Patents

Literature

185results about How to "Reduce warping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

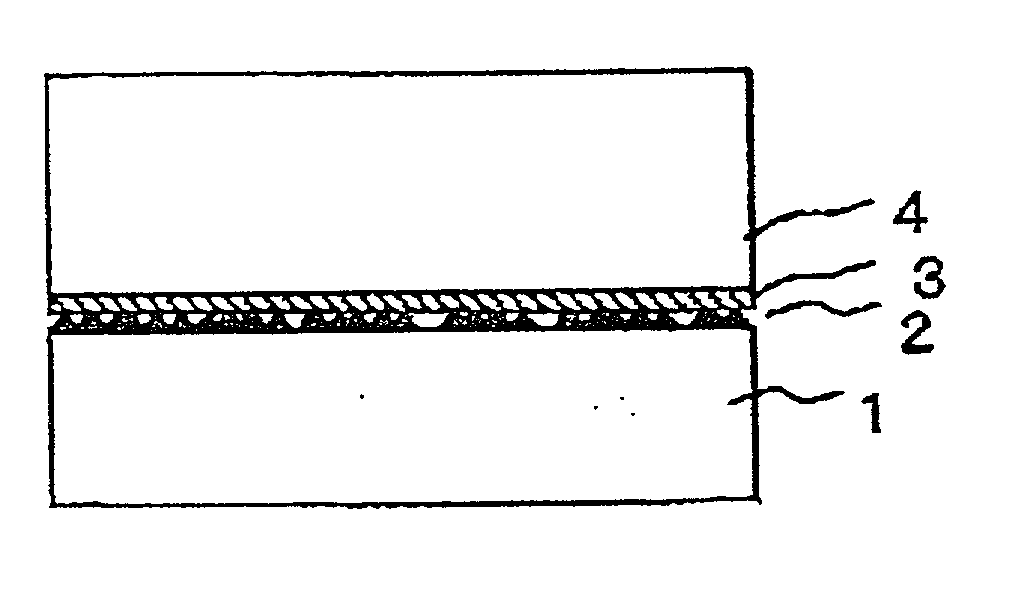

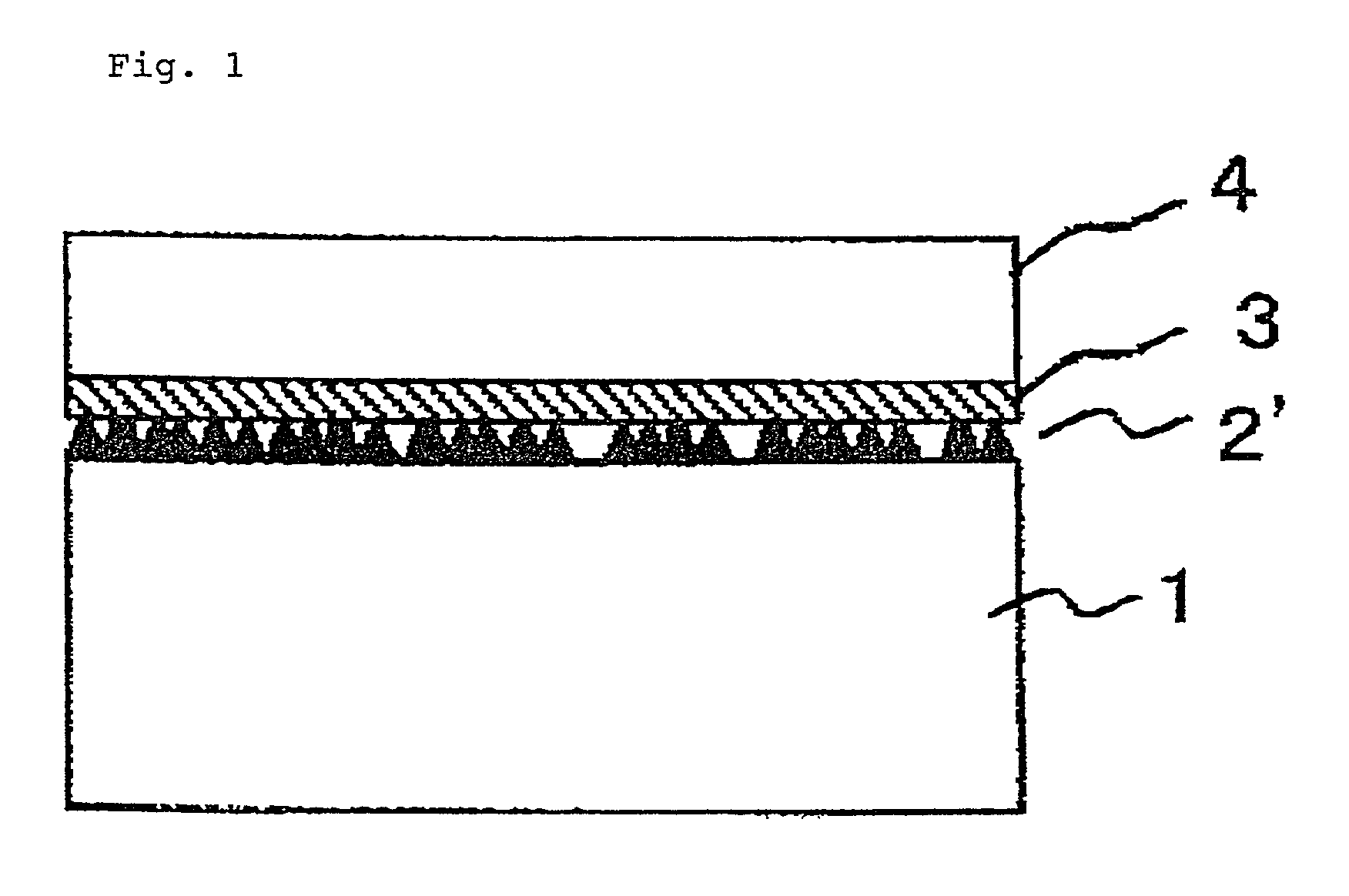

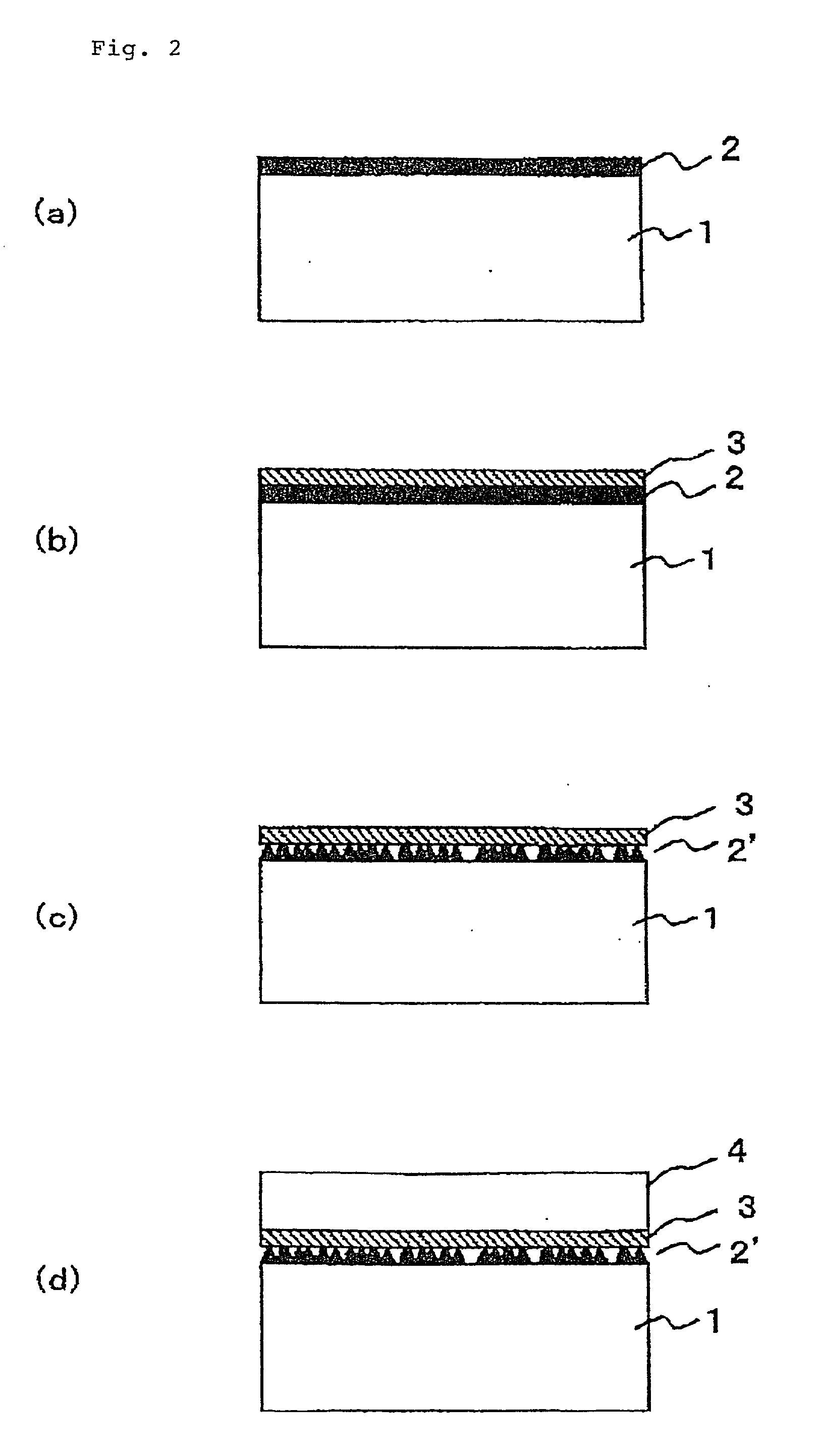

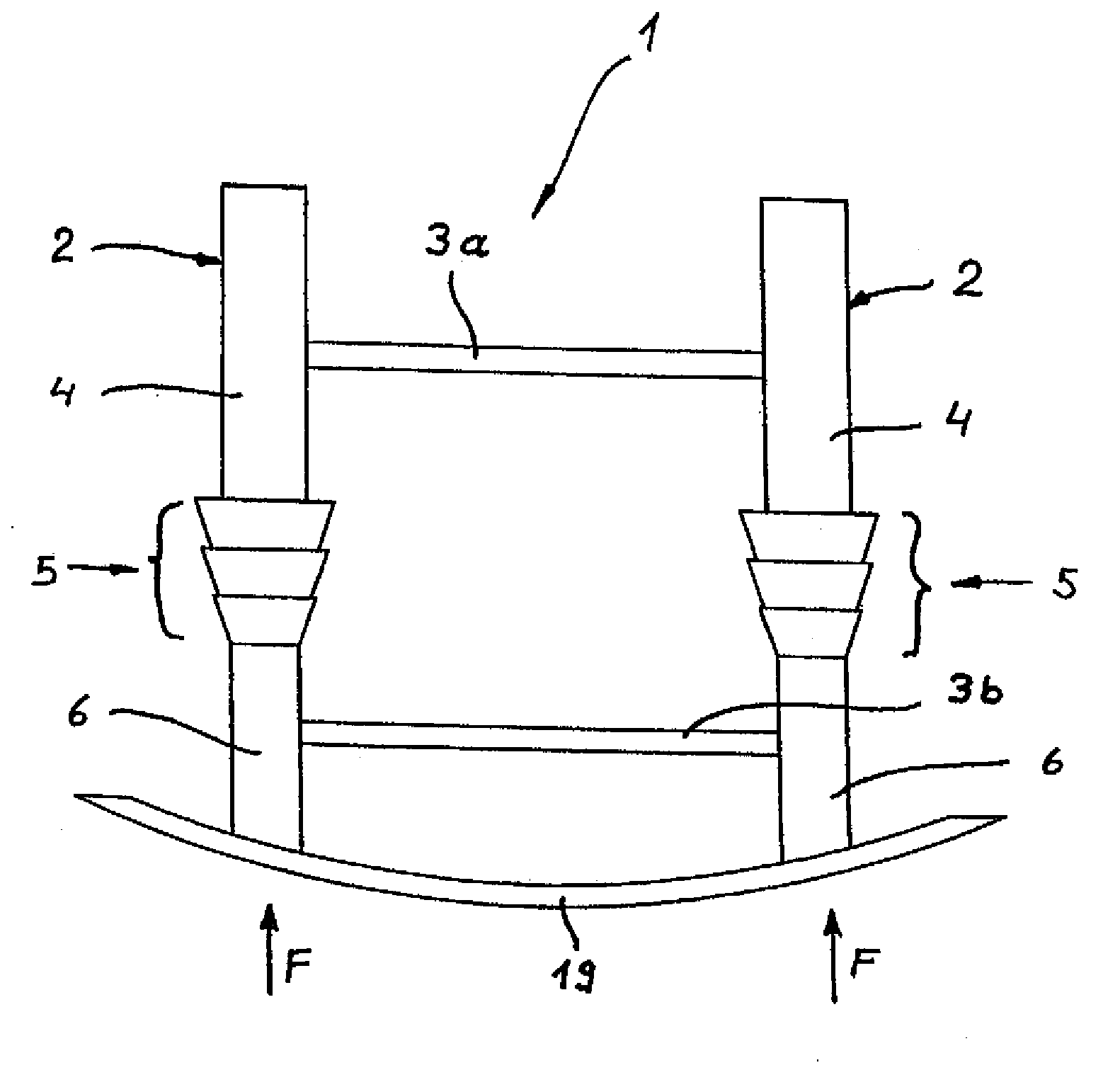

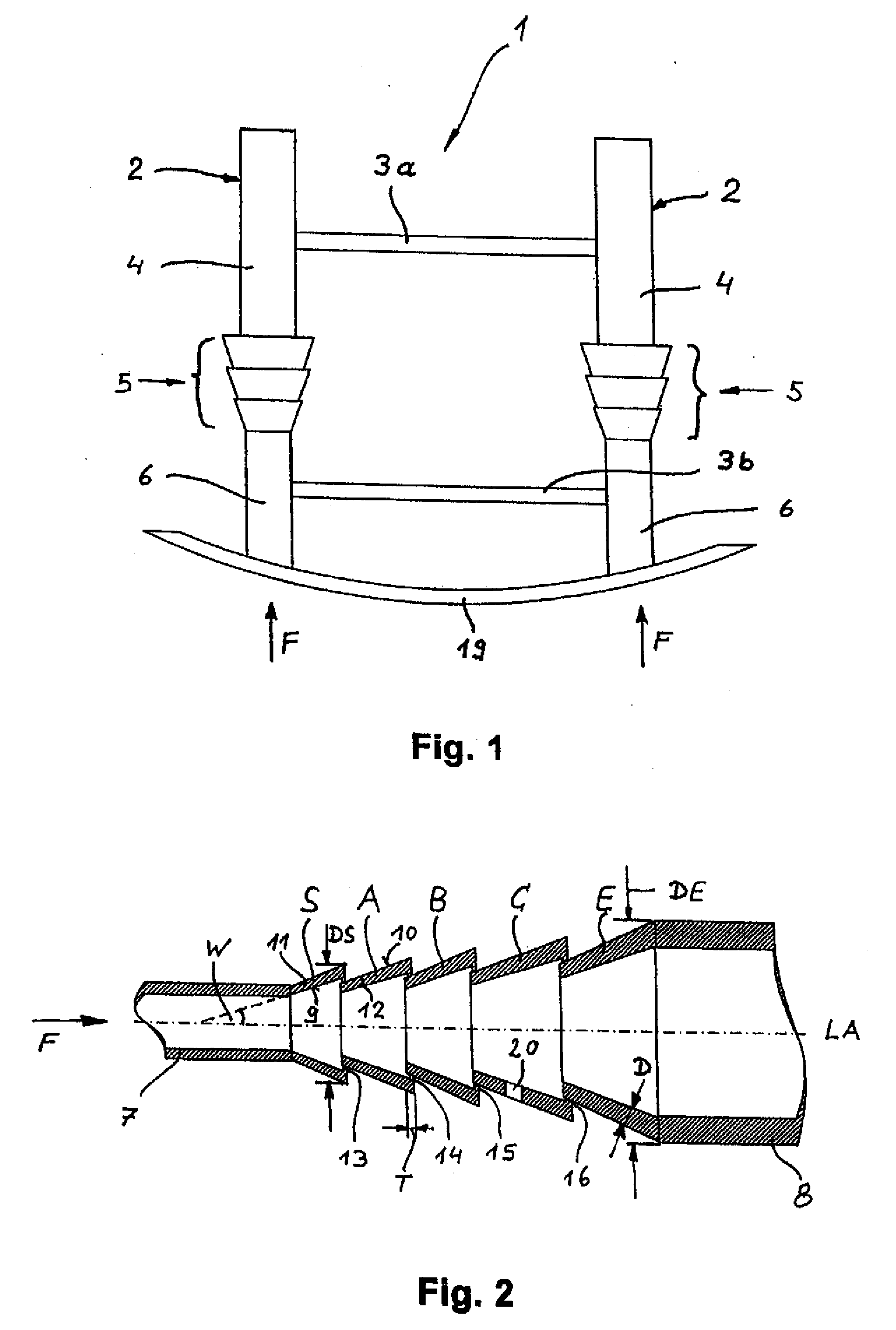

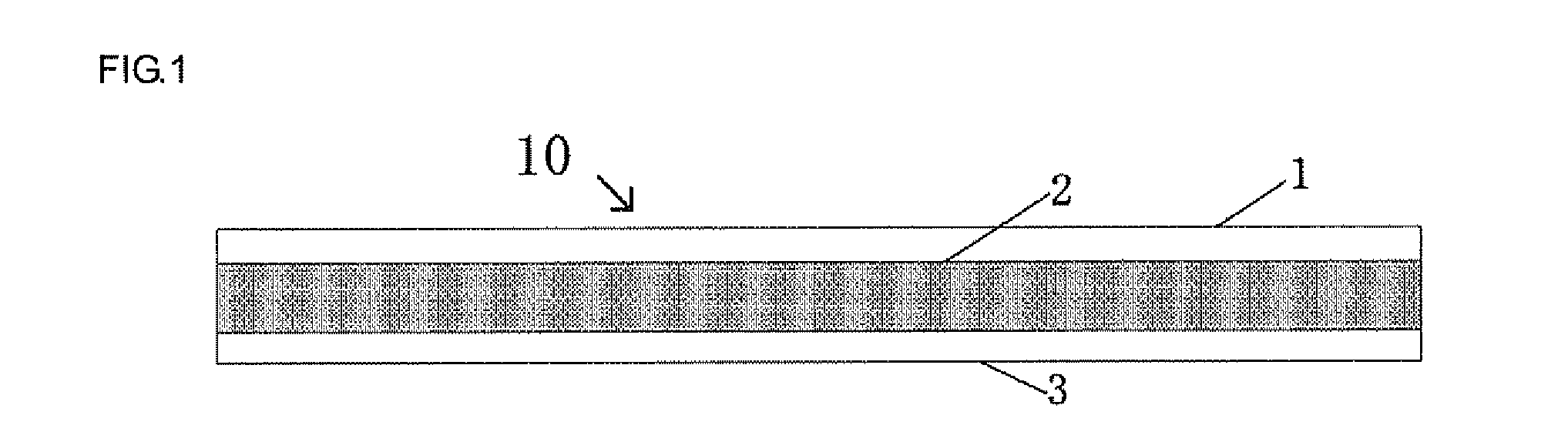

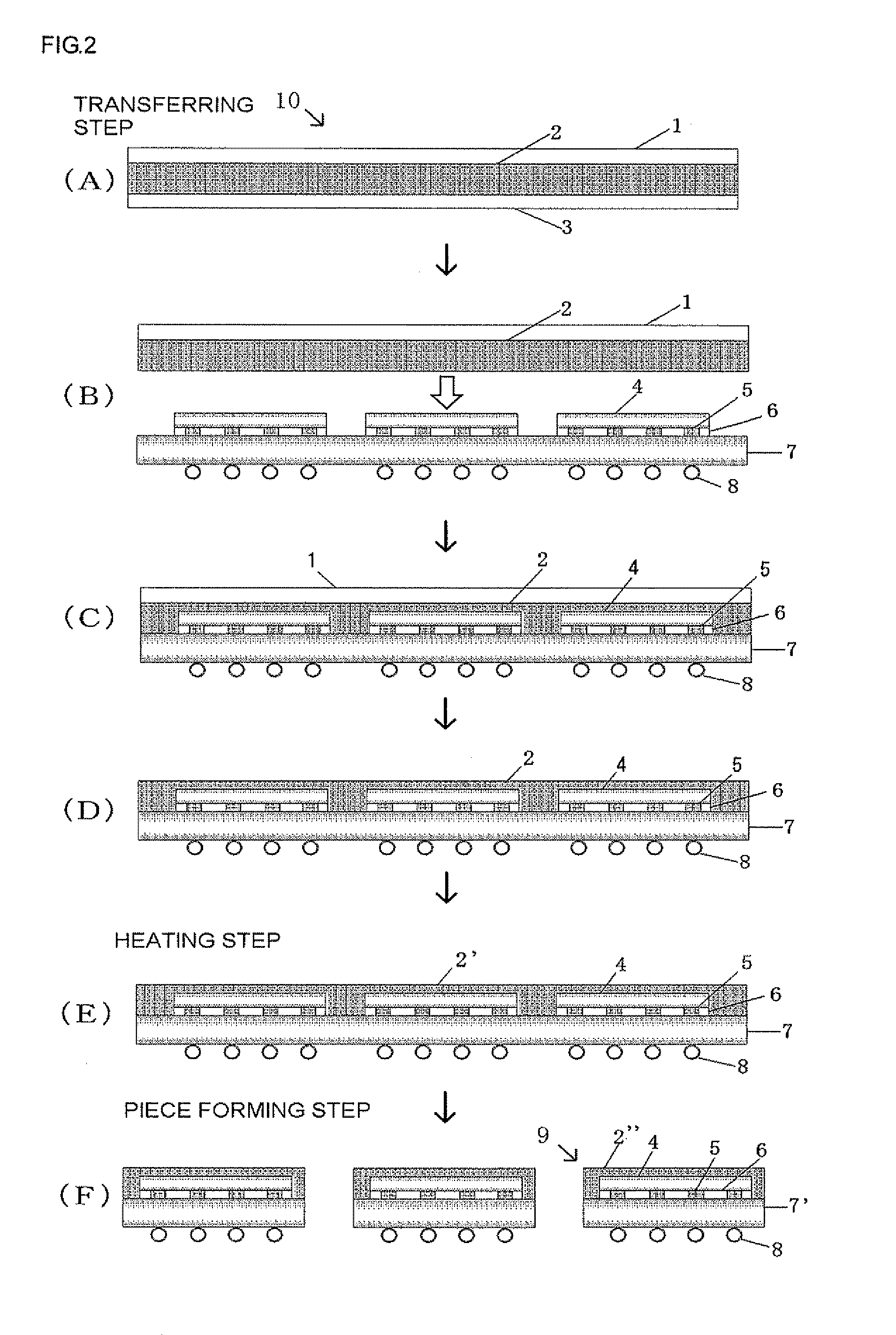

Semiconductor substrate made of group III nitride, and process for manufacture thereof

InactiveUS20020197825A1Reduce defect densityImprove crystal qualityPolycrystalline material growthSemiconductor/solid-state device manufacturingHydrogen compoundsTitanium

To provide a semiconductor substrate of a group III nitride with low defect density and little warp, this invention provides a process comprising such steps of: forming a GaN layer 2 on a sapphire substrate 1 of the C face ((0001) face); forming a titanium film 3 thereon; heat-treating the substrate in an atmosphere containing hydrogen gas or a gas of a compound containing hydrogen to form voids in the GaN layer 2; and thereafter forming a GaN layer 4 on the GaN layer 2'.

Owner:SUMITOMO CHEM CO LTD

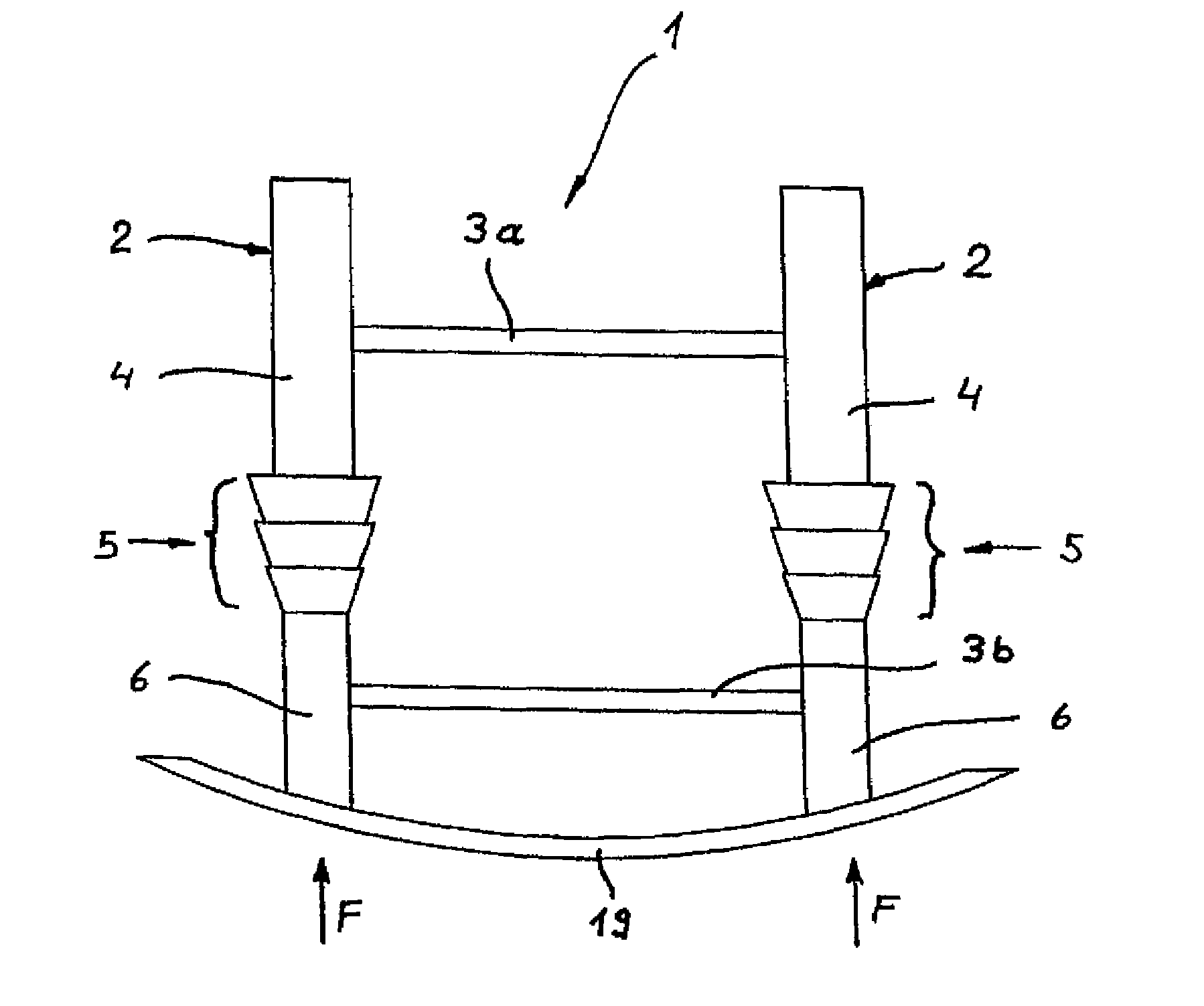

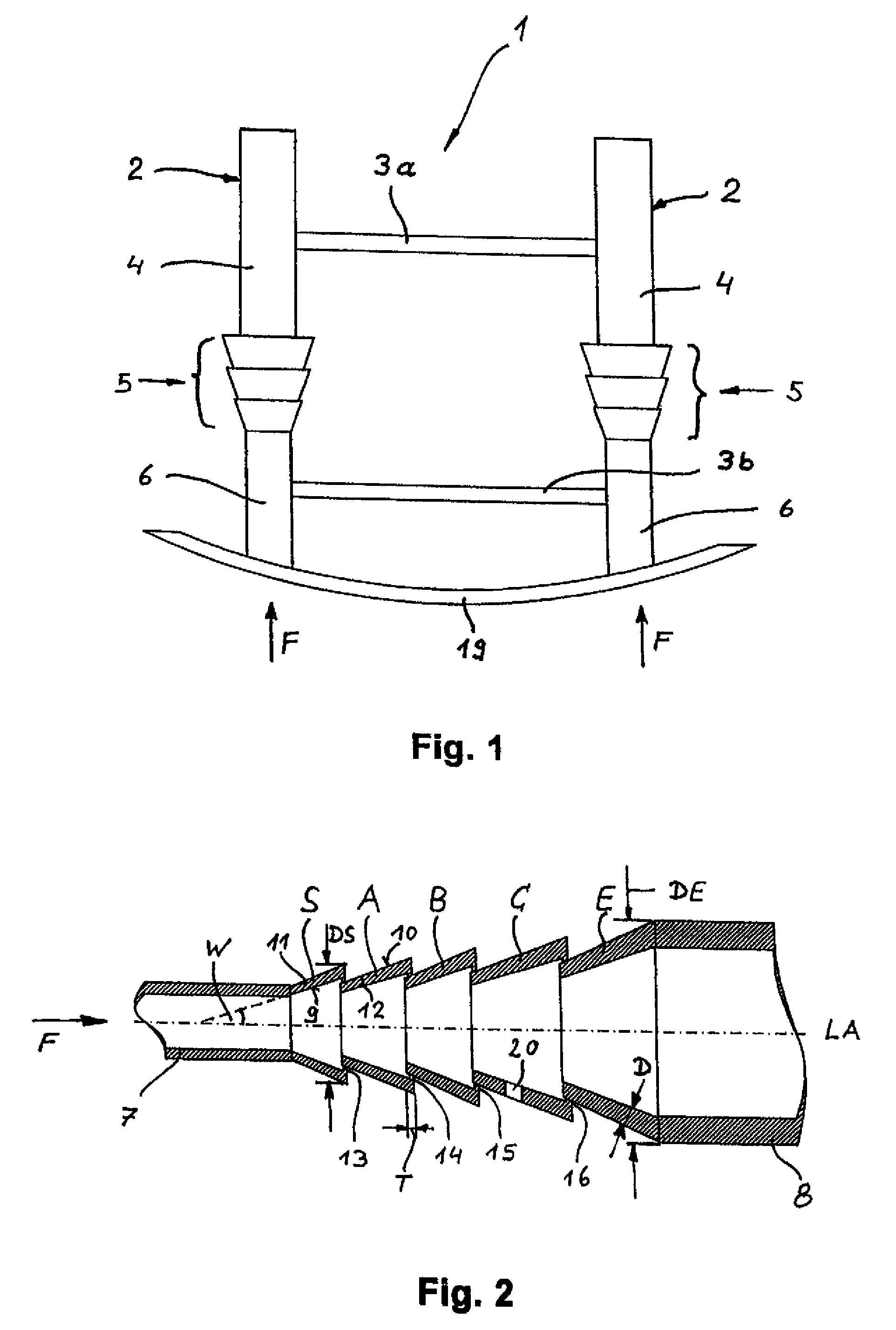

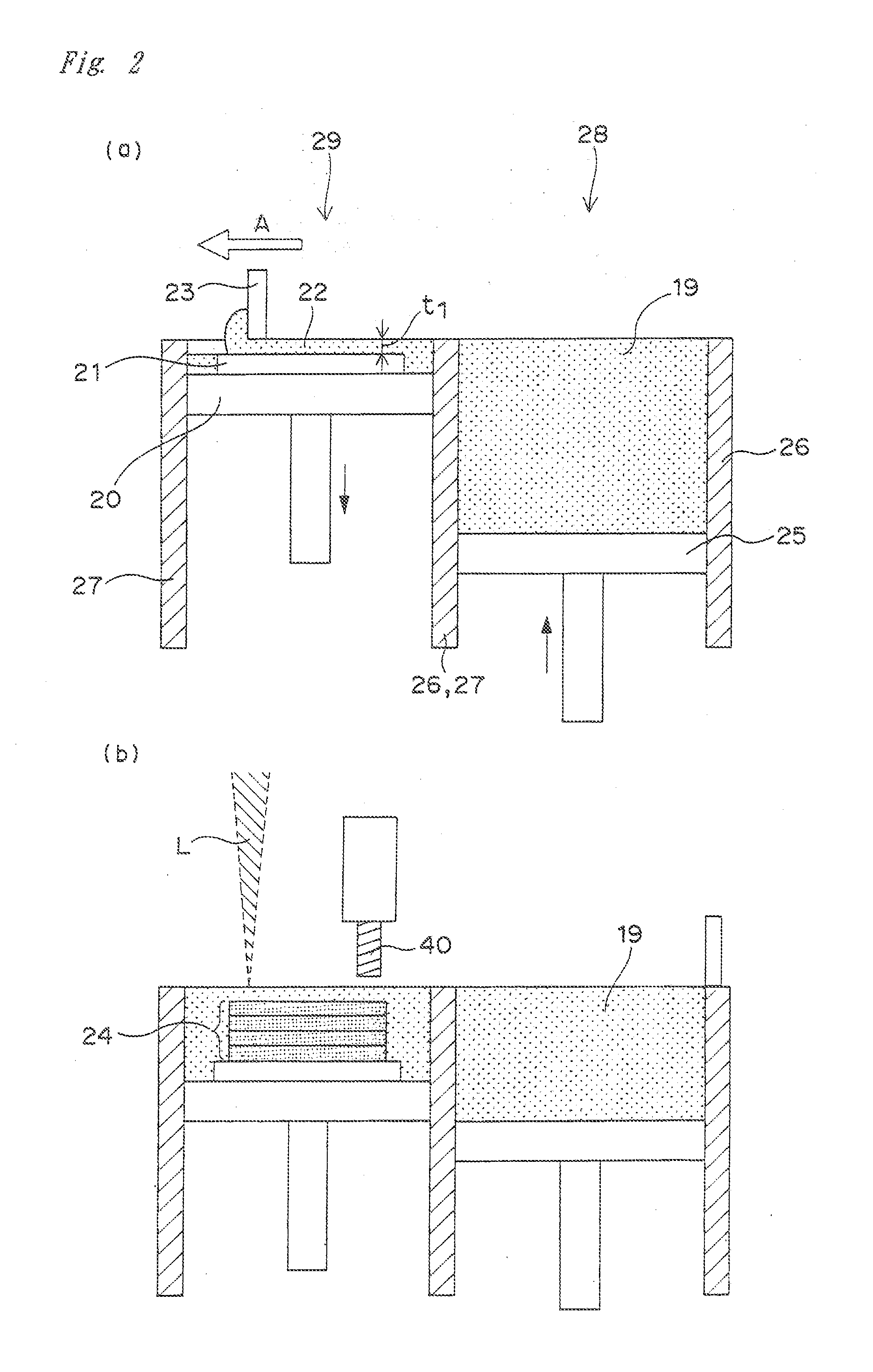

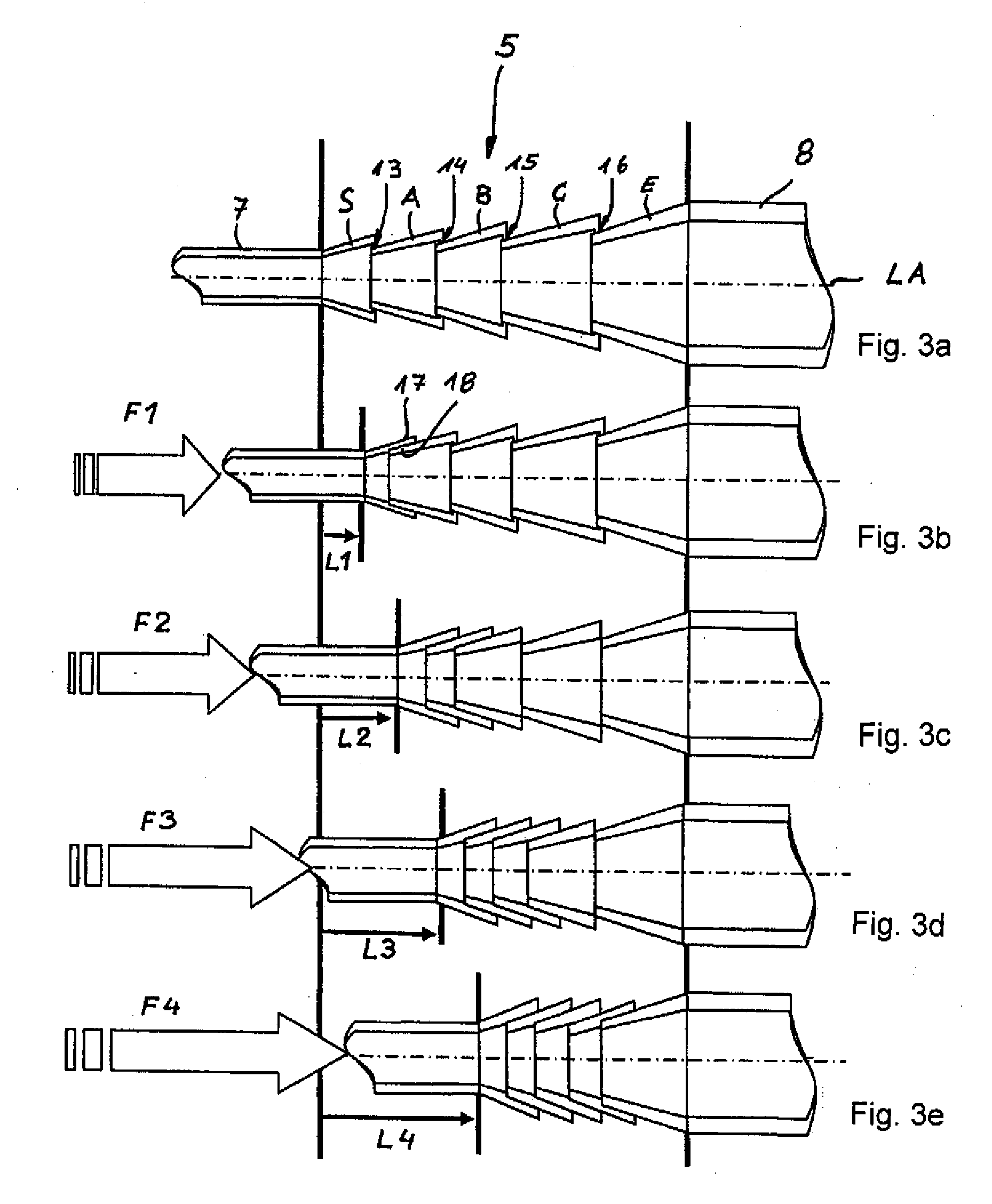

Adaptive crash structure for a vehicle body or chassis of a motor vehicle

InactiveUS7357445B2Reduce warpingAvoid accidental separationVehicle seatsUnderstructuresMobile vehicleMotor vehicle part

An adaptive crash structure of a vehicle body or chassis of a motor vehicle includes a first metal casting and a second metal casting. A deformation element in the form of a metal casting for absorbing energy interconnects and forms with the first and second metal castings a single piece construction through a casting process. The deformation element is comprised of a plurality of funnel-shaped wedge bodies which are disposed in succession, with neighboring wedge bodies being connected through intervention of a predetermined breaking web. Each wedge body is defined by a diameter, wherein the diameters of the wedge bodies are sized to allow the wedge bodies to move telescopically into one another when a limit stress is reached and the predetermined breaking webs rupture so as to effect a tight intergrip of the telescoping wedge bodies in a self-locking manner.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

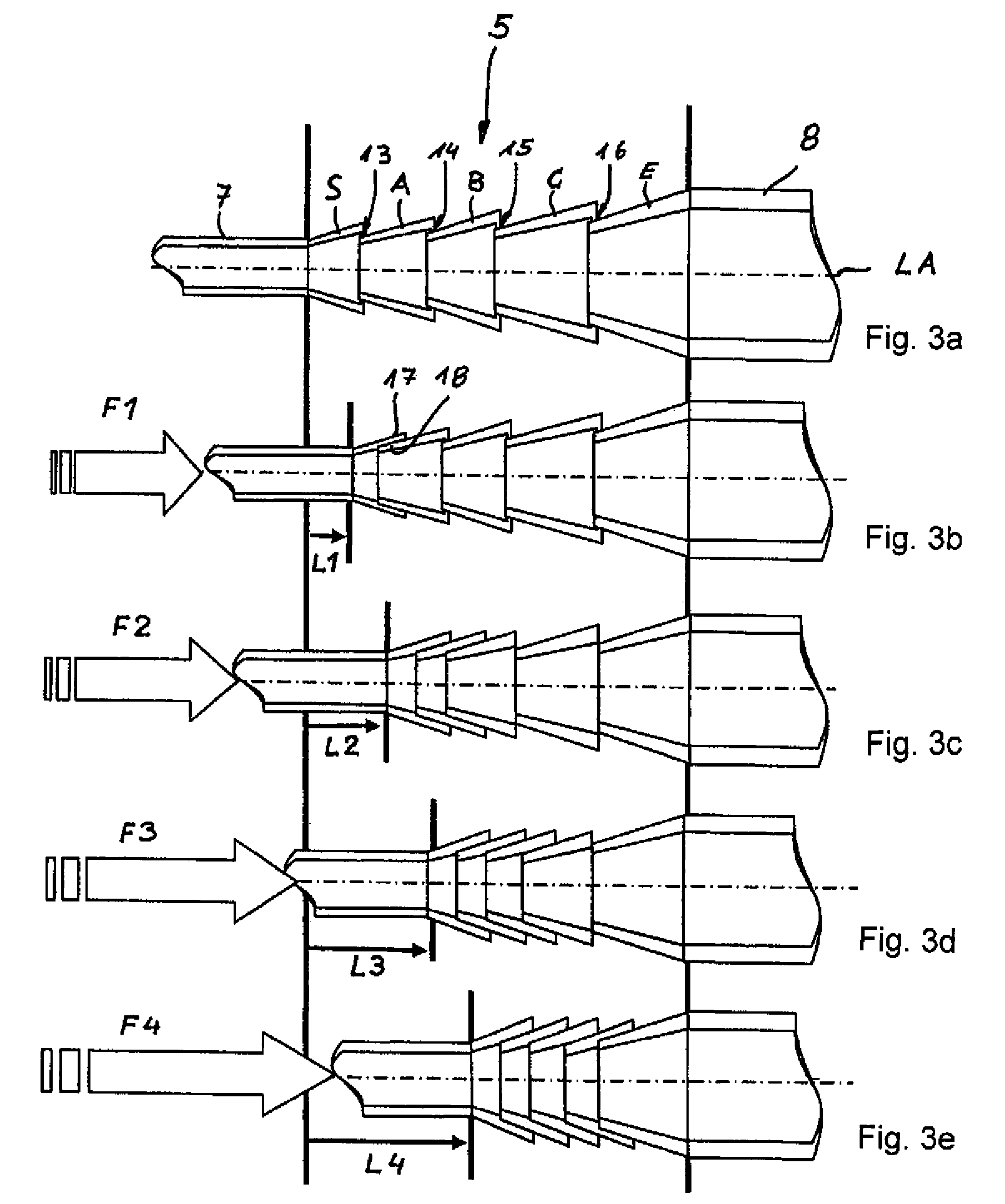

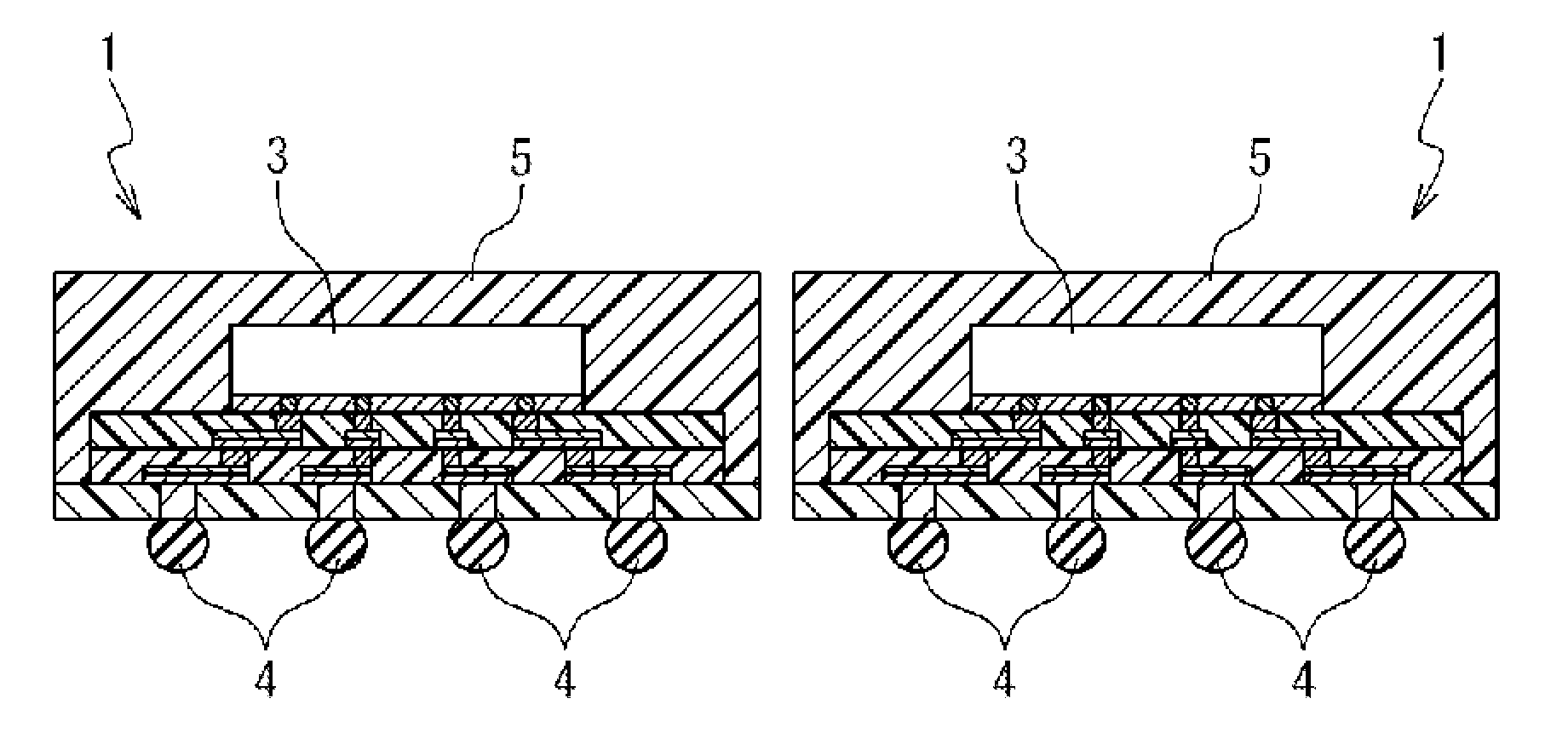

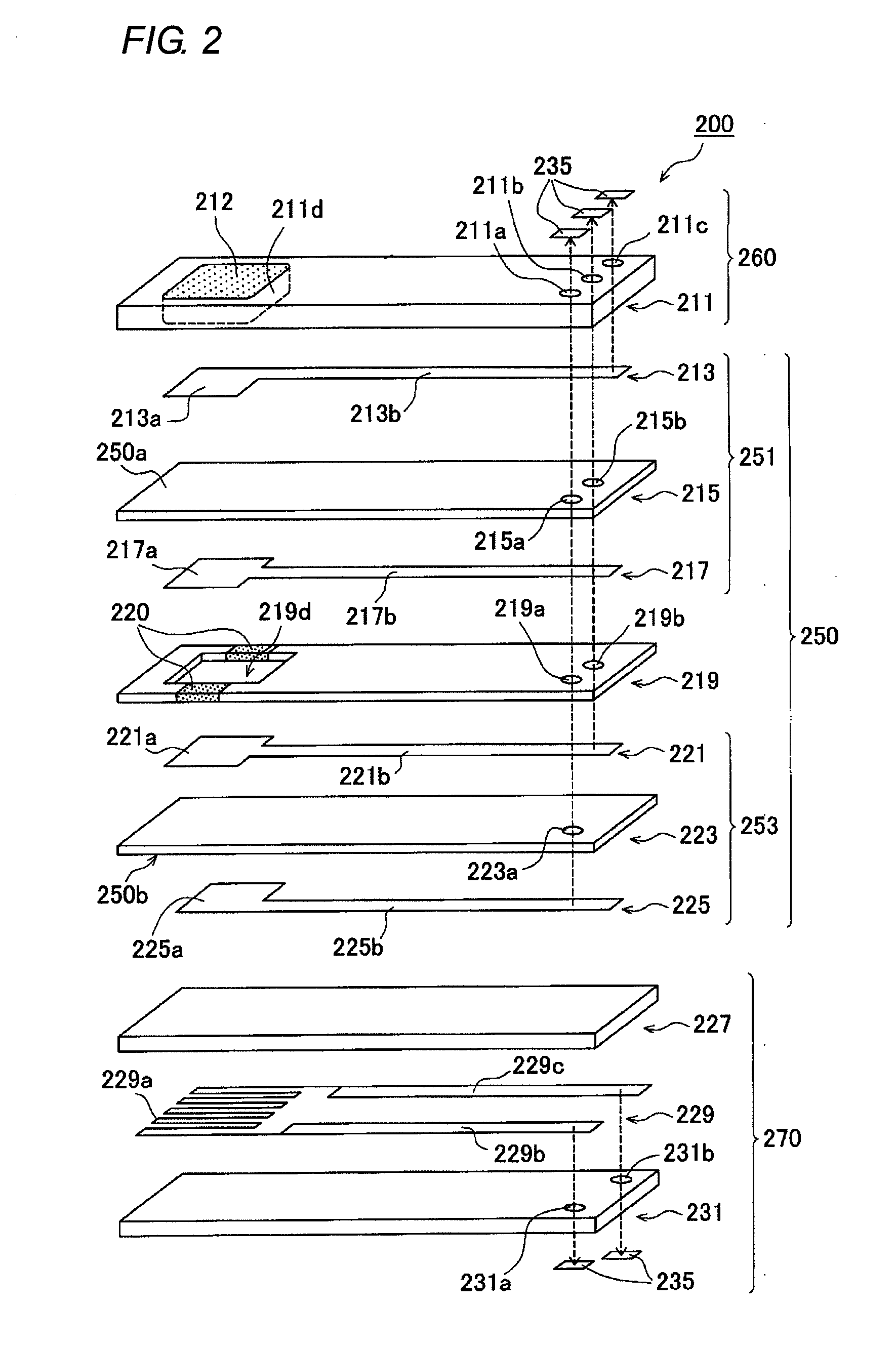

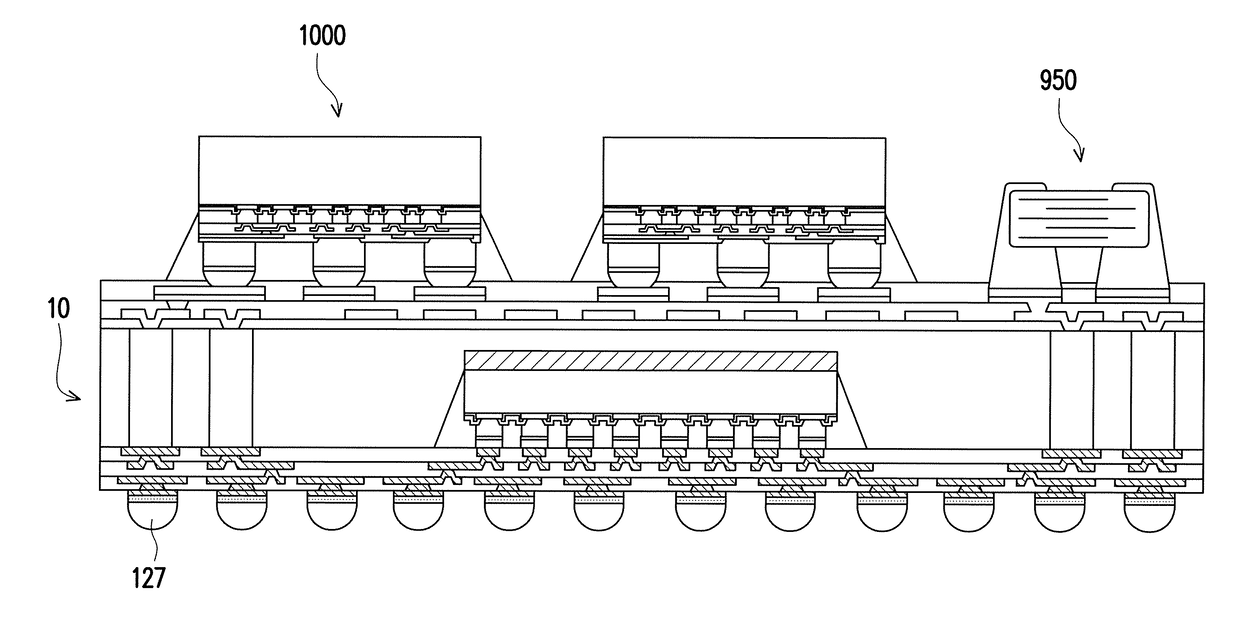

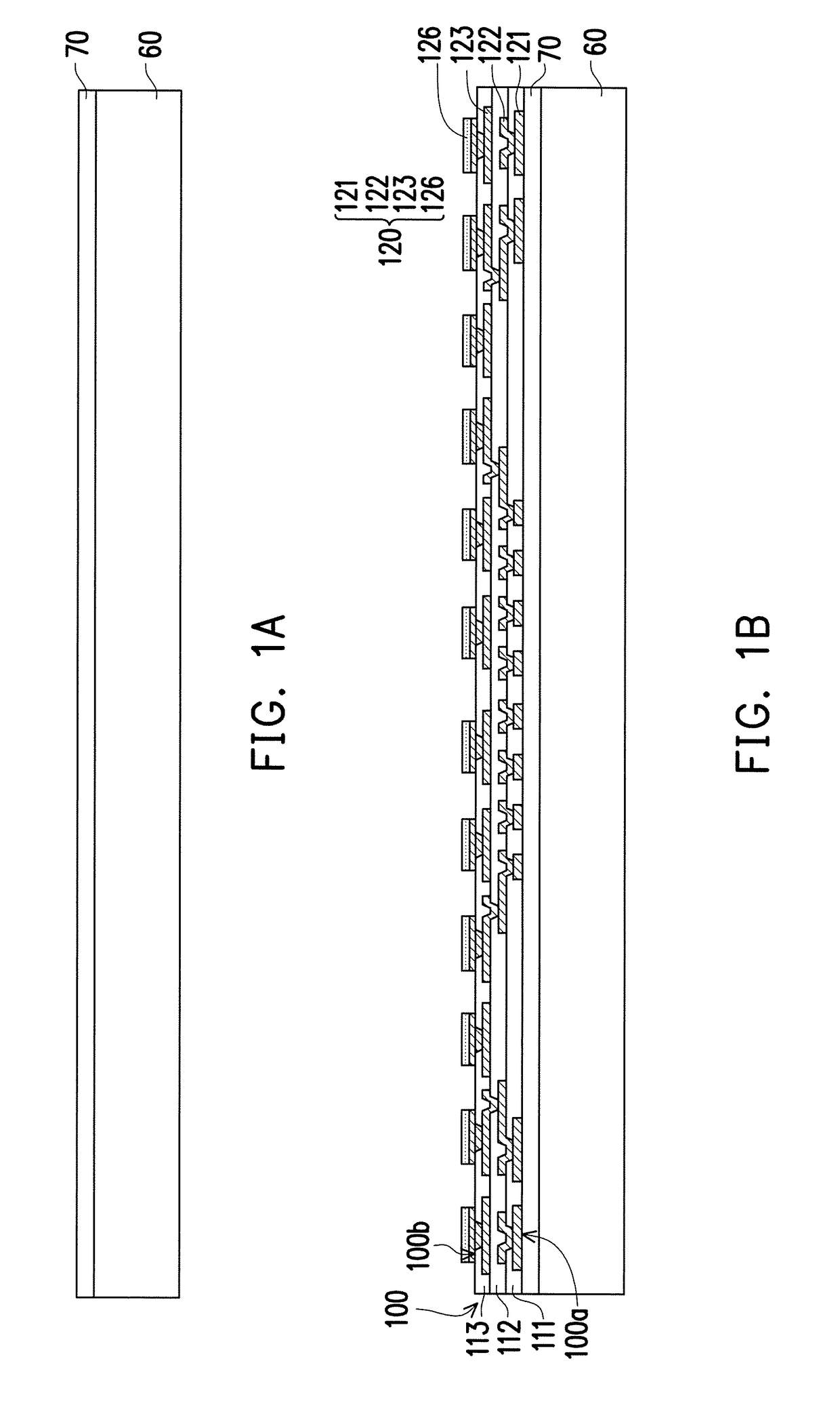

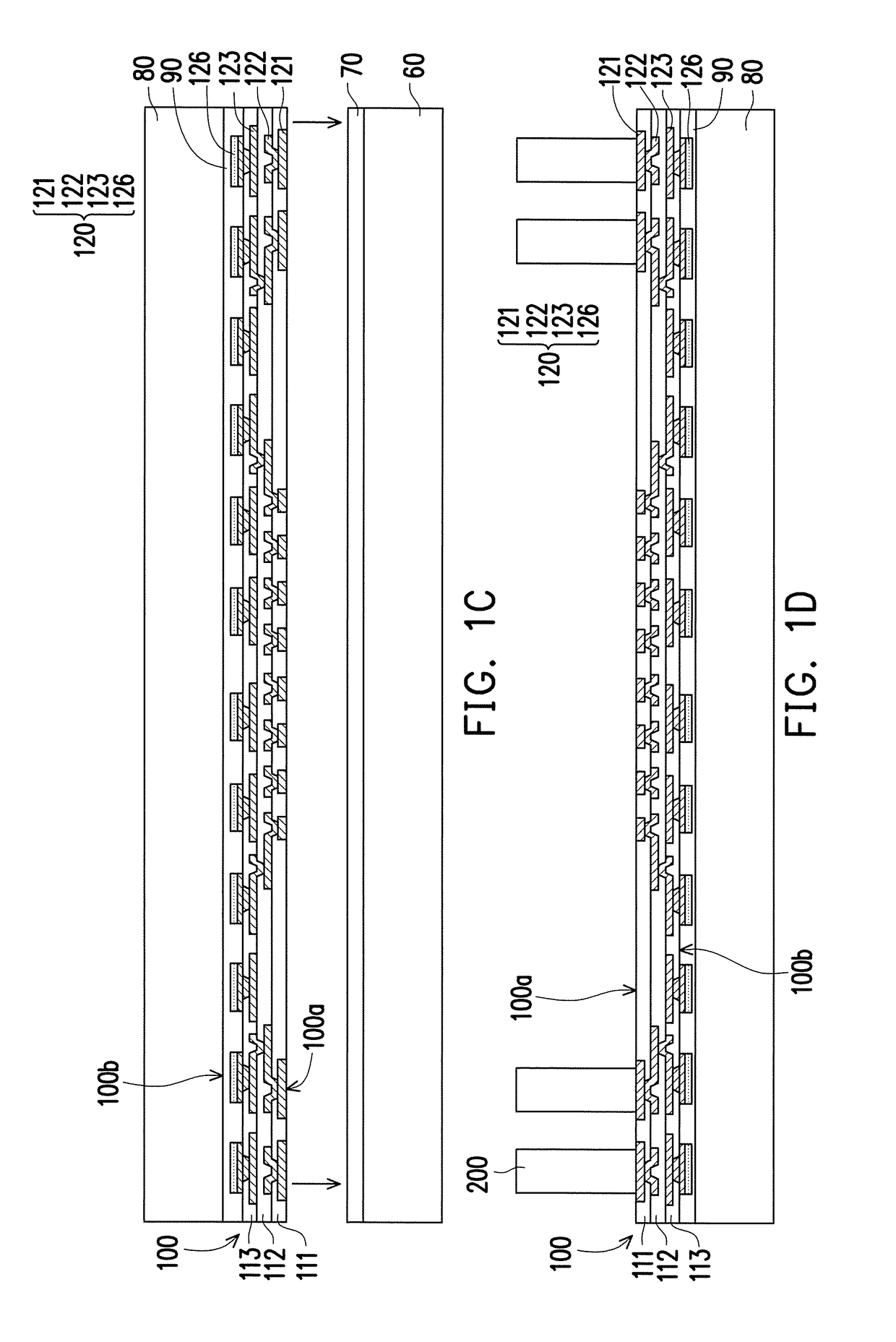

Electronic device and manufacturing method of electronic device

InactiveUS20110221071A1Reduce supportReduce warpingSemiconductor/solid-state device detailsSolid-state devicesEngineeringElectrical and Electronics engineering

In an electronic device having multilayer resin interconnection layers, it is desired to reduce the warp of its support substrate. It is manufactured by: forming a lower layer including a via and a first insulating part on the support substrate; and forming an intermediate layer including a first interconnection and a second insulating part covering the first interconnection on the lower layer. The lower layer is formed by: forming the first insulating part on a first circuit region and a first region surrounding it; and forming the via on the first circuit region. The intermediate layer is formed by: forming the first interconnection on the first circuit region; forming a film of the second insulation part to cover the lower layer; and removing the second insulating part on the first region such that an outer circumferential part of an upper surface of the lower layer part is exposed.

Owner:RENESAS ELECTRONICS CORP

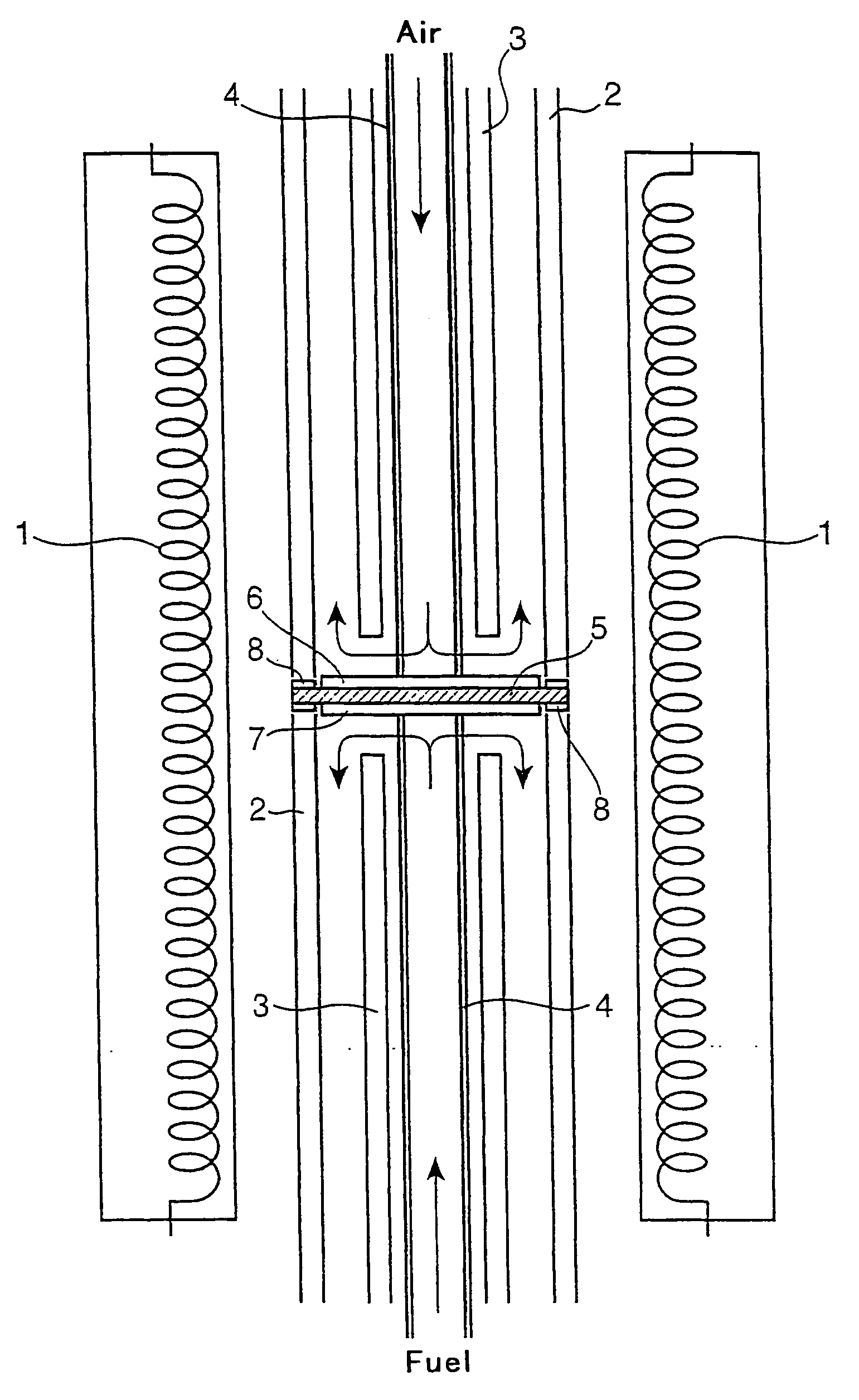

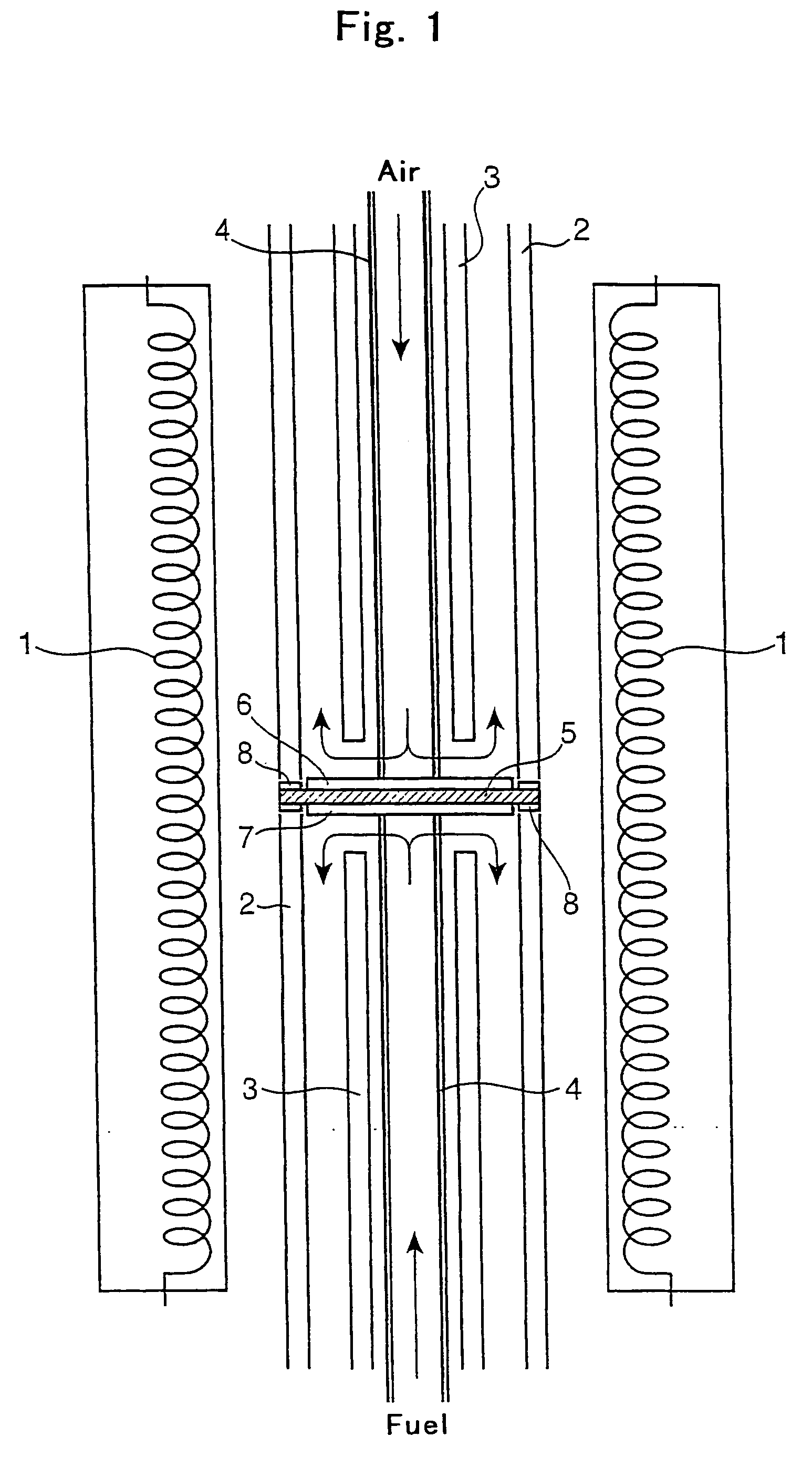

Electolyte sheets for solid oxide fuel cell and method for manufacturing same

InactiveUS20050271919A1Reduce warpingImprove productivitySolid electrolytesCell electrodesFuel cellsSurface roughness

The present invention provides electrolyte sheets for solid oxide fuel cells, the electrolyte sheets being able to improve their adhesion to electrode films formed on both surfaces thereof and being also able to improve electric power generation characteristics of fuel cells by an increase in their electrode reaction areas. There is disclosed an electrolyte sheet for solid oxide fuel cells including a sintered sheet, wherein surface roughness of the sheet as measured by an optical and laser-based non-contact three-dimensional profile measuring system is 2.0 to 20 μm in Rz and 0.20 to 3.0 μm in Ra, and wherein a ratio of Rz of one surface (having a greater Rz and a greater Ra) to Rz of the other surface having a smaller Rz and a smaller Ra is in a range of 1.0 to 3.0, and a ratio of Ra of one surface (having a greater Rz and a greater Ra) to Ra of the other surface having a smaller Rz and a smaller Ra is in a range of 1.0 to 3.0, and a ratio of Rmax to Rz (Rmax / Rz ratio) of at least one surface is in a range of 1.0 to 2.0.

Owner:NIPPON SHOKUBAI CO LTD

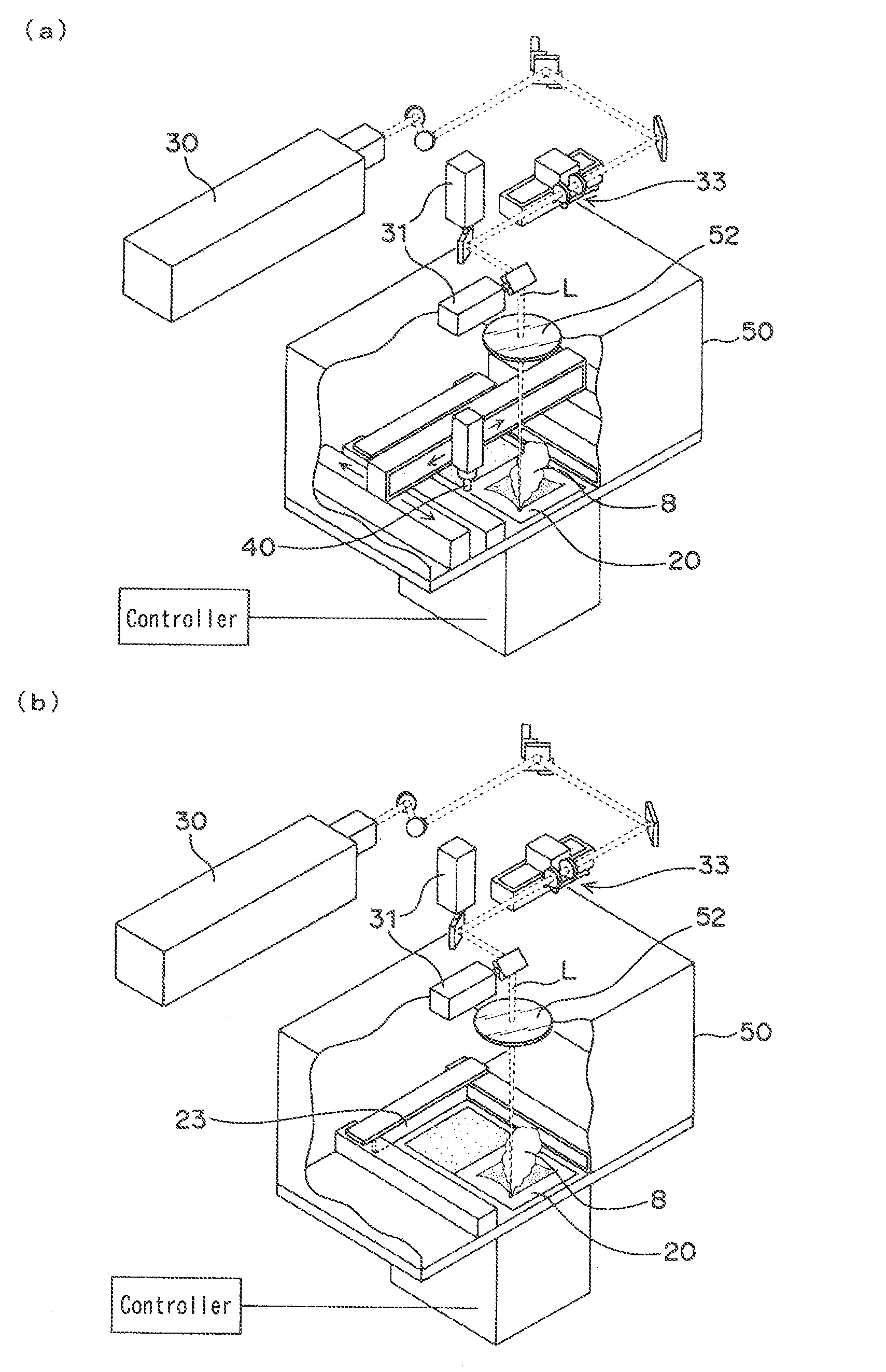

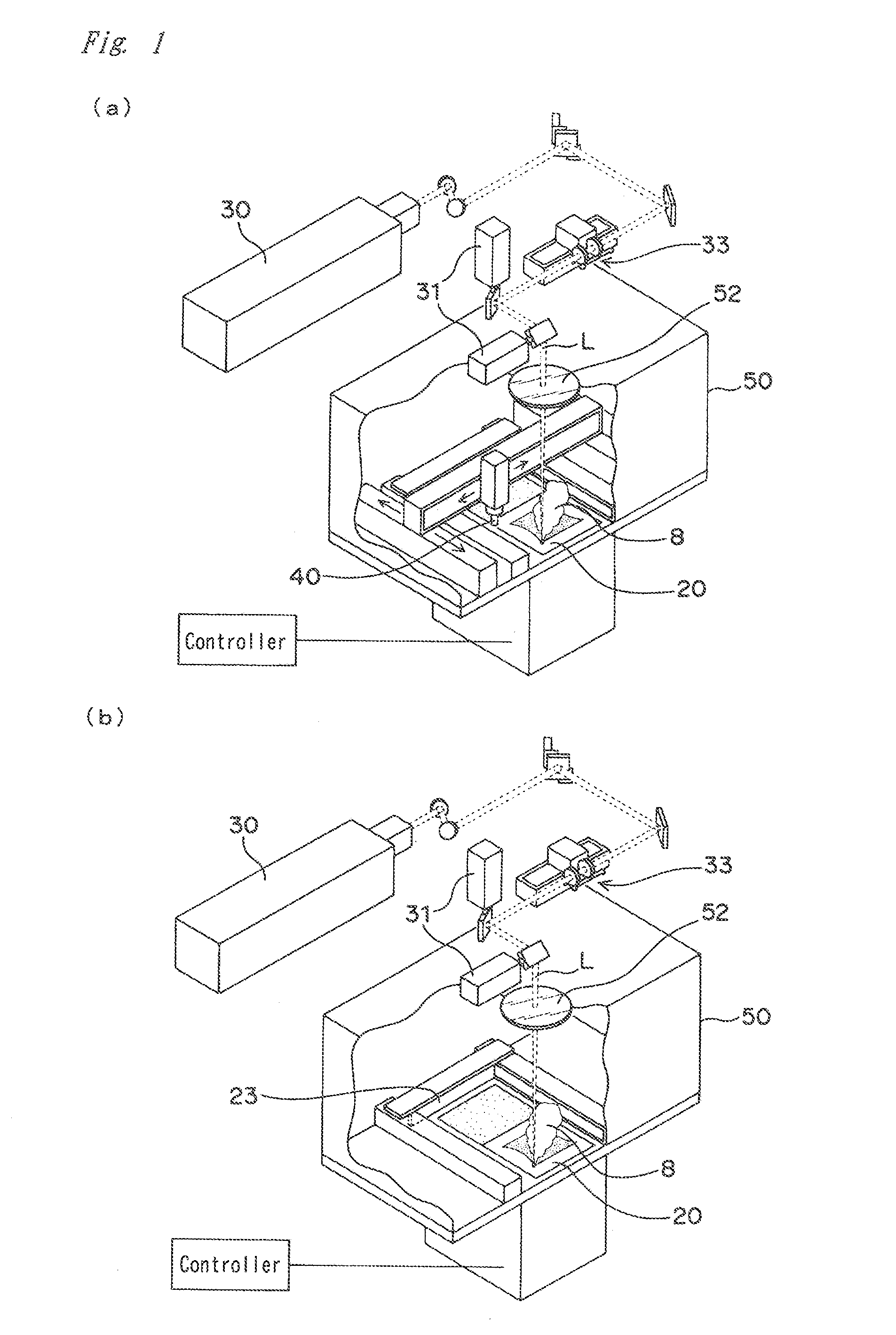

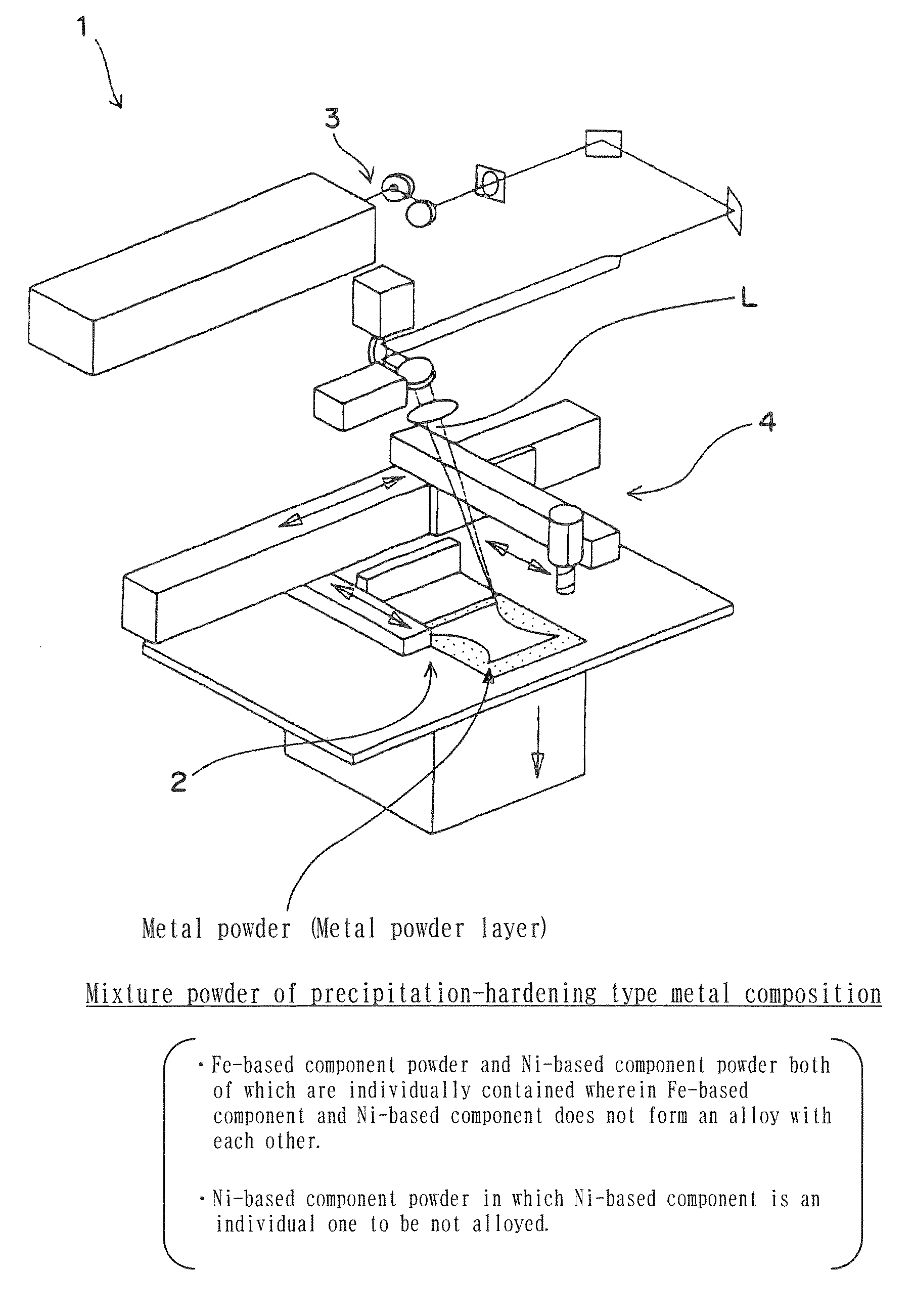

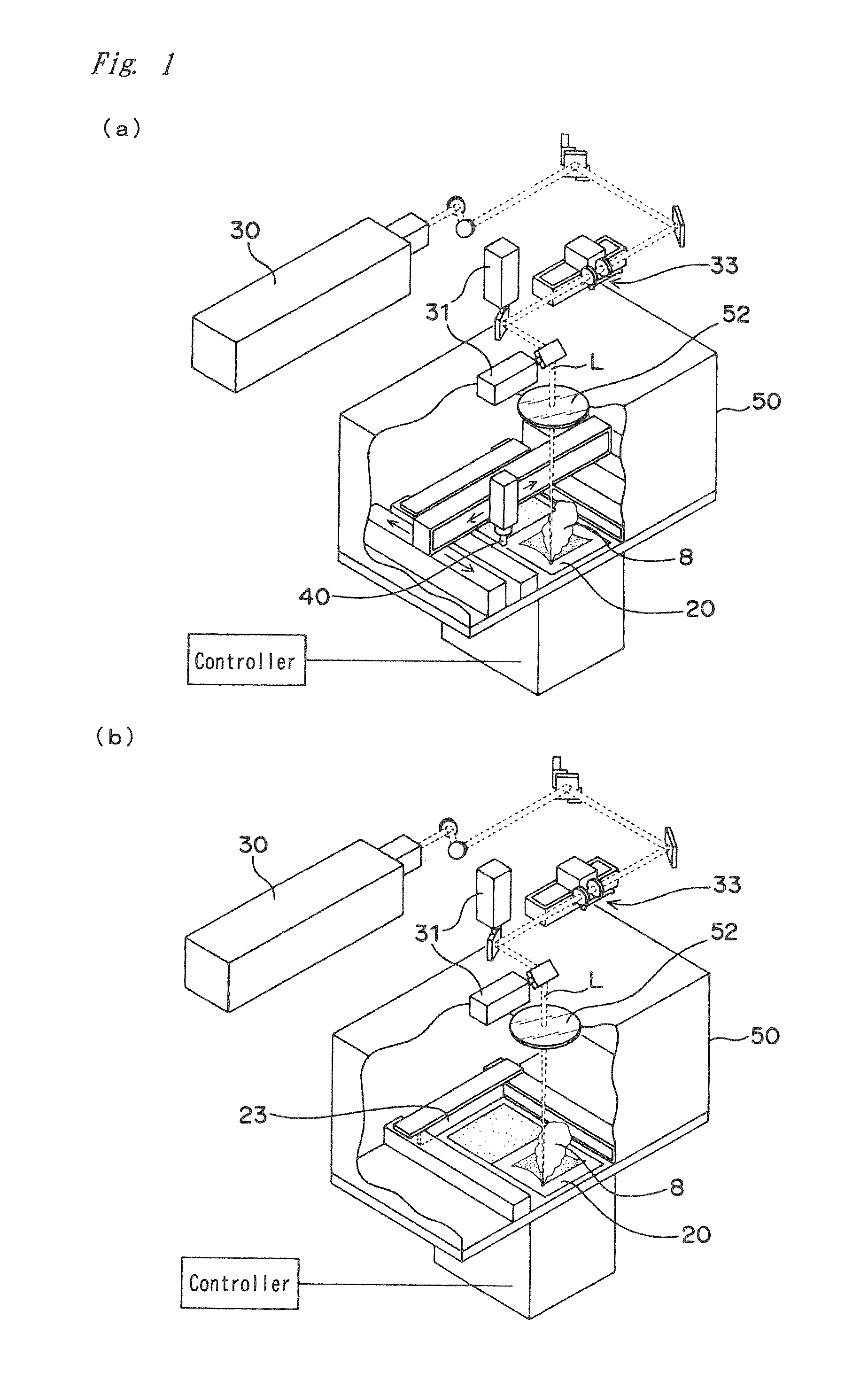

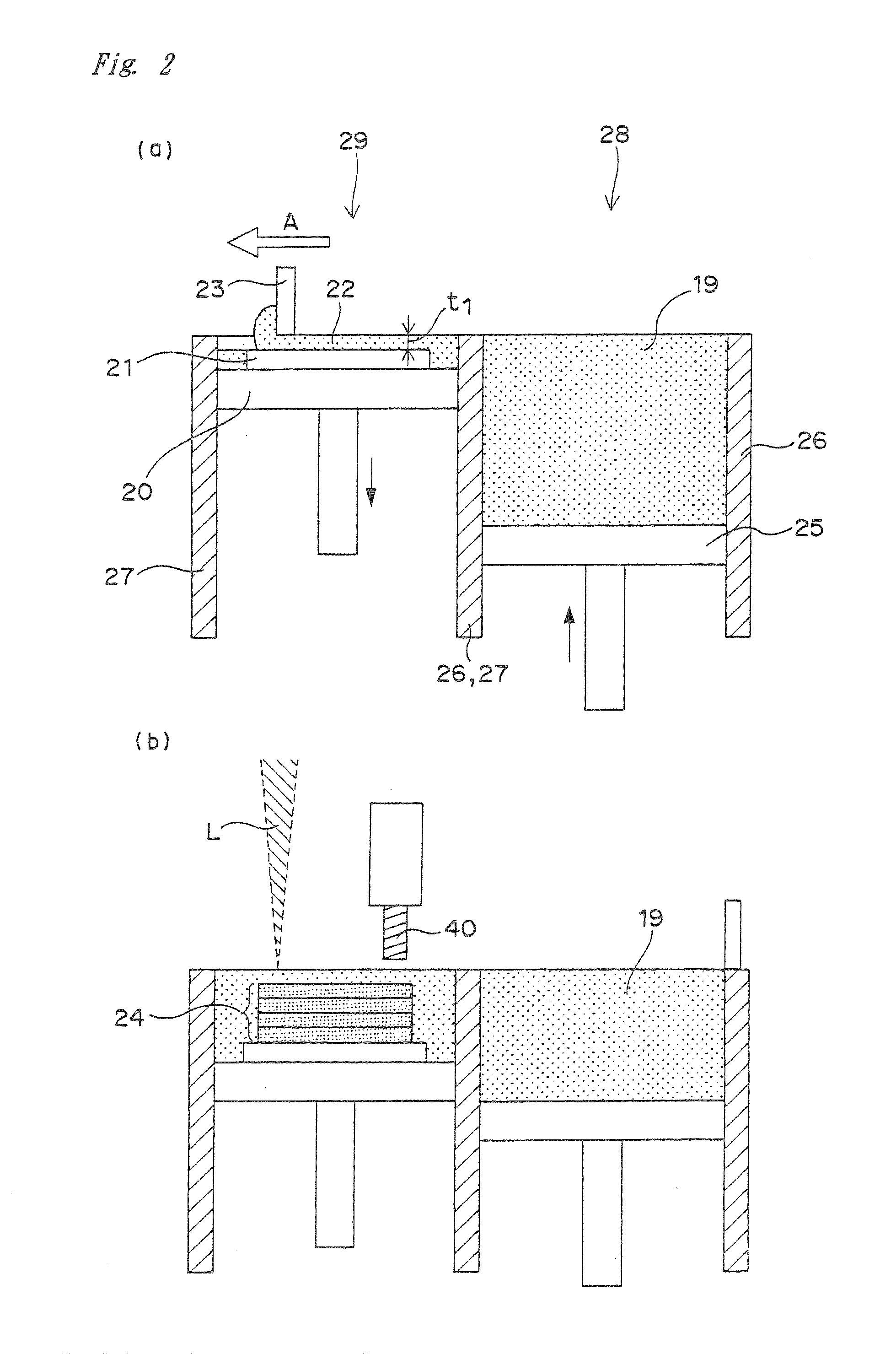

Metal powder for selective laser sintering, method for manufacturing three-dimensional shaped object by using the same, and three-dimensional shaped object obtained therefrom

InactiveUS20130065073A1Reduce warpingReduce deformationAdditive manufacturing apparatusPig casting plantsSelective laser sinteringPowder mixture

There is provided a metal powder for use in a selective laser sintering method for producing a three-dimensional shaped object, wherein the metal powder comprises a powder mixture of a precipitation-hardening metal composition. In particular, the metal powder of the present invention is configured to have a Fe-based component powder and a Ni-based component powder which are individually included in the powder mixture wherein a powder made of an alloy of Fe-based and Ni-based components is not included as a main powder in the powder mixture.

Owner:PANASONIC CORP

Adaptive crash structure for a vehicle body or chassis of a motor vehicle

InactiveUS20070114804A1Reduce warpingAvoid accidental separationUnderstructuresElastic dampersAbsorbed energySelf locking

An adaptive crash structure of a vehicle body or chassis of a motor vehicle includes a first metal casting and a second metal casting. A deformation element in the form of a metal casting for absorbing energy interconnects and forms with the first and second metal castings a single piece construction through a casting process. The deformation element is comprised of a plurality of funnel-shaped wedge bodies which are disposed in succession, with neighboring wedge bodies being connected through intervention of a predetermined breaking web. Each wedge body is defined by a diameter, wherein the diameters of the wedge bodies are sized to allow the wedge bodies to move telescopically into one another when a limit stress is reached and the predetermined breaking webs rupture so as to effect a tight intergrip of the telescoping wedge bodies in a self-locking manner.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

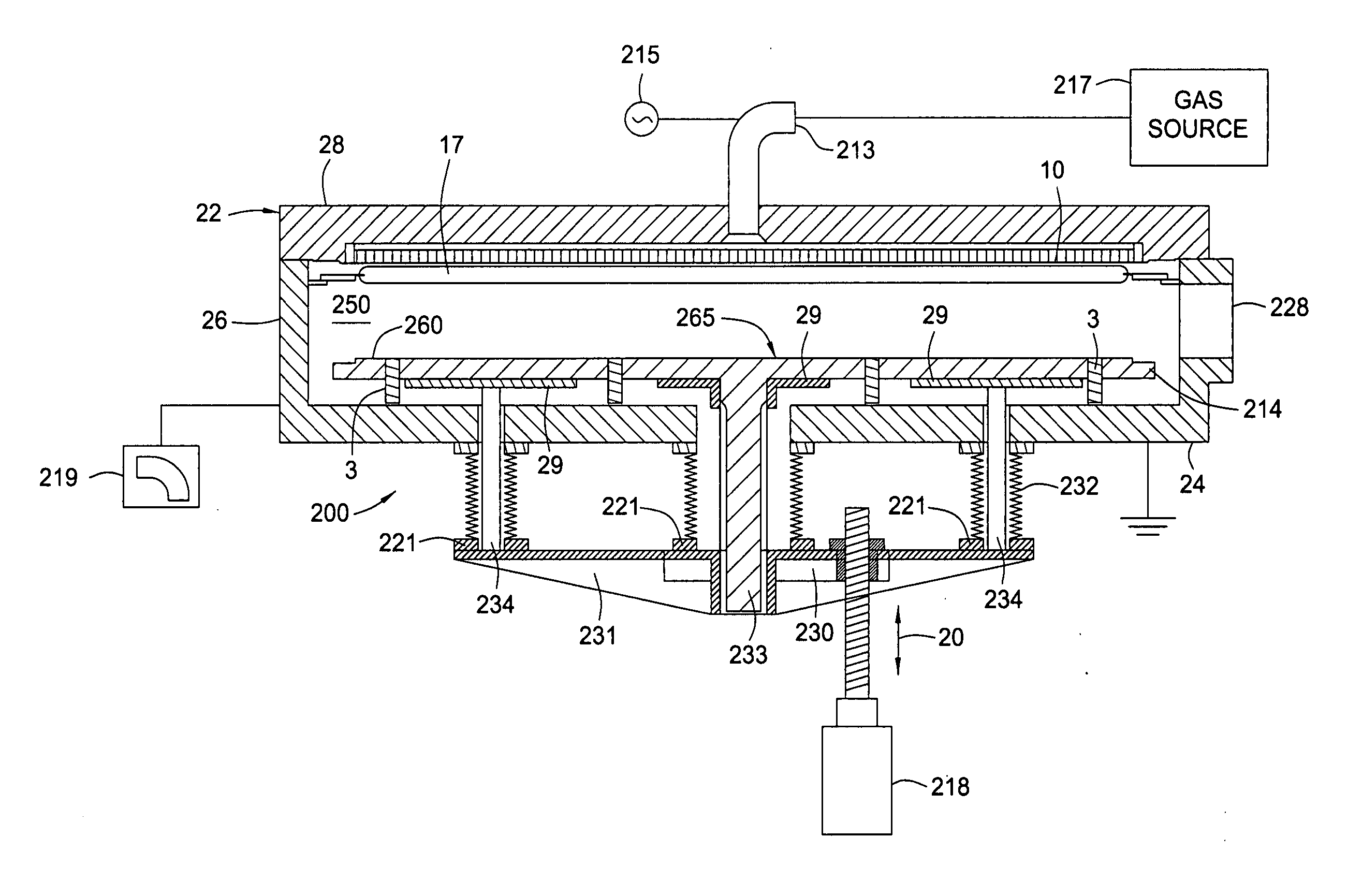

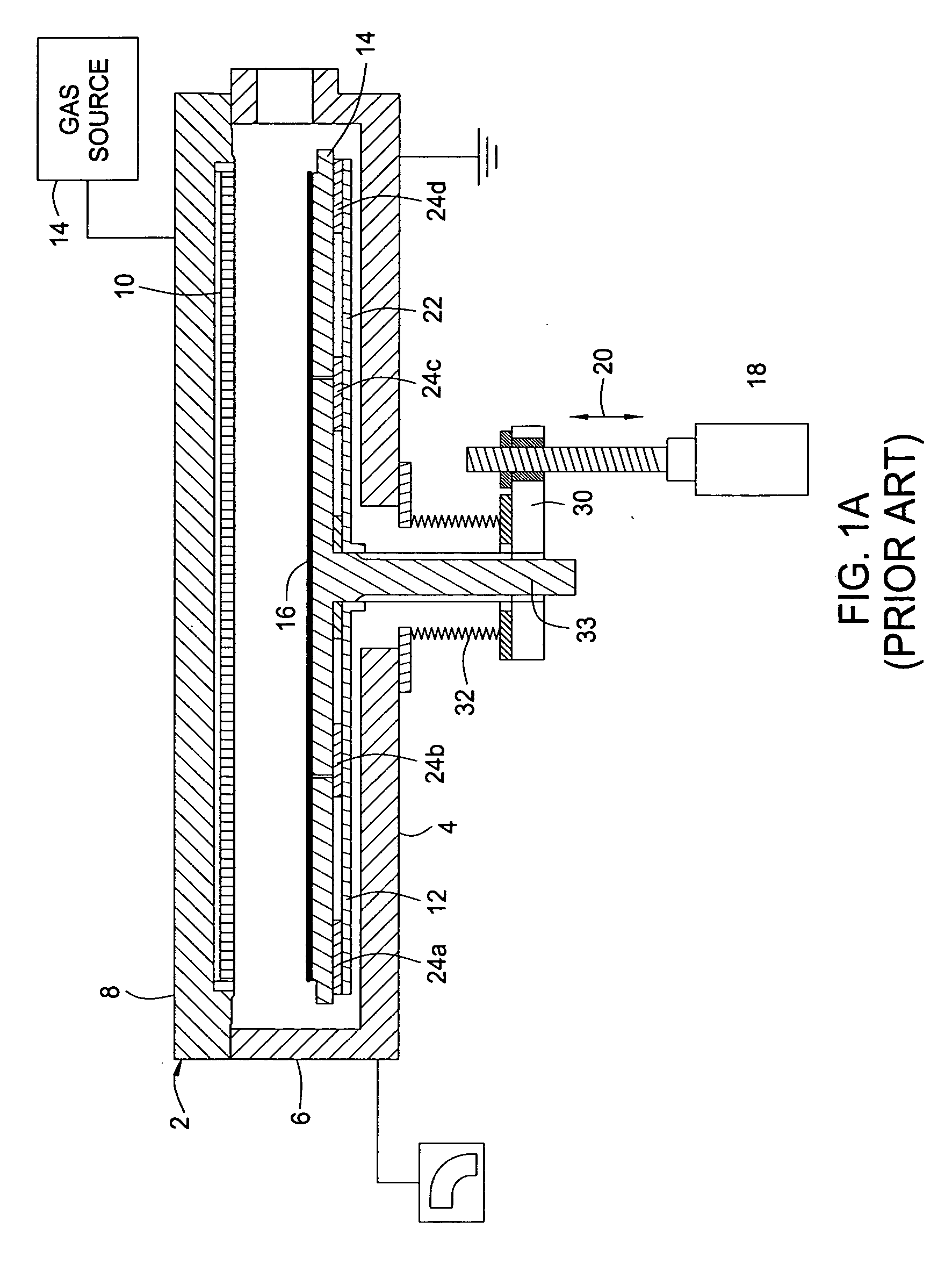

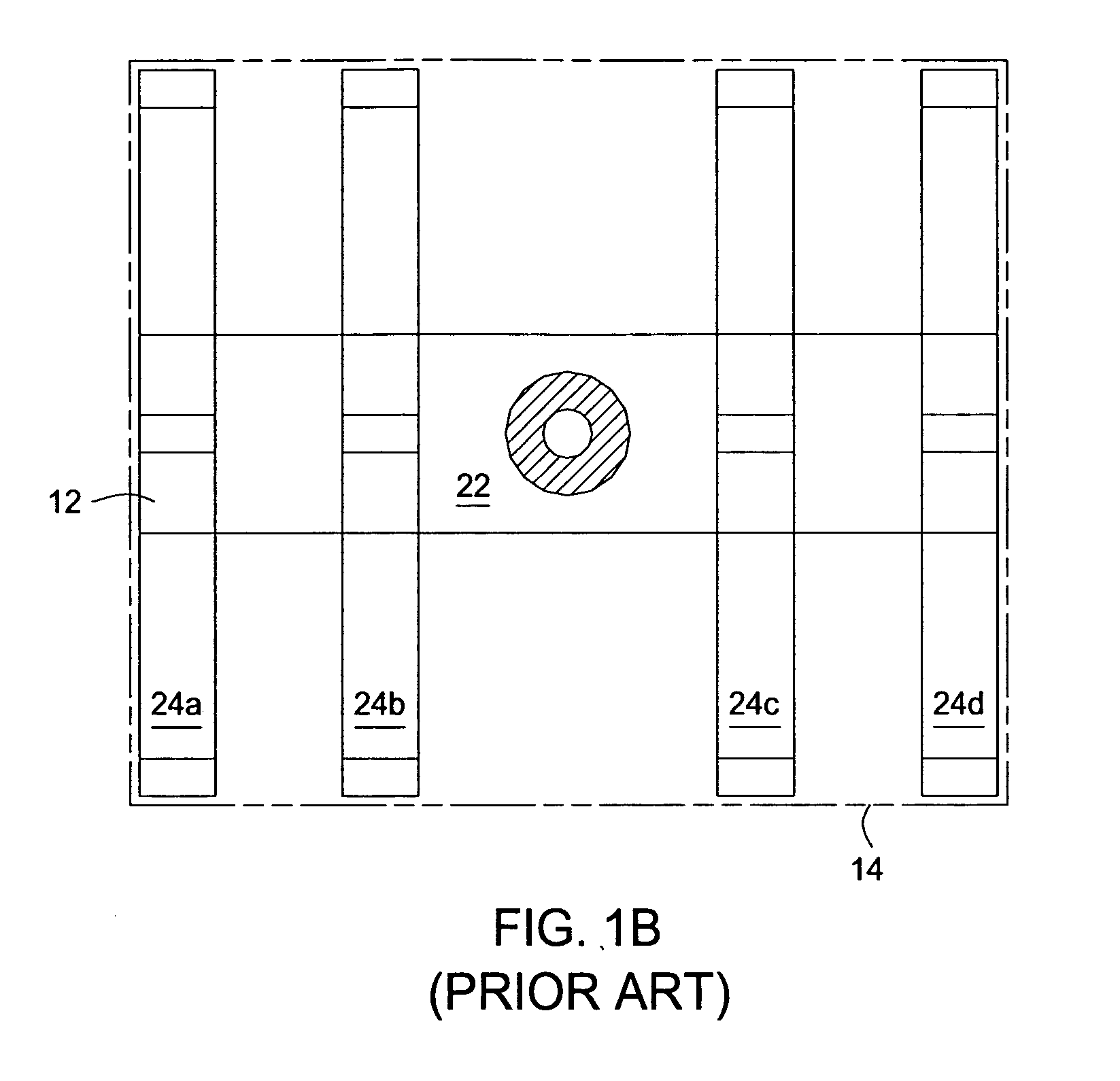

PECVD susceptor support construction

InactiveUS20060054090A1Reduce warpingReduce warpageSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringSusceptor

An apparatus and method for maintaining or adjusting the orientation of a large area substrate is disclosed by using multiple support plates disposed below a susceptor adapted to support the large area substrate. The multiple support plates are supported by a plurality of support shafts that are coupled to at least one actuator. The apparatus is designed to selectively adjust the horizontal cross-sectional profile of the susceptor to promote even and uniform processing. The horizontal profile may be one of planar, concave, or convex. The apparatus allows any adjustment to be made before, during, or after processing.

Owner:APPLIED MATERIALS INC

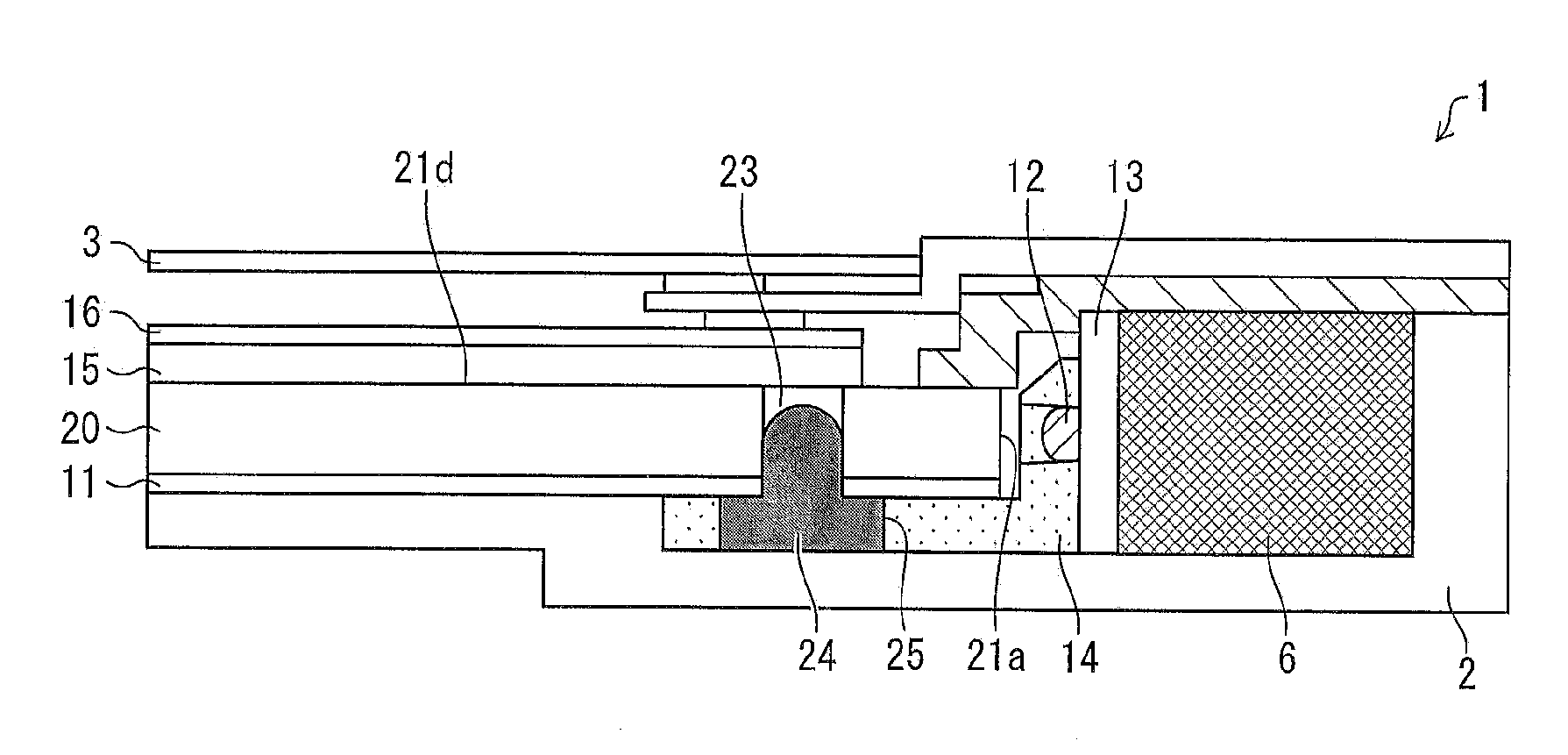

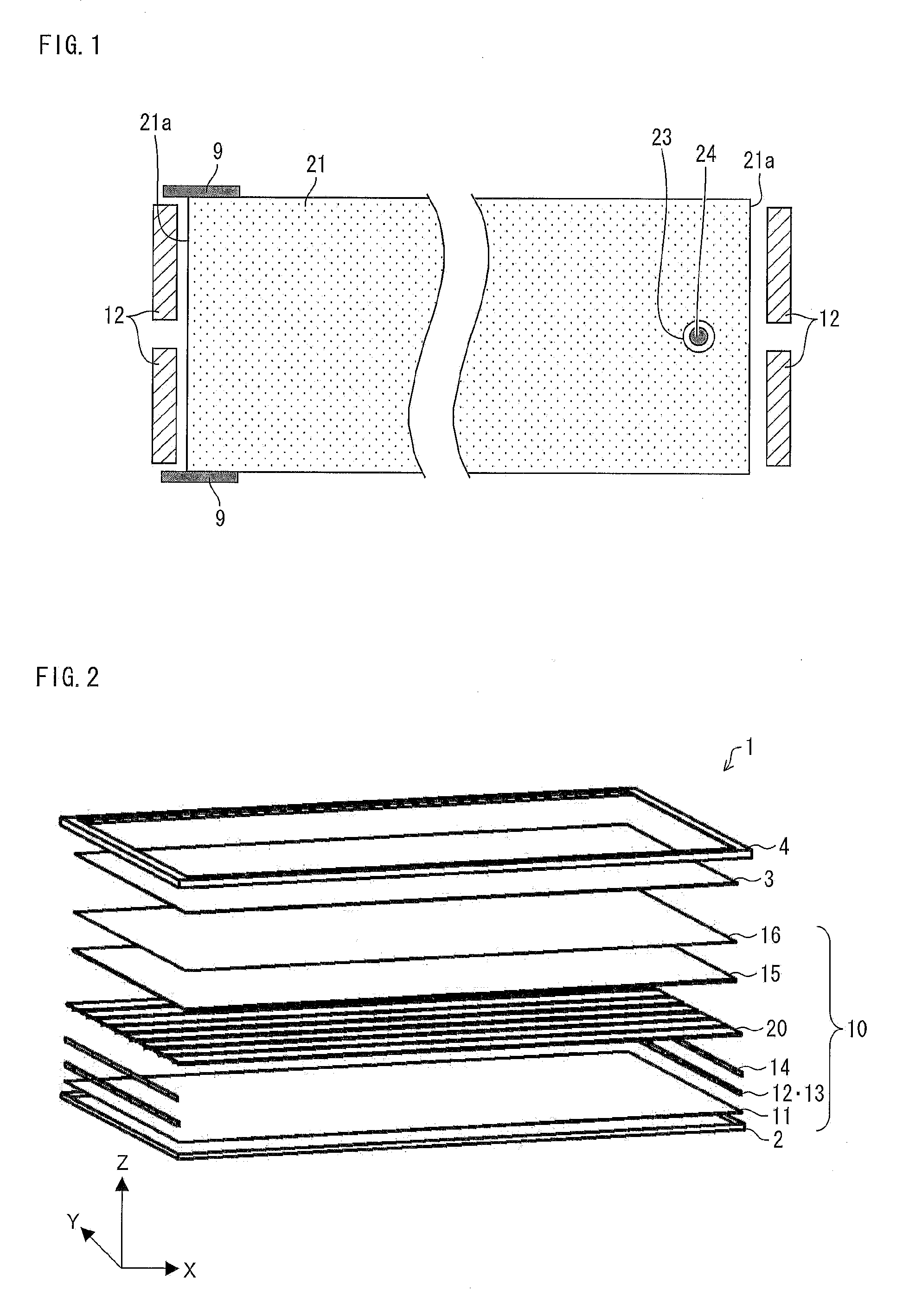

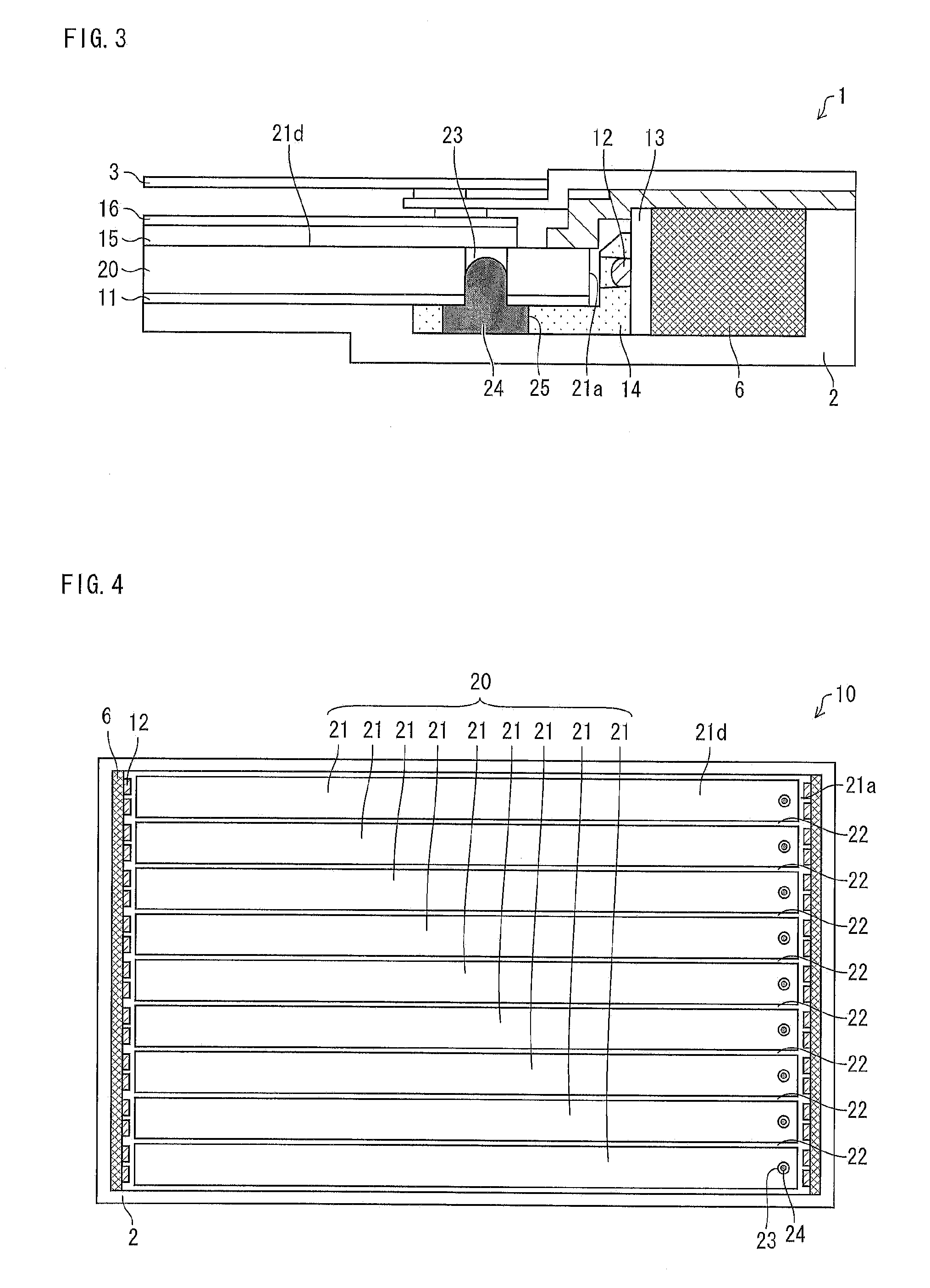

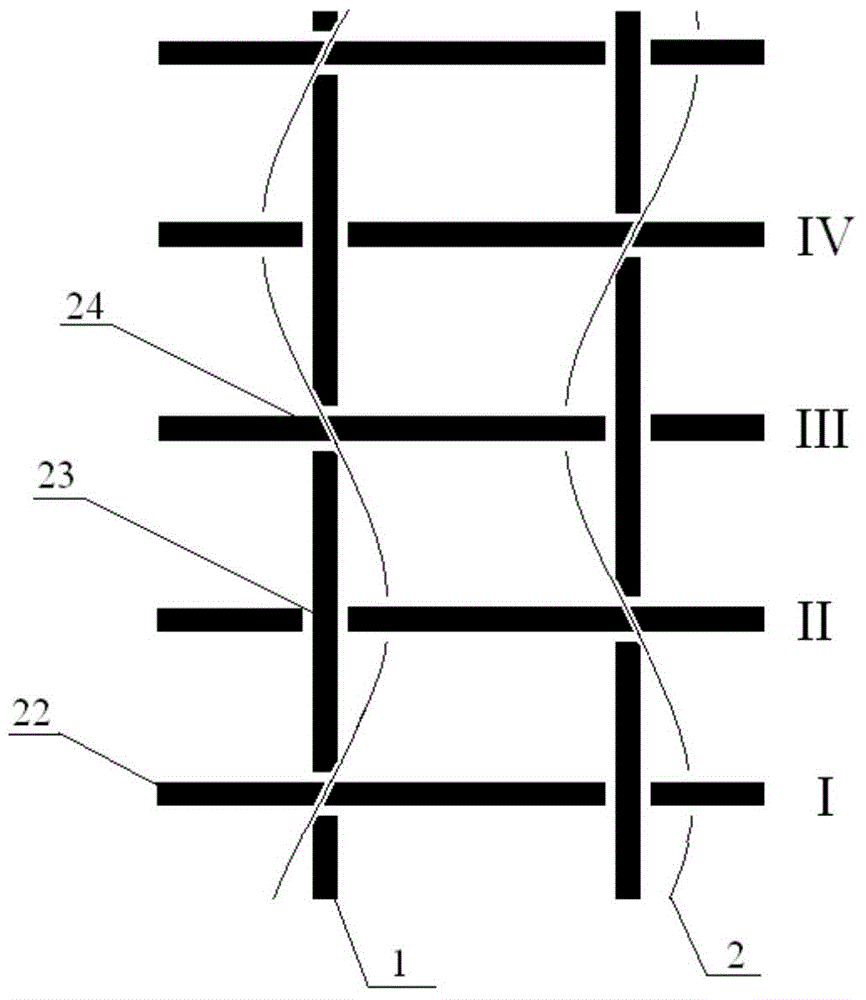

Light source module and electronic apparatus provided with same

InactiveUS20120287670A1Reduce warpingReduce crackingMechanical apparatusPlanar/plate-like light guidesLight guideComputer module

A light source module of the present invention is configured such that there is a through hole (23) in one longitudinal end portion of a light guide (21) that constitutes a light guide plate, into which through hole (23) a positioning pin (24) for positioning an LED light source (12) and the light guide (21) fits. Further, a guide (9) is provided to the other end portion of the light guide (21), which guide (9) restrains the light guide (21) in a direction of a short side but does not restrain the light guide (21) in a direction of a long side. This makes it possible to provide a light source module that can reduce warping and cracking caused by expansion of a light guide, and an electronic apparatus including the light source module.

Owner:SHARP KK

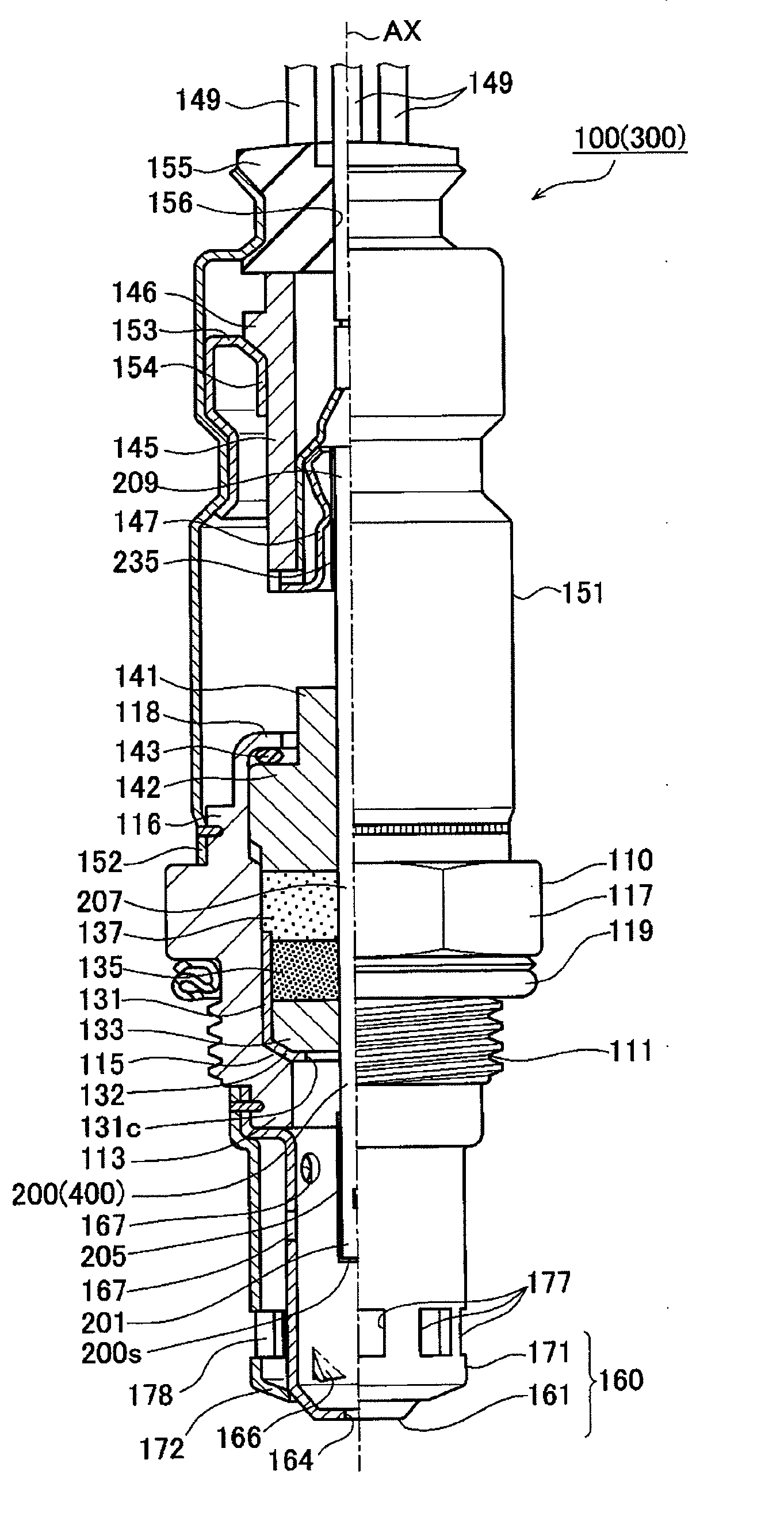

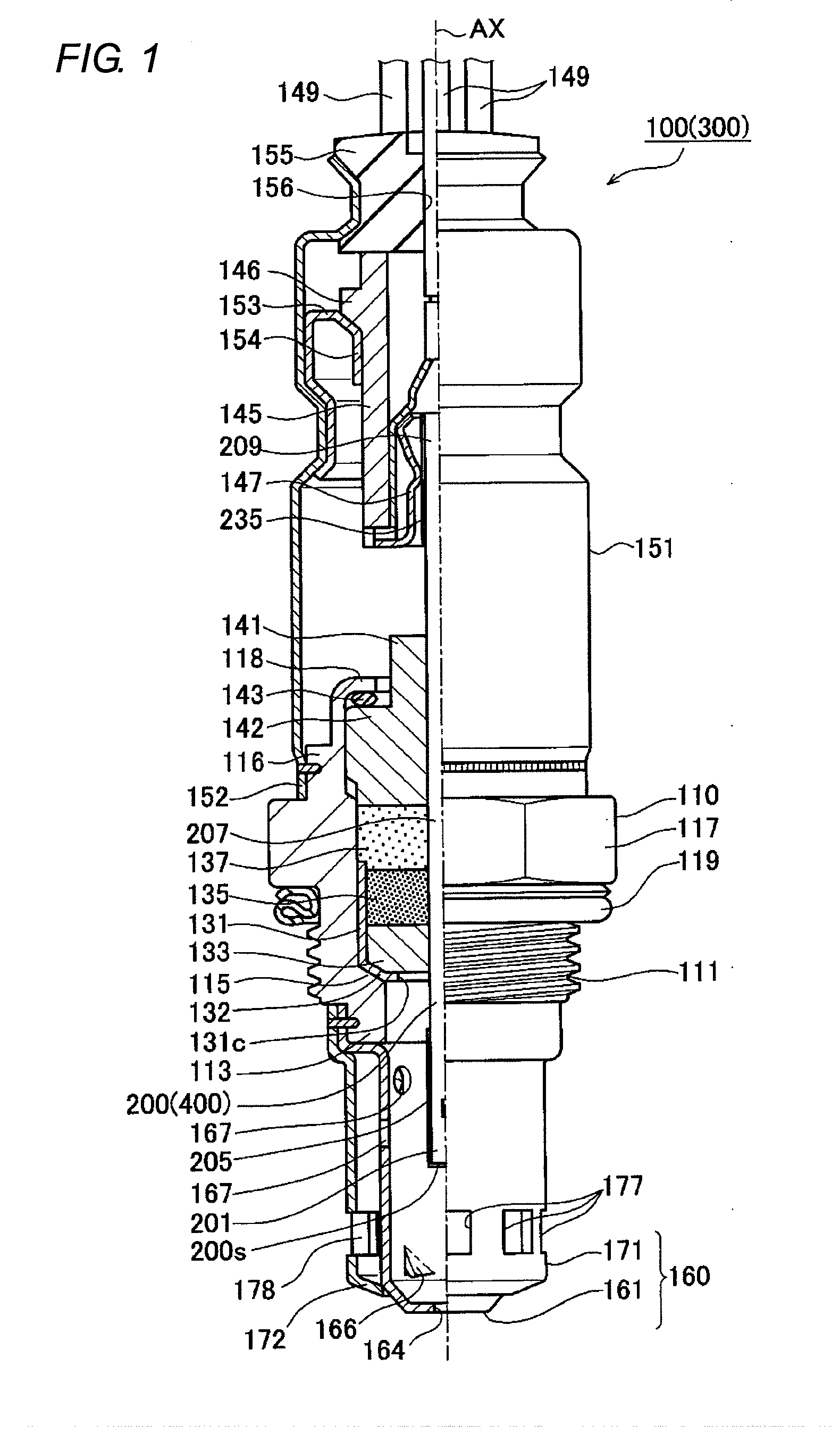

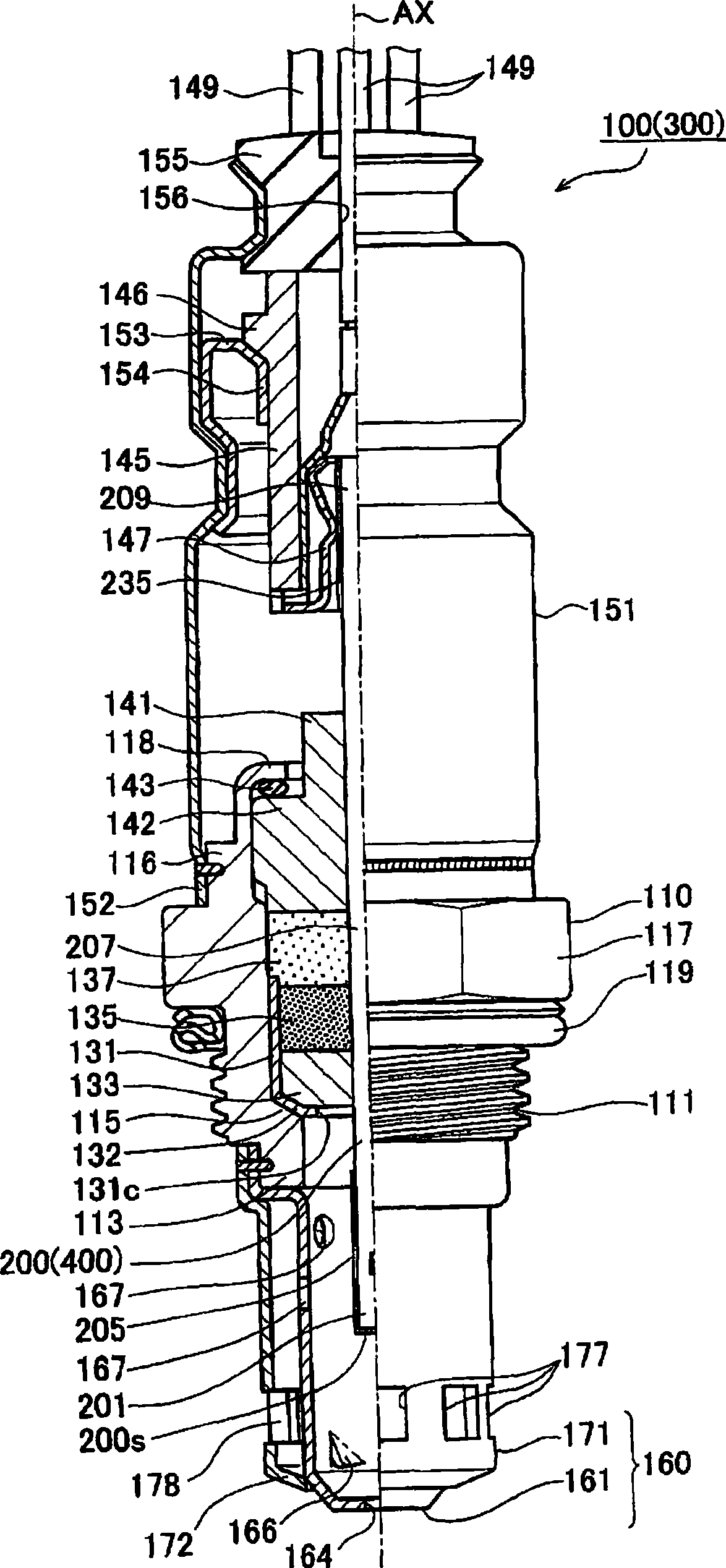

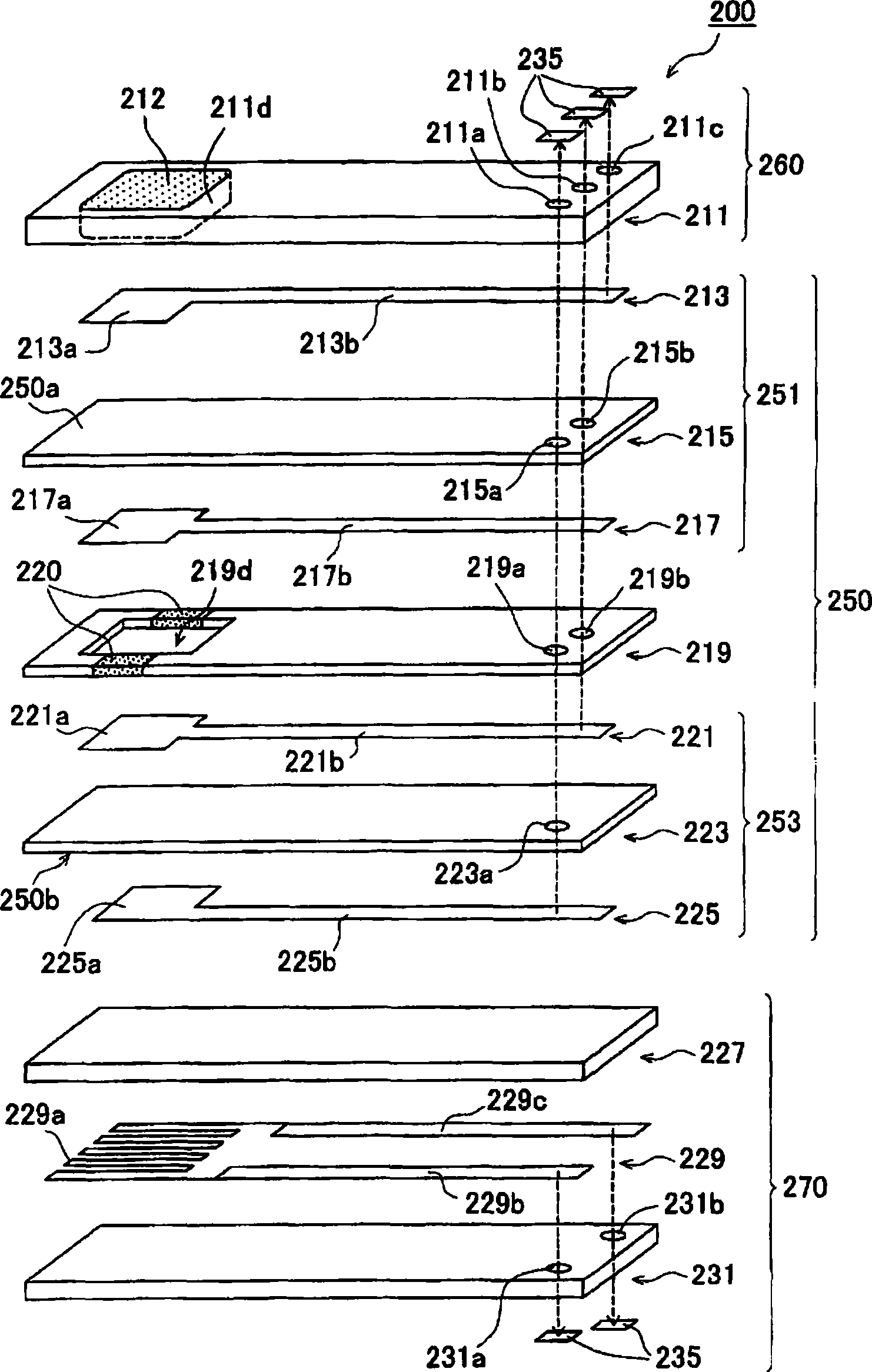

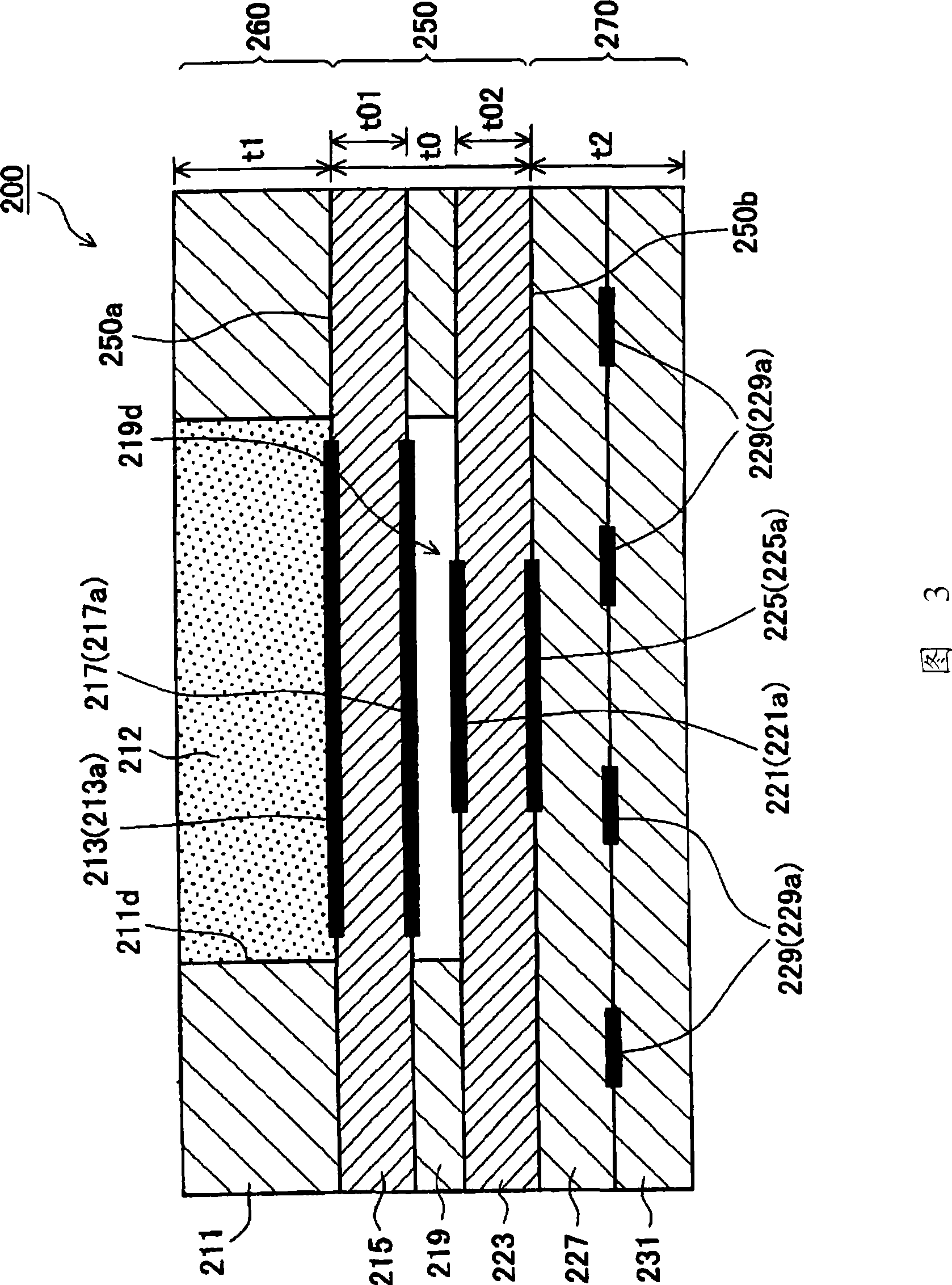

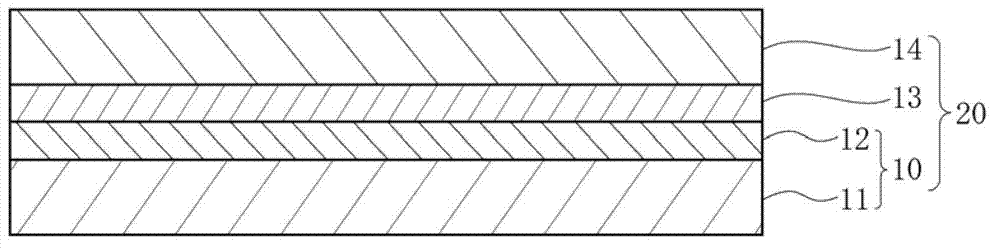

Gas sensor

ActiveUS20090117007A1Improve reliabilityReduce warpingWeather/light/corrosion resistanceVolume/mass flow measurementGas compositionEngineering

A gas sensor including a detection element having a stacked structure configured to detect a specified gas component contained in a gas to be detected. The detection element includes: a sensing portion including one or more solid electrolyte layers containing a first material as a main component and having a first surface and a second surface opposite the first surface; a first portion stacked on the first surface and including one or more first base layers containing a second material as a main component different from the first material; and a second portion stacked on the second surface and including one or more second base layers containing the second material. A total thickness of the one or more second base layers in a stacking direction is not less than 80% but not more than 120% of a total thickness of the one or more first base layers.

Owner:NGK SPARK PLUG CO LTD

Woven fabric structure of glass fiber leno mesh and weaving method thereof

The invention provides a woven fabric structure of a glass fiber leno mesh and a weaving method thereof. In the woven fabric structure, ground warps and weft yarns are woven into the plain weave in a one-to-one up-and-down staggered manner; doup warps are orderly and regularly shuttled back and forth to extend into a strand by surrounding the same ground warp or a ground warp group composed of two adjacent ground warps in the extension direction of the ground warps; the doup warps are twisted with the ground warps to form the leno structure. The woven fabric structure is more stable than the existing woven fabric structure; the weaving method of the woven fabric structure is simple and convenient in process and low in cost, and thus is capable of completely taking the place of the traditional mesh weaving process.

Owner:JUSHI GRP CO

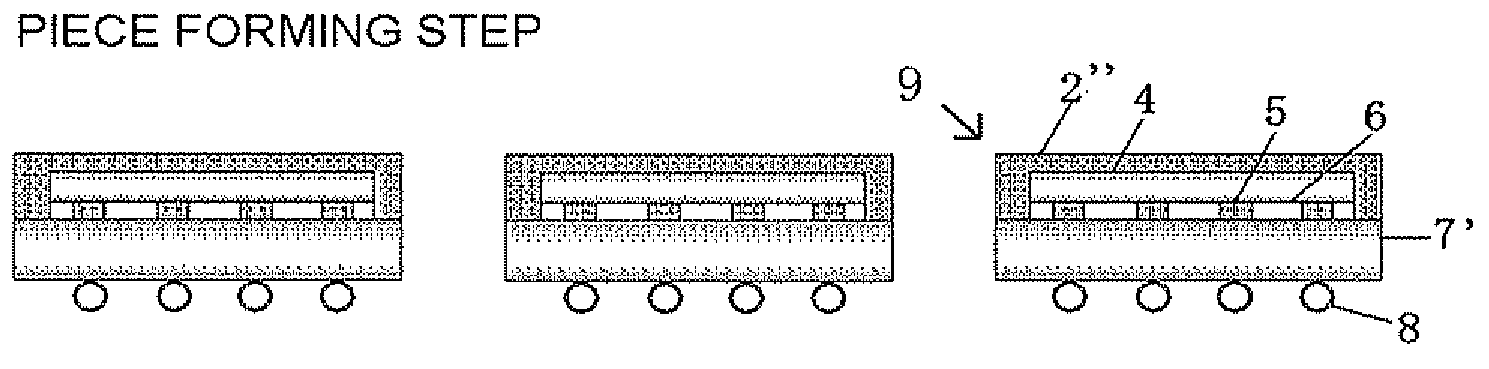

Wafer mold material and method for manufacturing semiconductor apparatus

InactiveUS20120139131A1Excellently transferredUniform qualitySemiconductor/solid-state device detailsSolid-state devicesShell moldingAcrylic resin

The invention provides a wafer mold material for collectively subjecting a wafer having semiconductor devices on a surface thereof to resin molding, wherein the wafer mold material has a resin layer containing a filler and at least any one of an acrylic resin, a silicone resin having an epoxy group, an urethane resin, and a polyimide silicone resin, and the wafer mold material is formed into a film-like shape. There can be a wafer mold material that enables collective molding (wafer molding) with respect to a wafer having semiconductor devices formed thereon, has excellent transference performance with respect to a large-diameter thin-film wafer, can provide a flexible hardened material with low-stress properties, and can be preferably used as a mold material in a wafer level package with less warp of a formed (molded) wafer.

Owner:SHIN ETSU CHEM IND CO LTD

Alumina fiber-enhanced nano-alumina foam ceramic and preparation method thereof

The invention belongs to the field of foam ceramic, and particularly relates to an alumina fiber-enhanced nano-alumina foam ceramic and a preparation method thereof. The alumina fiber-enhanced nano-alumina foam ceramic comprises the following raw materials: a nanometer aluminum oxide powder, a premix solution, a dispersing agent, aluminum oxide fiber, a foaming agent, an initiator and a catalyst, wherein premix solution is formed by adding a monomer and a crosslinking agent into an alcohol-water mixed solution; and the mass ratio of the alumina fiber to nano-alumina powder is (5-30): (95-70). By adopting the alcohol-water mixed solution as a solvent for gel casting, the surface tension among particles can be reduced, and the quality of dry blanks can be increased; the compressive strength of the finished product is more than 30MPa, the porosity is more than 50%, the volume density is less than 3g / cm<3>; the usage temperature is 1500-1750DEG C, the alumina fiber-enhanced nano-alumina foam ceramic is a lightweight and high temperature-resistant refractory material, and can be used in the field of lining materials of a high-temperature electric resistance furnace. The invention further provides a preparation method of the alumina fiber-enhanced nano-alumina foam ceramic, thus being suitable for industrial production.

Owner:JINING UNIV

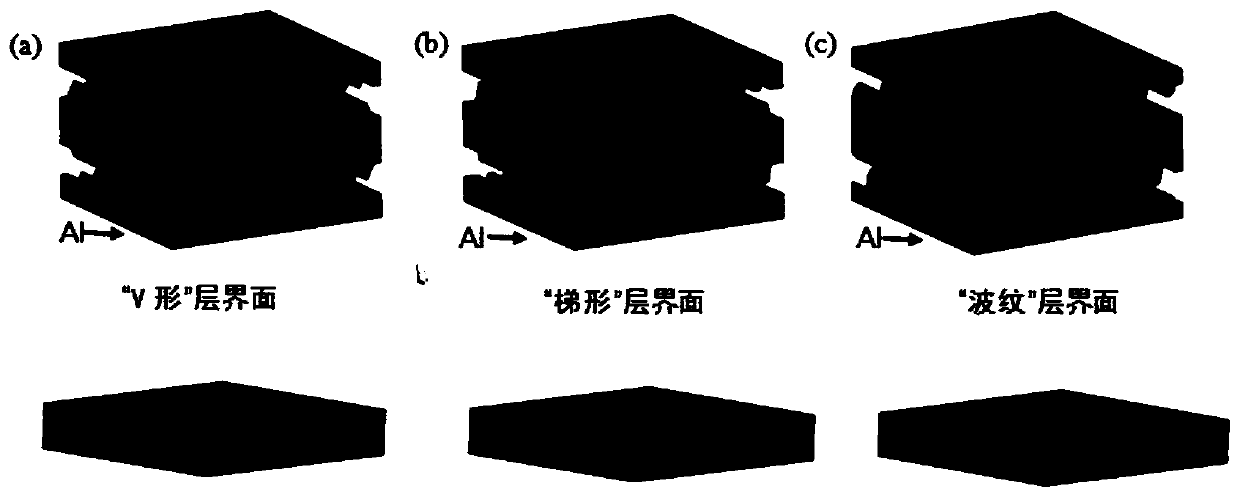

Method for manufacturing aluminum/magnesium/aluminum composite plate on three-dimensional layer interface

ActiveCN110181227AIncrease the bonding force between platesImprove interface bonding strength and bonding efficiencyMetal rolling arrangementsNon-electric welding apparatusAluminum compositesSmooth surface

The invention discloses a method for manufacturing an aluminum / magnesium / aluminum composite plate on a three-dimensional layer interface. The method comprises the steps of firstly, machining the three-dimensional interfaces matched with each other on magnesium alloy plates and aluminum alloy plates; cleaning to-be-bonded surfaces of the magnesium alloy plates and the aluminum alloy plates; stacking and assembling the magnesium alloy plates and the aluminum alloy plates alternately in a mutually meshing mode to obtain a composite plate blank; repeatedly carrying out unidirectional ultrasonic temperature change and load change hot pressing to fill a mold; and carrying out hot rolling to obtain the tightly bonded composite plate. According to the method, a two-step thermal deformation methodcombining hot pressing and rolling is adopted to obtain the laminated plate with uniform thickness, smooth surface and relatively high surface quality, the process is simple, the energy consumption islow, the quality of the composite plate is high, and the method is suitable for application and popularization.

Owner:TAIYUAN UNIV OF TECH

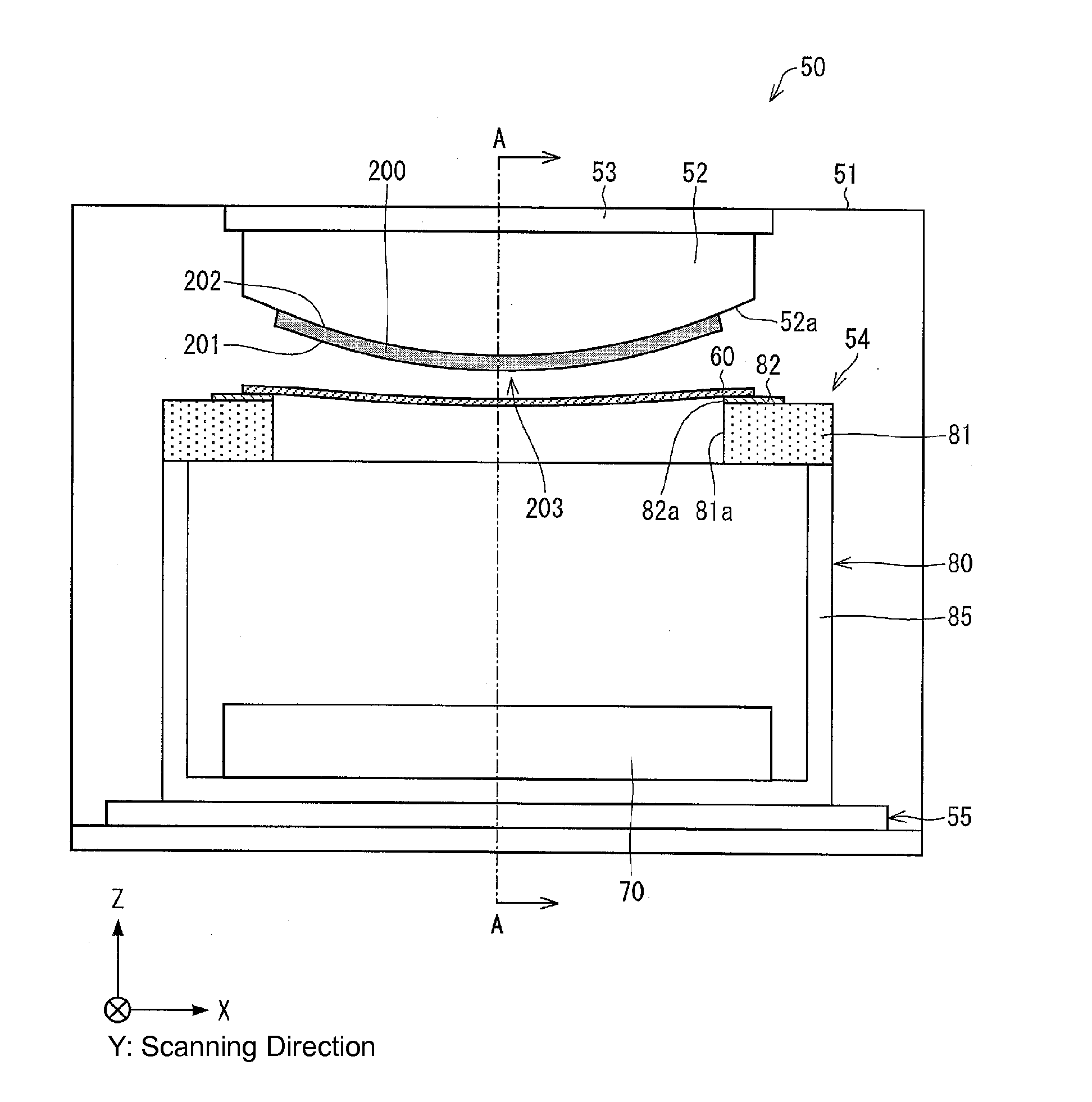

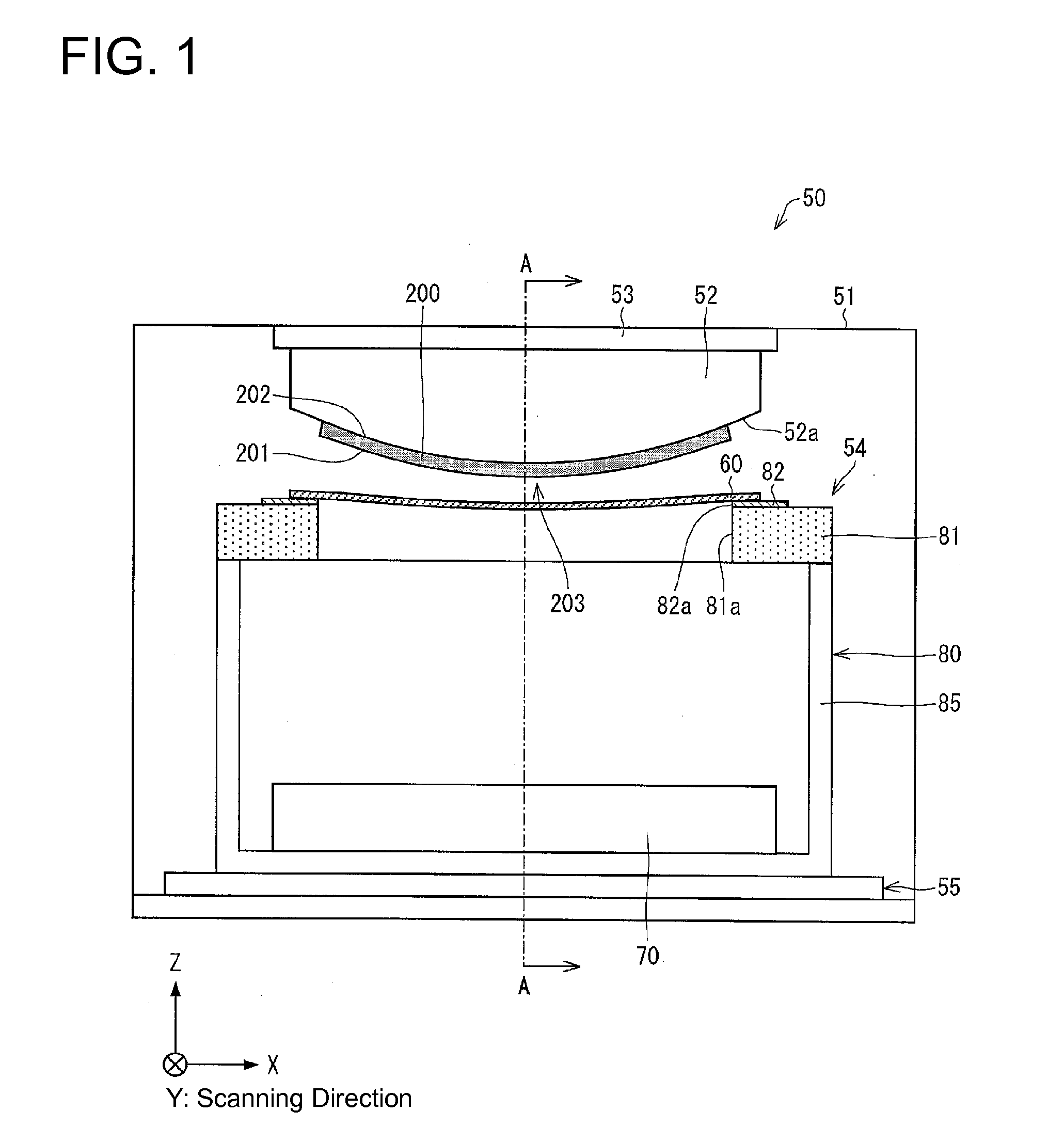

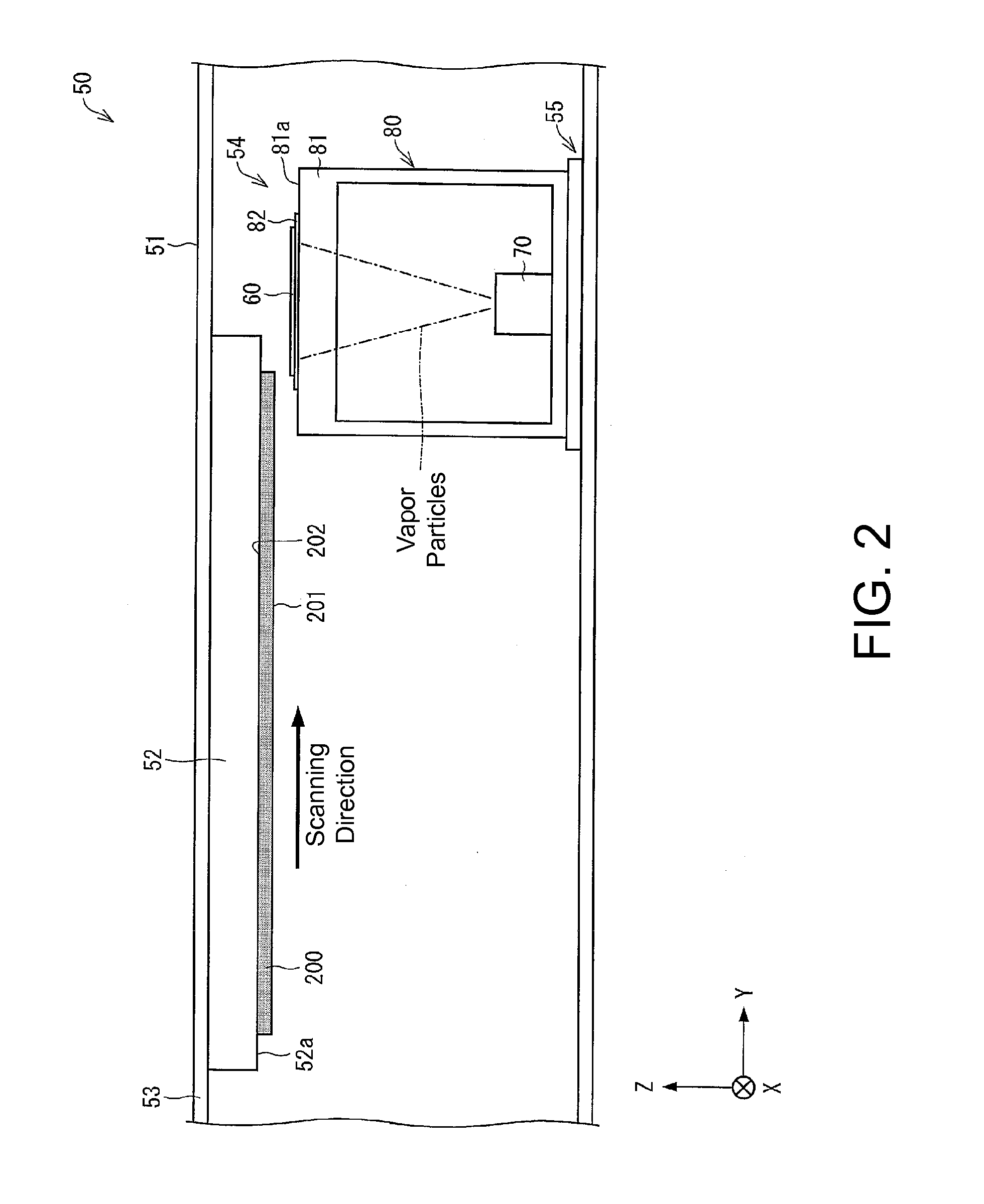

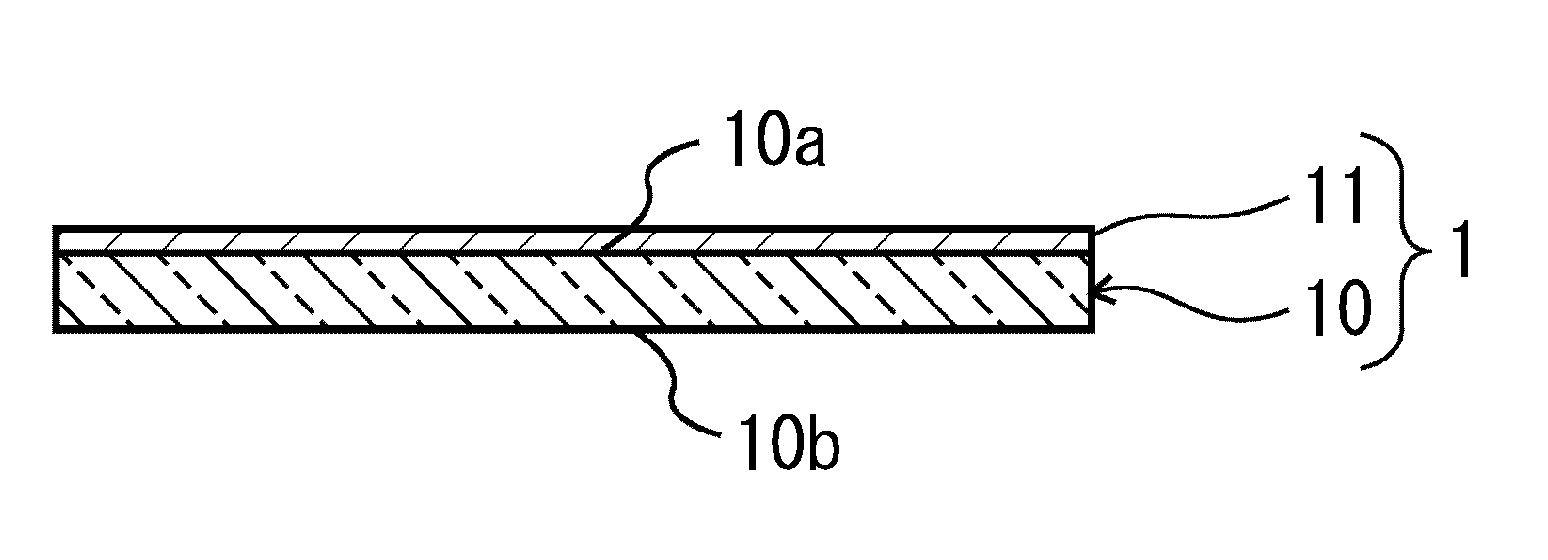

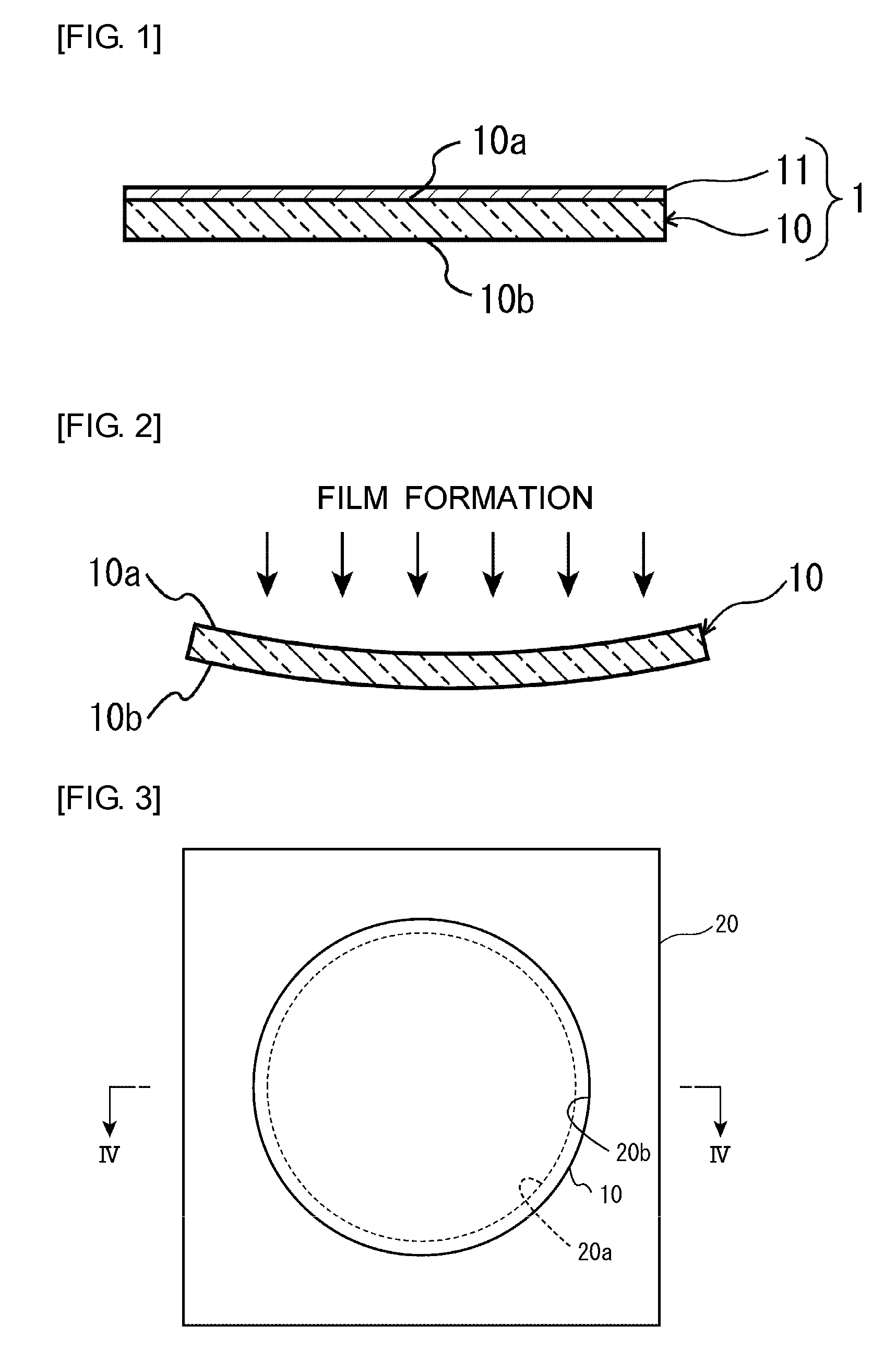

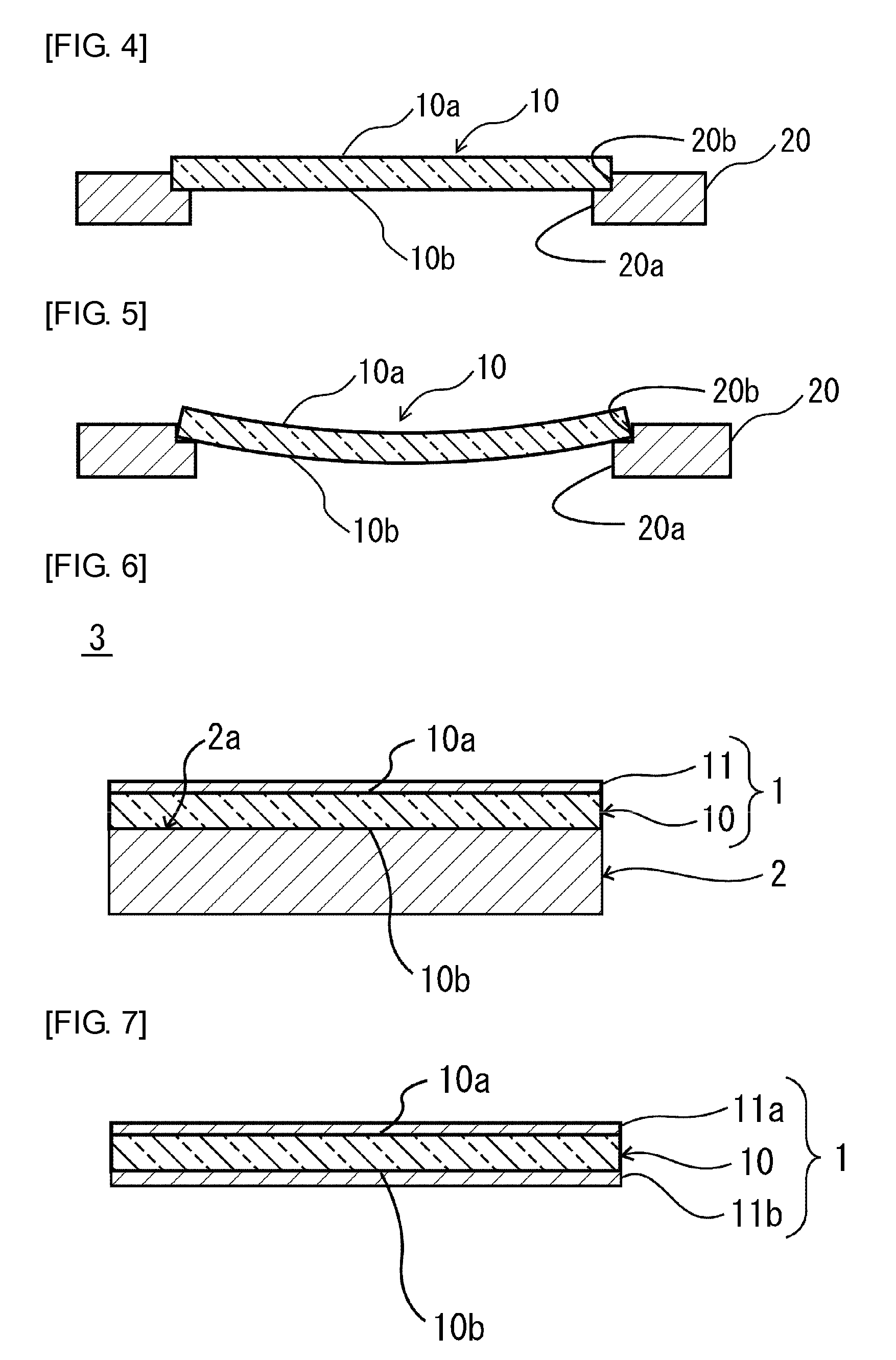

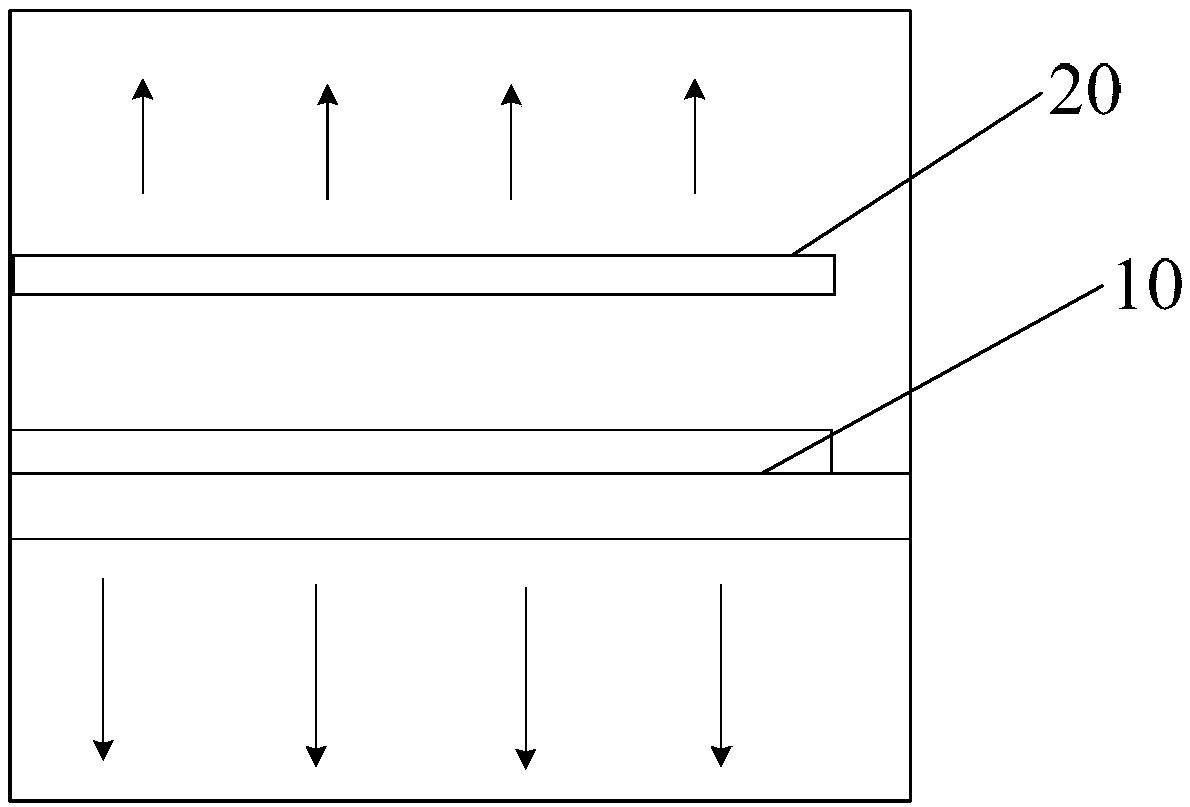

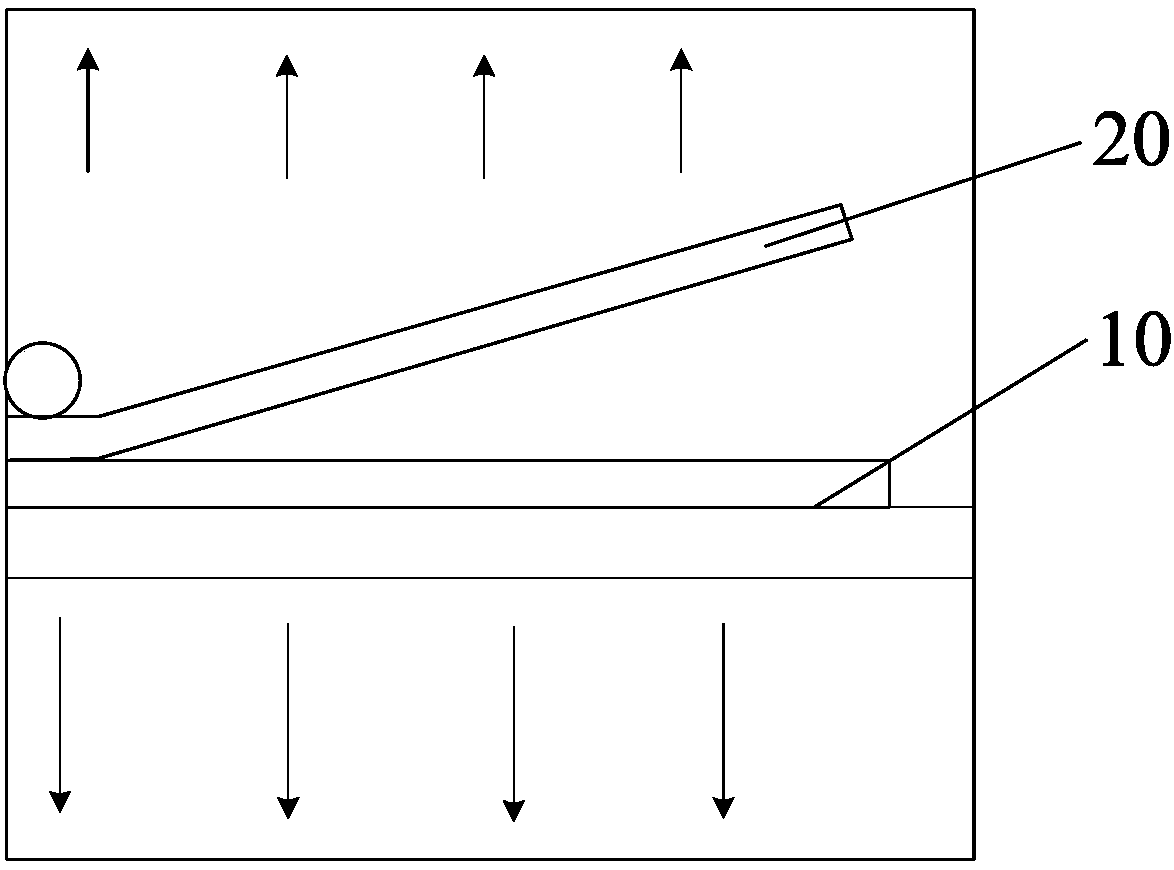

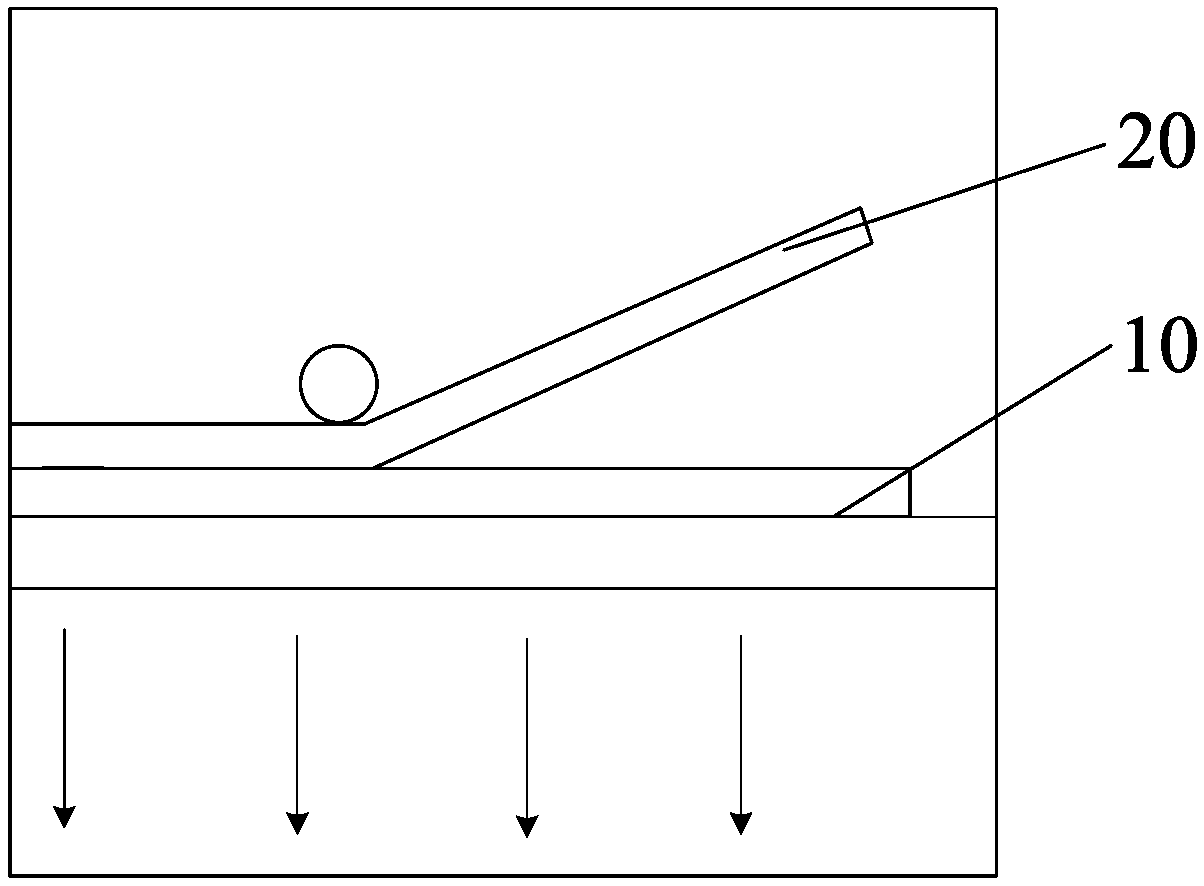

Vapor deposition device

InactiveUS20150114297A1Reduce stressReduce warpingVacuum evaporation coatingSputtering coatingGas phaseOptoelectronics

In a deposition device, a deposition mask of a mask unit (54) has a width in the scanning (movement) direction thereof that is less than a width of a target substrate (on which film will be deposited) in the same scanning direction. A substrate holder includes a substrate holding surface that has at least one curve along the scanning direction matching a bend in the target substrate caused by the weight thereof, and this curve occurs in the direction perpendicular to the scanning direction.

Owner:SHARP KK

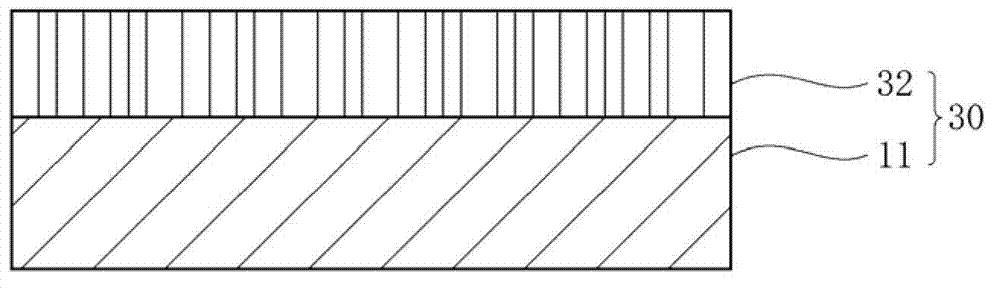

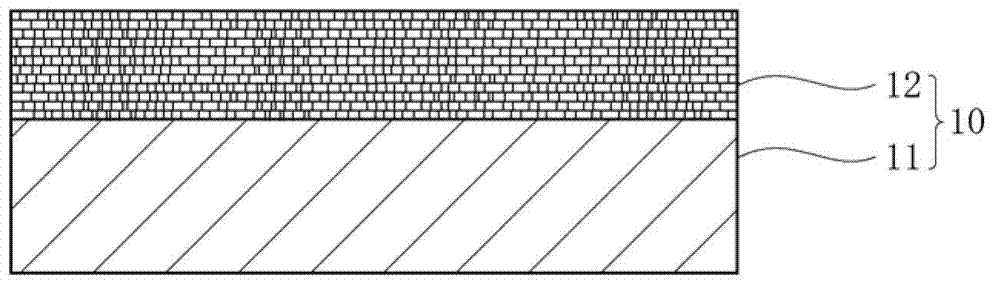

Manufacturing method for glass substrate with thin film

InactiveUS20110154861A1Easy to manufactureReduce warpingVacuum evaporation coatingSputtering coatingComposite material

Owner:NIPPON ELECTRIC GLASS CO LTD

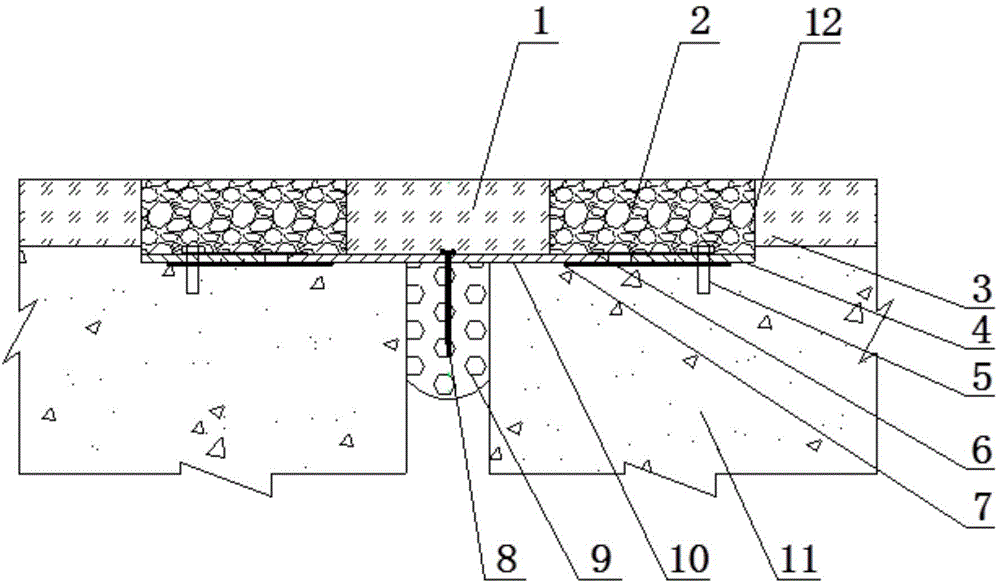

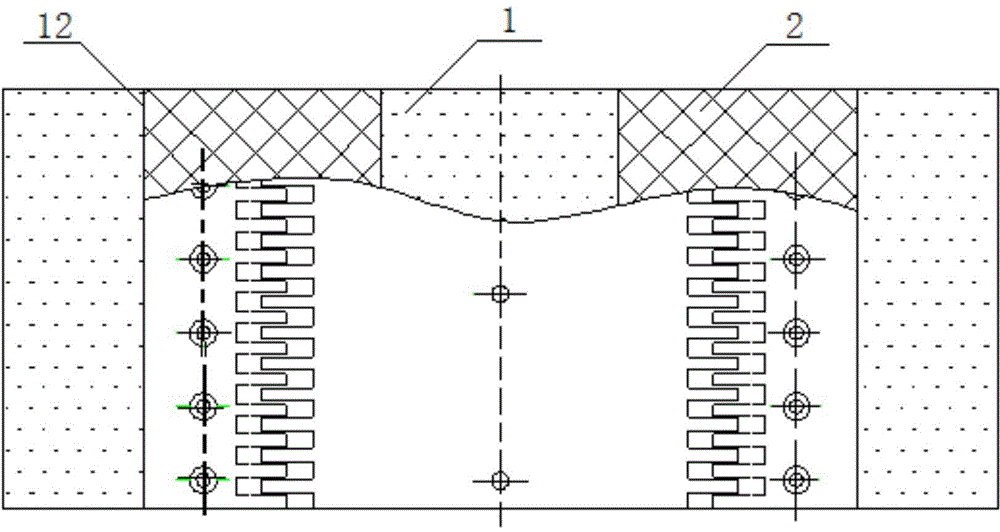

Slipping type seamless telescopic device

InactiveCN104818669AReduce warpingAlleviation deficiencyBridge structural detailsElastomerArchitectural engineering

The invention discloses a slipping type seamless telescopic device. A telescopic seam is arranged between main beams, upper surfaces of the main beams are provided with comb plates, and the comb plate arranged at the upper part of the telescopic seam is a trans-seam comb plate, and a fixing comb plate is connected with the trans-seam comb plate; a top paving layer is arranged at the upper part of the trans-seam comb plate, and both sides of the top paving layer are respectively provided with elastomer prefabricating blocks; left and right sides of the elastomer prefabricating blocks are respectively arranged with bituminous concrete paving layers. The slipping type seamless telescopic device and a bridge face paving layer can be formed to be a continuous body, so as to guarantee stable and comfortable driving; the driving noise is small and waterproof performance is good, and the slipping type seamless telescopic device is convenient to clean and remove snow, and other maintaining works; the structural design is more reasonable, and construction is convenient; the comb plates are respectively arranged beneath the paving layer and above the main beam, and can be fixedly moved; and thereby, the problem of empty lower part of the tooth end of the comb plate is effectively solved, and the shortcoming that the traditional seamless telescopic device is easy to crack is overcame.

Owner:JSTI GRP CO LTD +1

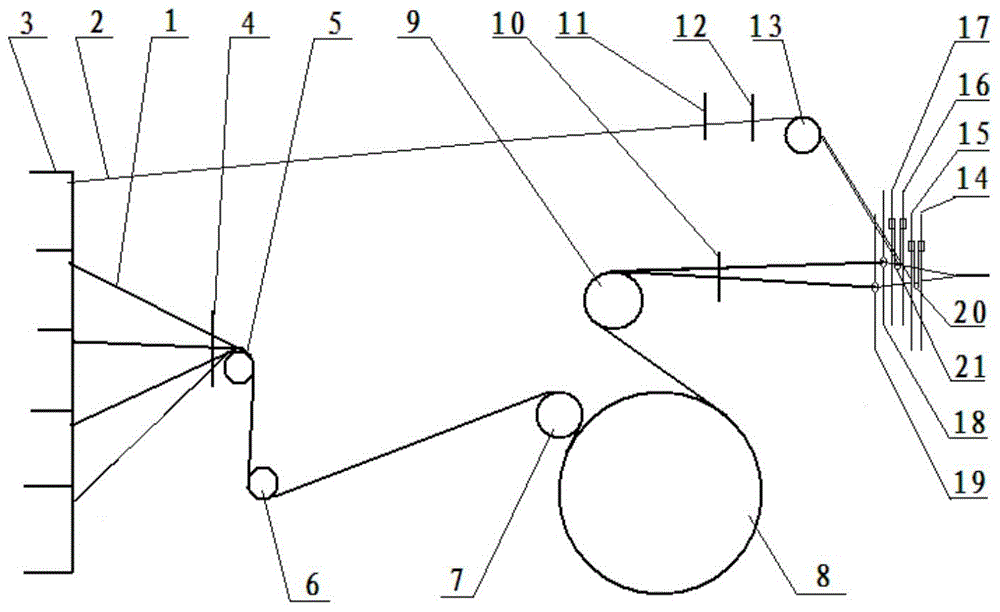

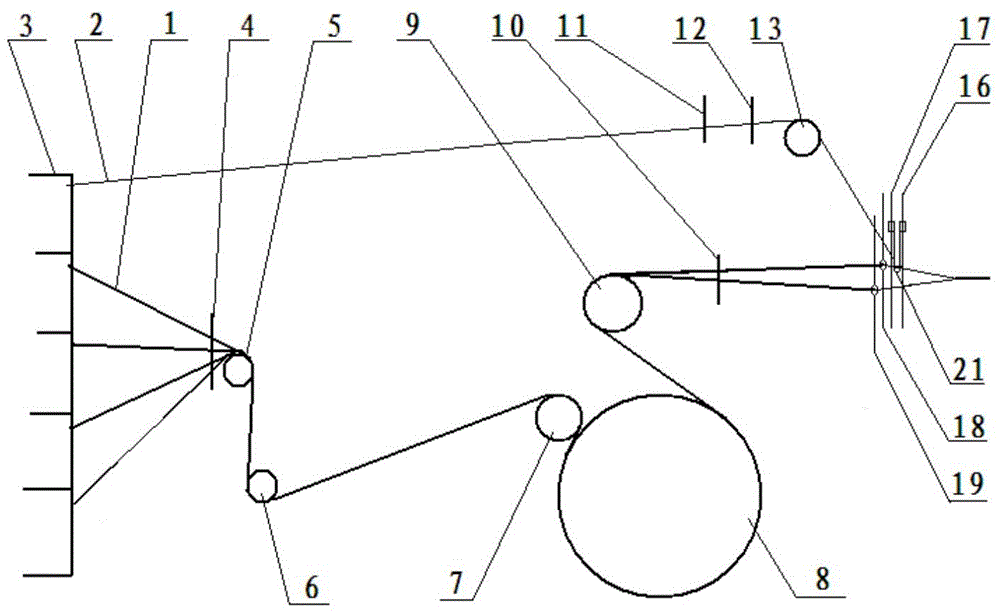

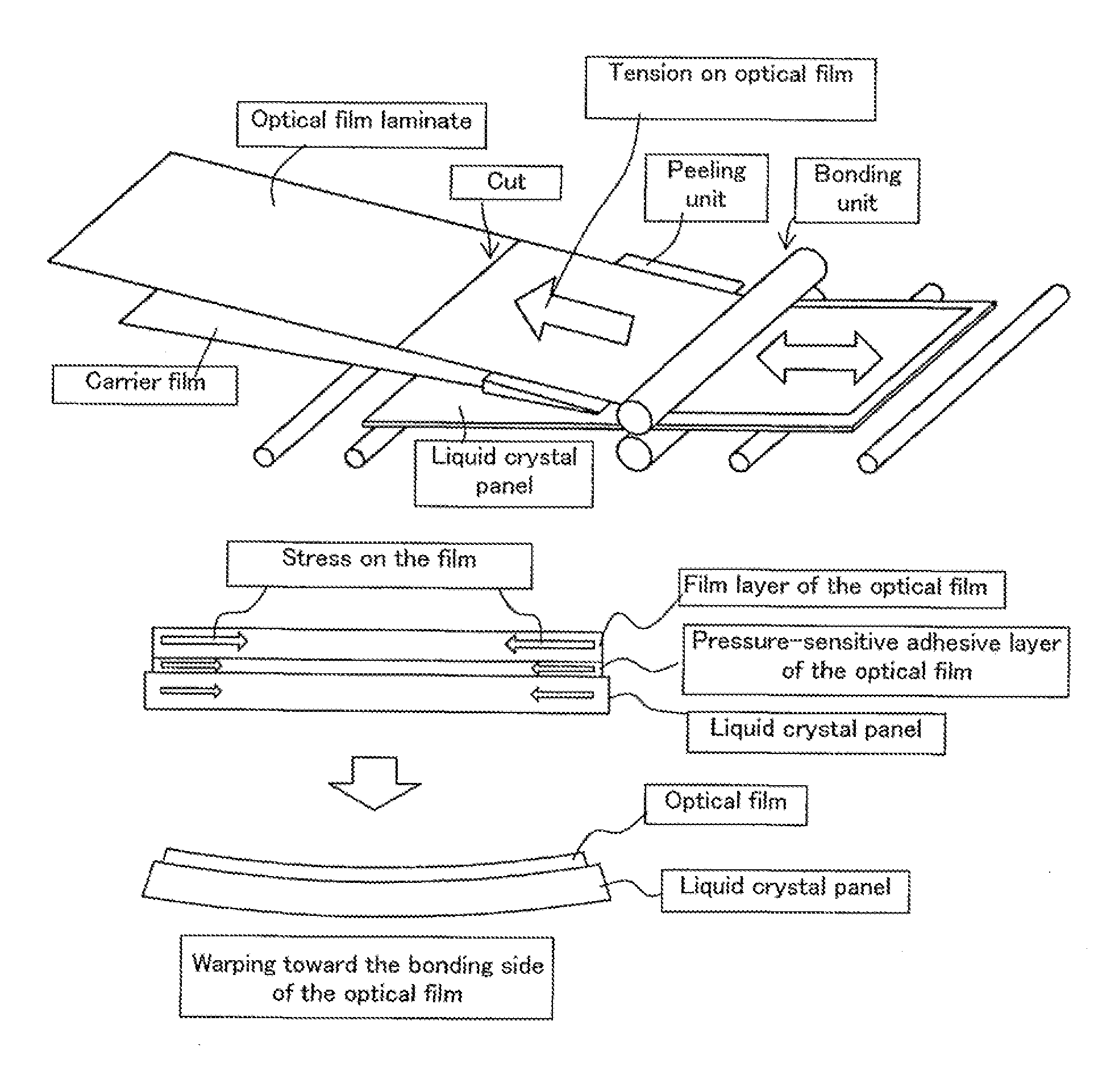

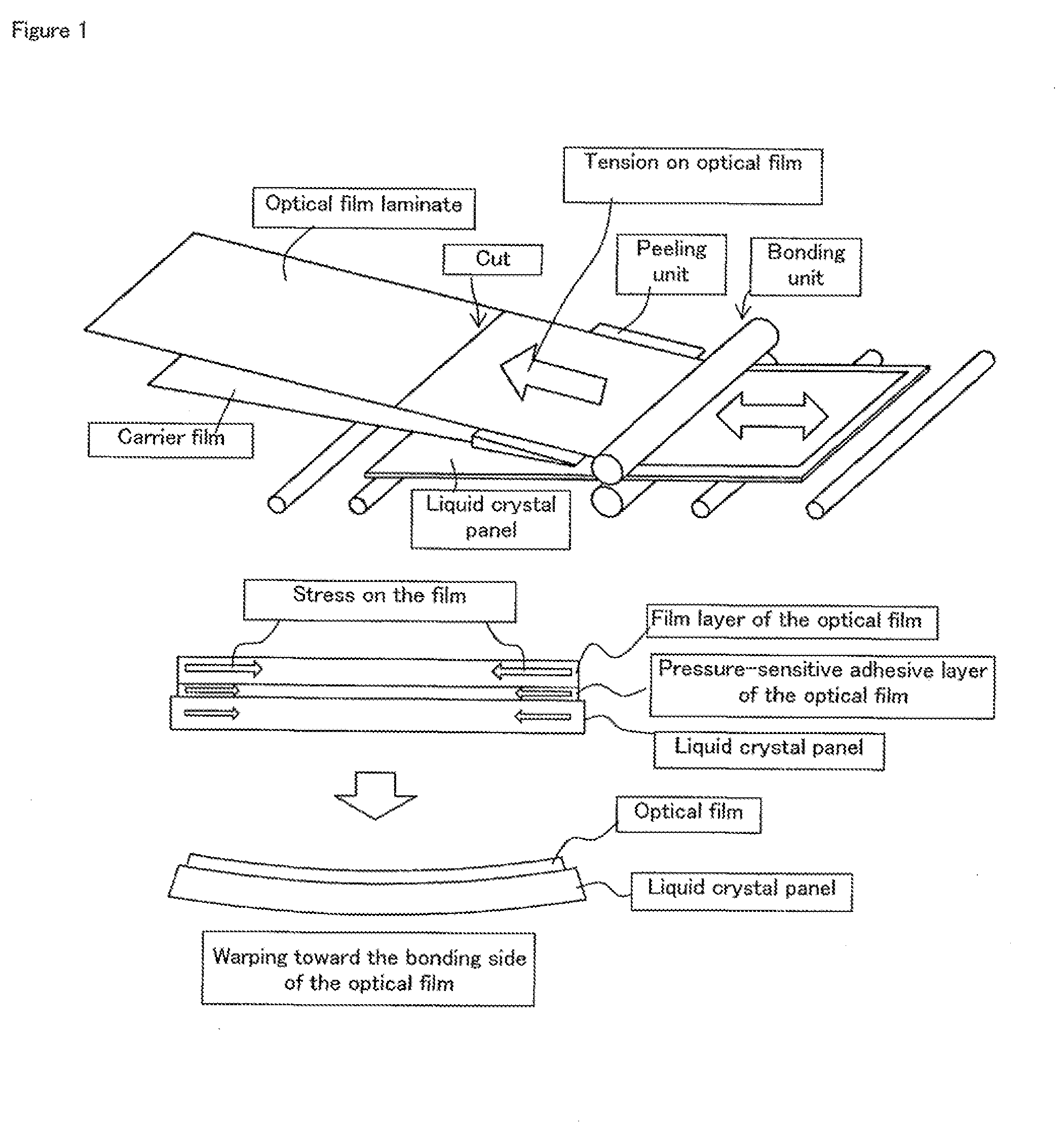

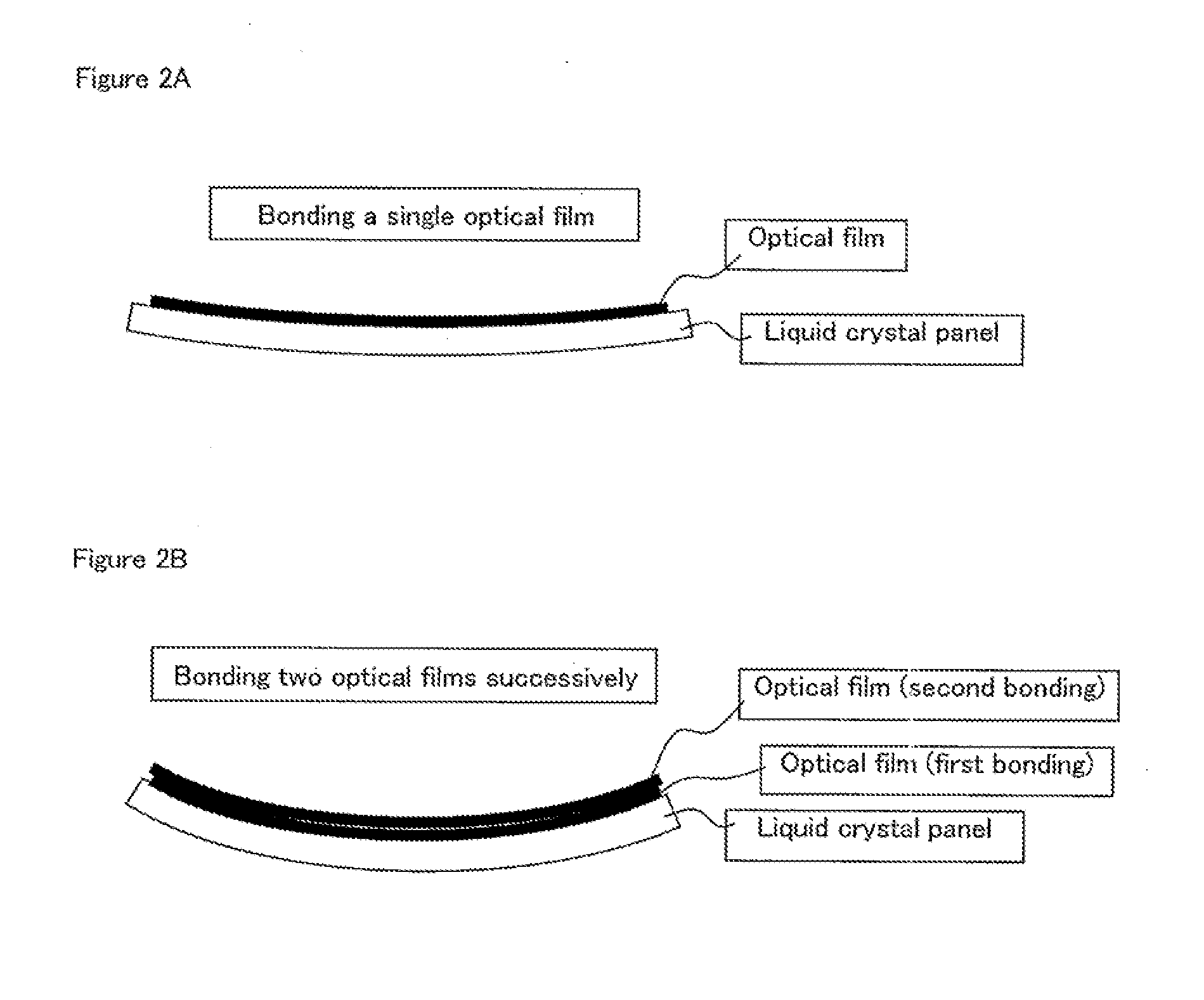

Method and system for manufacturing liquid crystal display device

InactiveUS20120312462A1Reduce warpingInhibition formationLamination ancillary operationsDecorative surface effectsLiquid-crystal displayLiquid crystal

Provided are a method and a system for manufacturing a liquid crystal display device, which can reduce warping of a liquid crystal panel by bonding optical films alternately to the first and second panel surfaces of the liquid crystal panel, in which the method includes: feeding carrier films from continuous rolls, respectively; and bonding steps including bonding optical films, which are peeled off or being peeled off from the carrier films, to the first and second panel surfaces of a liquid crystal panel, respectively, wherein in the bonding steps, bonding the optical film to the first panel surface of the liquid crystal panel and bonding the optical film to the second panel surface of the liquid crystal panel are performed alternately.

Owner:NITTO DENKO CORP

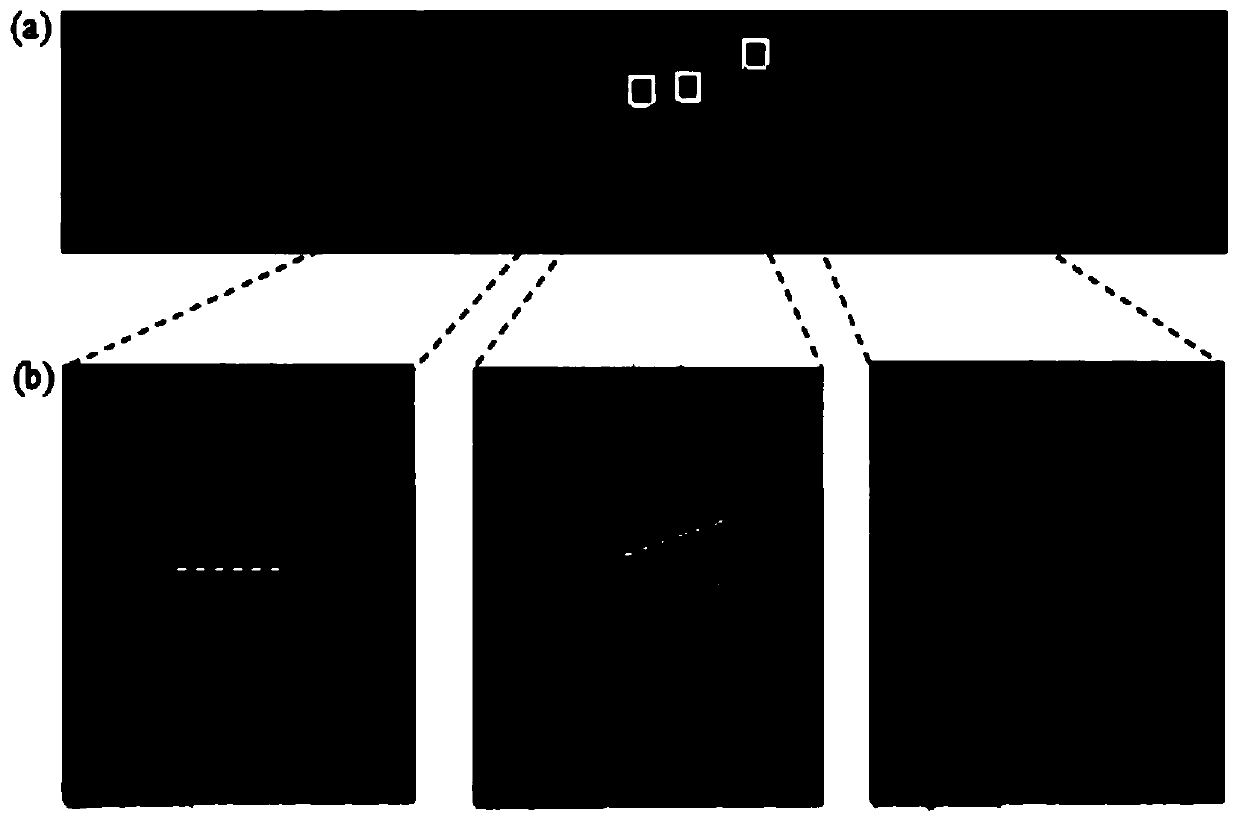

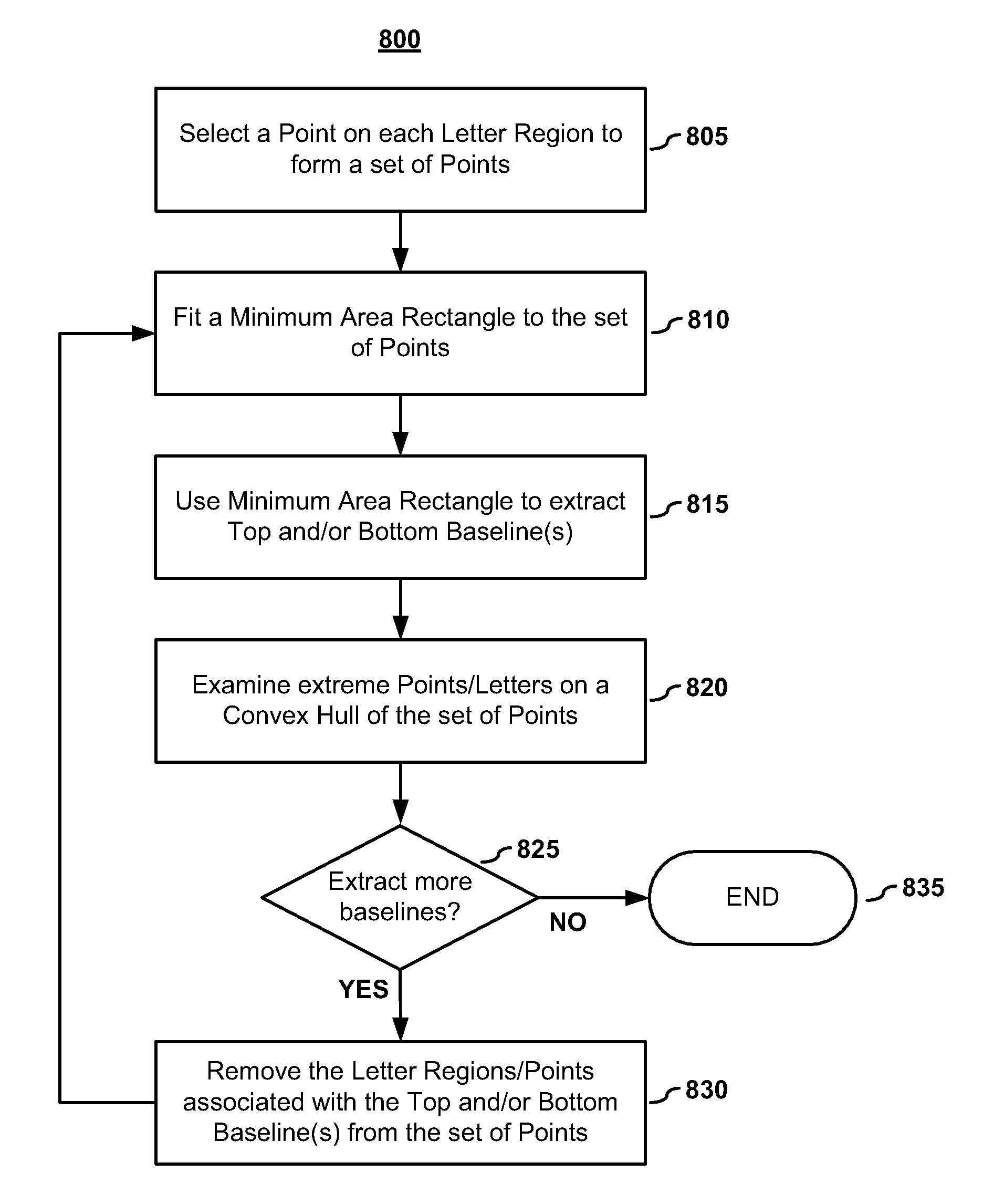

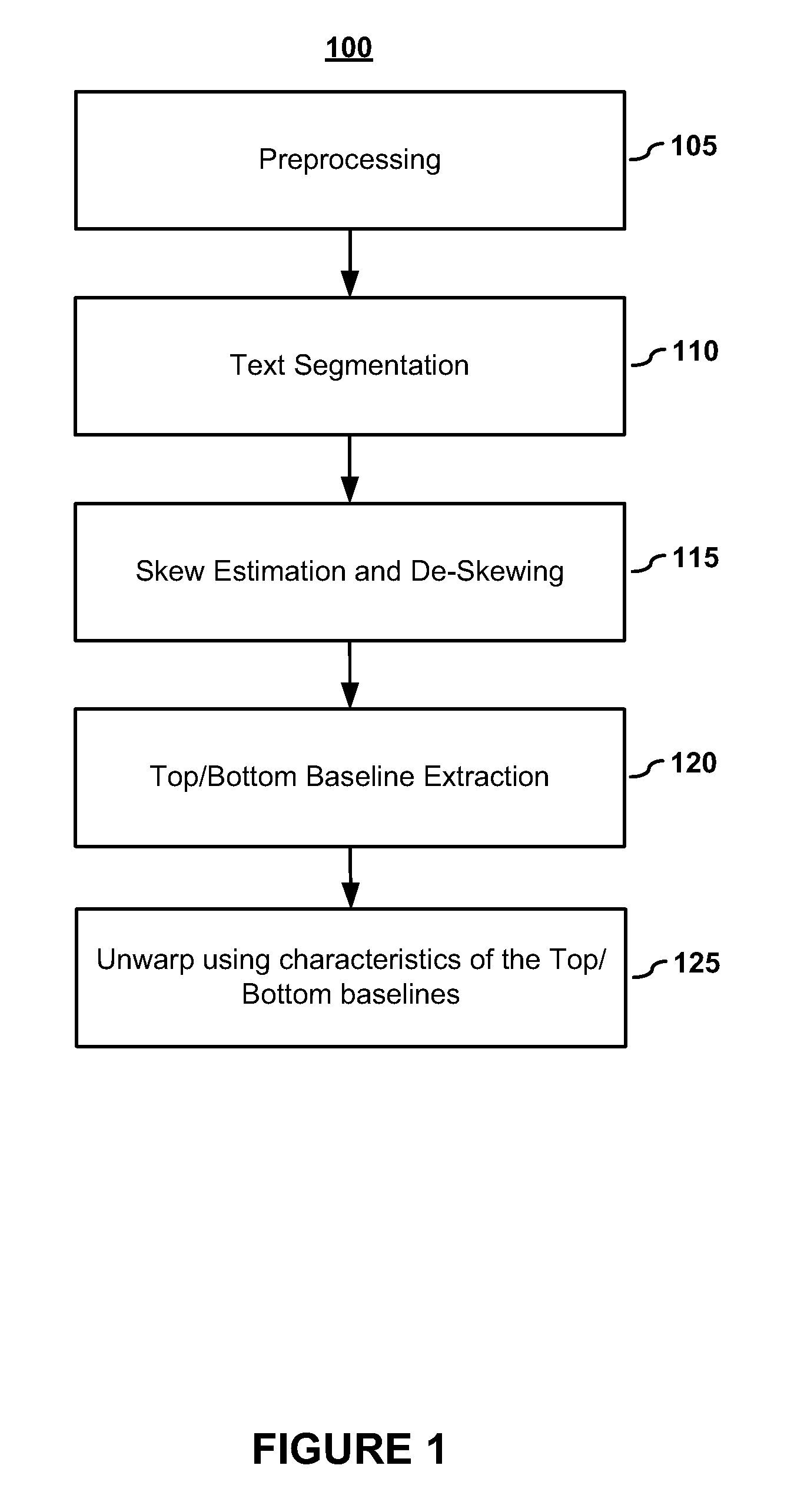

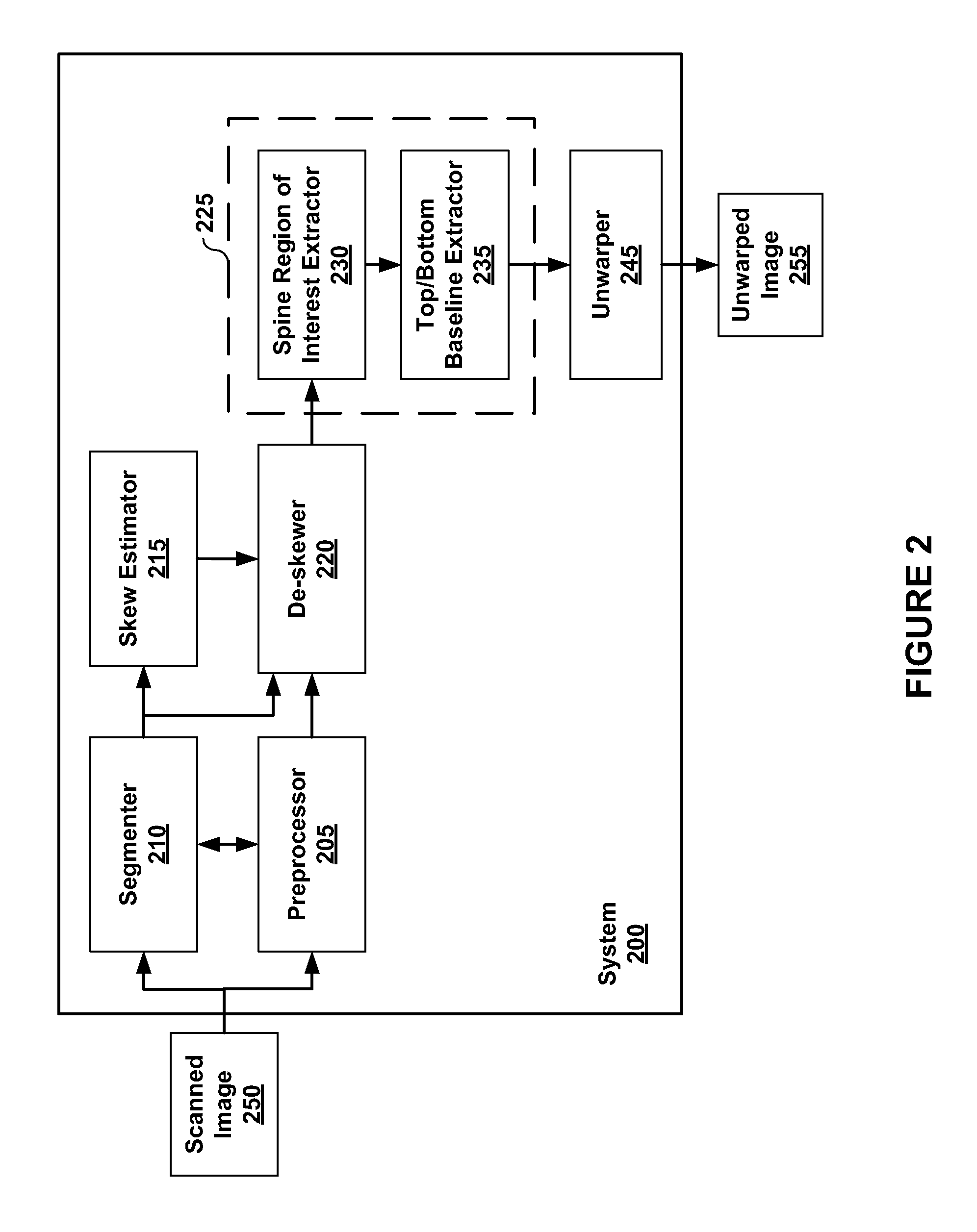

Distortion correction of a captured image

InactiveUS7903876B2Removing and reducing distortionDeformation fastImage enhancementGeometric image transformationComputer visionDocument preparation

Disclosed are embodiments of systems and methods for eliminating or reducing the distortion in a scanned image. Embodiments of the present invention allow for the automatic pruning, de-skewing, and unwarping of an image using document layout information. In embodiments, dominant baselines may be selected by examining the letter regions on boundary baselines rather than examining the entire document layout. The dominant baselines may then be used to reduce distortion in the image. It shall be noted that present invention is robust enough to handle many types of content, including different languages, as well as documents with different layouts. The present invention may also be applied to images obtained from bound documents and flat documents.

Owner:SEIKO EPSON CORP

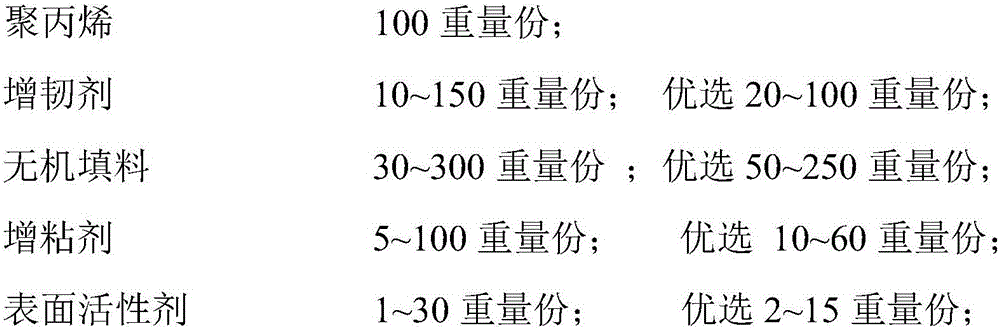

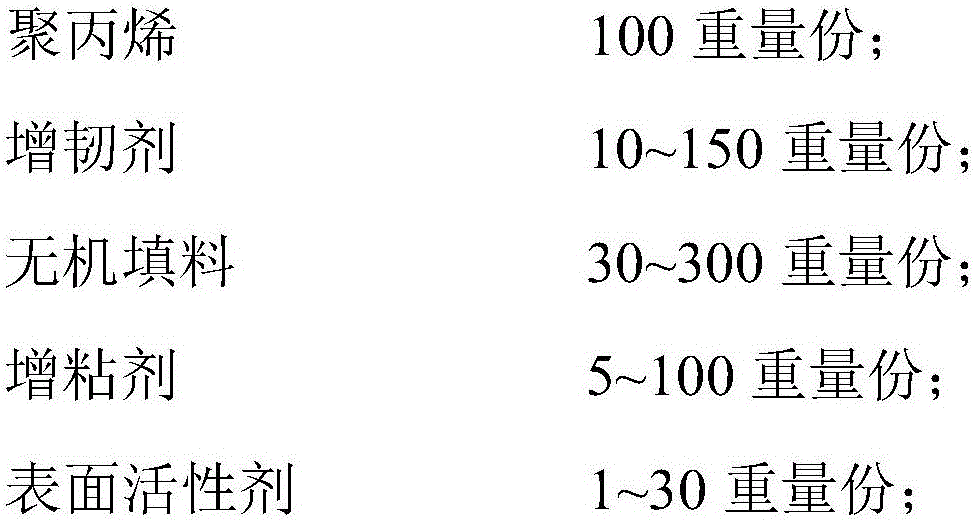

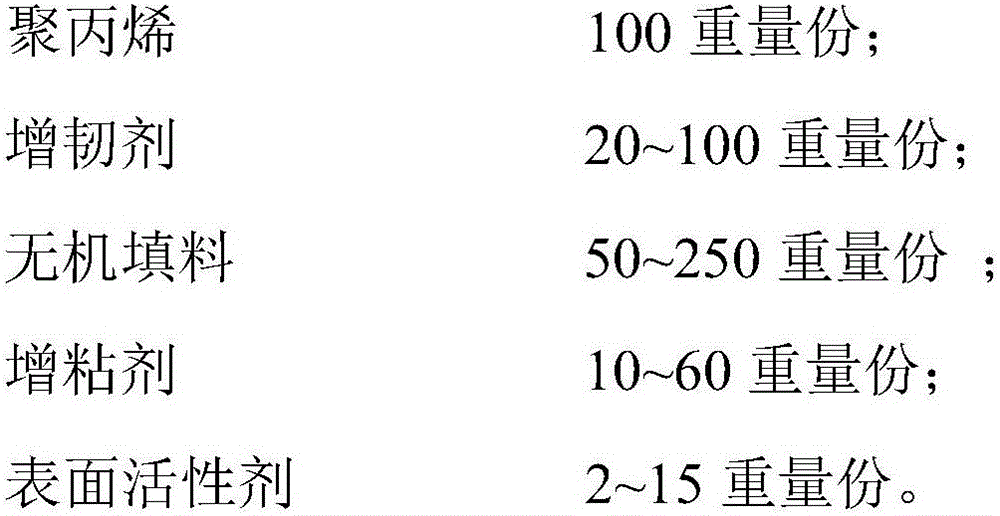

Polypropylene composite material capable of realizing 3D (three-dimensional) printing and preparation method thereof

InactiveCN106633411AImprove surface activityImprove liquidityAdditive manufacturing apparatusPolypropylene compositesPolymer science

The invention discloses a polypropylene composite material capable of realizing 3D (three-dimensional) printing and a preparation method thereof. The polypropylene composite material is prepared by mixing the following raw material ingredients in parts by weight: 100 parts of polypropylene, 10 to 150 parts of toughening agents, 30 to 300 parts of inorganic filler, 5 to 100 parts of thickening agents and 1 to 30 parts of surfactants, wherein the toughening agents are thermoplastic vulcanized rubber; the inorganic filler is calcium carbonate and / or talcum powder; the thickening agents are chlorinated polyethylene; the surfactants are stearic acid and / or titanate. The preparation method comprises the following steps that firstly, the inorganic filler and the surfactants of the quantities are stirred at high speed; then, a mixture and other ingredients of the quantities are subjected to melt blending; the polypropylene composite material capable of realizing the 3D printing is prepared. The polypropylene composite material has high toughness and low shrinkage, and is a good 3D printing material.

Owner:许家萁

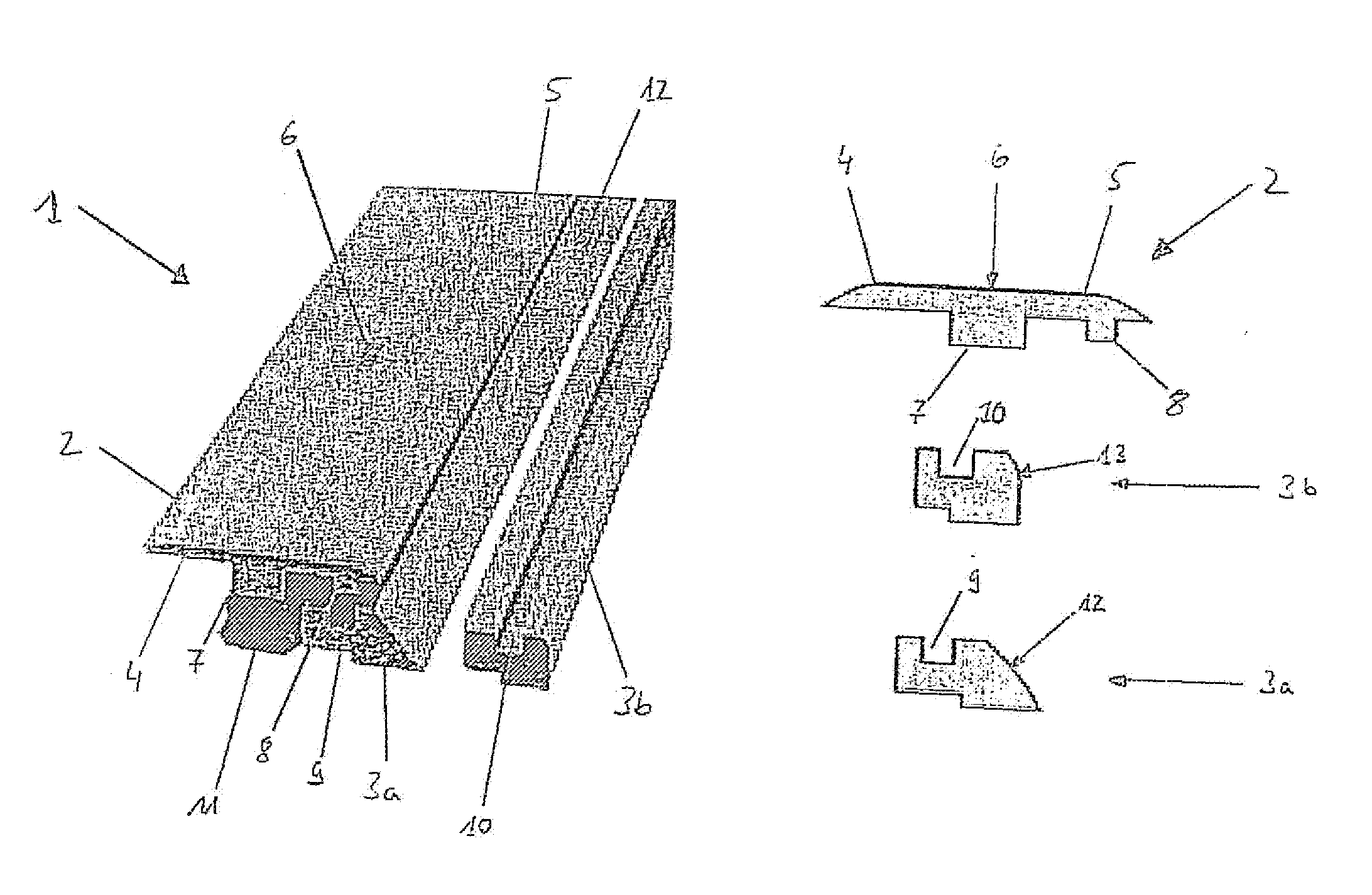

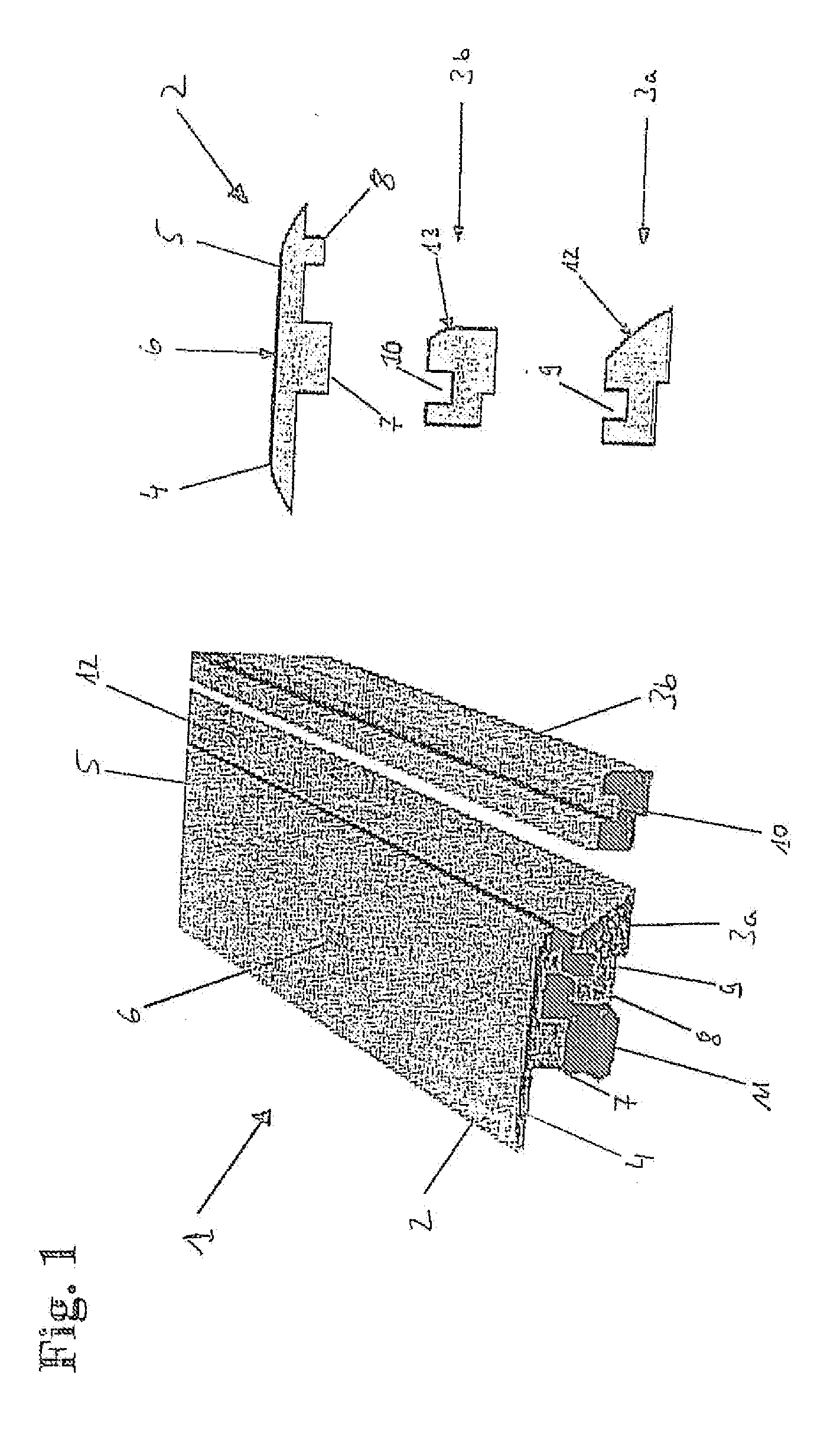

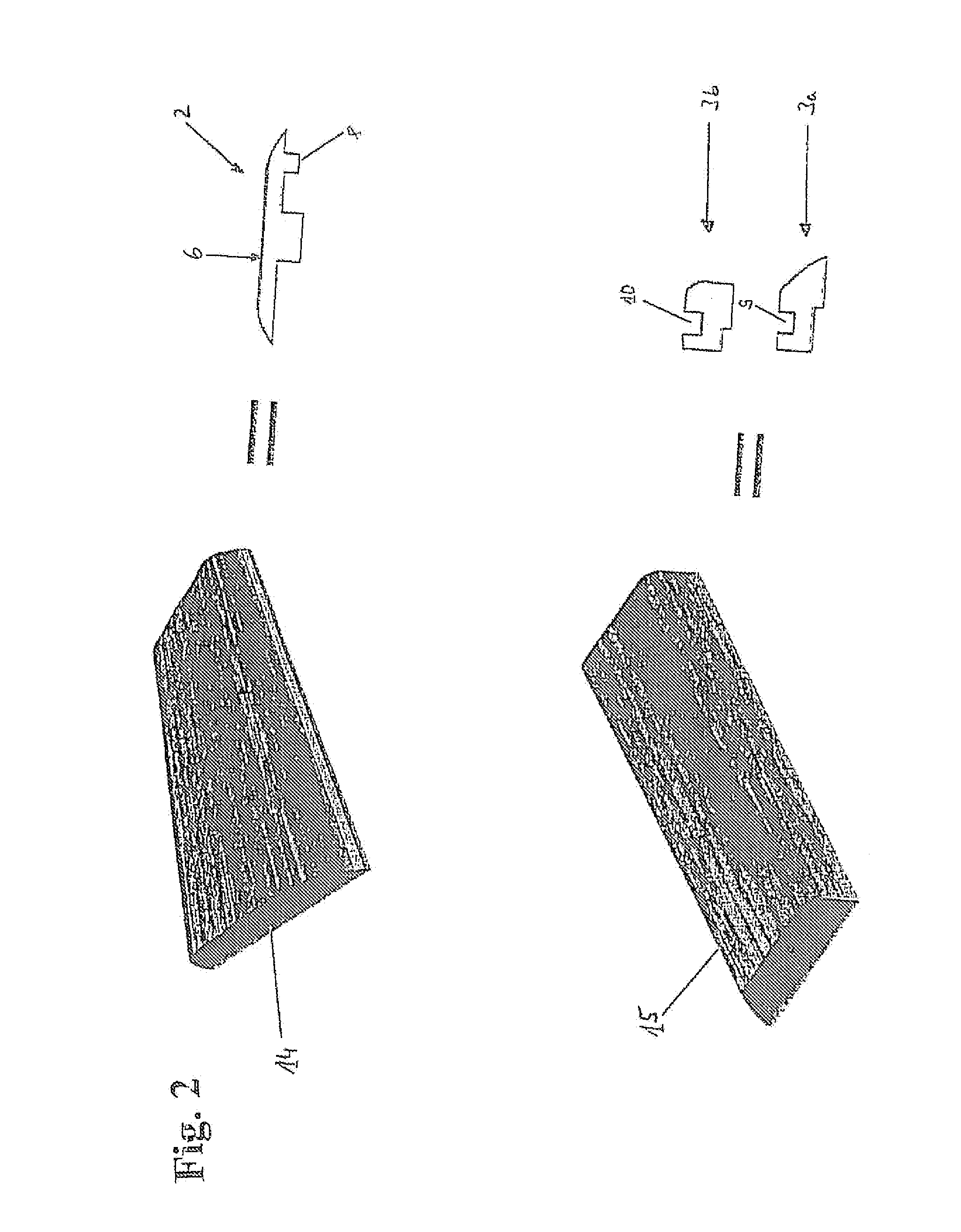

Joint cover assembly and kit comprising this joint cover assembly as well as installation method thereof

InactiveUS20100242393A1Reduce warpingReduce deteriorationRoof covering using tiles/slatesBuilding repairsShell moldingBiomedical engineering

The invention relates to a joint cover assembly for covering a gap between two floor elements covering a subsurface, the assembly comprising a first molding element comprising an upper section having an exposed surface, the exposed surface comprising a décor, and a foot depending therefrom, wherein the foot has a gripping groove extending towards the exposed surface and being defined by two side walls; and a second molding element comprising an upper surface and a lower surface, to be joined to the first molding element, as well as an exposed surface comprising a décor, wherein the lower surface has a groove extending towards the upper surface and being defined by two side walls; characterised in that the joint cover assembly furthermore comprises a track having two upstanding sections, wherein the distance between the upstanding sections corresponds substantially to the width of the foot and also to the distance between a gripping groove's side wall and a proximal side wall of the second molding element's groove. Furthermore, the invention relates to a kit comprising such joint cover assembly. Finally, the invention relates to a method of covering a sub floor adjacent a floor element by using this joint cover assembly or this kit.

Owner:PERGO

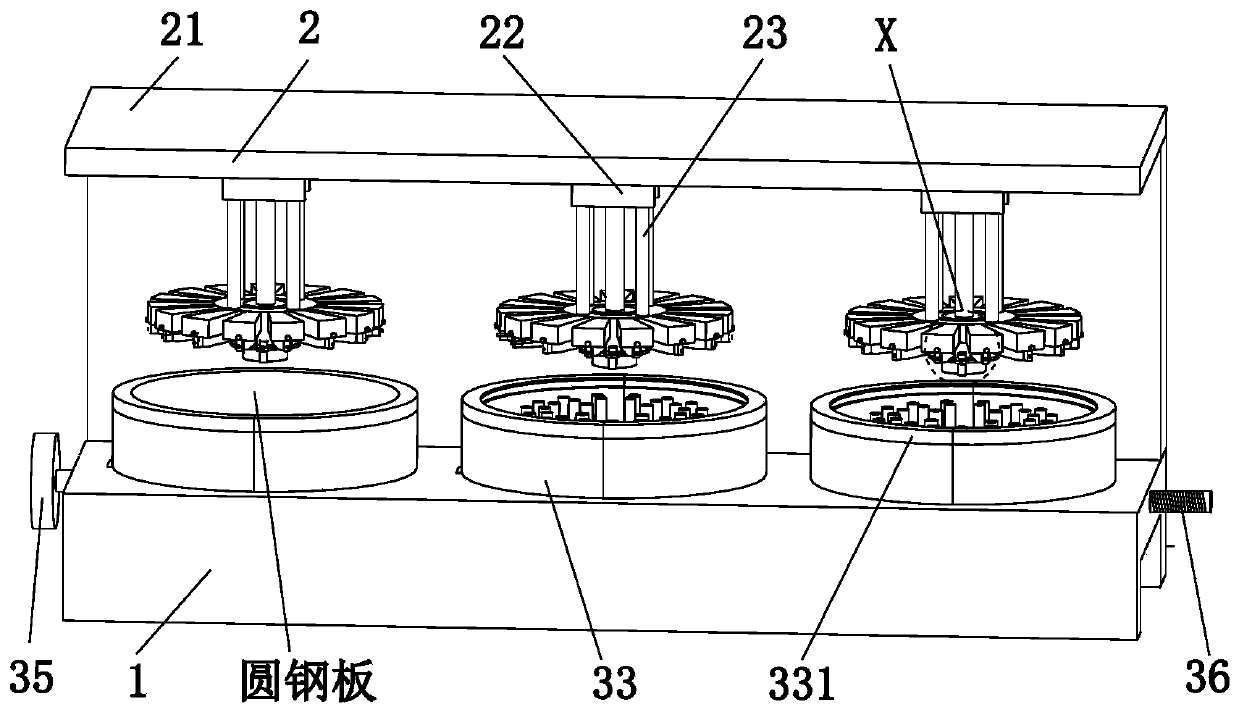

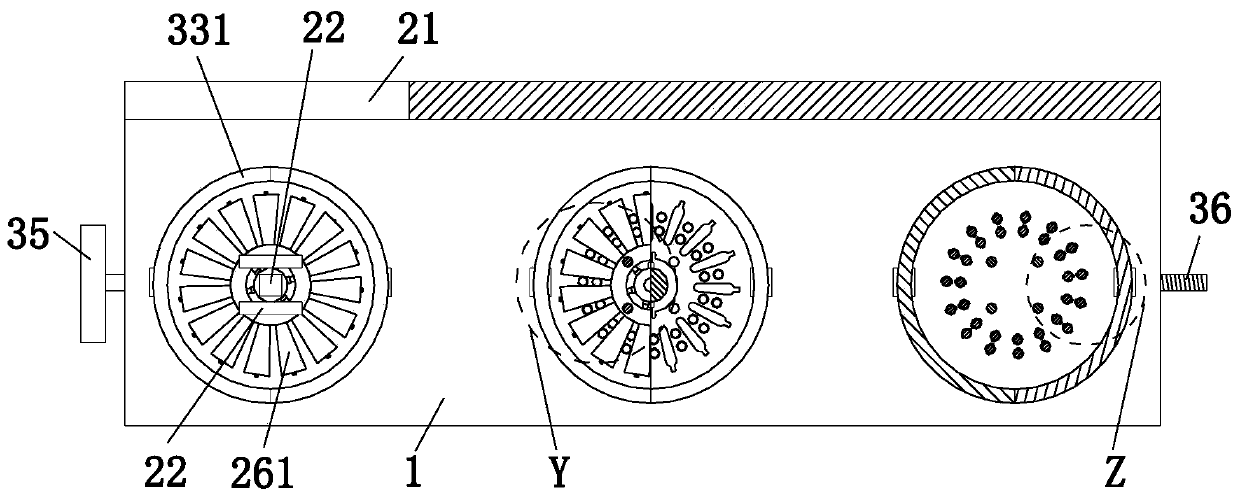

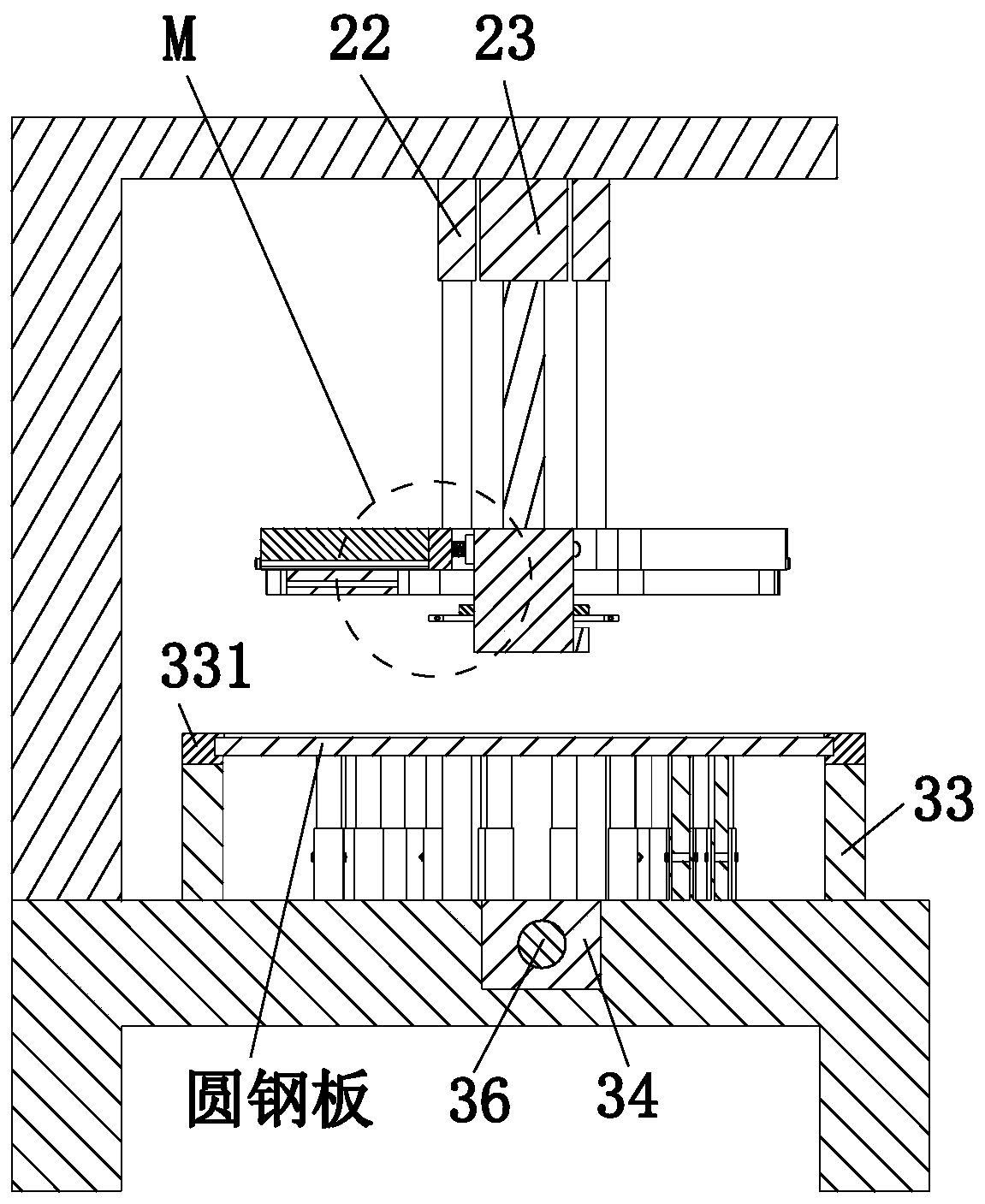

Motor stator punching machining machine

ActiveCN110773626AHigh precisionImprove the stabilityManufacturing stator/rotor bodiesPunchingElectric machine

The invention relates to a motor stator punching machining machine. The machine comprises a workbench, a punching device and clamping devices, wherein the punching device is mounted at the upper end of the workbench, the clamping devices are arranged below the punching device, the clamping devices are connected with the workbench in a slide fit mode, and the clamping devices is arranged at equal distance from left to right. According to the motor stator punching machining machine, a multi-stage adjustable design concept is adopted for motor stator punching machining, the stability degree of round steel plate machining is improved, the accuracy of punching points is guaranteed, then the precision of the motor stator punching machining is improved, and meanwhile, a motor stator with the required number of slots can be machined according to requirements due to the fact that spacing of edge punching blocks and stretching and retracting of a second jacking support column are both controllable.

Owner:湖北宝达机电有限公司

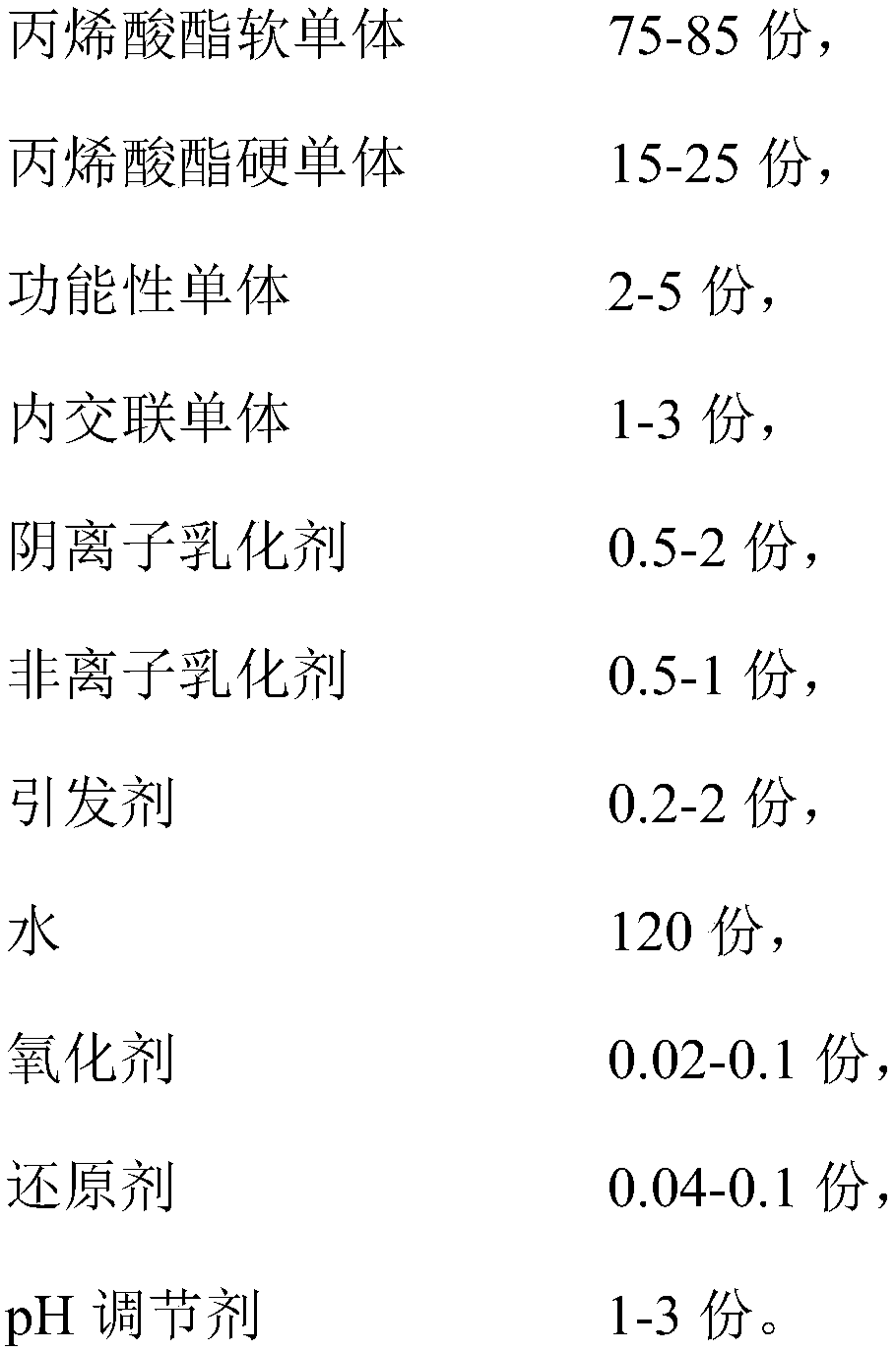

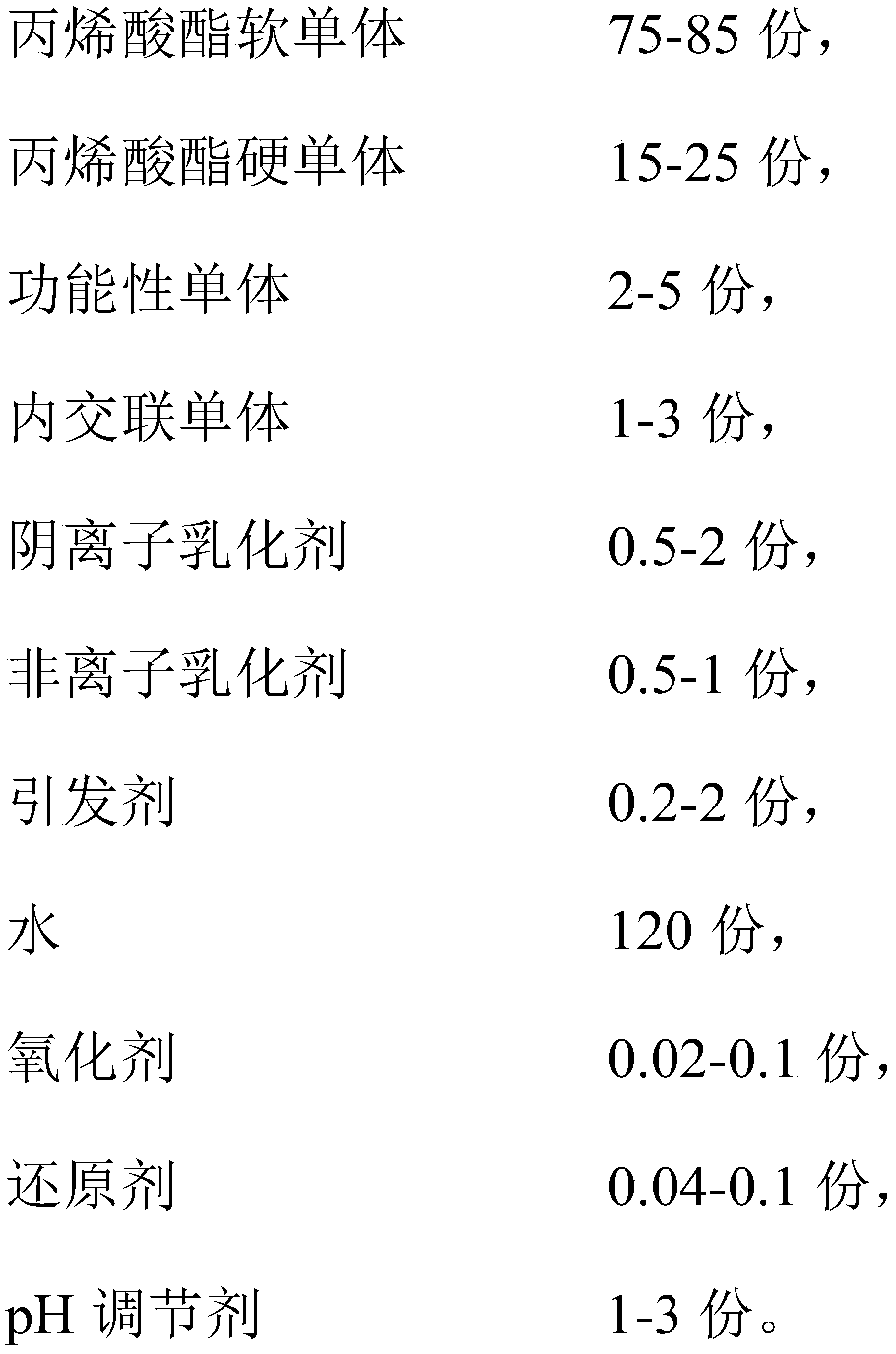

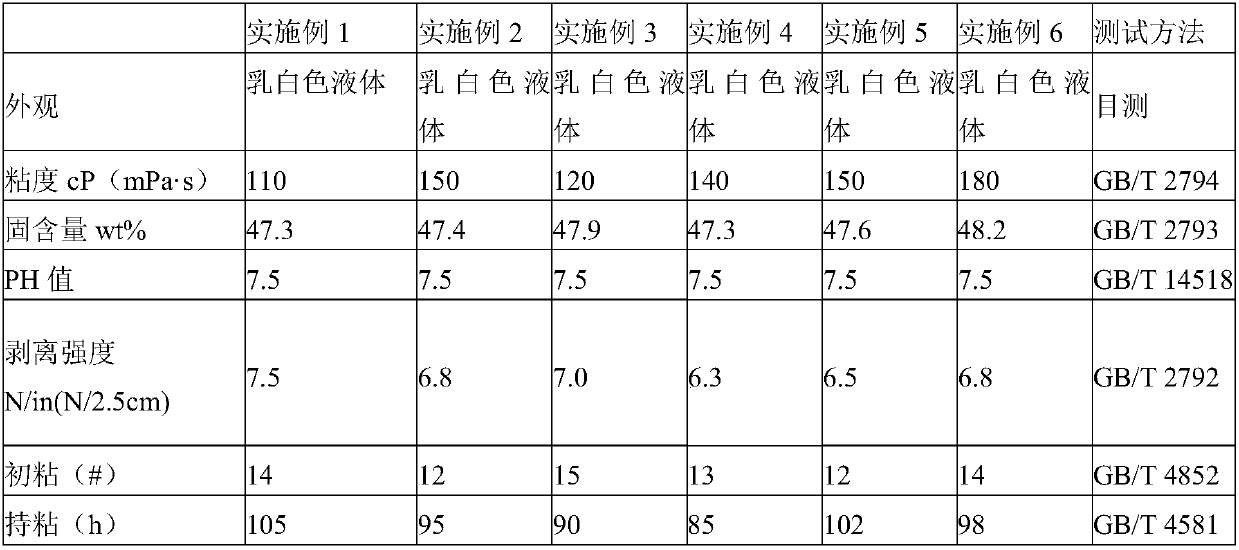

Acrylate pressure sensitive adhesive emulsion of PET substrate for battery packaging, preparation method and application thereof

ActiveCN107603527AHigh fastnessReduce warpingEster polymer adhesivesPressure sensitive film/foil adhesivesFunctional monomerEmulsion

The invention discloses an acrylate pressure sensitive adhesive emulsion of a PET substrate for battery packaging, a preparation method and application thereof. The pressure sensitive adhesive emulsion comprises the following components by weight: 75-85 parts of an acrylate soft monomer, 15-25 parts of an acrylate hard monomer, 2-5 parts of a functional monomer, 1-3 parts of an internal crosslinking monomer, 0.5-2 parts of an anionic emulsifier, 0.5-1 part of a non-ionic emulsifier, 0.1-0.3 part of a buffering agent, 0.02-0.1 part of a defoaming agent, 0.02-0.08 part of a wetting agent, 0.02-2parts of an initiator, 120 parts of water, 0.02-0.1 part of an oxidant, 0.04-0.1 part of a reducing agent, and 1-3 parts of a pH regulator. The pressure sensitive adhesive emulsion provided by the invention has good mechanical properties, can reduce the warping and cracking probability of the PET substrate and ensure the adhesive durability, and is green, low-carbon and environment-friendly.

Owner:WUXI HAITE NEW MATERIAL RES INST +1

Gas sensor

ActiveCN101430301AImprove reliabilityReduce warpingMaterial analysis by electric/magnetic meansEngineeringTotal thickness

A gas sensor including a detection element having a stacked structure configured to detect a specified gas component contained in a gas to be detected. The detection element includes: a sensing portion including one or more solid electrolyte layers containing a first material as a main component and having a first surface and a second surface opposite the first surface; a first portion stacked onthe first surface and including one or more first base layers containing a second material as a main component different from the first material; and a second portion stacked on the second surface and including one or more second base layers containing the second material. A total thickness of the one or more second base layers in a stacking direction is not less than 80% but not more than 120% of a total thickness of the one or more first base layers.

Owner:NGK SPARK PLUG CO LTD

Package structure and manufacturing method thereof

InactiveUS20180301418A1Low of failureReduce riskSemiconductor/solid-state device detailsSolid-state devicesProtection layerActive surface

A package structure includes a first redistribution structure, a chip, an insulation encapsulation and a protection layer. The first redistribution structure has a first surface and a second surface opposite to the first surface. The chip is disposed on the first surface of the first redistribution structure and has an active surface and a rear surface opposite to the active surface. The insulation encapsulation encapsulates the chip and the first surface of the first redistribution structure. The protection layer is directly disposed on the rear surface of the chip.

Owner:POWERTECH TECHNOLOGY

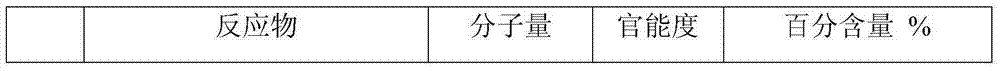

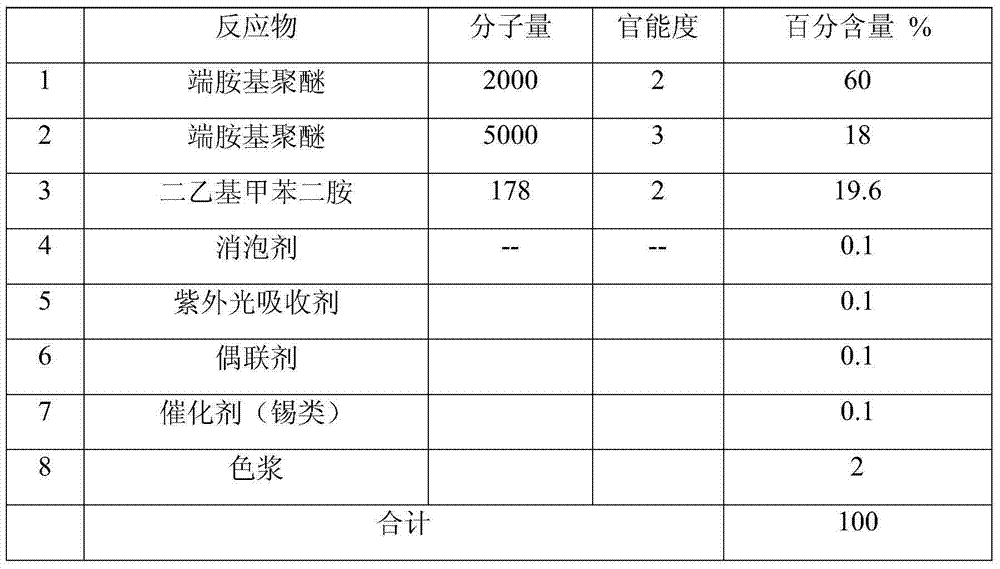

Polycarbonate polyol type spraying polyurea elastomer coating and preparation method

The invention discloses a polycarbonate polyol type spraying polyurea elastomer coating and a preparation method, belonging to the technical field of coatings. The polycarbonate polyol type spraying polyurea elastomer coating comprises a component A and a component B, wherein the component A comprises the following components in percentage by mass: 1.0-50% of polycarbonate polyol, 0-50% of polyether polyol, 1.0-60% of diisocyanate, 0.01-0.1% of a catalyst and 0-50% of a plasticizer; and the component B comprises the following components in percentage by mass: 0-80% of polyether polyol, 1.0-80% of end amino polyether, 0.1-30.0% of a chain extender, 0-40% of a plasticizer, 0.1-0.5% of a defoaming agent, 0.1-1.0% of a catalyst, 0.1-0.5% of an ultraviolet absorbing agent, 0.3-2.0% of a coupling agent and 0-3% of other additives. By adopting the polycarbonate polyol type spraying polyurea elastomer coating, problems of edge warping, falling and the like of a sprayed polyurea material in the practical use process are reduced.

Owner:SHANGHAI ORIENTAL YUHONG WATERPROOF TECH

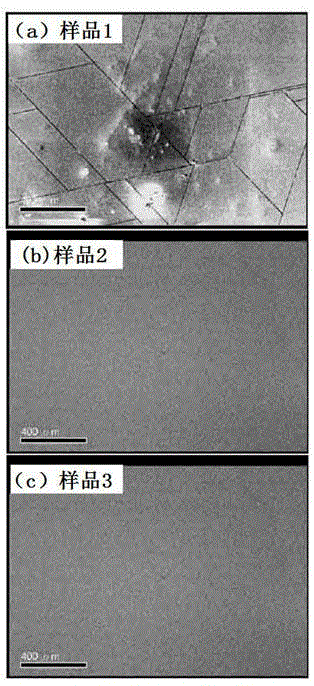

Method of preparing high electron mobility transistor (HEMT) on large-sized Si substrate

ActiveCN105374677AAddress stressFix bugsSemiconductor/solid-state device manufacturingFrom chemically reactive gasesGas phaseChemical vapor deposition

The invention provides a method of preparing a high electron mobility transistor (HEMT) on a large-sized Si substrate, and particularly relates to a method of preparing a crack-free and high-crystal quality AlGaN / GaN HEMT device by adopting a selective area growth (SAG) method and by adopting carbon nanotubes as a periodic dielectric mask. On the Si substrate, a metal organic chemical vapor phase epitaxy technology is adopted to grow an AlN nucleation layer and an AlGaN seed layer; then, a low pressure chemical vapor deposition (LPCVD) method is adopted to grow multiple layers of carbon nanotubes arranged neatly, and through growth and weaving, a continuous carbon nanotube film is formed finally; on the basis, the SAG method is adopted, growth selectivity of GaN on the dielectric mask and the substrate is used, a GaN epitaxial layer is limited to grow in a region without a concealed film, a discrete window is formed, and tensile stress in the overall epitaxial layer is released; and multi-cycle Al component-gradient Aly1Ga1-y1N / GaN superlattices or AlN / Aly1Ga1-y1N / GaN superlattices are adopted as a stress control layer, and the crack-free and high-crystal quality GaN epitaxial layer is acquired. On the basis, the AlGaN / GaN HEMT device is prepared.

Owner:SINO NITRIDE SEMICON +1

Metal powder for selective laser sintering, method for manufacturing three-dimensional shaped object by using the same, and three-dimensional shaped object obtained therefrom

InactiveUS8828116B2Reduce warpingReduce deformationAdditive manufacturing apparatusIncreasing energy efficiencySelective laser sinteringPowder mixture

There is provided a metal powder for use in a selective laser sintering method for producing a three-dimensional shaped object, wherein the metal powder comprises a powder mixture of a precipitation-hardening metal composition. In particular, the metal powder of the present invention is configured to have a Fe-based component powder and a Ni-based component powder which are individually included in the powder mixture wherein a powder made of an alloy of Fe-based and Ni-based components is not included as a main powder in the powder mixture.

Owner:PANASONIC CORP

Optical Disc and an Ultraviolet-Curable Resin Composition Therefor

InactiveUS20090148651A1Reduce warpingHigh transparencyLayered productsRecord information storageEpoxyMeth-

The present invention relates to an optical disc having a cured product layer of an ultraviolet-curable resin composition containing (A) dicyclopentenyloxyethyl acrylate, (B) urethane (meth)acrylate and / or (C) epoxy (meth)acrylate, and (D) photopolymerization initiator, and a resin composition for the cured product layer thereof and a cured product therewith; and the optical disc of the present invention has less warping after curing and is excellent in transparency and durability and therefore suitable for next generation high density optical discs where recording and / or reproducing are performed using a blue laser; the resin composition for said cured product layer has less deterioration with age and less viscosity change in recycle and is suitable for a coating agent of optical discs and for efficient production of optical discs.

Owner:NIPPON KAYAKU CO LTD

Sputtering target and manufacturing method thereof, film obtained by the method, film sheet and stacking sheet

ActiveCN102965629AImprove occlusion effectIncreased durabilityVacuum evaporation coatingSputtering coatingSputteringZinc

The invention provides a sputtering target suitable for forming a film having excellent transparent and gas shielding performances and a manufacturing method thereof, the film obtained by the method, a film sheet and a stacking sheet. A zinc oxide-silicon dioxide group sputtering target consists of zinc oxide and silicon dioxide as a main component. The relative density of the sintered compact is 95% or more. The molar ratio of zinc oxide and silicon dioxide is 40:60-95:5.

Owner:MITSUBISHI MATERIALS CORP

Soft-to-hard film sticking process and film sticking product

ActiveCN108262941AGuarantee smooth implementationSmall amount of deformationScratchingTectorial membrane

The invention provides a soft-to-hard film sticking process and a film sticking product. The film sticking process includes the steps that step S1, vacuuming is respectively conducted on the upper andlower portions of a hard planar assembly of which film sticking needs to be conducted, a flexible protective film is placed on the upper portion of the hard planar assembly, and the vacuum degree atthe lower portion is greater than the vacuum degree at the upper portion; step S2, the flexible protective film is laminated on a sticking start end of the hard planar assembly by using a roller; stepS3, the vacuuming of the upper portion of the hard planar assembly is stopped, and the flexible protective film is rolled by using the roller until the film sticking of the hard planar assembly is completed. The deformation of the flexible protective film during the rolling process of the flexible protective film by using the roller is greatly reduced, and the tensile stress on the hard planar assembly is greatly reduced, so that the problem of warping of the hard planar assembly due to the tensile stress is effectively alleviated or even avoided, and the formation of pits and creases in thevacuum hole-adsorbed place after rolling by the roller and the protective film scratching due to the friction between the roller and the flexible protective film are avoided.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com