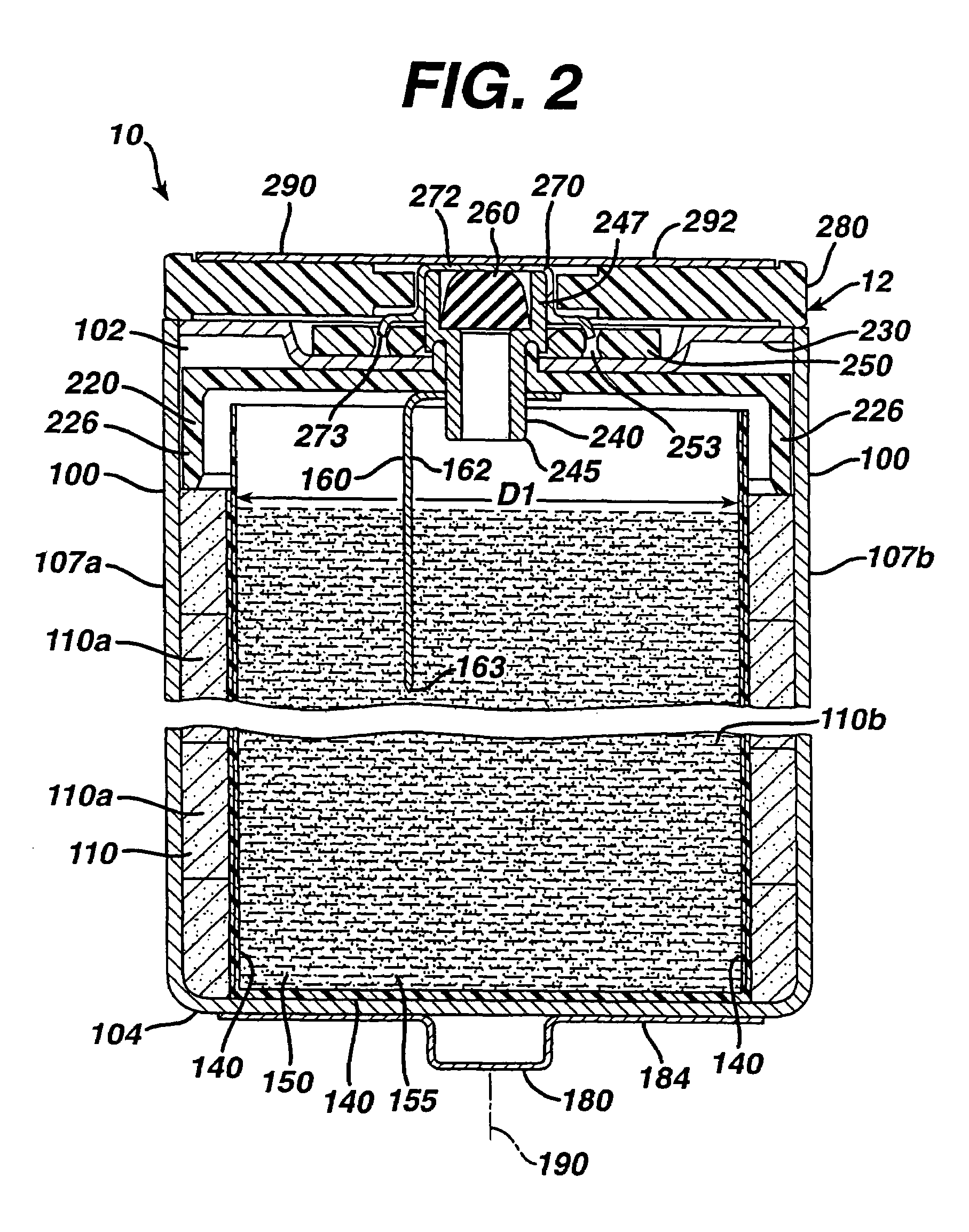

Alkaline cell with flat housing and nickel oxyhydroxide cathode

An alkaline cell having a flat casing, preferably of cuboid shape. The cell can have an anode comprising zinc and a cathode comprising nickel oxyhydroxide. The casing can have a relatively small overall thickness, typically between about 5 and 10 mm, but may be larger. Cell contents can be supplied through an open end in the casing and an end cap assembly inserted therein to seal the cell. The end cap assembly includes a vent mechanism, preferably a grooved vent, which can activate, when gas pressure within the cell reaches a threshold level typically between about 250 and 800 psig (1724×103 and 5515×103 pascal gage). The cell can have a supplemental vent mechanism such as a laser welded region on the surface of the casing which may activate at higher pressure levels.

Owner:DURACELL U S OPERATIONS

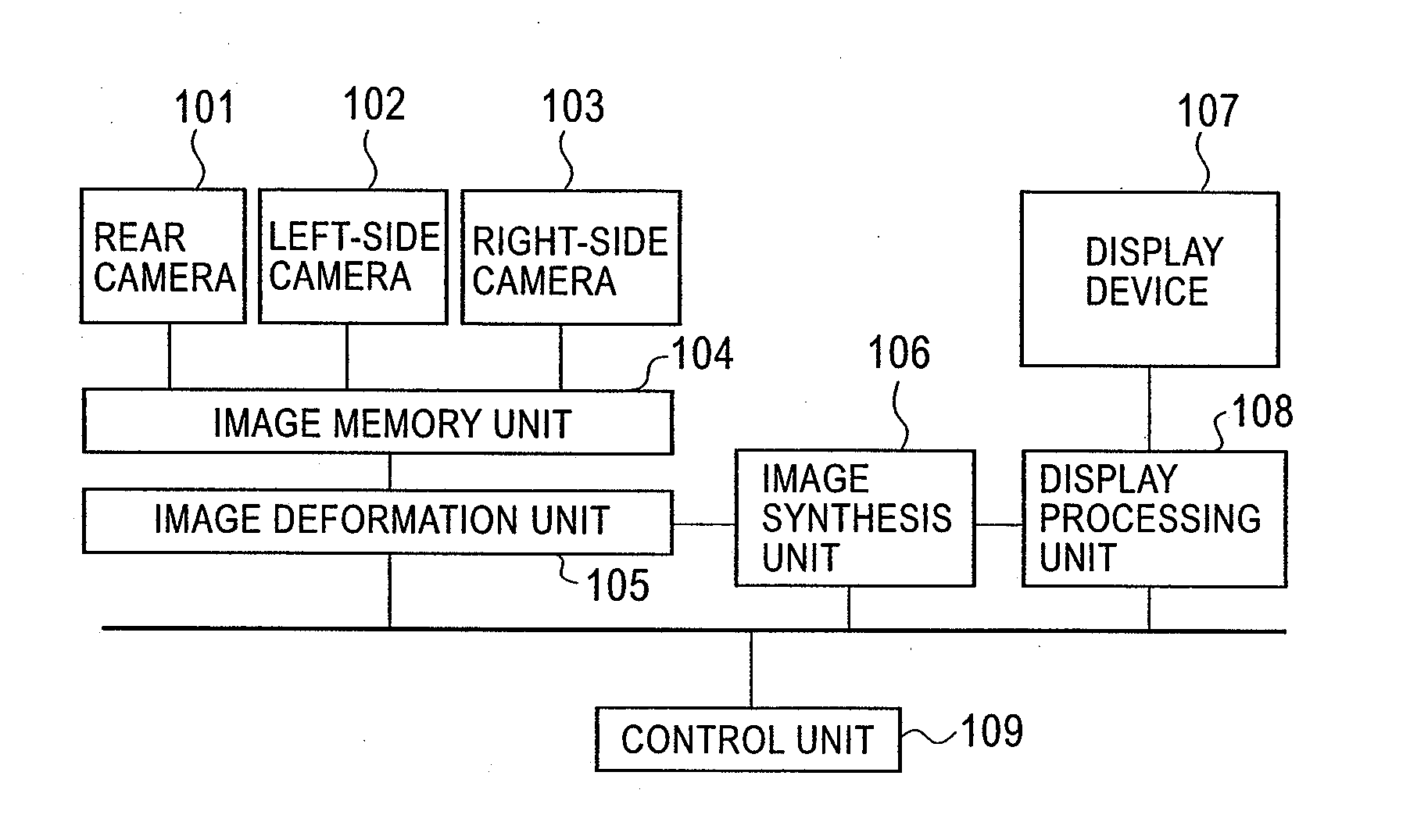

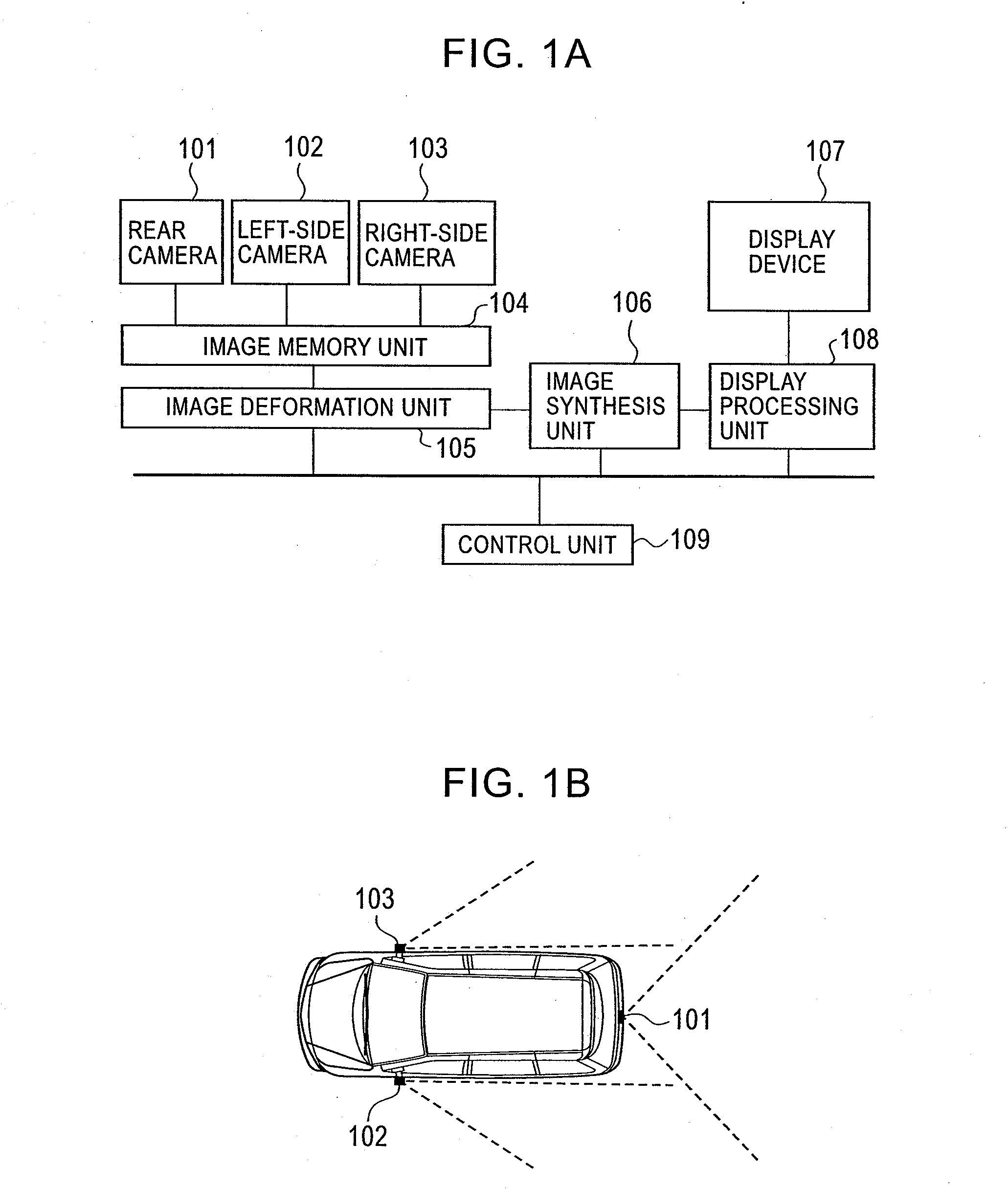

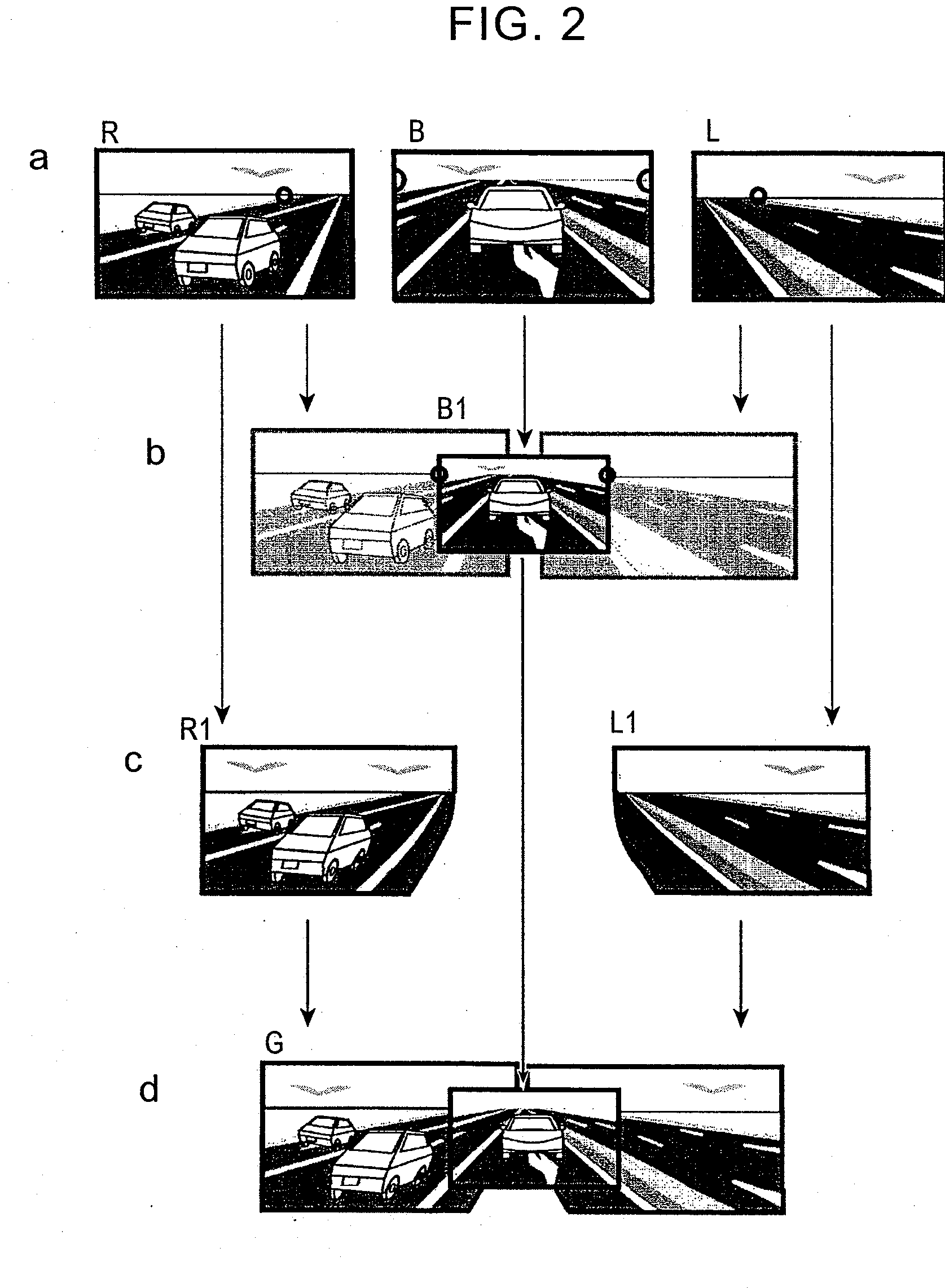

Vehicle Surrounding Image Display Device

ActiveUS20070165108A1Prevent dislocationReduce deformationCharacter and pattern recognitionColor television detailsViewpointsComputer graphics (images)

A vehicle surrounding image display device according to the present invention combines an image obtained by reducing in size an image taken by a camera provided at the center of the rear side of a vehicle, and images obtained by deforming images taken by cameras provided at the left and right sides of the vehicle such that the outward inclination of the inner side in the vehicle width direction of each of the left and right side images is gradually increased toward the lower end of the inner side. The vehicle surrounding image display device then generates a single image simulating the circumstances behind the user's own vehicle as observed from a single virtual viewpoint in a realistic form, and displays the generated image on a display device.

Owner:ALPINE ELECTRONICS INC

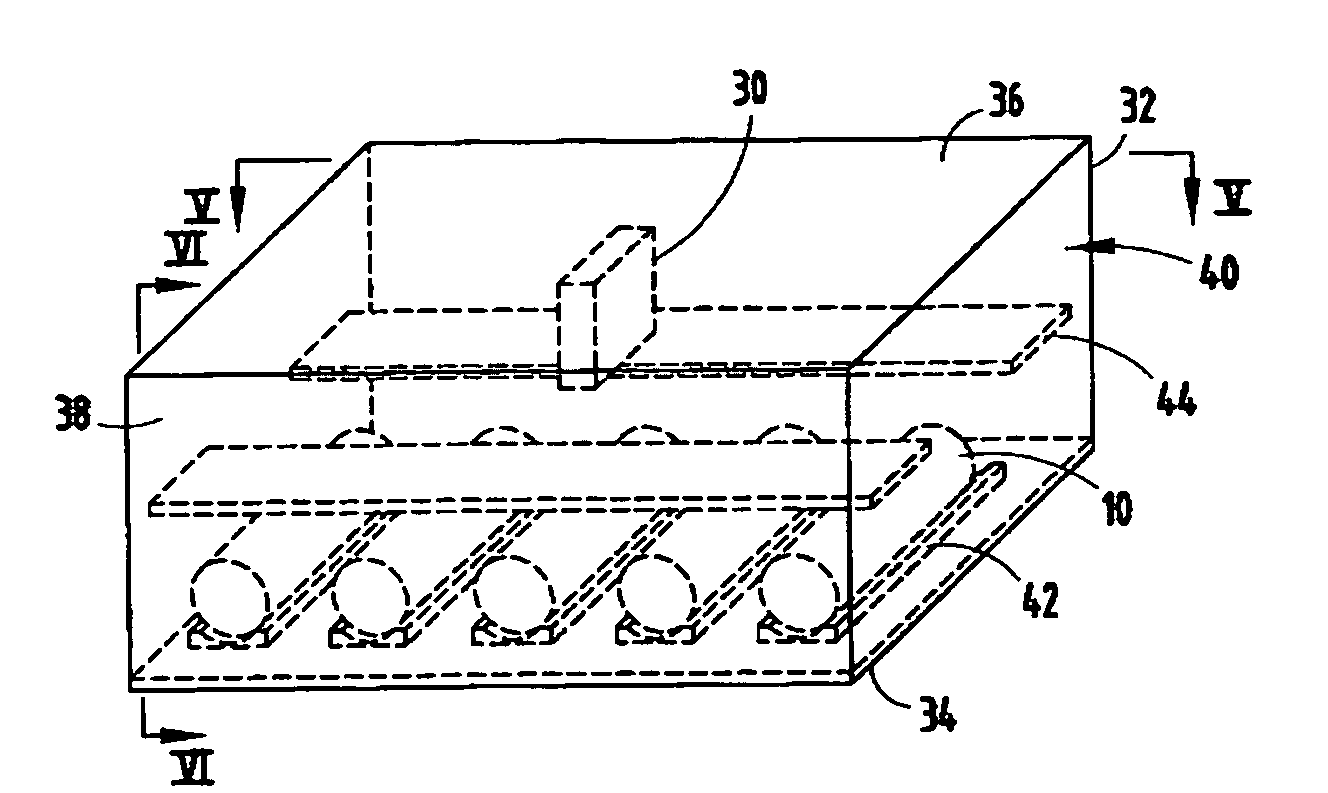

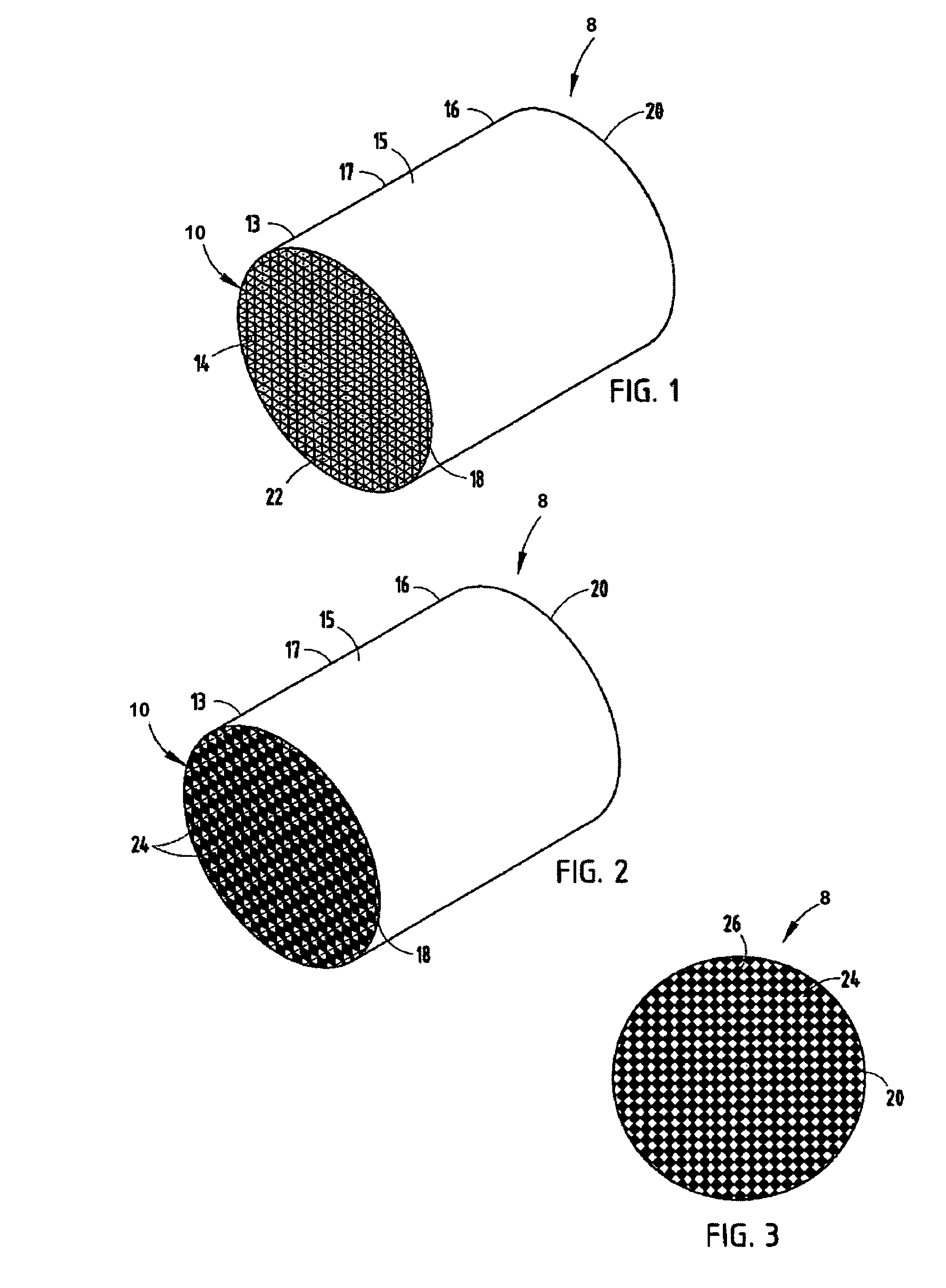

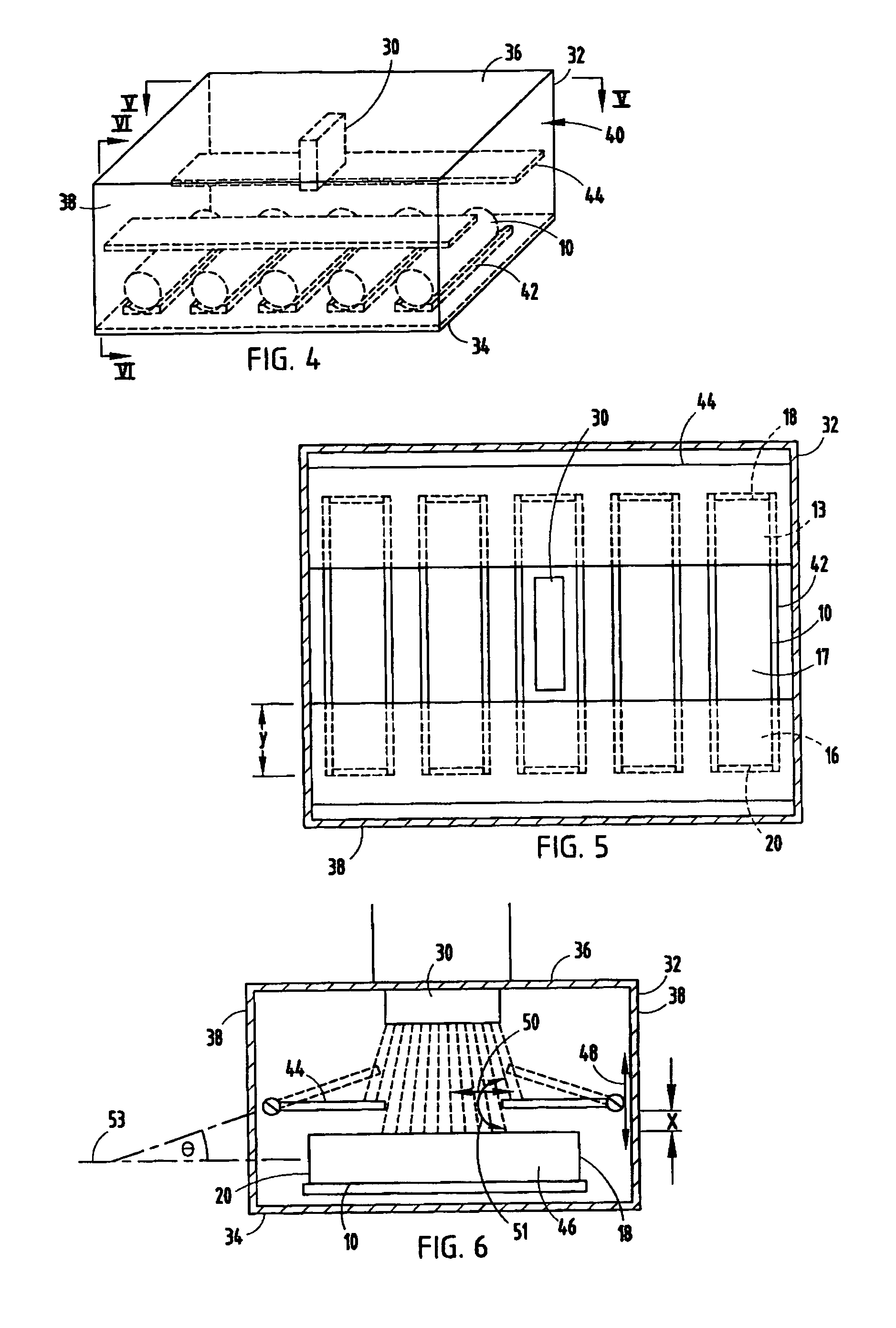

Microwave drying of ceramic structures

ActiveUS7596885B2Dry evenlySimple structureDielectric heatingDrying solid materials with heatStructural degradationMetallurgy

Owner:CORNING INC

Plastic container closure

Owner:JAPAN CROWN CORK CO LTD

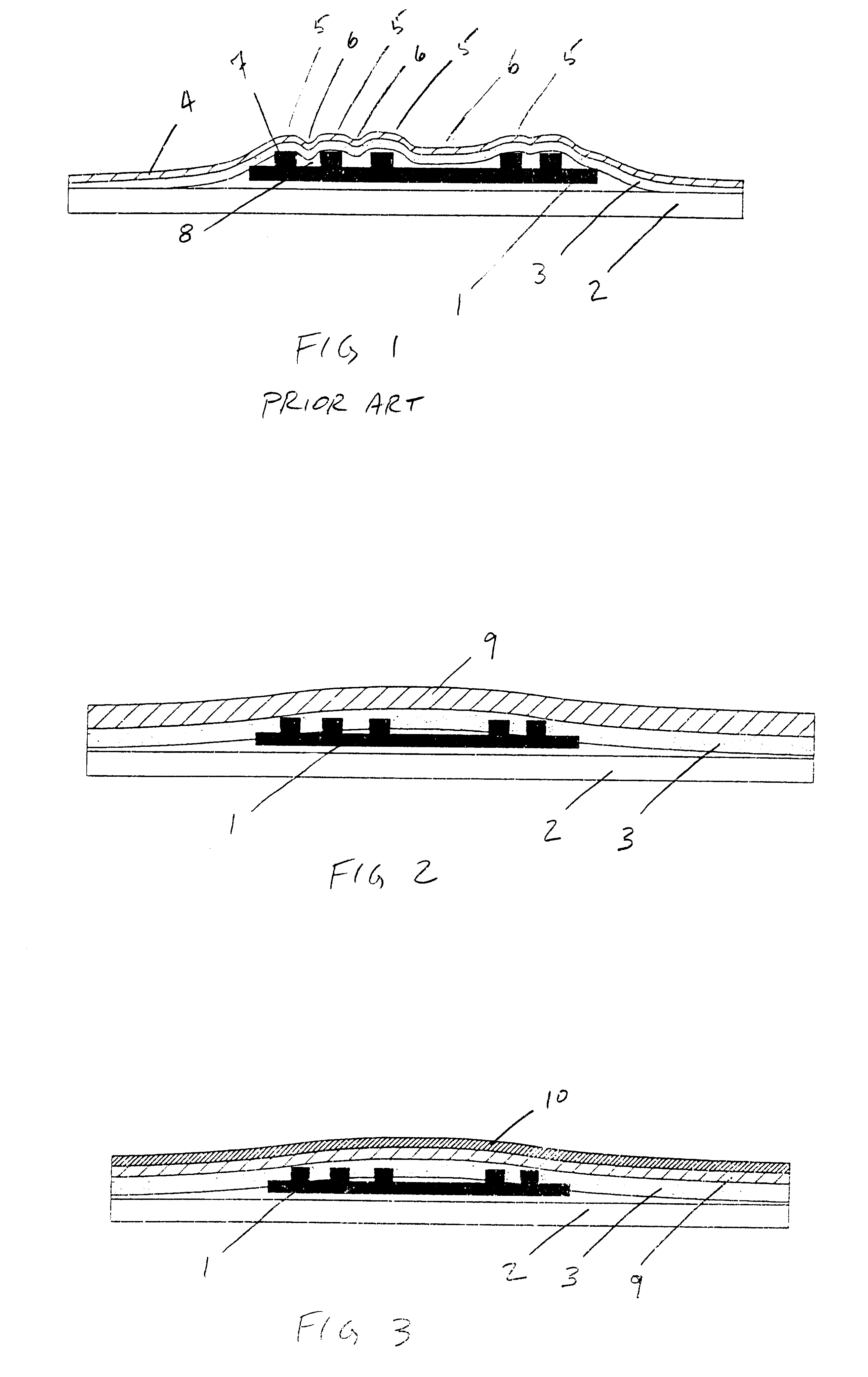

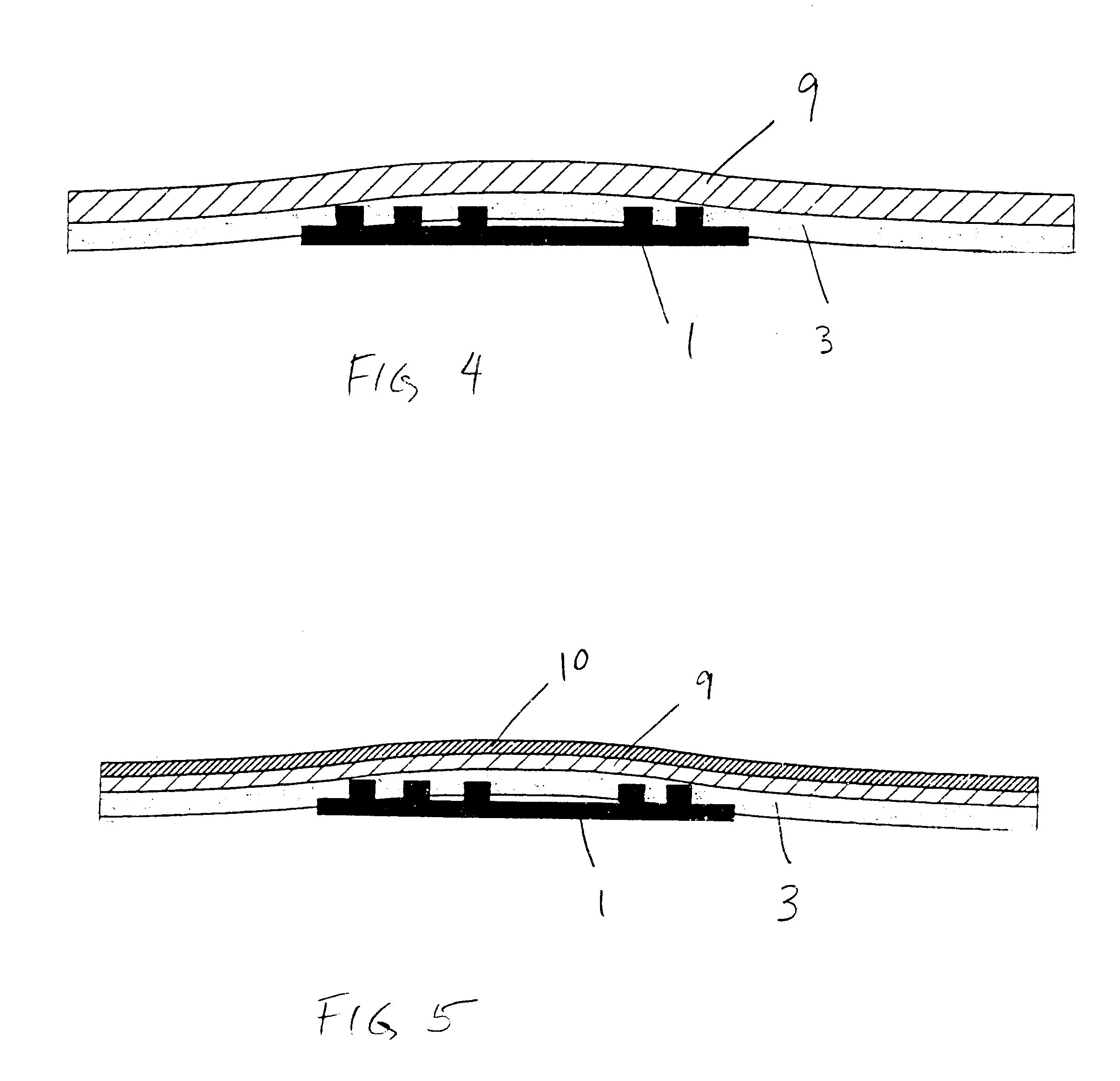

Profile corrected label with RFID transponder and method for making same

InactiveUS6369711B1Reduce deformationReduce bendingConcealed burglar systemsRecord carriers used with machinesEngineeringFace sheet

The present invention sets out a label containing an RFID transponder having a uniform printable surface. The present invention presents a face sheet having an increased rigidity and / or thickness which does not readily conform to the profile of an RFID transponder contained beneath the face sheet. This results in a label having a more readily printable surface, and also presents a label having higher security as a result of the masking of the profile of the contained RFID responder.

Owner:INTERMEC IP

Battery protection structure for automobile

ActiveUS20130026786A1Add additional massReduce deformationVehicle seatsElectric propulsion mountingAutomotive batteryEngineering

Owner:TOYOTA JIDOSHA KK

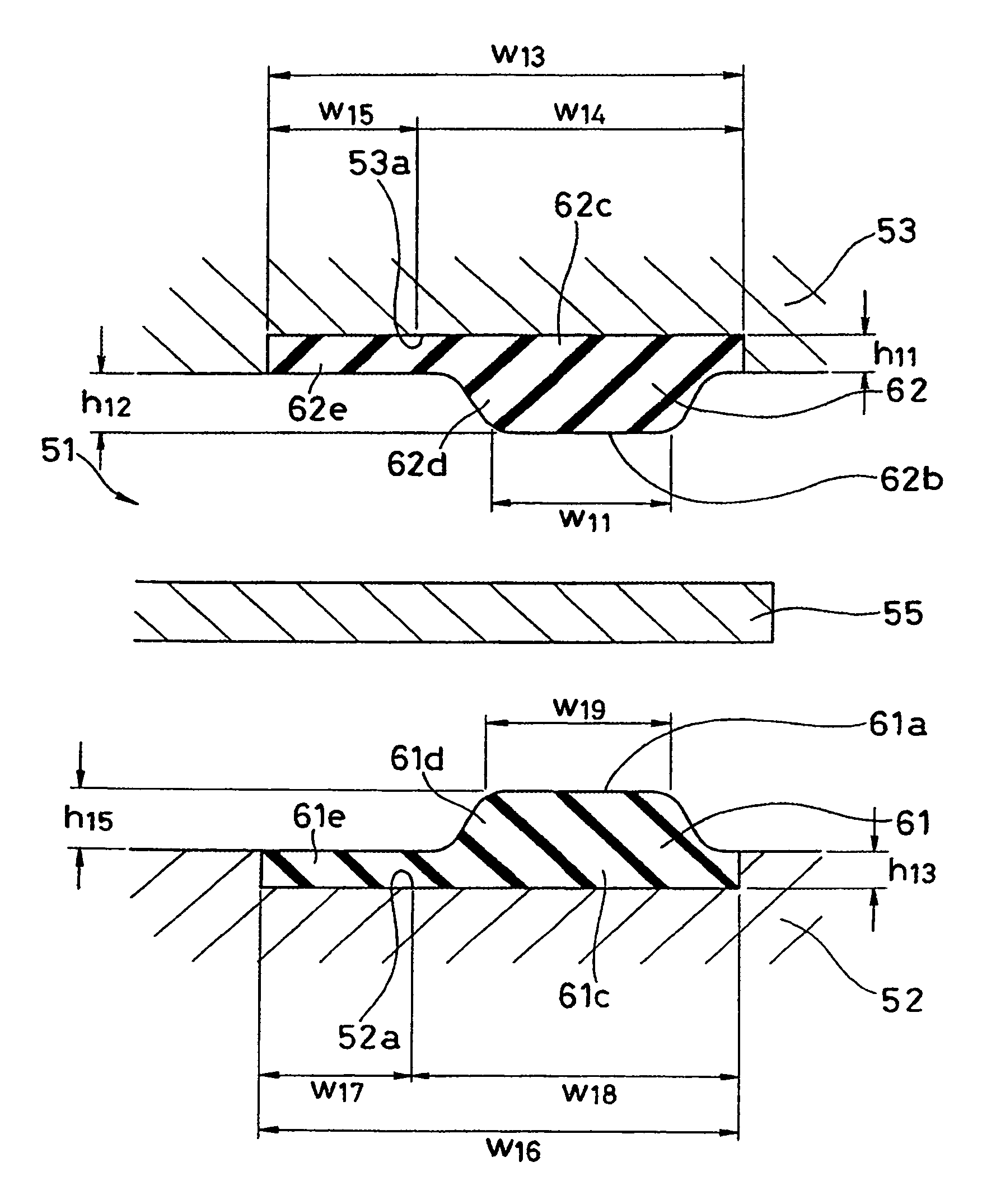

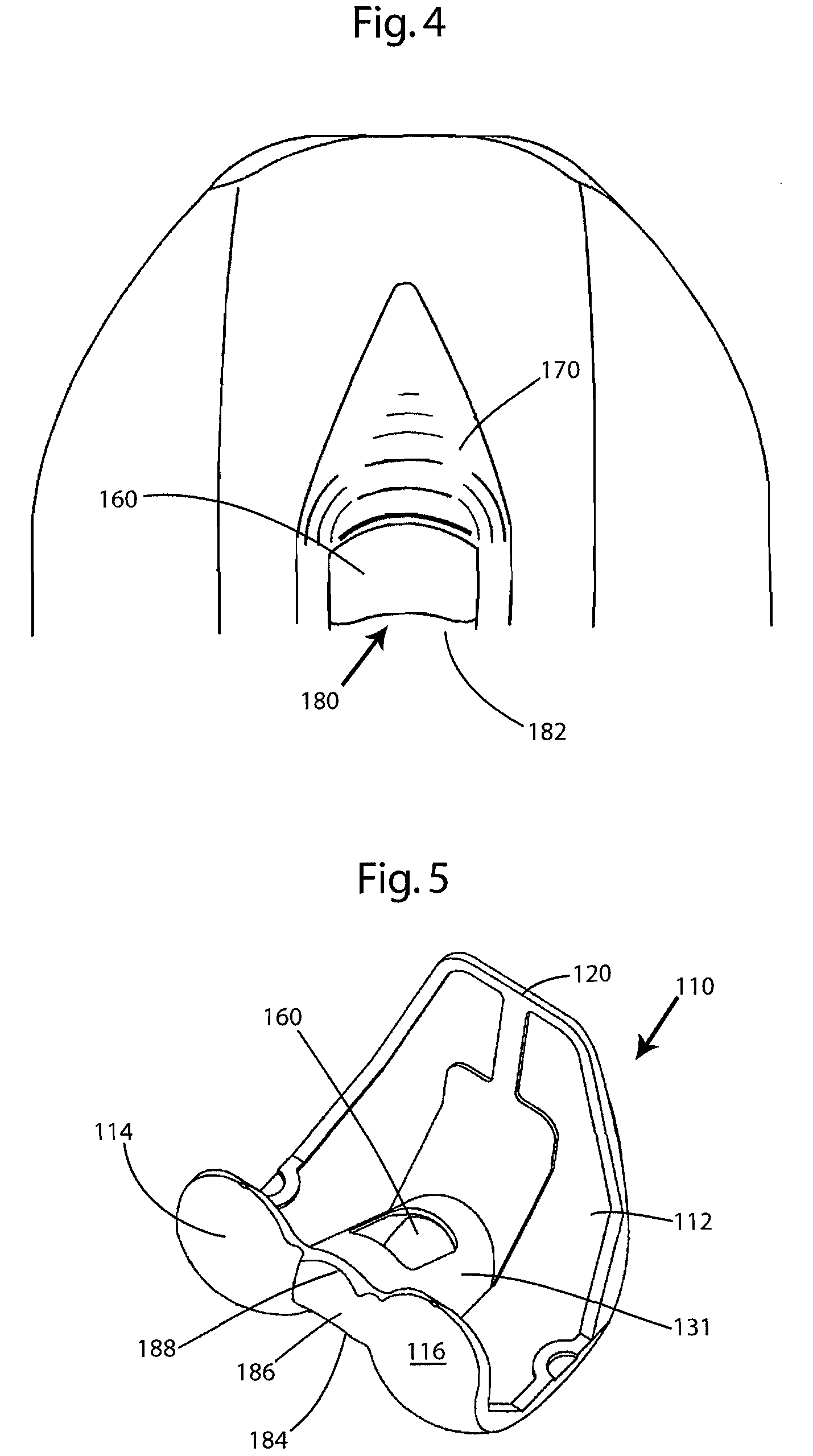

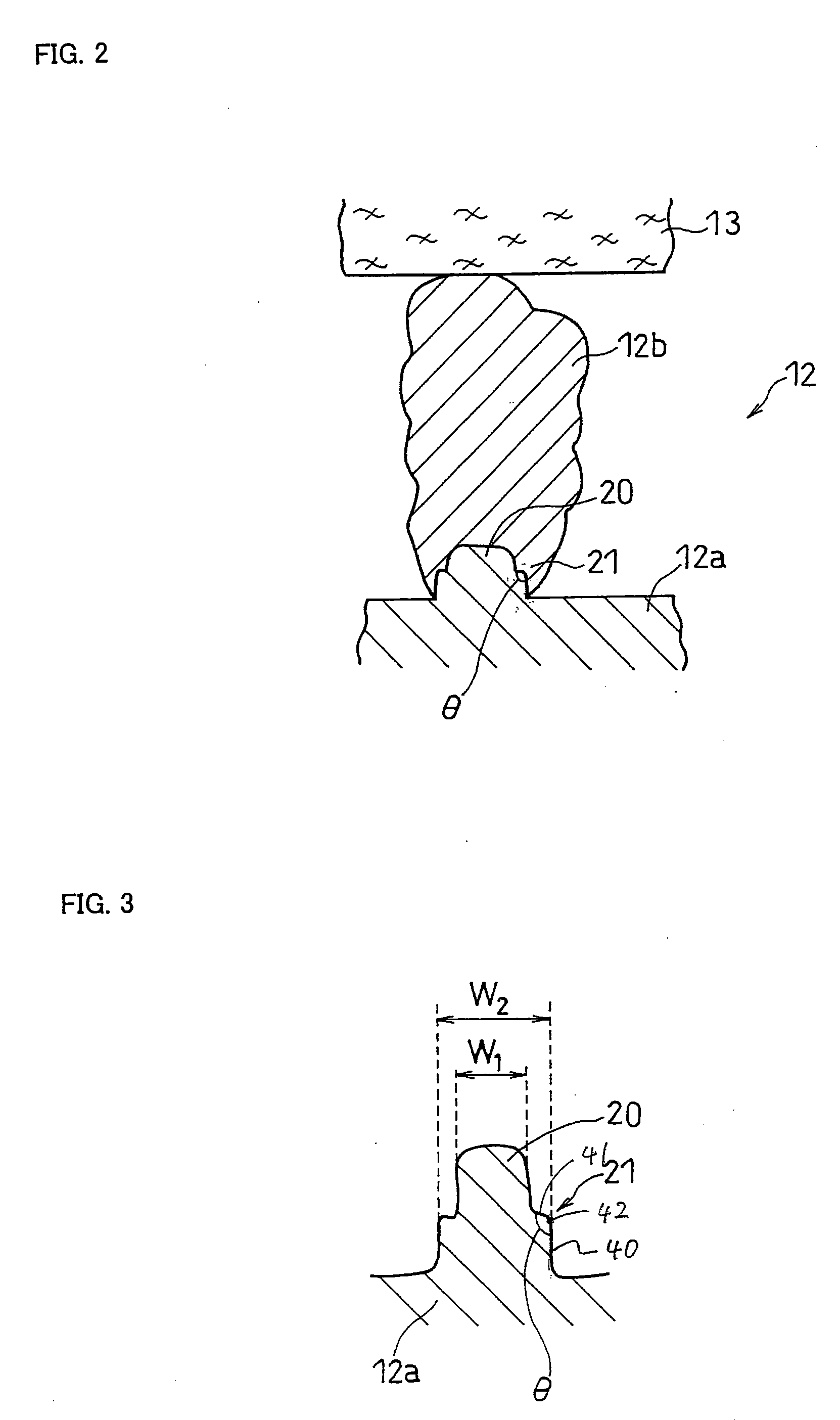

Gasket for fuel cell and method of forming it

In a gasket used for a fuel battery, in order to solve problems with respect to making a seal portion thin, improving an assembling property, preventing a position shift, making a surface pressure low, making the surface pressure uniform, and the like, a gasket lip made of a liquid rubber hardened material is integrally formed on a surface of a flat plate made of a carbon, a graphite, a conductive resin such as a conductive phenol resin or the like, an ion exchange resin, or a metal such as a stainless steel, a magnesium alloy or the like, or on a groove portion applied to the surface.

Owner:NOK CORP

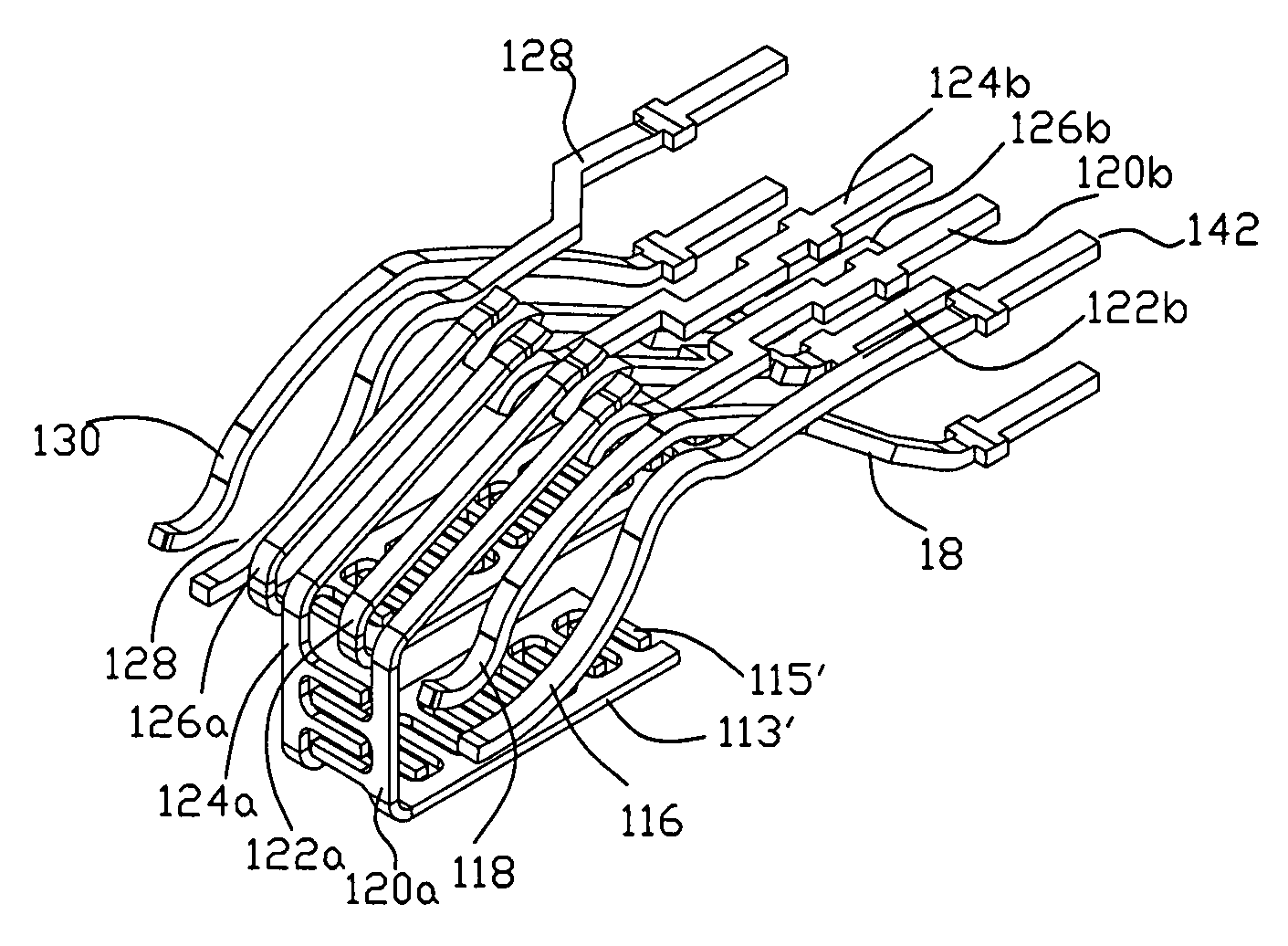

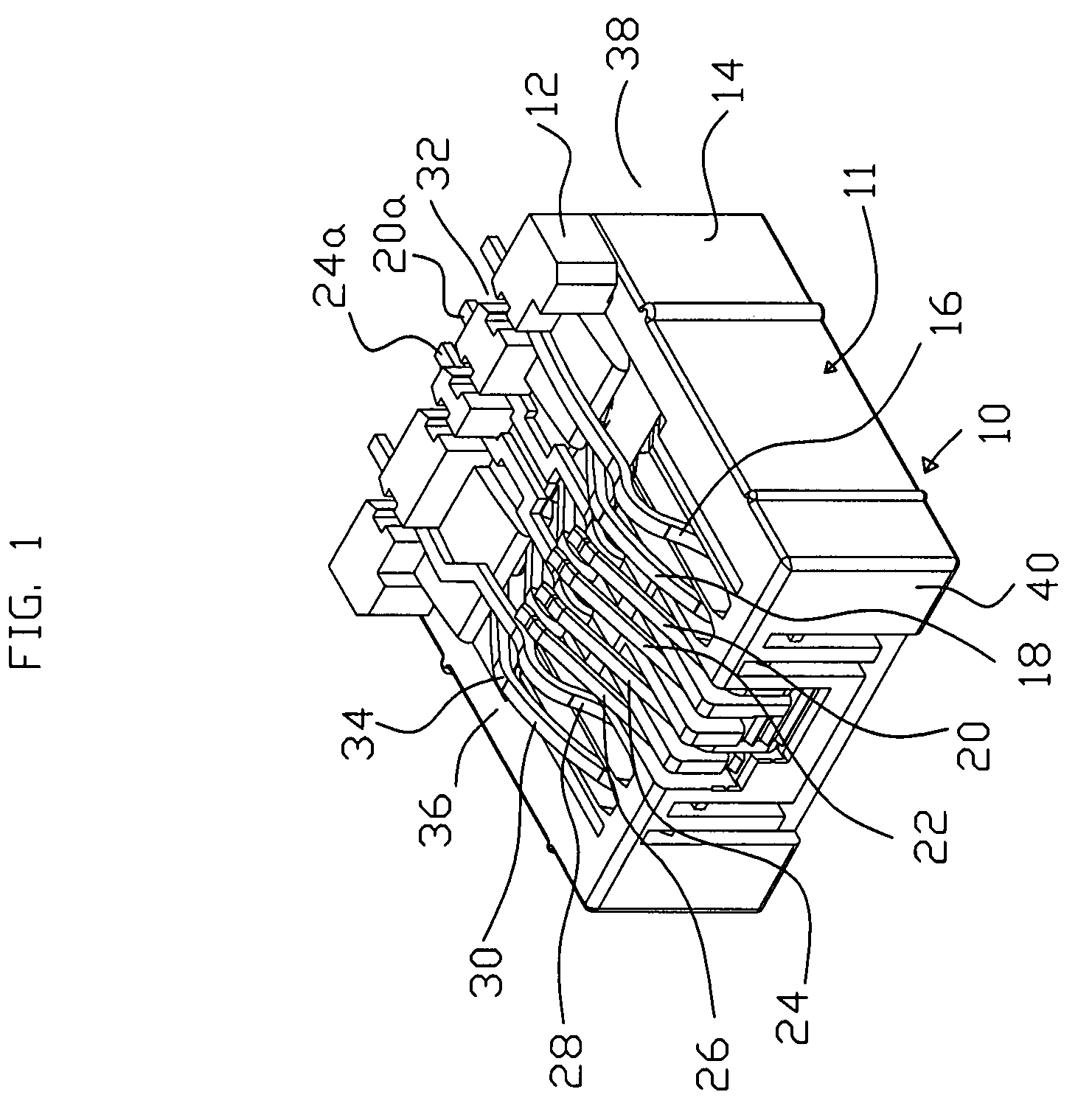

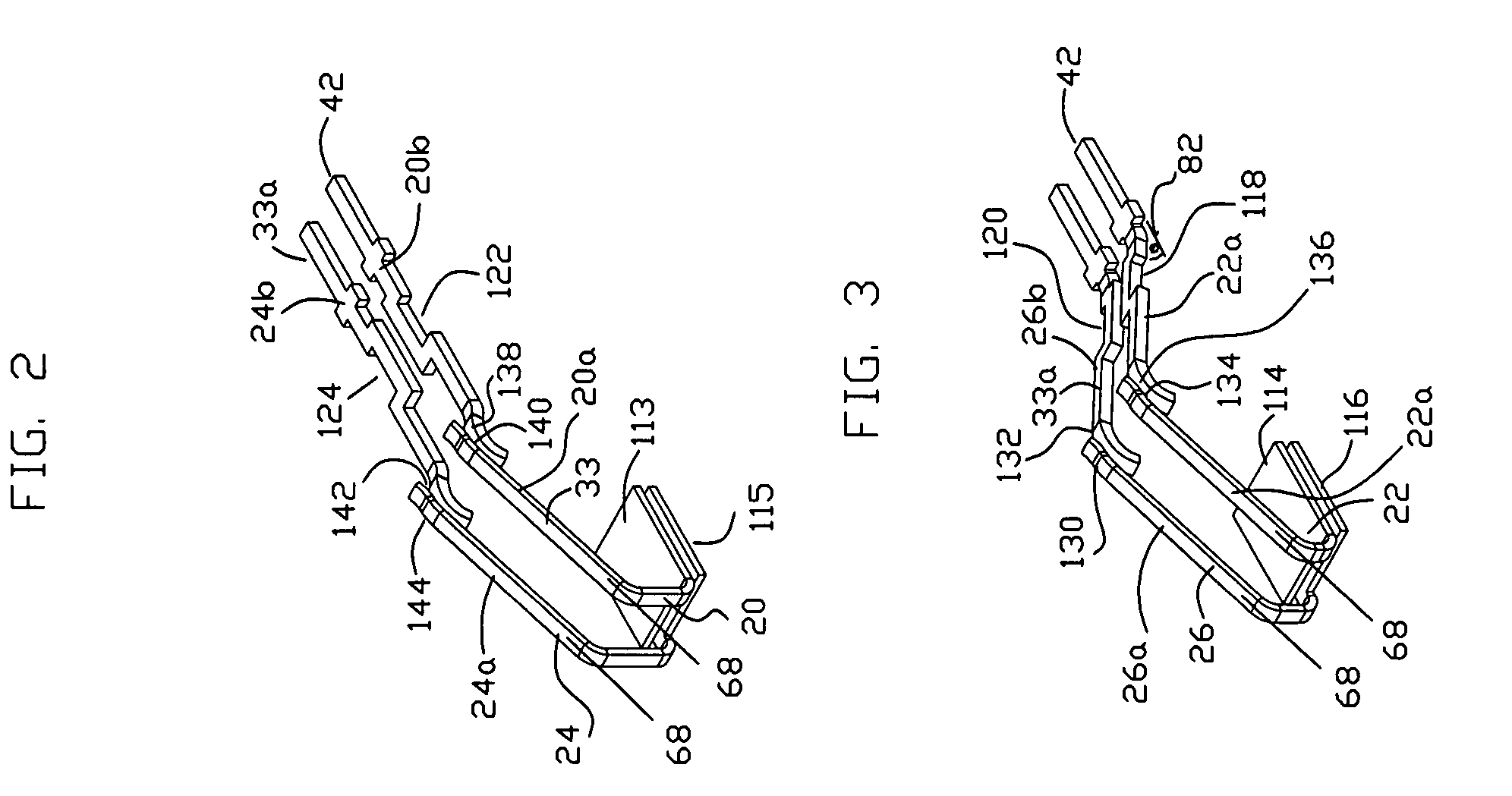

Modular insert and jack including bi-sectional lead frames

ActiveUS7481678B2Without altering impedance characteristicReduce noiseCoupling device detailsTwo-part coupling devicesInterference (communication)Electromagnetic interference

The present disclosure is related to a modular insert and associated jack assembly used in telecommunication connector systems that reduces the adjacent lines electro magnetic interference from an adjacent transmitter for different plug assemblies. The internal contacts / lead frames feature a bi-sectional design. Internal EMI line reduction is allowed only when the bi-sectional contacts are electrically mated by a plug with corresponding contact layout. By isolating the contact sections in the interface system, the coupled signal for EMI balance is optionally utilized in a low cost and manufacturable design.

Owner:LEGRAND DPC LLC

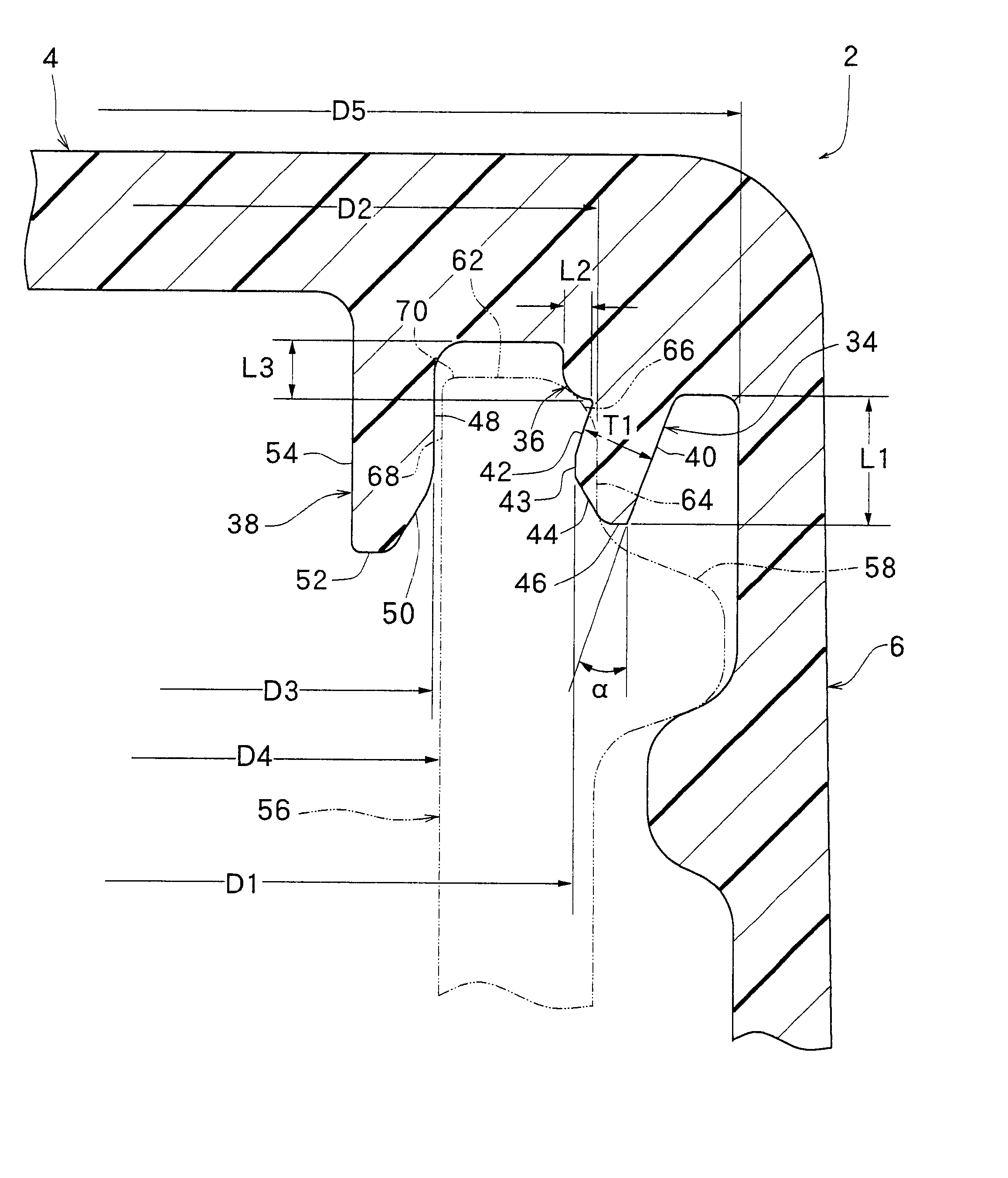

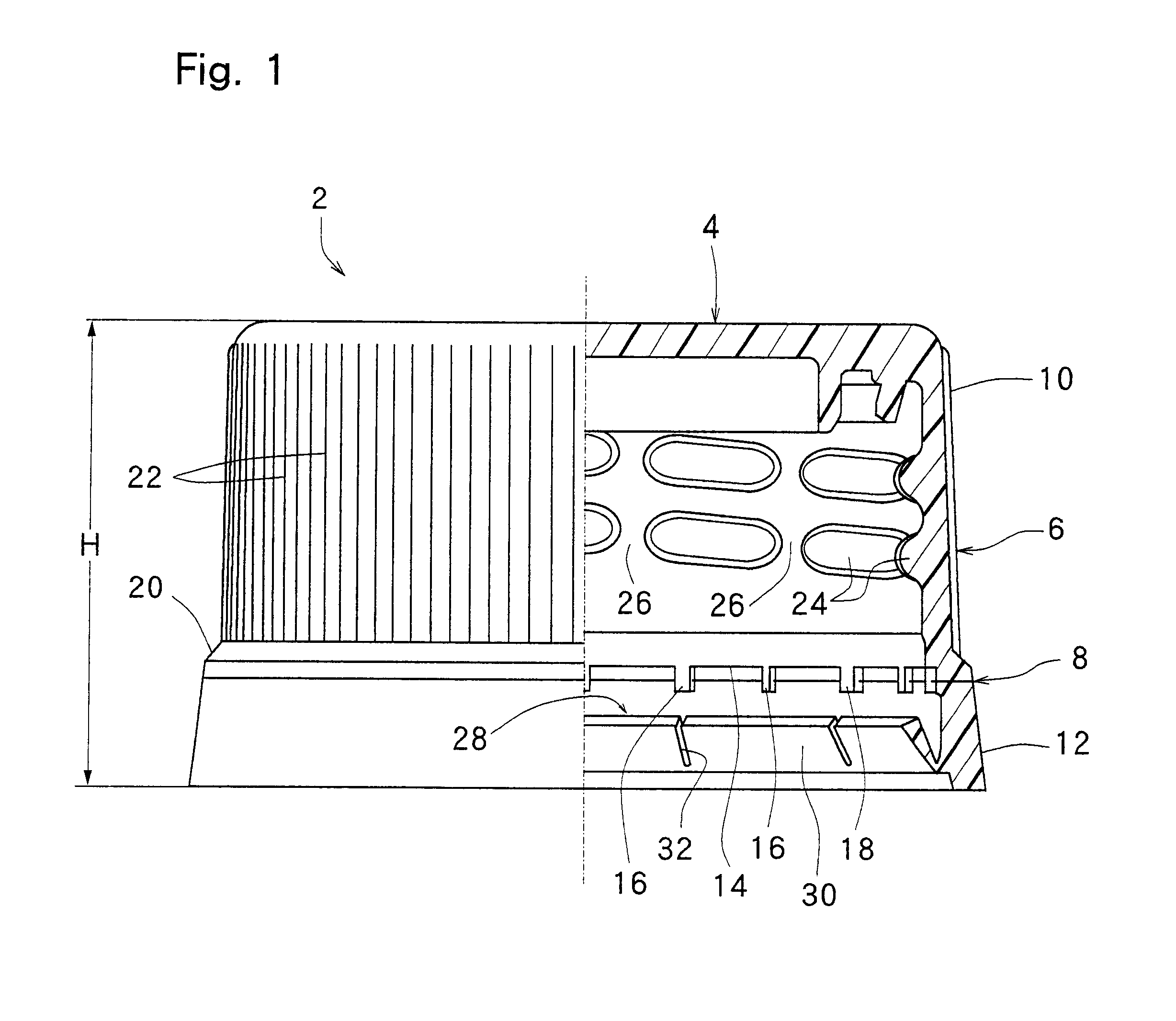

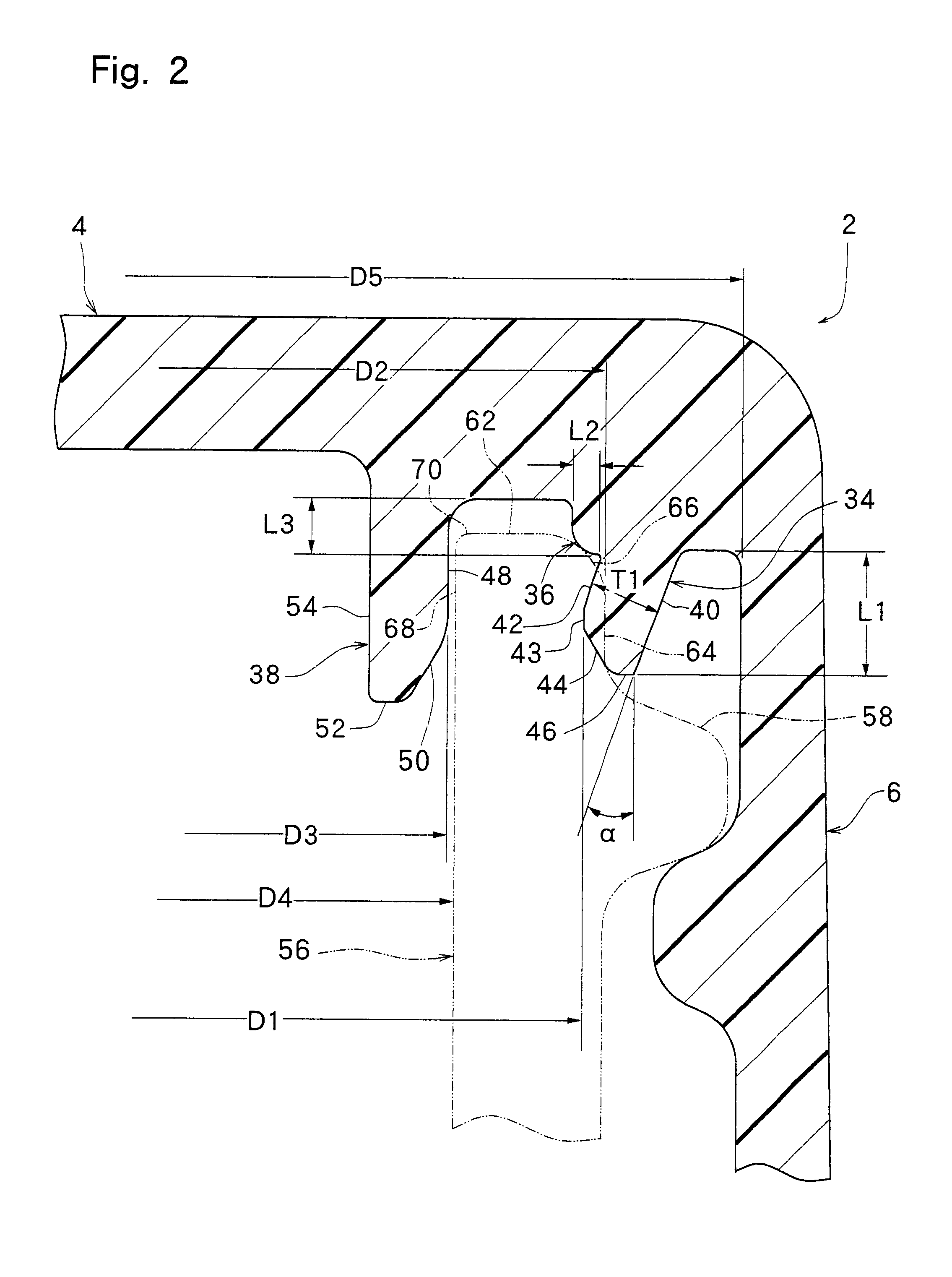

Posterior stabilized knee prosthesis

A knee joint prosthesis includes a femoral component having an anterior side, a posterior side, a pair of laterally spaced condylar portions, and an intercondylar portion joining the condylar portions and including a recess. A cam surface is located adjacent the intercondylar recess on the anterior side of the femoral component and has a saddle shape that is defined by an at least substantially concave first radius of curvature and a convex third radius of curvature that is perpendicular to the concave first radius of curvature. The prosthesis also includes a tibial component including a platform having an upper surface that includes first and second laterally spaced concavities. Each concavity is adapted for receiving one condylar portion of the femoral component. The tibial component has a tibial post for reception in the intercondylar recess of the femoral component. The tibial post has a saddle shaped anterior cam surface that is complementary to the saddle shaped anterior cam surface of the femoral component and is defined by an at least substantially convex second radius of curvature and a concave fourth radius of curvature that is perpendicular to the convex second radius of curvature.

Owner:NEW YORK SOC FOR THE RUPTURED & CRIPPLED MAINTAINING THE HOSPITAL FOR SPECIAL SURGERY

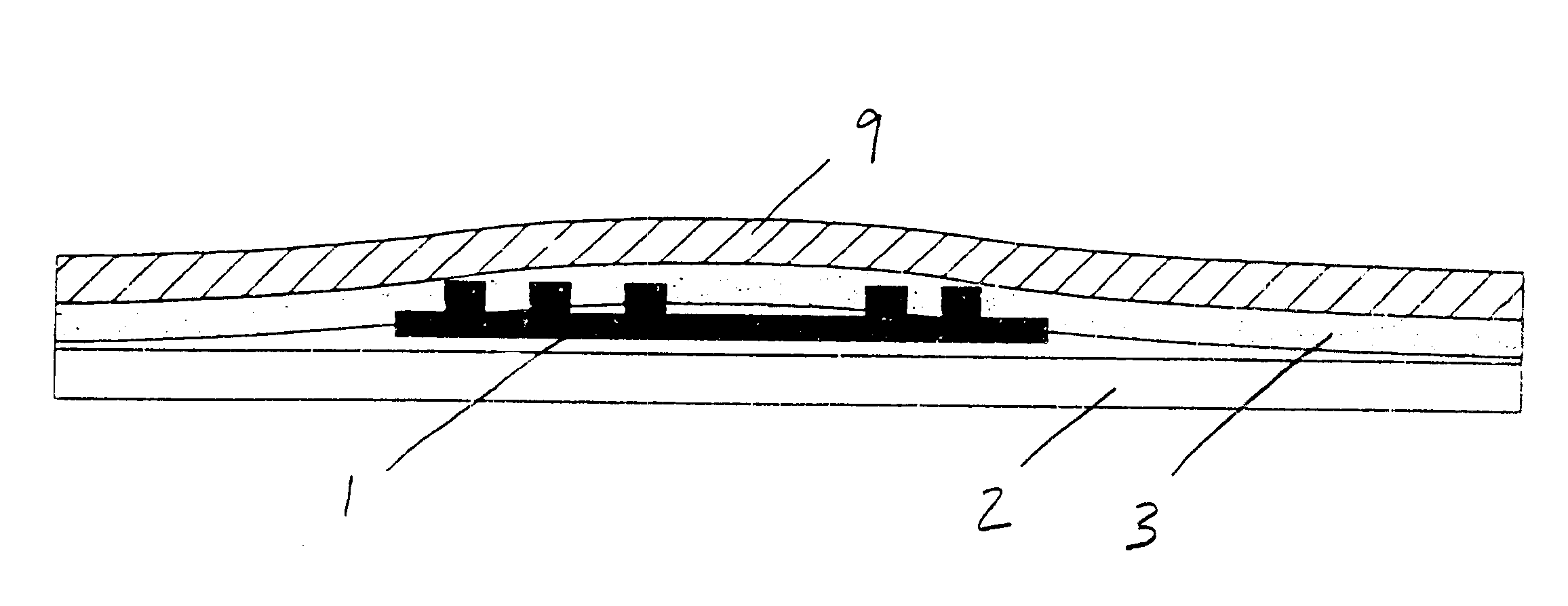

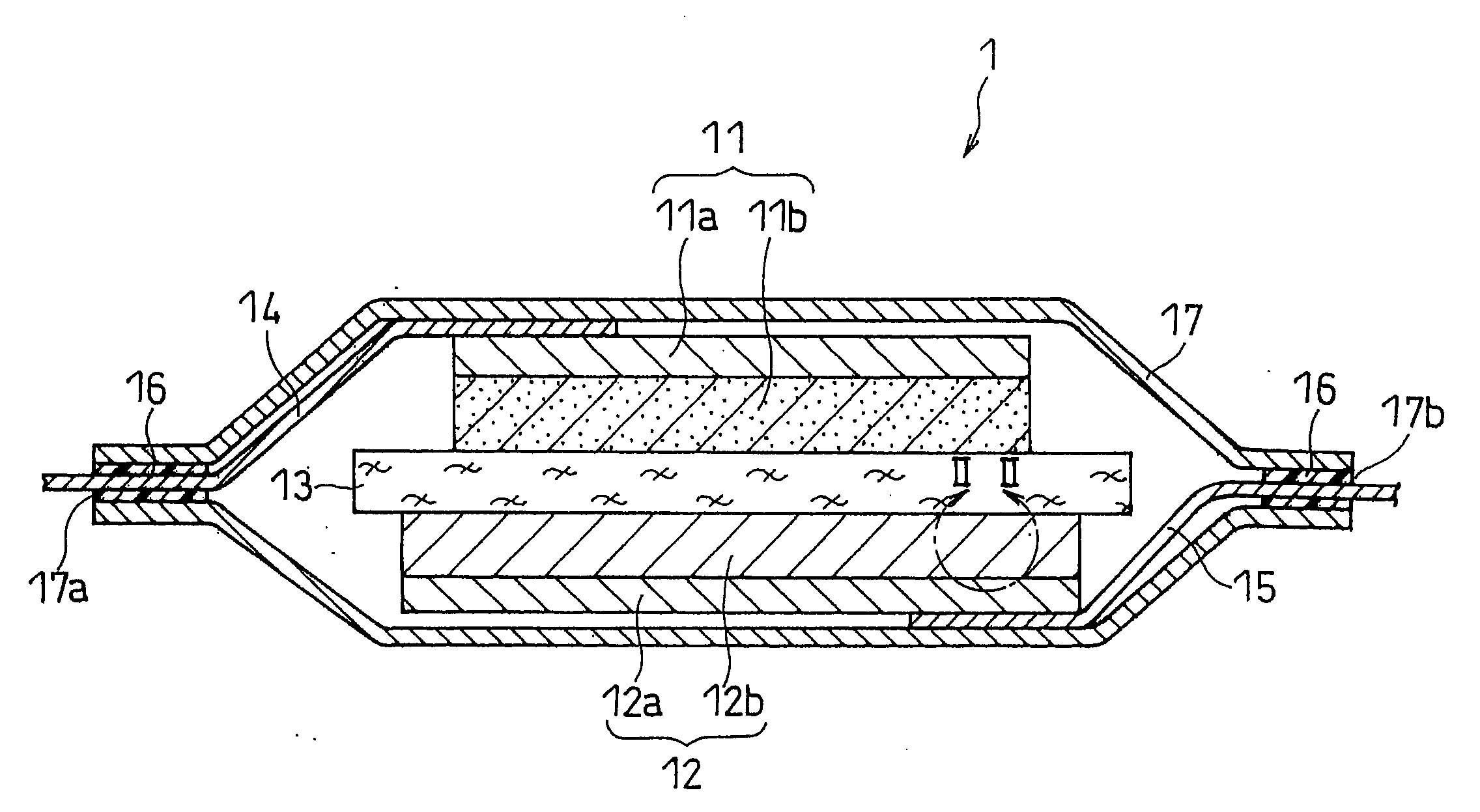

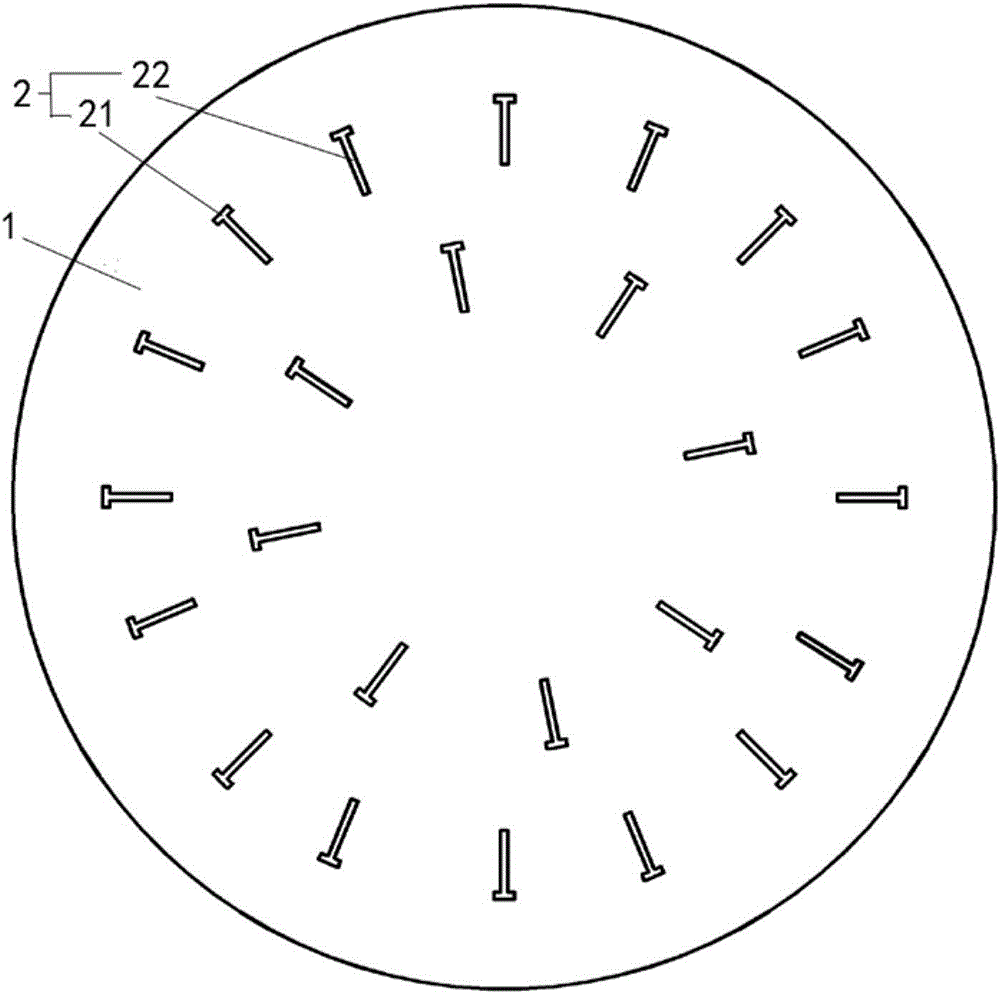

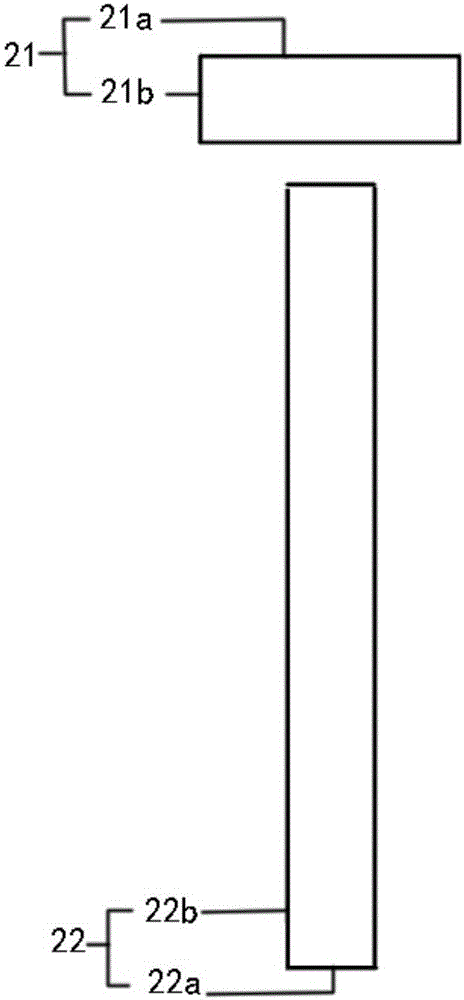

Negative electrode for lithium ion secondary battery and lithium ion secondary battery

InactiveUS20080213671A1Improve Coulombic efficiencyImprove lithium ion conductivityElectrode carriers/collectorsNegative electrodesLithiumHigh energy

A negative electrode including a negative electrode current collector, first protrusions on a surface of the negative electrode current collector, a separation-stopping area on at least a part of a surface of each first protrusion, and a negative electrode active material layer including a negative electrode active material and formed on at least a top face of the first protrusion. This structure suppresses the separation of the negative electrode active material layer from the negative electrode current collector, the degradation of the current collecting ability, and the deformation of the negative electrode itself. A lithium ion secondary battery including this negative electrode has a high battery capacity, a high energy density, and an excellent charge / discharge cycle characteristic, and is capable of stably maintaining a high power over an extended period of time.

Owner:PANASONIC CORP

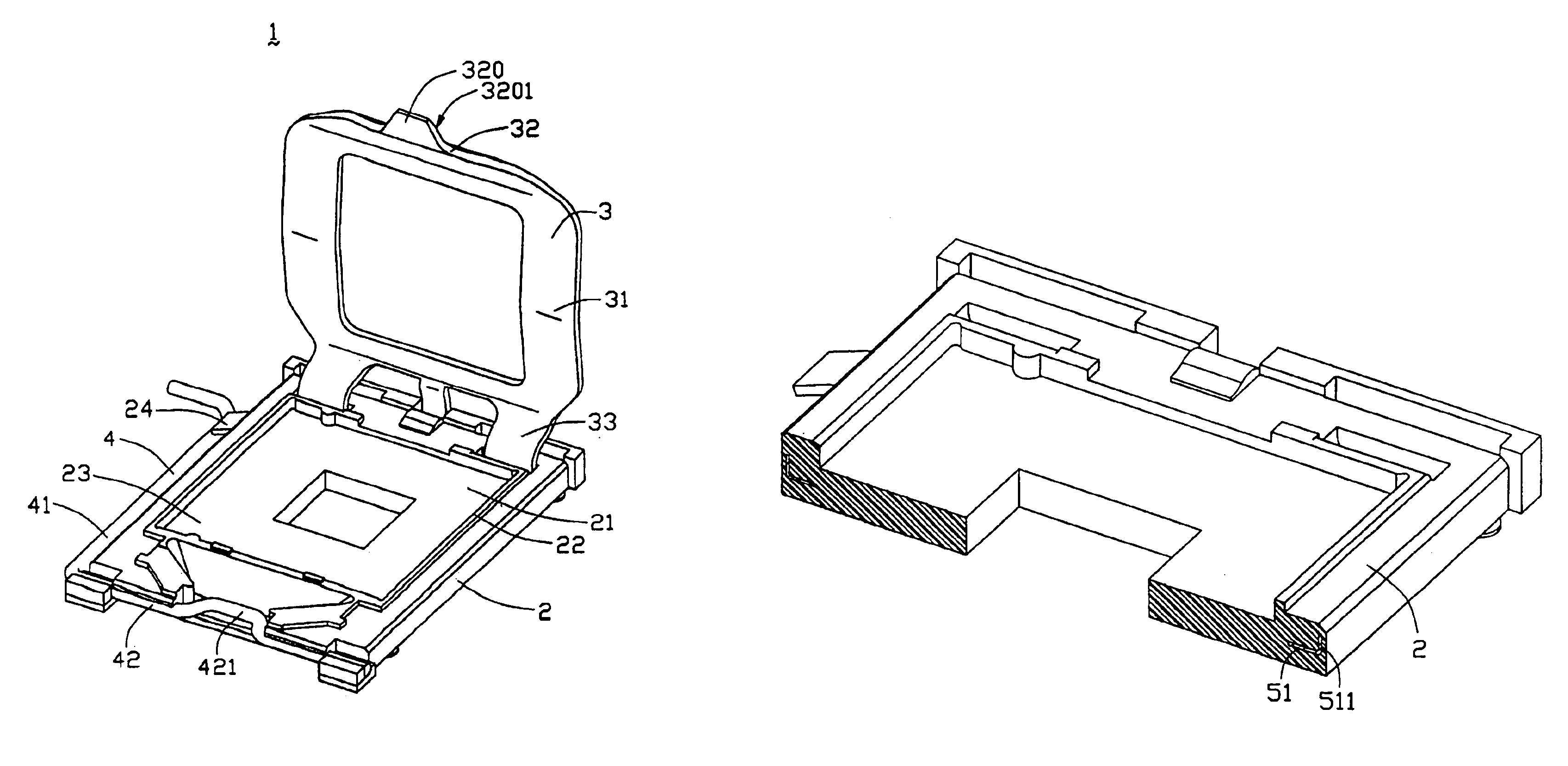

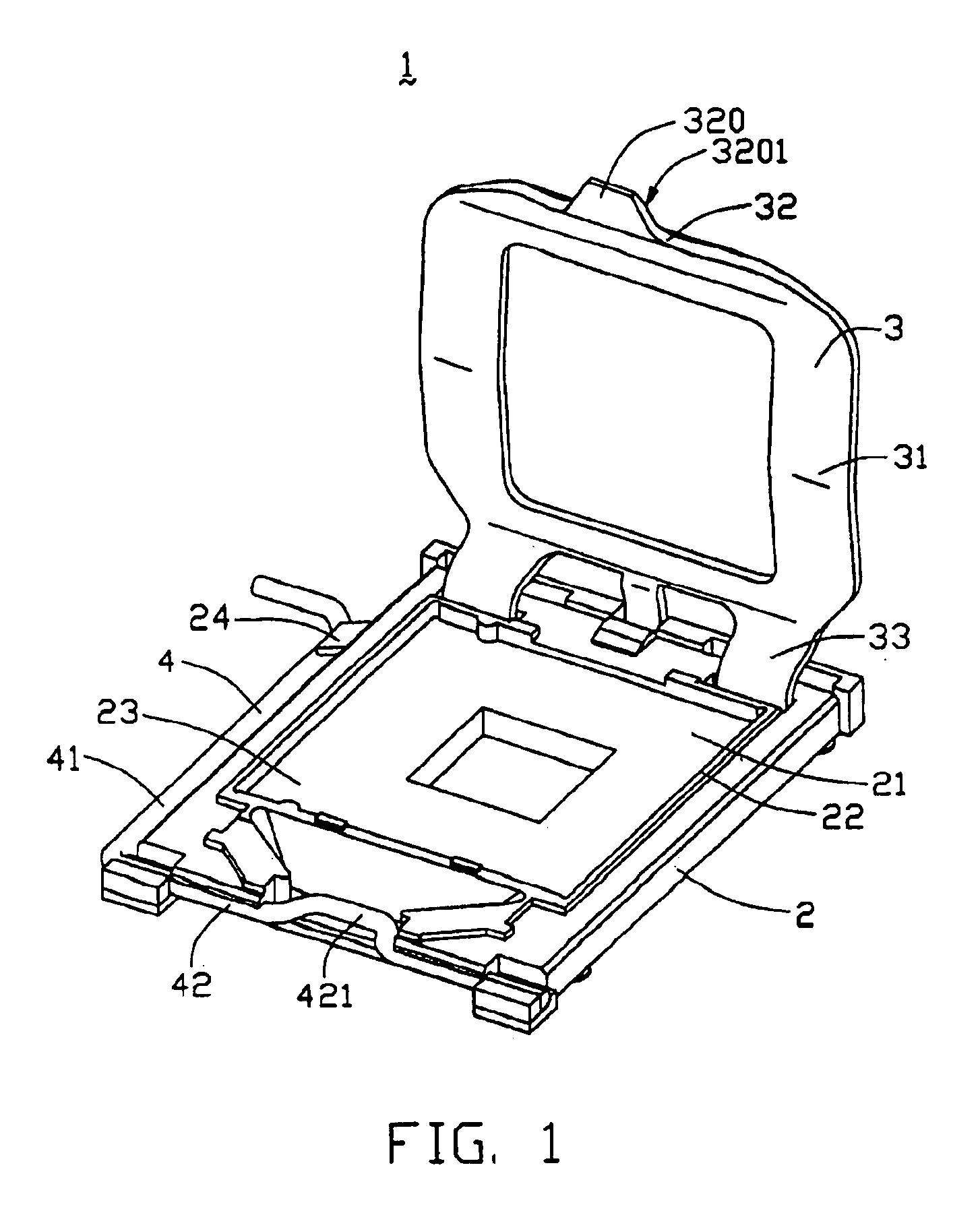

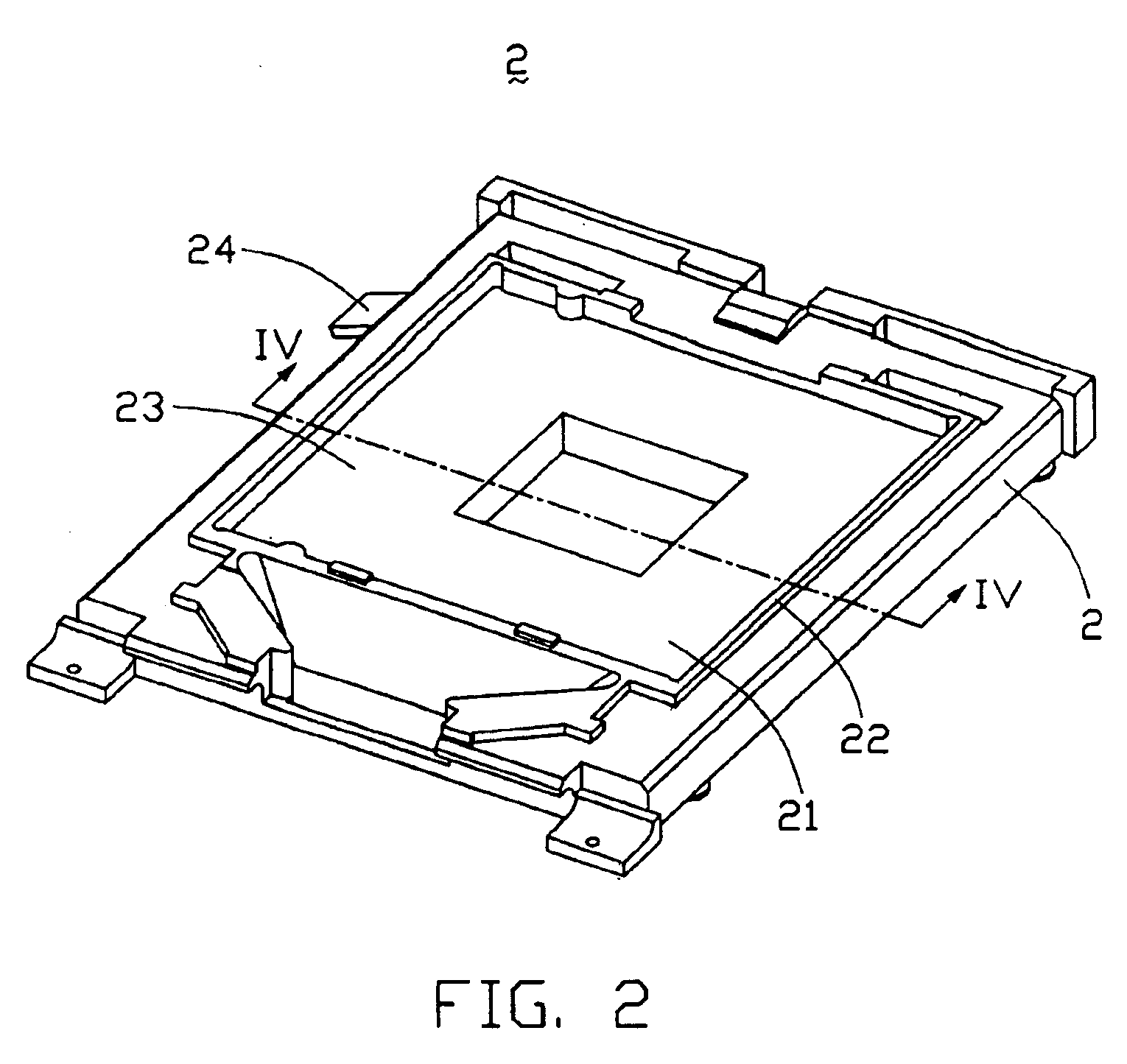

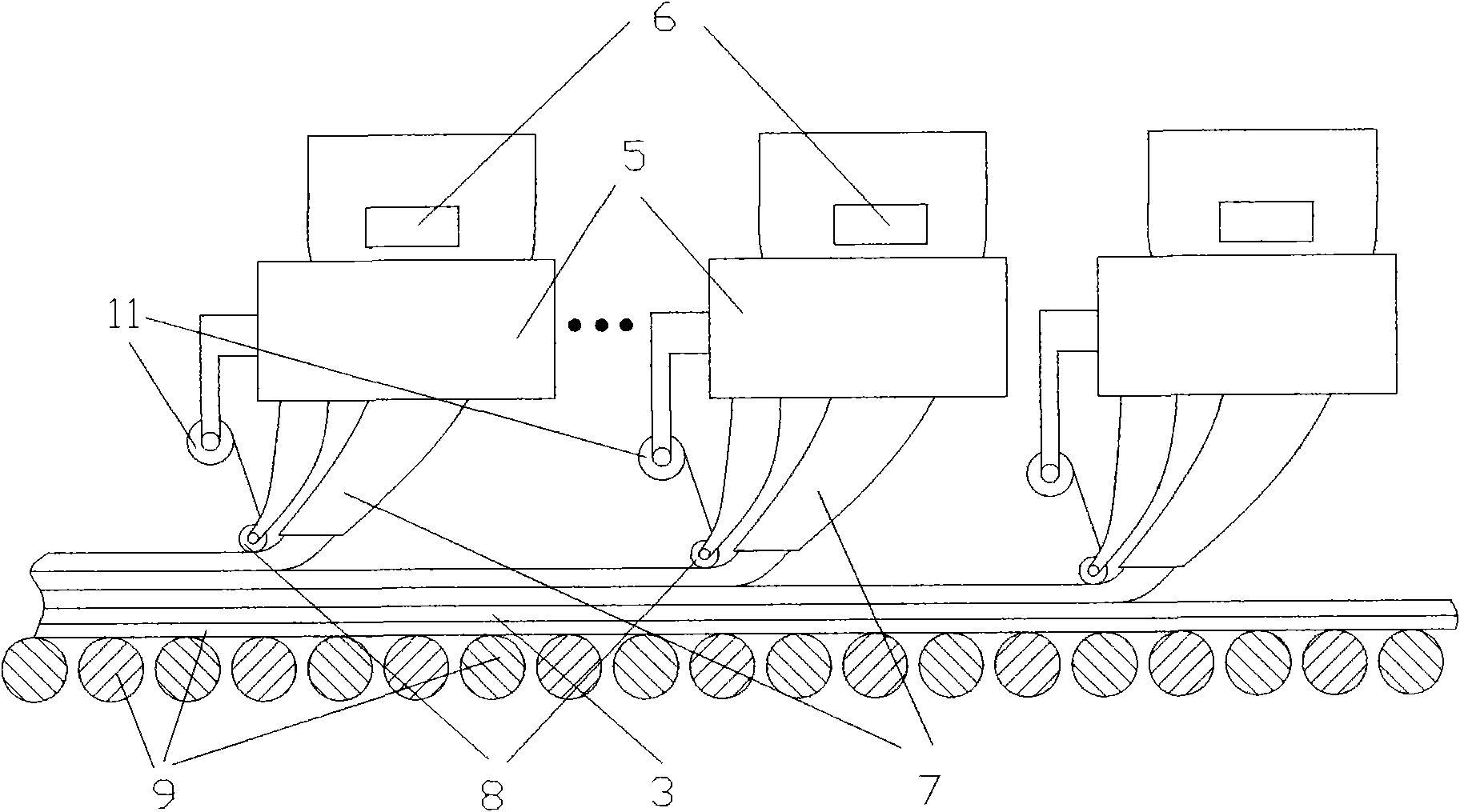

Land grid array socket with reinforcing plate

InactiveUS6848929B2Resists deformation and warpageImprove rigidityEngagement/disengagement of coupling partsComponent plug-in assemblagesPull forceContact pad

A land grid array socket (1) includes an insulative base (2) mounted on a printed circuit board, a metal clip (3) pivotably engaged on the base, and a lever (4) for fastening the clip onto the base. The clip (3) and the lever are respectively mounted on two opposite ends of the base to fasten an LGA package. A reinforcing plate (5) made of rigid material is insert molded into the base. The reinforcing plate is generally a rectangular frame, and it includes four integrated sides (51). A substantially rectangular opening (52) is defined among the sides. Therefore, the rigidity of the base is improved, and the deformation or warpage under the pulling forces on two opposite ends of the base is diminished, thereby ensuring steady electrical connection between the contacts pads of the LGA package and respective contacts of the base.

Owner:HON HAI PRECISION IND CO LTD

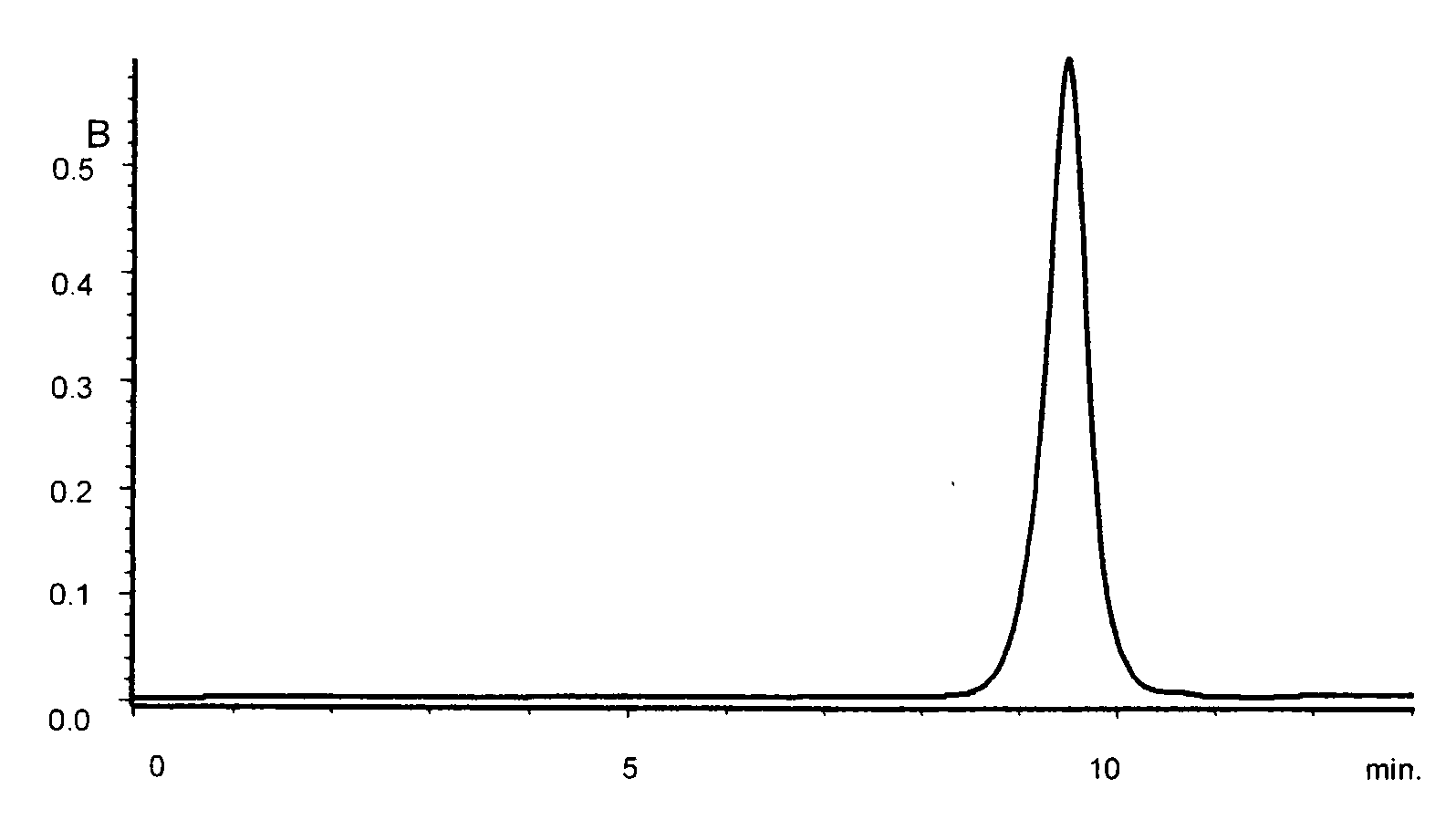

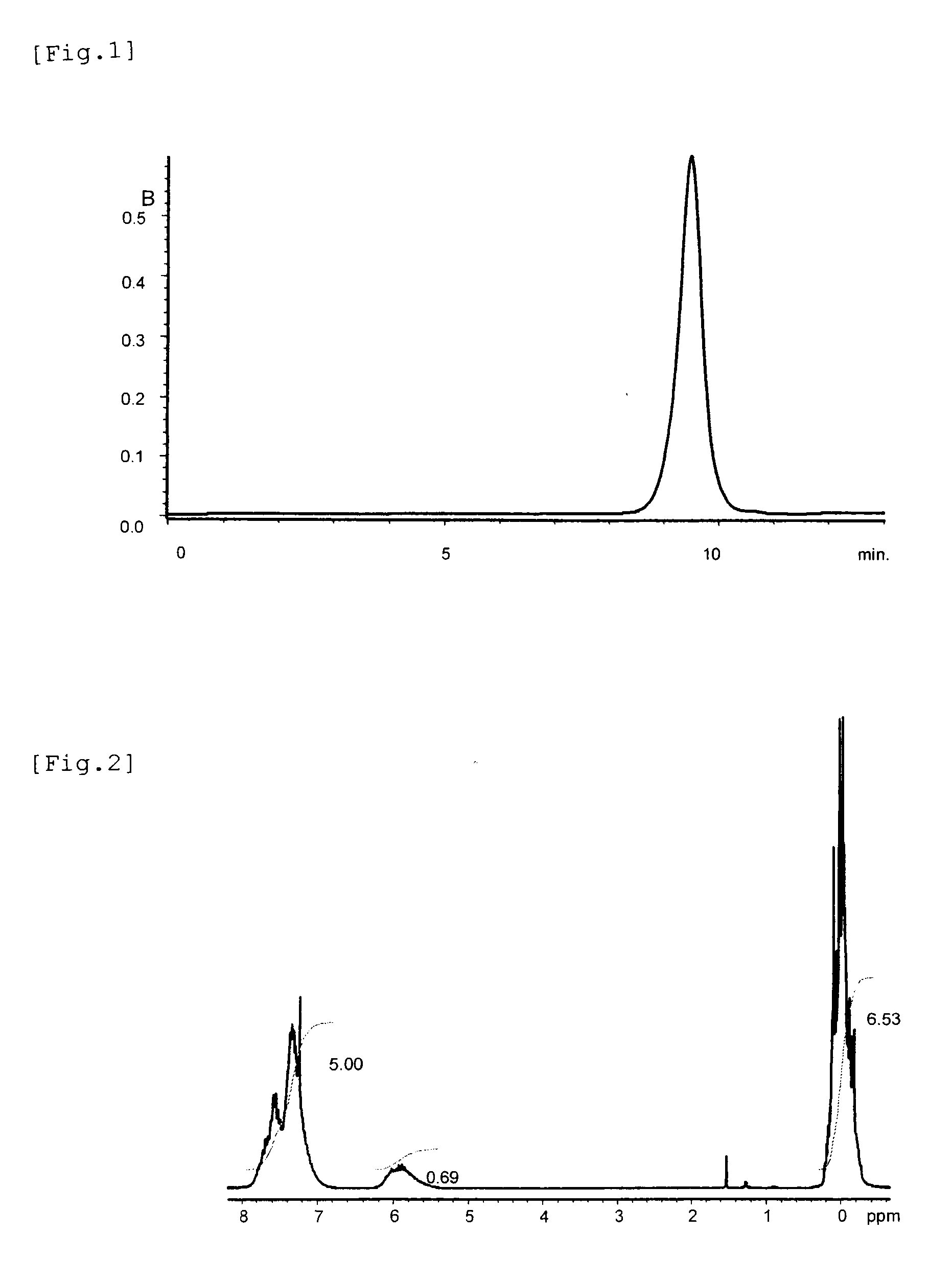

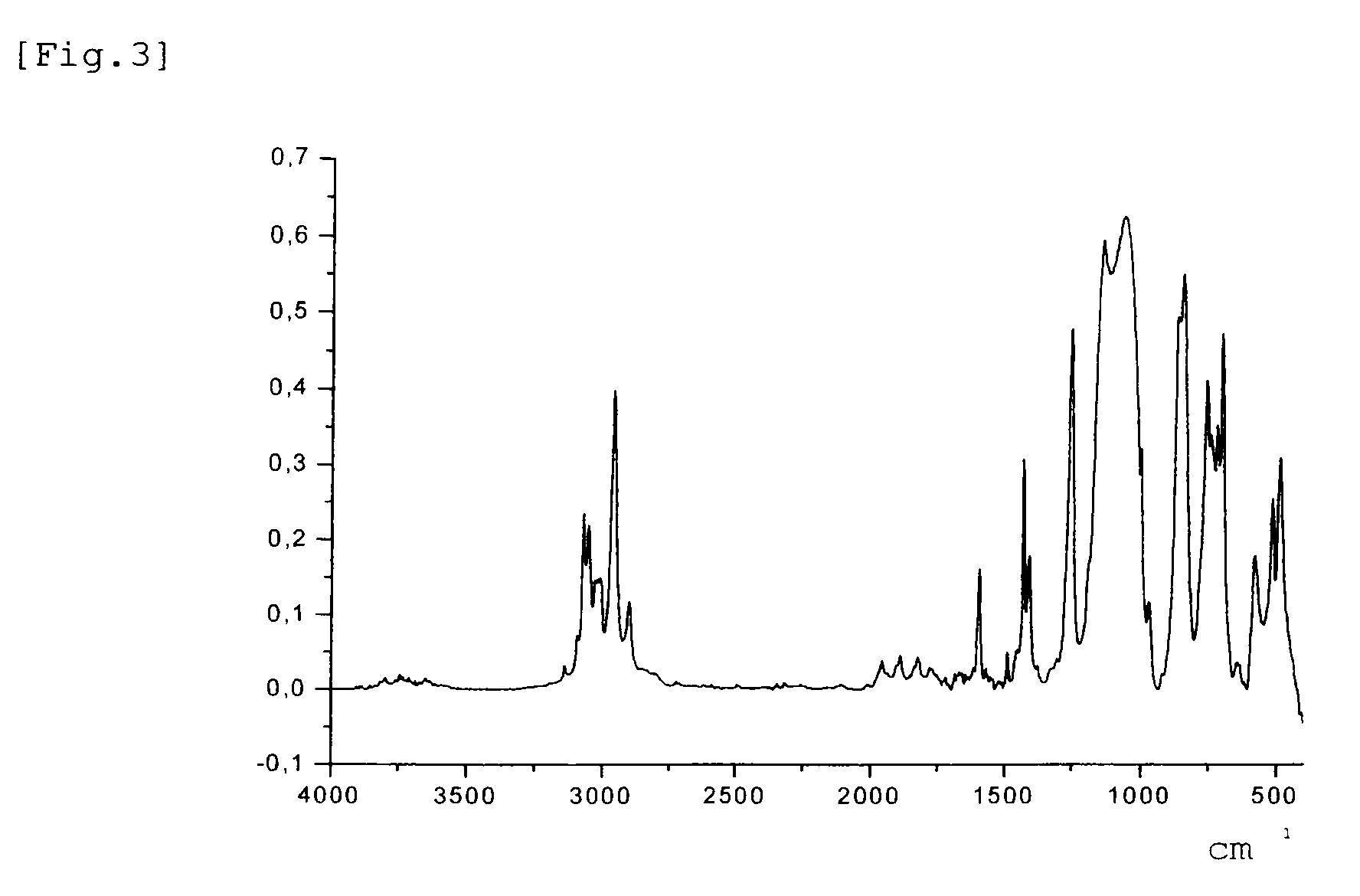

Curable resin composition

InactiveUS20090105395A1High transparencyHigh refractive indexSemiconductor/solid-state device detailsSolid-state devicesSolventPhenyl group

The present invention is directed to a novel functional polyorganosiloxane having on average two or more vinyl groups in one molecule thereof.The polyorganosiloxane is represented by the following formula (I):(R23SiO1 / 2)a(Ph2SiO2 / 2)b(R1SiO3 / 2)c(PhSiO3 / 2)d(R1R2SiO2 / 2)e (I)(wherein “a” to “e” represent compositional proportions by mole, satisfying the conditions: 0.15≦a≦0.4, 0.1≦b≦0.2, 0.15≦c≦0.4, 0.2≦d≦0.4, 0≦e≦0.2, and “a+b+c+d+e”=1; R1 represents a vinyl group; R2 represents a methyl group or a phenyl group; and Ph denotes a phenyl group) and is produced through polycondensation of an alkoxysilane mixture in the presence of an active solvent.The present invention also relates to a curable resin composition containing the polyorganosiloxane, which composition is suitably employed for encapsulating optical devices such as LEDs, photo-sensors, and lasers as well as optical materials.The invention further relates to a composition for encapsulating an LED suitable for encapsulating LEDs emitting blue to UV light and white light-emitting devices.

Owner:ENIKOLOPOV INST OF SYNTHETIC POLYMERIC MATERIALS ISPM OF THE RUSN ACAD OF SCI +1

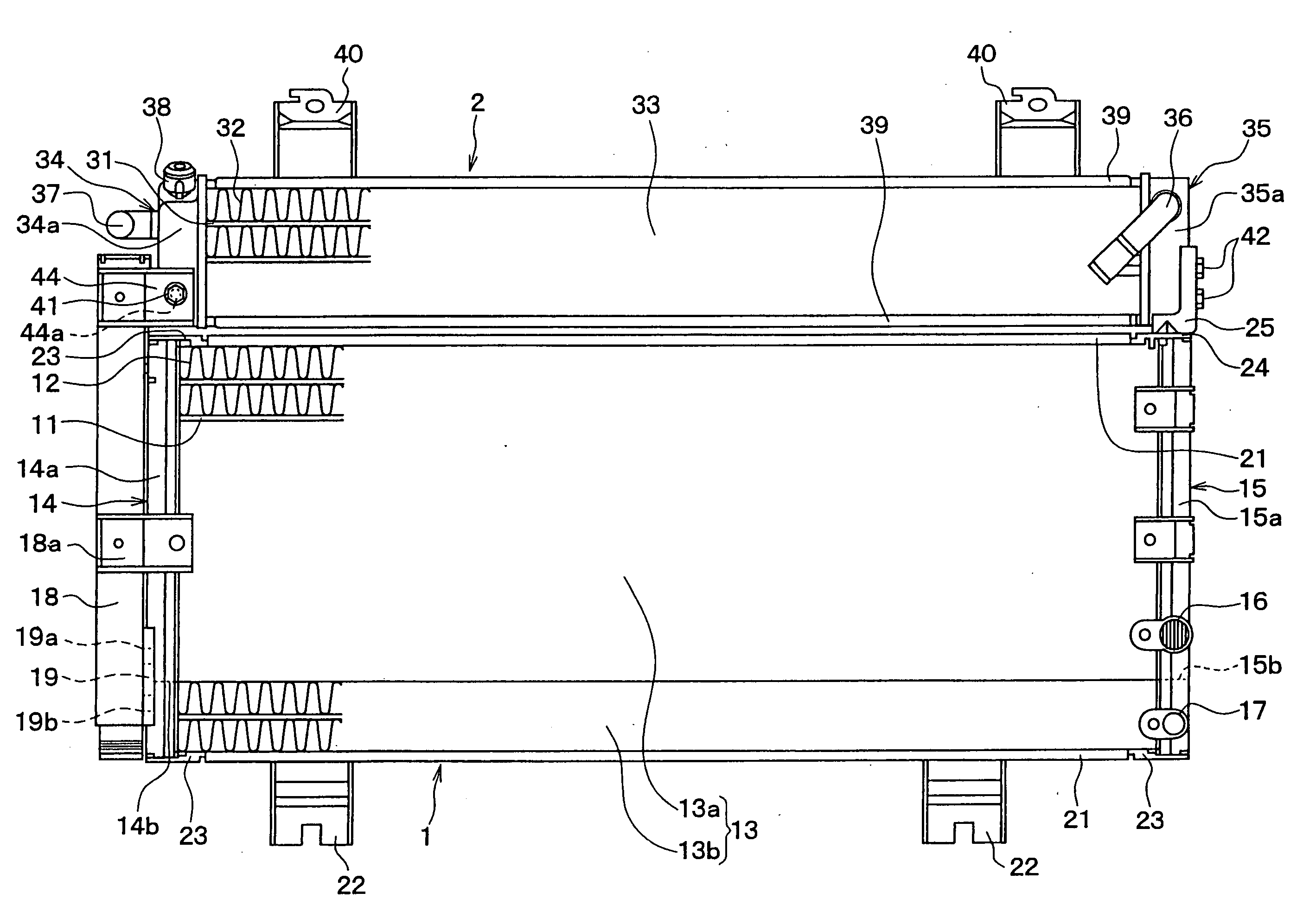

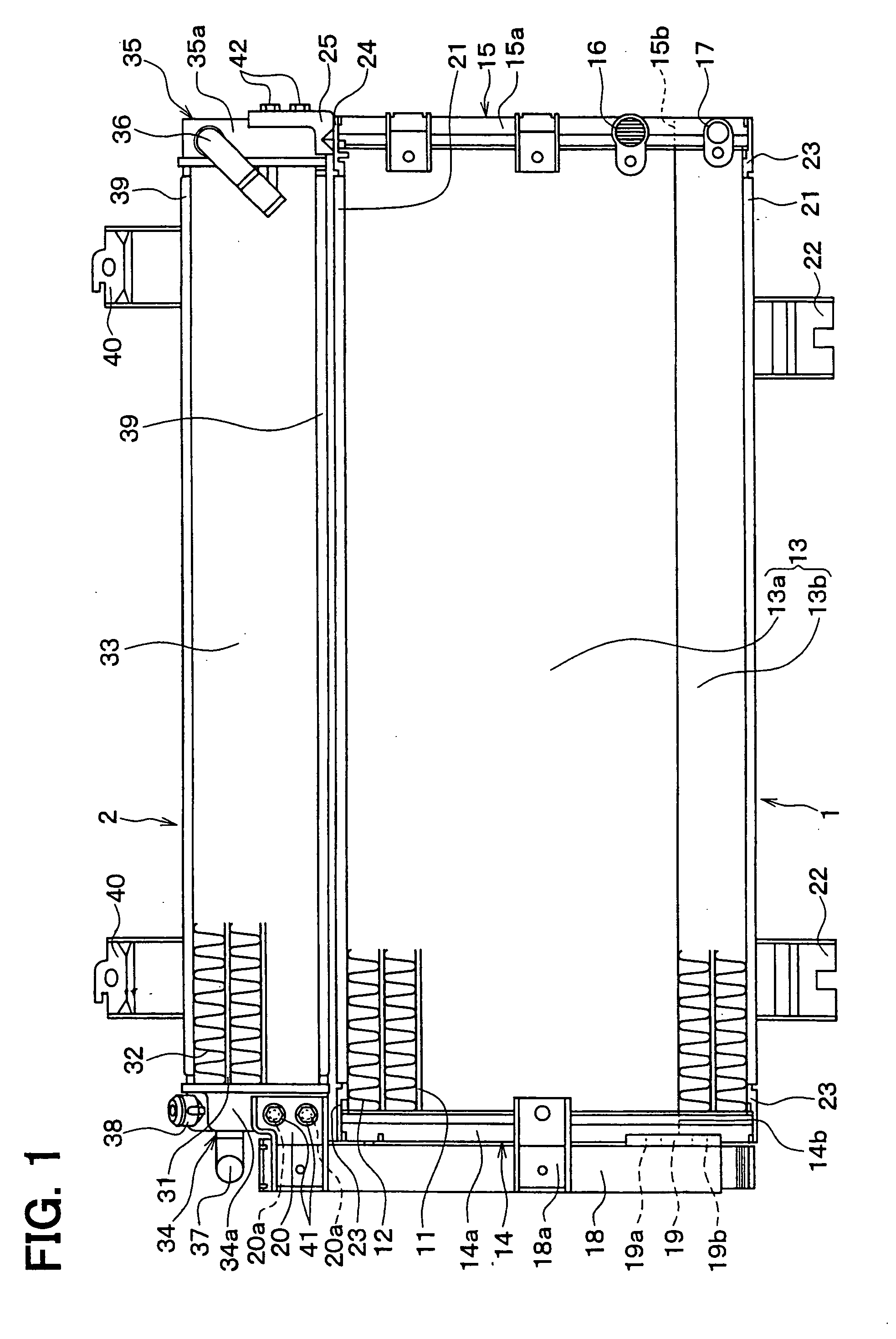

Integrated heat exchanger and heat exchanger

ActiveUS20070144713A1Connection securityReduce deformationElectric propulsion mountingStationary conduit assembliesEngineeringHeat exchanger

An integrated heat exchanger has a first heat exchanger and a second heat exchanger. The first heat exchanger has a first bracket and a second bracket on header parts thereof, respectively. The first bracket and the second bracket are connected to header parts of the second heat exchanger with a first bolt and a second bolt, respectively, for integrating the first heat exchanger with the second heat exchanger. The header parts of the second heat exchanger are provided with a first bolt-receiving portion and a second bolt-receiving portions for receiving the first bolt and the second bolt therein, respectively. The first bolt-receiving portion and the second bolt-receiving portion define a first axis and a second axis, respectively. The first axis and the second axis are nonparallel to each other. Thus, the first bolt and the second bolt are disposed nonparallel to each other.

Owner:DENSO CORP

Friction stir weld tool and method

ActiveUS20050121497A1Increase mixingReduce deformationWelding/cutting auxillary devicesAuxillary welding devicesEngineeringFriction stir welding

A rotatable tool for friction stir welding a workpiece and an associated apparatus and method are provided. The tool includes a first pin portion that extends from a shoulder and defines a contour surface opposite the shoulder. A second pin portion extends from the contour surface of the first pin portion. The contour surface, which mixes the material of the workpiece during welding, can increase the mixing of the material at the interface, thereby increasing the strength of the joint.

Owner:THE BOEING CO

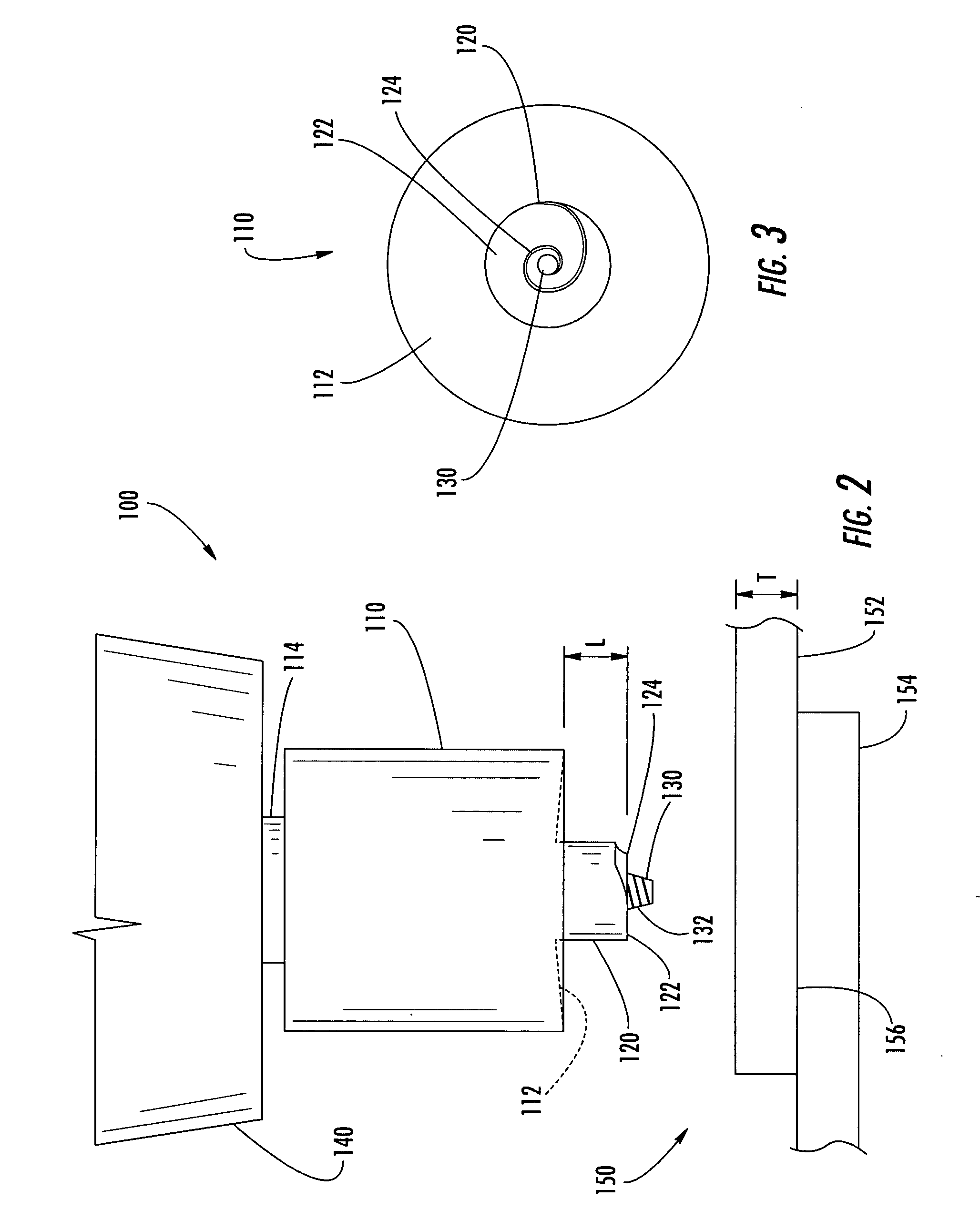

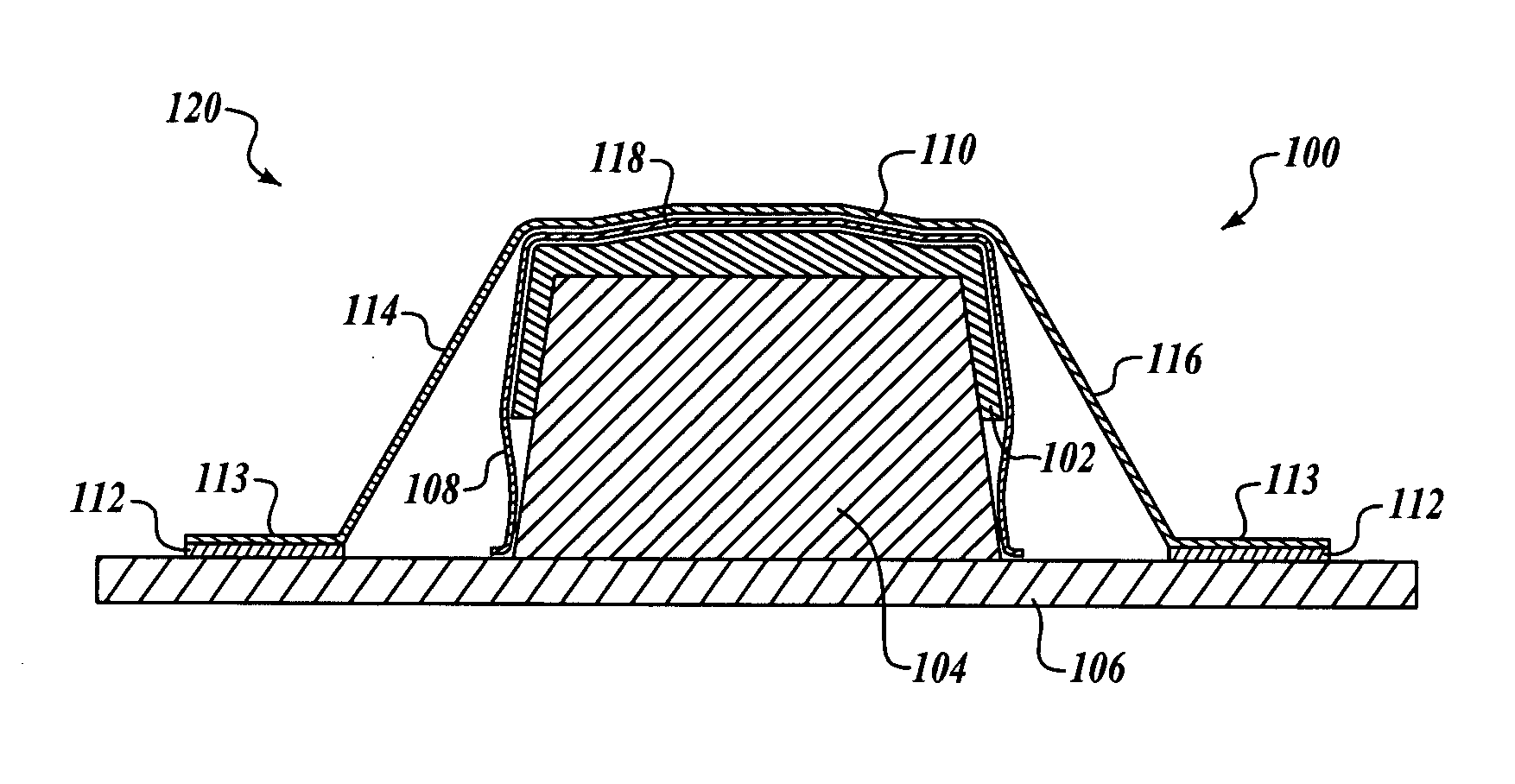

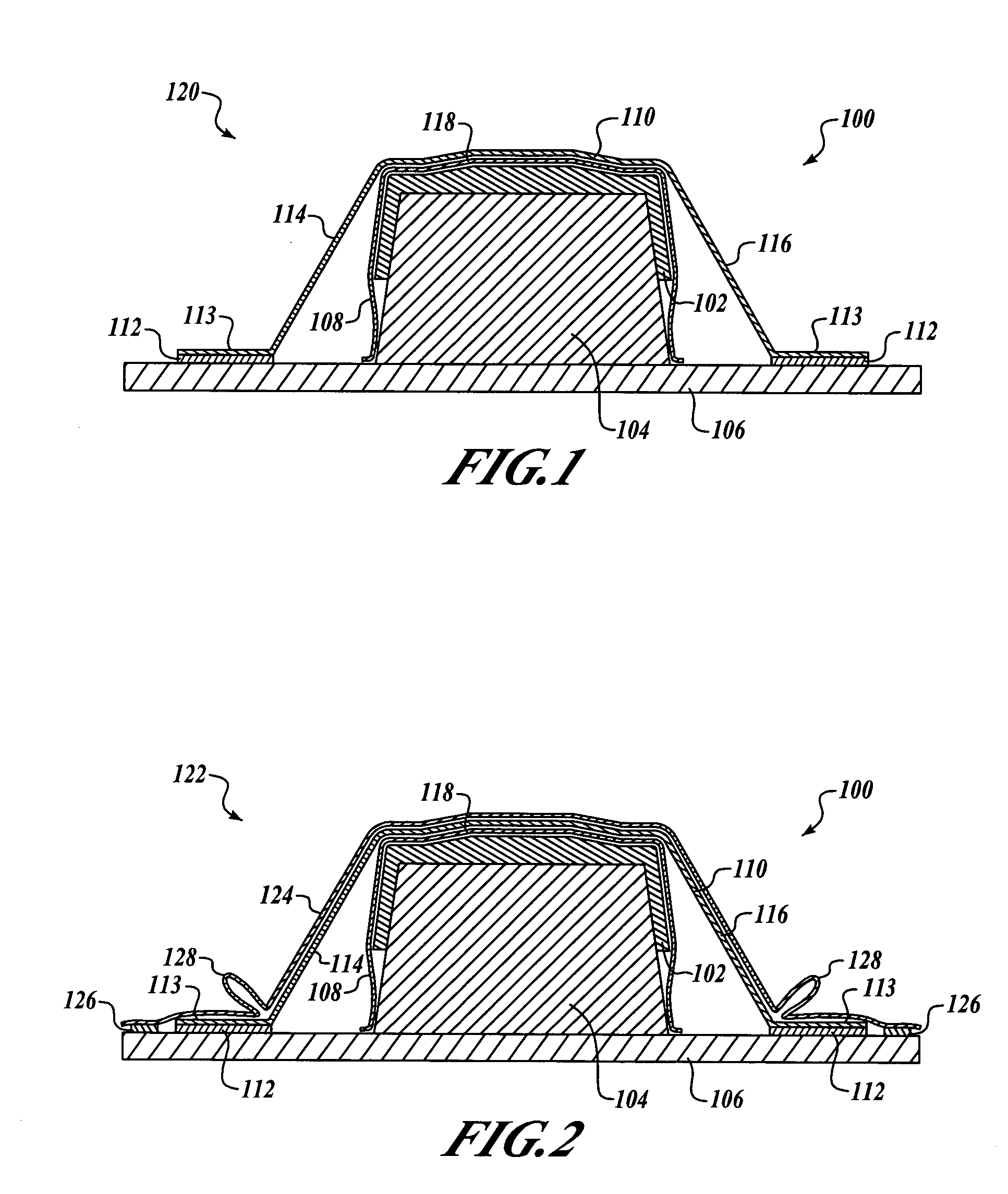

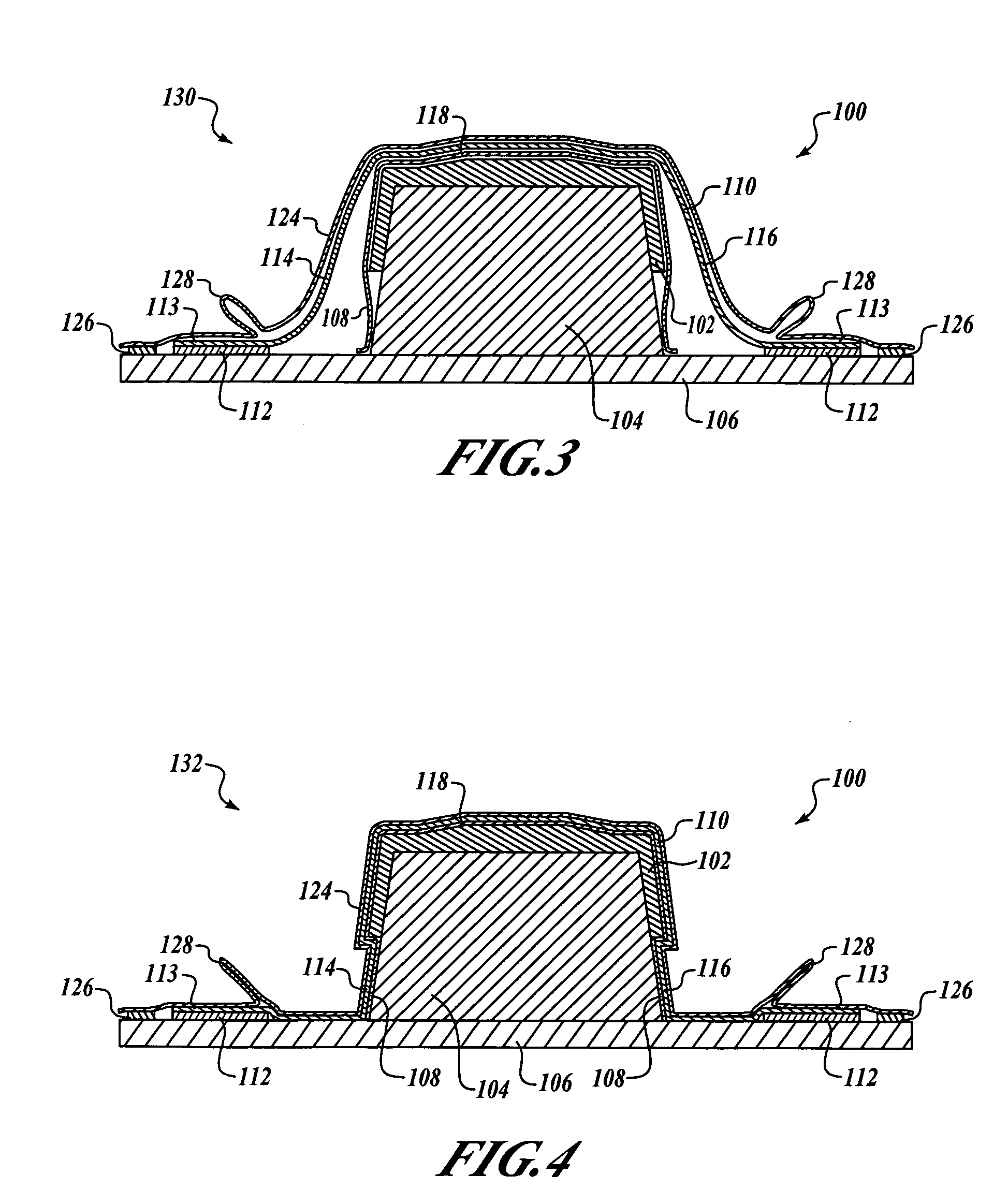

Apparatus and methods for processing composite components using an elastomeric caul

ActiveUS20050183818A1Reduce componentsReduce deformationLaminationLamination apparatusEngineeringMechanical engineering

Apparatus and methods for processing composite components using an elastomeric caul are disclosed. In one embodiment, a method includes forming a prepreg material on a non-planar portion of a lay-up mandrel, and providing an elastomeric caul over the prepreg material in an initial position such that a first portion of the elastomeric caul is proximate the prepreg material on the lay-up mandrel, and a second portion of the elastomeric caul adjacent the first portion is spaced apart from the prepreg material. Next, a pressure is reduced within a space disposed between the elastomeric caul and the lay-up mandrel proximate the non-planar portion. Simultaneously with the reducing of the pressure with the space, the elastomeric caul is stretched into a second position such that the second portion of the elastomeric caul is drawn proximate to at least one of the prepreg material and the lay-up mandrel.

Owner:THE BOEING CO

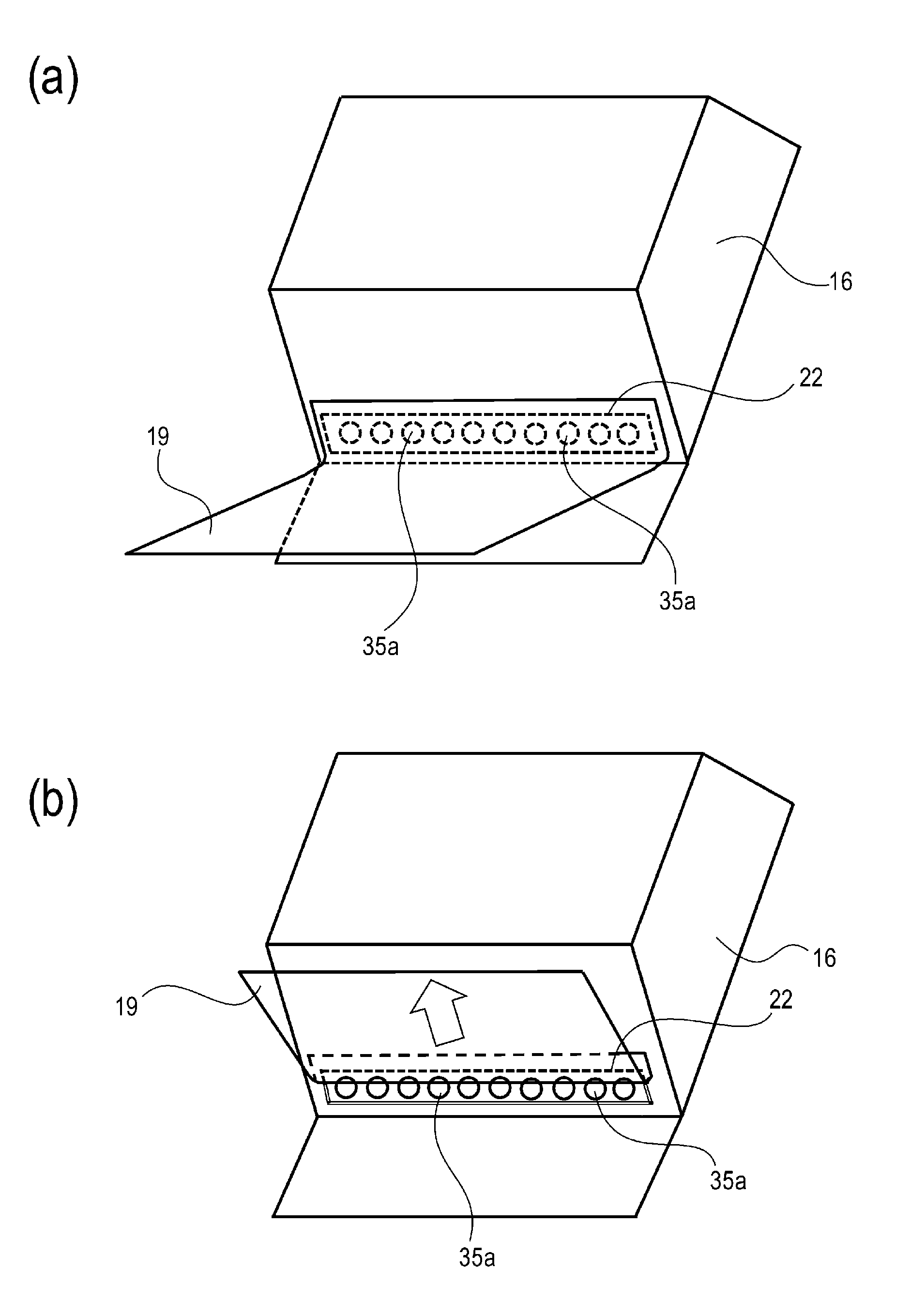

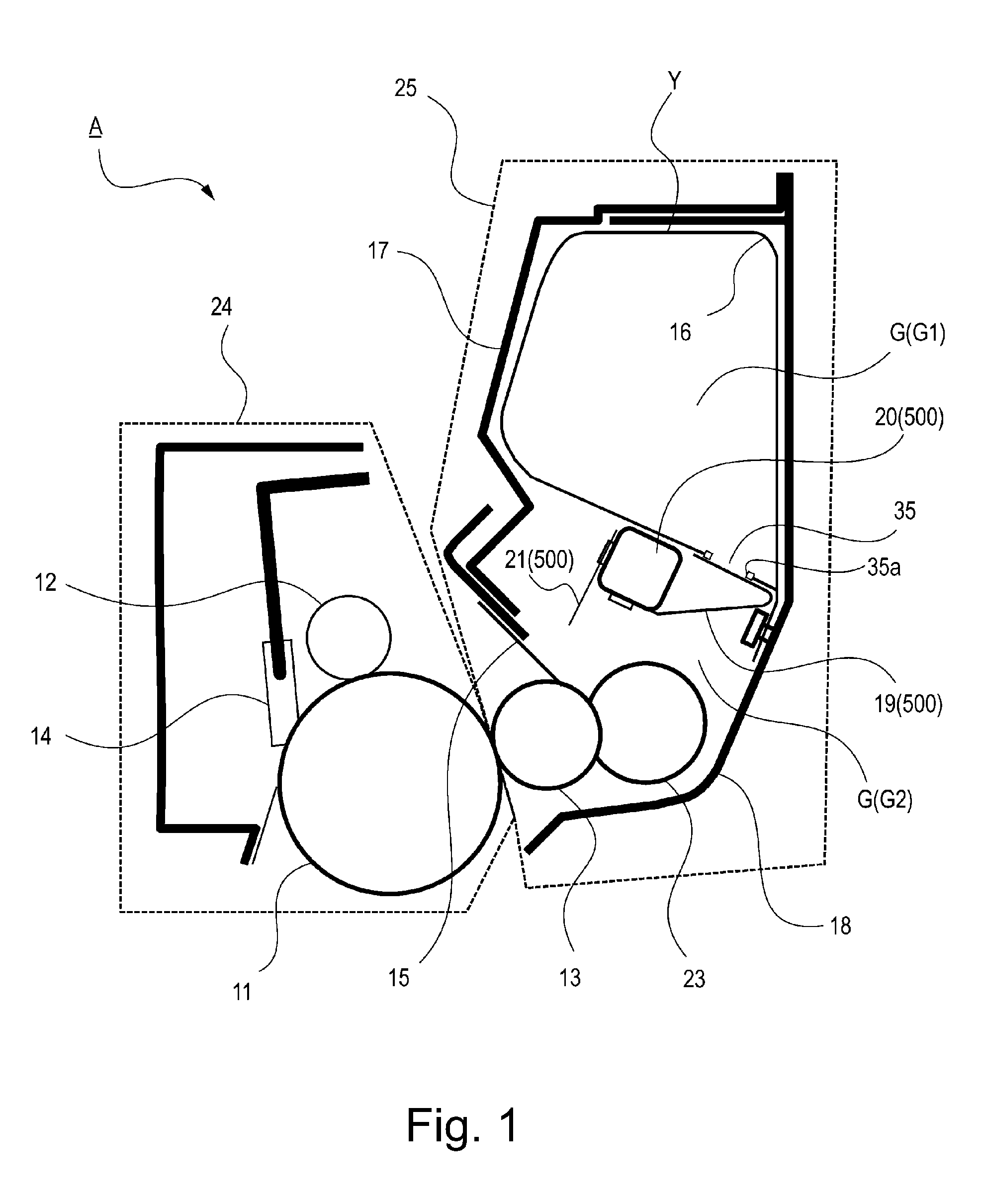

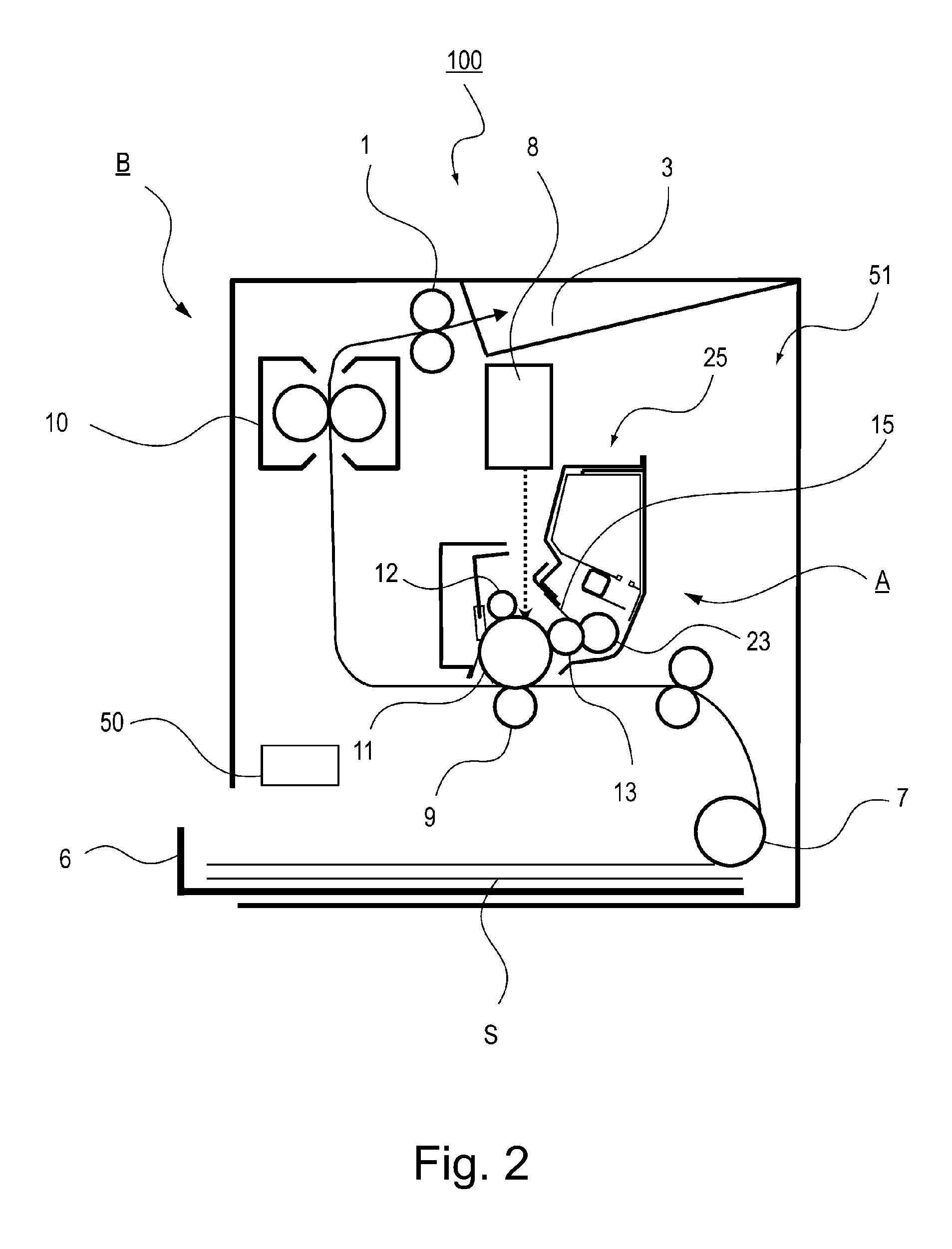

Developer accommodating container, process cartridge and electrophotographic image forming apparatus

ActiveUS9354553B2Reduce deformationReduce loadElectrographic process apparatusEngineeringMechanical engineering

A developer accommodating container for accommodating a developer includes: a flexible container provided with an opening for permitting discharge of the developer; a sealing member for sealing the opening in a state in which the sealing member is bonded to a periphery of the opening, wherein the sealing member is capable of exposing the opening by being removed by pulling; and a reinforcing portion, provided at least as a part of the periphery of the opening, for decreasing a degree of deformation of the opening.

Owner:CANON KK

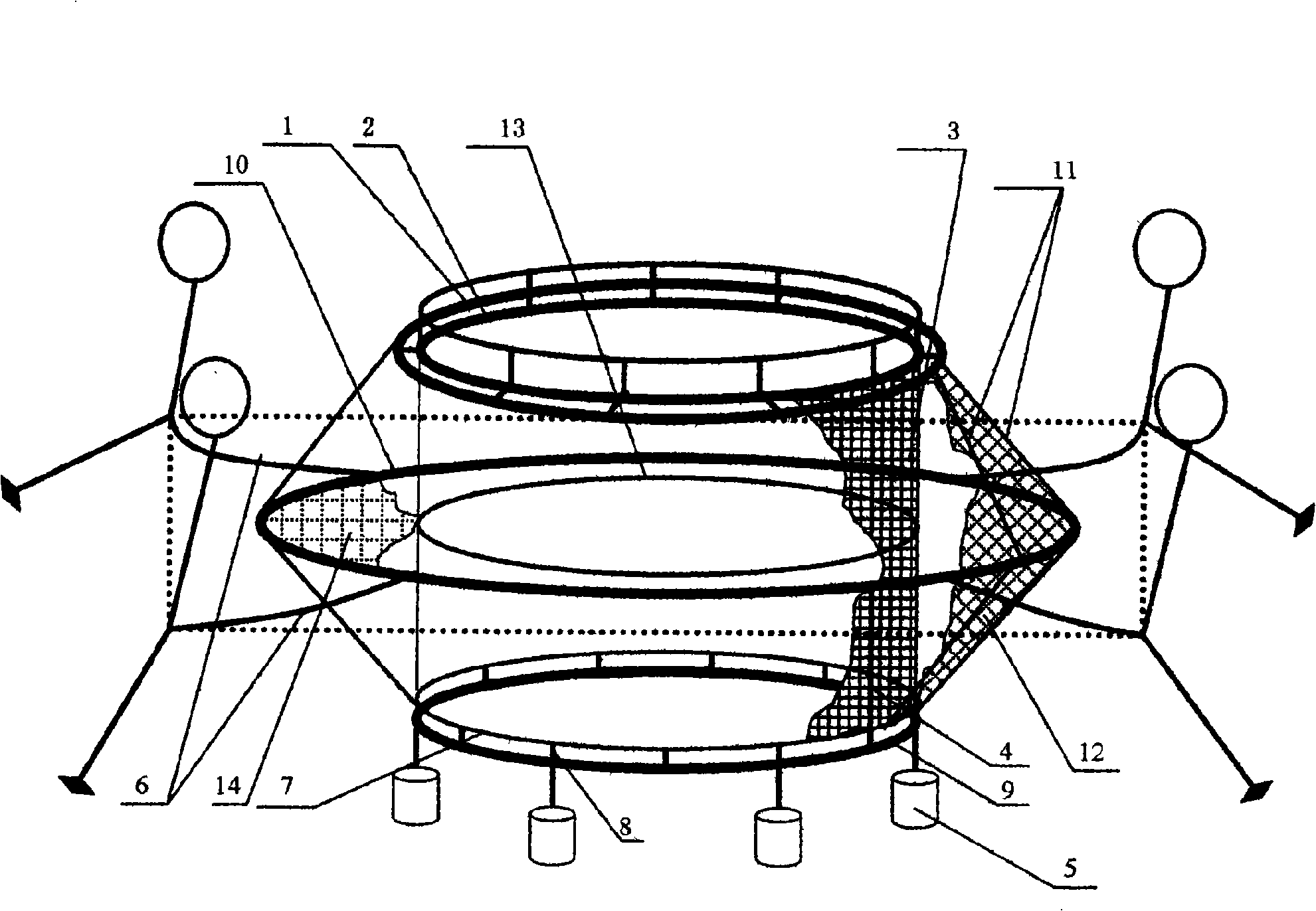

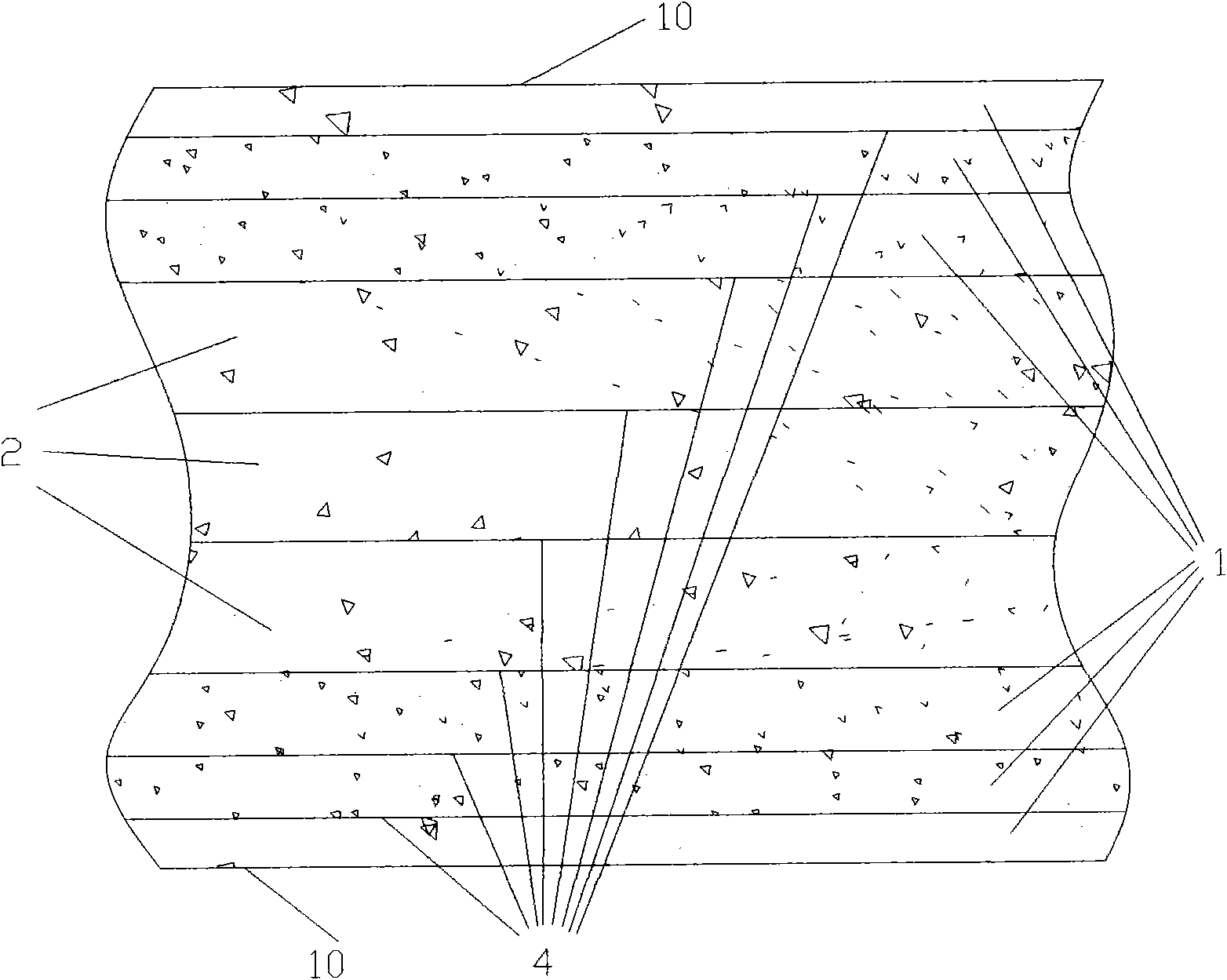

Self-reducing flow low-shape change off land deep water net cage

ActiveCN101326898AAdjust liftRegulation stateClimate change adaptationPisciculture and aquariaShape changeBand shape

The invention discloses an automatic reducing low-deformation offshore deep-water cage, relating to a cage for marine aquiculture. The invention is capable to reduce the deformation of the cage and the flow rate of the sea water inside the cage. The invention comprises a buoyancy frame, a cage, a sinking ring, a sinking block and an anchoring rope. A supporting and lifting control ring bigger than the buoyancy frame and the diameter of the sinking ring is arranged at the one second depth of the cylindrical cage; a water inlet and a water outlet are arranged in the pipe wall of the supporting and lifting control ring; a girdle rubber inner bag which regulates the lifting and descending of the cage is arranged in the ring pipe; an air-valve is installed in the rubber inner bag and connected with the air supply by a pressure hose; between the outer ring and the supporting and lifting control ring of the double-ring buoyancy frame, the bottom outline of the cylindrical cage and the bottom sinking ring, a plurality of flexible ropes are located and connected according to the ring at geometric proportion, and a netting is arranged among the connecting ropes of the three rings; and finally, a flexibly connected automatic reducing low-deformation offshore deep-water cage with a cylindrical inside and a two-cone platform outside is formed, the stress point of the anchoring rope of the cage is arranged at the supporting and lifting control ring.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Battery protection structure for automobile

ActiveUS8708402B2Add additional massReduce deformationVehicle seatsElectric propulsion mountingAutomotive batteryEngineering

Owner:TOYOTA JIDOSHA KK

Slip sheet

InactiveUS7013814B2Substantial shock absorbingCompact and durableRigid containersEngineeringSlide plate

A slip sheet pallet comprising a first sheet engageable with a stacked array which is to be supported; a second sheet attached to the first sheet; at least one flap connected to and extending outwardly from at least one of the first and second sheets and gripable by a lift truck gripping assembly; at least one of the first and second sheets comprising a compound sheet with a plurality of distinct connected layers.

Owner:SIGNODE IND GRP

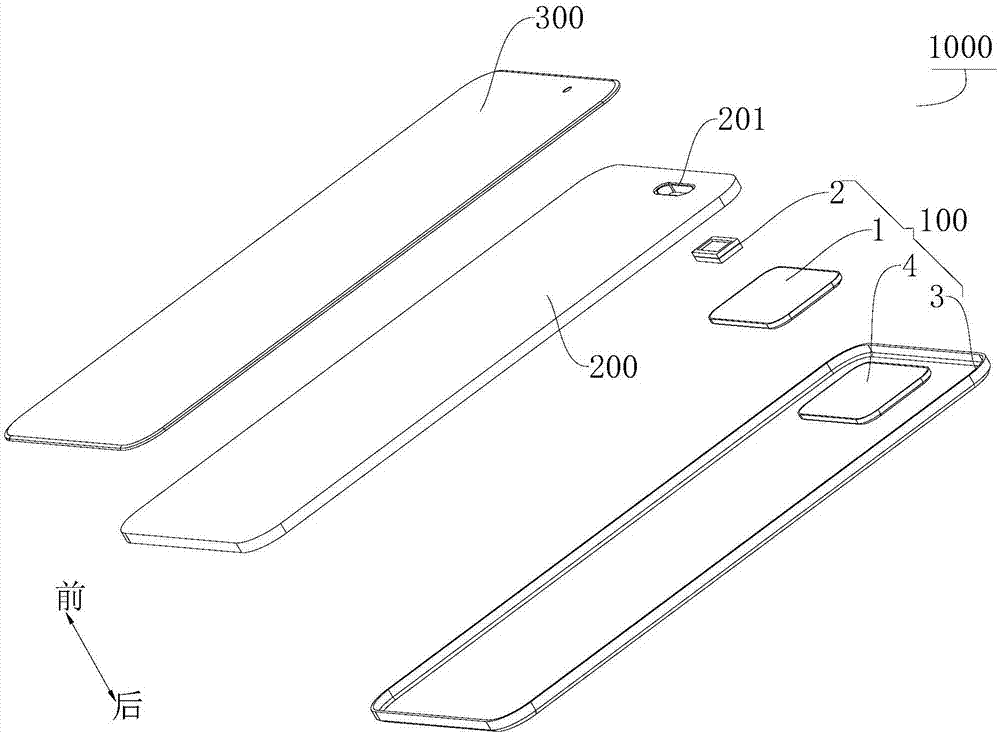

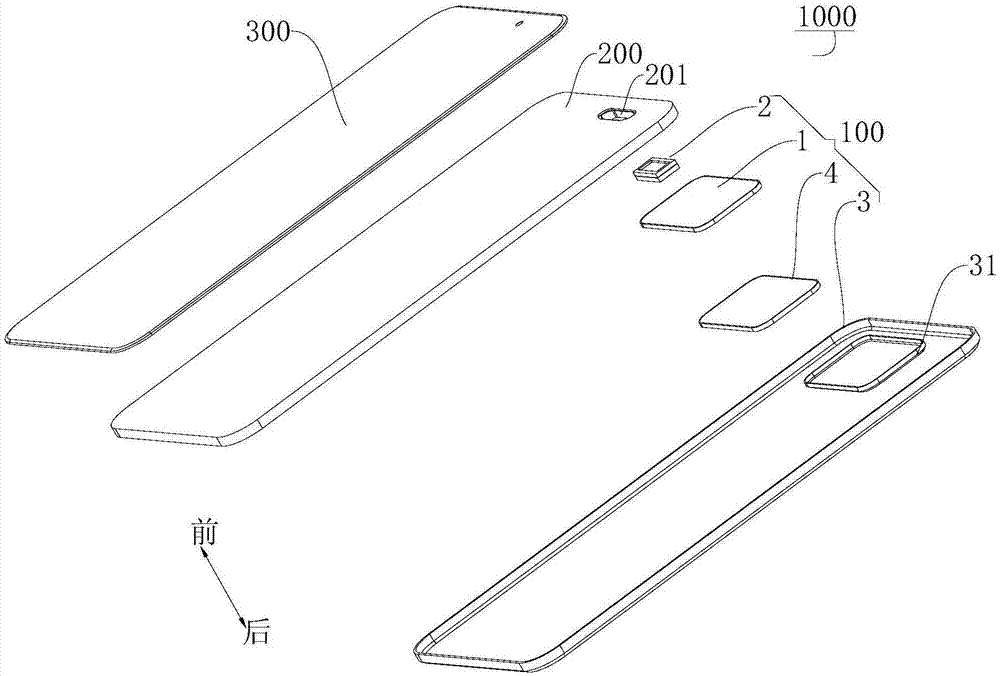

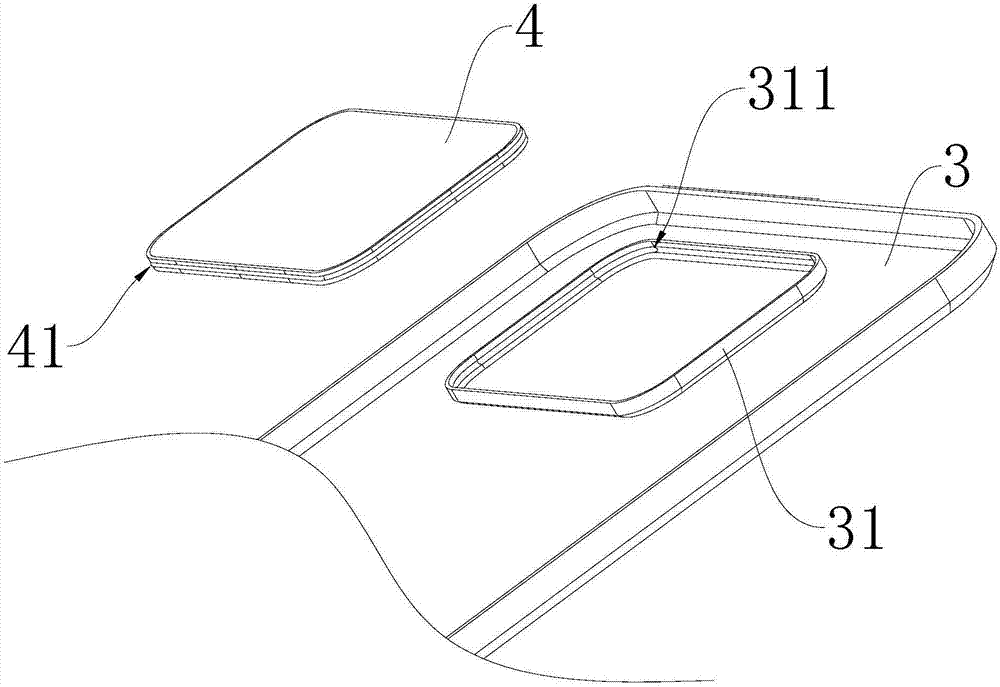

Cover assembly, shell assembly, shell assembly processing method and mobile terminal

InactiveCN107483692AReduce deformationAvoid impact deformationTelephone set constructionsComputer moduleComputer terminal

The invention discloses a cover assembly, a shell assembly, a shell assembly processing method and a mobile terminal. The cover assembly comprises a circuit board, a front camera module, a plastic cover and a reinforcing plate, wherein the front camera module comprises an image sensor, and the image sensor is arranged on the circuit board; the plastic cover is located at one side, away from the front camera module, of the circuit board; and the reinforcing plate is arranged on the surface of one side, facing the front camera module, of the plastic cover and is arranged correspondingly to the front camera module. According to the cover assembly of the invention, when the plastic cover is impacted, the reinforcing plate plays a role of reinforcement, the deformation generated by the plastic cover can be greatly reduced, the plastic cover can be prevented from being impacted and deformed to a certain degree, the impact force can be prevented from being transferred to the image sensor, reliable protection on the image sensor is further realized, and failure of the front camera module is prevented.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Preparation method of lodging-resistant multi-difference polyester low-elastic filament

ActiveCN106400179AImprove heat resistanceEasy to processMelt spinning methodsMonocomponent polyesters artificial filamentFiberPolyethylene glycol

The invention relates to a preparation method of a lodging-resistant multi-difference polyester low elastic filament. The preparation method comprises the following steps: firstly, mixing nano sepiolite fibers, organic magnesium hydroxide whisker, organic barium sulfate nano powder, ethylene glycol, propylene glycol, p-hydroxybenzoic acid and sodium germanate to obtain a high-modulus composite alcohol solution; secondly, mixing organic wollastonite nano needle-like fibers, mica powder, polyethylene glycol, the propylene glycol, an antioxidant 1010, ethylene glycol antimony and protonated agent phosphoric acid to obtain a high-modulus composite promoter; thirdly, co-polycondensing the high-modulus composite multifunctional alcohol solution and the high-modulus composite promoter with purified terephthalic acid and the ethylene glycol to obtain high-modulus modified polyester; a melt of the high-modulus modified polyester is sprayed from a T-shaped spinneret orifice in a spinneret plate; the lodging-resistant multi-difference polyester low elastic filament is prepared by a special cooling mode and a low-temperature texturing process. The fiber prepared by the preparation method has multiple different properties of different crystallization, different orientation and different shrinkage; after different shrinkage, the appearance is good, and a brushed fabric prepared from the lodging-resistant multi-difference polyester low elastic filament is not easy to lodge.

Owner:荣翔化纤有限公司

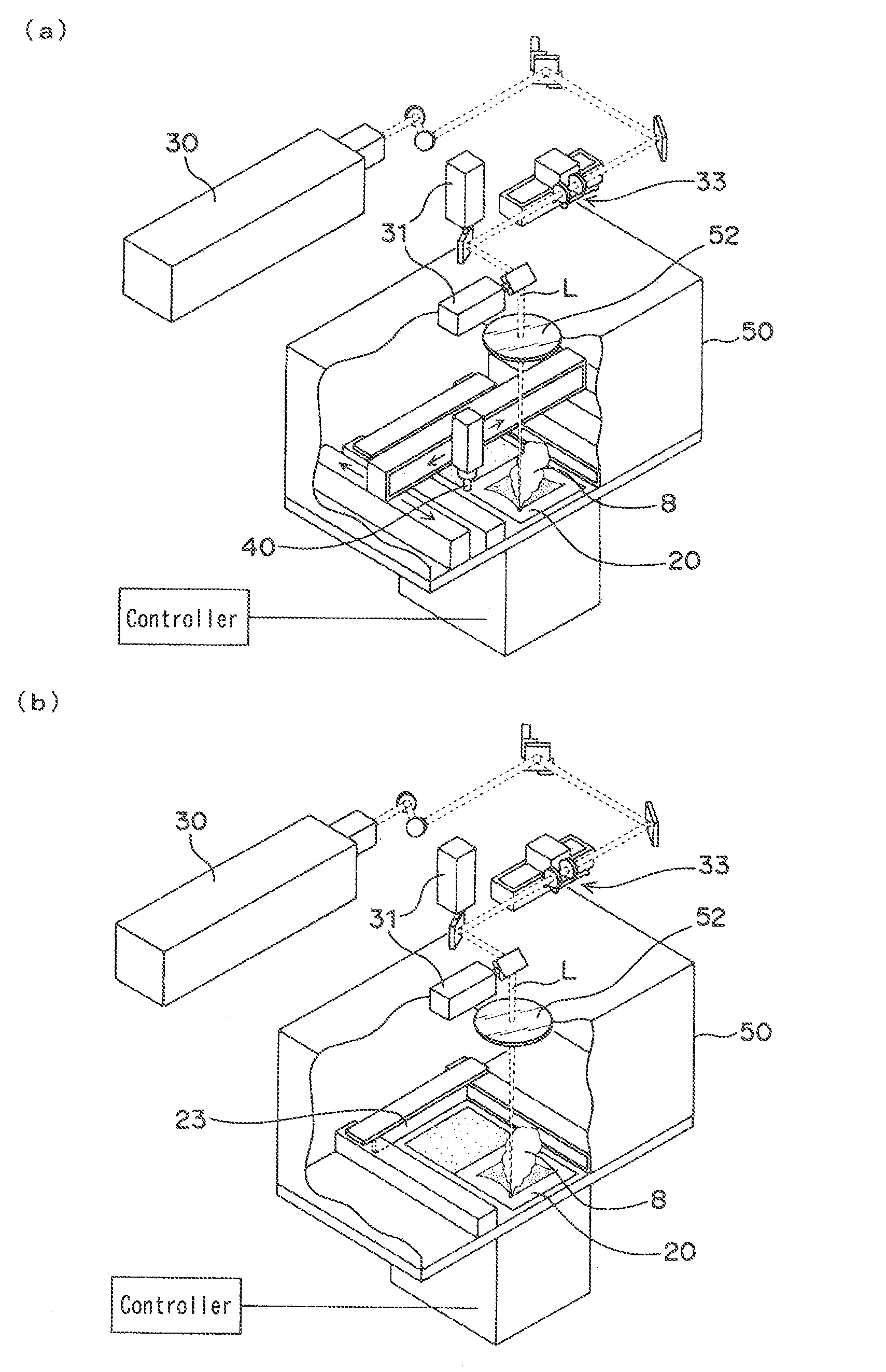

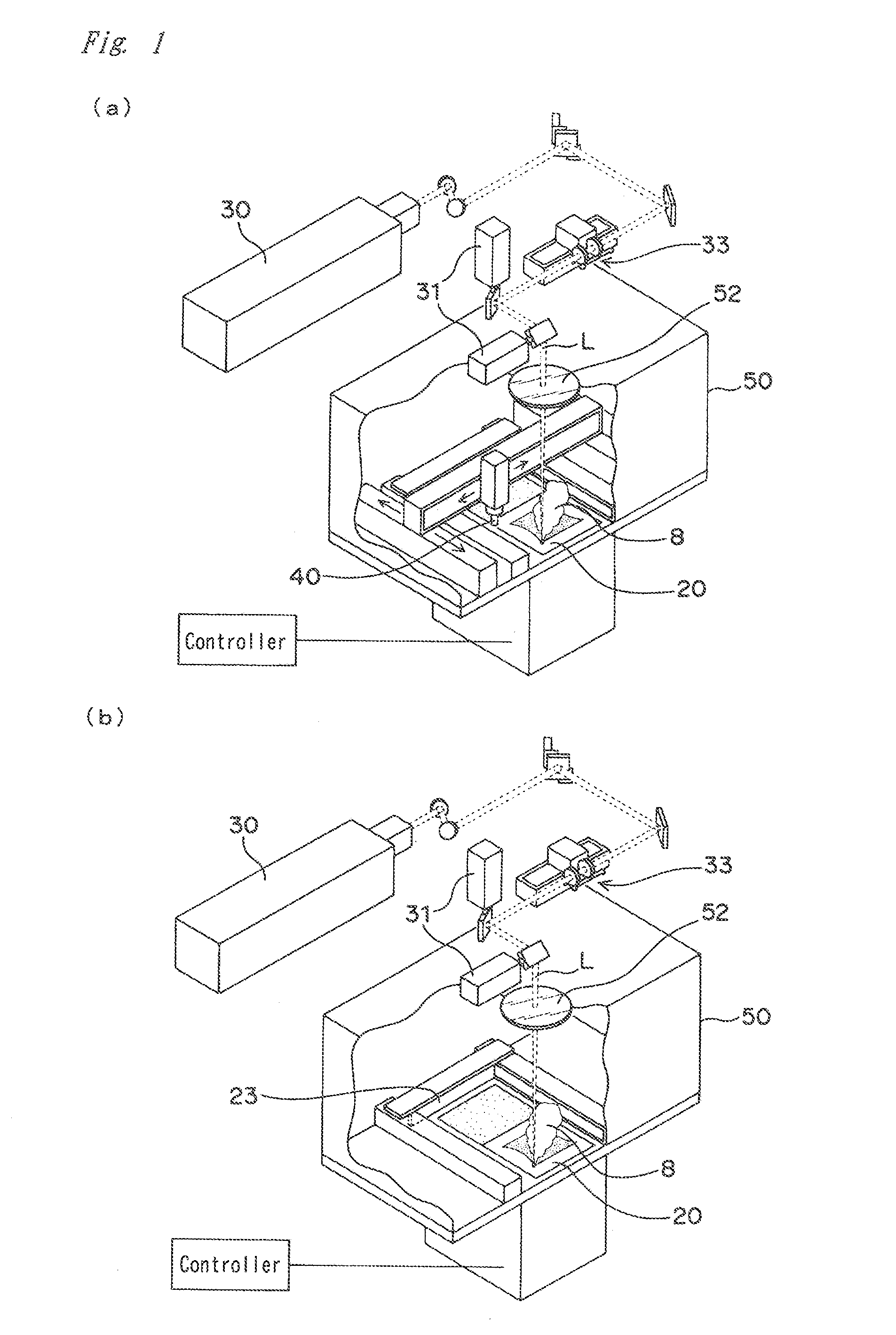

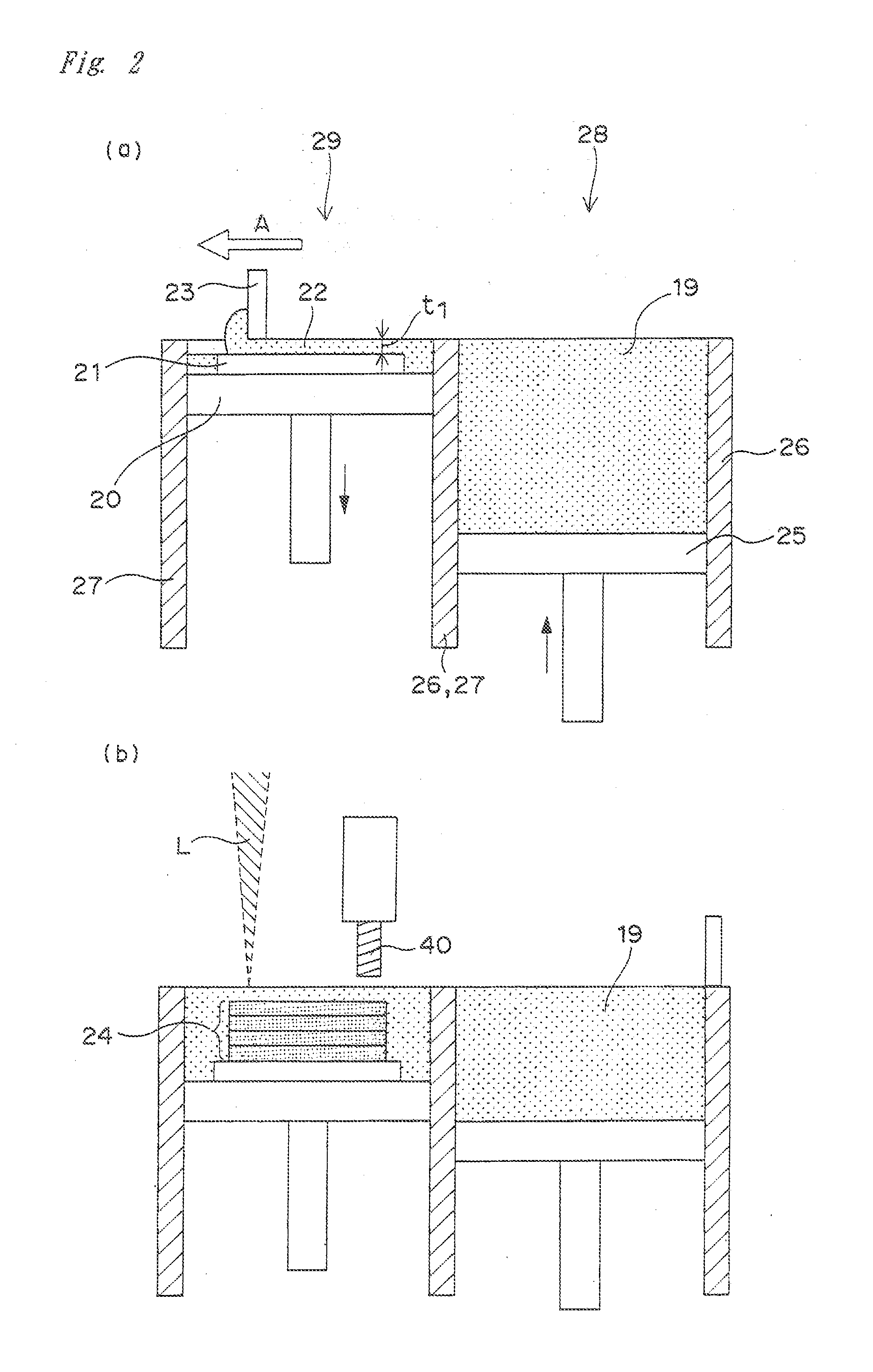

Metal powder for selective laser sintering, method for manufacturing three-dimensional shaped object by using the same, and three-dimensional shaped object obtained therefrom

InactiveUS20130065073A1Reduce warpingReduce deformationAdditive manufacturing apparatusPig casting plantsSelective laser sinteringPowder mixture

There is provided a metal powder for use in a selective laser sintering method for producing a three-dimensional shaped object, wherein the metal powder comprises a powder mixture of a precipitation-hardening metal composition. In particular, the metal powder of the present invention is configured to have a Fe-based component powder and a Ni-based component powder which are individually included in the powder mixture wherein a powder made of an alloy of Fe-based and Ni-based components is not included as a main powder in the powder mixture.

Owner:PANASONIC CORP

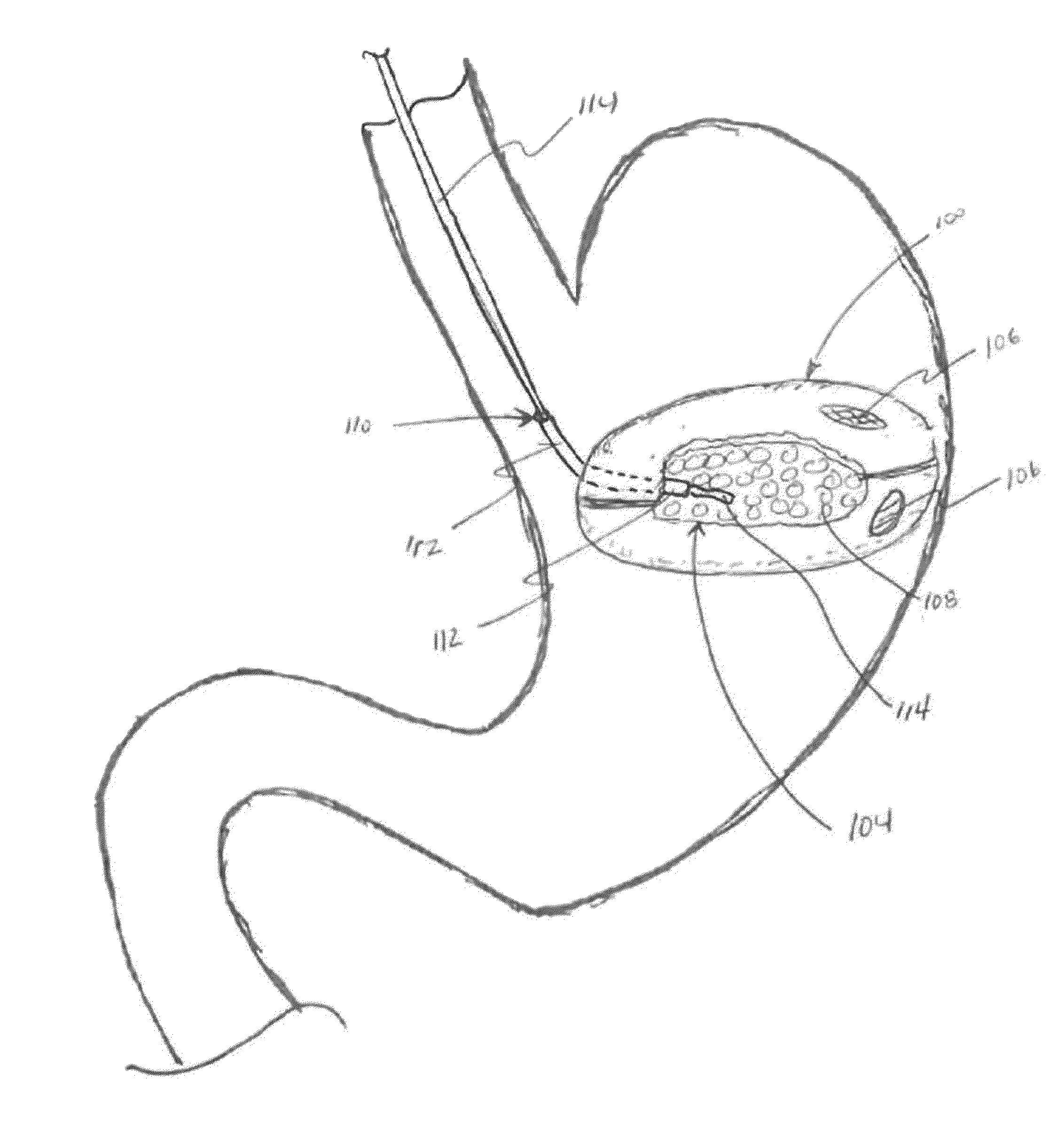

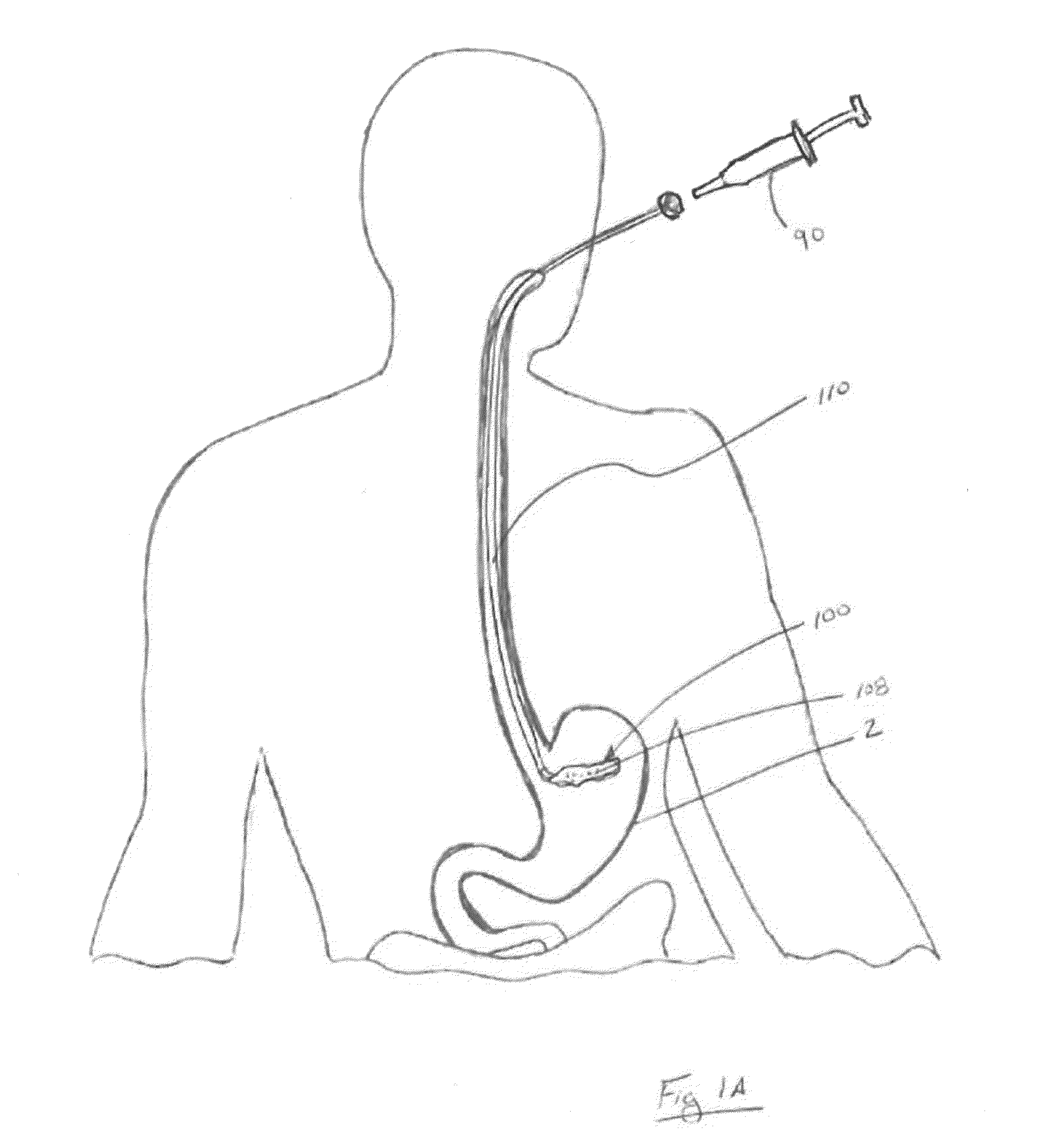

Methods and devices for deploying and releasing a temporary implant within the body

Methods, devices and systems for delivering a device assembly into a gastric or other space within the body, allowing the device to expand to occupy volume within the gastric space and after an effective period of time, delivering a substance or stimulus to begin breakdown of the expanded device so that it may release from the body.

Owner:ALLURION TECH

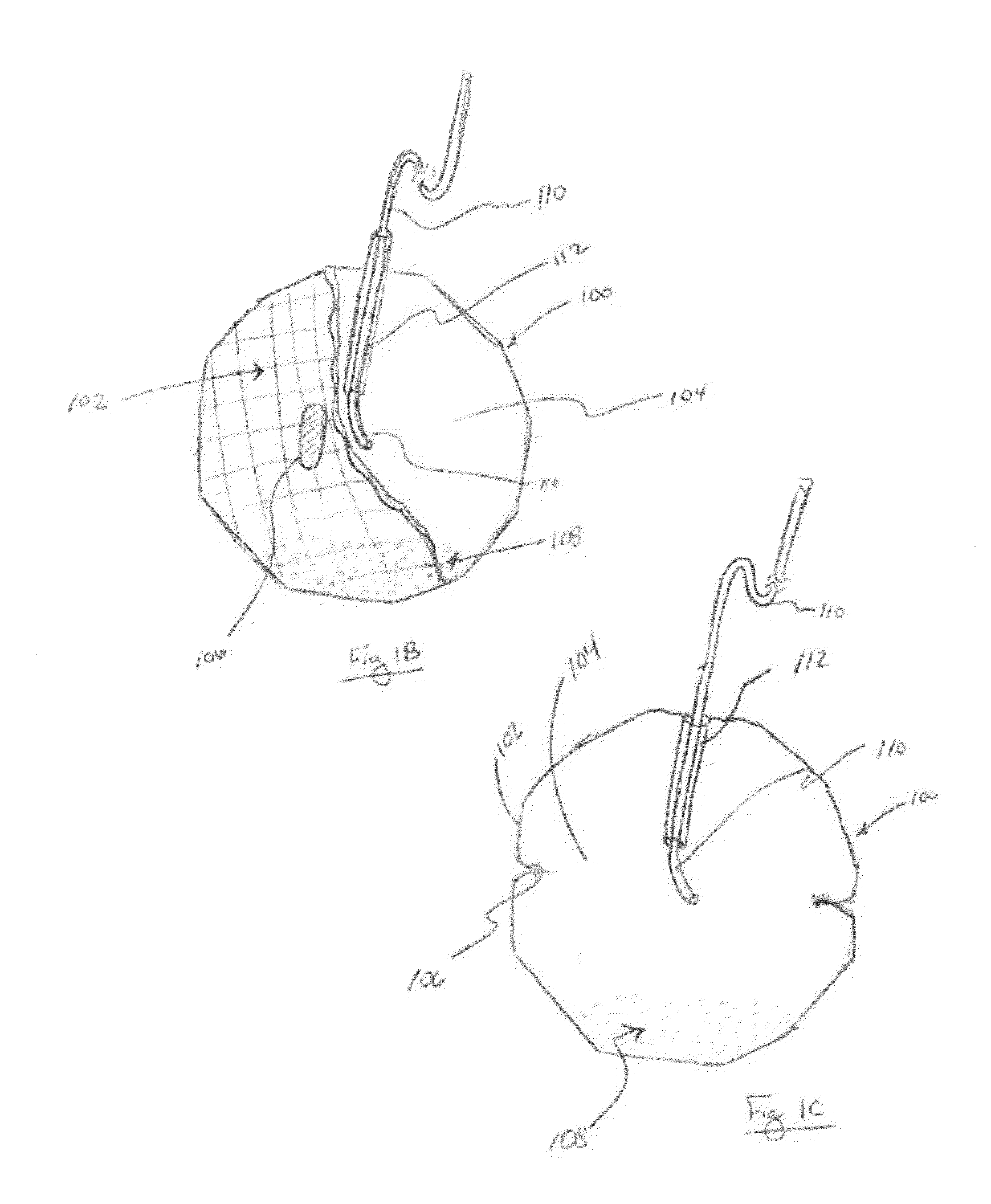

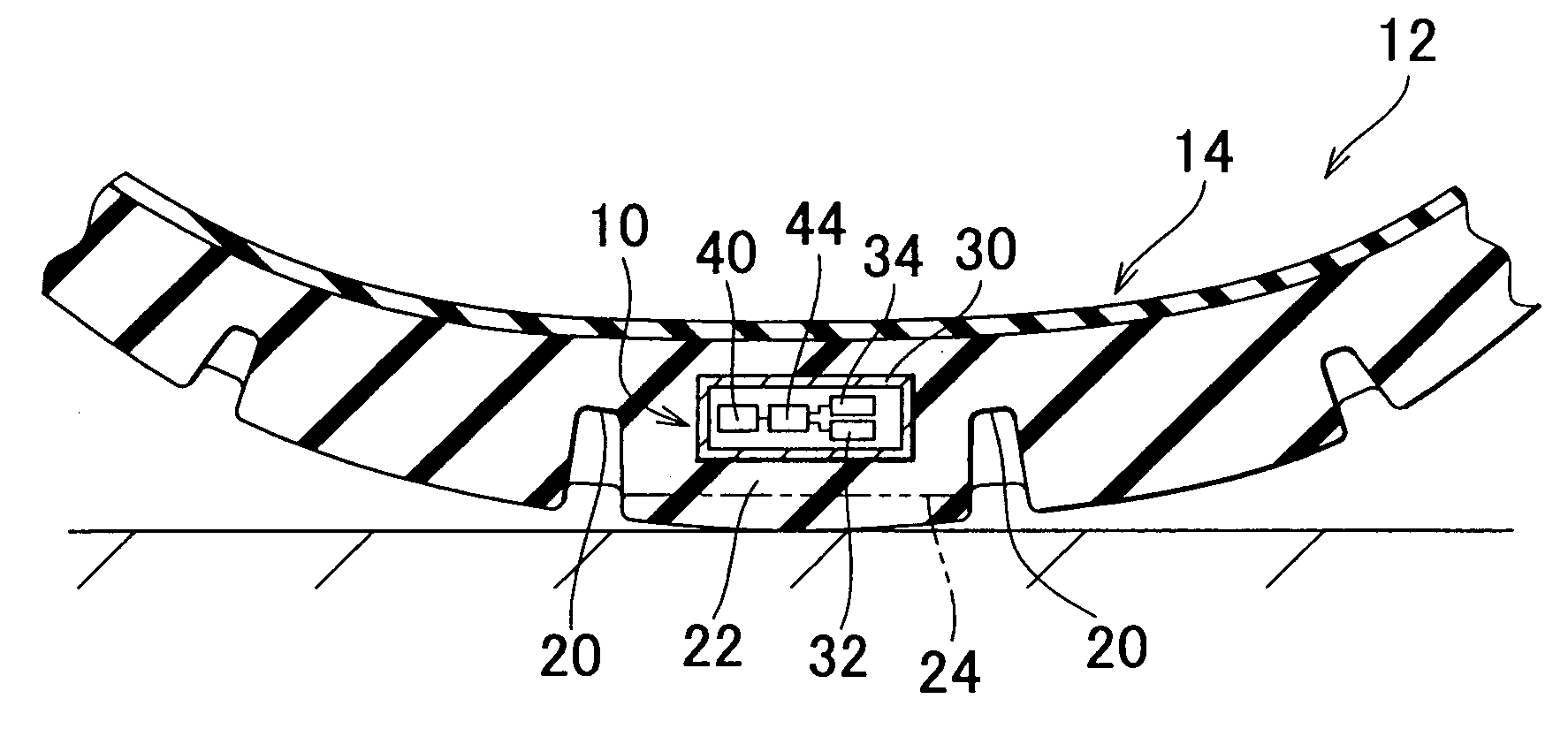

Tire state quantity detecting apparatus and method

InactiveUS20050057346A1Reliable signal transmissionReduced reliabilityOptical signallingTyre measurementsEngineering

In a tire state quantity detecting apparatus, a detector that deforms by force exerted from a tire and that outputs a signal corresponding to the quantity of deformation is embedded within the tire. The detector is enclosed in a capsule within the tire, so that the quantity of deformation of the detector is reduced relative to the quantity of deformation of the tire.

Owner:TOYOTA JIDOSHA KK

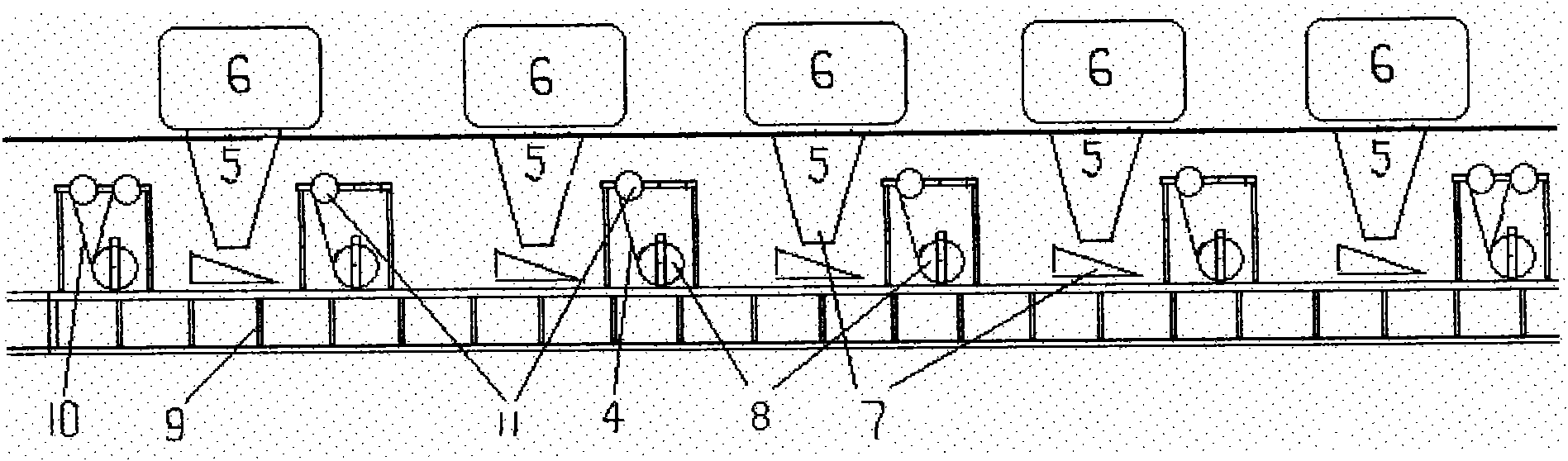

Multilayer composite plate for building templates and brick pallets and preparation process thereof

InactiveCN101633254AWith glazed effectEasy to demouldMouldsMixing operation control apparatusBrickSurface layer

The invention discloses a multilayer composite plate for building templates and brick pallets, which is prepared from magnesium cement gel added with a reinforcing material and a filler, and comprises surface layers (1) and sandwich layers (2); the surface layers (1) or / and the sandwich layers (2) comprise the filler or / and the reinforcing material with even content or gradient change; the number of the sandwich layers (2) is totally between 1 and 5; and the reinforcing material is arranged between adjacent sandwich layers (2). The invention also comprises a preparation process for the multilayer composite plate, which comprises that: production equipment with the capacity of stirring and preparing materials at multiple positions and rolling at multiple positions orderly rolls the surface layers (1) or / and the sandwich layers (2) on a subplate (3); and the reinforcing material is used as a reinforced structure between adjacent surface layers (1) or / and sandwich layers (2). The products corresponding to the invention have the characteristics of strong applicability, good technical effect and suitability for mechanical continuous production, and have predictable great economic and social values.

Owner:LIAONING FENGCHENG INDAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com