Patents

Literature

5867results about How to "Improve recycling efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrocarbon gas processing

ActiveUS20060283207A1Reduce the valueReduce investmentSolidificationLiquefactionFractionationFractionating column

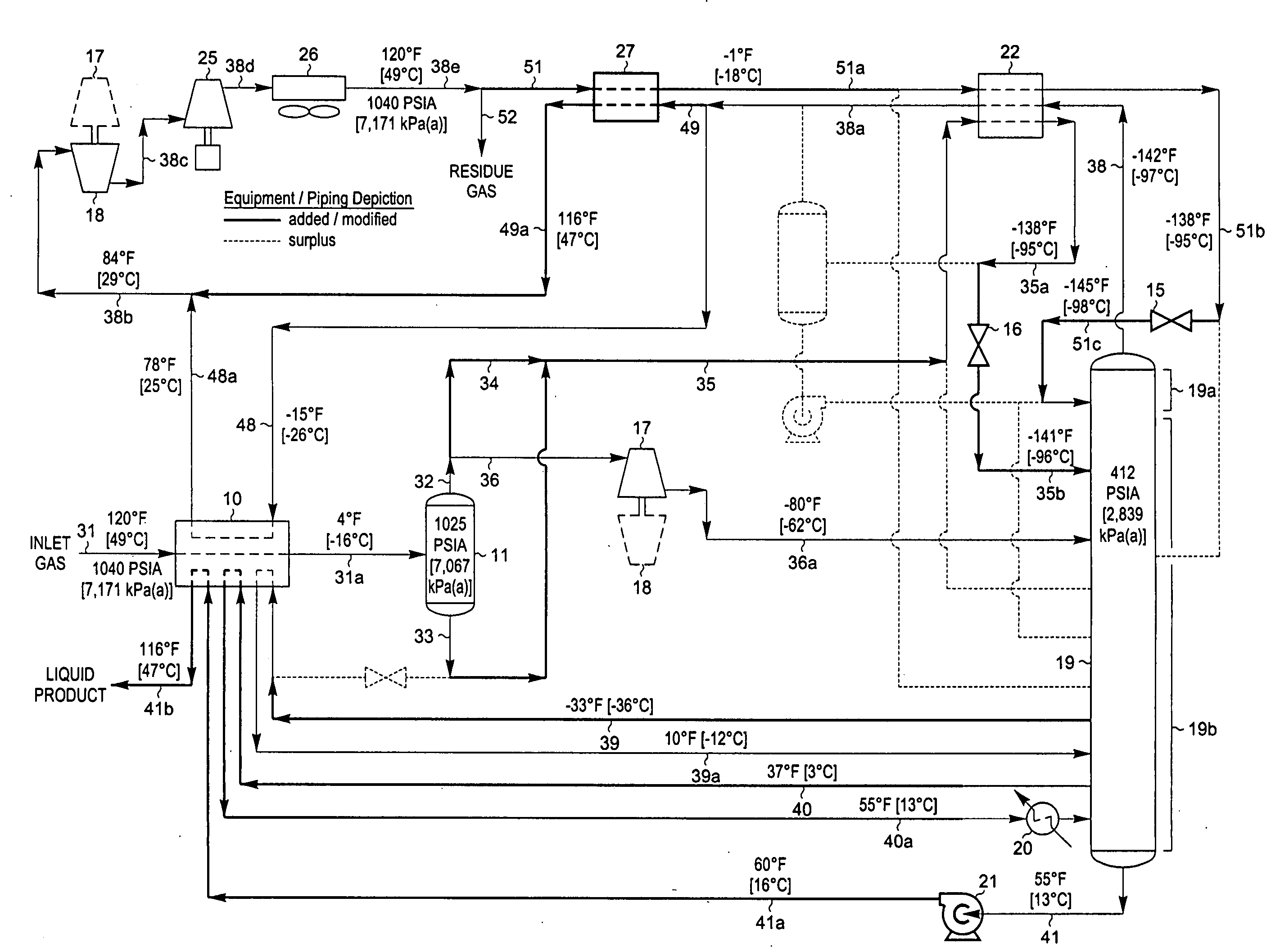

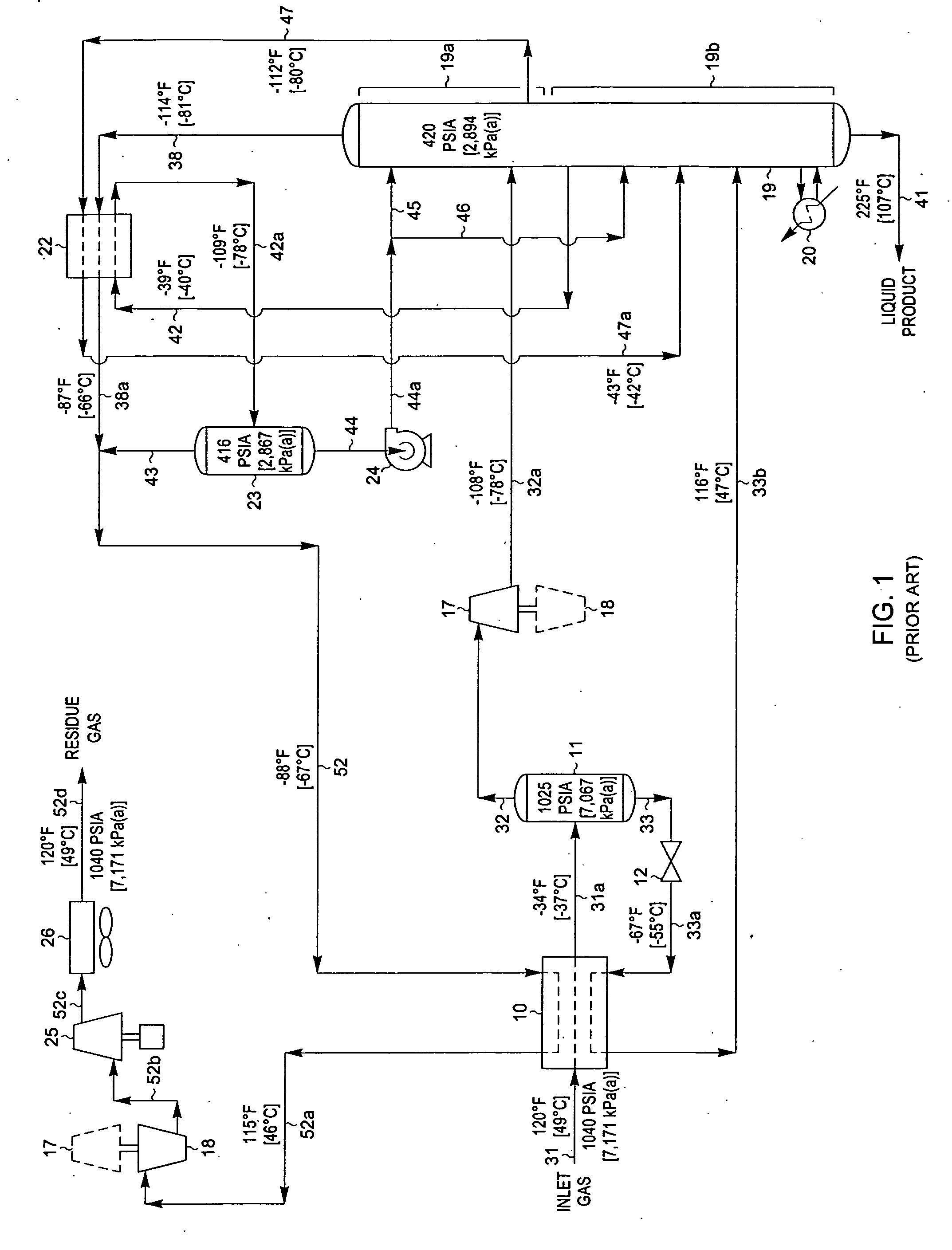

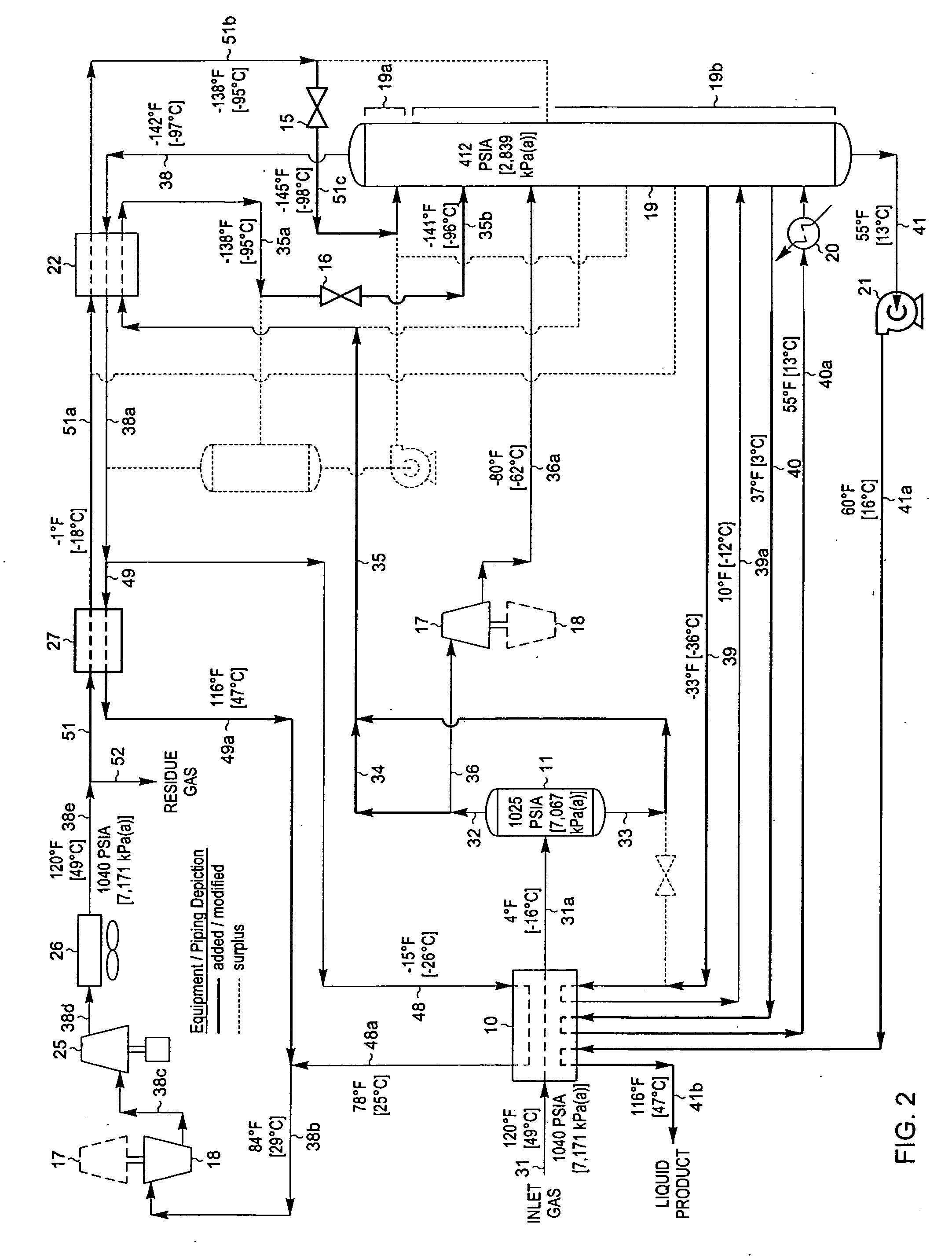

A process for the recovery of ethane, ethylene, propane, propylene, and heavier hydrocarbon components from a hydrocarbon gas stream is disclosed. The stream is cooled and is thereafter expanded to the fractionation tower pressure and supplied to the fractionation tower at a lower mid-column feed position. A distillation stream is withdrawn from the column below the feed point of the stream and is then directed into heat exchange relation with the tower overhead vapor stream to cool the distillation stream and condense at least a part of it, forming a condensed stream. At least a portion of the condensed stream is directed to the fractionation tower at an upper mid-column feed position. A recycle stream is withdrawn from the tower overhead after it has been warmed and compressed. The compressed recycle stream is cooled sufficiently to substantially condense it, and is then expanded to the pressure of the fractionation tower and supplied to the tower at a top column feed position. The quantities and temperatures of the feeds to the fractionation tower are effective to maintain the overhead temperature of the fractionation tower at a temperature whereby the major portion of the desired components is recovered.

Owner:UOP LLC

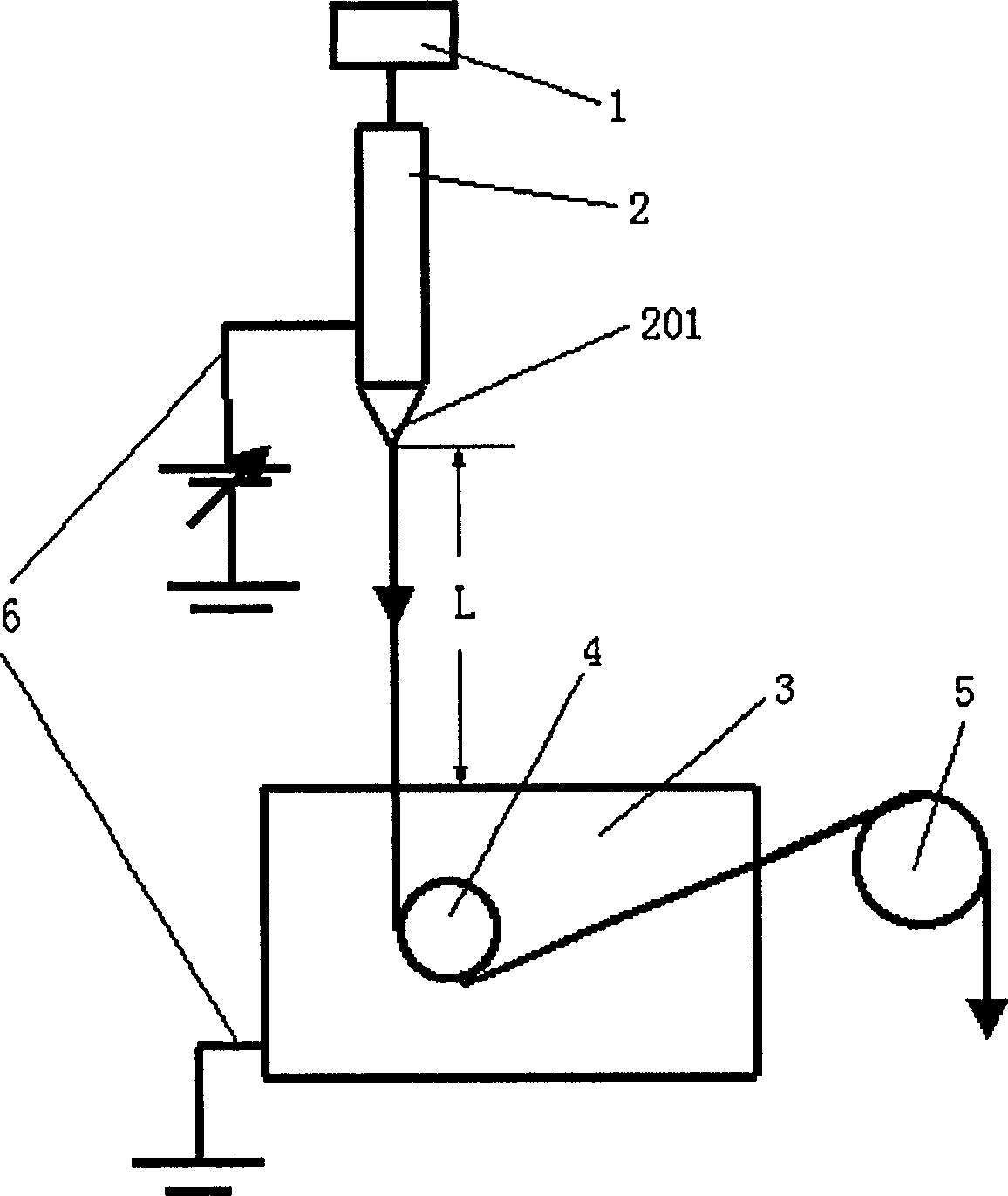

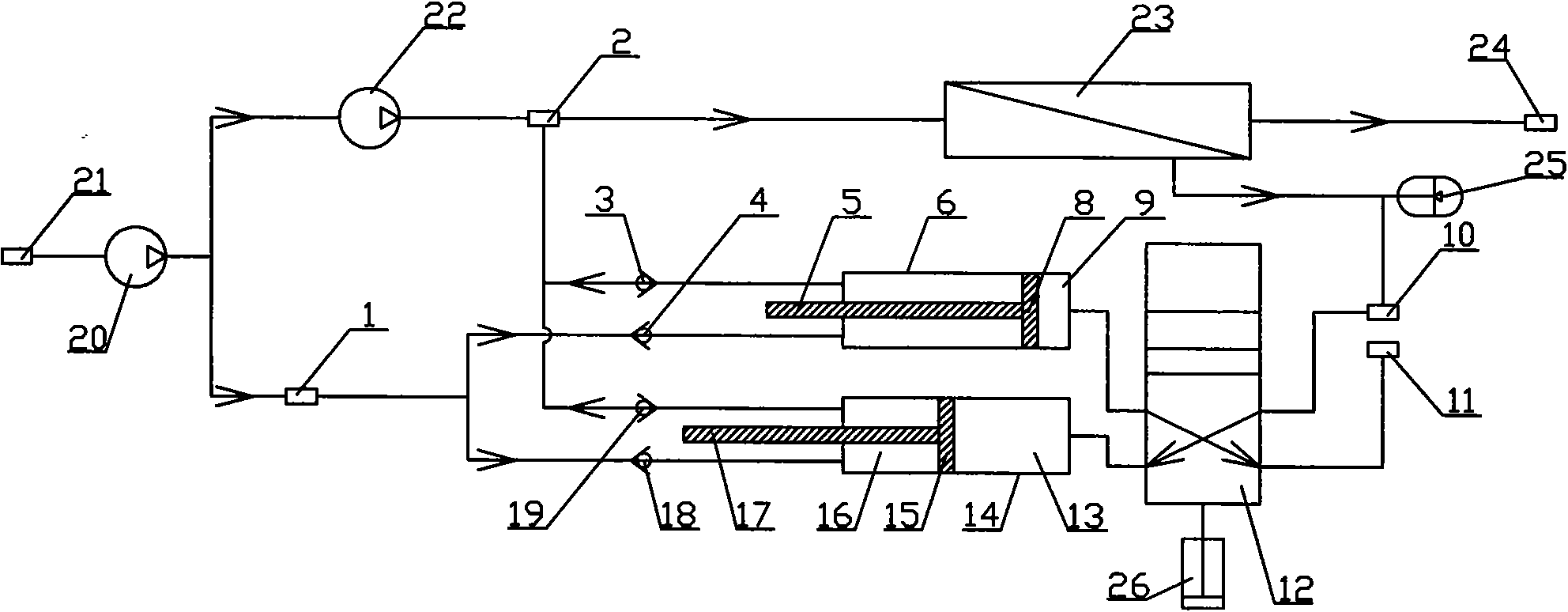

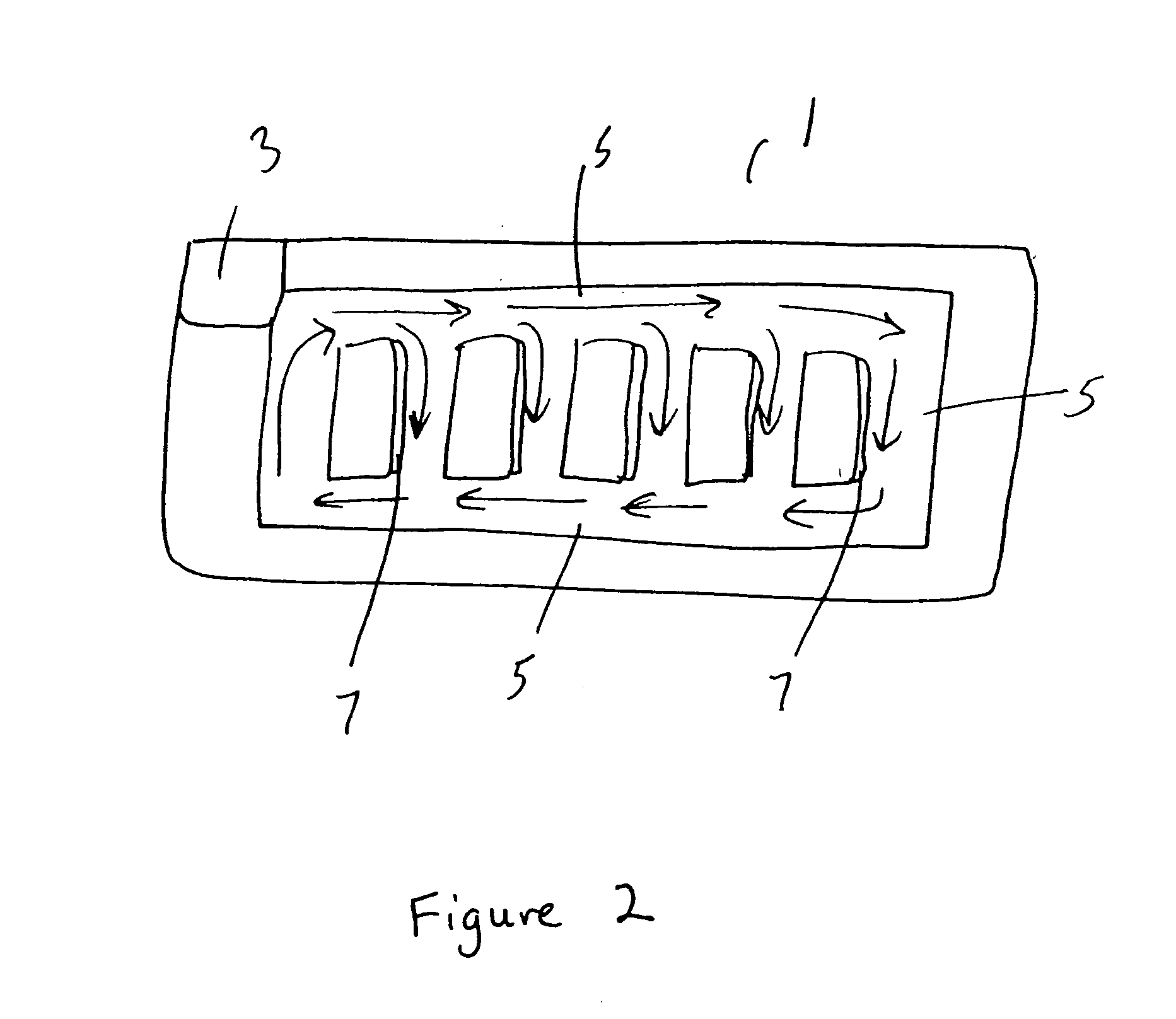

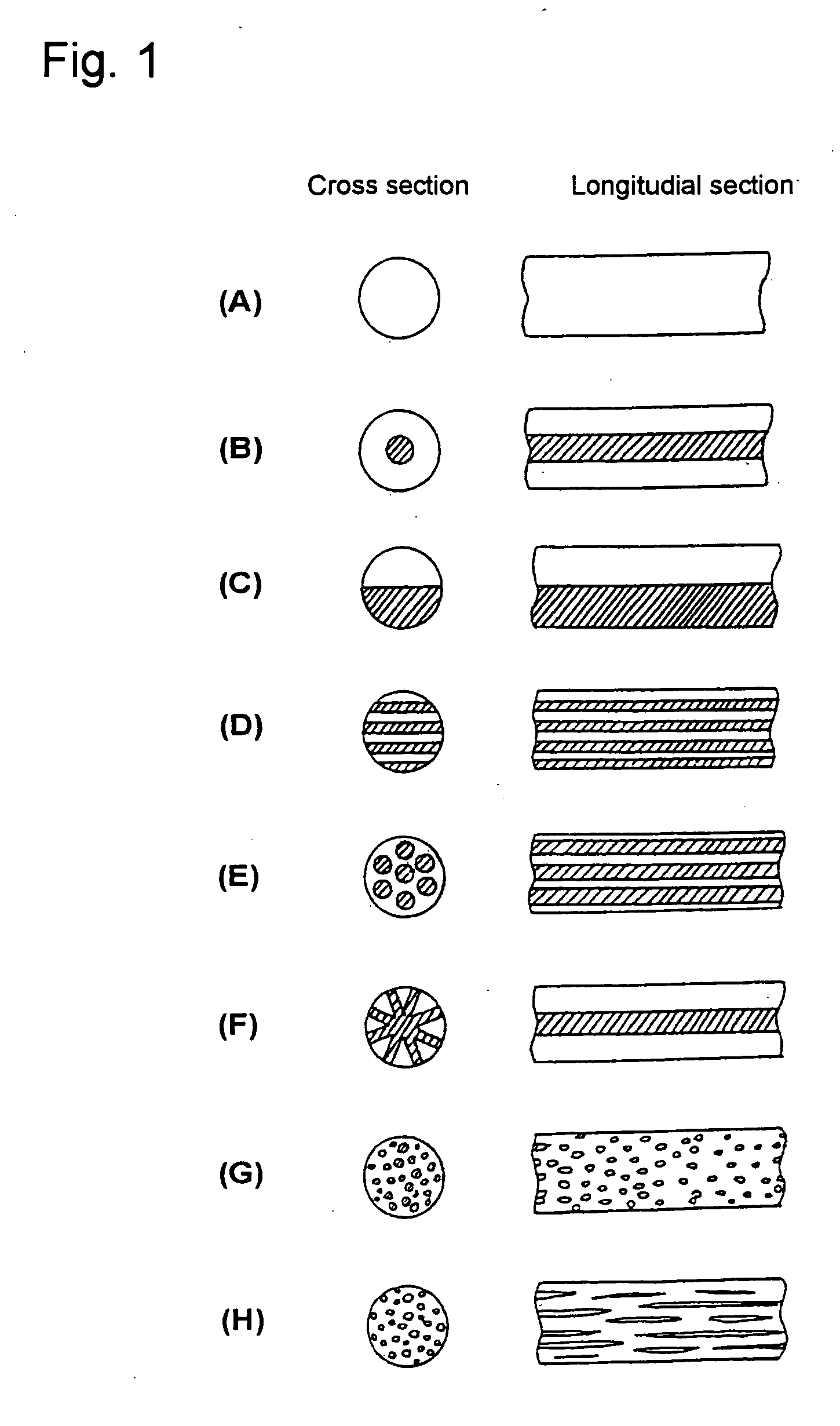

Static spinning device and its industrial use

InactiveCN1715463AHigh speedImprove mechanical propertiesFilament/thread formingElectrospinningMagnification

The present invention provides electrostatic spinning apparatus and its industrial application. The apparatus includes polymer solution conveying machine, spinning nozzle device connected to the outlet of the polymer solution conveying machine, spinning bath below the spinning nozzle device, fiber turning guide roller set inside the spinning bath and electrodes set on the spinning nozzle device and the spinning bath. The apparatus of the present invention is used in spinning polymer, and has greatly raised wet spinning speed, great fiber drafting magnification, well oriented fiber molecule chain, compact fiber structure, greatly raised mechanical performance of fiber, wide solvent selecting range, simplified electrostatic spinning equipment, raised solvent recovering rate and less environmental pollution caused by the solvent.

Owner:DONGHUA UNIV

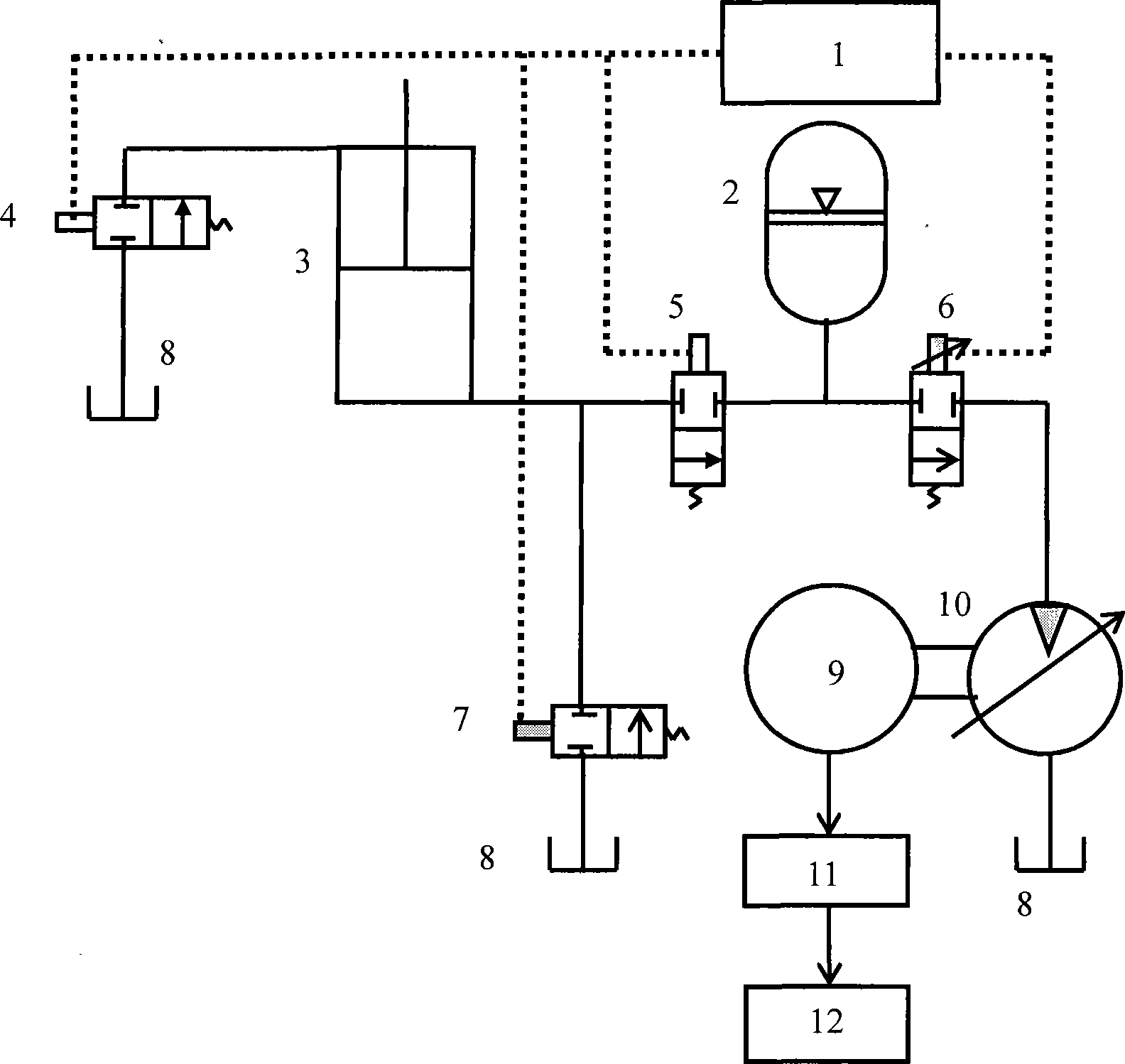

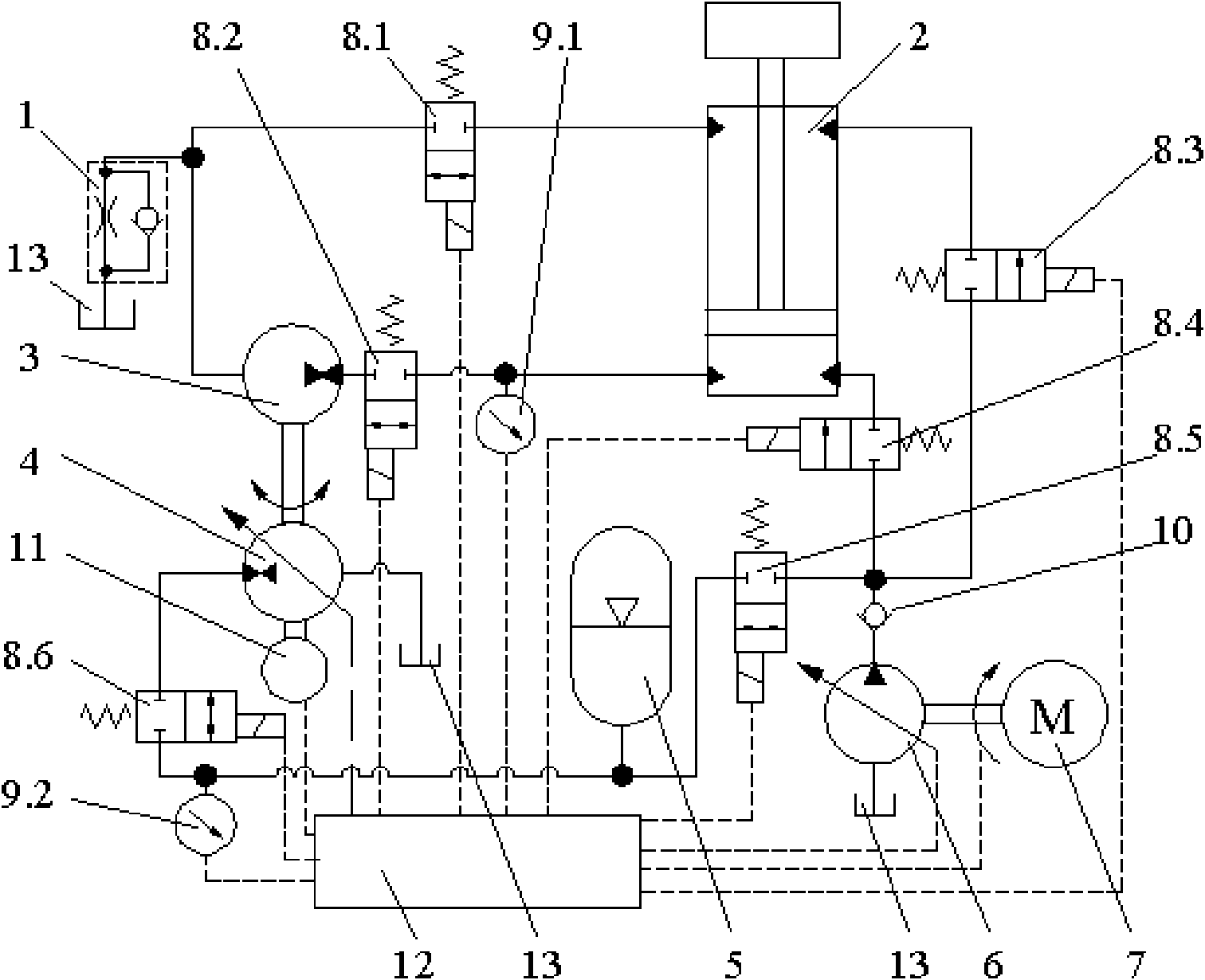

Movable arm potential energy recovery method and apparatus of hydraulic excavator

InactiveCN101435451ASmall pressure fluctuationsWorking speed adjustmentBatteries circuit arrangementsMechanical machines/dredgersRecovery methodThrottle control

The invention discloses a method for recovering potential energy of a movable arm of a hydraulic digging machine and a device thereof. The method comprises the following steps: firstly, the potential energy is stored through an energy accumulator in the retraction process of a hydraulic cylinder; and secondly the stored energy in the energy accumulator drives a generator to generate electricity, thereby realizing the recovery of the potential energy of the movable arm of the hydraulic digging machine. A mode for storing the potential energy is to convert the potential energy into pressure energy. The energy accumulator and the generator are connected through a proportioning valve so as to control the rotational speed of the generator. The method realizes high-efficiency recovery of the potential energy of the movable arm of the hydraulic digging machine; the principle of the method is to skillfully change the working time of hydraulic oil for power generation through the function of energy storage of the energy accumulator and provide effective buffering for recovering the potential energy; in addition, through the throttling control of the proportioning valve, the method reduces pressure fluctuation of the hydraulic oil in the power generation process, realizes the adjustment of the working rotational speed of the generator, improves the working efficiency of the generator and further improves the efficiency of energy recovery.

Owner:CENT SOUTH UNIV

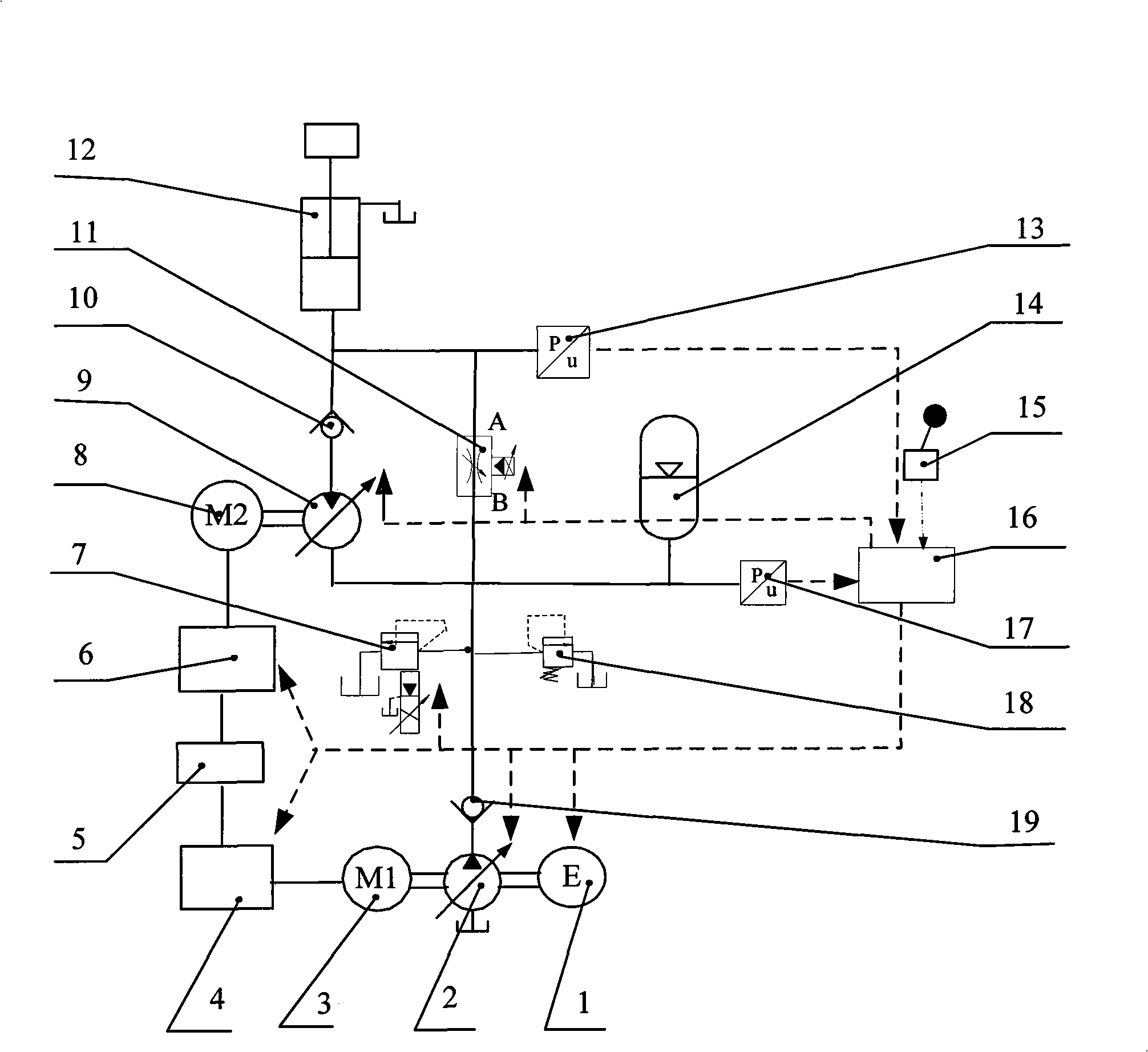

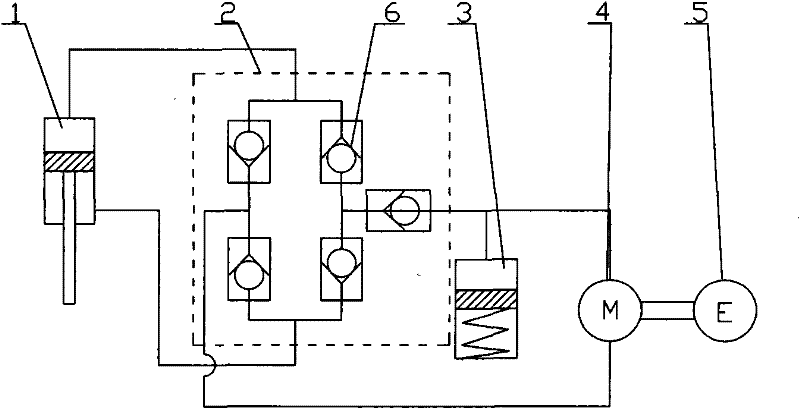

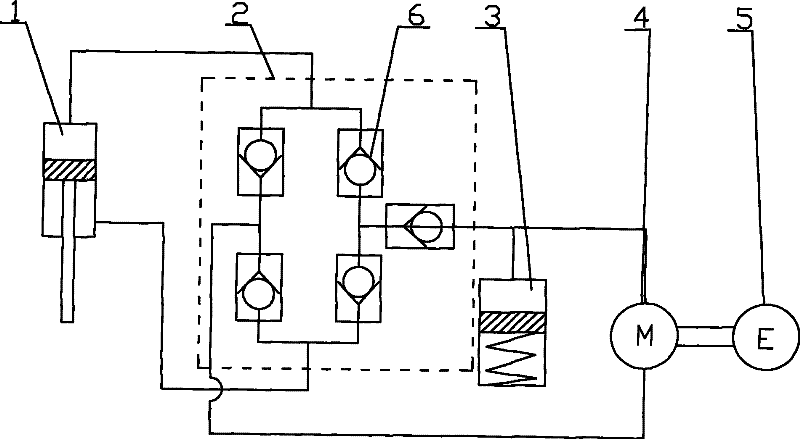

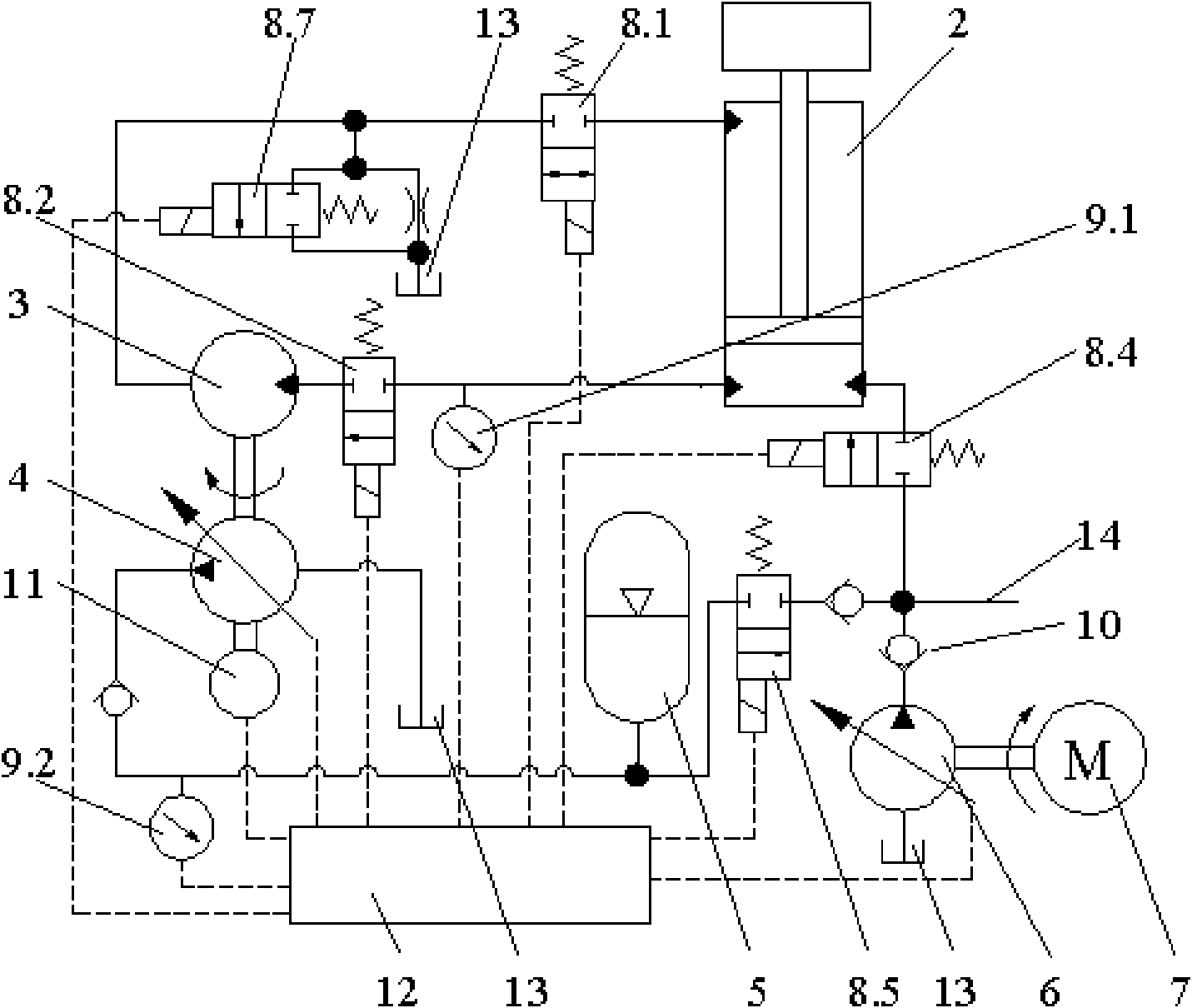

Energy recovery system of hybrid power engineering machinery energy accumulator-hydraulic motor

InactiveCN101408213AHigh specific powerFast absorptionAccumulator installationsGas pressure propulsion mountingHydraulic motorEnergy recovery

The invention discloses a hybrid power engineering mechanical accumulator-hydraulic motor energy recovery system. The system mainly comprises an engine, a variable pump, variable frequency motors, a variable motor, a signal control unit, an accumulator and a hydraulic implementation element, and the like. In the system, the variable motor is coaxially connected with a variable frequency motor M2 and forms a composite energy recovery system with the accumulator so as to recover the gravitational potential energy and braking energy in the lowering process of an implementation mechanism. The variable pump, the engine and a variable frequency motor M1 are coaxially connected; a hybrid power system which consists of the engine and the variable frequency motor M1 drives the hydraulic implementation mechanism to rise and lift heavy objects together with the accumulator. The system overcomes the defects that the variable motor-power generator energy recovery system responds slowly and the specific energy of the accumulator is low, enhances the dynamic response performance of the energy recovery system, improves the working conditions of power generation of an electric generator, and simultaneously can directly recover part of potential energy by the accumulator, thus raising the energy recovery efficiency of the system.

Owner:ZHEJIANG UNIV

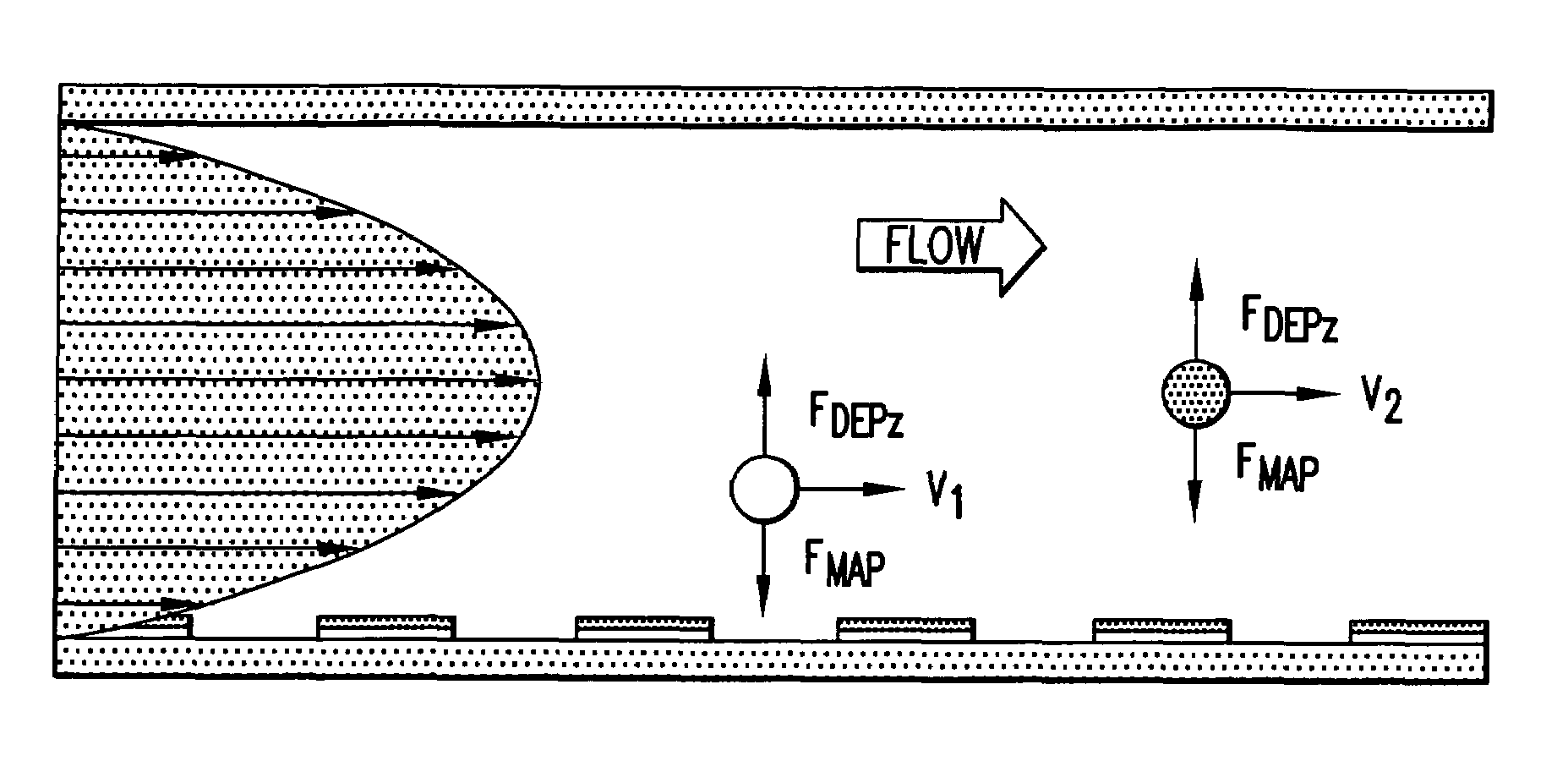

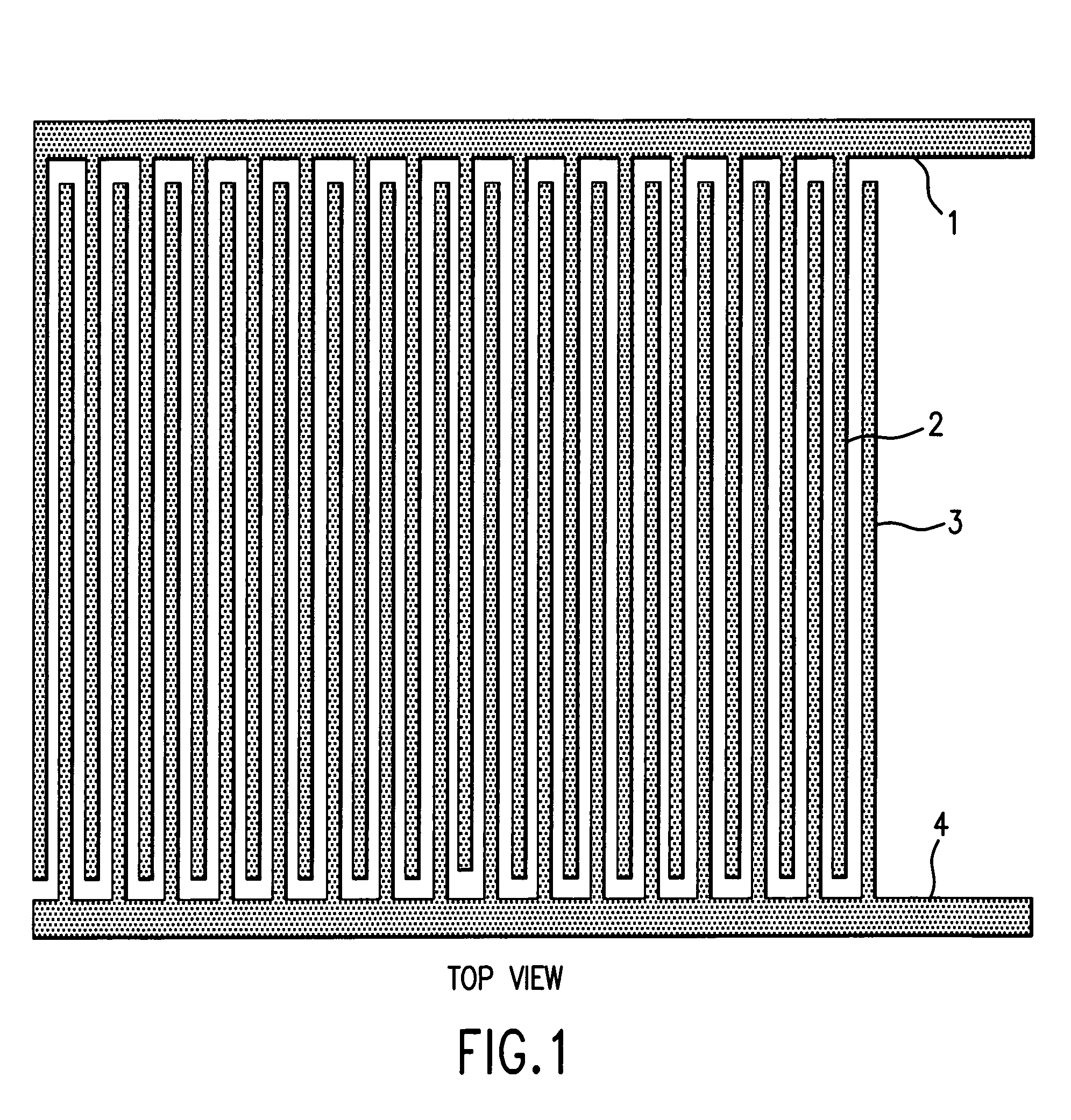

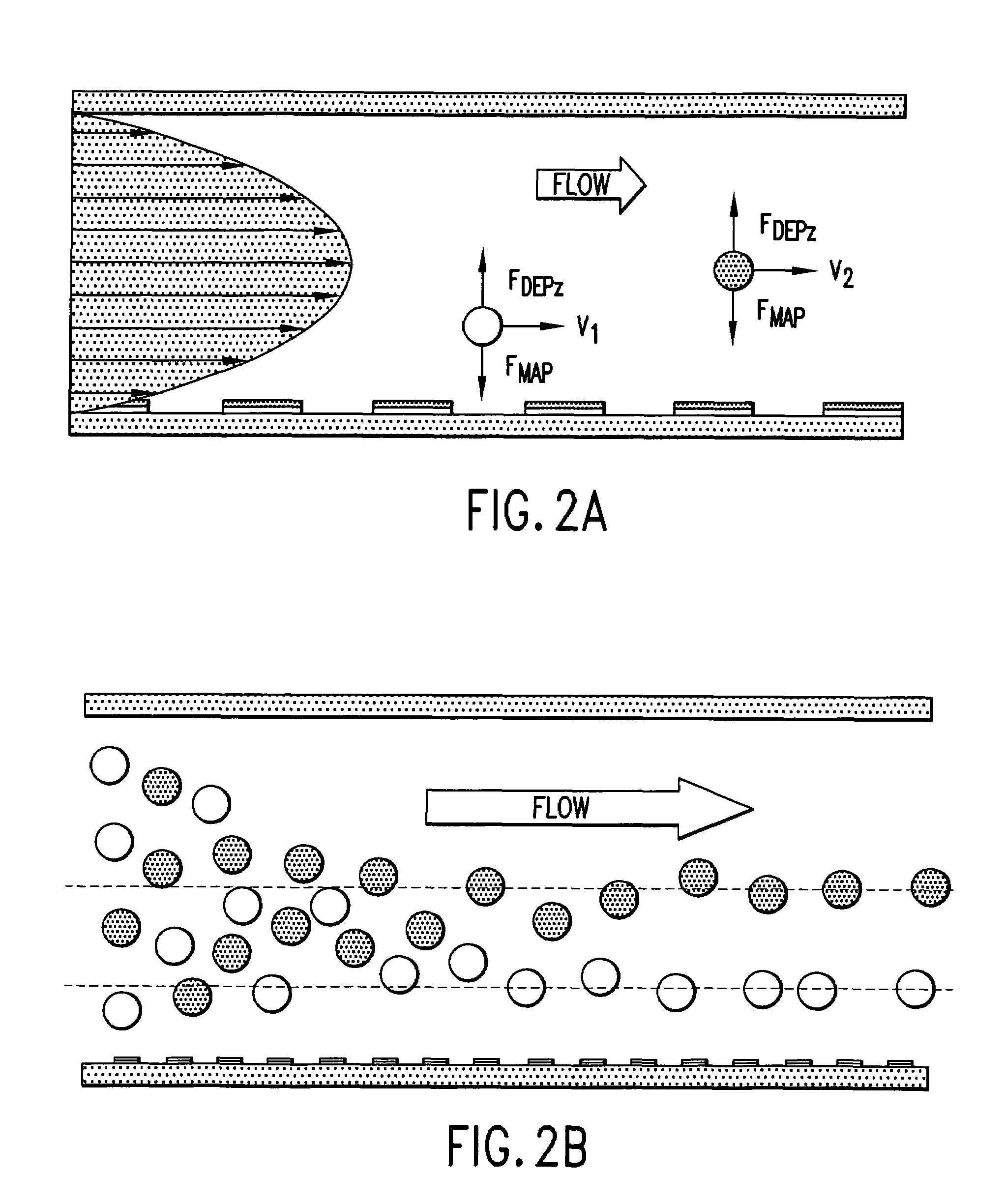

Method and apparatus for combined magnetophoretic and dielectrophoretic manipulation of analyte mixtures

InactiveUS7033473B2Improves analyte recovery efficiencyReduces and eliminates “ relaxation time ”Sludge treatmentElectrostatic separatorsElectricityAnalyte

Methods and apparatuses for discriminating matter utilizing dielectrophoresis combined with magnetophoresis. A sample having one or more constituents is injected into an inlet port of a chamber. A carrier medium flow is initiated at the inlet port to establish a flow within the chamber. A dielectrophoretic force is generated to act on the constituents of the sample. A magnetophoretic force is generated to act on the constituents of the sample. The dielectrophoretic force and magnetophoretic forces are balanced to position the constituents within the chamber. The constituents are then collected at one or more outlet ports of the chamber according to the dielectric and magnetic characteristics of the constituents. The constituents may be collected as a function of time-of-exit from the chamber and / or position within the chamber.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

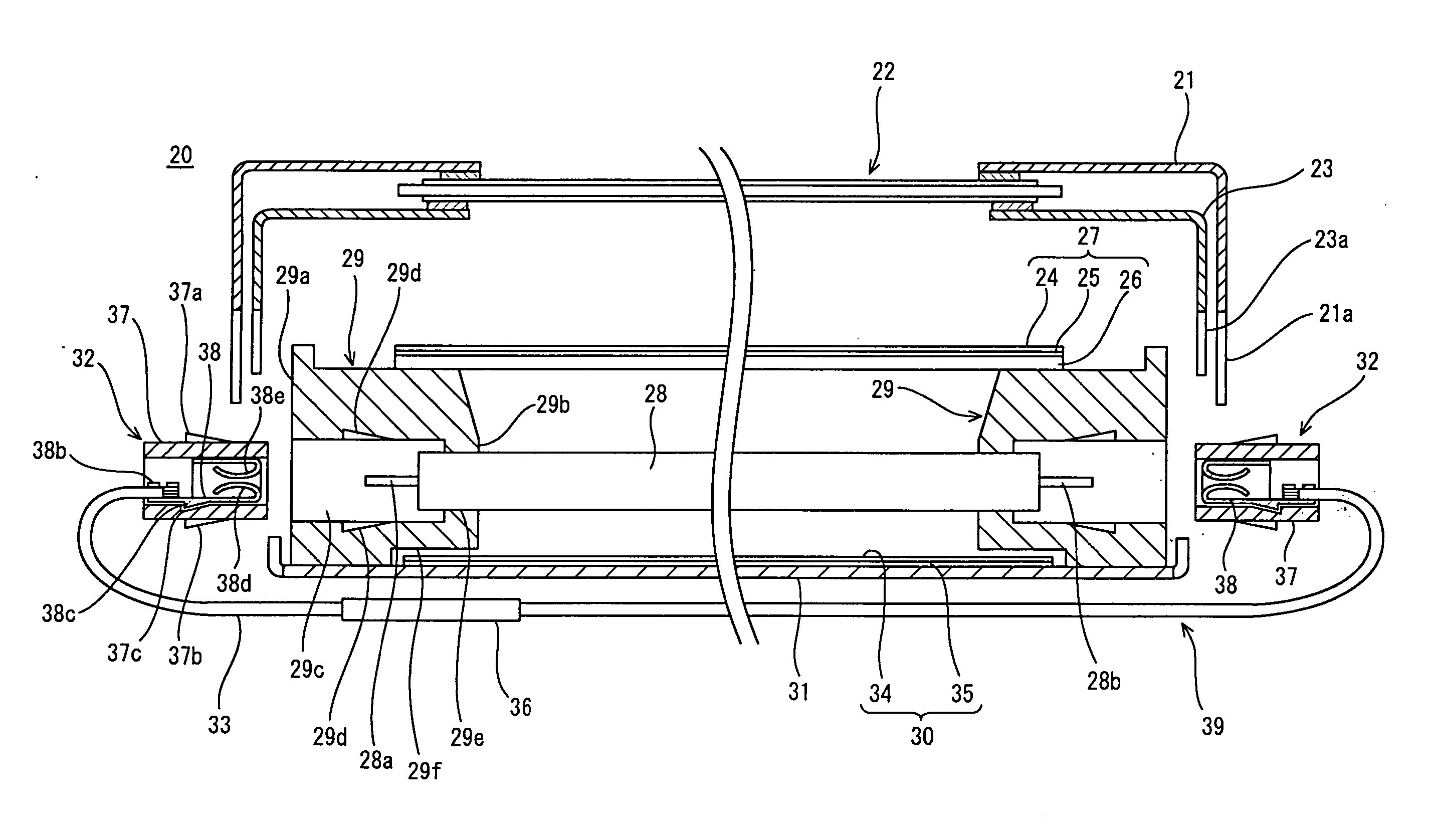

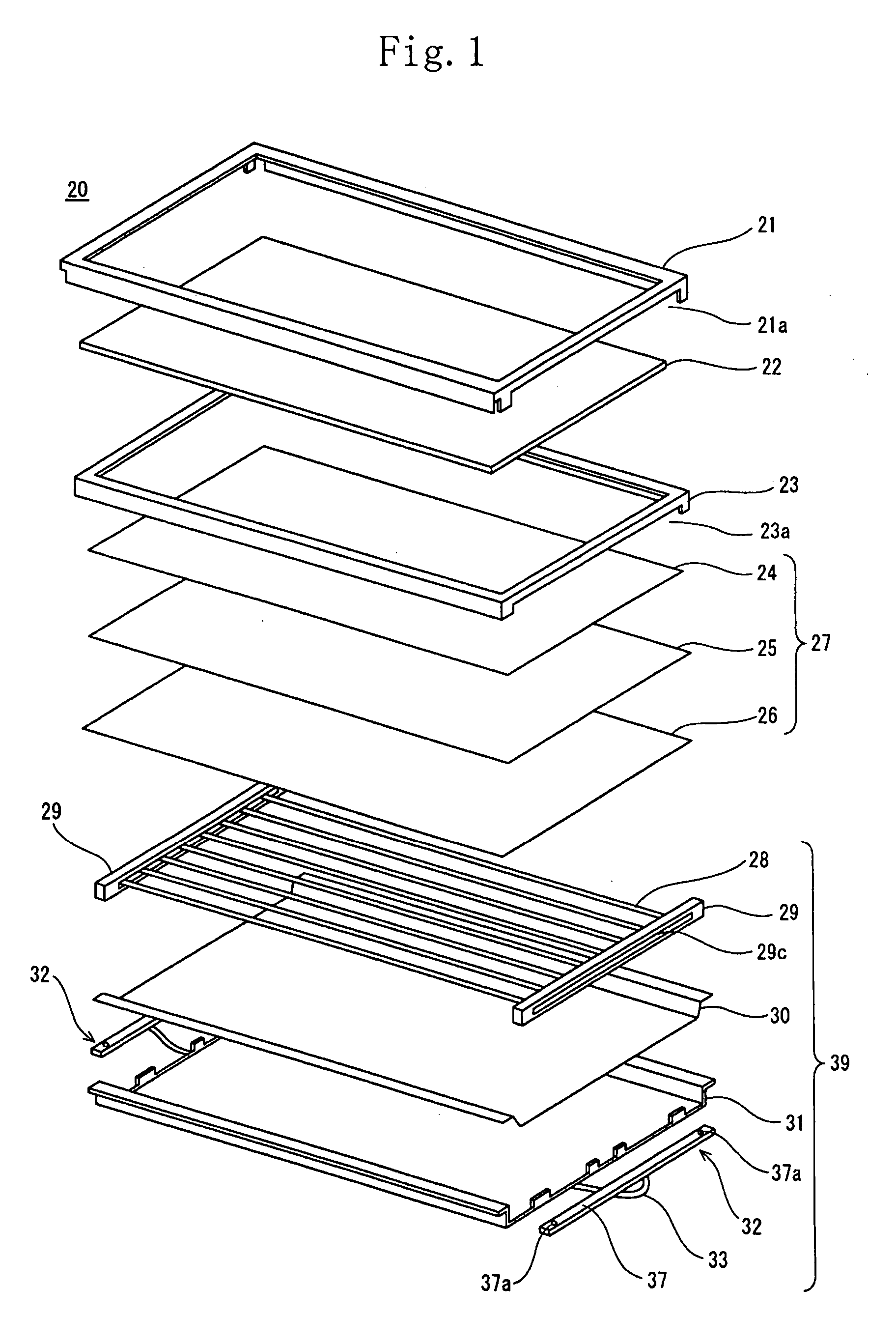

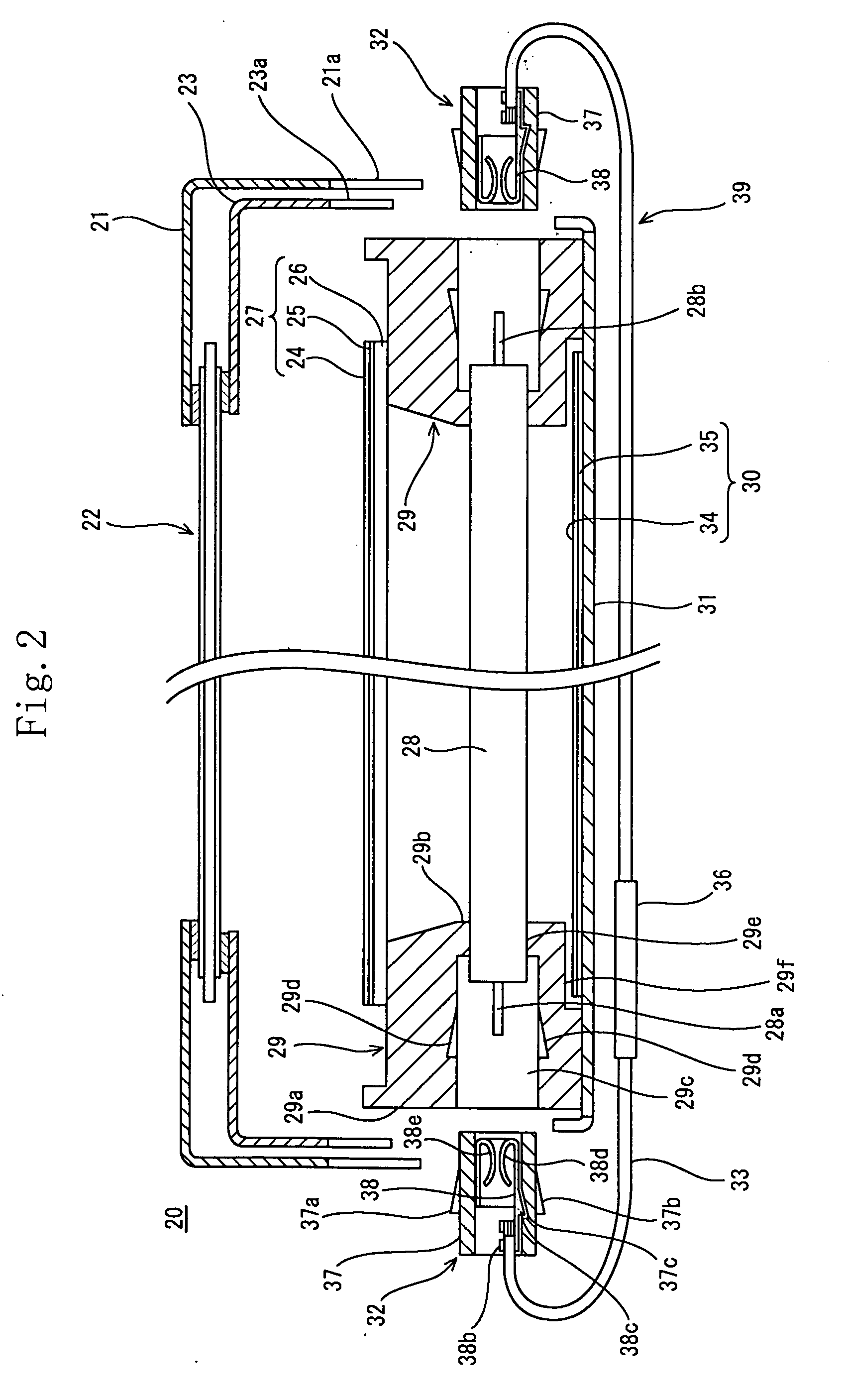

Lighting device for display

InactiveUS20050226002A1Easy maintenanceImprove recycling efficiencyCoupling device connectionsMechanical apparatusDisplay deviceEffect light

An object of the invention is to make a light source and a power supply line detachable easily so as to enable the light source to be replaced easily for maintenance. The invention provides a lighting device for a display, which includes a light source having electrode terminals provided at both ends thereof, connectors attached to the ends of a power supply line for supplying power to the light source, light source-holding chassis placed at the ends of the light source, and insertion portions opened in the chassis. The electrode terminals of the light source are placed inside the insertion portions, and the connectors are fitted detachably in the insertion portions from the outside, whereby the terminals in the connectors are connected to the electrode terminals.

Owner:SHARP KK

Preparation of wear resistant rubber composite material

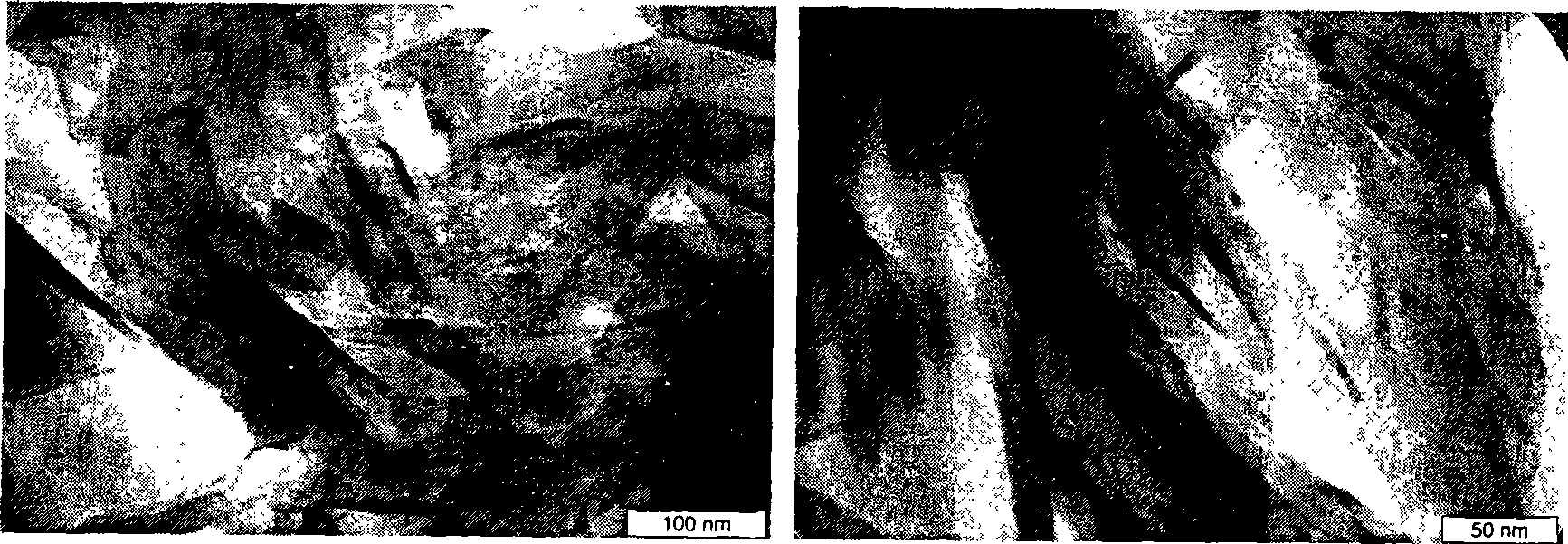

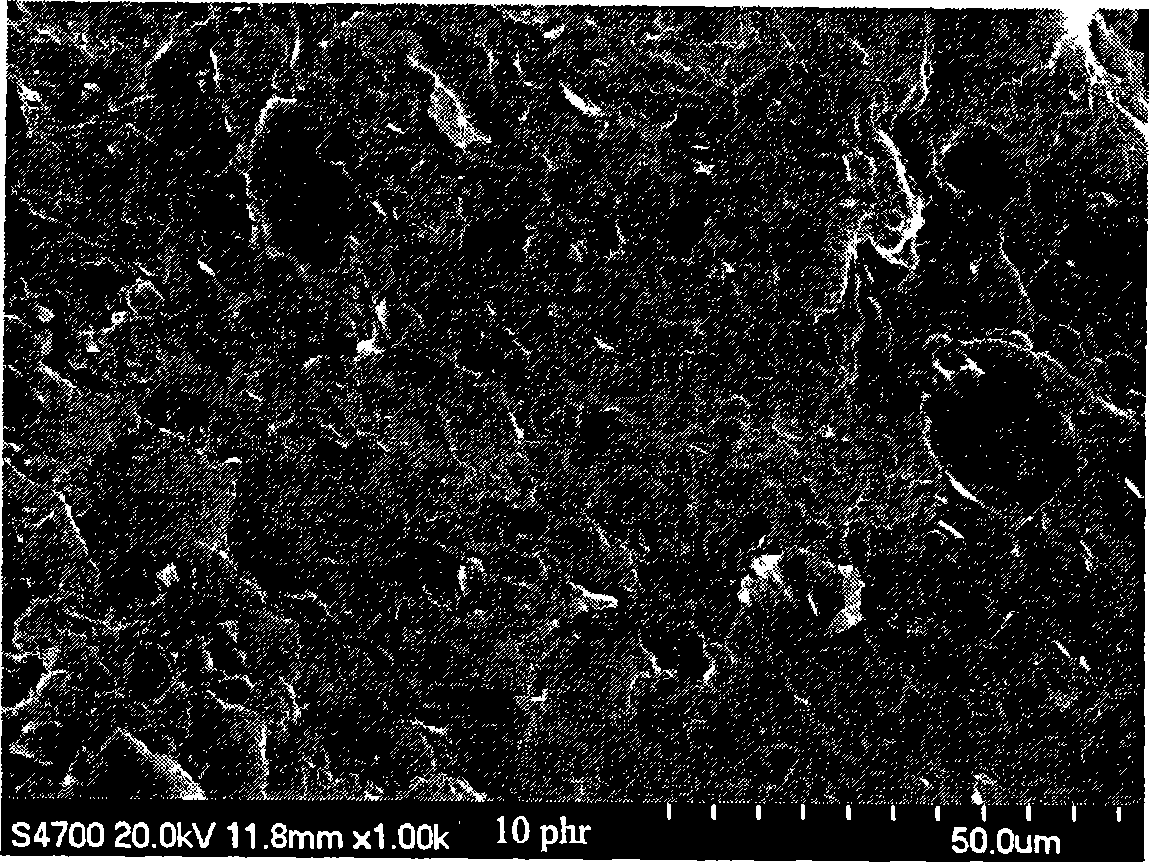

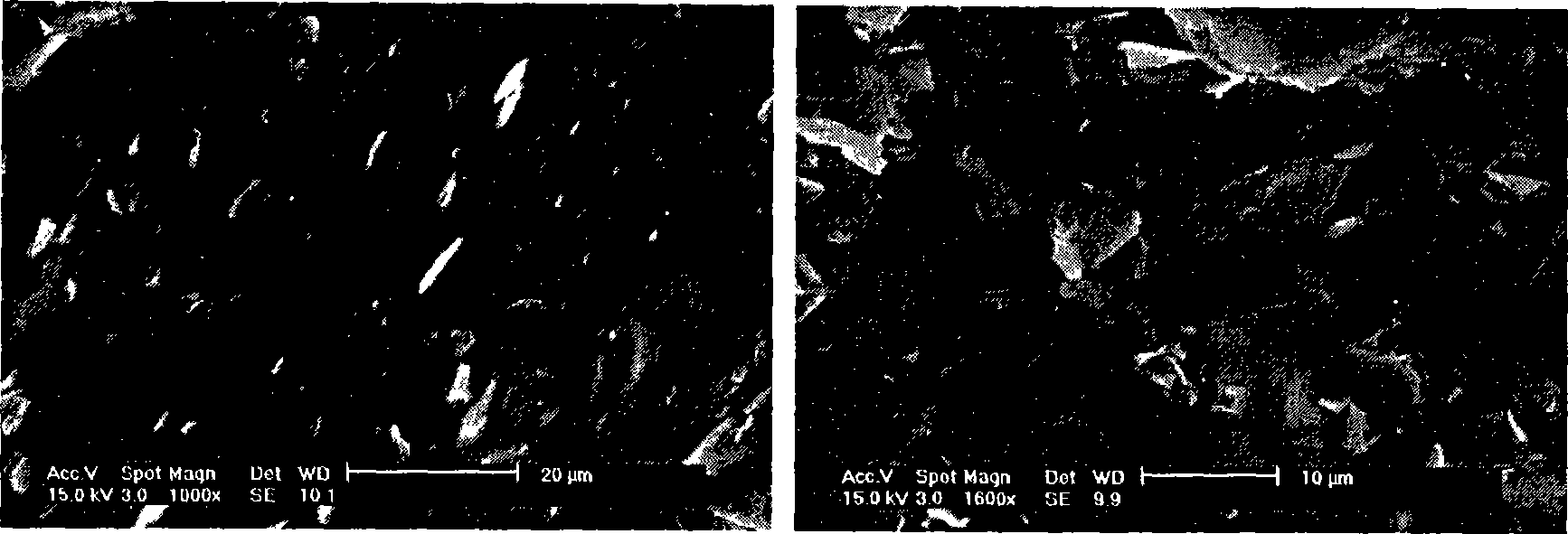

InactiveCN101463149AImprove mechanical propertiesImprove recycling efficiencyOrganic solventPolymer science

The invention relates to a preparation method of a graphite-modified abrasive resistant rubber composite material. The method comprises the following steps: soaking expandable graphite with laminar crystal layer structure in water or an organic solvent containing a surfactant; preparing a suspension system of nano flaky graphite by stirring and ultrasonic treatment; mixing the suspension system with rubber latex or rubber solution, and then adding a flocculant for breaking latex and flocculating or adding a poor solvent for precipitation; and drying flocculate or precipitate, mixing and vulcanizing to obtain the graphite / rubber composite material. The latex (solution) blending process is introduced into preparation of the graphite / rubber nano-composite material to realize homogeneous dispersion of the graphite in a rubber matrix compound system by a nanoscale size, to cause good strengthening effect and prepare the rubber composite material with excellent mechanical property, low frictional coefficient and high abrasive resistance.

Owner:BEIJING UNIV OF CHEM TECH

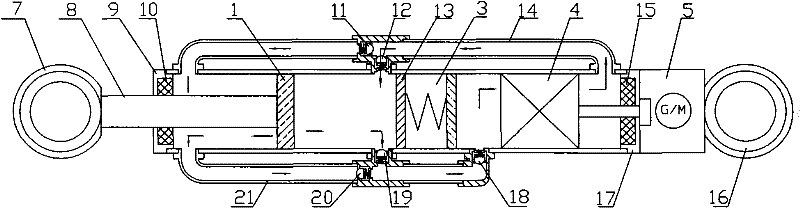

Electrohydraulic energy-regenerative type shock absorber

ActiveCN101749353APrevent reversalExtend your lifeLiquid based dampersMechanical energy handlingHydraulic motorDrive shaft

The invention relates to an electrohydraulic energy-regenerative type shock absorber, which comprises a hydraulic circuit, a working chamber and a piston, wherein the working chamber is divided into a piston working cavity and an accumulating power-generating cavity by a partition plate (13), and the piston is positioned in the piston working cavity and is connected with an external upper mounting base (7) through a piston push rod (8); a hydraulic motor (4) is positioned in the energy storage power-generating cavity and is connected with an external rotary generator (5) through a driving shaft, and an accumulator (3) is positioned in the accumulating power-generating cavity and is positioned below the partition plate (13); and the hydraulic circuit and a plurality of one-way valves (6) form a hydraulic rectifier bridge, and the hydraulic circuit adopts the method that an external pipeline is arranged outside the piston or the piston is designed to form internal and external cavities. The invention has simple structure, fewer components and small volume, can allow the energy generated by vehicle vibration to be fully used for doing work, can effectively recover vibration energy, has better shock absorbing effect than the existing shock absorber, and also prolongs the service life of the generator.

Owner:武汉经开科创运营有限公司

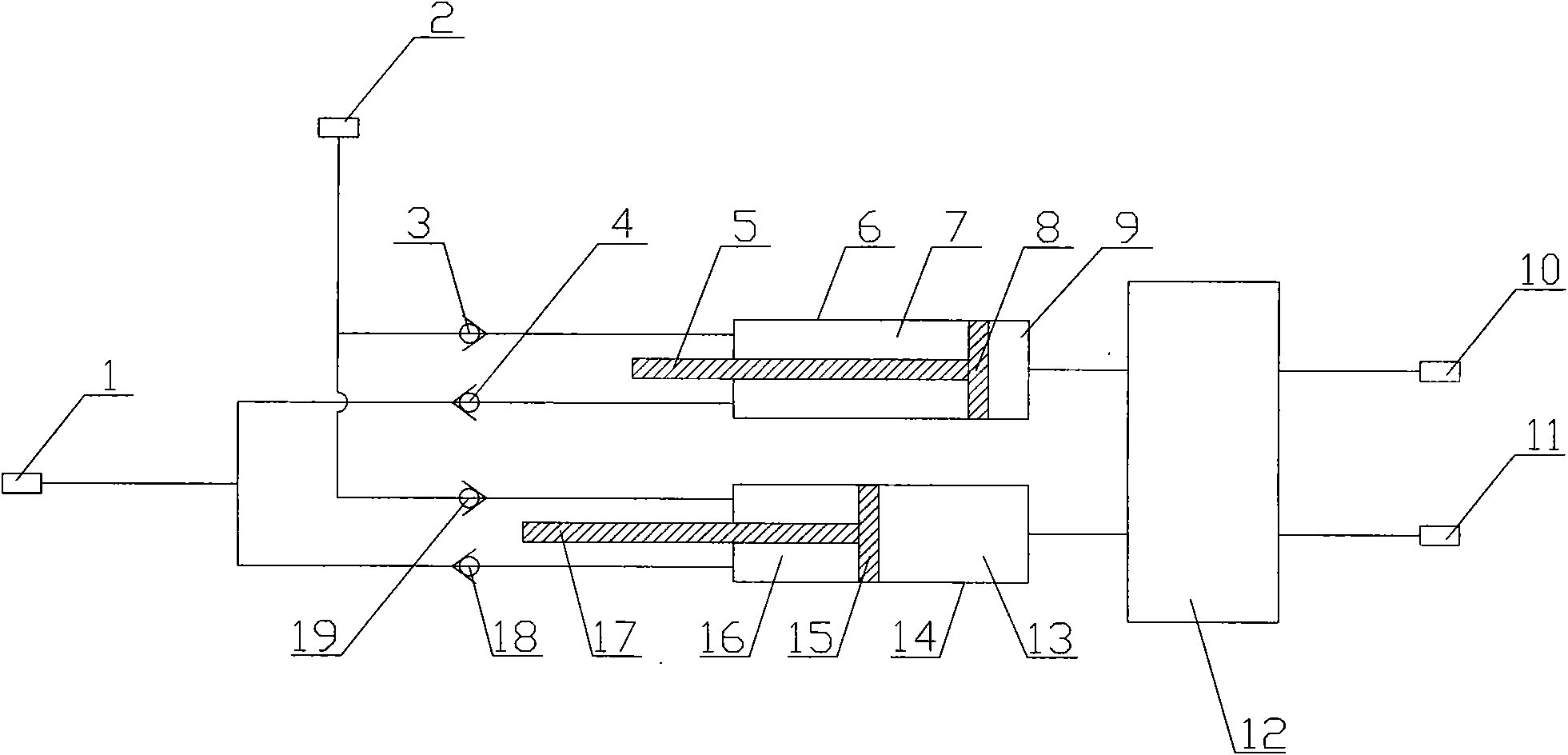

Differential energy recovery device and method for seawater desalination system

InactiveCN101782095AReduce energy consumptionImprove energy conversion efficiencyFluid-pressure actuator componentsSpecial designInlet valve

The invention discloses a differential energy recovery device and a method for a seawater desalination system. The differential energy recovery device comprises two hydraulic cylinders connected in parallel. A piston divides each hydraulic cylinder into two cavities. The piston is fixedly connected with a piston rod. A low-pressure raw water inlet is connected with two left cavities through liquid inlet valves. The left cavities are connected with a high-pressure raw water outlet through liquid drain valves. Two right cavities are connected with reversing valves. The reversing valves are connected with a high-pressure concentrated water inlet and are connected with a low-pressure concentrated drain outlet. The method is that high-pressure concentrated water coming from a reverse osmosis device is enabled to enter the right cavities of the two hydraulic cylinders through the reversing valves, and low-pressure raw water in the left cavities is pushed and pressurized to enter the reverse osmosis device. Since the direct pressurization principle of the hydraulic cylinders is used for the special design, one-time energy conversion is adopted and the pressure of high-pressure seawater after pressure exchange is larger than the pressure of concentrated saline water, the invention has the advantages that the pressurizing pumps are not required for pressurization once more, the energy conversion efficiency is high, the operating cost is saved and the energy consumption of the reverse osmosis system is further reduced.

Owner:TIANJIN SEA WATER DESALINATION & COMPLEX UTILIZATION INST STATE OCEANOGRAPHI

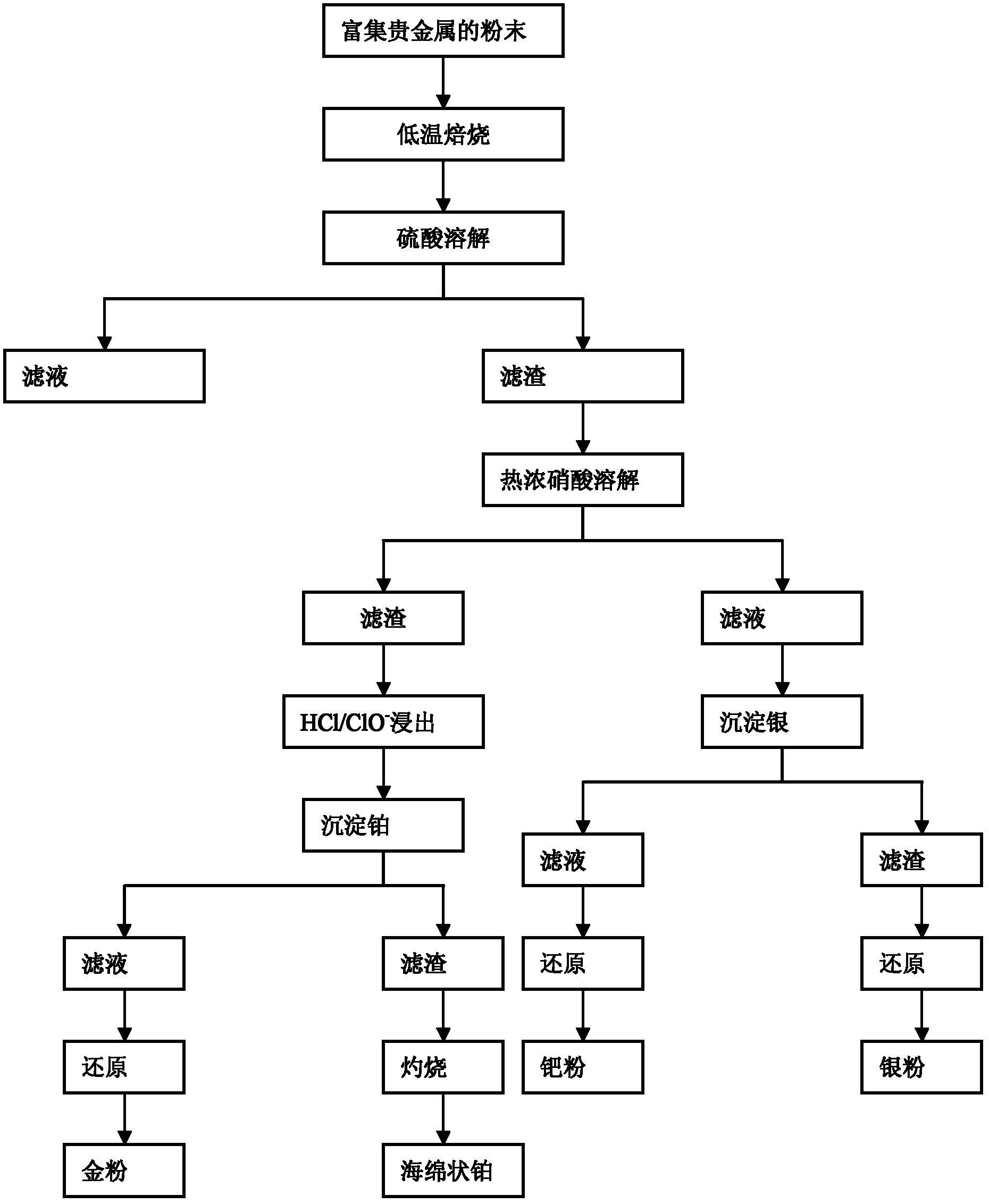

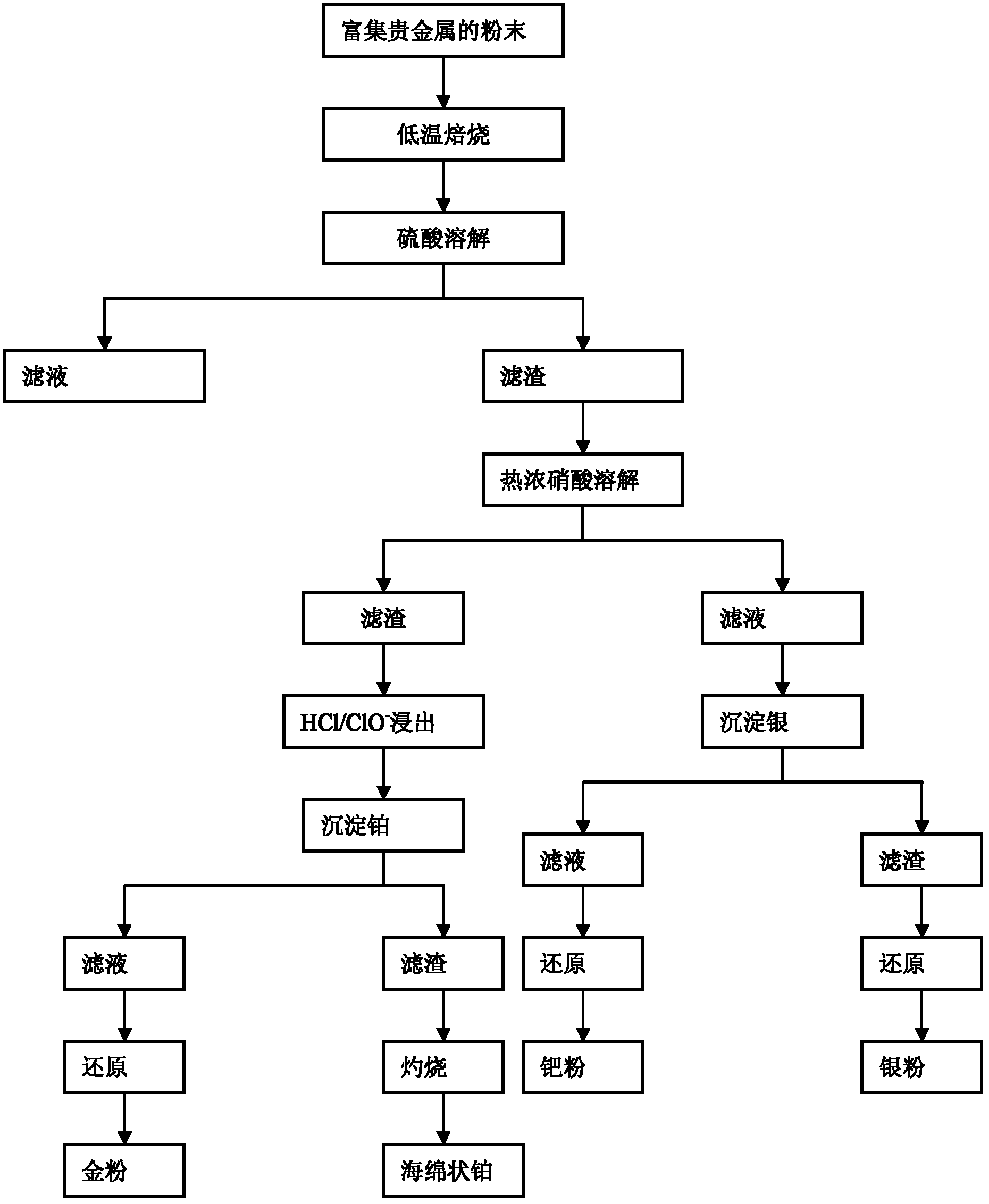

A method for recovering gold, palladium, platinum and silver from waste circuit boards

ActiveCN102277497AEmission reductionIncrease profitProcess efficiency improvementElectronic waste recyclingPlatinumCopper

The invention relates to the field of industrial waste recycling and in particular relates to a method of reclaiming gold, palladium, platinum and silver from a waste circuit board. The method comprises the following steps: (1) removing impurities of a waste circuit board which is subjected to extraction of copper, nickel, lead and tin; (2) separating and reclaiming palladium and silver; and (3) separating and reclaiming platinum and gold. Compared with the prior art, the method provided by the invention has the advantages of lower reclaiming cost, higher recycling rate and higher purity of the reclaimed metals.

Owner:荆门格林循环电子废弃物处置有限公司

Comprehensive heat energy utilizing type active coke purifying and regenerating process system and active coke purifying and regenerating process method

ActiveCN102580705AImprove regeneration efficiencyIncrease profitOther chemical processesDispersed particle separationProcess systemsHeat conducting

The invention discloses a comprehensive heat energy utilizing type active coke purifying and regenerating process system and an active coke purifying and generating process method. The process system comprises a regenerating device, a preheating device, a heating device and a heat exchanging device, wherein the regenerating device comprises a regenerating tower; the preheating device comprises a drying tower; the heating device comprises a hot-blast stove and a first fan; and the heat exchanging device comprises a second fan, a normal-temperature air input pipeline and a hot air output pipeline, wherein the second fan is used for sending the hot air after heat exchange to the drying tower so as to preheat the active coke. The method comprises the following steps: (1) preheating: preheating the active coke in the drying tower; (b) heating: heating the active coke due to the action of a high-temperature heat-conducting medium; (c) regenerating; and (d) cooling: cooling the regenerated active coke entering a cooling section. The system and method disclosed by the invention are suitable for restoring and regenerating the active coke.

Owner:SHANGHAI CLEAR ENVIRONMENTAL PROTECTION SCI & TECH

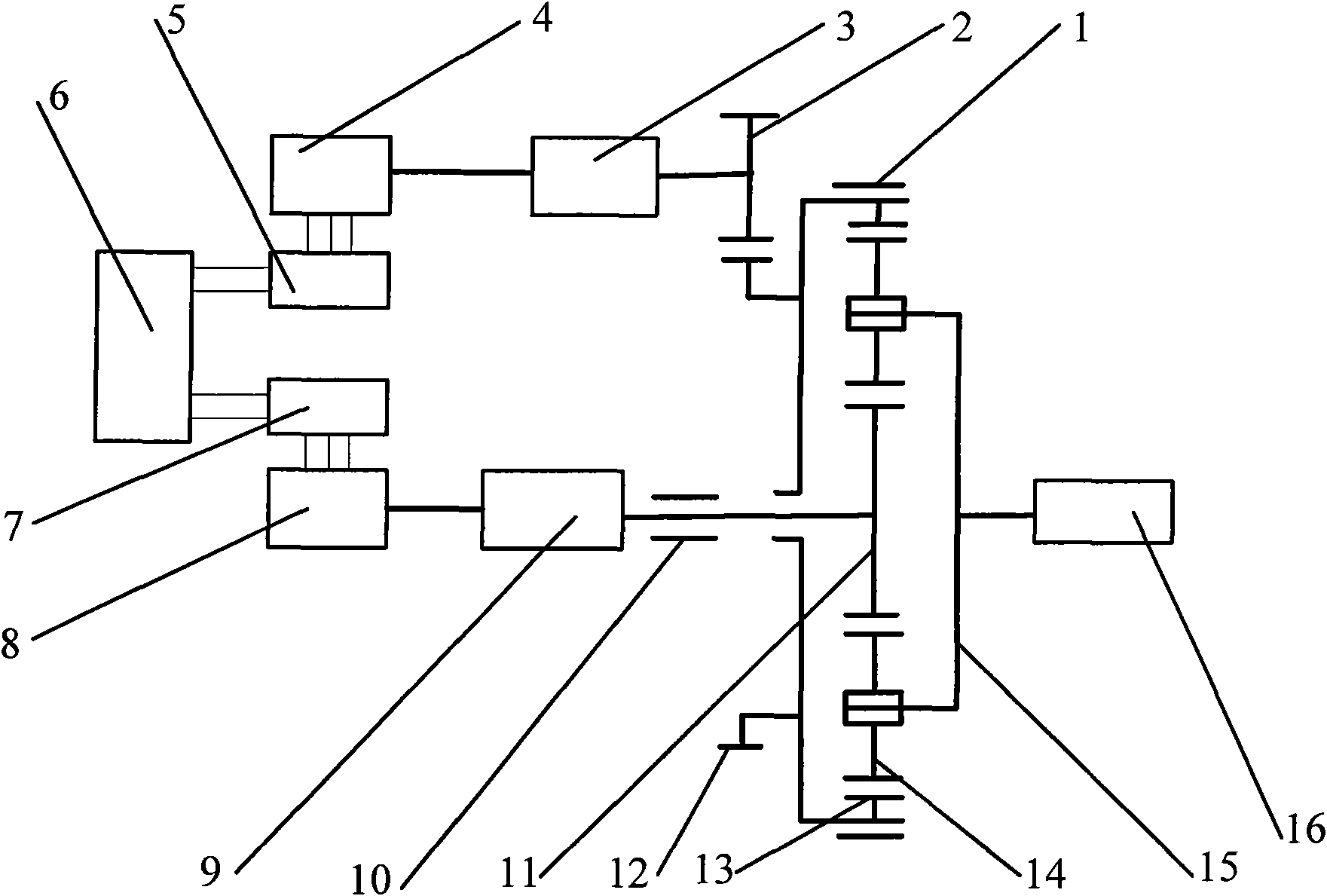

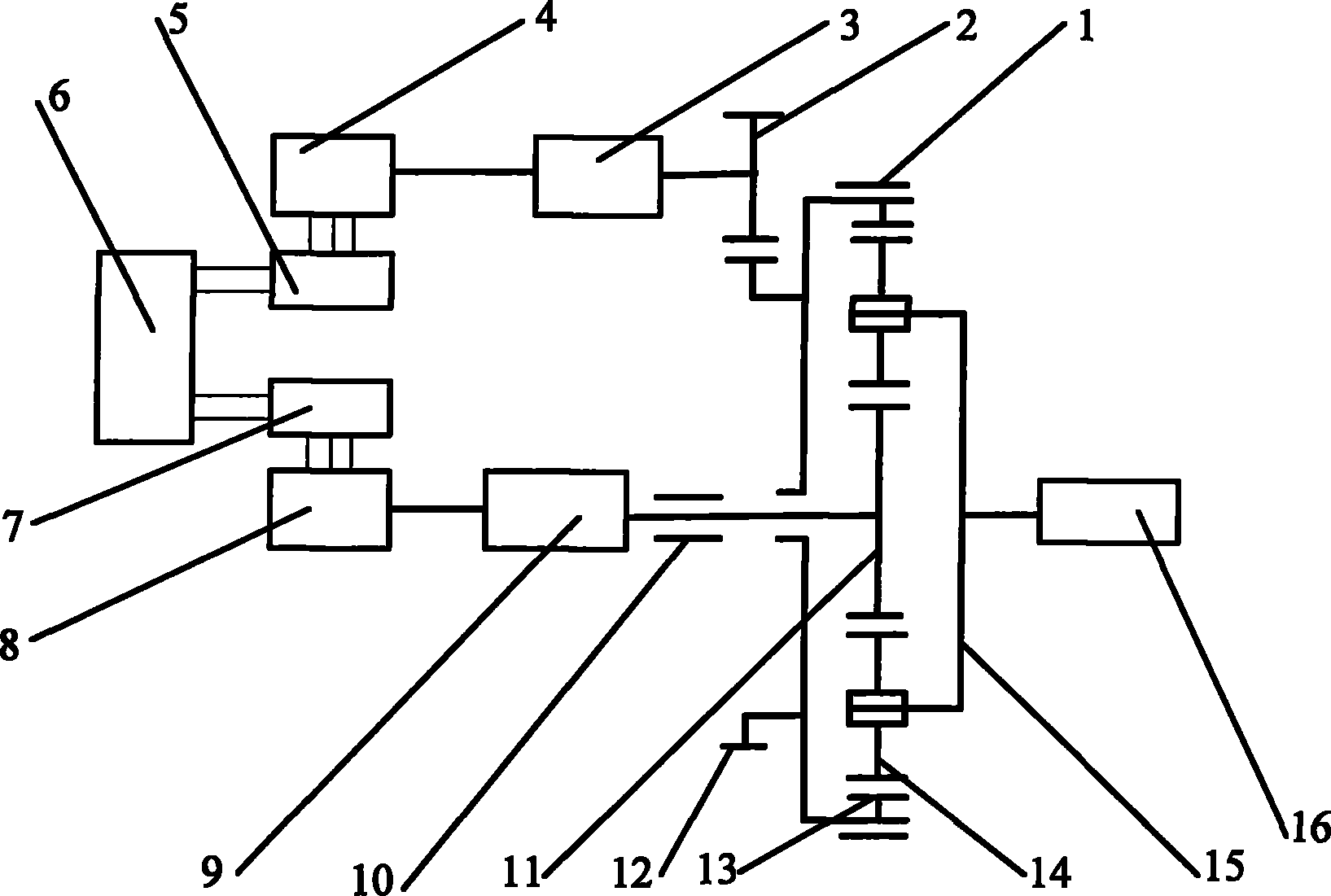

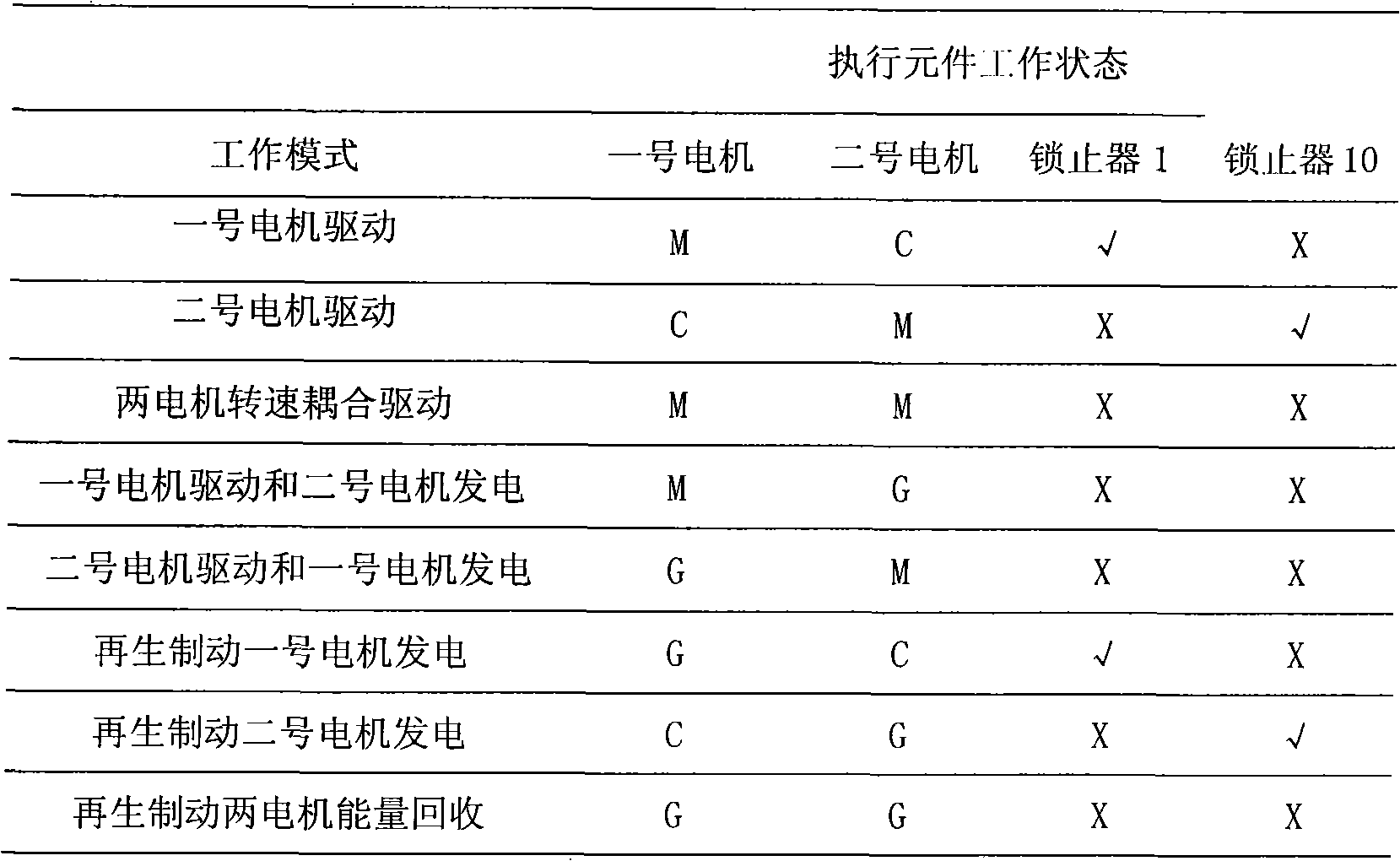

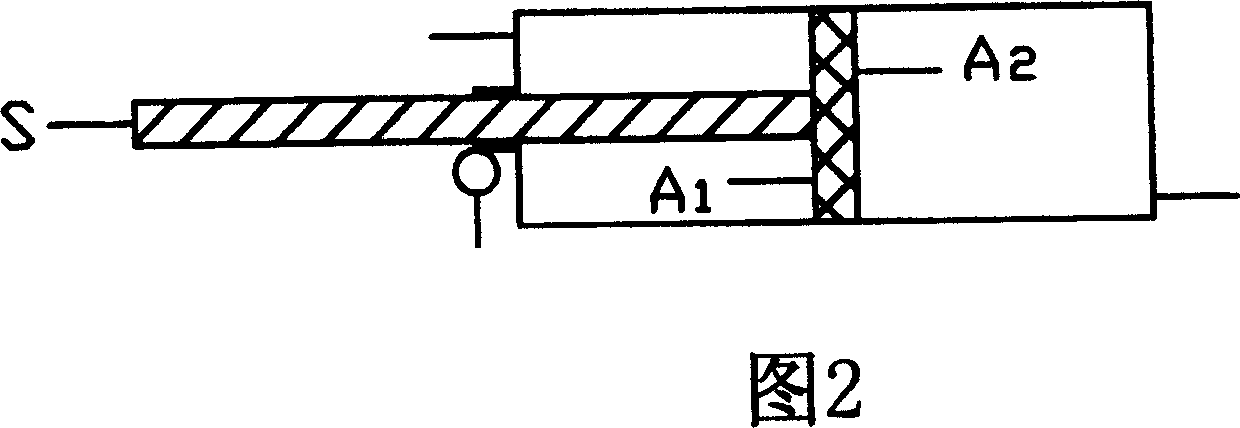

Dual-motor rotating speed coupling drive assembly

InactiveCN102133856AShorten the transmission pathImprove recycling efficiencyElectrodynamic brake systemsElectric propulsion mountingPower couplingDrive wheel

The invention provides a dual power coupling drive assembly adopting a dual-motor rotating speed coupling drive mode, and the dual power coupling drive assembly can meet the power demands of heavy vehicles in the process of running. In the invention, the rotating speed coupling of a planetary gear is used as the power coupling of a first motor 4 and a second motor 8; the first motor 4 and the second motor 8 are arranged at the same side, and the shafts of the first motor 4 and the second motor 8 are parallel to each other, the power output by the first motor 4 passes through a first speed reducer 3, a power input gear 2 and a gear ring external gear 12, the power output by the second motor 8 passes through a second speed reducer 9 and a sun gear 11, then the rotating speed coupling of the two motors are realized by the planetary gear, and a planet carrier 15 outputs power to a driving wheel 16.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Strong brine energy recovery device based on reverse osmosis desalination technology

InactiveCN100341609CGuaranteed uptimeReduce consumptionGeneral water supply conservationReverse osmosisHydraulic cylinderSaline water

This invention discloses energy-recovery device for strong brine based on desalination technique by reverse osmosis, which comprises hydraulic cylinder with guide bar connected to piston; water inlet three-way solenoid valve with one end connected to end of guide bar, and other two ends connected separately to water outlets of low and high pressure water-feed pumps; drainage three-way solenoid valve with one end connected to the hydraulic cylinder end far away guide bar, and other two ends connected to strong brine discharge pipes of reverse osmosis membrane; sensor, to obtain the position signal of piston; controller, to control the synchronized open and shut of two aforementioned three-way solenoid valves. It has high efficiency, runs stably, switches quickly and fit to spread in industry.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

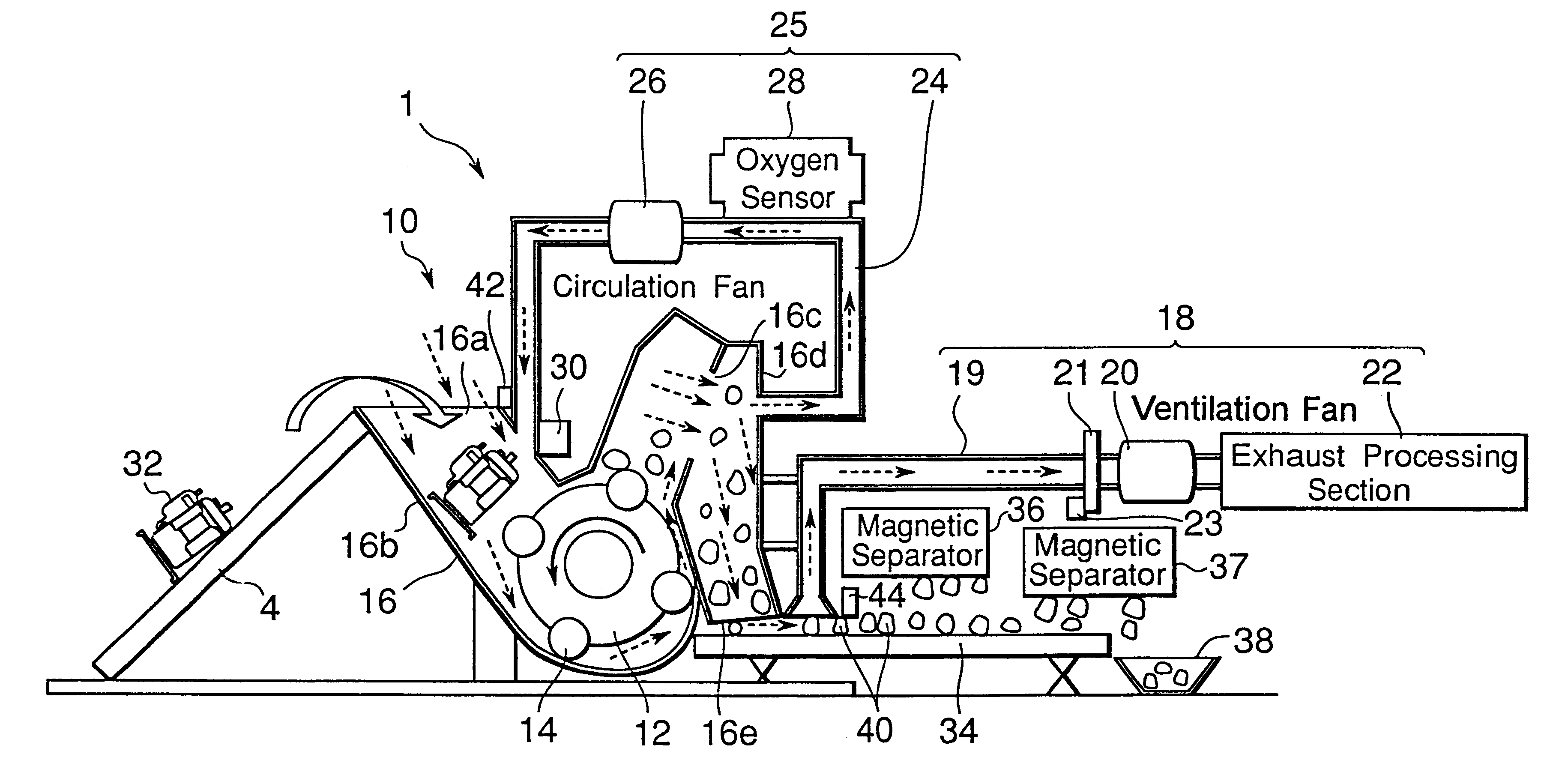

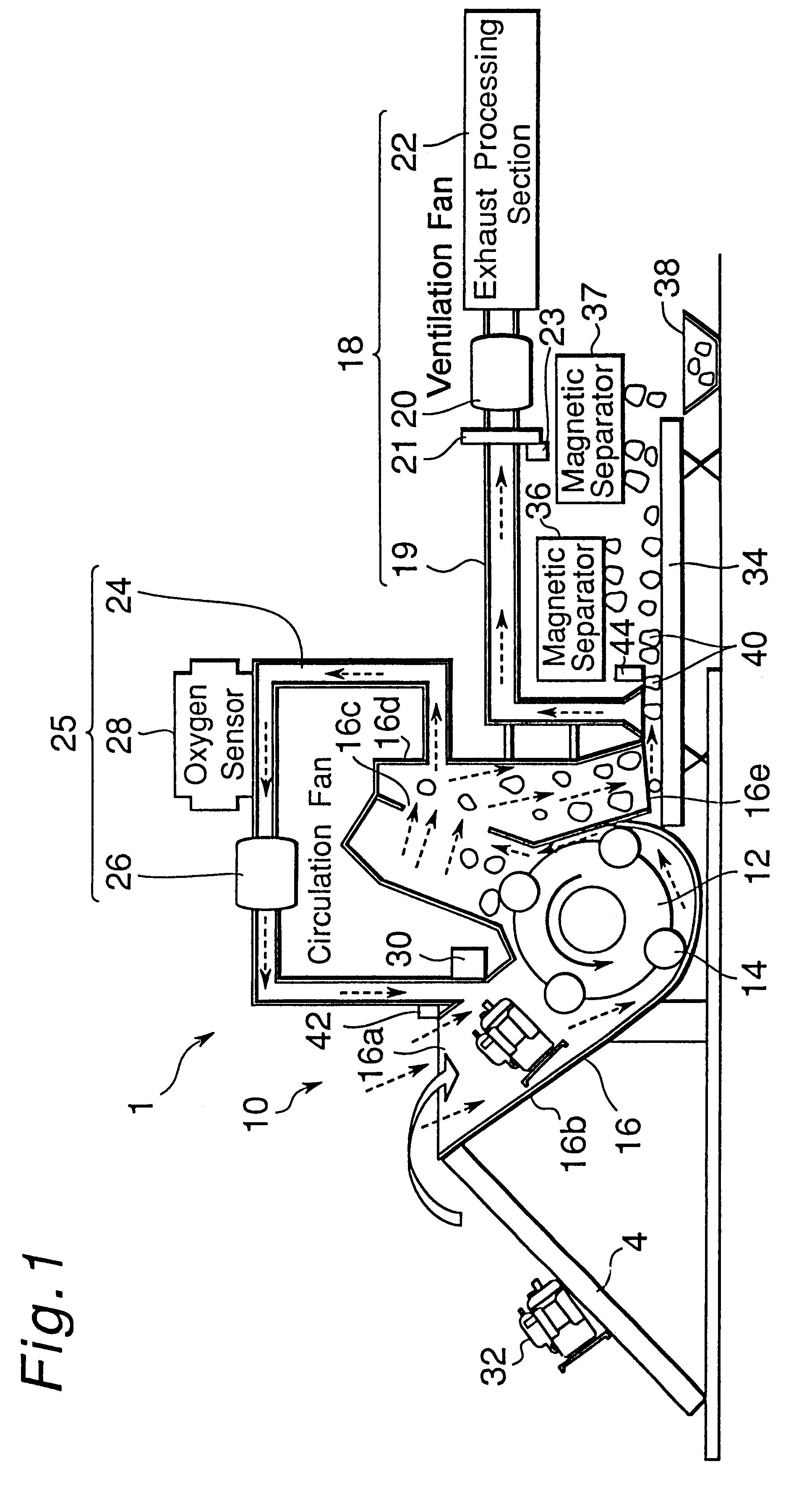

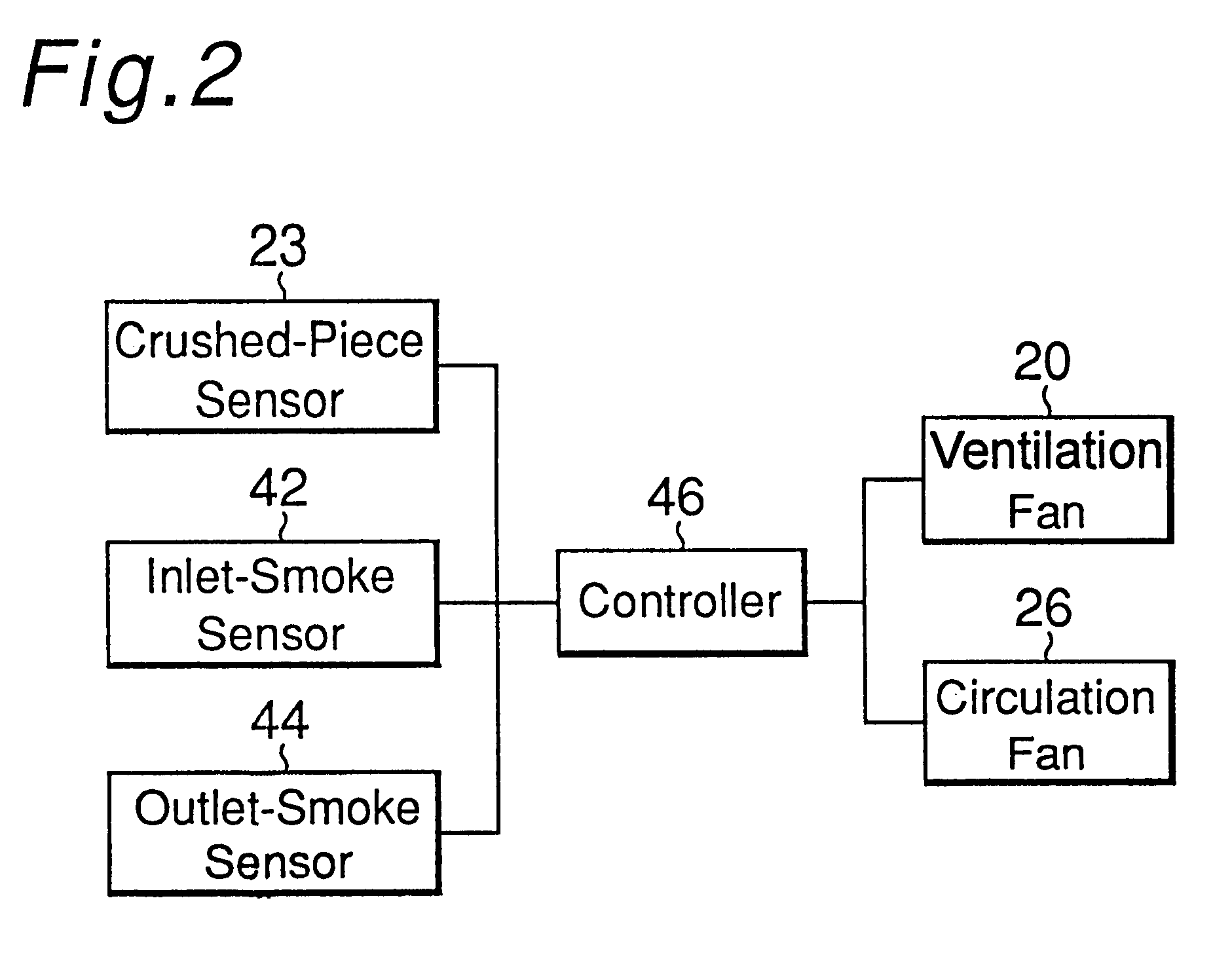

Apparatus for crushing waste products and method of operating the same

InactiveUS6390396B1Reduce outgassingGuaranteed uptimeGas current separationSolid waste disposalWaste productProduct gas

Owner:PANASONIC CORP

Method for recycling electrolyte of waste lithium ion battery

ActiveCN102496752AEasy to handleSimple processWaste accumulators reclaimingBattery recyclingSocial benefitsHydrogen fluoride

The invention discloses a method for recycling the electrolyte of a waste lithium ion battery. The method mainly comprises the following steps of: collecting and cleaning the lithium ion battery; after discharge, putting the lithium ion battery in a drying room or a glove box under protection of inert gas; opening the battery, carefully taking out the electrolyte and placing in a material tank; performing high-vacuum decompressed rectification and separation to obtain the organic solvent contained in the electrolyte; performing rectification and purification for recycling; putting a rough product of lithium hexafluorophate into a dissolution kettle, and adding a hydrogen fluoride solution for dissolving the recycled lithium hexafluorophate; filtering the solution and then putting into a crystallization kettle for crystallization and purification; and screening, drying, packaging and recycling to obtain the product lithium hexafluorophate. The method has simple technology, is practical, efficient, clean and environment-friendly and easy to control, and realizes close integration of economic benefits and environmental social benefits.

Owner:CHINA NAT OFFSHORE OIL CORP +1

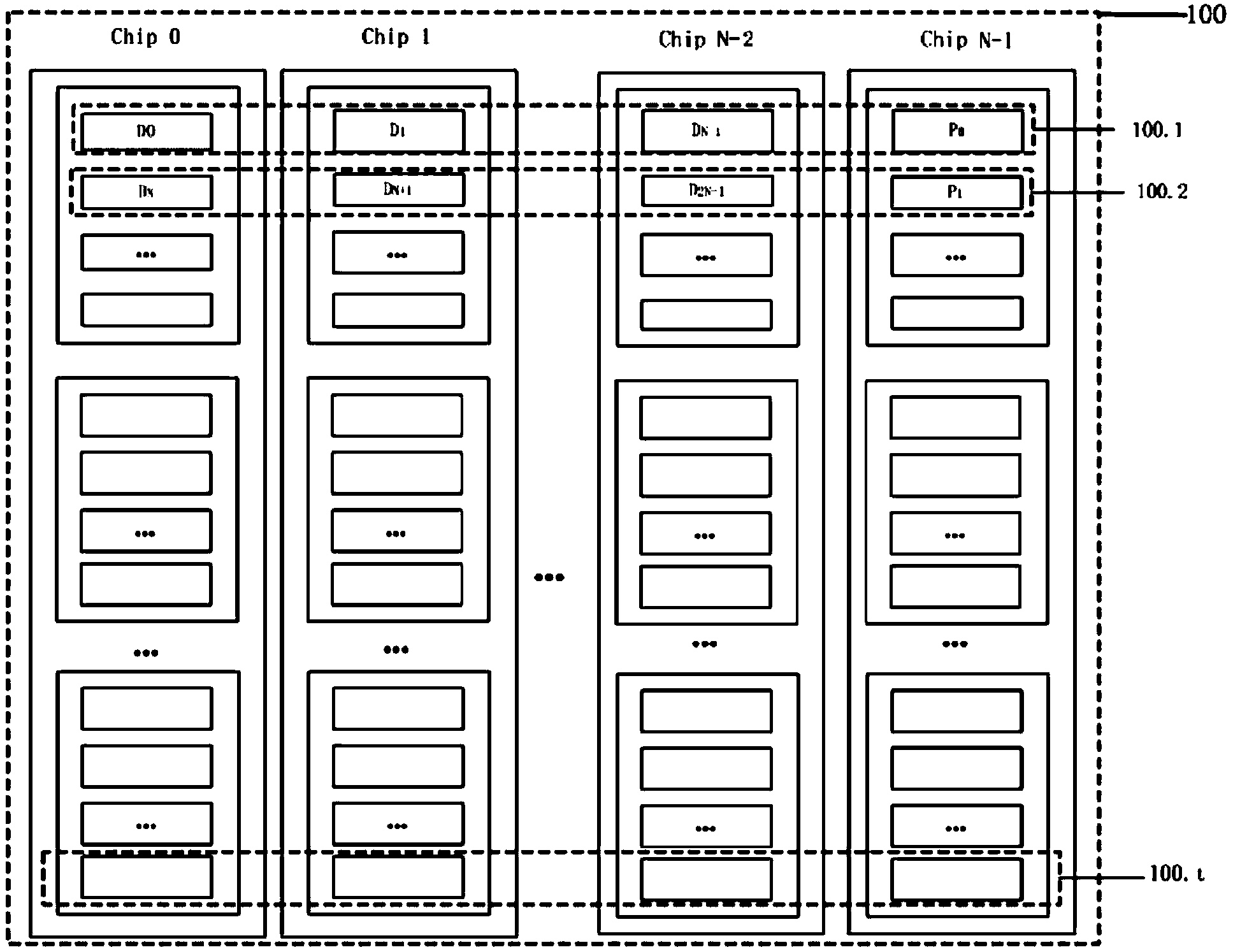

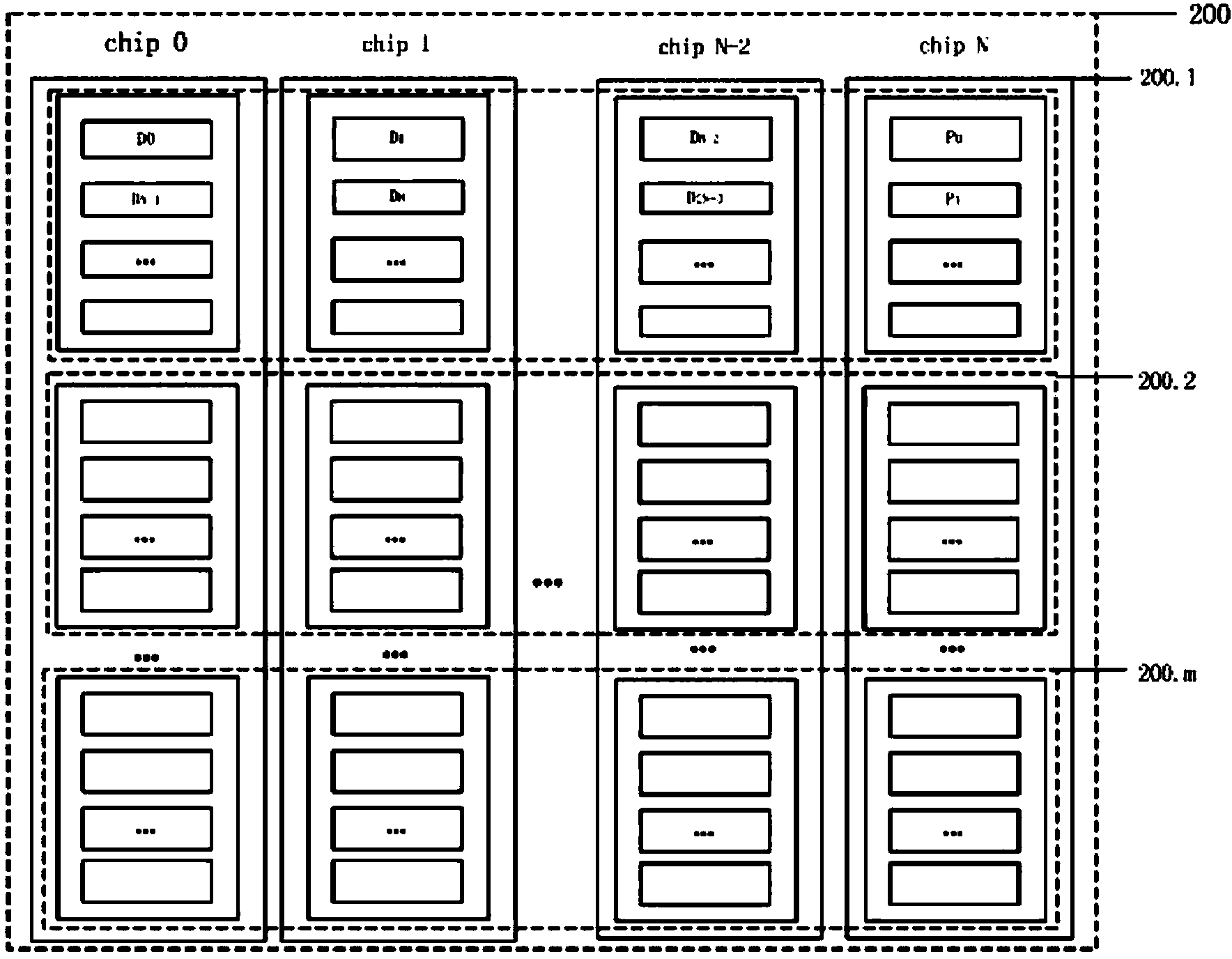

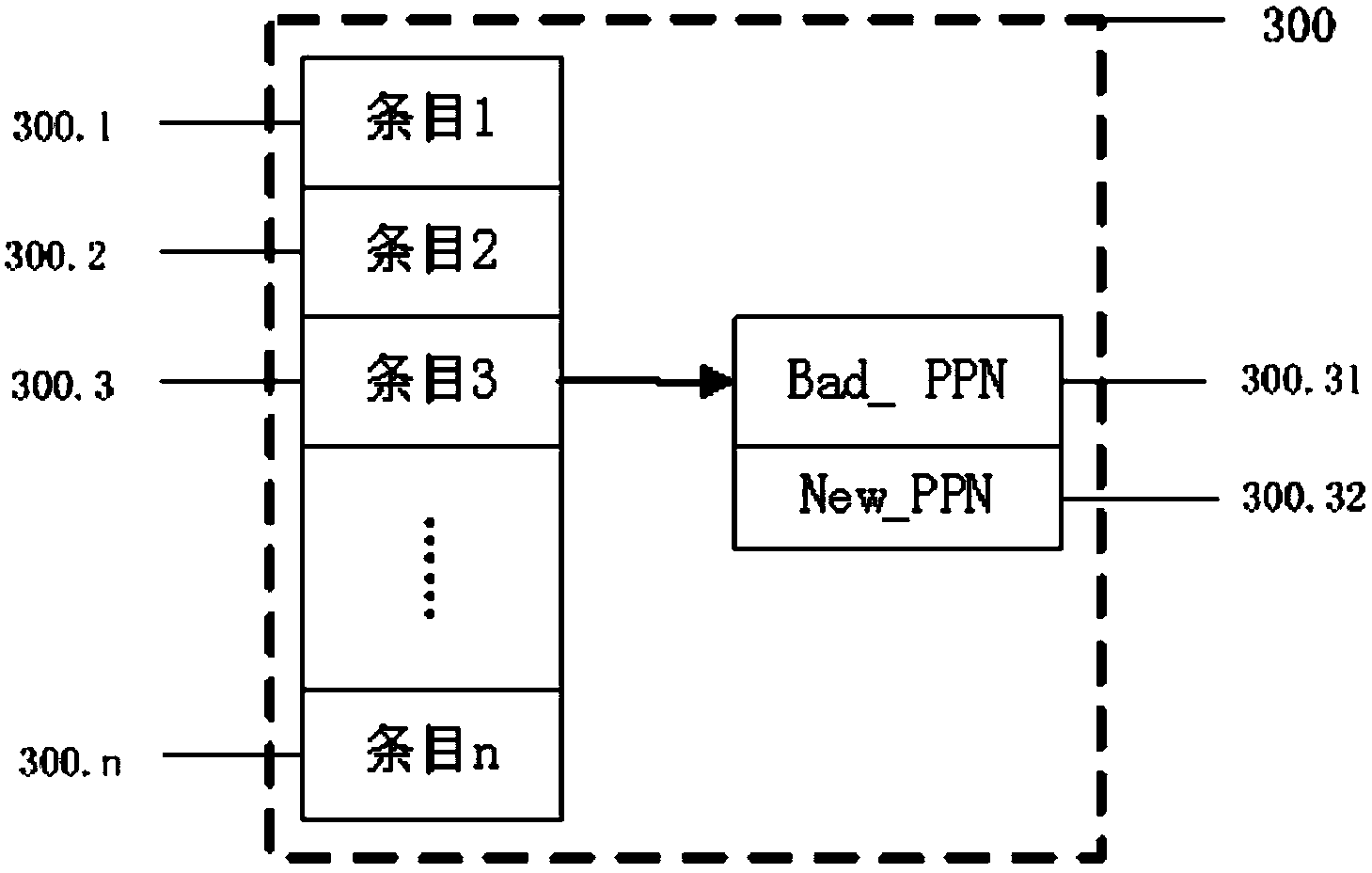

High-performance reliable solid-state disk realizing method

ActiveCN103488583AImprove performanceImprove reliabilityInput/output to record carriersMemory adressing/allocation/relocationRAIDData error

The invention provides a high-performance reliable solid-state disk realizing method. The method includes: (1), dividing all flash memory chips in a solid-state disk into groups and forming an RAID (redundant array of independent disks) 4-level flash array in each group by N successive flash chips; (2), receiving and storing data through a cache; (3), judging whether the cache is filled up or not, if yes, entering the step (4), and if not, returning to the step (2); (4), extracting N-1 data blocks from the cache and computing check values of the N-1 data blocks; making up the N-1 data blocks and the check values into filled stripe data and writing back the flash array; returning to the step (2). The flash chips in the solid-state disk are used for establishing the RAID4-level physical array to assure data reliability. Faults at different levels including page level, block level, or even chip level can be processed. Besides, writing-in performance is improved by writing of filled stripes and sequence, and spatial and performance loss resulted from data errors can be reduced to the utmost.

Owner:HUAZHONG UNIV OF SCI & TECH

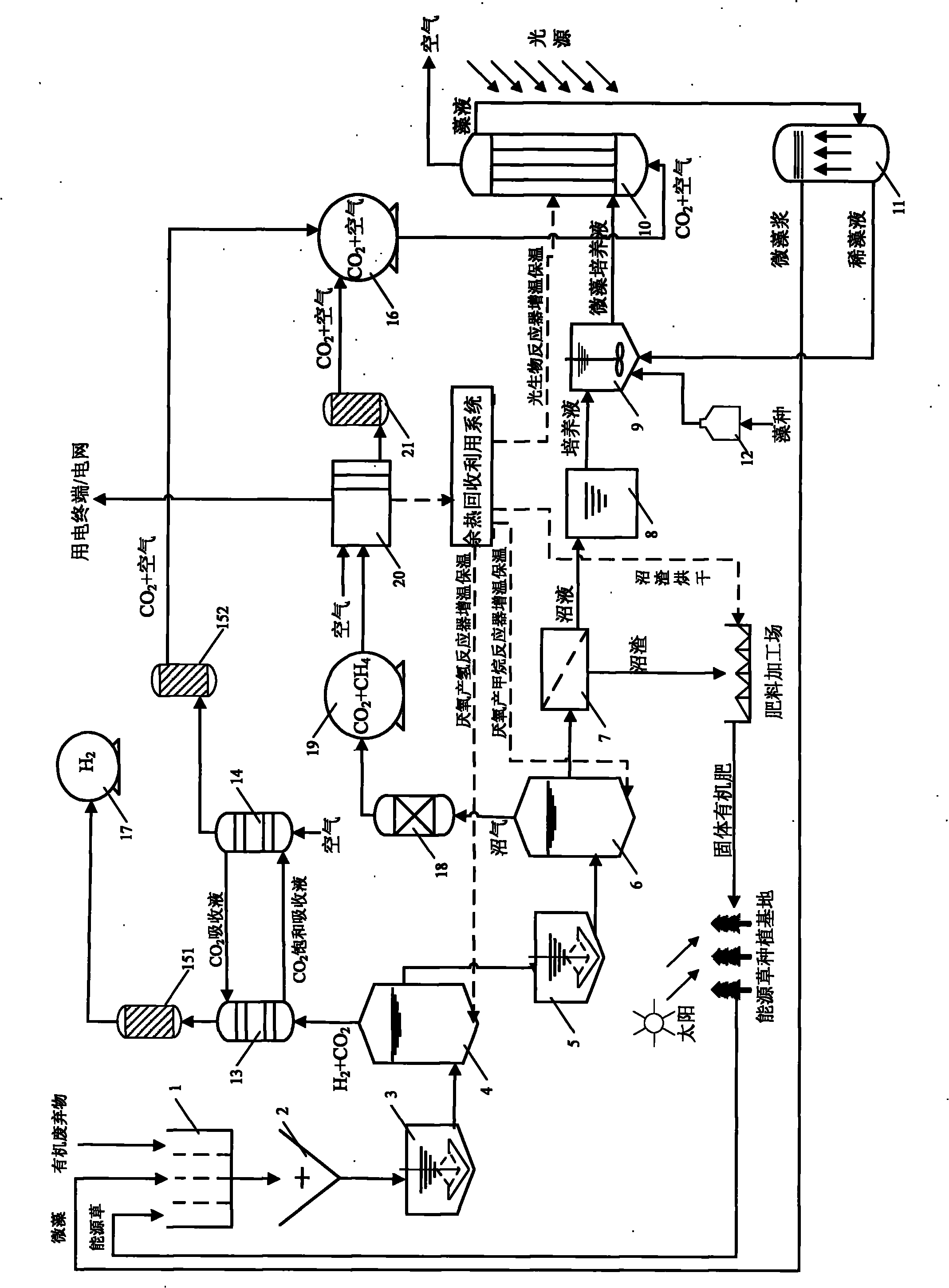

Energy utilization method of carbon dioxide zero-emission type organic waste

ActiveCN101914572AReduce the cost of trainingAvoid emissionsBio-organic fraction processingInternal combustion piston enginesNew energySludge

The invention provides an energy utilization method of carbon dioxide zero-emission type organic wastes, comprising the following steps of: (1) collecting and pretreating raw materials; (2) preparing hydrogen by anaerobic fermentation and purifying hydrogen; (3) fermenting methane and generating power by the methane; (4) treating biogas slurry and fixing carbon dioxide with microalgae; (5) processing biogas residues and planting energy grass; and (6) recycling afterheat. The method is suitable for treating various types of organic wastes, can be used for treating agricultural organic wastes, industrial organic wastes, domestic organic garbage, mud, and the like and the industries of developing new energy, and the like. The method can carry out a concrete application example of cyclic economy, eliminates environmental pollution, obtains clean energy at the same time, has no greenhouse gas emission in the process and can realize three effects of treating wastes, generating renewable clean energy and reducing carbon dioxide emission.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Sludge treatment method based on hydrothermal carbonization

InactiveCN103755124AEmission reductionIncrease organic carbon contentSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningSludgeToxic material

The invention relates to a treatment method of sludge generated by urban sewage treatment plant and industrial sludge and discloses a sludge treatment method based on hydrothermal carbonization. The sludge treatment method comprises four steps: sludge preheating treatment, hydrothermal carbonization, waste heat recovery and dehydration desiccation. By adopting the sludge treatment method, as the sludge is converted to hydrothermal carbon by adopting a hydrothermal carbonization technology, pathogenic microorganisms in the sludge are completely killed, most heavy metal pollutants in the sludge are dissolved out, and organic toxic substances in the sludge are effectively decomposed, so that the energy recovery utilization rate is high, and the sludge treatment method is clean, environment-friendly, rapid and effective and has high product additional values.

Owner:HANGZHOU HUHUI ENVIRONMENTAL PROTECTION TECH

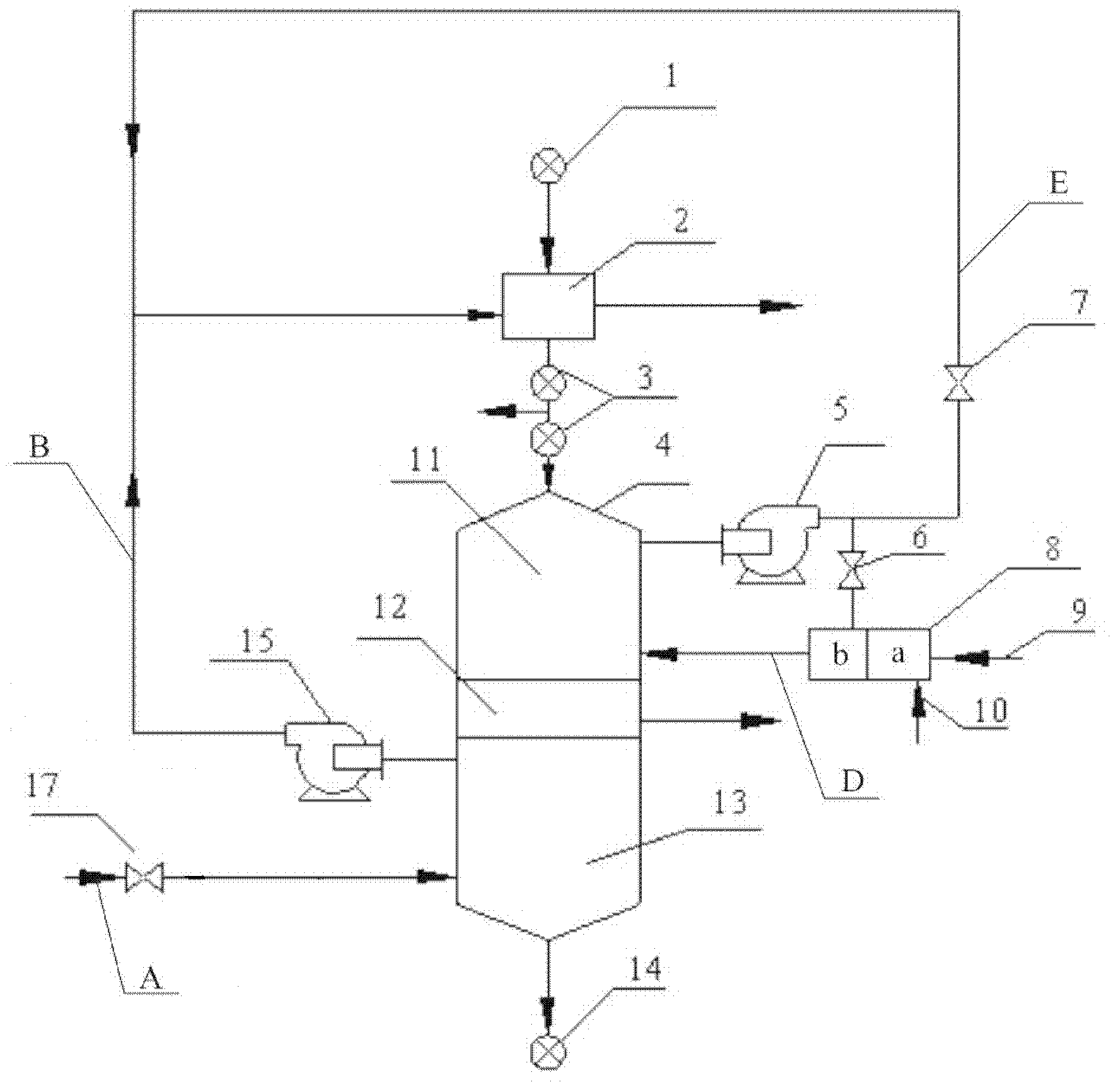

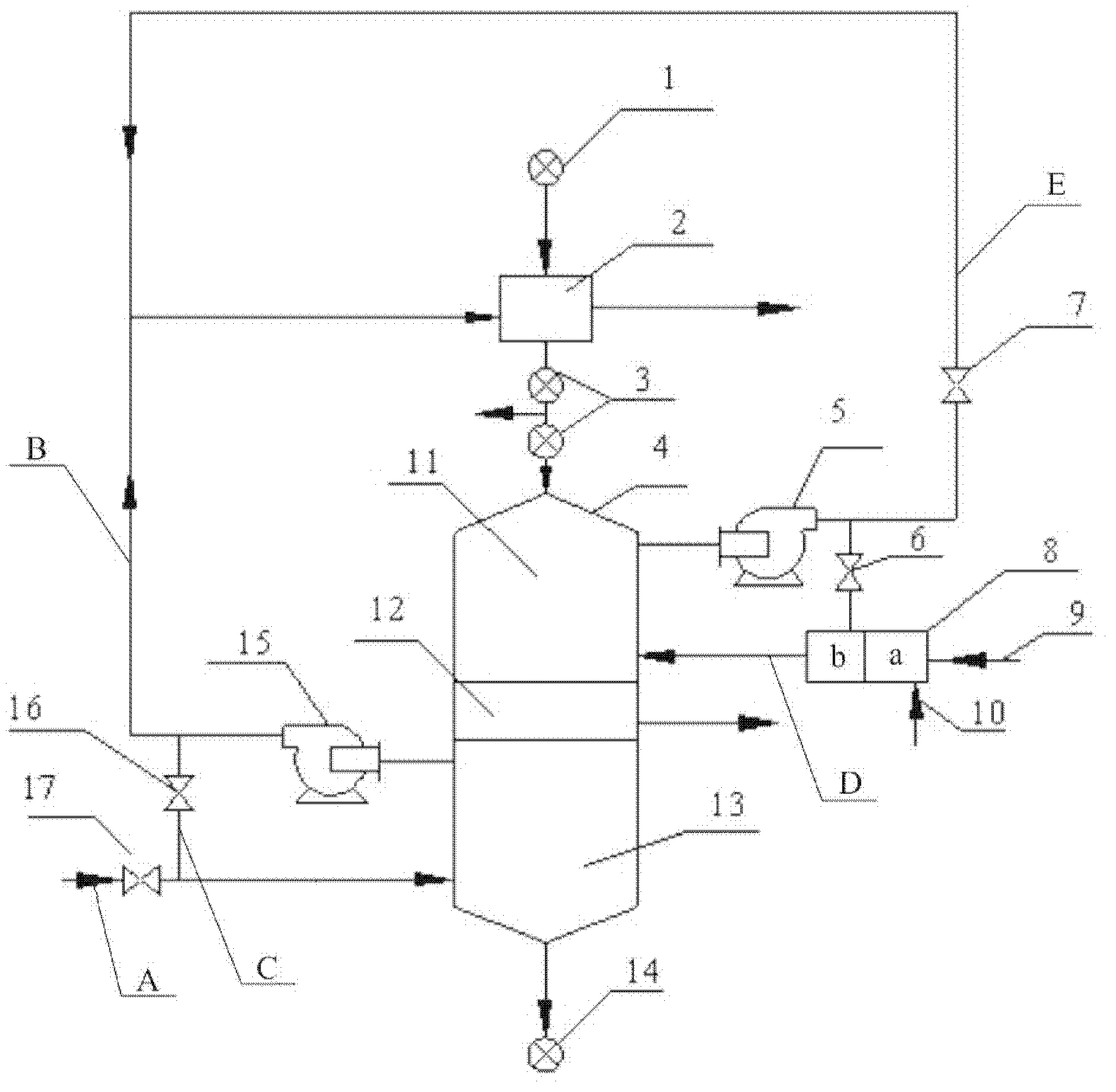

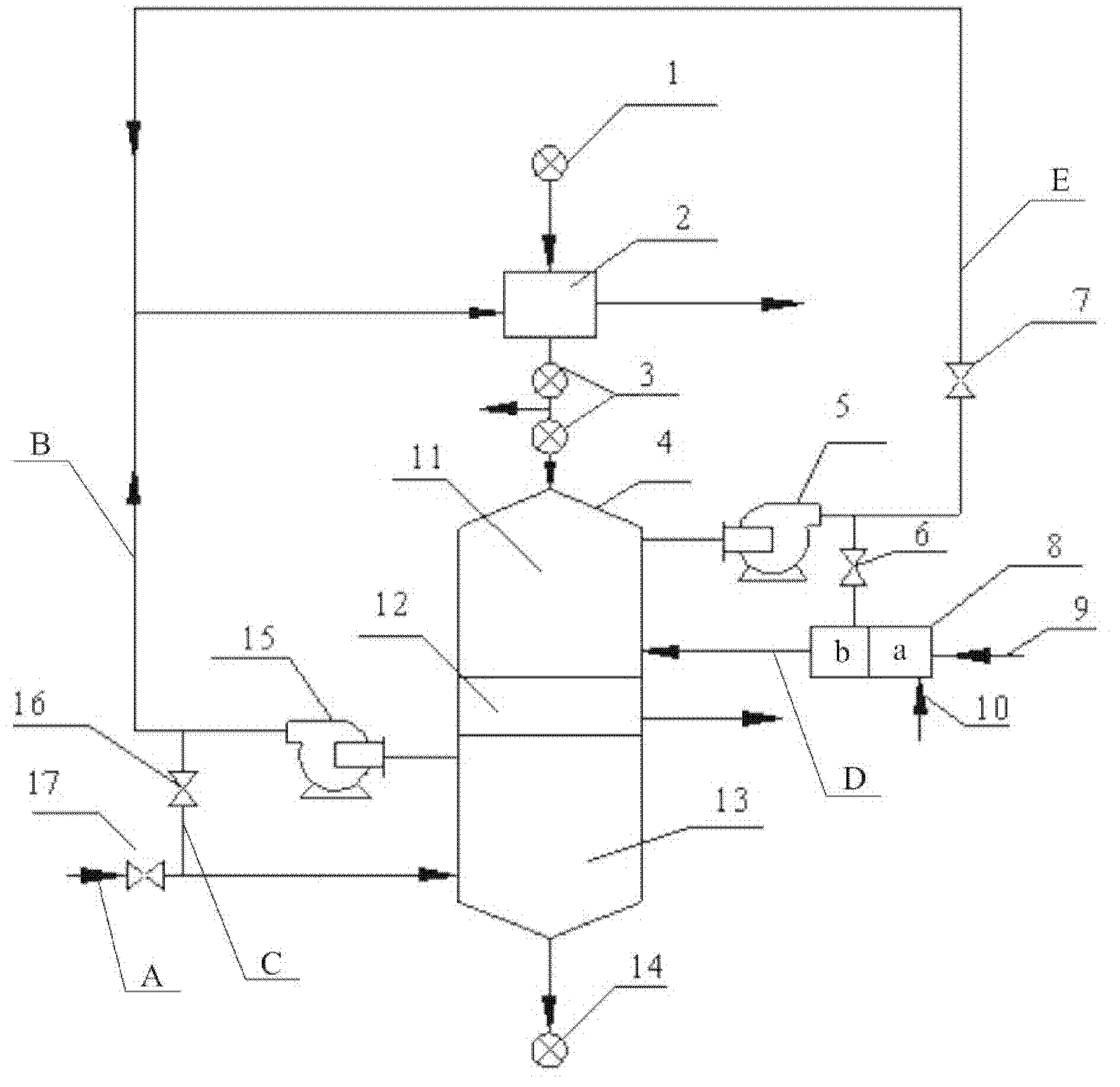

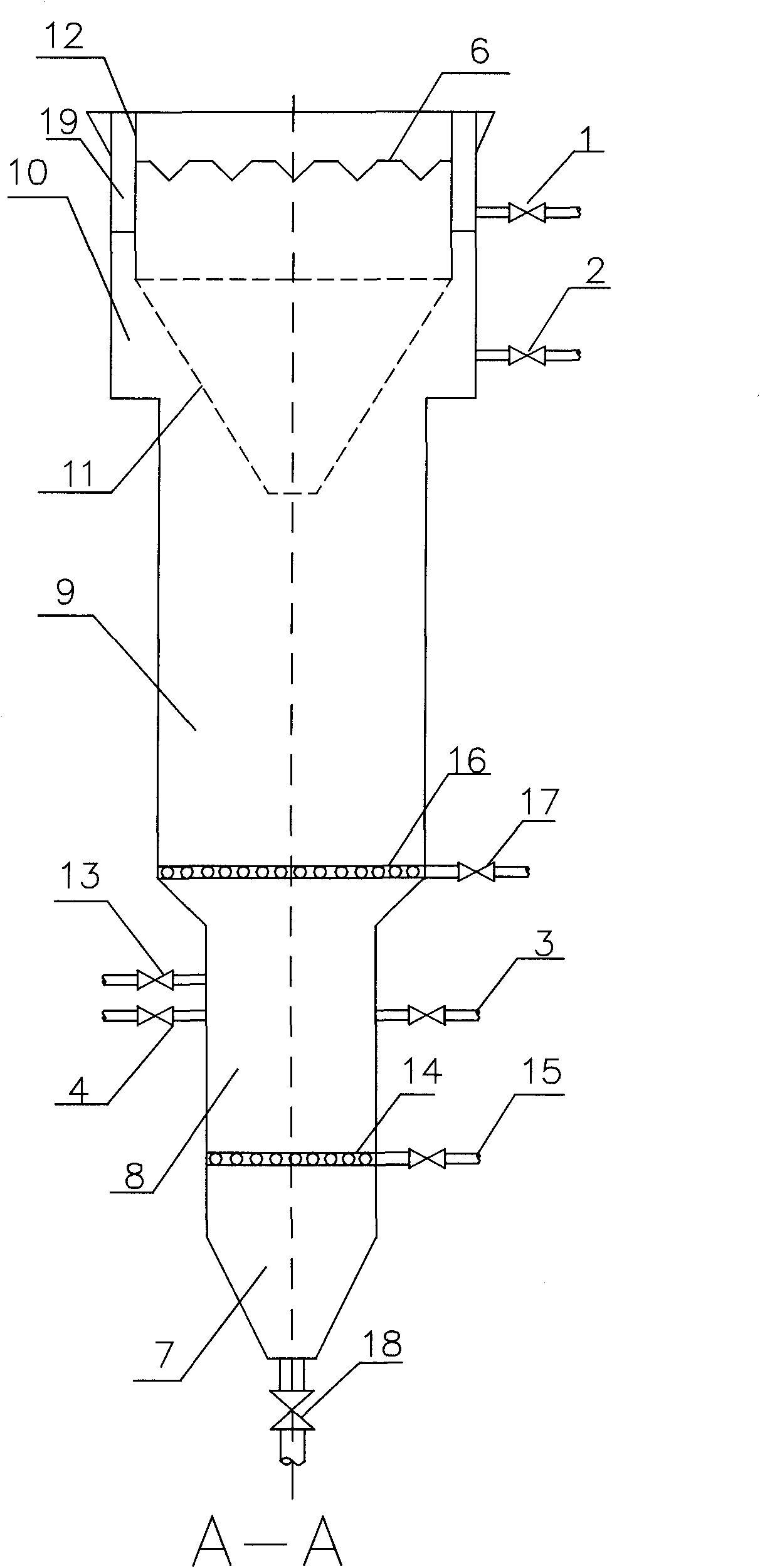

Integrated nitrogen and phosphorus recovery device in struvite method

InactiveCN101817581AImprove recycling efficiencyAvoid churnWater/sewage treatment by flocculation/precipitationPhosphorus compoundsTrappingStruvite Crystals

The invention discloses an integrated nitrogen and phosphorus recovery device in a struvite method, which relates to the field of environmental engineering water treatment and is a reactor for treating nitrogen and phosphorus-containing wastewater in a physicochemical method. Substances nitrogen and phosphorus in the wastewater are removed in a magnesium ammonium phosphate (struvite) form, and the substances are recovered and reused. The reaction device is in an integrated form, which comprises a precipitation zone, a mixing reaction zone, a crystal growth zone and a crystal trapping and water discharging zone from bottom to top sequentially, the mixing reaction zone is provided with a first-grade aerator, which is mainly a wastewater and reagent fully mixing and reacting zone; the crystal growth zone is provided with a second-grade aerator, which is mainly a struvite growth zone; in the precipitation zone, large-grain struvite crystals are mainly precipitated; and the crystal trapping and water discharging zone recovers the struvite crystals by a filter screen. In addition, the device uses external reflux to reinforce and to control the supersaturated rate of the struvite reaction, thus promoting the crystal growth. The device has simple technological process and has the advantages of short hydraulic retention time, high nitrogen and phosphorus recovery efficiency, high recovery pureness, little occupied area, low operation and maintenance cost and the like.

Owner:TONGJI UNIV

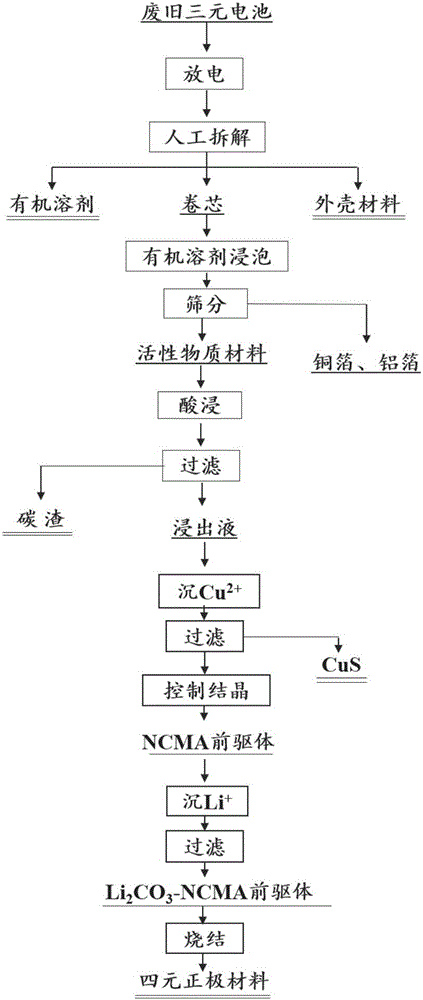

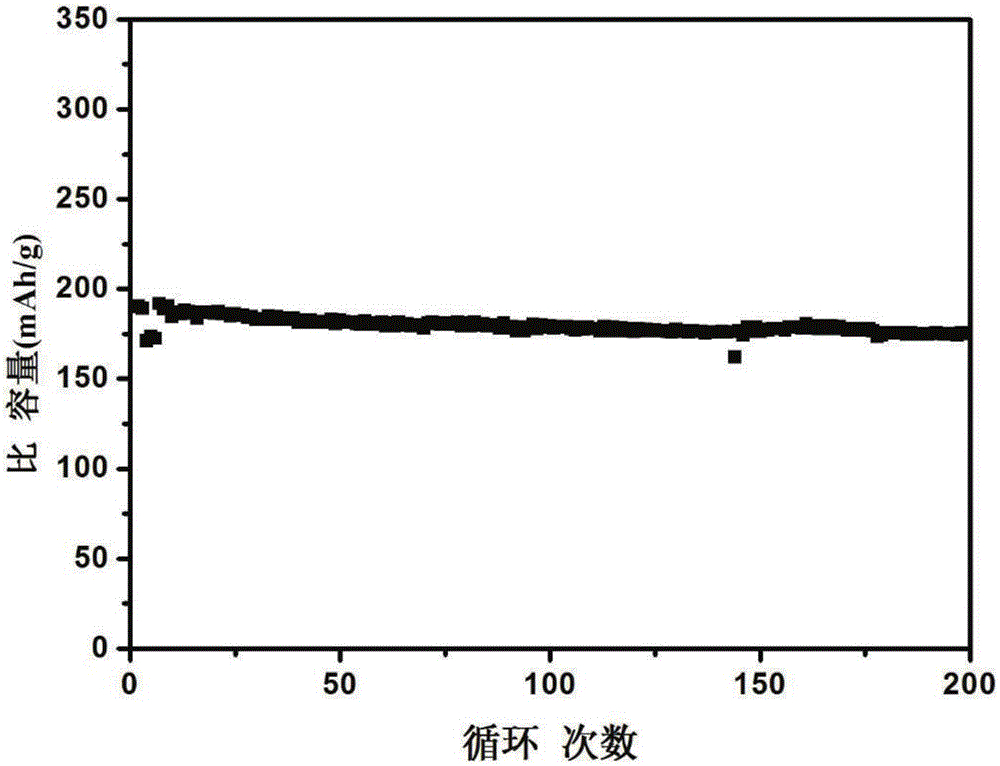

Method for recovering and preparing nickel-cobalt-manganese-aluminum quaternary positive electrode material from waste nickel-cobalt-manganese ternary lithium-ion battery

ActiveCN106785177AAvoid separationAvoid it happening againWaste accumulators reclaimingBattery recyclingManganeseLithium-ion battery

The invention discloses a method for recovering and preparing a nickel-cobalt-manganese-aluminum quaternary positive electrode material from a waste nickel-cobalt-manganese ternary lithium-ion battery. The method comprises the following steps of (1) obtaining a leach solution containing Cu<2+>, Al<3+>, Li<+>, Ni<2+>, Co<2+> and Mn<2+> from the waste ternary lithium-ion battery through manual disassembly, magnetic separation, crushing, organic solvent soaking, screening and sulfuric acid leaching, and carrying out purification (Cu<2+>) treatment on the leach solution to obtain a purified liquid; (2) adjusting the molar ratio of Al to Ni to Co to Mn in the purified liquid, adding alkali metal hydroxide, adjusting the pH of a system until the pH is greater than or equal to 10 and carrying out primary precipitation to obtain a turbid liquid in which NCM hydroxide is precipitated; (3) adding carbonate to the turbid liquid in the step (2) for secondary precipitation, and carrying out solid-liquid separation to obtain a quaternary material precursor; and (4) burning the quaternary material precursor in air to obtain an Al-doped NCM quaternary positive electrode material. The method is simple in technology, wide in raw material source and high in repeatability; the prepared quaternary positive electrode material is excellent in cycle performance; and large-scale production can be carried out.

Owner:CENT SOUTH UNIV

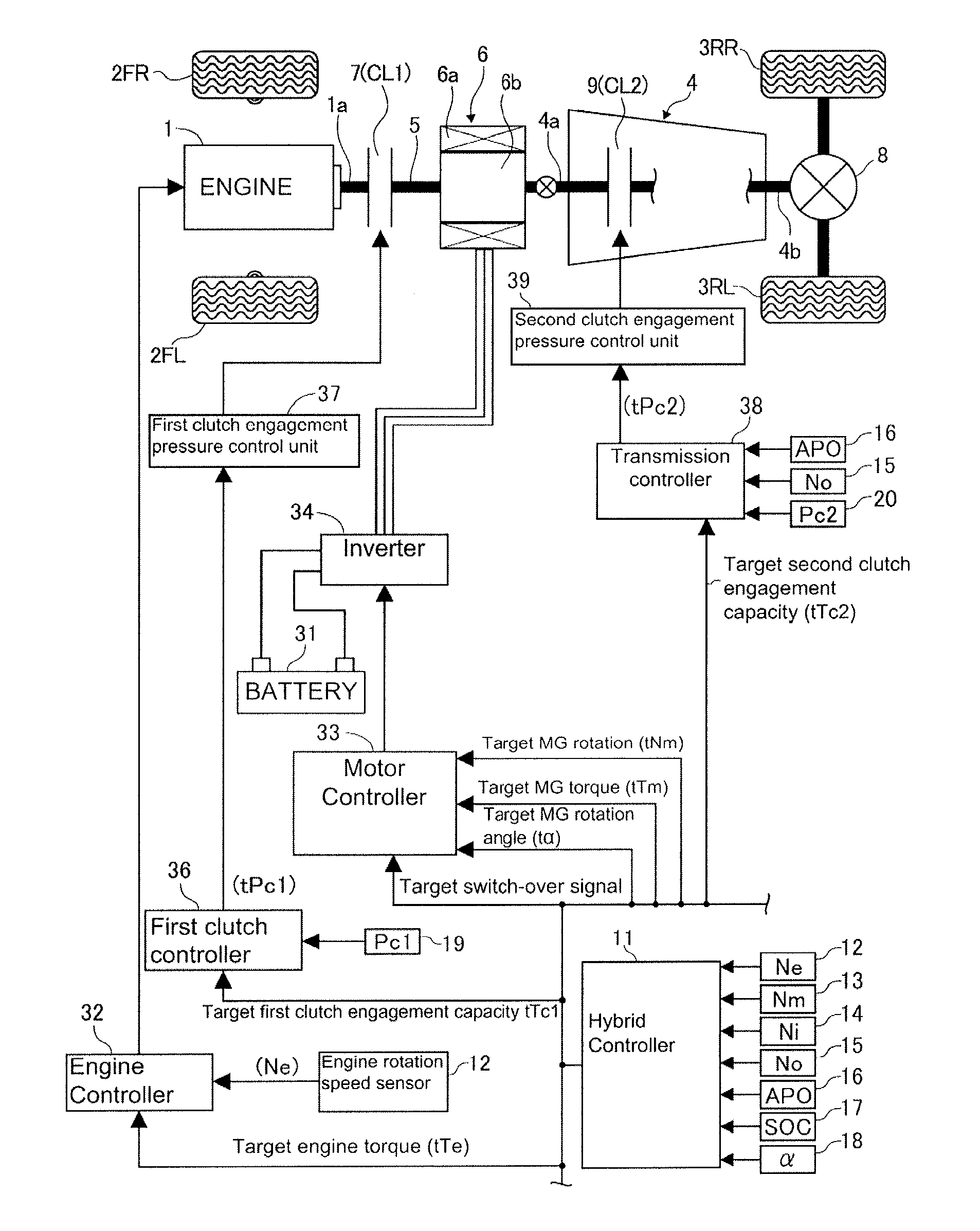

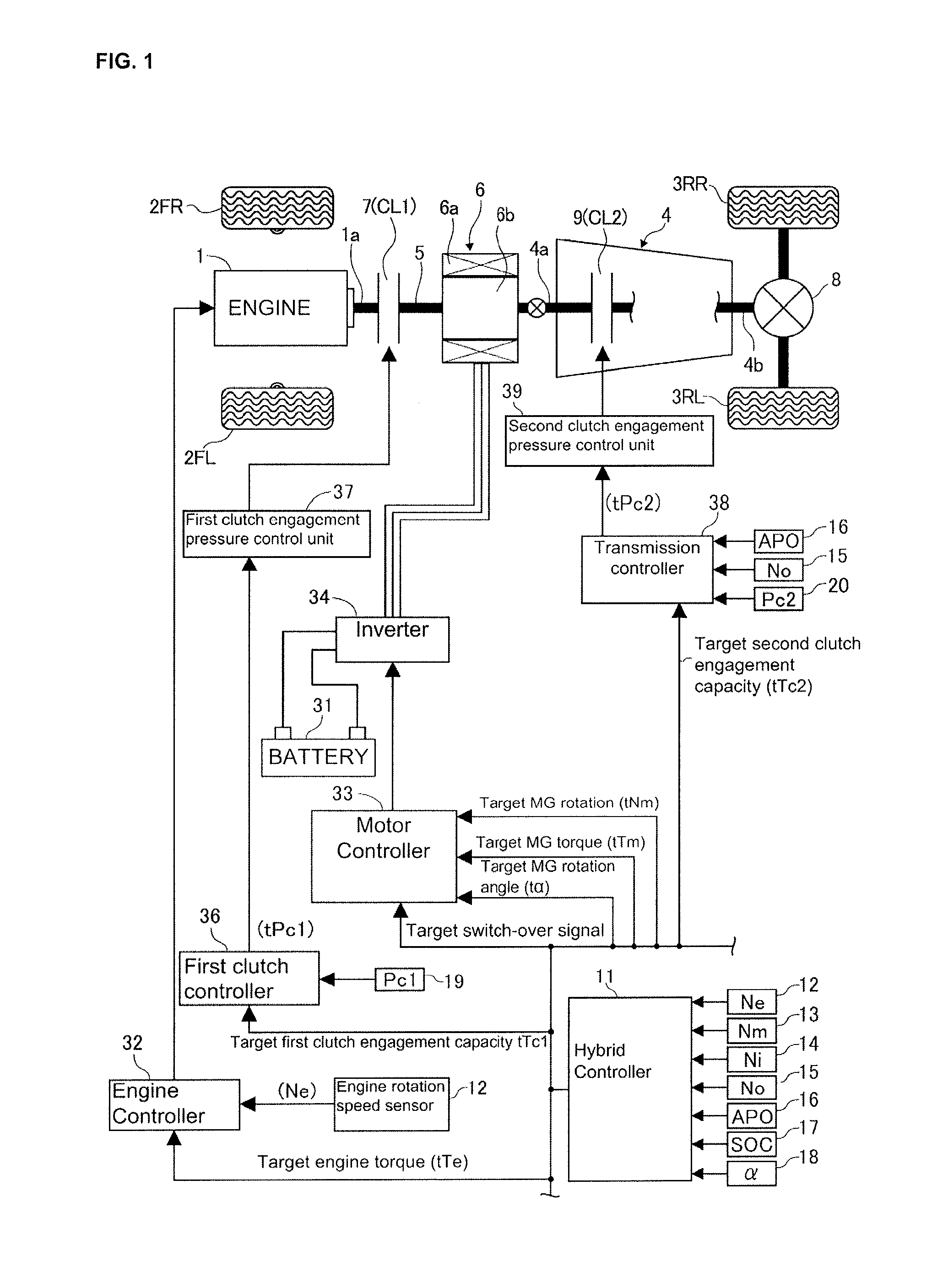

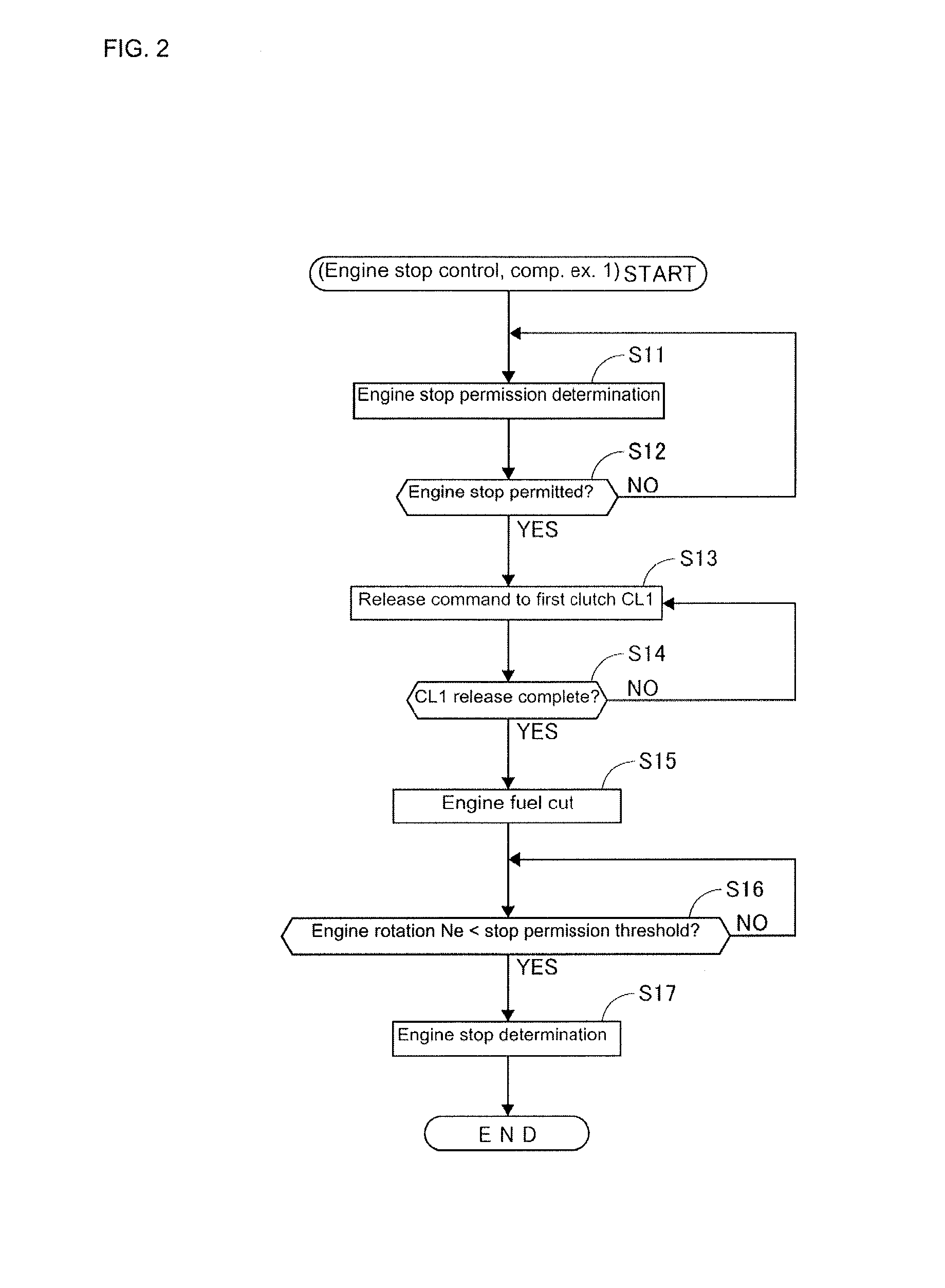

Engine stop control system for hybrid electric vehicle

ActiveUS20120309587A1Deterioration in energy recovery efficiencyImprove performanceInternal combustion piston enginesPropulsion using engine-driven generatorsDrive wheelControl system

An engine stop control system for a hybrid electric vehicle including a powertrain having an engine, an electric motor / generator, and driving wheels, including a first clutch coupling the engine to the motor / generator, a second clutch coupling the motor / generator to the driving wheels, a controller configured to select between two driving modes of the vehicle by controlling engagement and disengagement of the first clutch and the second clutch so that the vehicle may be driven either solely by the motor / generator or a combination of the engine and the motor / generator, and to control the stop position of the engine to be a desired stop position by controlling the rotation speed of the motor / generator while the first clutch in complete engagement and the second clutch in a slip state.

Owner:NISSAN MOTOR CO LTD

Repetitive affinity separation and uses therefor

InactiveUS20050247563A1Improve recycling efficiencyMaintaining specificity of bindingSludge treatmentVolume/mass flow measurementElectrophoresisTissue sample

Improved methods for the separation, isolation, enrichment, or detection of target molecules, such as nucleic acids and proteins, within dilute or heterogeneous samples, such as bodily fluids, excreta or tissue samples, are disclosed. The methods include repetitively and rapidly passing a sample across at least one region of a conduit in which at least one region includes a binding partner specific for the target molecule. In certain methods, at least one other region includes binding partners specific for non-target molecules. The sample may be passed over the binding partner in the same direction if the conduit is a loop or in an antiparallel direction (i.e., back and forth over the binding partner). In an embodiment, the sample is electrophoresed through or over an electrophoretic medium, in which at least one region includes a binding partner for the target molecule. The invention also provides apparatus and sample preparation systems adapted for use in the methods.

Owner:EXACT SCI CORP

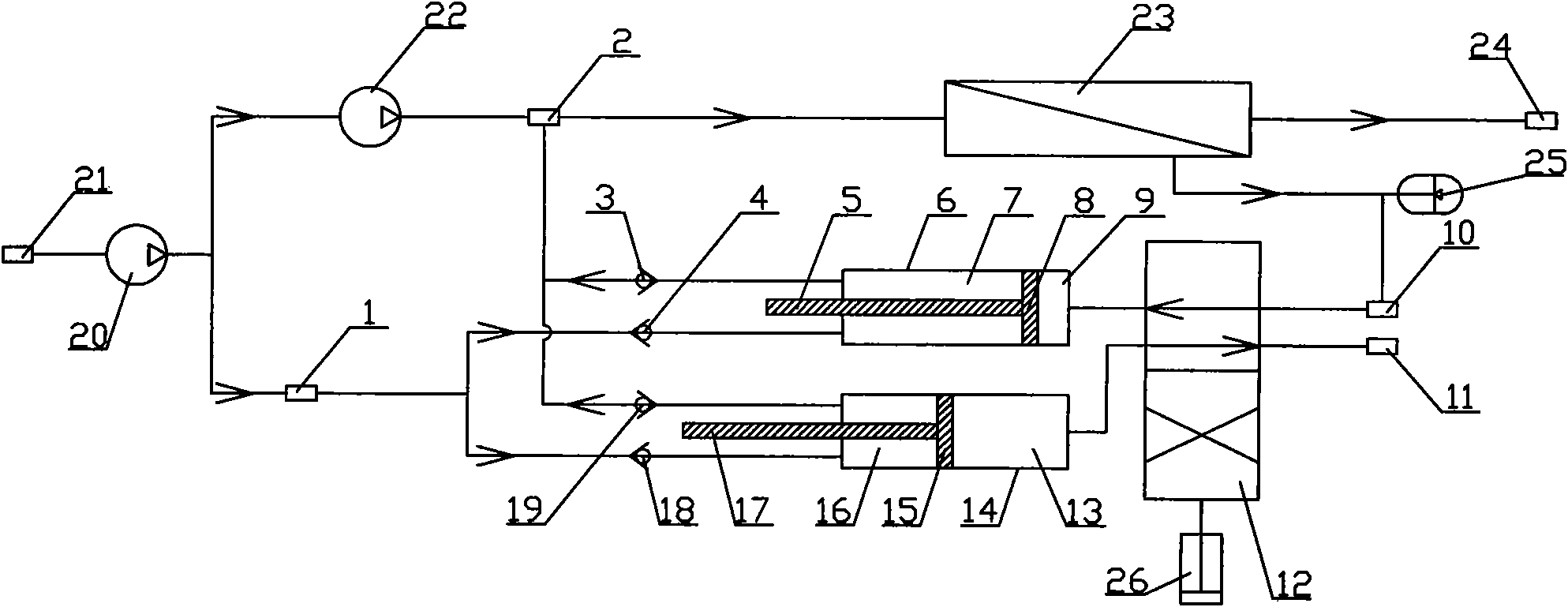

Excavator energy-recuperation system

InactiveCN101654915ARealize the regeneration functionImprove energy utilizationMechanical machines/dredgersHydraulic cylinderFuel tank

An excavator energy-recuperation system relates to an excavator moving arm energy saving system, comprising a hydraulic cylinder, a fuel tank, a quantitative pump, a valve and an engine. The key technology is that a first variable pump and a speed determining photoelectric encoder are coaxial equipped with the quantitative pump. One end of the quantitative pump is connected with a hydraulic cylinder through a reversing valve and the other end of the quantitative pump is respectively connected with the fuel tank and the hydraulic cylinder on two branches. One end of the first variable pump is connected with the fuel tank and the other end is connected with an accumulator through the reversing valve. A second variable pump is coaxial arranged with the engine, one end of the second variable pump is connected with the fuel tank and and the other end is connected with a check valve; a fuel outlet of the check valve has three branches, wherein the first one is connected with the accumulatorthrough the reversing valve; the second one is connected with a hydraulic cylinder through the reversing valve; and the third one is connected with a hydraulic cylinder through the reversing valve. The invention combines the flow regeneration and potential energy recuperation, thus simultaneously realizing the flow regeneration and the energy-recuperation recycling, improving the utilization rateof the excavator energy and prolonging the service life of the excavator.

Owner:四川升腾元创机电技术研究有限公司

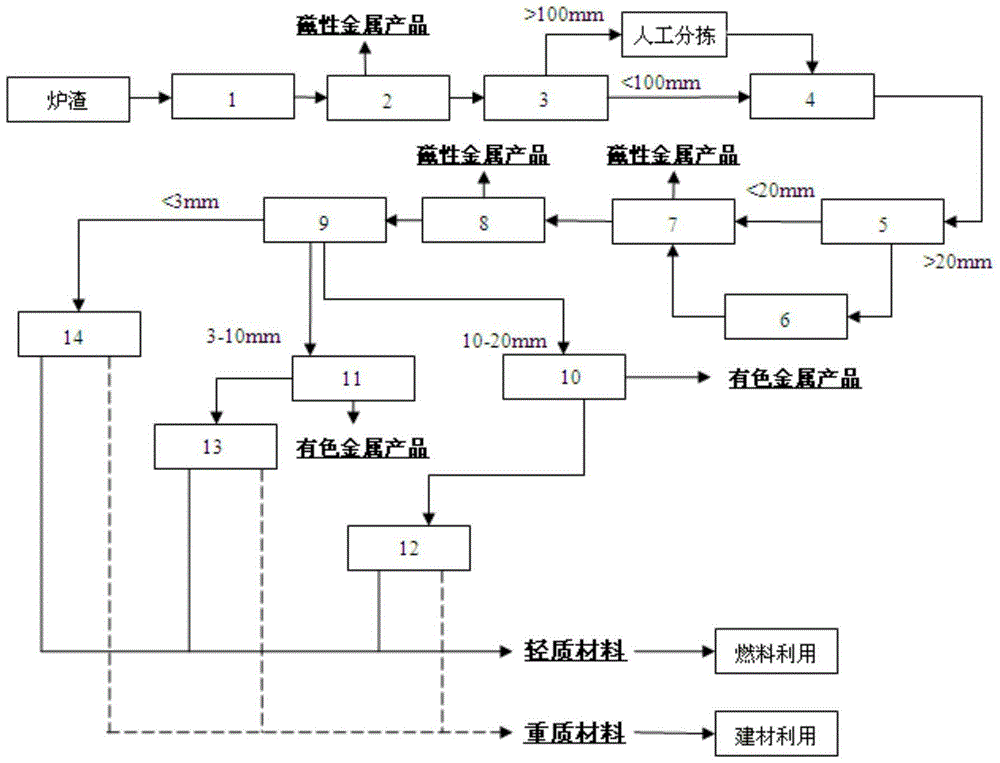

Method for recycling metal and combustibles from domestic waste incineration slag

The invention relates to a method for recycling metal and combustibles from domestic waste incineration slag, and belongs to the field of the solid waste harmless and recycling technology. By means of multi-stage gradient magnetic separation, separation of magnetic metal in the slag is achieved. By means of two-stage eddy current, nonferrous metal in the slag is separated and recycled. According to the grain size distribution and chemical morphological characteristics of the metal in the slag, the metal is crushed and screened in multiple steps so that separated slag particles can be uniform, the recycling rate of magnetic separation and eddy current separation is effectively increased, and finally, according to the density difference of materials, air separation is used for recycling the combustibles in the slag. Finally, the magnetic separation recycling rate of iron in the technological process is 60-80%, the recycling rate of the nonferrous metal aluminum is 60-70%, the recycling rate of the nonferrous metal copper is 40-50%, and separation of the metal in the slag and slag particles can be effectively achieved. The separated metal products can be directly sold or sold after refining, the combustibles can serve as waste incinerator fuel, and the remaining slag can be used as building materials.

Owner:TONGJI UNIV

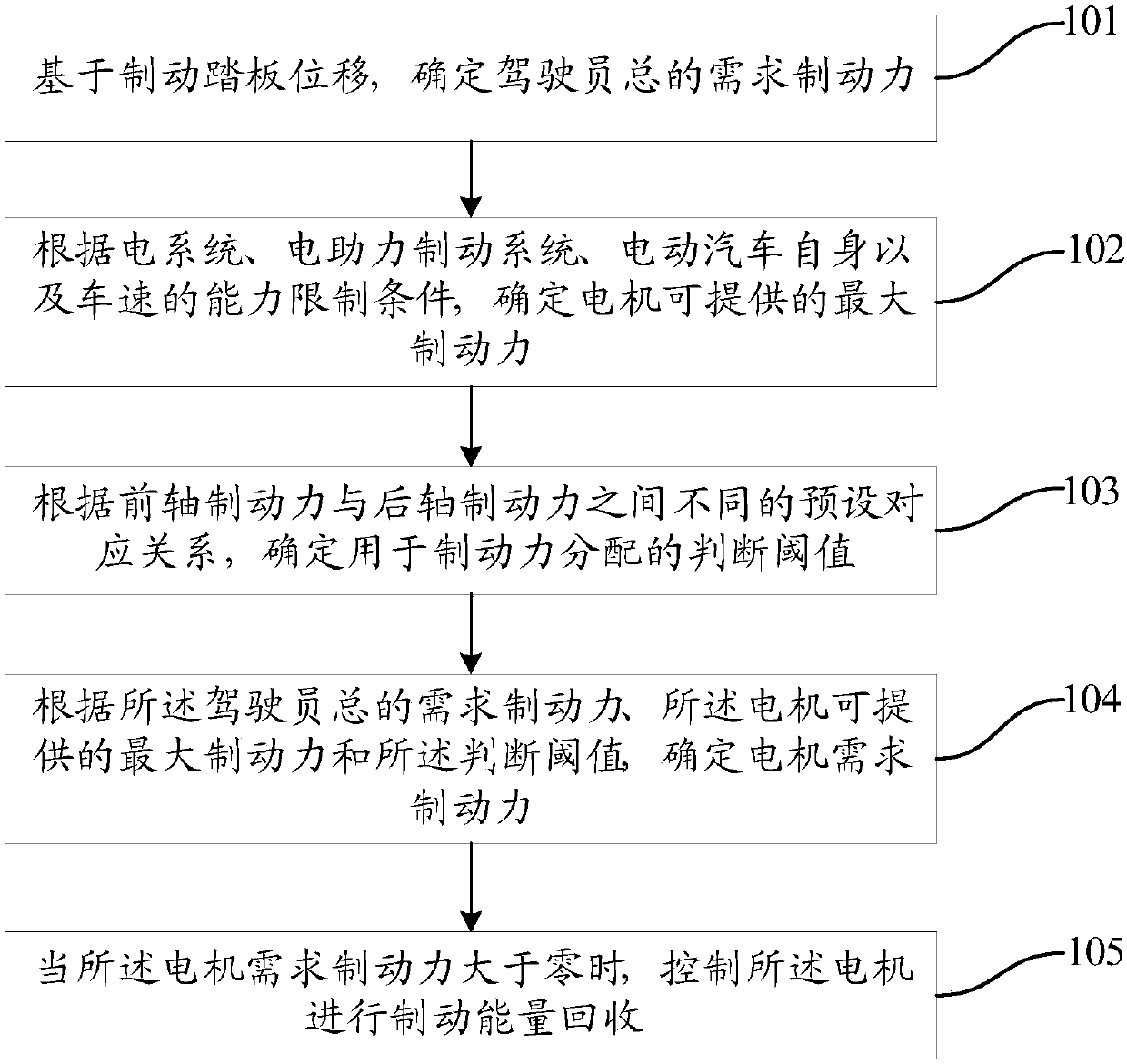

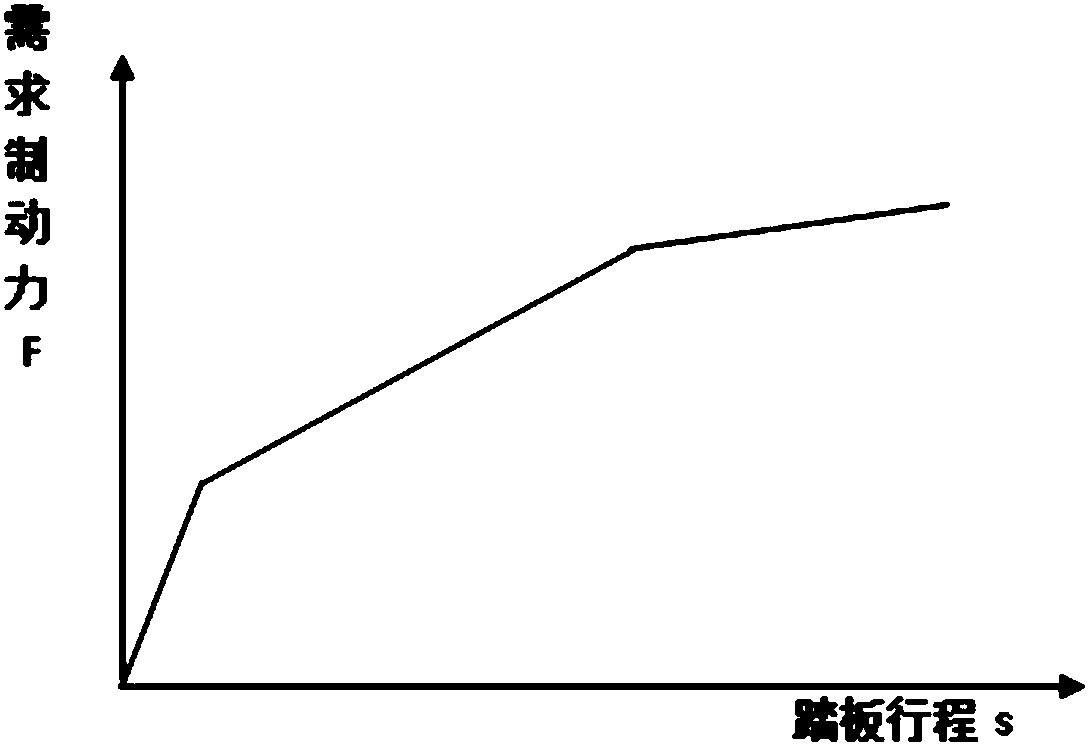

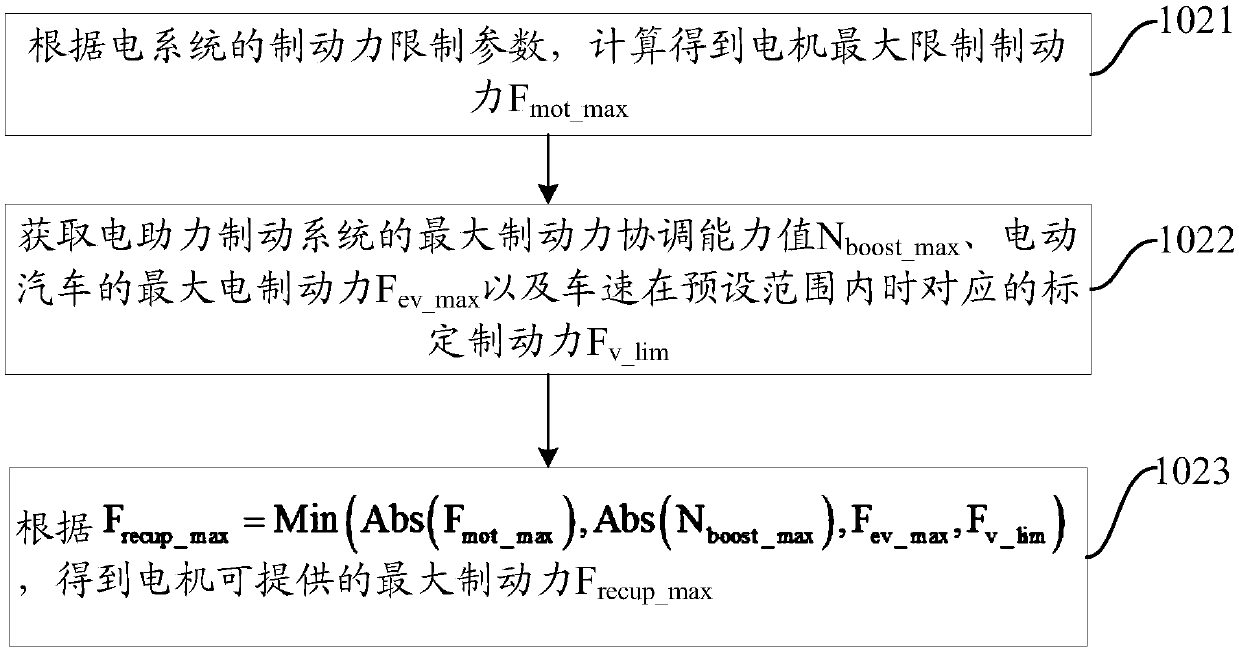

Braking energy recovery control method and device and electric automobile

ActiveCN108081961AGood braking comfortImprove recycling efficiencySpeed controllerElectrodynamic brake systemsElectricityElectric machinery

The invention provides a braking energy recovery control method and device and an electric automobile. The method includes the steps that on the basis of brake pedal displacement, the total required braking force of a driver is determined; according to capacity limiting conditions of a power system, an electric assistance braking system, the electric automobile and the automobile speed, the largest braking force capable of being provided by a motor is determined; according to different preset corresponding relationships between front axle braking force and rear axle braking force, a judgment threshold value used for braking force distribution is determined; according to the total required braking force of the driver, the largest braking force capable of being provided by the motor and thejudgment threshold value, the required braking force of the motor is determined; and when the required braking force of the motor is larger than zero, the motor is controlled to conduct braking energyrecovery. On the premise that the total required braking force of the driver is not changed, electric braking recovery is conducted to the maximum degree, the purposes that energy recovery efficiencyis high, and the overall braking comfort level of the electric automobile is high are achieved, and driving experience of a user is improved.

Owner:BEIJING ELECTRIC VEHICLE

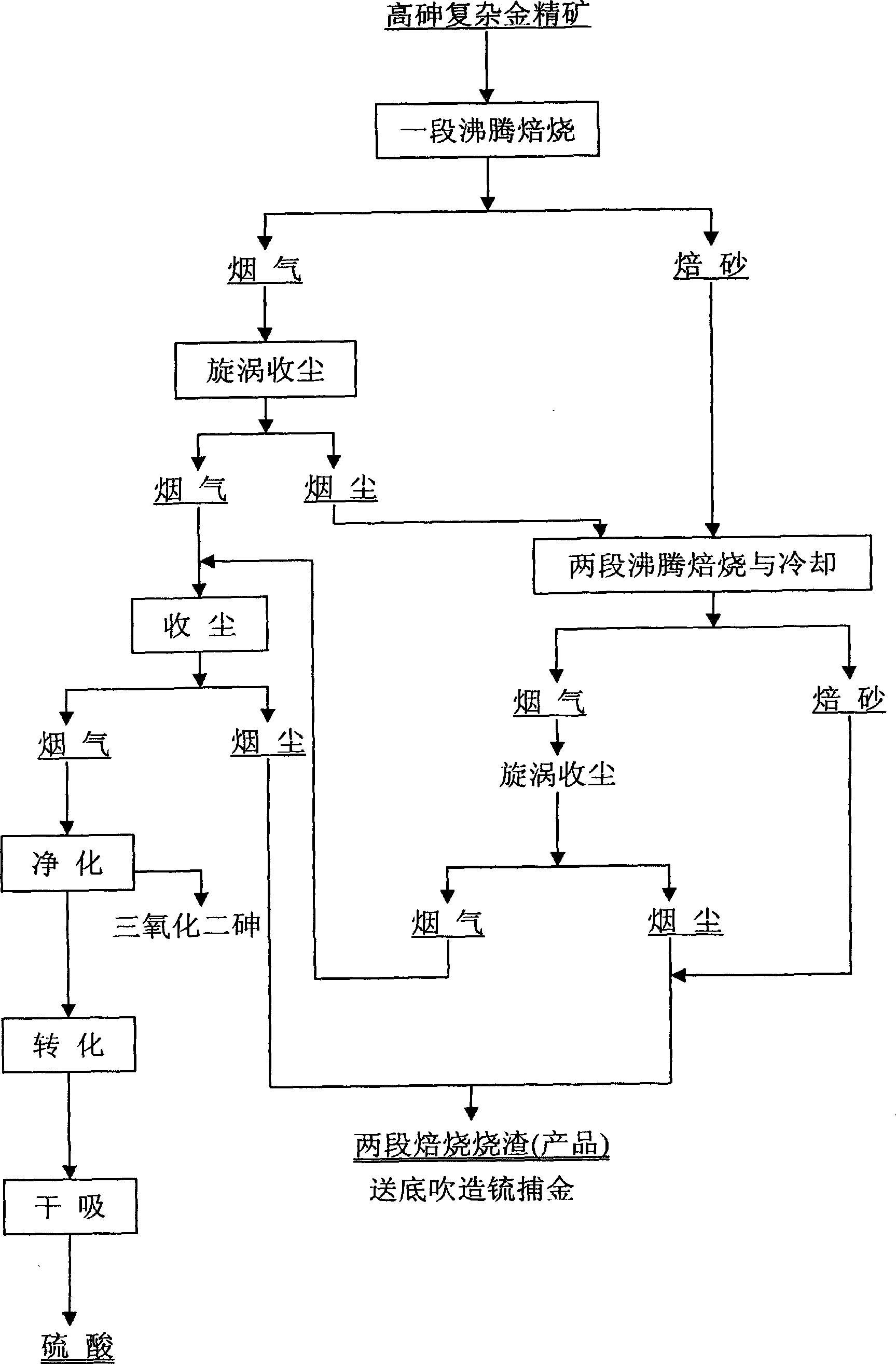

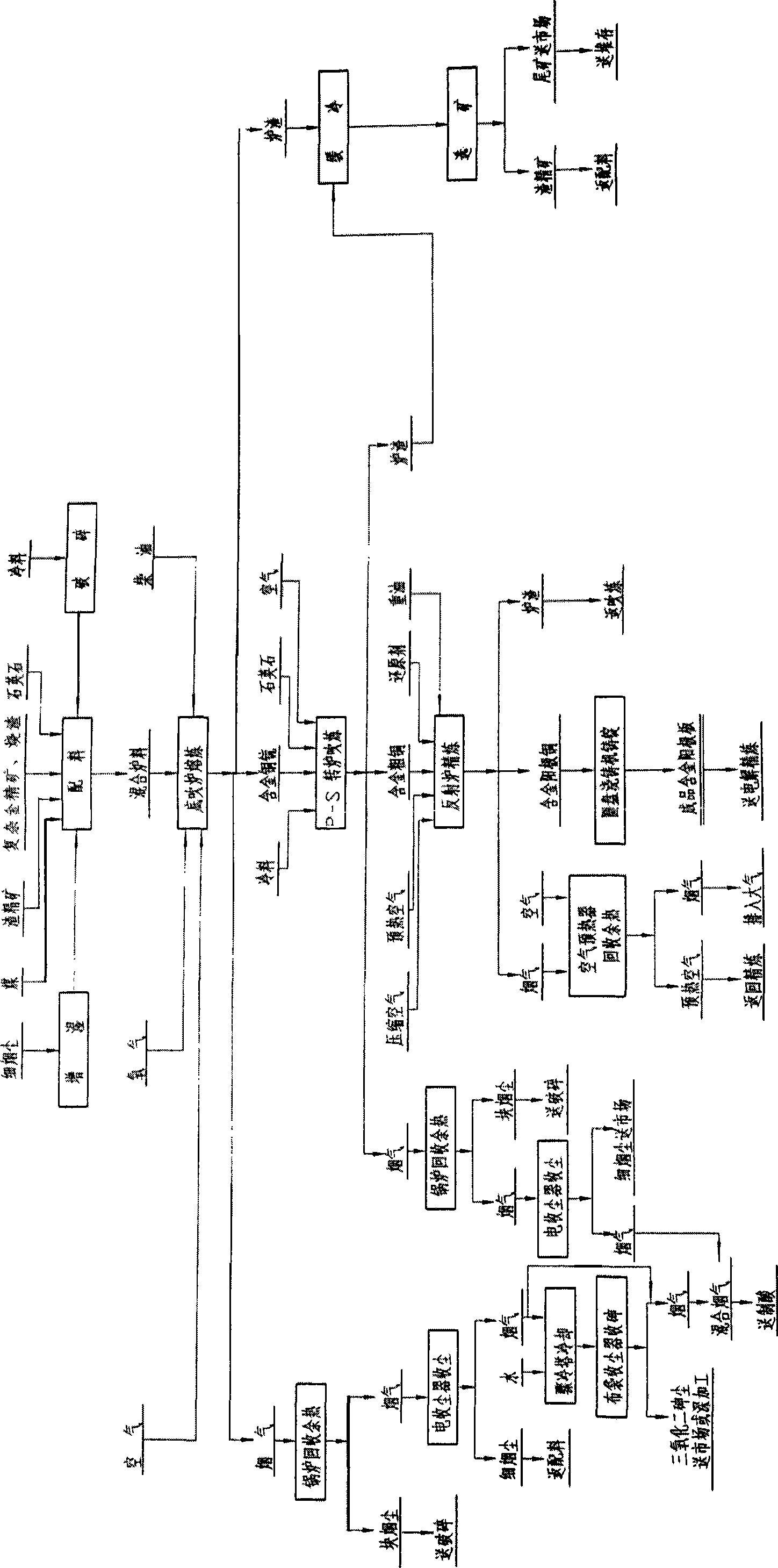

Method for extracting high arsenic complicated golden ore concentrate multielement

ActiveCN101519731AImprove recycling efficiencyReduce low altitude pollutionPhotography auxillary processesReverberatory furnaceElectrolysisMaterials science

The invention discloses a method for extracting high arsenic complicated golden ore concentrate multielement. The method comprises the following steps that: the multielement complicated golden ore concentrate with extra-high arsenic is subjected to the roast dearsenification technique treatment, part of sulfur in the multielement high arsenic golden ore concentrate converted into sulfur dioxide and the arsenic converted into arsenic trioxide enter flue gas which is subjected to dust and arsenic collection, and then enter an acid making system to produce sulphuric acid; the multielement smelting slag and multielement low arsenic golden ore concentrate obtained by roast dearsenification, return products and flux are mixed to obtain copper matte regulus, and the like by adopting oxygen enrichment bottom blowing matte smelting gold collecting process to carry out the smelting process; the copper matte regulus is subjected to converting and refining to cast an anode plate which is sent to an electrolysis system to obtain an electrolytic copper product by refining; anode mud generated through electrolysis is sent to a noble metal refine system to produce gold and sliver, and the like; smelting slag and converting slag are subjected to floatation treatment to obtain copper and iron ore concentrate; and the generated gangue belongs to harmless slag and can be used. The method has the characteristics of wide range of the raw material application, high synthesized recovery efficiency of valuable element, and obvious economic and environment benefits.

Owner:SHANDONG HUMON SMELTING

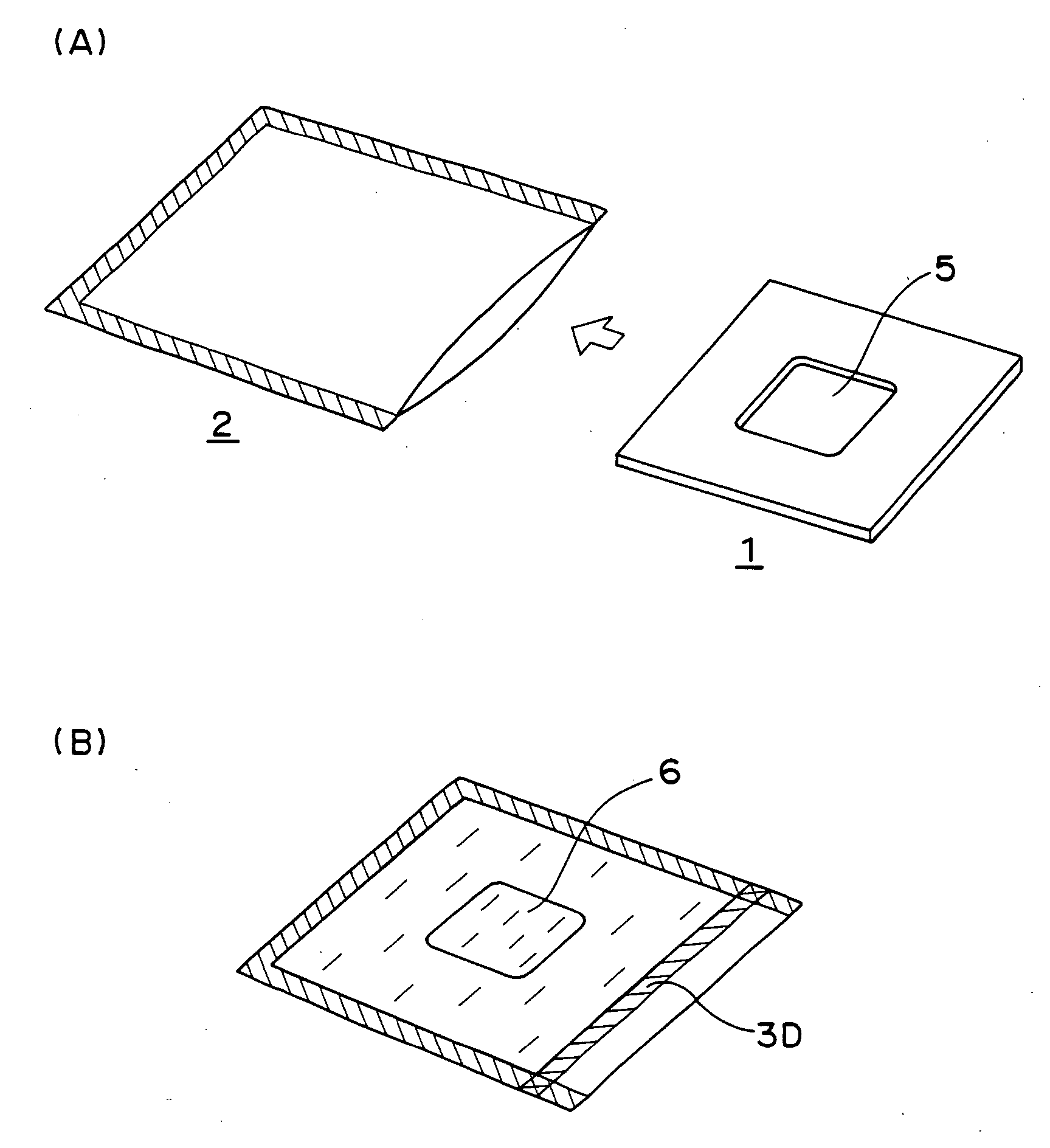

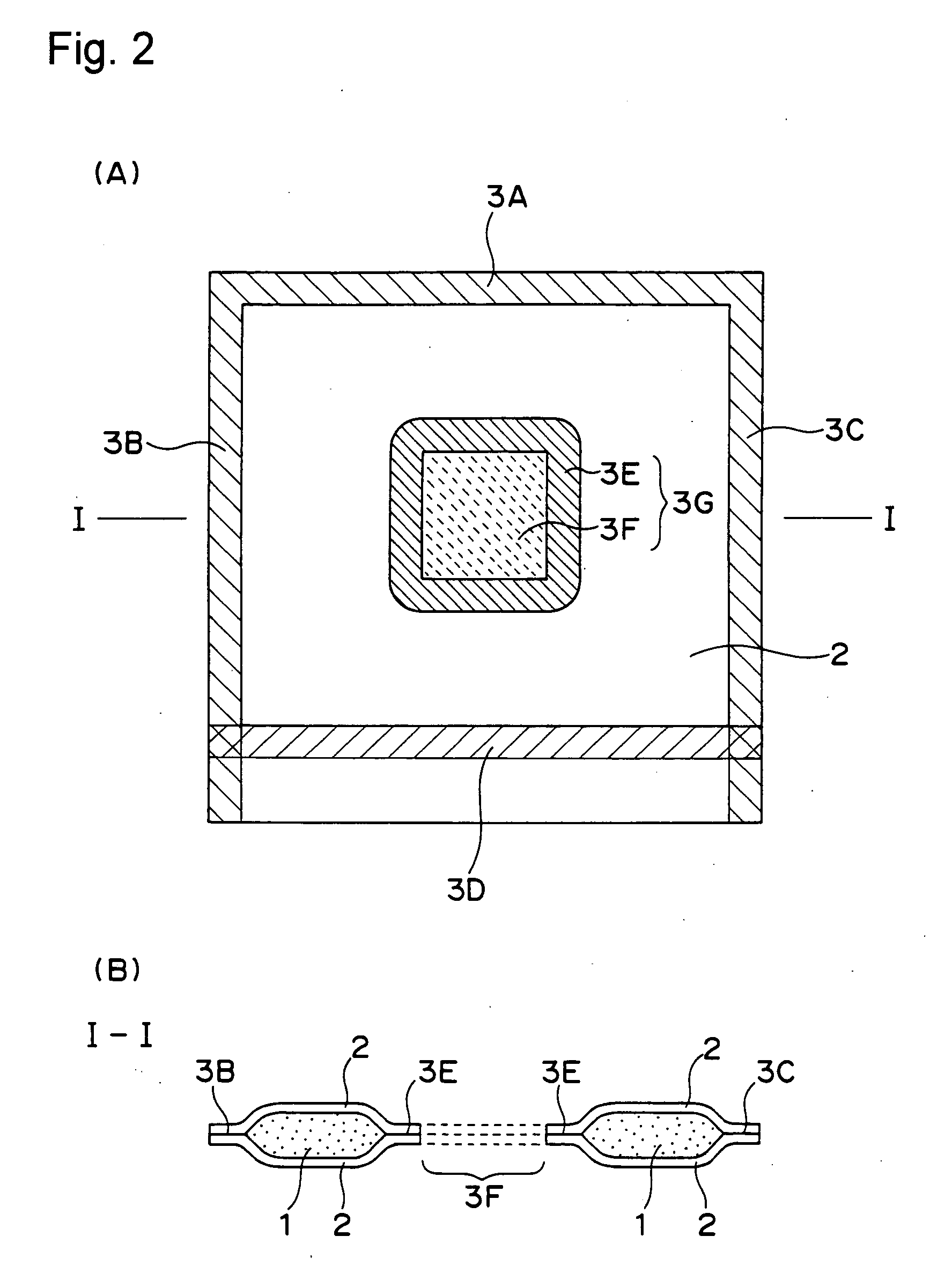

Vacuum Heat Insulator

InactiveUS20080095970A1Low environmental loadImprove recycling efficiencyEnvelopes/bags making machineryThermal insulationPolyesterMaterials science

The present invention provides a heat insulator that is extremely low in environmental load during production and recycling, is superior in handleability and workability, and shows favorable heat-insulating properties over an extended period of time. The present invention relates to vacuum heat insulator, comprising at least a core member and an external packaging member that stores the core member and can keep inside under reduced pressure, wherein the core member is a sheet-shaped fiber aggregate containing a polyester fiber having fiber size of 1 to 6 deniers in an amount of 50 wt % or more.

Owner:SAMSUNG R&D INSTITUTE JAPAN CO LTD

Method for recovering positive pole material of Li-ion battery

InactiveCN101212074AImprove recycling efficiencyShorten production timeSolid waste disposalWaste accumulators reclaimingOrganic solventAlcohol

The invention relates to a method for recycling anode material of a lithium ion battery, which includes the processes: organic solvent is used for soaking anode plates of the battery so as to separate the anode material from a current collector; the current collector is taken out and filtered to obtain anode active substances; the anode active substances are parched. The organic solvent is the mixed solvent of the N, N - dimethylformamide and liquid alcohol and / or liquid ketone. By adopting the mixed solvent, the invention greatly promotes the recycling efficiency of the anode material; in the method of the invention, the recycling rate of the anode material is higher by over 20 per cent compared with the prior art in the situation of adopting different used organic solvent but other same conditions; besides, by adopting the method provided by the invention, the needed production time is greatly shortened and the production efficiency is promoted.

Owner:SHANGHAI BYD

Method for reclaiming valuable metals from waste lithium batteries

ActiveCN101921917AReduce recycling costsSimple methodProcess efficiency improvementBattery recyclingCopperCobalt

The invention discloses a method for reclaiming valuable metals from waste lithium batteries, which comprises the following steps of: crushing discharged waste lithium batteries, calcining at the high temperature of 350-400 DEG C to obtain a material containing cobalt, copper and aluminum, adding 5-10% sodium hydroxide solution to the material, making the sodium hydroxide solution react with the material for 2-3 hours, filtering alkaline liquor, washing and drying to obtain a material containing cobalt and copper; adding sulfuric acid with a certain concentration and Na2S2O3 to the material containing cobalt and copper, mixing, dissolving, adding an extractant to extract copper, and adding an extractant to the copper-extracted solution to extract cobalt. The method is simple and effective and has low reclamation cost.

Owner:深圳前海吉祥环保科技有限公司

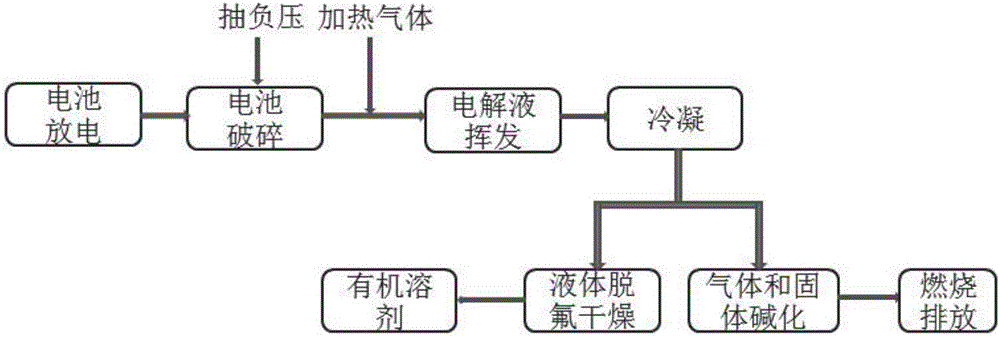

Recovery method for electrolyte of waste lithium ion battery

ActiveCN106684487ALow costPrevent leakageWaste accumulators reclaimingBattery recyclingRecovery methodOrganic solvent

The invention discloses a method for safe dismantling of a waste lithium ion battery and green recovery of an internal electrolyte. The method mainly comprises the steps of (1) performing short-circuit discharging on a waste battery; (2) performing dismantling and smashing on the battery in a negative pressure space; (3) blowing drying hot gas to battery fragments smashed in the negative pressure space to volatilize the electrolyte; and (4) performing condensing, filtering and alkali adding and fluorine removing on volatile components to obtain a relatively pure organic solvent, and performing innocent treatment on the residual gas and solid-state granules. According to the method, the battery is dismantled by the negative pressure environment, a contact area with the battery fragments can be enlarged by hot air flow, so that air flow with high stability is formed, the electrolyte solvent is recycled effectively and simply, and the advantage of low cost is realized; and meanwhile, the harmful substances in the electrolyte are subjected to the innocent treatment, so that environment friendliness and industrial recovery and utilization can be realized.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com