Patents

Literature

5957 results about "Aluminium salts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminium sulfate is a chemical compound with the formula Al2(SO4)3. It is soluble in water and is mainly used as a coagulating agent (promoting particle collision by neutralizing charge) in the purification of drinking water and waste water treatment plants, and also in paper manufacturing.

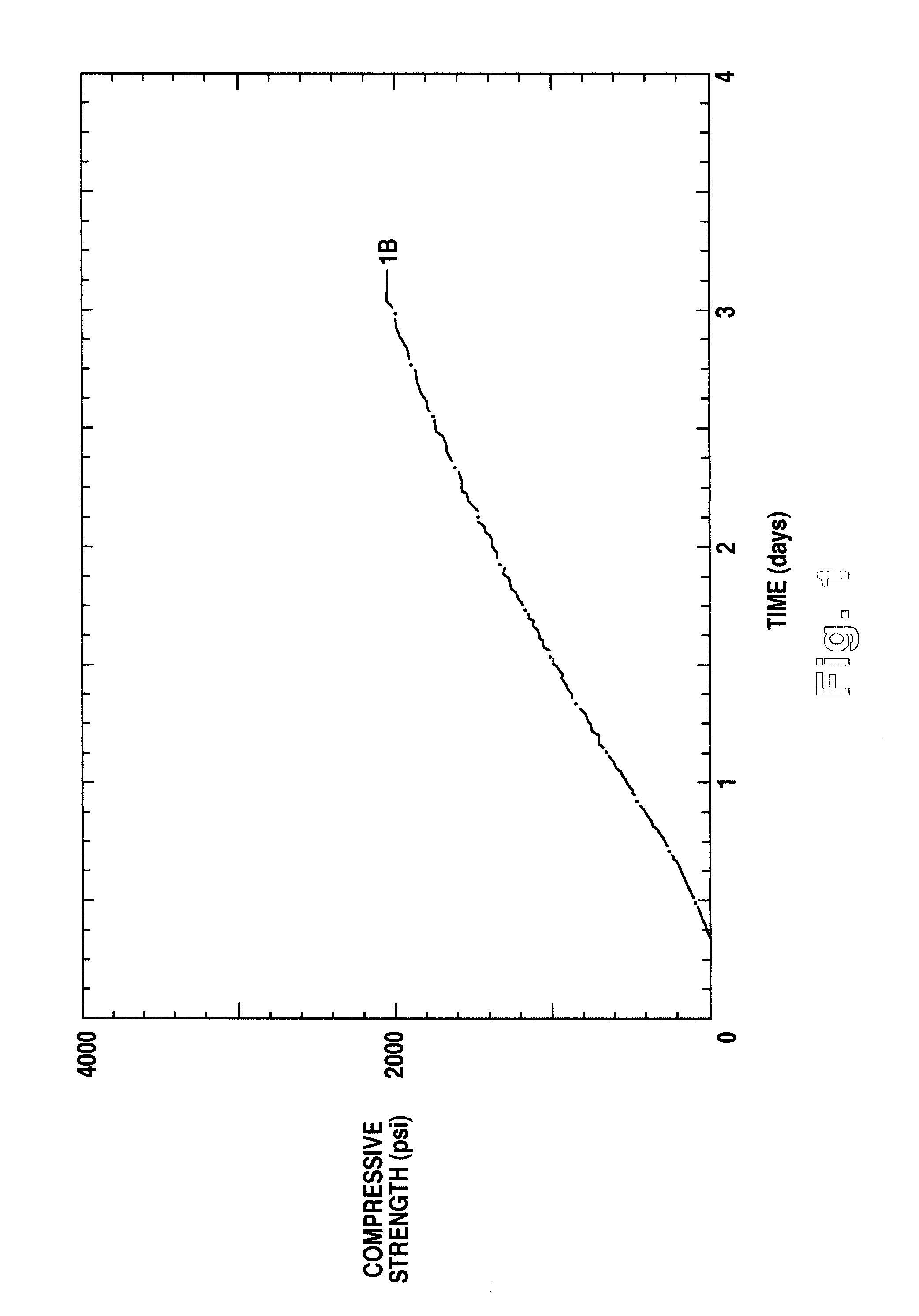

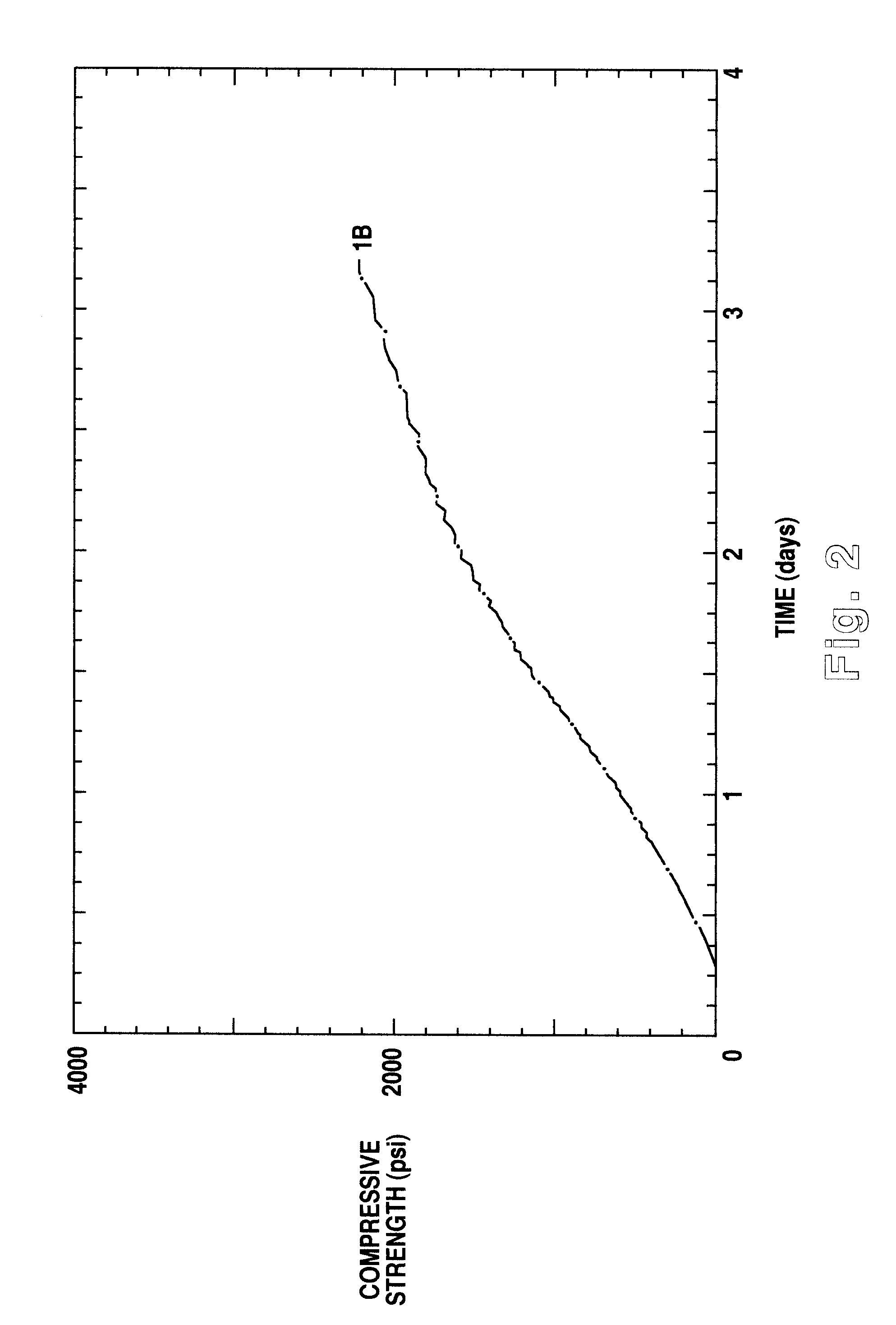

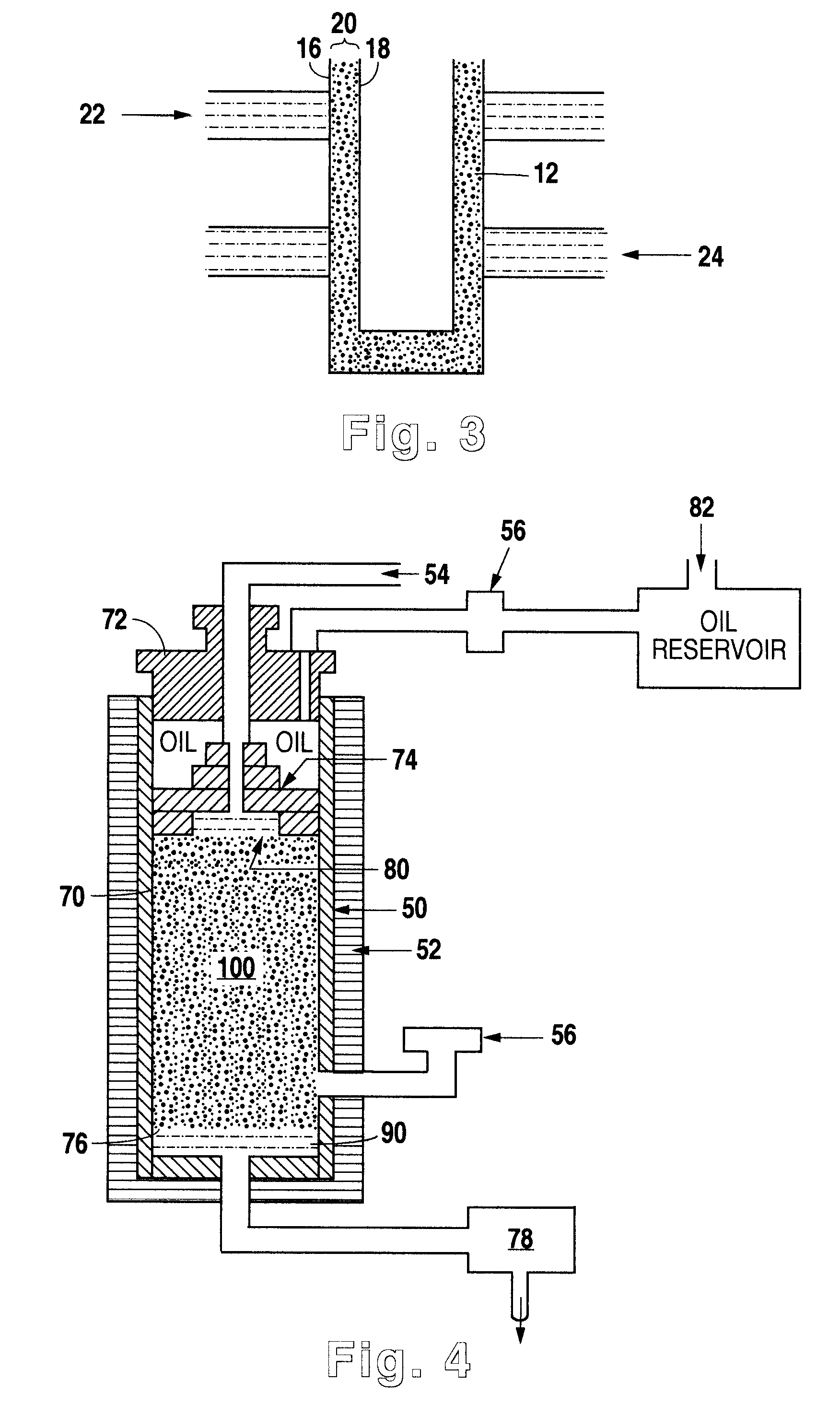

Methods and compositions for use in cementing in cold environments

Cement compositions for cementing wellbores in cold environments. The cement compositions may include a mixture of a reactive aluminum silicate, aluminum sulfate and hydraulic cement, and may include one or more other additives. The cement compositions may be formulated to have reduced heat of hydration as compared to conventional cements, making them suited for cementing in permafrost environments. The cement slurries may optionally be foamed using a foaming agent and energizing phase.

Owner:AMERICAN CEMENTING LLC

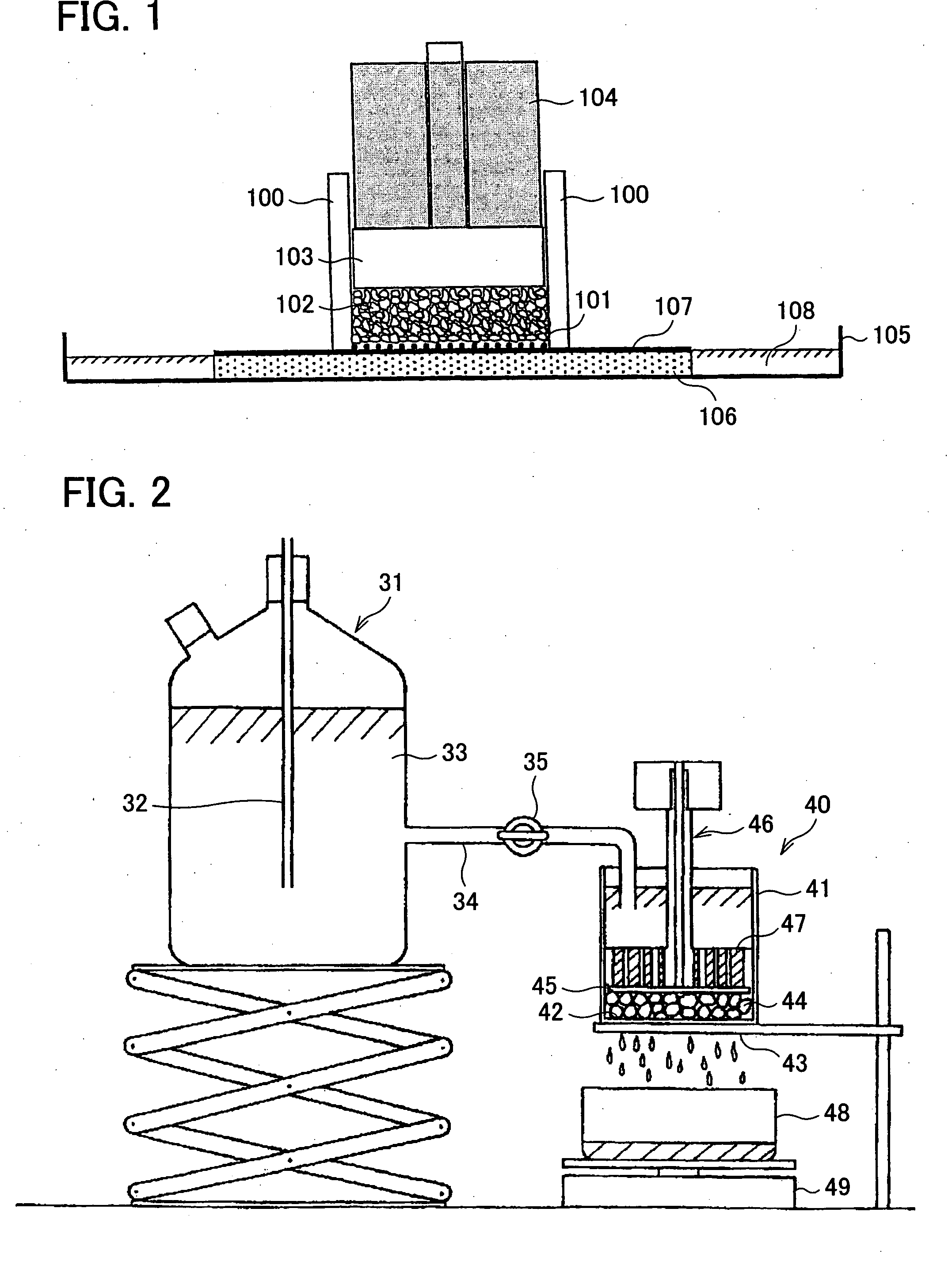

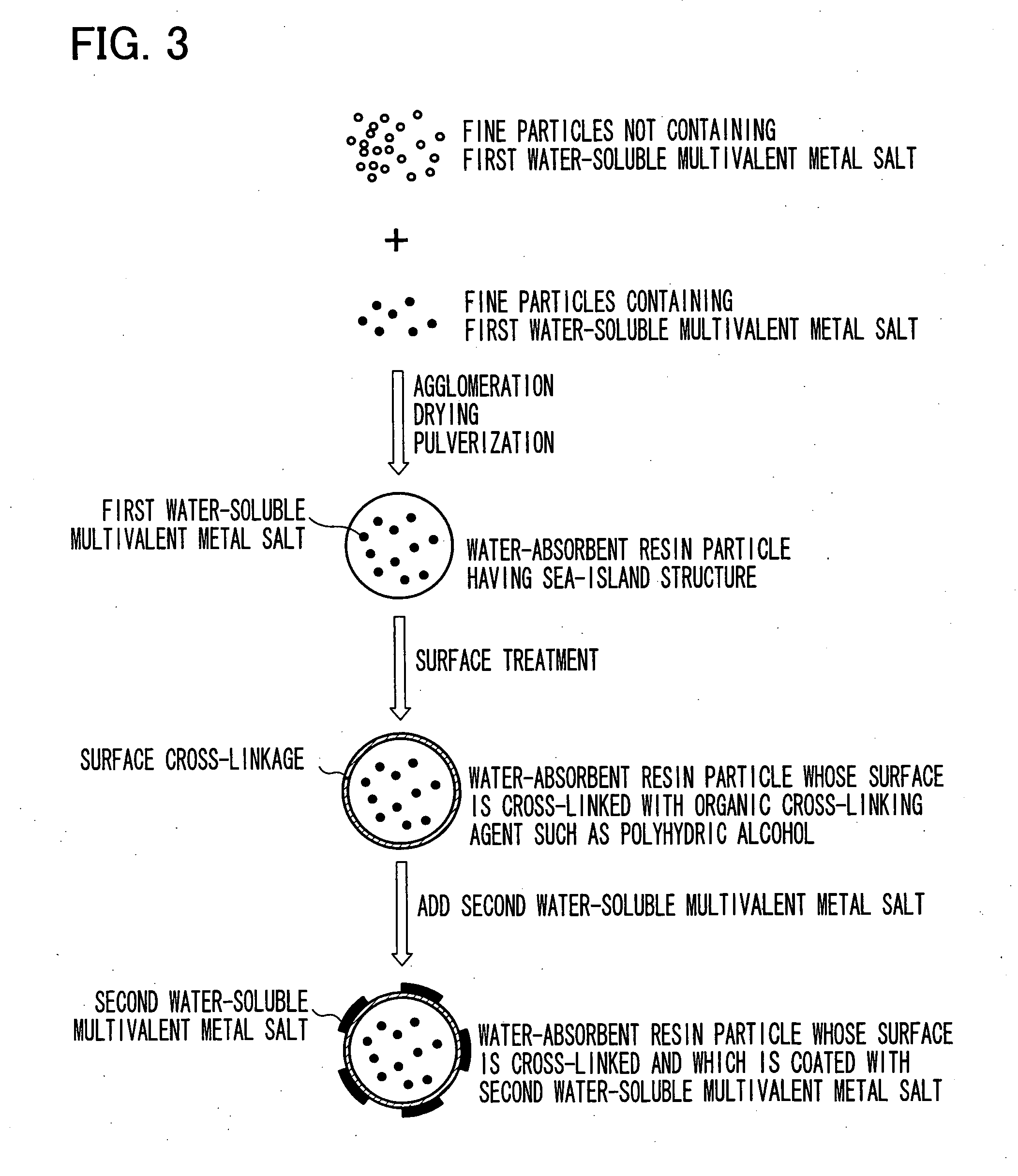

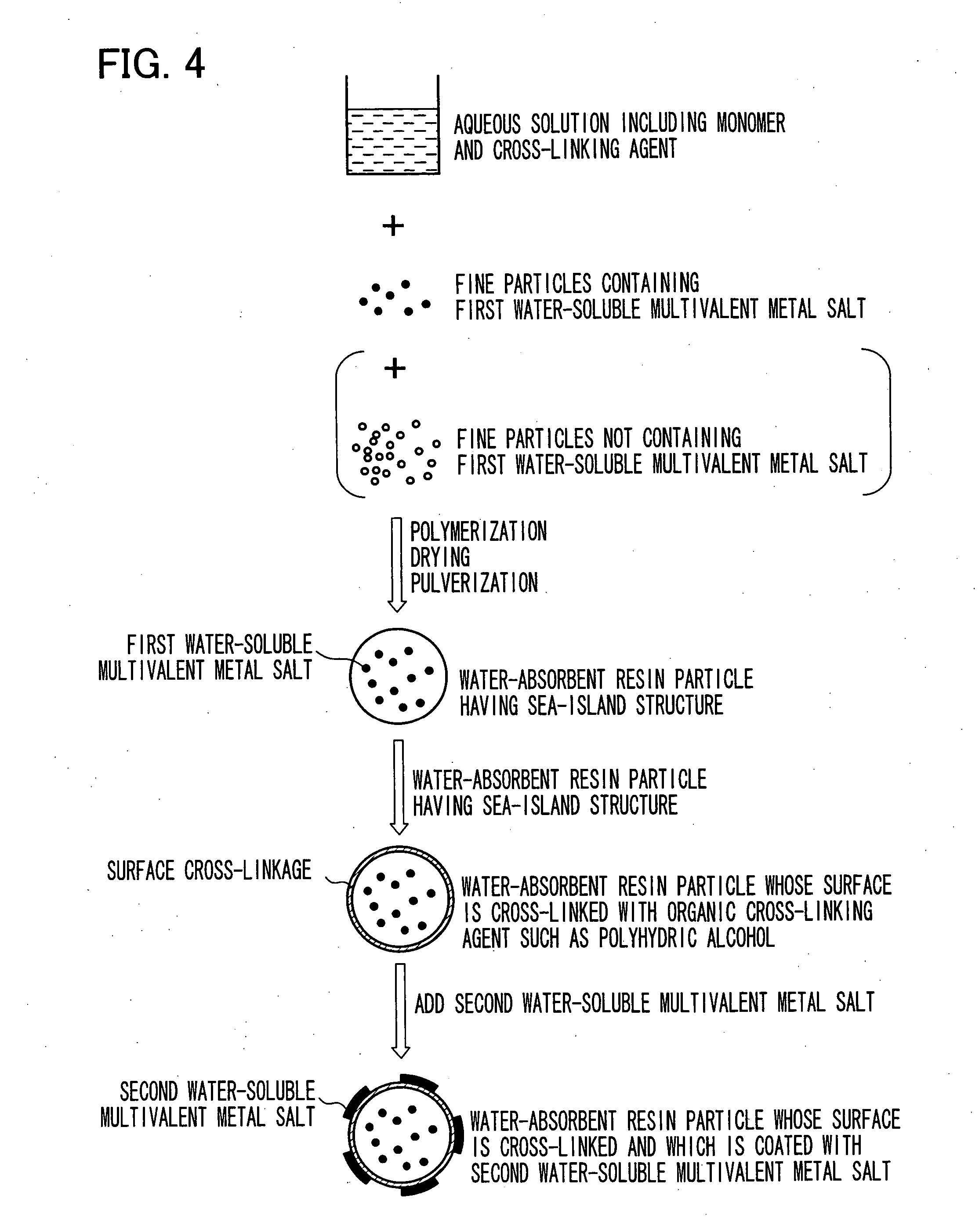

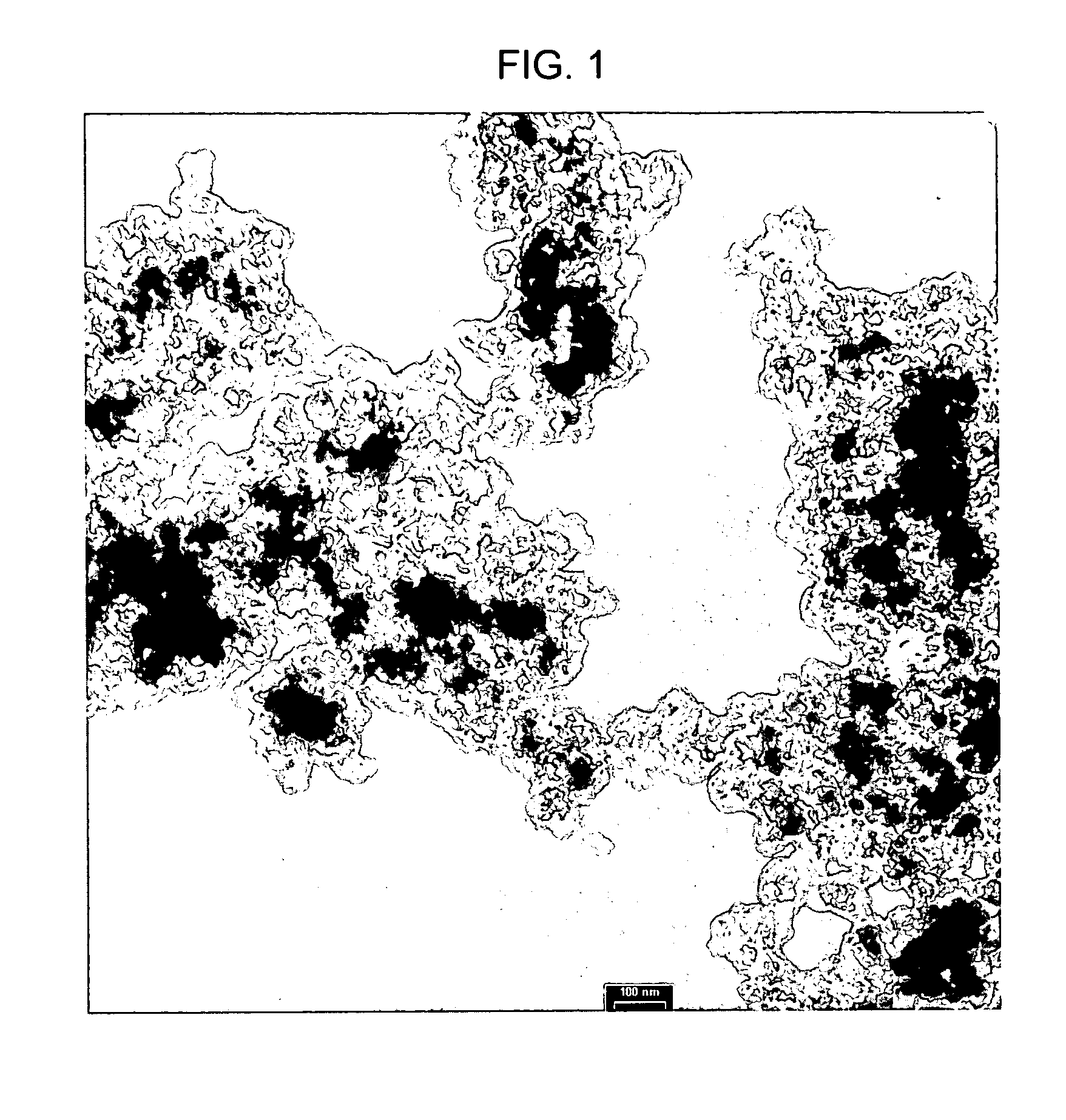

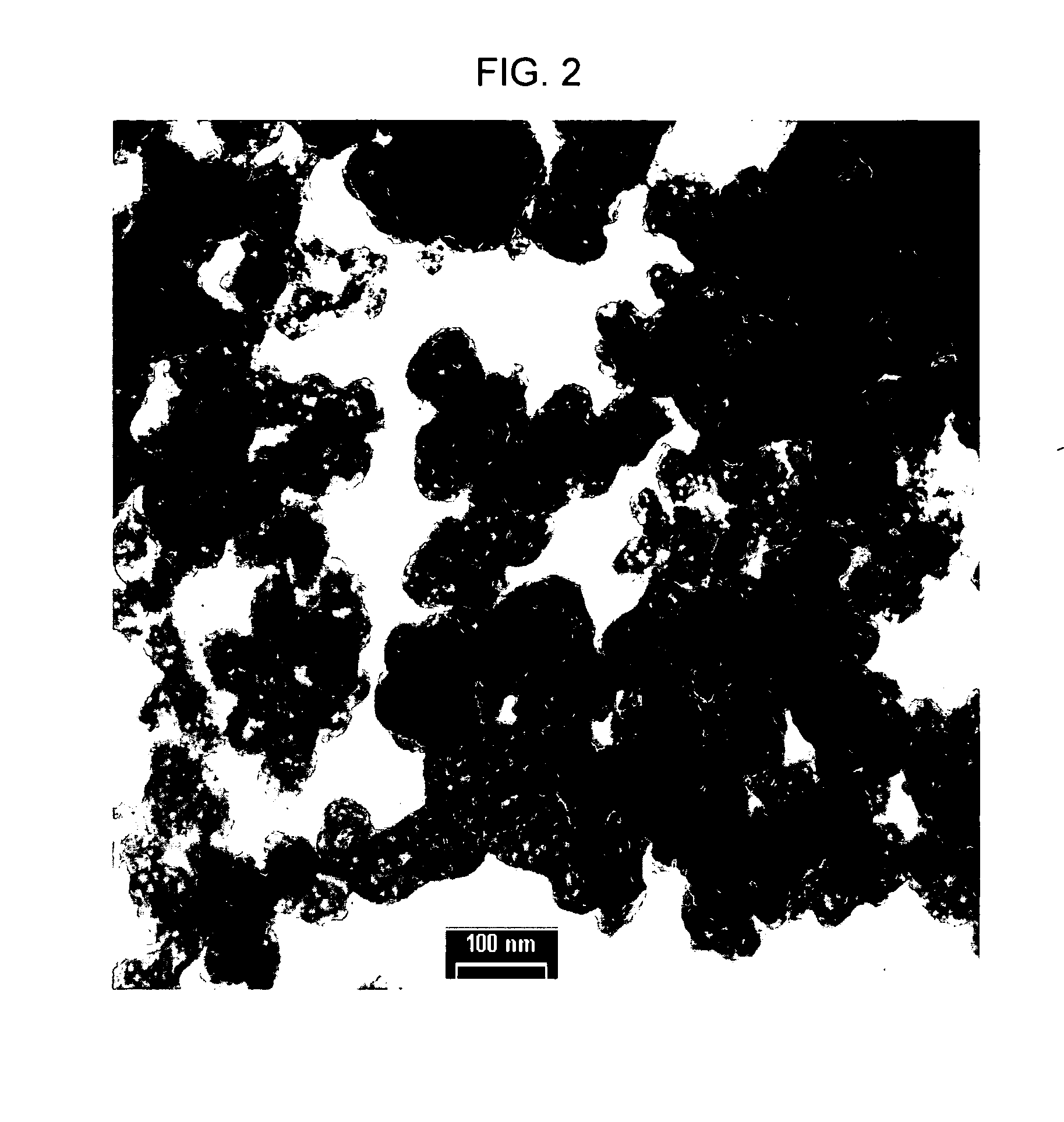

Water-absorbing agent and its production process

ActiveUS20060247351A1Less water-soluble component contentImprove water retentionSynthetic resin layered productsCellulosic plastic layered productsAluminium sulfateCross-link

A water-absorbing agent according to the present invention includes water-absorbent resin particles having an internal cross-linked structure,.wherein a vicinity of a surface of the water-absorbent resin particle is cross-linked with a surface cross-linking agent, and the water-absorbent resin particle has therein a sea-island structure having (i) part containing a first water-soluble multivalent metal salt such as aluminum sulfate and (ii) part not containing the first water-soluble multivalent metal salt. With this arrangement, it is possible to provide a water-absorbing agent having less water-soluble component content, more excellent liquid permeability, and more excellent water retention under pressure than the conventional water-absorbing agent.

Owner:NIPPON SHOKUBAI CO LTD

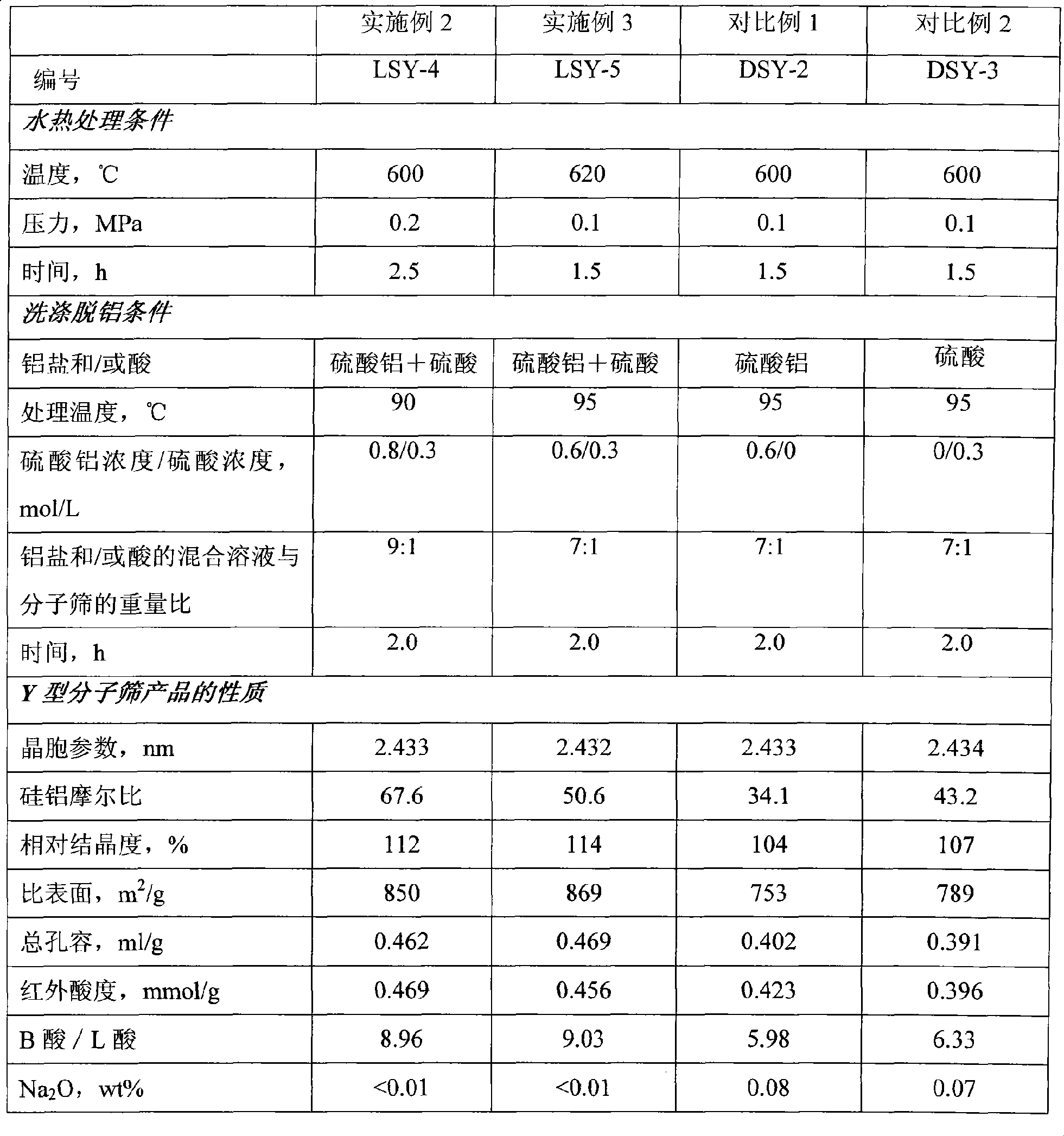

Hydrocracking catalyst and preparation method thereof

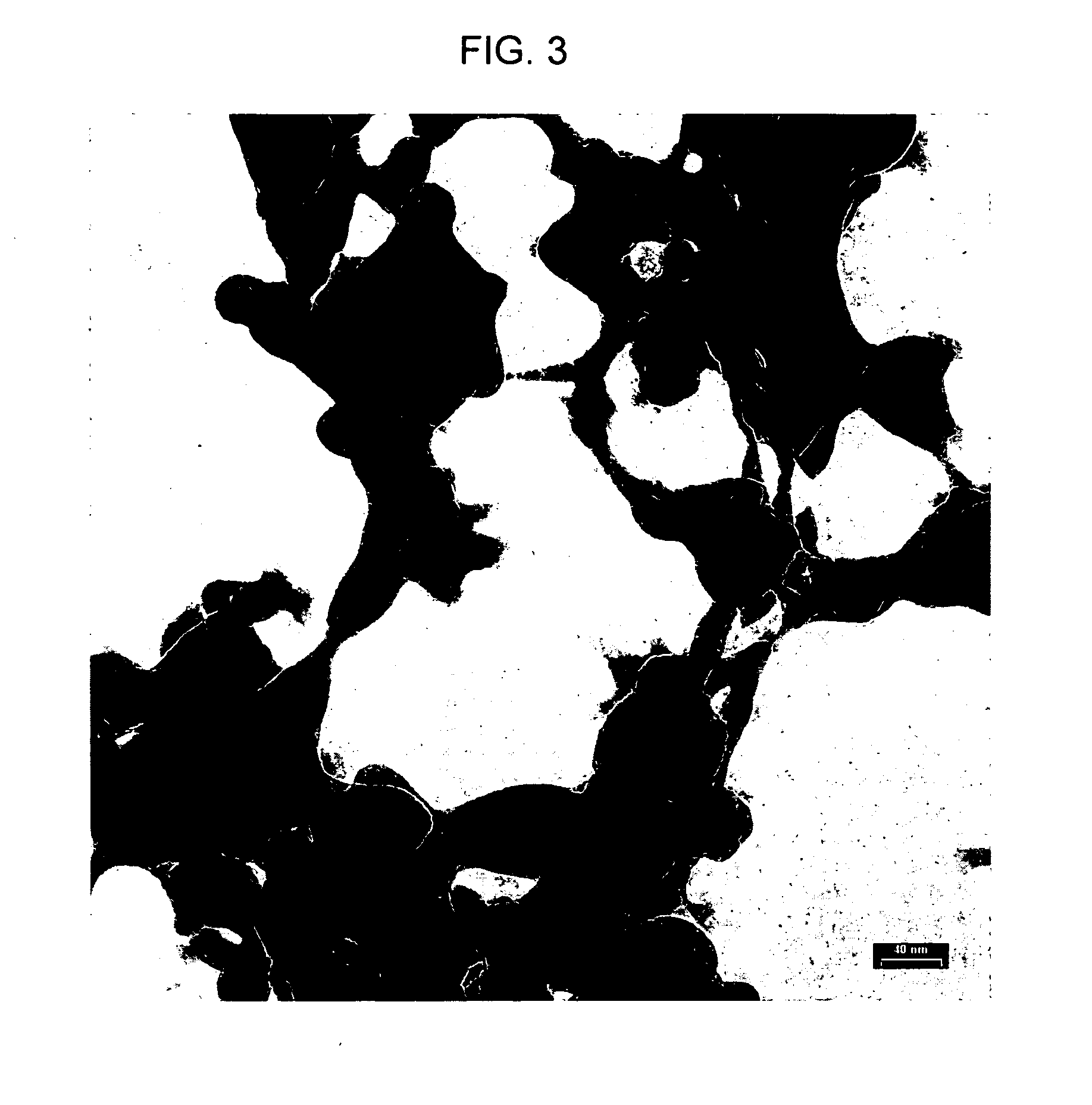

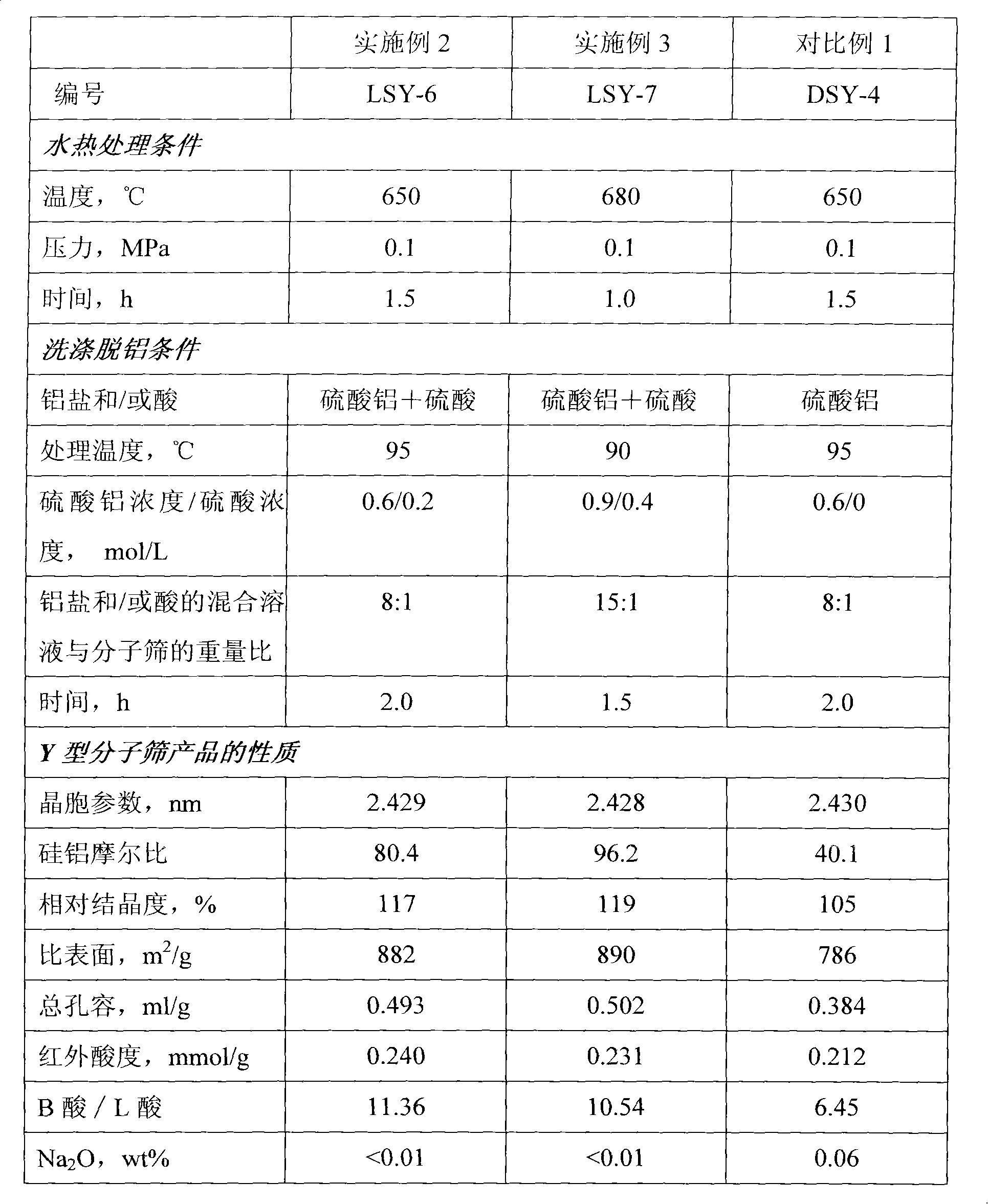

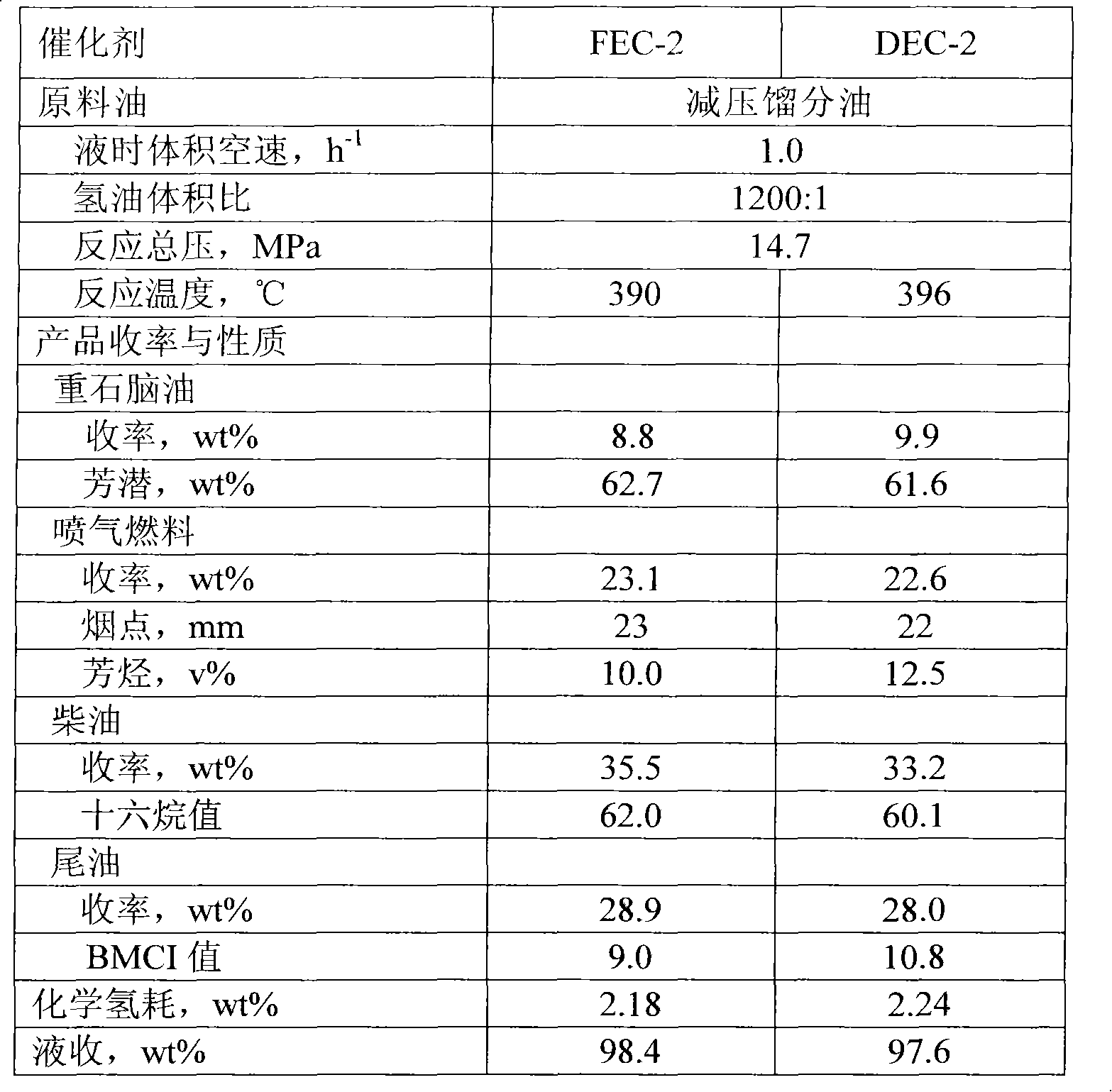

ActiveCN101380589AHigh ratio of silicon to aluminumLarger than surfaceMolecular sieve catalystsHydrocarbon oil crackingCrystallinityCell parameter

The invention discloses a hydrocracking catalyst and a preparation method thereof. The catalyst comprises hydrogenation active metals and a carrier containing modified Y molecular sieve, alumina and amorphous aluminium silicon, wherein, the Y molecular sieve is prepared by the following method: the Y molecular sieve undergone hydro-thermal treatment by mixed water solution of aluminium salt and acid is adopted; the performance of the Y molecular sieve is as follows: specific surface is 800m<2> / g-900m<2> / g, total aperture volume is 0.40ml / g-0.50ml / g, relative crystallinity is 90%-130%, cell parameter is 2.434-2.440nm, aluminium silicon mol ratio is 20-100, infrared acid volume is 0.3-0.8mmol / g, the mol ratio of acid B and acid L is above 7.0, sodium oxide content is less than or equal to 0.05wt%. The catalyst prepared by the invention has the advantages of high catalytic activity, good target product selectivity and can produce heavy naphtha, aviation fuel and diesel fuel, and the like, with high yield and good quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

Vaccines comprising aluminium adjuvants and histidine

To improve the stability of vaccines comprising aluminum salt(s), the invention uses the amino acid histidine. This can improve pH stability and adjuvant adsorption and can be reduce antigen hydrolysis. Histidine is preferably presen during adsorption to the aluminium salt(s). The antigen in the vaccine may be a protein or a saccharide and is preferably from N. meningitidis.

Owner:GLAXOSMITHKLINE BIOLOGICALS SA

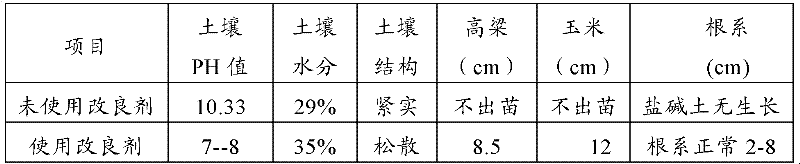

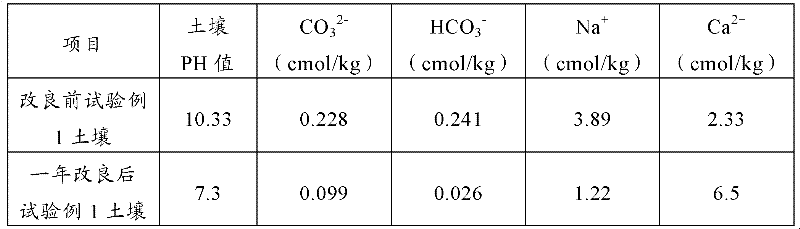

Saline-alkali soil improver

InactiveCN102517030ALower pHRaise the pHOther chemical processesOrganic fertilisersCis-Butenedioic AcidFatty alcohol

The invention relates to an improver for saline-alkali soil. The improver comprises a powder agent and a water agent, wherein the powder agent comprises the following components: organic matters, plant mycelium protein powder, active calcium, calcium superphosphate, aluminum sulfate, fatty alcohol polyoxyethylene ether ammonium sulfate, amino acid powder, bacillus subtilis and photosynthetic bacteria, and the water agent comprises the following components: citric acid, fulvic acid, humic acid, malic acid, maleic acid, fumaric acid, L-tartaric acid, pyrophosphoric acid, humic acid, lactic acid, oxalic acid, salicylic acid, sodium ion adsorbent, Tween-80 and water. The improver disclosed by the invention can improve the soil from multiple angles, namely soil structure, microorganism species, a chemical method and the like, obviously promote the release of iron and phosphorus in the soil, improve the soil structure, effectively reduce the content of sodium ions in the soil, reduce the pH value of the soil and restore land to a normal planting state after being used continuously for two years.

Owner:孙东军 +1

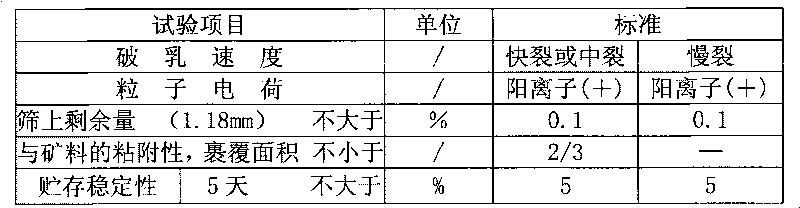

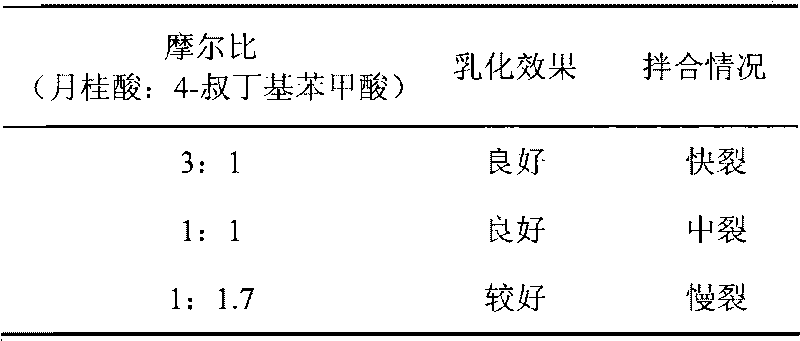

Cationic asphalt emulsifier and preparation method and application thereof

ActiveCN101745340AWide selectionWide applicabilityTransportation and packagingMixingChloroacetic acidsFatty alcohol

The invention relates to cationic asphalt emulsifier and preparation method and application thereof. The main agent of the cationic asphalt emulsifier is prepared through the reaction of quaternarization reagent and intermediate at molar ratio of 0.5-3:1, wherein the intermediate is produced in the reaction of organic acid mixture and organic amine at molar ratio of 1: 1-3. The adjuvant agent of the cationic asphalt emulsifier is the combination of, based on the main agent by weight, 0.1-2.5% of nonionic surfactant and 0.1-2.5% of modifier. The organic acid mixture is the mixture of linear, branched or naphthene-containing organic acid with small relative pace steric effect and organic acid with big relative space steric effect at molar ratio of 1: 3- 3: 1. The quaternarization reagent is epichlorohydrin, hydrochloric acid, chloromethane, dimethyl sulfate or chloroacetic acid. The modifier is one or more of aluminum sulfate, ammonium chloride and calcium chloride and the nonionic surfactant is fatty alcohol-polyoxyethylene ether. The emulsifier has no bad effects to the property of the asphalt, has wide application range and can satisfy different construction conditions.

Owner:PETROCHINA CO LTD +1

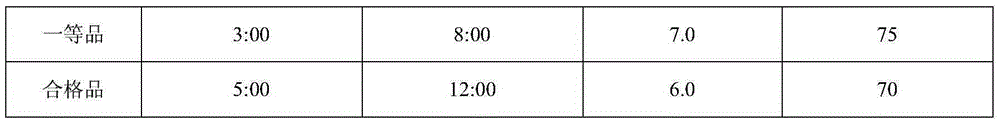

Process for extracting aluminium hydroxide from flyash

InactiveCN1792802AAchieve recyclingEffective leachingAluminium oxide/hydroxide preparationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminium sulfateAluminium hydroxide

A process for extracting aluminum oxide from powdered coal ash includes such steps as grinding, calcining, mixing with H2SO4 solution, heating while reaction for extracting aluminum oxide, boiling in water, concentrating, cooling while educing out aluminum sulfate crystals, heating for dewatering, heating for decomposing to obtain gamma-Al2O3, and further preparing metallurgy-class aluminum oxide.

Owner:朔州市人民政府 +2

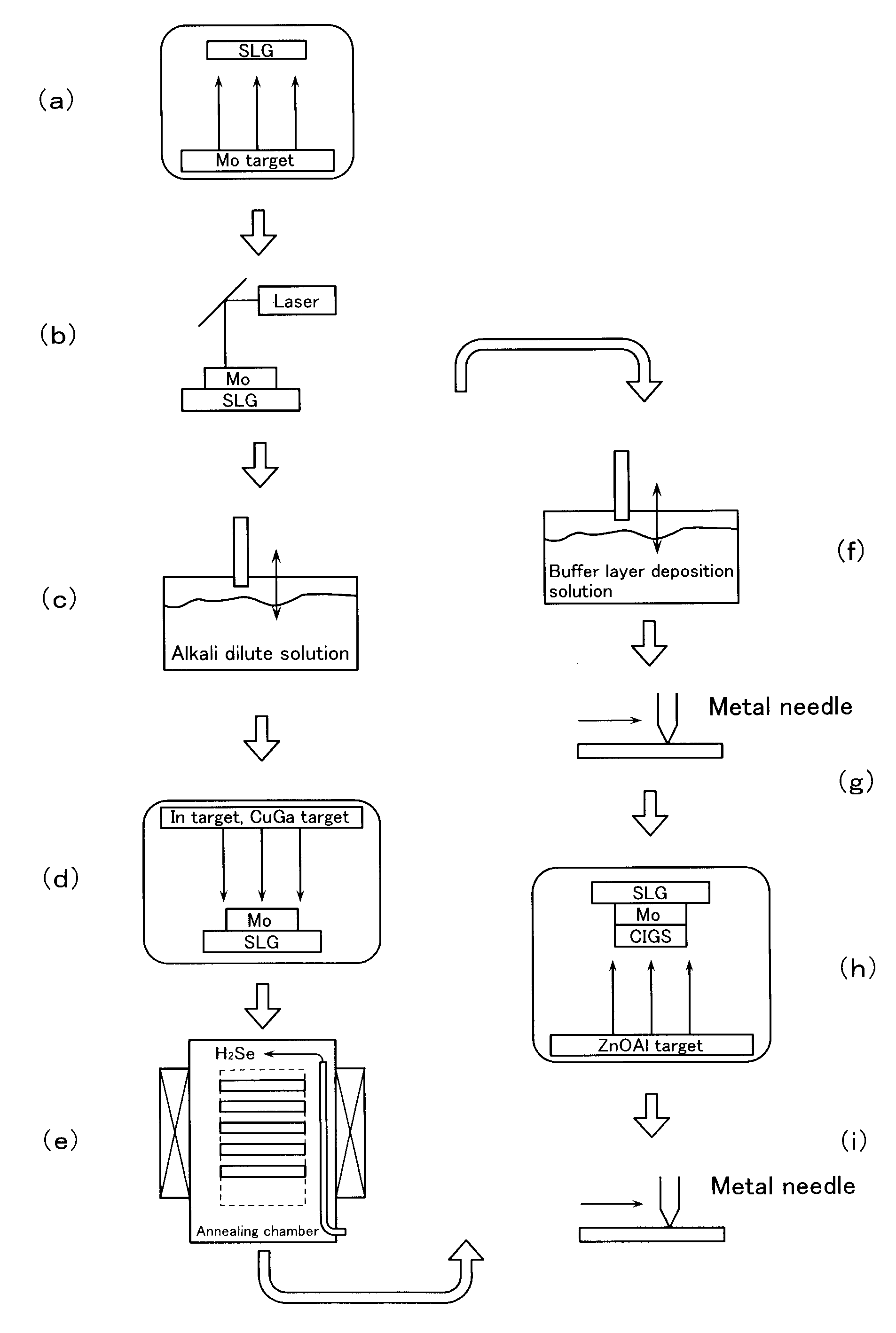

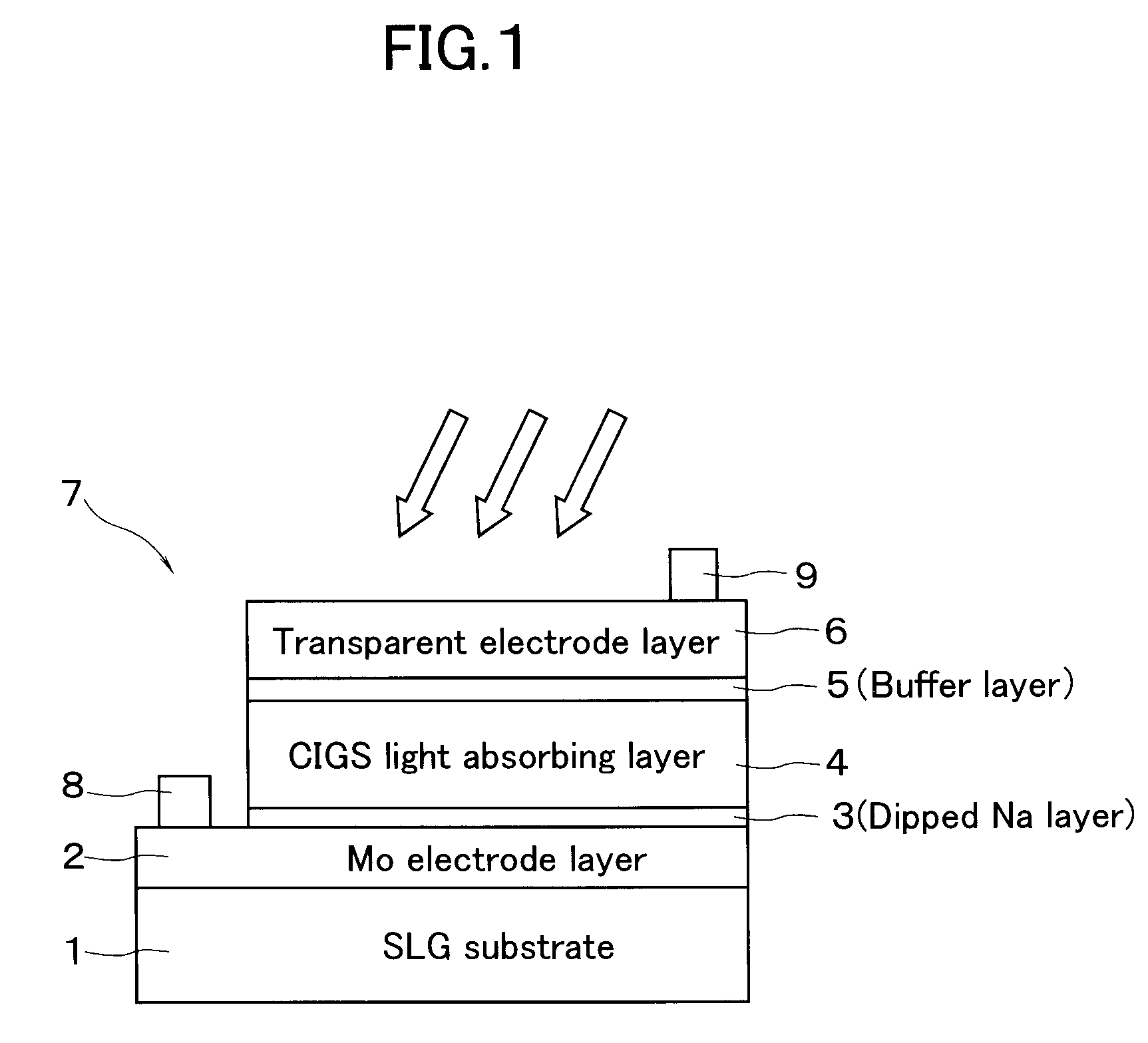

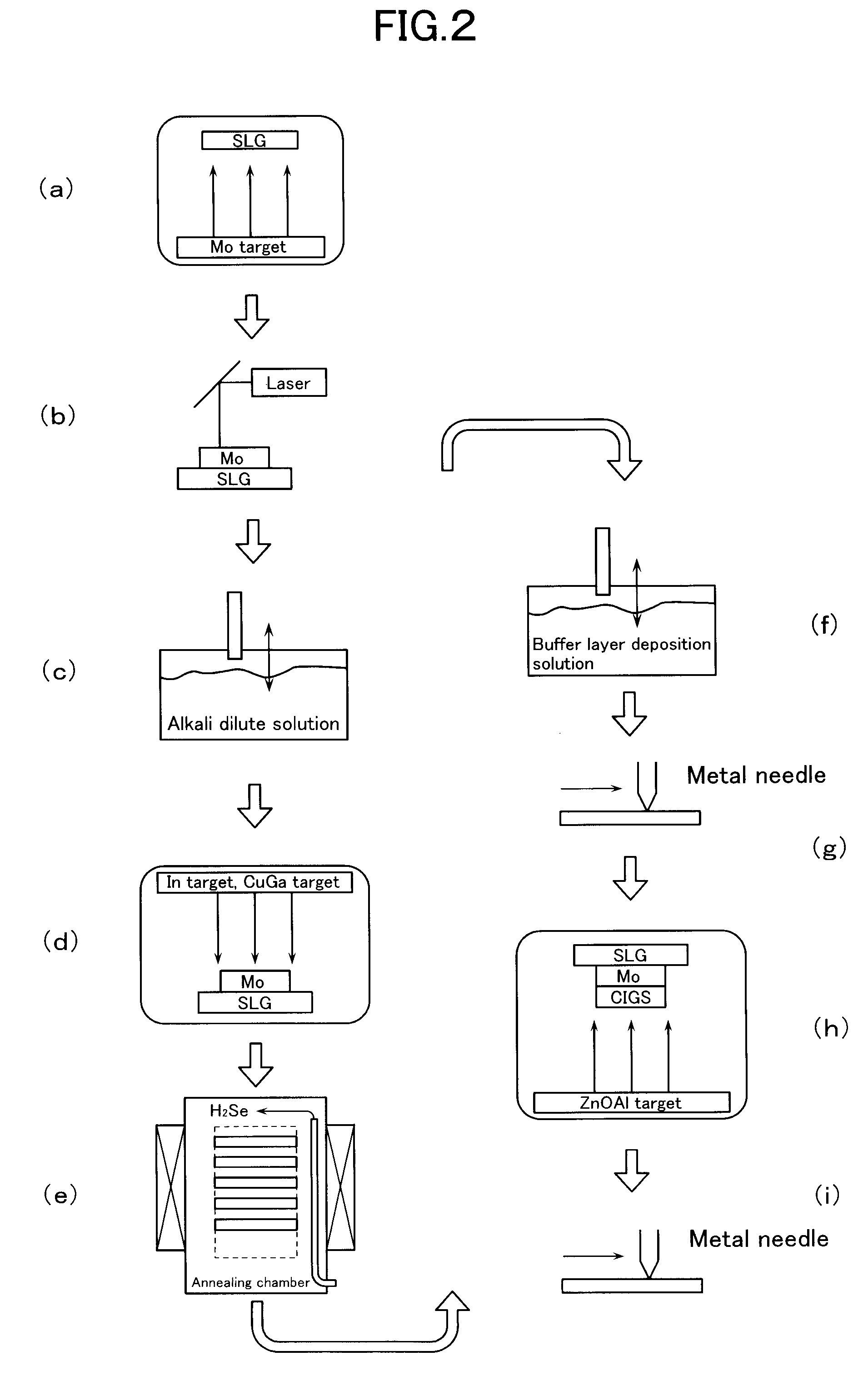

Method for Manufacturing Chalcopyrite Thin-Film Solar Cell

InactiveUS20080283389A1External appearance defectImprove photoelectric conversion efficiencyFinal product manufacturePV power plantsSputteringAlloy

A method for fabricating a chalcopyrite-type thin film solar cell includes a first step of forming onto a Mo electrode layer 2 a precursor including an In metal layer and a Cu—Ga alloy layer by sputtering, a second step of attaching an alkali-metal solution onto the precursor, a selenization step of subjecting the substrate 1 which has undergone both the first and the second steps to a selenization treatment, and a transparent electrode forming step of depositing an optically transparent conductive layer. As the alkali-metal solution, an aqueous solution of an alkali metal compound, such as sodium tetraborate, sodium sulfide, and sodium aluminum sulfate, can be used.

Owner:HONDA MOTOR CO LTD

Synthesis method of fine grain ZSM-5 zeolite molecular sieve with high silicon aluminium ratio

InactiveCN1699173AUniform particle sizeHigh ratio of silicon to aluminumPentasil aluminosilicate zeoliteSynthesis methodsSurface-active agents

The invention relates to a synthesis method of fine grain ZSM-5 zeolite molecular sieve with high silicon aluminium ratio, which comprises using a surface active agent, charging it into acidified aluminium salt solution, then slowly dropping alkaline solution formed from sodium silicate, template agent and seed crystal into aluminium saline solution, the overall composition of the obtained reaction mixture being Na2O:Al2O3:SiO2:H2O=1.5-4.0:1:20-280:500-2000 by mol ratio, then subjecting the reaction mixture to thermal crystallization through the conventional method.

Owner:DALIAN LIGONG QIWANGDA CHEM TECH

Aluminum phosphate or polyphosphate particles for use as pigments in paints and method of making same

InactiveUS20060045831A1PhosphatesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesAluminium sulfateOrganic acid

An aluminum phosphate or polyphosphate-based pigment product is made by a process comprising contacting phosphoric acid with aluminum sulfate and an alkaline solution to produce an aluminum phosphate based product; and optionally calcining the aluminum phosphate based product at an elevated temperature, wherein the process is substantially free of an organic acid. The aluminum phosphate or polyphosphate-based pigment is amorphous. The amorphous aluminum phosphate or polyphosphate characterized by a bulk density of less than 2.30 grams per cubic centimeter and a phosphorus to aluminum mole ratio of greater than 0.8. The composition is useful in paints and as a substitute for titanium dioxide.

Owner:BUNGE AMORPHIC SOLUTIONS +1

Hydrocracking catalyst carrier and preparation method thereof

ActiveCN101618348AHigh activityHigh selectivityCatalyst carriersMolecular sieve catalystsMolecular sieveCrystallinity

The invention discloses a hydrocracking catalyst carrier and a preparation method thereof. The catalyst carrier comprises a modified Y-type molecular sieve, amorphous silica-alumina and alumina, wherein the modified Y-type molecular sieve is Y-type molecular sieve treated by mixed aqueous solution of an aluminum salt and an acid and by hydrothermal process. In the carrier, the modified Y-type molecular sieve has a high crystallinity, high silicon to aluminum ratio and proper total acidity and acid distribution and can form an acid component with the amorphous silica-alumina. Therefore, the carrier is particularly suitable for serving as a hydrocracking catalyst carrier to improve the activity of a hydrocracking catalyst and the selectivity of middle distillates.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method of preparing aluminum oxide from fly ash

ActiveCN1923695AHigh dissolution rateFewer separation stepsAluminium oxide/hydroxide preparationAluminium oxides/hydroxidesAluminium sulfateSlag

The invention discloses a preparing method of alumina through fly ash, which comprises the following steps: grinding fly ash; sintering; activating; stirring with H2SO4 evenly to sinter into dried slag; immersing through hot water; stripping aluminum sulfate; condensing; cooling to evolve aluminum sulfate; crystallizing; heating; dehydrating to obtain anhydrous aluminum sulfate; heating; decomposing to obtain gamma-Al2O3.

Owner:PINGSHUO INDAL

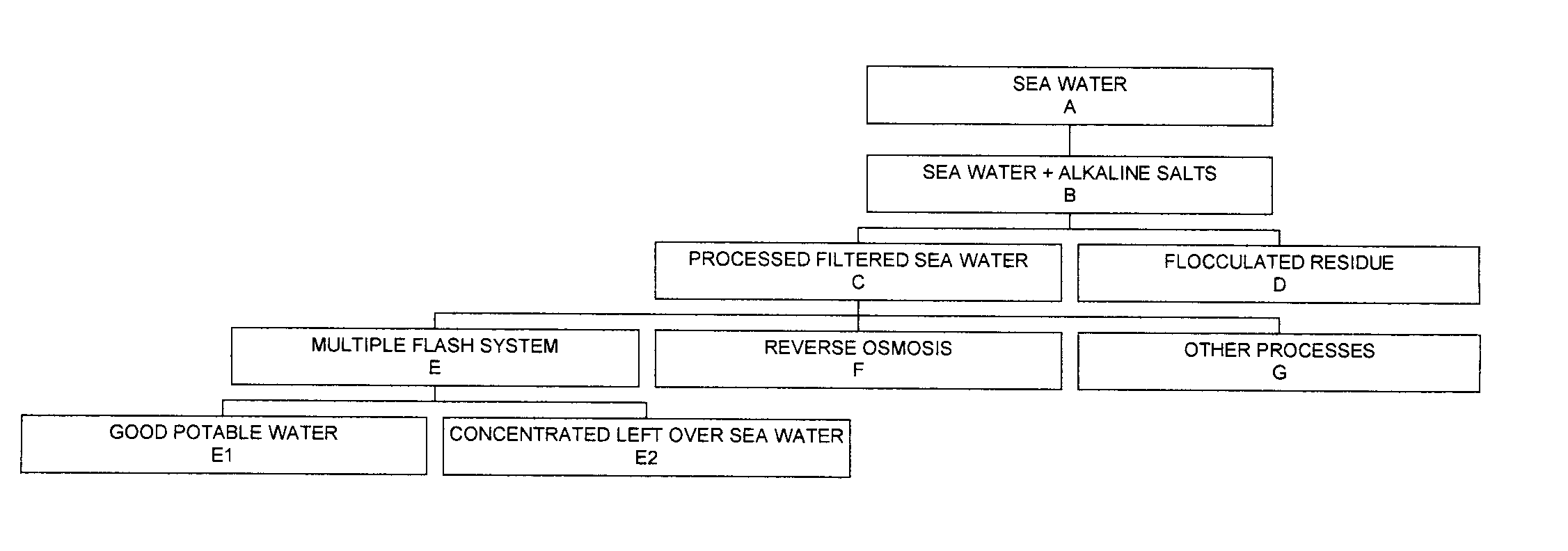

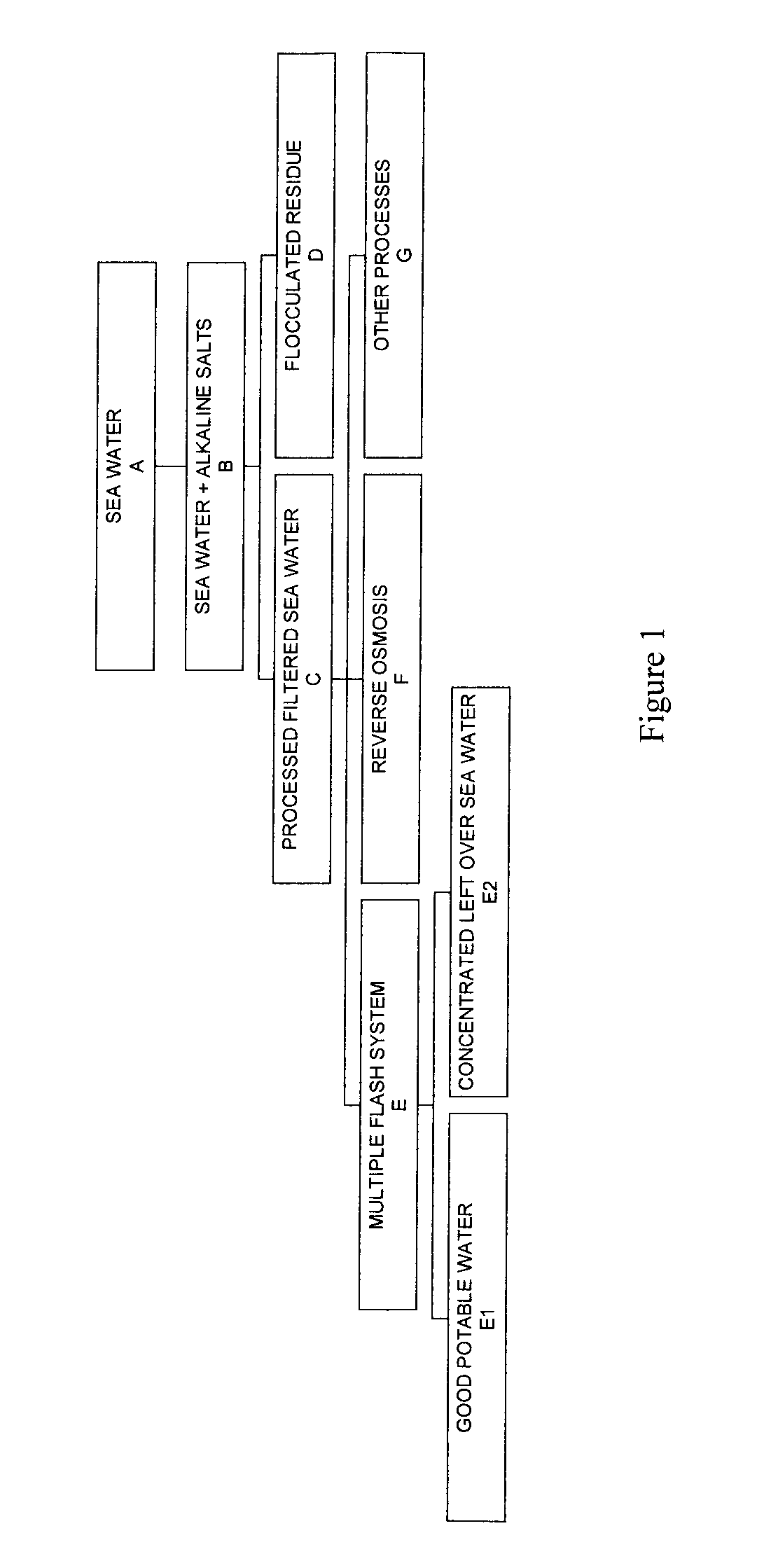

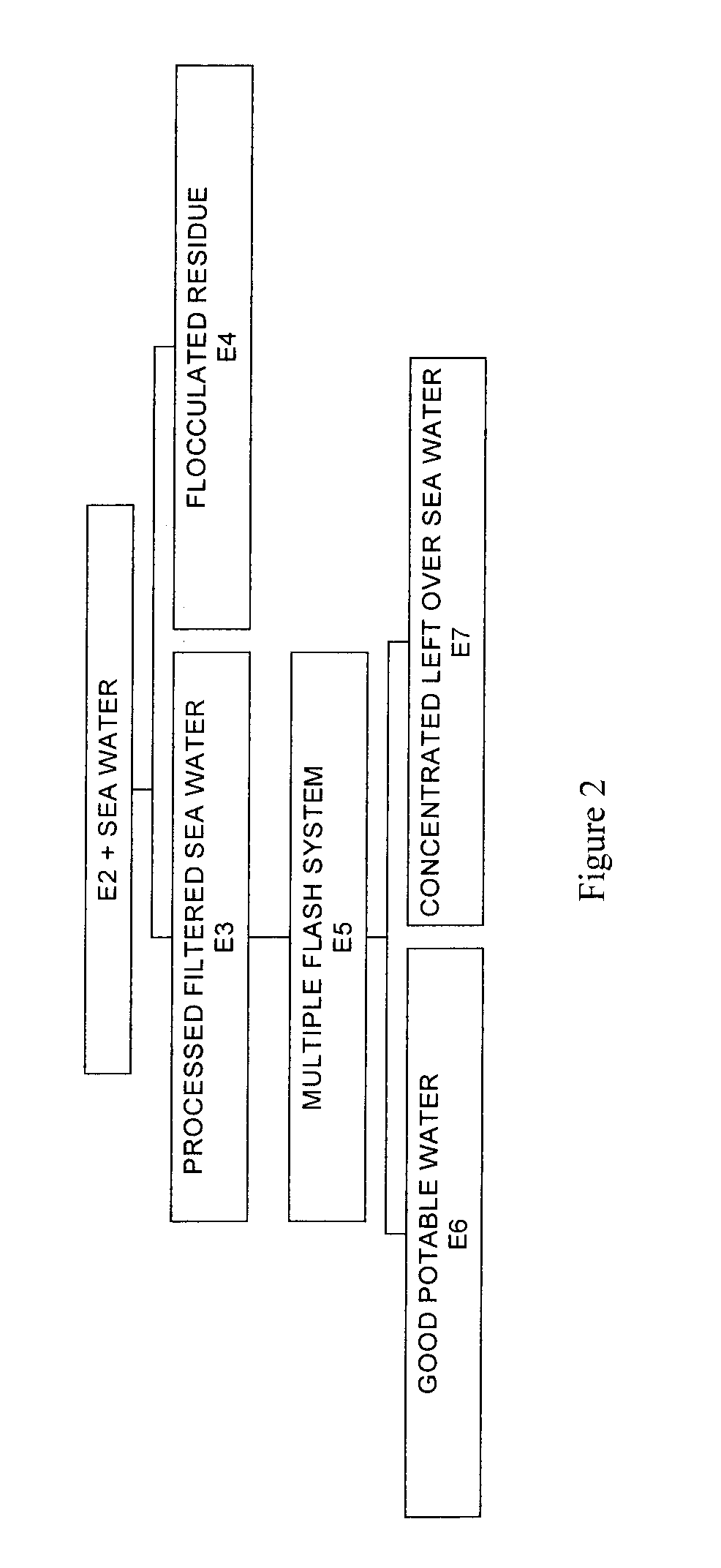

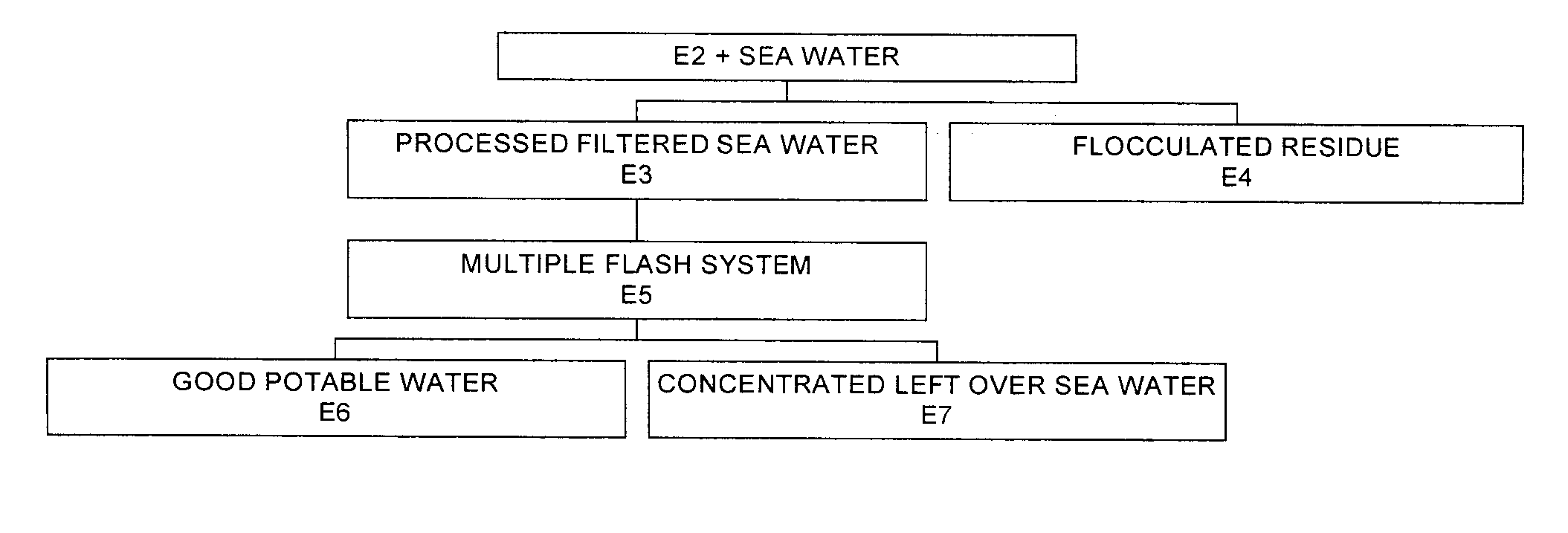

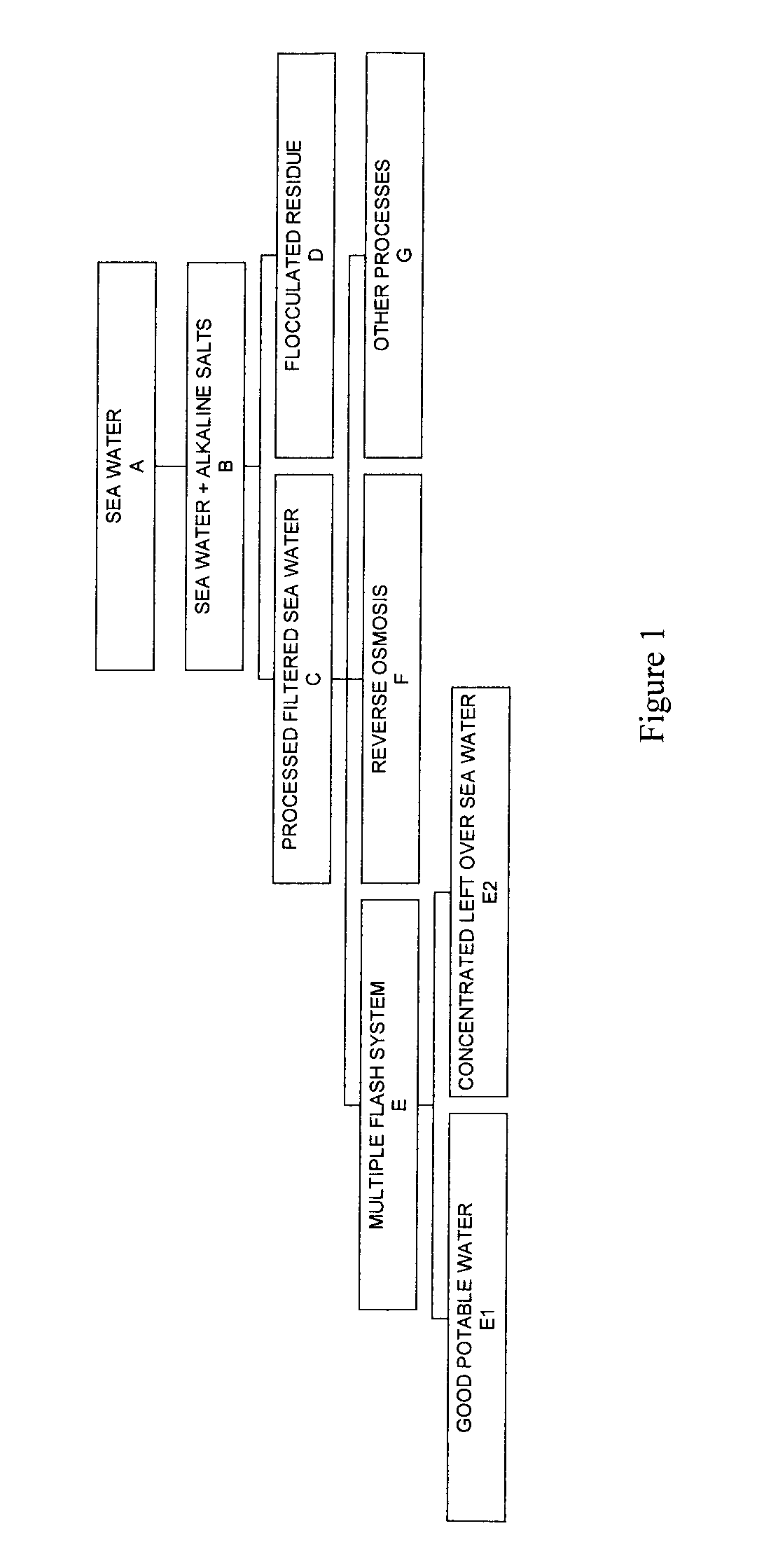

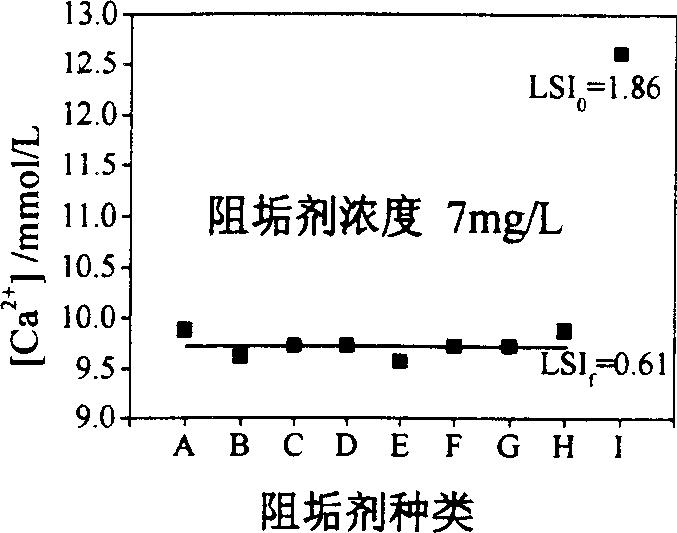

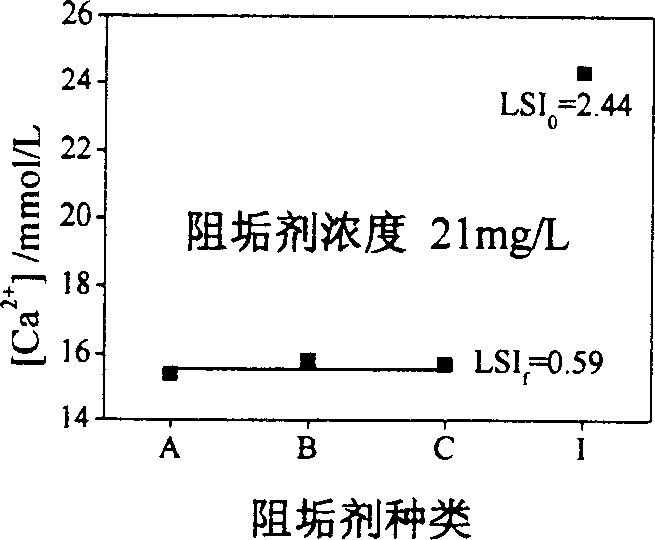

Process for pre-treating and desalinating sea water

ActiveUS20050098499A1Reduce maintenanceExtend equipment lifeGeneral water supply conservationSeawater treatmentCalcium bicarbonatePotassium hydroxide

Water containing dissolved salts, such as calcium sulfate, calcium chloride, magnesium sulfate, magnesium chloride, sodium carbonate, sodium chloride, sodium sulfate, calcium bicarbonate, and mixtures thereof, is treated to reduce the concentration of those salts. About 0.1 to about 60 g / L of sodium hydroxide, sodium carbonate, potassium hydroxide, potassium carbonate, calcium hydroxide, calcium carbonate, aluminum hydroxide, aluminum sulfate, aluminum potassium sulfate, and mixtures thereof is added to the water, whereby a precipitate forms in the water. The precipitate is separated from said water and the water is desalinated using reverse osmosis, flash evaporation, or another method. The process is preferably performed by first adding calcium oxide or calcium hydroxide, separating the precipitate that forms, then adding sodium hydroxide and sodium carbonate to form a second precipitate.

Owner:HUSSAIN MOHAMMED AZAM

Process for pre-treating and desalinating sea water

ActiveUS7198722B2Extend equipment lifeReduce maintenanceGeneral water supply conservationSeawater treatmentCalcium bicarbonateReverse osmosis

Owner:HUSSAIN MOHAMMED AZAM

Small crystal grain molecular sieve preparation method

The invention discloses a method for preparing the NaY molecular screen of high alumina silica ratio and fine grain, firstly synthesizing NaY molecular screen guilding agent according to current technology, then producing gel with sodium silicate, guilding agent, acid aluminium salt and sodium metaaluminate, blooming the gei under the temperature of 50-100 Deg C for 0-70 hours, adding some silicon, then blooming continuously under temperature of 90-120 Deg C for 0.5-50 hours, finally filtering, washing and drying. The NaY molecular screen with the alumina silica ratio being 5.2-7.0, and fine grain being 100-400 nm can be prepared by using the method in this invention.

Owner:CHINA PETROLEUM & CHEM CORP +1

Multicomponent composite flocculating setting agent and use in arsenic contamination water treatment

ActiveCN101503239AEfficient removalGood arsenic removal effectWater/sewage treatment by flocculation/precipitationArsenic pollutionEarth surface

The invention belongs to the technical field of river water body pollution control and in particular relates to a multiple-element compound flocculating settling agent and the application of the multiple-element compounded flocculating settling agent in arsenic pollution water body treatment. The multiple-element compounded flocculating settling agent is prepared by compounding malysite, aluminium salt, hypermanganate, polyacrylamide and aqueous solution. The multiple-element compounded flocculating settling agent can be applied in the arsenic pollution water body treatment to remove arsenic in the arsenic pollutant water body. The concentration of the arsenic in the treated water can meet or is superior to the specified requirement of three types of water on the arsenic concentration in the national earth surface water environment quality standard (less than 0.05 mg / L). The invention also can be used for removing heavy metals such as copper, chromium, cadmium, lead and the like in water by sedimentation. The multiple-element compounded flocculating settling agent can be used together with a multiple-element compounded metal oxide arsenic removal setting agent in static or flowing arsenic pollution water body treatment for removing the arsenic in the water body polluted by arsenic.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

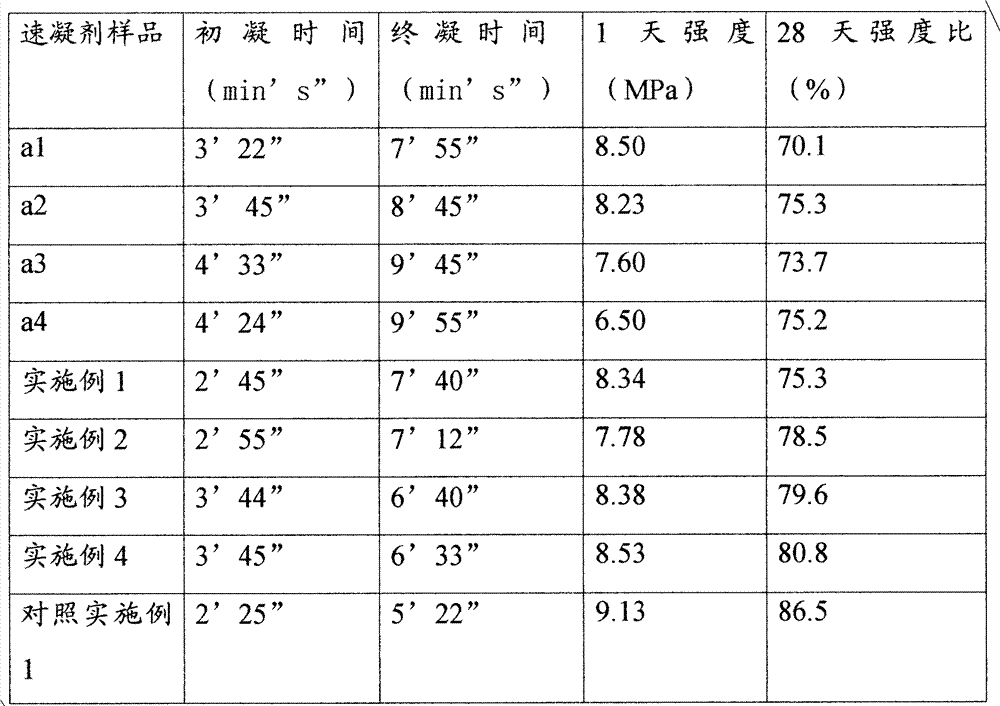

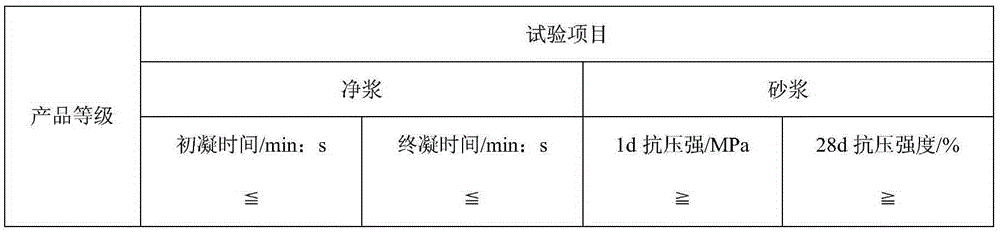

Environment-friendly type alkali-free liquid accelerator for sprayed concrete and preparation method thereof

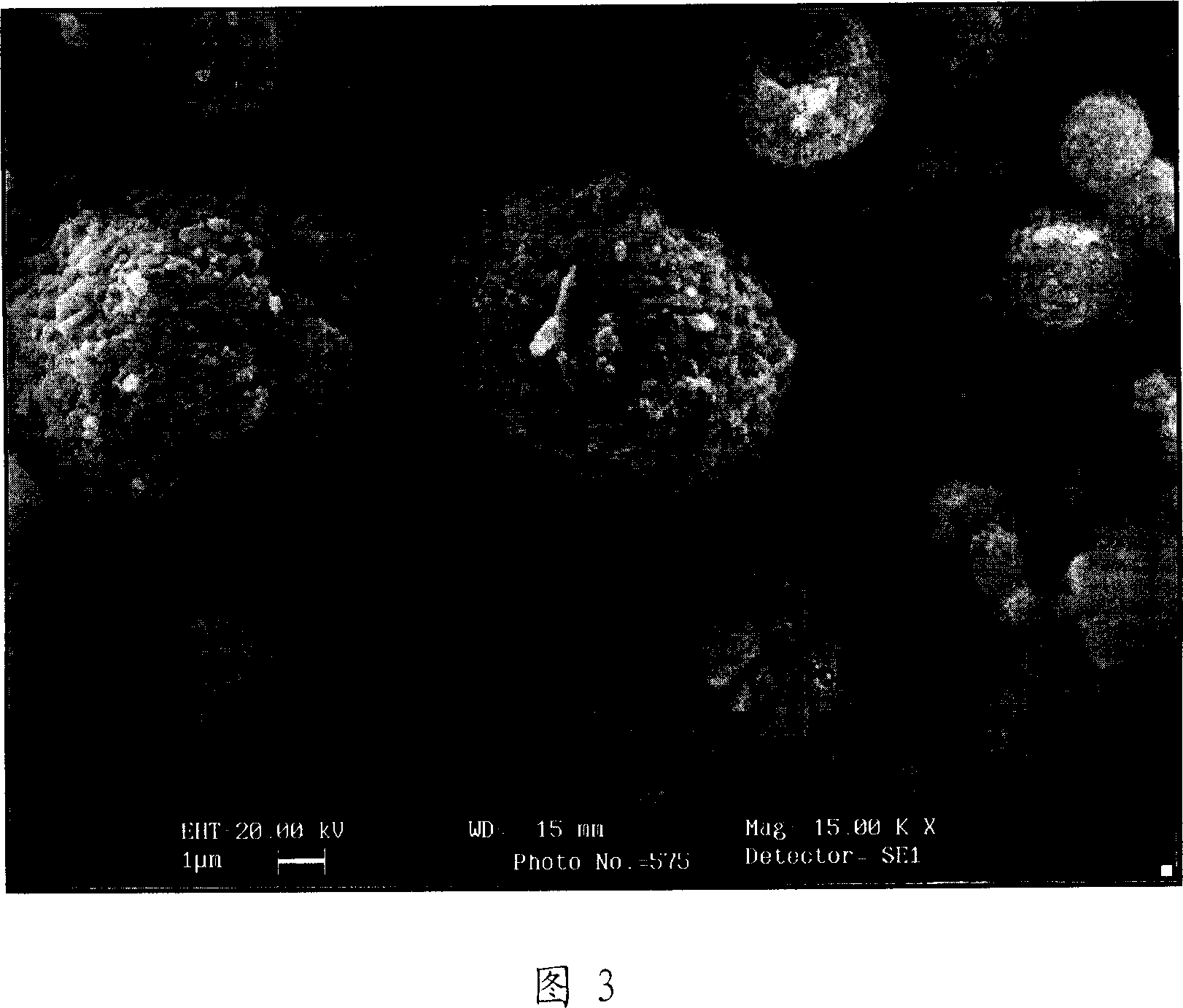

The invention belongs to the technical field of building materials, and in particular relates to an environment-friendly alkali-free liquid quick-setting agent used for shotcrete and a method for preparing the same. The alkali-free liquid quick-setting agent is a light green viscous liquid prepared from aluminum sulfate, sodium fluoride, triethanolamine and polyacrylamide, wherein the aluminum sulfate and the sodium fluoride are main quick-setting components, the aluminum sulfate can significantly reduce the initial setting time of cement, while the sodium fluoride can significantly shorten the final setting time of the cement, promote the formation of a hydrate structure, and improve the shear strength of the concrete and the binding power of a reinforcing steel bar. The triethanolamine shortens the setting time of the concrete to csertain extent and greatly improves the 1d compressive strength of mortar, and the polyacrylamide is an organic tackifying component to improve the thickness of a primarily sprayed layer, improve the bond strength between the concrete and a substrate, reduce the rebound loss in the spraying process, and save materials. The environment-friendly alkali-free liquid quick-setting agent has the advantages of wide source of raw materials, low cost, simple production method, and high production efficiency, and is suitable for industrial mass production.

Owner:TONGJI UNIV

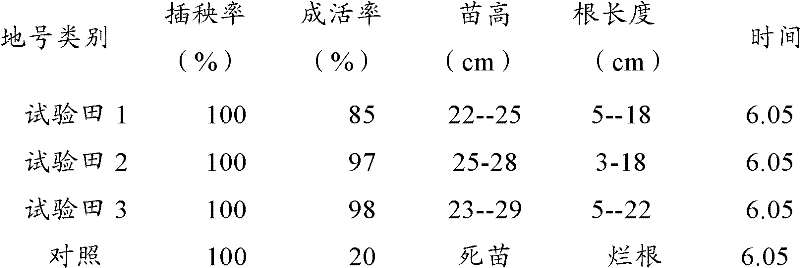

Saline-alkali soil amendment

InactiveCN101624523ALow costImprove convenienceOther chemical processesOrganic fertilisersAmmonium ferrous sulfateAlkali soil

The invention discloses a saline-alkali soil amendment, and relates to a soil amendment. The soil amendment of the invention solves the problem of the waste of land resources caused by a condition that saline-alkali soil is wasted and can not be used throughout the year because only artemisia anethifolia can grow in the saline-alkali soil at present, while other plants can not grow thereon. Besides, the existing saline-alkali soil amendment is mainly prepared from alum which has high cost and poor soil amendment effect. The saline-alkali soil amendment of the invention is prepared by weight percent from aluminum sulfate, ammonium ferrous sulfate and magnesium sulfate, which are mixed, and the weight ratio of the three materials is 1-1.8:1-2:0.2-0.5. The saline-alkali soil amendment of the invention can ensure that crop plants can be planted in the saline-alkali soil; thus, the saline-alkali soil, a wide land resource, can be made good use of. In addition, the saline-alkali soil amendment of the invention has the advantages of low cost and obvious effect of soil amendment.

Owner:张炳辉

Alkali-free liquid setting accelerator for spray concrete

The alkali-free liquid setting accelerator for spray concrete is compounded with aluminum sulfate 40-70 wt%, magnesium sulfate in 5-50 wt% of the aluminum sulfate, alcohol amine 2-10 wt%, stabilizer 0-10 wt%, defoaming agent in 0-10 wt% of the stabilizer, glycerin 0-1 wt%, and water for the rest. The present invention has excellent cement adaptability, and can provide excellent early strengthening performance and spray construction performance even if to difficult cement with lower C3A content, such as modified cement.

Owner:BOTE NEW MATERIALS TAIZHOU JIANGYAN CO LTD +1

Precipitated silicic acid

InactiveUS6268424B1Easily dispersible in tire carcassExtended service lifePigmenting treatmentSilicaSilicic acidPhysical chemistry

Precipitated silica having the following parameters:is prepared by reacting alkali silicate with mineral acids and aluminum sulfate solution at temperatures of 60-95° C. at a pH of 7.0-10.0 while stirring constantly, wherein the reaction is continued to a solids concentration of 40-110 g / l, the pH is adjusted to a value between 3 and 5, and the precipitated silica is filtered off, washed and then dried, and optionally ground or granulated.

Owner:EVONIK DEGUSSA GMBH

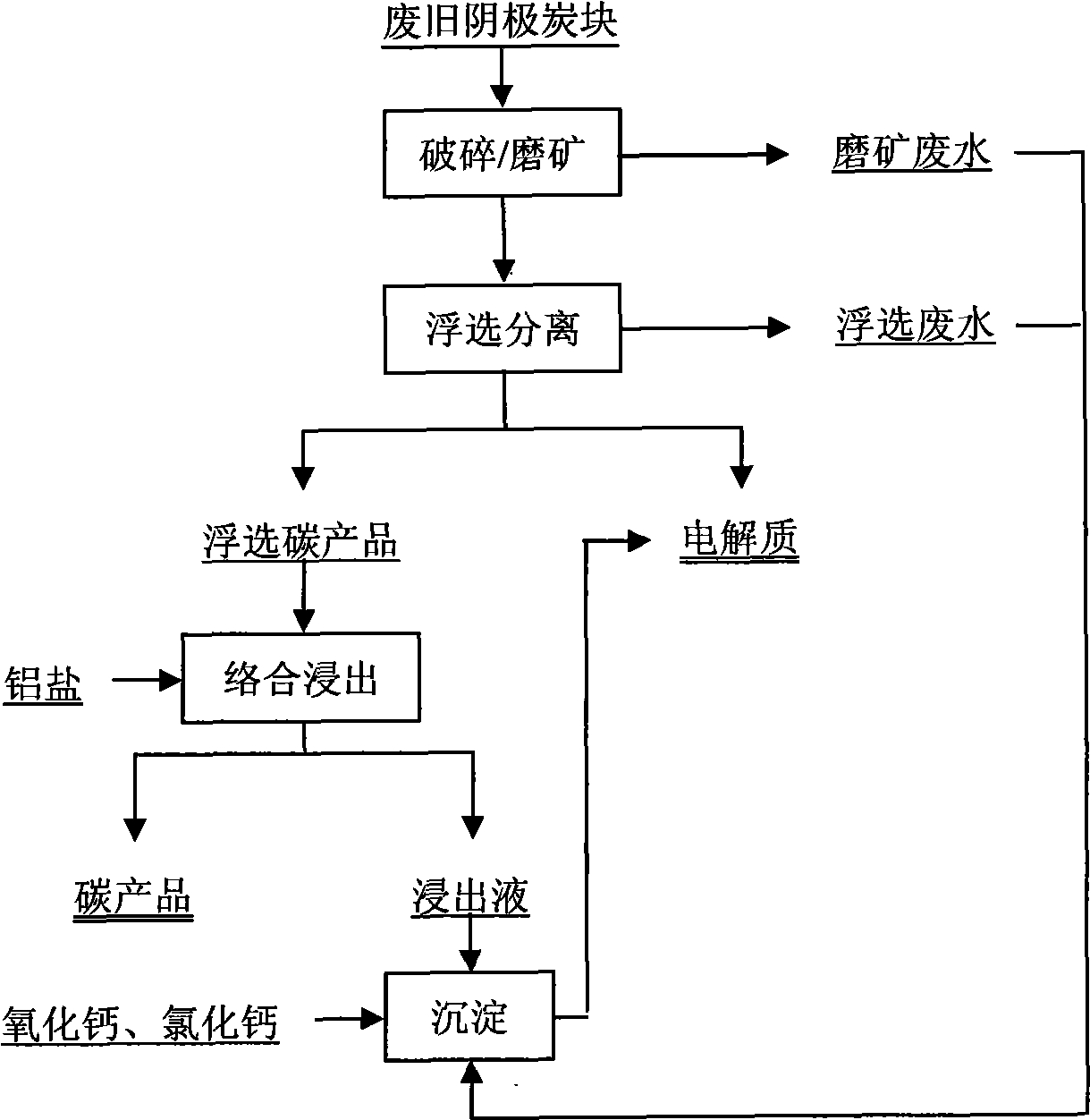

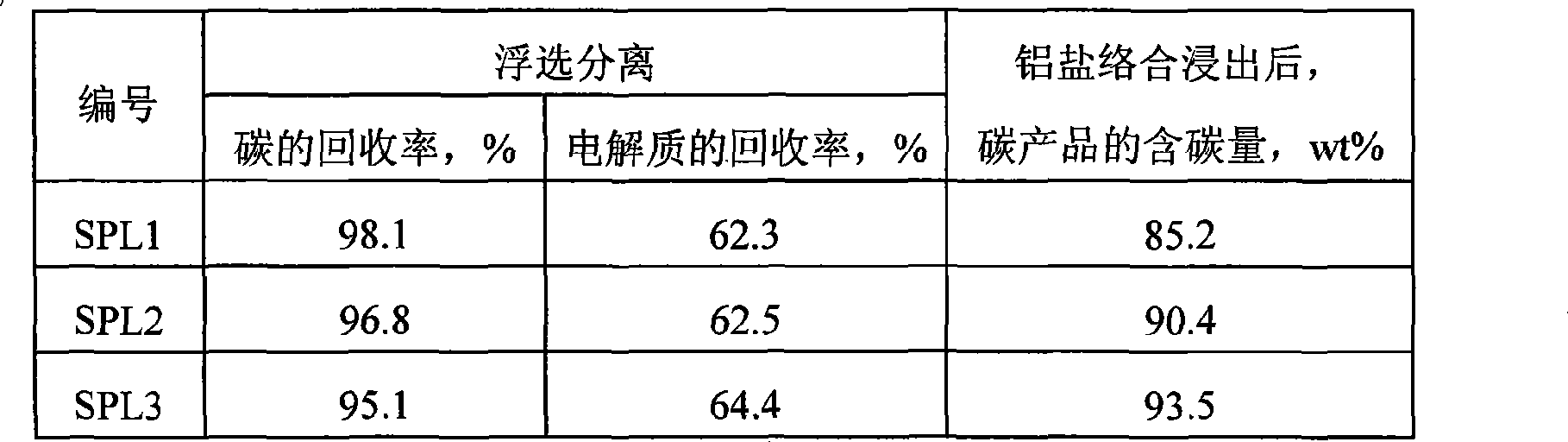

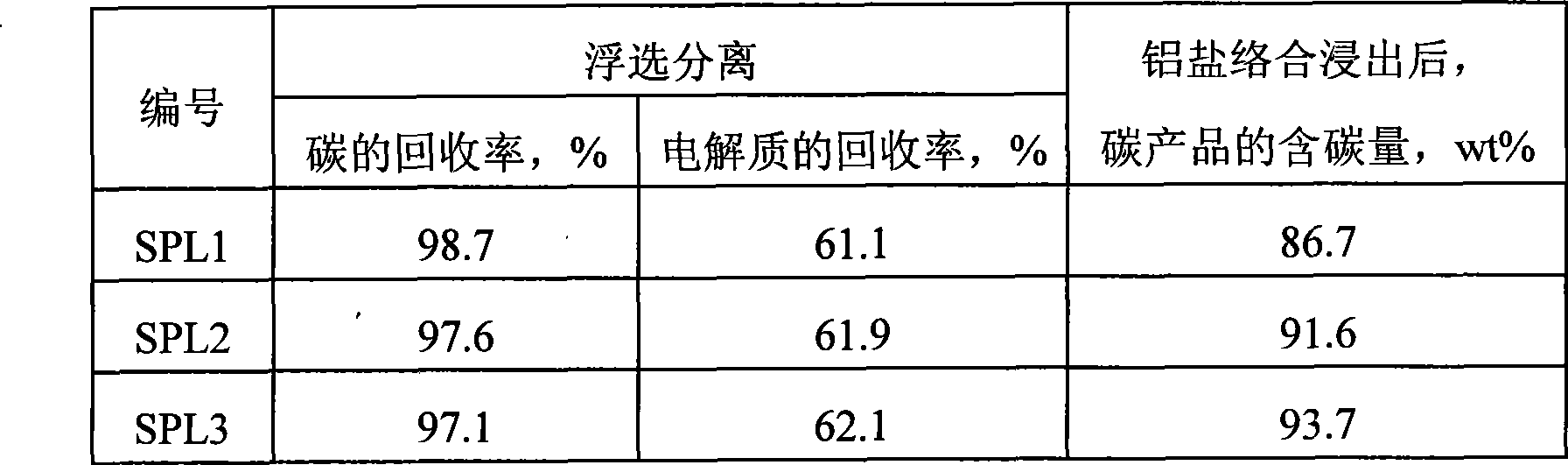

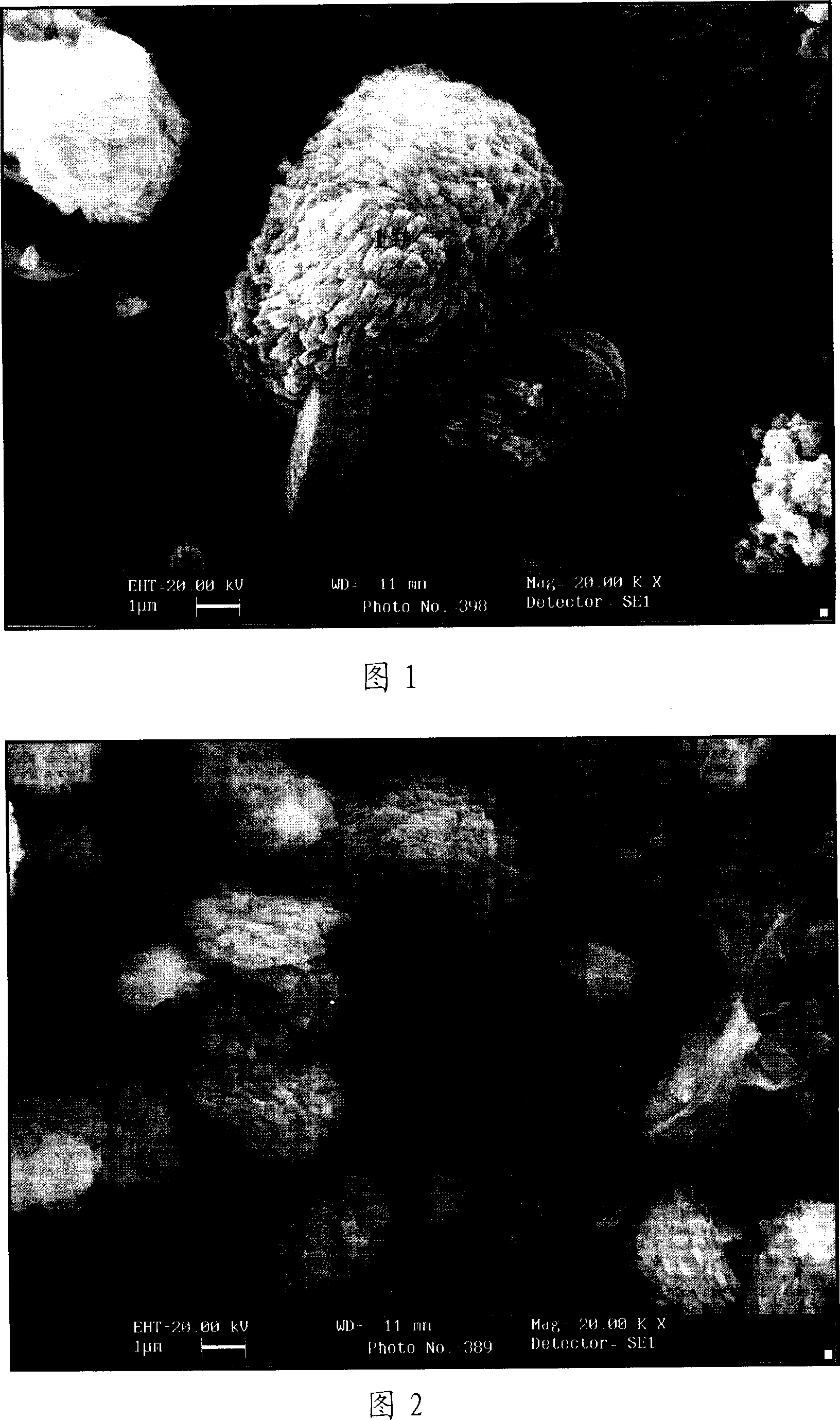

Method for electrolyzing waste and old cathode carbon block by comprehensive utilization of aluminum

ActiveCN101480658ARealize flotation separationHigh carbon contentFluoride preparationWaste processingPregnant leach solutionHigh carbon

The invention relates to a method for comprehensively using aluminium to electrolyze a waste cathode carbon block, which belongs to the technical field of environment protection and comprises the following steps: crushing and grinding the waste cathode carbon block; adjusting the concentration and the PH value of ore slurry after the grinding, then using floatation equipment to carry out floatation treatment, and separating electrolyte and carbon which are contained in the waste cathode carbon block; using an aluminium salt solution to soak for extracting the electrolyte contained in a carbon product obtained from the floatation, and further improving the grade of a high-carbon product; mixing the grinding waste water, the floatation waste water and the soaking solution, and adding CaO and CaCl2 to precipitate and recover aluminium and fluothane in the mixture. The method for comprehensively using aluminium to electrolyze a waste cathode carbon block has simple operating condition, low energy consumption, high recovery ratio of valuable substances and good application prospect.

Owner:NORTHEASTERN UNIV

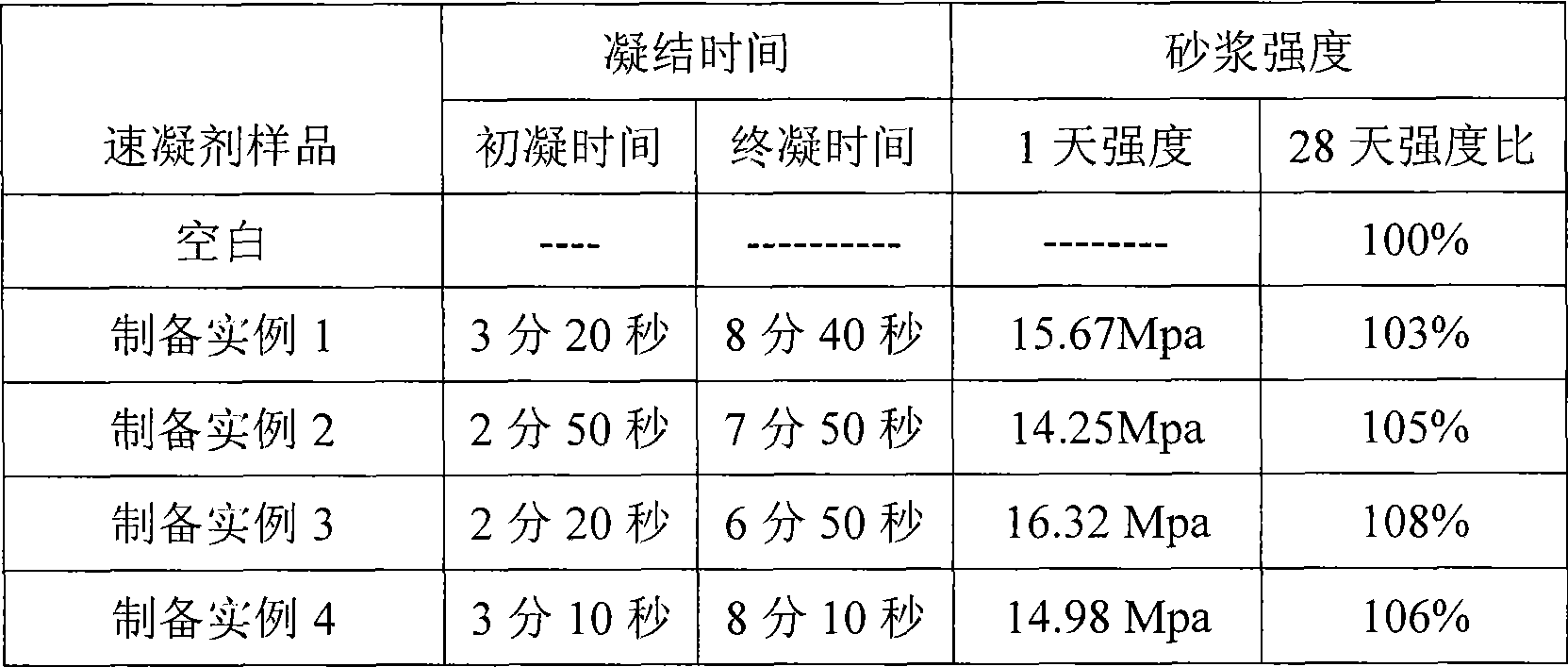

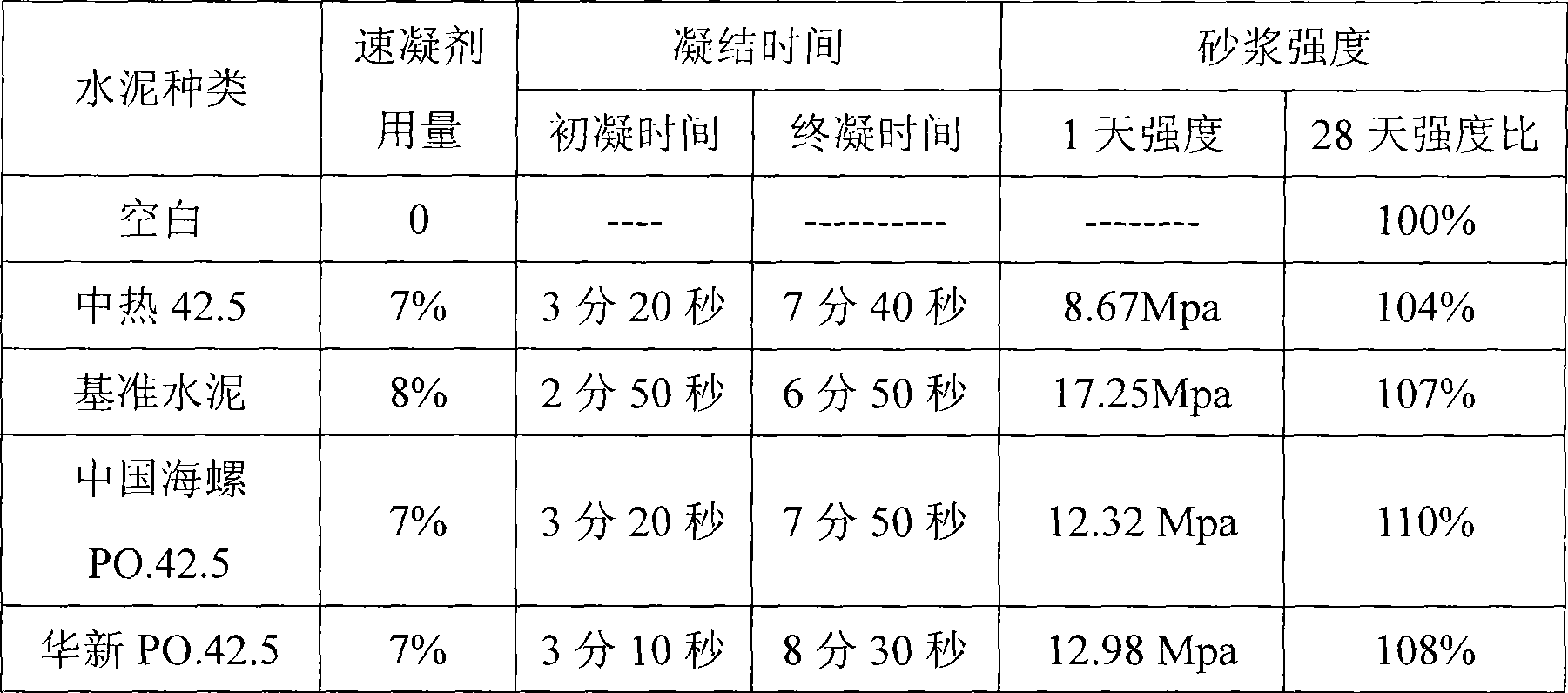

Alkali-free chlorine-free high-early-strength liquid accelerator and preparation method thereof

The invention discloses an alkali-free chlorine-free high-early-strength liquid accelerator and a preparation method thereof, and belongs to the technical field of building materials. The alkali-free chlorine-free high-early-strength liquid accelerator is synthesized by aluminum sulfate (a), alkaline earth metal salt (b), aluminum hydroxide (c), hydroxy carboxylic acid (d), an organic amine compound (e) and a stabilizing agent (f). The invention is characterized in that: the organic amine compound, a polyhydroxy organic matter and inorganic salt are subjected to complex reaction, and the molecular structure of the product is regulated by regulating a ratio of (a) to (b) to (c) to (d) to (e) to (f) so as to improve the performance of the product. Mortar doped with the product has the advantages of adjustable setting time, one-day compressive strength of over 20MPa and a 28-day compressive strength ratio of about 100 percent, the synthesis process is simple, reaction conditions are mild, and the alkali-free liquid accelerator has good performance.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES +2

ZSM-5/SAPO-11 composite zeolite and catalytically cracked gasoline hydrogenation quality-improved catalyzer and the methoer for preparing the same

ActiveCN101081370AImprove product qualityEquilibrium HydrodesulfurizationMolecular sieve catalystsHydrocarbon oils refiningIsomerizationHydrodesulfurization

The present invention is one kind of catalyst with ZSM-5 / SAPO-11 composite zeolite for hydrogenating and modifying catalytically cracked gasoline and its preparation process. The composite zeolite is prepared through compounding solution A with aluminum sulfate, sulfuric acid and water; compounding solution B with water glass, tetraethyl ammonium hydroxide and water; mixing solution A and solution B to form homogeneous colloid; crystallizing the colloid mixture at 150-180 deg.c for 24-72 hr; adding phosphoric acid, pseudoboehite, silica sol and SAPO-11 synthesizing template agent; and final crystallizing at 170-200 deg.c for 24-48 hr to obtain sodium type composite zeolite. The catalyst with the composite zeolite as carrier has excellent hydrogenating and desulfurizing performance, high stability, high gasoline yield, high isomerization activity and certain aromatization activity, and may be applied in producing high quality clean gasoline product.

Owner:BEIJING CUP GREEN CATALYTIC TECH

Liquid accelerator for sprayed concrete and preparation thereof

The invention relates to a liquid accelerator for shotcrete and a method for preparing the same. The liquid accelerator is prepared from the following components in percentage by weight: 25 to 70 percent of aluminum sulfate, 0 to 8 percent of metal fluoride, 1 to 10 percent of amine substance, 0.5 to 7 percent of pH regulator, 0.01 to 1 percent of thickening agent, and the balance being water. The method for preparing the liquid accelerator comprises the following steps: firstly, dissolving the fluoride into the water; secondly, adding the amine substance to the mixture and heating the solution to a temperature of between 40 and 80 DEG C; thirdly, adding the aluminum sulfate to the solution to perform heat preservation reaction until the solution becomes a uniform liquid; and fourthly, adding the pH regulator and the thickening agent to the uniform liquid and stirring the mixture evenly to finally obtain a uniform liquid substance which is the liquid accelerator for the shotcrete. The liquid accelerator is free from corrosion, has no penetrating odor, has good storage stability so that the phenomena of deposition, crystallization and the like do not appear after the storage of more than 6 months at a temperature of between 0 and 35 DEG C, and does not influence the effect in practice. Using the liquid accelerator with lower mixing proportion (5 to 8 percent), cement can be initially set within 4 minutes and finally set within 10 minutes, and the strength of cement mortar within one day is more than 10 MPa and the storage rate of the strength within 28 days is more than 100 percent.

Owner:JIANGSU SUBOTE MATERIAL

Liquid alkali-free chloride-free accelerating agent as well as methods for preparing and using same

The invention discloses a liquid alkali-free chloride-free accelerating agent and methods for preparing and using the same. Raw materials for preparing the accelerating agent include one or a plurality of the following components of aluminum sulfate, magnesium sulfate, hydramine, an early strength agent, a synergist and water. The aluminum sulfate is the purchasable industrial-grade aluminum sulfate hydrate Al2(SO4)3.18H2O and has the solid content of 51%-52%. The magnesium sulfate is MgSO4.7H2O with the solid content of 48%-49%. The hydramine is one or a plurality of mono ethanol amine, diethanolamine, triethanolamine or isopropoxide. The early strength agent is one or a plurality of calcium sulfate, calcium formate or calcium nitrite. The synergist is magnesium fluosilicate and / or magnesium fluoride. The liquid alkali-free chloride-free accelerating agent provided by the invention has the characteristics of good adaptability, low price, low mixing amount, good performance, good stability and the like; and moreover, the liquid alkali-free chloride-free accelerating agent is added into the concrete to be used as sprayed concrete, has the characteristics of low resilience, small dust pollution and the like and can satisfy the requirements of the 'JC477-2005 sprayed concrete accelerating agent' standard.

Owner:北京冶建特种材料有限公司 +1

E-Fenton oxidation technique of dirty blocking agent in reverse osmosis concentrating liquid

InactiveCN1541757AHigh salt concentrationImprove conductivityWater/sewage treatment bu osmosis/dialysisReverse osmosisElectrolysisProcess scaling

The electric Fenton oxidation process for processing scale inhibitor in reverse osmosis concentrated liquid adopts anode of iron plate and cathode of porous graphite and ventilated with air pump and processes reverse osmosis concentrated liquid through electrolyzing in stirring, stirring coagulation via adding aluminum sulfate and filtering the coagulated solution. Bivalent iron ion produced intelligent the electric Fenton process is made to react with hydrogen peroxide to produce strong oxidizing free hydroxy radical oxidizing and destructing the scale inhibitor; and the subsequent coagulation separates out scaling salt to lower the scaling trend, so that the concentrated liquid may be utilized as influent water to raise the water recovering rate of reverse osmosis system.

Owner:SHANGHAI JIAO TONG UNIV

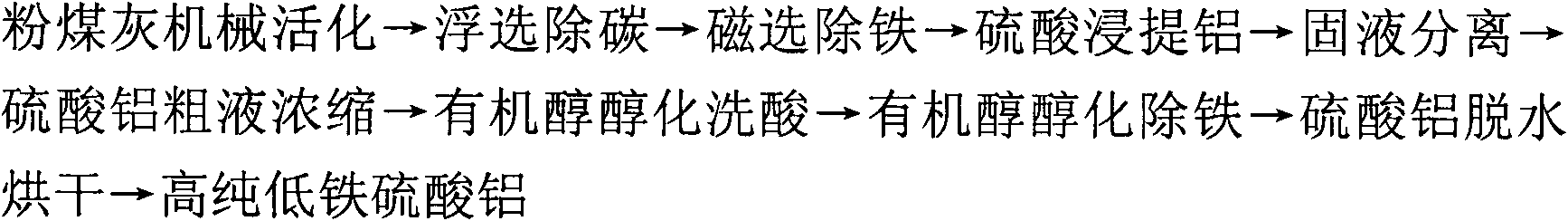

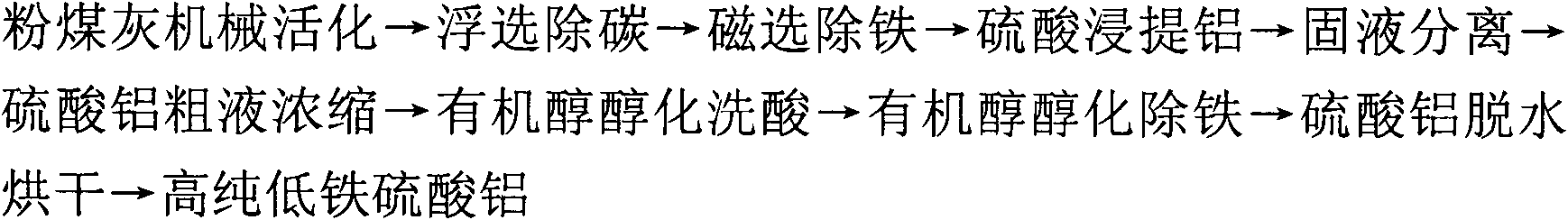

Technological method for producing high-purity low-iron aluminum sulfate by using coal ash and comprehensively utilizing coal ash

InactiveCN102101689AEasy industrial iron removalLow costPigmenting treatmentSolid waste disposalBiological activationCoal

The invention discloses a technological method for producing high-purity low-iron aluminum sulfate by using coal ash and comprehensively utilizing the coal ash, comprising the following steps of: carrying out mechanical activation, flotation decarburization, magnetic separation for deferrization, aluminum extraction with sulfuric acid, solid-liquid separation, concentration of aluminum sulfate crude liquor, organic alcohol alcoholization for acid rinse, organic alcohol alcoholization for deferrization and aluminum sulfate dewatering and drying on the coal ash to obtain the high-purity low-iron aluminum sulfate with low Fe content. The invention solves the problems on impurity removal and purification of the aluminum sulfate in the recycling process of the coal ash, simplifies the process flow, reduces the energy consumption, solves the technical problem of overlarge accumulation of secondary residue quantity, achieves high extraction ratio of aluminum contained in the coal ash, and realizes the recycling of organic alcohol and sulfuric acid and the comprehensive utilization of side products including unburnt black, magnetic iron powder, iron-containing aluminum sulfate crystals, high-silicon-dust active mineral blending materials or novel silicon-magnesium cement, and the like. The technological method has the advantages of simple process, short flow, easiness for control of a production process, high aluminum extraction ratio, low impurity content of products and stable quality.

Owner:内蒙古昶泰资源循环再生利用科技开发有限责任公司 +2

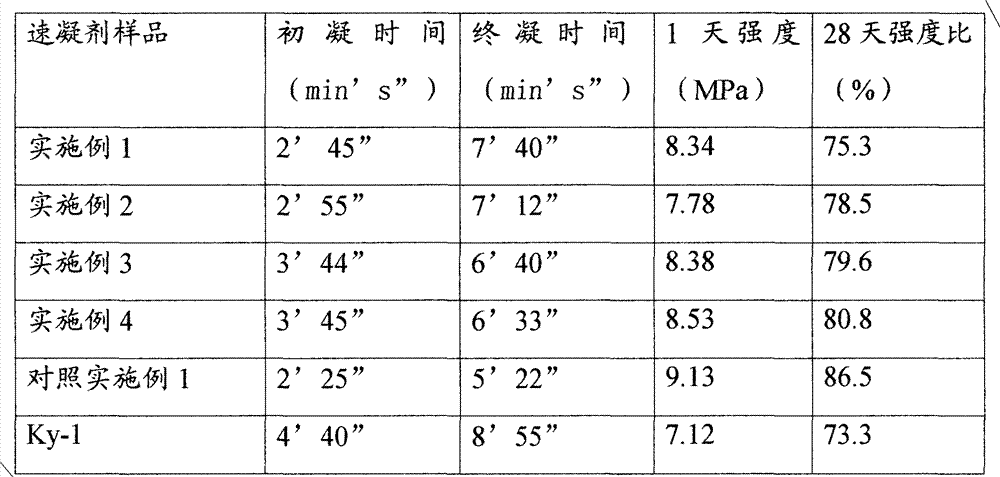

Novel alkali-free liquid accelerator based on synthesis of polymeric aluminum sulfate

ActiveCN105271867ALow alkali contentReduce the risk of alkali-aggregate reactionAlkali freeSynthesis methods

The invention discloses a polymeric aluminum sulfate synthesis method and discloses a preparation method of a novel alkali-free liquid accelerator based on synthesis of polymeric aluminum sulfate. According to the alkali-free accelerator, an aluminum sulfate solution is neutralized by ammonia water, active aluminum hydroxide gel is prepared, active aluminum hydroxide is filtered, dried and ground into powder, then the aluminum sulfate solution is added, and the polymeric aluminum sulfate is prepared. The alkali-free accelerator comprises, in percentage, 45%-55% of the polymeric aluminum sulfate, 0%-5% of inorganic acid, 0%-2% of a stabilizer, 0%-2% of an organic early strength agent, 0%-2% of an organic tackifier and the balance of water. The cement setting time and the colloidal mortar strength of the accelerator can meet the requirement of first-class accelerators for JC477-2005 sprayed concrete under the condition of the lower mixing amount, and meanwhile, the accelerator is an alkali-free liquid accelerator and can effectively avoid adverse effects caused by excessively high alkali content. The cement types of the accelerator have good adaptability.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

Flame resistant fibrous insulation and methods of making the same

InactiveUS20050236606A1Improve flame retardant performanceCeilingsHeat proofingFiberAluminium sulfate

The invention relates to fibrous insulation products that exhibit improved flame resistance, relative to previously known products. The insulation product has a fibrous mineral matrix, into which is incorporated a phosphate-containing compound (e.g., an inorganic phosphate salt) and a refractory mineral filler (e.g., alumina or aluminum sulfate). The product exhibits flame resistance superior to the fibrous mineral matrix alone.

Owner:CERTAINTEED CORP

Method of acid extracting aluminium from high-silicon alumina-containing raw mineral materials

The invention relates the method of extracting aluminium from high-silicon siliceous mineral. The method comprises the following steps: mixing the aluminous ore and sulfuric acid, baking, leaching with water, filtering leachate, getting aluminium sulphate solvent, thickening filter liquor, separating out aluminium sulphate, drying, dewatering, getting anhydrous aluminium sulphate; calcining aluminium sulphate, and getting Al2O3. The invention can extracte aluminium from high-silicon siliceous mineral, coal gangue, coal ash, China clay, andalusite, feldspath, ganister, nepheline and vermiculite without baking. The method has the advantages of simple technology, little corrosion, easy operation and high recovery ratio.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com