Release film, compression molding method, and compression molding apparatus

A technology of compression molding and release film, which is applied in the direction of chemical instruments and methods, lamination, lamination devices, etc., can solve the problems of difficult release film, low strength, and insufficient detachability of molded products, and achieve good Effects of efficiency, good processability, and good detachability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0056] The release film, compression molding method, and compression molding apparatus of the present invention will now be described in detail with reference to practical examples. Note that the viscosity in the practical examples is a value at 25°C.

[0057] [Practical example 1]

[0058] An addition reaction curable silicone composition was prepared by mixing 100 parts by mass of dimethylsiloxane terminated with trimethylsiloxy groups at both molecular ends and a raw material of methylhexenylsiloxane. Rubber-like copolymer (hexenyl group content: 0.5% by weight), 2 parts by mass of methylhydrogenpolysiloxane having a viscosity of 150 mPa·s, chloroplatinic acid, and 1,3-divinyltetramethyldisiloxane A complex of alkanes (in an amount such that the amount of platinum metal is 200 ppm), 1 part by mass of 3-methyl-1-butyn-3-ol, and 1,957 parts by mass of toluene.

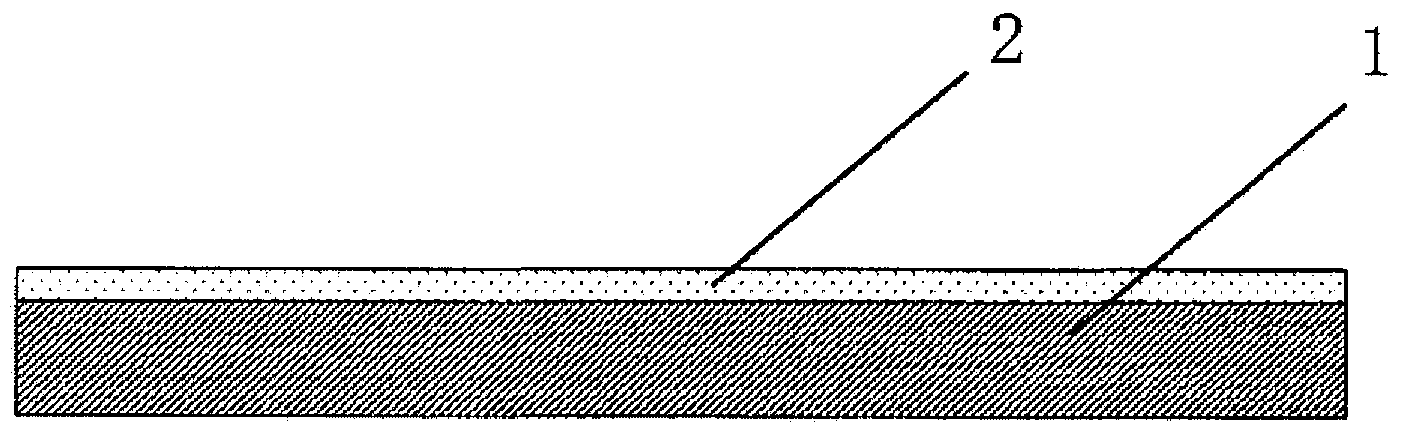

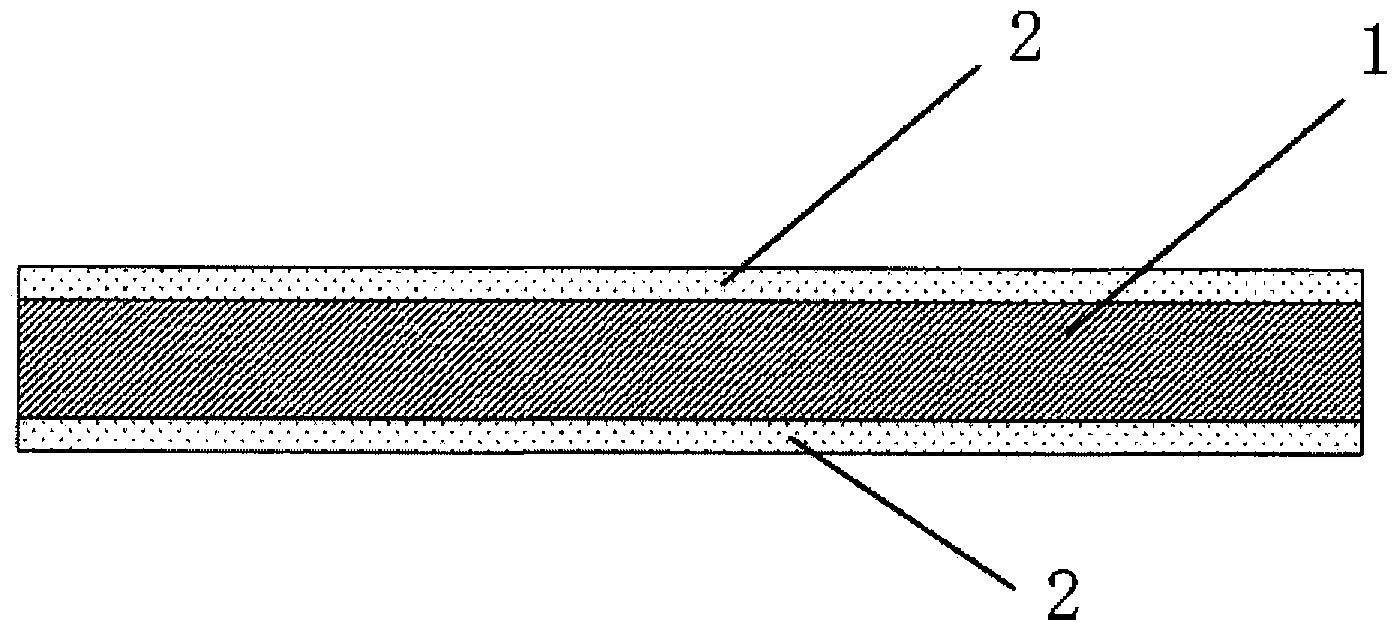

[0059] A PET film having a silicone-based cured product layer with a thickness of 4 μm was prepared by coating ...

reference example 1

[0070] [Reference Example 1] (Preparation of silicone-modified epoxy resin molding material)

[0071] By uniformly mixing 5.96 g of an epoxy-modified silicone resin (epoxy equivalent: 299; viscosity: 13.4 Pa·s; mass average molecular weight: 2,600) represented by the following average unit formula,

[0072] Formula 1

[0073]

[0074] 6.04 g 3,4-epoxycyclohexenylmethyl-3',4'-epoxycyclohexenecarboxylate (Celoxide 2021P, manufactured by Daicel Chemical Industries Ltd.) ), 11.16g of 3- or 4-methyl-hexahydrophthalic anhydride (HN 5500E, manufactured by Hitachi Chemical Co., Ltd.), and 0.194g of methyl tributyl dimethylphosphonate A transparent silicone-modified Epoxy molding compound.

reference example 2

[0075] [Reference Example 2] (Preparation of epoxy resin molding material)

[0076] By uniformly mixing 10.07 g of 3,4-epoxycyclohexenylmethyl-3',4'-epoxycyclohexene carboxylate (Celoxide 2021P, manufactured by Daicel Chemical Industries, Ltd.), 12.93 g 3- or 4-methyl-hexahydrophthalic anhydride (HN 5500E, manufactured by Hitachi Chemical Co., Ltd.) and 0.188 g of methyltributylphosphonium dimethylphosphonate (Hishicolin PX-4MP, manufactured by Nippon Chemical A transparent epoxy resin molding material was prepared from a curable epoxy resin composition obtained by Industrial Co., Ltd.

[0077] [Practical example 5]

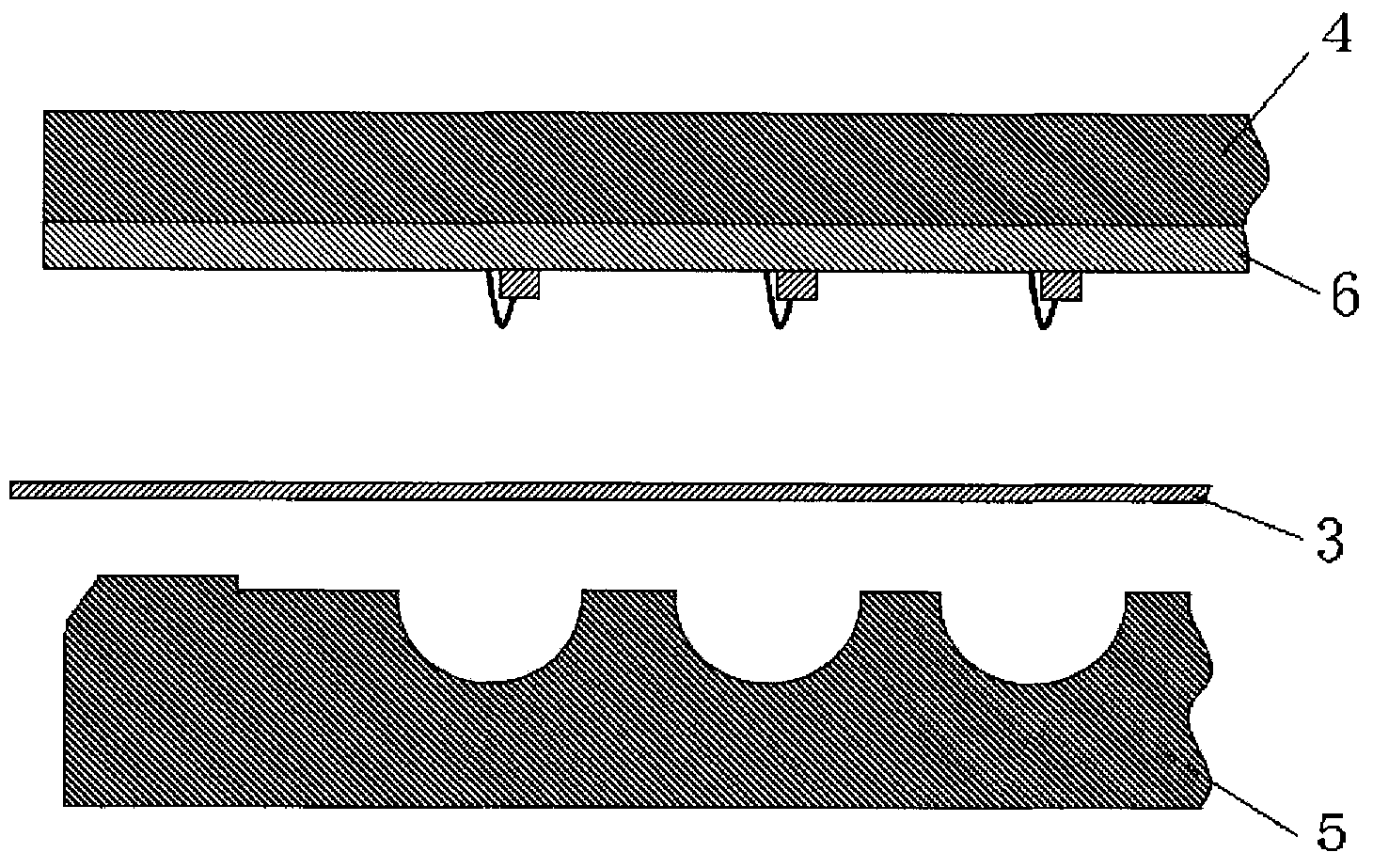

[0078] As a compression molding machine, FFT1005 manufactured by Towa Co., Ltd. consisting of a top mold and a bottom mold having a cavity in the bottom mold and a release film feeding mechanism on the side of the bottom mold was used. Set the glass epoxy substrate on the top mold of the compression molding machine. The mold of the bottom mold has 100 cavi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com