Patents

Literature

198 results about "Product layer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

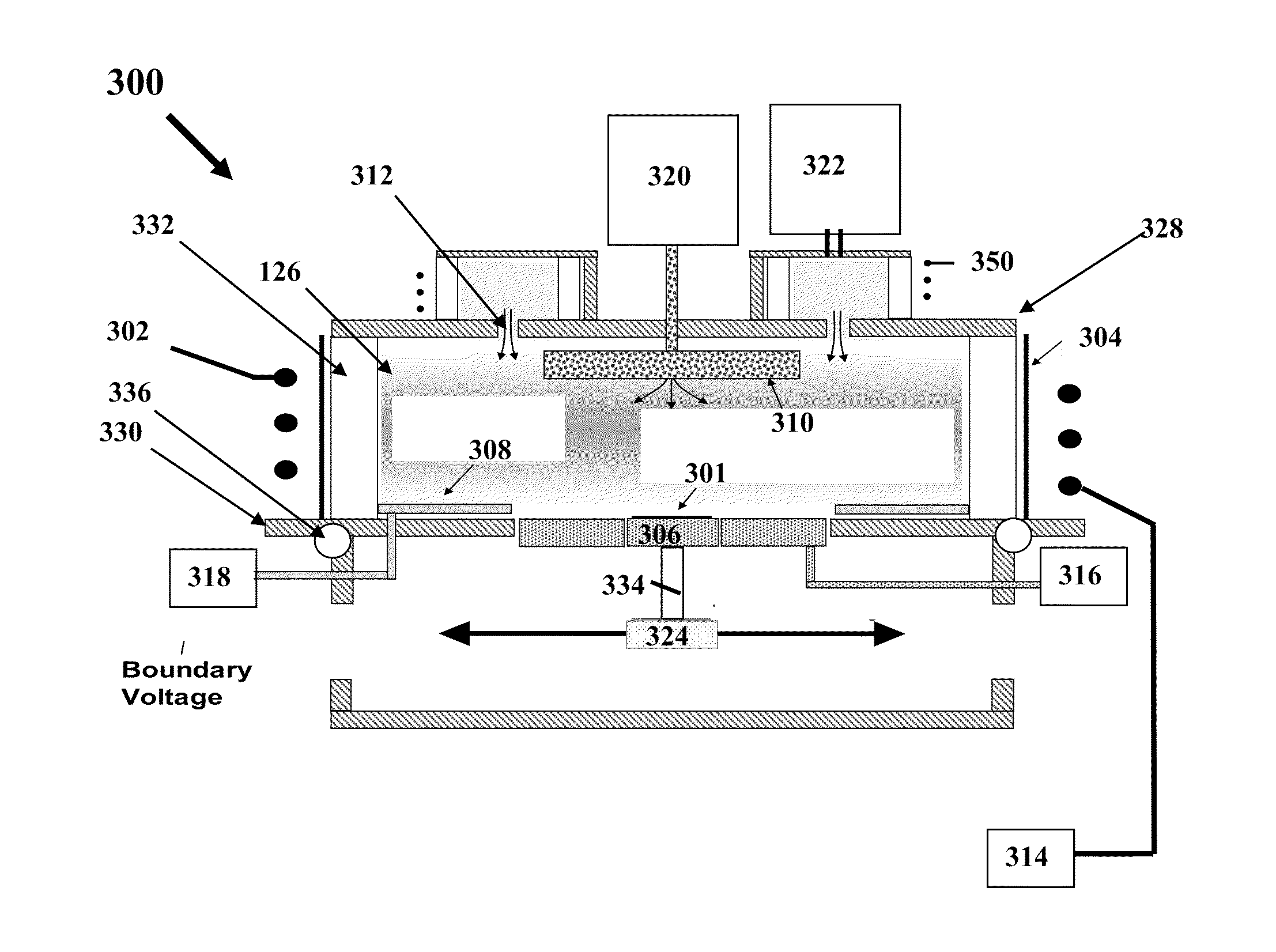

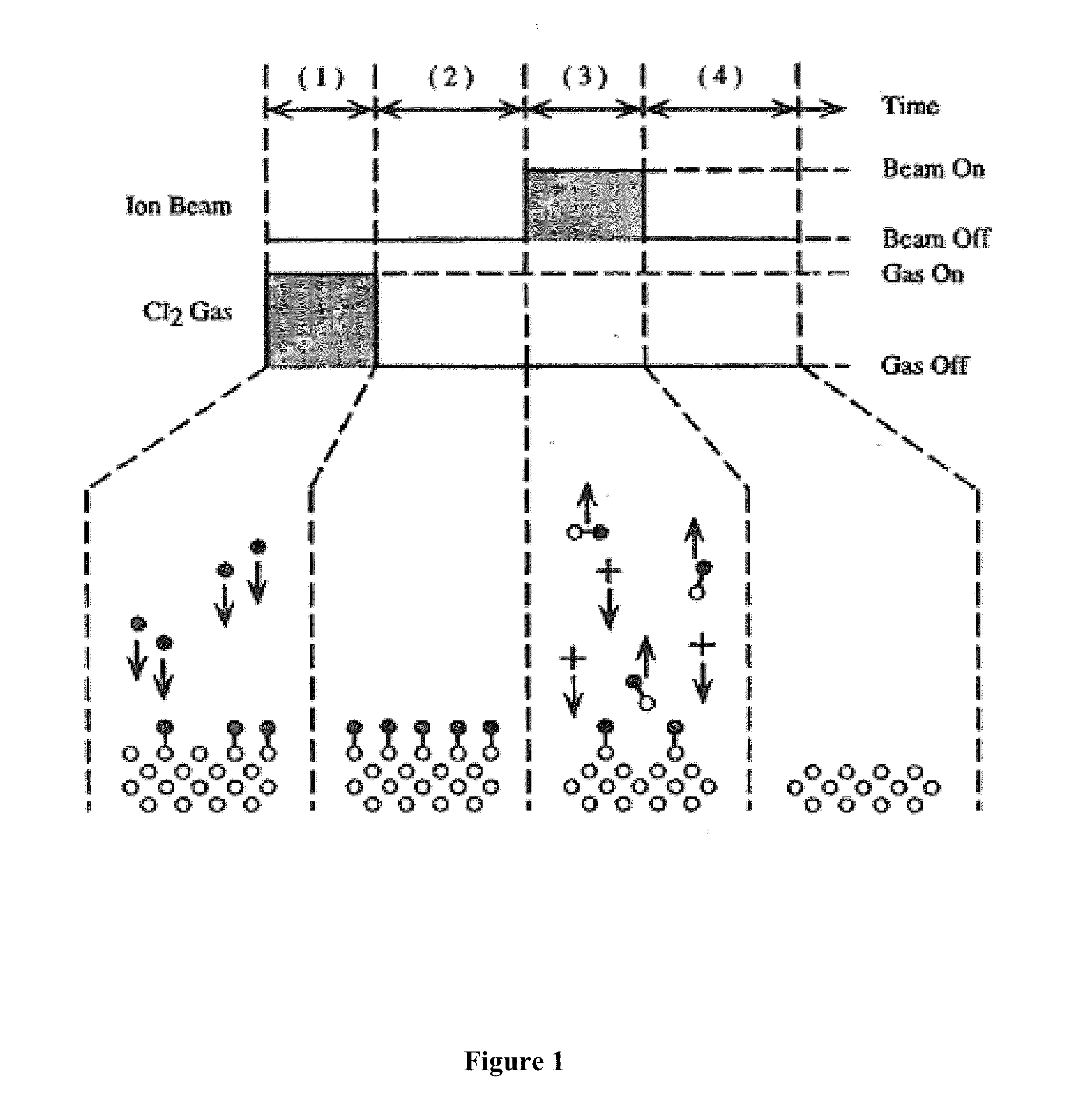

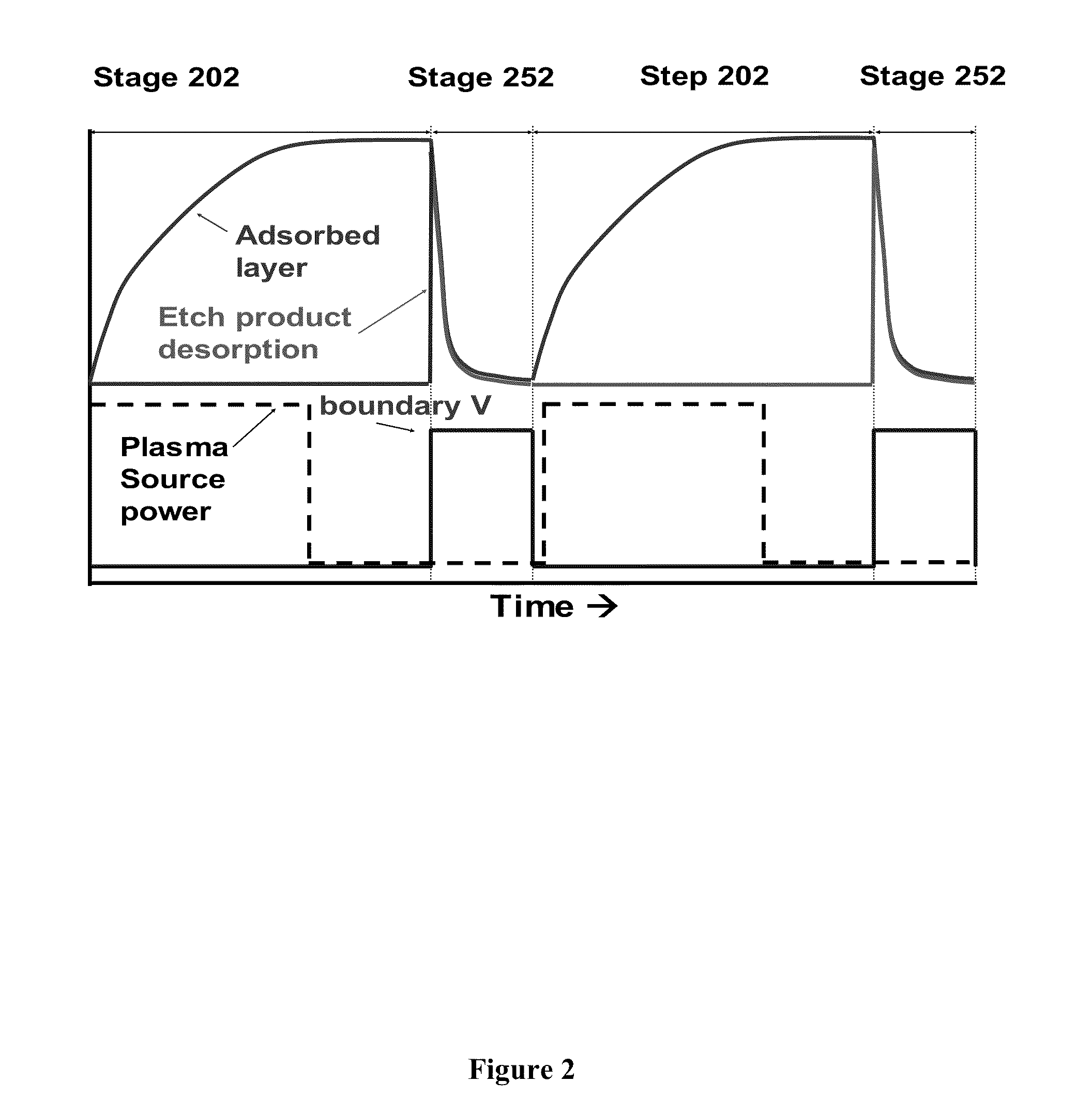

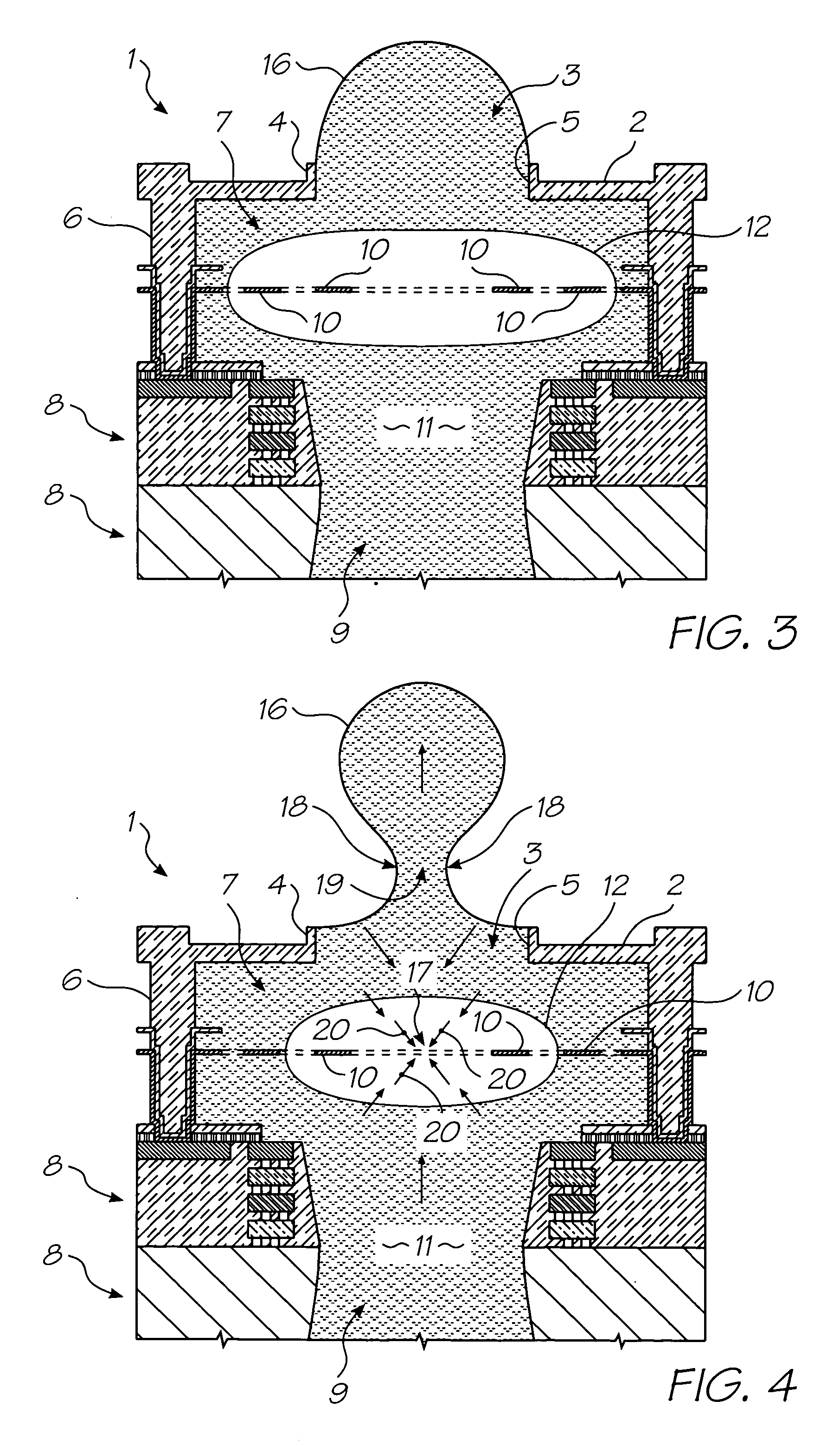

Atomic layer etching with pulsed plasmas

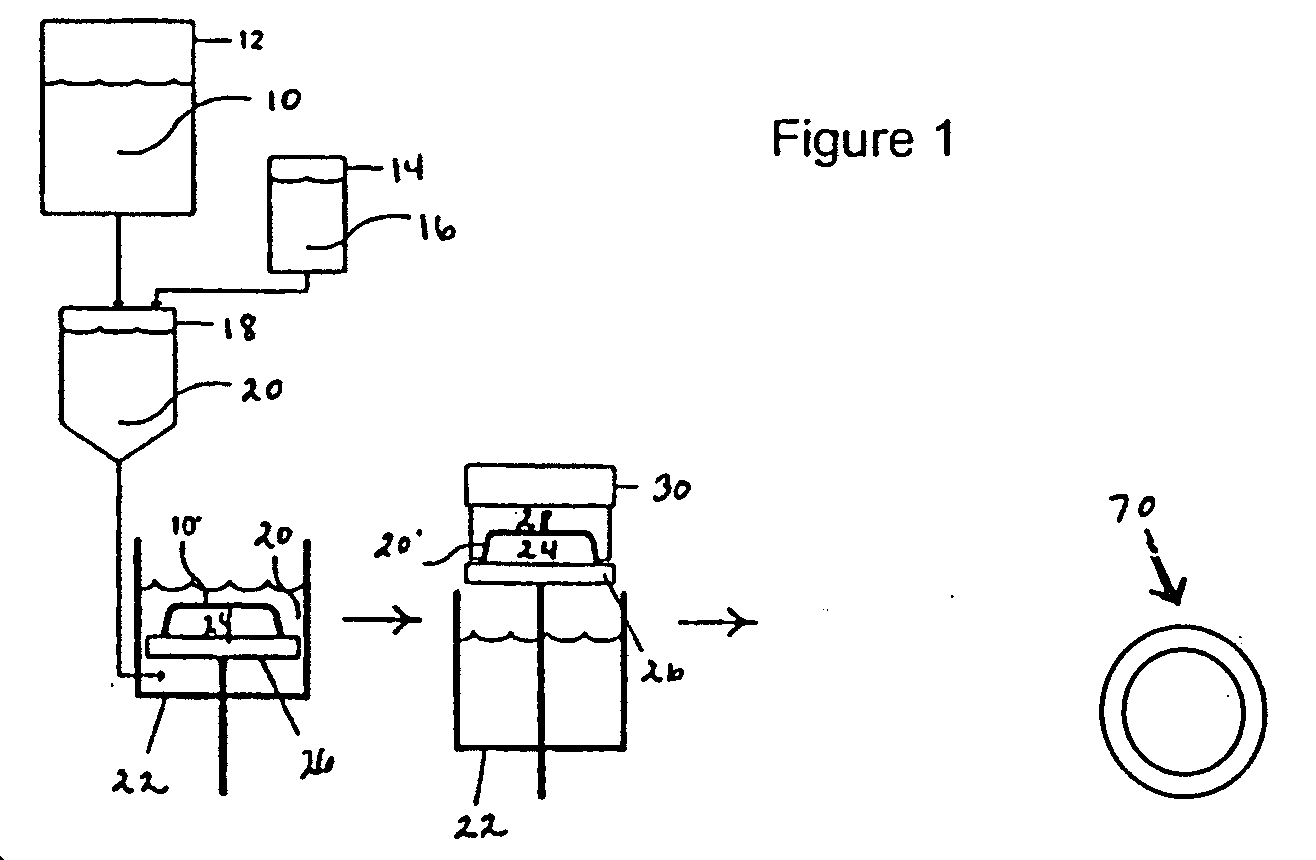

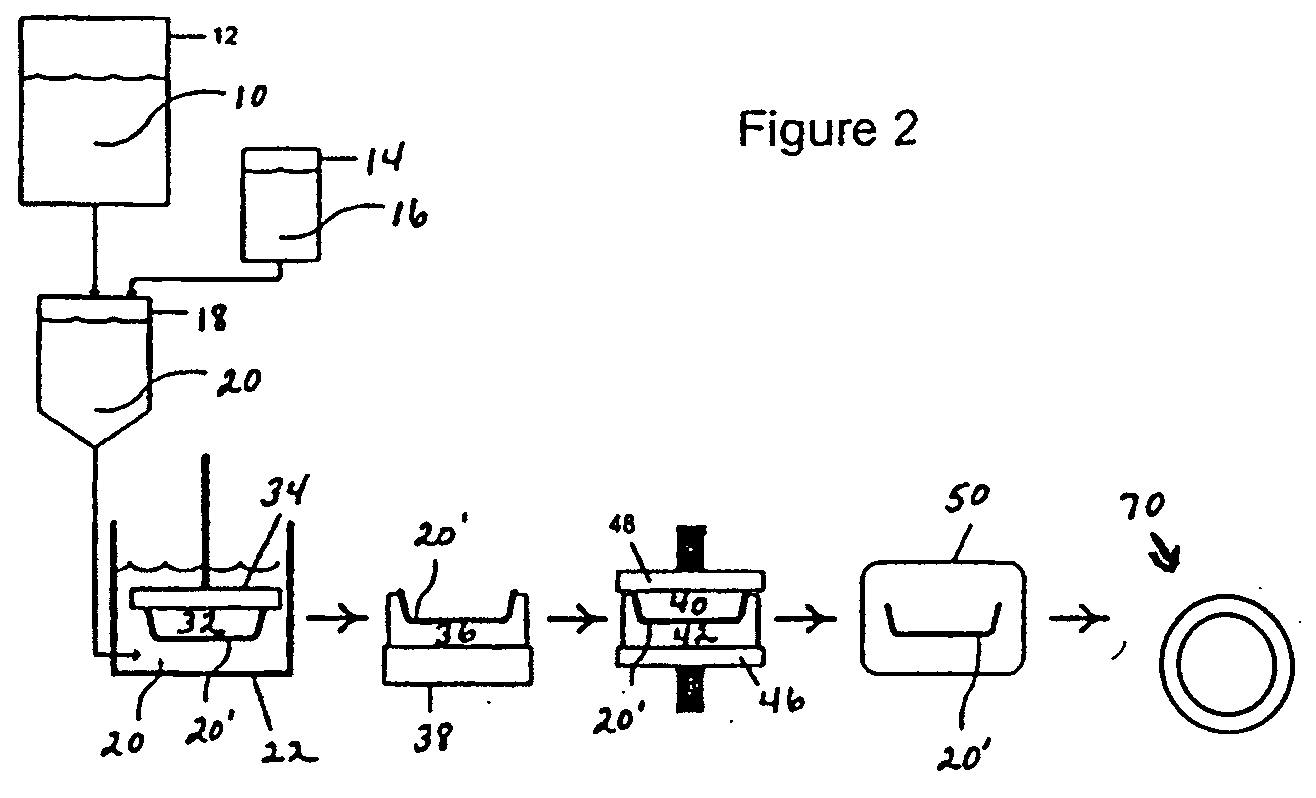

A system and method for rapid atomic layer etching (ALET) including a pulsed plasma source, with a spiral coil electrode, a cooled Faraday shield, a counter electrode disposed at the top of the tube, a gas inlet and a reaction chamber including a substrate support and a boundary electrode. The method includes positioning an etchable substrate in a plasma etching chamber, forming a product layer on the surface of the substrate, removing a portion of the product layer by pulsing a plasma source, then repeating the steps of forming a product layer and removing a portion of the product layer to form an etched substrate.

Owner:UNIV HOUSTON SYST

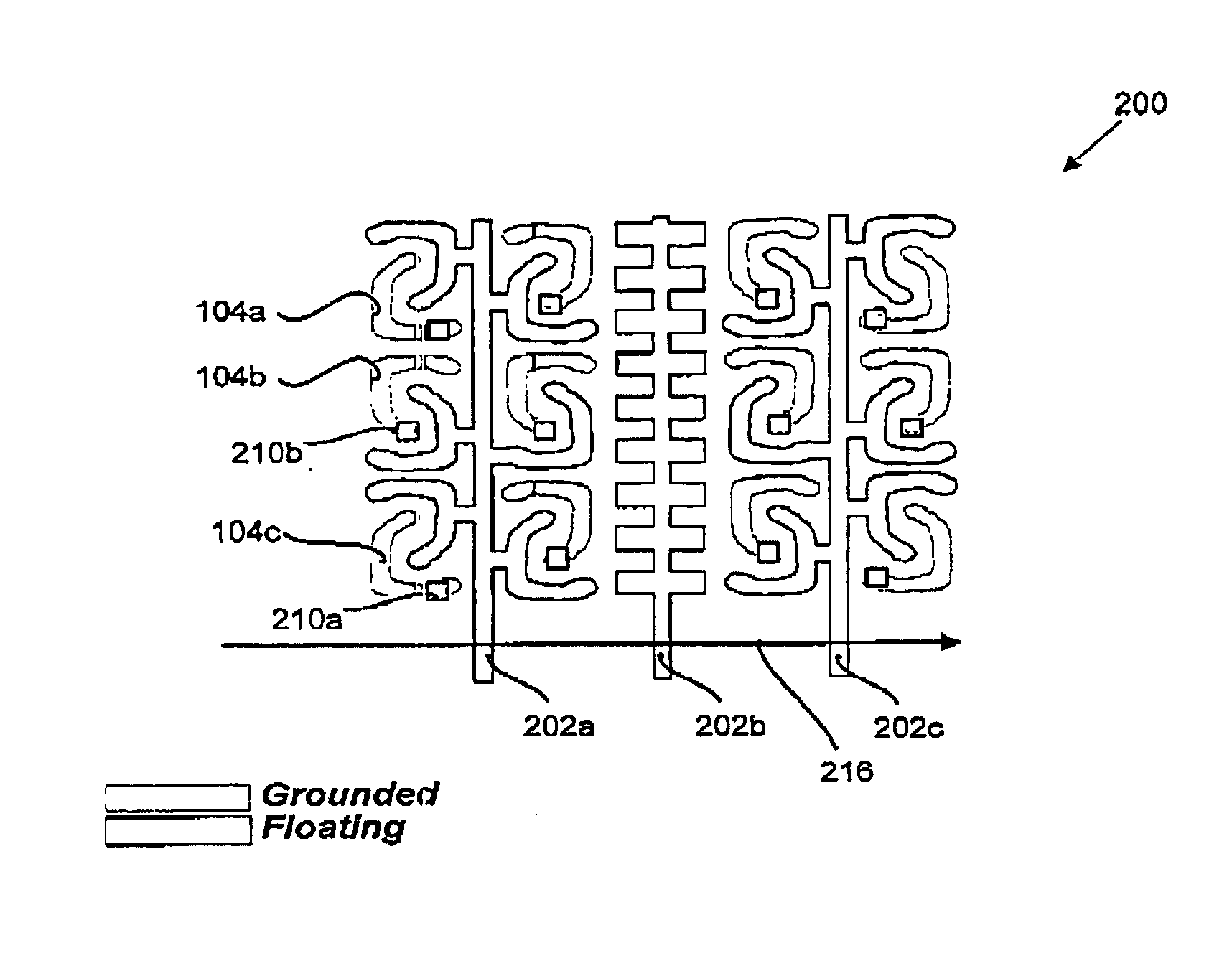

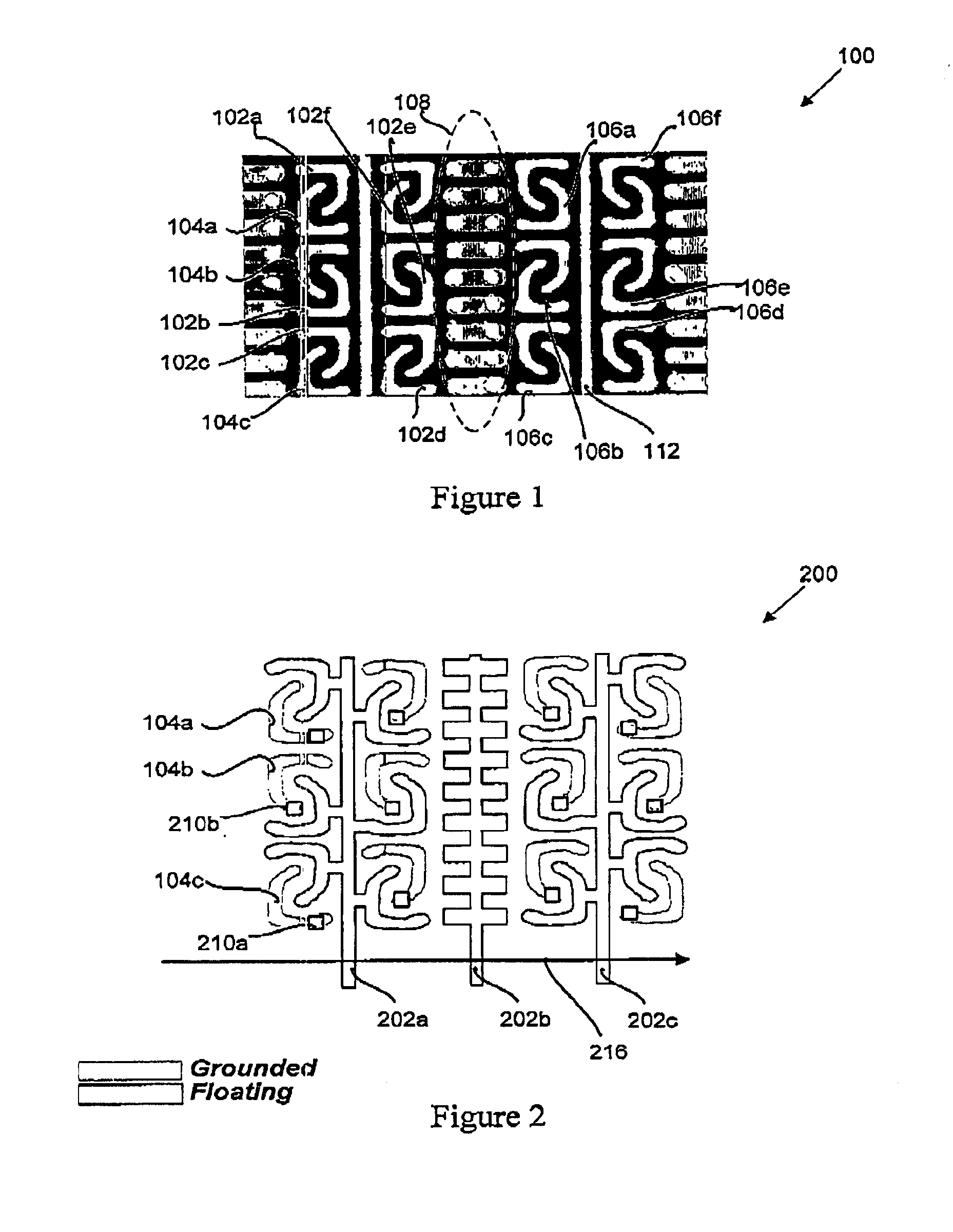

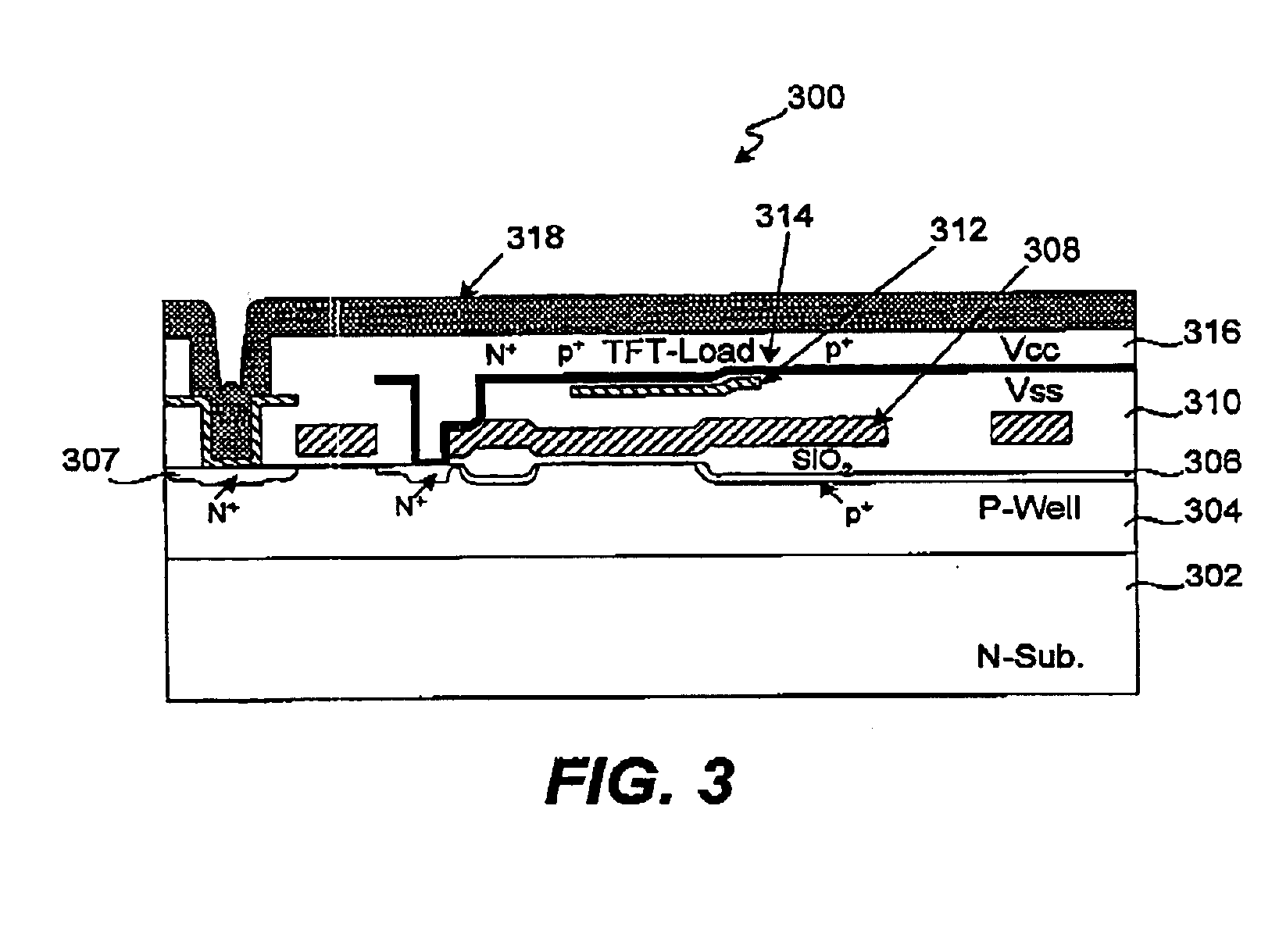

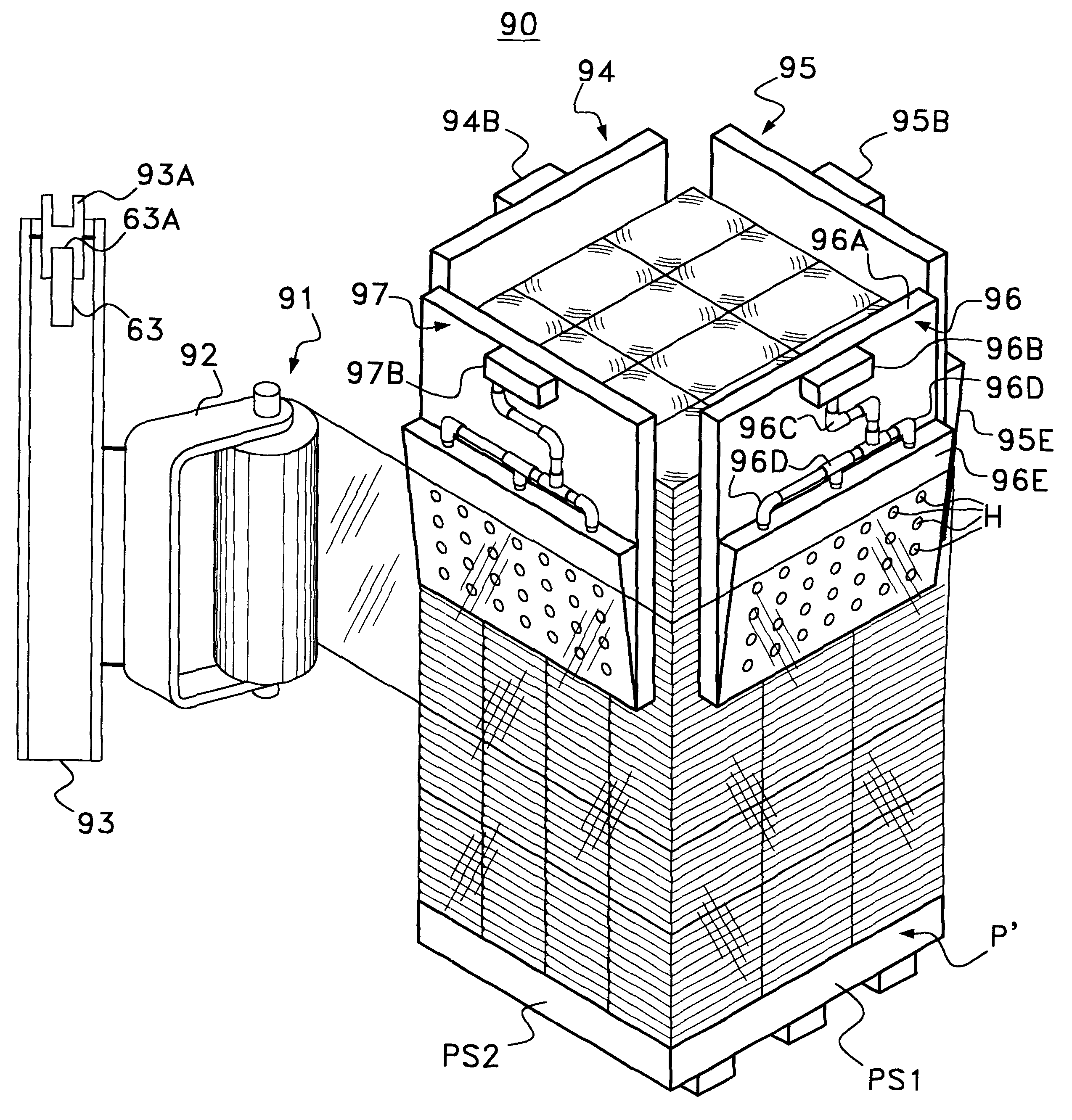

Apparatus and methods for determining and localization of failures in test structures using voltage contrast

InactiveUS6861666B1Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsVoltage contrastProduct layer

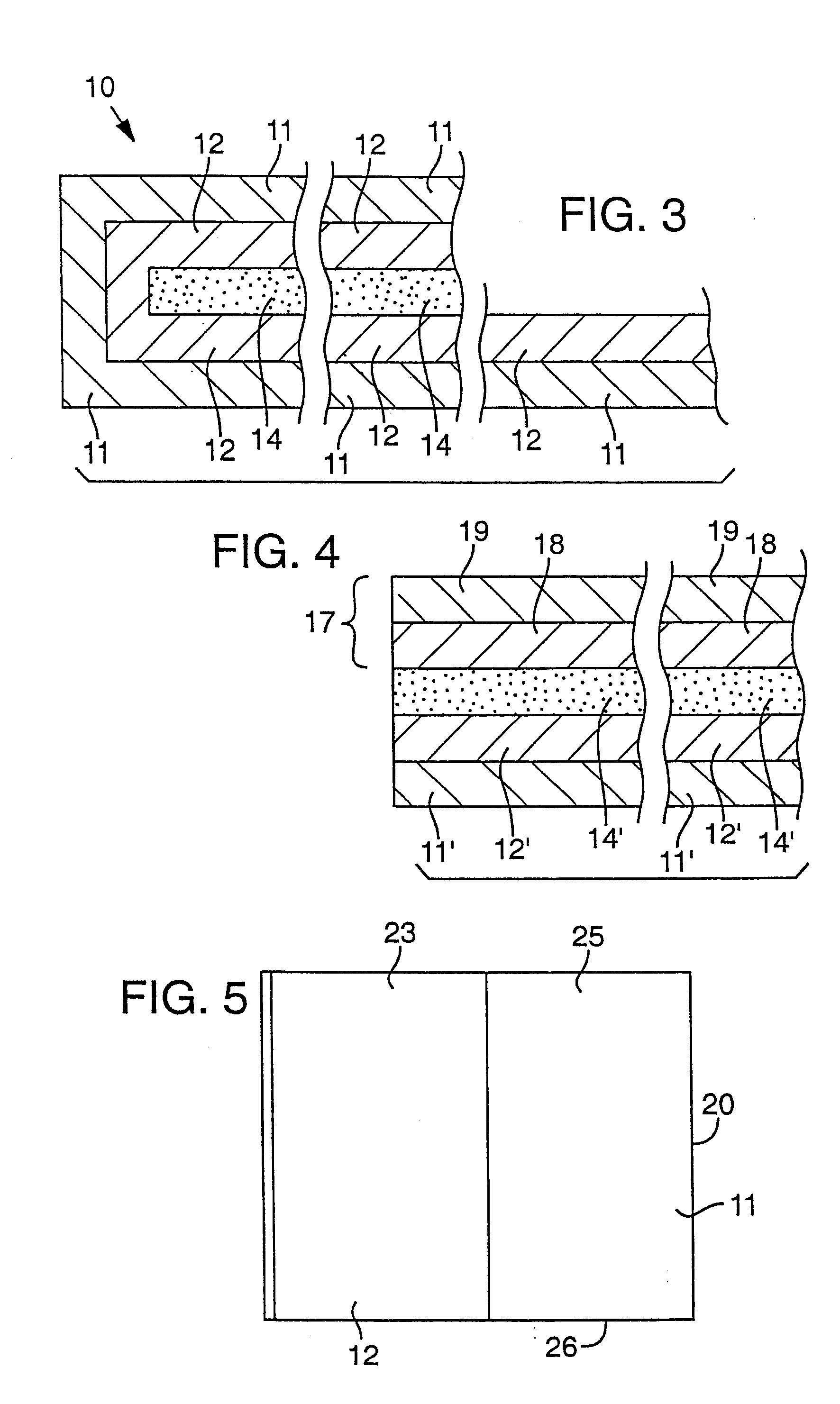

Disclosed is test structure that can be fabricated with minimal photolithography masking steps and in which defects may be localized to specific layers. Mechanisms for fabricating such test structures are also provided. In one embodiment, a semiconductor test structure suitable for a voltage contrast inspection is provided. The test structure includes one or more test layers corresponding to one or more product layers selected from a plurality of product layers of an integrated circuit (IC) product structure. The number of the selected one or more test layers is less than a total number of the plurality of product layers of the product structure, and the test layers include at least a first portion that is designed to have a first potential during the voltage contrast inspection and a second portion that is designed to have a second potential during the voltage contrast inspection. The first potential differs from the second potential. The selected one or more test layers which correspond to product layers are selected from the plurality of product layers such that defects found in the test layers of the test structure during the voltage contrast inspection represent a prediction of defects in the corresponding product structure.

Owner:KLA TENCOR TECH CORP

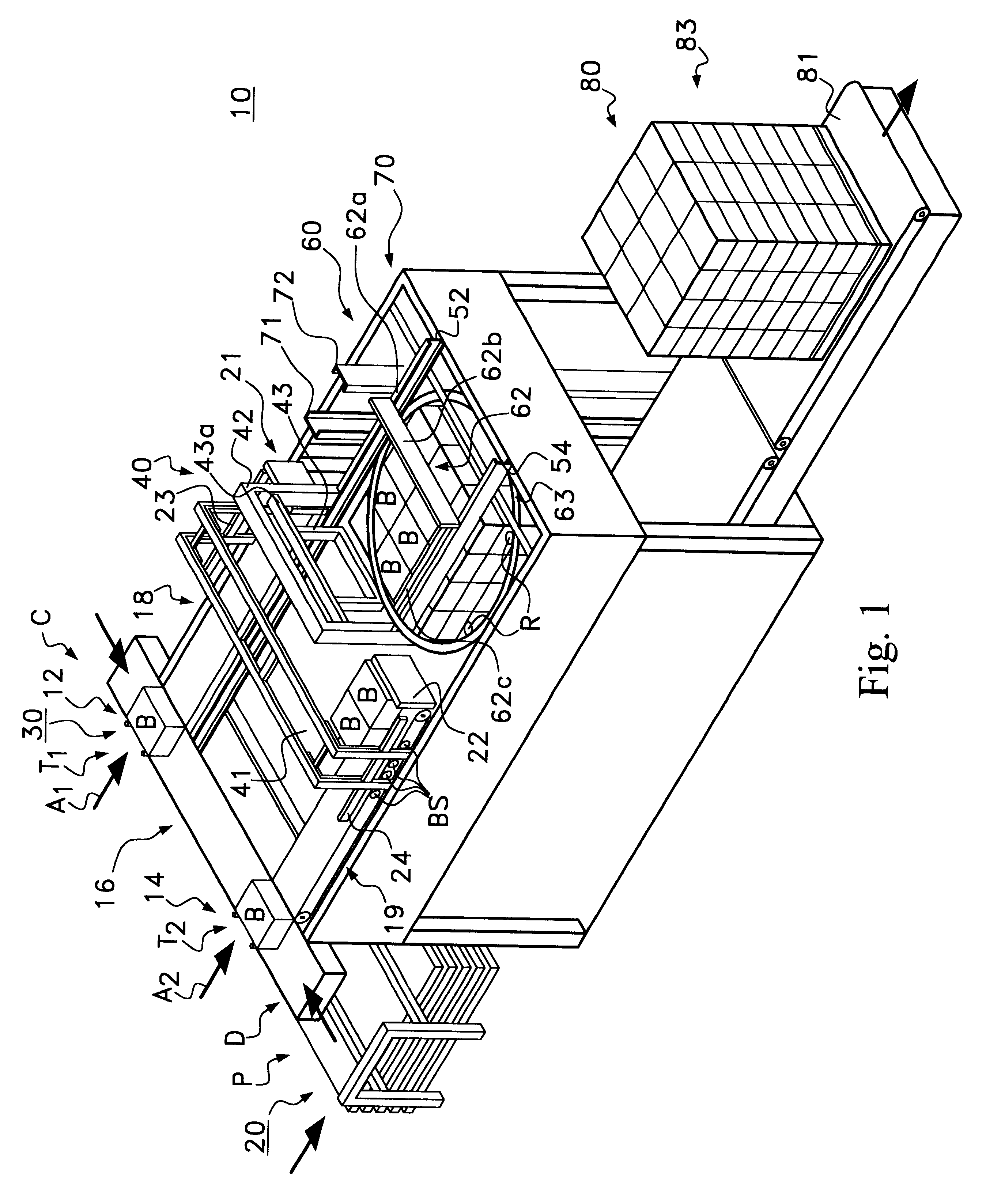

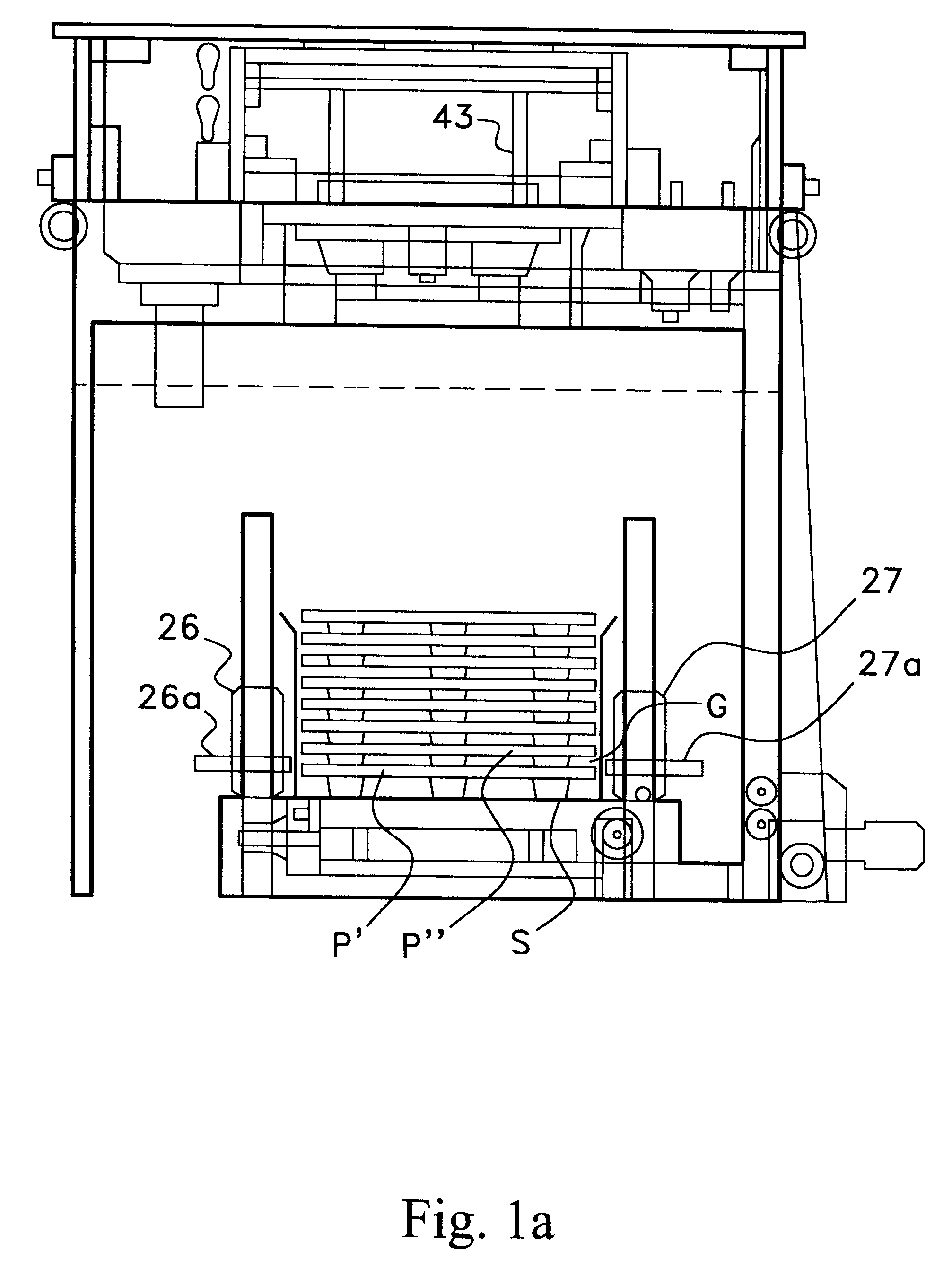

Method and apparatus for wrapping palletized bundles

InactiveUS6594970B1Prevent fallingPrevent crashWeb rotation wrappingBinding material applicationEngineeringProduct layer

A method and apparatus for wrapping a loop of film about a pallet, which supports a layer of products, and a guide, through which said layer passes, to prevent crushing and / or displacement of the product layer. Subsequent product layers are similarly protected by looping film about a previous loop of film and said guide. The guide is designed to facilitate removal of the film looped thereabout as the product layers are lowered.

Owner:PREMARK PACKAGING LLC

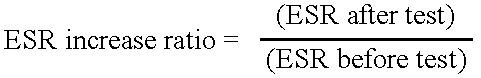

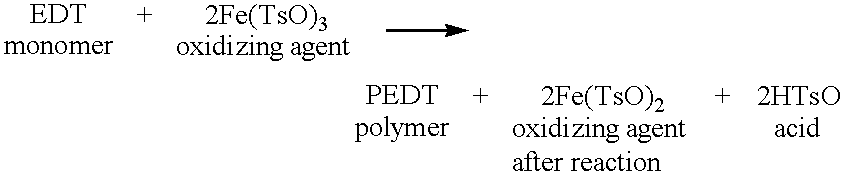

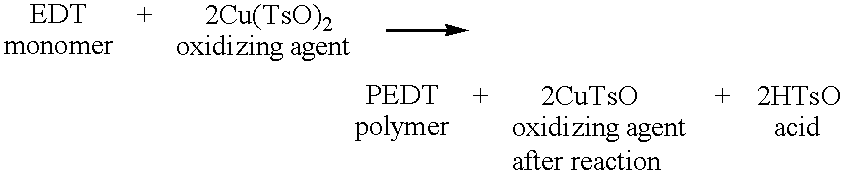

Solid electrolyte capacitor and method for manufacturing the same

InactiveUS6229689B1Increase resistanceImprove efficiencyHybrid capacitor electrolytesLiquid electrolytic capacitorsOrganic sulfonic acidProduct layer

A solid electrolyte capacitor having a solid electrolyte layer that is formed of a polymeric product layer of a polymerizable monomer. The polymeric product layer is doped with an organic sulfonic acid selected from the group consisting of an aromatic polysulfonic acid, an organic sulfonic acid having a hydroxy group, an organic sulfonic acid having a carboxyl group, an alicyclic sulfonic acid, and a benzoquinone sulfonic acid.

Owner:TOKIN CORP

Method of treating an aqueous suspension of kaolin

InactiveUS6615987B1Improve effectivenessImproves floc formationPigmenting treatmentSedimentation separationFlocculationSolid particle

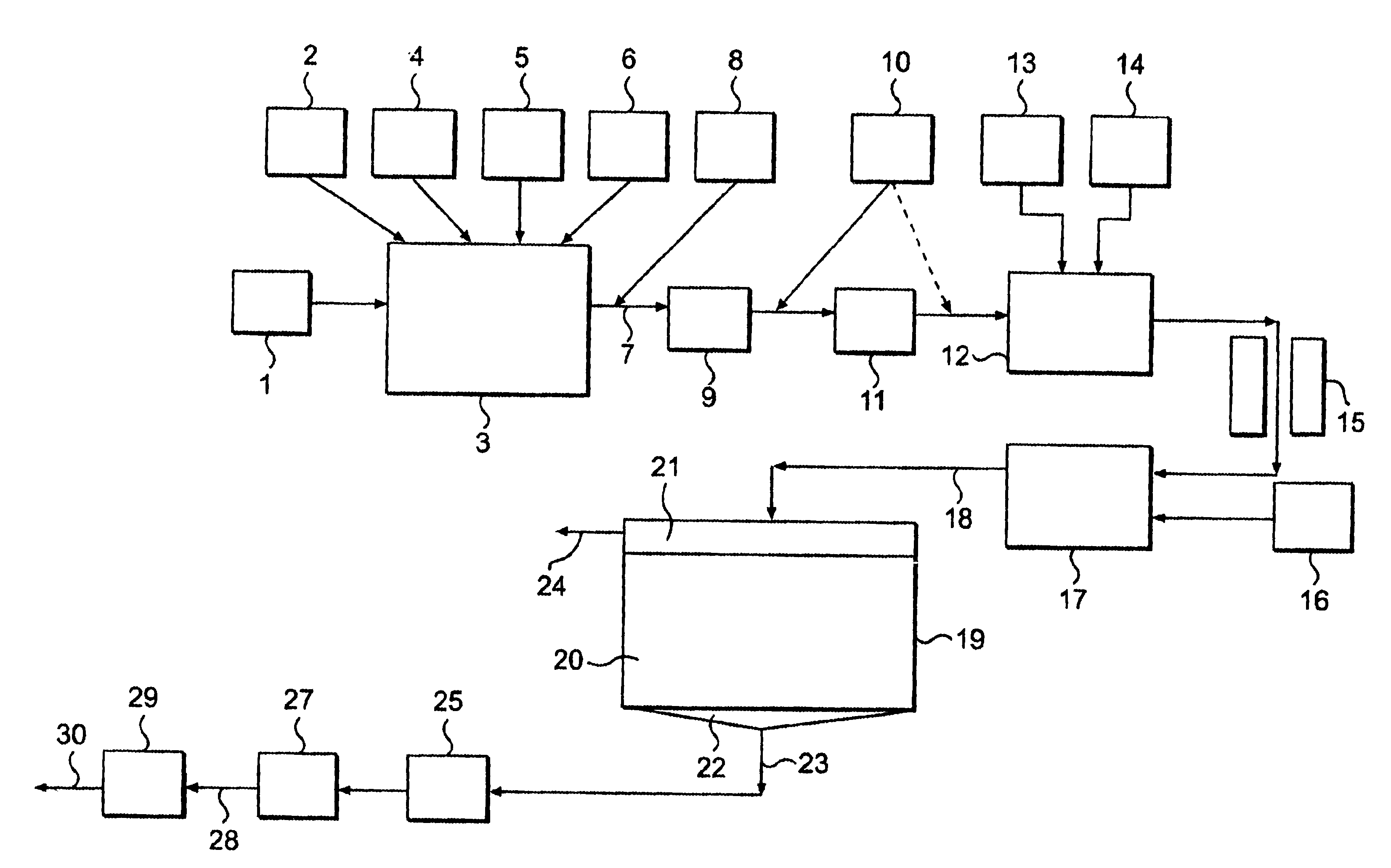

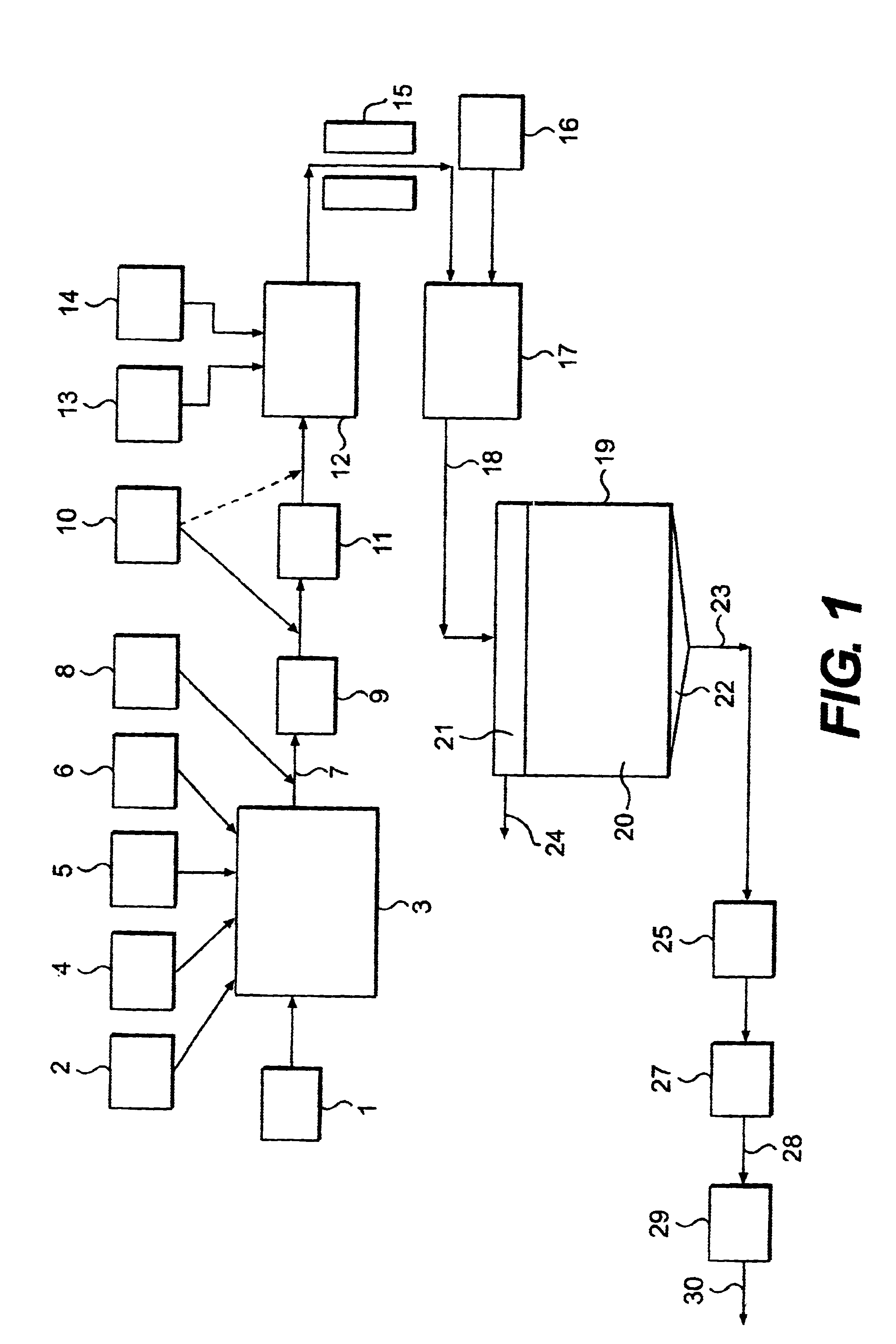

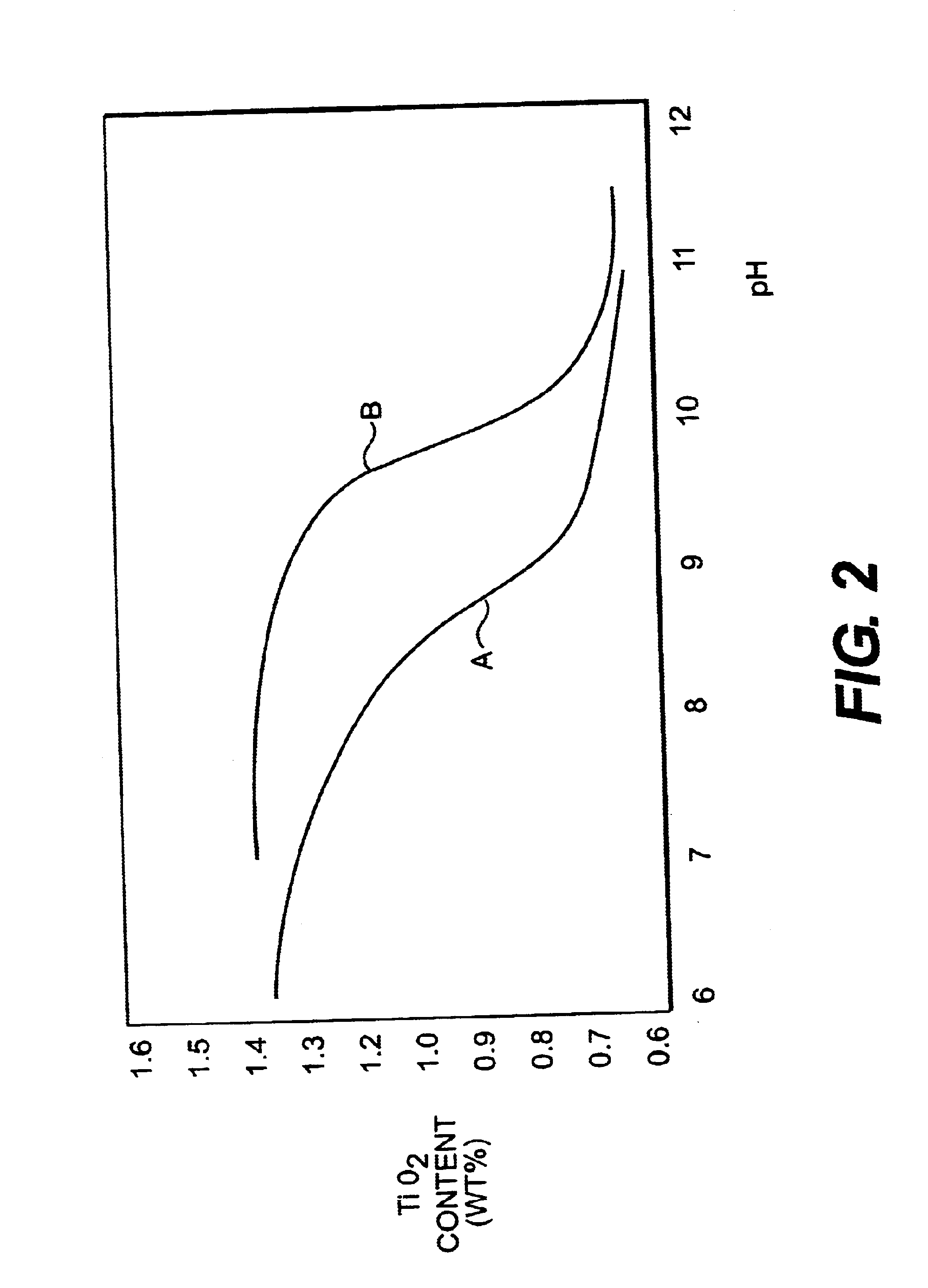

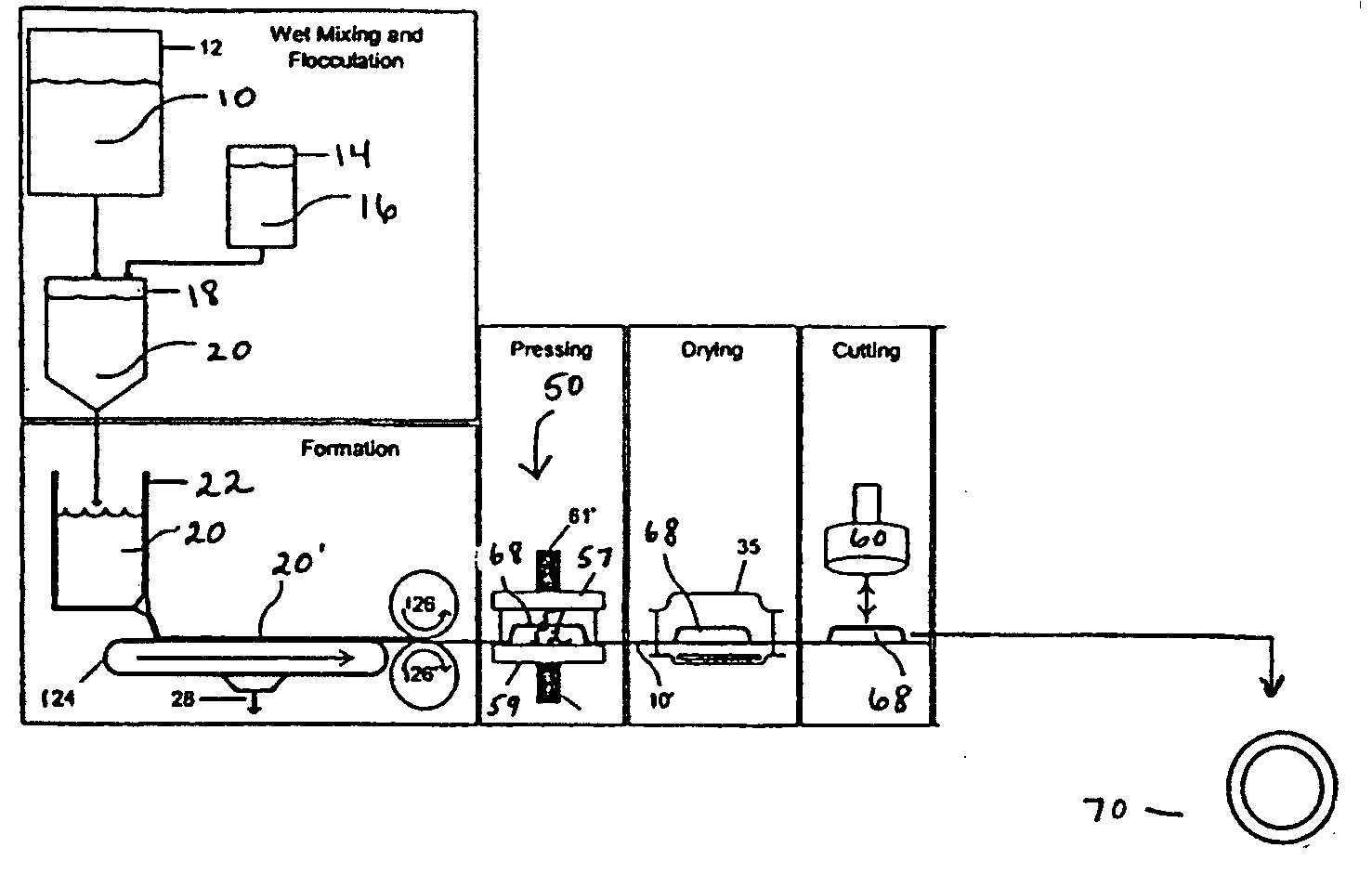

A method of treating a kaolin particulate material to improve its properties by removal of impurities which includes the steps of:(a) producing a dispersed aqueous suspension of a kaolin particulate material containing at least 0.1% by weight, based on the dry weight of the kaolin particulate material, of separable impurity by adding a dispersing agent to the kaolin particulate material to deflocculate solid particles of the material in the suspension;(b) conditioning the suspension prior to adding selective flocculation polymer thereto by allowing the suspension to age for a period of at least 30 minutes and optionally by adding one or more conditioning chemicals thereto;(c) adjusting the pH of the suspension to be at least about 9.5;(d) adding to the suspension at a pH of at least about 9.5 a selective flocculation polymer which facilitates separation of the separable impurity from the kaolin by flocculating the kaolin and allowing the separable impurity to be or remain deflocculated;(e) allowing the suspension at a pH of at least about 9.5 in a selective flocculation separator to separate into layers comprising a flocculated product layer and a deflocculated impurity layer containing the separable impurity; and(f) extracting the separated layers from the separator.

Owner:IMERYS USA INC

Engineered wood product

InactiveUS20100310893A1Lamination ancillary operationsSynthetic resin layered productsWood veneerCellulose fiber

Engineered wood products, methods of making the products, laminates including the products, and articles of manufacture which include the engineered products or composites, are disclosed. The products include wood and / or other cellulosic fibers, and can include non-cellulosic fibers, all or part of which can be derived from post-industrial and / or post-consumer materials. The products also include a binding agent, such as a latex dispersion, as well as hydrophobic materials, processing aids, colorants, and the like. The product can be in the form of a sheet, a three dimensional article or a plurality of laminated sheets, and can include one or more additional layers, such as top coat layers, reinforcing layers, cushioning layers, wood veneer layers, and / or additional product layers. The products can be used as flooring, and in construction, cabinetry, and the like.

Owner:SSI HOLDCO INC A DELAWARE +1

Product sampler

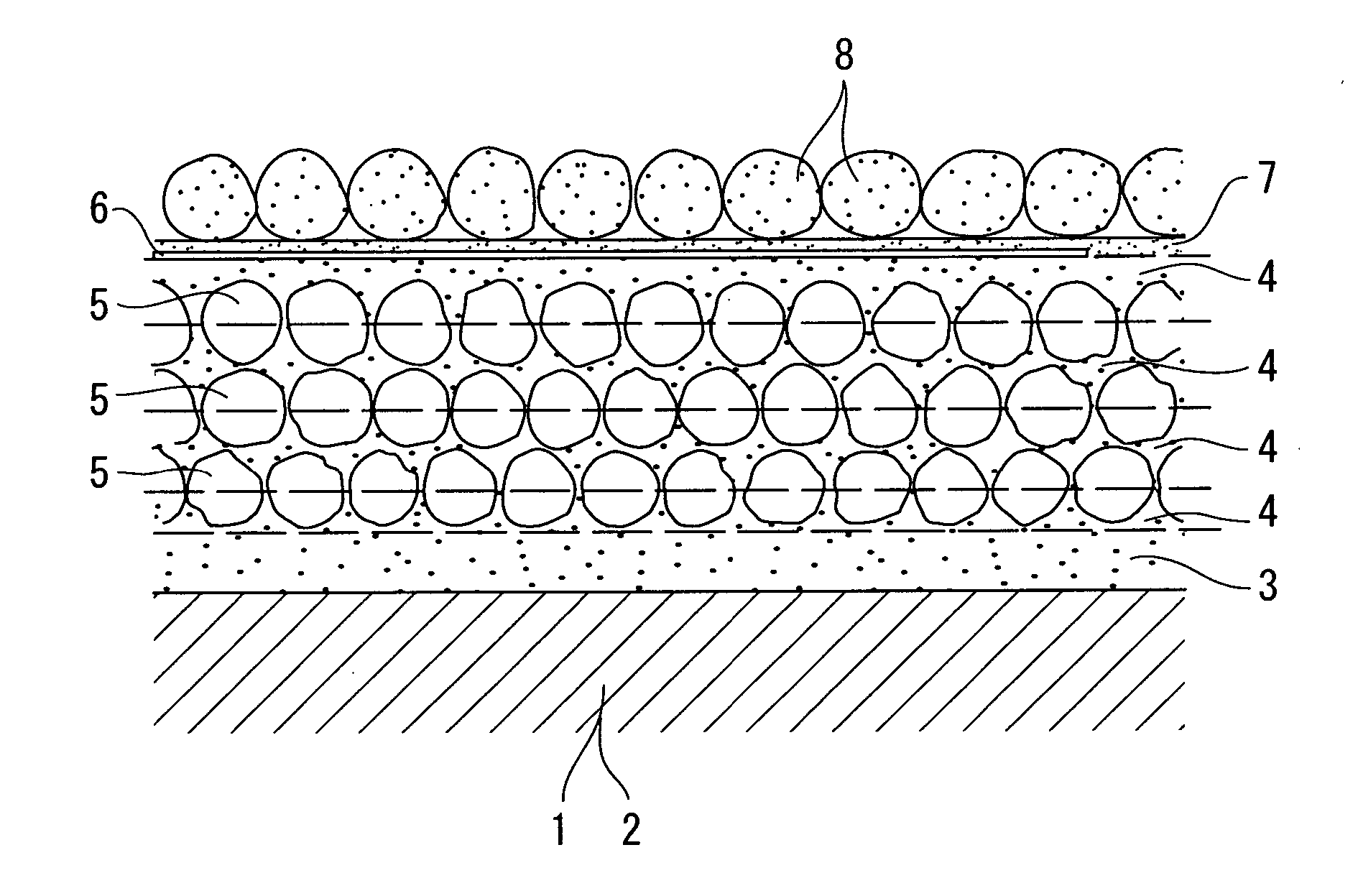

InactiveUS6403186B1Sufficient barrier propertyPrevent and substantially inhibit emissionPowder deliveryCosmetic preparationsPolyethylene glycolEngineering

A product sampler including a substrate layer, a barrier layer covering the substrate layer, a gelatinoid product layer covering and in contact with the barrier layer, and a barrier layer covering and in contact with the product layer is provided. The gelatinoid product layer may include a microencapsulated product, such as a fragrance. In preferred embodiments of the invention, the gelatinoid product layer includes a microencapsulated fragrance carried in a gelatinoid liquid vehicle, which vehicle may comprise, for example, propylene glycol, polyethylene glycols, glycerin, or mixtures thereof. In a highly preferred embodiment of the invention, the product sampler is in the form of a magazine insert having a protruding trimmable non-barrier substrate tab portion, whereby a user may remove a trim portion from the trimmable edge portion after binding the insert into a magazine without removing barrier material with the removed trim portion. Also disclosed is a product sampler in the form of a label.

Owner:AKI INC

Internet banking business platform and operation method thereof

InactiveCN101877111AEmbody the idea of integrated customer serviceAdapt to service needsFinanceEngineeringApplication software

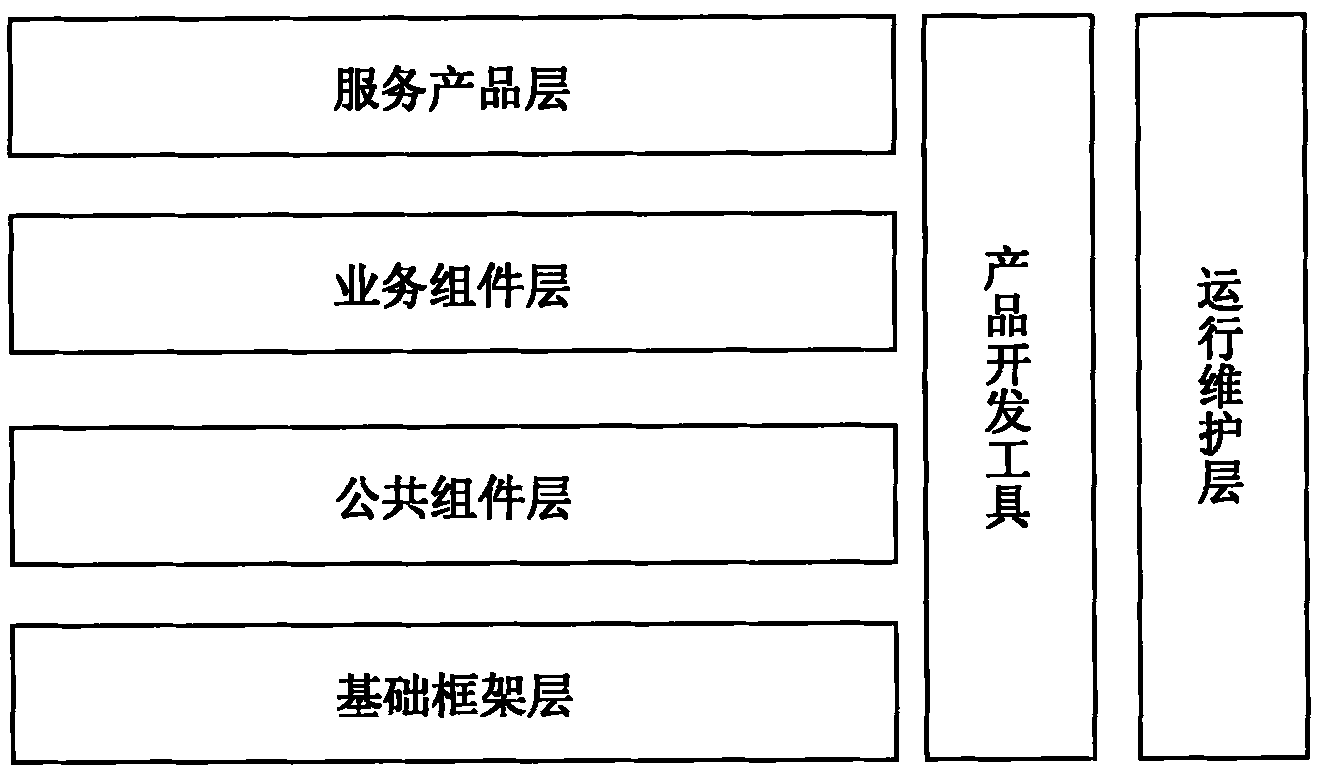

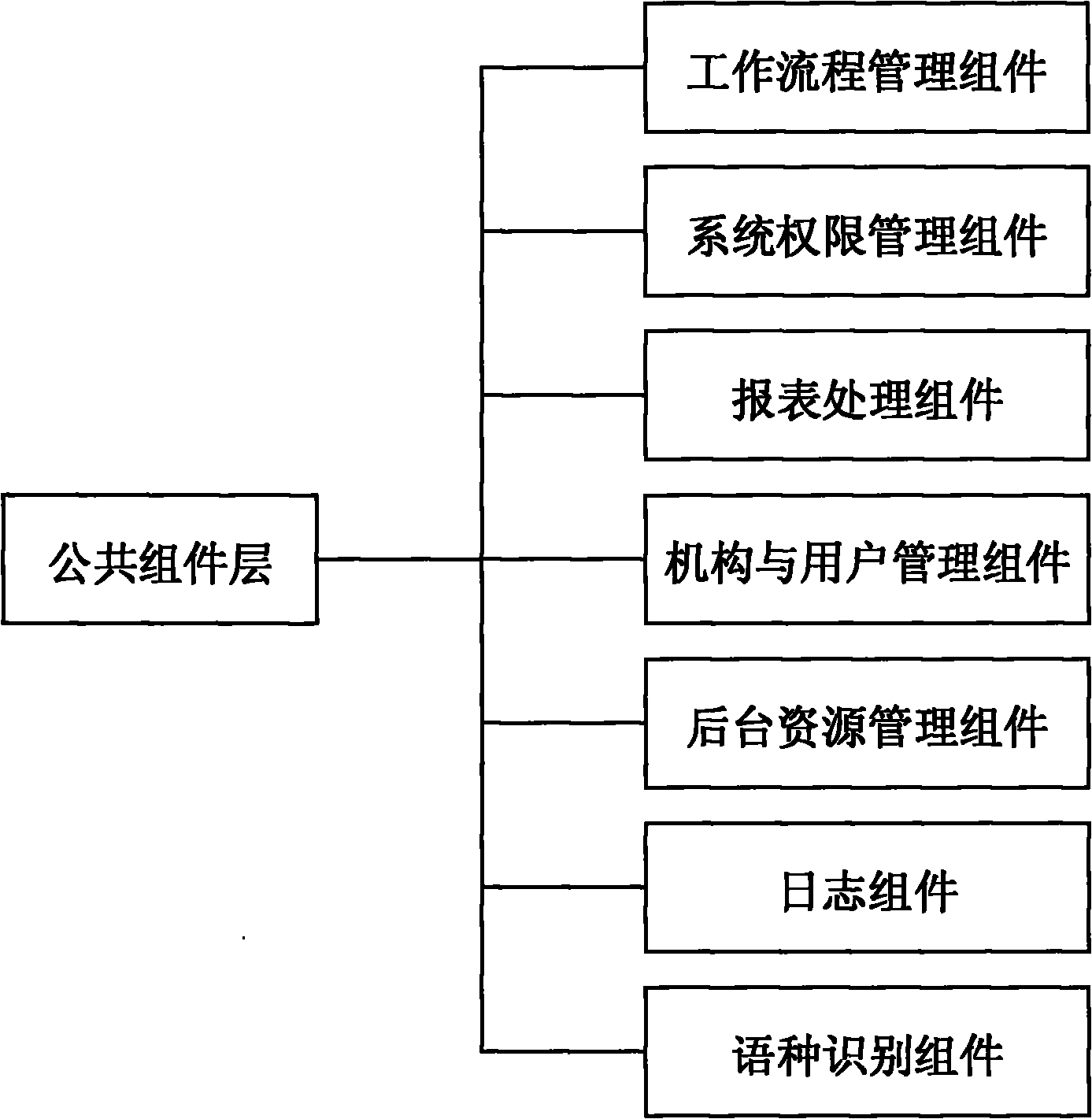

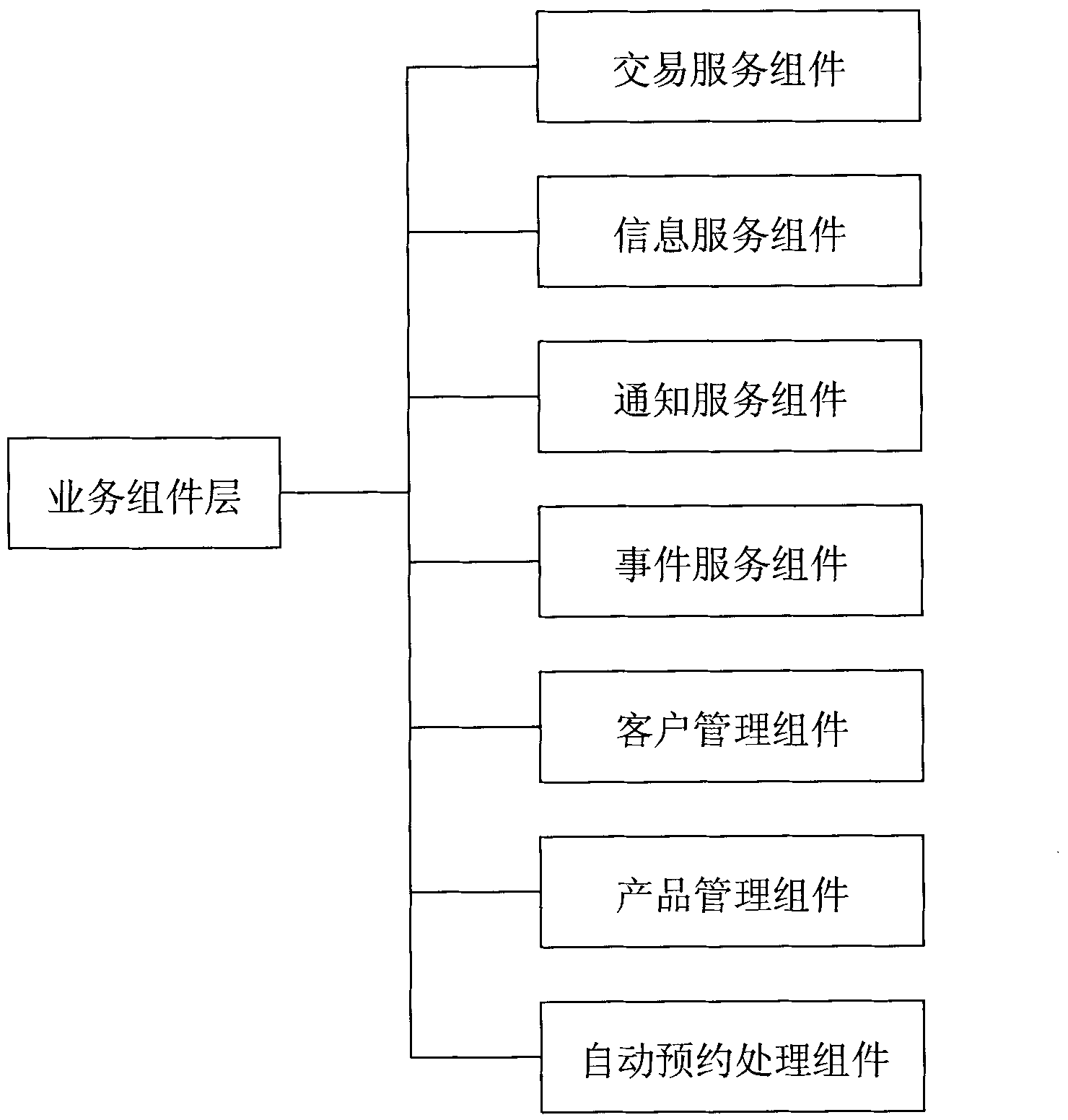

The invention provides an internet banking business platform, comprising a basic framework layer, a common assembly layer, a business assembly layer, a service product layer, an operation maintenance layer and a product development tool, wherein the basic framework layer is used for providing a basic operation environment for the internet banking business platform; the common assembly layer is used for providing common assemblies and application program commonly used by general systems for the internet banking business platform; the business assembly layer is used for providing basic modules required by specific business products of internet banking; the service product layer is used for providing customer-oriented final business varieties; the operation maintenance layer is used for providing tools capable of ensuring system normal operation; and the product development tool is used for displaying patterned view product development tools in a system operation environment for application developers. The invention has the beneficial effects of reflecting the thinking of integrative customer service of banks, adapting to various customer business requirements, and enabling the banks to rapidly build an internet banking service platform and activate online service according to own business requirements.

Owner:苏州德融嘉信信用管理技术股份有限公司

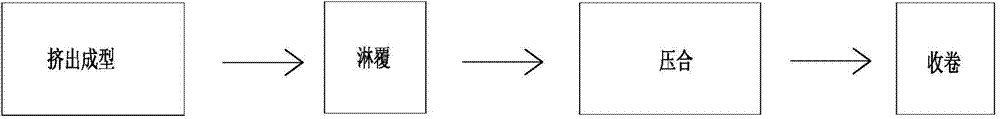

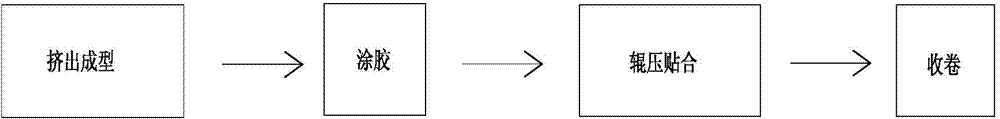

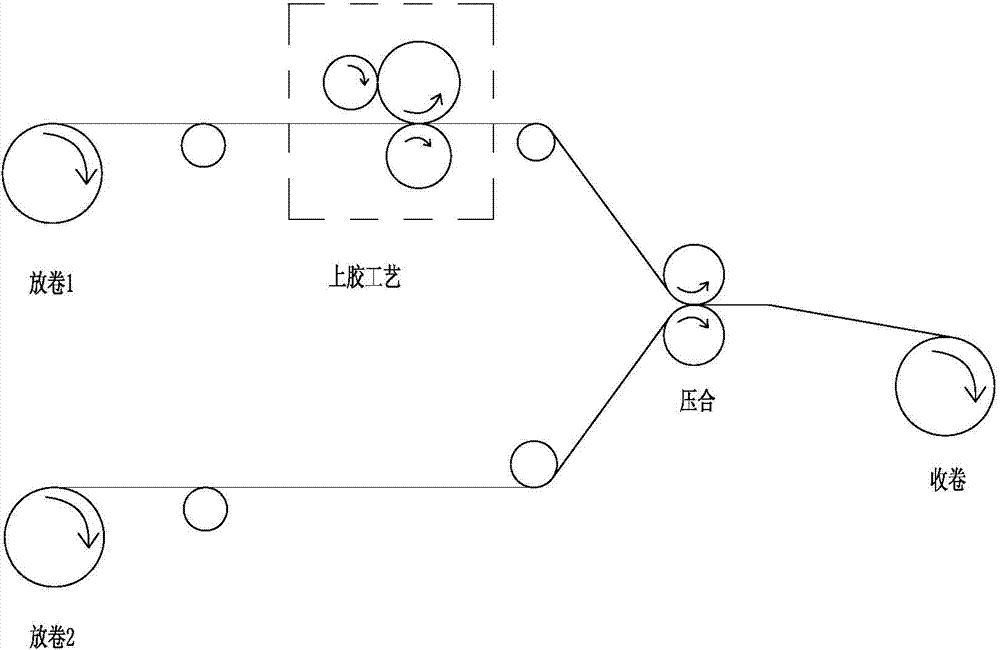

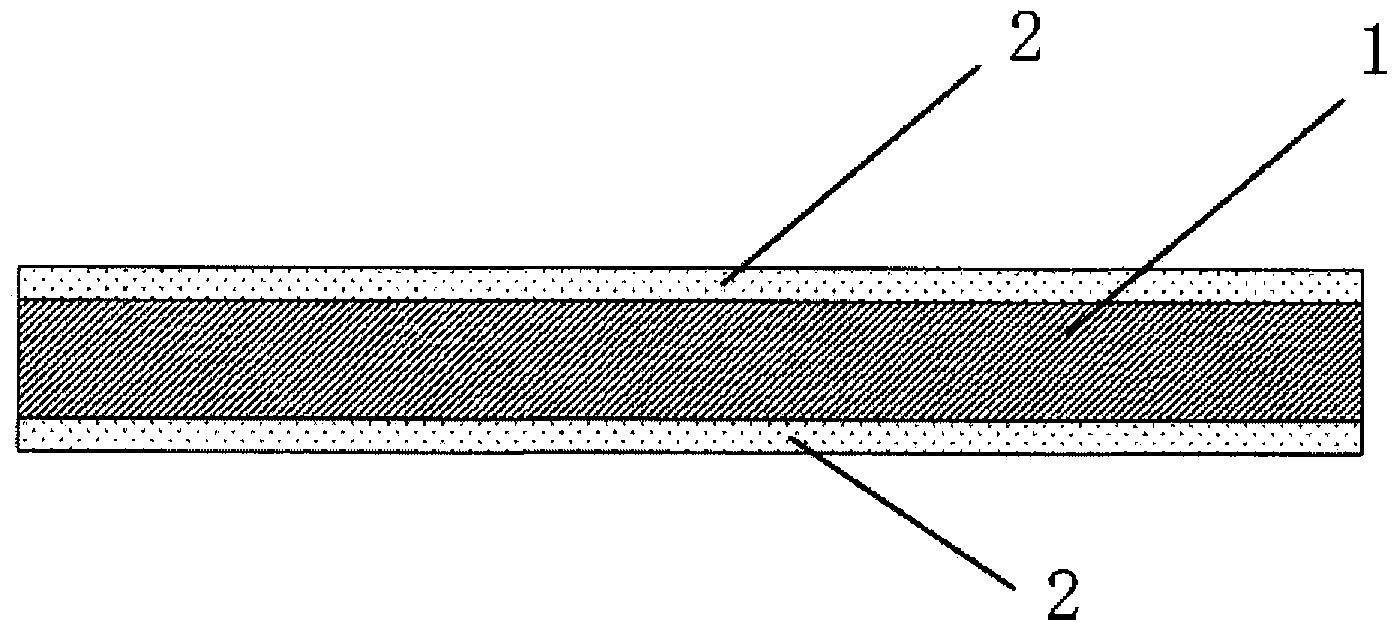

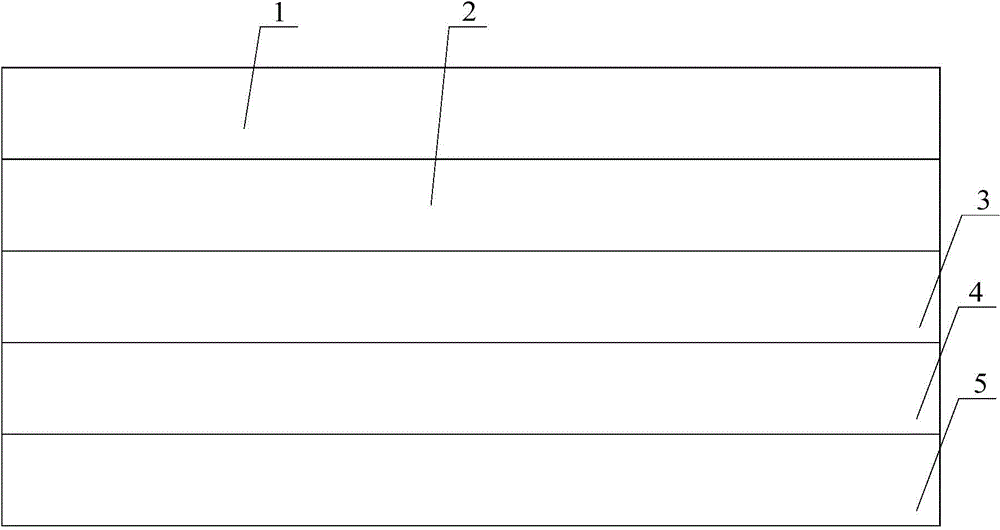

Thermoplastic resin film laminate and preparation method thereof

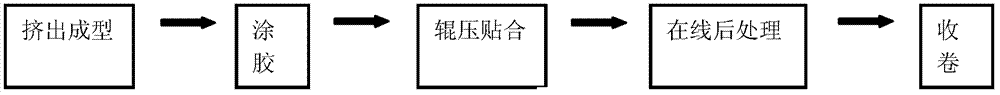

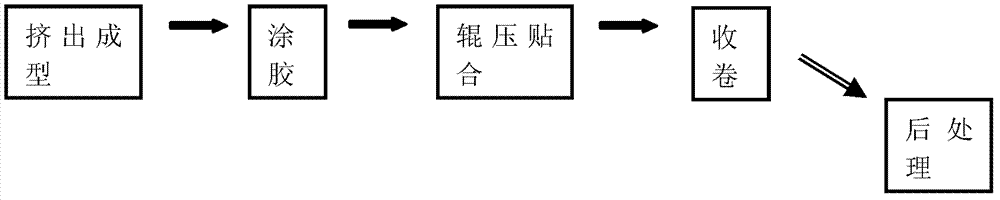

ActiveCN103192567ALamination ancillary operationsLayered product treatmentTextile fiberMoisture permeability

The invention relates to a thermoplastic resin film laminate prepared by a hot-pressing method. The laminate comprises at least one thermoplastic resin film layer with thickness of 1-250 mum, at least one thermoplastic resin product layer, and an adhesive layer between the thermoplastic resin film layer and the thermoplastic resin product layer and formed by glue. The thermoplastic resin product layer is a thermoplastic resin film or a thermoplastic resin fiber product, which can be textile fiber and / or non-woven. In the laminate provided by the invention, the fiber product has gram weight of 1-250g / m<2>; and the adhesive layer has gram weight of 0.1g / m<2>. The laminate provided by the invention has excellent air permeability, moisture permeability, smooth and wrinkle-free appearance and soft handle.

Owner:FOSHAN KING WONDER HI TECH CO LTD +1

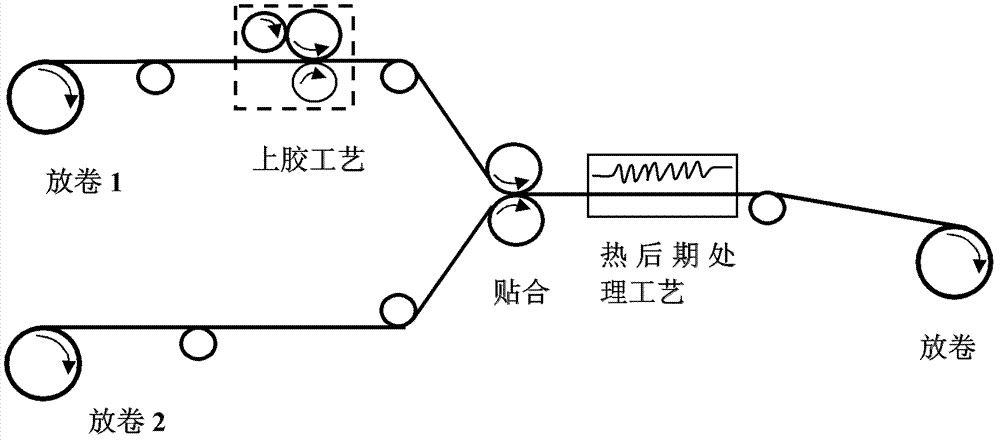

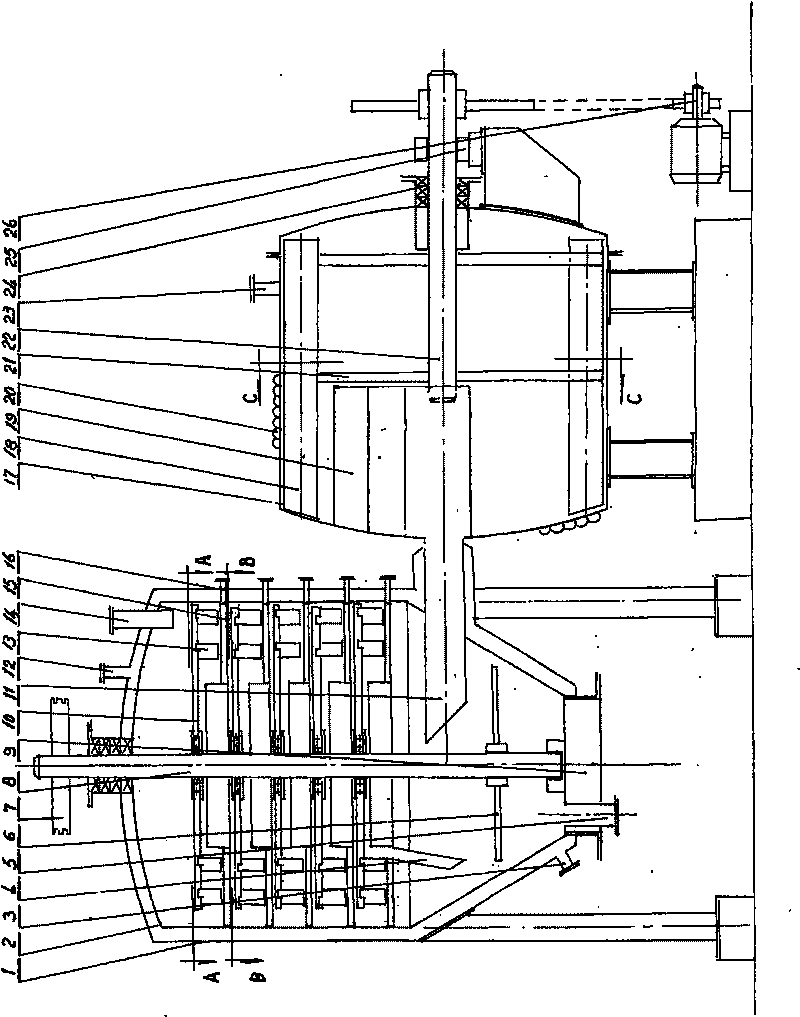

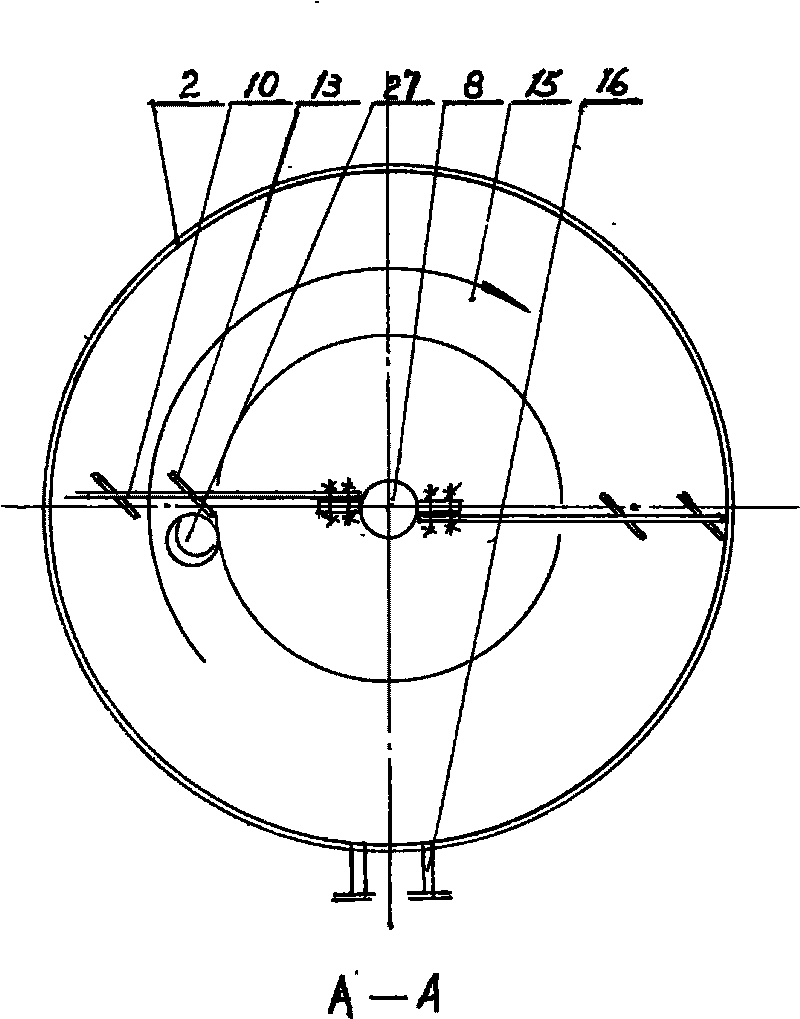

Sorting and grading device of pulsating liquid-solid fluidized bed and method thereof

InactiveCN101804382AGood for automatic dischargeHigh densityWet separationAutomatic controlVolumetric Mass Density

The invention provides a sorting and grading device of a pulsating liquid-solid fluidized bed and a method thereof. The sorting and grading device comprises a light product overflow trough, a central feed pipe, a sorting tank, a pulsating liquid distributor, a pulsating current generator, a heavy product collecting base-cone section, a sensor for measuring the concentration of the heavy product layer, a programmable controller, a heavy product discharging fluidized chamber and an underflow discharging automatic control actuator. The method comprises the following steps: firstly, water is thrown into a sorting machine in a pulsating way by the pulsating current generator, to form an upward varying-accelerated pulsating-type ascending current; accordingly, low-density or fine-fraction materials can be subjected to upward accelerated movement under the action of the accelerated pulsating-type ascending current, thus achieving the overflow discharge of the low-density or fine-fraction materials as the light or fine-fraction products; and high-density or coarse-fraction materials can be settled downwards in the fluidized bed, thus achieving the discharge of the high-density or coarse-fraction materials as the heavy or coarse-fraction products. Accordingly, the process for sorting materials by density on the basis of pulsating fluidization or the process for grading materials by fraction on the basis of pulsating fluidization can be achieved. The device and method of the invention have the advantages of simple operation, low energy consumption, low sorting lower limit, wide fraction range, high sorting accuracy and high reliability.

Owner:CHINA UNIV OF MINING & TECH

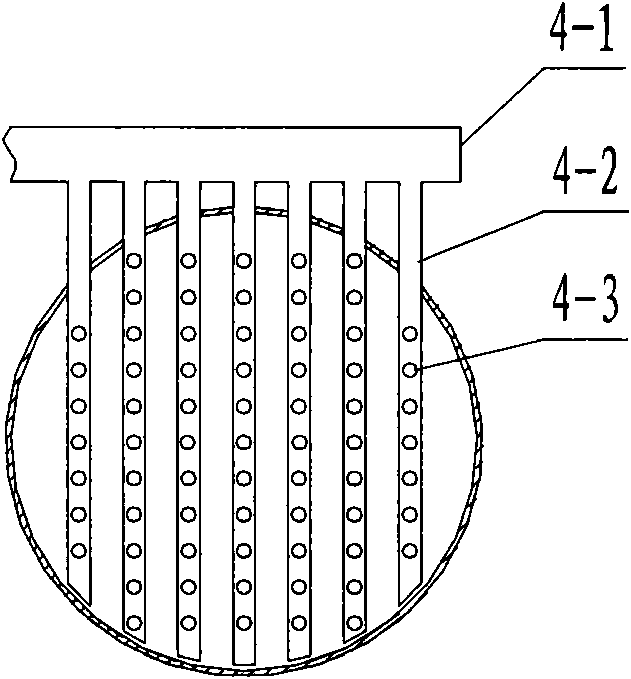

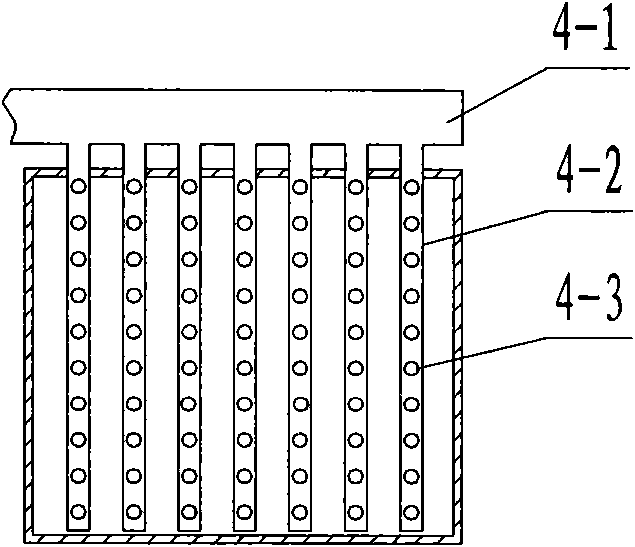

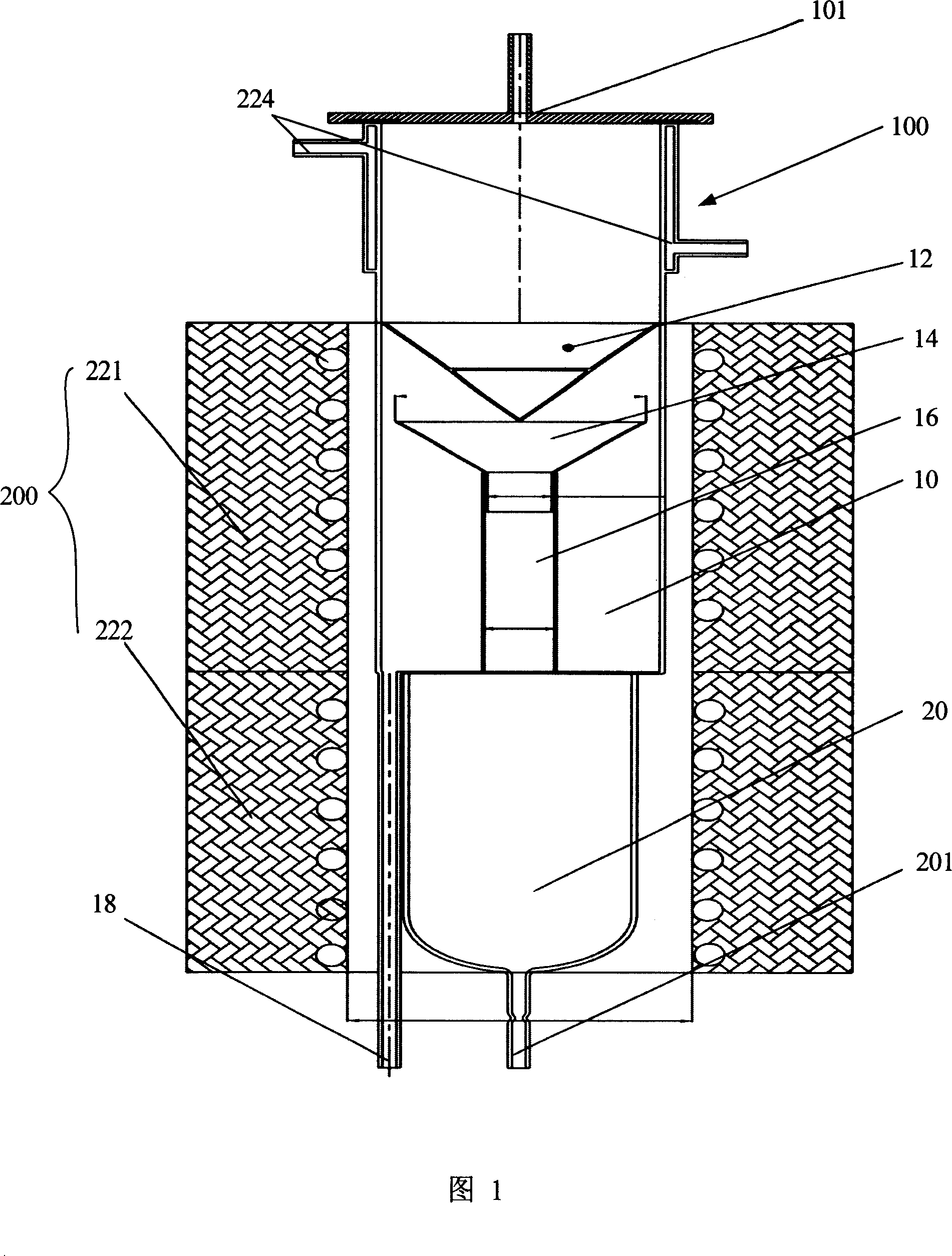

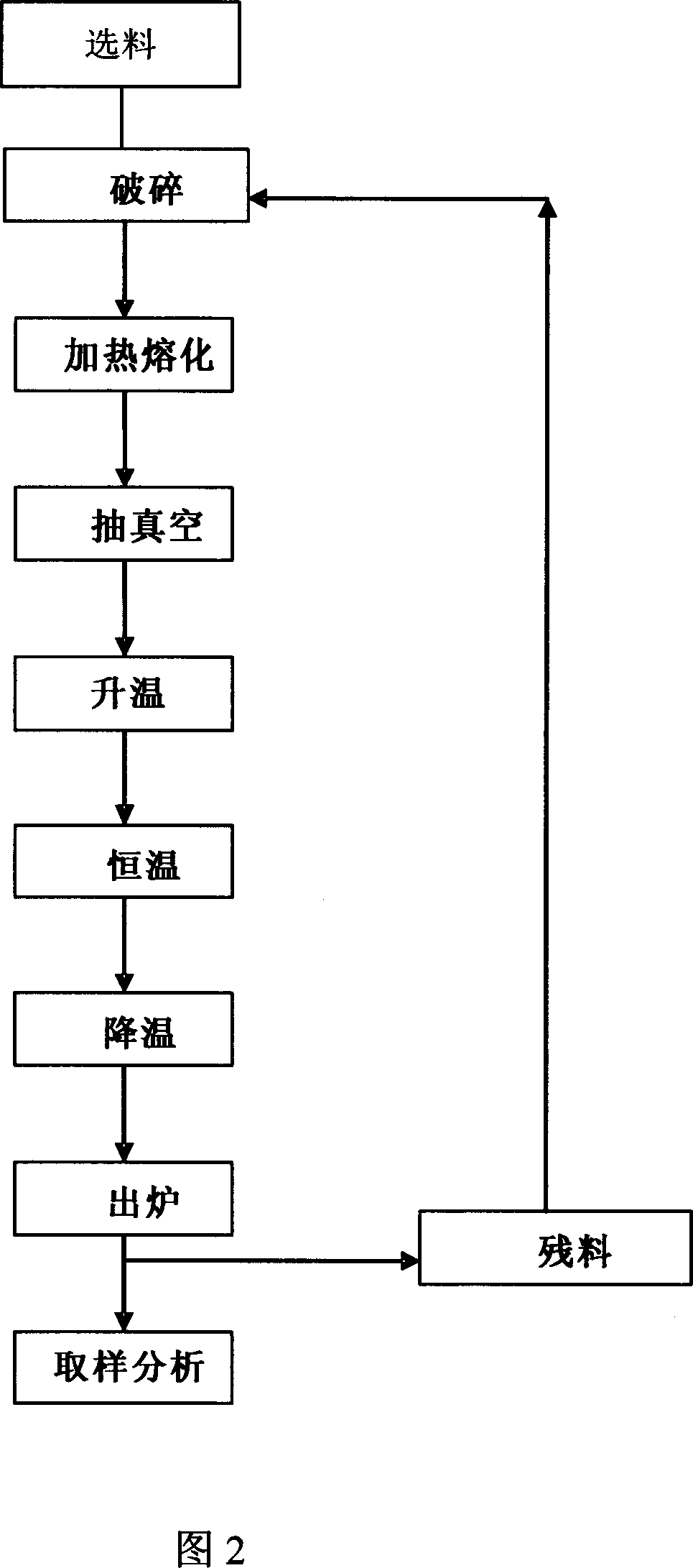

Producing device of high-purity selenium and producing process

ActiveCN1927701AEasy to collectHelp to separateElemental selenium/telluriumTemperature controlBoiling point

High purity selenium producing apparatus and process are disclosed. The producing apparatus includes one rectifying unit coated with heat insulating layer, one temperature controlling system and one vacuum system comprising one mechanical pump and one diffusion pump. The rectifying unit with vacuum gland in the upper part is divided into one material layer and one product layer communicated mutually. The material layer includes one conical condenser, one umbrella shaped material accepter and one connecting pipe vertically distributed successively; and the product layer is provided with one product kettle connected through the connecting pipe to the material accepter. The rectifying unit in inside multilayer structure is favorable to the separation of selenium from other impurity elements, and has high yield and high product purity.

Owner:广东先导稀贵金属材料有限公司

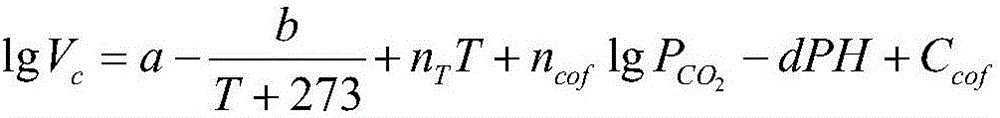

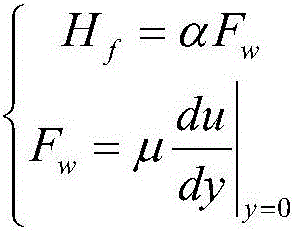

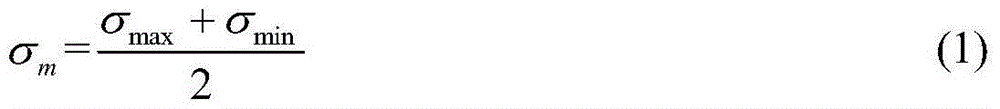

Method for determining corrosion rate of natural gas injection and production well pipe column under erosion-carbon dioxide corrosion coupling action

ActiveCN106021659ALow fluid fractionReduce flow rateDesign optimisation/simulationSpecial data processing applicationsCouplingLiquid water

The invention belongs to the technical field of oil field equipment and particularly provides a method for determining a corrosion rate of a natural gas injection and production well pipe column under an erosion-carbon dioxide corrosion coupling action. The method comprises the steps of 1) establishing a pipe column internal component heat transfer, flow and dispersion model; 2) establishing a pipe column wall surface carbon dioxide corrosion model and determining influence of a product layer on the corrosion rate in a carbon dioxide corrosion process; 3) establishing a model of wear of medium erosion on a pipe wall substrate and a corrosion layer; and 4) coupling the three models and determining the corrosion rate of the natural gas injection and production well pipe column. According to the method, a gas well pipe column corrosion rate prediction model is established through an erosion-electrochemical corrosion coupling action mechanism in the natural gas injection and production well pipe column, so that the corrosion rate of the natural gas injection and production well pipe column can be effectively predicted and a technical reference is provided for the security of the natural gas injection and production well pipe column carrying carbon dioxide and liquid water.

Owner:PETROCHINA CO LTD

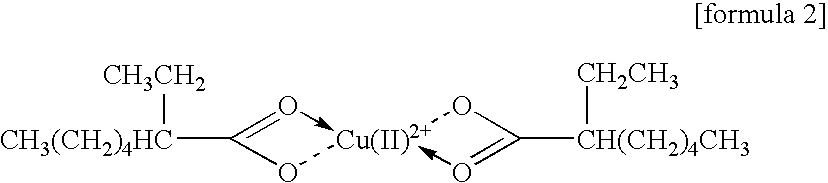

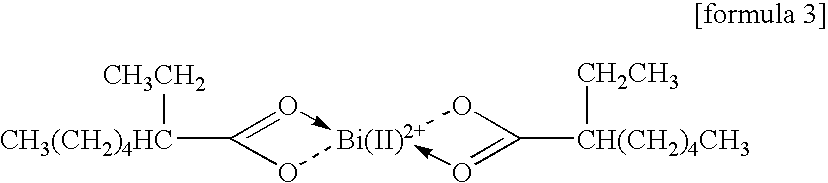

Conductive Metal Paste

ActiveUS20080105853A1Improve adhesionReduce layeringNanotechLiquid surface applicatorsOrganic solventSulfur

The present invention provides a conductive metal paste, available for fabrication of a metal fine particle sintered product layer, which has excellent adhesion to a surface of an underlying substrate such as a glass substrate and also has good conductivity. The conductive metal paste according to the present invention contains, per 100 parts by mass of the metal fine particles whose average particle size is 1 to 100 nm, 10 to 60 parts by mass in total of one or more compounds which are used in a coating molecular layer on a surface of a metal fine particle and which have a group capable of coordinate bonding to a metal element contained in the metal fine particles via a lone pair held by a nitrogen, oxygen, or sulfur atom, and also contains one or more metal compounds which are reduced by heating up to 250° C. or higher to be able to precipitate a metal atom such that a total amount of metals contained in the metal compound is within a range from 0.3 to 7 parts by mass, and further, 100 to 500 parts by mass of an amine-based solvent capable of dissolving the metal compounds blended per 10 parts by mass in total of metals in the metal compounds, wherein all of these components are uniformly dissolved and dispersed in an organic solvent used as a dispersion solvent for the metal fine particles.

Owner:HARIMA CHEM INC

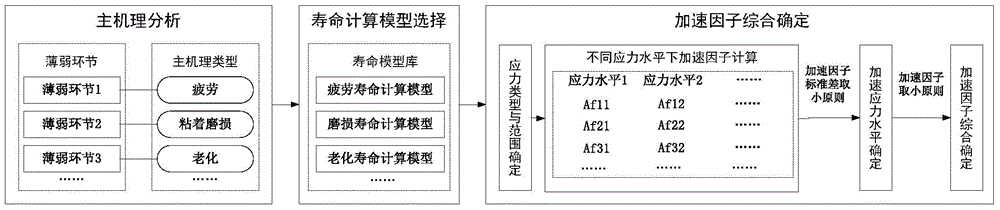

Actuator product acceleration factor determining method based on theoretical lifetime calculation

ActiveCN104156600AClear thinkingEasy to operateSpecial data processing applicationsAcceleration factorStress level

The invention discloses an actuator product acceleration factor determining method based on theoretical lifetime calculation. The method comprises the specific steps that (1) conducting main mechanism analysis, wherein actuator product weak links and main mechanisms corresponding to the actuator product weak links are determined; (2) selecting lifetime calculation models, wherein the corresponding lifetime calculation models are selected according to the types of the main mechanisms; (3) comprehensively determining acceleration factors, wherein the acceleration factors, corresponding to the product weak links, of the main mechanisms under different stress levels are calculated according to the determined stress types and ranges, the acceleration stress level is determined according to the acceleration factor standard deviation minimum principle, and the acceleration factors are determined according to the acceleration factor minimum principle. The actuator product acceleration factor determining method can be directly applied to products, the acceleration factors of the products are determined through the acceleration factors of the product weak links obtained through main mechanism analysis calculation, theoretical supports are provided for a product layer acceleration lifetime test method, and the actuator product acceleration factor determining method has the advantages of being clear in thought, high in operability and the like.

Owner:BEIHANG UNIV

Composite material for building and preparation method thereof

InactiveCN103770418ALong-lasting waterproofLong-term high and low temperature resistanceSynthetic resin layered productsLaminationTextile fiberUltraviolet

The invention provides a composite material for a building. The composite material is a laminated material with at least two layers. The composite material comprises at least one thermoplastic resin thin film layer which is 1-250 microns thick, and at least one thermoplastic resin product layer, wherein the thermoplastic resin product layer is a thermoplastic resin thin film or a thermoplastic resin fiber product; the thermoplastic resin fiber product is a textile fiber and / or non-woven cloth; the density of the thermoplastic resin fiber product is 1-250 g / m<2>; the thermoplastic resin thin film layer and the thermoplastic resin product layer are combined together through spraying laminating or thermoplastic hot melt adhesive pressing. The invention also provides a method for preparing the composite material for the building. The composite material for the building has the functions of preventing water for a long time, resisting high and low temperature, resisting weather, stopping ultraviolet (UV), retarding fire, drying wet air, preventing dampness, breathing, protecting the environment, completely stopping germs, realizing high intensity and the like.

Owner:FOSHAN KING WONDER HI TECH CO LTD

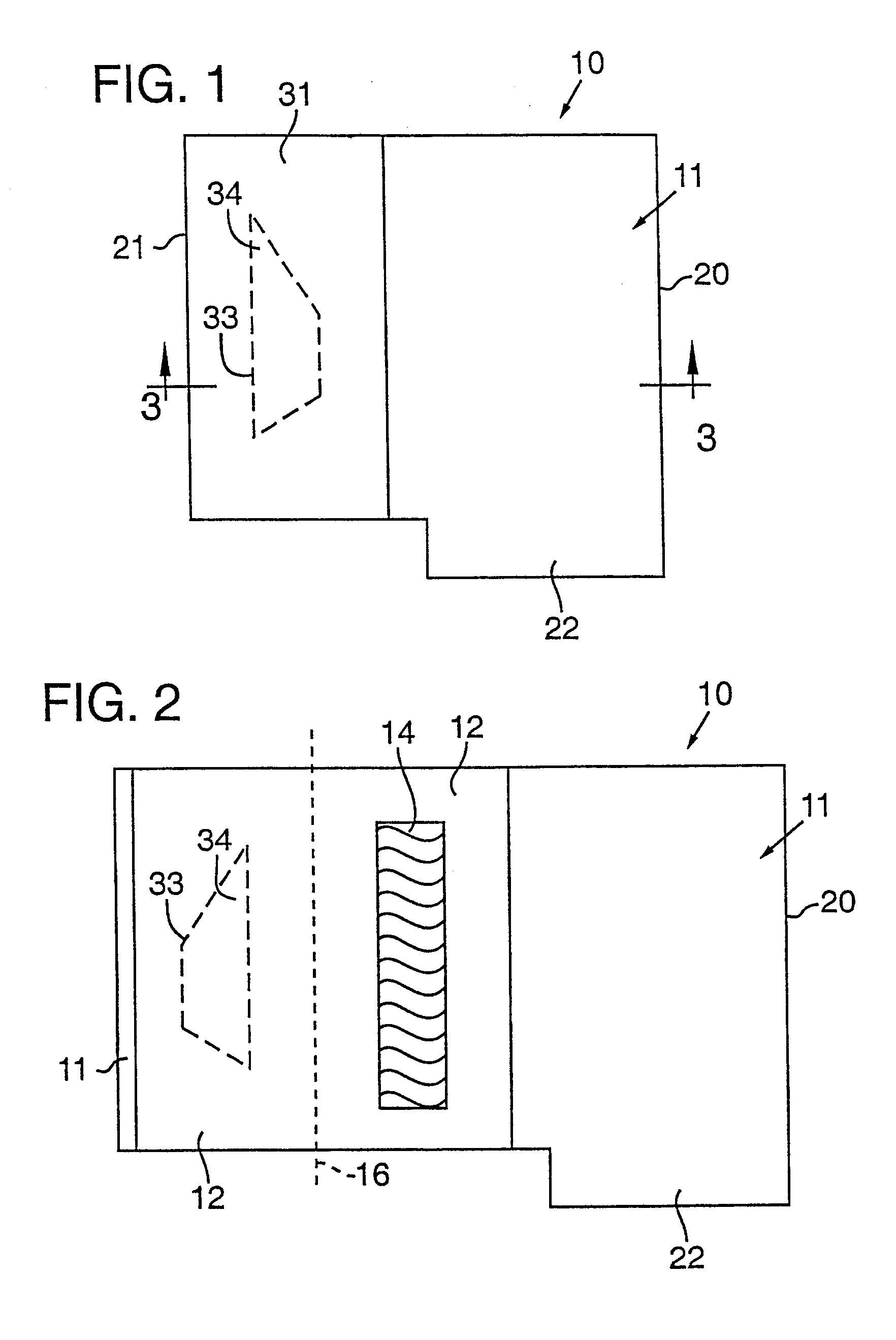

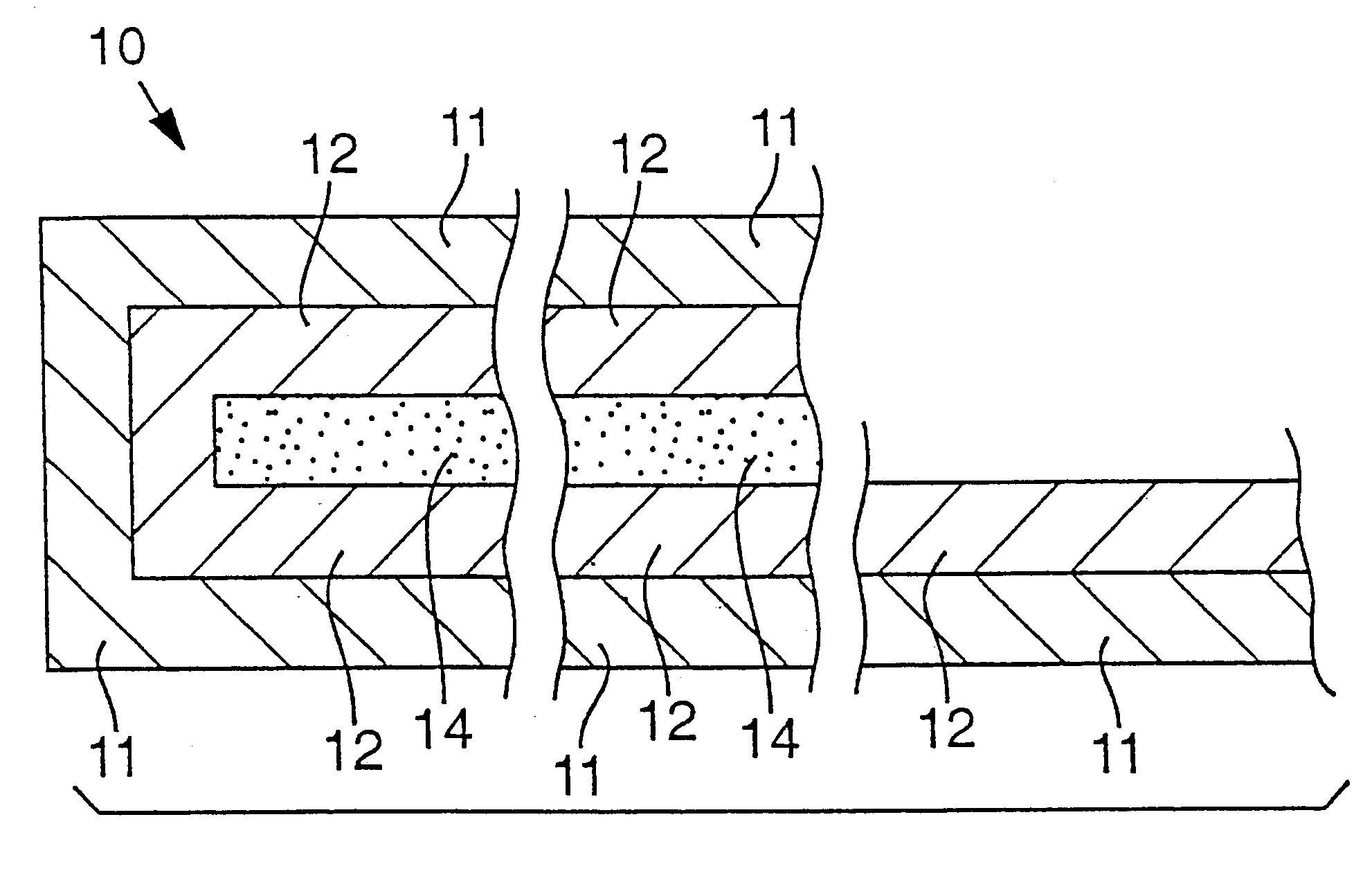

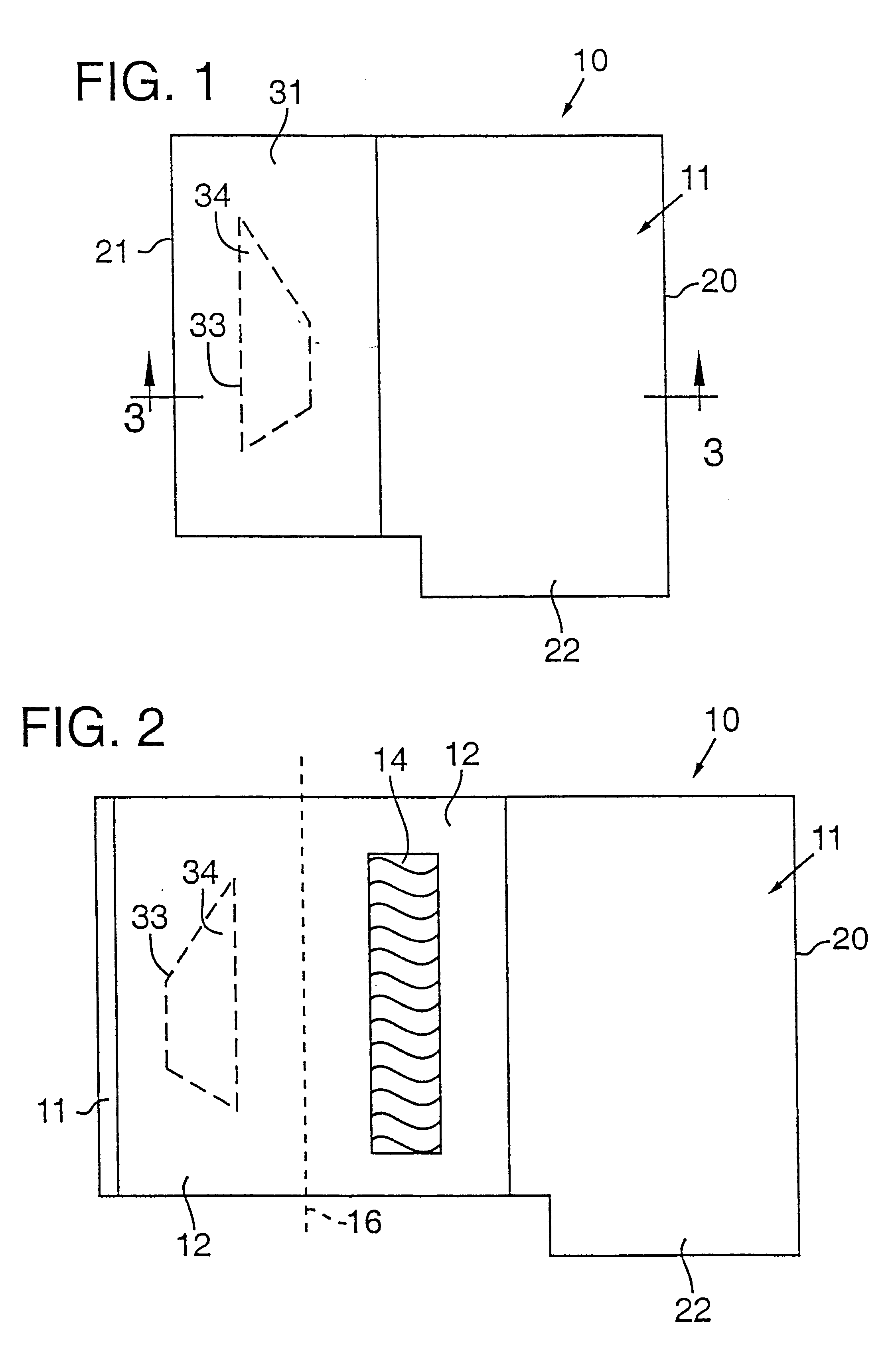

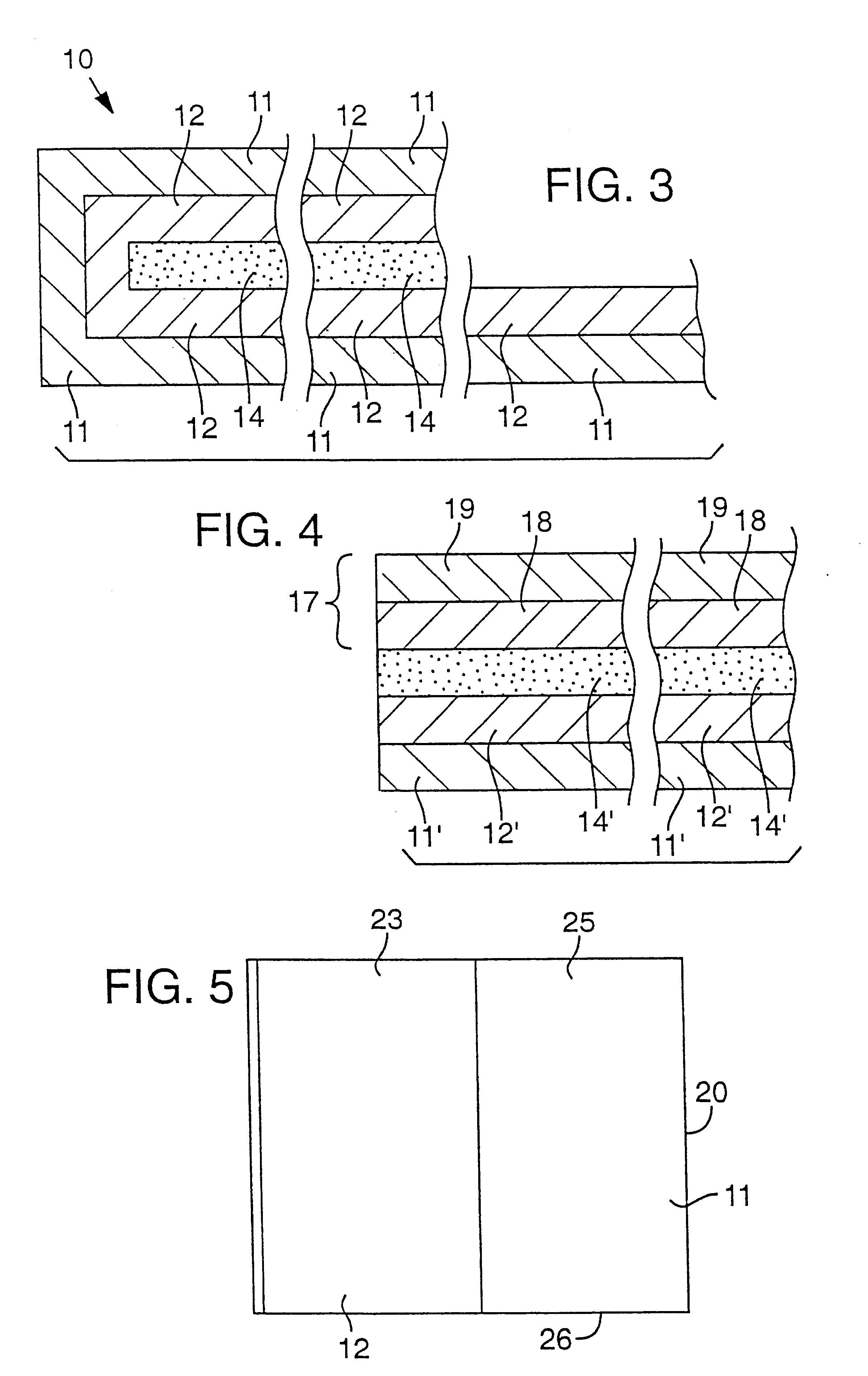

Back end of line clone test vehicle

ActiveUS20050086617A1Impact yieldSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsEngineeringProduct layer

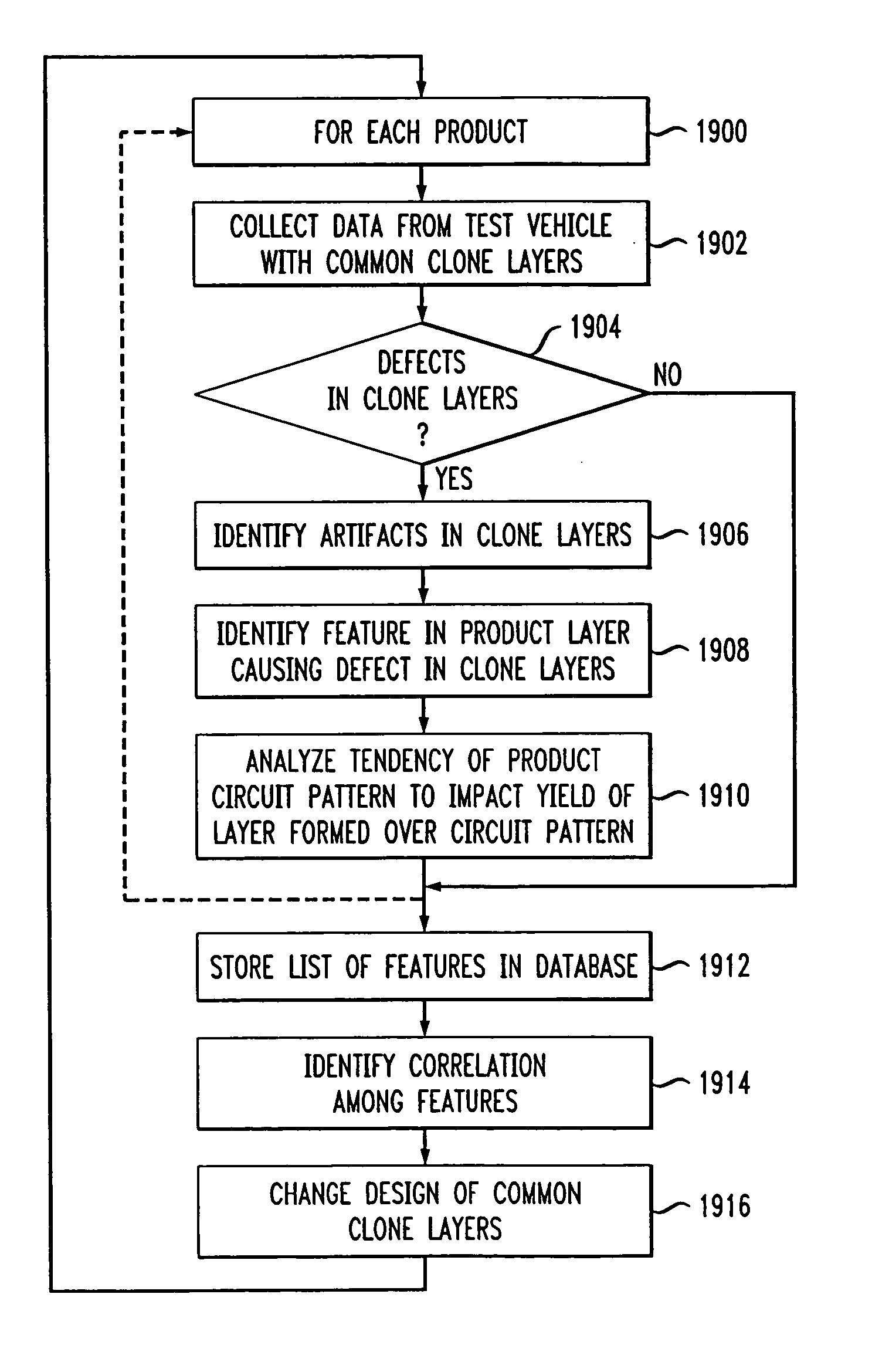

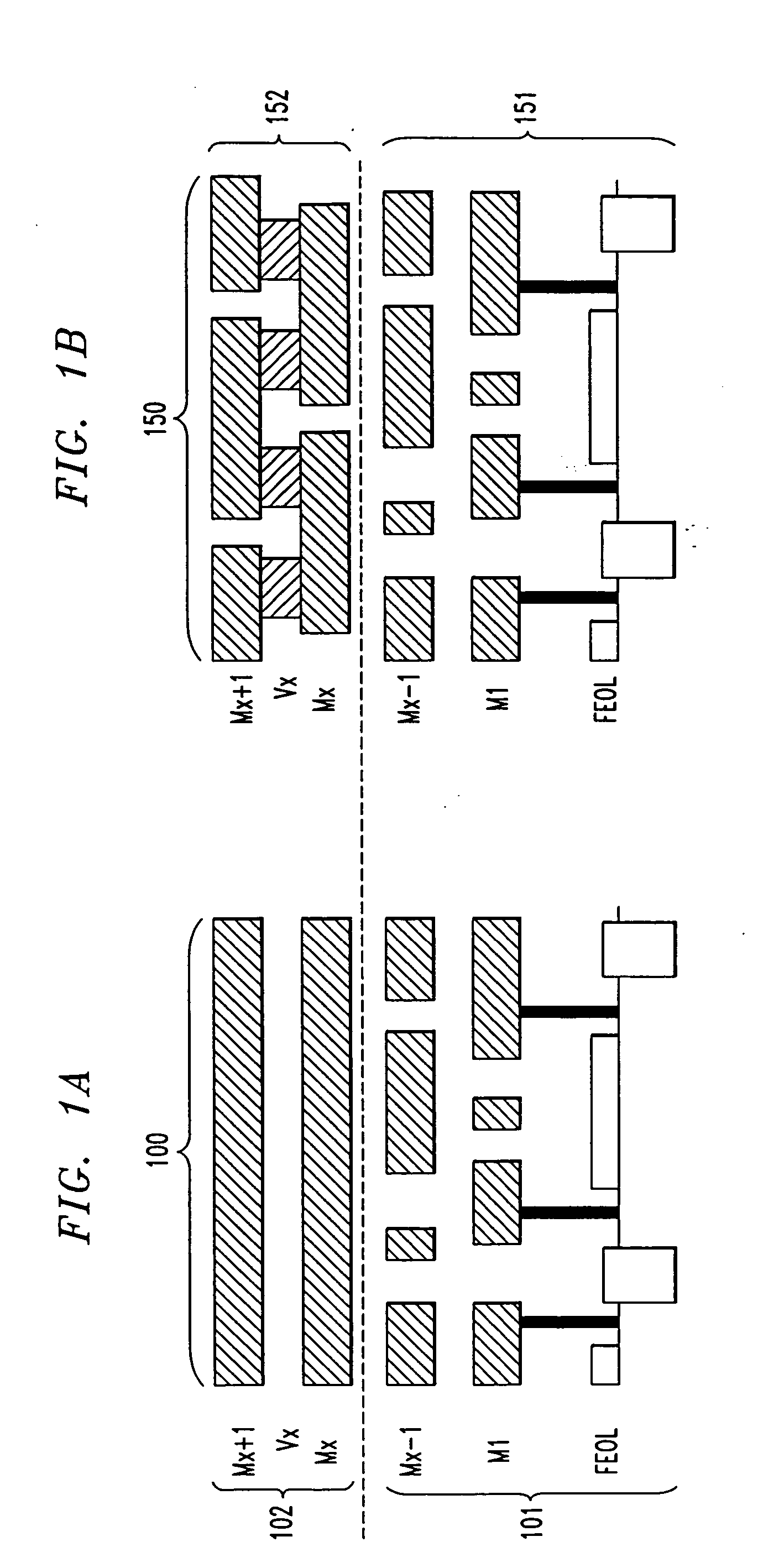

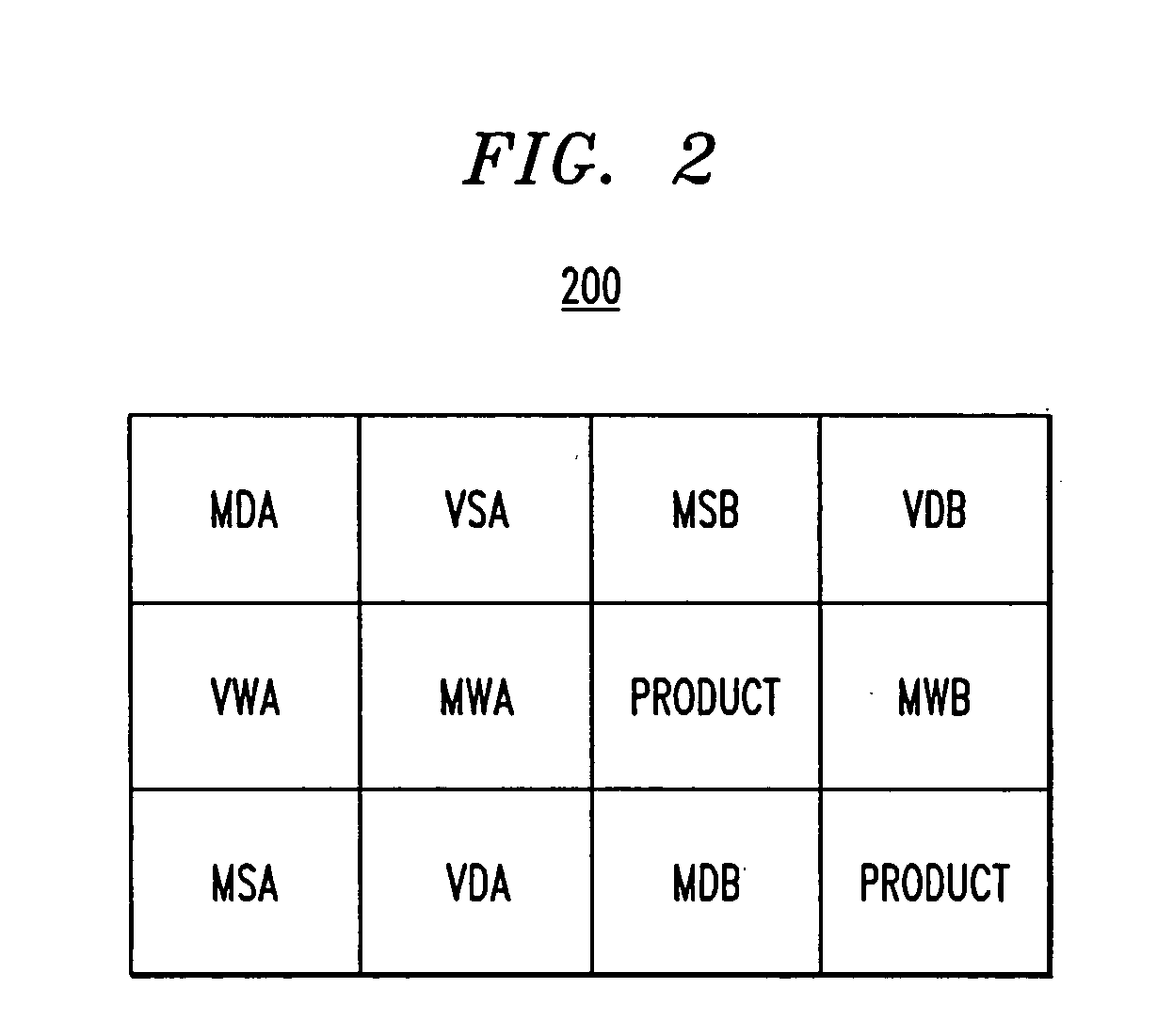

A test vehicle comprises at least one product layer having a east one product circuit pattern on the product layer, and one or more clone layers formed over the product layer (1902). The one or more clone layers include a plurality of structures, which may include clone test vehicle circuit patterns and / or clone test vehicle vias (1902). The presence of one or more defects (1904) in the one or more clone layers (1908) is an indicator of a tendency of the product circuit pattern to impact yield of a succeeding layer to be formed over the product circuit pattern in a product (1910).

Owner:PDF SOLUTIONS INC

Forcible wet desulphurization process for lead plaster

The invention provides a forcible wet desulphurization process for lead plaster. The process comprises the following steps of adding water to stir the lead plaster in a lead plaster stirring tank to dilute the lead plaster into 10 to 30 mass percent ore pulp, pumping 20 cubic meters of ore pulp into a desulphurization stirring tank by using a slurry pump, simultaneously adding Na2CO3 into the desulphurization stirring tank according to the mass ratio of Na2CO3 to PbSO4 of (1-1.2):1, pumping the ore pulp out of the desulphurization stirring tank at the same time of desulphurization stirring, enabling the ore pulp to flow through a forcible desulphurizer, and circulating the ore pulp between the desulphurization stirring tank and the forcible desulphurizer. According to the process, PbCO3 product layers wrapped on the outer surfaces of PbSO4 particles can be crushed through the forcible desulphurizer in a desulphurization process to completely expose PbSO4 in a solution of Na2CO3, so that the efficiency of transformation of PbSO4 into PbCO3 is improved, and the aim of forcible desulphurization is fulfilled; rolling and grinding modes are adopted for crushing large PbSO4 crystalline particles through the forcible desulphurizer, and a supergravity stirring mode is adopted for crushing the large PbSO4 crystalline particles and stirring the ore pulp, so that the aims of crushing the large PbSO4 crystalline particles and accelerating desulphurization transformation are fulfilled.

Owner:HUNAN JIANG YE MECHANICAL & ELECTRICAL TECH CO LTD

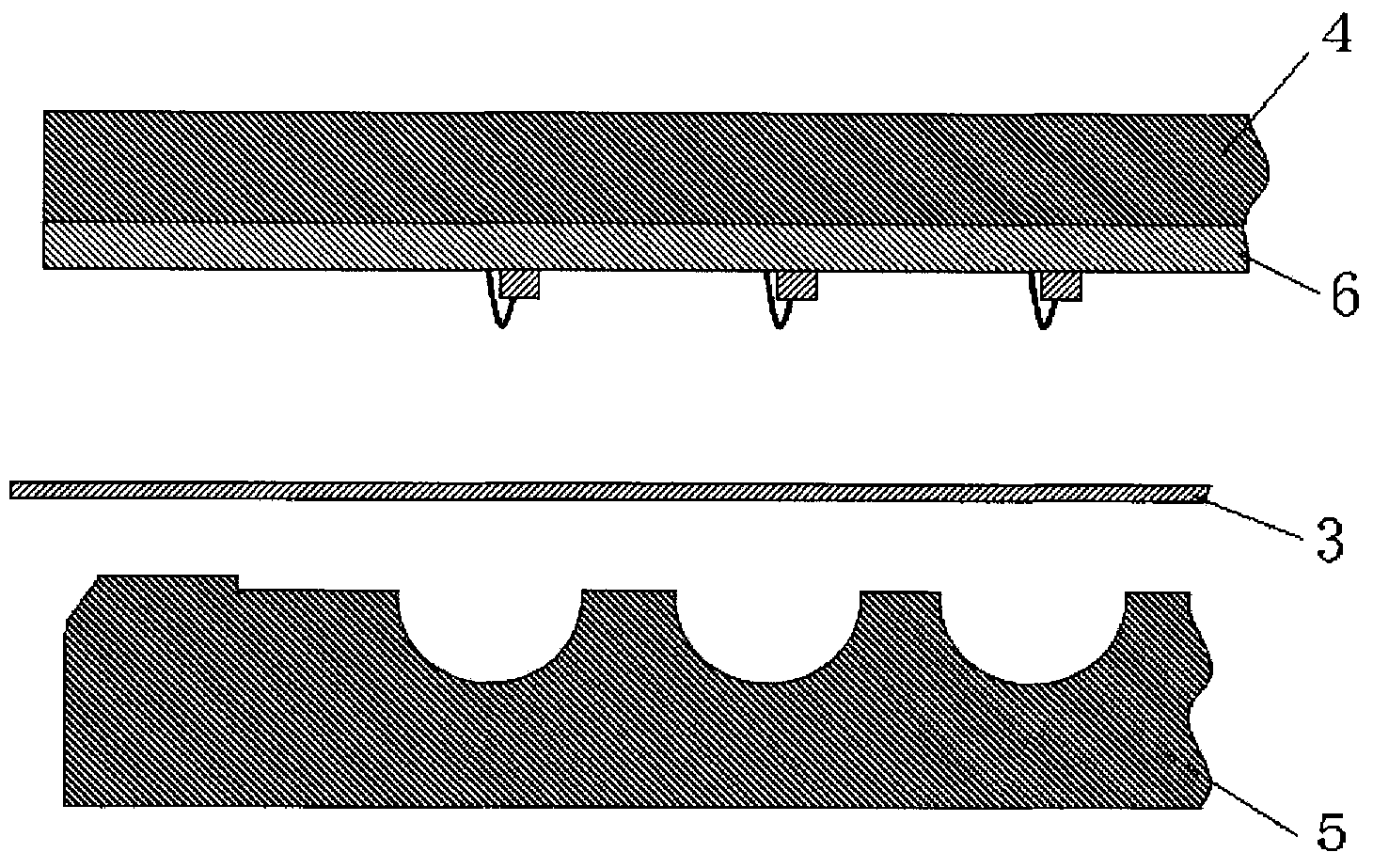

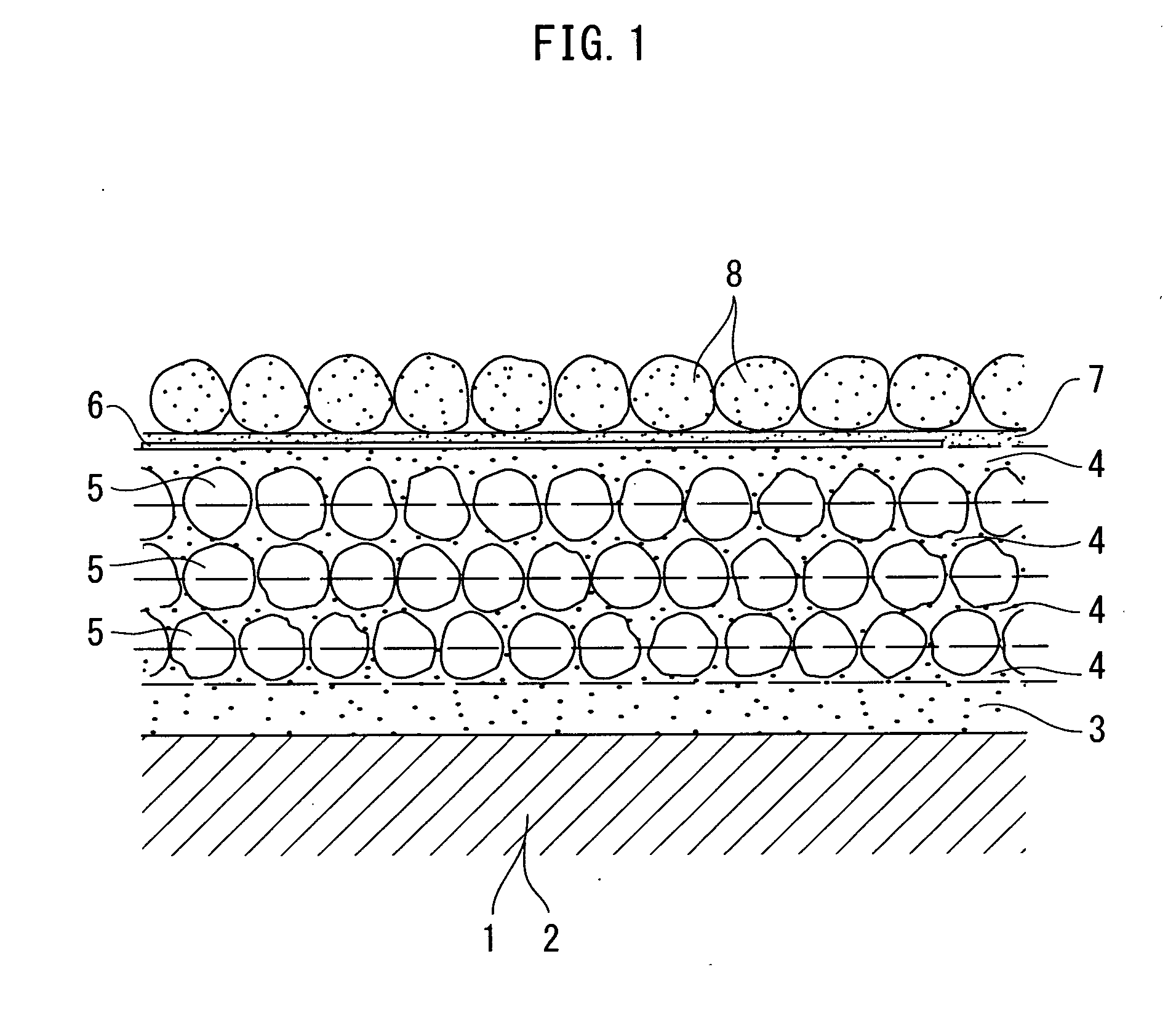

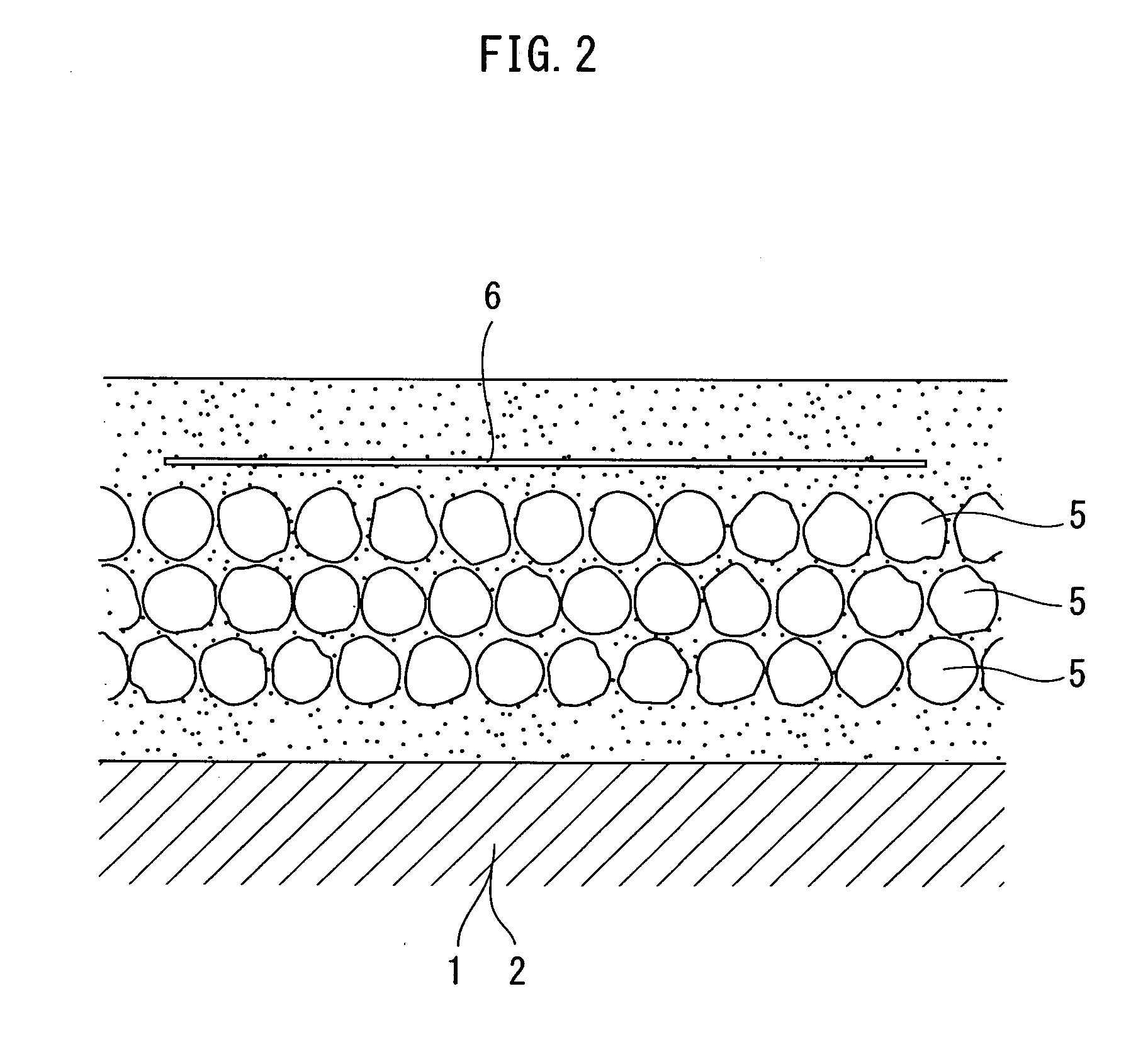

Release film, compression molding method, and compression molding apparatus

InactiveCN104284764AImprove machinabilityImprove detachabilitySynthetic resin layered productsSolid-state devicesCompression moldingShell molding

Owner:DOW CORNING TORAY CO LTD

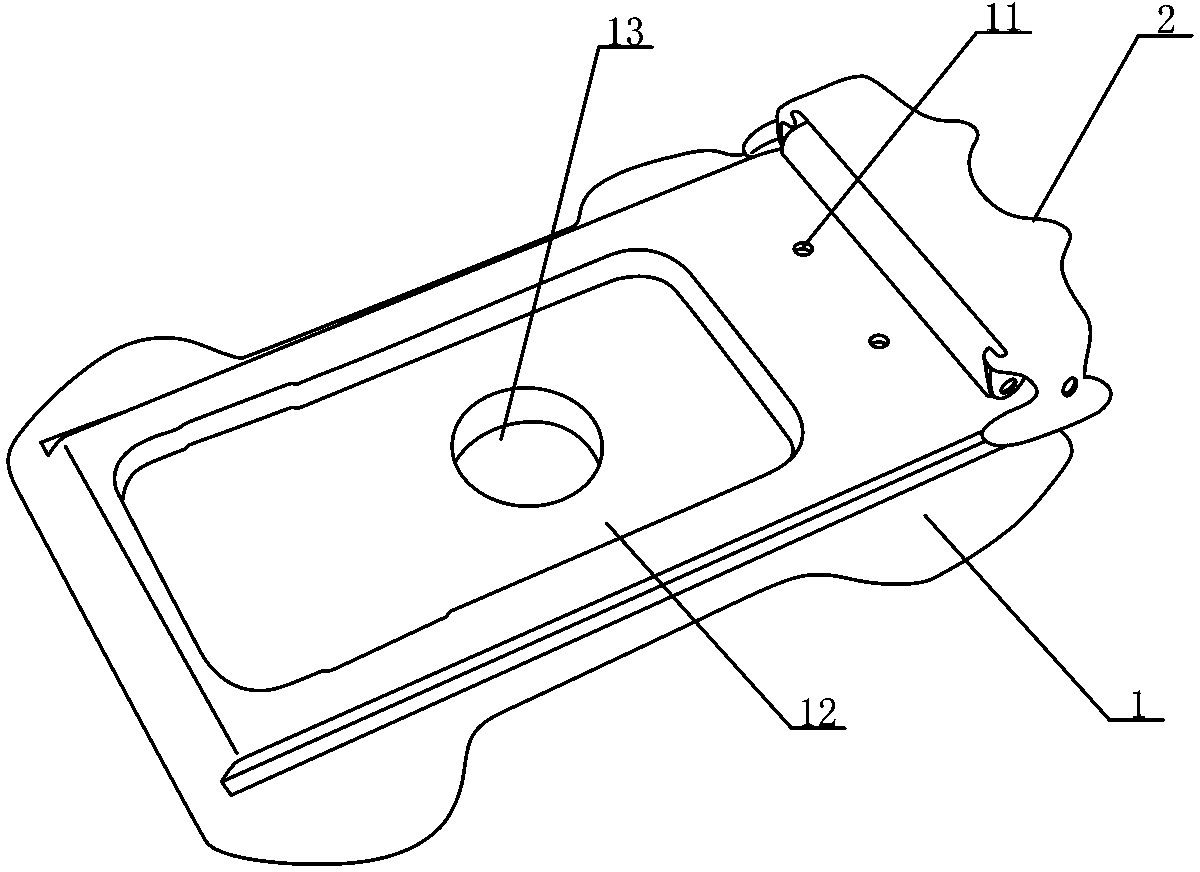

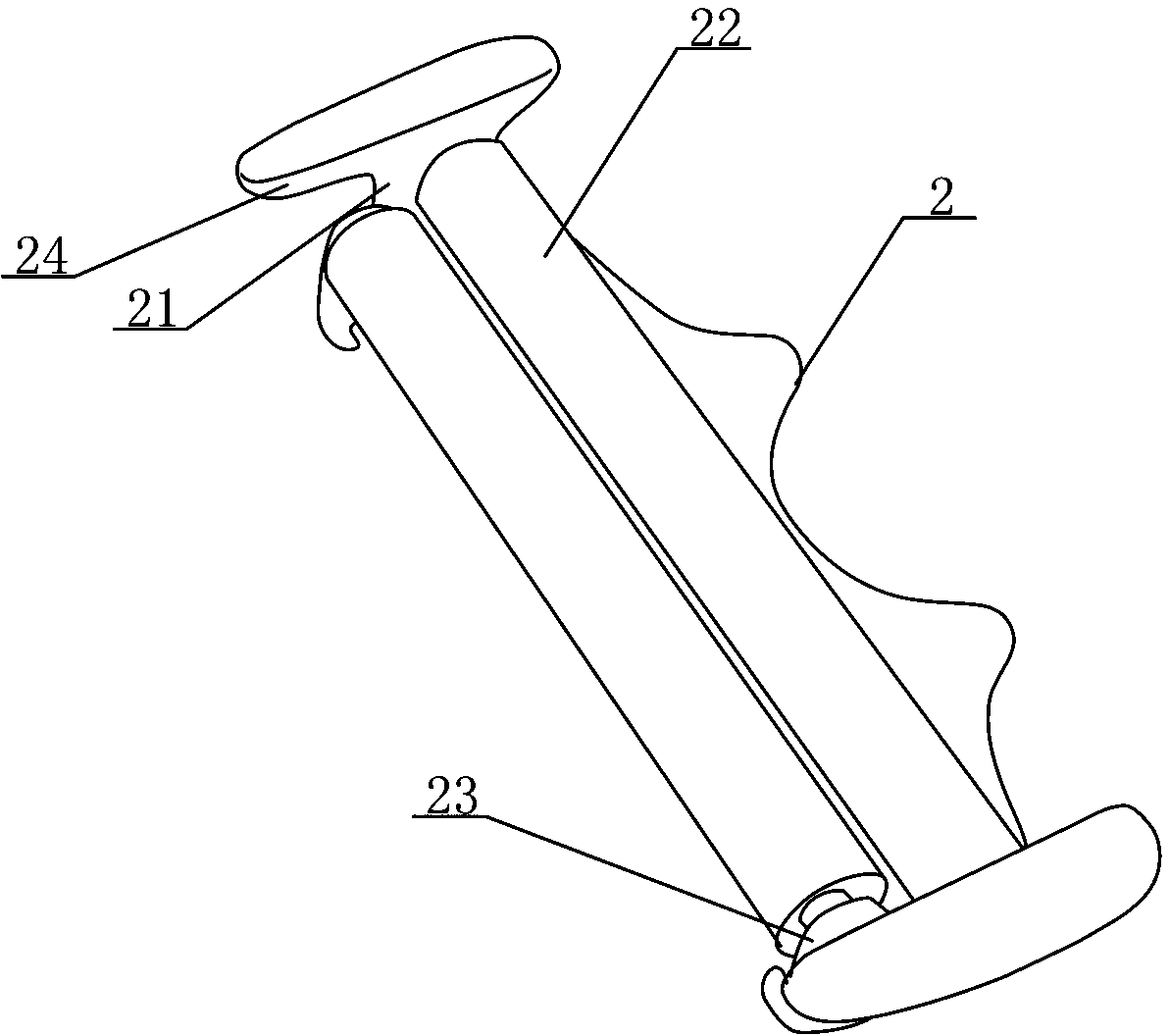

Method and device for adhering film on screen by shearing protective film in staggered mode

InactiveCN103448943APhenomenon that will not be strippedPrecise positioningPackagingStructural engineeringProtection layer

The invention discloses a method and device for adhering a film on a screen by shearing a protective film in a staggered mode. The device comprises a base, a rolling wheel seat and a stripping roller. The method comprises the following steps: shearing the screen protective film in a staggered mode; adhering an adhering sheet and a positioning sheet on an adhering layer; and adhering the stripping roller on a release layer. An equipment positioning cavity, a sliding rail and a positioning hole are arranged on the front surface of the base of the device; the rolling wheel seat consists of a rolling wheel shell and a roller; a roller shaft seat and a sliding rail are arranged on the rolling wheel shell; the roller is arranged in the roller shaft seat; and the rolling wheel seat spans on the base and moves on the sliding rail. The method and the device have the advantages that in the link of adhering the protective film to the screen, when the stripping roller turns over a stripping layer and a product layer, the phenomenon that the product layer is stripped is avoided and operation is simple, convenient and quick; the device is accurate in positioning; adhesion is time-saving and labor-saving; and operation error is avoided even for a green hand, so the adhesion quality is guaranteed.

Owner:王旭辉

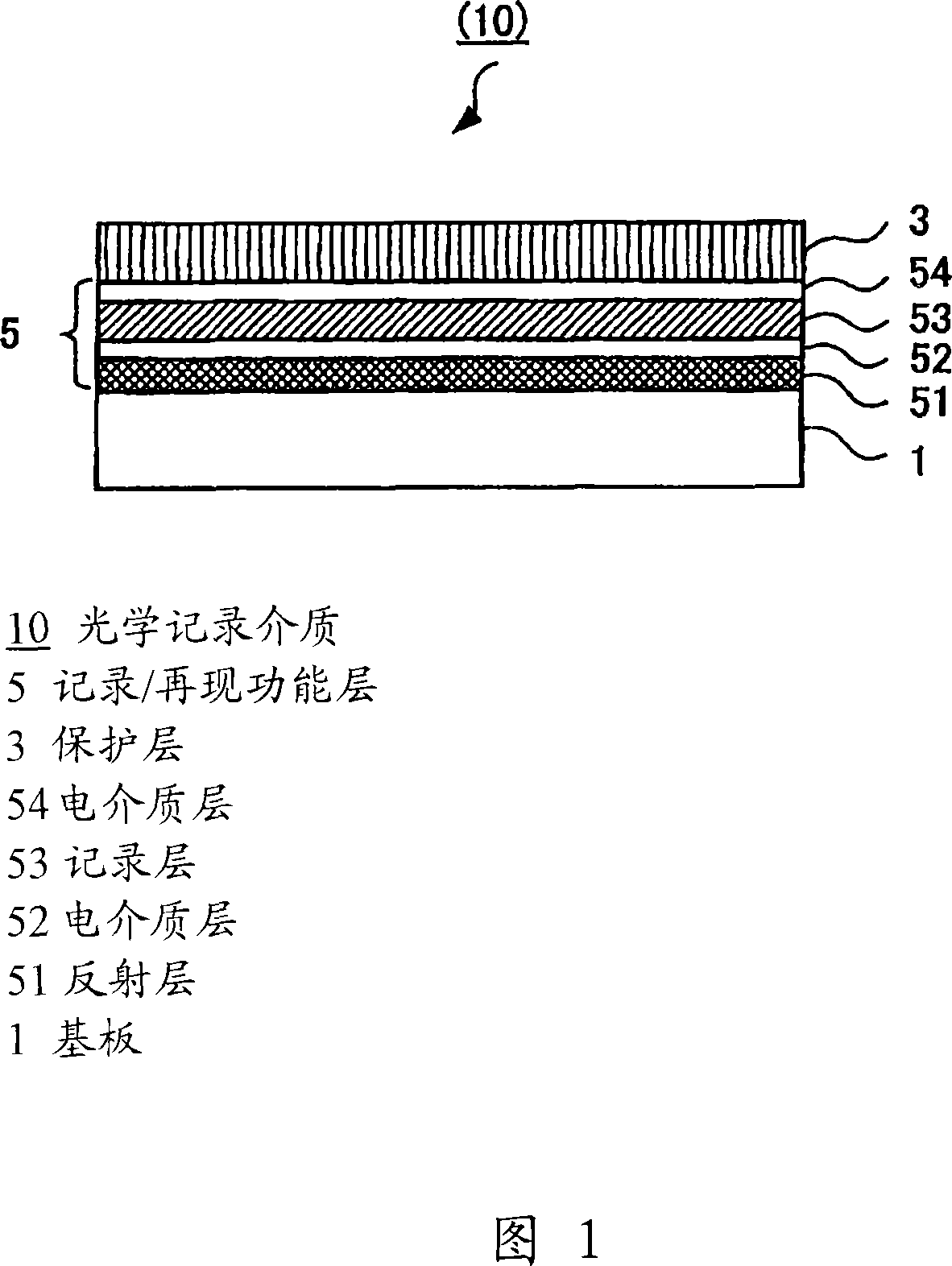

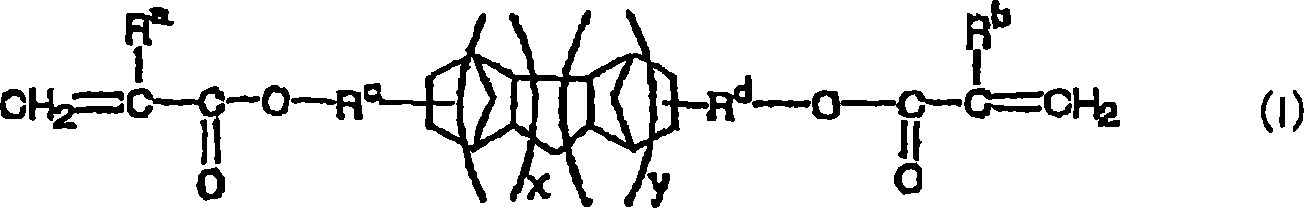

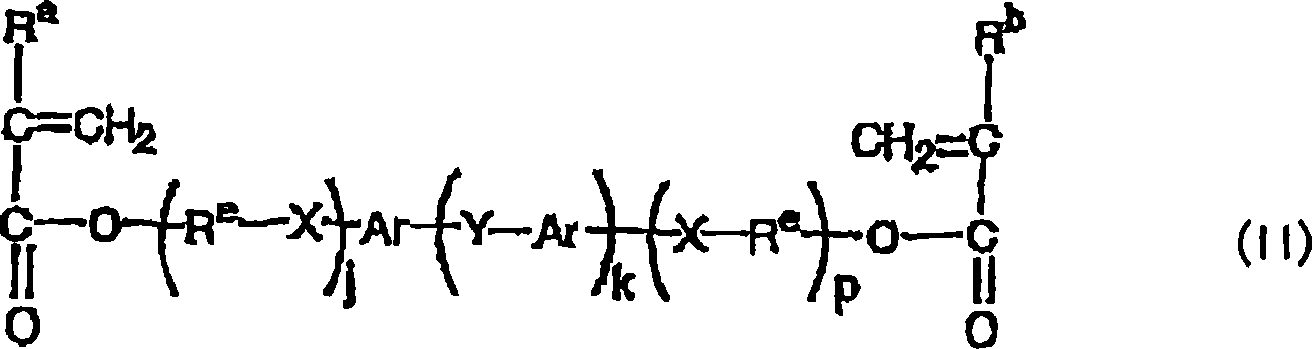

Radiation curable composition and curing product thereof, and laminate including the same

InactiveCN101052681AHigh transparencyHigh mechanical strengthLiquid surface applicatorsSynthetic resin layered productsPolyethylene terephthalateHeat resistance

A radiation curable composition that can provide a curing product not only having excellent transparency and mechanical strength but also excelling in a balance between surface hardness and heat resistance / moisture deformation resistance; and a curing product thereof; and a laminate including a layer of the curing product that is suitable for use as an optical recording medium, etc. There is provided a radiation curable composition comprising a monomer having a radiation curing group, which radiation curable composition is cured to provide a curing product having properties such that (1) the light transmittance at a film thickness of 100+-5 [mu]m and a wavelength of 550 nm is = 80%, (2) with respect to a laminate composed of a polyethylene terephthalate film and, superimposed thereon, a curing product of 100+-5 [mu]m film thickness, the surface hardness is = HB, and (3) with respect to a laminate composed of a polycarbonate disk and, superimposed thereon, a curing product layer of 100+-5 [mu]m thickness, the absolute value of warpage (a mm) measured after being disposed in an environment of 80 DEG C 85% RH for 100 hr, |a|, is = 0.5 mm.

Owner:MITSUBISHI CHEM CORP

Production method of archaistic ceramic chip

The embodiment of the invention discloses a production method of an archaistic ceramic chip. The archaistic ceramic chip has prominent product layering and three-dimensional appearance. Compared withthe traditional ceramic chip, the archaistic ceramic chip can be printed with various archaistic patterns on the surface, and the surface has a sand granular structure and natural sandstone texture, forms strong contrast between light and shade, has strong stereoscopic sensation and is suitable for a variety of decorative requirements. The archaistic ceramic chip has matte effects and a certain effect of human vision protection and light pollution prevention. The production method comprises A, taking raw materials and carrying out slurry ball milling, spray milling and aging in a fine ore bin,B, carrying out pressing molding through feeding the slurry into a press mold and carrying out molding, drying and biscuiting, C, carrying out glazing on the brick blank surface, D, carrying out inkjet through printing prepared ink on the brick blank surface in an inkjet printing way, E, preparing dry granules and applying the dry granules to the glazed brick blank and F, carrying out firing through feeding the product obtained by the step E into a kiln and carrying out sintering to obtain the archaistic ceramic chip.

Owner:广东博华陶瓷有限公司

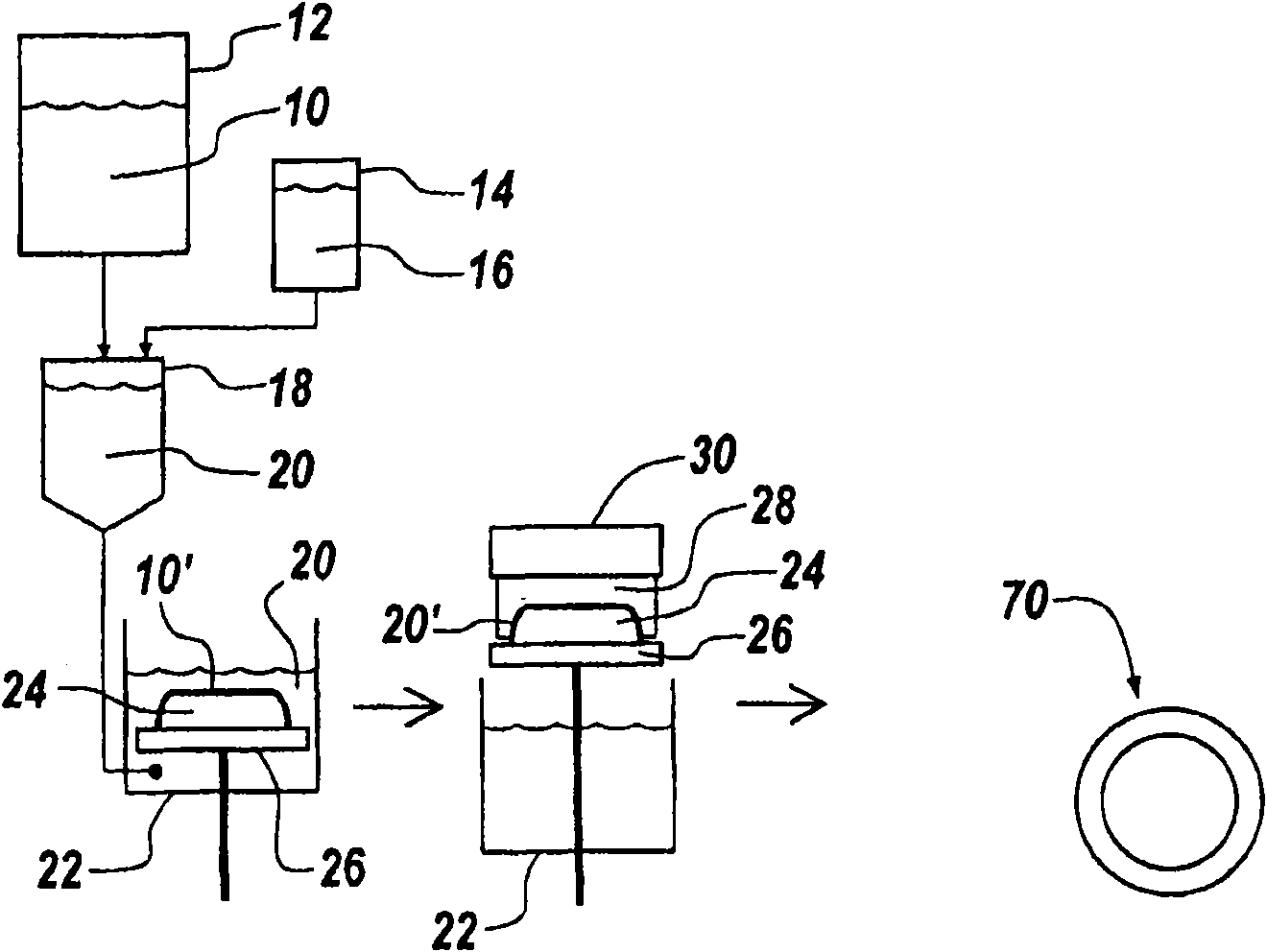

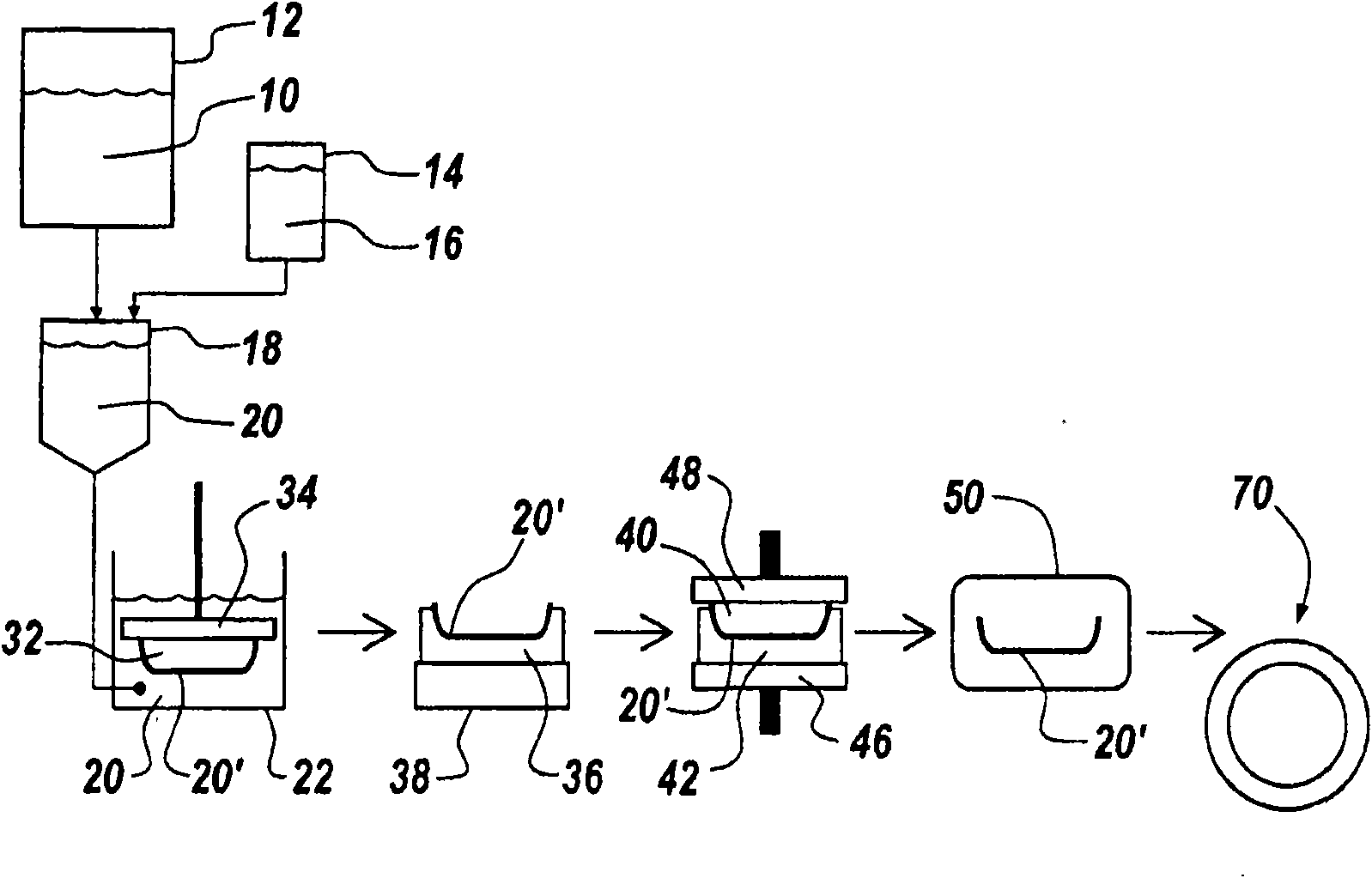

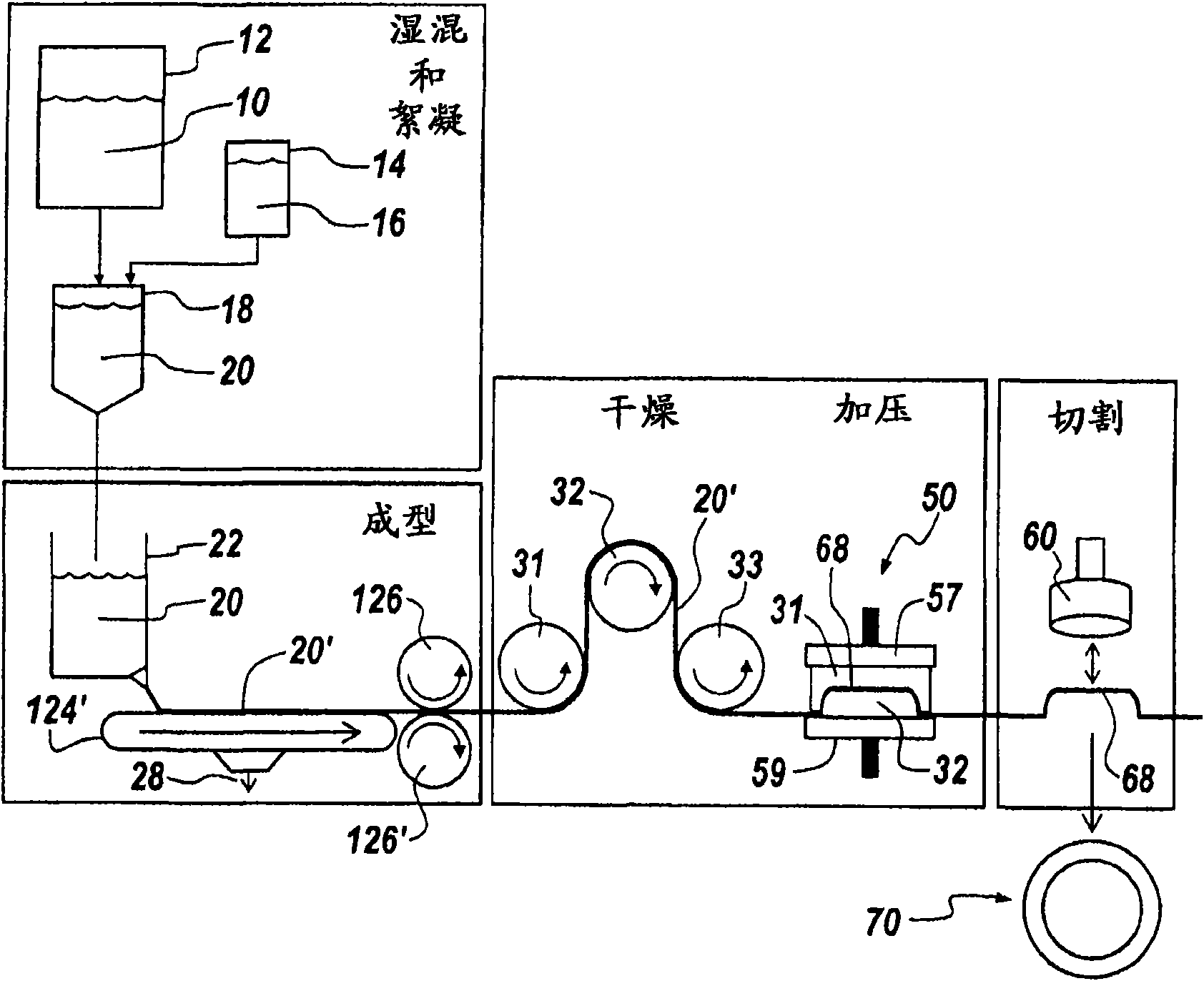

Method of making product sampler

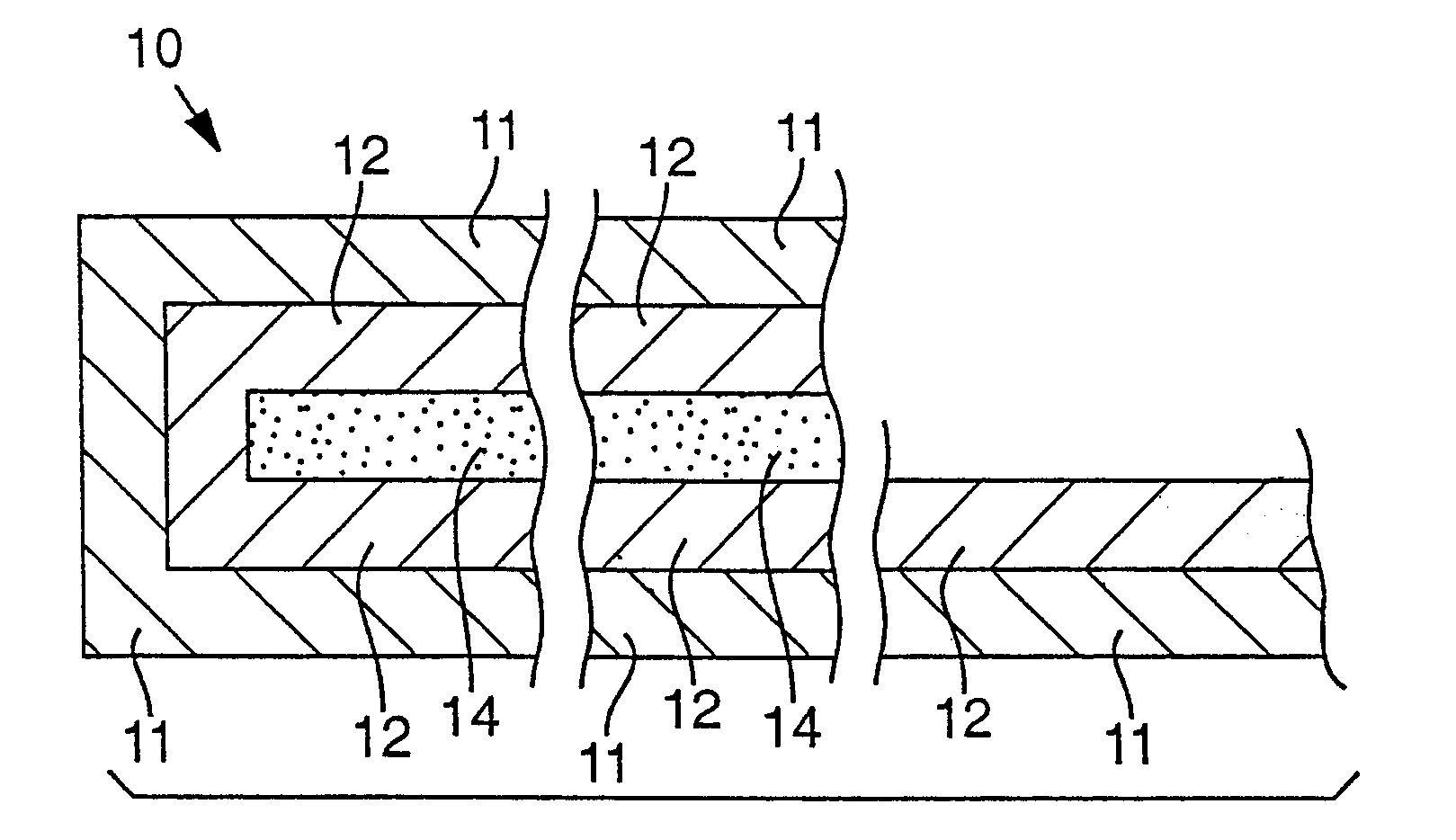

InactiveUS6726797B2Sufficient barrier propertyPrevent and substantially inhibit emissionCosmetic preparationsToilet preparationsPolyethylene glycolEngineering

A product sampler including a substrate layer, a barrier layer covering the substrate layer, a gelatinoid product layer covering and in contact with the barrier layer, and a barrier layer covering and in contact with the product layer is provided. The gelatinoid product layer may include a microencapsulated product, such as a fragrance. In preferred embodiments of the invention, the gelatinoid product layer includes a microencapsulated fragrance carried in a gelatinoid liquid vehicle, which vehicle may comprise, for example, propylene glycol, polyethylene glycols, glycerin, or mixtures thereof. In a highly preferred embodiment of the invention, the product sampler is in the form of a magazine insert having a protruding trimmable non-barrier substrate tab portion, whereby a user may remove a trim portion from the trimmable edge portion after binding the insert into a magazine without removing barrier material with the removed trim portion. Also disclosed is a product sampler in the form of a label.

Owner:AKI INC

Continuous vacuum dynamic sublimating and condensing machine

The invention relates to a continuous vacuum dynamic sublimating and condensing machine, which belongs to the technical field of heat exchange and is suitable for sublimating and refining chemical products with sublimation properties. The continuous vacuum dynamic sublimating and condensing machine is formed by a sublimation gas outlet of a cone on the lower part of a sublimating machine and a horizontal condensing machine together, wherein the sublimating machine is formed by a hot oil heating outer jack and a plurality of hot oil heating flat plates; the outside of the horizontal condensing machine is provided with a semicircular cooling water coil; the inside of the horizontal condensing machine is provided with a plurality of rotary material stirring grooves; a central scraping rotating shaft of the sublimating machine drives a scraping rake to rotate so as to scrape a crude product layer by layer; the crude product is heated to sublimate in vacuum; a sublimation hot gas enters the condensing machine to contact cooled qualified product powder removed by the rotary material stirring grooves; the hot sublimation gas is condensed on the cooled powder; and residues raked layer by layer fall to the bottom of the sublimating machine. A sublimation material is heated uniformly, has short retention time, few side reactions and high yield; the product is condensed on the powder without knocking by a shovel and has good quality; and the heat efficiency of the overall machine and the equipment efficiency are much higher than those of batch-type sublimating and condensing equipment.

Owner:沈善明

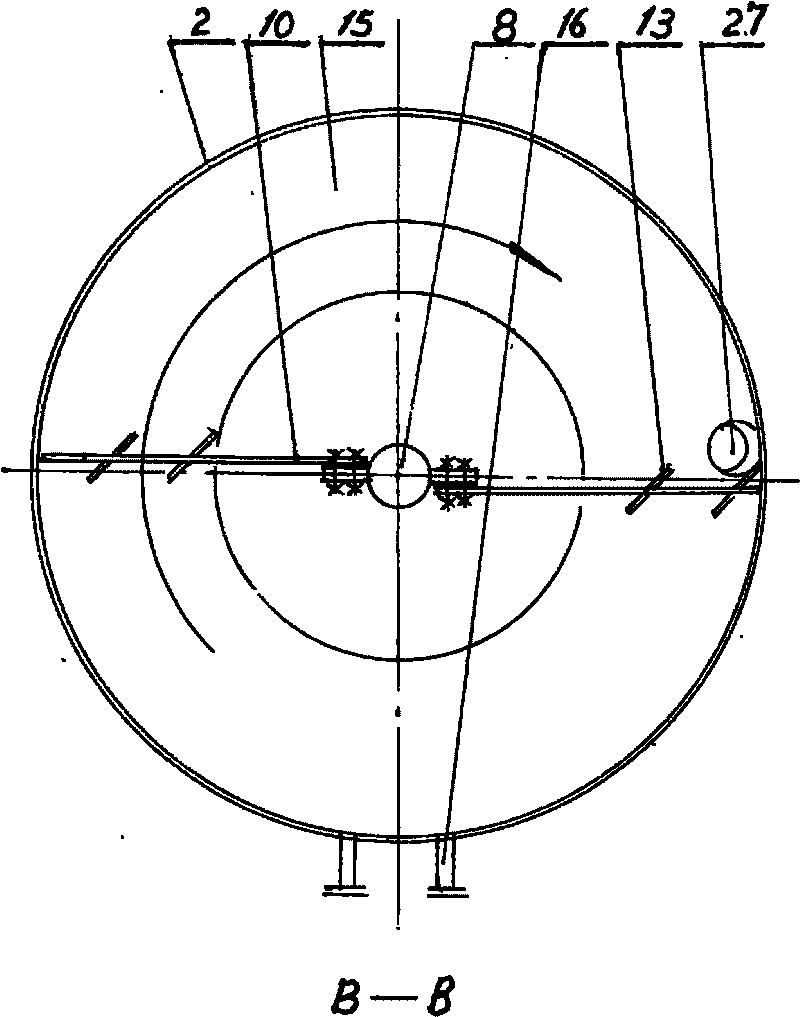

Software development platform for embedded industrial control instrument

ActiveCN103077039AImprove reuse rateIncrease profitSpecific program execution arrangementsSoftware development processResource utilization

The invention relates to a software development platform for an embedded industrial control instrument. The software development platform comprises a hardware driving layer, a system platform scheduling layer, a product application layer and a product customization layer, wherein the hardware driving layer and the system platform scheduling layer form a platform core layer; the product application layer and the product customization layer form a product layer; the hardware driving layer comprises driving codes of correlated hardware modules of the industrial control instrument; the system platform scheduling layer comprises codes of basic scheduling and managing functions of an embedded operation system and codes of basic processing functions of the industrial control instrument; the product application layer comprises related common codes of varied products of the industrial control instrument; the product customization layer comprises various customization codes for different specific products; and codes of the hardware driving layer and the system platform scheduling layer are compiled and packaged to form an LIB library file for the codes of the product application layer and the product customization layer to call. The software development platform benefits standardization, normalization and collaboration of product development; and according to the software development platform, the development efficiency is increased, the utilization rate of development resources is increased, and the development and maintenance cost is reduced.

Owner:福州昌晖自动化系统有限公司

Wallpaper and preparation process of wallpaper

InactiveCN104481106AAvoid Situations That Damage WallpaperExtended service lifeCovering/liningsSpecial paperBiochemical engineeringProduct layer

The invention discloses wallpaper. The wallpaper comprises a wallpaper semi-finished product layer with patterns, an alkali-resistant layer, a gold-plated layer and a dry adhesive layer, wherein the gold-plated layer and the dry adhesive layer are arranged on two sides of the wallpaper semi-finished product layer, and the alkali-resistant layer is arranged between the gold-plated layer and the dry adhesive layer. The wallpaper comprises the alkali-resistant layer, and the alkali-resistant layer is arranged between the gold-plated layer and the dry adhesive layer, so that the situation that alkaline substance of a wall penetrates the gold-plated layer to damage the wallpaper can be avoided. The service life of the wallpaper can be prolonged. The invention also discloses a preparation process of the wallpaper.

Owner:GUANGDONG YULAN GRP

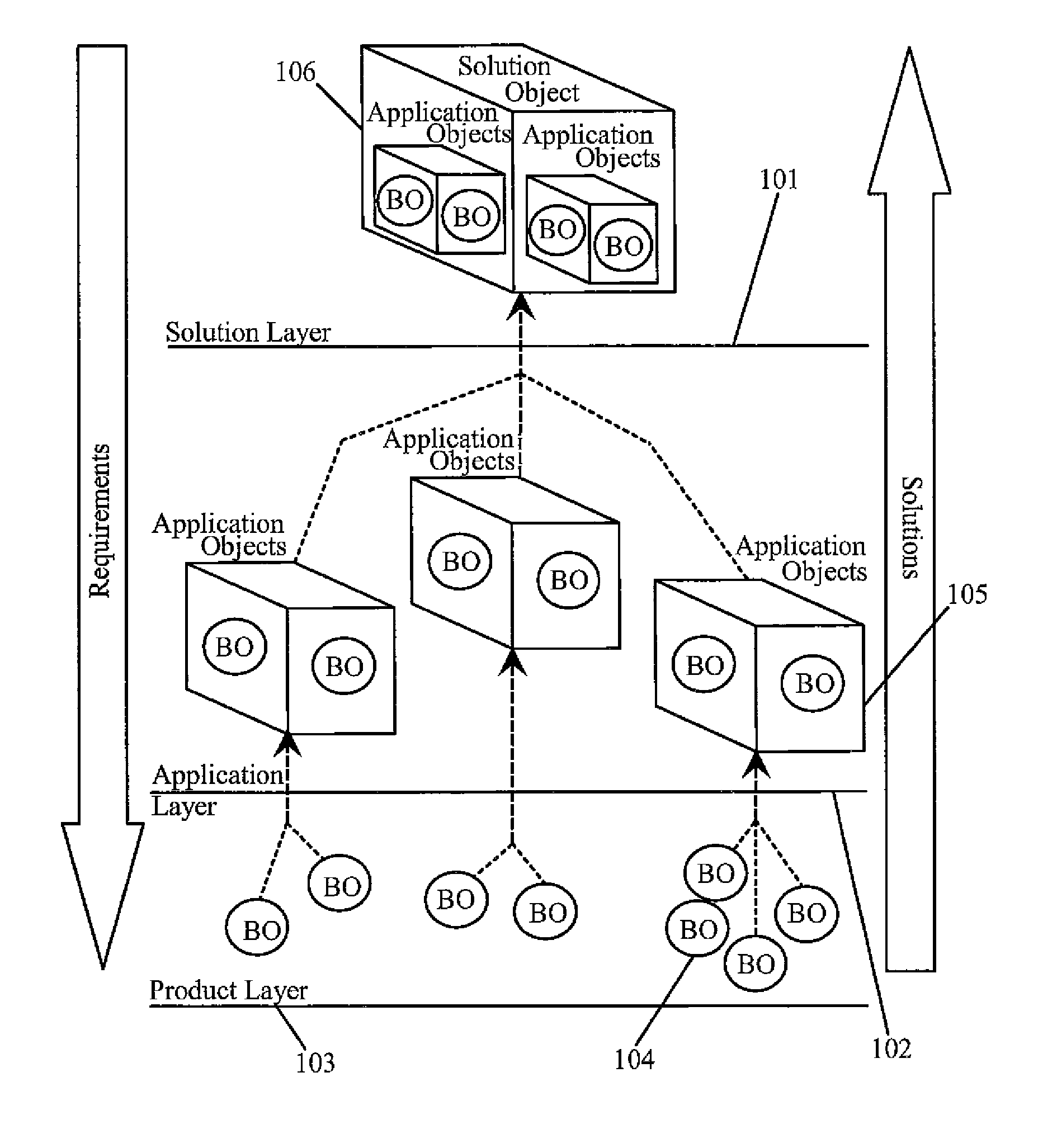

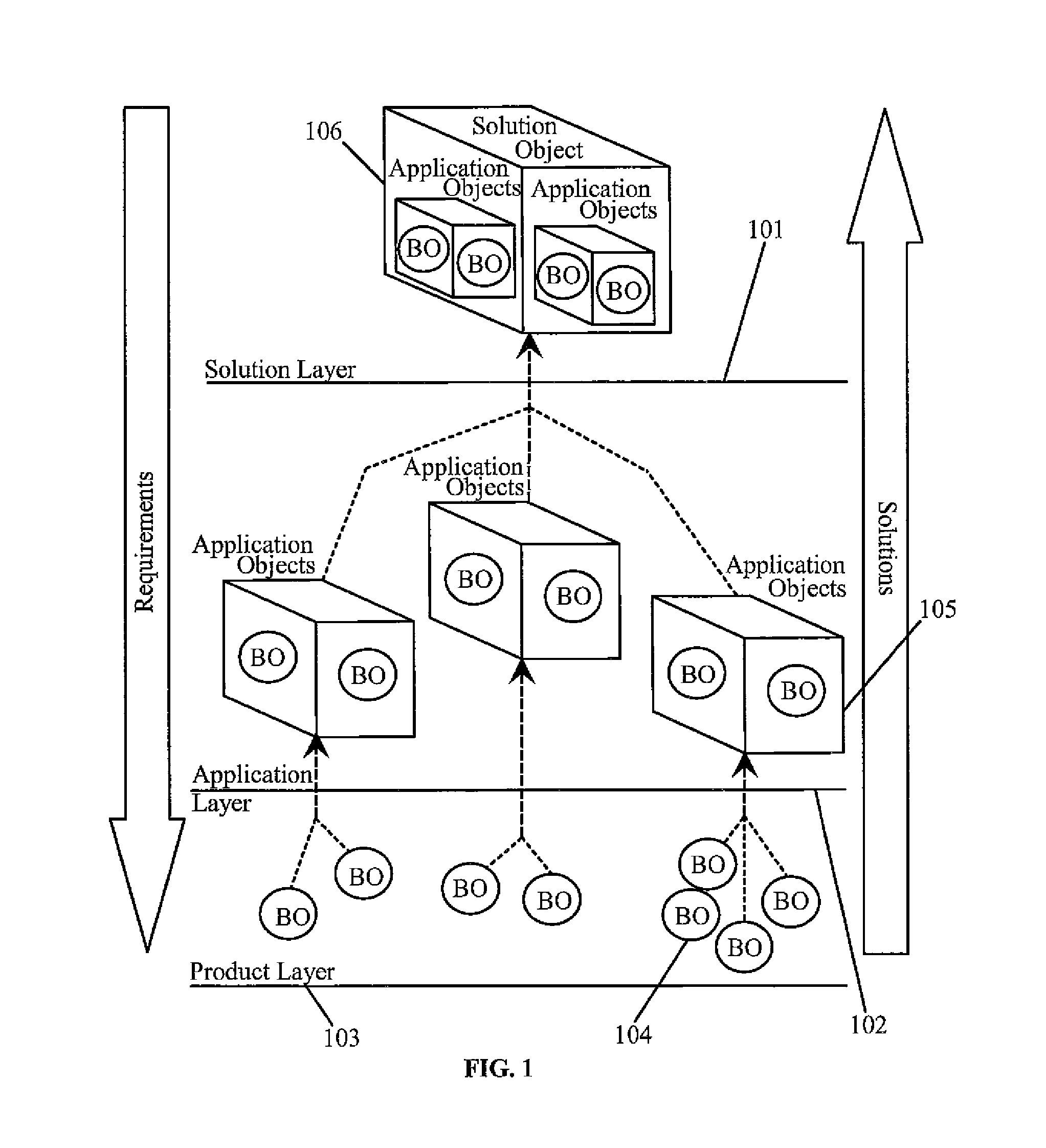

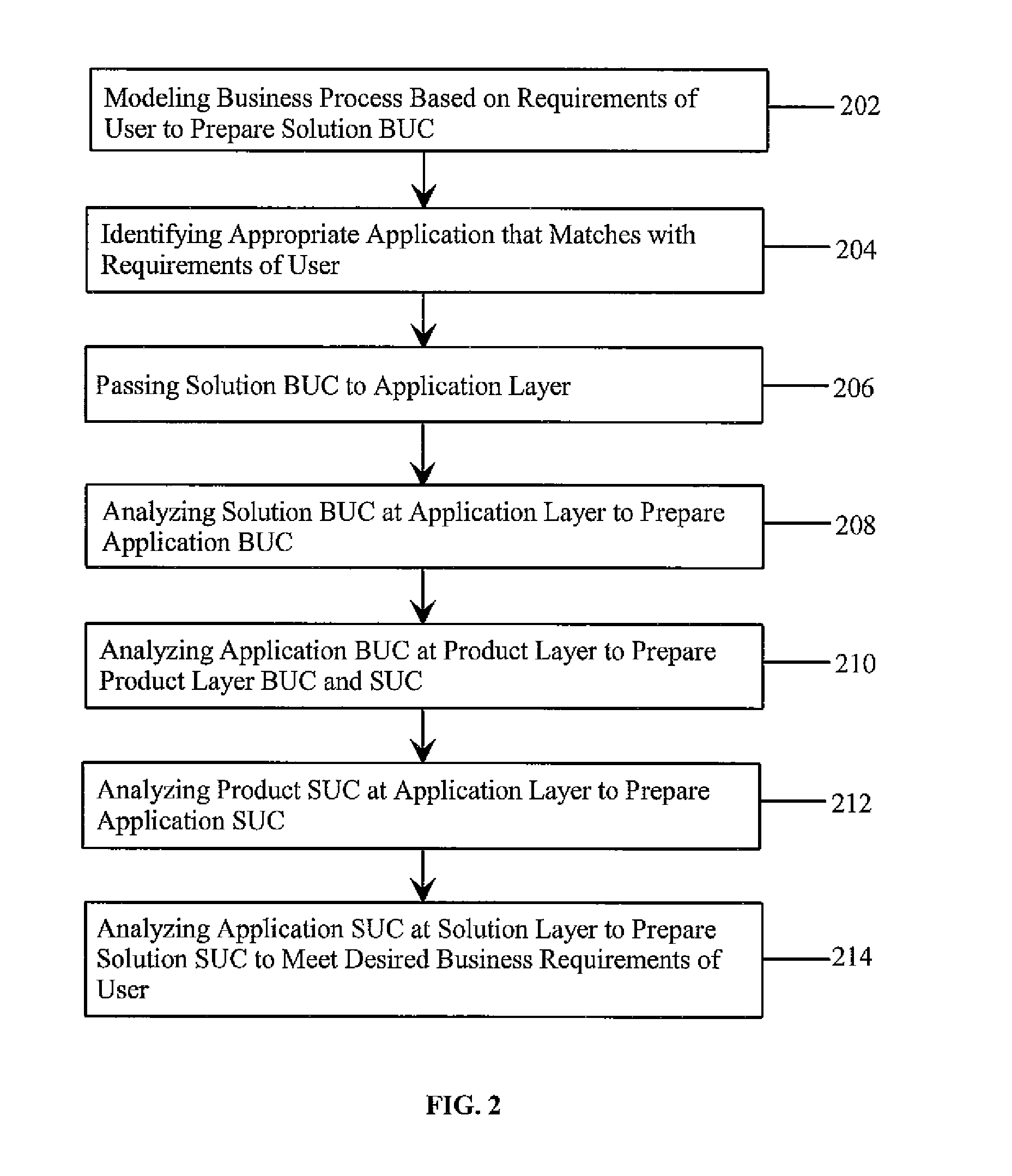

Product-application-solution (PAS) model for software design and development

The various embodiments of the present invention provide a PAS model for software design and development with a product layer including basic product level business objects (BO) to provide a basic functionality offered by software. An application layer is built on the product layer to include the application level business objects to provide inputs for a solution required by a user and to achieve desired business requirements. A solution layer is built on the application layer to include the solution level business object to address the specific business requirement of the user. The solution level business object is created using the application level business objects which is in turn created using the product level business objects to provide solution to meet the specific business requirement of the user.

Owner:NANDAKUMAR KRISHNAN NAIR

Process for producing biological diesel oil

InactiveCN101294096AIncrease speedPromote generationBiofuelsLiquid hydrocarbon mixture productionOil and greaseBiodiesel

A preparation method of bio-diesel for solving the problems such as complex post-treatment and environmental pollution existing in the conventional method comprises the following steps: mixing animal and plant oil or waste grease with methanol or ethanol in the presence of nanometer crystal whisker catalyst with an amount of 0.1 to 5% the weight of the raw material oil and an alcohol / oil molar ratio of 4:1 to 10:1, carrying out ultrasonic transesterification reaction, standing the reactive mixture to obtain an upper layer containing the mixture liquid of glycerol and residual methanol or ethanol and a lower layer containing crude product, and pump-filtering the lower crude product layer to obtain the bio-diesel. The preparation method of the invention is efficient, safe and pollution-free and is conducive to industrial production, and meets the requirement of people for the environment. The yield of the bio-diesel prepared by the method is above 97%. The method has the advantages of simple operation, less consumption of catalyst, short time, greatly simplified post-treatment process, no environmental pollution, safe and reliable operation, and low production cost, and is suitable for industrial production.

Owner:BOHAI UNIV

Engineered wood product

Engineered wood products, methods of making the products, laminates including the products, and articles of manufacture which include the engineered products or composites, are disclosed. The products include wood and / or other cellulosic fibers, and can include non-cellulosic fibers, all or part of which can be derived from post-industrial and / or post-consumer materials. The products also include a binding agent, such as a latex dispersion, as well as hydrophobic materials, processing aids, colorants, and the like. The product can be in the form of a sheet, a three dimensional article or a plurality of laminated sheets, and can include one or more additional layers, such as top coat layers, reinforcing layers, cushioning layers, wood veneer layers, and / or additional product layers. The products can be used as flooring, and in construction, cabinetry, and the like.

Owner:MALLARD CREEK POLYMERS +1

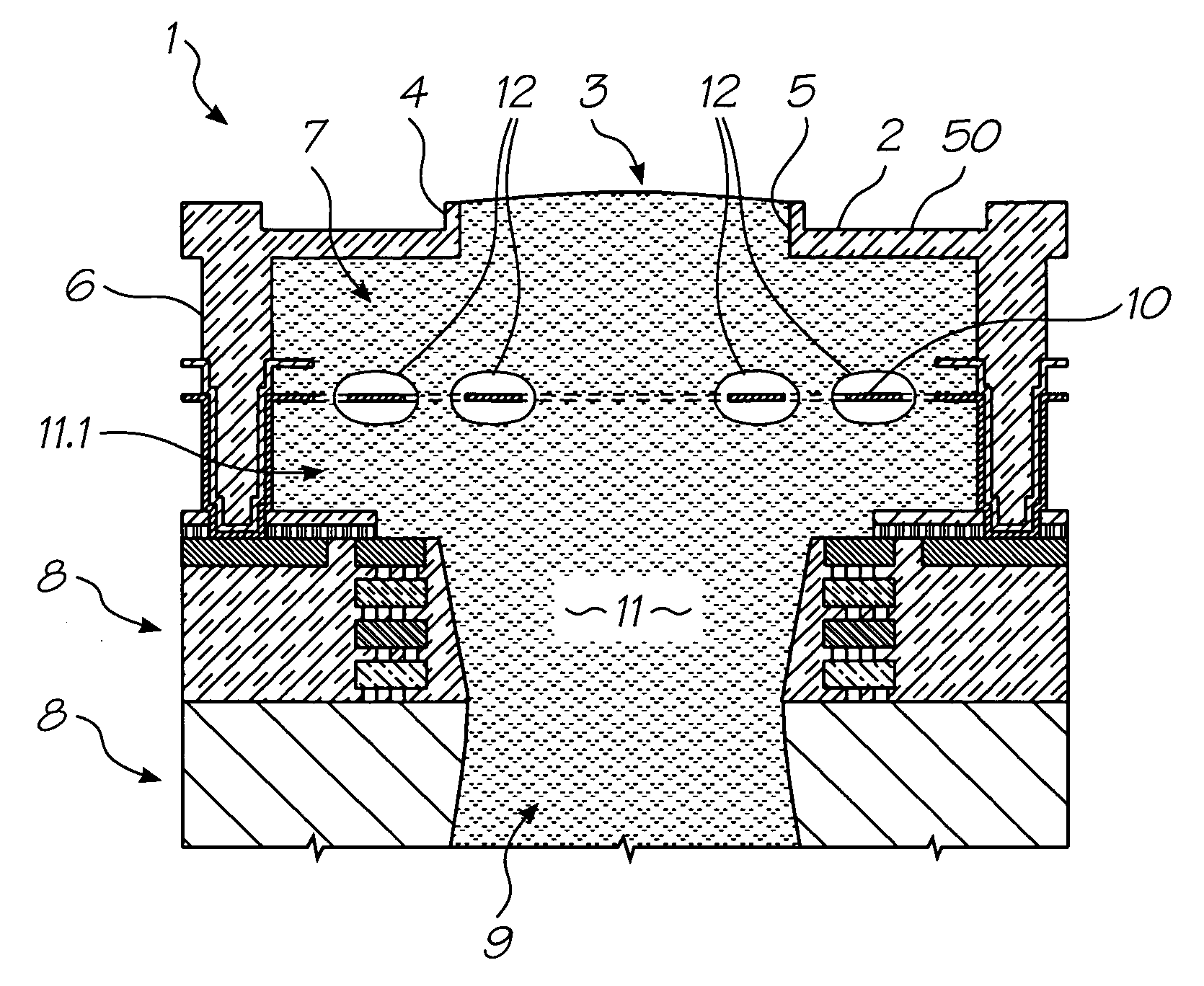

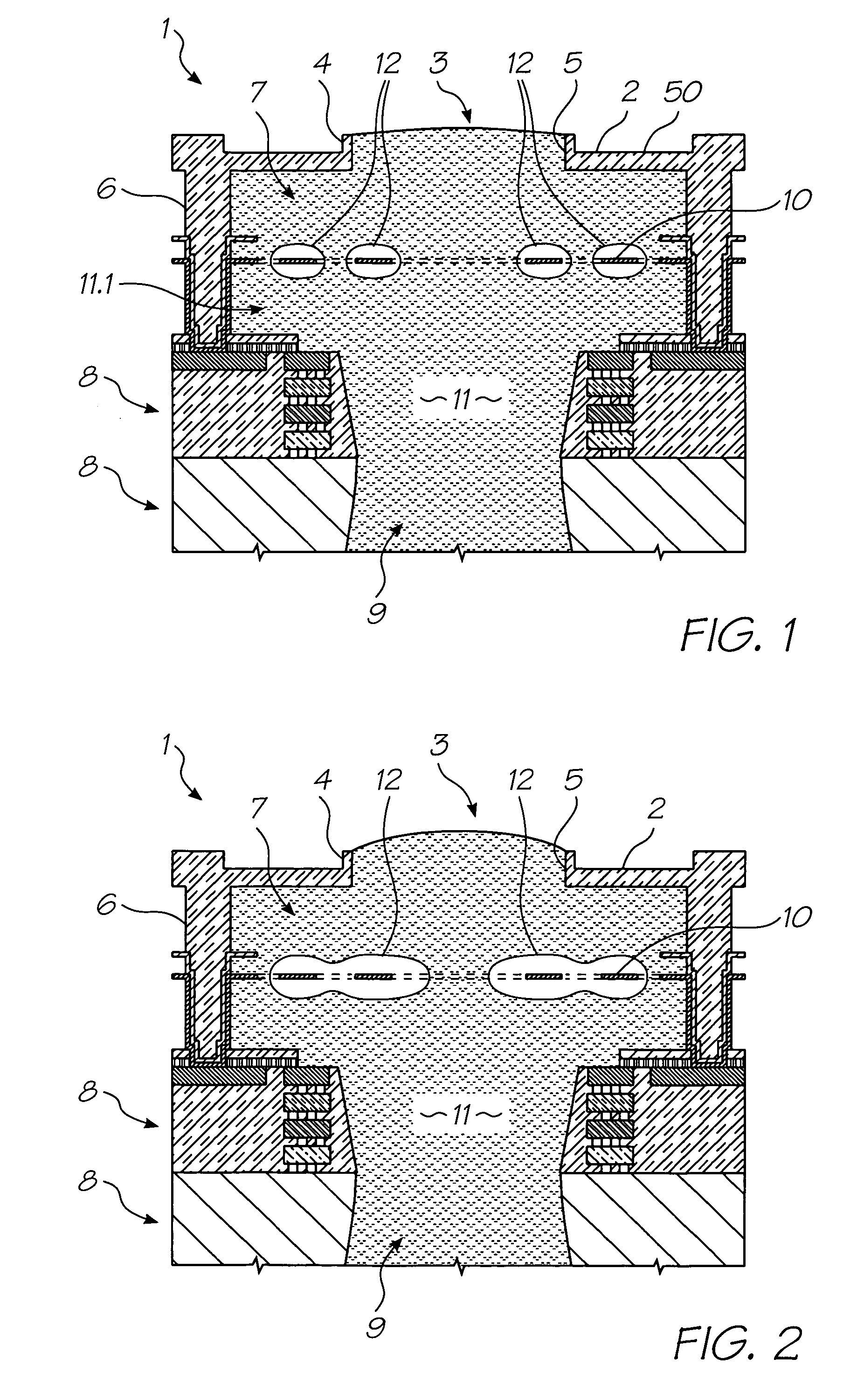

Method for manufacturing fired product having luminous function, fired product manufactured thereby, and evacuation route guiding sign device using fired product

InactiveUS20070036988A1Decrease of afterglow functionReduce oxidative degradationGlass/slag layered productsNatural mineral layered productsFritThermal expansion

A fired product having a luminous function is manufactured by: adhering material-adapting glass frit to a surface of a ceramic material; adhering coating glass frit to the surface of the material-adapting glass frit after drying of the material-adapting glass frit; adhering luminous material particles having a particle size of 50 to 250 μm in one uniform layer to the coating glass frit layer before drying of the coating glass frit so that the upper portions of the luminous material particles are partly exposed from the coating glass frit; alternately stacking coating glass frit and luminous material particles several times; covering the topmost luminous material particles partly exposing from the coating glass frit by adhering coating glass frit; printing an image portion on the surface of the coating glass frit after drying of the coating glass frit; adhering adapting glass frit at a predetermined thickness to the coating glass frit having the printed image portion; uniformly adhering protecting glass frit particles having a large particle size to the surface of the adapting glass frit; and firing the adhered stack at high temperature, wherein the material-adapting glass frit has a coefficient of thermal expansion of an intermediate value between those of the ceramic material and the luminous material particles, the coating glass frit has a coefficient of thermal expansion substantially the same as that of the luminous material particles, and the adapting glass frit has a coefficient of thermal expansion of an intermediate value between those of the luminous material particles and the protecting glass frit particles having a large particle size. This fired product is used in an image forming part of an evacuation route guiding sign device as a fired product layer.

Owner:UNIVERSAL LIGHT

Inkjet printhead with low thermal product layer

InactiveUS20060221137A1Low viscosityImprove insulation performanceInking apparatusOther printing apparatusThermal isolationBoiling point

A thermal inkjet printhead with generally planar heater elements disposed in respective bubble forming chambers such that they are bonded on one side to the chamber so that the other side faces into the chamber. Each heater element receives an energizing pulse to heat ejectable liquid above its boiling point to form a gas bubble on the side facing into the chamber, whereby the gas bubble causes the ejection of a drop of the ejectable liquid from the nozzle. The chamber has a dielectric layer proximate the side of the heater element bonded to the chamber. The dielectric layer has a thermal product less than 1495 Jm−2K−1s−1 / 2, the thermal product being (ρCk)1 / 2, where ρ is the density of the layer, C is specific heat of the layer and k is thermal conductivity of the layer. The present invention reduces the drop ejection energy and the heat dissipation into the printhead IC by improving the thermal isolation between the heater and the substrate.

Owner:SILVERBROOK RES PTY LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com