Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2088 results about "Coal chemical industry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coal Chemical Industry. Technologies in the coal chemical industry such as tar fractionation, benzol hydrogenation, anthraquinone production, device reaction and distillation, and rectification devices have a relatively high requirement for temperature regulation.

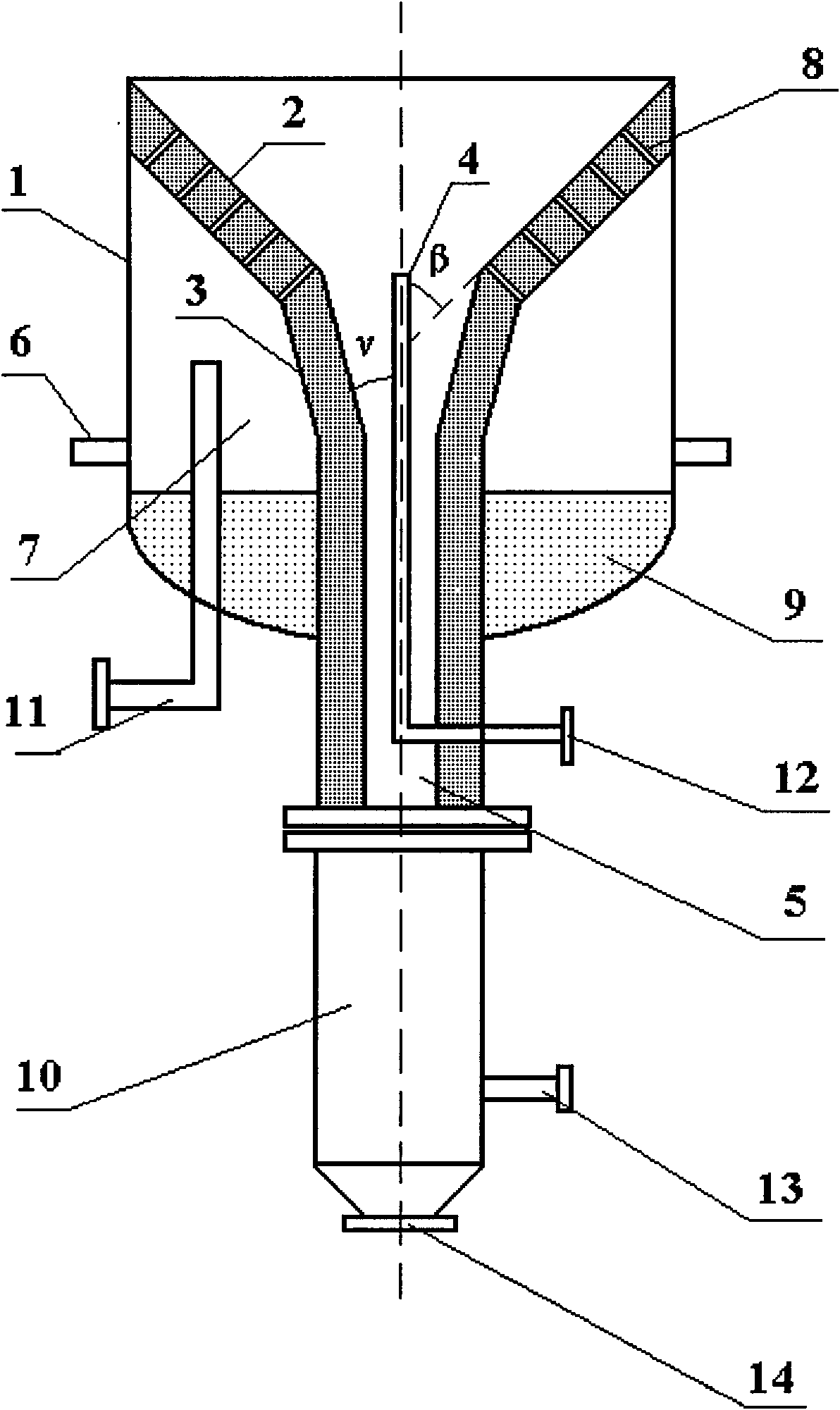

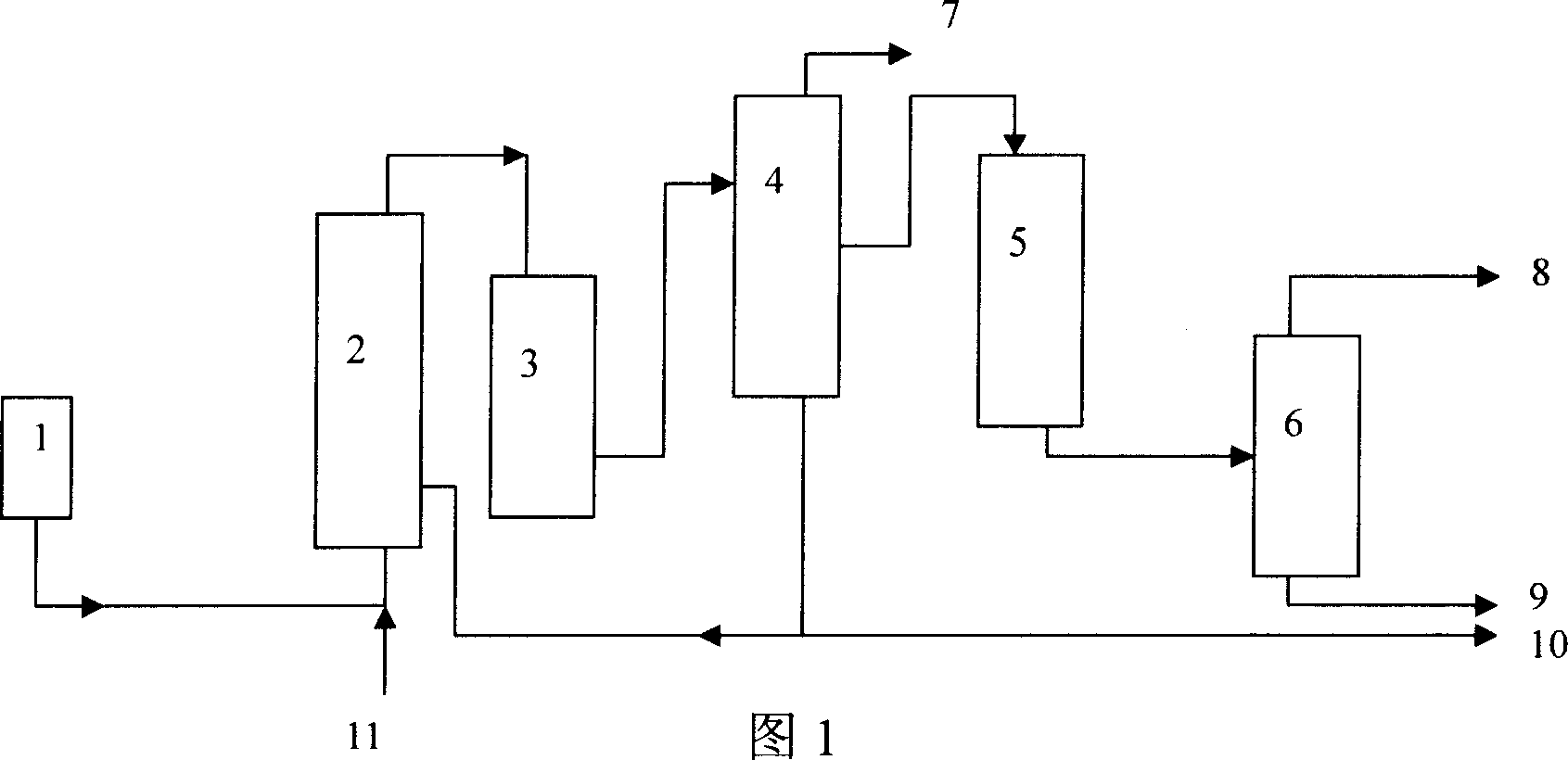

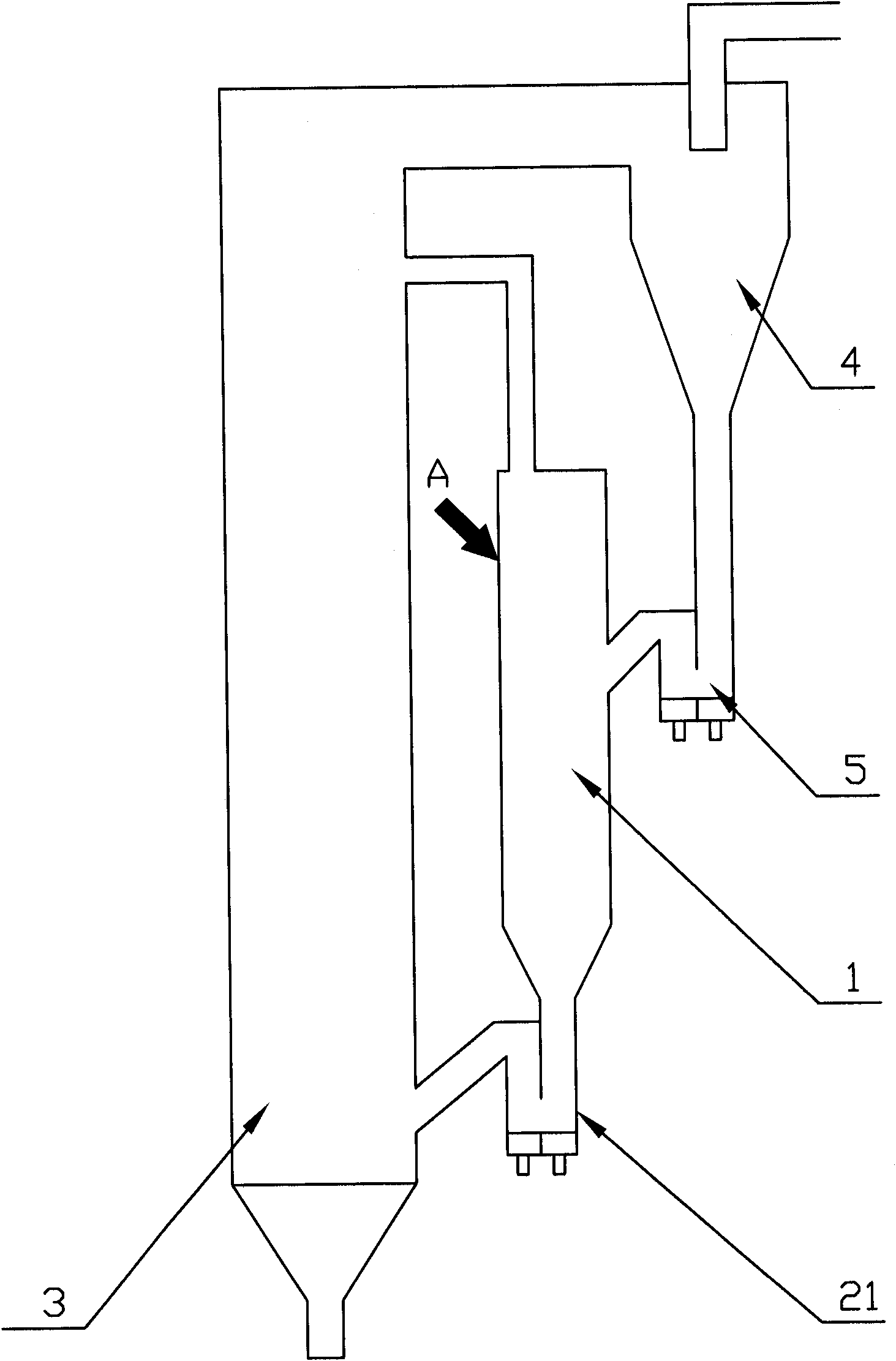

Method and device for gasifying multi-segment staged converted fluidized bed

ActiveCN101942344ALow ash carbon contentExtended stayEnergy inputCombined combustion mitigationFluidized bedProcess engineering

The invention relates to method and device for gasifying a multi-segment staged converted fluidized bed. The method comprises the following steps of: supplying coal; supplying gas; gasifying; slagging; and conveying fine powder. The device for gasifying the multi-grade staged converted fluidized bed comprises an agglomerating ash separating unit, a pyrolyzing and gasifying reactor of the multi-segment staged fluidized bed and a semicoke fine powder cyclic feeding unit. The invention has the advantages of high volume utilization rate of a gasifying oven, great handling capacity and high utilization rate of total carbon, is suitable for a coal staging and converting system and can be singly used for producing gas for mass coal-based methane synthesis and coal chemical industry.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

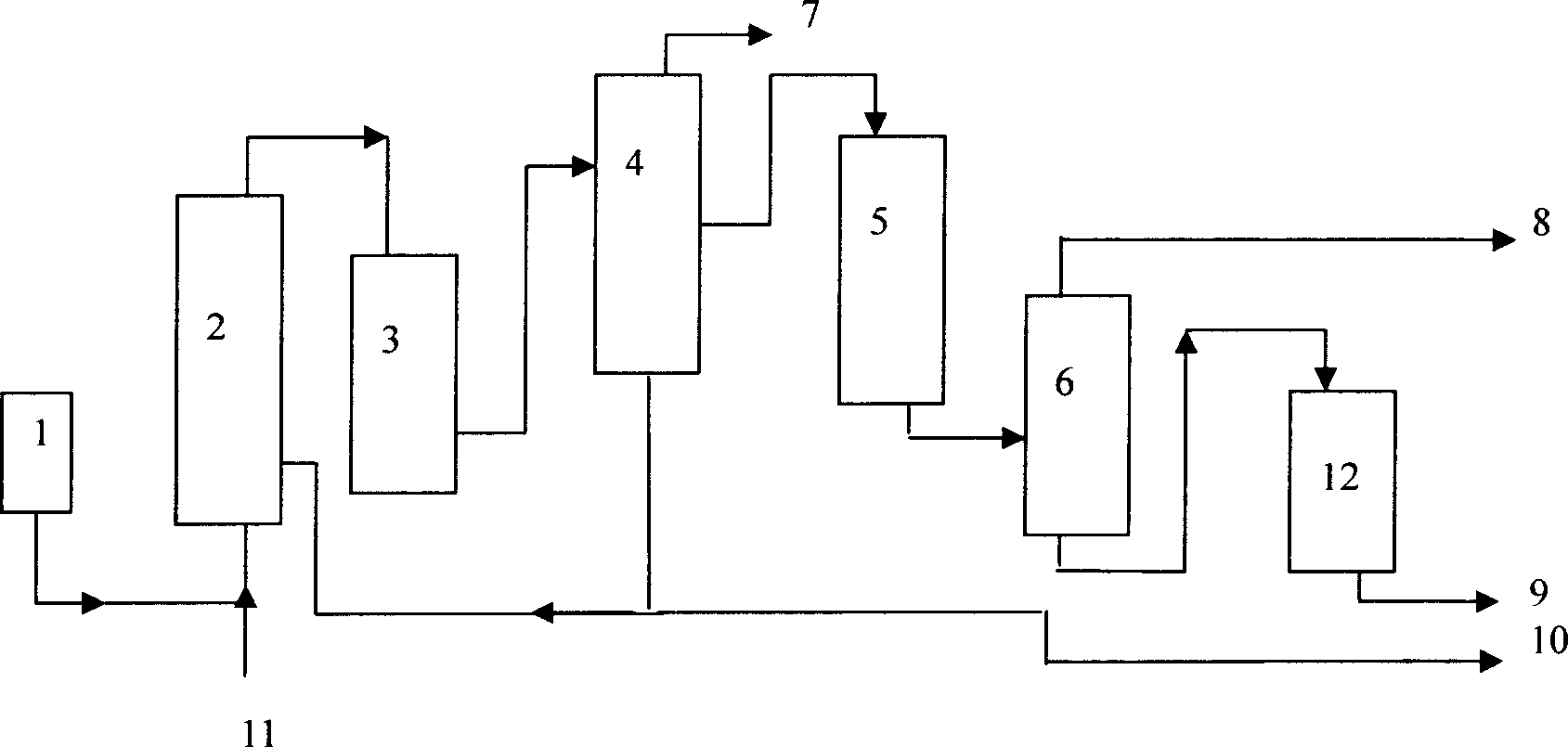

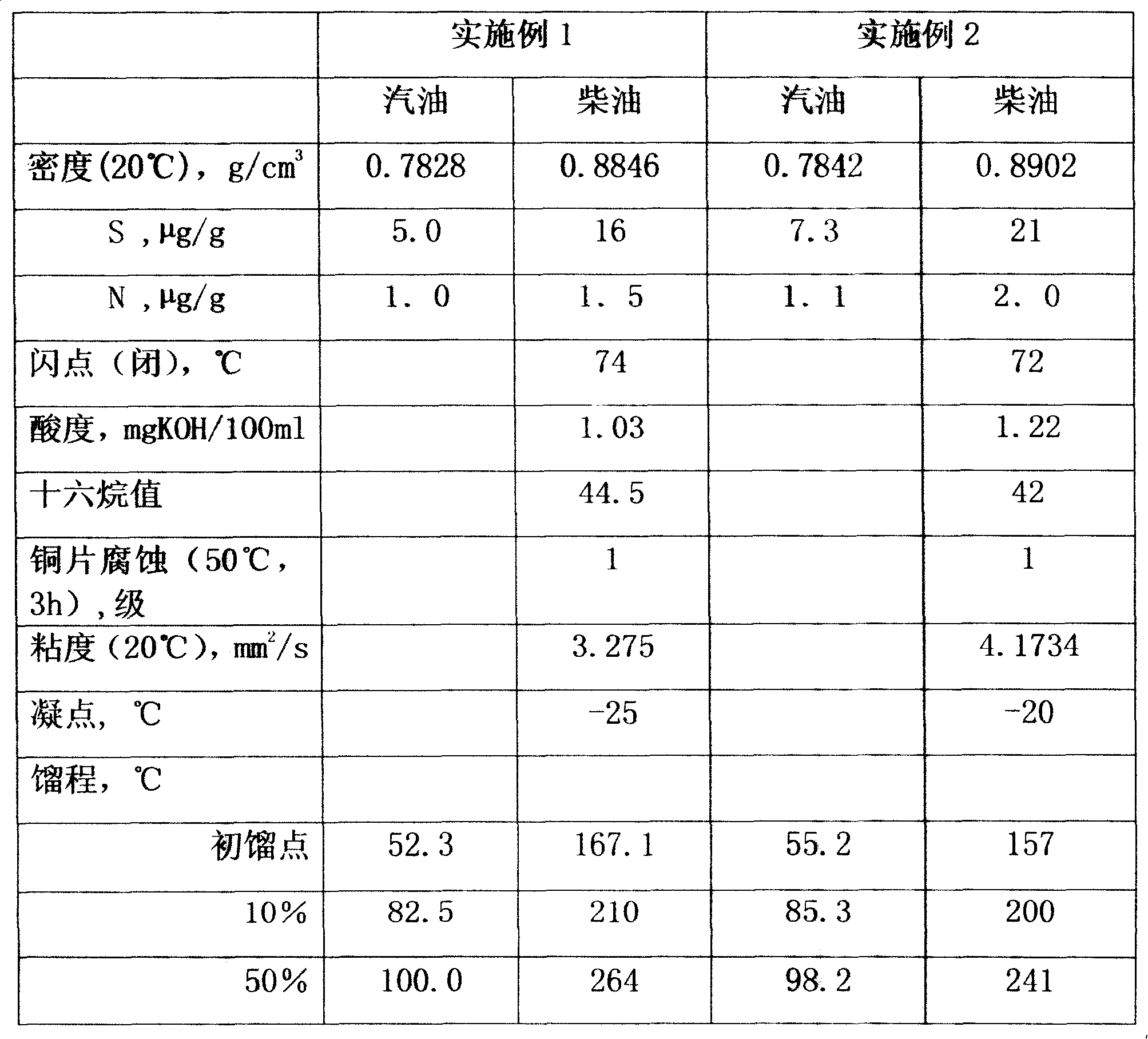

Coal tar whole fraction hydrotreatment process

ActiveCN1766058AImprove operating conditionsSimple processTreatment with hydrotreatment processesFixed bedGasoline

The invention discloses a hydrocracking treatment technique for coal tar total distillate, which comprises: first mixing with homogeneous catalyst, or adding impurity, gum, asphaltene and coal oil total distillate contained much oxygen element directly into suspended-bed hydrogenation device; cutting the stream with distilling plant to discharge water, distillate less than 370Deg that enters fixed bed reactor for hydrorefining reaction to cut gasolene less than 150Deg and diesel oil 150-370Deg, and tail oil less than 370Deg that recycles to said reactor and converts into light oil product. Compared with prior art, this invention is simple, but high conversion rate and stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

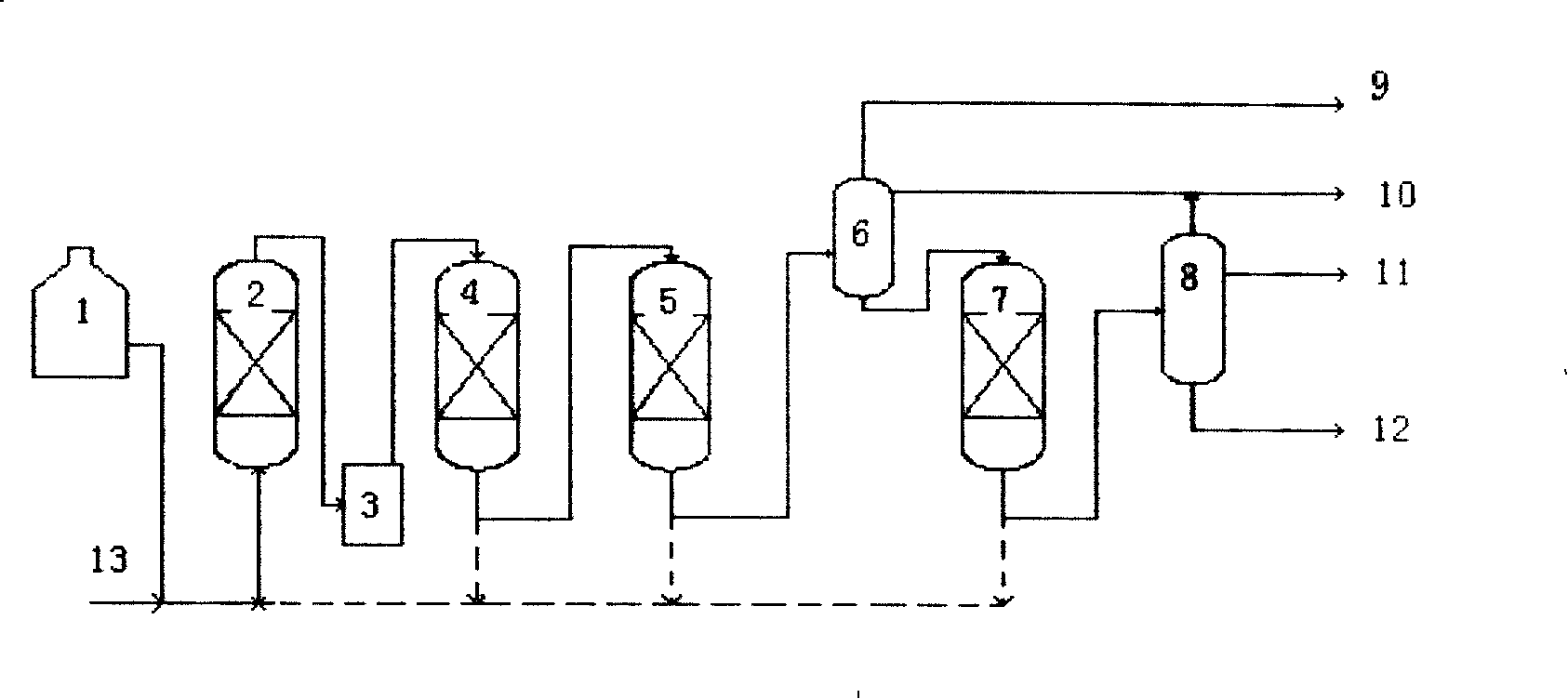

Technology for recovering water resources and salt from coking wastewater in coal chemical industry

ActiveCN105502782ANo secondary hazardous waste generatedLow running costMultistage water/sewage treatmentAlkali metal chloridesChemical treatmentAdvanced oxidation process

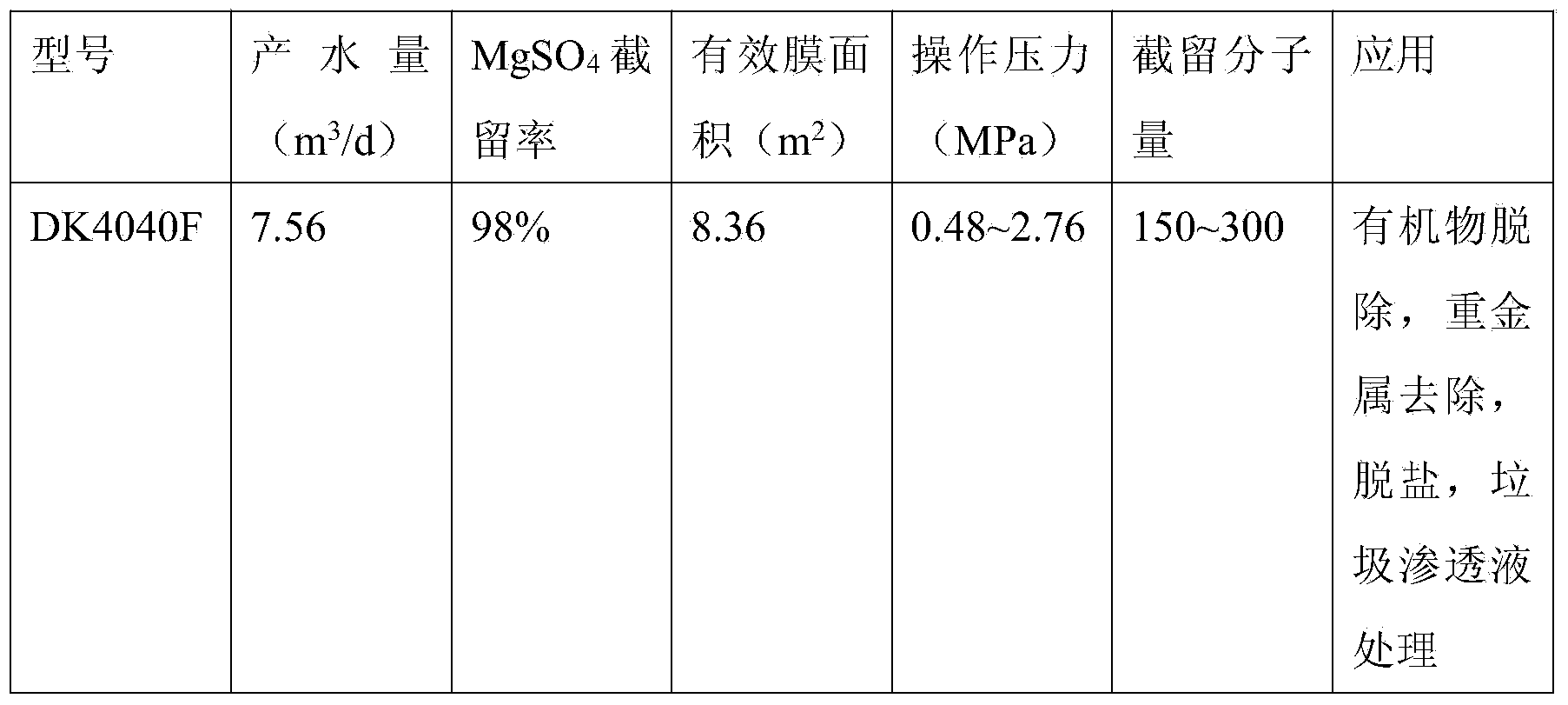

A technology for recovering water resources and salt from coking wastewater in the coal chemical industry comprises the following steps: the wastewater is subjected to defluorination chemical treatment and subjected to sodium carbonate softening and precipitating treatment simultaneously, an advanced oxidation process is used for TOC (total organic carbon) degradation, a multi-medium and activated carbon filter is used for filtering separation, ultrafiltration is performed, nanofiltration membrane separation is performed, calcium and magnesium ions are separated, the calcium and magnesium ions in water produced through nanofiltration are lower than 2 mg / L, CaF2 crystallization scaling is hard to form, and nanofiltration passing liquid and nanofiltration strong brine are obtained; the nanofiltration passing liquid and the nanofiltration strong brine are treated respectively. Fluoride ions, hardness and organic carbon in the wastewater are removed, separation of multivalent salt and monovalent salt as well as concentration and evaporative crystallization of the salt is realized, more than 98% of the water resources is recovered, more than 95% of the salt resources are recovered, secondary hazardous waste is not produced, the system operation cost is reduced, and the problem about resource recovery and the environmental problem are solved finally.

Owner:湖南湘牛环保实业有限公司

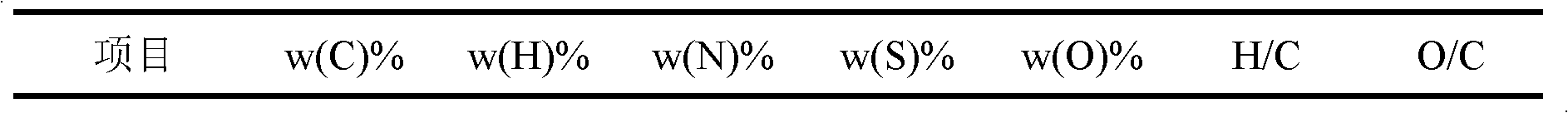

Method of extracting phenolic compound from coal liquefied oil or coal tar

ActiveCN102219649AHigh extraction rateHigh purityOrganic chemistryOrganic compound preparationWater vaporCoal chemical industry

The invention relates to the field of coal chemical industry, and more specifically relates to a method of extracting phenolic compounds from coal liquefied oil or coal tar. The method comprises the following steps: 1) distilling coal liquefied oil or coal tar and cutting to obtain fractions at a temperature of 260 DEG C; 2) mixing an extractant with the obtained fractions and layering the extractant; 3) separating and collecting the extractant layer which contains phenolic compounds; 4) carrying out multistage back extraction on the phenolic compounds so as to obtain a stripping agent-phenol solution and an extractant; 5) separating the stripping agent-phenol solution by rectification, recovering the stripping agent for cyclic utilization, and carrying out separation to obtain crude phenols; 6) removing entrained neutral oil in phenolic compounds by water vapour so as to obtain crude phenol products. The method of extracting phenolic compounds from coal liquefied oil or coal tar provided in the invention avoids the usage of soda acid, exerts no influence on subsequent treating processes, and guarantees high recovery rate and purity of phenols.

Owner:CCTEG CHINA COAL RES INST

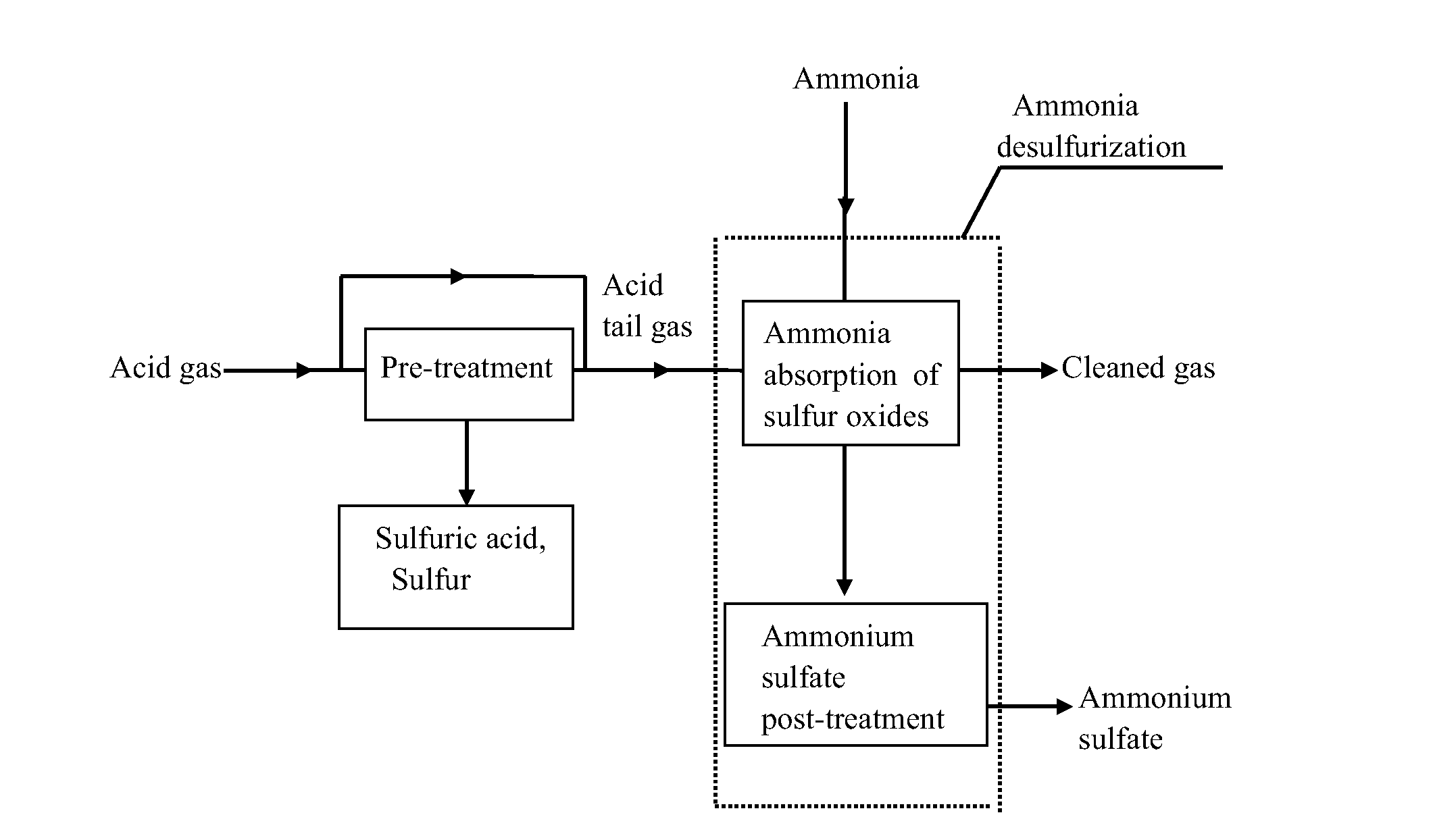

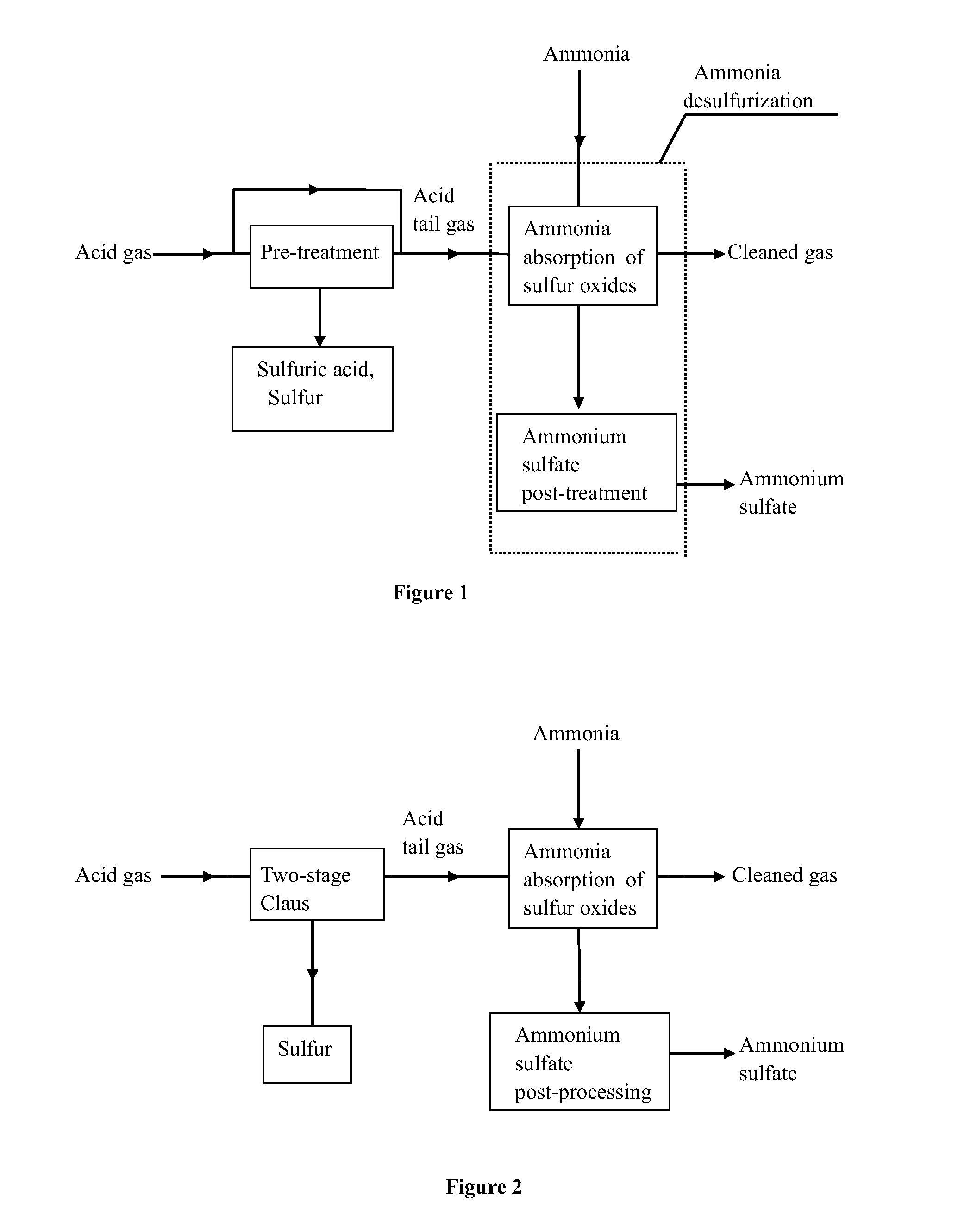

Ammonia process flue gas treatment method for acidic tail gas and device

ActiveCN103223292AIncreased self-concentrationGood desulfurization absorptionDispersed particle separationAmmonium sulfatesEnvironmental resistanceAmmonia storage

The invention relates to an ammonia process flue gas treatment method for acidic tail gas. The method includes the steps of: 1) controlling the sulfur dioxide concentration of tail gas entering an absorption tower at a level of less than or equal to 30000mg / Nm<3>; 2) arranging process water in an absorption tower entrance flue or in the absorption tower or cooperating with a ammonium sulphate solution to perform spray cooling; 3) disposing an oxidation section in the absorption tower, setting an oxidation distributor at the oxidation section to achieve oxidation of a desulfurized absorption liquid; 4) arranging an absorption section in the absorption tower, utilizing an absorption liquid distributor in the absorption section to realize desulfurization spray absorption by an ammonia-containing absorption liquid, which is fed through an ammonia storage groove; 5) arranging a water washing layer at an absorption section upper part in the absorption tower, washing the absorption liquid in the tail gas by the water washing layer and reducing the absorption liquid escape; and 6) setting a demister at the upper part of the water washing layer in the absorption tower to control the mist drop content in the purified tail gas. Employment of the Claus sulfur recovery and ammonia process desulfurization integrated desulfurization technology in the coal chemical industry can reduce the investment cost of after-treatment, the process can be simpler, and factory environmental protection treatment can form an intensive advantage.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

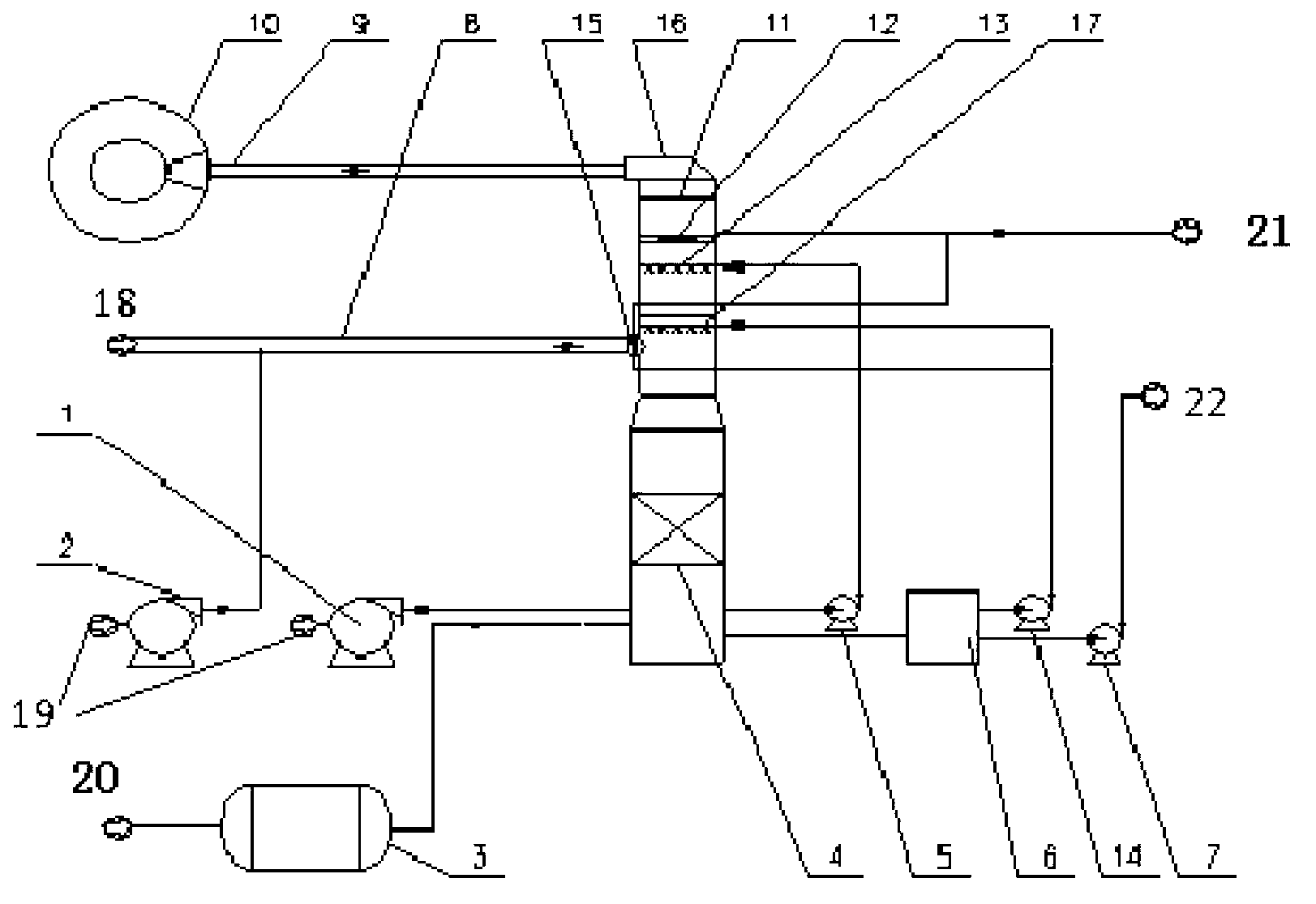

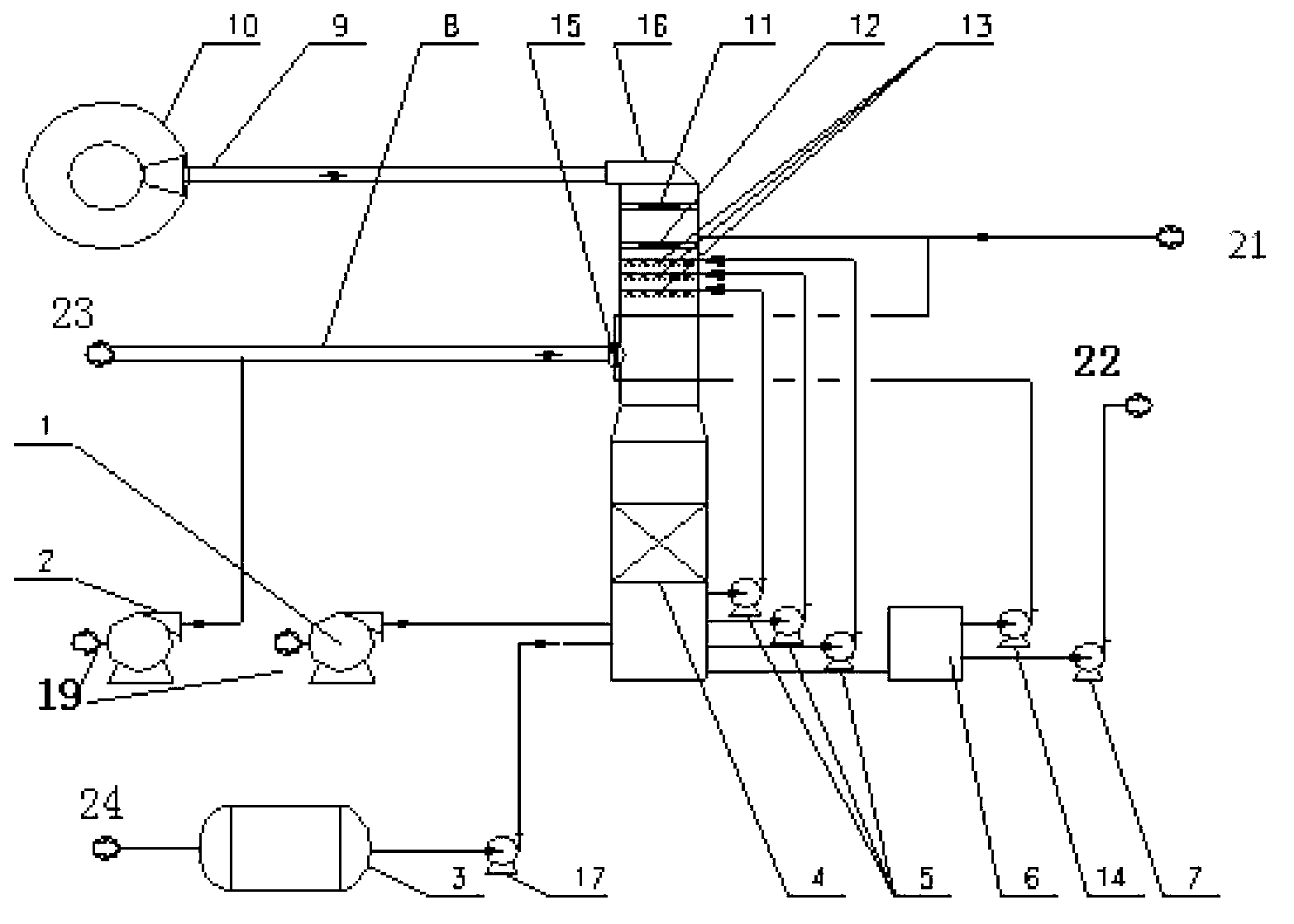

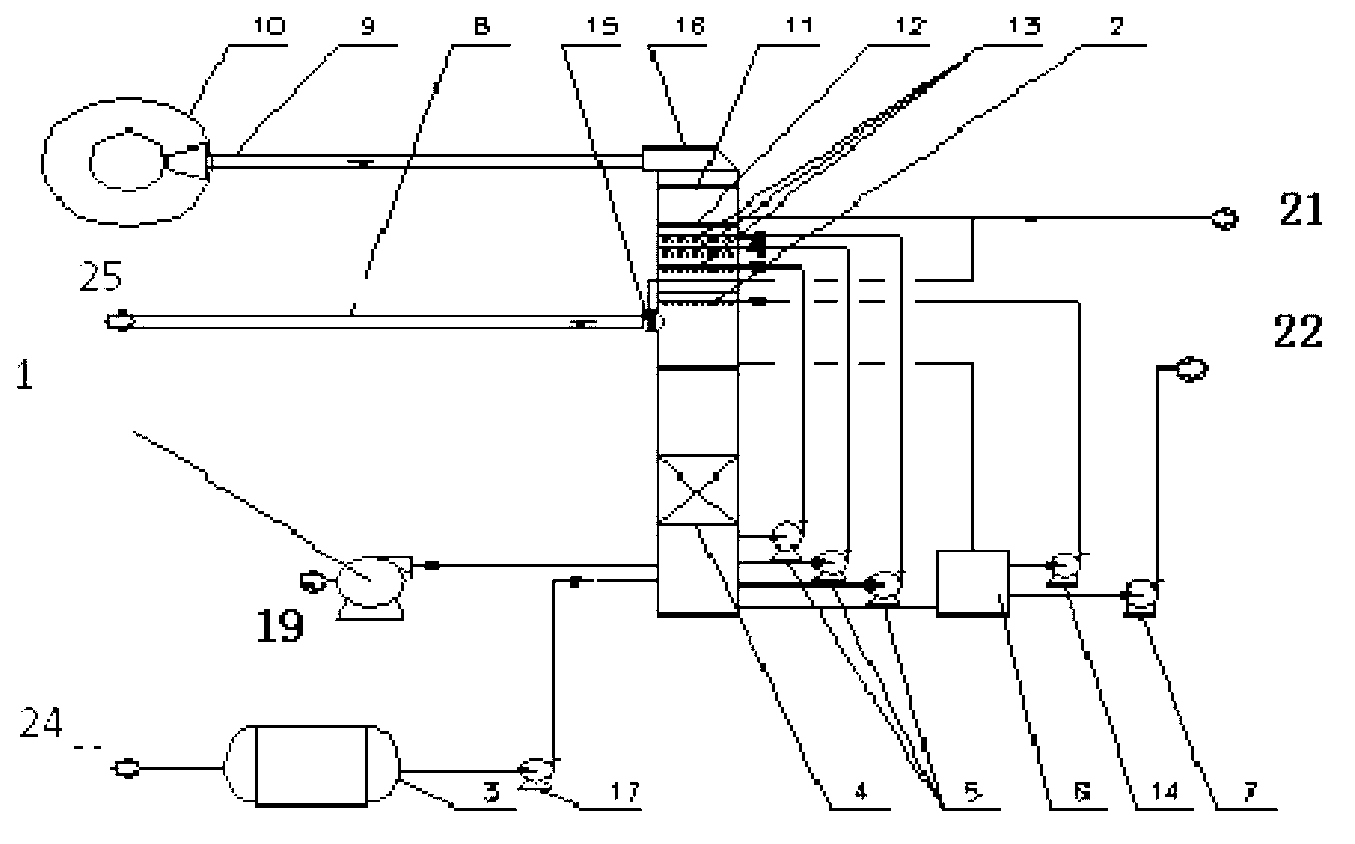

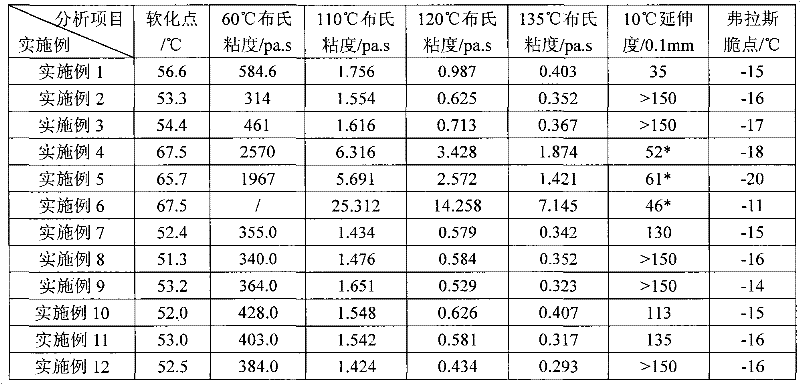

Warm mixed asphalt cement and preparation method thereof

ActiveCN102532920AWith viscosity reducing effectHas a lubricating effectIn situ pavingsClimate change adaptationEnvironmental resistanceChemical industry

Owner:PETROCHINA CO LTD +1

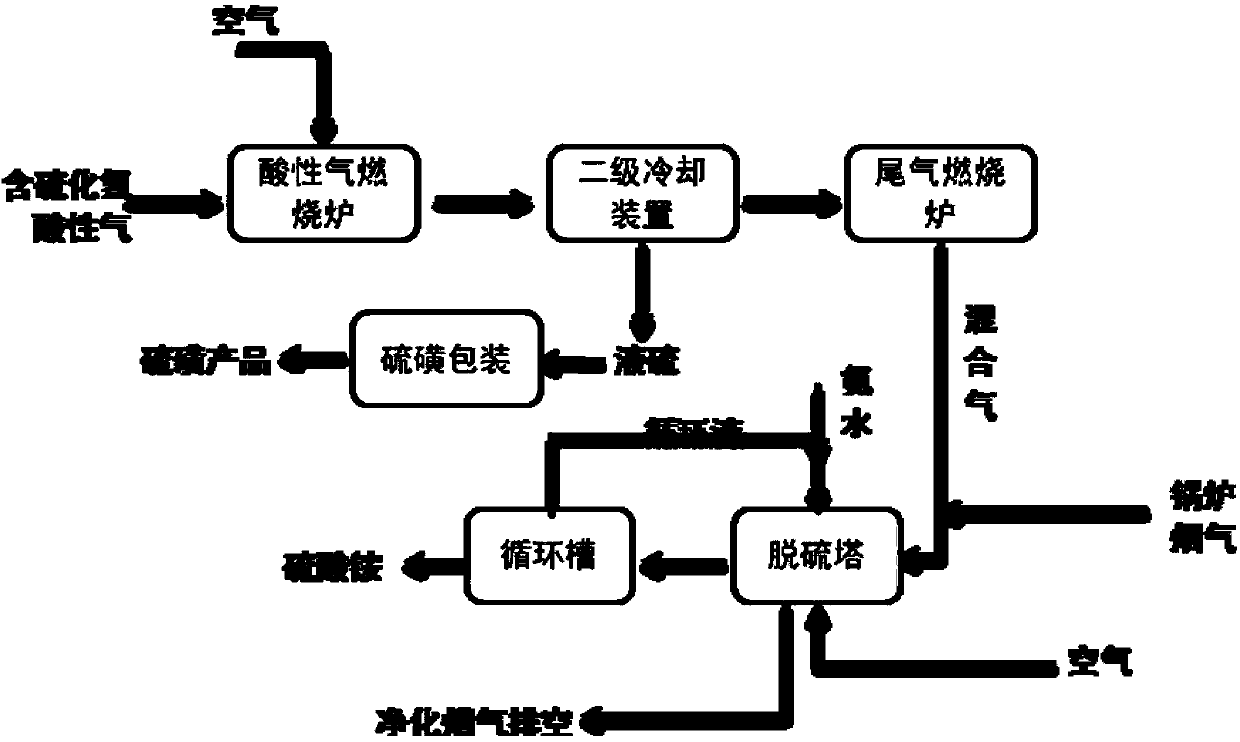

Comprehensive desulphurization technology in coal chemical industry

InactiveCN103418223AHigh recovery rateEmission reductionDispersed particle separationAmmonium sulfatesCombustionTower

The invention discloses a comprehensive desulphurization technology in the coal chemical industry. The comprehensive desulphurization technology comprises the following steps: acidic gas containing hydrogen sulfide and coming from a low-temperature methanol washing device burns to generate mixed gas, and the mixed gas is subjected to two stages of cooling to separate out liquid sulfur for producing solid sulfur; sulphuric mixed gas separated out after cooling is subjected to secondary combustion so that all sulphureous components in the mixed gas are changed into SO2, tail gas generated after combustion and boiler flue gas of a heating power station are fully mixed and enter a desulphurization tower, circulating liquid containing aqua ammonia is used as an absorbent to absorb SO2 in a countercurrent contact way and react to generate ammonium sulfite, and ammonium sulfite is further oxidized to change into ammonium sulfate; desulphurized and purified flue gas is discharged into air through a chimney; ammonium sulfate solution at the bottom of the desulphurization tower enters a circulation tank and is crystallized to form the ammonium sulfate product. The comprehensive desulphurization technology adopts a novel combined desulphurization technology to replace the traditional Klaus Scott or Super Claus technology, and can effectively lower investment, improve recovery rate of sulfur and reduce discharge of sulfur.

Owner:XINWEN MINING GROUP

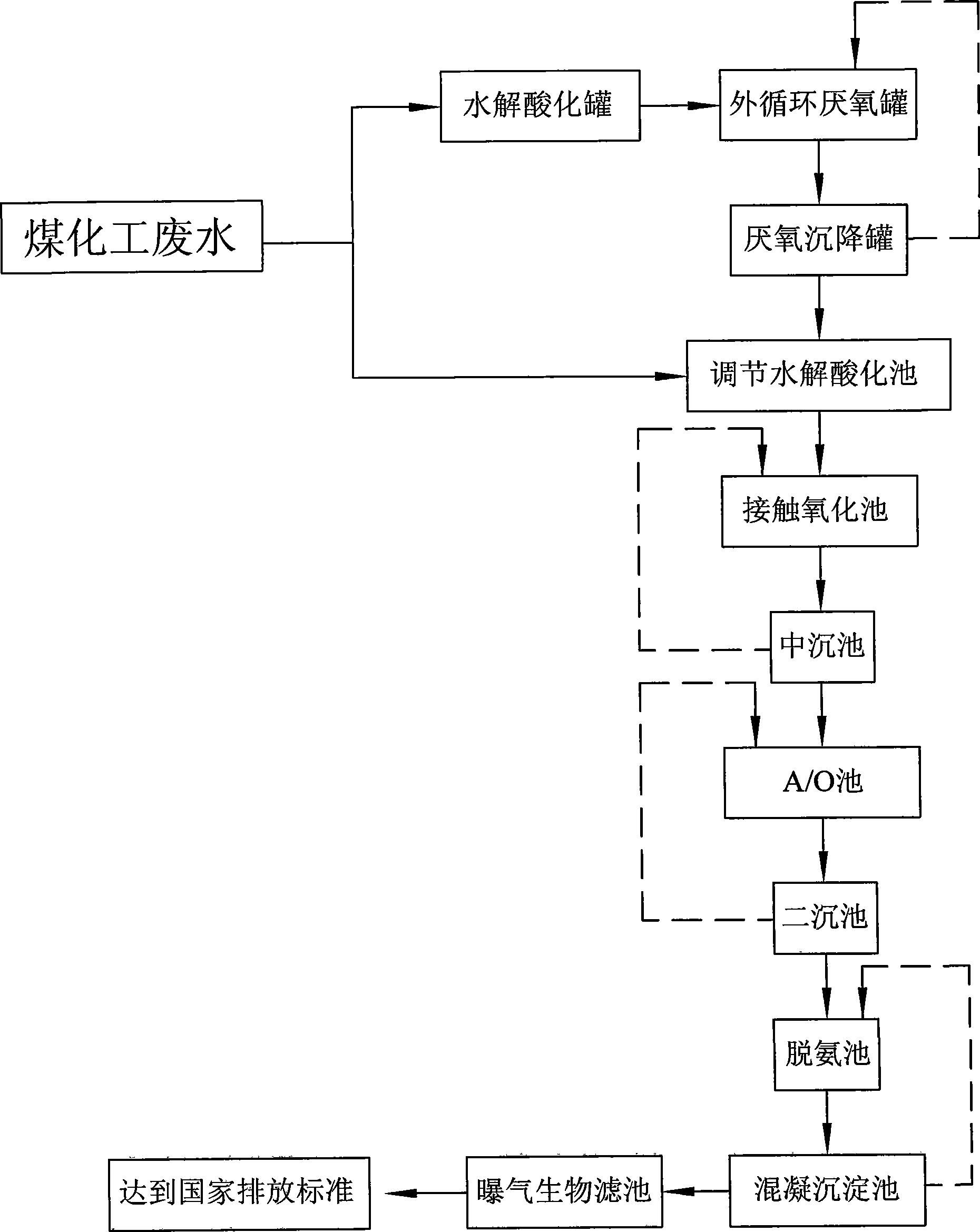

Coal chemical industry wastewater treating method

InactiveCN101503267AEasy to handleImprove the water effectWater contaminantsTreatment with aerobic and anaerobic processesOperational costsBiological filter

The invention relates to a coal chemical wastewater treatment method, in particular to a chemical wastewater treatment method. The invention aims to solve the problems of the chemical wastewater treatment method such as bad outlet water quality and high operational cost. The method comprises the following steps: pretreating coal chemical wastewater to be treated; then carrying out hydrolytic acidification treatment, external circulating anaerobic treatment, anaerobic sedimentation treatment, adjusting hydrolytic acidification treatment, contact oxidation treatment, sedimentation treatment, A / O treatment, sedimentation treatment, deamination treatment, coagulating sedimentation treatment and aeration biological filter tank treatment, wherein the temperature in an external circulating anaerobic tank is controlled within the scope of 32 to 35 DEG C; the hydraulic detention time is 24 to 36 h; the sludge concentration is controlled between 50 and 100 g / L; the volume load is 5 to 10 kg COD / m.d ; and the pH value is controlled between 7.0 and 7.5. The invention has the advantages of flexible operation, impact load resistance, low operating cost and good treatment effect; after the coal chemical wastewater is treated by the treatment method, the outlet water quality completely can achieve the wastewater comprehensive discharge standard regulated by the State.

Owner:HARBIN INST OF TECH

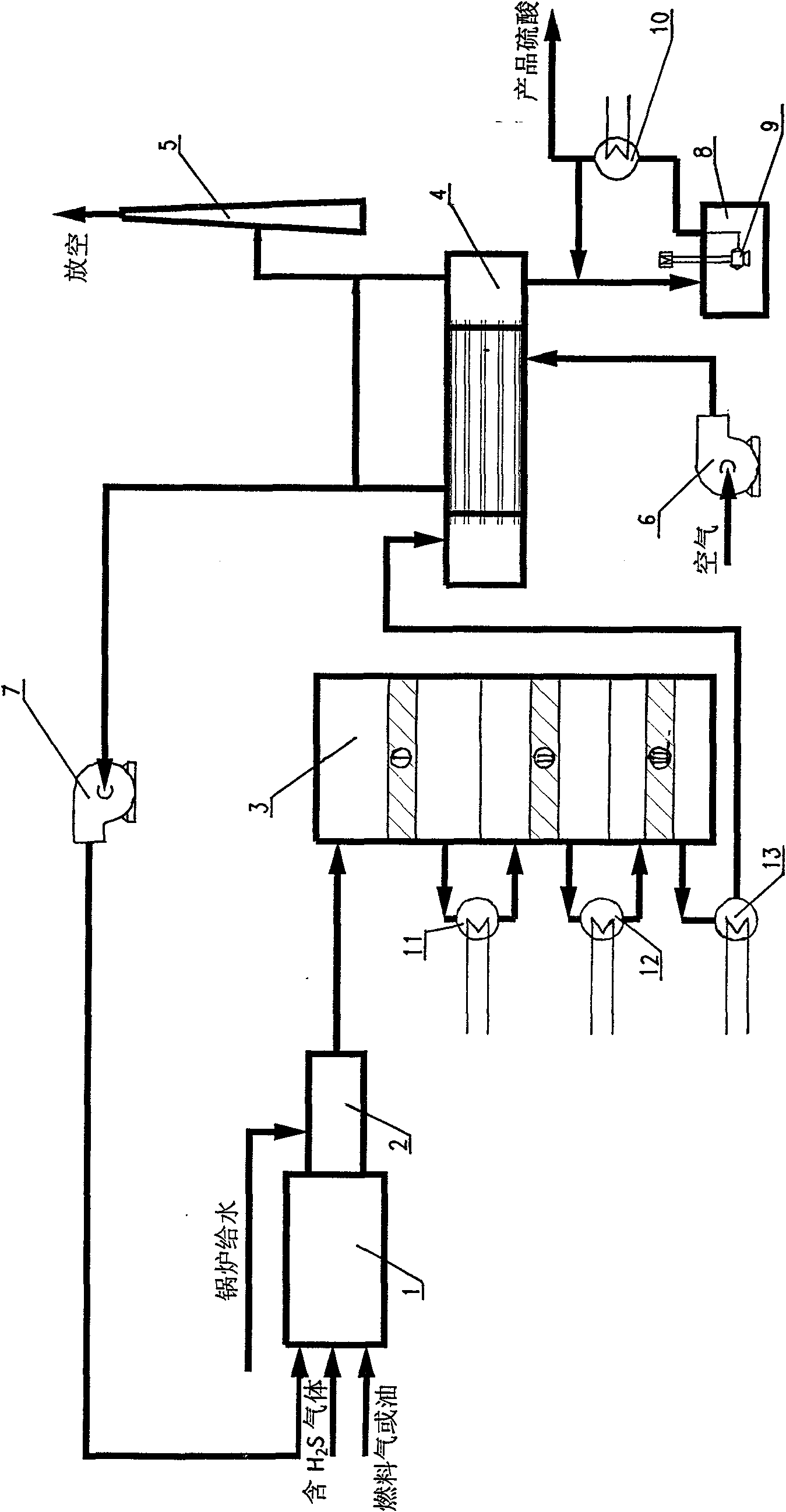

Method for producing sulfuric acid by using waste gas containing hydrogen sulfide

InactiveCN101618863ANo emissionsImprove recycling efficiencySteam generation heating methodsSulfur compoundsFiberWater vapor

Owner:SINOPEC NANJING ENG & CONSTR

Effective removal of acidic sulfide gas using ammonia-based desulfurization

InactiveUS20150352489A1Efficient removalPromote recoveryGas treatmentDispersed particle separationChemical industryPretreatment method

A method for effectively removing acidic sulfide gas using ammonia-based desulfurization includes the following steps of: 1) pre-treatment, wherein sulfide in acid gas undergoes through pre-treatment methods of sulfur recovery, acid making or / and incineration to convert remaining sulfur in the acid gas into sulfur oxides, and the acid tail gas with sulfur oxides is obtained; and the acid gas is derived from petrochemical industry, natural gas chemical industry, coal chemical industry, etc.; 2) ammonia absorption of sulfur oxides, wherein the acid tail gas with sulfur oxides is allowed to flow into an ammonia absorption apparatus, and a cyclic absorption solution is used to absorb sulfur oxides; and 3) post-treatment of ammonium sulfate, wherein a saturated or nearly saturated absorption solution undergoes concentration, crystallization, solid-liquid separation, and drying to obtain a solid product of ammonium sulfate. Sulfur oxides (including sulfur dioxide, sulfur trioxide and hydrates thereof) in the acid tail gas are removed and sulfuric acid, sulfur and ammonium sulfate are byproduced, and the cleaned gas is discharged upon meeting the emission standard.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

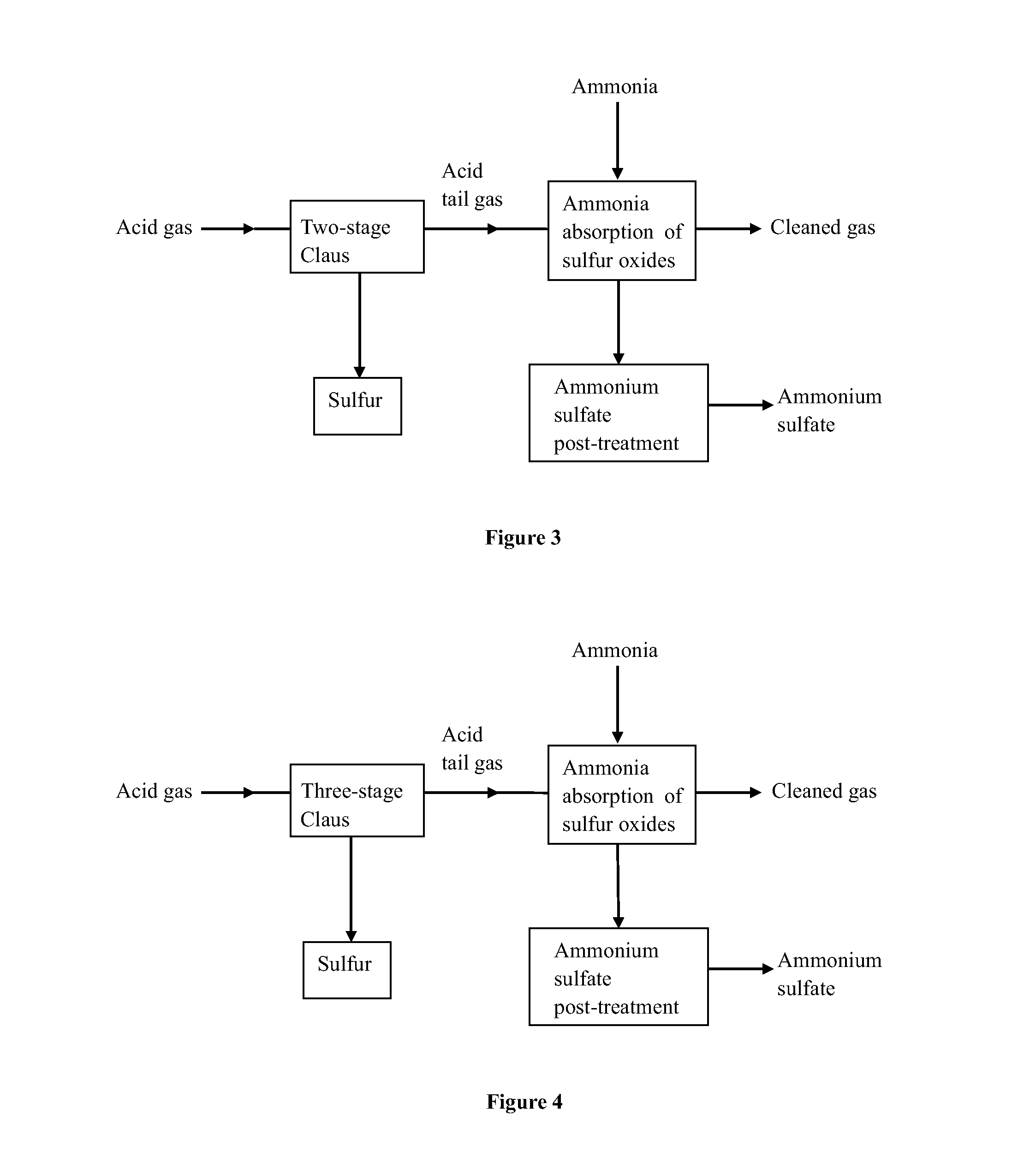

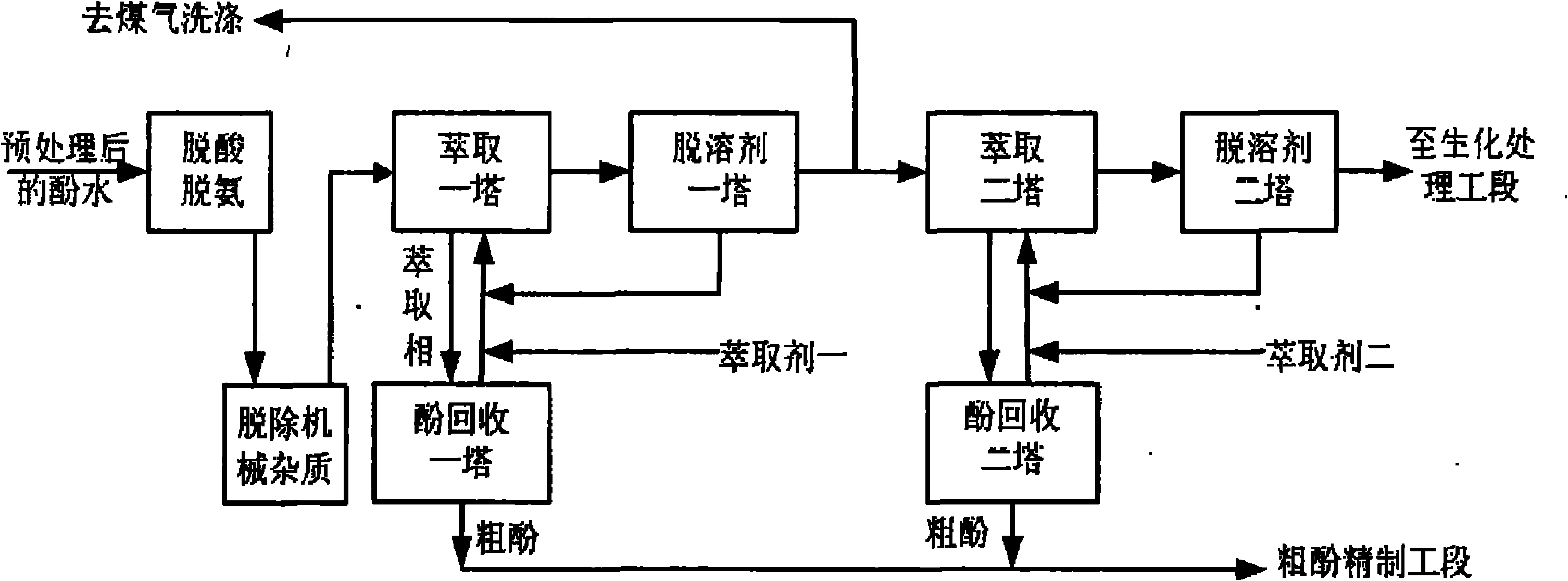

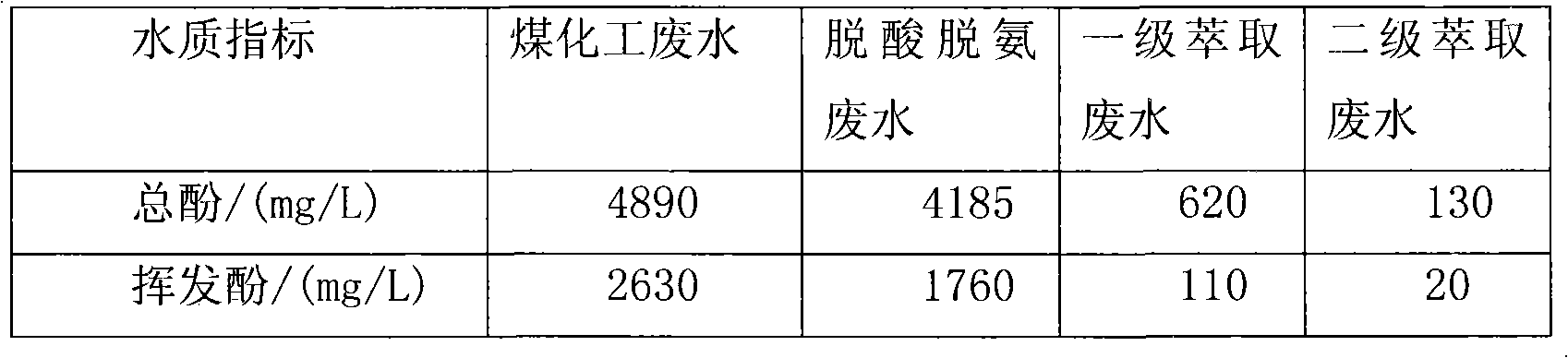

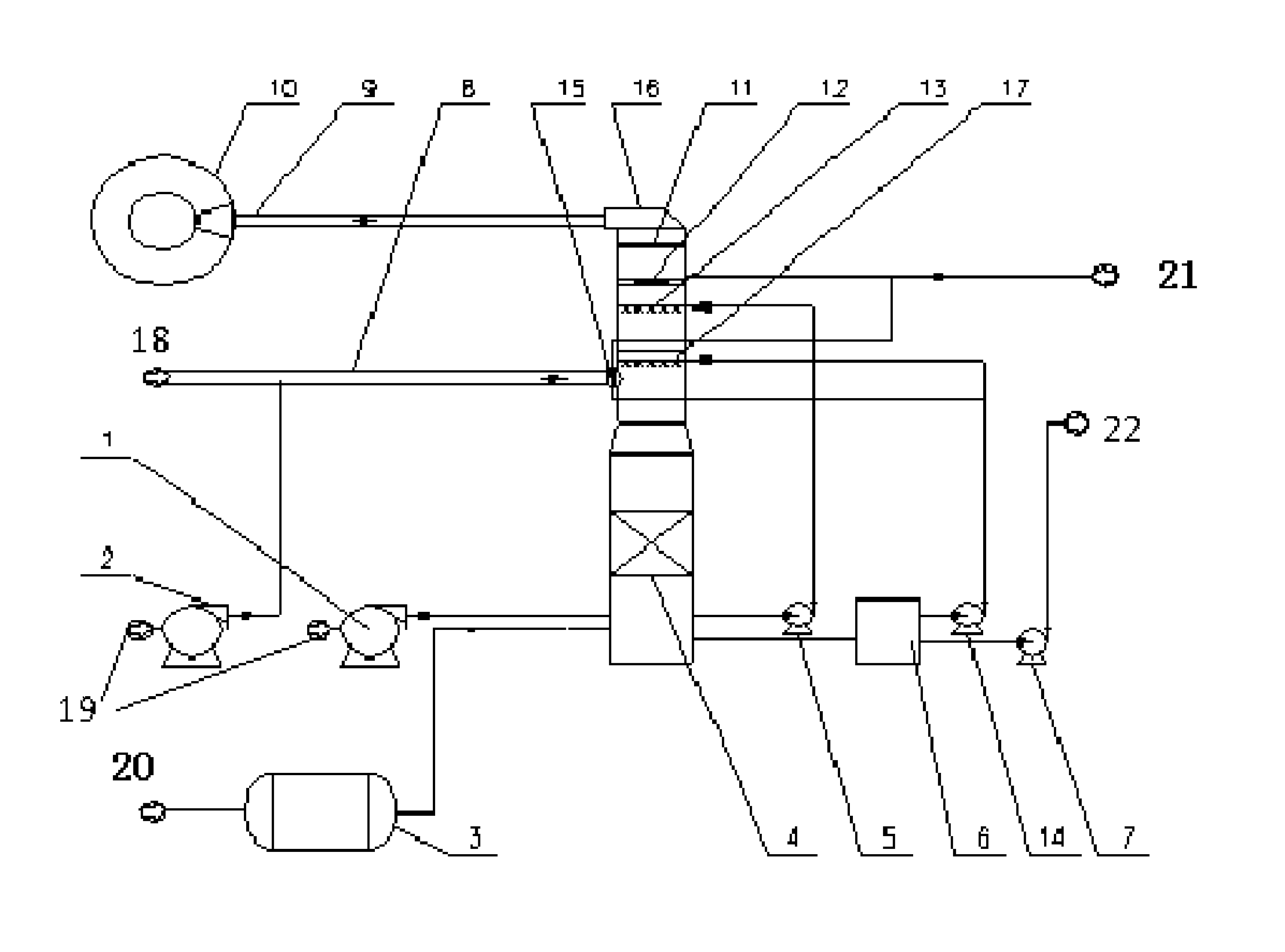

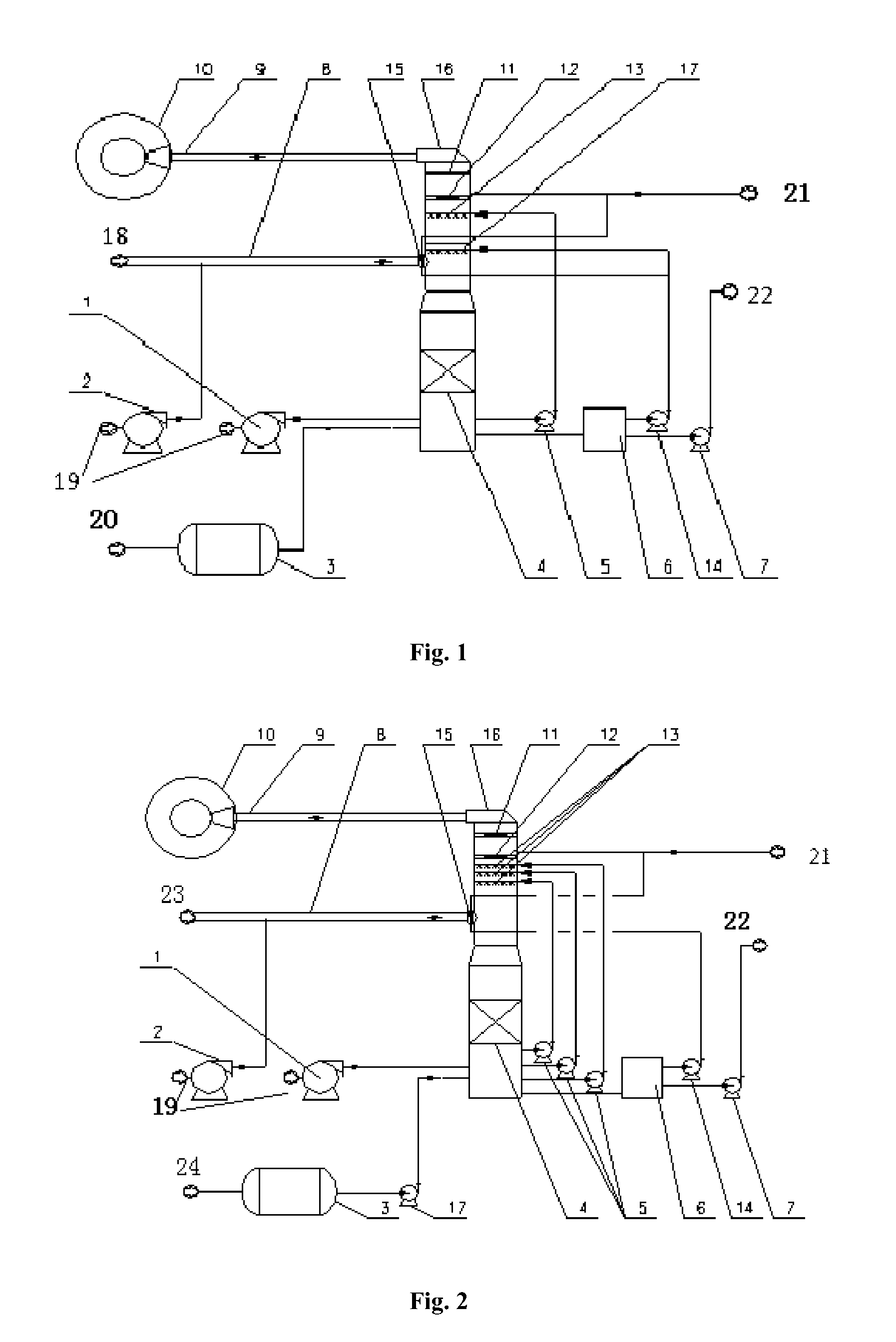

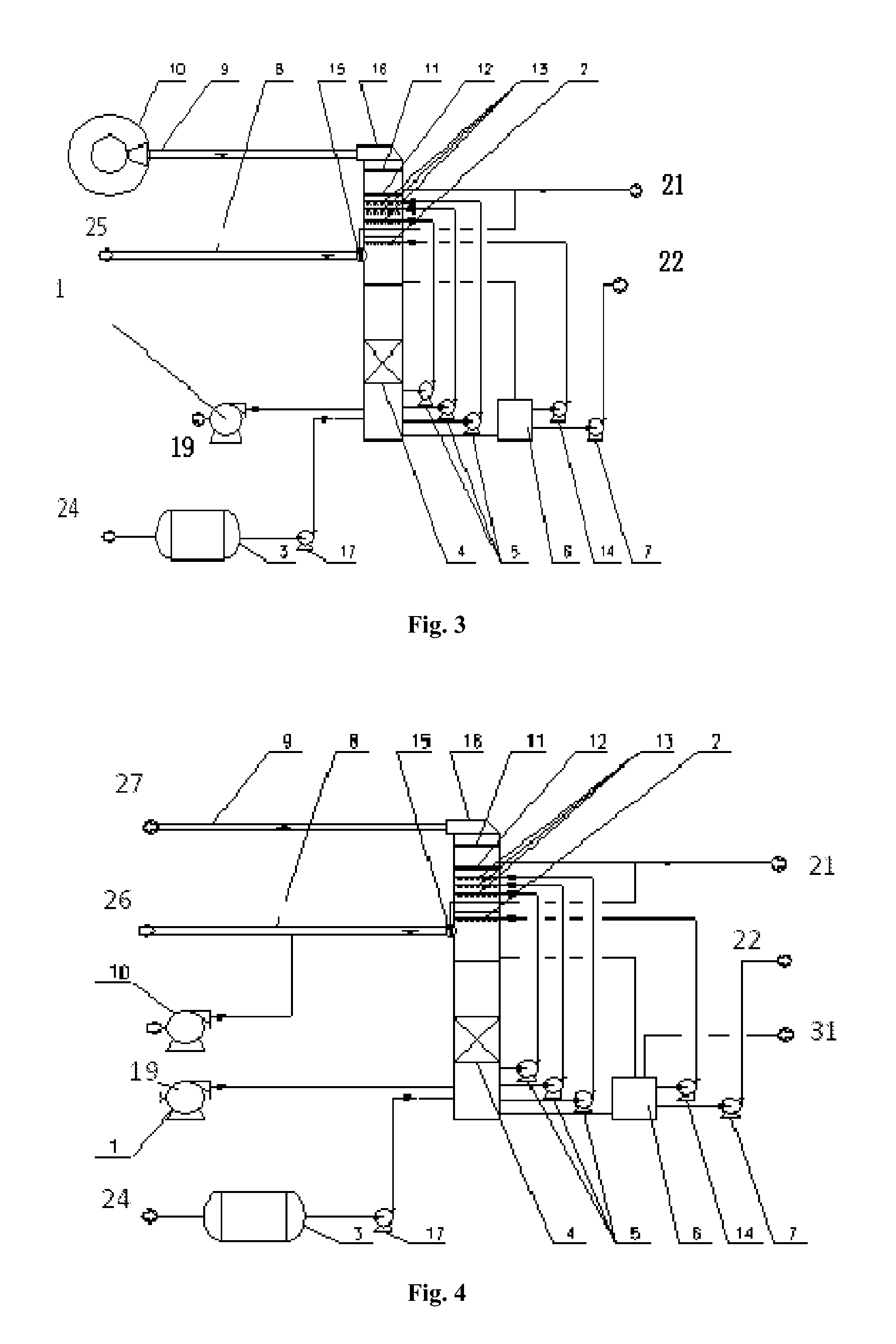

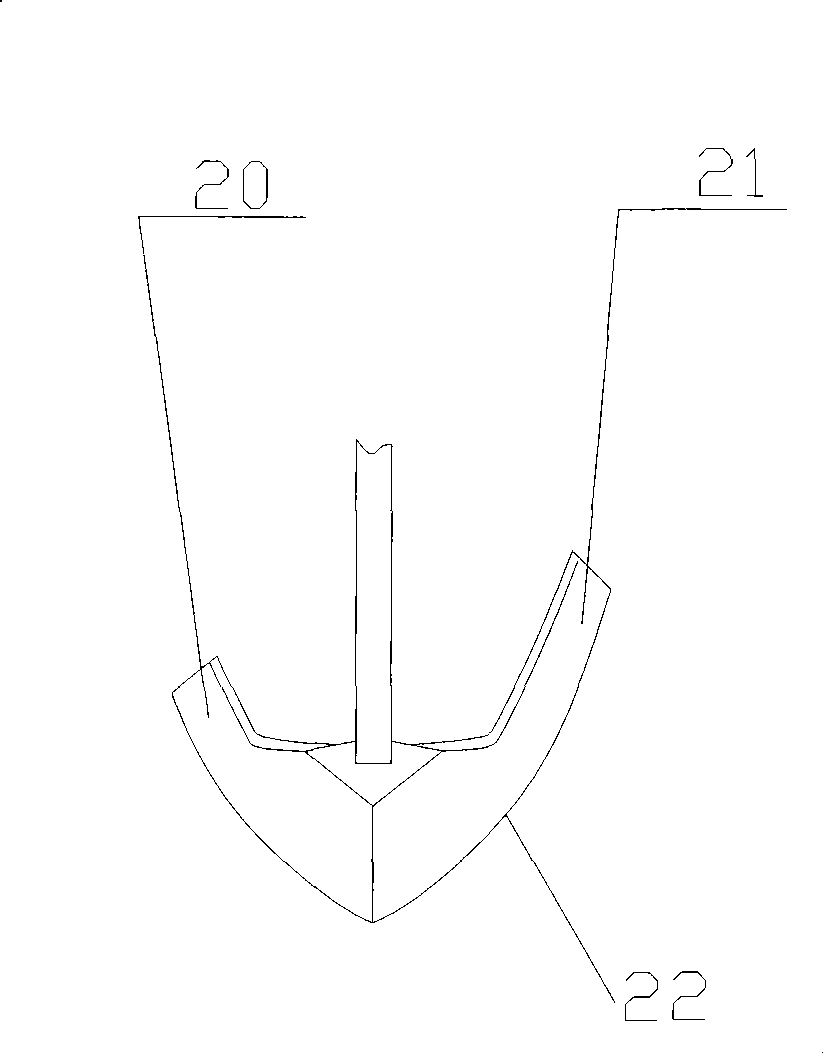

Method for extracting and dephenolizing coal chemical industry wastewater

ActiveCN101913718AReduce dosageImprove removal efficiencyMultistage water/sewage treatmentWater/sewage treatment by extractionHigh concentrationChemical industry

The invention discloses a method for extracting and dephenolizing coal chemical industry wastewater. Two different solvents are used as extracting agents, and serially-connected double-tower two-stage extracting dephenolization is adopted. The method comprises the following steps of: after carrying out gravity settling oil removal pretreatment on high-concentration phenol-contained wastewater produced in the coal chemical industry process and deacidifying, deaminizing and removing mechanical impurities, carrying out first-stage extracting dephenolization with the first solvent as the extracting agent; and carrying out second-stage extracting dephenolization with the second solvent as the extracting agent and conveying dephenolized water into a biochemical treatment working section. The wastewater subjected to first-stage dephenolization has the total phenol content of 400-1,000mg / l and the COD (Chemical Oxygen Demand) of 2,000-5,000mg / l; the wastewater subjected to second-stage dephenolization has the total phenol content of smaller than 300mg / l and the COD of smaller than 2,000mg / l; and the total phenol removal rate is larger than 90 percent, and the polyphenol removal rate is larger than 70 percent. The invention can meet the requirement of water quality of biochemical treatment, has the advantages of high phenol removal rate, less solvent dosage and low energy consumption and is particularly suitable for treating the wastewater which has high polyphenol content and is produced in the coal gasification, coking and chemical industry synthesis process.

Owner:哈尔滨瑞格能源环境技术发展有限责任公司 +1

Flue gas-treating method and apparatus for treating acidic tail gas by using ammonia process

ActiveUS9370745B2Improve desulfurization efficiencyEffectively control the ammonia slip and the aerosol generationGas treatmentDispersed particle separationFlue gasAmmonia storage

Owner:JIANGNAN ENVIRONMENTAL PROTECTION GRP INC

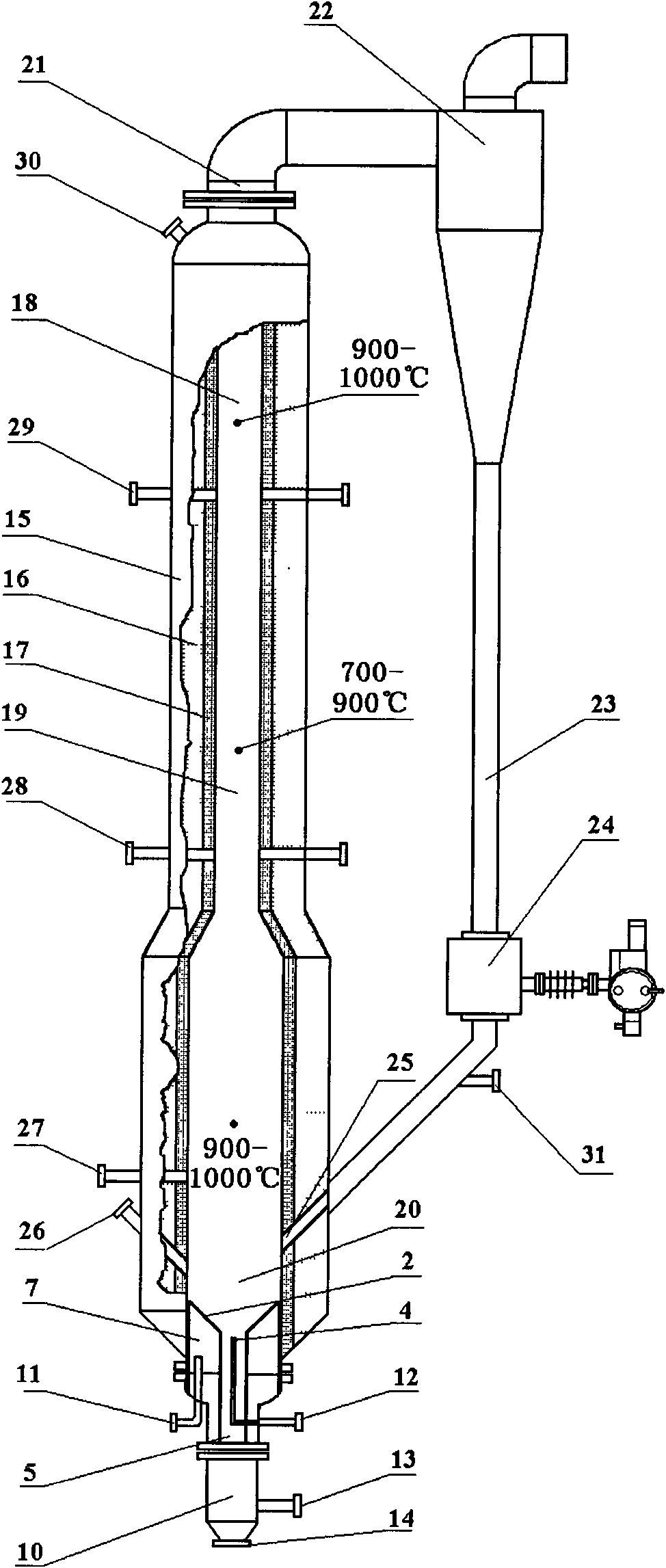

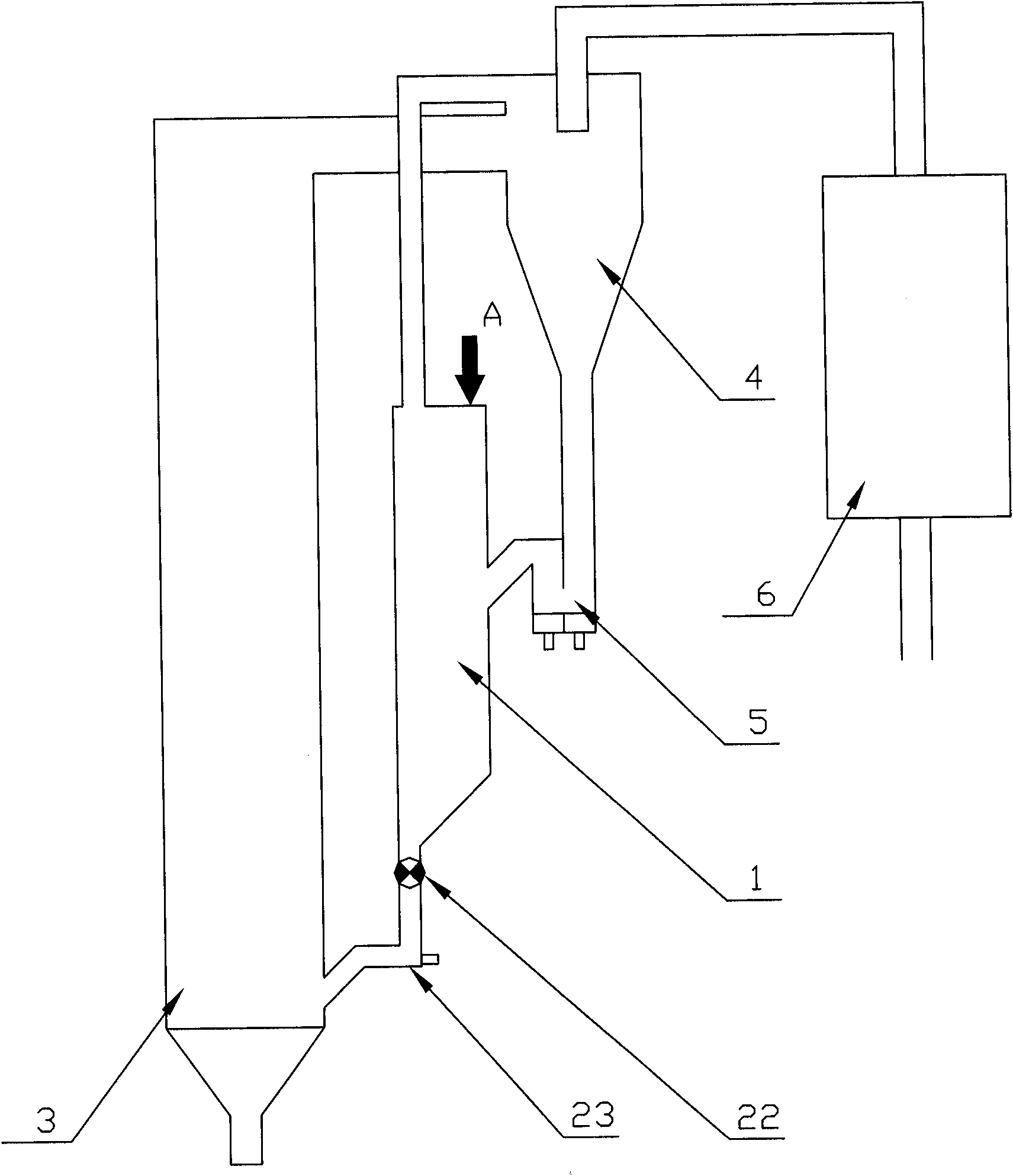

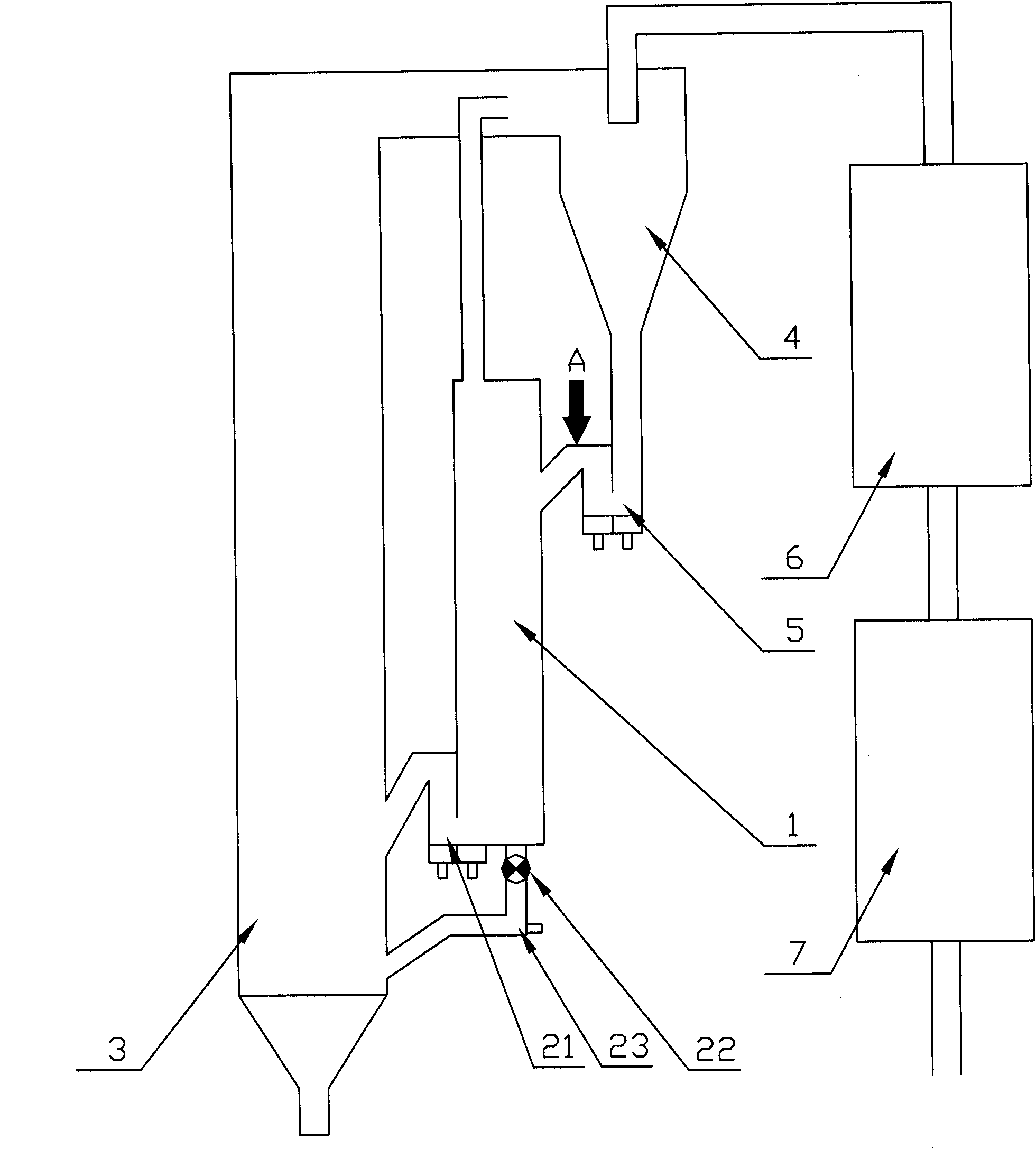

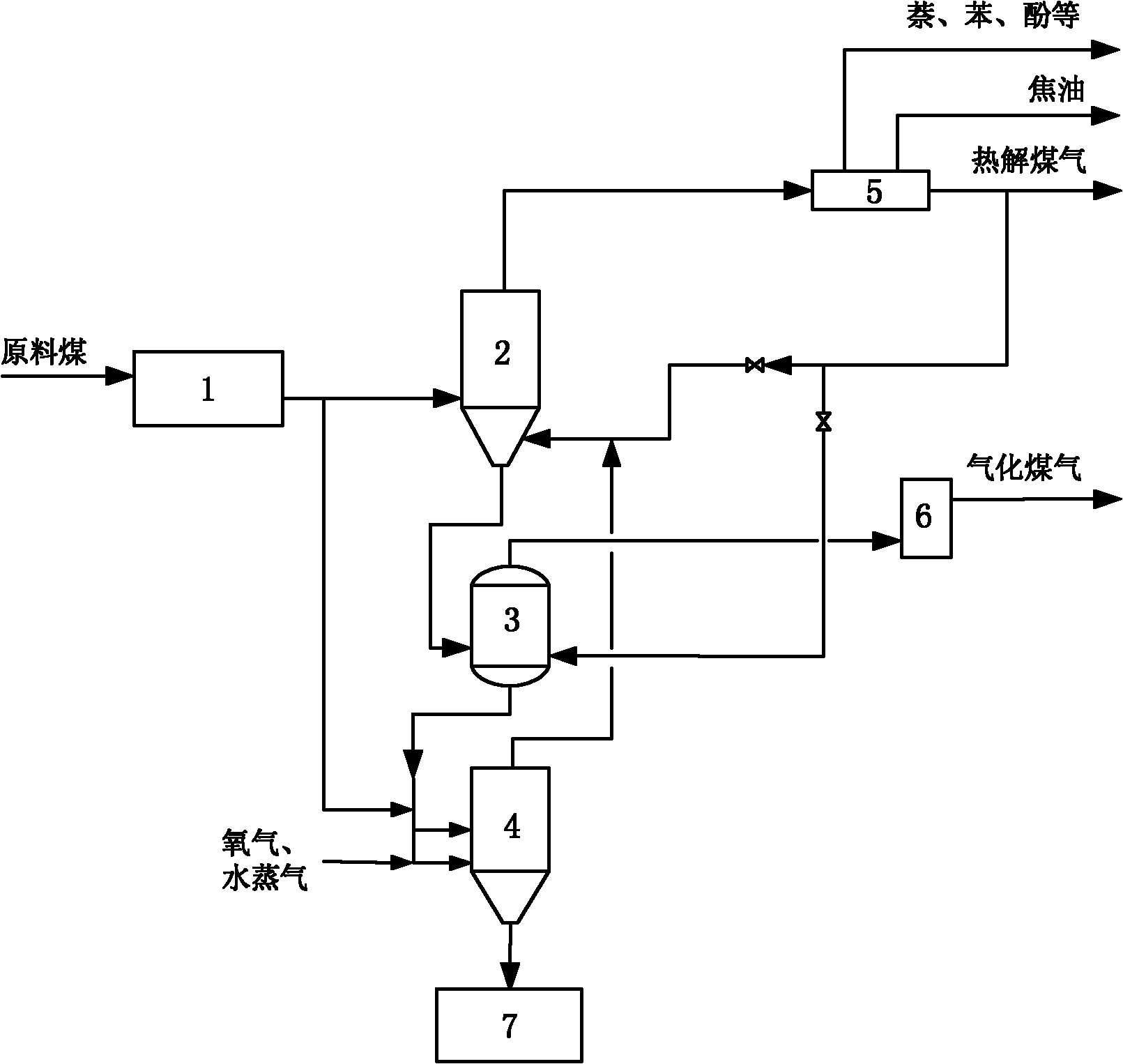

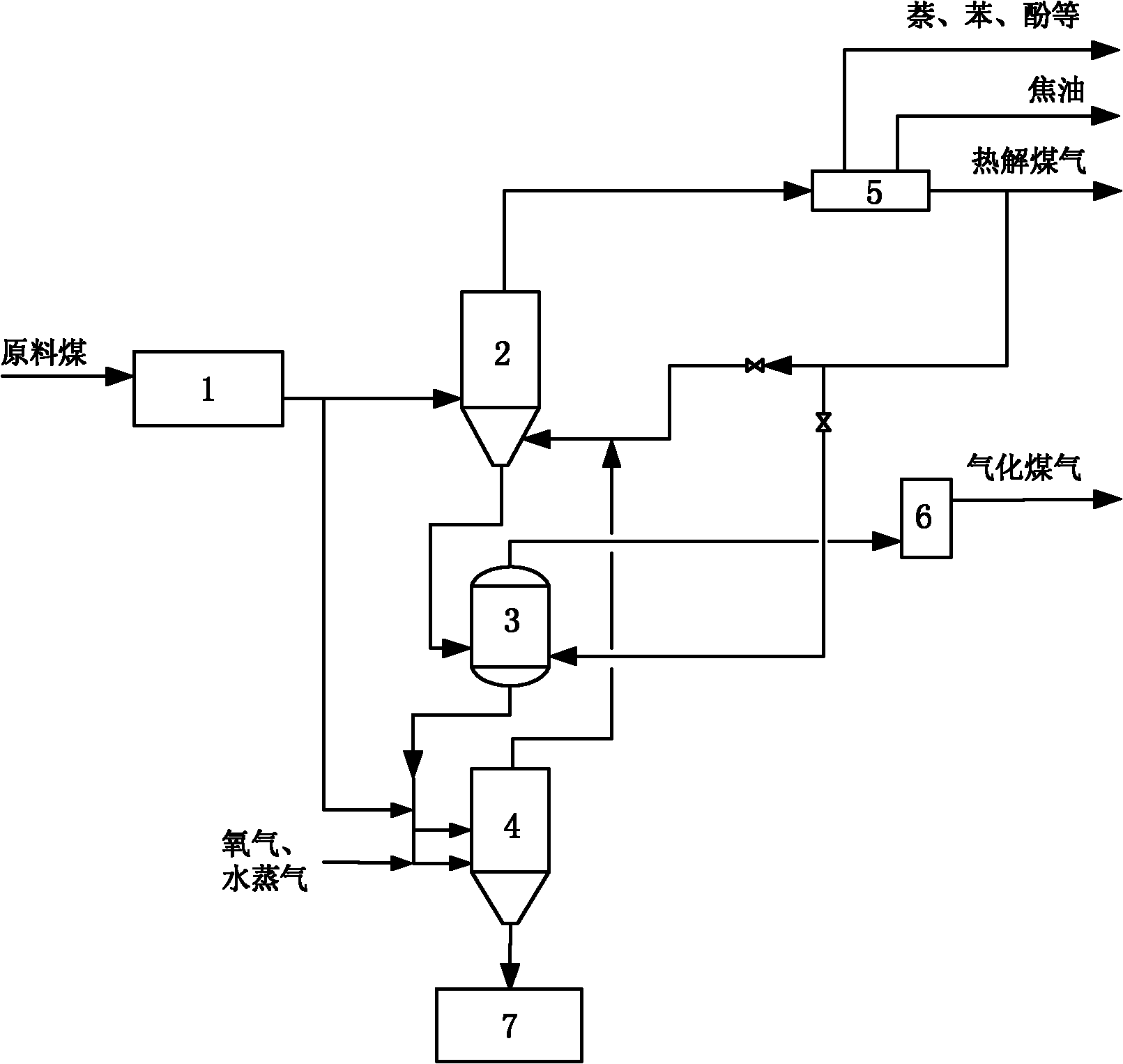

Thermal pyrolysis combination method and device

ActiveCN102212399AHigh calorific valueReduce tar contentGranular/pulverulent flues gasificationCycloneLow speed

The invention discloses a thermal pyrolysis combination method and device and relates to a coal chemical industry technology. A fuel is pyrolyzed in a low-speed bed pyrolyzing furnace, the generated semicoke is discharged from the bottom of the pyrolyzing furnace, sent into a circulating fluid bed gasifier by virtue of a semicoke returning device so as to be subjected to gasification, and coal gas generated by the gasifier, carrying solid particles, enters in a cyclone separator; the gasification temperature of the gasifier is 900-1,200 DEG C, the fuel thermal pyrolysis temperature in the thermal pyrolyzing furnace is 50-200 DEG C lower than the temperature of the gasifier; pyrolysis gas generated in the pyrolyzing furnace is introduced into the upper part of the gasifier or introduced into the cyclone separator together with the coal gas generated in the gasifier; and the solid particles gathered by the cyclone separator are sent above the dense phase area of the pyrolyzing furnace by virtue of the returning device so as to provide heat for pyrolysis of the fuel. The method and device disclosed by the invention are used for pyrolysis and gasification of coal, biomass and other carbon-containing fuels, the generated coal gas has the advantages of high thermal value and low tar content, and the system is simple.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

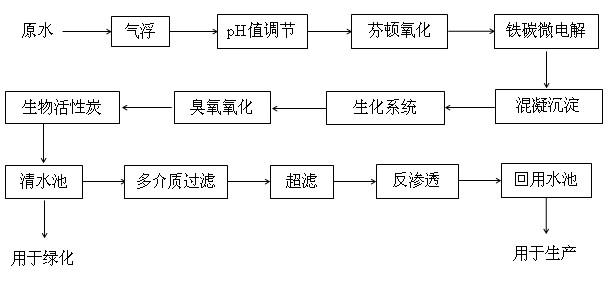

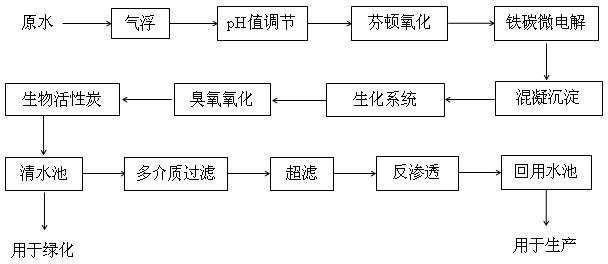

Treatment method for recycling complex waste water in coal chemical industry

InactiveCN102515442AImprove biodegradabilityRealize resourcesMultistage water/sewage treatmentWater useBiological activated carbon

The invention provides a treatment method for recycling complex waste water in the coal chemical industry and relates to recycling technologies for enhanced pretreatment, biochemical treatment, deep purification and regeneration process of waste water. The invention provides the process scheme as follows: first enhanced pretreatment for the complex waste water in the coal chemical industry is carried out by using the combined process of air floatation, Fenton oxidation and ferric-carbon micro-electrolysis, so as to improve the biodegradability of the waste water; then the waste water is poured into a biochemical system comprising a hydrolyze acidification zone pool, an anoxic pool and an aerobic pool; the biodegraded water is discharged into a deep purification system with the function ofozone-biological activated carbon filtration, so that materials which are difficult to degrade are further removed, and the discharged water can be used for green spaces and other landscapes; after that, most of salt ions are removed by using a regeneration recycling system with the functions of multi-media filtration, ultrafiltration and reverse osmosis, so as to obtain water can be reused for production.

Owner:蓝星环境工程有限公司

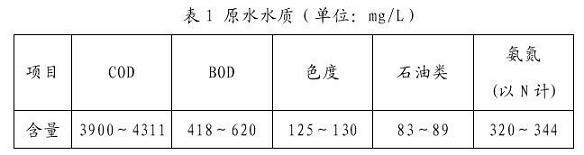

Coal tar multistage hydrogenation treatment technique

ActiveCN101240193AFully activeSolve cokingTreatment with hydrotreatment processesHydrogenation reactionGasoline

The invention discloses a coal-tar oil multistage hydrogenation craft, which belongs to coal chemical industry technology area. The method of the invention is that coal-tar oil fraction oils like impurities, sols, high content, asphaltenes, oxygen element, and so on, with high content or entire fraction are delivered into pre-hydrogenation reaction chamber by pump and are carried on pre-hydrogenation processing, then are successively followed by hydrogenation and demetallization, and depth hydrogenation reaction. After carried on separation of water and lightweight components, the generative fluid enters into a hydrocracking reactor, passes by a distiller to get gasoline fractions, diesel oil and hydrocracking tail oil out. Compared with the prior art, the invention can guarantee the long-period stability operation of the installation.

Owner:CHINA PETROLEUM & CHEM CORP +1

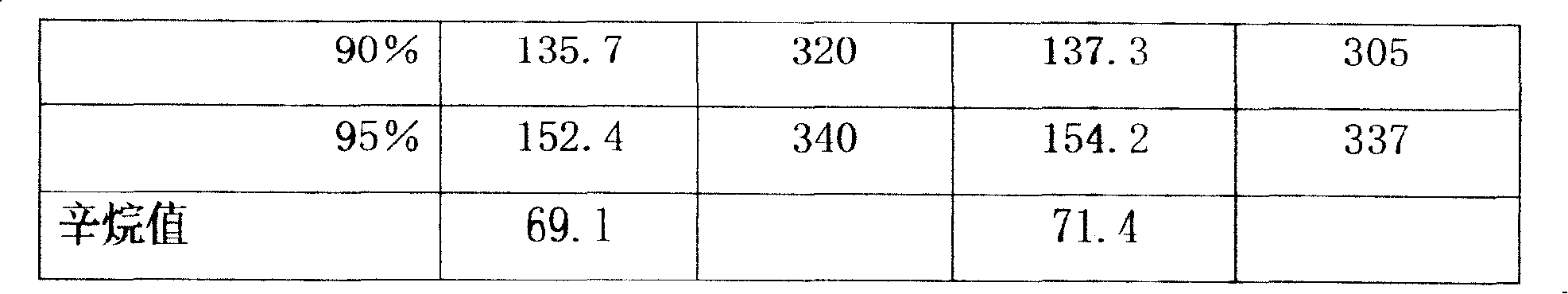

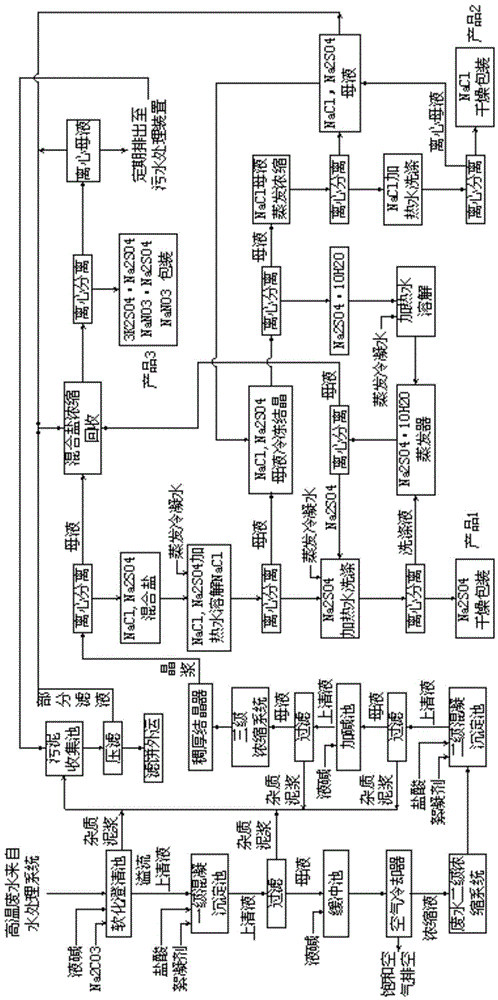

Comprehensive utilization method of high-concentration waste saline water containing Na<+>, Ka<+>, NH<4+>, Cl<->, SO4<2-> and NO<3-> in coal chemical industry

ActiveCN105585194AReduce consumptionReduce evaporative loadChemical industryTreatment involving filtrationHigh concentrationChemical oxygen demand

The invention relates to a comprehensive utilization method of high-concentration waste saline water containing Na<+>, Ka<+>, NH<4+>, Cl<->, SO4<2-> and NO<3-> in the coal chemical industry. After the high-concentration waste saline water is subjected to softening for impurity removal and subjected to coagulation sedimentation to remove COD (chemical oxygen demand), the water is concentrated by 20%-30% through an air cooler; then, the water enters second and third concentration systems and a salt mixture recovery system, and sodium sulfate, sodium chloride and sodium nitrate and potassium sulfate mixed salt are concentrated and separated with a multi-effect negative pressure evaporation method; condensed water is recycled. The purity of separated sodium chloride and the purity of separated sodium sulfate are higher than 99%, and sodium chloride and sodium sulfate can be directly sold. The method has remarkable economic benefits and social benefits, is environment-friendly, comprehensively reaches the standard and can be used for comprehensive treatment and utilization of similar high-concentration saline water in other industries, so that the environment-friendly and energy-saving requirements for full utilization of resources are met.

Owner:和易中诚环保科技有限公司

Coal tar heavy fraction suspension-bed hydrocracking method and system thereof

InactiveCN101962571AHigh yieldSimple structureTreatment with hydrotreatment processesHydrogenGasoline

The invention belongs to the technical field of coal chemical industry, and provides a coal tar heavy fraction suspension-bed hydrocracking method. The method comprises the following steps: mixing raw materials of coal tar heavy fractions with a catalyst and a vulcanizing agent to form a uniform mixed material; vulcanizing the catalyst in the mixed material under the action of hydrogen; preheating the vulcanized mixed material, and then allowing the preheated material to enter a suspension-bed reactor for hydrocracking reaction; and fractionating the product from the suspension-bed reactor to finally obtain gaseous hydrocarbon, gasoline fractions, diesel fractions and tail oil. In the invention, by directly adopting the hydrocracking method with a coal tar heavy fraction suspension bed and a system thereof, the coal tar heavy fractions can keep light weight, and the yield of the fuel oil product hydrogenated by coal tar can be effectively increased; and the suspension-bed hydrogenation reactor has simple structure without a bed layer, thus causing no phenomena such as blockage, increased pressure drop, overtemperature and the like occurred on the reaction bed layer, and the reactor further has the characteristics of great operation flexibility, long operation cycle, being safe and stable, easy control and the like.

Owner:DALIAN UNIV OF TECH

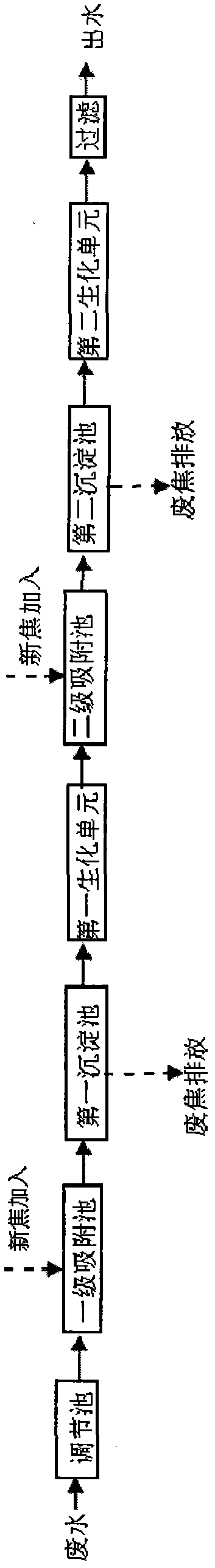

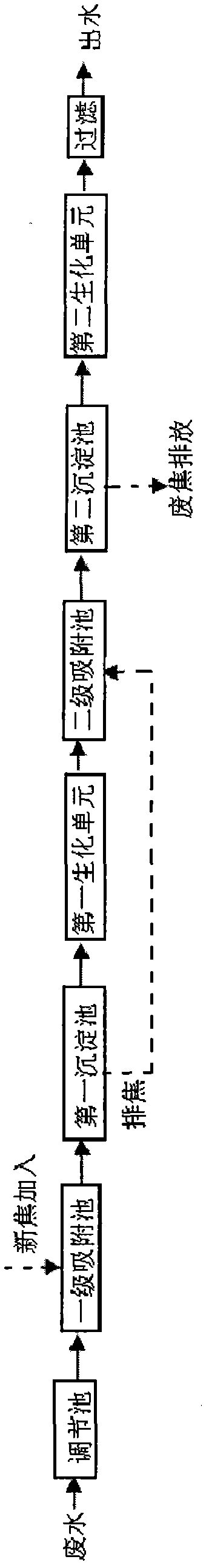

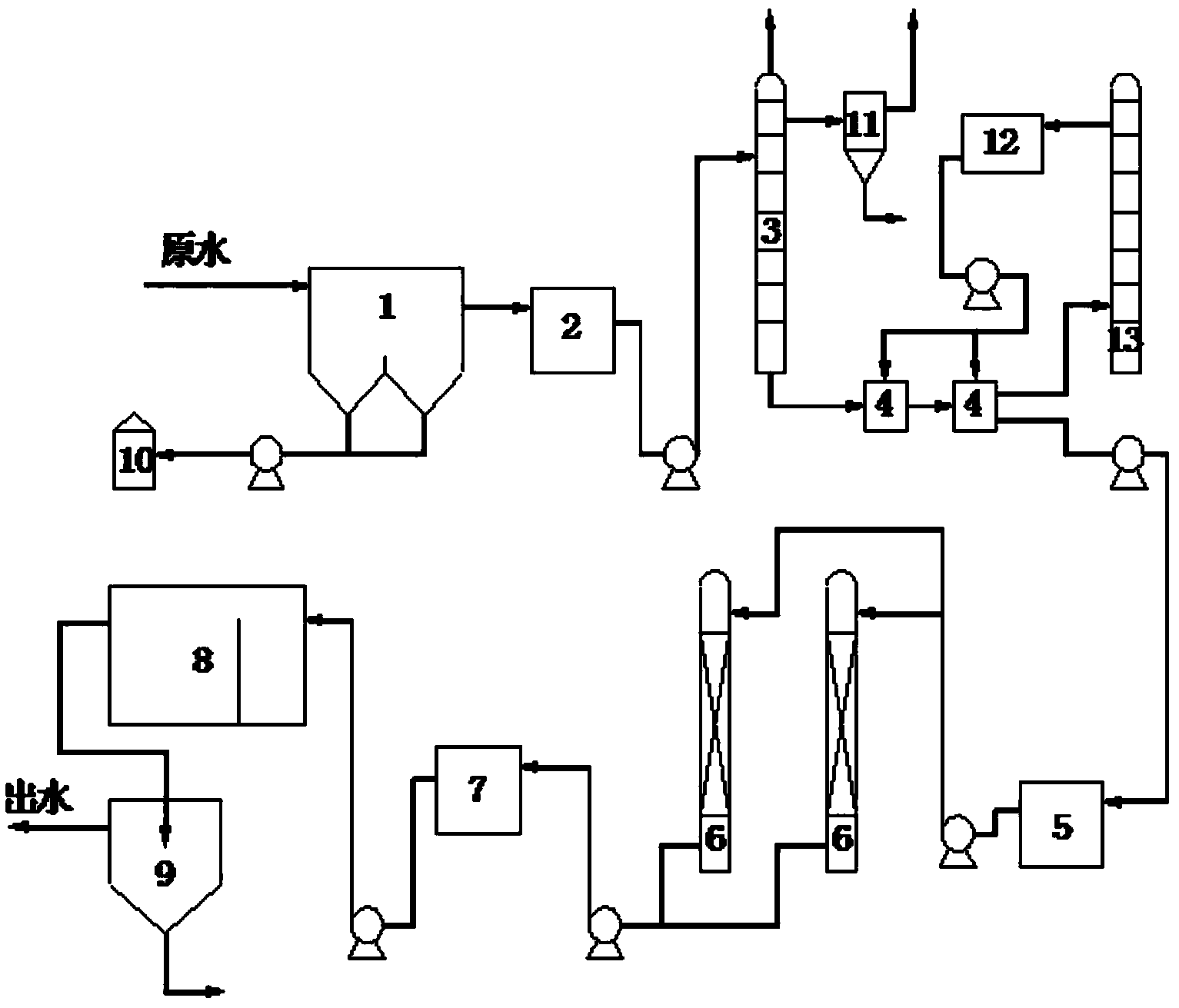

Coal gasification wastewater treatment process

InactiveCN102070277AImprove utilization efficiencyReduce dosageMultistage water/sewage treatmentCoal gasification wastewaterSalt content

The invention discloses a coal gasification wastewater treatment process, which comprises the following steps of: performing adsorption treatment in a primary adsorption tank; performing sedimentation treatment in a first sedimentation tank; performing biochemical treatment in a first biochemical unit; performing adsorption treatment in a secondary adsorption tank; performing sedimentation treatment in a second sedimentation tank; performing biochemical treatment in a second biochemical unit; and filtering and discharging. The coal gasification wastewater treatment process solves the technical problem that active carbon is added into an active sludge aeration tank to influence the effects of the biochemical treatment and the adsorption treatment in the conventional coal gasification wastewater treatment process, has the advantages of independent adsorption and biochemical treatment, combined arrangement, concise process, high treatment efficiency, no increase of salt content and stable operation, and is particularly suitable for treating coal gasification wastewater.

Owner:北京国能普华环保工程技术有限公司 +1

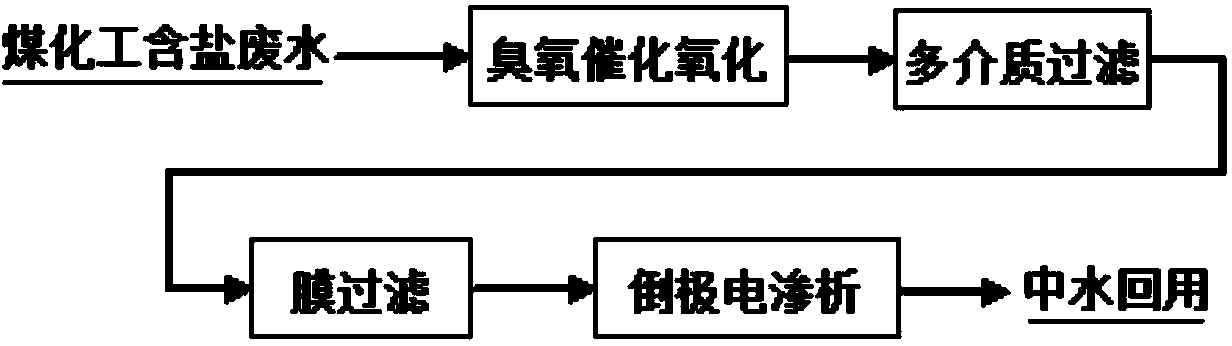

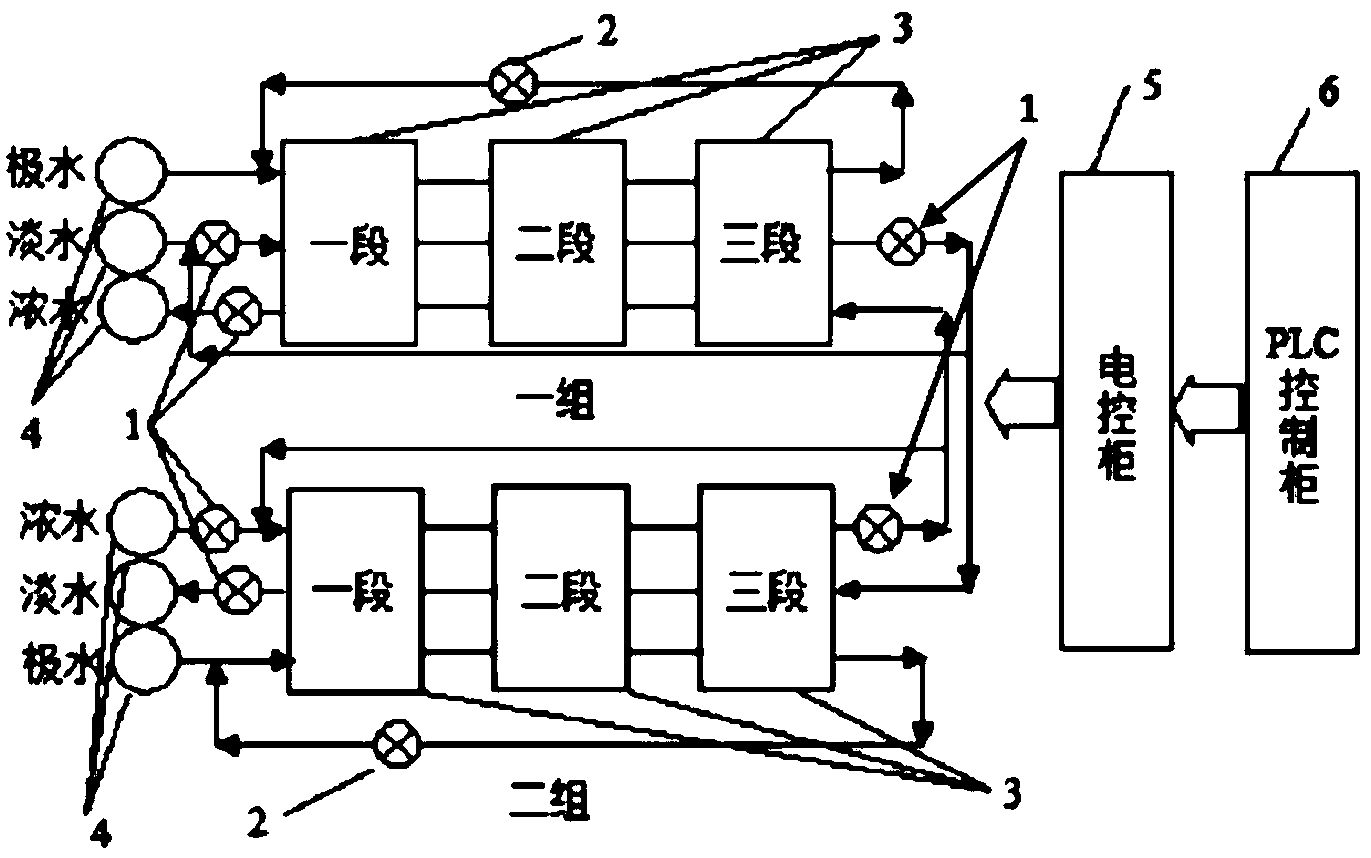

Multi-stage countercurrent electrodialyzer reversal-based method for treating saline wastewater in coal chemical industry

ActiveCN104016529AAchieving processing powerRealize desalination and reuseDispersed particle separationMultistage water/sewage treatmentFiltrationInstability

The invention relates to the field of industrial wastewater treatment processes and provides a multi-stage countercurrent electrodialyzer reversal-based method for treating saline wastewater in the coal chemical industry. The method comprises the following steps: 1) carrying out catalytic ozonation treatment on the saline wastewater in the coal chemical industry; 2) carrying out multi-media filtration and membrane filtration treatment on the wastewater subjected to catalytic ozonation in the step 1) in sequence; and 3) treating the effluent obtained after membrane filtration in the step 2) with a multi-stage countercurrent electrodialyzer reversal, thus achieving deep treatment, desalting and recycling of the saline wastewater in the coal chemical industry, wherein the multi-stage countercurrent electrodialyzer reversal comprises an electrodialysis membrane stack unit, a frequency reversal control unit and an online monitoring and process control unit. The method has the advantages of high fresh water recovery rate, low concentrated water discharge, low operating cost, stability in system operation and the like and can avoid the problems of low fresh water recovery rate, low concentration multiple, high treatment cost, serious membrane pollution, instability in system operation and the like in the routine techniques.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

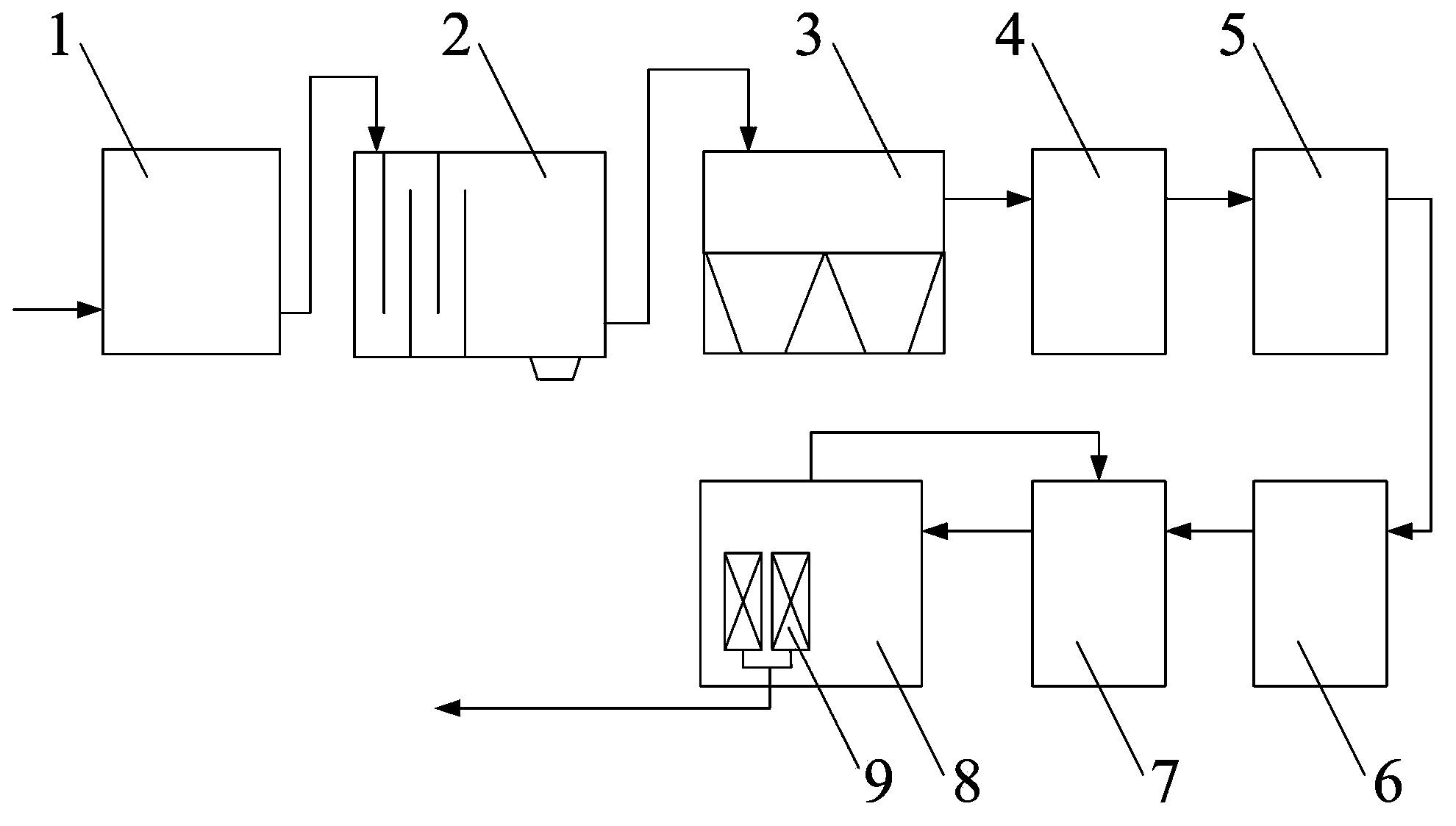

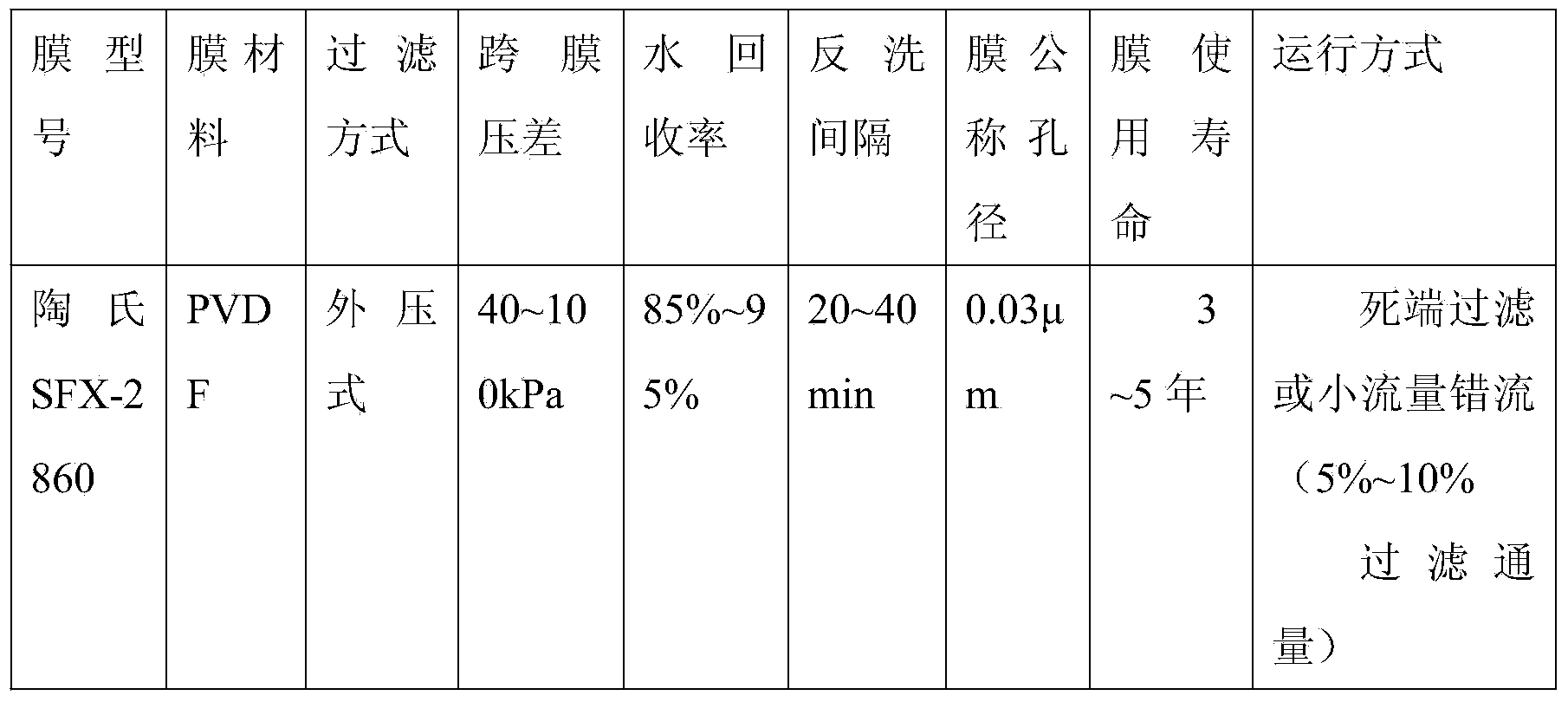

Coal chemical industry high-concentration wastewater treatment method and apparatus

ActiveCN103910460AImprove biodegradabilityReduce pollutionMultistage water/sewage treatmentHigh concentrationTreatment effect

The invention provides a coal chemical industry high-concentration wastewater treatment method and an apparatus which can solve the problems of low flux and high membrane pollution when an MBR (membrane bioreactor) is used for coal chemical industry wastewater treatment in the prior art. The coal chemical industry high-concentration wastewater treatment apparatus comprises an oil separation device, a flocculation reaction device communicated with the oil separation device, an ultra-micro air flotation device communicated with the flocculation reaction device, an advanced oxidation device communicated with the ultra-micro air flotation device, a hydrolysis and acidification device communicated with the advanced oxidation device, a denitrification device communicated with the hydrolysis and acidification device, an anoxic device communicated with the denitrification device, and an aerobic MBR device which comprises a plurality of MBR membranes arranged in the aerobic MBR device and is communicated with the anoxic device. The coal chemical industry high-concentration wastewater treatment method and the device provided by the invention have the beneficial effects that the pretreatment is complete, the subsequent treatment difficulty is low, and the biochemical treatment effect is ensured so as to be favorable for reducing membrane pollution; in addition, the cleaning frequency of the membranes is low and the service life is long; and furthermore, the MBR outlet water is stable, suspended matters are avoided, and the deep treatment effect can be further ensured.

Owner:GO HIGHER ENVIRONMENT GRP CO LTD

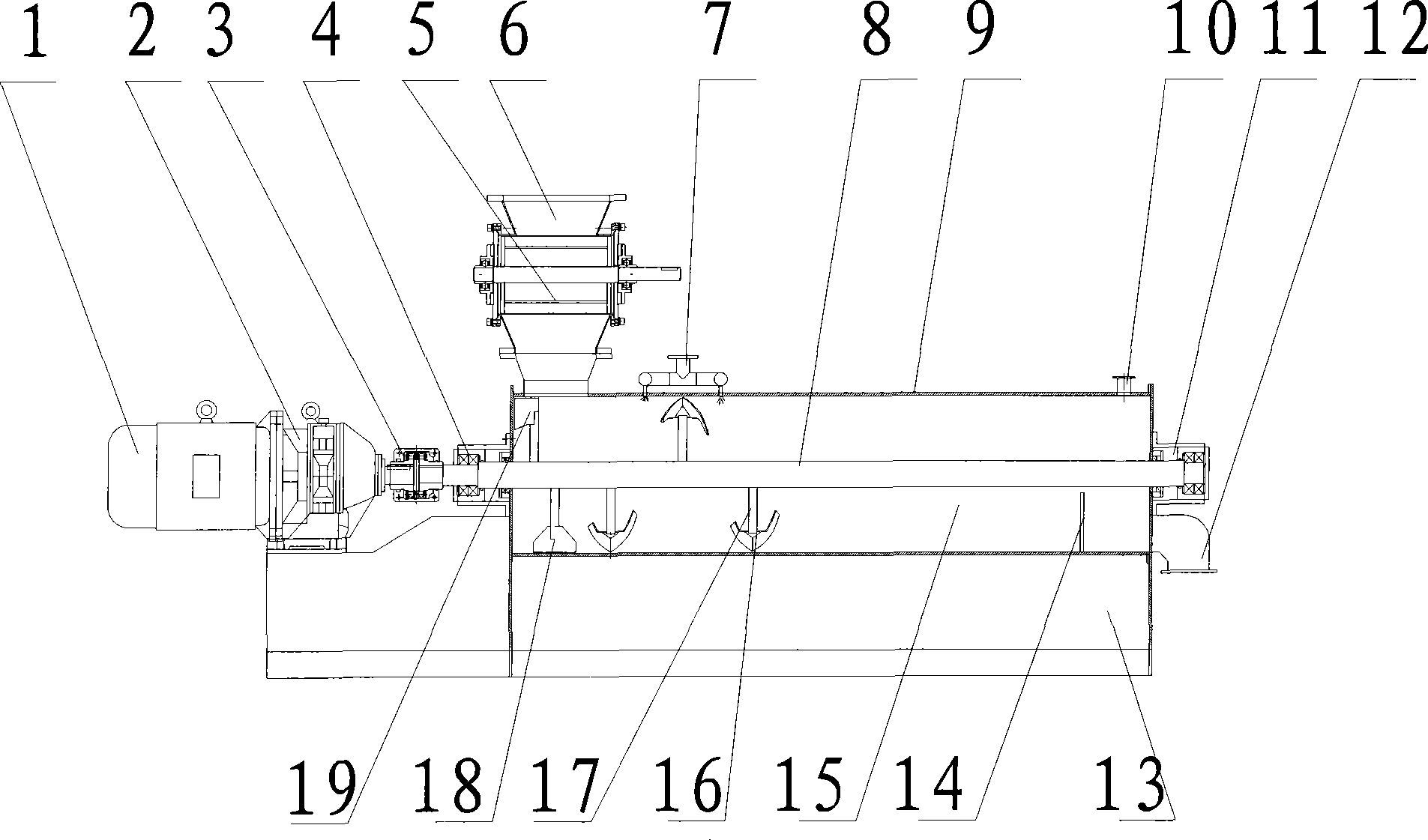

Horizontal solid-liquid mixing device and application thereof

InactiveCN101444705AWell mixedQuality improvementRotary stirring mixersMixing methodsChemical industryRotary valve

The invention relates to a horizontal solid-liquid mixing device and the application thereof. The mixing device comprises a motor, a reduction gearbox, a ratcheting, a front bearing end, a rotary valve, a solid feeding hole, a liquid feeding hole, a mixer shaft, a mixing cylinder, an exhaust hole, a rear bearing end, a discharge hole, a solid-liquid mixing room, a drawing template, a plough coulter, a fixed link of the plough coulter and a baffle; wherein, the drawing template is fixed on the mixer shaft and arranged under the solid feeding hole, the plough coulter is fixed on the mixer shaft by the fixed link of the plough coulter, a plowshare of the plough coulter forms an angle with the mixer shaft, the baffle is arranged inside the mixing cylinder, and a gap is arranged at the position of a contact surface between the baffle and the cylinder in front of the discharge hole. Compared with the prior art, the horizontal solid-liquid mixing device can fully mix two phases of solid and liquid within a short time, has high mixing efficiency, low energy consumption and even material mixing, does not produce 'powder balls' generated by mixing the powder and the liquid, is good in continuous operation effect and can be widely applied to industries such as petroleum, chemical industry, coal chemical industry, food, medicine, etc.

Owner:SHANGHAI RES INST OF CHEM IND +1

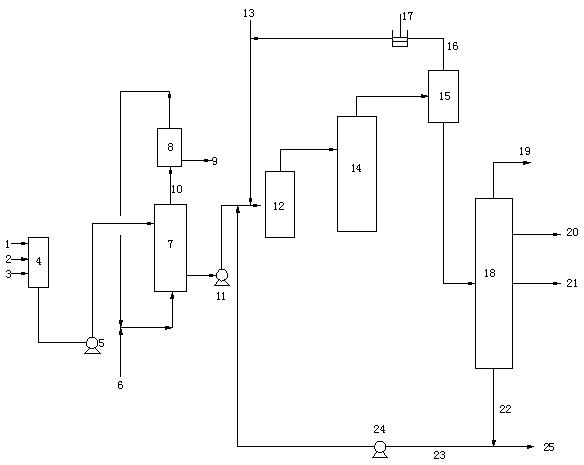

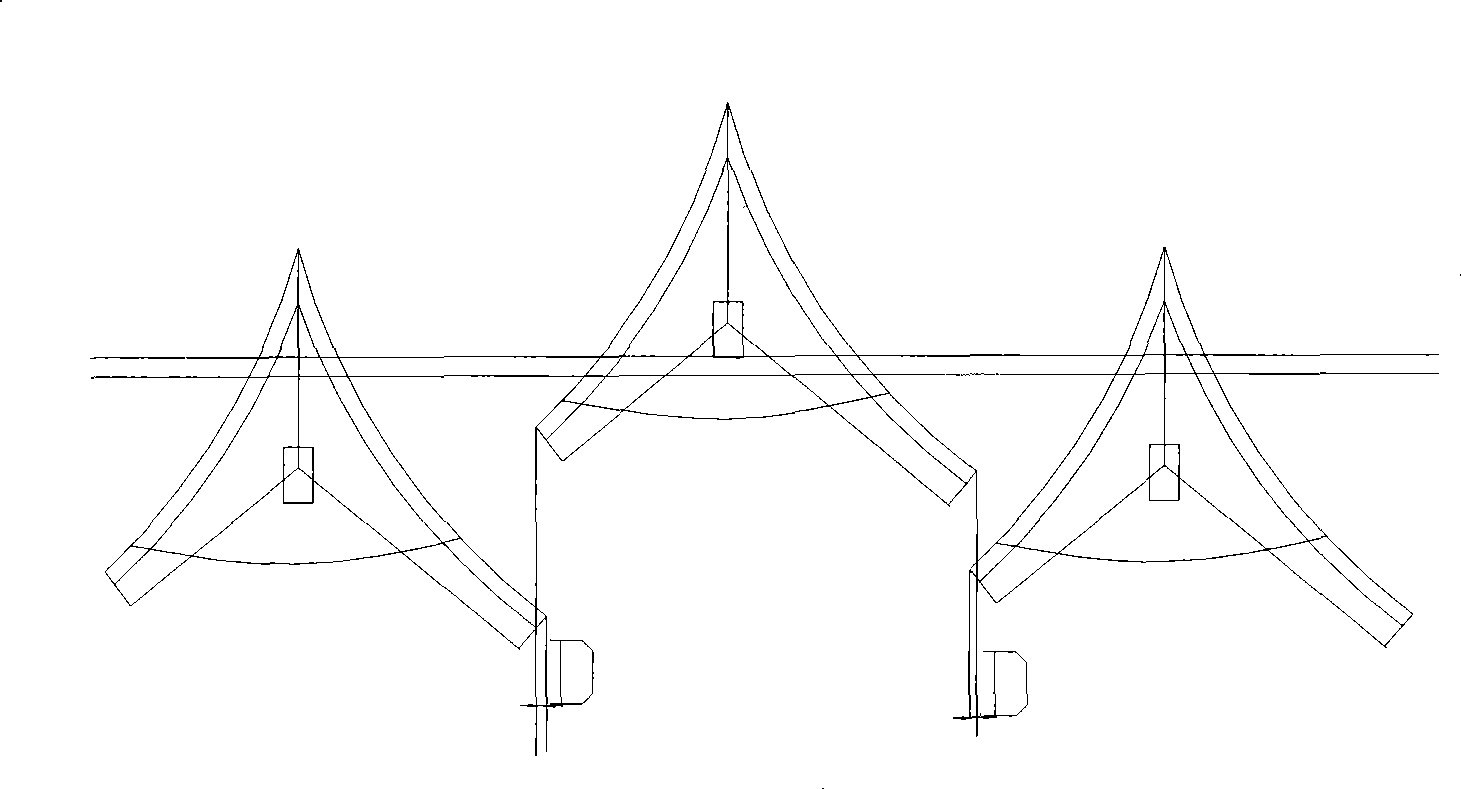

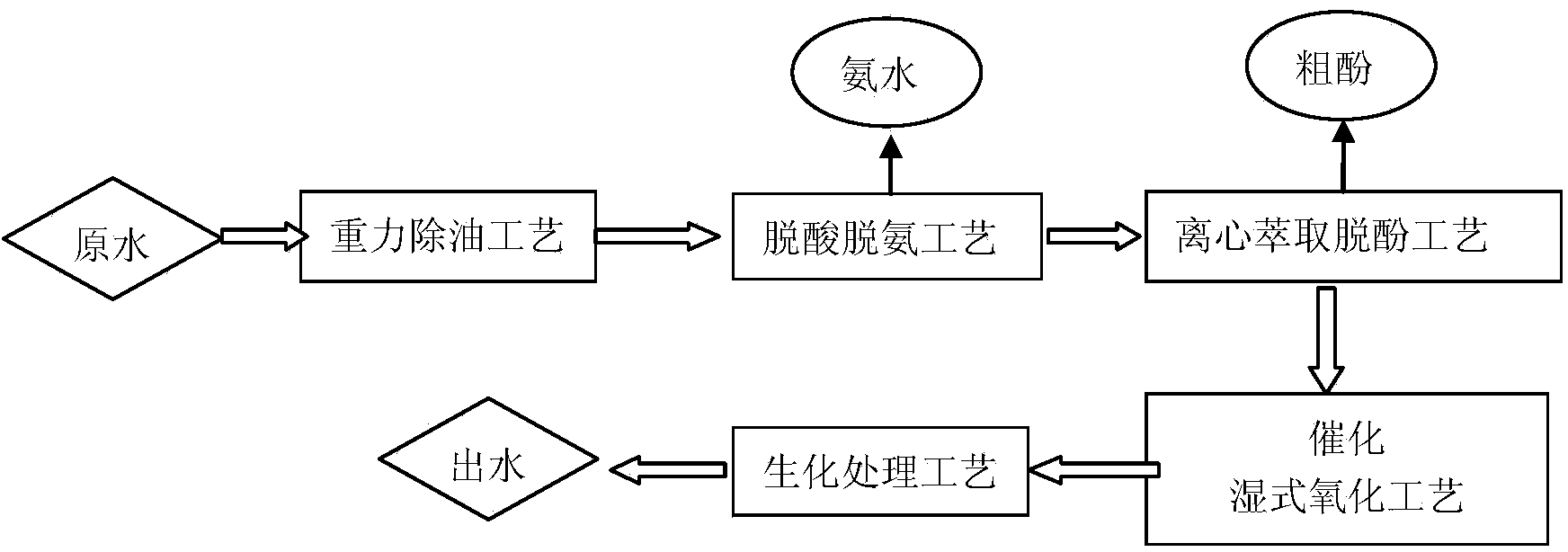

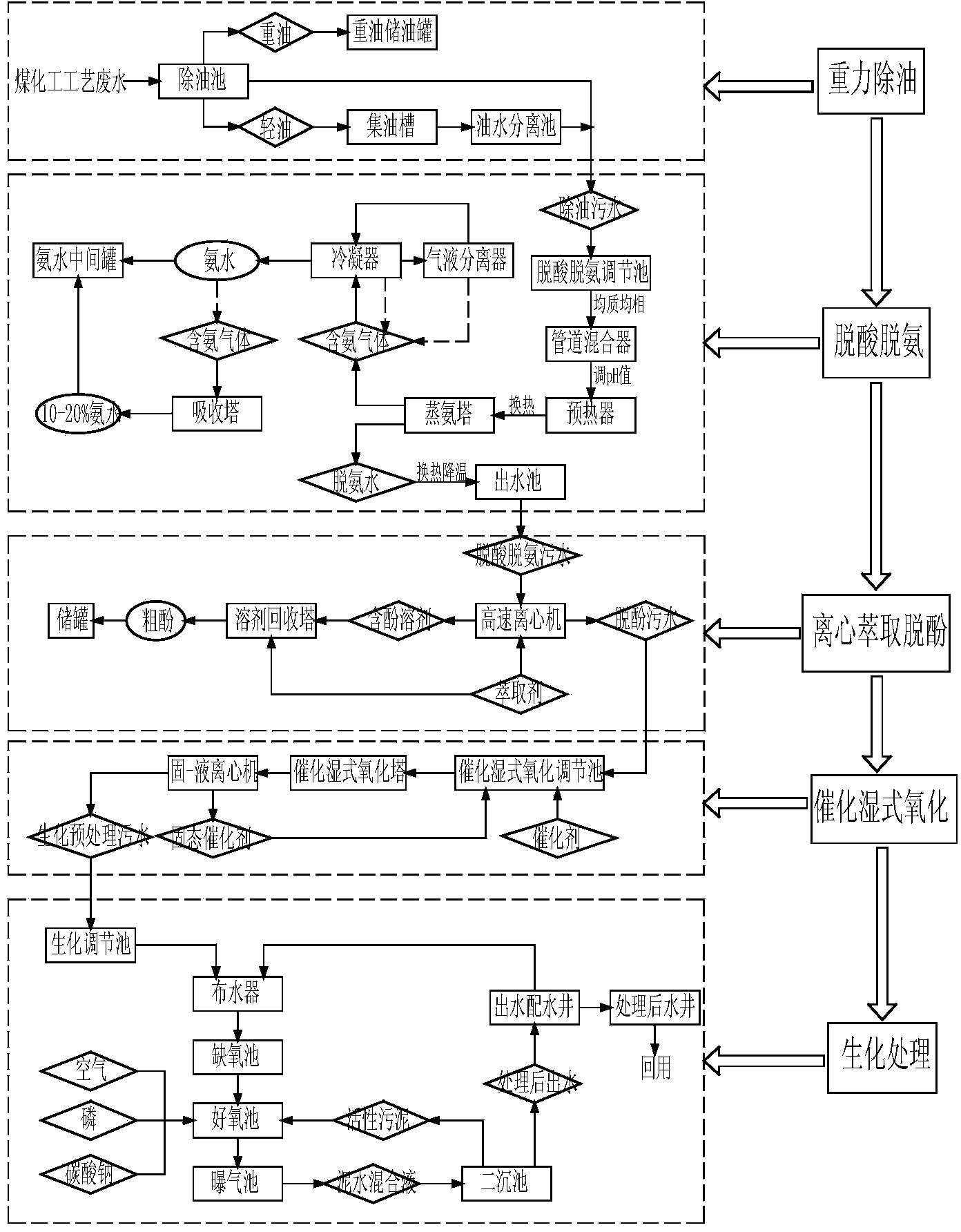

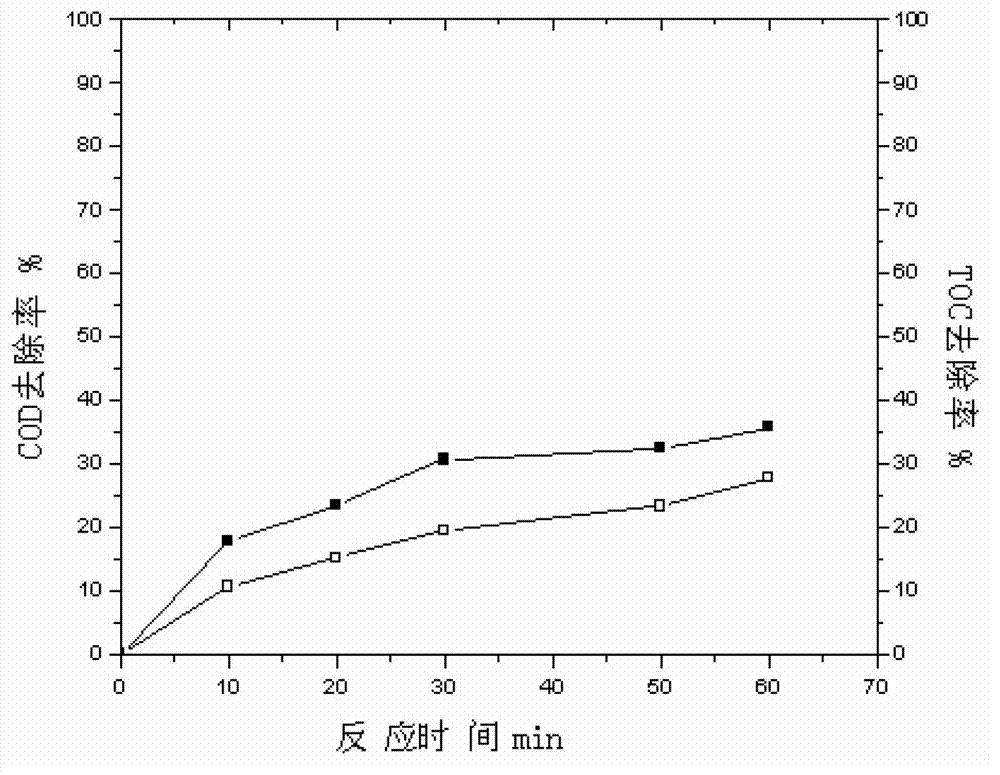

Advanced treatment process of coal chemical industry wastewater

ActiveCN103880242AAchieve water balanceMultistage water/sewage treatmentChemical industryEmission standard

The invention relates to an advanced treatment process and device of coal chemical industry wastewater. The process comprises the following steps: removing oil, performing deacidification and deamination, performing centrifugal extraction and dephenolization, performing catalytic wet oxidation and performing biochemical treatment. The device comprises an oil removal pool, a deacidification and deamination regulating reservoir, an ammonia still, a high speed centrifuge, a catalytic wet oxidation regulating reservoir, a catalytic wet oxidation tower, a biochemical regulating reservoir and an A / O biochemical system which are connected with one another sequentially. The indirect emission standard requirements in the national coking chemical industrial pollutant discharge standard (GB16171-2012) can be met after main pollutants such as chemical oxygen demand (COD), oil, ammonia nitrogen and phenol in coal chemical industry wastewater are treated, and ammonia water and crude phenol can be recovered. Compared with the prior art, the advanced treatment process of coal chemical industry wastewater has the beneficial effects that sewage produced in coal chemical industry is treated with a clear target on the basis of characteristics of the coal chemical industry production process, so that the indirect emission standard requirements are met, available resources in the sewage are recovered, and sewage resource treatment is really realized.

Owner:SINOSTEEL ANSHAN RES INST OF THERMO ENERGY CO LTD

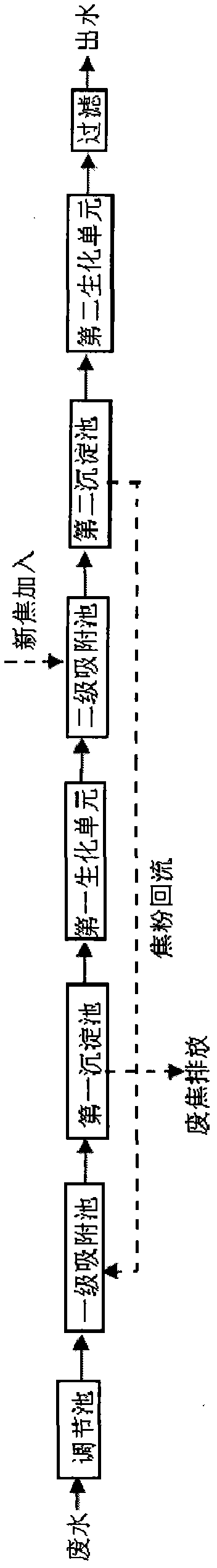

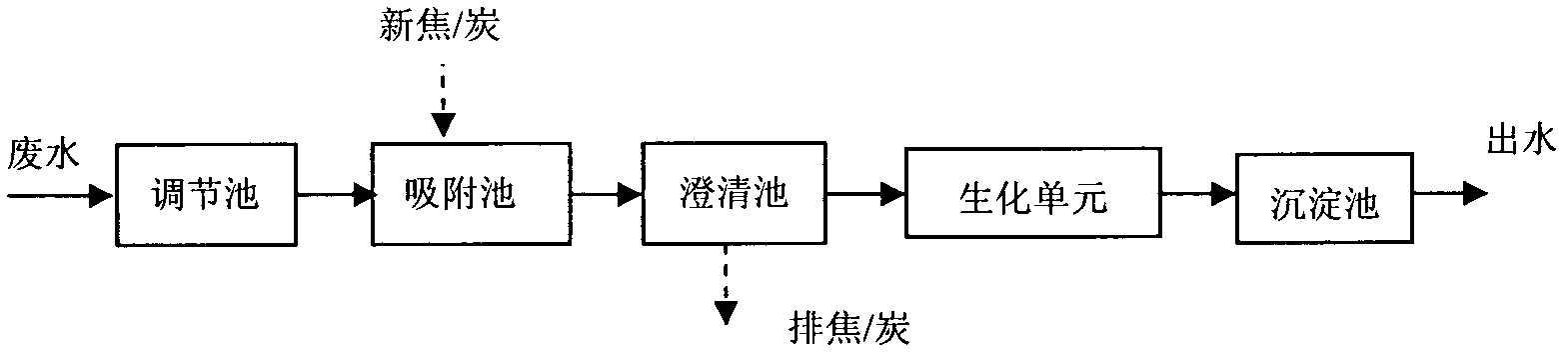

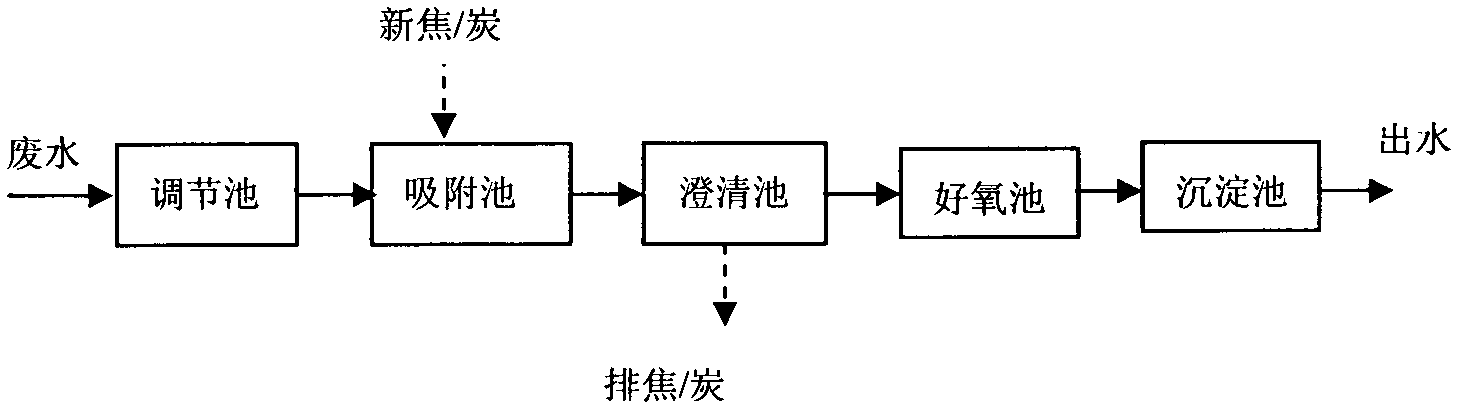

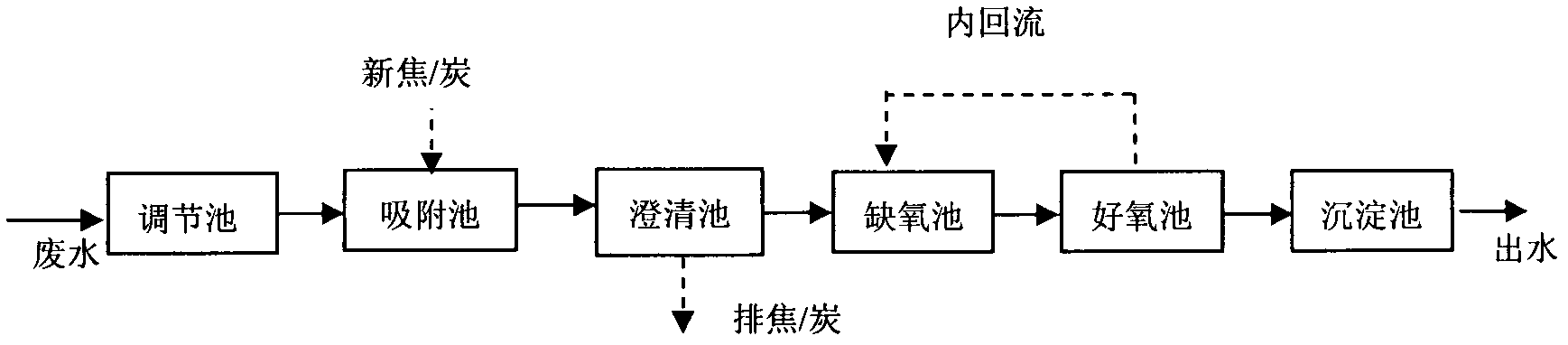

Process for treating coal chemical waste water

ActiveCN102001789AImprove biodegradabilityEasy to handleTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentActivated carbonActivated sludge

The invention relates to a process for treating coal chemical waste water, wherein a method combining active material adsorption and biochemical treatment is adopted. The method comprises the following steps of: firstly, introducing coal chemical waste water in a waste water regulating reservoir; secondly, introducing the waste water subjected to adsorption treatment by an adsorption tank into a clarification reservoir for sedimentation; then introducing the waste water subjected to the treatment of the clarification reservoir into a biochemical unit for biochemical treatment; and finally, introducing the waste water subjected to the biochemical treatment into a sedimentation reservoir for sedimentation treatment. In the technical scheme, macromolecular organic pollutants are removed through adsorption, therefore, the requirement of the subsequent biochemical treatment is met, and the problems of insufficient utilization of pores of activated carbon and incomplete exertion of the adsorbability of the activated carbon due to the influence of sludge when the activated carbon is added into an activated sludge aeration tank in the prior art are solved; and the process for treating coal chemical waste water has high efficiency and can sufficiently utilize the pores of the activated carbon and ensure the full exertion of the adsorbability of the activated carbon.

Owner:北京国能普华环保工程技术有限公司 +1

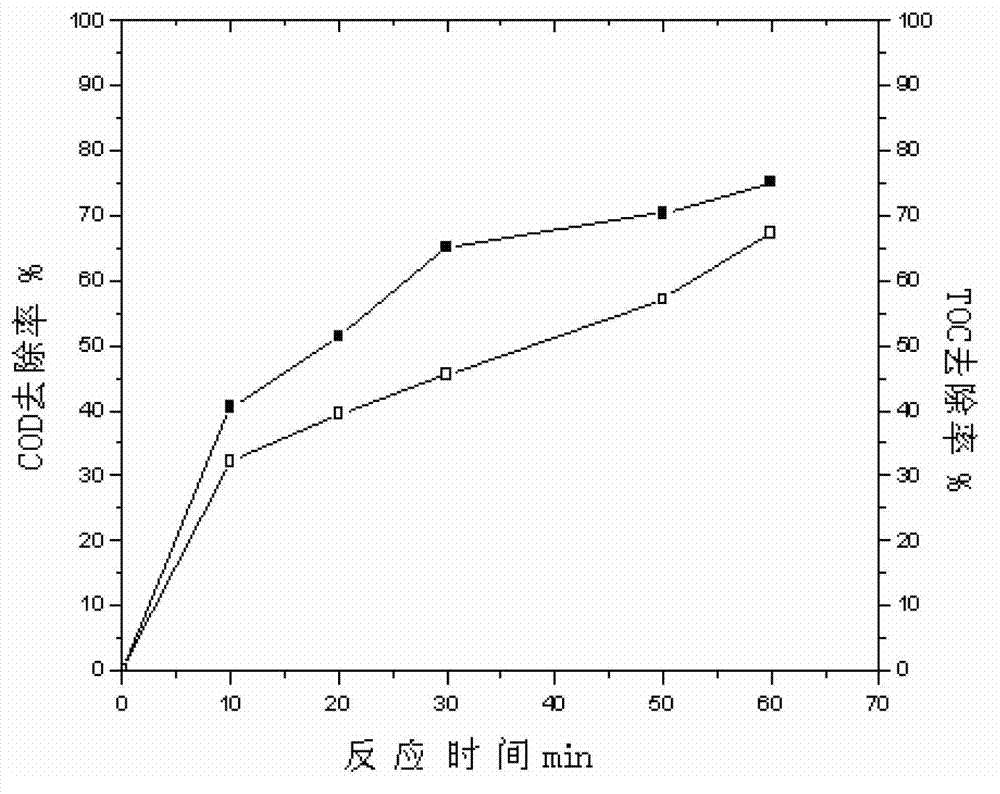

Preparation method of catalyst for catalyzing ozonation for advanced treatment of coal chemical wastewater

InactiveCN103111290AReduce pollution pressureLarge specific surface areaCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsSolubilityHazardous substance

The invention discloses a preparation method of a catalyst for catalyzing ozonation for advanced treatment of coal chemical wastewater and relates to a preparation method for the catalyst. The preparation method is used for solving the technical problems that the existing ozonation method is poor in ozone water solubility and low in degradation rate, successfully applied to the advanced treatment of the coal chemical wastewater, and capable of removing the degradation-resistant hazardous substances in water, improving the biodegradability of the wastewater and enabling the quality of the outlet water to reach the first-grade national emission standards. The preparation method comprises the following steps of: firstly, washing active carbon particles; secondly, soaking the active carbon in a metal nitrate solution, shaking for mixing and reacting, and taking out the active carbon 12 hours later; and thirdly, drying the active carbon and putting the dried active carbon to a muffle furnace, heating the muffle furnace to 200 DEG C by adopting nitrogen gas as the protective gas, roasting for one hour, continuing heating the muffle furnace to 600 DEG C and roasting for 3 hours at 600 DEG C to obtain the catalyst for treating the coal chemical wastewater. By using the catalyst prepared by the preparation method disclosed by the invention, the utilization rate of ozone is greatly improved, and the catalyst is very suitable for the field of coal chemical wastewater treatment.

Owner:HARBIN INST OF TECH

Method for preparing industrial salt through separation, evaporation and crystallization of coal chemical strong brine

ActiveCN104071808AWill not cause accumulationTake advantage ofAlkali metal chloridesAlkali metal halide purificationFiltrationUltrafiltration

The invention relates to a method for preparing industrial salt with coal chemical strong brine, particularly to a method for preparing the industrial salt through separation, evaporation and crystallization of the coal chemical strong brine, and aims to solve the problems that secondary pollution exists and resources are not recycled in existing coal chemical strong brine treatment processes. The method comprises the steps as follows: 1, adding lime milk, a coagulant and a magnesium agent into the coal chemical strong brine, and feeding the coal chemical strong brine into a clarifying tank or a coagulative precipitation tank for chemical precipitation treatment; 2, adjusting the pH; 3, performing ultra-filtration treatment; 4, performing nano-filtration treatment; 5, performing single-effect evaporating crystallization or quadruple-effect evaporating crystallization to obtain the industrial salt. The method is used for treating the coal chemical strong brine and preparing the industrial salt from the coal chemical strong brine.

Owner:中煤西安设计工程有限责任公司

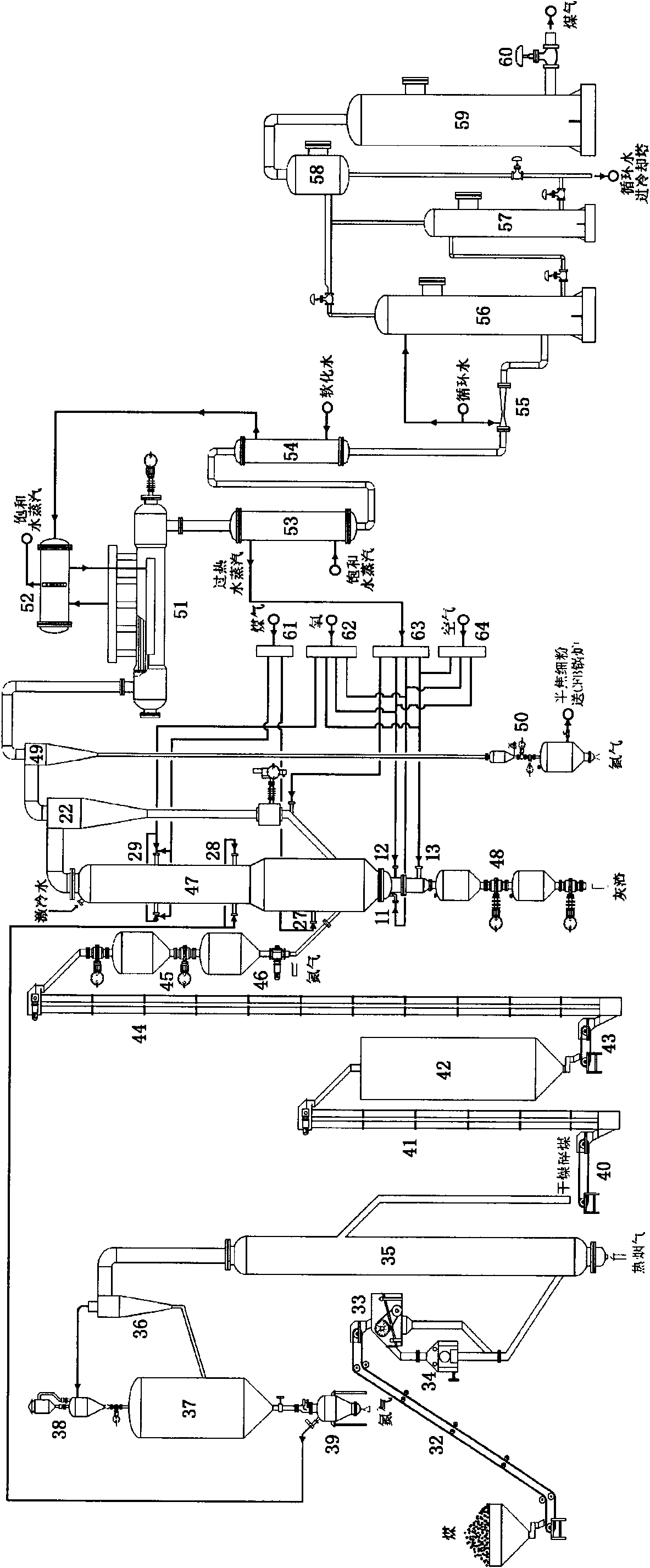

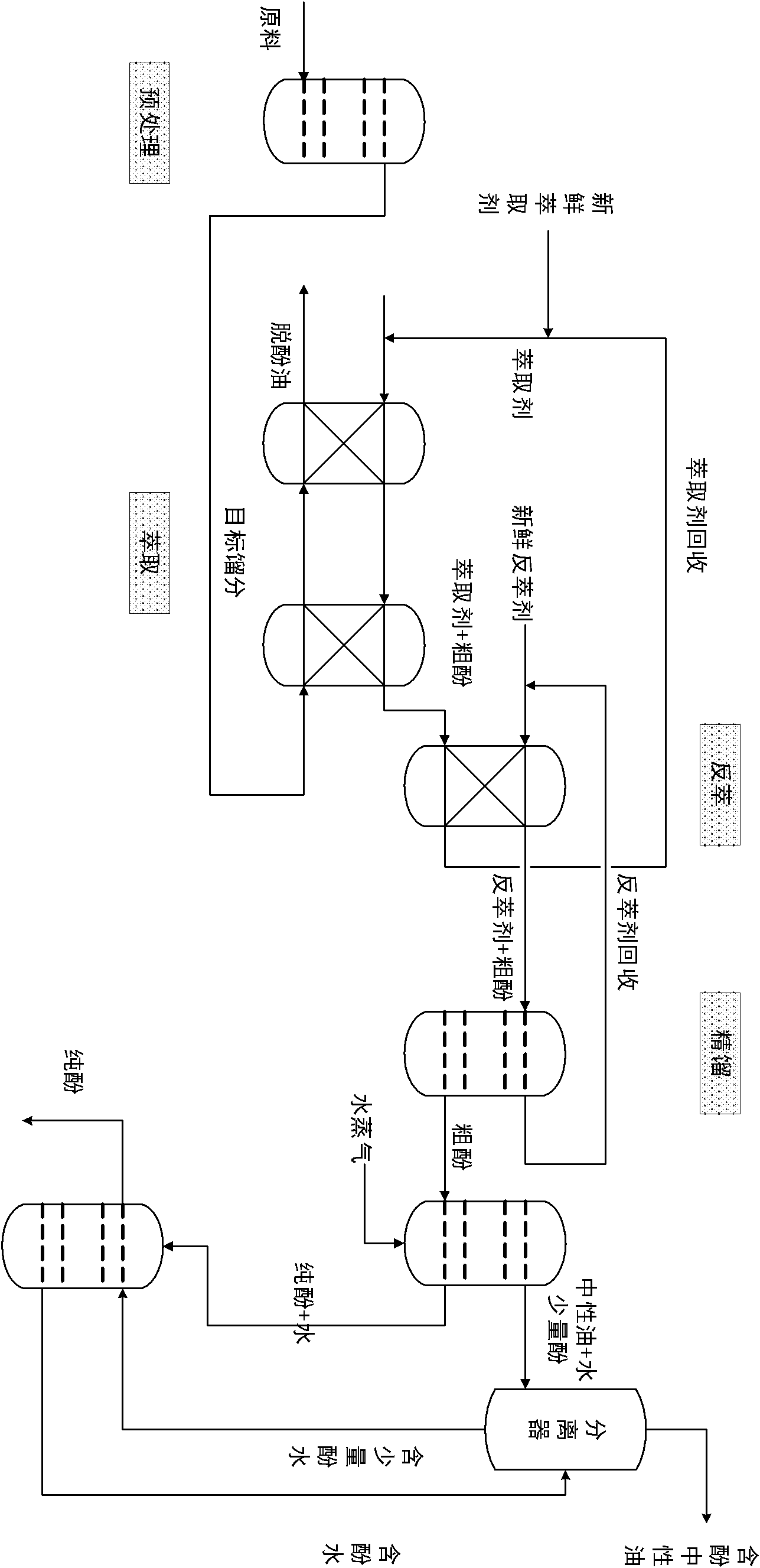

Method for coal hydrogenation pyrolysis and gasification coupling

ActiveCN102061182AFully extractedHigh yieldDirect heating destructive distillationGasification processes detailsWater vaporGas phase

The invention discloses a method for coal hydrogenation pyrolysis and gasification coupling, comprising the steps of: drying and preheating raw material coal with granularity less than or equal to 2mm in a coal drying and preheating system; putting 60-80% of the dried and preheated raw material coal in a coal hydrogenation pyrolysis furnace to carry out coal hydrogenation pyrolysis; putting a pyrolyzed gas-phase product in a pyrolyzed gas purification and separation system to carry out separation; putting all the semicoke generated by the coal hydrogenation pyrolysis furnace in a coke hydrogenation gasification furnace to carry out hydrogenation gasification; putting a gasified gas-phase product in a gasified gas purification and separation system; and causing 20-40% of the dried and preheated raw material coal and high-temperature coke granules from the coke hydrogenation gasification furnace to enter a hydrogen-rich generator from upper and lower paths under the combined action of oxygen and a water vapor mixed gasification agent so as to carry out gasification reaction. The coal hydrogenation pyrolysis, semicoke hydrogenation gasification and coke granule hydrogen production are combined; therefore, the tar yield and the light component content are effectively improved and methane-rich pyrolyzed gas, gasified gas and coal chemical products such as naphthalene, benzene, phenol and the like with high added value can be obtained.

Owner:北京锦泰诚瑞科技发展有限公司

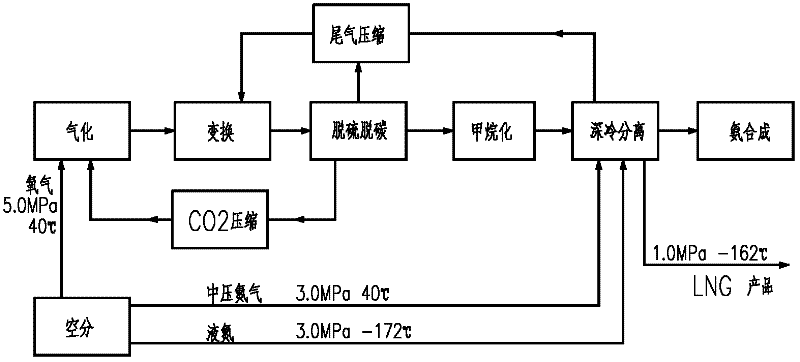

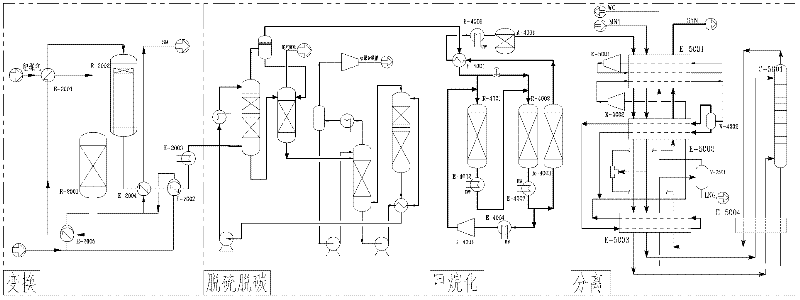

Process for coproducing liquefied natural gas (LNG) and synthetic ammonia

ActiveCN102533365ATake advantage ofOmit the step of separating nitrogenSolidificationLiquefactionMethanationNitrogen

The invention belongs to the technical field of coal chemical industry and particularly relates to a process for coproducing gasified synthetic ammonia and liquefied natural gas (LNG). The invention provides a method and equipment for coproducing the LNG and the synthetic ammonia by using raw coal gas generated by a high-temperature entrained bed; the desulphurization and the decarbonization are carried out by using a mature and advanced physical and chemical absorption process, methane is obtained by using an advanced methanation conversion technology, then, a deep cooling technology is adopted to produce liquid methane and hydrogen through staged cooling and washing separation, the produced liquid methane is outputted as a product, i.e. the LNG, meanwhile, the produced hydrogen is mixed with nitrogen to form a synthetic gas, and the synthetic gas is conveyed to an ammonia synthesizer for the production of the synthetic ammonia after the cold energy is recovered. The coproduction of natural gas and liquid ammonia is achieved, the equipment has corresponding capability for load adjustment, and the emission of vent gas in synthesis is not needed, so that the raw coal gas is maximally used in the production of products.

Owner:CHANGZHENG ENG

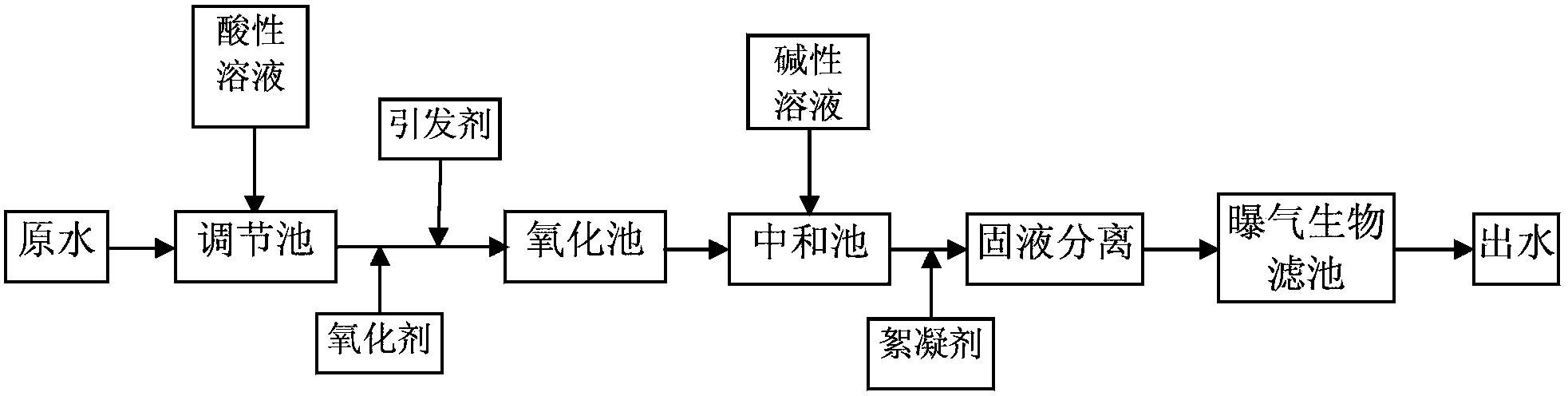

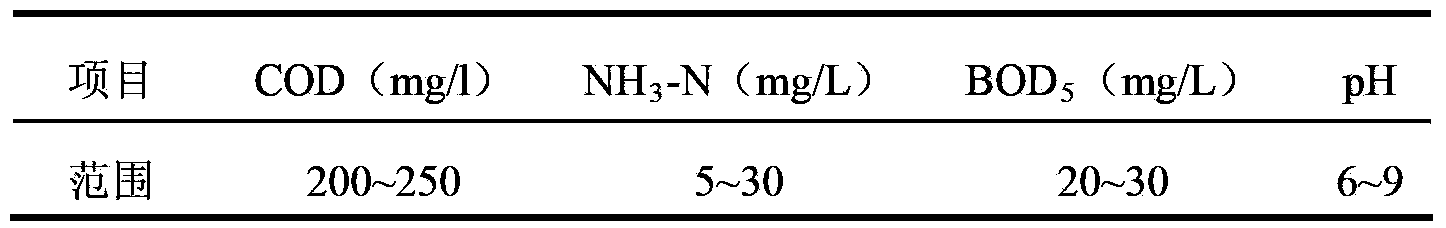

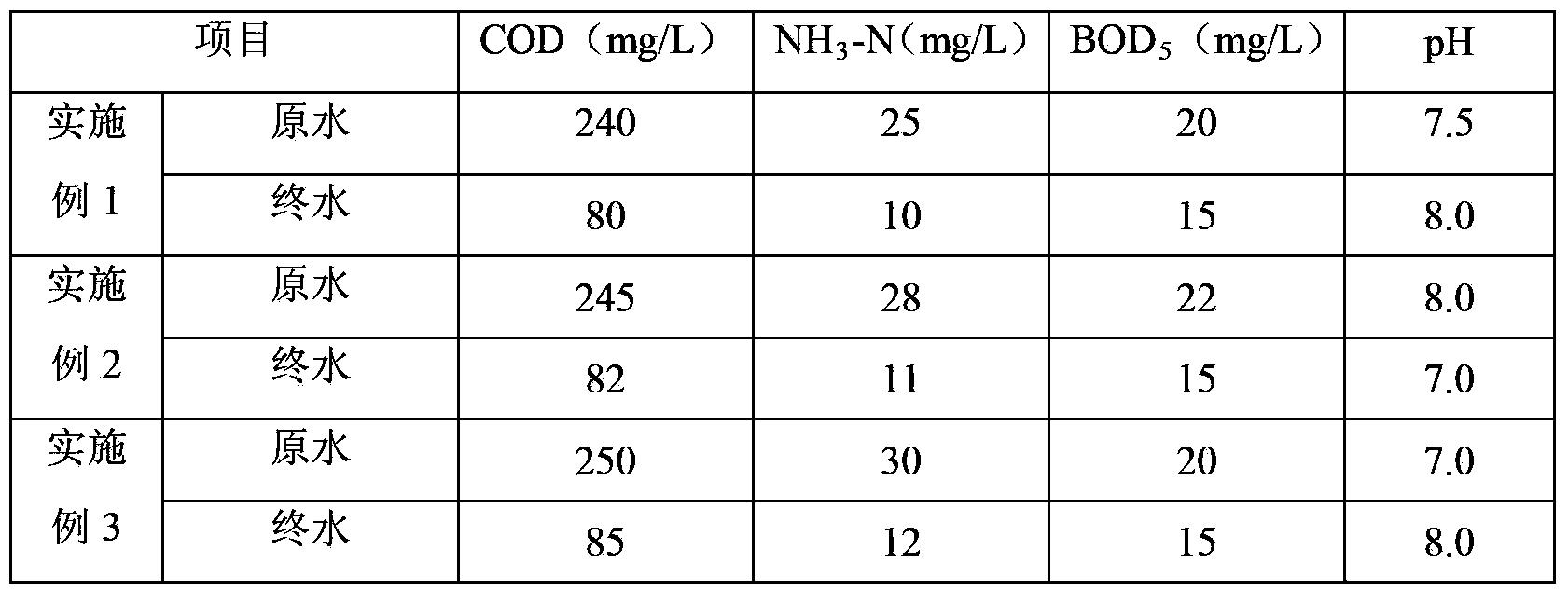

Processing method of wastewater in coal chemistry industry

ActiveCN104163539AReduce COD valueReduce CODMultistage water/sewage treatmentBiological oxidationCoal chemistry

The invention relates to a deep processing method of wastewater in the coal chemistry industry. The method comprises the following steps in sequence: subjecting the effluent, which has been processed by a secondary biochemical treatment for wastewater in coal chemistry industry, to a chemical oxidation treatment and a biological oxidation treatment in sequence. The processing method adopts a technology integrating the chemical oxidation and biochemical oxidation, thus overcomes the shortage of high operation cost of the chemical oxidation technology and the shortage of low COD elimination rate of the biochemical oxidation technology, and achieves the degradation of partial organic pollutants in wastewater. The processed wastewater reaches the discharge or recycle standard, and the pollution to the environment is reduced. The processing method has the advantages of high processing efficiency, low operation cost, and strong adaptability for wastewater in coal chemistry industry, the processed wastewater reaches the national environmental requirements, and thus the processing method can achieve good economic and social profits.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

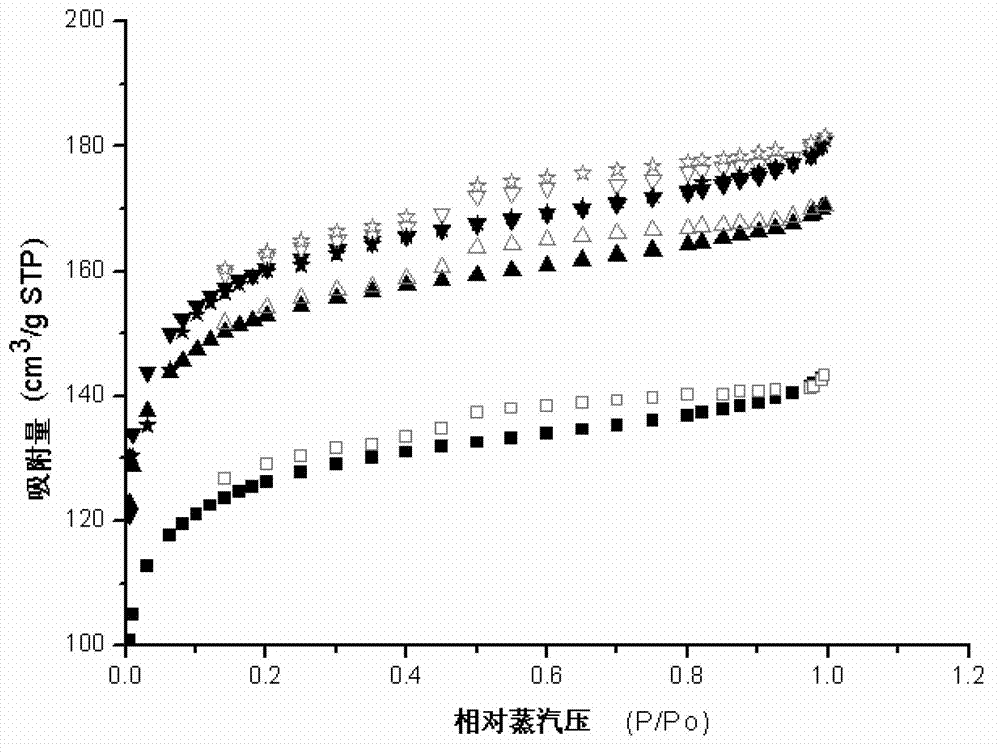

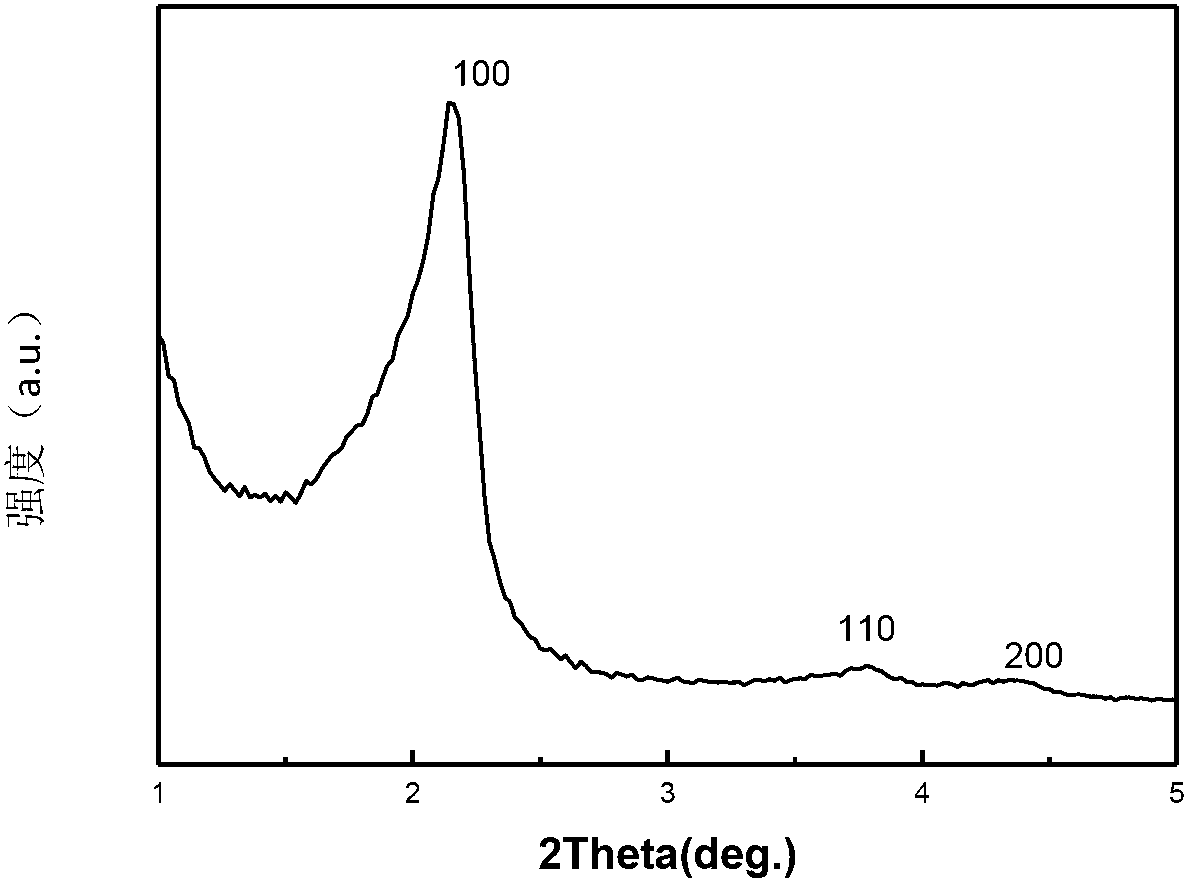

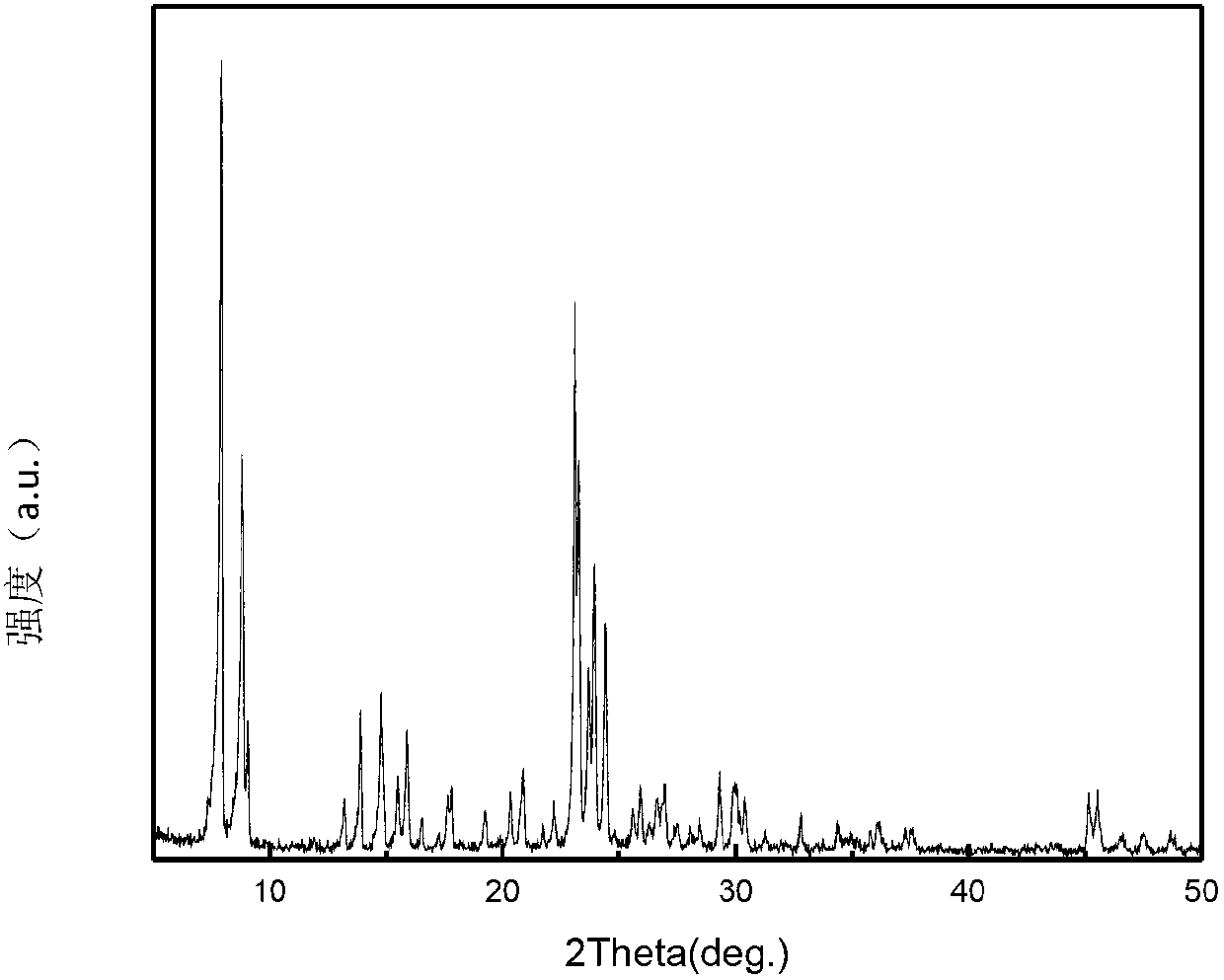

Ordered mesopore ZSM-5 molecular sieve and preparation method thereof

InactiveCN103101930AImprove performanceRemarkable resultsPentasil aluminosilicate zeolitePore diameterPetrochemical

The invention discloses a preparation method of an ordered mesopore ZSM-5 molecular sieve. The preparation method comprises the following steps of: firstly preparing an ordered mesopore silicon oxide molecular sieve serving as a silicon source through an organic template method; and then transforming the ordered mesopore silicon oxide molecular sieve into the ordered mesopore ZSM-5 molecular sieve in situ by adopting a hydrothermal method. The ordered mesopore ZSM-5 molecular sieve disclosed by the invention is provided with ordered micropores with pore diameter being 0.2-2 nanometers and ordered mesopores with pore diameter being 2-50 nanometers and has wide application prospect in the fields of petrochemical industry, petroleum processing, coal chemical industry, and the like.

Owner:SHANGHAI NORMAL UNIVERSITY

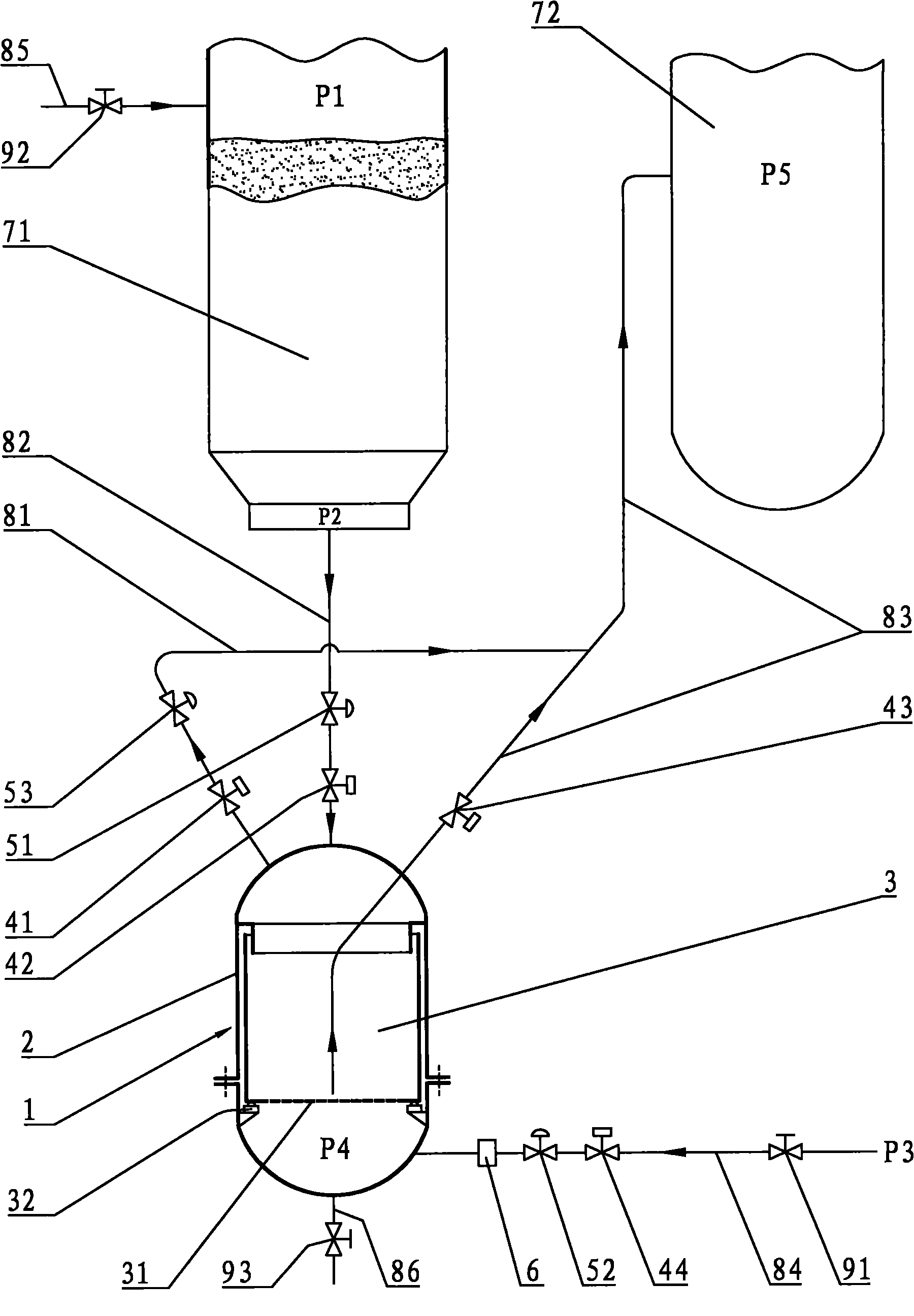

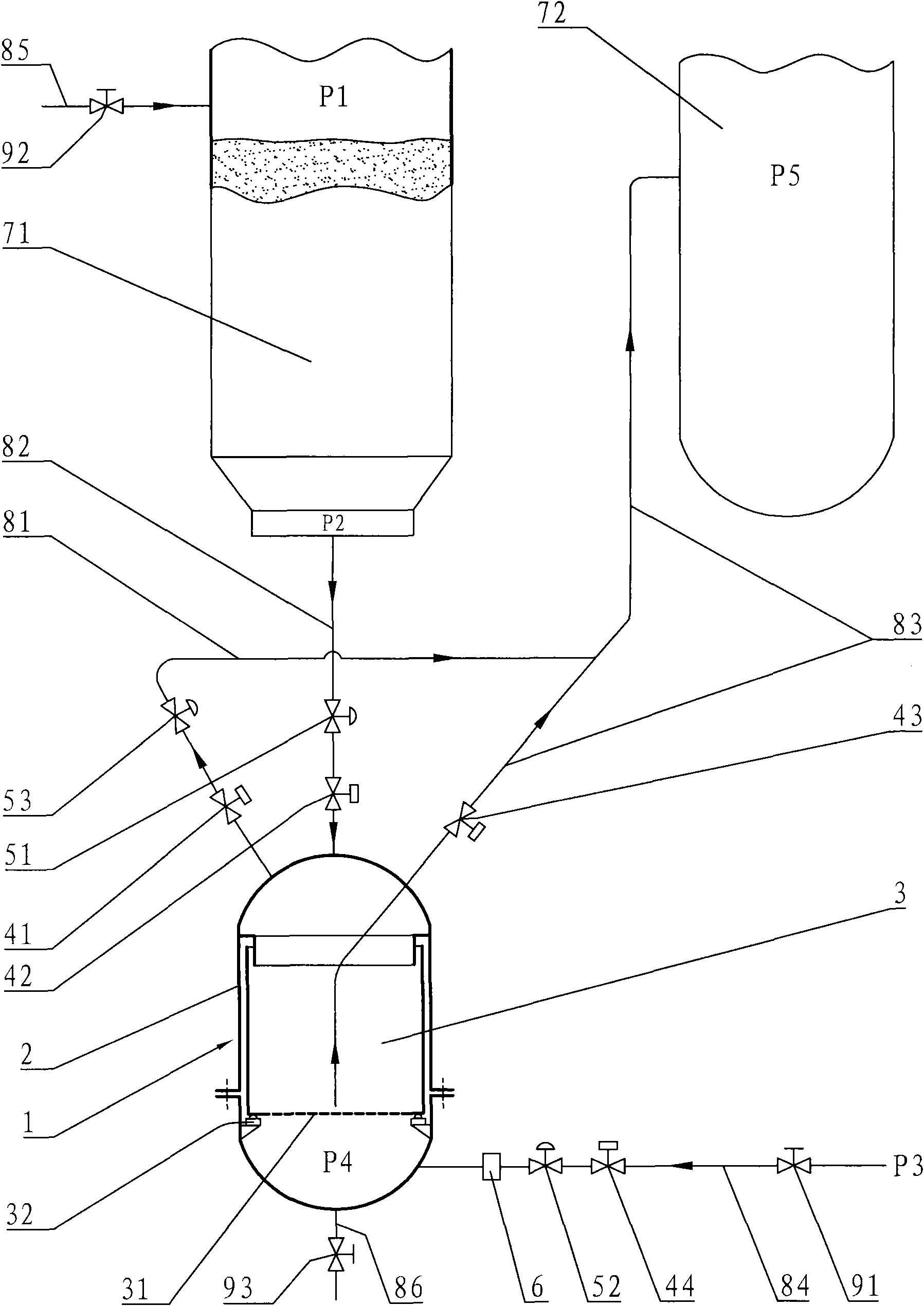

Automatic catalyst-feeding method

The invention discloses an automatic catalyst-feeding method in order to solve the problem that the feeding amount of the prior small feeder with a weighing function is small in the process of batch-by-batch feeding. In the process of operation, flow-conveying air is constantly charged into a feeder (1), and the pressure P4 of the feeder (1) is constantly lower than or equal to the pressurizing pressure P1 of a catalyst storage tank (71) and higher than the pressure P5 of a regenerator (72). The method mainly includes the following steps: (A) feeding speed regulation, (B) regulative discharge, (C) feeding, and (D) feeding standardization. The method is mainly used in the fluid catalytic cracking technique of the petrochemical industry and the methanol-to-olefins reaction technique of the coal chemical industry, and uses the small feeder (1) with a weighing function to continuously feed a great deal of catalyst in the catalyst storage tank (71) into the regenerator (72).

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com