Super-size and high-density lithium cobalt oxide and method for preparing the same

A lithium cobalt oxide, high-density technology, applied in the field of high-energy power supply materials, can solve the problems of complex process, low production efficiency, and no lithium cobalt oxide doping, and achieve simple and controllable process, reduced cost, and large particle size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

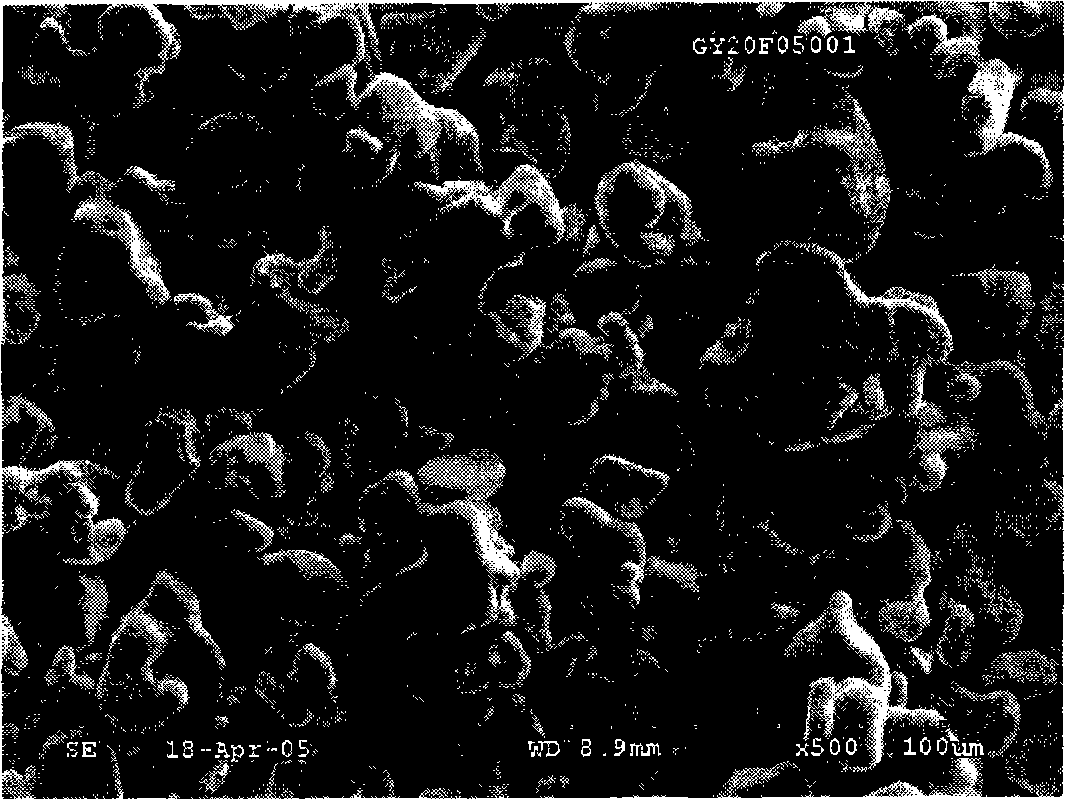

Image

Examples

Embodiment 1

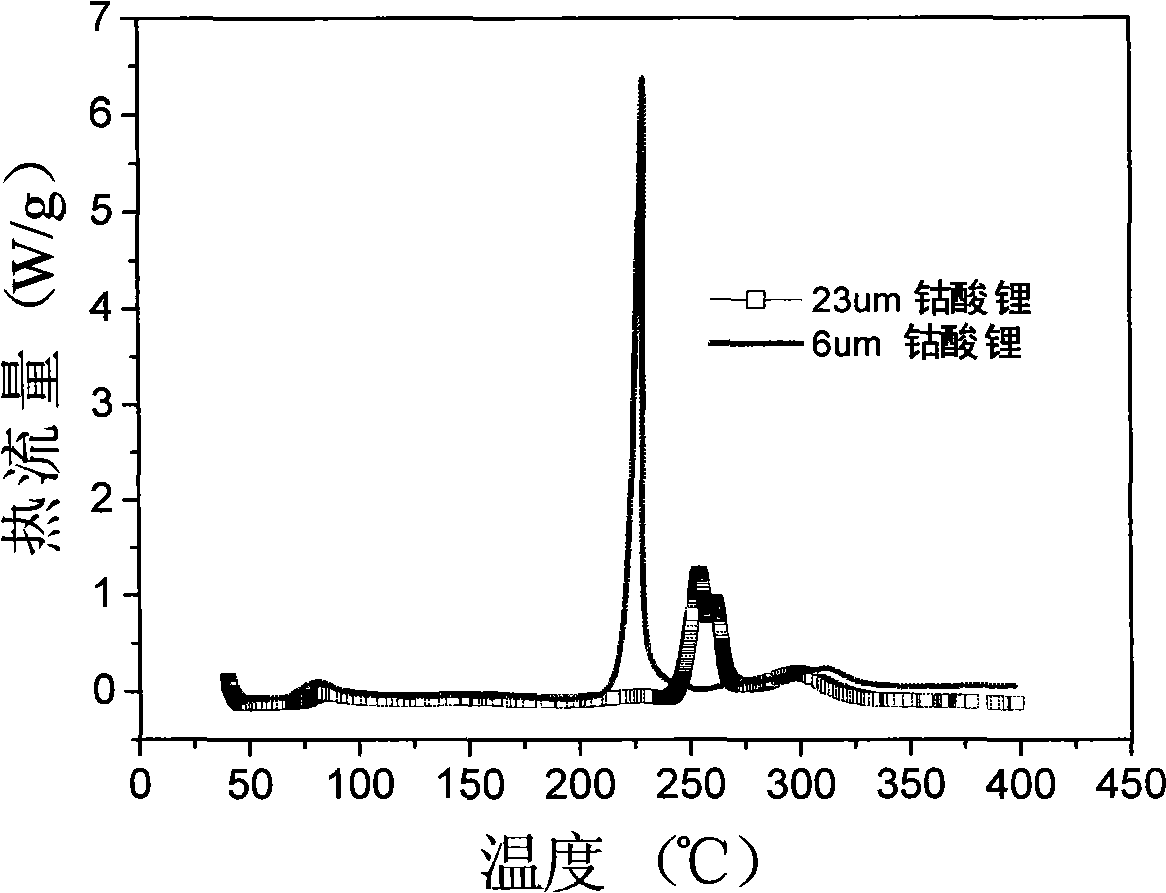

[0035] Lithium carbonate and cobalt oxide were weighed, poured into a mixing tank in turn and mixed thoroughly, and the molar ratio of Li / Co was controlled to be 1.05. Put the mixture into a ceramic sagger and compact it, then place it in a high-temperature furnace, raise the temperature at 10°C / min, and keep it at 980°C for 5 hours. After cooling down, the black block material obtained is ground and pulverized, and then passed through a 300-mesh sieve. The median diameter of the product is 21.35μm, and the tap density is 2.75g / cm 3 .

[0036] The material is mixed with carbon black and polyvinylidene fluoride (PVDF) according to a weight ratio of 94%: 3%: 3% and drawn into a pole piece. Form 053048 square aluminum shell battery; test the electrochemical performance and safety performance of the battery. The specific capacity of the material in the battery is 138mAh / g, the 3.6V platform capacity rate of the battery is 78%, 1C 5 A The capacity retention rate of 100 charge-d...

Embodiment 2

[0038] Lithium carbonate and cobalt carbonate were weighed, poured into a mixing tank in turn and mixed thoroughly, and the molar ratio of Li / Co was controlled to be 1.15. Put the mixture into a ceramic sagger and compact it, then place it in a high-temperature furnace, raise the temperature at 15°C / min, and keep it at 1050°C for 5 hours. After cooling down, the black block material obtained is ground and pulverized, and then passed through a 300-mesh sieve. The median diameter of the product is 37.35μm, and the tap density is 2.81g / cm 3 .

[0039] The material was processed into a 053048 battery by the same method as in Example 1, and the electrochemical performance and safety performance of the battery were tested. The specific capacity of the material in the battery is 136mAh / g, the capacity rate of the battery 3.6V platform is 76%, 100 times 1C 5 A The charge-discharge cycle capacity retention rate is 92.5%, and the thermal shock test result in a 150°C hot box shows tha...

Embodiment 3

[0041] Lithium hydroxide, cobalt oxide, and barium carbonate were weighed, poured into a mixing tank in turn and mixed thoroughly, and the molar ratio of Li / (Co+Ba) was controlled to be 1.05, and the molar ratio of Ba / (Co+Ba) to 0.05. Put the mixture into a ceramic sagger and compact it, then place it in a high-temperature furnace, raise the temperature at 10°C / min, and keep it at 1080°C for 5 hours. After cooling down, the black block material obtained is ground and crushed, and the product is obtained after passing through a 300-mesh sieve. The median diameter of the product is 27.43μm, and the tap density is 2.86g / cm 3 .

[0042] The material was processed into a 053048 battery by the same method as in Example 1, and the electrochemical performance and safety performance of the battery were tested. The specific capacity of the material in the battery is 136mAh / g, the 3.6V platform capacity rate of the battery is 78%, 100 times 1C 5 A The charge-discharge cycle capacity r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com