Water purifying agent for chemical industries such as coal chemical industry and coking industry and preparation method of water purifying agent

A technology for coal chemical industry and water purifying agent, which is applied in separation methods, adsorption water/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. It is beneficial to flocculation and sedimentation, the composition is reasonable, and the effluent quality is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

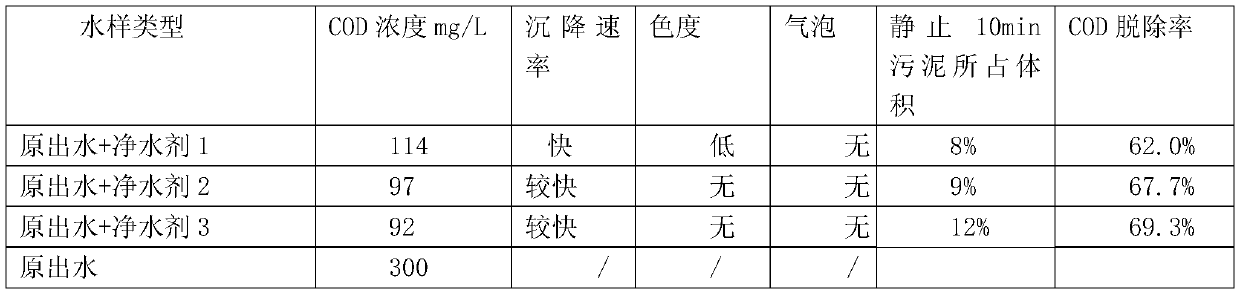

Examples

Embodiment Construction

[0026] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

[0027] The first embodiment of the present invention provides a water purifying agent (hereinafter referred to as "water purifying agent 1") used in coal chemical industry, coking and other chemical industries. Its components and parts by mass are as follows: 5 parts of CMC; modified shell 5 parts of polysaccharide CTS; 5 parts of phenolic formaldehyde; 25 parts of aluminum iron bis-acid; 1 part of xanthan gum; 1 part of cationic guar gum; 5 parts of acid solution; 25 parts of potassium aluminum sulfate dodecahydrate; 20 parts of polyacrylamide ; 25 parts of polyferric sulfate; ST: 2 parts.

[0028] The preparation method of the water purifying agent used in chemical industries such as coal chemical industry and coking is as follows:

[0029] A. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com