Patents

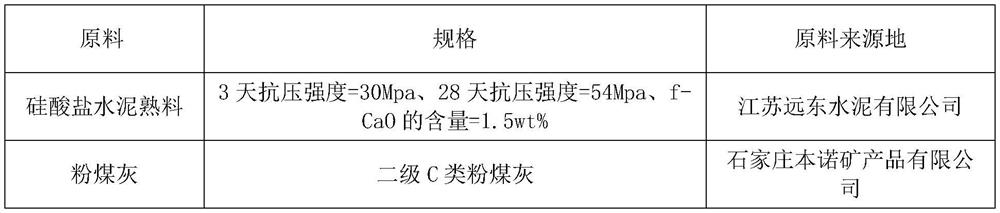

Literature

67 results about "Aluminum sulfate hydrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminum Sulfate Hydrate is a moderately water and acid soluble Aluminum source for uses compatible with sulfates. Sulfate compounds are salts or esters of sulfuric acid formed by replacing one or both of the hydrogens with a metal.

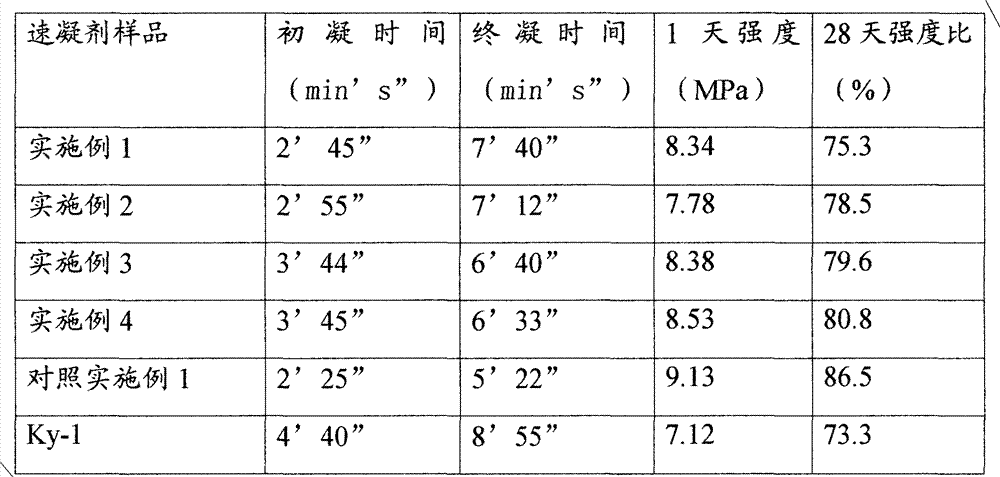

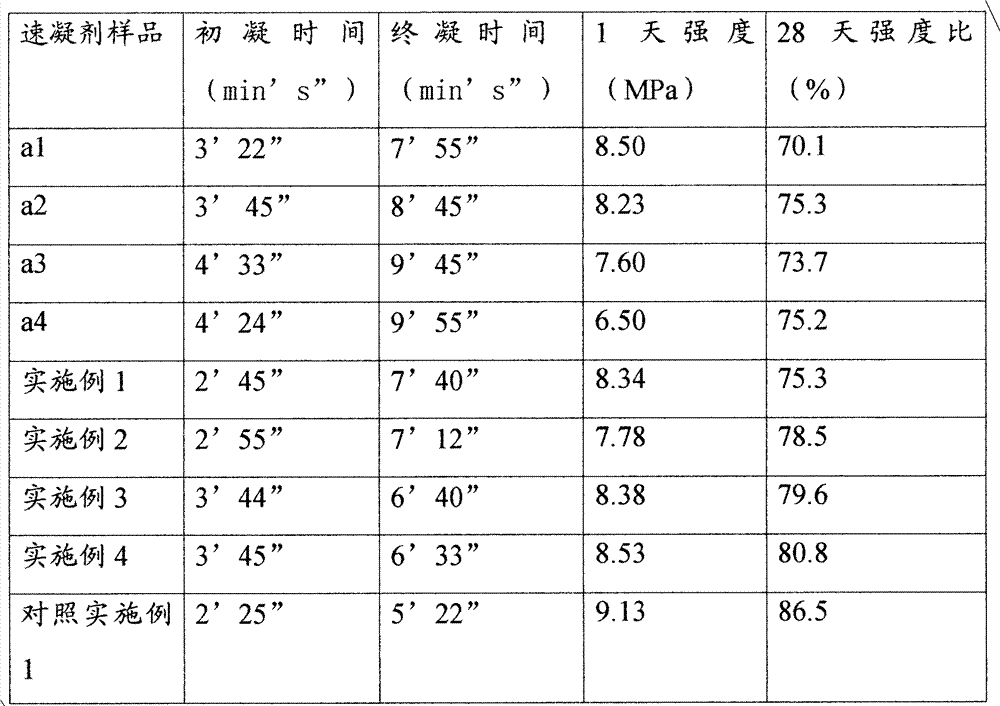

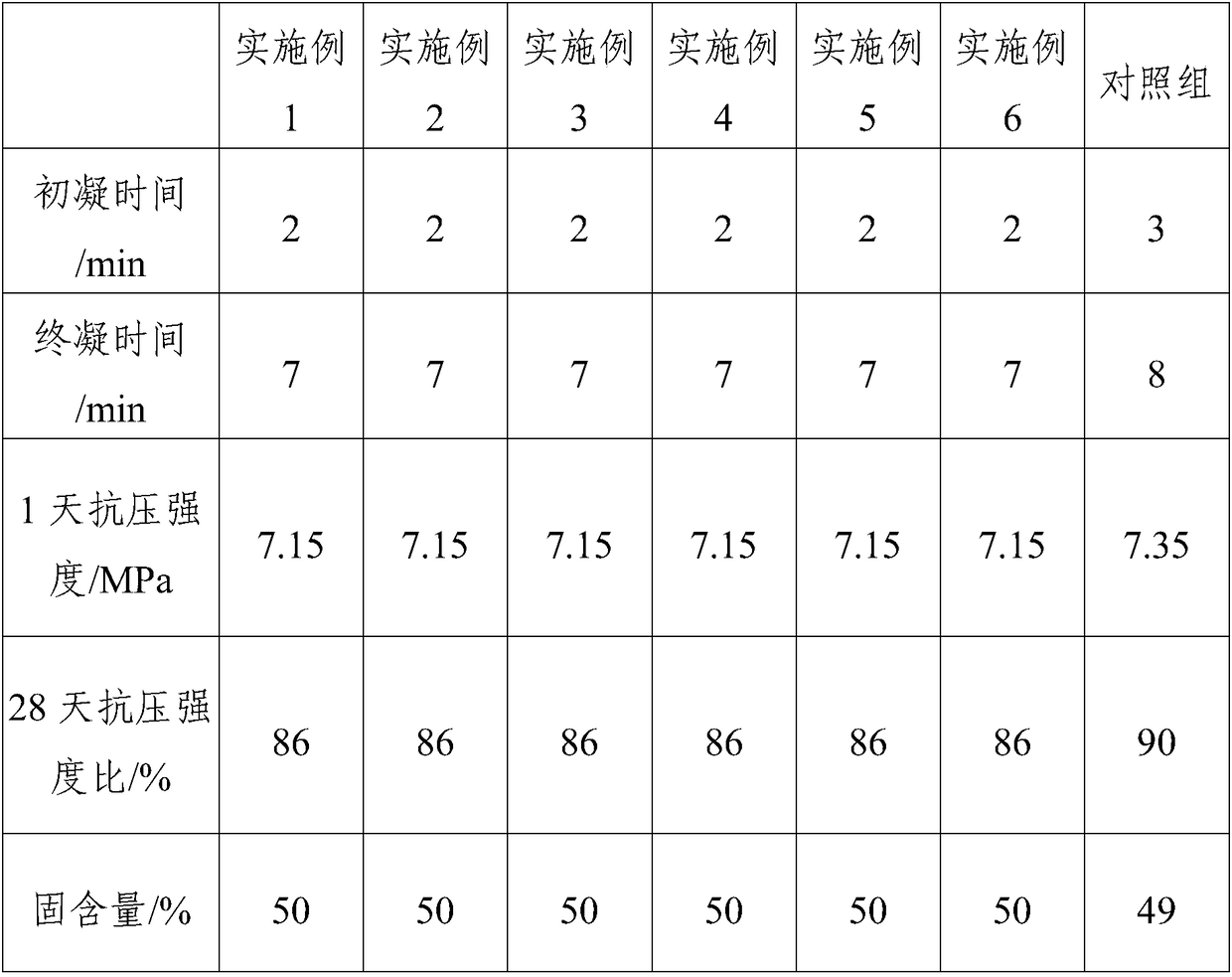

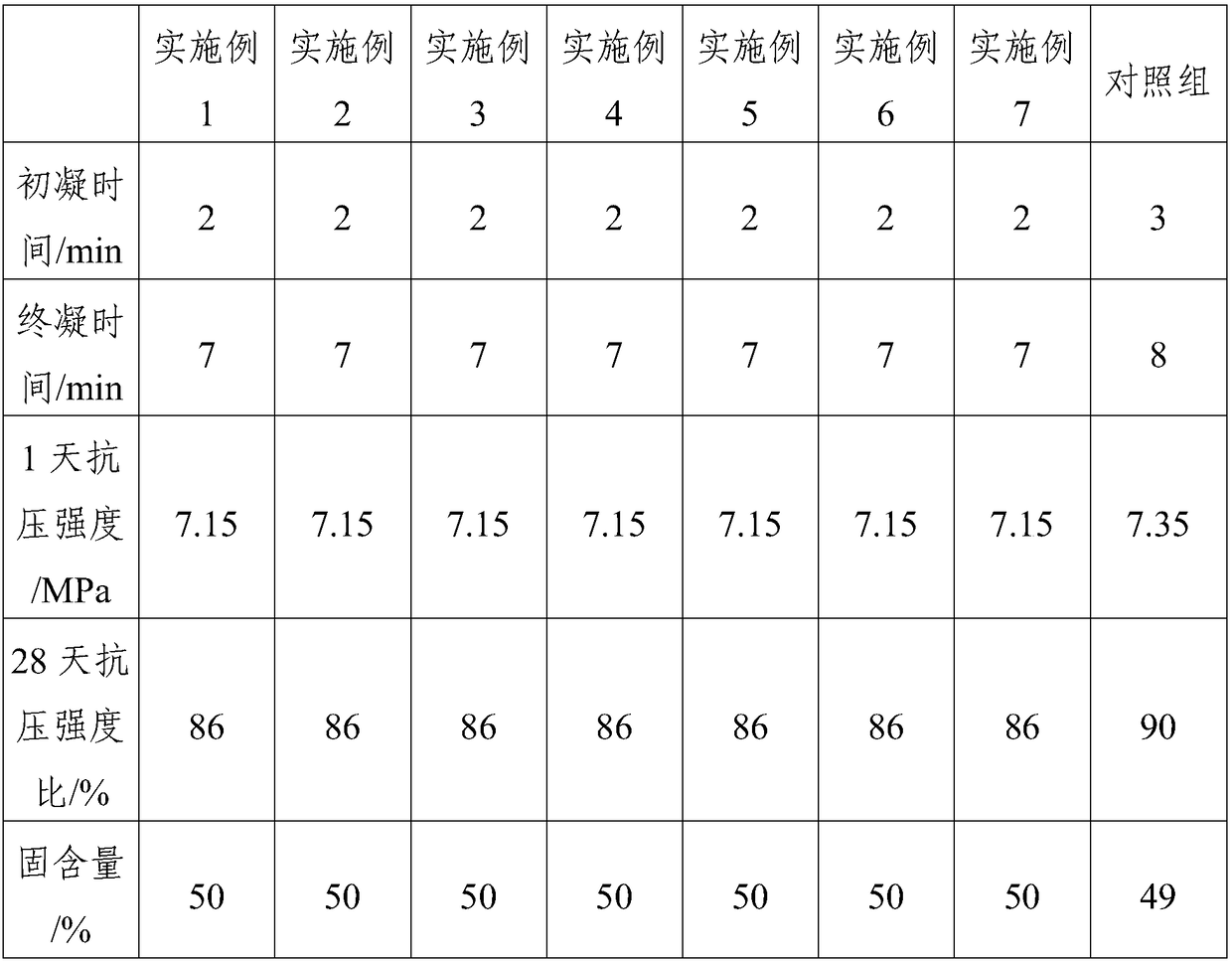

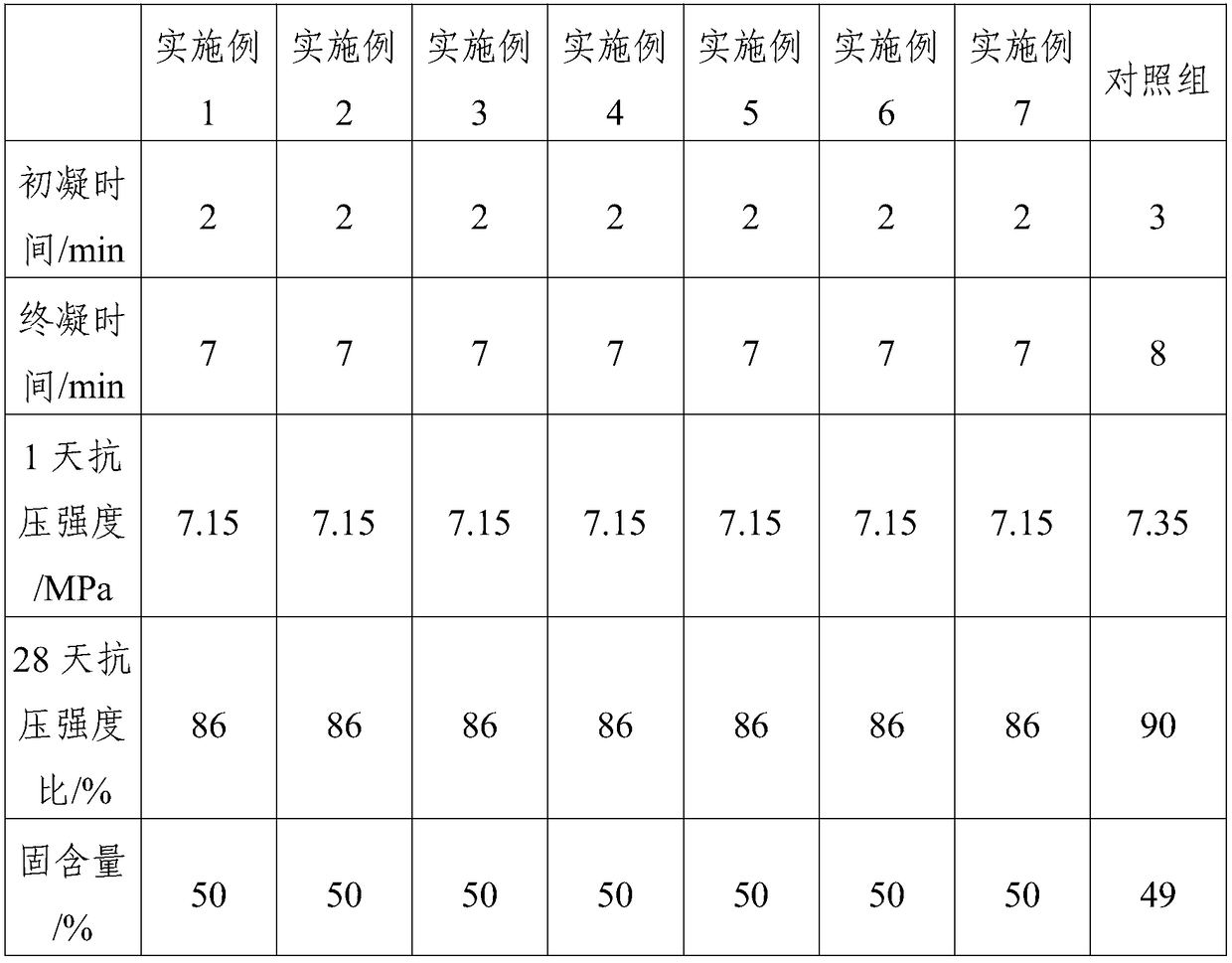

Liquid alkali-free chloride-free accelerating agent as well as methods for preparing and using same

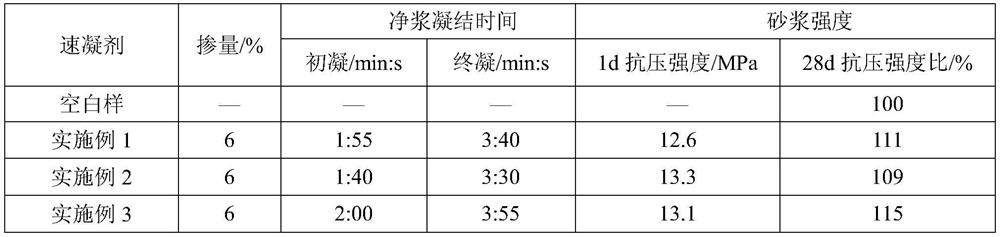

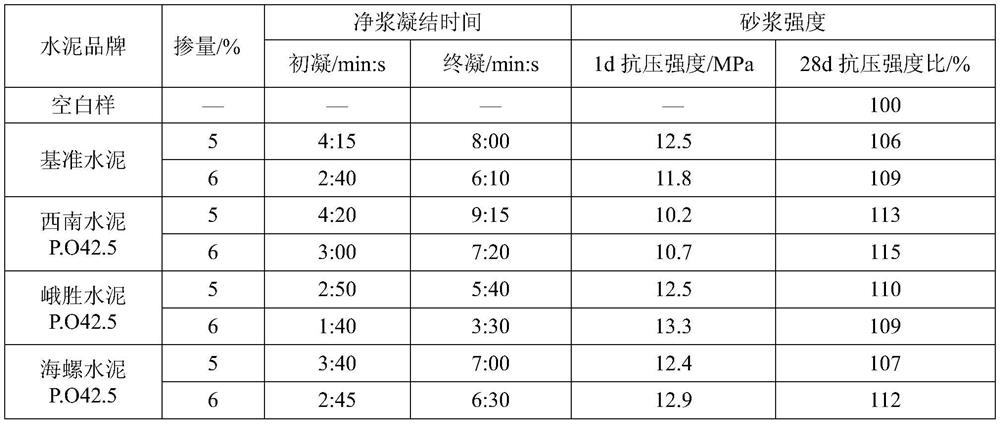

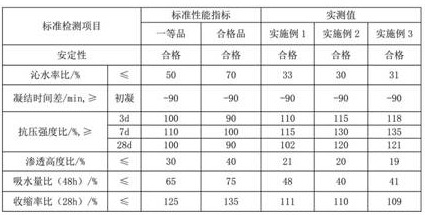

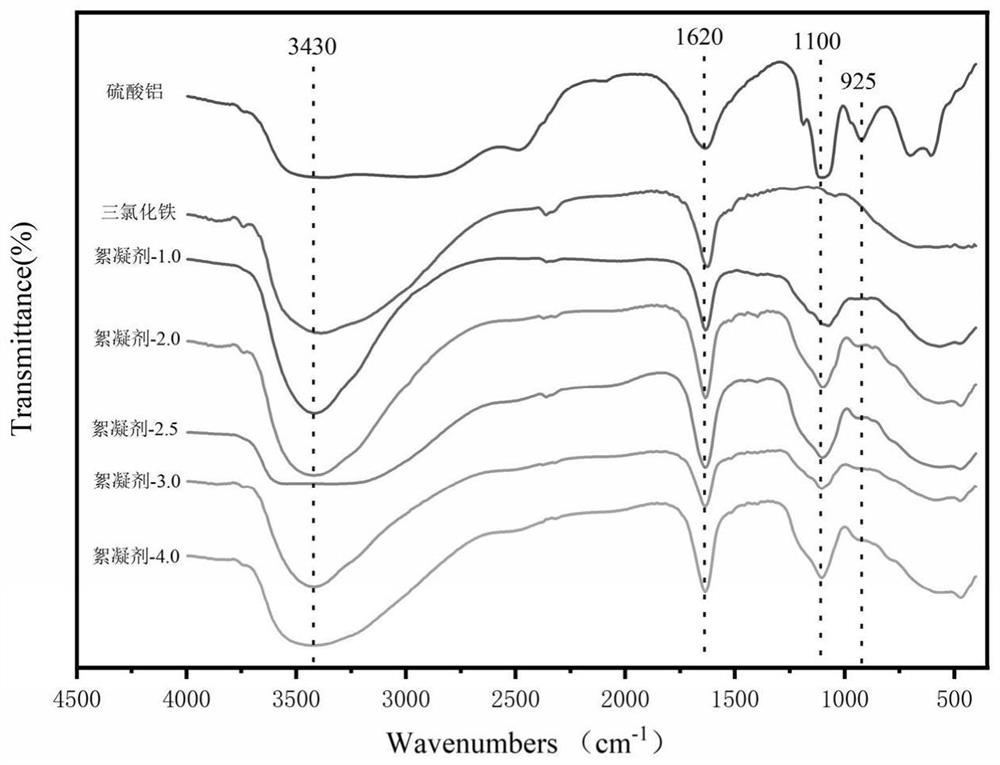

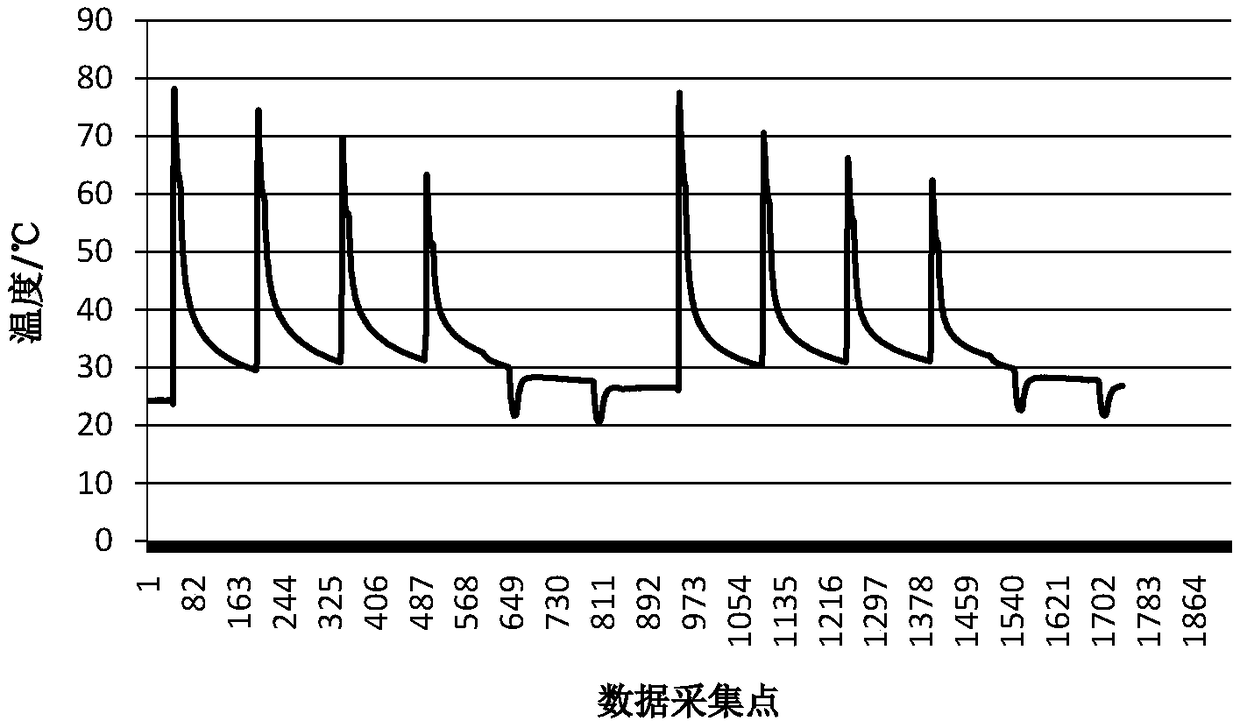

The invention discloses a liquid alkali-free chloride-free accelerating agent and methods for preparing and using the same. Raw materials for preparing the accelerating agent include one or a plurality of the following components of aluminum sulfate, magnesium sulfate, hydramine, an early strength agent, a synergist and water. The aluminum sulfate is the purchasable industrial-grade aluminum sulfate hydrate Al2(SO4)3.18H2O and has the solid content of 51%-52%. The magnesium sulfate is MgSO4.7H2O with the solid content of 48%-49%. The hydramine is one or a plurality of mono ethanol amine, diethanolamine, triethanolamine or isopropoxide. The early strength agent is one or a plurality of calcium sulfate, calcium formate or calcium nitrite. The synergist is magnesium fluosilicate and / or magnesium fluoride. The liquid alkali-free chloride-free accelerating agent provided by the invention has the characteristics of good adaptability, low price, low mixing amount, good performance, good stability and the like; and moreover, the liquid alkali-free chloride-free accelerating agent is added into the concrete to be used as sprayed concrete, has the characteristics of low resilience, small dust pollution and the like and can satisfy the requirements of the 'JC477-2005 sprayed concrete accelerating agent' standard.

Owner:北京冶建特种材料有限公司 +1

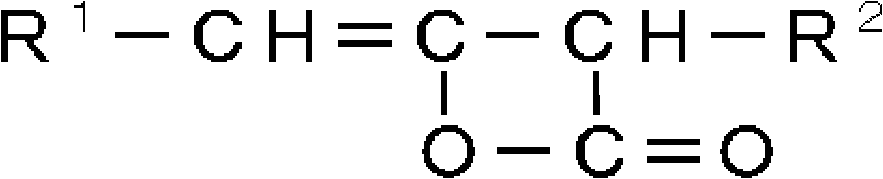

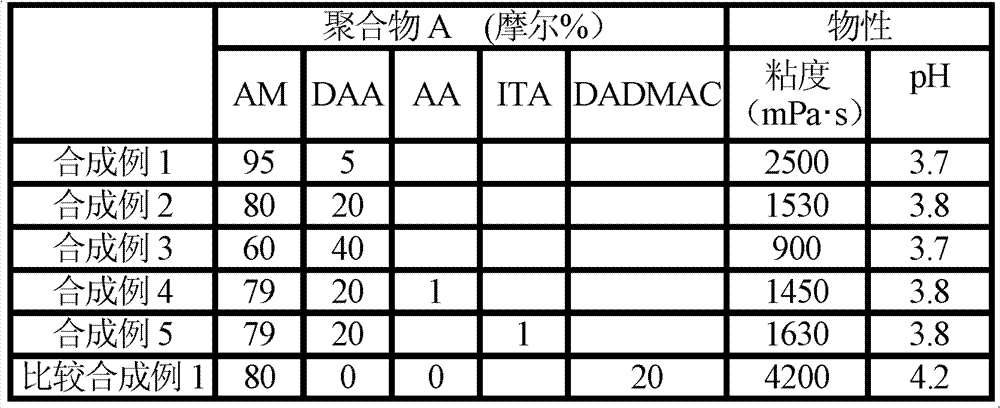

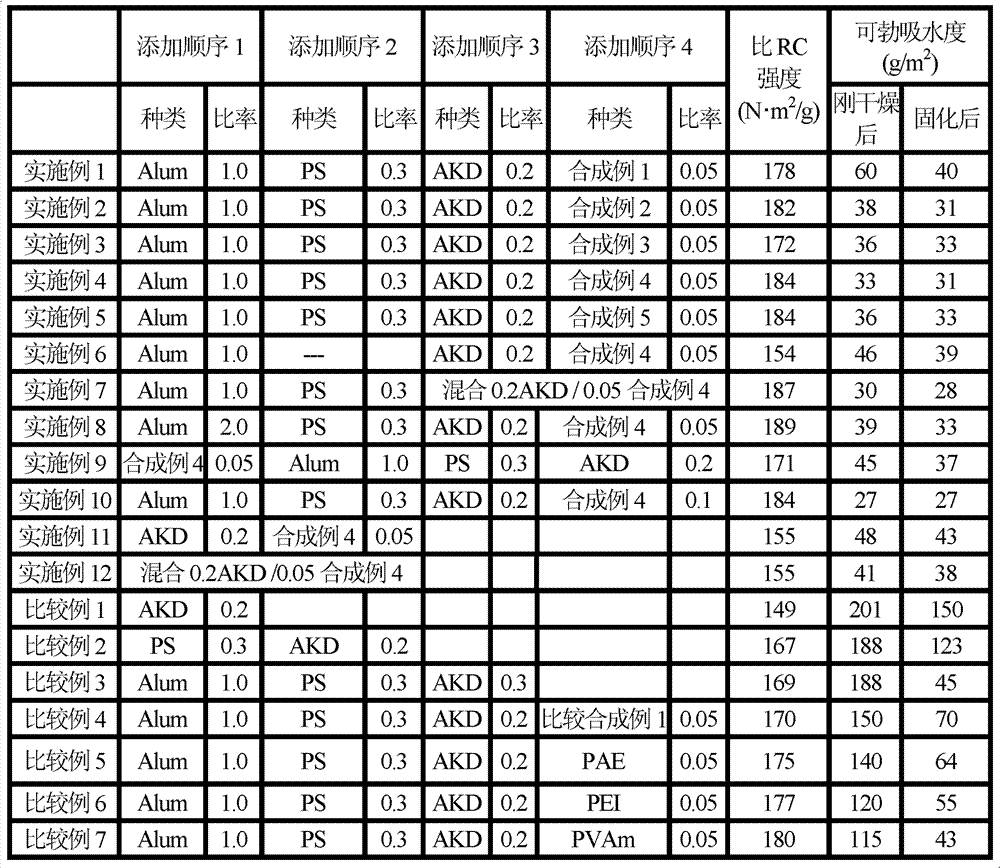

Method for manufacturing paper board

ActiveCN102733262AImprove sizing effectWater-repelling agents additionPaper/cardboardAluminium sulfatePaperboard

The present invention provides a method for manufacturing a paper board, wherein the paperboard is provided with an excellent sizing property and an excellent showing performance even if under a condition of using a paper pulp containing a lot of aluminium component or a condition of not adding calcium carbonate. The method for manufacturing a paper board comprises the steps of using a polymerized component at least containing (methyl) acrylamide (a1) and diallyl amine or salt thereof to obtain (methyl) acrylamide copolymer and ketene dipolymer sizing agent (B), and manufacturing papers with a base material paper pulp containing waste paper pulp and aluminium atoms converted for more than one wt.% from 16 aluminum sulfate hydrate relative to the drying weight of the base material paper pulp under a PH value of 6-8.

Owner:ARAKAWA CHEM IND LTD

Natural plant textile fabric dyeing agent

InactiveCN104846660AGood colorImprove vividnessDyeing processOXALIC ACID DIHYDRATEPotassium hydroxide

The invention discloses a natural plant textile fabric dyeing agent, which is prepared from the following raw materials in parts by weight: 6 to 9 parts of impatiens balsamina extract, 2 to 5 parts of chloroactic acid, 8 to 16 parts of an organic carboxylic acid compound, 7 to 14 parts of copper sulfate, 15 to 22 parts of aluminum potassium sulfate dodecahydrate, 4 to 6 parts of tetracarboxydiphthalic ether dianhydride, 6 to 8 parts of dibutyltin dilaurate, 5 to 10 parts of iron oxide red, 4 to 7 parts of cocoanut fatty acid diethanolamide, 5 to 12 parts of a natural plant pigment, 6 to 9 parts of oxalic acid, 4 to 7 parts of polyacrylate and 1.6 to 2.4 parts of potassium hydroxide. The natural plant textile fabric dyeing agent has the beneficial effects of easiness in dyeing, high brightness, nontoxicity, harmlessness and no chemical injury to a human body.

Owner:QINGDAO DONGCHANGRUI TEXTILE

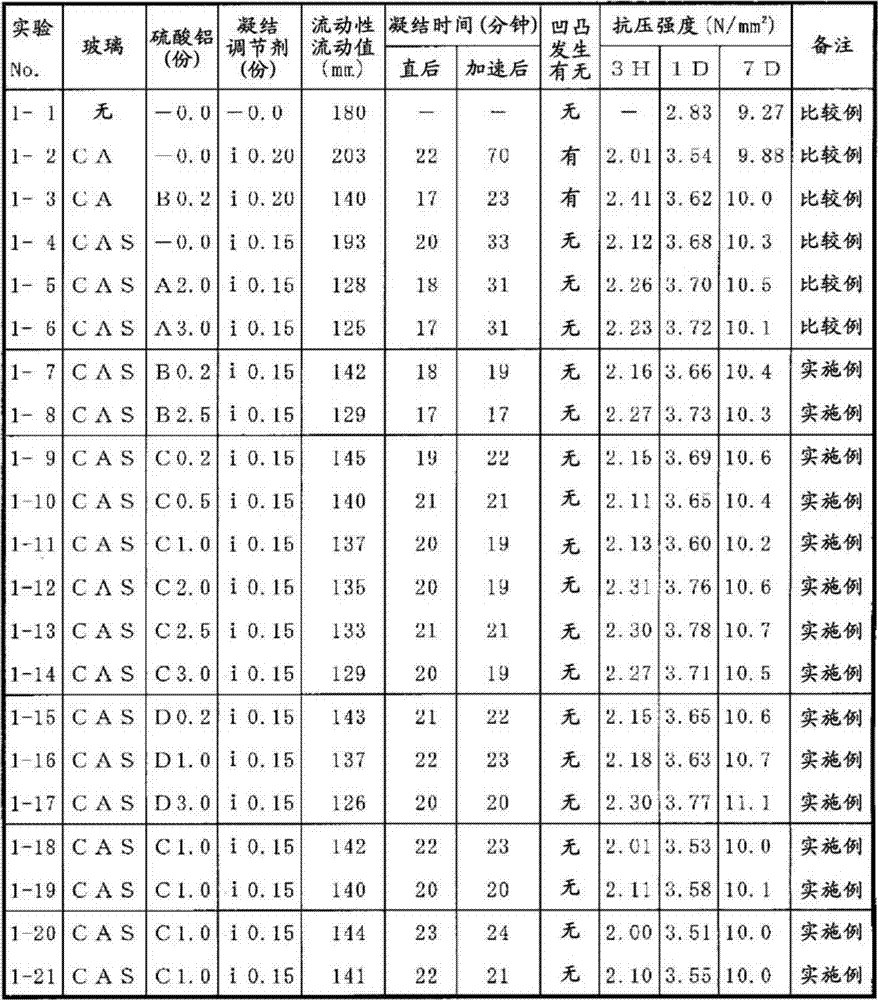

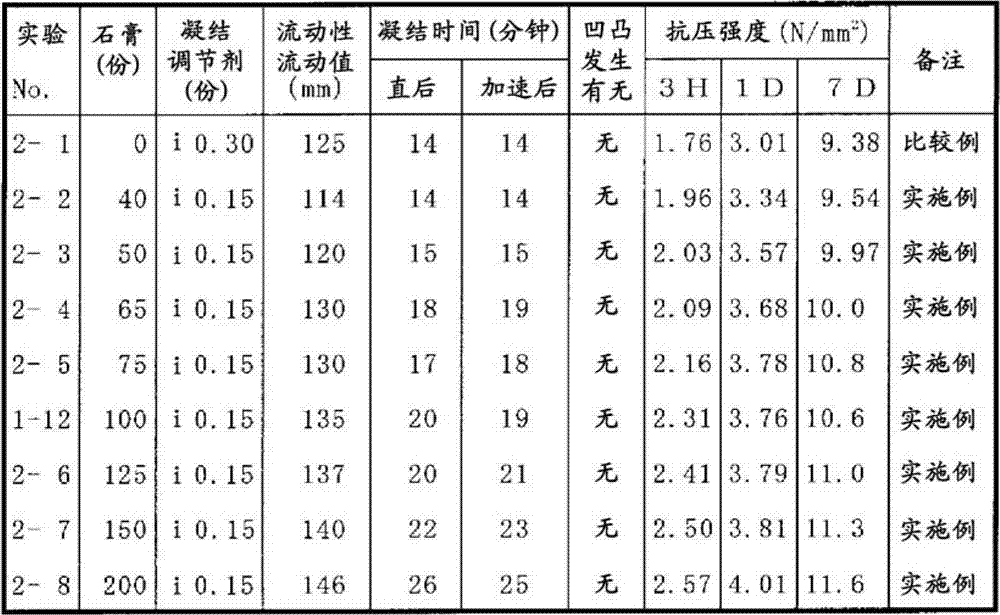

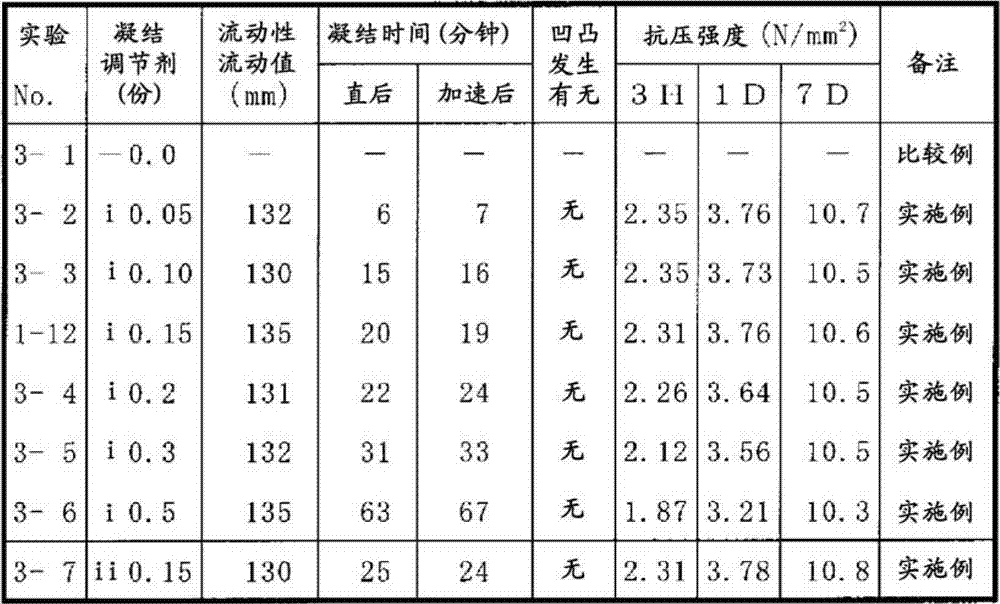

Cement admixture for repair, cement composition for repair using same, and cement mortar material for repair

Disclosed is a cement mortar which exhibits good workability free from recesses and projections, while having excellent storage stability. Specifically disclosed are: a cement admixture for repair, which contains calcium aluminosilicate glass, gypsum, aluminum sulfate hydrate and a setting regulating agent; the cement admixture for repair, which additionally contains a water reducing agent; a cement composition for repair, which contains the cement admixture for repair and cement; a cement mortar material for repair, which contains the cement composition for repair and fine aggregate; the cement mortar material for repair, wherein the maximum particle diameter of the fine aggregate is 0.3 mm or less; a cement mortar for repair, which contains the cement mortar material for repair and water; and a construction method wherein a cement mortar for repair, which contains cement, calcium aluminosilicate glass, gypsum, aluminum sulfate hydrate, a setting regulating agent, fine aggregate and water, is applied to a floor surface.

Owner:DENKA CO LTD

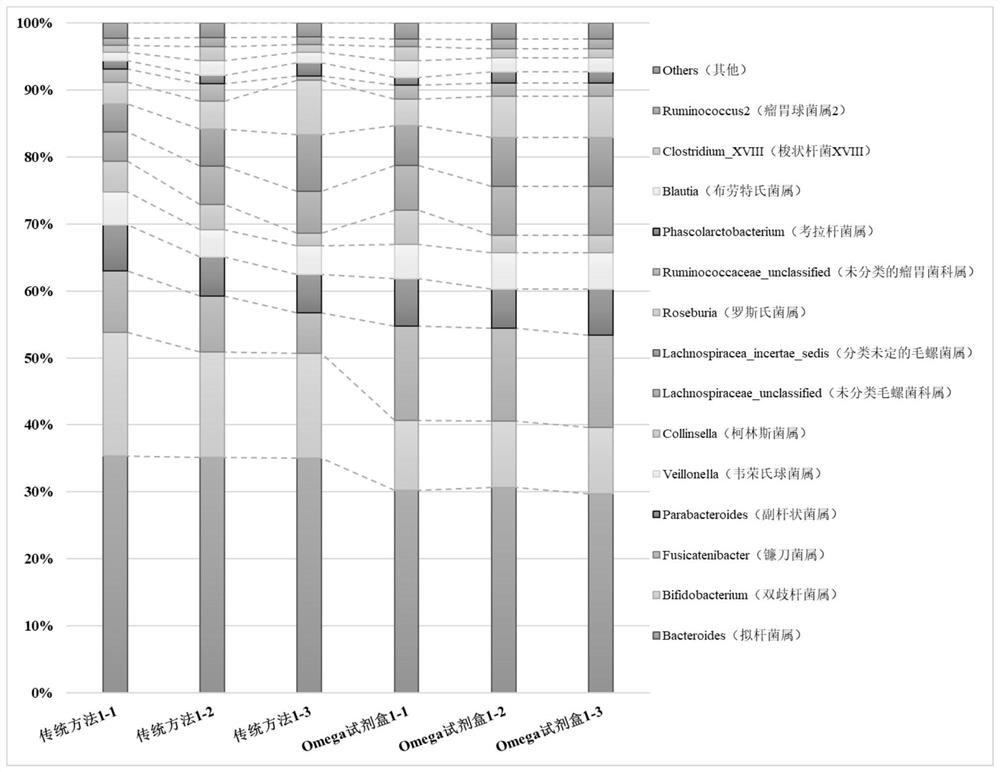

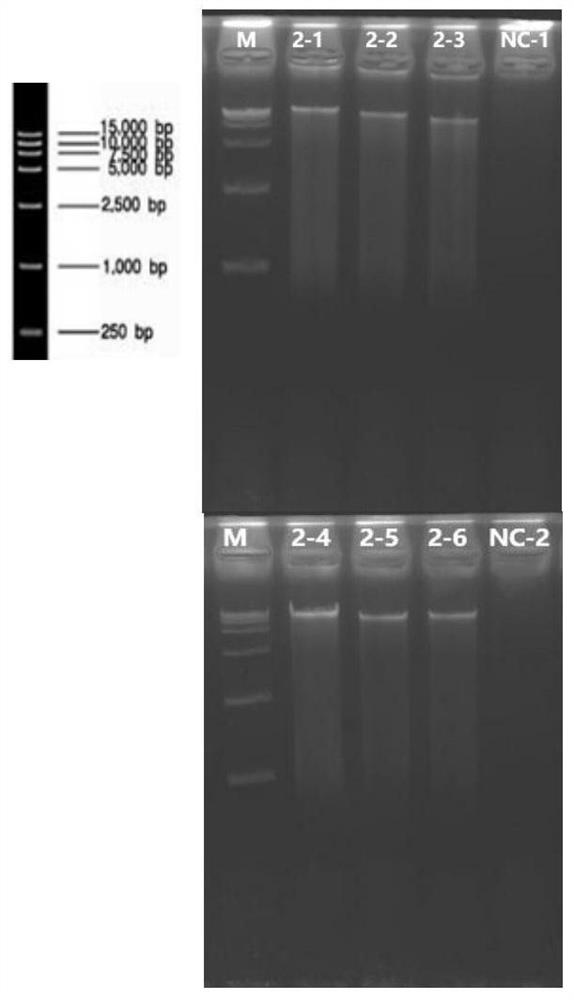

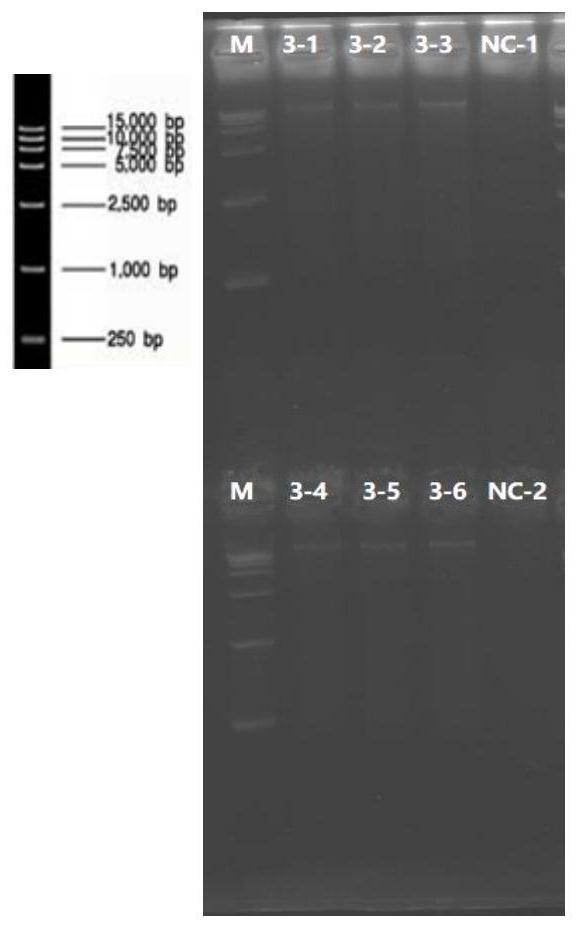

Nucleic acid extraction method and kit

ActiveCN112195177AGuaranteed broad-spectrum applicabilityGood removal effectMicrobiological testing/measurementDNA preparationAluminum ammonium sulfatePyrrolidinones

The present invention relates to the field of nucleic acid extraction, particularly to a nucleic acid extraction method and a kit. The kit comprises a nucleic acid chemical cracking solution and an inhibition component removing solution, wherein the nucleic acid chemical cracking solution comprises guanidinium isothiocyanate, N-lauroyl sarcosine sodium salt and PBS; and the inhibiting component removing solution comprises a mixed solution of an aluminum ammonium sulfate dodecahydrate solution and cross-linked polyvinylpyrrolidone (PVPP) and ammonium acetate. The nucleic acid extraction methodcomprises the following steps of chemically cracking a sample by adopting the nucleic acid chemical cracking solution, removing impurities, adsorbing the nucleic acid, and performing washing, eluting,and collecting to obtain the nucleic acid. According to the method, comprehensiveness and unbiased property in nucleic acid extraction are fully considered, purity and integrity of nucleic acid are also considered, loss in the process is reduced to ensure concentration, nesting can be formed for different types of biological or environmental samples, and broad-spectrum applicability of the extraction method is guaranteed.

Owner:上海慕柏生物医学科技有限公司 +1

Crystallized hydrate heat-insulation fireproof coating and preparation method

InactiveCN102604499AReduce the temperatureReduce spreadFireproof paintsAntifouling/underwater paintsHydration reactionPhysical chemistry

The invention provides crystallized hydrate heat-insulation fireproof coating, which combines noninflammability and low heat conductivity coefficient of decorative-surface coating. A preparation method is characterized by according to the principle that crystallized hydrate can lose crystallized water at a certain temperature and carry heat into atmosphere and can gain crystallized water at a certain temperature to realize circular heat exchange process by water loss and gain, preparing the crystallized hydrate heat-insulation fireproof coating for decorative surfaces. In the crystallized hydrate heat-insulation fireproof coating, crystallized hydrate can be any one of alum, magnesium sulfate heptahydrate or sodium tetraborate decahydrate or composition thereof.

Owner:SKSHU PAINT

Technology for preparing quick-setting agent by utilizing industrial waste phosphoric acid

InactiveCN108483965AGood quick setting effectShorten the setting timeChemical treatmentAluminium hydroxide

The invention discloses a technology for preparing a quick-setting agent by utilizing industrial waste phosphoric acid. The technology adopts the following raw materials in parts by weight: 50-200 parts of deionized water, 50-200 parts of aluminum hydroxide, 80-150 parts of industrial waste phosphoric acid, 20-50 parts of hydrofluoric acid, 5-15 parts of boric acid, 15-50 parts of triethanolamine,and 200-350 parts of aluminum sulfate hydrate. The technology directly utilizes waste phosphoric acid without any physical or chemical treatment, belongs to the hazardous wastes reuse, not only accords with the country's concept of promoting green production conformed with, but also reduces the cost of waste liquid disposal of enterprises, can also realize recycling of wastes and generate incomefor the enterprises to get three results with one action, and is suitable for promotion.

Owner:萧县沃德化工科技有限公司 +1

Filtrate reducer preparation method

InactiveCN107418528AStrong filtration capacityImprove temperature resistanceDrilling compositionPetroleumAcrylic acid

The invention relates to a filtrate reducer preparation method and belongs to the field of petrochemical engineering. The filtrate reducer preparation method disclosed by the invention comprises the steps: firstly mixing, reacting and evaporating tannin and a sodium hydroxide solution to obtain dry matter; then mixing and heating substances of acrylic acid, sodium p-styrene sulfonate and the like, adding substances of the prepared dry matter and the like to react to obtain jelly and drying and smashing to obtain reactant; then mixing substances of aluminum potassium sulfate dodecahydrate, palmitic acid and the like to obtain a mixed solution and mixing and heating the mixed solution and the obtained reactant; dropwise adding an initiator to react, adding an obtained product into absolute ethyl alcohol to be separated out, filtering and drying and smashing filter residues to obtain a filtrate reducer. The temperature-resistance and salt-tolerance filtrate reducer prepared by the preparation method disclosed by the invention still has higher filtrate reduction performance under high-salinity environment and further has better temperature resistance.

Owner:石磊

Chemical fiber dyeing technology with ultraviolet protection function

InactiveCN104695240AReduce pollutionAvoid damageFibre treatmentHeating/cooling textile fabricsFiberAnti bacteria

The invention provides a chemical fiber dyeing technology with the ultraviolet protection function. The chemical fiber dyeing technology comprises pretreatment, pre-shaping, dyeing, washing, soaping, color fixing, softening treatment, drying, shaping and rolling. The natural dyestuff of sophora flower bud is adopted, aluminum potassium sulfate dodecahydrate is used as a mordant, the dyeing effect is better, and the washability is greatly enhanced; meanwhile, due to the performance of the sophora flower bud, dyed chemical fiber has the good ultraviolet protection performance and the antibacterial and oxidation resistance; the washing technology and the color fixing technology are added, the dyeing firmness is good, green and environment-friendly and aldehyde-free TCD-R is adopted in the color fixing technology, and the chemical fiber obtained after color fixing is dried step by step, so that the firmness of the chemical fiber is greatly improved; the softening treatment technology is added, the fabric color firmness and flexibility are improved, the fabric roughness is lightened, and the fabric is fluffy and full of elasticity.

Owner:TAICANG TIANLONG CHEM FIBER

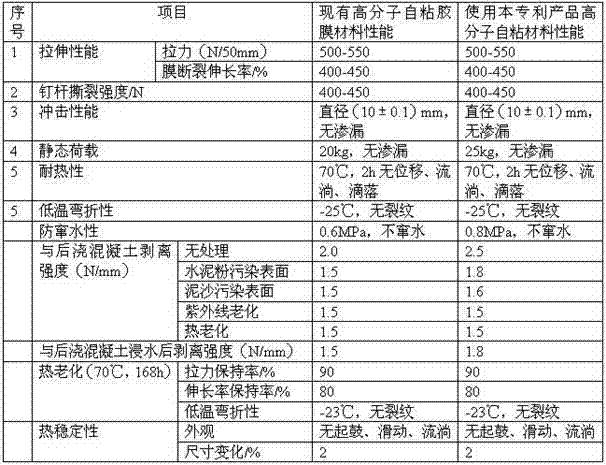

Environment-friendly water-based adhesive for root-resistant self-adhesion waterproof coiled material and preparation method thereof

The invention relates to an environment-friendly water-based adhesive for a root-resistant self-adhesion waterproof coiled material and a preparation method thereof. The preparation method is characterized in that each component raw material is measured according to the weight part ratio, siloxane emulsion is firstly uniformly mixed with bentonite in a blender, then nikasol-butyl acrylate copolymer, sulfonate dehydroabietic acid disodium salt, glycerol, isopropanol, methanol, aluminum potassium sulfate dodecahydrate, sodium dodecyl sulfate, calcium hydroxide, sodium silicate or sodium metasilicate, silica fume powder and nano zinc oxide are mixed into uniform slurry, finally polypropylene fibers are uniformly dispersed in the slurry after being blended, and a product can be obtained. The environment-friendly water-based adhesive has excellent adhesion performance, excellent permeability crystallization property and remarkable waterproof effect, has functions for supplementing the retraction of a material, healing cracks and resisting the root puncture, can be widely applied to different self-adhesion film of different self-adhesion coiled material, and also is applicable to the concrete crack resistance and crack repairing of building outer walls, roofs, basements, tunnels and the like.

Owner:北京立高殿梁防水保温建材科技有限公司

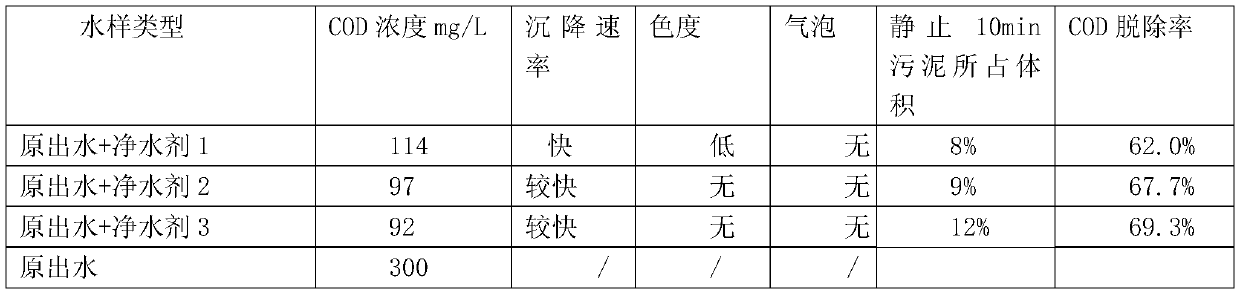

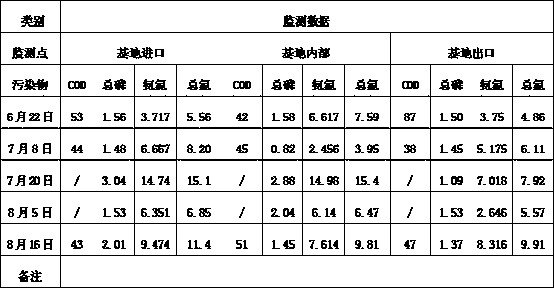

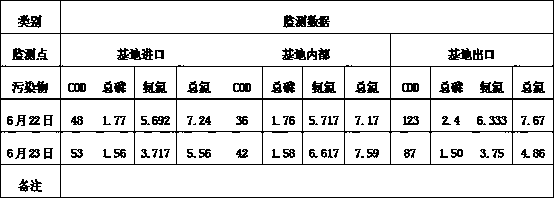

Water purifying agent for chemical industries such as coal chemical industry and coking industry and preparation method of water purifying agent

InactiveCN110577254APrevent floatingReduce usageFatty/oily/floating substances removal devicesLiquid separationChemical industryWater quality

The invention discloses a water purifying agent for chemical industries such as coal chemical industry and coking industry and a preparation method of the water purifying agent. The water purifying agent comprises the following components in parts by mass: 5 to 10 parts of carboxymethyl cellulose (CMC), 5 to 10 parts of modified chitosan, 5 to 10 parts of phenolic aldehyde, 25 to 40 parts of composite dual-acid aluminum iron, 1 to 3 parts of xanthan gum, 1 to 3 parts of cationic guar gum, 5 to 10 parts of an acid solution, 25 to 40 parts of aluminum potassium sulfate dodecahydrate, 20 to 40 parts of polyacrylamide, 25 to 60 parts of polyferric sulfate, and 2 to 5 parts of ST. Compared with a traditional water purifying agent, the use amount of a flocculating agent is greatly reduced, resources are saved, and the cost is low; the effluent quality is good; aiming at coal chemical industry wastewater and coking industry wastewater with complex components, the combined water purifying agent with different components and different functions is adopted, coagulation, adsorption, wrapping, sedimentation and decoloration occur quickly, and the effect of getting twofold results with half theeffort in COD removal rate can be achieved; and the effluent quality meets increasingly strict emission standards and laws and regulations.

Owner:ZHEJIANG BEROOT ENVIRONMENTAL PROTECTION TECH CO LTD

Efficient environment-friendly water lettuce prevention and control medicine and preparation method and application method thereof

ActiveCN102986735AAccelerated decayTo achieve the effect of upper control and lower governanceBiocideAnimal repellantsBiotechnologyVegetable oil

The invention relates to the technical field of pest prevention and control, particularly relates to a medicine for preventing and controlling water lettuce, and also relates to a preparation method and an application method thereof. An efficient environment-friendly water lettuce prevention and control medicine consists of the following components in percentage by weight: 30-40% of N-(3,4-dichlorophenyl)-N',N'-dimethylurea, 25-35% of N-(phosphonomethyl) glycine, 20-30% of aluminum potassium sulfate dodecahydrate, 0.2-5% of nonionic surfactant and 0.2-5% of vegetable oil. Through the invention, an effect of upper control and lower curing can be realized; 24 days later, the leaves and root tips of the water lettuce thoroughly die and are dissolved, the death rate reaches 100%, and regeneration is avoided; and moreover, the medicine is nontoxic and harmless and environment-free, and prevents influence on the organisms of water bodies (aquatic fish and poultry) as well as secondary pollution.

Owner:骆世鸿

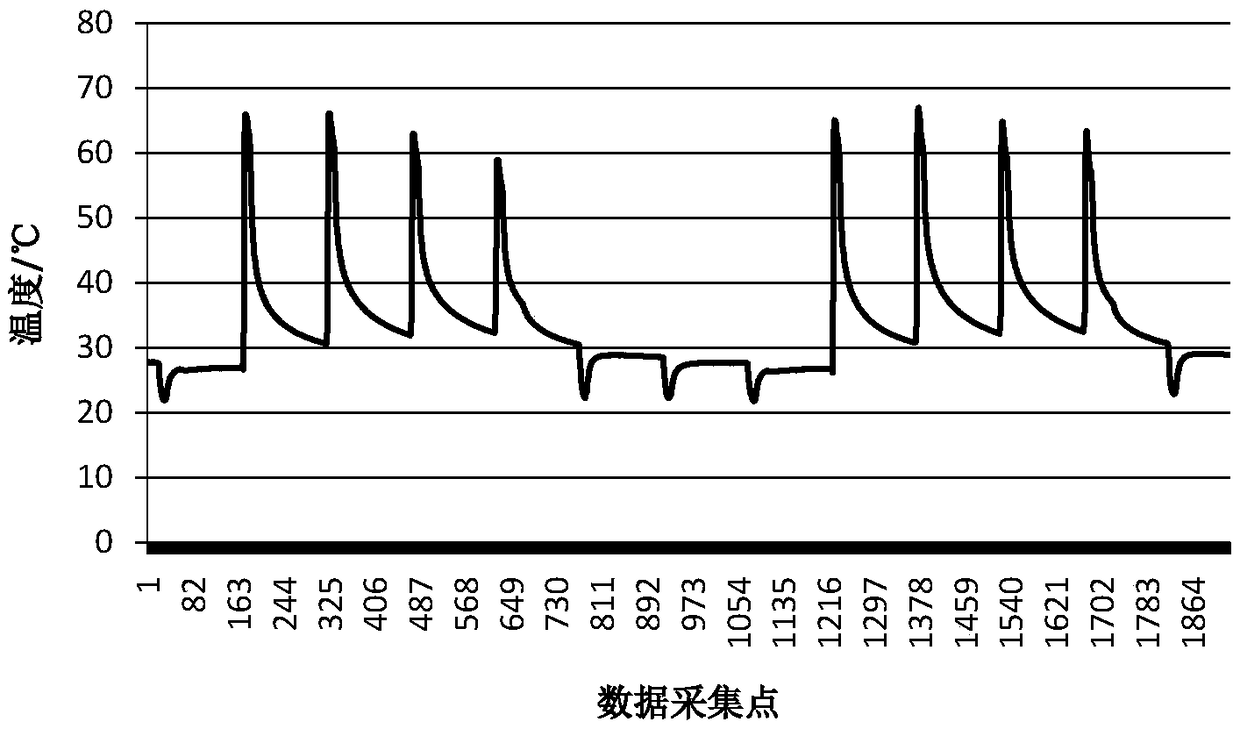

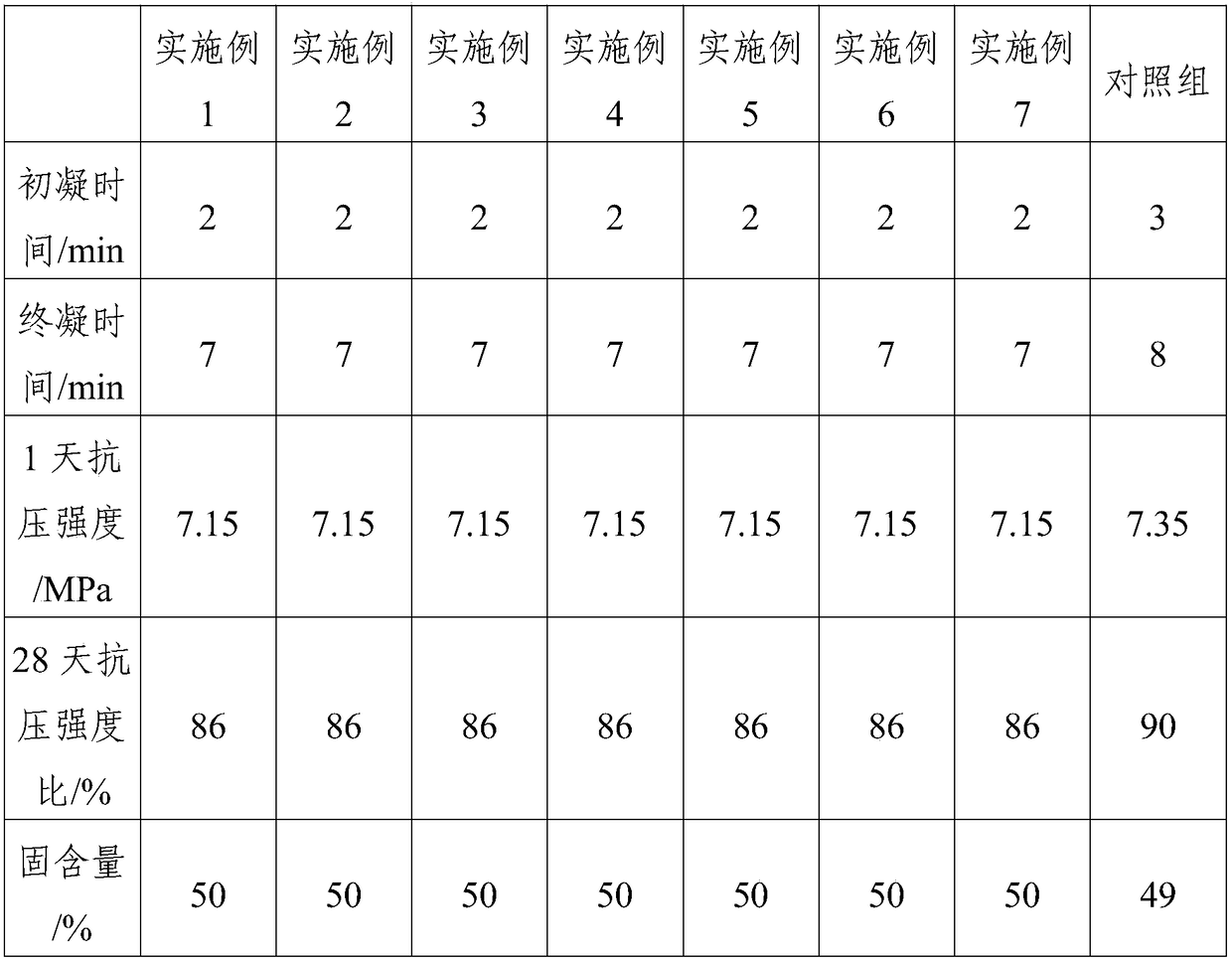

Elasticity-reducing low-sulfur alkali-free liquid setting accelerator and preparation method thereof

The invention relates to an elasticity-reducing low-sulfur alkali-free liquid setting accelerator and a preparation method thereof. The setting accelerator is prepared from the following raw materials: 28%-35% of a first quick-setting component, 7%-12% of a second quick-setting component, 1.5%-2.5% of a third quick-setting component, 2%-4% of an inorganic stabilizer, 2%-5% of an organic reinforcing agent, 0.4%-0.55% of a rebound inhibitor and the balance being water. The first quick-setting component is aluminum sulfate octadecahydrate, the second quick-setting component is aluminum dihydrogen phosphate, the third quick-setting component is sodium metaaluminate, the inorganic stabilizer is sulfuric acid, phosphoric acid and nitric acid, and the organic reinforcing agent is diethanol amine, N-methyldiethanolamine and diethanolisopropanolamine. The rebound inhibitor is formed by mixing hydroxypropyl methyl cellulose, polyacrylamide and redispersible latex powder. The invention also provides the preparation method of the setting accelerator. The high rebound rate in the wet spraying process can be reduced, the strength of concrete in the early stage, especially in the later stage, is increased, and the setting accelerator is good in stability, low in mixing amount, short in concrete setting time and good in adaptability to different kinds of cement.

Owner:SHIJIAZHUANG CHANGAN YUCAI BUILDING MATERIALS

High-efficiency sewage treatment agent and preparation method thereof

InactiveCN106430370AGood processing effectImprove stabilityWater/sewage treatmentSodium BentoniteTherapeutic effect

The invention discloses a high-efficiency sewage treatment agent and a preparation method thereof. The high-efficiency sewage treatment agent consists of the following raw materials in parts by weight: 25-30 parts of polyacrylamide, 3-6 parts of chitosan, 2-5 parts of aluminum potassium sulfate dodecahydrate, 4-7 parts of activated carbon, 12-15 parts of polyethyleneimine, 2-4 parts of ferrous sulfate, 1-3 parts of sodium citrate, 16-19 parts of leftover bits and pieces of edible mushrooms, 10-13 parts of bentonite and 3-5 parts of starch xanthate. The invention also discloses the preparation method of the high-efficiency sewage treatment agent. The sewage treatment agent prepared through the preparation method disclosed by the invention has good treatment effect to domestic sewage and good stability, a product of the sewage treatment agent can meet the requirements of the market on a domestic sewage treatment product, and the index of the treated domestic sewage can reach the national discharge standard.

Owner:ZHENGZHOU CHENGHE INFORMATION TECH CO LTD

GBL concrete waterproof compacting agent

The invention discloses a GBL concrete waterproof compacting agent. The compacting agent comprises, by weight, 10 to 17 parts of sodium silicate, 20 to 28 parts of aluminum potassium sulfate dodecahydrate, 1 to 4 parts of polyether, 0.05 to 0.5 part of a polyhydroxy compound, 1 to 6 parts of polyethylene glycol, 0.5 to 1.2 parts of n-butyl alcohol, 0.01 to 0.06 part of mineral fiber, 0.2 to 0.4 part of diethanol amine, 2 to 5 parts of lithium carbonate, 0.2 to 0.4 part of triethanolamine stearate, 0.05 to 0.1 part of a surfactant, 0.002 to 0.006 part of an NNO dispersing agent and 40 to 70 parts of water. The invention further discloses a preparation method of the compacting agent. The compacting agent can significantly improve the concrete anti-permeability, reduce the concrete shrinkage, prevent the concrete from cracking after hardening, and effectively prevent water molecule permeation, thereby improving the concrete strength and performance.

Owner:河南博浪实业有限公司

Coal gasification coarse slag-based composite flocculant as well as preparation method and application thereof

ActiveCN114368817AGive full play to the synergistic effectEasy to prepareWater/sewage treatment by flocculation/precipitationAluminum IonSlag

The invention relates to a coal gasification coarse slag-based composite flocculant as well as a preparation method and application thereof. The preparation method provided by the invention is simple, and the multi-ion composite flocculant can be prepared from the coal gasification slag in a bulk and high-valued manner. Due to the fact that the multi-ion composite flocculant contains various different ions, the use limitation of commercially available single-ion flocculants such as ferric trichloride hexahydrate and aluminum sulfate octadecahydrate is broken through, and due to the fact that the multi-ion composite flocculant contains various ions such as iron ions, aluminum ions and calcium ions. When the flocculant is used for treating wastewater, various ions generate a synergistic effect, so that the coagulation performance of the flocculant is improved, and practical application of wastewater with relatively complex components is facilitated.

Owner:QILU UNIV OF TECH

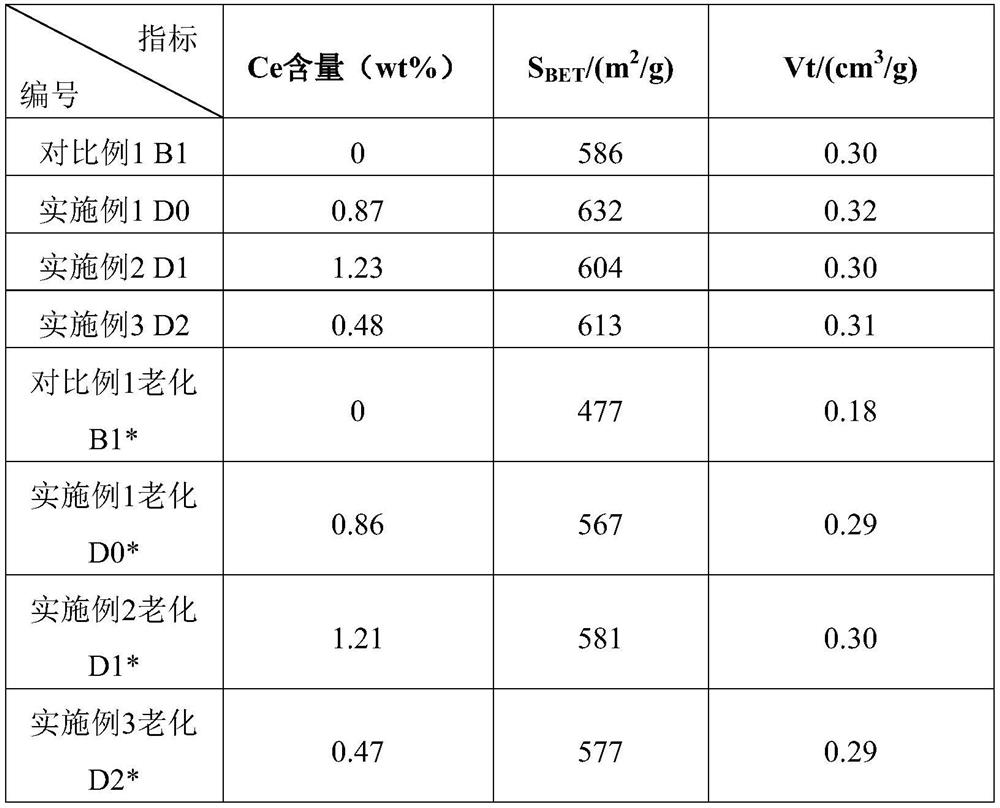

Preparation method of Ce modified Cu-Fe-SSZ-13 molecular sieve

ActiveCN112844463AIncrease damageImprove skeletal stabilityMolecular sieve catalystsDispersed particle separationHydration reactionSodium aluminate

The invention relates to a preparation method of a Ce-modified Cu-Fe-SSZ-13 molecular sieve. The method particularly comprises: slowly dropwise adding tetraethylenepentamine into a copper sulfate solution under intense stirring, sequentially adding cerous nitrate and ferric nitrate after the reaction is finished, fully and uniformly mixing, and adding sodium hydroxide to prepare a solution A; and adding sodium metaaluminate or aluminum sulfate octadecahydrate into the solution A, stirring for 1-2 hours, then adding silica sol, continuously stirring for 2-3 hours, then putting into a steel reaction kettle with a polytetrafluoroethylene lining, aging for 12-14 hours, carrying out homogeneous hydrothermal reaction on the obtained sol-gel precursor at 120-180 DEG C for 72-96 hours, after crystallization is finished, carrying out solid-liquid separation, washing the solid with water until the pH is neutral, drying, and calcining the solid at the temperature of between 500 and 550 DEG C for 4 to 8 hours to obtain the Cu-Fe-Ce-SSZ-13 molecular sieve.

Owner:SHANDONG SINOCERA FUNCTIONAL MATERIAL CO LTD

Efficient sewage treating agent specially used for sanitary sewage and preparing method thereof

InactiveCN106395942AGood processing effectImprove stabilityWater/sewage treatmentEmission standardStarch xanthate

The invention discloses an efficient sewage treating agent specially used for sanitary sewage. The efficient sewage treating agent specially used for sanitary sewage is prepared from, by weight, 25-30 parts of polyacrylamide, 3-6 parts of chitosan, 2-5 parts of aluminium potassium sulfate dodecahydrate, 4-7 parts of activated carbon, 12-15 parts of polyethyleneimine, 2-4 parts of ferrous sulfate, 1-3 parts of sodium citrate, 16-19 parts of perlite, 10-13 parts of soapstone and 3-5 parts of starch xanthate. The invention also discloses a preparing method of the efficient sewage treating agent specially used for sanitary sewage. The prepared sewage treating agent has a good treating effect on sanitary sewage and has good stability. The product can meet the requirements of the market on sanitary sewage treating products, and the index of the treated sanitary sewage can reach the national emission standard.

Owner:ZHENGZHOU CHENGHE INFORMATION TECH CO LTD

Heat-resistant iron oxide green pigment and synthesis method thereof

ActiveCN113388269AMeet the needs of coloringImprove temperature resistanceChemical industryPigment treatment with non-polymer organic compoundsAluminium chlorideSodium phosphates

The invention provides a heat-resistant iron oxide green pigment, which is prepared from the following components in parts by mass: 10 to 15 parts of iron oxide yellow, 4.0 to 8.2 parts of sodium hydroxide, 10.0 to 12 parts of aluminum sulfate octadecahydrate, 0.70 to 1.2 parts of sodium hexametaphosphate, 0.50 to 2 parts of zinc chloride, 2.4 to 3.0 parts of aluminum chloride hexahydrate, 2.20 to 2.5 parts of sulfonated cobalt phthalocyanine and the balance of water.

Owner:SHENGHUA GROUP DEQING HUAYUAN PIGMENT +1

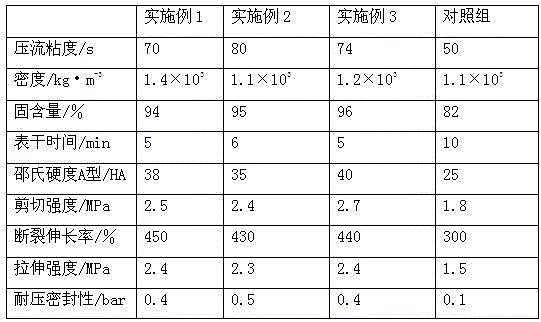

Smart home air conditioner pipe mounting sealant

InactiveCN105969305AThe preparation process is simpleGood flow viscosityNon-macromolecular adhesive additivesOil/fat/wax adhesivesPhosphoric Acid EstersSodium acetate

The invention relates to a smart home air conditioner pipe mounting sealant. The smart home air conditioner pipe mounting sealant consists of the following components: isothiazolinone, sodium diacetate, butadiene-styrene rubber, barium sulfate, brominated butyl rubber, citric acid, butyl cellosolve, silver nitrate, benzalkonium chloride, benzyl triphenyl phosphorous bromide, glycerol monocaprylocaprate, tetrachloroethylene, sodium gluconate, rosin water, lead tetraoxide powder, polytetrahydrofuran glycol, lauryl alcohol phosphate acid ester, chitosan, imidacloprid, polyoxyethylene ether, terpene resin, hexabromo benzene, glyceryl stearate, bamboo charcoal powder, aluminum potassium sulfate dodecahydrate, 2,2-dimethylolpropionic acid and castor oil. The product has good pressure flow viscosity, shore hardness, shearing strength, elongation at break, tensile strength, pressure resistance sealing property and excellent performance, and the performance of the product is improved. The product has good corrosion resistance, fireproofness, flame retardance, mildew and bacteria resistance.

Owner:王乔

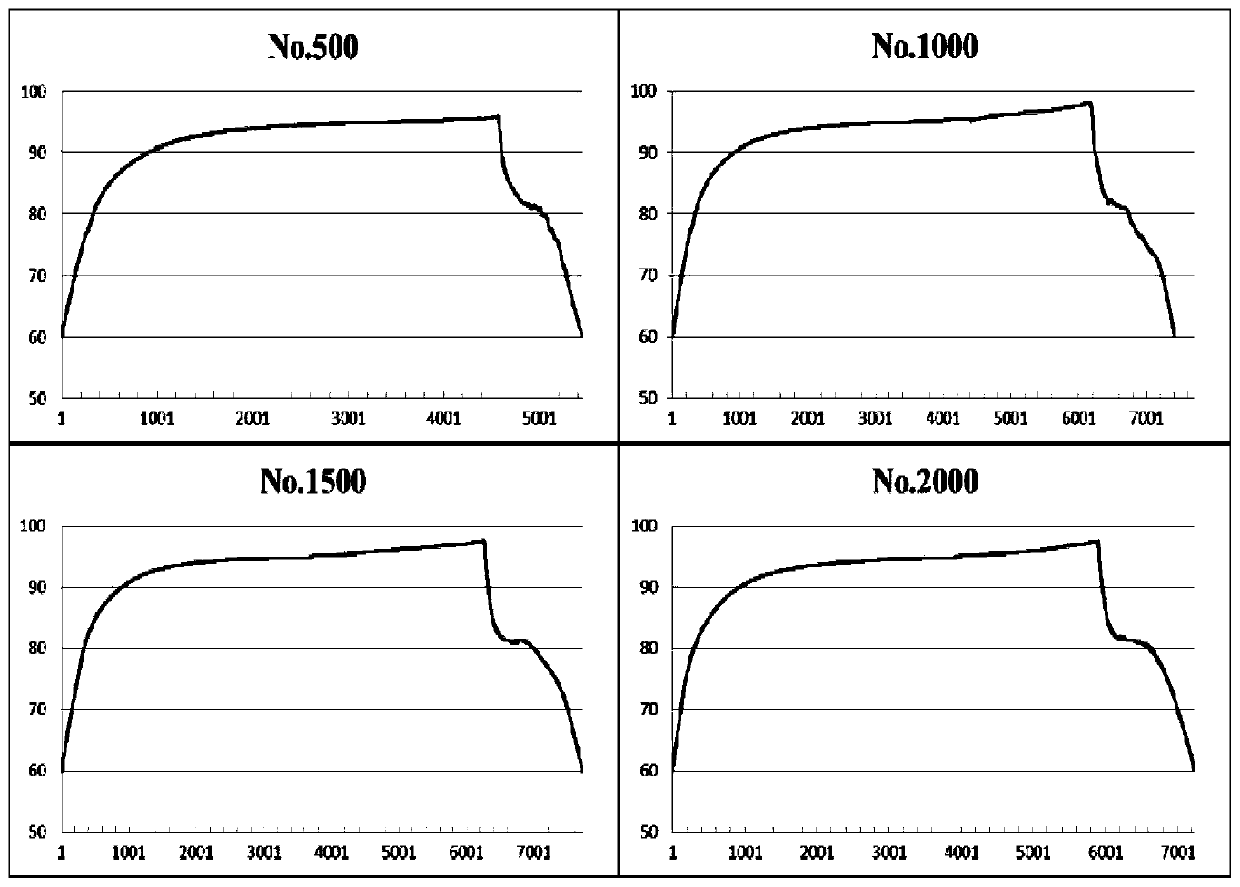

Constant-temperature phase-change energy storage material and preparation method thereof

InactiveCN110862805AImprove performanceLow priceHeat-exchange elementsAluminum ammonium sulfateSilicon oxide

The invention discloses a constant-temperature phase-change energy storage material and a preparation method thereof. The phase-change energy storage material comprises the following components by mass percentage: 94% of aluminum ammonium sulfate dodecahydrate, 3% of expanded graphite, 2% of deionized water and 1% of fumed silica. The preparation method of the phase-change energy storage materialis simple, the phase-change temperature of the obtained phase-change material is 81DEG C, the phase-change latent heat is 260J / g, and the temperature is constant in the phase-change process, the undercooling degree is smaller than 1DEG C, the cycling stability is good, and the material performance is not attenuated after 2000 times of heat charging and release cycles. The raw materials of the phase-change material are low in price, easily available, safe and non-toxic, therefore the constant-temperature phase-change energy storage material is suitable for wide application in distributed heat supply and industrial residual and waste heat recovery fields.

Owner:PIONEER ENERGY JIANGSU

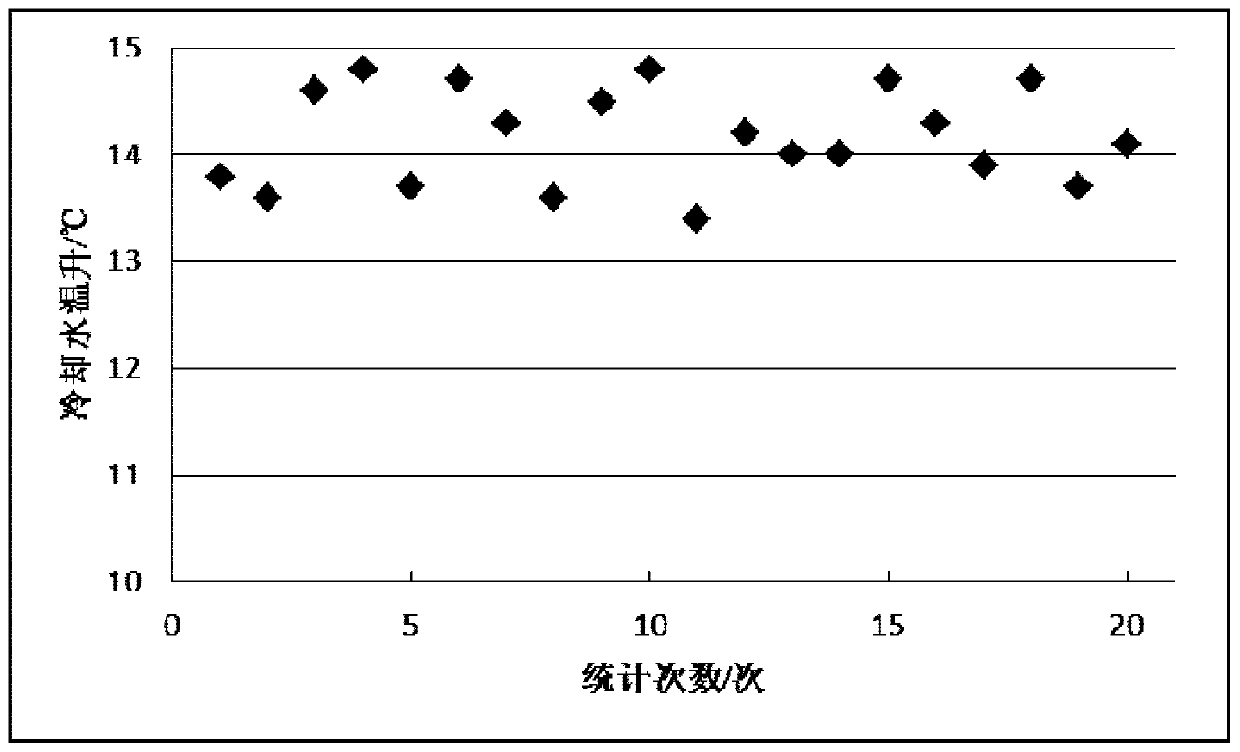

Cooling cigarette holder, preparation method and heated non-combustible cigarette

InactiveCN109430937AReduce the temperatureImprove drynessTobacco smoke filtersTobacco devicesSodium phosphatesEngineering

The invention relates to a cooling cigarette holder, a heated non-combustible cigarette and an application. The cooling cigarette holder comprises a cooling section, the cooling section comprises carriers, cooling materials are applied onto the surfaces of the carriers, the carriers are distributed in the cooling section to form a plurality of channels penetrating the cooling section, the coolingmaterials are provided with a crystallization water compound, the crystallization water compound is at least one of ferrous sulfate, aluminum potassium sulfate dodecahydrate, sodium phosphate dibasicdodecahydrate, magnesium sulfate heptahydrate, copper sulfate pentahydrate and sodium sulfate decahydrate, and preferably, the carriers are provided with paper. According to the cooling cigarette holder, the temperature of smoke entering a mouth of a smoker can be effectively reduced by 10 DEG C or more, the crystallization water compound absorbs heat and releases crystallization water, the temperature of smoke of the heated non-combustible cigarette can be effectively reduced in first, second and third times of smoking.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Application of waste hydrofluoric acid etching solution to accelerating agent synthesis

InactiveCN108623206AFast setting time is shortGood quick setting effectArray data structureAluminium hydroxide

The invention discloses an accelerating agent containing waste hydrofluoric acid etching solution and a preparation method of the accelerating agent. The accelerating agent comprises, by weight, 200-350 parts of deionized water, 50-100 parts of aluminum hydroxide, 20-80 parts of waste hydrofluoric acid etching solution, 10 parts of phosphoric acid, 10-25 parts of acid, 15-50 parts of triethanolamine and 300-450 parts of aluminum sulfate hydrate. According to the application of the accelerating agent, the waste hydrofluoric acid etching solution can be directly used without being treated, recycling of the dangerous waste is achieved, environmental pollution caused by waste discharge can be avoided, the application of the accelerating agent solves the problem of complicated process, high energy consumption and cost and the like of treatment of the waste hydrofluoric acid etching solution and meets national promoted green production requirements, the operation cost of enterprises is reduced, the prepared accelerating agent can increase economic income of the enterprises, and three purposes are achieved at one stroke.

Owner:萧县沃德化工科技有限公司 +1

Rubber-metal adhesive

InactiveCN104371629AImprove shock absorptionImprove wear resistanceNon-macromolecular adhesive additivesCellulose adhesivesSodium bicarbonateOXALIC ACID DIHYDRATE

The invention relates to a rubber-metal adhesive which is prepared from the following raw materials in parts by weight: 8-14 parts of hydrochloric acid, 3-8 parts of formaldehyde, 5-9 parts of zinc oxide, 5-11 parts of sodium bicarbonate, 6-10 parts of aluminum potassium sulfate dodecahydrate, 8-14 parts of polyoxyethylene, 3-8 parts of carbon black, 4-6 parts of lubricant, 4-7 parts of polymer emulsion, 5-10 parts of hydroxymethyl cellulose, 5-7 parts of organic functional silane, 2-8 parts of oxalic acid, 2-9 parts of styrene-butadiene rubber, 4-6 parts of m-phenylenediamine, 1-4 parts of quinhydrone and 2-5 parts of stearic acid. The rubber-metal adhesive has the advantage of favorable binding property, enhances the shock absorptivity and wear resistance of rubber, and is convenient to use.

Owner:田琳琳

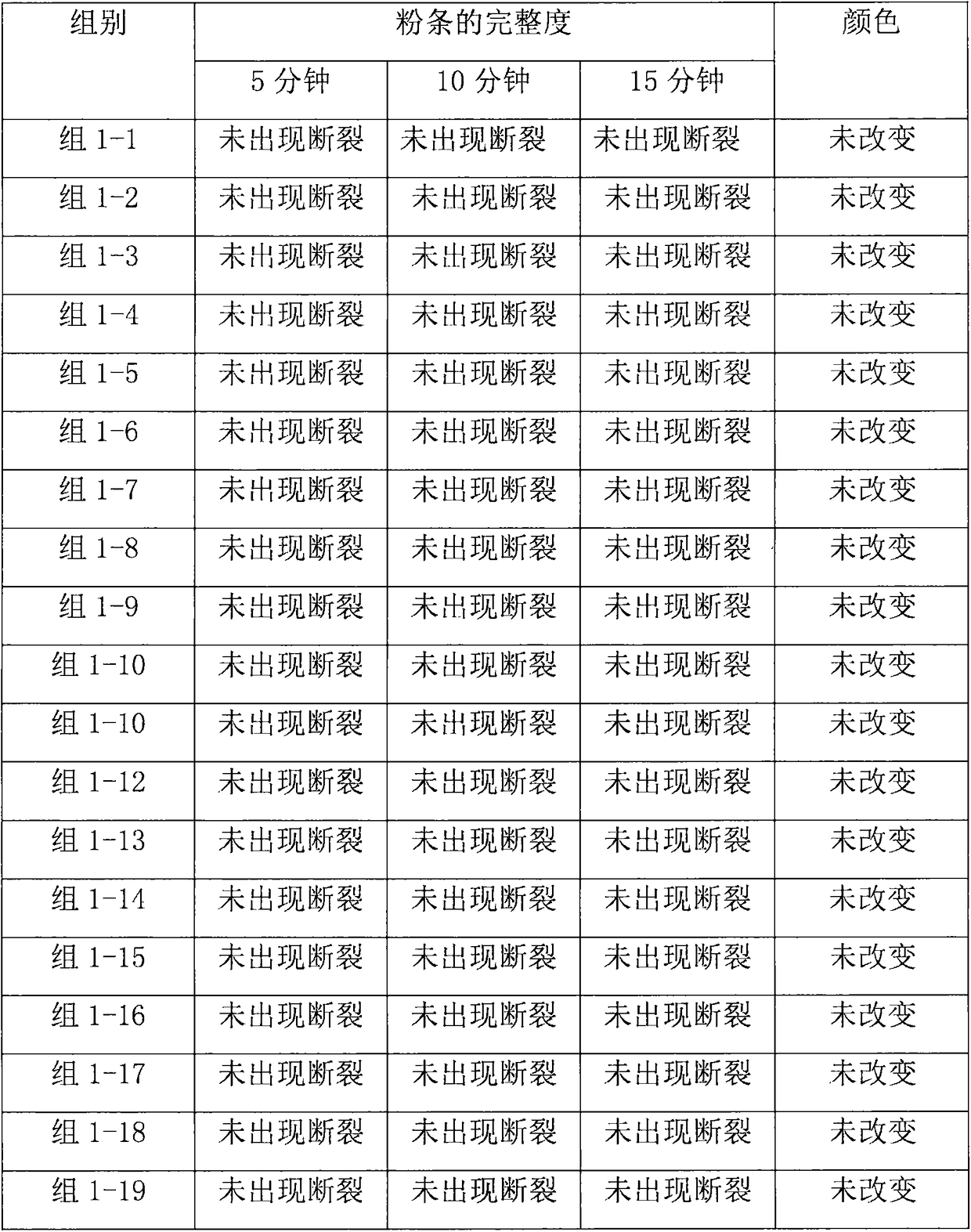

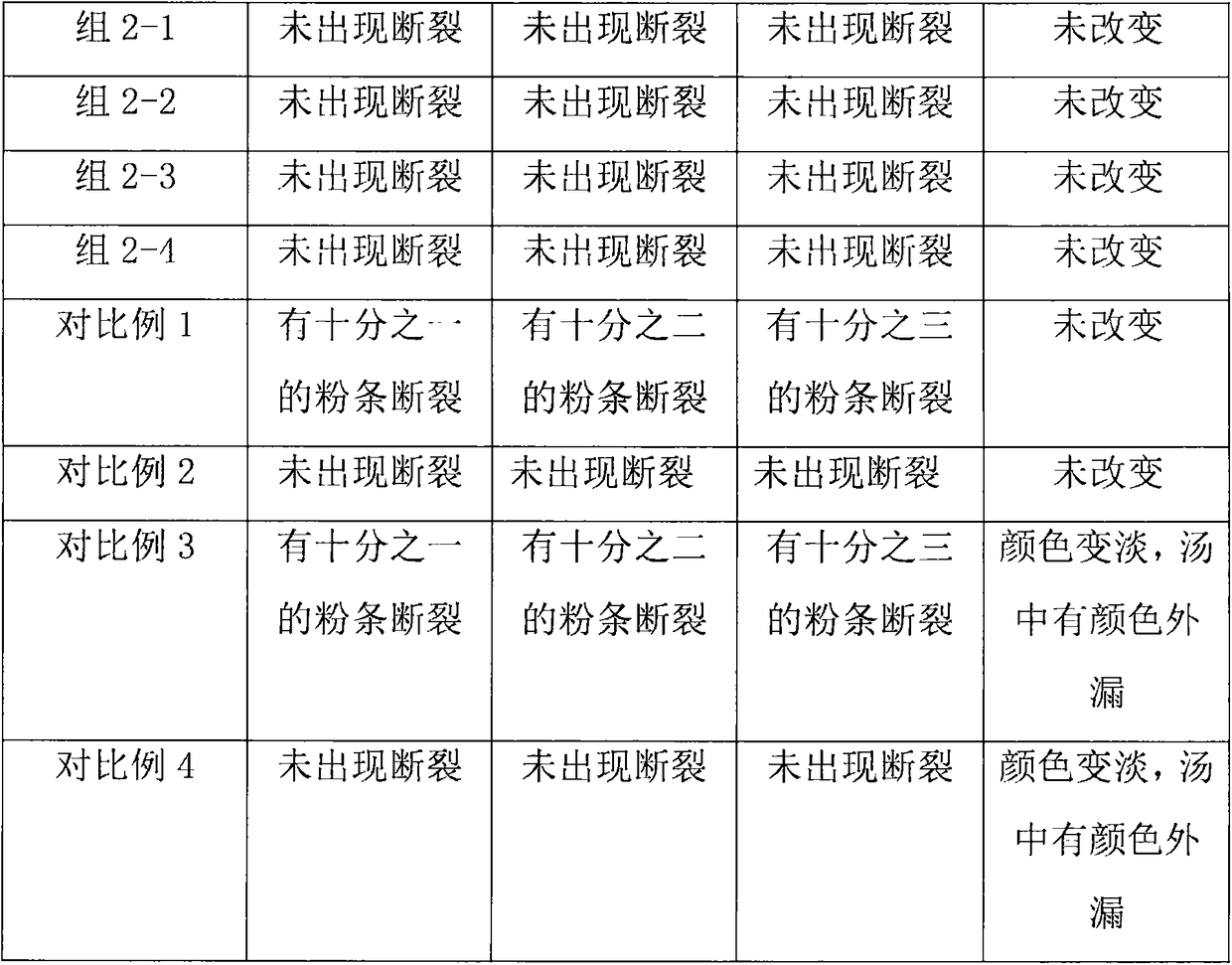

Jelly sheet and vermicelli and processing method thereof

InactiveCN109315754ALow selectivitySolve the problem of adding excessiveNatural extract food ingredientsFood ingredient functionsBiotechnologyStarch gelatinization

The invention relates to the field of food manufacturing, in particular to jelly sheets and vermicelli and a processing method thereof. The method comprises the following steps that starch, animal andplant processing materials, aluminum potassium sulfate dodecahydrate, additives and seasonings are mixed to obtain a second mixture, a small amount of starch is taken for gelatinization, a second mixture is added into gelatinization materials, and mixing and dough making are performed to obtain a second dough, wherein the consumption of aluminum potassium sulfate dodecahydrate is 0 to 0.35 percent of the total quantity of the starch in the step; at least one type of the second dough is made into the jelly sheet and vermicelli. The method solves the problems that the loss of the jelly sheet and vermicelli additives is serious; the additive cost is high; the cost is high; the environment is polluted; the processing efficiency is low; the color of the jelly sheet and vermicelli is single andnot attractive; the nutrition is single; the color is not natural, not original, and unreal; the content of the aluminum and aluminum potassium sulfate dodecahydrate exceeds the standard; the zero damage and loss of the animal and plant raw material nutrition pigments is ensured; the original state and odor are remained; the appearance is attractive; the color is original and real; the nutritionis rich; health, freshness, boiling resistance, soft and chewy mouthfeel, low processing cost, high production efficiency, great product competitiveness and green and environmental-friendly effects are realized.

Owner:闫金亮

Composition for preparing mortar, mortar prepared from composition, resin slurry composition containing mortar and preparation method of resin slurry composition

The invention discloses a composition for preparing mortar, mortar prepared from the composition, a resin slurry composition containing the mortar and a preparation method of the resin slurry composition. The composition for preparing mortar comprises, by weight, 69-72% of silica sand powder, 0.06-0.065% of aluminum sulfate octadecahydrate and the balance water. The mortar prepared from the composition has a concentration range of 330 to 340g / 200ml and an electrical conductivity range of 485 to 515. The resin slurry composition containing the mortar comprises, by weight, 78-80% of the mortar, 15-17% of epoxy resin 815, 0.2-0.7% of a TAP accelerator and the balance a 245 epoxy resin hardener. The method for preparing the resin slurry composition comprises controlling environmental parameters, weighing the components, cooling the mortar, adding the components into a preparation unit and carrying out stirring. A porous resin mold prepared from the resin slurry has a low cost and moderate strength, can be processed by simple processes and has the life and ventilatory capacity satisfying production requirements.

Owner:JOMOO KITCHEN & BATHROOM

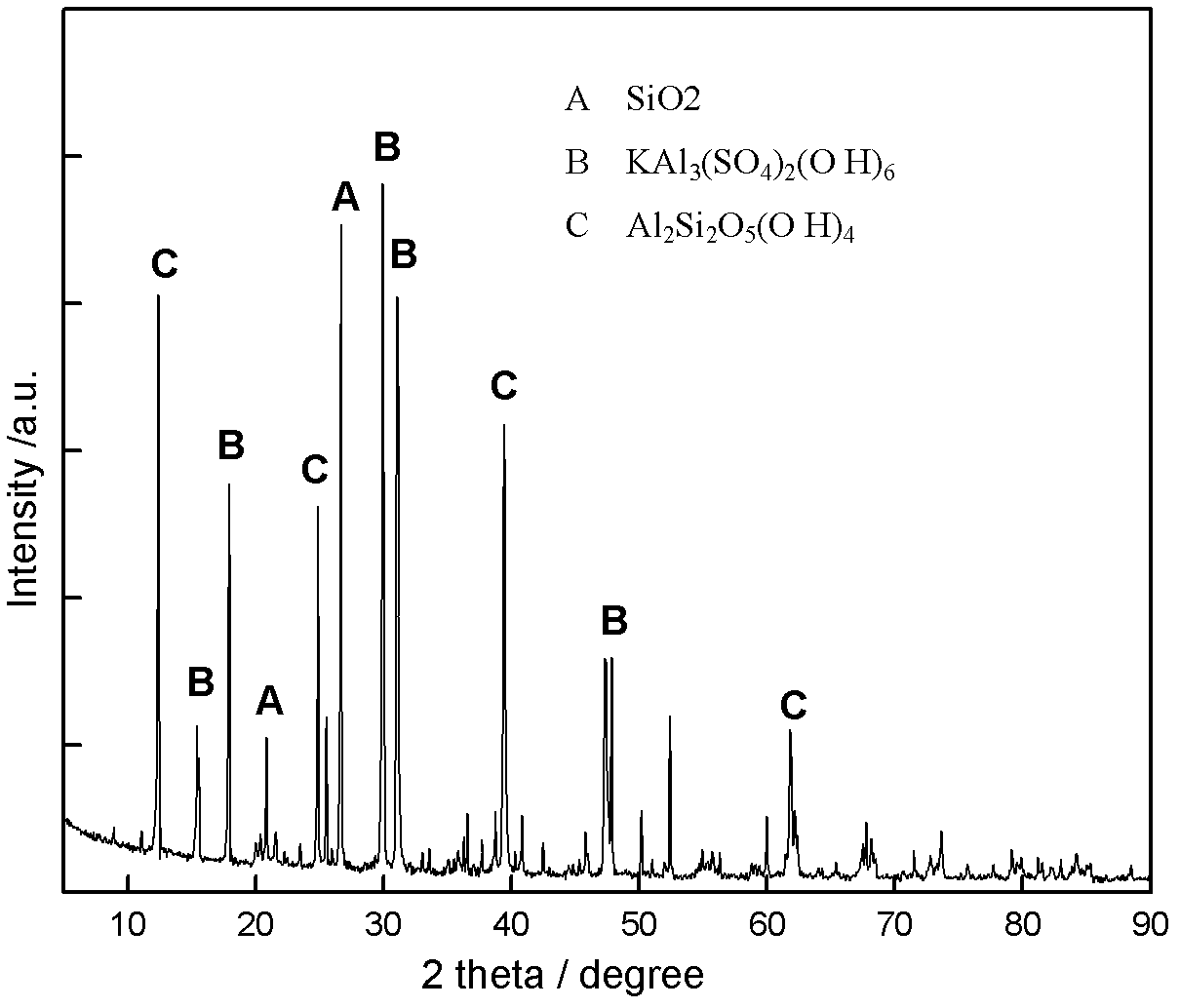

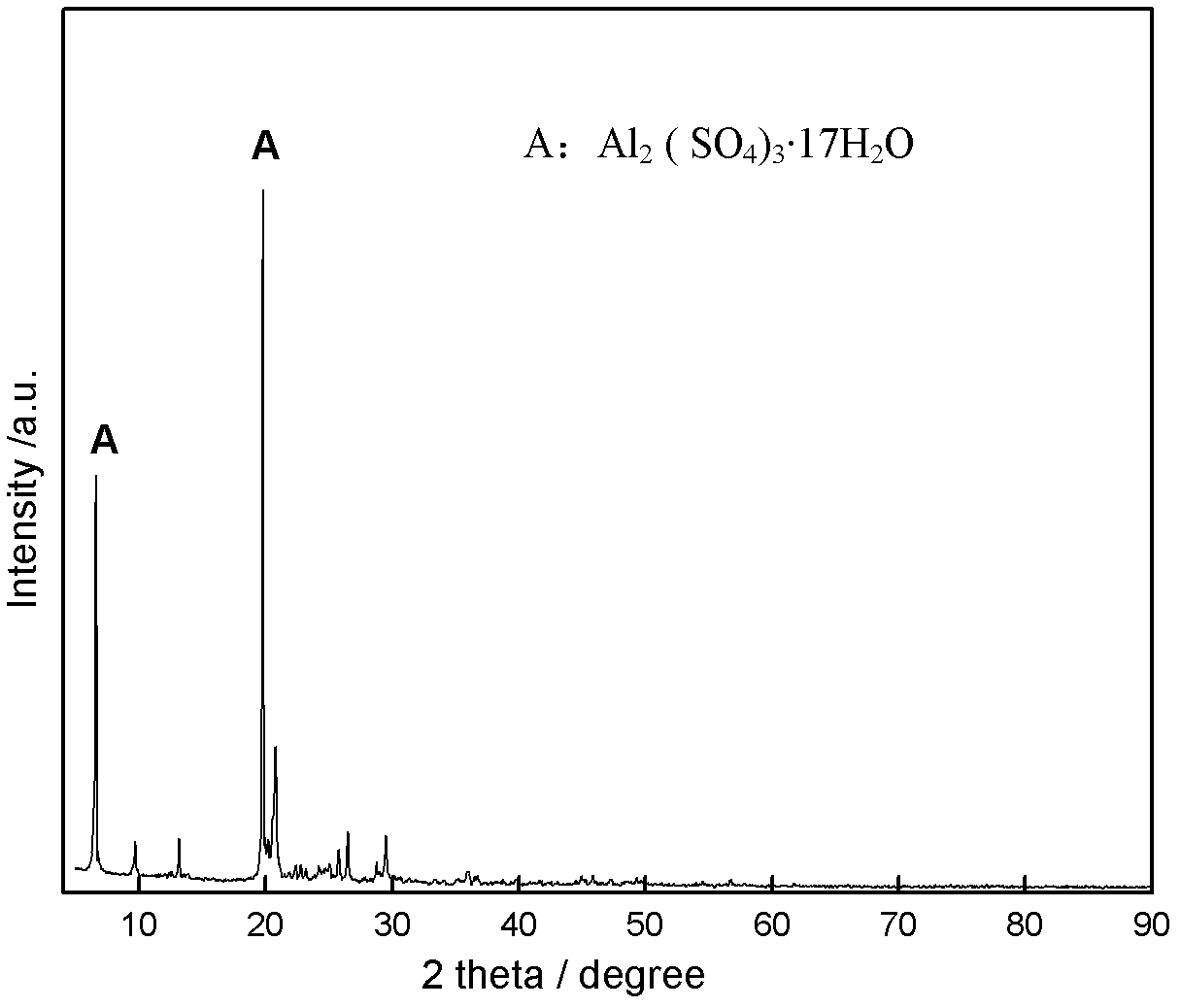

Method for extracting aluminum potassium product from associated alum quarry tailings

Aiming at the characteristic that associated alum quarry tailings in domestic enterprises are higher in aluminum potassium content and are simple in phase composition and contain main impurities, i.e. SIO2, the invention provides a novel acid fusion-water immersion method for treating the tailings to extract a high-value aluminum potassium product. After an ore sample is strengthened and roasted by low-temperature acid and is immersed into water with a temperature of 90 DEG C for treatment, the extraction rates of Al and K respectively reach 94.6 percent and 92.9 percent, which show better industrial application prospect. By adopting a fractional crystallization method, aluminum sulfate hydrate and alum crystals with higher purity are respectively obtained, and the preliminary separation of aluminum from potassium is realized.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

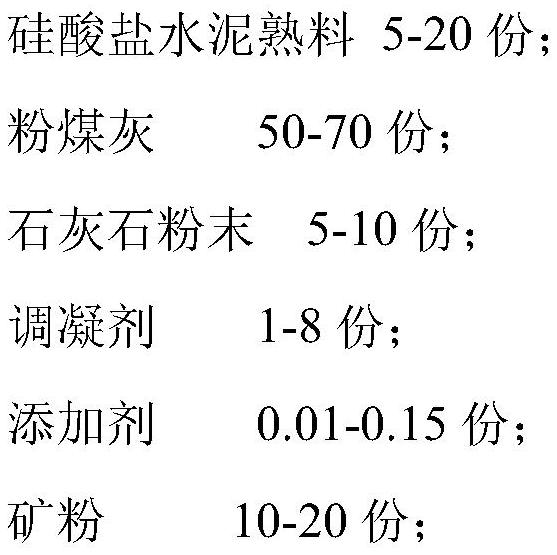

High-volume fly ash cement and preparation method thereof

InactiveCN111995271APromote hydrationThe effect of increasing the dosageCement productionHydration reactionMining engineering

The invention relates to the field of building materials, and particularly discloses high-volume fly ash cement and a preparation method thereof. The high-volume fly ash cement is prepared from the following components in parts by weight: 5 to 20 parts of Portland cement clinker, 50 to 70 parts of fly ash, 5 to 10 parts of limestone powder, 1 to 8 parts of a thickening time control agent, 0.01 to0.15 part of an additive and 10 to 20 parts of mineral powder, wherein the additive is composed of polyglutamic acid and aluminum potassium sulfate dodecahydrate according to the weight ratio of (1-10): 1, and the thickening time control agent is composed of fluorgypsum and desulfurized gypsum according to the weight ratio of (1-4): (1-8). The preparation method comprises the following steps of: grinding the raw materials according to the formula ratio, and uniformly mixing. The product provided by the invention has the advantages that a large amount of fly ash can be doped under the conditionof maintaining relatively high early strength, and the utilization rate of the fly ash is improved.

Owner:湖州昂狮环保有限公司

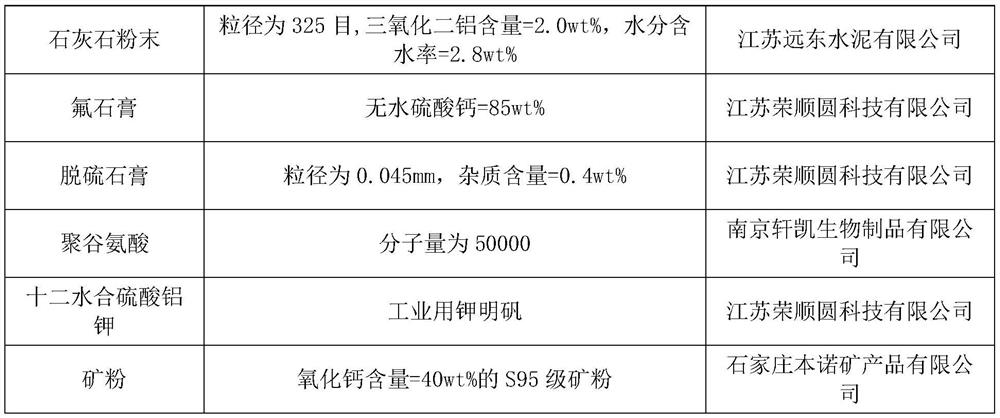

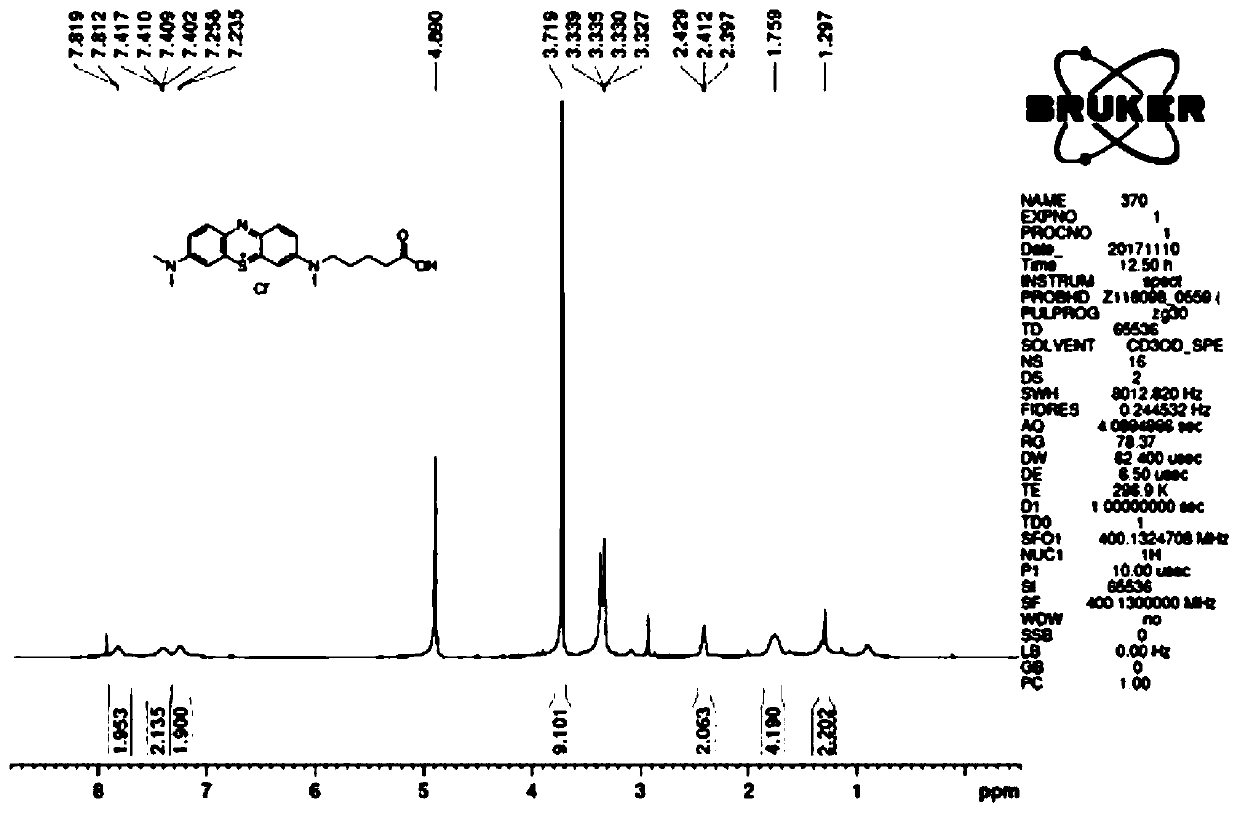

Preparation method of methylene blue hapten and methylene blue immunogen

InactiveCN111303076AEasy to operateRaw materials are easy to getSerum albuminMethylanilineAntiendomysial antibodies

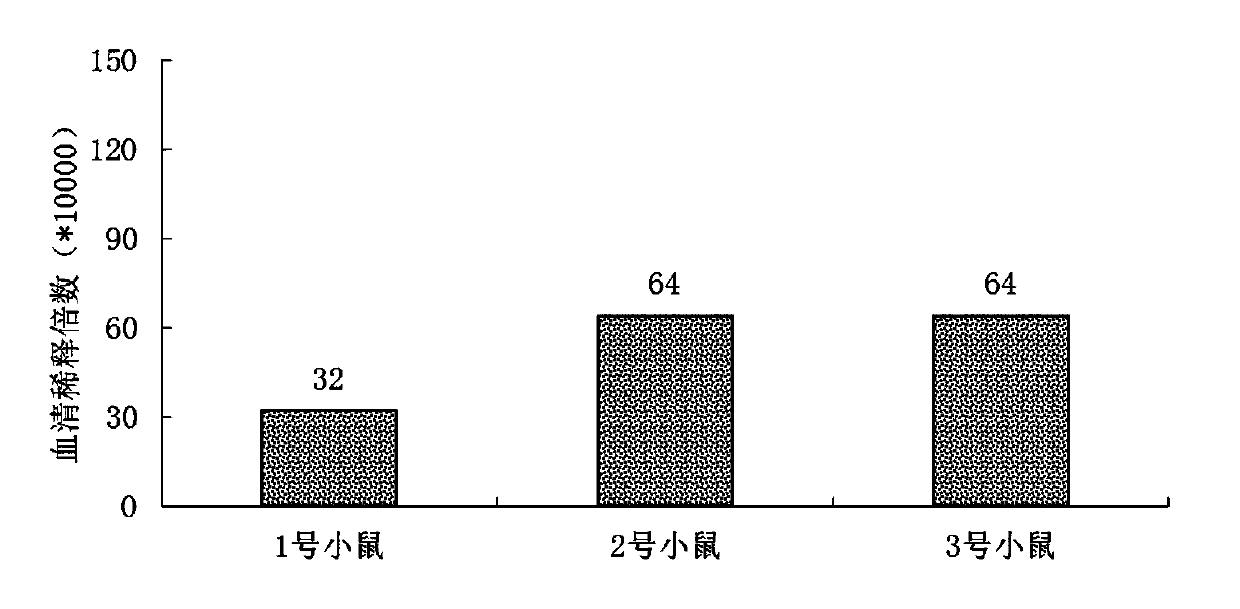

The invention relates to the technical field of medicines, and provides a preparation method of methylene blue hapten and immunogen. The preparation method comprises the following steps: carrying outchemical reaction on N, N-dimethyl p-phenylenediamine, aluminum sulfate hydrate, sodium thiosulfate, zinc chloride and potassium dichromate to obtain an intermediate 1; secondly, carrying out chemicalreaction on N-methylaniline, dimethyl pyridine, ethyl 5-bromovalerate and sodium hydroxide to obtain an intermediate 2, and carrying out chemical reaction on the intermediate 1 and the intermediate 2under the action of a catalyst silver carbonate to obtain the methylene blue hapten; and finally, after the methylene blue hapten reacts with dicyclohexylcarbodiimide (DCC) and N-hydroxysuccinimide (NHS), bovine serum albumin (BSA) is added for a reaction, and the methylene blue immunogen is prepared. According to the methylene blue immunogen prepared by the method, the coupling ratio is about 28: 1, the mouse can be stimulated to generate an antibody, the antibody titer is about 64000, the methylene blue concentration is 39.0 ng / mL when the inhibition rate is 50% and the competitive inhibition effect on methylene blue is excellent.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

A kind of molybdenite beneficiation inhibitor and preparation method thereof

The invention discloses a molybdenite beneficiation inhibitor and a preparation method thereof. A molybdenite beneficiation inhibitor is mainly composed of components A and B, and the weight ratio of component A to component B is 1:1-1:2.5; wherein the components in component A and the parts by weight of each component are as follows : 80-95 parts of sodium silicate, 5-20 parts of gum gum, the components in B component and the weight parts of each component are as follows, 50-80 parts of aluminum sulfate, 5-10 parts of potassium aluminum sulfate dodecahydrate, carboxylate 15-30 parts of sodium methylcellulose, 5-15 parts of tannin extract, and 10-25 parts of dextrin. A and B components are co-dissolved in water to prepare an aqueous solution with a weight fraction of 5-15%, and then the aqueous solution is fully stirred and homogenized to obtain a molybdenite beneficiation inhibitor. By organically combining various components, a water film can be formed on the gangue in molybdenite, which avoids hydrophobic foaming, and in addition, reduces the viscosity of pulp and foam, and reduces or blocks the interaction between the gangue and the collector. Adsorption, thus solving the problem of sticky pulp foam in the beneficiation process and improving the collection efficiency of the collector.

Owner:LUANCHUAN COUNTY QINYU SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com